Patents

Literature

590 results about "Lath" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A lath or slat is a thin, narrow strip of straight-grained wood used under roof shingles or tiles, on lath and plaster walls and ceilings to hold plaster, and in lattice and trellis work. Lath has expanded to mean any type of backing material for plaster. This includes metal wire mesh or expanded metal that is applied to a wood or metal framework as matrix over which stucco or plaster is applied, as well as wallboard products called gypsum or rock lath. Historically, reed mat was also used as a lath material.

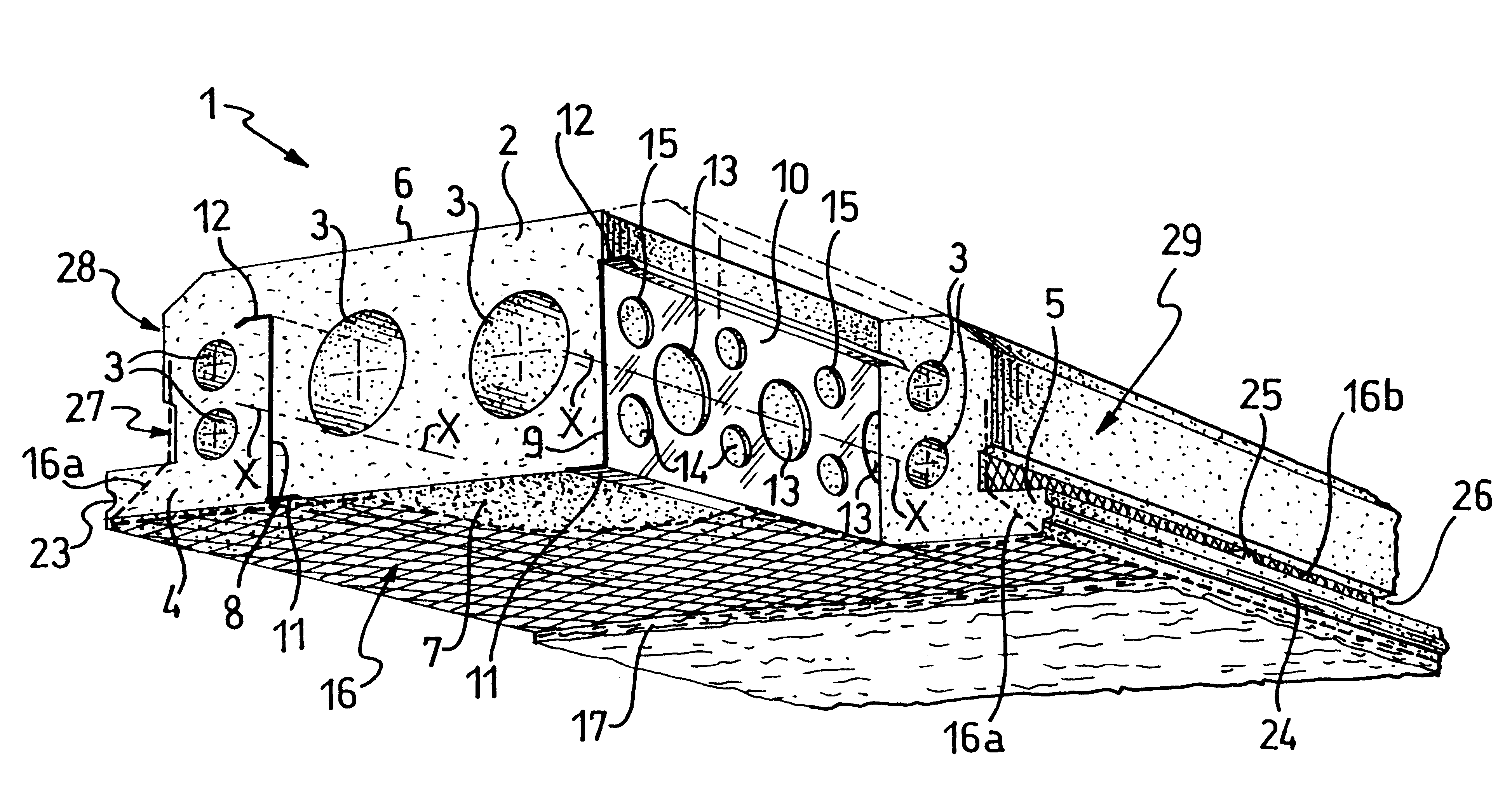

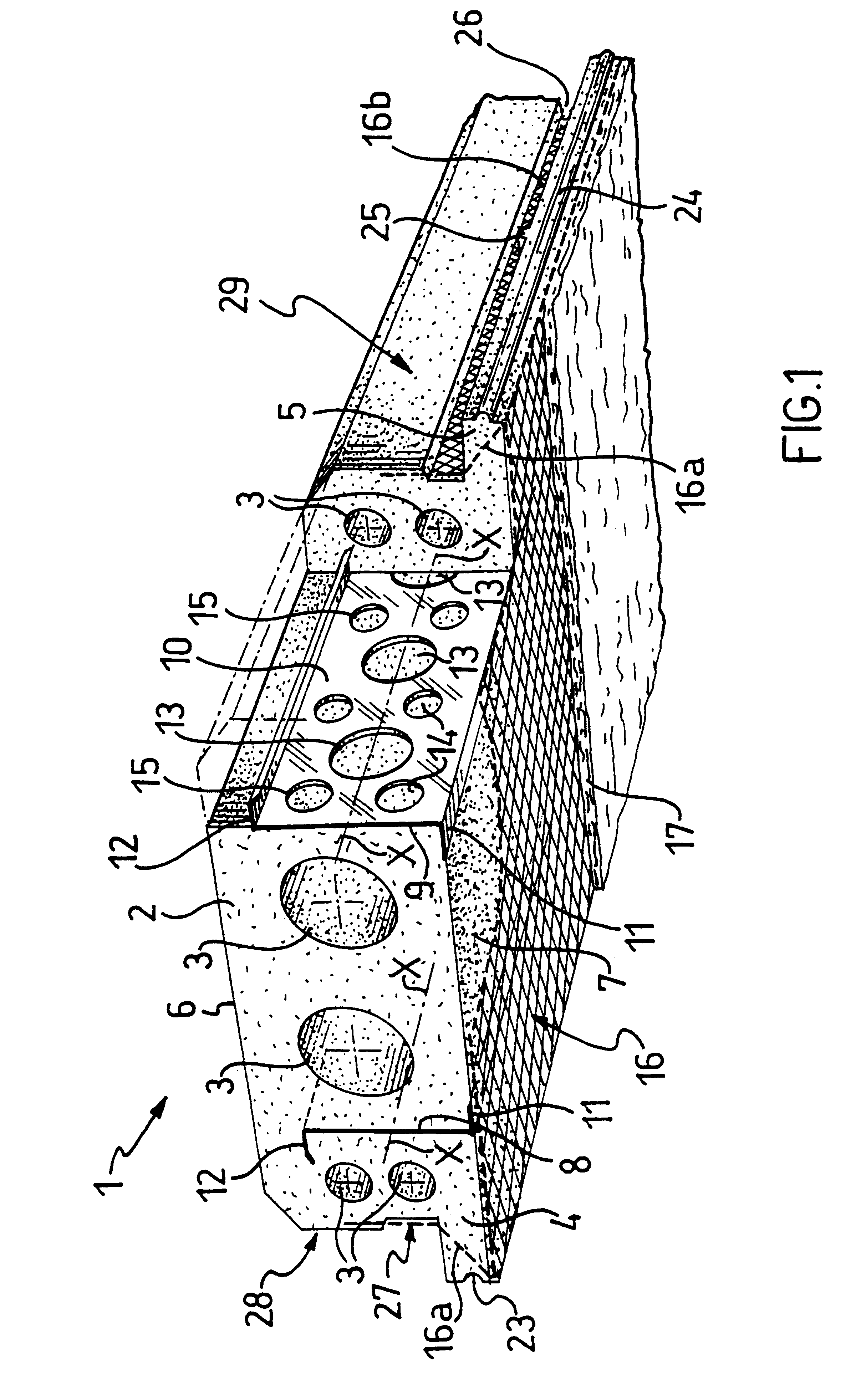

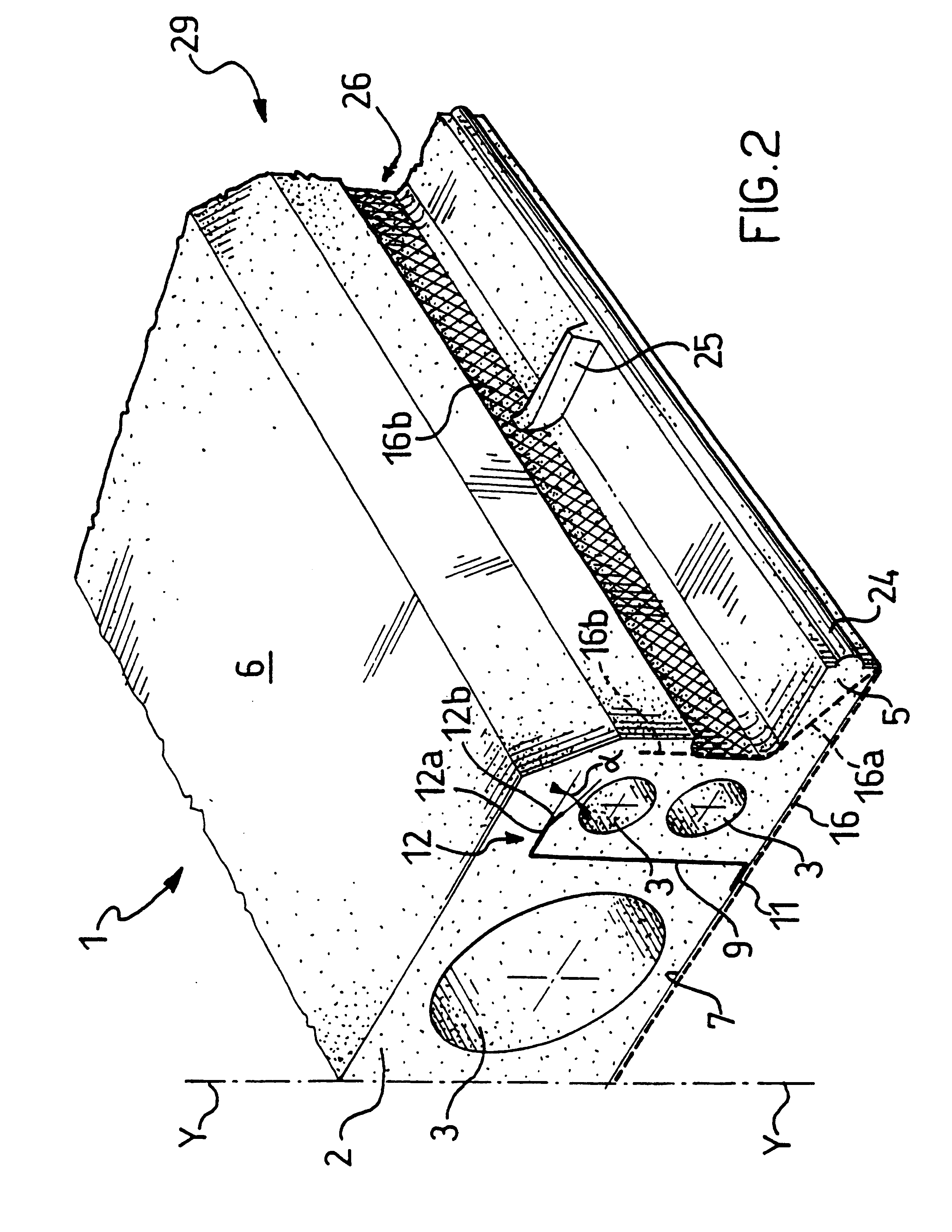

Self-supporting construction element of expanded plastics, in particular for manufacturing floor elements and walls of buildings in general

InactiveUS6298622B1Improving self-supporting propertyEasy to integrateConstruction materialFloorsLathBuilding construction

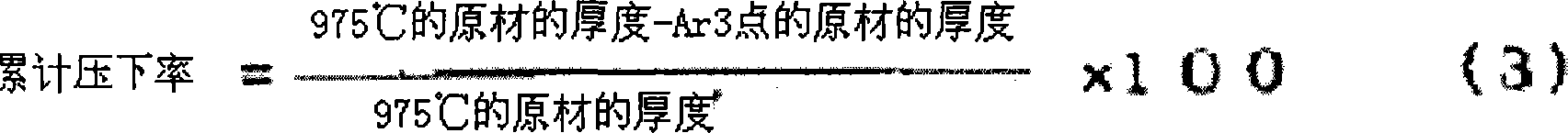

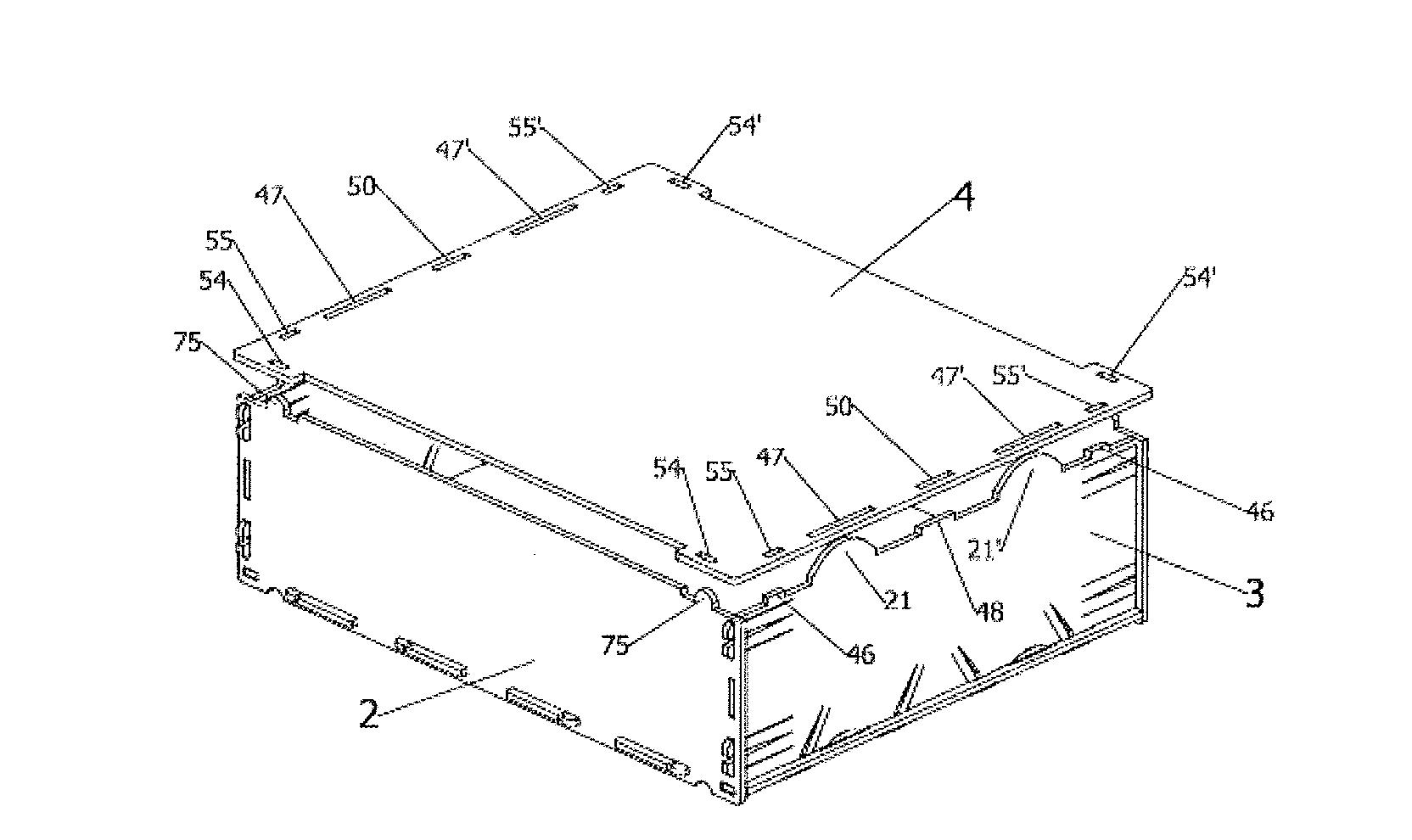

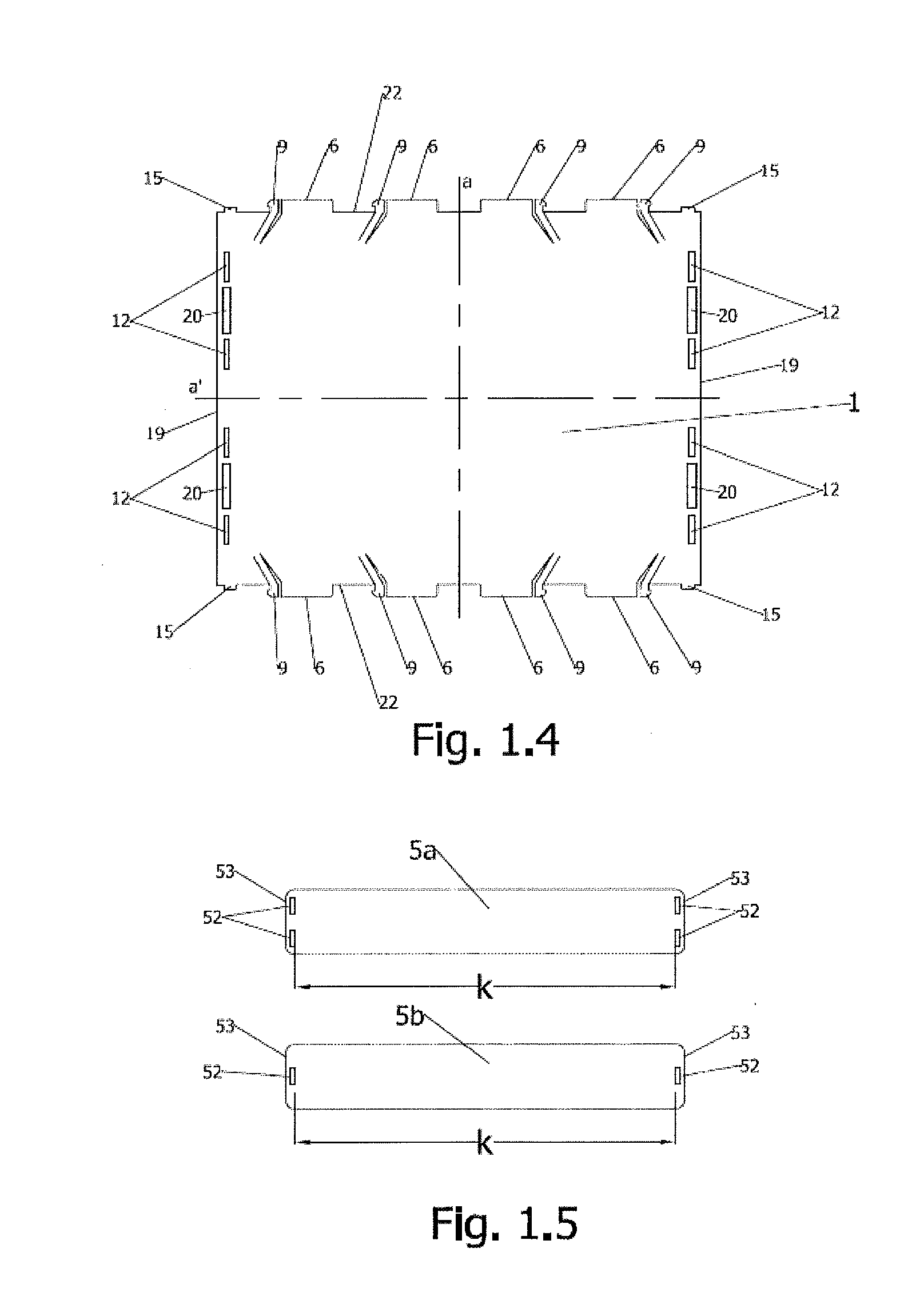

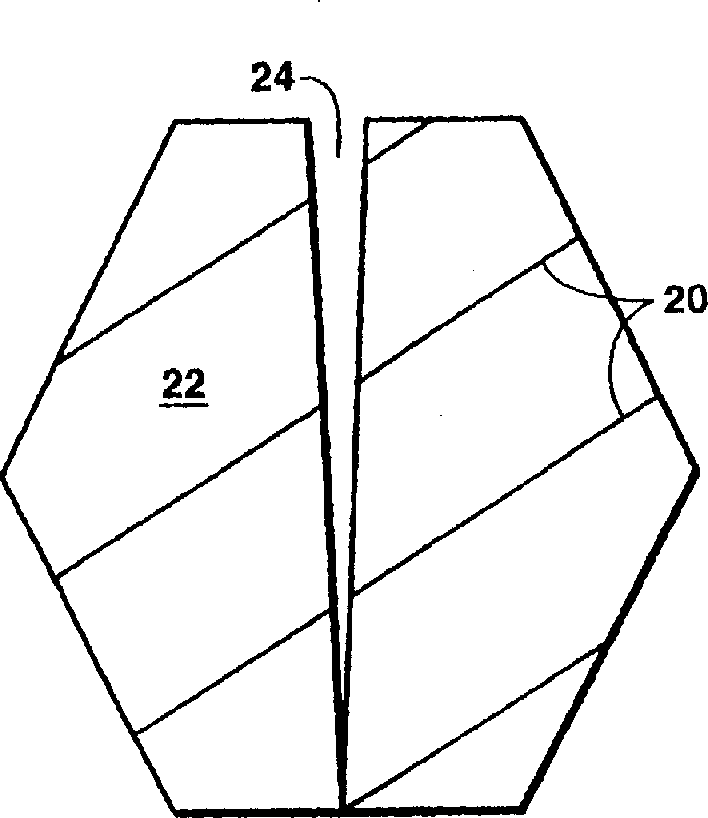

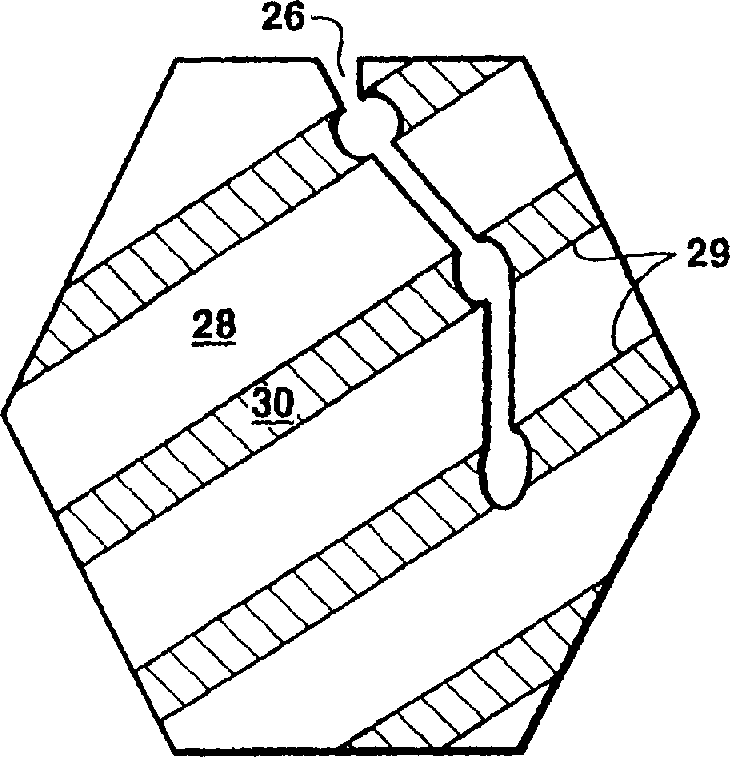

A self-supporting construction element (1, 101) of expanded plastics, in particular for manufacturing floor elements and walls of buildings in general comprises: (1) a central body (2), substantially parallelepipedic in shape and having two opposite faces (6, 7); at least one reinforcing section bar (8,9) transversally extending across the central body (2) between the faces (6,7) thereof and embedded in the expanded plastics; a lath (16) for supporting at least one layer (17) of a suitable covering material, associated to a fin (11,12) of the reinforcing section bar (8,9) lying flush with and substantially parallel to at least one of the faces (6,7) of the construction element (1,101).

Owner:PLASTEDIL

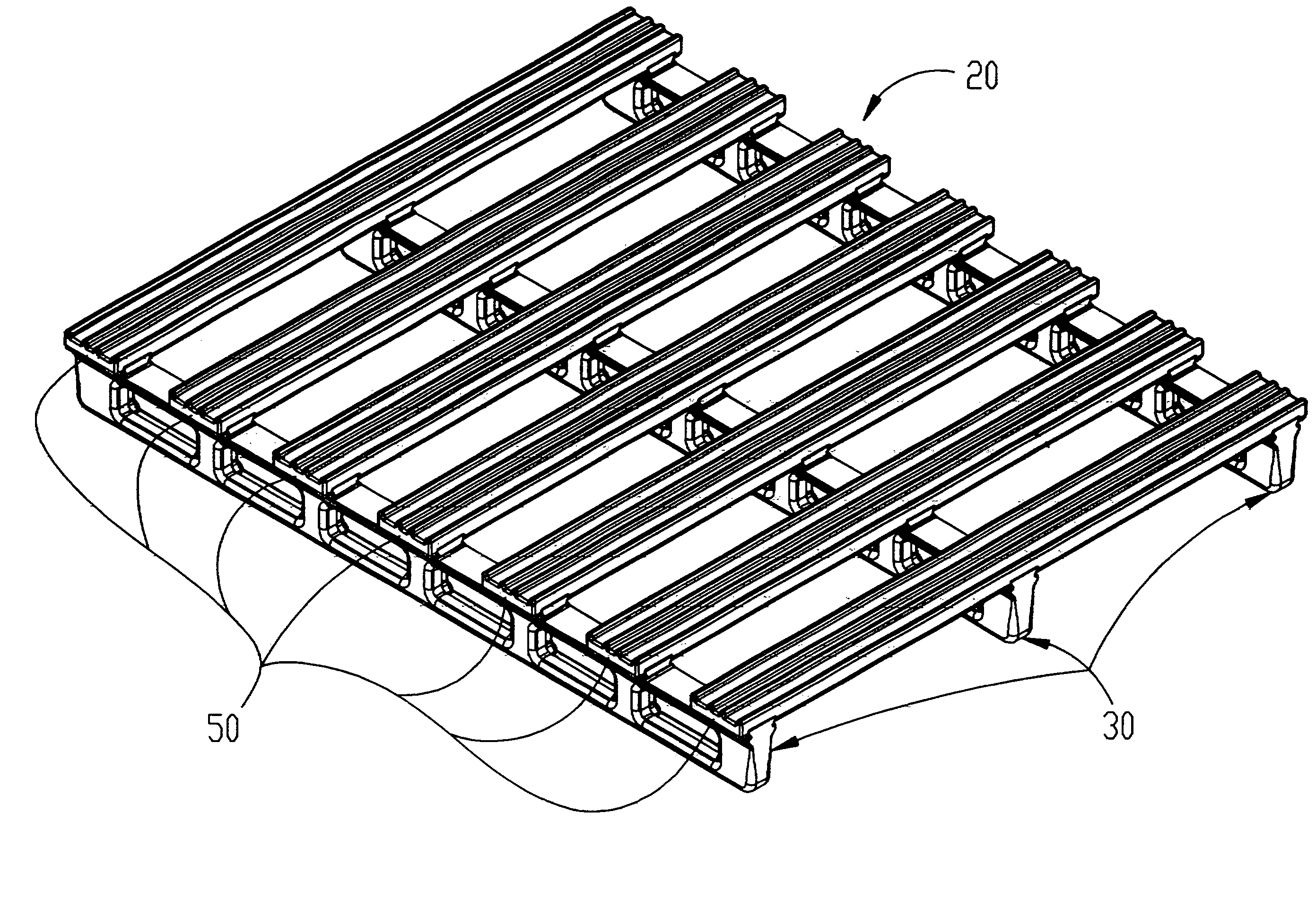

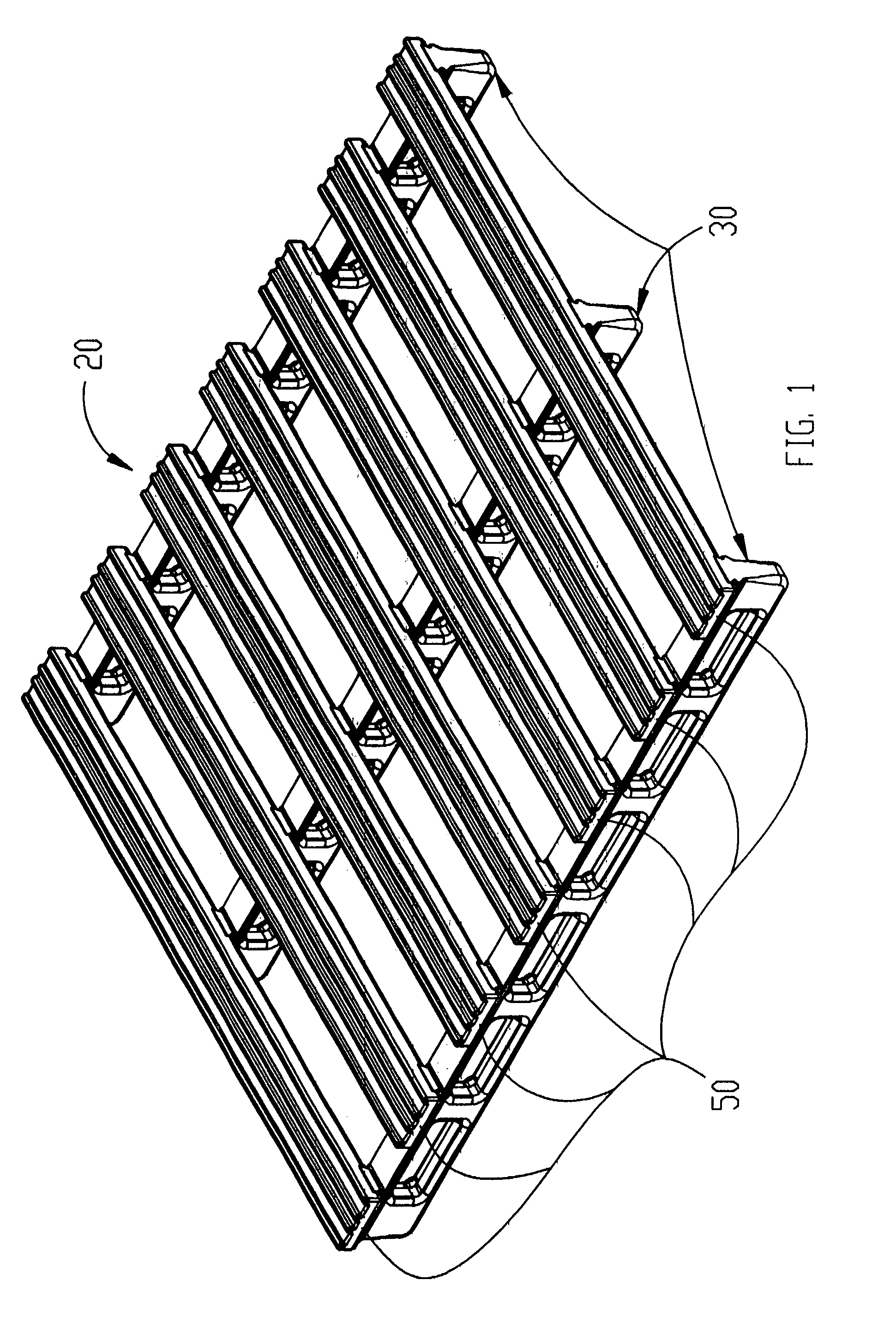

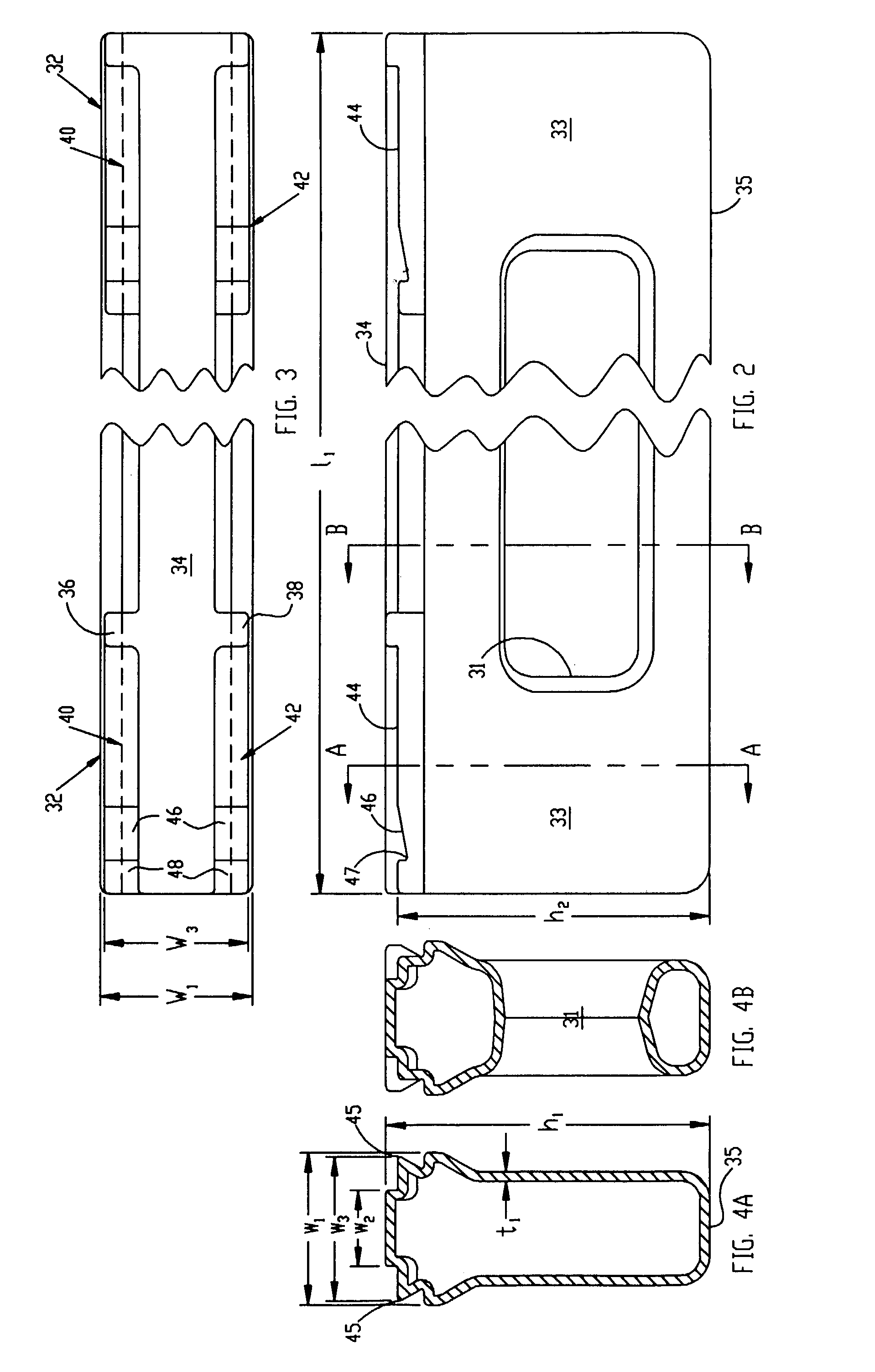

Plastic pallet

InactiveUS6938558B1Provide strengthThe process is convenient and fastOther manufacturing equipments/toolsRigid containersEngineeringLoad distribution

A two-part, blow-molded plastic pallet includes slats which lock onto support stringers by sliding, dovetail engagement. The upper and lower surfaces of the stringer are flat to enhance load distribution. A vertical staking through the slat at a plurality of locations affords structural rigidity.

Owner:PERES VICTOR L

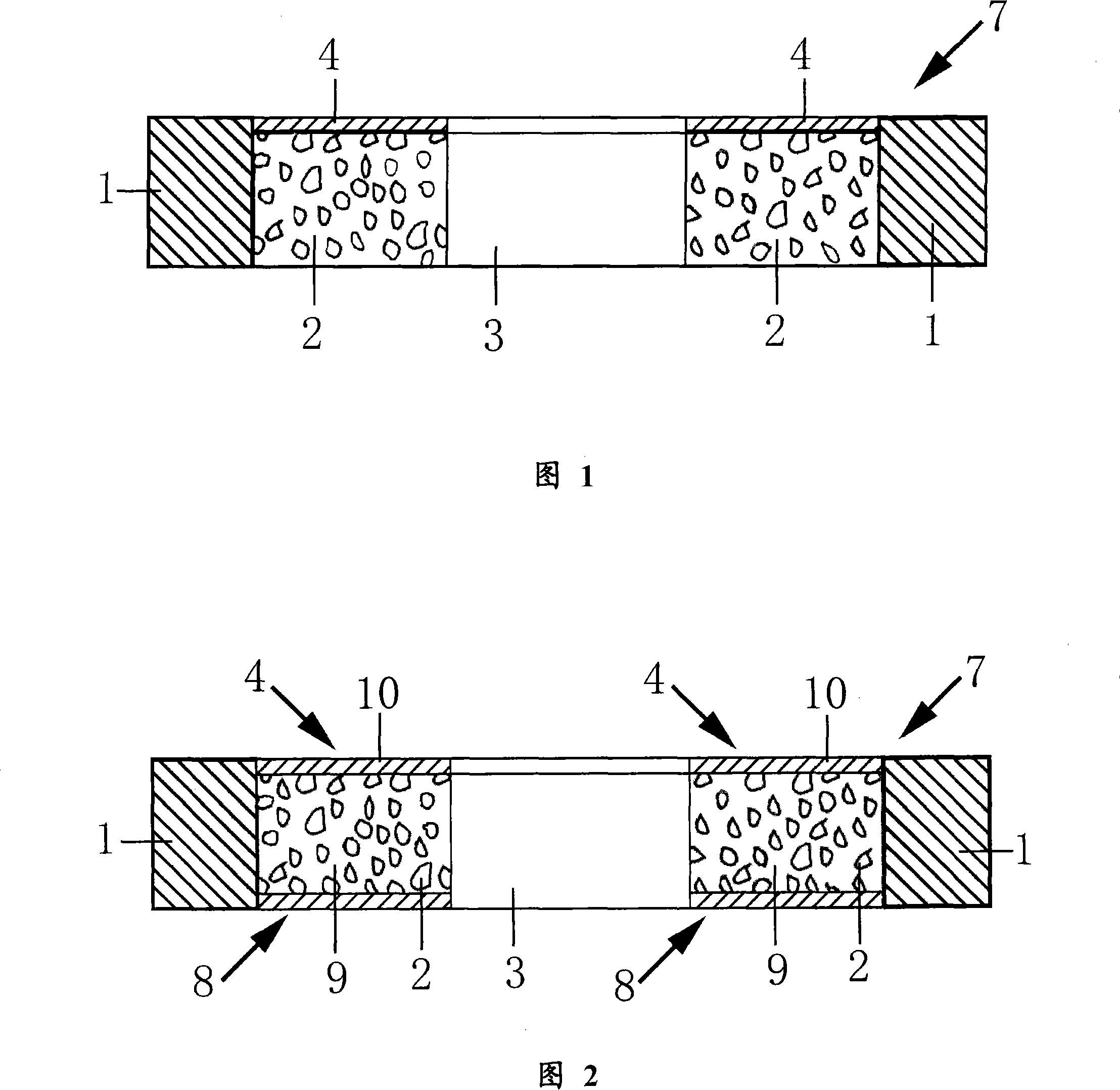

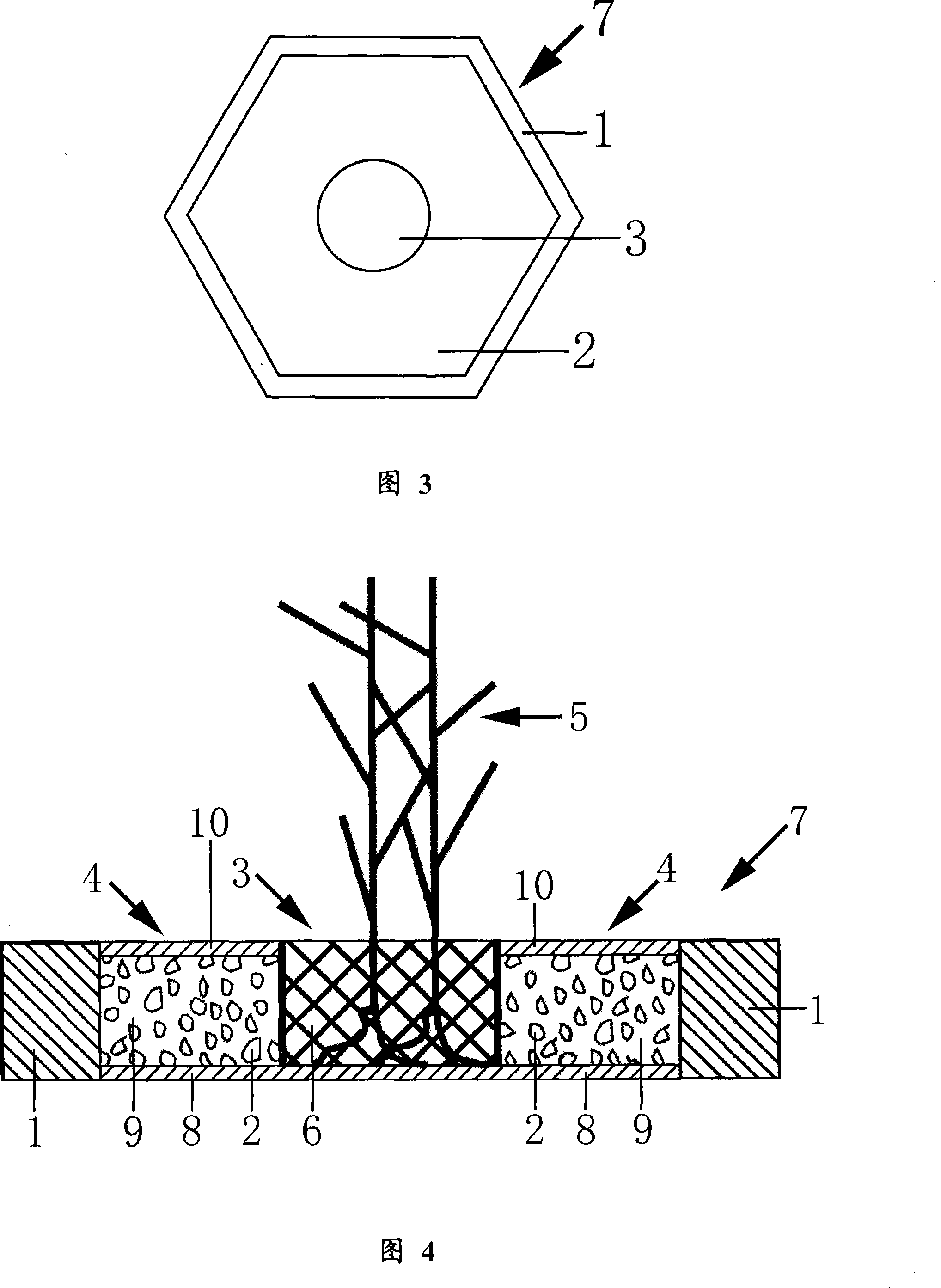

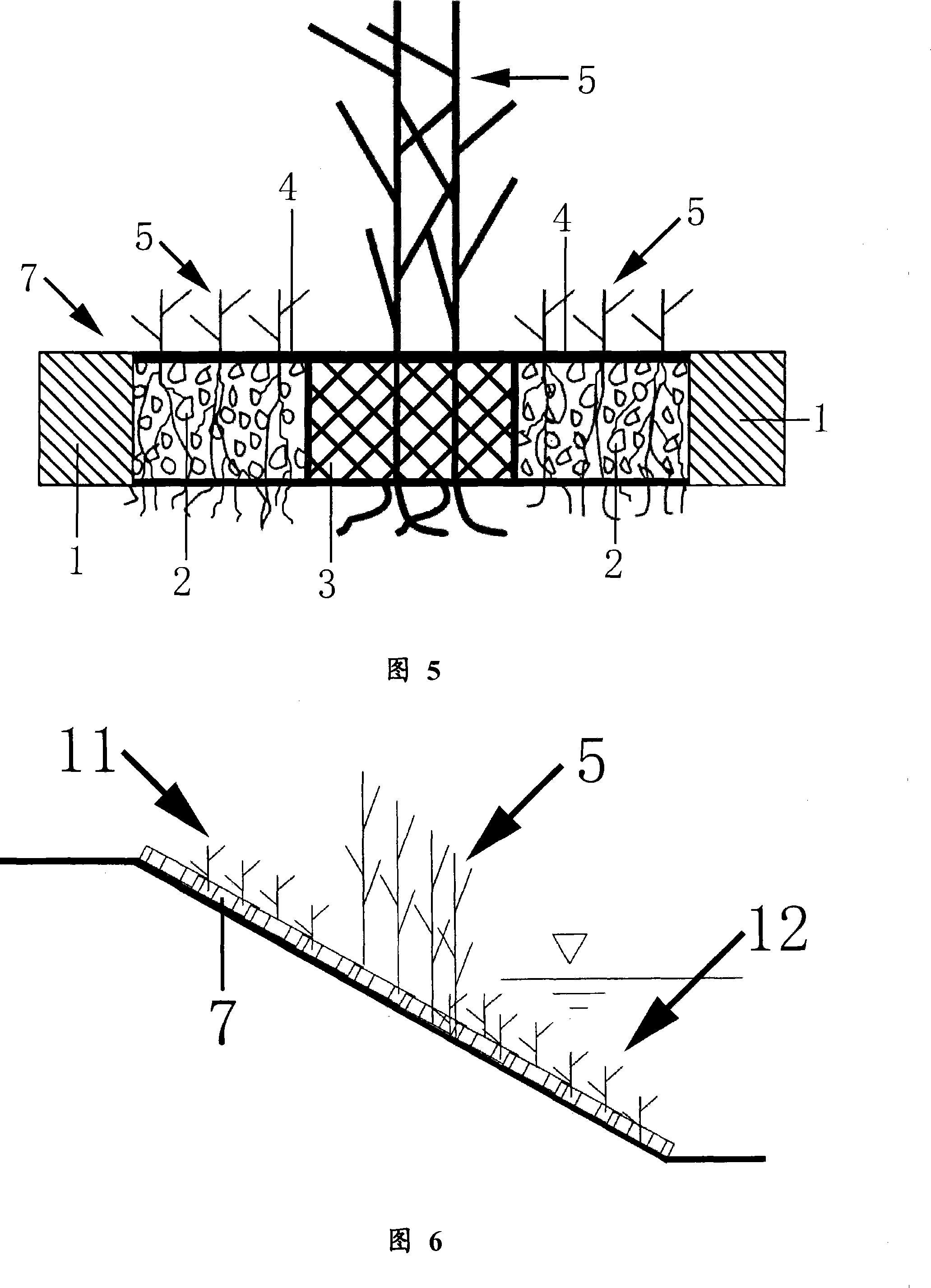

Ecological slope protection vegetation building blocks as well as making method and construction process

InactiveCN101200894APrevent collapseImprove the environmental landscapeSolid waste managementMixing operation control apparatusEngineeringLevee

The present invention relates to a building block of ecological slope protection vegetation, a fabrication method and a construction technique. The building block is composed of a growing bed body, a lath crib, planting troughs, a vegetation layer and a plant, the lath crib wraps the circumference of the growing bed body, the upper plane of the growing bed body is lower than the upper plane of the lath crib and concave, the vegetation layer is formed on the growing bed body, which matches the inner walls of the sectional area of the lath crib to form an integral building block, and more than one planting troughs are arranged on and run through the growing bed body. The design of the present invention is scientific, the structure is reasonable, the restoration of water ecology can reduce the operating cost, environment is improved, ecology is reinstated, harmonious natural beauty is enhanced, and the present invention is suitable for the nidification of small living creatures and the habitation and the survival of aquatic fishes, so that the cutting-off continuity of water and land regions is restored. The present invention is widely applied to channel slope protection, levee slopes, roadsides, airports, parks, public lands, household lawns, sports grounds, etc. The present invention is suitable for cold regions, damp regions, warm and damp intermediate zone, etc.

Owner:TIANJIN WATER RESOURCES RES INST +2

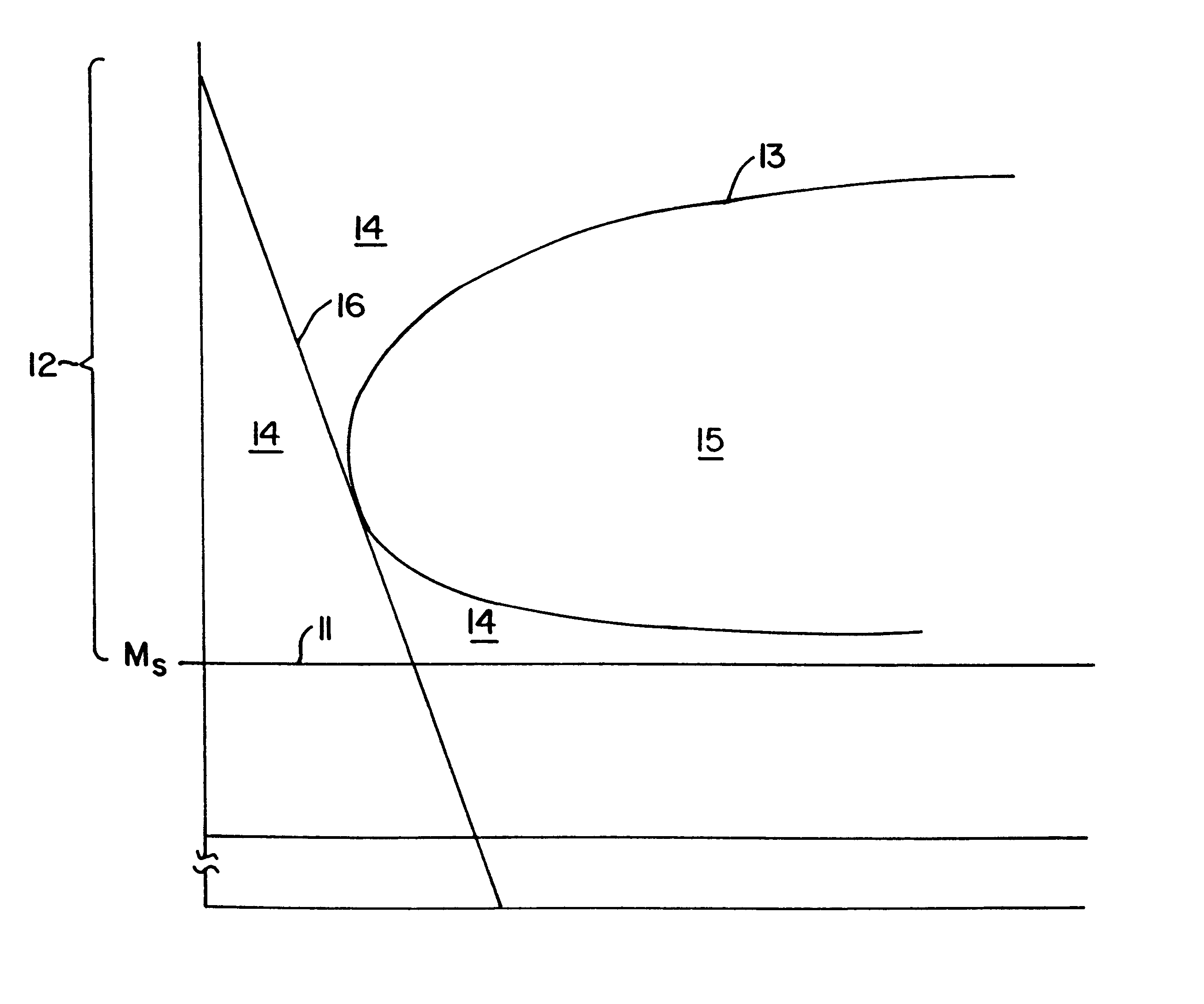

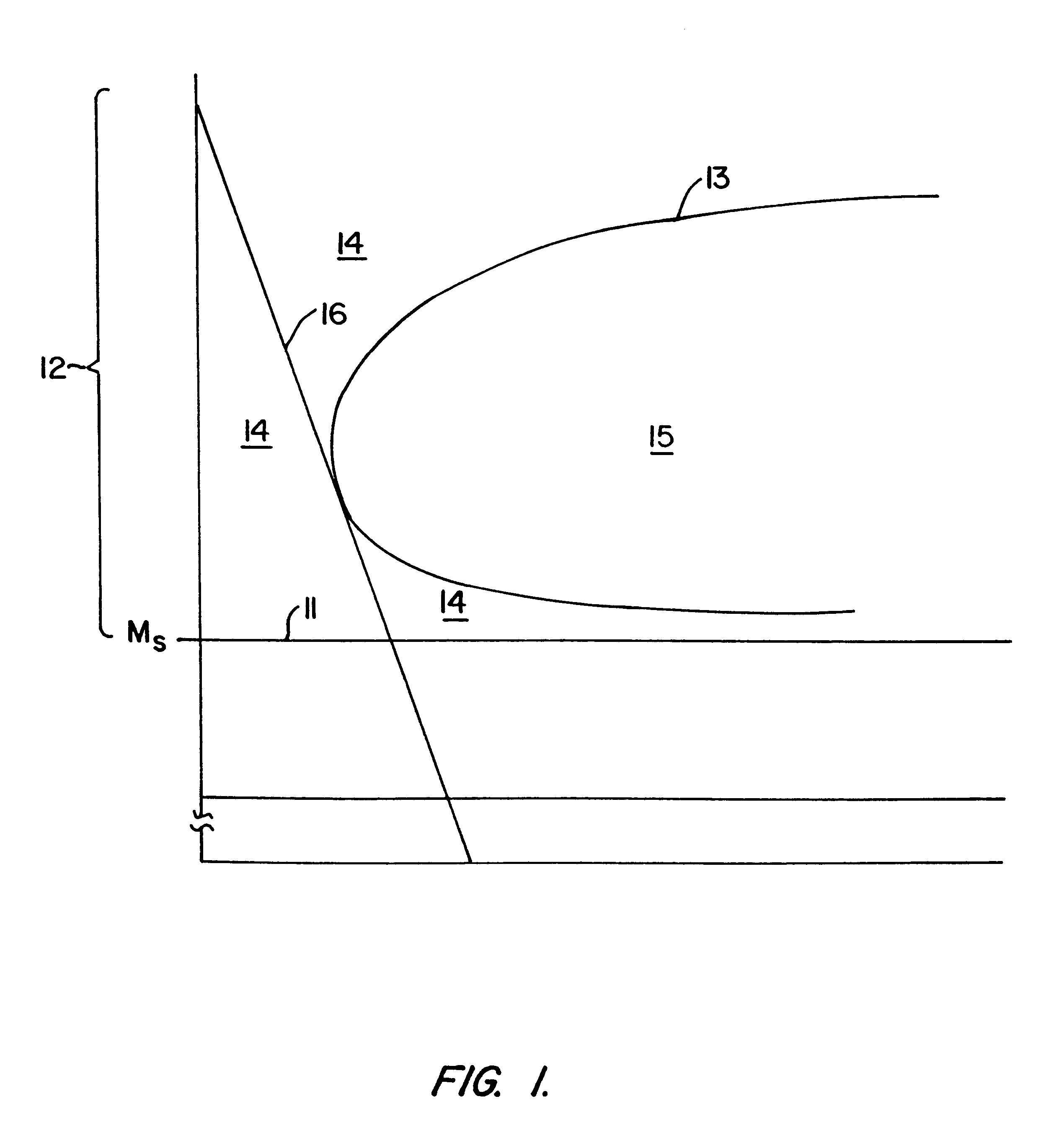

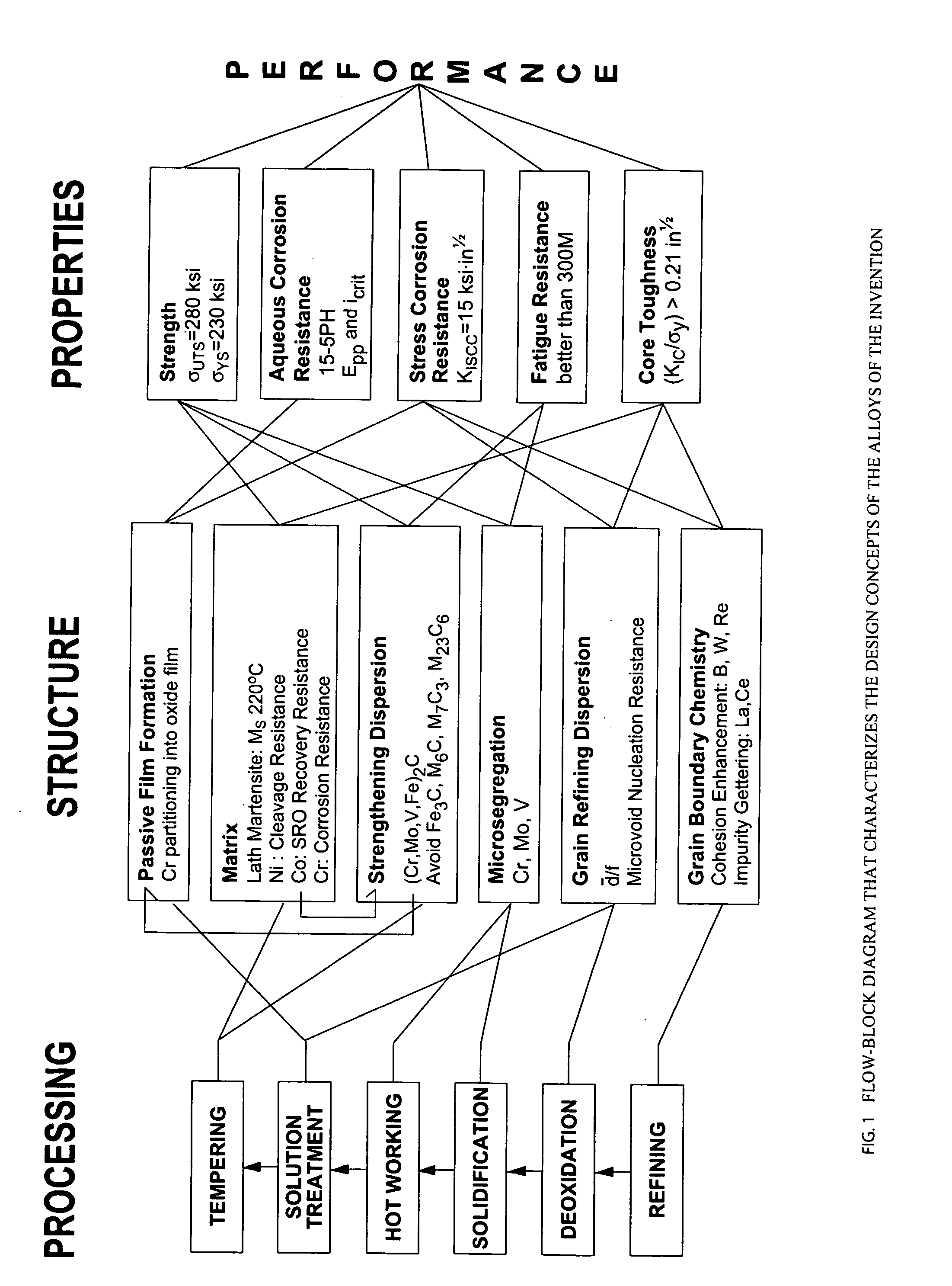

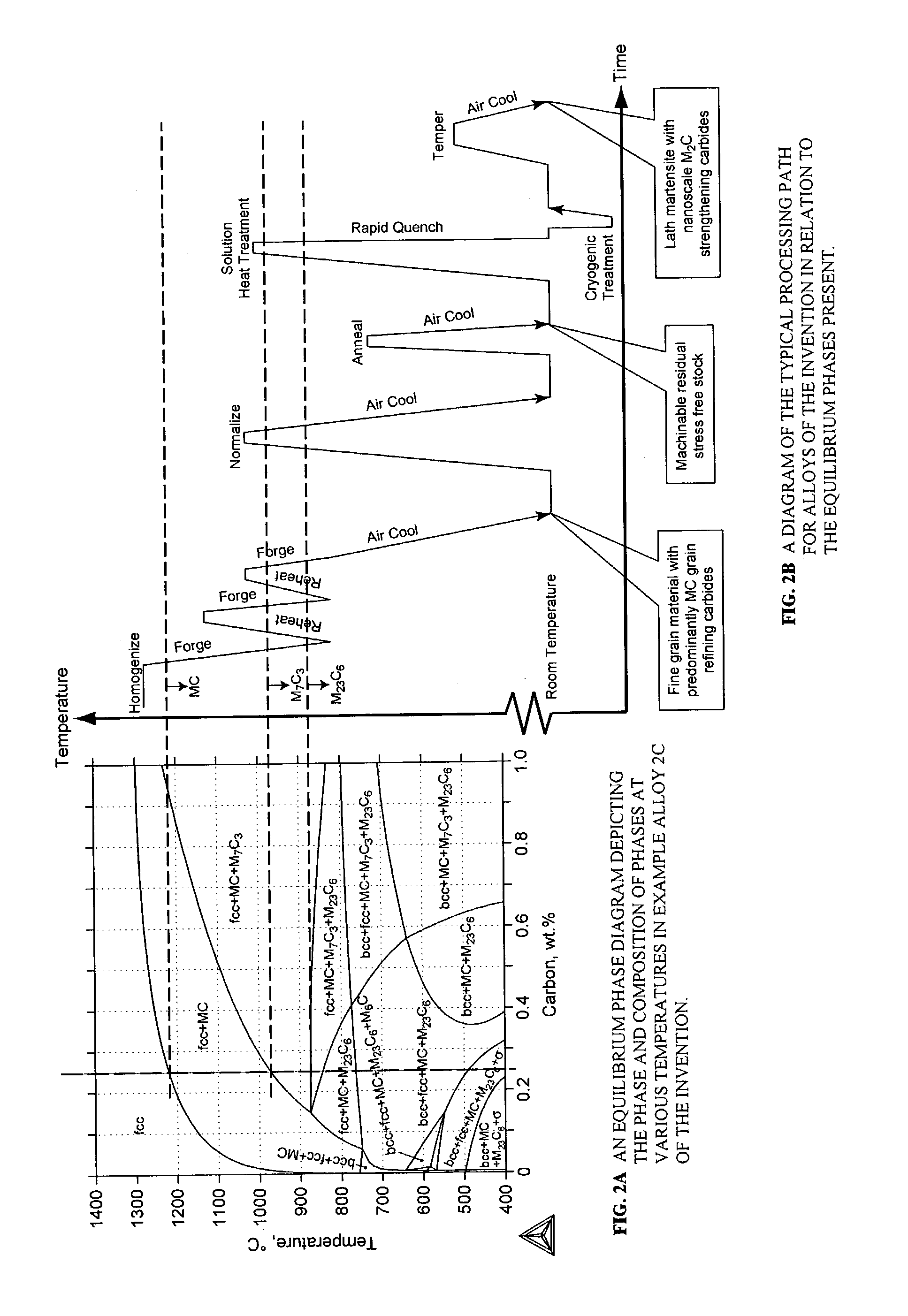

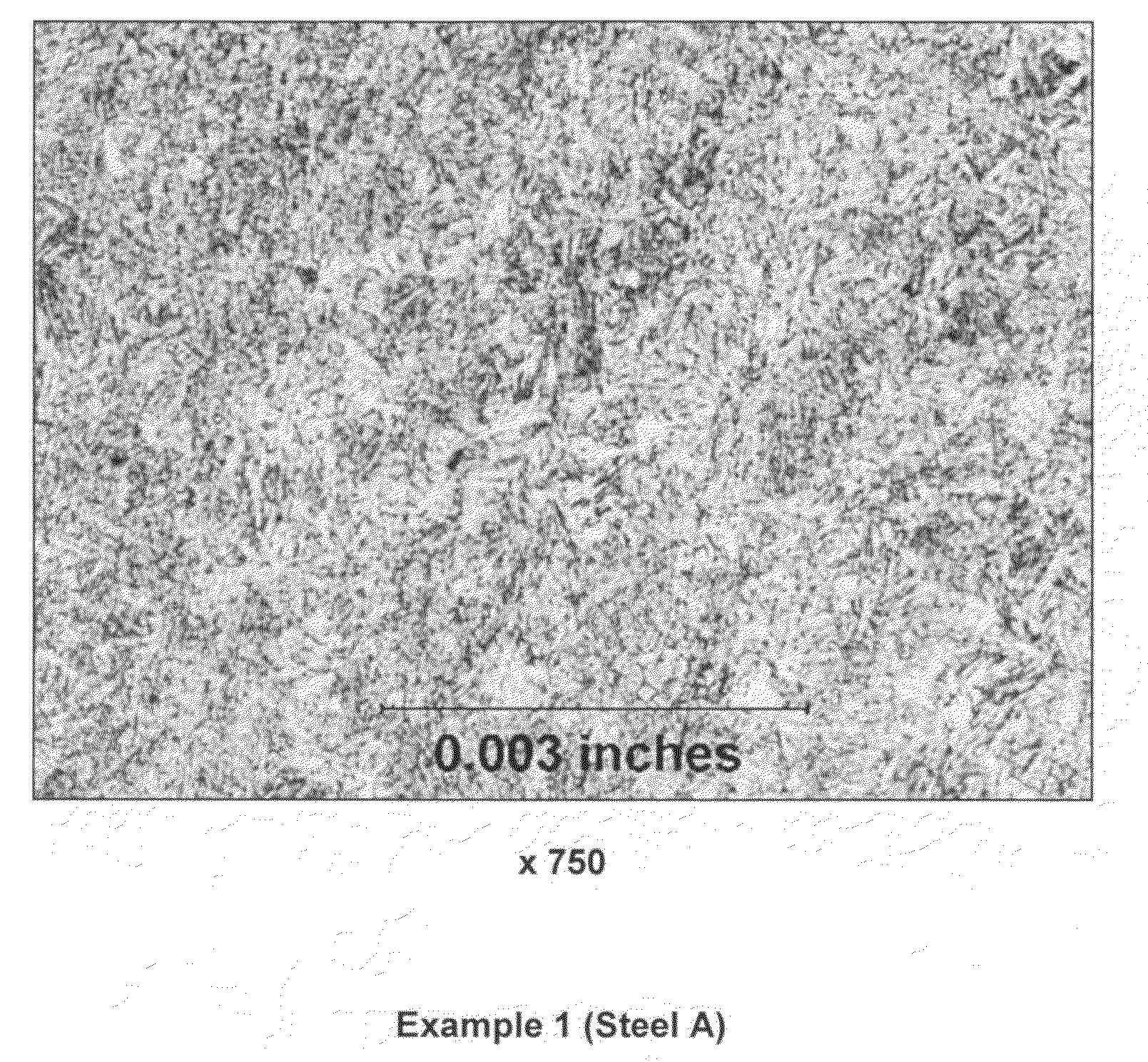

Low-carbon steels of superior mechanical and corrosion properties and process of making thereof

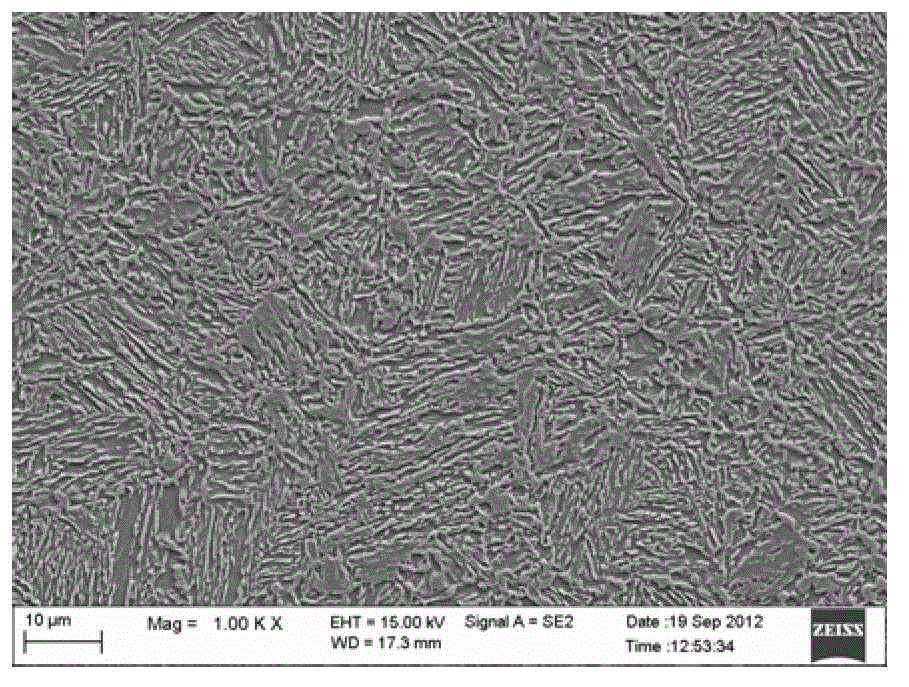

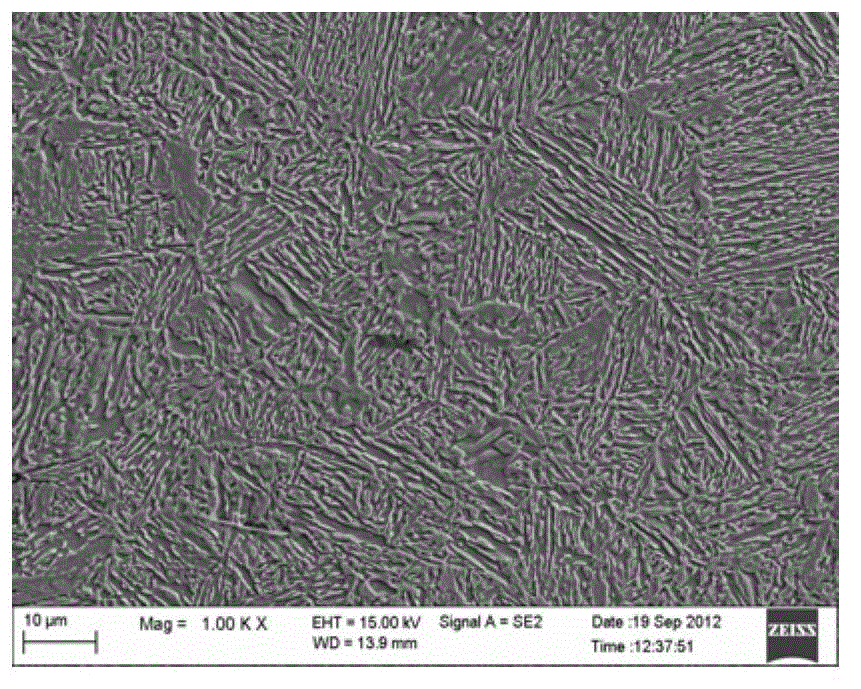

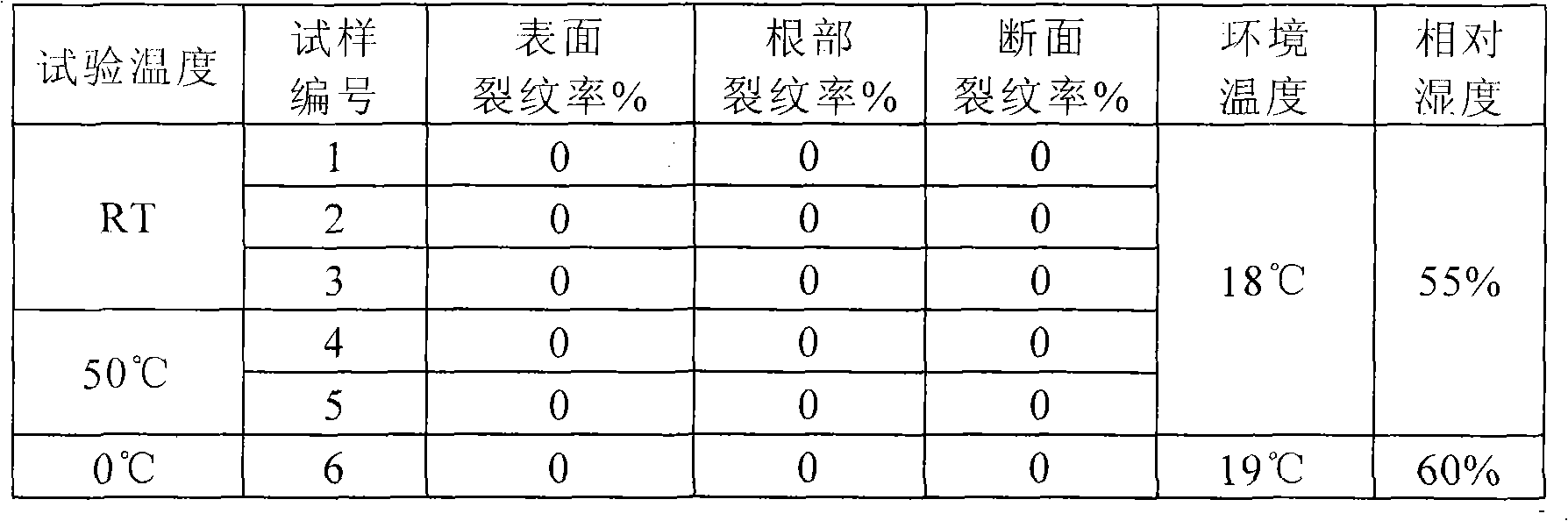

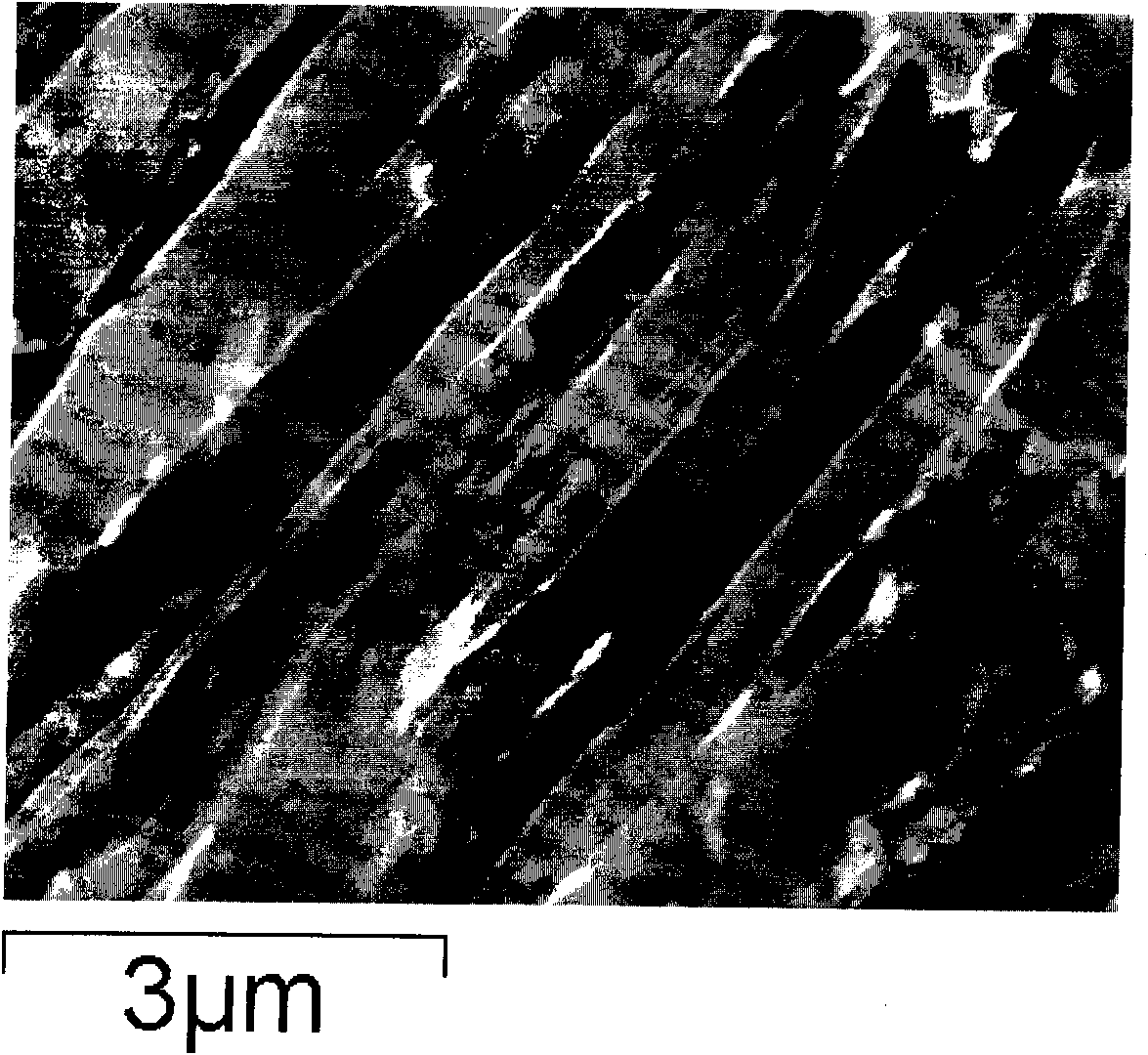

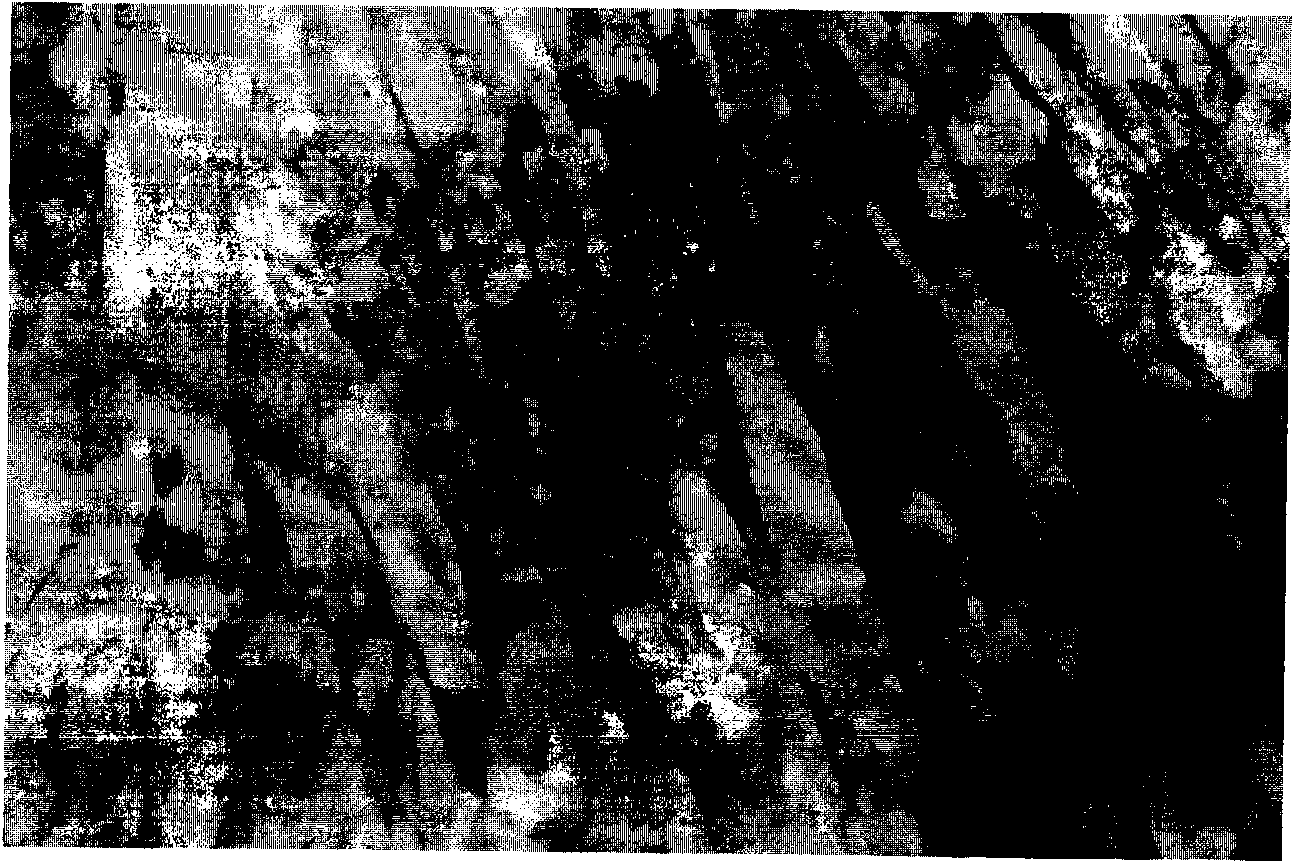

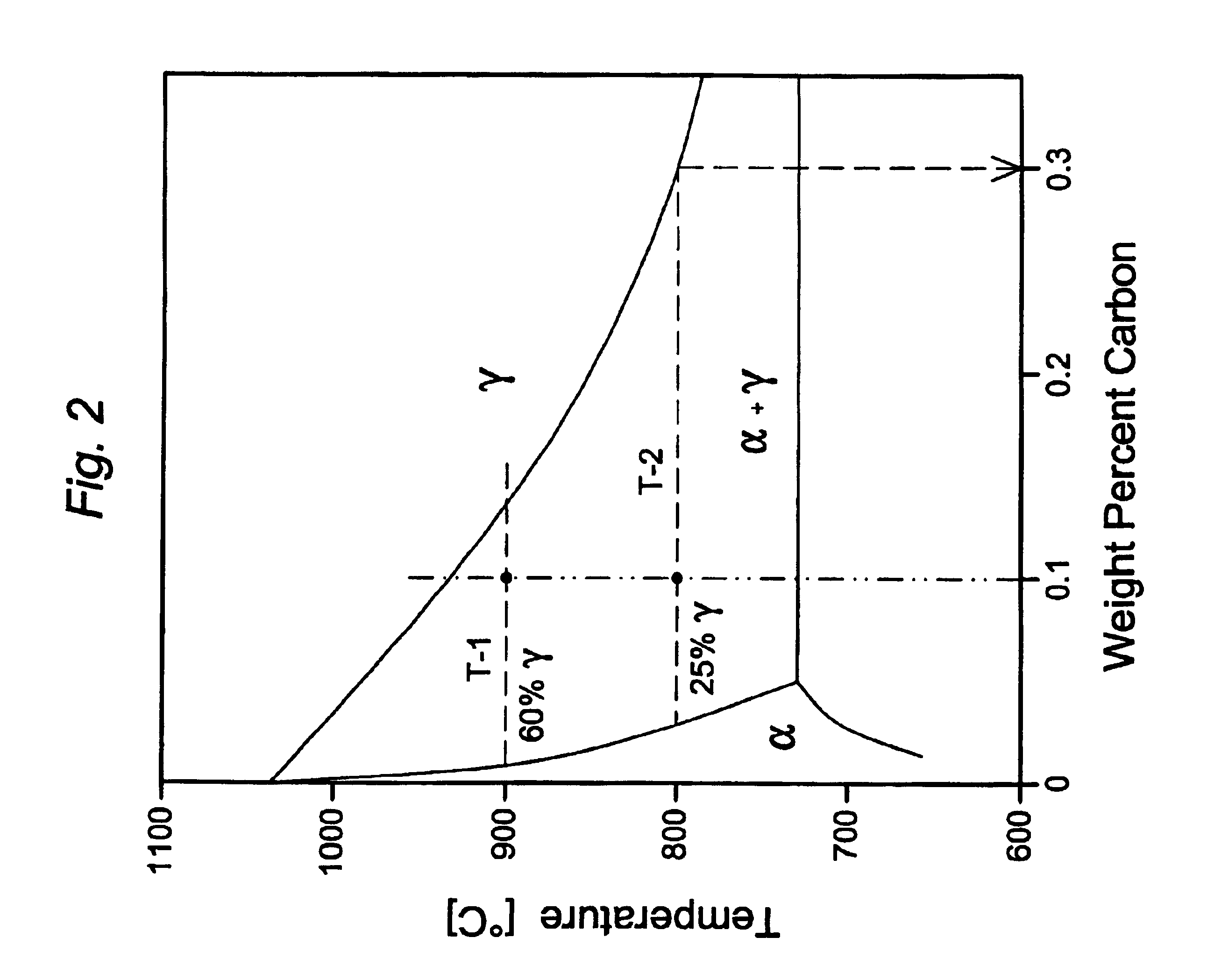

InactiveUS6273968B1Simple structureAccelerated corrosionFurnace typesHeat treatment furnacesCrystal twinningCarbide

Alloy steels that combine high strength and toughness with high corrosion resistance are achieved by a dislocated lath microstructure, in which dislocated martensite laths that are substantially free of twinning alternate with thin films of retained austenite, with an absence of autotempered carbides, nitrides and carbonitrides in both the dislocated martensite laths and the retained austenite films. This microstructure is achieved by selecting an alloy composition whose martensite start temperature is 350° C. or greater, and by selecting a cooling regime from the austenite phase through the martensite transition region that avoids regions in which autotempering occurs.

Owner:CMC STEEL FABTORS

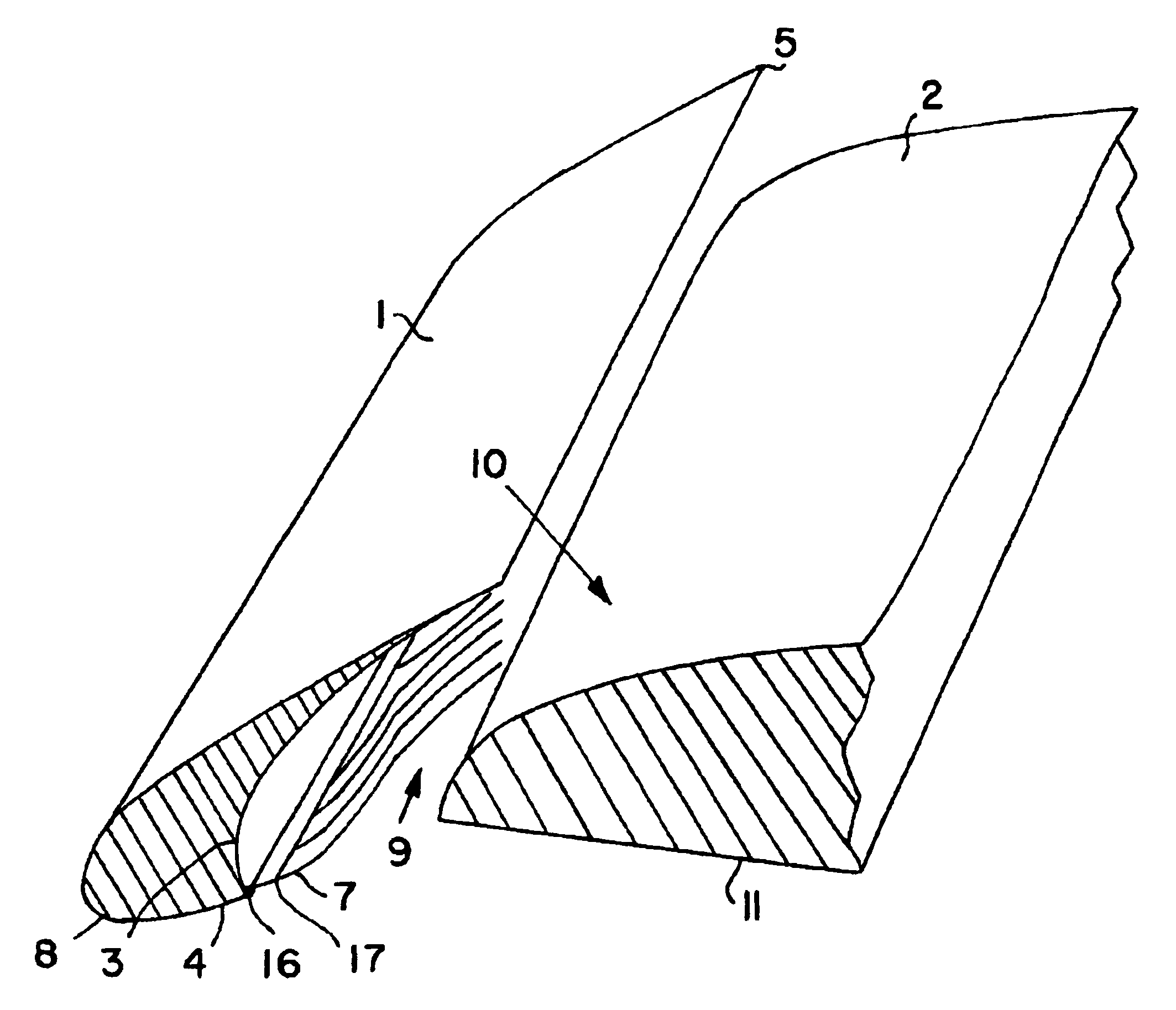

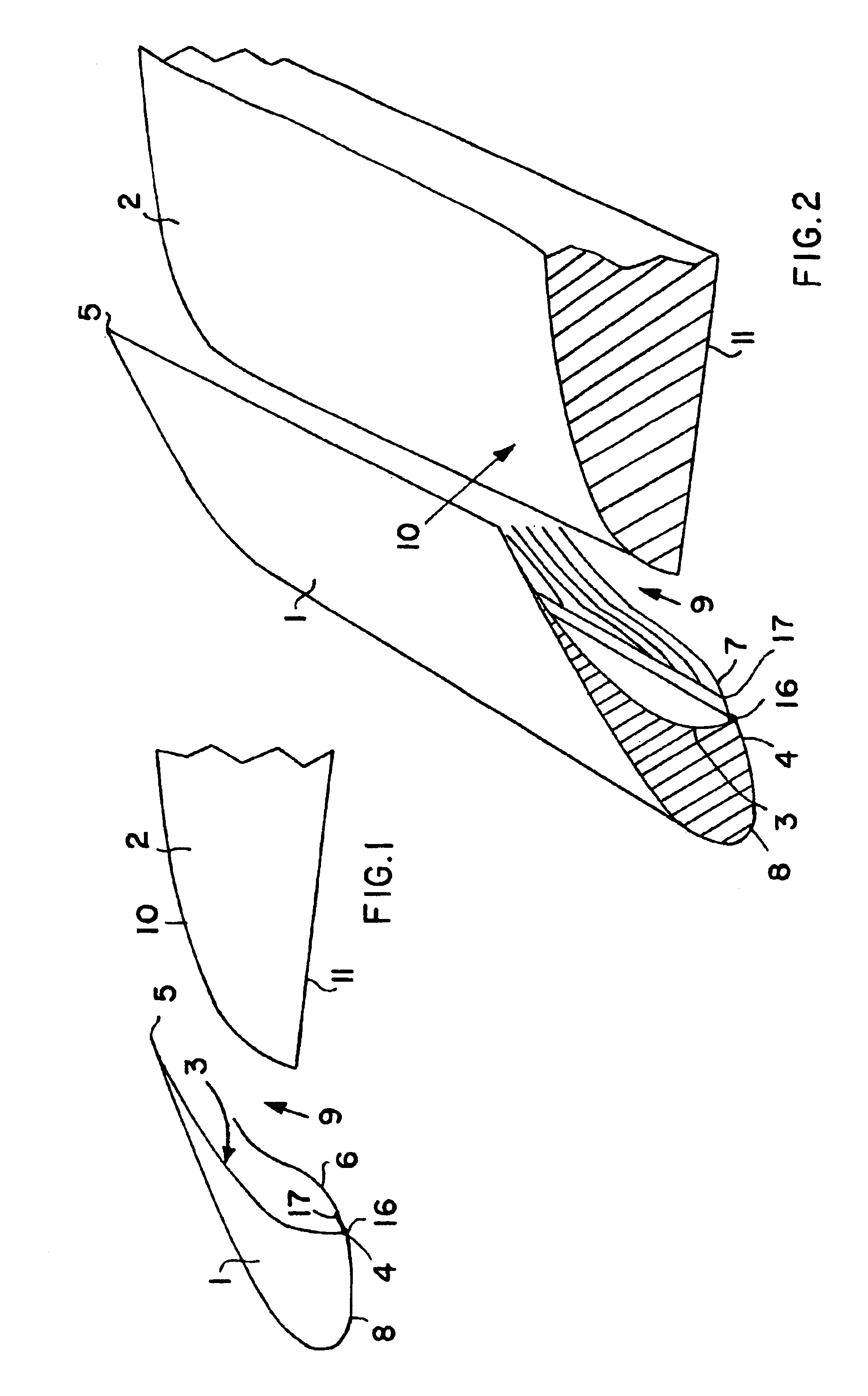

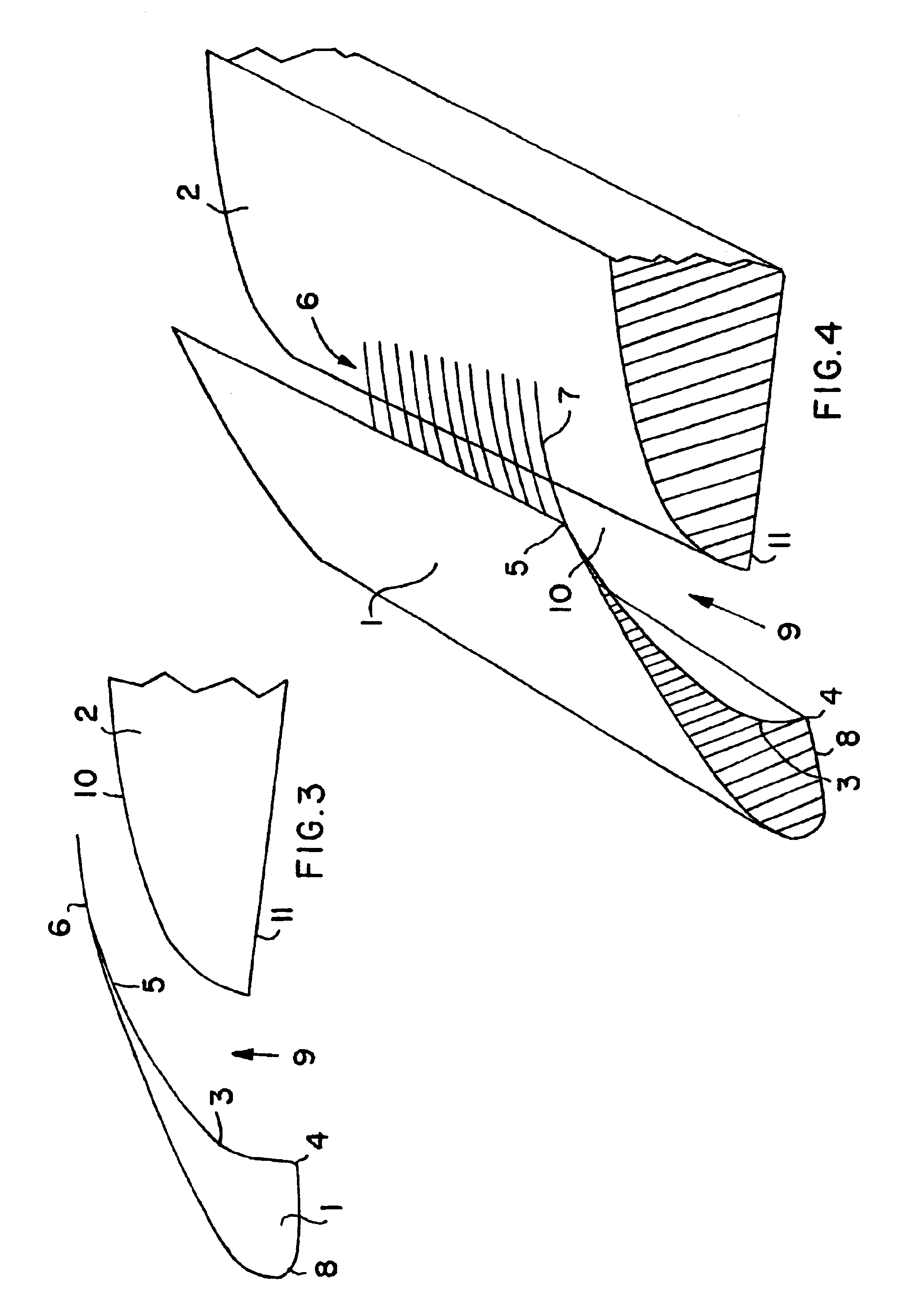

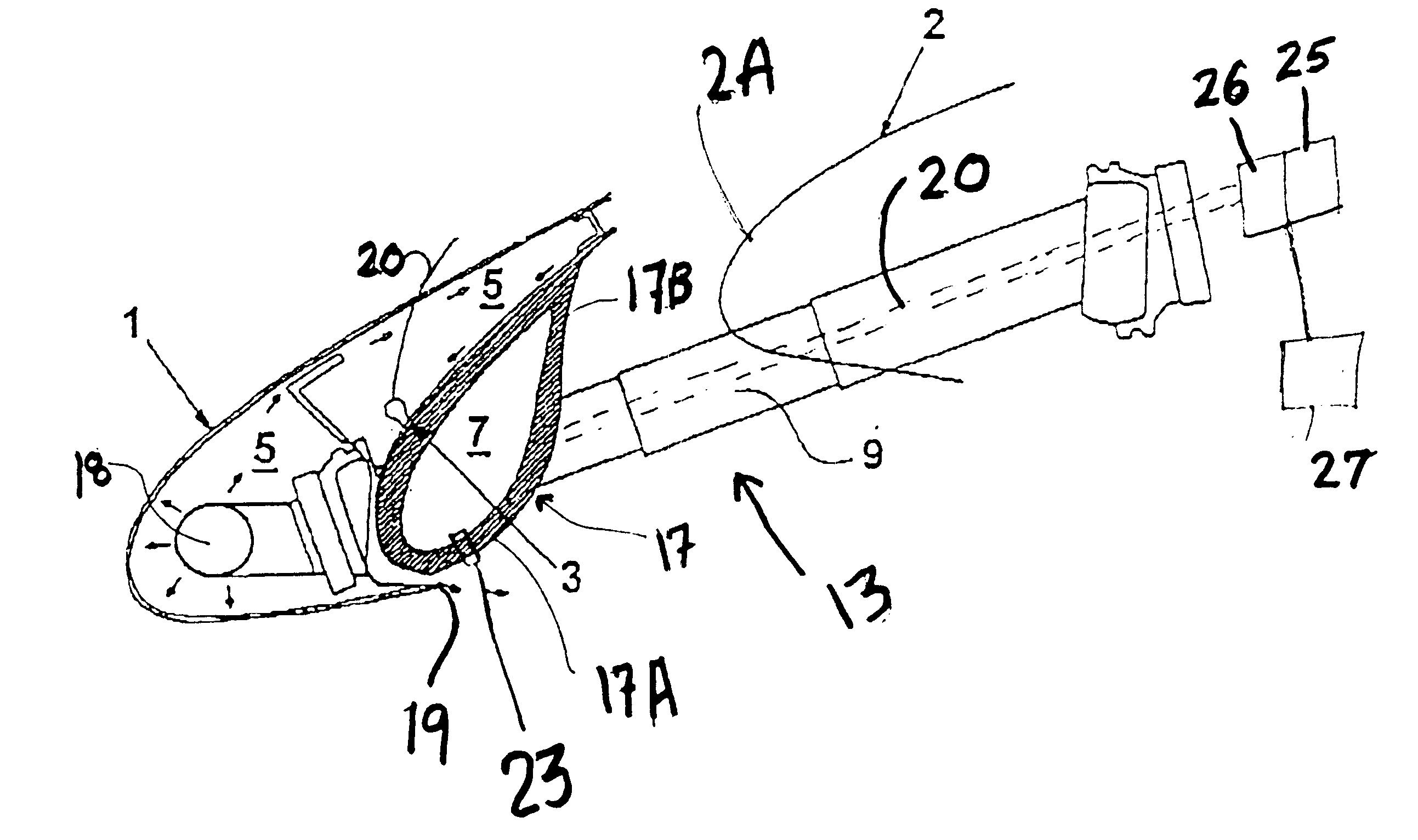

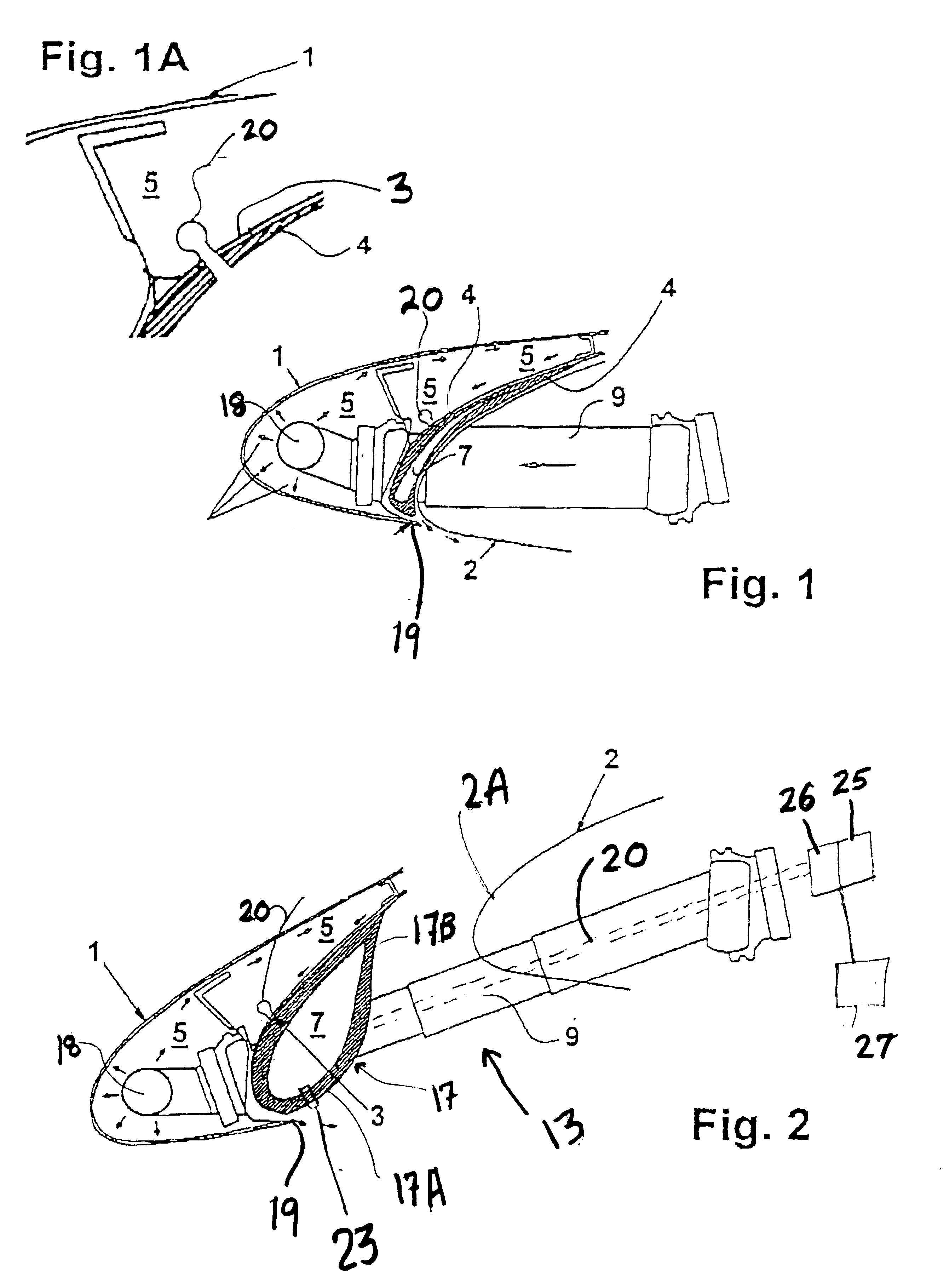

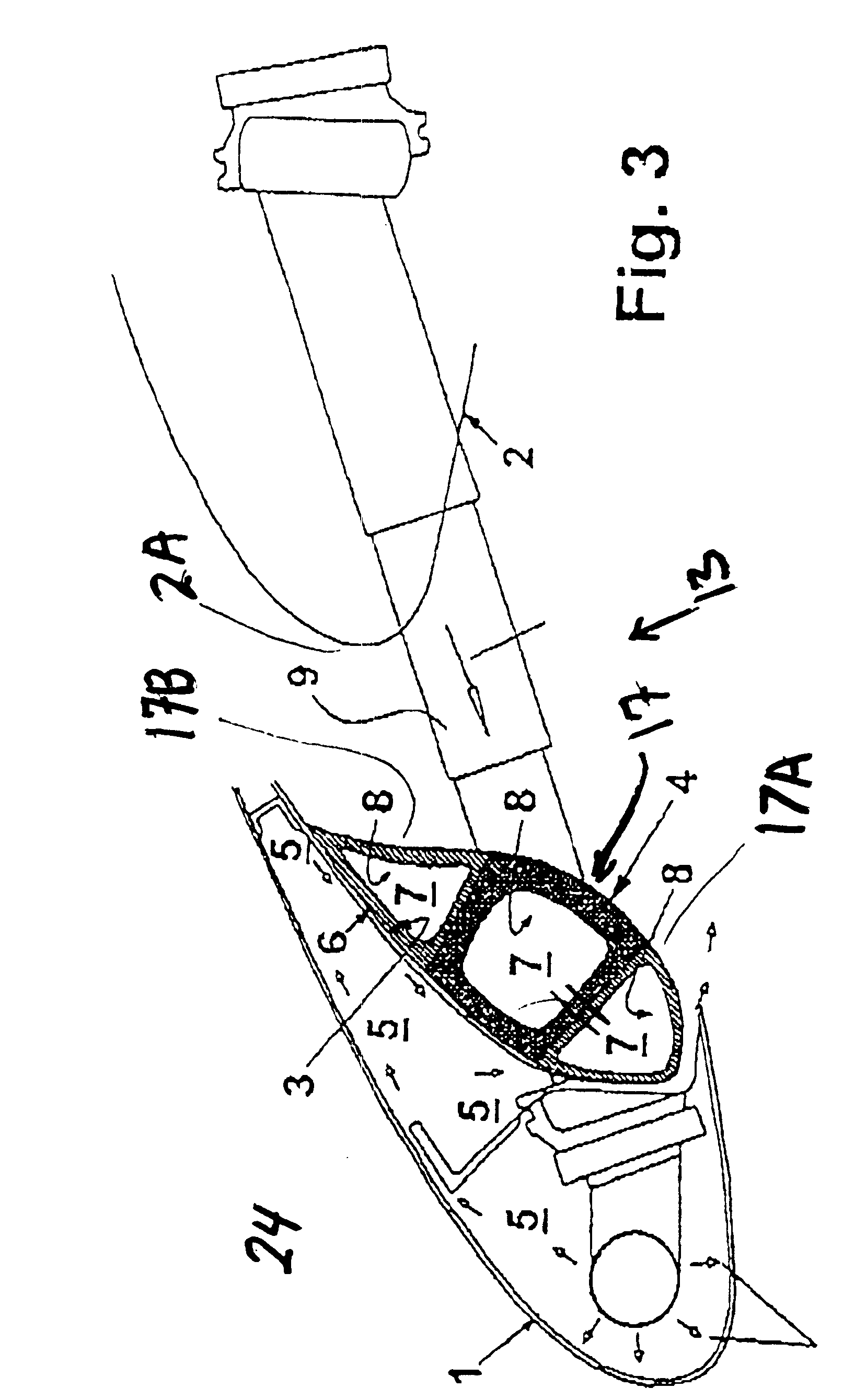

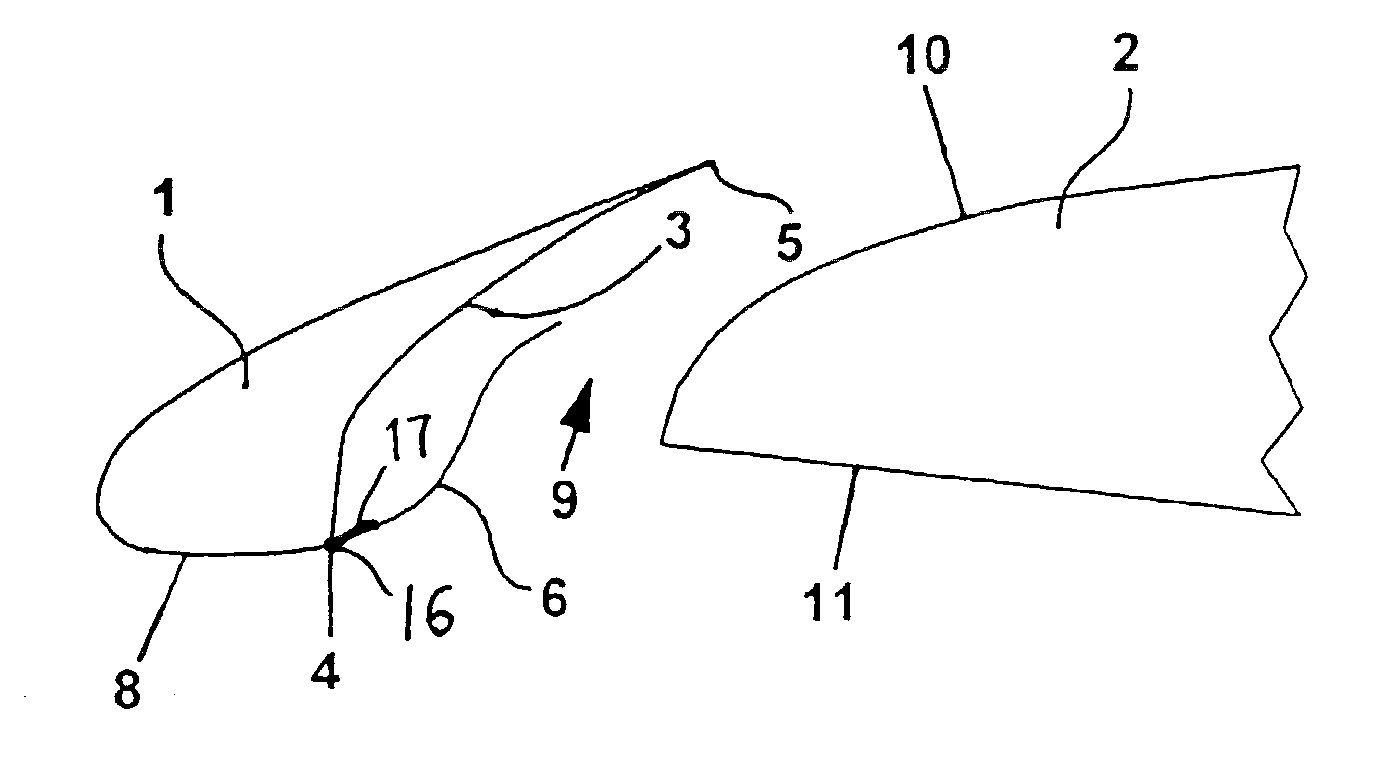

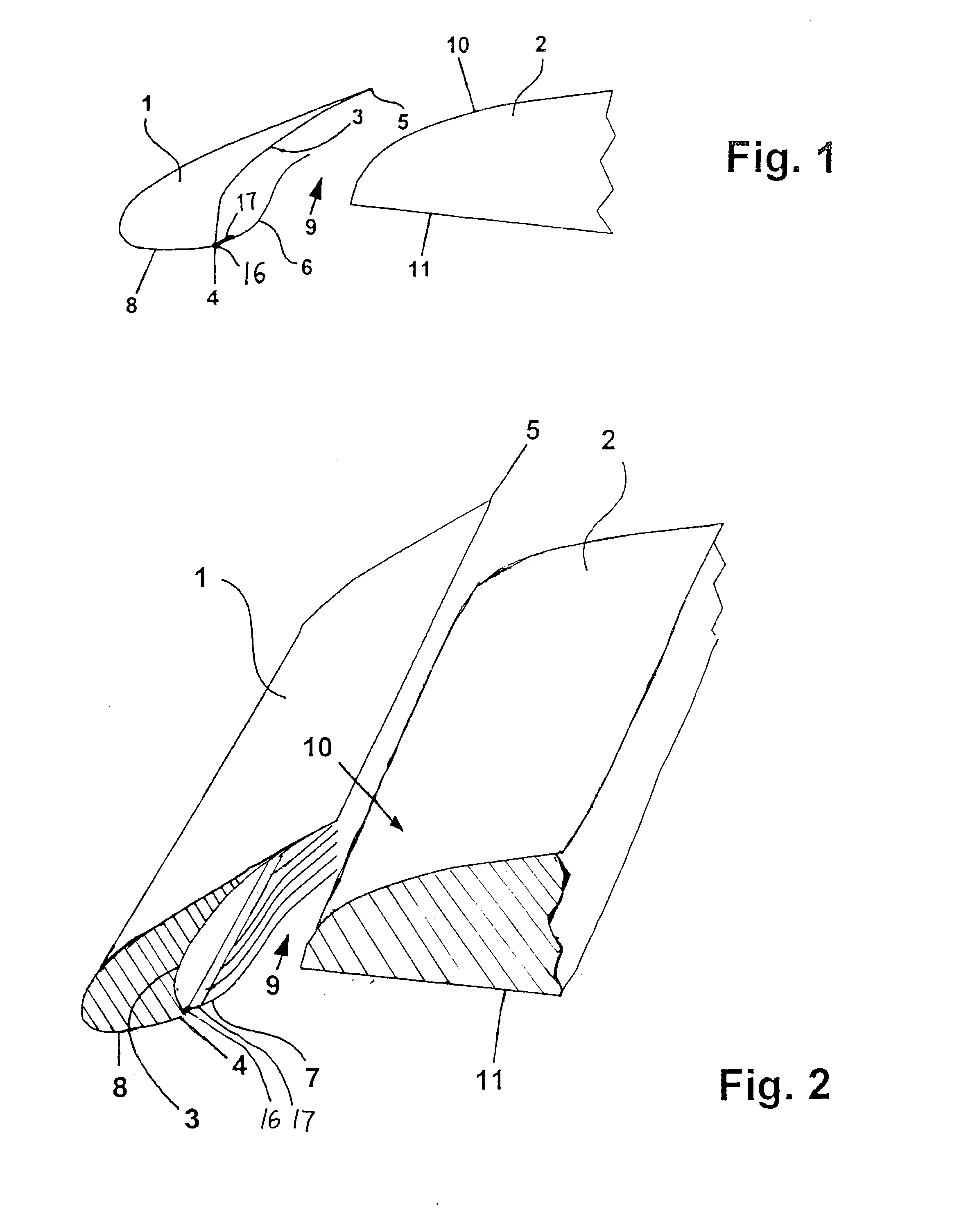

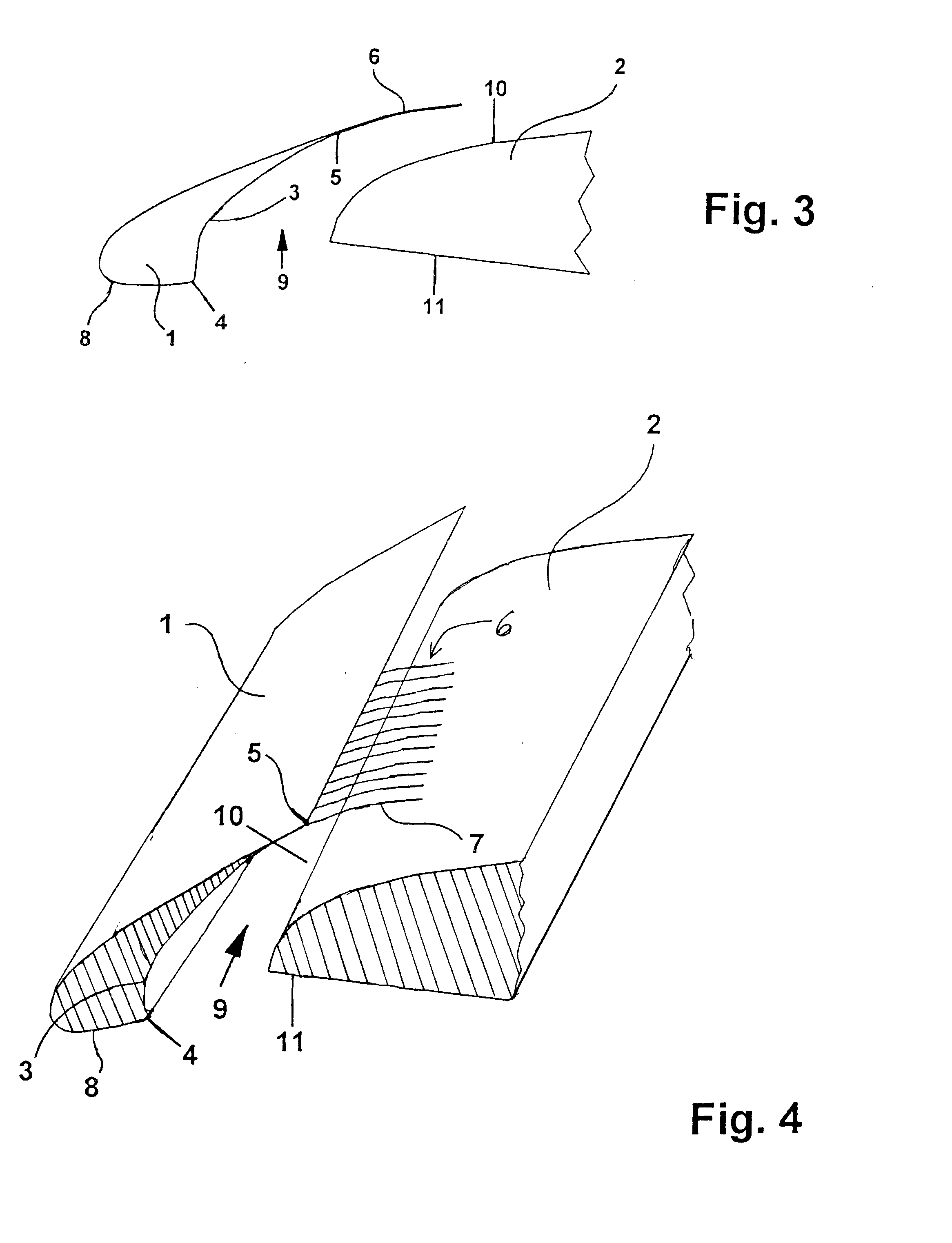

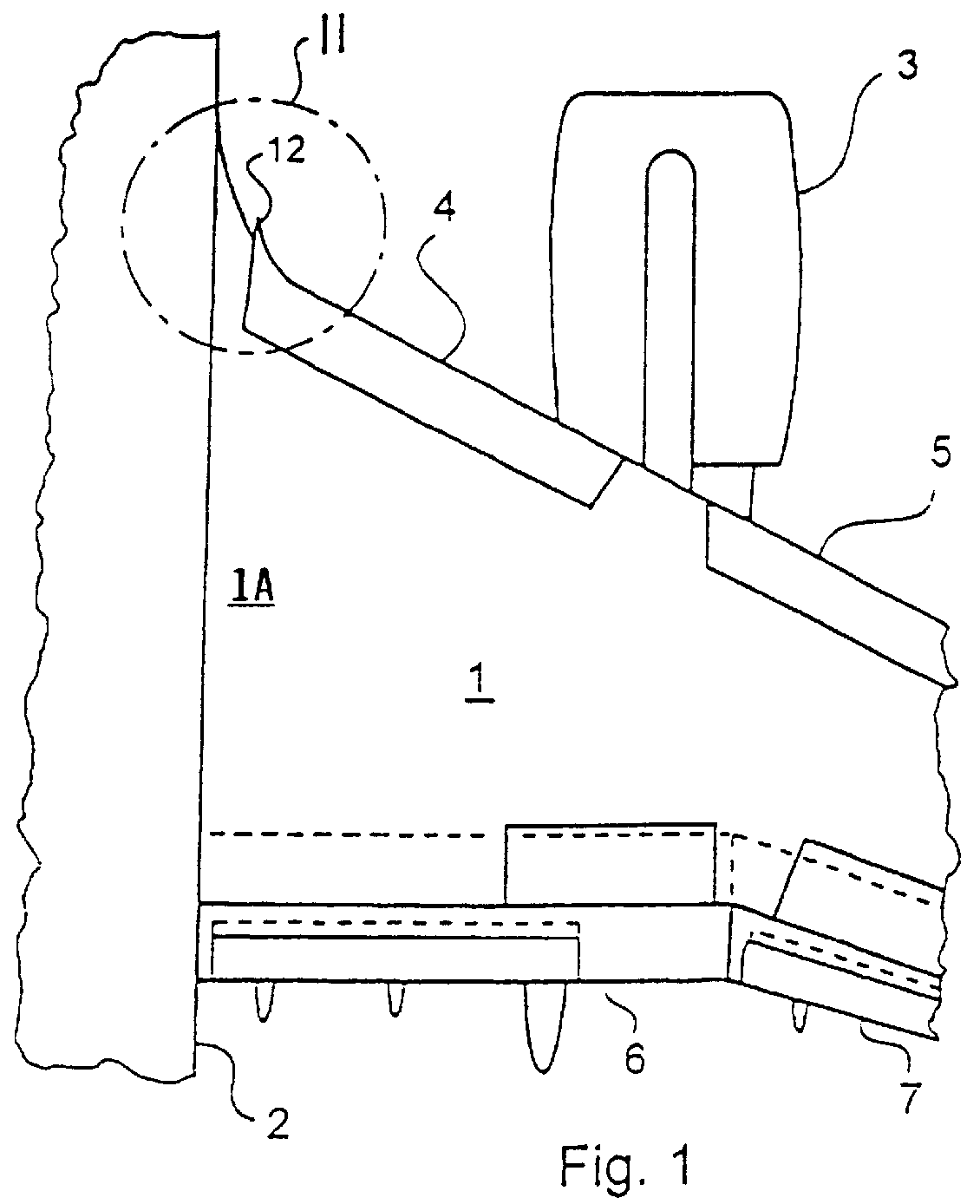

Flexible airflow separator to reduce aerodynamic noise generated by a leading edge slat of an aircraft wing

InactiveUS6789769B2Easy to transformStable separationInfluencers by generating vorticesDe-icing equipmentsLeading edgeBristle

A slat is selectively extended from a main wing body, with a concave rear surface of the slat facing a convex forward nose surface of the wing body, with a slat gap therebetween. At least one row of flexible bristles is movably arranged relative to the lower rear edge of the slat, to flexibly protrude up into the slat air gap. At least one row of flexible bristles is movably arranged along the upper rear edge of the slat to extend rearwardly over the slat air gap and the upper surface of the main wing body. The flexible bristles are flexibly self-positioning and self-contouring due to the aerodynamic forces acting thereon, to improve the air flow conditions through the slat gap, separate the slat gap airflow from an entrapped eddy vortex on the concave rear surface of the slat, and thereby reduce the aerodynamic noise generated along the slat gap.

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV +1

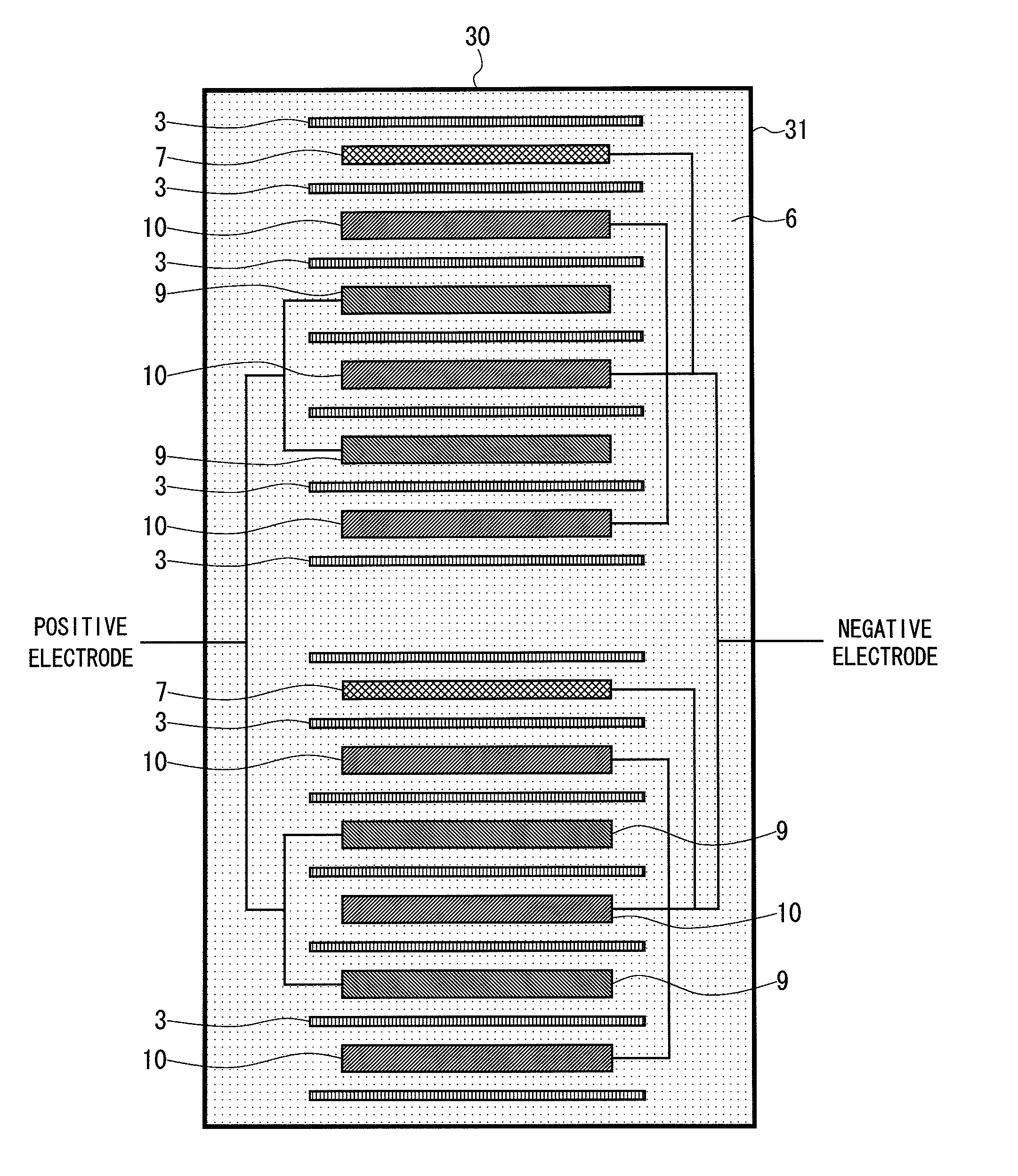

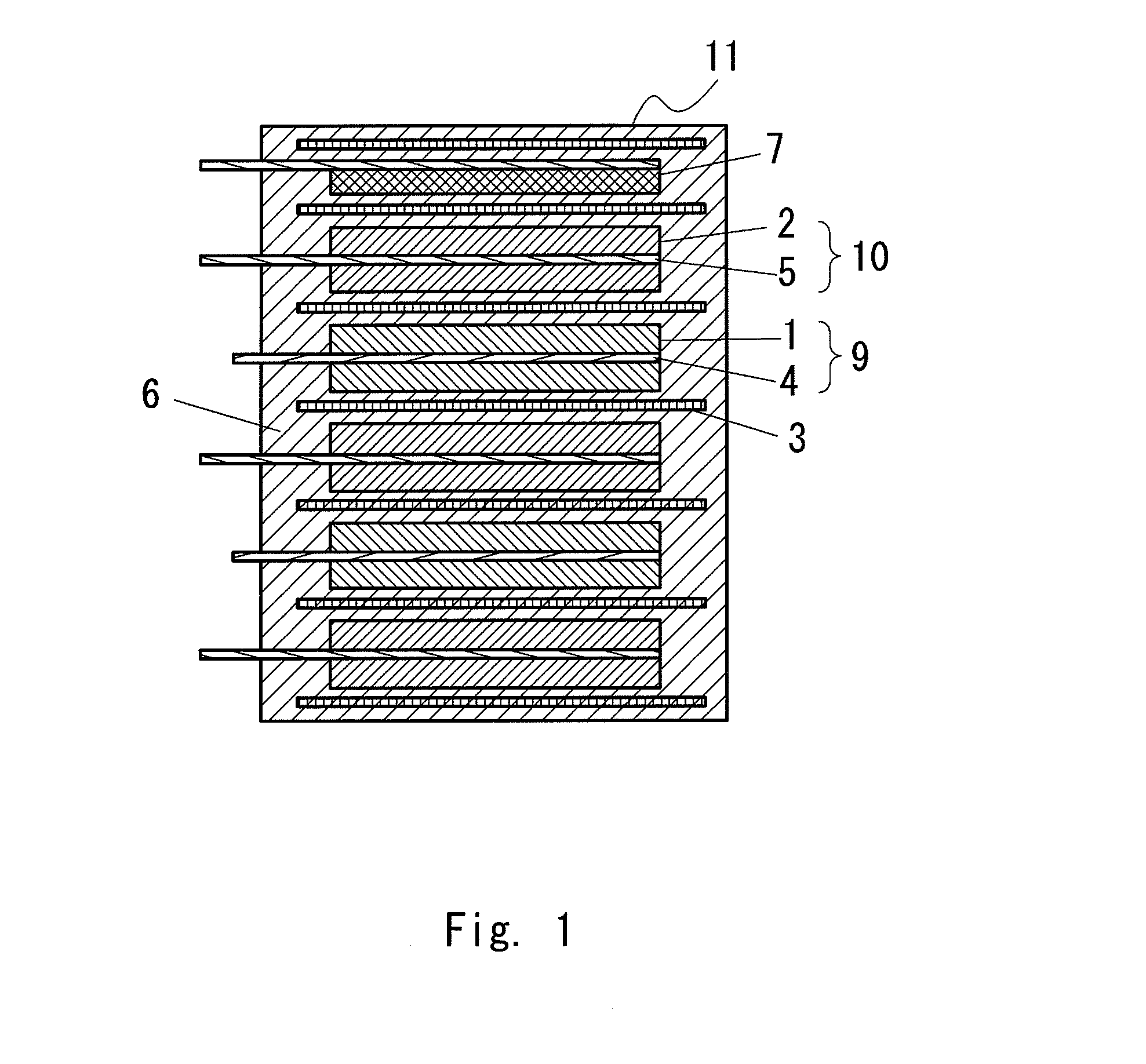

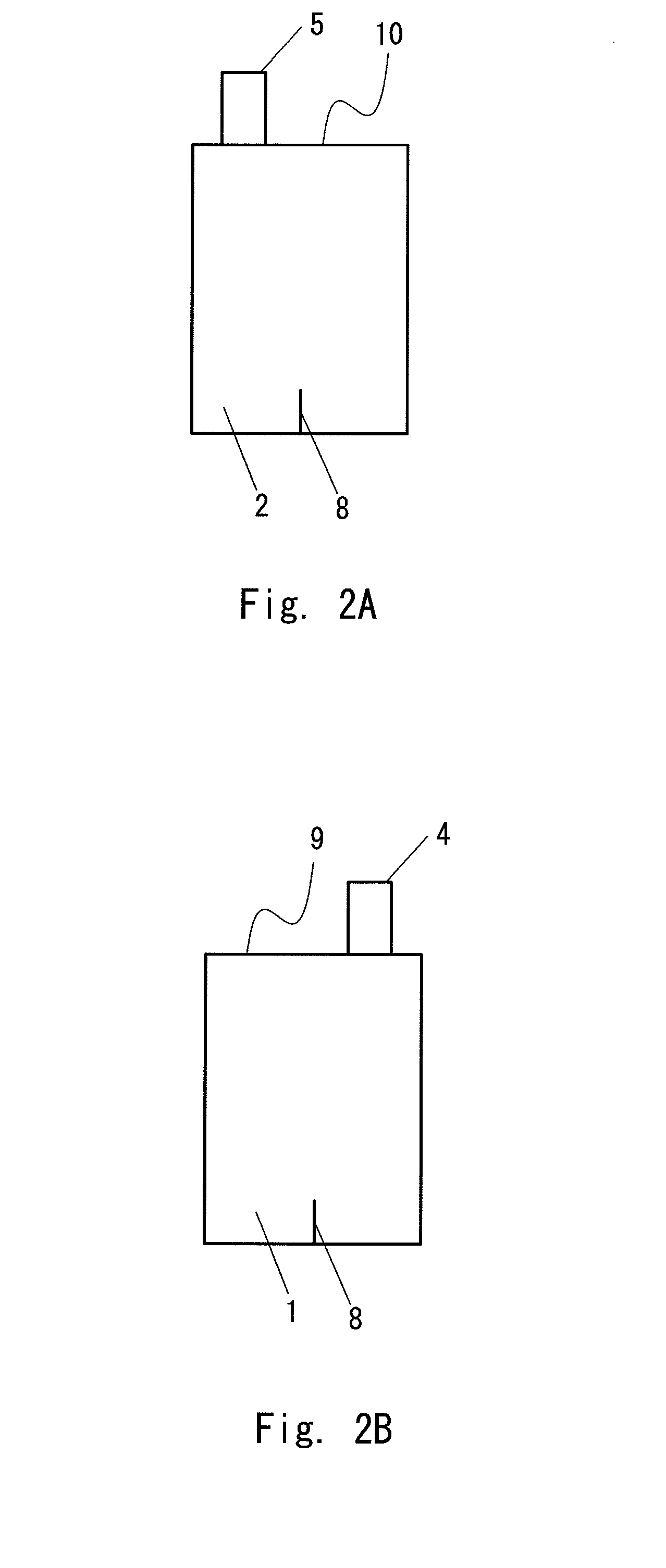

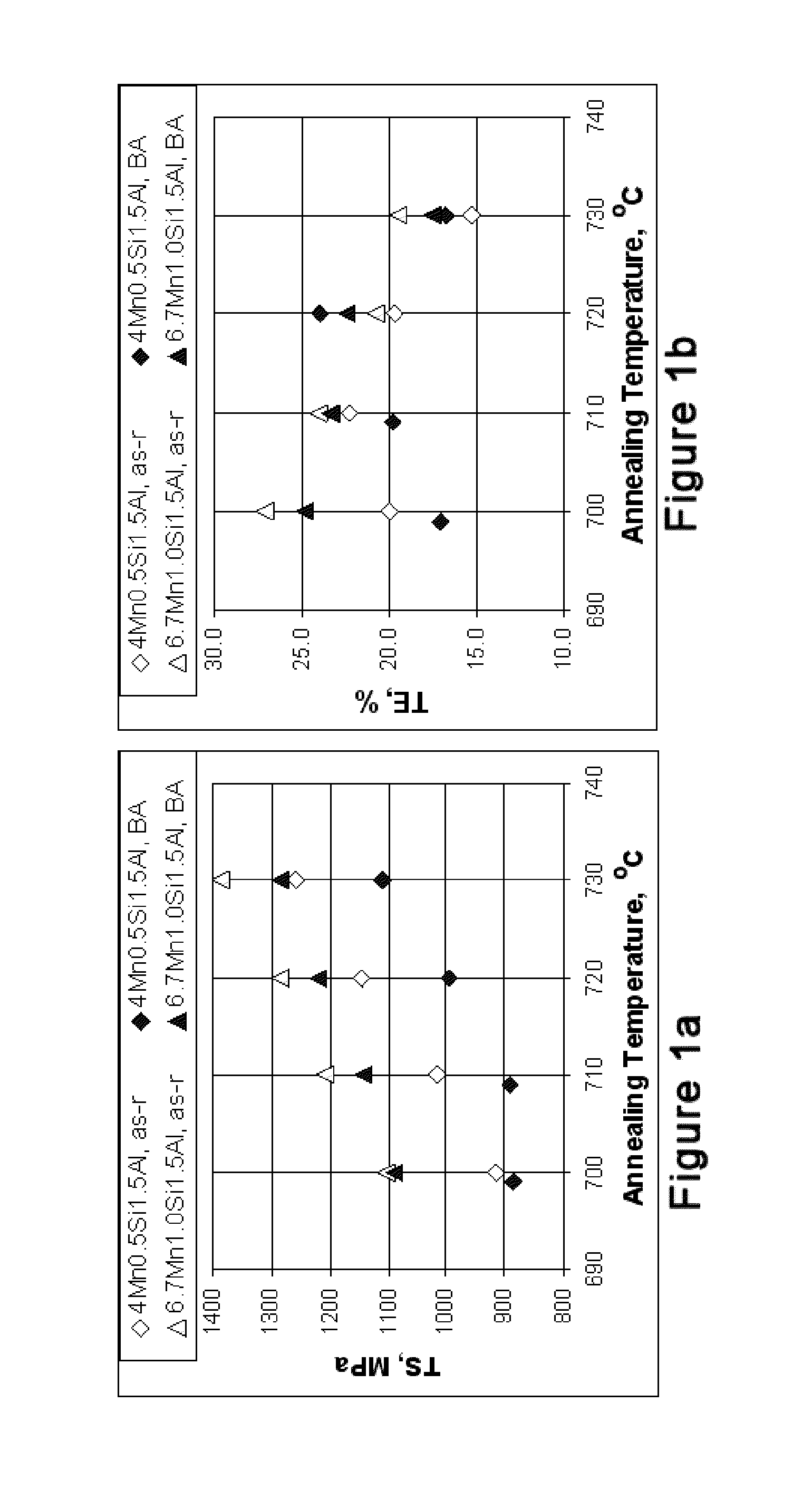

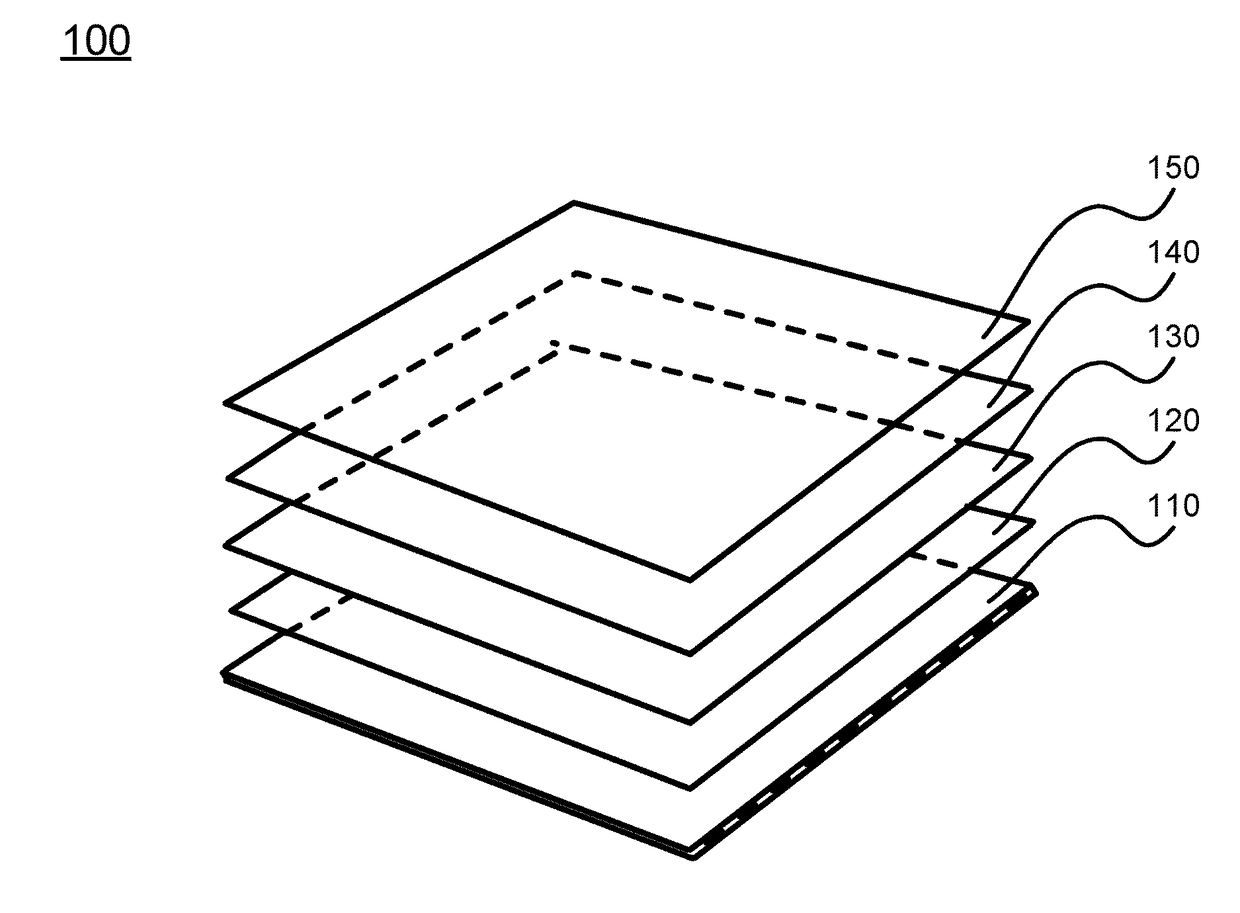

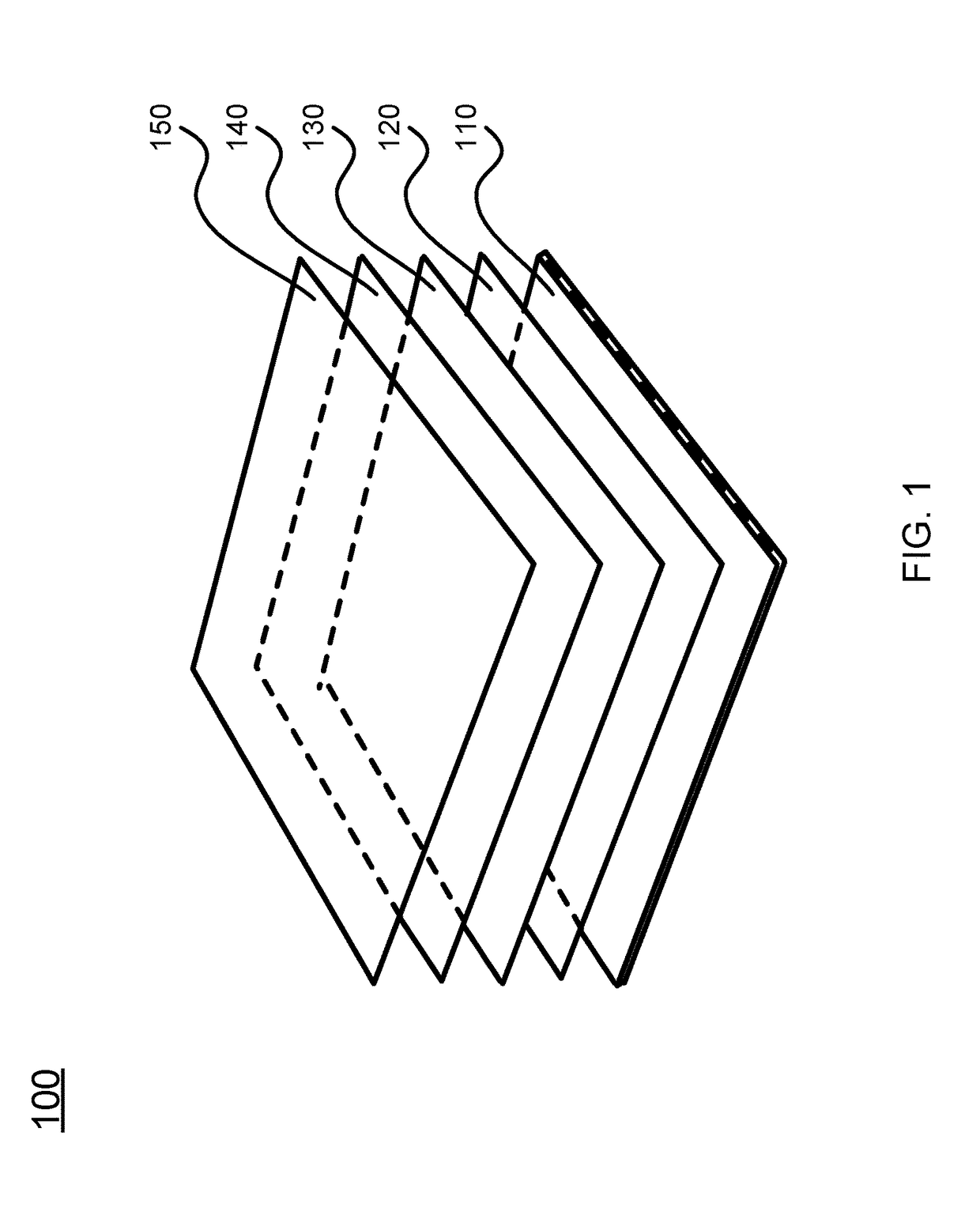

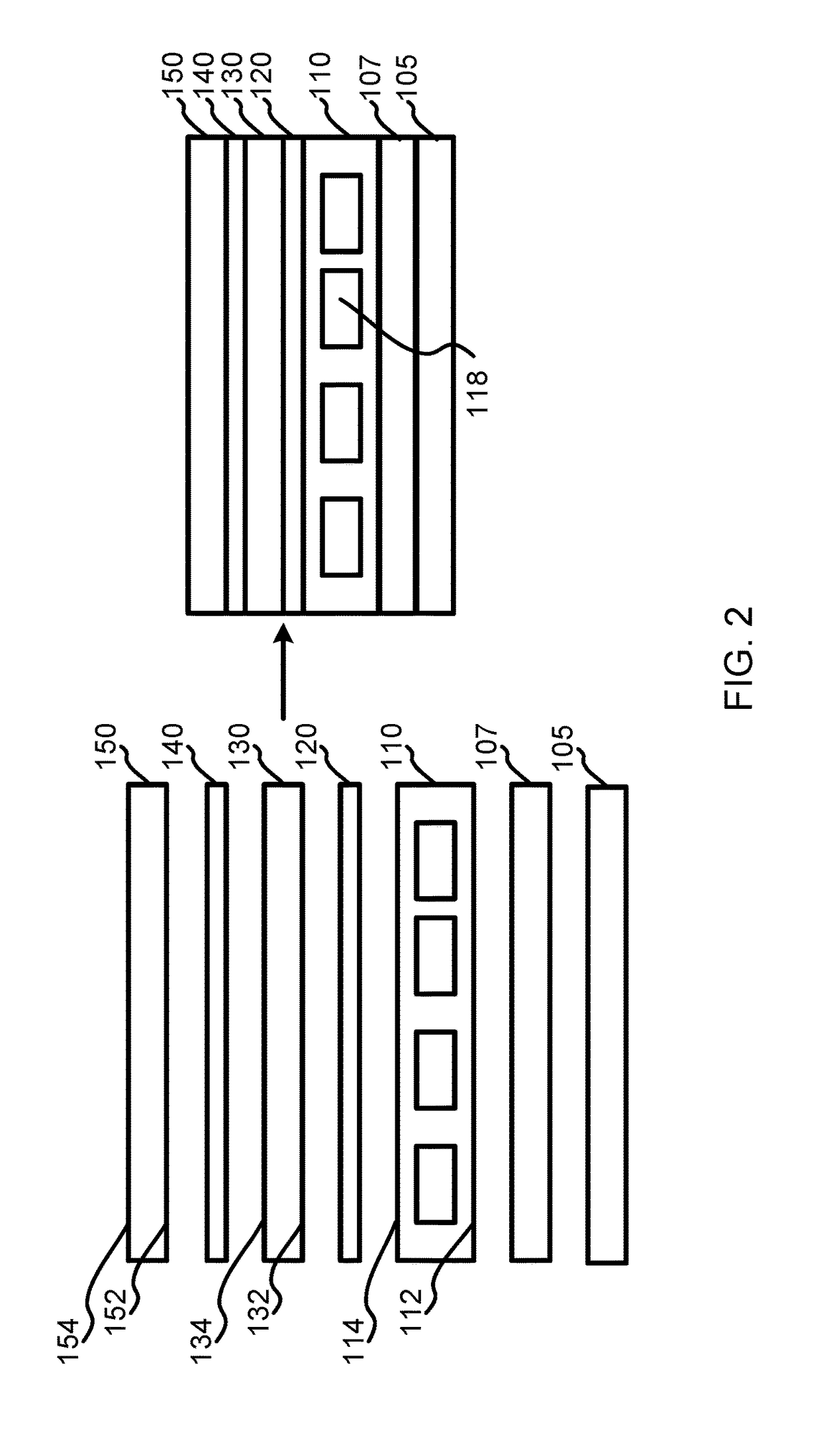

Electric storage device

InactiveUS20120045685A1Short timeReduce resistanceFinal product manufactureDouble layer capacitorsElectrical resistance and conductanceLithium

To provide an electric storage device whose negative electrode can be doped with lithium ions in a short time and whose resistance can be lowered. An electric storage device including a unit that is obtained by alternately stacking a positive-electrode sheet 9 and a negative-electrode sheet 10 with a separator 3 interposed therebetween, the positive electrode sheet 9 including a positive-electrode active material layer 1 and a positive-electrode charge collector 4, and the negative electrode sheet 10 including a negative-electrode active material layer 2 and a negative-electrode charge collector 5, in which a foil, an etching foil, or a porous lath foil is used as the positive-electrode charge collector 4 and the negative-electrode charge collector 5, a cut is made in a coating area of the positive-electrode active material layer 1 and the negative-electrode active material layer 2, and a lithium supply source is disposed so as to be opposed to the negative electrode sheet 10 of the unit.

Owner:TOKIN CORP

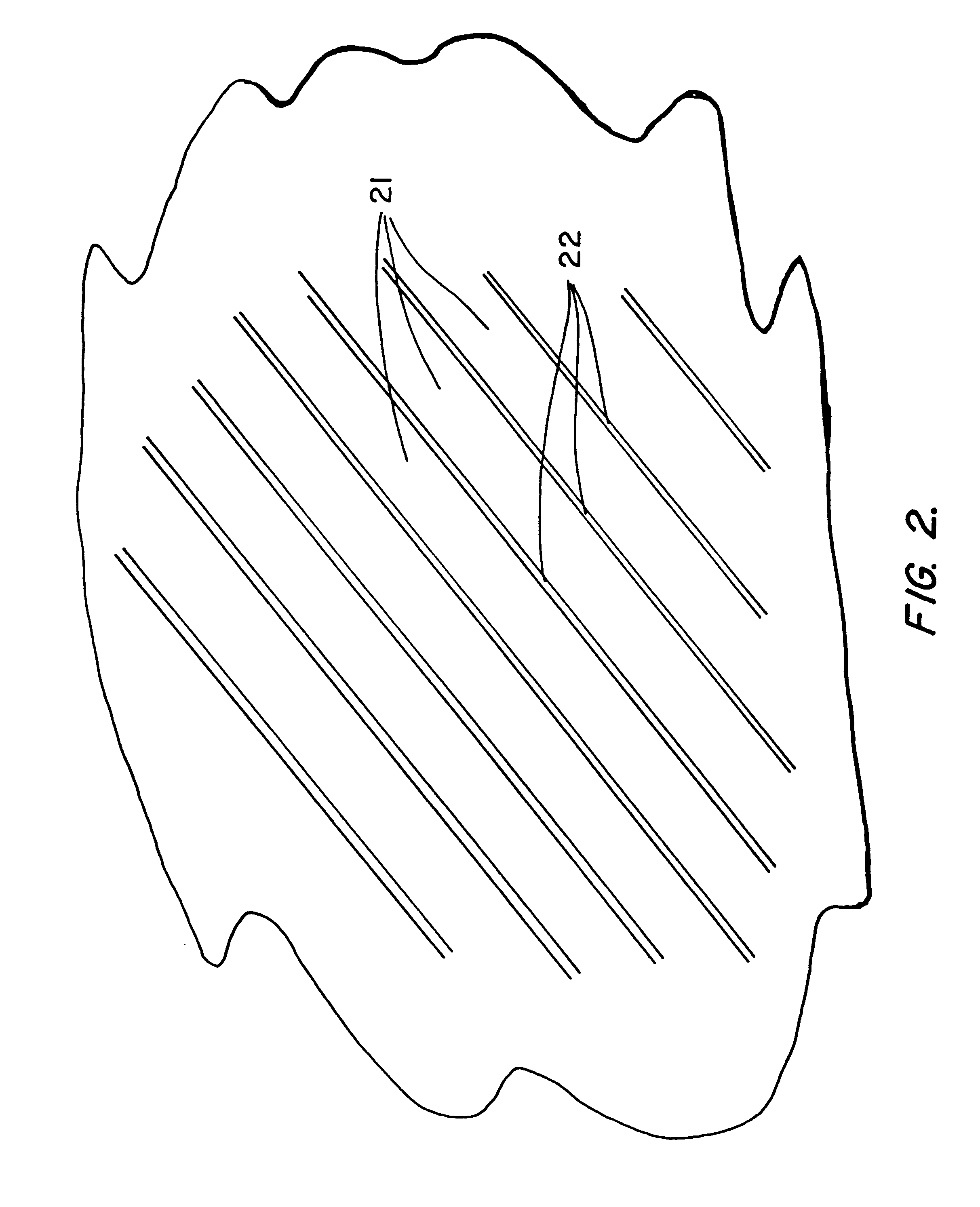

Nano-composite martensitic steels

Carbon steels of high performance are disclosed that contain dislocated lath structures in which laths of martensite alternate with thin films of austenite, but in which each grain of the dislocated lath structure is limited to a single microstructure variant by orienting all austenite thin films in the same direction. This is achieved by careful control of the grain size to less than ten microns. Further improvement in the performance of the steel is achieved by processing the steel in such a way that the formation of bainite, pearlite, and interphase precipitation is avoided.

Owner:MMFX STEEL CORP OF AMERICA +1

Aerodynamic noise reducing structure for aircraft wing slats

A hollow expandable and contractible displacement element is secured onto the concave rear surface of a slat facing the leading edge of an aircraft wing. A bleed air line supplies engine bleed air into the hollow displacement element to selectively expand or contract the displacement element, which is preferably elastically expandable. When the slat is extended, the displacement element is expanded to fill-out the concave cavity on the rear surface of the slat so as to prevent formation of a vortex in the slat air gap and thereby to reduce aero-acoustic noise. When the slat is retracted, the displacement element is contracted to be conformingly accommodated in the sickle-shaped space between the slat and the leading edge of the wing.

Owner:AIRBUS OPERATIONS GMBH

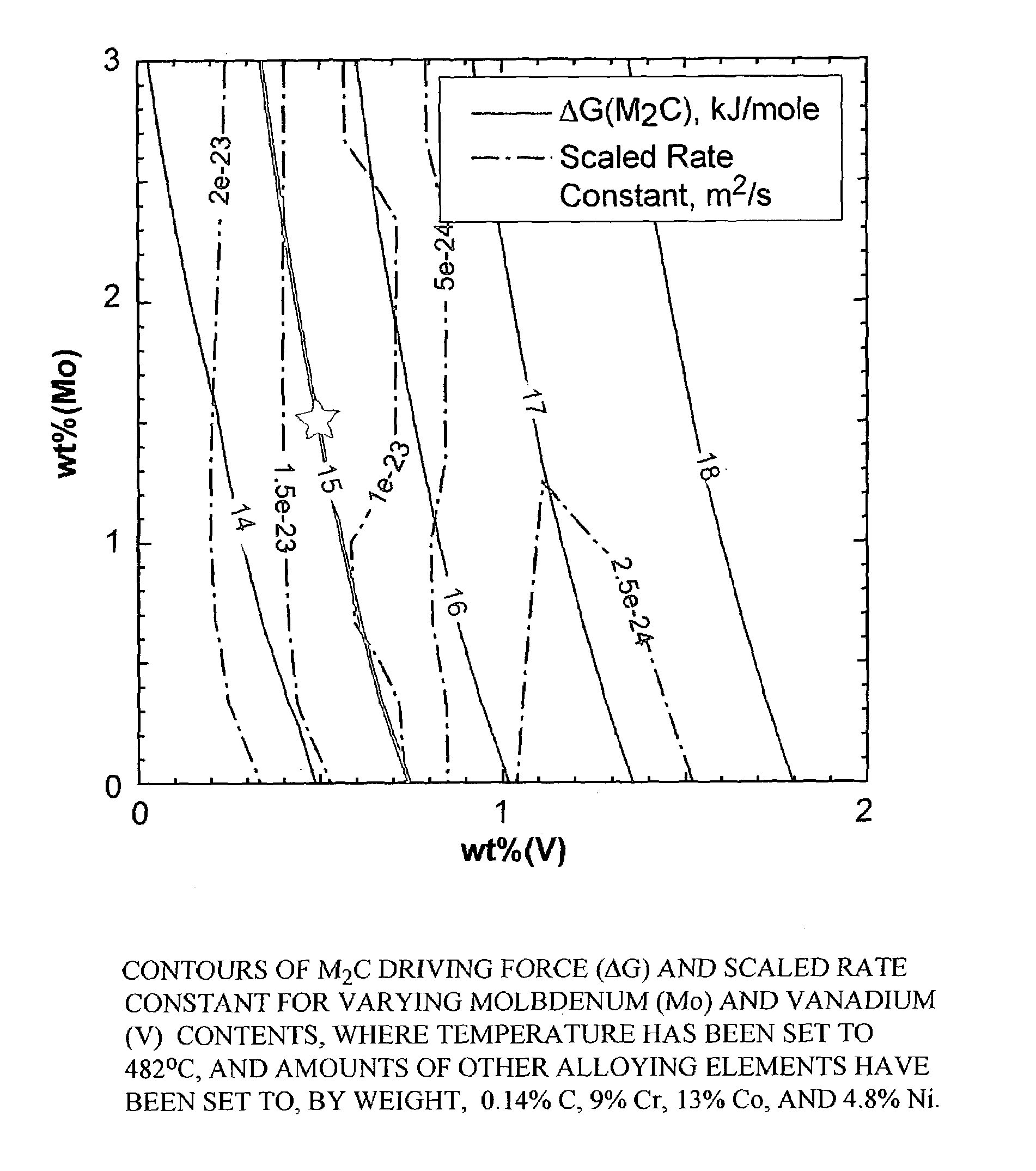

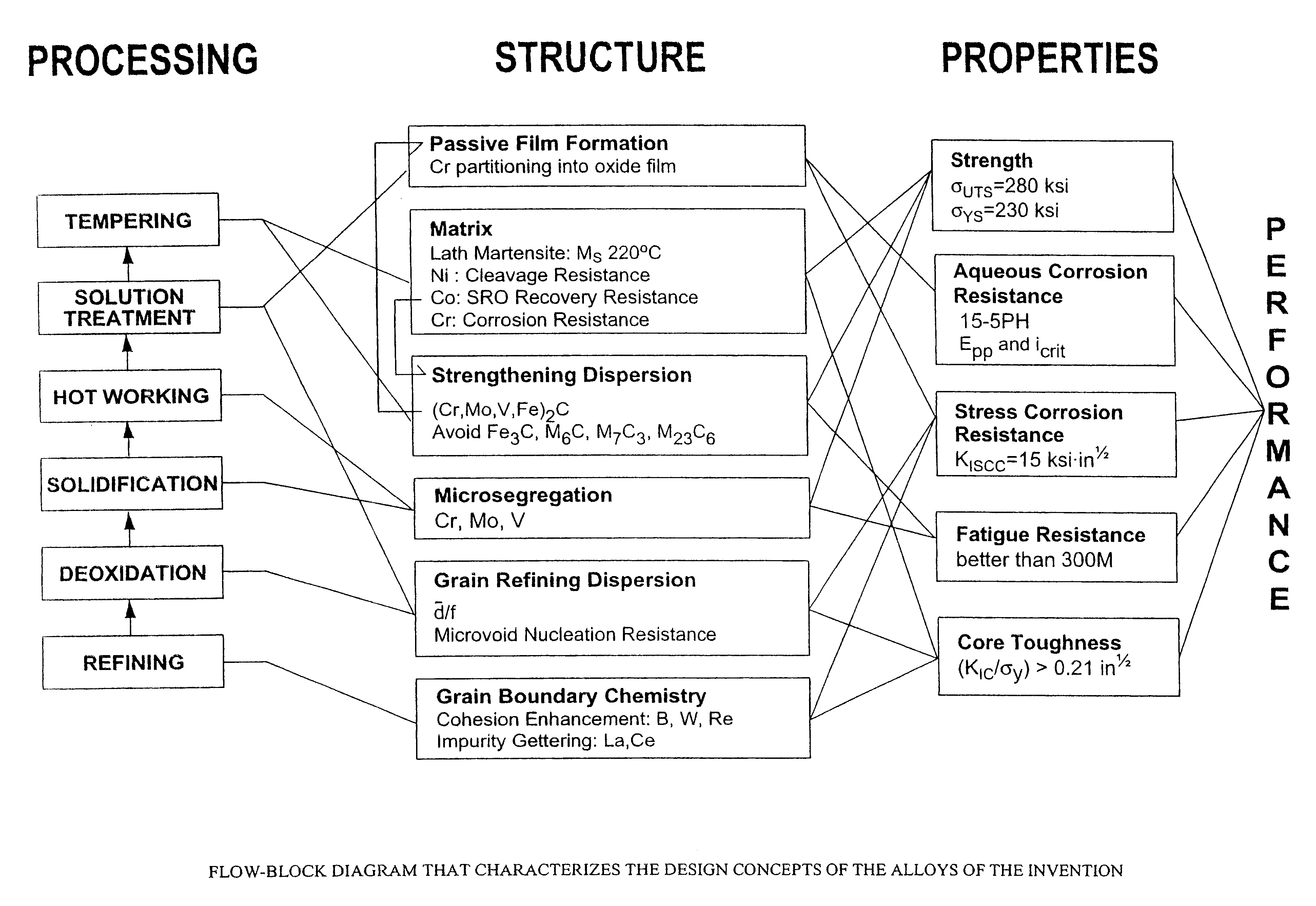

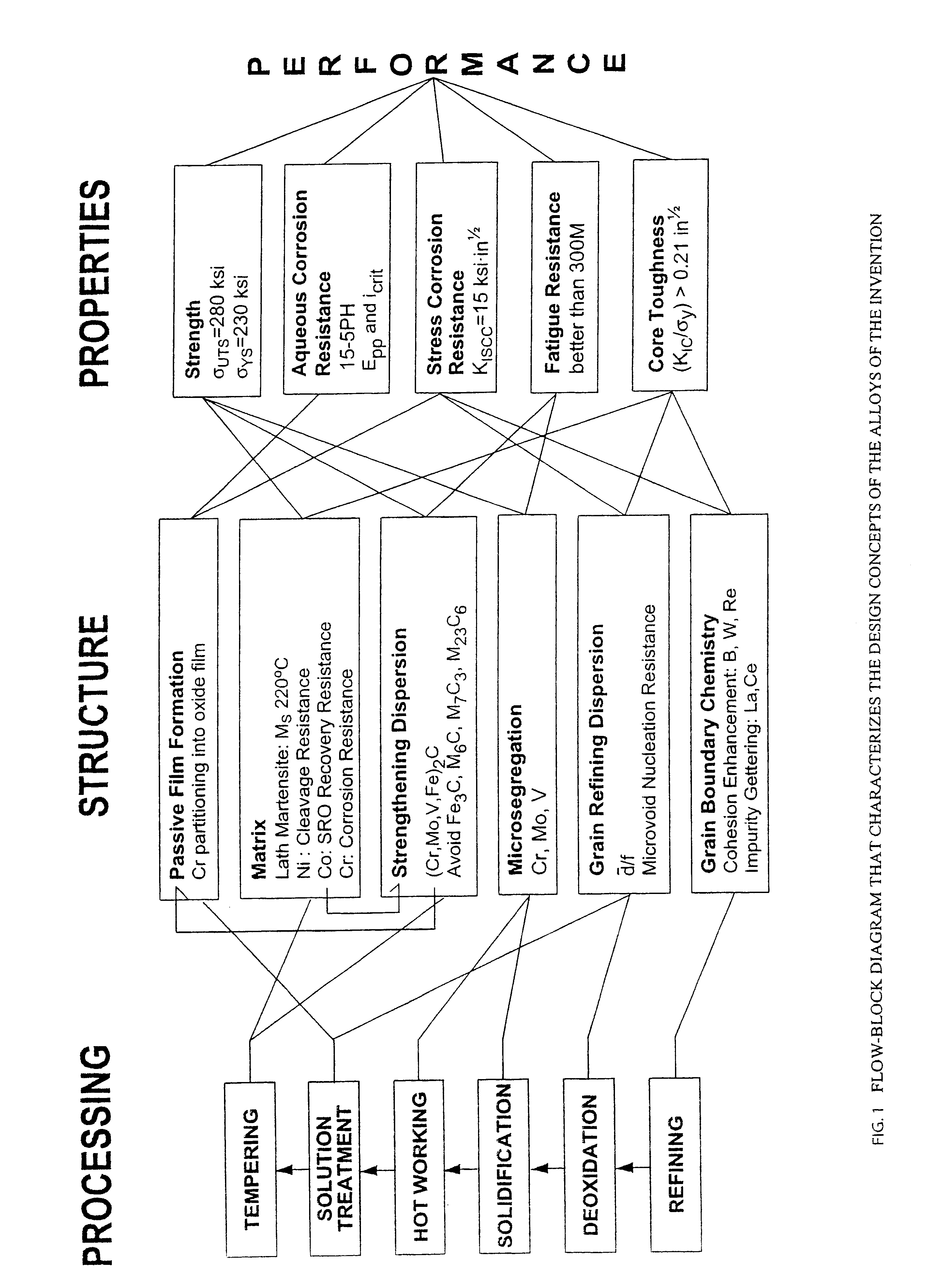

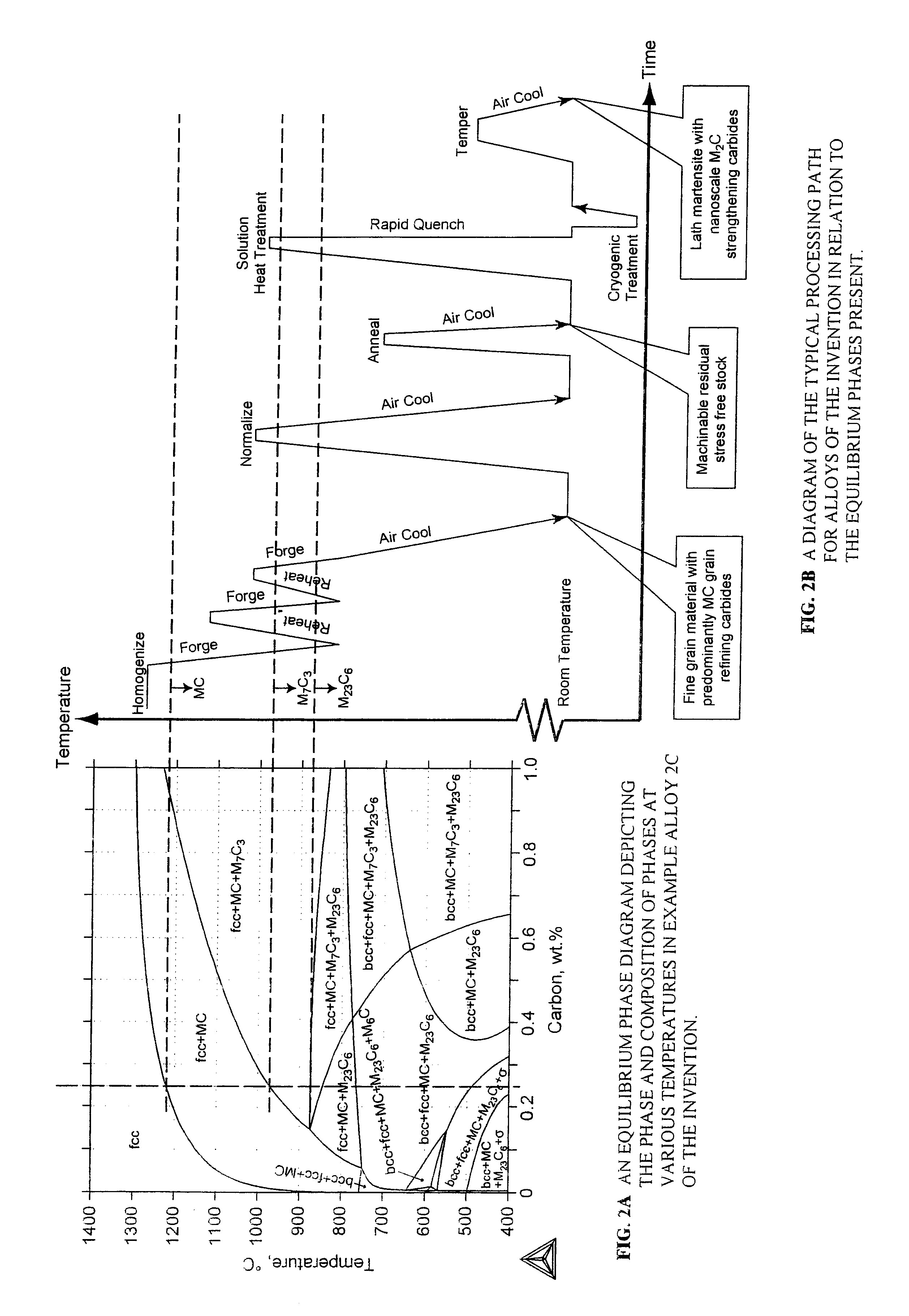

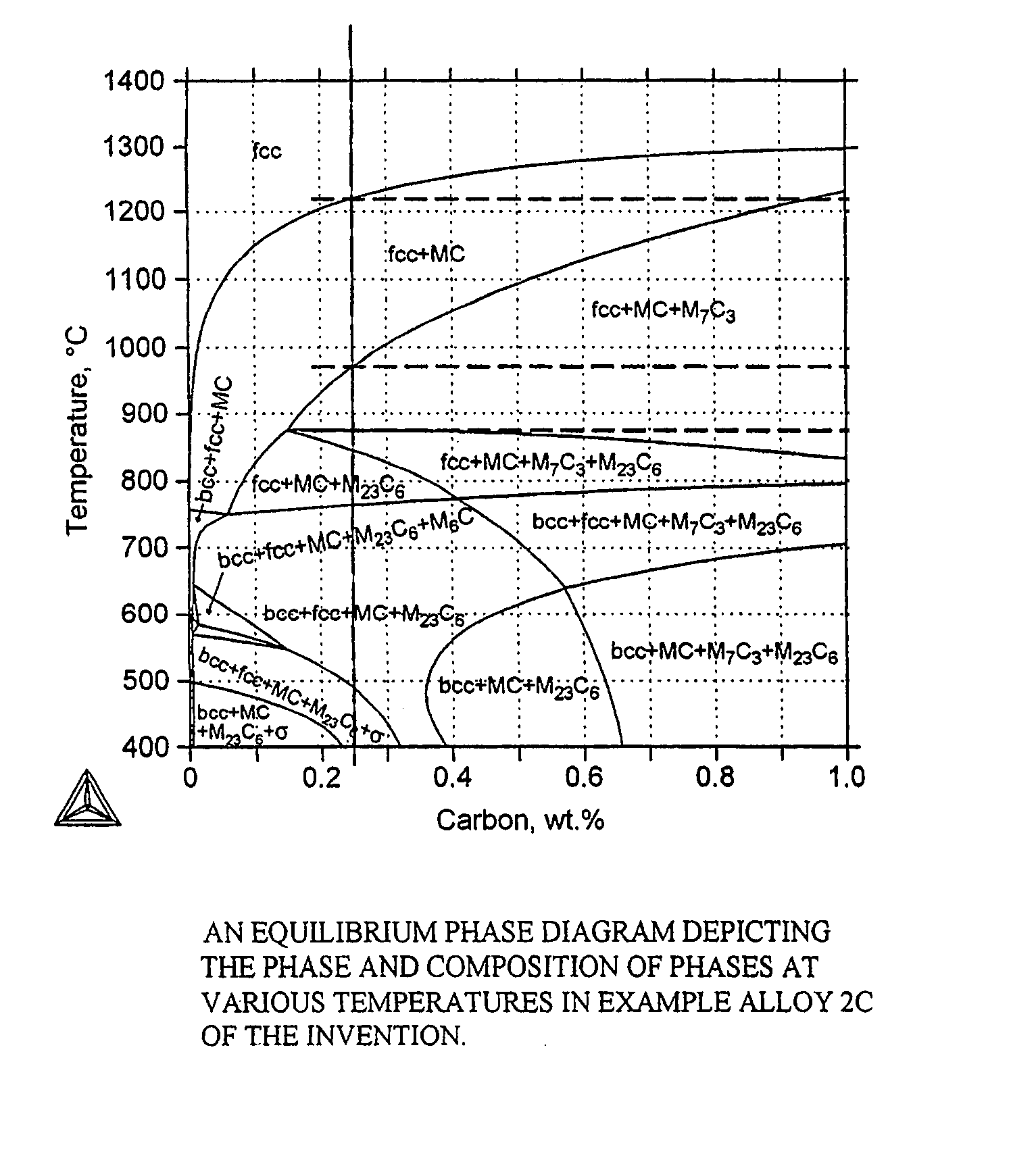

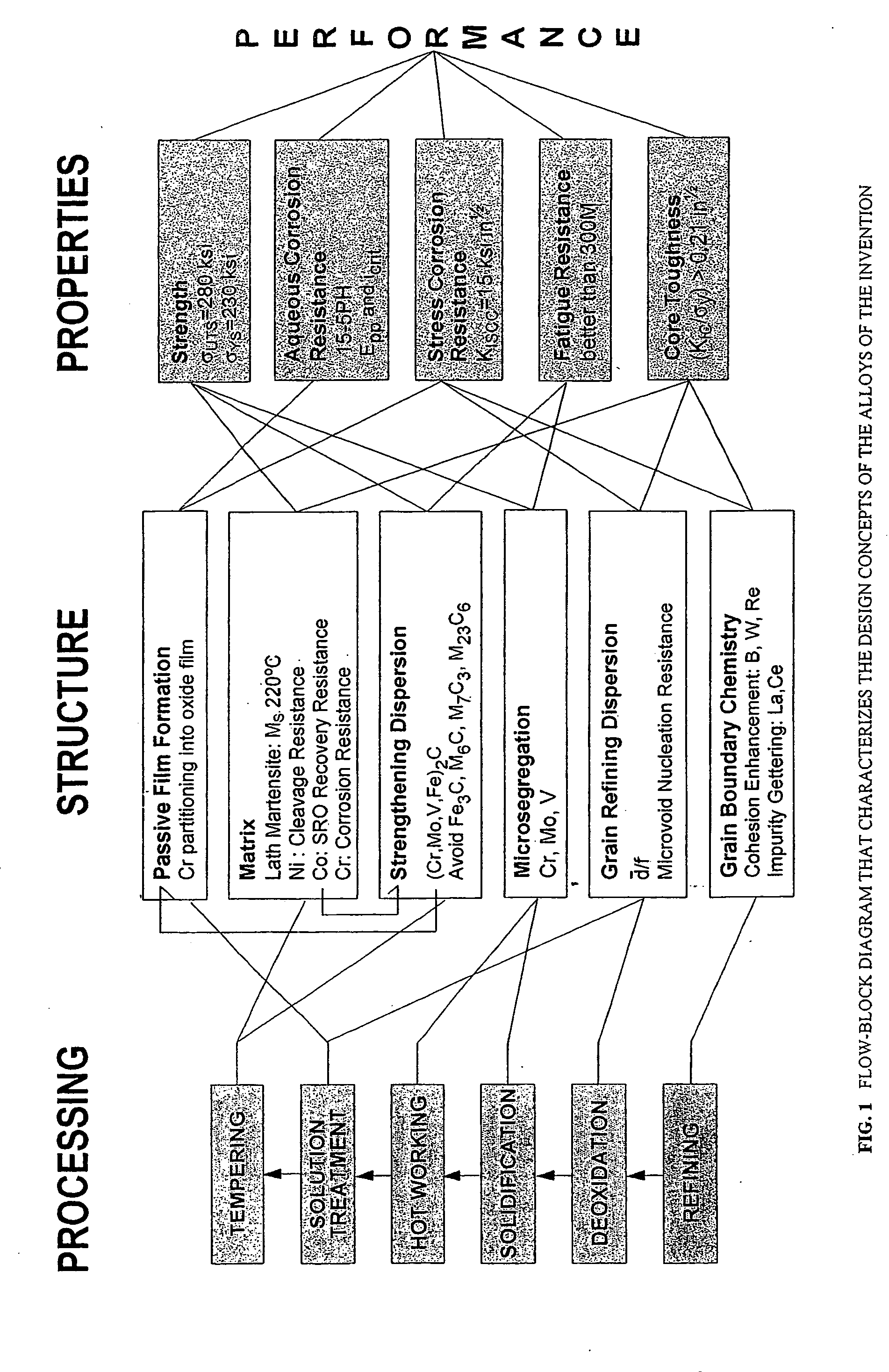

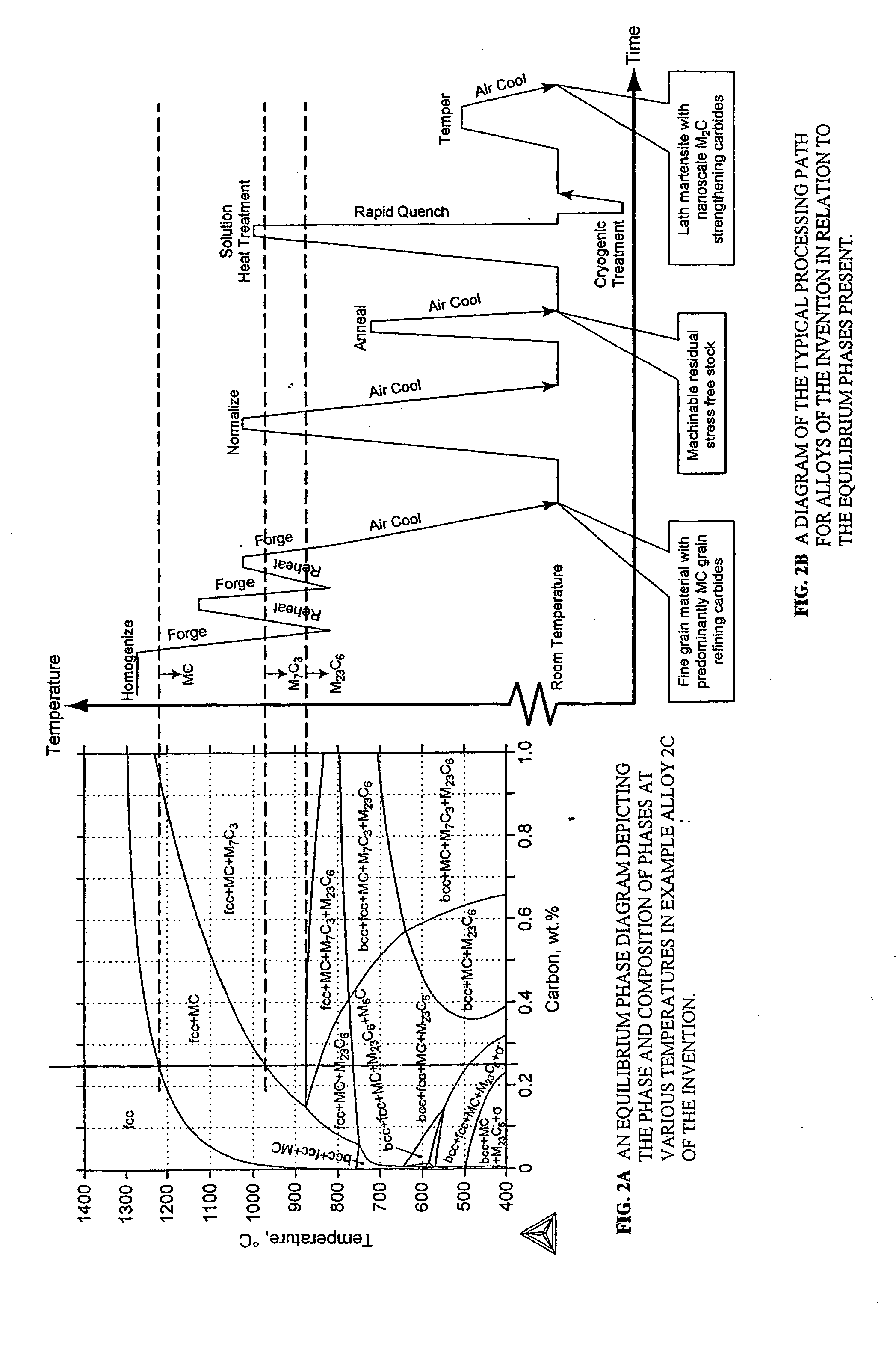

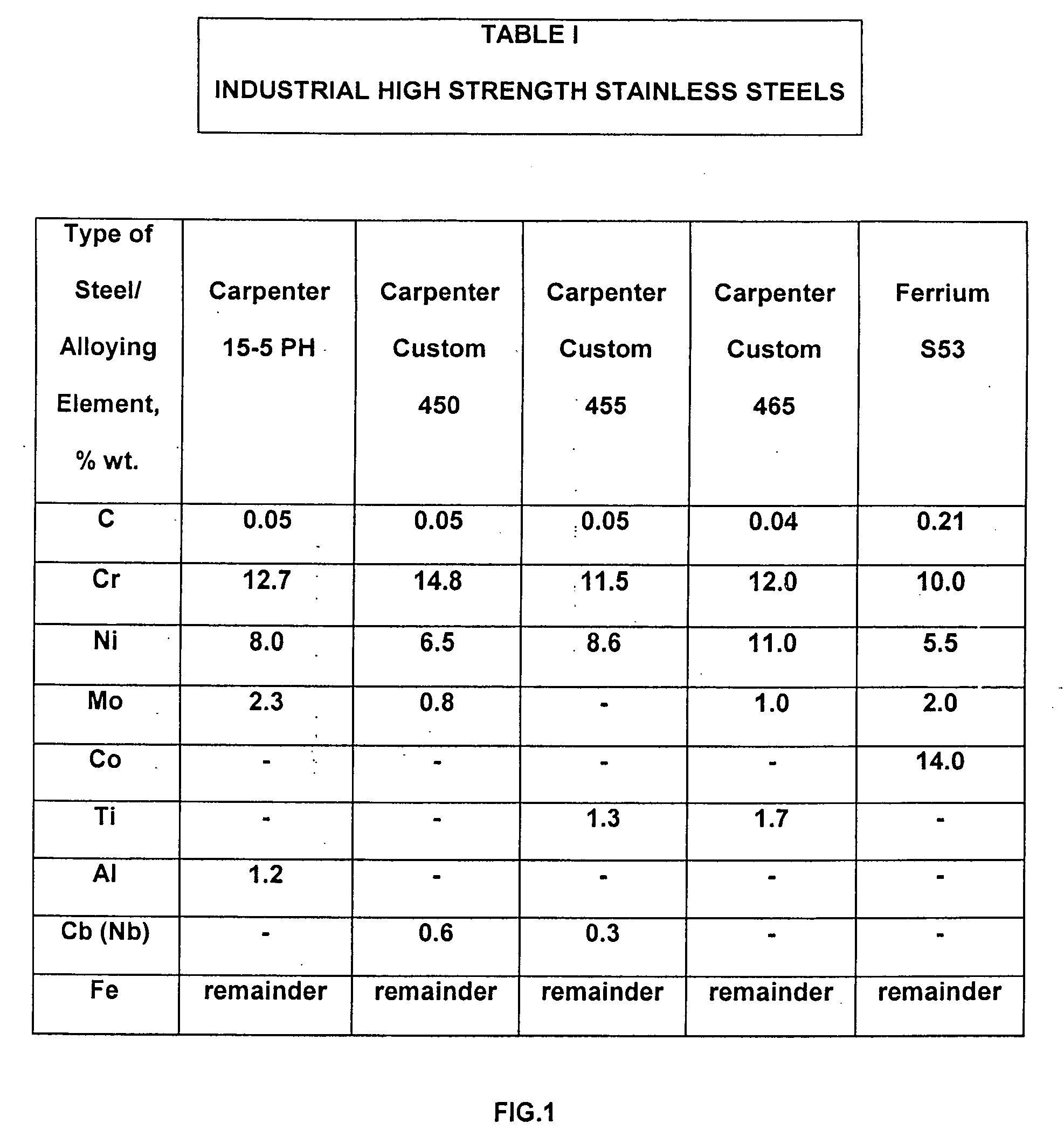

Nanocarbide precipitation strengthened ultrahigh-strength, corrosion resistant, structural steels

InactiveUS7160399B2Simple working processHigh strengthFurnace typesHeat treatment furnacesCobaltMaterials science

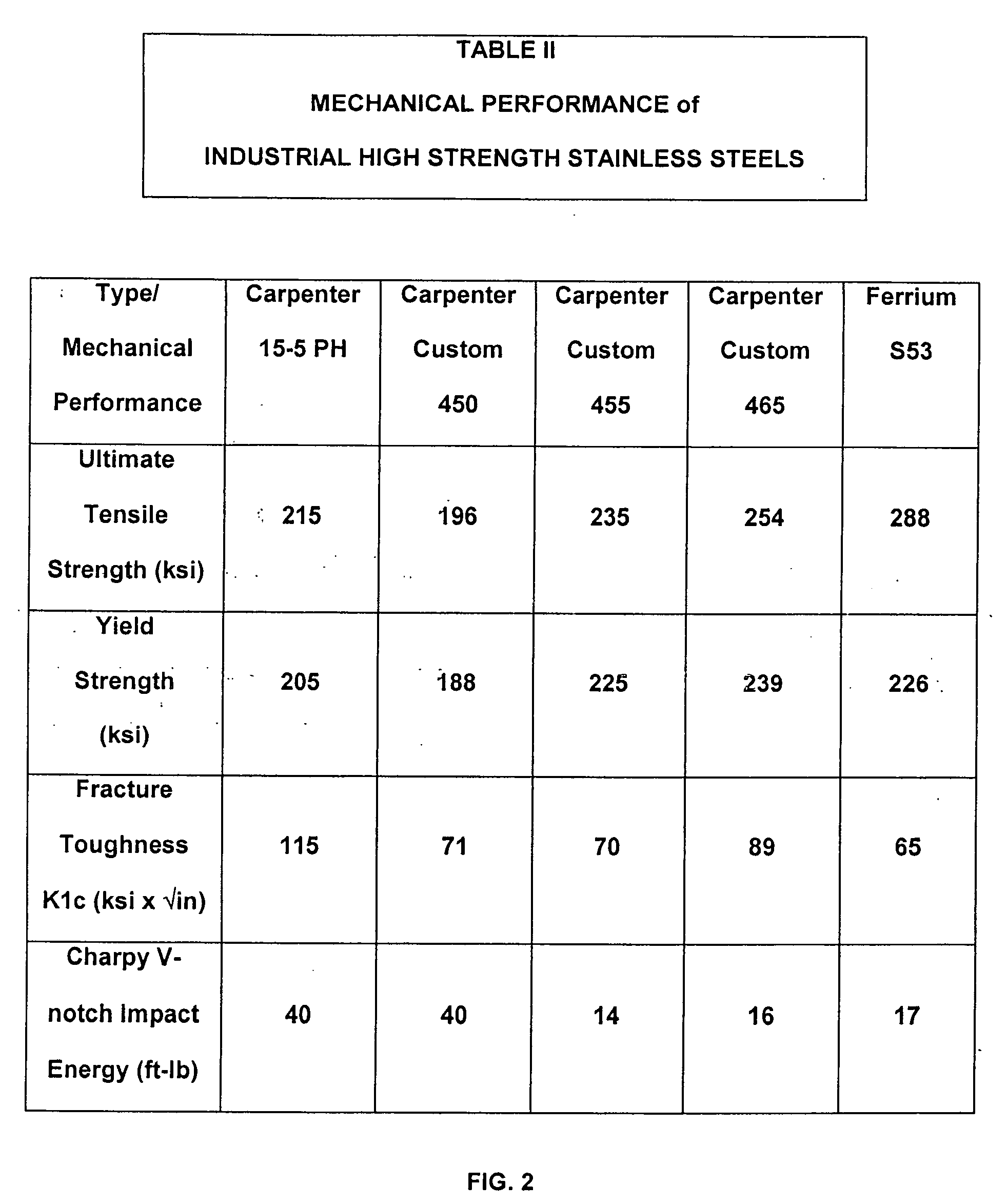

A nanocarbide precipitation strengthened ultrahigh-strength, corrosion resistant, structural steel possesses a combination of strength and corrosion resistance comprising in combination, by weight, about: 0.1 to 0.3% carbon (C), 8 to 17% cobalt (Co), 0 to 10% nickel (Ni), 6 to 12% chromium (Cr), less than 1% silicon (Si), less than 0.5% manganese (Mn), and less than 0.15% copper (Cu), with additives selected from the group comprising about: less than 3% molybdenum (Mo), less than 0.3% niobium (Nb), less than 0.8% vanadium (V), less than 0.2% tantalum (Ta), less than 3% tungsten (W), and combinations thereof, with additional additives selected from the group comprising about: less than 0.2% titanium (Ti), less than 0.2% lanthanum (La) or other rare earth elements, less than 0.15% zirconium (Zr), less than 0.005% boron (B), and combinations thereof, impurities of less than about: 0.02% sulfur (S), 0.012% phosphorus (P), 0.015% oxygen (O) and 0.015% nitrogen (N), the remainder substantially iron (Fe), incidental elements and other impurities. The alloy is strengthened by nanometer scale M2C carbides within a fine lath martensite matrix from which enhanced chemical partitioning of Cr to the surface provides a stable oxide passivating film for corrosion resistance. The alloy, with a UTS in excess of 280 ksi, is useful for applications such as aircraft landing gear, machinery and tools used in hostile environments, and other applications wherein ultrahigh-strength, corrosion resistant, structural steel alloys are desired.

Owner:QUESTEK INNOVATIONS LLC

Flexible airflow separator to reduce aerodynamic noise generated by a leading edge slat of an aircraft wing

InactiveUS20030226936A1Easy to transformStable separationInfluencers by generating vorticesDe-icing equipmentsLeading edgeBristle

A slat is selectively extended from a main wing body, with a concave rear surface of the slat facing a convex forward nose surface of the wing body, with a slat gap therebetween. At least one row of flexible bristles is movably arranged relative to the lower rear edge of the slat, to flexibly protrude up into the slat air gap. At least one row of flexible bristles is movably arranged along the upper rear edge of the slat to extend rearwardly over the slat air gap and the upper surface of the main wing body. The flexible bristles are flexibly self-positioning and self-contouring due to the aerodynamic forces acting thereon, to improve the air flow conditions through the slat gap, separate the slat gap airflow from an entrapped eddy vortex on the concave rear surface of the slat, and thereby reduce the aerodynamic noise generated along the slat gap.

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV +1

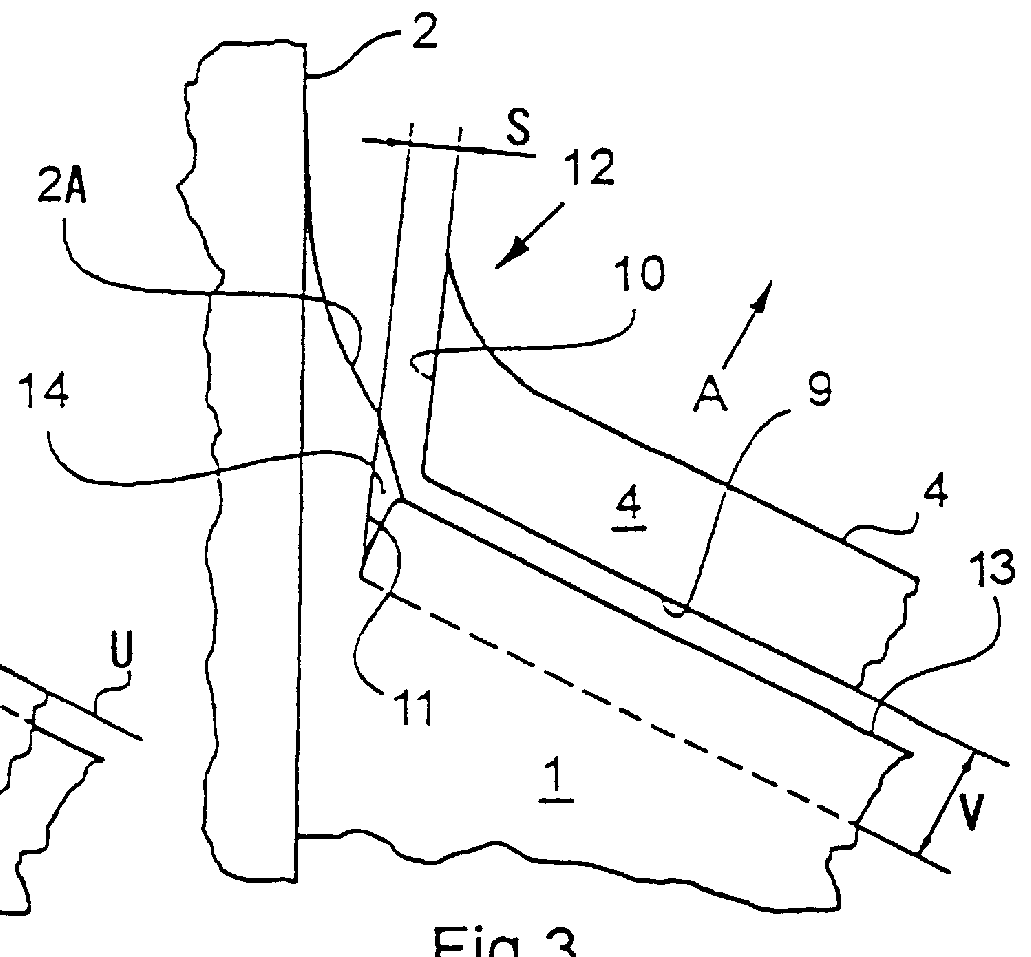

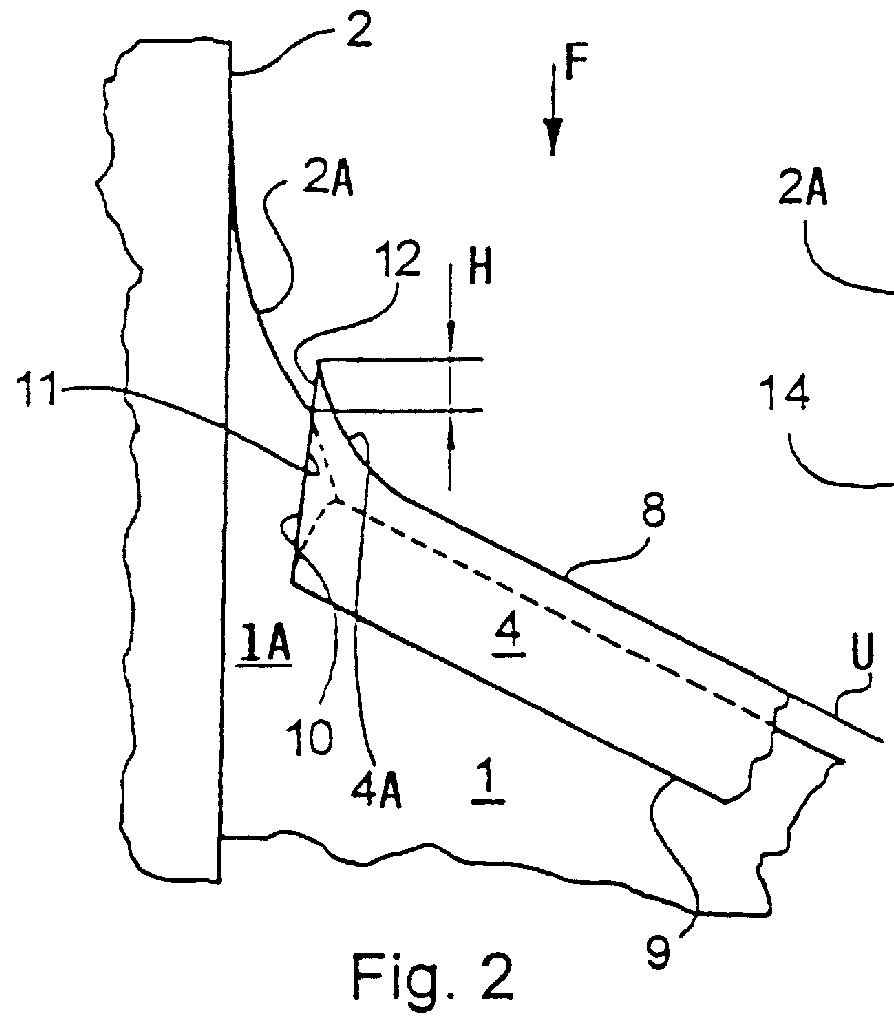

Apparatus for influencing a wing root airflow in an aircraft

An apparatus advantageously influences the wing root airflow along the wing root of an aircraft having a high lift system including leading edge slats provided on the main wings. The apparatus includes a respective vortex generator arranged on the inboard end of each leading edge slat in the area of the wing root, and further includes a respective transition fairing arranged on a separation edge that is let into the leading edge of the wing root and that borders along the inboard edge of the respective slat. The vortex generator is a rigid member fixed to the leading edge slat and may be in the shape of a horn, a disk, or a winglet. The transition fairing may be a rigid member fixed to the wing root along the separation edge, or may be a flexible elastic member that can be inflated to have a variable outer contour. The present system avoids the need of additional independently movable auxiliary flaps, and thus achieves a reduced weight, complexity, and maintenance requirement.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

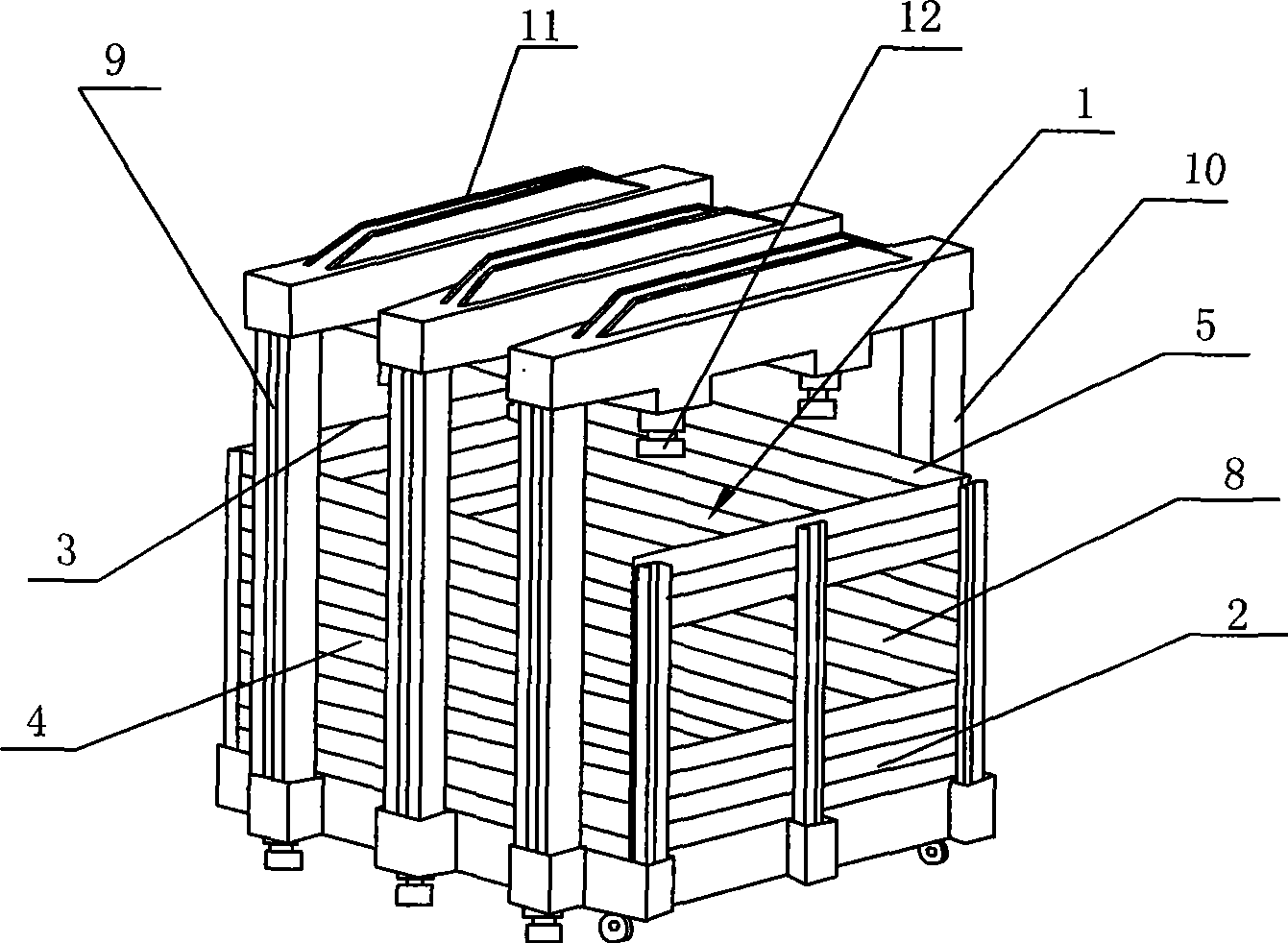

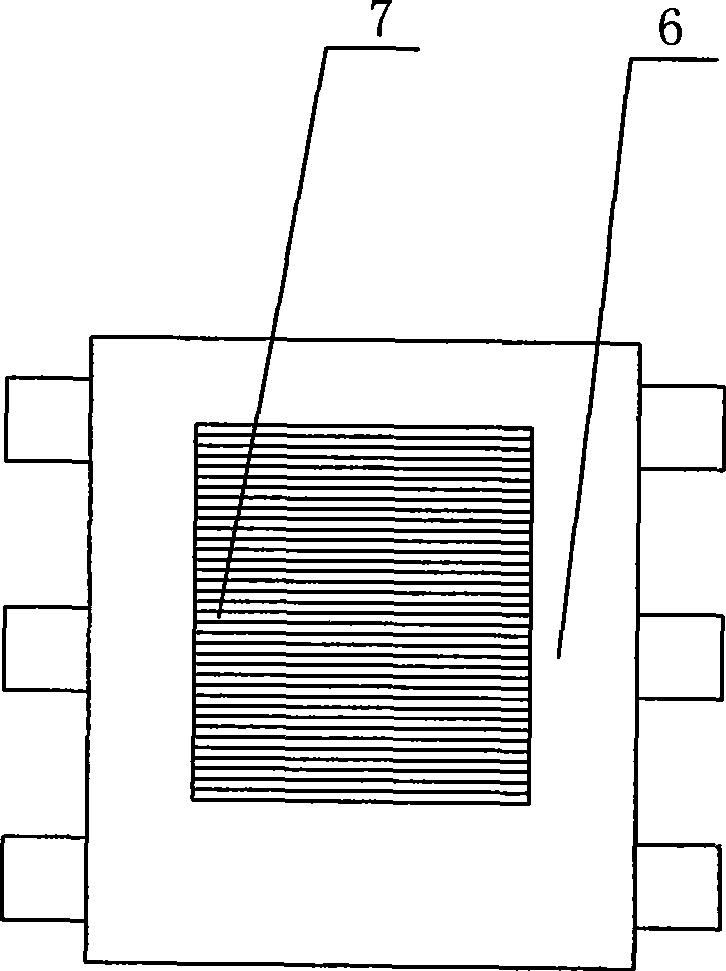

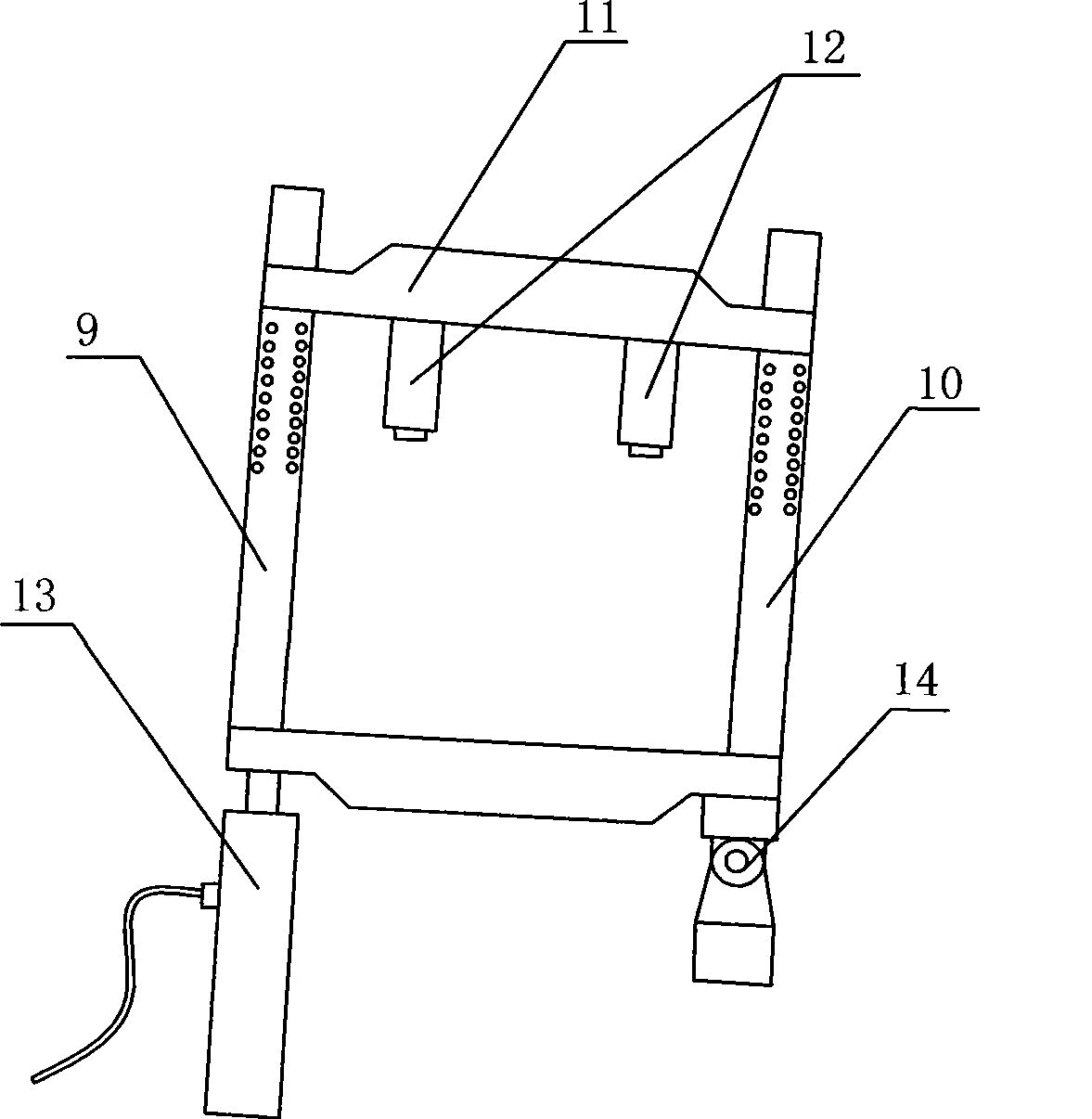

Stope mine pressing three-dimensional physical simulation test stand

The invention discloses an underground pressure three dimensional physical simulation test platform, which is characterized in that a frame type model platform used for bearing a model, a swing structure used for causing the frame type model platform to incline in a whole in a range of set maximum inclination angle, and a loading device used for pressing on the model in the direction of the opening of the frame type model platform are included, wherein, the frame type model platform comprises an upper opening, side wall plates arranged at the front, at the back, at the left and at the right, as well as a base plate; the base plate is provided with at least a mining hole, and the mining hole is provided with a demountable sealing lath. The invention can simulate a big inclination angle coal seam mining experiment and simulate a coal seam deep mining experiment, and meanwhile, can also simulate a bottom plate coal mining experiment, simulate a middle coal mining experiment, and the like.

Owner:SHANDONG UNIV OF SCI & TECH

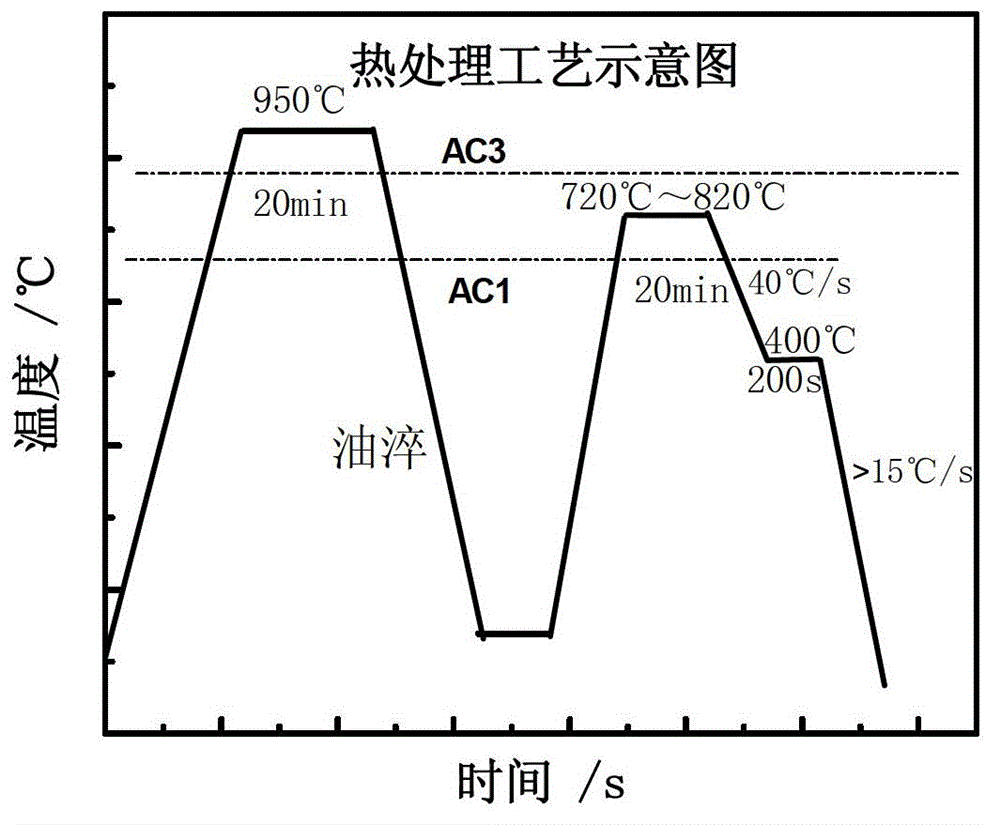

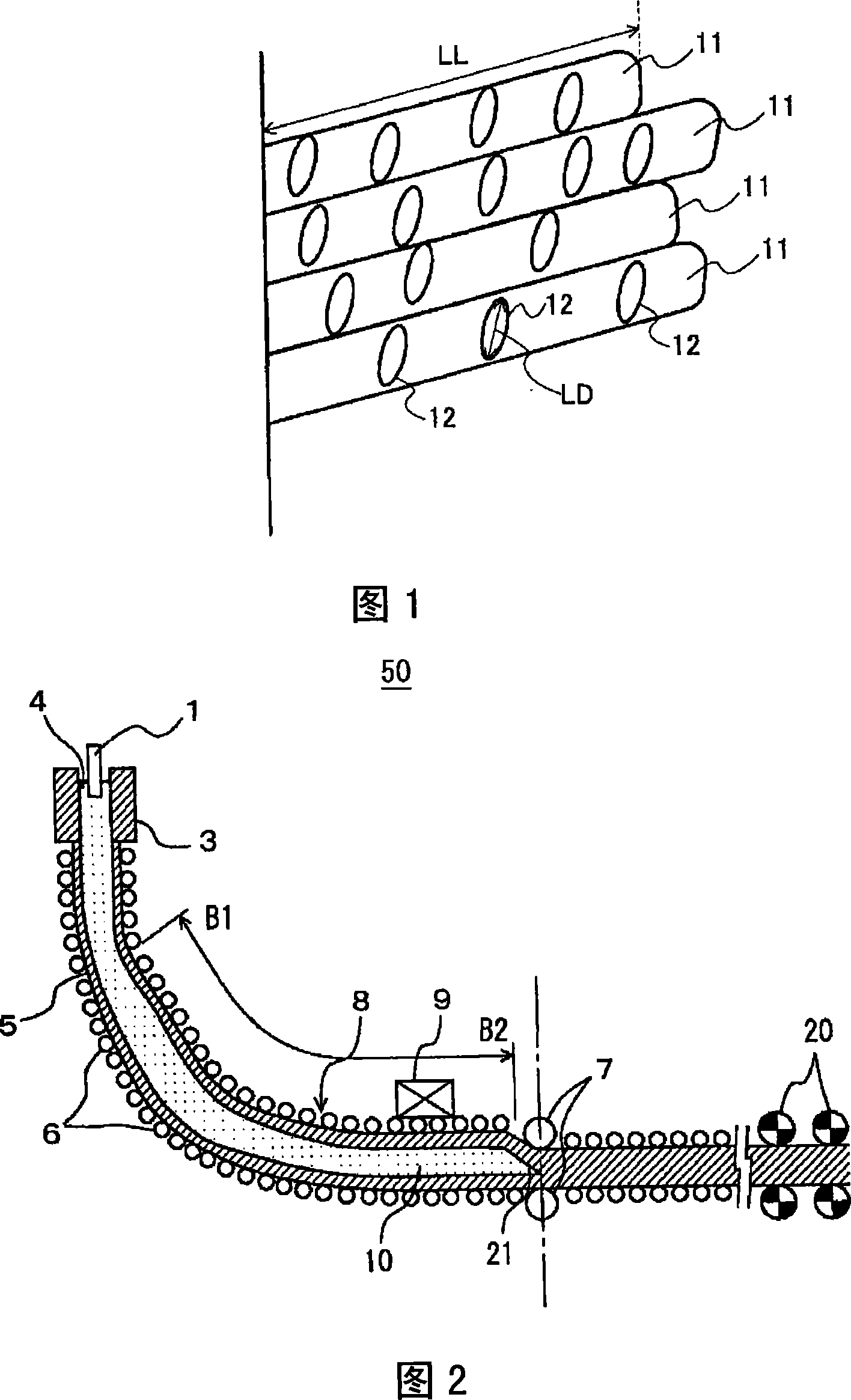

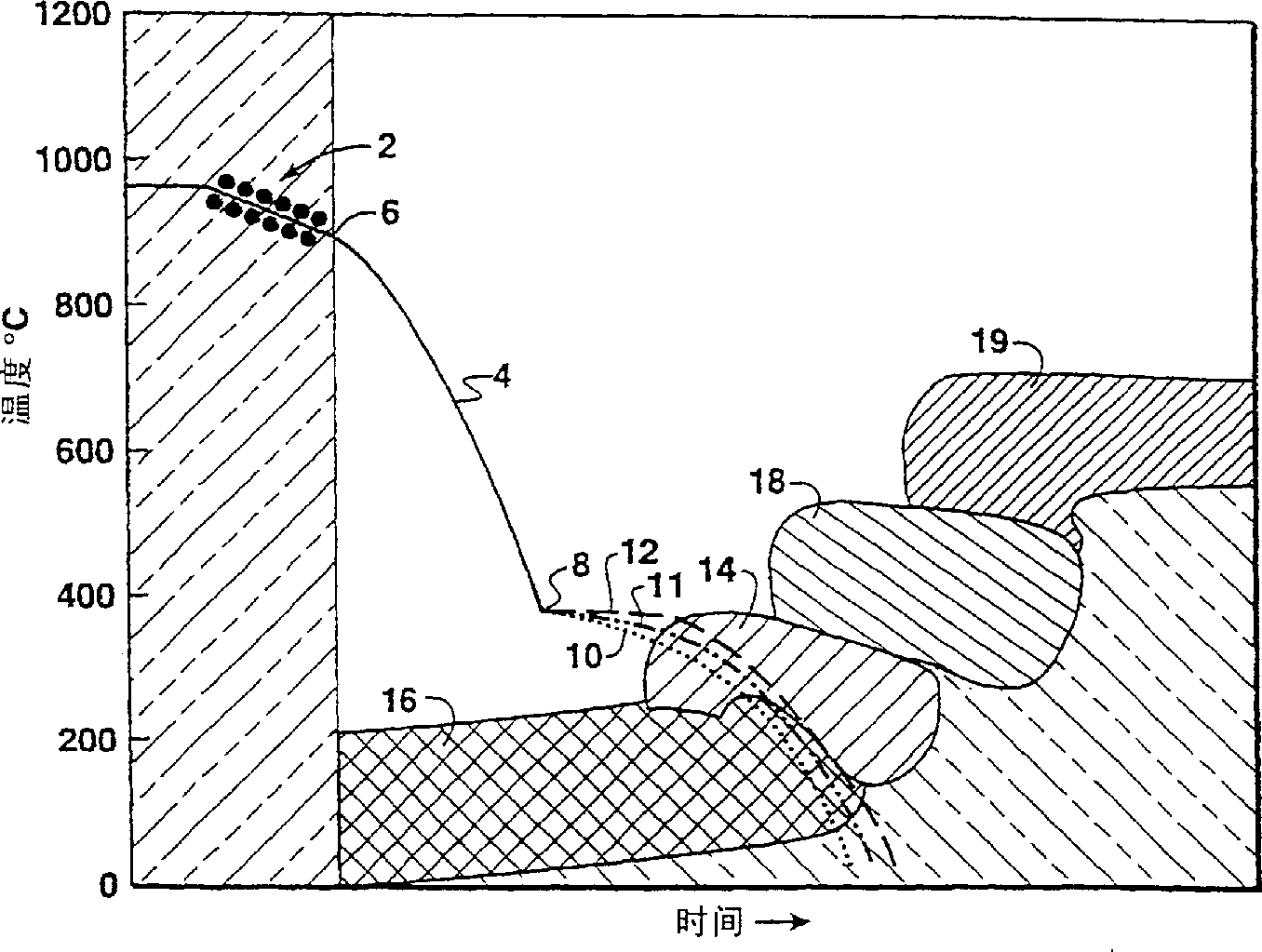

Quenching and annealing preparation method of ultrahigh-strength thin steel plate for automobiles

ActiveCN102943169AImprove mechanical propertiesHeat treatment process control is simple and feasibleFurnace typesHeat treatment furnacesMetallic materialsQuenching

A quenching and annealing preparation method of an ultrahigh-strength thin steel plate for automobiles belongs to the field of metal material heat treatment. The method comprises the steps of: firstly, heating a low-carbon steel cold-rolled sheet containing microalloy elements such as Si, Mn and Nb to a fully austenitic area and performing quenching heat treatment after austenization; secondly, heating the low-carbon steel cold-rolled sheet to a two-phase area so that the lath martensite quenched previously is decomposed and partially inverted to form the austenite, and then quickly cooling the steel sheet above Ms point and preserving heat for secondary partition; and finally, rapidly cooling to the room temperature. The steel sheet has a complex-phase structure composed of a quasi-recrystallized ferrite, a carbide, residual austenite and tiny bainite or martensite structure; and the quasi-recrystallized ferrite structure formed after annealing inherits the lath morphology feature of the martensite, which is advantageous for improving the ductility. The ultrahigh-strength thin steel prepared through the process is high in product of strength and elongation, and has the tensile strength of more than 1100 MPa, the ductility of 20% and the product of strength and elongation of 22000 MPa.%.

Owner:UNIV OF SCI & TECH BEIJING

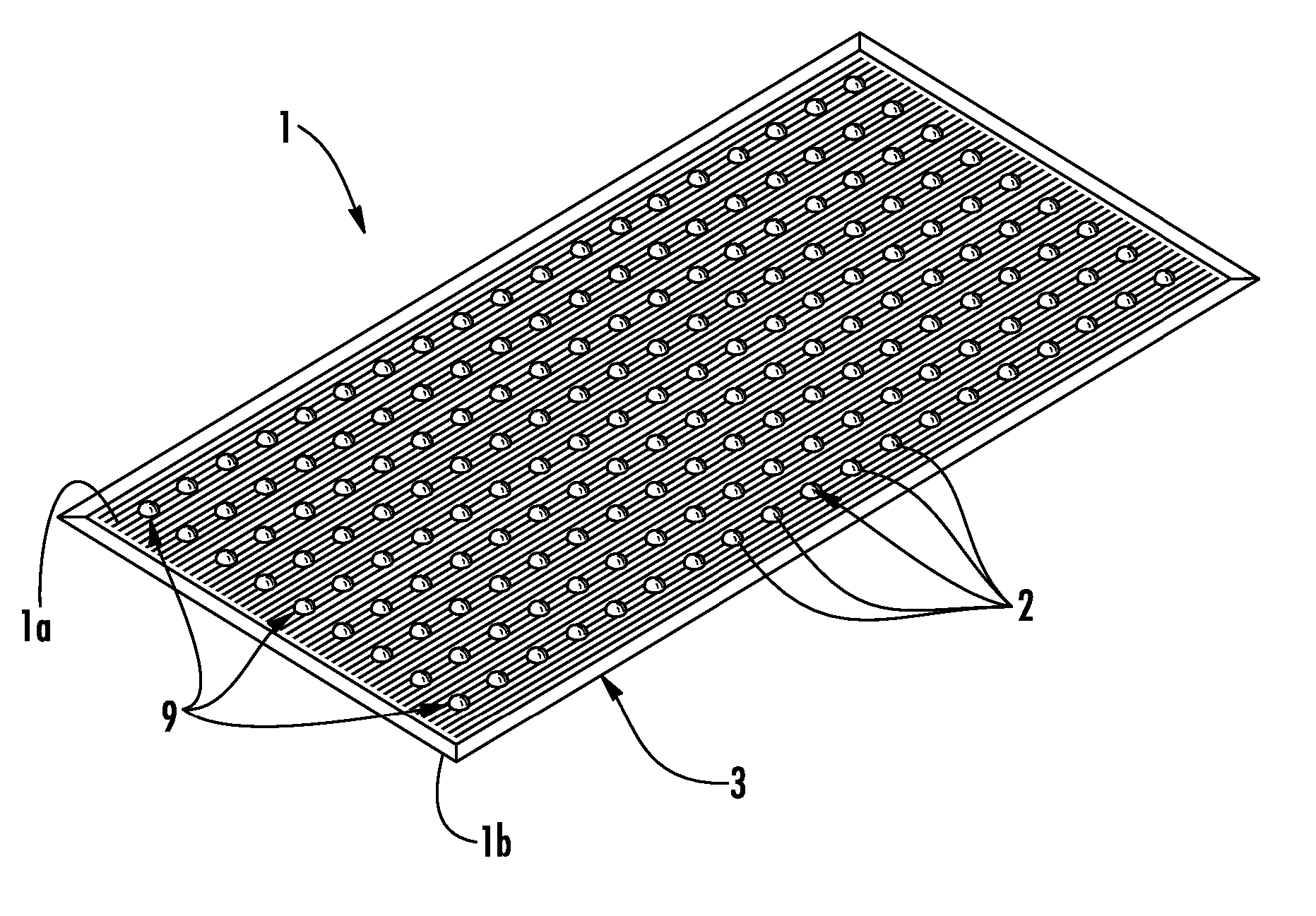

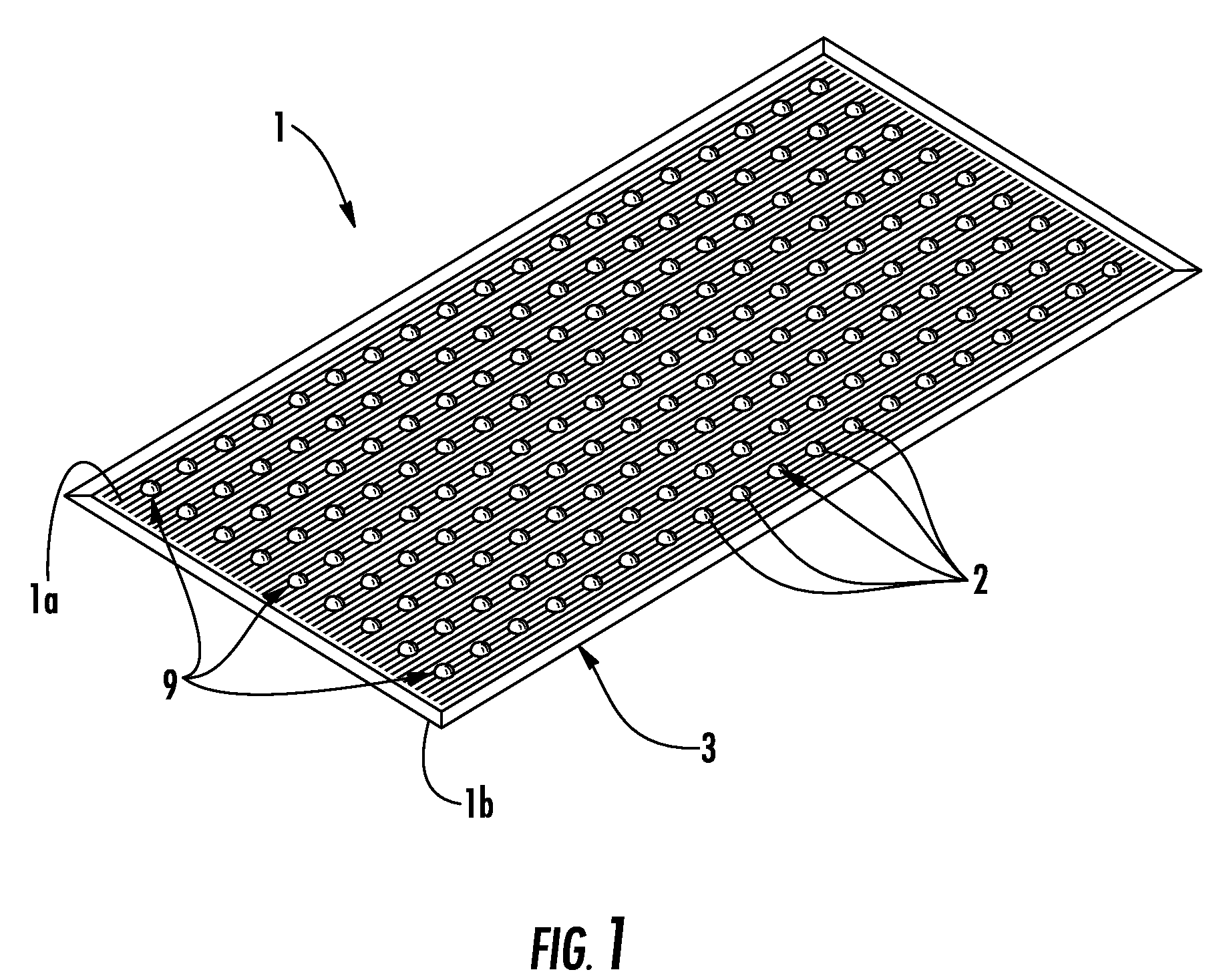

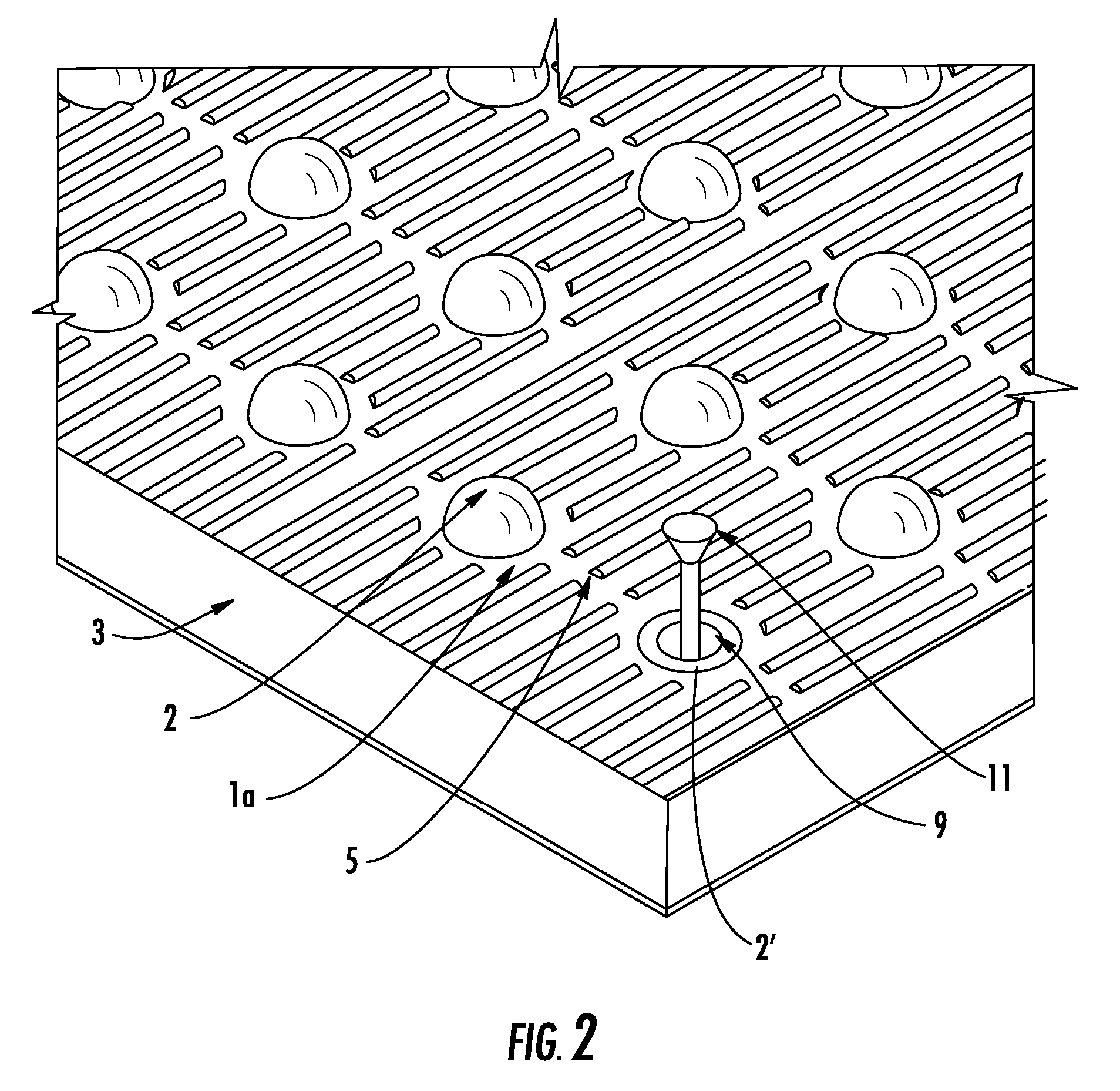

Conformable and removable tactile warning mat systems

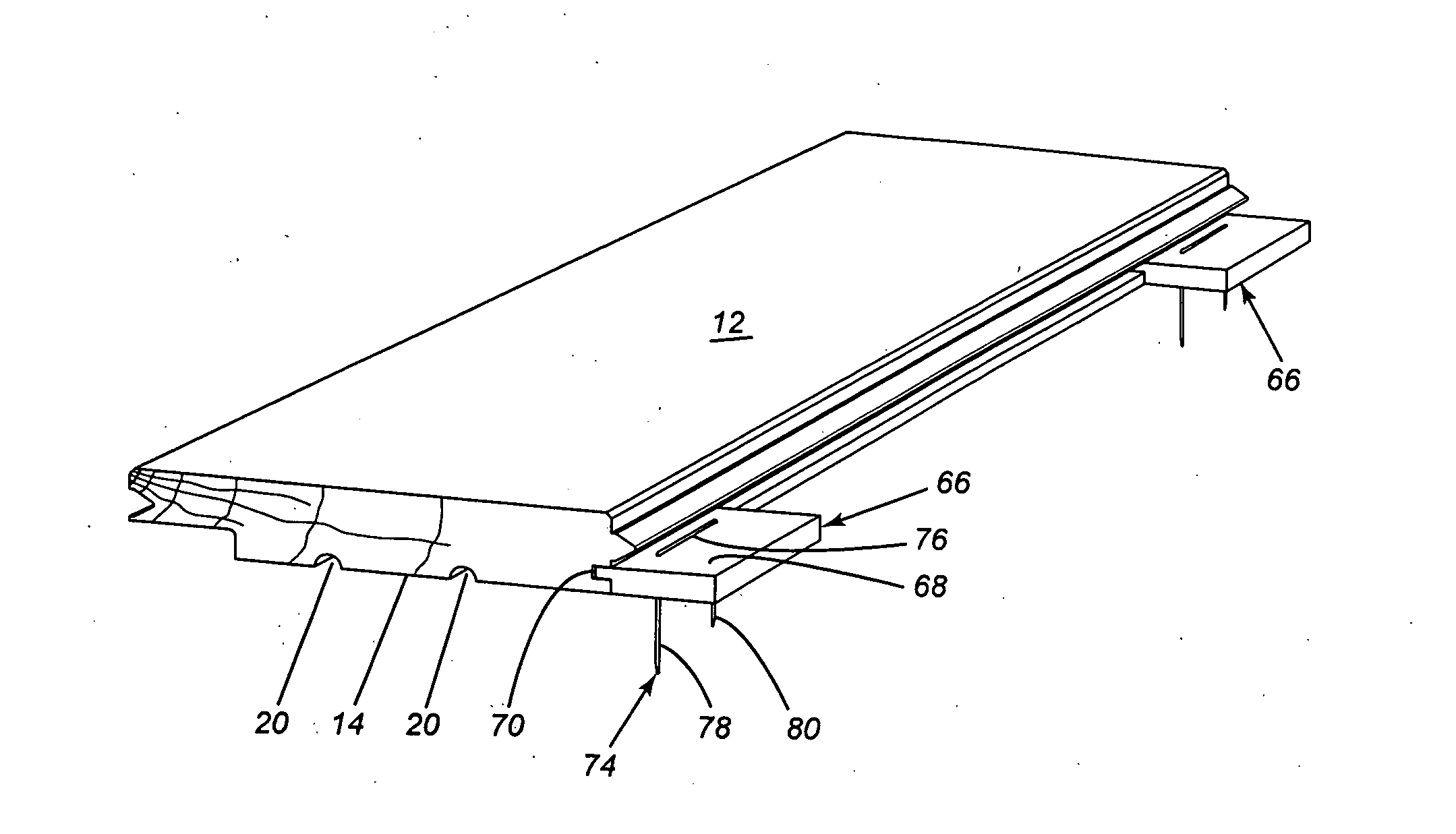

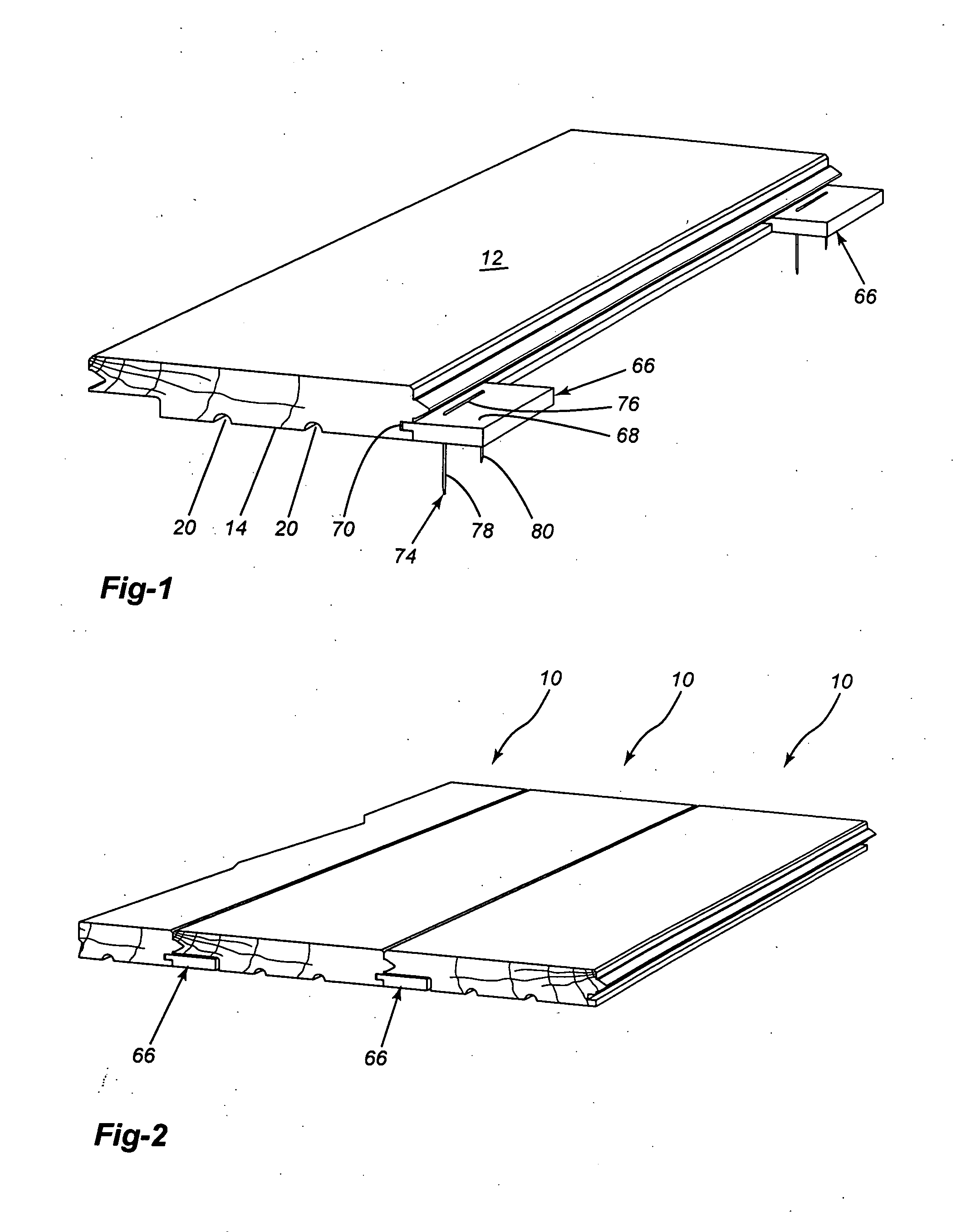

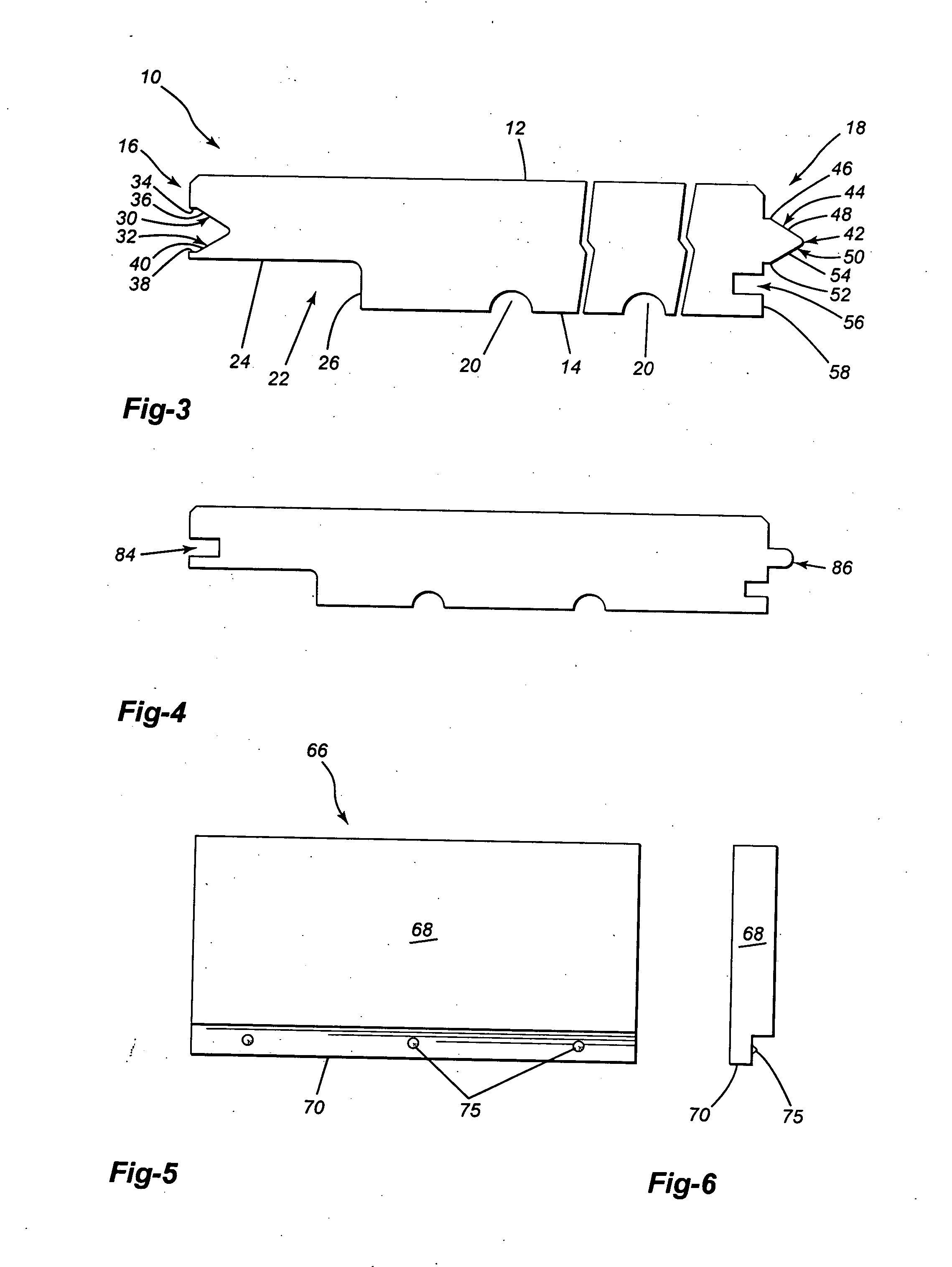

InactiveUS20060245827A1Easily and inexpensively replacedGood removal effectSingle unit pavingsIndication apparatusEngineeringLath

A tactile warning mat system includes a tactile warning mat and a plurality of elongated underlayment laths removably secured to the tactile warning mat via fasteners. The warning mat includes opposite upper and lower surfaces. The upper surface of the warning mat includes a plurality of raised projections that extend outwardly therefrom in a tactile pattern, The warning mat also includes a plurality of apertures formed therethrough. The elongated underlayment laths are removably secured to the tactile warning mat lower surface in spaced-apart relationship. The underlayment laths are adapted to be embedded within an uncured walkway surface material and each underlayment lath has a cross-sectional configuration that locks the underlayment lath within the walkway surface material when cured. Each underlayment lath includes at least one fastener receiving passageway that terminates at the underlayment lath upper surface and that is configured to removably receive a respective fastener therein.

Owner:RYDIN RICHARD W +1

Nanocarbide precipitation strengthened ultrahigh strength, corrosion resistant, structural steels and method of making said steels

InactiveUS7235212B2Corrosion resistanceReduce contentFurnace typesHeat treatment furnacesCobaltTa element

A nanocarbide precipitation strengthened ultrahigh-strength, corrosion resistant, structural steel possesses a combination of strength and corrosion resistance comprising in combination, by weight, about: 0.1 to 0.3% carbon (C), 8 to 17% cobalt (Co), 0 to 5% nickel (Ni), 6 to 12% chromium (Cr), less than 1% silicon (Si), less than 0.5% manganese (Mn), and less than 0.15% copper (Cu), with additives selected from the group comprising about: less than 3% molybdenum (Mo), less than 0.3% niobium (Nb), less than 0.8% vanadium (V), less than 0.2% tantalum (Ta), less than 3% tungsten (W), and combinations thereof, with additional additives selected from the group comprising about: less than 0.2% titanium (Ti), less than 0.2% lanthanum (La) or other rare earth elements, less than 0.15% zirconium (Zr), less than 0.005% boron (B), and combinations thereof, impurities of less than about: 0.02% sulfur (S), 0.012% phosphorus (P), 0.015% oxygen (O) and 0.015% nitrogen (N), the remainder substantially iron (Fe), incidental elements and other impurities. The alloy is strengthened by nanometer scale M2C carbides within a fine lath martensite matrix from which enhanced chemical partitioning of Cr to the surface provides a stable oxide passivating film for corrosion resistance. The alloy, with a UTS in excess of 280 ksi, is useful for applications such as aircraft landing gear, machinery and tools used in hostile environments, and other applications wherein ultrahigh-strength, corrosion resistant, structural steel alloys are desired.

Owner:QUESTEK INNOVATIONS LLC

Ultrafine crystal bainite high-strength steel and manufacturing method thereof

The invention relates to ultrafine crystal bainite high-strength steel and a manufacturing method thereof. The ultrafine crystal bainite high strength steel comprises the components by mass percent: 0.03-0.06% of C, 0.05-0.90% of Si, 1.00-2.00% of Mn, 0.05-0.25% of Cr, 0.03-0.08% of Nb, 0.02-0.04% of Al, 0.004-0.020% of Ti, 0.0010-0.0020% of B, 0.01-0.03% of Zr as well as balance of Fe and inevitable impurities, and P cm is<=0.20%. 13.14C+14.21Nb+6.32Cr+680B-1.98Mn<(Si)<12.22C+9.87Nb+8.11Cr+1210B-1.25Mn. By adopting control thermal mechanical rolling and accelerated cooling technology, the invention can obtain an ultrafine bainite ferrite lath and structure with mahaud components distributed along the interface of the lath; and the yield strength is more than 690MPa, the tensile strength is more than 780MPa, and the Charpy impact power Akv (-20 DEG C) is>=120J. A steel plate has good welding performance, is welded at the room temperature and has no welding cold crack after being placed for 48h.

Owner:BAOSHAN IRON & STEEL CO LTD

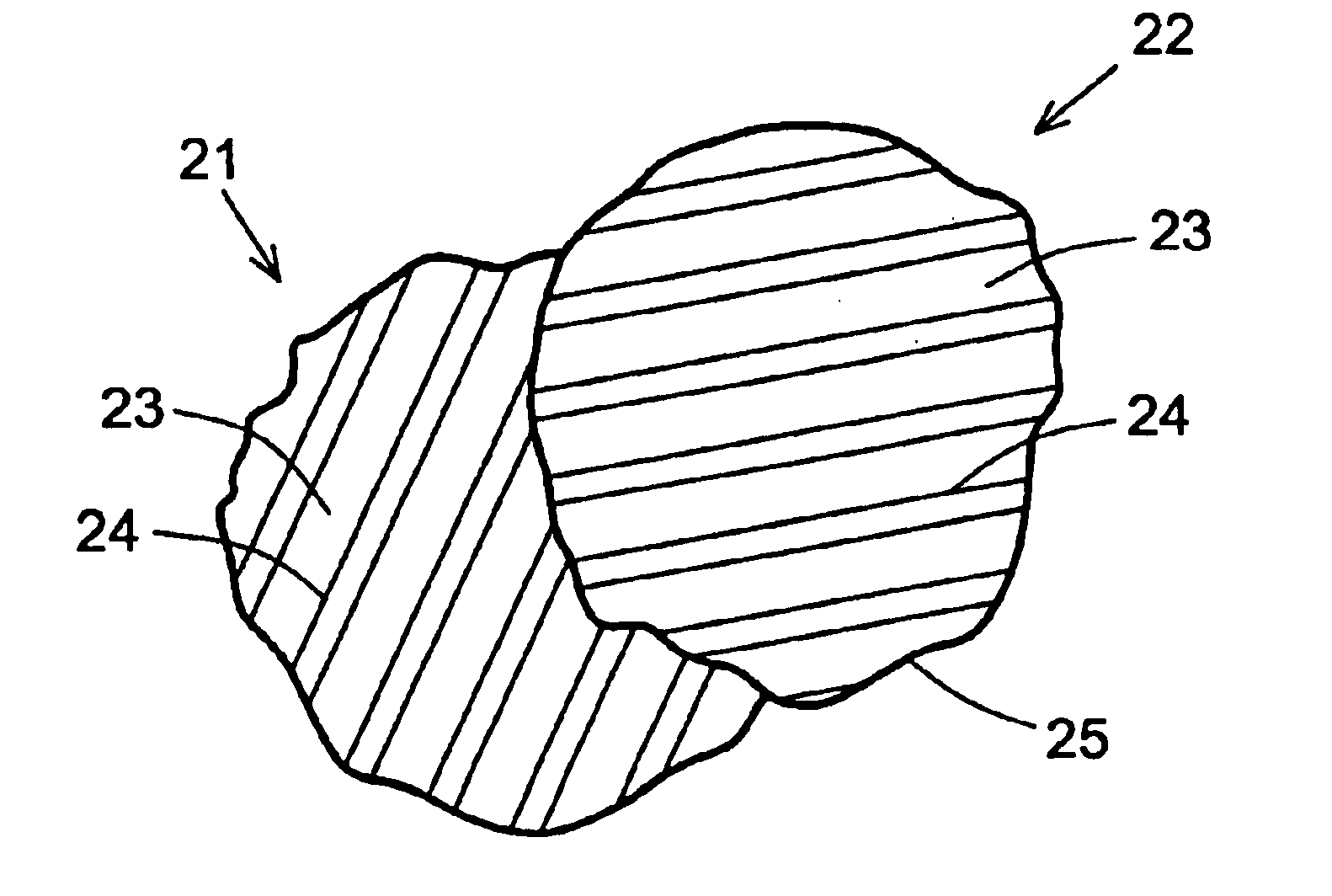

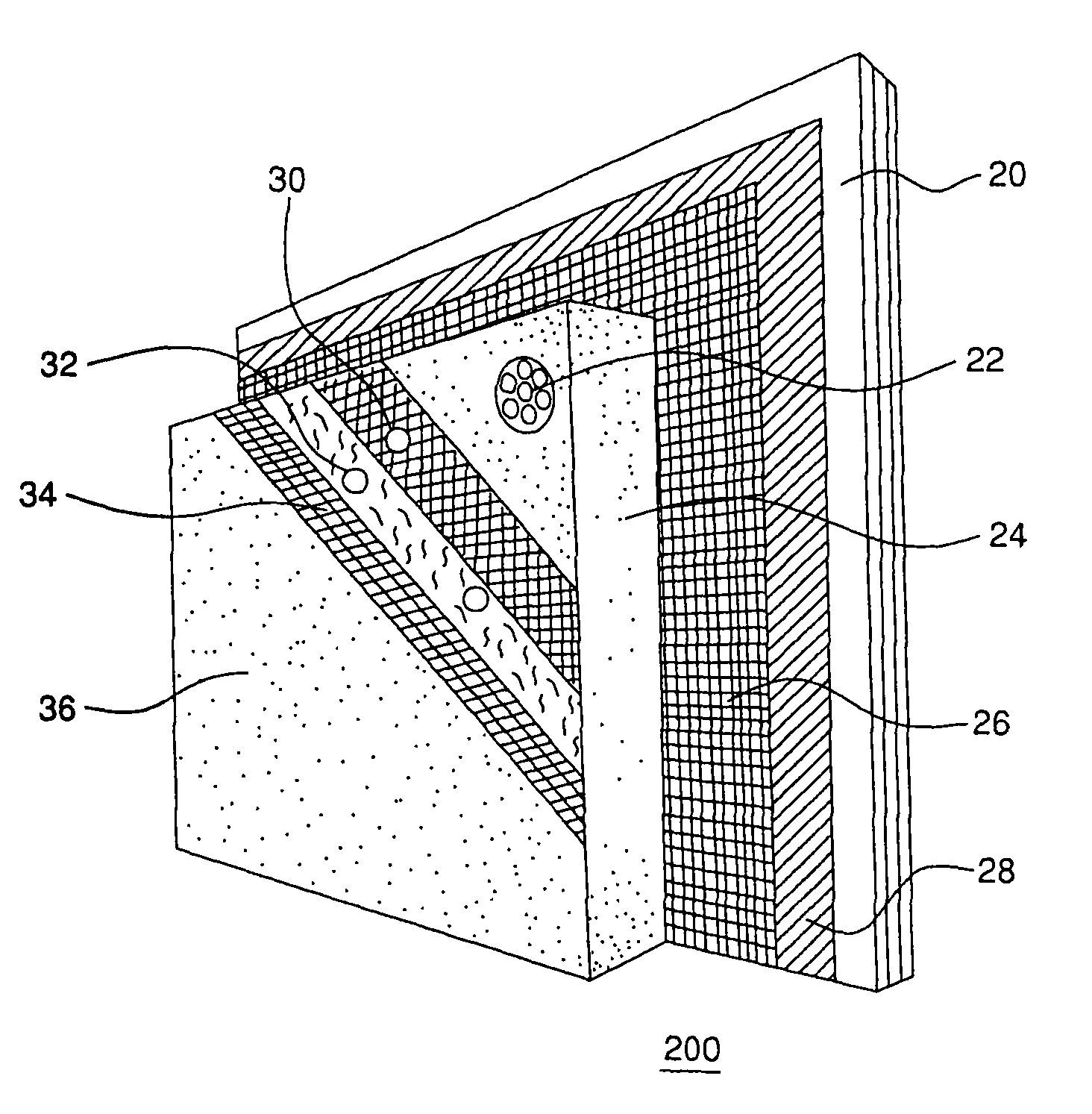

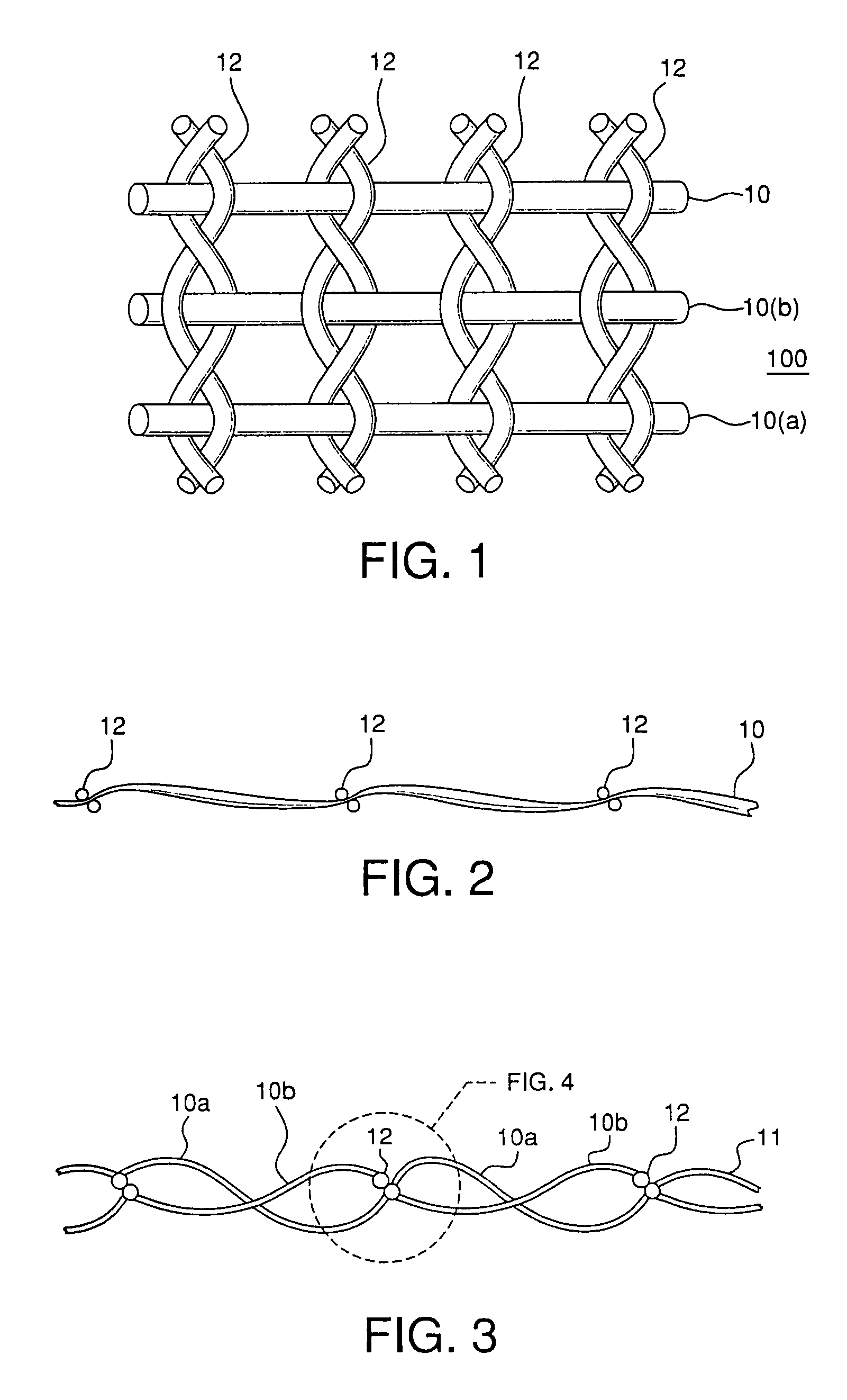

Exterior finishing system and building wall containing a corrosion-resistant enhanced thickness fabric and method of constructing same

A corrosion-resistant lath is provided for use in exterior finishing systems, such as stucco systems and exterior insulation and finish systems (“EIFS”). The lath includes in a first embodiment an open, woven fabric comprising weft and warp yarns containing non-metallic fibers, such as glass fibers. A portion of the weft yarns are undulated, resulting in an increased thickness for the fabric. The fabric is coated with a polymeric resin for substantially binding the weft yarns in the undulated condition. This invention also includes methods for making an exterior finish system and building wall including an exterior finish system using such a lath.

Owner:BASF LEC CONSTR CHEM

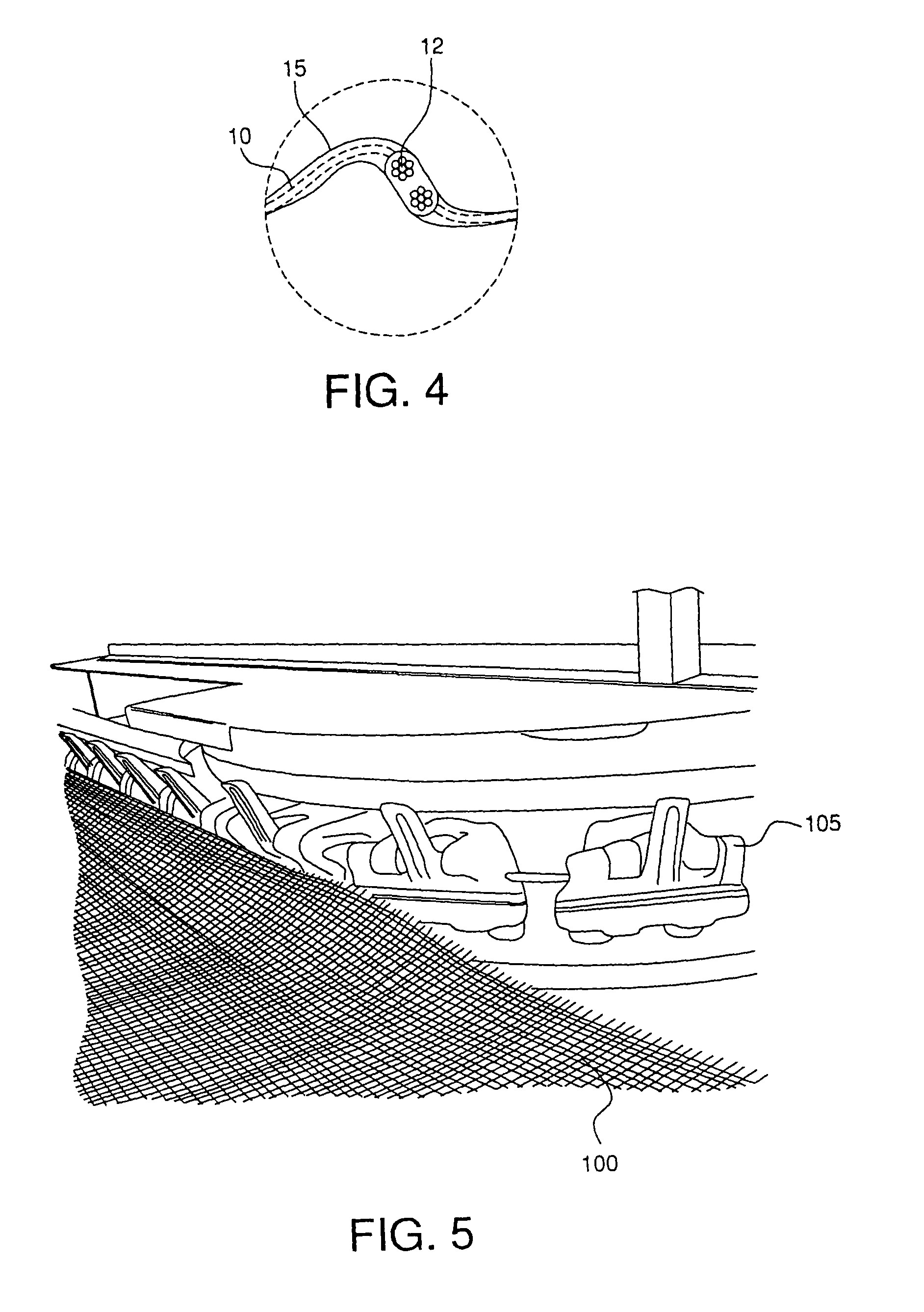

Ultra Fine-Grained Advanced High Strength Steel Sheet Having Superior Formability

ActiveUS20140205488A1Superior combination of strengthSuperior combination of ductilityTRIP steelUltra fine

A cold rolled, annealed TRIP steel sheet which has a composition including (in wt. %): C: 0.1-0.3; Mn: 4-10, Al: 0.05-5, Si: 0.05-5; and Nb: 0.008-0.1, the remainder being iron and inevitable residuals. The cold rolled sheet has an ultimate tensile strength of at least 1000 MPa, and a total elongation of at least 15%. The cold rolled sheet may have at least 20% retained austenite in its microstructure and may have greater than 50% lath-type annealed ferrite structure. The cold rolled sheet may have an ultra fine grain size of less than 5 micron for the retained austenite and ferrite.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

High tension steel plate, welded steel pipe and method for production thereof

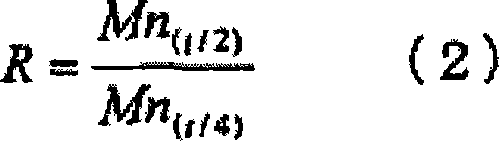

A high tension steel plate, which has a content of carbon equivalent Pcm represented by the following formula (1) of 0.180 to 0.220 % and a surface hardness of 285 or less in terms of Vickers, and has a structure wherein the percentage of a martensite austenite constituent in a surface layer portion is 10 % or less, the percentage of a mixed structure of ferrite and bainite in a portion inside the surface layer portion is 90 % or more and the percentage of bainite in the mixed structure is 10 % or more, a lath of bainite has a thickness of 1 [mu]m or less and a length of 20 [mu]m or less, and the segregation level, which is the ratio of an Mn concentration in the central segregated portion to an Mn concentration in a part having a depth from the surface of 1 / 4 of the thickness of the plate, is 1.3 or less. Pcm = C + Si / 30 + (Mn + Cu + Cr) / 20 + Ni / 60 + Mo / 15 + V / 10 + 5B (1) wherein each symbol in the formula (1) represents the mass % of each element. The high tension steel plate has a yield strength of 551 MPa or greater and a tensile strength of 620MPa or greater, and is excellent in toughness, high-speed ductile fracture characteristics and weldability.

Owner:NIPPON STEEL CORP

Petroleum casing pipe with high strength and high toughness and preparing method thereof

InactiveCN101586450ALow alloy contentLow costDrilling rodsProcess efficiency improvementAlloyMechanical property

The present invention provides a petroleum casing pipe with high strength and high toughness, wherein the weight of the component element of the casing pipe steel is characterized proportionally. The invention also provides a preparing method for preparing the petroleum casing pipe with high strength and high toughness, wherein the method comprises the following steps: 1. smelting the ingredients and casting the tube blank; 2. punching and tandem rolling of the steel tube; and 3. heat treating. The invention has the following beneficial effects: the performance of the petroleum casing pipe obtained by the method is the performance of the steel with lower content of alloy and the cost is low; a low carbon content is adopted so that the lath martensite tissue is obtained after heat treatment, the high toughness is provided after tempering and a delayed fracture resistance is provided; the complex micro-alloying processing techniques of V, Nb, Ti, B, etc. are adopted for strengthening the matrix, strengthening the grain-boundary strength, increasing the tempering resistance, reducing the content of manganese element, reducing the content of the impurity elements and improving the shape of the inclusion. The rolling ratio is optimized so that the aeolotropism of the material is remarkably reduced and the horizontal and vertical impact toughness of the material is larger than 0.8. The casing pipe of the invention far exceeds the prior highest steel grade requirement of the API standard.

Owner:TIANJIN PIPE GROUP CORP

Self-assemblable container for generic use and manufacturing method thereof

ActiveUS20110309072A1Ensure structural stabilityAvoid disassemblyBoxes/cartons making machineryPaper-makingNatural resinMoisture penetration

The present invention refers to a self-assemblable container, preferably manufactured from ecologic materials such as standard fiberboard, comprising as its main structural elements a bottom, two longitudinal sides and two transverse sides of a basically rectangular shape having cauterized perimetrical faces to prevent moisture penetration into the structural elements that make up the container, thus providing long term structural stiffness to the perimetrical faces of the container's structural elements comparable to that of the fiberboard surface. Each of the main structural elements comprises in one side adjacent to another corresponding main structural element, tensile-resistant flexible tabs or receiving slots, the other corresponding main structural element in said side adjacent to the first main structural element respectively comprising slots or flexible tensile resistant tabs, said main structural elements being assembled together by the insertion of the flexible tabs into the receiving slots. In addition, the container may comprise an antisagging brace, a lid and / or two transverse laths. The invention also refers to a method of manufacturing the structural elements of a self-assemblable container by means of perimetrical laser cutting that by reason of the extremely high cutting temperature causes a reaction of the natural resins contained in the raw material and the resulting perimetrical cauterization.

Owner:COMPANIA DE PATENTES DEL PACIFICO

Method for installing wood flooring

InactiveUS20050005558A1Quick to useAvoid debrisStrutsCovering/liningsEngineeringStructural engineering

There is provided a flooring system for hardwood floors comprised of a plurality of elongated slats wherein the slats are held in position by a plurality of connectors, each connector having a base secured to a substrate, a vertical portion extending upwardly from the base, and a generally horizontal portion extending into a groove formed in a sidewall of the elongated slat. The system permits the slats to be installed with a minimum of labor and also permits removal of the slats and their later re-use.

Owner:FLOORINNOV

Nanocarbide precipitation strengthened ultrahigh-strength, corrosion resistant, structural steels

A nanocarbide precipitation strengthened ultrahigh-strength, corrosion resistant, structural steel possesses a combination of strength and corrosion resistance comprising in combination, by weight, about: 0.1 to 0.3% carbon (C), 8 to 17% cobalt (Co), 0 to 10% nickel (Ni), 6 to 12% chromium (Cr), less than 1% silicon (Si), less than 0.5% manganese (Mn), and less than 0.15% copper (Cu), with additives selected from the group comprising about: less than 3% molybdenum (Mo), less than 0.3% niobium (Nb), less than 0.8% vanadium (V), less than 0.2% tantalum (Ta), less than 3% tungsten (W), and combinations thereof, with additional additives selected from the group comprising about: less than 0.2% titanium (Ti), less than 0.2% lanthanum (La) or other rare earth elements, less than 0.15% zirconium (Zr), less than 0.005% boron (B), and combinations thereof, impurities of less than about: 0.02% sulfur (S), 0.012% phosphorus (P), 0.015% oxygen (O) and 0.015% nitrogen (N), the remainder substantially iron (Fe), incidental elements and other impurities. The alloy is strengthened by nanometer scale MZC carbides within a fine lath martensite matrix from which enhanced chemical partitioning of Cr to the surface provides a stable oxide passivating film for corrosion resistance. The alloy, with a UTS in excess of 280 ksi, is useful for applications such as aircraft landing gear, machinery and tools used in hostile environments, and other applications wherein ultrahigh-strength, corrosion resistant, structural steel alloys are desired.

Owner:KUEHMANN CHARLES J +2

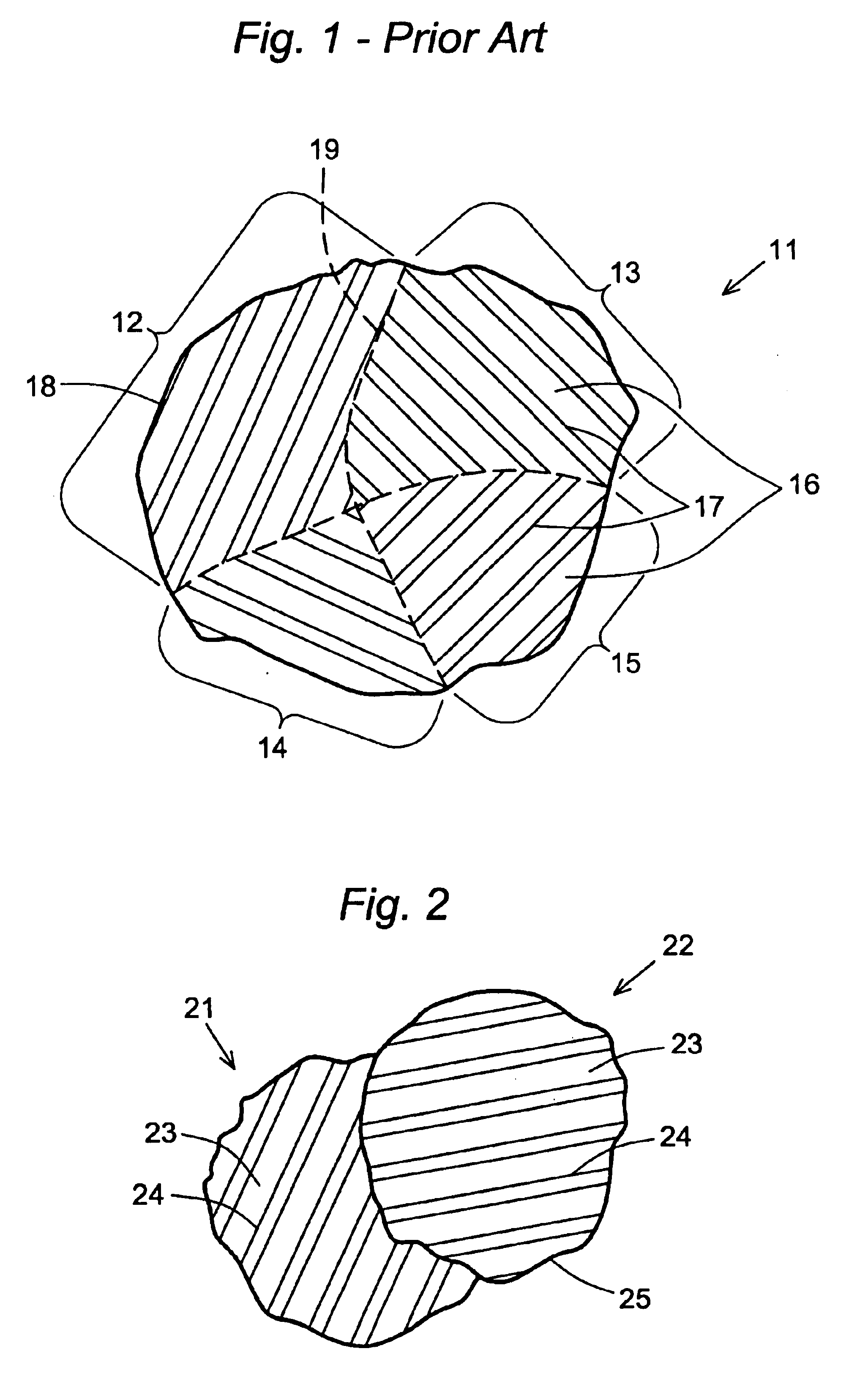

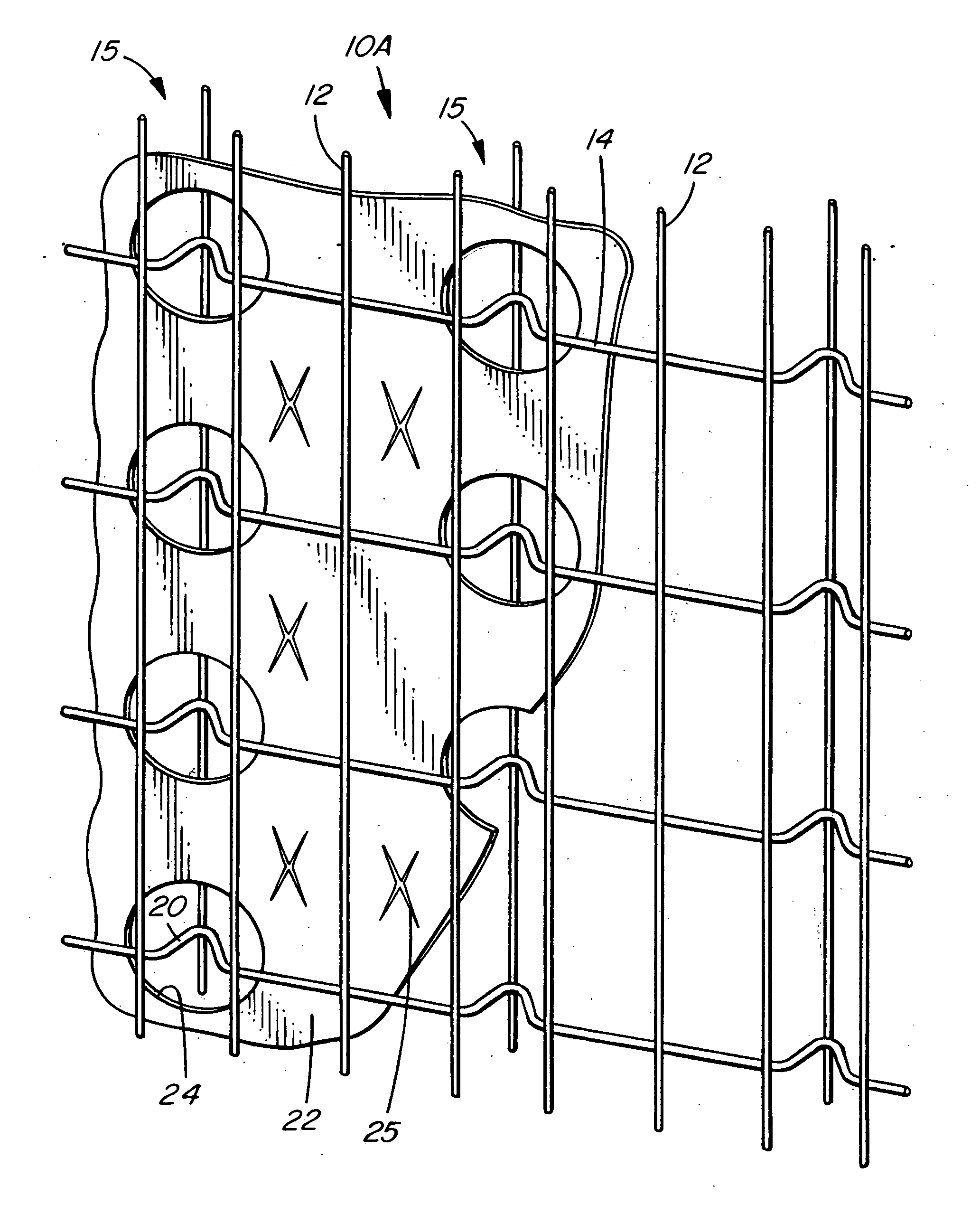

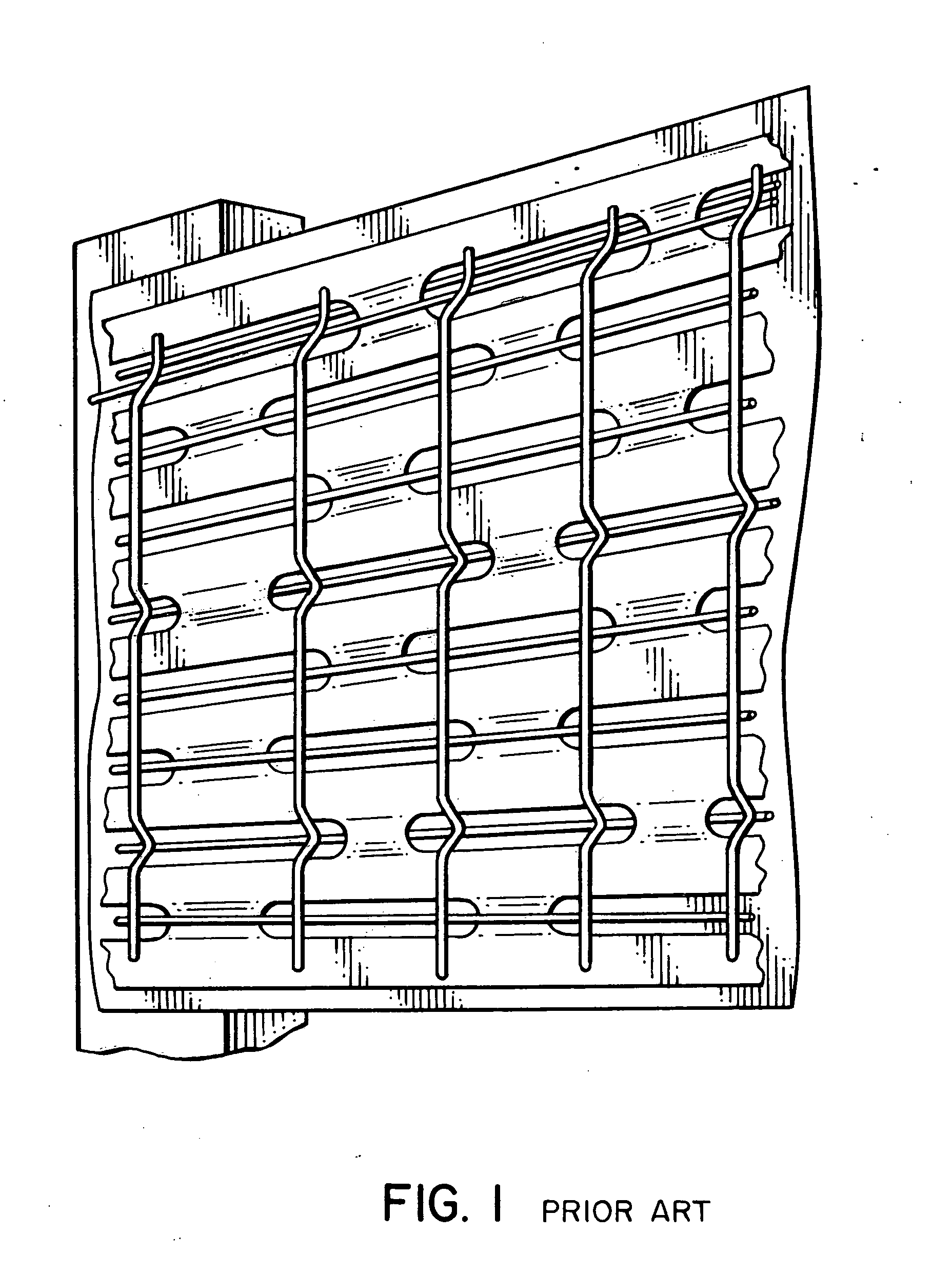

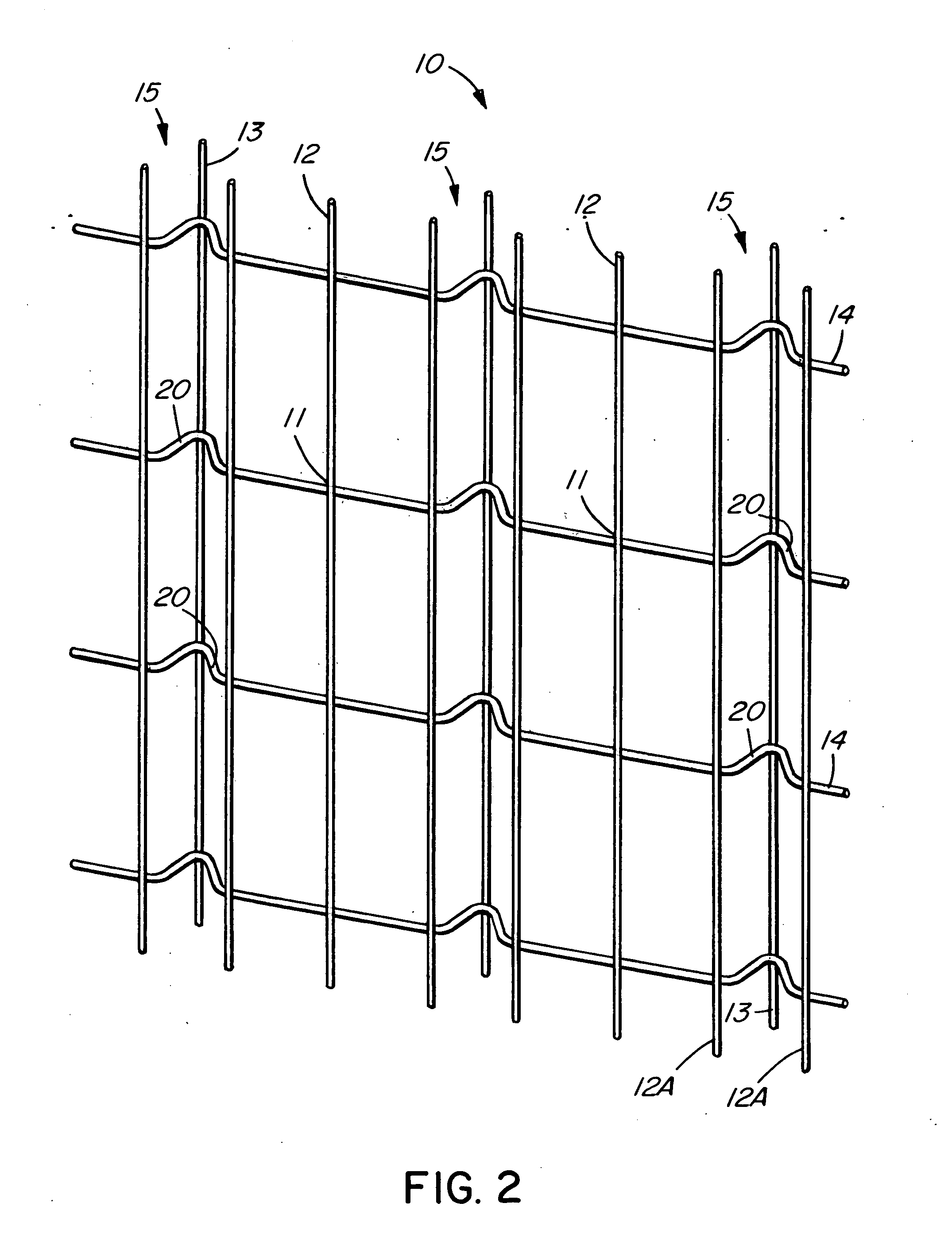

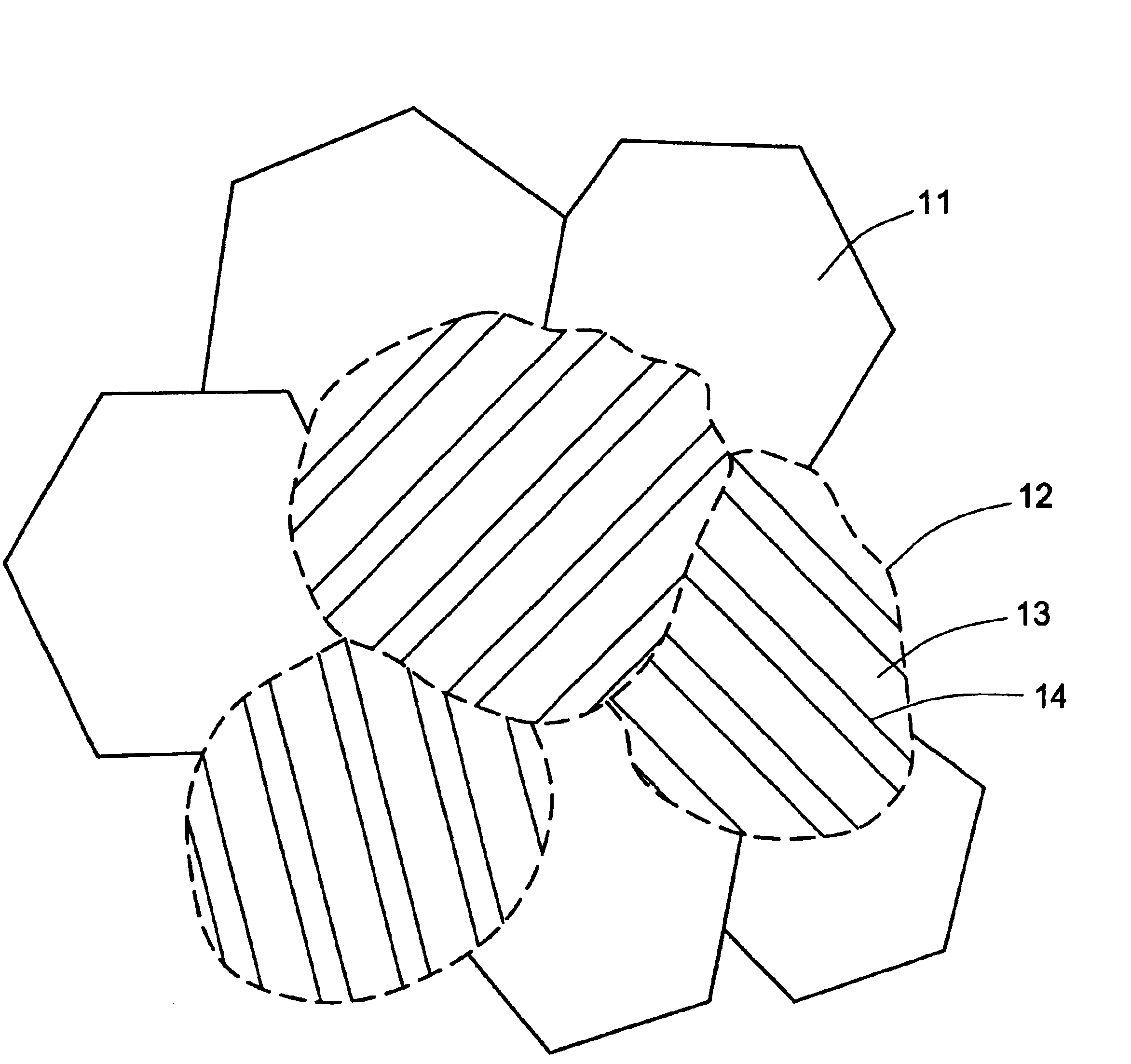

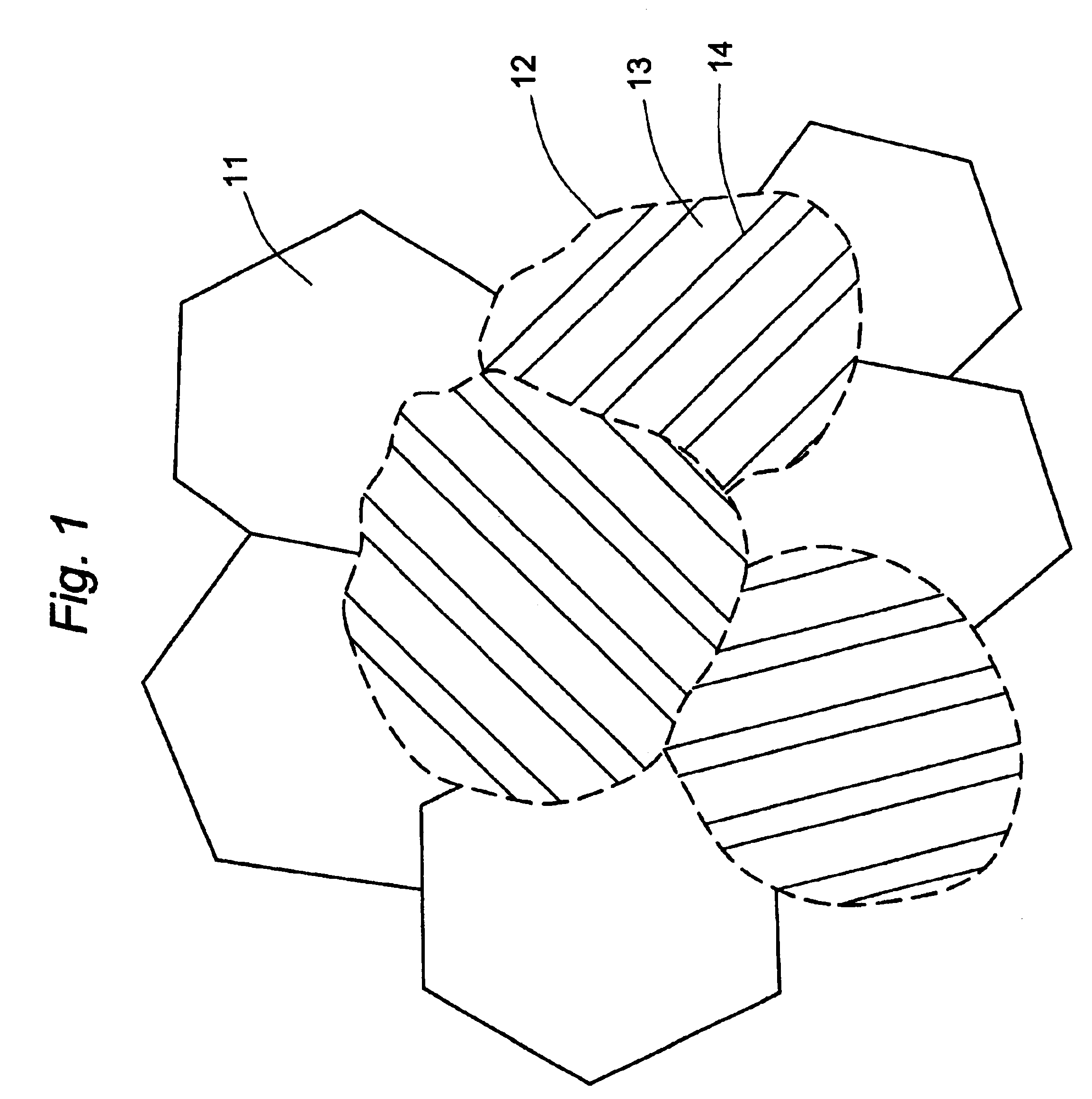

Self-stiffened welded wire lath assembly

A self-furring wire lath comprises a mesh of transverse and longitudinal wires welded at their intersections. Stiffening trusses are formed by bent sections in the transverse wires and longitudinal wires attached to the shoulders of the bent sections. A barrier layer material is retained in the lath between the apex of the bent sections and the principal plane of the lath mesh. The barrier layer material has apertures that coincide with the intersections only at the bent sections to enable mesh size reduction without compromising the barrier layer but still allow the fabrication of the lath. The lath provides good embedment in the stucco, reduces cracking and wastage of stucco while remaining easy to work with.

Owner:SACKS ABRAHAM +4

Low cost high strength martensitic stainless steel

A cobalt-free low cost high strength martensitic stainless steel, with concentration of Ni up to 3.0% and Mo up to 1.0% of weight, has HRC of 53, UTS of 297 ksi, YS of 220 ksi, Charpy V-notch impact energy of 17.8 ft-lb, corrosion resistance in salt spray test ASTM 117. The steel was melted in an open induction furnace and vacuum arc remelting (VAR) and / or electroslag remelting (ESR) were not used to refine the steel. Further processing included homogenized annealing, hot rolling, and recrystallization annealing. The steel was heat treated by oil quenching, refrigeration, and low tempering. The steel has a microstructure consisting essentially of small packets of fine martensite laths, retained austenite, and carbides as centers of growth of the martensite laths. The cost and energy in making the steel are substantially reduced.

Owner:FEDCHUN VLADIMIR A +1

Blind cut down machine

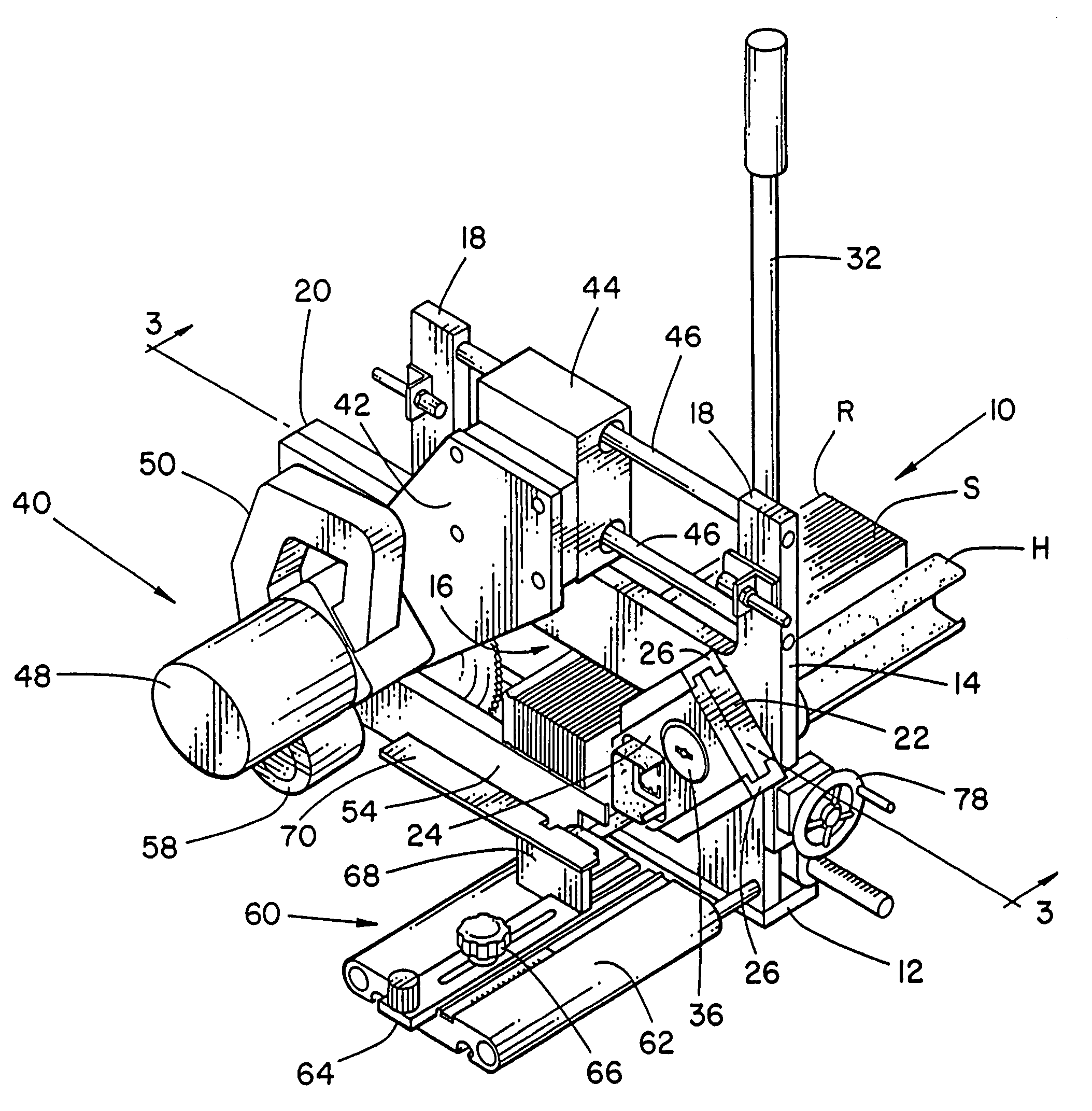

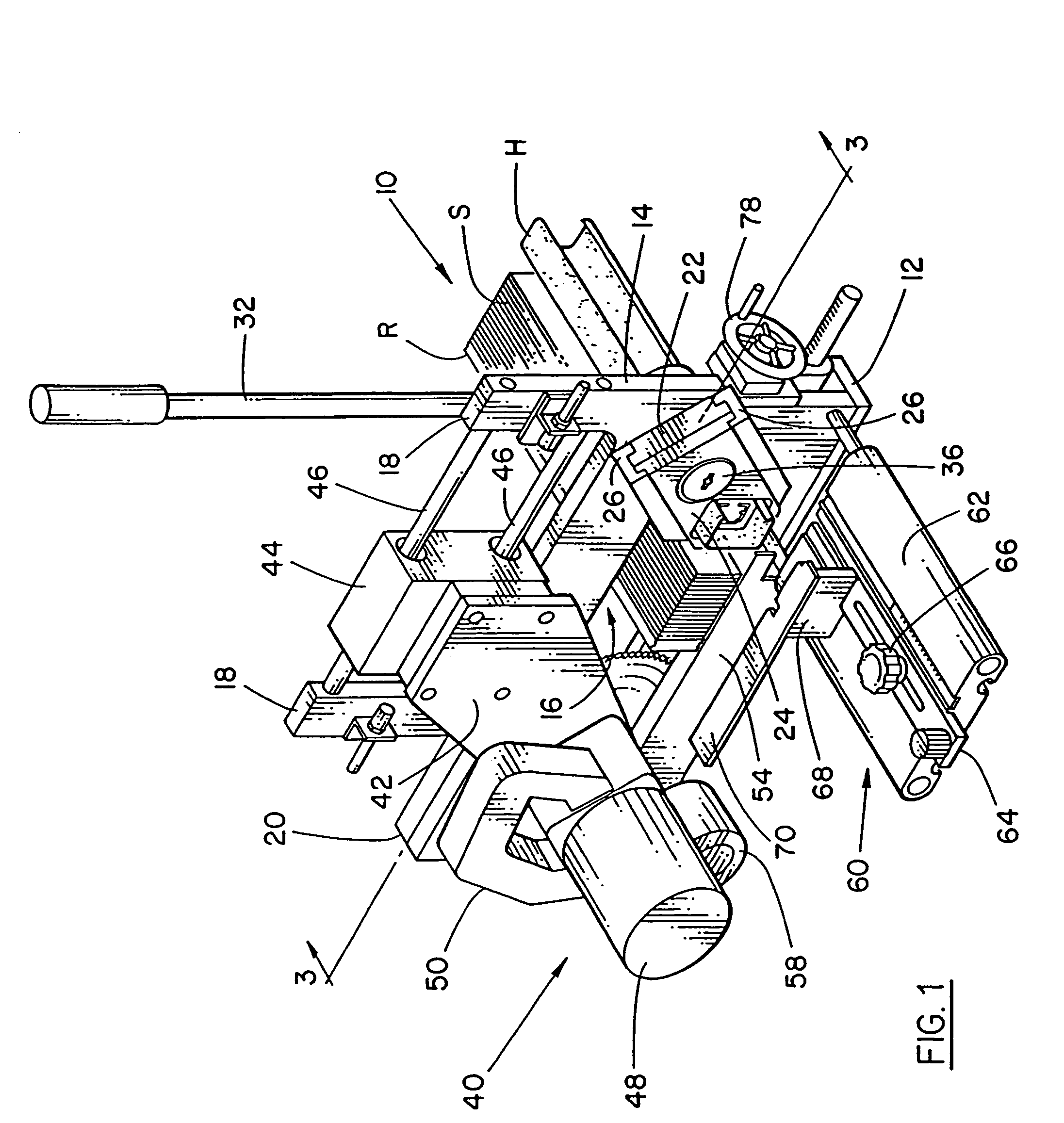

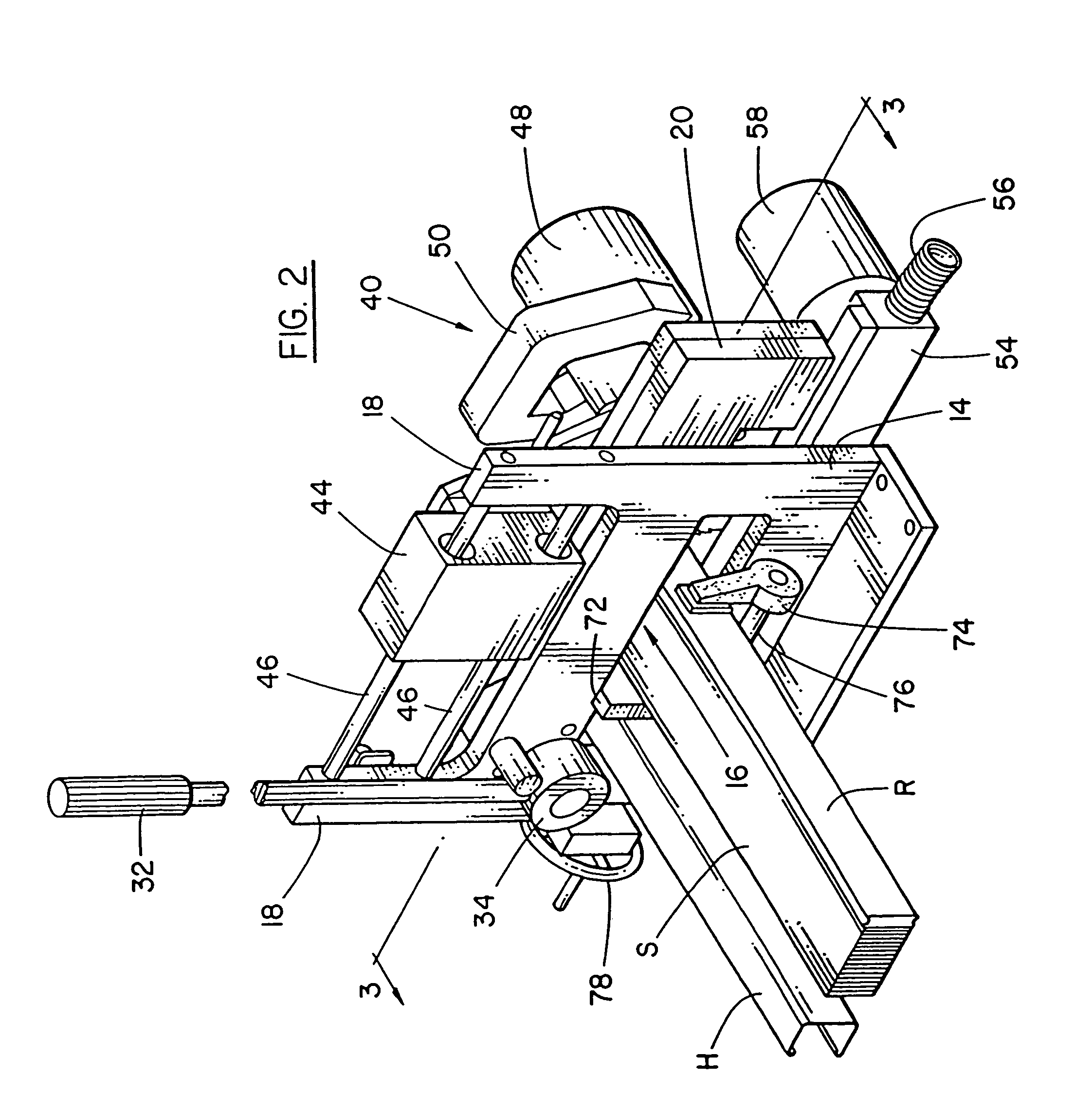

InactiveUS7017459B2Easy to cutMetal sawing devicesDoor/window protective devicesWindow shutterEngineering

A blind cut-down apparatus for trimming a blind down to size the blind having at least a head rail component, and blind slats suspended from the head rail, and having a blind holding plate with an opening for holding the components in position for cutting, a slat cutter moveable relative to the holding plate for cutting blind components held in the holding plate, and including a movement device for moving the cutter. Also disclosed is a method of saw cutting ends of blind components in which the blind components are held in a head plate and in which a cutter cuts the components. Also disclosed is a blind cut down machine having a moveable head rail support mounted on a blind holder plate, with a moveable head rail opening in the support, with the support being selectively moveable into and out of position for accommodating various types of head rail.

Owner:SHADE O MATIC

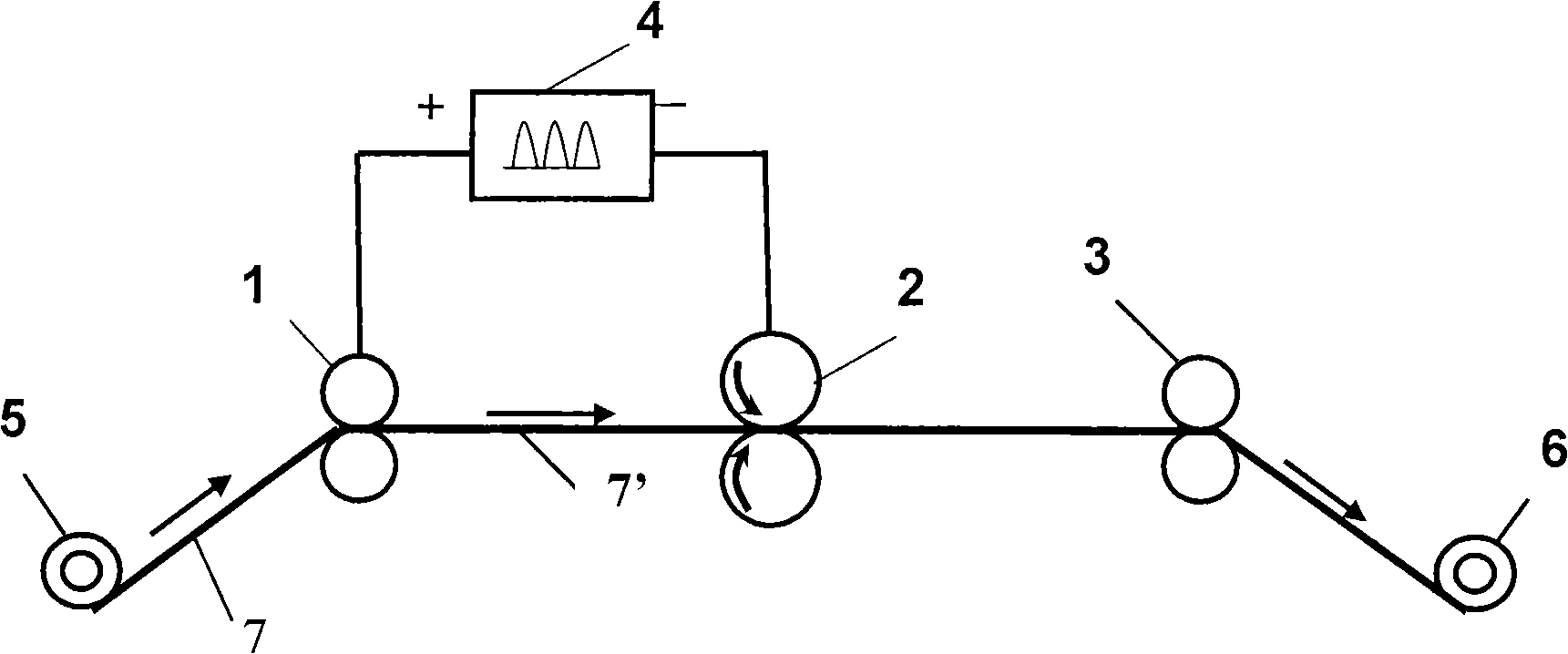

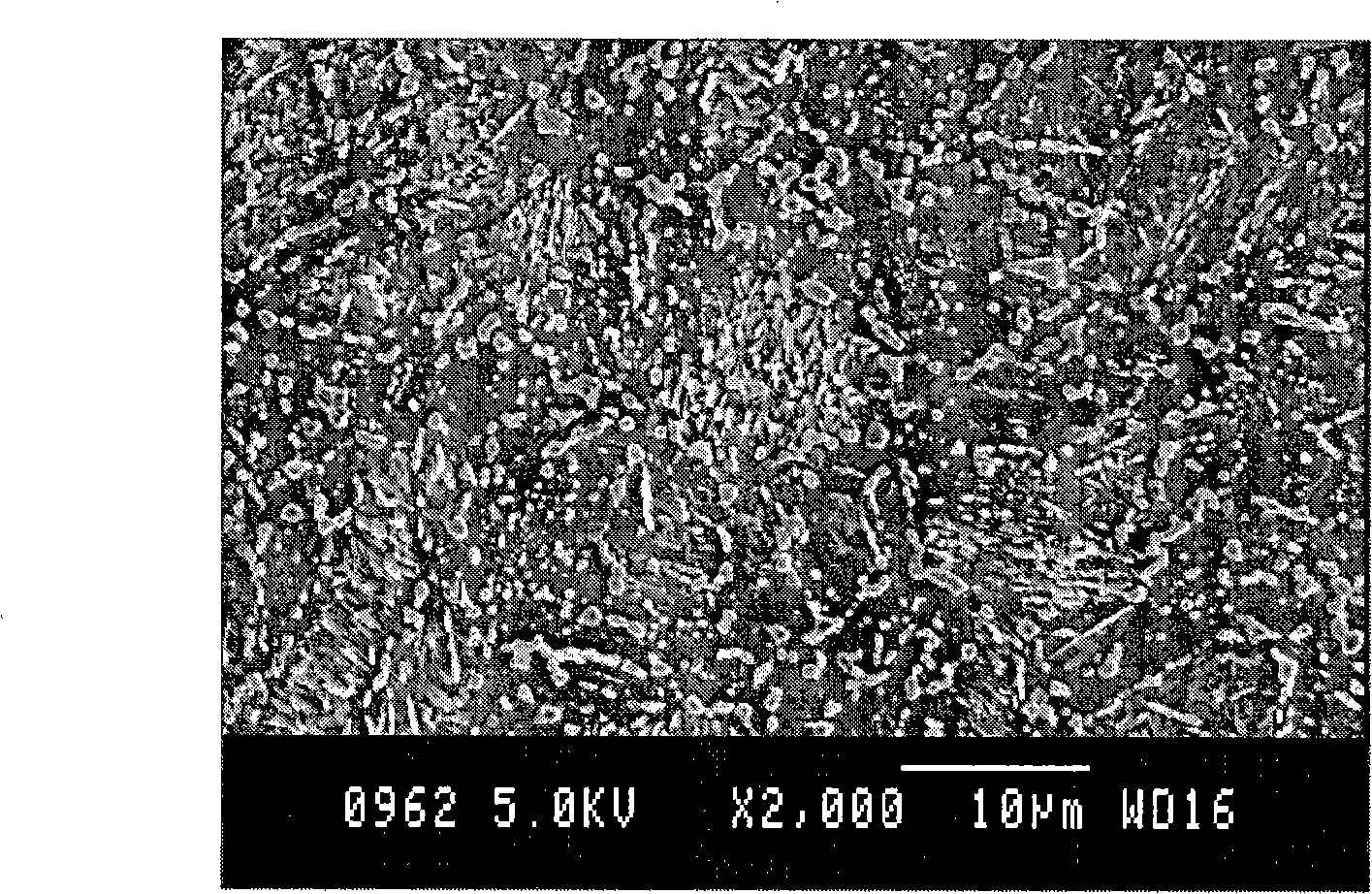

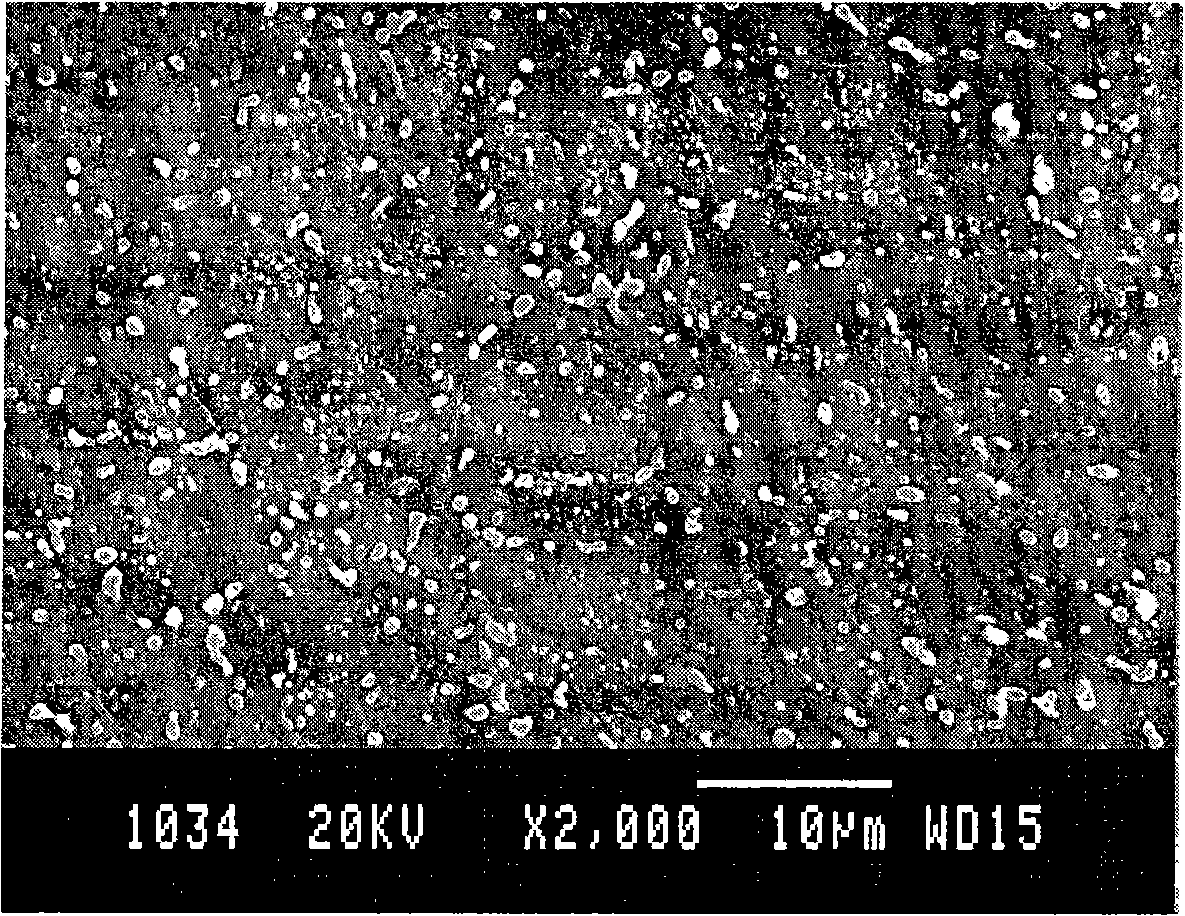

High-strength high-toughness AZ91 magnesium alloy strip eletrotoughening process method and system

InactiveCN101298653AOxidation does not occurToughening treatment is widely applicableHigh energyRoom temperature

The invention discloses an electro-strengthening and toughening processing method of a belt material of AZ91 magnesium alloy and a system thereof. The electro-strengthening and toughening processing method comprises following steps: when the belt material of magnesium alloy is transmitted at a certain speed which is driven by a roller on an electro plastic rolling machine, high-energy impulse current that is output by an impulse power source through an electrode is input into an electriferous region section of the moving belt material of magnesium alloy, and the Joule heating effect and the non-heating effect are generated in the electriferous region section, thus causing the phase transition of internal microscopic constitution from bulky lath-shaped Beta-Mg17Al12 that are gathering and agglomerating in an initial state to Beta-Mg17Al12 particles that are evenly distributed and approximately sphere-shaped, or causing the solid solution effect that leads Beta-Mg17Al12 to be dissolved in a substrate; the processed belt material can be naturally air cooled at room temperature. The electro-strengthening and toughening processing method of the belt material of AZ91 magnesium alloy has short processing time and high production efficiency, and simultaneously avoids the high-temperature oxidation of the magnesium alloy. After the electro-strengthening and toughening processing, the microscopic constitution of the belt material of magnesium alloy can be remarkably improved, the unit extension of the microscopic constitution is increased from 11.8 percent in the initial aging state to over 20 percent, and the tensile strength of the microscopic constitution is not dramatically lowered.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Ultra-high strength Ausaged steels with excellent cryogenic temp. toughness

An ultra-high strength, weldable, low alloy steel with excellent cryogenic temperature toughness in the base plate and in the heat affected zone (HAZE) when welded, having a tensile strength greater than 830 MAP (120 KS) and a micro-laminate microstructure comprising austenite film layers and fine-grained marten site / lower bainite laths, is prepared by heating a steel slab comprising iron and specified weight percentages of some or all of the additives carbon, manganese, nickel, nitrogen, copper, chromium, molybdenum, silicon, niobium, vanadium, titanium, aluminum, and boron; reducing the slab to form plate in one or more passes in a temperature range in which austenite recrystallizes; finish rolling the plate in one or more passes in a temperature range below the austenite recrystallization temperature and above the Ar3 transformation temperature; quenching the finish rolled plate to a suitable Quench Stop Temperature (QST); stopping the quenching; and either, for a period of time, holding the plate substantially isothermally at the QST or slow-cooling the plate before air cooling, or simply air cooling the plate to ambient temperature.

Owner:EXXONMOBIL UPSTREAM RES CO

Triple-phase nano-composite steels

Carbon steels of high performance are disclosed that contain a three-phase microstructure consisting of grains of ferrite fused with grains that contain dislocated lath structures in which laths of martensite alternate with thin films of austenite. The microstructure can be formed by a unique method of austenization followed by multi-phase cooling in a manner that avoids bainite and pearlite formation and precipitation at phase interfaces. The desired microstructure can be obtained by casting, heat treatment, on-line rolling, forging, and other common metallurgical processing procedures, and yields superior combinations of mechanical and corrosion properties.

Owner:MMFX STEEL CORP OF AMERICA +1

Floor and Wall Covering Assembly

InactiveUS20170217133A1Reduce in quantityLow costCovering/liningsSynthetic resin layered productsThermoplasticUv protective

A floor and wall covering plank includes sequentially, from bottom to top, a waterproof substrate, an adhesive layer, a veneer layer, a paint protective layer, a UV protective layer. The plank may further include optionally one or more of a padding layer and veneer layer below the waterproof substrate. The edges of the planks are routed to form a click locking system, squared or angled edges, or a tongue and groove configuration for assembling different planks together to form a floor or a wall covering. The waterproof substrate includes, in weight percentage, about 20-50% polymer material such as vinyl containing thermoplastics resin, about 20-50% calcium carbonate filler, and about 3-20% of the wood flour. A method is provided to make the floor and wall covering plank. The method includes extruding the waterproof core substrate.

Owner:AMERICAN AQUAWOOD INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com