Patents

Literature

171 results about "TRIP steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

TRIP steel are a class of high-strength steel alloys typically used in naval and marine applications and in the automotive industry. TRIP stands for "Transformation induced plasticity," which implies a phase transformation in the material, typically when a stress is applied. These alloys are known to possess an outstanding combination of strength and ductility.

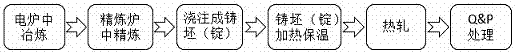

High-strength plastic accumulation TRIP (Transformation-Induced Plasticity) steel plate and preparation method thereof

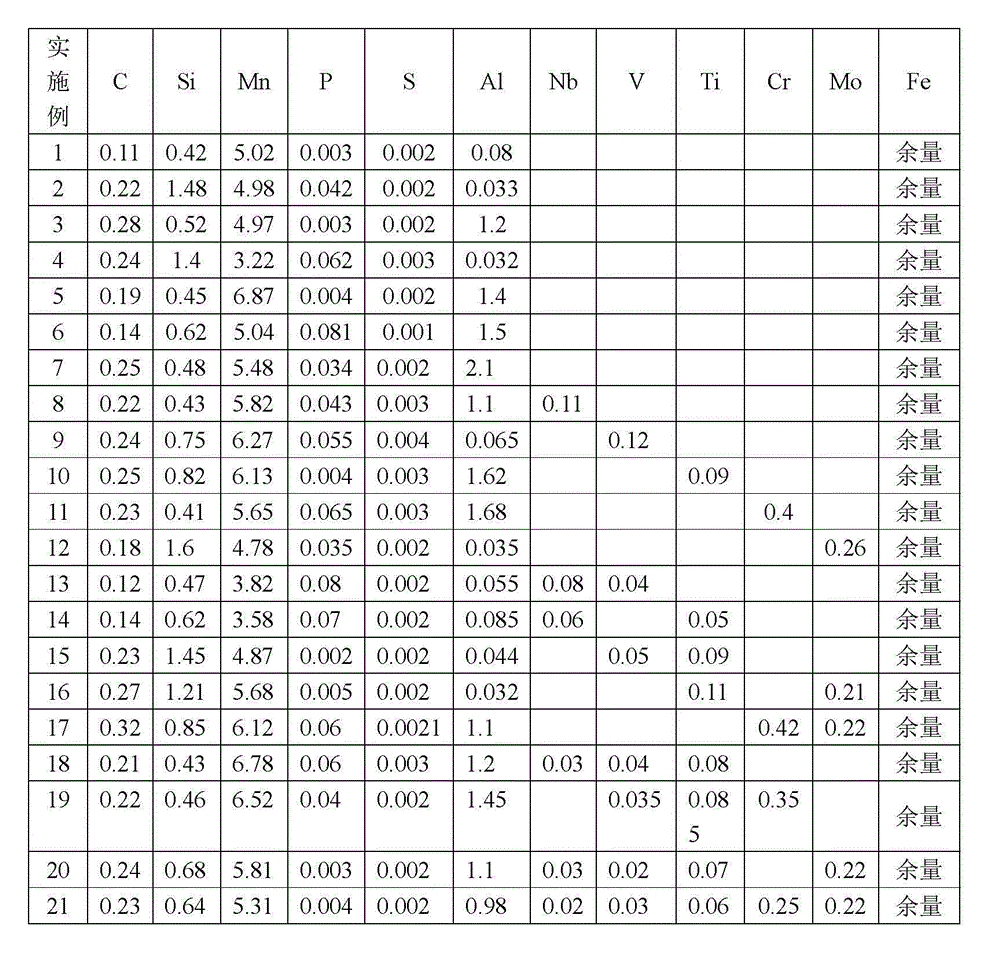

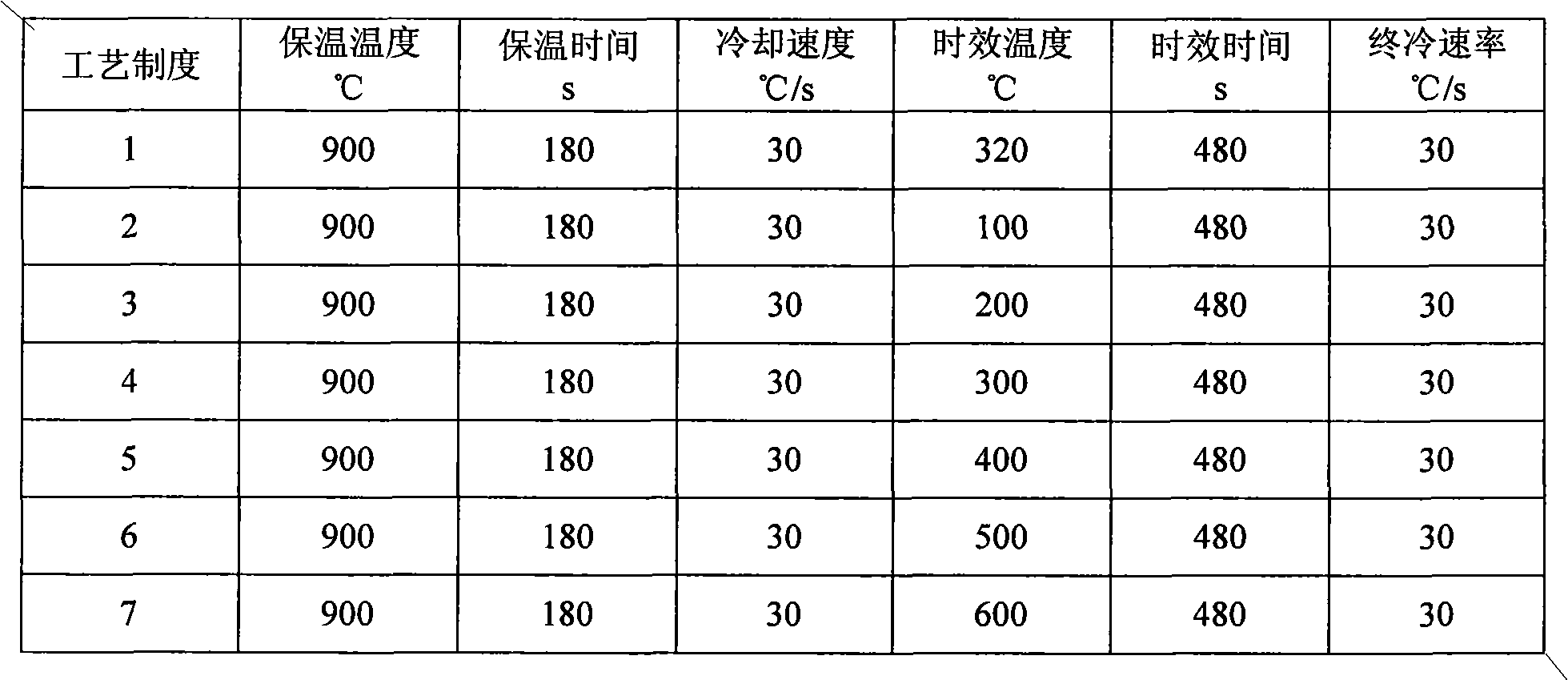

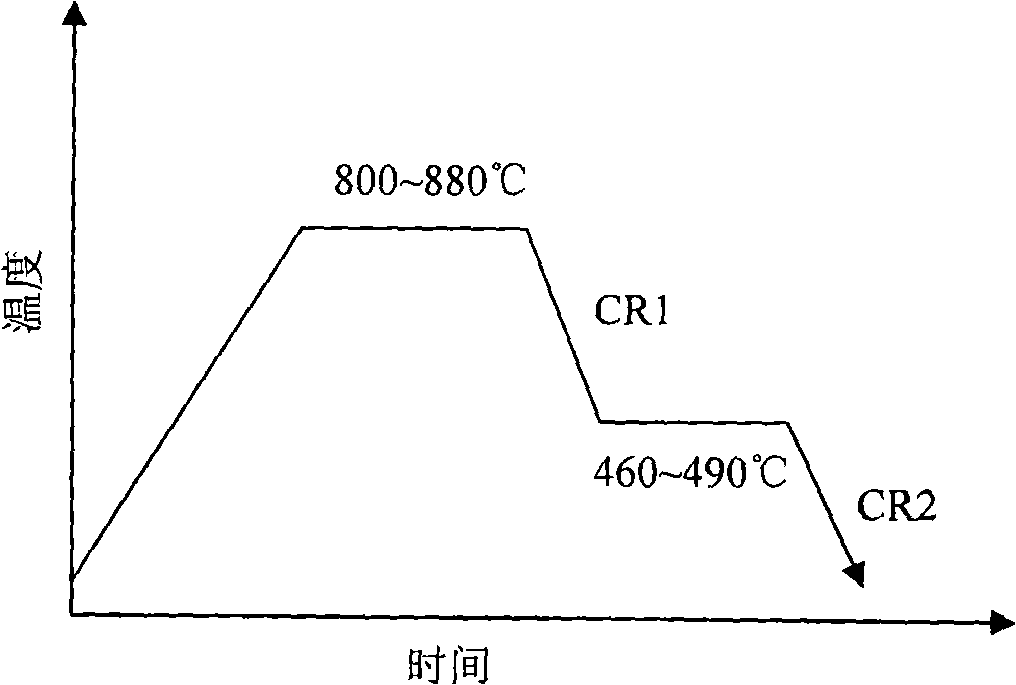

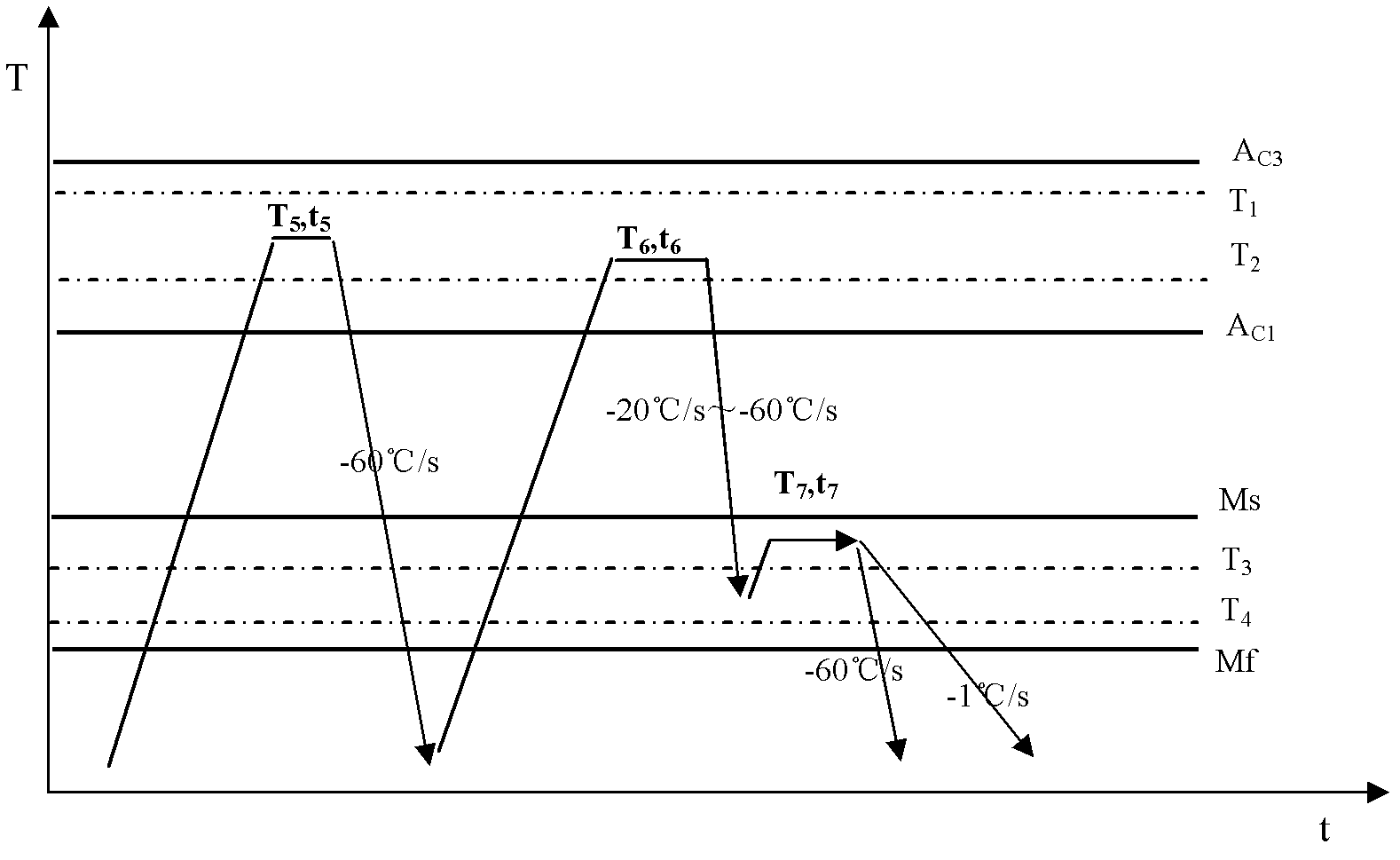

The invention discloses a high-strength plastic accumulation TRIP (Transformation-Induced Plasticity) steel plate and a preparation method thereof, wherein the high-strength plastic accumulation TRIP steel plate consists of the following elements: 0.08%-0.5% of C, 0.4%-2.0% of Si, 3%-8% of Mn, smaller than or equal to 0.10% of P, smaller than or equal to 0.02% of S, 0.02%-4% of Al, smaller than or equal to 0.01% of N, 0-0.5% of Nb, 0-0.5% of V, 0-0.5% of Ti, 0-2% of Cr, 0-1% of Mo, and the balance of Fe and unavoidable impurities. In a microstructure, martensites account for 30%-90% by area occupation ratio, austenites account for 5%-30% by volume fraction, and the remaining is few ferrites and cementites. The hot rolling heating-up temperature is 1100-1250 DEG C, the holding time is more than or equal to 2 hours, the initial rolling temperature is higher than or equal to 1100 DEG C, the final rolling temperature is 850-950 DEG C, and the coiling temperature is lower than 720 DEG C; a hot rolled plate is 2-4mm in thickness; and the cover annealing is furnace heating for heat preservation at 550-750 DEG C for 1-20 hours and then furnace cooling.

Owner:ANGANG STEEL CO LTD

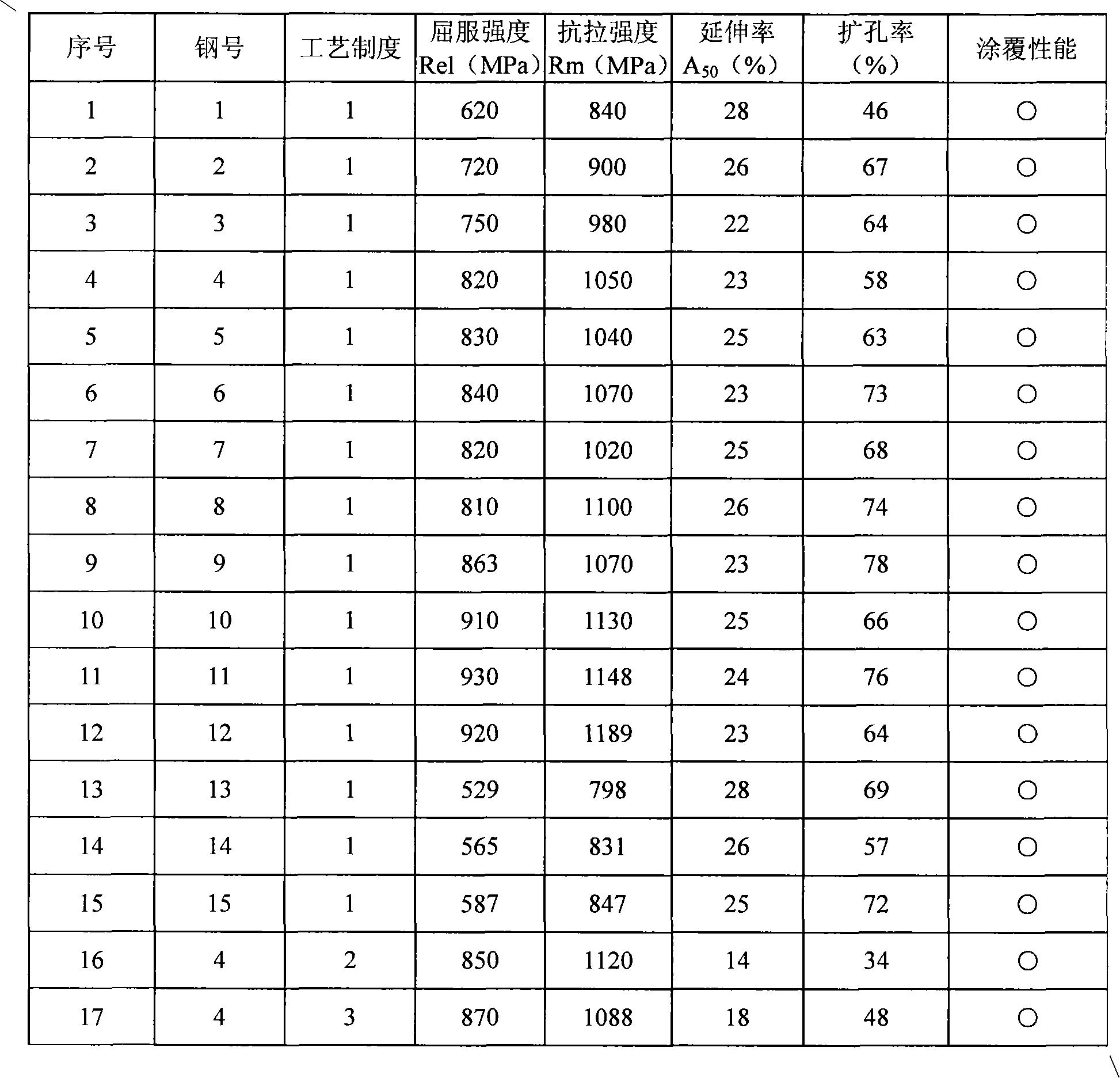

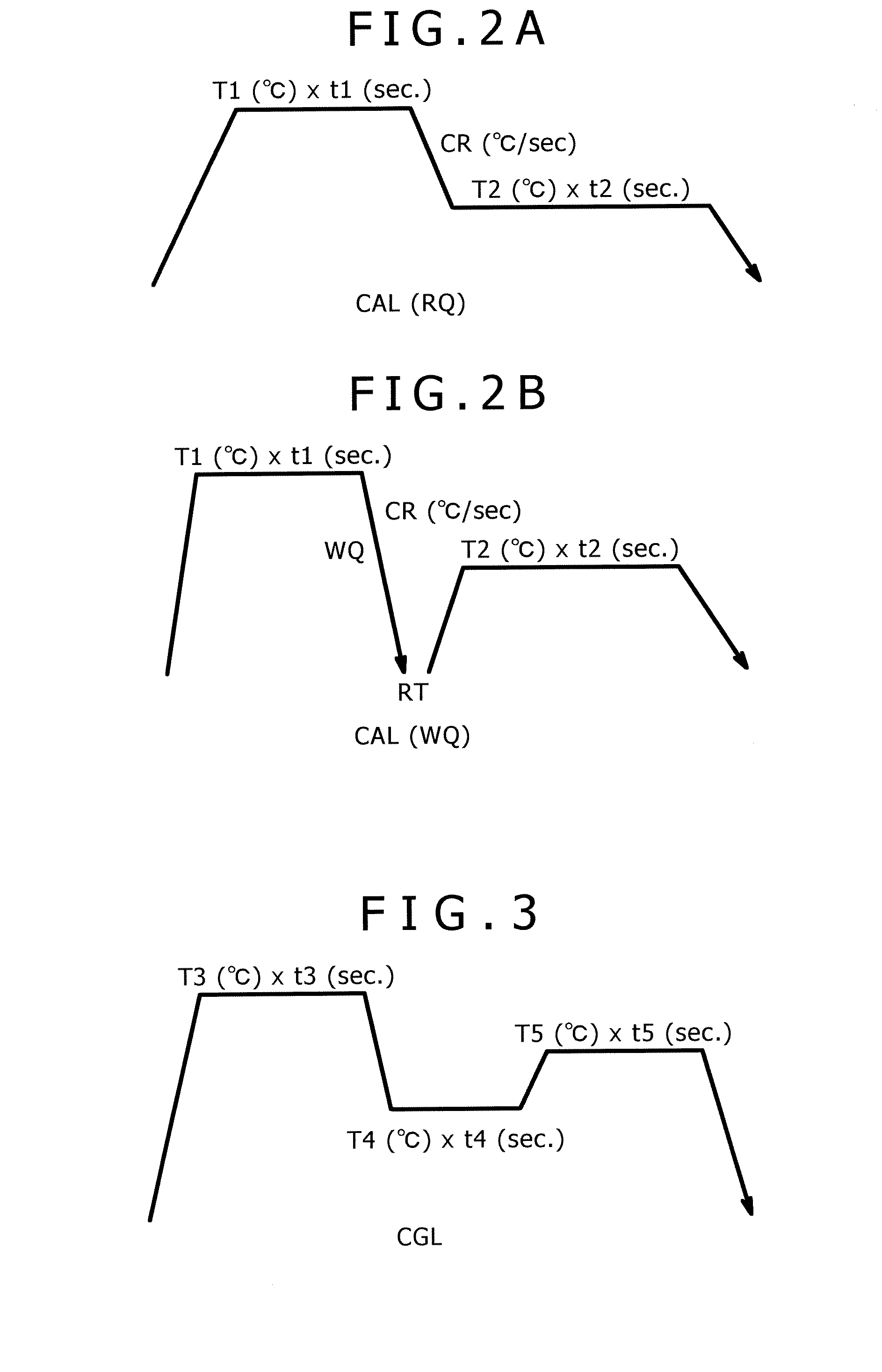

High-strength cold-rolled plate with favorable forming property and preparation method thereof

The invention provides a high-strength cold-rolled plate with favorable forming property and a preparation method thereof. The high-strength cold-rolled plate comprises the following chemical components: 0.05-0.6% of C, being more than or equal to 0.3% and being less than 0.8% of Si, 0.5-4.0% of Mn, being more than ore equal to 0.2% of P, being more than or equal to 0.002% of S, being more than or equal to 0.1% of Al, being more than or equal to 0.01% of N, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: smelting, continuous-casting, hot-rolling, cold-rolling and continuous-annealing, wherein annealing temperature is higher than that of Ac3, holding time is 3-30 minutes; quickly cooling to 100-600 DEG C at the rate of 30-100 DEG C / s, keeping the temperature for 3-30 minutes, and finally cooling to room temperature at the rate of 5-30 DEG C / s. The invention adopts low-silicon low-aluminum component design and heat treatment technique; the strength level of the produced bainite TRIP steel is greater than 780 MPa; and the produced bainite TRIP steel has favorable strength, plasticity, extensibility, chambering property and coating property.

Owner:ANGANG STEEL CO LTD

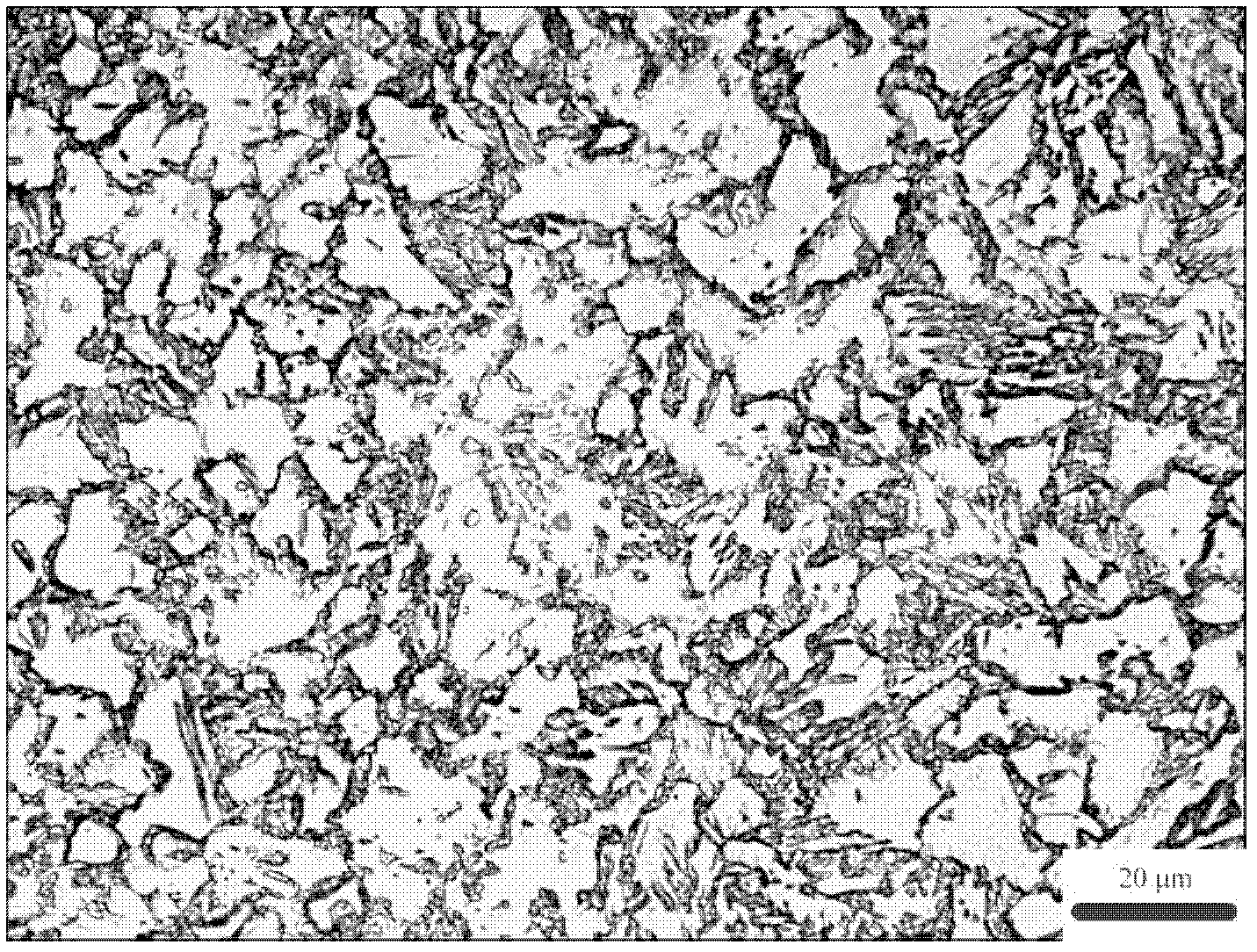

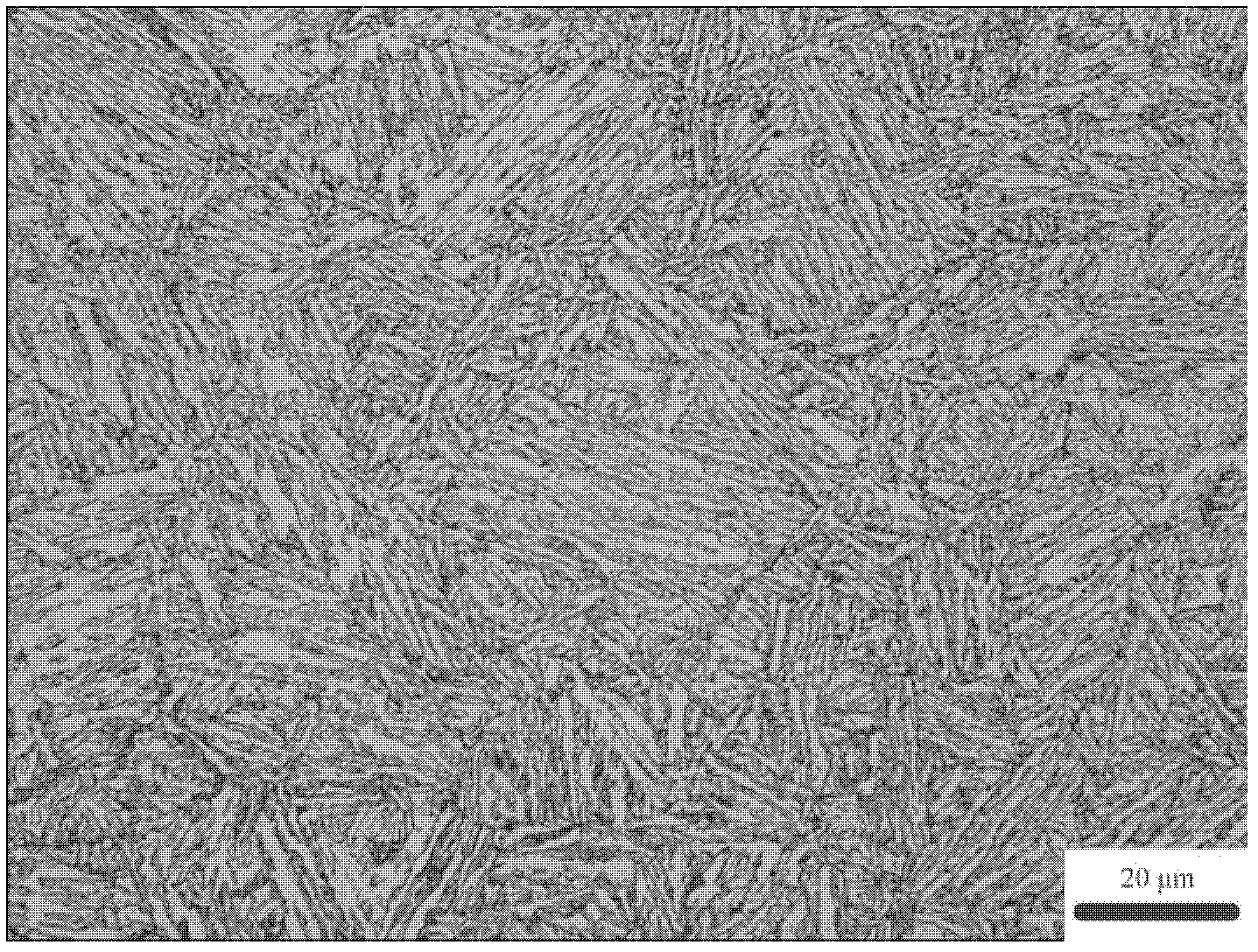

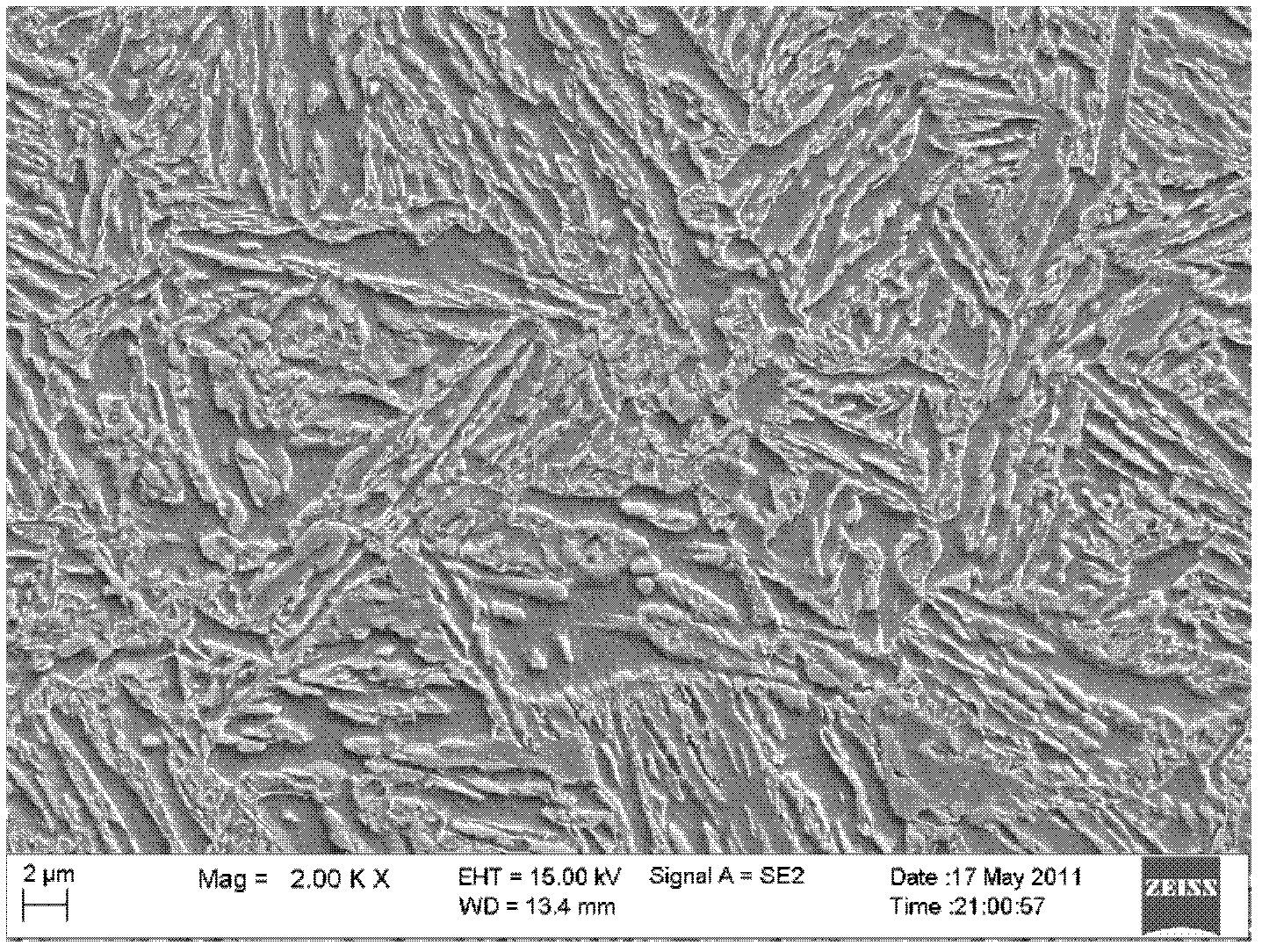

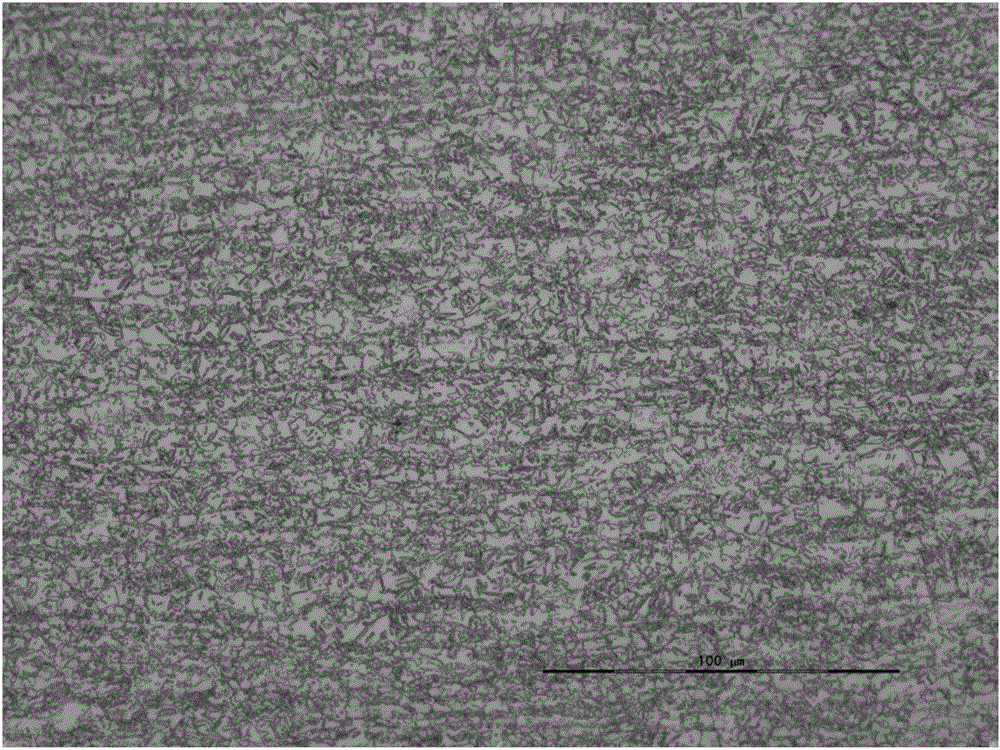

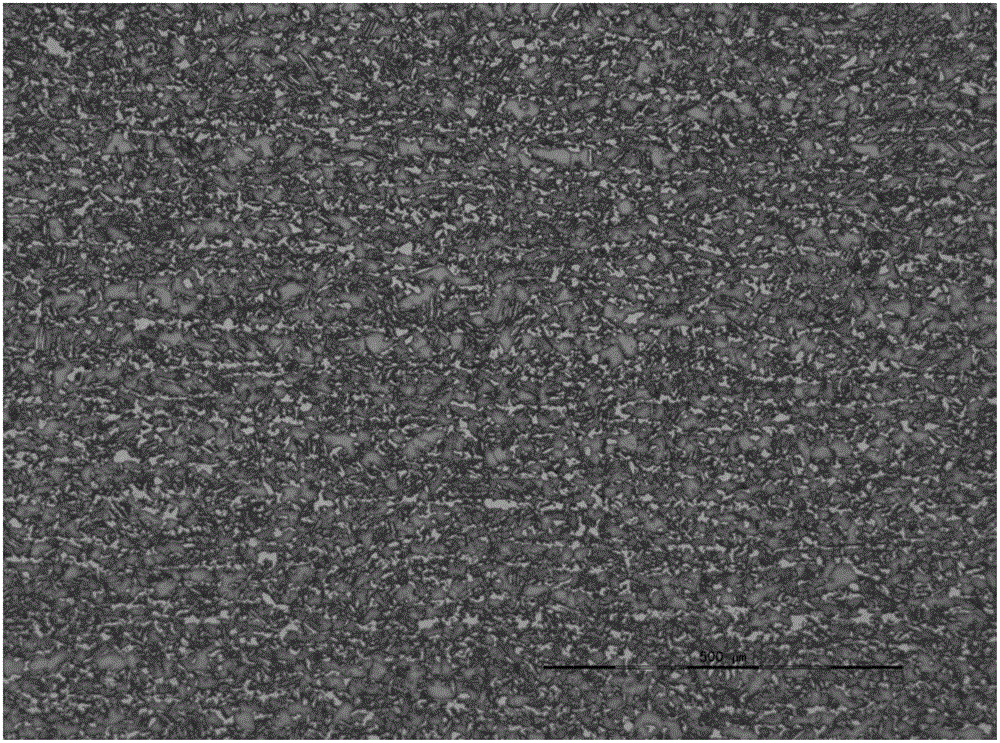

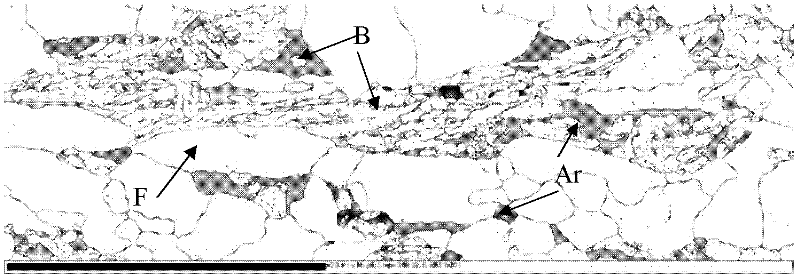

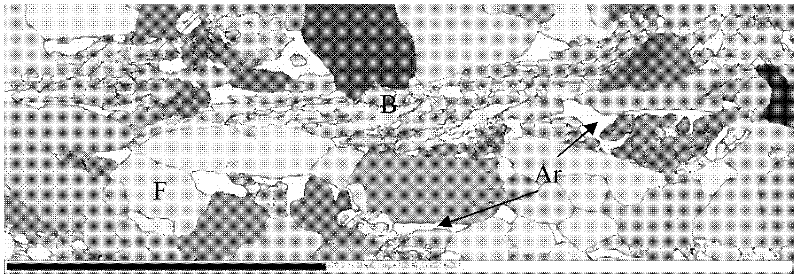

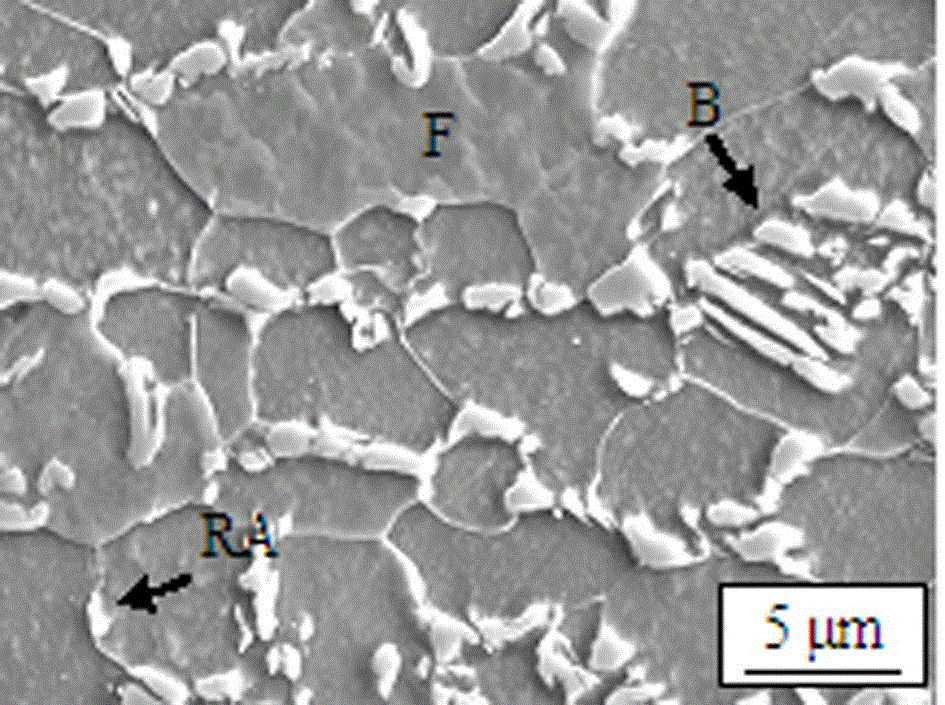

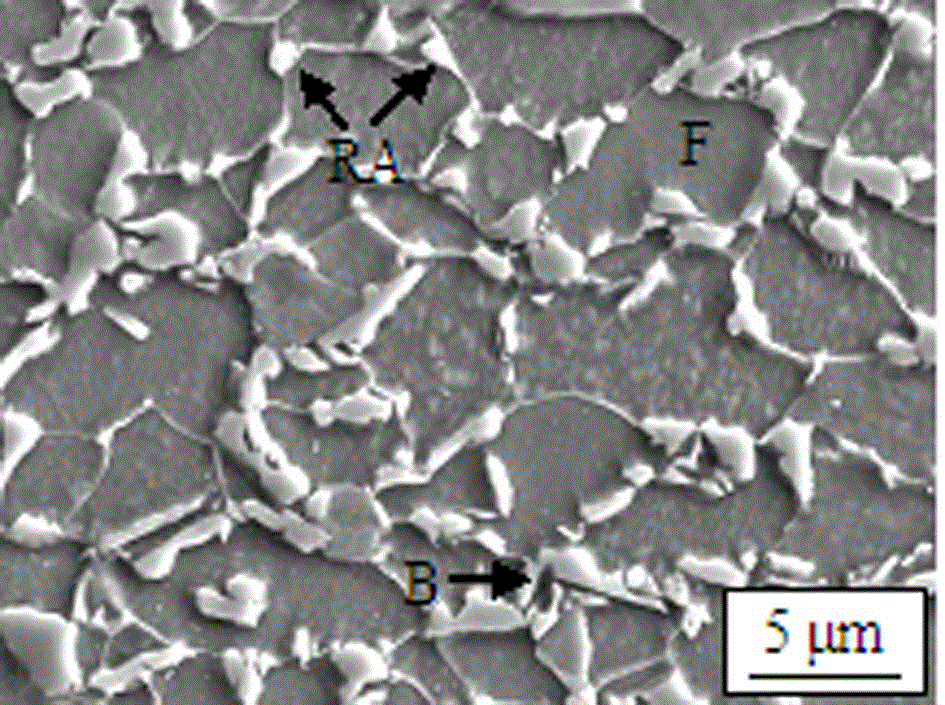

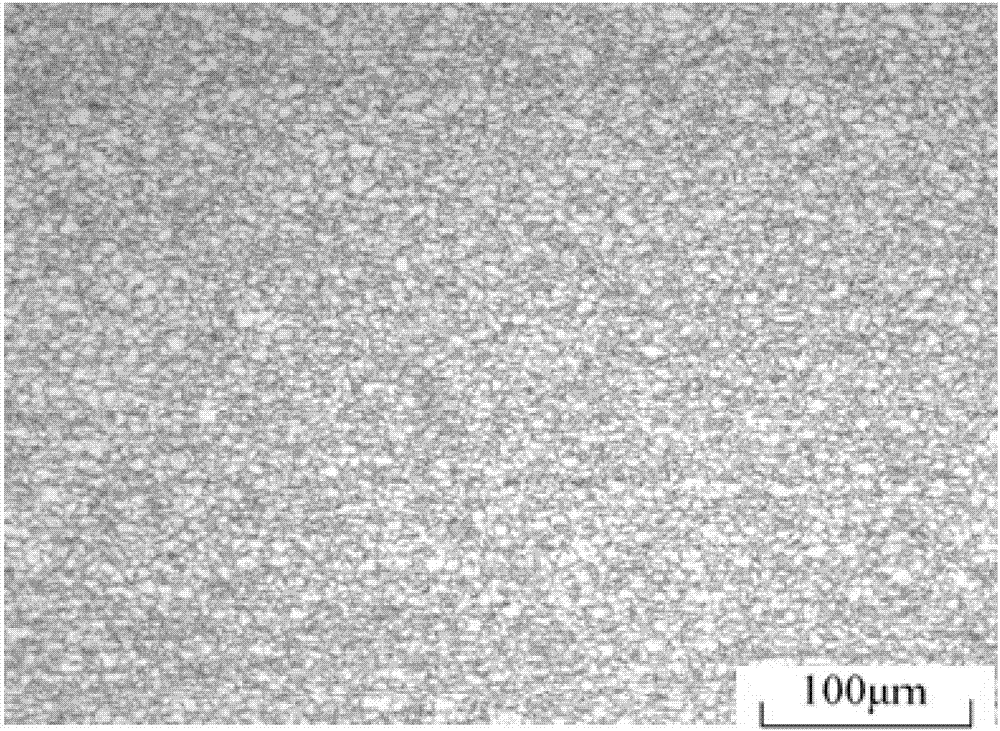

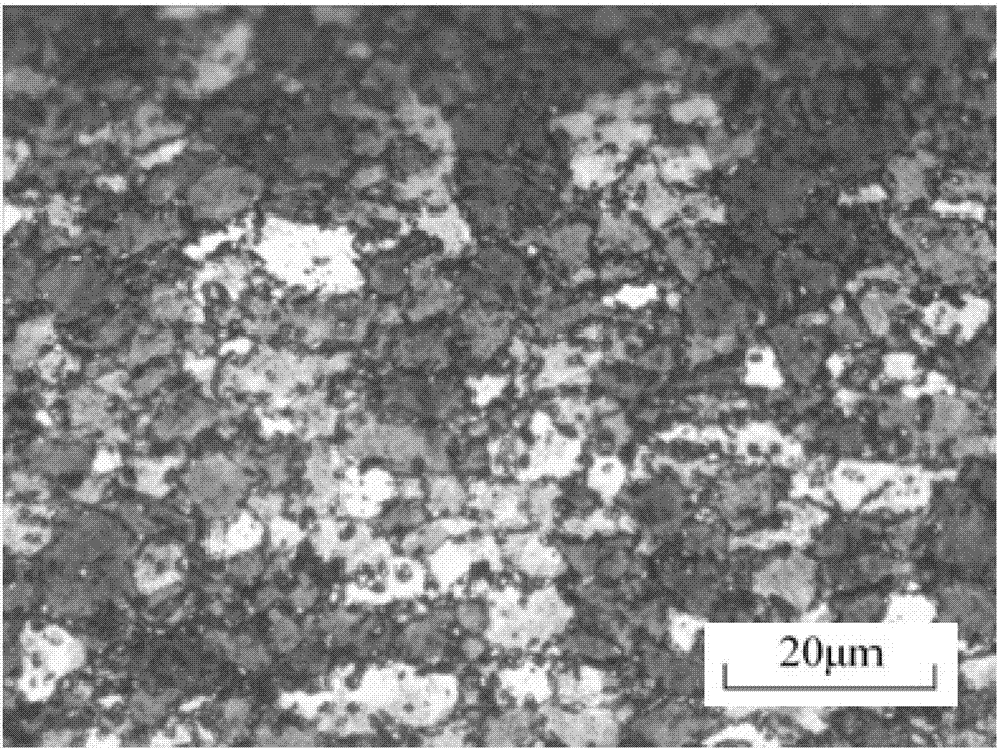

Method for displaying and quantitatively determining retained austenite or island martensite- austenite in TRIP steel

InactiveCN101382494AEasy extractionImprove accuracyMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationObject structureTRIP steel

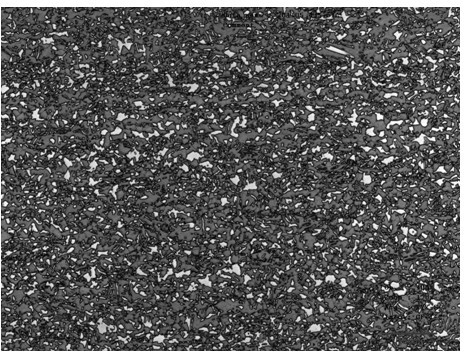

The invention relates to a display and quantitative detection method of residual austenite or island martensite-austenite (MA island for short) in TRIP steel. The method comprises the steps: (1) a TRIP tapping sample is prepared into a metallographic specimen; (2) after grinding and polishing, the metallographic specimen is light etched for 5 to 8 seconds in Nital of 1 to 3 percent by weight, and water is sprinkled on a flannel polishing disk for 1 to 2 seconds; sodium pyrosulfite water solution of 1 to 3 percent by weight and picral of 2 to 6 percent by weight are mixed by volume ratio of 1:1 to prepare corrosive liquid, then the metallographic specimen is put into the corrosive liquid for etching of 55 to 65 seconds; (3) the structure of the TRIP steel is observed under a metallurgical microscopy: the delta ferrite is minus blue, the residual austenite or MA island is white, and bainite is brownish-black; and (4) each phase in the structure is carried out quantitative analysis. The method presents different colors, each phase of structure has distinct layers which are easy to distinguish; and a quantitative image analysis method is utilized to fix amount of the feature object structure, which is objective and accurate and has good repeatability.

Owner:WUHAN IRON & STEEL (GROUP) CORP

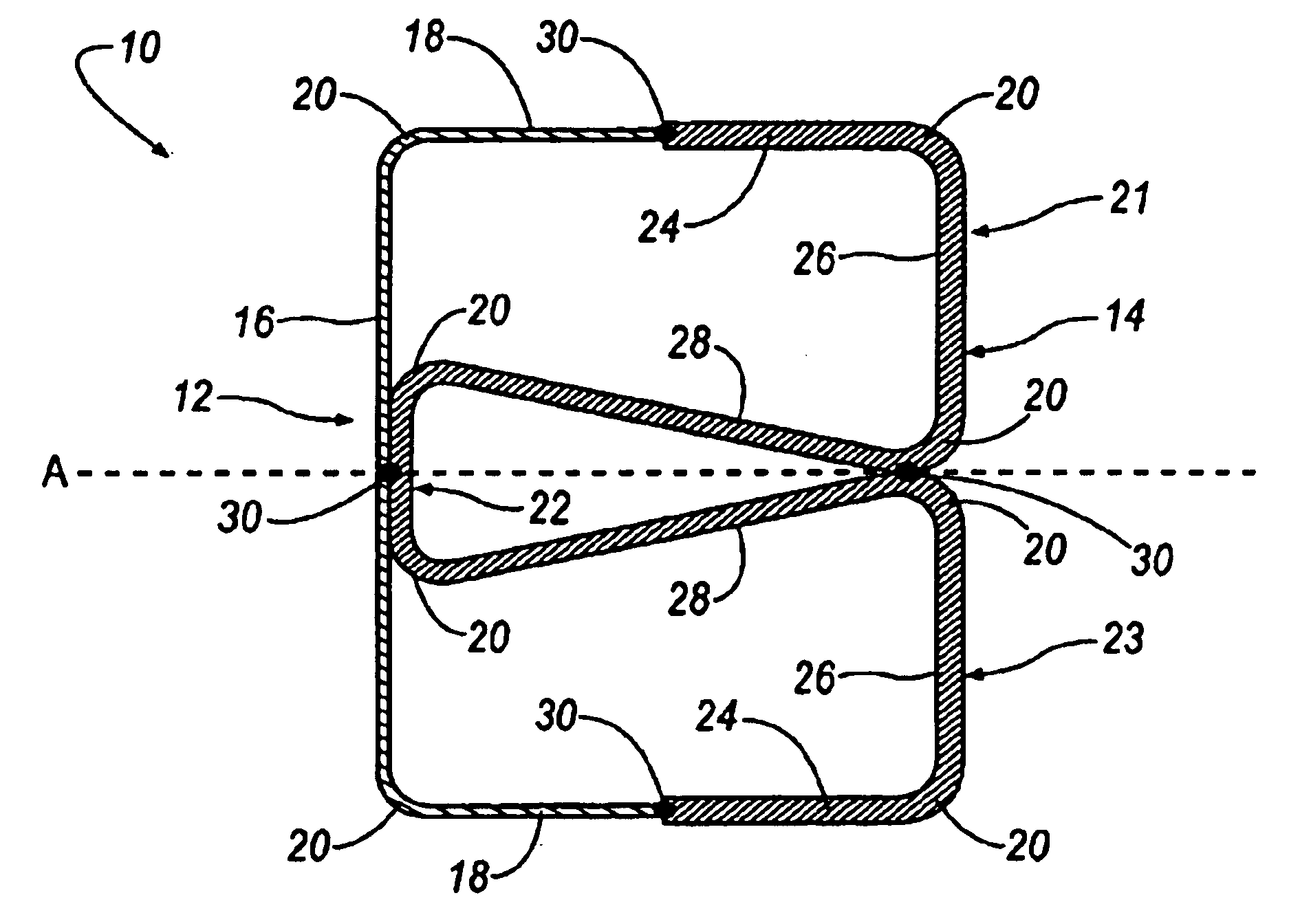

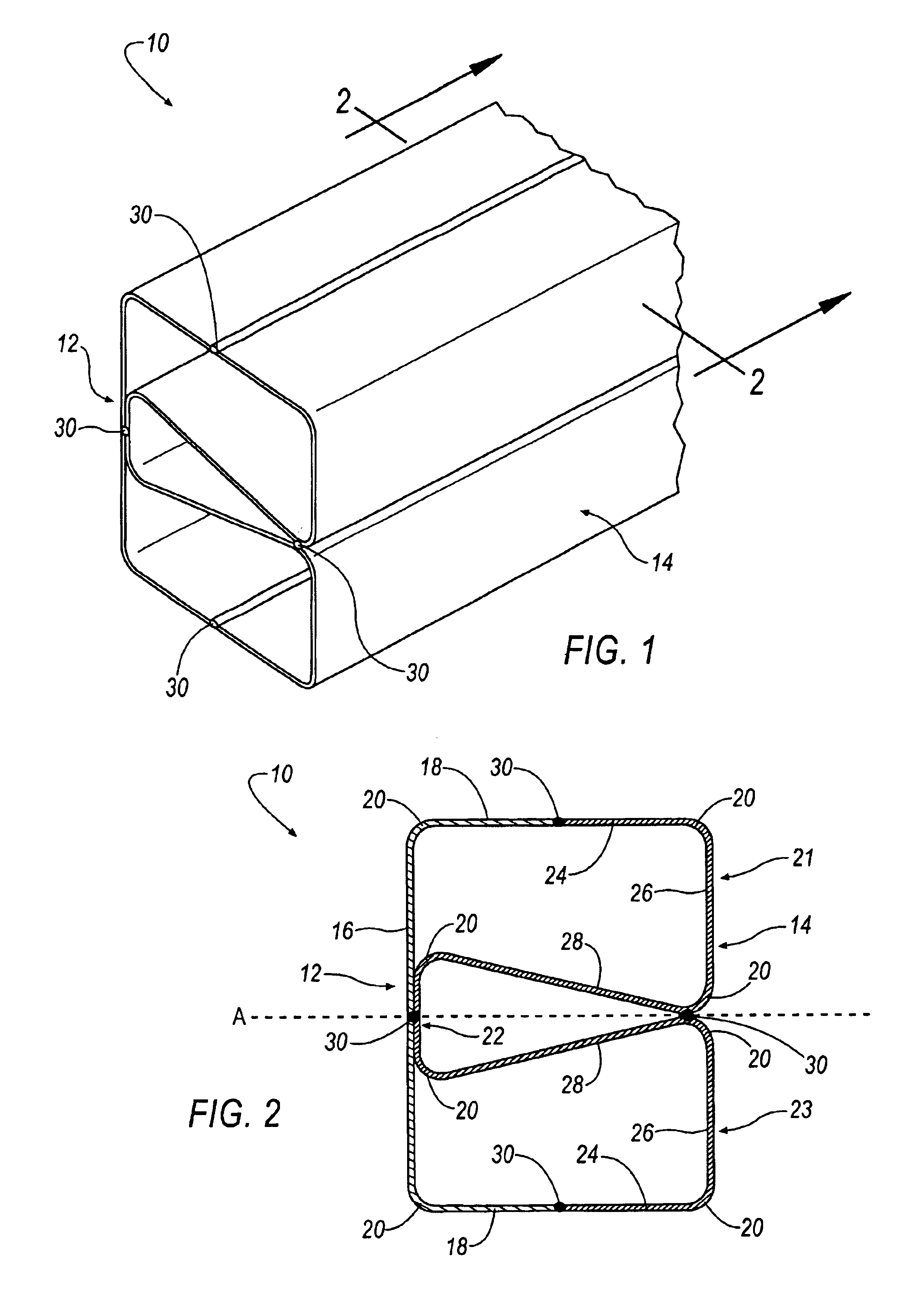

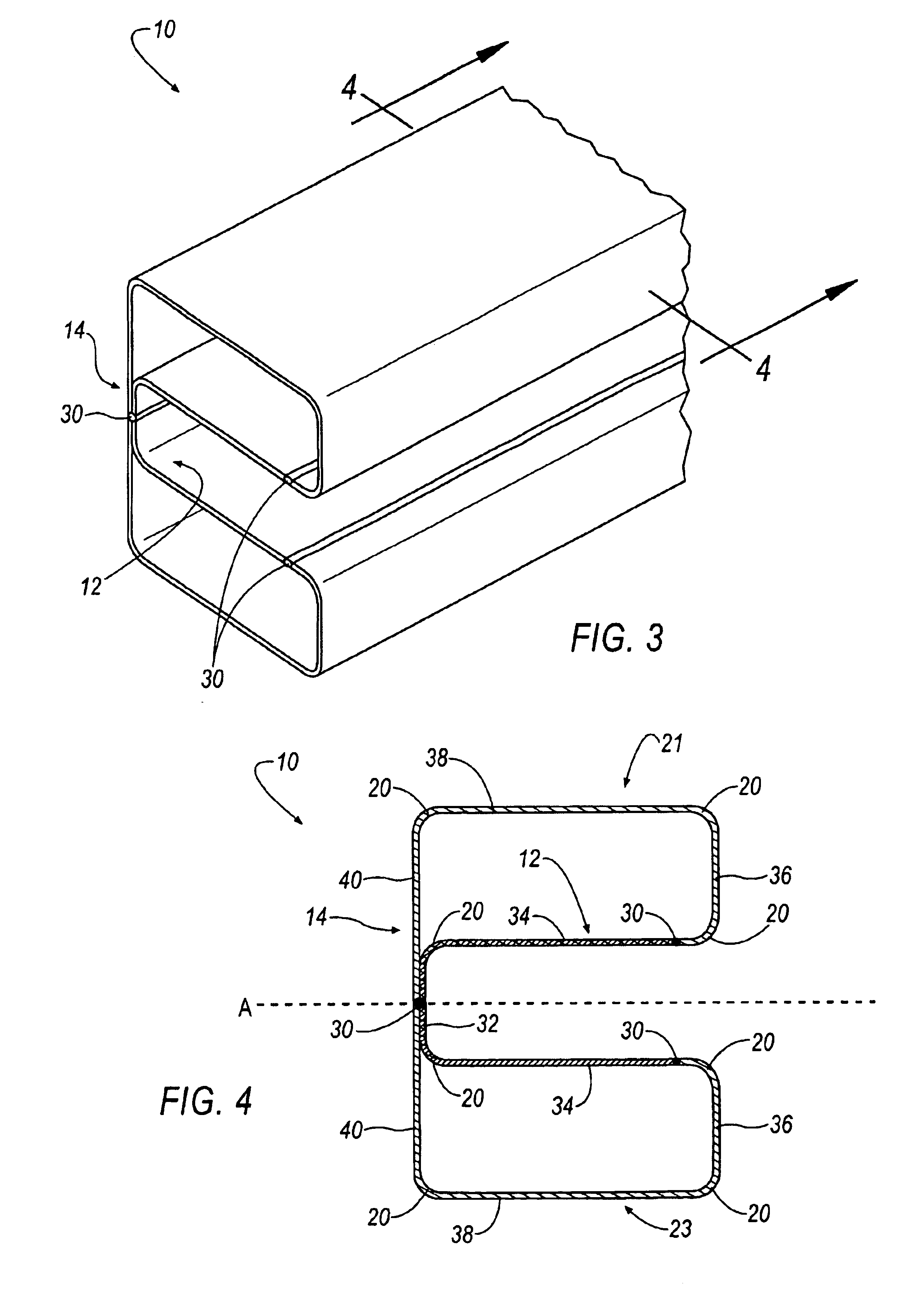

Multiple material bumper beam

InactiveUS6923482B2Raise quality standardsWeighs lessLoad-supporting elementsBumpersMulti materialTRIP steel

A bumper beam includes a first portion of a first material and a second portion of a second material. The first material has different material properties than the second material. For example, the first material may have a generally higher tensile or yield strength than the second material. In one embodiment, the first material comprises martensitic steel, while the second material comprises a dual-phase, multiphase, complex-phase or TRIP steel. In addition, the first material may have a different thickness than the second material. The bumper beam provides an improved strength to weight ratio than conventional bumper beams. This abstract is provided to comply with the rules requiring an abstract that allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope of the claims. 37 CFR 1.72(b).

Owner:MAGNA INTERNATIONAL INC +1

TRIP steel plate for high strength cold rolling hot dip galvanizing and preparation thereof

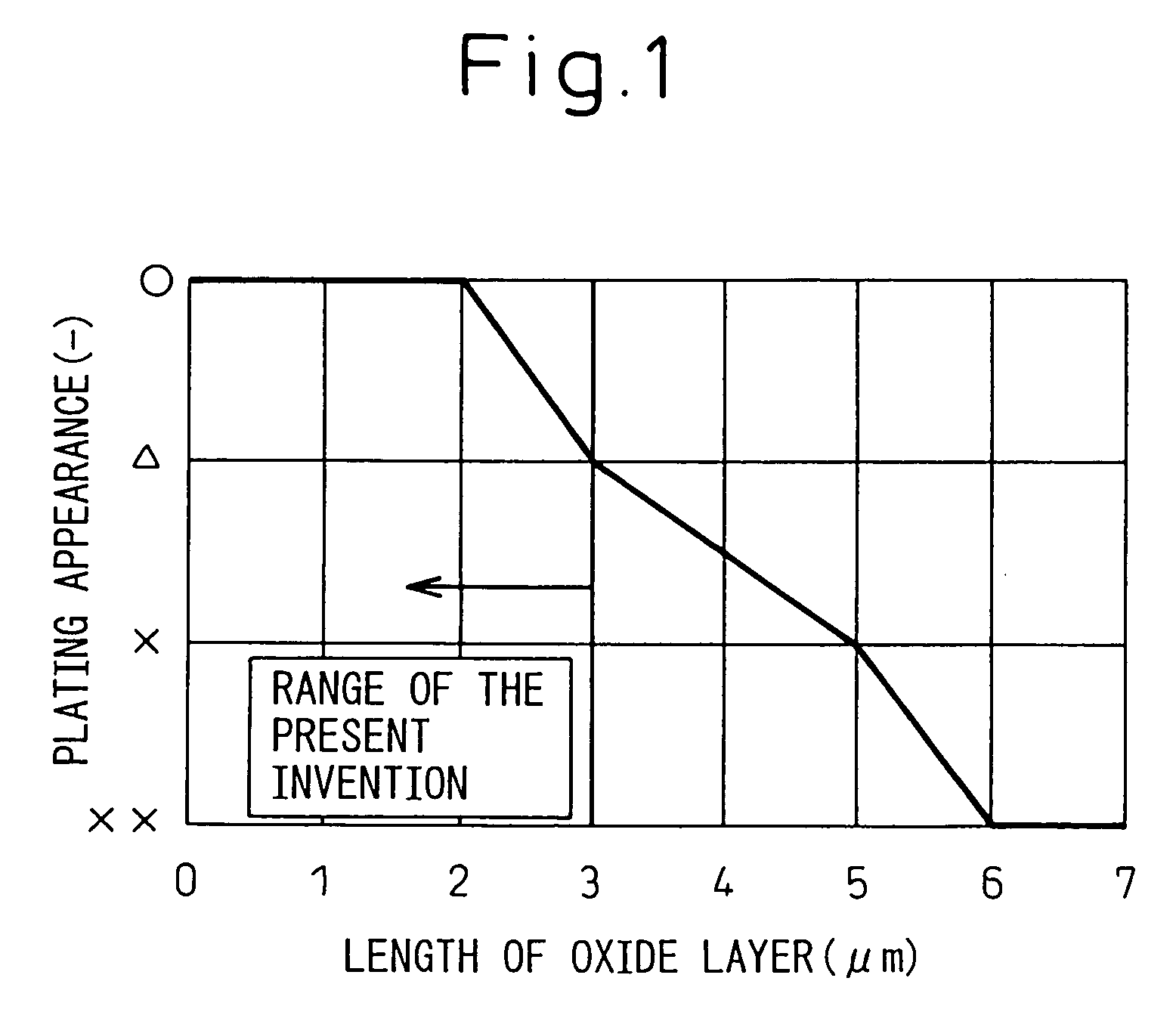

InactiveCN101353761AImprove PlatabilityGood coating performanceHot-dipping/immersion processesSheet steelTRIP steel

The invention pertains to the metal material processing field and particularly provides a TRIP steel sheet used for high-strength cold rolling and hot galvanizing and a manufacturing method thereof. The TRIP steel sheet comprises the following components: 0.1wt percent to 0.4wt percent of C, not more than 0.06wt percent of Si, 0.5wt percent to 2.5wt percent of Mn, 0.5wt percent to 2.0wt percent of Al, not more than 0.03wt percent of P, not more than 0.02wt percent of S, 0.01wt percent to 0.10wt percent of Nb, 0.01wt percent to 0.10wt percent of Ti, 0.1wt percent to 1.0wt percent of Cu, 0.1wt percent to 0.6wt percent of Ni and the rest is iron. Through the measures of controlling the content of the elements such as C, Mn, Nb and Ti in the steel, and the temperature and time of hot rolling, reeling, cold rolling, annealing and the like, the comprehensive performance of the TRIP steel sheet is improved. Compared with the traditional TRIP steel, the TRIP steel sheet has the following advantages of: 1) good platability: due to the low silicon adopted, the requirements of the plating layer of hot plated pure zinc and alloy plated zinc can be met to obtain the plating layer with good performance; and 2) good grain refining effect: due to Nb micro-alloying, grain can be effectively refined.

Owner:UNIV OF SCI & TECH BEIJING +1

Ultra Fine-Grained Advanced High Strength Steel Sheet Having Superior Formability

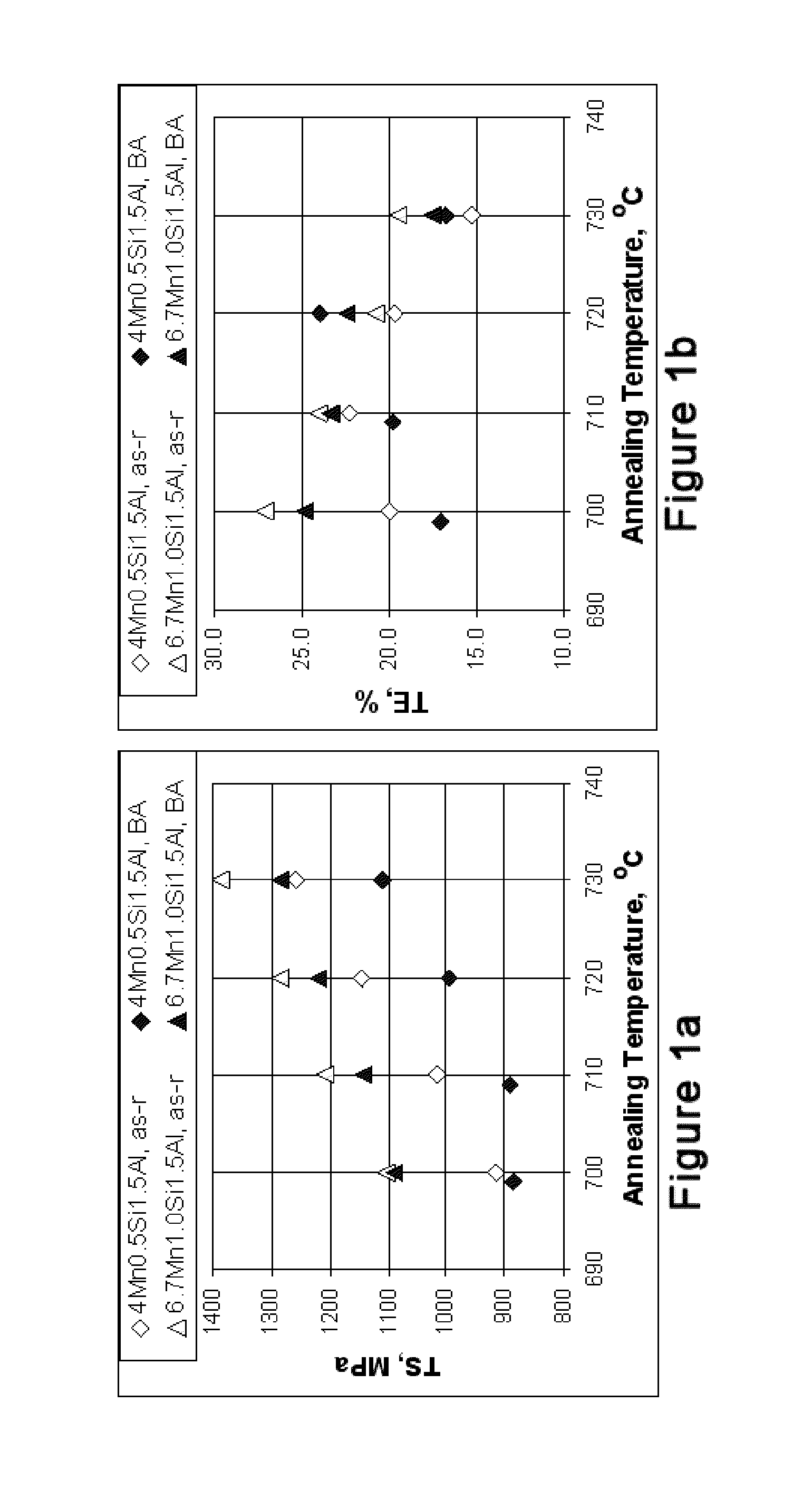

ActiveUS20140205488A1Superior combination of strengthSuperior combination of ductilityTRIP steelUltra fine

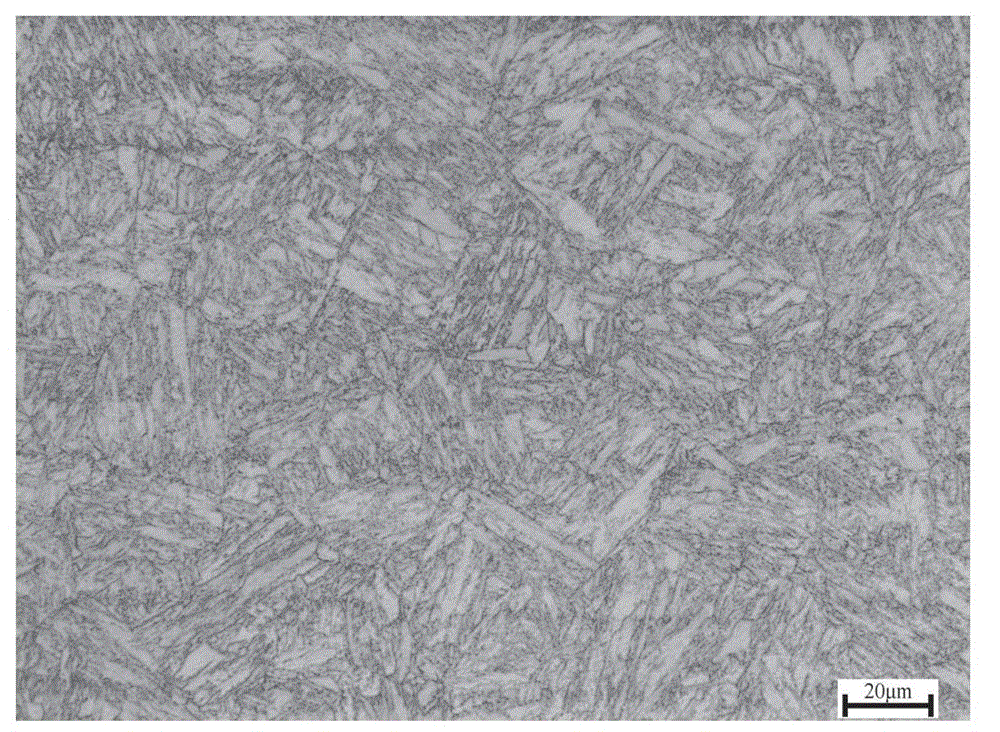

A cold rolled, annealed TRIP steel sheet which has a composition including (in wt. %): C: 0.1-0.3; Mn: 4-10, Al: 0.05-5, Si: 0.05-5; and Nb: 0.008-0.1, the remainder being iron and inevitable residuals. The cold rolled sheet has an ultimate tensile strength of at least 1000 MPa, and a total elongation of at least 15%. The cold rolled sheet may have at least 20% retained austenite in its microstructure and may have greater than 50% lath-type annealed ferrite structure. The cold rolled sheet may have an ultra fine grain size of less than 5 micron for the retained austenite and ferrite.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

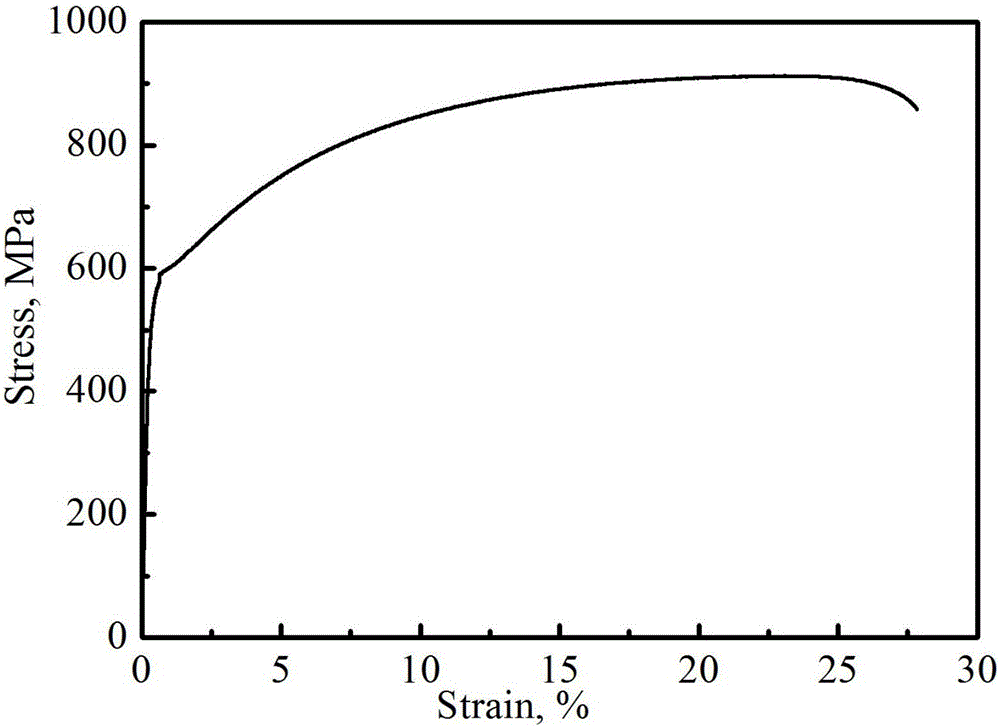

Cold-rolled medium manganese steel with high strength and high plasticity and preparation method thereof

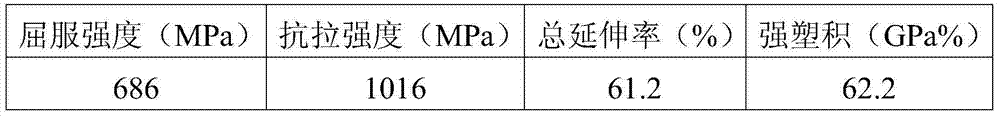

The invention discloses cold-rolled medium manganese TRIP (Transformation Induced Plasticity) steel of which the tensile strength is over 1000MPa, the total ductility is over 60%, and the product of strength and elongation is about over 60GPa%, and a preparation method thereof, and belongs to the technical field of cold-rolled steel with high strength and high ductility. The cold-rolled medium manganese TRIP steel comprises the following chemical ingredients by weight percent: 0.15-0.20% of C, 8.0-11.0% of Mn, 3.0-40% of Al, 0-0.040% of Nb, and the balance of Fe and impurities. The preparation method of the cold rolled TRIP steel comprises smelting, forging, hot rolling, thermal treatment after rolling, pickling, cold rolling and thermal treatment after rolling. The cold-rolled TRIP steel is high in strength, good in plasticity, and simple in thermal treatment technology after rolling, and is a new generation of ideal automotive steel.

Owner:蔡志辉

Cold-rolled TRIP steel at over 1000 MPa and preparation method thereof

ActiveCN102312157AHigh strengthHigh elongationFurnace typesHeat treatment furnacesTRIP steelContinuous annealing

The invention discloses cold-rolled TRIP steel at over 1000 MPa and a preparation method thereof, and belongs to the technical field of high-strength high-plasticity cold-rolled steel. The weight percentage of chemical components of the cold-rolled TRIP steel is respectively as follows: by weight, 0.18-0.23% of C, 1.3-1.6% of Si, 2.1-2.3% of Mn, 0.03-0.05% of Nb, 0.03-0.09% of V, P being less than or equal to 0.01%, S being less than or equal to 0.01%, 0.8-1.2% of Alt, N being less than or equal to 0.005%, and the balance being F and impurities. The production method of the cold-rolled TRIP steel comprises steps of smelting, hot rolling, cold rolling and continuous annealing. The cold-rolled TRIP steel provided by the invention has high strength and strong plasticity. When applied in automobiles, the cold-rolled TRIP steel is in favor of reducing the automobile weight.

Owner:SHOUGANG CORPORATION

Method for preparing N80 steel-grade expansion tubes for petroleum and natural gas exploitation

The invention discloses a method for preparing N80 steel-grade expansion tubes for petroleum and natural gas exploitation, and belongs to the field of metal materials. An N80 steel-grade expansion tube comprises the following chemical compositions in percentage by mass: 0.1 to 0.3 percent of C, 1.0 to 2.5 percent of Mn, 0.3 to 1.5 percent of Si, 0 to 1.0 percent of Al, 0.02 to 0.1 percent of Nb, 0 to 0.02 percent of Ti and the balance of Fe and inevitable impurities. After related alloy plates are obtained through smelting and rolling, the alloy plates are bent and welded into expansion tubes, and through a heat treatment process consisting of two procedures, namely two-phase region quenching and sub-temperature tempering-quenching-partitioning treatment, the expansion tubes reach the expected strength standard and plastic deformation capacity, and the mechanical properties of the tubes before and after expansion can meet the requirements of American Petroleum Institute (API) and other related standards. Test results show that the N80 steel-grade multiphase high-uniformity extended expansion tubes have high strength, plasticity, toughness and elongation, and the comprehensive mechanical properties are superior to those of the conventional dual-phase steel and Trip steel.

Owner:UNIV OF SCI & TECH BEIJING

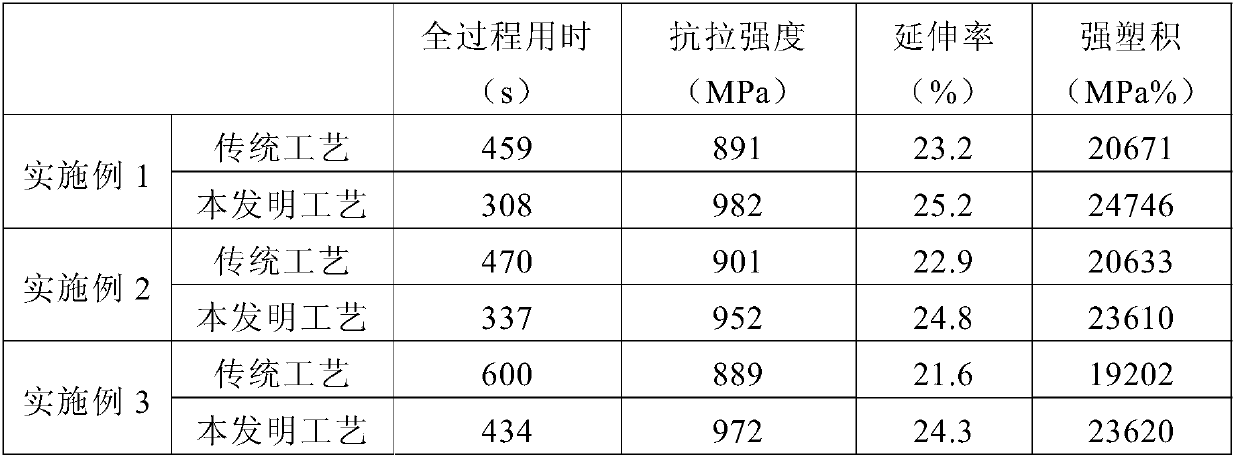

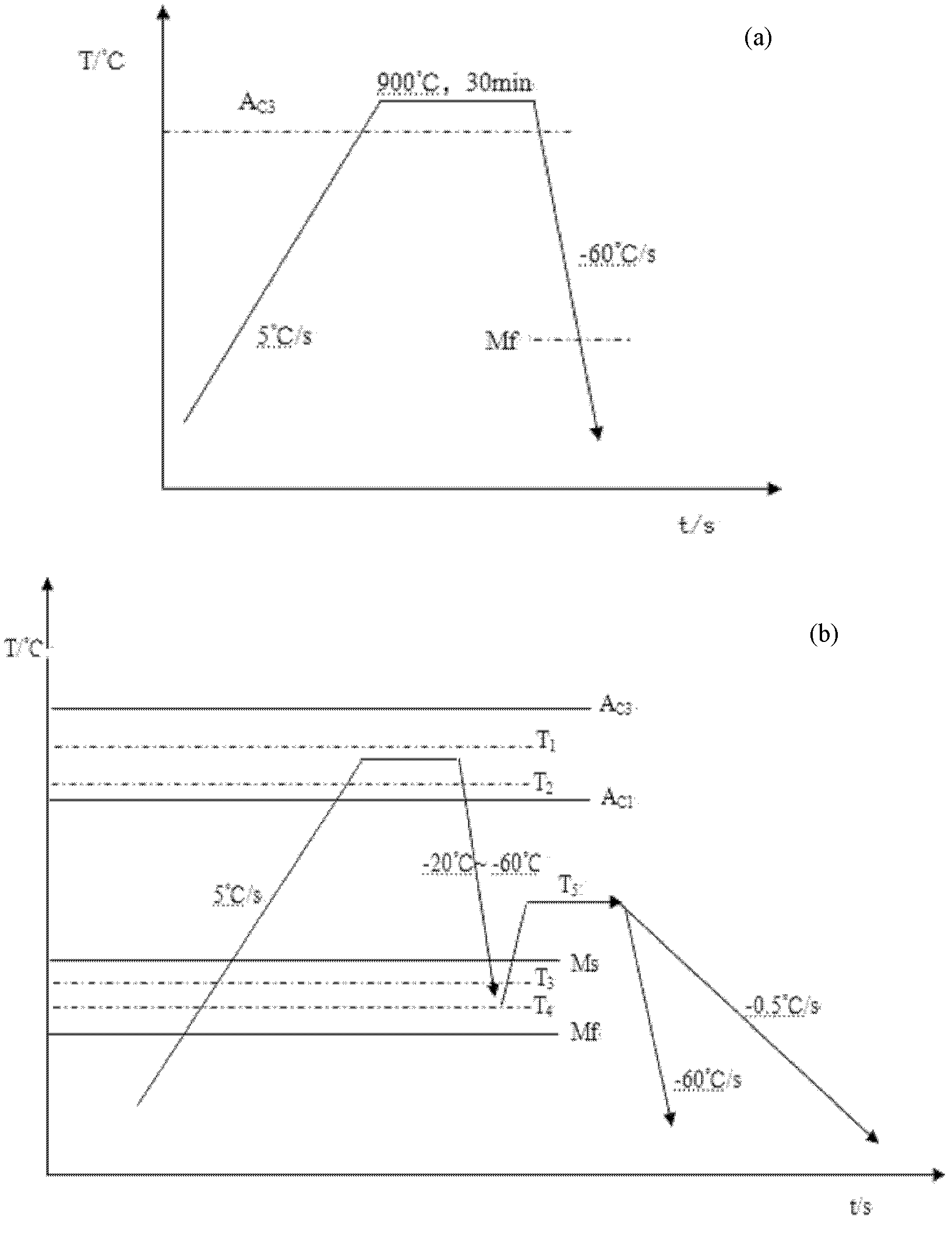

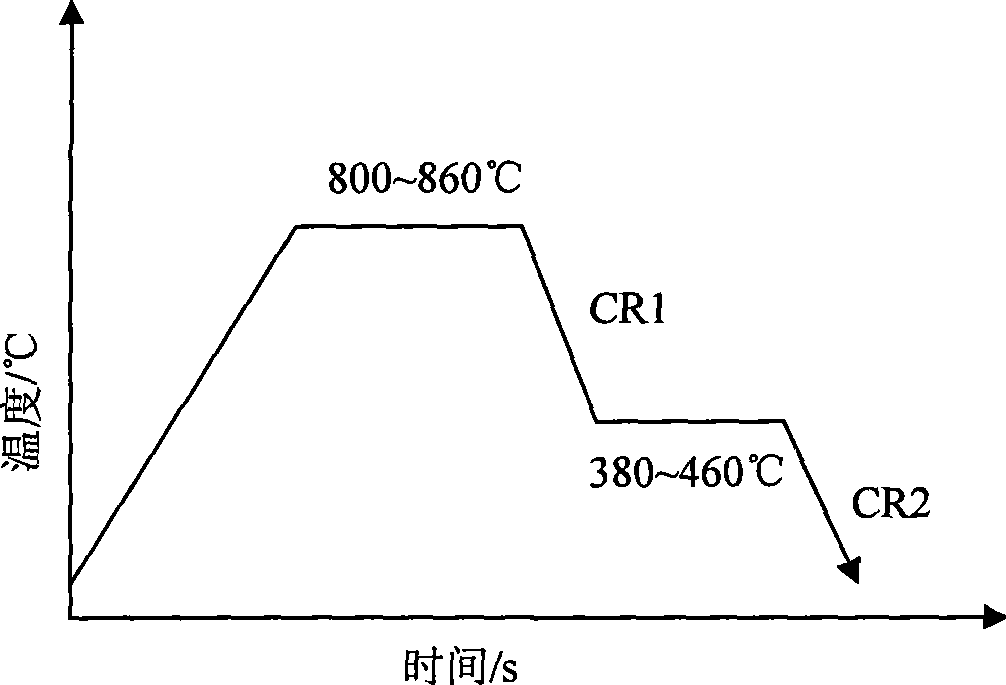

780 MPa-grade low-carbon low-alloy hot-dip galvanized TRIP steel and rapid heat treatment method thereof

ActiveCN109943770AShorten the timeReduce energy consumptionHot-dipping/immersion processesFurnace typesAlloyMechanical property

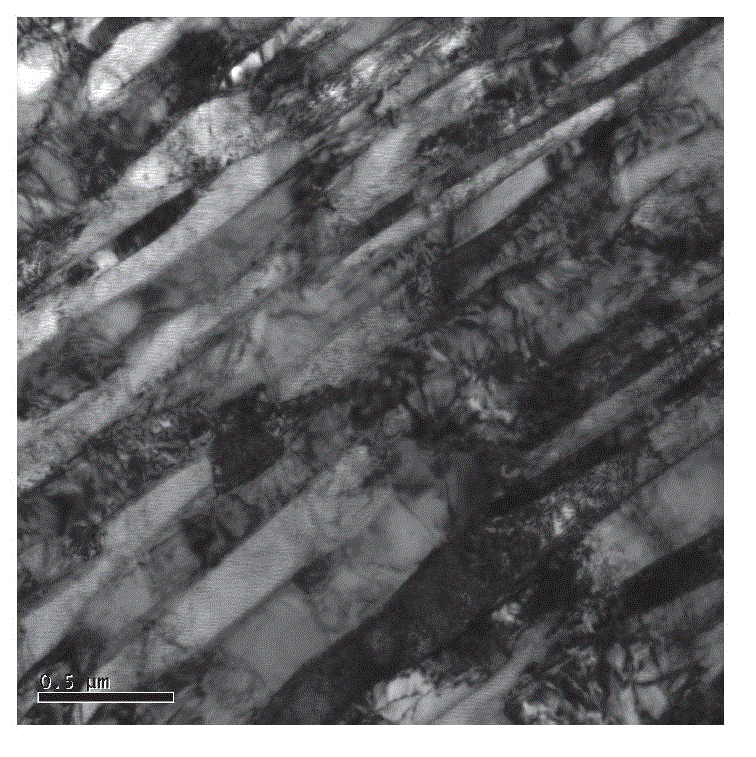

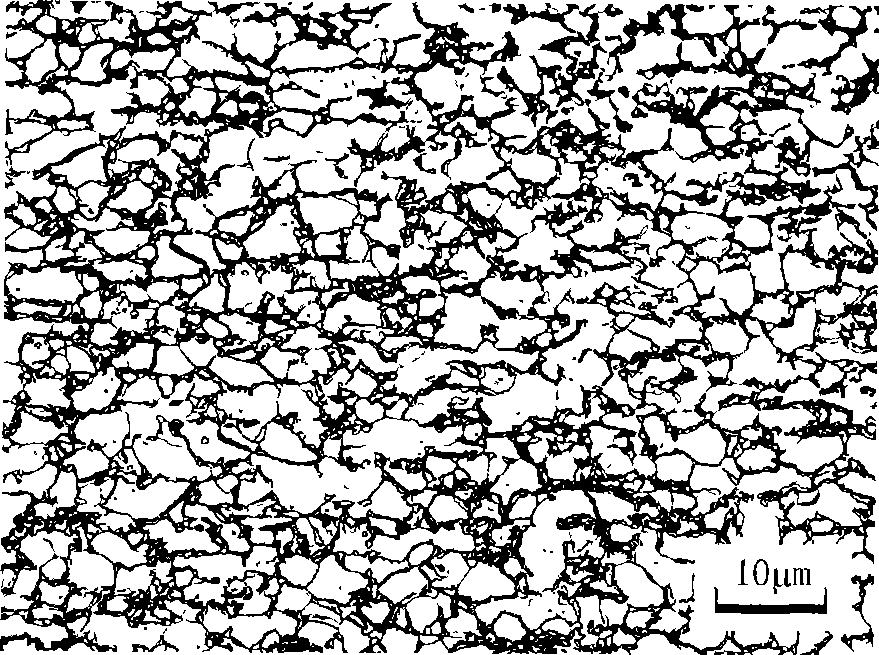

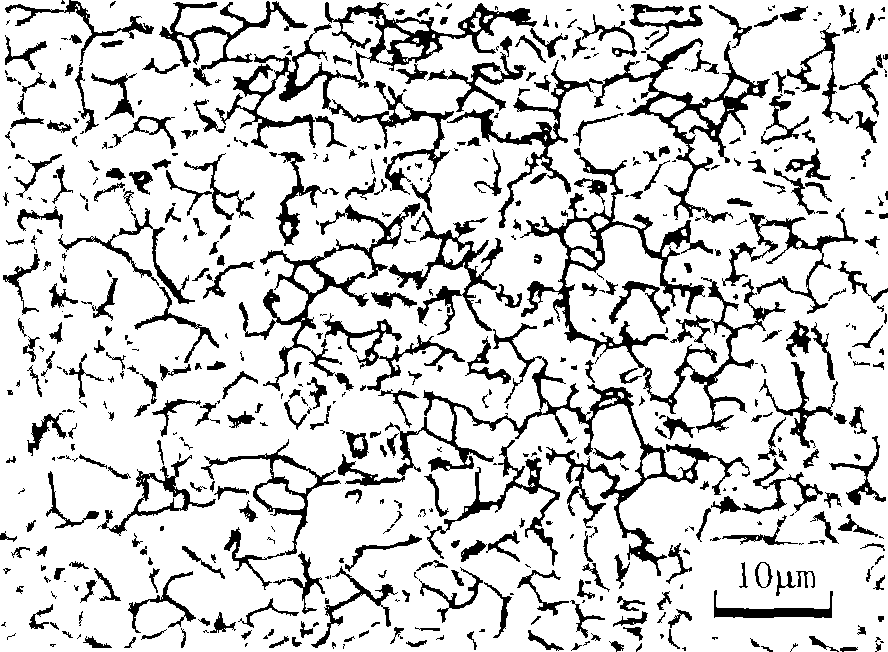

The invention discloses a 780 MPa-grade low-carbon low-alloy hot-dip galvanized TRIP steel and a rapid heat treatment method thereof. The steel comprises the following chemical components of, in percentage by mass, 0.16-0.22% of C, 1.2-1.6% of Si, 1.6-2.2% of Mn, and the balance Fe and inevitable impurities. According to the 780 MPa-grade low-carbon low-alloy hot-dip galvanized TRIP steel and therapid heat treatment method thereof, the recrystallization and phase change processes in the heating process and the phase change process in cooling process are controlled, and finally a three-phase structure which is uniformly distributed on a ferrite matrix by bainite and austenite is obtained; the average grain size of the bainite and the austenite is 1-3 microns; the bainite is submicron granular; the austenite is in the shape of an island-shaped and are uniform-distributed isometric crystal; in the whole of the three-phase structure, the volume fraction of the bainite is 35% -75%, the volume fraction of the ferrite is 10%-60%, and the volume fraction of the austenite is 5%-15%; and through the rapid heat treatment, the mechanical property of the material is improved while the heat treatment efficiency is improved, and the material performance interval range is expanded.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of P110-grade expansion tube for exploiting petroleum and gas

InactiveCN102534372ALow alloy contentHigh strengthDrilling rodsDrilling casingsMetallic materialsAlloy

The invention relates to a preparation method of a P110-grade expansion tube for exploiting petroleum and gas. The expansion tube comprises the following chemical components by mass percentage: 0.10-0.30 of C, 0.70-2.0 of Mn, 0.3-1.5 of Si, 0-1.0 of Al, 0.02-0.1 of Nb, 0-0.02 of Ti and the balance of Fe and inevitable impurities. The preparation method comprises the following steps of: after performing smelting and rolling to obtain a related alloy plate, performing plate rolling to the alloy plate and welding to prepare the expansion tube, and finally, performing complete austenitizing and then carrying out heat treatment process of quenching and subsequent subtemperature tempering-quenching-partitioning to enable an expansion tube to reach expected strength criterion and plastic deformation ability and ensure the mechanical property of the tube after and before tube expansion to meet provisions of API (American Petroleum Institute) and other relevant standards. Test results show that the P110 steel grade multiphase expansion tube with high uniformity extension has high strength, plasticity, toughness and elongation rate, and has comprehensive mechanical property superior to the conventional quenching-tempering steel, trip steel and Q-P (quenching--partitioning) steel.

Owner:UNIV OF SCI & TECH BEIJING

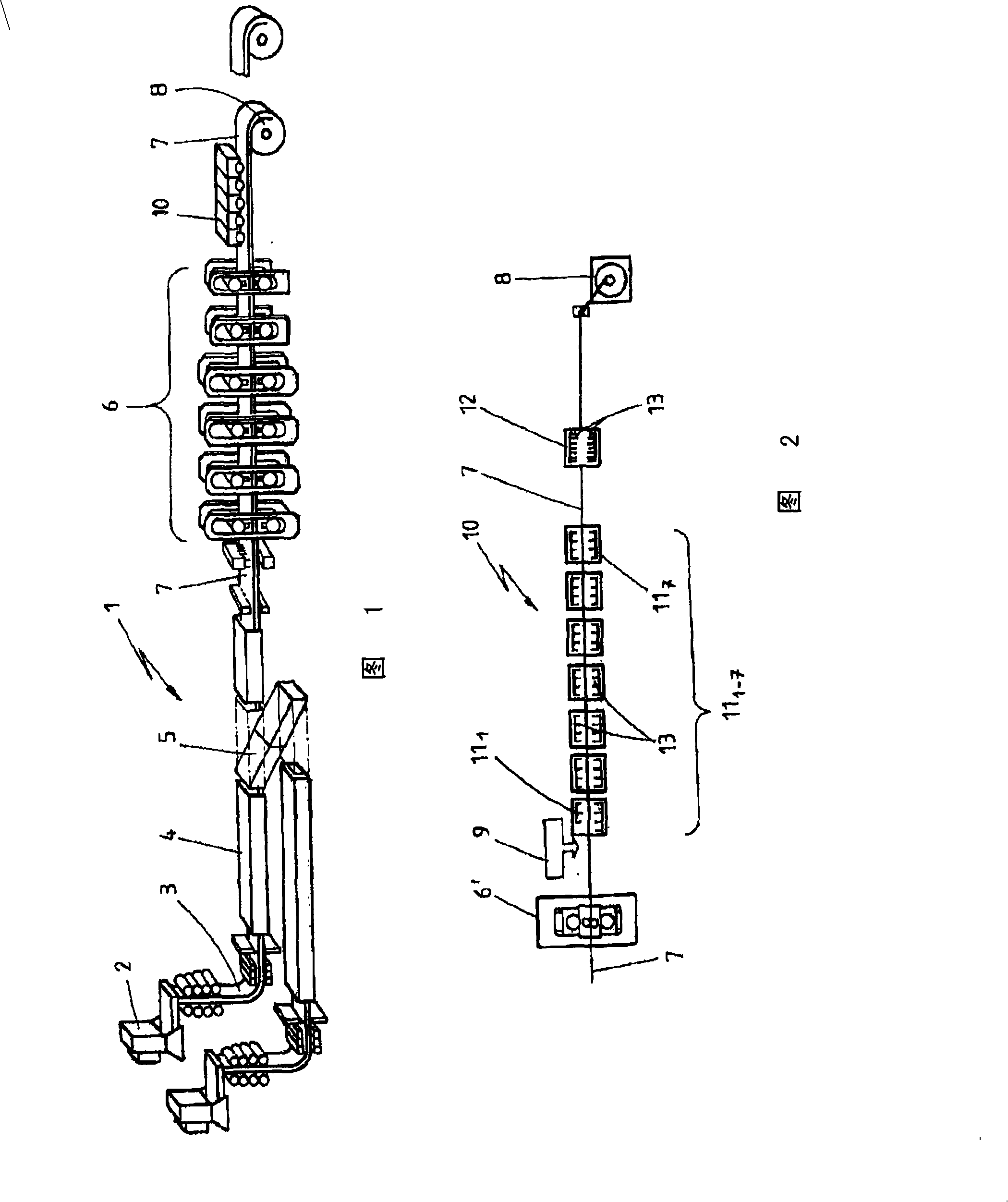

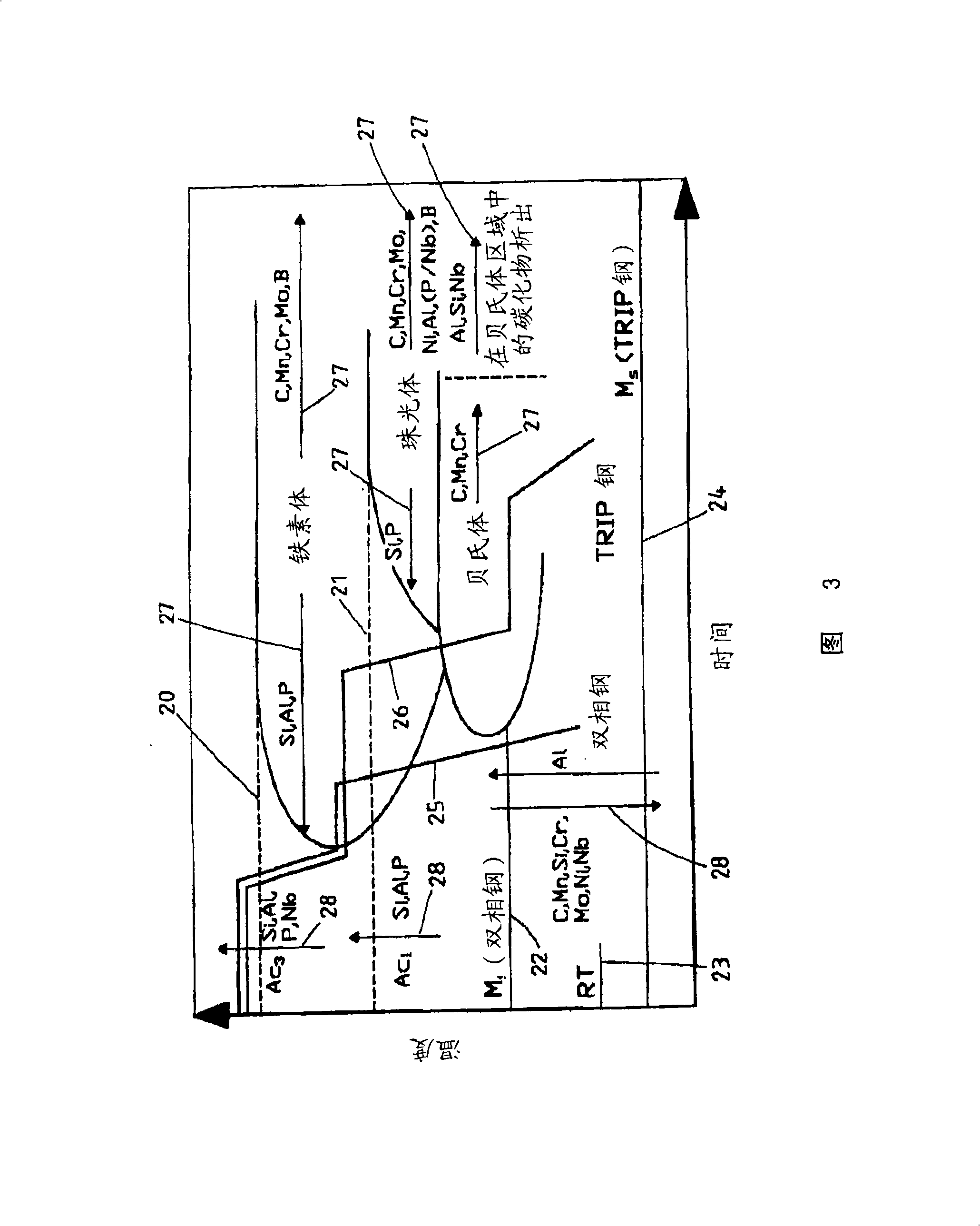

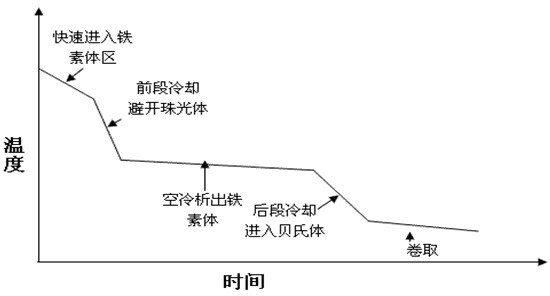

Method for producing hot strip with a multiphase structure

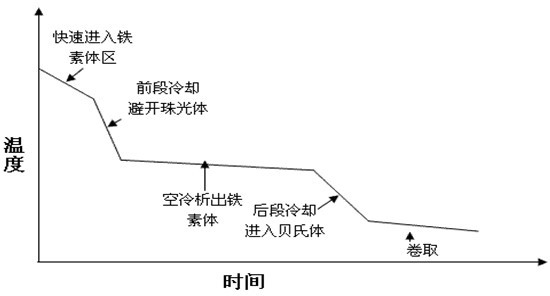

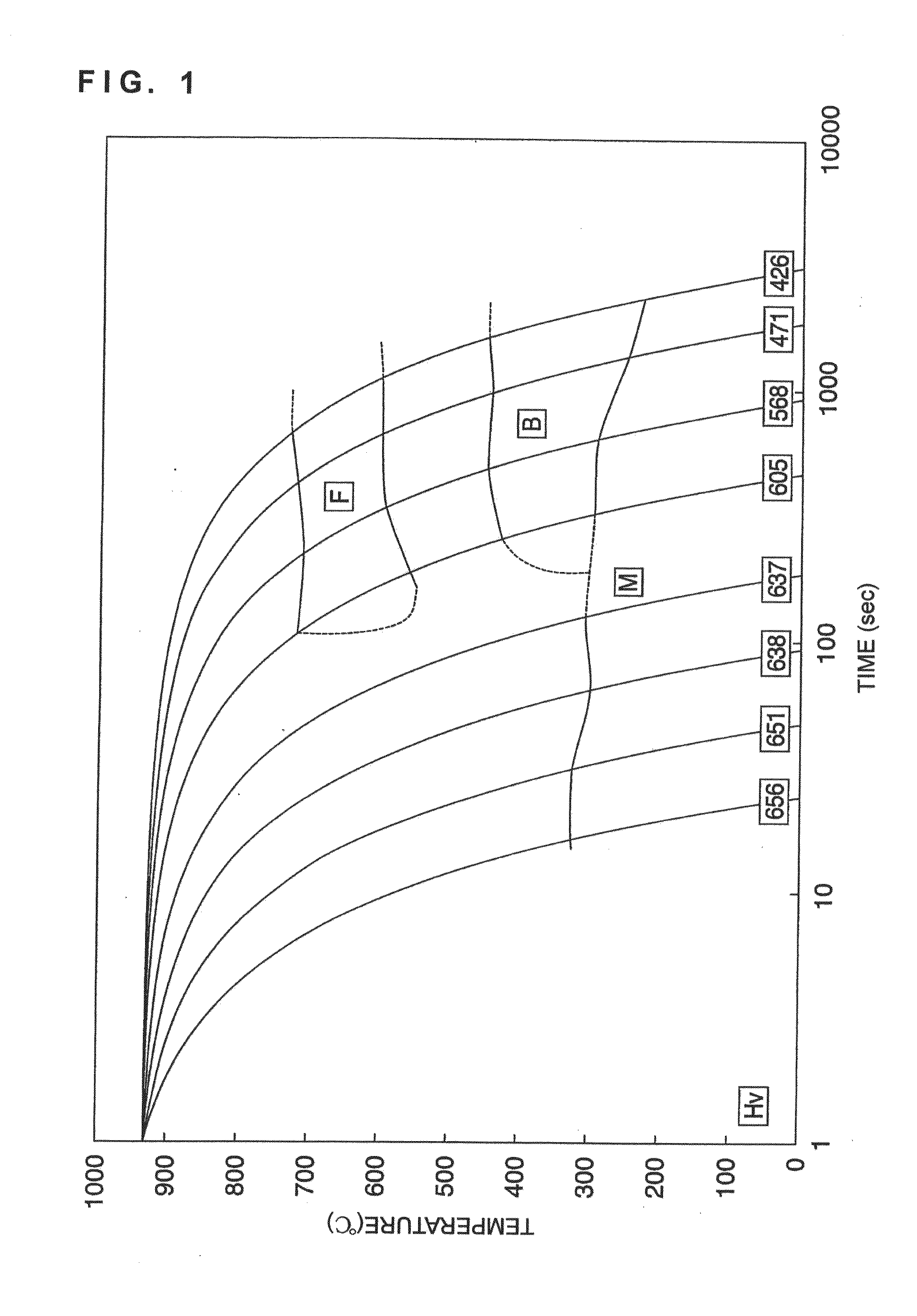

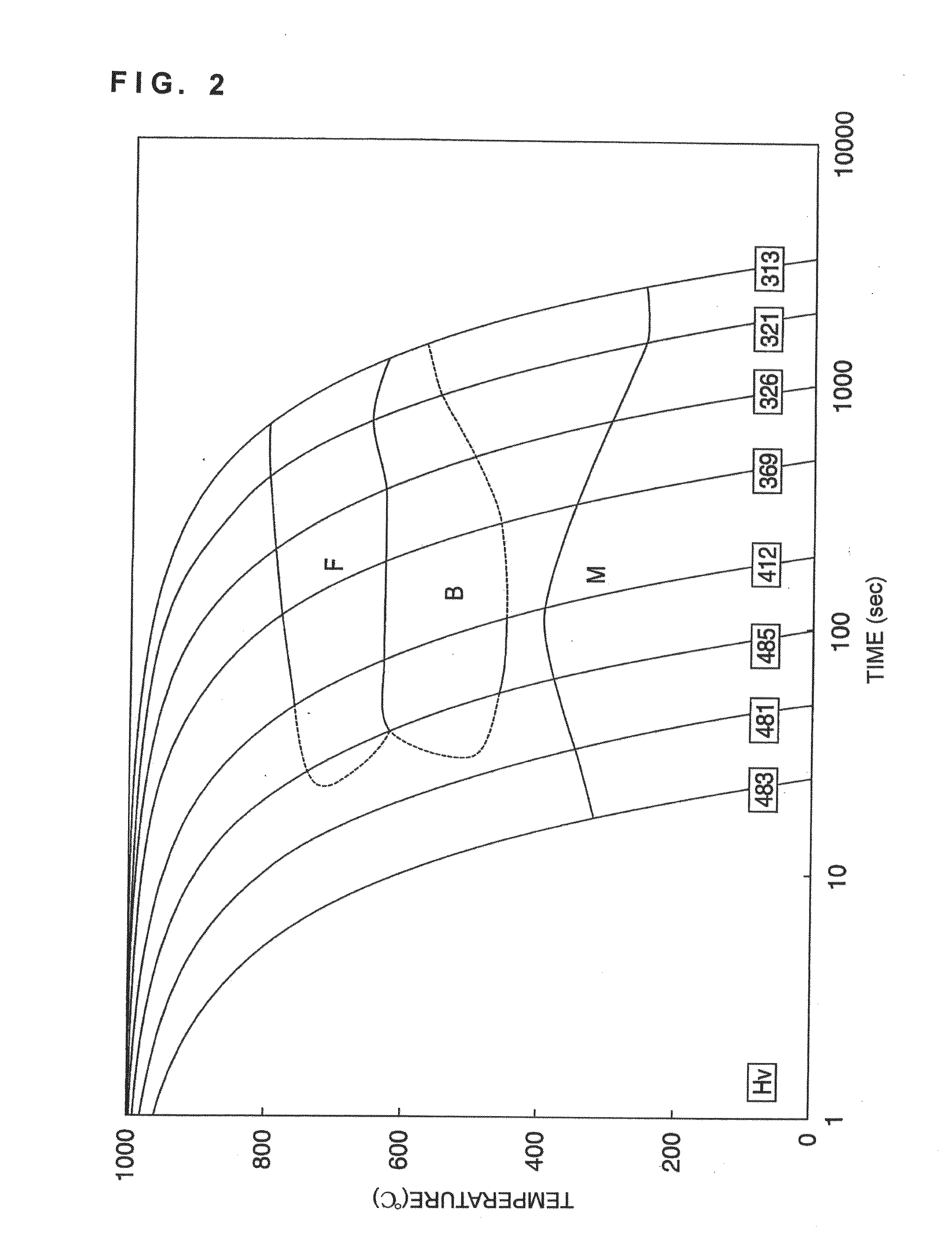

For the production of hot strip referred to as TRIP steel (transformation induced plasticity), with a multiphase structure and with outstandingly good deformation properties along with high strengths, from the hot-rolled state, the invention proposes a method which is carried out with a predetermined chemical composition of the steel grade used within the limits 0.12 - 0.25% C; 0.05 - 1.8% Si; 1.0 -2.0% Mn; the remainder Fe and customary accompanying elements and with a combined rolling and cooling strategy in such a way that a structure comprising 40 - 70% ferrite, 15 - 45% bainite and 5 - 20% residual austenite is obtained, wherein the finish rolling of the hot strip (7) is performed to set a very fine austenite grain (d < 8 [mu]m) in the final forming operation (6') at temperatures between 770 and 830 DEG C just above Ar3 in the region of the metastable austenite, and a controlled two-stage cooling (10, 11, 12) is carried out after the last rolling stand (6') of the hot strip (7) to a strip temperature in the range of bainite formation of 320 - 480 DEG C, with a holding time of about 650 - 730 DEG C,; the beginning of which is determined by the entry of the cooling curve into the ferrite region and the duration of which is determined by the transformation of the austenite into at least 40% ferrite.

Owner:SMS DEMAG AG

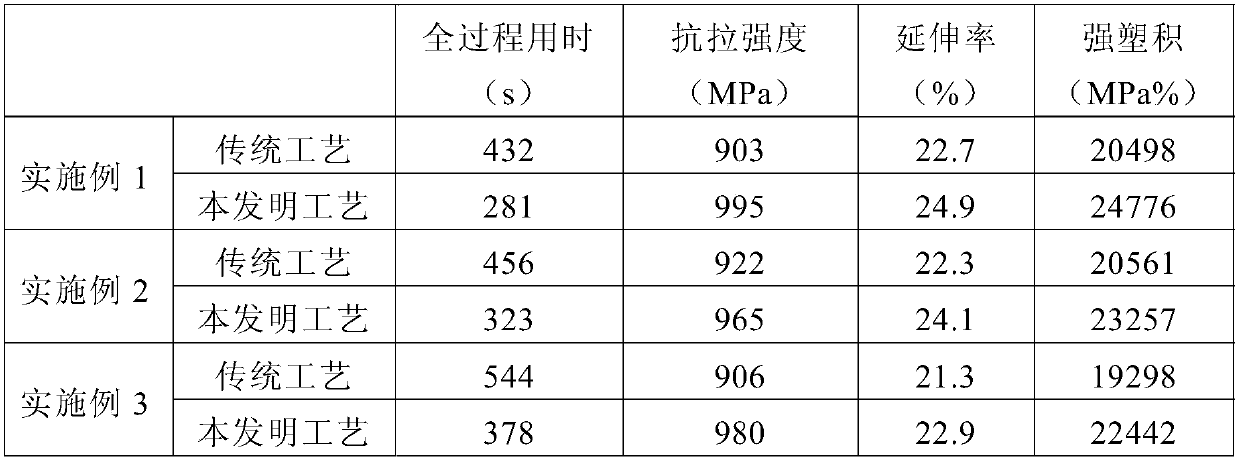

Economic high-strength cold-rolled TRIP steel with product of strength and elongation greater than 20 GPa*% and manufacturing method of TRIP steel

The invention relates to a production method of economic high-strength cold-rolled TRIP steel with the tensile strength no less than 800 MPa and the product of strength and elongation greater than 20 GPa*%. The steel is made from main chemical components, by weight percentage, 0.15-0.25% of C, 1.3-1.7% of Si, 1.5-2.5% of Mn, no more than 0.030% of P, no more than 0.020% of S, and 0.02-0.06% of Al, with the balance being Fe and inevitable impurities. The manufacturing method comprises the following steps: (1) melting and solidification; (2) hot continuous rolling of a casting blank or ingot casting; (3) pickling and cold rolling; and (4) continuous annealing. The product of strength and elongation of the TRIP steel is greater than 20 GPa*%, and can reach as high as 26.3 GPa*%. At the same time, the sheet shape, the surface quality, the stamping property and the welding property of the TRIP steel are ensured.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

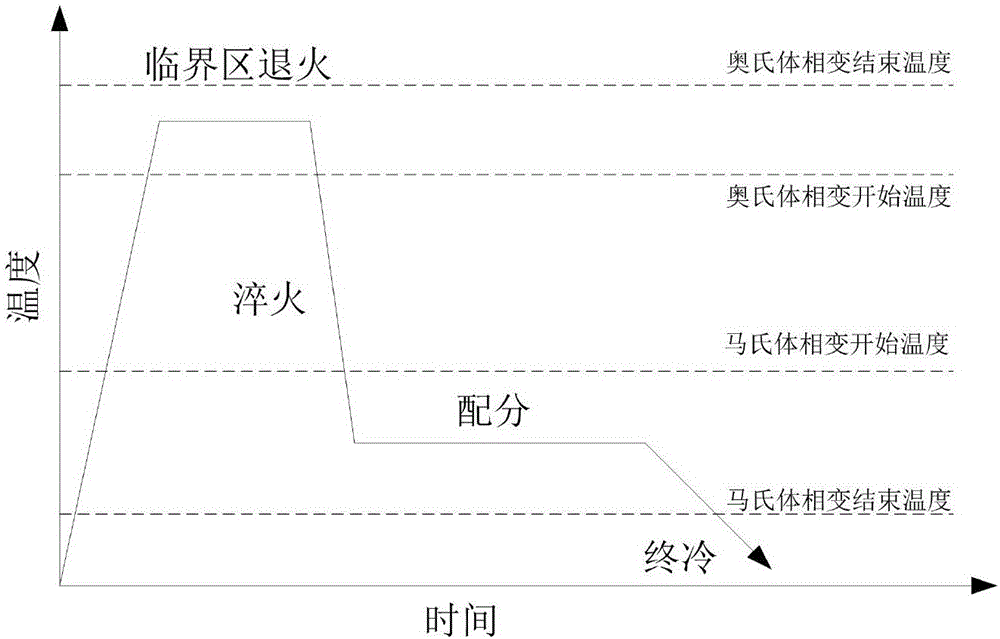

Medium-manganese TRIP (Transformation-Induced Plasticity) steel and preparation method thereof

The invention provides medium-manganese TRIP (Transformation-Induced Plasticity) steel and a preparation method thereof. According to the medium-manganese TRIP steel and the preparation method thereof, medium-manganese cold rolled steel is taken as a raw material; the cost is low; the performance of a final product is realized by adopting critical region heat preserving, quenching cooling and partitioning processes; the structure of the medium-manganese steel is controlled by utilizing an over-aging stage in a continuous annealing production line, and the residual austenite volume fraction of the structure is improved in a relatively short critical annealing time, so that mechanical properties of a product are ensured, and meanwhile, the cost is reduced as much as possible; the performance of the steel is stable, the process fluctuation has little influence on performance, and industrial production is facilitated; and the prepared medium-manganese TRIP steel is high in strength, high in elongation and good in forming property, can be widely applied to reinforcing structural parts, such as a B-pillar reinforcing plate, to improve the collision safety of an overall vehicle, and achieves the effects of reducing weight and reducing emission.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

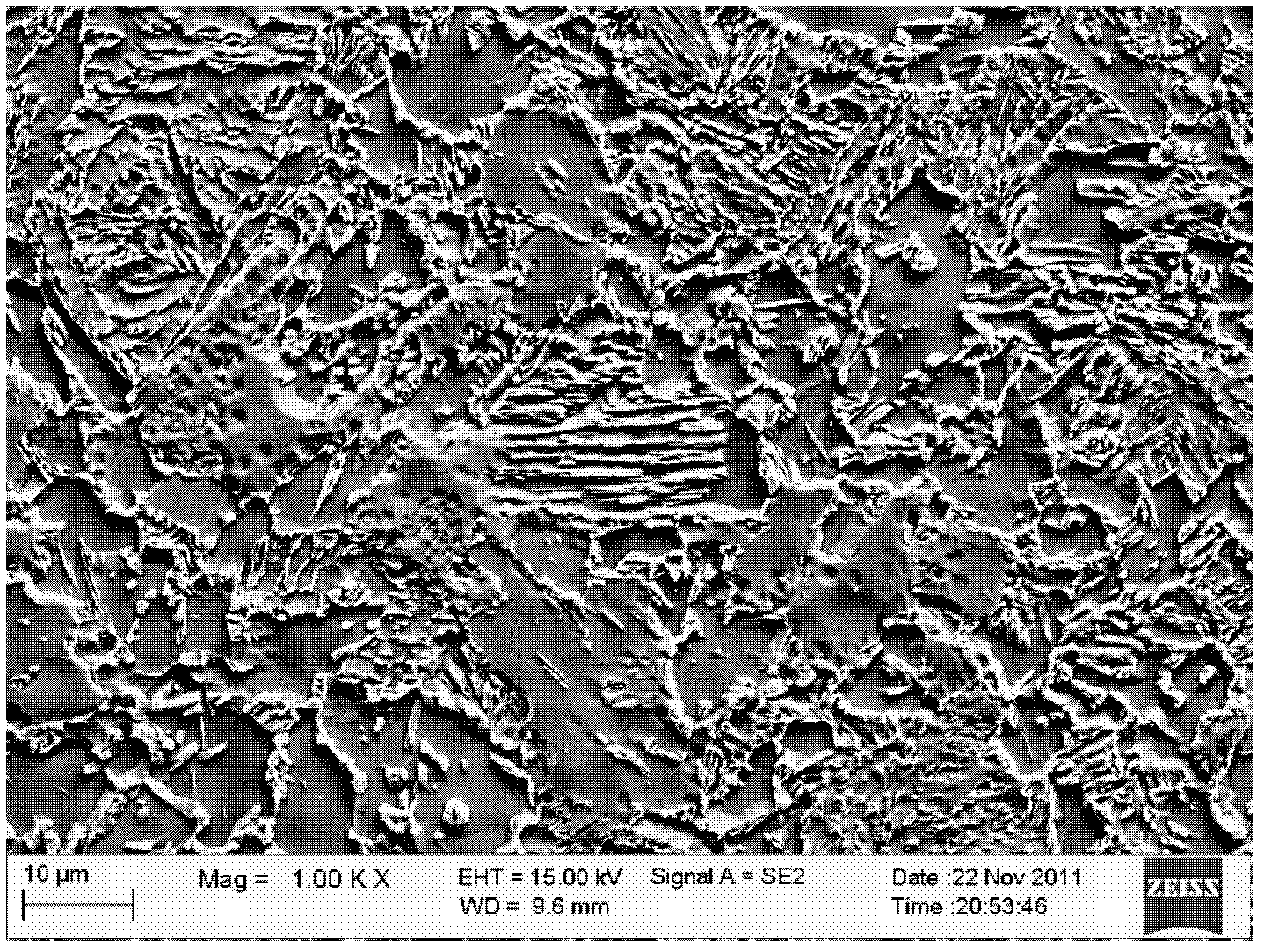

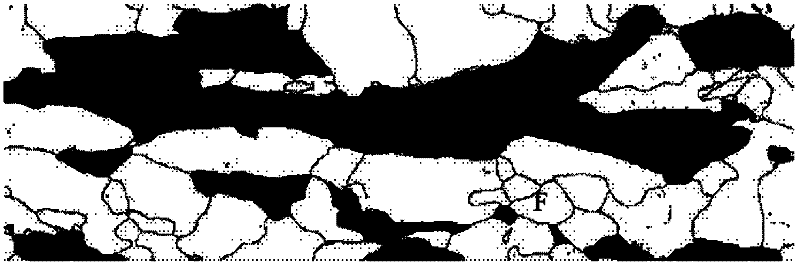

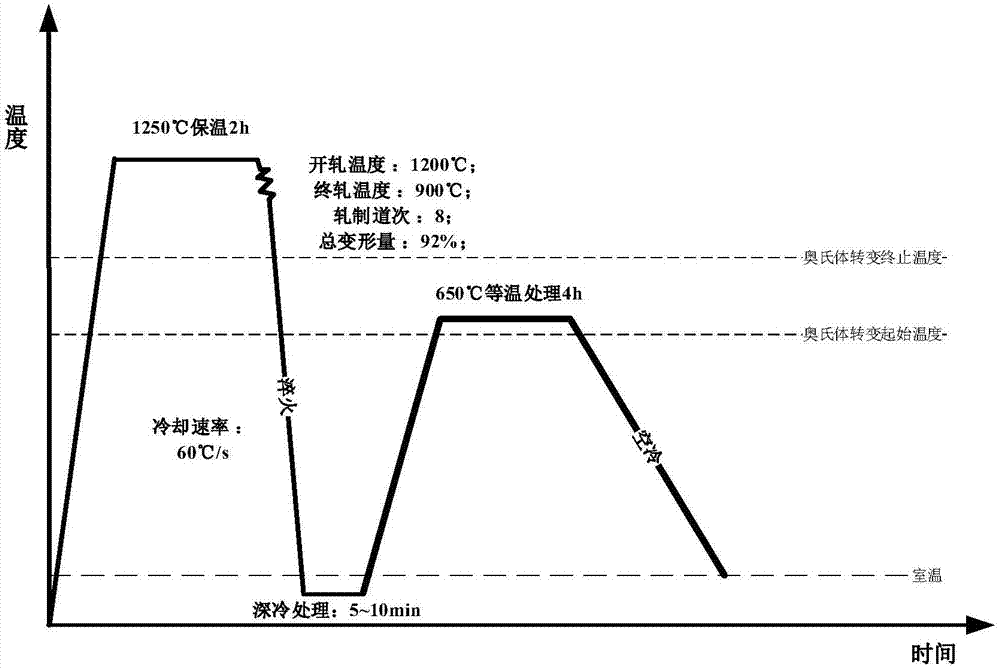

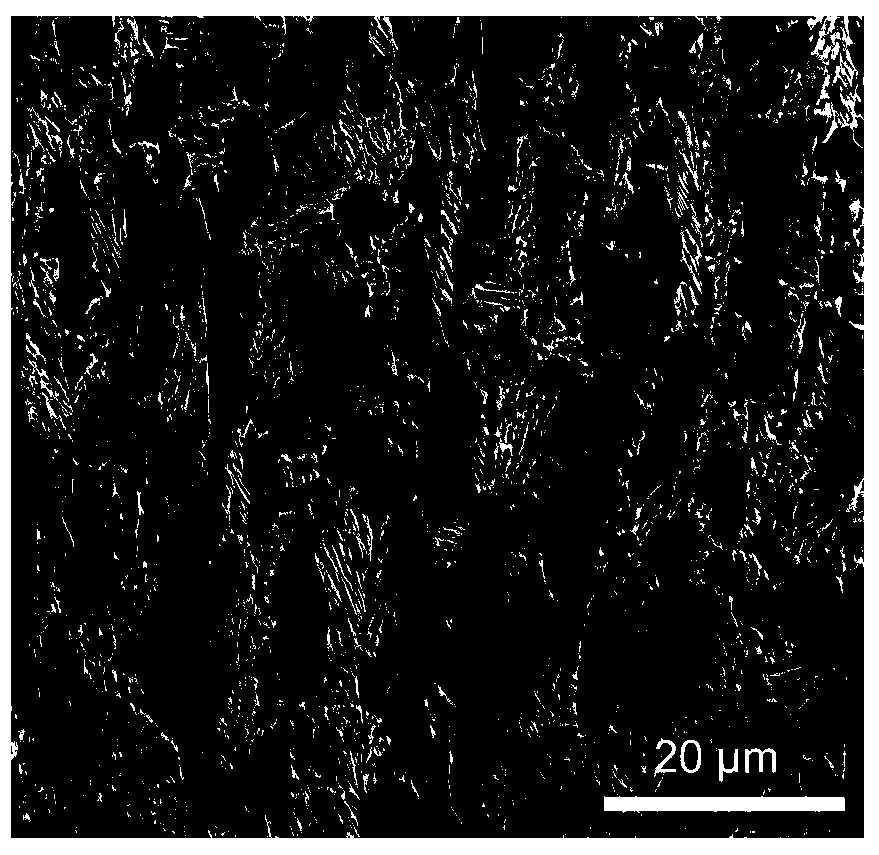

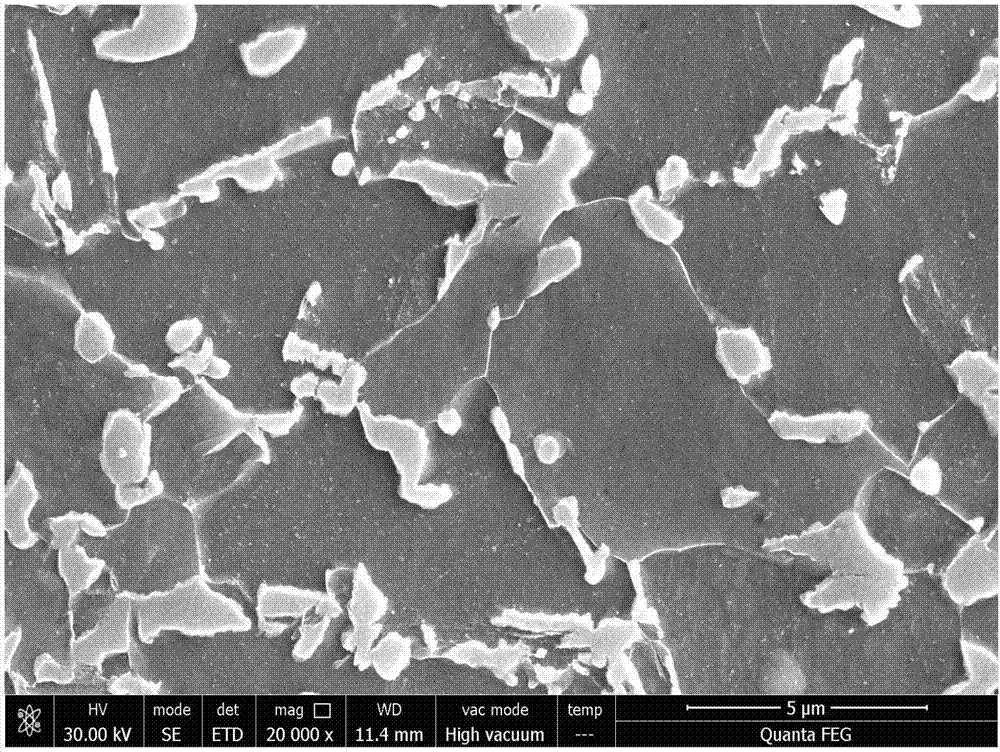

Method for discriminating bainite in hot rolled TRIP steel and calculating three phase ratio of hot rolled TRIP steel

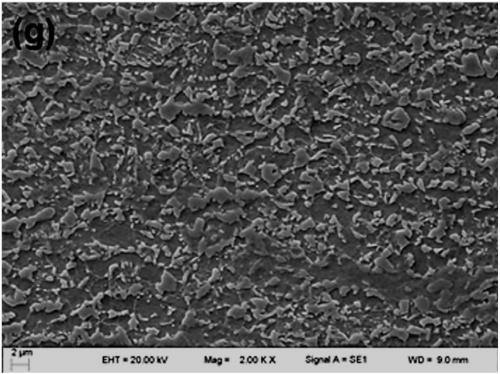

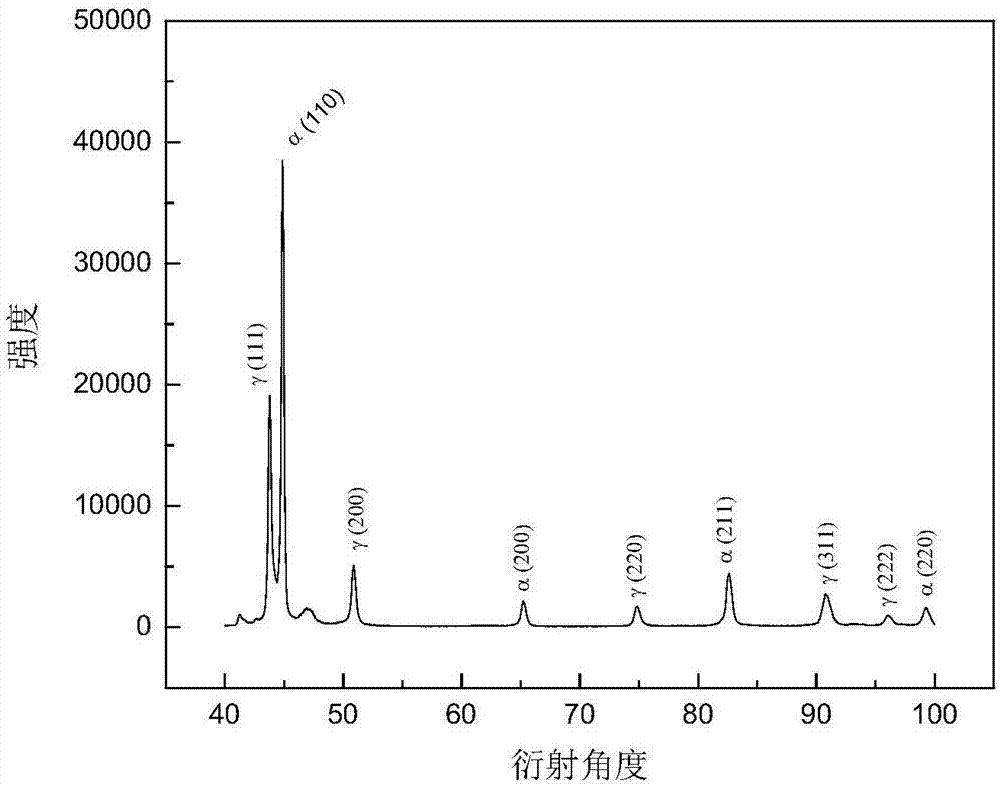

InactiveCN102353690AAccurate CalibrationEasy to calculateMaterial analysis using radiation diffractionMaterial analysis by measuring secondary emissionTRIP steelScanning electron microscope

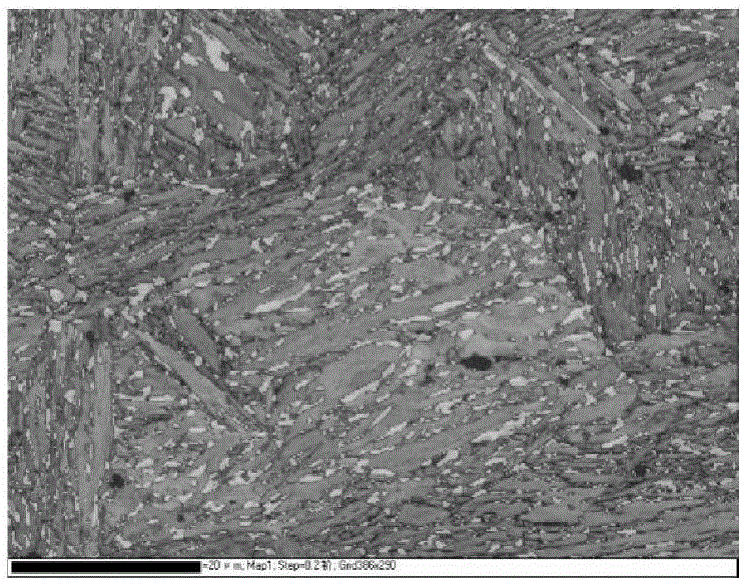

The invention relates to a method for discriminating bainite in a hot rolled TRIP steel and calculating a three phase ratio of the hot rolled TRIP steel. According to the method, an electron backscatter diffraction (EBSD) apparatus arranged on a scanning electron microscope is utilized to carry out quantitative measurement on FCC phase ( residual austenite) and BCC phase (ferrite+ bainite) of a hot rolled TRIP steel; processing is carried out on EBSD pattern data; a bainite structure is distinguished from the BCC phase by utilizing addition of a low angle grain boundary; Image Tool software is utilized to carry out statistics and calculation on three phase structure phase distinguishment graph of the hot rolled TRIP steel so as to obtain a content of a ferrite; and finally, a ration of the residual austenite to the ferrite to the bainite in the hot rolled TRIP steel is determined. Beneficial effects of the method is as follows: calibration on a phase structure can be carried out accurately and it is convenient to calculate all phase structures; and orientation information obtained by an EBSD technology can be utilized to carry out processing on various data according to own researches; therefore, researchers can accurately calibrate all phase structures in controlled rolling and controlled cooling steel with multi-phase structures without increased extra work.

Owner:UNIV OF SCI & TECH BEIJING

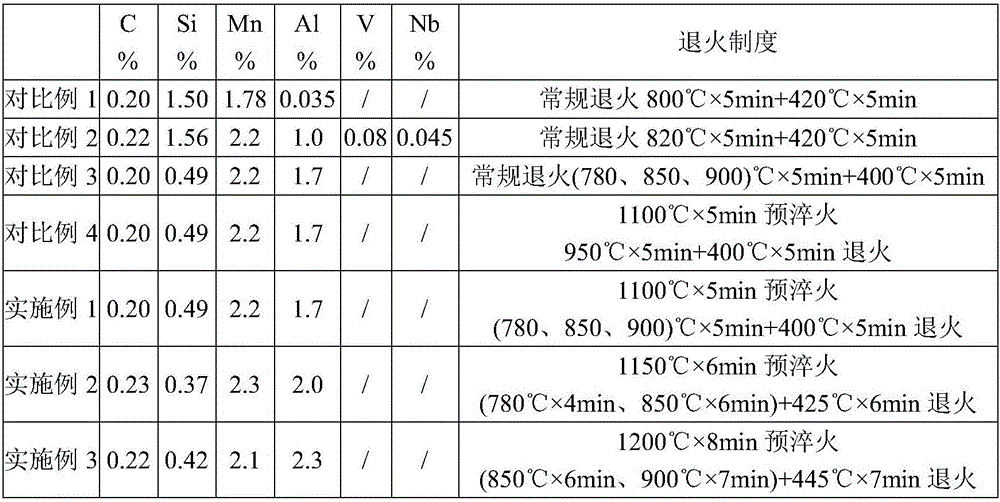

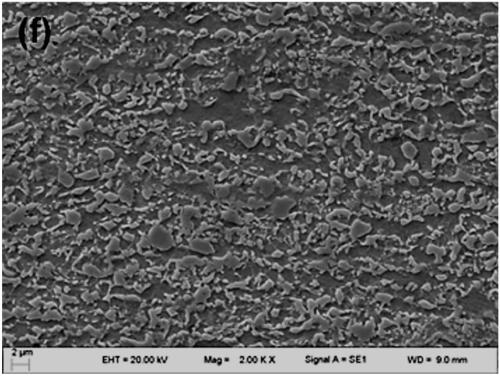

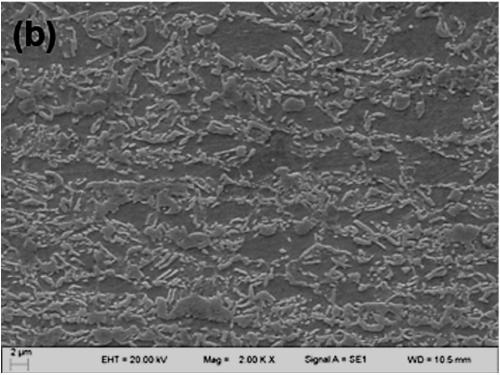

High-strength-and ductility-product cold-rolled TRIP steel and preparing method thereof

The invention discloses high-strength-and ductility-product cold-rolled TRIP steel and a preparing method thereof and belongs to the technical field of high-strength-and ductility-product cold-rolled automobile steel. The high-strength-and ductility-product cold-rolled TRIP steel comprises, by mass percent, 0.20%-0.23% of C, 0.35%-0.50% of Si, 2.0%-2.4% of Mn, 1.6%-2.5% of Al, smaller than or equal to 0.01% of P, smaller than or equal to 0.005% of S and the balance Fe and inevitable impurities. The preparing method includes smelting, hot rolling, cold rolling, pre-quenching and annealing. The high-strength-and ductility-product cold-rolled TRIP steel is high in strength, large in elongation rate, high in strength and ductility product and good in strength and ductility matching, and the forming performance and collision absorbing energy of the steel are greatly improved. Alloys of the steel grade are low in cost, the steel plate welding performance is good, the coating performance is good, the surface quality is good, and the strength and ductility product of the steel can reach 25 GPa.% to 33 GPa.%.

Owner:UNIV OF SCI & TECH BEIJING

780MPa-level low-carbon and low-alloy TRIP steel and rapid heat treatment method thereof

ActiveCN109943769AShort timeShorten the timeFurnace typesHeat treatment furnacesFerrite substrateAlloy

The invention provides 780MPa-level low-carbon and low-alloy TRIP steel and a rapid heat treatment method thereof. The steel comprises the following chemical components in percentage by mass: 0.16-0.22% of C, 1.2-1.6% of Si, 1.6-2.2% of Mn, and the balance Fe and other inevitable impurities. The method comprises the steps of rapidly heating, maintaining temperature within short time, and rapidly cooling. According to the steel and the method, the recrystallizing and phase changing processes in the heating and the phase change process in cooling are controlled, thus a three-phase structure thatbainite and austenite are uniformly distributed on a ferrite substrate can be obtained; the average crystal grain size of bainite and austenite is 1-3 microns; bainite is of a submicron particle form; austenite is of an island uniformly-distributed equiaxial crystal grain form; the whole three-phase structure comprises 35-75% by volume of bainite, 10-60% by volume of ferrite, and 5-15% by volumeof austenite; with the adoption of the rapid heat treatment, the mechanical performance of the material is improved while the heat treatment efficiency is improved; and the material performance area range is expanded.

Owner:BAOSHAN IRON & STEEL CO LTD

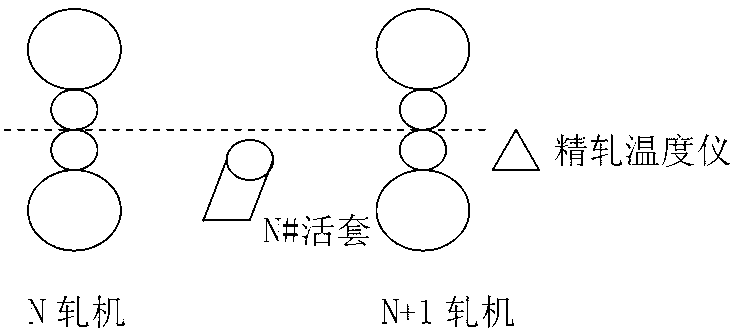

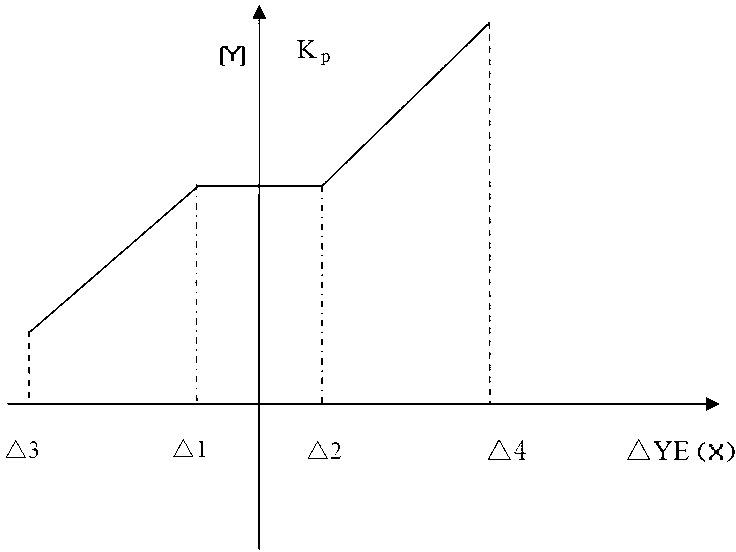

Hot continuous rolling stainless steel strip steel tail portion loop control method

The invention belongs to the field of hot rolling strip steel, and particularly relates to a hot continuous rolling stainless steel strip steel tail portion loop control method. Step 1, a broken line is designed, a rectangular plane coordinate system is built, a force moment deviation value of a trip steel tail portion loop, namely, the difference between the given moment and the actual moment, serves as the X axis of the rectangular plane coordinate system, and a loop moment control coefficient value serves as the Y axis of the rectangular plane coordinate system, and the broken line is a three-section linear equation; step2, the algorithm of a strip steel tail portion loop moment controller is that Yn=Yn-1 +Kpn*{[1+TA / TN]*deltaYEn-deltaYEn-1}; step 3, if being within the range between delta1 and delta2, the moment deviation value of the trip steel tail portion loop is calculated according to the step 1, and if being beyond the range between the delta1 and the delta2, the moment deviation value of the trip steel tail portion loop is calculated according to the broken line, maximum amplitude limiting and minimum amplitude limiting are also adopted, the maximum amplitude limiting value is 8*10<-6>, and the minimum amplitude limiting value is 1*10<-6>; step 4, the loop is controlled by a hydraulic loop servo valve according to the result, calculated through the step 3, of the loop moment control coefficient.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

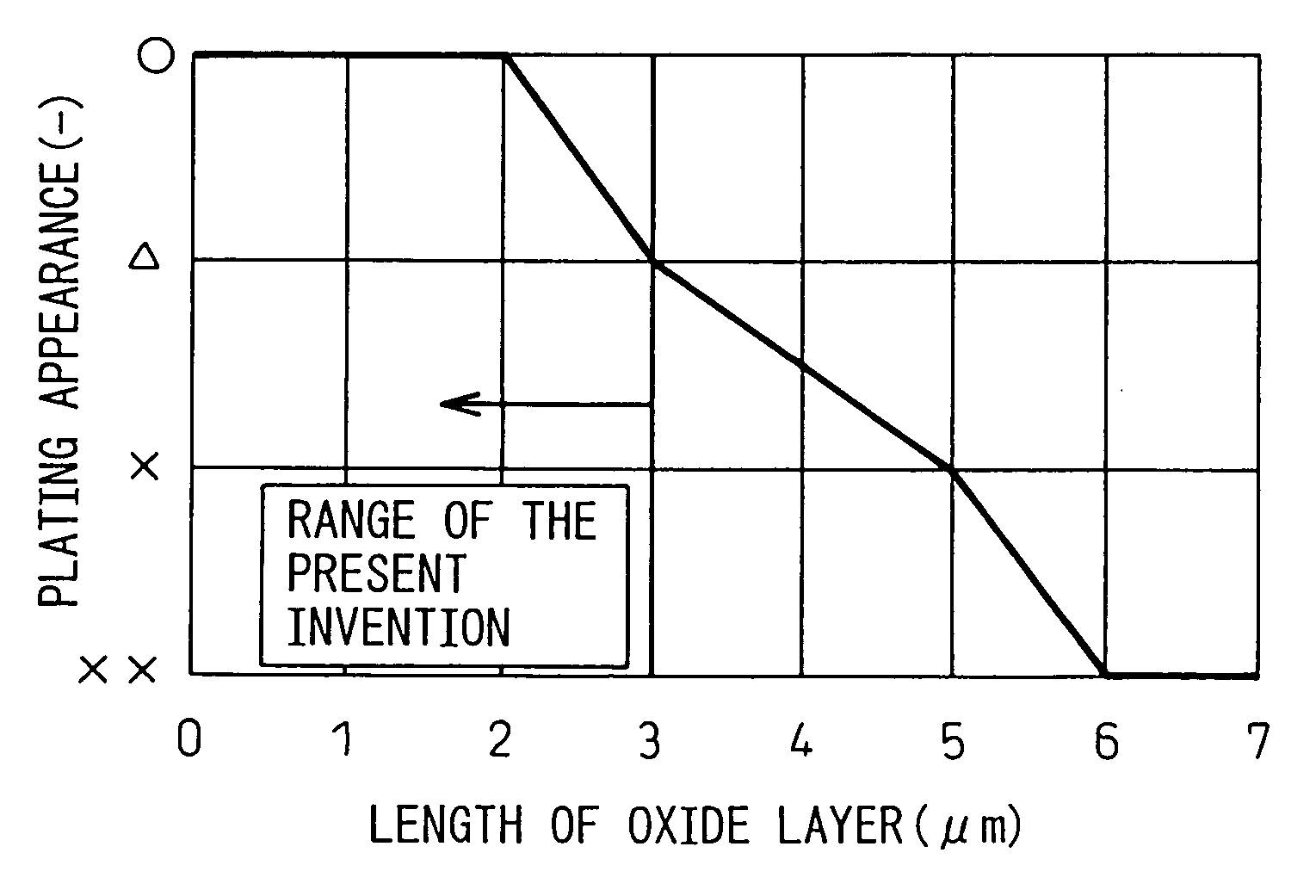

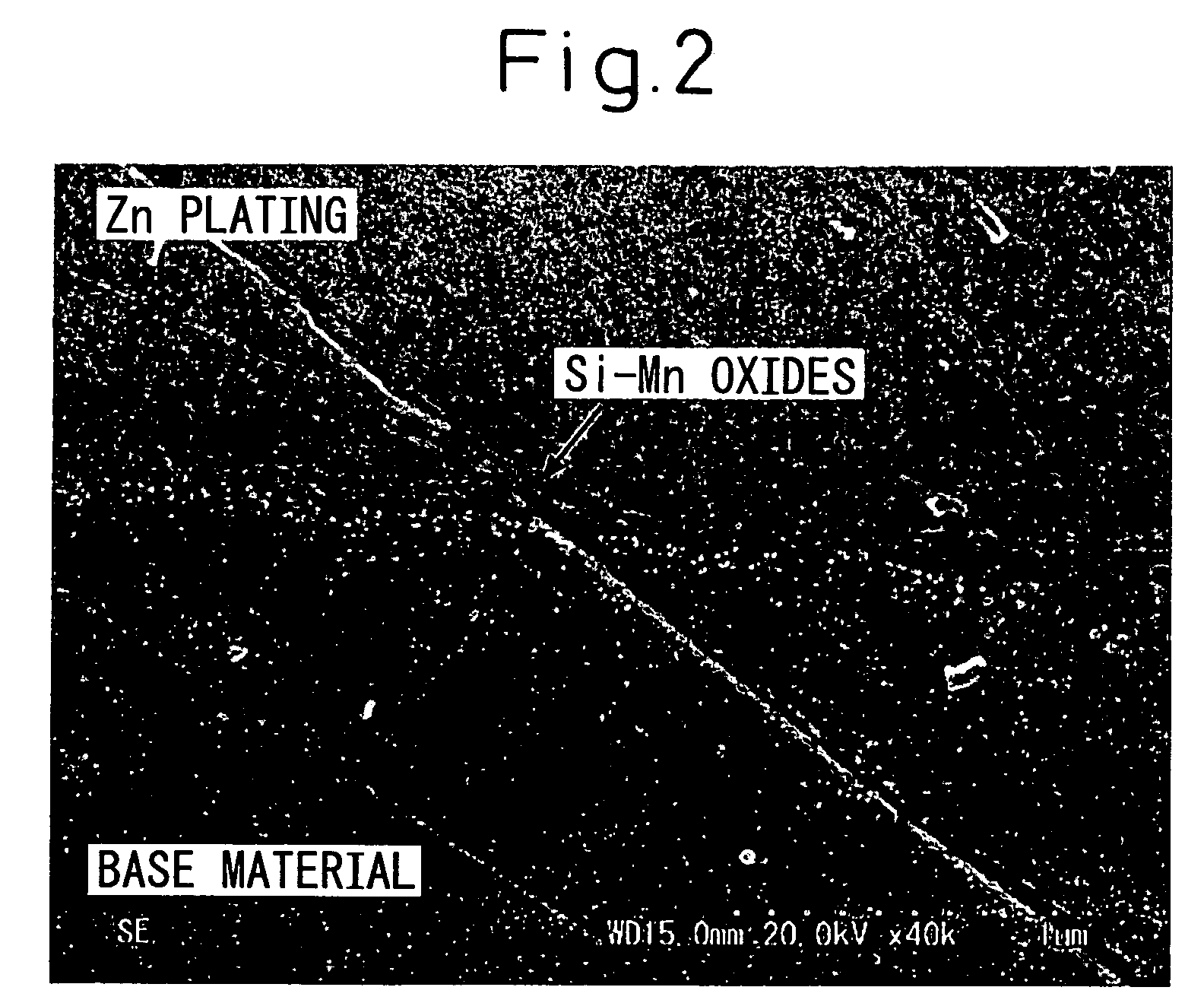

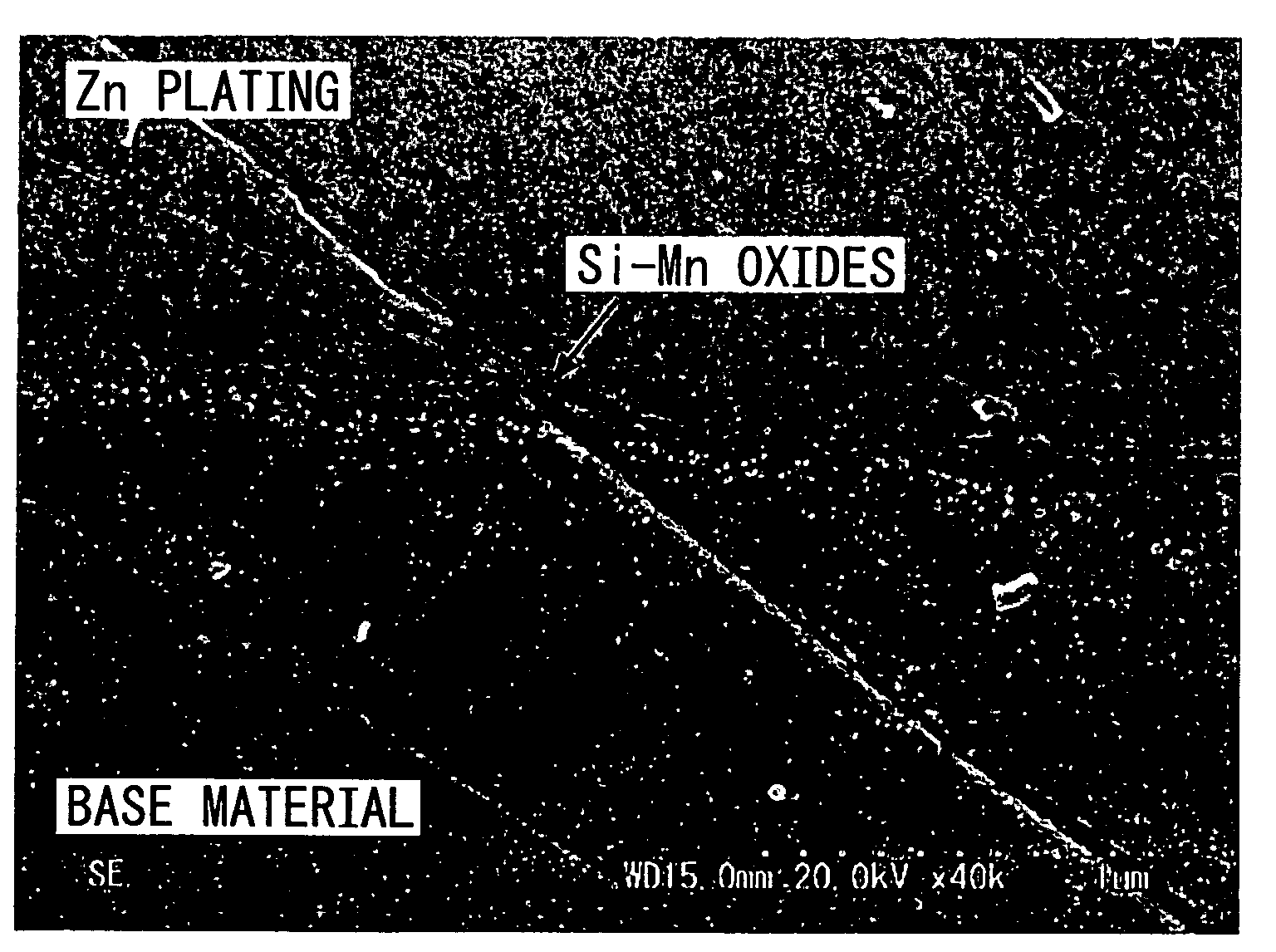

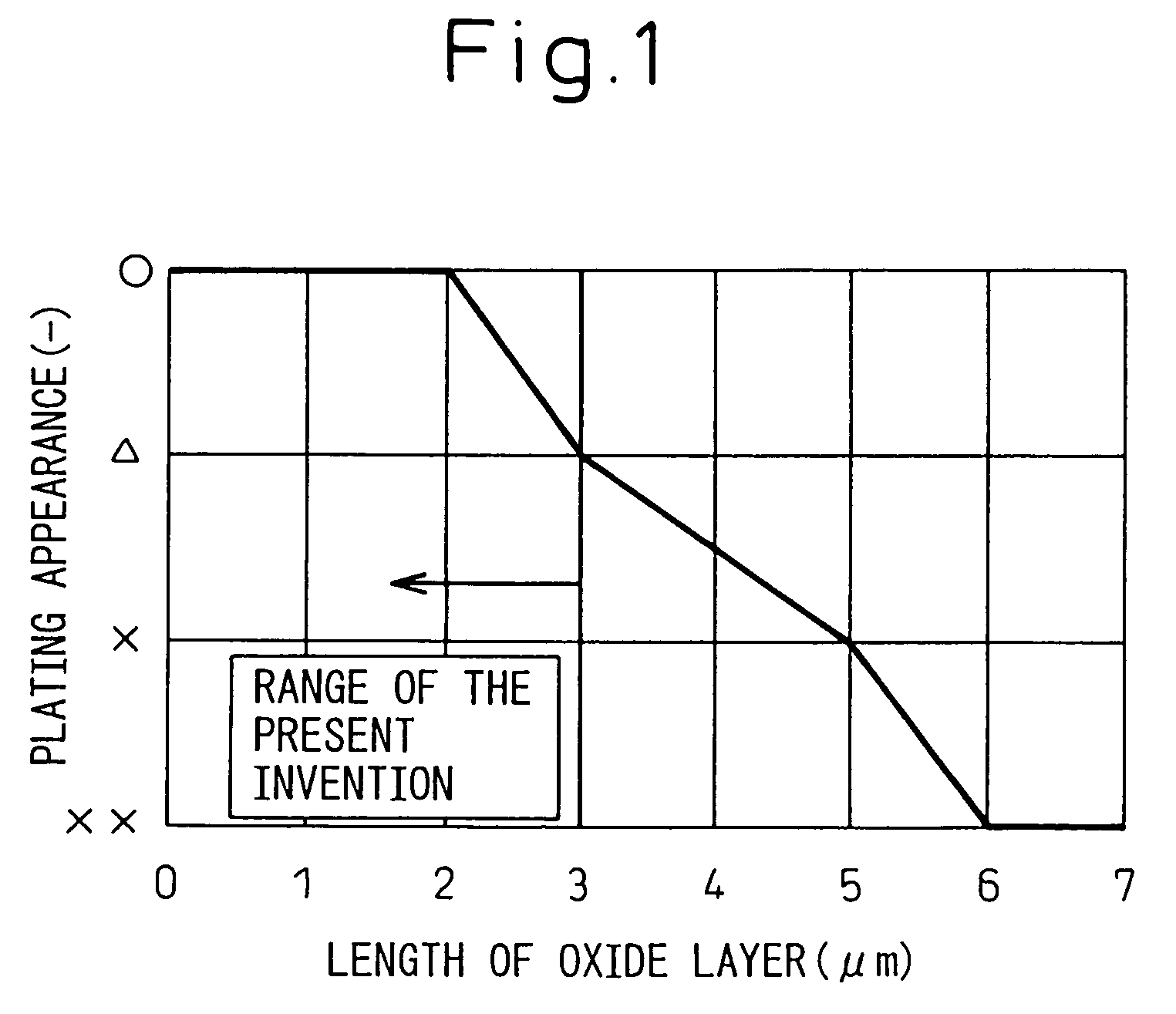

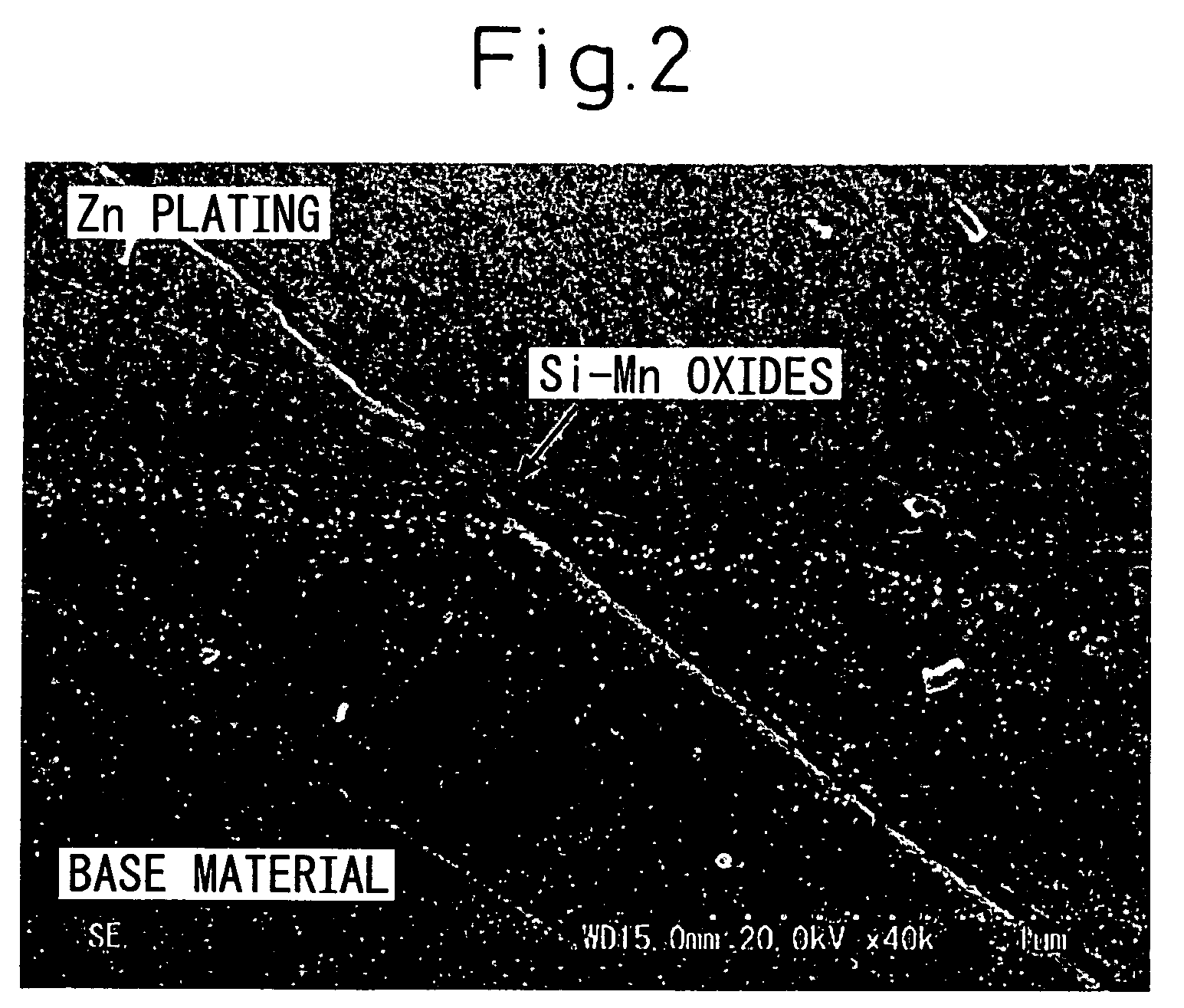

High-strength hop-dip galvanized steel sheet and method for producing the same

ActiveUS20060124907A1High tensile strengthNo non-plated portionHot-dipping/immersion processesConductive materialHydrogen concentrationTRIP steel

The present invention stably provides a high-strength hot-dip galvanized steel sheet having a high tensile strength and no non-plated portions and being excellent in workability and surface properties even when the employed equipment has only a reduction annealing furnace and a steel sheet containing relatively large amounts of Si, Mn and Al that are regarded as likely to cause non-plated portions is used as the substrate. The present invention: secures good plating performance even when the steel sheet contains Si, Mn and Al by adding Ni to a steel sheet, thus forming oxides at some portions in the steel sheet surface layer, and resultantly suppressing the surface incrassation of Si, Mn and Al at the portions where oxides are not formed; enhances the effect of Ni and accelerates the formation of oxides by further adding Mo, Cu and Sn; and moreover, in the case of a TRIP steel sheet, secures austenite by determining the ranges of Si and Al strictly, avoiding the deterioration of plating performance caused by the addition of Ni, and further adding Mo in a balanced manner. In addition, the present invention, in a TRIP steel sheet, improves press formability by regulating a retained austenite ratio and accelerates the formation of oxides by regulating a hydrogen concentration and a dew point in annealing before plating.

Owner:NIPPON STEEL CORP

TRIP steel sheet for high strength cold rolled continuous annealing and preparation method thereof

A high-strength and cold-rolled TRIP steel plate for continuous annealing and a preparation method thereof belong to the technical field of high-strength cold rolled steel. The components of the steel plate are as follows according to mass percentages: 0.1-0.4% of C, 0.5-2.5% of Si, 0.5-2.5% of Mn, 0.01-0.10% of Nb, 0.01-0.10% of Ti, 0.1-1.0% of Cu, 0.1-1.0% of Ni, not more than 0.03% of P, not more than 0.02% of S, and Fe. The steel plate has the advantages of superior workability and surface properties, the mechanical properties of the steel plate are improved by adding Nb, Ti, Cu, Ni, and the like, which provides the plate with the combination of high tensile strength and high specific elongation.

Owner:UNIV OF SCI & TECH BEIJING +1

Production process for shock-proof disaster-relieving hot rolled transformation-induced plasticity (TRIP) steel plates

Owner:HEBEI IRON & STEEL GRP

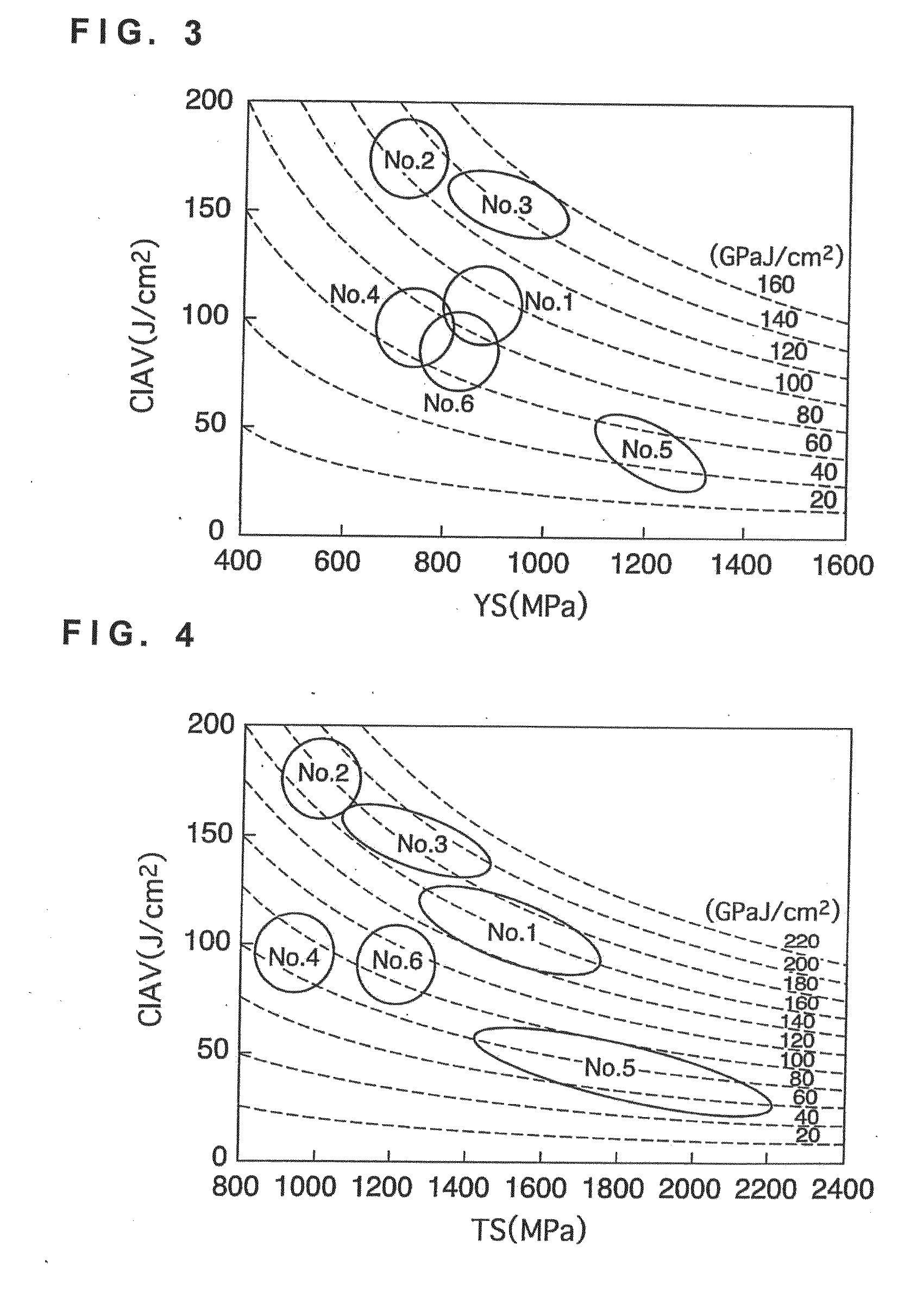

High-Strength Steel Machined Product and Method for Manufacturing the Same, and Method for Manufacturing Diesel Engine Fuel Injection Pipe and Common Rail

InactiveUS20110209803A1Improve hardenabilityImprove balanceFuel injection apparatusFurnace typesTRIP steelCommon rail

A high-strength steel machined product giving excellent hardenability has a metal microstructure with excellent balance of strength and toughness and high stability of retained austenite. The product is composed of an ultra-high low-alloy TRIP steel having a metal microstructure which contains an appropriate quantity of two or more of Cr, Mo, and Ni, and an appropriate quantity of one or more of Nb, Ti, and V, and having an appropriate value of carbon equivalent; the metal microstructure has a mother-phase structure composed mainly of lathy bainitic ferrite with a small amount of granular bainitic ferrite and polygonal ferrite, and has a secondary-phase structure composed of fine retained austenite and martensite.

Owner:USUI KOKUSAI SANGYO KAISHA LTD +1

Component design and production method of 1500 MPa-grade low-carbon and medium-manganese copper-contained steel

The invention relates to component design and a production method of 1500 MPa-grade low-carbon and medium-manganese copper-contained steel. The 1500 MPa-grade low-carbon and medium-manganese copper-contained steel comprises the following chemical components in percentage by mass: 0.20-0.23% of C, 0.5-0.8% of Si, 3.5-4.0% of Mn, 1.2-2.0% of Al, 0.5-1.0% of Cr, 0.6-1.0% of Cu, 0.2-0.5% of Ni, 0.003-0.012% of N, 0.00051-0.003% of B, and the balance of Fe and inevitable impurities. One part of alloy elements are added based on traditional TRIP steel to largely increase the content of manganese to reach the medium-manganese range; when Al is used for replacing the Si elements, a proper amount of Si elements are retained, so that the Al and Si elements are matched for use; and a certain quantity of precipitation-hardened Cu elements are added to match with a proper amount of Ni elements for use to eliminate the hot brittle phenomenon caused by Cu in hot working. In addition, few Cr elements are added; a proper amount of N elements are added to match with the Al elements for use; through matching between hot rolling and hot partition processes, a martensite+residual austenite+separated second-phase particle structure with ultrahigh strength and excellent plasticity is obtained; and the tensile strength exceeds 1500 MPa.

Owner:SHANDONG JIANZHU UNIV

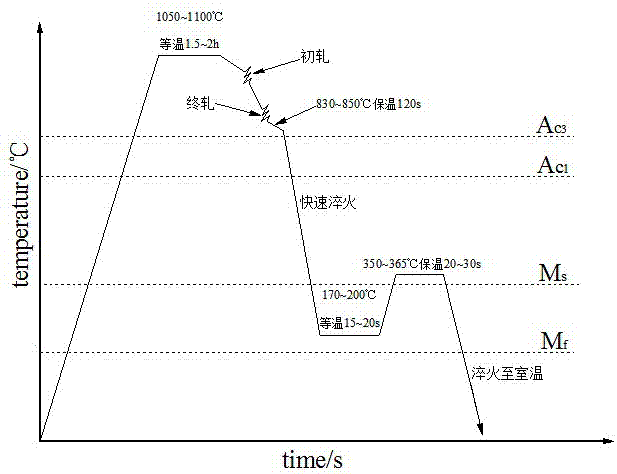

Ultrahigh strength TRIP steel with pressure intensity being 1.5GPa or higher and preparation method thereof

The invention discloses ultrahigh strength TRIP steel with the pressure intensity being 1.5GPa or higher and a preparation method thereof, and belongs to the technical field of hot-rolled steel plates with the high product of strength and ductility. The ultrahigh strength TRIP steel comprises the chemical components of 0.1-0.25wt.% of C, 5-10% wt.% of Mn, 1-3wt.% of Si, 0-0.2wt.% of P, 0-0.005wt.% of S, and the balance Fe and inevitable impurities. The preparation method comprises the steps of smelting, casting, forging, rolling and annealing; in the rolling process, quenching is conducted after multiple passes of hot rolling; the rolling starting temperature is 1100-1250 DEG C; the finish rolling temperature is 850-950 DEG C; a TMCP technology is applied to quenching; and in the annealing process, the temperature is increased to 600-750 DEG C in the two-phase region, heat preservation is carried out for 2-5 h, and air cooling is conducted till the temperature is equal to the room temperature. A prepared ultrahigh strength TRIP steel plate has the ultrahigh strength mechanical property characteristic, the tensile strength is higher than or equal to 1500MPa, the yield strength is higher than or equal to 800MPa, the percentage elongation is larger than or equal to 20%, and the product of strength and ductility is higher than or equal to 30GPa.%.

Owner:NORTHEASTERN UNIV

High-strength hop-dip galvanized steel sheet

ActiveUS7294412B2High tensile strengthNo non-plated portionHot-dipping/immersion processesFurnace typesHydrogen concentrationSurface layer

Owner:NIPPON STEEL CORP

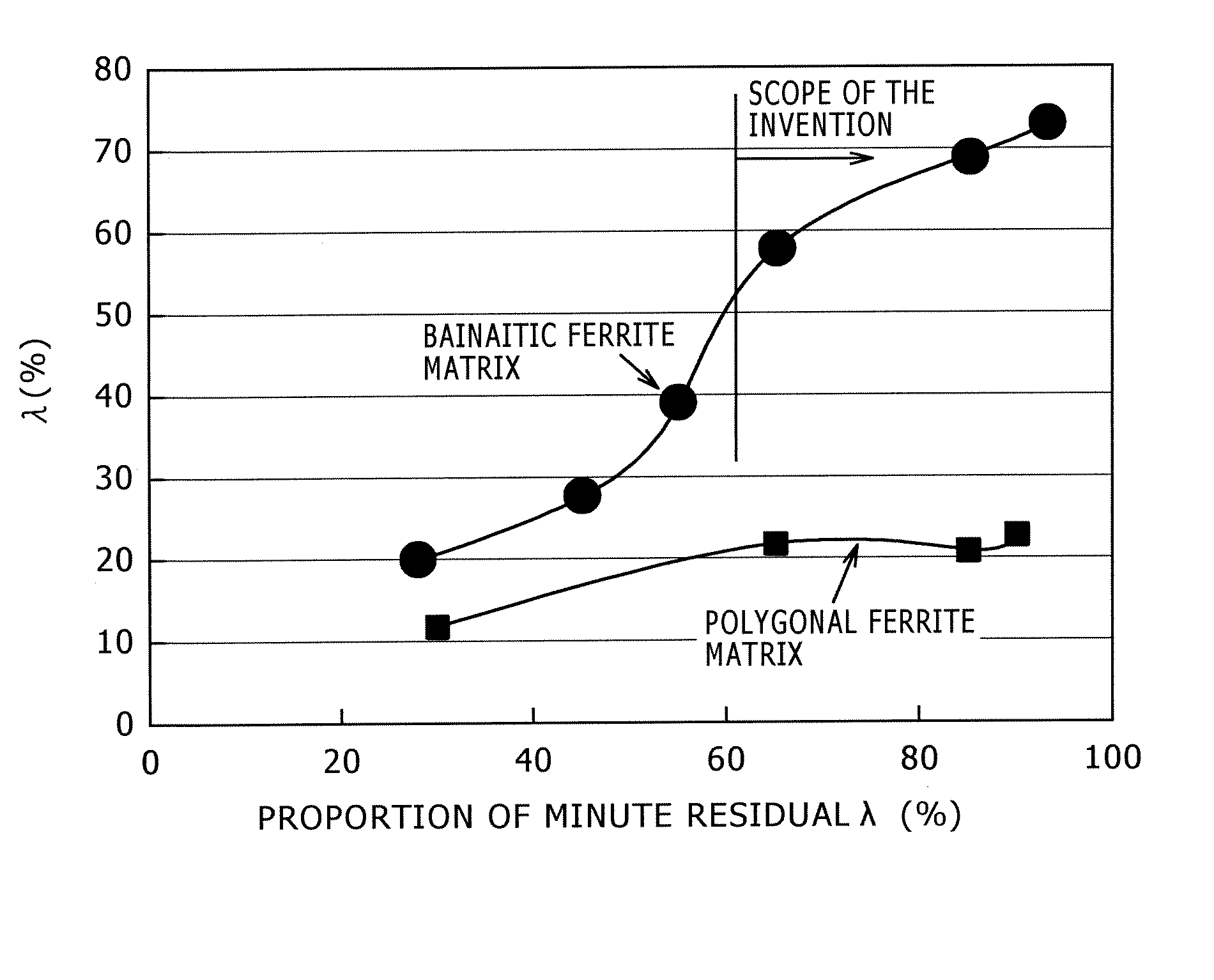

High strength steel sheet having excellent stretch flangeability

ActiveUS7468109B2High strengthExcellent stretch-flangeabilityFurnace typesHeat treatment furnacesTRIP steelHigh intensity

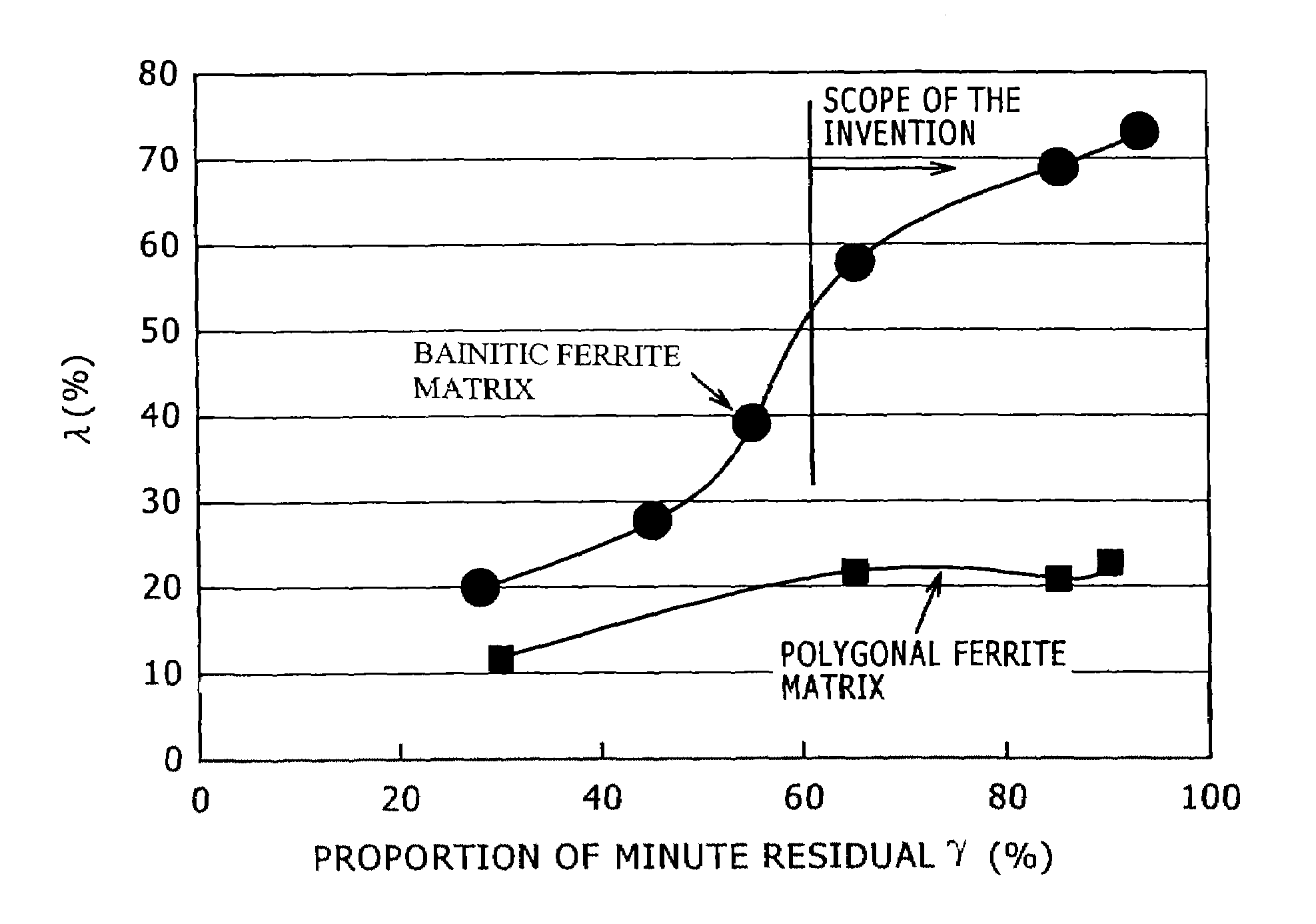

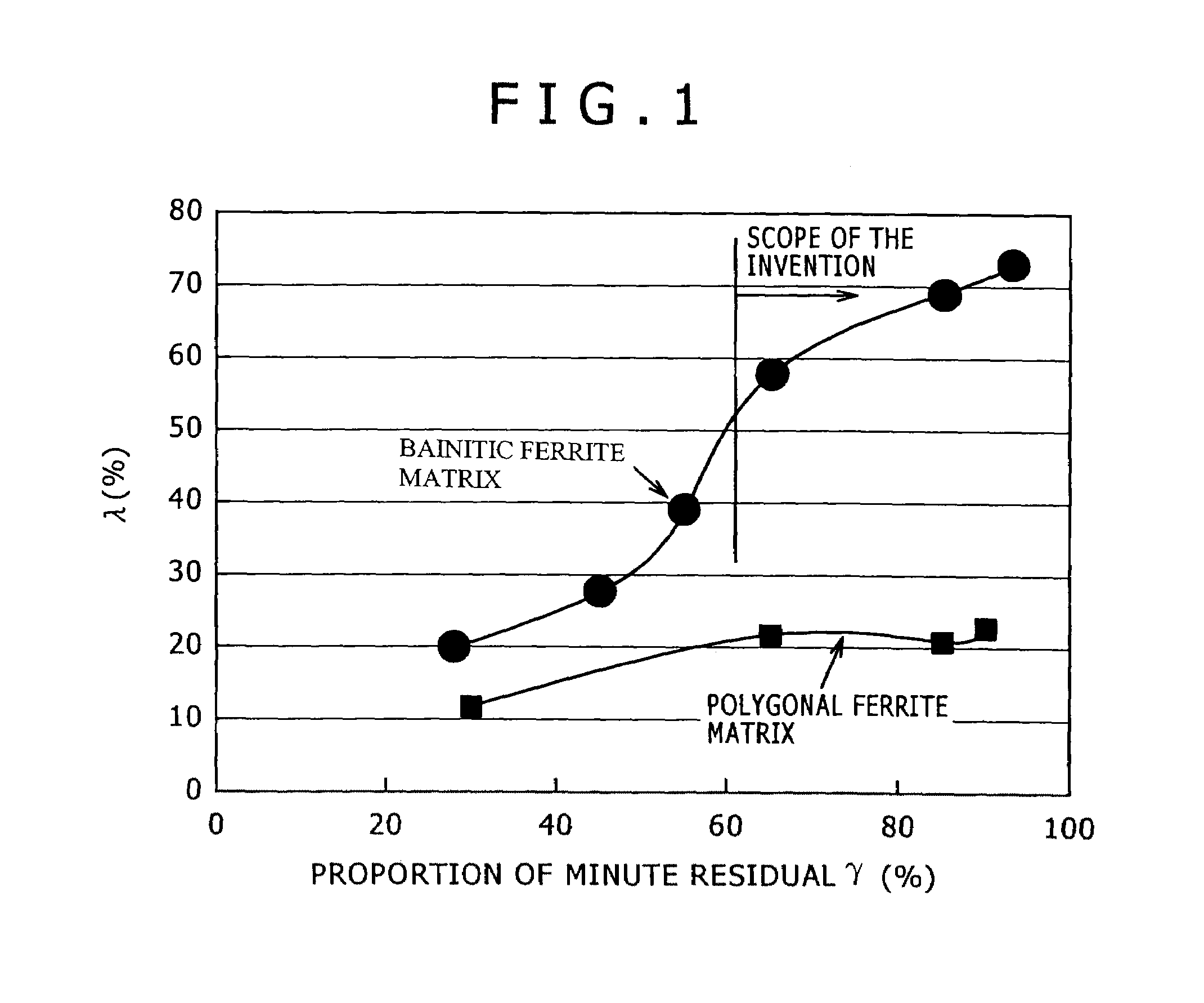

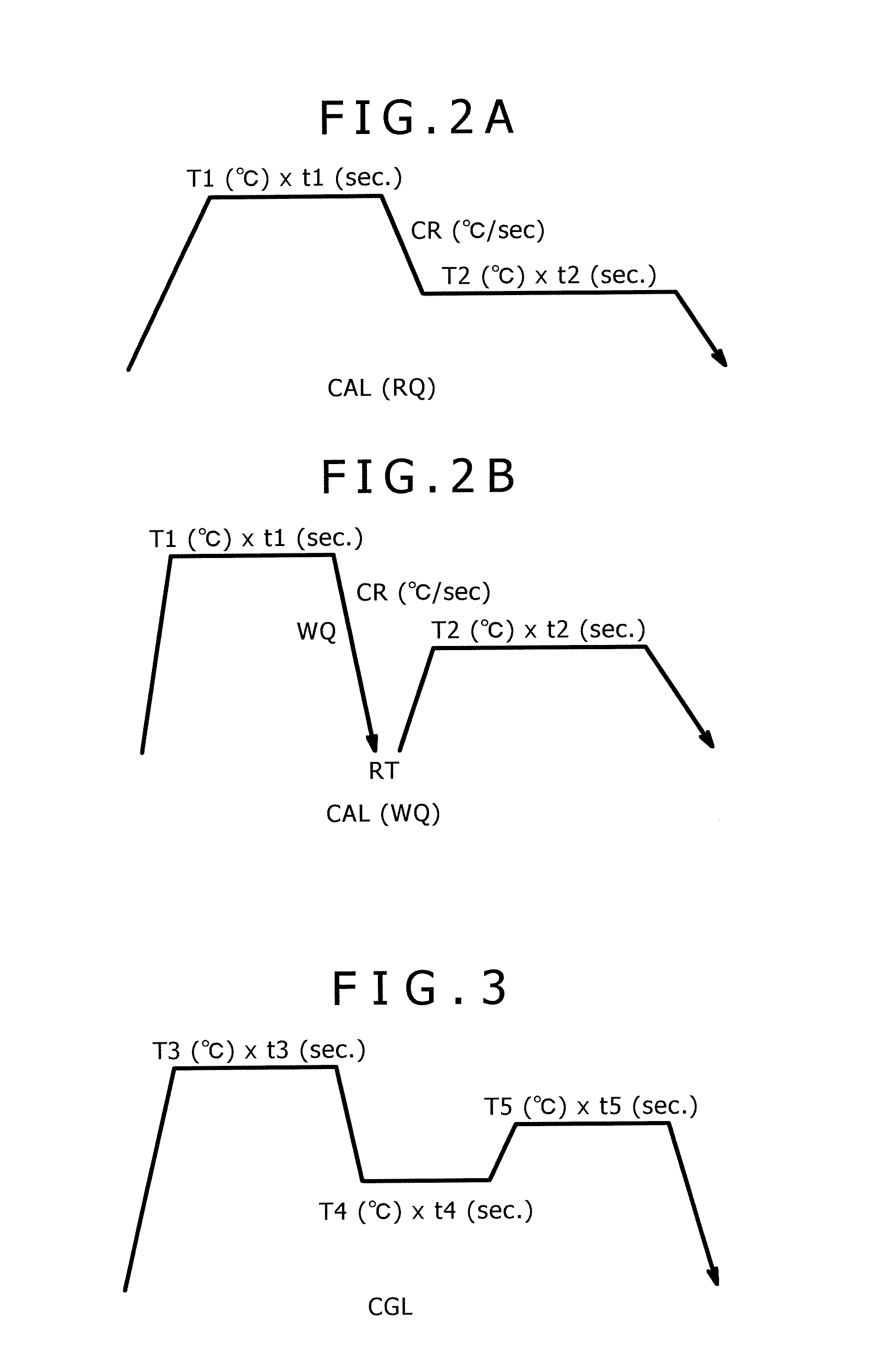

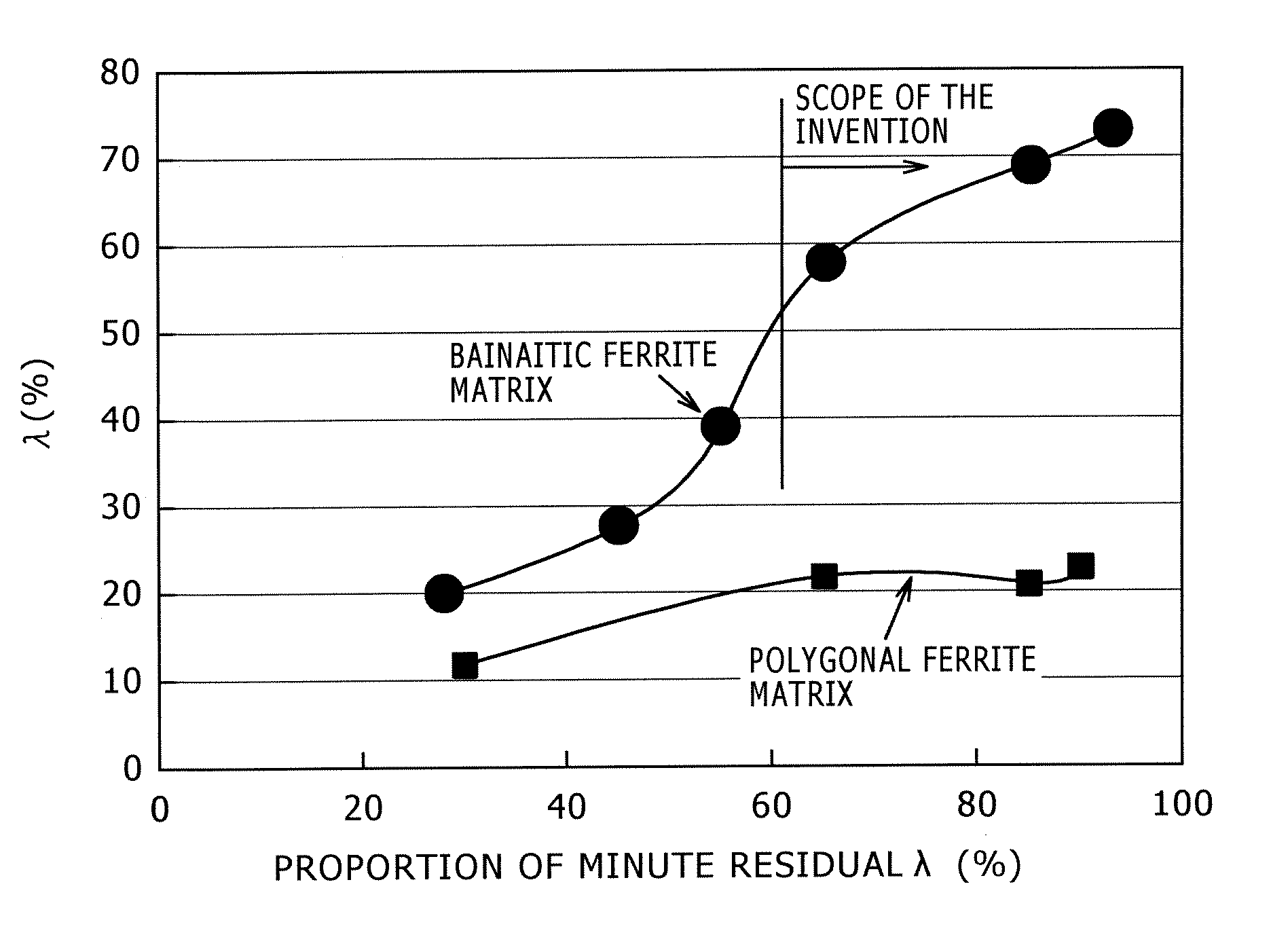

Disclosed is a steel sheet including 0.10 to 0.20 mass % of C, 0.8 to 2.5 mass % of Si, 1.5 to 2.5 mass % of Mn, and 0.01 to 0.10 mass % of Al, wherein P is limited to less than 0.1 mass %, and S is limited to less than 0.002 mass % and more than 0 mass %, and the structure includes bainitic ferrite and residual austenite such that area percentage of the bainitic ferrite in relation to the entire structure is at least 70%, area percentage of the residual austenite is 2 to 20%, and total area percentage of polygonal ferrite and quasi-polygonal ferrite is up to 15%, and proportion of the residual austenite having an average particle size of up to 5 μm in the residual austenite is at least 60%. The steel sheet is a TRIP steel sheet which has bainitic ferrite as its matrix, and it has a tensile strength (TS) of at least 980 MPa as well as an excellent stretch flangeability.

Owner:KOBE STEEL LTD

High strength steel sheet having excellent stretch flangeability

ActiveUS20080023112A1High strengthExcellent stretch-flangeabilityFurnace typesHeat treatment furnacesTRIP steelHigh intensity

Disclosed is a steel sheet including 0.10 to 0.20 mass % of C, 0.8 to 2.5 mass % of Si, 1.5 to 2.5 mass % of Mn, and 0.01 to 0.10 mass % of Al, wherein P is limited to less than 0.1 mass %, and S is limited to less than 0.002 mass % and more than 0.1 mass %, and the structure includes bainitic ferrite and residual austenite such that area percentage of the bainitic ferrite in relation to the entire structure is at least 70%, area percentage of the residual austenite is 2 to 20%, and total area percentage of polygonal ferrite and quasi-polygonal ferrite is up to 15%, and proportion of the residual austenite having an average particle size of up to 5 μm in the residual austenite is at least 60%. The steel sheet is a TRIP steel sheet which has bainitic ferrite as its matrix, and it has a tensile strength (TS) of at least 980 MPa as well as an excellent stretch flangeability.

Owner:KOBE STEEL LTD

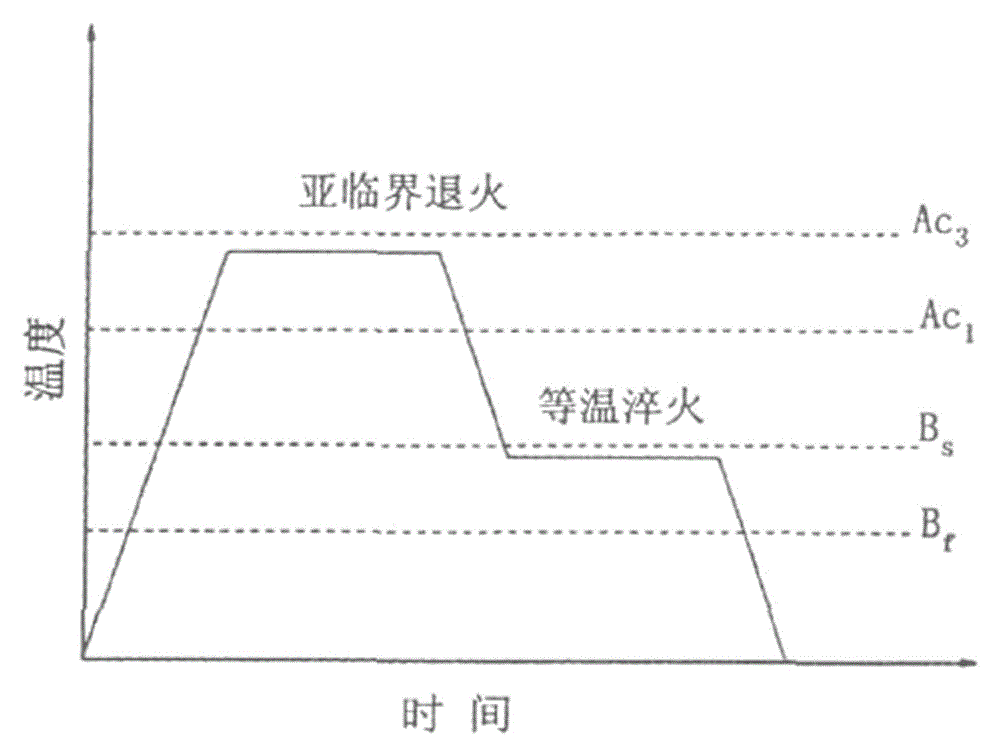

Processing method for improving surface quality of TRIP steel

InactiveCN105063311AImprove the shortcoming of narrow annealing process windowImprove surface qualityChemical compositionTRIP steel

The invention provides a processing method for improving surface quality of TRIP steel, comprising the following steps: (1) preparing the TRIP steel from the following raw materials by weight percent: 0.10-0.25% of C, 1.0-4.0% of Mn, less than or equal to 0.5% of Si, 1.0-5.0% of Al, less than or equal to 0.1% of Cr, less than or equal to 0.01% of P, less than or equal to 0.01% of S, and the balance of Fe and inevitable impurities by virtue of smelting, and cogging the TRIP steel into a steel plate; (2) rolling the steel plate to the thickness of 4mm; (3) rolling the steel plate to the thickness of 1mm; (4) annealing the steel plate; and (5) performing isothermal quenching on the high aluminum TRIP steel plate obtained in the step (4). According to the scheme in the invention, by setting the annealing temperature of the high aluminum TRIP steel plate to be above Ac3 and below the liquidus temperature, the defect that the heat treatment temperature of conventional TRIP steel only can be limited between Ac1-Ac3, so as to cause a narrower annealing process window can be improved.

Owner:NORTHEASTERN UNIV

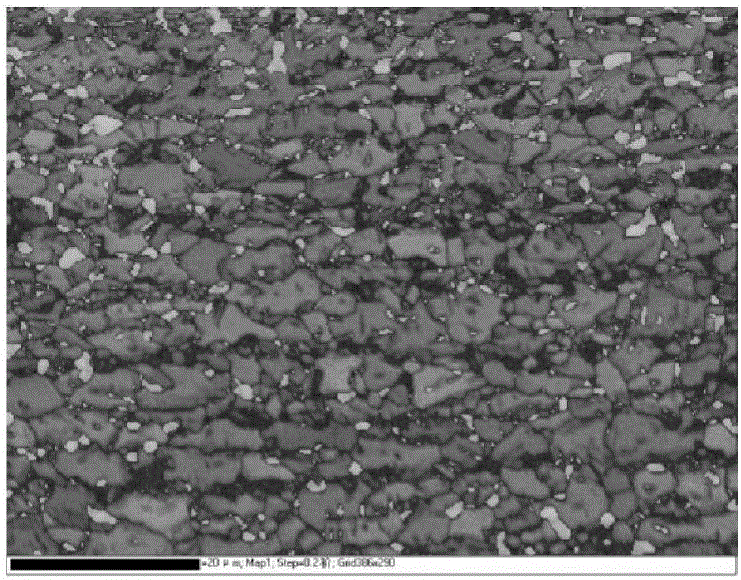

Method for quantitatively evaluating each phase structure in hot rolling TRIP (transformation-induced plasticity) steel

ActiveCN103454294AQuantitative results are accurateIncrease reflectionMaterial analysis using wave/particle radiationTRIP steelScanning electron microscope

The invention relates to a method for quantitatively evaluating each phase structure in hot rolling TRIP (transformation-induced plasticity) steel. The method comprises the following steps: quantitatively measuring an FCC phase (retained austenite) and a BCC phase (ferrite, bainite and martensite) of the hot rolling TRIP steel by using an electronic backscattered diffraction device arranged on a scanning electron microscope; firstly recognizing the retained austenite according to a distinct difference of the FCC phase and the BCC phase in structure, and then quantitatively distinguishing the three phases by using a gray value difference in a kikuchi band contrast BC (Band Contrast) image in EBSD (electron backscattered diffraction) processing software according to the difference of the three similar structure phases of the ferrite, the bainite and the martensite in kikuchi pattern quality, so as to achieve multi-phase separation and quantitative analysis of the hot rolling TRIP steel. The method is accurate and reliable, and can be applied to the technical field of measurement of tissues in the steel.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com