Method for quantitatively evaluating each phase structure in hot rolling TRIP (transformation-induced plasticity) steel

A quantitative evaluation and organization technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of difficulty in distinguishing retained austenite and martensite, and inability to distinguish retained austenite and martensite, etc. The effect of reflecting and quantifying the results accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Use wire cutting to cut a sample of appropriate size, and use coarse sandpaper to roughly grind the six sides of the sample so that the upper and lower surfaces are parallel, and then finely grind the surface where the data is to be collected on the automatic grinding machine;

[0026] 2) Put the sample on a fully automatic polishing machine for fine mechanical polishing, select a particle size of about 0.02 μm, and polish for about 3 minutes until no obvious scratches can be observed on the surface of the sample under a metallographic microscope at 50 to 100 times, then polish The samples were quickly washed in absolute ethanol and dried with hot air with a hair dryer;

[0027] 3) Carry out rapid and light corrosion on the polished and scratch-free samples, and the degree of corrosion should be such that the grain boundaries can be seen under the optical microscope; the etchant used is: 4% nitric acid alcohol solution;

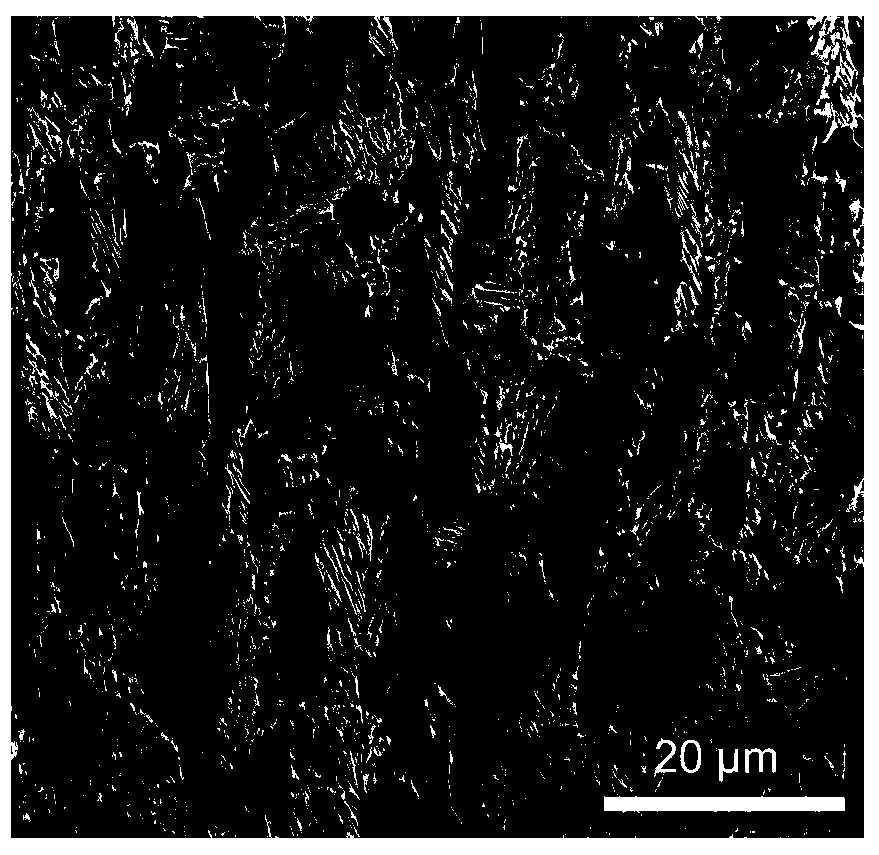

[0028] 4) Observe the microstructure of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com