Patents

Literature

93 results about "Pole figure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

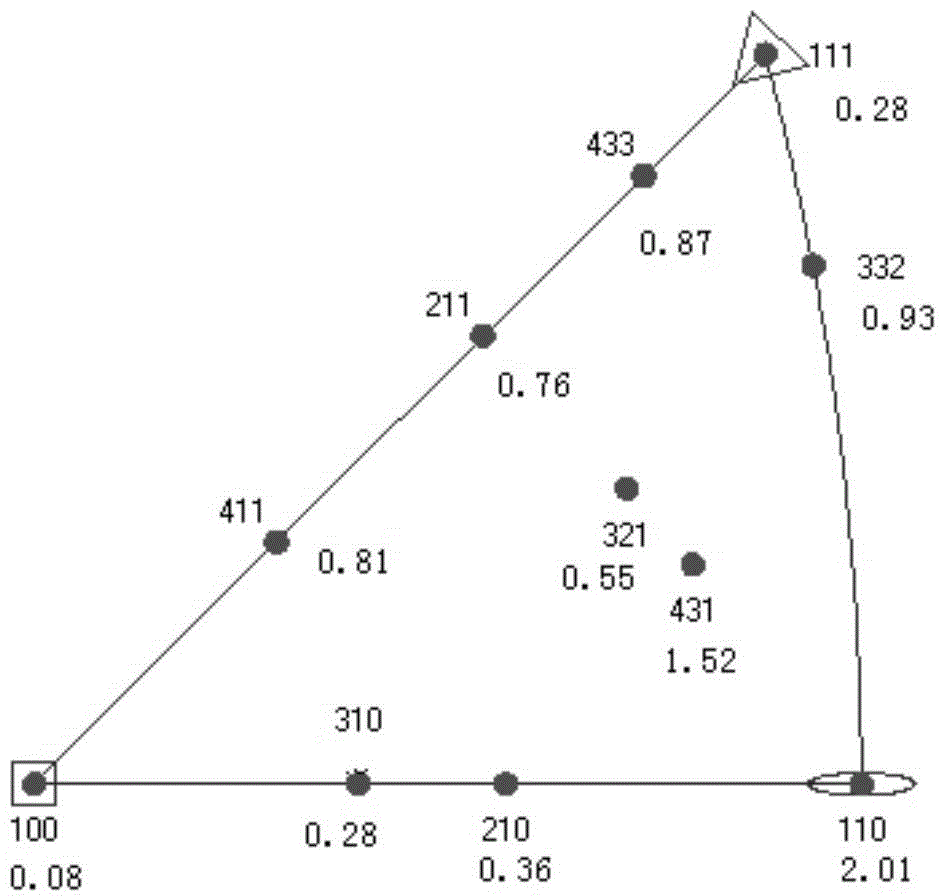

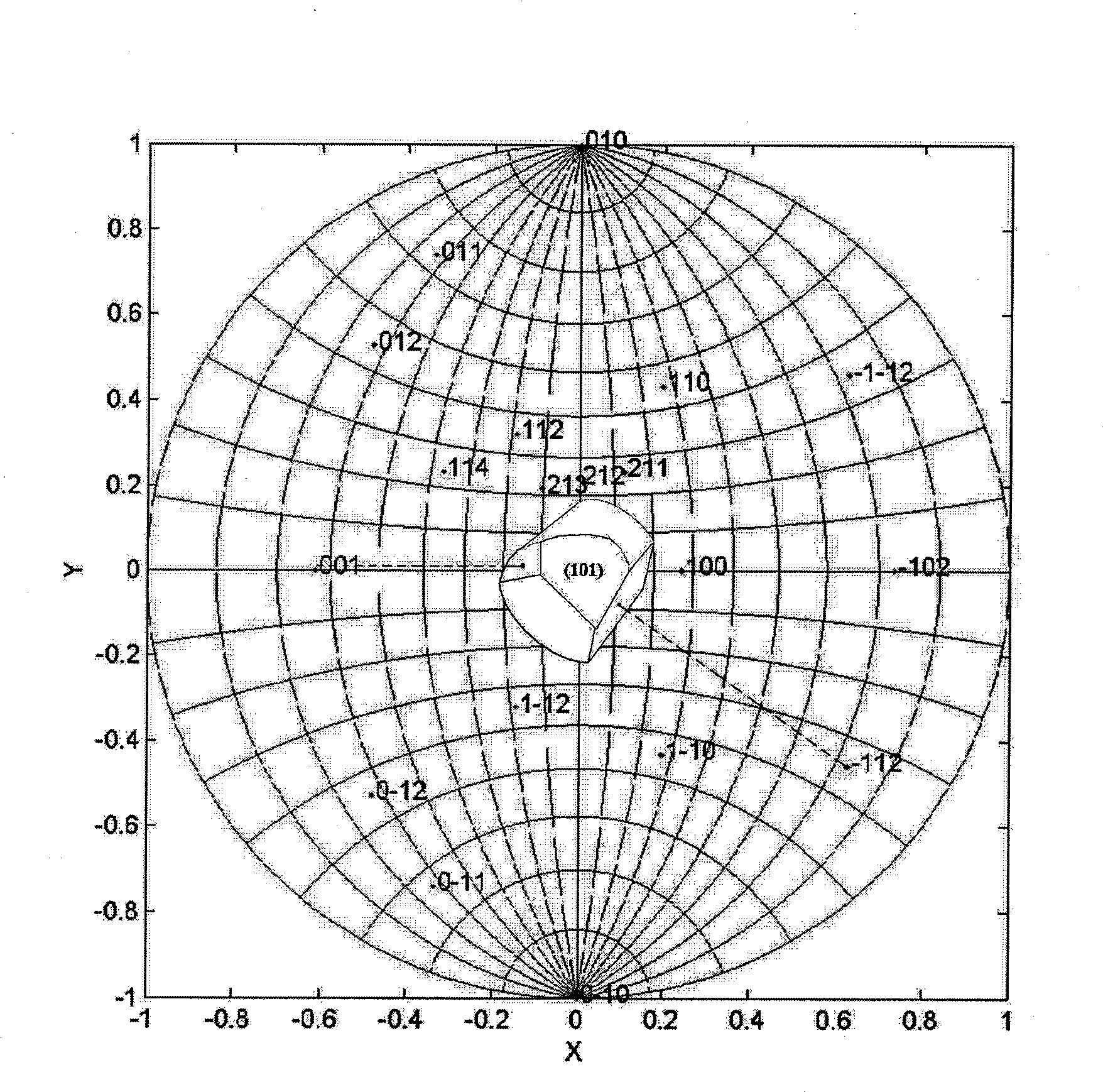

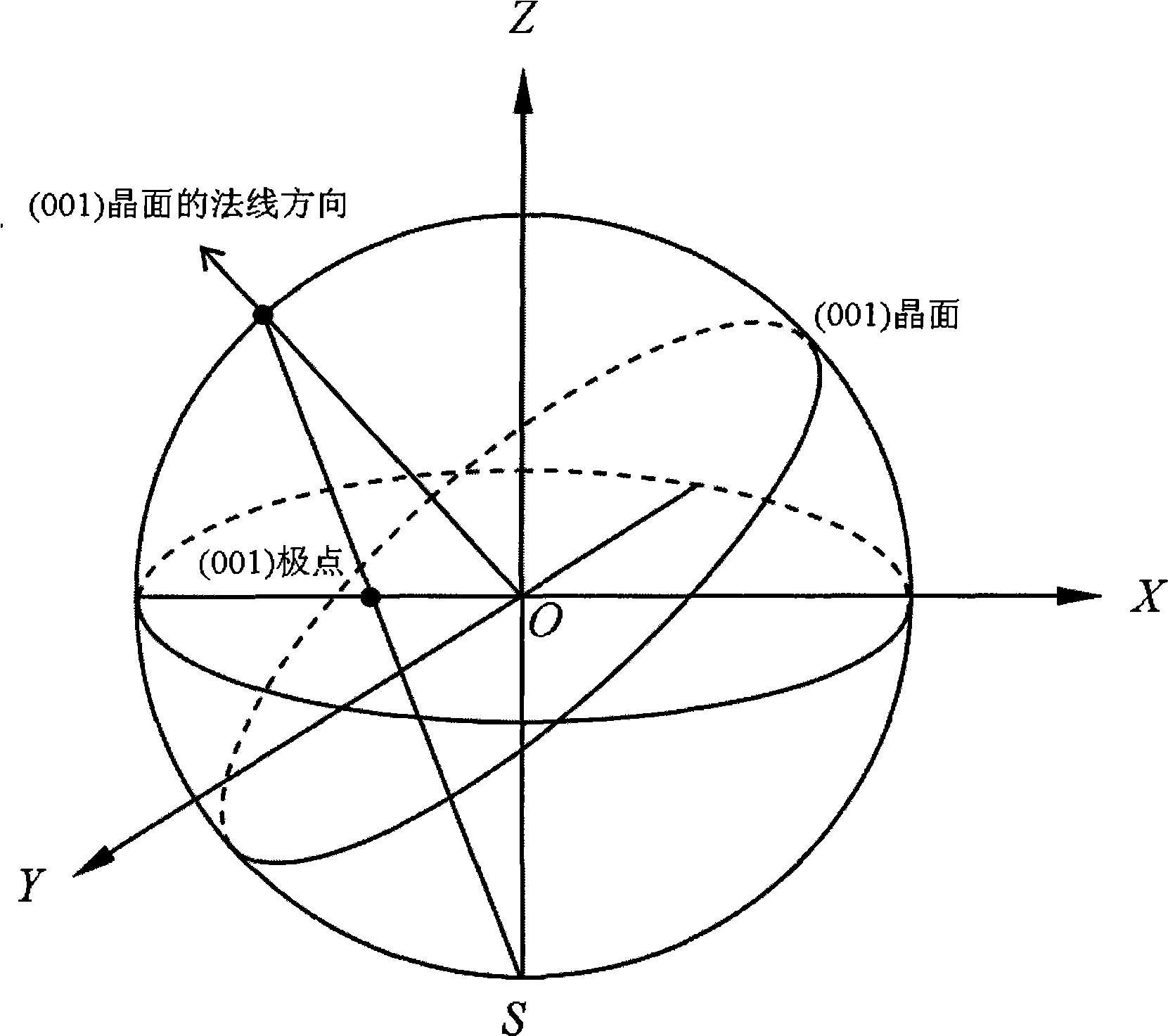

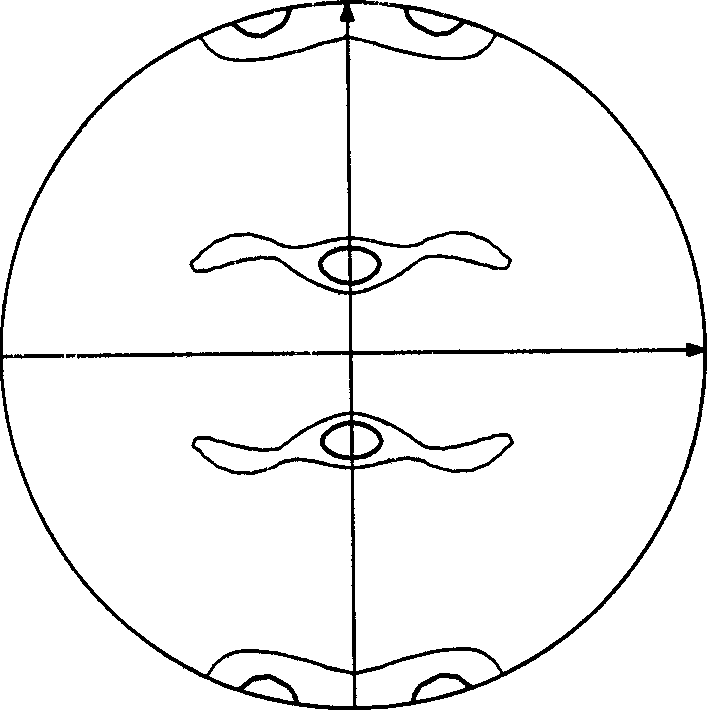

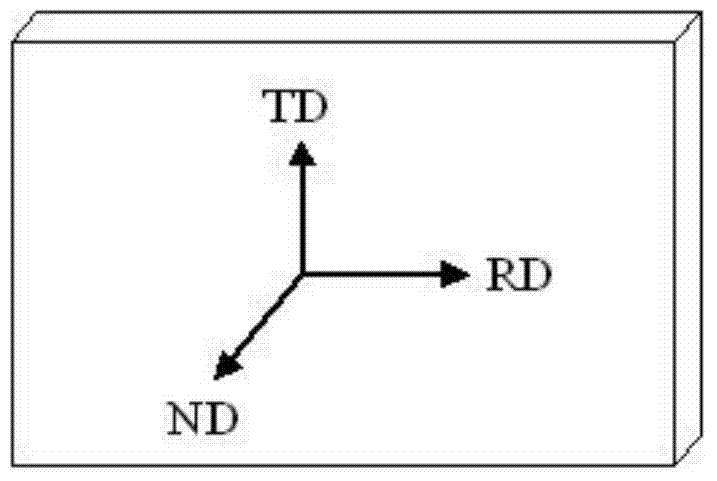

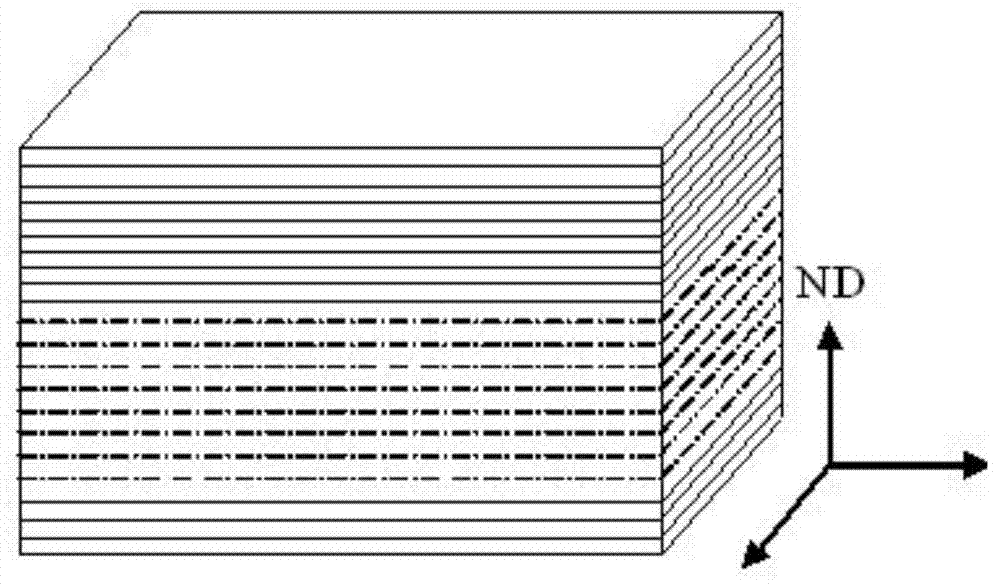

A pole figure is a graphical representation of the orientation of objects in space. For example, pole figures in the form of stereographic projections are used to represent the orientation distribution of crystallographic lattice planes in crystallography and texture analysis in materials science.

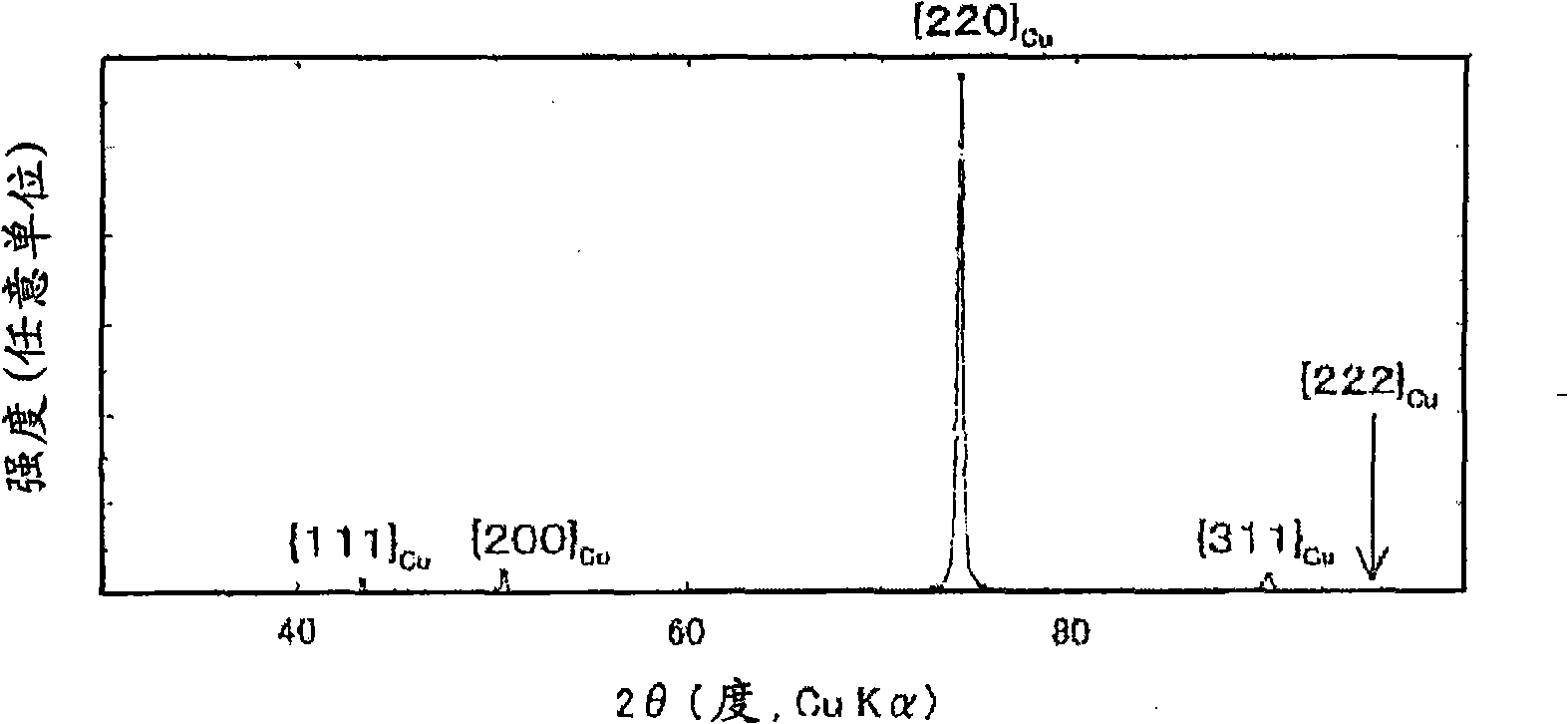

Rolled copper foil and manufacturing method thereof

ActiveUS20080099110A1Excellent flexible fatigue propertyPrinted circuit aspectsPrinted circuit manufactureX-rayTotal work

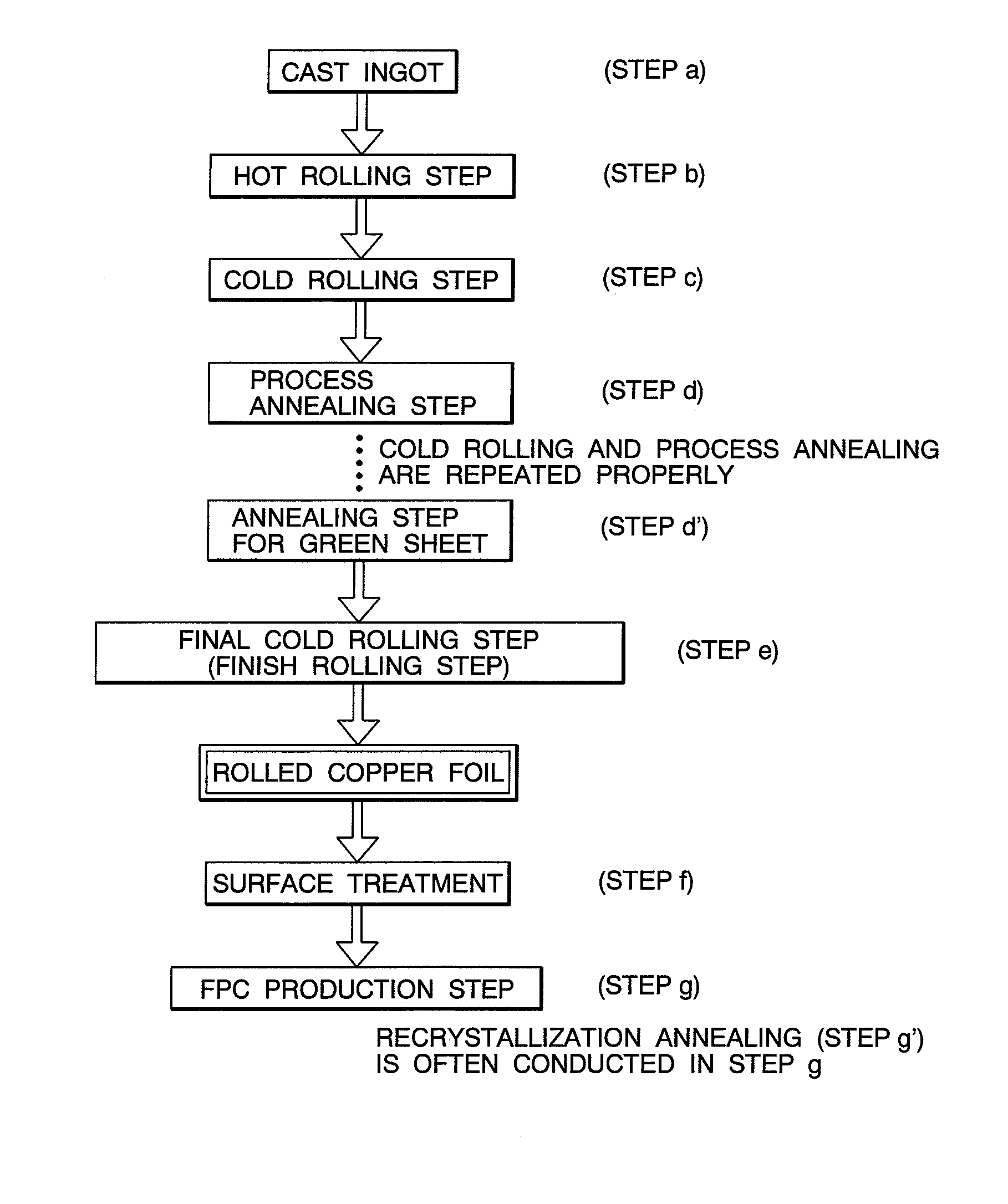

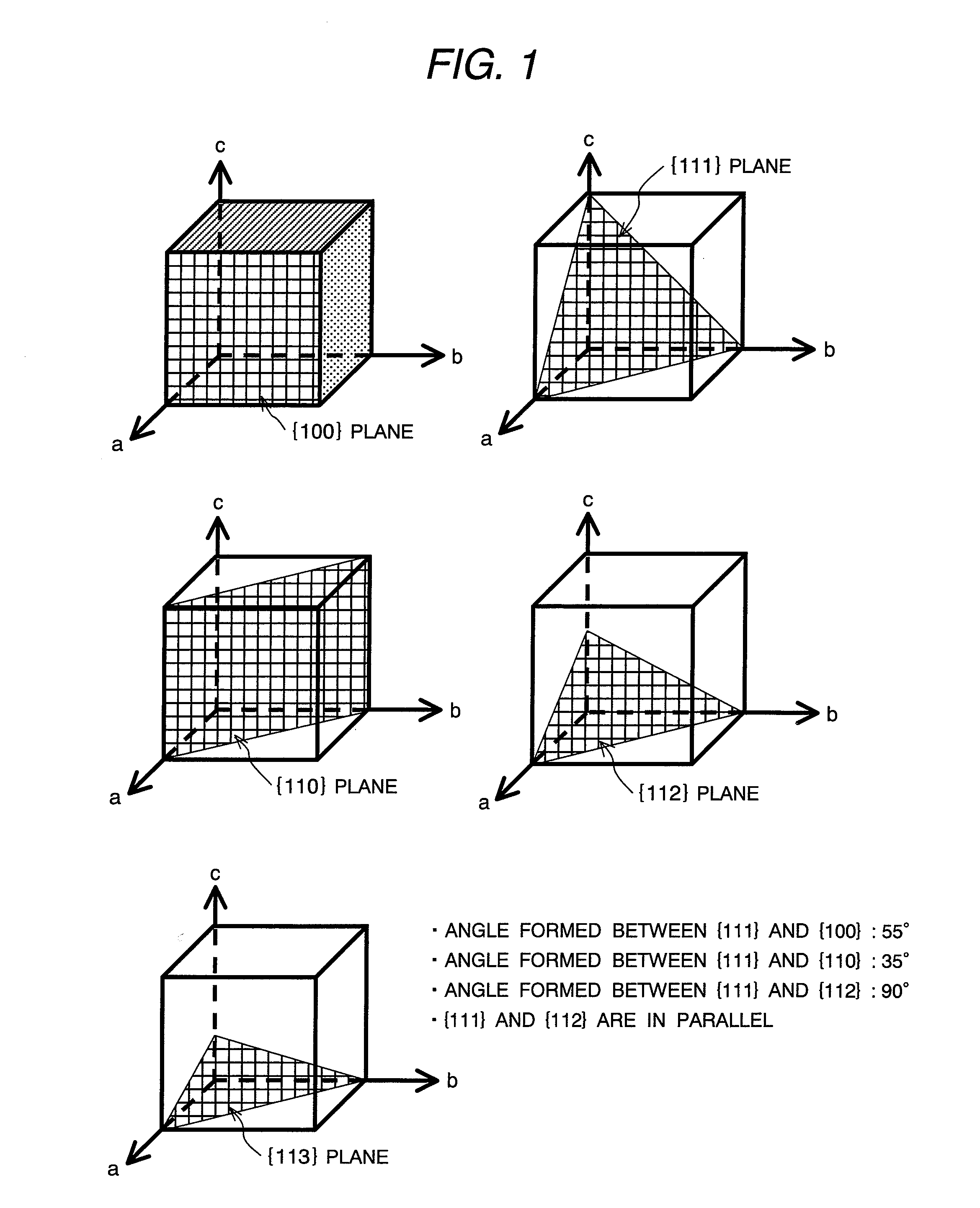

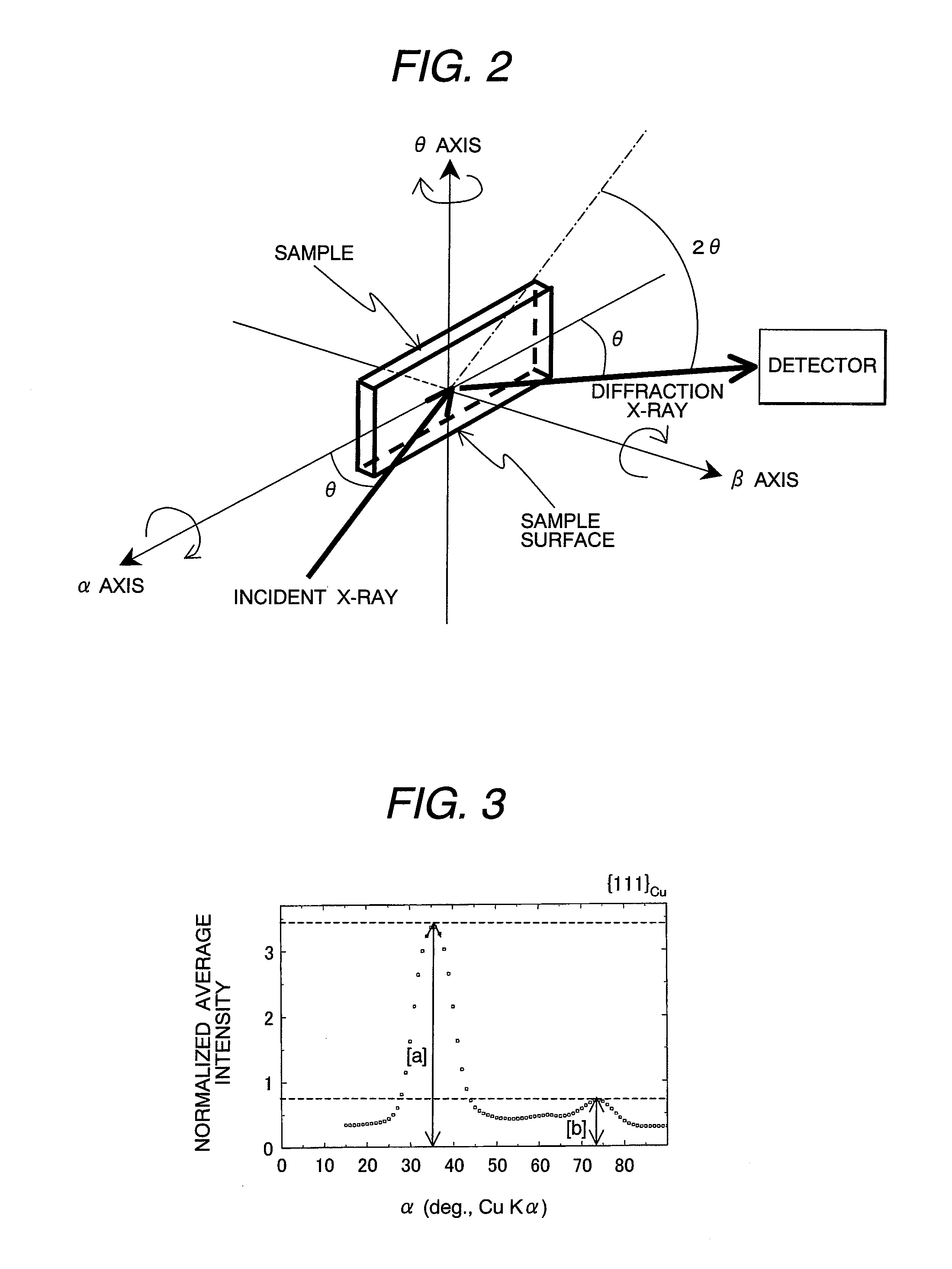

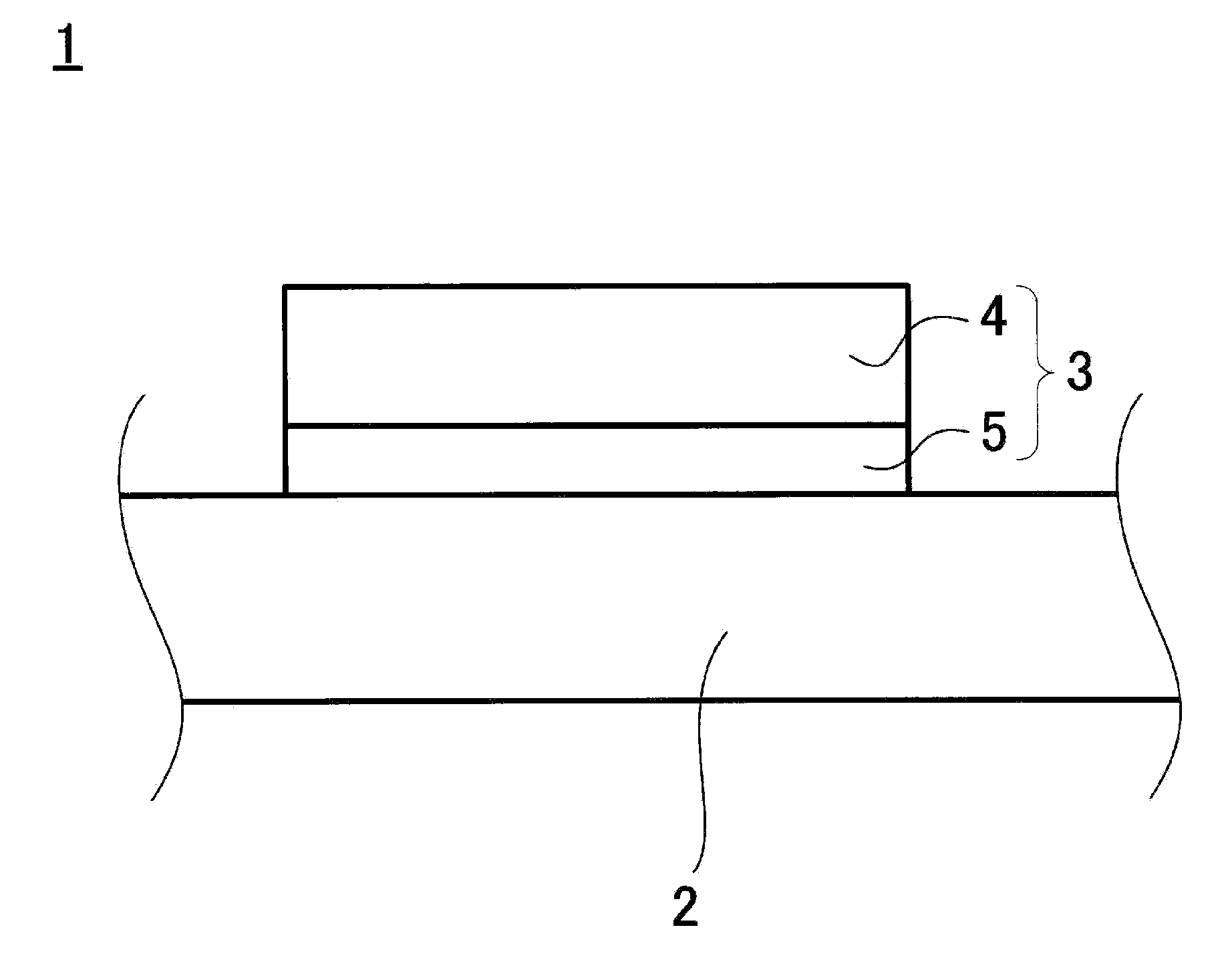

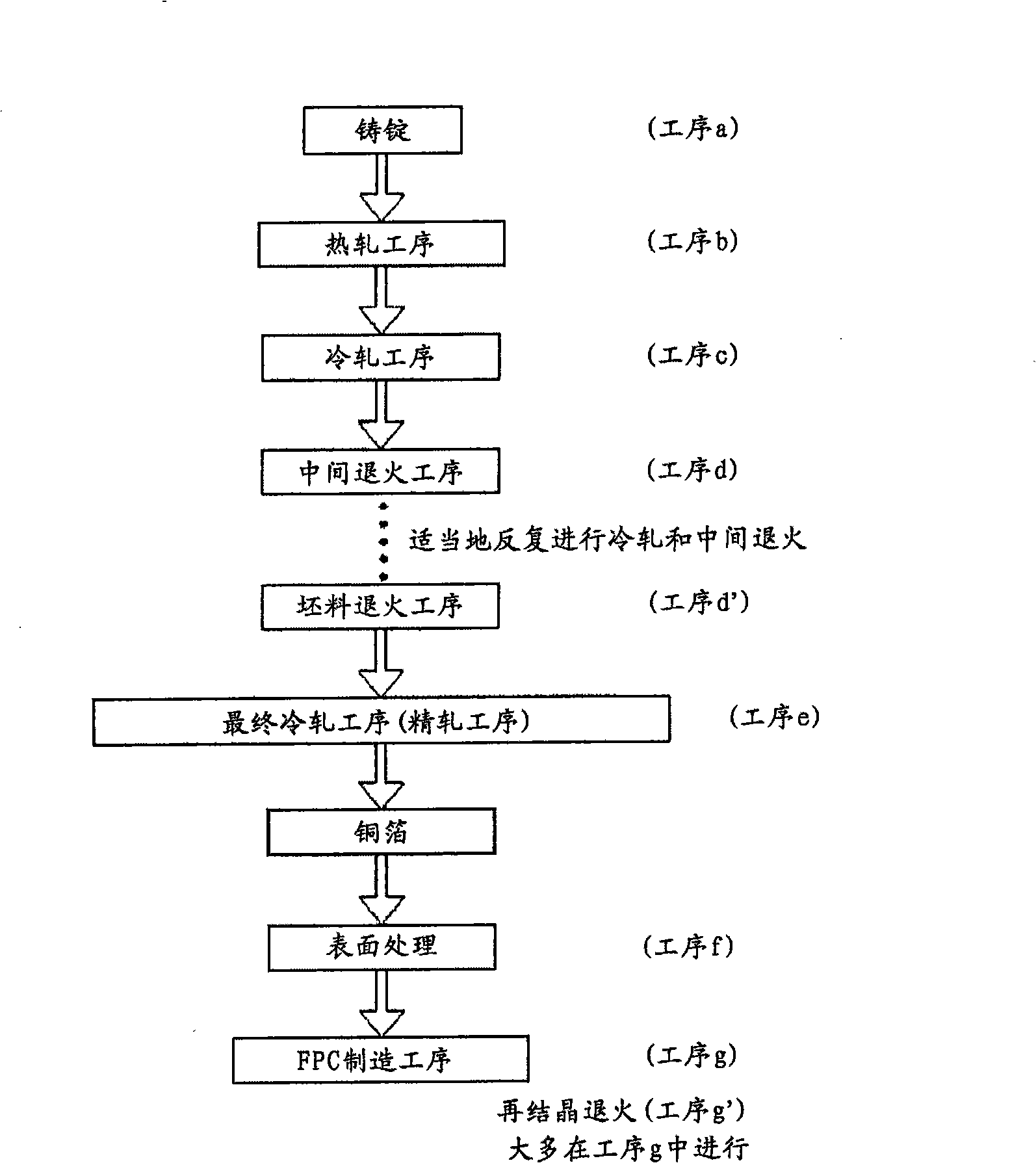

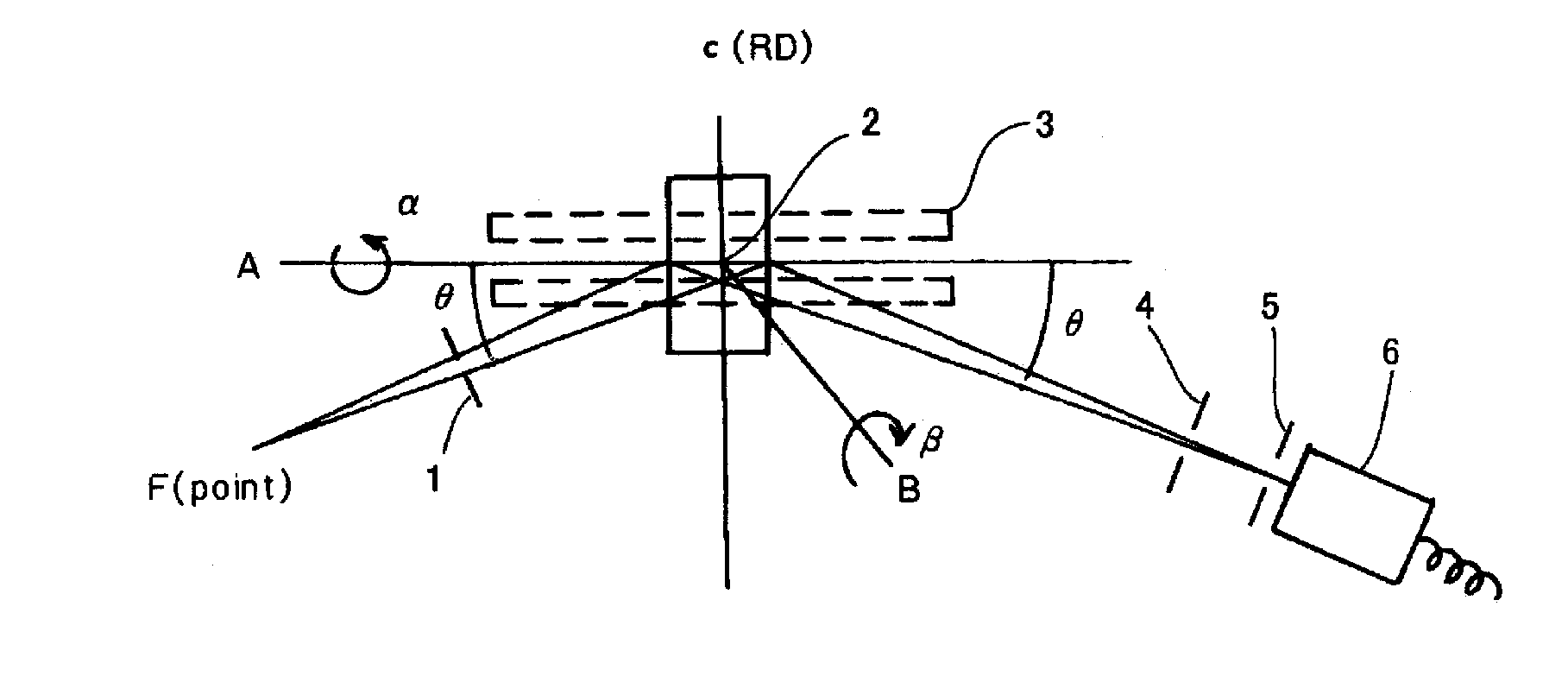

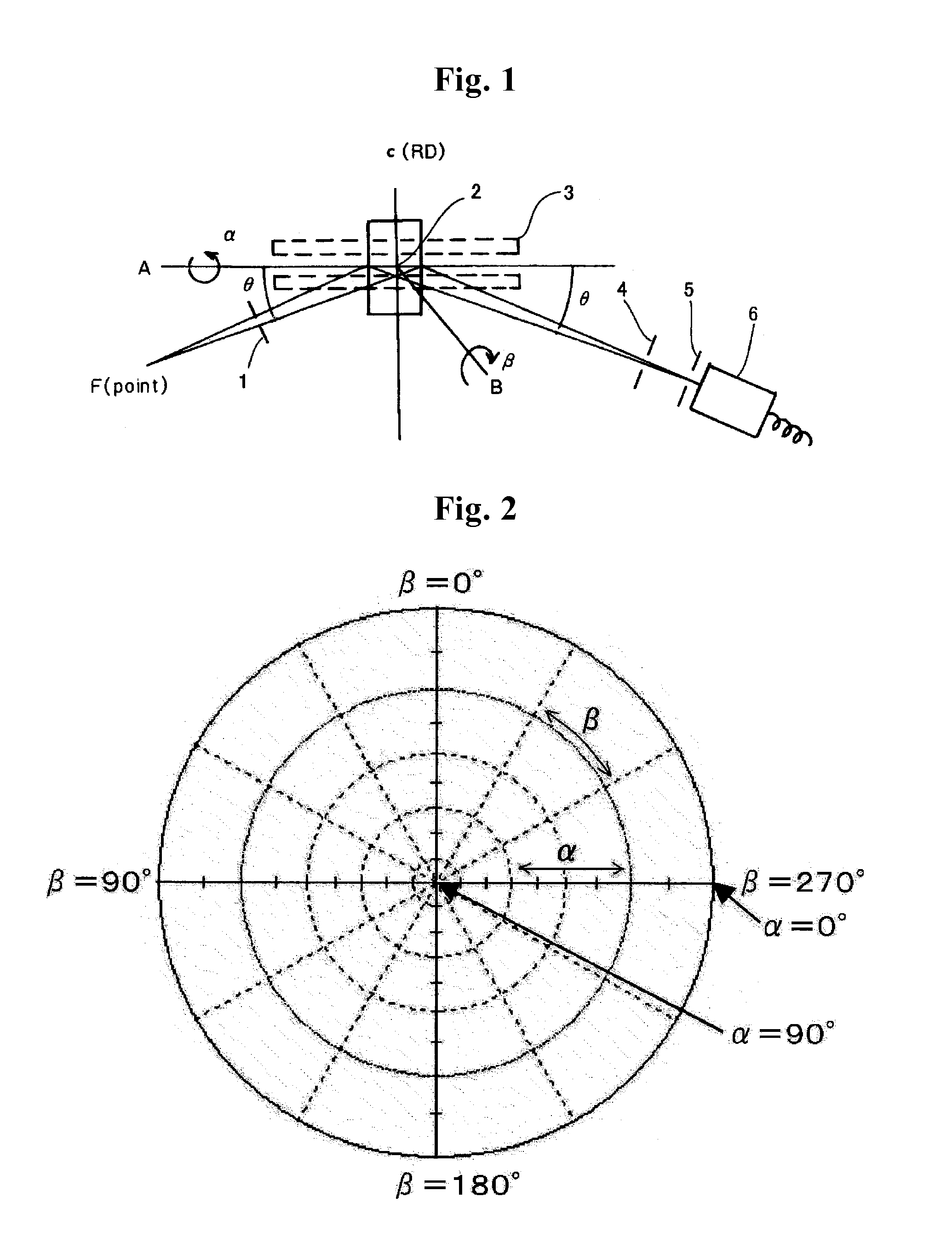

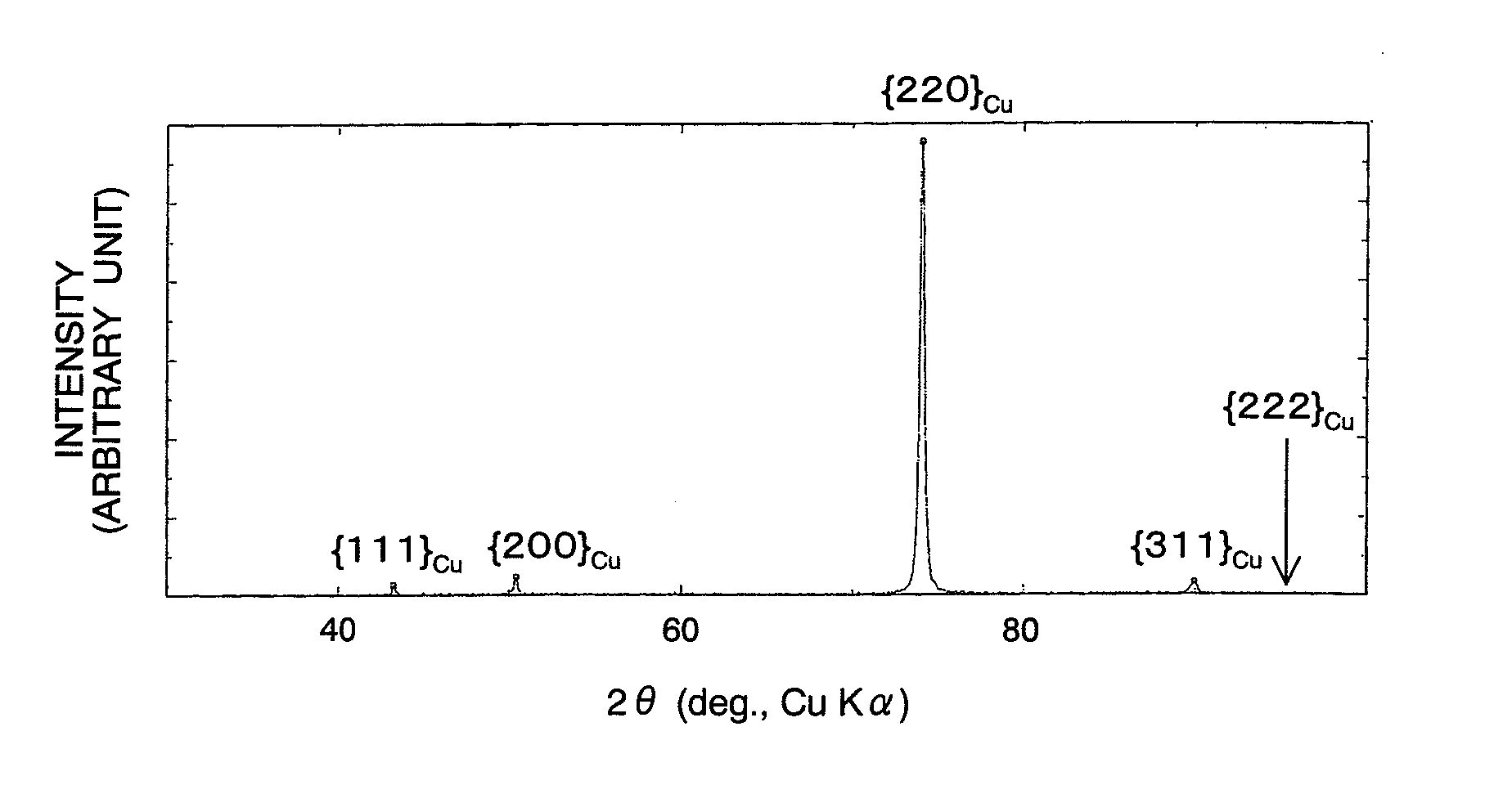

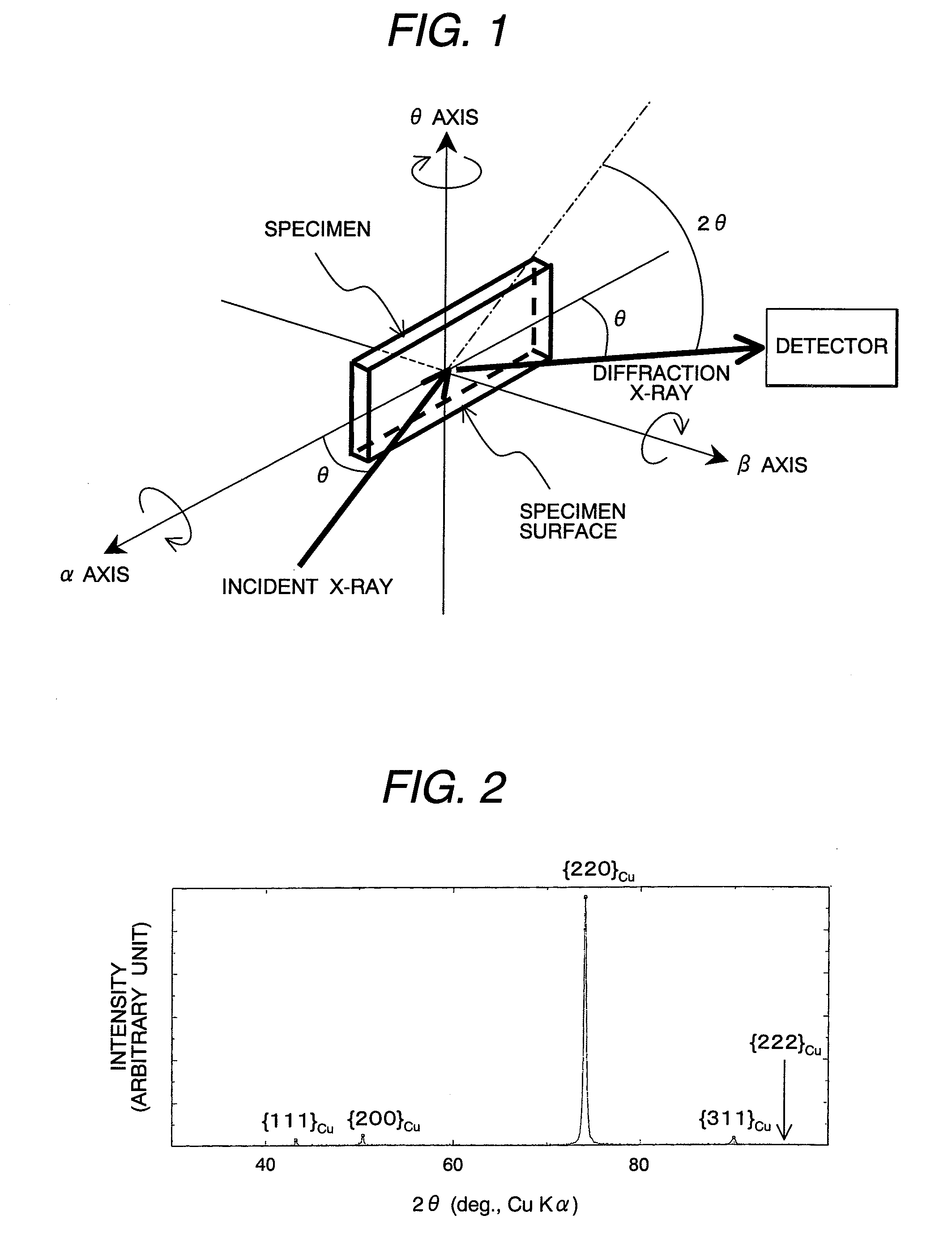

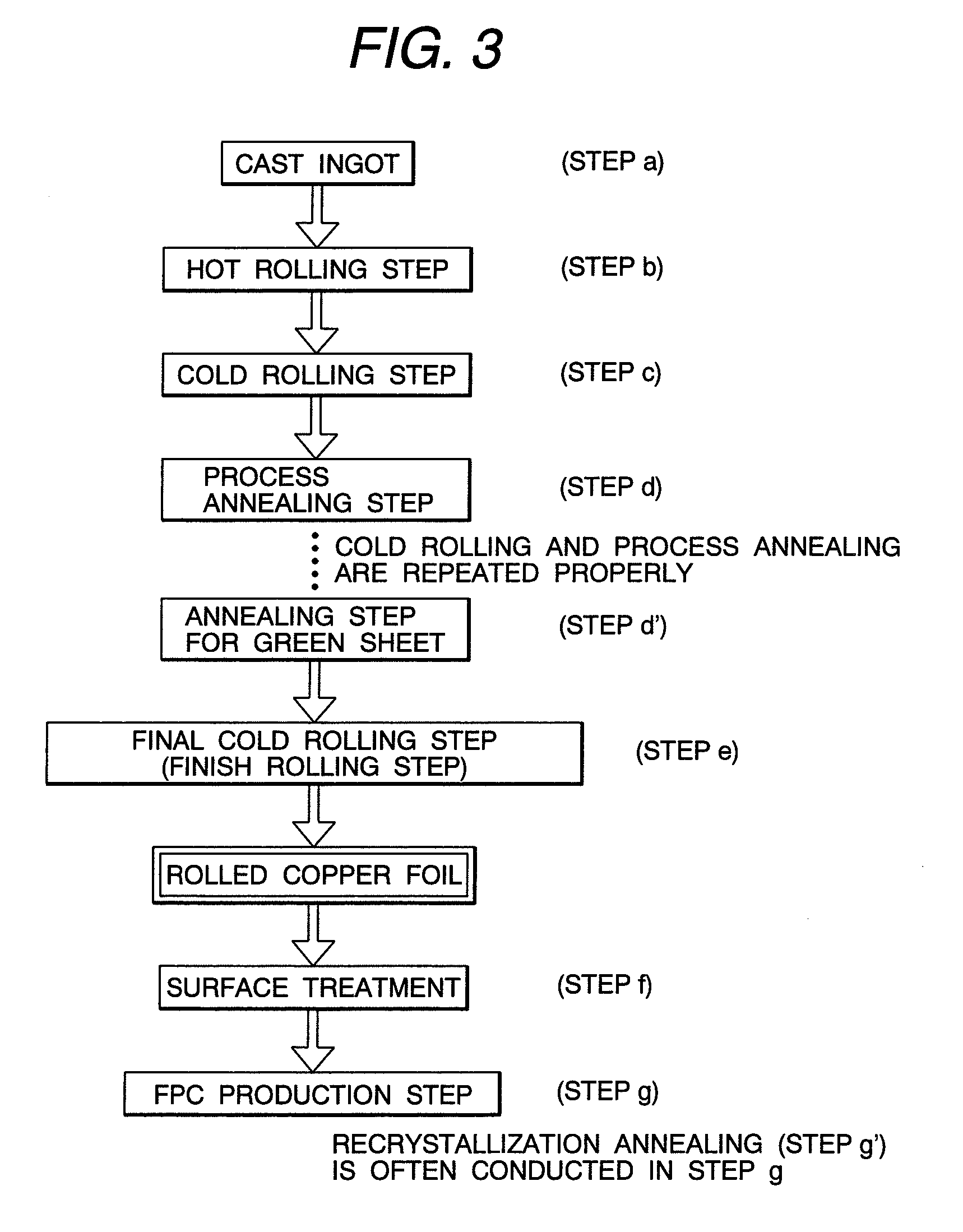

A rolled copper foil applied with a recrystallization annealing after a final cold rolling step and having a crystal grain alignment satisfying a ratio of [a] / [b]≧3, where [a] and [b] are normalized average intensities of a {111}Cu plane diffraction of a copper crystal by β-scanning at α=35° and 74°, respectively, in an X-ray diffraction pole figure measurement to a rolled surface is manufactured by controlling a total working ratio in the final cold rolling step before the recrystallization annealing to be 94% or more; and controlling a working ratio per one pass in the final cold rolling step to be 15 to 50%.

Owner:JX NIPPON MINING& METALS CORP

Surface acoustic wave element

InactiveUS20110115334A1High electrical power handling capabilityImproved electric power handling capabilityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksGrown filmCrystal structure

A surface acoustic wave element includes a piezoelectric substrate made of a LiNbO3 or LiTaO3 single crystal, a base electrode layer disposed on the piezoelectric substrate and primarily including at least one of Ti and Cr, and an Al electrode layer primarily including Al disposed on the base electrode layer. The Al electrode layer is an epitaxially grown film with an orientation, and has a twin crystal structure exhibiting six-fold symmetry spots in an XRD pole figure. The average grain size of the Al electrode layer is about 60 nm or less.

Owner:MURATA MFG CO LTD

Rolled copper foil

ActiveCN101346042AGood bending propertiesInsulating substrate metal adhesion improvementPrinted circuit aspectsHigh densityX-ray

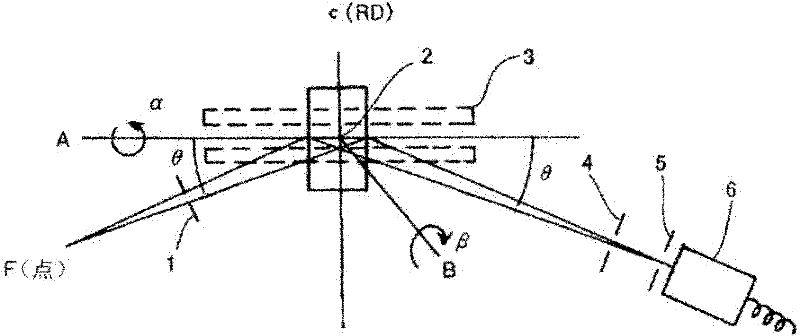

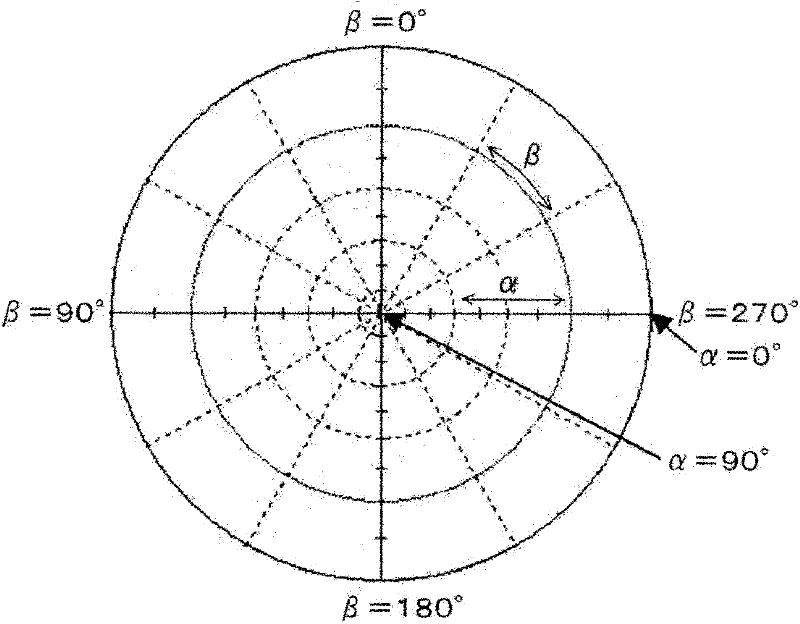

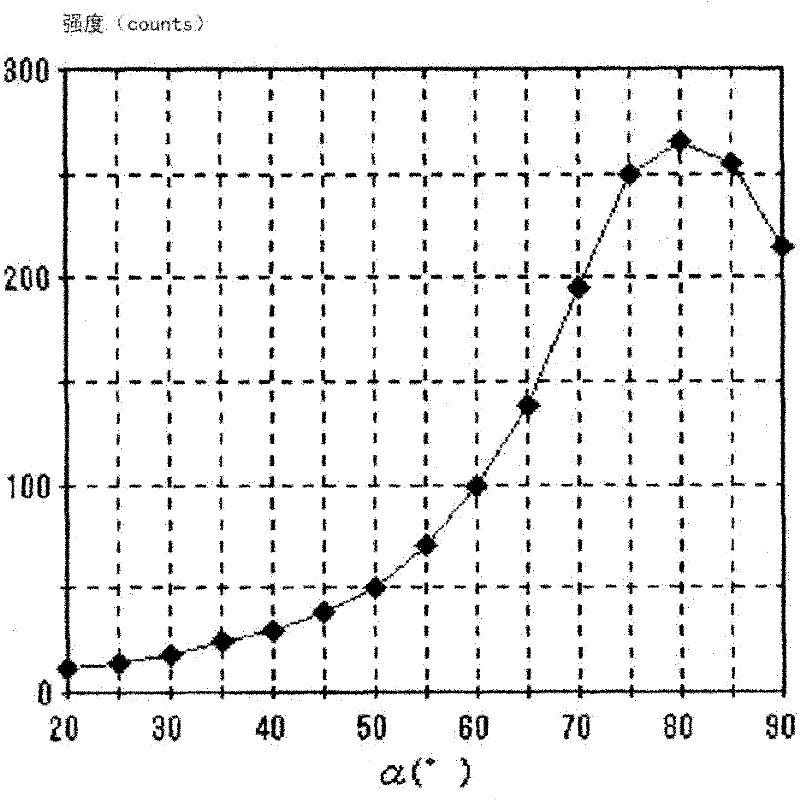

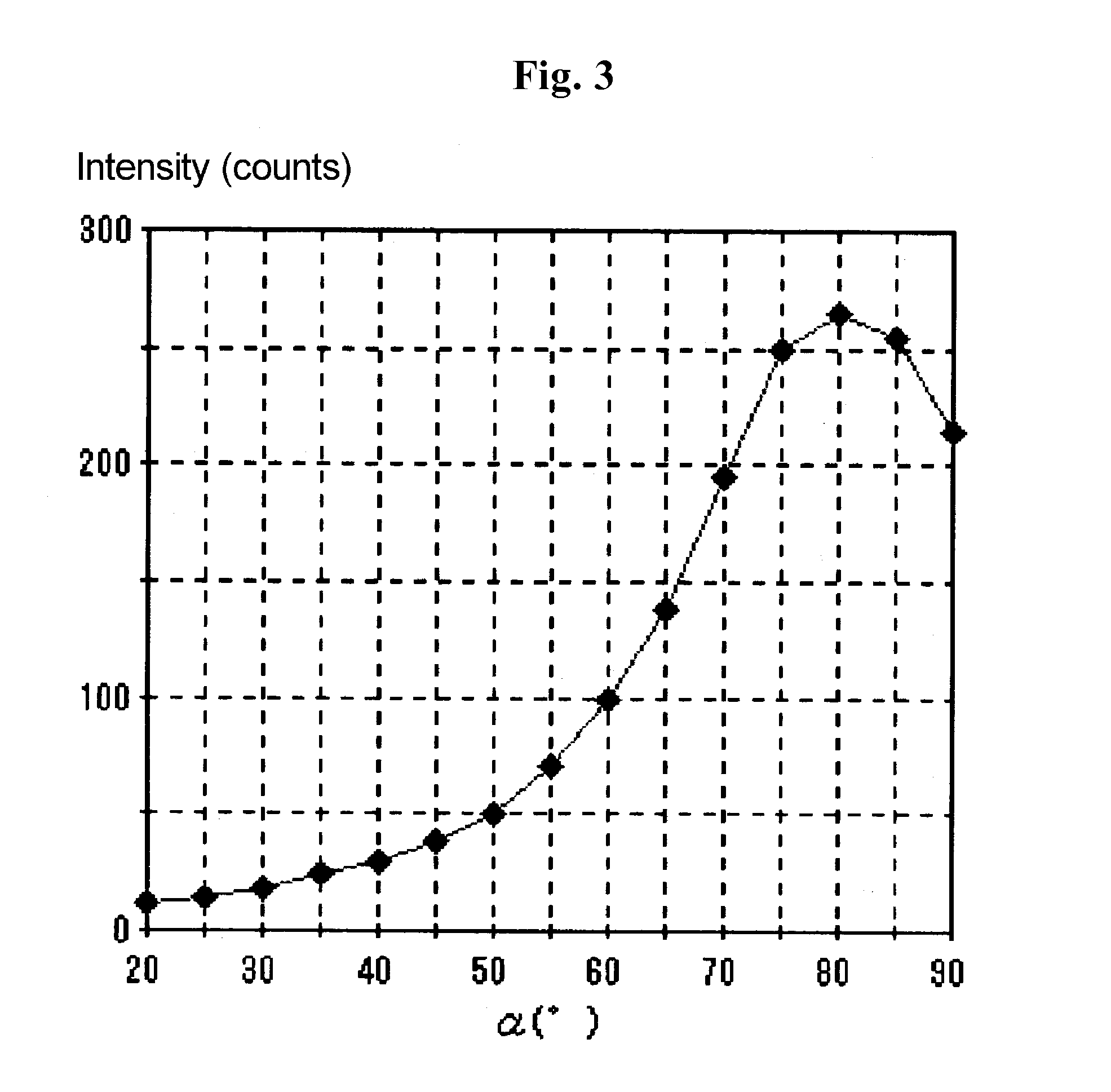

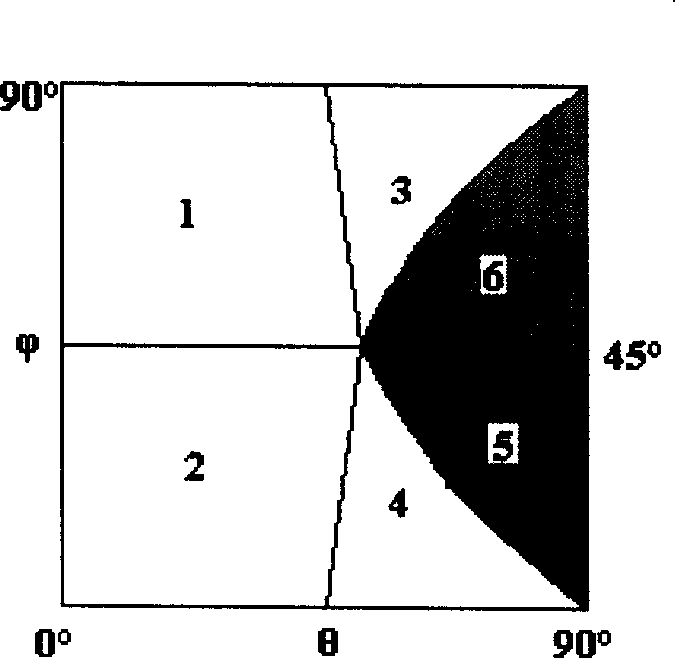

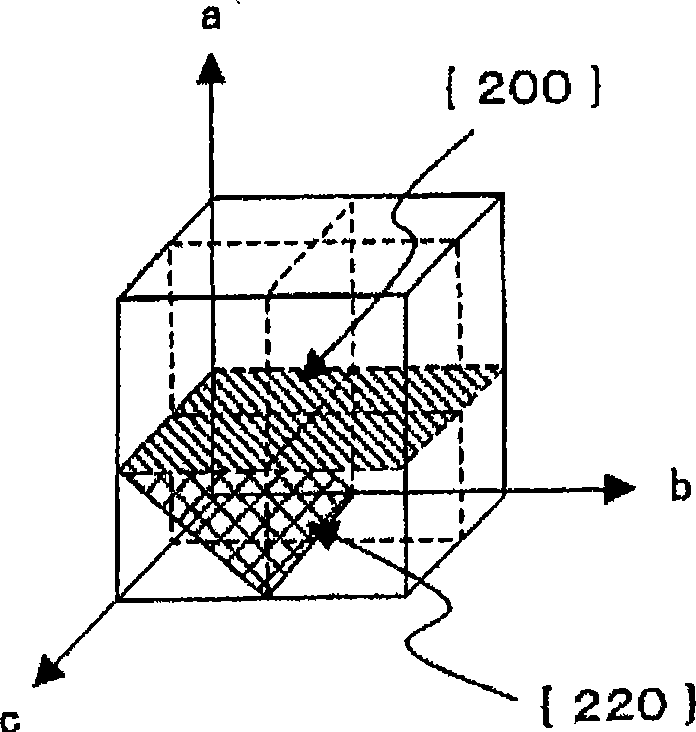

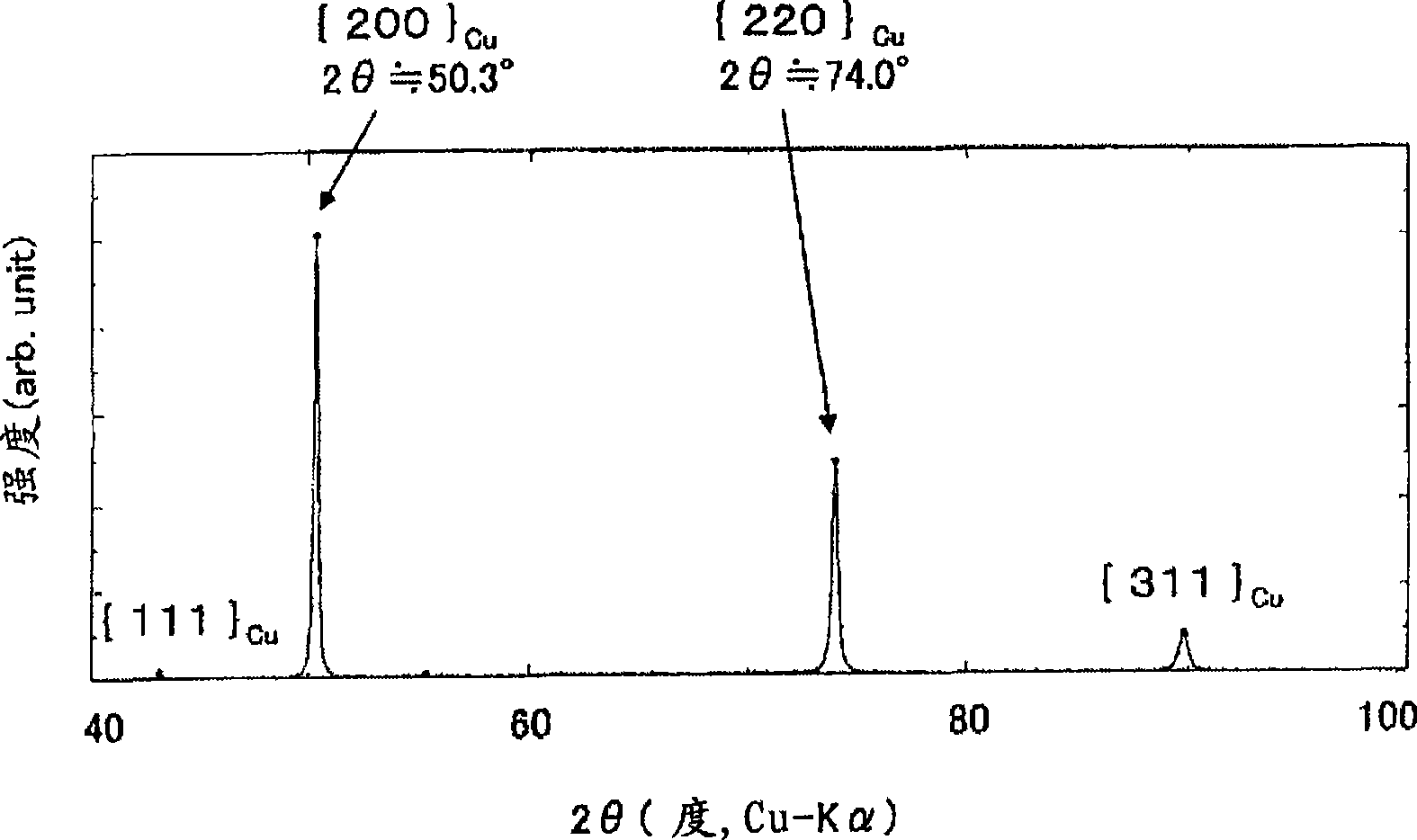

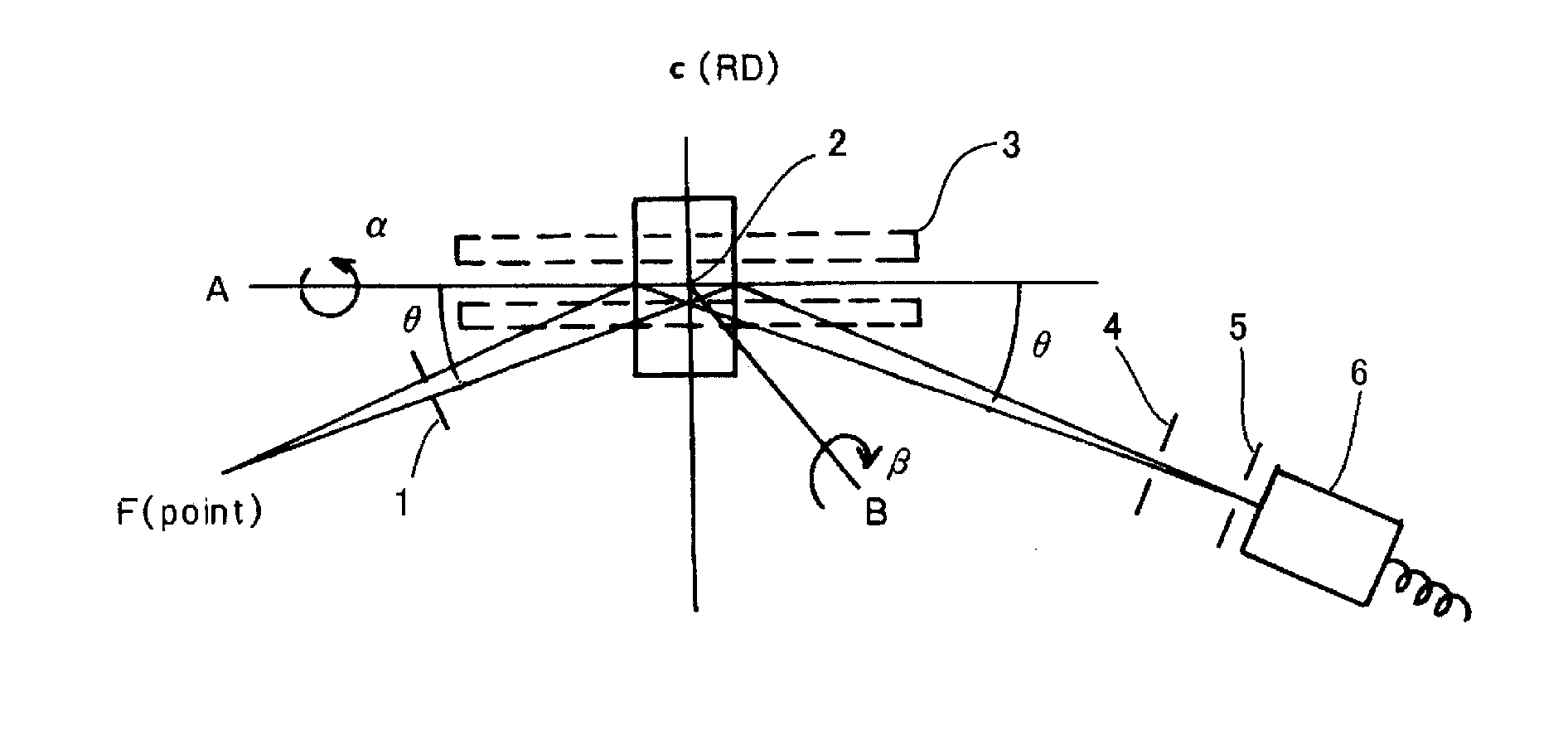

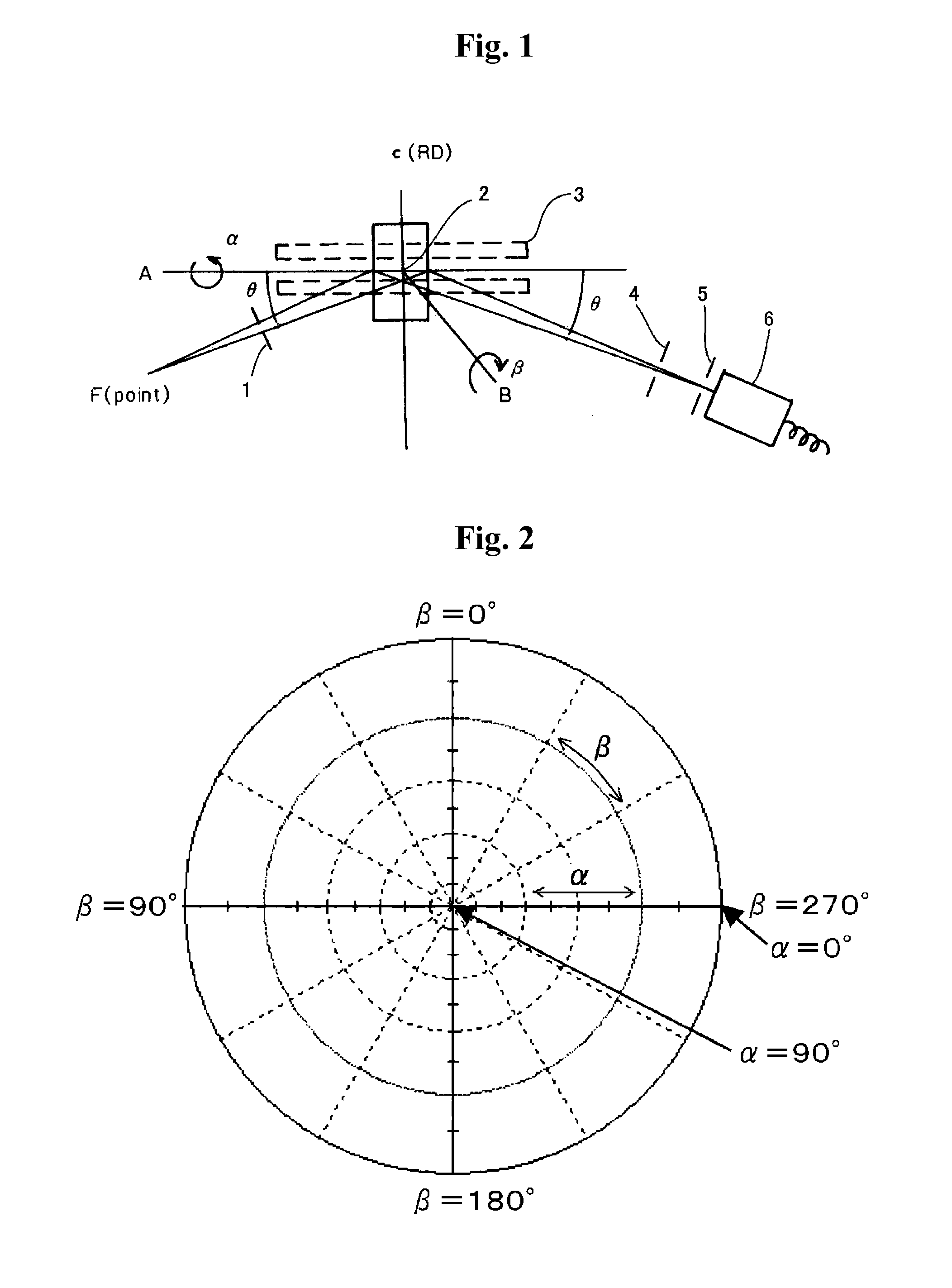

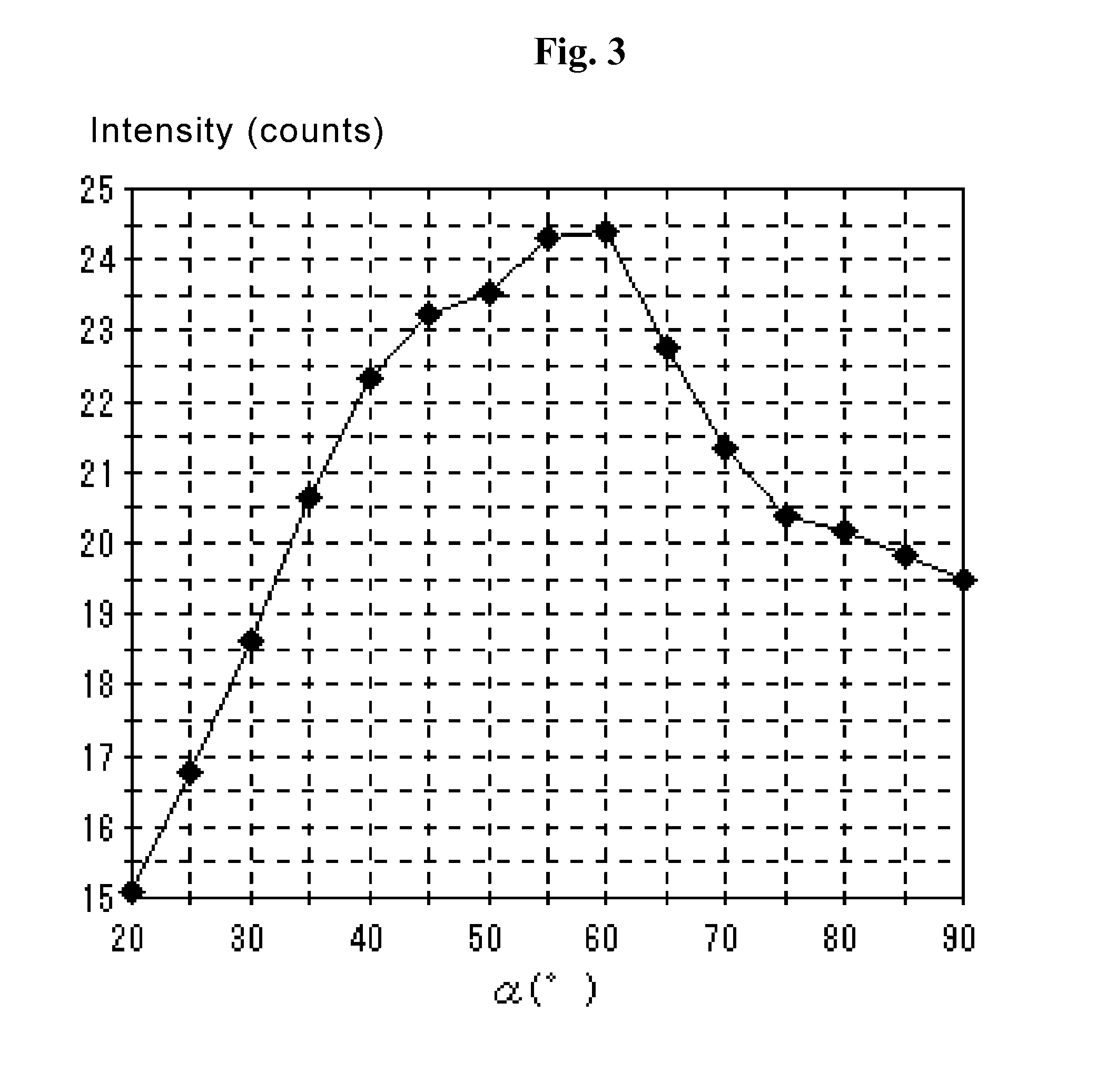

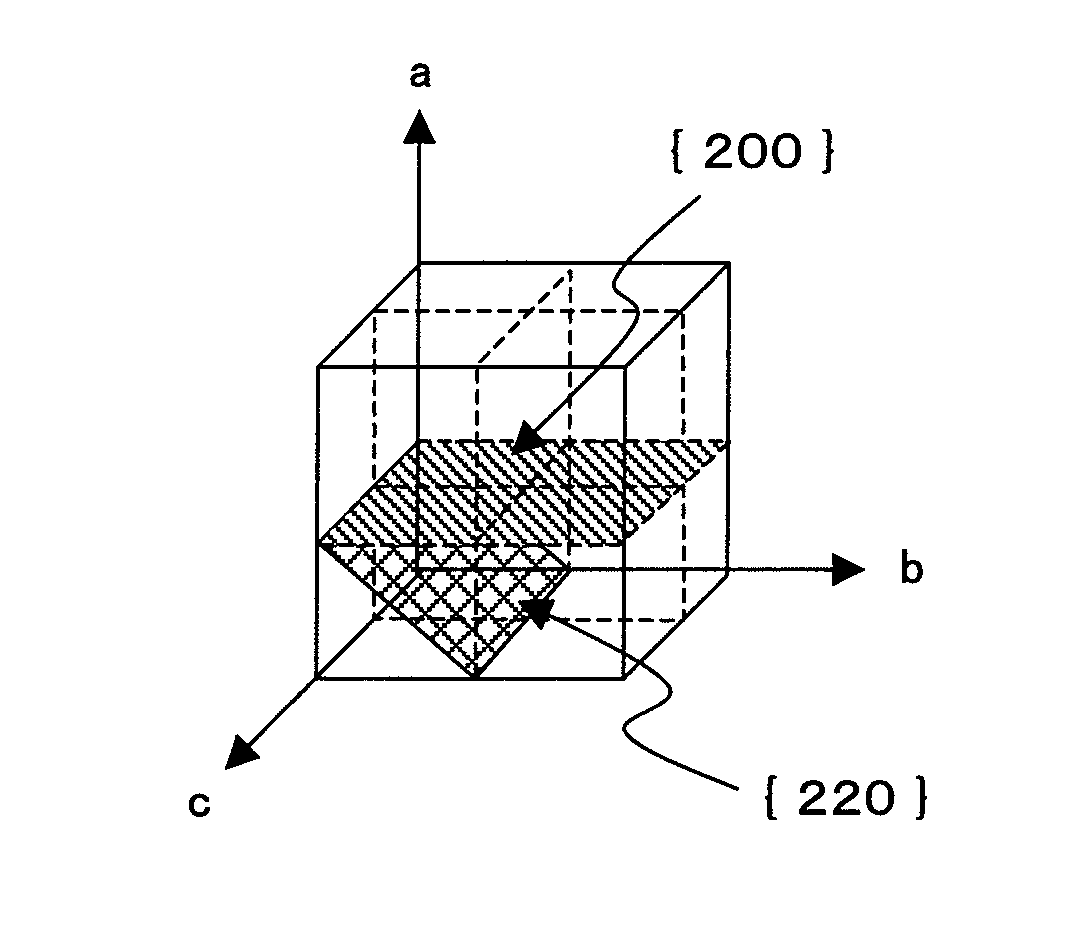

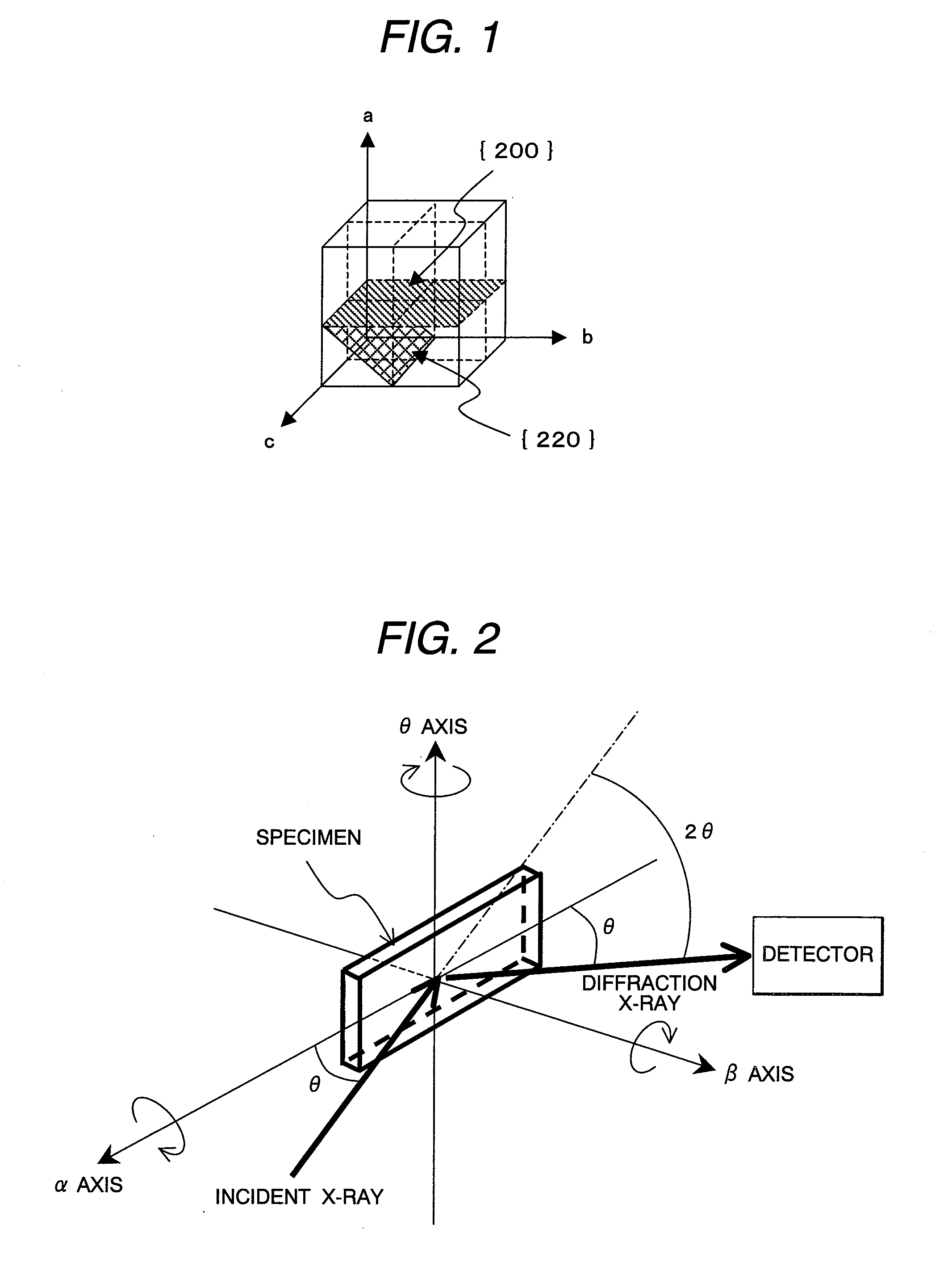

Along with development in downsizing, increase in the integration degree (higher density mounting) and higher performance of electronic equipment in recent years, further higher requirement for flexible fatigue property has been increased more and more than usual for the flexible printed circuit. The invention provides a rolled copper foil with more excellent flexible fatigue property, characterized in that: the rolled copper foil obtained after a final cold rolling step but before a recrystallization annealing includes a crystal grain alignment wherein: when normalized intensity of {200}Cu plane diffraction of a copper crystal in results obtained by an X-ray diffraction pole figure measurement with respect to a rolled surface is plotted against at different values of angle [alpha], the normalized intensity being obtained during a [beta] scanning in the pole figure measurement, a ratio of a maximum value A of the normalized intensity with angle [alpha] in a range of 40[deg.] to 60[deg.] to a maximum value B of the normalized intensity with angle [alpha] in a range of 80[deg.] to 90[deg.] is equal to or greater than 4 (A / B>=4); and [0018] when the normalized intensity increases with increasing angle [alpha] in a range of 25[deg.] to 45[deg.], there is essentially no area in which the normalized intensity increases stepwise. It is possible to provide a rolled copper foil having more excellent flexible fatigue property than usual by the recrystallization annealing.

Owner:JX NIPPON MINING & METALS CORP

Coated member

ActiveCN102099138AStrong adhesionImprove abrasion resistanceMilling cuttersVacuum evaporation coatingX-rayHardness

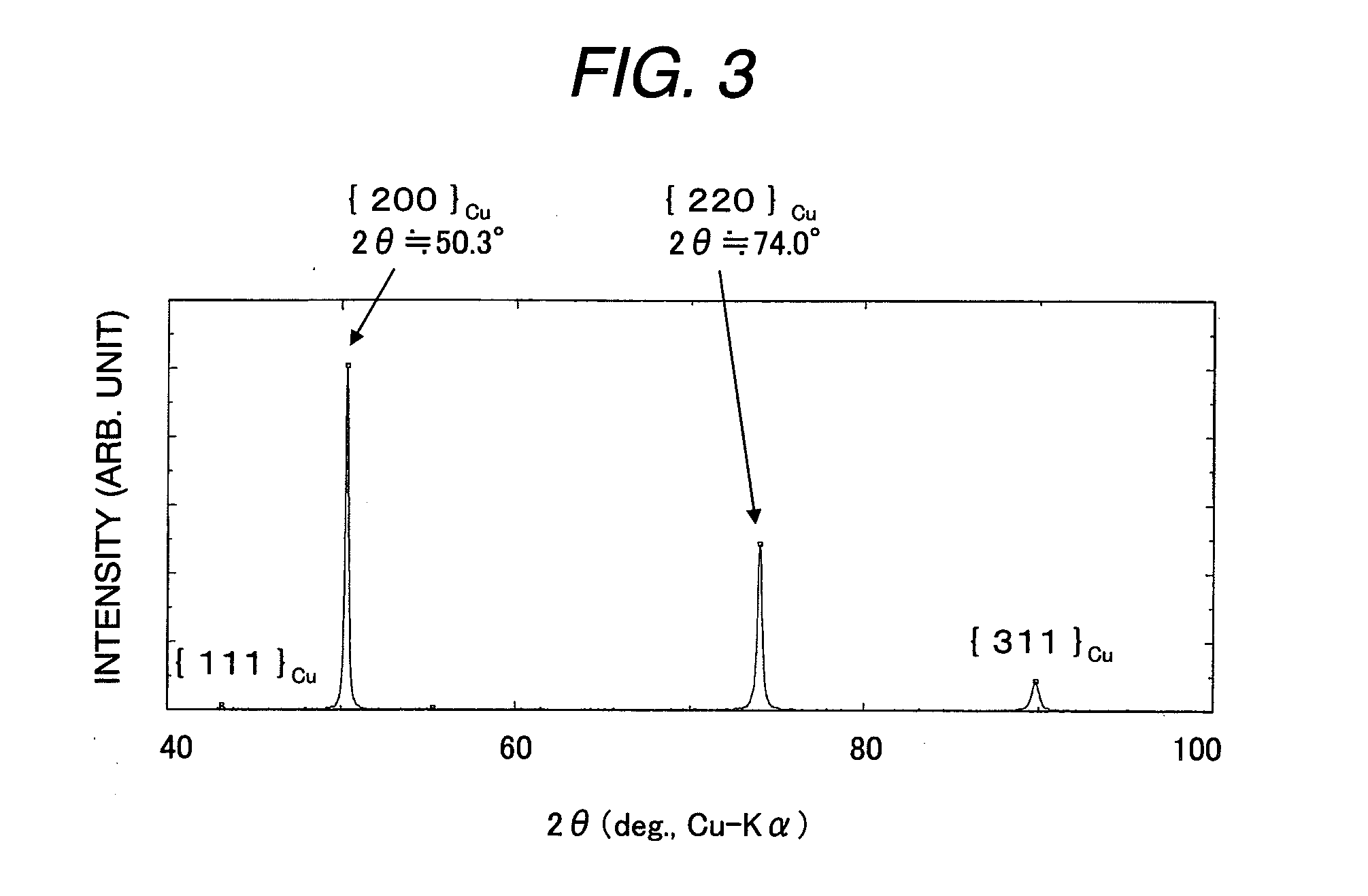

The invention provides a coated member for cutting tools which renders a long life possible under severe cutting conditions as in high-speed processing, high-feed-rate processing, cutting of works having enhanced hardness, and cutting of works difficult to cut. The coated member comprises a base having a surface coated with one or more coating films. At least one of the coating films is a hard film of a cubic metallic compound comprising at least one metallic element (M) selected from Al, Si, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, and W and at least one element (X) selected from C, N, and O. In the pole figure for the (111) plane of the hard film, the X-ray intensity distribution in the alpha axis has a maximum intensity in the alpha-angle range of 75-90 DEG. In the pole figure for the (220) plane of the hard film, the X-ray intensity distribution in the alpha axis has a maximum intensity in the alpha-angle range of 75-90 DEG .

Owner:TUNGALOY CORP

Coated Material

InactiveUS20110117344A1Improve adhesionEfficient processMilling cuttersVacuum evaporation coatingX-rayHardness

A coated material for a cutting tool can realize long life-time under severe cutting processing conditions such as high-speed processing, high-feed-rate processing, higher hardness of a material to be cut, cutting of a difficult-to-cut material, etc. In a coated material in which a coating is coated on the surface of a substrate, at least one layer of the coating is a hard film having a cubic metallic compound which includes at least one metal element M selected from Al, Si, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo and W, and at least one element selected from C, N and O. An X-ray intensity distribution of an α axis in a pole figure for a (111) plane of the hard film has a maximum intensity in an α angle range of 75 to 90°, and an X-ray intensity distribution of an α axis in a pole figure for a (220) plane of the hard film has a maximum intensity in an α angle range of 75 to 90°.

Owner:TUNGALOY CORP

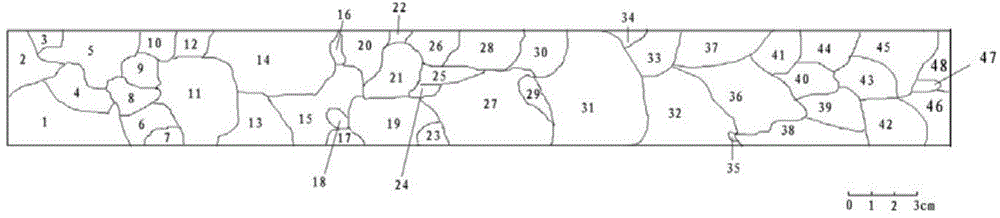

Analysis method for measuring large-grained silicon steel texture

InactiveCN104155323AMaterial analysis using wave/particle radiationImage analysisAnalysis methodSilicon

The invention discloses an analysis method for measuring a large-grained silicon steel texture. The analysis method comprises the following steps: I, preparing a to-be-tested electron backscatter diffraction sample from a silicon steel plate; II, cutting a to-be-tested area of the to-be-tested electron backscatter diffraction sample, and distinguishing each crystalline grain in the to-be-tested area according to a crystal boundary; III, calculating the area Am of each crystalline grain and the total area A of the total to-be-tested areas of the sample; IV, carrying out no-texturing treatment, and calculating a ratio A0 of each crystalline grain in the to-be-tested area; V, testing an orientation (hkl) of each crystalline grain in an electron backscatter diffraction way and acquiring an absolute value; VI, dividing Am by A and then by A0 to obtain a relative pole density P(hkl); and VII, marking the relative pole density P(HKL) on a position on a corresponding crystal face in an inverse pole figure. The analysis method has the characteristic that a correct corresponding relationship between a test result and the performance of a material can be established and can be widely applied to the field of the testing of large-grained materials.

Owner:武汉钢铁有限公司

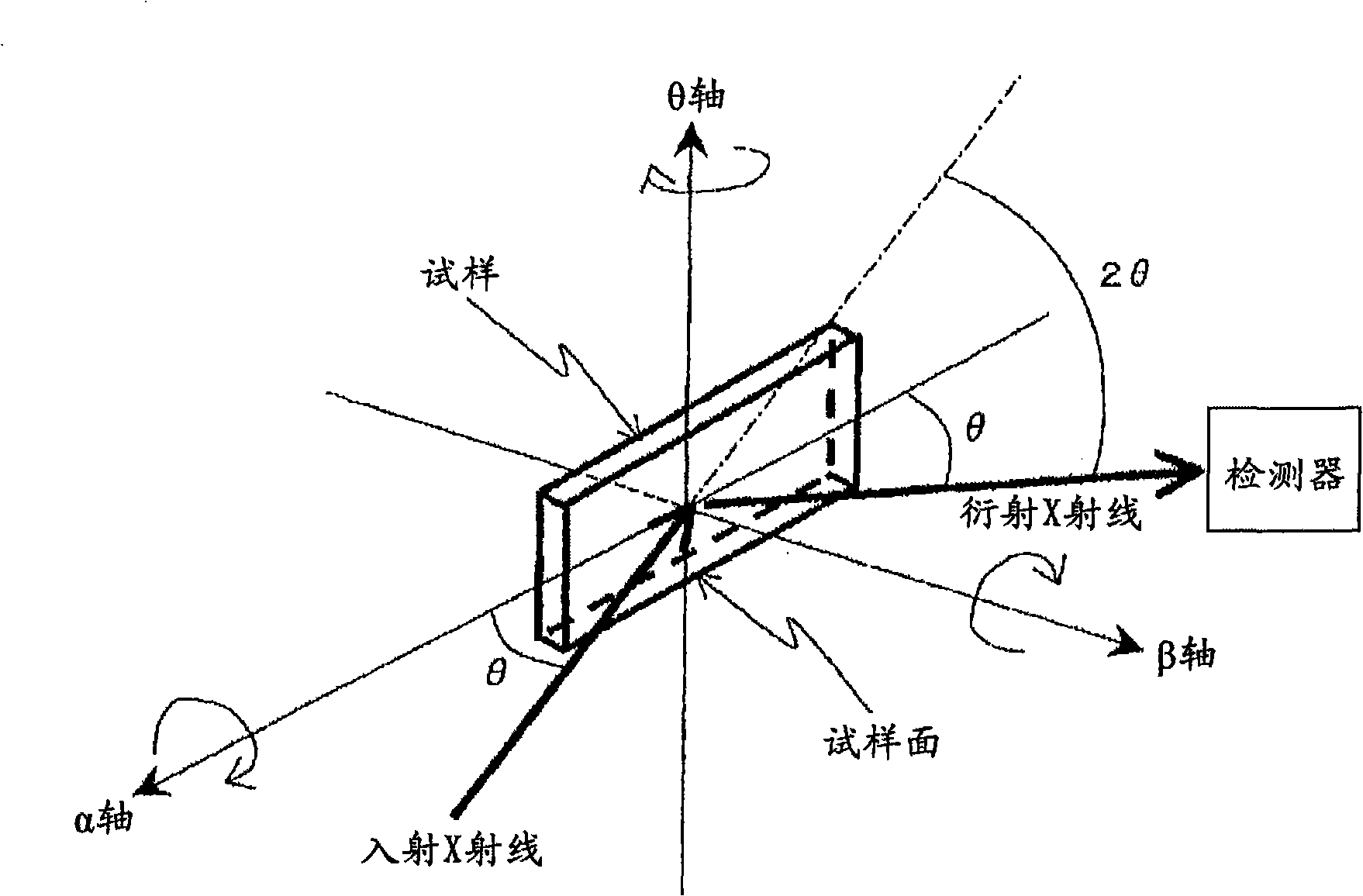

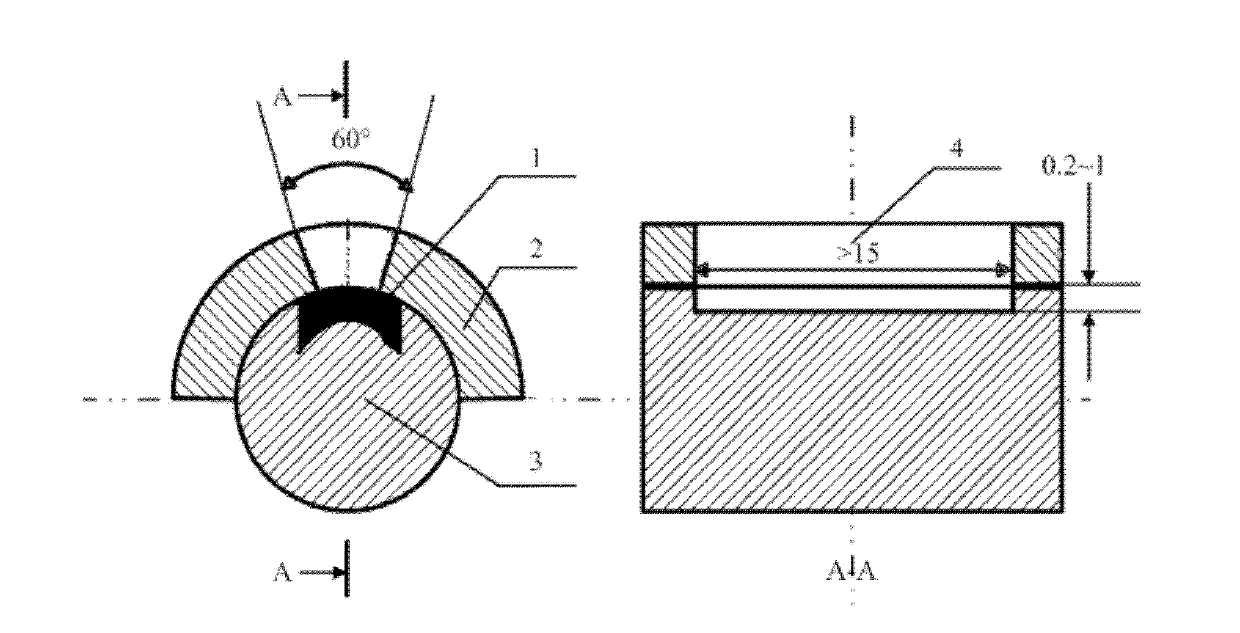

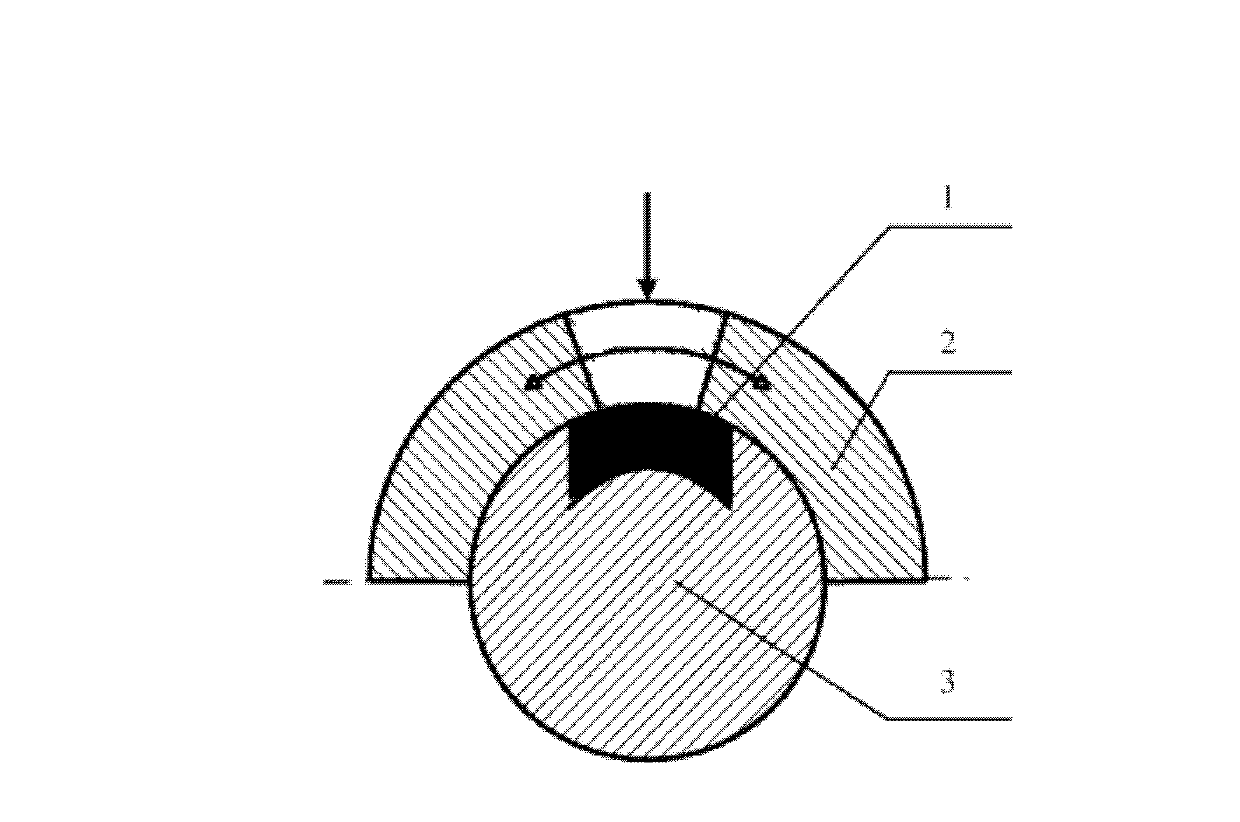

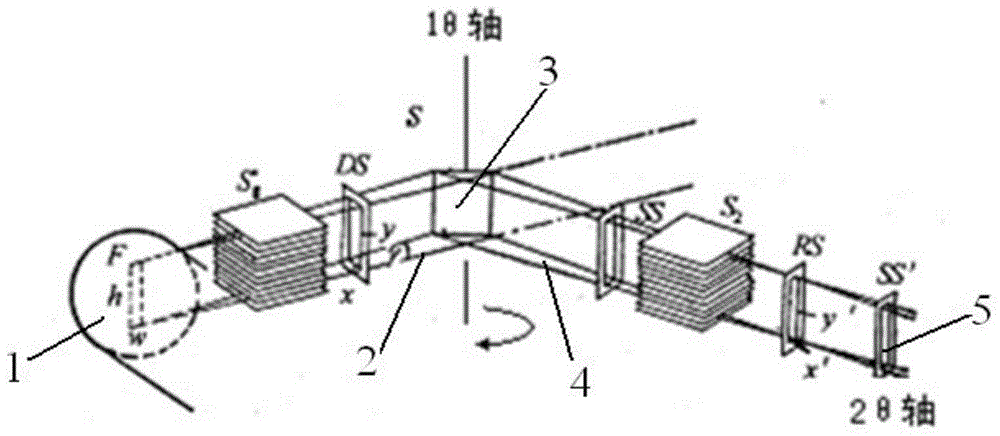

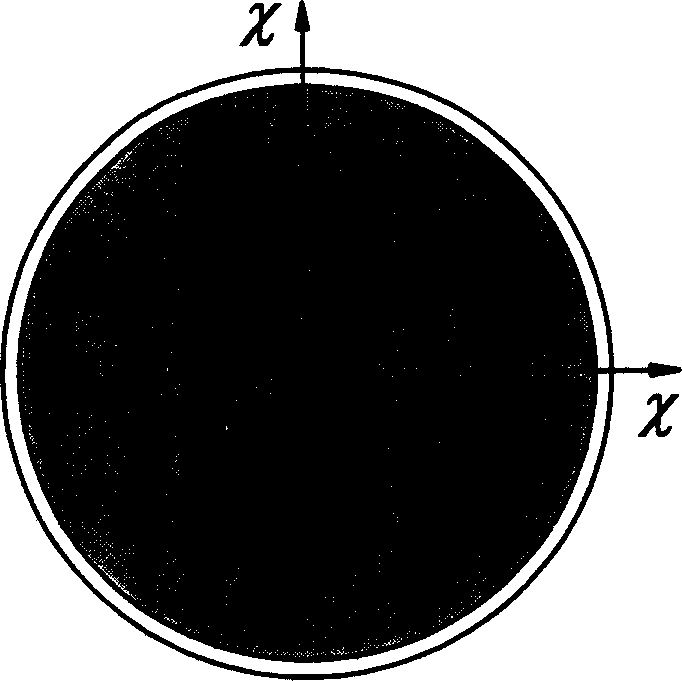

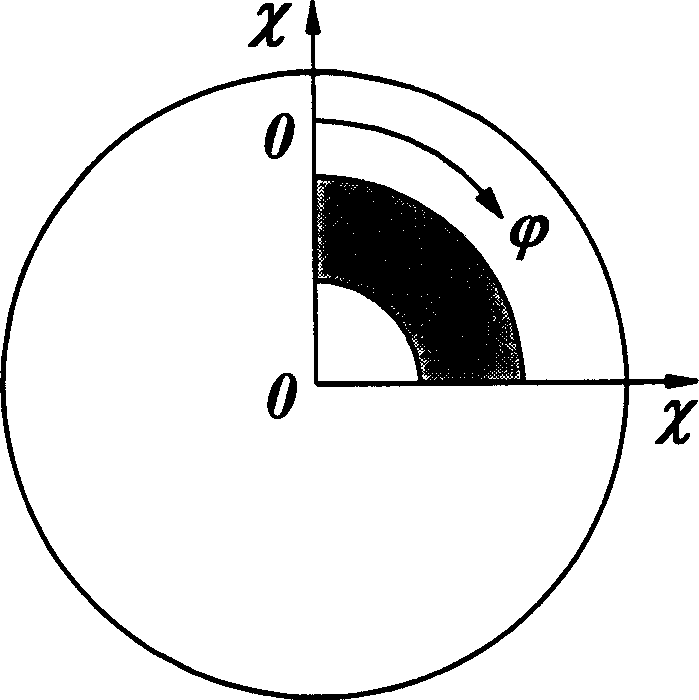

Method and device for measuring metal pipe texture

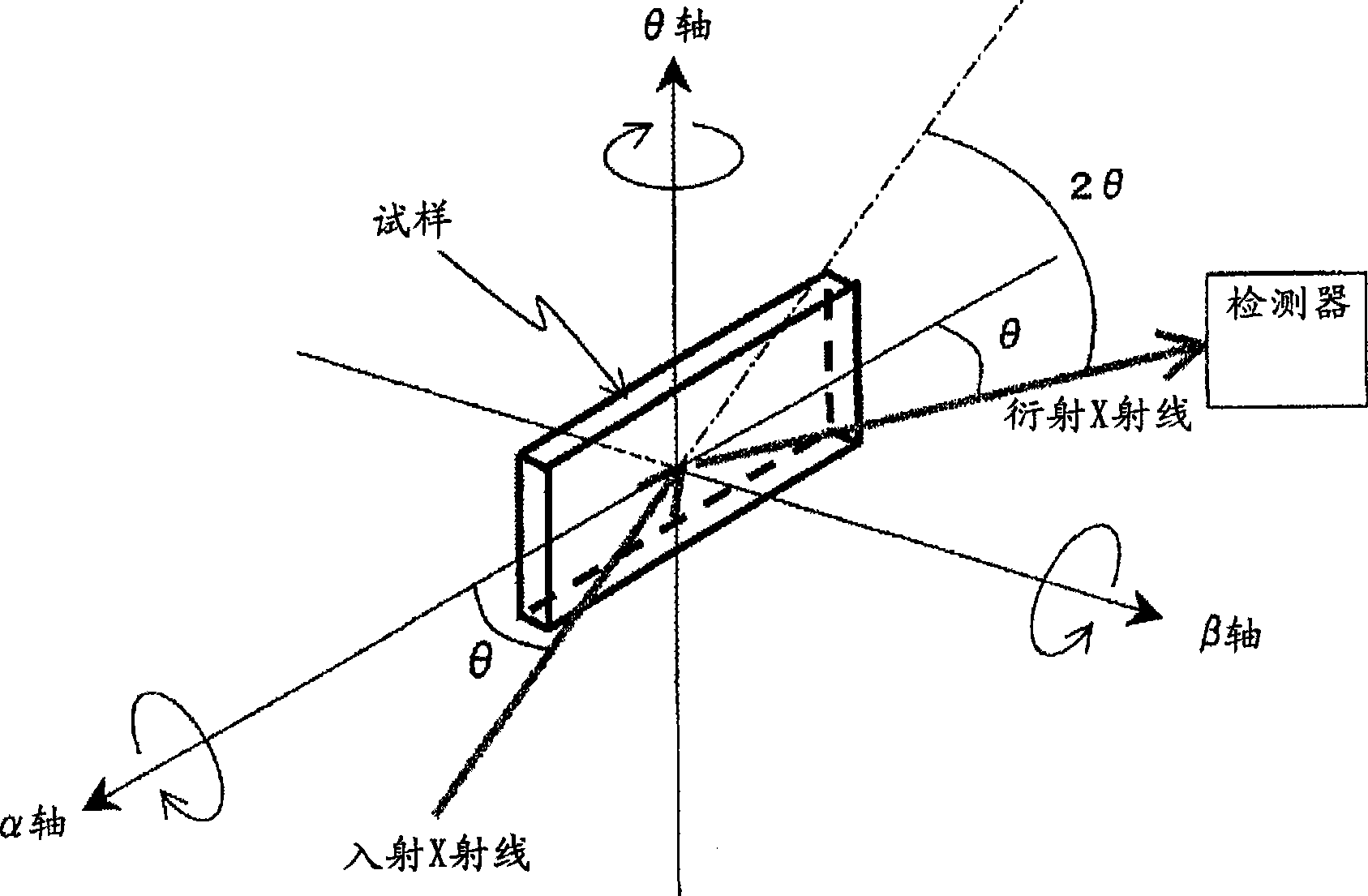

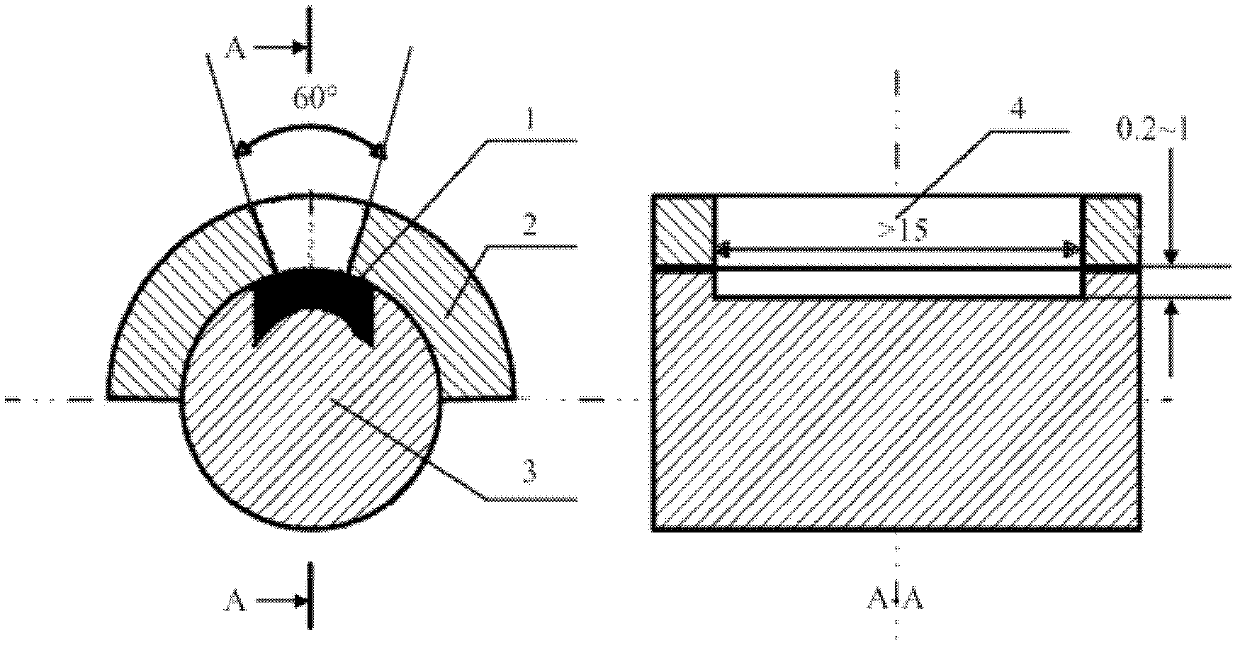

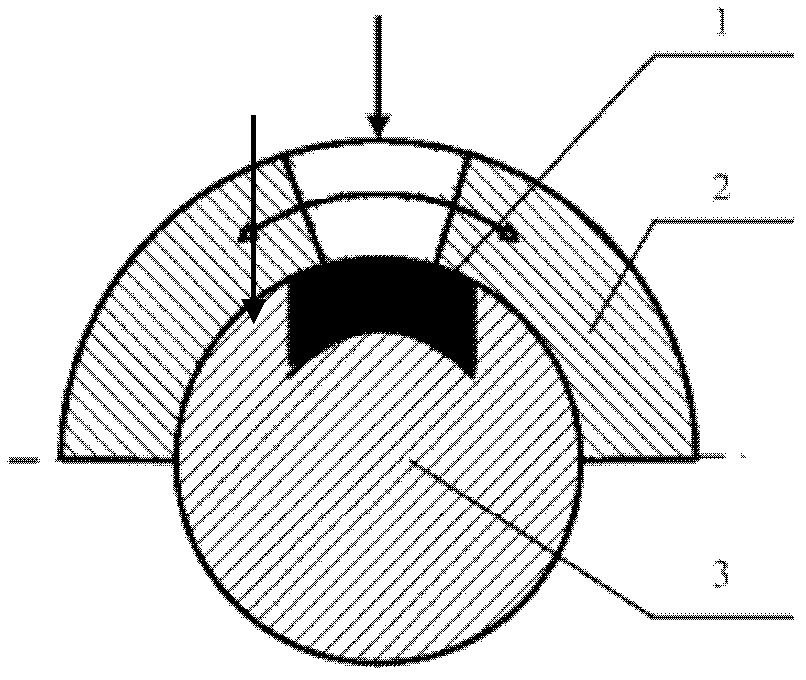

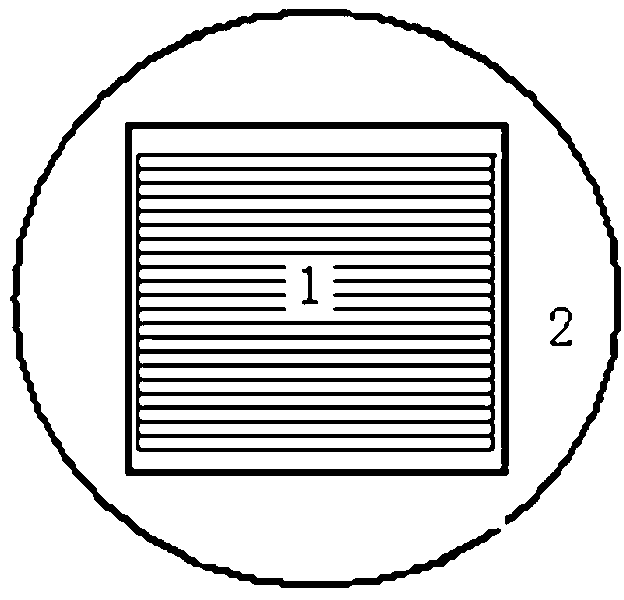

ActiveCN102721712ASolve the problem of not being able to measure the textureImprove test accuracyPreparing sample for investigationMaterial analysis using radiation diffractionX-rayCrystal plane

The invention belongs to measuring technology and relates to the improvement of a method for measuring metal pipe texture. The method comprises the steps of: processing a standard sample rack, compacting metal powder on a columnar sample rack as an amorphous standard sample, drawing a pole figure with an X ray reflection method, measuring different diffracted intensities of a pipe and a standard sample with different tilting angles x and different rotation angles, calibrating relative pole density in the pole figure by using correction intensity after compensation, drawing a pole figure of a certain crystal plane {HKL} of the pipe to obtain a complete pole figure and an orientation distribution function ODF of the texture. The invention assists in solving a problem that impact of curved surface sample shapes on X ray diffraction intensities can not be corrected, and precise measurement of the metal pipe texture is realized.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

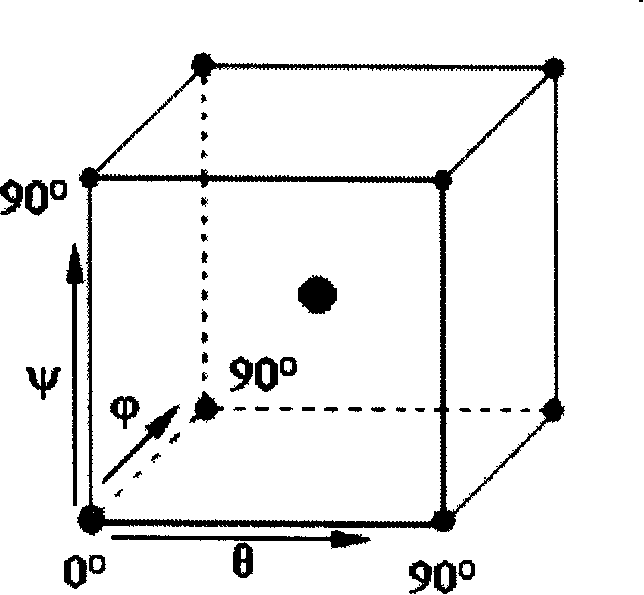

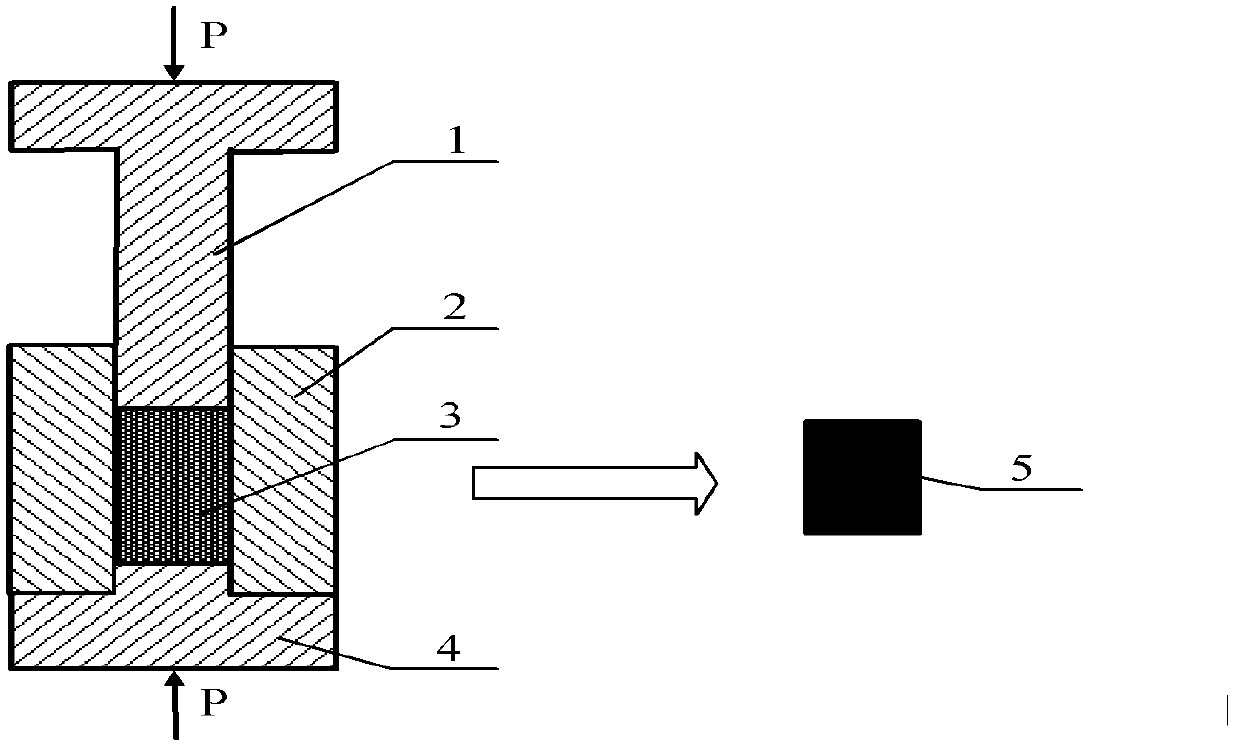

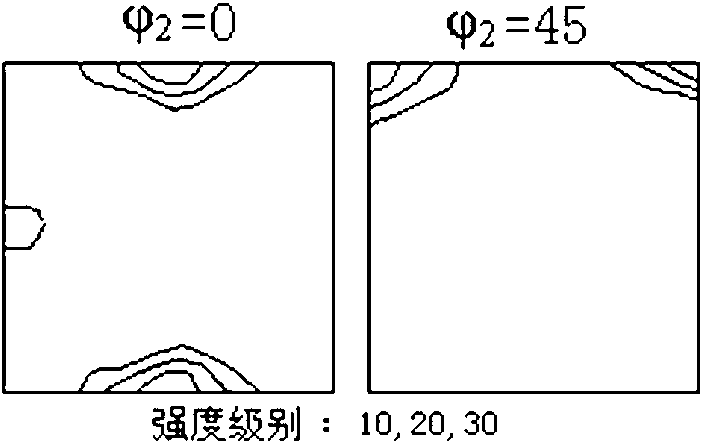

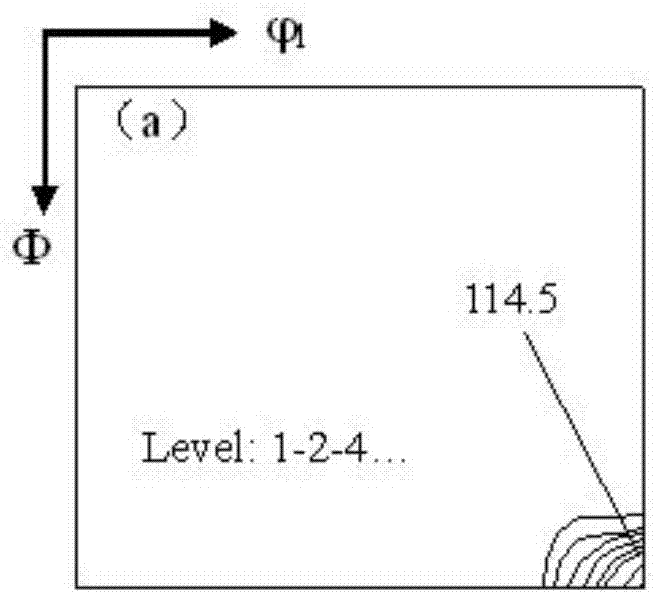

Cubic System Material texture quantitative test and analysis method

InactiveCN101210891AMaterial analysis using wave/particle radiationSpecial data processing applicationsTest analysisTwo step

The invention provides a quantitative test analysis method for cubic system material texture, which comprises the following steps of: testing three incomplete pole figure data with the reflection method; calculating orientation distribution function (ODF) coefficient W1mn with two step method; dividing an Euler space with 1 DEG interval, and calculating the orientation density of the entire Euler space; and selecting asymmetrical sub-Euler space 5 zone and 6 zone as a quantitative range for texture component, reducing the orientation points outside the 5 zone and 6 zone with an equivalent orientation manner, and performing addition to the texture component in a specified texture volume model with micro-volume manner to complete the whole quantifying process. The invention solves the technical problem of quantitation of ODF texture, and puts the quantitative analysis technique of cubic system material texture into practical application. The inventive method is especially suitable for composition and performance determination and technological optimization of oriented Goss texture.

Owner:ANGANG STEEL CO LTD

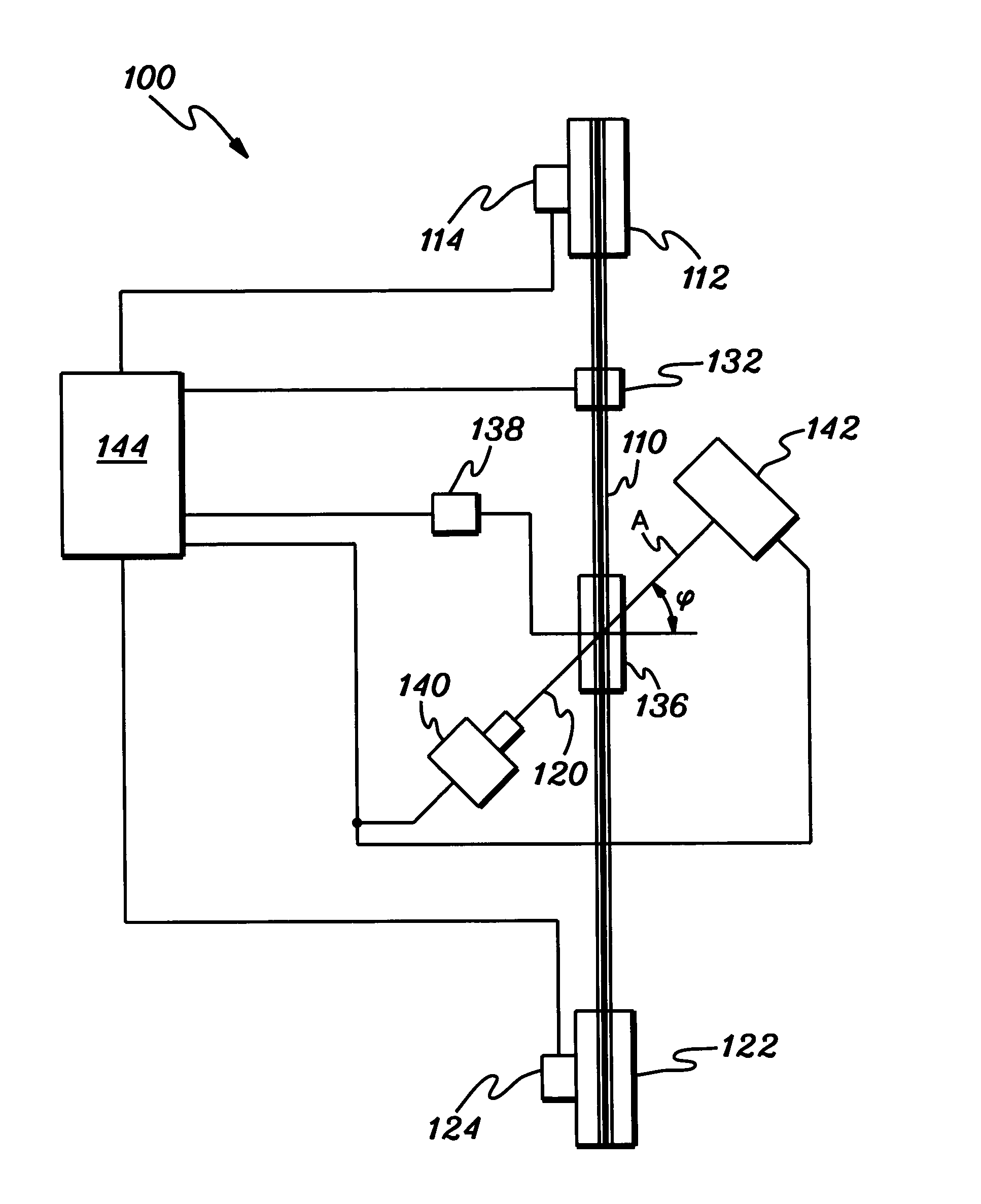

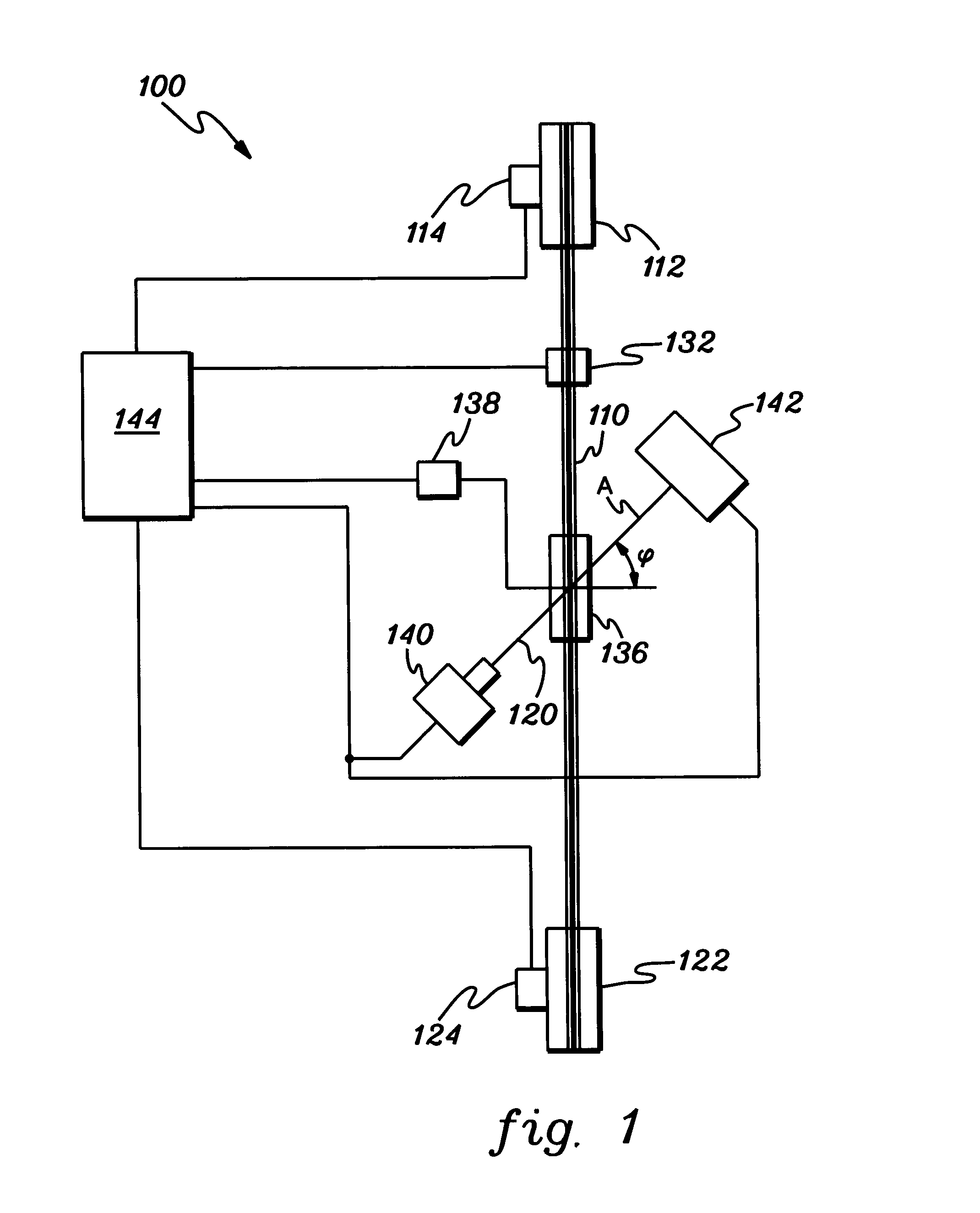

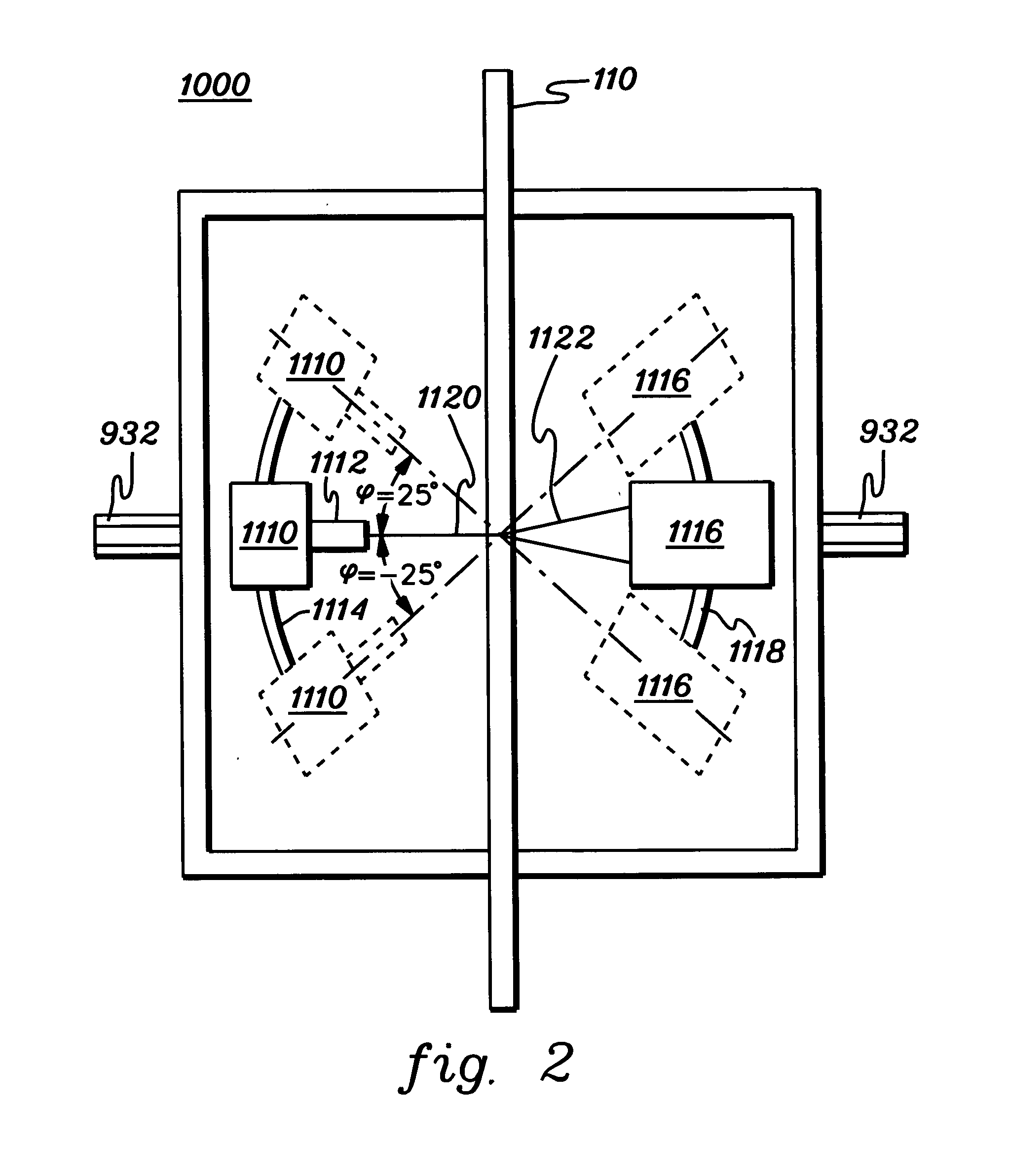

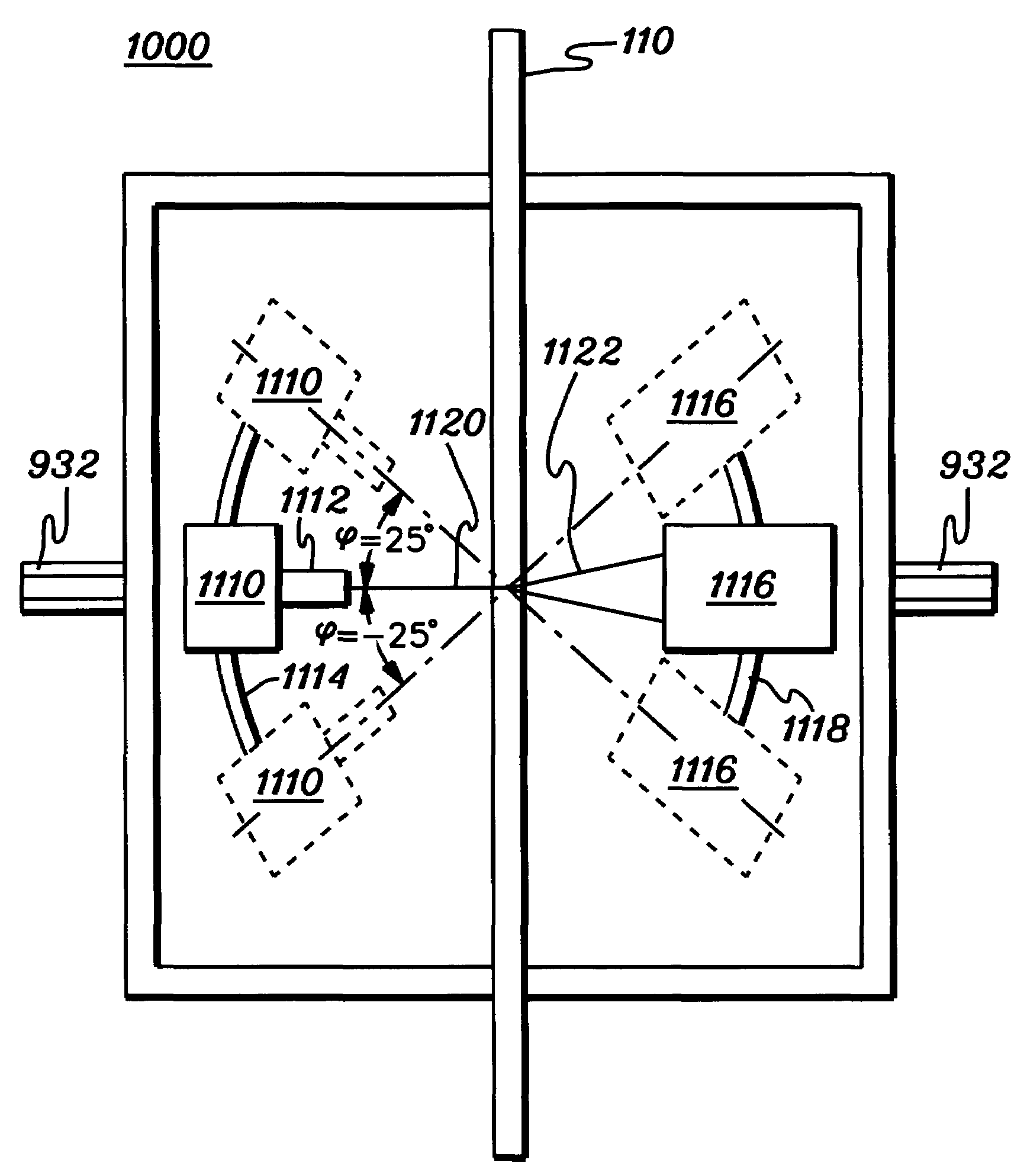

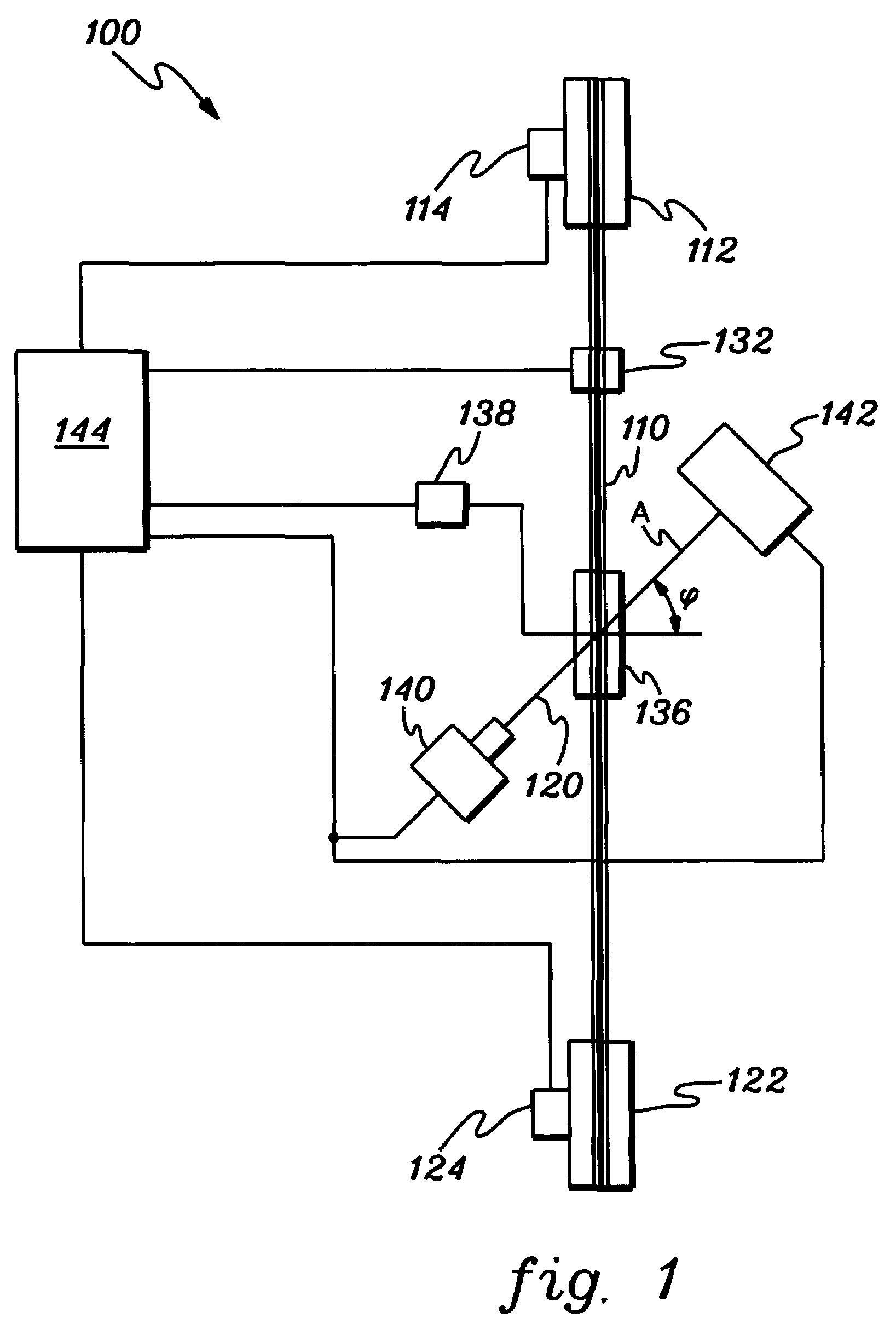

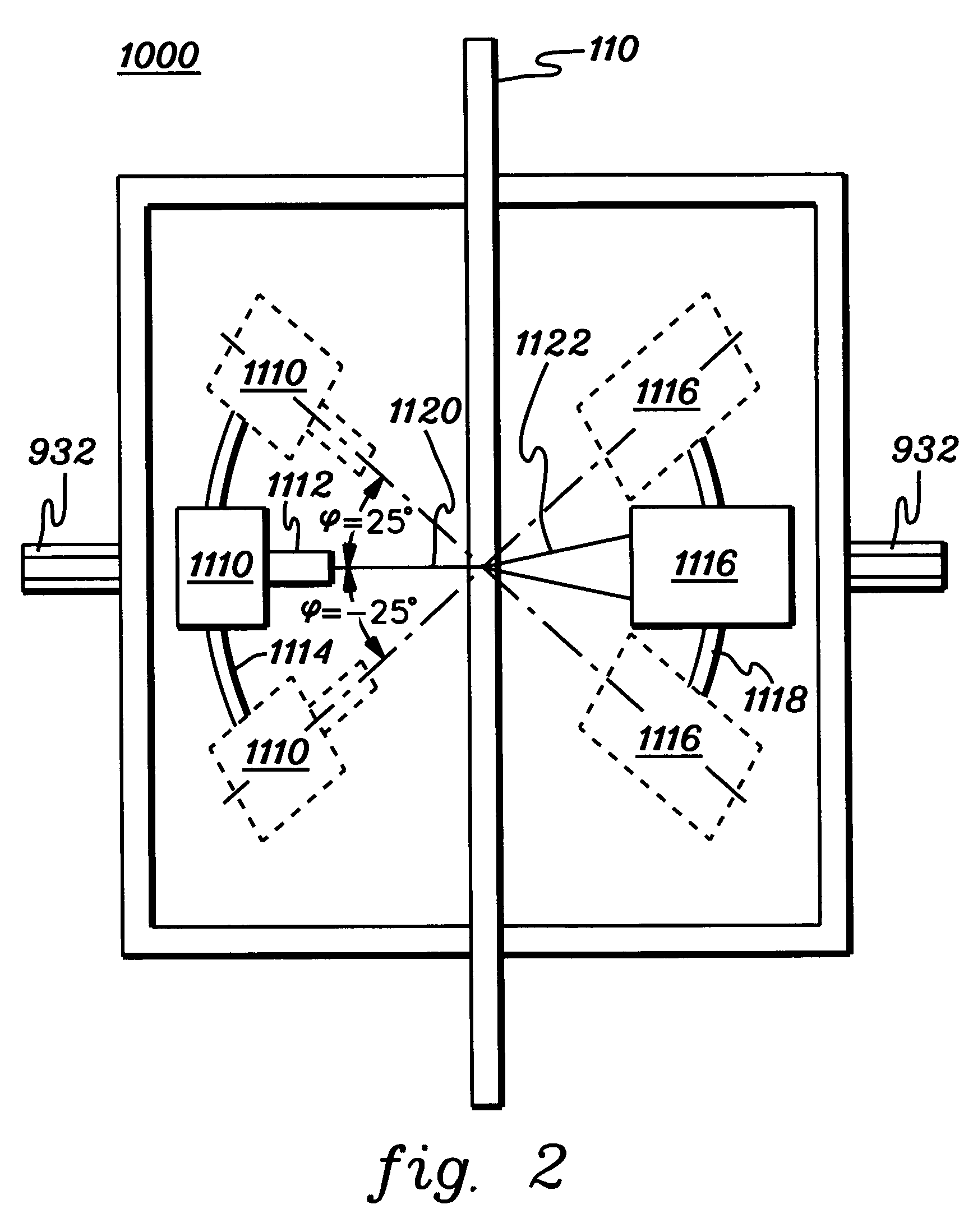

Method and system for X-ray diffraction measurements using an aligned source and detector rotating around a sample surface

An x-ray diffraction measurement apparatus for measuring a sample, having an x-ray source and detector coupled together in a combination for coordinated rotation around the sample, such that x-ray diffraction data can be taken at multiple phi angles. The apparatus may provide a pole figure representation of crystal orientation of the sample, wherein the pole figure represents the crystal alignment, and a full width half maximum value is calculated from the pole figure for crystal alignment quantification. Data may be taken at discrete positions along a length of the sample, and the sample is in a fixed position during measuring; or data may be taken continuously along a length of the article, as the sample continuously moves along its length in a movement path between the source and detector. The sample may be in the form of a tape, linearly passing through a measurement zone.

Owner:X-RAY OPTICAL SYSTEM INC +1

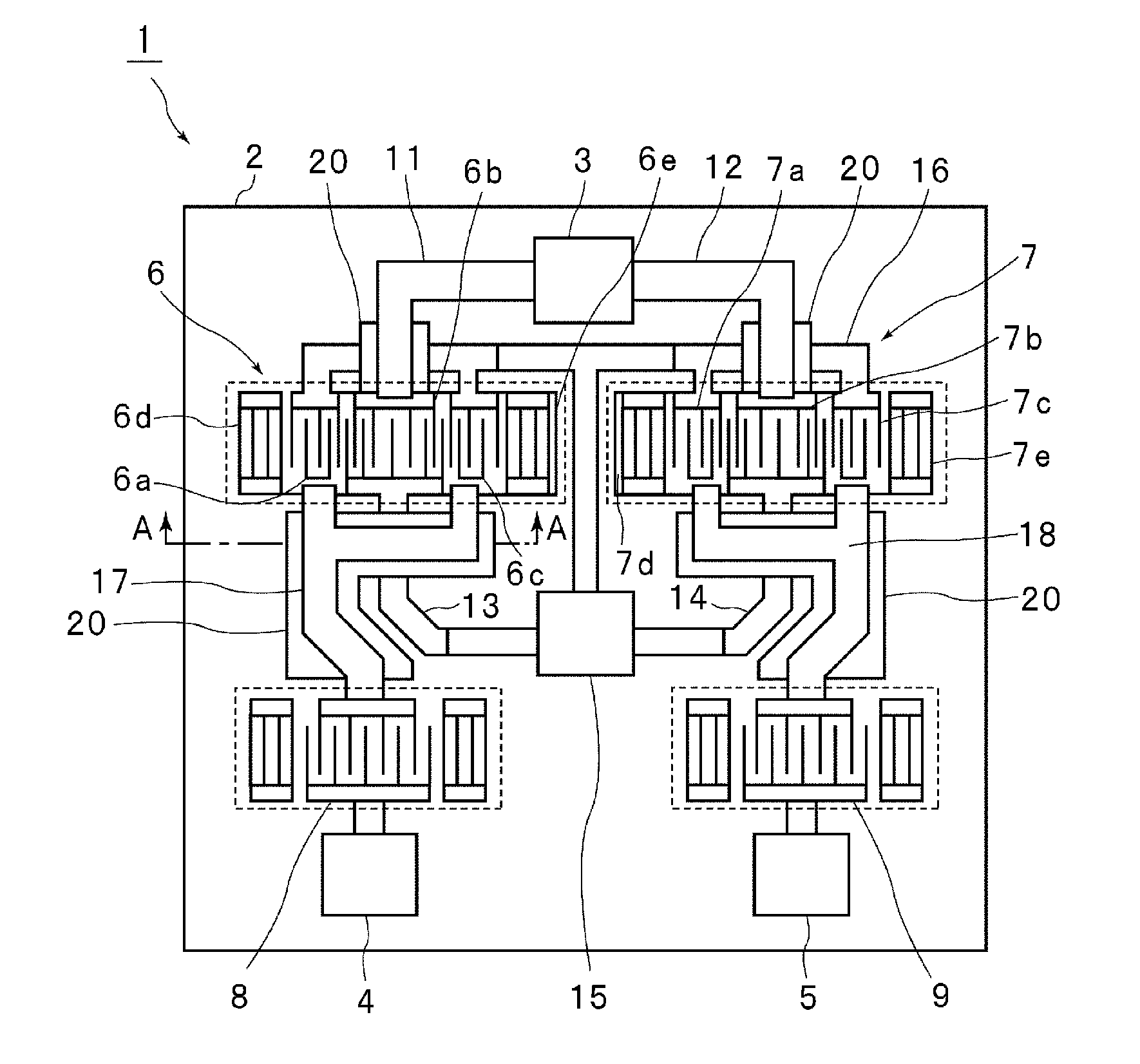

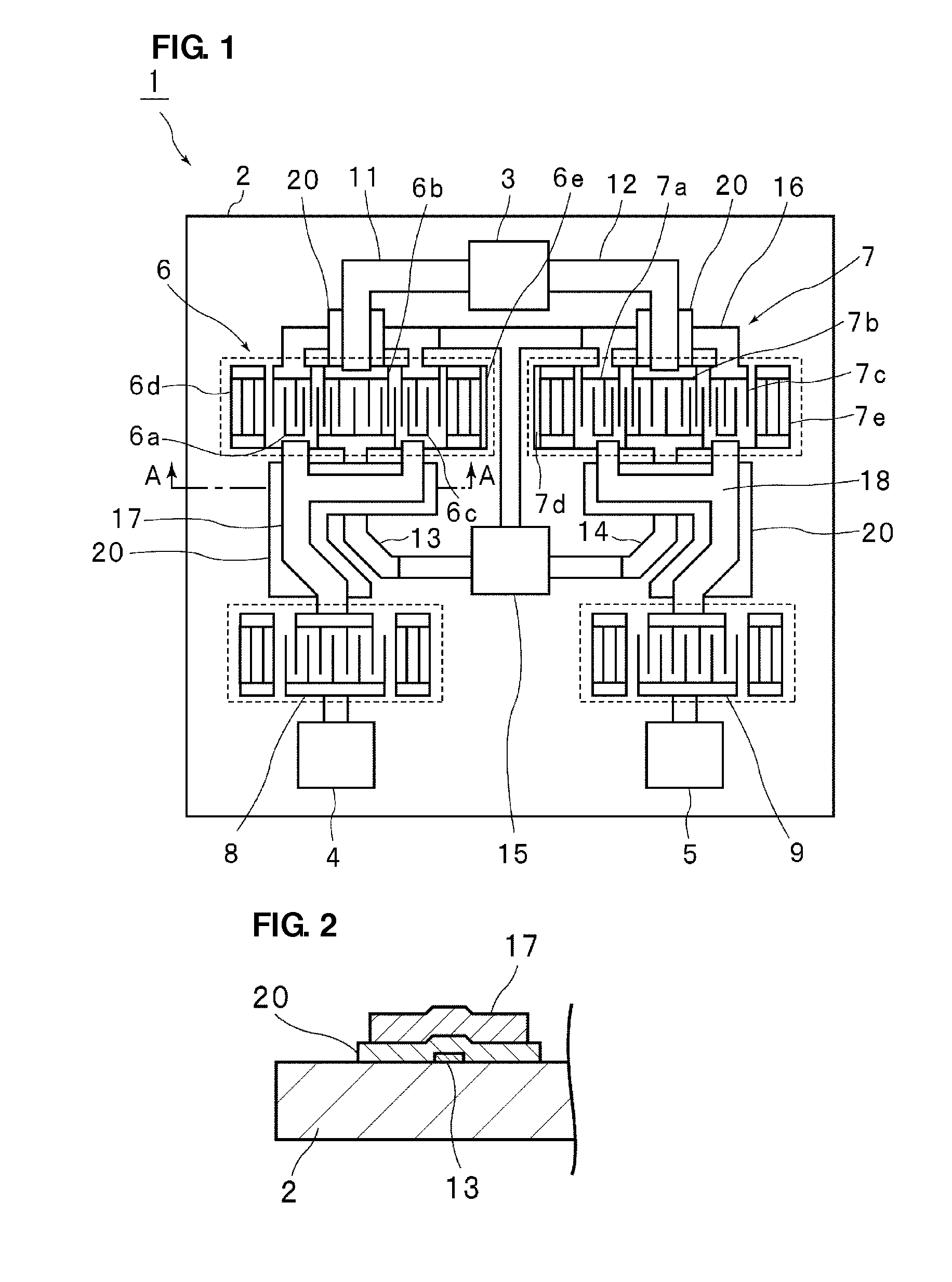

Surface acoustic wave device and method for manufacturing the same

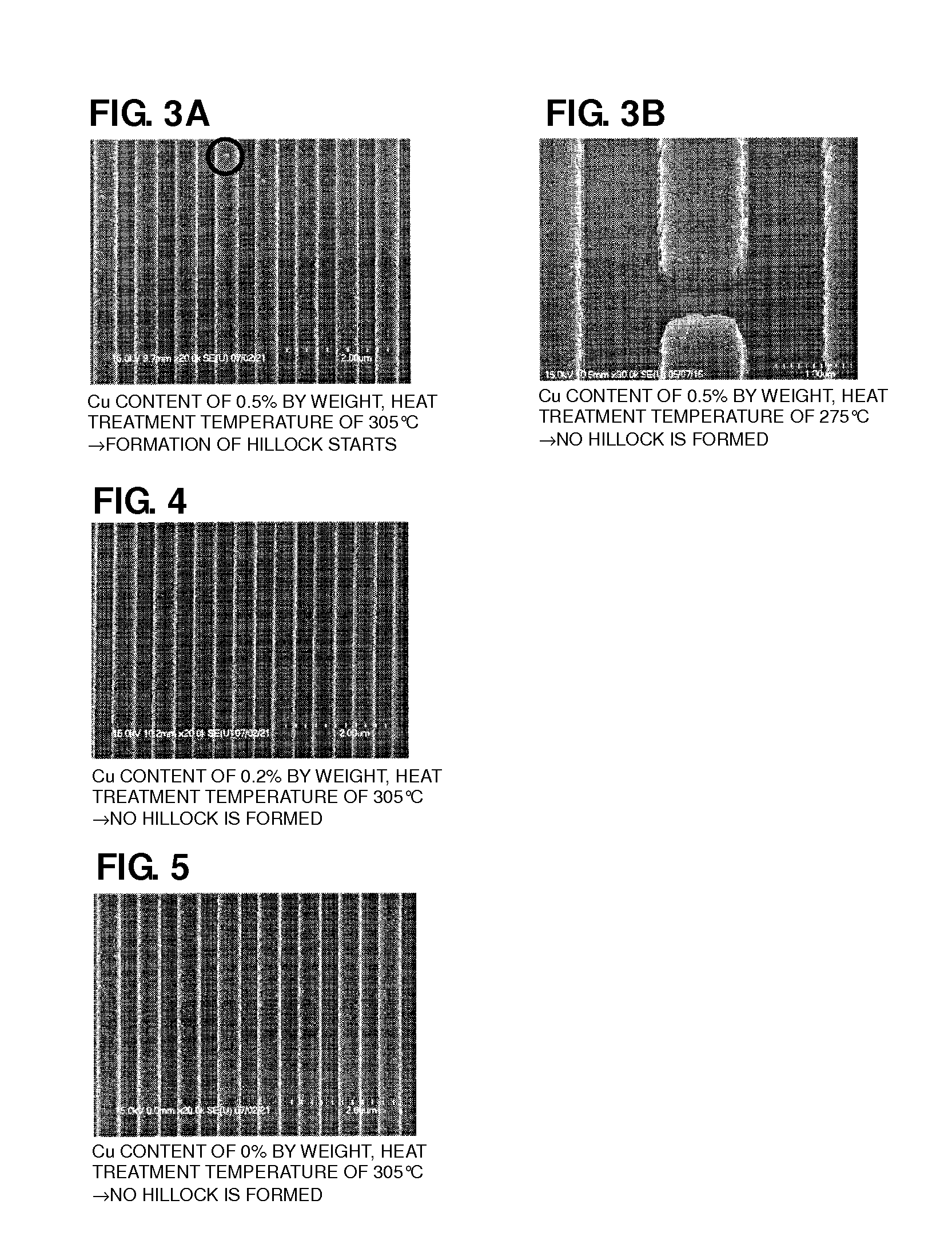

ActiveUS20110102108A1Increased durabilityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksSolubilityInterconnection

A surface acoustic wave device includes first interconnections and second interconnections connected to a potential different from a potential connected to the first interconnections that are arranged on a piezoelectric substrate. The first interconnections three-dimensionally intersect with the second interconnections with insulating layers made of a thermosetting resin, disposed therebetween. Interdigital electrodes defining IDTs are films which have six-fold rotational symmetric spots appearing in an XRD pole figure and which are defined by Al films or Al—Cu alloy films containing Cu in an amount not greater than the solubility limit at about 25° C.

Owner:MURATA MFG CO LTD

Method and system for X-ray diffraction measurements using an aligned source and detector rotating around a sample surface

ActiveUS7711088B2Handling using diffraction/refraction/reflectionMaterial analysis using radiation diffractionSoft x rayMeasurement device

Owner:X-RAY OPTICAL SYSTEM INC +1

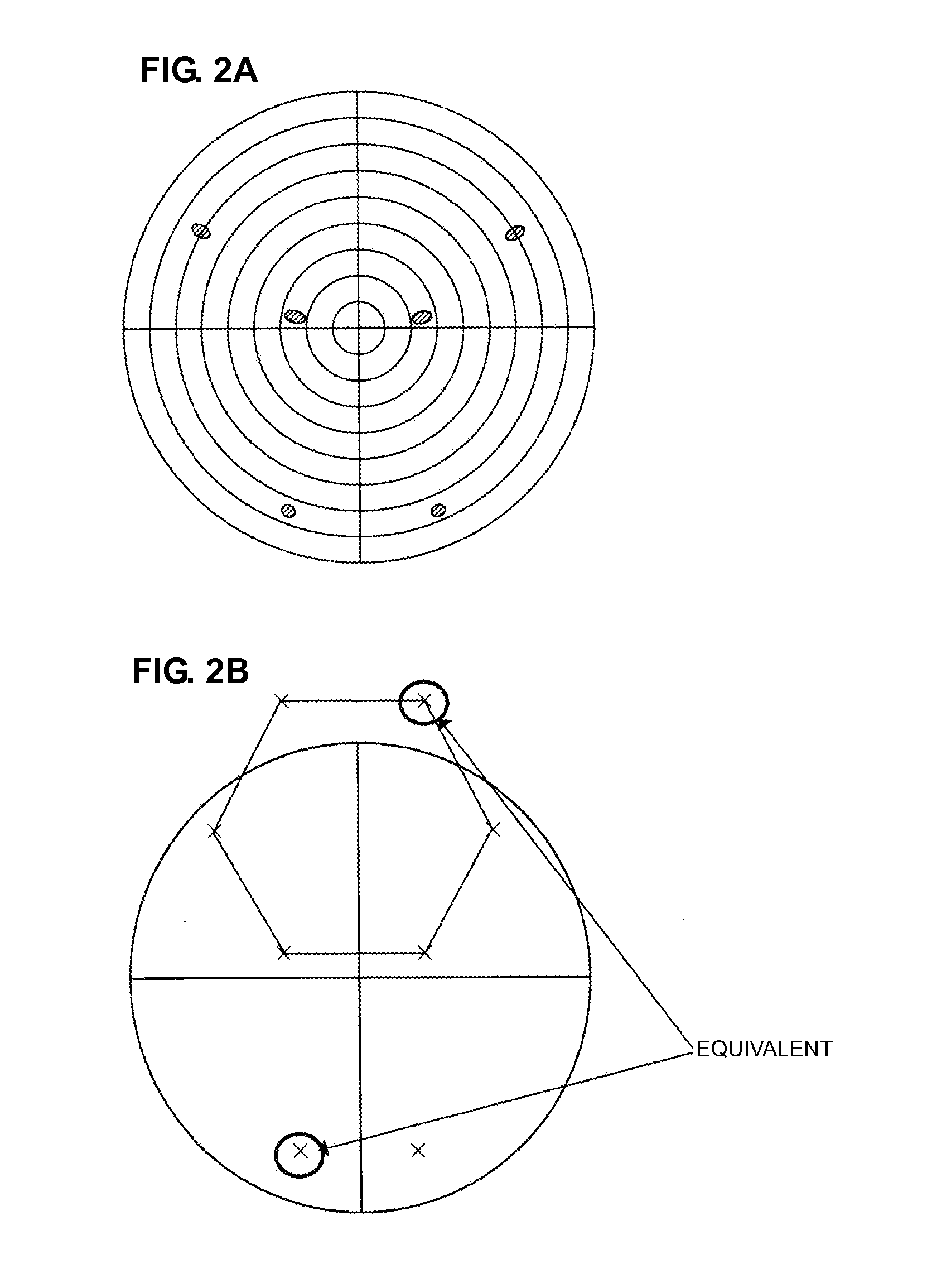

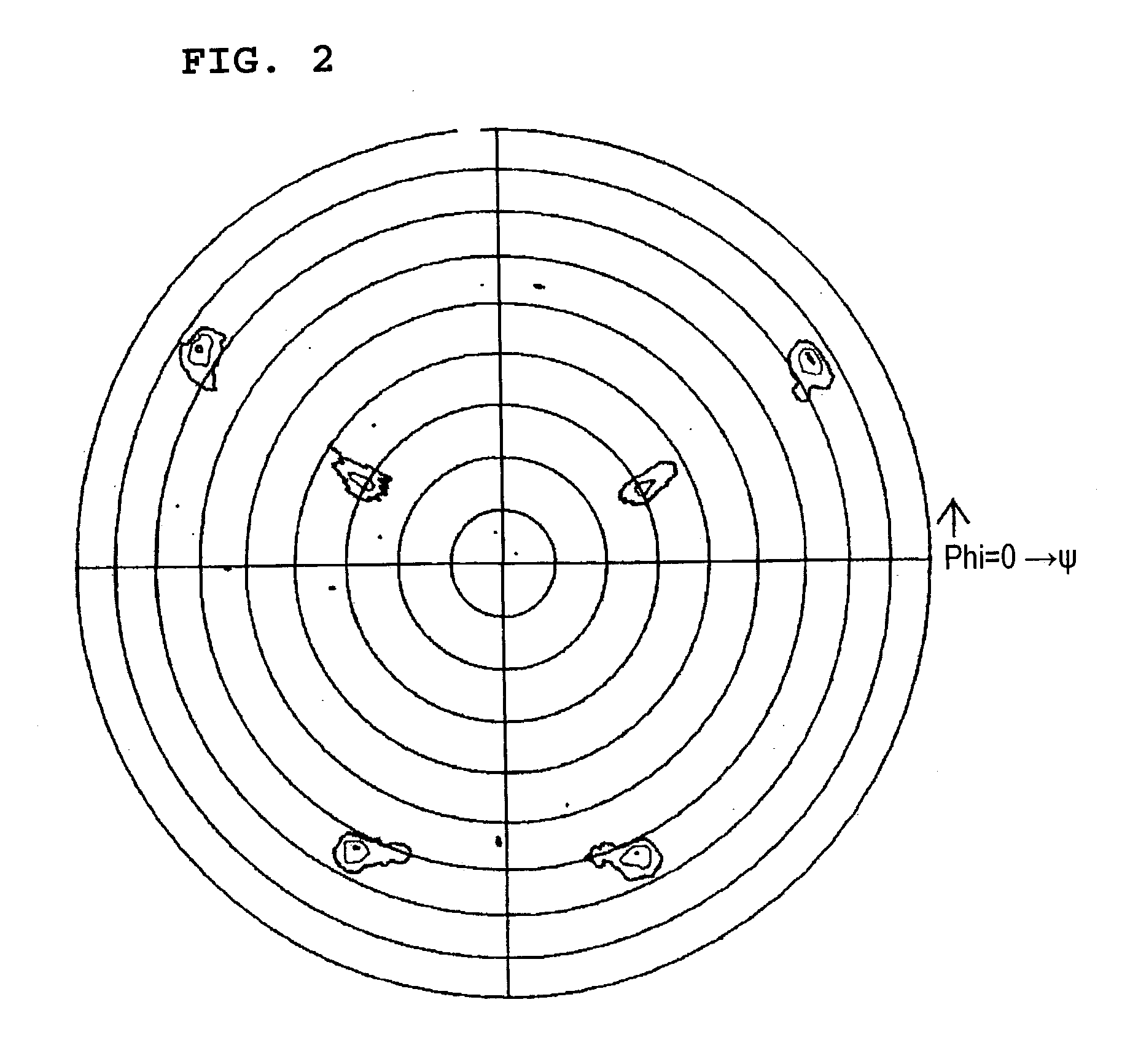

Rolled copper foil and manufacturing method of rolled copper foil

InactiveCN101481760AGood bending propertiesImprove bending characteristicsRoll mill control devicesMetal rolling arrangementsBeta angleX-ray

A rolled copper foil, according to the present invention, obtained after a final cold rolling step but before recrystallization annealing includes a group of crystal grains which exhibits four-fold symmetry in results obtained by X-ray diffraction (XRD) pole figure measurement with respect to a rolled surface. In the XRD pole figure measurement, at least four peaks of a {220}Cu plane diffraction of a copper crystal due to the group of crystal grains exhibiting the four-fold symmetry, which is obtained during beta axis scanning with an alpha angle set to 45 DEG , appear at intervals of 90 DEG +-5 DEG along the beta angle.

Owner:SH COPPER PROD CO LTD

Method for measuring metal bar textures

ActiveCN102680502ASolve the problem that the texture cannot be directly measuredImprove test accuracyMaterial analysis using wave/particle radiationTest sampleX-ray

The invention belongs to the measuring technology, and relates to the improvement of the method for measuring metal bar textures. The method includes the steps of processing a concave standard sample frame in which powder can be filled; pressing a column base standard sample; drawing pole figures through an X ray reflection method, respectively measuring diffracted intensity of different tilting angles x and rotation angles of a bar and the standard sample under the same measuring condition and parameters for compensating defocusing caused by compensation tilting angles x, and correcting the influence of shapes on diffracted intensity caused by the rotation angles; and calculating the orientation distribution function (ODF) of a complete pole figure and textures. According to the method for measuring metal bar textures, the difficulty that the influence of curved surface test sample shapes on X ray diffracted intensity cannot be corrected is overcome, and direct accurate measurement of metal bar textures is achieved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

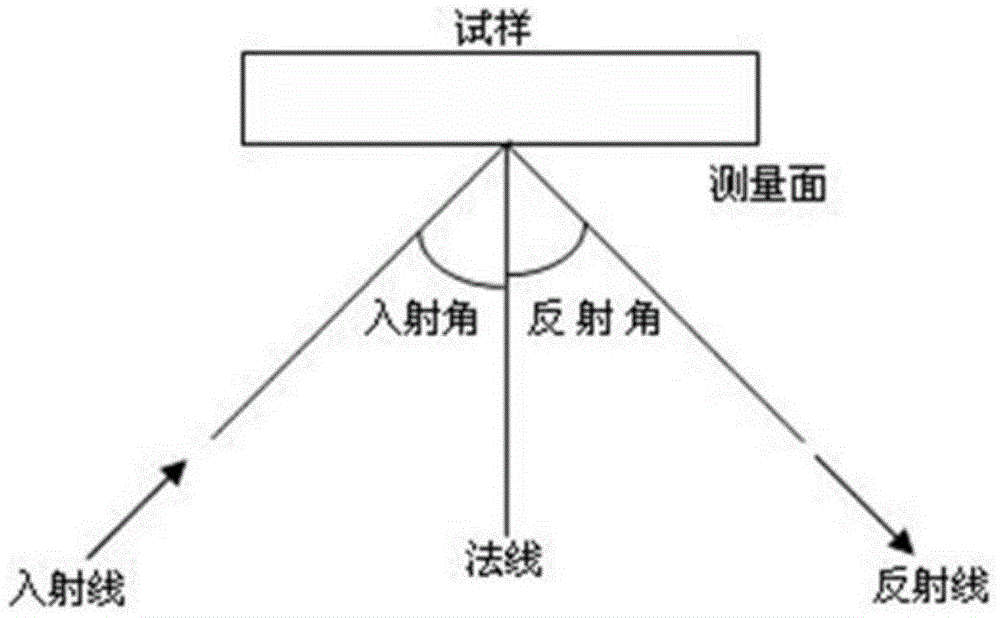

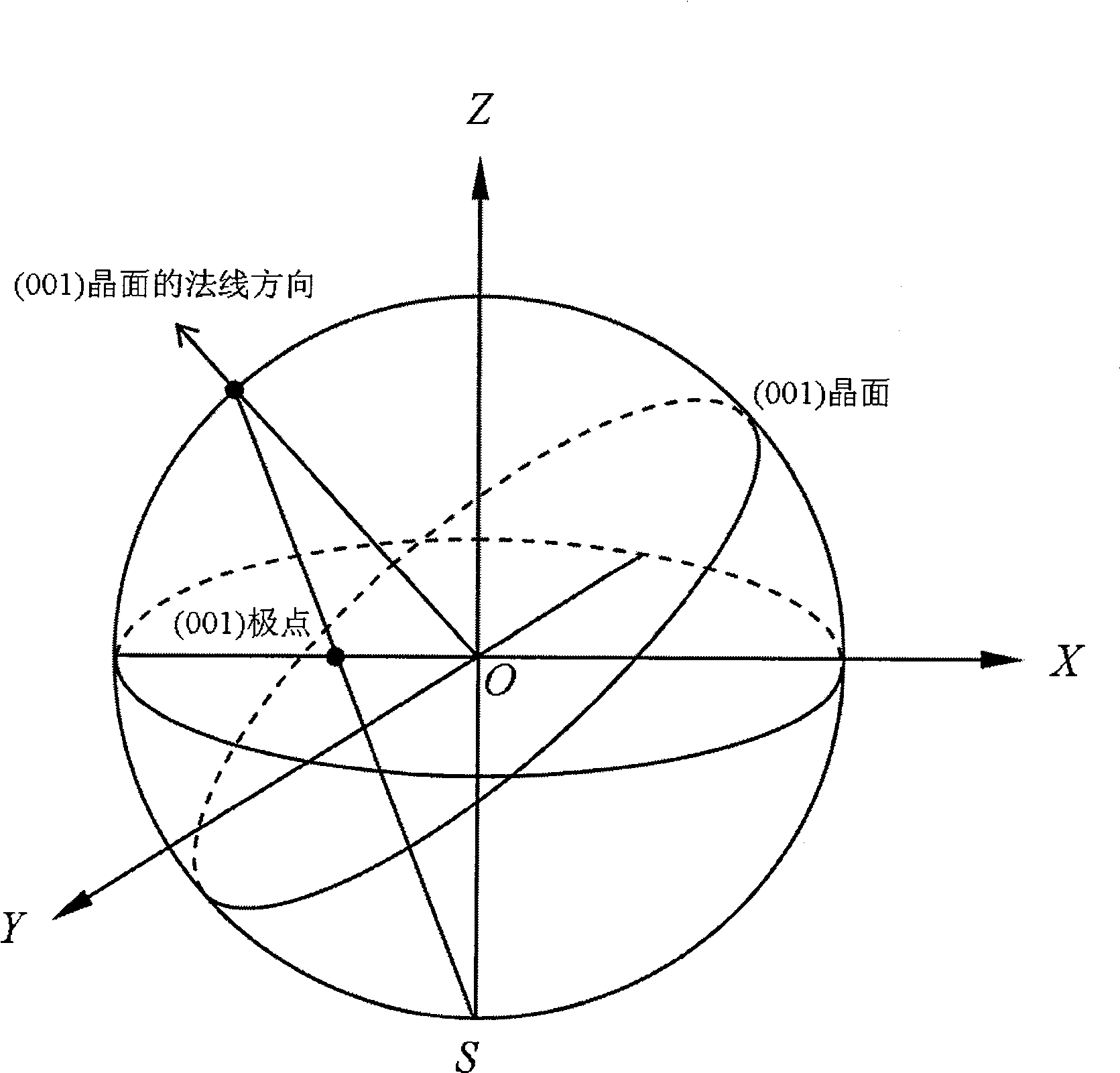

Method for measuring inverse pole figure

InactiveCN103323473AAccurately reflect performanceMaterial analysis using wave/particle radiationMeasurement deviceX-ray

The invention discloses a method for measuring an inverse pole figure. The method comprises the following steps of: determining the peak position of each diffraction peak of a sample and a standard sample and the background positions of the left and right sides of each peak; putting the sample on a 1 theta-axis of an X-ray instrument measurement device, and arranging a detector on a 2 theta-axis, wherein the 1 theta-axis and the 2 theta-axis are positioned in the position of 0 degree; acquiring the intensity of the X-ray of the diffraction peak on the detector; acquiring the background intensity of the diffraction peak; calculating the net intensity of the (hkl) diffraction peak; detaching the sample from the 1 theta-axis, loading the standard sample, and measuring the net intensity of the diffraction peak of the standard sample; calculating the ratios of the net intensity of the sample to that of the standard sample, and averaging all the ratios to obtain the net intensity of the (hkl) diffraction peak; and marking the polar density value of each (hkl) diffraction peak on the inverse pole figure of the sample, thus finishing the measurement process. The measurement result contains contribution of crystalline grains which can generate symmetrical diffraction and have small grain orientation errors on the measurement result, and the measurement result can more accurately reflect the performance of the material.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Coated Member

ActiveUS20120128971A1Improve adhesionExcellent in wear resistance and fracture resistance and oxidation resistancePigmenting treatmentOther chemical processesX-rayGroup 6 element

A coated member includes a base material and a coating film formed on the surface thereof. At least one layer in the coating film is a hard film of a cubic metal compound including at least one element selected from the group consisting of the group 4 elements (Ti, Zr, Hf, etc.), group 5 elements (V, Nb, Ta, etc.) and group 6 elements (Cr, Mo, W, etc.) of the periodic table, Al, Si, B, Y and Mn together with at least one element selected from the group consisting of C, N and O. In the pole figure for the face (111) of the hard film, the X-ray intensity distribution in the α-axis shows the maximum intensity in the α-angle range of 50-65°. In the pole figure for the face (200), the X-ray intensity distribution in the α-axis shows the maximum intensity in the α-angle range of 60-80°.

Owner:TUNGALOY CORP

Rolled copper foil

A rolled copper foil according to the present invention includes a crystal grain alignment wherein: when normalized intensity of {200}Cu plane diffraction of a copper crystal in results obtained by an X-ray diffraction pole figure measurement with respect to a rolled surface is plotted against at different values of angle α, the normalized intensity being obtained during a β scanning in the pole figure measurement, a ratio of a maximum value A of the normalized intensity with angle α in a range of 40° to 60° to a maximum value B of the normalized intensity with angle α in a range of 80° to 90° is equal to or greater than 4; and when the normalized intensity increases with increasing angle α in a range of 25° to 45°, there is essentially no area in which the normalized intensity increases stepwise.

Owner:SH COPPER PROD CO LTD

Rolled Copper Foil and Manufacturing Method of Rolled Copper Foil

InactiveUS20090173414A1Excellent flexible fatigue propertyImproved flexible fatigue propertyPrinted circuit aspectsPrinted circuit manufactureX-rayCopper foil

A rolled copper foil, according to the present invention, obtained after a final cold rolling step but before recrystallization annealing includes a group of crystal grains which exhibits four-fold symmetry in results obtained by X-ray diffraction (XRD) pole figure measurement with respect to a rolled surface. In the XRD pole figure measurement, at least four peaks of a {220}Cu plane diffraction of a copper crystal due to the group of crystal grains exhibiting the four-fold symmetry, which is obtained during β axis scanning with an α angle set to 45°, appear at intervals of 90°±5° along the β angle.

Owner:SH COPPER PROD CO LTD

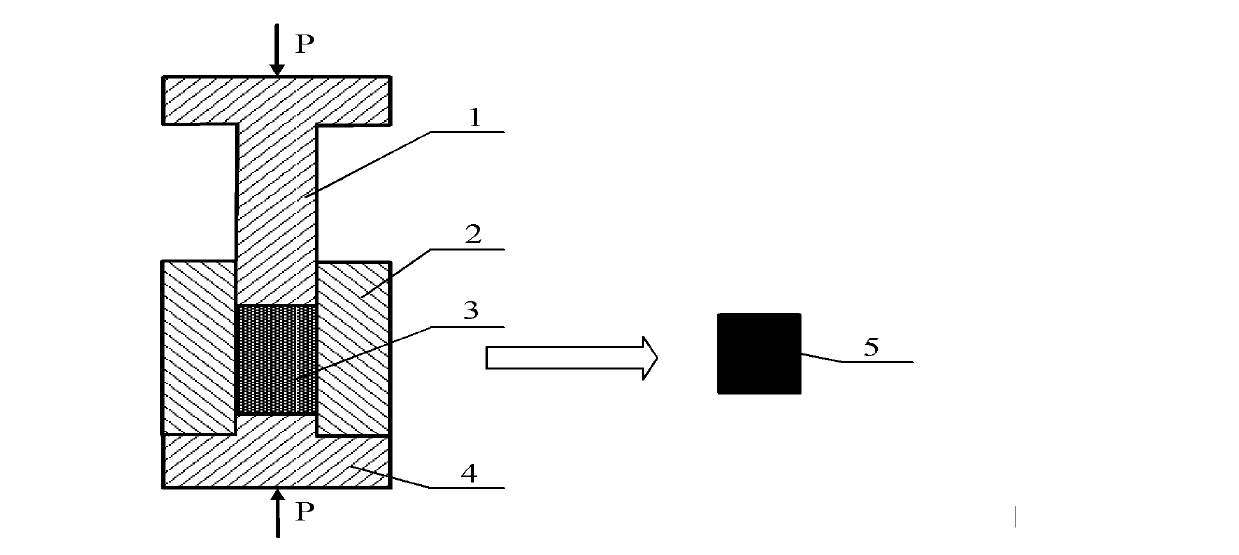

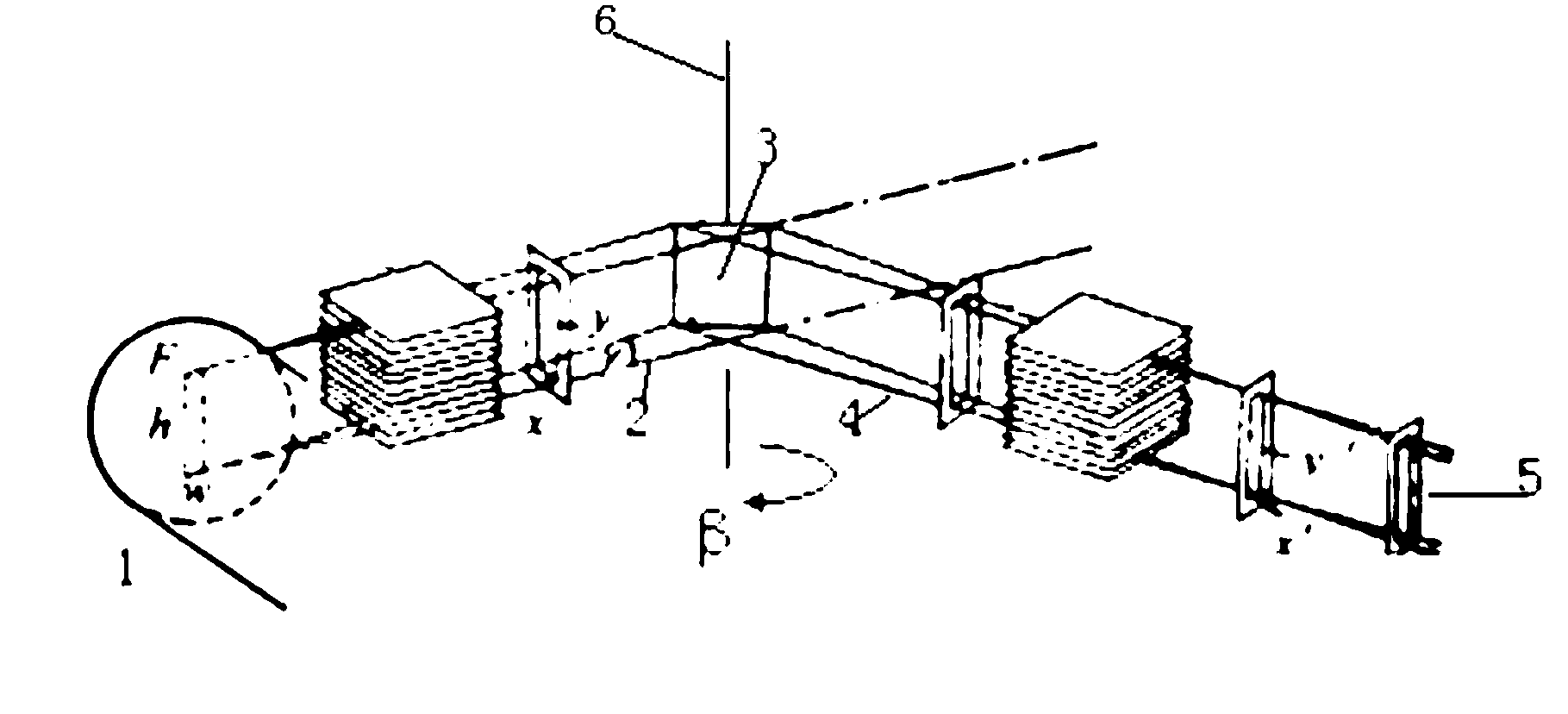

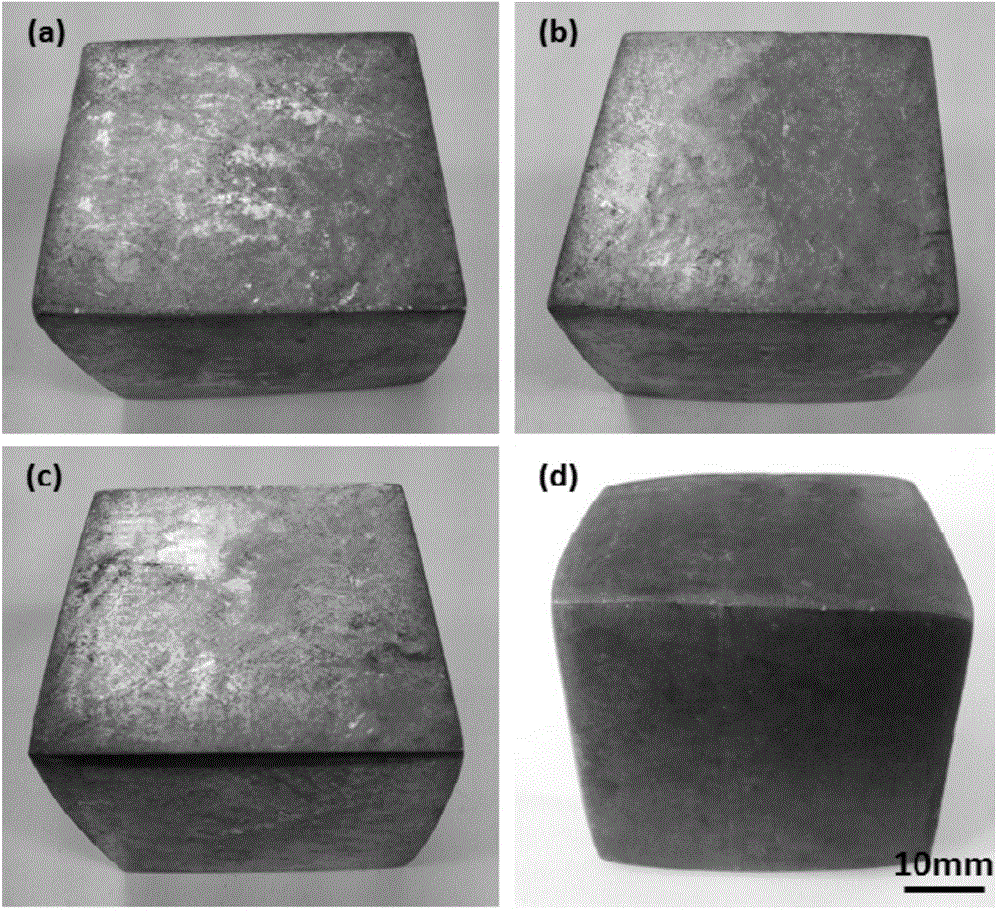

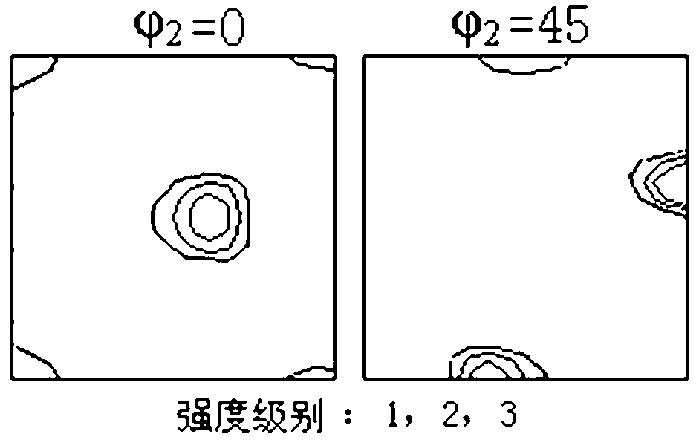

AZ61 magnesium alloy with weak-basal/non-basal texture and low anisotropy, and preparation method of AZ61 magnesium alloy

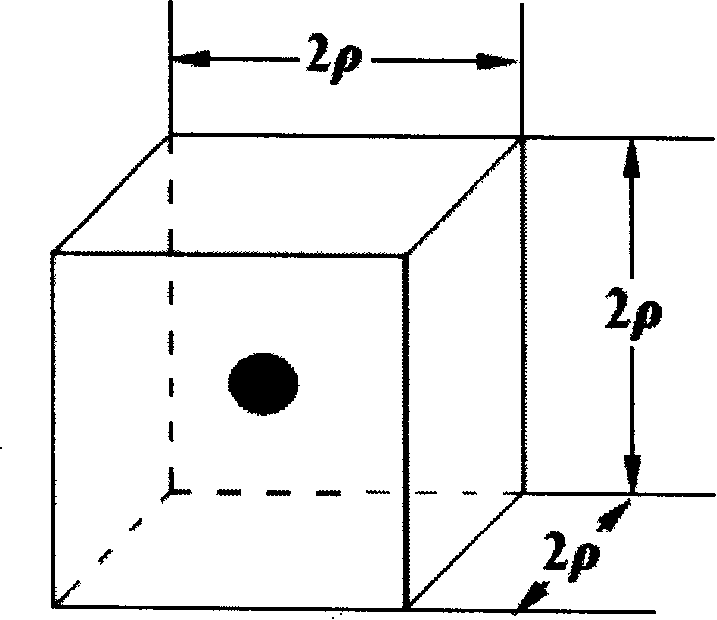

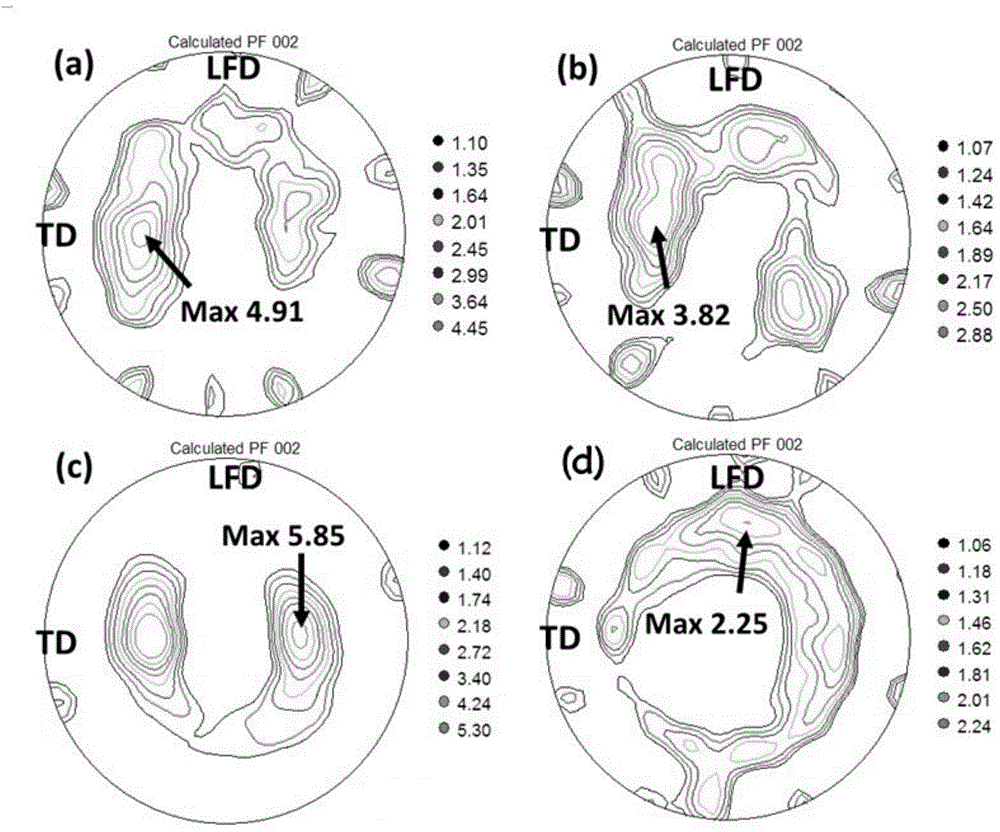

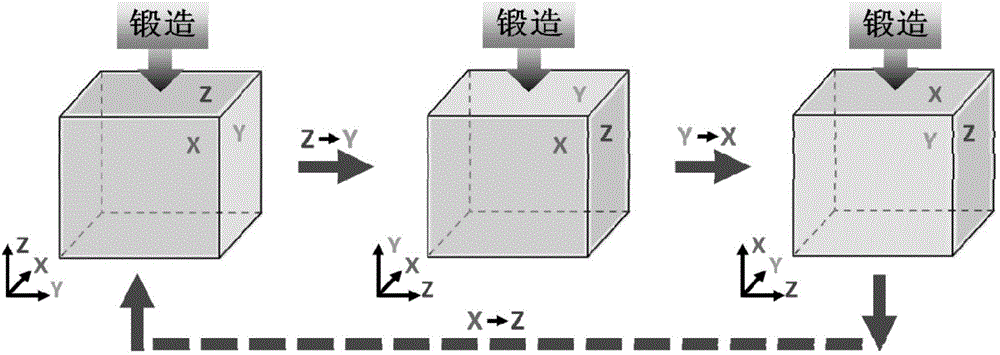

ActiveCN105483580APowerful industrial production and processingShort production processOne passSolid solution

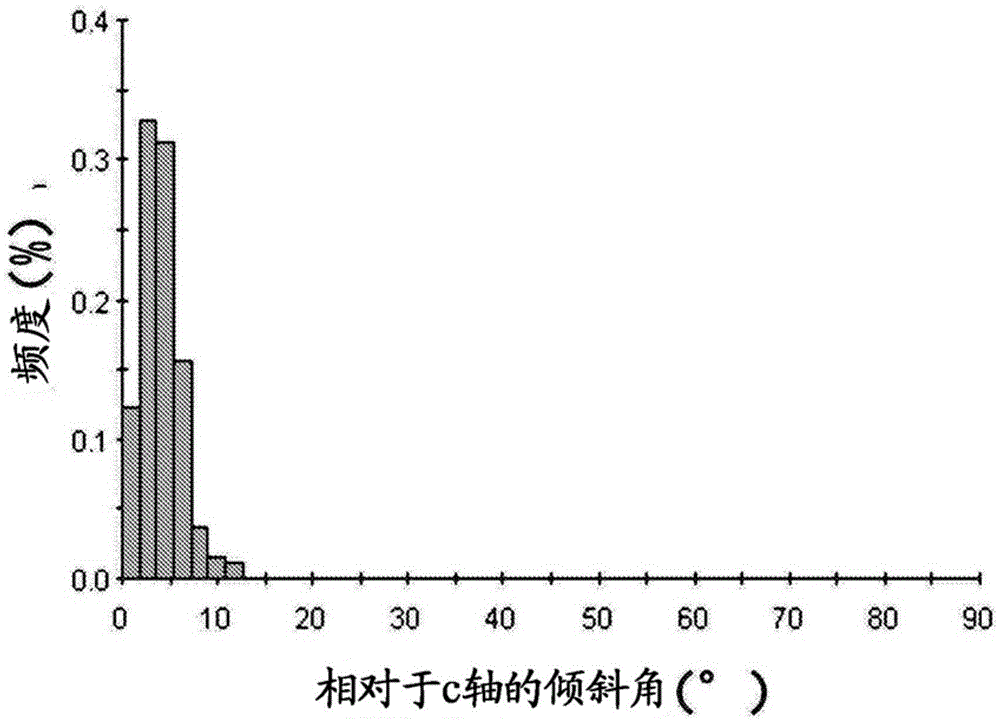

The invention discloses an AZ61 magnesium alloy with weak-basal / non-basal texture and low anisotropy, and a preparation method of the AZ61 magnesium alloy, and belongs to the technical field of magnesium alloy plastic processing. A molten AZ61 magnesium alloy is subjected to solid-solution treatment at a deformation temperature of 250-350 DEG C. Continuous cyclic hammer forging is performed through an industrial air hammer forging machine along three axial directions orthogonal to one another; one time of hammer forging in one direction is one pass; and the direction is changed every pass of hammer forging. Strain of each pass is 3-10%, and an average strain rate of hammer forging is 15-200 s<-1>. Hammer forging is continuously performed for 20-250 passes. The grain size of a hammer-forged sample is 12-30 [mu]m; the texture peak intensity is less than 6; a deviation angle of a texture peak location relative to a pole figure center is more than 30 degrees. In each direction of the sample, yield strength sigma<y>, tensile strength sigma, and elongation percentage sigma are no less than 90 MPa, 270 MPa, and 20%, respectively.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

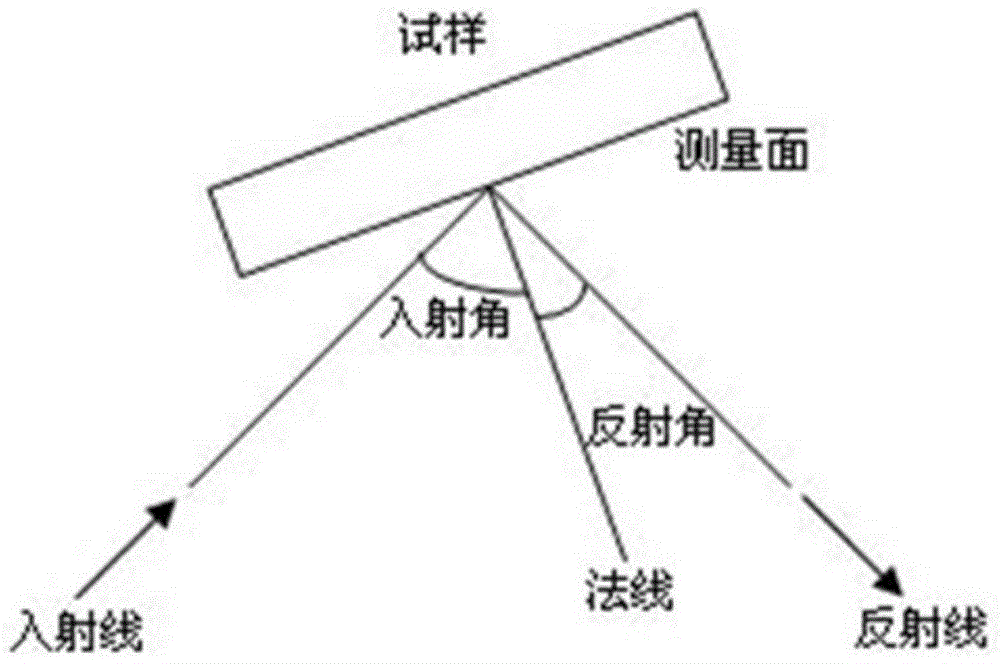

Method for measuring inverse pole figure by inclining and rotating test sample

InactiveCN104062311AImprove correspondenceImprove scienceMaterial analysis using wave/particle radiationTest sampleComputational physics

The invention discloses a method for measuring an inverse pole figure by inclining and rotating a test sample. The method comprises the following steps of determining peak positions of diffraction peaks of the test sample and a standard sample and back bottom positions of the left side and the right side of the peaks; arranging the test sample and a detector at initial positions; obtaining the intensity and the back bottom intensity of all the diffraction peaks of the test sample under different inclination angles during rotation, calculating the net intensity of the diffraction peaks to obtain the net intensity of the diffraction peaks of the standard sample, calculating a ratio of the net intensity of the diffraction peaks of the test sample to the net intensity of the diffraction peaks of the standard sample under the different inclination angles, and calculating an average value of all the ratios to obtain an extreme density value of each diffraction peak; and marking the extreme density values of all the diffraction peaks on the inverse pole figure to finish a measurement process. During the measurement of the inverse pole figure, the test sample can be inclined and is rotated around 360 degrees by taking a normal of the test sample as a rotating shaft, so that all orientation crystal particles make contributions to the extreme density of the inverse pole figure. A measurement result and the material performance have a good corresponding relationship, and the scientificity is high.

Owner:武汉钢铁有限公司

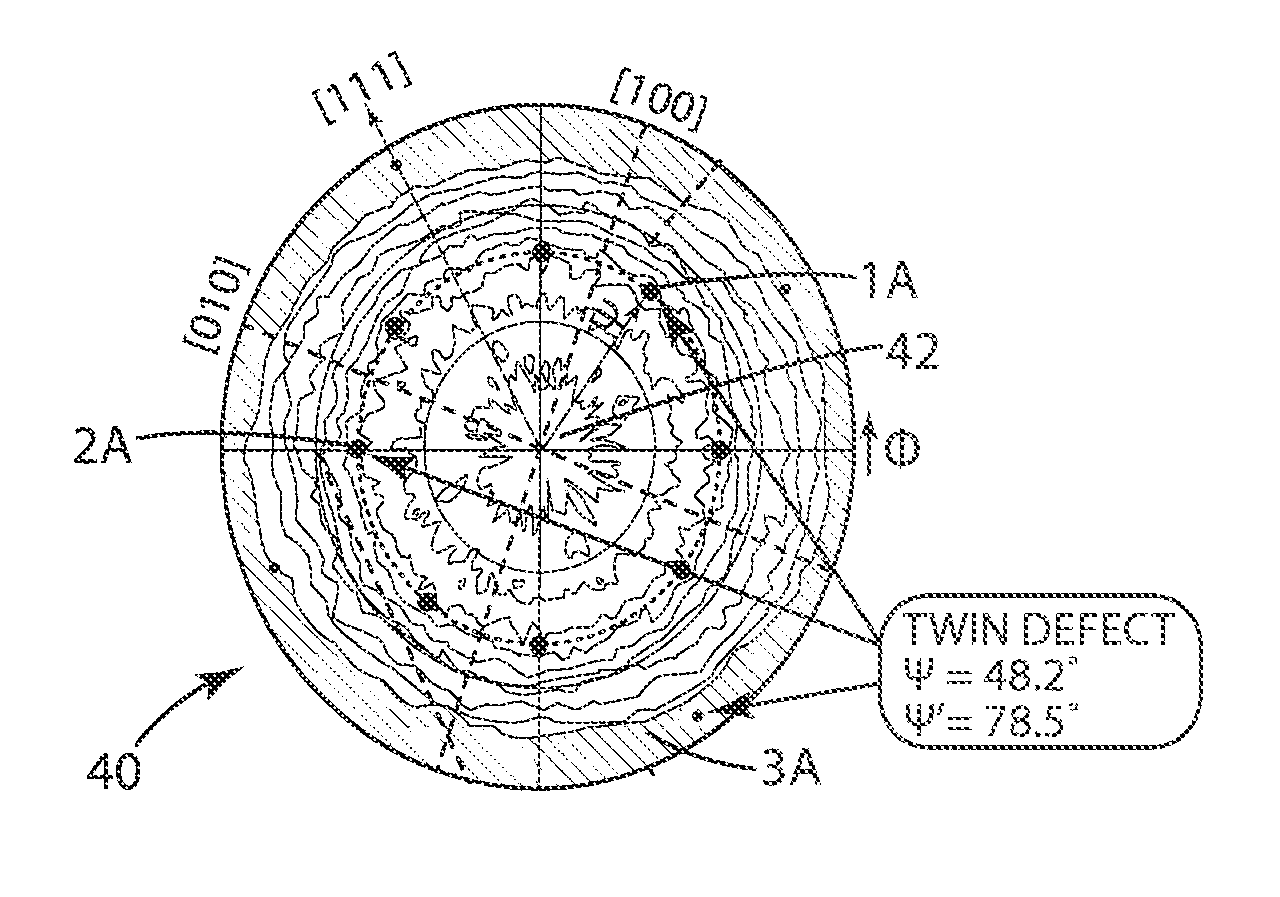

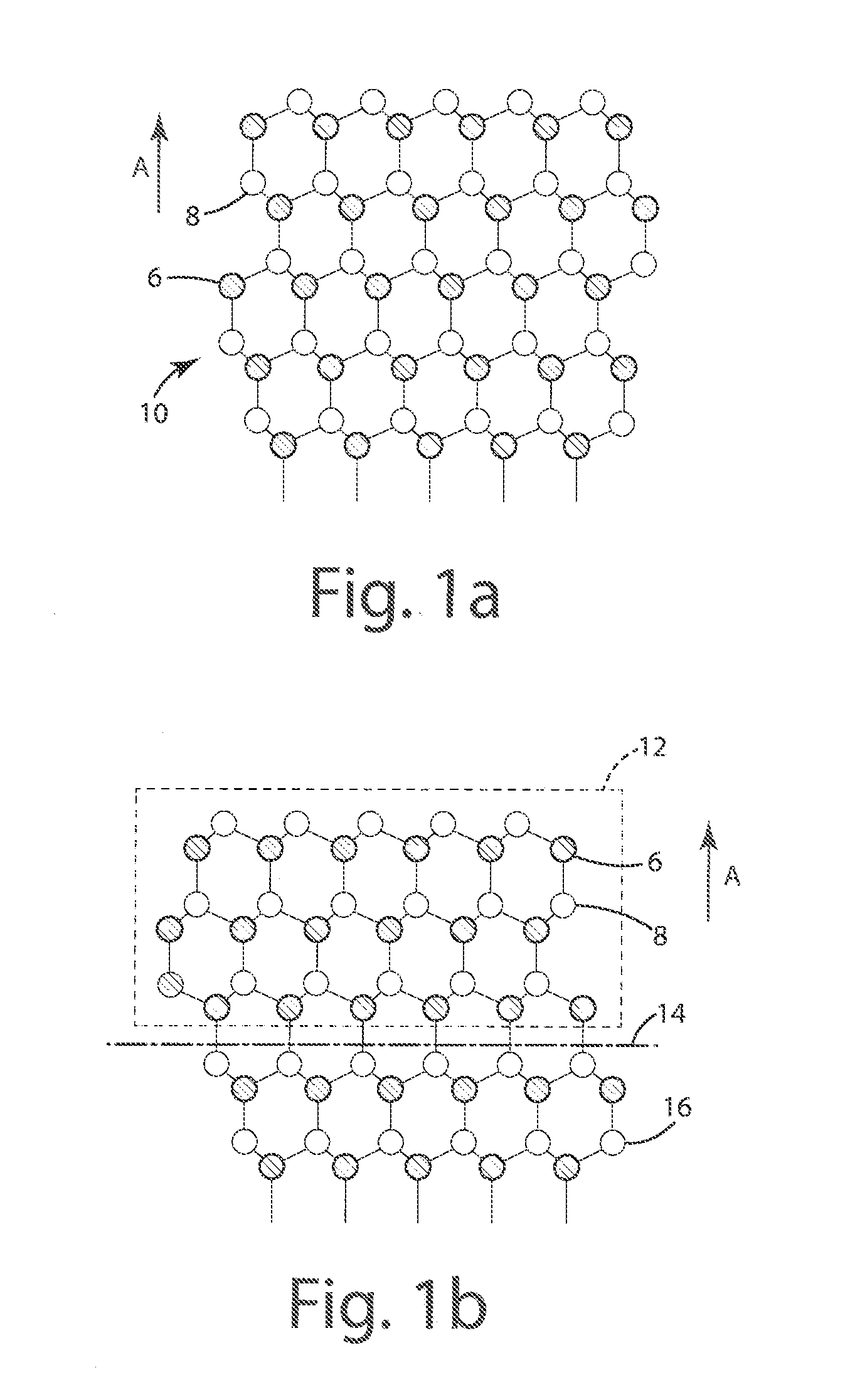

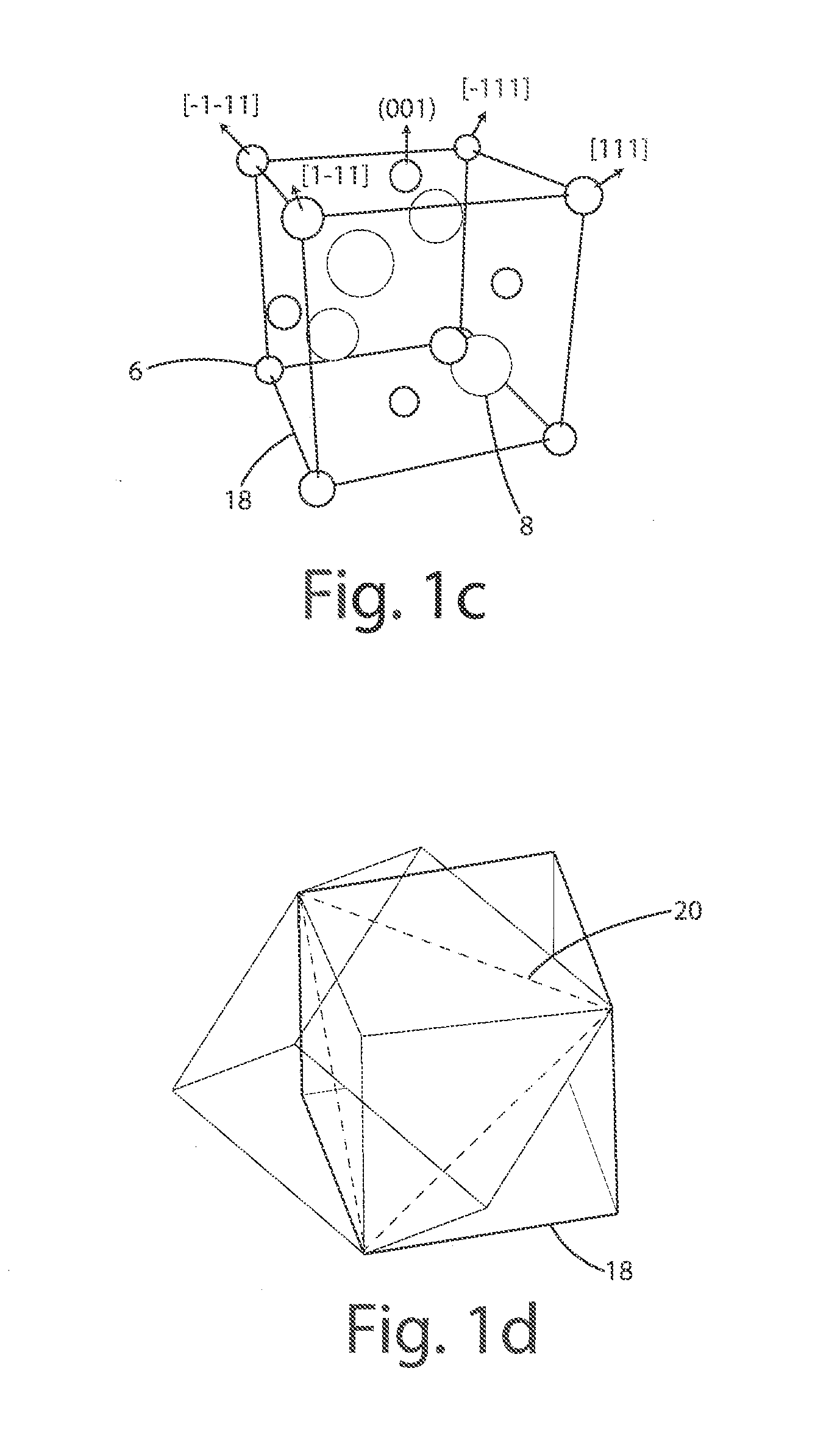

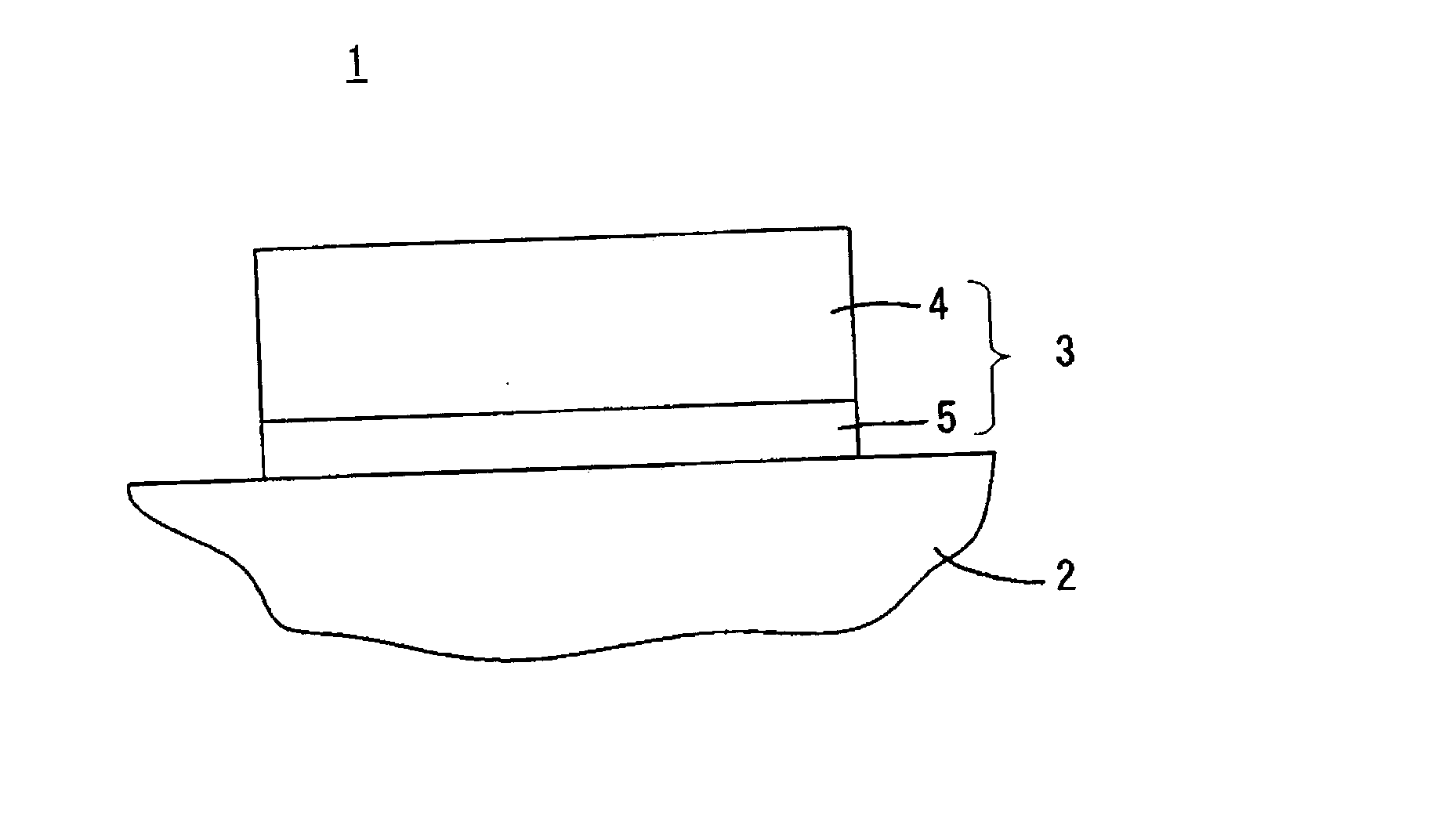

X-ray Diffraction (XRD) Characterization Methods for Sigma=3 Twin Defects in Cubic Semiconductor (100) Wafers

ActiveUS20150078526A1Reduce/eliminate defectQuick modificationMaterial analysis using radiation diffractionX-rayGreek letter sigma

An X-ray defraction (XRD) characterization method for sigma=3 twin defects in cubic semiconductor (100) wafers includes a concentration measurement method and a wafer mapping method for any cubic tetrahedral semiconductor wafers including GaAs (100) wafers and Si (100) wafers. The methods use the cubic semiconductor's (004) pole figure in order to detect sigma=3 / {111} twin defects. The XRD methods are applicable to any (100) wafers of tetrahedral cubic semiconductors in the diamond structure (Si, Ge, C) and cubic zinc-blende structure (InP, InGaAs, CdTe, ZnSe, and so on) with various growth methods such as Liquid Encapsulated Czochralski (LEC) growth, Molecular Beam Epitaxy (MBE), Organometallic Vapor Phase Epitaxy (OMVPE), Czochralski growth and Metal Organic Chemical Vapor Deposition (MOCVD) growth.

Owner:NASA

Surface acoustic wave device and manufacturing method therefor

InactiveUS20030132684A1High mechanical strengthAvoid breakingImpedence networksPiezoelectric/electrostriction/magnetostriction machinesX-rayOptoelectronics

A surface acoustic wave device has superior electrical power resistance that is obtained by improving stress migration resistance of electrodes. In order to form at least one electrode, for example, on a theta rotation Y-cut (theta=36° to 42°) LiTaO3 piezoelectric substrate, an underlying electrode layer including Ti or Cr as a primary component is formed, and an Al electrode layer including Al as a primary component is then formed on this underlying electrode layer. The Al electrode layer is an oriented film grown by epitaxial growth and is also a polycrystalline thin film having a twin structure in which a diffraction pattern observed in an X-ray diffraction pole figure has a plurality of symmetry centers.

Owner:MURATA MFG CO LTD

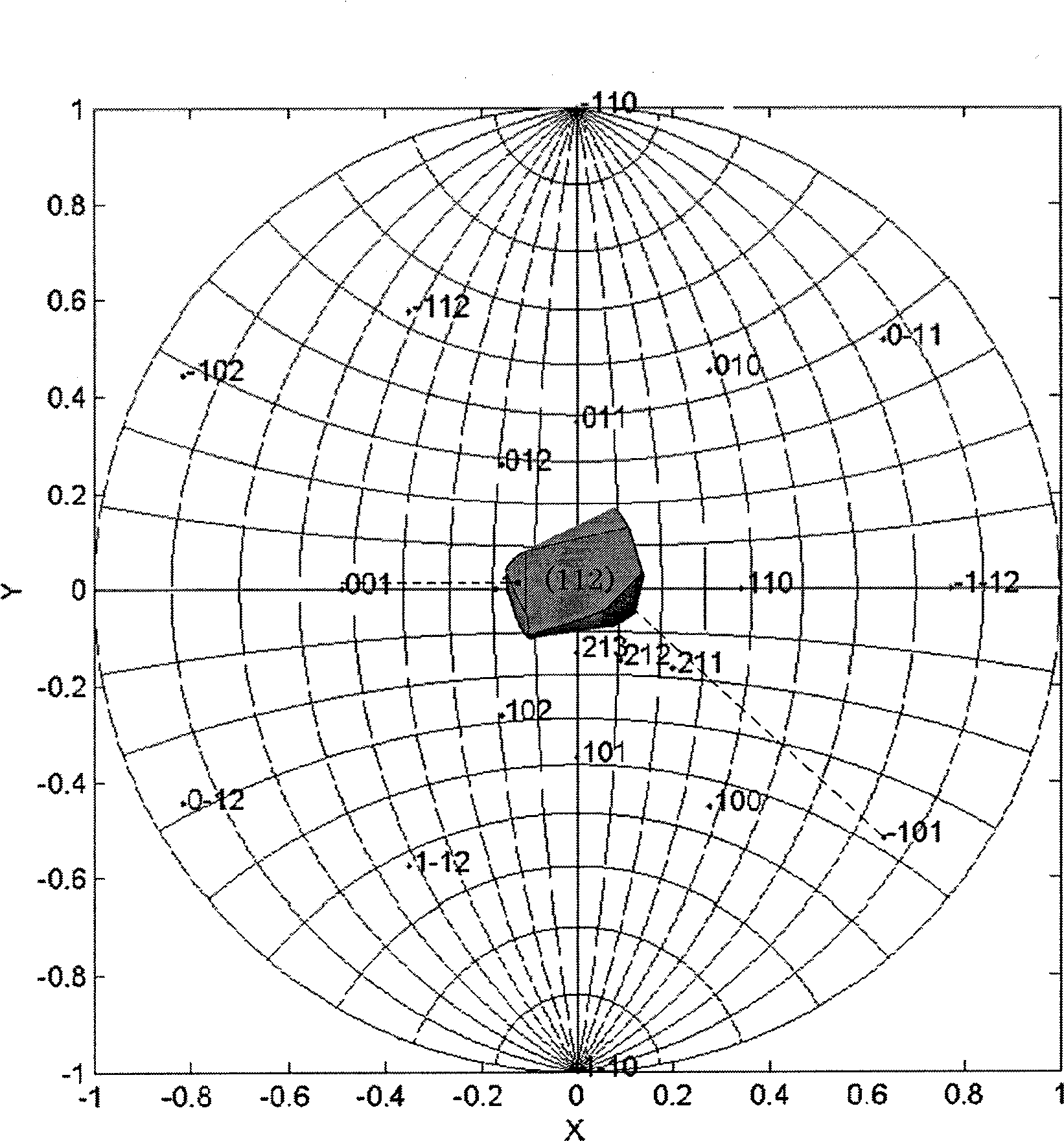

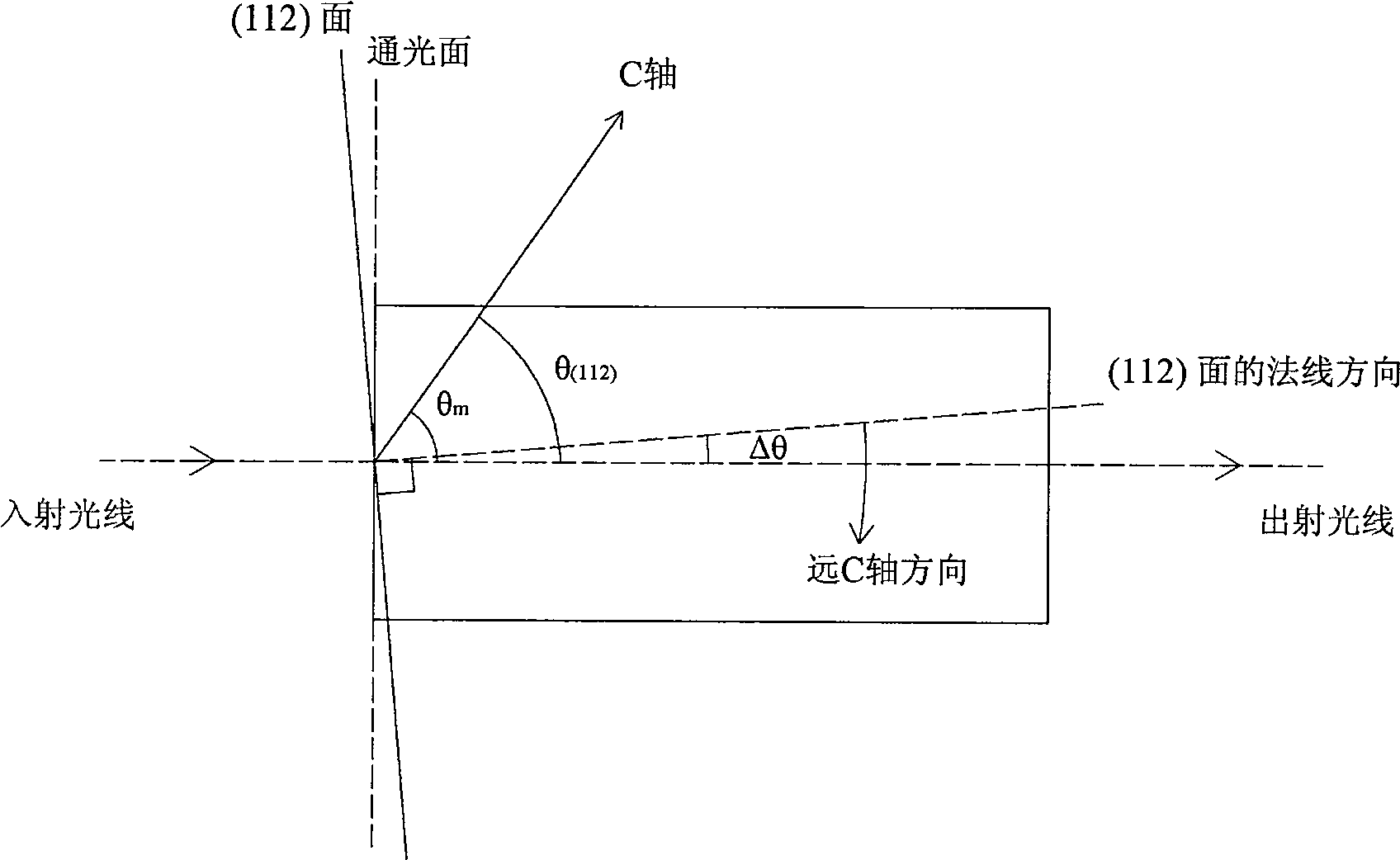

Oriented cutting method for preparing infrared non-linear optics element from yellow copper uniaxial negative crystal

InactiveCN101486231AEasy to operateQuick orientationFine working devicesContinuous scanningDiffractometer

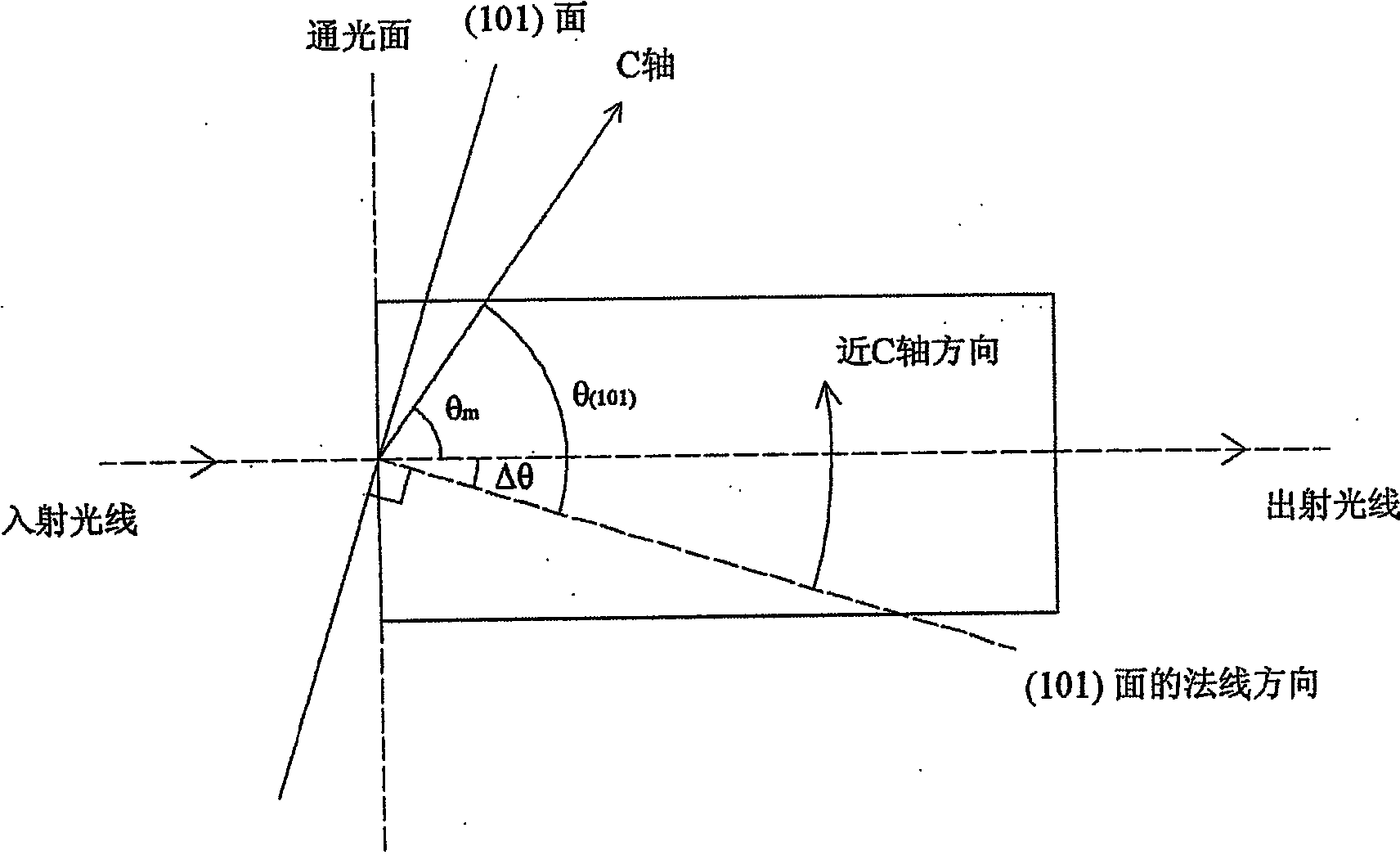

The invention relates to a directional cutting method for preparing infrared nonlinear optical elements from a chalcopyrite uniaxial negative crystal, which comprises the following steps: (1) according to cleavage surfaces {112} and {101} of the chalcopyrite uniaxial negative crystal, utilizing a crystal standard pole figure with Wuwov's intersection ruler and an X-ray diffractometer to determine the direction of a C axis of the crystal through theta-2theta continuous scanning; (2) putting the crystal of which the direction of the C axis is determined on a cutting machine, rotating a sample stage for delta theta far away from the direction of the C axis according to a phase matching angle theta m required by an optical element, and cutting the crystal to obtain an original sample of the optical element, wherein the delta theta= theta m - theta (112); (3) putting the original sample of the optical element on the sample stage of the X-ray diffractometer, determining an oscillation photograph of a cutting surface of the original sample of the optical element, and obtaining a diffraction peak place value theta' and delta theta', wherein the delta theta'=absolute (theta'- theta'(112)); and (4) finishing the optical element, and correcting the cutting surface of the original sample of the optical element until the delta theta'=the delta theta.

Owner:SICHUAN UNIV

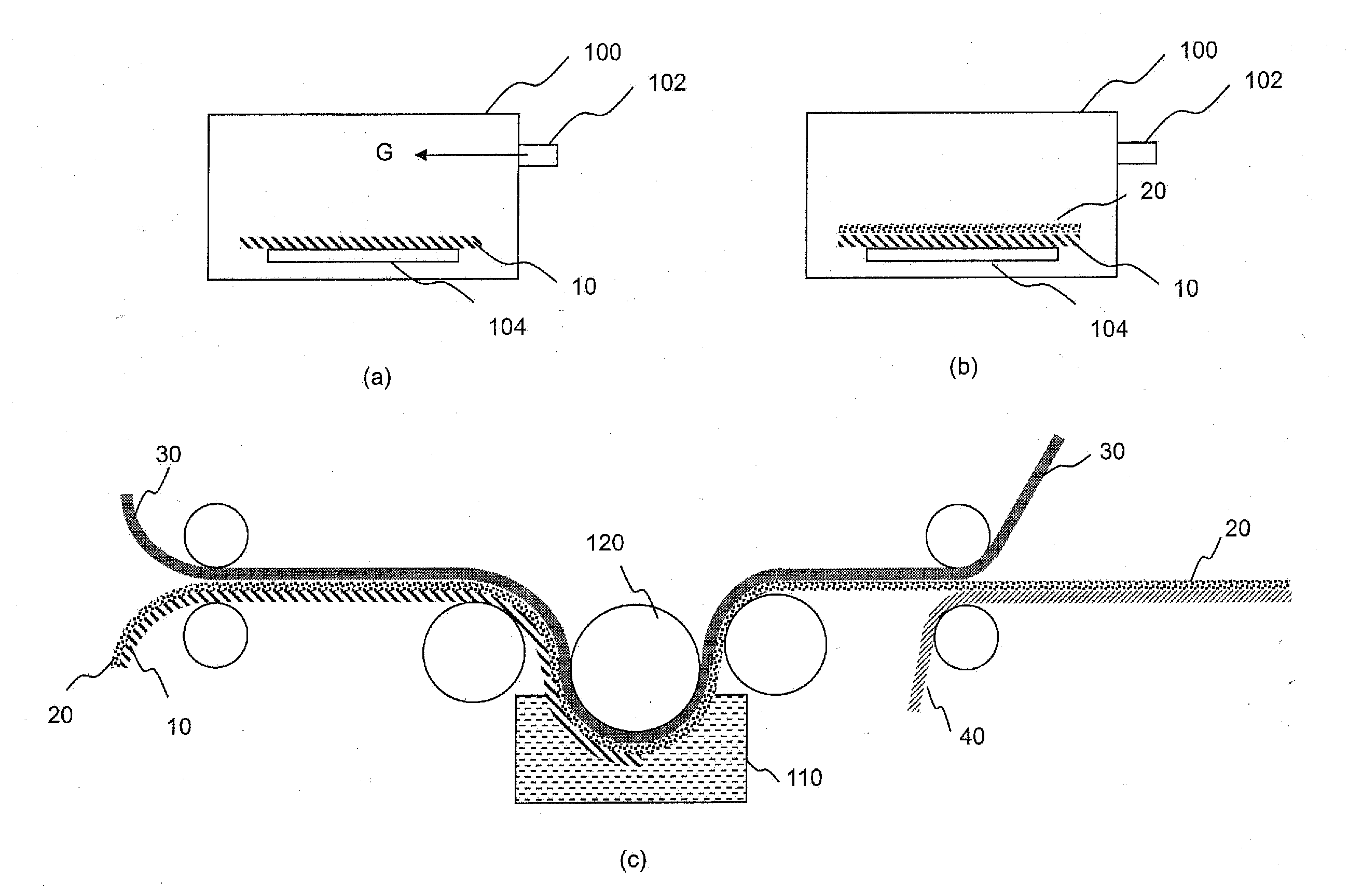

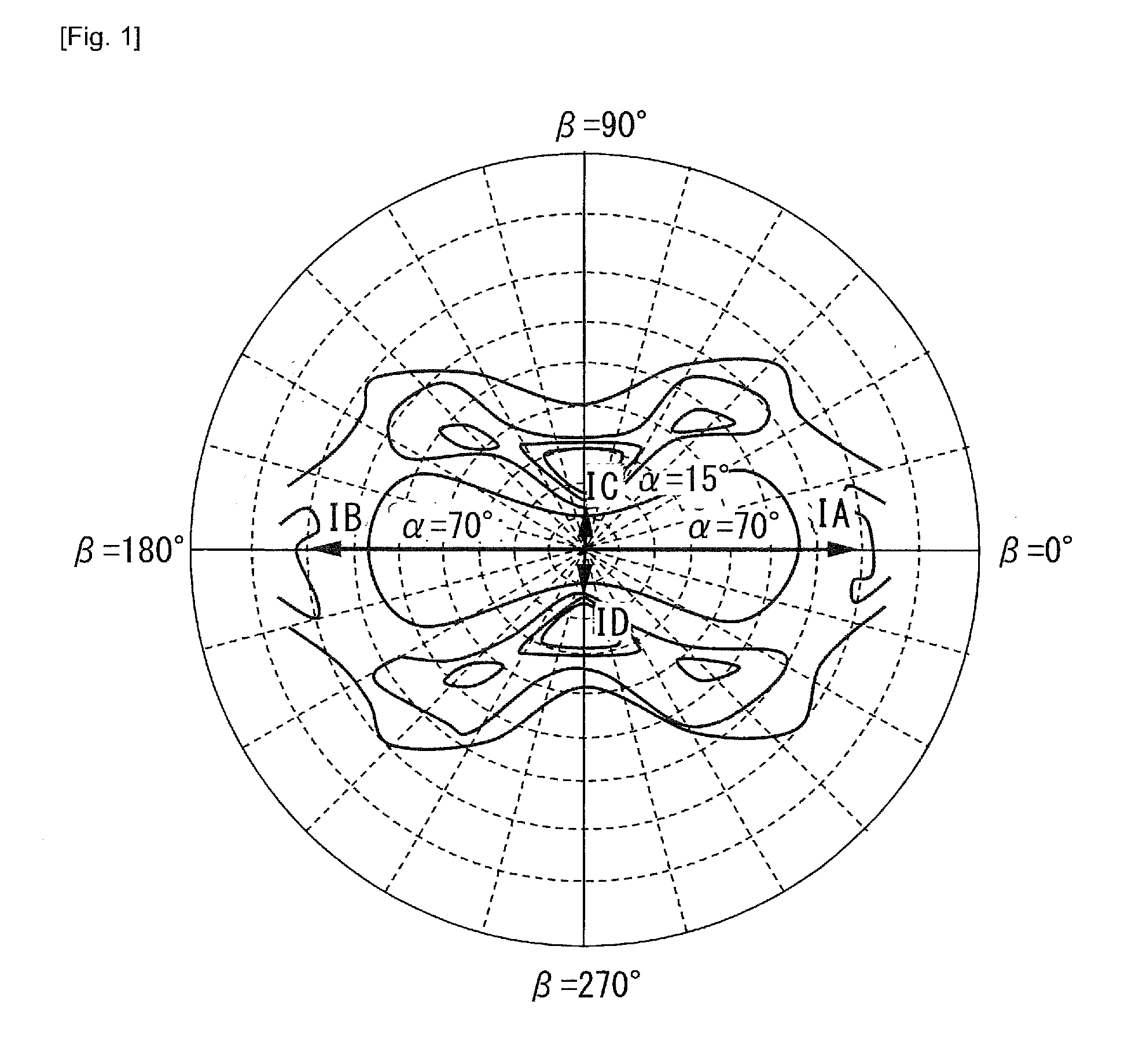

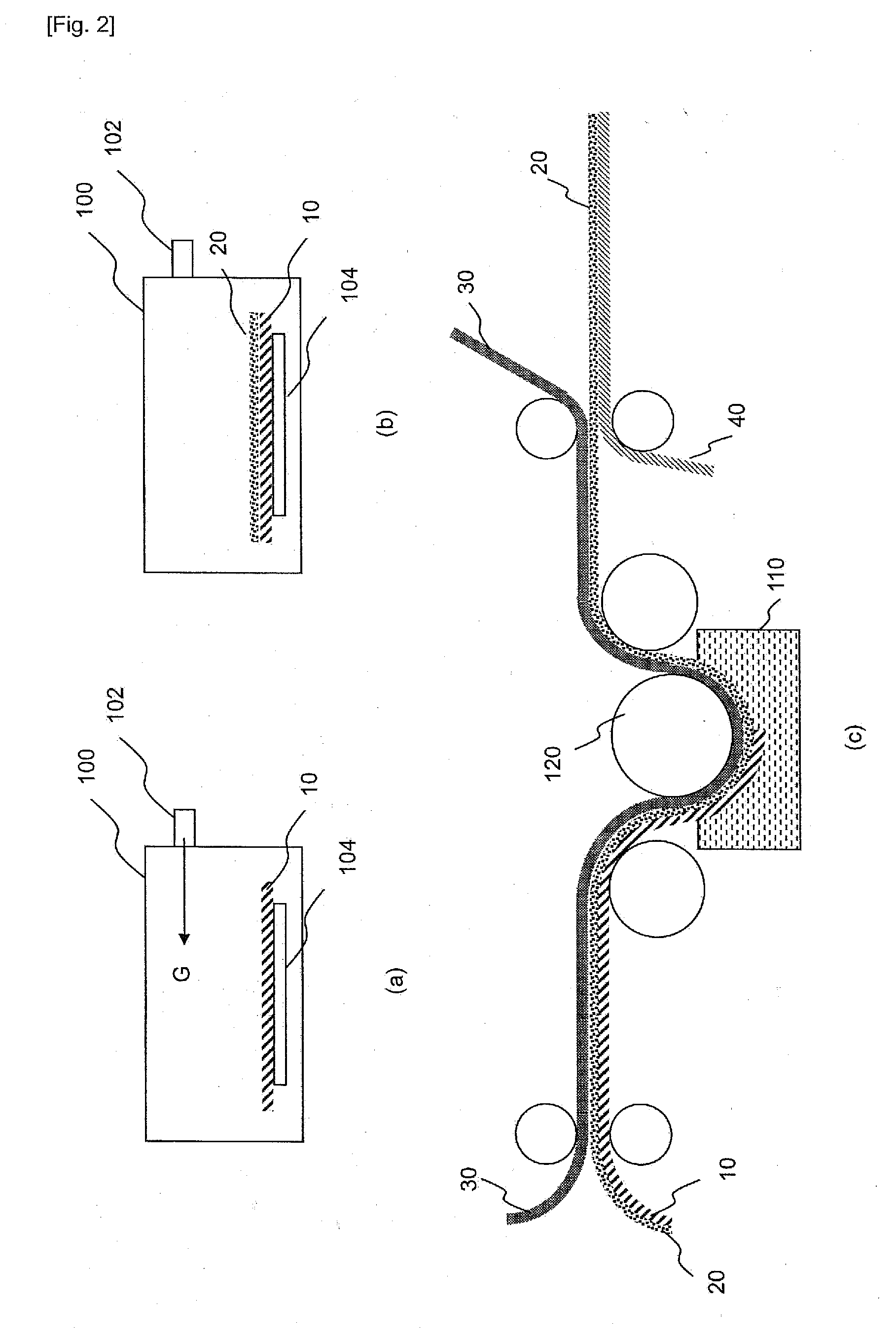

Rolled copper foil for producing graphene and method of producing graphene using the same

InactiveUS20150232342A1Increase the areaLow costMaterial nanotechnologyDecorative surface effectsMetallurgyCopper foil

A rolled copper foil for producing graphene, wherein a ratio (IC / IA) of a maximum value of a detected intensity (IC) at α=15 degrees and β=90 degrees±2 degrees and a maximum value of a detected intensity (IA) at α=70 degrees and β=0 degree±2 degrees is less than 1, and a ratio (ID / IB) of a maximum value of a detected intensity (ID) at α=15 degrees and β=270 degrees±2 degrees and a maximum value of a detected intensity (IB) at α=70 degrees and β=180 degrees±2 degrees is less than 1, shown in {111} pole figure.

Owner:JX NIPPON MINING & METALS CO LTD

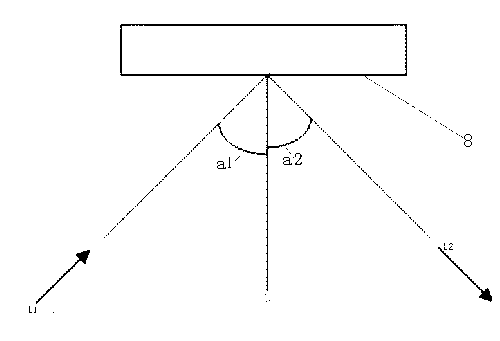

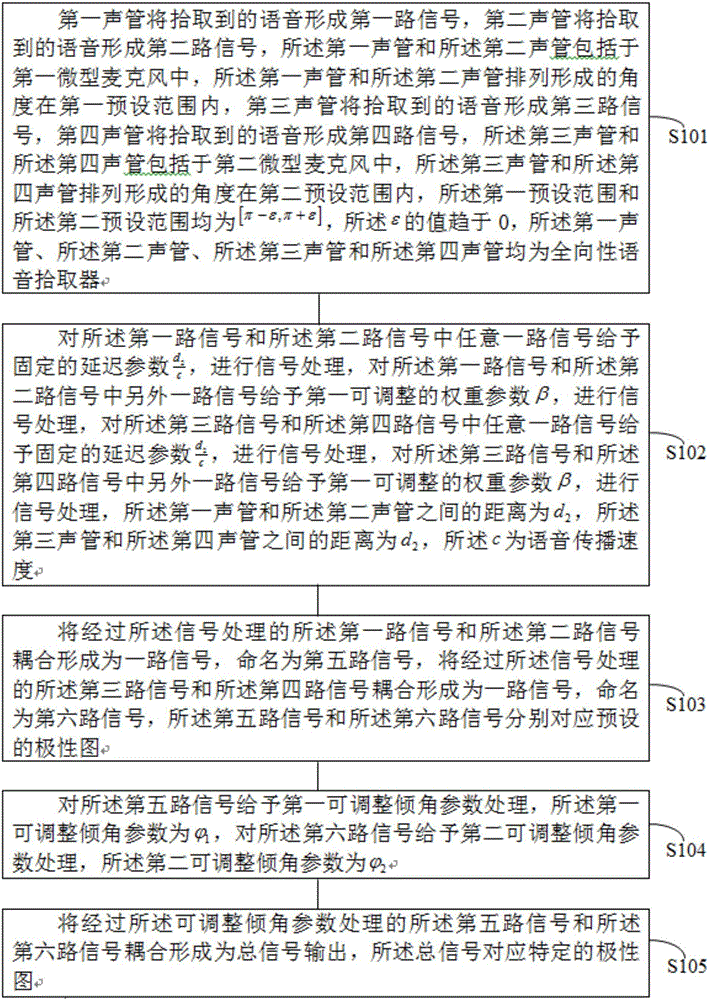

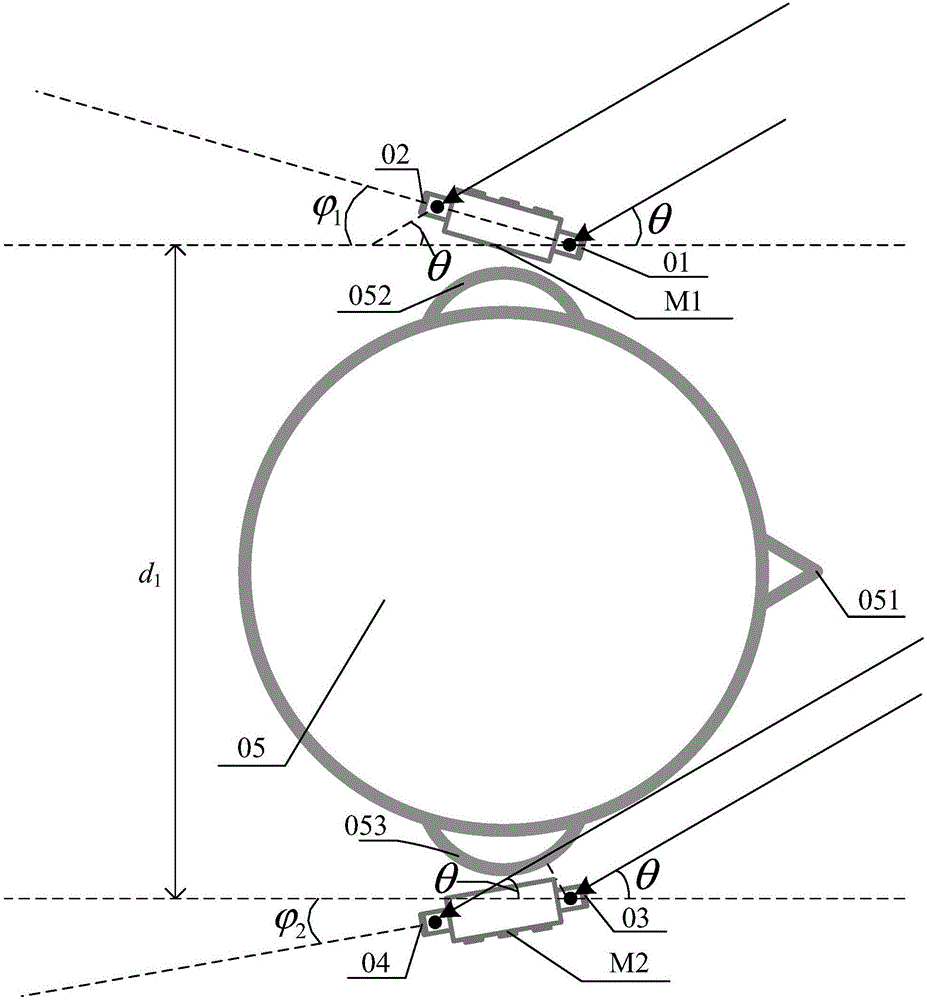

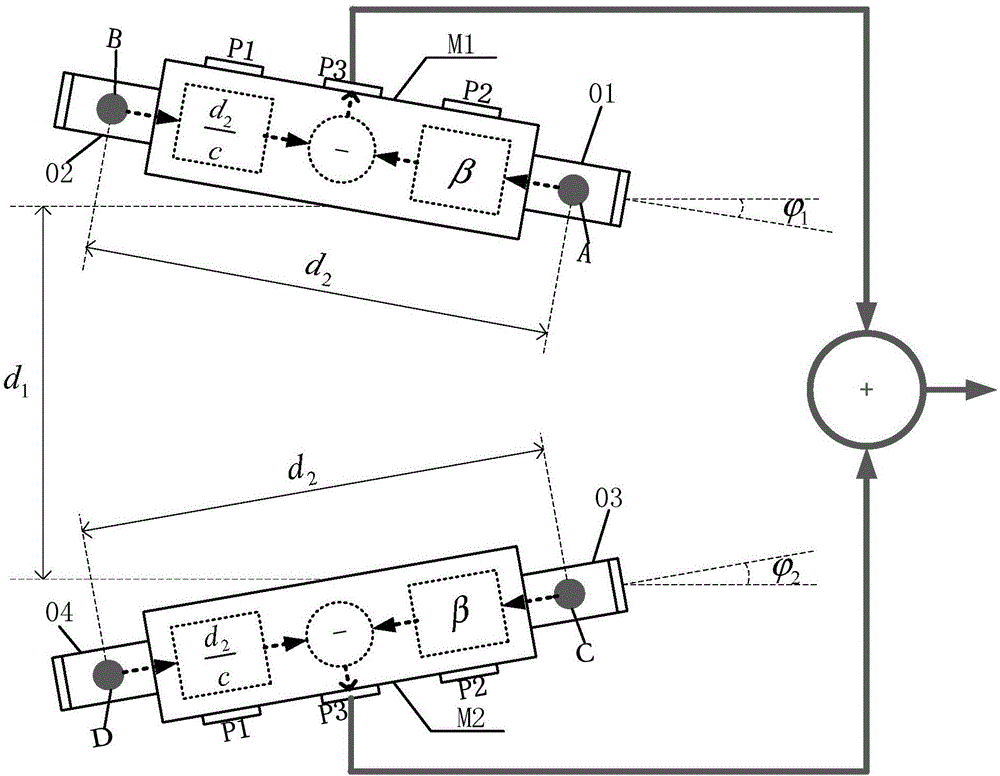

Beam forming method and system of microphone voice signals of hearing aid device, and hearing aid device

ActiveCN106714063AImprove spatial resolutionIncrease the number ofMicrophonesLoudspeakersSpatial OrientationsImage resolution

The invention belongs to the technical field of signal processing, and provides a beam forming method and system of microphone voice signals of a hearing aid device, and the hearing aid device. The invention aims at solving the following problems: spatial orientation information picked up by a double-microphone voice signal beam forming method used on the existing hearing aid device is limited, the spatial resolution is relatively low, and the number of formed pole figures is small, such that when the directional noise is serious, the beams cannot be controlled conveniently and flexibly to form proper pole figures. According to the beam forming method and system provided by the invention, double miniature microphones are used, each miniature microphone comprises two sound pipes with opposite directions in the space to pick up voice signals, thereby improving the spatial resolution of voice pickup and the spatial orientation information of voice. More importantly, weight parameters and adjustable inclination angle parameters of signals are processed, so that the number of the pole figures corresponding to the final output voice signals is greatly increased, convenient and flexible control is realized, proper pole figures are formed, and the speech recognition rate of a user of the hearing aid device is improved.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

Oriented cutting method for preparing infrared non-linear optics element from yellow copper positive uni-axial crystal

InactiveCN101486232AEasy to operateQuick orientationFine working devicesContinuous scanningDiffractometer

The invention relates to a directional cutting method for preparing infrared nonlinear optical elements from a chalcopyrite uniaxial positive crystal, which comprises the following steps: (1) according to cleavage surfaces {112} and {101} of the chalcopyrite uniaxial positive crystal, utilizing a crystal standard pole figure with Wuwov's intersection ruler and an X-ray diffractometer to determine the direction of a C axis of the crystal through theta-2theta continuous scanning; (2) putting the crystal of which the direction of the C axis is determined on a cutting machine, rotating a sample stage for delta theta toward the direction of the C axis according to a phase matching angle theta m required by an optical element, and cutting the crystal to obtain an original sample of the optical element, wherein the delta theta= theta (101) - the theta m; (3) putting the original sample of the optical element on the sample stage of the X-ray diffractometer, determining an oscillation photograph of a cutting surface of the original sample of the optical element, and obtaining a diffraction peak place value theta' and delta theta', wherein the delta theta'=absolute (theta'- theta'(101)); and (4) finishing the optical element, and correcting the cutting surface of the original sample of the optical element until the delta theta'=the delta theta.

Owner:SICHUAN UNIV

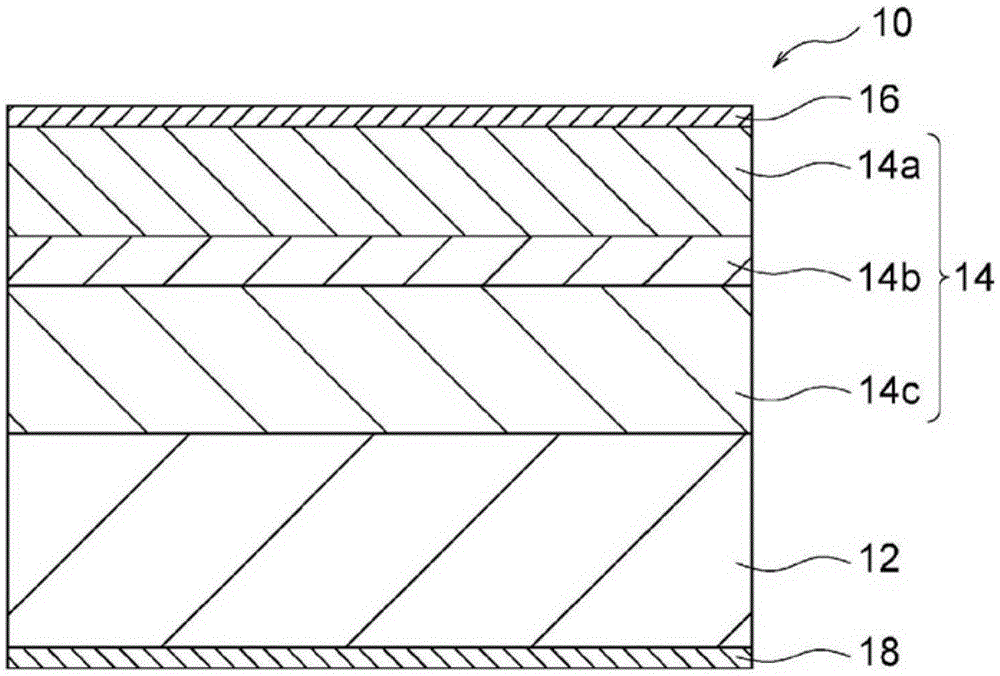

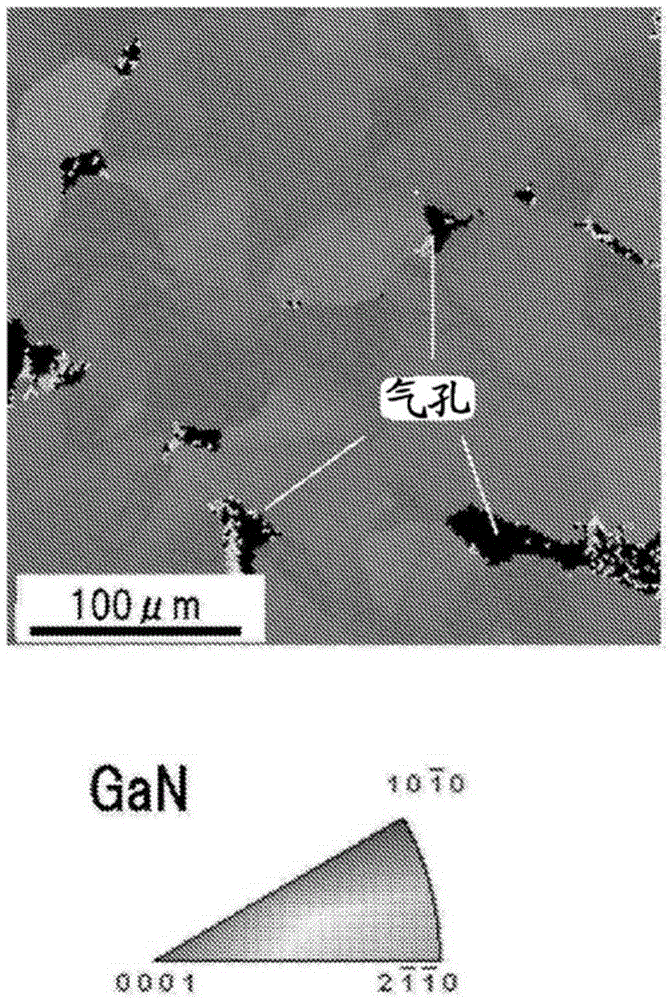

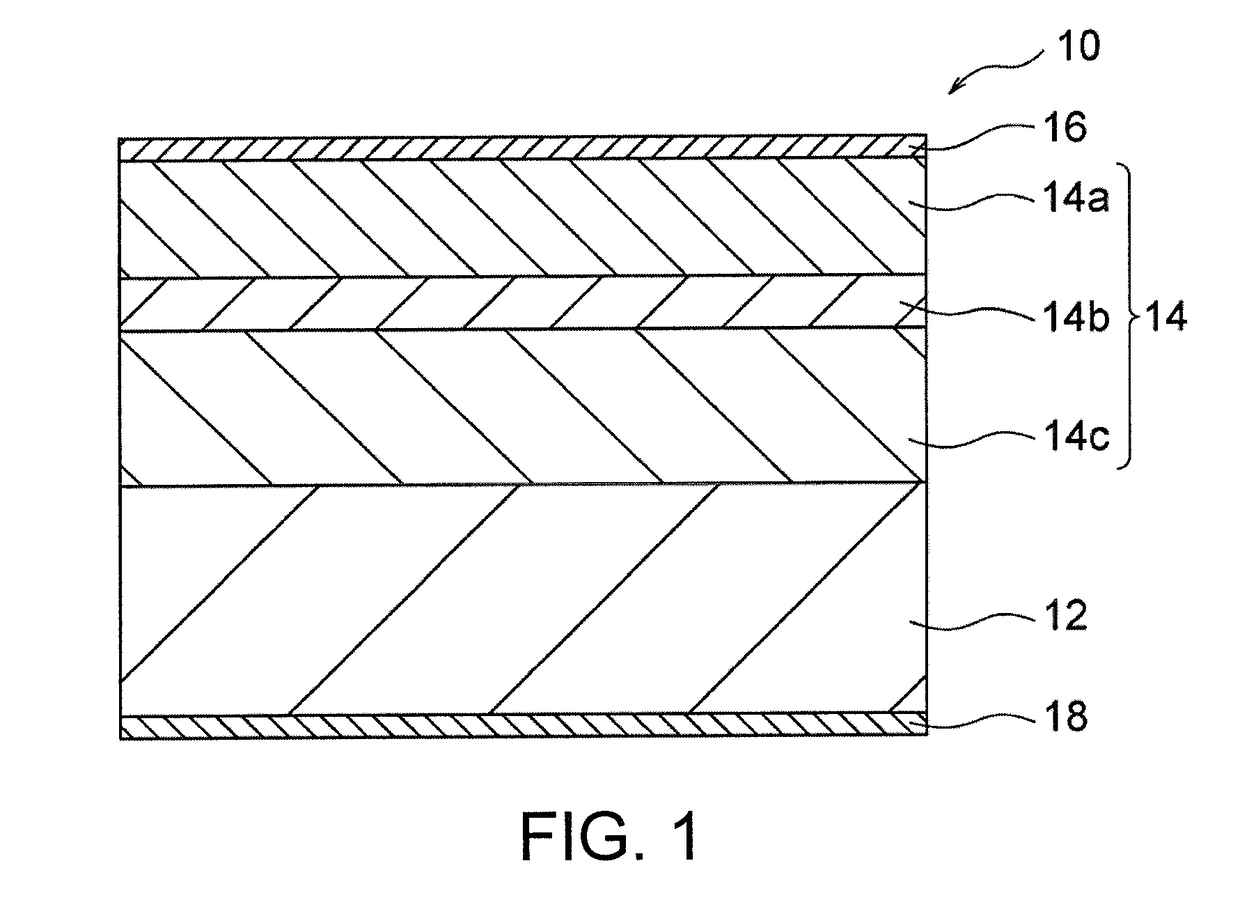

Polycrystalline gallium-nitride self-supporting substrate and light-emitting element using same

ActiveCN105556685AReduce areaHigh pricePolycrystalline material growthLiquid-phase epitaxial-layer growthCrystal orientationVolumetric Mass Density

This invention provides a polycrystalline gallium-nitride self-supporting substrate comprising a plurality of gallium-nitride-based single-crystal grains aligned to a specific crystal orientation in a direction that is substantially parallel to the normal direction. The crystal orientations of said gallium-nitride-based single-crystal grains, as measured by subjecting the surface of the self-supporting substrate to electron backscatter diffraction (EBSD) and performing inverse-pole-figure mapping, form a variety of angles with the aforementioned specific crystal orientation, and the mean value of the distribution of said angles is between 1degrees and 10 degrees, inclusive. This light-emitting element comprises the abovementioned self-supporting substrate and a light-emitting functional layer that is formed on top of the substrate and contains one or more layers each comprising a plurality of semiconductor single-crystal grains each exhibiting a single-crystal structure that is substantially parallel to the normal direction. This invention makes it possible to provide a polycrystalline gallium-nitride self-supporting substrate with a reduced defect density in the surface thereof. A light-emitting element that uses said polycrystalline gallium-nitride self-supporting substrate and exhibits a high luminous efficacy can also be obtained.

Owner:NGK INSULATORS LTD

Polycrystalline gallium nitride self-supported substrate and light emitting element using same

ActiveUS20180351038A1Maintain good propertiesHigh luminous efficiencyPolycrystalline material growthLiquid-phase epitaxial-layer growthCrystal orientationSingle crystal

There is provided a self-supporting polycrystalline gallium nitride substrate having excellent characteristics such as high luminous efficiency and high conversion efficiency when used for devices, such as light emitting devices and solar cells. The self-supporting polycrystalline gallium nitride substrate is composed of gallium nitride-based single crystal grains having a specific crystal orientation in a direction approximately normal to the substrate, and has a top surface and a bottom surface. The crystal orientations of individual gallium nitride-based single crystal grains as determined from inverse pole figure mapping by electron backscatter diffraction (EBSD) analysis on the top surface are distributed at various tilt angles from the specific crystal orientation, in which the average tilt angle thereof is 0.1° or more and less than 1° and the cross-sectional average diameter DT of the gallium nitride-based single crystal grains at the outermost surface exposed on the top surface is 10 μm or more.

Owner:NGK INSULATORS LTD

Method for quick testing data of pole figure for deep drawn sheet plate made from aluminium alloy

InactiveCN1540322AFast measurementHigh precisionMaterial analysis using radiation diffractionClassical mechanicsX-ray

Aluminous index of crystal face in face centered cubic structure includes nine different pole figures: {111}, {200}, {220}, {311}, {222}, {400}, {331}, {420} and {422}. 2-4 crystal faces selected from the said nine different pole figures are as pole figures to be tested. In 2D detection system of X ray measuring each data of pole figure is carrying out at same time under Chi angle Pi / 6-Pi / 3 and Phi angle Pi / 2. Based on their tested data, it is guaranteed that calculated precision of orientation distribution function and inverse computed integrated pole figure are accordant between invented method and traditional algorithm. But, measuring time in the invented method is only 1%-2% of time needed by traditional algorithm. Thus, the invented method can realize measuring in real time under precision.

Owner:UNIV OF SCI & TECH BEIJING

Multi-sample combination method for detecting crystal orientation distribution

The invention provides a multi-sample combination method for detecting crystal orientation distribution. The method comprises the following steps: (1) selecting a plurality of samples at different parts of a steel plate; (2) processing the samples into a plurality of rectangular steel sheets in the same specification, stacking the rectangular steel sheets in a pole figure measurement sample rack and fastening, polishing and corroding the rectangular steel sheets to form R.D section samples; (3) measuring three imperfect pole figures (110), (200) and (211) of the R.D section samples; (4) computing an ODF (Orientation Distribution Function) figure by utilizing the conventional ODF software and acquiring Phi, Phi1, and Phi2 of a Bung coordinate system or Theta, Phi and Psi of a Roe coordinate system; and (5) utilizing the formulas (a) and (b) of the Bung coordinate system or the formulas (c) and (d) of the Roe coordinate system to compute the texture. The multi-sample combination method can reflect the crystal orientation condition of the samples in the whole thickness and has strong representativeness; for a laboratory with conventional ODF analysis software, specially planning or purchasing ODF software for computing the cross sections combined by dozens of samples is not needed, so that the use is convenient; and for a laboratory without the ODF analysis software, the only requirement is to plan or purchase the conventional ODF software, so that the cost is lower.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Method for measuring macroscopic texture of high-magnetic induction oriented electrical steel

InactiveCN104237274AGood effectTrue reflective strengthMaterial analysis using wave/particle radiationElectrical steelTransformer

The invention relates to a method for measuring macroscopic texture of high-magnetic induction oriented electrical steel, which is applicable to detection of the high-magnetic induction oriented electrical steel with the average sample grain size of above 10mm. The method comprises the following steps: acquiring a synthetic sample and a contrast sample; measuring an incomplete pole figure of the synthetic sample and determining an orientation distribution function; obtaining the macroscopic texture of the high-magnetic induction oriented electrical steel. Through reasonable distribution of the samples and mathematical transformation, the representativeness of a result and the working efficiency can be significantly improved, so that the method can be widely applicable to the fields of production and research of the high-magnetic induction oriented electrical steel for an electrical transformer.

Owner:STATE GRID CORP OF CHINA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com