Patents

Literature

92 results about "Grown film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fabrication of strained heterojunction structures

ActiveUS20060134893A1Improve featuresHigh carrier mobilitySolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionLayer interface

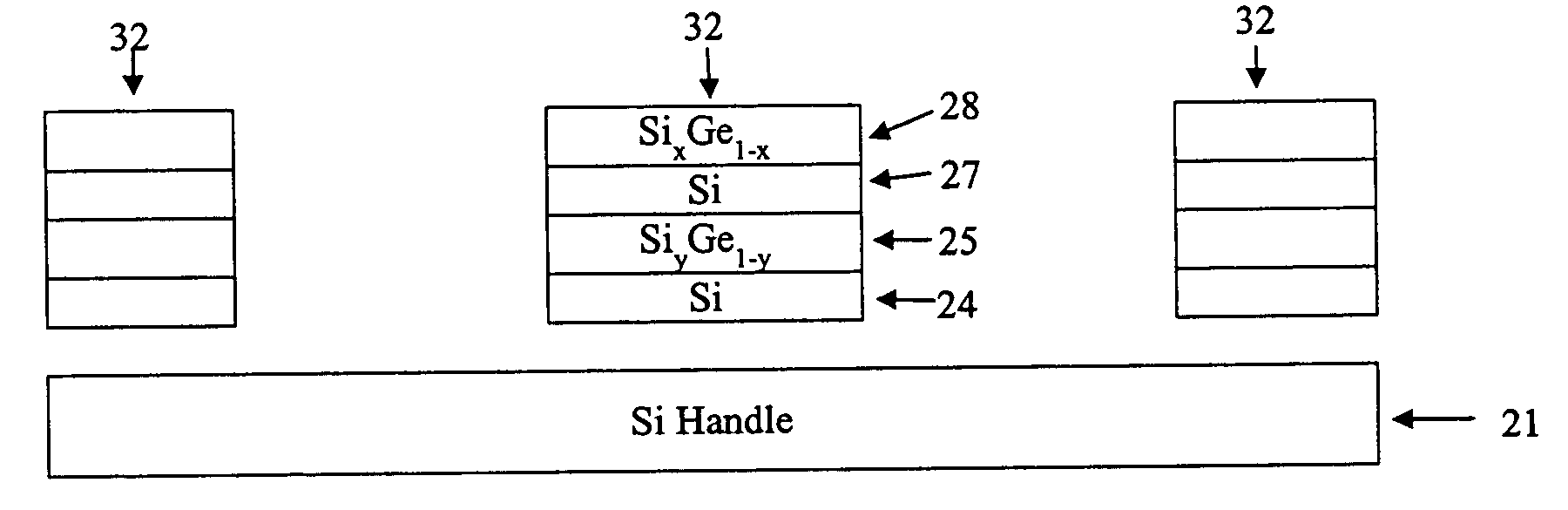

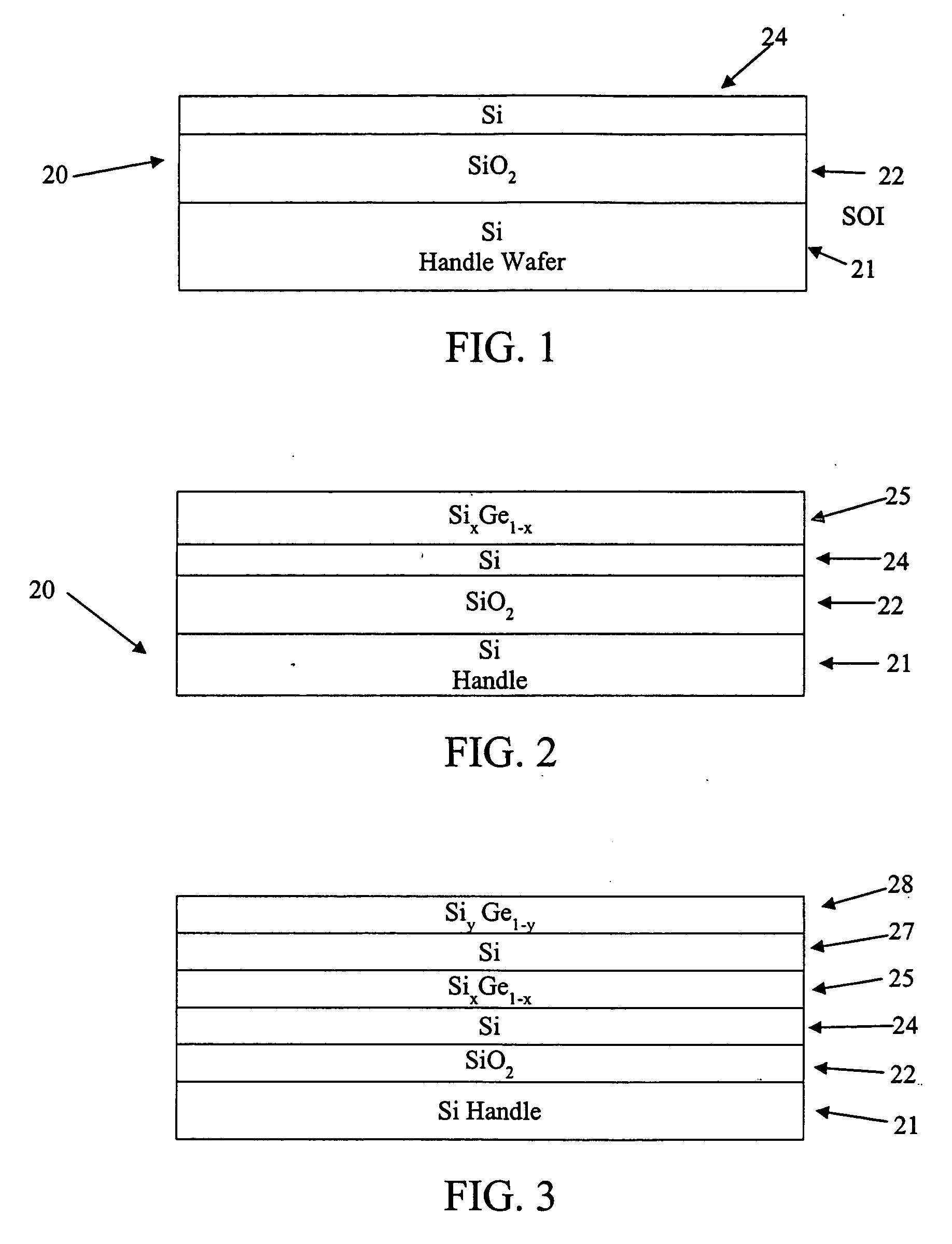

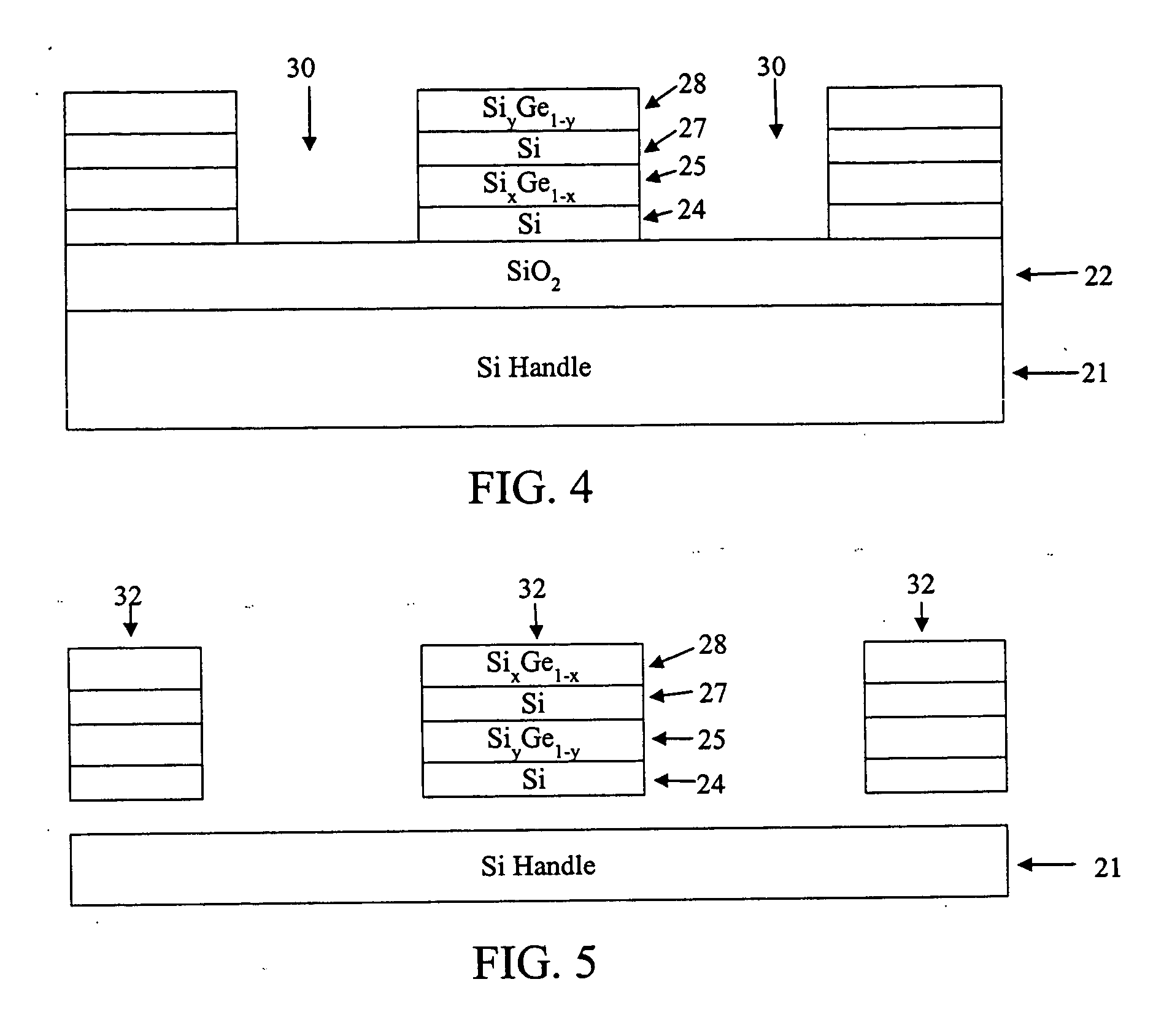

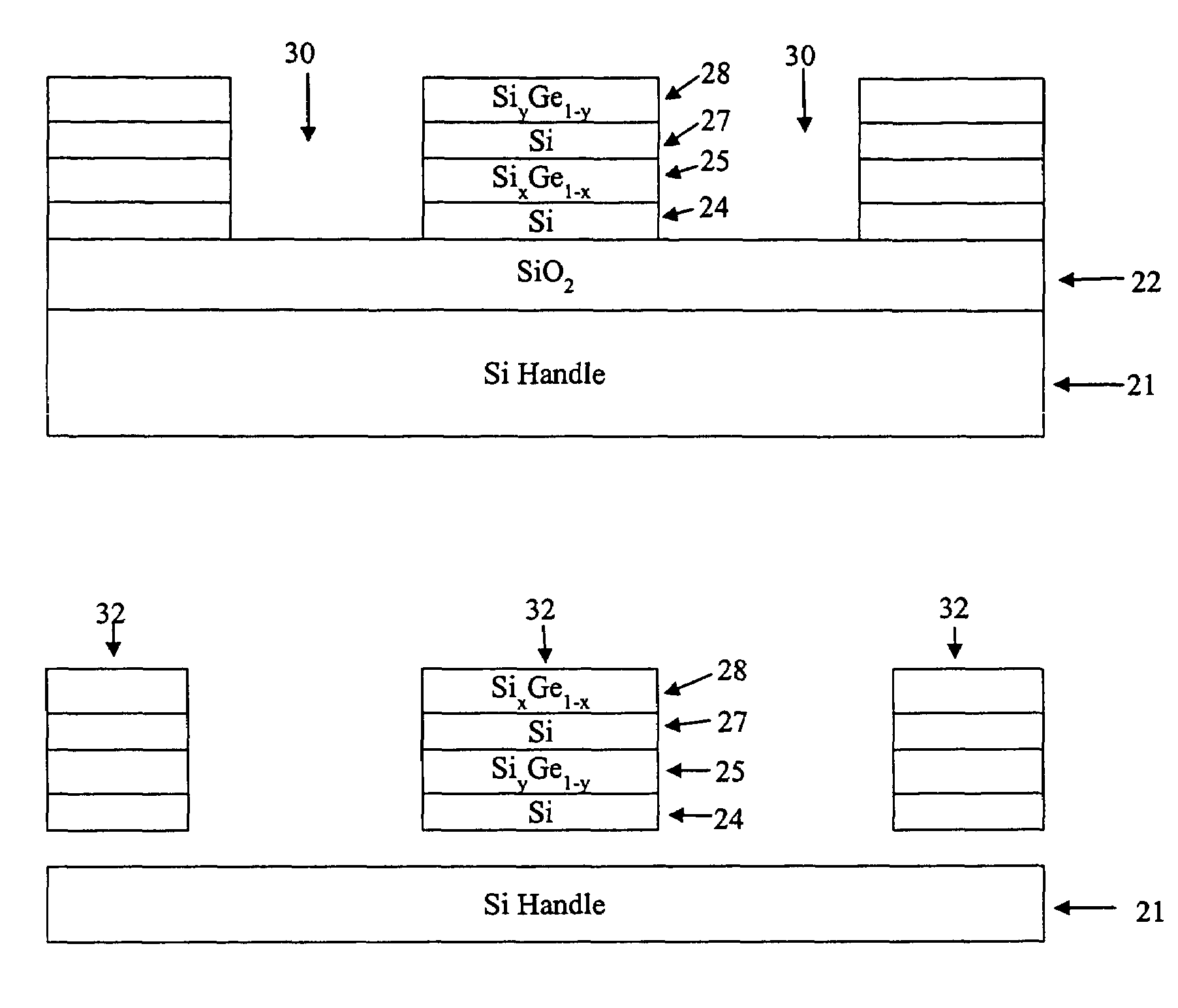

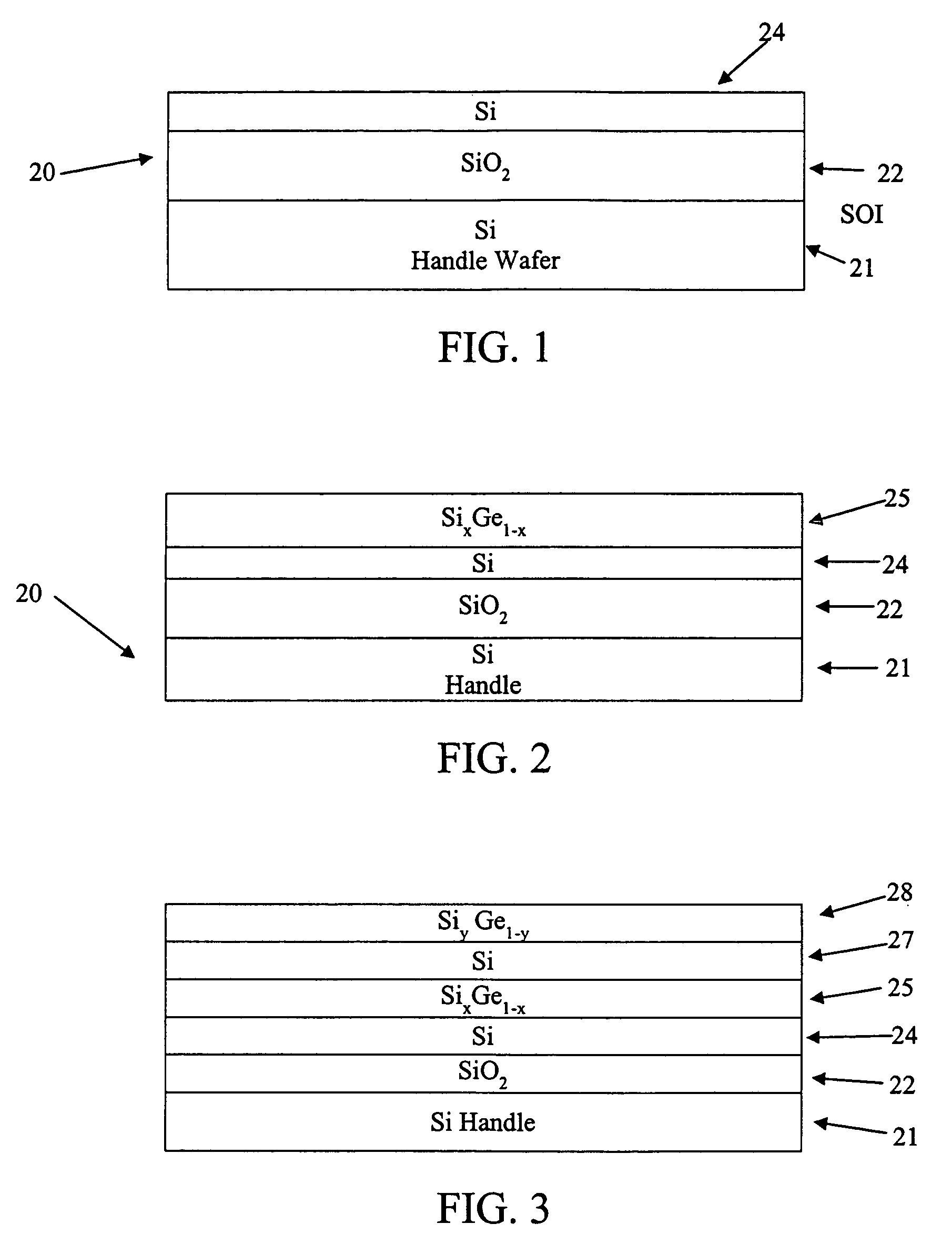

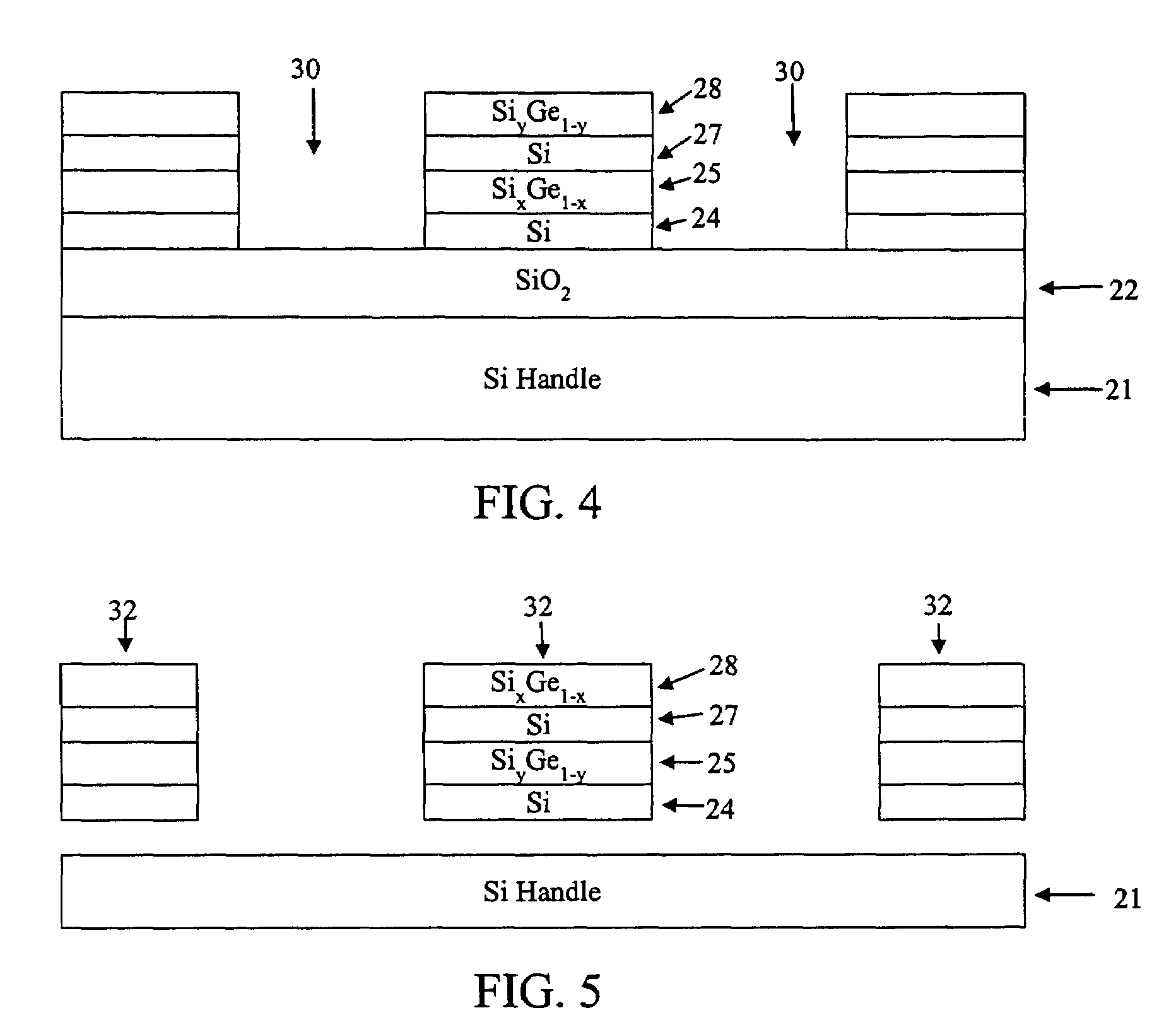

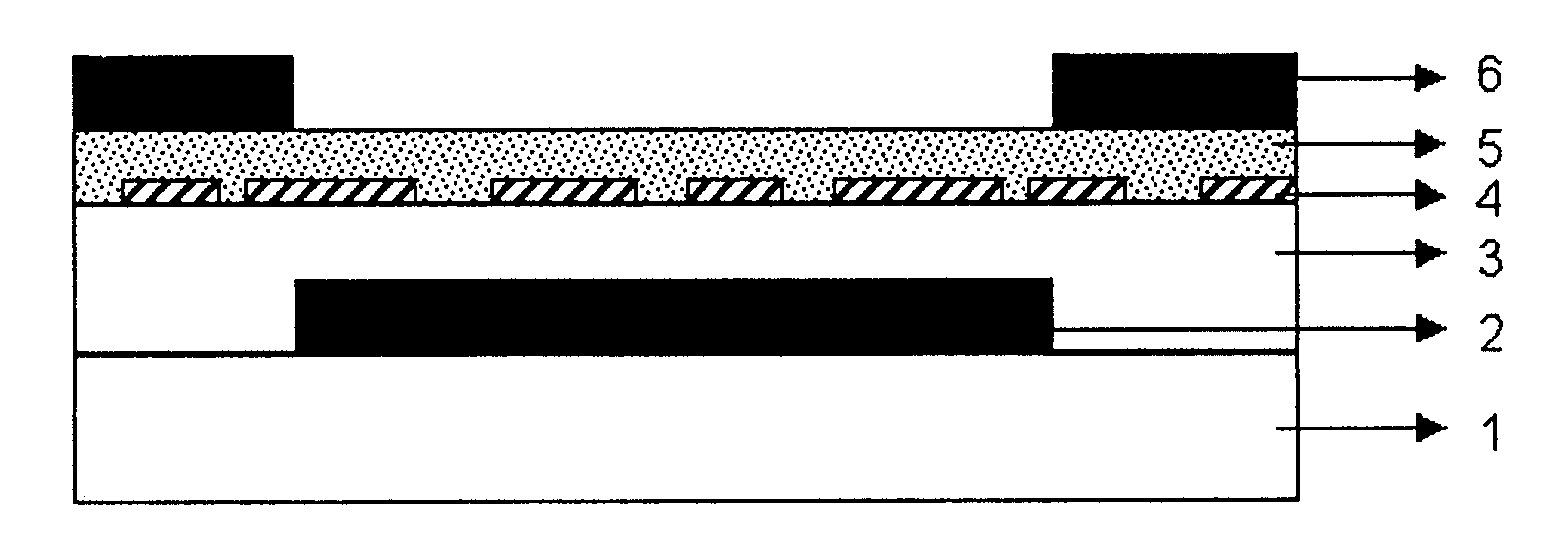

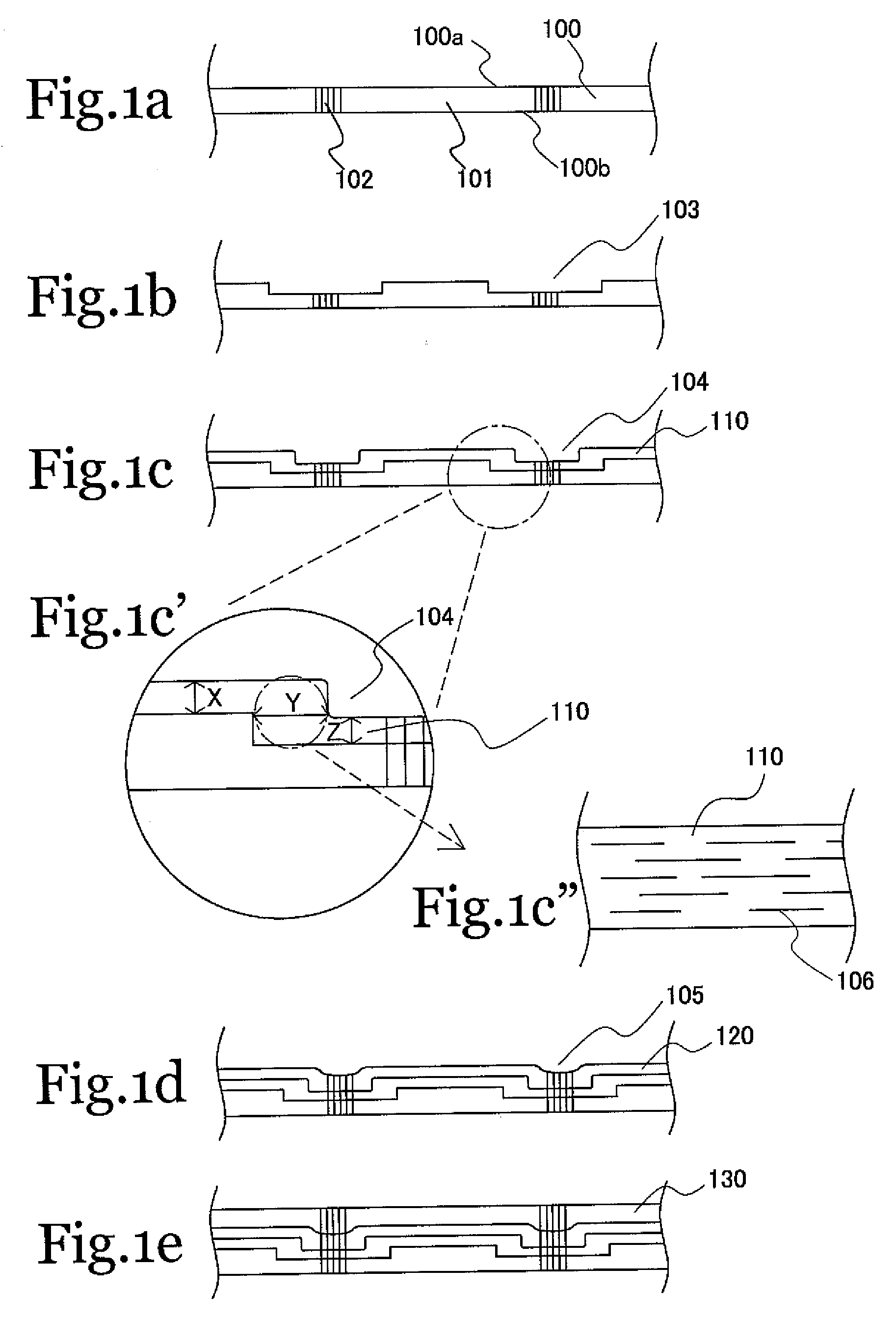

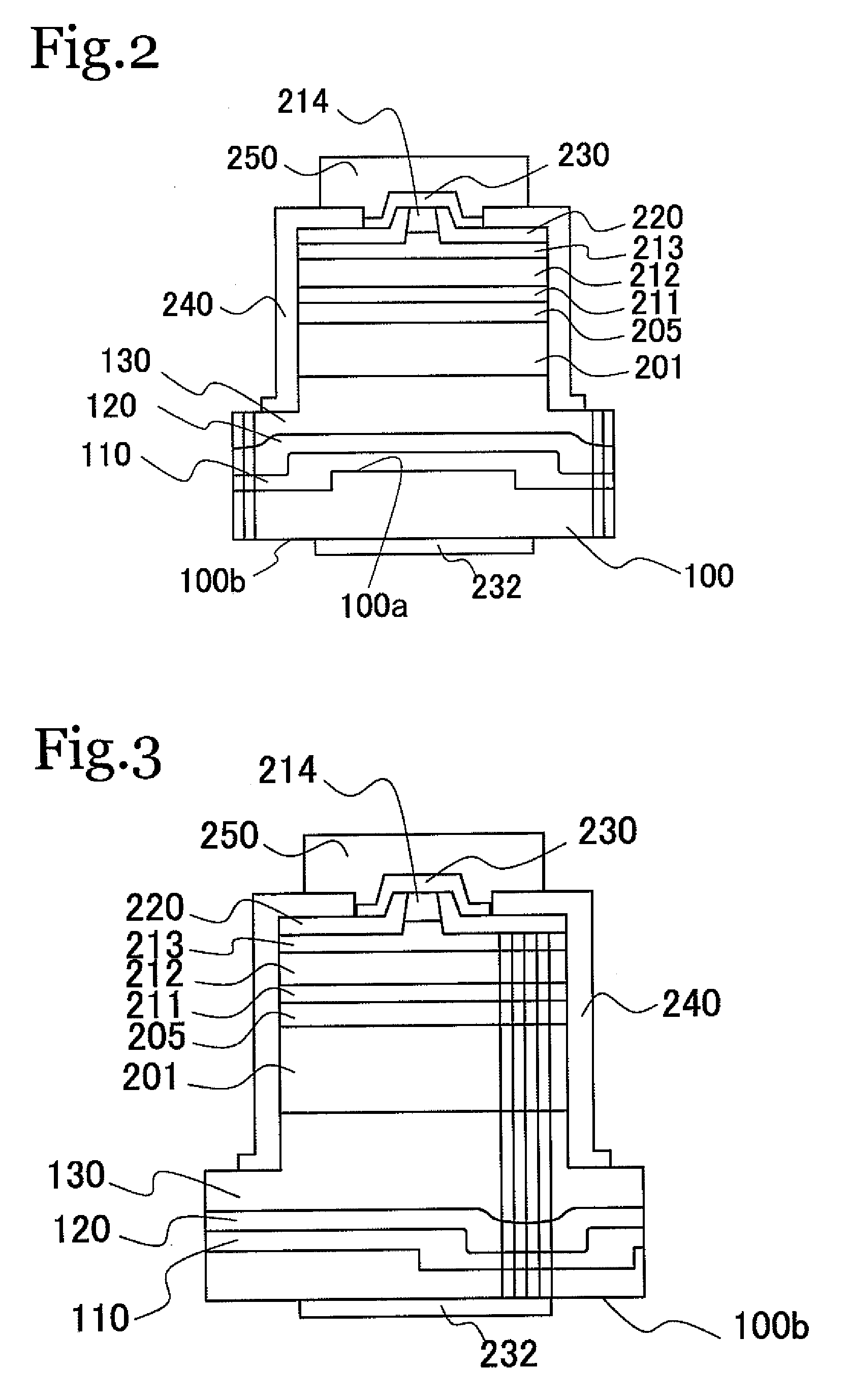

Growth of multilayer films is carried out in a manner which allows close control of the strain in the grown layers and complete release of the grown films to allow mounting of the released multilayer structures on selected substrates. A layer of material, such as silicon-germanium, is grown onto a template layer, such as silicon, of a substrate having a sacrificial layer on which the template layer is formed. The grown layer has a lattice mismatch with the template layer so that it is strained as deposited. A top layer of crystalline material, such as silicon, is grown on the alloy layer to form a multilayer structure with the grown layer and the template layer. The sacrificial layer is preferentially etched away to release the multilayer structure from the sacrificial layer, relaxing the grown layer and straining the crystalline layers interfaced with it.

Owner:WISCONSIN ALUMNI RES FOUND

Fabrication of strained heterojunction structures

ActiveUS7229901B2Improve featuresHigh carrier mobilitySolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionGrown film

Growth of multilayer films is carried out in a manner which allows close control of the strain in the grown layers and complete release of the grown films to allow mounting of the released multilayer structures on selected substrates. A layer of material, such as silicon-germanium, is grown onto a template layer, such as silicon, of a substrate having a sacrificial layer on which the template layer is formed. The grown layer has a lattice mismatch with the template layer so that it is strained as deposited. A top layer of crystalline material, such as silicon, is grown on the alloy layer to form a multilayer structure with the grown layer and the template layer. The sacrificial layer is preferentially etched away to release the multilayer structure from the sacrificial layer, relaxing the grown layer and straining the crystalline layers interfaced with it.

Owner:WISCONSIN ALUMNI RES FOUND

Multi-ion-beam sputter-deposition technology for doping with diamond-like carbon (DLC) coating

InactiveCN101787518AImprove performanceRealize complementary advantagesVacuum evaporation coatingSputtering coatingDlc coatingGrown film

The invention relates to a multi-ion-beam sputter-deposition technology for doping a diamond-like carbon (DLC) coating. The technology is characterized by comprising the following steps of: firstly, washing to removing a polluted layer on the surface of a workpiece by utilizing ultrasonic waves, and carrying out ion beam bombardment washing on the surface of the workpiece by utilizing an argon-ion beam generated by an ion source to obtain an atomic scale clean surface; then preparing a gradient transition layer by utilizing an auxiliary ion beam sputter-deposition method; and finally, synthesizing a multi-element doped DLC coating on the gradient transition layer by utilizing multi-ion-beam sputtering and low-energy ion beam auxiliary deposition. In the process of synthesizing the multi-element doped DLC coating by utilizing the multi-ion-beam sputtering and the low-energy ion beam auxiliary deposition, carbon particles and metallic particles which are generated by bombarding a graphite target and a metallic target are deposited by using a sputtering ion source, and gas ions generated by an auxiliary deposition ion source continuously bombard the surface of a grown film layer to regulate and control the microstructure of the film layer and realize multi-element doping.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

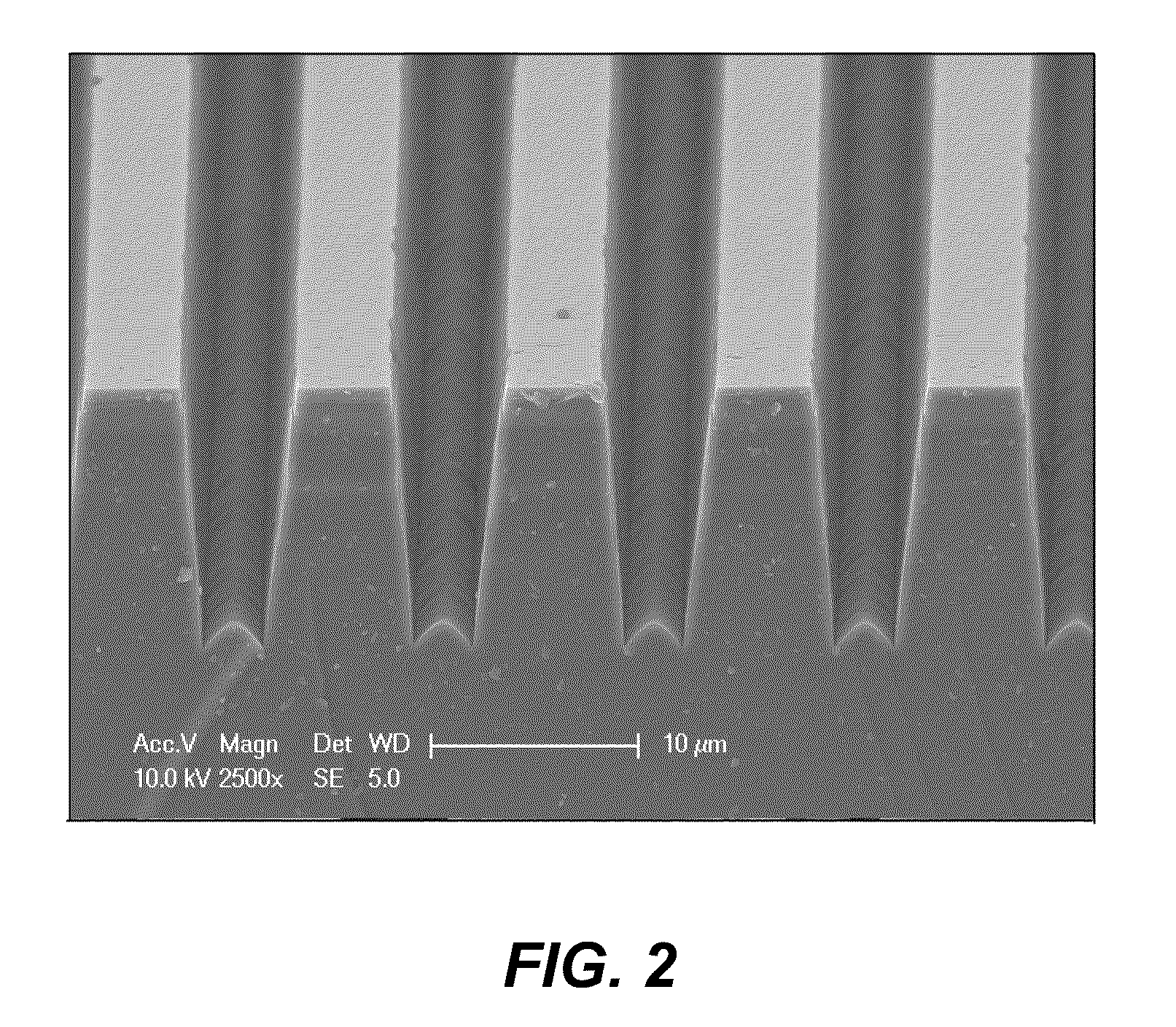

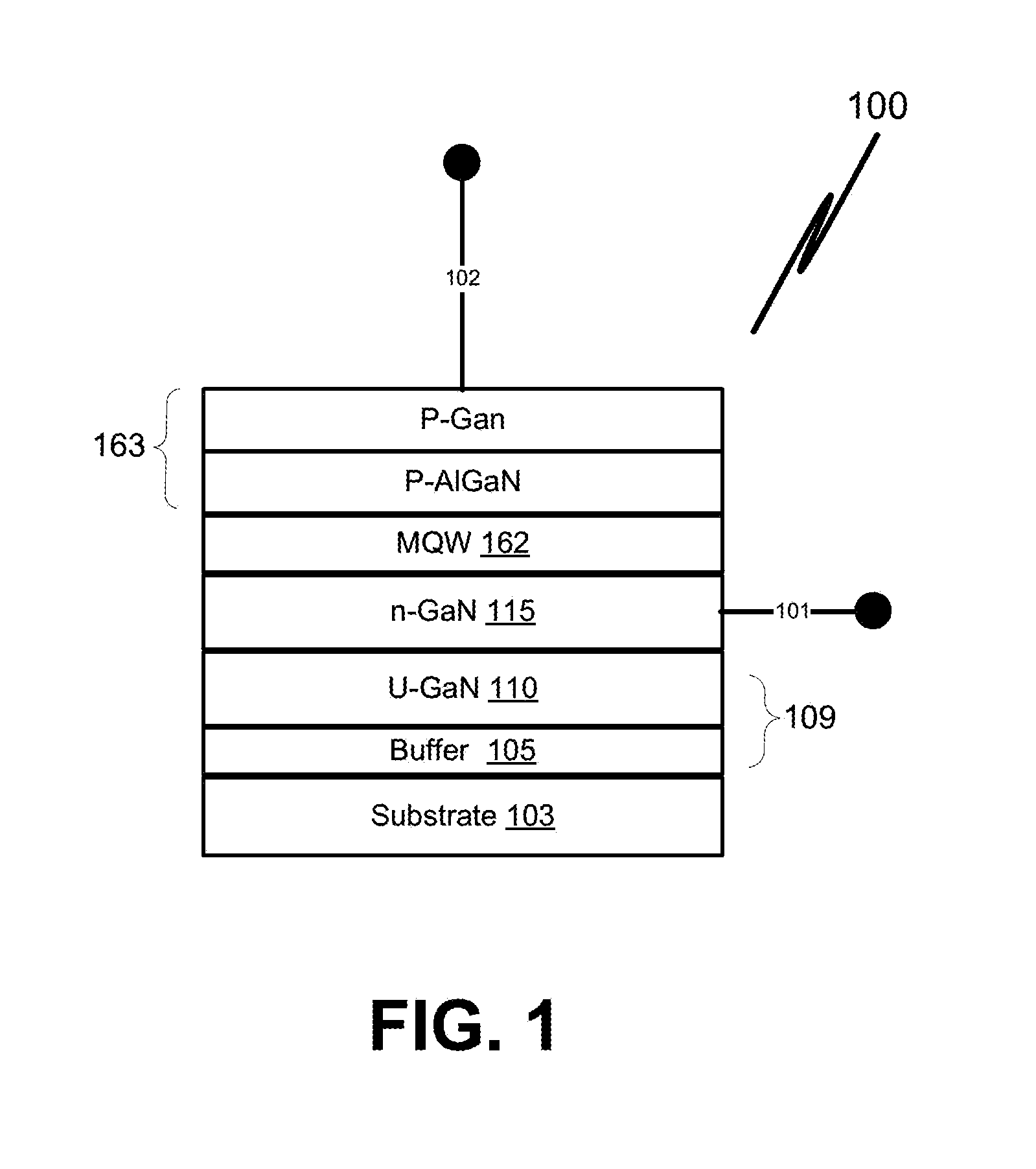

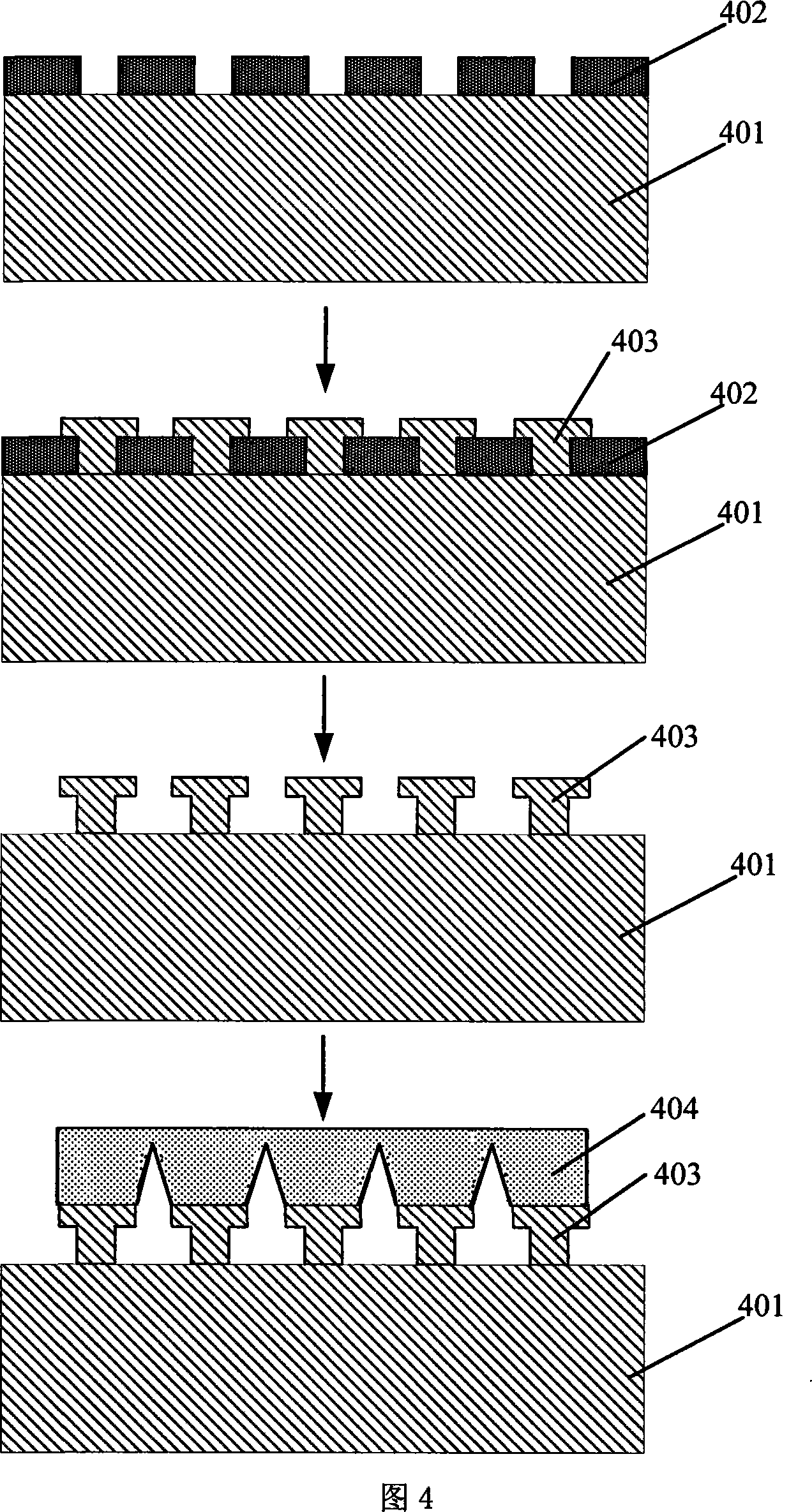

Growth and manufacture of reduced dislocation density and free-standing aluminum nitride films by hydride vapor phase epitaxy

InactiveUS20100065854A1Simple methodReduce defect densityPolycrystalline material growthSemiconductor/solid-state device manufacturingGrown filmVapor phase

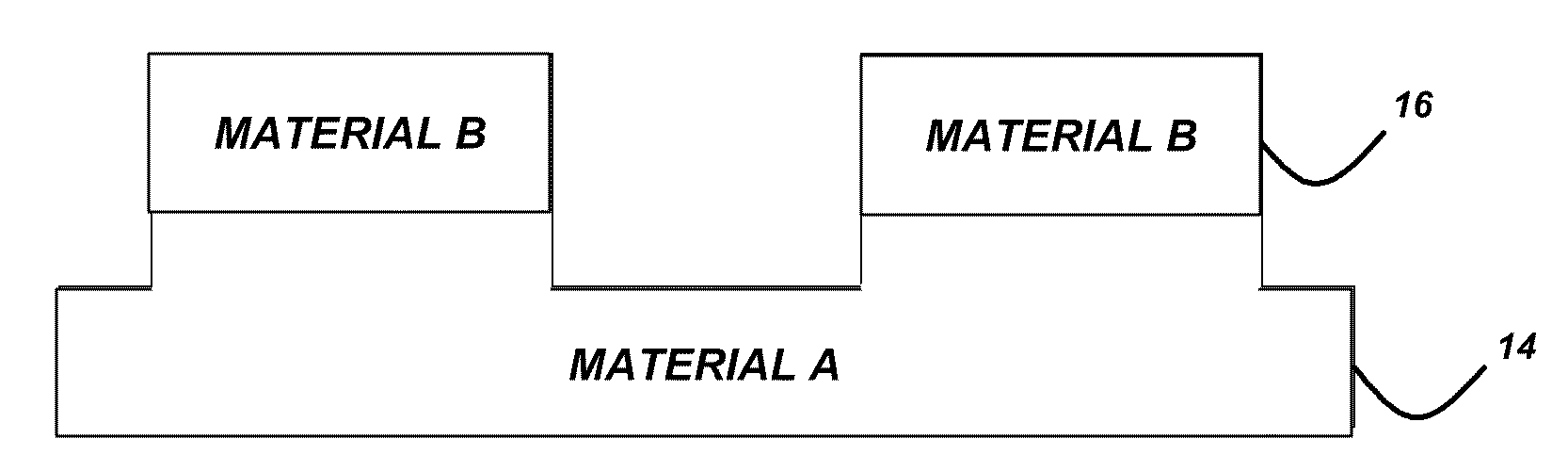

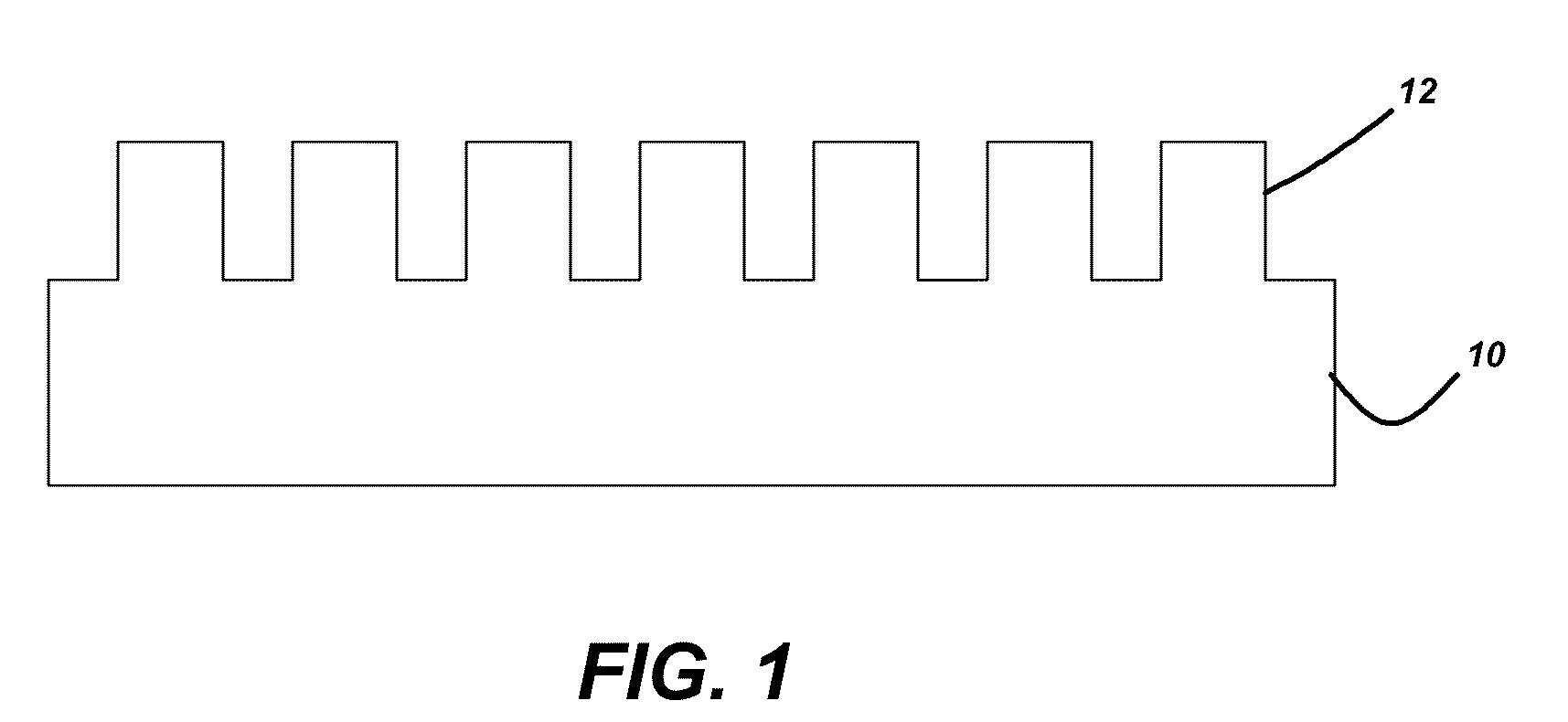

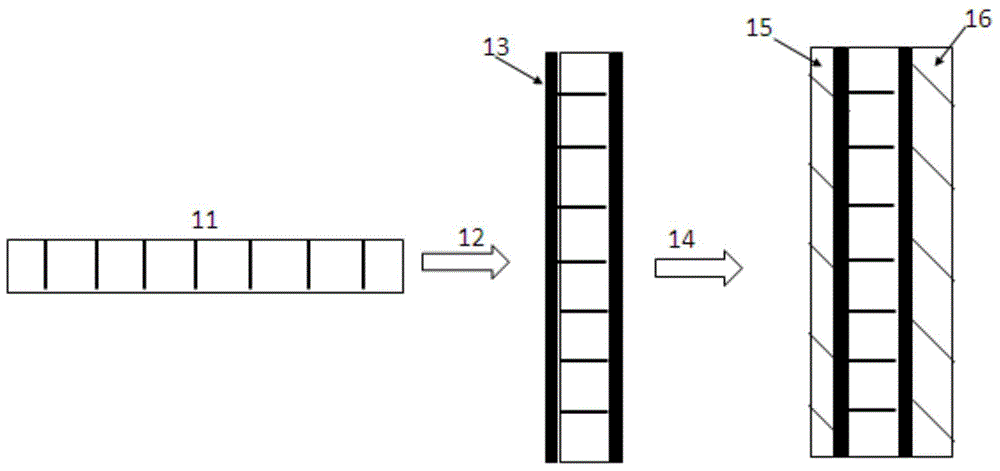

A Group III-nitride semiconductor film containing aluminum, and methods for growing this film. A film is grown by patterning a substrate, and growing the Group III-nitride semi-conductor film containing aluminum on the substrate at a temperature designed to increase the mobility of aluminum atoms to increase a lateral growth rate of the Group III-nitride semiconductor film. The film optionally includes a substrate patterned with elevated stripes separated by trench regions, wherein the stripes have a height chosen to allow the Group III-nitride semiconductor film to coalesce prior to growth from the bottom of the trenches reaching the top of the stripes, the temperature being greater than 1075° C., the Group III-nitride semiconductor film being grown using hydride vapor phase epitaxy, the stripes being oriented along a (1-100) direction of the substrate or the growing film, and a dislocation density of the grown film being less than 107 cm−2.

Owner:JAPAN SCI & TECH CORP

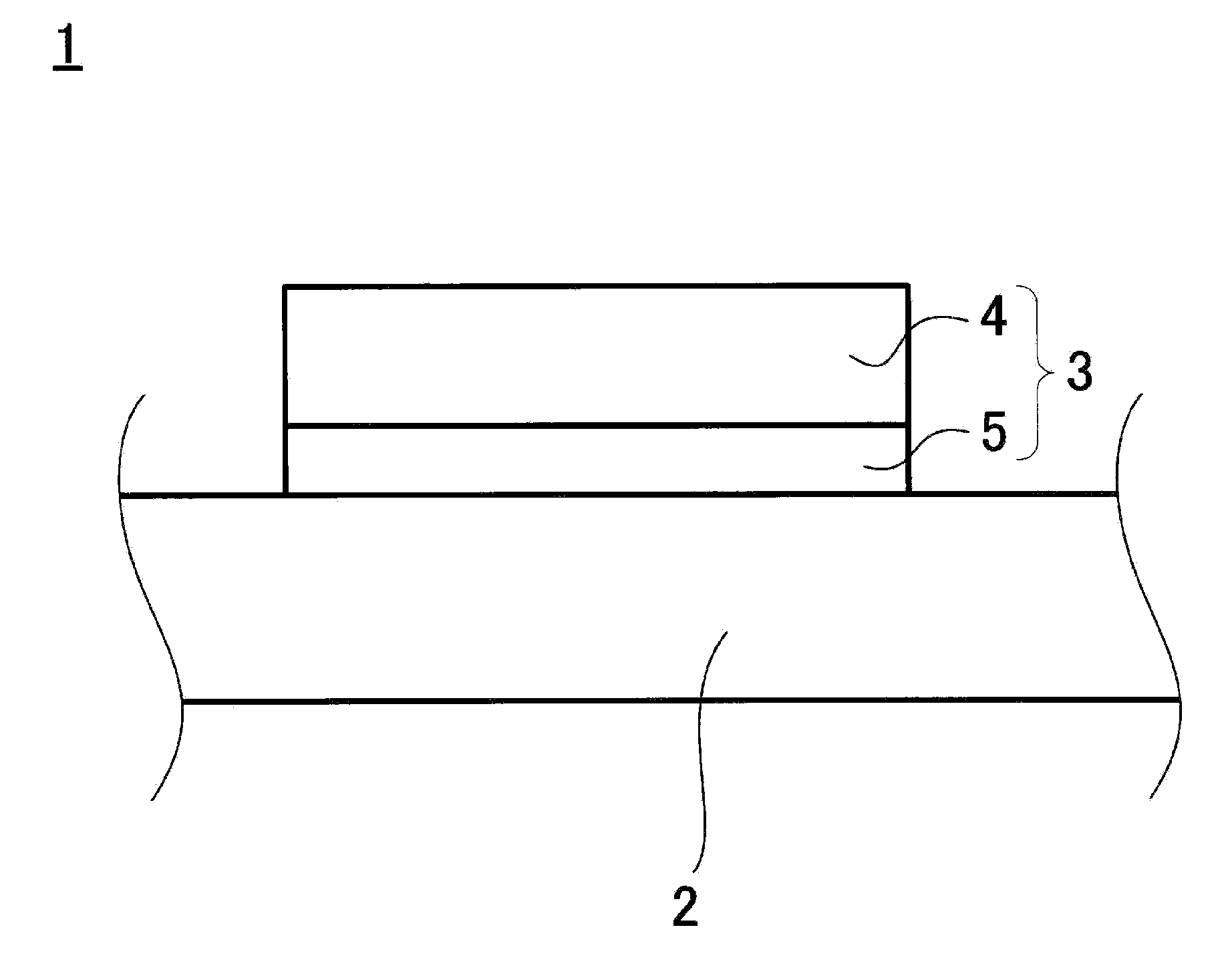

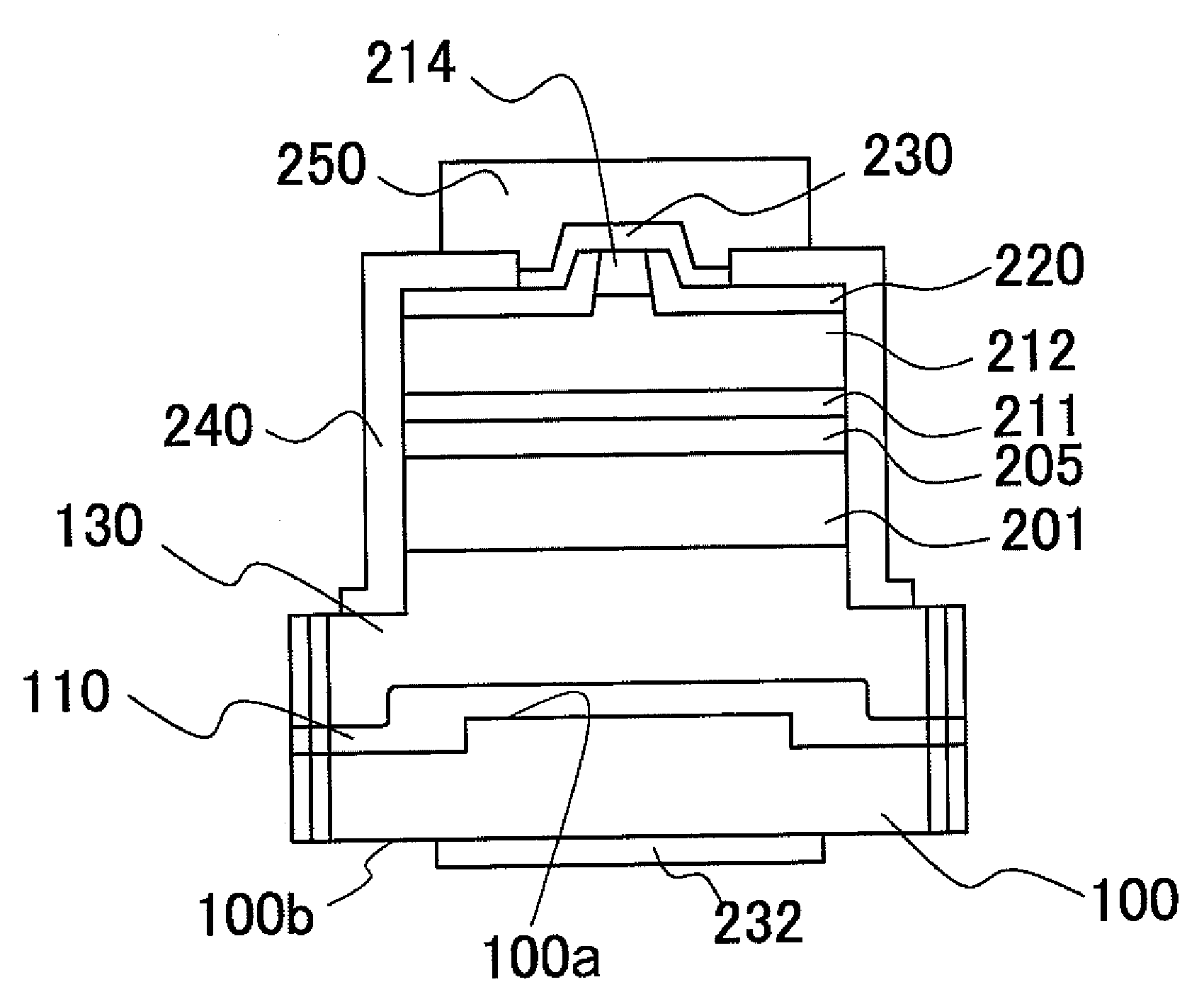

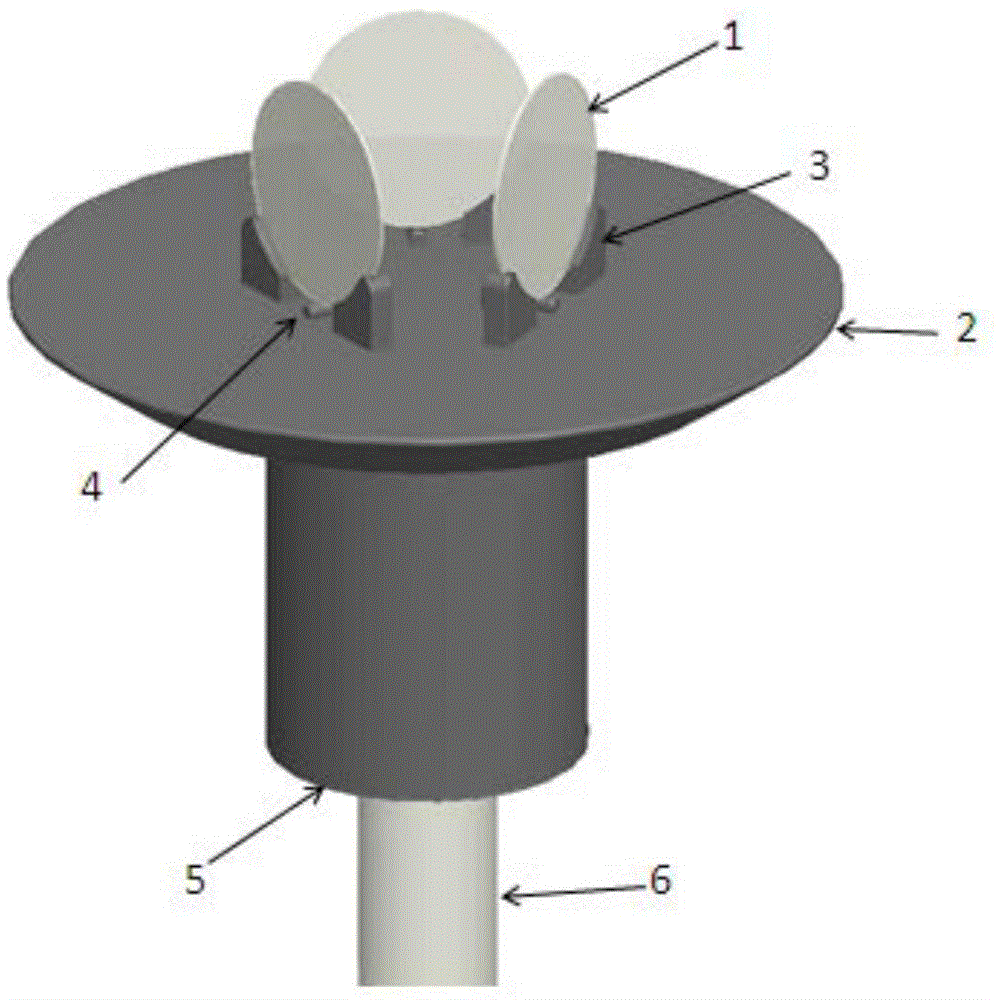

Surface acoustic wave element

InactiveUS20110115334A1High electrical power handling capabilityImproved electric power handling capabilityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksGrown filmCrystal structure

A surface acoustic wave element includes a piezoelectric substrate made of a LiNbO3 or LiTaO3 single crystal, a base electrode layer disposed on the piezoelectric substrate and primarily including at least one of Ti and Cr, and an Al electrode layer primarily including Al disposed on the base electrode layer. The Al electrode layer is an epitaxially grown film with an orientation, and has a twin crystal structure exhibiting six-fold symmetry spots in an XRD pole figure. The average grain size of the Al electrode layer is about 60 nm or less.

Owner:MURATA MFG CO LTD

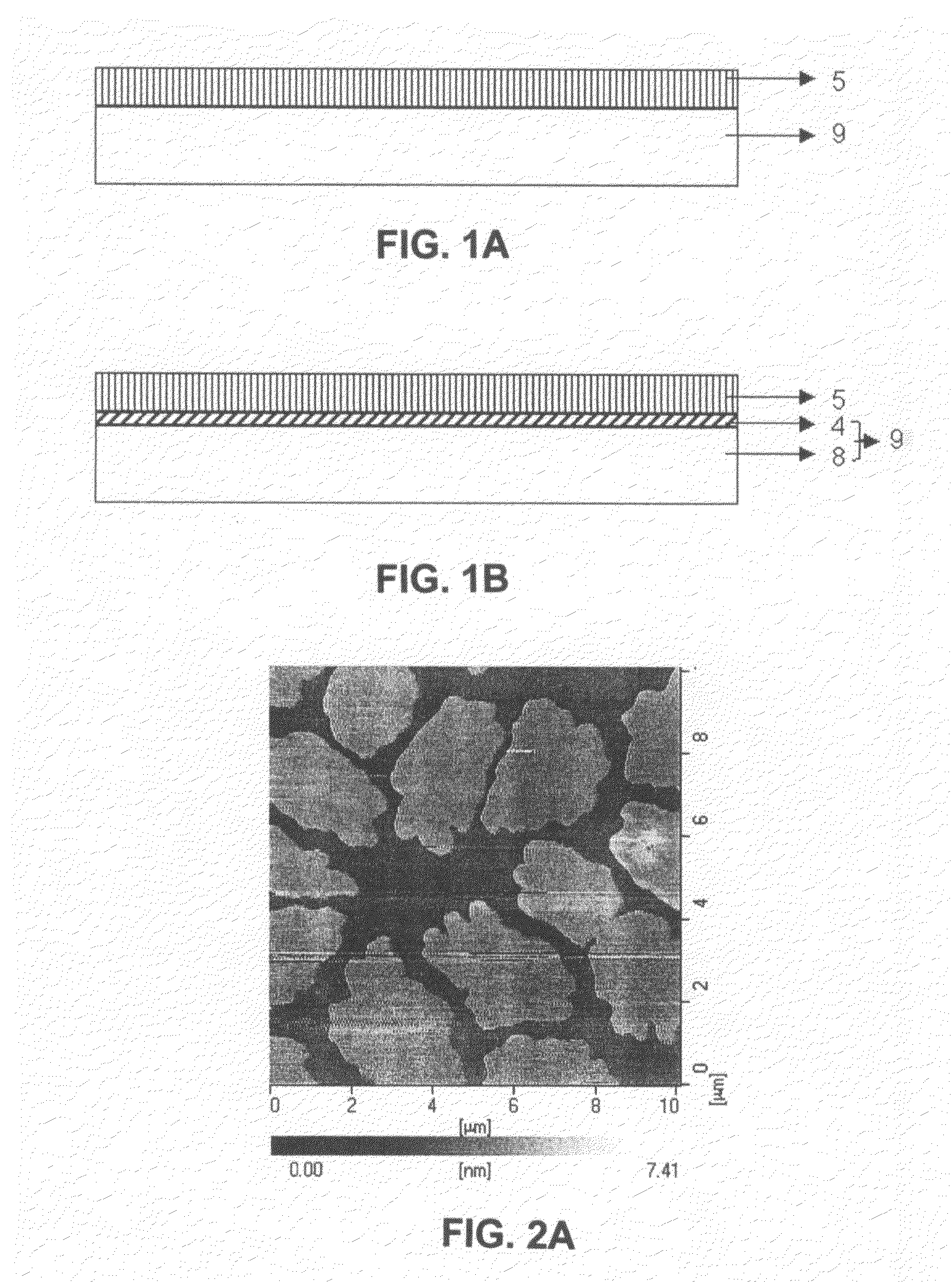

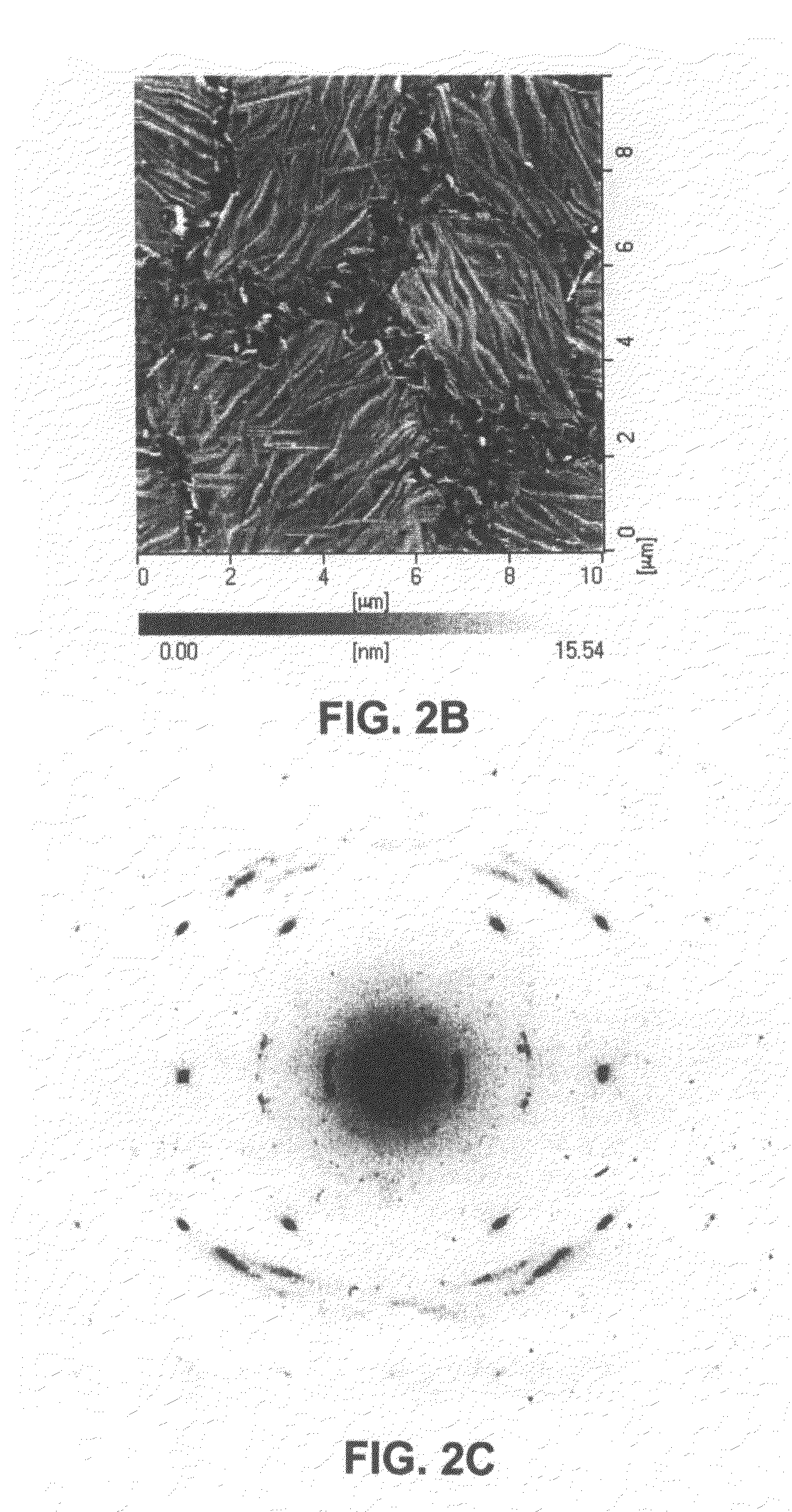

Organic semiconductor crystalline film, method for preparing the same, organic transistor, and organic phototransistor

ActiveUS20070262303A1High propertySolid-state devicesSemiconductor/solid-state device manufacturingGrown filmCharge carrier mobility

An organic semiconductor crystalline film and weak oriented epitaxy growth preparation method thereof. The organic semiconductor crystalline film is a n-type semiconductor or a p-type semiconductor, and organic semiconductor crystal molecules in the organic semiconductor crystalline film are oriented in a stand-up manner on the ordered substrate, and have an oriented relationship with the ordered substrate. The organic semiconductor crystalline film prepared by the present invention is useful for organic transistor and organic phototransistor devices. The method of the present invention can control the high carrier mobility direction of organic semiconductor crystals to have ordered orientation in the film, enhance contacts between crystals, improve mechanical strength and micro-machining property of the film, and give a high carrier mobility. The carrier mobility of weak oriented epitaxially grown film of the present invention is 0.32 cm2 / Vs, which is 5 times as large as that of a vapor phase deposited film, and is similar to that of single crystal. The present invention is adapted to glass substrates and plastic substrates.

Owner:CHANGCHUN INST APPLIED CHEM CHINESE ACADER +1

Nitride semiconductor laser element and method for manufacturing same

InactiveUS20080056322A1Tensile strain can be suppressedSuppress generationOptical wave guidanceLaser detailsIndiumGrown film

A nitride semiconductor laser element comprises a nitride semiconductor substrate and a nitride semiconductor layer laminated thereon, wherein the nitride semiconductor substrate has a high dislocation density region and a low dislocation density region containing lower dislocation than that of the high dislocation density region, and has at least one recess formed in at least the high dislocation density region, the nitride semiconductor layer has a first nitride semiconductor layer in which the grown film thickness in the lateral direction from the side faces of the recess in the substrate is greater than the grown film thickness in the heightwise direction from a region other than the recess, and a second nitride semiconductor layer that is disposed on the first nitride semiconductor layer and contains indium, and the first nitride semiconductor layer and second nitride semiconductor layer have recess over the recess in the nitride semiconductor substrate.

Owner:NICHIA CORP

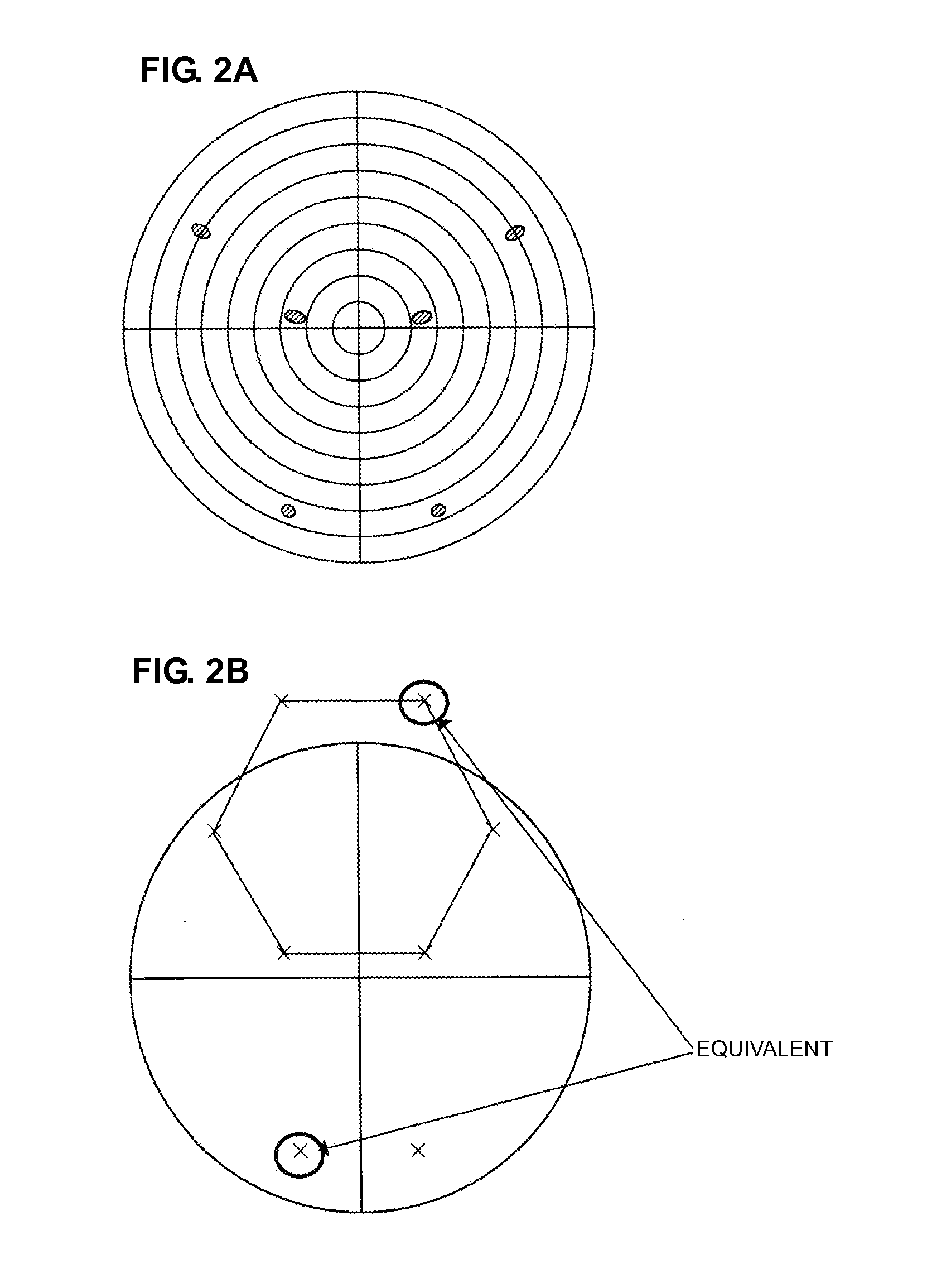

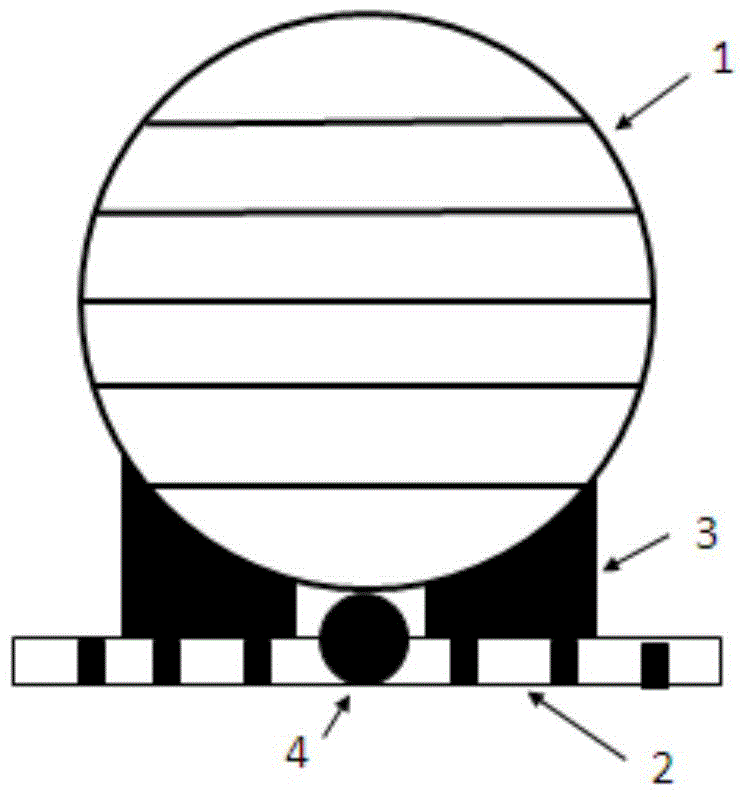

Method of preparing warp-free group-III nitride composite substrate and substrate placing device

ActiveCN105845798AQuality improvementGuaranteed uniformitySemiconductor devicesGrown filmComposite substrate

The invention discloses a method of preparing a warp-free group-III nitride composite substrate and a substrate placing device. A substrate with both sides polished is erected on the substrate placing device and placed in a reaction chamber, a group-III nitride film or microstructure is grown on the both sides at the same time in an epitaxial manner to form a buffer layer, thick-film group-III nitride is grown on the both sides at the same time, and the epitaxial thickness of one side of the AL surface of sapphire is slightly greater than the epitaxial layer thickness of one side of the O surface. The substrate placing device is a multi-piece graphite frame, and comprises a base, a hole, rollers, and slots. The substrate can be rotated, and the uniformity in thickness of the grown films is ensured. Warping is inhibited, the quality of crystal is improved, and the obtained composite substrate can be used as a group-III nitride quasi-homogeneous epitaxial substrate to prepare related optoelectronic devices. According to the invention, the space of the reaction chamber is fully utilized, the production cost is reduced, the process is simple and easy to control, and different substrates can be selected and a variety of equipment can be used to grow a variety of thick-film group-III nitride substrates.

Owner:PEKING UNIV +1

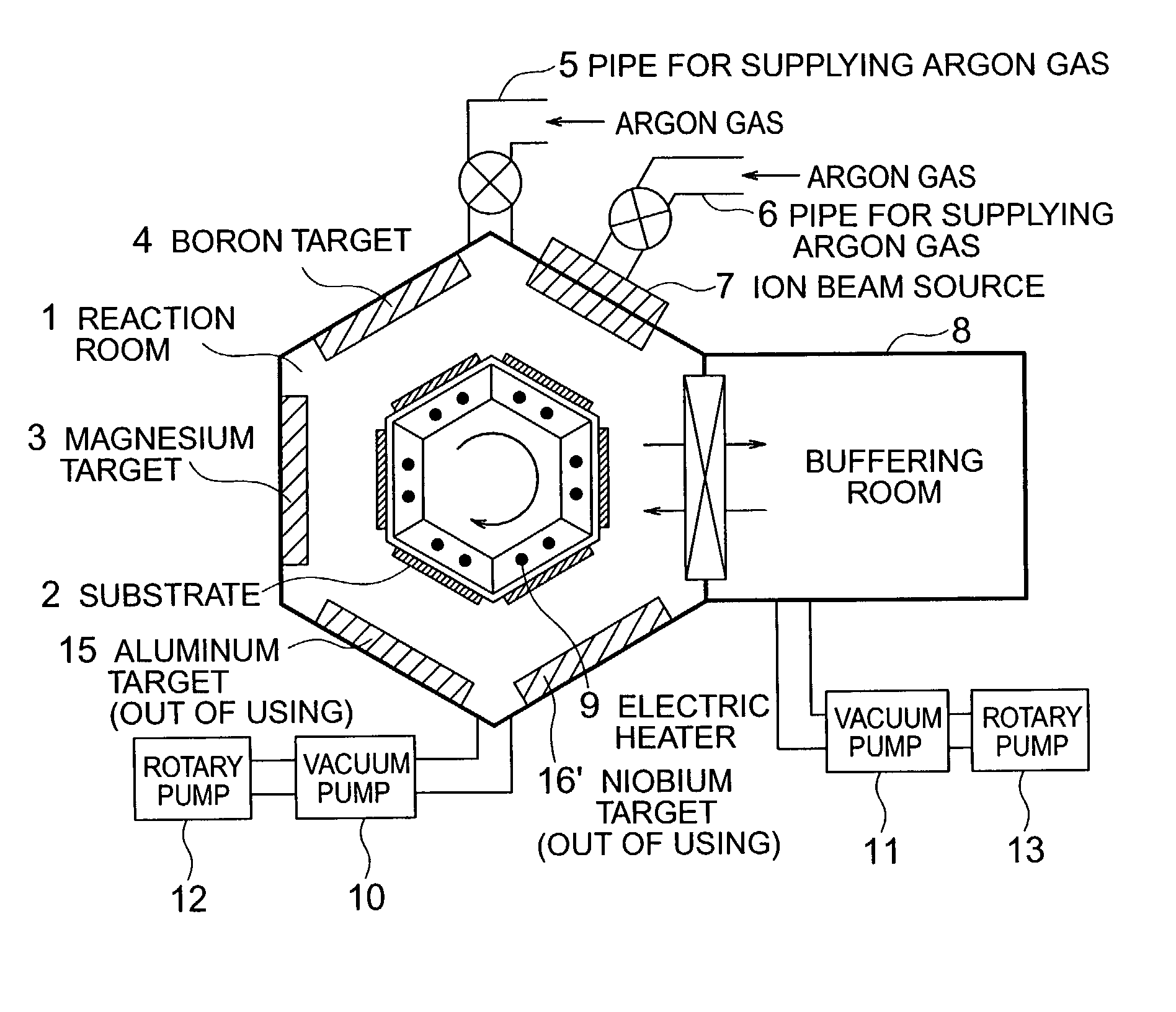

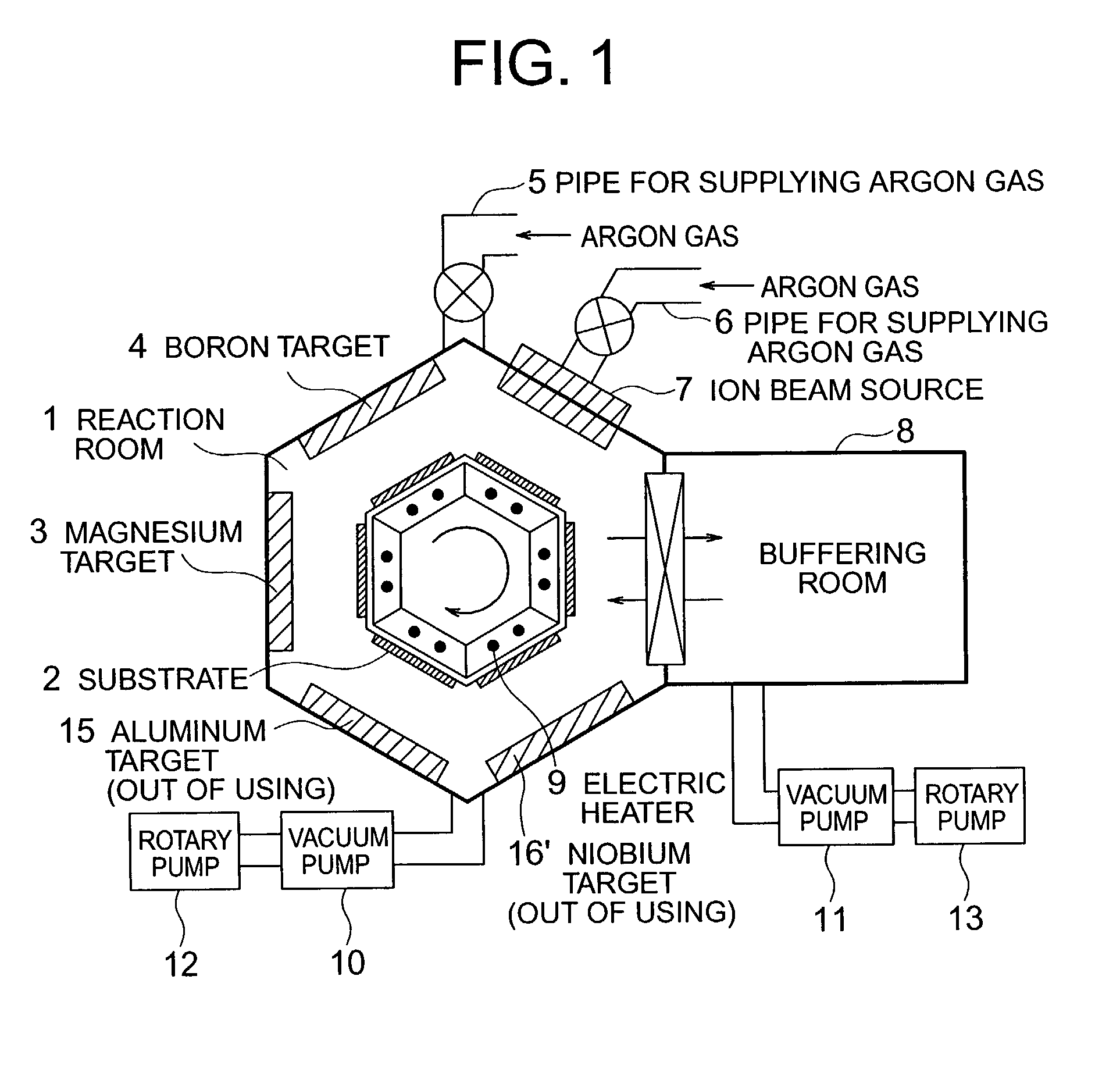

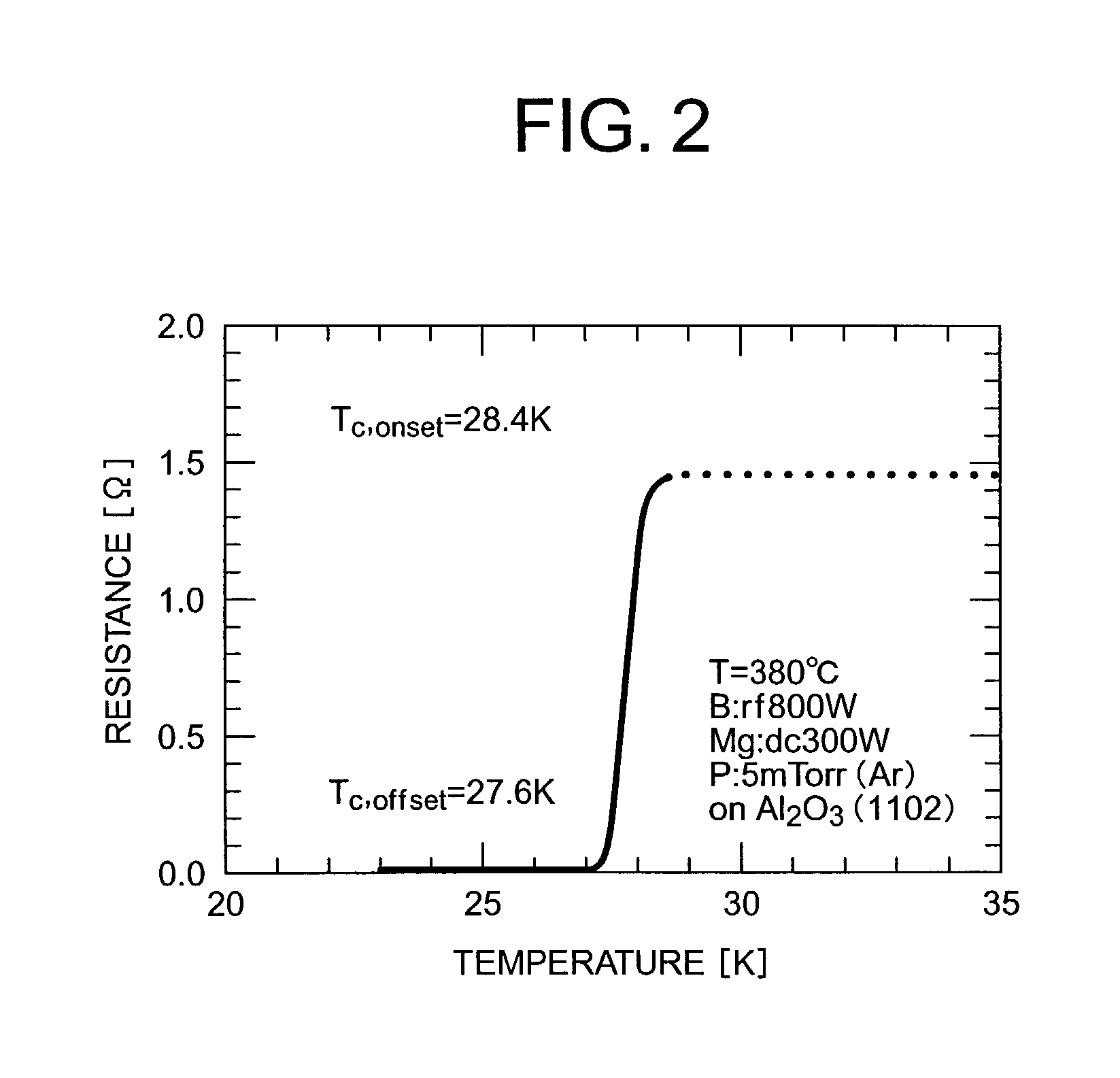

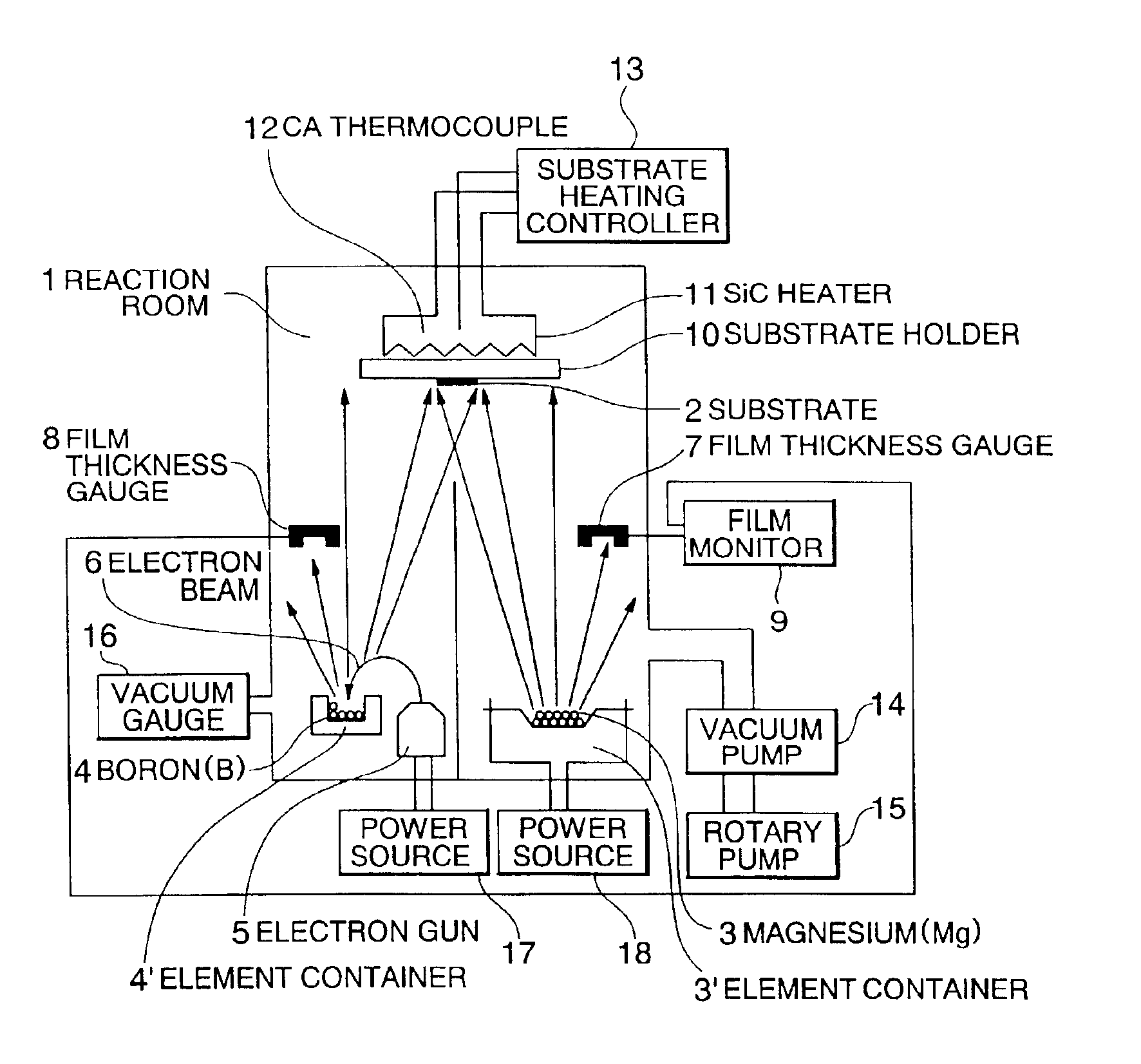

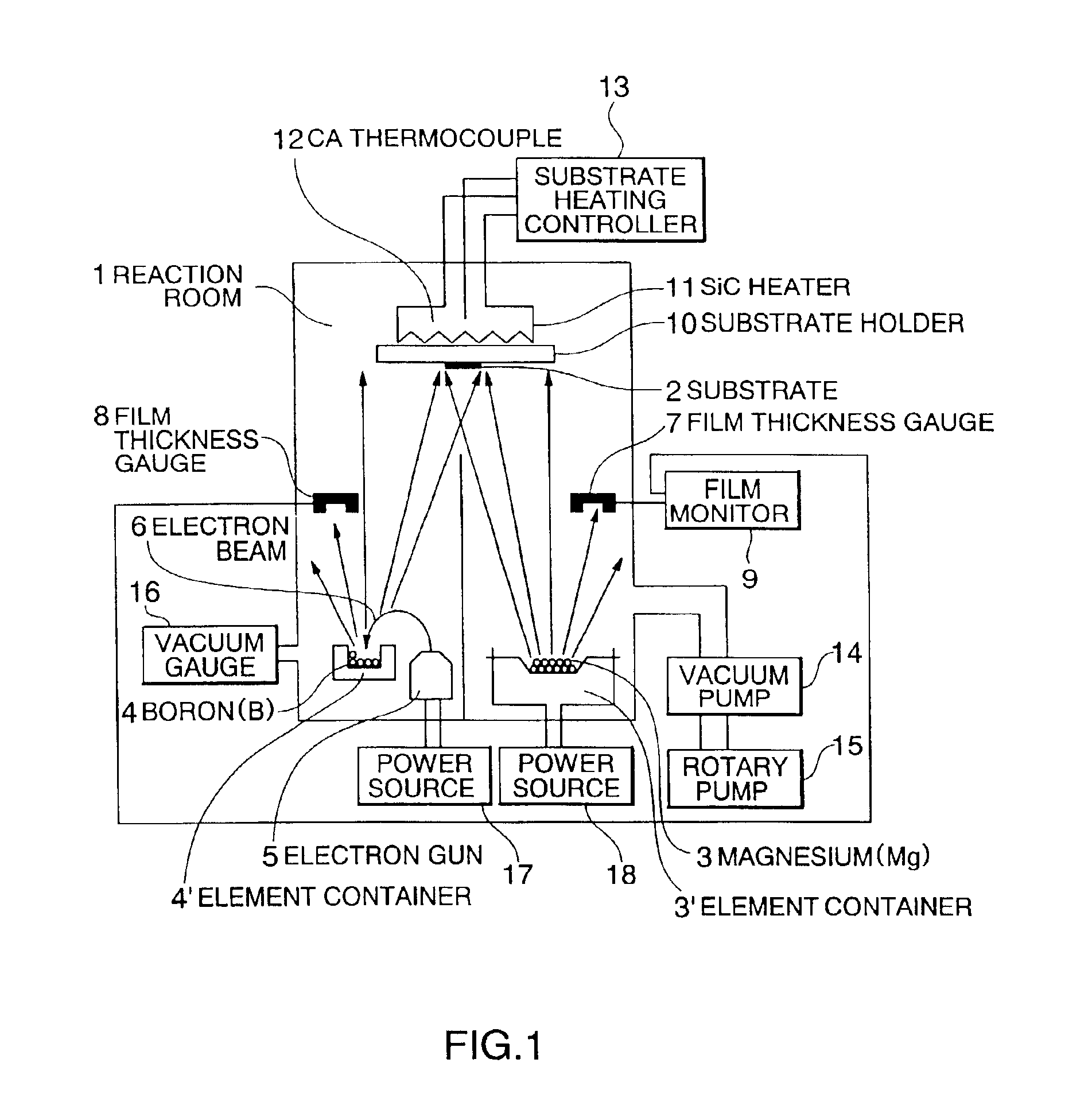

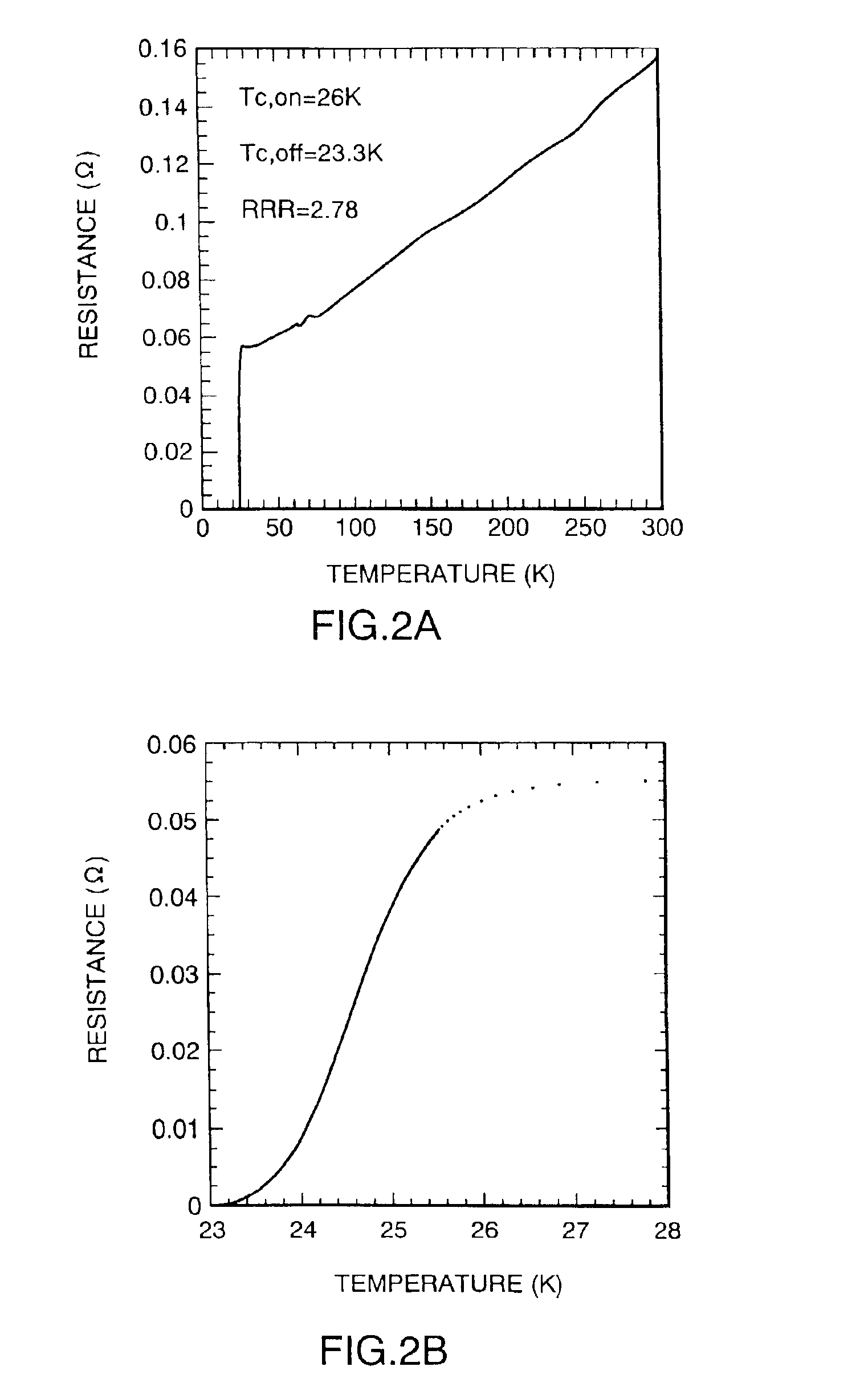

Method of forming a superconductor film

The present invention provides methods forming the superconductor of as-grown film of MgB.sub.2 which is made with magnesium and boron ejected from a magnesium target and a boron target respectively each in simultaneously sputtering process. The as-grown film composed of a compound of magnesium and boron is a superconductor without annealed. The present invention can be applied to fabricate an integrated circuit of superconductor film, because the high temperature annealing process for the as-grown film of MgB.sub.2 is not needed.

Owner:NAT INST OF INFORMATION & COMM TECH

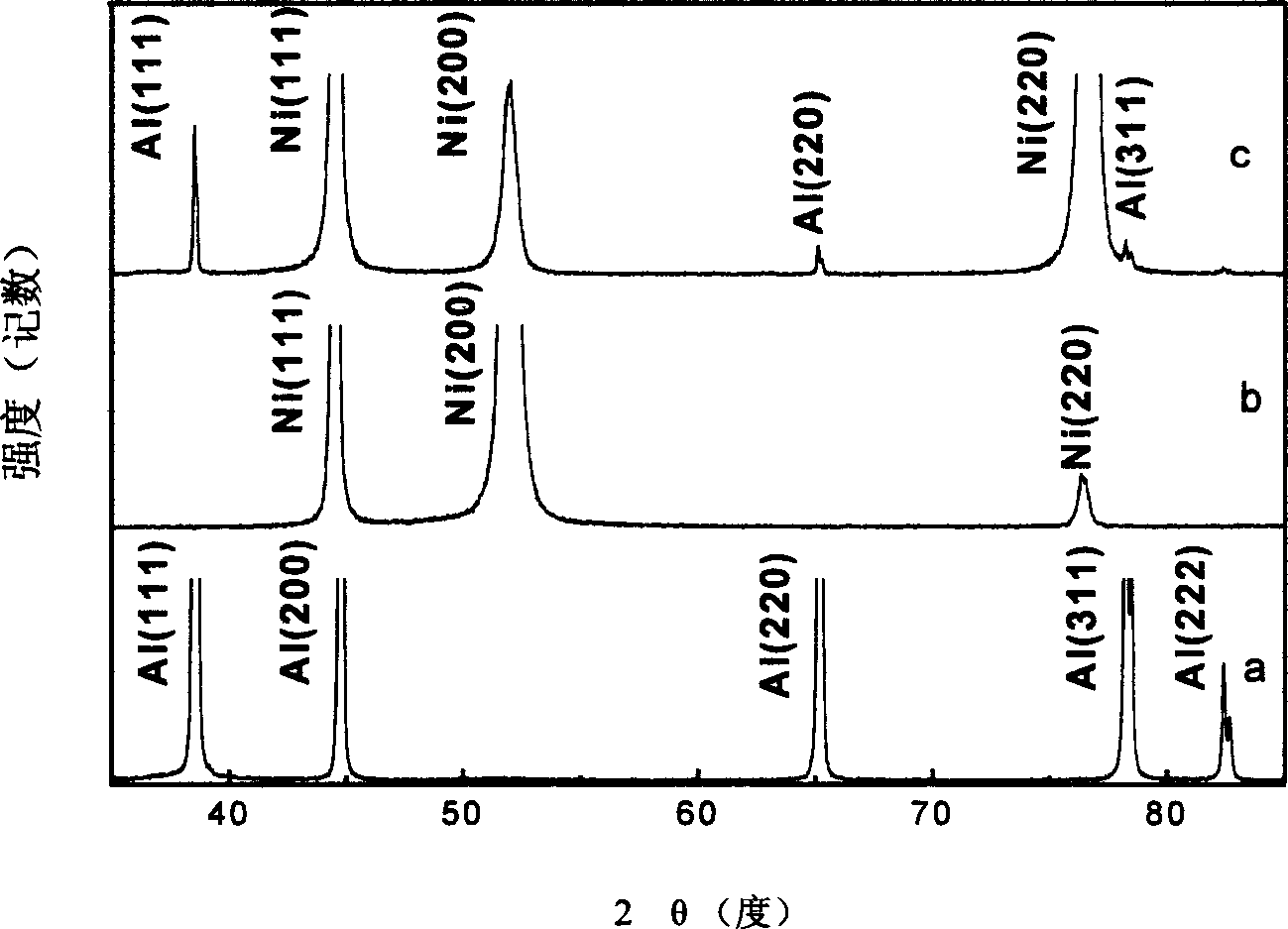

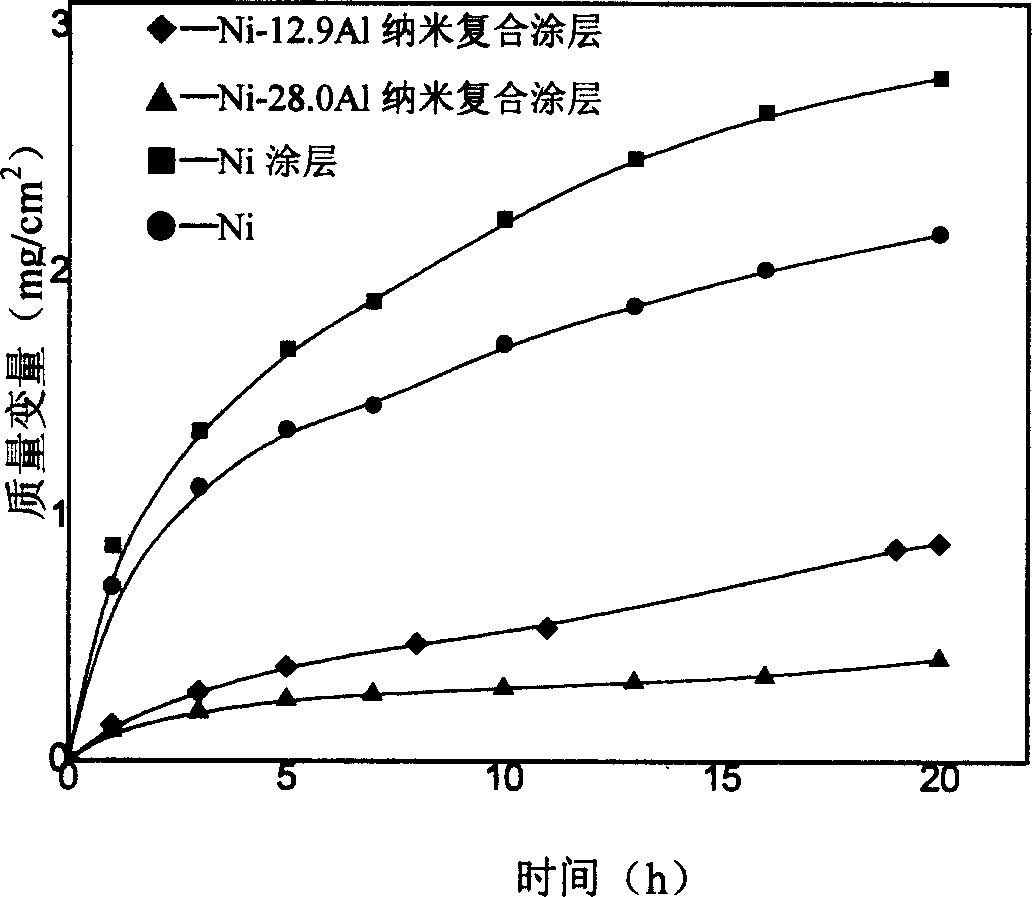

Thermal growth AL2O3 film type M A1 nano composite plating and producing process and application

InactiveCN1576398AIncrease the number of nucleiDiffusion fastElectrolytic coatingsGrown filmNanoparticle

The thermally grown Al2O3 film type M-Al nano composite coating consists of nano crystal M coating and nano metal Al grains dispersed in the coating, where M is Ni, Fe or Co. The Al content is 9.8-35 wt%, and M is the rest. The nano composite Ni-Al, Fe-Al or Co-Al coating is prepared through composite electroplating process to deposit metal M and Al coating on to the base material of Ni, Fe or Co, carbon steel or alloy steel. The present invention has the features of simple technological process, low cost, high and controllable compounded amount, compact coating, no need of vacuum diffusion treatment of the nano composite coating, direct thermally growth of protecting Al2O3 film, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

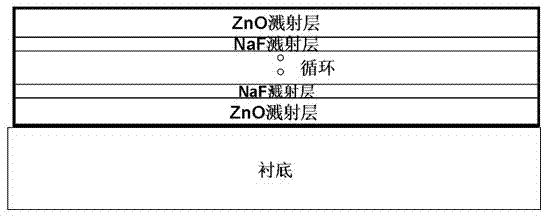

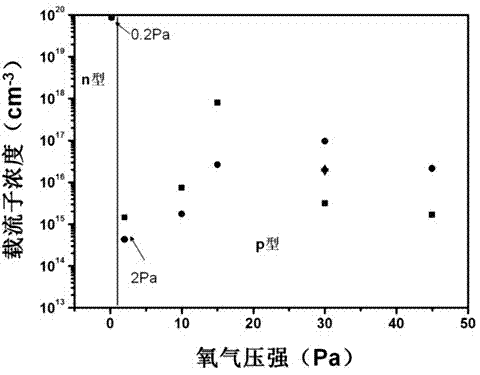

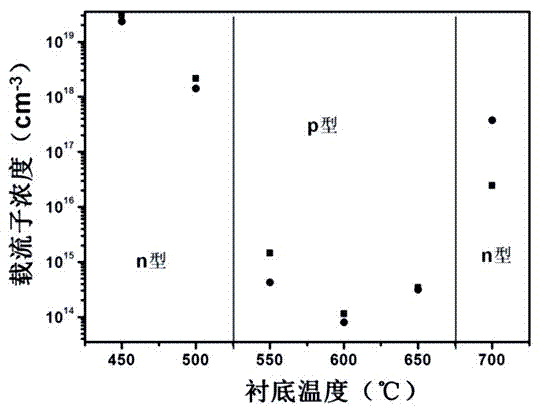

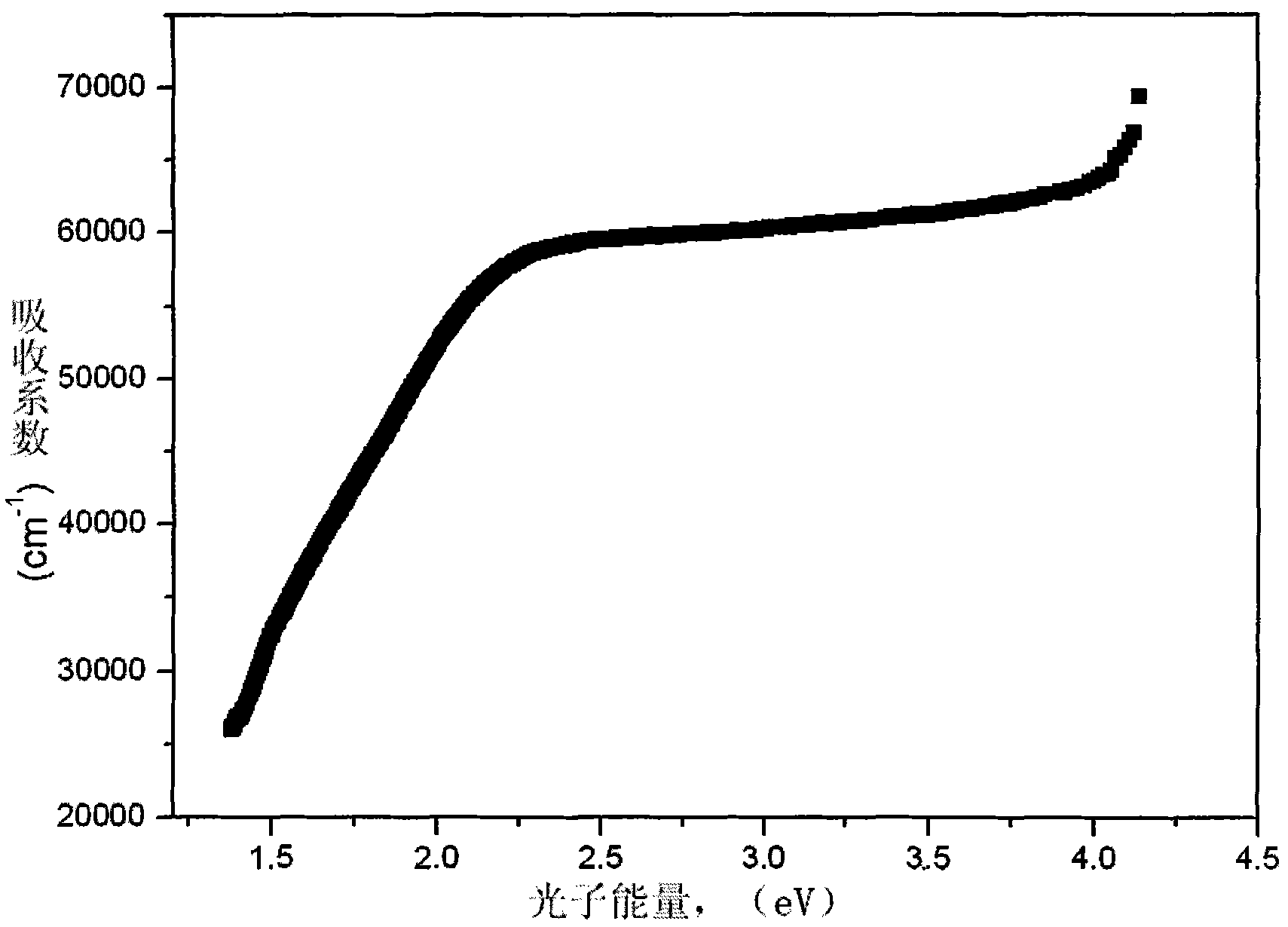

Method for preparing Na-doped p-type NnO film

InactiveCN102373425AQuality improvementInhibit entryVacuum evaporation coatingSputtering coatingSputteringGrown film

The invention discloses a method for preparing a Na-doped p-type NnO film. A pulse laser deposition method is adopted. In the method, a NnO layer and a Na layer are grown by alternately sputtering high-purity NnO and high-purity NaF ceramic target materials as sputtering target materials to prepare the p-type Na-doped NnO film. The distance between the target materials and a substrate is 4.5-5.5 cm, the backland vacuum degree of a growth chamber is pumped to 1*10<-4>-1*10<-3> Ps, the substrate is heated to increase the temperature of the substrate to 400-700 DEG C, the laser frequency is 3-10Hz, and the laser energy is 250-350 mJ. The grown film is cooled at 3-5 DEG C / min to room temperature. The Na-doped p-type NnO film preparation method provided by the invention is simple, and the used device and the current technology are compatible.

Owner:ZHEJIANG UNIV

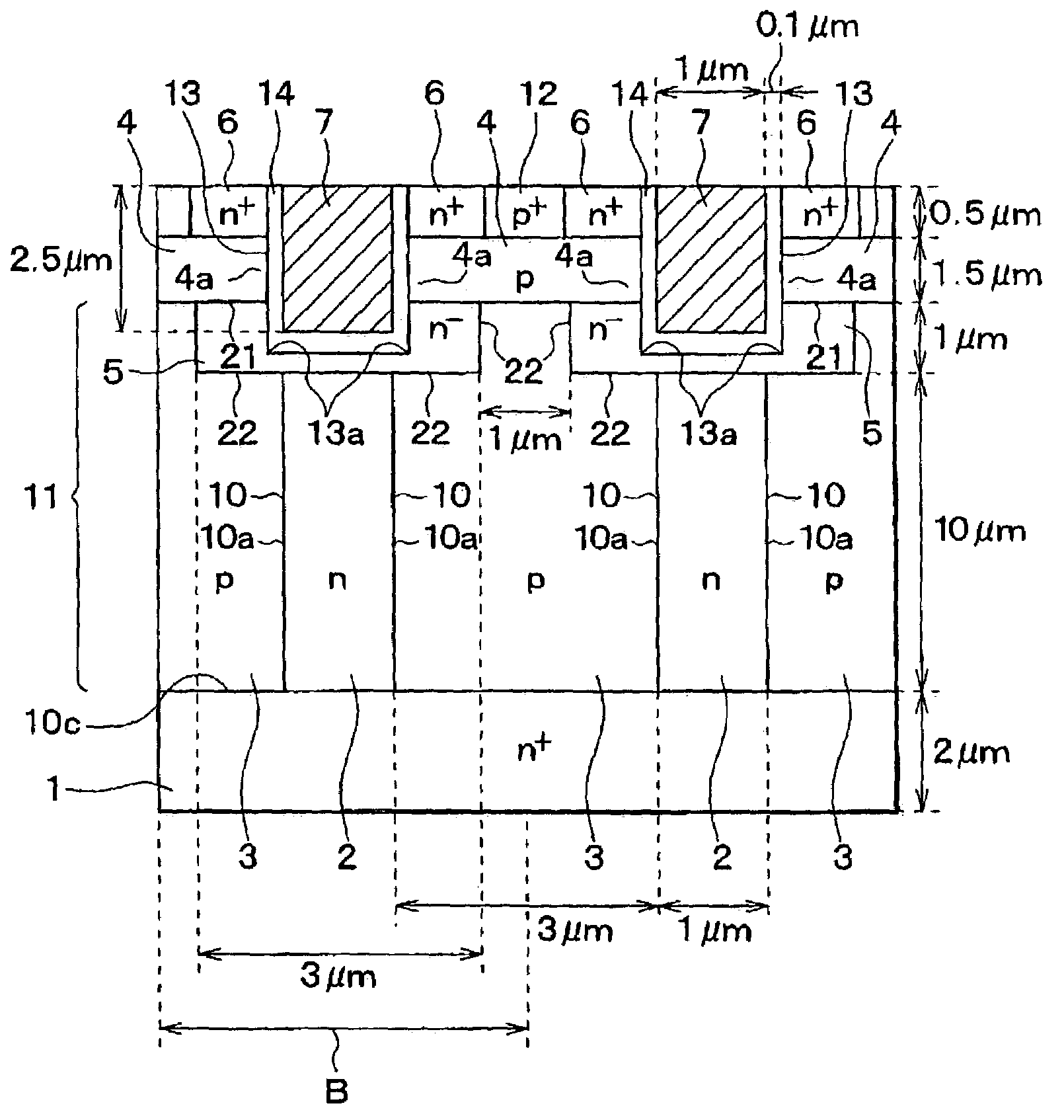

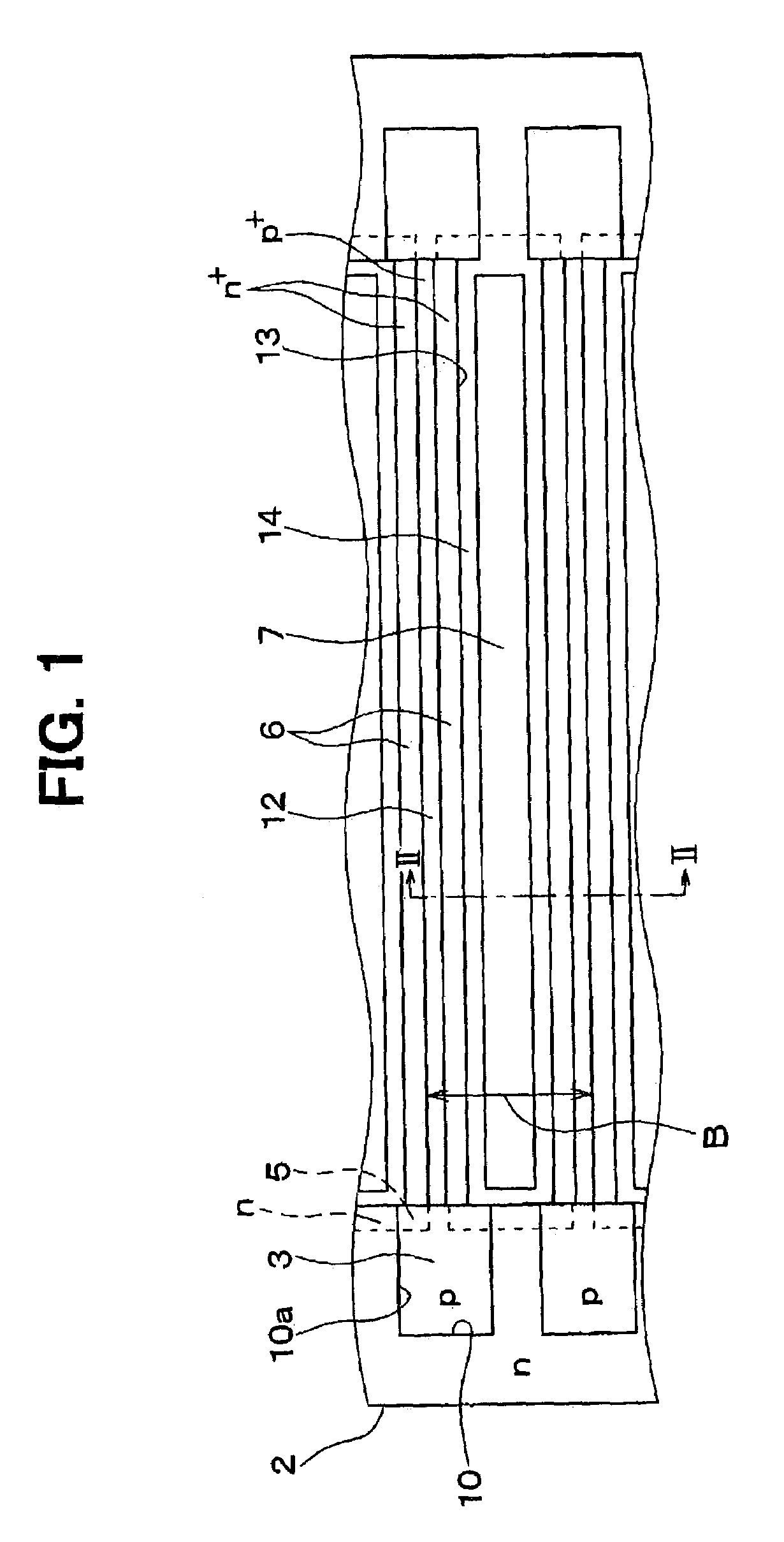

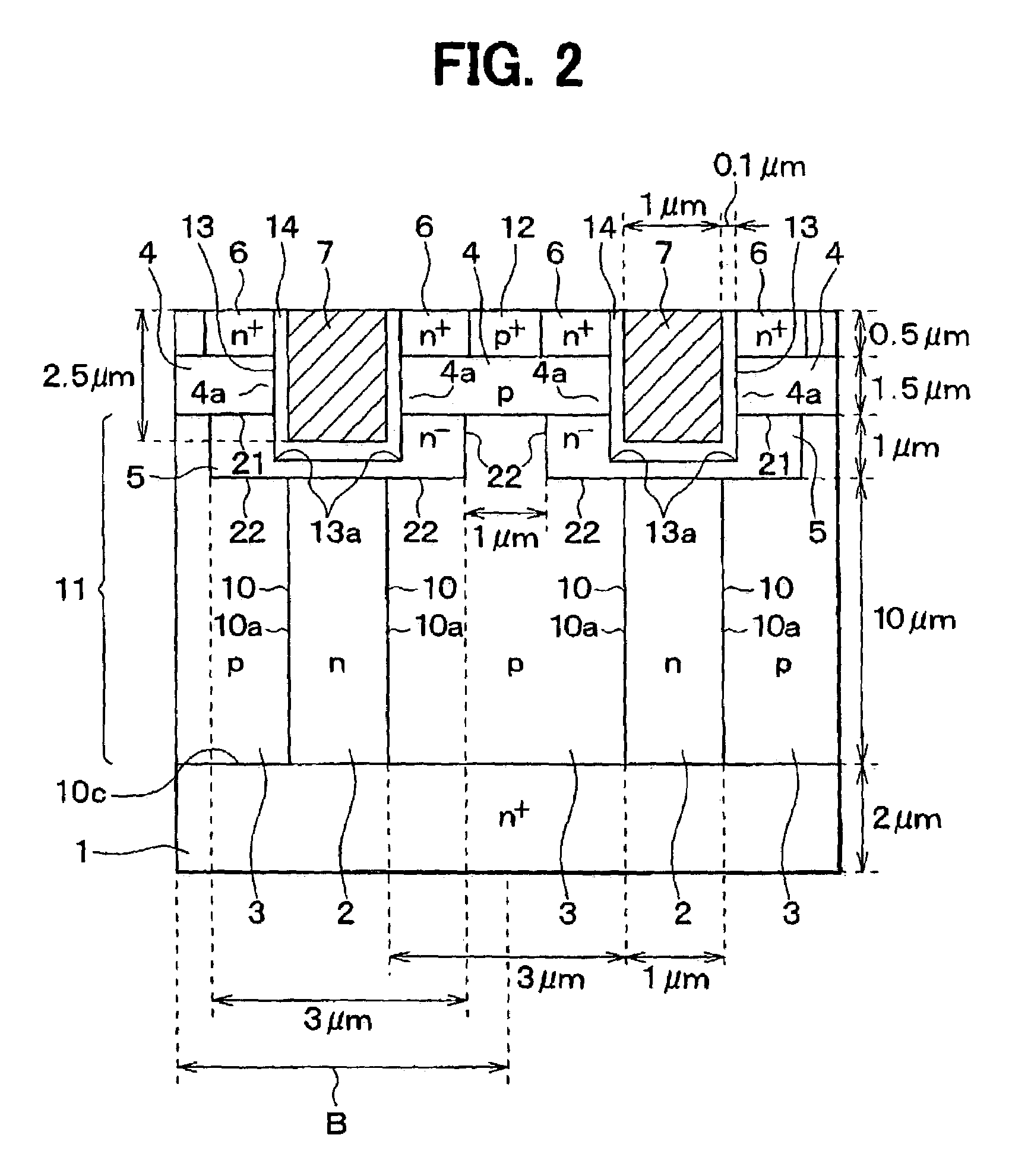

Stabilization of dopant concentration in semiconductor device having epitaxially-filled trench

InactiveUS7037789B2Semiconductor/solid-state device manufacturingSemiconductor devicesDopantGrown film

A method for manufacturing a semiconductor device includes: forming a trench in a predetermined layer of a semiconductor substrate; heating the substrate having the trench in a non-oxidizing and non-nitridizing atmosphere containing a dopant or a compound that includes the dopant in order to smooth the surfaces defining the trench and to maintain the dopant concentration in the predetermined layer to be a predetermined concentration before the heating is treated; and forming an epitaxially grown film to fill the trench. The conductivity type of the dopant contained in the non-oxidizing and non-nitridizing atmosphere is the same as that of the dopant initially contained in the predetermined layer.

Owner:DENSO CORP

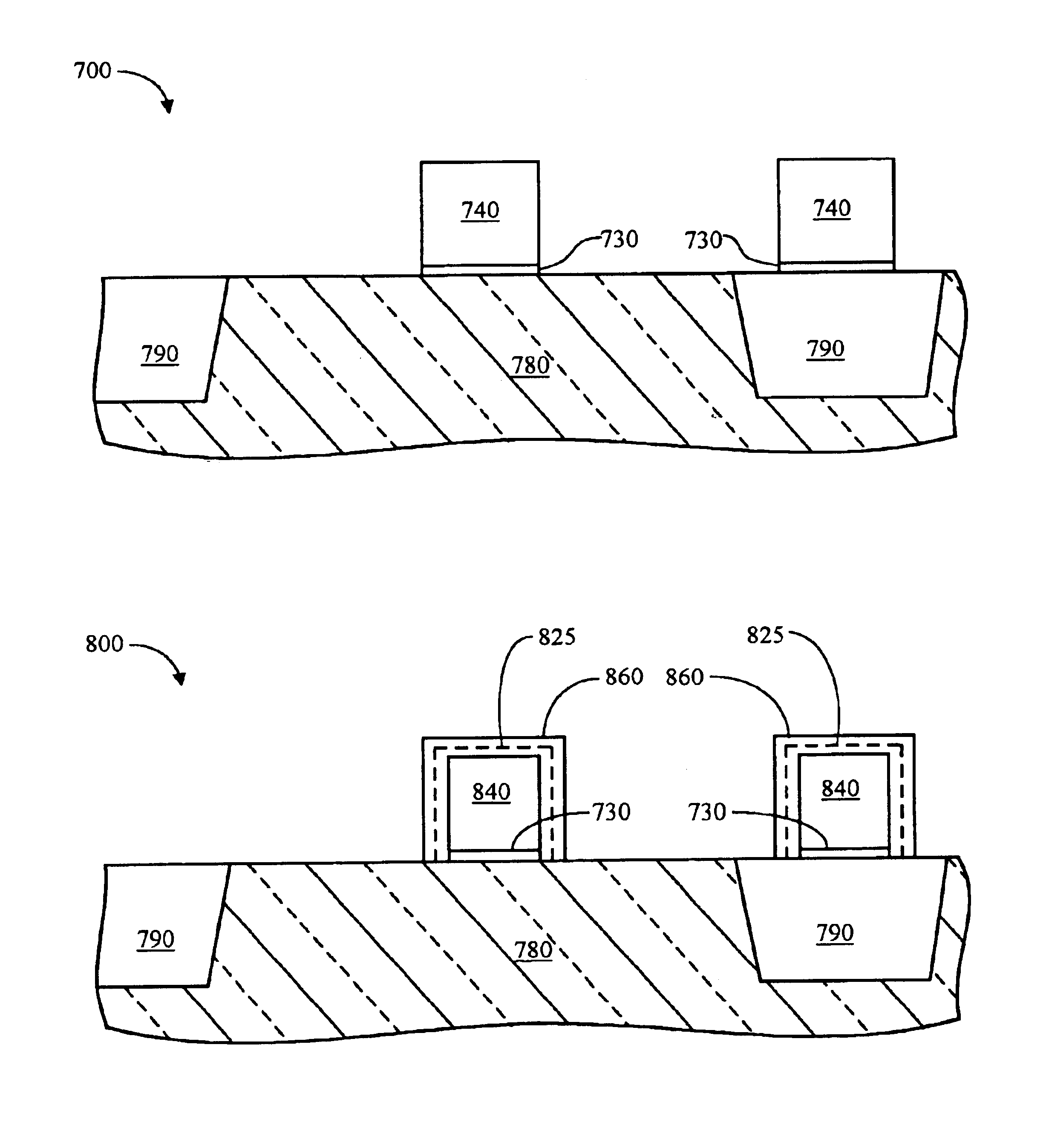

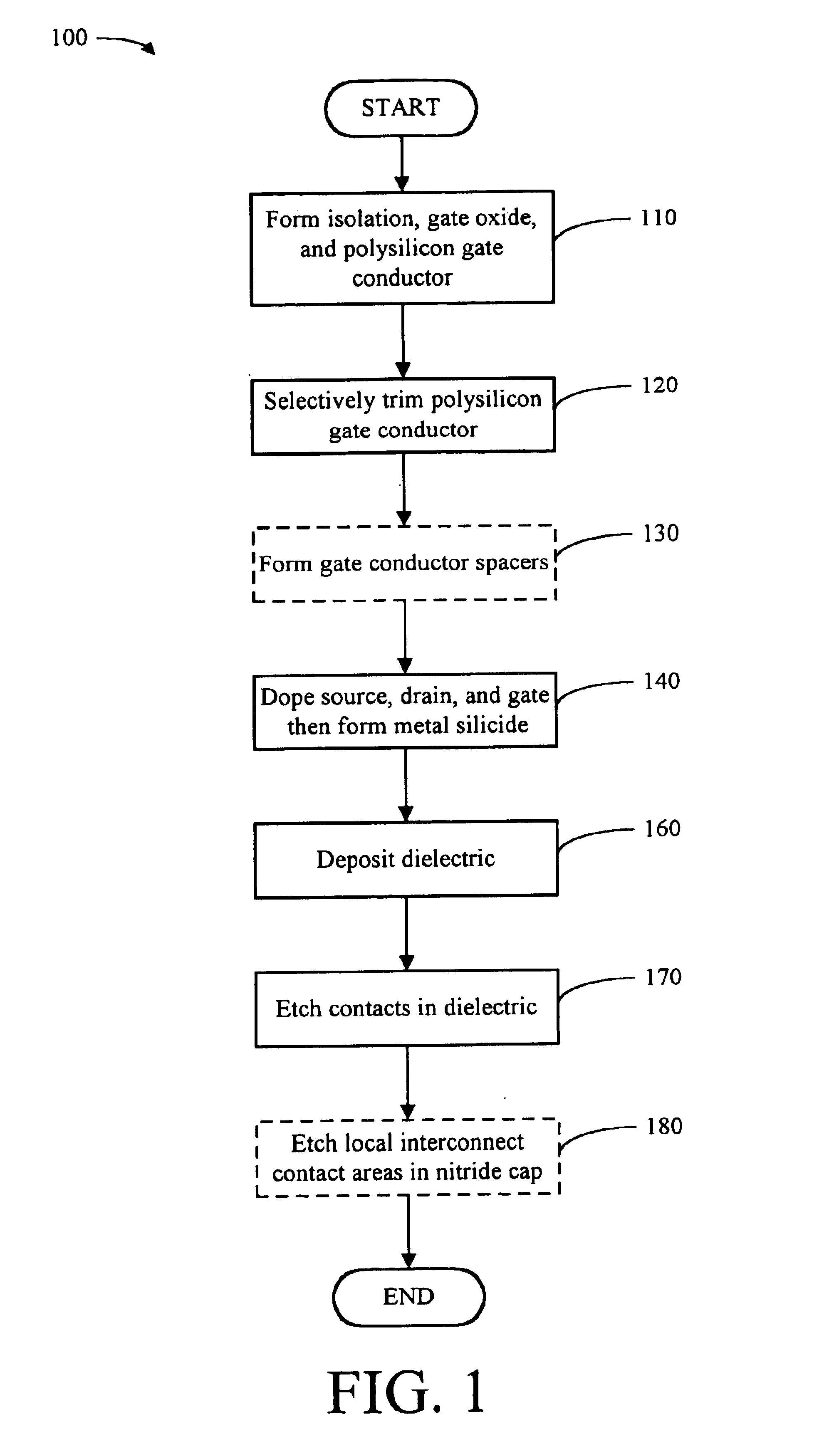

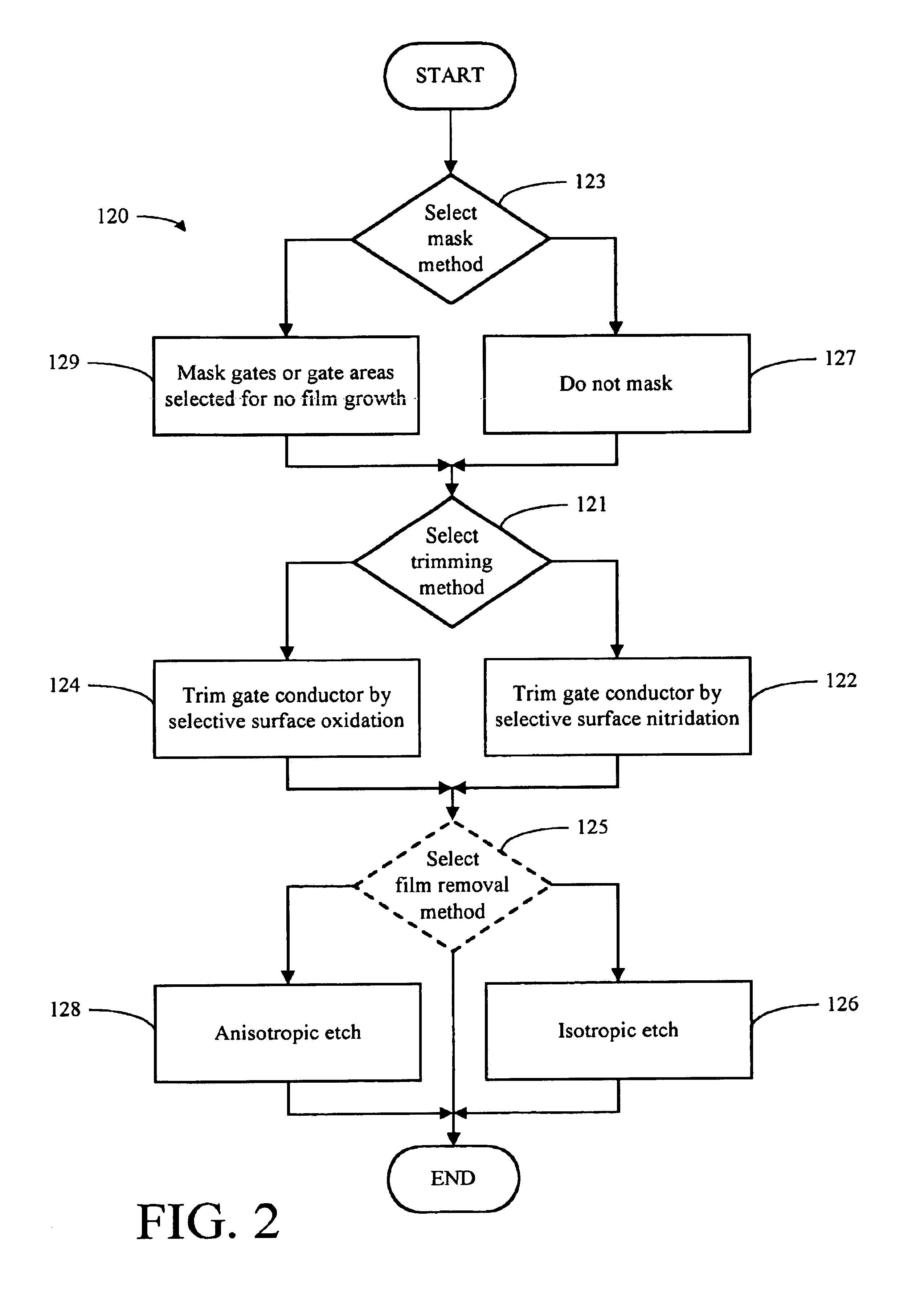

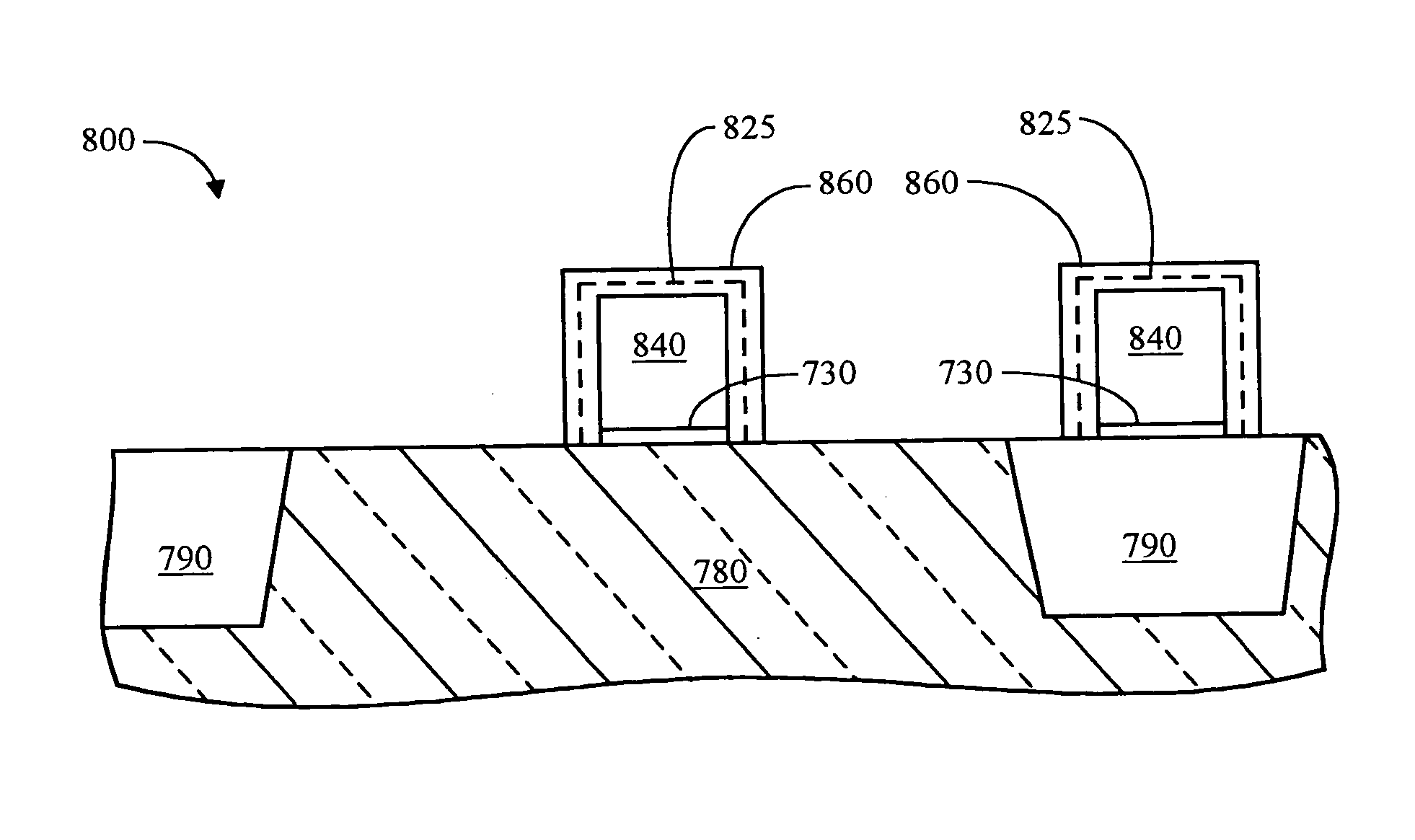

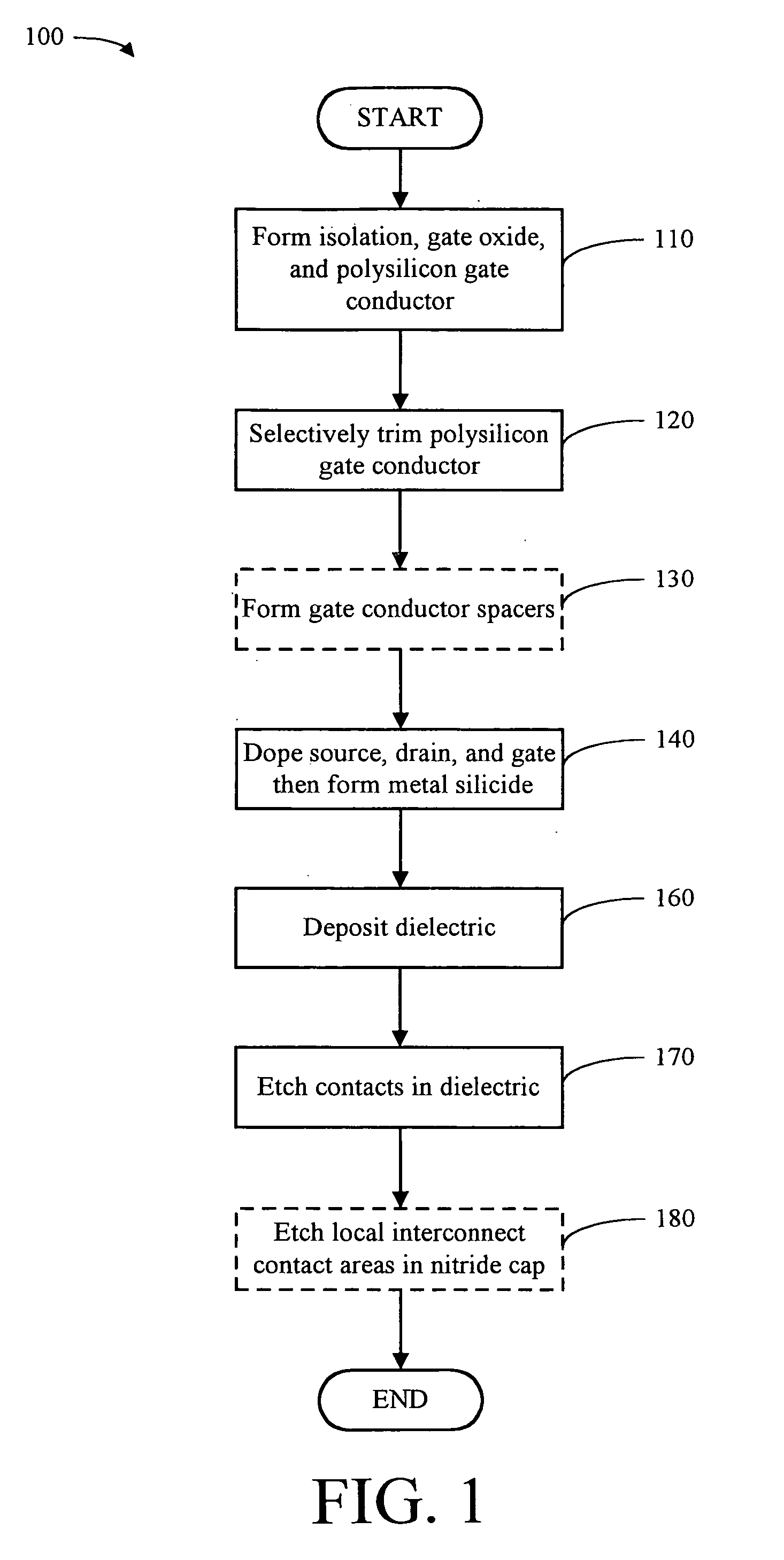

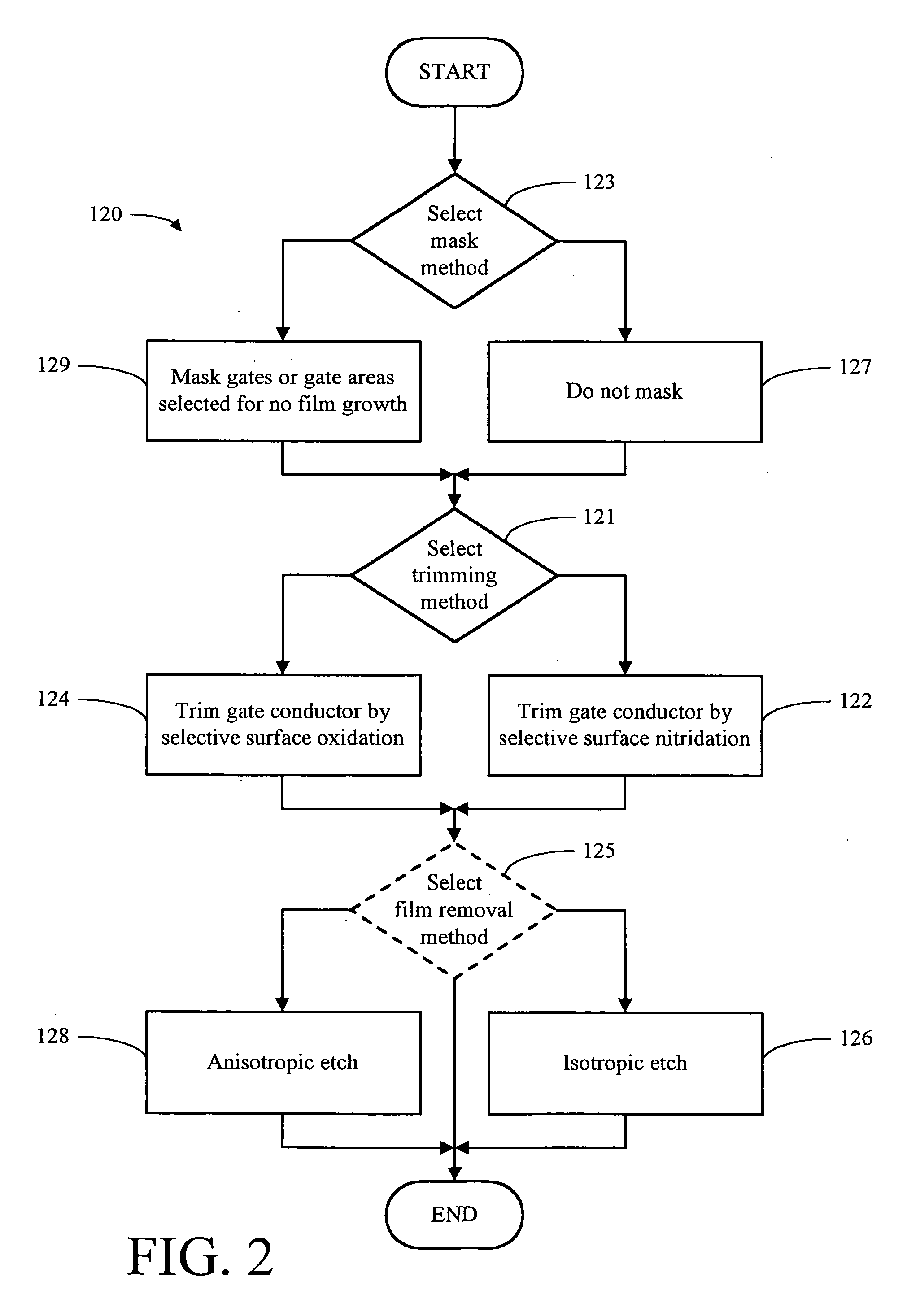

Method for selective trimming of gate structures and apparatus formed thereby

InactiveUS6759315B1Low powerSmall sizeSemiconductor/solid-state device manufacturingElectrical conductorGrown film

A method for forming a trimmed gate in a transistor comprises the steps of forming a polysilicon gate conductor on a semiconductor substrate and trimming the polysilicon portion by a film growth method chosen from among selective surface oxidation and selective surface nitridation. The trimming step may selectively compensate n-channel and p-channel devices. Also, the trimming film may optionally be removed by a method chosen from among anisotropic and isotropic etching. Further, gate conductor spacers may be formed by anisotropic etching of the grown film. The resulting transistor may comprise a trimmed polysilicon portion of a gate conductor, wherein the trimming occurred by a film growth method chosen from among selective surface oxidation and selective surface nitridation.

Owner:INT BUSINESS MASCH CORP

Method for manufacturing metal laminated substrate for semiconductor element formation and metal laminated substrate for semiconductor element formation

InactiveUS20110290380A1Low rolling reductionSmooth interfaceDecorative surface effectsSemiconductor/solid-state device detailsEtchingMetal foil

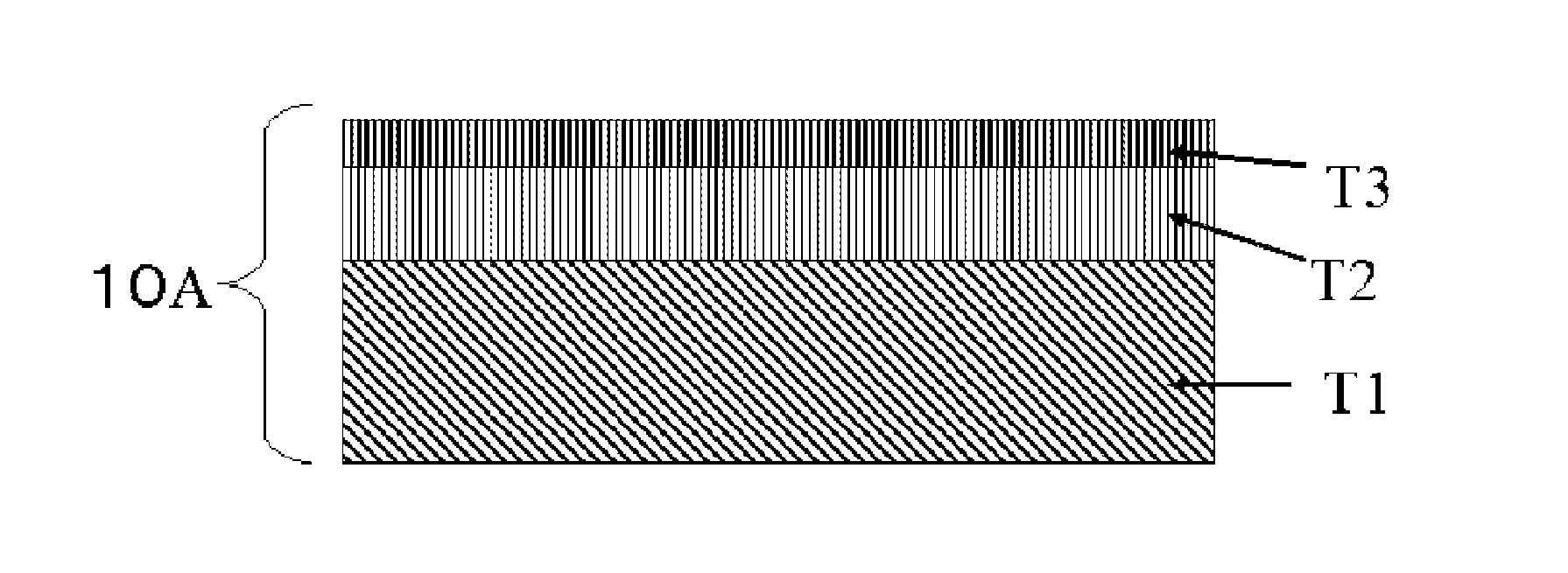

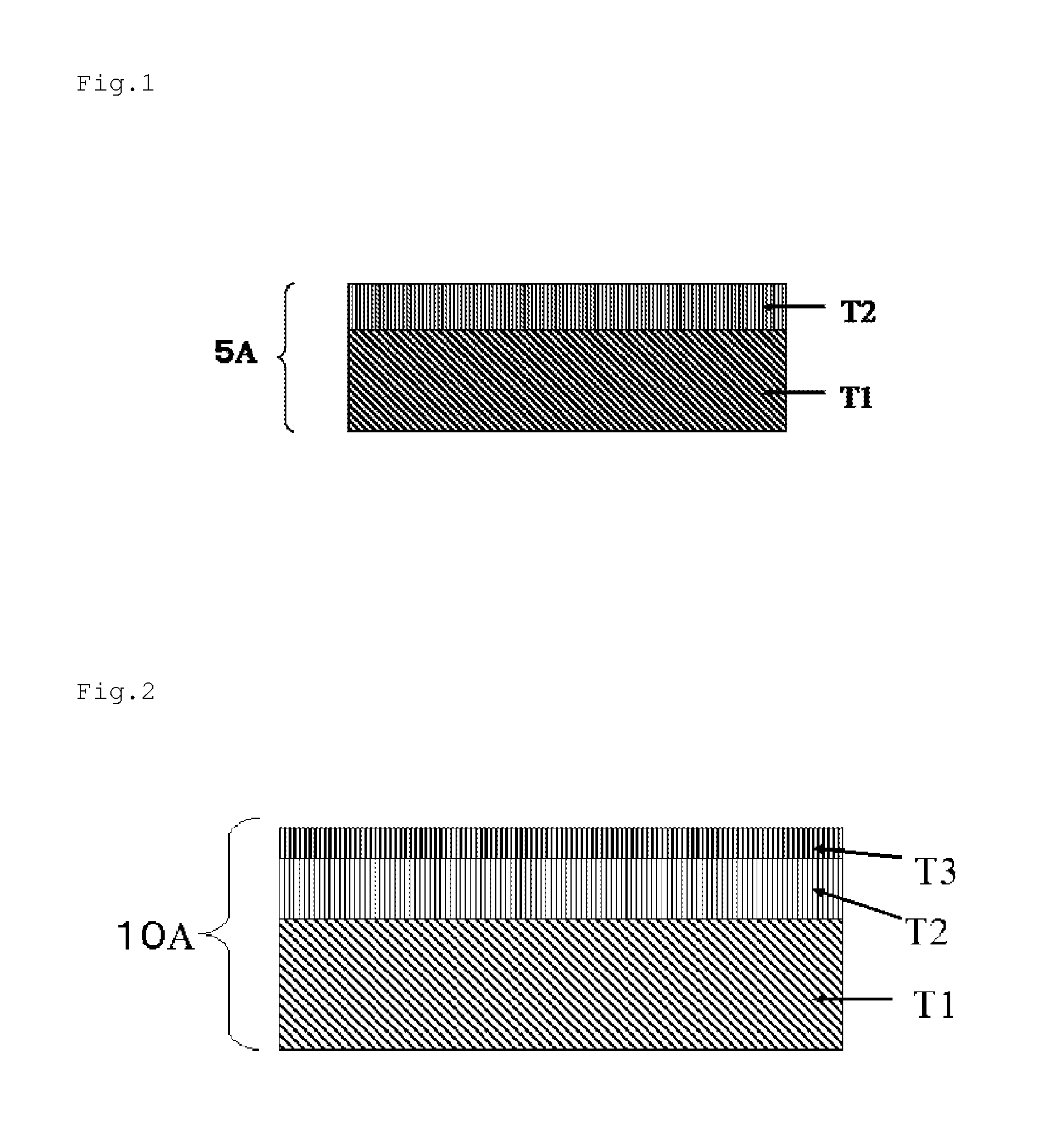

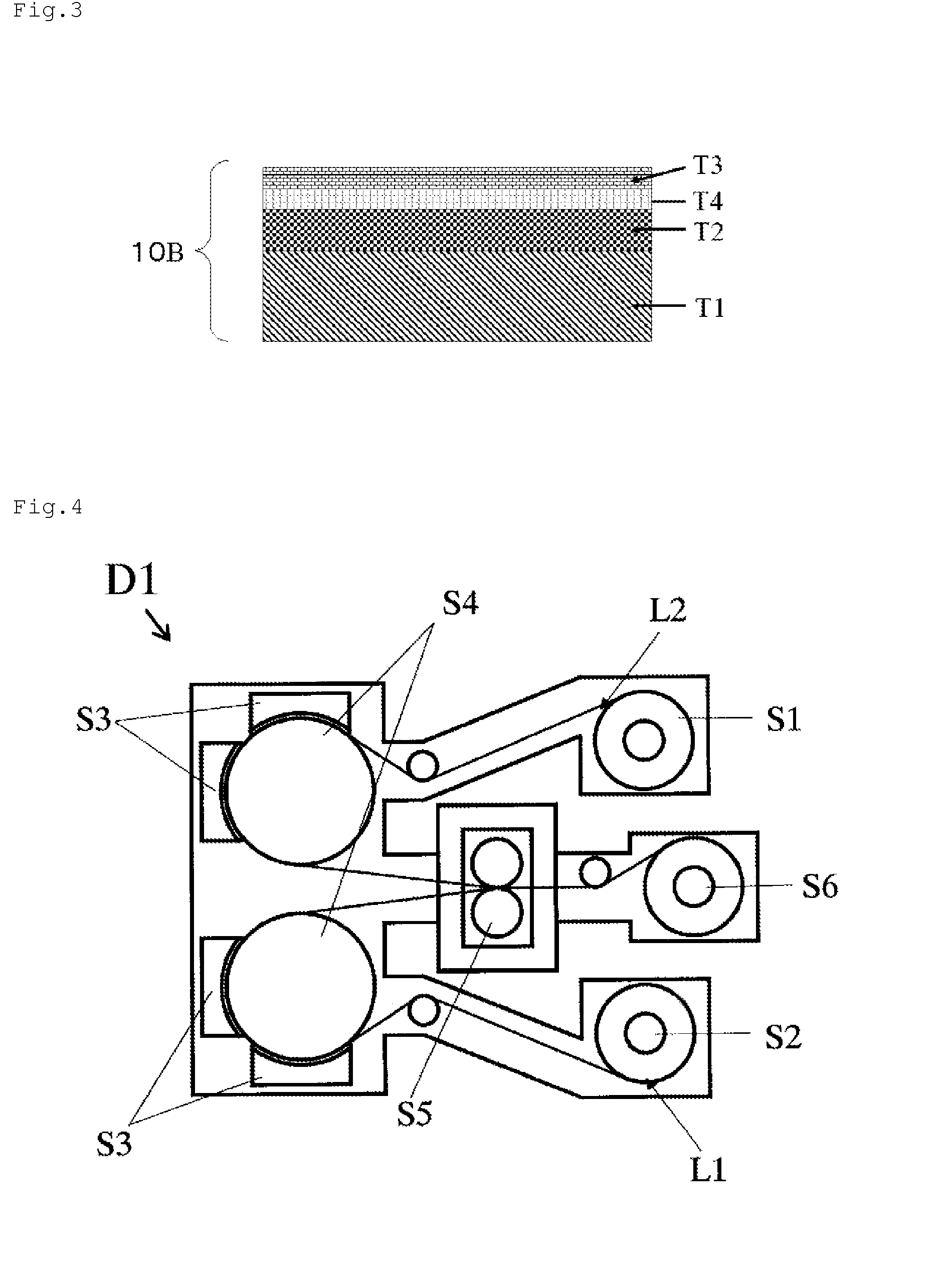

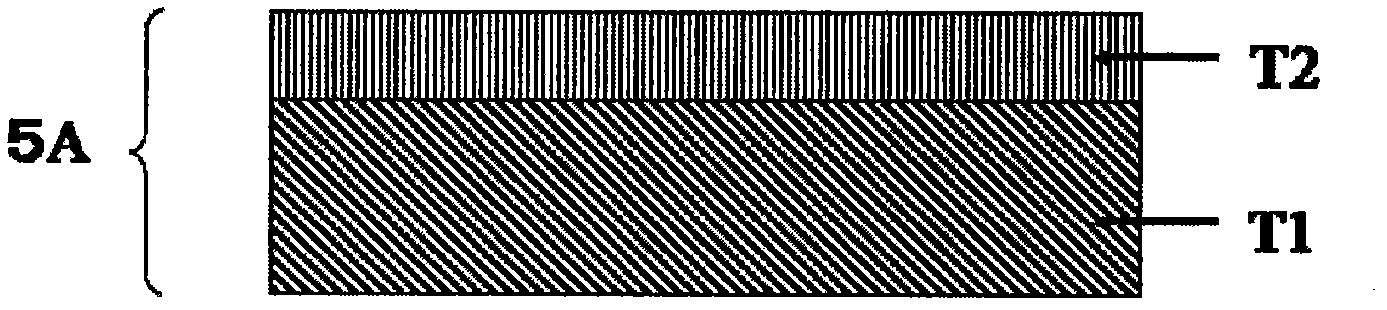

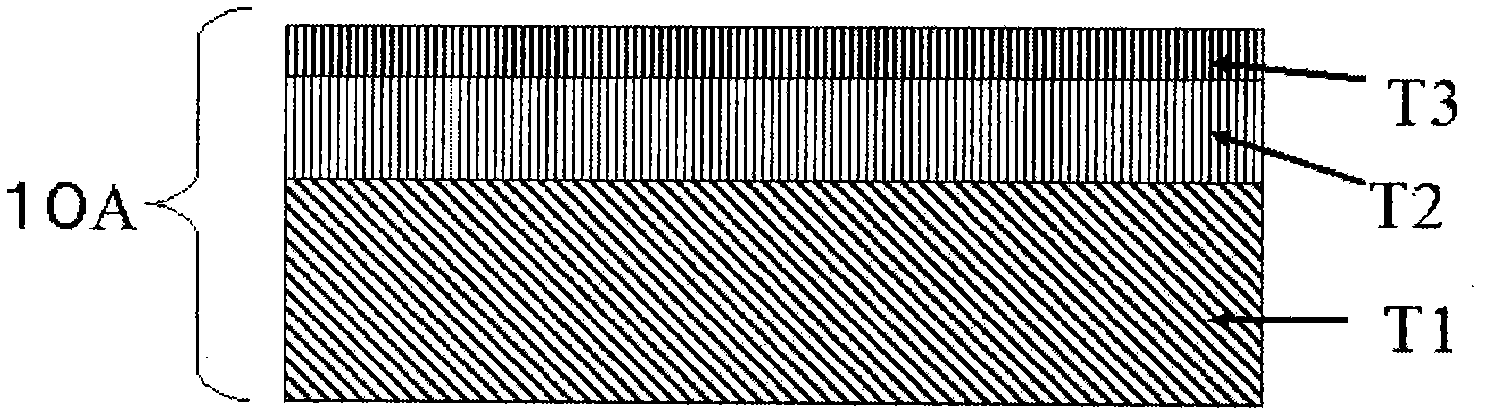

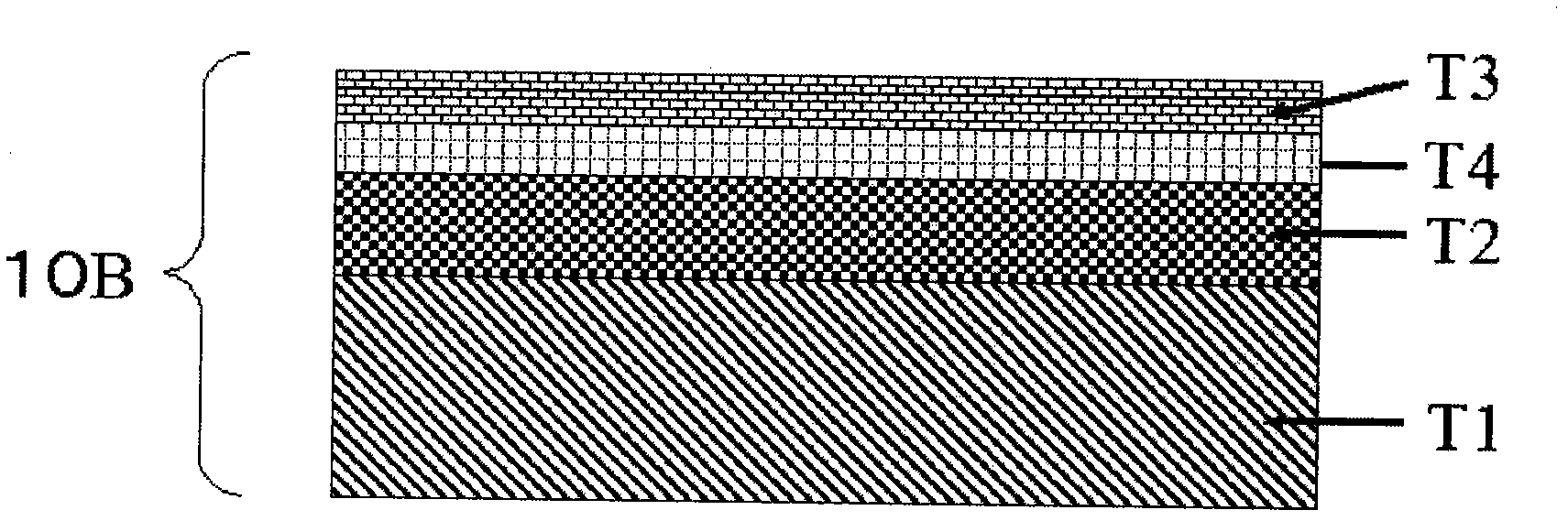

Disclosed is a metal laminated substrate for forming an epitaxial growth film for forming a semiconductor element having high biaxial crystal orientation on a surface of a metal substrate and a method of manufacturing the metal laminated substrate. The manufacturing method includes the steps of activating at least one surface of a metal plate T1 by sputter etching or the like; activating at least one surface of a metal foil T2 made of Cu or a Cu alloy which is cold-rolled at a rolling reduction of 90% or more; laminating the metal plate and the metal foil such that an activated surface of the metal plate and an activated surface of the metal foil face each other in an opposed manner and applying cold rolling to the metal plate and the metal foil which are laminated to each other at a rolling reduction of 10% or less, for example; and biaxially orienting crystals of the metal foil by heat treatment at a temperature of not lower than 150° C. and not higher than 1000° C.

Owner:TOYO KOHAN CO LTD

Method of forming a superconductor film

A method includes forming an as-grown film of a superconductor composed of a MgB2 compound which is made by simultaneous evaporation of magnesium and boron. The as-grown film is superconductive without an annealing process to make the film superconductive. The method can be applied to fabricate an integrated circuit of the superconductor film, because a high temperature annealing process to make the as-grown film superconductive is not needed.

Owner:NAT INST OF INFORMATION & COMM TECH

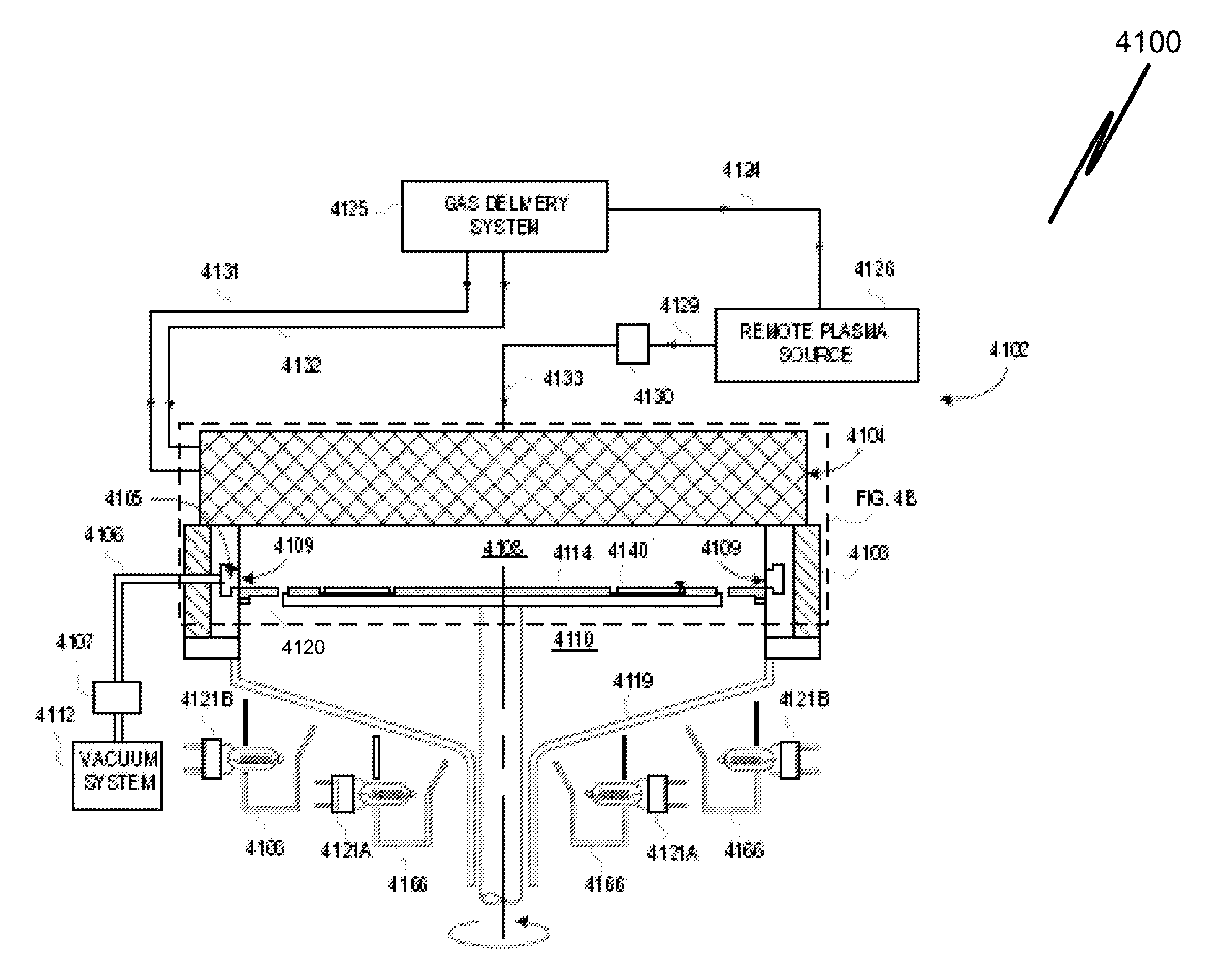

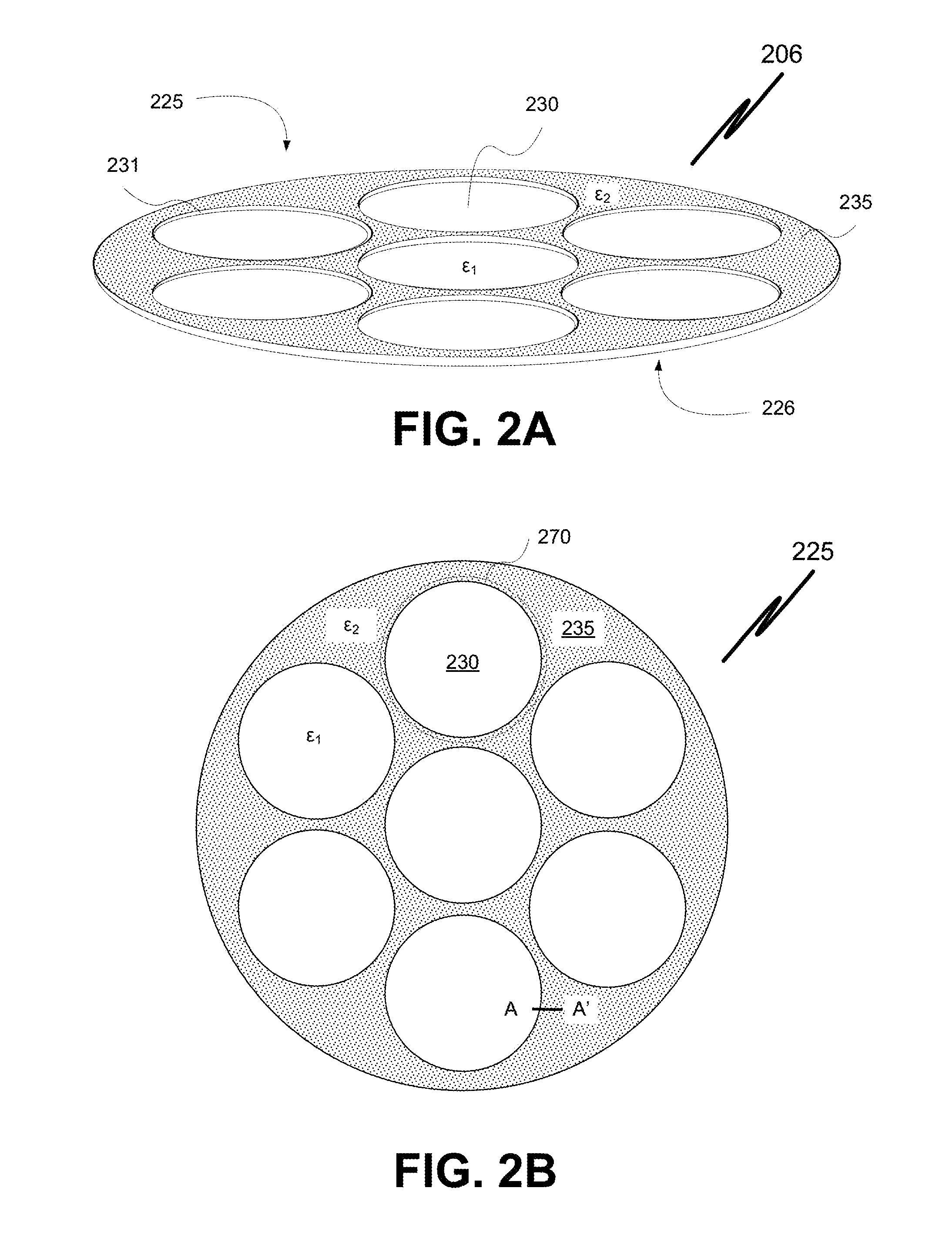

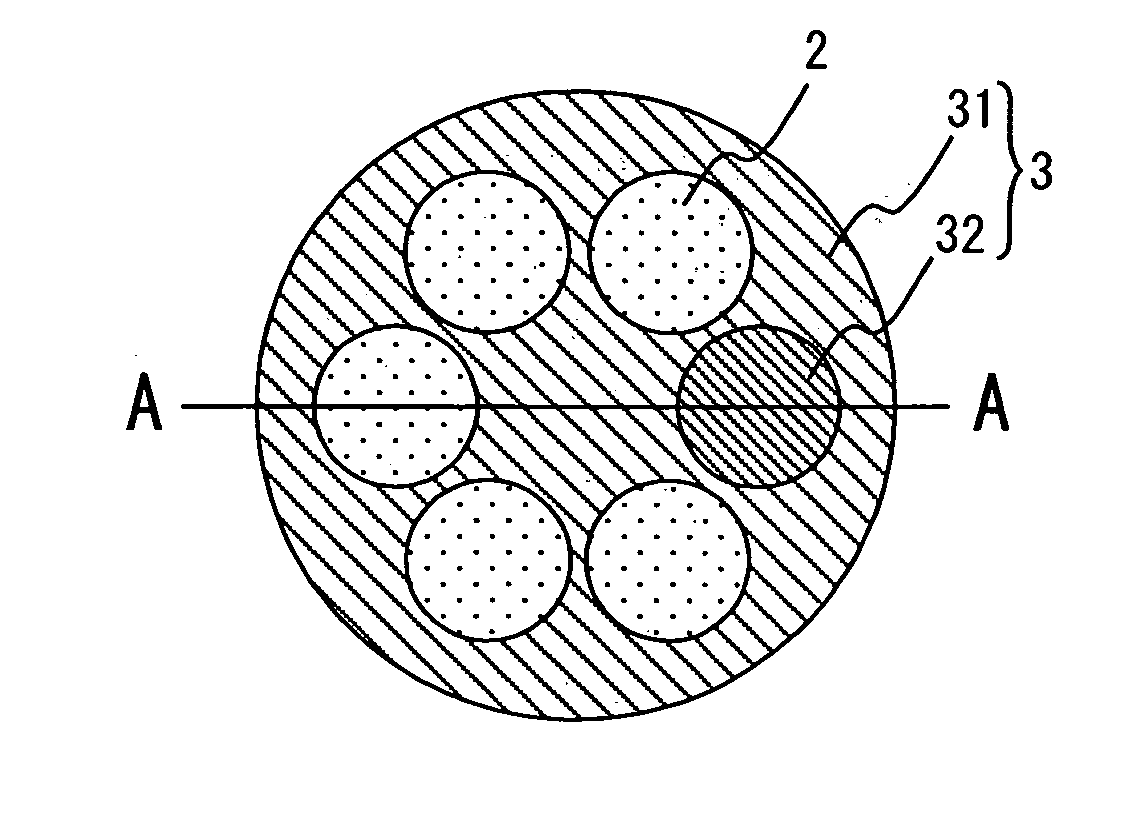

Substrate carrier with multiple emissivity coefficients for thin film processing

InactiveUS20120227667A1Enhance heat source transferringHigh materialPolycrystalline material growthSemiconductor/solid-state device manufacturingEnergy transferEmissivity

Substrate carrier having multiple emissivity coefficients for thin film processing and more particularly for support of a substrate during a deposition process epitaxially growing a film on the substrate. A front side of the carrier has a first carrier surface upon which the substrate is to be disposed, the first carrier surface having a first emissivity coefficient different than a second emissivity coefficient of a second carrier surface adjacent to the first carrier surface. Selection of the second emissivity coefficient independent of the first emissivity coefficient may modify an amount of energy radiated from the second carrier surface during processing of the substrate. In one embodiment, the second carrier surface has a second emissivity coefficient which is lower than the first emissivity coefficient to reduce heat loss from the carrier surface while maintaining high efficiency energy transfer between the carrier and a substrate.

Owner:APPLIED MATERIALS INC

Method for titania film growth in fluorine-based aqueous solution

InactiveCN101439873AHigh densityHigh light transmittanceTitanium dioxideGratingTithonia longiradiata

The invention relates to a method for preparing an anatase titania film with high compactness and high catalytic activity on various matrixes. The method mainly comprises the following steps: firstly, precipitating a titania seed layer with an amorphous form on a matrix; secondly, placing the seed layer in a titanium salt solution which contains a titanium salt stabilizer and has the mol concentration of 0.01 to 0.2mol.L<-1> for growth; and cleaning and drying the grown film to obtain a product. The method improves the compactness of the film and enables the film to have the light transmittance as high as more than 80 percent in the visible light area; and the method also realizes the epitaxial growth of the film in a single c axis direction and greatly improves the crystallinity. In addition, the method adopts a low temperature process and cheap raw material and has little raw material consumption and a simple process, thereby greatly reducing the production cost. The prepared film has potential application prospect in the fields of solar cells, antifog and self-cleaning coating, interference coating, gratings, and microelectronic and electroluminescent devices.

Owner:UNIV OF JINAN

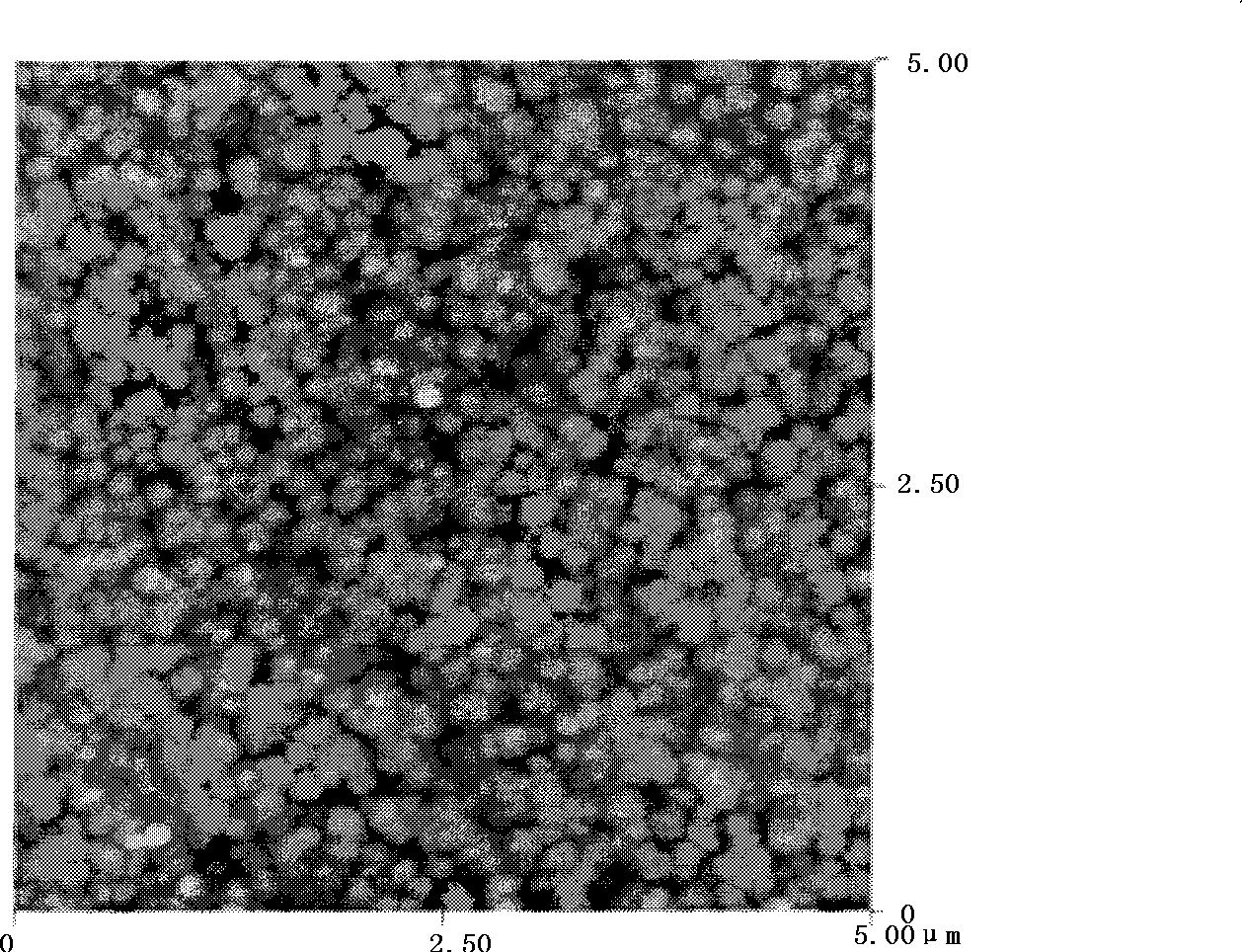

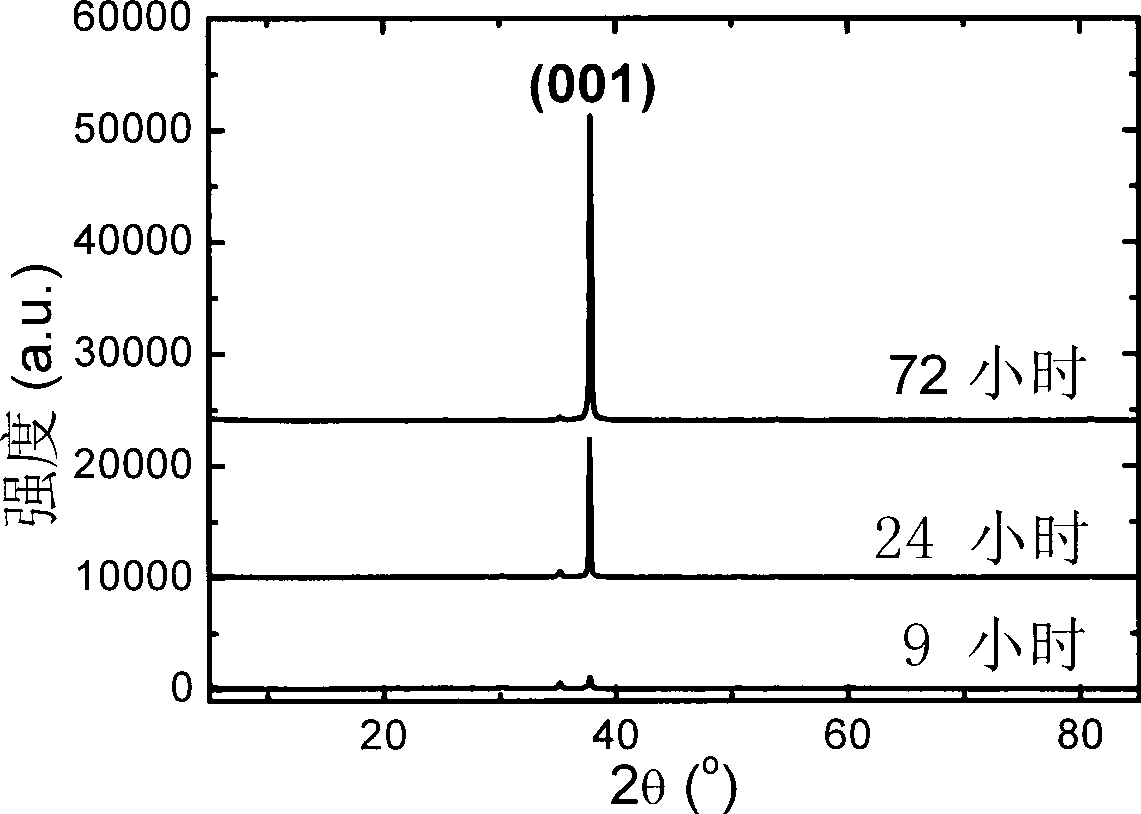

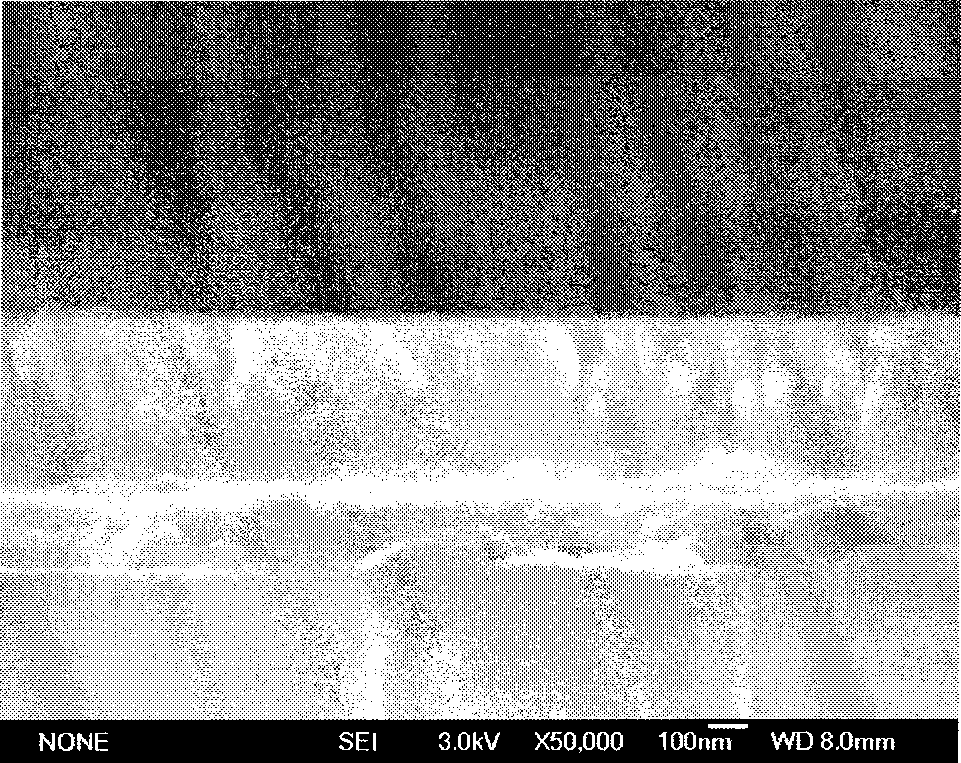

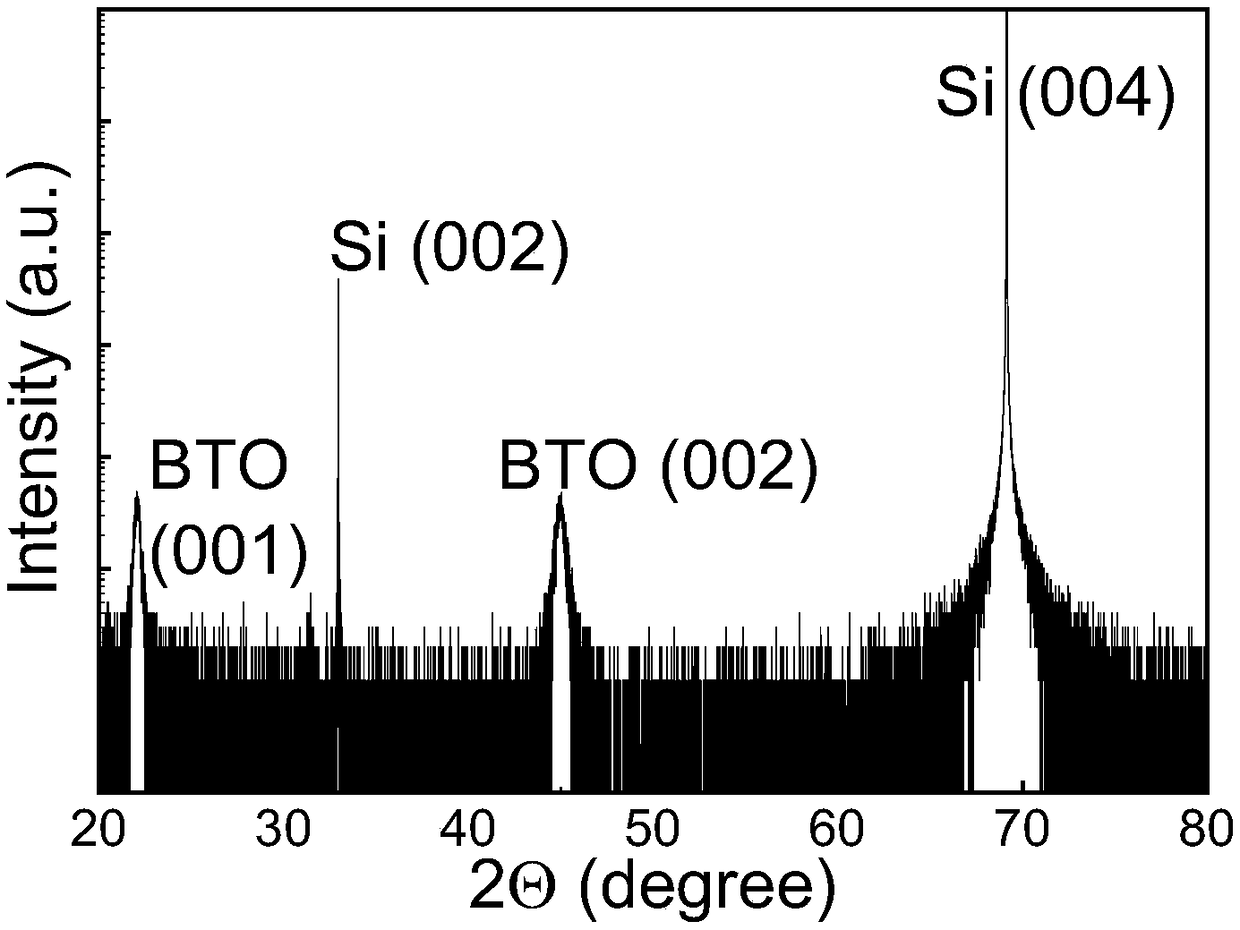

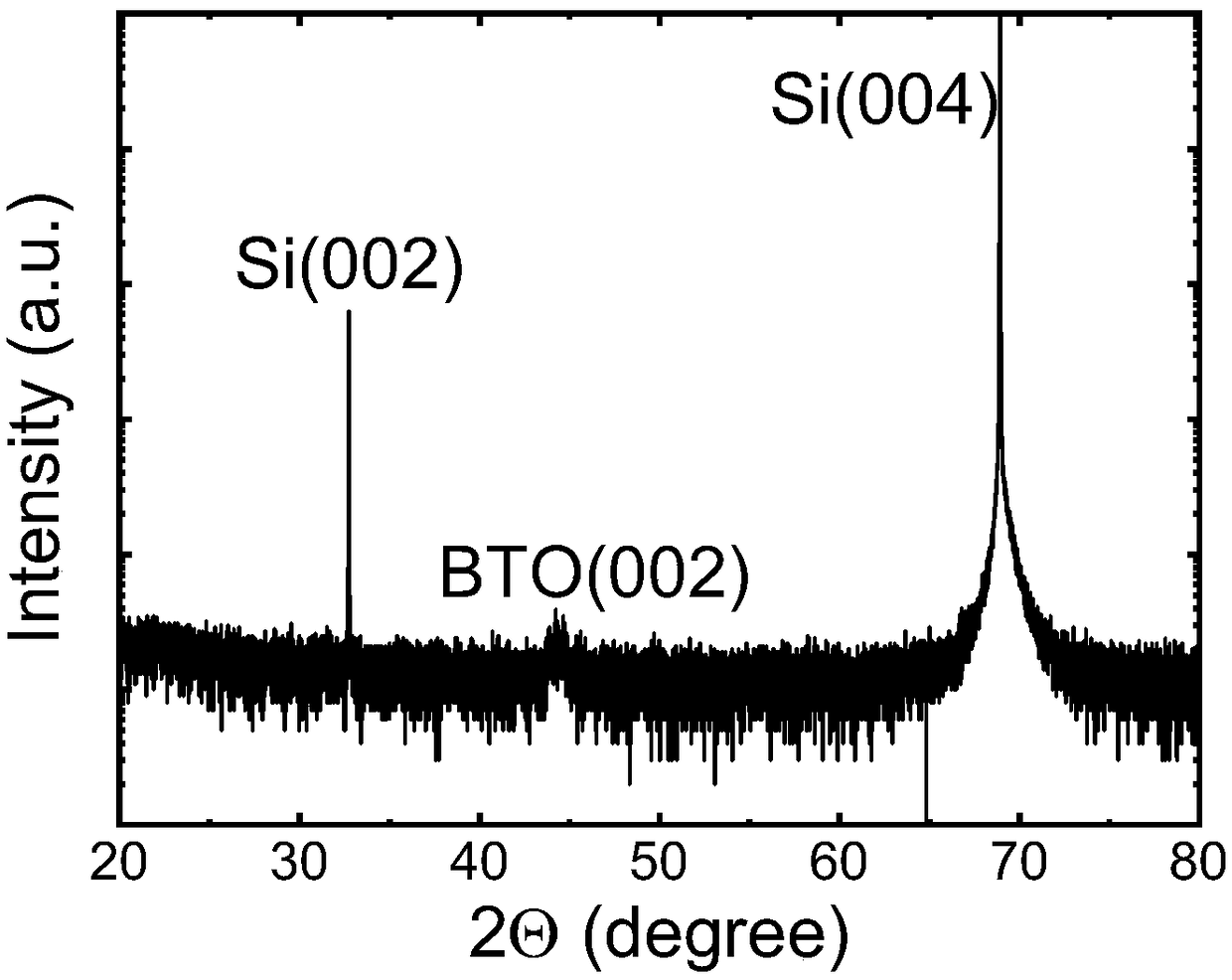

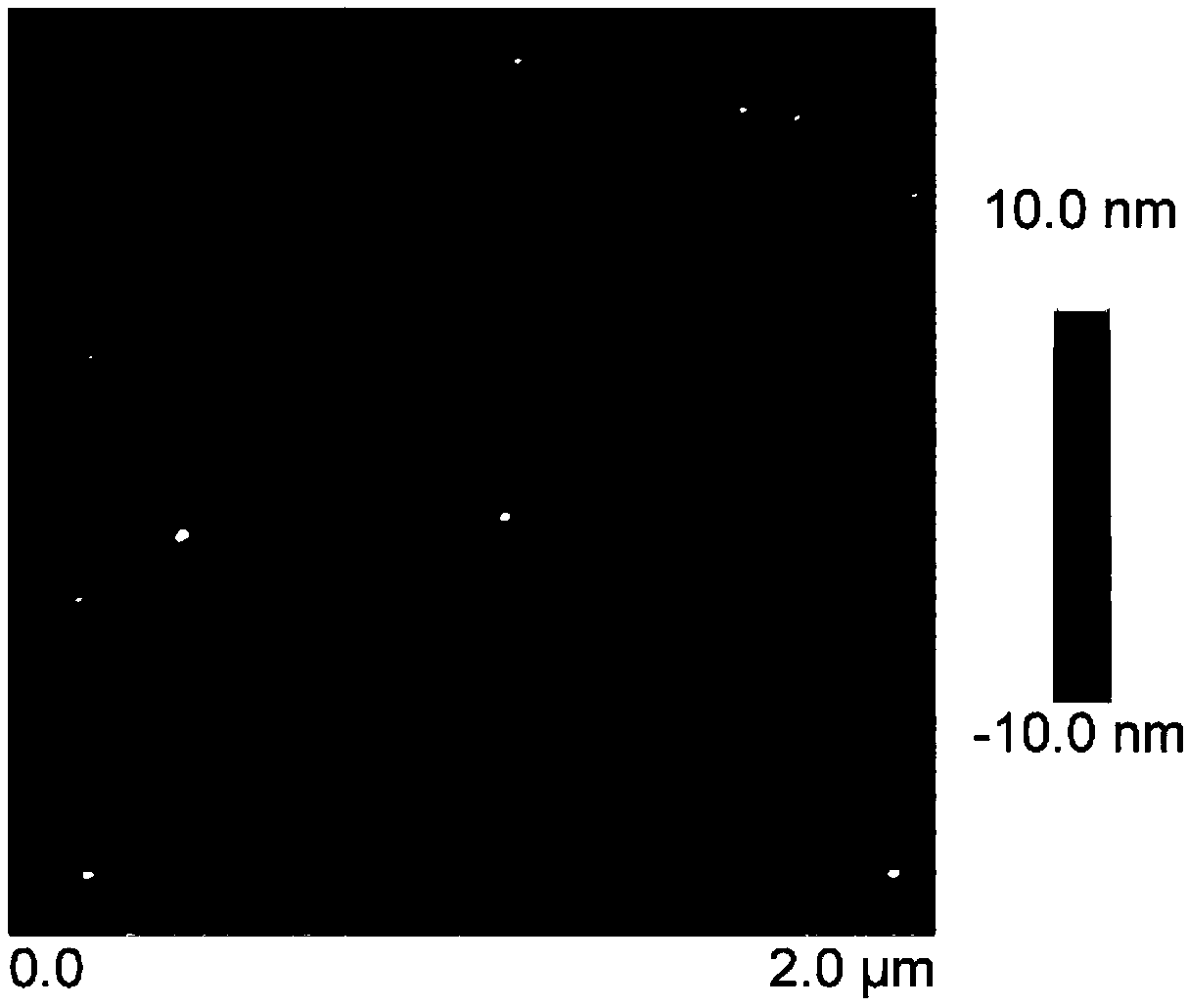

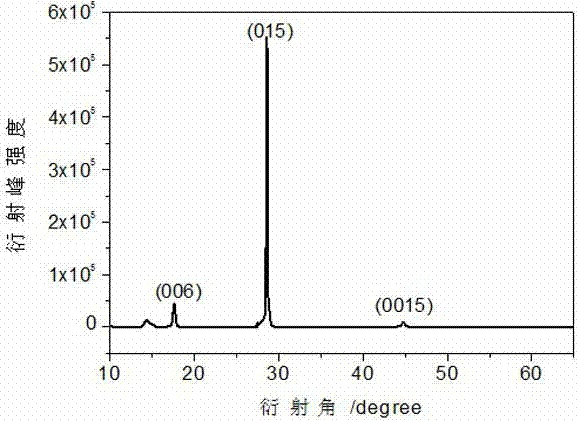

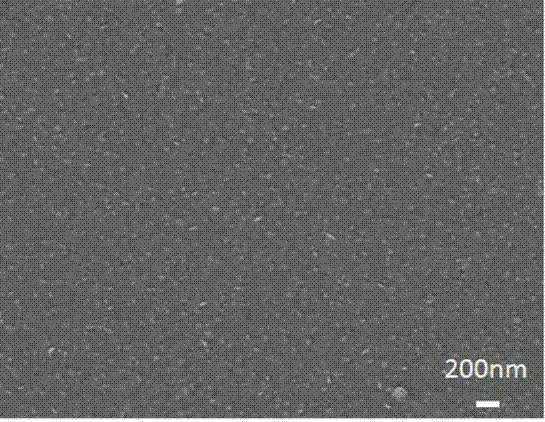

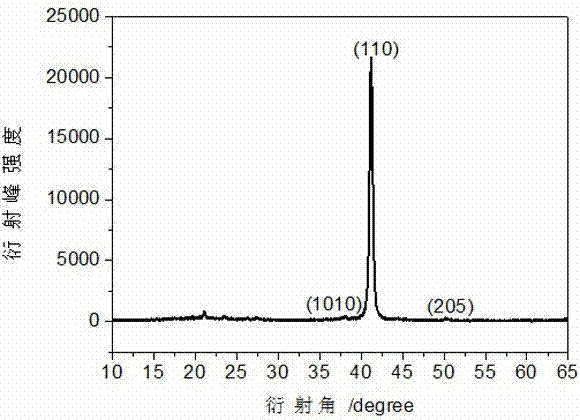

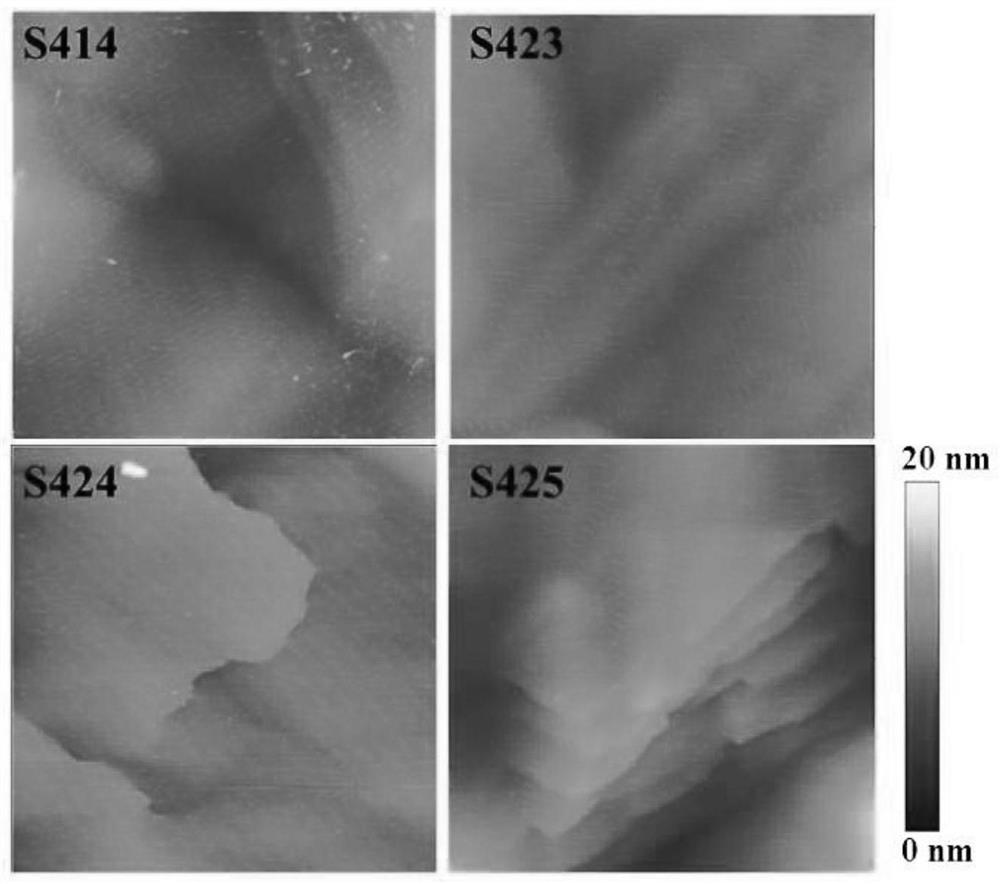

Preparation method of transferable perovskite oxide piezoelectric texture film for promoting crystallization by graphene

The invention discloses a preparation method of a transferable perovskite oxide piezoelectric texture film for promoting crystallization by graphene. The preparation method comprises the following steps: 1) graphene is selected as an interlayer material of an oxide and a substrate; and 2) a pulse laser deposition technology is selected to use as a film growth method; the growth temperature is controlled within 500-800 DEG C; the oxygen partial pressure is controlled within 10-20 Pa; the laser energy is controlled within 1.5-3 J / cm2; and the frequency is 1-10 Hz. The prepared film with a perovskite structure is analyzed by X-ray diffraction (XRD), an atomic force microscope (AFM) and a piezoelectric force microscope (FPM); the film obtained by growth has excellent texture crystallization characteristic; the film layer thickness is controllable within 300 nm; the film surface is smooth; the RMS roughness is within 1 nm; and the grown film achieves the piezoelectricity and the potential of transferring to any substrate.

Owner:XI AN JIAOTONG UNIV

Method for selective trimming of gate structures and apparatus formed thereby

InactiveUS20040180484A1Low powerSmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorGrown film

A method for forming a trimmed gate in a transistor comprises the steps of forming a polysilicon gate conductor on a semiconductor substrate and trimming the polysilicon portion by a film growth method chosen from among selective surface oxidation and selective surface nitridation. The trimming step may selectively compensate n-channel and p-channel devices. Also, the trimming film may optionally be removed by a method chosen from among anisotropic and isotropic etching. Further, gate conductor spacers may be formed by anisotropic etching of the grown film. The resulting transistor may comprise a trimmed polysilicon portion of a gate conductor, wherein the trimming occurred by a film growth method chosen from among selective surface oxidation and selective surface nitridation.

Owner:INT BUSINESS MASCH CORP

Method for electrochemically preparing thermoelectric film by using seeding layer

InactiveCN102867906ADefinite growth orientationLow growth temperatureThermoelectric device manufacture/treatmentGrown filmElectrochemistry

The invention belongs to the field of electrochemical preparation of a thermoelectric material, and relates to a method for electrochemically preparing a thermoelectric film by using a seeding layer, which comprises the following steps: preparing a seeding layer having a nano-level thickness on a substrate through molecular beam epitaxy, magnetron sputtering and other modes; and electrochemically growing a thermoelectric film material, wherein the thickness of the film can be of the nano level. By using the method, the growth orientation of the epitaxial film can be controlled, and a thermoelectric film having an obviously column structure orientation is prepared, so that the thermoelectric properties of the electrochemically grown film can be improved. Due to the self characteristics of electrochemistry such as low cost and convenient growing process, a material preparation foundation is provided for the assembly of a thermoelectric device in future.

Owner:SHANGHAI UNIV

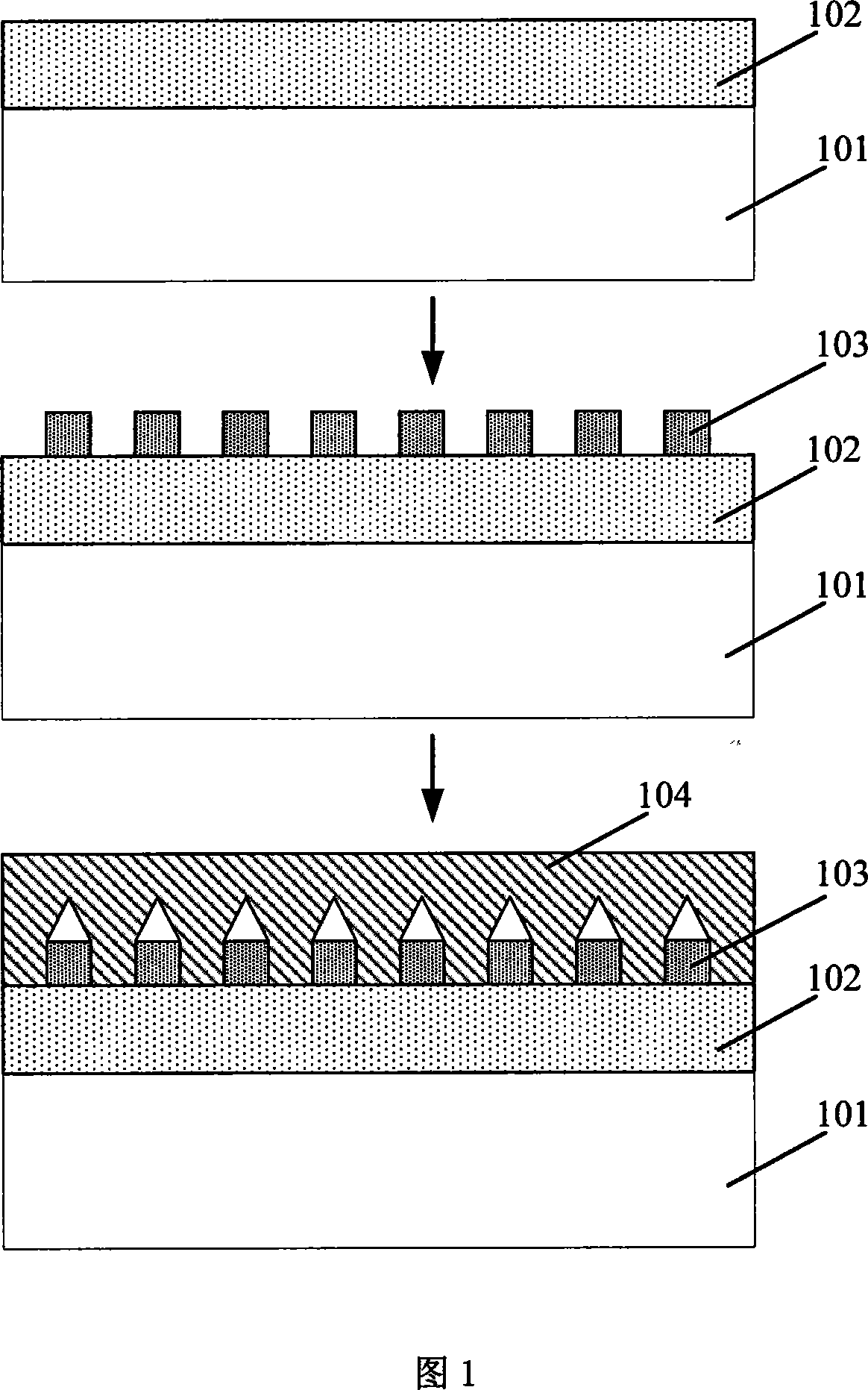

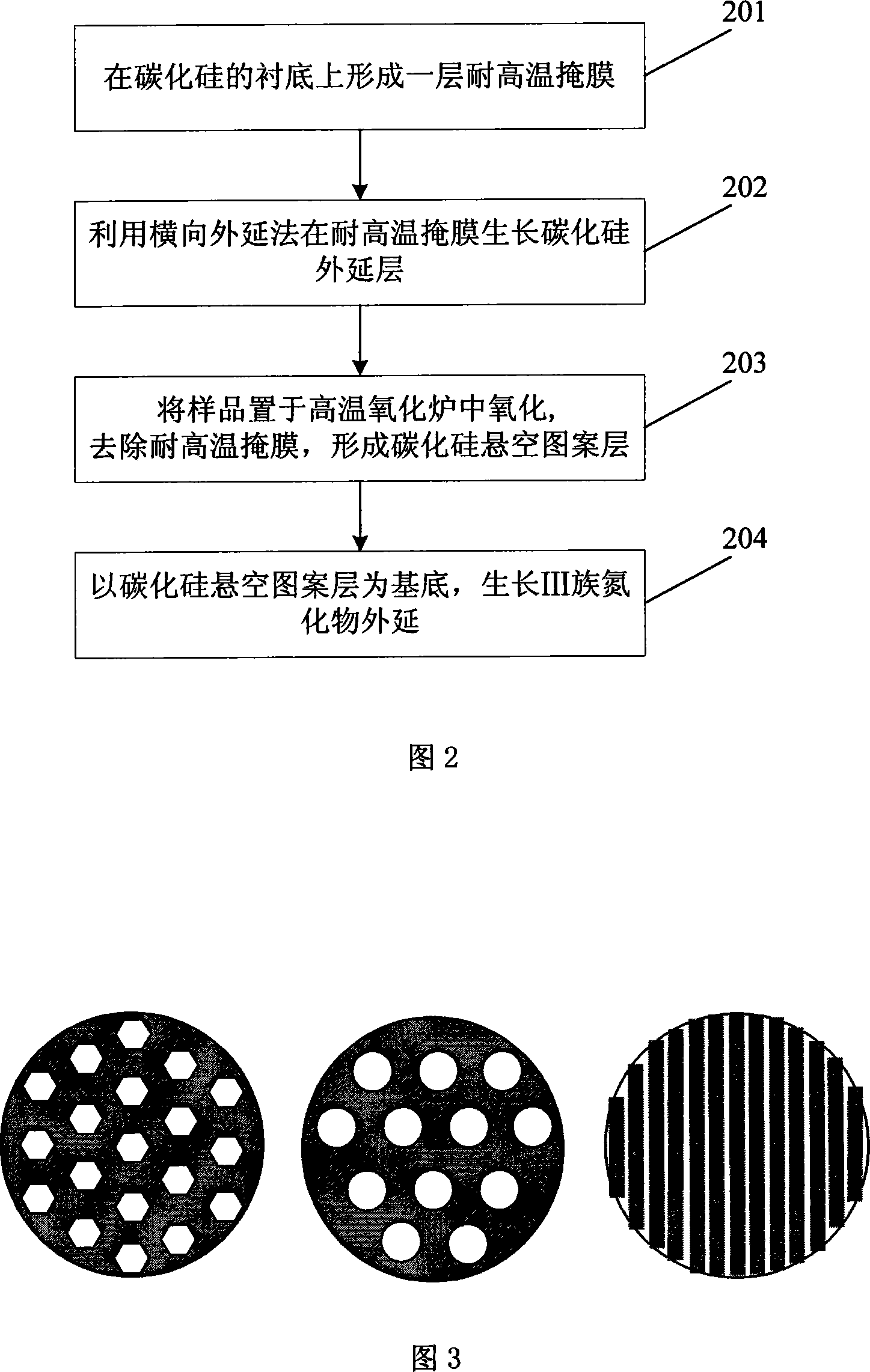

III nitride semi-conductor material and growing method thereof

InactiveCN101140865AReduce the cost of growthEasy to achieve strippingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor materialsGrown film

The invention discloses a semiconductor material for nitride of group III and its growing directions, which belongs to the field of semiconductor technology. The said method is composed of: forming a heat-resistant mask layer on the semiconductor substrate; growing the epilayer homogeneous with the said substrate on the said heat-resistant mask layer by epitaxial method; oxidize the said semiconductor into the oxidation furnace and eliminate the heat-resistant mask to form impending pattern homogeneous with the said substrate; Taking the said impending pattern as the base, growing the epitaxis of the nitride of group III to form the semiconductor material for nitride of group III, which comprises a substrate, impending pattern on the base of the substrate formed by epitaxial technology and the epitaxis of the nitride of group III on the impending pattern by epitaxial technology of the nitride of group III. The invention lowers the growing cost and reduces the stress between growing-finishing grown film and substrate through the impending pattern, thus to grow flawless thick film.

Owner:MAANSHAN JASON SEMICON CO LTD

Method for manufacturing metal laminated substrate for semiconductor element formation and metal laminated substrate for semiconductor element formation

ActiveCN102210009AFit evenlyGood precisionSemiconductor/solid-state device detailsSolid-state devicesEtchingMetal foil

Disclosed is a metal laminated substrate for epitaxially grown film formation for semiconductor element formation, the metal laminated substrate comprising a metal substrate having a high biaxially crystal-aligned surface. Also disclosed is a method for manufacturing the metal laminated substrate, comprising the steps of activating at least one surface of a metal plate (T1) by sputter etching or the like, activating at least one surface of a metal foil (T2) formed of Cu or a Cu alloy which has been cold rolled with a reduction of not less than 90%, stacking the metal plate and the metal foil on top of each other so that the activated surface of the metal plate faces the activated surface of the metal foil, cold rolling the laminate, for example, with a reduction of not more than 10%, and heat treating the cold rolled laminate at 150 to 1000 DEG C for biaxial crystal alignment of the metal foil.

Owner:TOYO KOHAN CO LTD

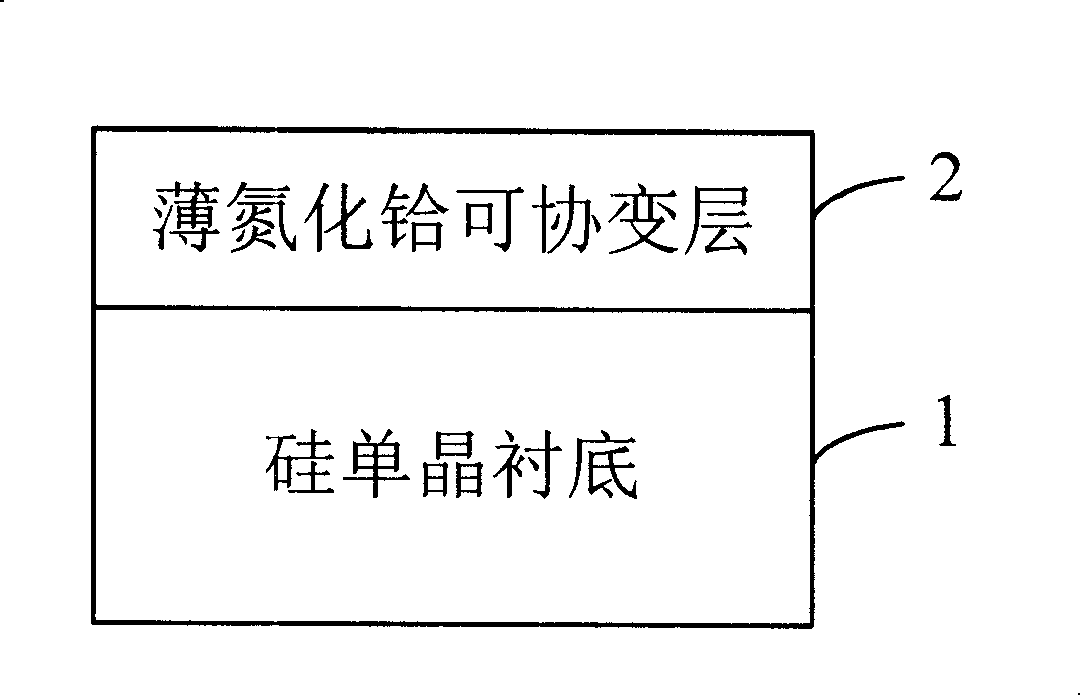

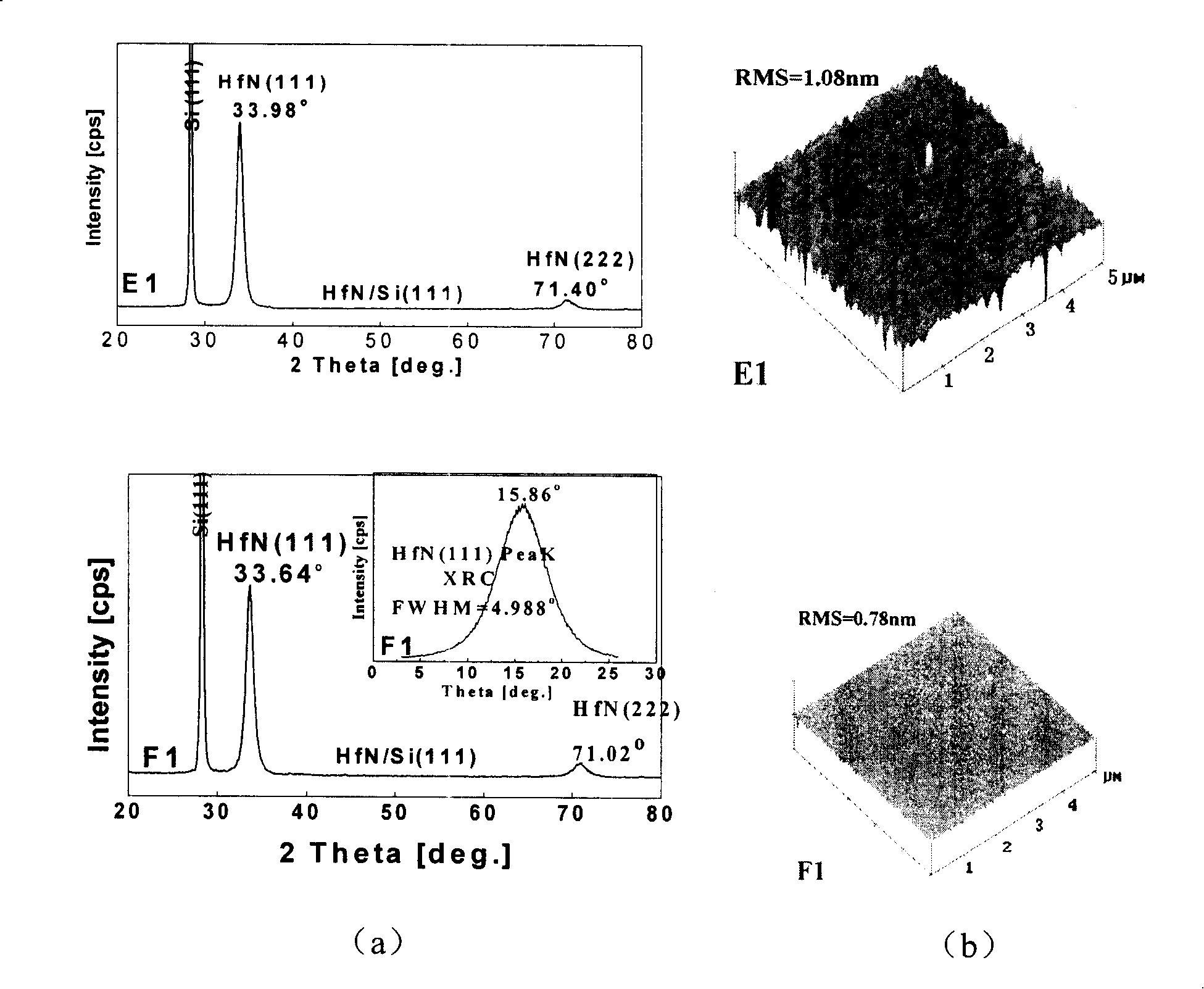

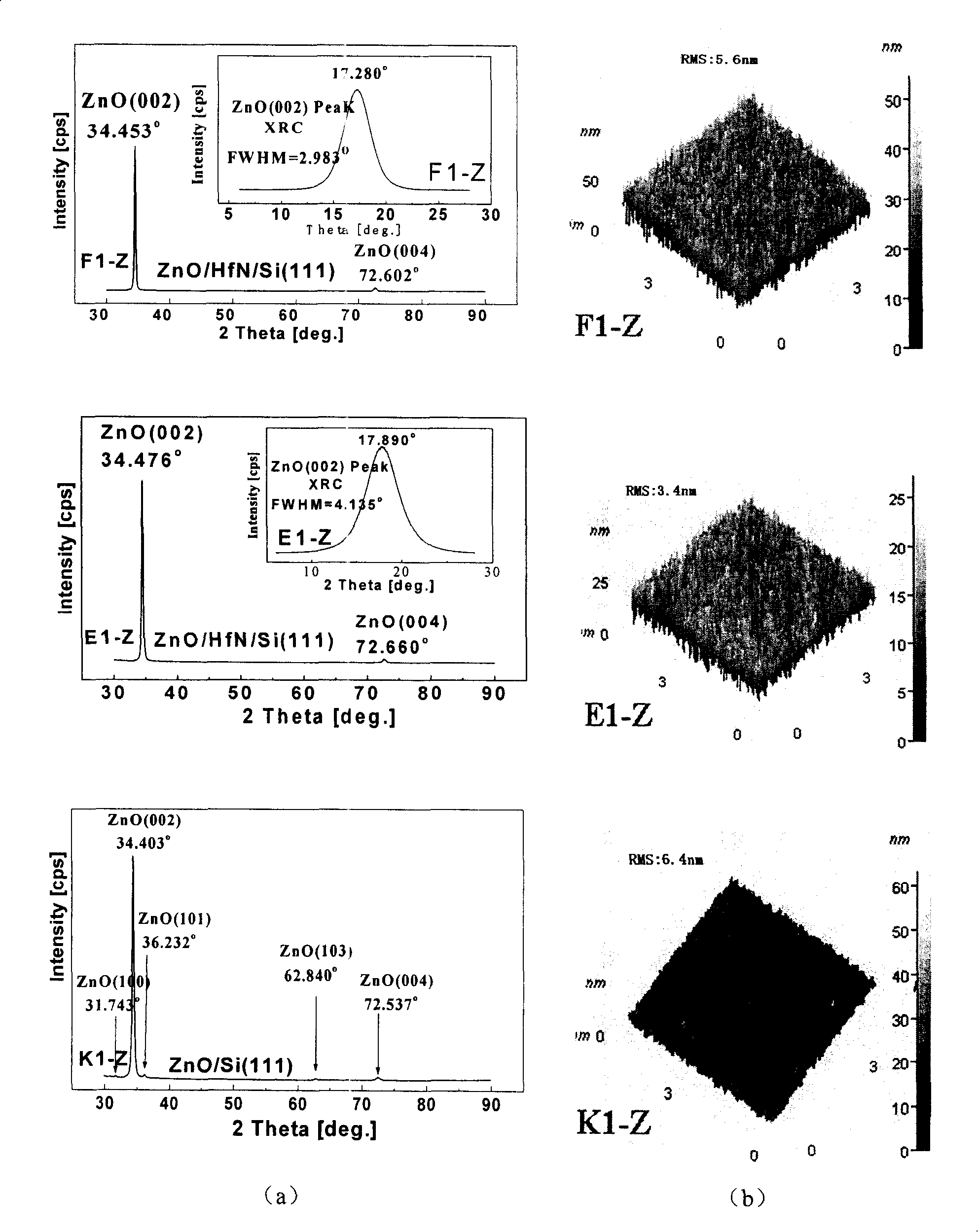

Silicon based compliant substrate material possessing thin hafnium nitride compliant layer

InactiveCN101211989ACoordination mismatch strainGood chemical and thermal stabilityLaser detailsSemiconductor/solid-state device detailsSemiconductor materialsGrown film

The invention relates to the technical field of epitaxial film preparation of zinc oxide of semiconductor materials and discloses a silicon-based compliant substrate material with thin hafnium nitride compliant layer. The material includes the following components: a single crystal silicon substrate which is used for supporting the whole silicon-based compliant substrate material; a thin hafnium nitride compliant layer, whose preparation is on the single crystal silicon substrate and is used for adjusting mismatch strain of epitaxial grown film of zinc oxide. By adopting the invention, mismatch strain of epitaxial film of zinc oxide on silicon substrate can be adjusted and residual stress be reduced, thus improving the crystal quality and surface appearance and laying a foundation for research of silicon-based optoelectronic devices.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

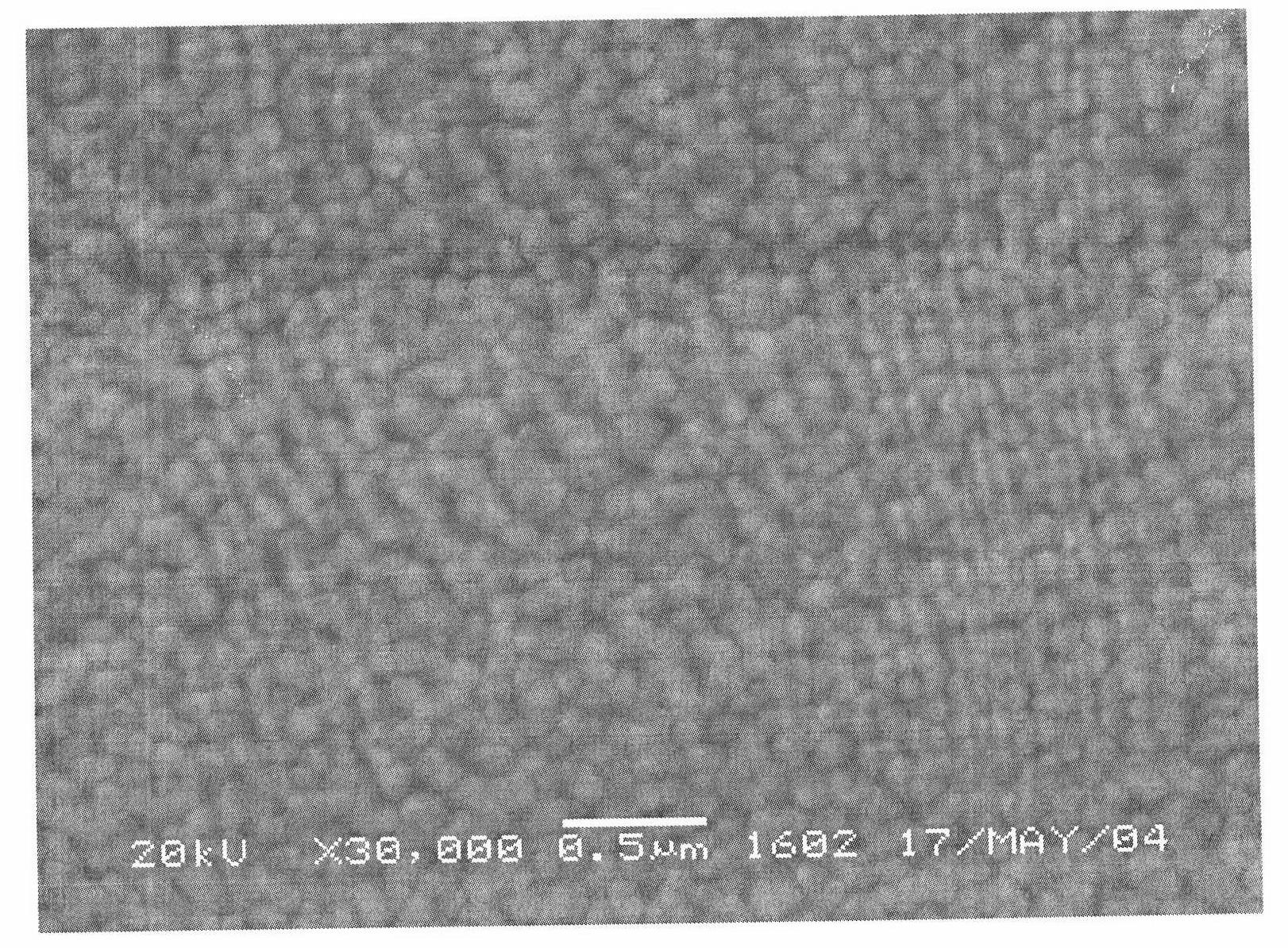

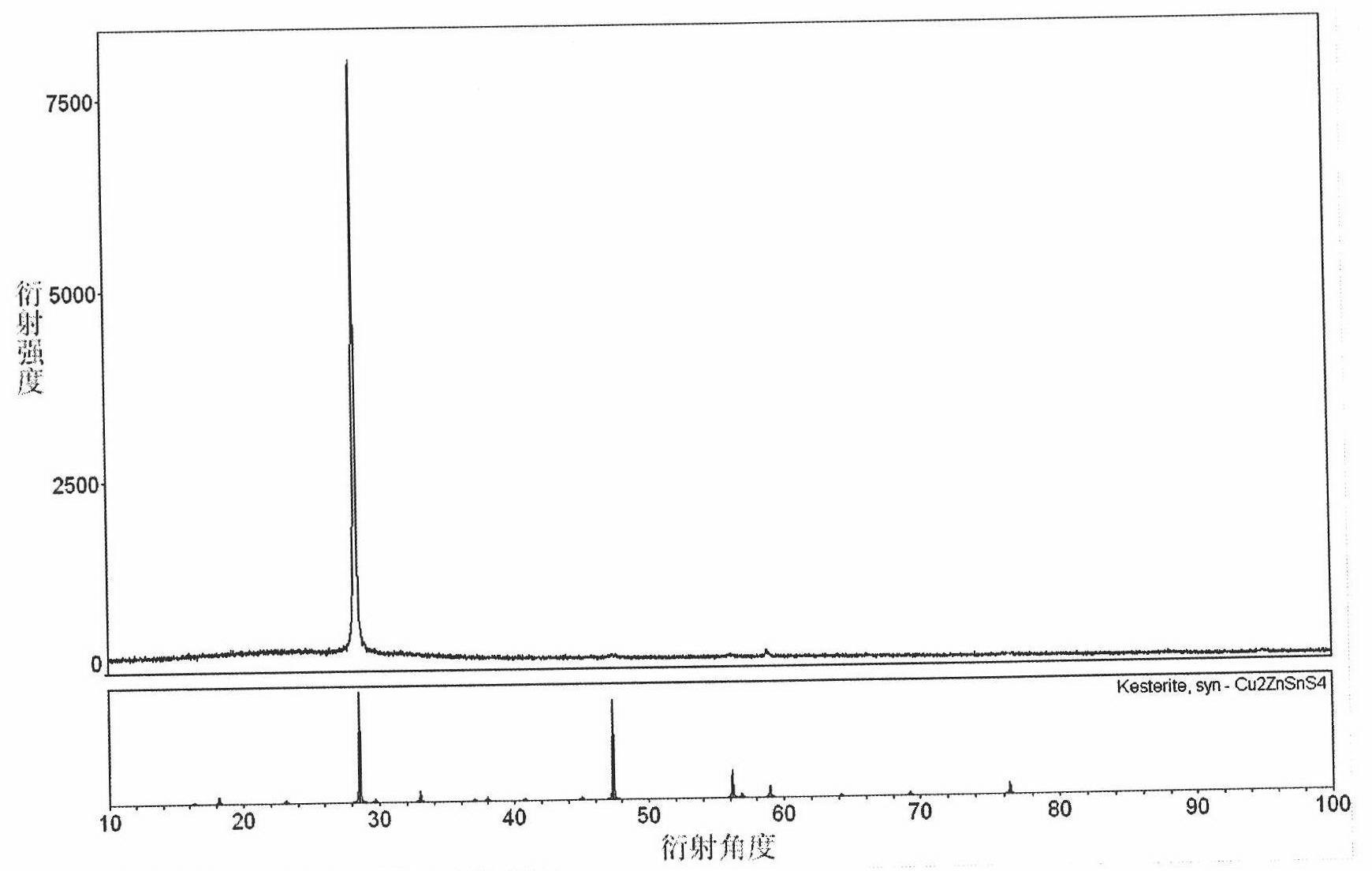

Preparation method of Cu2ZnSnS4 photovoltaic film

InactiveCN101967624AImprove crystal qualityQuadratic phase suppressionFinal product manufactureVacuum evaporation coatingGrown filmMetallic materials

The patent refers to the field of 'coating metallic material; coating material with metallic material; surface treatment of metallic material by diffusion into the surface, by chemical conversion or substitution; coating by vacuum evaporation, by sputtering, by ion implantation or by chemi'. The invention relates to a preparation method of a Cu2ZnSnS4 photovoltaic film, which is characterized by comprising the following step of: depositing a film in a magnetron reactive sputtering way by taking a mixed gas of hydrogen sulfide and argon as a sputtering gas and a Cu-Zn-Sn alloy target as a cathode target, wherein the alloy target comprises the following components with the atomic ratio of Cu:Zn:Sn=1:0.1-2:0.1-2, pressure intensity inside a sputtering chamber during sputtering is 0.05-10 Pa, the distance between the alloy target and a substrate is 3-15 cm, the sputtering power of the cathode target is 15-300 W, the temperature of the substrate is 20-700 DEG C, the substrate rotates at the speed of 0-1000 turns / minute, and the thickness of the grown film is 0.2-5 micrometers. Compared with the traditional technology based on thermal activation, the Cu2ZnSnS4 photovoltaic film prepared by the method has good large-area component uniformity, high crystallization quality and few impure phase; in addition, the method also has the advantages of simple process, low cost, good repeatability, and the like.

Owner:CENT SOUTH UNIV

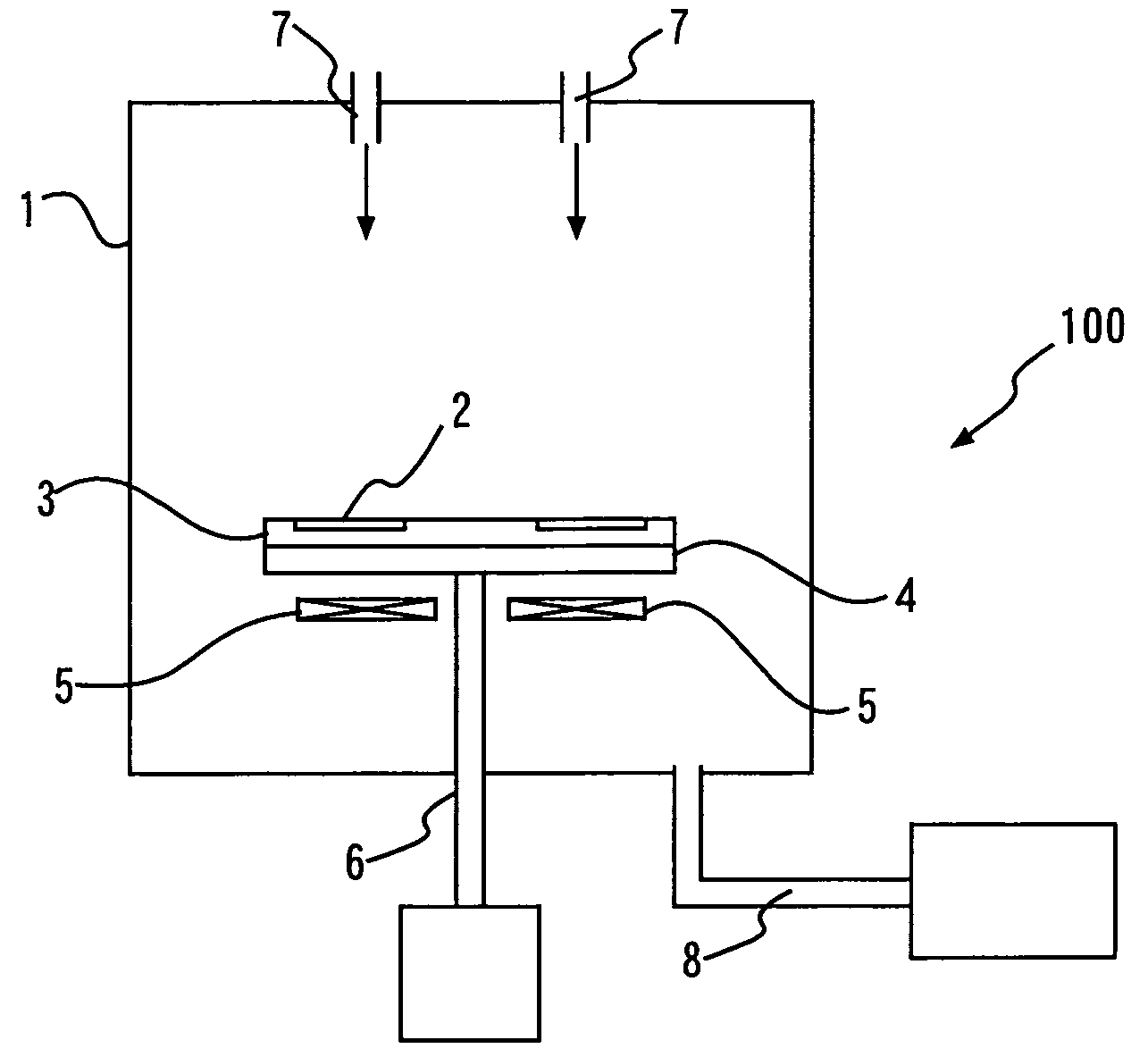

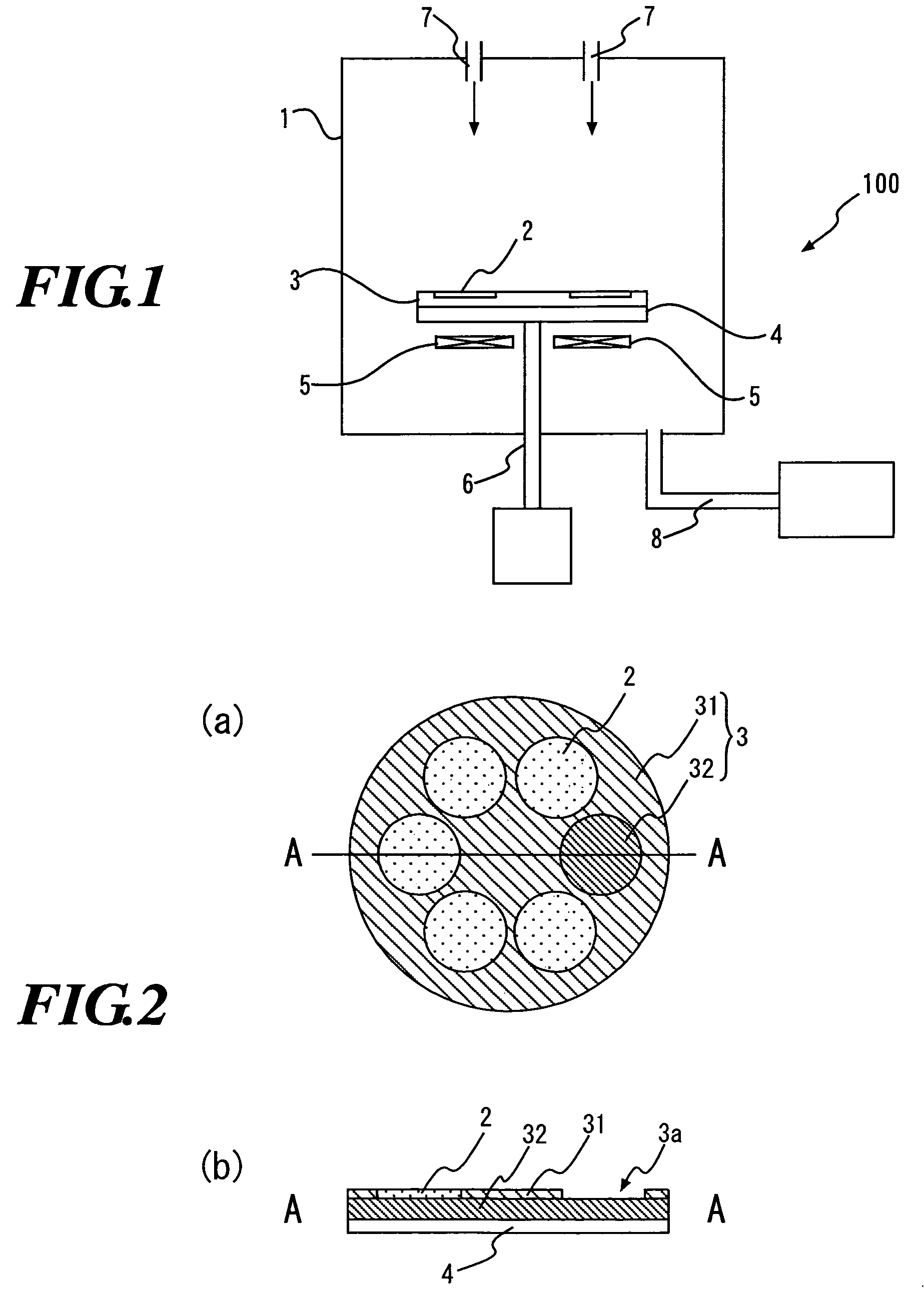

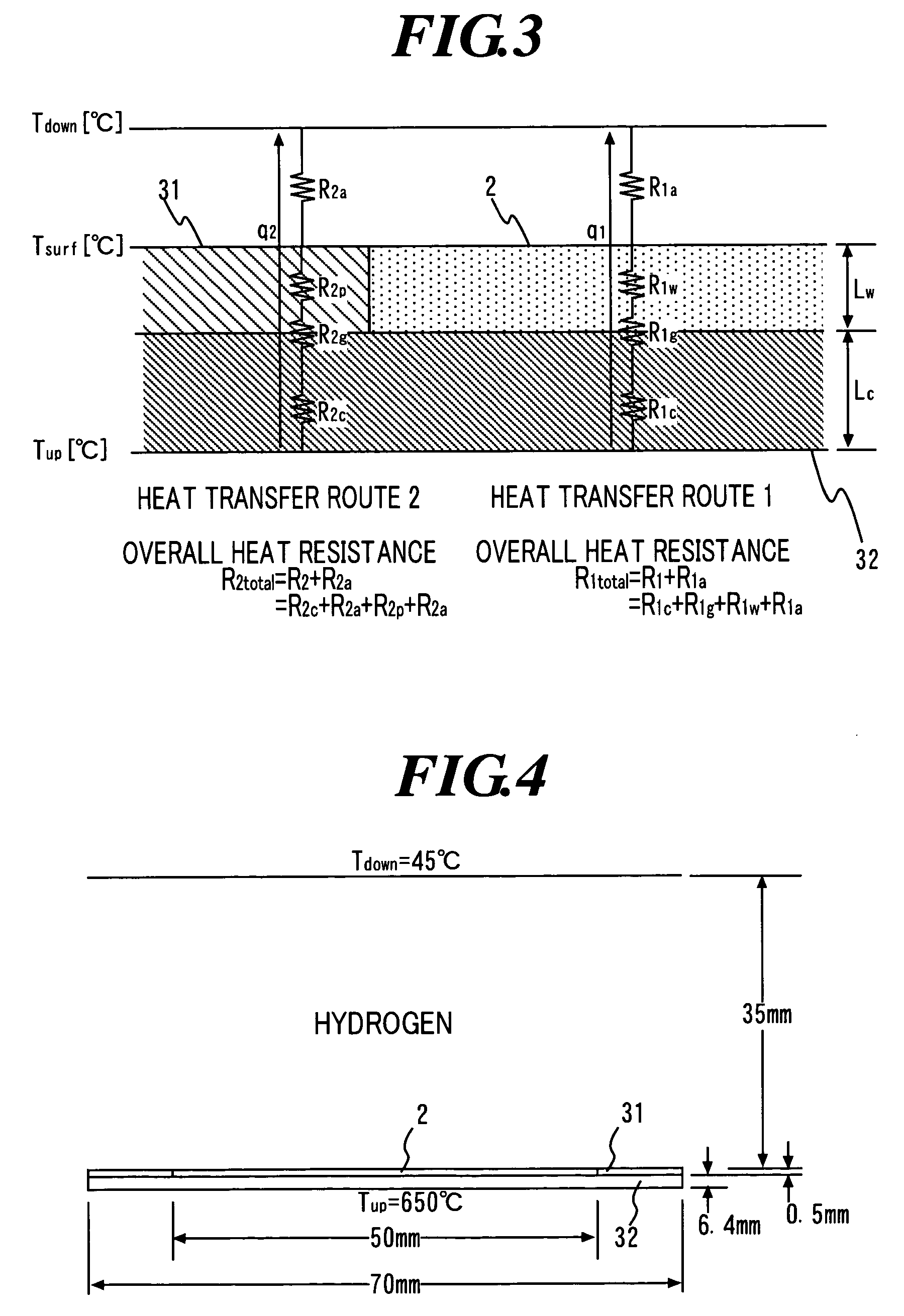

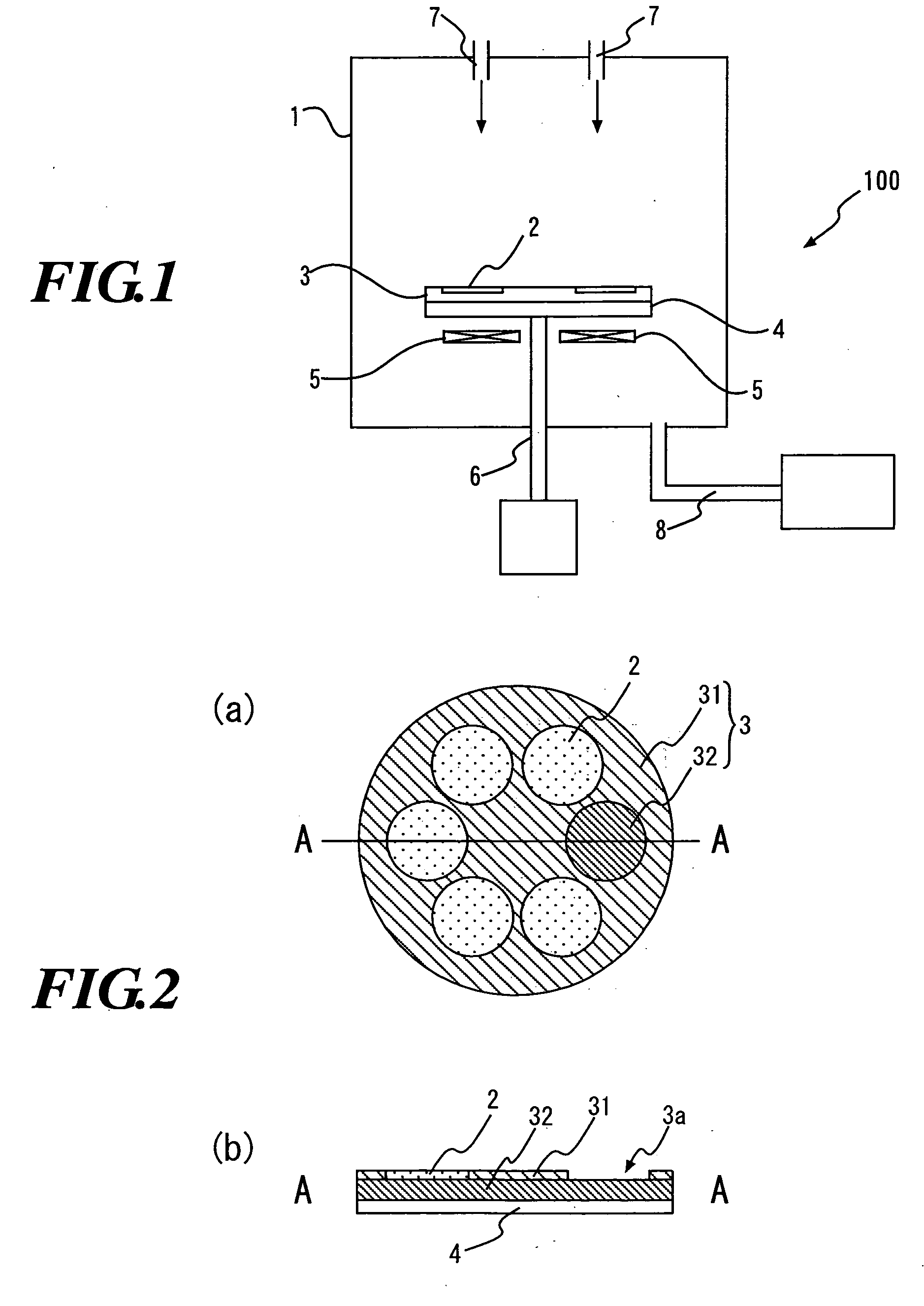

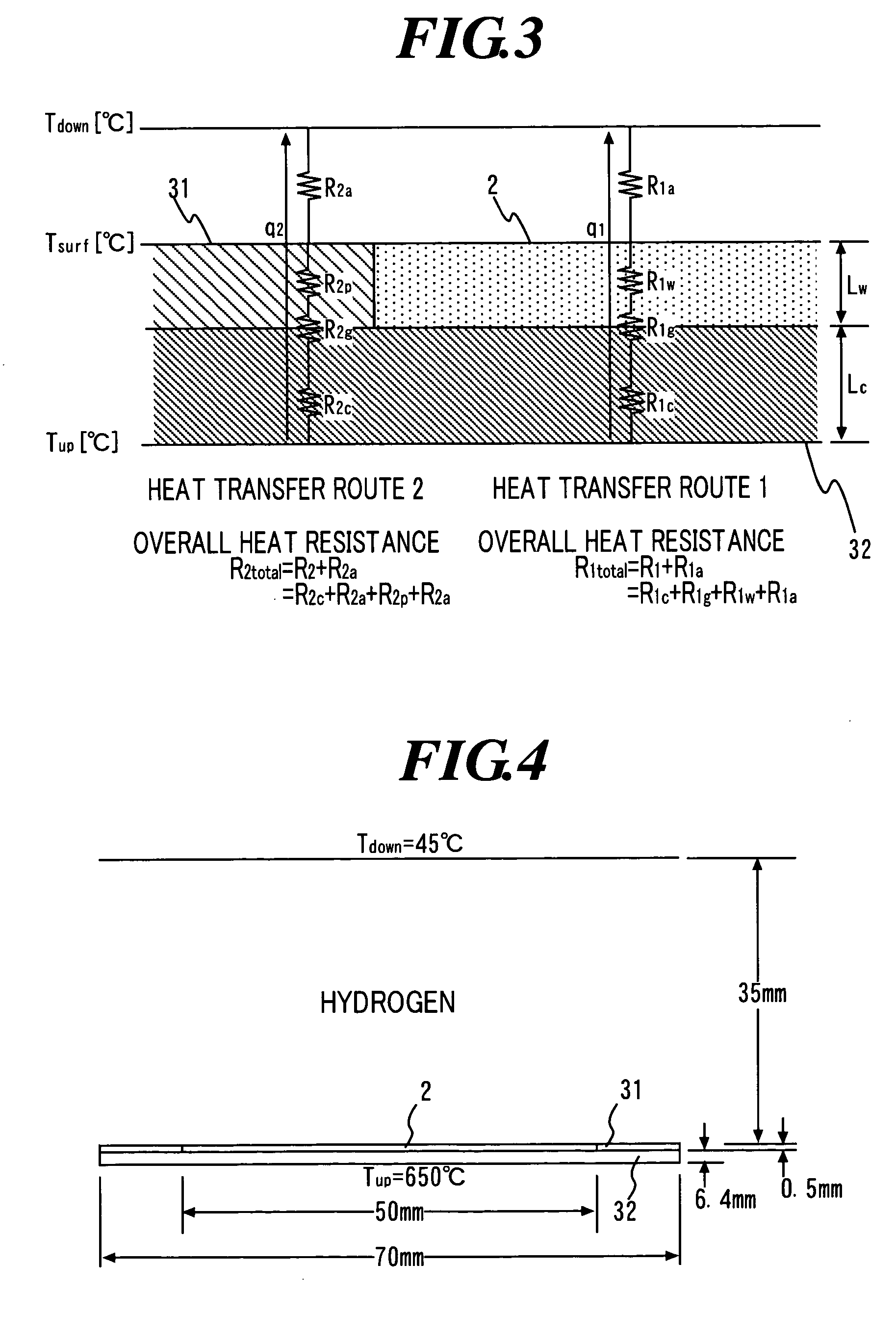

Vapor-phase epitaxial apparatus and vapor phase epitaxial method

InactiveUS7314519B2Adjust ratioUniform heat resistanceAfter-treatment apparatusPolycrystalline material growthHeat flowGrown film

A vapor-phase growth apparatus including a reaction furnace, a wafer container disposed in said furnace, a gas supply member, and a heating member, wherein the apparatus is designed to form a grown film on a front surface of the wafer by supplying a source gas in a high temperature state while the heating member heats the wafer in the reaction furnace through the wafer container. The wafer container includes a heat flow control section having a space for disposing a wafer; and a heat flow transmitting section joined to the heat flow control section. The contact heat resistance Rg between the heat flow control section and the heat flow transmitting section is not less than 1.0×10−6 m2K / W to not more than 5.0×10−3 m2K / W. The heat flow control section is made of a material having a coefficient of thermal conductivity 5 to 20 times that of the wafer.

Owner:JX NIPPON MINING & METALS CORP

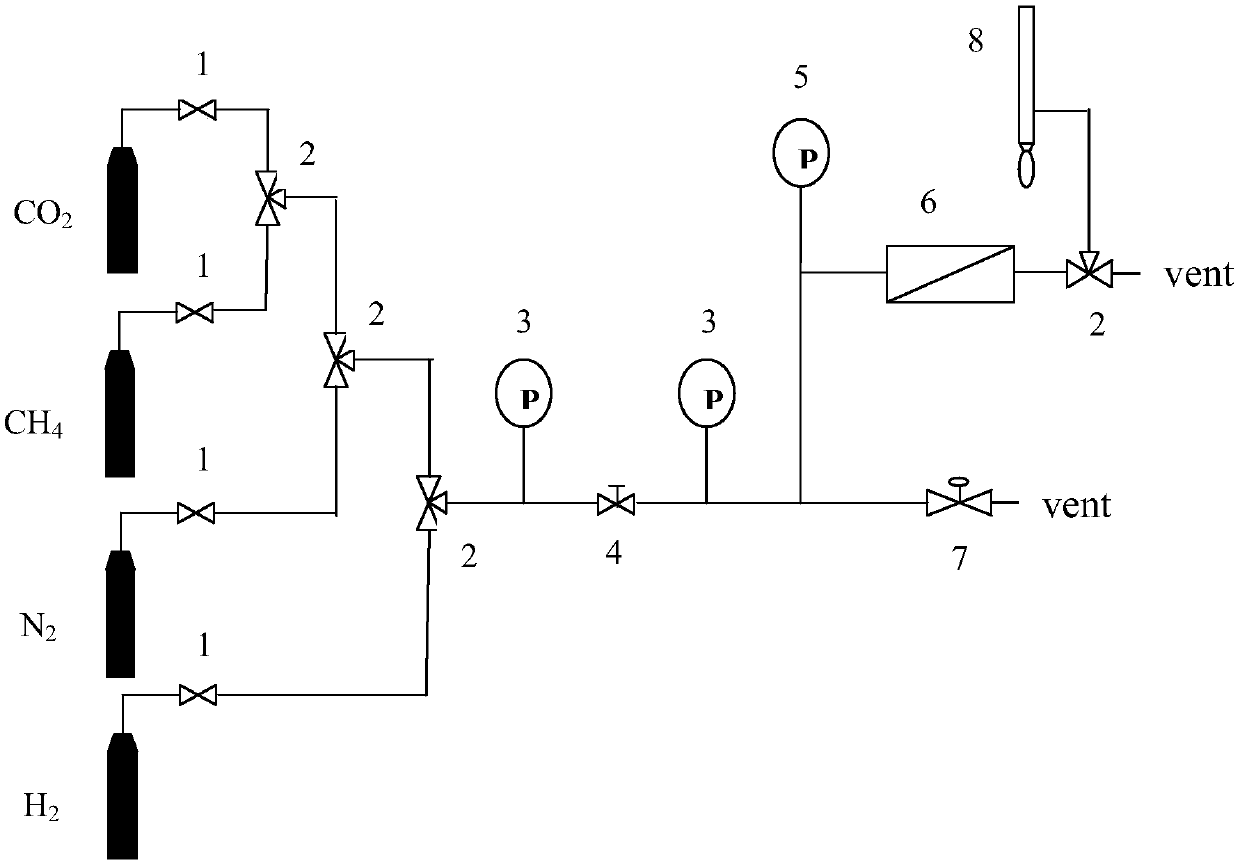

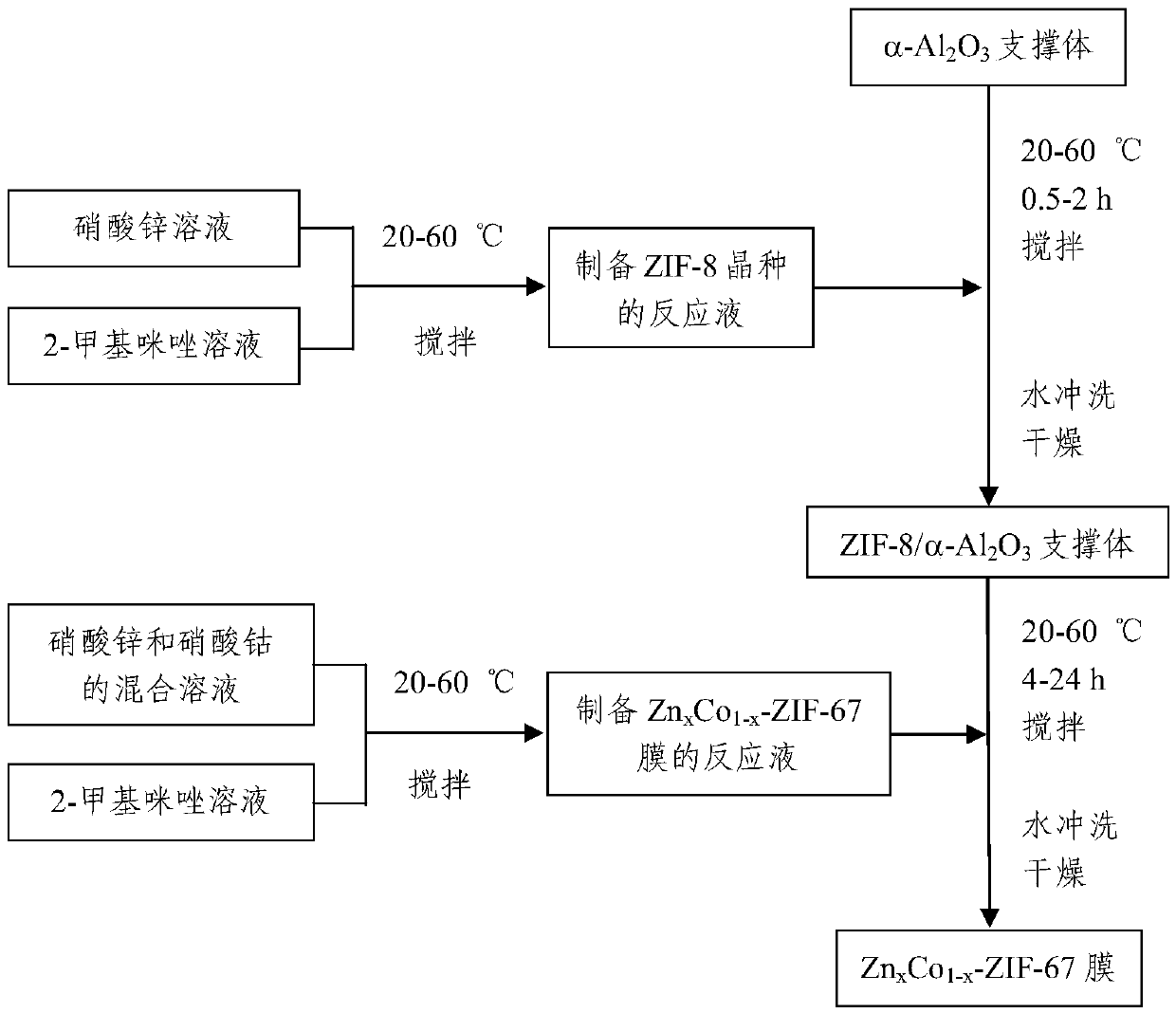

ZnxCo1-x-ZIF-67 membrane and preparation method thereof

InactiveCN109621735ASolve the problem of easy falling offWith separation performanceSemi-permeable membranesDispersed particle separationChemical structureUltimate tensile strength

The invention discloses a ZnxCo1-x-ZIF-67 membrane and a preparation method thereof, wherein the preparation method comprises the following steps of: growing a layer of ZIF-8 seed crystal on the surface of a porous support in advance, and using the ZIF-8 seed crystal as an induction core of the growth membrane to prepare a continuous ZnxCo1-x-ZIF-67 membrane; the prepared ZnxCo1-x-ZIF-67 membranecan be used in the technical field of H2 / CO2, H2 / N2, H2 / CH4 and other gas separation. According to the ZnxCo1-x-ZIF-67 membrane and a preparation method thereof, the ZIF-8 crystal grains grow on the surface of the porous support body to be used as the seed crystal for growing the ZnxCo1-x-ZIF-67 film, so that the problem that the seed crystal is easy to fall off due to insufficient bonding strength of the seed crystal layer and the porous support body can be effectively solved; and the preparation conditions adopted by the method are mild, the process is simple and controllable, the prepared ZnxCo1-x-ZIF-67 film has stable chemical structure and performance, excellent gas separation performance, wide application prospect and great theoretical and practical significance.

Owner:BEIHANG UNIV

Preparation method of silicon-doped HfO2-based ferroelectric film

InactiveCN110218979AHigh purityLayered structure controllableVacuum evaporation coatingSputtering coatingGrown filmHigh energy

The invention discloses a preparation method of a silicon-doped HfO2-based ferroelectric film, and belongs to the technical field of material preparation. The preparation method comprises the steps that by taking yttrium-doped zirconia as a substrate, firstly the substrate is cleaned and annealed to fully remove internal stress and surface organic matters of the substrate; then, by taking self-made Si-doped HfO2 as a target, a Si-doped HfO2-based film grows on the surface of the substrate by a pulsed laser molecular beam epitaxy method in an ultra-vacuum state; and then the grown film is annealed in situ in an oxygen atmosphere to obtain the stable Si-doped HfO2-based film. By adopting the pulsed laser deposition epitaxy method in combination with a reflective high-energy electron diffractometer for real-time monitoring, and by optimizing oxygen pressure, laser energy, the substrate temperature and the annealing temperature, precise control on atomic-scale epitaxial growth of the filmis realized; the preparation method has the advantages of high purity and controllable layered structure; and ideas are provided for ferroelectric research on the Si-doped HfO2-based film.

Owner:DONGGUAN UNIV OF TECH

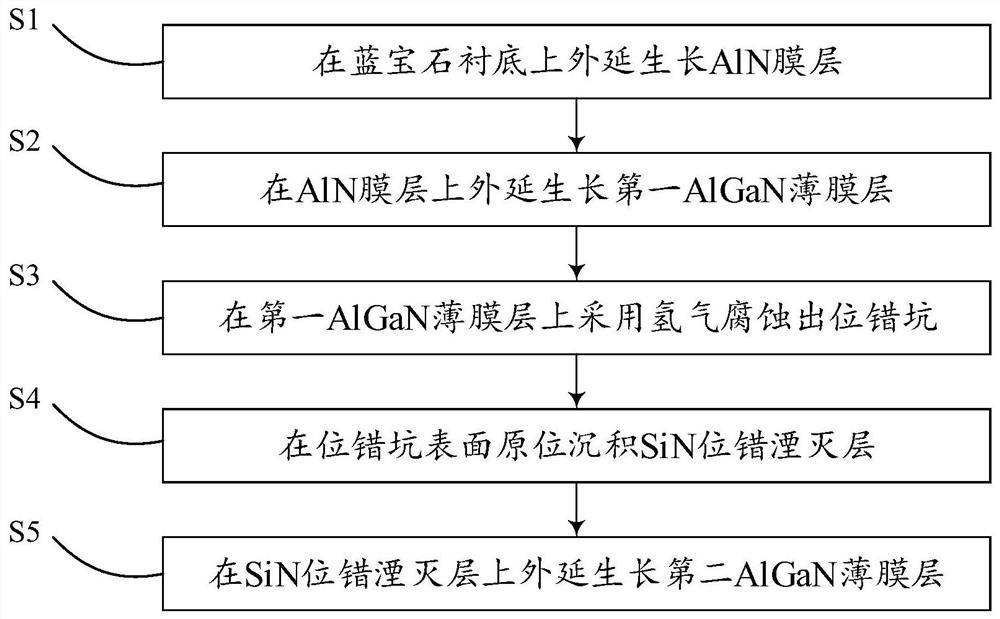

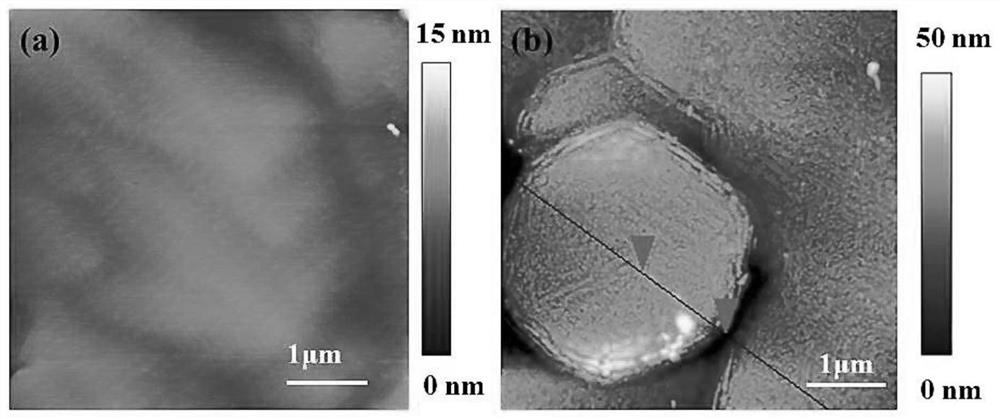

AlGaN film with in-situ SiN dislocation annihilation layer and epitaxial growth method of AlGaN film

ActiveCN112242459APromote growth and healingAvoid the introduction of impuritiesFinal product manufactureSemiconductor devicesCrystallographyGrown film

The invention discloses an AlGaN thin film with an in-situ SiN dislocation annihilation layer and an epitaxial growth method of the AlGaN thin film. The method comprises the steps that an AlN film layer is grown on a sapphire substrate in an epitaxial mode; a first AlGaN thin film layer is grown on the AlN film layer in an epitaxial mode; a dislocation pit is formed in the first AlGaN thin film layer through hydrogen corrosion; a SiN dislocation annihilation layer is deposited on the surface of the dislocation pit in situ; a second AlGaN thin film layer is epitaxially grown on the SiN dislocation annihilation layer. According to the method, the dislocation pits are etched in the first AlGaN thin film layer and then SiN in-situ filling is carried out; on one hand, the second AlGaN thin filmlayer and the subsequent film layer can be synchronously subjected to graphical processing in the growth process; the problems that an epitaxial wafer is taken out to be subjected to a complex etching process and impurities are introduced when the epitaxial wafer is taken out to be etched are solved; on the other hand, the SiN dislocation annihilation layer is of an island-shaped distribution structure corresponding to the same dislocation pit, and therefore the structure is more beneficial to growth and healing of the second AlGaN thin film layer.

Owner:SUZHOU UVCANTEK CO LTD

Vapor-phase epitaxial apparatus and vapor phase epitaxial method

InactiveUS20050166836A1Uniform temperature distributionEasy to adjustAfter-treatment apparatusPolycrystalline material growthHeat flowGas phase

A vapor-phase growth apparatus includes: a reaction furnace which is hermetically closable, a wafer container which is disposed in the reaction furnace, for disposing a wafer at a predetermined position, a gas supply member for supplying a source gas toward the wafer, and a heating member for heating the wafer, wherein the apparatus is designed to form a grown film on a front surface of the wafer by supplying the source gas in a high temperature state while the heating member heats the wafer in the reaction furnace through the wafer container. The wafer container includes: a heat flow control section having a space for disposing a wafer; and a heat flow transmitting section joined to the heat flow control section, for transmitting heat to the wafer disposed in the space; and contact heat resistance Rg between the heat flow control section and the heat flow transmitting section is not less than 1.0×10−6 m2K / W to not more than 5.0×10−3 m2K / W, and the heat flow control section is made of a material having a coefficient of thermal conductivity which is not less than 5 times to not more than 20 times that of the wafer disposed on the heat flow transmitting section.

Owner:JX NIPPON MINING& METALS CORP

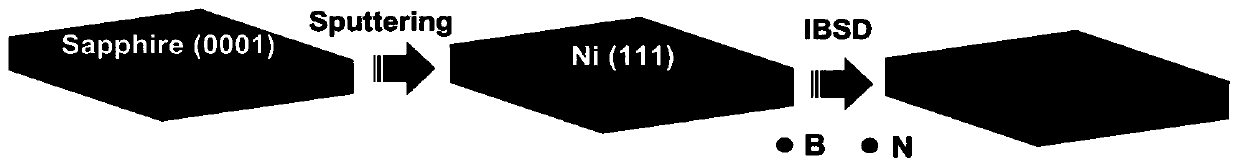

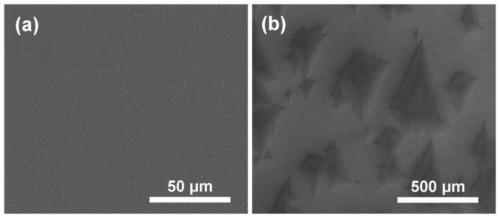

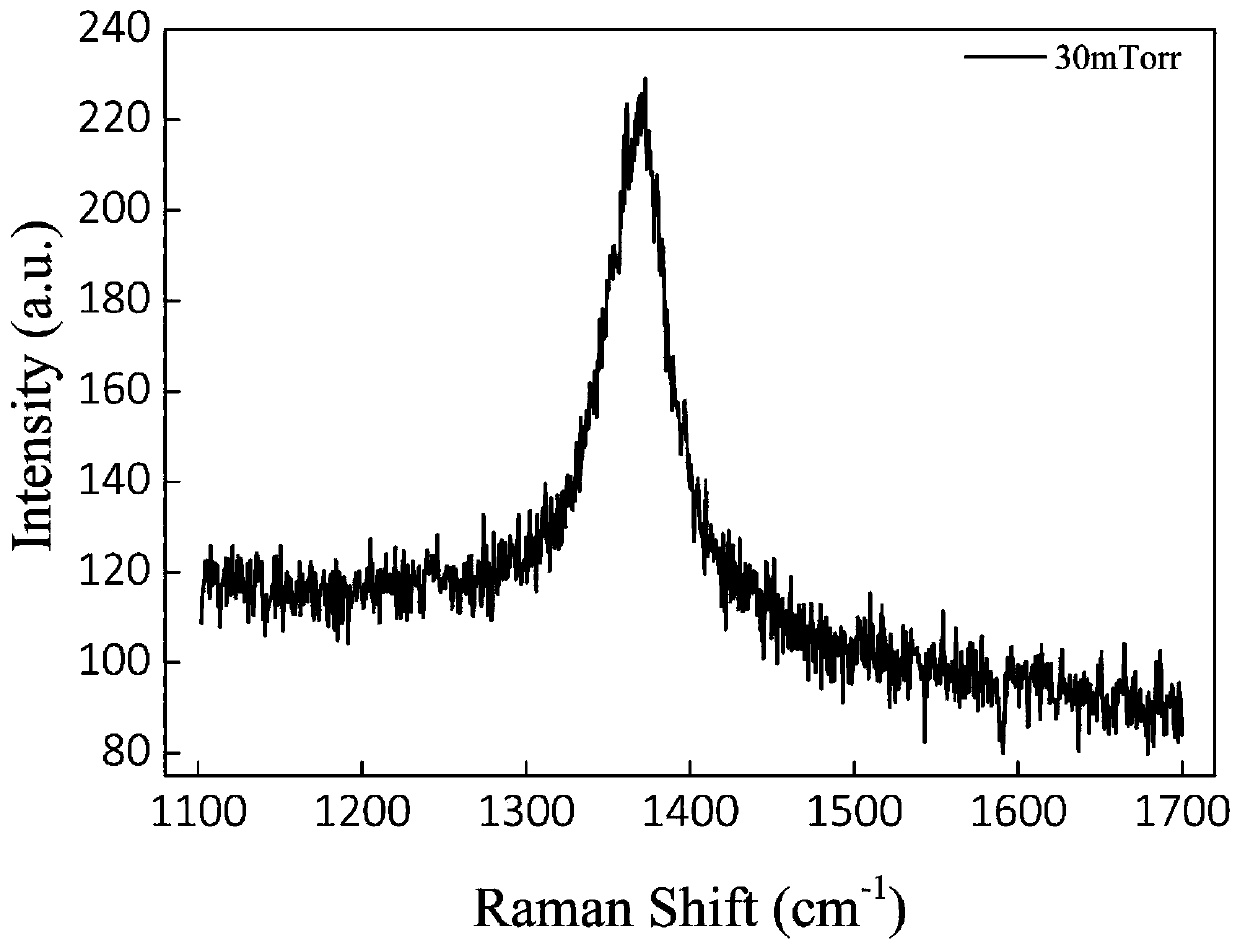

Method for obtaining single-crystal boron nitride film by ion beam sputtering deposition

InactiveCN111139526AEasy to controlEasy and controllable preparationPolycrystalline material growthAfter-treatment detailsGrown filmSingle crystal

The invention relates to the field of researches on two-dimensional layered materials, in particular to a method for obtaining a single-crystal boron nitride film through ion beam sputtering deposition. The method comprises the following steps: ultrasonically cleaning a single crystal substrate by using acetone, ethanol and deionized water in sequence; immersing the cleaned single crystal substrate into a hydrofluoric acid solution for treatment; placing a high-purity Ni target on a target position of a direct-current magnetron sputtering instrument, and epitaxially growing a Ni (111) orientedfilm on the single crystal substrate; fixing a nickel / single crystal substrate on a sample support, putting the sample support into a growth chamber of ion beam sputtering deposition equipment, and carrying out film growth through hydrogen and argon treatment; and cooling the grown film to obtain the large-size single-crystal boron nitride film.

Owner:LANZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com