Method for titania film growth in fluorine-based aqueous solution

A titanium dioxide, aqueous solution technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of increasing the supersaturation of the solution, unable to control the film orientation, unable to use the growth temperature, etc., to improve the crystallinity and realize the large-scale industry. The effect of less production and raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The seed layer was deposited on the substrate by the sol-gel method. Preparation of the gel: dissolve 0.1M butyl titanate in 50ml of ethanol, stir evenly, add 2ml of acetylacetone, and stir for 2 hours; continue to add 1ml of water and stir A stable and uniform pale yellow sol was obtained after 1 hour.

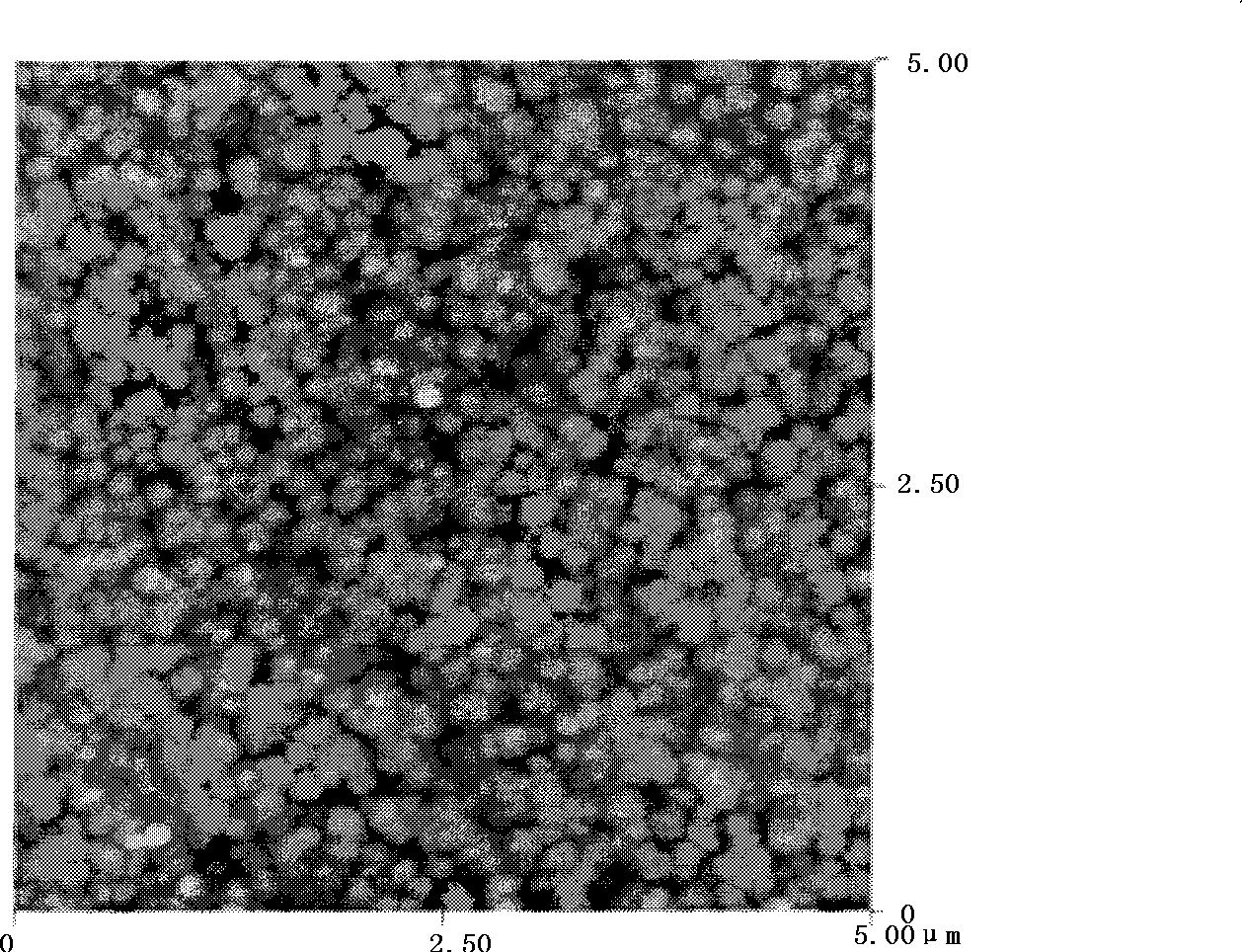

[0033] The coating method adopts spin coating method. The sol is coated on the cleaned ITO conductive glass substrate at a rotation speed of 3000rpm for 30s. After drying the wet film at 120℃ for 60 minutes, it is transferred to a muffle furnace at 450℃ and kept for 1h. , take out and naturally cool to room temperature to obtain a seed layer with a thickness of 30 nm.

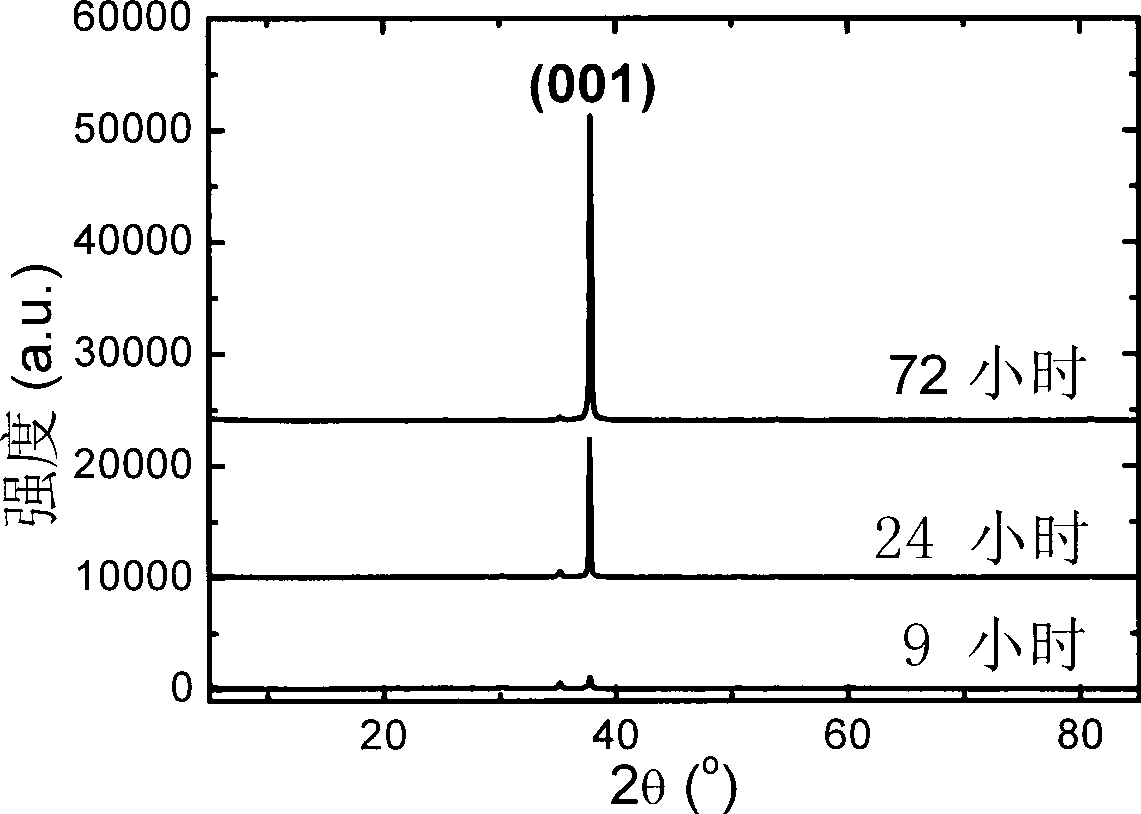

[0034] Place the seed layer in growth solution for growth: formulation containing 0.05M ammonium hexafluorotitanate (AHFT) and 0.05M ammonium fluoride (NHFT) 4 F) growth solutions, stabilized for 2 h and pretreated at 95 °C for 6 h, respectively. The above seeded ITO substrate was placed vertically in...

Embodiment 2

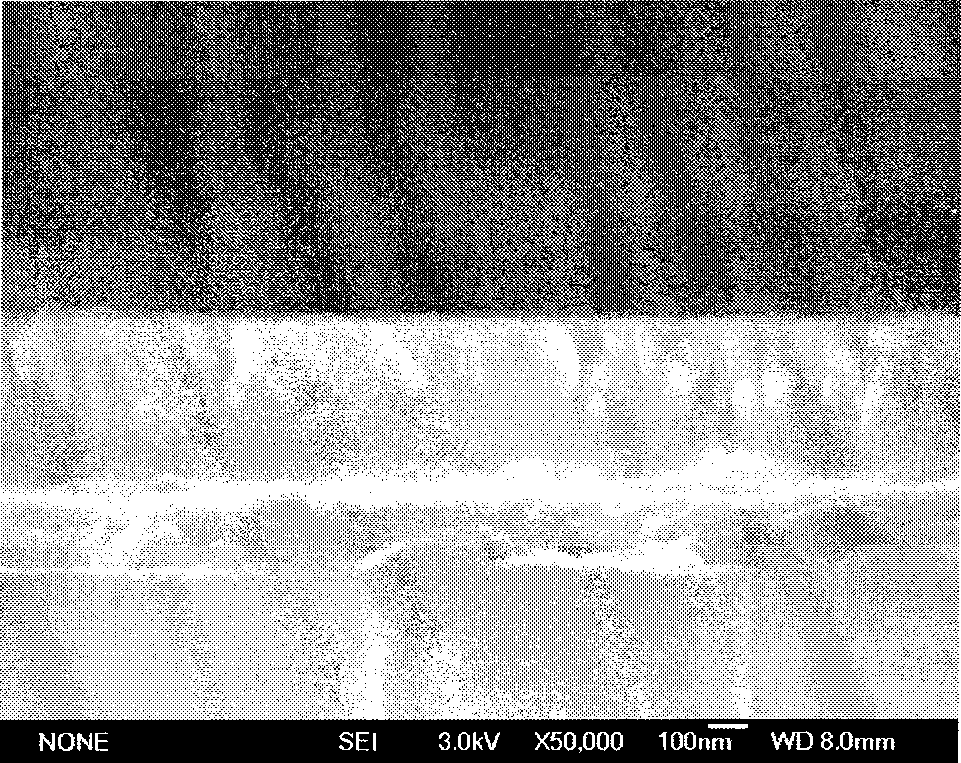

[0039] Other conditions are the same as those in Example 1, except that the substrate is a single crystal silicon substrate and the growth time is 24h. The surface morphology of the obtained titanium dioxide film is similar to that of Example 1, and the cross-sectional morphology is as follows. Figure 5 shown. The thickness of the film is about 700 nm, which is thicker than the 300 nm film grown on ITO, indicating that the film has a relatively uniform growth rate in the growth solution. The density, crystal structure and crystallographic orientation of the films are similar to those grown on ITO.

Embodiment 3

[0041] The other conditions are the same as in Example 1, except that the substrate is ITO and the growth temperature is 75°C. The surface morphology of the obtained titanium dioxide film is similar to that of Example 1, and the cross-sectional morphology is as follows. Figure 6a shown. The thickness of the film is about 300 nm, showing a state of particle orientation accumulation, and the half-width of the (001) diffraction peak of the film in XRD is significantly larger than that of the film obtained at 95 °C, indicating that temperature is the main factor affecting the crystallinity. The better the crystal quality. In addition, using the detection method in Example 1, it was found that under the same conditions, methyl orange was degraded by 40%, which indicated that the crystallinity of the film decreased and the catalytic efficiency decreased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com