Patents

Literature

52results about How to "High filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pulsed bias having high pulse frequency for filling gaps with dielectric material

InactiveUS7514375B1High densityHigh fillingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPulse frequencyPhysics

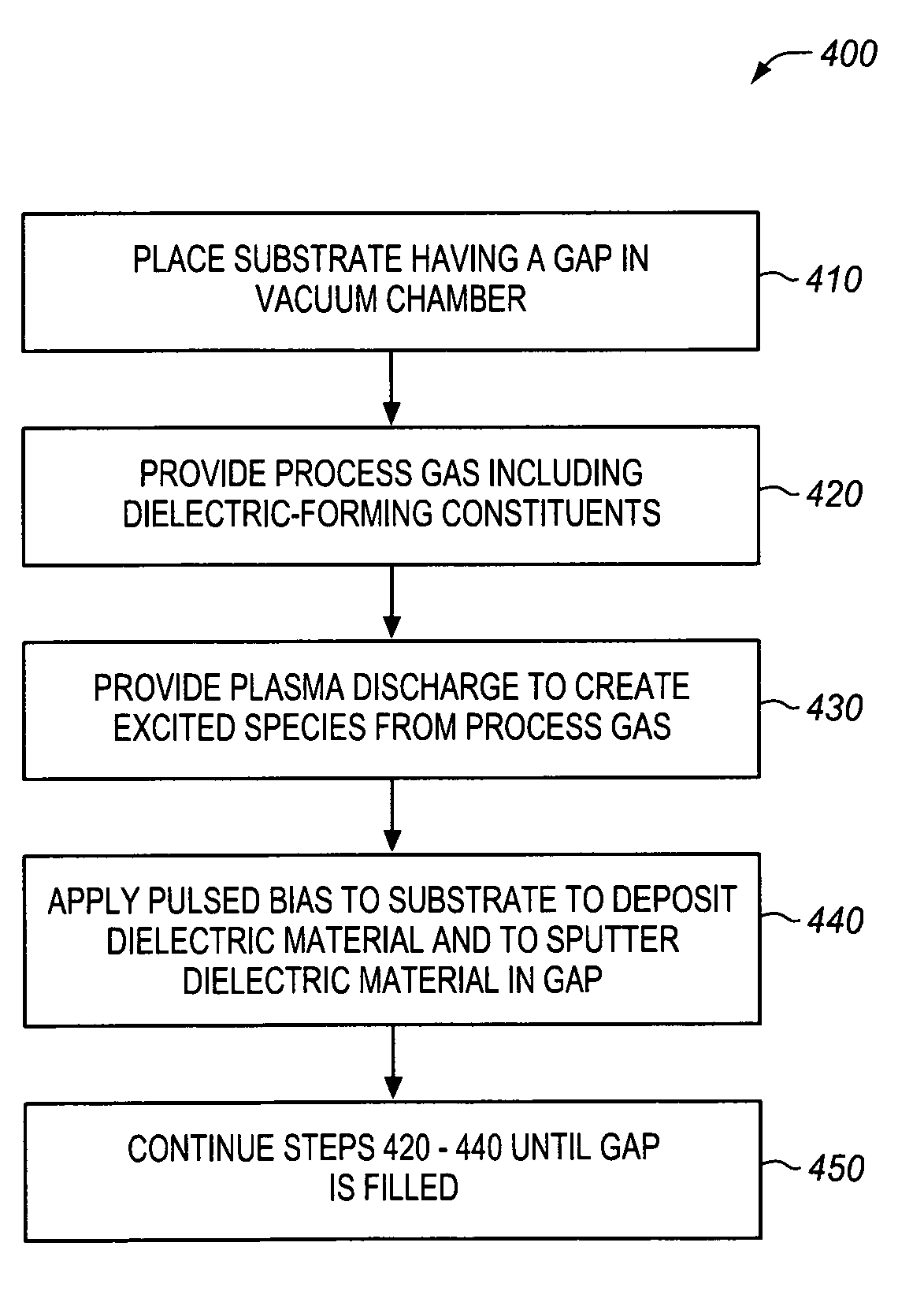

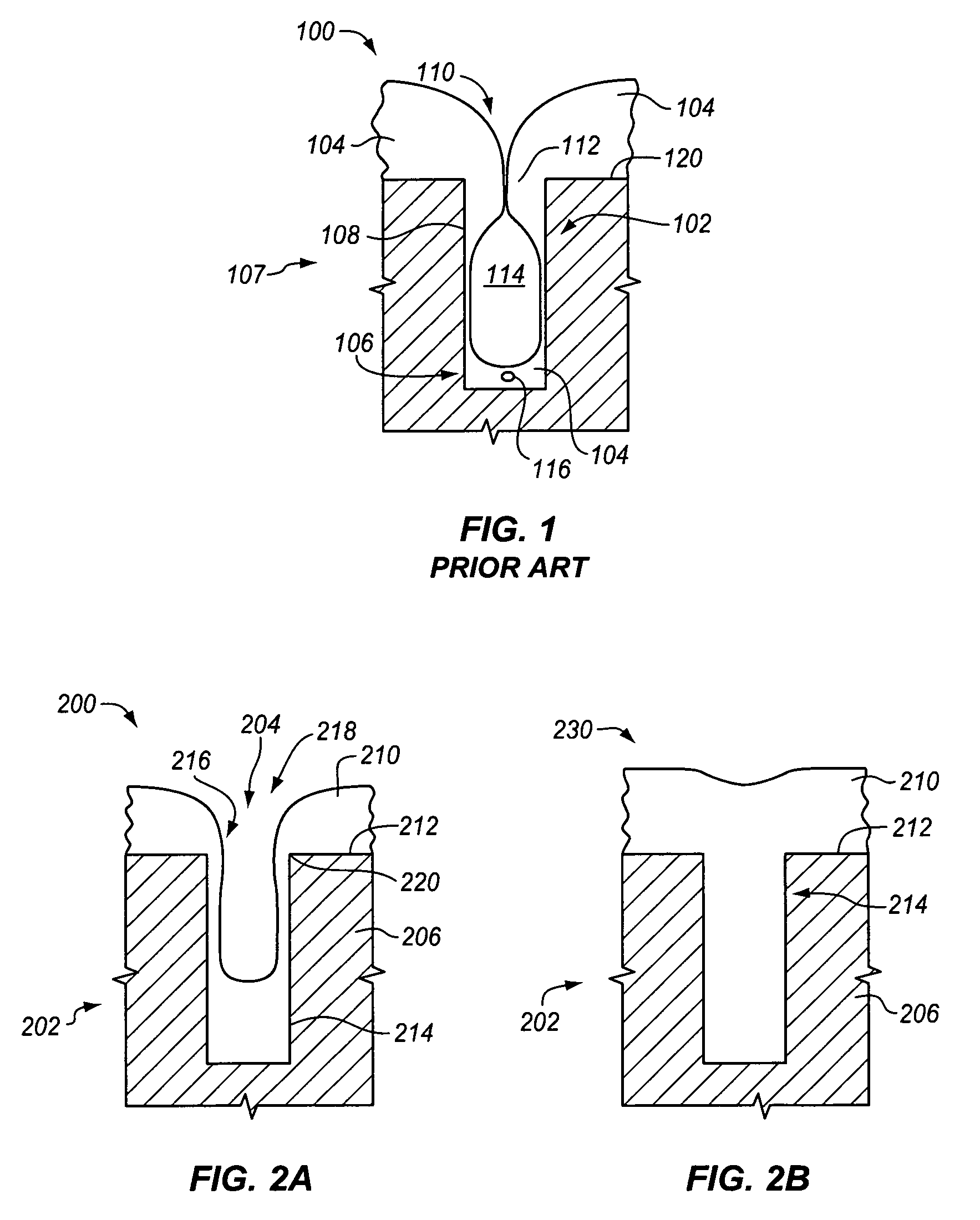

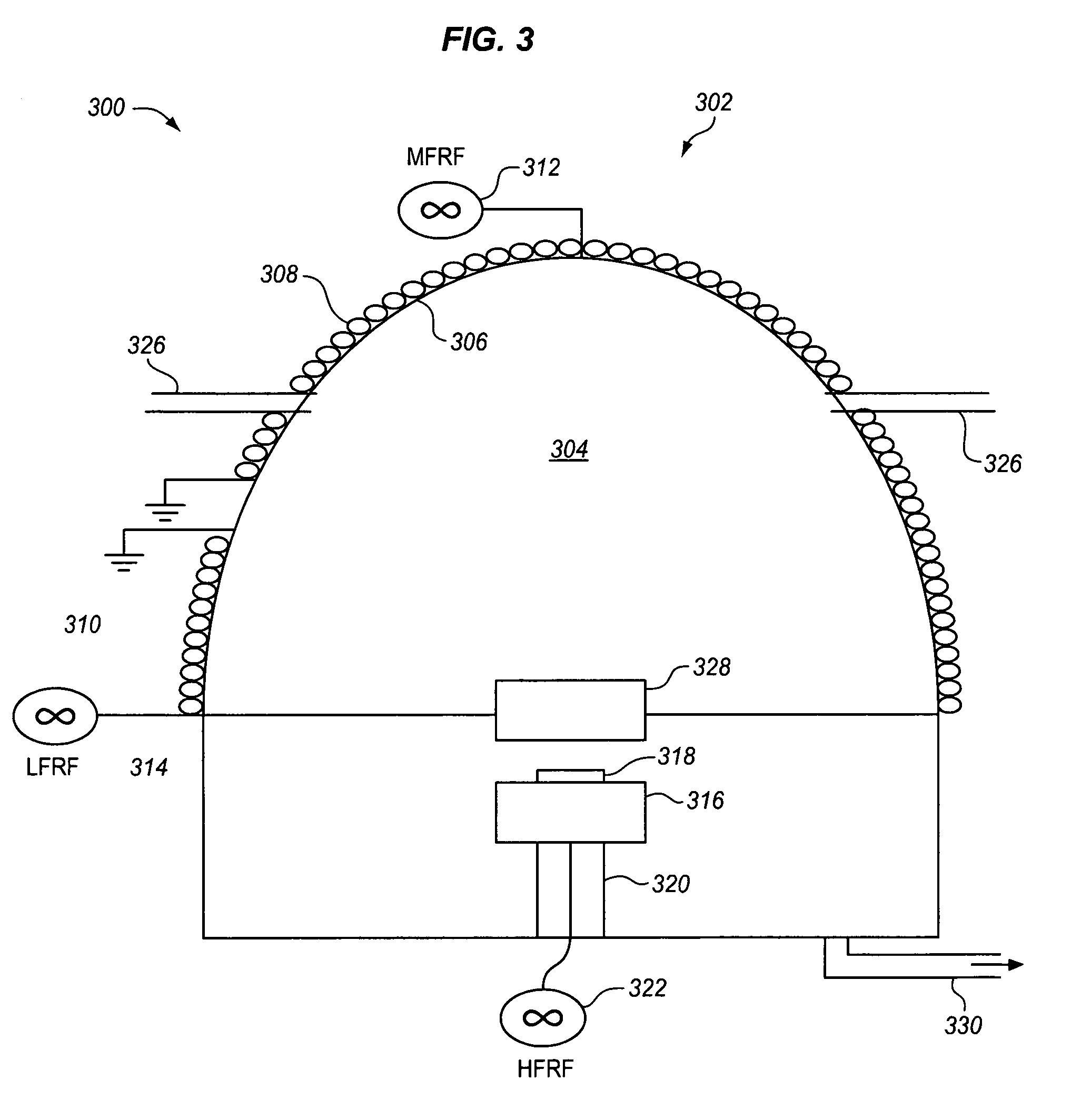

During bottom filling of high aspect ratio gaps and trenches in an integrated circuit substrate using HDP-CVD, a pulsed HF bias is applied to the substrate. In some embodiments, pulsed HF bias is applied to the substrate during etching operations. The pulsed bias typically has a pulse frequency in a range of about from 500 Hz to 20 kHz and a duty cycle in a range of about from 0.1 to 0.95.

Owner:NOVELLUS SYSTEMS

Wood-polymer composites and additive systems therefor

The present invention provides a method of forming a wood-polymer composite structure and additive systems for use therein. The method of the invention includes extruding a heated mixture that includes from about 20 wt % to about 80 wt % by weight of a thermoplastic polymer, from about 20 wt % to about 80 wt % by weight of a cellulosic filler material, and from about 0.1 wt % to about 10 wt % by weight of an additive system. The additive system according the invention includes a 12-hydroxystearic acid salt or amide.

Owner:FERRO CORP

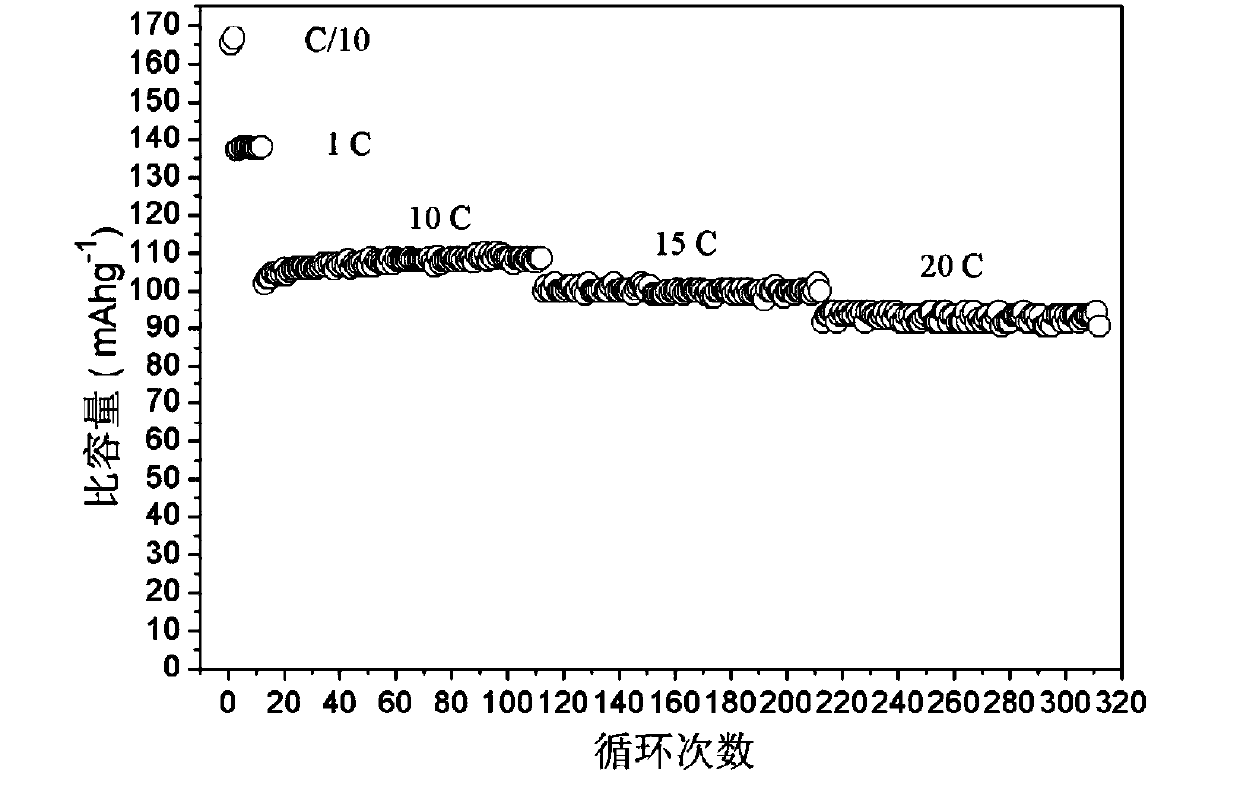

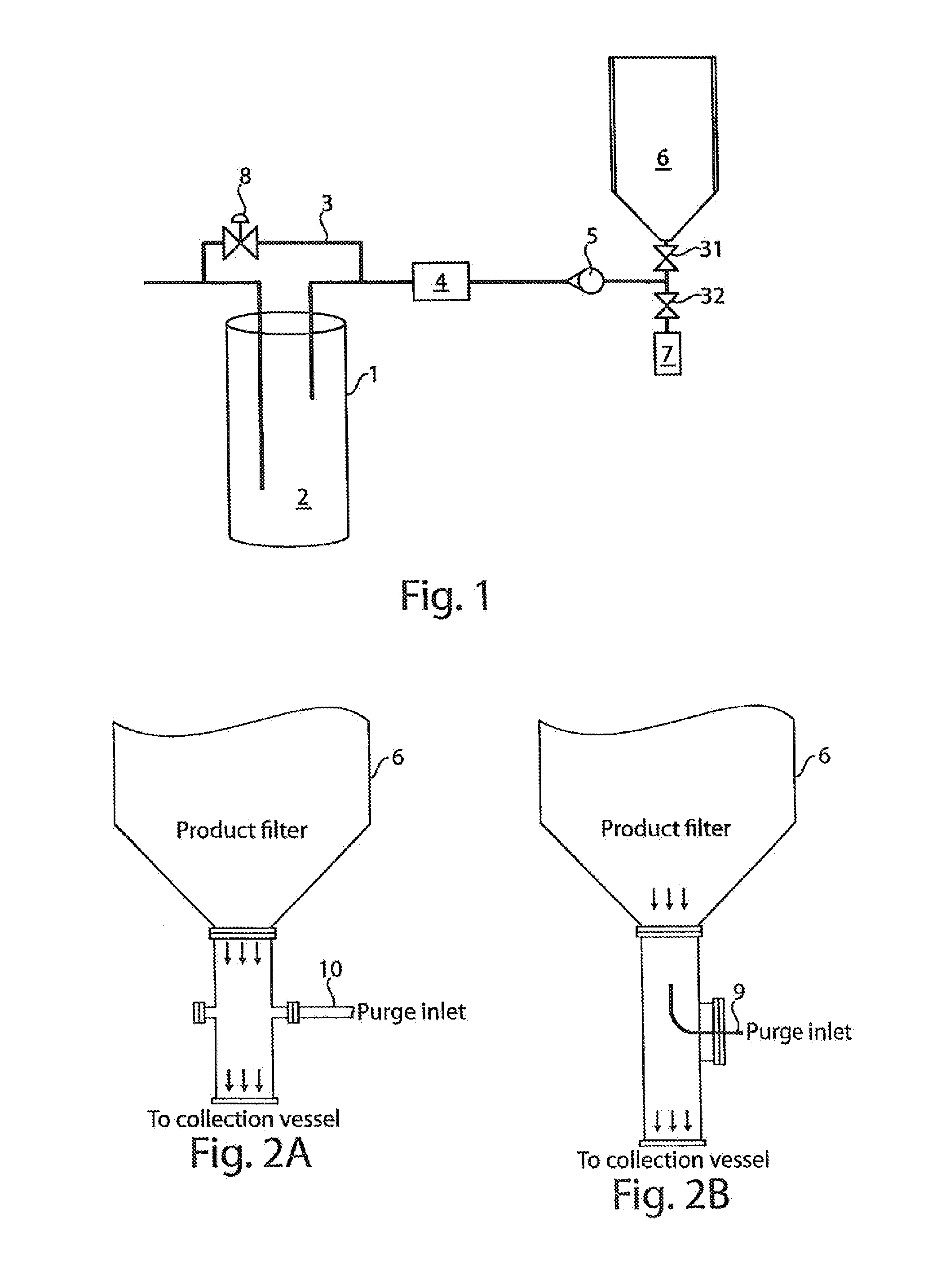

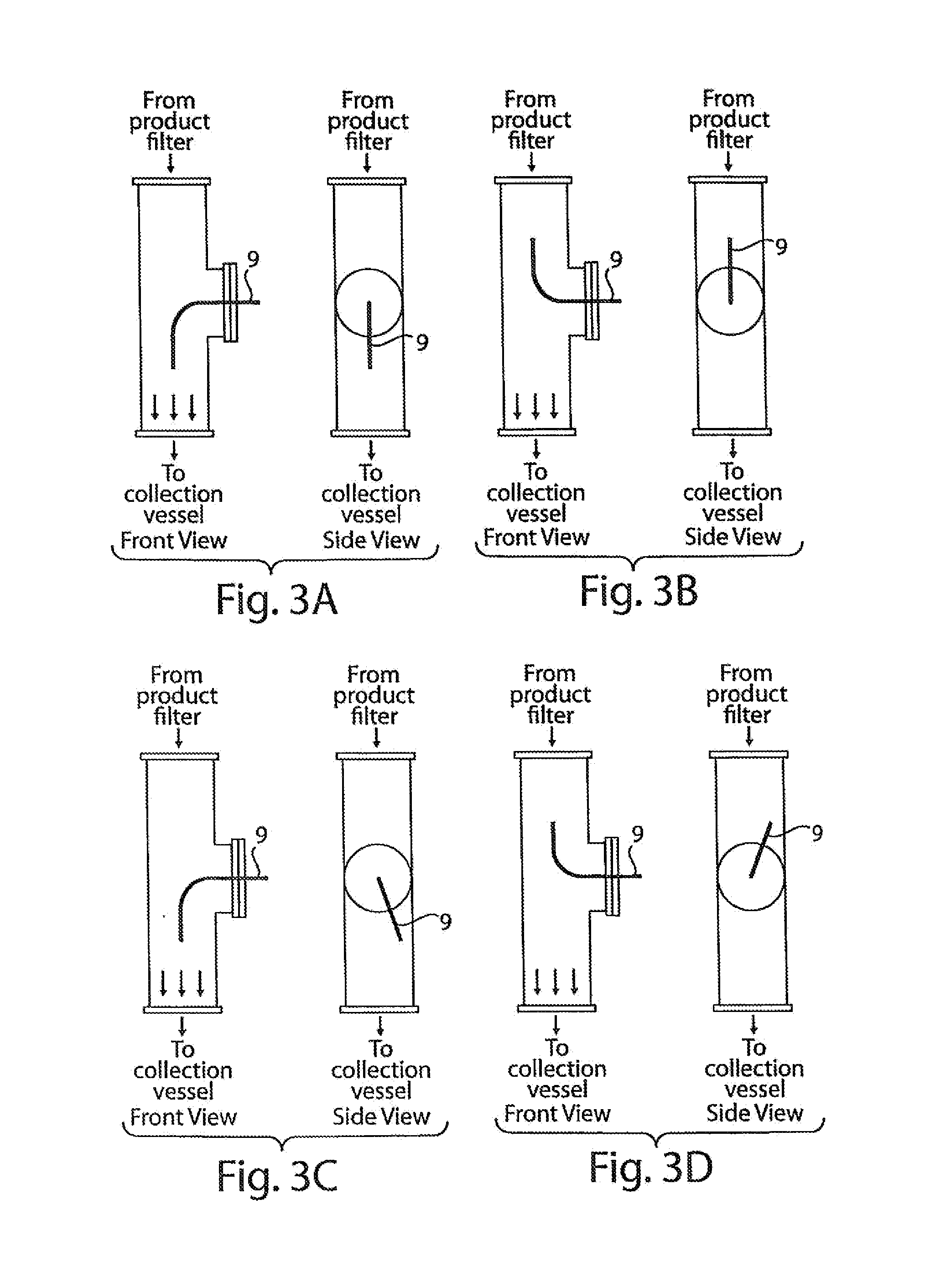

Preparation method of iron phosphate, iron phosphate prepared by method, preparation method of lithium iron phosphate, lithium iron phosphate prepared by method and lithium battery

ActiveCN107565132AEasy to moveHigh densityPhosphatesCell electrodesPhosphoric acidLithium-ion battery

The invention discloses a preparation method of an iron phosphate precursor particularly suitable for preparation of lithium iron phosphate, iron phosphate prepared by the method, a preparation methodof the lithium iron phosphate and the lithium iron phosphate prepared by the method. The preparation method of the iron phosphate comprises the following steps of adding reduced iron powder to an aqueous solution containing sulfuric acid and organic acid, performing reaction for 5-10 hours at 60-90 DEG C, and performing high-magnetic filtering after reaction is completed to obtain a ferrous sulfate aqueous solution; and dropwise adding a mixture liquid comprising ammonium persulfate, ammonium phosphate and a nanoparticle control agent into the ferrous sulfate aqueous solution, performing precipitation at 60-80 DEG C and a pH value being 3, performing stirring and mixing reaction for 5-8 hours, performing demagnetization and filtering after reaction is completed, pressing to form a filtercake, and performing rinsing, spraying, drying and powder making to obtain an iron phosphate product. By improving a lithium iron phosphate preparation process, preparation processes of a raw materialand the iron phosphate and constituents of the raw material and initial raw material ferrous sulfate, the conductivity, the tap density and the performance stability of the finally-obtained lithium iron phosphate can be fully improved.

Owner:GUANGZHOU TINCI MATERIALS TECH

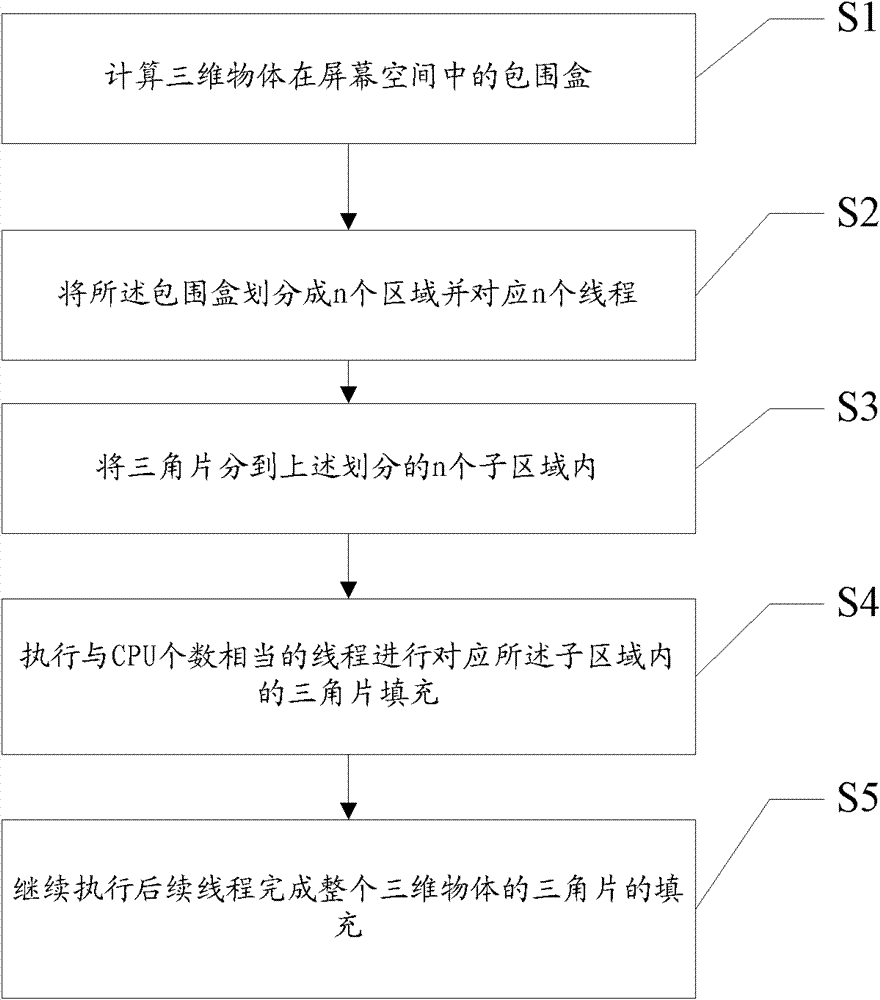

Multithread realization method for rasterization stage in graphic rendering

InactiveCN102736947AHigh fillingAchieve parallelismMultiprogramming arrangements3D-image renderingFilling-inComputational science

The invention discloses a multithread realization method for a rasterization stage in graphic rendering. The method comprises the following steps of: calculating a bounding box of a three-dimensional object, and dividing the bounding box into n areas corresponding to n threads; dividing triangular plates into corresponding subareas of the n divided areas; executing triangular plate filling in the subareas corresponding to the threads with number equal to that of CPUs (Central Processing Units); continuously executing other threads until all n threads are entirely executed, thus completing filling of the triangular plates. By utilizing the multithread realization method for the rasterization stage in graphics rendering, disclosed by the embodiment of the invention, the filling speed of the triangular plates in the graphic rendering can be greatly increased, the graphic rendering method can not be depended on CPU operation, graphic rendering can be directly carried out on the basis of CPUs, the multithread method can be used for realizing the parallelism of the three-dimensional rasterization stage.

Owner:CHINA DIGITAL VIDEO BEIJING

Method for adding tobacco ash during paper-making method type prodn. of tobacco sheet

ActiveCN1757334AHigh fillingImproved physical properties including filling propertiesTobacco preparationPulp and paper industryCoating

A method for using the fume dust as the filler in the process for preparing tobacco sheet by paper making method features that the fume dust (5-30 Wt%) can be added at 5 technological sites: pulp pool, pipeline between pulp stabilizing tank and pulp flowing tank, long screen, the position between vacuum floating roller and primary pressing, and the coating unit. It can improve the quality of tobacco sheet and low cost.

Owner:CHINA TOBACCO HUNAN INDAL CORP

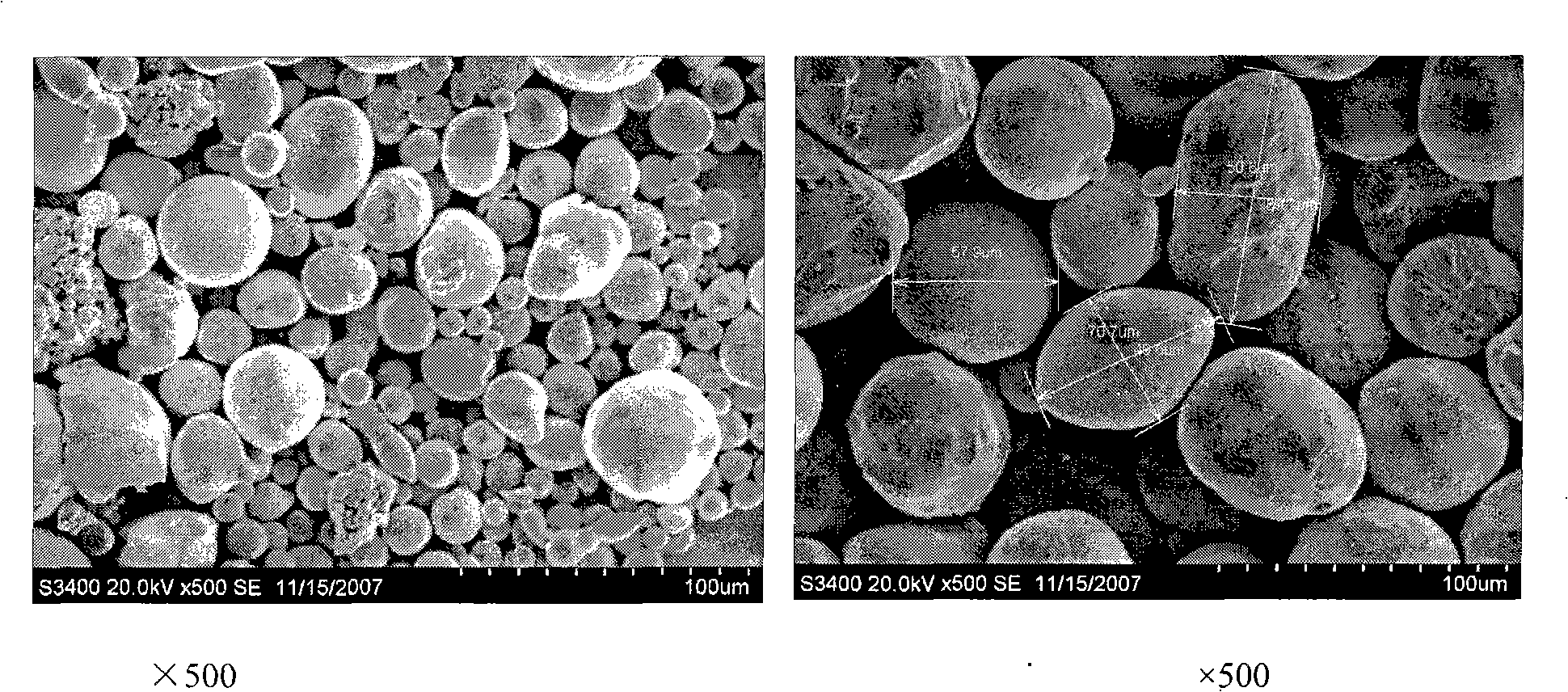

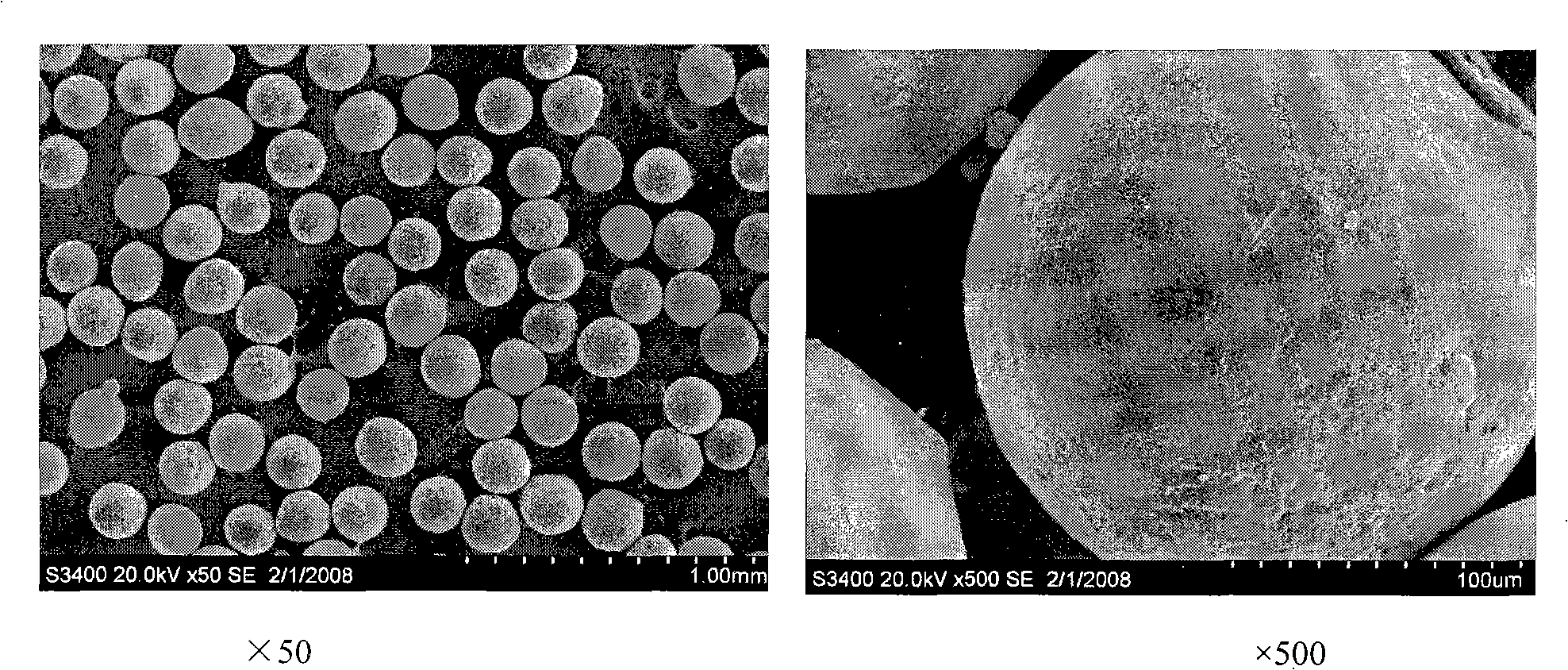

Method for preparing special type molybdenum powder

A method for preparing a special molybdenum powder relates to a method for preparing the molybdenum powder specially used for the industries of thermal spraying and machining as well as pressing fine apparatuses. The powder is characterized in that the preparing process includes the steps as follows: (1) sintering normal molybdenum powder for increasing the granularity; (2) grading the molybdenum powder, the granularity of which is increased; carrying out spheroidisation on the molybdenum powder with approximate granularity by a plasma device, then cooling and collecting the molybdenum powder; (3) reducing the molybdenum powder after being spheroidized, screening, grading and then obtaining the special molybdenum powder. The molybdenum powder prepared by the method of the invention has the advantages of good fluidity, simple technique, high finished product rate and relates to a technique for preparing the special molybdenum powder used in the fields of thermal spraying and pressing fine apparatuses.

Owner:JINDUICHENG MOLYBDENUM CO LTD

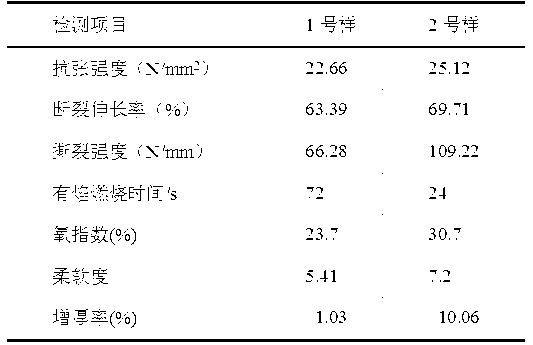

Wear-resistant heat-resistant anti-aging rubber material

The invention discloses a wear-resistant heat-resistant anti-aging rubber material. The raw materials comprises the following components in parts by weight: 30-40 parts of styrene butadiene rubber, 10-18 parts of butyl rubber, 10-20 parts of chloroprene rubber, 1-3 parts of a silane coupling agent, 1.5-3 parts of LH-C96 vulcanizing agent, 0.5-1.5 parts of CZ accelerator, 2-4 parts of magnesium oxide, 5-8 parts of phenolic resin, 4.0-4.4 parts of trioctyl trimellitate, 0.3-0.5 part of paraffin, 2-4 parts of environment-friendly flame retardant FR-T801, 0.5-1.5 parts of antimony trioxide, 18-23 parts of nanometer carbon black, 15-20 parts of white carbon black, 20-30 parts of carbon black N375, 15-20 parts of modified kaolin, 2-5 parts of anti-aging agent RD and 2-4 parts of anti-aging agent 4010NA. The rubber material disclosed by the invention has the advantages of excellent abrasion resistance, heat resistance and aging resistance.

Owner:宁国日格美橡塑股份有限公司

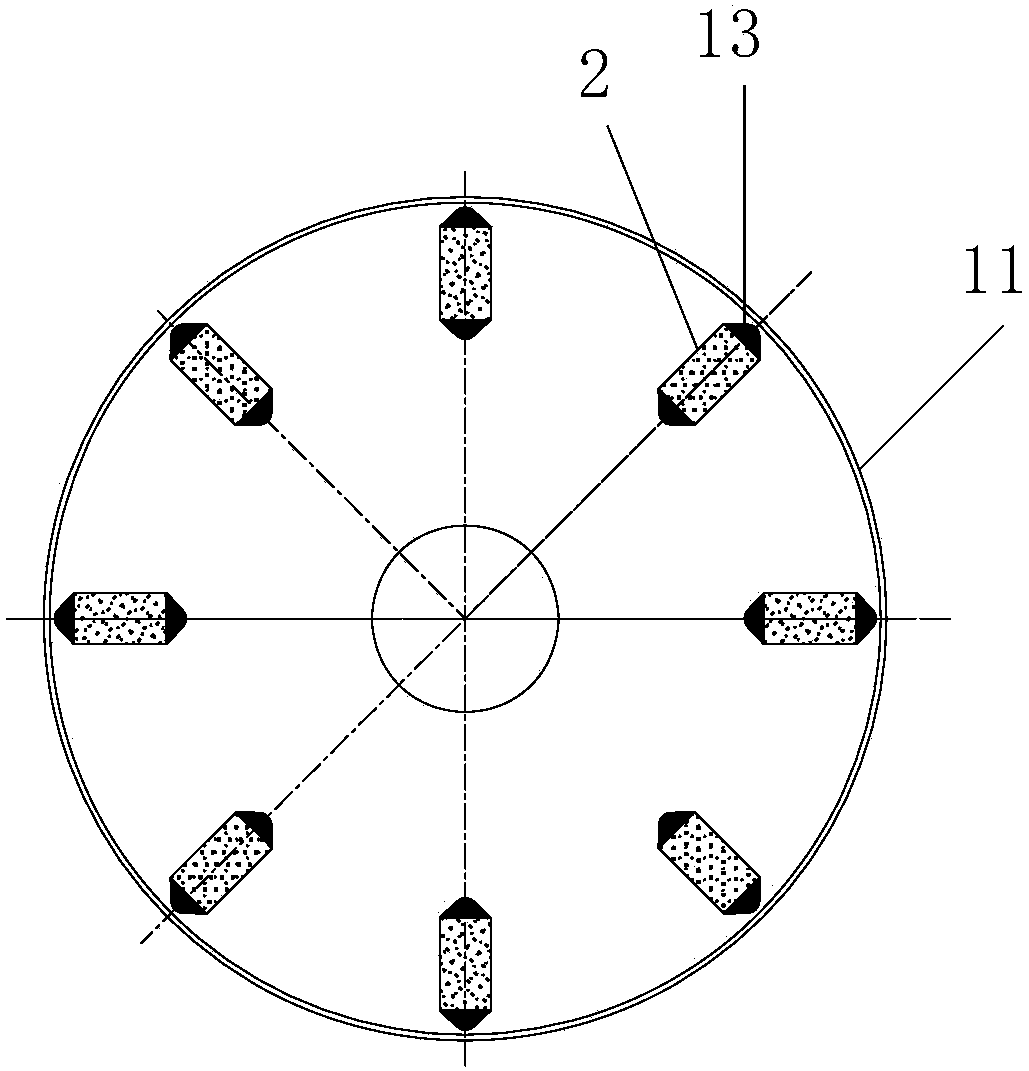

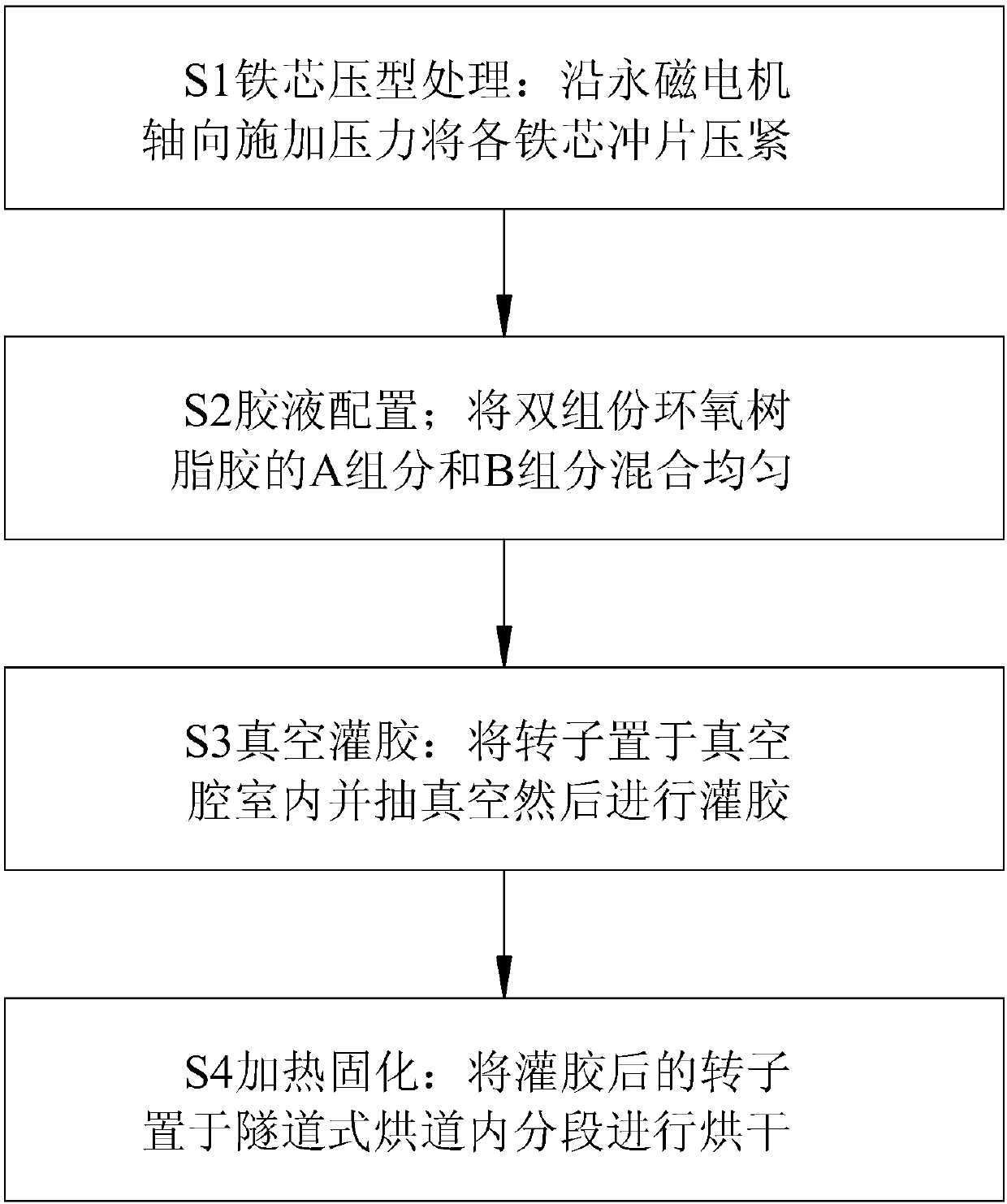

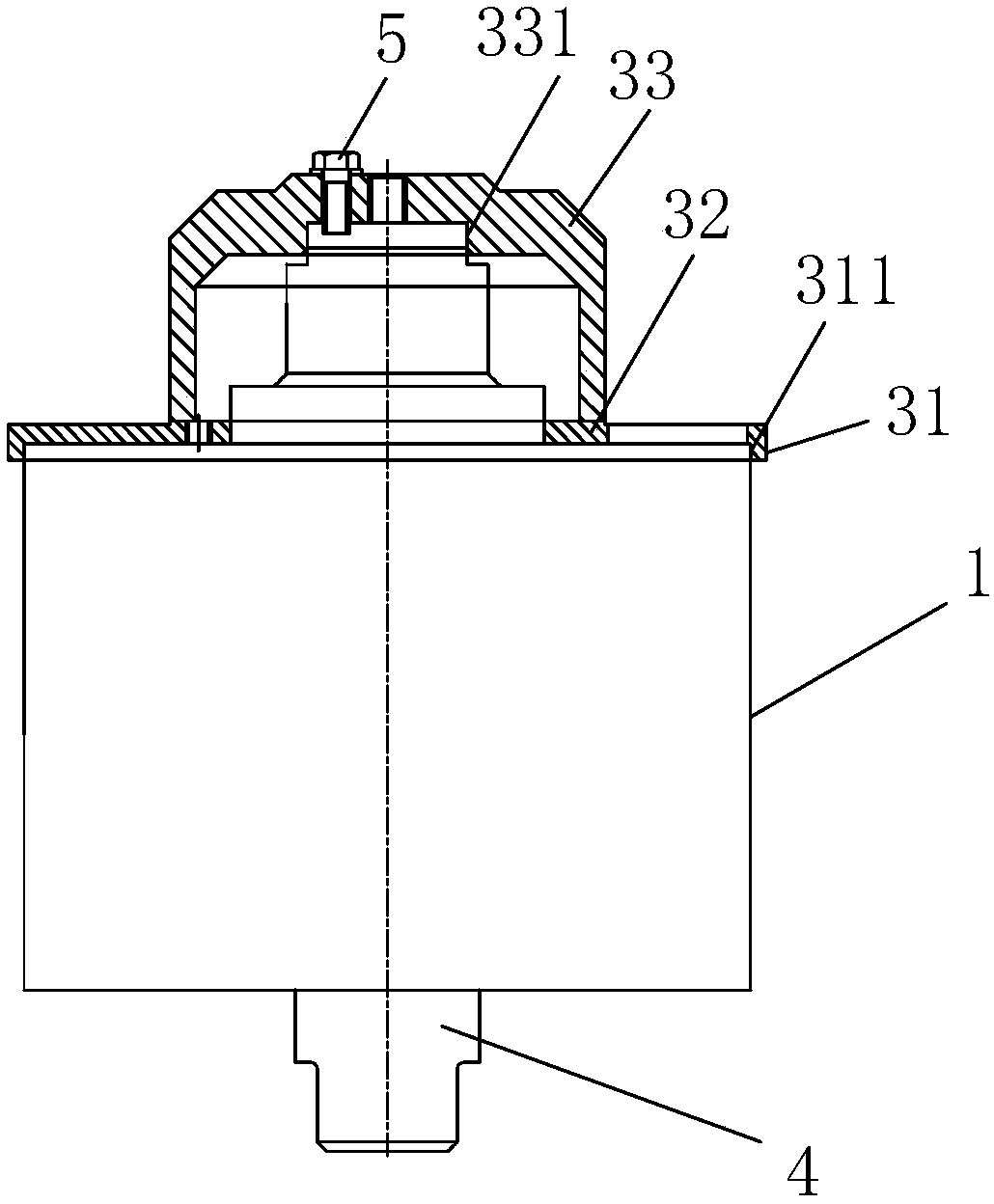

Vacuum glue pouring method for permanent magnetism motor rotors

ActiveCN109698590AReduce gapAvoid churnPretreated surfacesManufacturing stator/rotor bodiesEpoxyVacuum pumping

The invention discloses a vacuum glue pouring method for permanent magnetism motor rotors. The method includes the following steps: S1, a step of iron core profiling processing, namely the step of applying pressure to compress iron core punching sheets in an axial direction of a permanent magnetism motor; S2, a step of glue solution configuration, namely the step of uniformly mixing an A componentand B component of a two-component epoxy resin adhesive; S3, a step of vacuum glue pouring, namely the step of placing a rotor into a vacuum cavity to perform vacuum pumping, and then performing gluepouring; and S4, a step of heating and curing, namely the step of placing the rotor after glue pouring into a tunnel type baking channel to perform segment drying. The method has high glue pouring efficiency, tooth tension and glue loss phenomenon is not easy to occur, and the quality of products can meet the filling technical requirements of the permanent magnetism motor rotor.

Owner:湖南中车商用车动力科技有限公司

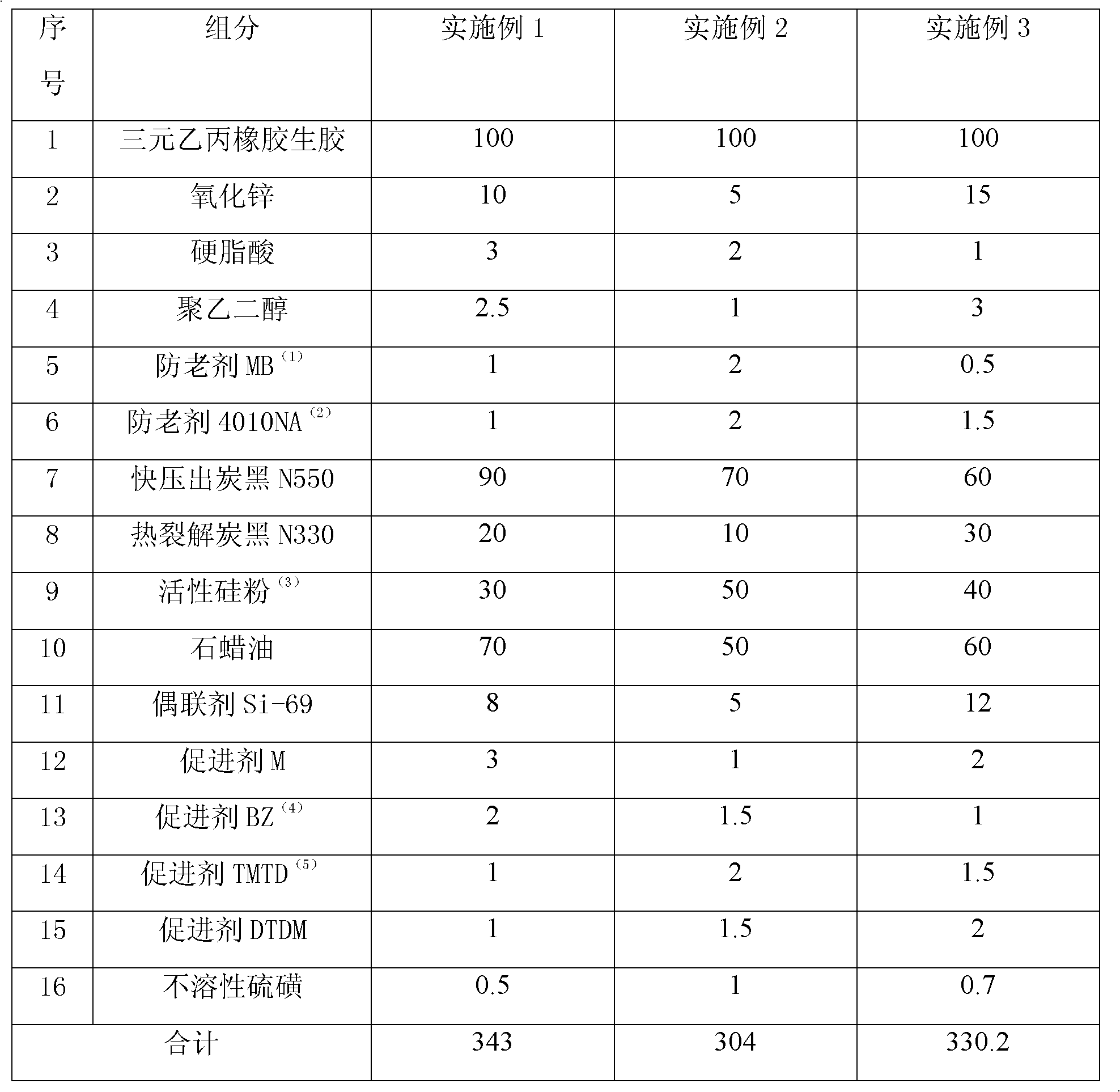

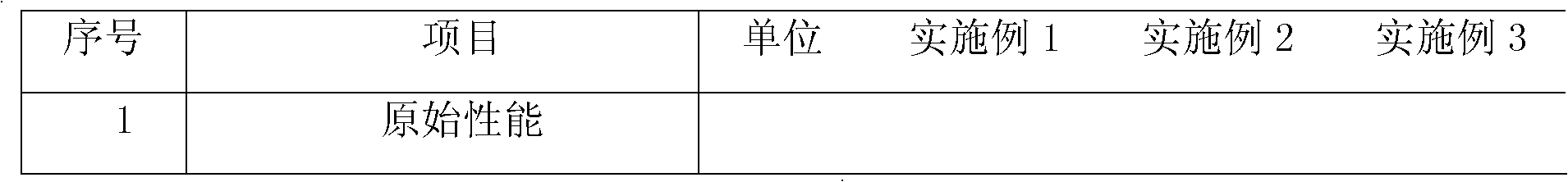

Cleaning and draining rubber hose of sedan trunk

ActiveCN102120851AImprove stiffnessSmall shrinkageGeneral water supply conservationFlexible pipesPolymer scienceCrack resistance

The invention relates to a cleaning and draining rubber hose of a sedan trunk. The cleaning and draining rubber hose of the sedan trunk consists of raw ternary ethylene propylene rubber, zinc oxide, stearic acid, polyethylene glycol, an anti-aging agent MB, an anti-aging agent 4010NA, fast extruded carbon black N550, thermal cracking carbon black N330, paraffin oil, a coupling agent Si-69, an accelerator M, an accelerator BZ, an accelerator TMTD, an accelerator DTDM and insoluble sulfur. The cleaning and draining rubber hose of the sedan trunk can better meet the conventional requirements of thermal aging resistance, weathering aging resistance, ozone resistance, flexible cracking resistance, acid resistance, electric insulativity and low temperature resistance. Compared with plastic pipes, the cleaning and draining rubber hose of the sedan trunk can further resist rainwater erosion, ozone aging, weathering aging, low temperatures and flexible cracking, so the significance of development of the cleaning and draining rubber hose of the sedan trunk is very important, and the cleaning and draining rubber hose of the sedan trunk can be applied to trunk drainage pipelines and headlamp cleaning pipes of automobiles, skylight drainage pipes and the like.

Owner:TIANJIN PENGYI GRP CO LTD

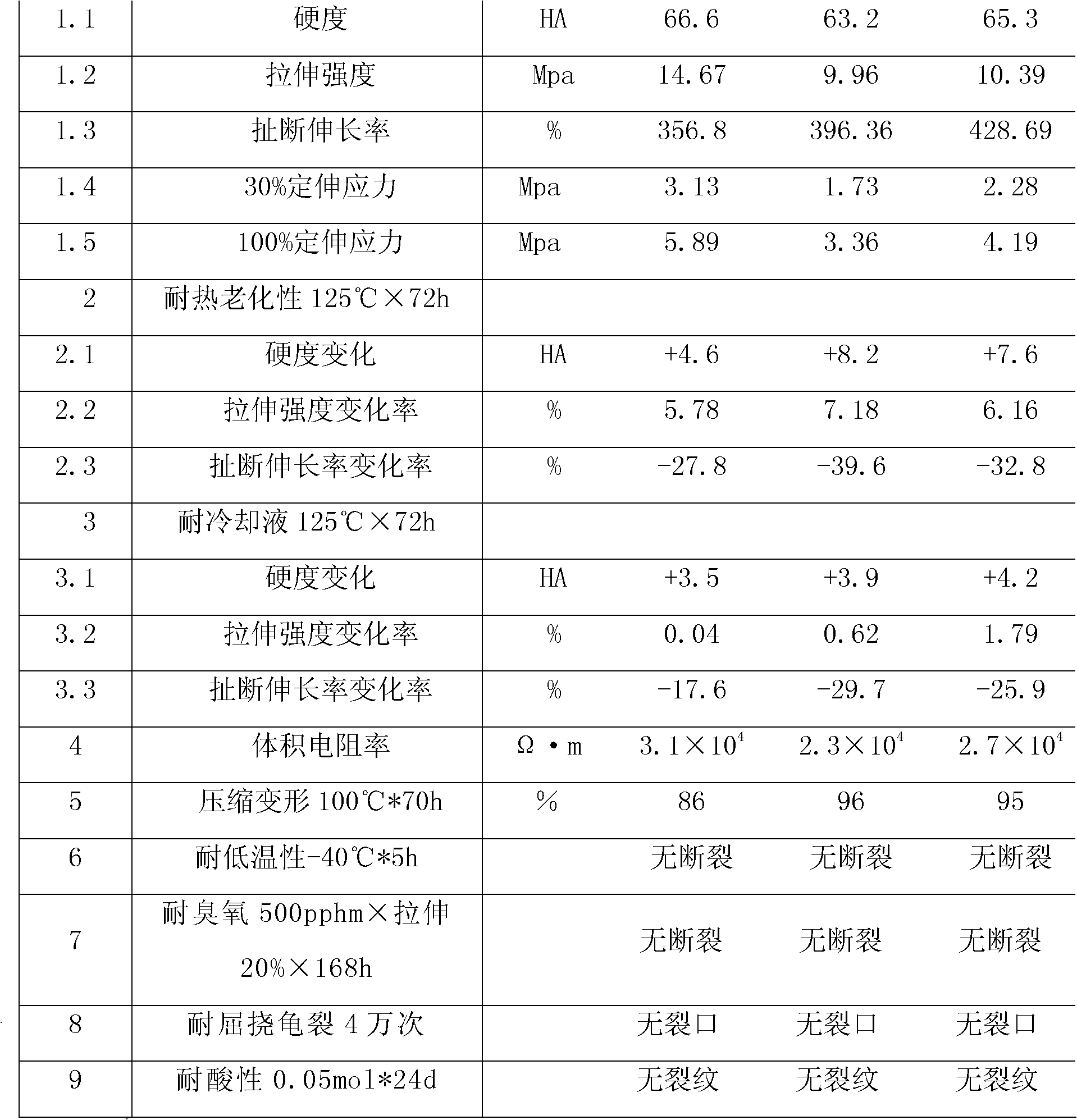

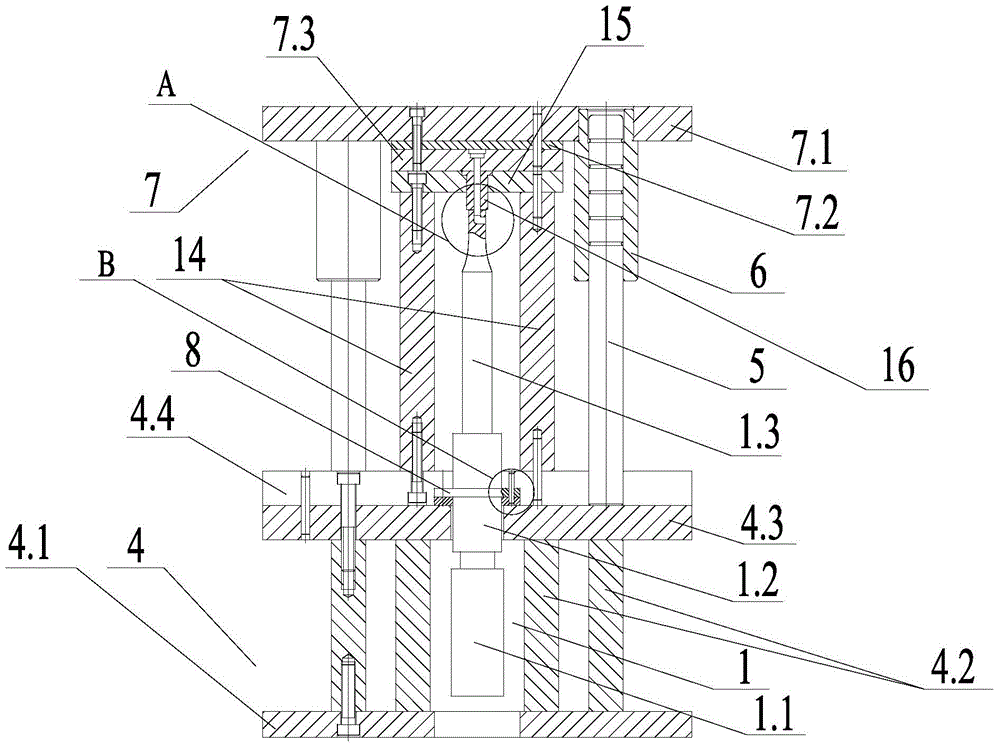

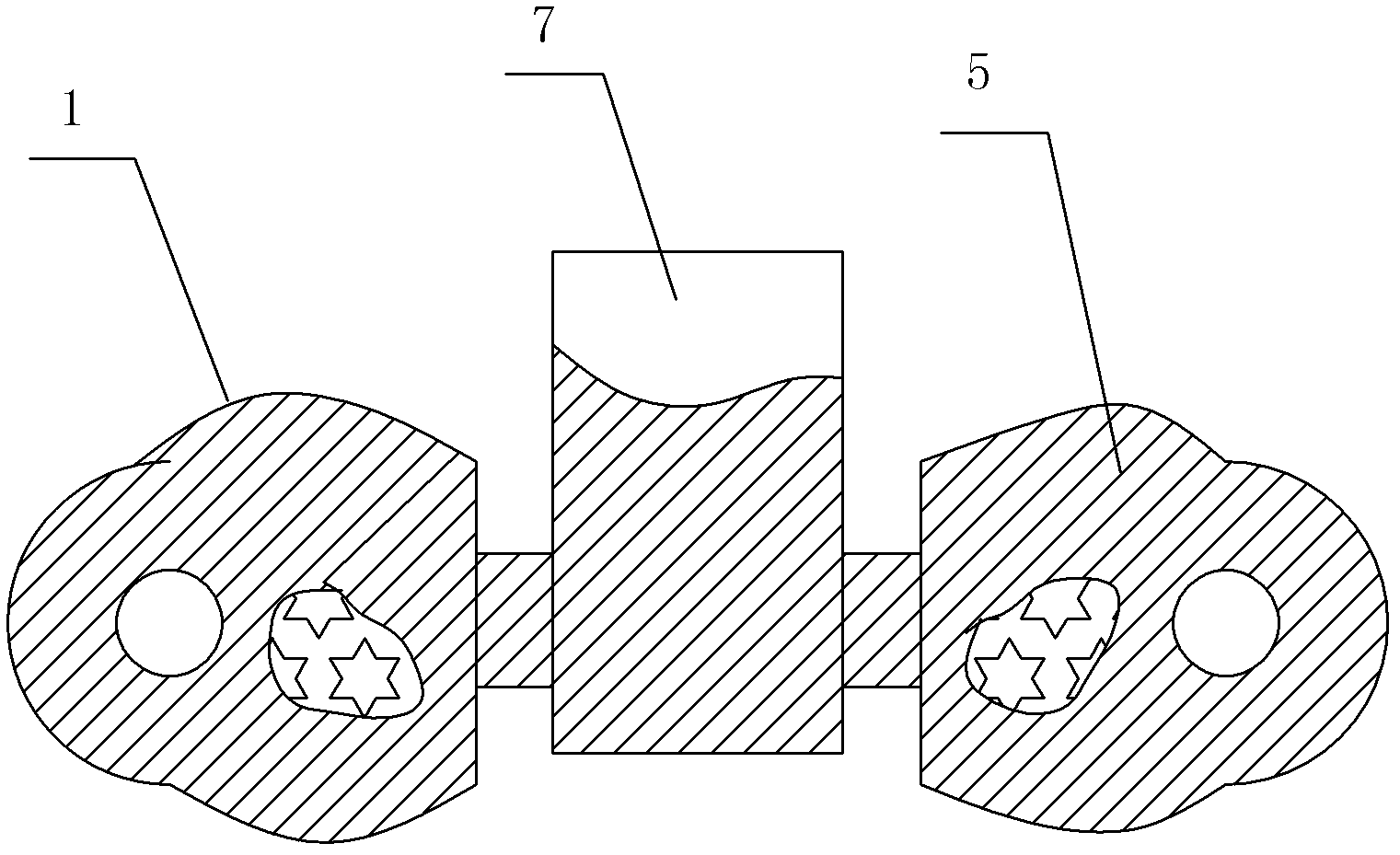

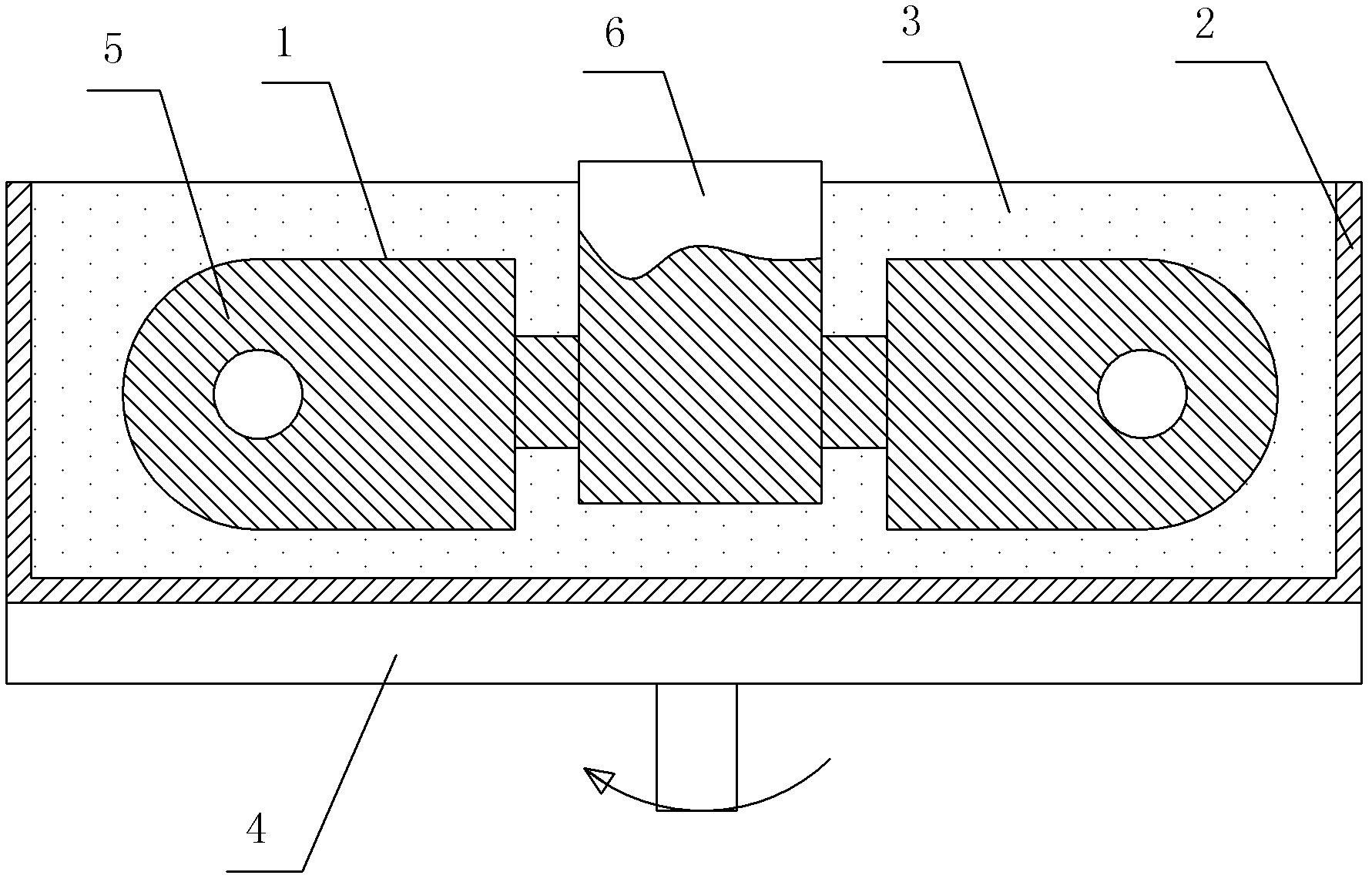

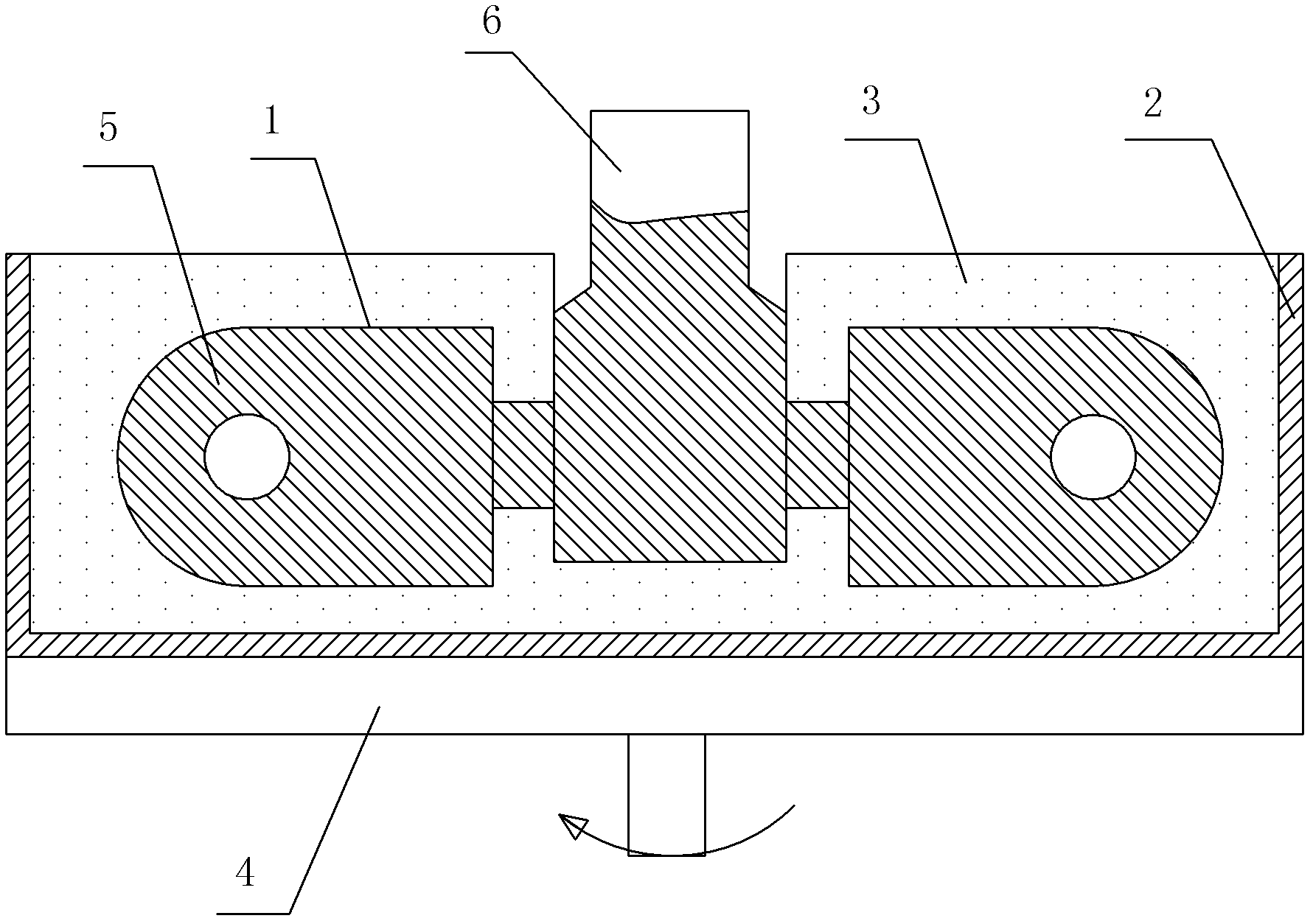

Ultrasonic wave vibration equal channel angular extrusion combined mold

ActiveCN104307910ALower yield stressHigh fillingExtrusion diesMechanical vibrations separationFlow stressEqual channel angular extrusion

The invention discloses an ultrasonic wave vibration equal channel angular extrusion combined mold. An ultrasonic wave vibration system is fixed on a mold base in the vertical direction; an L-shaped concave mold hole is formed in the output end of the ultrasonic wave vibration system; the feeding direction of the concave mold hole is parallel to the ultrasonic wave vibration direction; the discharge direction of the concave mold hole is perpendicular to the ultrasonic wave vibration direction; guide columns are uniformly arranged on the mold base; guide sleeves which relatively move in match with the guide columns are arranged on the guide columns; the guide sleeves are fixed on a top base of the mold; a convex mold is also fixed on the top base of the mold; a plurality of material guide sleeve support rods are uniformly fixed on the mold base; material guide sleeve fixing plates are fixed on the tops of the material guide sleeve support rods; material guide sleeves in match with the convex mold are fixed on the material guide fixing plates; the material guide sleeves are positioned above the convex mold hole; gaps are formed between the material guide sleeves and the concave mold hole. The ultrasonic wave vibration system and an equal channel angular extrusion mold are reasonably combined to form the ultrasonic wave vibration equal channel angular extrusion combined mold, so that both the yield stress and the flowing stress of a material are reduced, and crystal grains of the material are refined, and the comprehensive mechanical property of the material is improved.

Owner:JIANGHAN UNIVERSITY

Preparation method of silane coupling agent modification montmorillonite functionality nanometer fat liquoring complex agent

InactiveCN102994660AImprove flame retardant performanceImprove performanceLeather impregnationEthylenediaminePolymer science

The invention relates to a preparation method of a silane coupling agent modification montmorillonite functionality nanometer fat liquoring complex agent. Leather flame-retardant technology and flame-resistant materials are rarely studied and developed in China, and studies of obtaining a functionality nanometer fat liquoring complex agent by using silane coupling agent modification montmorillonite and introducing the silane coupling agent modification montmorillonite to preparation of a fatting agent are rare. The preparation method includes fetching methanol and water, adding asilane coupling agents and Na-montmorillonite to the methanol and the water so as to obtain the silane coupling agent modification montmorillonite, enabling the silane coupling agent modification montmorillonite to thermostatically react with colza oil, and adding quadrol Al2O3, dropping a solution of acrylic acid and sodium hydrogen sulfite to obtain the silane coupling agent modification montmorillonite functionality nanometer fat liquoring complex agent. The silane coupling agent modification montmorillonite functionality nanometer fat liquoring complex agent is excellent in flame resistant property, improves mechanical properties, filling ability, binding ability and the like of a product, and has the advantages of being reproducible in sources, non-toxic and pollution-free, good in biological degradability and the like.

Owner:SHAANXI UNIV OF SCI & TECH

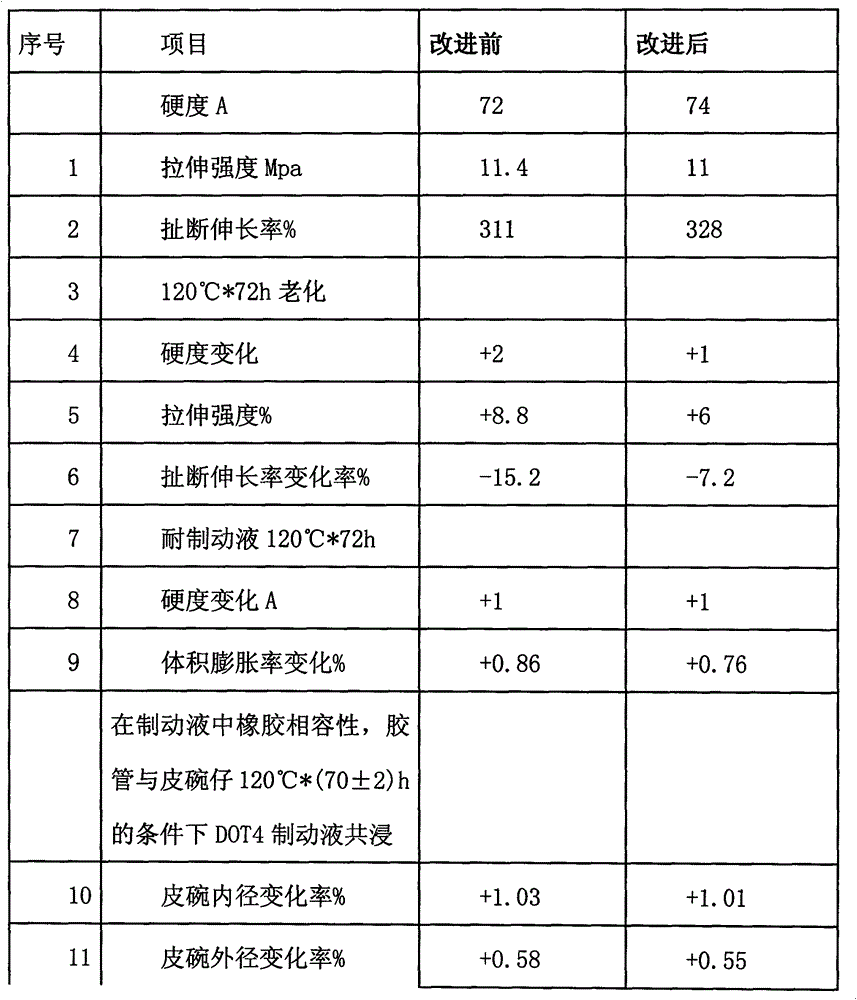

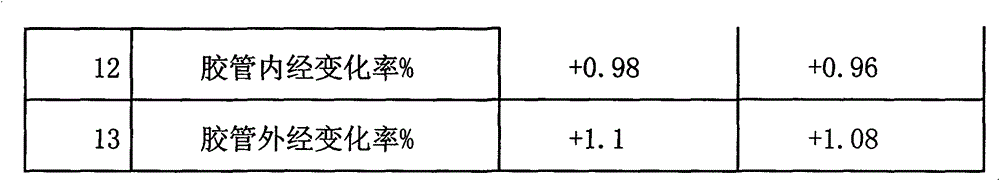

EPDM/EPM engine synthetic brake fluid and expansion resistance rubber material and manufacturing process thereof

The invention discloses an EPDM / EPM engine synthetic brake fluid and expansion resistance rubber material. The material is characterized in that the following components are proportionally mixed in parts by mass: 70-90 parts of EPDM (ethylene propylene diene monomer); 2-4 parts of zinc oxide; 1-3 parts of stearic acid SA; 2.5-4 parts of antiager BLE (liquid); 2-3.5 parts antiager SP (liquid) of 0.5-2 parts of antiager RD; 55-65 parts of N550 carbon black; 18-21 parts of EPM (binary ethylene propylene copolymer); 19-22 parts of StronWiNTC; 19-21 parts of liquid EPDM; 0.5-1.5 parts of assistant crosslinker IS; 1-2 parts of accelerant DM; 0.5-1.5 parts of crosslinker 96% peroxide vulcanizing agent DCP; 1.5-2.5 parts of polyethylene glycol; the invention further discloses a manufacturing process of the rubber material; the rubber material disclosed by the invention is high in quality and low in cost, does not expand in brake liquid, softener is not extracted, and volume expansion, solution, contraction and other phenomena of master and assistant cups are not caused.

Owner:ZHEJIANG KEDALI IND

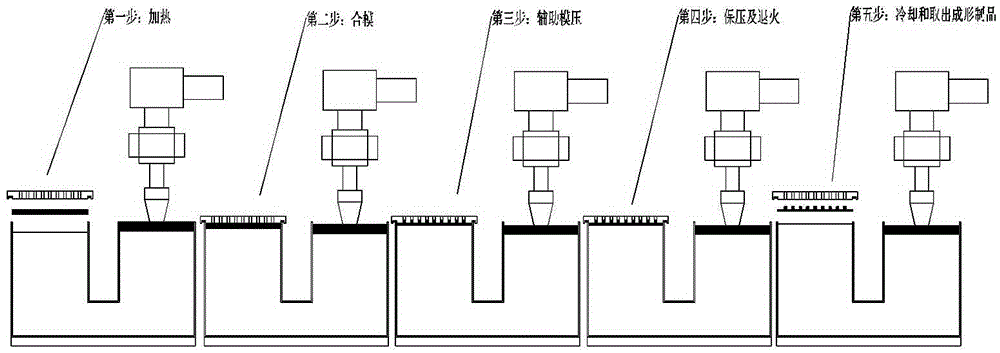

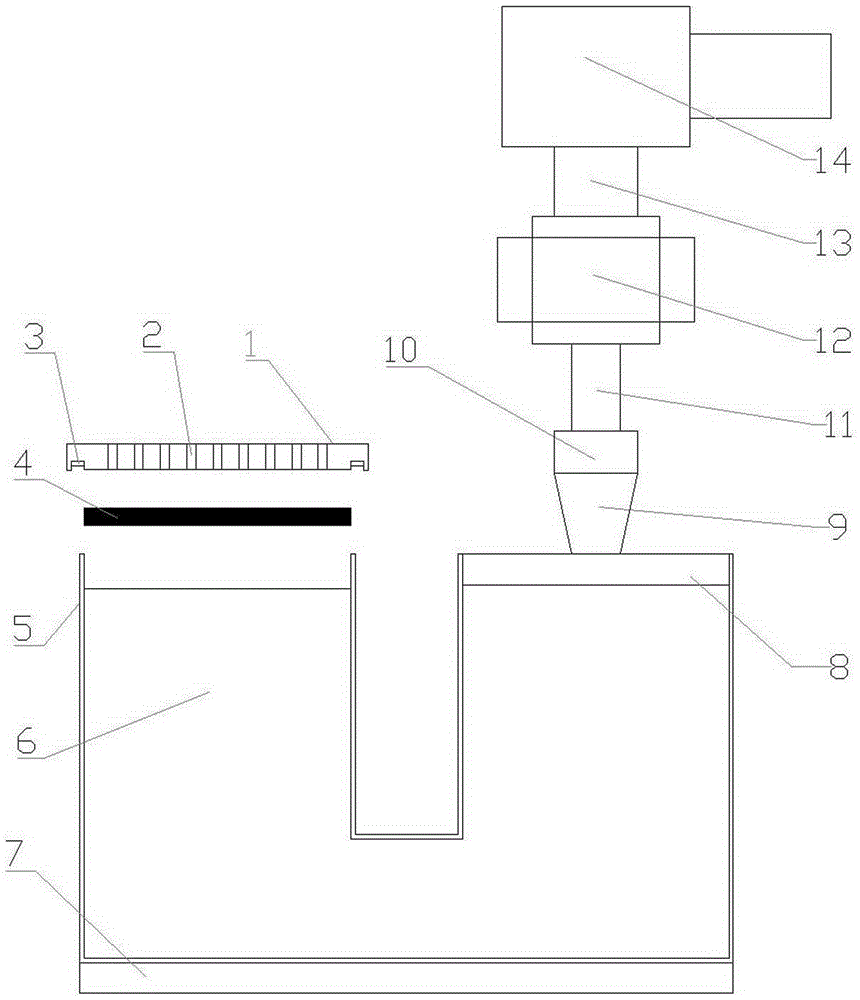

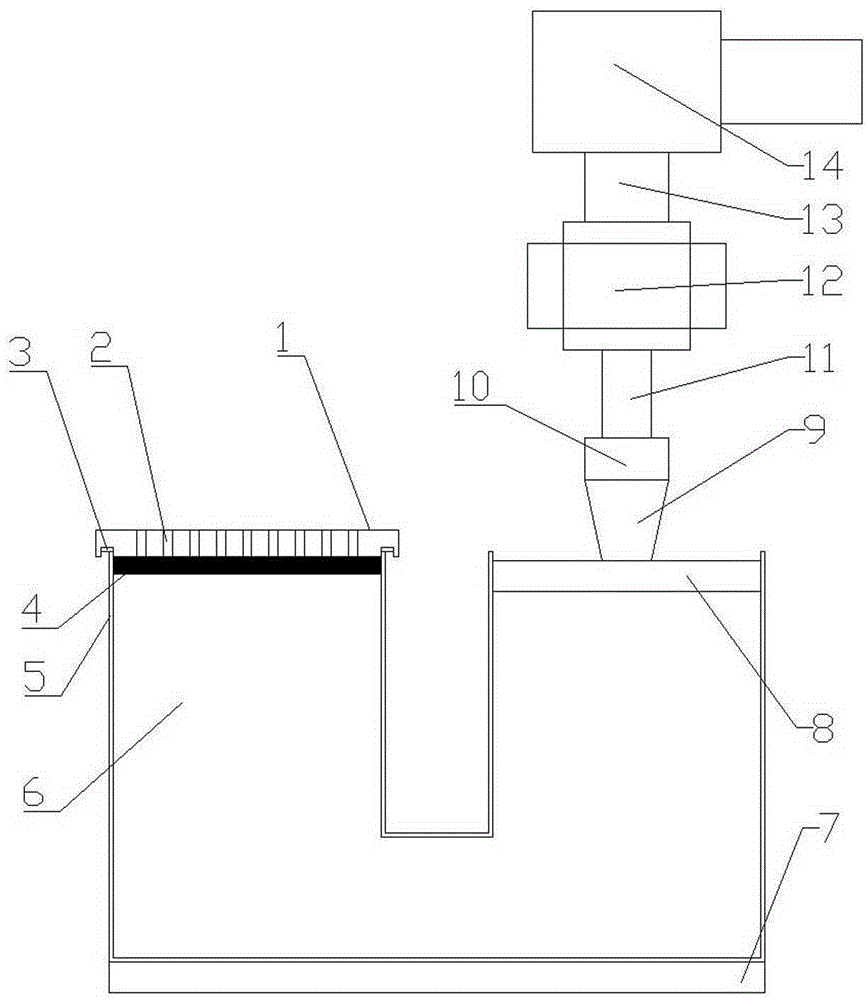

Ultrasonic vibration-assisted mould pressing forming method based on tin liquid medium and special forming device thereof

InactiveCN105366918AImprove liquidityImprove uniformityGlass pressing apparatusMolten stateLiquid medium

The invention discloses an ultrasonic vibration-assisted mould pressing forming method based on a tin liquid medium and a special forming device thereof, and mainly aims at solving the technical problems that an existing mould pressing forming is low and inconsistent in filling ratio and the like. According to the technical scheme, the tin liquid medium which is better in heat conducting property is introduced between a heating plate and a preformed glass body, the pressure of a piston is transmitted to the surface of the preformed glass body through the tin liquid medium, and then glass in a molten state is driven to be evenly filled in a mould which is installed at one port of a tin liquid container, wherein the forming surface of the mould is arranged to be in a microstructural shape; an ultrasonic vibration assistant system is installed over a piston of the other port of the tin liquid container and can apply assistant vibration with the certain frequency and the controllable amplitude to the piston, and ultrasonic vibration of the piston is transmitted to the preformed glass body through the tin liquid medium. Accordingly, the filling ratio of the glass in the molten ratio is increased, and then high-precision mould pressing forming of microstructural thin glass elements is achieved.

Owner:XIANGTAN UNIV

Self-compaction composite concrete, preparation method therefor and concrete wall bricks

ActiveCN109279861AImprove liquidityIncreased strength lossCeramic shaping apparatusBuilding componentsBrickSlag

The invention relates to the technical field of building materials and particularly relates to self-compaction composite concrete, a preparation method therefor and concrete wall bricks. According tothe self-compaction composite concrete, Portland cement and thiophosphate cement are compounded as a cement ingredient, and thiophosphate cement is creatively selected; specific furnace slag, steel slag and ferrum tailings are compounded as an aggregate ingredient; cellulose ether and beta-cyclodextrin are combined as a dispersant; the cement ingredient, the aggregate ingredient and an auxiliary ingredient are divided into three ingredients and are separately packaged to form the self-compaction composite concrete; and in a process of casting the concrete wall bricks by forming slurry by usingthe concrete disclosed by the invention, the ingredients can be added and mixed in groups according to characteristics of each ingredient. The fluidity, filling property, segregation resistance and strength of the self-compaction composite concrete disclosed by the invention are improved.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

950-DEG G grade heat-insulating high-temperature-resisting and wear-resisting coating and preparation method thereof

InactiveCN104650698AReduce transfer speedChange delivery routeAnti-corrosive paintsEpoxy resin coatingsCelluloseCarbide silicon

The invention discloses a 950-DEG G grade heat-insulating high-temperature-resisting and wear-resisting coating which comprises components I and II, wherein the component I is a double component composition which is mixed by components A and B in a proportion of 1:1.5, and the component A in the component I comprises the following components: nano-montmorillonite silicate, a coupling agent and blocking function filler in a mass ratio of 1: 1: 1.5; the component B comprises the following components in parts by mass: 20-35 parts of black silicon carbide, 25-30 parts of fine crystal aluminum oxide, 5-10 parts of a dispersant, 1-5 parts of zinc oxide, 10-15 parts of modified epoxy resin and 2-6 parts of a delustering agent; the component II comprises the following components in parts by mass: 2-6 parts of a delustering agent, 2-6 parts of a wetting agent, 20-50 parts of a curing agent, 5-10 parts of a thickening agent, 5-10 parts of hydroxyethyl cellulose, 1-5 parts of a pH adjustor, 50-60 parts of organosilicone modified epoxy resin, 20-30 parts of filler, 5-10 parts of antimonous oxide and 5-10 parts of a coalescing agent. The invention further designs a preparation method of the 950-DEG G grade heat-insulating high-temperature-resisting and wear-resisting coating.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Environmental protection paint for building exterior wall

InactiveCN104860630ALight weightFunction increaseSolid waste managementFilling pastesDimethylaniline N-oxideLacquer

The invention belongs to the field of building materials, and relates to environmental protection paint for a building exterior wall. The environmental protection paint comprises the following components in part by weight: 10-15 parts of water, 40-50 parts of hand feeling filler, 15-20 parts of quartz sand, 8-13 parts of silicon substrate active glue, 6-9 parts of putty, 12-18 parts of diphenyl guanidine, 2-5 parts of hydroxyethylmethylcellulose, 2-4 parts of zinc stearate, 1-3 parts of organic zirconium complex, 3-5 parts of dimethylaniline, 4-7 parts of tetramethylolmethane, 3-6 parts of modified floating bead, and 1-3 parts of texture particle; putty is composed of A and B components according to the mass ratio of 50: 1-5, wherein A component includes 10-15 parts of polymer powder, 1-3 parts of polycarboxylic ammonium salt, 3-5 parts of silicone acrylic emulsion, 20-30 parts of heavy coarse whiting, 3-10 parts of talcum powder, 10-15 parts of lightweight clay brick, 5-10 parts of perlite, 3-6 parts of high-alumina cement, 4-6 parts of dispersible latex powder, 10-15 parts of composite suspension liquid formed by aluminum oxide sol and silicon dioxide soil according to the mass ratio of 1: 1; B component is 15-20 wt% of acrylic emulsion. The environmental protection paint is excellent in water-retaining property, high in caking property, good in alkali resistance, and safe and environment-friendly.

Owner:肖先波

Processing method of tobacco stem and the device thereof

InactiveCN101095556AImprove the quality of sensory inhalationHigh fillingTobacco preparationTobacco treatmentPulp and paper industry

The invention relates to a method for treating tobacco stem, and device used for tobacco stem processing. The stem is stored for 1-6 hours after feeding process, and then is fed into drying and expanding process. The invention can improve tobacco stem quality and reduce cost.

Owner:CHINA TOBACCO HUNAN INDAL CORP

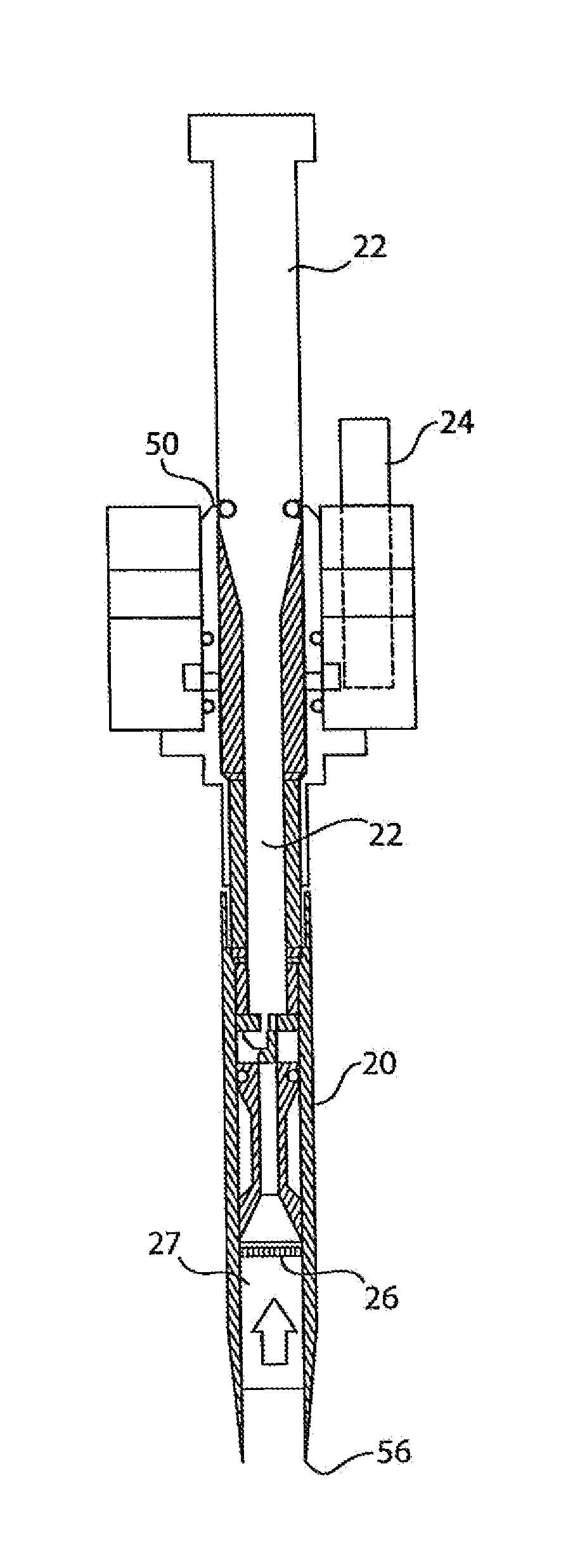

Dosator Apparatus for Filling a Capsule with Dry Powder

ActiveUS20150342890A1High fillingAccuracy and repeatabilityPowder deliveryNervous disorderDry powderMaterials science

The present invention provides a dosator apparatus and methods for dispensing low density, high flowing powders into capsules at high target fill weights with accuracy and repeatability.

Owner:CIVITAS THERAPEUTICS

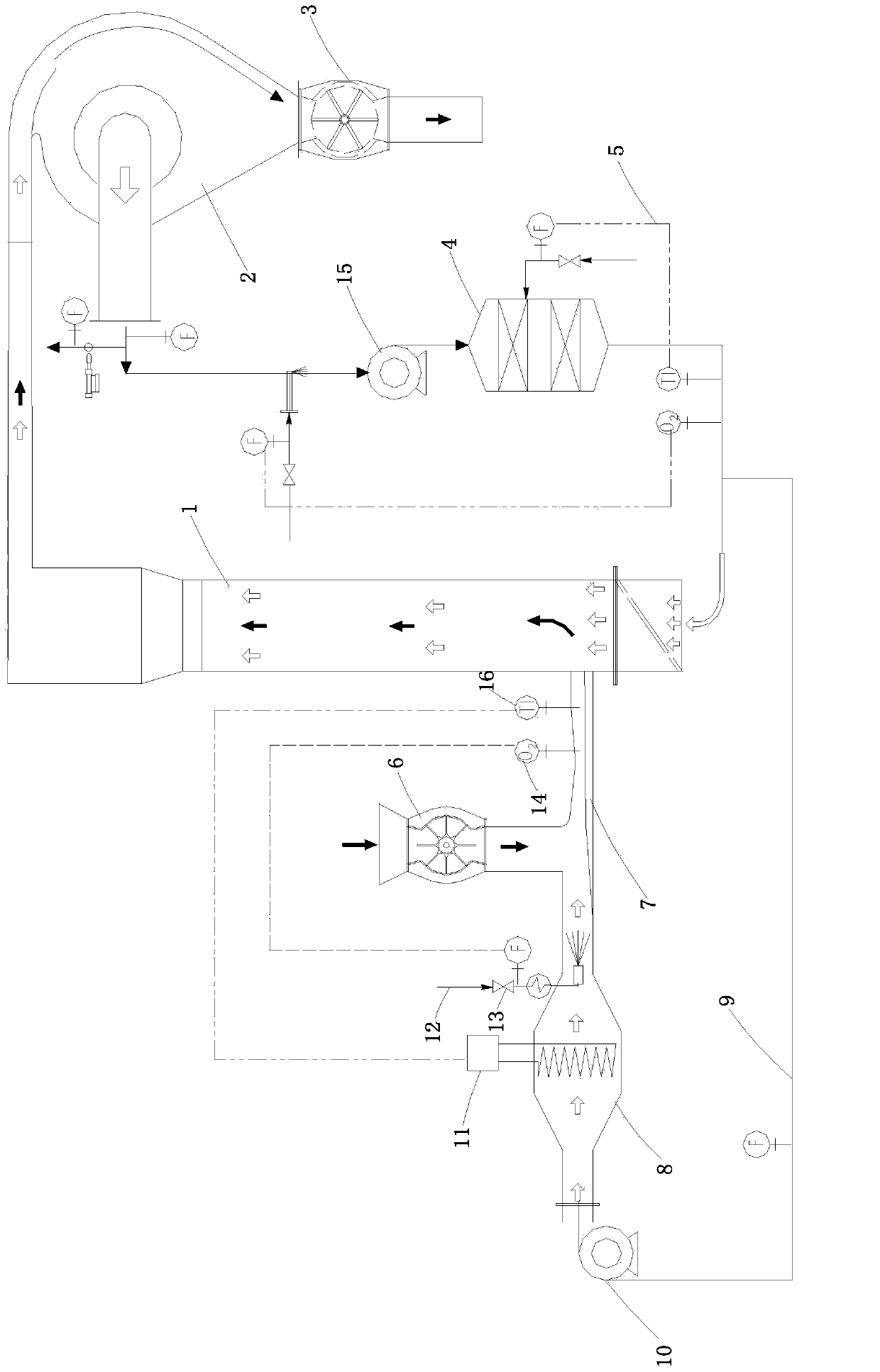

Online expanding and drying device of cut tobacco

ActiveCN103767056AFacilitate fine controlExtend the scope of controlTobacco preparationProcess engineeringHeating furnace

The invention discloses an online expanding and drying device of cut tobacco, wherein the upper part of a drying tower is communicated with a tangential separator through a material delivery pipe, the cut tobacco enters a discharge airlock and then is discharged therefrom after being separated from superheated steam, the superheated steam is recycled and communicated with a heating furnace through a pipe and a fan, and the heating furnace is communicated with the bottom of the drying tower through a superheated steam pipe; a feed airlock is communicated with an inlet formed in the lower part of the drying tower through a flat venturi, a heating unit is arranged at the front end of the feed airlock, the superheated steam pipe is communicated with the heating unit through an injection pipe, and an injection fan is arranged on the injection pipe at the front end of the heating unit; a heat exchanger is arranged in the heating unit and connected with a temperature sensor arranged at the inlet of the flat venturi to form a control loop; a steam injection pipe is communicated to the heating unit, and a flow control valve arranged on the steam injection pipe is connected with an oxygen content detector located at the inlet of the flat venturi to form a control loop. Expansion and drying are controlled independently so that the filling property of the cut tobacco can be improved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

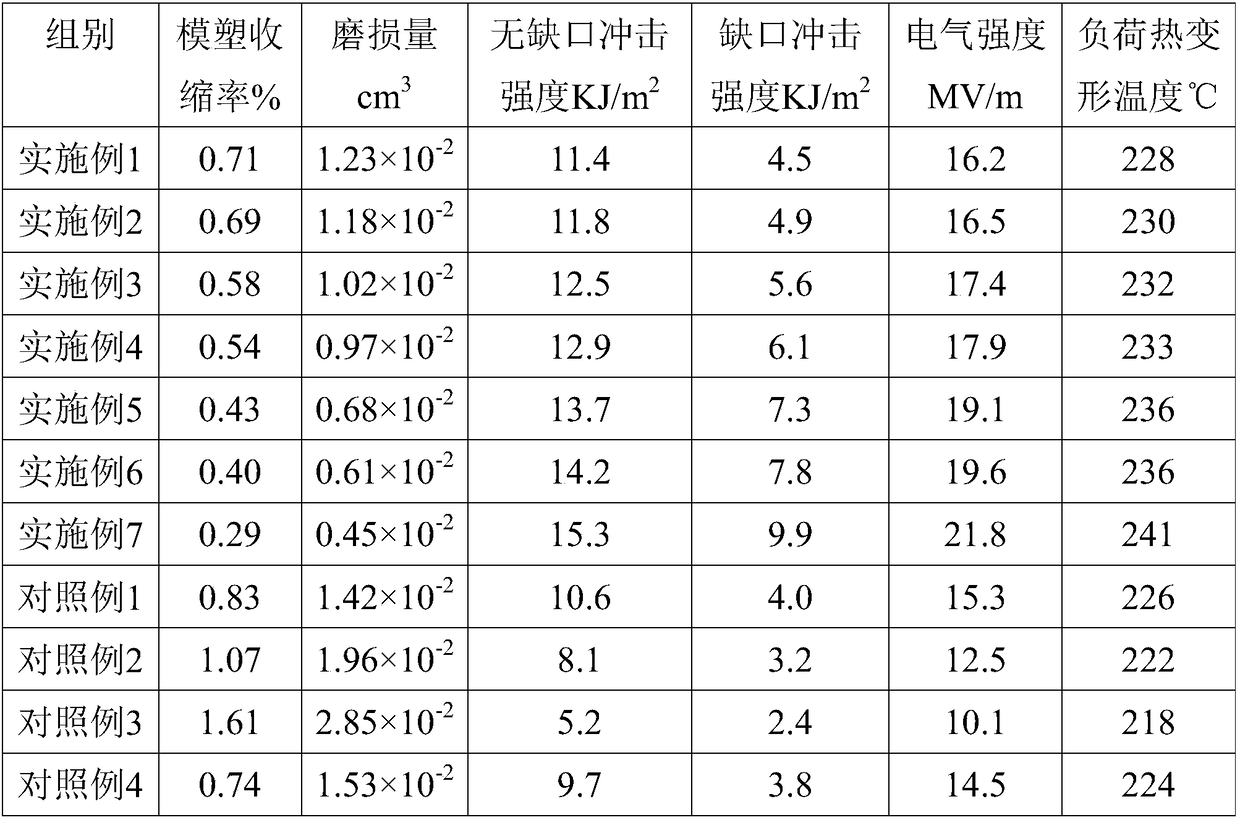

Processing method of self-lubrication wear-proof unsaturated polyester molding compound

The invention discloses a processing method of a self-lubrication wear-proof unsaturated polyester molding compound and relates to the technical field of thermosetting molding compounds. The processing method comprises the following steps of: (1) batching, (2) mixing and (3) granulation. The method prepares the self-lubrication wear-proof unsaturated polyester molding compound by taking solid unsaturated polyester resin as a main material, kaoline as filling and C5 hydrogenated petroleum resin and chlorinated polyethylene rubber as forming assistants, a lubricant, a releasing agent, a cross-linking agent, an initiator, a pigment, a polymerization inhibitor as functional assistants, can significantly reduce a wear extent and therefore prolongs a service life when the molding compound is applied to a moving component of an electric appliance product.

Owner:马斌祥

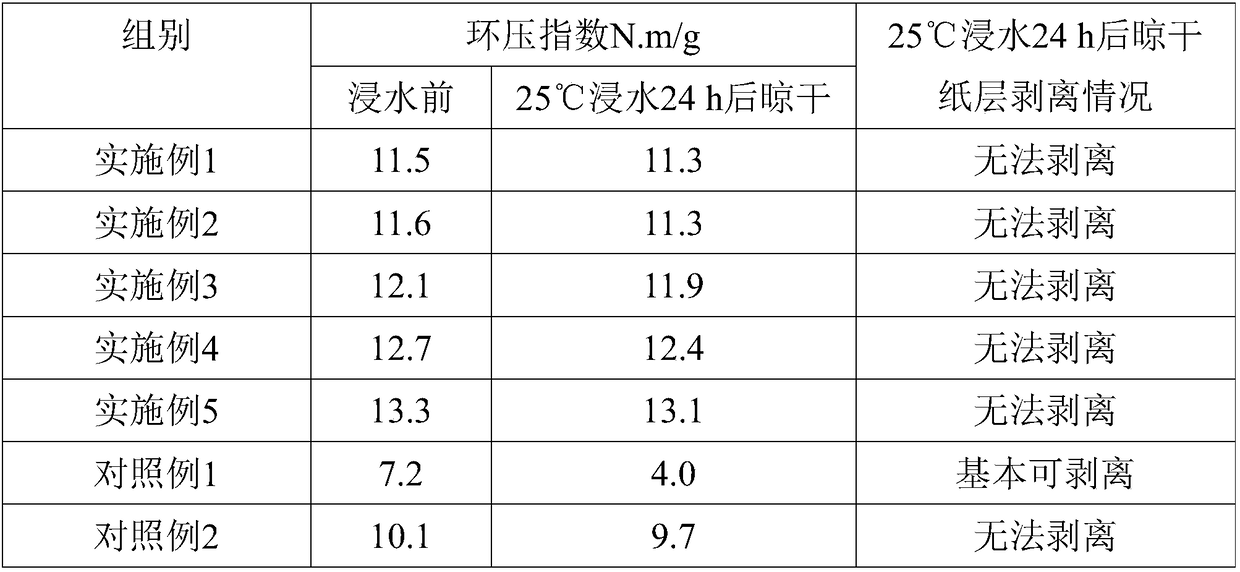

Preparation method of water-resistant adhesive for processing corrugated paperboard

InactiveCN108410400AGood adhesivenessGuaranteed water solubilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a preparation method of a water-resistant adhesive for processing a corrugated paperboard, and relates to the technical field of adhesives. The preparation method includes thesteps: (1) polyglutamic acid modification; (2) filler preparation; (3) adhesive preparation. In the modification process of polyglutamic acid, double bonds are introduced to a polyglutamic acid structure by esterification reaction of N-hydroxymethyl acrylamide and the polyglutamic acid, acrylamide copolymers are introduced to the polyglutamic acid structure by polymerization reaction of the N-hydroxymethyl acrylamide and diacetone acrylamide, the adhesive performance of the polyglutamic acid is enhanced, and the water resistance of the adhesive is improved by adding adhesive auxiliaries and modifying 4A molecular sieve activation powder.

Owner:江兵

A centrifugal pouring method for water glass investment casting

The invention discloses a centrifugal pouring method for water glass investment casting, relates to a casting pouring method, and solves the problem that castings are prone to unqualified castings during pouring of water glass investment casting. Put the water glass shell into the iron box, put steel sand in the iron box, the steel sand completely covers the water glass shell, then put the iron box on the centrifugal rotary table, pour the molten iron into the water glass through the sprue In the mold shell, after the pouring is completed, let it stand for 30 seconds, turn on the centrifugal rotary table, and rotate the centrifugal rotary table at a speed of 80-100 rpm for 10-15 minutes to obtain qualified castings. The invention strengthens the shell mold by embedding steel sand, prevents the volume expansion of the shell mold during the pouring process, makes the casting casting uniform by adopting the centrifugal rotating workbench, accelerates the filling and filling of the hot joint part of the casting, and reduces the static pressure by reducing the volume of the sprue , Reduce the pressure on the shell, avoid the problems of shrinkage cavity, shrinkage porosity or shell deformation, and the qualified rate of castings has increased from the original 75% to more than 98%.

Owner:临清市中远精铸有限责任公司

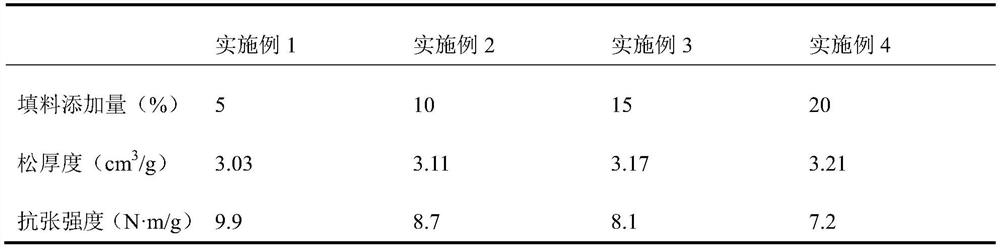

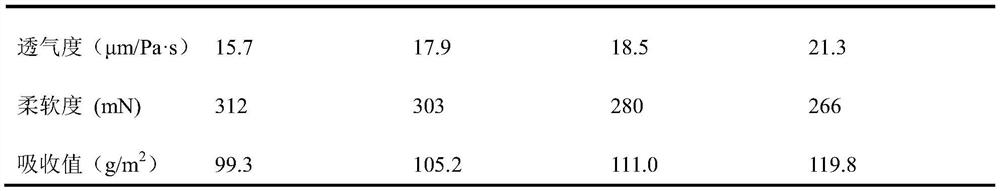

Method for preparing paper-making reconstituted tobacco substrate with high air permeability and high absorptivity

PendingCN111887465AImprove breathabilityPromote absorptionTobacco preparationCalcium hydroxidePlant fibre

The invention discloses a method for preparing a paper-making reconstituted tobacco substrate with high air permeability and high absorptivity; a fluffy auxiliary agent is added into the paper-makingreconstituted tobacco substrate, and the adopted fluffy auxiliary agent is derived from agricultural wastes and has the characteristics of light weight, looseness and porosity. The fluffy auxiliary agent is prepared by soaking inorganic waste powder generated after agricultural biomass wastes such as straws, rice husks, barks and the like are subjected to power generation by a biomass power plantin sodium hydroxide, separating a solid phase and a liquid phase, and reacting the liquid phase with calcium hydroxide. The goal of improving the air permeability and the absorptivity of the paper-making reconstituted tobacco is achieved. Firstly, tobacco stems and tobacco powder which are subjected to leaching, solid-liquid separation and defibering are mixed with additional plant fibers and fluffy auxiliary agents to prepare pulp, and finally, the pulp is made into the substrate. By improving the air permeability and absorptivity of the paper-making reconstituted tobacco, the smoking performance of cigarettes is improved, the combustion performance is improved, the effects of reducing tar and harm are achieved, and a new method is provided for continuous industrial production of the paper-making reconstituted tobacco.

Owner:SHAANXI UNIV OF SCI & TECH

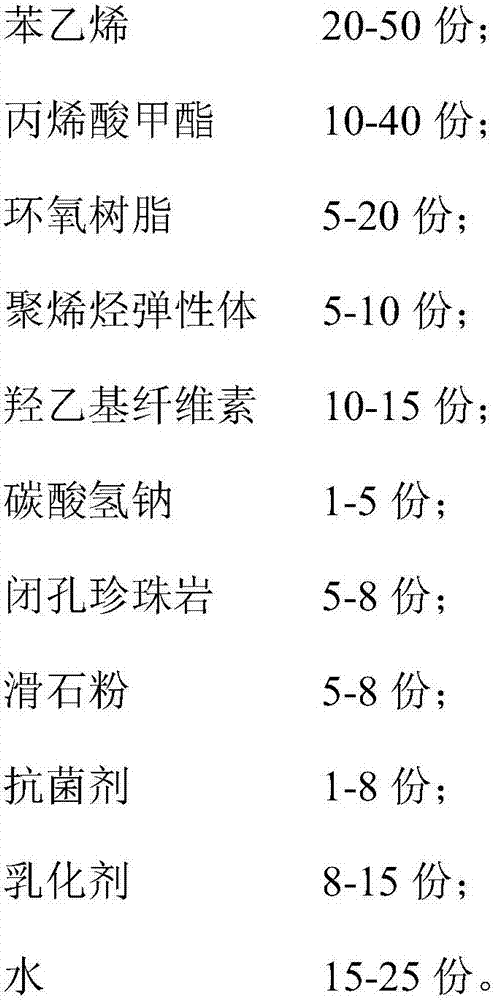

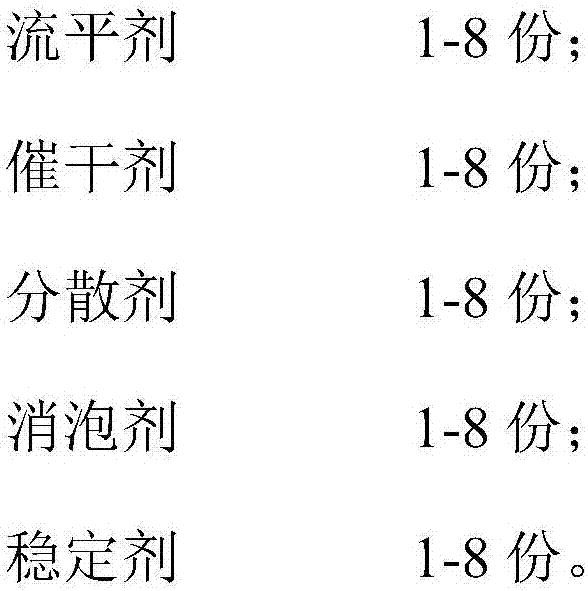

Environment-friendly styrene-acrylic emulsion paint and preparation method thereof

InactiveCN107033682AWon't block outPrevent adhesionAntifouling/underwater paintsPaints with biocidesSodium bicarbonateElastomer

The invention discloses environment-friendly styrene-acrylic emulsion paint. The paint is prepared from the components in parts by weight as follows; 20-50 parts of styrene, 10-40 parts of methyl acrylate, 5-20 parts of epoxy resin, 5-10 parts of polyolefin elastomers, 10-15 parts of hydroxyethyl cellulose, 1-5 parts of sodium bicarbonate, 5-8 parts of closed cell perlite, 5-8 parts of talc powder, 1-8 parts of an antibacterial agent, 8-15 parts of an emulsifier and 15-25 parts of water. The paint adopts simple and reasonable composition, is non-toxic and odorless, has the clean and smooth surface and good water resistance, cannot fall off easily and is applicable to painting of internal walls, and a paint coat is dried quickly; besides, the paint is antibacterial, anti-mildew, washable, wear-resistant and long in service life; the paint cannot fall off easily, cannot pulverize and decolorize and is excellent in fouling resistance and weather resistance and convenient to use; meanwhile, a paint film is smooth and compact, and the thermal insulation effect is good. The invention further discloses a preparation method of the environment-friendly styrene-acrylic emulsion paint. The method is simple and safe in process and high in operability.

Owner:ZHONGSHAN MOORE CHEM IND CO LTD

Preparation method of environmentally-friendly suede leather

InactiveCN110777223AGood compatibilityFine foamTanning treatmentPre-tanning chemical treatmentEpoxyPolymer science

The invention discloses a preparation method of environment-friendly suede leather, and belongs to the field of leather production. The method comprises the treatment processes of soaking in water, liming, deliming, pickling, tanning, shaving, retanning, neutralizing, dyeing and fat liquoring, and drying and finishing. Epoxy silicone oil, isocyanate crosslinked silane and polyurethane crosslinkedsilica gel are added in the tanning process, and drum tanning is performed; and a chromium retanning agent, epoxy silicone oil, fat liquoring silicone oil and retanning silica gel are added in the retanning treatment process, and mixing retanning is carried out. The epoxy silicone oil, isocyanate crosslinked silane and polyurethane crosslinked silica gel are added in tanning and retanning processes, so that the compatibility of all process additives can be effectively improved, the foaming feeling and the flexibility of leather are enhanced, and the foaming feeling, the filling property, the flexibility, the velvet feeling and the folding resistance of the leather are effectively improved; and the leather has good compatibility, and can directly enters neutralizing, dyeing and fat liquoring processes without water washing, so sewage discharge is reduced, energy conservation and emission reduction are achieved, the process time is shortened by 20%, and the water consumption is reduced by 50-60%.

Owner:NINGXIA JINHAI LEATHER IND

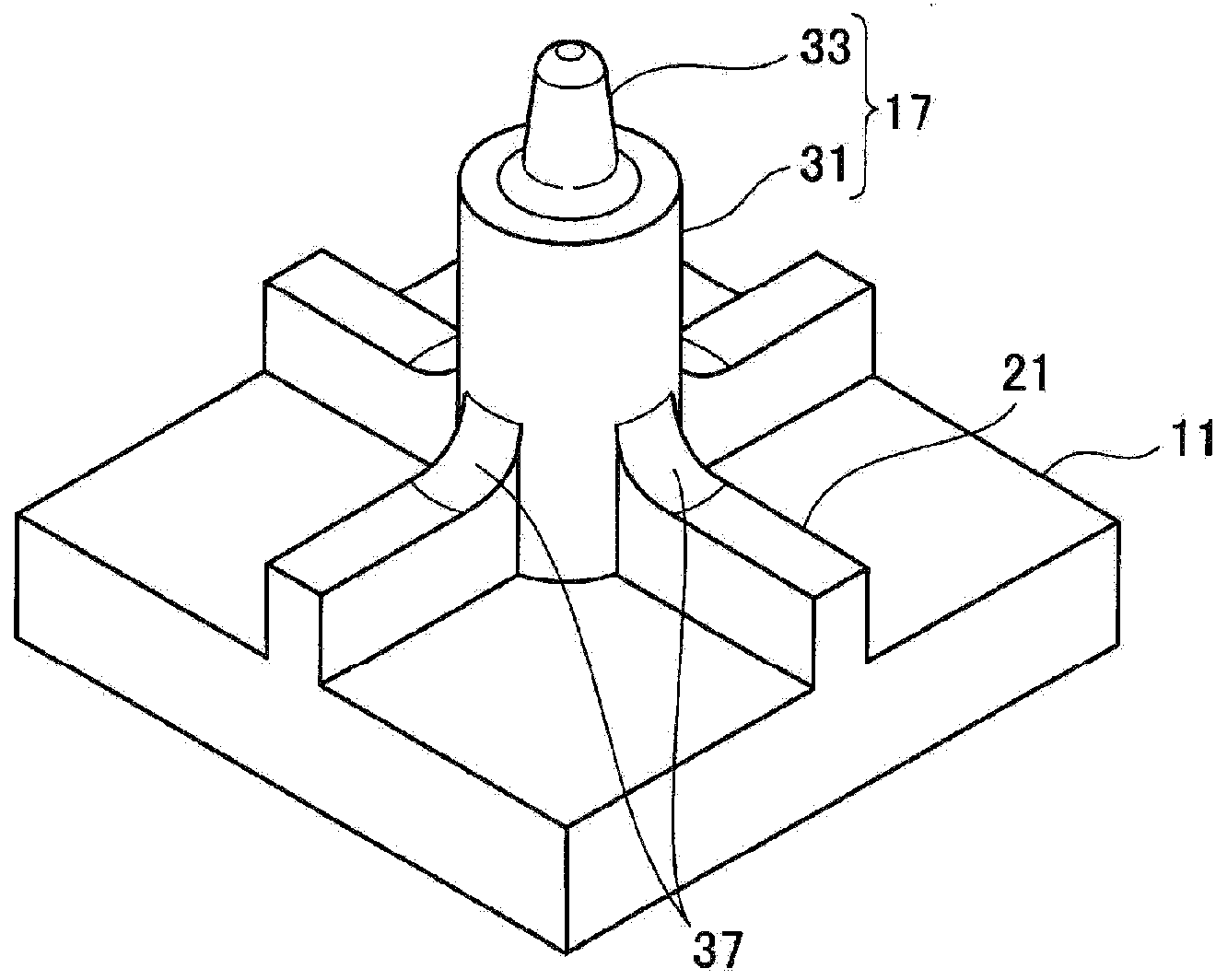

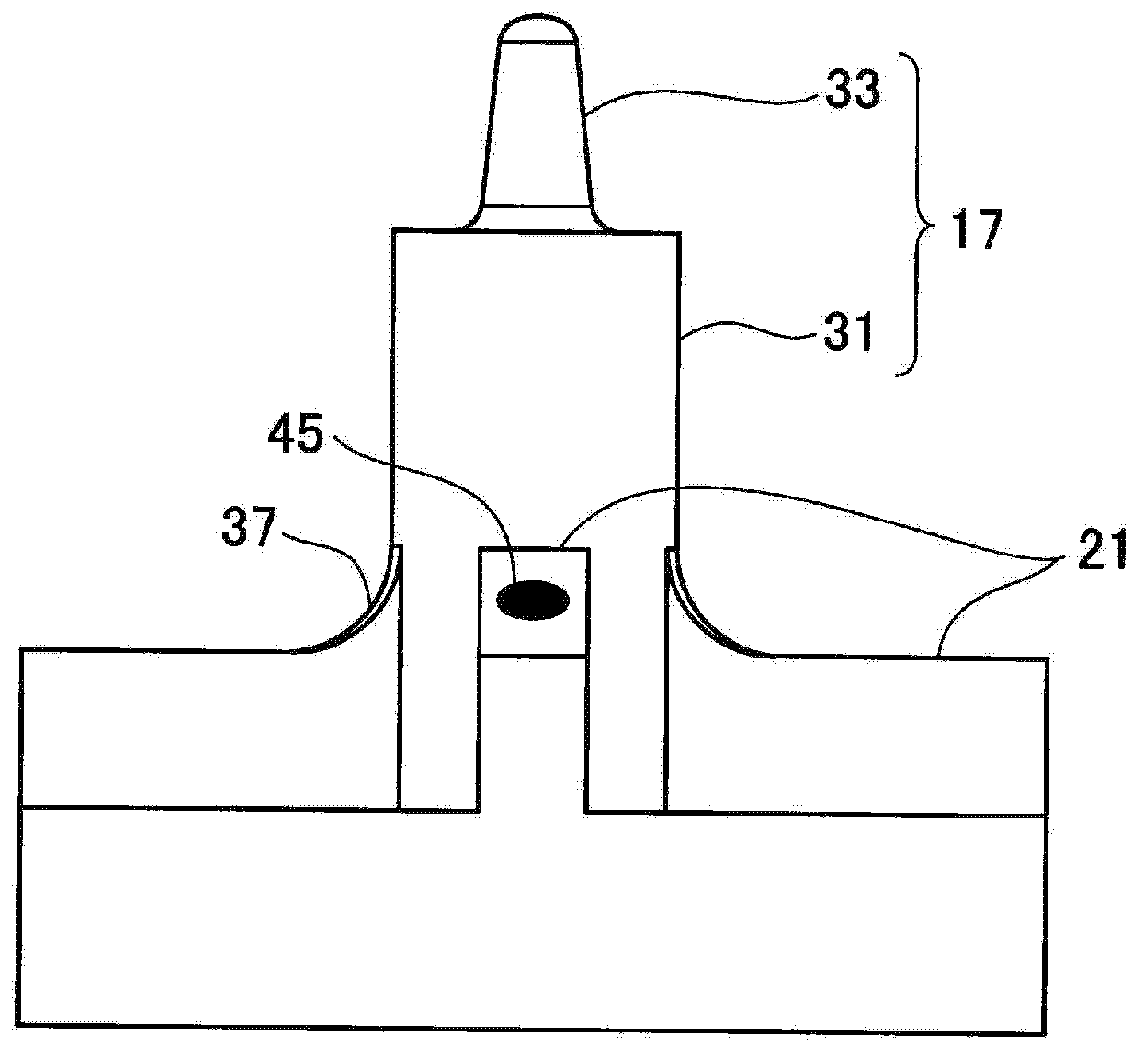

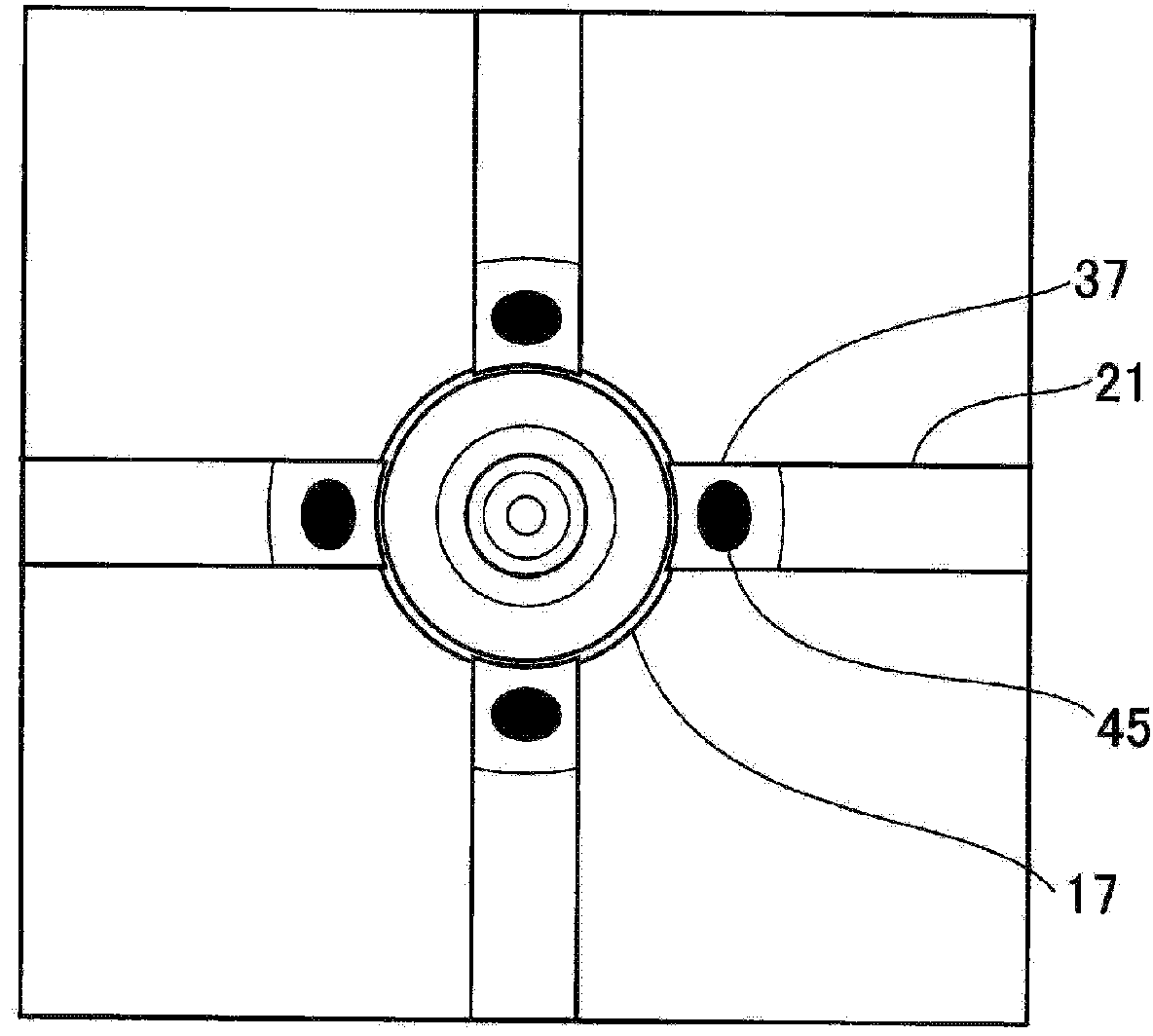

Support structure for boss

ActiveCN103022784AHigh fillingLow flow resistanceBus-bar installationCouplings bases/casesMechanical engineeringEngineering

Owner:YAZAKI CORP

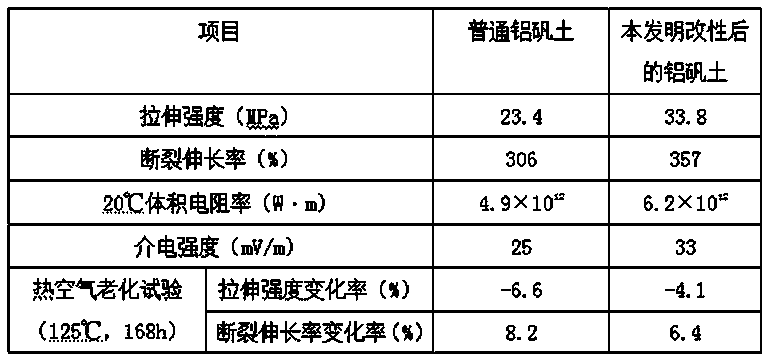

Modified bauxite for thermal ageing resistant polyurethane cable material and preparation method of modified bauxite

InactiveCN104194414AGood lipophilic and hydrophobic propertiesImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPhosphateBoronic acid

The invention discloses modified bauxite for a thermal ageing resistant polyurethane cable material and a preparation method of the modified bauxite. The modified bauxite is prepared from the following raw materials in parts by weight: 55-65 parts of bauxite, 7-13 parts of 4A molecular sieve powder, 5-10 parts of triethyl borate, 2-3 parts of peroxidized di(2-ethylhexyl) dicarbonate, 10-15 parts of calcined pottery clay powder, 8-14 parts of methyl MQ silicon resin, 1.5-2.5 parts of N-phenyl maleimide, 3-5 parts of trihydroxymethylpropyl trioleate, 4-7 parts of divinyl benzene, 5-10 parts of tung oil anhydride, 2-3 parts of cerous fluoride, 2.5-4.5 parts of 3, 3'- dichloro-4,4'- diaminodiphenyl methane, 4-6 parts of isodecyl salicylate, 5-10 parts of butoxytriethyl phosphate, 0.5-1.5 parts of 2-(4-morpholinyldithio) benzothiazole and 3-5 parts of auxiliaries. After being subjected to modified treatment, the bauxite has very good oleophylic and hydrophobic performances, is very easily dispersed in a polyurethane system, and is good in compatibility, high in filling performance, capable of improving performances such as chemical corrosion resistance and heat-proof aging performance while improving the mechanical performances of the polyurethane cable material and wide in application prospect.

Owner:ANHUI MINGDU ELECTRIC WIRE

Filling modifier for plastic product and preparation method thereof

Owner:ANHUI BEIMA TECH CO LTD

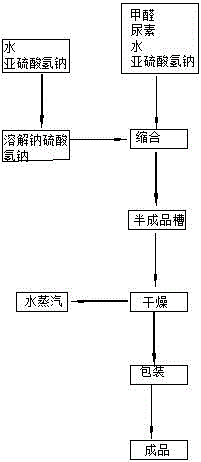

Preparation method of dicyandiamide resin tanning agent

The invention discloses a preparation method of a dicyandiamide resin tanning agent. The dicyandiamide resin tanning agent is prepared through steps of preparation of a sodium hydrogen sulfite solution, a condensation reaction and drying. The dicyandiamide resin tanning agent has the advantages as follows: the preparation technology of the resin tanning agent is improved, so that the prepared resin tanning agent has high filling performance, has an extremely high filling effect on soft parts of leather and has a good napping effect; excessive ammonium sulfite is added during condensation to react with free formaldehyde in materials, thus, the content of free formaldehyde in the product is reduced, and the product is more environmentally friendly.

Owner:南通双狮化工有限公司

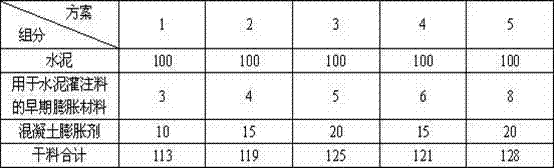

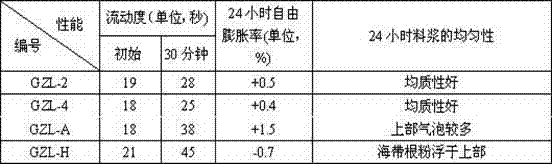

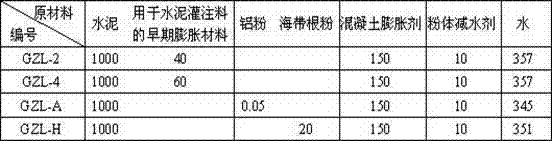

Slightly expansive cement grouting material

InactiveCN103113059AConsistent volumeThe amount of expansion is easy to controlCement groutChemistry

The invention relates to a slightly expansive cement grouting material. The slightly expansive cement grouting material consists of early expanding material of the cement grouting material, cement and a cement expansive agent. The early expanding material and the expansive agent are used for respectively offsetting early volume reducing caused by cement paste sedimentation and drying shrinkage and the long-term chemical shrinkage generated by cement continuous hydration, so that the volume stability of the cement grouting material is remarkably improved. The material has no influence to the fluidity of the cement paste, and the early expansion capacity is easily controlled, so that the cost is low, and the preparation is simple, and therefore, the slightly expansive cement grouting material is particularly applicable to engineering which has a big fluidity requirement to the cement grouting material.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com