Online expanding and drying device of cut tobacco

A drying device and shredded tobacco technology, applied in tobacco, tobacco preparation, application, etc., can solve problems such as easy agglomeration of shredded tobacco and uneven feeding, and achieve the effects of reducing oxygen content, improving filling performance, and reducing superheated steam temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

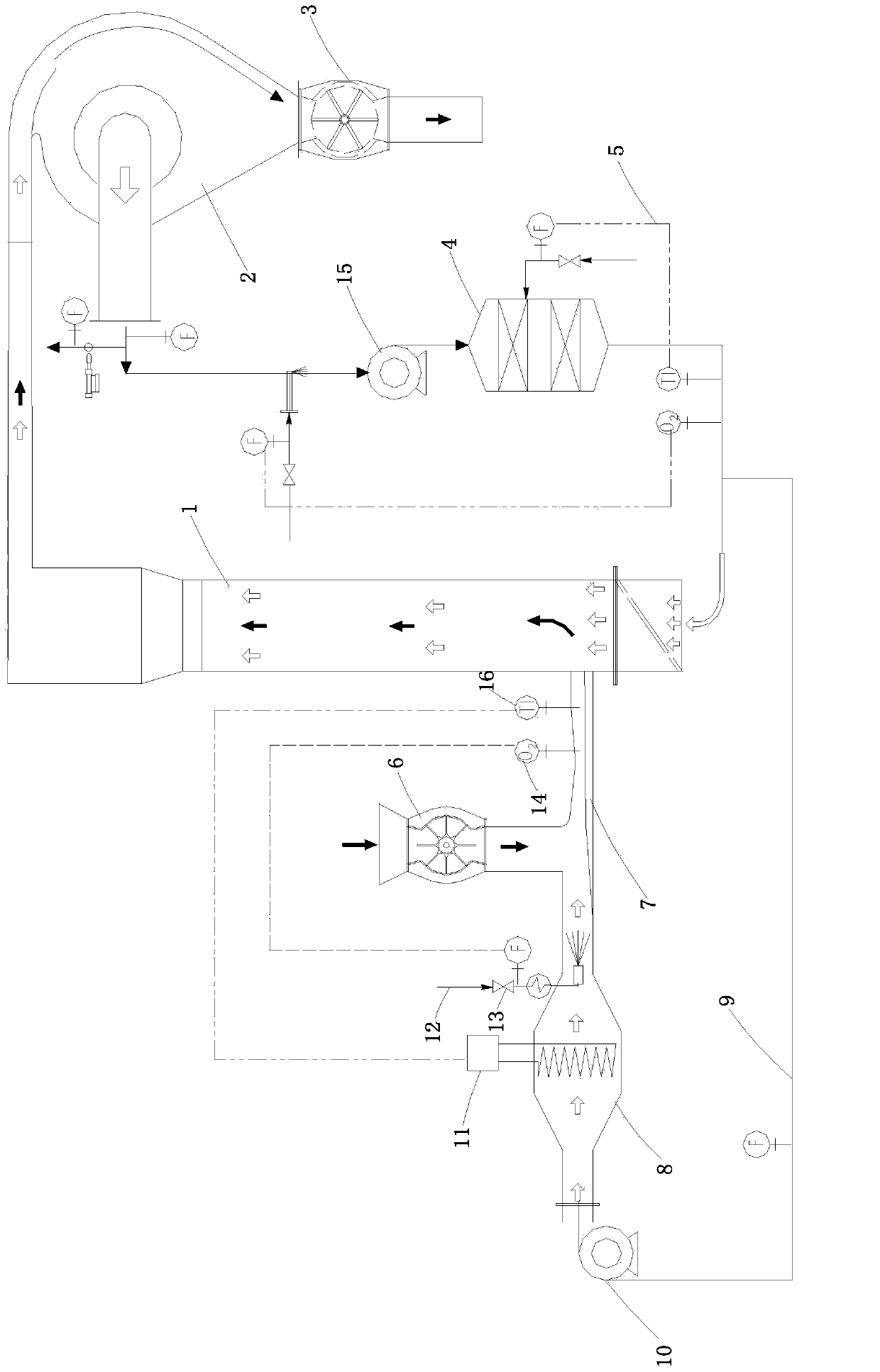

[0037] Embodiment: shredded tobacco online expansion and drying device, its hardware structure is as follows figure 1 As shown, it includes a drying unit and an expansion unit; the upper part of the drying tower 1 of the drying unit is connected to the tangential separator 2 through the material conveying pipeline, and the shredded tobacco is separated from the superheated steam and then enters the discharge air lock 3, and the upper end of the discharge air lock 3 is separated The superheated steam that goes out communicates with heating furnace 4 through pipeline, blower fan 15, and heating furnace communicates with drying tower 1 bottom through superheated steam pipe 5;

[0038] The feed air lock 6 of the expansion unit communicates with the lower inlet of the drying tower through a flat venturi tube 7;

[0039] A heating unit 8 is arranged at the front end of the feed air lock 6, and the superheated steam pipe 5 communicates with the heating unit 8 through the injection pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com