Patents

Literature

463 results about "Steam injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steam injection is an increasingly common method of extracting heavy crude oil. It is considered an enhanced oil recovery (EOR) method and is the main type of thermal stimulation of oil reservoirs. There are several different forms of the technology, with the two main ones being Cyclic Steam Stimulation and Steam Flooding. Both are most commonly applied to oil reservoirs, which are relatively shallow and which contain crude oils which are very viscous at the temperature of the native underground formation. Steam injection is widely used in the San Joaquin Valley of California (USA), the Lake Maracaibo area of Venezuela, and the oil sands of northern Alberta (Canada).

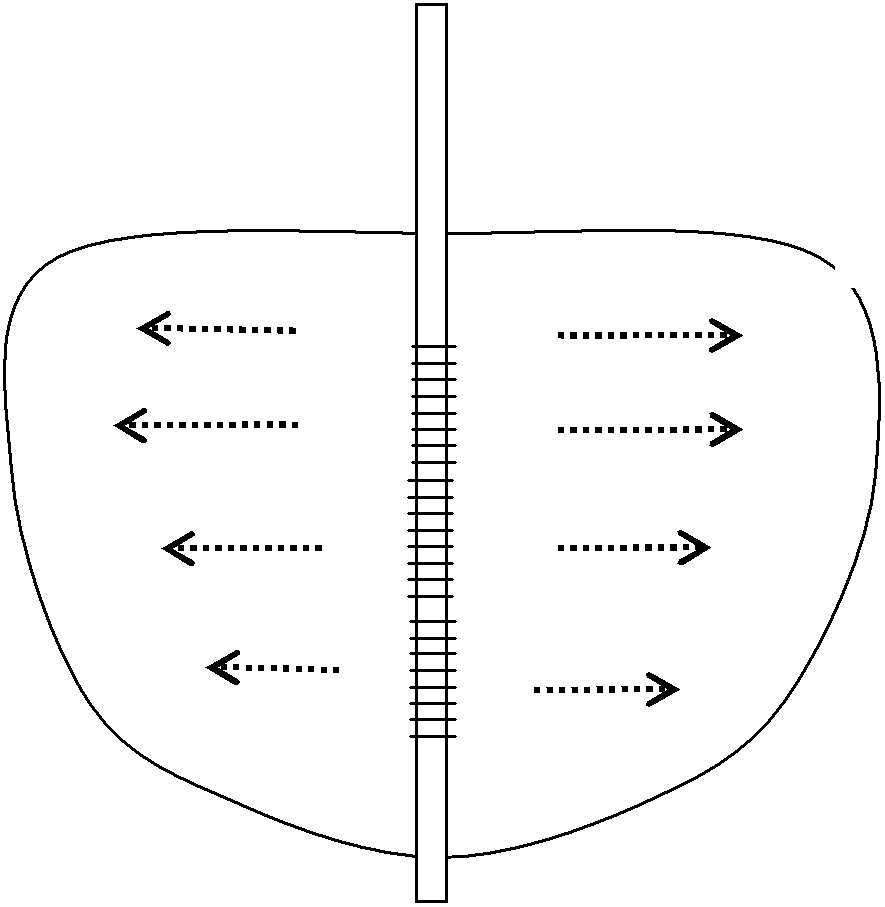

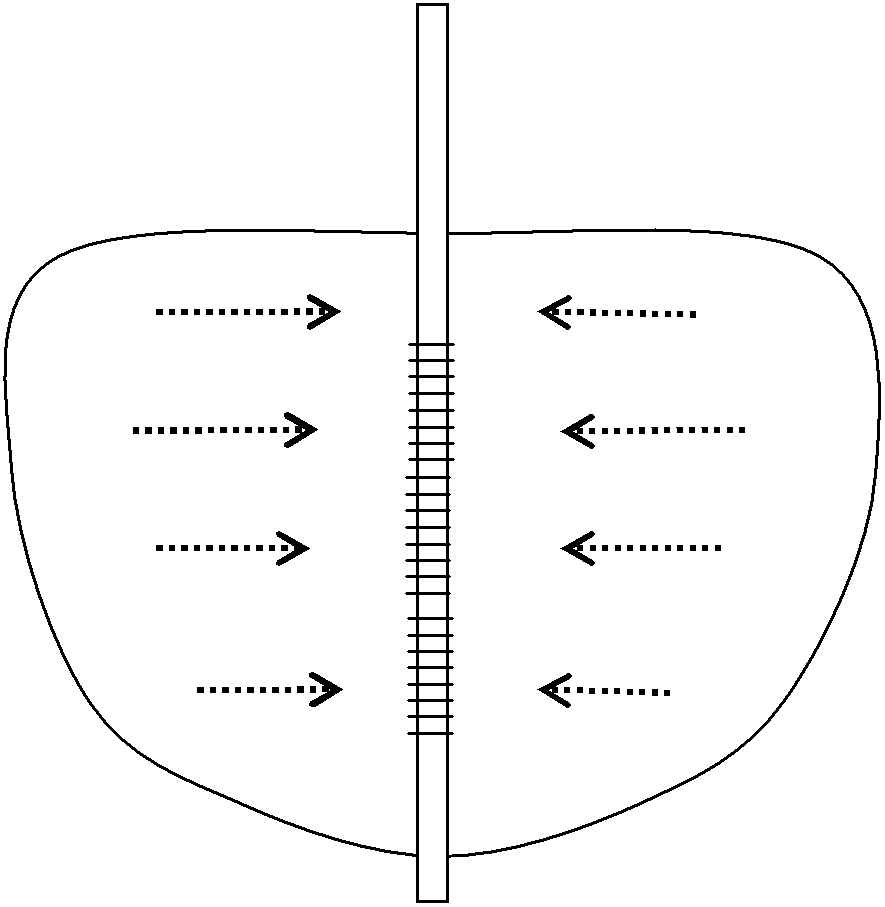

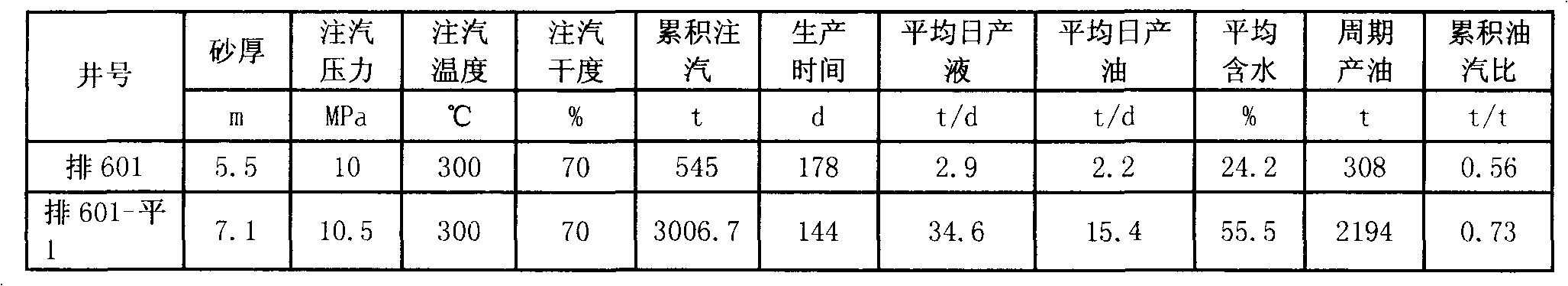

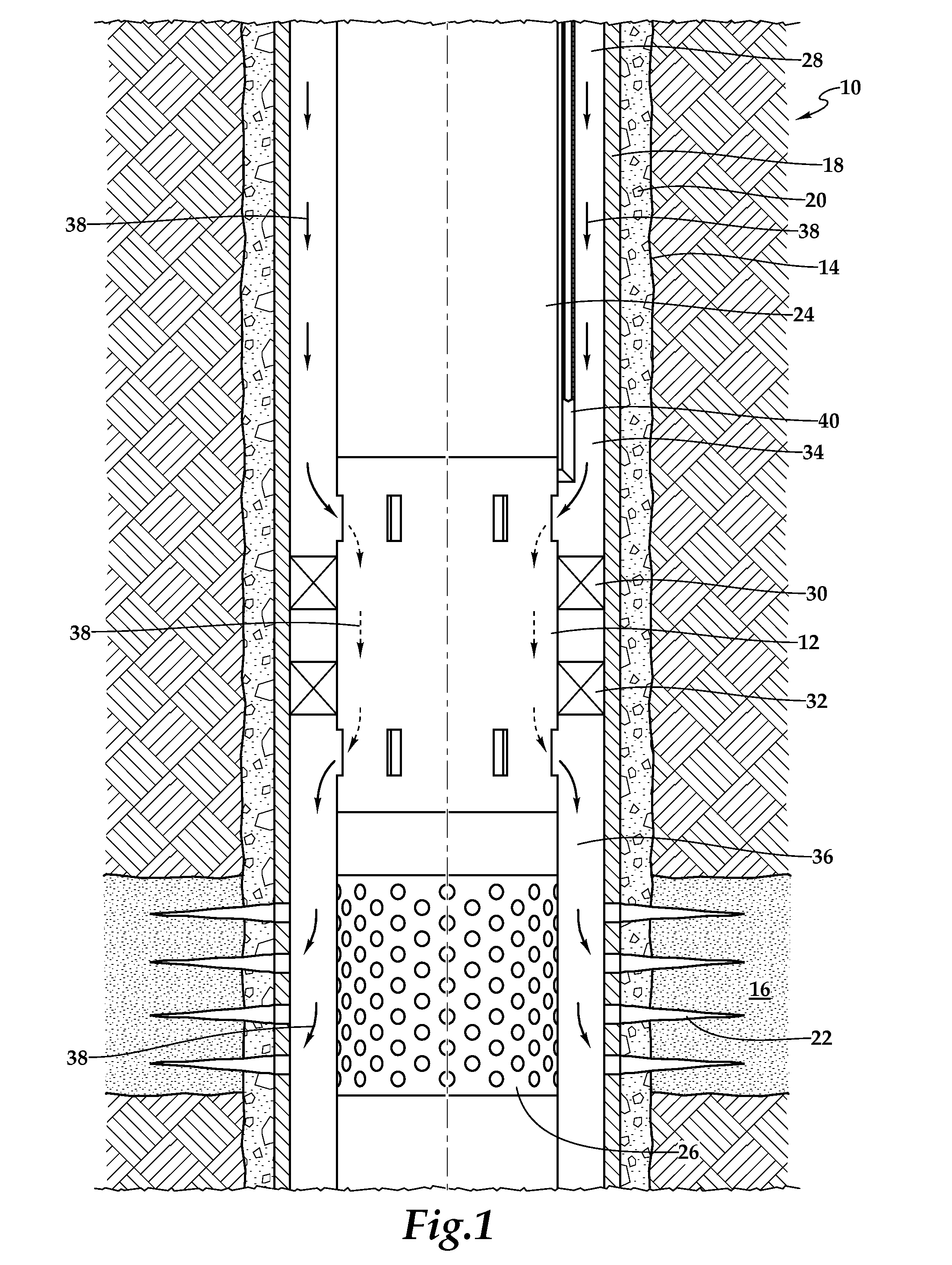

A method of gravity drainage assisted steam flooding to enhance the recovery of deep ultra-heavy oil reservoirs

The invention relates to a method for improving the oil deposit recovery ratio of deep massive extremely-viscous oil in an extraction mode of gravity drainage assisted steam flooding. In the method, superposition horizontal wells are arranged among wells by combining results of researches on the fine contrast of small geological strata of massive oil deposit, the distribution rule of interlayer, the distribution rule of remaining oil and the like and a fine research on numerical simulation; an upper superposition horizontal well is used for injecting steam, a peripheral vertical shaft is used for production, and a lower superposition horizontal well is used for discharging liquid (crude oil between condensate water and the horizontal wells); and thus, a production-injection ratio of high-speed steam injection of deep oil deposit is improved, the dryness of steam on the well bottom is improved, the pressure of an oil layer is reduced, a steam cavity is easy to expand, the swept volume is improved, a development effect is improved, and the aim of improving the recovery ratio finally is fulfilled.

Owner:PETROCHINA CO LTD

Displacement developing method for artificial foamed oil of heavy oil reservoir

ActiveCN104265252AViscosity reduction by a large marginNot easy to degasFluid removalDrilling compositionFoaming agentHorizontal wells

The invention provides a displacement developing method for artificial foamed oil of a heavy oil reservoir. The method comprises the following steps: adopting a vertical well or a horizontal well to displace a well pattern; injecting an oil soluble viscosity reducer and a solvent based foaming agent in an injection well repeatedly and alternatively, or injecting an oil-in-water emulsified viscosity reducer solution and a high oil-resisting foaming agent in an injection well repeatedly and alternatively, wherein during the injection process, a producing well produces continuously. With the adoption of the method, the purposes that the heavy oil reservoir mined through steam injection and the heavy oil reservoir difficulty produced by a conditional mining method can be effectively produced and developed, heavy oil is economically and efficiently developed and the recovery efficiency is improved greatly are achieved.

Owner:PETROCHINA CO LTD

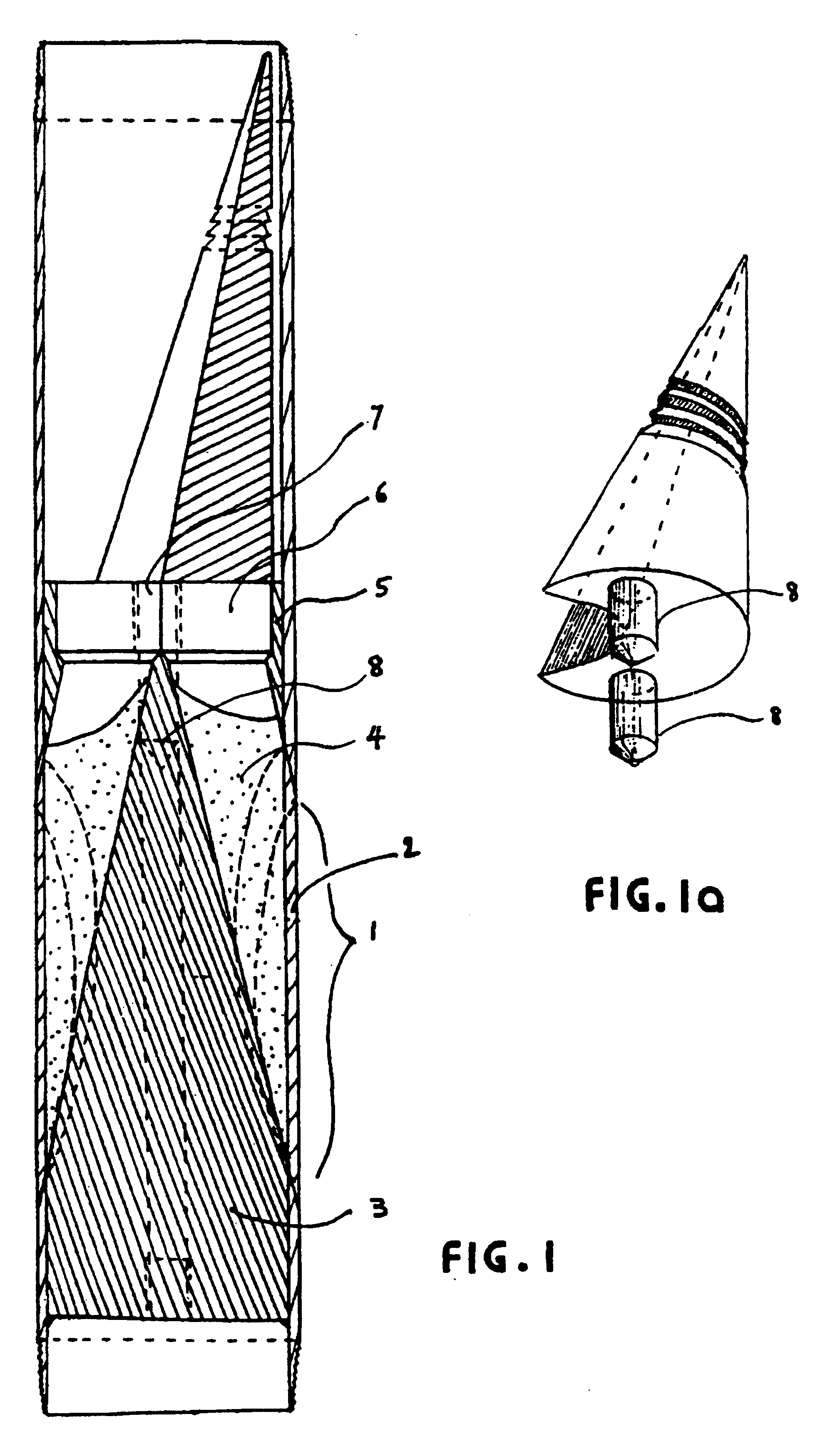

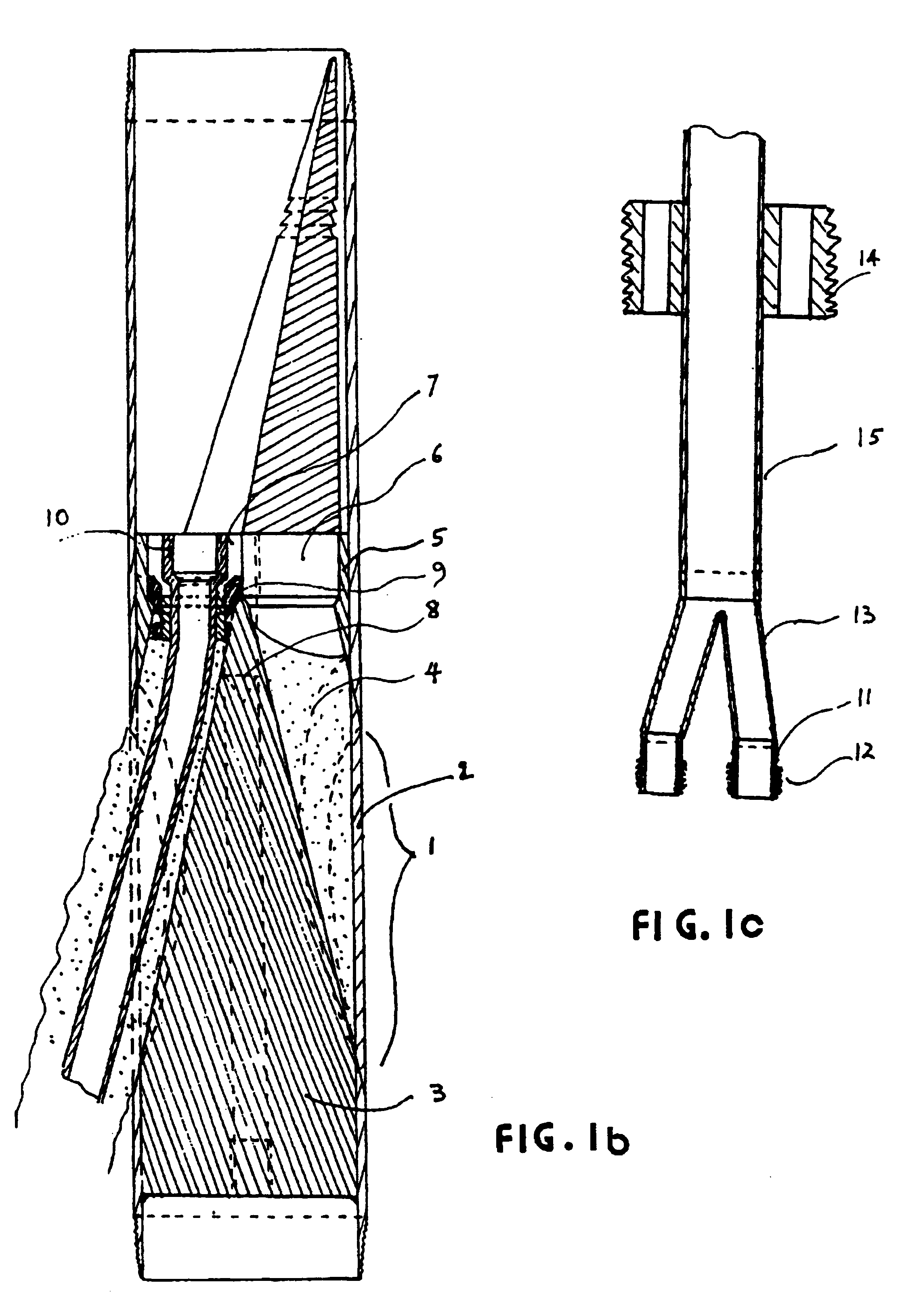

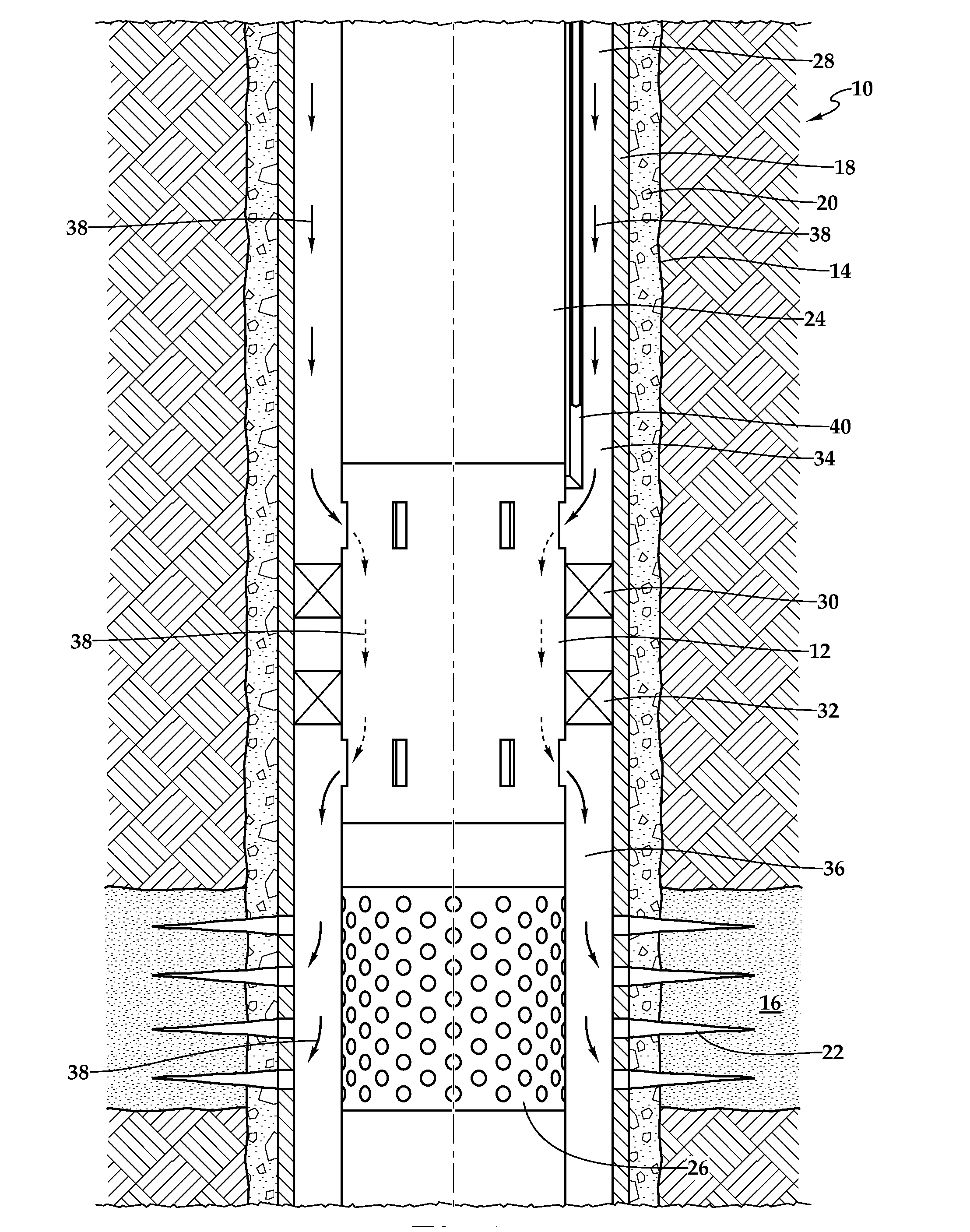

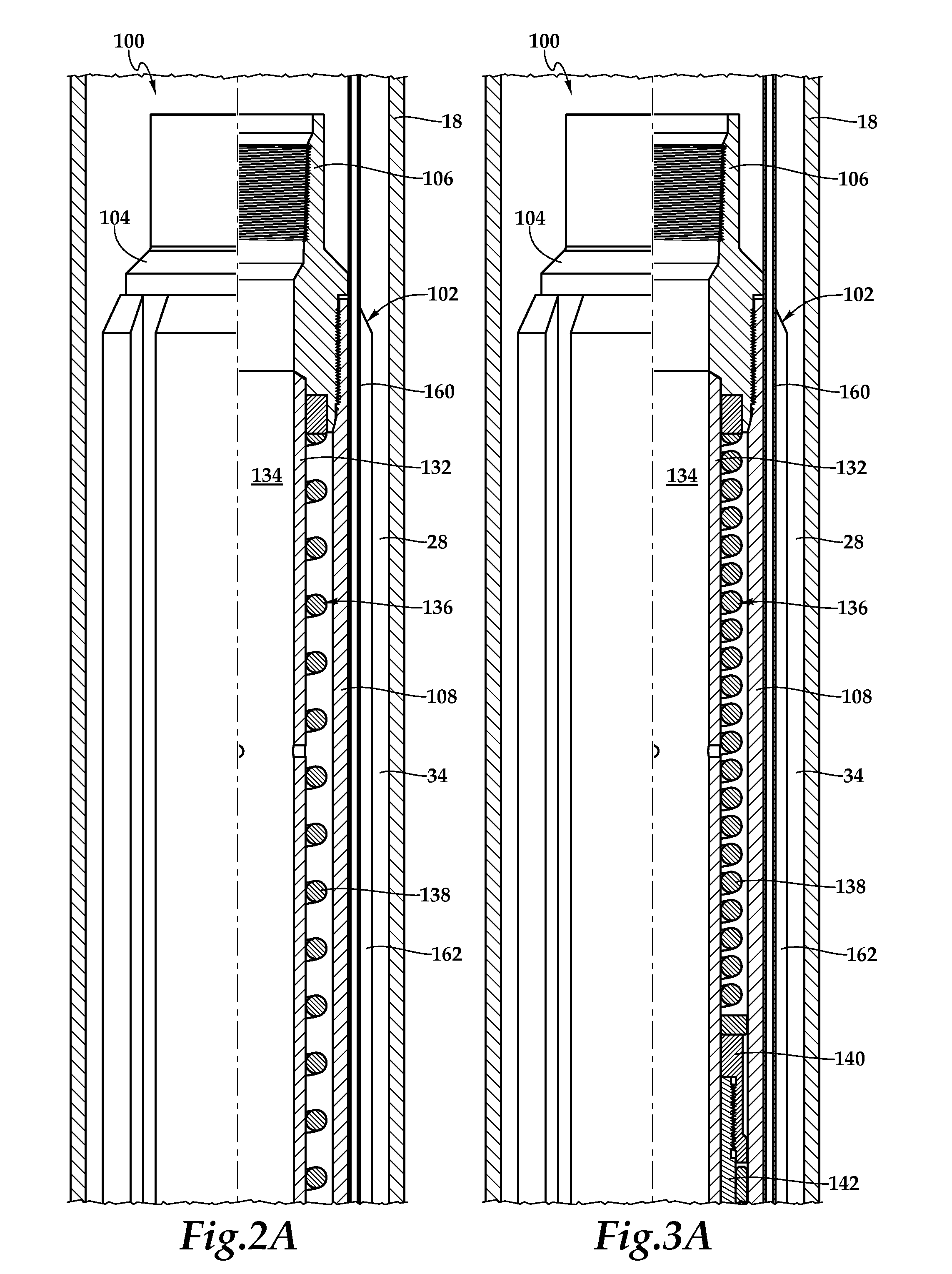

Downhole equipment, tools and assembly procedures for the drilling, tie-in and completion of vertical cased oil wells connected to liner-equipped multiple drainholes

Single horizontal wells drilled through heterogeneous reservoirs are capable of greater oil productivity than vertical wells, often with lower produced GOR and WOR. Multiple drainholes tied-in to a vertical cased well are even more beneficial. Completion of such drainholes in many sandy reservoirs must use cemented liners. Well configurations comprising multiple drainholes liners, each of them tied-in to a vertical casing by pressure-tight connections require novel technologies making use of some novel downhole equipment, tools and procedures for drilling, tie-in and completion of such wells. These may be for newly-drilled wells or may be obtained by re-entry into an existing vertical cased well. Specific equipment, including novel casing joints, whipstocks, intermediate liners and tubing completion assembly components applicable to new wells are described herein. Equipment comprising novel casing inserts and patches applicable to re-entry wells, and the corresponding tubing completion assembly components for a variety of well exploitation modes are also described, together with the required tools and procedures. The liners of the drainholes are such that known well logging and cleaning tools may be used throughout the well's life. The various tubing completion assemblies can all be run-in and installed in a single trip. They allow either commingled flow from all drainholes or selective injection into some drainholes while others are under production. They are adapted to a variety of reservoir pressure conditions and of oil types, including heavy oil produced by sequential "huff and puff" steam injection.

Owner:HALLIBURTON ENERGY SERVICES INC

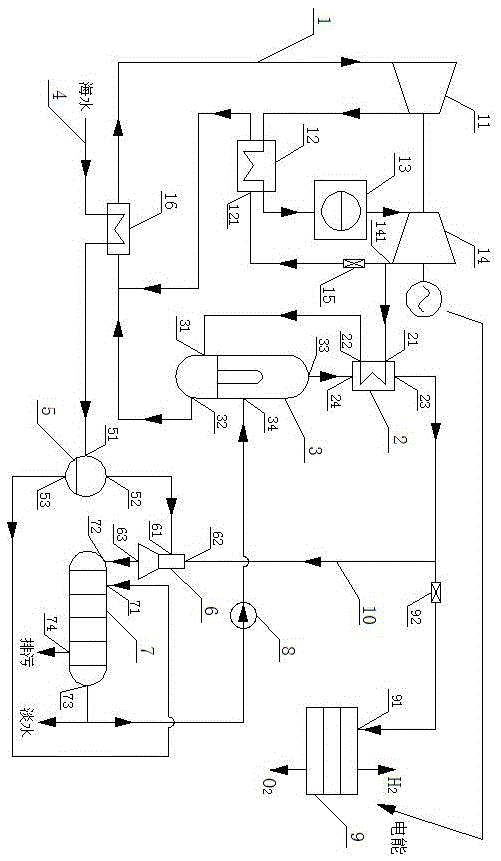

Tri-cogeneration system and tri-cogeneration method for generating power, producing hydrogen and producing fresh water by aid of high-temperature gas-cooled reactor of nuclear power plant

InactiveCN105645499AImprove cycle thermal efficiencyMeet the changing requirements of different needsGeneral water supply conservationSeawater treatmentNuclear powerSuperheater

The invention discloses a tri-cogeneration system and a tri-cogeneration method for generating power, producing hydrogen and producing fresh water by the aid of a high-temperature gas-cooled reactor of a nuclear power plant. The tri-cogeneration system comprises a closed helium circulating system of the nuclear power plant, a superheater, a steam generator, a raw seawater pipeline, a flash evaporator, a steam ejector, a seawater desalting device, a water feeding pump, a solid oxide electrolytic tank and an auxiliary steam pipeline. The tri-cogeneration system and the tri-cogeneration method have the advantages that the circulating system of the nuclear power plant, steam electrolysis and hydrogen production processes and distillation seawater desalination processes are coupled with one another, the power is generated by the aid of a helium gas turbine at first, waste heat of partial exhaust gas of the helium gas turbine is used for electrolyzing steam and producing the hydrogen, low-temperature waste heat cooling water of a cooler is used for carrying out distillation seawater desalination by means of coupled flash evaporation and steam injection, and accordingly diversified water, power and hydrogen tri-cogeneration modes can be implemented; the electric power and the fresh water which are required for steam electrolysis and hydrogen production can be provided by means of seawater desalination and nuclear power generation, accordingly, the tri-cogeneration system is high in circulating heat efficiency and good in adjustment performance and has a good economic benefit, the reliability of equipment can be improved, environmental pollution can be reduced, the tri-cogeneration system and the tri-cogeneration method have excellent application prospects, and the like.

Owner:陈志强

Chemical assistant for thermal recovery of thick oil and application thereof

The invention discloses a chemical assistant for thermal recovery of thick oil. The chemical assistant is prepared from the following components in percentage by mass: 0.5-10% of alkaline material, 0.05-5% of surfactant, 0.5-10% of alcohol and 75-98.95% of water through mixing and stirring. When the chemical assistant provided by the invention is added under the condition of steam injection in the thermal recovery of thick oil, the viscosity of the thick oil can be greatly reduced, the viscosity reduction rate reaches up to 98%, the fluidity of the thick oil can be improved effectively, and the yield of the thick oil reservoir is improved, and furthermore, the chemical assistant can be widely used in the field of development of thermal recovery thick oil reservoir.

Owner:NORTHEAST GASOLINEEUM UNIV

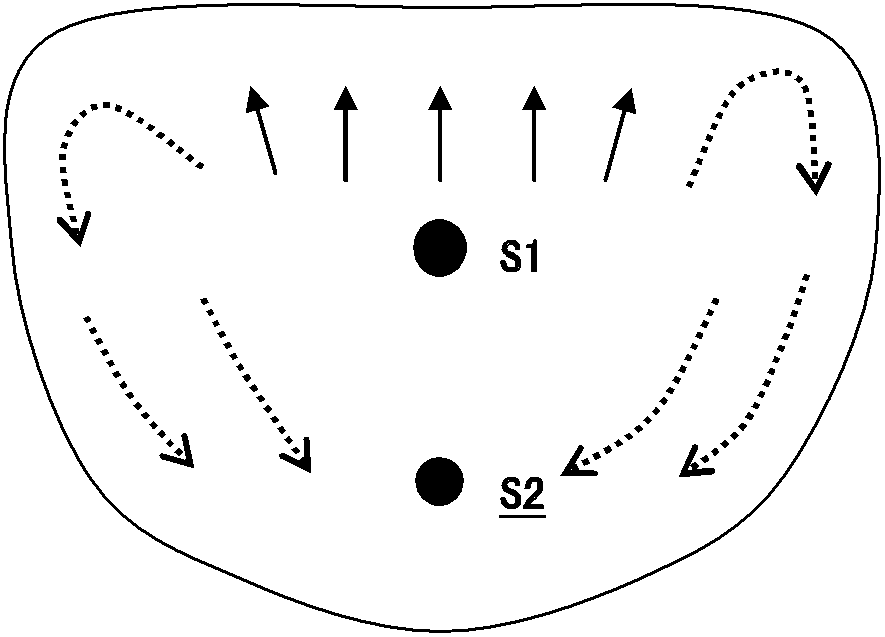

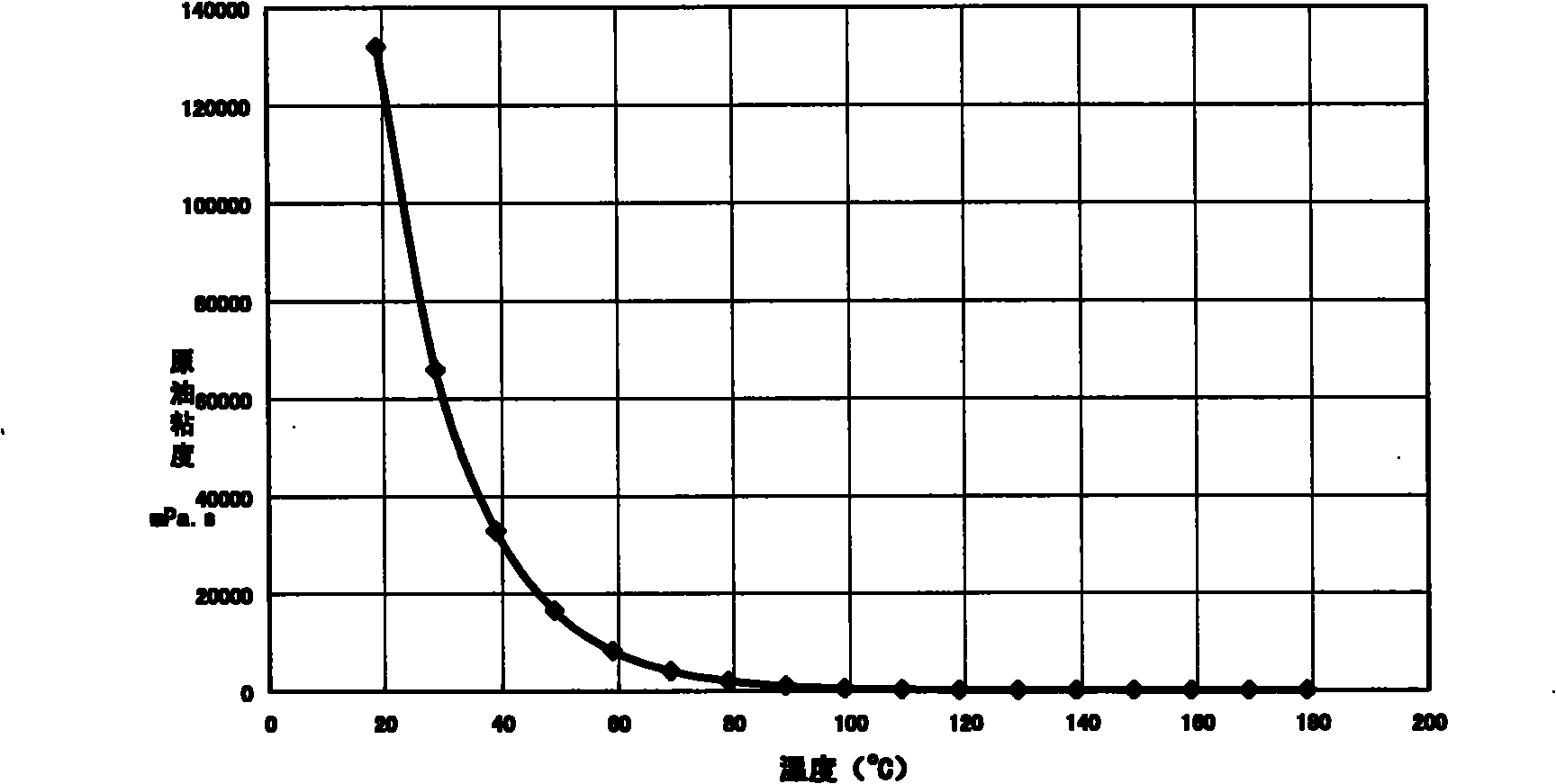

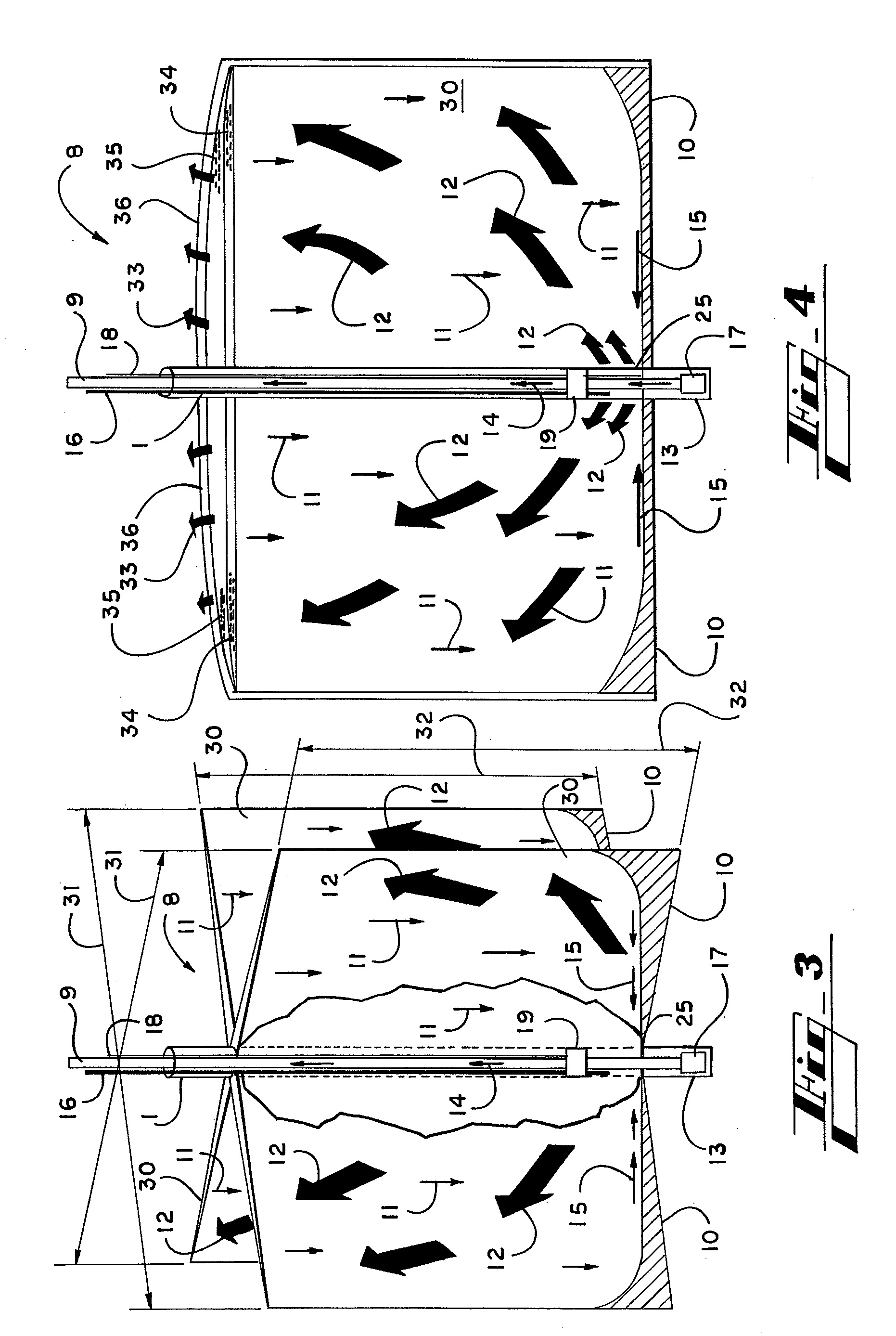

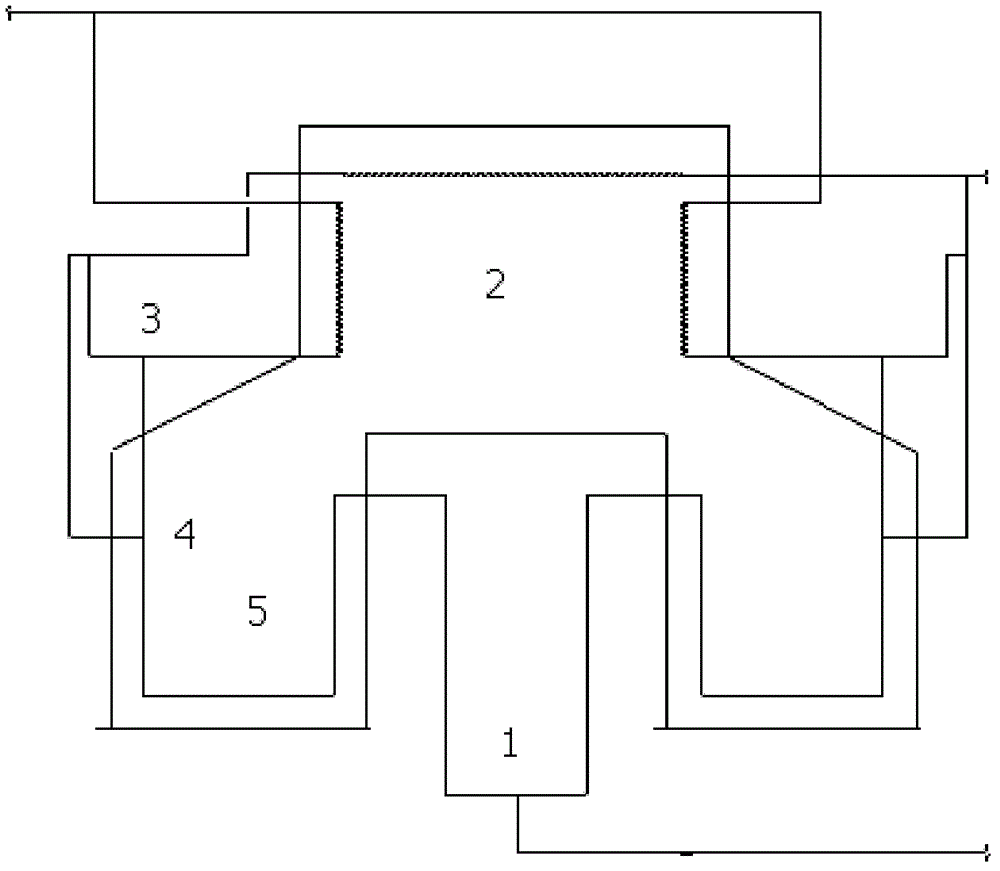

Method and system for exploiting lamellar super-heavy oil deposit

The invention relates to a method and a system for exploiting lamellar super-heavy oil deposit. The method comprises the following steps of: arranging a multi-bore well, a central steam injection well and a producing well in an exploitation region; closing the central steam injection well and the producing well and performing steam stimulation by using the multi-bore well until the temperature ofeach oil layer reaches the temperature corresponding to a second-order inflection point of a crude oil viscosity-temperature relation curve; opening the multi-bore well and the central steam injection well and injecting steam into the oil layers; closing the multi-bore well and the central steam injection well for soaking; and opening the producing well to perform steam driving exploitation. In the method, the multi-bore well is used for performing the steam stimulation according to the characteristics of the multi-layer super-heavy oil deposit; a plurality of branch wells are drilled in a main pitshaft by a side-tracking method and are embedded into each oil layer of the oil deposit; the whole exploitation range is heated comprehensively and three-dimensionally; steam waves and regions as big as possible are formed with the cooperation of the central steam injection well; and the mobility of the super-heavy oil and the oil-water mobility ratio are improved, and the problems that the lamellar super-heavy oil has high viscosity and is difficult to drive and the steam sweeping range is small are solved.

Owner:PETROCHINA CO LTD

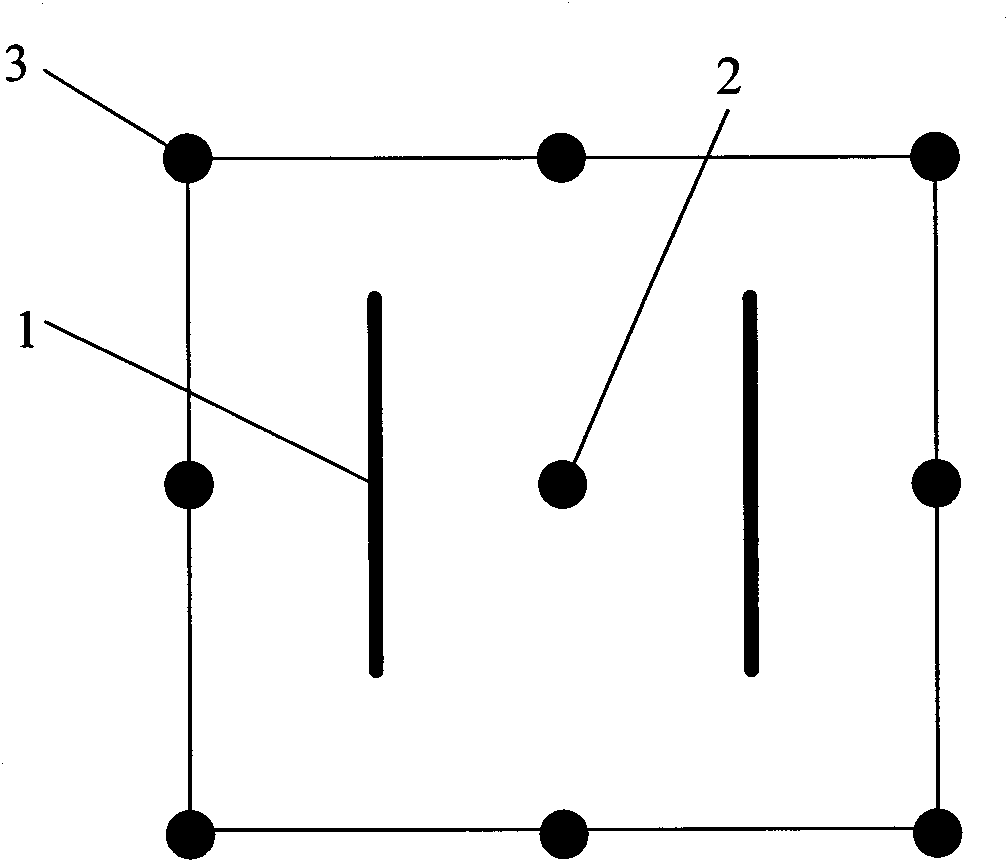

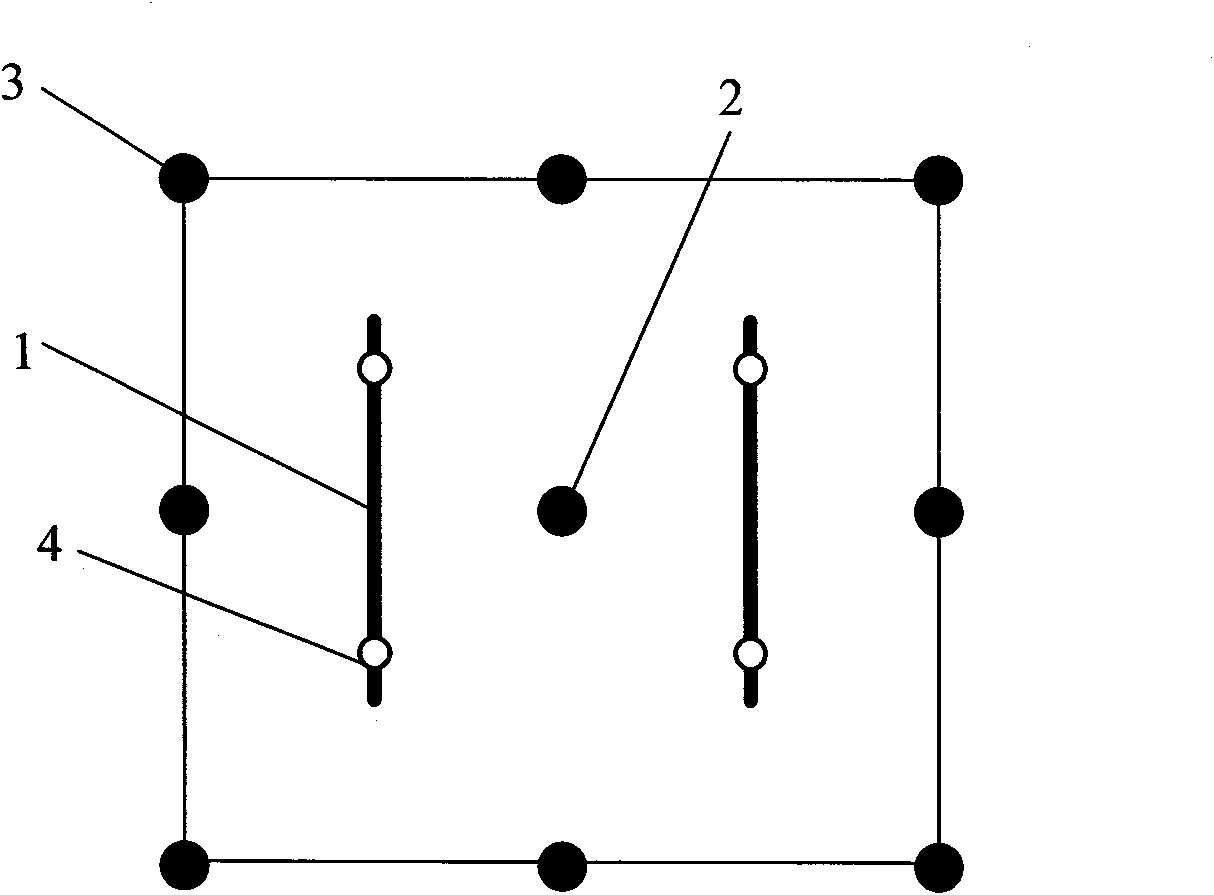

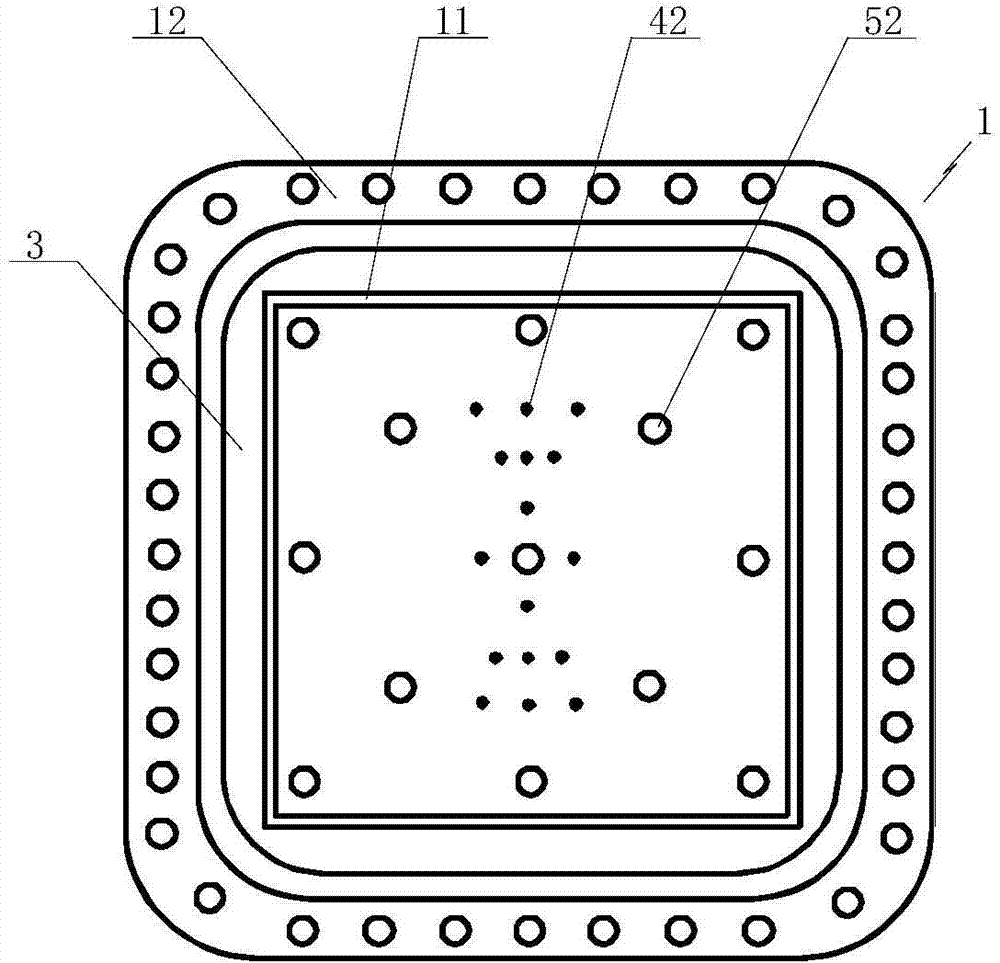

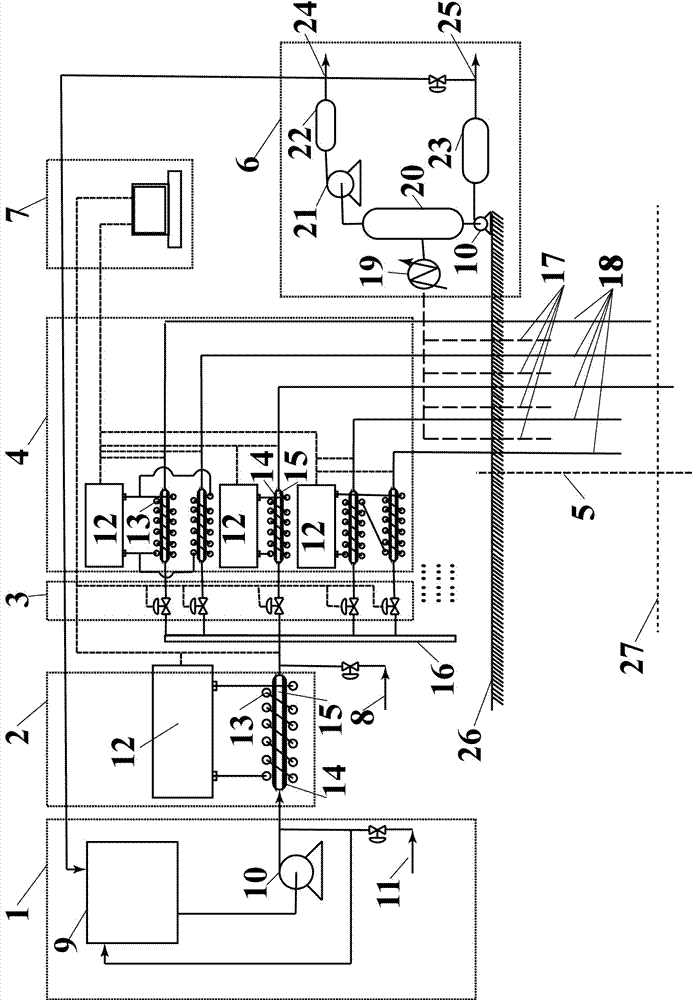

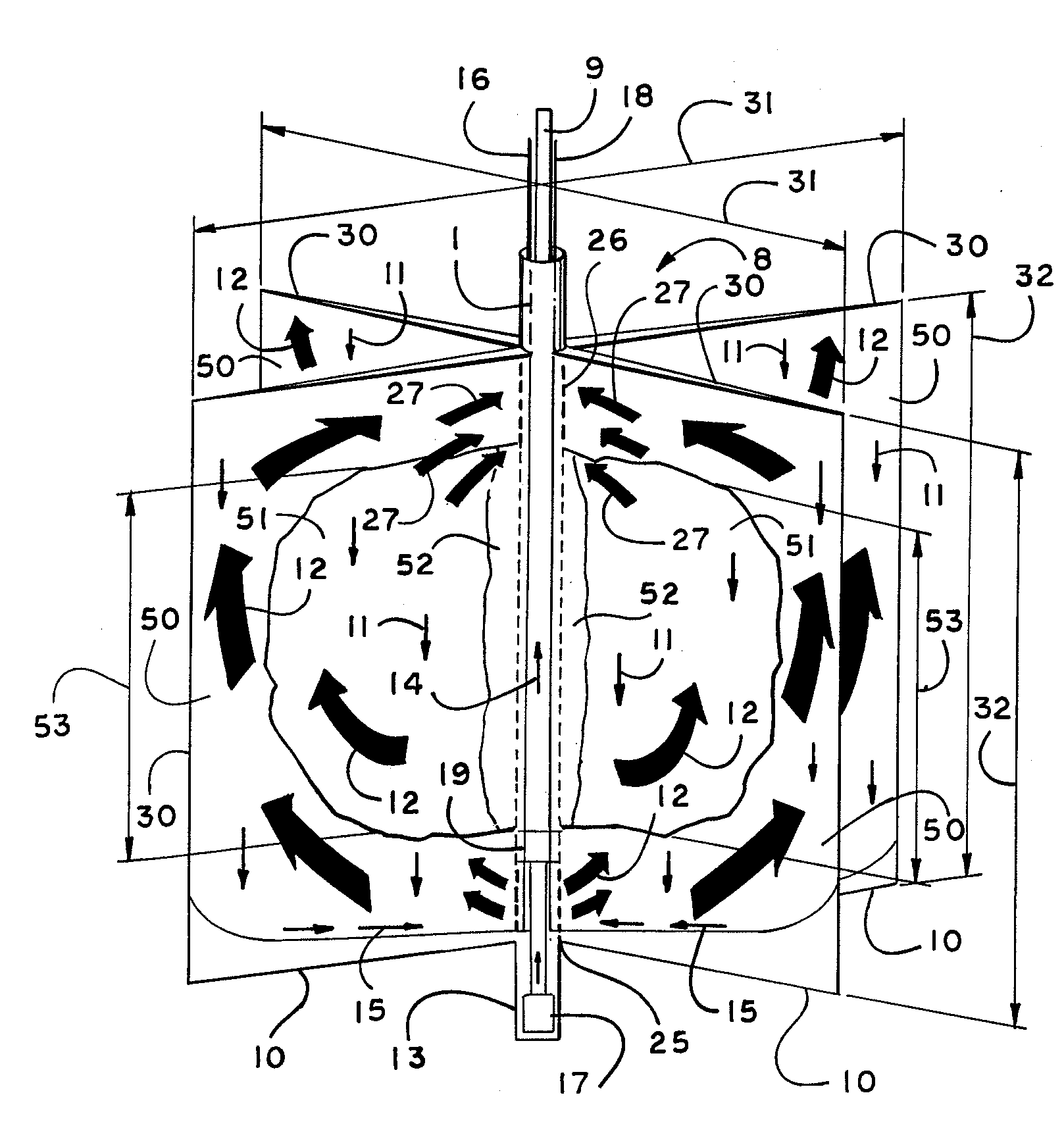

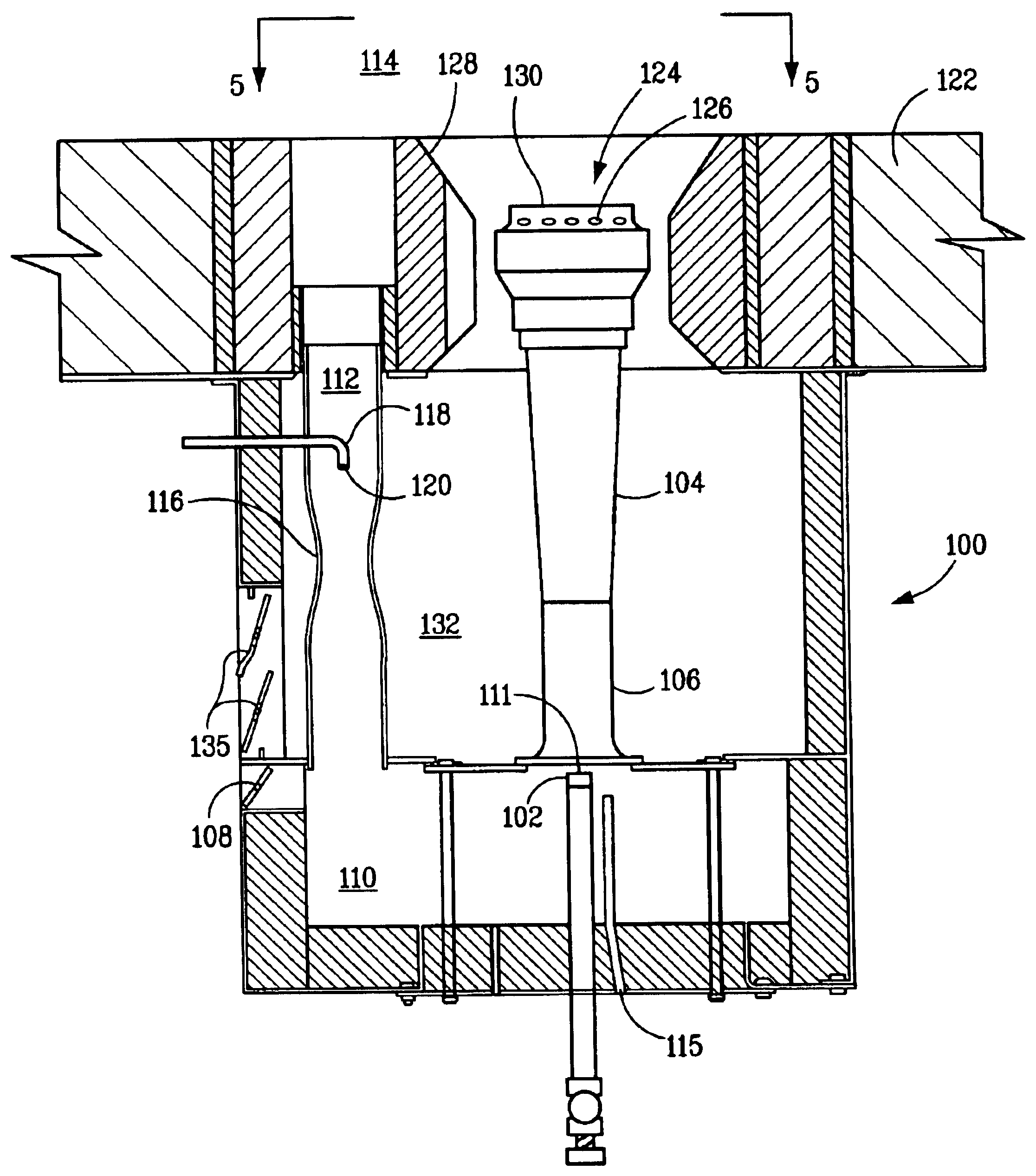

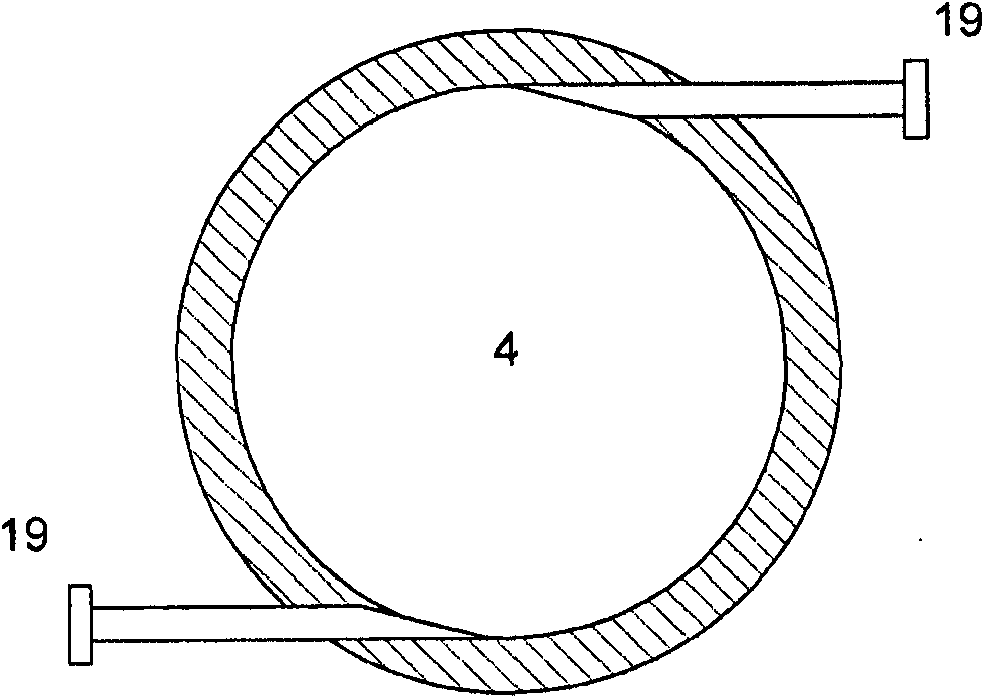

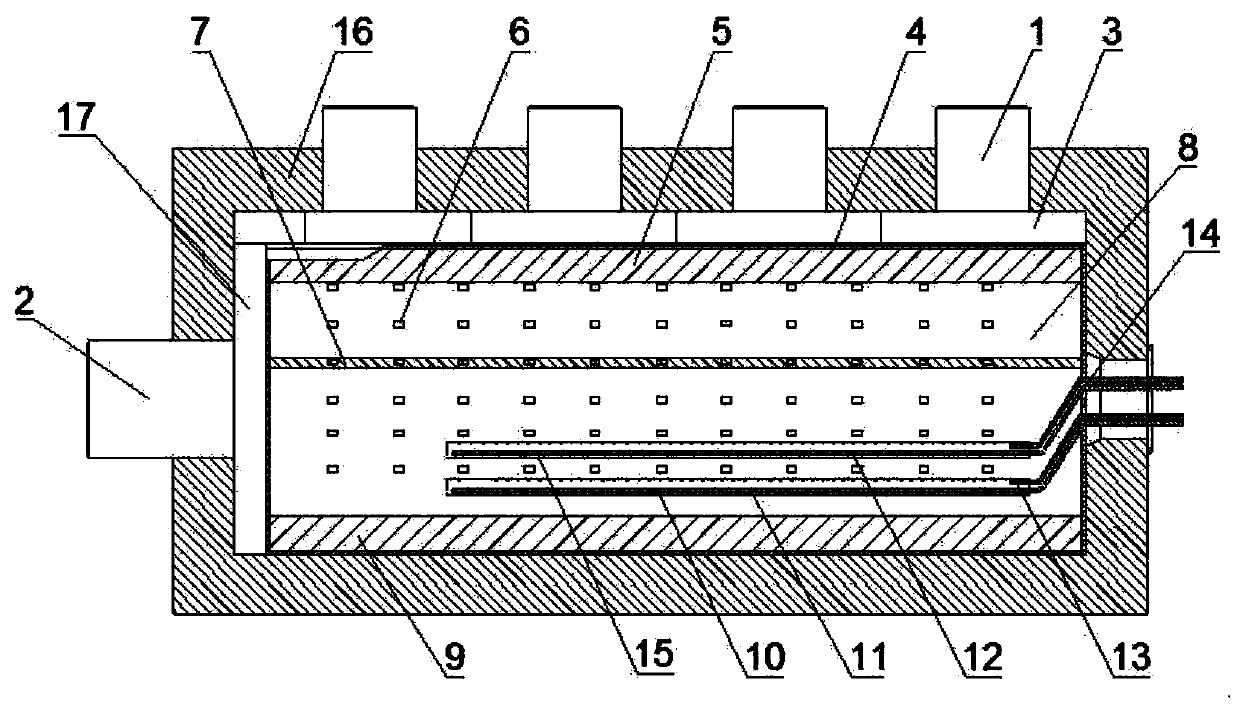

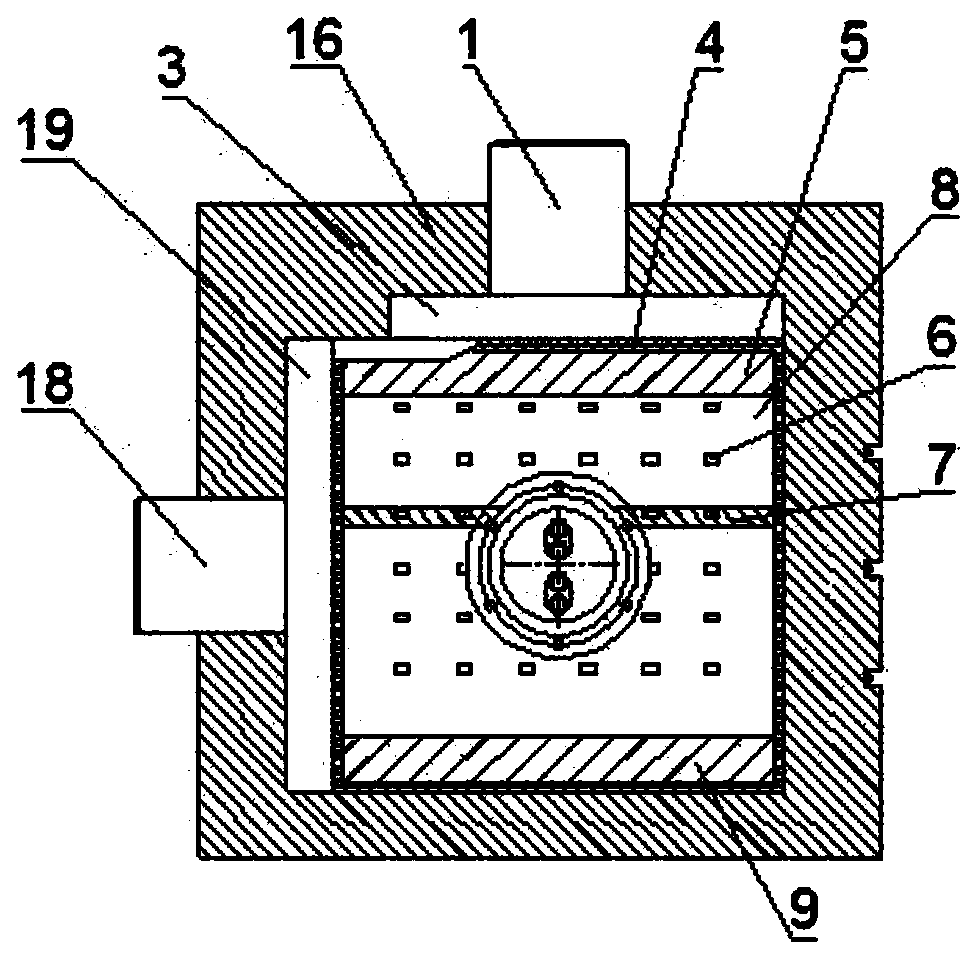

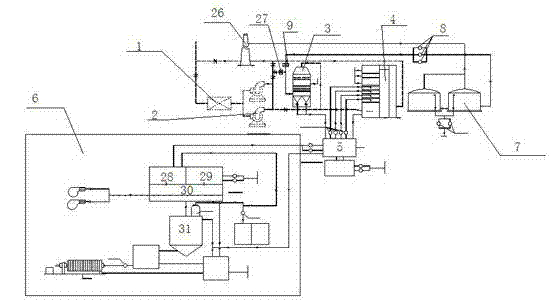

Multifunctional three-dimensional physical simulation experimental apparatus for thermal recovery by steam injection

ActiveCN104500013AImprove temperature and pressure resistanceAchieve storageFluid removalTemperature controlReservoir type

The invention relates to a multifunctional three-dimensional physical simulation experimental apparatus for thermal recovery by steam injection. The apparatus comprises a three-dimensional model body, a temperature control box, an injection and recovery device, an energy storage and buffer device and a data collector; the three-dimensional model body comprises an inner chamber and an outer chamber connected in a sleeving manner; an annulus is provided between the inner chamber and the outer chamber; the annulus is used as part of energy buffering so as to better accumulate and release energy during steam huff and puff; a perforation combination of the three-dimensional model body allows simulation of different well types, reservoir types and injection fluid combinations; the three-dimensional model body is moved into the temperature control box, simulation study on development manners and development mechanisms under different reservoir temperatures is achieved by changing the interior temperature of the temperature control box; the apparatus is suitable for the physical simulation of the heat injection development of heavy oil reservoirs with bottom water; experimental conditions are provided for the study on different injection fluids, well pattern types and development modes.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

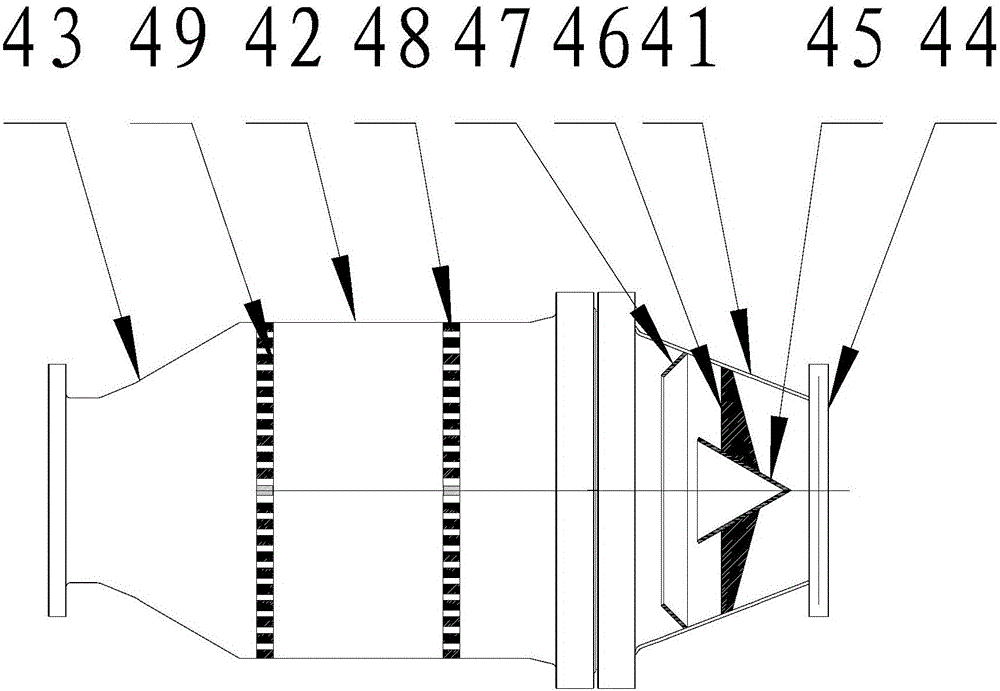

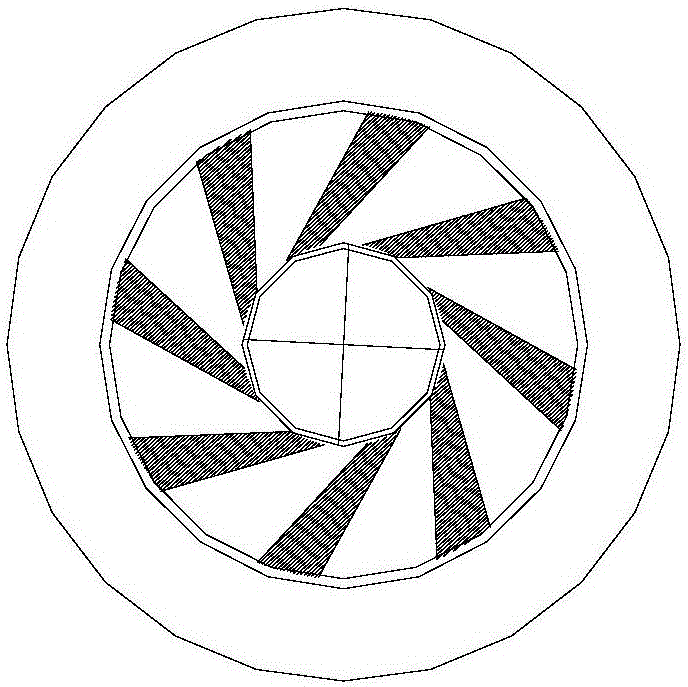

Injecting equipment for direct connection test of novel stamping engine and environment simulation system

The invention discloses injecting equipment and an environment simulation system based on the injecting equipment, wherein the injecting equipment and the environment simulation system are used for the direct connection test of a novel stamping engine. According to the technical scheme of the invention, the equipment and the system solve the problems in the prior art that an existing test environment simulation system cannot simulate the air inflow condition and meet the requirement on the injecting capacity, and is low in injecting efficiency and large in investment scale. The injecting equipment comprises a plurality of steam injecting units arranged on the gas collecting pipe of the simulation system. Each steam injecting unit comprises a high-flow steam generator and a set of two-stage steam injection pumps, wherein the set of two-stage steam injection pumps is formed through the serial connection of a first steam injection pump and a second steam injection pump. The output end of the high-flow steam generator is respectively connected with the first steam injection pump and the second steam injection pump. The first steam injection pump is connected with the gas collecting pipe through a steam injection pipe. A first steam injection and isolation valve is arranged between the first steam injection pump and the gas collecting pipe. A second steam injection and isolation valve is arranged between the first steam injection pump and the second steam injection pump.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

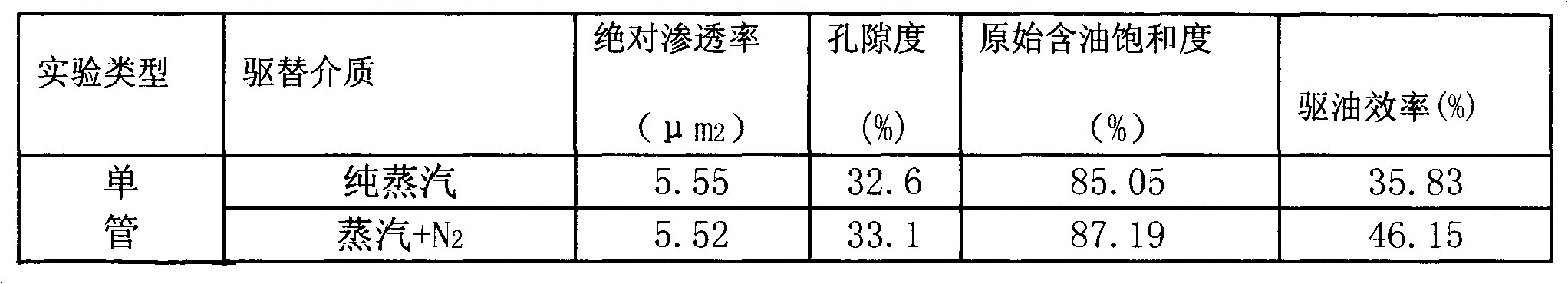

Steam and nitrogen composite swallowing-spitting oil extraction method

InactiveCN102146782AImprove displacement efficiencyIncrease drainage areaFluid removalThermodynamicsNitrogen gas

The invention provides a steam-and-nitrogen composite swallowing-spitting oil production method, comprising the following steps: a, steam injection string laying: a pipe column structure successively comprises an even steam distribution pipe column provided with an even steam distribution valve and a compensator, an injection and extraction integrated pump connected to the even steam distribution pipe column, an oil pipe arranged on the pump, and a subcritical steam injection well from bottom to top; b, N2 and steam injection: steam is injected through an oil jacket annulus, meanwhile, nitrogen is injected into an oil well through the oil pipe, nitrogen injection speed is regulated to evenly allocated and injected during the whole steam injection process; c, soaking: soaking is carried out for 2-7 days after steam injection and nitrogen injected are over; d, blowout: when the well pressure drops to 0.5Mpa / day, blowout is controlled by an oil nozzle; and e, pumping start: when open-flow liquid amount reaches 3t / d, the injection and extraction integrated pump is used to start pumping.

Owner:CHINA PETROLEUM & CHEM CORP +1

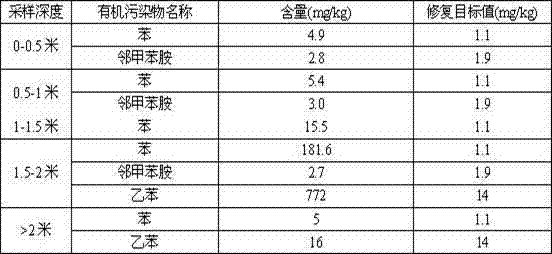

Device for in-situ environmental remediation in organic pollution site

InactiveCN103203354AReduce heat lossImprove heating speed and utilization efficiencyContaminated soil reclamationPollutantHeating system

The invention relates to a device for in-situ environment remediation in an organic pollution site. The device comprises a water supply system, a water heating system, a flow valve, a superheated steam in-situ injection system, a monitoring well, a soil gas stripping and ground waste gas and wastewater processing system and the like. Water from the water supply system is fast heated by using the high-frequency water heating system and then enters the high-frequency superheated steam in-situ injection system through control of the flow valve, so that the superheated steam in-situ injection is realized; and meanwhile, the remediation effect is enhanced by using the soil gas stripping and ground waste gas and wastewater processing system, and a remediation effect is observed by the monitoring well. The device has the advantages that the problems that the heating speed is low, the steam injection temperature s low and the like of the traditional heating system are solved, organic pollutants which are high in boiling point and difficult to volatilize are efficiently removed, and meanwhile, energy can be saved by 50 percent.

Owner:陈云

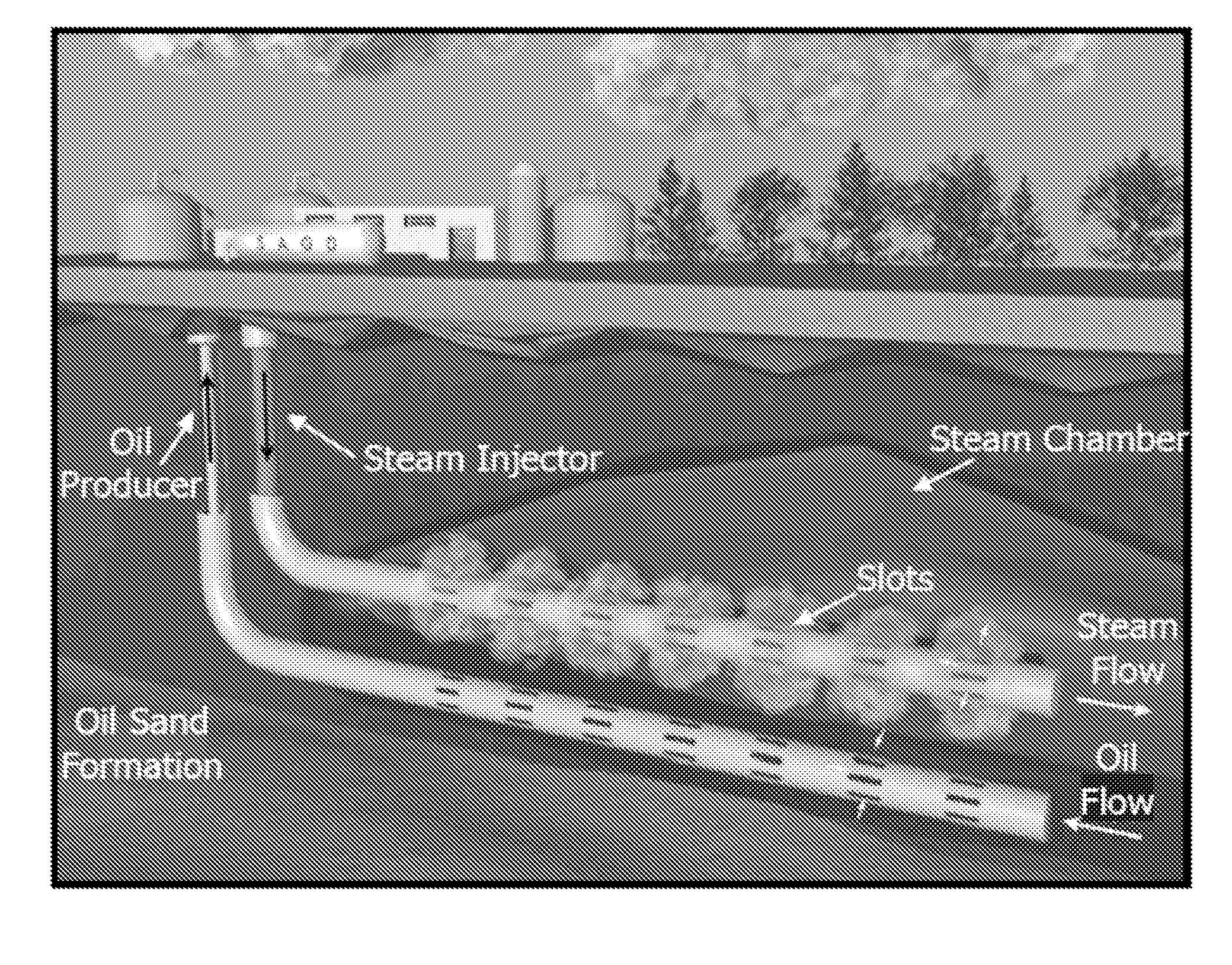

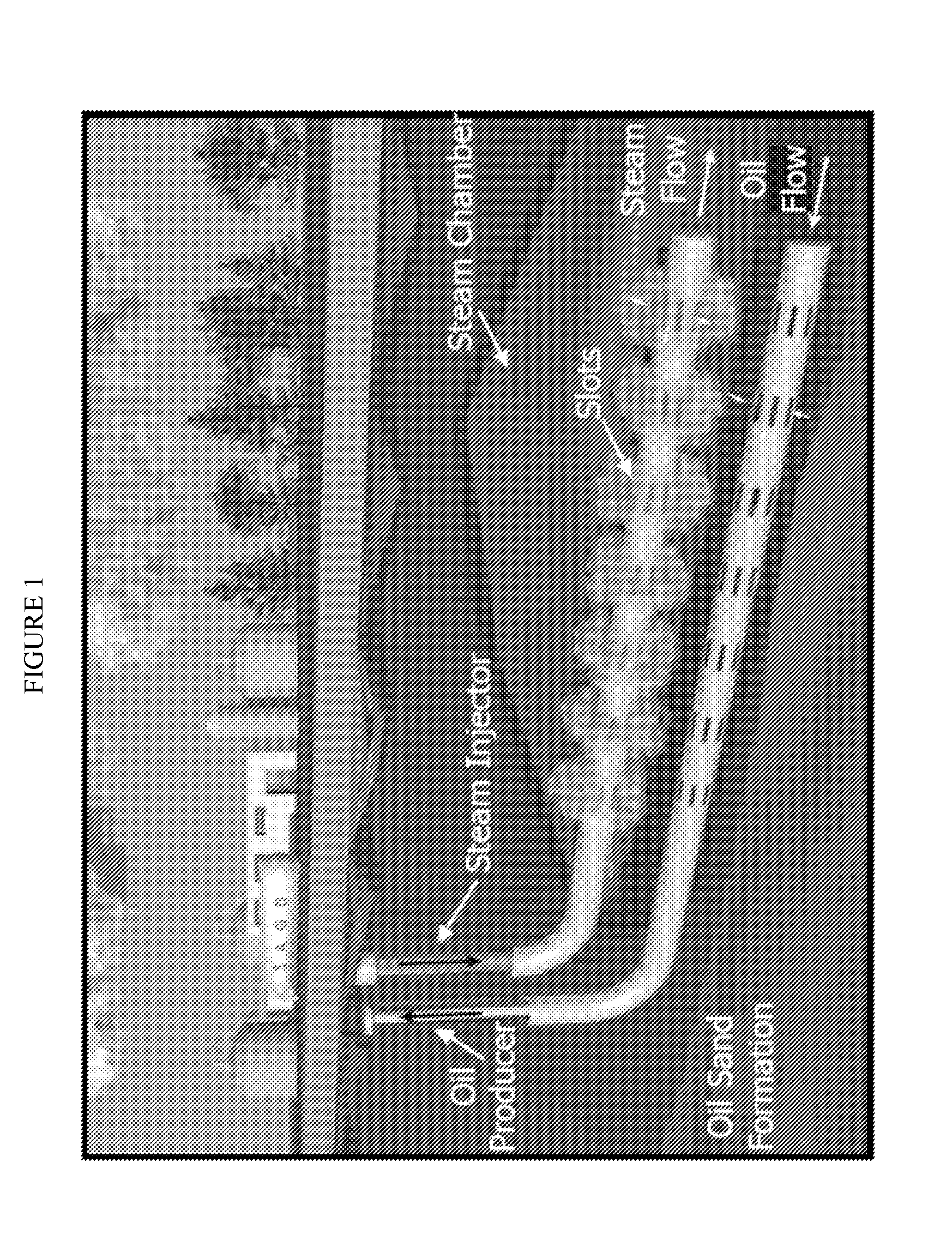

Enhanced Hydrocarbon Recovery By Steam Injection of Oil Sand FOrmations

InactiveUS20090145606A1Promote recoveryLimit upward growthInsulationFluid removalHydrocarbon solventsFuel oil

The present invention involves a method and apparatus for enhanced recovery of petroleum fluids from the subsurface by injection of a steam and hydrocarbon vaporized solvent in contact with the oil sand formation and the heavy oil and bitumen in situ. Multiple propped hydraulic fractures are constructed from the well bore into the oil sand formation and filled with a highly permeable proppant. Steam, a hydrocarbon solvent, and a non-condensing diluent gas are injected into the well bore and the propped fractures. The injected gas flows upwards and outwards in the propped fractures contacting the oil sands and in situ bitumen on the vertical faces of the propped fractures. The steam condenses on the cool bitumen and thus heats the bitumen by conduction, while the hydrocarbon solvent vapors diffuse into the bitumen from the vertical faces of the propped fractures. The bitumen softens and flows by gravity to the well bore, exposing fresh surface of bitumen for the process to progressively soften and mobilize the bitumen in a predominantly circumferential, i.e. orthogonal to the propped fracture, diffusion direction at a nearly uniform rate into the oil sand deposit. The produced product of oil and dissolved solvent is pumped to the surface where the solvent can be recycled for further injection.

Owner:GEOSIERRA

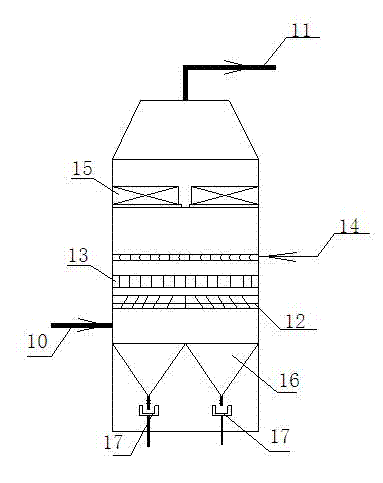

Offshore platform thermal recovery fuel oil or fuel gas steam injection boiler

ActiveCN101865450ALow thermal efficiencyReduce drynessFluid removalWater-tube boilersAutomatic controlFuel oil

The invention relates to an offshore platform thermal recovery fuel oil or fuel gas steam injection boiler used in the thermal recovery operation of an offshore oilfield platform. The invention mainly solves the problems that land petroleum thermal recovery devices can not meets the demands of the offshore platform on devices such as compact layout, light weight, safety, mental protection, high efficiency and high degree of automation. The boiler mainly comprises a boiler main body and auxiliary equipment, wherein the main body mainly contains a radiant section, a convection section and a water heat exchanger; and the auxiliary equipment mainly contains a steam-water system, a ventilation system, a combustion system and an automatic control system. All the parts of the boiler main body are assembled in the vertical mode and all the water channels and tube bundles in the boiler main body are arranged in a vertical structure and use the high-strength tubing with small wall thickness, thus the floor space of the boiler of the invention can be reduced by about one third and the weight can be reduced by about 20% compared with the conventional boiler used on land; the special insulating layer and insulating material are adopted simultaneously so that the economic and technical norms of the boiler such as heat efficiency, dryness, safety and environmental protection are all higher than the existing norms of the land boiler; and the boiler is combined with the automatic control system so that the boiler is safe, environmentally friendly and efficient, and has high degree of automation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

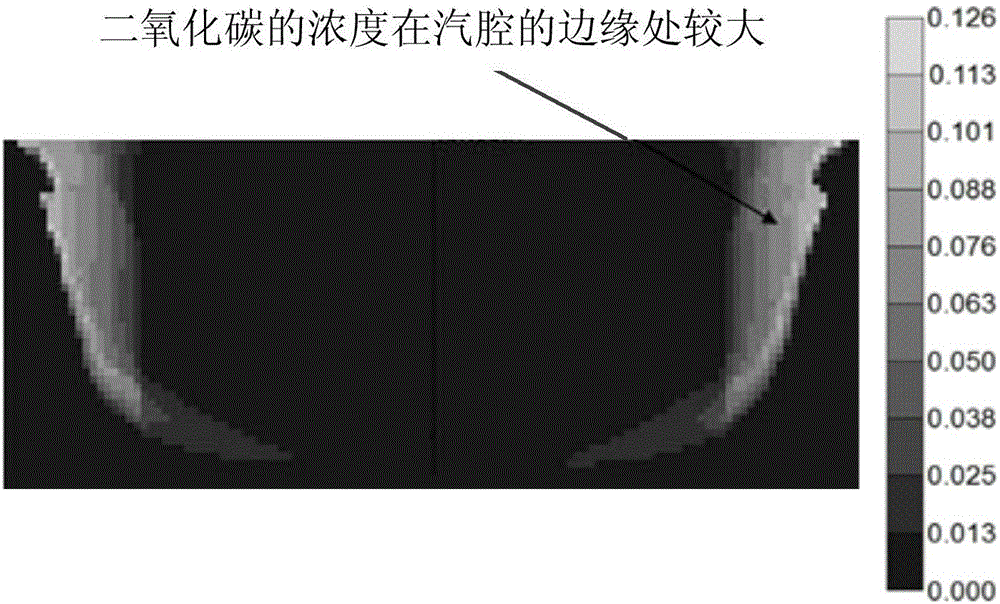

Alternating sagd injections

Methods produce heavy oil with steam assisted gravity drainage. Such methods alternate a traditional steam injection with an injection of a steam-plus-non-condensable gas (such as CO2 or CO2-plus-diluent) mixture. The CO2 / diluent mixture is soluble in bitumen, leading to a reduction in viscosity of the heavy oil. Additionally, the steam-only injection reduces the accumulation of vapor NCG along the edge of the steam chamber, leading to improved thermal efficiency.

Owner:CONOCOPHILLIPS CO

Supercritical hydrothermal combustion device suitable for high-viscosity fuel

PendingCN110645555AAvoid lostImprove heat utilizationFluid removalSteam generationThermodynamicsCombustion chamber

The invention provides a supercritical hydrothermal combustion device suitable for high-viscosity fuel. The supercritical hydrothermal combustion device suitable for the high-viscosity fuel is mainlycomposed of an upper end cover, a middle end cover, a first combustion stabilization chamber body and a second combustion chamber body which are sequentially connected and assembled. The upper end cover is provided with a first-grade fuel inlet, a high-energy heating rod and a first-grade oxidizing agent inlet. The middle end cover is provided with a second-grade fuel inlet, a second-grade oxidizing agent inlet and a reactant first-grade spray nozzle. The reactant first-grade spray nozzle communicates with the first-grade fuel inlet. The inner wall of the first combustion stabilization chamberbody is a double-layer-spiral wall, the bottom end of the first combustion stabilization chamber body is provided with a second-grade spray nozzle communicating with the second-grade fuel inlet and the second-grade oxidizing agent inlet. The inner wall of the second combustion chamber main body is a double-spiral cooling wall, and the bottom end of the second combustion chamber main body is provided with an outlet hole group. Finally, a combustion stabilization chamber is formed between the first-grade spray nozzle and the second-grade spray nozzle. A combustion chamber is formed between thesecond-grade spray nozzle and the outlet hole group. A mixing chamber is formed between the outlet hole group and a bottom outlet of a reactor. The supercritical hydrothermal combustion device suitable for the high-viscosity fuel directly generates steam in an oil layer, so that the problems of high energy consumption and heavy pollution caused in the steam injection process of a heavy oil thermalrecovery ground boiler are solved.

Owner:XI AN JIAOTONG UNIV

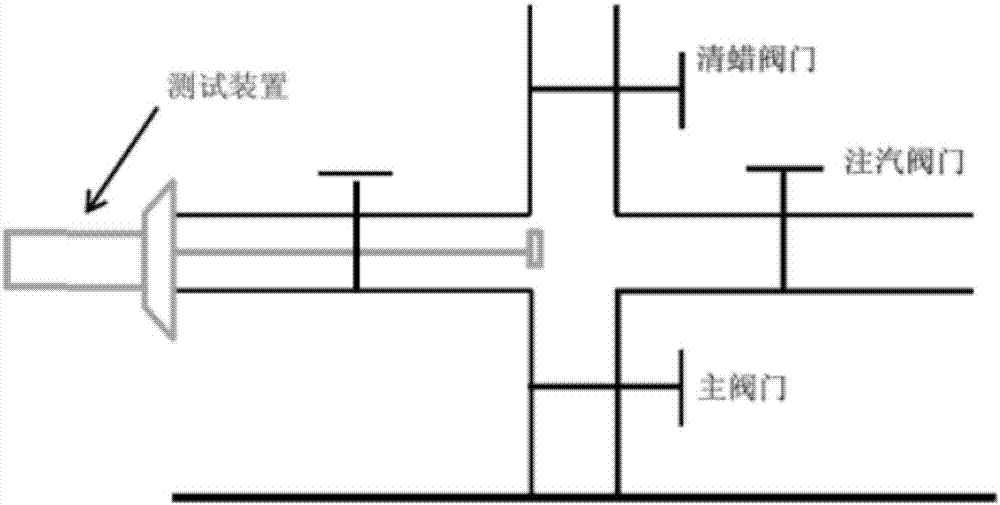

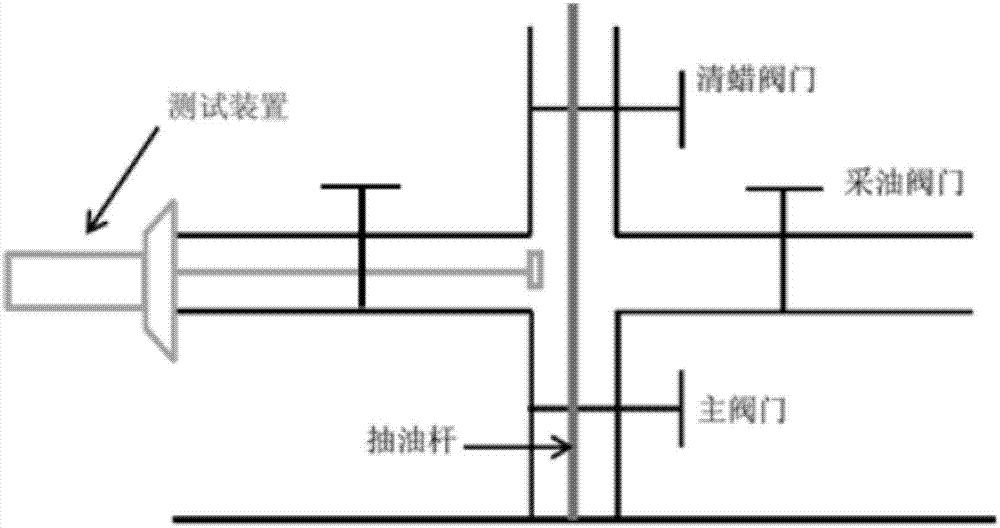

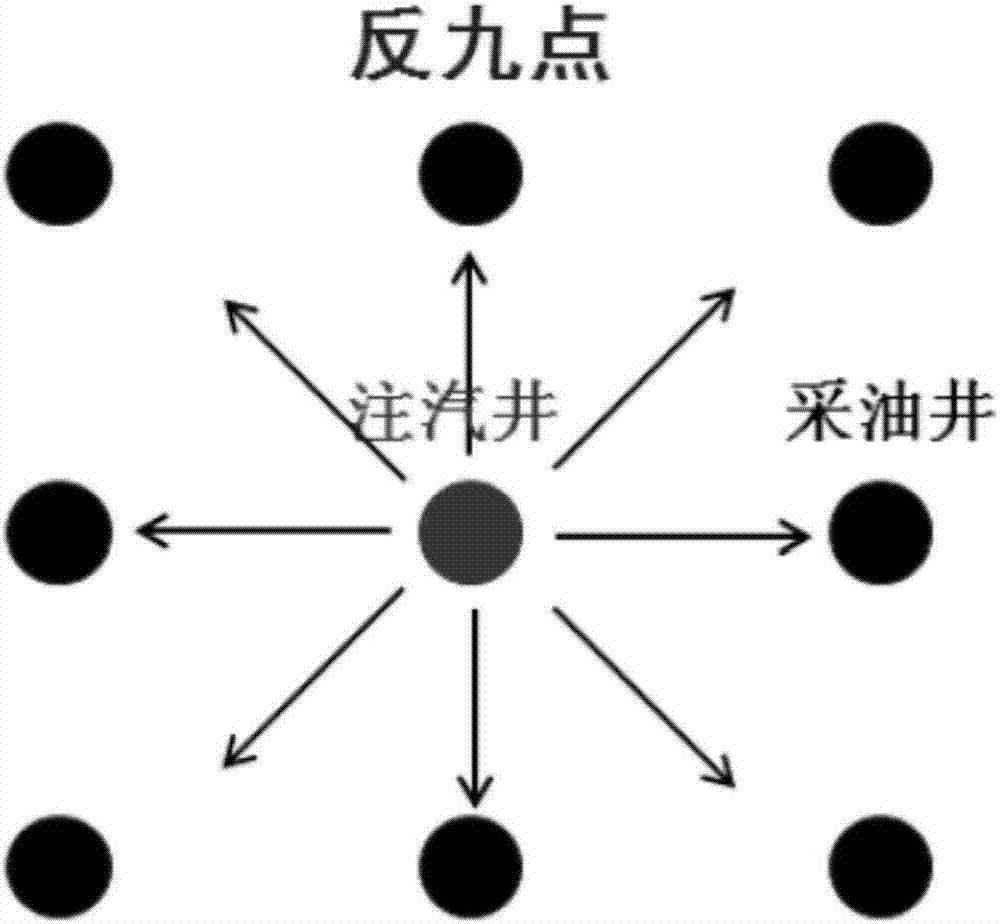

Method for monitoring communication state of steam flooding wells and system

ActiveCN107130951ARealize qualitative evaluationLearn about connectednessSurveyConstructionsDiffusionMathematical model

The invention provides a method for monitoring communication states of steam flooding wells and system. The method for monitoring the communication state of the steam flooding wells comprises the following steps: performing pulse well trail testing on a steam flooding well group, wherein the pulse well testing process is well testing process for performing periodic adjustment on steam injection output of a steam injection well; in the well testing process, the steam injection well is an excitement well, and a production well is an observation well; according to temperature and pressure variations of mouths of the production well and the steam injection well in the pulse well testing process, performing qualitative evaluation on communication of the steam injection well and the production well; and establishing mathematic models, achieving quantitative splitting of steam amounts of the steam injection well and corresponding production well, thereby performing quantitative evaluation upon the communication states of steam flooding, injection and production wells. By adopting the scheme of the invention, on the basis of monitoring upon conduction and diffusion of substances and energy under formation conditions, practical effects of stream to oil wells under the formation conditions can be directly reflected, and thus conclusions are direct and reliable.

Owner:PETROCHINA CO LTD

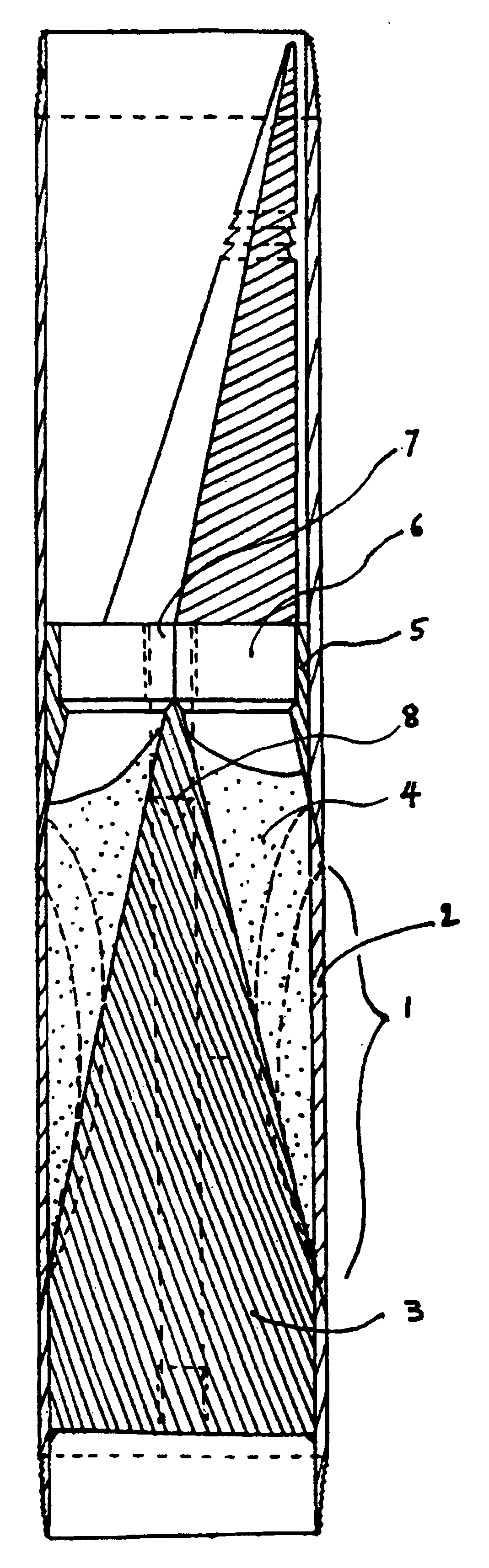

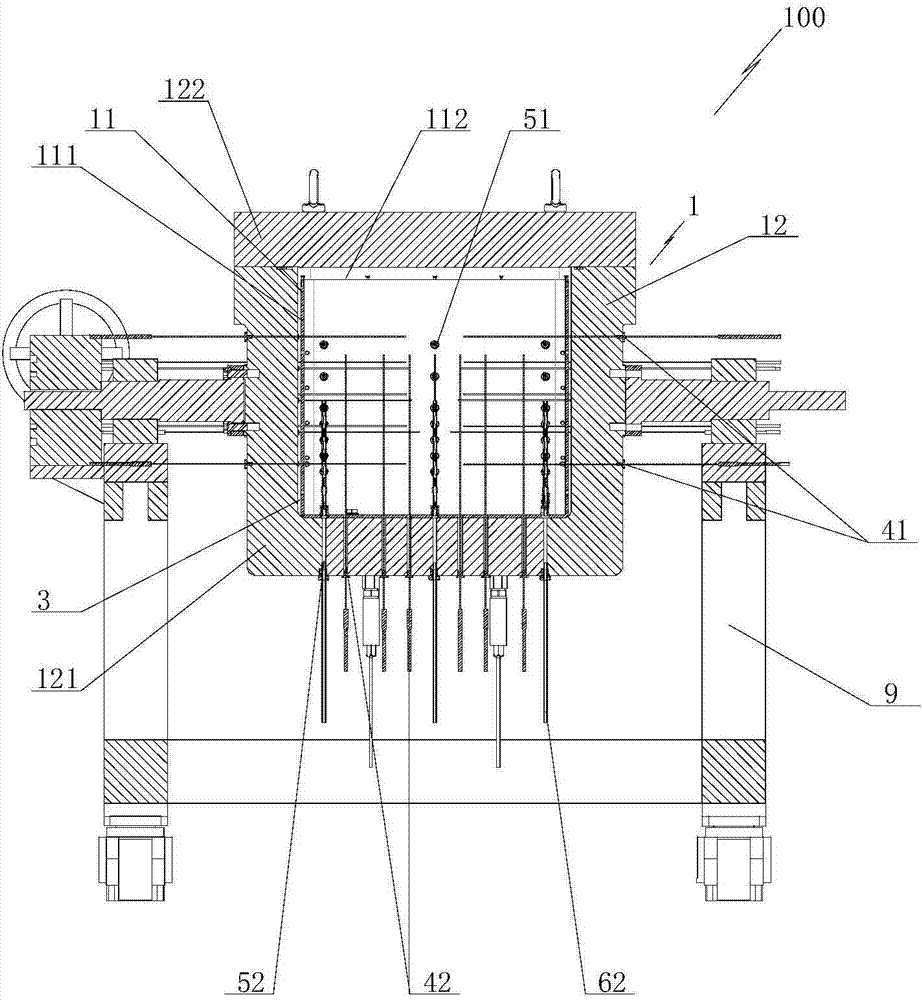

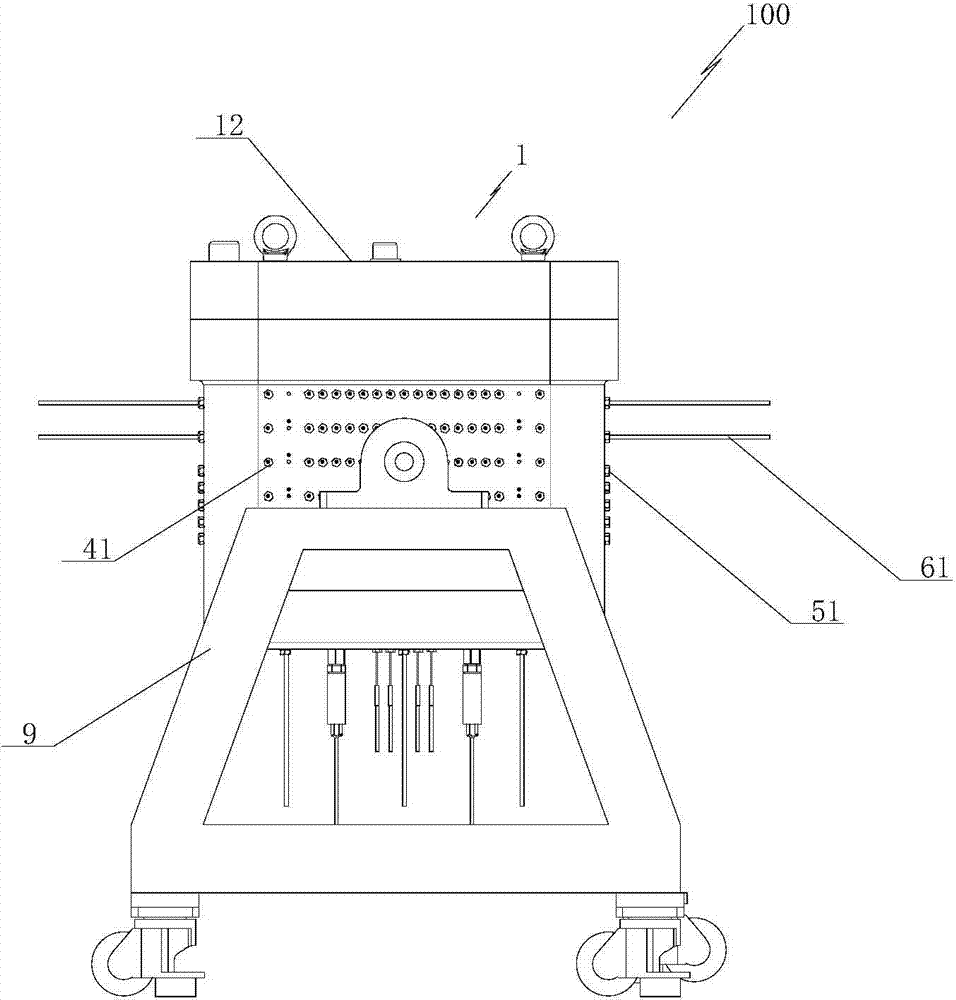

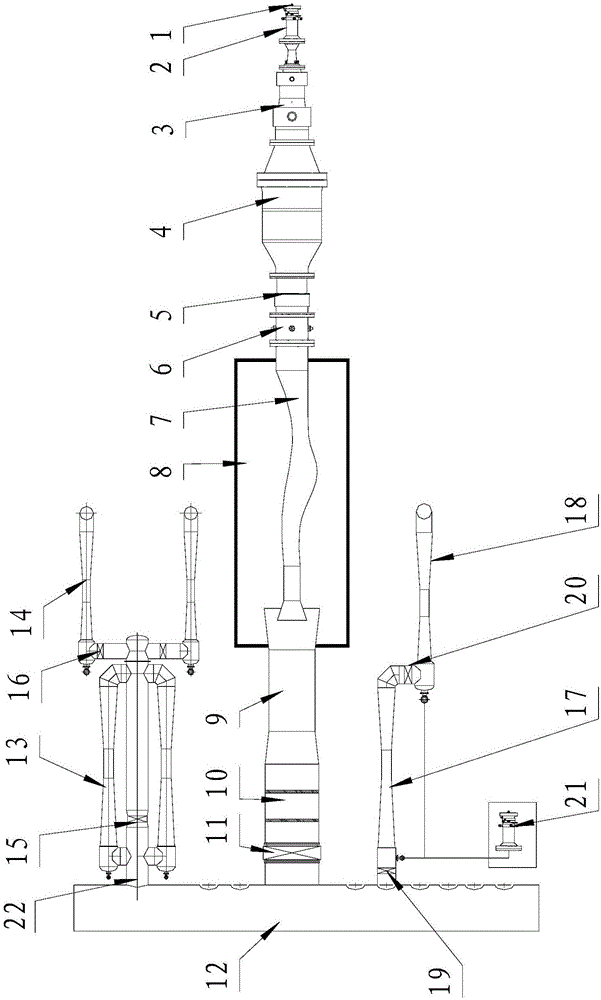

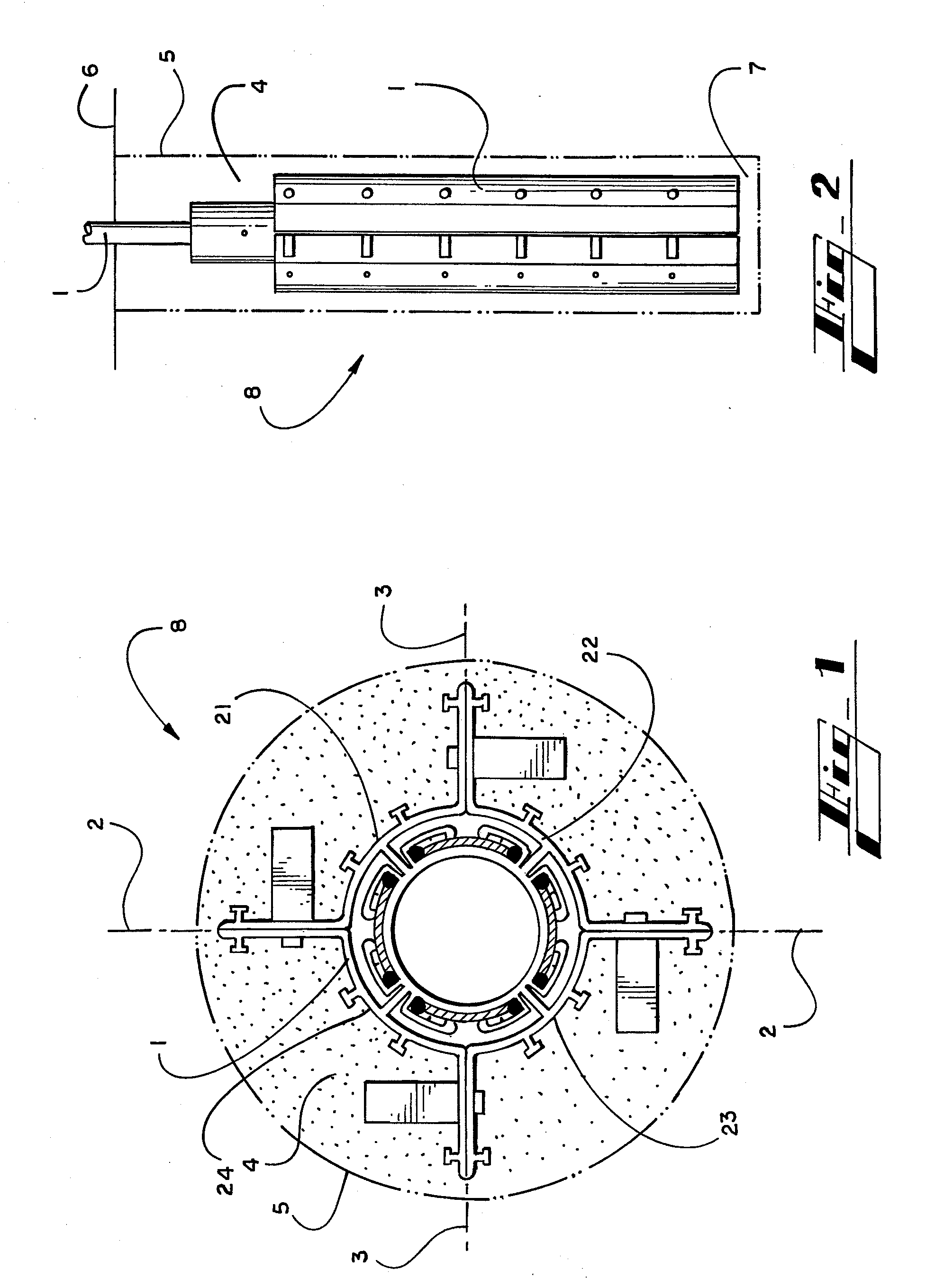

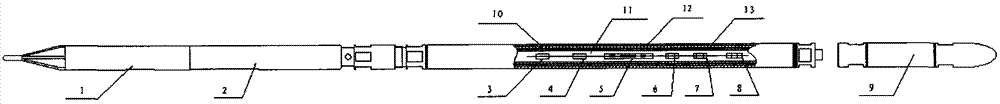

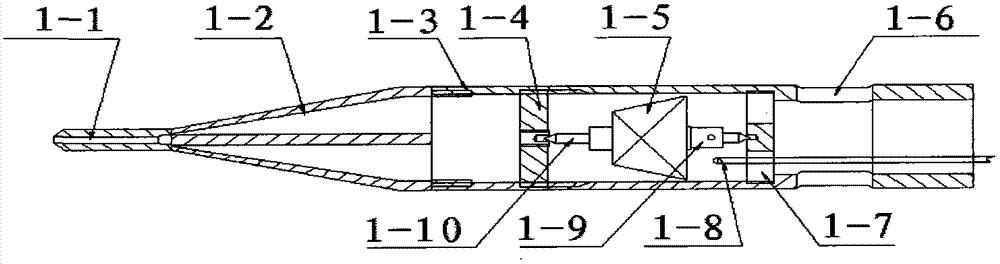

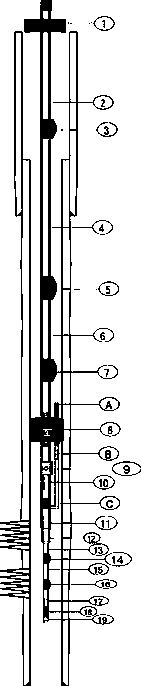

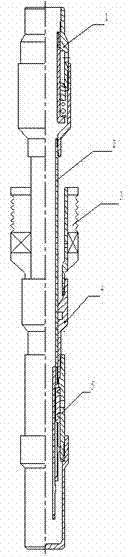

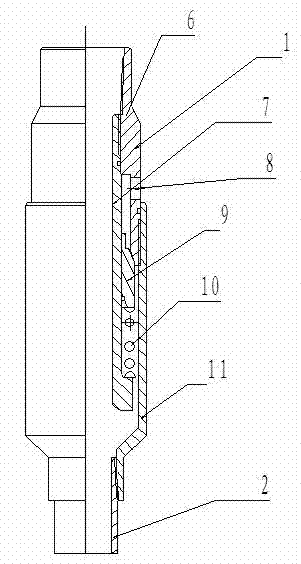

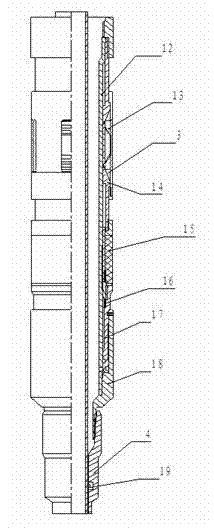

High-temperature six-parameter combination tester, test system and test method

The invention discloses a tester for testing six or five or four or three parameters of a steam injection profile including downhole steam flow, dryness, downhole temperatures, pressure, magnetic localization and natural gamma in the oil field heavy oil well heating power mining technology, a test system and a test method. The six-parameter combination tester is formed by sequentially connecting a guide flow type rotor wing wheel flow meter assembly (1), a dryness measuring assembly (2), a machine core and an isotope detection assembly (9) through threads. The machine core is mainly formed by connecting a temperature sensor (3), a pressure sensor (4), a fixed-frequency emission and data acquisition unit (5), a natural gamma detector (6), a magnetic locator (7) and a power supply system (8) in sequence. The six-parameter combination tester has the advantages of being high in precision, capable of calibrating the depth, more accurate in test data, more comprehensive in test item, wider in adaptability, novel and capable of being applied to air injection and steam injection mining new techniques.

Owner:辽宁瑞达石油技术有限公司

Method for improving recovery ratio of sensitive heavy oil reservoir

ActiveCN103573231AEfficient developmentReduce interfacial tensionCleaning apparatusFluid removalThermodynamicsHorizontal wells

The invention provides a method for improving the recovery ratio of a sensitive heavy oil reservoir. The method utilizes combined application of a high-temperature clay stabilizer, a sustained-release acidizing fluid system, an efficient oil-displacing agent and carbon dioxide in the development of the sensitive heavy oil reservoir to improve the single-well development effect and the recovery ratio of the sensitive heavy oil reservoir. The technical scheme is that the method comprises the steps of first utilizing the temperature-sensitive sustained-release acidizing fluid system to treat a polluted treat near-well-bore zone, then injecting the liquid carbon dioxide, utilizing the high-temperature clay stabilizer to protect an oil layer before steam injection and injecting a high-temperature oil-displacing agent system while the steam injection; then performing well shut-in for soaking and well opening for gushing and putting a pump into a well to perform continuous oil extraction. A field test shows that the oil-steam ratio of an average period of a vertical well reaches to 0.4, the oil-steam ratio of an average period of a horizontal well reaches to 0.6, and the periodic oil yield exceeds 1000t. A laboratory test shows that the final recovery ratio can reach to higher than 35% by adopting a process related to the method for improving the recovery ratio of the sensitive heavy oil reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

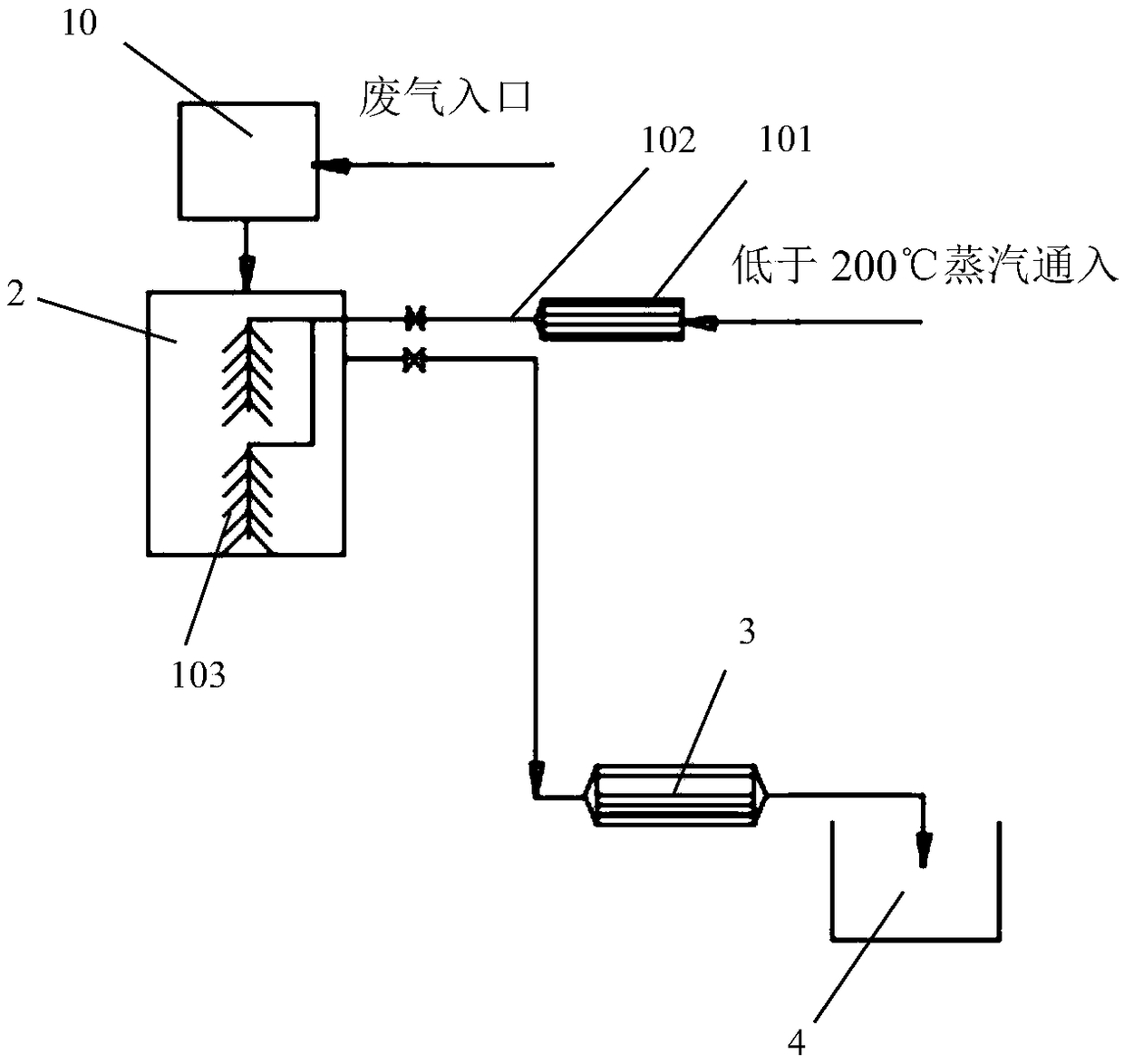

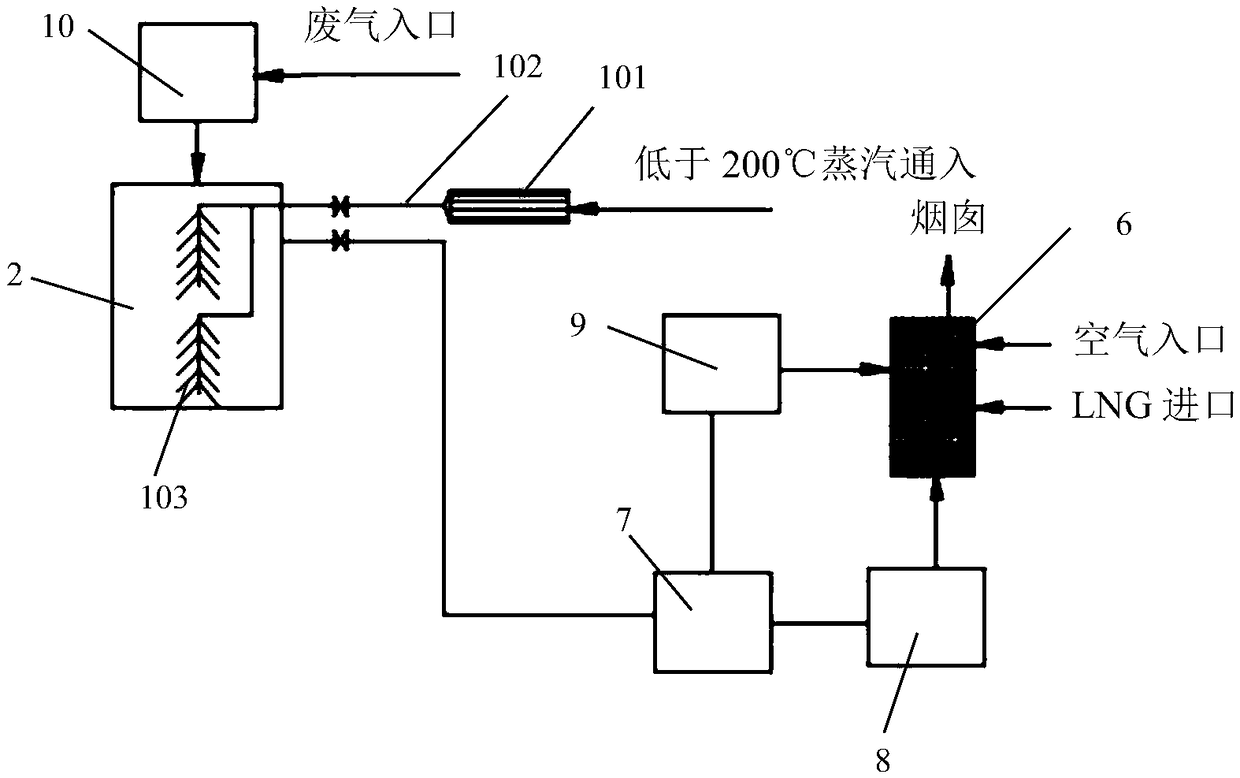

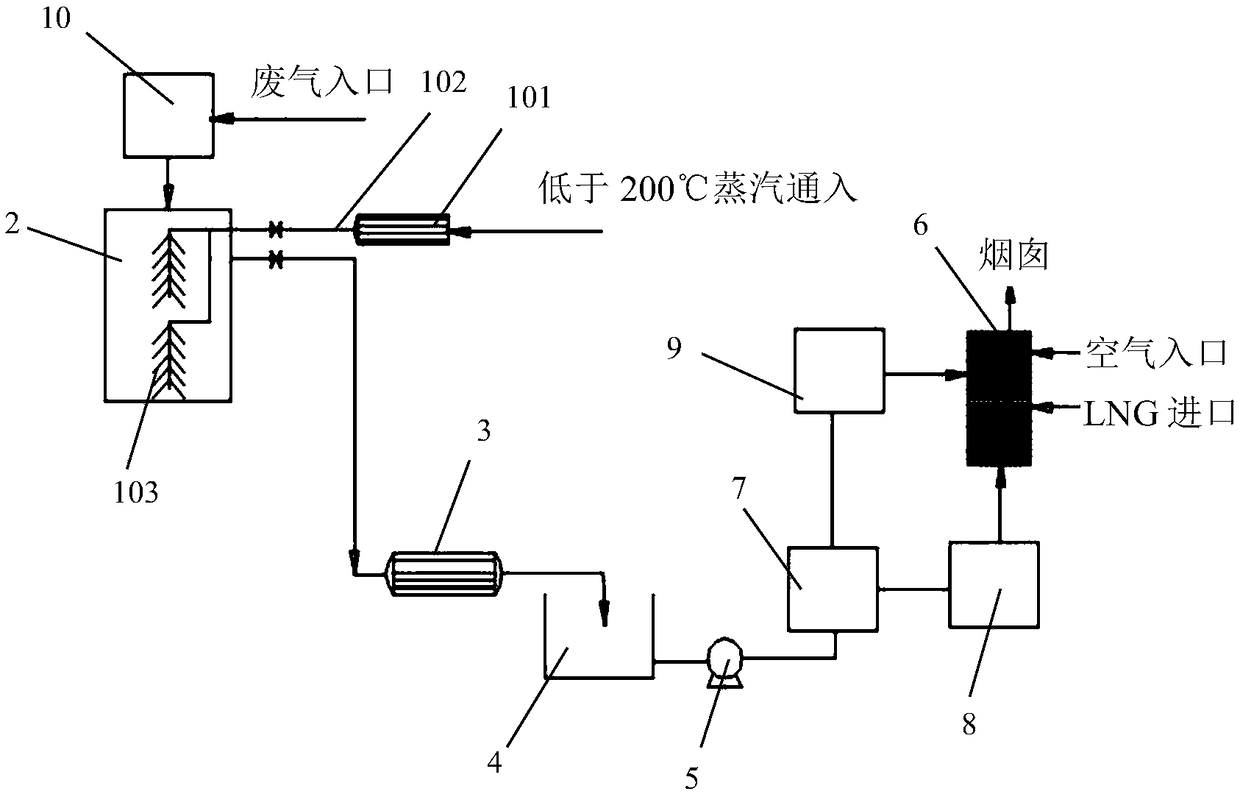

Adsorption treatment of organic waste gas and desorption and regeneration process of adsorbent

InactiveCN109482036AImprove efficiencyImprove the safety of useGas treatmentDispersed particle separationActivated carbonDesorption

The invention provides a desorption and regeneration process after adsorption saturation of an adsorbent (comprising activated carbon, activated coke, zeolite and the like) for adsorbing organic matters in organic waste gas and a treatment process of tail gas generated in the desorption and regeneration process. The desorption and regeneration process includes desorbing and regenerating the adsorbent in a regeneration tank embedded with a steam injection system, wherein the steam injection system comprises a main steam pipeline and a plurality of dendritic secondary steam pipelines arranged onthe main steam pipeline, a steam nozzle is arranged on each secondary steam pipeline, and the steam injection system is embedded by the adsorbent; introducing superheated steam to heat the adsorbentin the regeneration tank, wherein most of the organic matters adsorbed by the adsorbent are desorbed at high temperature or are pyrolyzed and carbonized; and removing the organic matters and carbidesin pores of the adsorbent by steam purging to activate and regenerate the adsorbent. The treatment process includes treating the tail gas generated in the regeneration process is by tail gas treatmentequipment, wherein the tail gas treatment equipment specifically refer to tail gas condensation treatment equipment, tail gas incineration treatment equipment or tail gas condensation and incineration treatment equipment.

Owner:WUXI SIFANG GRP CO LTD

Downhole Packer Assembly Having a Selective Fluid Bypass and Method for Use Thereof

ActiveUS20130160996A1Prevent backflowSurveyFluid removalMechanical engineeringStructural engineering

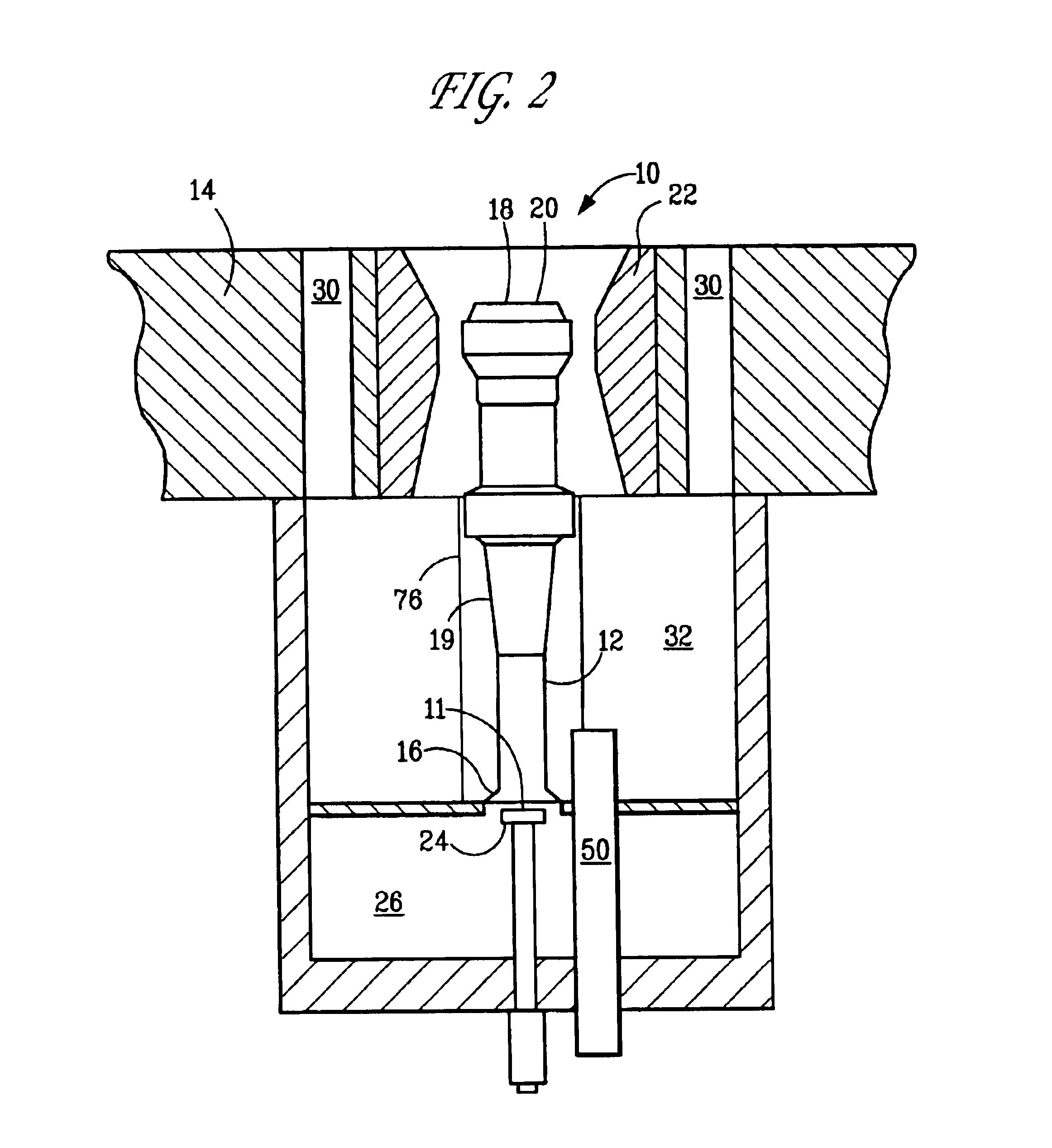

A downhole packer assembly for steam injection and casing pressure testing. The downhole packer assembly includes a housing assembly having intake and discharge ports. A seal assembly is positioned around the housing assembly between the intake and discharge ports and is operable to provide a fluid seal with a casing string. A mandrel is positioned within the housing assembly forming a micro annulus therewith and providing an internal pathway for fluid production therethrough. A valve assembly is disposed between the housing assembly and the mandrel and is operable between closed and open positions by a piston assembly such that the intake and discharge ports and the micro annulus provide a bypass passageway for steam injection around the seal assembly when the valve assembly is open and the seal assembly provides a downhole surface for pressure testing of the casing string uphole thereof when the valve assembly is closed.

Owner:HALLIBURTON ENERGY SERVICES INC

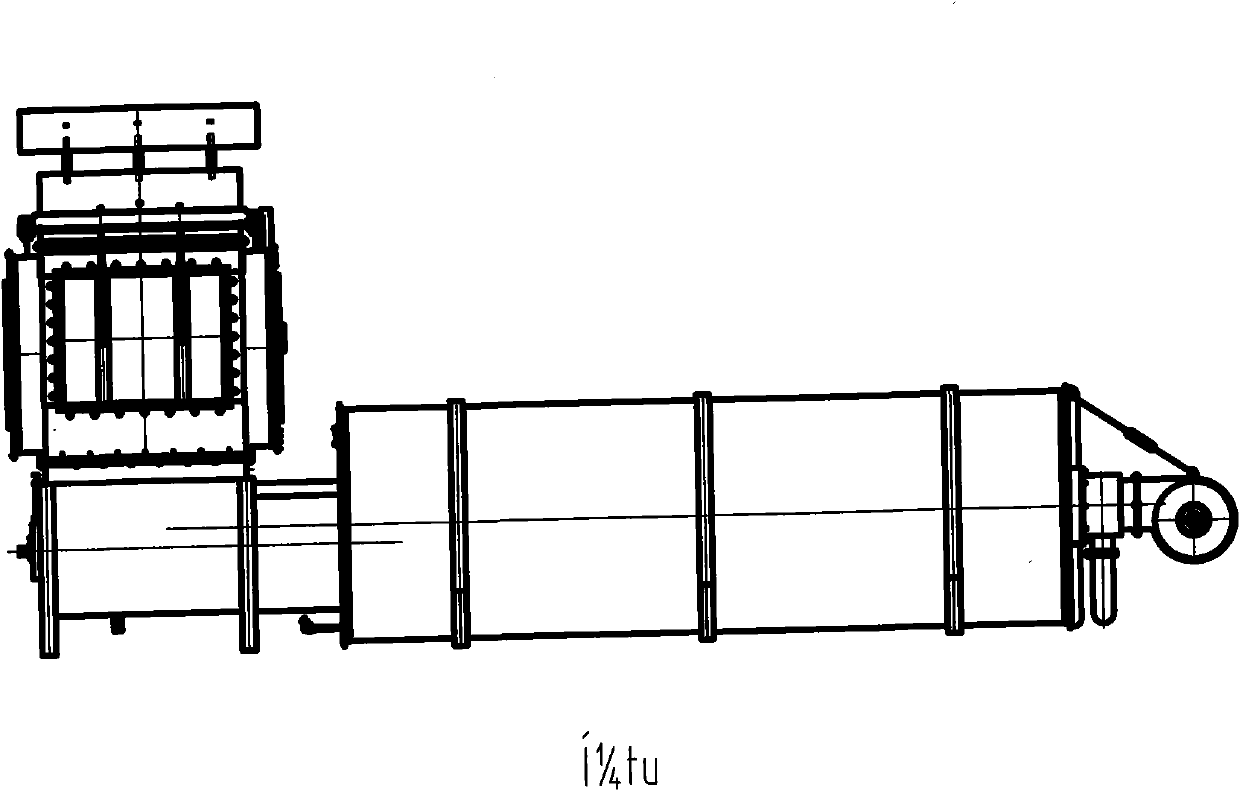

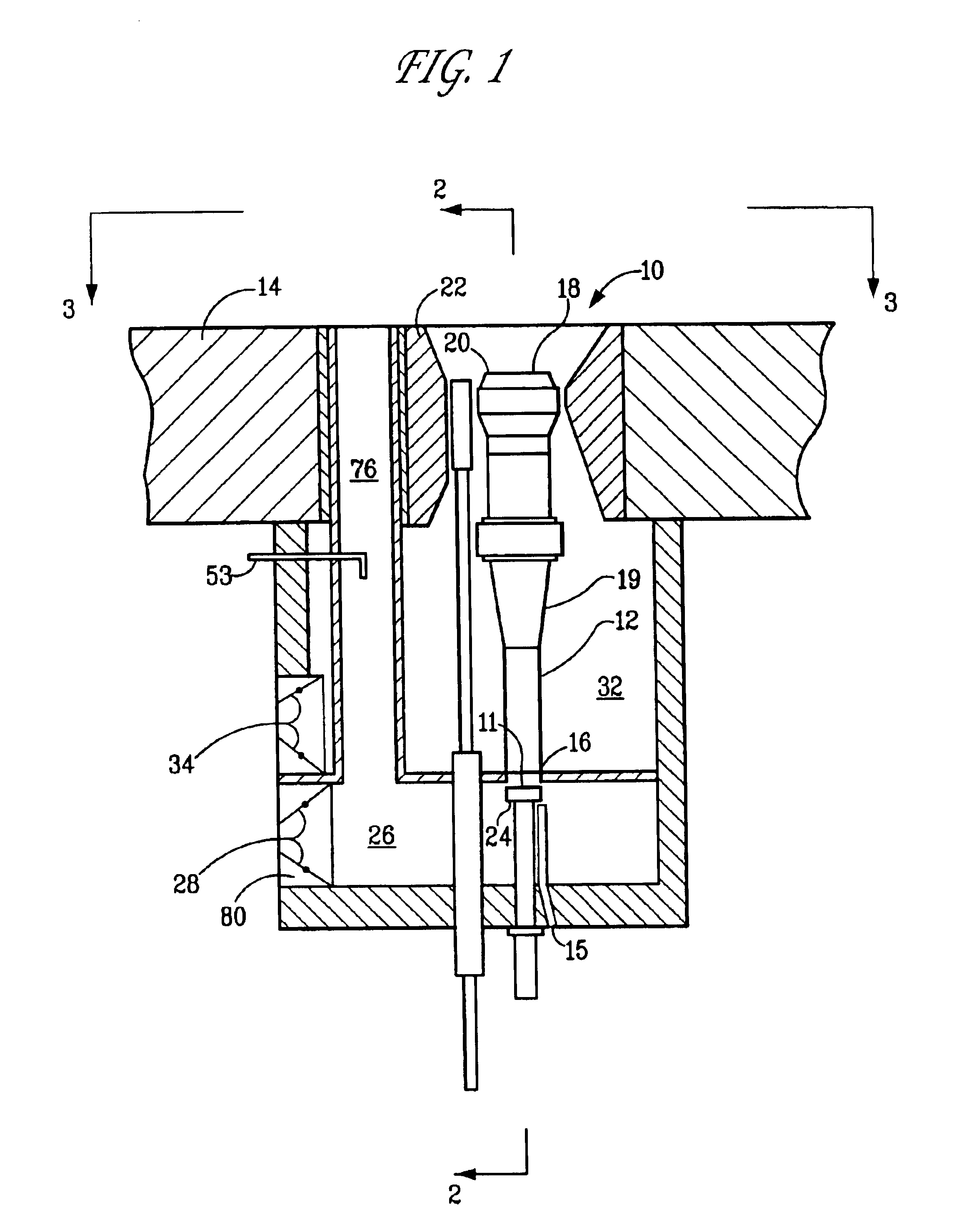

Burner employing steam injection

InactiveUS6986658B2Reduce the temperatureLarge capacityFluegas recirculationCasings/liningsCombustorFlue gas

Method and apparatus for use in burners of furnaces such as those used in steam cracking. The apparatus includes a burner tube having a downstream end and an upstream end for receiving fuel and air, flue gas or mixtures thereof. A burner tip is mounted on the downstream end of the burner tube adjacent a first opening in the furnace, so that combustion of the fuel takes place downstream of the burner tip. At least one passageway has a first end at a second opening in the furnace and a second end in a primary air chamber adjacent the upstream end of the burner tube. The passageway also has structure for injecting steam into the passageway and a means for drawing flue gas from the furnace through the passageway.

Owner:EXXONMOBIL CHEM PAT INC

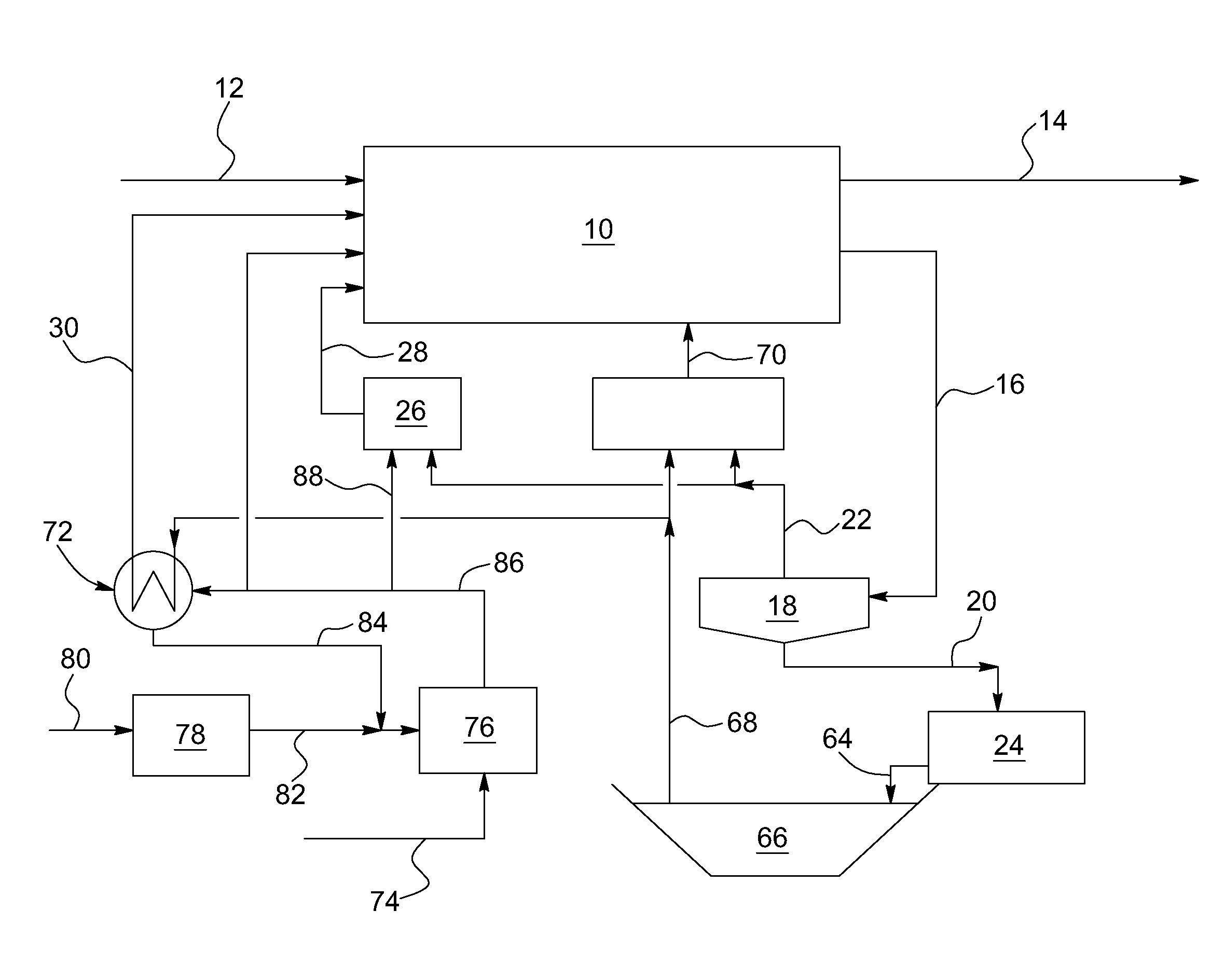

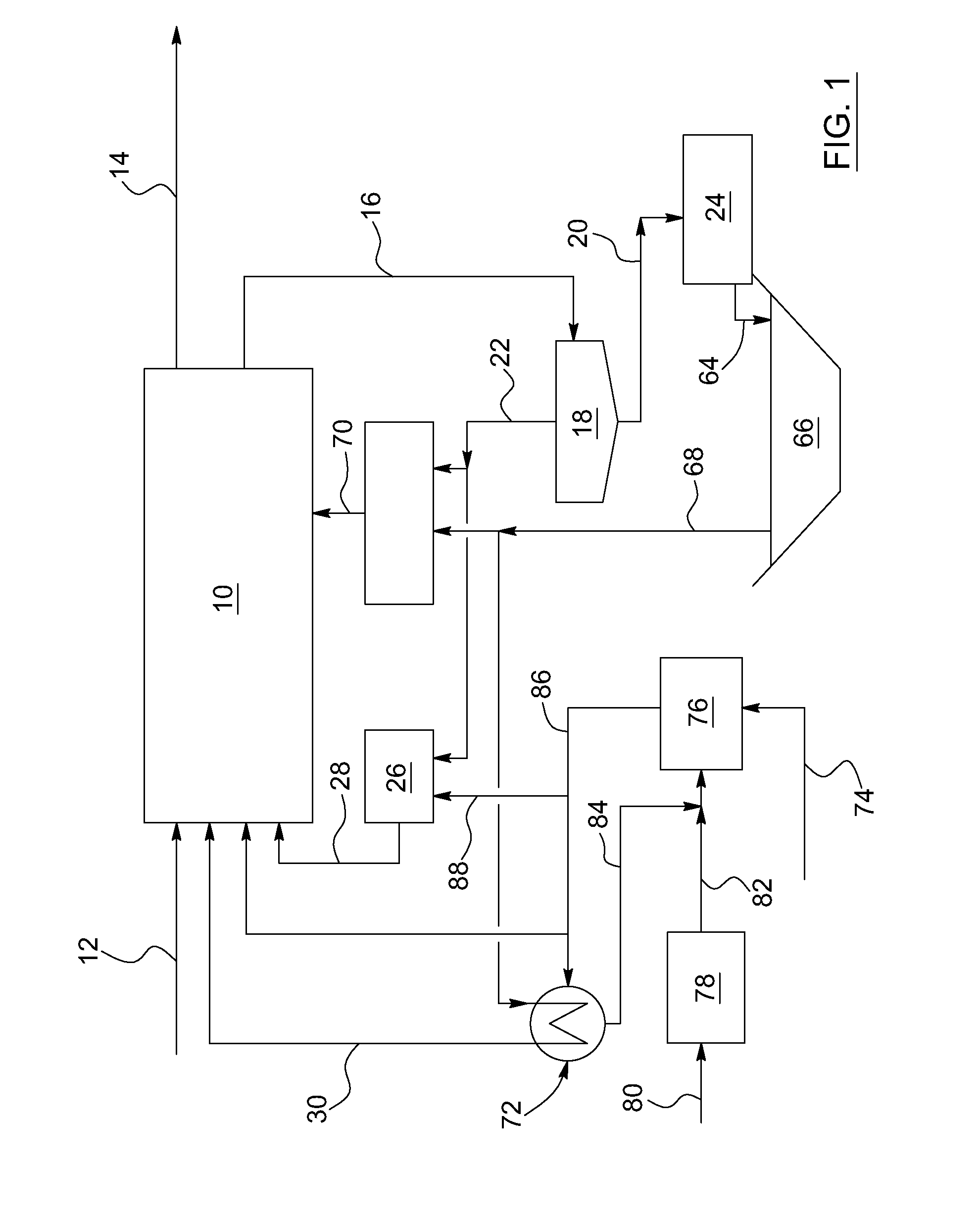

Heat and water integration process for an oil sand operation with direct steam injection of warm thickener overlfow

InactiveUS20140076785A1Sedimentation separationLiquid hydrocarbon mixture productionThermodynamicsWarm water

A heat and water integration process for an oil sands operation includes subjecting warm oil sands tailings to thickening to produce thickened tailings and warm water overflow; subjecting the warm water overflow to direct steam injection (DSI) to produce steam heated thickener water; providing the steam heated thickener water to a unit of the oil sand operation; and producing the warm oil sands tailings from the oil sands operation. The oil sand operation unit may be an oil sand ore preparation unit and / or a primary separation unit, for example. The heated thickener water can replace water taken from pond inventories. The DSI may use excess, low quality, wet, low pressure and / or blow-down steam. The process enables improved heat and water usage in oil sands processing.

Owner:TRUENORTH ENERGY CORP

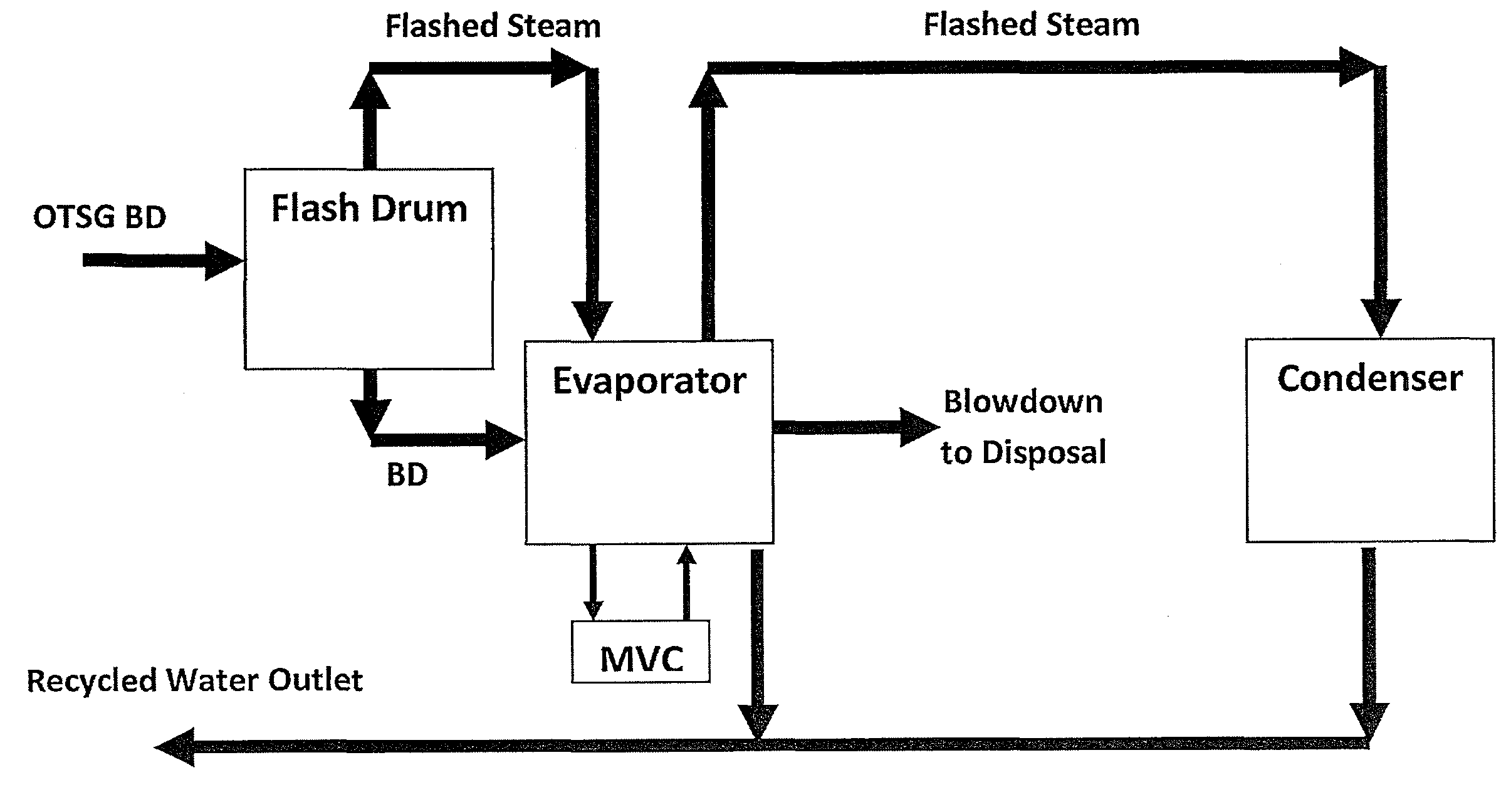

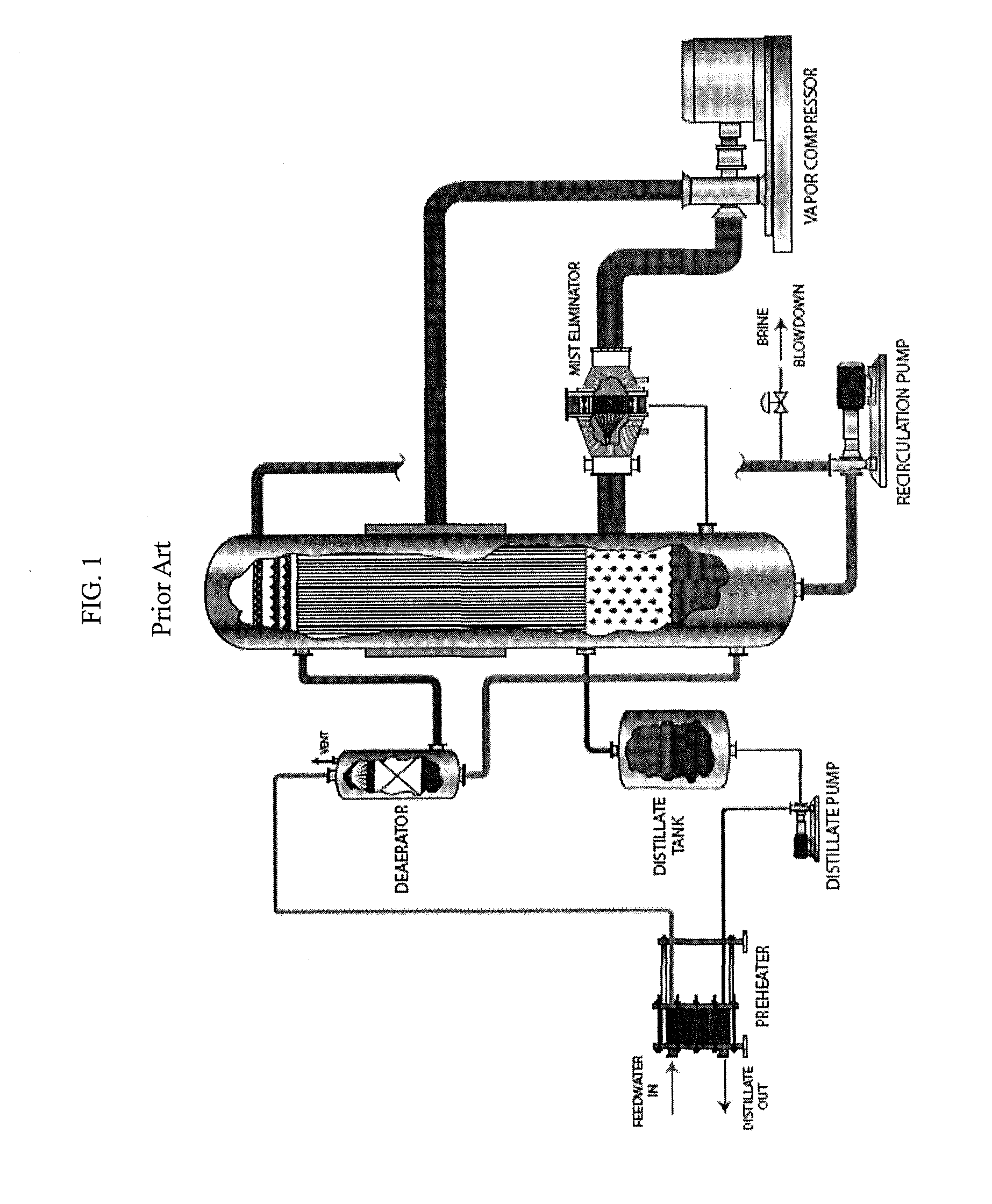

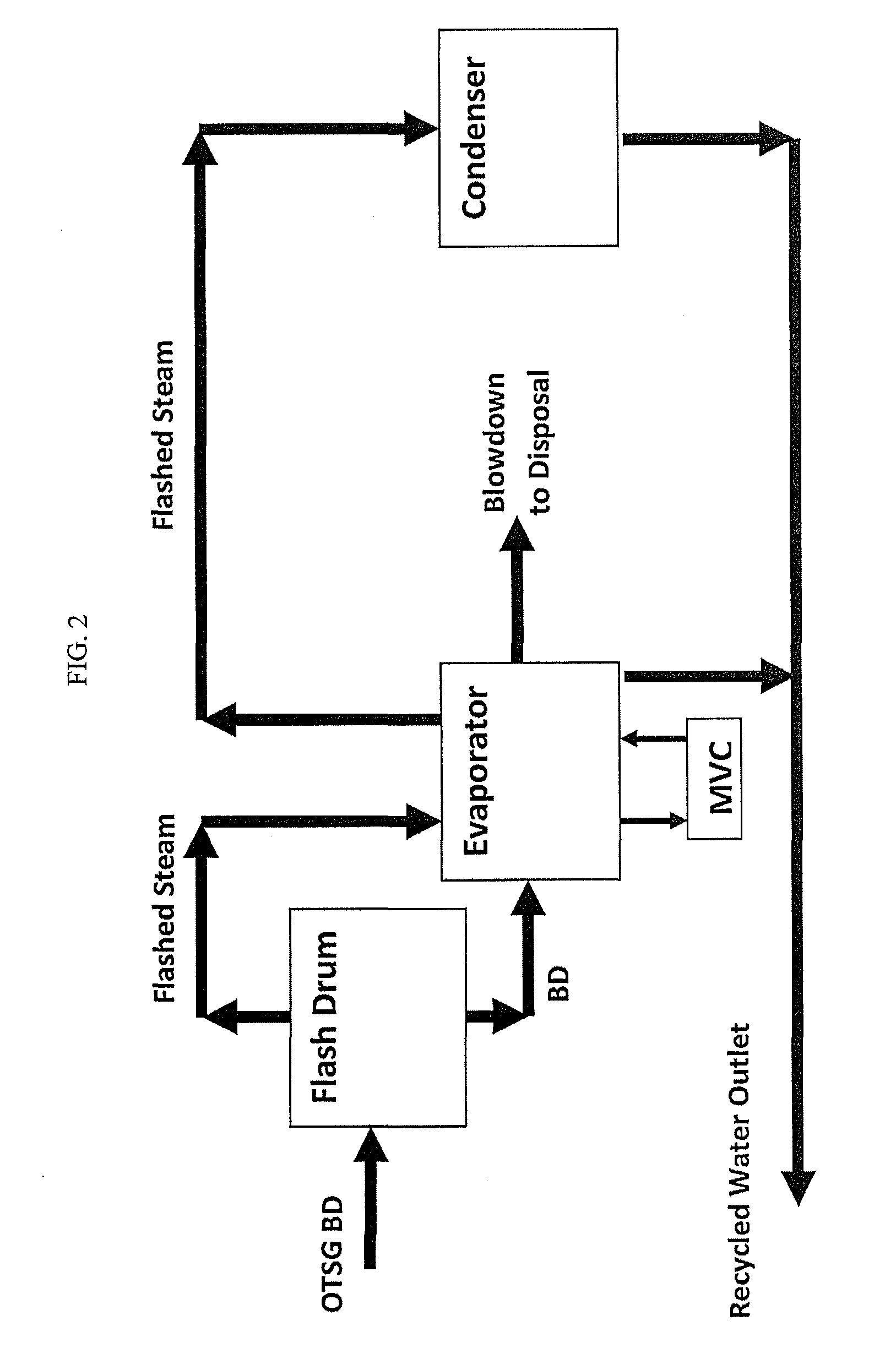

Method and apparatus for recycling water

ActiveUS20150000914A1Reducing and eliminating MVC power consumptionImprove economyWaste water treatment from quariesAuxillariesLiquid wasteEvaporation

We provide an evaporation based zero-liquid discharge method for generation of steam for enhanced oil recovery (EOR) processes utilizing once-through steam generators (OTSGs). The method includes feeding the OTSG(s) with produced water, vaporizing a fraction of this water for steam injection and blowing down the balance of the water. This water, referred to as OTSG blowdown, can be flashed to produce a vapor stream and a liquid that is fed to a mechanical vapor compression (MVC) evaporative process. The latent energy contained in the vapor stream generated by the upstream flash is beneficially recycled to substantially reduce or eliminate the energy consumption of the MVC process. The evaporative process can be used to reduce the liquid waste for disposal or eliminate the need for liquid disposal by achieving zero liquid discharge.

Owner:AQUATECH INT LLC

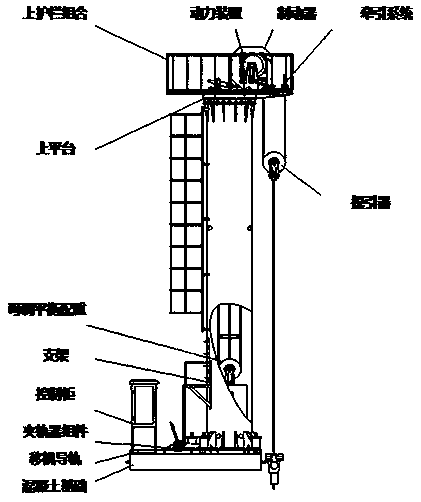

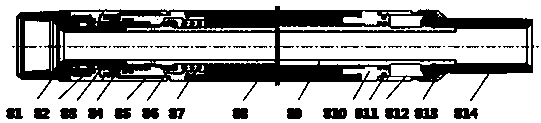

Oil pumping unit system with multiple sections of steam injection packer parts

ActiveCN110344787AImprove integrityImprove flow efficiencySurveyDrilling rodsTraction systemUnit system

The invention discloses an oil pumping unit system with multiple sections of steam injection packer parts. The oil pumping unit system comprises an oil pumping unit body, a steam injection thermal production oil pump and a packer assembly. The oil pumping unit body is connected with the steam injection thermal production oil pump through a traction system of the oil pumping unit body. The steam injection thermal production oil pump is connected with the packer assembly through a release sub. The packer assembly comprises the release sub, a first oil discharging pipe, a first side sealing spindle, a second oil discharging pipe, a second side sealing spindle, a third oil discharging pipe, a third side sealing spindle, a packer body, a one-way valve, a first spraying head, a second spraying head, a sealing ring, a fourth oil discharging pipe, a third side sealing spindle, a fifth oil discharging pipe, a fourth side sealing spindle, a third spraying head, a ventilation pipe, a cable inletguiding part and a side gas pipeline.

Owner:胜利方兰德石油装备股份有限公司

Method of improving deep super-thick oil reservoir recovery efficiency

The invention relates to a novel method capable of improving deep super-thick oil reservoir recovery efficiency. According to the method, in the steam huff and puff and steam flooding processes, a water-soluble nano-catalyst is injected to make the viscosity of super-thick oil under the condition of an oil reservoir be reduced substantially, as a result, the fluidity of the super-thick oil under the condition of the oil reservoir is improved, the shortcomings that a deep super-thick oil reservoir is high in steam injection pressure and low in well bottom steam dryness are effectively overcome, steam injection quantity also can be reduced, and the purpose of economical and efficient development of the deep super-thick oil reservoir is achieved. On the basis of steam huff and puff and steam flooding, the method of improving deep super-thick oil reservoir recovery efficiency can reduce the velocity of crude oil by more than 80%, increase the recovery percent by about 15%, and increase the gas-oil ratio in a huff and puff well period by 0.15.

Owner:CHINA PETROLEUM & CHEM CORP +1

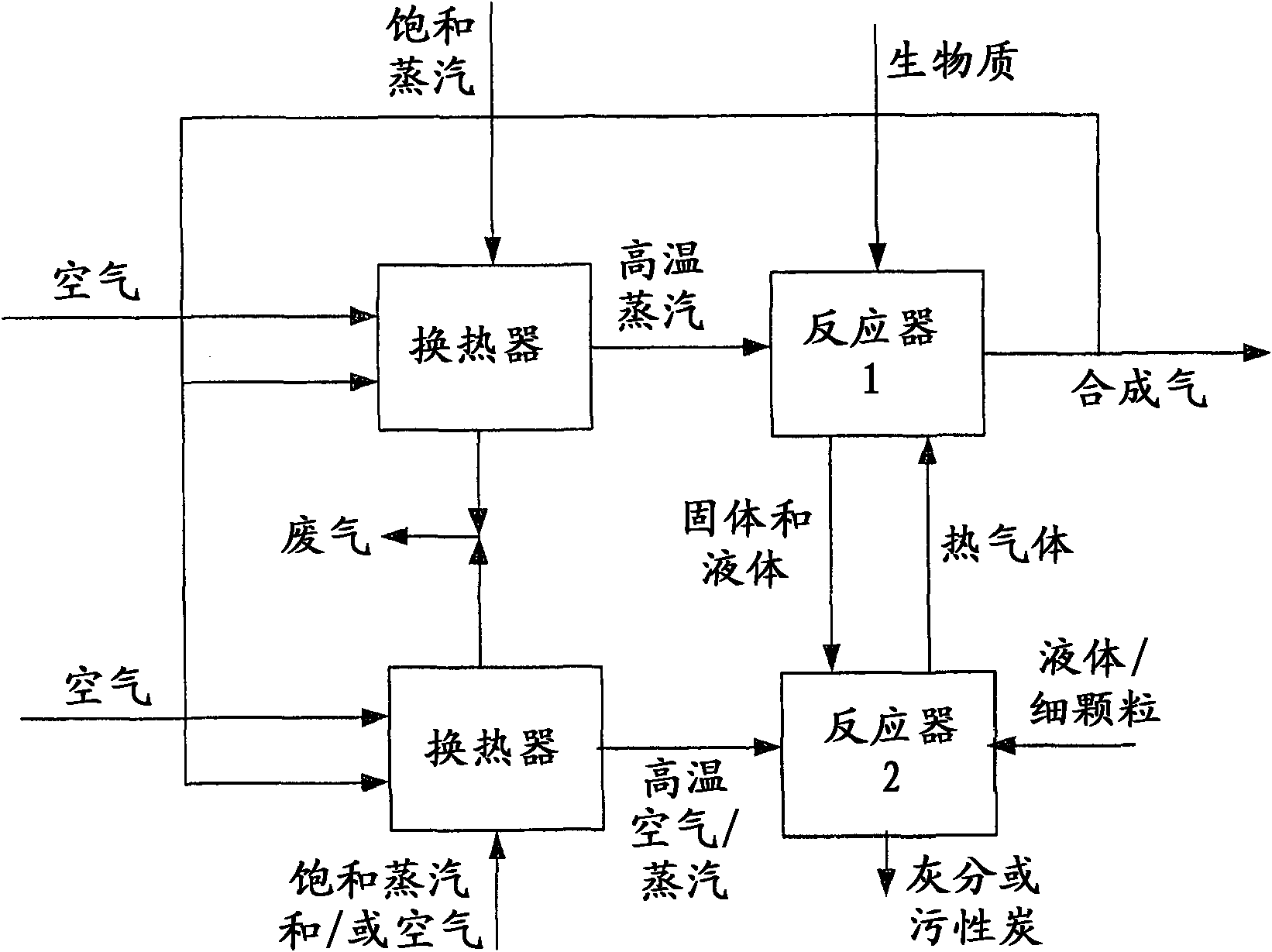

A two-stage high-temperature preheated steam gasifier

A gasifier is disclosed combing two reactors using externally generated preheated high temperature steam injection into the first reactor, where the heating demand for gasification is supplied by the sensible energy from the steam. The gasifier can produce a medium and higher LCV syngas. The first reactor is a fixed bed gasification section where the coarse feedstock is gasified, and the second reactor is an entrained-bed gasification section where the liquid and fine feedstock is gasified. Solid coarse feedstock is devolatilized in the first fixed bed reactor of the gasifier by means of high-temperature steam, and subsequently, in the second reactor subjected to a higher temperature sufficient to crack and destroy tars and oils. Activated carbon may be formed as co-product. The gasifier may be used with various solid and liquid feedstocks. The gasifier is capable of gasifying such different feedstocks simultaneously.

Owner:BOSON ENERGY

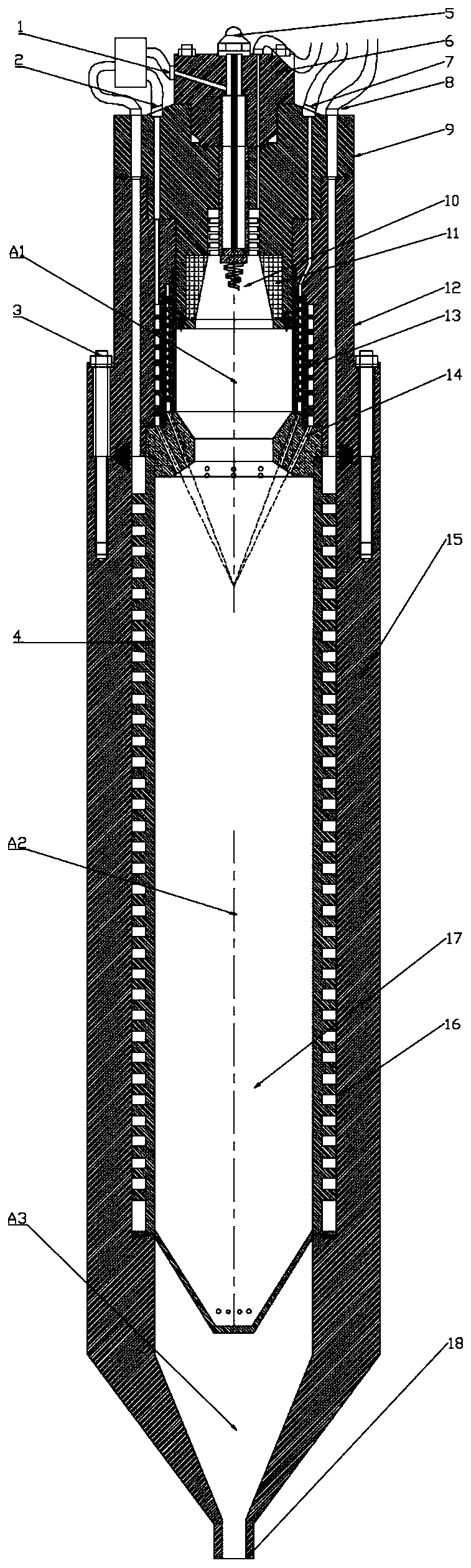

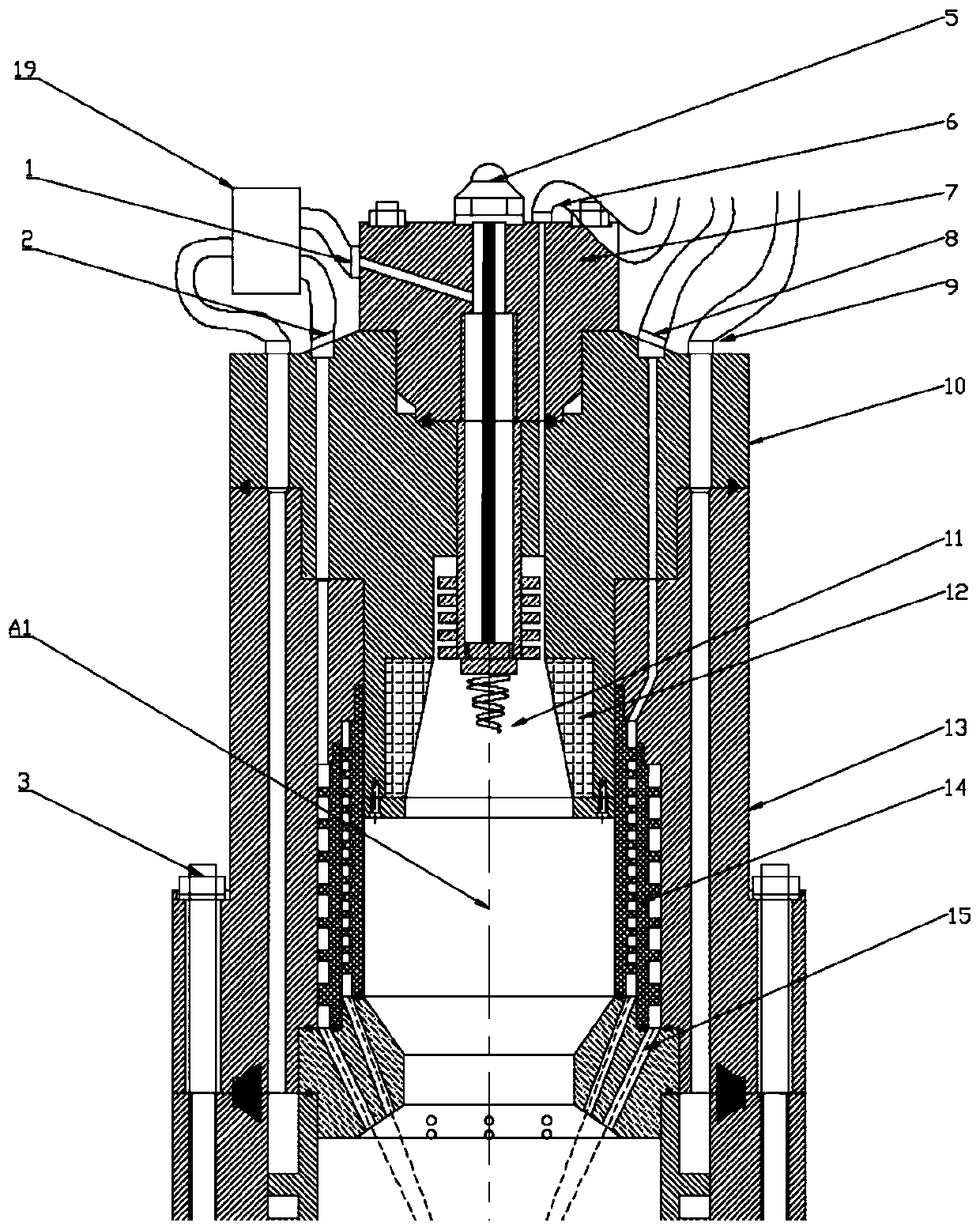

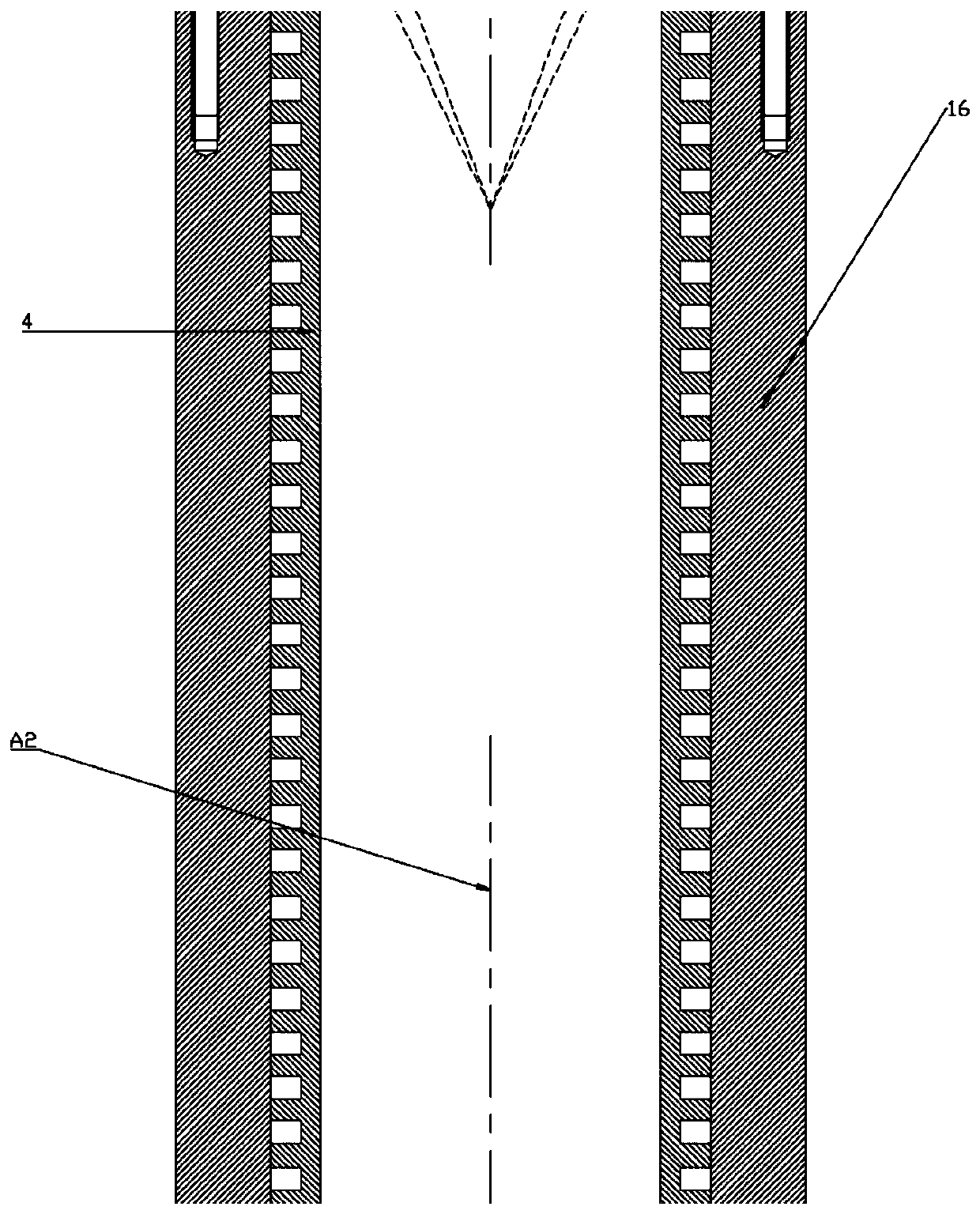

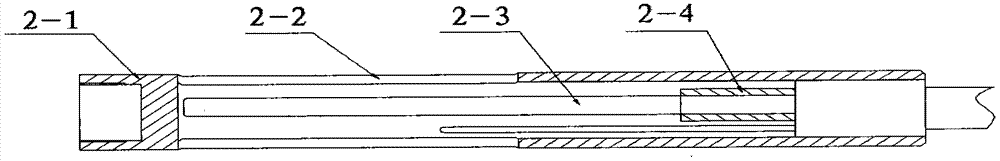

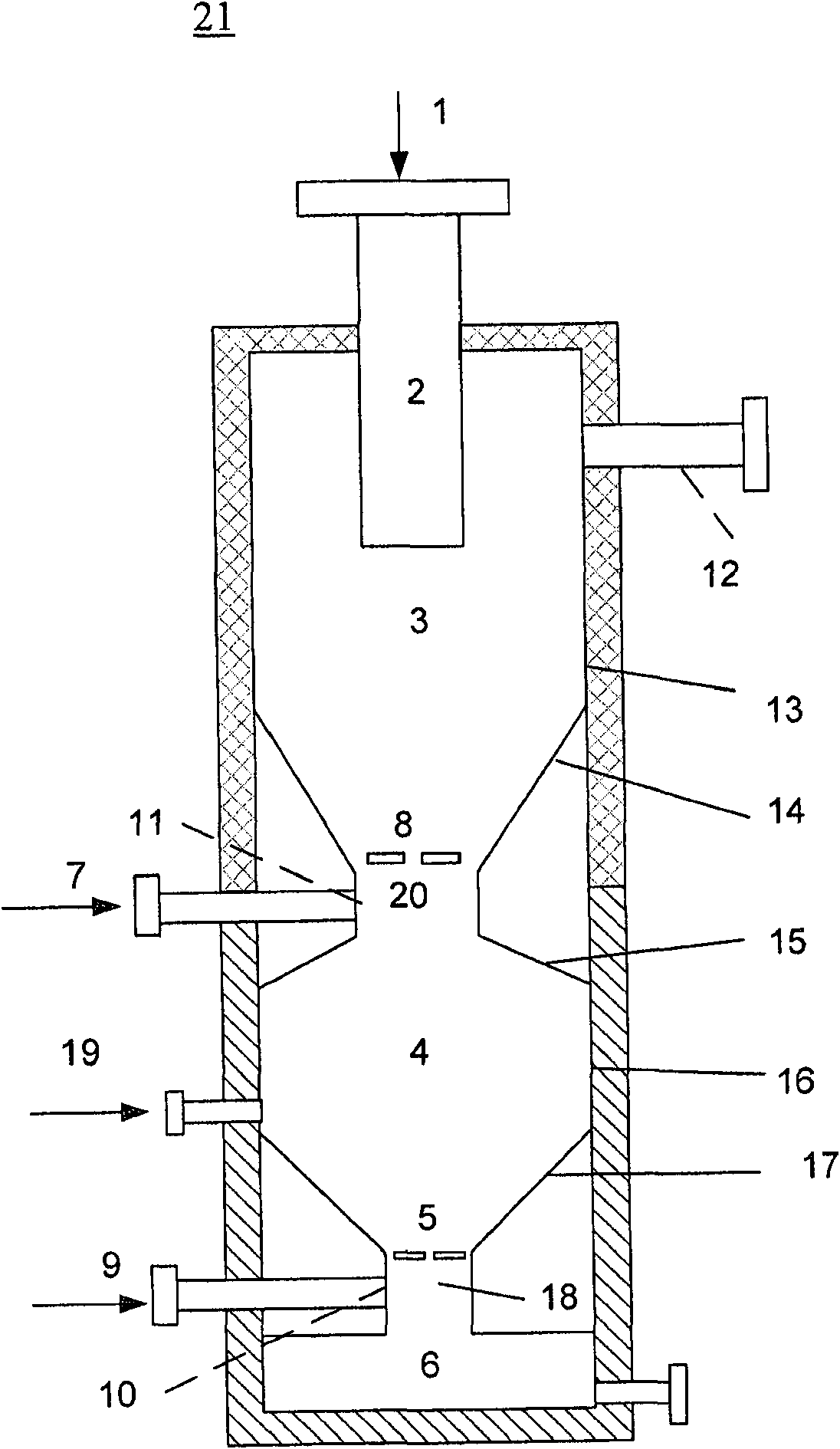

Down-hole steam injection string of thick-oil thermal production well

The invention discloses a down-hole steam injection string of a thick-oil thermal production well. The down-hole steam injection string is capable of protecting a casing in a steam injected well, improving the dryness of steam at the bottom of the well, and improving the steam injection heat efficiency and the steam injection effect. The steam injection string comprises a heat insulation pipe and a wall-hook packer; the heat insulation pipe, a backwashing valve and a sealed telescopic pipe are orderly connected to form an internal steam injection string; the wall-hook packer is orderly connected with a sealing sleeve and a switch assembly to form an external steam injection string; the wall-hook packer of the external steam injection string is down and sealed and hung on the inner wall of the casing; the sealed telescopic pipe of the internal steam injection string is inserted in the switch assembly of the external steam injection string and is capable of sliding in the sealing sleeve. The down-hole steam injection string of the thick-oil thermal production well can be reused after being put down once; the steam injection quality is obviously improved, the oil-steam ratio is increased, and an obvious oil increasing effect is achieved. The down-hole steam injection string of the thick-oil thermal production well is simple in structure and reliable in working; besides, the swept volume of the steam and multi-turn steam injection efficiency are improved, the energy source is thoroughly saved, the casing is effectively protected, and the defect of leakage at the wellhead casing head of the existing steam injection string is eliminated.

Owner:CHINA PETROLEUM & CHEM CORP +1

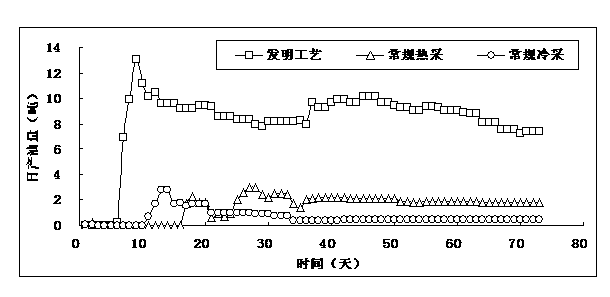

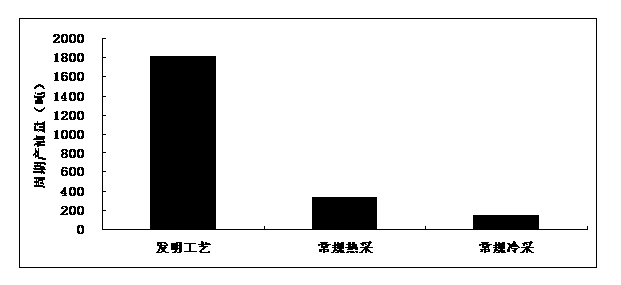

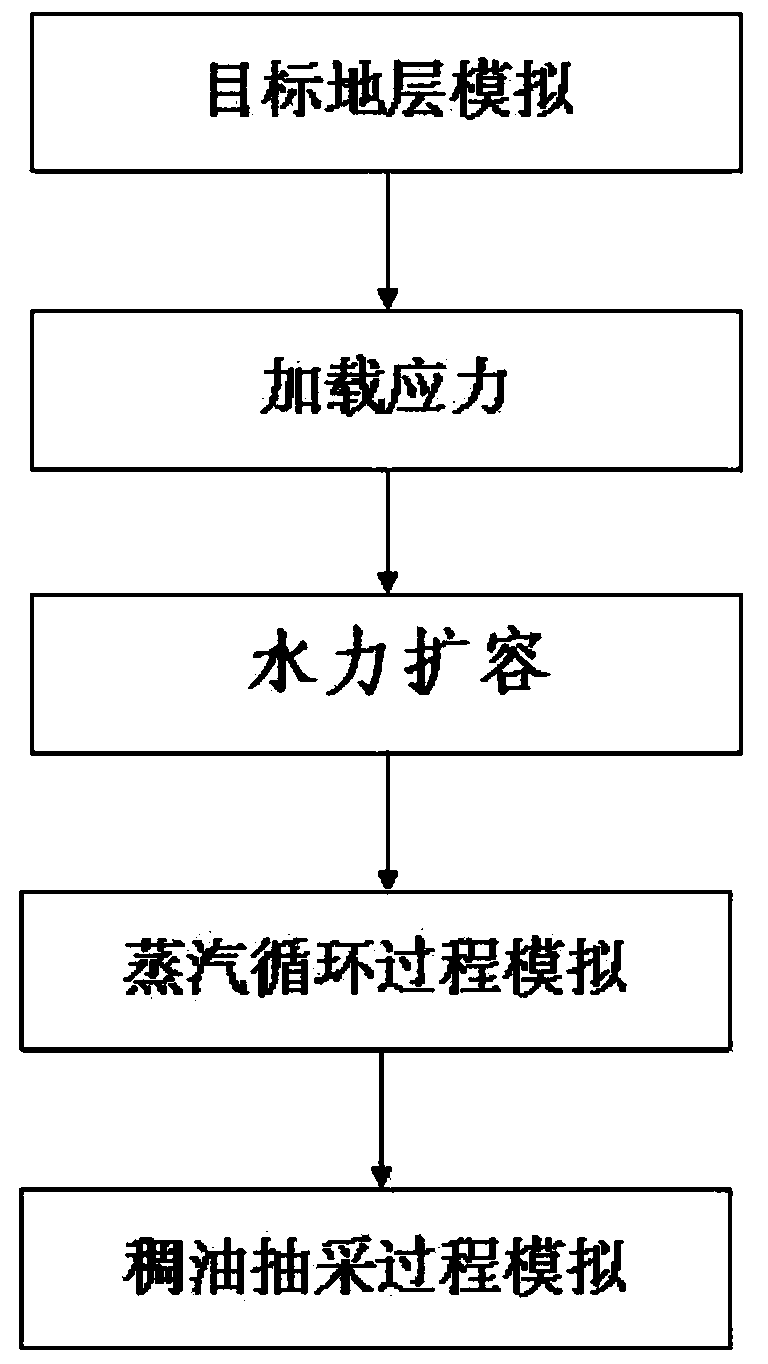

Large-scale three-dimensional simulation method for exploiting super-heavy oil reservoir through FUSE technology

InactiveCN110761781AShorten cycle timeOvercoming heterogeneityConstructionsFluid removalThree dimensional simulationDimensional simulation

The invention discloses a three-dimensional simulation method for exploiting a super-heavy oil reservoir through an FUSE technology. The method is implemented under the true triaxial loading conditionand comprises the following steps of target stratum simulation, stress loading, hydraulic expansion, steam circulating process simulation and heavy oil extracting and exploiting process simulation. Asimilar material and natural oil sand are adopted to simulate the stratum, stress loading is conducted to restore the true reservoir stratum stress environment, and oil sand reservoir stratum hydraulic expansion is conducted through a high-pressure water pump and a pre-buried stainless steel pipe; temperature data of different time and stratum positions are collected through a temperature sensor;the communication performance of double horizontal wells and the developing situation of the expansion area are detected; then, high-temperature steam injection circulation operation is conducted through a steam generator, temperature data are collected through a temperature sensor, and real-time monitoring of steam cavity expanding is achieved; and after the reservoir stratum temperature reachesthe transferring temperature, heavy oil exploiting is conducted through an external negative-pressure extracting exploiting system. The three-dimensional simulation method provides an effective testing measure and method for studying the mechanism of exploiting the super-heavy oil reservoir through the FUSE technology.

Owner:CHONGQING UNIV

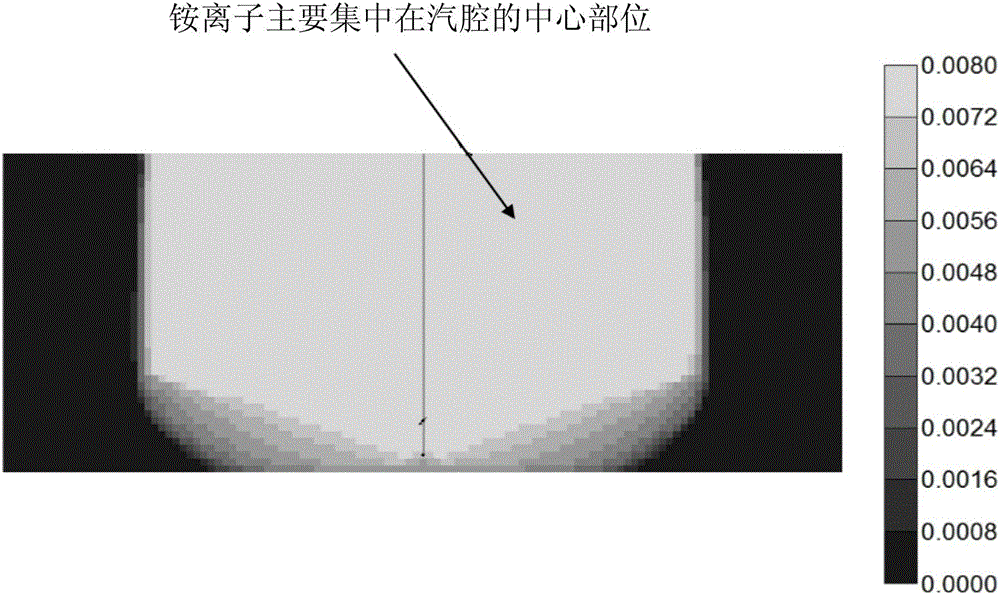

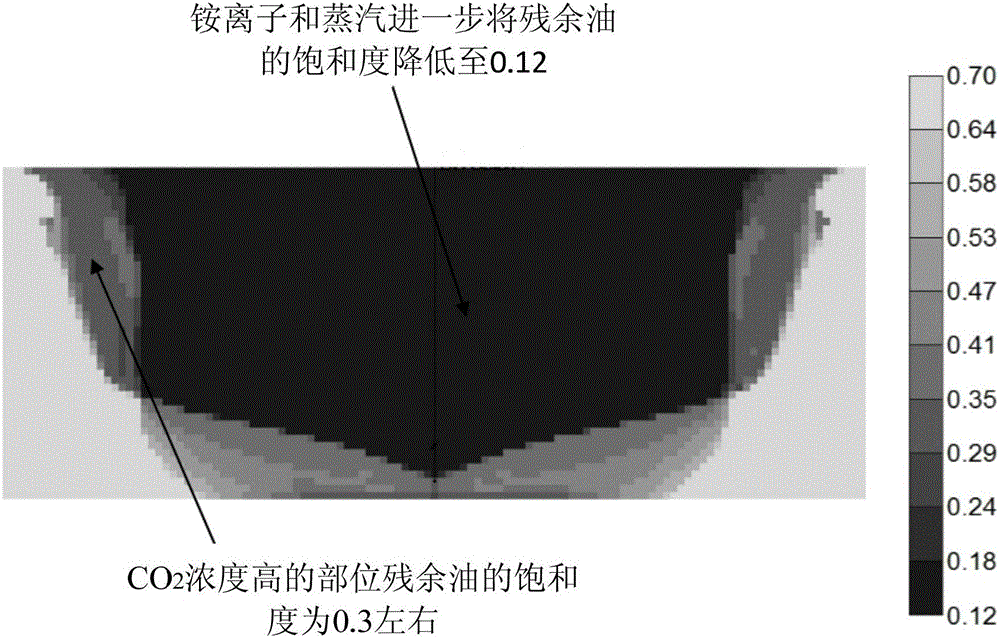

Method for improving development effect of steam assisted gravity drainage (SAFD) through ammonium carbonate

InactiveCN106640003AImprove oil displacement efficiencyImprove the development effectFluid removalAmmonium carbonateSteam-assisted gravity drainage

The invention provides a method for improving the development effect steam assisted gravity drainage (SAFD) through ammonium carbonate. The method comprises the steps that a, a double-horizontal-well pair or a vertical well-horizontal well set is arranged, wherein in the double-horizontal-well pair, a steam injection well is located above a production well, and in the vertical well-horizontal well set, a vertical well is a steam injection well, and a horizontal well is a production well; and b, in the continuous production stage of the production well, an ammonium carbonate solution is injected into the steam injection well in a continuous injection mode or a segmental injection mode till the instantaneous oil-steam ratio is decreased to 0.1-0.2, injection of the ammonium carbonate solution is stopped, and production is completed. By adoption of the technical scheme, the production degree of a deep heavy oil reservoir can be effectively improved, the heat energy utilization rate and development efficiency are improved, the recovery ratio of the oil reservoir is increased, and the development effect of the oil reservoir is improved.

Owner:PETROCHINA CO LTD

Method for preventing coking of visbreaking and heating furnace used for inferior heavy oil

ActiveCN103160308BImprove securityIncreased security againstThermal non-catalytic crackingResidual oilFuel oil

The invention relates to a method for preventing coking of a visbreaking and heating furnace used for inferior heavy oil. The inferior heavy oil is a residual oil fraction of crude oil obtained at a temperature of 420 DEG C; a horizontal tube box-type furnace is used as the visbreaking and heating furnace, and temperature of a furnace outlet is controlled to be 425 to 435 DEG C; steam is injected into a furnace tube of a transfer line between a convection chamber and a radiation chamber and into a furnace tube in the middle of the radiation chamber, and steam accounting for 0.5 to 4% of the weight of raw materials is injected; 70% of the steam is injected into the furnace tube of the transfer line between the convection chamber and the radiation chamber, and 30% of the steam is injected into the furnace tube in the middle of the radiation chamber; and a line rate of the visbreaking and heating furnace is 1.2 to 2.0 m / s. According to the method, through optimization of an arrangement pattern of furnace tubes of the visbreaking and heating furnace, furnace outlet temperature and the flowing line rate of a medium in the furnace tubes and increase of steam injection points, coking in the visbreaking and heating furnace is effectively avoided, and safe and long-period production of the furnace is realized.

Owner:PETROCHINA CO LTD +1

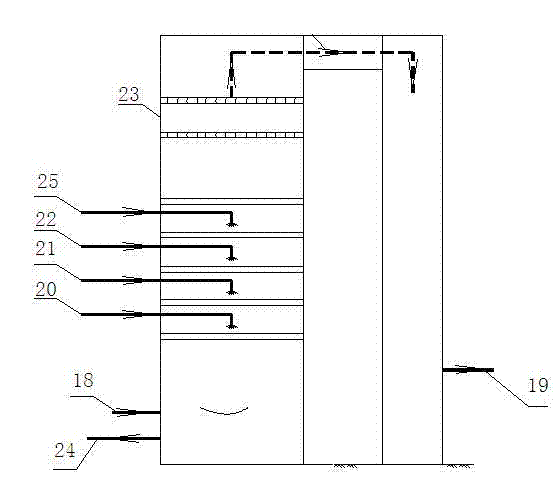

Low-temperature synchronous denitration and desulfurization equipment and process for flue gas

ActiveCN103691267AEfficient removalSave energyDispersed particle separationAir quality improvementThermodynamicsFlue gas

The invention belongs to the field of flue gas purification technology, and particularly relates to low-temperature synchronous denitration and desulfurization equipment and process for flue gas. The low-temperature synchronous denitration and desulfurization equipment for the flue gas comprises a residual heat boiler (1), a reaction tower (3), an absorption tower (4) and a water circulation system (5); the residual heat boiler (1) is arranged at the outlet end of the flue gas of the equipment, the reaction tower (3) is arranged at the flue gas outlet end of the residual heat boiler (1), the reaction tower (3) is arranged at the flue gas outlet end, the reaction tower (3) is provided with a flue gas inlet I (10) and a flue gas outlet I (11); the reaction tower (3) is internally provided with an ammonia steam injection system (5), an inlet of the ammonia steam injection system (5) is formed between the flue gas inlet I (10) and the flue gas outlet I (11); the absorption tower (4) is provided with a flue gas inlet II (18) and a flue gas outlet II (18). According to the low-temperature synchronous denitration and desulfurization equipment and process for the flue gas, the effective removal of NOX and SO2 in the flue gas can be realized, the standard flue gas is emitted, and products can be used as an inorganic fertilizer, and thus the zero emission is realized.

Owner:AVIC (HAINAN) SPECIAL GLASS MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com