Patents

Literature

66results about How to "Solve viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

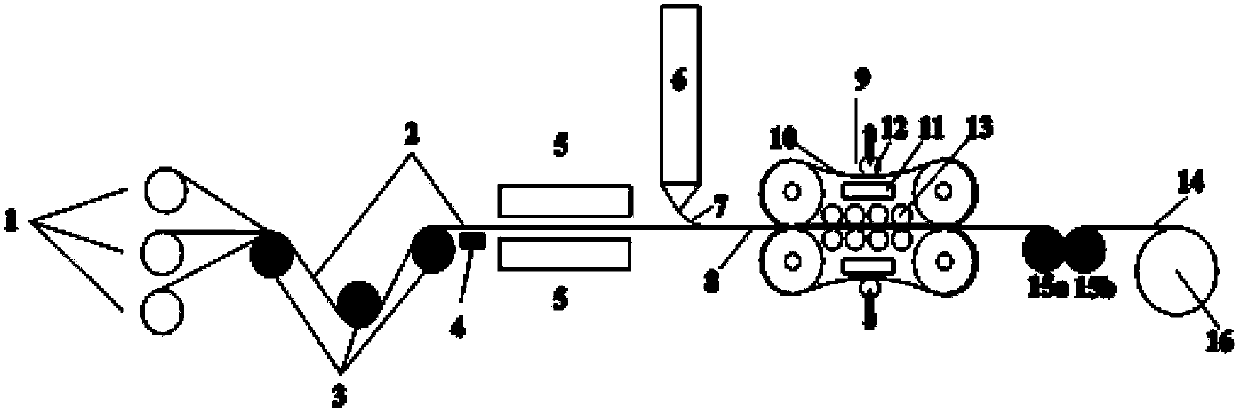

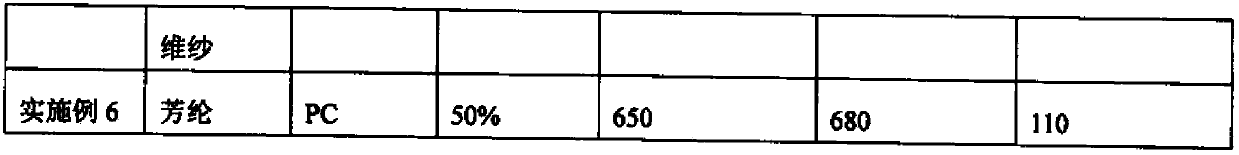

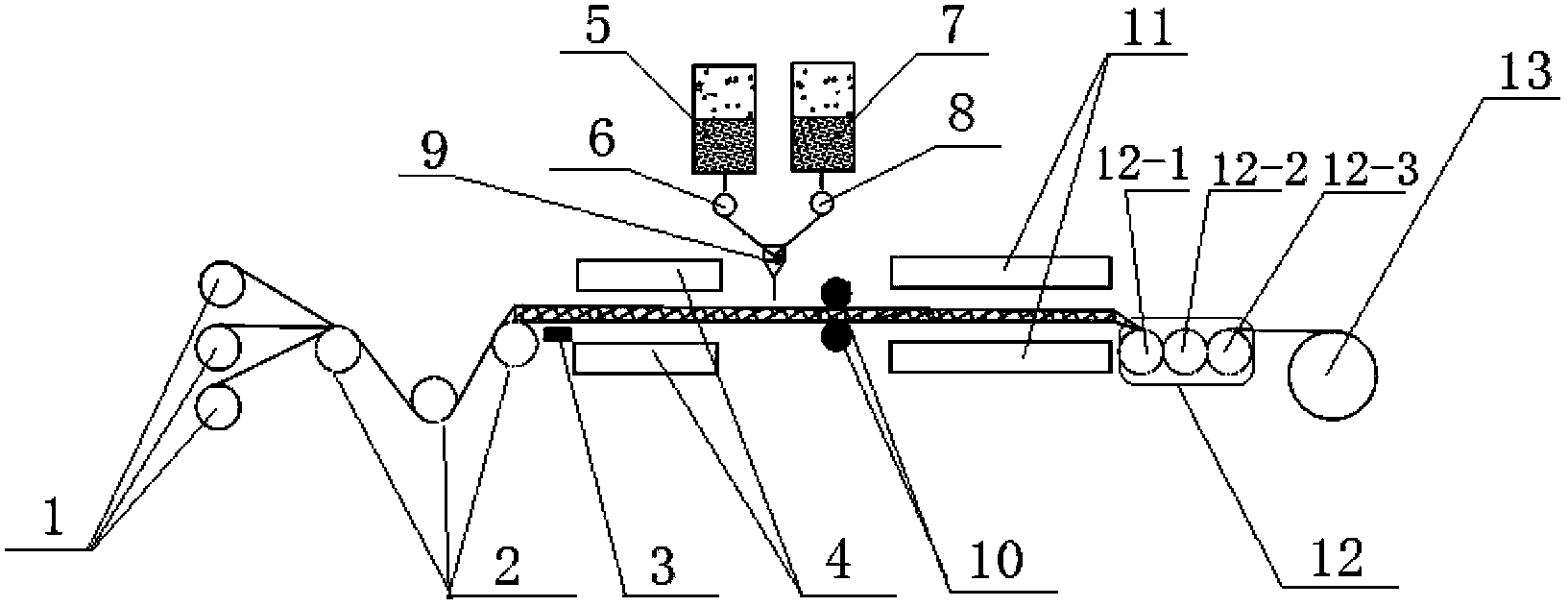

Continuous fiber fabric reinforced thermoplastic resin composite material and production method thereof

The invention relates to a continuous fiber fabric reinforced thermoplastic resin composite material and a production method thereof. The composite material is produced from continuous fiber through thermoplastic resin melting and impregnating, cooling and molding, with the thickness of 0.20mm-0.35mm, wherein the content of the continuous fiber reinforced fabric is 40wt%-65wt%, the continuous fiber fabric is uniformly spread out and subjected to tension adjustment and static electricity elimination, then enters thermoplastic resin for melting and impregnating, and finally is cooled in a cooling unit and wound and formed to obtain the continuous fiber fabric reinforced thermoplastic resin composite material. Compared with the prior art, the continuous fiber fabric reinforced thermoplastic resin composite material and the production method solve a series of problems caused by too high resin viscosity in the existing thermoplastic resin and fiber reinforcing process, such as complex equipment process, too high equipment cost, not environment-friendly technological operation process, dry gauze easily caused by poor impregnation and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

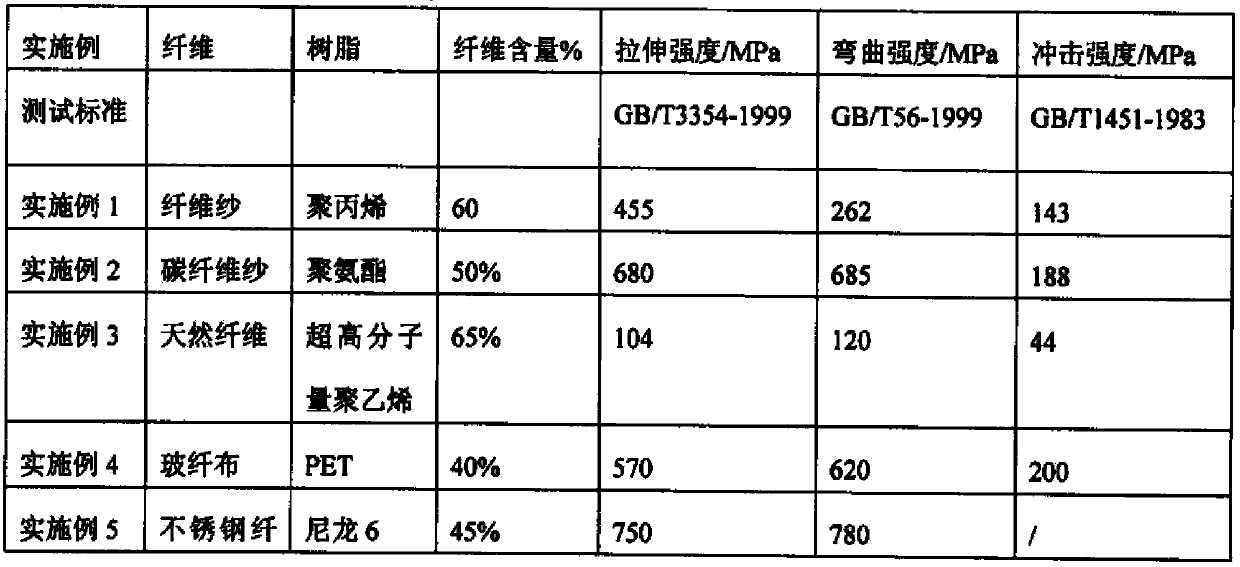

Ocean deepwater water-based constant-rheology drilling fluid

The invention relates to an ocean deepwater water-based constant-rheology drilling fluid and belongs to the technical field of petroleum drilling engineering chemical agents. The drilling fluid is characterized by comprising the following components in percentage by weight: 2-4% of clay, 3-8% of flow control agent, 2-5% of inhibitor, 1-3% of fluid loss additive, 2-6% of lubricant, 0.1-0.6% of pH regulator, 0-40% of weighting agent and the balance of water. The drilling fluid provided by the invention can be used for solving the problems that the viscosity of the conventional drilling fluid increases at low temperature and decreases at high temperature and reducing the sensitivity of viscosity change along with the temperature of the whole drilling fluid system, thus realizing a constant-rheology state; and the drilling fluid has strong inhibition and lubrication properties and is an effective deepwater low-temperature water-based constant-rheology drilling fluid system.

Owner:湖北江汉石油技术有限公司

High-performance conductive silver paste and preparation method thereof

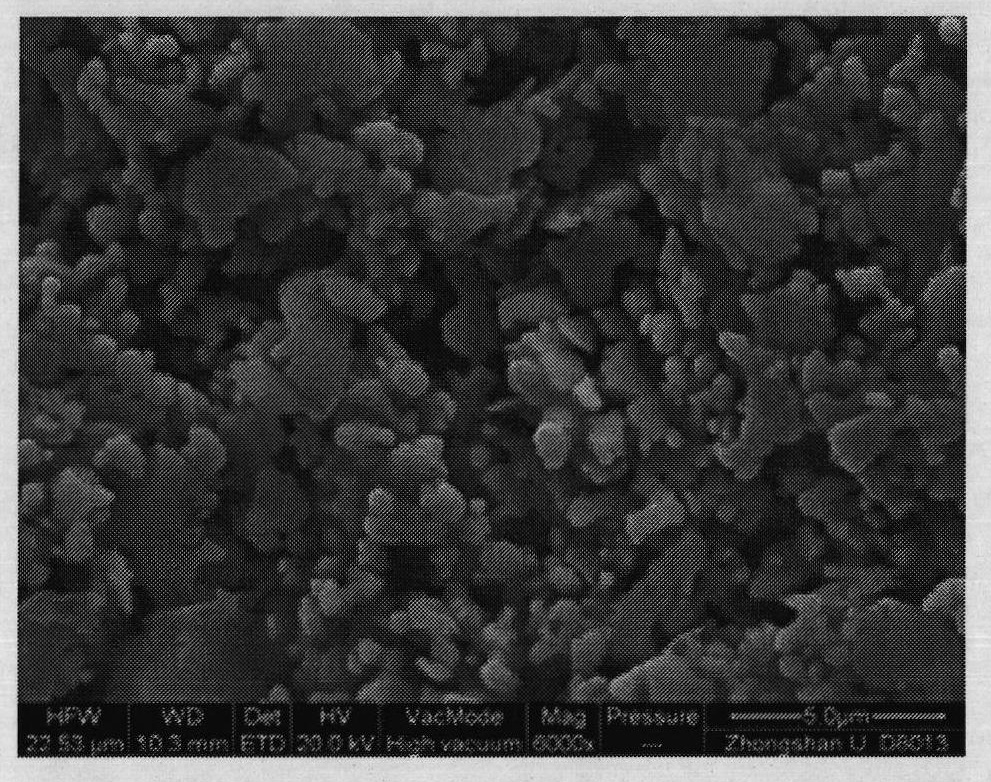

ActiveCN101805575AEvenly dispersedUniform size distributionNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

The invention relates to a high-performance conductive silver paste, which is characterized by comprising the following raw materials in percentage by weight: 65-80% of micron-sized metal silver powder, 10-20% of epoxy resin, 1.4-3.5% of curing agent, 6-9% of solvent, 0.5-1.2% of accelerator, 0.05-0.1% of flexibilizer and 1-2% of additive. The invention also discloses a preparation method of the high-performance conductive silver paste. The conductive silver paste of the invention has high conductivity, very high thermal conductivity, high working temperature, strong viscosity and very high shear strength, and the performance indexes are apparently higher than the working performance of the conductive silver paste in the prior art, thereby solving the technical problems of poor shear performance, low working temperature, poorer thermal conductivity, long curing time, high curing temperature, poor viscosity, easy pollution of environment and the like in the field of the conductive silver paste in the prior art.

Owner:连云港市昭华光电科技有限公司

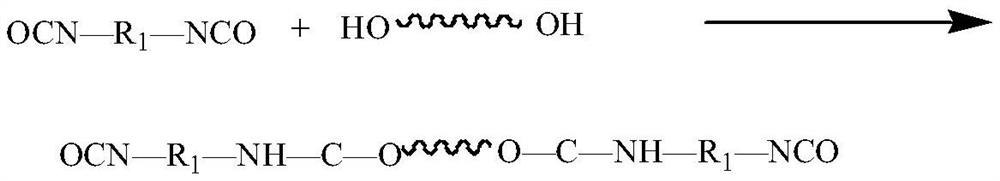

Continuous fiber fabric reinforced thermoplastic polyurethane composite material and preparation method thereof

InactiveCN103570961AMake up for the shortcomings of high melt viscosity and poor melt fluiditySolve viscosityPorosityPolyurethane elastomer

The invention relates to a continuous fiber fabric reinforced thermoplastic polyurethane composite material and a preparation method thereof. The composite material is prepared by heating, curing and cooling a continuous fiber reinforced fabric which is steeped in thermoplastic polyurethane elastomer reaction liquid, wherein the continuous fiber reinforced fabric is selected from one or more of organic fibers, metal fibers or inorganic fibers, and the thermoplastic polyurethane elastomer reaction liquid is formed by polymerizing a polyether component and an isocyanate component. Compared with the prior art, the continuous fiber fabric reinforced thermoplastic polyurethane composite material prepared by using the continuous fiber reinforced fabric as a reinforcing material and a thermoplastic polyurethane elastomer as a reinforced matrix has the advantages of good steeping, low porosity, adjustable thickness, high glass fiber content and the like. The preparation method has the advantages that the production line is simple, equipment can realize the high-efficient continuous production, no environmental pollution is caused in the production process and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

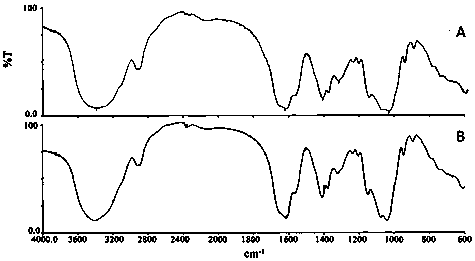

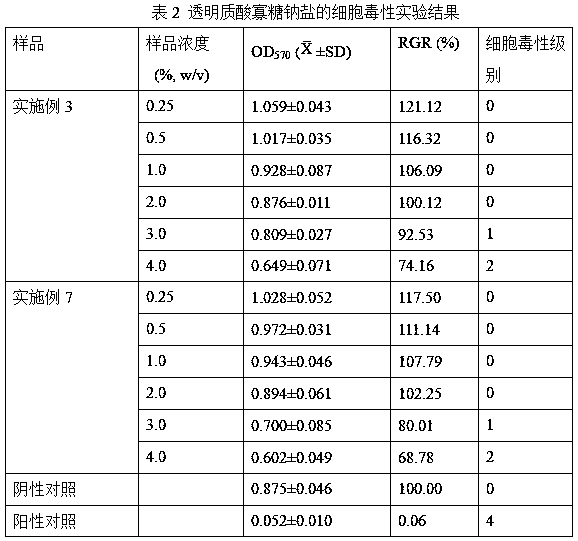

Method for preparing ultra-low molecular weight hyaluronic acid oligosaccharides and salt thereof through combination of solid-liquid biphasic enzymolysis and ultrafiltration

ActiveCN108220364AReduce dosageIncrease enzyme activityFermentationHigh concentrationUltrafiltration

The invention discloses a method for preparing ultra-low molecular weight hyaluronic acid oligosaccharides and a salt thereof through combination of solid-liquid biphasic enzymolysis and ultrafiltration. The method comprises the following steps: degrading hyaluronic acid and a salt thereof by utilizing hyaluronidase produced by bacilli; preparing high-concentration hyaluronic acid enzymatic hydrolysate by adopting the method of combining a solid-liquid biphasic enzymolysis system and an ultrafiltration system, and then performing inactivating, activated carbon adsorption and impurity removal,filtering and spray-drying to obtain the ultra-low molecular weight hyaluronic acid oligosaccharides and the salt thereof with the molecular weight of less than or equal to 3 kDa. The product preparedby the method is high in stability, ultra-low in molecular weight, good in inflammation resistance and percutaneous absorptivity, high in purity, strong in oxidation resistance, does not have cytotoxicity, has the advantages of repairing skin cell damage and the like, and can be widely applied to the fields of cosmetics, food and medicines. According to the method, the process flow is easy to operate; conditions are mild; various alcohols are not used; the energy consumption is relatively low; the method does not have damage to a product structure, does not have environmental pollution, and is suitable for large-scale industrial production.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD +1

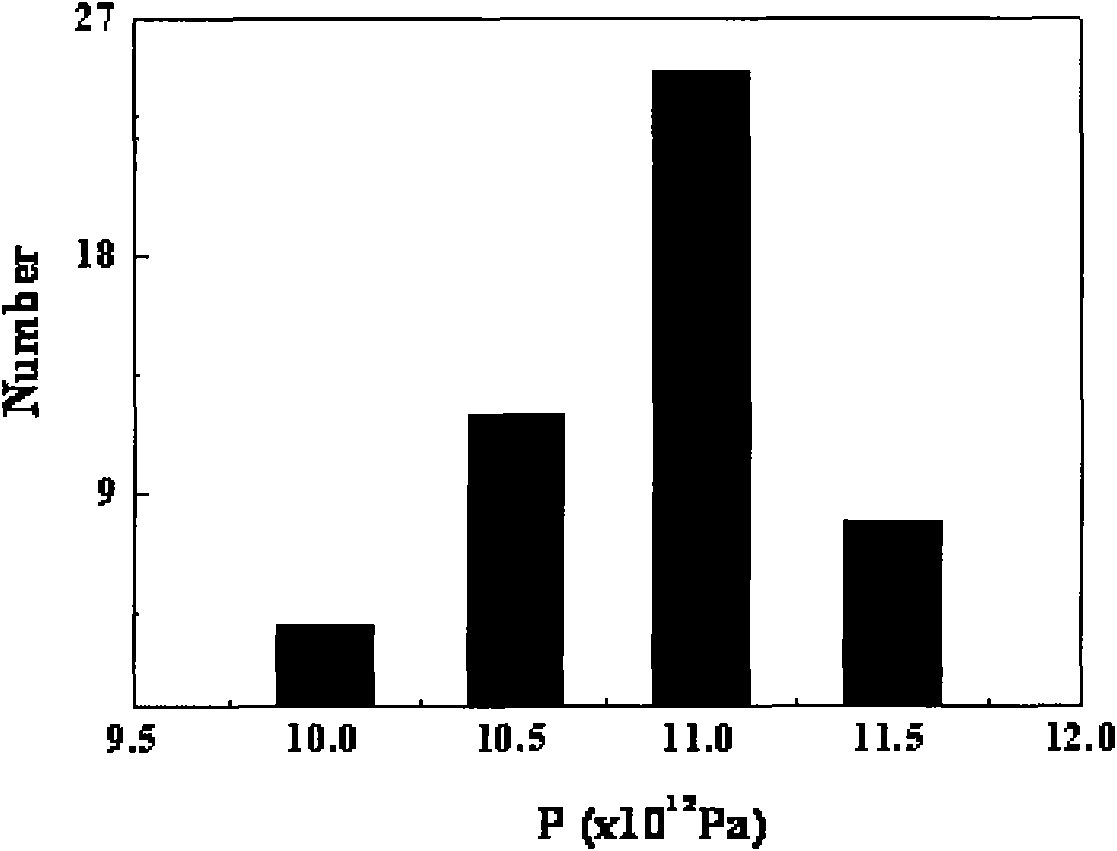

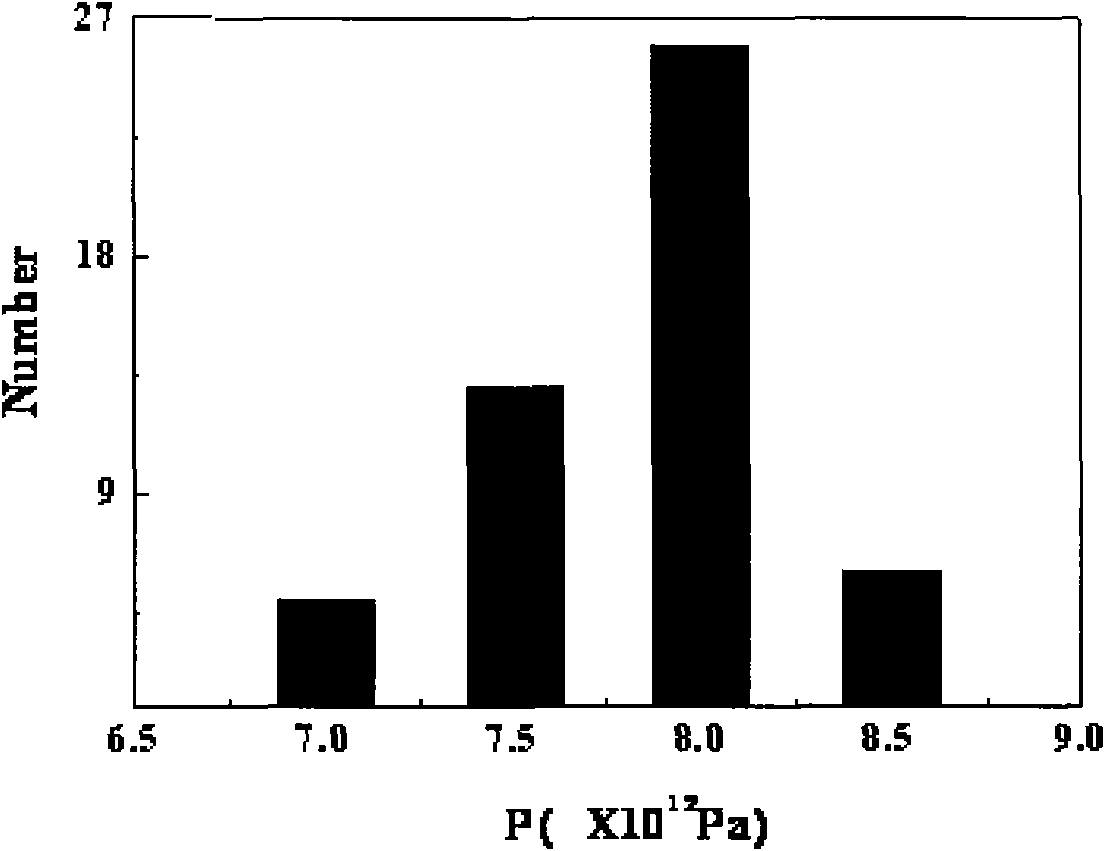

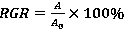

Method and apparatus for preparing superfine powder by super high pressure supercritical fluid micro jetting technology

The present invention belongs to the field of superfine powder preparing technology and proposes one new kind of superfine powder preparing method and apparatus. Super high pressure technology, supercritical fluid technology and micro jet crushing technology are combined and used in preparing submicron level superfine powder. The new method needs no grinding medium and solvent, and has high energy utilization and easy separation between the product and the work medium.

Owner:EAST CHINA UNIV OF SCI & TECH

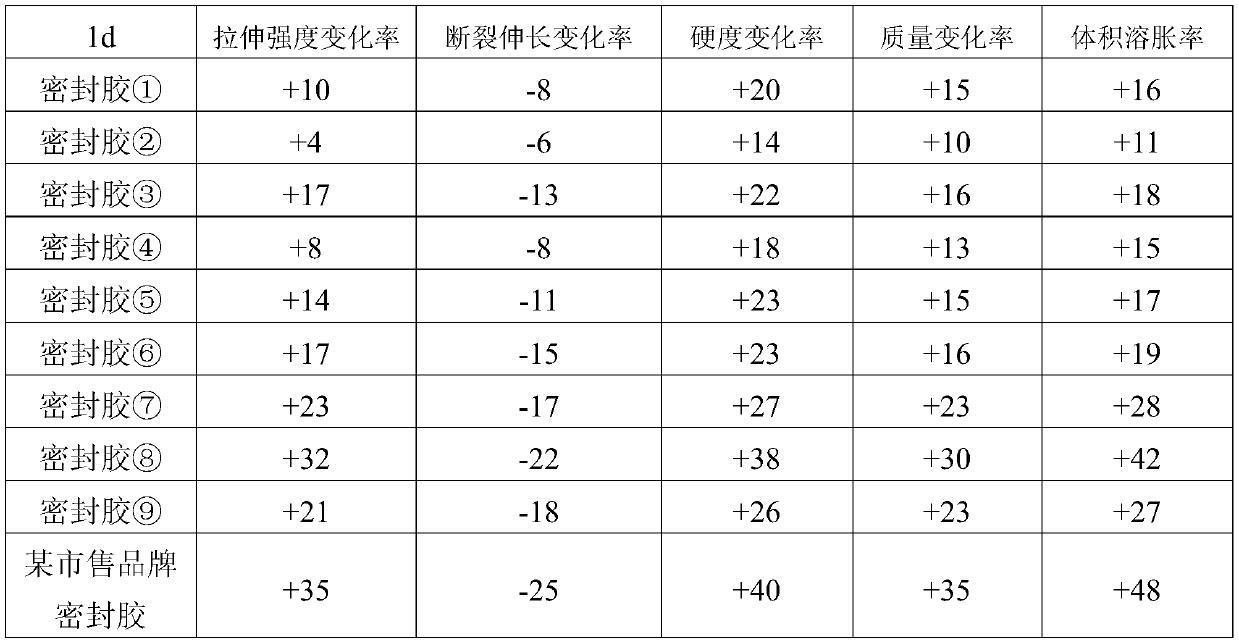

Solvent-resistant epoxy modified polyurethane sealant and preparation method thereof

ActiveCN110172323AGood chemical resistanceGood mechanicalNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxySolvent

The invention relates to the technical field of sealants, in particular to a solvent-resistant epoxy modified polyurethane sealant and a preparation method thereof. The sealant is prepared from, by weight, 20-40% of an epoxy modified polyurethane prepolymer A, 10-30% of a low-viscosity polyurethane prepolymer B, 29.4-59.4% of an inorganic filler, 0.01-30% of a thixotropic agent, 0.01-2% of a curing promoter, 0.01-2% of a water removal stabilizer and 0.01-2% of an adhesion promoter. The epoxy modified polyurethane sealant has excellent chemical corrosion resistance and mechanical properties, through a chemical corrosion test in the industry standard of a membrane-type gas meter, after liquid immersion, the mechanical properties, mass change rate and volume change rate of the sealant can allbe kept at a very small change rate, the adhesive sealing effect is good, and the sealant can keep the good adhesive sealing function during long-term use in the gas meter.

Owner:广东盛业化学科技有限公司

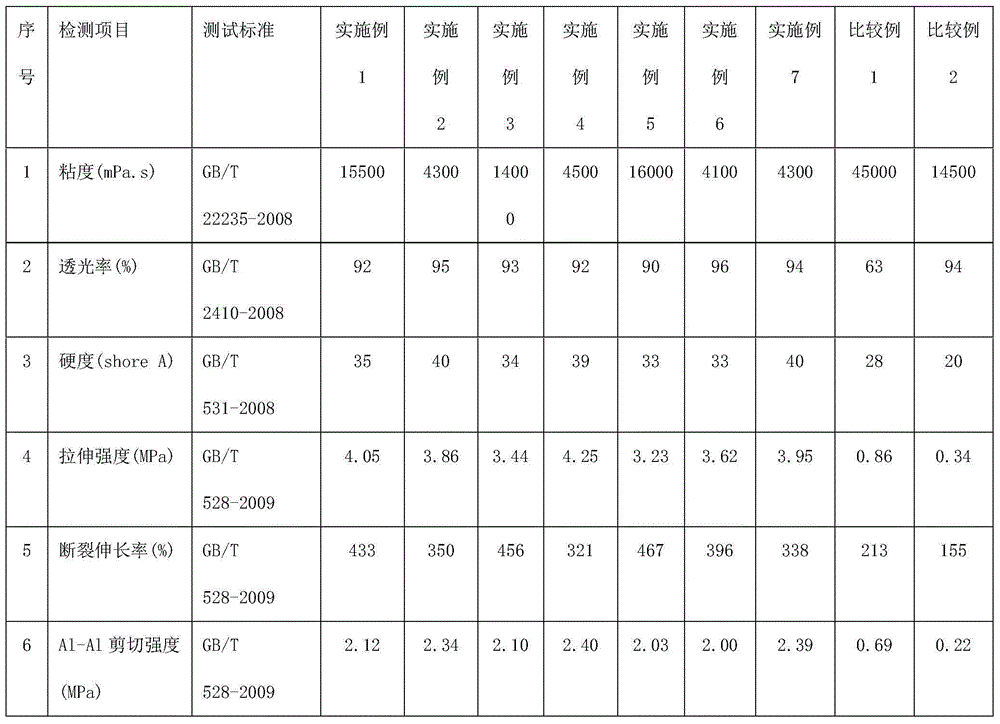

Low-viscosity and high-strength transparent organic silicon compound as well as preparation method and application thereof

InactiveCN104693805AGood compatibilityHigh transparencyNon-macromolecular adhesive additivesOther chemical processesEnd-groupPolydimethyl siloxane

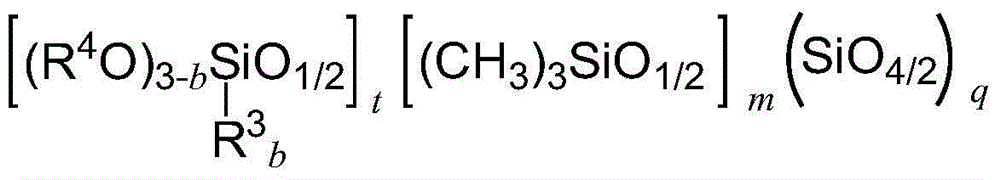

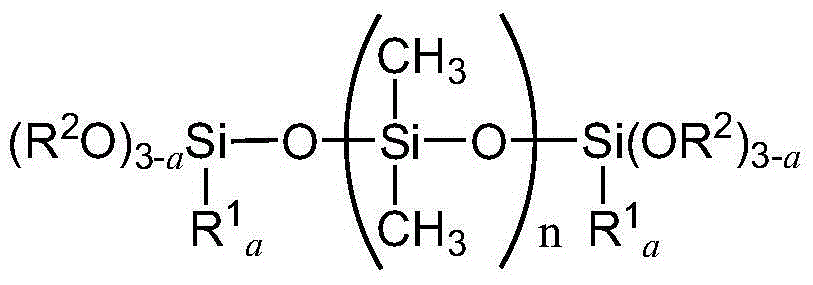

The invention discloses a low-viscosity and high-strength transparent organic silicon compound. The low-viscosity and high-strength transparent organic silicon compound comprises the following raw materials in parts by weight: 60-90 parts of end alkoxy polydimethyl siloxane, 10-40 parts of end methyl polydimethyl siloxane, and 20-80 parts of end alkoxy methyl MQ silicon resin, wherein the end alkoxy polydimethyl siloxane is a direct-chain type polymer with two or three hydrolysable groups in the end group; the structure formula of the end alkoxy methyl MQ silicon resin is as shown in the specification, wherein b is 0 or 1, R3 and R4 are monovalent hydrocarbyl with 1-4 carbon atoms; t, m and p are positive integers, (t+m) / q is 0.7-1.50, t / m is 0.04-0.20. The organic silicon compound provided by the invention has the advantages of low viscosity, easy flow, high strength and good transparency, and is very suitable for the shallow encapsulation of the electronic elements such as a circuit board and an intelligent water meter, the adhesion of the LED illuminator lampshade and the lamp holder, the bonding and sealing of the small household appliances such as a glass electric kettle body and a chassis.

Owner:GUANGZHOU HUITIAN FINE CHEM

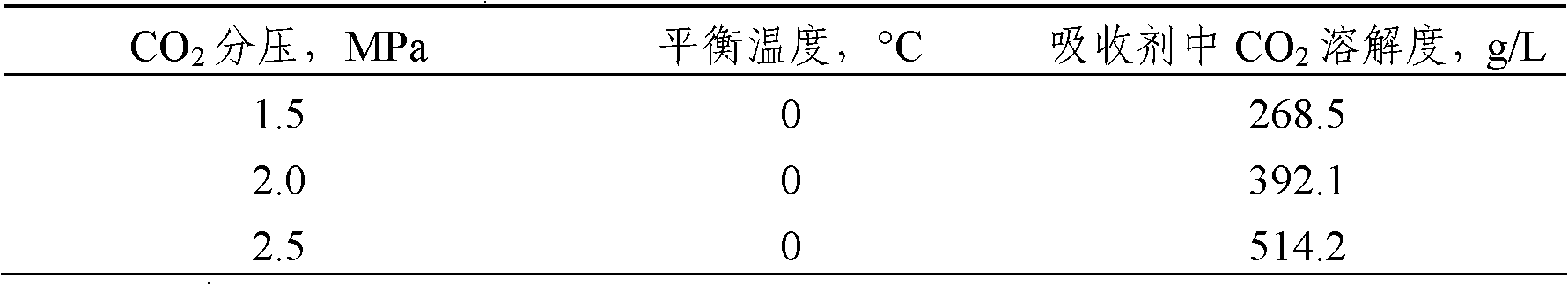

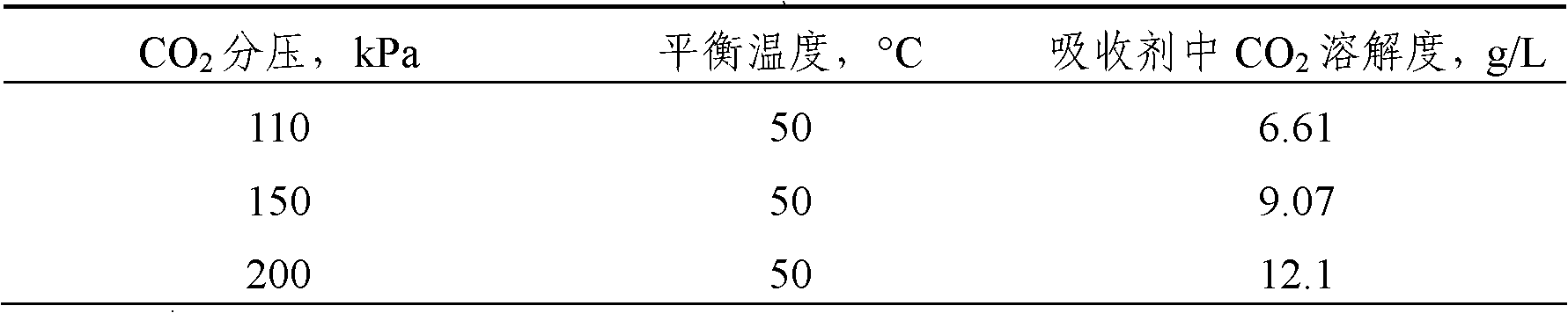

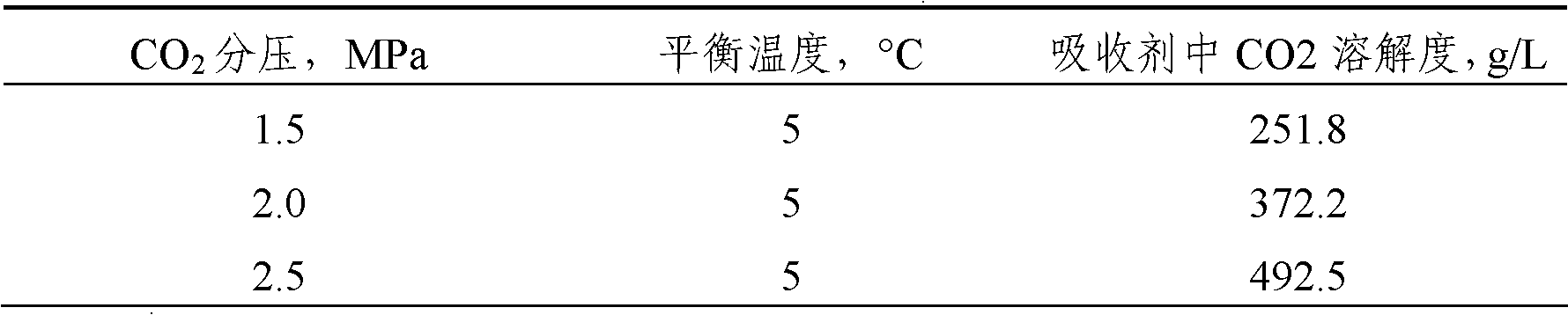

Absorbent for collecting and separating CO2 and use thereof

InactiveCN102151458ASolve viscositySolve the problem of solidificationProductsCarbon compoundsOrganic solventCo2 absorption

The invention provides an absorbent for collecting and separating CO2, which contains 5 to 95 weight percent of dimethyl carbonate and 95 to 5 weight percent of organic solvent, wherein the organic solvent is one or more of hydrocarbon, ether or ester solvents. The invention has the advantages that: the absorbent is prepared by mixing the dimethyl carbonate and the organic solvent, so the freezing point of the dimethyl carbonate can be lowered, the CO2 absorption effect of the dimethyl carbonate is not changed, but even is increased; the problem that sharp viscosity increase or freezing during the use of the dimethyl carbonate at a lower temperature influence the use effect of the dimethyl carbonate is solved; and thus, the process is simplified effectively and cost is reduced.

Owner:TSINGHUA UNIV

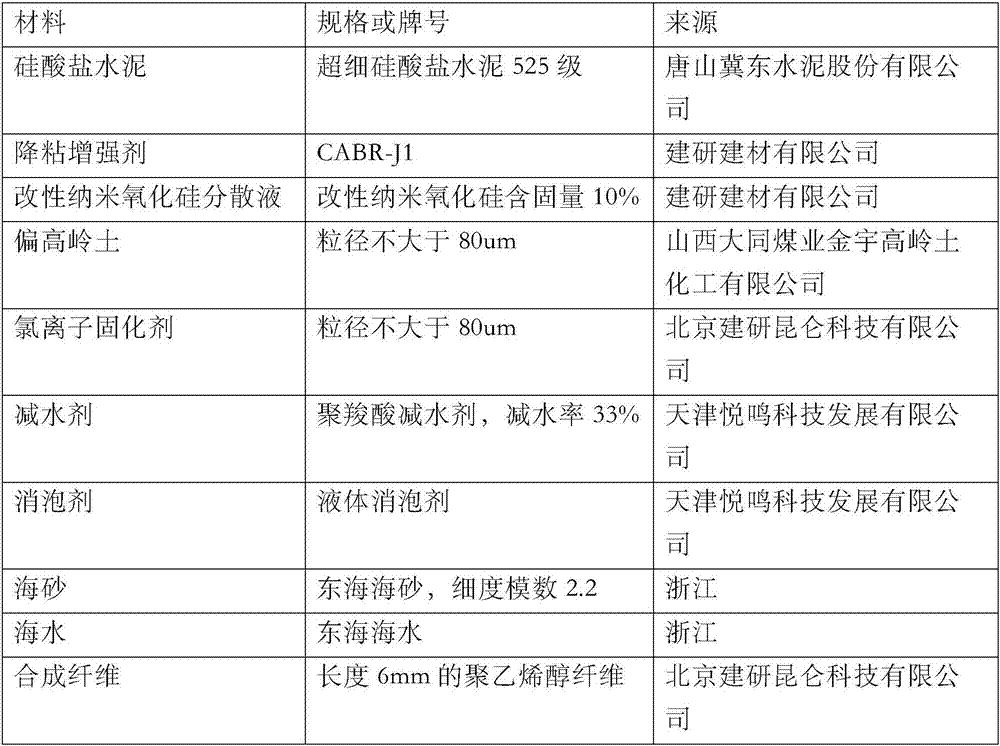

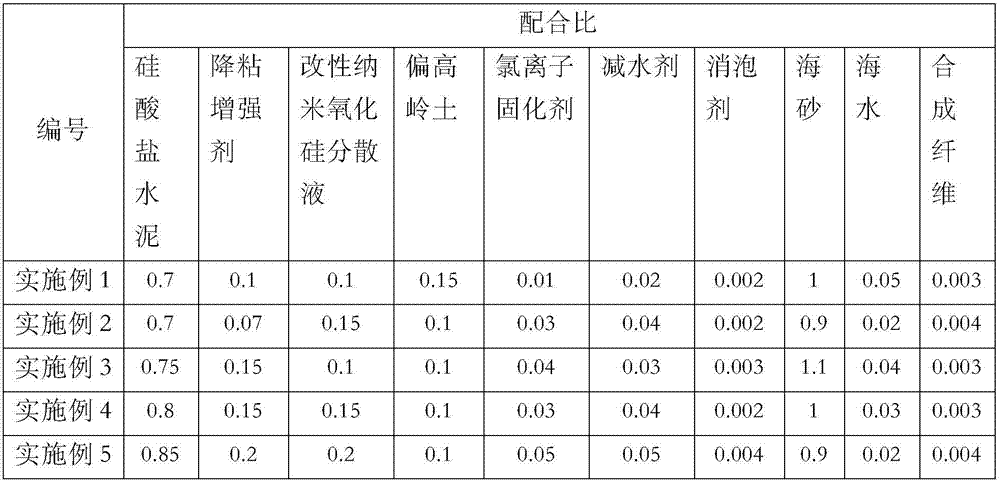

Ultrahigh performance sea sand concrete and preparation method thereof

The invention belongs to the technical field of a novel construction material and specifically relates to an ultrahigh performance sea sand concrete and a preparation method thereof. The ultrahigh performance sea sand concrete is prepared from cement, viscosity-reducing reinforcing agent, modified nanometer silicon dioxide dispersing solution, metakaolin, chloride ion curing agent, water reducingagent, de-foaming agent, sea sand, seawater and synthetic fiber at certain ratio. According to the invention, the viscosity-reducing reinforcing agent is adopted, so that the ultrahigh performance concrete still has better working property under the condition of lower water binder ratio; the modified nanometer silicon dioxide dispersing solution and the chloride ion curing agent are respectively adopted, so that the strength and durability of the ultrahigh performance concrete under normal temperature curing condition are greatly higher than those of the ultrahigh performance concrete at traditional silicon fume ratio; according to the invention, the sea sand and the seawater are used as some raw materials and are used for preparing the ultrahigh performance concrete, higher mechanical property and durability can be uniquely achieved in the manner of normal temperature moisturizing curing, the technical method is novel, the cost is lowered and the engineering can be practically popularized.

Owner:CHINA ACAD OF BUILDING RES +1

Polyester resin capable of rapidly cured at low temperature and preparation method thereof

InactiveCN109503820AIncrease the degree of branchingHigh activityPowdery paintsPolyester coatingsPolyolLow temperature curing

The invention provides polyester resin capable of rapidly cured at low temperature and a preparation method thereof. The polyester resin is prepared from the following raw materials in parts by weight: 6.5-9.5 parts of polyalcohol, 13.5-14.5 parts of acid, 0.015-0.025 part of an esterification catalyst and 0.2-0.3 part of a curing accelerant. Compared with the prior art, according to the polyesterresin capable of rapidly cured at low temperature, high-activity monomers are combined, so that the finally prepared polyester resin is high in activity; softening point of the polyester resin is slightly reduced; a powder paint prepared by the polyester resin can be fully cured in short time under the low-temperature condition; the energy consumption is greatly reduced; in addition, good low-temperature leveling property and storage stability of the powder paint can also be ensured; meanwhile, the powder paint has excellent curing property and film formation property.

Owner:ANHUI HENGMING MOLD TECH

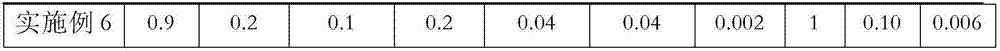

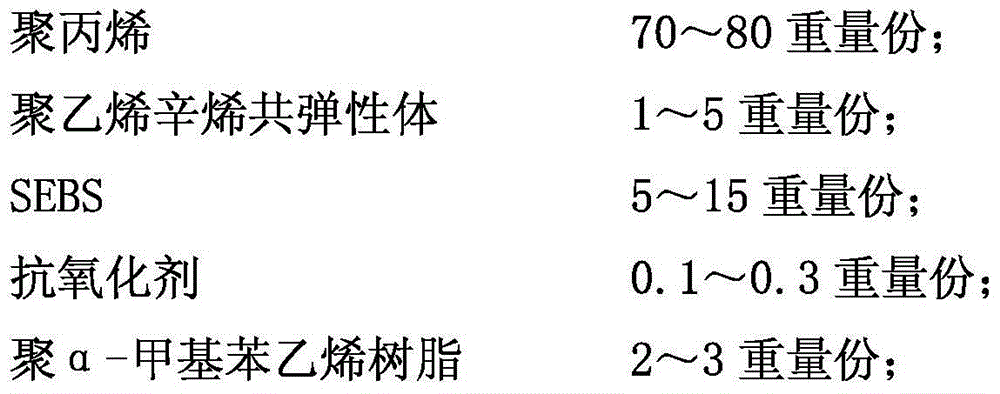

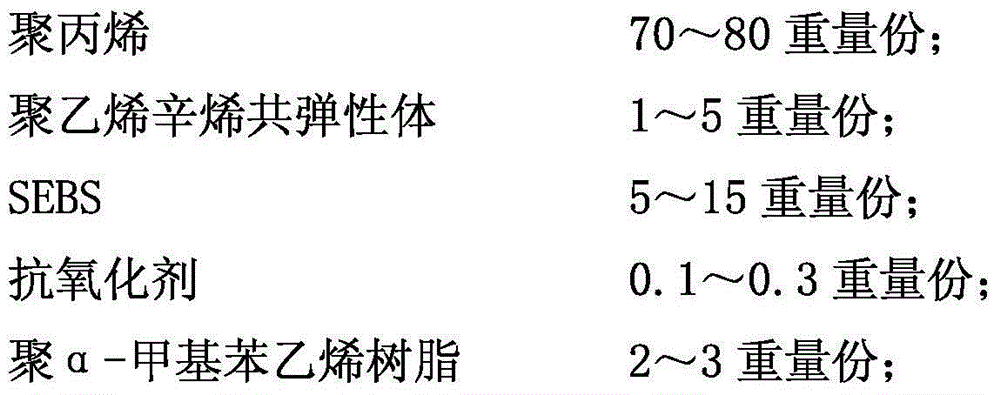

Special PP protecting membrane formula for ITO

The invention discloses a special PP protecting membrane formula for ITO. The special PP protecting membrane formula comprises the following raw materials in parts by weight: 70-80 parts of polypropylene, 1-5 parts of a polyethylene octylene co-elastomer, 5-15 parts of SEBS, 0.1-0.3 part of an antioxidant and 2-3 parts of poly alpha-methyl styrene resin, wherein the content of octylene in the polyethylene octylene co-elastomer is 37-41wt%. As SEBS is adopted as a self-adhering layer, the temperature resistance of polypropylene is improved and the viscosity of SEBS is adjusted by adding POE, and the softening point of SEBS is increased and separation of oil components in SEBS can be controlled by adding the poly alpha-methyl styrene resin, the problems that a coated protecting membrane has residual adhesives, is low in viscosity and poor in temperature resistance, and the like can be solved; as PP is taken as a substrate in the formula, the temperature resistance of the protecting membrane can be effectively improved.

Owner:昆山金华安电子科技有限公司

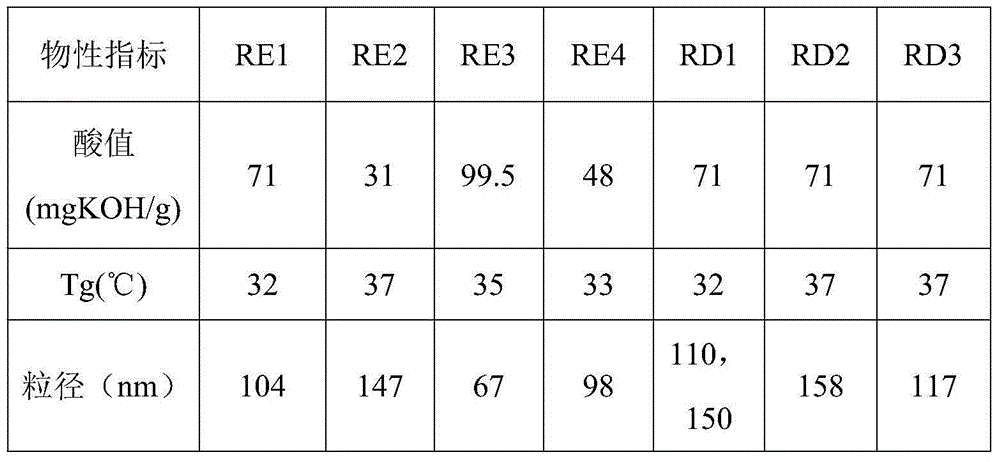

Resin for water-based ink as well as preparation method and application of resin

The invention provides resin for water-based ink as well as a preparation method and an application of the resin. The water-based ink is prepared from the following components in percentage by weight: 0.5-30% of pigment colorant, 0.5-10% of the resin for the water-based ink, 5-20% of wetting agent, 0.5-20% of impregnating agent, 5-15% of dissolution stabilizer and the balance of deionized water. The resin for the water-based ink is a polymer microparticle emulsion which is prepared from free radical polymerization monomers in a semi-continuous emulsion copolymerization manner by taking an alkali-soluble high-molecular polymer as an emulsifier and in the presence of a water-soluble peroxide initiator; the particle size of the polymer microparticle emulsion is 50-180nm, the acid value of the emulsion is 30-100mgKOH / g and the glass-transition temperature Tg of the emulsion is from -50 to 50 DEG C. The change of the viscosity of the resin for the water-based ink along with temperatures is low, and therefore, a nozzle cannot be blocked; the water-based ink is suitable for printing on glossy paper and common painting paper; besides, the printed materials are clear in image, good in glossiness, and excellent storage stability and scratch resistance.

Owner:CHINA BANKNOTE INK +1

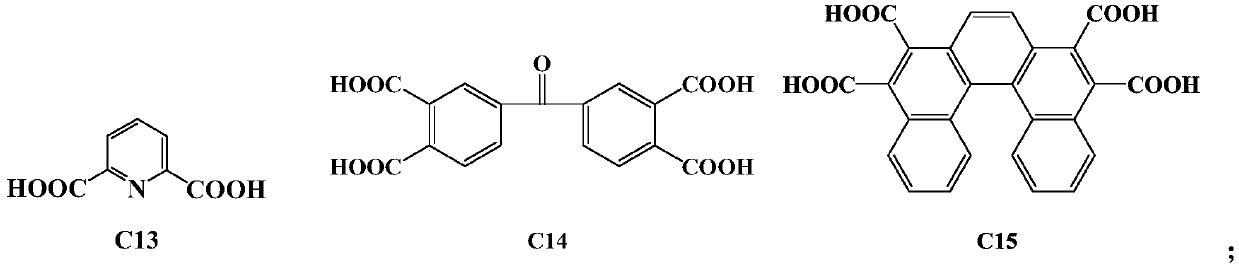

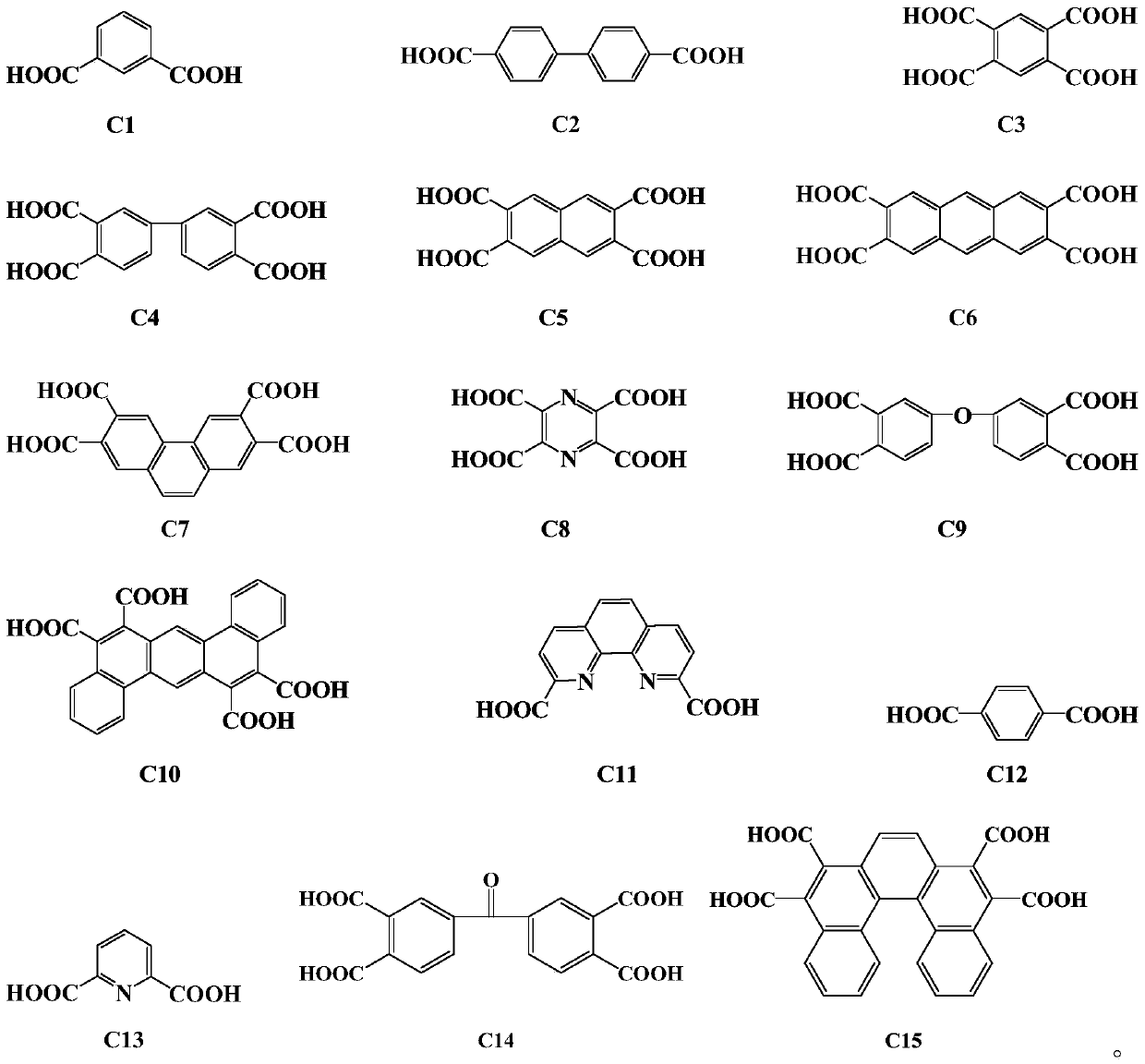

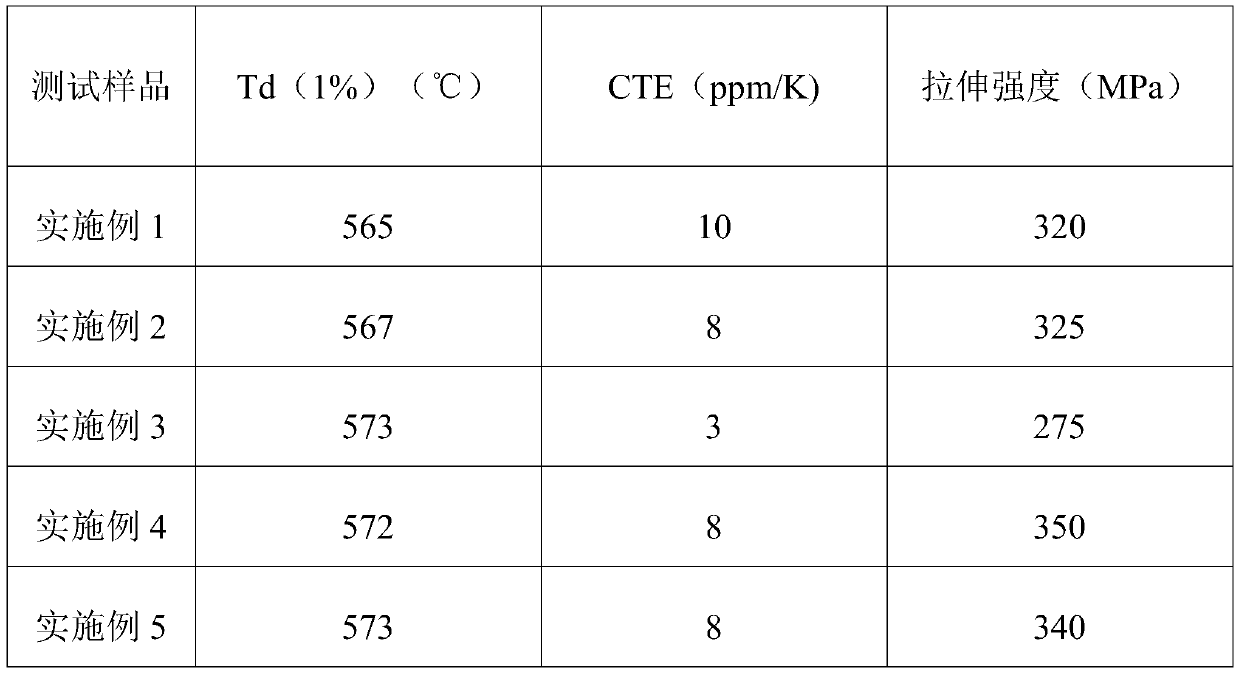

Polyamic acid solution, and polyimide film and applications thereof

ActiveCN111087619ARestricted movementImprove heat resistancePhotovoltaic energy generationThermal dilatationImide

The invention provides a polyamic acid solution, and a polyimide film and applications thereof, wherein the polyamide acid solution is prepared from the following raw materials: an aromatic tetracarboxylic dianhydride monomer, an aromatic diamine monomer, a polycarboxylic acid compound and a solvent. The polyamide acid solution prepared by the method has the characteristics of high solid content and low viscosity, has excellent casting film-forming performance, and is particularly suitable for a solution printing process. The polyimide film formed by the polyamic acid solution prepared by themethod has high heat resistance, low thermal expansion coefficient and good mechanical properties, and is suitable for being used as a flexible substrate in a display panel.

Owner:BEIJING SINEVA TECH +2

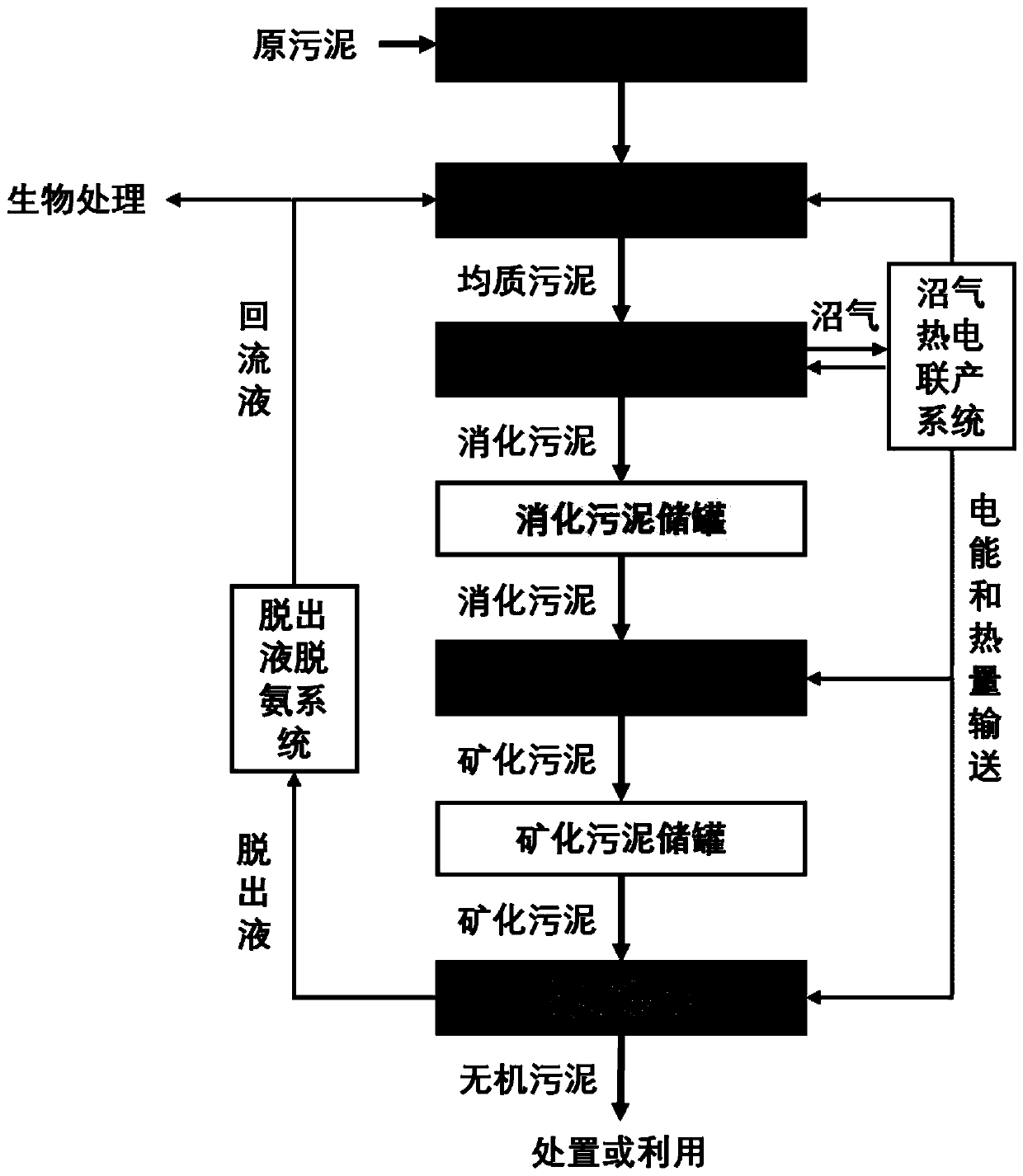

Sludge separation treatment method

ActiveCN109867428ASolve viscositySolve the difficulty of stirringSludge treatment by oxidationSludge treatment by pyrolysisMoistureSolid phases

The invention discloses a sludge separation treatment method. The method comprises the following steps: S1: conveying raw sludge into a low-temperature pyrohydrolysis reactor, introducing a backflow liquid generated in a step S5 into the low-temperature pyrohydrolysis reactor, carrying out a low-temperature pyrohydrolysis reaction to obtain hydrolyzed homogenized sludge; S2, conveying the homogenized sludge to a high-solid anaerobic digestion reactor to carry out a high-solid anaerobic digestion reaction, and discharging digested sludge; S3, conveying the digested sludge to a wet-type catalytic air oxidation reactor, adding a catalyst, and carrying out a wet-type catalytic air oxidation reaction to obtain mineralized sludge; S4, conveying the mineralized sludge to a dewatering device, andseparating the solid phase and moisture to separately obtain inorganic sludge and a separated liquid; and S5, carrying out deamination treatment on the separated liquid to obtain the backflow liquid,and conveying the backflow liquid to the low-temperature pyrohydrolysis reactor in the step S1. According to the method, coordinated distribution of substances and energy is realized, great reductionof the sludge can be realized at relatively low cost, and inorganic residues are convenient to dispose.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Deep well polysulfonate drilling fluid and preparation method thereof

ActiveCN107245329ASolve viscositySolving difficult-to-govern problemsDrilling compositionSodium BentoniteWell drilling

The invention relates to the field of deep well drilling fluid and discloses deep well polysulfonate drilling fluid and a preparation method thereof. The deep well polysulfonate drilling fluid is prepared from the following components in parts by weight: 100 parts of water as a datum, 3.5-5 parts of bentonite, 0.15-0.35 part of sodium carbonate, 6-8 parts of sulfomethylated phenol formaldehyde resin, 6-8 parts of sulfonated brown coal, 7.5-12 parts of halide salt, 0.5-1.2 parts of filtrate reducer, 0.8-1.7 parts of sodium polyacrylate, 3-5 parts of sodium bisulfite and 250-300 parts of barite. The deep well polysulfonate drilling fluid has excellent performance of low viscosity, low HTHP (High Temperature and High Pressure) water loss and the like.

Owner:SOUTHWEST PETROLEUM UNIV

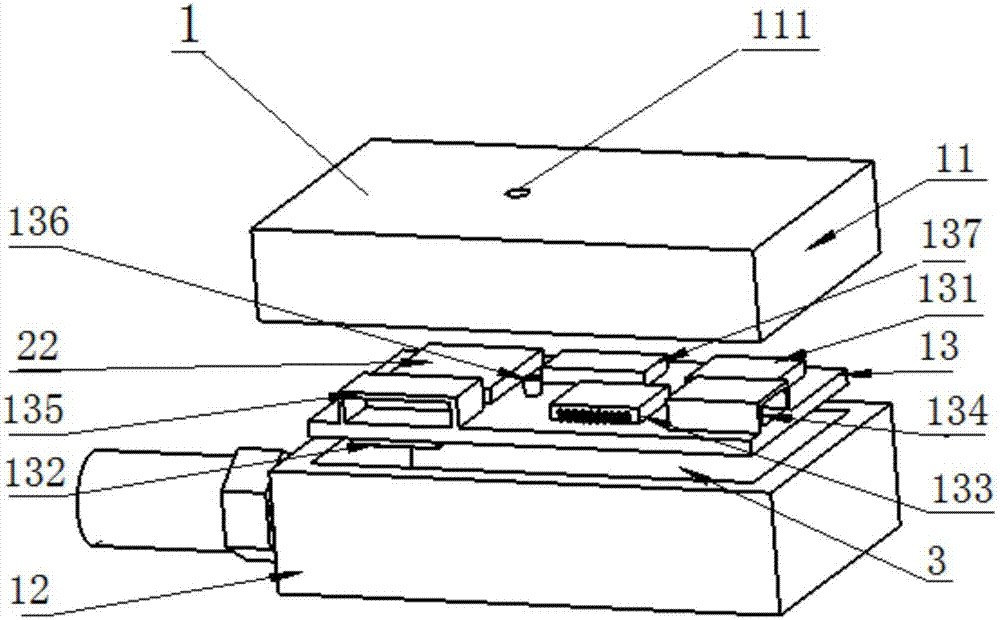

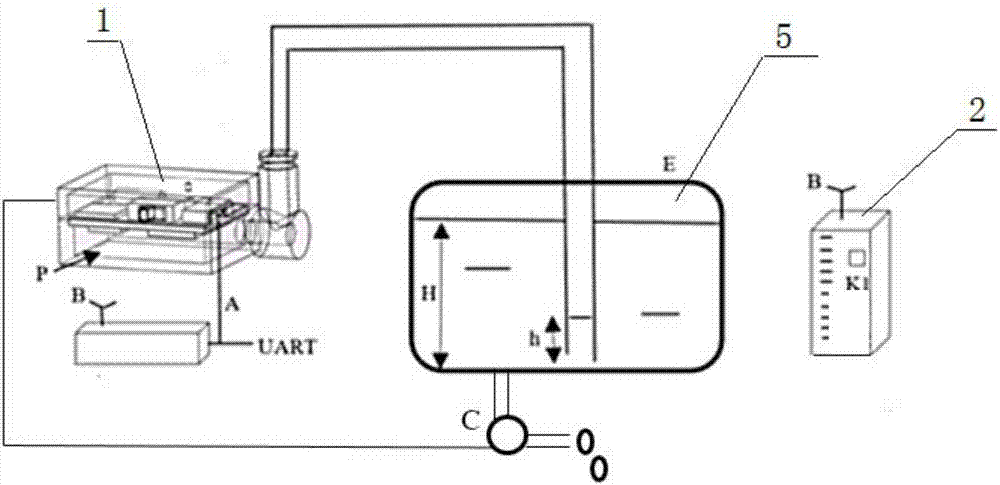

Liquid volume monitoring device and monitoring method

ActiveCN107421598AFilter out measurement effectsSmall fluctuationVolume measurement apparatus/methodsEngineeringMonitoring methods

The invention relates to the technical field of monitoring, in particular to a liquid volume monitoring device and monitoring method. The liquid volume monitoring device comprises an external corrector, and a liquid volume monitor is in communication connection with the external corrector; the liquid volume monitor comprises a first cover body and a second cover body which cover each other, a circuit board is arranged between the first cover body and the second cover body, the circuit board and the second cover body bond closely to form a closed air chamber, and an air vent is formed in the first cover body; a first detecting device and a second detecting device are arranged on the circuit board, and a third detecting device used for detecting the liquid volume flows out of a medical kit is arranged on the external corrector; a processor used for processing detection numerical values of the liquid volume monitoring device is arranged on the circuit board. According to the liquid volume monitoring device, through the intensity of pressure of the closed air chamber detected by the first detecting device and the ambient atmosphere detected by the second detecting device, liquid level information of the medical kit can be obtained through the difference value between the intensity of pressure of the closed air chamber and the ambient atmosphere.

Owner:SOUTH CHINA AGRI UNIV

Flaky molding compound resin composition, flaky molding compound and preparation method of flaky molding compound

The invention discloses flaky molding compound resin composition, a flaky molding compound and a preparation method of the flaky molding compound. The flaky molding compound resin composition is prepared from substances in parts by weight as follows: 40-60 parts of epoxy resin, 1-20 parts of a thickening agent, 1-5 parts of a thickening accelerant and 1-5 parts of a curing agent. The flaky moldingcompound prepared from the flaky molding compound composition has good mechanical strength, good toughness, low VOC (volatile organic compound) content and good environmental protection performance.

Owner:BYD CO LTD

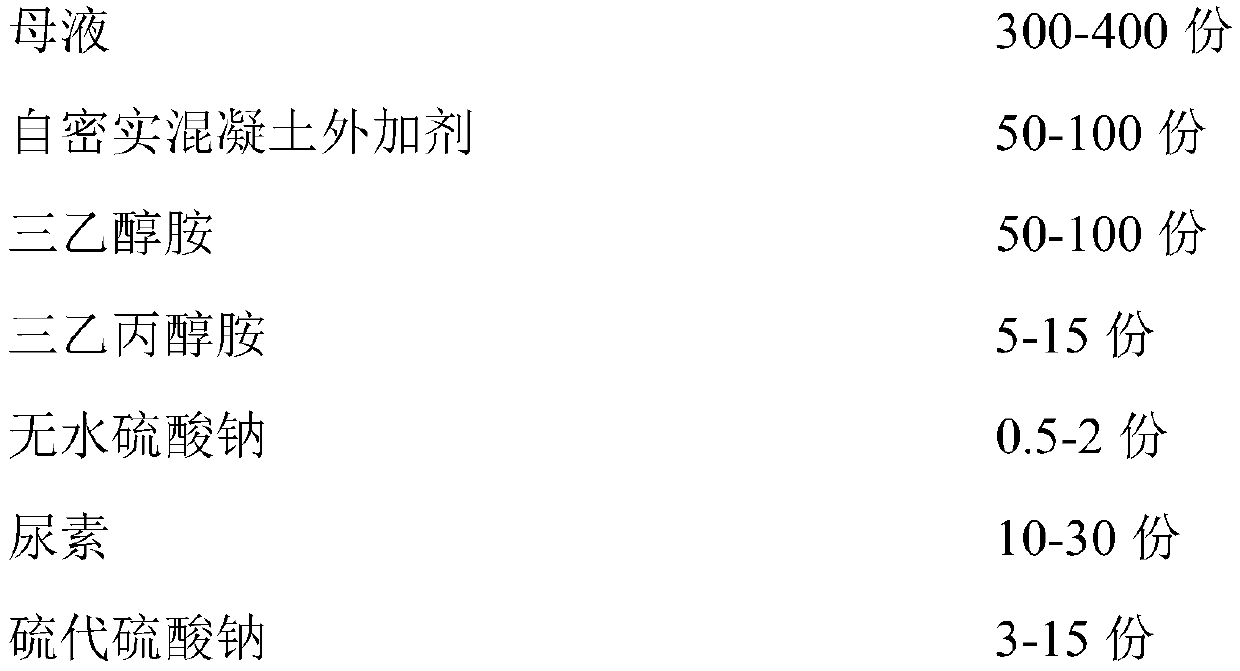

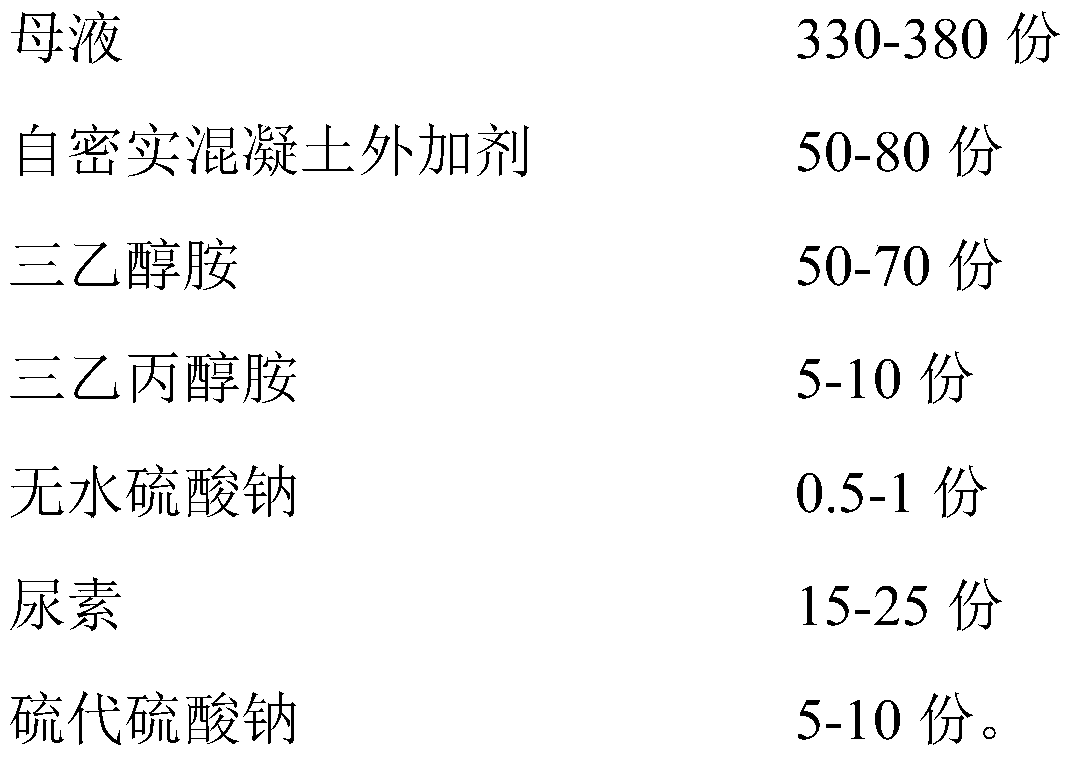

Anti-mud additive suitable for machine-made sand concrete and compounding method thereof

The invention relates to an anti-mud additive suitable for machine-made sand concrete and a compounding method thereof. The anti-mud additive comprises the following components in parts by weight: 30-50 parts of a lignosulfonate water reducing agent, 20-35 parts of a viscosity reduction type polycarboxylic acid water reducing agent, 0.2-0.25 part of a defoaming agent and 20-45 parts of water. Thecompounding method specifically comprises the following steps: mixing and compounding the mud-resistant admixture and the machine-made sand concrete, wherein the performance of the machine-made sand concrete can be changed by changing the adding sequence of the lignosulfonate water reducing agent. Compared with the prior art, the anti-mud additive can be used for improving the mud resistance of the machine-made sand concrete, and the cohesiveness and compressive strength of the machine-made sand concrete can be remarkably improved.

Owner:TONGJI UNIV

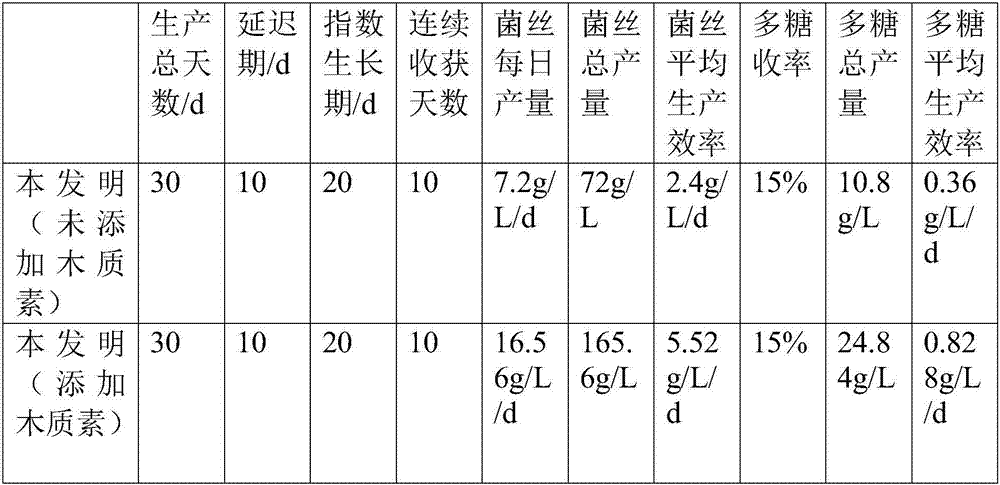

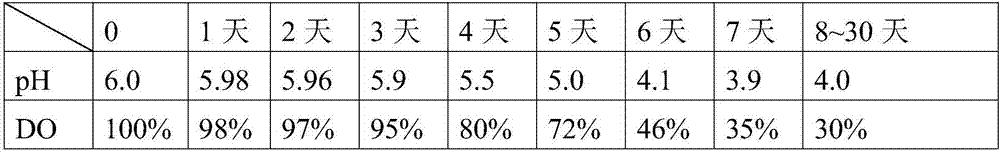

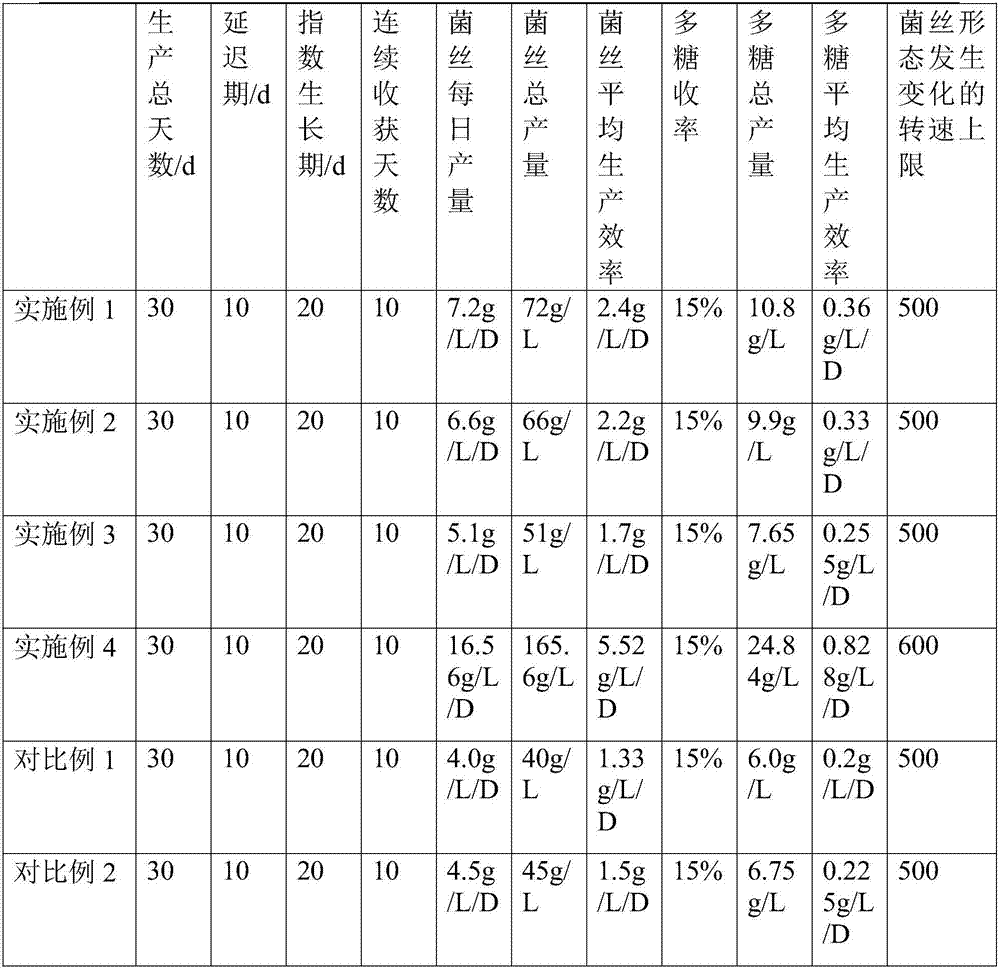

Supplementary culture medium for shiitake mushroom fermentation and liquid submerged continuous culture method for shiitake mushrooms

InactiveCN107418902AExtended growing seasonShorten the delay periodFungiMicroorganism based processesMonopotassium phosphateShiitake mushrooms

The invention belongs to the technical field of liquid submerged fermentation of edible fungi and particularly relates to a supplementary culture medium for shiitake mushroom fermentation and a liquid submerged continuous culture method for shiitake mushrooms. The supplementary culture medium is prepared from, by weight, 4-6% of glucose, 0.5-1% of polypeptone, 0.5-1% of yeast extract powder, 0.1-0.3% of monopotassium phosphate, 0.05-0.15% of magnesium sulfate, 0.05-0.15% of calcium chloride, 0.3-0.5% of soybean oil, 0.01-0.03% of tween 80, 0.05-0.15% of acetic acid and 91-93% of water. The supplementary culture medium is comprehensive and balanced in nutrition and capable of effectively prolonging an exponential growth phase of the shiitake mushrooms, improving liquid submerged culture efficacy of the shiitake mushrooms and increasing biomass and lentinan yield when being used for liquid submerged continuous culture of the shiitake mushrooms.

Owner:SHANDONG LUKANG SHELILE PHARMA

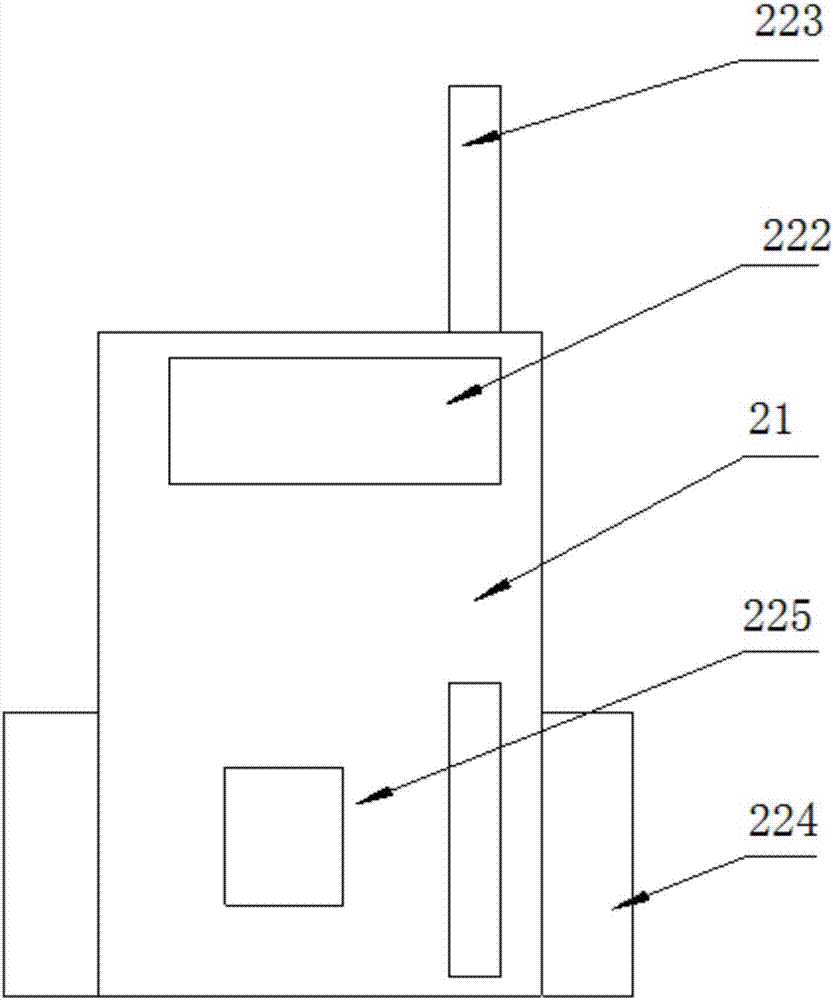

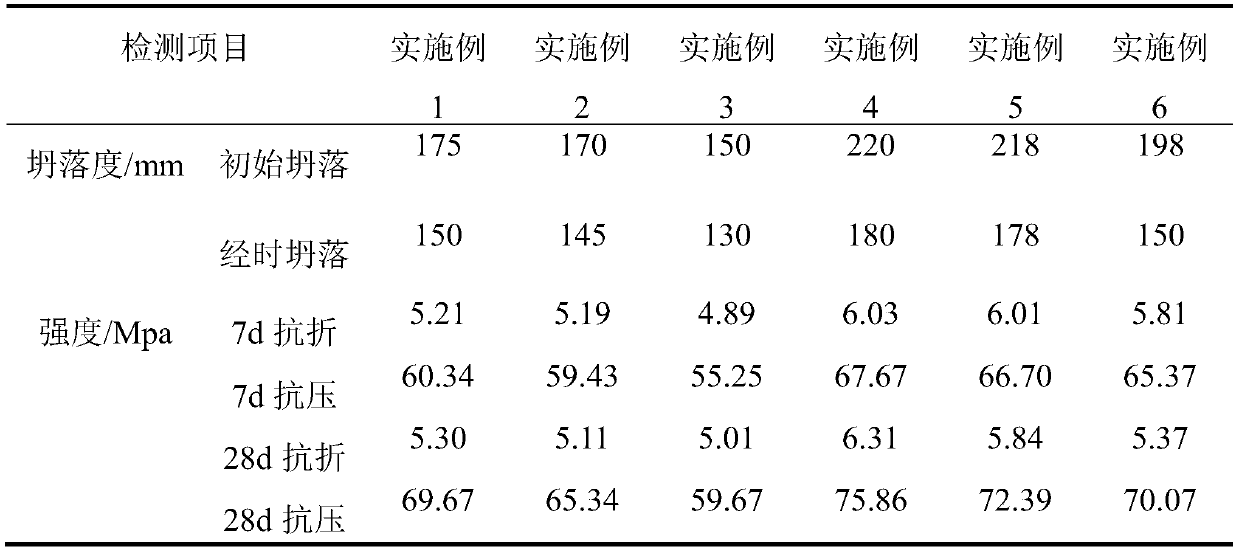

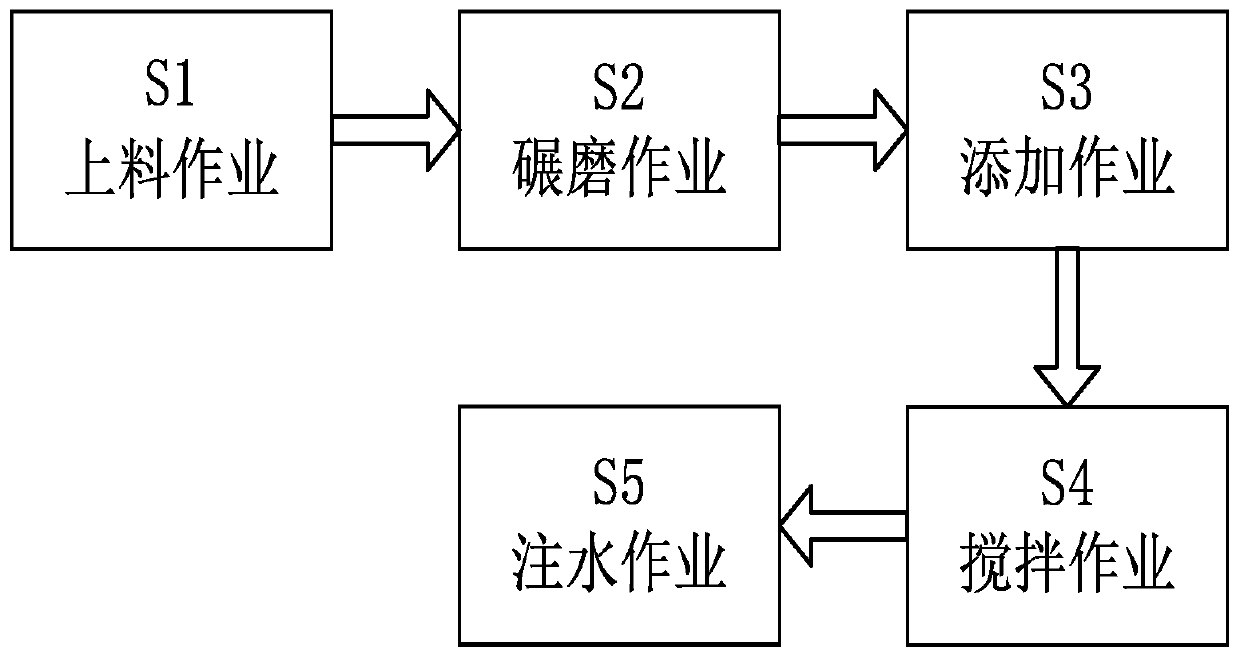

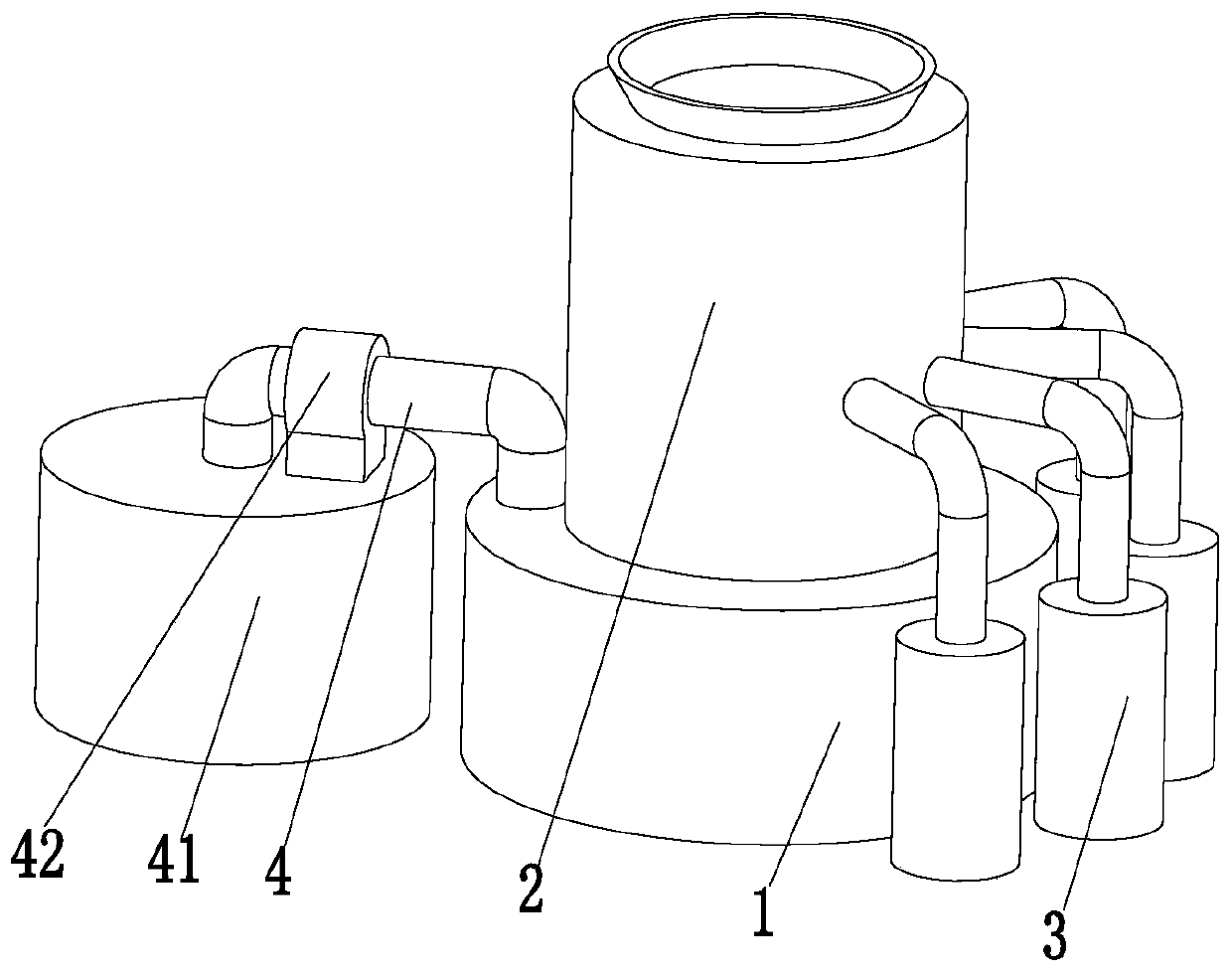

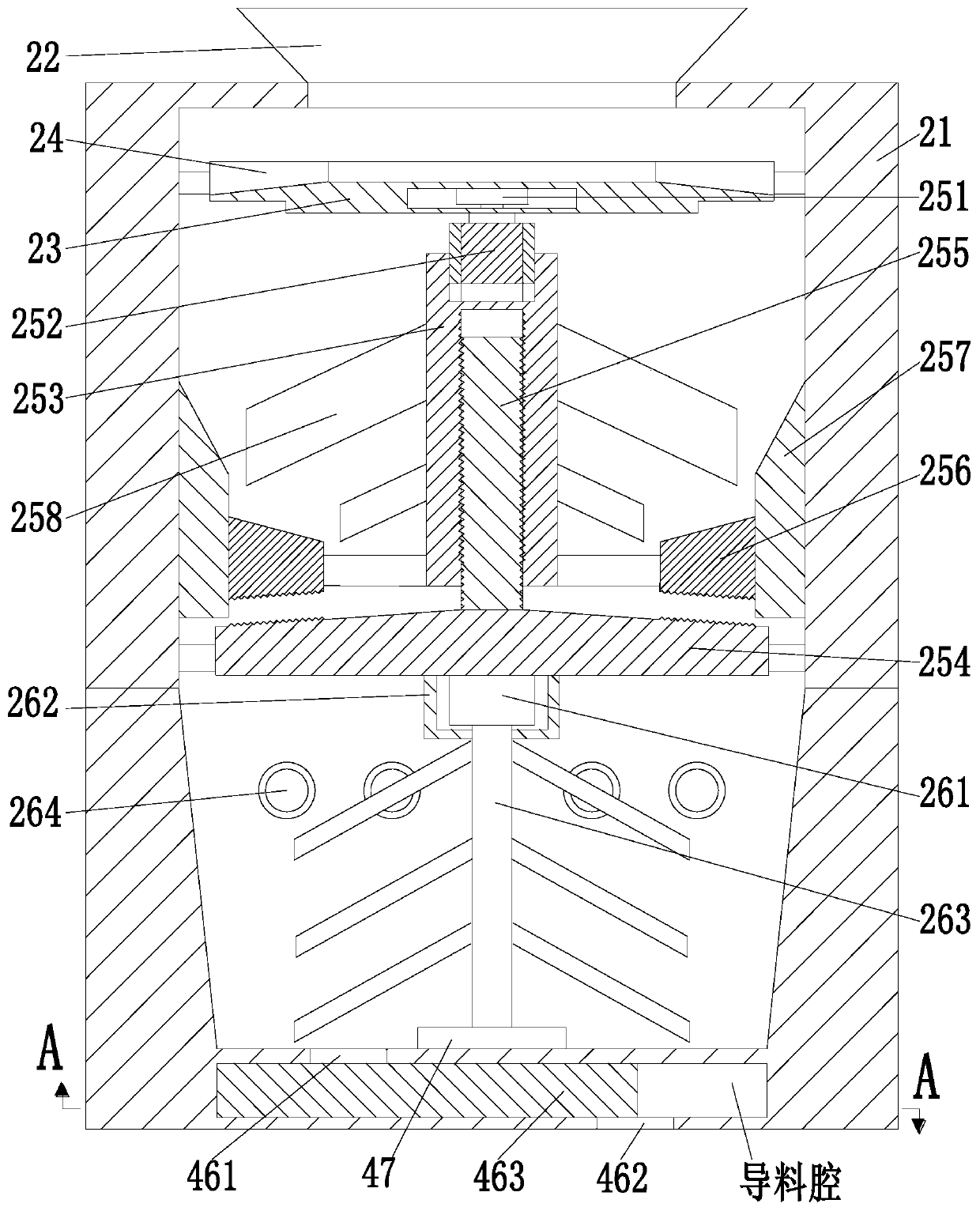

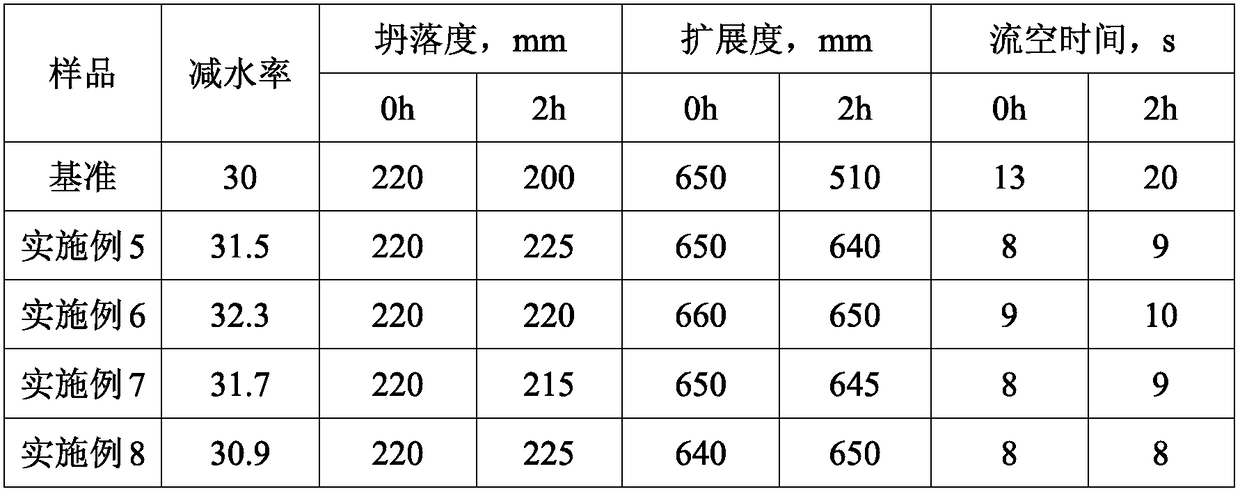

Hierarchical multi-grade type concrete mortar preparation material mixing treatment technology

ActiveCN111300643ASolve the strength problemSolve viscosityMixing operation control apparatusPretreatment controlMaterials scienceTreatment unit

The invention relates to a hierarchical multi-grade type concrete mortar preparation material mixing treatment technology adopting a concrete mortar preparing device. The concrete mortar preparing device comprises a mixing cylinder, a treatment unit, an additive cylinder and a water feeding unit. The treatment unit is arranged at the upper end of the mixing cylinder. The left end of the mixing cylinder is connected with the water feeding unit through a pipeline. The right end of the treatment unit is connected with the additive cylinder through a pipeline. By designing the pagoda type multi-grade structure of the material mixing device, the manner of feeding sand, stone and cement at the first grade, feeding various additives at the second grade, feeding water at the third grade is adopted, each step of the technology is treated in a separated manner, and then the problem that since residual additives and moisture can conduct a reaction with the sand, stone and cement earlier, the strength of the concrete is lowered is solved. According to the hierarchical multi-grade type concrete mortar preparation material mixing treatment technology, by feeding the mortar at a fixed quantity and then feeding water at a fixed volume, the problem that due to excessively fed water, the strength and viscosity of the concrete are influenced is solved.

Owner:江西萍乡南方建材有限公司

Preparation method of starch-based hard capsule

ActiveCN108498478ALow viscositySolve viscosityPharmaceutical non-active ingredientsCapsule deliverySmooth surfaceHard Capsule

The invention belongs to the technical field of medicine preparation, and particularly discloses a preparation method of a starch-based hard capsule. The preparation method comprises the following steps of acid degradation of starch, etherification, solation, insulating, defoaming, glue dipping and forming, drying and the like. According to the preparation method disclosed by the invention, the starch is treated by acid degradation and etherification composite modification, and further the viscosity of the starch is reduced; meanwhile, the film forming property of the starch is improved; the starch-based hard capsule is prepared by adopting high-amylose starch with the amylase content of 80 percent as a matrix and the modified starch as a reinforced phase and using a traditional dipping forming process. The starch-based hard capsule prepared by the method disclosed by the invention has the advantages of high transparency, smooth surface, good bending resistance, short disintegration time limit and the like; a production process is also simplified; the preparation method is suitable for being popularized and applied on a large scale.

Owner:SOUTH CHINA AGRI UNIV

Powder coating polyester resin which can be stably stored and preparation method thereof

InactiveCN110041511AStable storageGuaranteed levelPowdery paintsPolyester coatingsNitrogen gasGlass transition

The invention discloses powder coating polyester resin which can be stably stored and a preparation method thereof. The polyester resin is prepared from the ingredients in weight percentage: 15 to 55%of polyhydric alcohol, 45 to 85% of polyatomic acid, a catalyst and an additive, wherein the use amount of the catalyst is 0.005 to 0.1% of the total weight of the polyhydric alcohol and the polyatomic acid, and the use amount of the additive is 0.01 to 0.03% of the total weight of the polyhydric alcohol and the polyatomic acid. An acid value of the polyester resin is 50 to 80 mg KOH / g, the viscosity of the polyester resin is 1000 to 3000 cps@200 DEG C, and a glass transition temperature of the polyester resin is 50 to 70 DEG C. According to the polyester resin disclosed by the invention, theraw material proportion is controlled; under the nitrogen environment, organic tin is utilized to catalyze the polyhydric alcohol and the polyatomic acid to prepare the powder coating polyester resinwith the high acid value, the low viscosity and the high glass transition temperature through esterification and condensation polymerization reaction. As the resin simultaneously has the characteristics of high acid value and high glass transition temperature, good leveling property and storage stability are both taken into consideration.

Owner:JIANGSU RAP RESIN TECH CO LTD

Semi-solidified epoxy glue film as well as preparation method and use thereof

ActiveCN109321186ASolve viscositySolve the problem of not being able to prepare hot-melt adhesive filmsFilm/foil adhesives without carriersEpoxy resin adhesivesEpoxyPolymer science

The invention relates to a semi-solidified epoxy glue film as well as a preparation method and use thereof, in particular to a semi-solidified heat-fusion method low-temperature epoxy glue film and apreparation and use method thereof. Through a semi-solidifying method, a flexible chain section is added into an epoxy resin molecular chain, and a heat-fusion method is used for preparing the epoxy glue film which is suitable for being applied to a low-temperature environment, and a preparation and use method of the epoxy glue film. The low-temperature epoxy glue film is suitable for preparing asandwich structure and a glue joint structure under a the low-temperature environment. The semi-solidified epoxy glue film can be applied to the fields such as low-temperature wind tunnel blades, low-temperature composite material storage boxes and, low-temperature super-conduction, and the low-temperature is a temperature -150 DEG C or less.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

GF-3 anti-radiation coating

The invention provides a GF-3 anti-radiation coating which comprises five types of metal compounds including ferric oxide, tungsten powder, rectorite ore, barium sulfate and ferric sulfate, and the GF-3 anti-radiation coating is prepared by mixing the five types of metal compounds with cement, borax and diatom ooze, wherein the ferric oxide accounts for 14 wt%-22 wt%, and the granularity is 0.1 mm-1.3 mm; the tungsten powder accounts for 3 wt%-6 wt%, and the granularity is 0.1 mm-1.3 mm; the rectorite ore accounts for 4 wt%-10 wt%, and the granularity is 100 meshes-200 meshes; the barium sulfate accounts for 30 wt%-40 wt%, and the granularity is 0.1 mm-2.0 mm; the ferric sulfate accounts for 0.5 wt%-1.5 wt%; the cement accounts for 15 wt%-18 wt%, the borax accounts for 1.0 wt%-1.5 wt%, and the diatom ooze accounts for 10 wt%-20 wt%.According to the GF-3 anti-radiation coating, the diatom ooze is added, the proportion of all components is improved, viscosity of the anti-radiation coating is improved, construction can be more convenient, radiation absorptivity of the anti-radiation coating is improved, the anti-radiation effect is better, and the defect that existing anti-radiation coating is low in viscosity and low in radiation absorptivity is overcome.

Owner:ZHEJIANG KAICHENG ENVIRONMENT ENG CO LTD

Viscosity-reducing type polycarboxylic acid water reducing agent preparation method

ActiveCN109180876ALightly crosslinkedStructural stretchCross-link2-methacryloyloxyethyl phosphorylcholine

The invention discloses a viscosity-reducing type polycarboxylic acid water reducing agent preparation method, which comprises: (1) preparing an esterification monomer; (2) carrying out a copolymerization reaction; and (3) carrying out a neutralization reaction. According to the present invention, the viscosity-reducing type polycarboxylic acid water reducing agent is prepared by co-polymerizing 2-allyloxyethanol, a blend, VPEG, 2-methacryloyloxyethyl phosphorylcholine and an unsaturated acid, such that the phosphate radical, the carboxylate radical, the quaternary ammonium salt and the estergroup are introduced into the molecular structure of the polymer while the polymer structure is lightly cross-linked, wherein the product obtained by the esterification of the single carboxy in 2-phosphonobutane-1,2,4-tricarboxylicacid prepared by a 2-phosphonobutane-1,2,4-tricarboxylicacid esterification reaction, the product obtained by the esterification of the two carboxy in a small amount of2-phosphonobutane-1,2,4-tricarboxylicacid and the product obtained by the esterification of the three carboxy in a small amount of 2-phosphonobutane-1,2,4-tricarboxylicacid form the blend; and the prepared viscosity-reducing type polycarboxylic acid water reducing agent has advantages of viscosity reducing, water reducing, slump retaining and mud resistance, and can solve the problems of high viscosity, poor workability and rapid loss due to the high mud content in the current concrete raw materials.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

Low-heat silicate cement clinker for maritime work and preparation method thereof

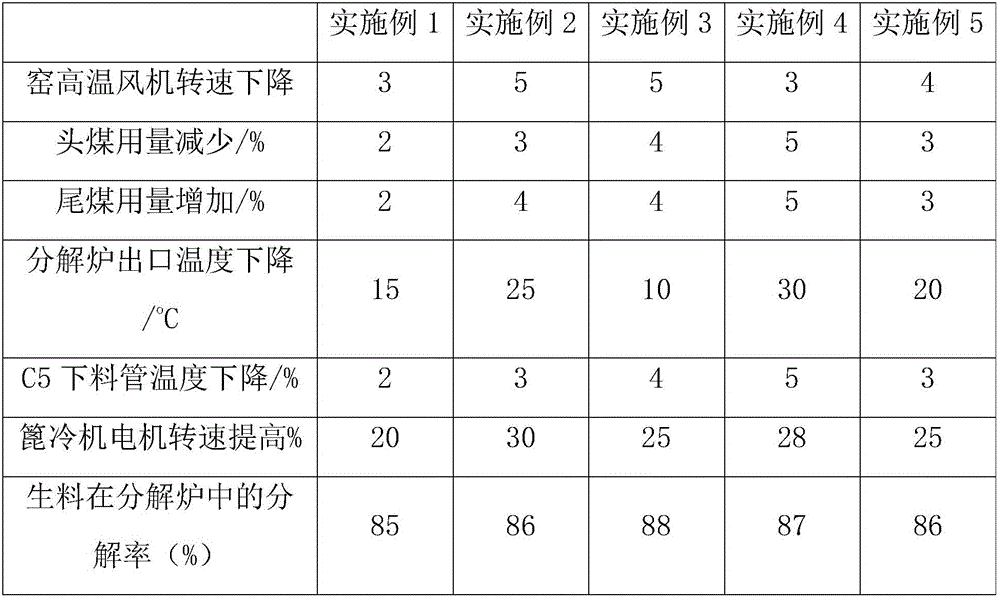

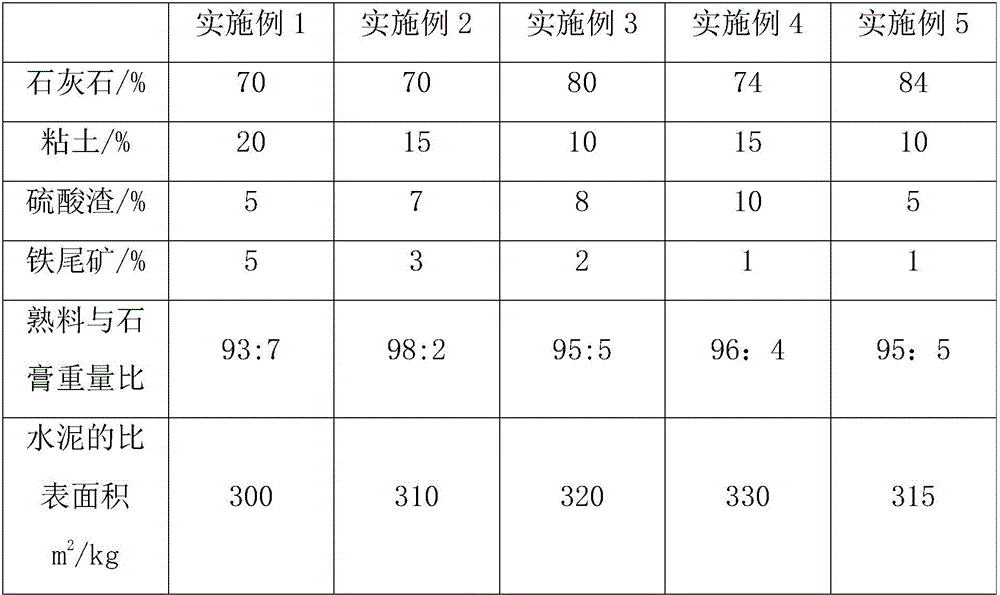

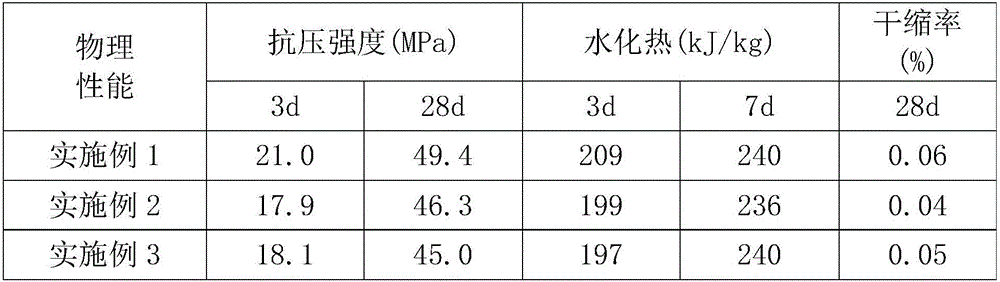

The invention relates to a preparation method of low-heat silicate cement clinker for maritime work. The preparation method comprises the following steps: (1) mixing and grinding the following components in percentage by mass into powder: 70 to 84 percent of limestone, 10 to 20 percent of clay, 5 to 10 percent of sulfate slag and 1 to 5 percent of iron tailings to obtain a cement raw material; (2) decomposing the cement raw material in a decomposing furnace, then calcining at the temperature of 1,350 to 1,400 DEG C for 30 to 45 min, and cooling to obtain the cement clinker, wherein on the basis of the parameters of the decomposing and calcining production processes of the existing cement raw material of the same yield, the following parameters of the calcining process of the cement raw material are adjusted respectively according to the yield of the cement clinker of 500 to 10,000 t / day: the rotating speed of a high-temperature fan of a kiln is reduced by 3 to 5 percent, the use amount of head coal is reduced by 2 to 5 percent, the use amount of tailings is increased by 2 to 5 percent, the outlet temperature of the decomposing furnace is reduced by 10 to 30 DEG C, the temperature of a C5 discharging pipe is reduced by 2 to 5 percent, and the rotating speed a motor of a grate cooler is increased by 20 to 30 percent. Cement prepared from the cement clinker disclosed by the invention is low in water heat and dry shrinkage rate.

Owner:CHINA BUILDING MATERIALS ACAD +1

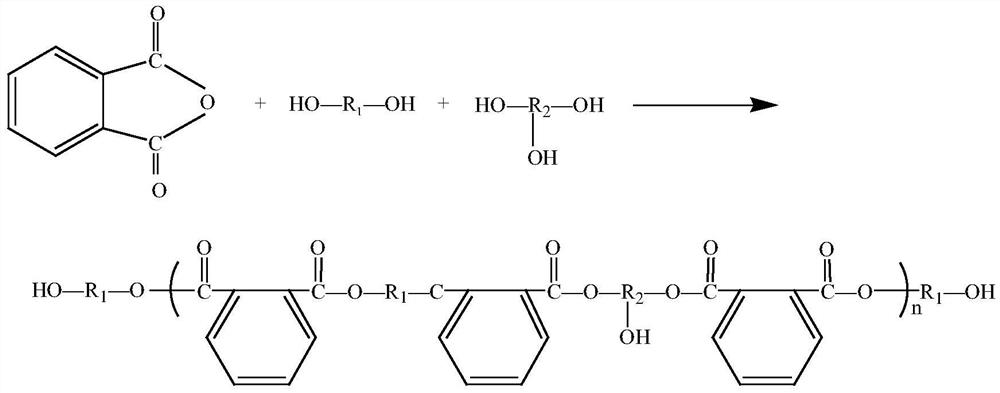

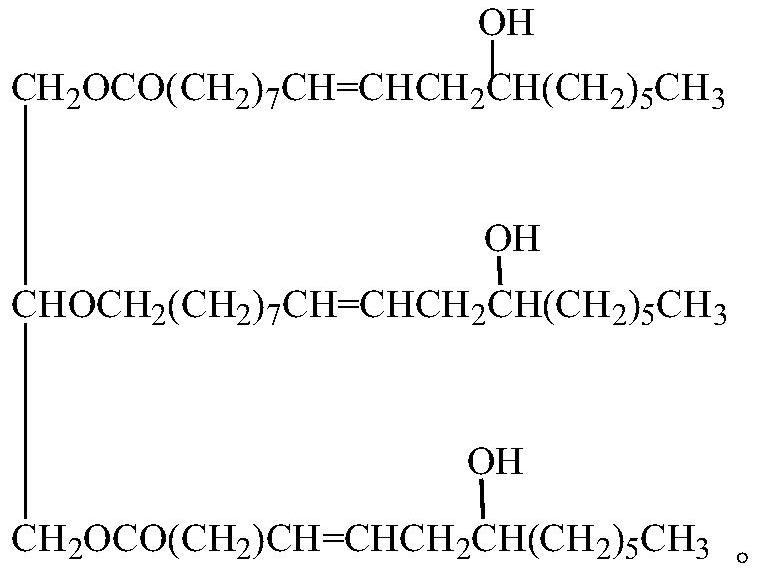

Two-component solvent-free polyurethane adhesive and preparation method thereof

PendingCN113583611ALow viscositySolve viscosityPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention relates to the technical field of polyurethane adhesives, in particular to a two-component solvent-free polyurethane adhesive and a preparation method thereof. The two-component solvent-free polyurethane adhesive is composed of a component A and a component B according to the mass ratio of 1: 1 to 3: 2. The component A is an isocyanate-terminated prepolymer prepared through a reaction of polyisocyanate and polyether glycol. The component B is castor oil modified polyester polyol prepared by reacting castor oil with phthalic anhydride, small molecular dibasic acid and small molecular dihydric alcohol under the action of a catalyst. The two-component solvent-free polyurethane adhesive has low viscosity, high shear strength and high flame retardant property, and overcomes the defects of poor adhesive strength and poor high temperature resistance of a polyurethane adhesive in a flexible package.

Owner:GUANGDONG HERUN PRECISION METAL MATERIALS CO LTD

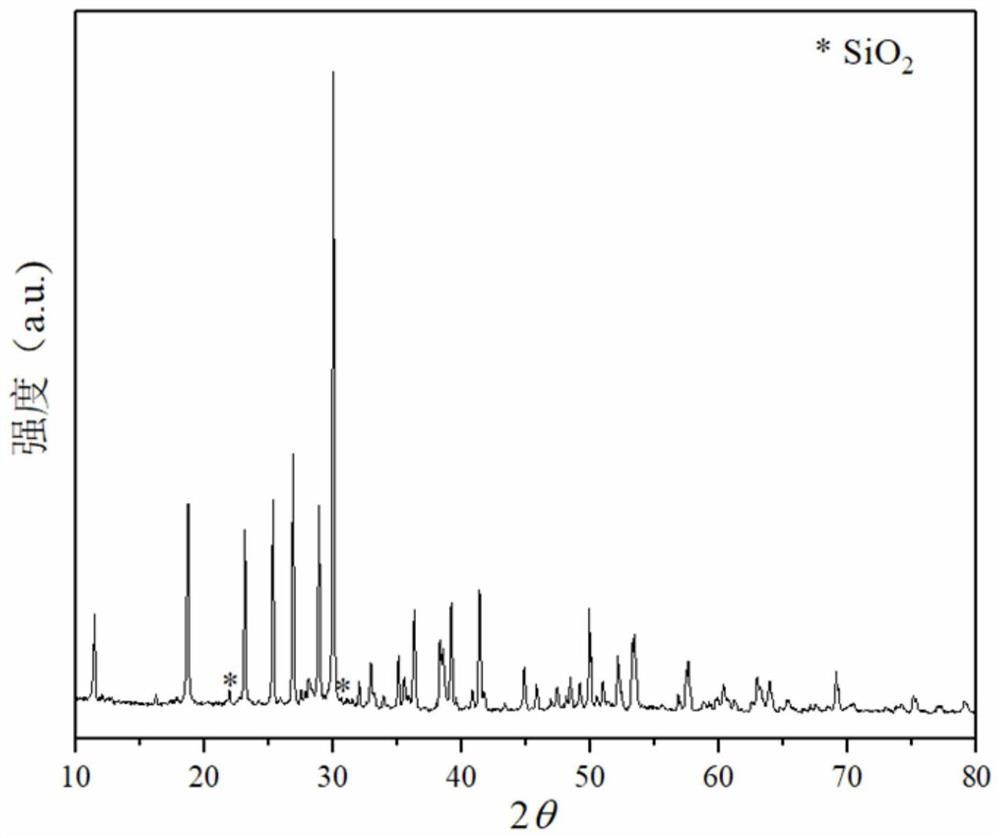

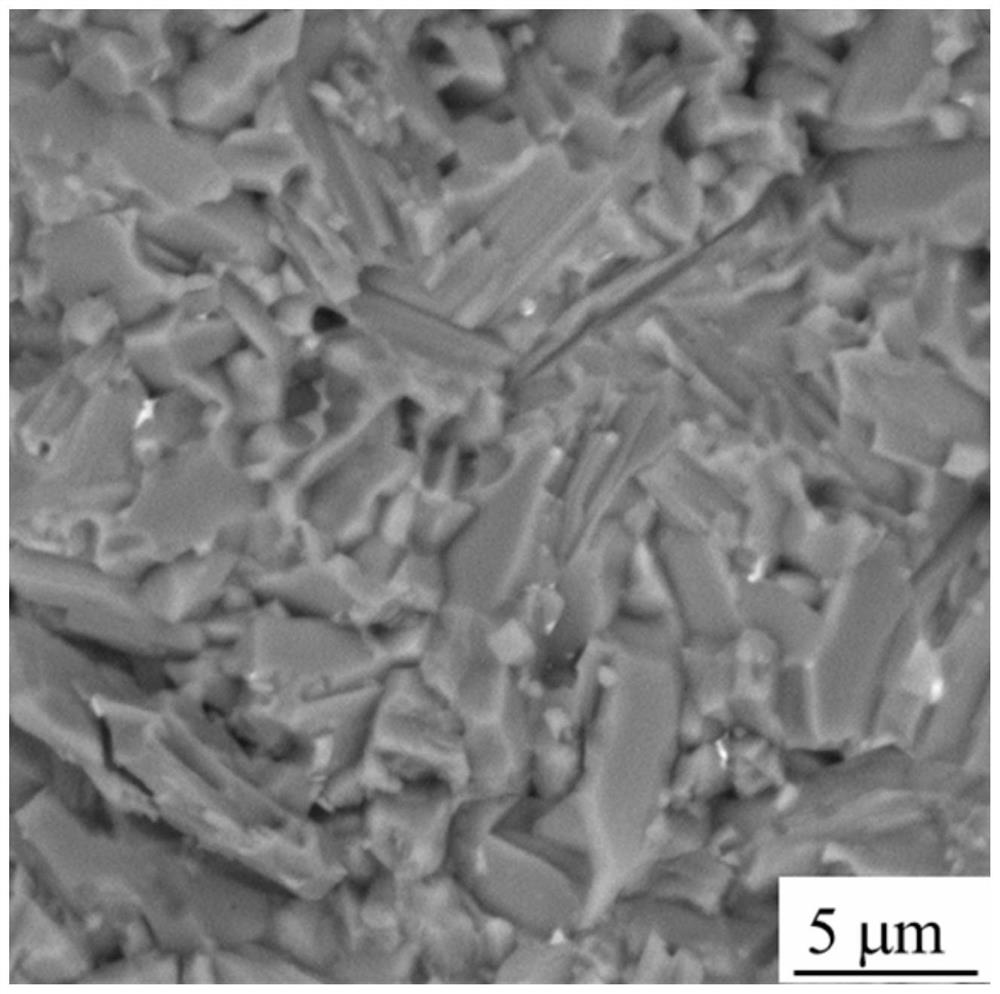

Low-dielectric wollastonite series low-temperature co-fired ceramic material and preparation method thereof

ActiveCN114573333AComposition controllableImprove cooling effectCeramic materials productionWollastoniteMillimetre wave

The invention discloses a low-dielectric wollastonite series low-temperature co-fired ceramic material and a preparation method thereof, and relates to the technical field of electronic materials. The formula of the ceramic material comprises the following components: CaxSiO3, awt% of SiO2, bwt% of R2O, cwt% of Bi2O3, dwt% of B2O3 and ewt% of MO, wherein x is more than or equal to 0.9 and less than or equal to 1.1, 0lt A < = 30, 1 < = b < = 5, 0lt; c < = 3, 0lt; d < = 6, 0 < = e < = 10; r2O is at least one of Li2O and K2O; and MO is one or more of ZnO, MgO, BaO, CoO, CuO, La2O3 and MnO2. The low-temperature co-fired ceramic material provided by the invention meets the requirements of low dielectric, low loss and low-temperature sintering, and can be applied to the fields of millimeter wave LTCC devices and the like.

Owner:JIAXING GLEAD ELECTRONICS CO LTD

Reactive powder concrete as well as preparation and application thereof

The invention discloses reactive powder concrete as well as a preparation and an application thereof. The reactive powder concrete comprises the following components: cement, silica fume, mineral powder, sand, an additive, steel fibers and water. The preparation method comprises the step of uniformly mixing the cement, the silica fume, the mineral powder, the sand, the additive, the steel fiber and the water to obtain the active powder concrete. The problems that the traditional building outer wall material is poor in texture, short in service life, high in manufacturing cost, thick and heavyare solved. By using the reactive powder concrete material with ultrahigh durability and ultrahigh mechanical property, the fabricated architectural decoration outer wall with the artistic effect is manufactured, and compared with traditional concrete, the reactive powder concrete has the material characteristics of high strength, high compactness, high durability and high toughness.

Owner:上海城建建设实业集团新型建筑材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com