Patents

Literature

1267results about How to "Adjustable tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intervertebral connection system

Owner:DEPUY ACROMED INC

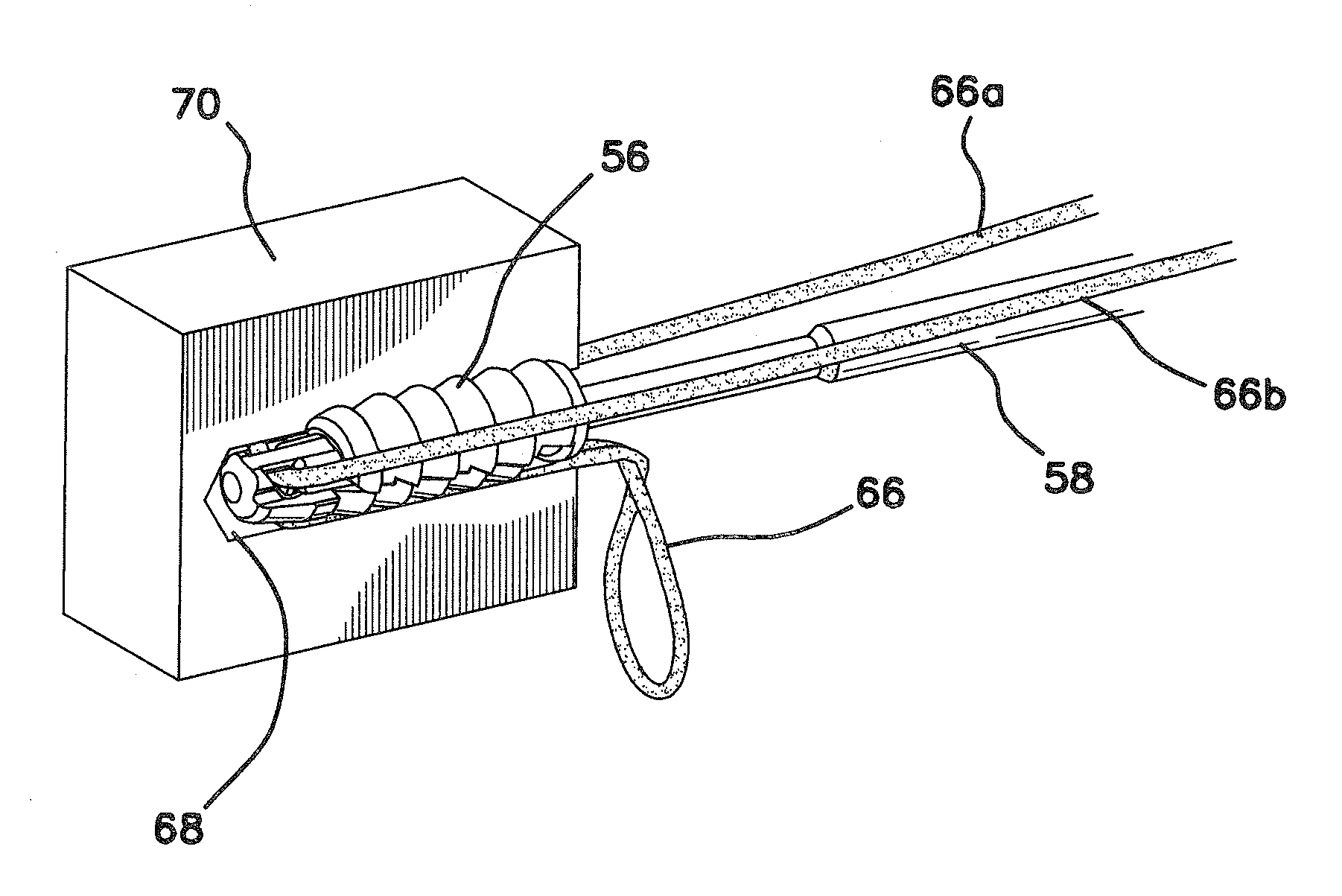

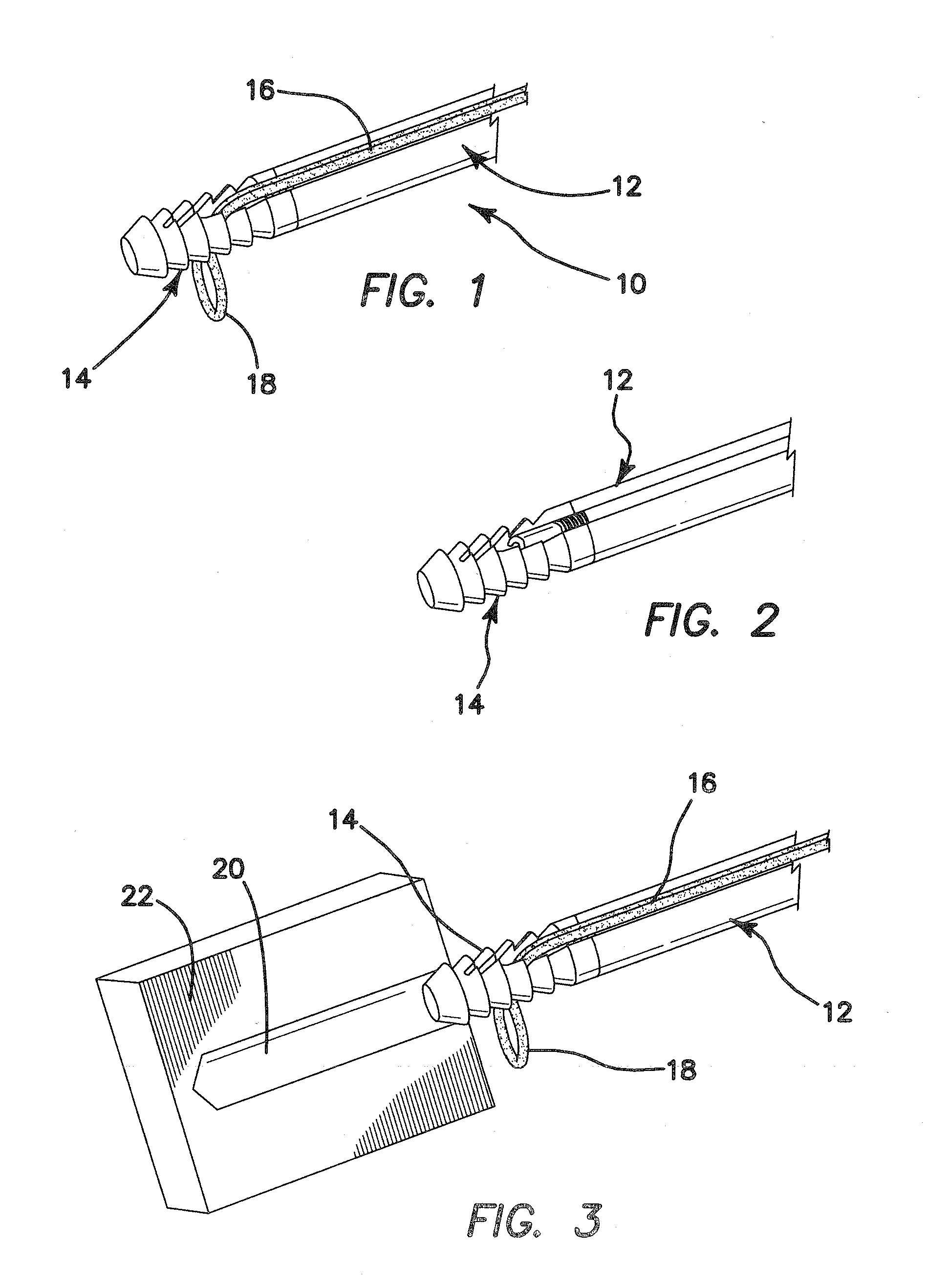

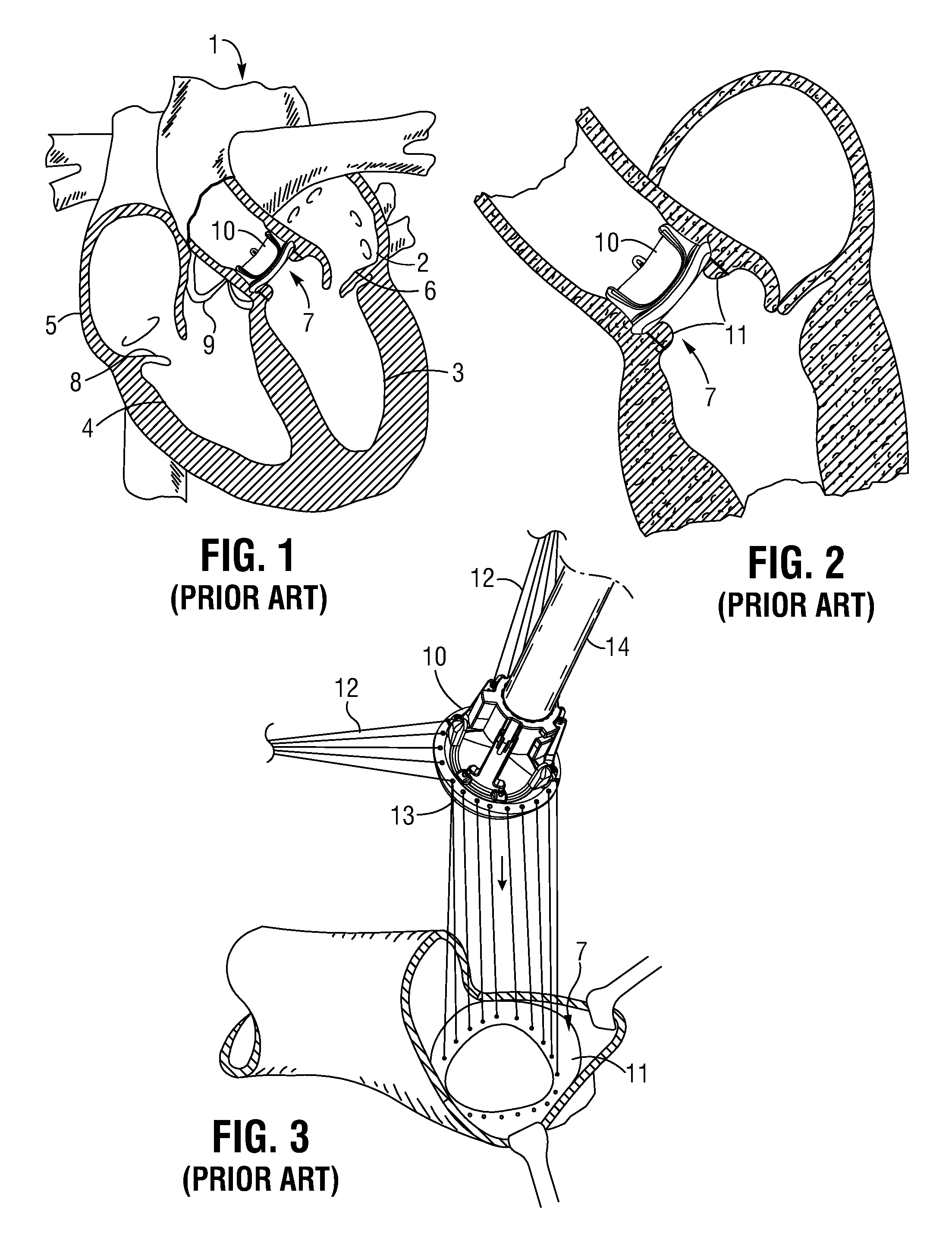

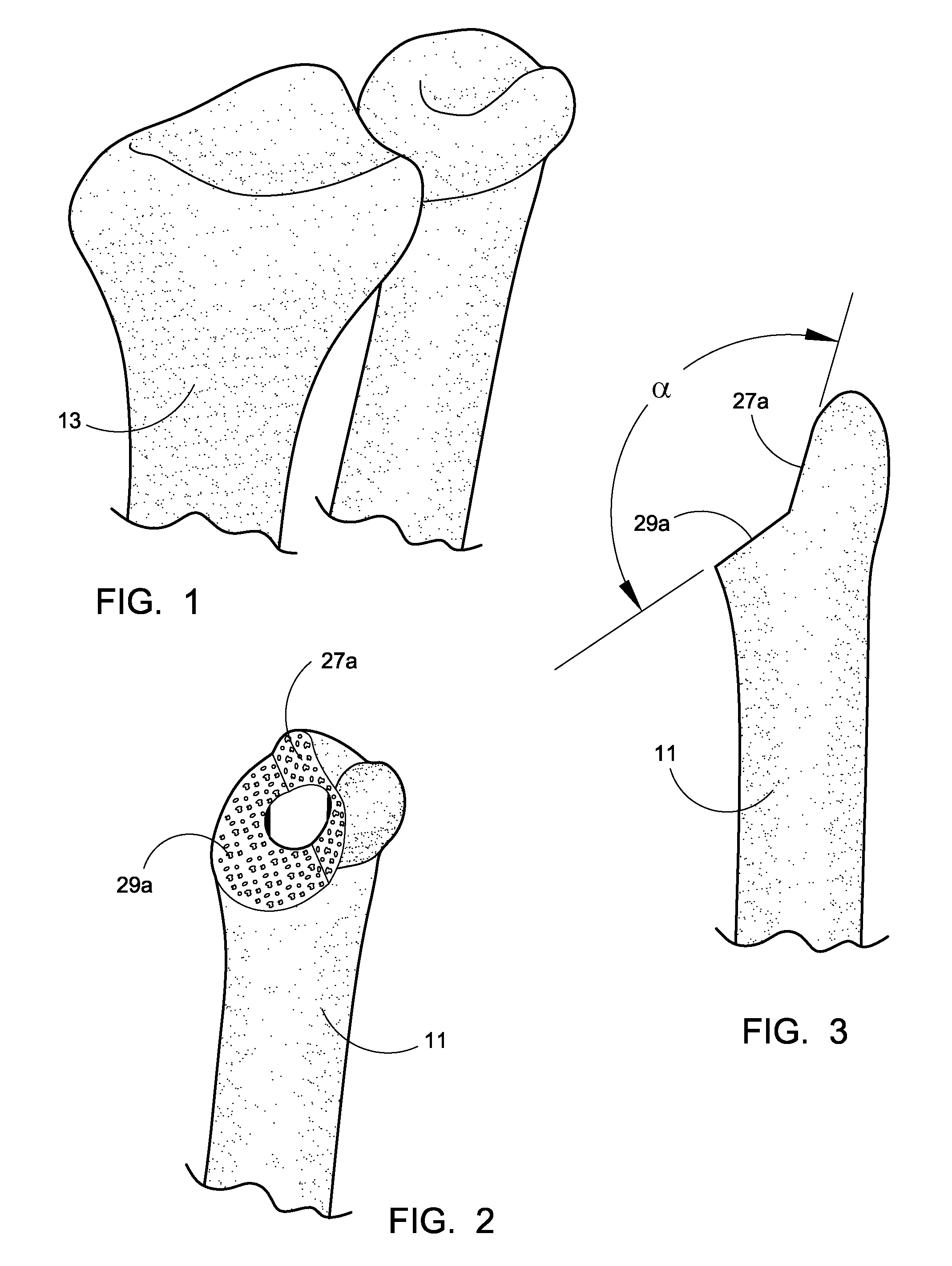

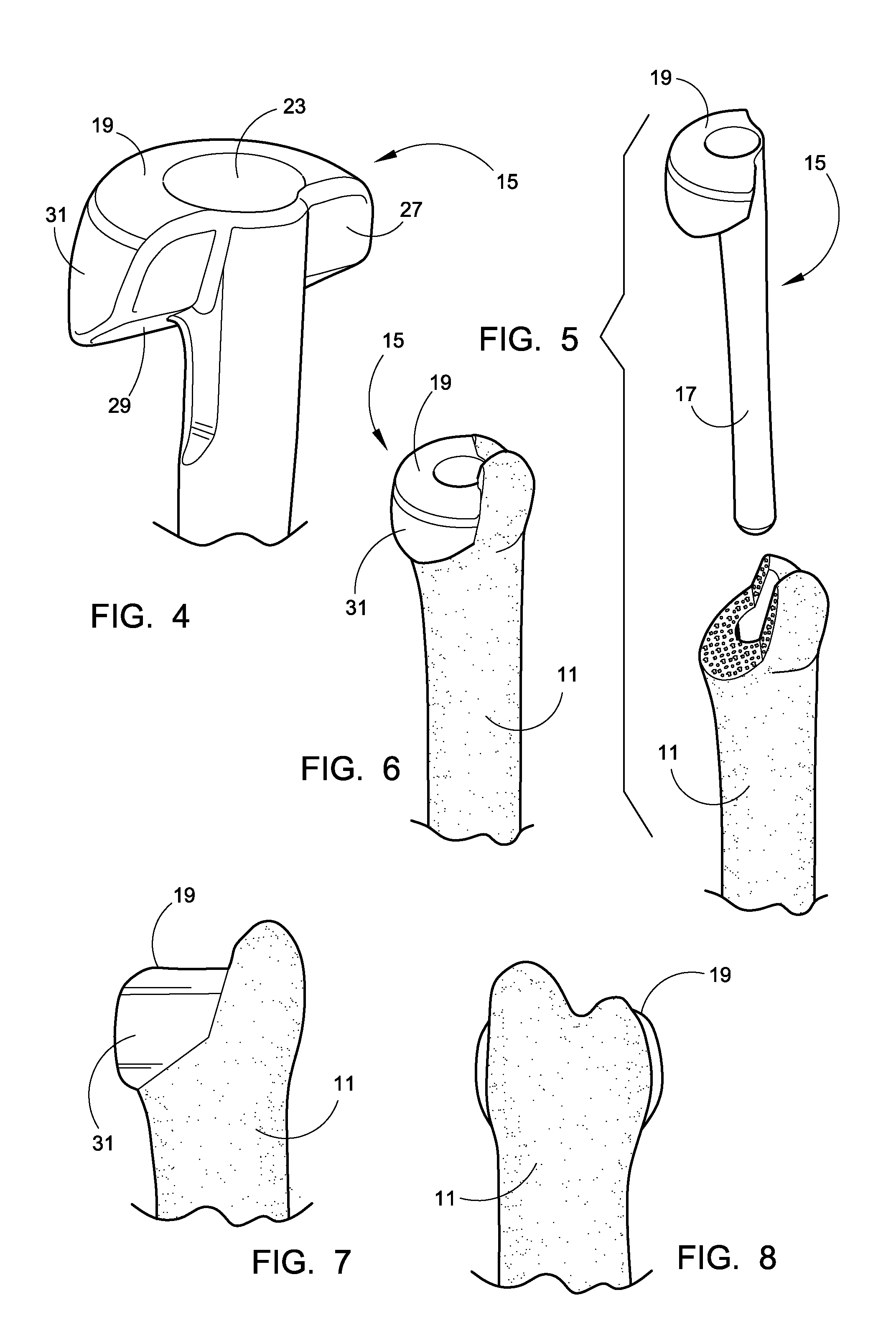

Anchors and methods for securing suture to bone

ActiveUS20090312794A1Adjustable tensionEasy accessSuture equipmentsDiagnosticsSurgical siteSoft tissue

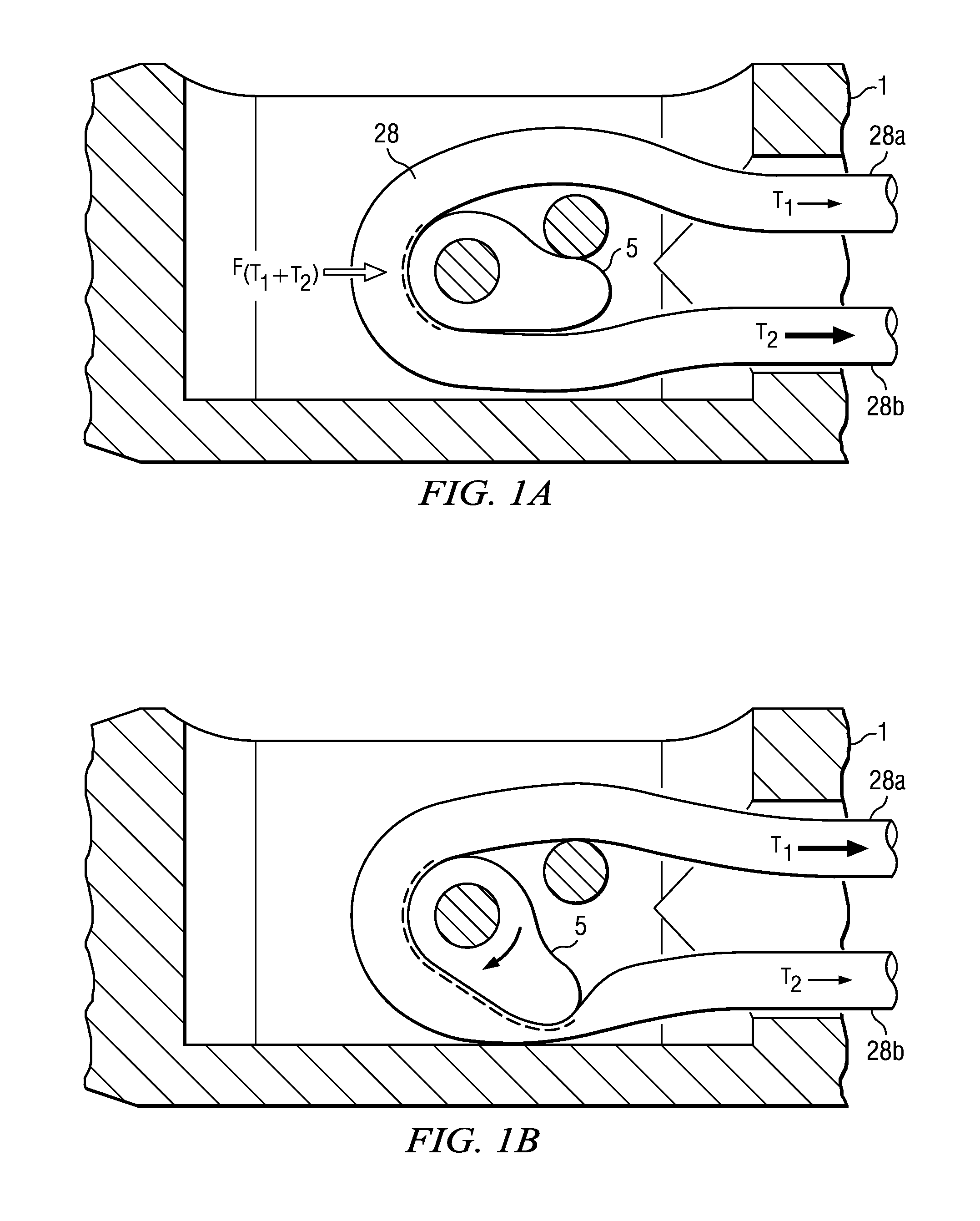

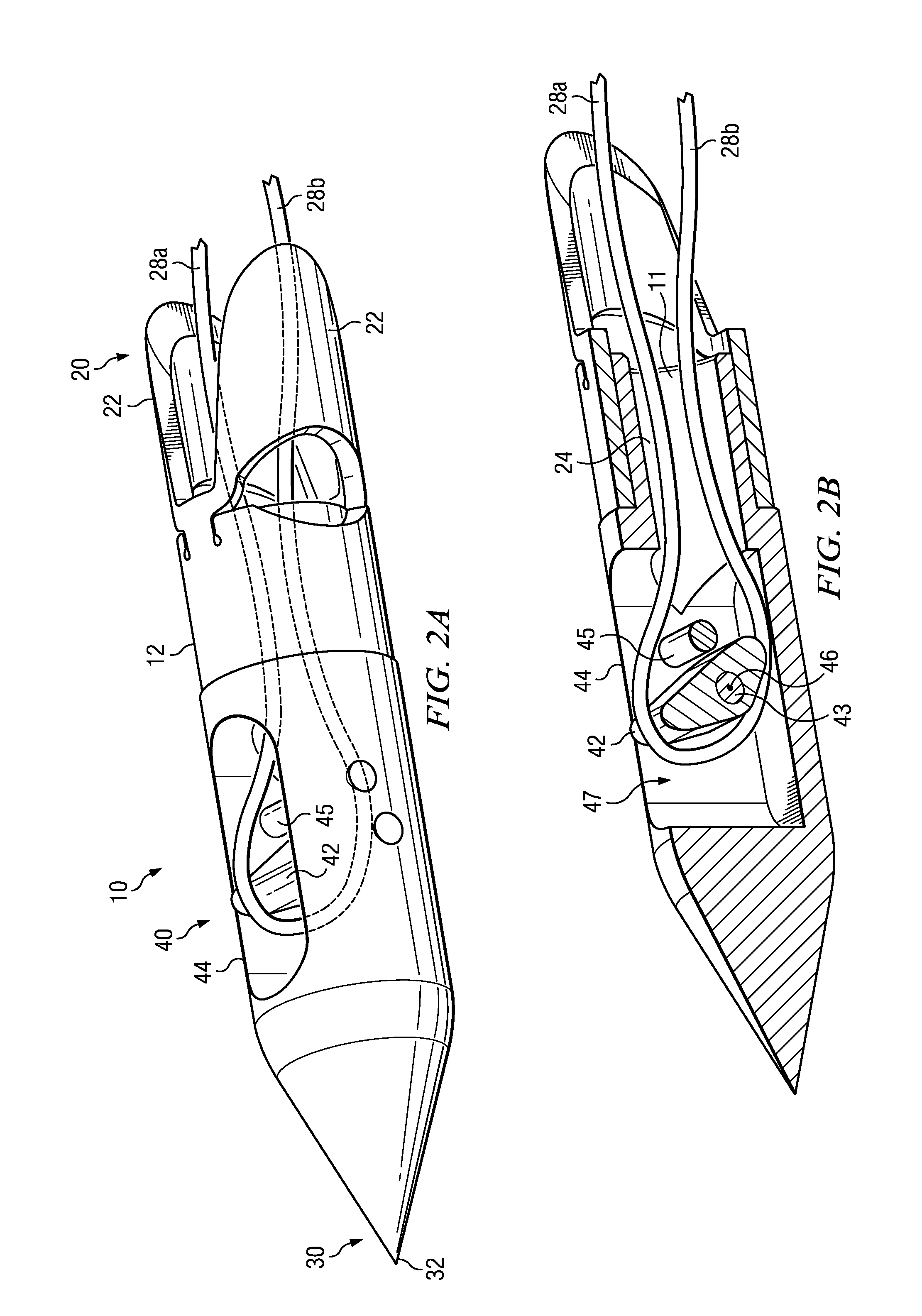

A method for securing suture to bone comprises drilling a hole in a desired portion of bone at a desired procedural site, passing a strand of suture through a portion of soft tissue to be approximated to the portion of bone, and extending the free suture ends proximally from the soft tissue. The suture is loaded into an anchor implant. Using an inserter, on a distal end of which is attached the anchor implant, the anchor implant is manipulated into the bone hole. The suture is then tensioned to a desired level by pulling on the free suture ends, after the anchor implant is positioned in the bone hole. The free suture ends are wrapped about a suture cleat on an inserter handle once the desired tension level is achieved. A proximal anchor component is moved distally to engage with a distal anchor component to lock the anchor in place within the bone hole, and to lock the suture in place within the anchor. Then, the inserter is removed from the procedural site.

Owner:CAYENNE MEDICAL INC

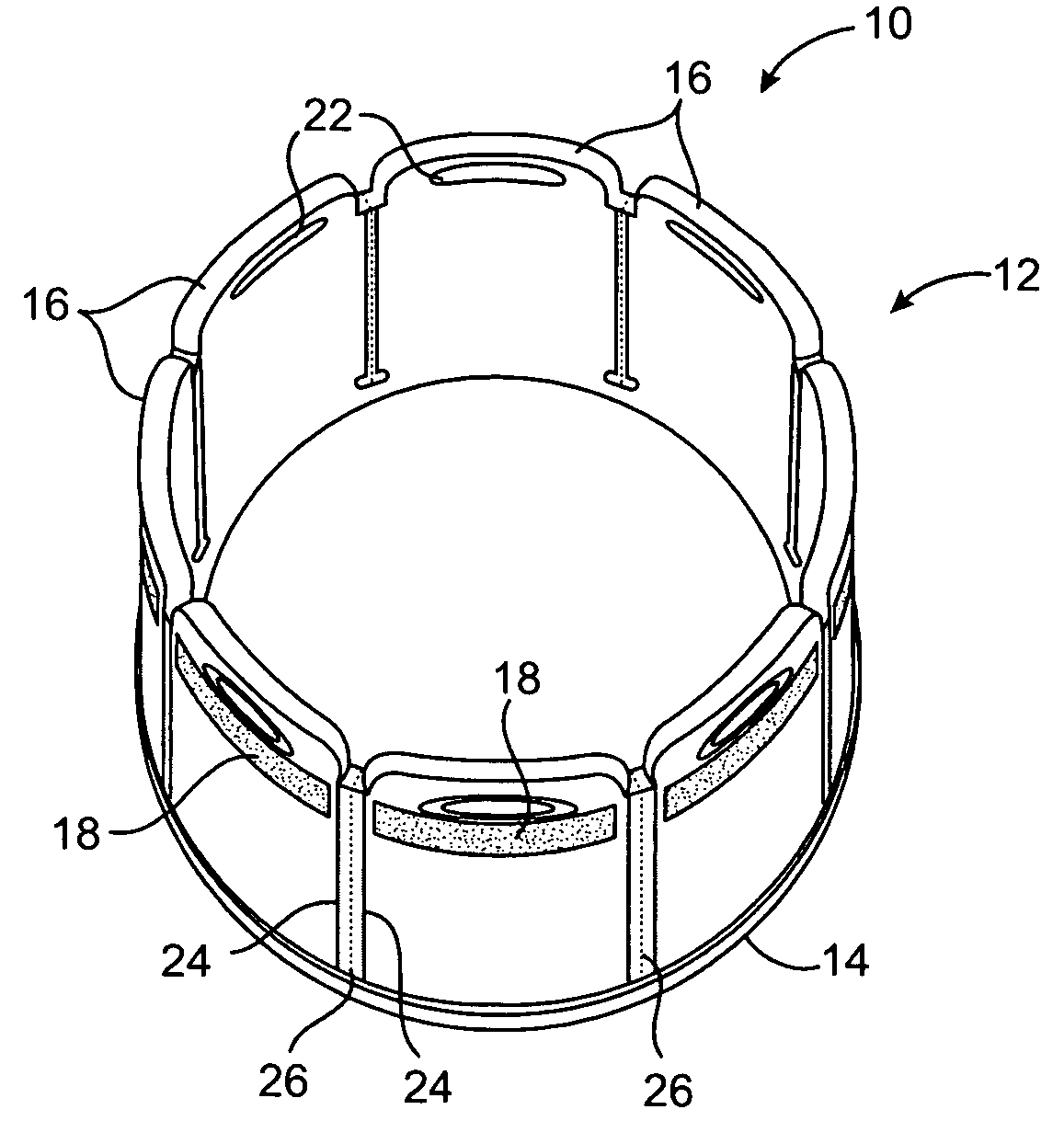

Atraumatic tissue retraction device

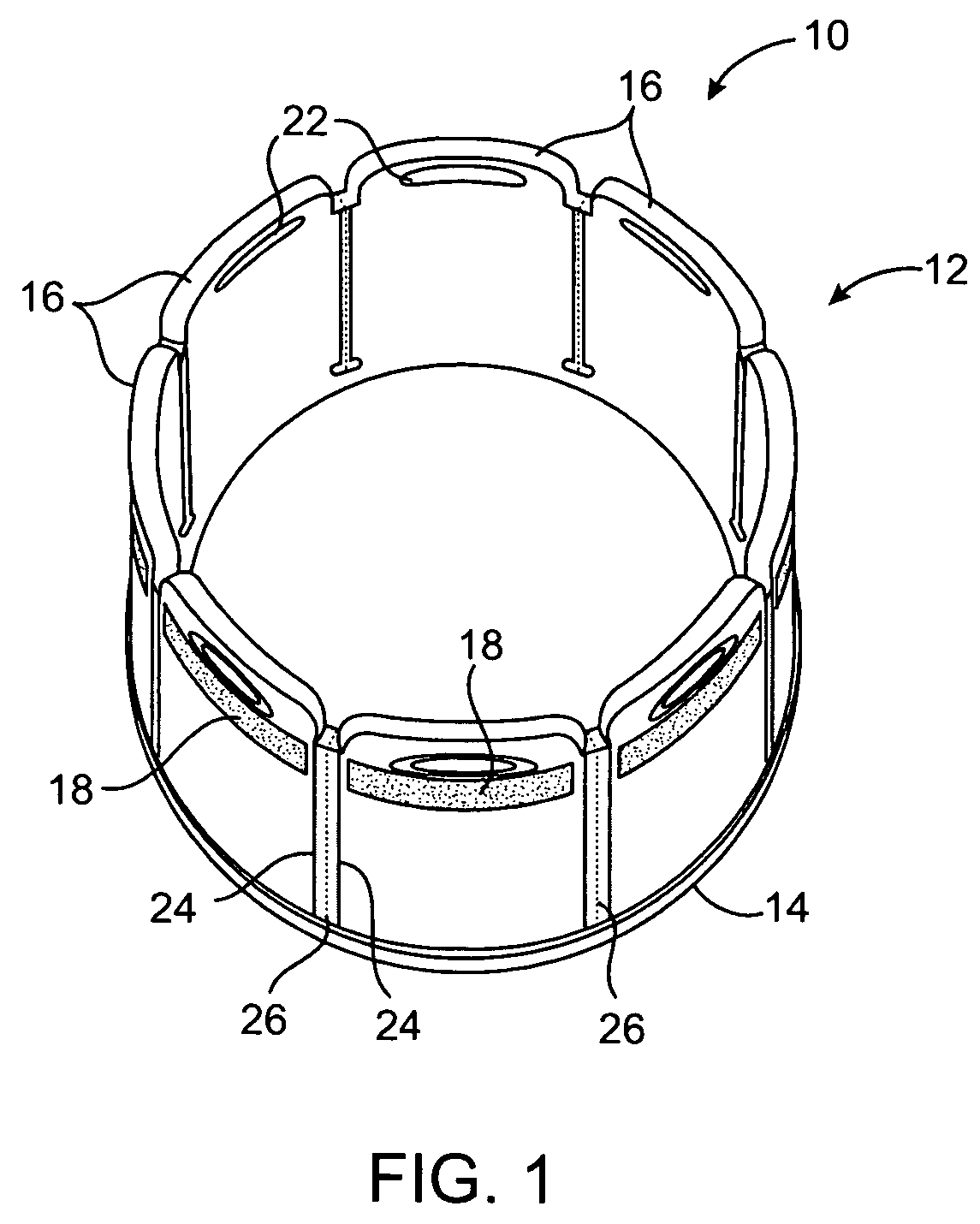

ActiveUS20080103366A1Increase in sizeAdjustable tensionCannulasEndoscopesSurgical incisionSurgical site

Methods and apparatus for a surgical retractor include a ring, a plurality of flexible straps connected to the ring, a patch of hook or loop material connected to each strap, a coordinating patch of hook or loop material connectable to the patient's skin or the surgical drape. The flexible straps of the surgical retractor may be frangibly connected together. LEDs molded into the distal end create a light source to illuminate the surgical site. The ring may take several forms including a flexible or adjustable ring and an inflatable bladder. The ring of the surgical retractor is inserted into the surgical incision, a patch of loop fastener is attached to the patient, a set of straps connected to the ring are pulled outward and the hook portion is applied to the loop portion to hold the incision open. The retractor is useable for thoracic and other types of surgery.

Owner:ATRICURE

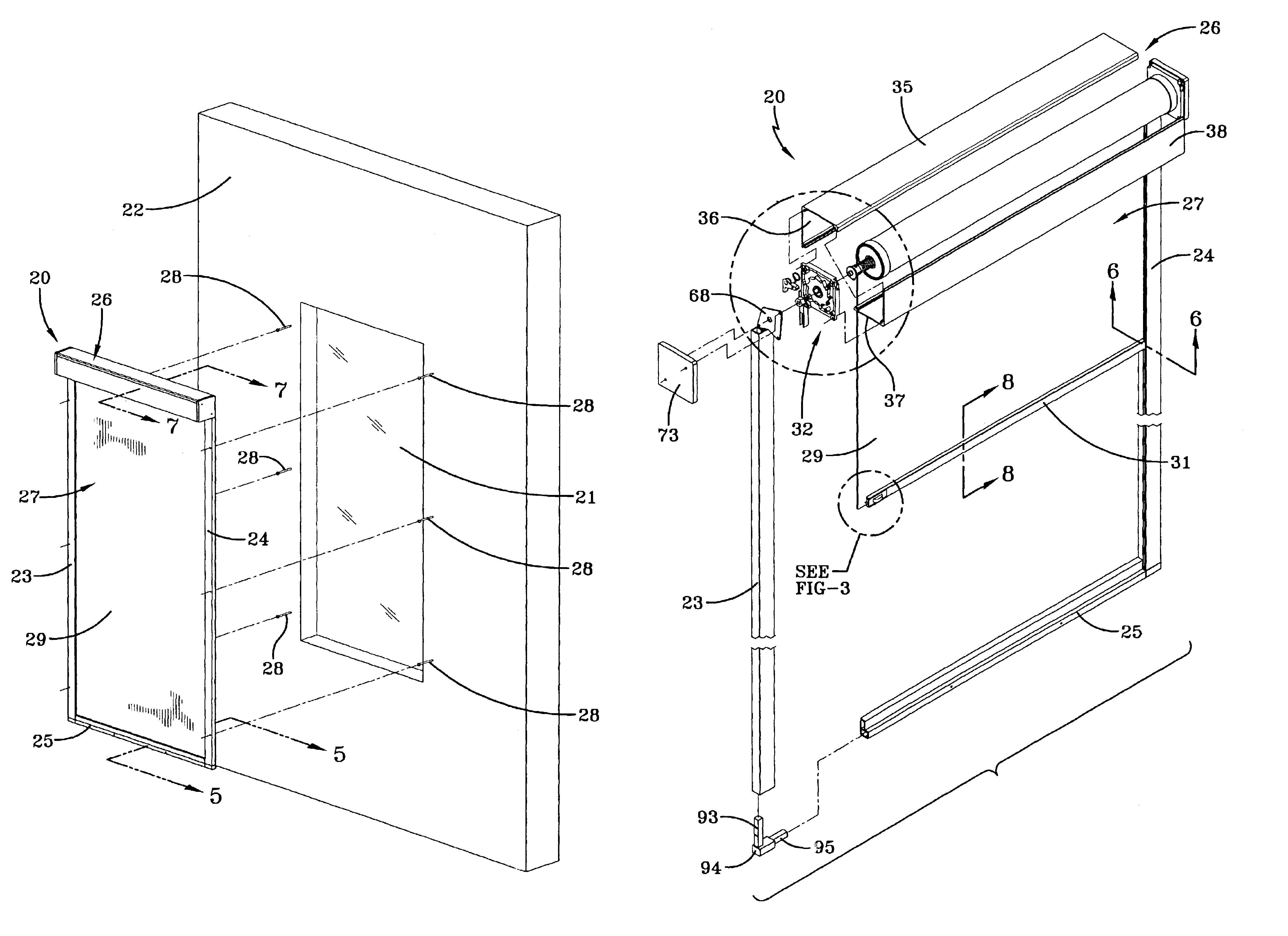

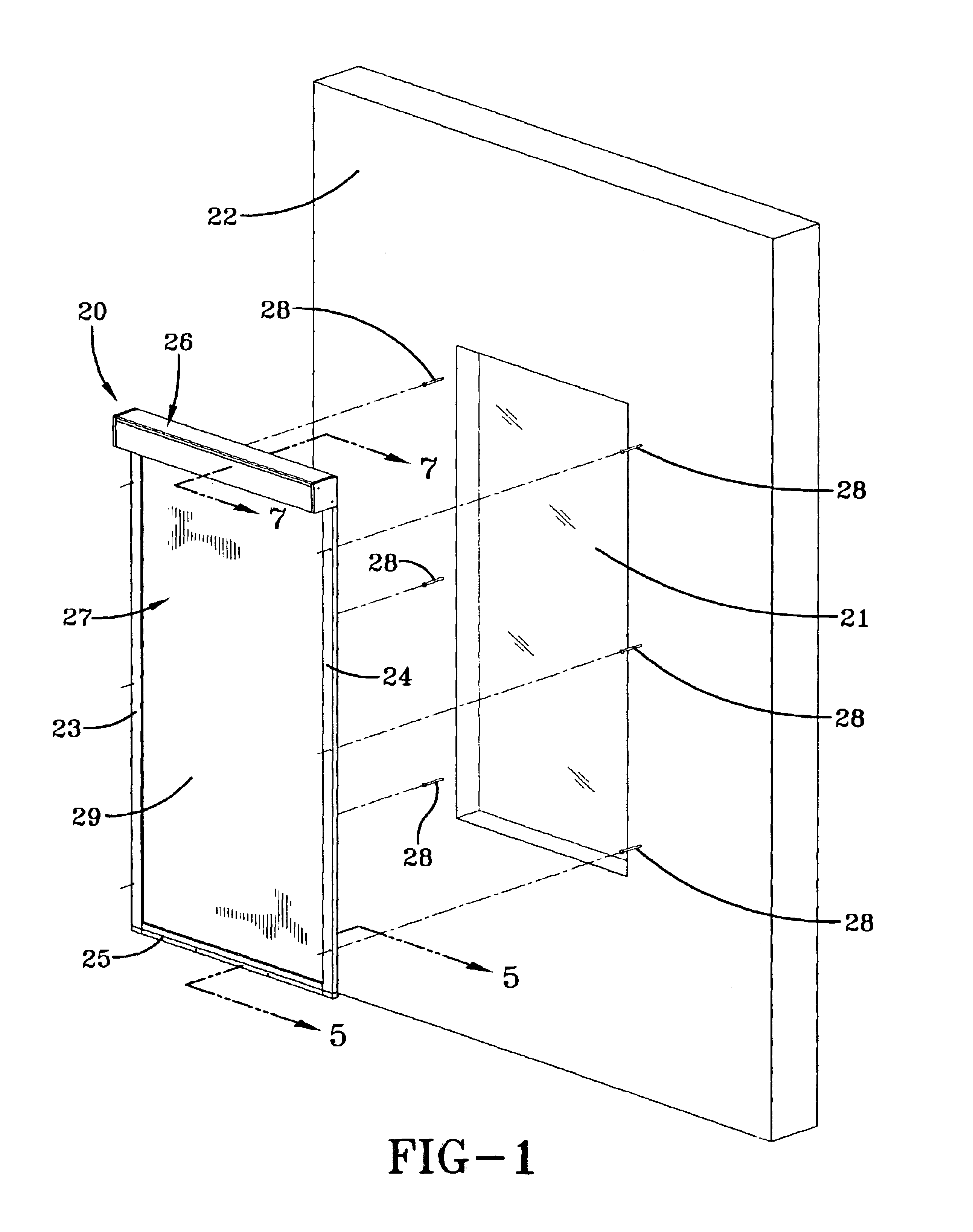

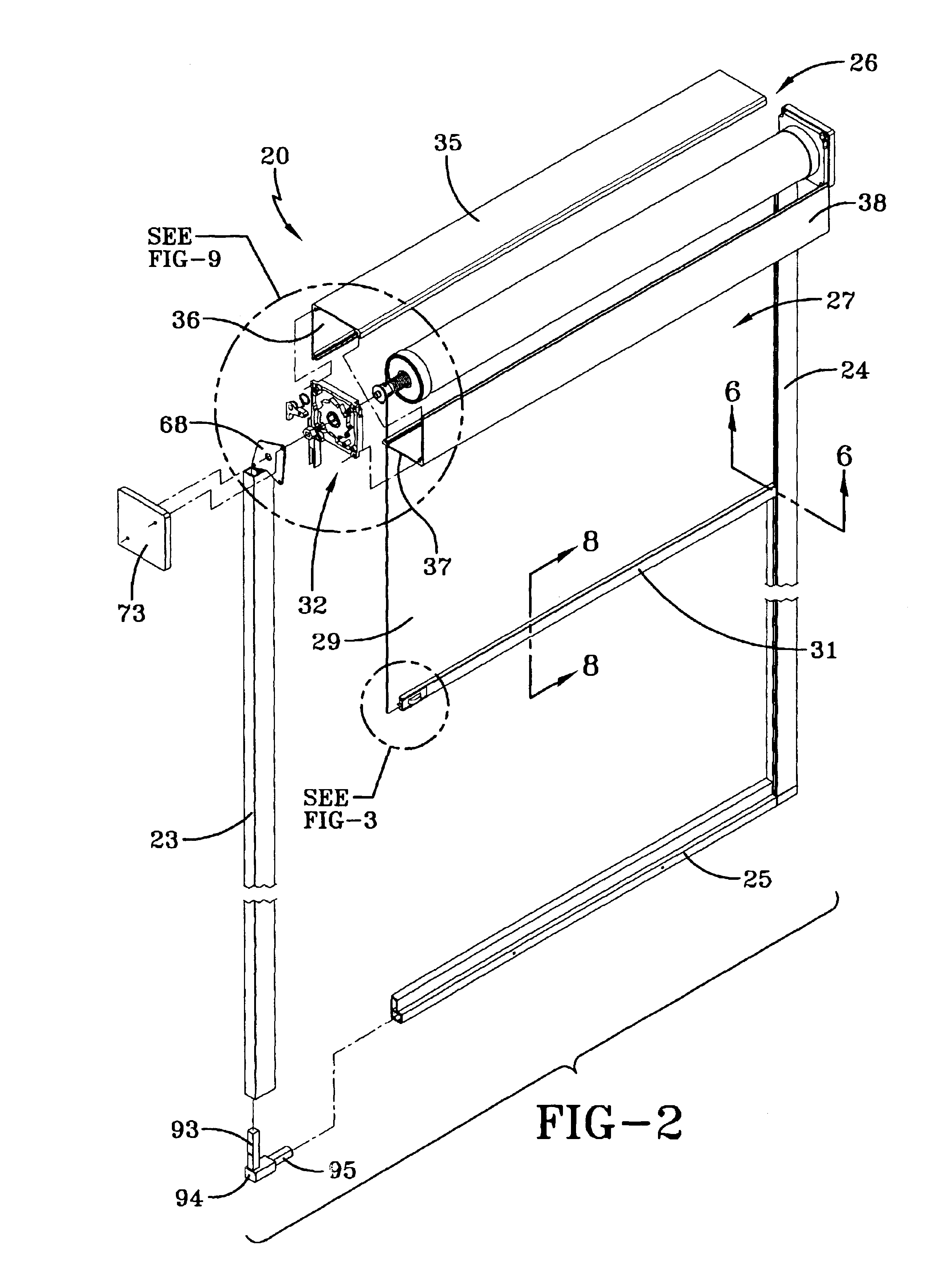

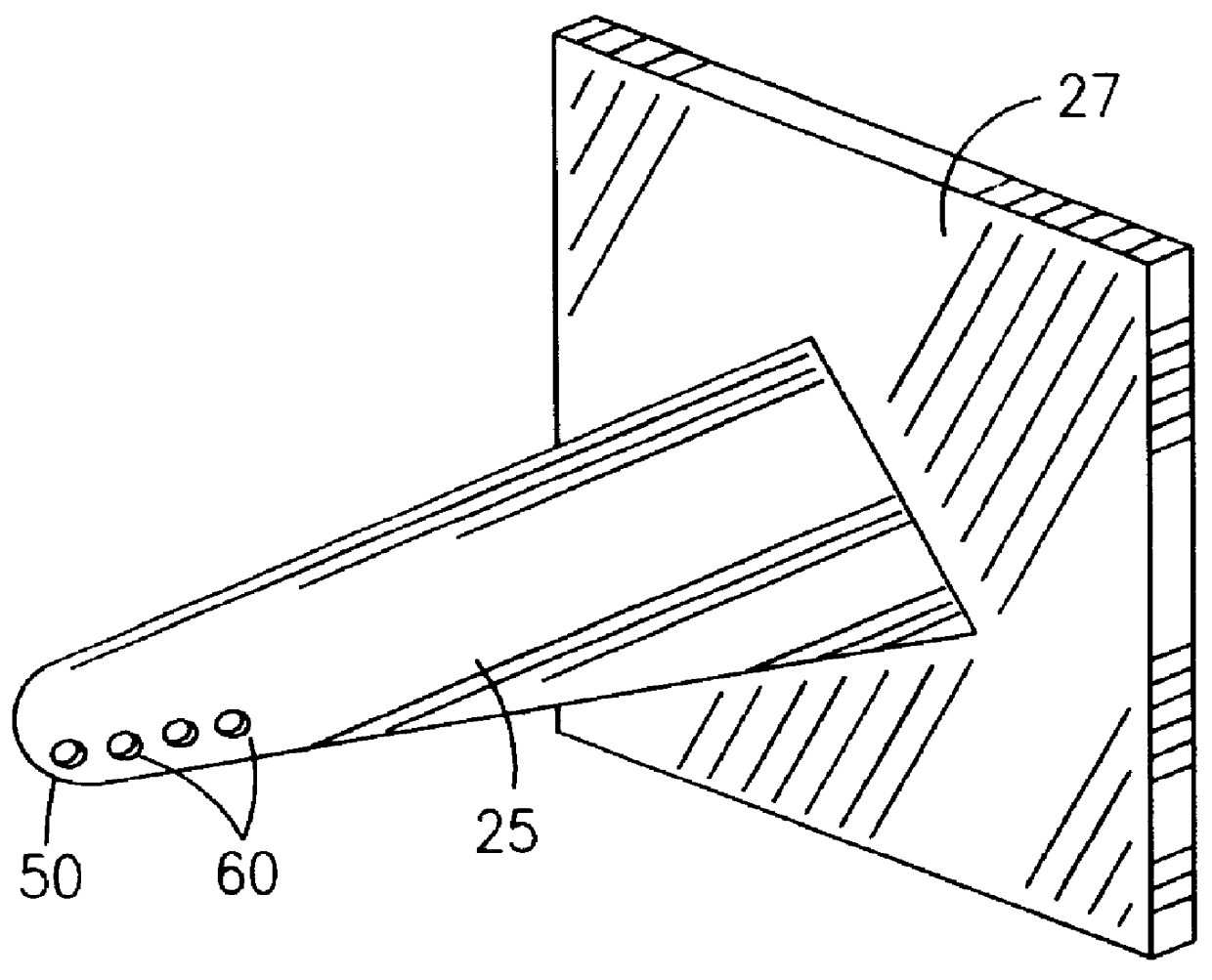

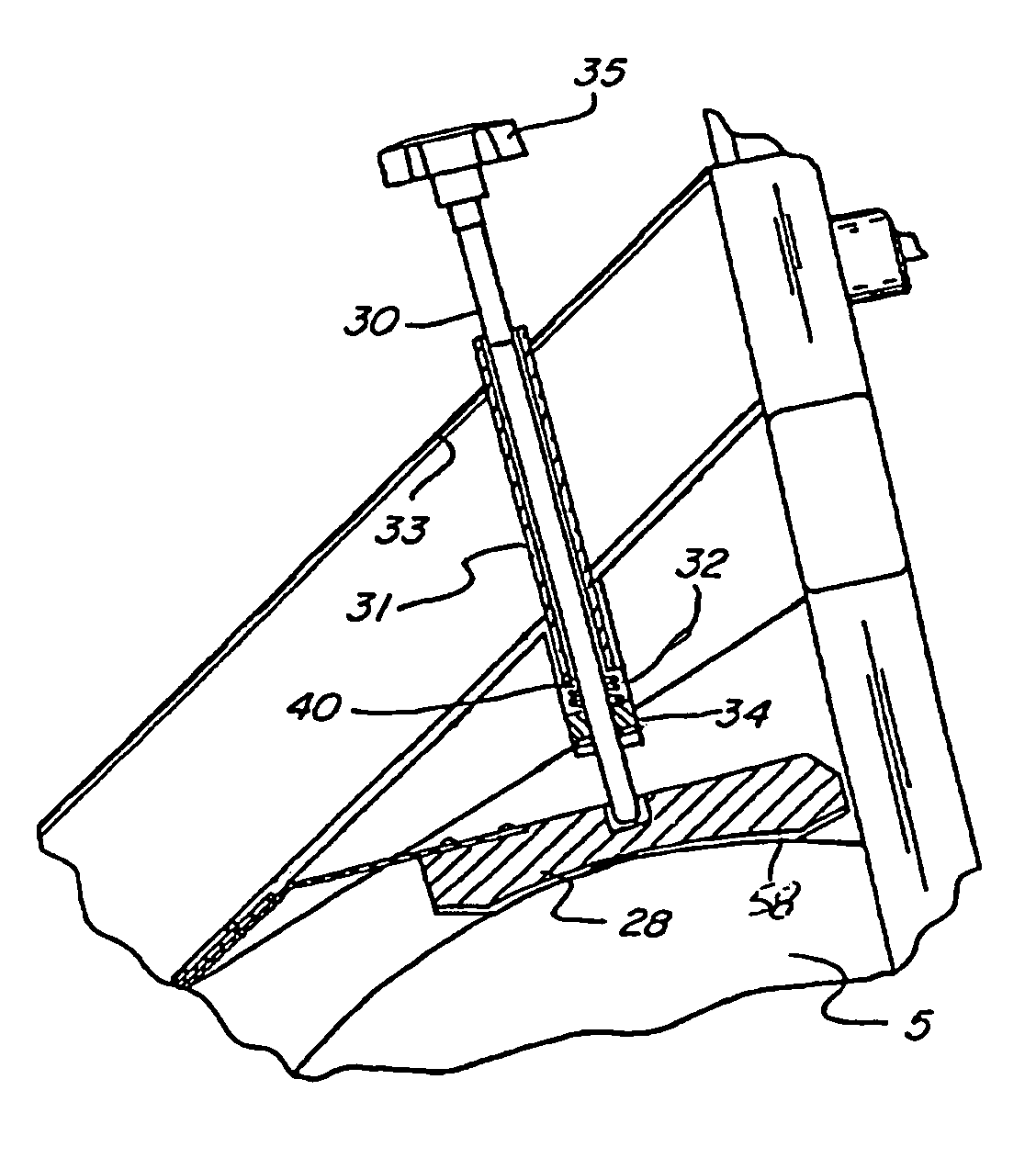

Apparatus for covering an opening in a building

InactiveUS6959748B2Adjust the tensionAdjustable tensionShutters/ movable grillesCurtain suspension devicesWindow openingEngineering

A storm protector (20) to be attachable over a window (21) or other opening of a building (22) includes a header (26), a bottom sill (25) and side frames (23, 24) extending between the ends of the header (26) and the sill (25). The header (26) carries a tube (53) which has one end of a curtain assembly (27) attached thereto. The curtain assembly (27)is biased by a spring (54) to be normally coiled on the tube (53), but the curtain assembly (27) may be manually moved along the frames (23, 24) to the sill (25) to cover the window opening (21). A bar (31) is formed at the other end of the curtain assembly (27), and the bar (31) carries a guide and lock assembly (110) which rides in and can engage at least one of the side frames (23, 24) to guide and selectively hold the curtain assembly (27) at any selected position along the side frames (23, 24). A tensioning assembly (32) is positioned in the header (26) and, without disassembling the protector (20), it may be accessed to adjust the tension of the spring (54). The header (26) includes a sealing surface (50), the sill (25) includes a sealing surface (105) and each side frame (23, 24) includes a sealing surface (89). A force upon the curtain assembly (27) causes it to engage the sealing surfaces (50, 89, 105) to provide a full perimeter seal around the window opening (21).

Owner:OVERHEAD DOOR

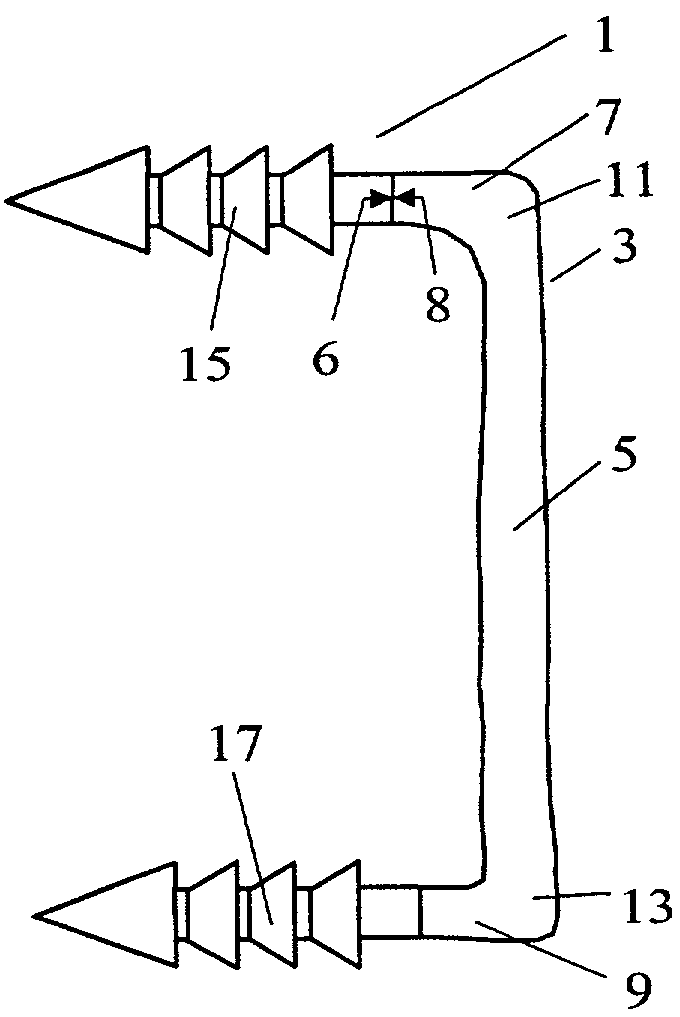

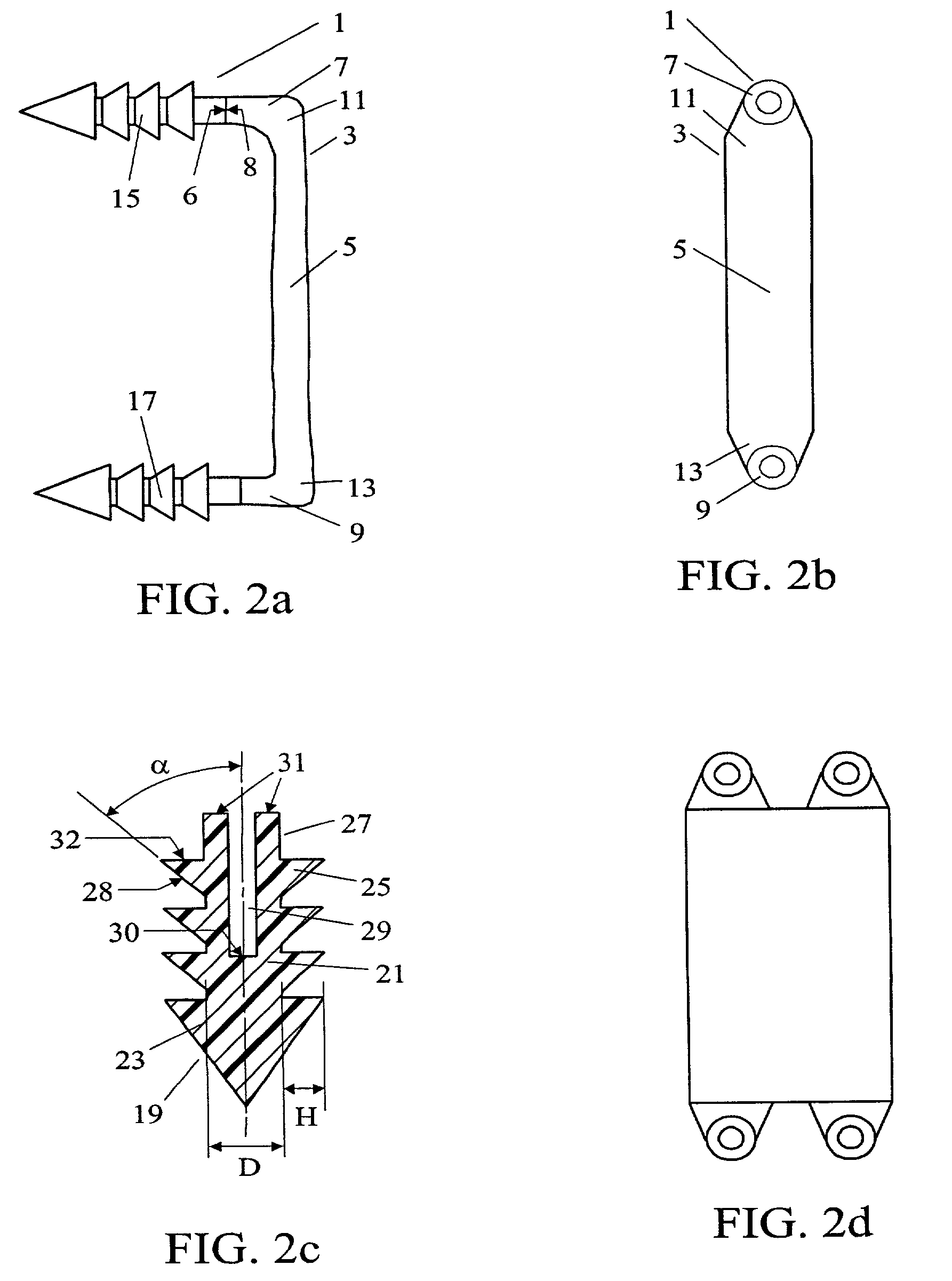

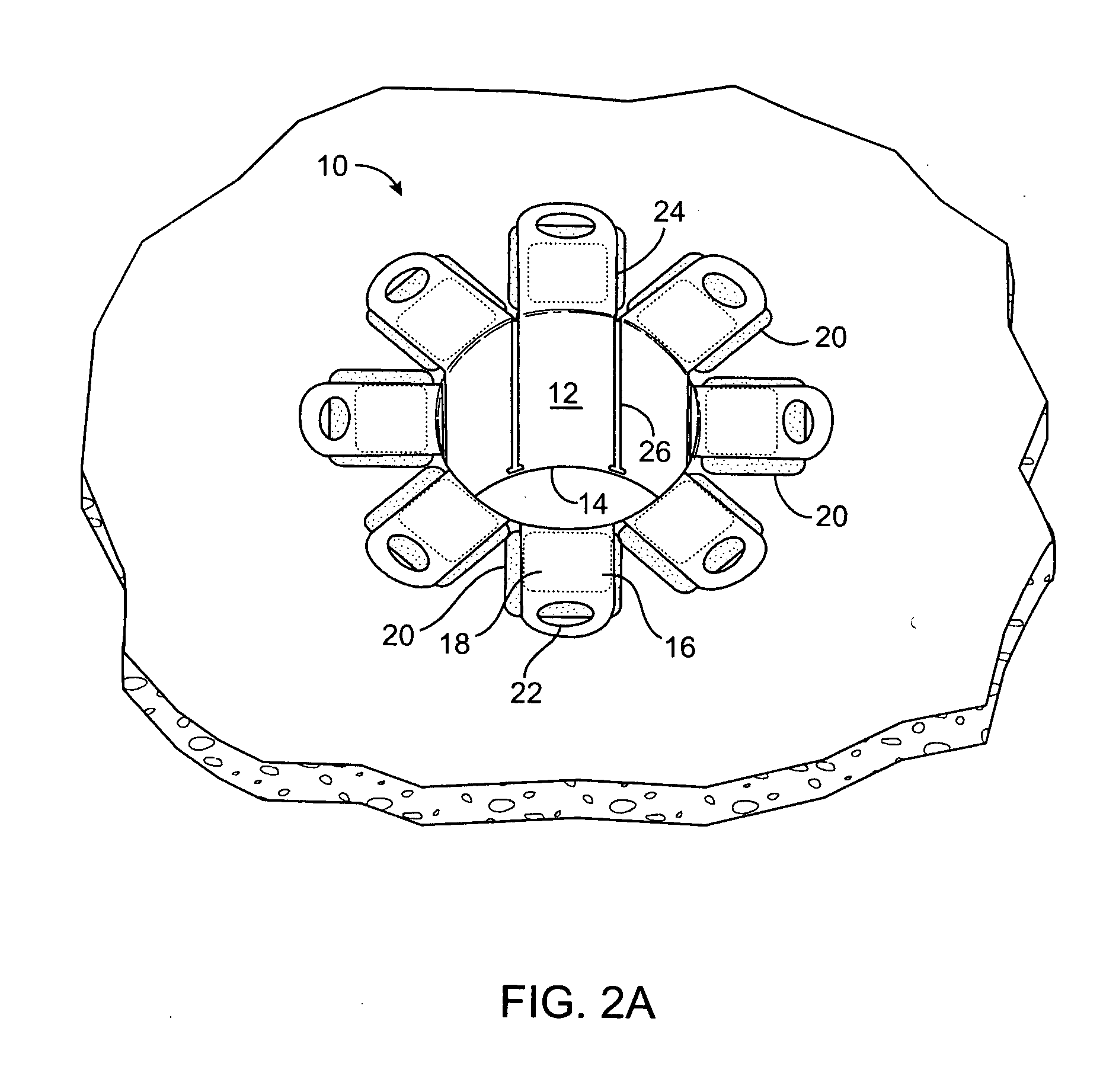

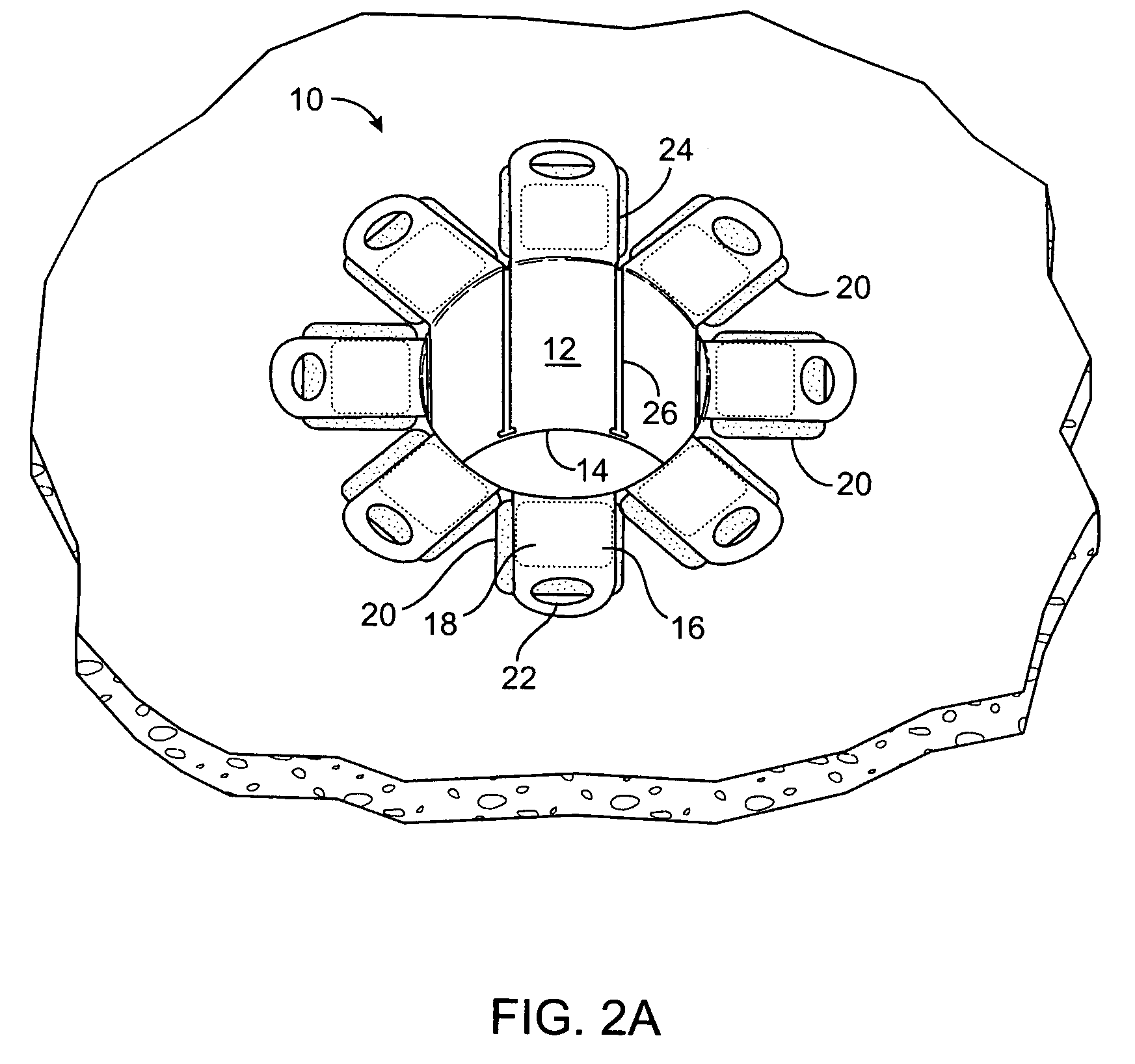

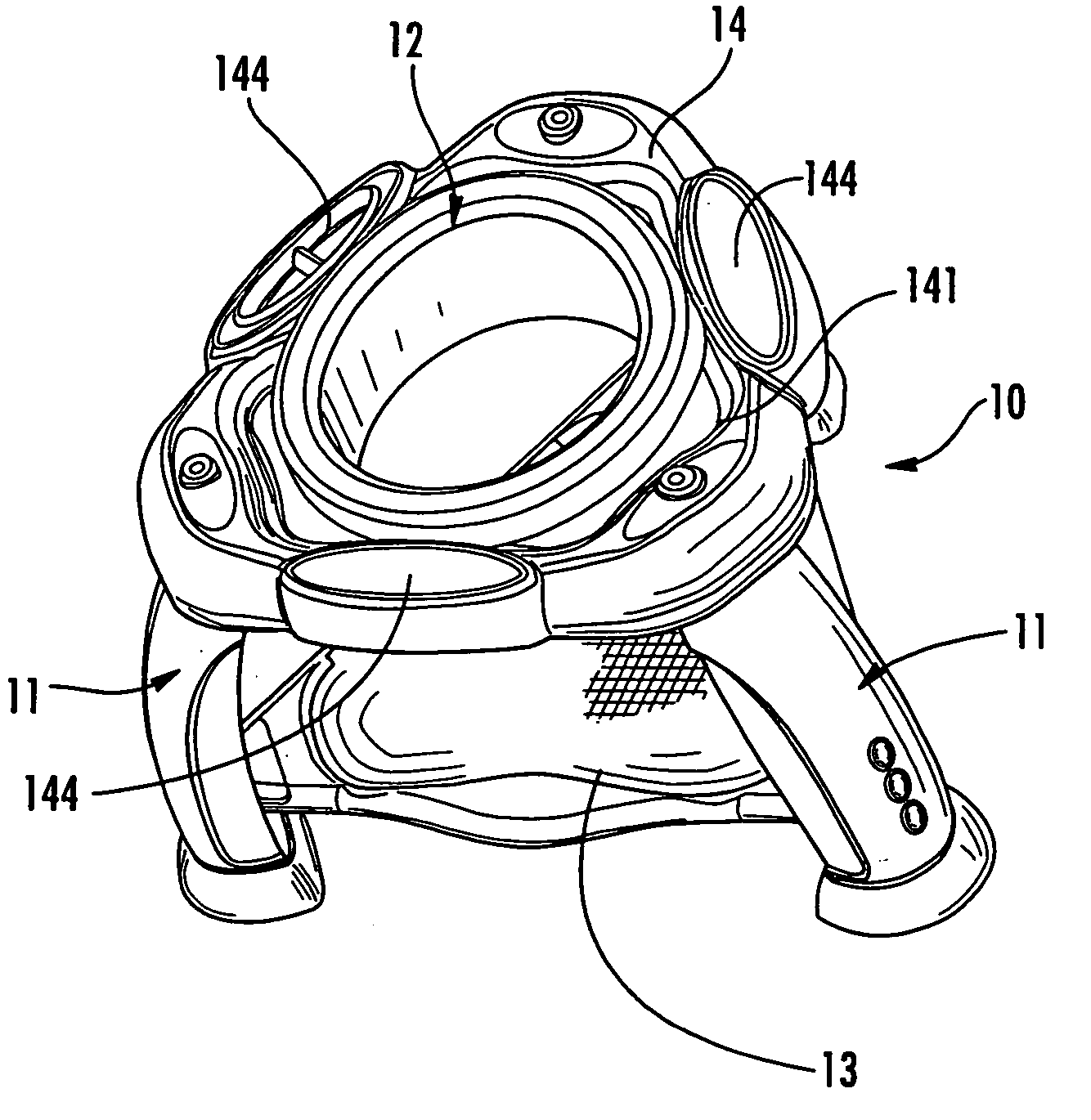

Skin Tensioner for Hair Transplantation

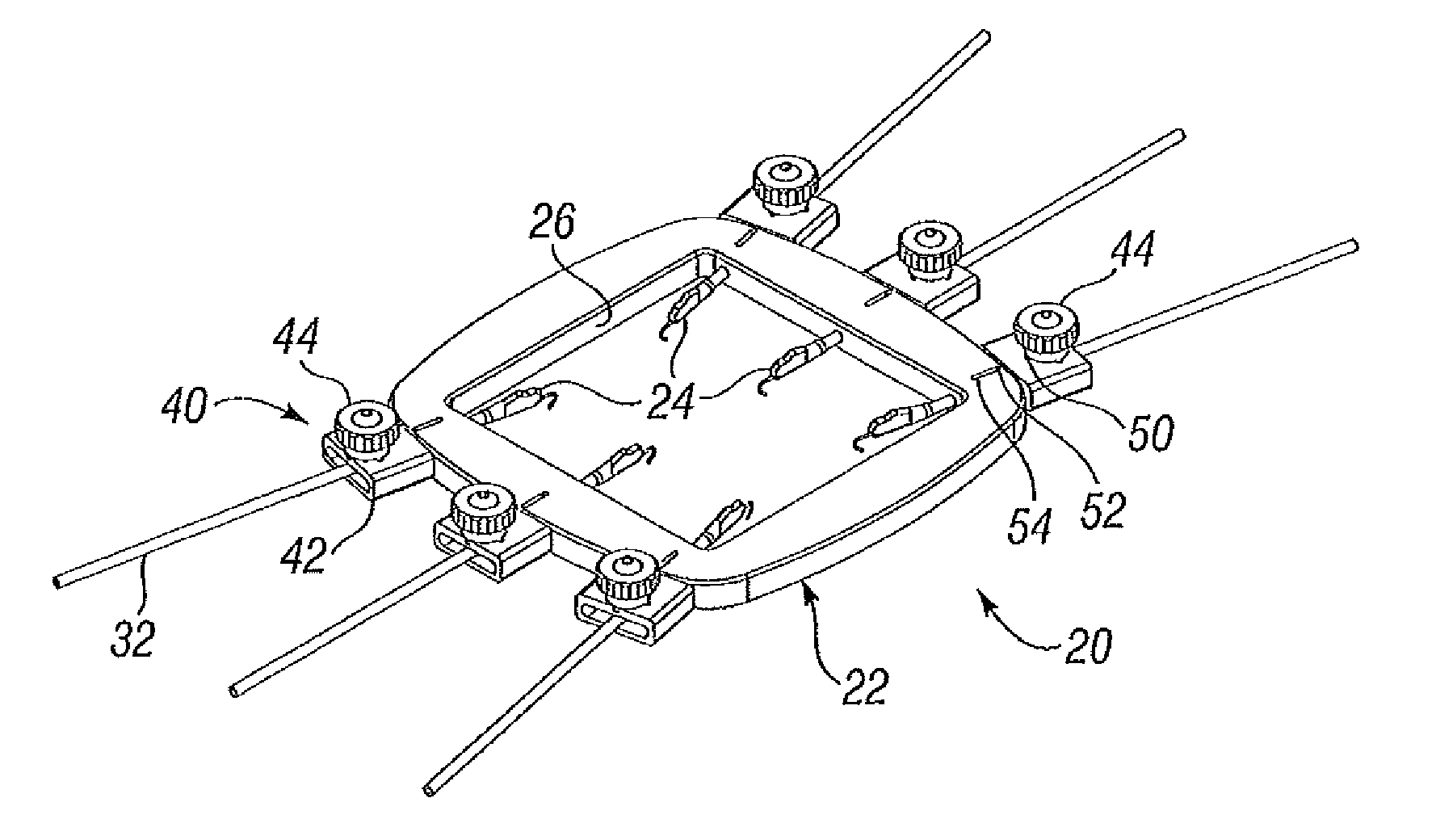

ActiveUS20100191253A1Efficient use ofEasy to disassembleSkin implantsDiagnosticsPull forceGraft transplant

Devices and methods for applying tension to an area of skin, in particular for follicular unit removal and implant in a hair transplantation procedure are provided. The devices may include a frame with at least two skin contact members that hold to the skin. Also disclosed are various ways to apply a force displacing the skin contact members apart, thus creating tension in the skin therebetween. The devices and methods may incorporate suction that helps the skin contact members securely hold to the skin. Barbs or microbarbs also may be used to help secure the skin contact members to the skin. The frame may surround the skin area with tensile forces applied outward in multiple directions, or the frame may be a bifurcated pair of fingers that applies tension substantially uni-directionally. Adjusting members and indicators may be provided to control and display the magnitude of tensile force applied to skin. The tensioning devices and methods may be incorporated into a robotic hair transplantation system.

Owner:VENUS CONCEPT INC

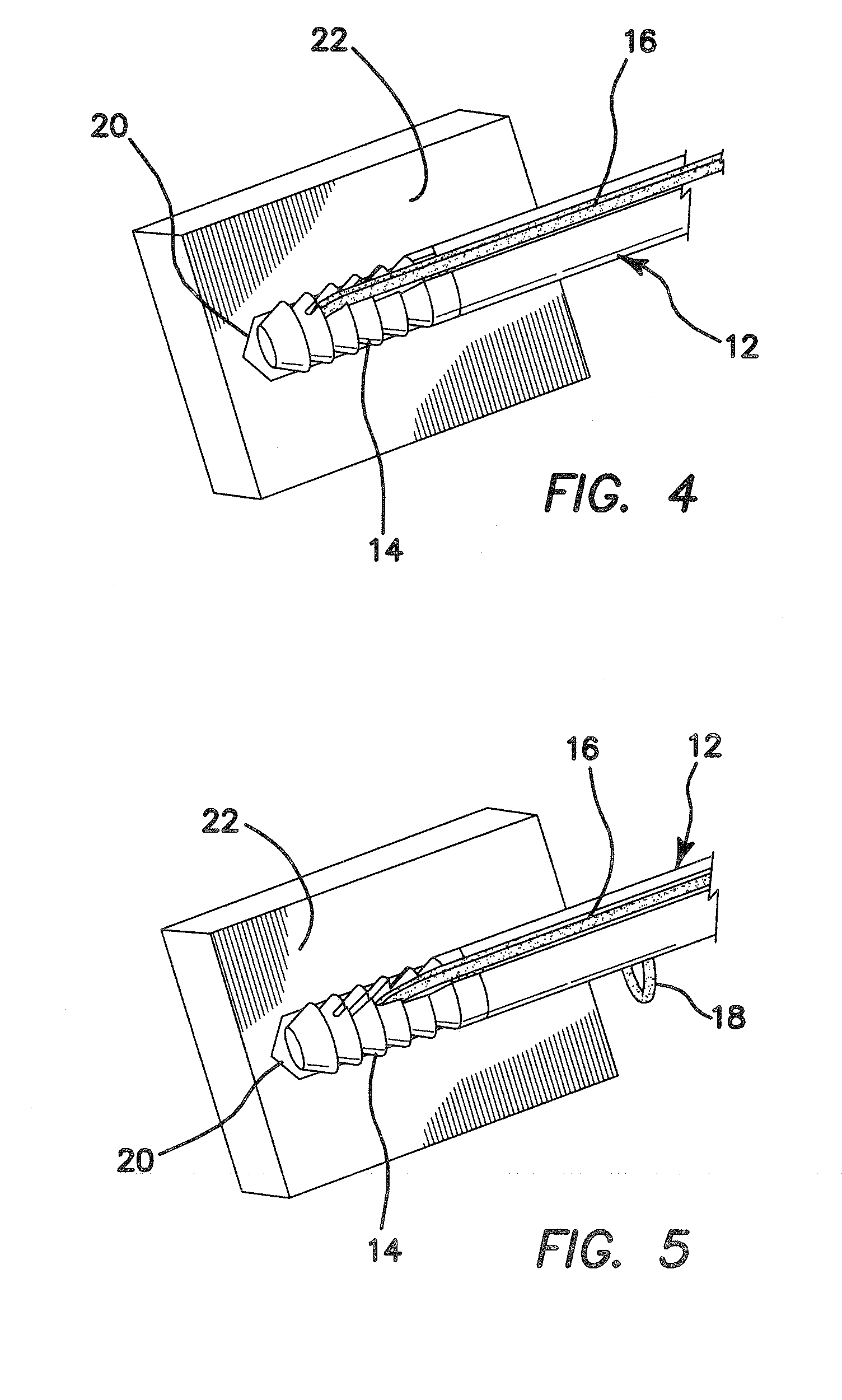

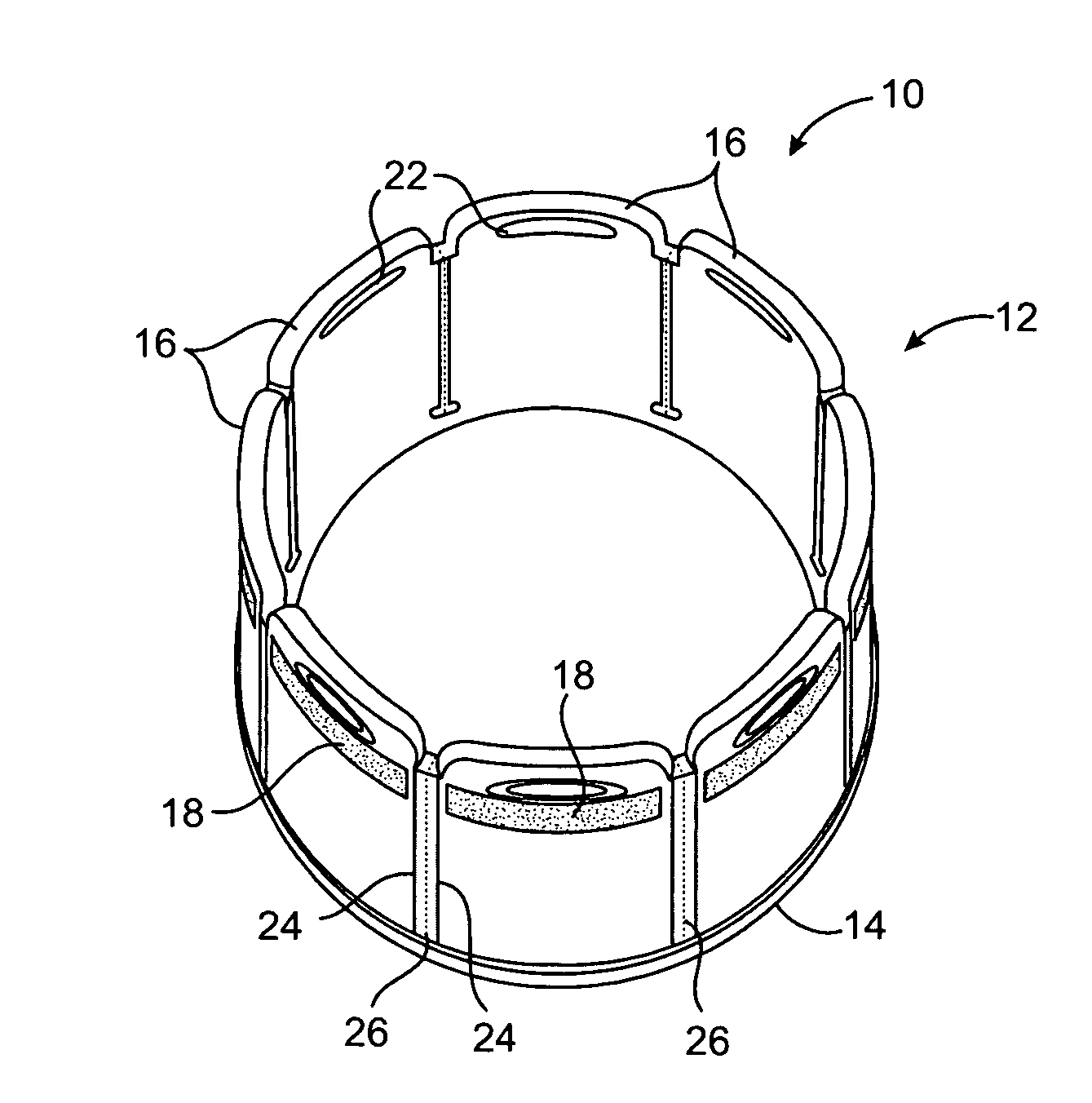

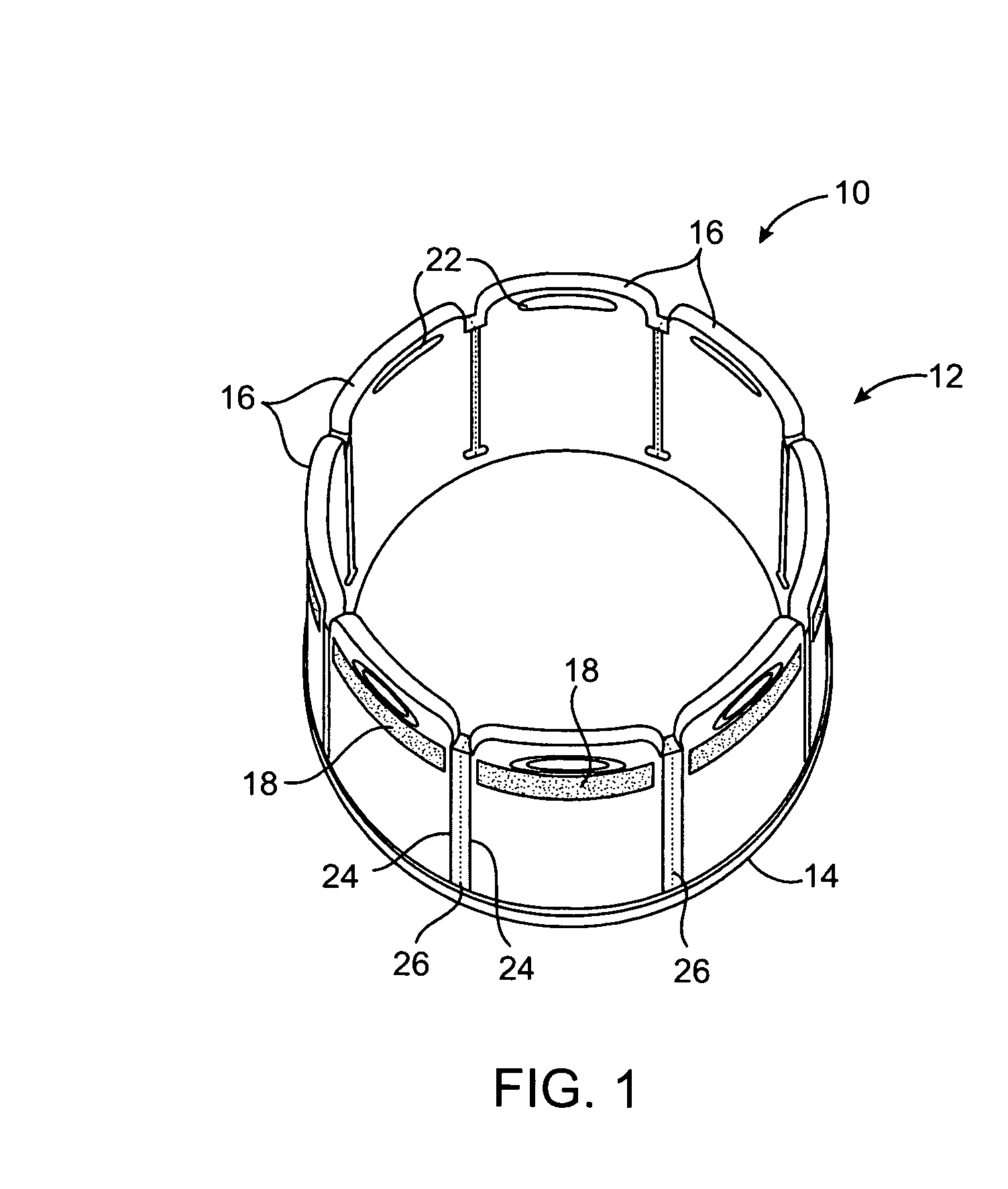

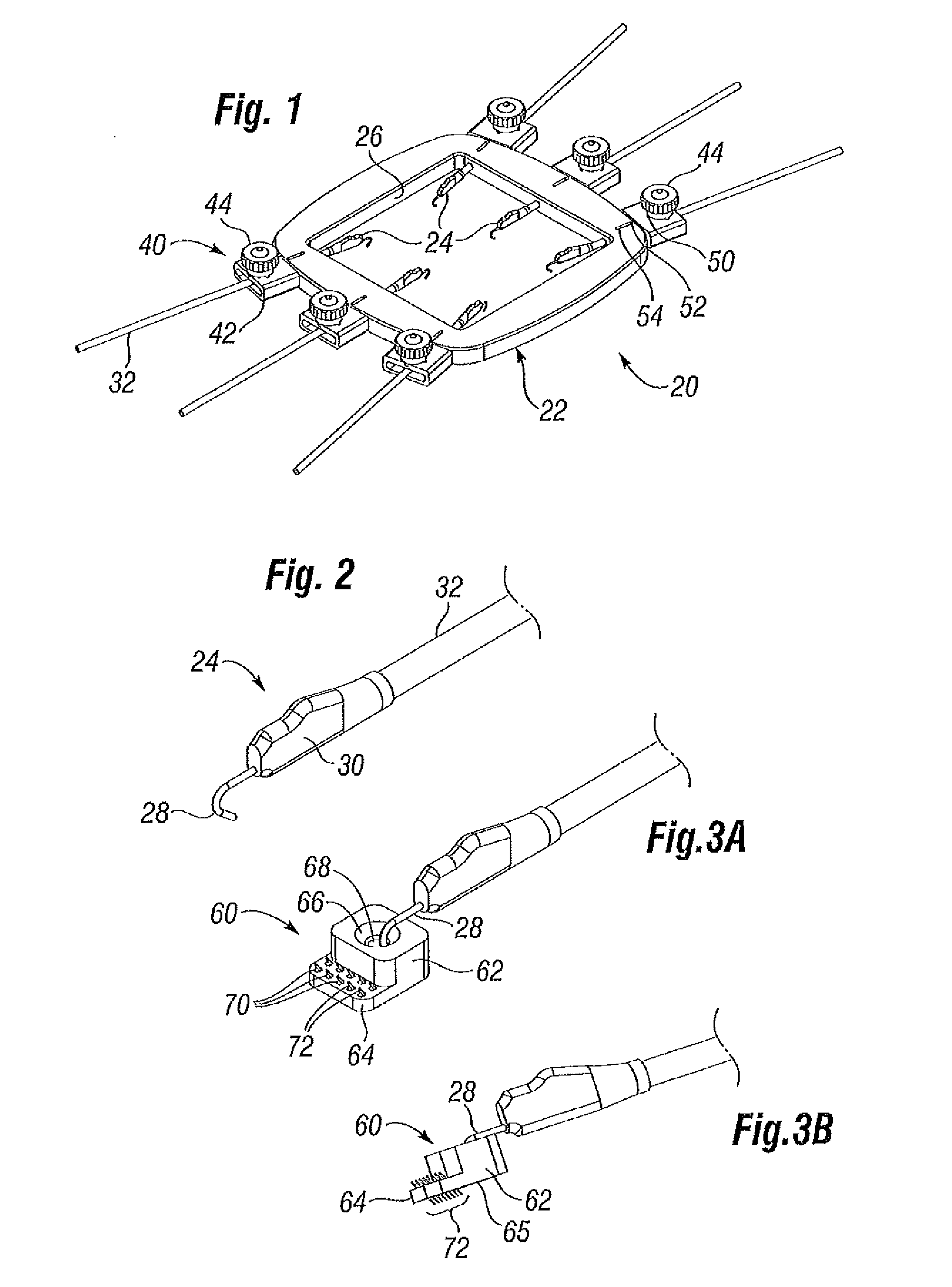

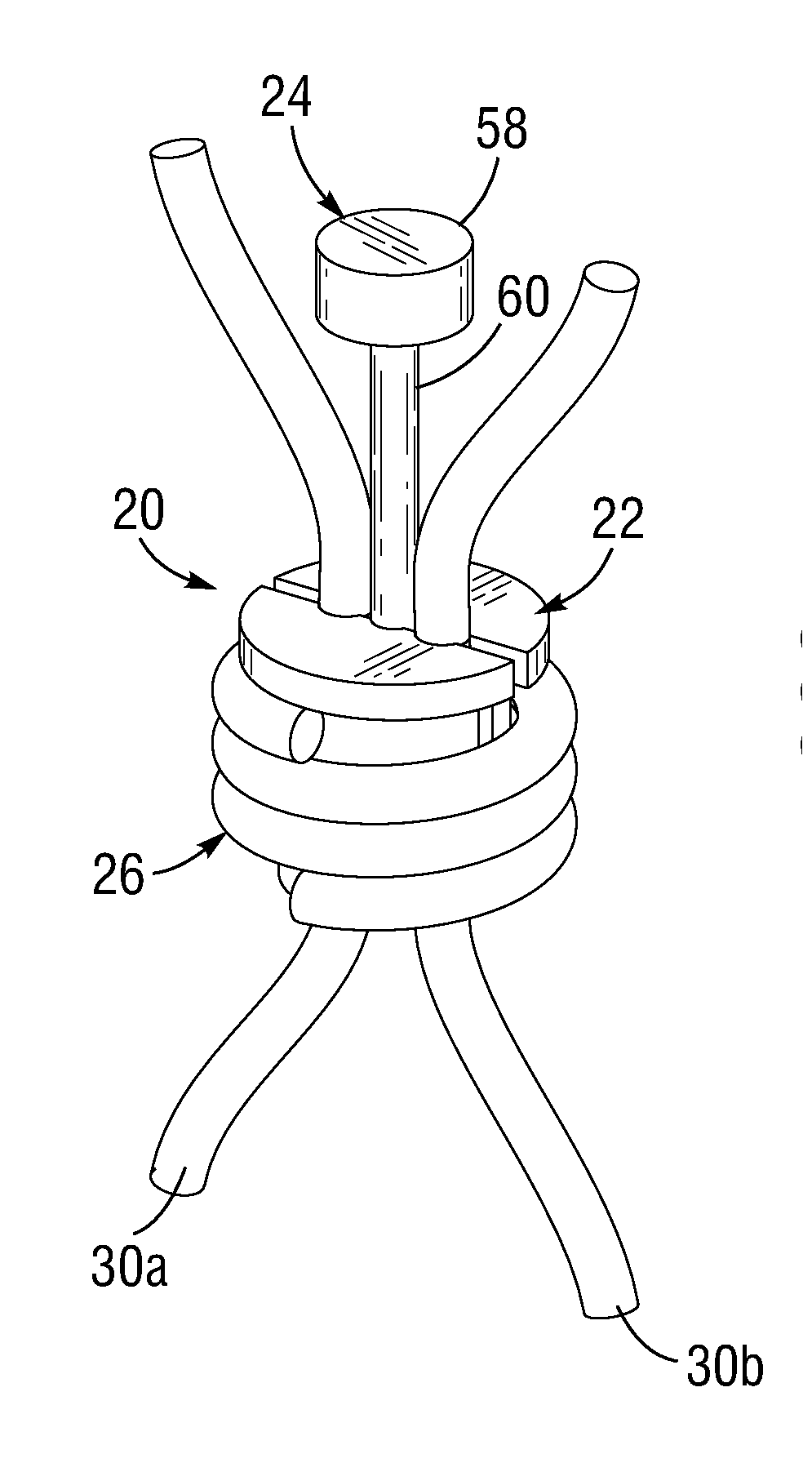

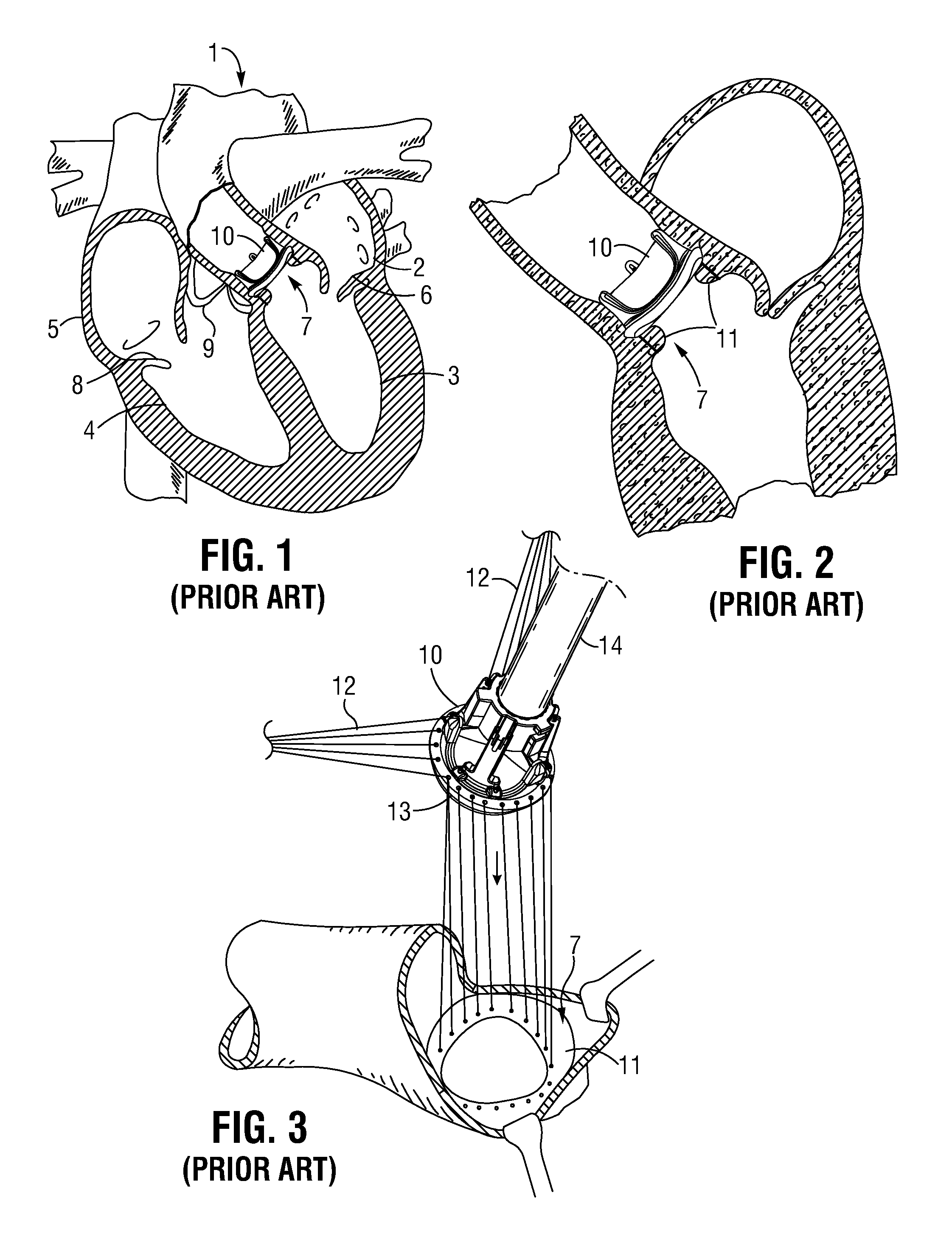

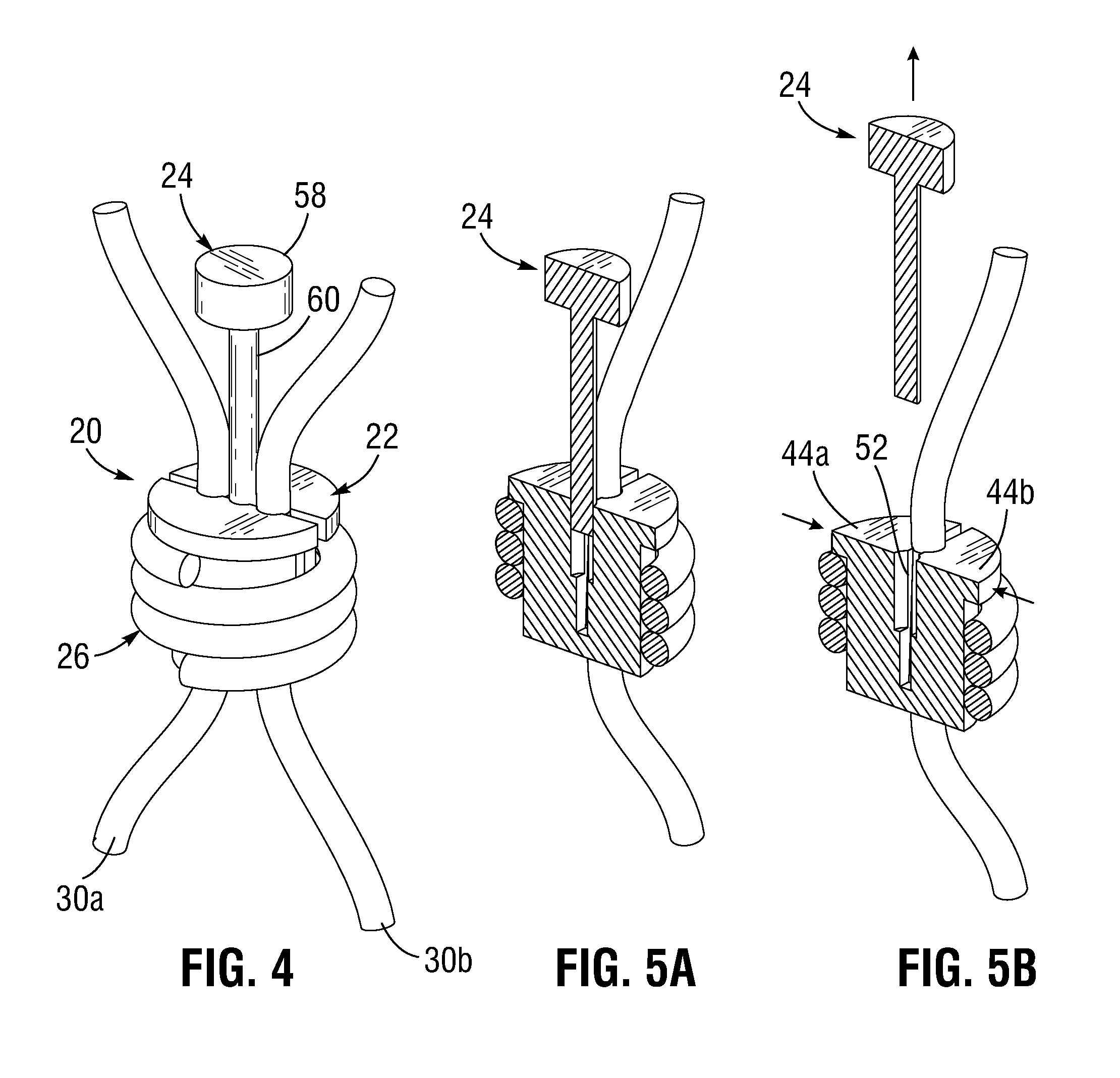

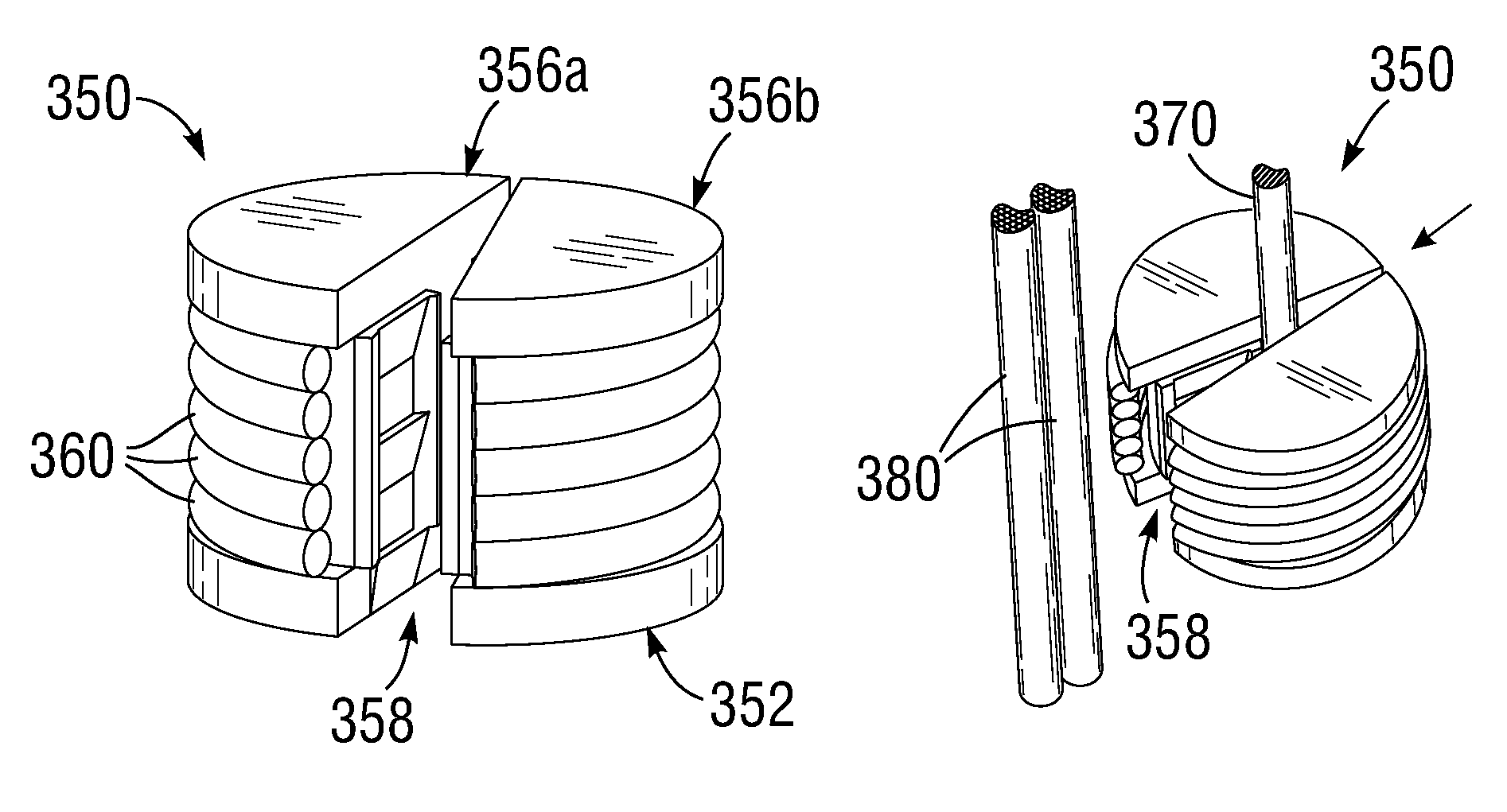

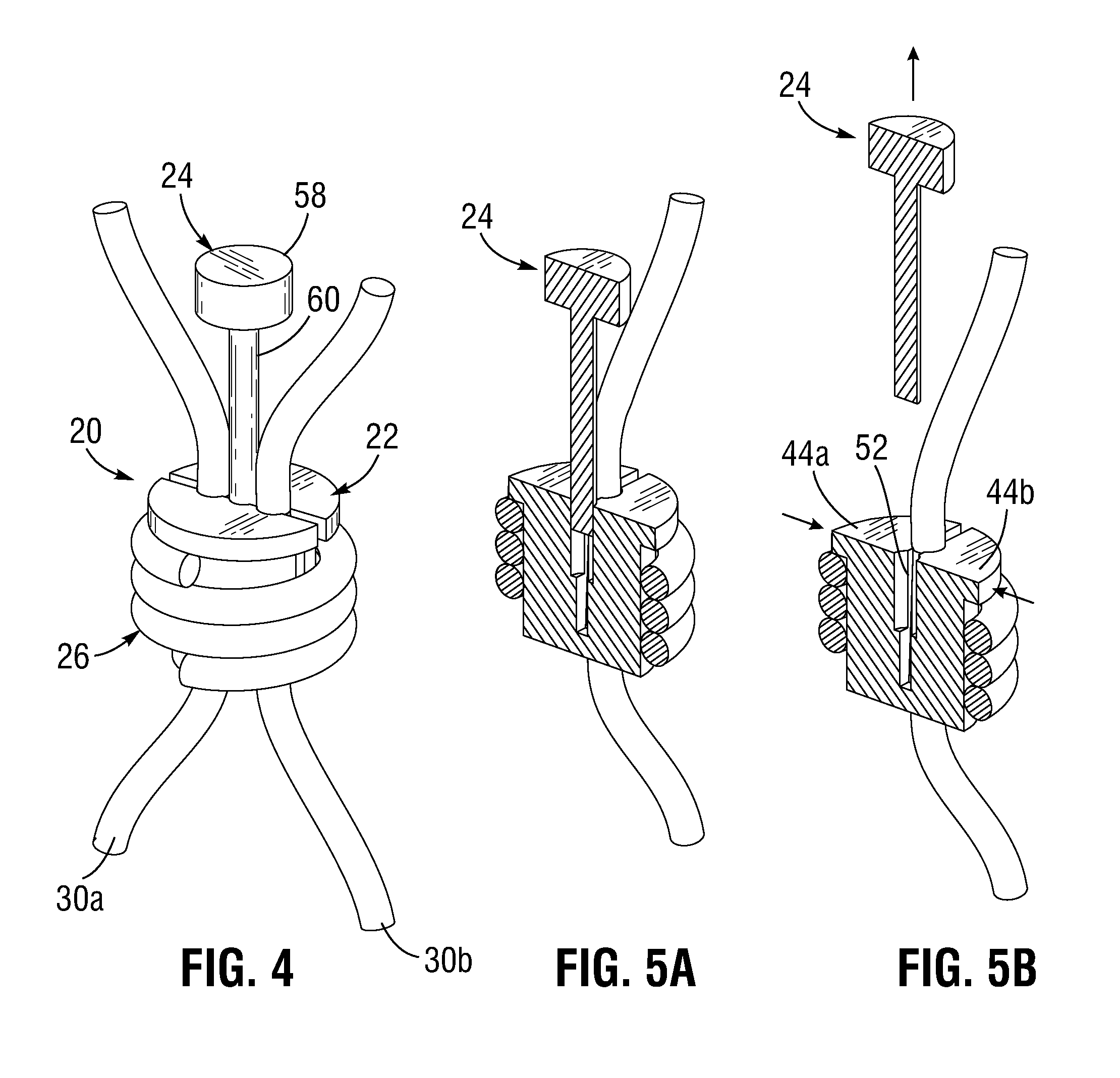

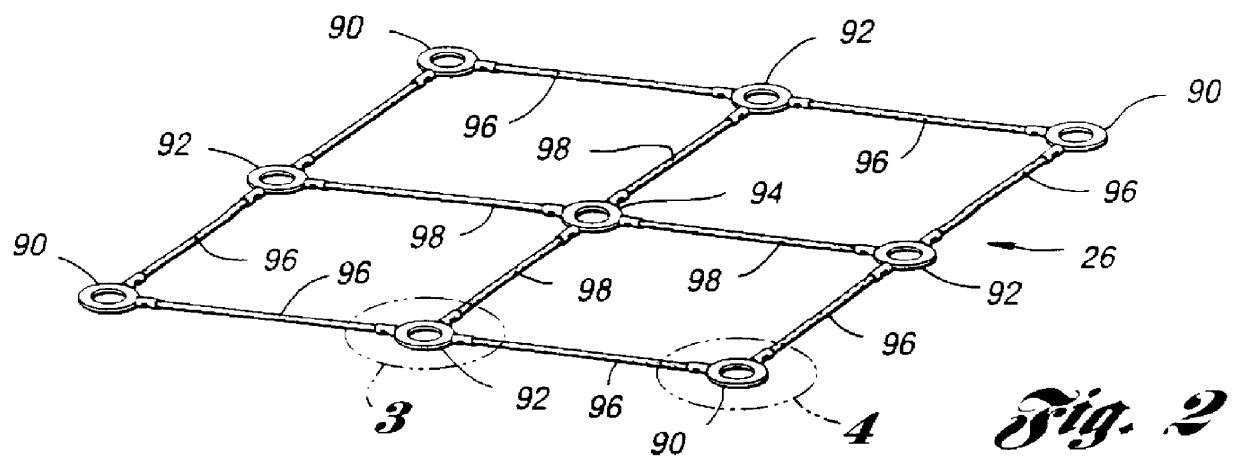

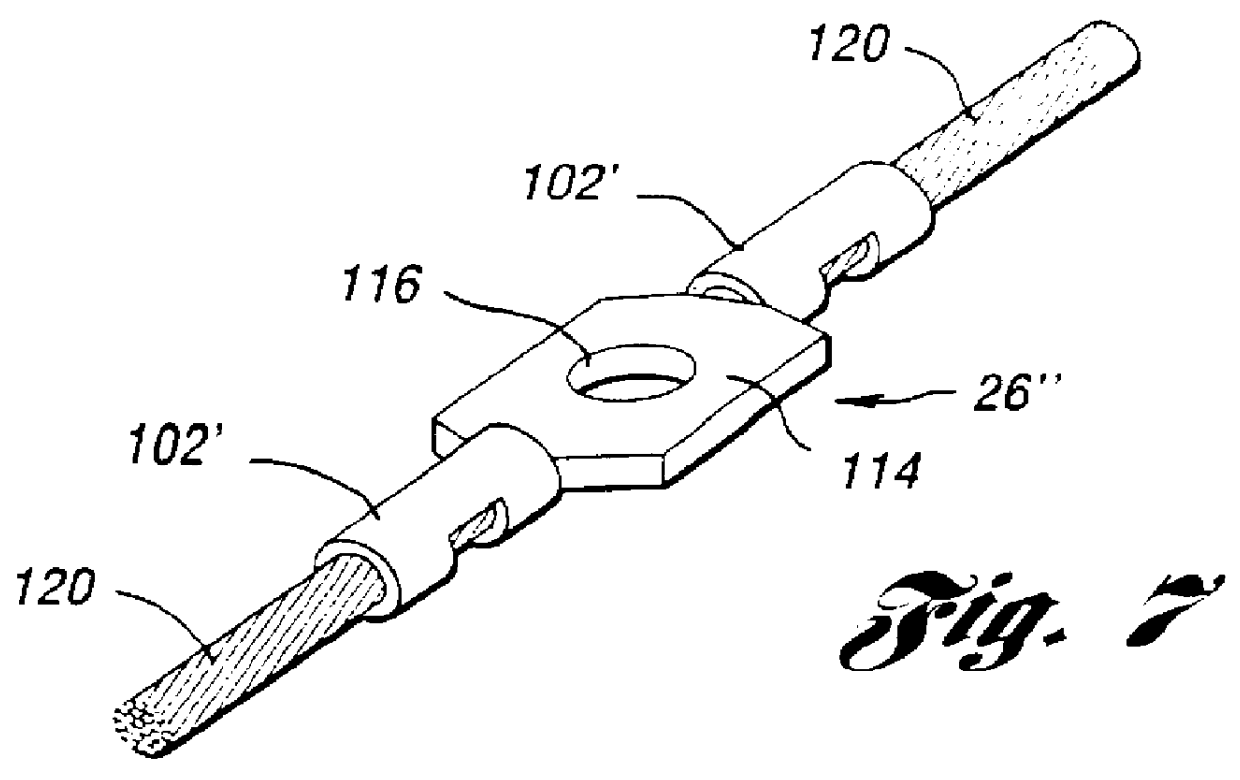

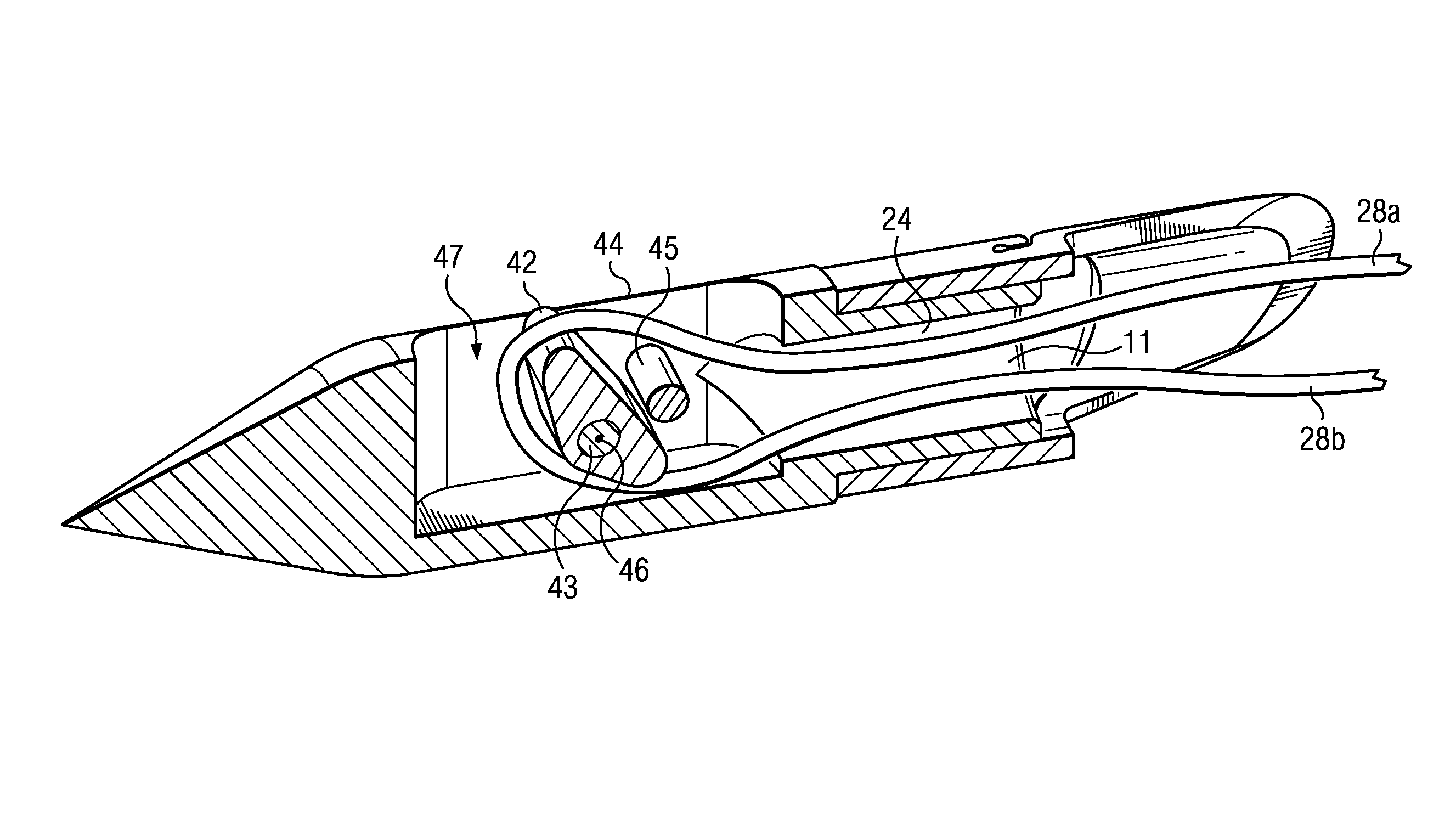

Knotless suture anchoring devices and tools for implants

ActiveUS20130158600A1Improve ease of implantationReduce exposureSuture equipmentsHeart valvesLess invasive surgerySuture anchors

Devices for securing prostheses such as heart valves or annuloplasty rings with sutures and without using knots are disclosed. The devices are particularly well suited for traditional surgery or minimally invasive surgery, and improve the ease of implantation by eliminating surgical knots a clinician would normally tie in the limited space in and around the implant site. The devices have opposed the clamp halves surrounded by a coil spring. Sutures pass between the clamp halves and the coil spring has an inner coil diameter sufficient to compress the sutures between the clamp. A retention member positioned between the clamp halves maintains a minimum space and therebetween to enable the locking device to be slid along the sutures into position, and to adjust the tension of the sutures therethrough. A delivery tool may be used to deliver and deploy the locking devices.

Owner:EDWARDS LIFESCIENCES CORP

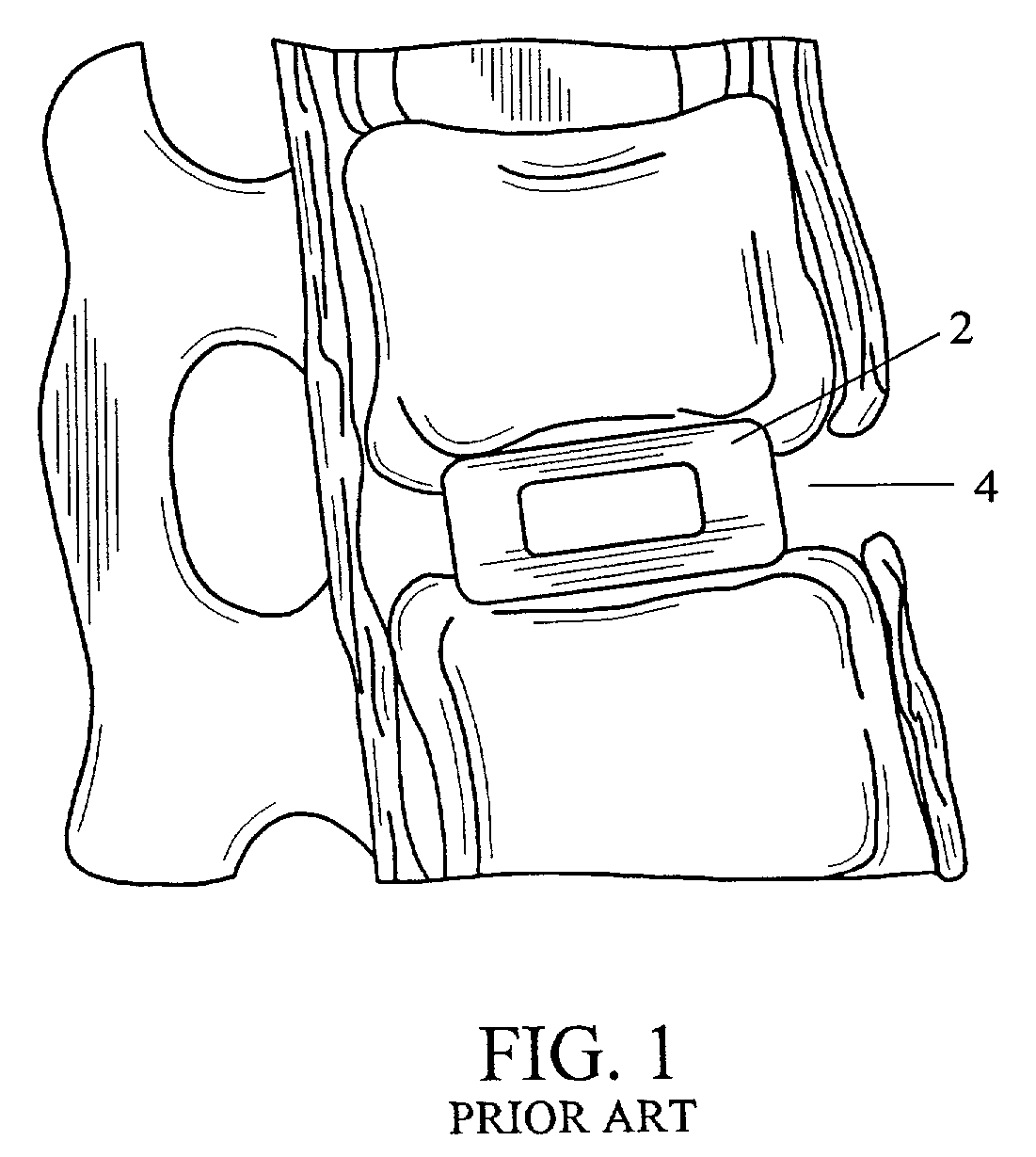

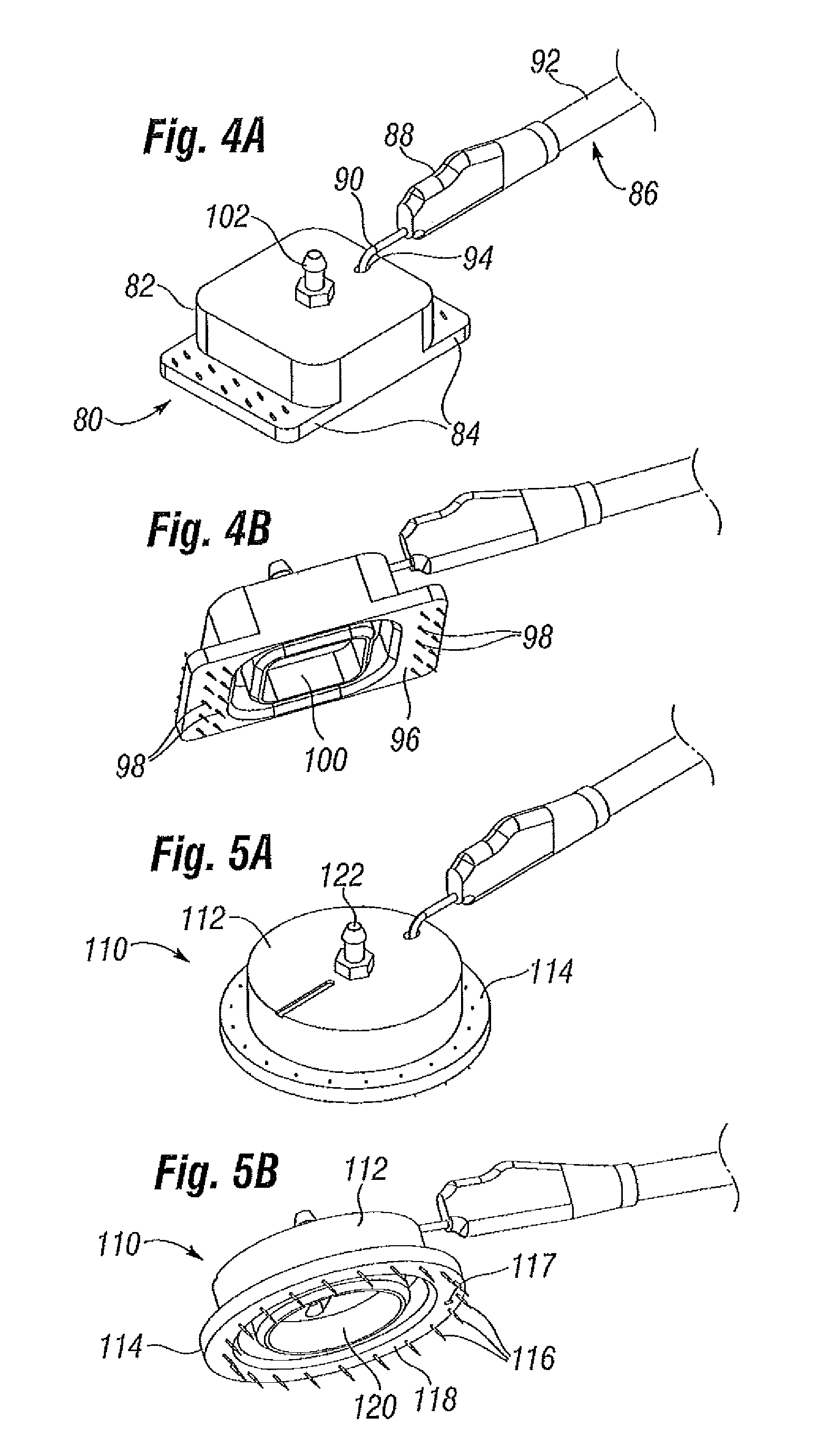

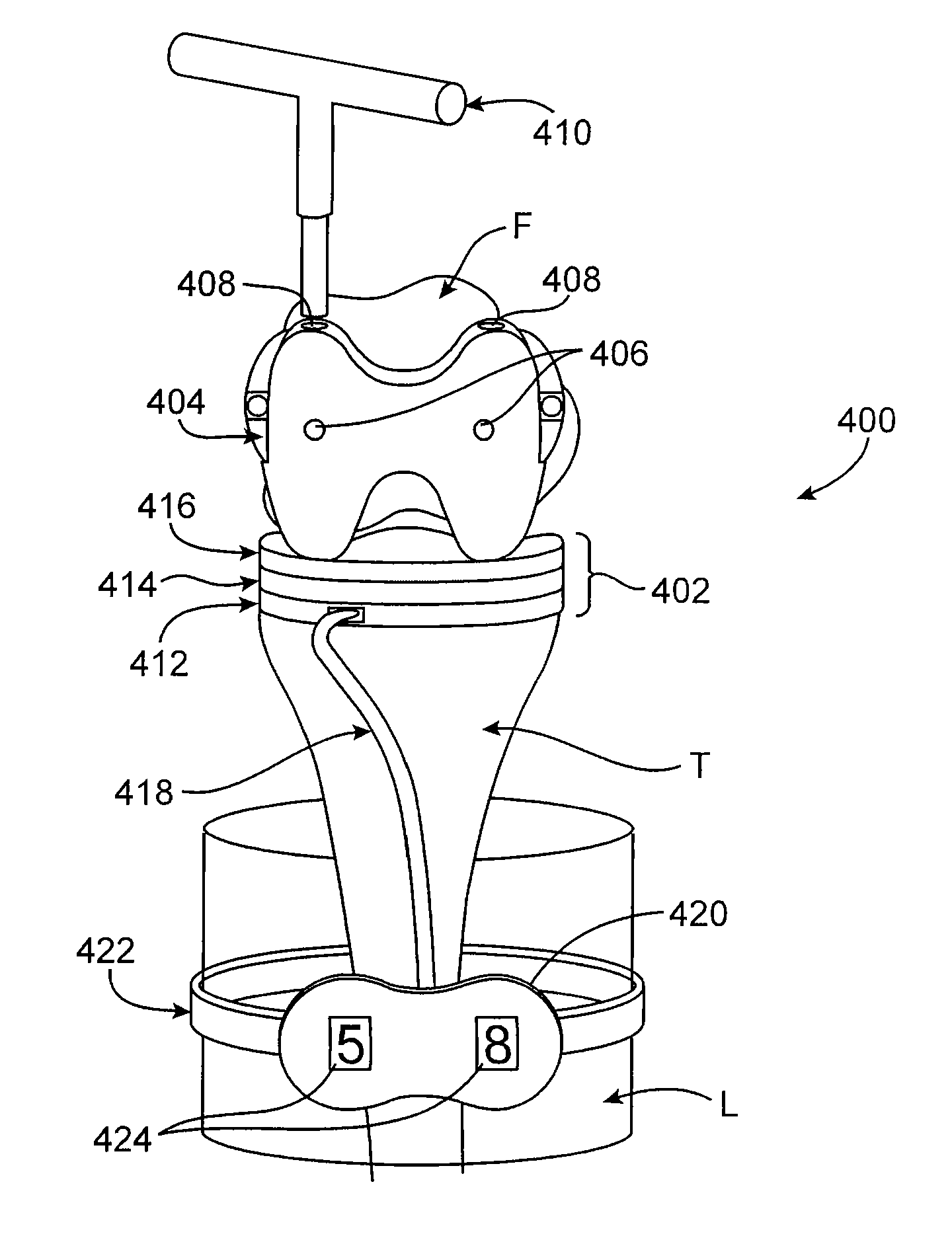

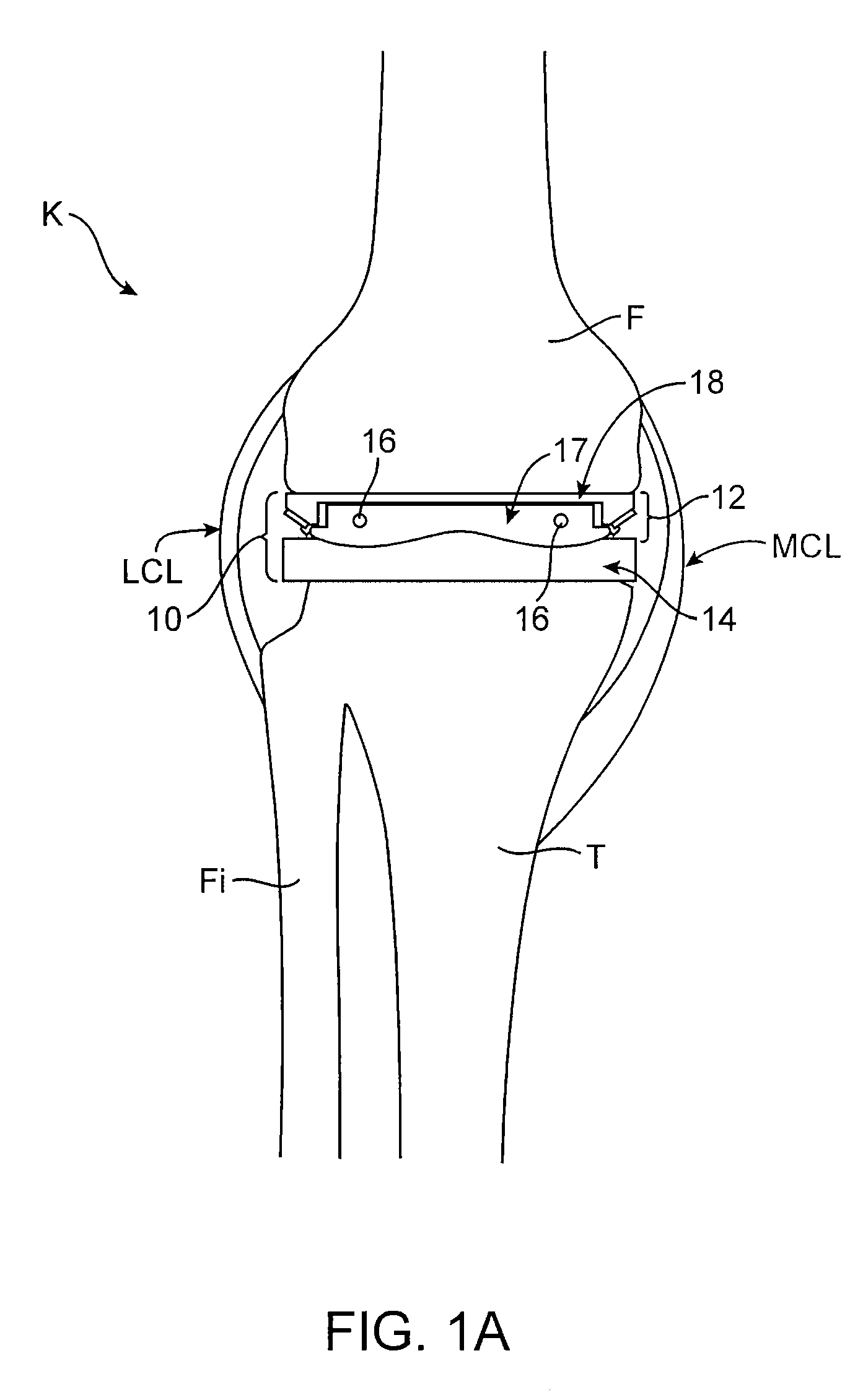

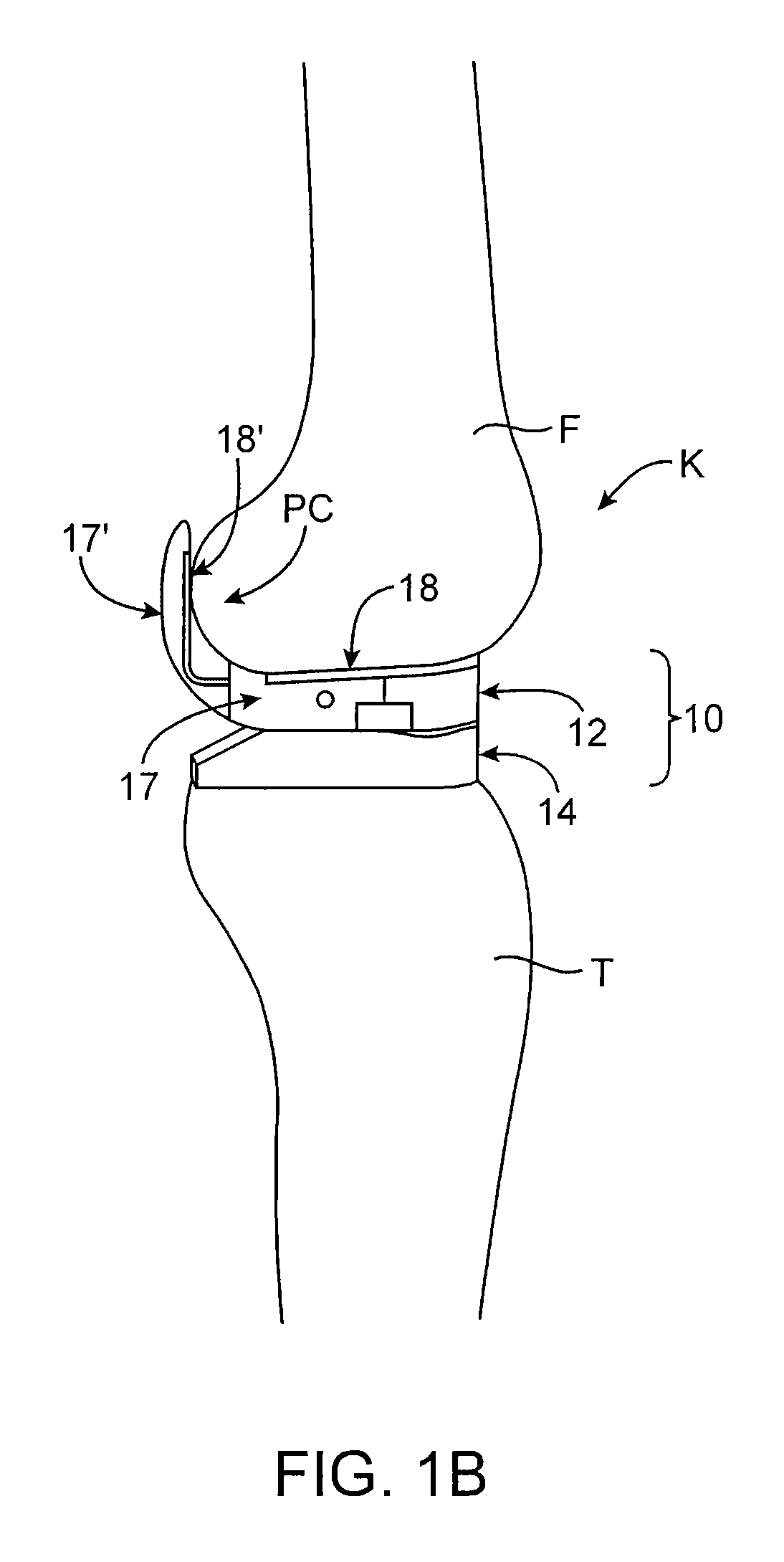

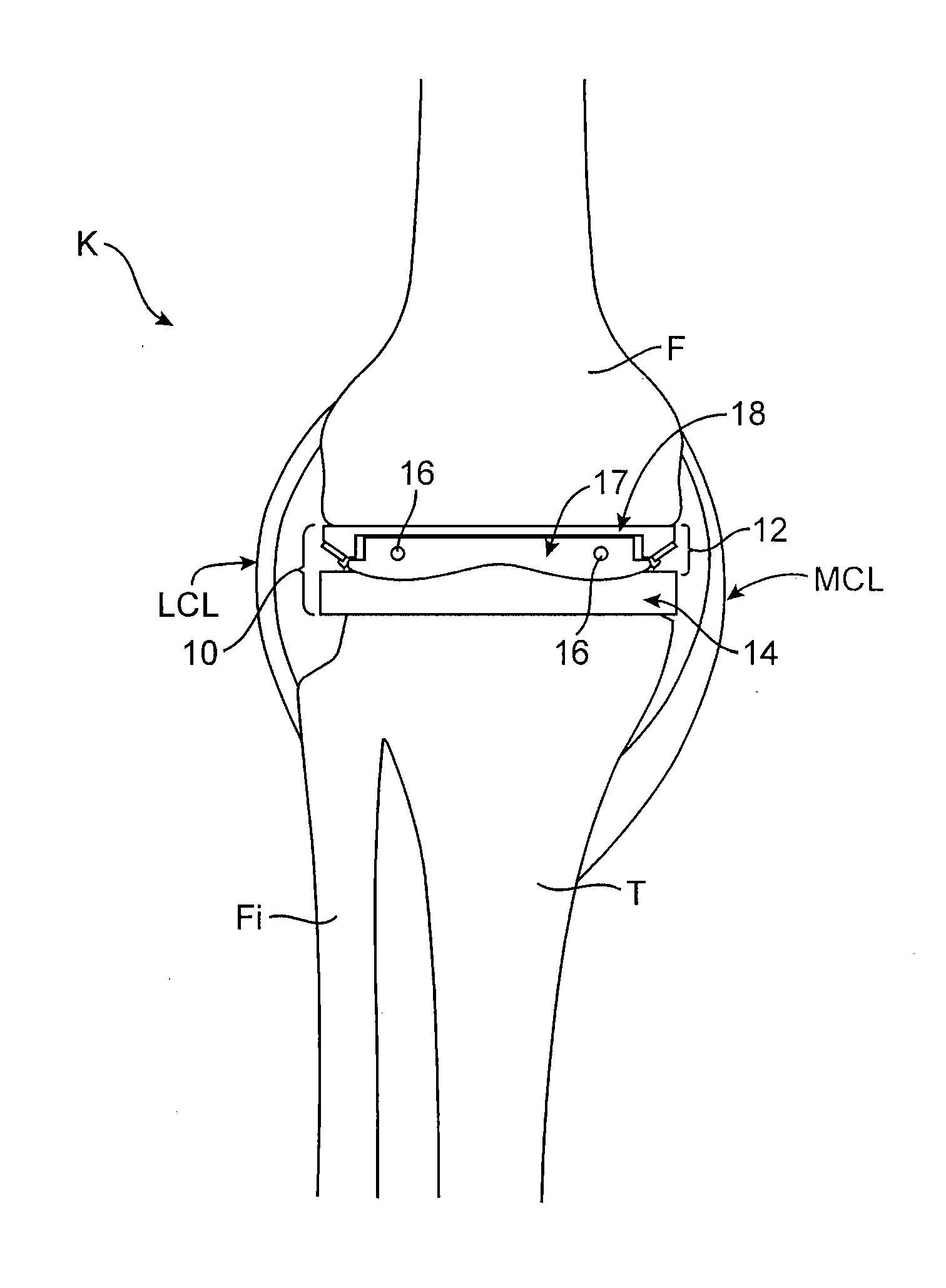

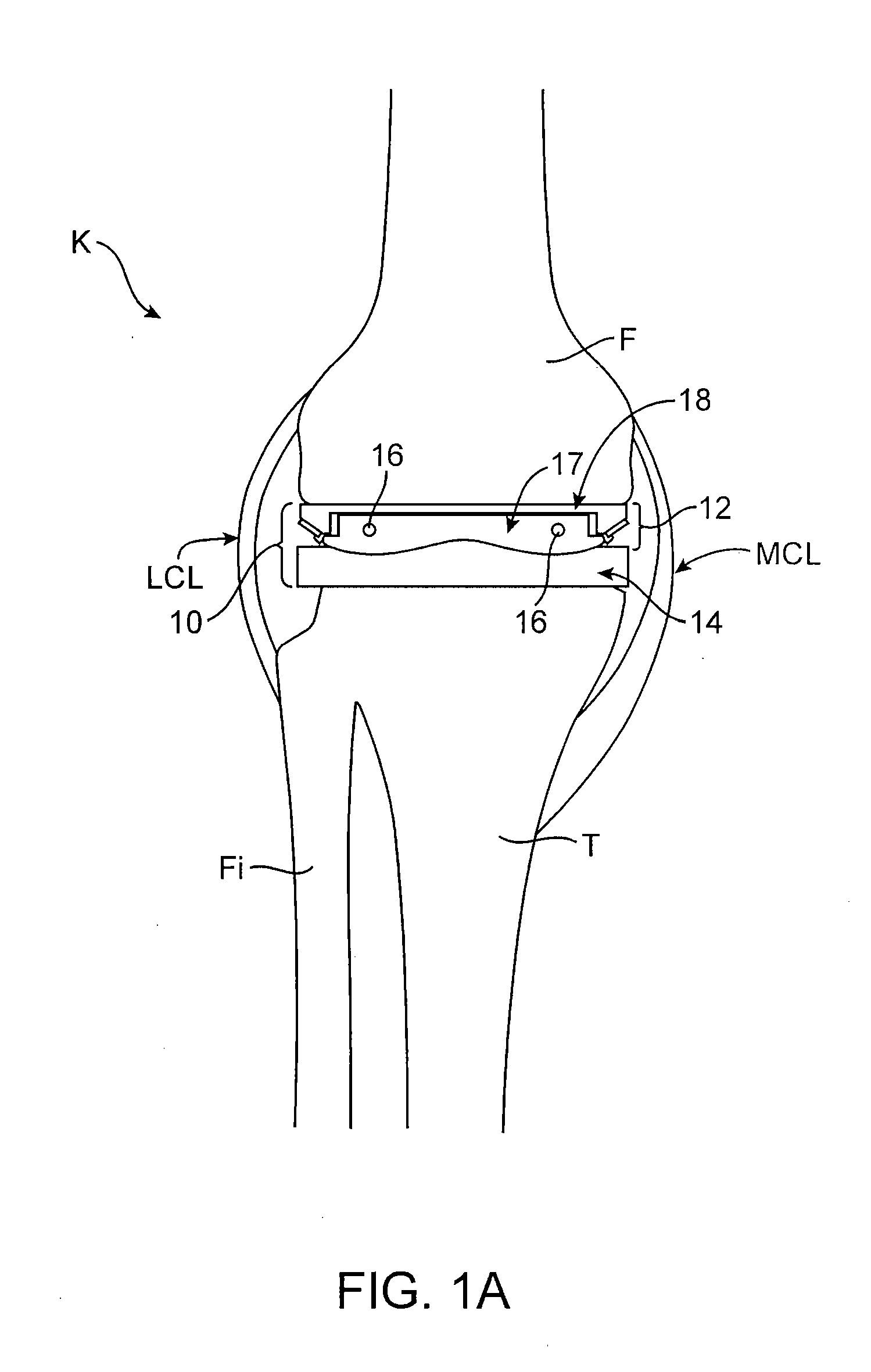

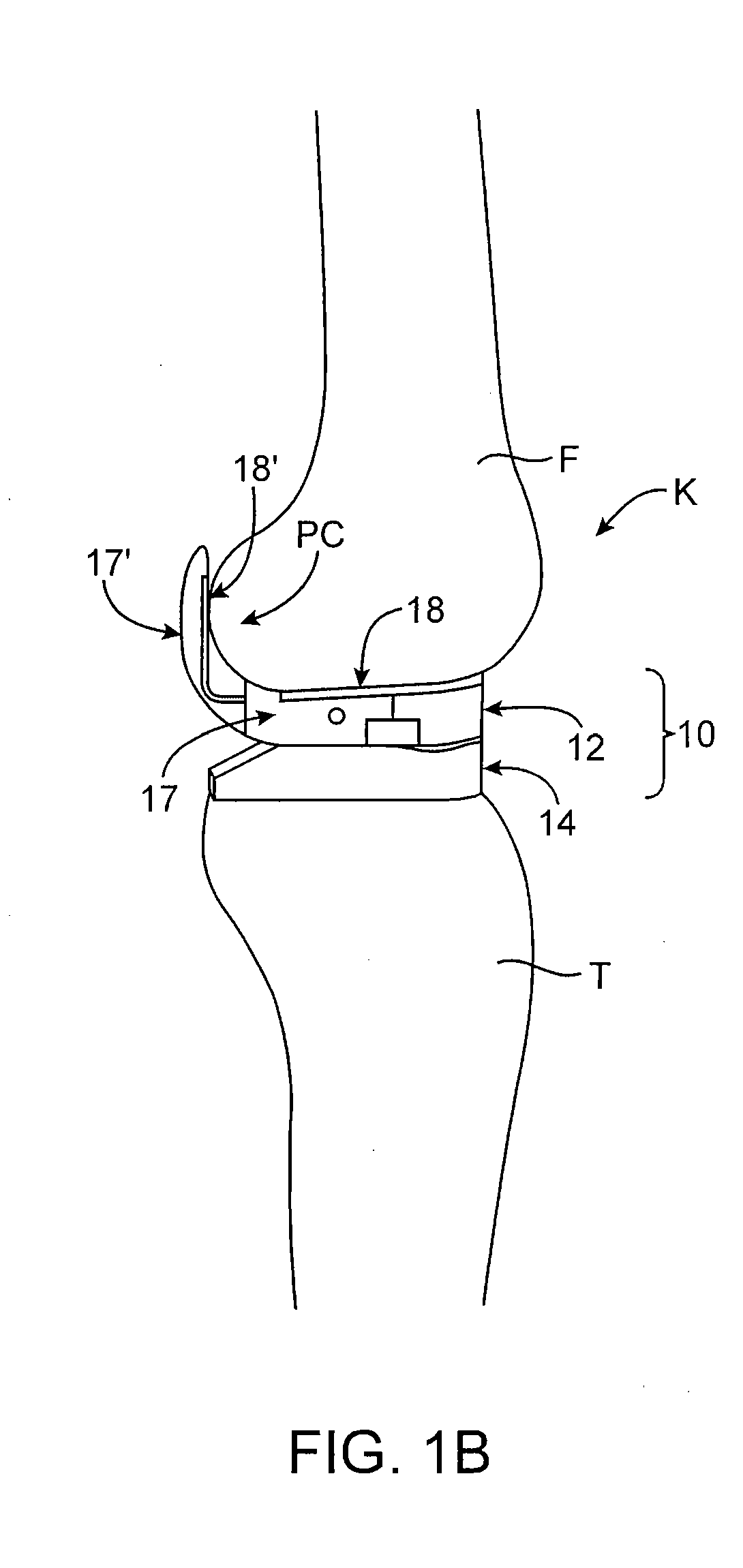

Dynamic knee balancer with pressure sensing

InactiveUS8758355B2Accelerated programDesired stability and range of motion and patellar trackingJoint implantsSurgical robotsTibiaRelative pressure

A device for performing a surgical procedure on a knee includes an adjustable femoral portion, a tibial portion and at least one sensor coupled with the femoral and / or tibial portions to sense pressure exerted by the a moral and tibial portions against one another. The femoral portion is adapted for removably coupling with a distal end of a femur to adjust tension in soft tissue adjacent the knee and has at least one positioning feature adapted to move relative to the distal end of the femur as the femoral portion is adjusted, thus helping position a femoral prosthetic on the distal end of the femur. The sensor(s) may be adapted to sense pressure at medial and lateral sides of the knee, and relative pressures may be displayed as data on a visual display. Adjustments to the femoral member may be made to balance pressure at flexion and extension of the knee.

Owner:SYNVASIVE TECH

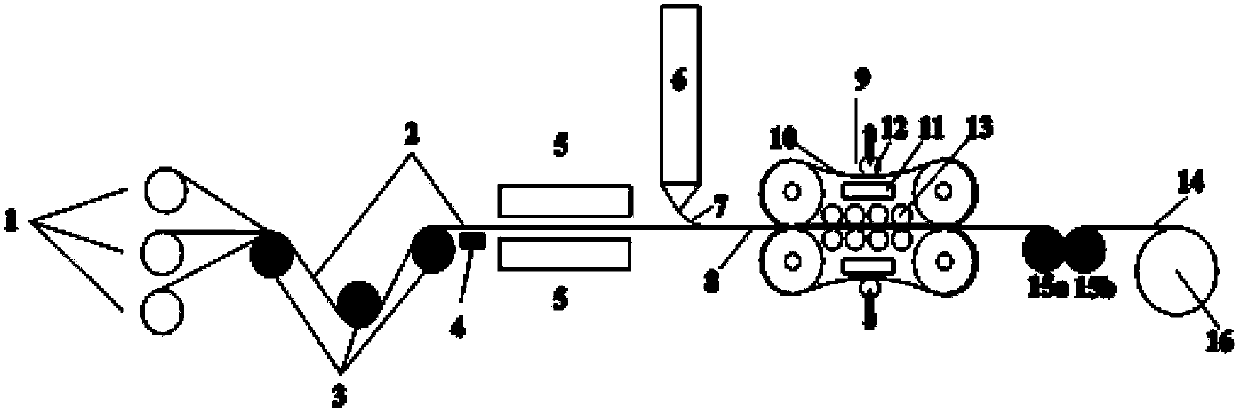

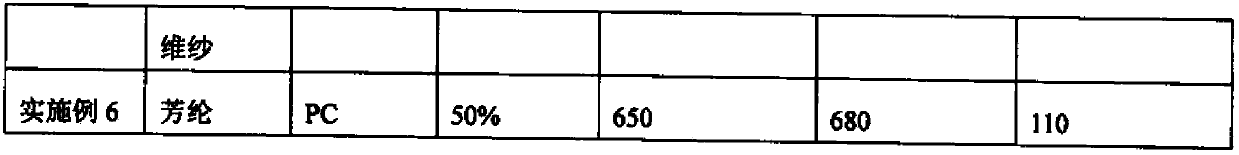

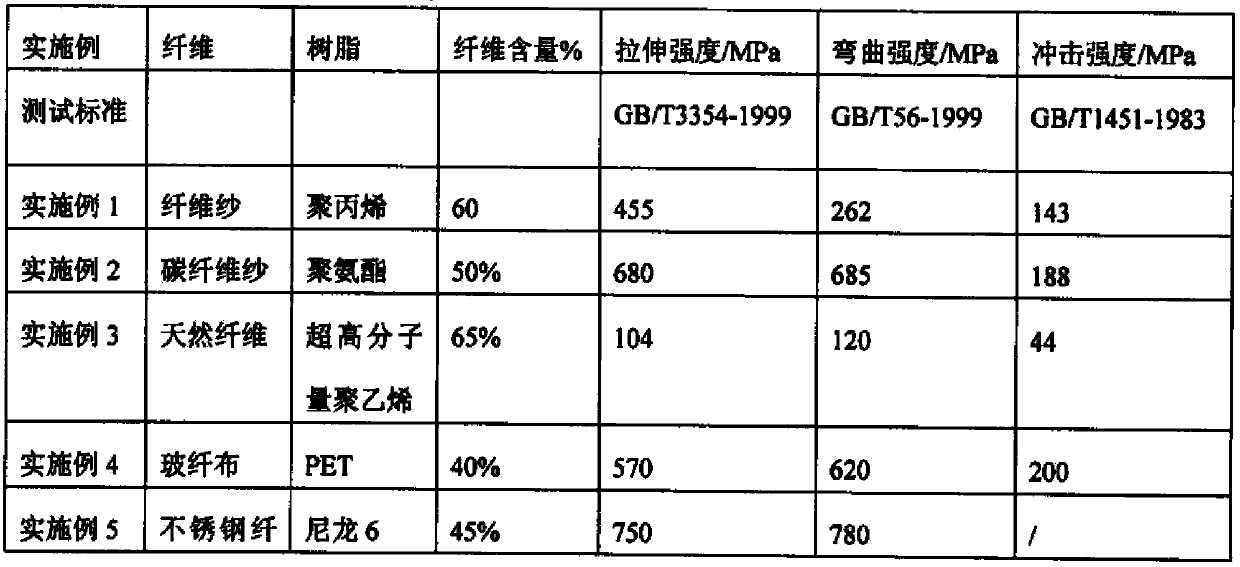

Continuous fiber fabric reinforced thermoplastic resin composite material and production method thereof

The invention relates to a continuous fiber fabric reinforced thermoplastic resin composite material and a production method thereof. The composite material is produced from continuous fiber through thermoplastic resin melting and impregnating, cooling and molding, with the thickness of 0.20mm-0.35mm, wherein the content of the continuous fiber reinforced fabric is 40wt%-65wt%, the continuous fiber fabric is uniformly spread out and subjected to tension adjustment and static electricity elimination, then enters thermoplastic resin for melting and impregnating, and finally is cooled in a cooling unit and wound and formed to obtain the continuous fiber fabric reinforced thermoplastic resin composite material. Compared with the prior art, the continuous fiber fabric reinforced thermoplastic resin composite material and the production method solve a series of problems caused by too high resin viscosity in the existing thermoplastic resin and fiber reinforcing process, such as complex equipment process, too high equipment cost, not environment-friendly technological operation process, dry gauze easily caused by poor impregnation and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

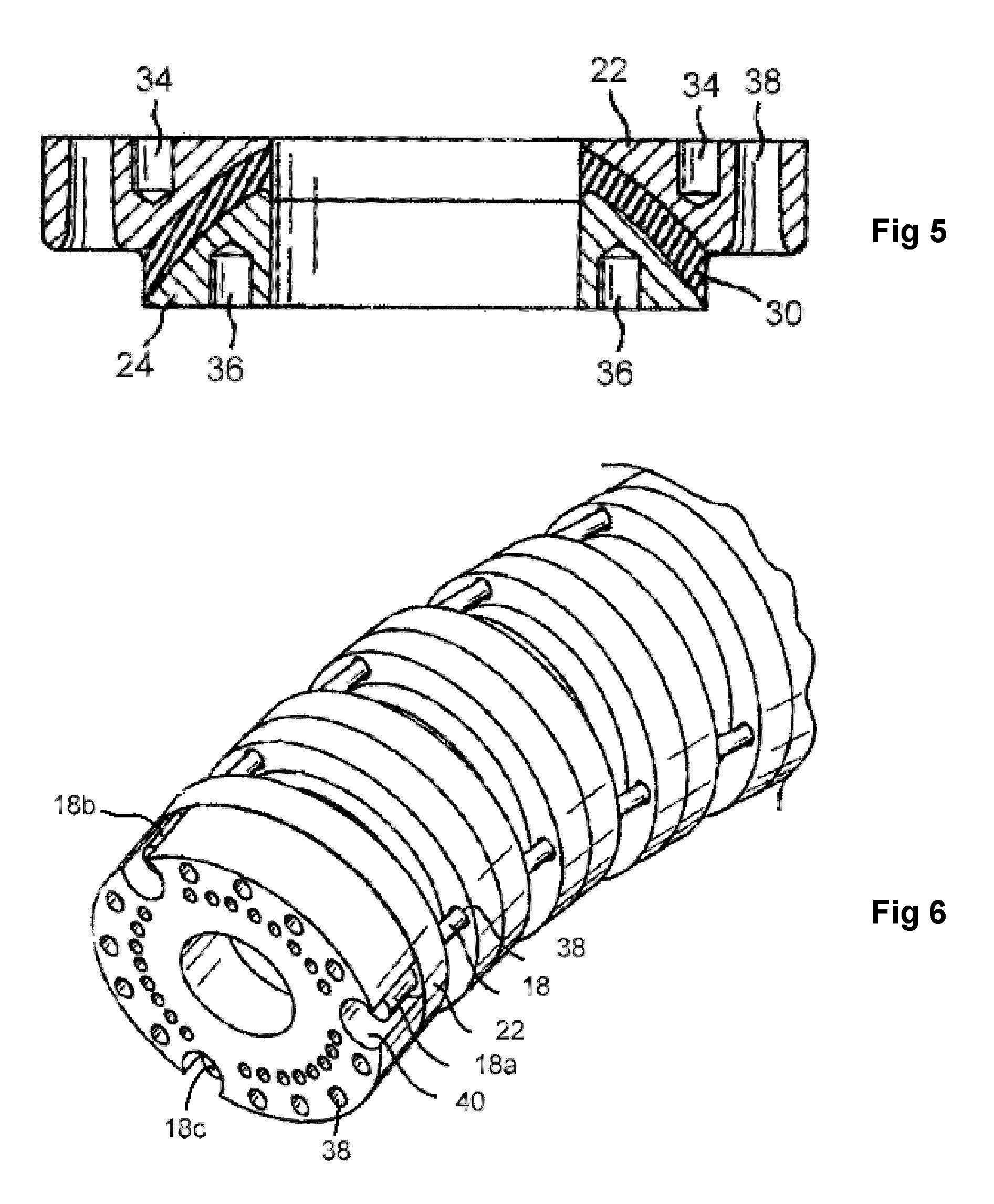

Knotless suture anchoring devices and tools for implants

ActiveUS9078645B2Improve ease of implantationReduce exposureSuture equipmentsHeart valvesLess invasive surgerySuture anchors

Devices for securing prostheses such as heart valves or annuloplasty rings with sutures and without using knots are disclosed. The devices are particularly well suited for traditional surgery or minimally invasive surgery, and improve the ease of implantation by eliminating surgical knots a clinician would normally tie in the limited space in and around the implant site. The devices have opposed the clamp halves surrounded by a coil spring. Sutures pass between the clamp halves and the coil spring has an inner coil diameter sufficient to compress the sutures between the clamp. A retention member positioned between the clamp halves maintains a minimum space and therebetween to enable the locking device to be slid along the sutures into position, and to adjust the tension of the sutures therethrough. A delivery tool may be used to deliver and deploy the locking devices.

Owner:EDWARDS LIFESCIENCES CORP

Dynamic knee balancer with force or pressure sensing

ActiveUS20130096567A1Accelerated programDesired stability and range of motion and patellar trackingJoint implantsSurgical robotsTibiaRelative pressure

A device for performing a surgical procedure on a knee includes an adjustable femoral portion, a tibial portion and at least one sensor coupled with the femoral and / or tibial portions to sense pressure exerted by the femoral and tibial portions against one another. The femoral portion is adapted for removably coupling with a distal end of a femur to adjust tension in soft tissue adjacent the knee and has at least one positioning feature adapted to move relative to the distal end of the femur as the femoral portion is adjusted, thus helping position a femoral prosthetic on the distal end of the femur. The sensor(s) may be adapted to sense pressure at medial and lateral sides of the knee, and relative pressures may be displayed as data on a visual display. Adjustments to the femoral member may be made to balance pressure at flexion and extension of the knee.

Owner:SYNVASIVE TECH

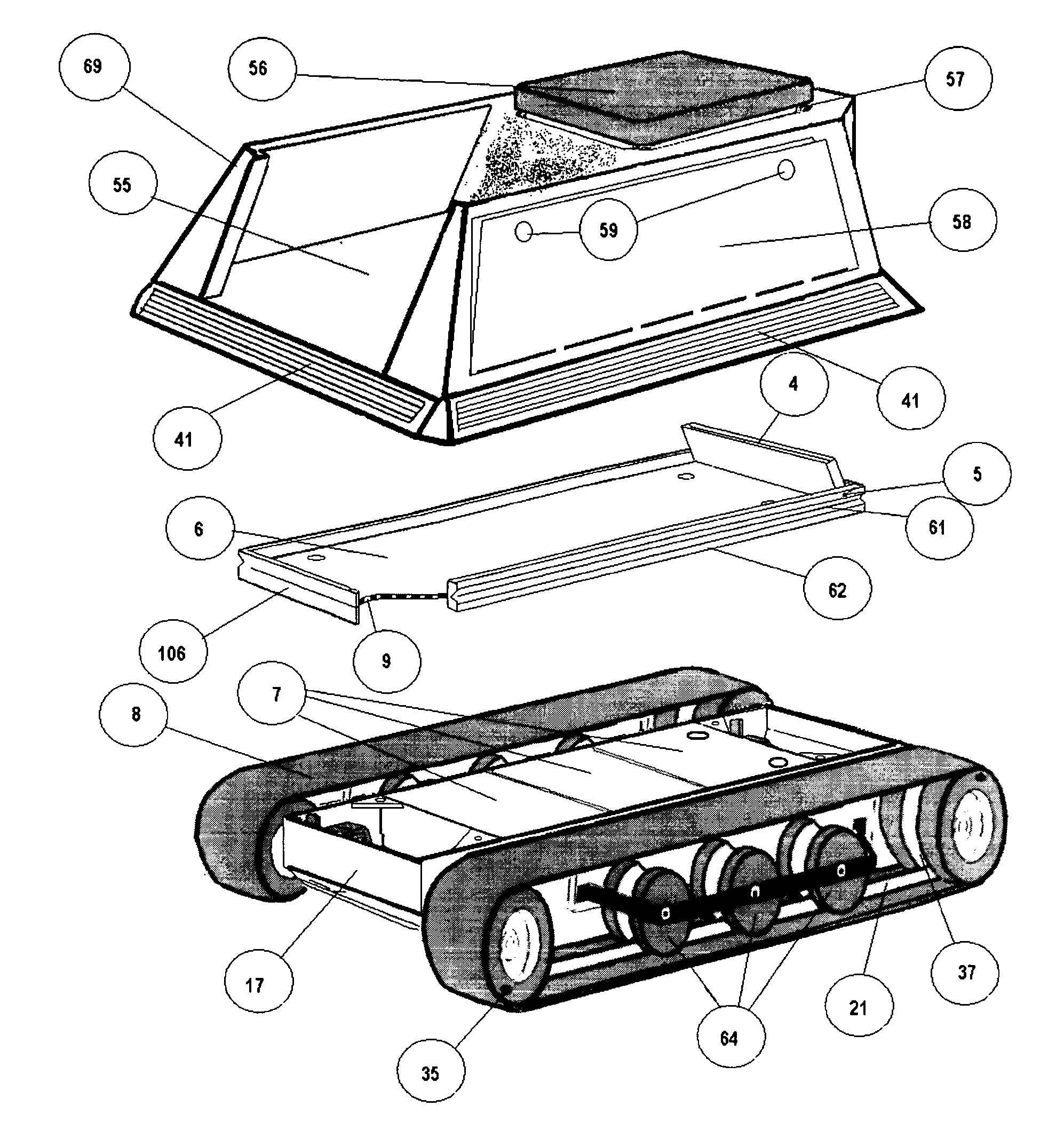

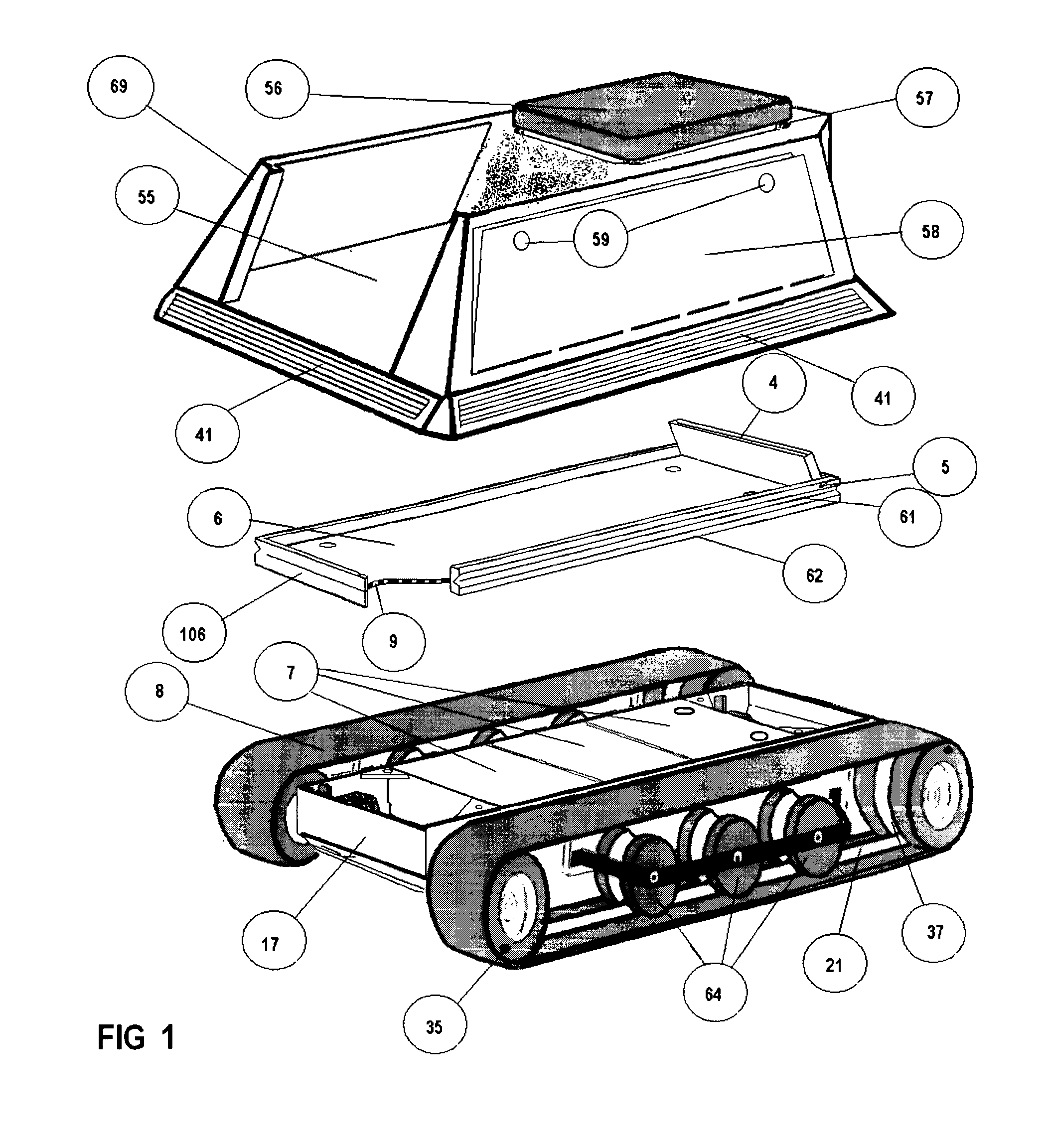

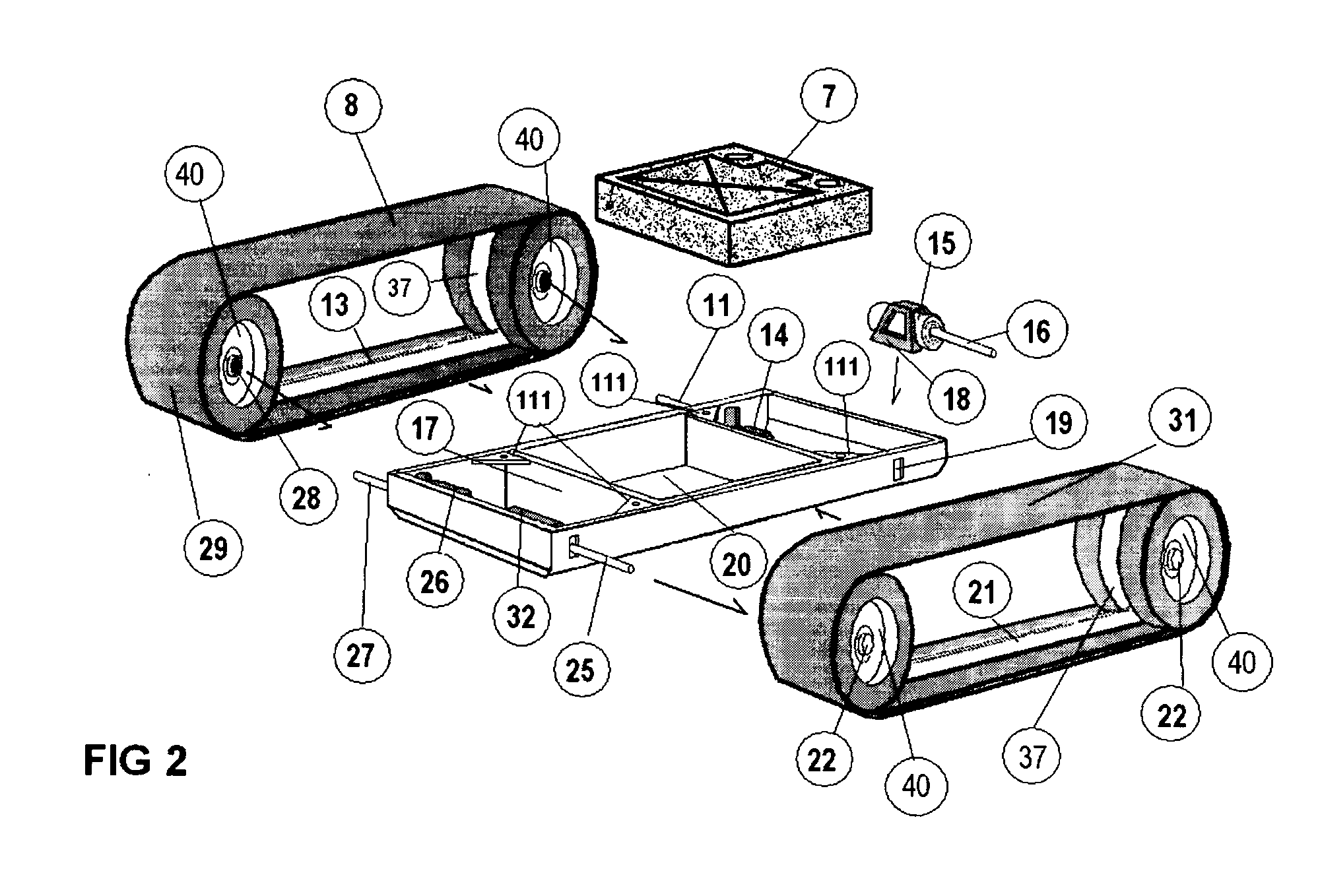

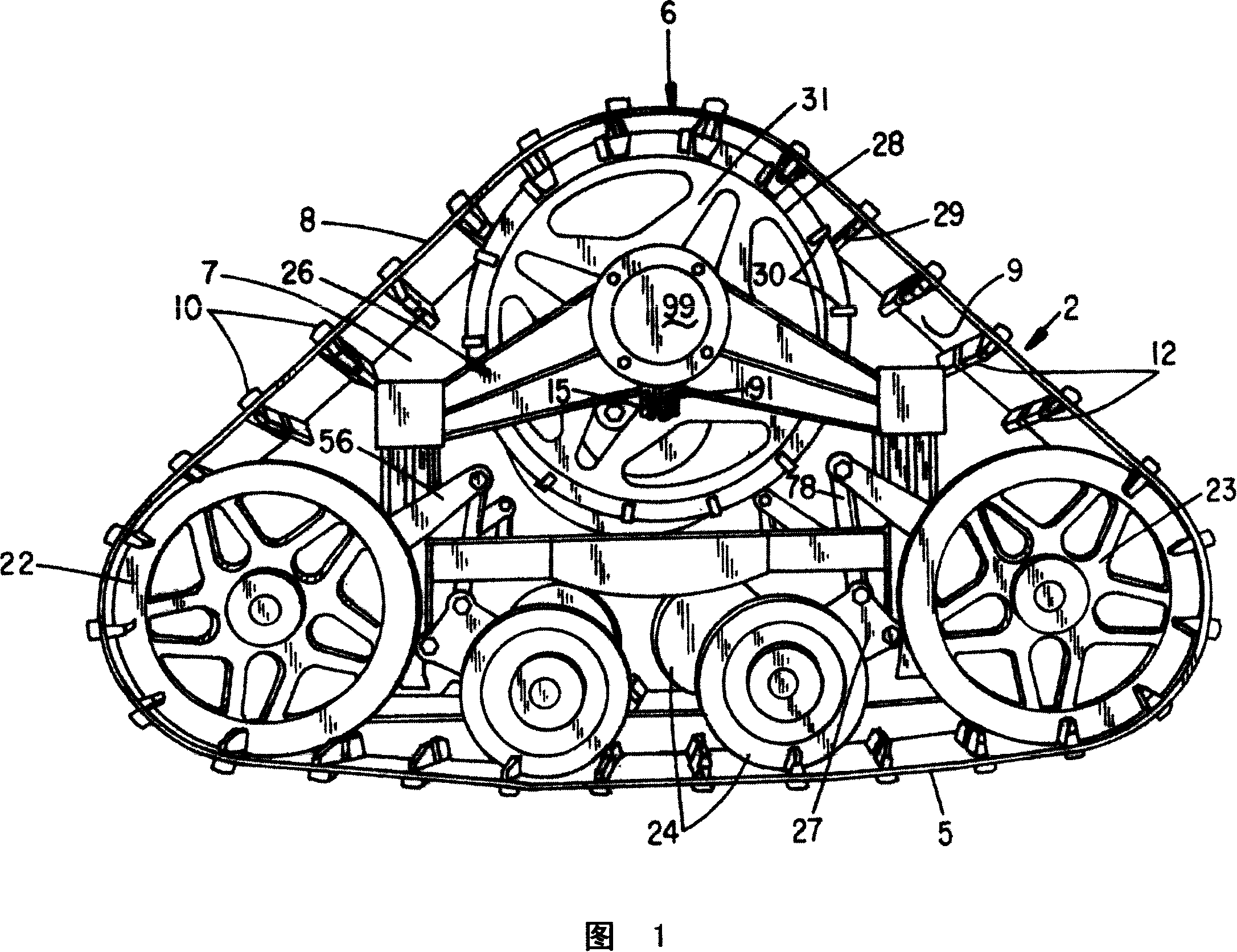

Personal utility vehicle (PUV)

InactiveUS20060237239A1Easily configureIncrease and or decrease of energyDigital data processing detailsSteering initiationsCarrier signalPlug and produce

A powered personal utility vehicle having a quick-change body configuration with a mating tray assembly and a universal chassis is disclosed. The upper level of the mating tray houses electronics while the lower level engages with the universal chassis to form the personal utility vehicle. Reconfigurations are simplified with plug and play design electronics. Vehicle traction is increased through a specialized track and drive wheel design that improves contact between the between the surfaces allowing operation in multiple environments. The two-piece wheel design allows assembly of the inflatable drive molded balloon tire. Adjustment of inflation levels of the balloon tires controls track tension. Control is either manually programmed into the on board central processing unit, or via carrier signals. Semi and fully autonomous operation is disclosed. Advanced operator interaction functions using two-way real time video and audio are disclosed along with LED and GPS systems. The invention as disclosed is configurable for a range of uses, load capacities and sizes.

Owner:BRUNER DANIEL +1

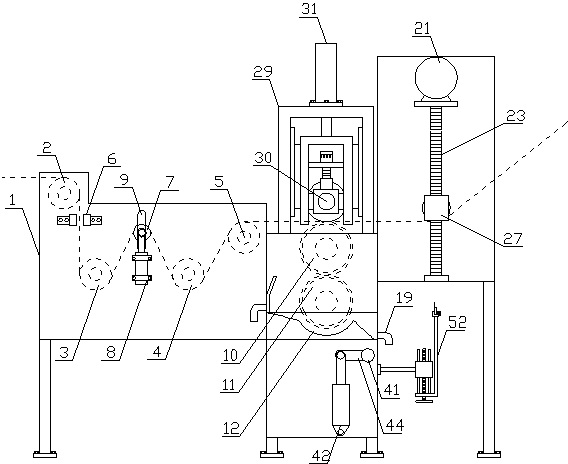

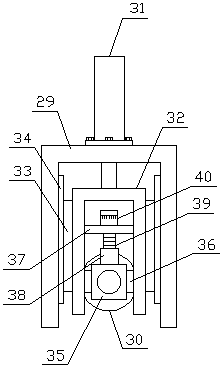

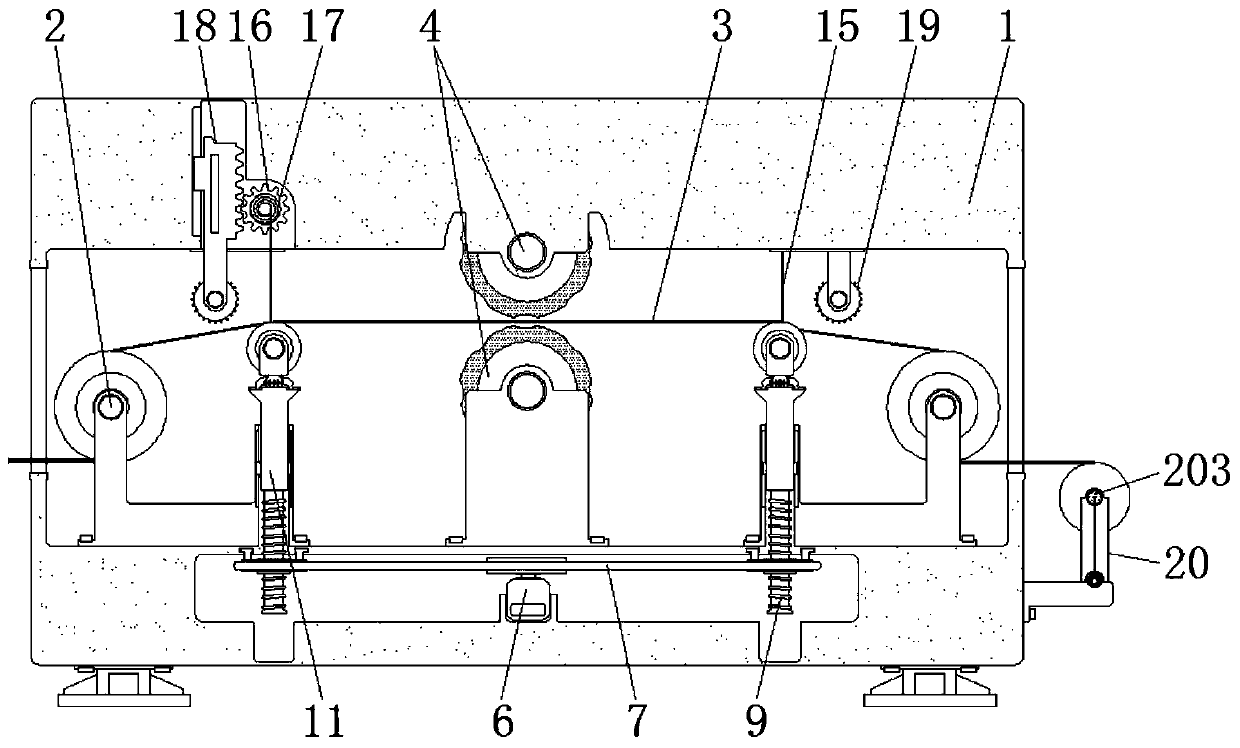

Thin film conveying gluing device

ActiveCN104163356AAdjustable tensionGuarantee stabilityArticle deliveryWebs handlingDrive shaftEngineering

The invention discloses a thin film conveying gluing device and belongs to the field of thin film processing equipment. The thin film conveying gluing device comprises a main support, a film guide mechanism, a film gluing mechanism and a film discharging mechanism, wherein the film guide mechanism, the film gluing mechanism and the film discharging mechanism are sequentially arranged on the main support in the thin film conveying direction. The film guide mechanism comprises a first film guide roller, a second film guide roller, a third film guide roller and a fourth film guide roller, wherein the first film guide roller, the second film guide roller, the third film guide roller and the fourth film guide roller are sequentially connected to the main support horizontally and rotationally in the thin film conveying direction. A static electricity eliminating board is arranged between the first film guide roller and the second film guide roller. A tension adjusting roller is arranged between the second film guide roller and the third film guide roller. The film gluing mechanism comprises a film pressing mechanism, a gluing roller, a glue feeding roller and a film gluing groove, wherein the film pressing mechanism, the gluing roller, the glue feeding roller and the film gluing groove are sequentially arranged from top to bottom. The surface of the gluing roller is attached to the surface of the glue feeding roller. The film gluing groove is an arc-shaped groove matched with the glue feeding roller in shape. The film discharging mechanism comprises a driving motor, a driving shaft, a driving screw and a film discharging roller. The thin film conveying gluing device is simple in structure, thin films can be glued rapidly, efficiently and evenly, and the requirement for production is met.

Owner:浙江耀阳新材料科技有限公司

Distal radioulnar joint prosthesis

ActiveUS20070198095A1Adjustable tensionEffectively resurfacingWrist jointsAnkle jointsArticular surfacesUlnar head

A prosthetic implant for partial resurfacing of the ulna at the distal radioulnar (DRU) joint which comprises a stem and an ulnar head. The combination of the anchoring stem and the head that is shaped and proportioned to replace only a portion of the distal ulnar head and the radial articulating surface and to interface with the resected ulna at a proximal stabilizing surface provides excellent stability in the completed implant. In the preferred embodiment, a pair of strategically located surfaces aligned at an obtuse angle provides the stabilizing surface arrangement. The provision of a set of such implants with different head and stem sizes allows a surgeon to best accommodate the physiology of a particular patient and locate a resurfaced head section offset from the canal center in order to provide a convex articular surface adjacent the radius which will allow the radius to smoothly pivot and translate around such resurfaced ulnar head during pivoting of the forearm.

Owner:ASCENSION ORTHOPEDICS

Atraumatic tissue retraction device

ActiveUS7909761B2Reduce the amount requiredIncrease in sizeCannulasEndoscopesSurgical incisionSurgical site

Methods and apparatus for a surgical retractor include a ring, a plurality of flexible straps connected to the ring, a patch of hook or loop material connected to each strap, a coordinating patch of hook or loop material connectable to the patient's skin or the surgical drape. The flexible straps of the surgical retractor may be frangibly connected together. LEDs molded into the distal end create a light source to illuminate the surgical site. The ring may take several forms including a flexible or adjustable ring and an inflatable bladder. The ring of the surgical retractor is inserted into the surgical incision, a patch of loop fastener is attached to the patient, a set of straps connected to the ring are pulled outward and the hook portion is applied to the loop portion to hold the incision open. The retractor is useable for thoracic and other types of surgery.

Owner:ATRICURE

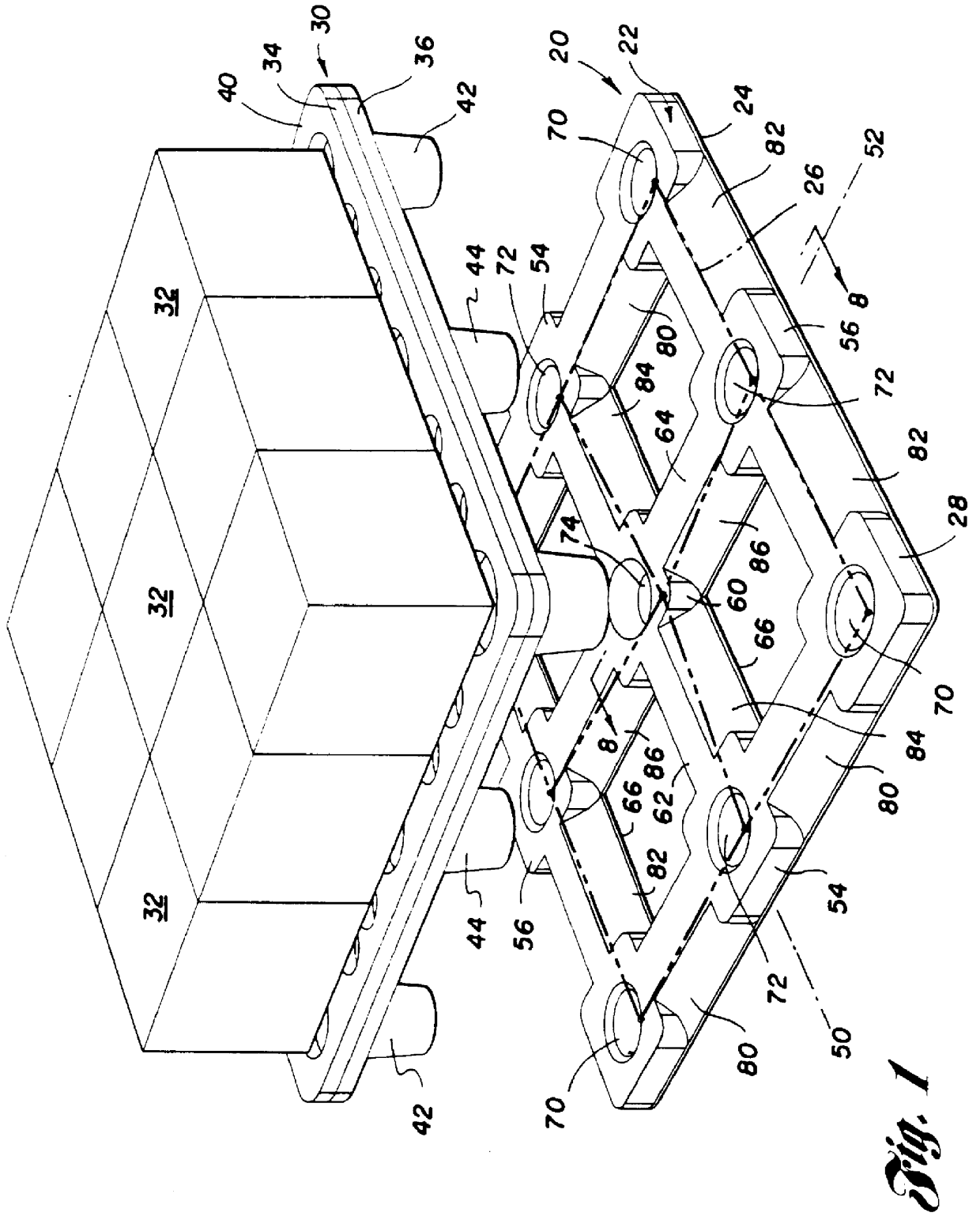

Pallet with flexible tensile reinforcement

InactiveUS6053466AMinimize saggingMinimize deflectionStands/trestlesKitchen equipmentEngineeringPallet

A reinforced pallet (20) and method for making the same are disclosed. The pallet (20) includes a body (28) having a pair of laterally spaced apart edge portions (56) with a central span (60) extending therebetween. A flexible tensile member (26) extends between the edge portions (56) and generally beneath the central span (60). The tensile member (26) may be in the form of a mesh affixed between upper and lower decks (22,24) of the pallet (20). When the edge portions (56) of the pallet (20) are simply supported and a load is place atop the pallet (20), the central span (60) of the pallet (20) will vertically deflect in response to the load. The central span (60) will bear upon the tensile member (26) with the tensile member providing support against deflection. A method for retrofitting a pallet (200) includes adding a tensile member (210) to the pallet (200) to reduce the amount of deflection of the pallet (200) when simply supported in response to a load placed atop the pallet (200).

Owner:CADILLAC PROD

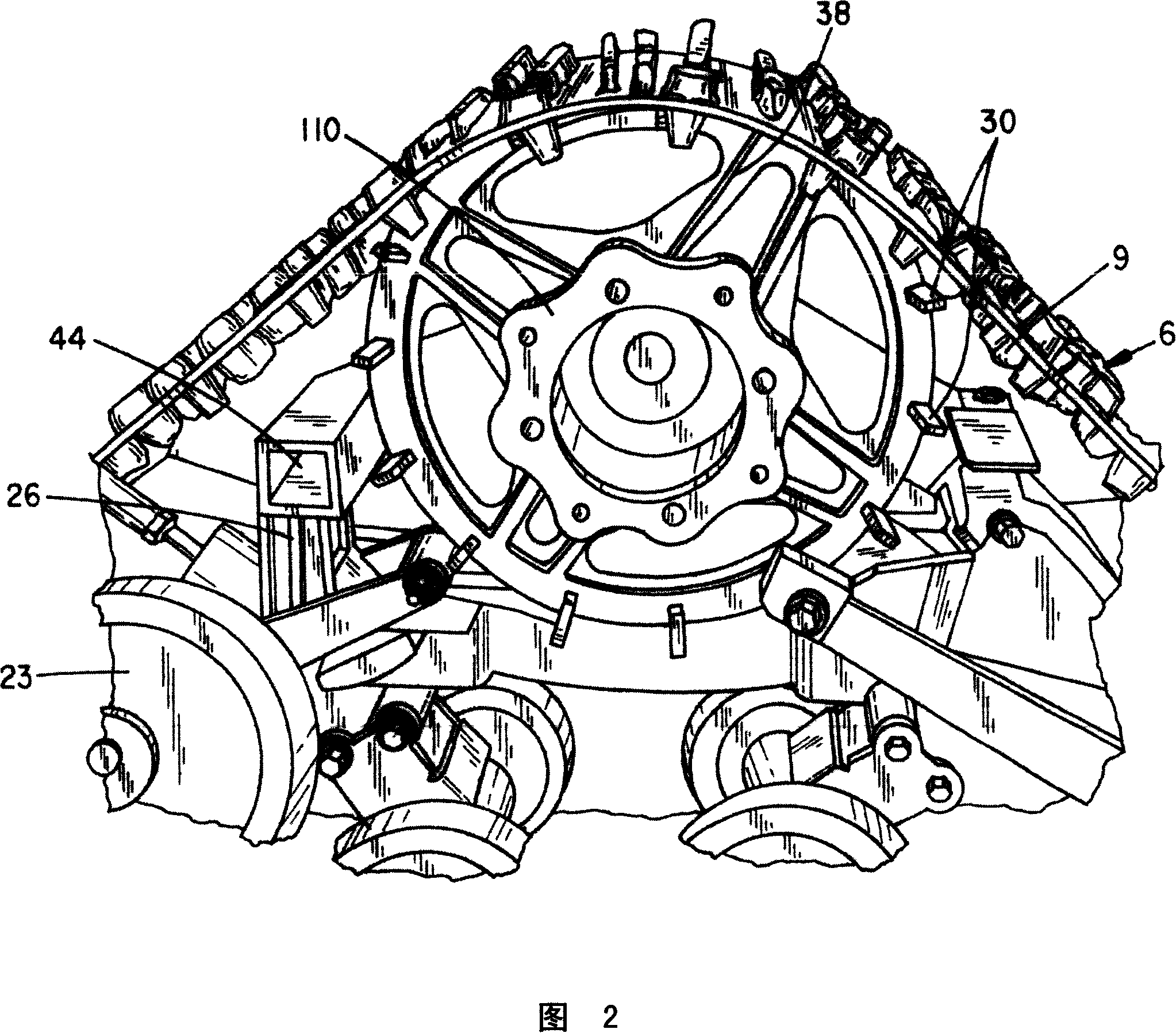

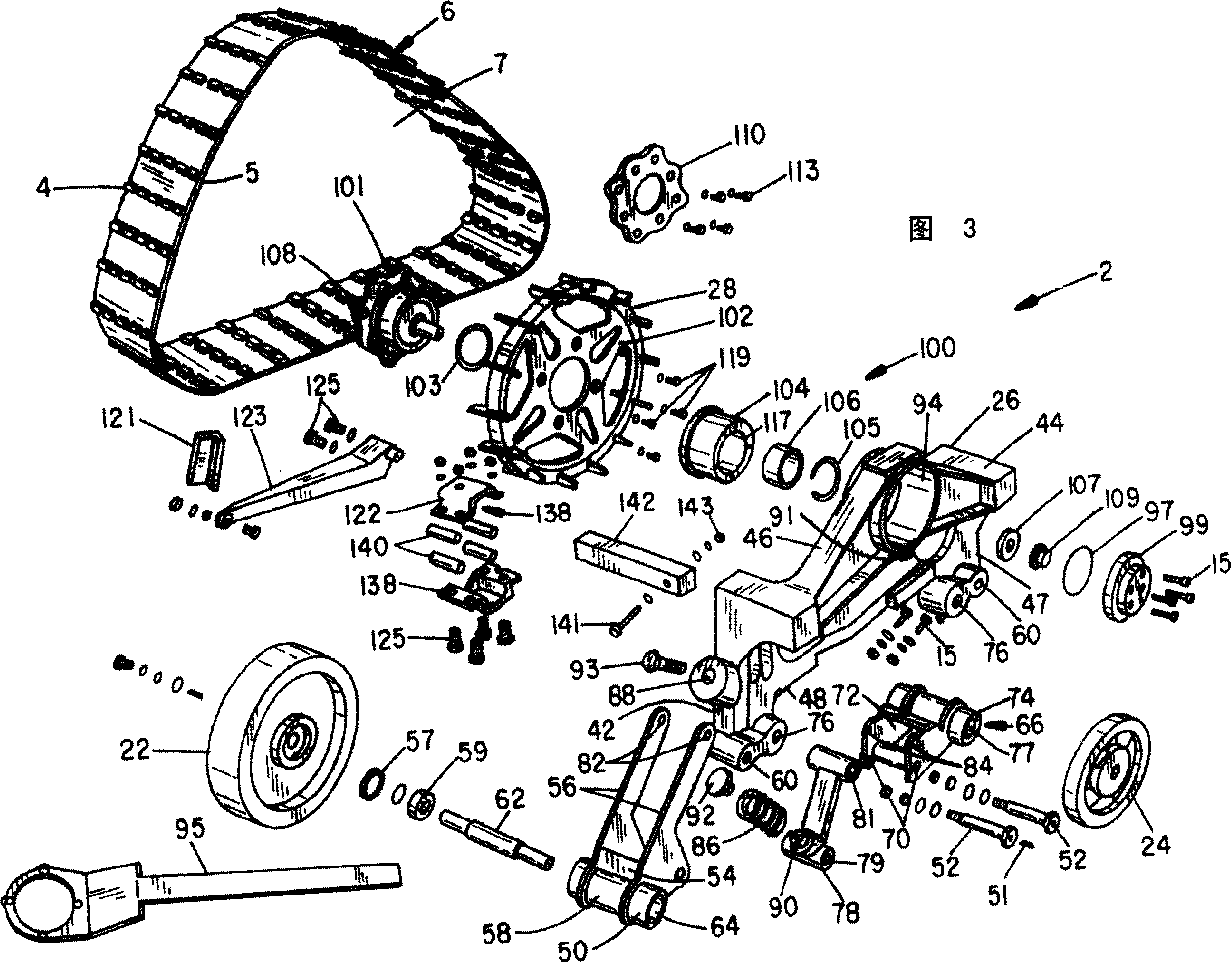

Terrain conforming track assembly

ActiveCN101138992AAdapt to terrain contour changesConducive to manipulationEndless track vehiclesTerrainShape change

An endless track assembly that mounts to a wheeled vehicle. The assembly provides 1) a track suspension having fixed or adjustable, independently biased sets of idler wheels to vary the track contour without affecting track tension, 2) an eccentric bearing housing at a drive sprocket controls track tension, 3) a contoured peripheral edge at the drive sprocket prevents ice and mud buildup, 4) rubber-coated, plastic idler wheels facilitate track movement, 5) a multi-vehicle compatible adapter mounting plate accommodates a variety of vehicles, 6) a rotation limited torsion coupler and / or rotation limiting coupler arms prevent track contact with the vehicle, 7) a locking steering arm coupler prevents loss of steering control, 8) shaped track lugs and channels clear and direct debris away fromthe track suspension and drive assembly, and 9) a center, spring biased coupling suspension stabilizes and enhances the contour following and load handling capabilities in the center region of the track. The improved suspension particularly supports sets of idler wheels in pivotal relation to the track support frame and resiliently biases a pre-tensioned rocker arm that links adjacent suspension arms mounted to the adjoining idler wheels. Suspension arm movement induces expansion and contraction of tension springs coupled to the rocker arms to augments shape changes at the track contact surface to optimize traction and steering control.

Owner:G·布拉齐尔

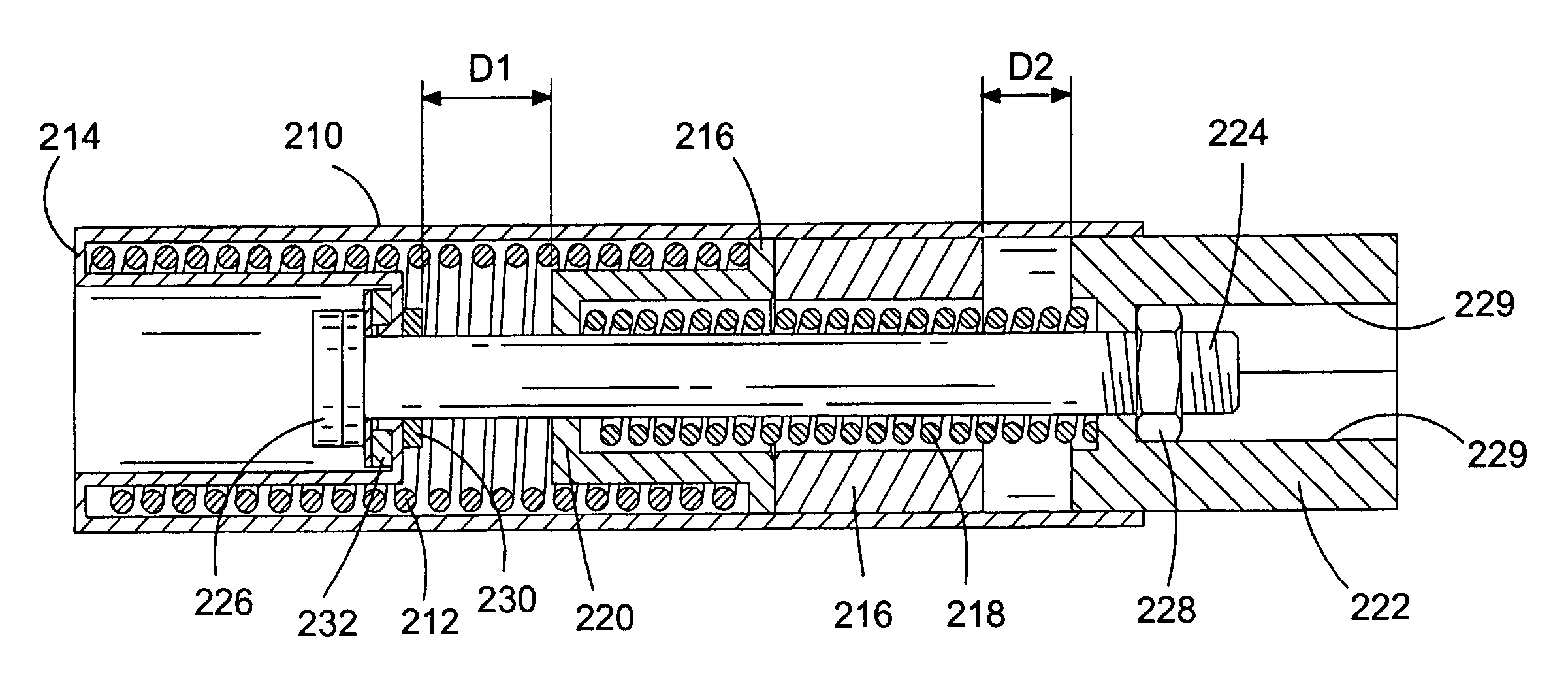

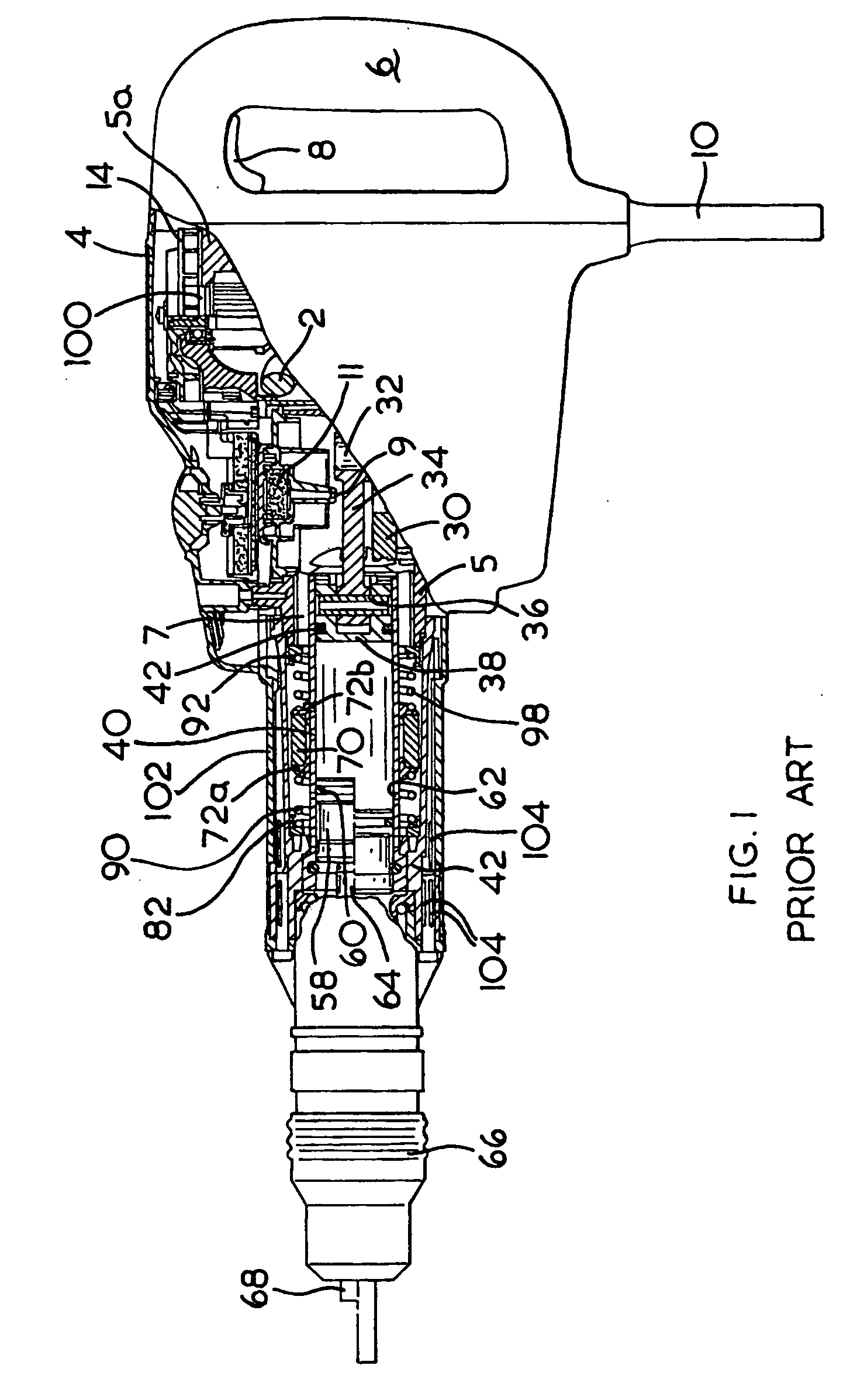

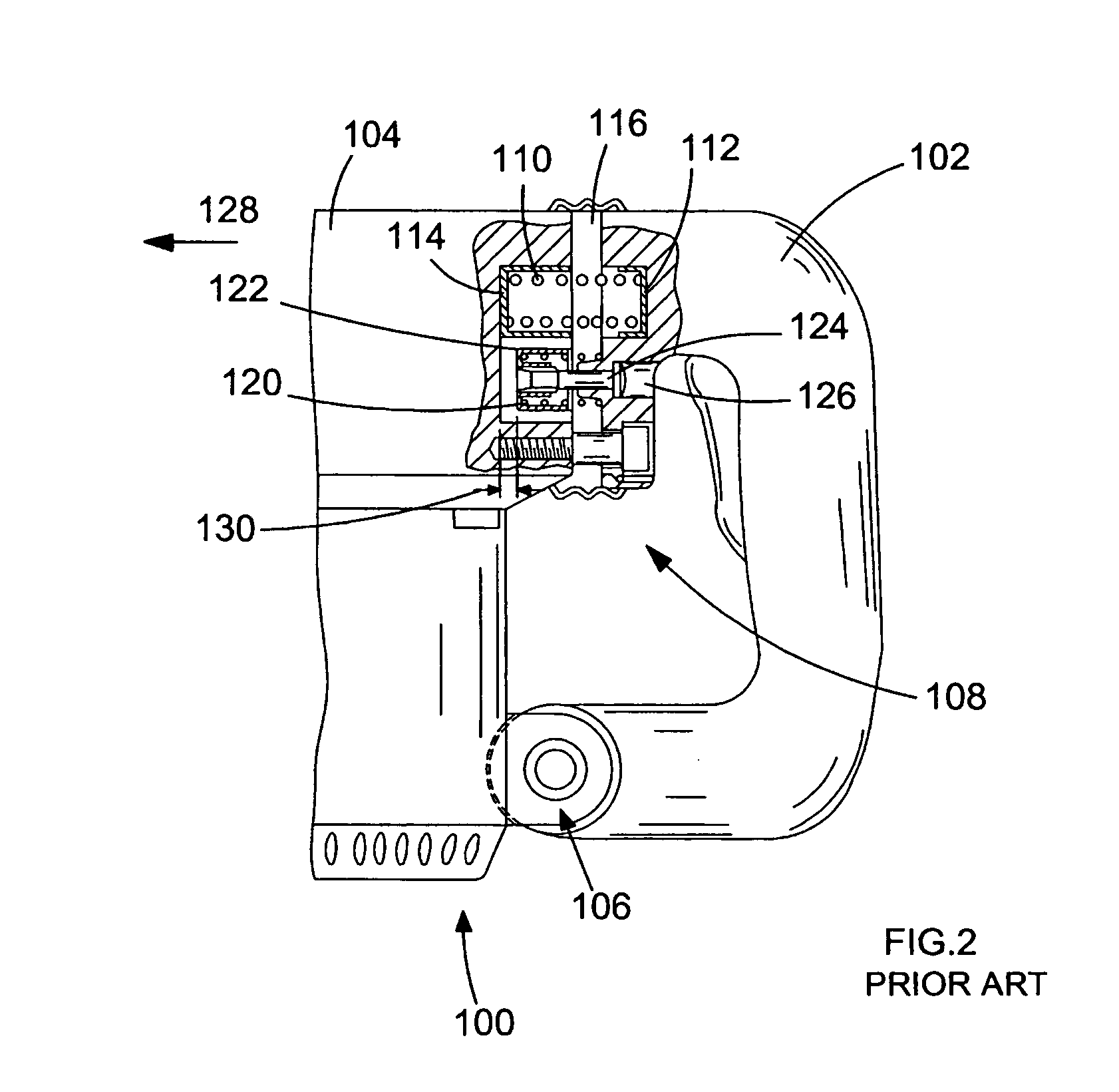

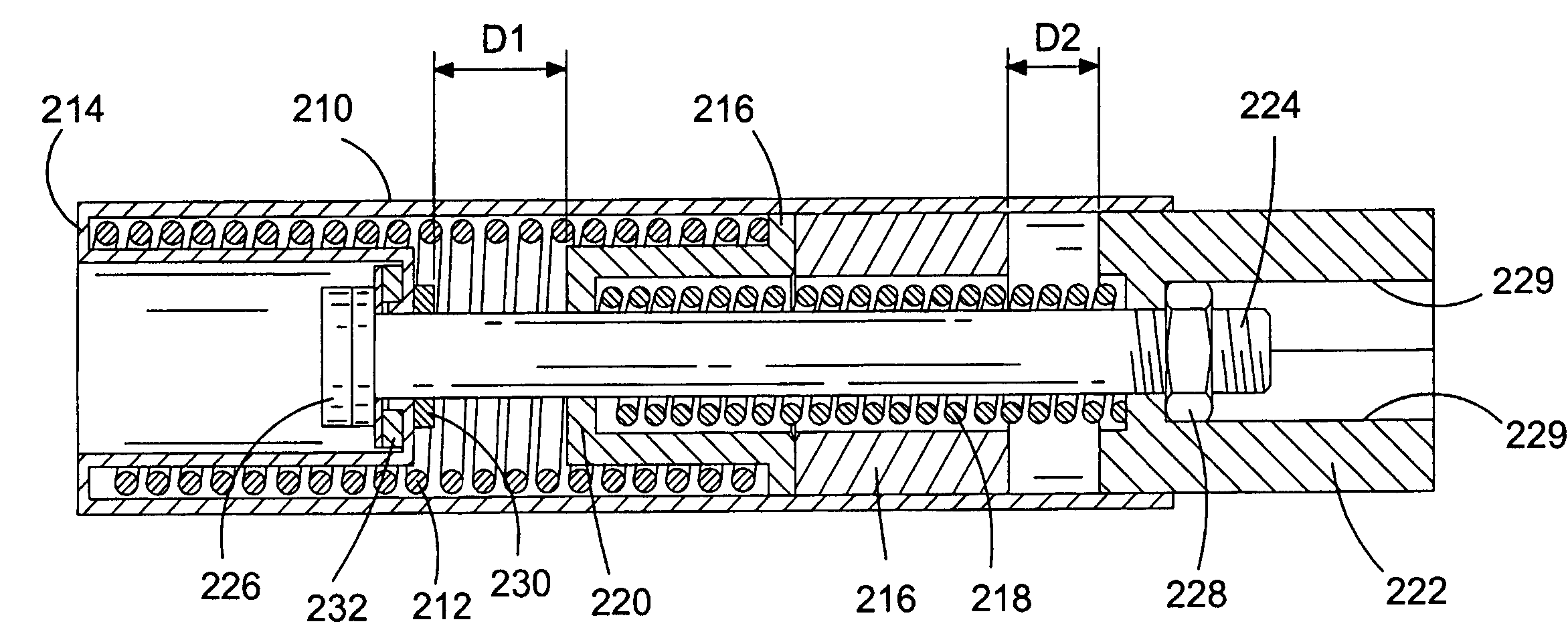

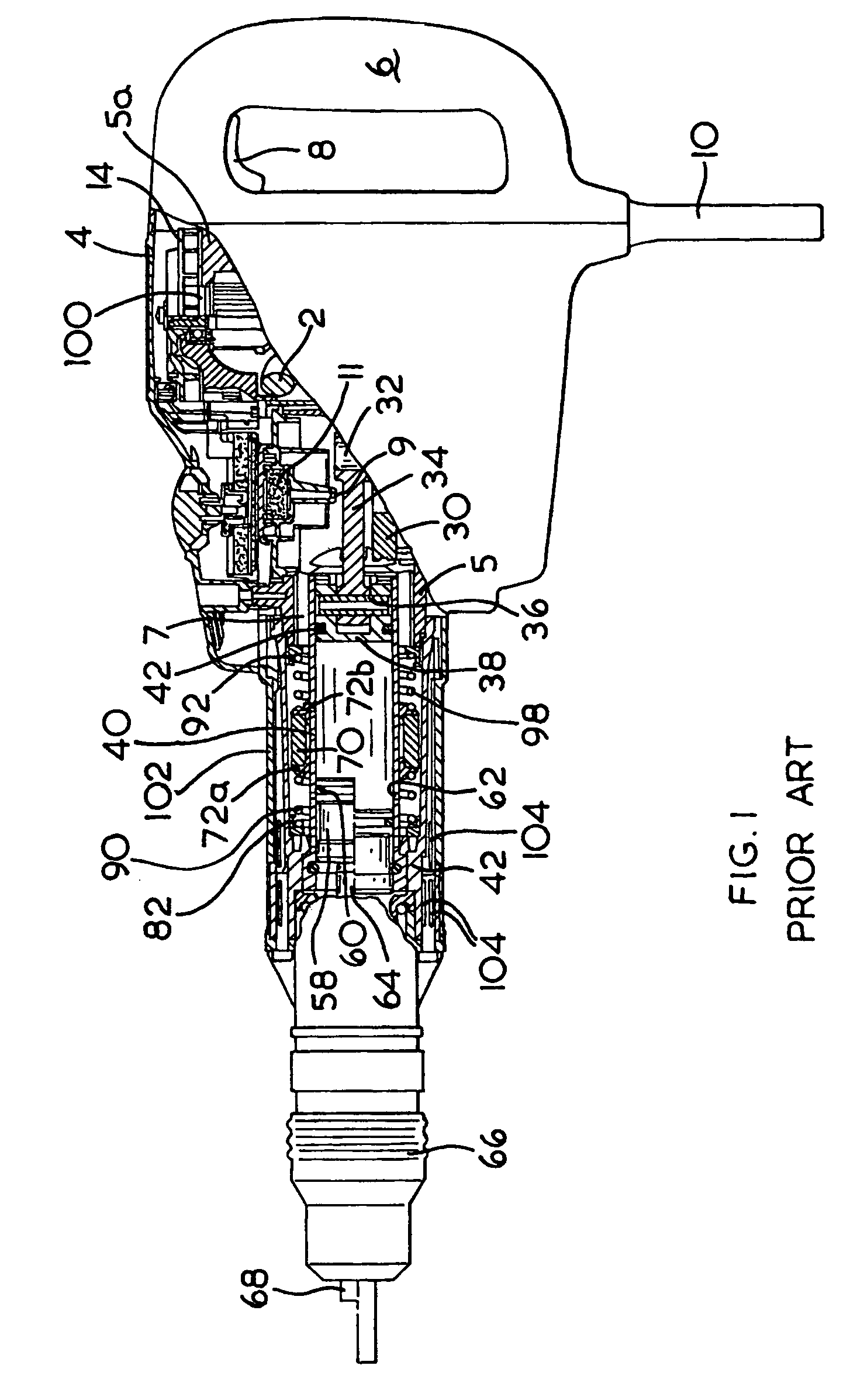

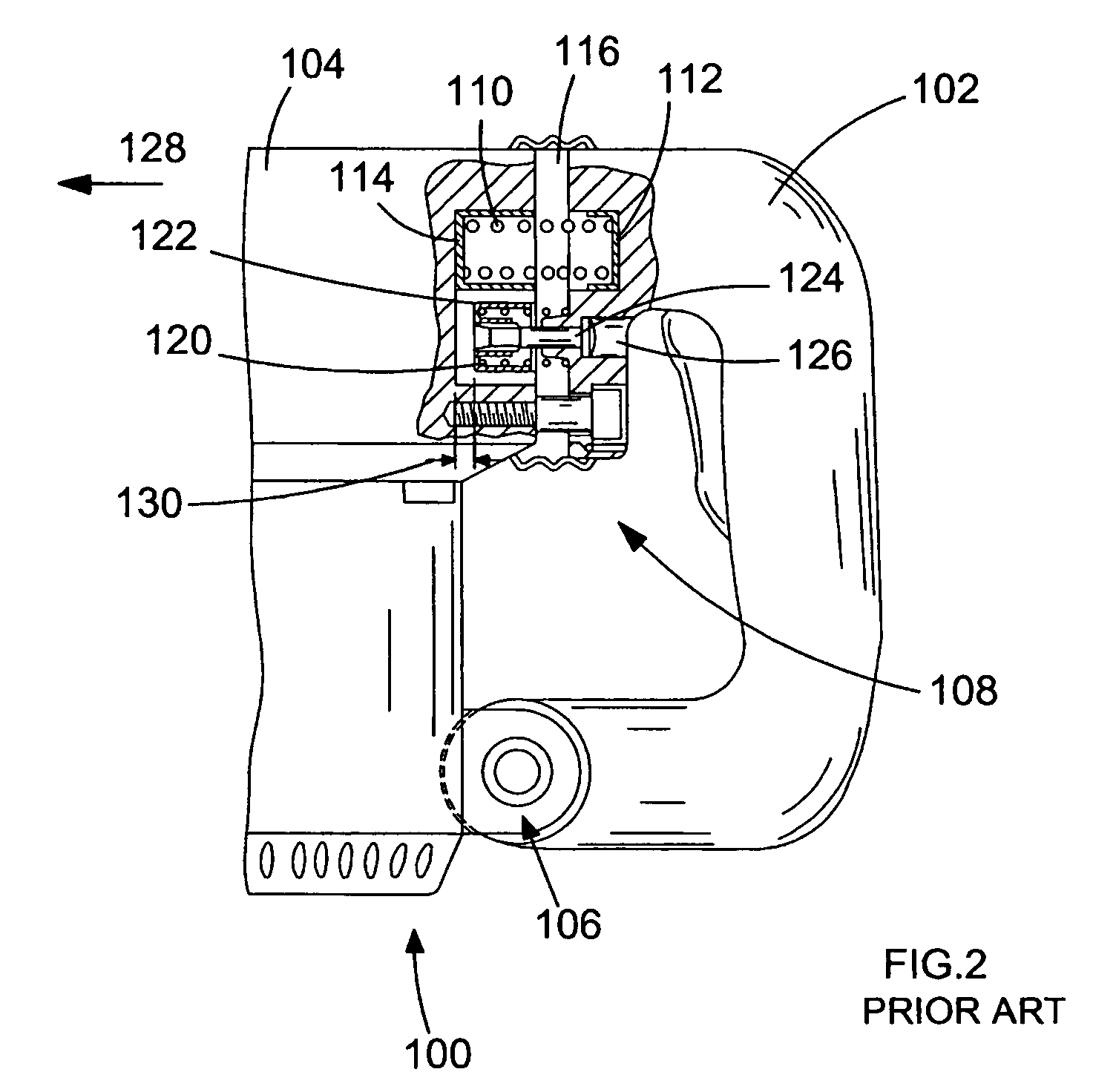

Vibration reduction apparatus for power tool and power tool incorporating such apparatus

InactiveUS20050284646A1Reduce the possibilityLess discomfortPortable percussive toolsPortable power-driven toolsPower toolThird body

A handle assembly for a power tool is described and includes a first substantially tubular body portion 210 which contains a first spring 212. A second body portion 216 is slidably mounted within first body portion 210 and contains a second spring 218. A third body portion 222 is also slidably mounted within first body portion 210. The biasing coefficient, or spring constant, of the first spring 212 is less than that of the second spring 218. The first, second and third body portions 210, 216 and 222, and first and second springs, 212 and 218, are all mounted coaxially on threaded bolt 224. In use the third body portion 222 moves within first body portion 210 in a direction towards end portion 214 and the first and softer spring 212 becomes compressed more rapidly than the second and harder spring 218. When the distance D1 has reduced to zero, by compression of first spring 212, the rubber washer 230 engages end portion 220 of second body portion 216 and the biasing effect of first spring 212 is eliminated The biasing force of the harder second spring 218 acts alone up to a distance D2.

Owner:BLACK & DECKER INC

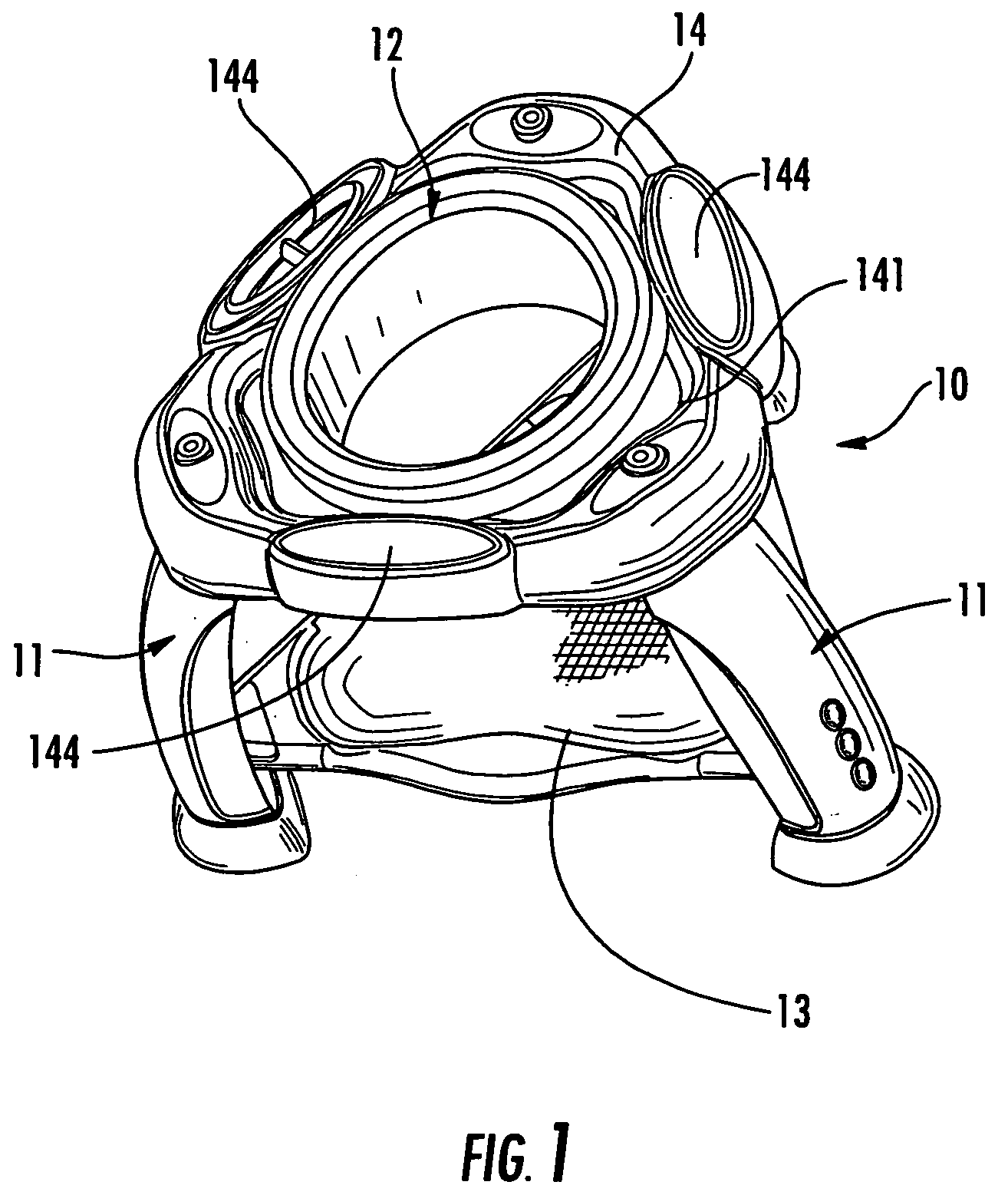

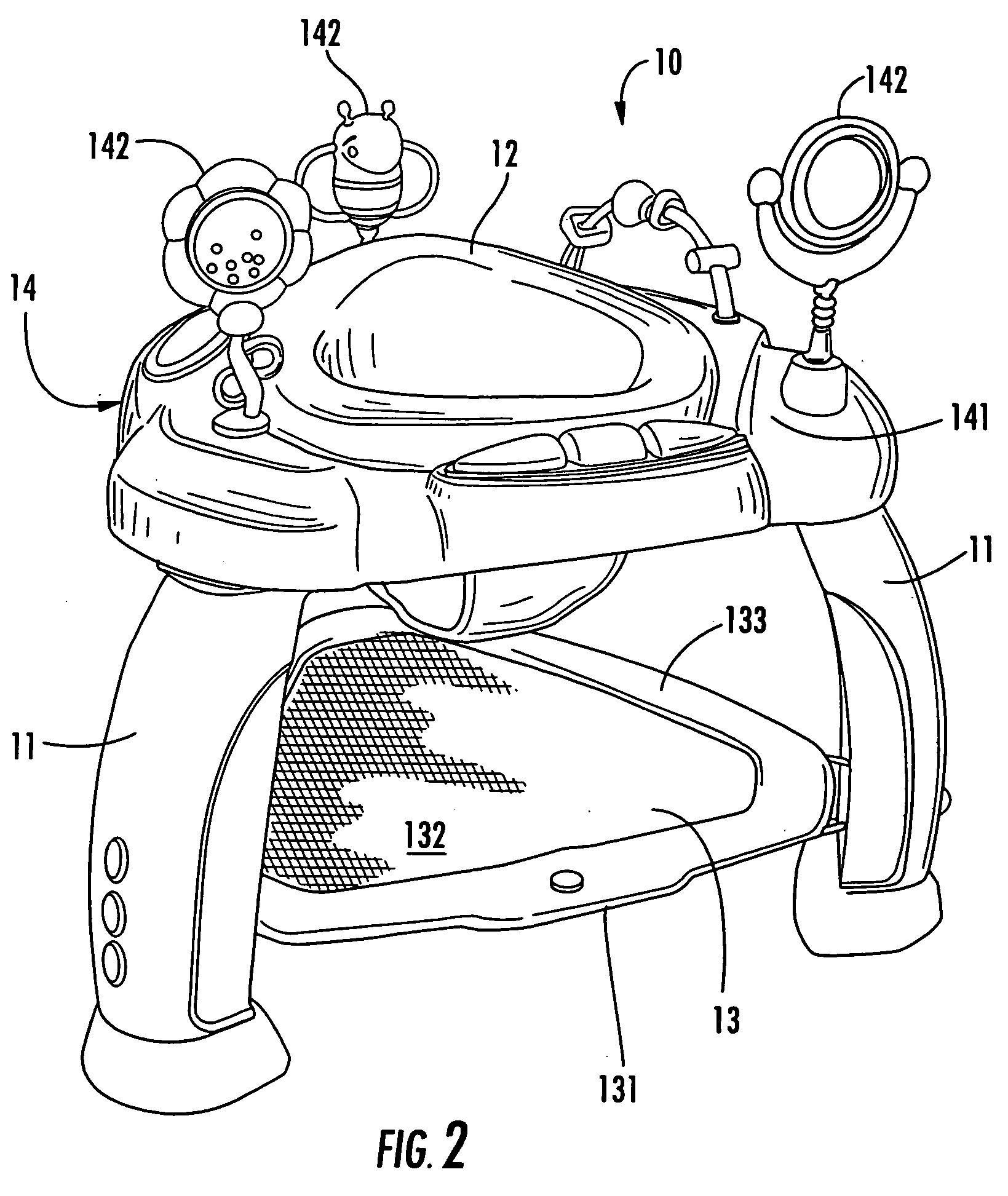

Stationary child exercise apparatus with bouncing pad

ActiveUS20050264088A1DistanceAdjustable tensionTablePedestrian/occupant safety arrangementEngineeringSupport surface

The invention is directed to a stationary exercise apparatus for small children. The apparatus includes an activity table adapted for receiving one or more children's activity items, one or more legs, a seat supported by the legs, and a resilient support surface suspended generally horizontally from at least one of the legs. The seat has a pair of leg openings that allow the child to touch the resilient support surface with its legs, and the resilient support surface has a resiliency that allows the child to bounce vertically by pushing its legs downwardly against the resilient support surface. Furthermore, the distance between the resilient support surface and the seat can be increased or decreased to account for the height of the child placed within the apparatus by moving the resilient support surface, and a tension element of the resilient support surface can be adjusted to account for the child's strength.

Owner:KIDS II INC

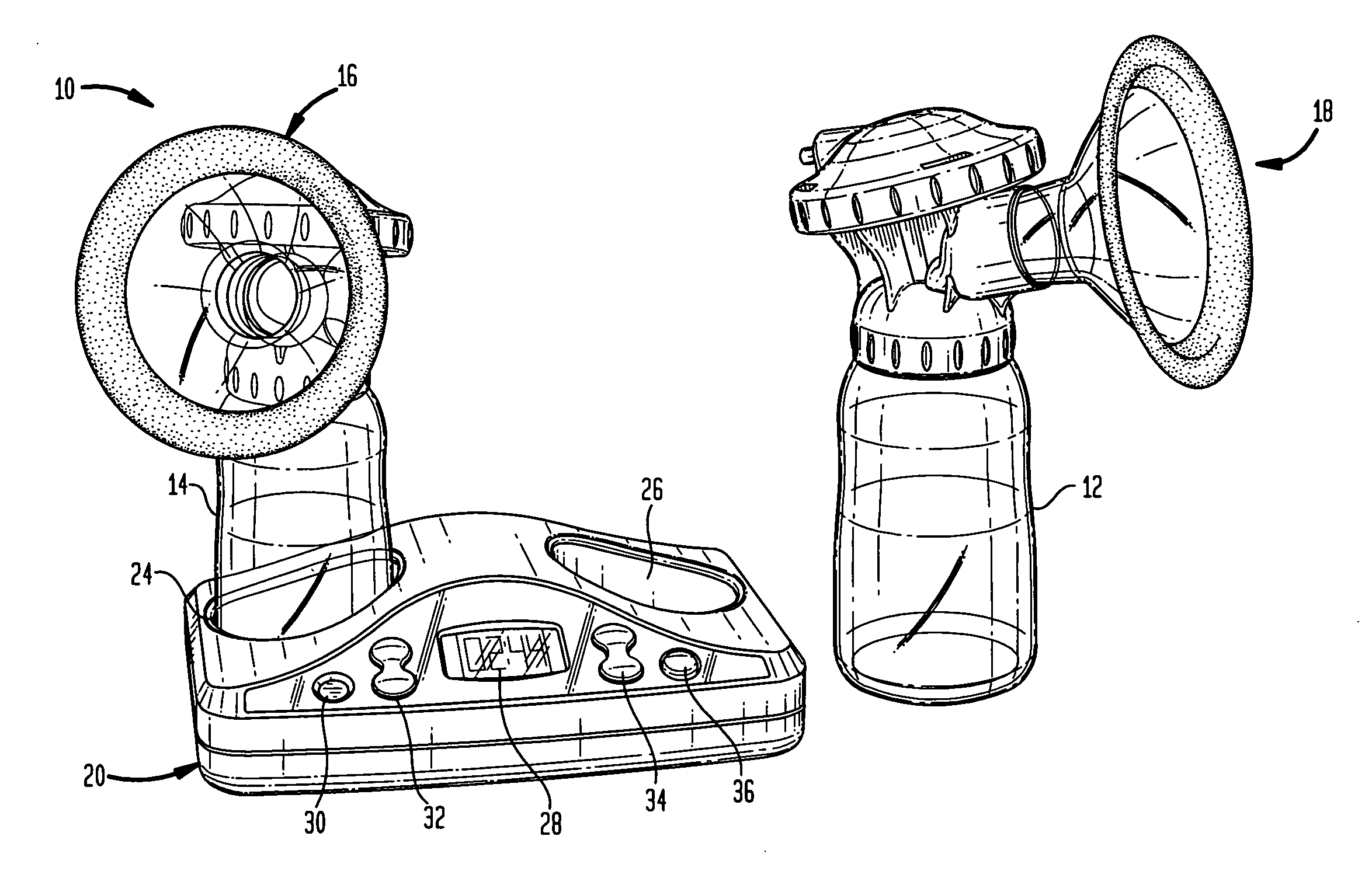

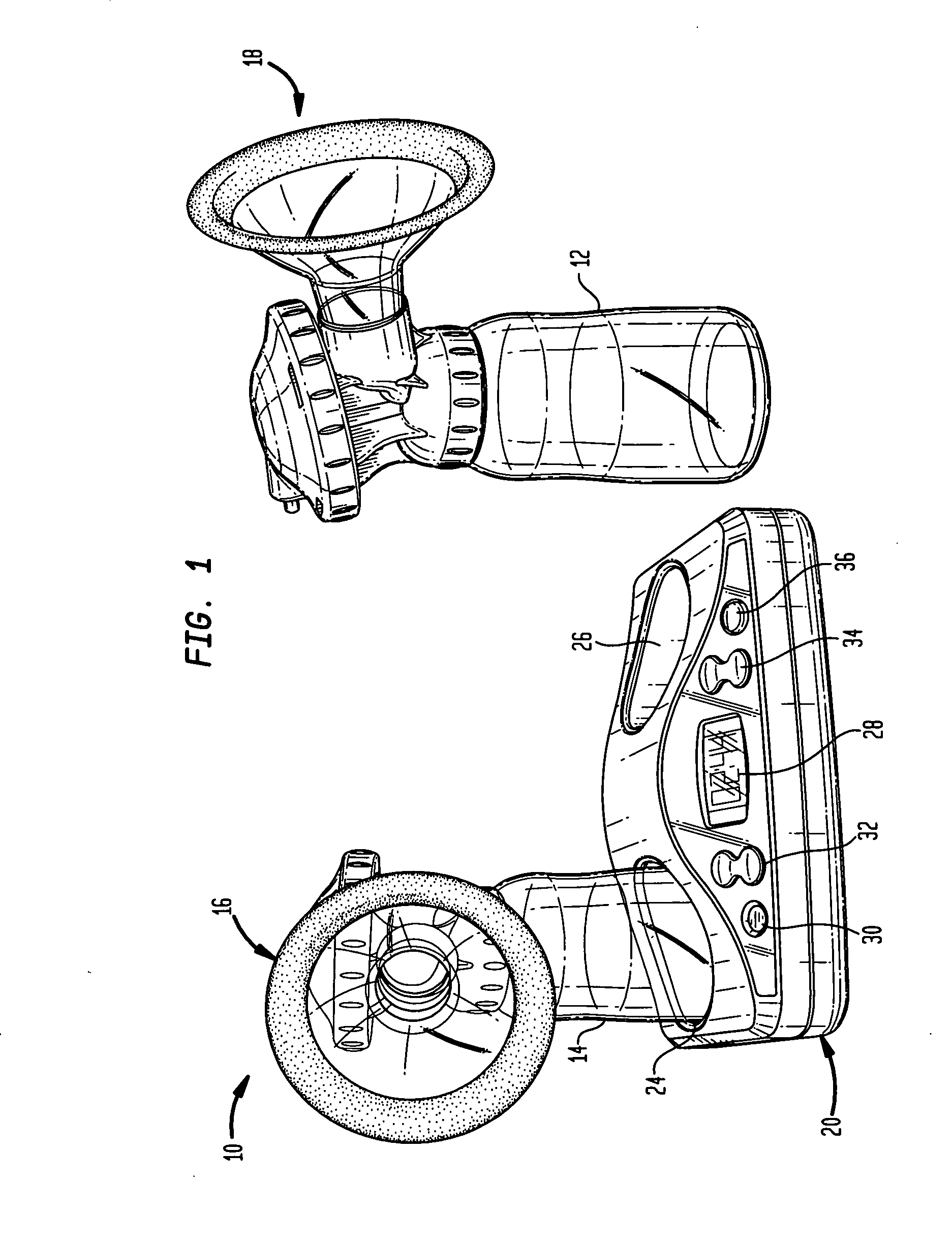

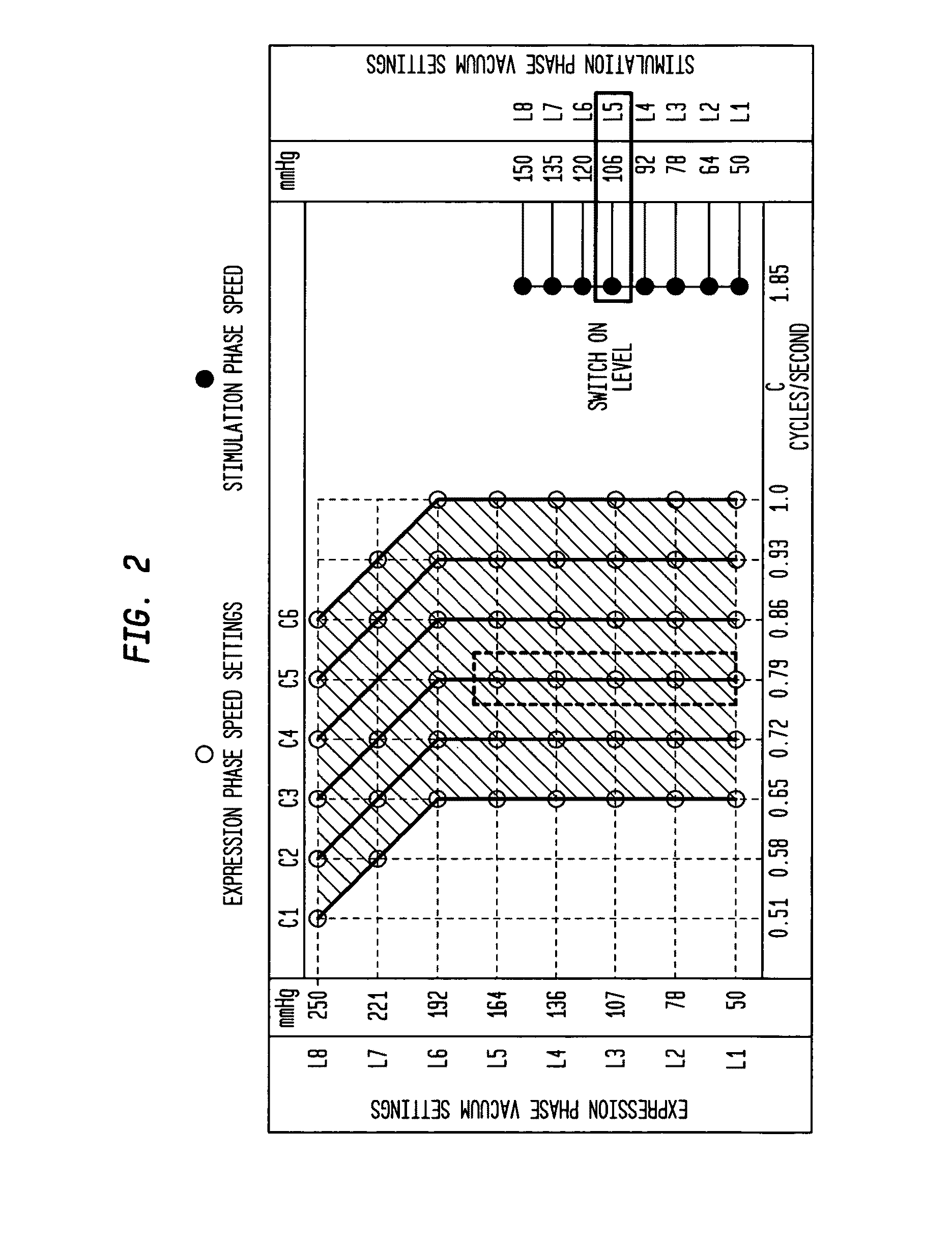

Breast pump

An electronically controlled breast pump for generating cyclical suction includes a cumulative vacuum pump and a plurality of switches including at least an expression mode cycle time selection switch, a peak vacuum level selection switch, and a stimulation mode switch. A controller coupled to the cumulative vacuum pump controls the apparatus which optionally further includes a four-layer assembly of the various features, an adjustable safety valve, and / or a pump head with a groove traversing top dead center of the pump head.

Owner:LANSINOH LAB

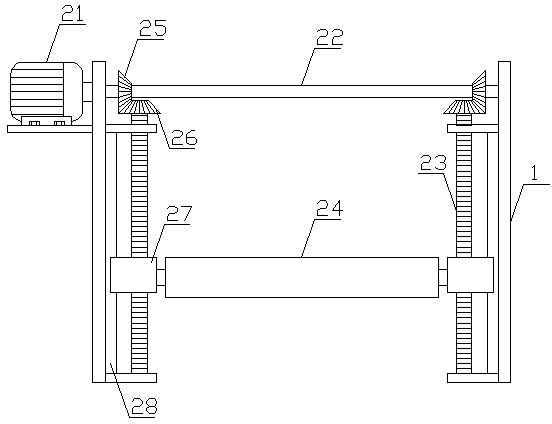

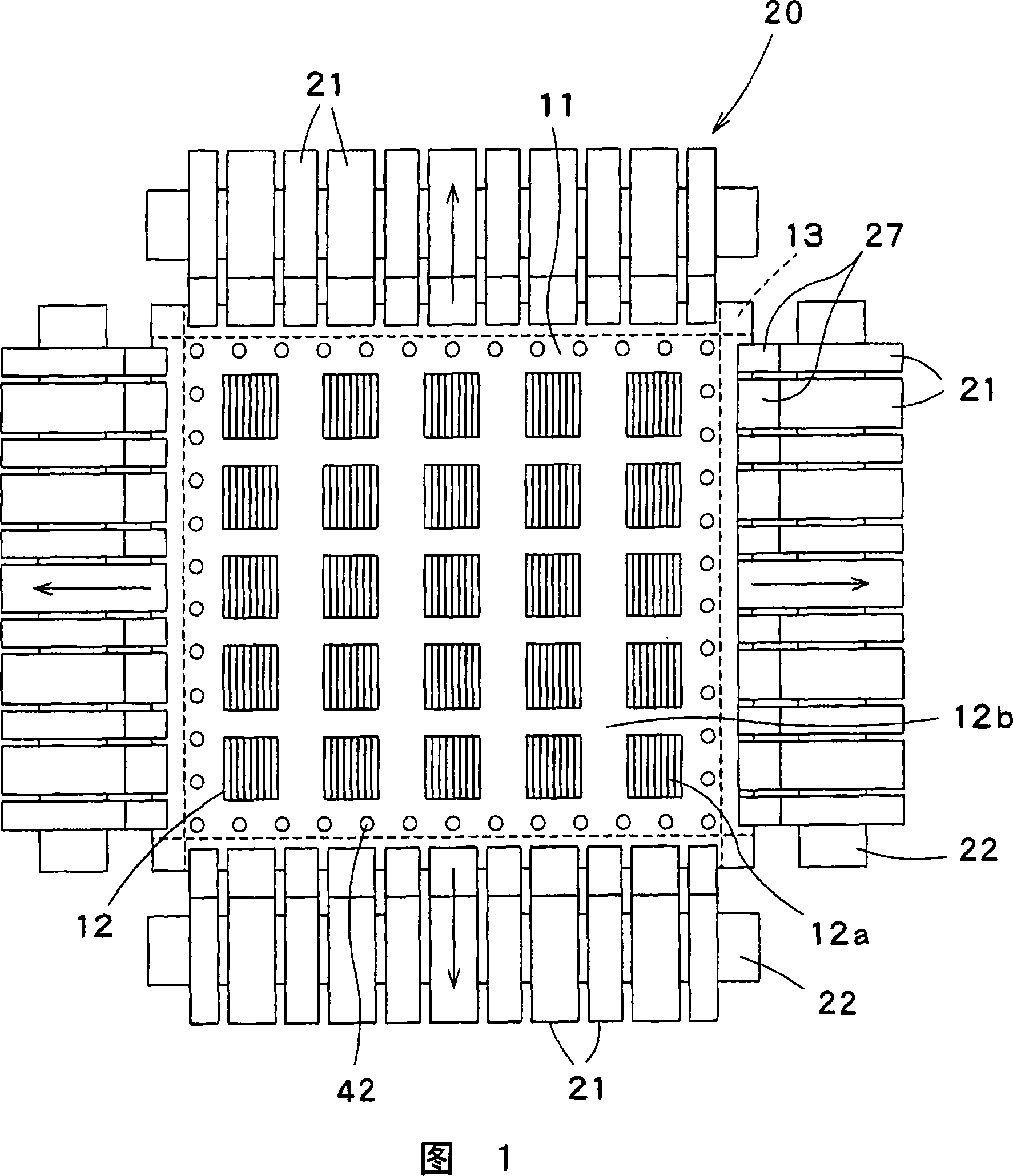

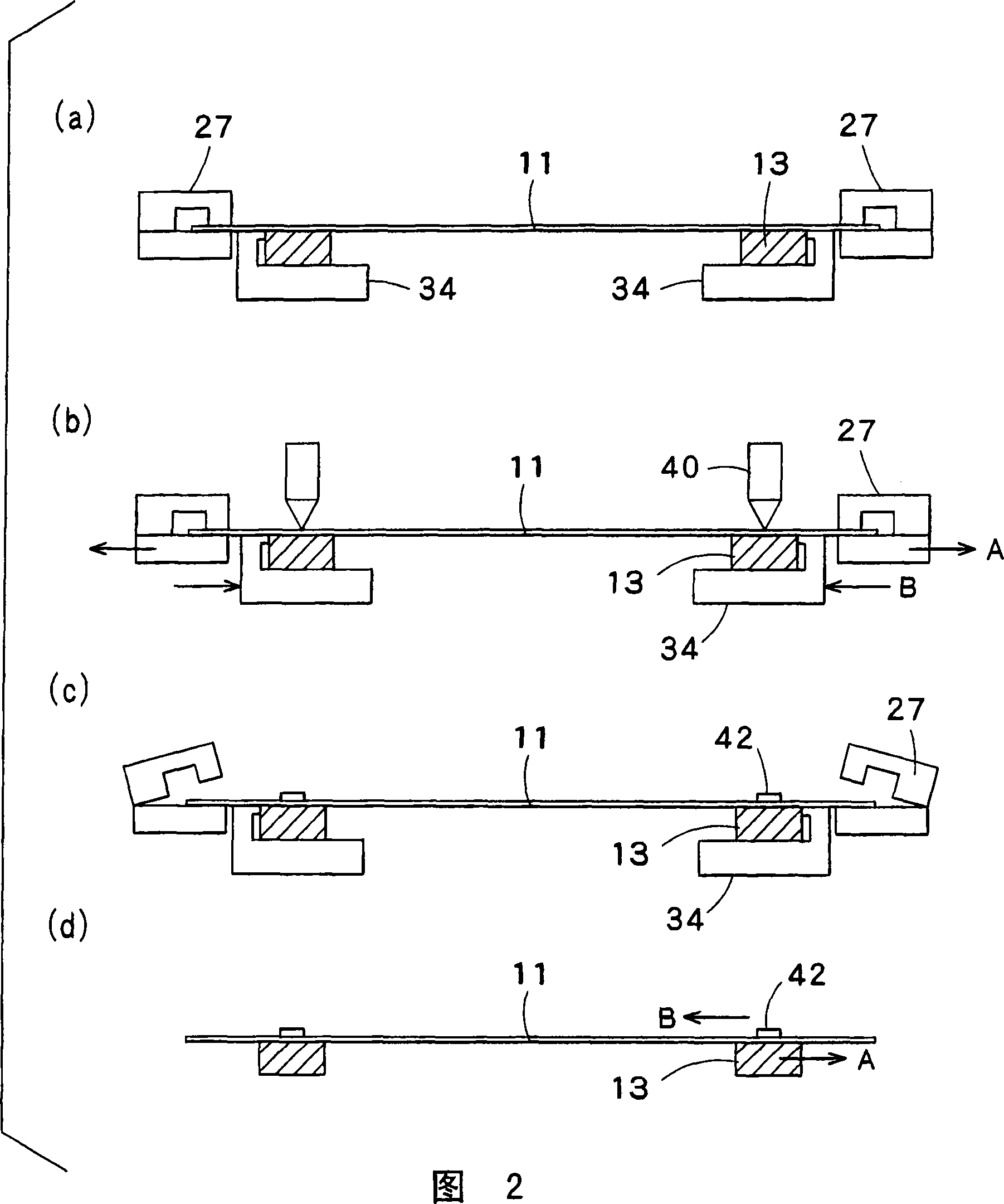

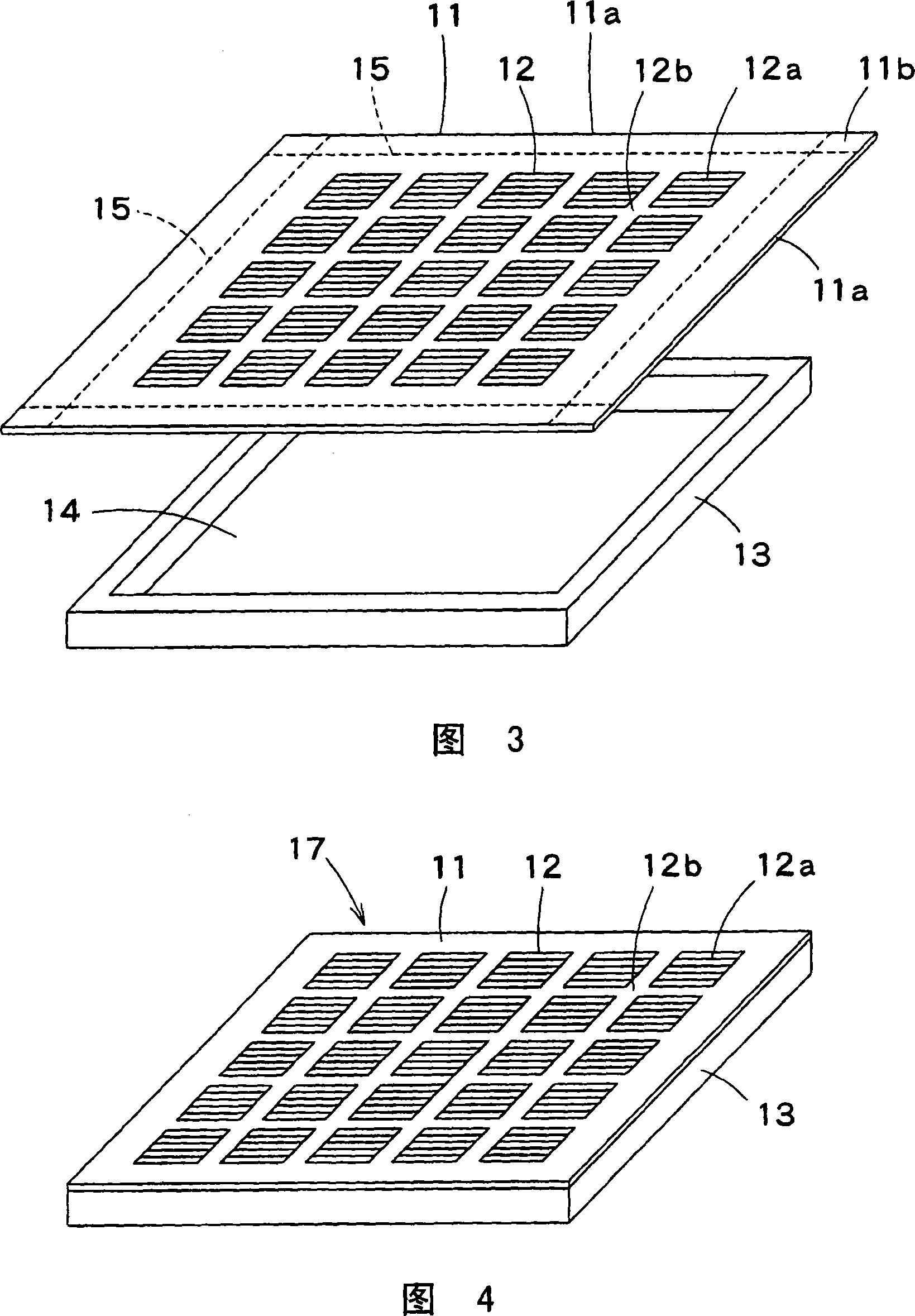

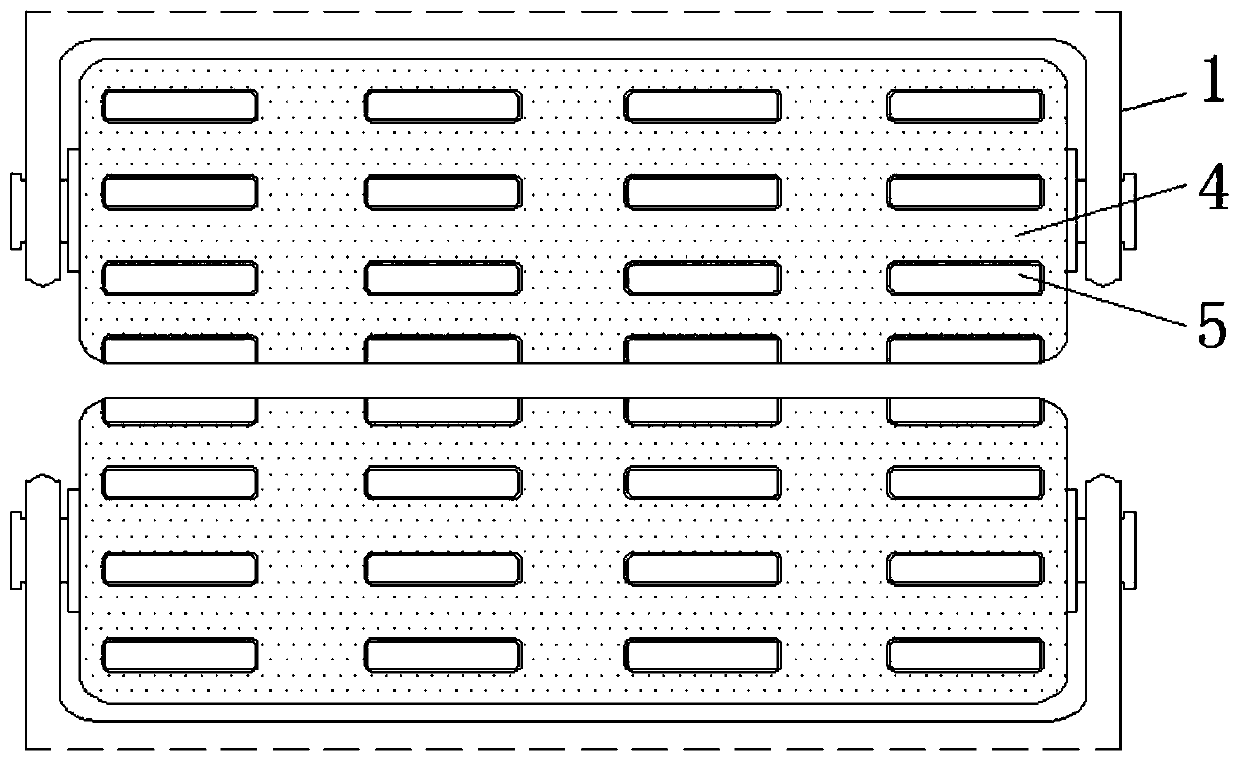

Method for sticking metallic thin sheet to frame, and device therefor

ActiveCN101001972AAvoid deformationNo deformationElectrical apparatusElectroluminescent light sourcesThin metalThin slab

Each side (11a) of a thin metal plate (11) is held with clamps (27). The thin metal plate (11) is pulled by the clamps (27), and tensile force by each clamp is adjusted to hold the thin metal plate (11) in a flat state without distortion and sagging. At the same time, a frame (13) is elastically deformed by pressing it, with a force having the same magnitude as the tensile force applied to the thin metal plate (11), in the opposite direction to the tensile force. Then, in this state the thin metal plate (11) is welded and fixed to the frame (13) by a spot welding machine (40). When the thin metal plate (11) and the frame (13) are freed, tensile force remaining in the plate (11) is cancelled by restoring force of the frame (13). This prevents the frame (13) from being pulled by the thin metal plate (11) and deformed, and the frame (13) can hold the thin metal plate (11) in a state without distortion and sagging.

Owner:DAI NIPPON PRINTING CO LTD

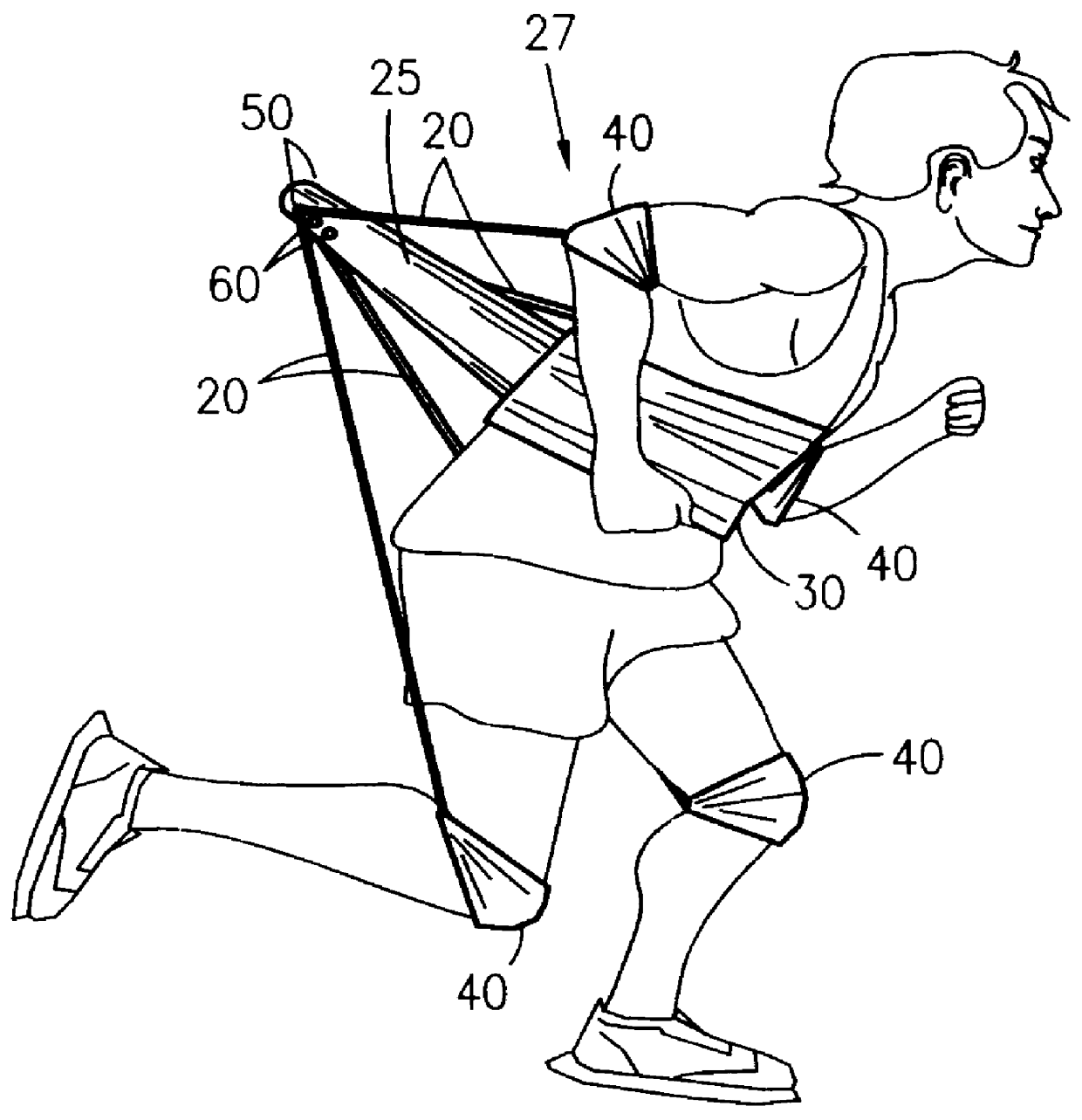

Full mobility resistance exercise system

InactiveUS6132346AAdjustable tensionUniform strengthResilient force resistorsEngineeringElbow joints

A full mobility resistance exercise system including a nylon vest with a posterior surface and worn around a user's chest. The vest utilizes a fastening means for adjustment of size. A rectangular support plate is attached flatly against and included within the posterior surface of the nylon vest. A horizontally elongated, inverted V-shaped rigid member is attached to the support plate on the posterior surface and perpendicular to the plane formed by the support plate. The rigid member extends horizontally outward and behind the user from the posterior surface of the nylon vest. Two pairs of adjustable nylon straps are worn around the user's knees and elbows. A plurality of elastic cables extends from each nylon strap, at the knee or elbow, to the end of the rigid member in a taut position.

Owner:WEEKS JAMES N

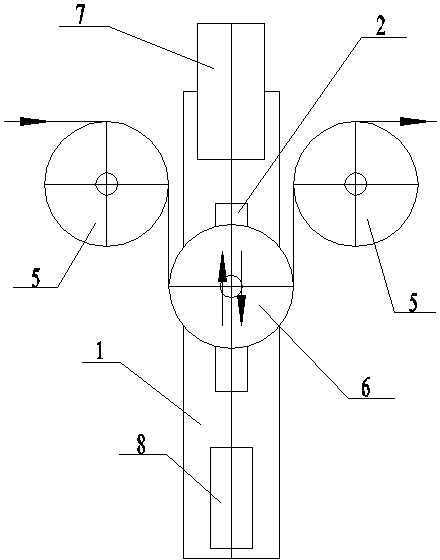

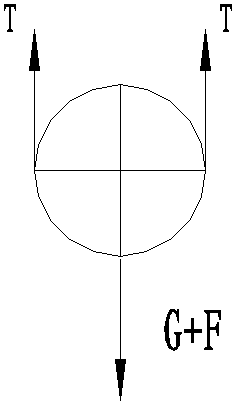

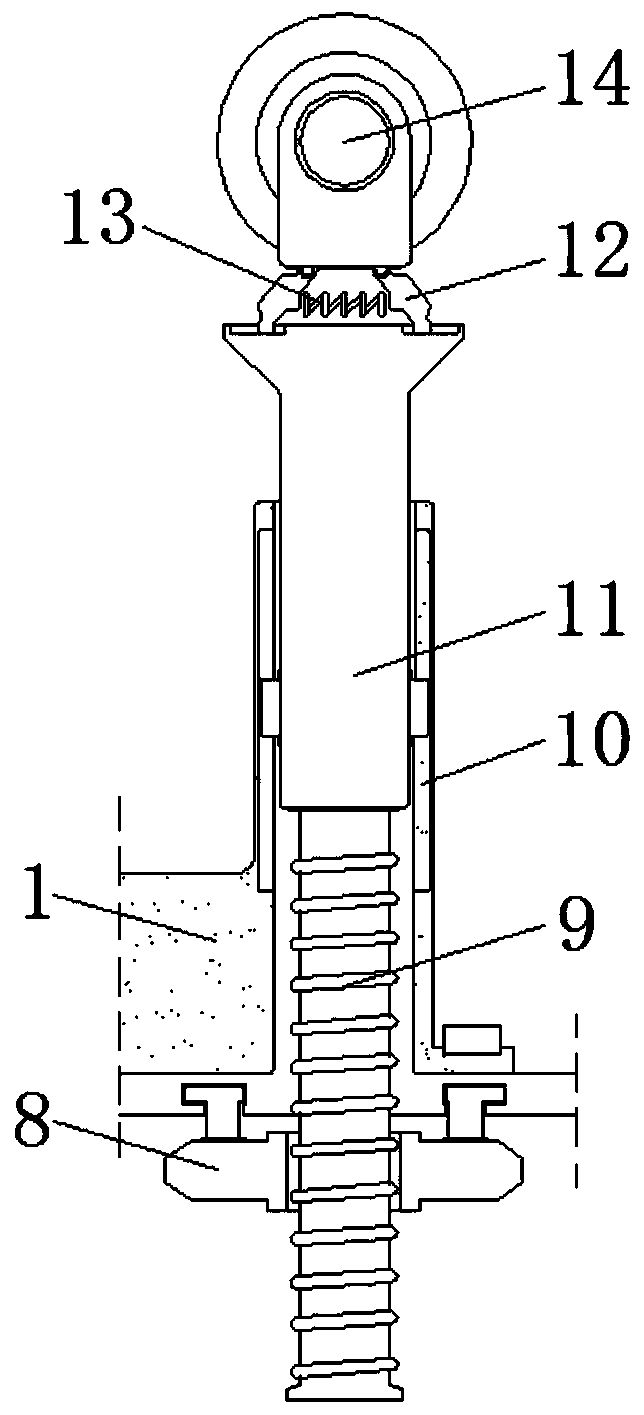

Linear guide track functional pulley group for bundle-like winding machine

A linear guide track functional pulley group for a bundle-like winding machine comprises a movable pulley used for guiding materials to be wound, and fixed pulleys which are arranged at two sides of the movable pulley; the movable pulley is arranged on a linear guide track and can reciprocate along the linear guide track; the movable pulley is connected with a displacement sensor connected with a control system; the control system controls the winding speed of the winding machine according to the displacement measured by the displacement sensor. The movable pulley is also connected with a forcing mechanism adopting any one from a spring, a cylinder or an oil cylinder, and the cylinder or the oil cylinder is connected with the control system. The linear guide track functional pulley group for the bundle-like winding machine is simple in structure, high in automation degree, safe and reliable in use, wide in application range, capable of fully meeting the demands of a production line and suitable for being promoted and used.

Owner:LUOYANG MINGWEI MACHINERY TECH

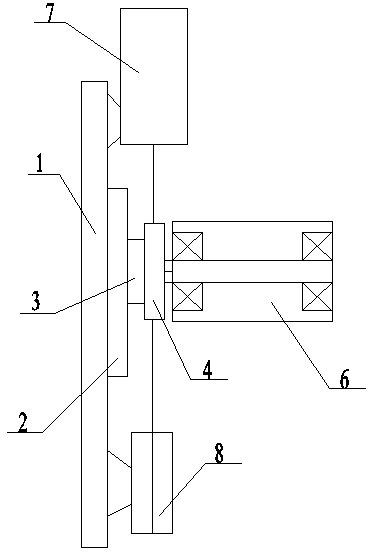

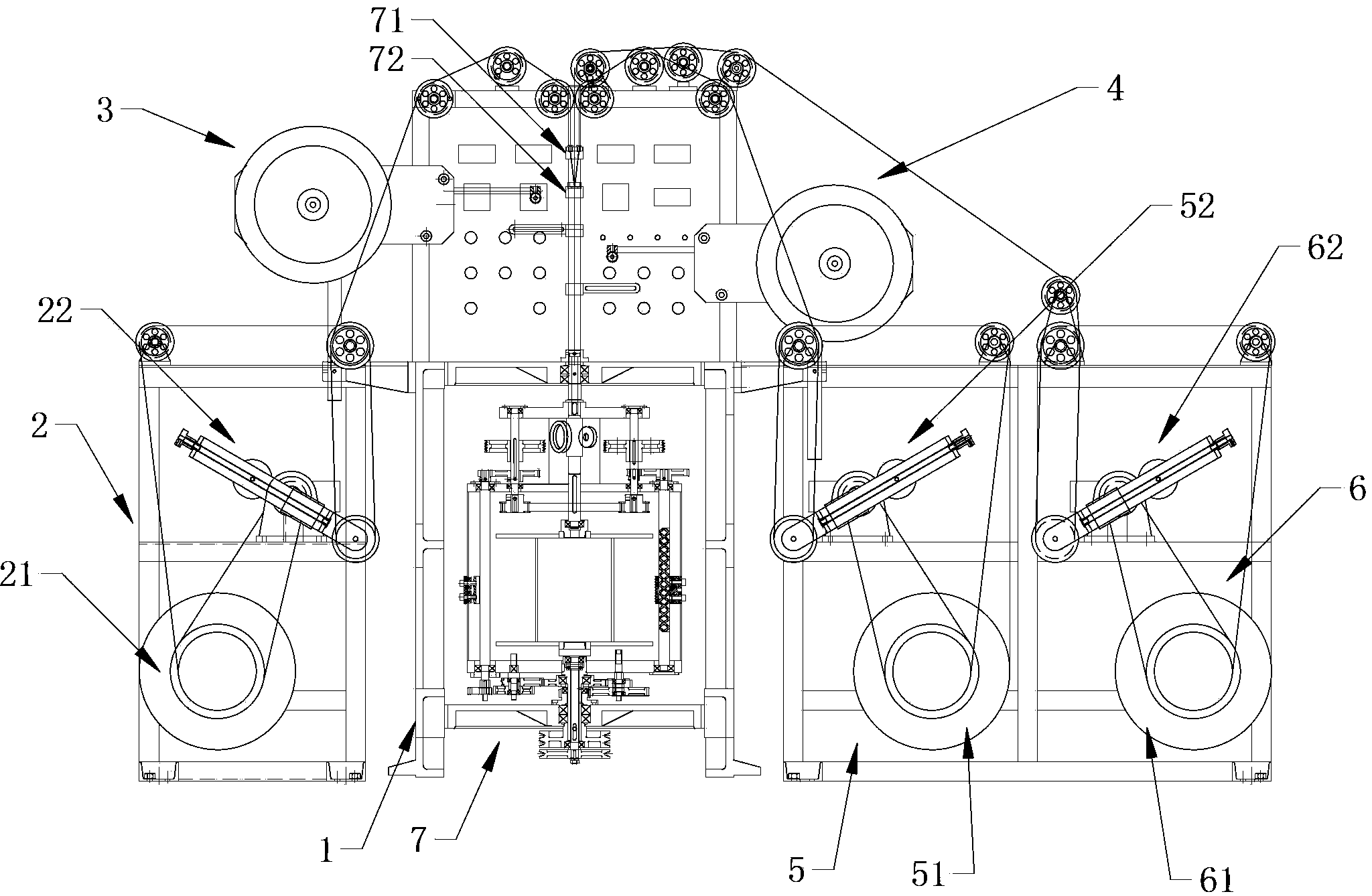

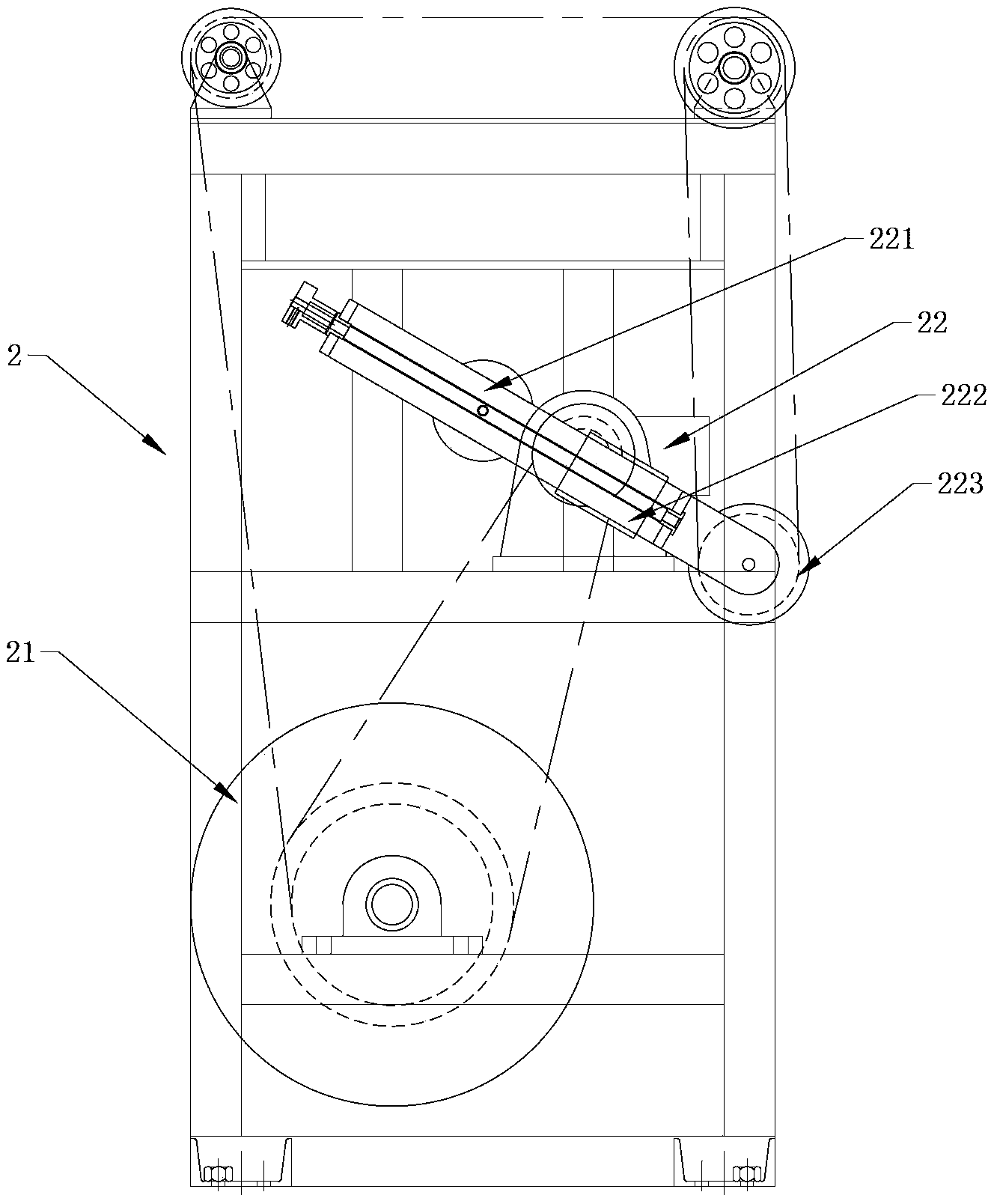

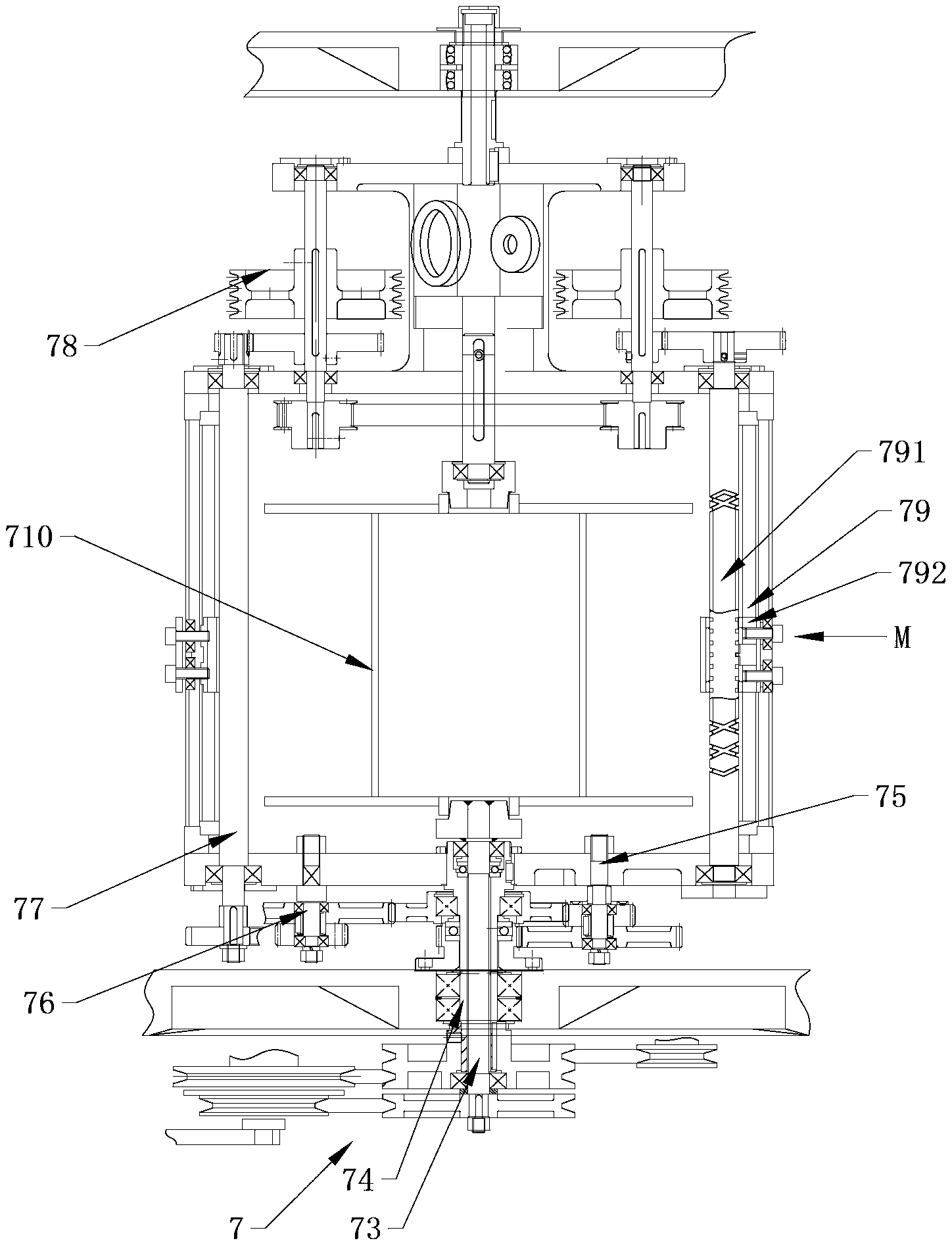

Vertical-type wire stranding machine of high-definition multimedia interface (HDMI) cables

ActiveCN103413618ASuitable for automated productionReasonable driveCable/conductor manufacturePaper sheetTension control

The invention discloses a vertical-type wire stranding machine of high-definition multimedia interface (HDMI) cables. The vertical-type wire stranding machine comprises a rack, a first wire core releasing mechanism, a second wire core releasing mechanism, a ground wire releasing mechanism, a wire stranding main machine, a first paper layer wrapping mechanism and a second paper layer wrapping mechanism; the first wire core releasing mechanism makes a wire core in the high-definition multimedia interface (HDMI) cable pass through a first tension control device and thereafter makes the wire core enter a wire concentrating board and a narrowing and modeling model; the second wire core releasing mechanism makes the other wire core in the high-definition multimedia interface (HDMI) cable pass through a second tension control device and makes the wire core enter the second wire concentrating board and the narrowing and modeling model; the ground wire releasing mechanism makes a ground wire in the high-definition multimedia interface (HDMI) cable pass through a third tension control device and thereafter enables the ground wire to enter the wire concentrating board and the narrowing and modeling model; the wire stranding main machine winds up two wire cores and one ground wire; the first paper layer wrapping mechanism wraps a first player of paper on the cable which is subjected to narrowing and modeling; and the second paper layer wrapping mechanism wraps a second layer of paper on the cable which is wrapped with the first layer of paper. The vertical-type wire stranding machine of the high-definition multimedia interface (HDMI) cable of the invention is advantageous in simple structure and high production efficiency, and can be applicable to completing wire stranding and wrapping processes of the high-definition multimedia interface (HDMI) cable.

Owner:JIANGSU JIACHENG TECH

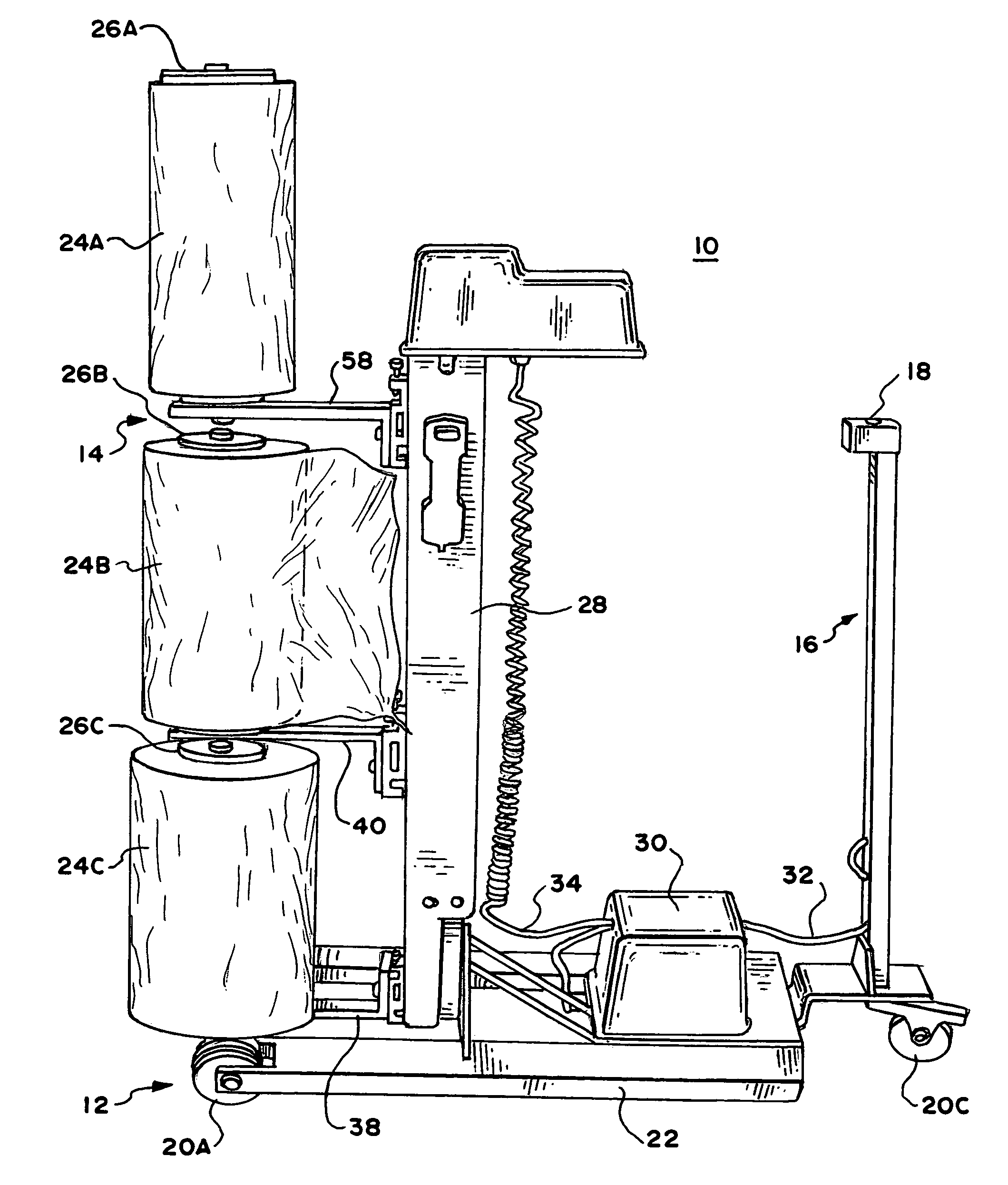

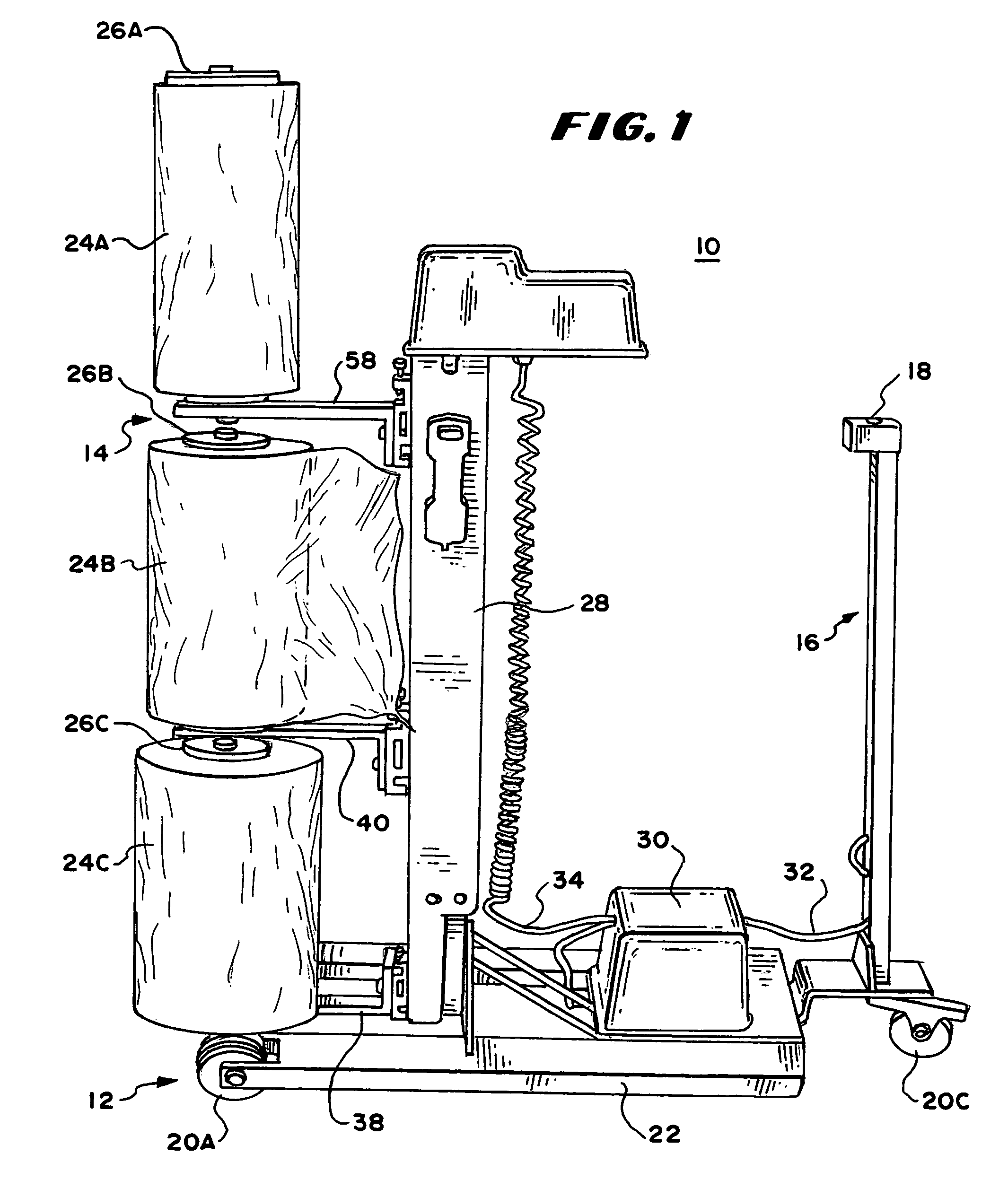

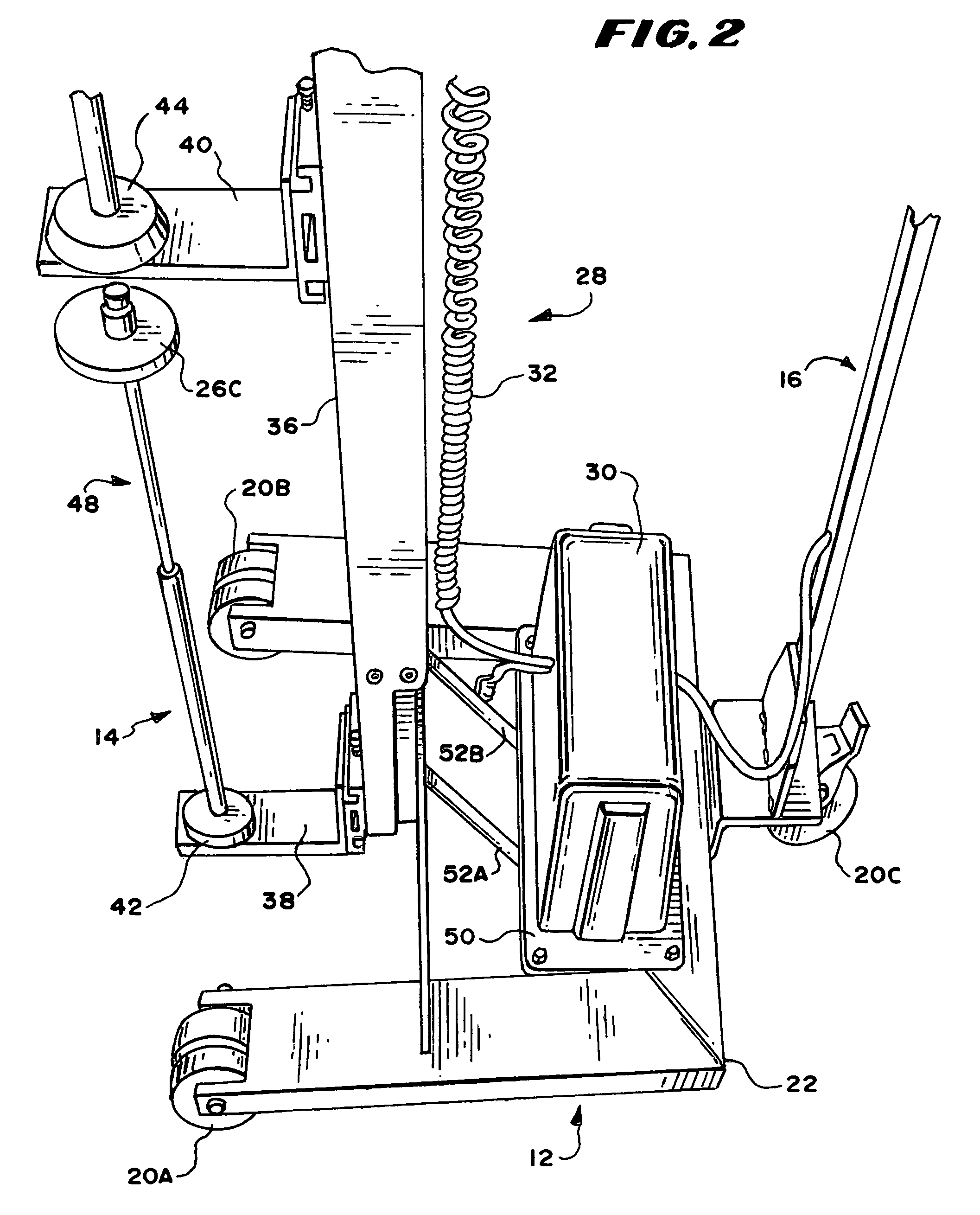

Wrapping cart machine and method of wrapping

InactiveUS7621107B2Fast and economical methodExceptional speedWrappers shrinkageWrapping material feeding apparatusEngineeringCantilever

To palletize packages, a wrapping vehicle includes a vertically mounted drive screw having a plurality of ball nuts mounted at wrapping-effective distances from each other on the vertically mounted drive screw. Each ball-nut has a corresponding cantilever mounted to the ball nut to support a roll of wrapping material. A tension adjustment mechanism is mounted to adjust the resistance to motion of each roll of wrapping material and thus the tension on the wrapping material. The ball nuts are each connected to side support guide plates positioned to slide against the sides of mast housing the drive screw wherein said ball nuts are supported against tilting movement.

Owner:VANDERHEIDEN PATRICK J +1

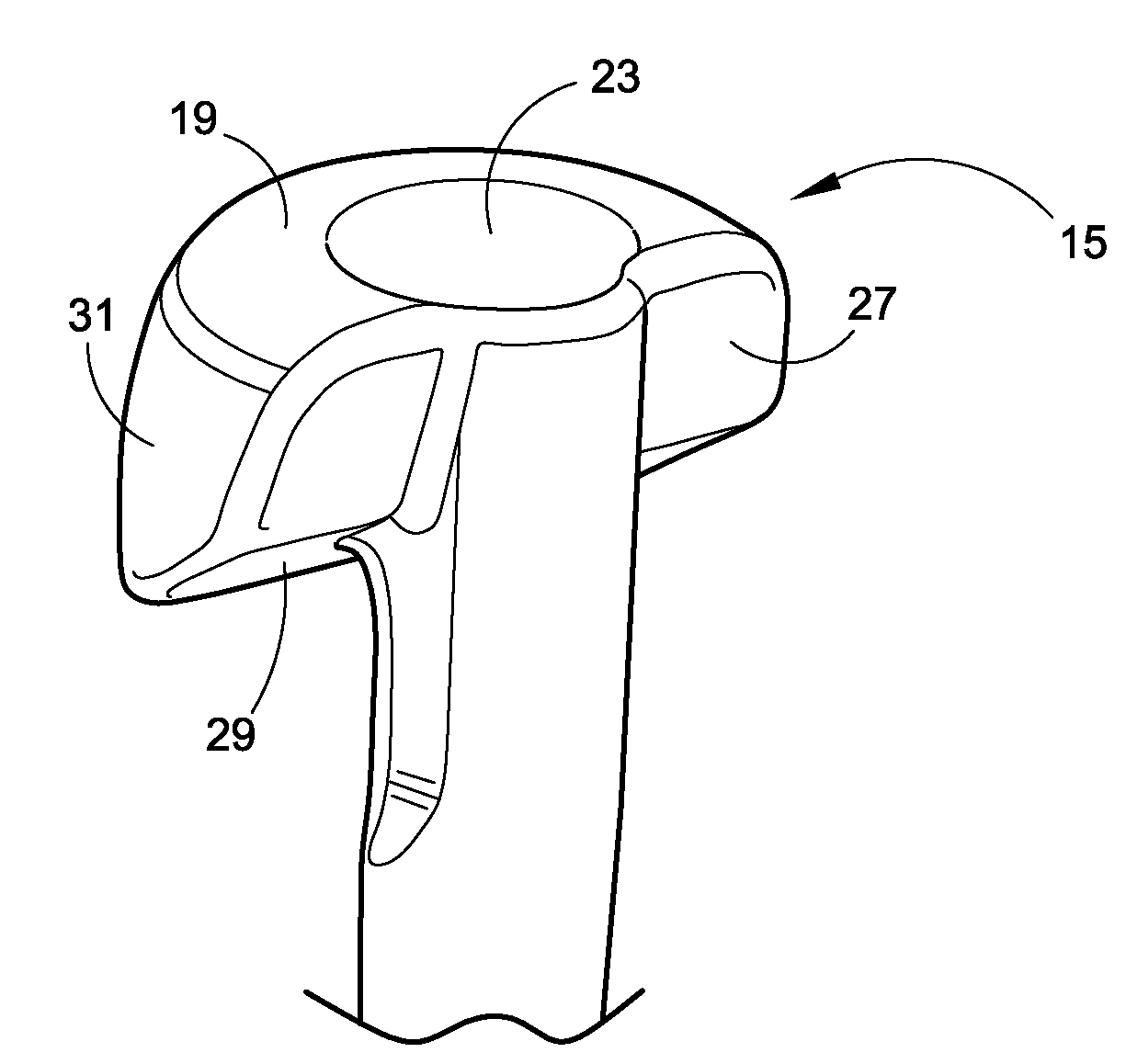

Rotating locking member suture anchor and method for soft tissue repair

A suture anchor apparatus and method for anchoring a length of suture with respect to a target tissue has an anchor body with an anchoring structure for fixing the anchor body within the target tissue and a suture locking member. The moveable suture locking member is disposed at least partially within an anchor body lumen while a portion of the length of suture is looped around the suture locking member such that a first and second limb of suture exits the lumen. A suture locking member includes at least two elongate arms, and each arm has an extension dimension respectively, such that the first arm extension dimension is substantially greater than the second arm extension dimension.

Owner:ARTHROCARE

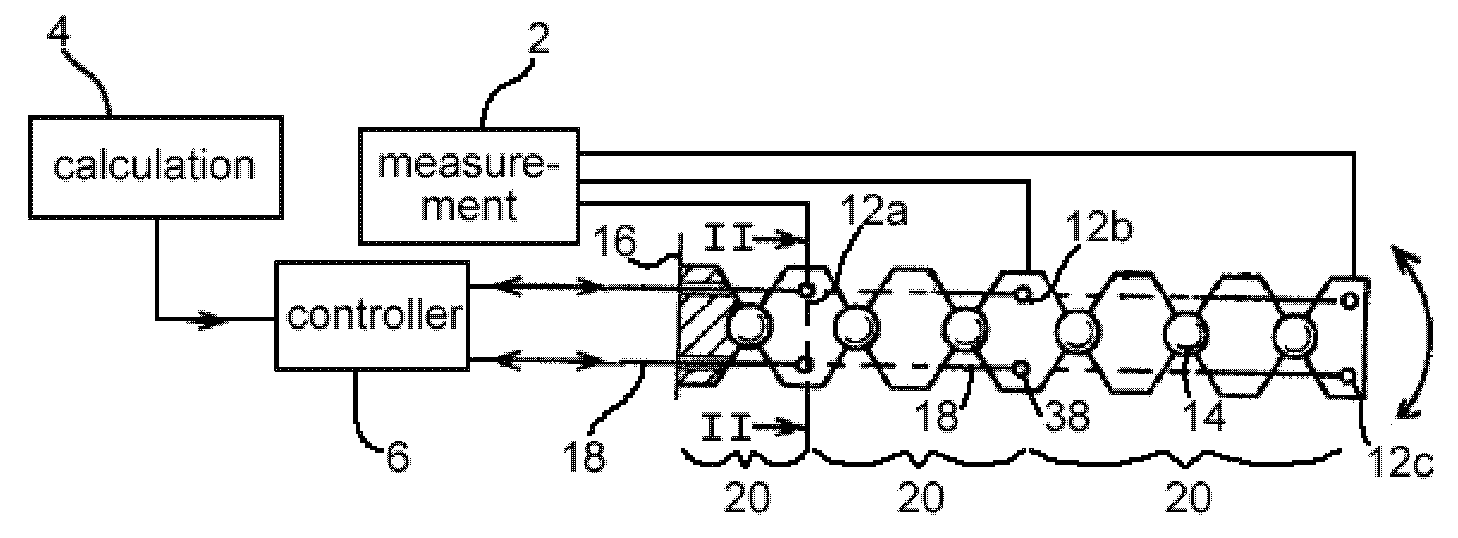

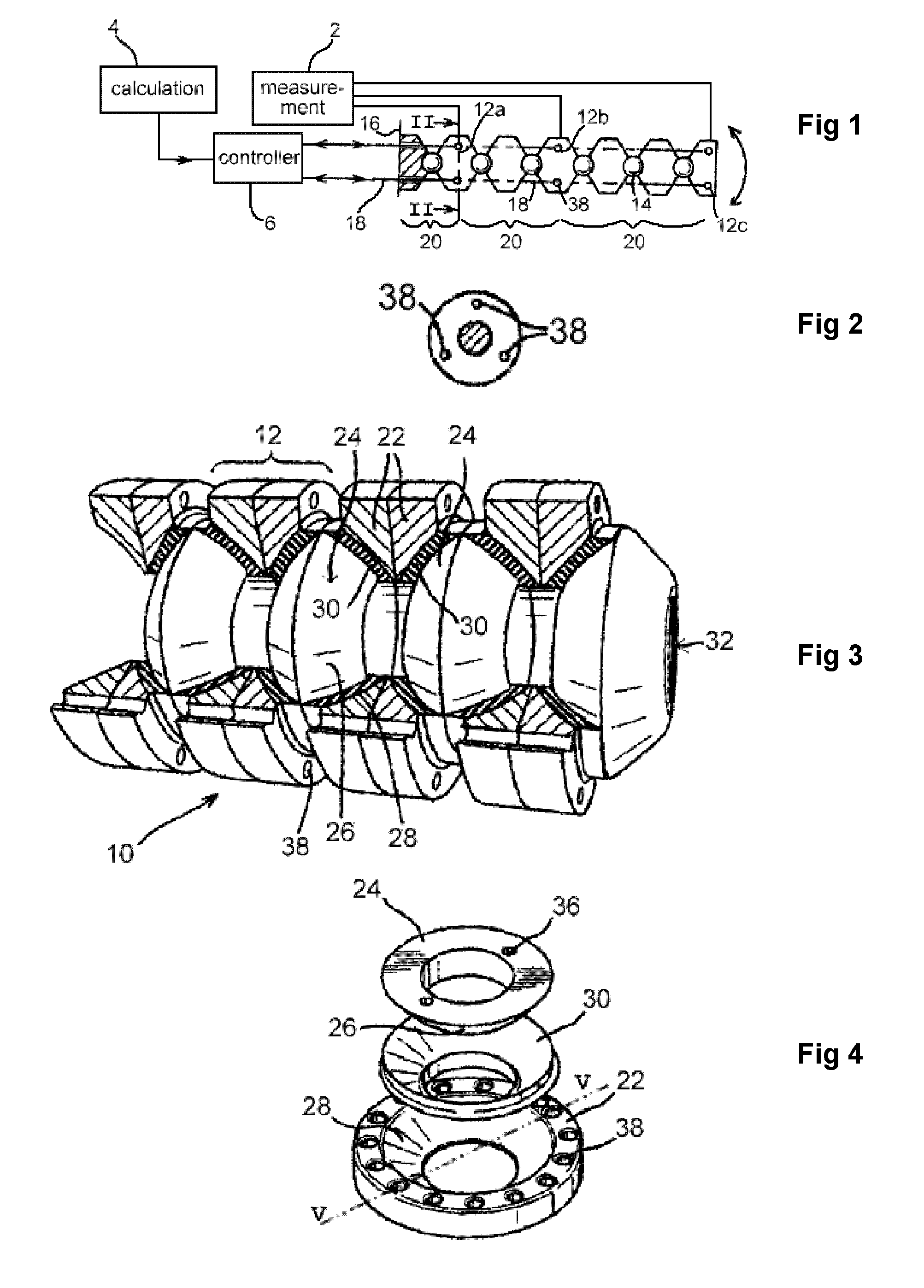

Robotic Arms

ActiveUS20080161971A1Complex structureTensionWalking sticksProgramme-controlled manipulatorRobotic armEngineering

A robotic arm comprises a plurality of articulated elements, and control means for controlling the position of various of the elements such that the arm may adopt serpentine shape for tip following movement. Means for measuring directly the relative positions of at least some of the elements are provided in order to calculate deviation from the theoretical shape, and apply corrections to the arm control means.

Owner:OLIVER CRISPIN ROBOTICS

Double-side drape-proof ironing device with adjustable tensity for textile processing

InactiveCN110983709AImprove processing efficiencyGuaranteed ironing qualityMechanical cleaningPressure cleaningElectric machineryDrive motor

The invention discloses a double-side drape-proof ironing device with adjustable tensity for textile processing. The double-side drape-proof ironing device with adjustable tensity for textile processing comprises a base body, ironing rollers and a driving motor, wherein transmission rollers are arranged at the inner side of the base body through screw bolts; the upper ends of the transmission rollers are provided with a cloth body; the ironing rollers are arranged at the middle end inside the base body, and are connected with the cloth body; ventilation holes are formed in the outer surfaces of the ironing rollers; the driving motor is arranged at the inner surface of the lower end of the base body; and the output end of the driving motor is provided with a conveying belt. The double-sidedrape-proof ironing device with adjustable tensity for textile processing has the advantages that a user can realize the control on the support intensity of cloth by regulating the position of movingblocks for limiting positions; meanwhile, when moving, position limiting rollers can drive dust removal rollers to do synchronous downward displacement in an opposite direction; and the end parts of the cloth are further clamped in a staggered way, so that when the adjustable tensity is realized, the double-side drape-proof position limiting treatment is stably performed.

Owner:关庚

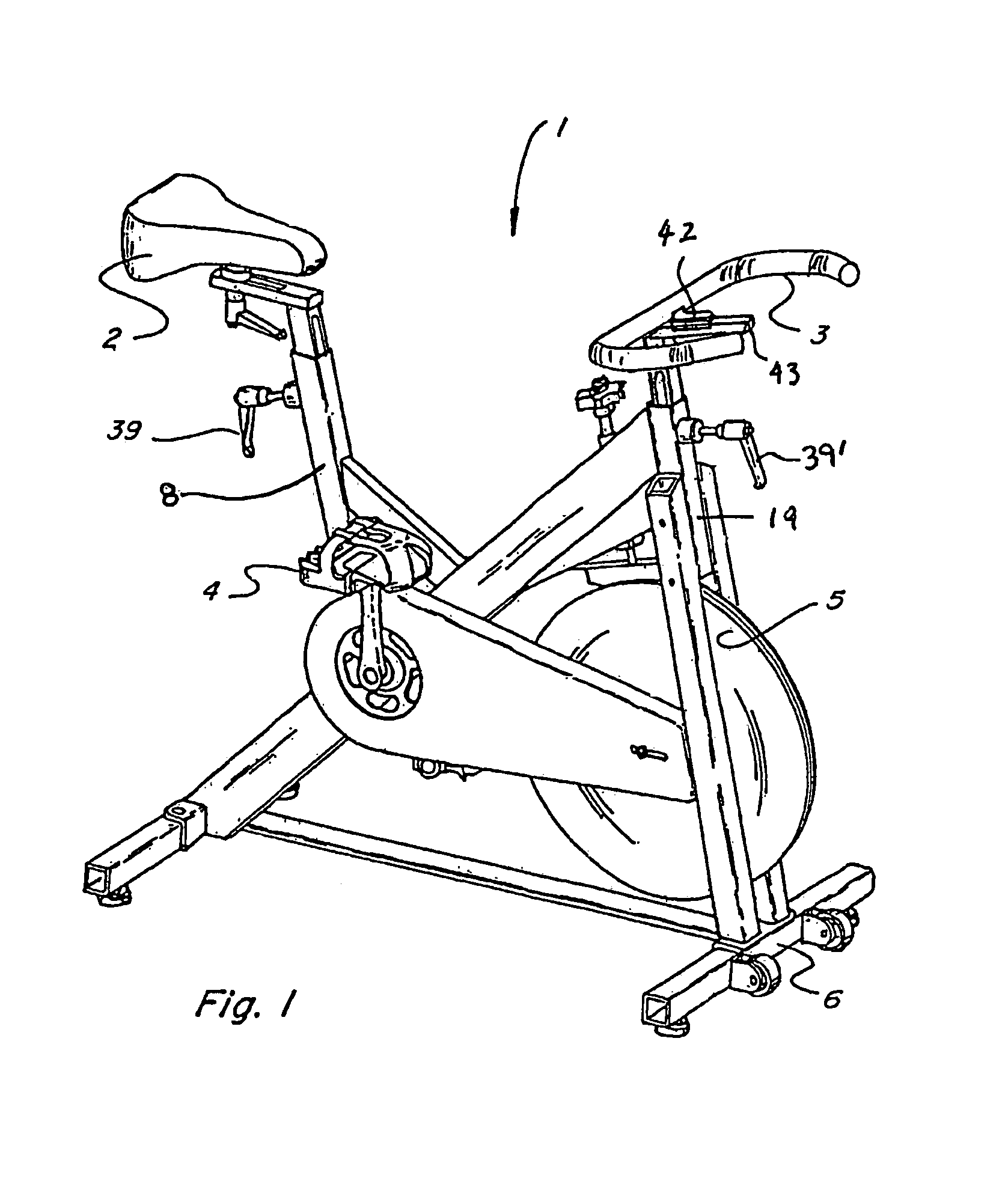

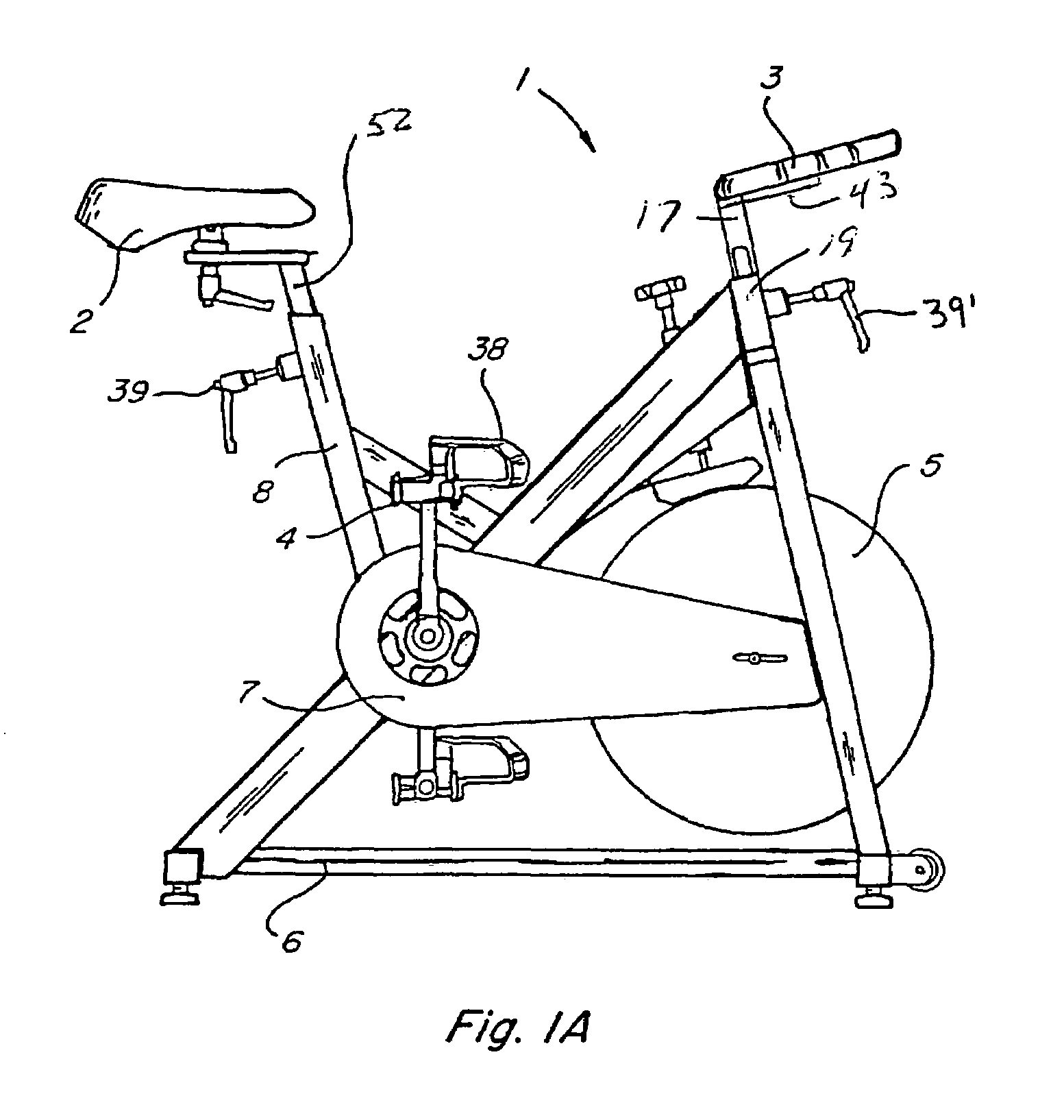

Adjustable stationary exercise bicycle

InactiveUS7419458B2Easy to disassembleAdjustable tensionFrictional force resistorsMovement coordination devicesEngineeringLubrication

A new and unique highly adjustable stationary exercise bicycle is presented incorporating a number of features specifically designed for youthful stationary bicycle users. The improvements over the prior art include infinitely adjustable vertical and horizontal seat heights and handlebar heights which are secured in their positions by a quick release lever rather than the standard pop pins. Also included is a lubrication port that allows the surface between the friction member and the working wheel to be lubricated. An emergency brake for the working wheel as well as a quick way to disengage the working wheel from the pedals is provided. Special pedal cage brackets are placed around each pedal so that the youth's use of such an exercise bicycle is made much more safely. All of the above elements combine to make this stationary exercise bicycle safe for use by children or adolescents.

Owner:MAD DOGG ATHLETICS

Vibration reduction apparatus for power tool and power tool incorporating such apparatus

A handle assembly for a power tool is described and includes a first substantially tubular body portion 210 which contains a first spring 212. A second body portion 216 is slidably mounted within first body portion 210 and contains a second spring 218. A third body portion 222 is also slidably mounted within first body portion 210. The biasing coefficient, or spring constant, of the first spring 212 is less than that of the second spring 218. The first, second and third body portions 210, 216 and 222, and first and second springs, 212 and 218, are all mounted coaxially on threaded bolt 224. In use the third body portion 222 moves within first body portion 210 in a direction towards end portion 214 and the first and softer spring 212 becomes compressed more rapidly than the second and harder spring 218. When the distance D1 has reduced to zero, by compression of first spring 212, the rubber washer 230 engages end portion 220 of second body portion 216 and the biasing effect of first spring 212 is eliminated The biasing force of the harder second spring 218 acts alone up to a distance D2.

Owner:BLACK & DECKER INC

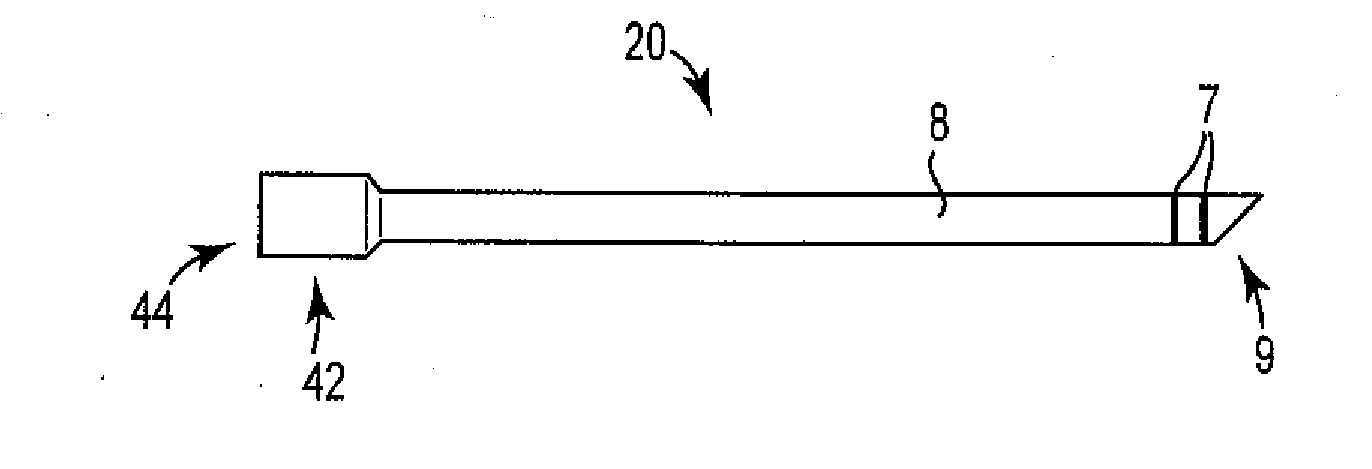

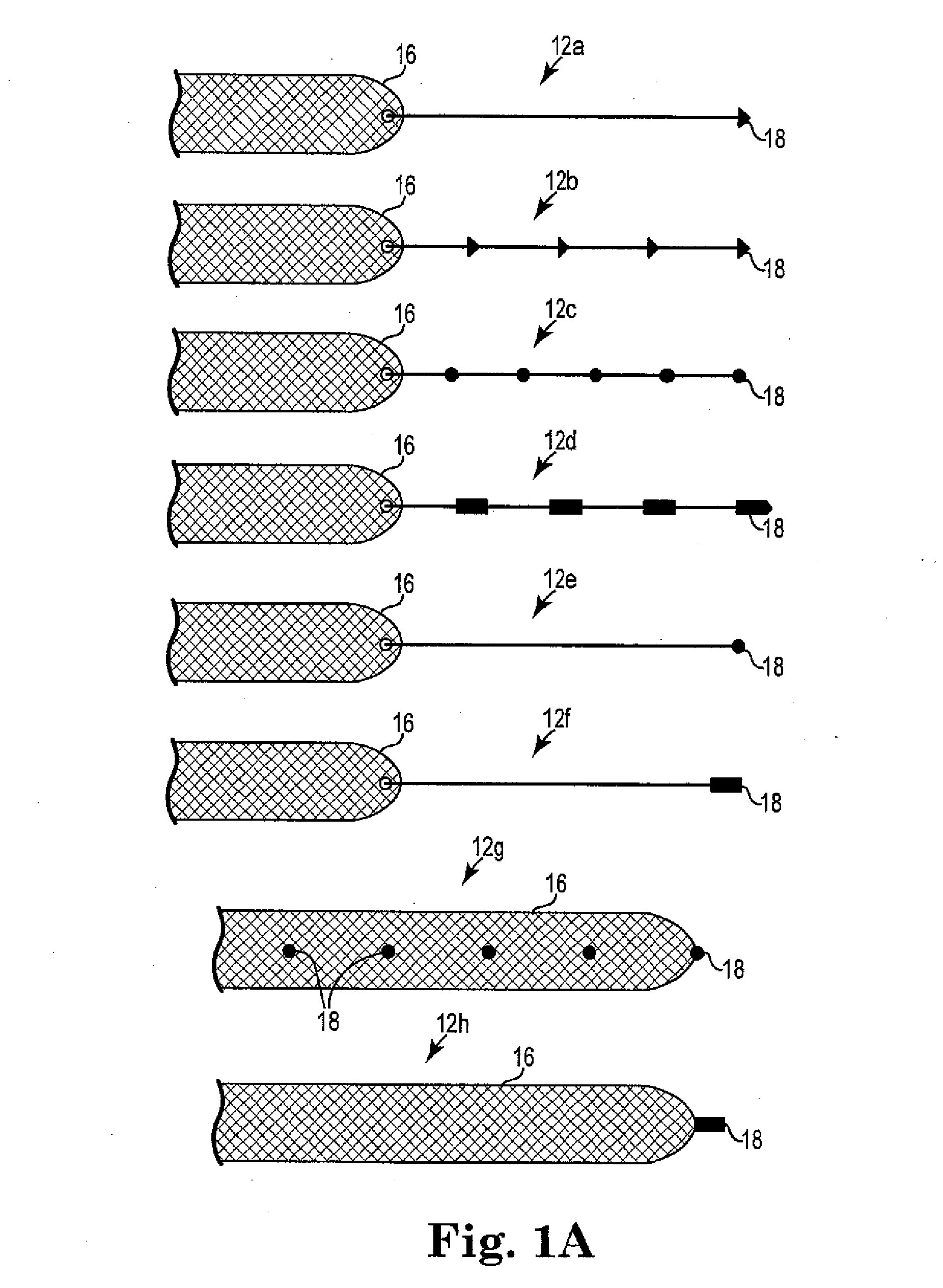

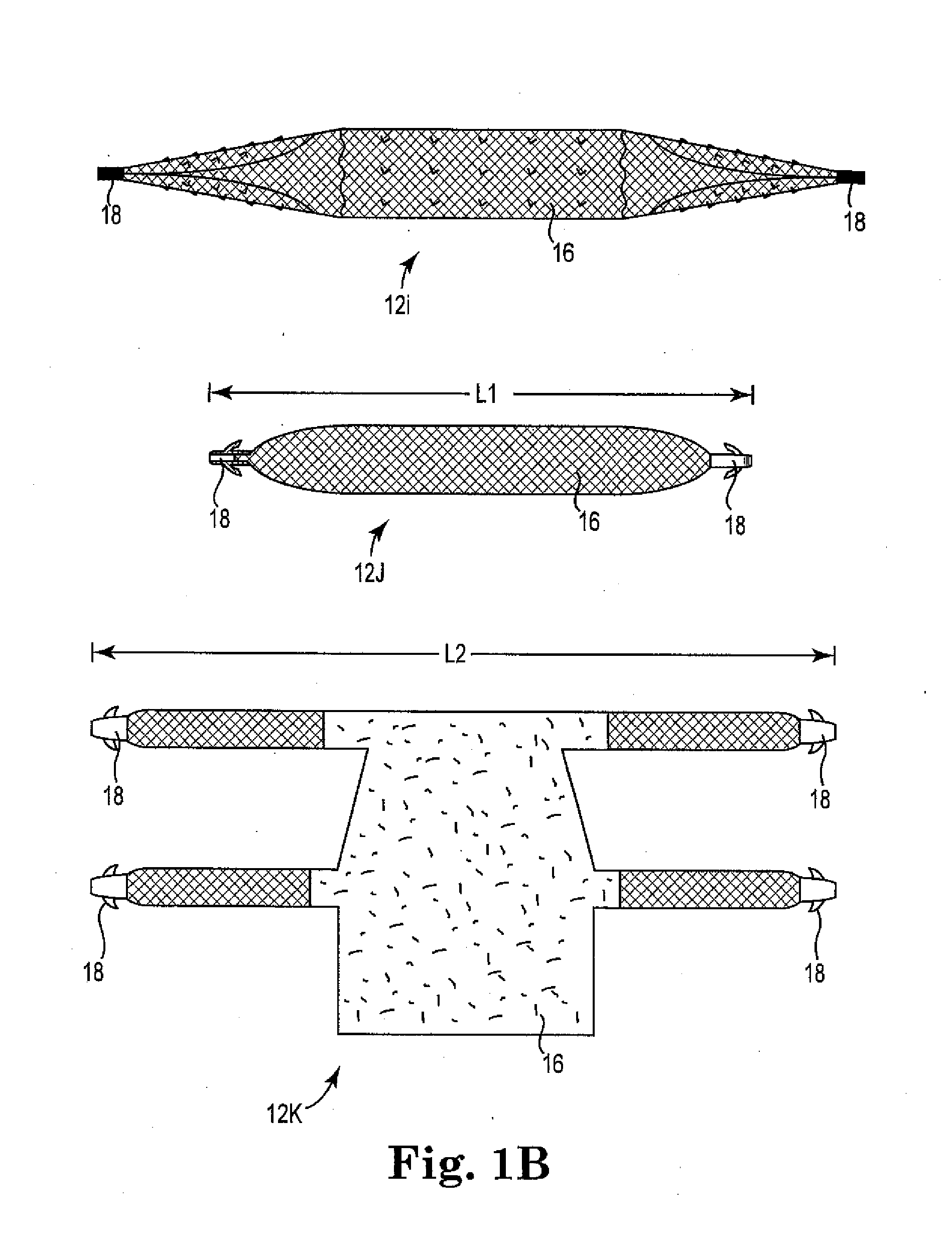

Surgical tools, systems, and related implants and methods

ActiveUS20130253260A1Facilitate open and easilyAdjustable tensionSuture equipmentsAnti-incontinence devicesDiseasePelvis

Described are implants and tools for use in treating pelvic conditions such as incontinence, including urinary incontinence in a male or female, for example an incontinence sling and delivery system that can include a sling implant and delivery tool system, wherein the implant can include a mesh sling and one or more anchors provided at or extending from a portion of the sling to facilitate tissue fixation; the delivery tool system can include at least a tunneler having a lumen, and an insertion tool; and wherein useful methods can involve inserting the tunneler through an incision and into a pelvic region of a patient, connecting the insertion tool to the sling, and inserting the sling into the tunneler to place the sling to provide tissue support.

Owner:BOSTON SCI SCIMED INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com