Patents

Literature

275results about How to "Suitable for automated production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

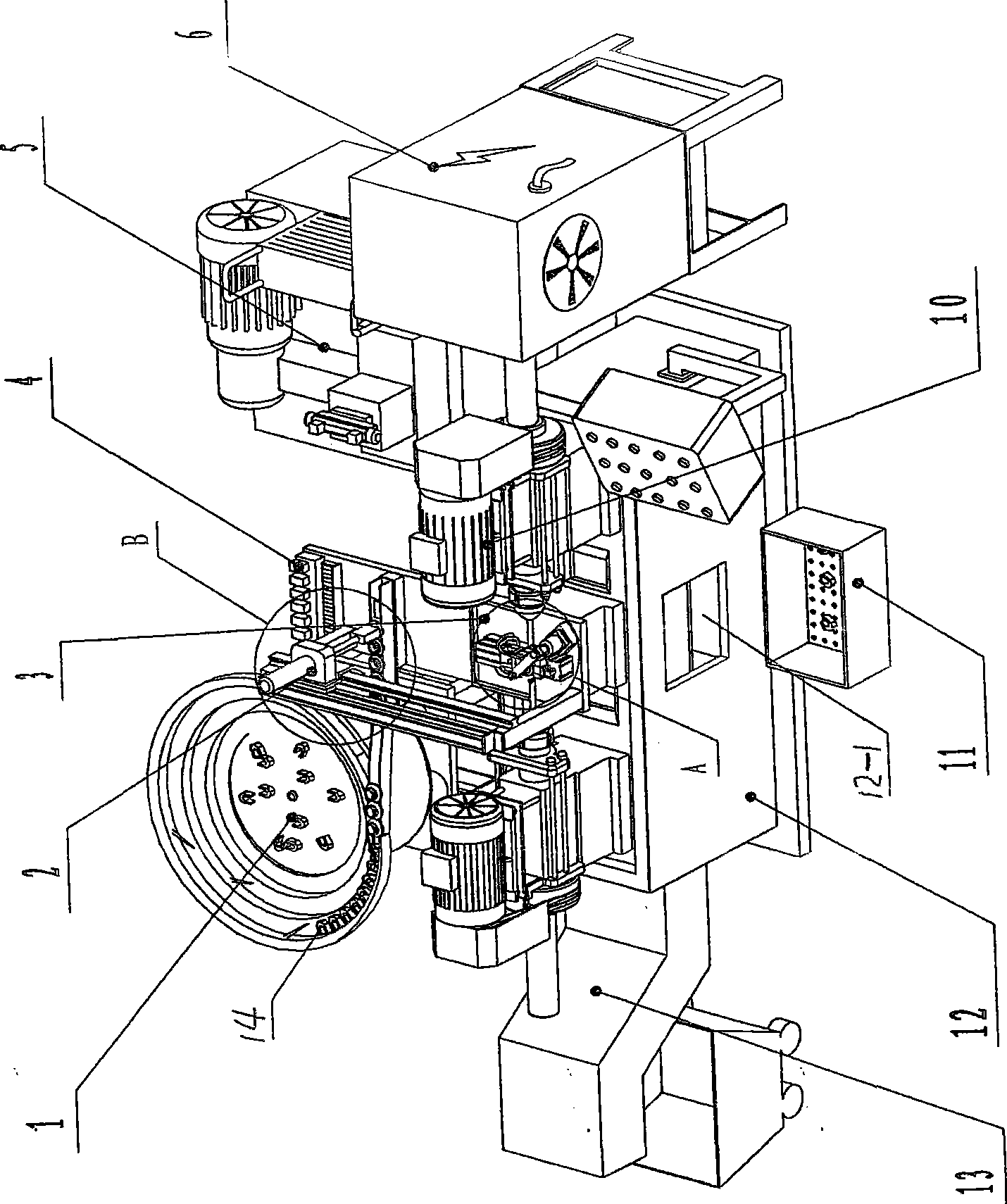

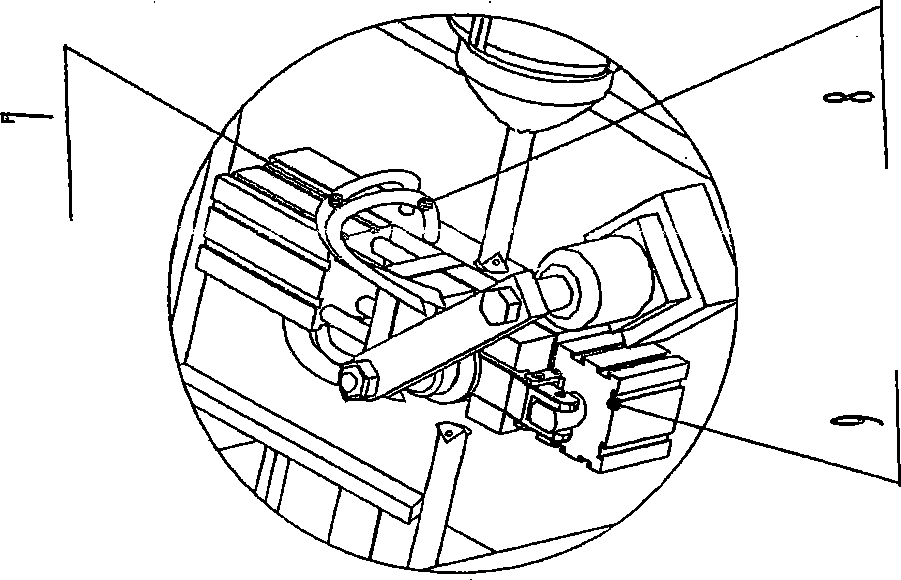

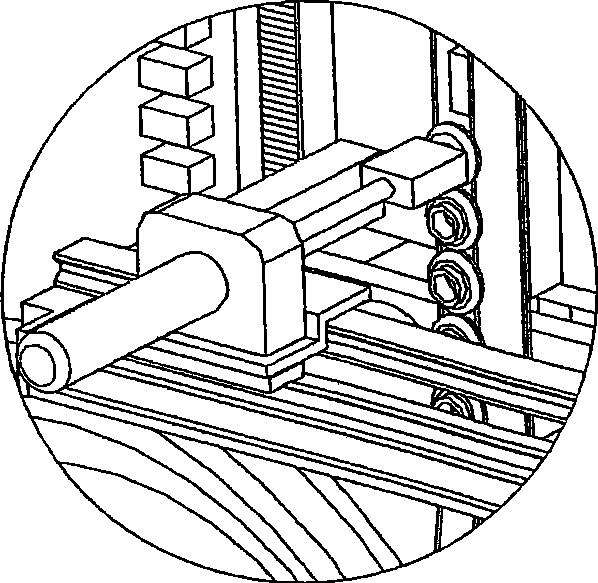

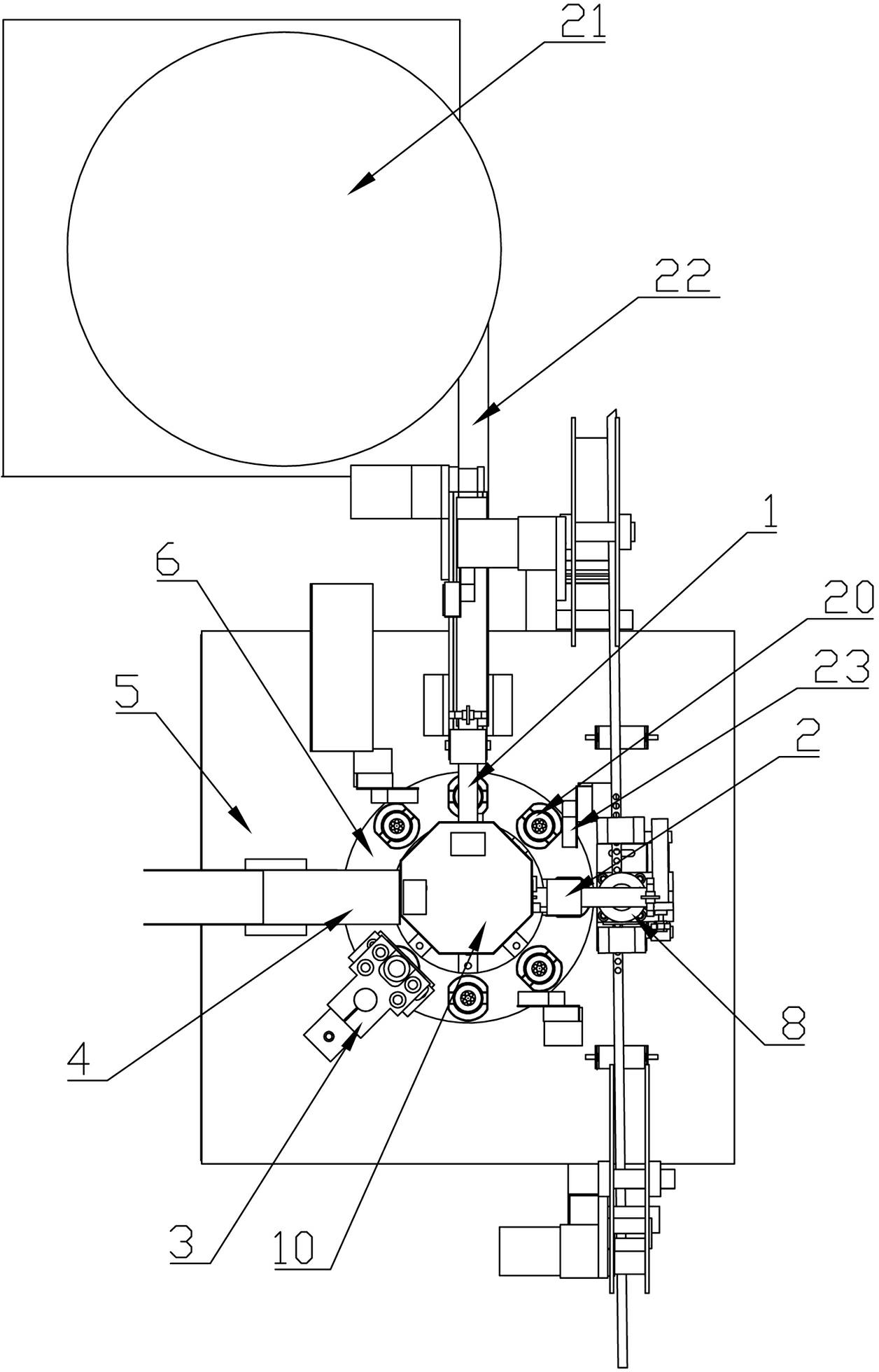

Equipment for automatically processing vehicle steering universal-joint fork ear punch

InactiveCN101474685ASave human effortSave moneyBoring/drilling machinesUniversal jointMachining process

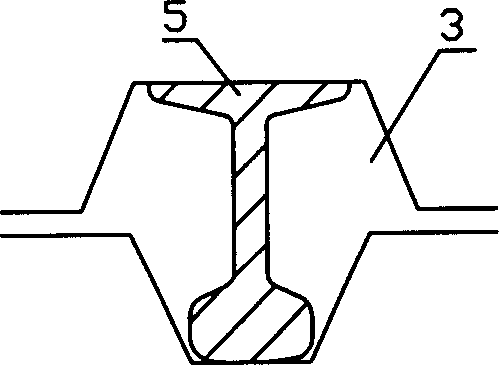

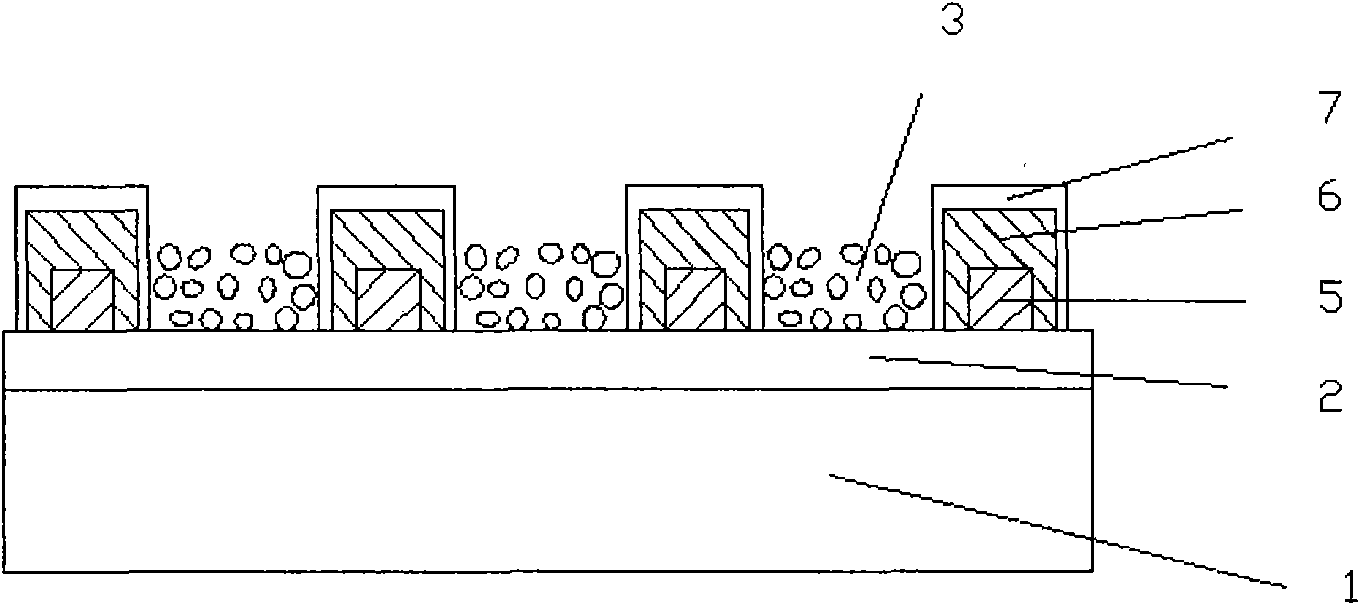

The invention relates to an automatic processing equipment of universal joint fork ear hole for motor turning. The equipment comprises an engine seat (12), a directional order vibratory hopper (1), a grasping feeding device (2), a positioning clamping device (3), a knockout device (9) and a hole processing unit (10), wherein, the directional order vibrating hopper (1) comprises a spiral groove vibratory hopper (1-5), a base (1-3), a select materials bar (1-4), an out-feed channel (1-6) and a straight track slot (1-7); the grasping feeding device (2) comprises a soleplate (2-1), a upright post (2-10), a linear guide way (2-4), a stockless cylinder (2-5), a link block (2-8), a lifting cylinder (2-7), a gas claw (2-3) and a gas claw chuck (2-2); the positioning clamping device (3) comprises a horizontal clamping cylinder (3-5), a positioning core axle (3-3), a locating block (3-2), a clamp block (3-4) and a rotating clamping cylinder (3-1); the hole processing device (10) comprises a base (10-1), left-right drilling head and left-right U-drill (10-8); the knockout device (9) comprises a knockout cylinder (9-2) and a knockout plate (9-1). The whole processing of the invention is robotized completely and the invention saves manpower and materials, lowers the production cost and improves production quality and productivity.

Owner:JIANGSU GOLDEN TRANSMISSION

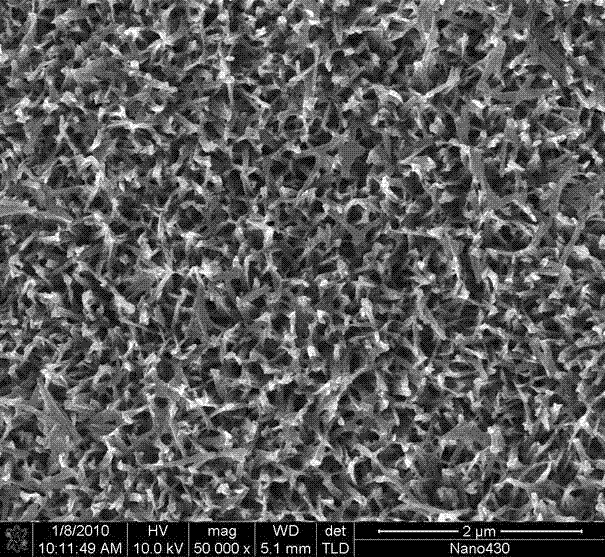

Process for preparing carbon nano tube film through electrophoresis deposition

InactiveCN1570220AShort preparation cycleControl thicknessElectrophoretic coatingsHigh volume manufacturingElectrophoresis

A method for electrophoretic deposition preparation of the carbon nanotube film belongs to the field of the nano materials technology. The preparing method comprises the following steps: purification treatment and face finish for the carbon nanotube, the formation of the carbon nanotube stable suspension, electrophoretic deposition for the carbon nanotube film, film drying, and second electrophoretic deposition. The invention has the advantages of simple production equipment, rapid film forming speed, controllable film thickness, and unlimited substrate shape.

Owner:TSINGHUA UNIV

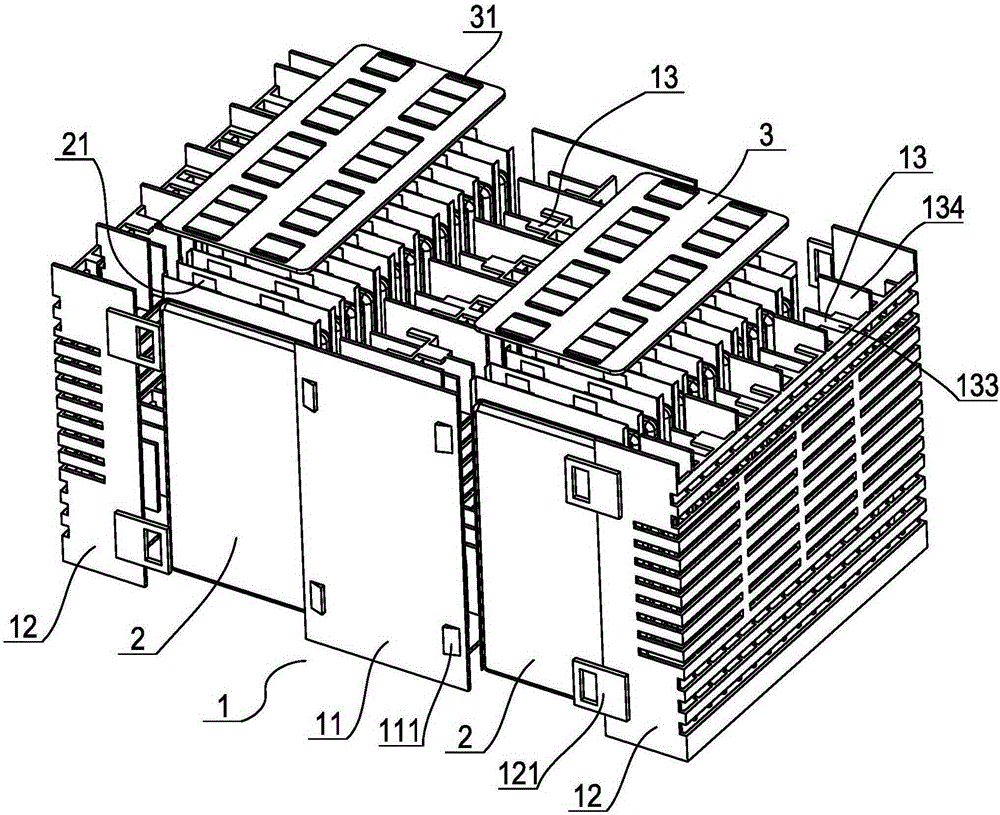

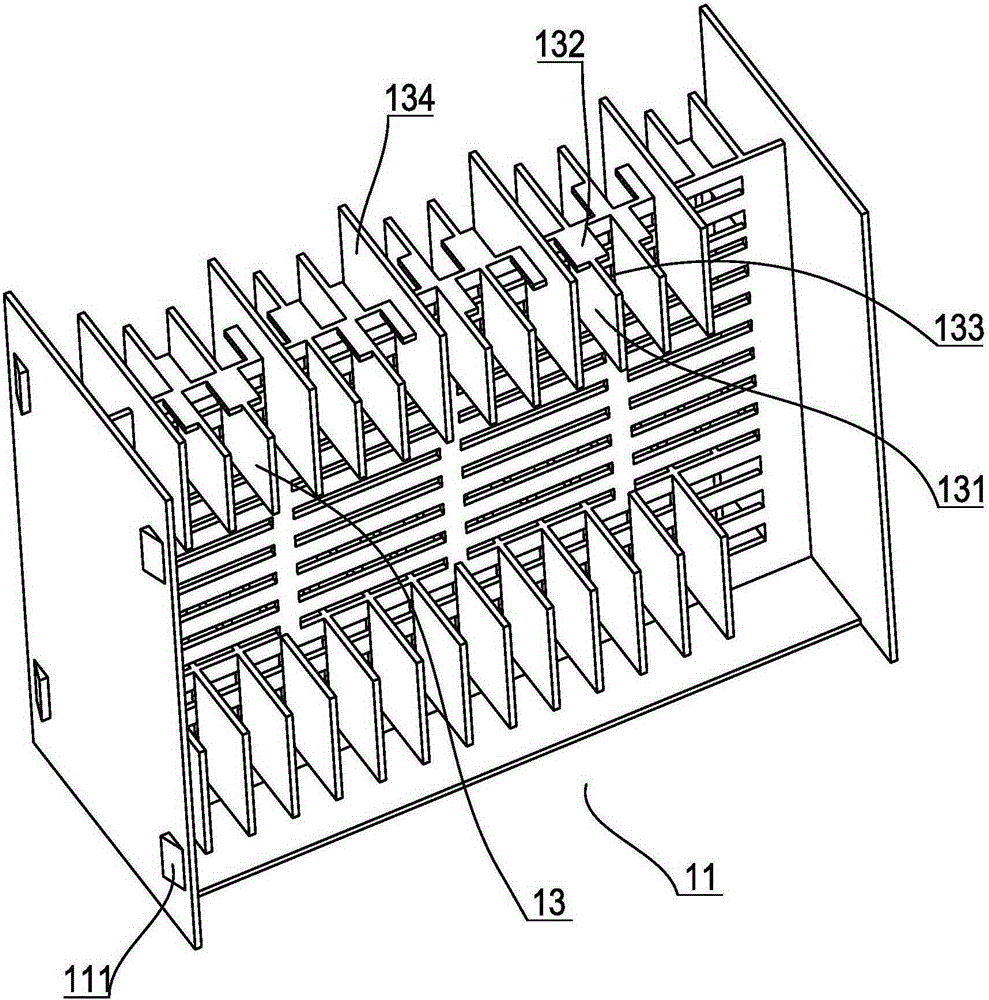

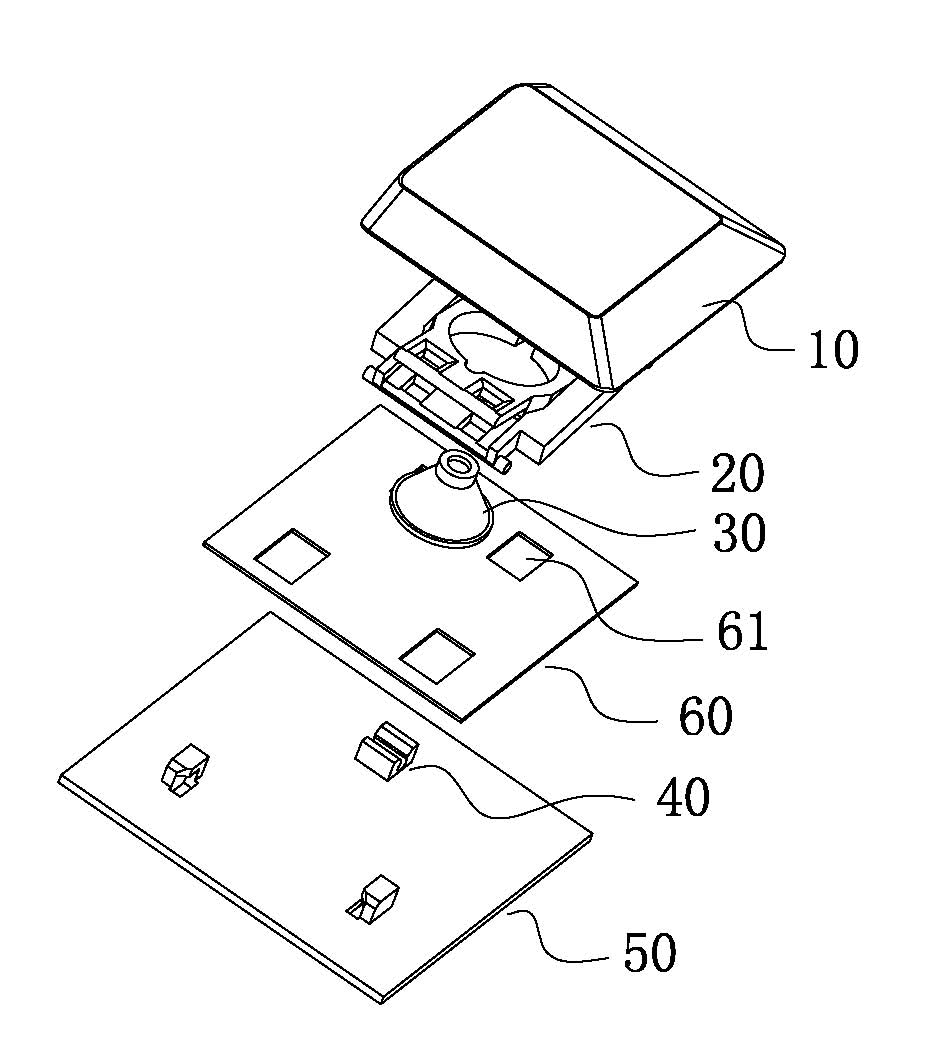

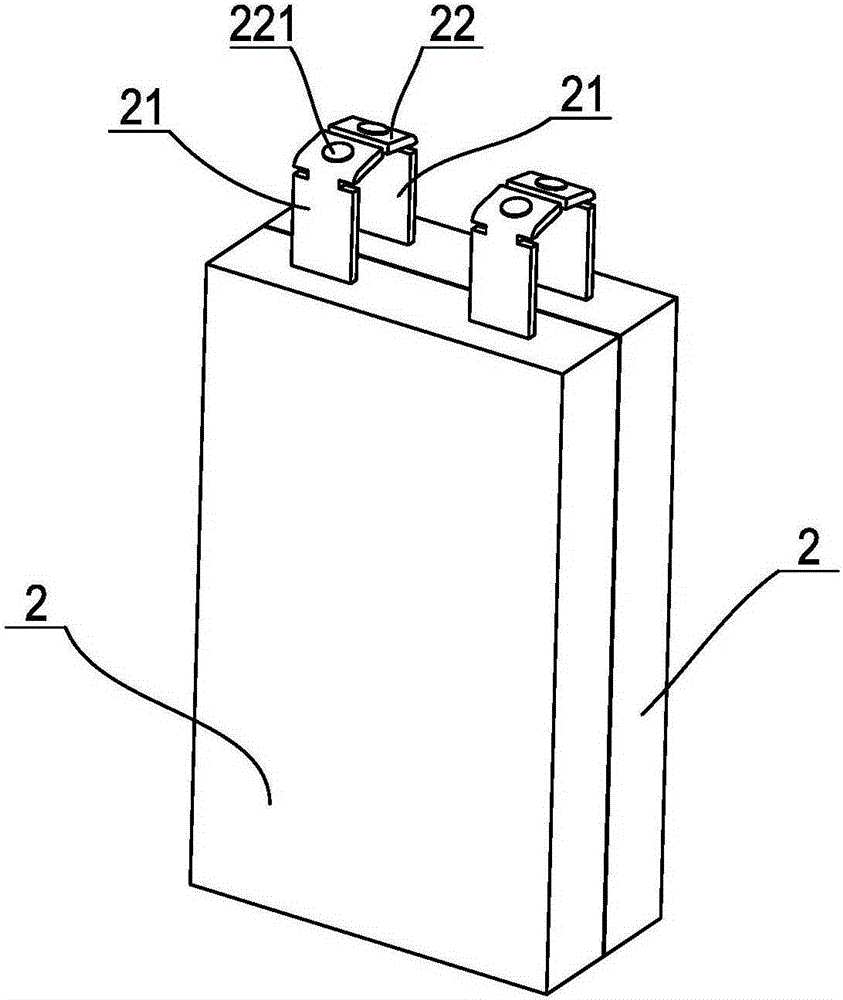

Power battery module, assembling method and electric vehicle

The invention discloses a power battery module, an assembling method and an electric vehicle. The power battery module comprises a battery compartment, flexibly packaged electric cores and a PBC plate arranged at the upper part of the battery compartment; a tab is arranged on the upper side of each flexibly packaged electric core; the battery compartment comprises a main fixed bracket in the middle; spliced brackets are arranged on the left and right sides of the main fixed bracket in a clamping manner; a plurality of electric core clamping grooves spliced by the main fixed brackets and the spliced brackets are formed in the left and right sides of the battery compartment; the electric core clamping grooves are longitudinally arranged along the battery compartment; the flexibly packaged electric cores are clamped in each of the electric core clamping grooves in sequence; tab perforating holes are formed in the position, corresponding to the tabs, in the PCB plate; the positive electrode tabs and the negative electrode tabs of the flexibly packaged electric cores upwardly penetrate through the corresponding tab perforating holes to form connection parts; the connection parts are bent to be clung to the PCB plate; and the connection parts are in spot welding connection with conductive nickel sheets on the surface of the PCB plate. The power battery module can avoid damage of the flexibly packaged electric cores and the environment pollution caused in the tin soldering process; and in addition, the power battery module is high in the assembling efficiency, suitable for industrial production and capable of ensuring reliable connection as well.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

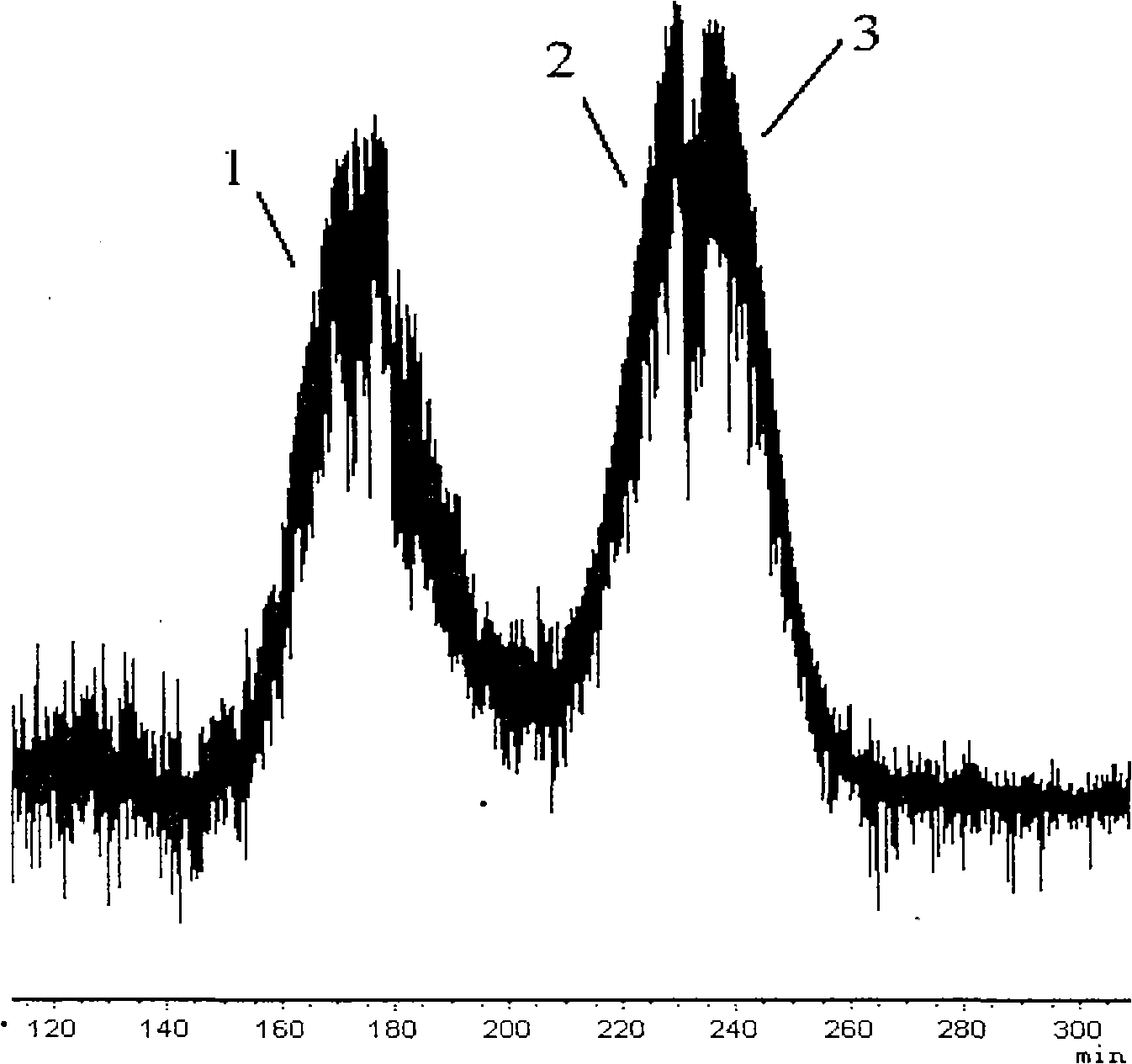

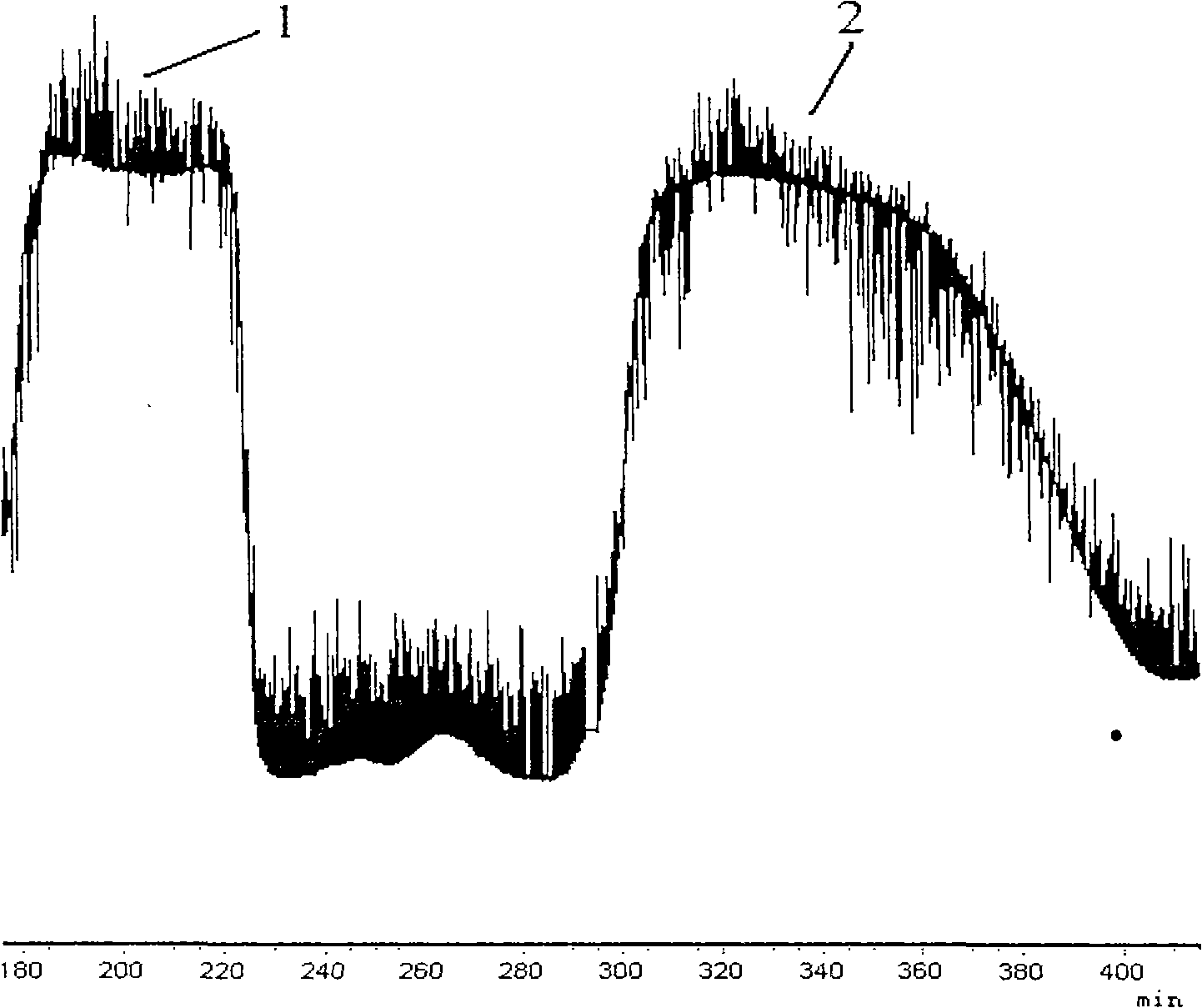

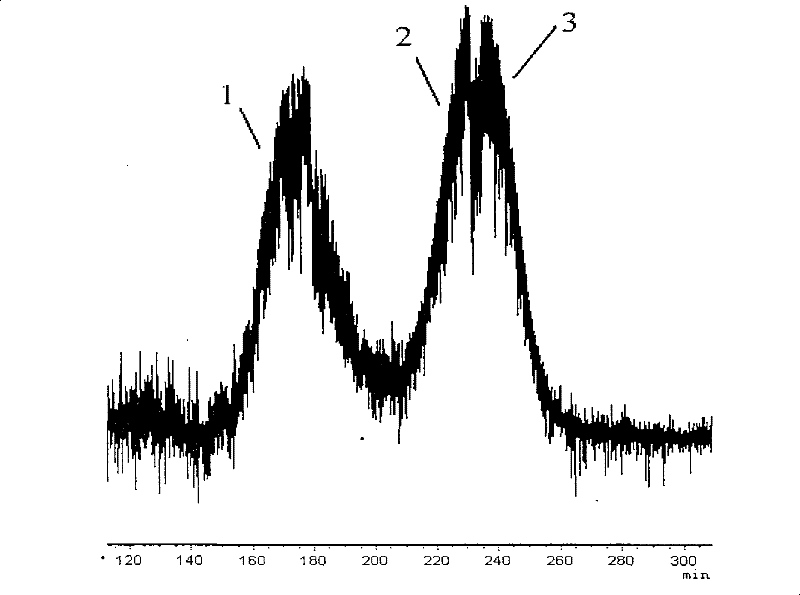

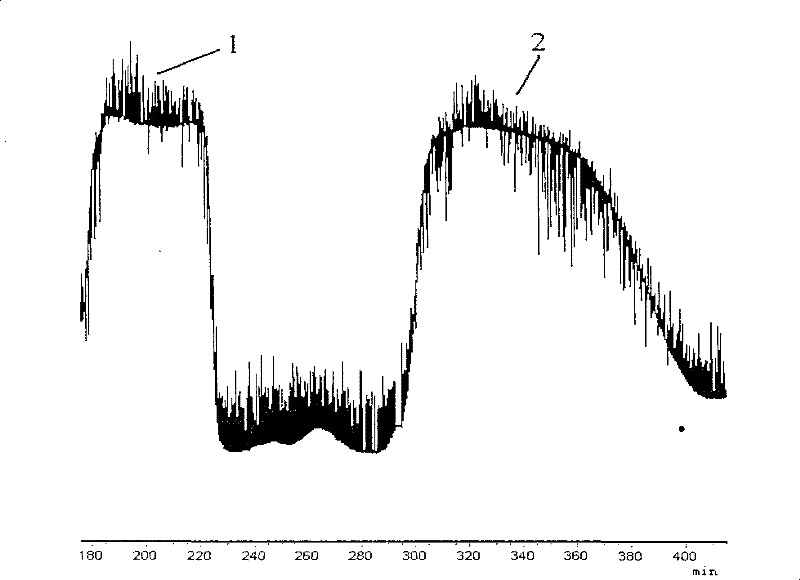

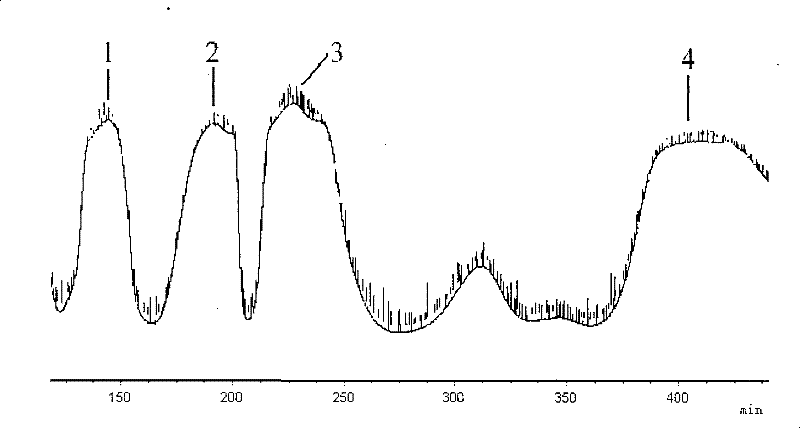

Method for separating and preparation of Gelsemium elegans alkaloid monomer by high speed counter current chromatography

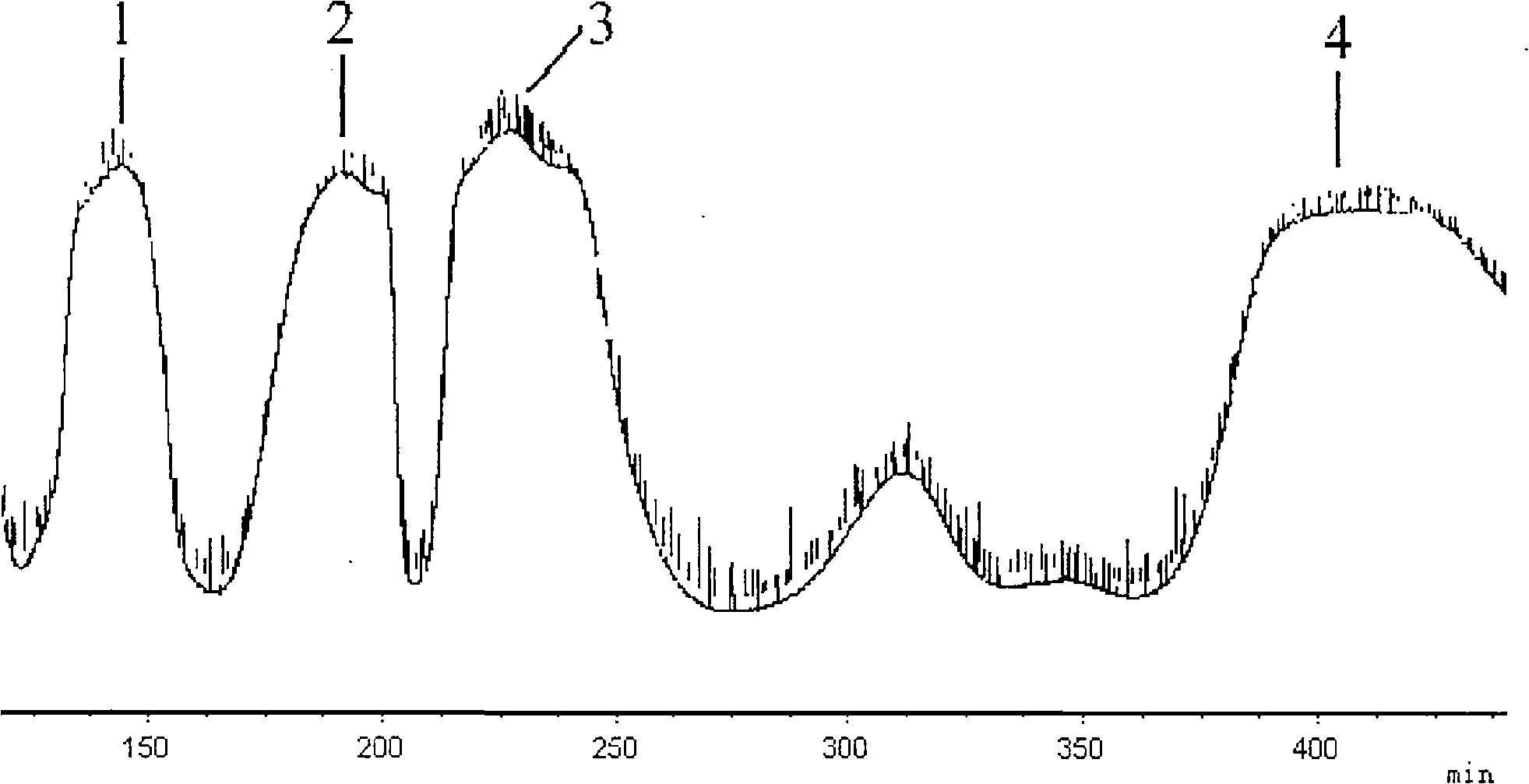

ActiveCN101323618ASimple and fast operationShort separation cycleOrganic chemistrySolid sorbent liquid separationGelsemium elegansGelsemium

The invention discloses a method for separating and preparing a gelsemium alkaloid monomer from gelsemium by adopting high-speed counter current chromatography, which pertains to the separation method of medicinal plant monomers. The invention takes total alkaloids of gelsemium as a raw material and a high-speed counter current chromatograph as a separating device and the method comprises that a solvent system which is composed of stationary phase and mobile phase is prepared; the high-speed counter current chromatograph is filled with the stationary phase and then the mobile phase is pumped in and balanced; and then sampling is conducted by a sample valve; target components are collected according to the map of a detector or in combination of the detection methods of high efficiency liquid chromatography and thin layer chromatography, and distilled under reduced pressure and then recrystallized to obtain the gelsemium alkaloid monomer with high purity. By adjusting the specific proportional parameters of the solvent system, single or multiple target gelsemium alkaloid monomers can be separated by one step or step by step. The method is convenient and efficient, large in preparation amount, less in sample loss, good in separation effect and high in controllability and applicable to automatic production and the obtained gelsemium alkaloid monomer from separation has diverse pharmacological activities and application prospect to be prepared into medicines.

Owner:FUJIAN MEDICAL UNIV

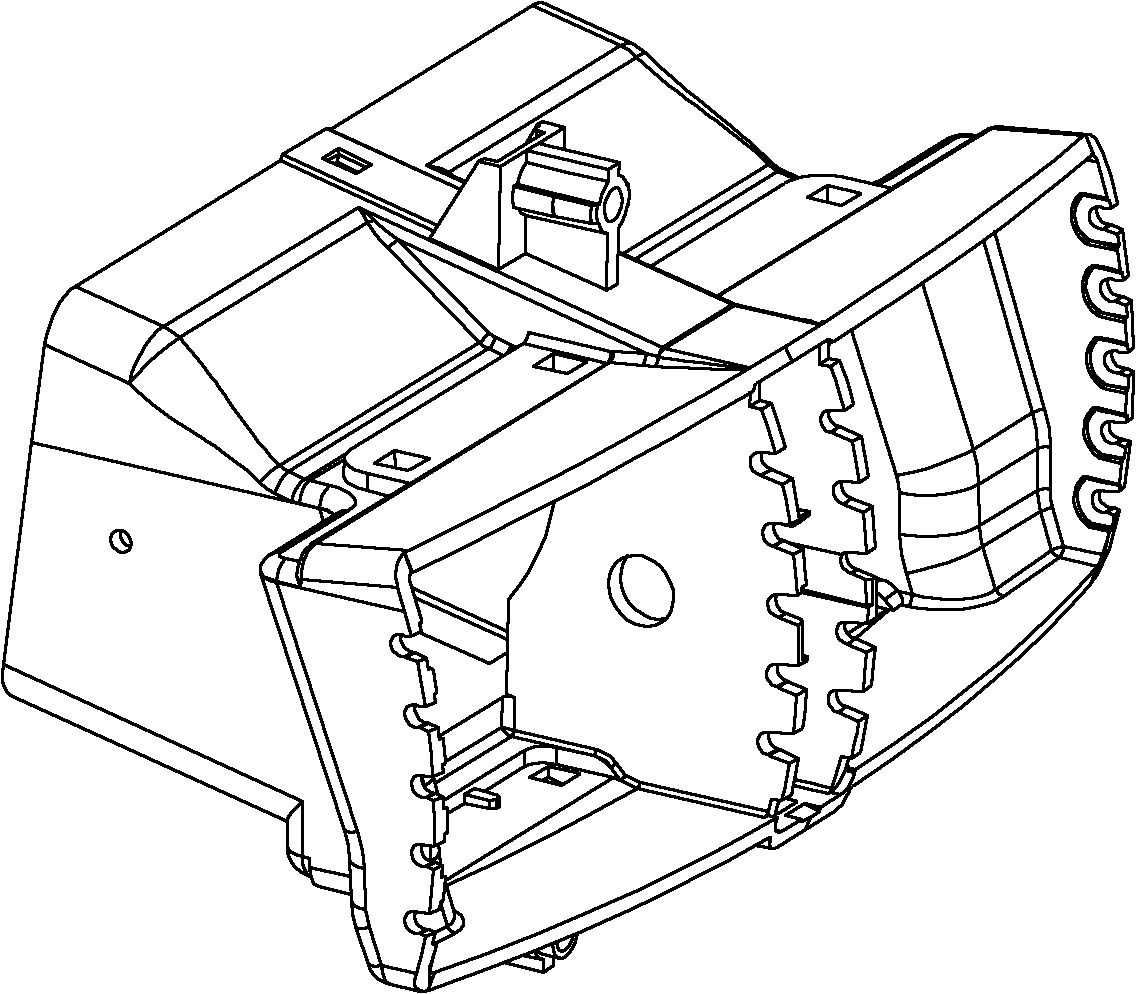

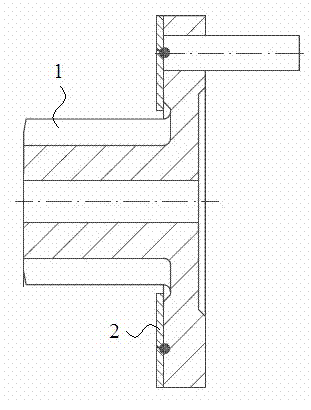

Slide block demolding mechanism with function of coring twice

The invention discloses a slide block demolding mechanism with a function of coring twice, comprising a fixed die plate, a movable die plate, a slide block, a cylinder, a locking block and a check block, wherein the locking block is matched with the slide block through a slope, and the fixed die plate, the movable die plate and the slide block are enclosed to form a molding piece die cavity in a die assembly state; the slide block comprises a main slide block for pressing a molding piece and a side slide block which is installed on the main slide block in a sliding way and realizes the purpose of coring a feature hole of the molding piece, and the main slide block is connected with the cylinder; the fixed die plate is provided with an inclined guide post capable of enabling the side slideblock to be away from a die core during die sinking, and a spring for preventing the main slide block from sliding with the side slide block is arranged between the main slide block and the side slide block; and the main slide block is provided with a mold insert for molding the feature hole of the molding piece, and the side slide block drives the mold insert to be away from the feature hole of the molding piece when being away from the die core. The slide block demolding mechanism disclosed by the invention has a function of coring twice in two different directions in one demolding process and can adapt to fully-automatic production, thereby saving the labor, lowering the production cost and improving the size precision of the molding piece.

Owner:NINGBO TIANLONG ELECTRONICS

Method for separating and preparation of Gelsemium elegans alkaloid monomer by high speed counter current chromatography

ActiveCN101323618BSimple and fast operationShort separation cycleOrganic chemistrySolid sorbent liquid separationGelsemium elegansGelsemium

The invention discloses a method for separating and preparing a gelsemium alkaloid monomer from gelsemium by adopting high-speed counter current chromatography, which pertains to the separation method of medicinal plant monomers. The invention takes total alkaloids of gelsemium as a raw material and a high-speed counter current chromatograph as a separating device and the method comprises that a solvent system which is composed of stationary phase and mobile phase is prepared; the high-speed counter current chromatograph is filled with the stationary phase and then the mobile phase is pumped in and balanced; and then sampling is conducted by a sample valve; target components are collected according to the map of a detector or in combination of the detection methods of high efficiency liquid chromatography and thin layer chromatography, and distilled under reduced pressure and then recrystallized to obtain the gelsemium alkaloid monomer with high purity. By adjusting the specific proportional parameters of the solvent system, single or multiple target gelsemium alkaloid monomers can be separated by one step or step by step. The method is convenient and efficient, large in preparation amount, less in sample loss, good in separation effect and high in controllability and applicable to automatic production and the obtained gelsemium alkaloid monomer from separation has diverse pharmacological activities and application prospect to be prepared into medicines.

Owner:FUJIAN MEDICAL UNIV

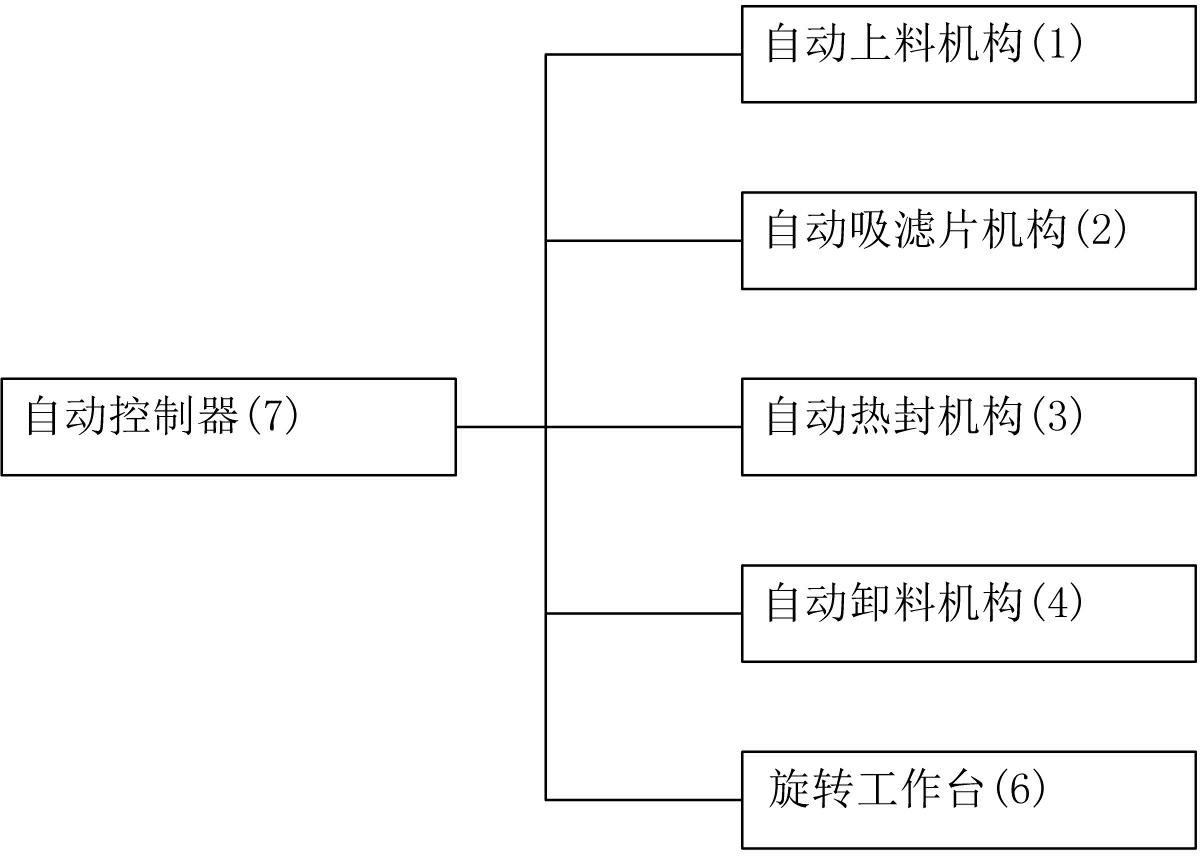

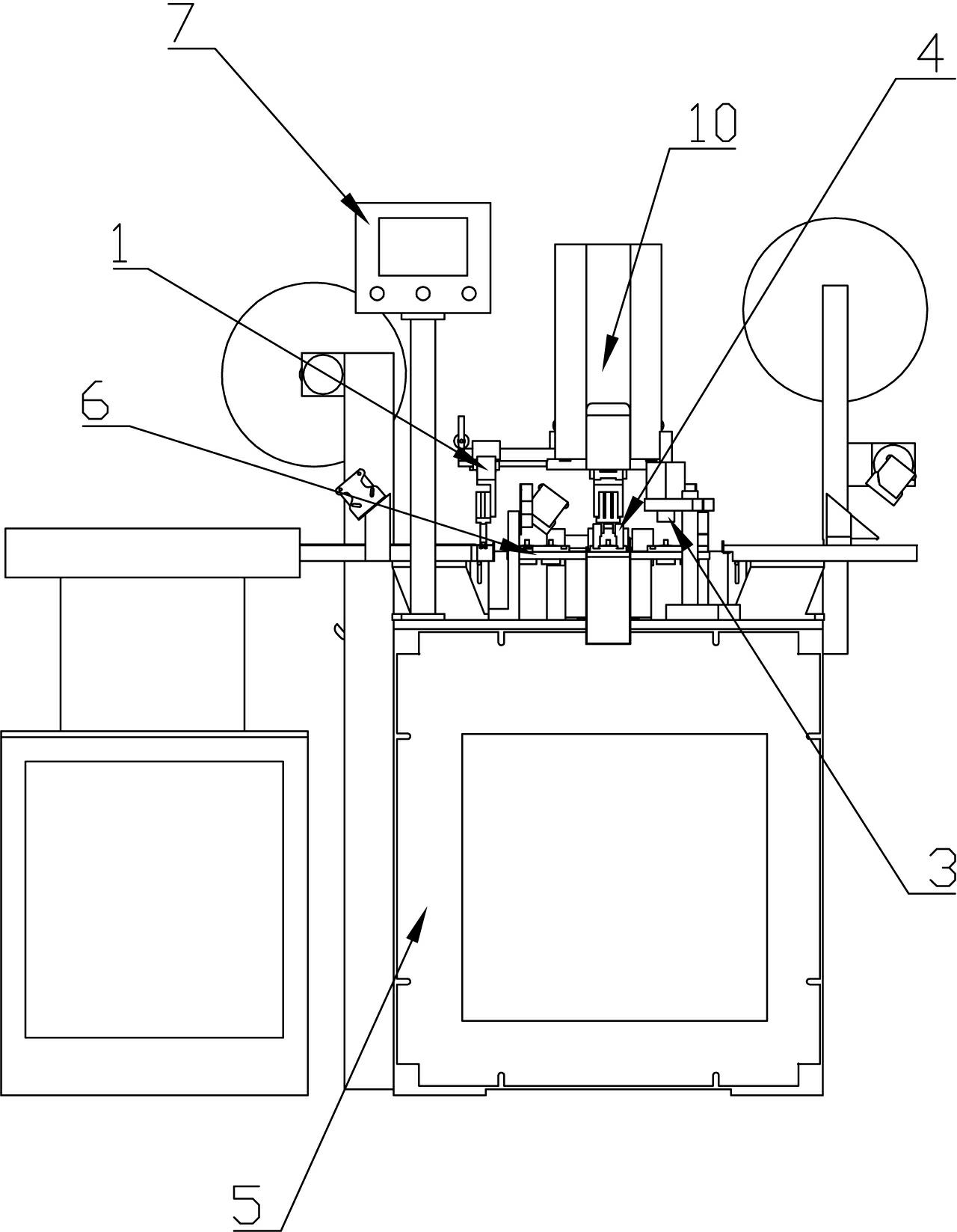

Assembly machine of breathable covers of disposable cell culture flasks

ActiveCN102528449AImplement automatic placementRealization of automatic heat sealingBiochemistry apparatusAssembly machinesAssembly machineAutomatic controller

The invention discloses an assembly machine of breathable covers of disposable cell culture flasks, which comprises a bracket, an automatic controller and a rotary workbench, wherein the automatic controller and the rotary workbench are arranged on the bracket; an automatic feeding mechanism, an automatic filter-disc adsorbing mechanism, an automatic heat-sealing mechanism and an automatic discharging mechanism are arranged above the rotary workbench; and the automatic controller is electrically connected with the rotary workbench, and the automatic feeding mechanism, the automatic filter-disc adsorbing mechanism, the automatic heat-sealing mechanism and the automatic discharging mechanism arranged above the rotary workbench. The assembly machine can realize automatic feeding, automatic placing of filter discs of the breathable covers of the disposable cell culture flasks and automatic heat-sealing of the breathable covers of the disposable cell culture flasks and the filter discs and realize automatic production of the breathable covers of the disposable cell culture flasks through the automatic feeding mechanism, the automatic filter-disc adsorbing mechanism, the automatic heat-sealing mechanism, the automatic discharging mechanism and the automatic controller. The assembly machine is suitable for the automatic production of the breathable covers of the disposable cell culture flasks.

Owner:GUANGZHOU JET BIOFILTRATION CO LTD +1

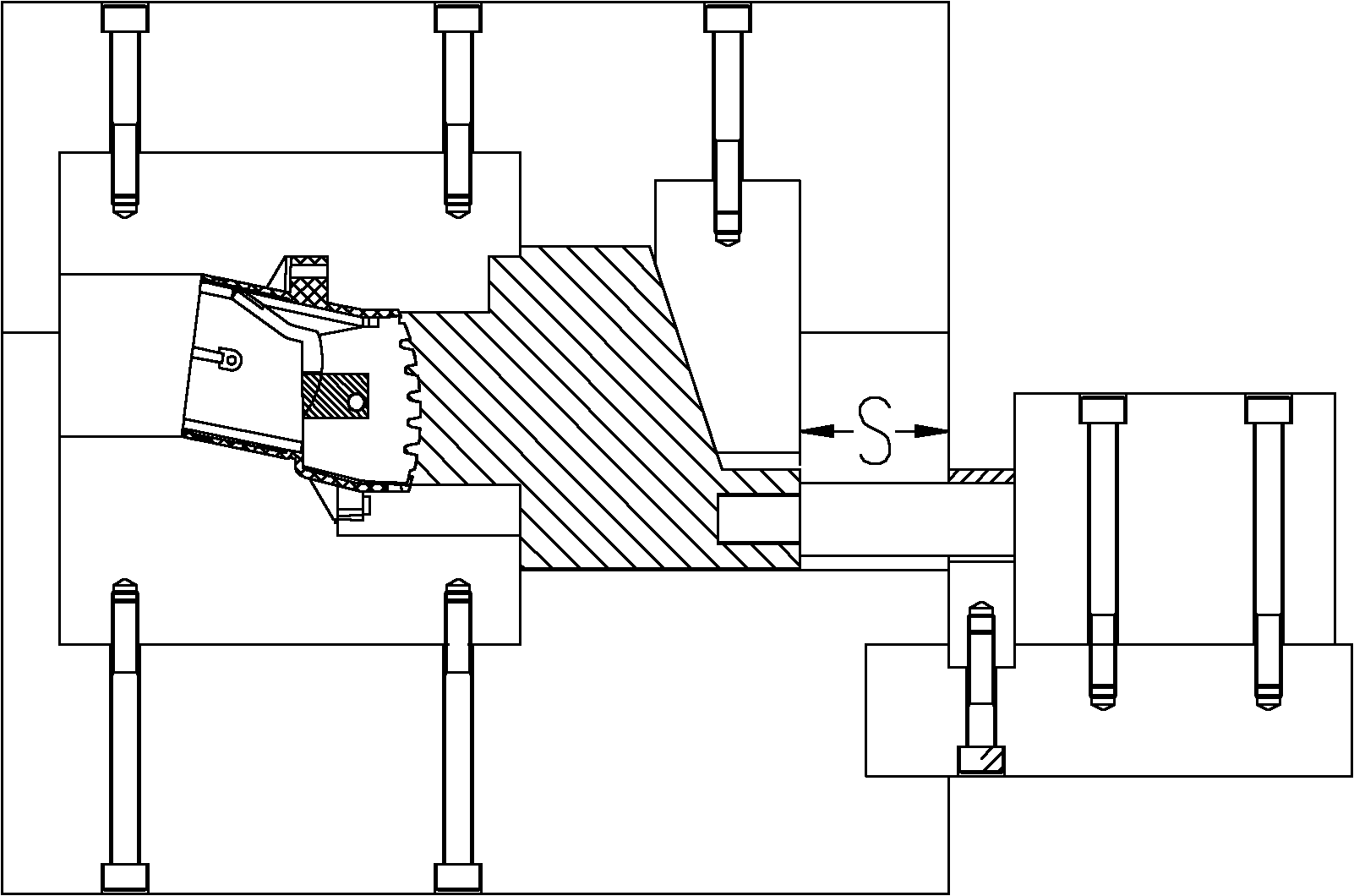

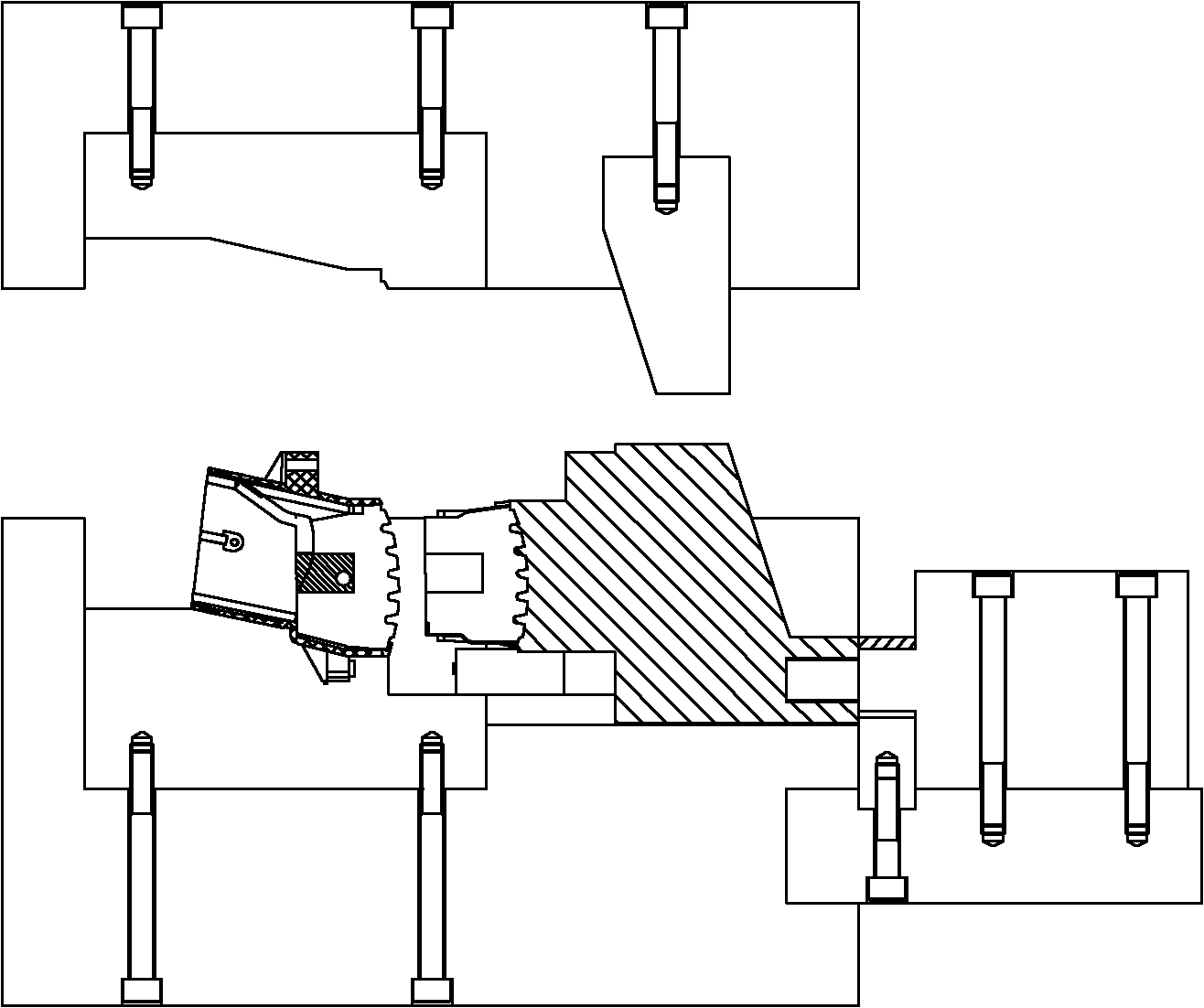

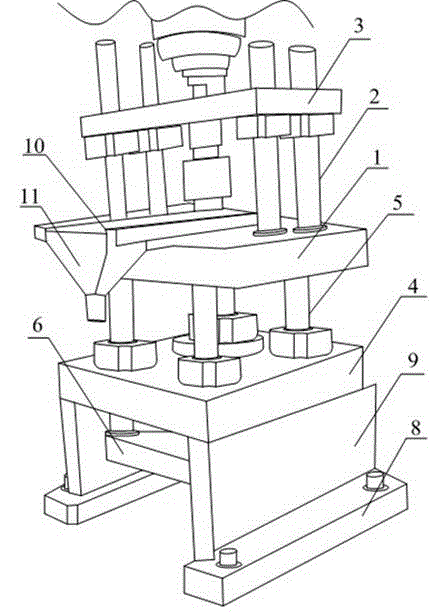

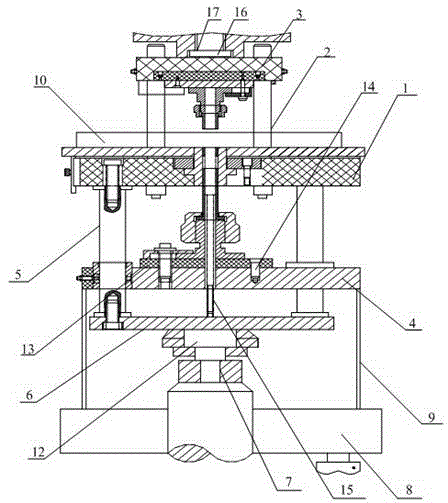

Automatic powder forming die carrier based on powder metallurgy press and implementation method thereof

The invention discloses an automatic powder forming die carrier based on a powder metallurgy press, which solves the problems in the prior art that the structure of the die carrier is complex, the manufacture cost is high, and the die replacement operation is fussy. The automatic powder forming die carrier comprises a parent plate, an upper die plate, a lower die plate, a linkage mechanism and a fixing mechanism, wherein the upper die plate is arranged above the parent plate and is movably connected with the parent plate through an upper guide post; the lower die plate is fixedly arranged under the parent plate; the linkage mechanism is used for driving the parent plate to do a reciprocatory motion; and the fixing mechanism is used for supporting and fixing the lower die plate. In order to realize the automatic powder forming die carrier, a feeding plate is arranged at the upper end surface of the parent plate, and a material collecting funnel communicated with the feeding plate is also arranged at the end part of the feeding plate. The invention also discloses an implementation method based on the die carrier. Under the premise that a main structure is not chanced, the structure of the die carrier is simplified, the implementation is very convenient, and the die carrier can be suitable for continuous and automatic production, so that the production cost is reduced, and the production efficiency is increased. Thus, the die carrier is suitable for promotion and application.

Owner:黄彬

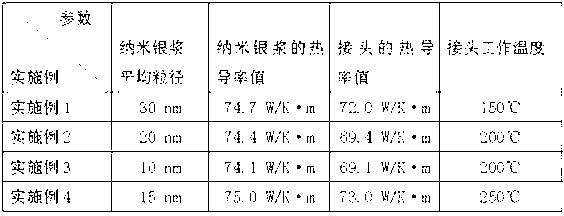

Nano silver paste for chip mounting and method for preparing nano silver paste

ActiveCN102935518ANo pollution in the processLower sintering temperatureMaterial nanotechnologyFlocculationSilver paste

The invention provides a method for preparing a nano silver paste. The method includes step A, a reducing agent and a dispersing agent are dropwise added in a silver nitrate solution and stirred; step B, the solution obtained through the step A is subjected to centrifugation to obtain nano silver particles with upper layers as mixed solutions and lower layers as sedimentation; step C, the nano silver particles separated through the step B is cleaned by deionized water and subjected to flocculation by a electrolyte solution, and nano silver particles capable of being subjected to centrifugation are re-precipitated; step D, the nano silver particles are subjected to cleaning, flocculation and centrifugation for a plurality of times to obtain a water-soluble nano silver paste; and step E, the nano silver paste is applied to a chip and a substrate surface to be interconnected, and the interconnected chip and substrate surface is heated in a hot air work bench or a stove to form a sintering joint.

Owner:深圳市先进连接科技有限公司

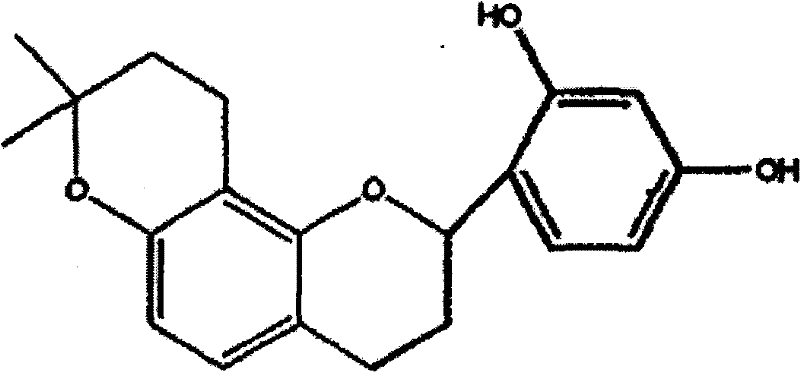

Method for preparing glabridin

InactiveCN102250107AShort production cycleEasy to operateOrganic chemistryBulk chemical productionEthyl acetateChemistry

The invention belongs to the field of natural product separation and in particular relates to a method for preparing glabridin. The method comprises the following steps of: A, crushing glycyrrhiza glabra serving as a raw material, performing microwave extraction by using 70 to 80 percent ethanol in an amount which is 7 to 8 times weight of the raw material, concentrating an extracting solution under reduced pressure, regulating a concentrated solution to be neutral by using a sodium hydroxide solution, extracting by using ethyl acetate, performing back extraction on extract liquor by using a 5 percent sodium hydroxide solution, concentrating an organic phase until a small volume, and adding polyamide resin for drying to obtain a sample; and B, adding the sample into a supercritical CO2 extraction kettle, introducing CO2 fluid and an entrainer, extracting for 2 to 3 hours, resolving an extract, and crystallizing by using ethanol to obtain the high-purity glabridin. The method has the advantages of simple operation, short production period, high yield and suitability for industrial production.

Owner:NANJING ZELANG AGRI DEV

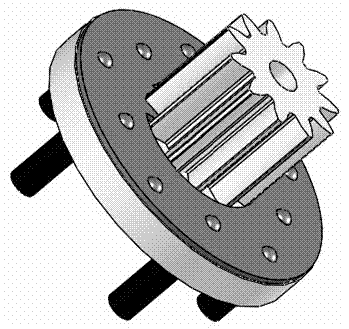

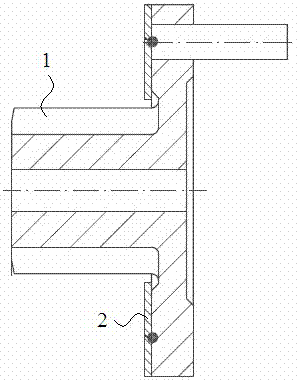

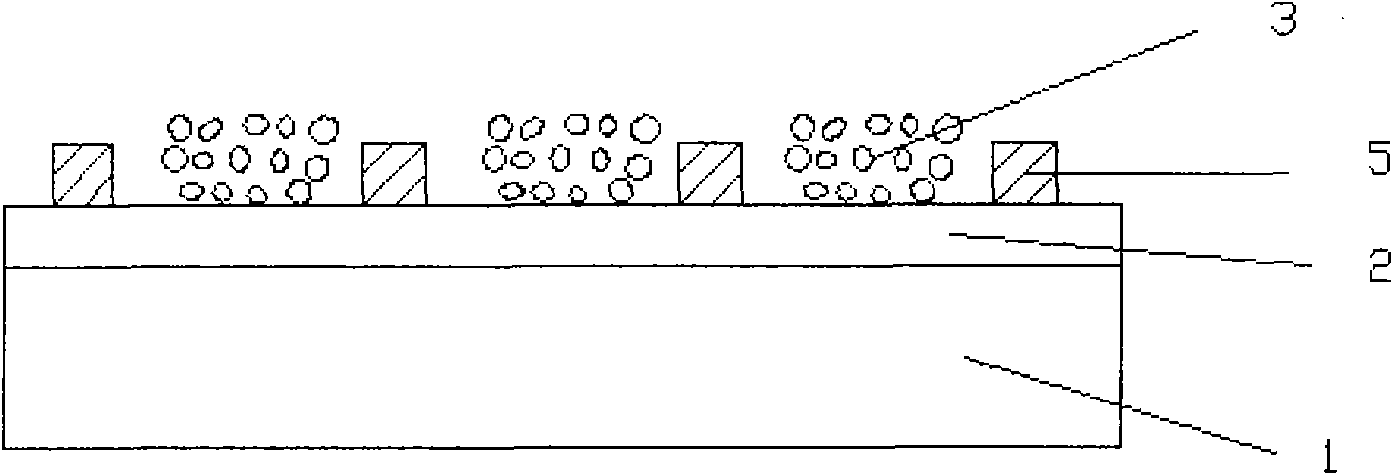

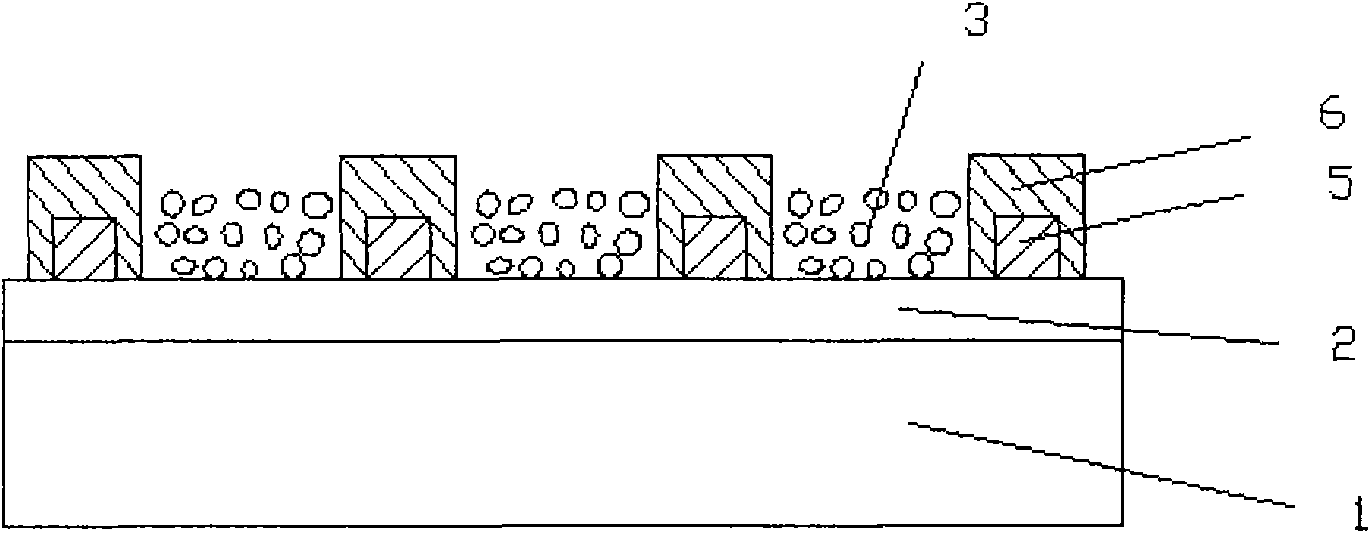

Special powder metallurgy gear wheel and preparation method thereof

InactiveCN102401109AEasy to operateSuitable for automated productionPortable liftingGearing elementsPowder metallurgyEvery Eight Hours

The invention discloses a special powder metallurgy gear wheel and a preparation method. The special powder metallurgy gear wheel consists of a gear wheel and a gasket; the contact end faces of the gear wheel and the gasket are connected in a welding mode; and the gear wheel is prepared from the following powder metallurgy raw materials in part by weight: 90.0 to 98.0 parts of Fe, 0 to 1.0 part of C, 1.0 to 5.0 parts of Ni, 0 to 1.0 part of Mo, and 1.0 to 3.0 parts of Cu. Compared with the prior art, the special power metallurgy gear wheel can meet various using performance requirements. The preparation method for the special powder metallurgy gear wheel is easy to operate, and is suitable for automatic production, and high in production efficiency; 4,000 pieces (PCS) of products can be prepared every eight hours, production cost is low, product intensity is high, and the special powder metallurgy gear wheel has high practicability, a good economic prospect, and better social benefits.

Owner:扬州保来得科技实业有限公司

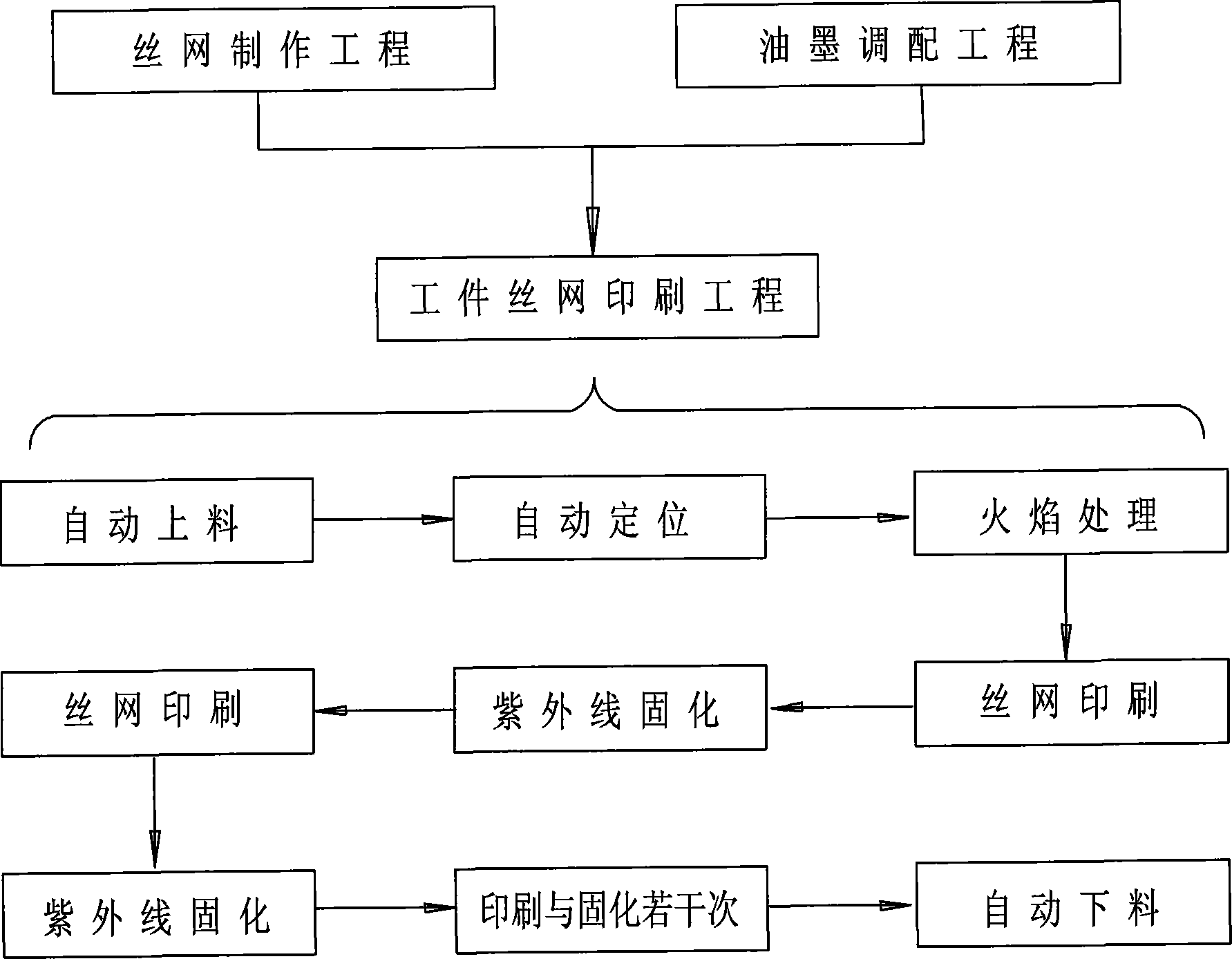

Screen printing technique for polyolefin plastic products

InactiveCN101085578AReduce manufacturing costEase of mass productionScreen printersPhotomechanical exposure apparatusScreen printingUV curing

The fine and highly effective polyolefin silk screening process comprises the silk screen making, oil paint modulation and working piece printing, features in the UV solidified oil paint, working piece silk screen painting composed of the surface flame treatment at the surface to be painted, silk screen painting, ultraviolet solidification treatment, with steady painting and ready for automatic production.

Owner:NINGBO BEIFA GRP CO LTD

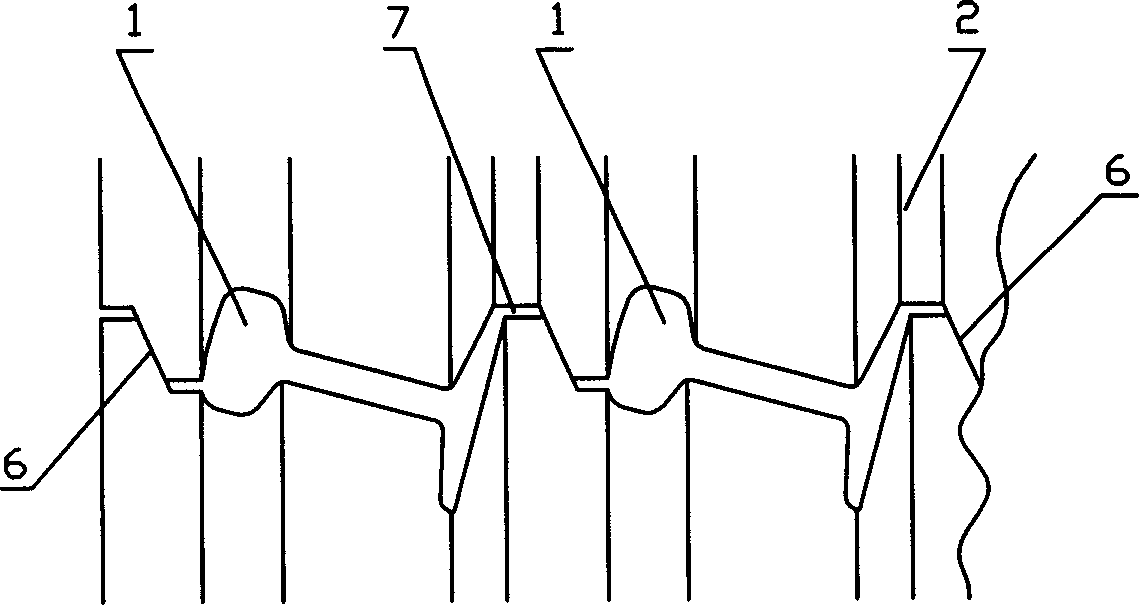

Process for rolling large-scale rails into miniature type rails and rollers therefor

InactiveCN1546247ALow powerLow running costRollsMetal rolling arrangementsEngineeringMechanical engineering

Owner:周燕雄 +1

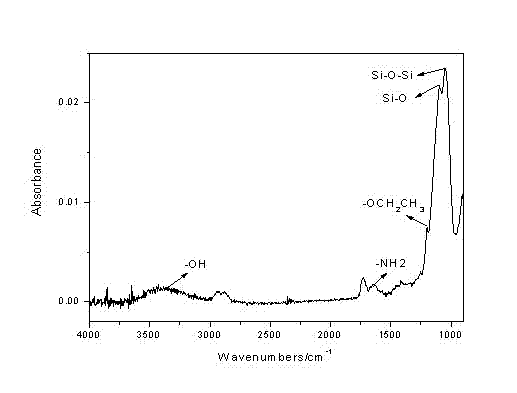

Preparation method of self-assembly silanization of pure titanium metal surface

InactiveCN102851656AStable structureEasy to operateMetallic material coating processesTitanium surfaceTitanium metal

The invention discloses a preparation method of self-assembly silanization of a pure titanium metal surface; according to the invention, various silane coupling agents are grafted on a titanium surface; various active groups, such as amino, hydroxyl, and carboxyl groups, are introduced into the pure titanium surface so as to functionalize the titanium based surface and maintain the porous structure of the substrate; the preparation method of the invention is easy to control, simple in operation, and easy to popularize; and the material is expected to be used in the preparation of in-vitro tissue engineering bone scaffolds and in-vivo materials for repairing bone defects.

Owner:GUANGDONG UNIV OF TECH

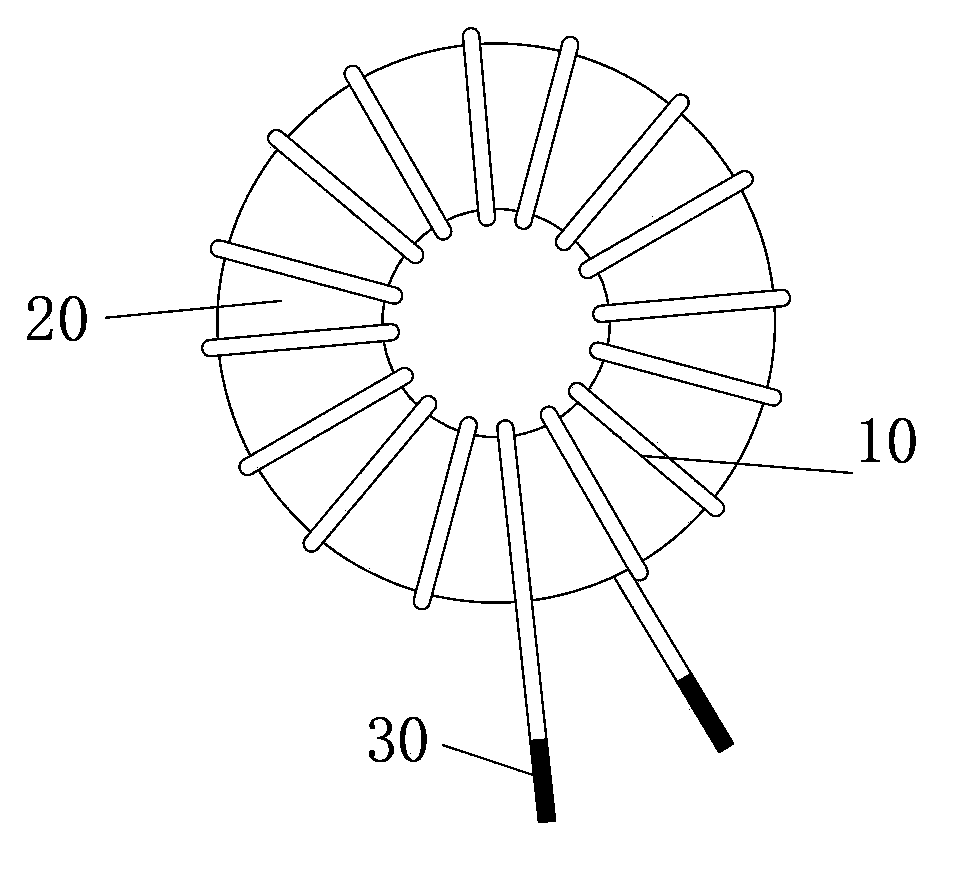

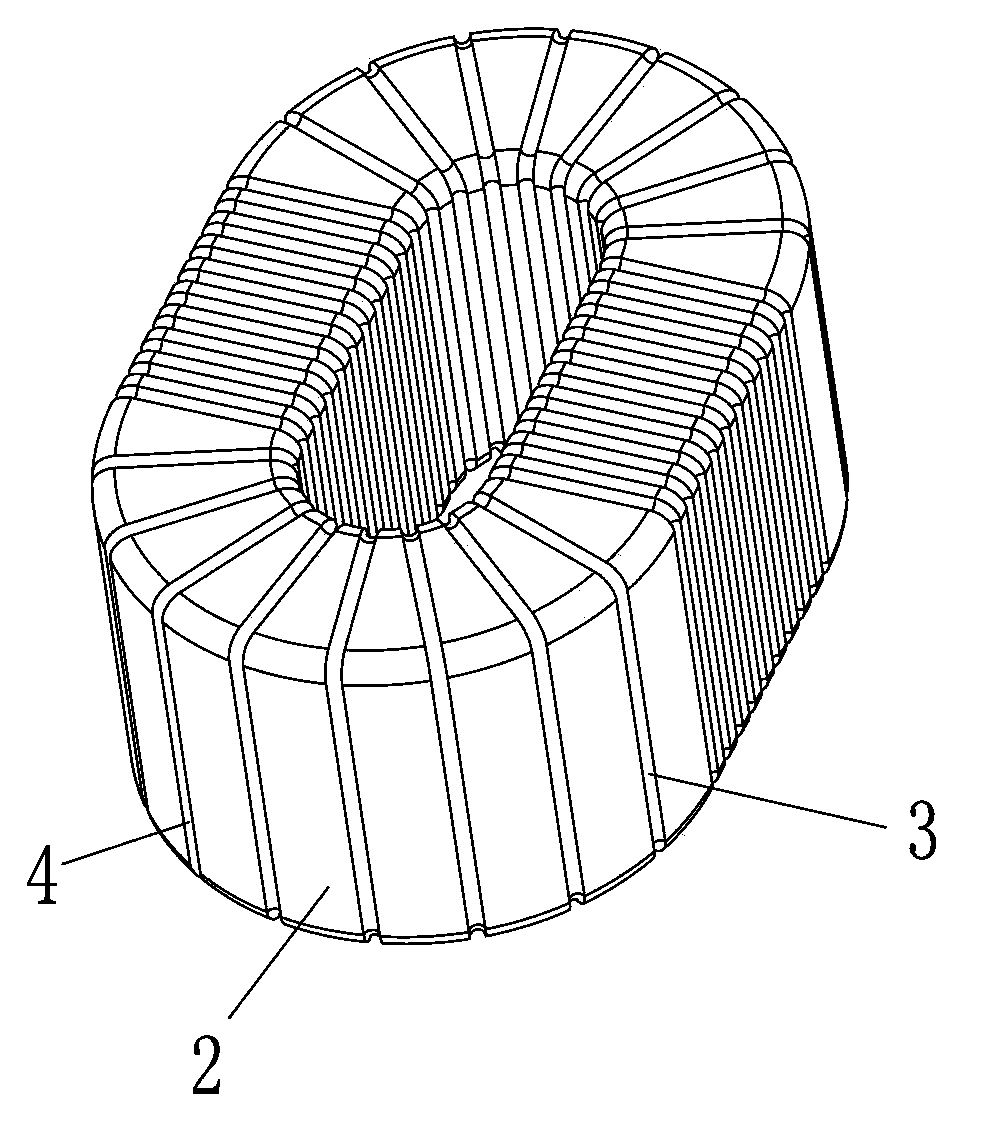

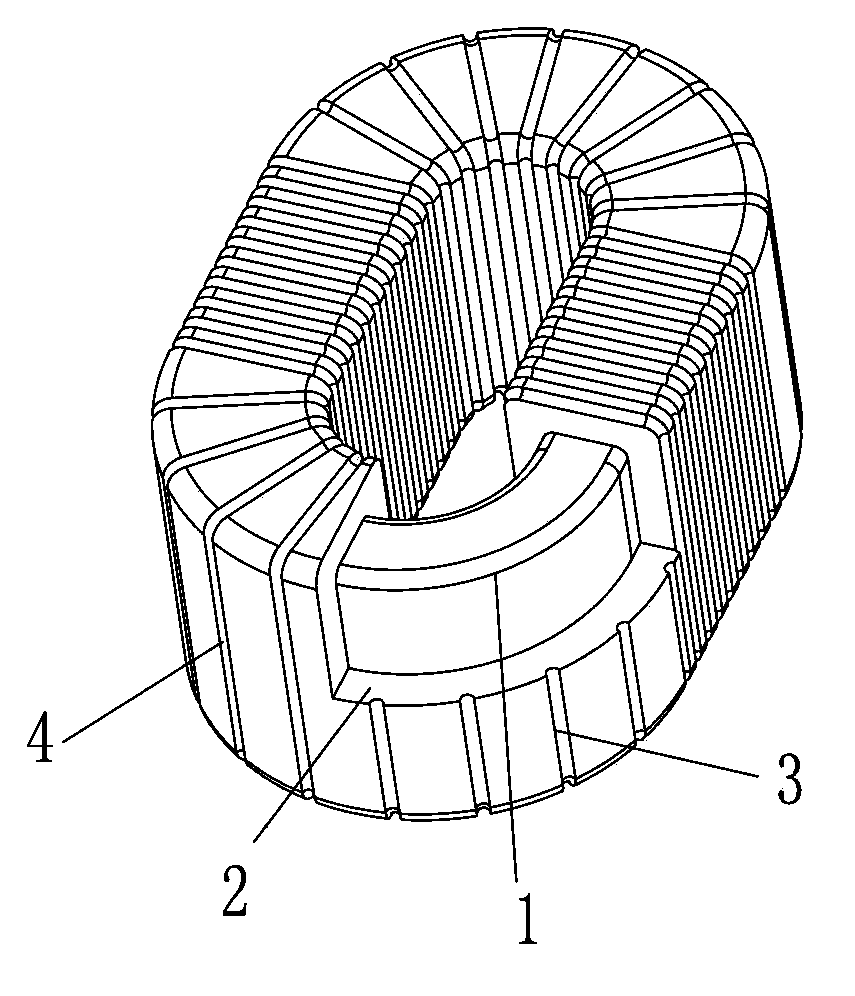

Magnetic passive element and manufacturing method thereof

InactiveCN103854825ASuitable for automated productionReduce manufacturing costTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEngineeringPath cover

The invention provides a magnetic passive element and a manufacturing method thereof. The magnetic passive element comprises a magnetic core and a metal wire layer twined and covered at the outer surface of the magnetic core; an insulating layer is arranged between the magnetic core and the metal wire layer, and the insulating layer is an insulating material layer including metal ions and is tightly covered on the outer surface of the magnetic core; the insulating layer is provided with one or a plurality of communicated metal ion guide paths covered at the outer surface of the insulating layer, wherein the metal ion guide paths are spiral and can form one or a plurality of electrical loops. The manufacturing method of the magnetic passive element comprises the following steps of setting the magnetic core; directly molding the insulating material layer including the metal ions on the magnetic core by using a die; molding the spiral metal ion guide paths on the surface of the insulating layer; depositing the metal wire layer on the surfaces of the metal ion guide paths to finally form the metal winding on the surface of the magnetic core. The magnetic passive element and the manufacturing method thereof provided by the invention have the advantages of simple process, low production cost and capability of realizing the automatic production with the stable and reliable quality.

Owner:DELTA ELECTRONICS CHEN ZHOU

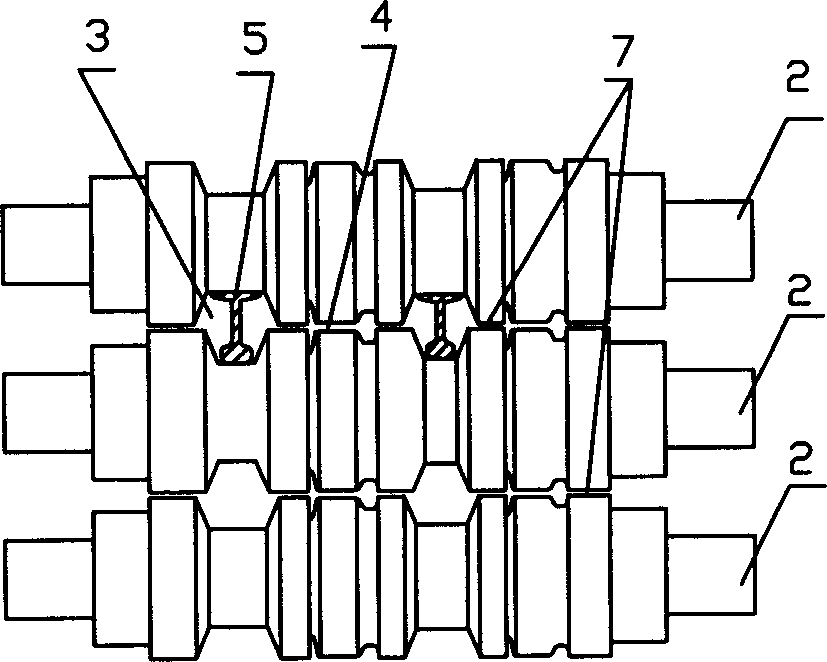

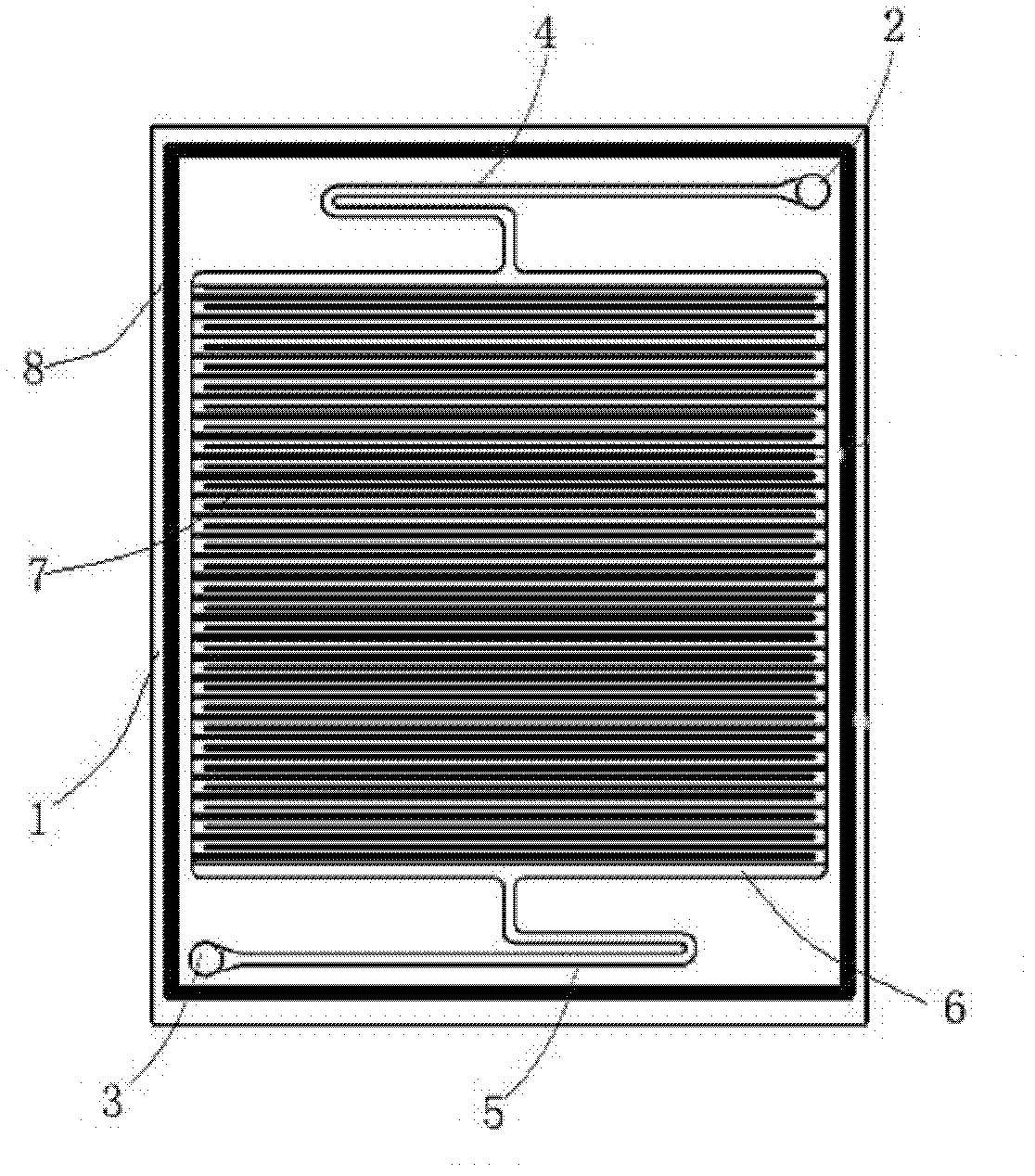

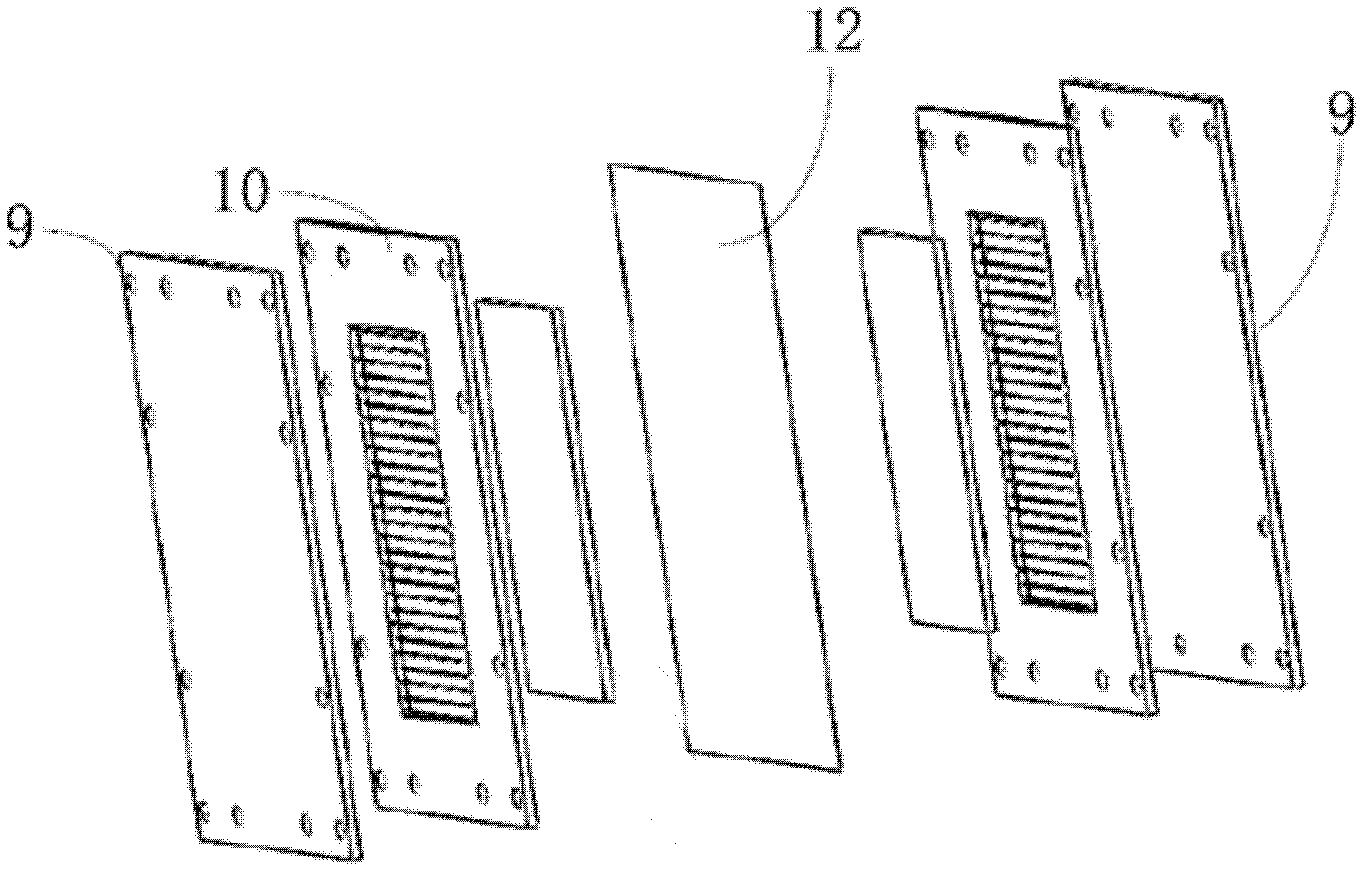

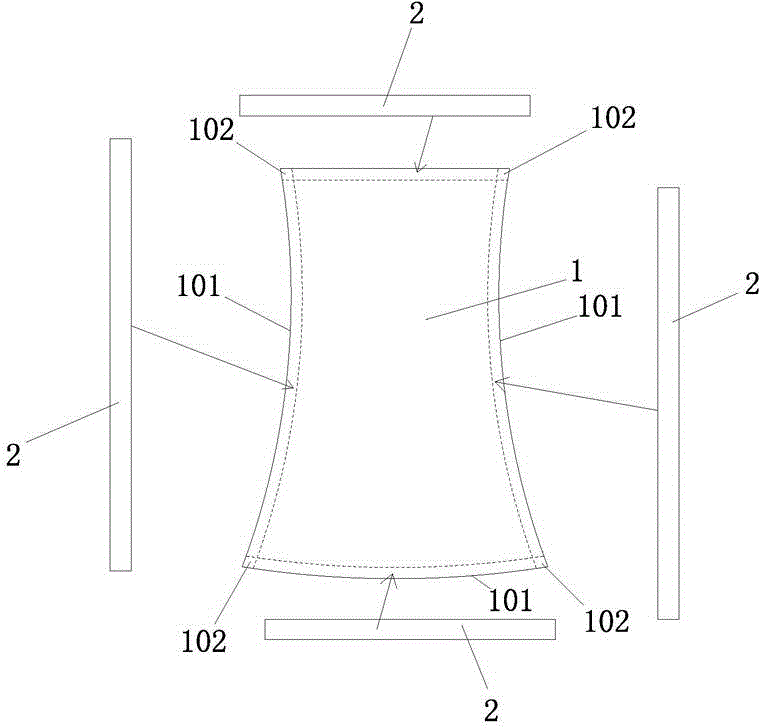

Flow cell frame with diversion structure, galvanic pile and processing method of galvanic pile

InactiveCN102623719AAvoid deformationReduce spawn probabilityFuel cells groupingRegenerative fuel cellsZincEngineering

The invention discloses a flow cell frame with a diversion structure, a galvanic pile and a processing method of the galvanic pile. The flow cell frame comprises a frame body (1), a frame inlet (2), a frame outlet (3), an inlet diversion channel (4) and an outlet diversion channel (5), wherein the frame inlet (2) and the inlet diversion channel (4) are arranged on the upper part of the frame body (1), the frame outlet (3) and the outlet diversion channel (5) are arranged on the lower part of the frame body (1), the middle part of the frame body (1) is provided with an active area (6), the active area (6) is respectively connected with the frame inlet (2) and the frame outlet (3) through the inlet diversion channel (4) and the outlet diversion channel (5), a diversion field (7) is arranged in the active area (6), and sealing lines (8) are arranged around the frame body (1). The invention can solve the problem of structural deformation in a cell and has the function of electrolyte diversion so as to uniformly distribute electrolyte and reduce the zinc dendrite generating probability, thereby improving the performance and the life of the cell. Additionally, the galvanic pile disclosed by the invention has the advantages of simplicity in installation and low failure rate.

Owner:北京百能汇通科技有限责任公司

Heat barrier composite plating and preparation technique thereof

InactiveCN101358363AReduce surface roughnessHigh bonding strengthElectrophoretic depositionThermal conductivity

The invention discloses a heat barrier composite cladding layer which consists of a MCrAlY alloy adhesive layer, a NiAl alloy barrier layer, a ZrO2-CeO2 ceramic layer and an Al2O3 protective layer; the NiAl alloy barrier layer is arranged between the MCrAlY alloy adhesive layer and the ZrO2-CeO2 ceramic layer, and the Al2O3 protective layer is arranged on the surface of the ZrO2-CeO2 ceramic layer. The invention adopts a preparation process integrated with electrophoretic deposition, high-speed electrical spray-plating and plasma arc plating layer scanning, and has the advantages of simple operation method, quite low preparation cost, capability of realizing industrialized production and the like, and the prepared heat barrier composite cladding layer also has the advantages of low heat conductivity, low roughness of the cladding layer surface, high integration strength of the cladding layer and the matrix, good hot corrosion resistance performance, good hot oxidation resistance performance and the like, solves the difficulties of poor high-temperature oxidation resistance and high-temperature corrosion resistance of high temperature resistant parts, and prolongs the service life of the high temperature resistant parts.

Owner:SHANGHAI UNIV OF ENG SCI

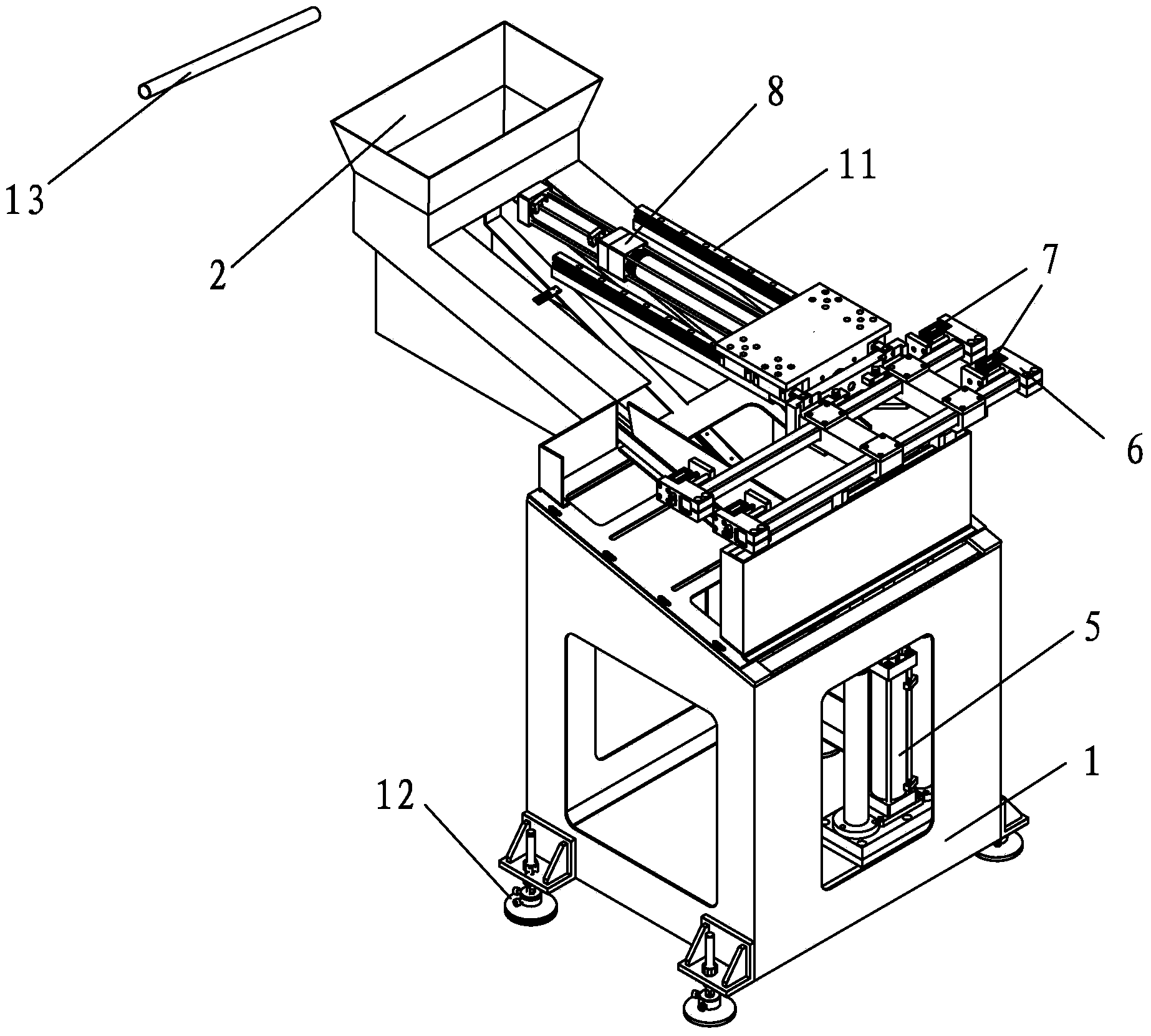

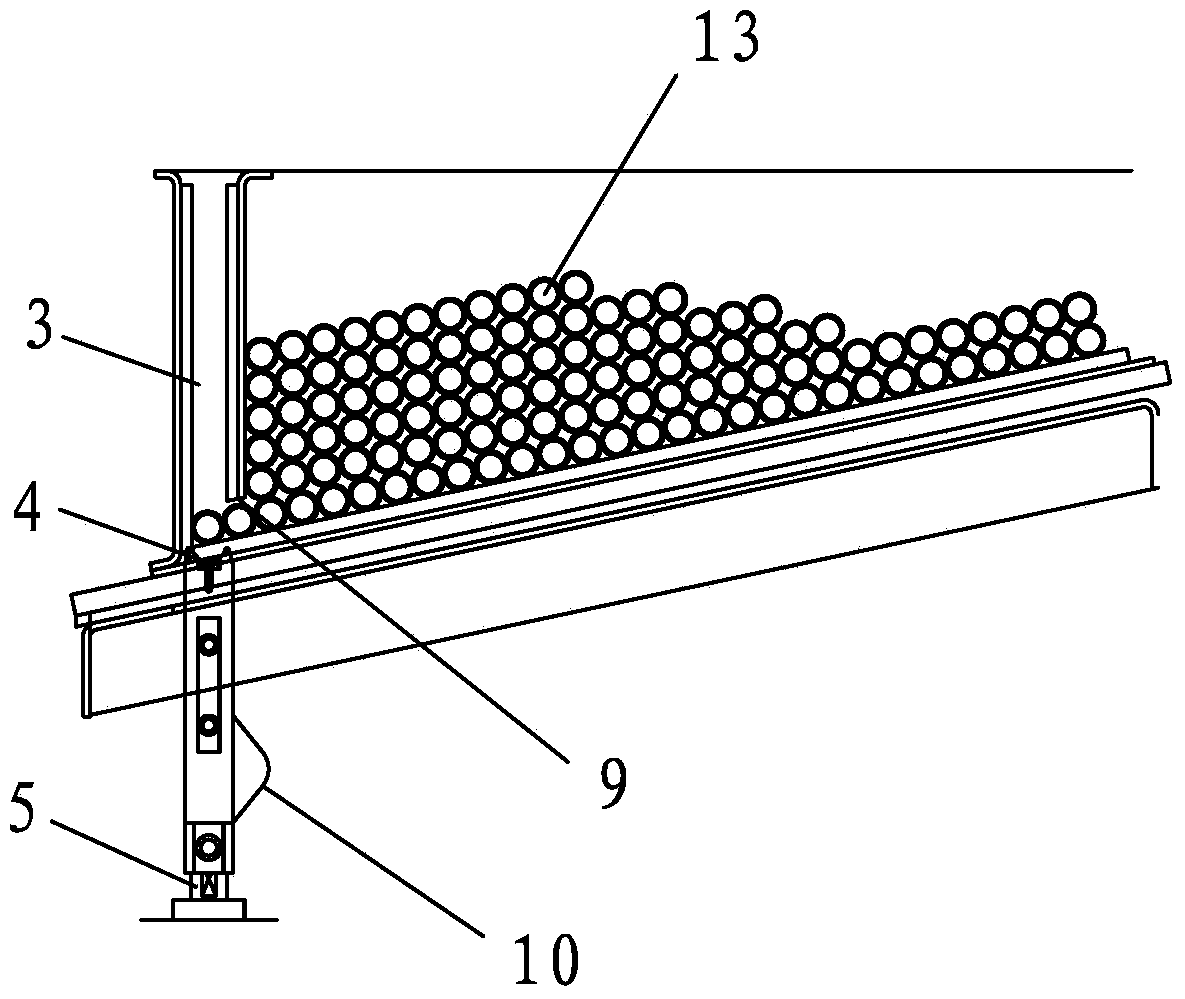

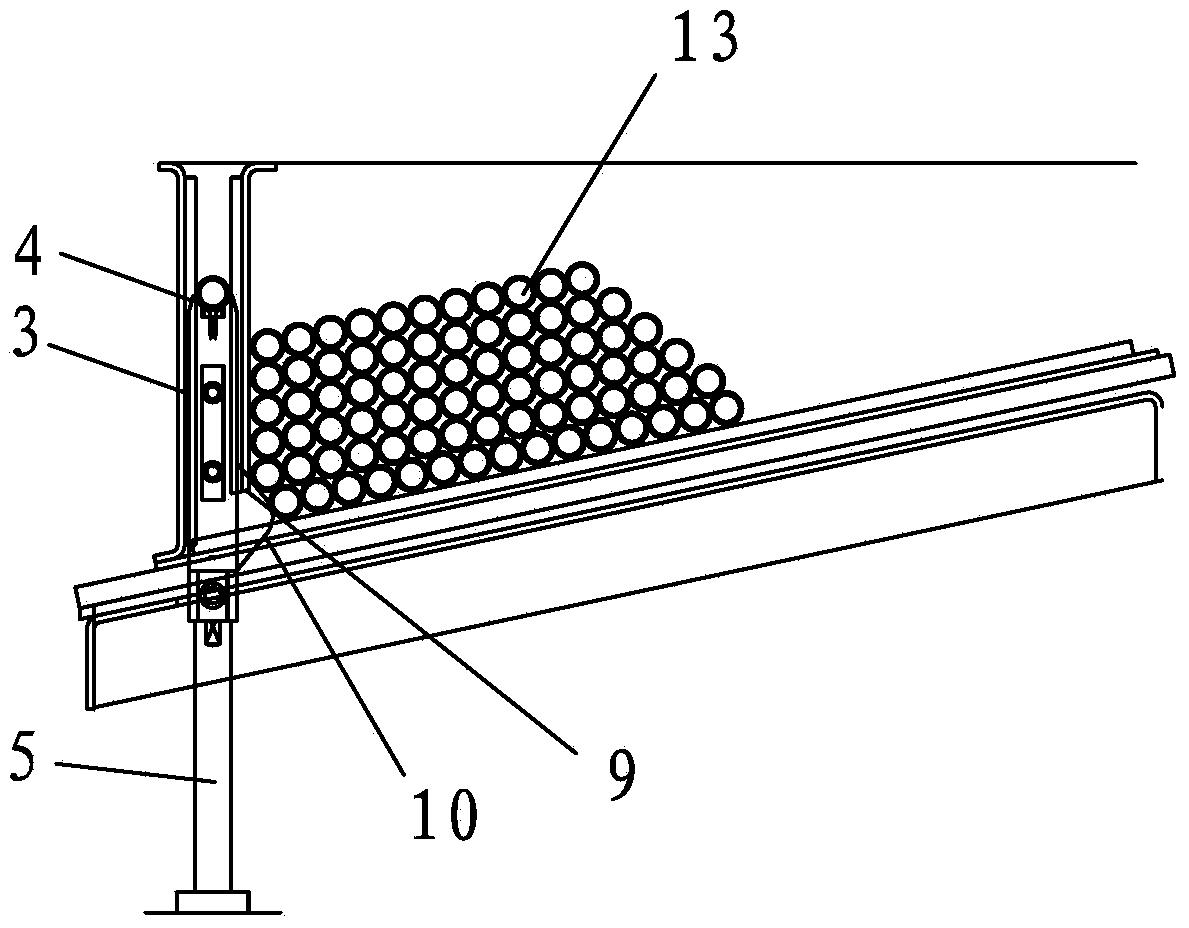

Pipe fitting feed device and working method thereof

ActiveCN104108583AImprove efficiencySuitable for automated productionConveyor partsPipe fittingStructural engineering

The invention discloses a pipe fitting feed device and a working method of the pipe fitting feed device. The device comprises a rack, a material bin arranged on the rack, a conveying slope opposite to a lower outlet of the material bin and arranged on the upper portion of the rack, a material lifting pathway vertically arranged on the rack, a material lifting fork arranged in the material lifting pathway and capable of sliding upwards and downwards, a material lifting air cylinder arranged on the rack and used for pushing the material lifting fork, an air cylinder fixing base arranged above the material lifting pathway, a clamping air cylinder arranged on the air cylinder fixing base and a material conveying air cylinder horizontally arranged. According to the pipe fitting feed device, the material lifting air cylinder, the clamping air cylinder and the material conveying air cylinder are controlled by a magnetic reed sensing device to automatically arrange, lift and convey pipe fittings to the machining position, so that one worker can operate multiple machine tools simultaneously, and the pipe fitting feed device is not only high in efficiency but also safe in operation and is suitable for automation batch production.

Owner:旭东机械(昆山)有限公司

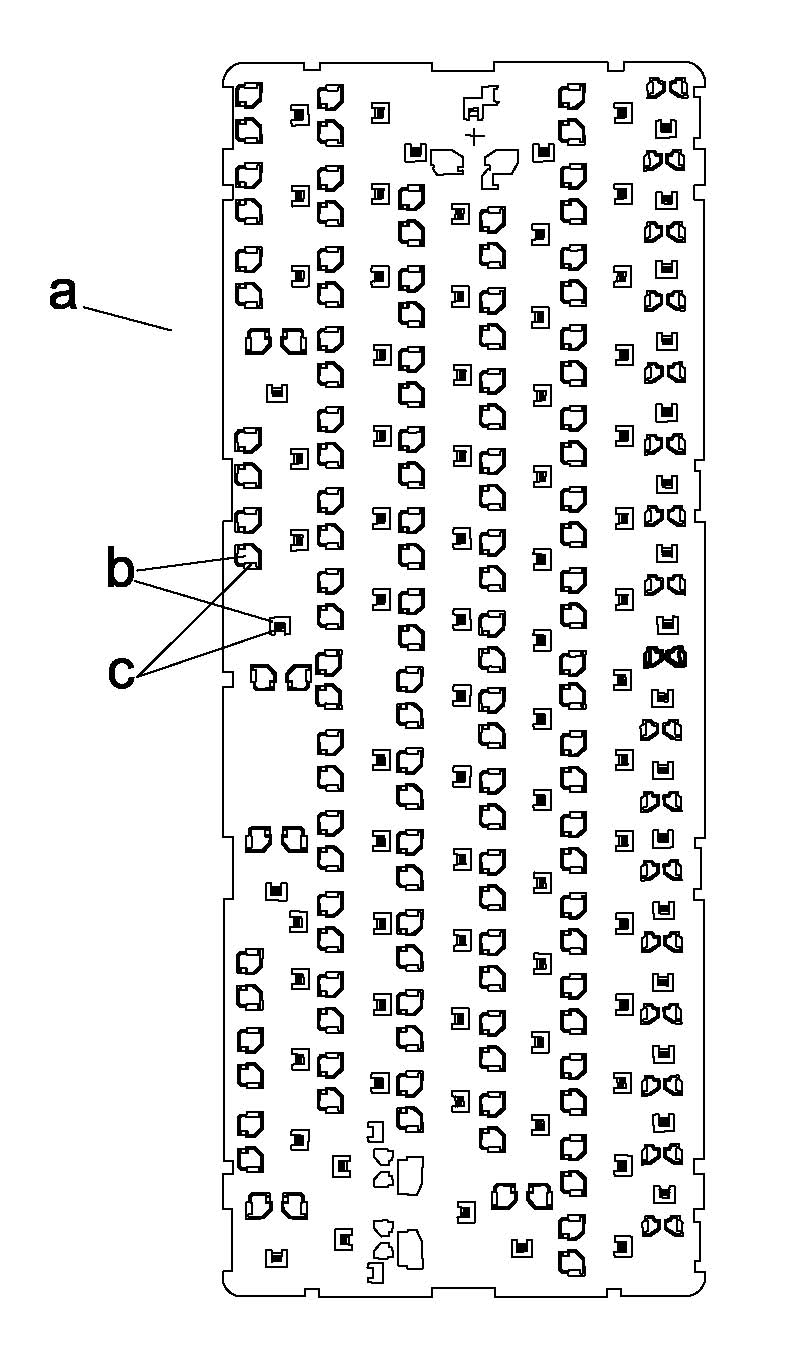

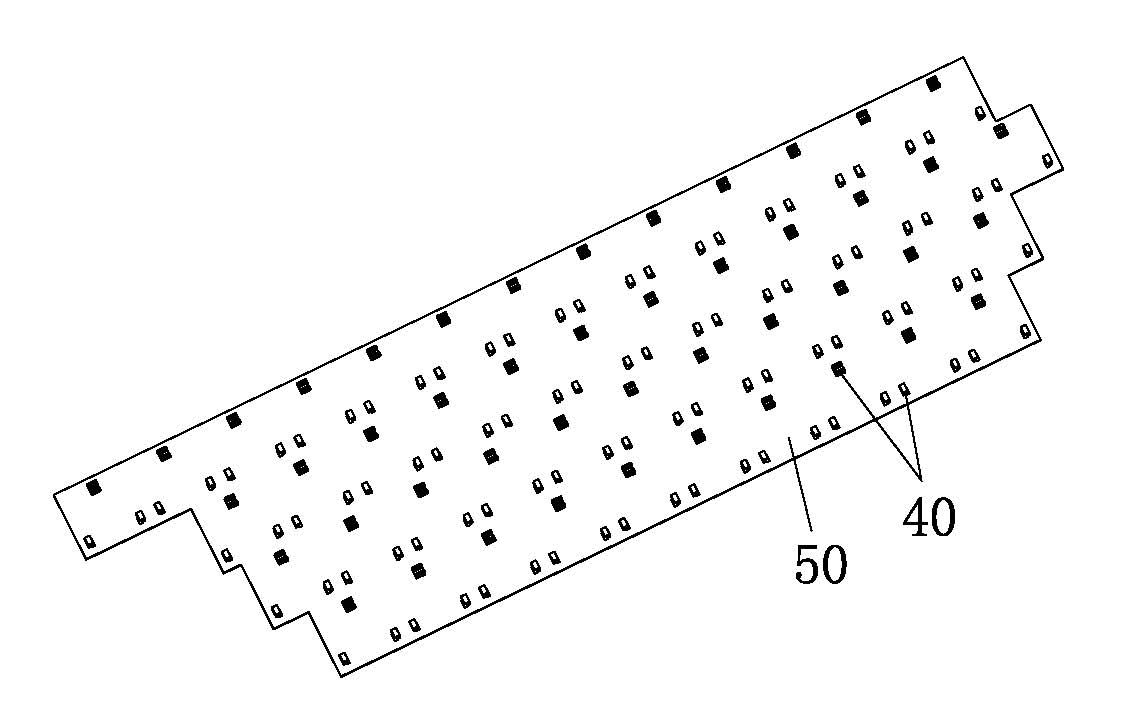

Keyboard adopting plastic-injection baseboard and production method of keyboard

InactiveCN102110543ALow costStable structureInput/output for user-computer interactionKey modulesKey pressingColloidal silica

The invention relates to a keyboard adopting plastic-injection baseboard and a production method of the keyboard, and the keyboard is used for laps or desktop computers. The keyboard comprises a plurality of button caps arranged at interval, scissor legs, a plurality of elastic colloidal silica, a plurality of lower pin fixing seats, a keyboard baseboard and a printed circuit film covered on the surface of the keyboard baseboard, wherein the bottom surface of the button cap is provided with upper pin fixing seats; after the components are assembled, the upper pins of the scissor legs are spliced and fixed on the upper pin fixing seats; the lower pins of the scissor legs are spliced and fixed on the lower pin fixing seats; the top of the elastic colloidal silica is propped against the bottom surface of the button cap; the bottom of the elastic colloidal silica is positioned on the button switch of the printed circuit film; and each lower pin fixing seat and the keyboard baseboard are the same plastic piece injected and shaped once by a plastic material. According to the invention, the production process is simplified, production cost is lowered, assembling accuracy and automated assembling efficiency are improved, product quality is guaranteed, and the invention is suitable for automated production.

Owner:江海波

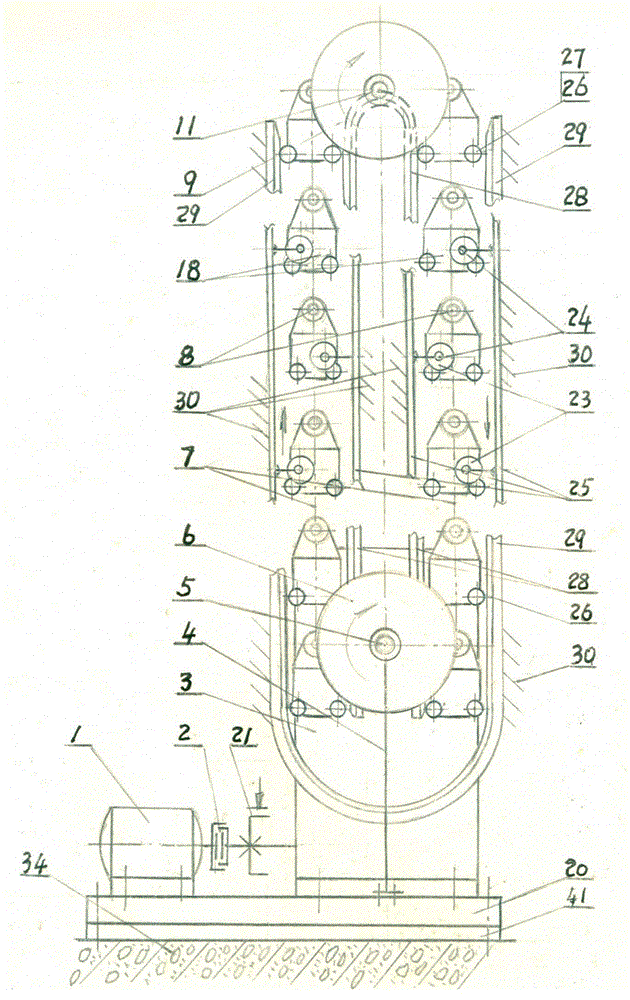

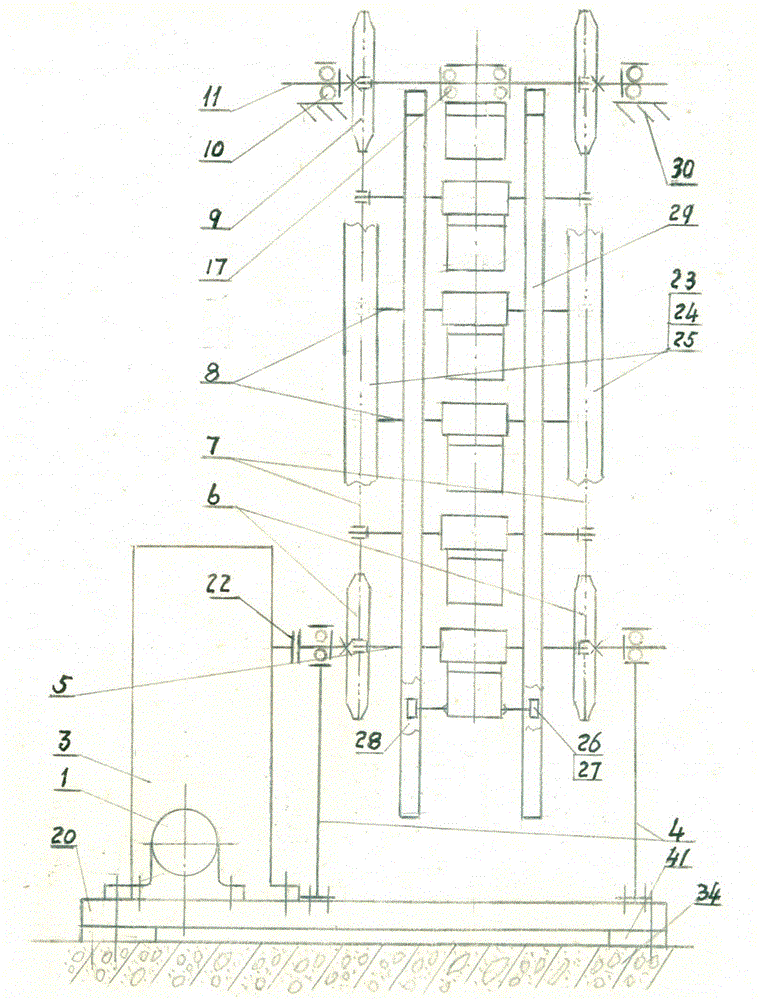

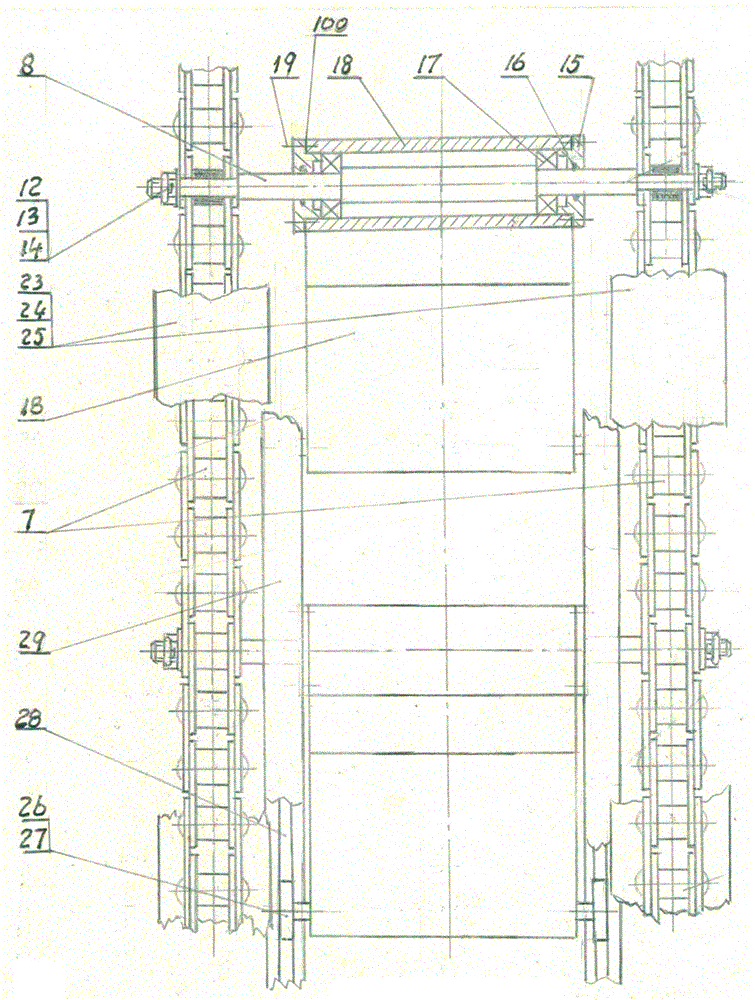

Circulating lifting device

ActiveCN105545040AImprove work efficiencyNo major lossParkingsReciprocating motionMechanical equipment

Provided is a circulating lifting device. A transmission device is installed on ground, a reversing device is installed on another fixed object, and two chains connect the transmission device and the reversing device. A rotating shaft is connected with the two chains. A moving box is installed on the middle part of the rotating shaft in a vertical oscillating manner. Driven by the transmission device, the device realizes circulation, roundtripping, carrying, loading and unloading, and storage of personnel, materials and goods, and materials. The device is formed by the transmission device, the reversing device, a carrying device, and a stabilizing device. The circulating lifting device has four types. The types are a basic circulating lifting device, an energy-efficient circulating lifting device, a comprehensive circulating lifting device, and an efficient circulating lifting device. The common characteristics are that through changing the structure, the number, and operating methods (circulating or reciprocating motion), circulating paths of the moving box, and changing placing methods (vertical, inclined, horizontal, reversed inclined, and reversed) of the moving boxes, the device has new purposes and becomes a new product. Mechanical equipment manufactured according to principles of the equipment has characteristics of high efficiency, energy conservation, land saving, and cost saving, and the equipment is suitable for automation production in large batch.

Owner:BEIHANG UNIV

Preparation method of diced meat-mustard pickle

The invention discloses a preparation method of diced meat-mustard pickle. The preparation method comprises the following steps: cutting the mustard into mustard shreds, and drying until the moisture content is 8-12% by weight; carrying out deep-frying on the diced pork until the diced pork is in toast tan; weighing diced pepper, Sichuan pepper powder and sugar in a weight ratio of 7:4:4 and uniformly mixing to obtain a mixture I; weighing peanut oil in a weight ratio of peanut oil to the mixture I being1.5:1, and pouring the peanut oil into the mixture I to obtain a mixture II; steaming the mustard shreds in a steam box at 100 DEG C for 10 minutes; putting the steamed mustard shreds, the diced pork and edible salt into a closed container, and fermenting for 6-8 days; weighing the fermented mustard shreds and the mixture II in a weight ratio of (95-100):(13-16); and uniformly stirring and sterilizing to obtain the diced meat-mustard pickle. In the preparation method disclosed by the invention, the drying is performed before steaming, the steamed mustard shreds easily get tasty and are soft with tenacity, and the mouthfeel is great; the diced meat-mustard pickle is suitable for different people at all ages. The preparation method disclosed by the invention is simple in the processing technology and suitable for automatic production in a factory.

Owner:刘诗茵

Manufacturing process of aluminum alloy wheel

The invention discloses a manufacturing process of an aluminum alloy wheel. The manufacturing process of the aluminum alloy wheel comprises casting, deburring, soaking, spinning, heat treatment, gateremoving, X-ray, and machine addition. According to the manufacturing process of the aluminum alloy wheel, the cost is saved by about 18 yuan / part from the casting production efficiency, the improvingof products quality, the saving of original cooling compressed air, the cancelling of pre-machine addition, the temperature preheating and spinning of blank strip and the temperature pretreating of blank strip and the like; the weight of finished products are reduced by 0.7-1.1 kg, the comprehensive manufacturing cost of the aluminum alloy wheel is even with that of a common casting wheel, and and the market competitiveness of a casting and spinning wheel is improved; and short-flow, lightweight and low-cost technology for manufacturing the cast and spinning wheel is realized, the intelligentization of machining is realized, and the manufacturing process is suitable for automatic production of large-scale casting and spinning wheels.

Owner:CITIC DICASTAL

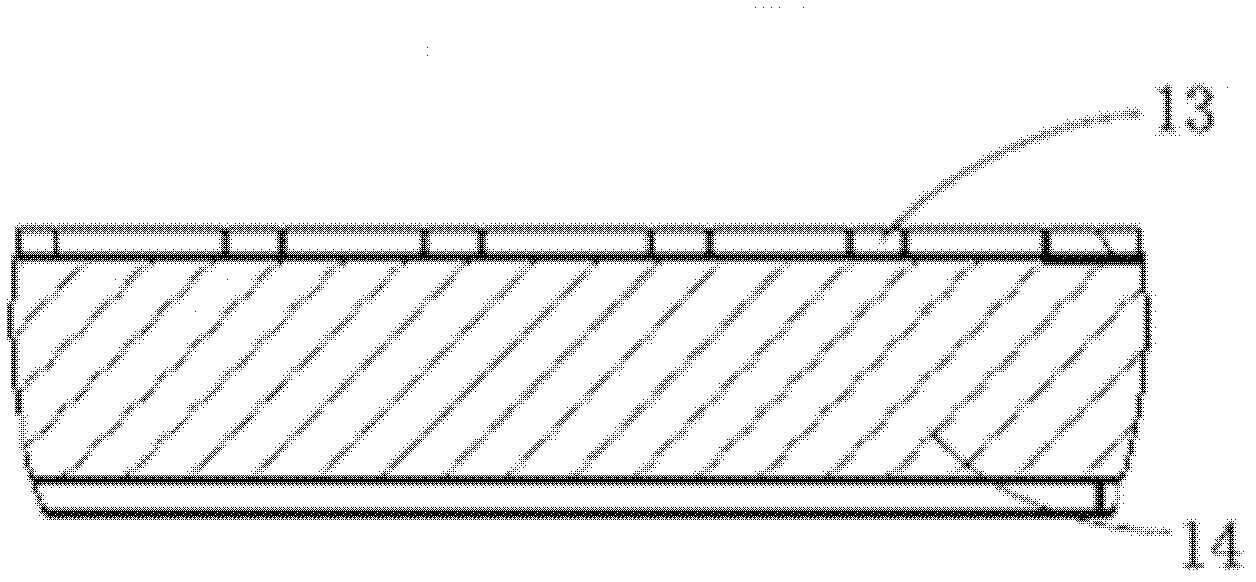

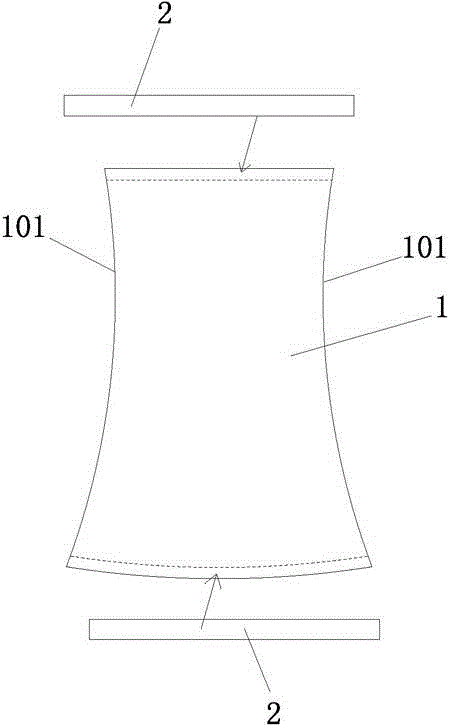

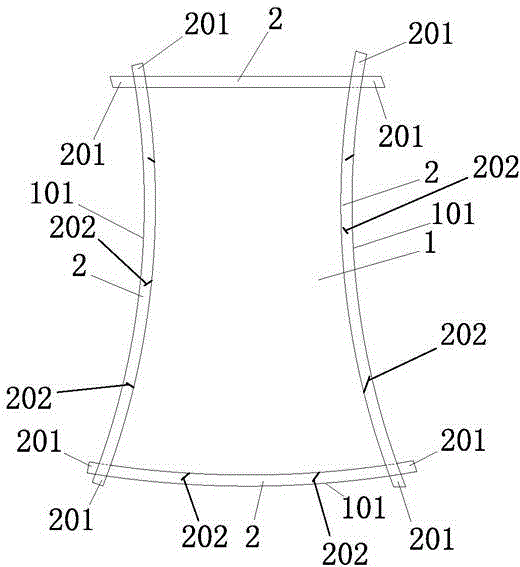

Seamless wave bottom of underpants and technology for compounding wave bottom and hot melting adhesive tape

InactiveCN106263047ANo archingReduce individually cut fabricsLamination ancillary operationsLaminationPhysicsHot pressing

The invention relates to a seamless wave bottom of underpants and a technology for compounding the wave bottom and a hot melting adhesive tape. The seamless wave bottom comprises a wave bottom fixing area arranged on an underpants main body, and the wave bottom is formed on the wave bottom fixing area through seamless pressure pasting; the seamless wave bottom is characterized in that the hot melting adhesive tape with the width being L is arranged on the wave bottom close to the contour edge, the hot melting adhesive tape is arranged in a manner of integrally extending along the contour edge of the wave bottom, and the wave bottom is formed on the wave bottom fixing area through hot-pressing laminating by adopting the hot melting adhesive tape. The technology for compounding the wave bottom and the hot melting adhesive tape comprises the following steps: (1) slitting a hot melting adhesive film and a fabric of the wave bottom; (2) punching a positioning hole and an inner frame hole; (3) carrying out thermal compounding on the hot melting adhesive film and the fabric; and (4) forming the wave bottom finished product through die cutting and integrated blanking. The process is simple and reasonable, the processing efficiency is high, the operation is safe and reliable, the technology is energy-saving and environmentally friendly, and the production cost is greatly reduced.

Owner:佛山市真北工业技术材料有限公司

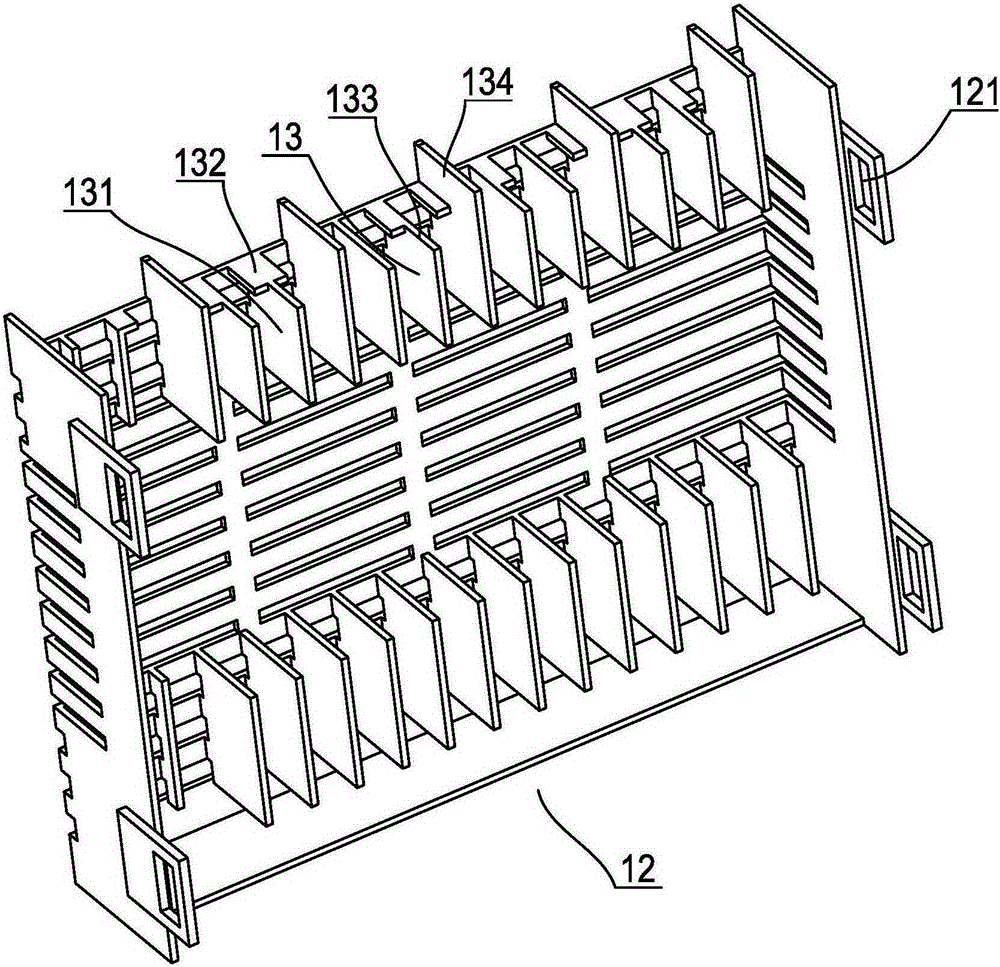

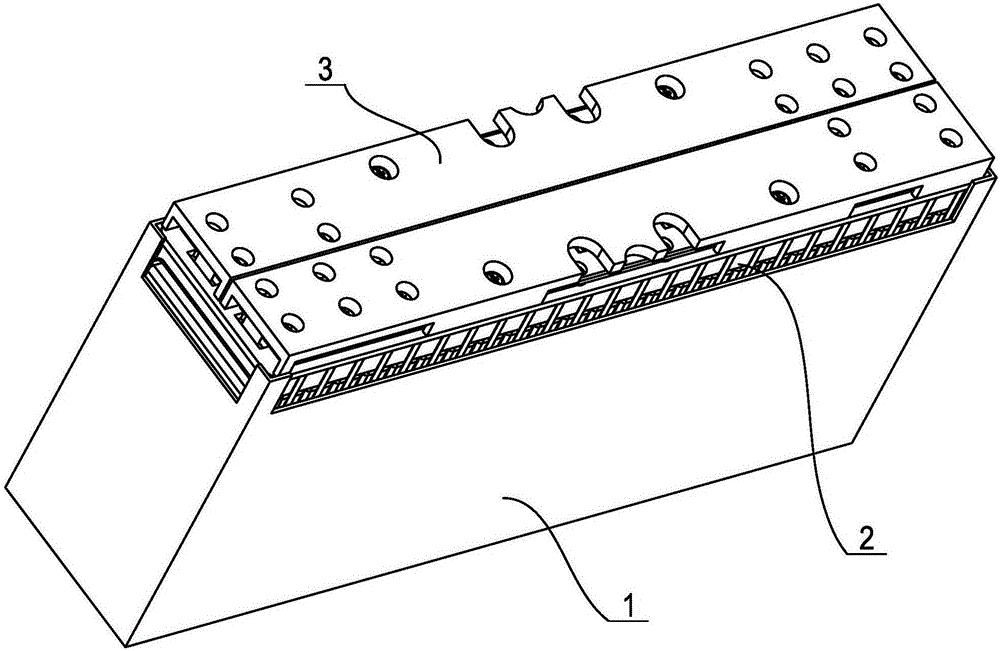

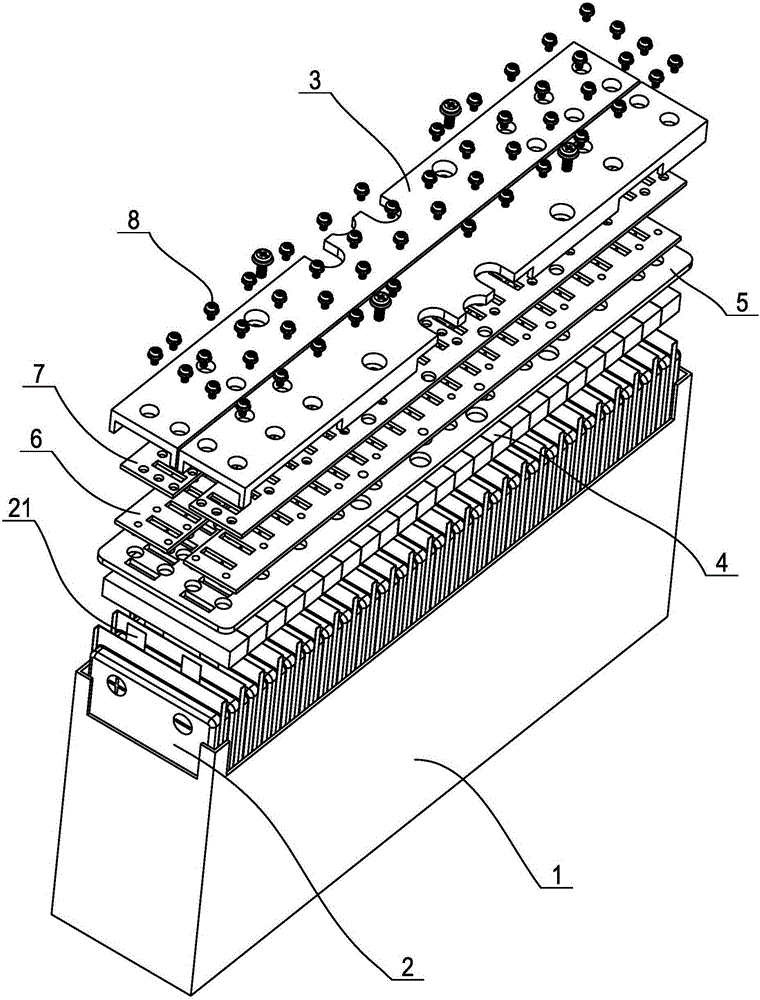

Compression joint type power battery assembly structure, assembling method and electric vehicle

ActiveCN105244467AAvoid damageAvoid pollutionCell component detailsBatteriesPower batteryEngineering

The invention discloses a compression joint type power battery assembly structure, an assembling method and an electric vehicle. The compression joint type power battery assembly structure comprises an upper part battery compartment, flexibly packaged electric cores and a protection cover arranged in a battery compartment; two tab-fixing copper plates are arranged on the opening side of the battery compartment; a positive electrode tab and a negative electrode tab of each flexibly packaged electric core are covered by the two tab-fixing copper plates respectively; tab perforating holes are formed in the position, corresponding to the tabs, in the tab-fixing copper plates; the tabs of the flexibly packaged electric cores penetrate through the tab perforating holes to be bent to form pressing parts clung to the upper surfaces of the tab-fixing copper plates; compressing copper plates for propping and pressing the pressing parts are arranged on the tab-fixing copper plates; the compressing copper plates are connected with the tab-fixing copper plates through threaded fastening parts; the compressing copper plates are further provided with connection member parts; and the compressing copper plates are covered by the protection cover. The compression joint type power battery assembly structure can avoid damage of the flexibly packaged electric cores and the environment pollution caused in the tin soldering process; and in addition, the assembly structure is suitable for industrial production and capable of ensuring reliable connection as well.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

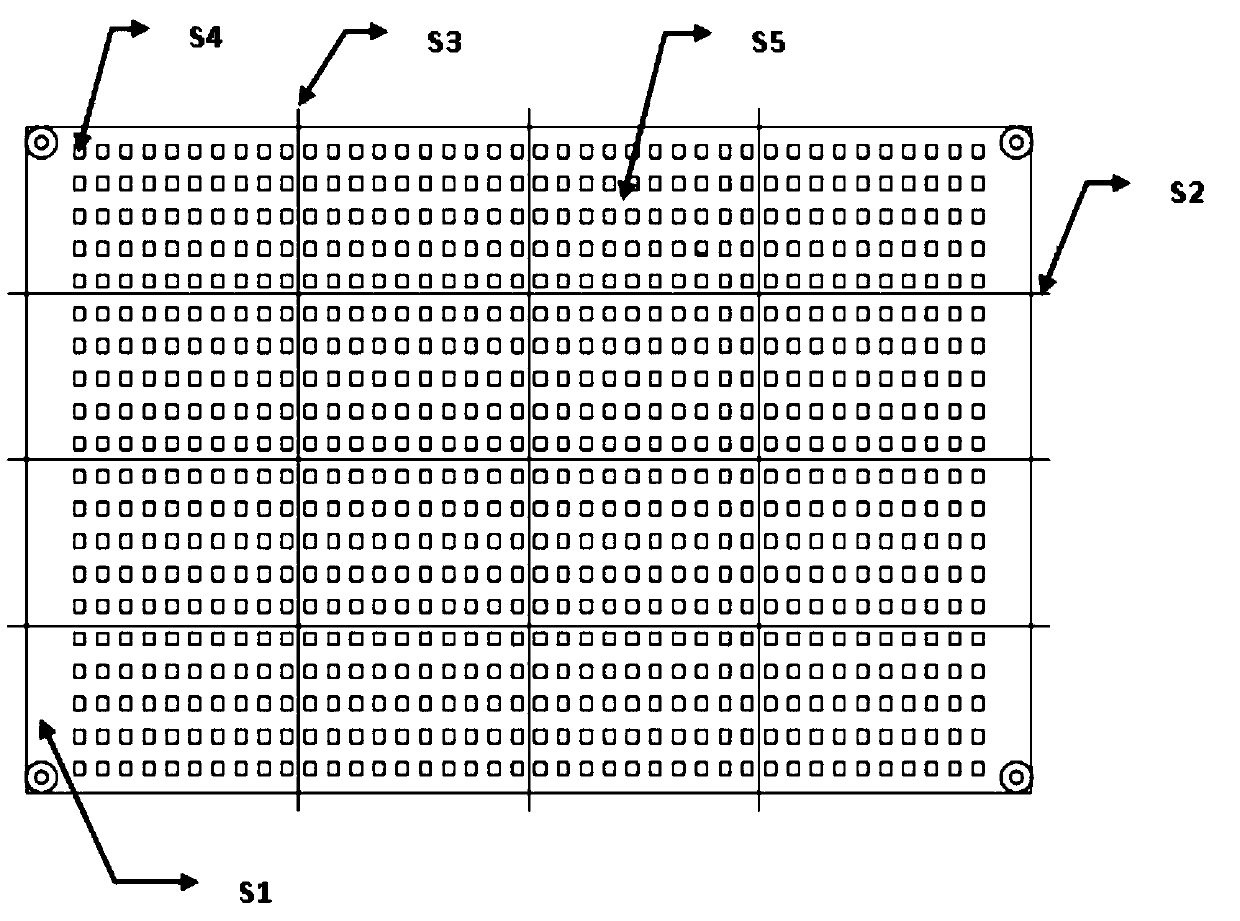

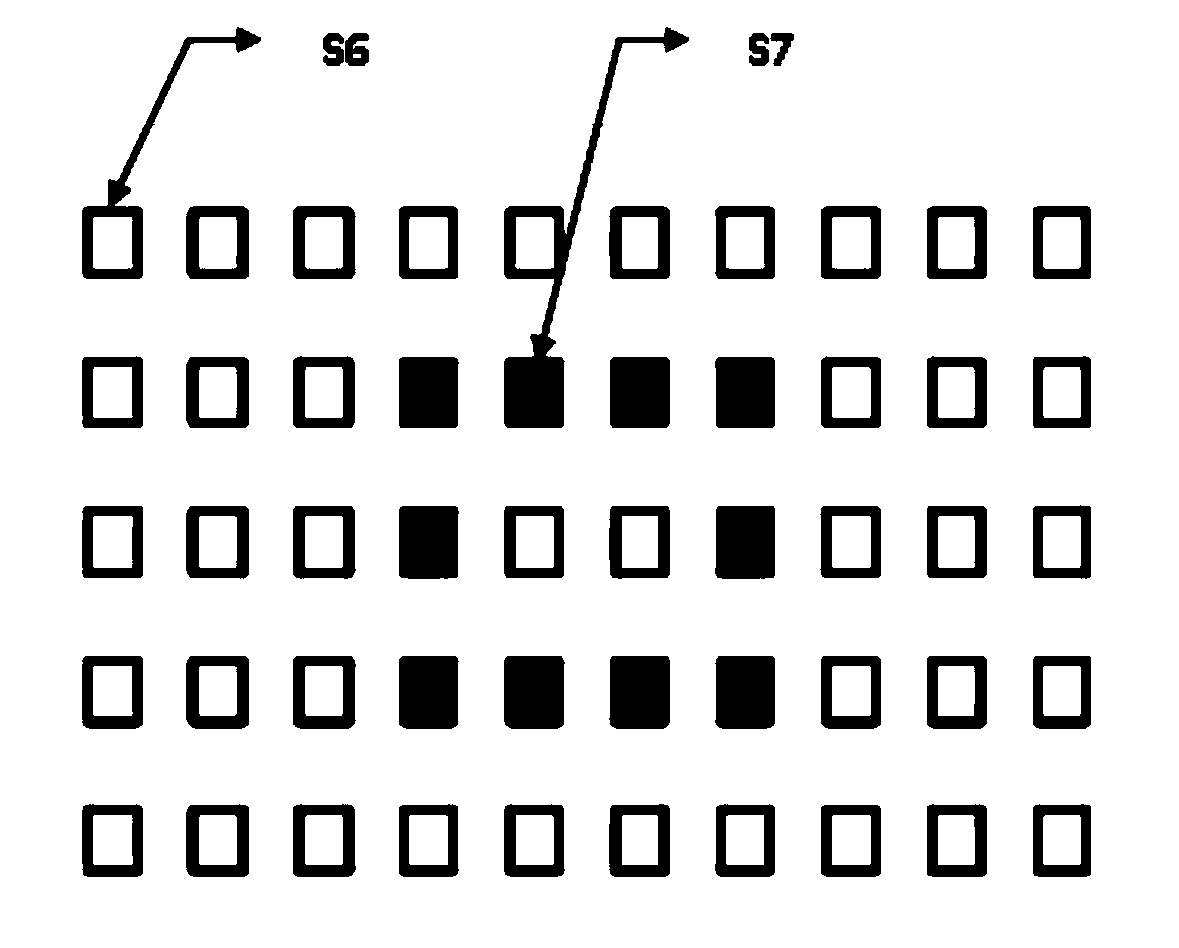

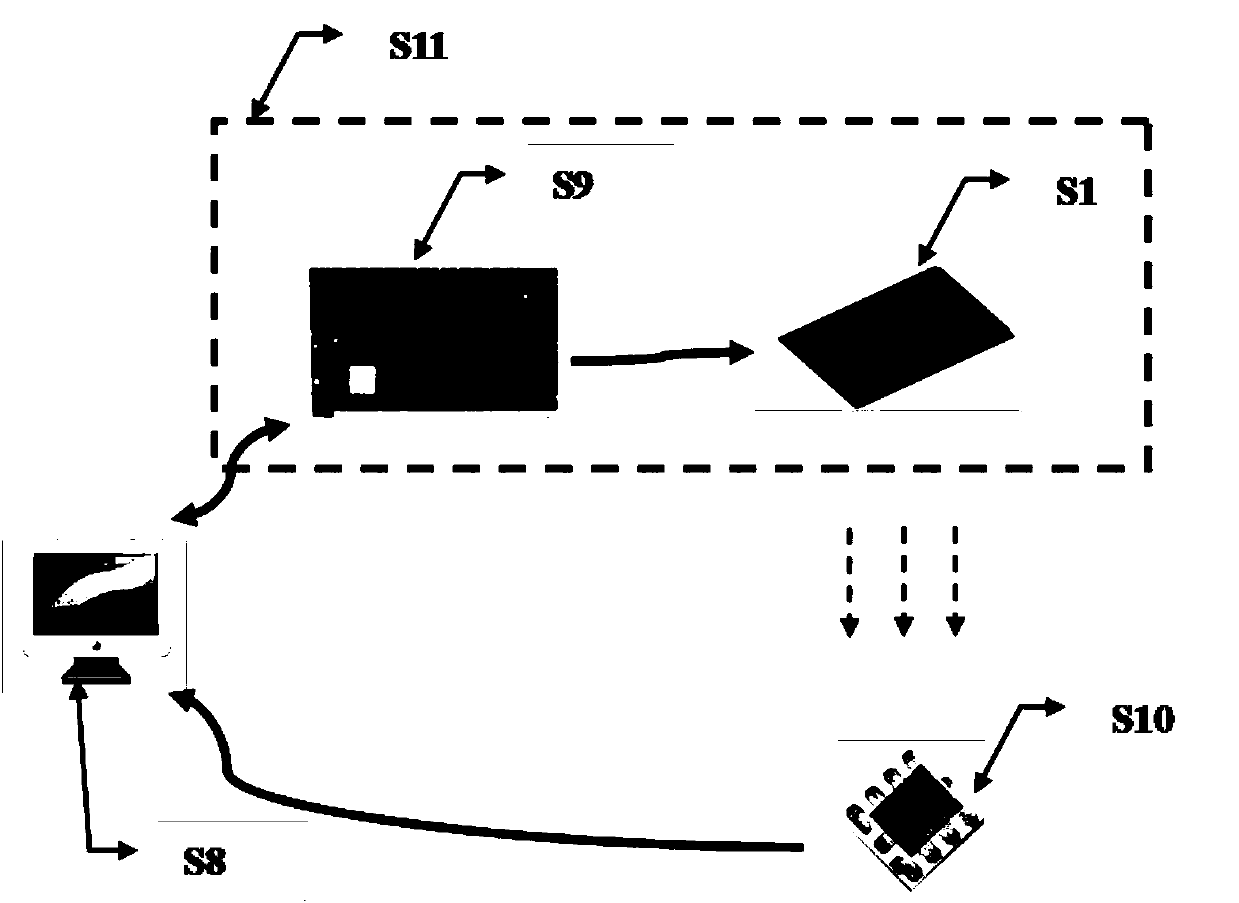

LED backlight source and brightness and brightness uniformity automatic adjusting method thereof

PendingCN107644626ARealize automatic adjustmentMeet the requirements of high brightness and high uniformityStatic indicating devicesNon-linear opticsCommunication interfaceLower grade

The invention discloses an LED backlight source and a brightness and brightness uniformity automatic adjusting method thereof. The LED backlight source comprises an LED light board, an LED light string which is arranged in an array on the light emitting surface of the LED light board and comprises a constant current light string and a variable current light string, a row division line, a column division line, and a multi-channel LED constant current control substrate. The LED light string is uniformly divided into a number of partially adjustable units. The variable current light string is arranged around the center of the partially adjustable units. The multi-channel LED constant current control substrate is used for controlling current flowing through the constant current light string and the variable current light string, is provided with an RS232 communication interface, and has a data storage function. According to the invention, automatic adjustment of the brightness and brightness uniformity of the LED backlight source is realized; the requirements of high brightness and high uniformity are met; and the LED backlight source is free of manual adjustment, is suitable for automated production, and is suitable for a variety of high, medium and low grade design applications.

Owner:SUZHOU HUAXING YUANCHUANG TECH CO LTD

Vacuum brazing paste solder free of brazing flux, preparing method and using method of solder

ActiveCN111299898AImprove stabilityIncrease productivityWelding/cutting media/materialsSoldering mediaWeld seamElectrochemical corrosion

The invention discloses a vacuum brazing paste solder free of brazing flux, a preparing method and a using method of the solder, relates to a paste solder free of brazing flux for vacuum brazing aluminum matrix composites, a preparing method and a using method of the solder, and aims at solving the problems that it is difficult to weld and operate members in a complex shape with a foil solder, automatic production is hindered, and the brazing flux of the existing paste solder is stacked in brazing seams and cannot be discharged out, resulting in electrochemical corrosion at welding beams and lowering of performance of welded joints. The paste solder is prepared by mixing solder alloy powder and a binding agent and is free of brazing flux. The preparing method comprises the steps of preparing the solder alloy powder and the binding agent, and mixing the solder alloy powder and the binding agent in a proportion to obtain the vacuum brazing paste solder free of brazing flux. The using method comprises the steps of adopting a brush for brushing the paste solder onto the surface of a composite, and then putting the composite in a vacuum furnace for welding. According to the vacuum brazing paste solder, the preparing method and the using method, in addition to the reduction of cost and simplification of operation, the intensity, air impermeability and safe reliability of the welded joints are also improved.

Owner:허난징타이에어로우스페이스하이테크머터리얼스테크놀로지컴퍼니리미티드 +1

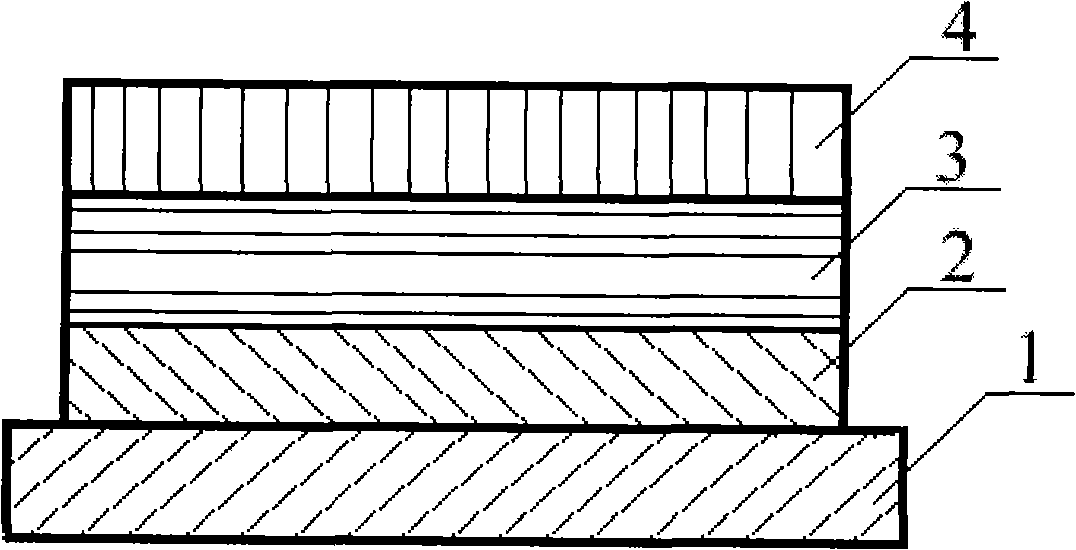

Packaging structural element of dye-sensitized cell and packaging method thereof

ActiveCN101783248ALow priceReduce manufacturing costLight-sensitive devicesSolid-state devicesState of artSensitized cell

The invention discloses a packaging structural element of dye-sensitized cell and a packaging method for preparing the packaging structural element of dye-sensitized cell; the dye-sensitized cell comprises a photocathode component, a counter electrode component and an electrolyte (8) packaged together; the packaging structural element is characterized in that the packaging structural element combined with two or more layers is covered on the surface of the conductive electrode (5) in the photocathode component and / or the counter electrode component, wherein the packaging structural element combined with two or more layers at least comprises a rigid insulation layer (6) covered on the surface of the conductive electrode (5) and a binder bonding layer (7) covered on the surface of the rigid insulation layer (6). In the packaging structural element combined with two or more layers, the defects of material in the prior art are avoided, thereby solving the technical problem of short circuit due to the easily deforming of the bonding layer at high temperature and pressure which makes the bonding layer become thinner, and the conductive electrodes of the photocathode and the counter electrode have contact points.

Owner:ENN SCI & TECH DEV

Method for on-line detection of coagulation bath concentration in production of polyacrylonitrile strands for carbon fibers

InactiveCN101871887AImprove timelinessFast test methodPhase-affecting property measurementsChemistryStandard curve

The invention relates to a method for the on-line detection of coagulation bath concentration in the production of polyacrylonitrile strands for carbon fibers, which comprises the following steps: 1) preparing a dimethyl sulfoxide standard solution; 2) manufacturing a standard curve equation; 3) connecting devices; 4) carrying out on-line detection; and 5) calculating the concentration. The invention solves the technical problems that the existing coagulation bath concentration detecting method is time-consuming, the detection result is inaccurate and the on-line detection can not be realized. Besides, the invention is beneficial to improving the timeliness, the dynamic nature and the accuracy of the concentration control of dimethyl sulfoxide in the coagulation bath. The detecting method is fast, accurate and visual, and is suitable for automatic production.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

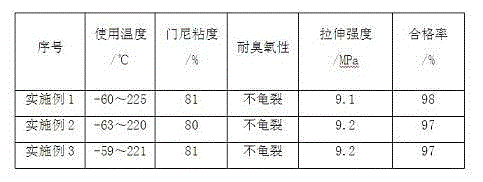

Production technology for chloroprene rubber

Relating to the rubber field, the invention discloses a production technology for chloroprene rubber. The technology comprises the processes of: rubber drying, plastication, mixing, semi-finished product cutting and vulcanization. According to the method, by strictly controlling the rubber drying temperature and time in the rubber drying process, the quality of the dried rubber material is improved. The mixing process adopts a two-stage mixing process, well controls the mixing time and discharge temperature, so that scorching phenomenon of chloroprene rubber is significantly reduced, and the rubber guiding, discharge and batch-out of an open mill are smooth, and no roll sticking phenomenon appears. The vulcanization process adopts N-tert-butyl-2-bisbenzothiazole sulfenamide as a vulcanization accelerator, which is safe and pollution-free and has no harm to the human body. The technological process adopts a drum type vulcanizing machine, the vulcanization efficiency and quality are greatly improved, and the produced product has high Mooney viscosity and good quality. The technological method has the advantages of good technology, simple operation, and good technological stability, thus being suitable for factory automation production.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

Environmentally friendly glass frosting paste

The invention relates to the field of frosting material manufacture and especially relates to environmentally friendly glass frosting paste. A preparation method of the environmentally friendly glass frosting paste comprises crushing ammonium fluoride, ammonium hydrogen fluoride, magnesium hydrogen fluoride, aluminum hydrogen fluoride, oxalic acid, sodium acetate, sodium silicate, ammonium fluoroborate, sodium fluoroborate, Al2O3, SiO2, sodium dodecanesulphonate, cellulose MCC, sodium hexametaphosphate and sodium polyacrylate according to a certain ratio, carrying out stirring to obtain uniform powder, putting the mixture into a rotation stirrer, carrying out sealing stirring for 25min, carrying out blending and reaction process on the stirred frosting powder and technical hydrochloric acid according to a ratio of 1: 1 for 50h so that a frosting liquid is produced, filtering the frosting liquid by a common screen or nylon net of 10-100 meshes to obtain an uniform emulsified frosting liquid, wherein 100g of the frosting liquid comprises 35g of an emulsified frosting liquid, 6g of acetone with a concentration of 99%, 5g of polyacrylic resin, 7g of white sugar, 45g of barium carbonate and 2g of nonpolar organic lipid compound propyl acetate, carrying out intense agitation on the mixture so that the mixture undergoes a reaction to produce paste cured to appropriate denseness, and sealing the paste in a plastic container so that the frosting paste is obtained.

Owner:黄淼

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com