Patents

Literature

70results about How to "Reduce scorching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric oven

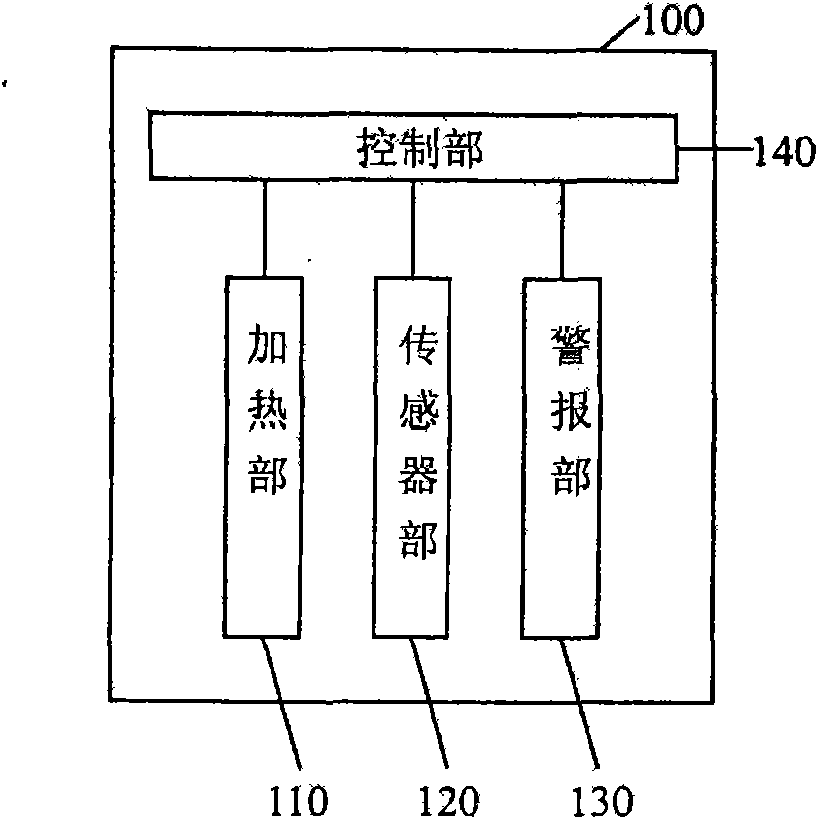

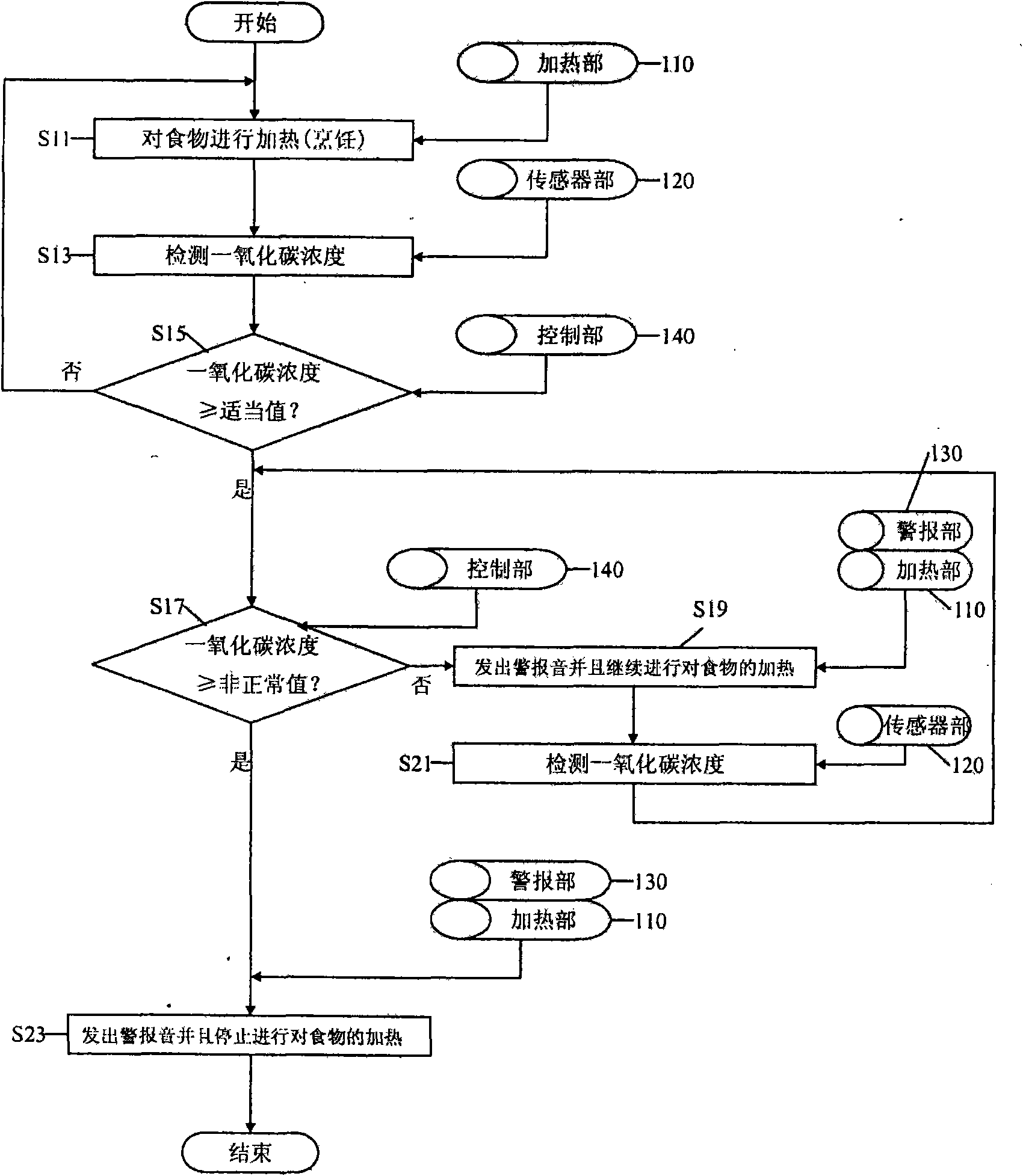

InactiveCN101658392AEfficient and safer heatingReduce scorchingRoasters/grillsProduct gasEngineering

The invention relates to an electric oven. The electric oven can judge whether the heating of food is excessive or not according to the concentration of gas generated in the process of heating the food in a cooking cavity so as to transfer information to a user or stop heating the food. Therefore, the electric oven has the advantage of reducing the phenomenon of scorching caused by heating the food excessively.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

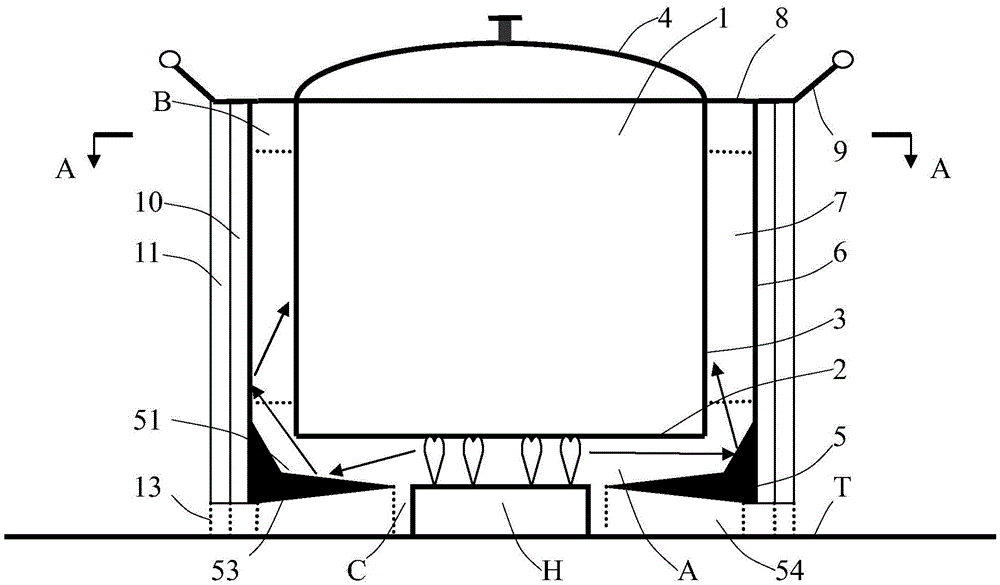

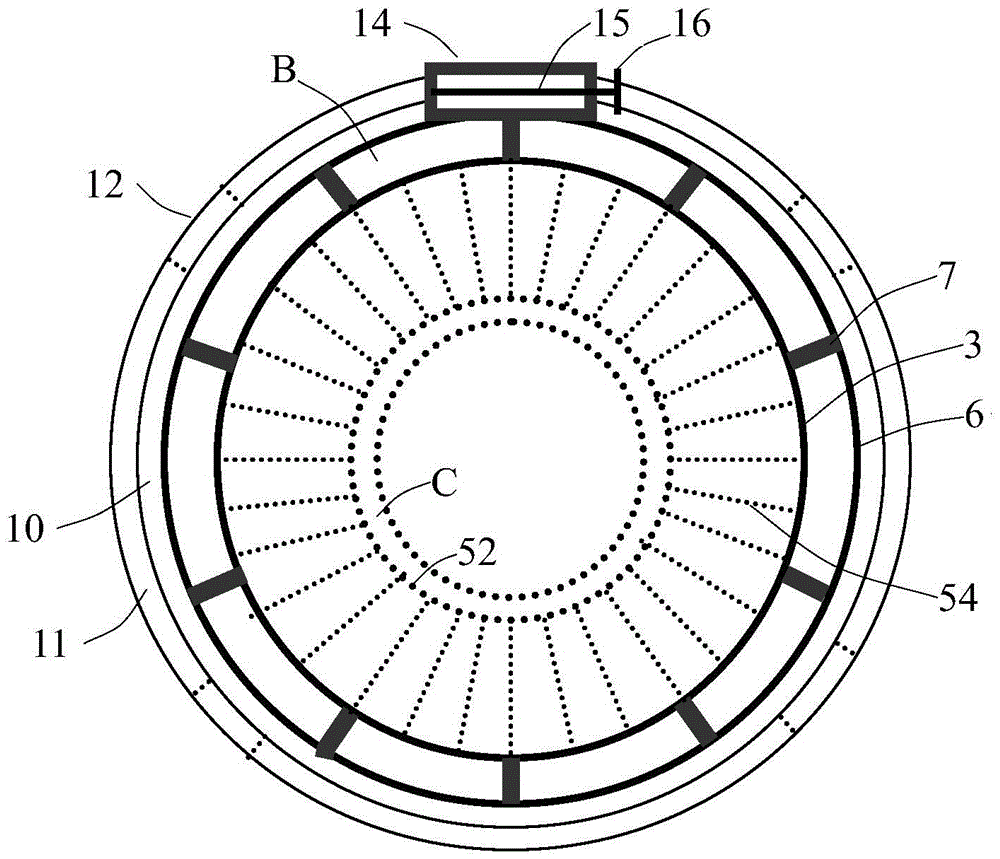

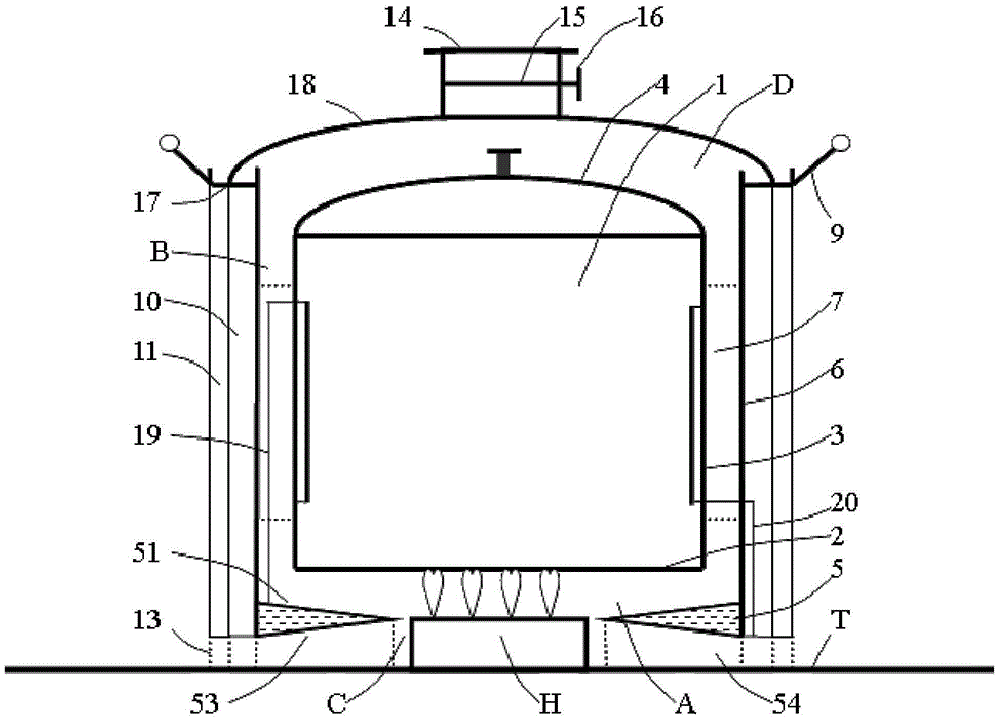

Efficient energy-saving cooking utensil and support thereof

InactiveCN105455608AIngenious designImprove performanceWarming devicesCooking vessel supportPhysical well beingPollutant emissions

The invention relates to an efficient energy-saving cooking utensil and a support thereof. The efficient energy-saving cooking utensil comprises an inner pot, a heat collecting disc and a cylinder, wherein the inner pot comprises an inner pot bottom, an inner pot wall and an inner pot cover, the inner pot wall is connected with the inner pot bottom, and the inner pot cover is arranged on an opening of the upper portion of the inner pot wall; the heat collecting disc is arranged below the inner pot bottom, a gap A is formed between the upper surface of the heat collecting disc and the inner pot bottom, the outer edge of the heat collecting disc is connected with the cylinder, an annular gap B is formed between the inner wall face of the cylinder and the outer wall face of the inner pot wall, connecting pieces connected with the inner wall face of the cylinder and the outer wall face of the inner pot wall are installed in the annular gap B, and an open pore is formed in the heat collecting disc and adapts to a heating device (H) in position and size. The efficient energy-saving cooking utensil is high in heating efficiency, high in heating speed, uniform in heating, good in heat preservation performance, low in pollutant emission quantity, beneficial for body health of a user and convenient to place stably and has the functions of preventing wind and stabilizing flames, overflowing is easy to handle, and a pot body is attractive and not prone to breakage.

Owner:GUANGDONG UNIV OF TECH

Method for regulating quality of dasheens through hot air energy-far infrared energy-microwave energy integration drying

ActiveCN105509416AAvoid localized overheatingImprove conditions with low moisture content that is difficult to dryDrying solid materials with heatHearth type furnacesMicrowaveEconomic benefits

The invention relates to a method for regulating quality of dasheens through hot air energy-far infrared energy-microwave energy integration drying, and belongs to the technical field of deep processing of agricultural products. The method mainly comprises the following steps: taking fresh dasheens as raw materials, selecting, cleaning and slicing the dasheens, carrying out blanching and color protection on the dasheens, soaking, freezing, carrying out hot air energy-far infrared energy-microwave energy integration drying, and packaging. A hot air energy-far infrared energy-microwave energy integration drying technology is adopted, water in materials is rapidly vaporized and transferred through early-stage high-power microwave heating, and a porous structure is generated; by later-stage low-power microwave drying, local overheating of the materials due to single-power heating is avoided; through far infrared radiation, water inside and outside the materials is removed by ducts formed by microwave heating; and blowing heating is carried out in a whole drying cavity, so that water on the surfaces of the materials and in air is removed rapidly. Obtained dasheen crisp chips are good in uniformity and high in quality. By the method, continuous and automatic production is realized, material treatment amount is large, and economic benefit is high.

Owner:JIANGSU ACAD OF AGRI SCI

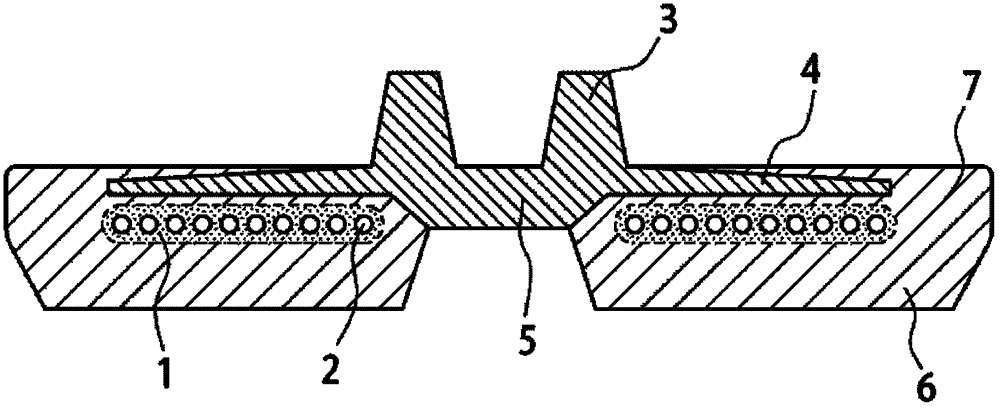

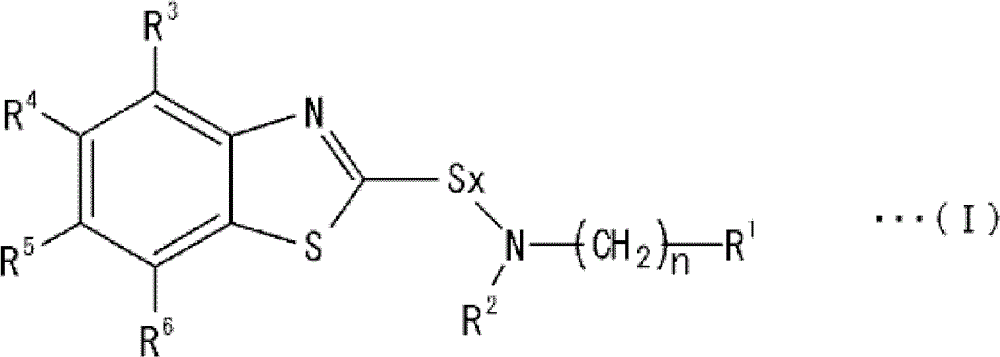

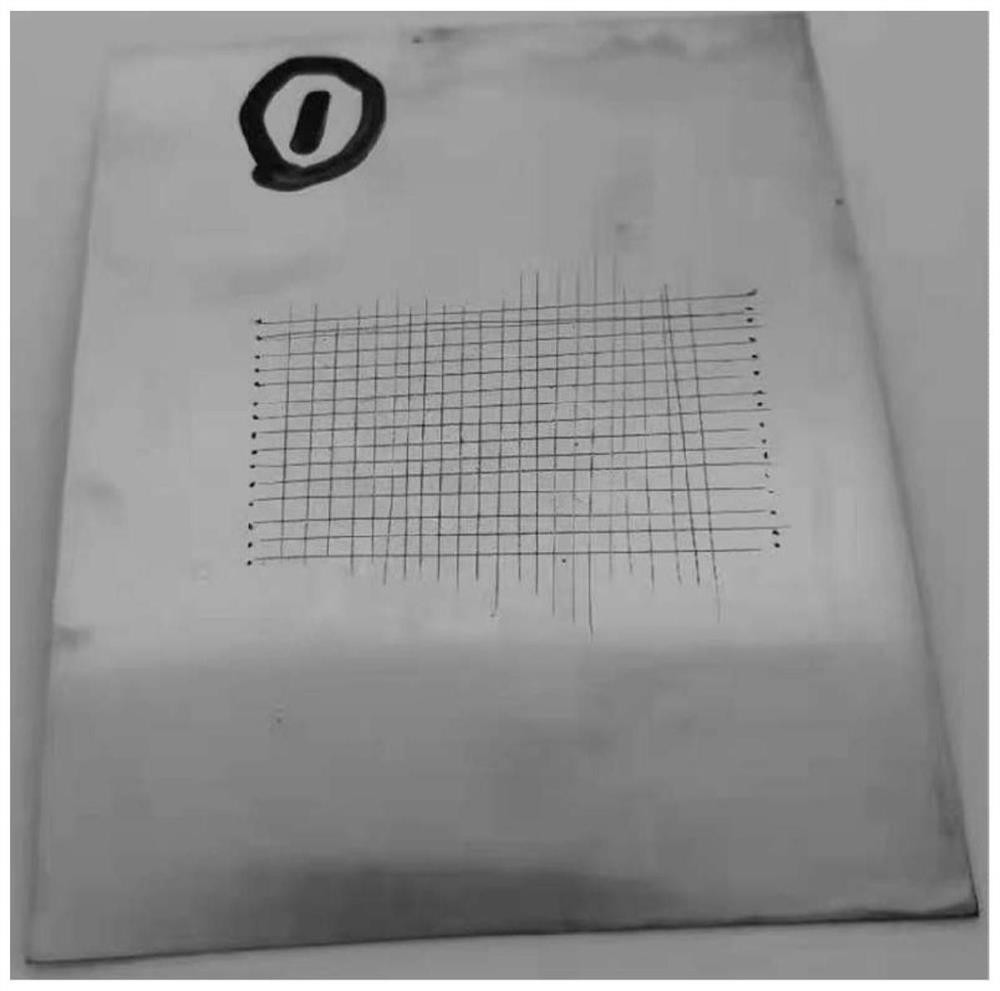

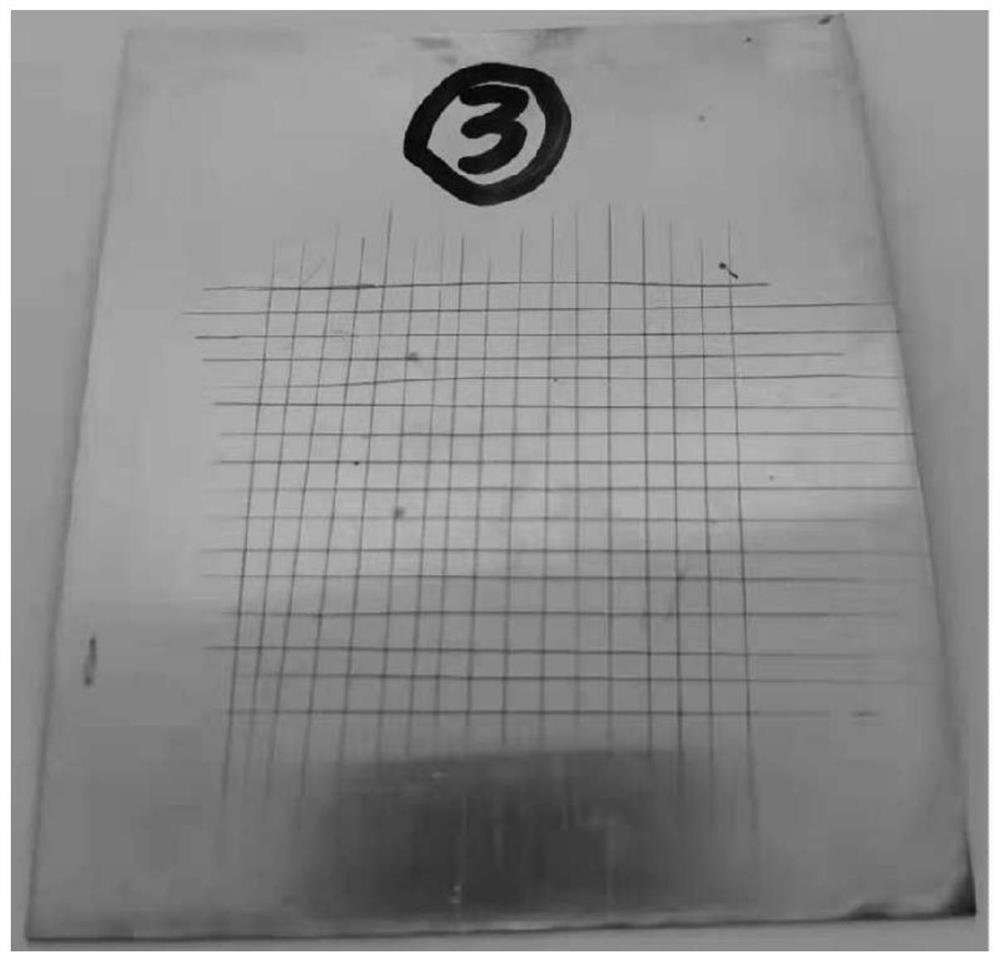

Rubber crawler

InactiveCN102803371AStay scorchedKeep scorch timeOrganic chemistryEndless track vehiclesPolymer scienceHigh humidity

Provided is a highly durable rubber crawler using a rubber composition which contains a vulcanization accelerator having a moderate vulcanization-retarding effect and which does not contain any vulcanization retarder (such as CTP) causative of deterioration of physical properties of vulcanized rubber, blooming, or other problems. The rubber composition ensures good workability with the scorch of rubber minimized, and can achieve an improvement in the adhesiveness between rubber and a metal reinforcement such as steel cord, particularly in the adhesiveness therebetween after thermal aging or under high-humidity conditions. The rubber crawler is characterized by using, as the treat rubber, a rubber composition which contains, per 100 parts by weight of a rubber component, 0.1 to 10 parts by weight of a vulcanization accelerator based on a sulfenamide represented by general formula (I), 0.03 to 3 parts by weight (in terms of cobalt) of a cobalt-containing compound, and 0.3 to 10 parts by weight of sulfur.

Owner:BRIDGESTONE CORP

Mixture of popcorn kerneles and pellets

InactiveCN1340997AReduce cokingReduce scorchingFood shapingFood preparationHeating timeMicrowave oven

Microwave snacks that include mixtures of popcorn and an expandable or puffable food pellet are disclosed. The pellets are gelatinized dough pellets which puff or expand upon microwave heating in a microwave oven. The pellets may be in the shape of cylinders, hollow barrels, spheres, chips, flakes, and the like. The popcorn and pellet mixture is preferably contained in an expandable bag or rigid tub with an oil / fat slurry. Although the popcorn requires a longer heating period to pop, the explosions created by the popcorn agitate the pellets to minimize burning and clumping of the pellets.

Owner:SMTM GROUP

Production technology for chloroprene rubber

Relating to the rubber field, the invention discloses a production technology for chloroprene rubber. The technology comprises the processes of: rubber drying, plastication, mixing, semi-finished product cutting and vulcanization. According to the method, by strictly controlling the rubber drying temperature and time in the rubber drying process, the quality of the dried rubber material is improved. The mixing process adopts a two-stage mixing process, well controls the mixing time and discharge temperature, so that scorching phenomenon of chloroprene rubber is significantly reduced, and the rubber guiding, discharge and batch-out of an open mill are smooth, and no roll sticking phenomenon appears. The vulcanization process adopts N-tert-butyl-2-bisbenzothiazole sulfenamide as a vulcanization accelerator, which is safe and pollution-free and has no harm to the human body. The technological process adopts a drum type vulcanizing machine, the vulcanization efficiency and quality are greatly improved, and the produced product has high Mooney viscosity and good quality. The technological method has the advantages of good technology, simple operation, and good technological stability, thus being suitable for factory automation production.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

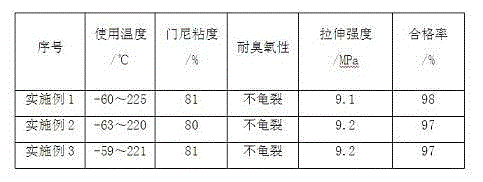

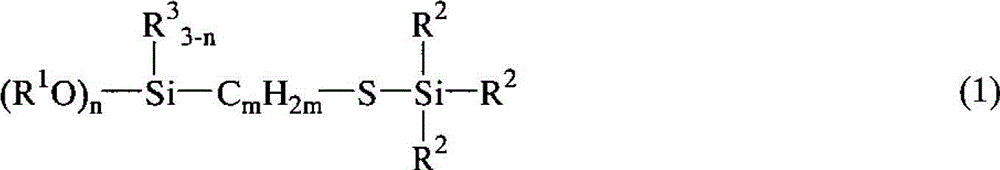

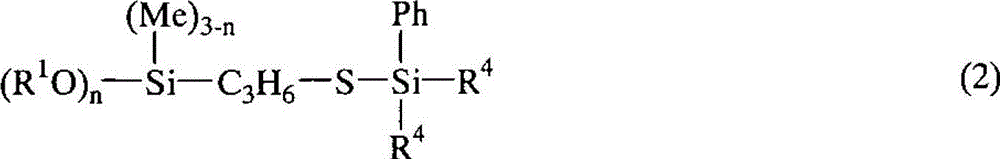

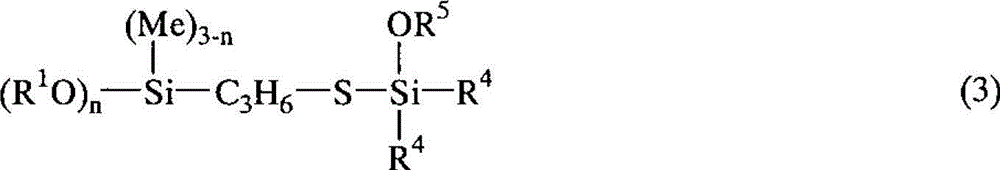

Organosilicon compound and method for preparing same, compounding agent for rubber, and rubber composition.

InactiveCN103145750ASmall smellMeet consumption tire characteristicsSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsArylPolymer science

There is disclosed an organosilicon compound of the following general formula (1): wherein R 1 is an alkyl group or an aryl group, R 2 is an alkyl group, an aryl group, an aralkyl group, an alkenyl group or an organoxy group, R 3 is an alkyl group or an aryl group, n is an integer of 1 to 3, and m is an integer of 1 to 3.

Owner:SHIN ETSU CHEM CO LTD

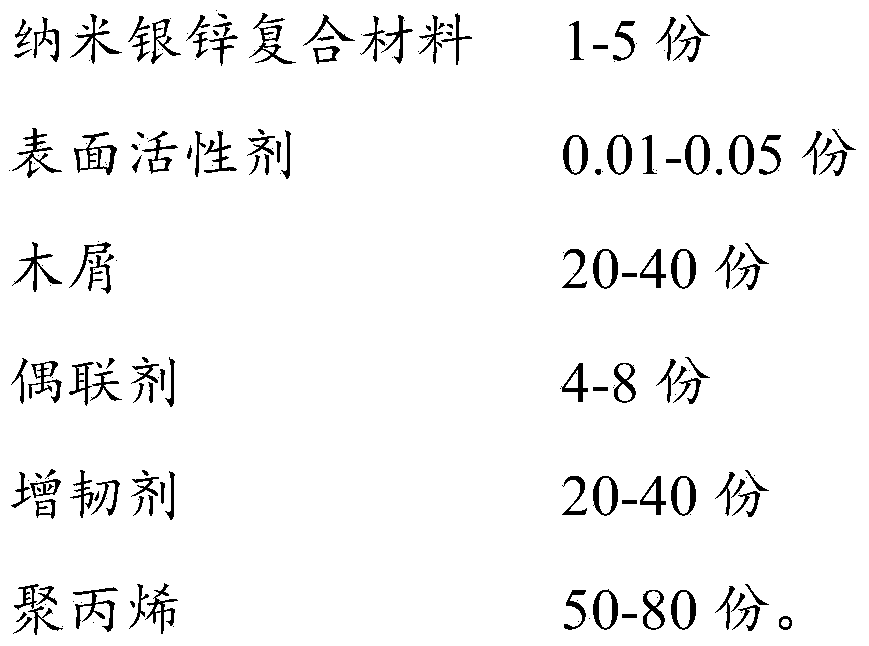

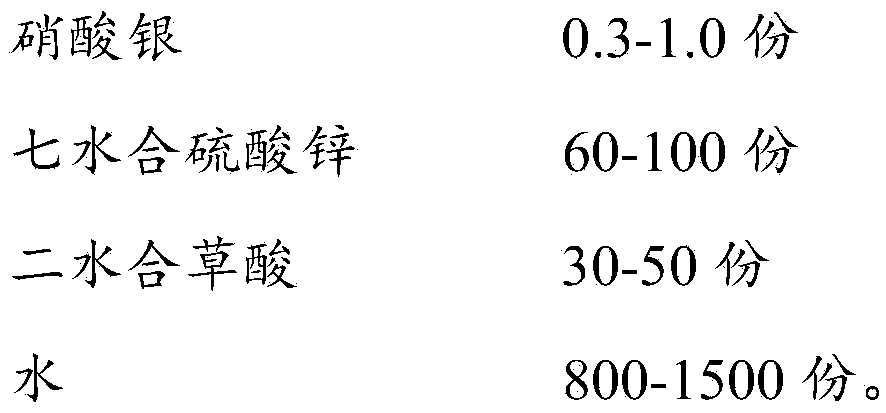

Environment-friendly nano antibacterial wood plastic composite and preparation method thereof

InactiveCN105367895AGood antibacterial and antifungal effectGood compatibilityCouplingFlexural strength

The invention discloses an environment-friendly nano wood plastic composite, which includes the following components by weight: 1-5 parts of nano silver zinc composite, 0.01-0.05 part of a surfactant, 20-40 parts of sawdust, 4-8 parts of a coupling agent, 20-40 parts of a toughening agent and 50-80 parts of polypropylene (PP). The environment-friendly nano antibacterial wood plastic composite employs nano silver and zinc composite material to modify sawdust, in order to improve the antibacterial and antifungal properties of the wood plastic composite; and a suitable coupling agent is used for pretreating the hydroxyl and amino groups on the sawdust surface to improve the compatibility of sawdust with a non-polar matrix such as polypropylene, thereby greatly improving the mechanical properties of tensile strength, flexural strength and impact strength of the wood plastic composite. Therefore, the environment-friendly nano antibacterial wood plastic composite is green and environment-friendly, and has the advantages of good mechanical, antifungal and mildew-proof properties, no worm damage and long service life.

Owner:泉州斯达纳米科技发展有限公司

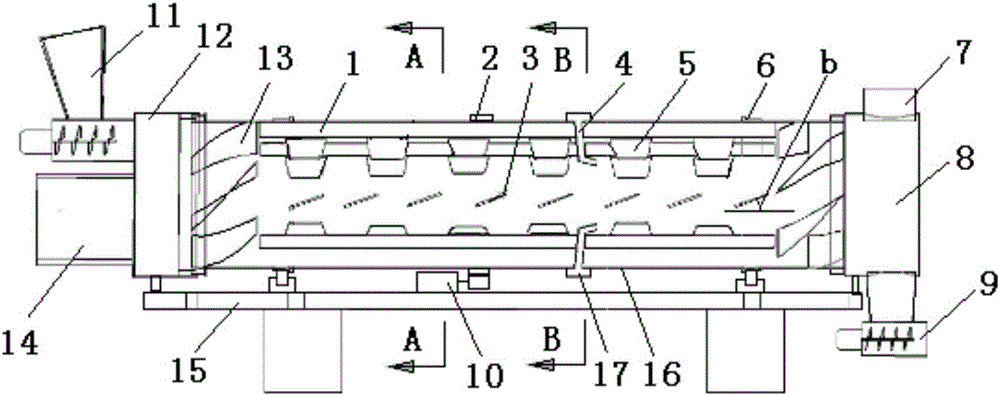

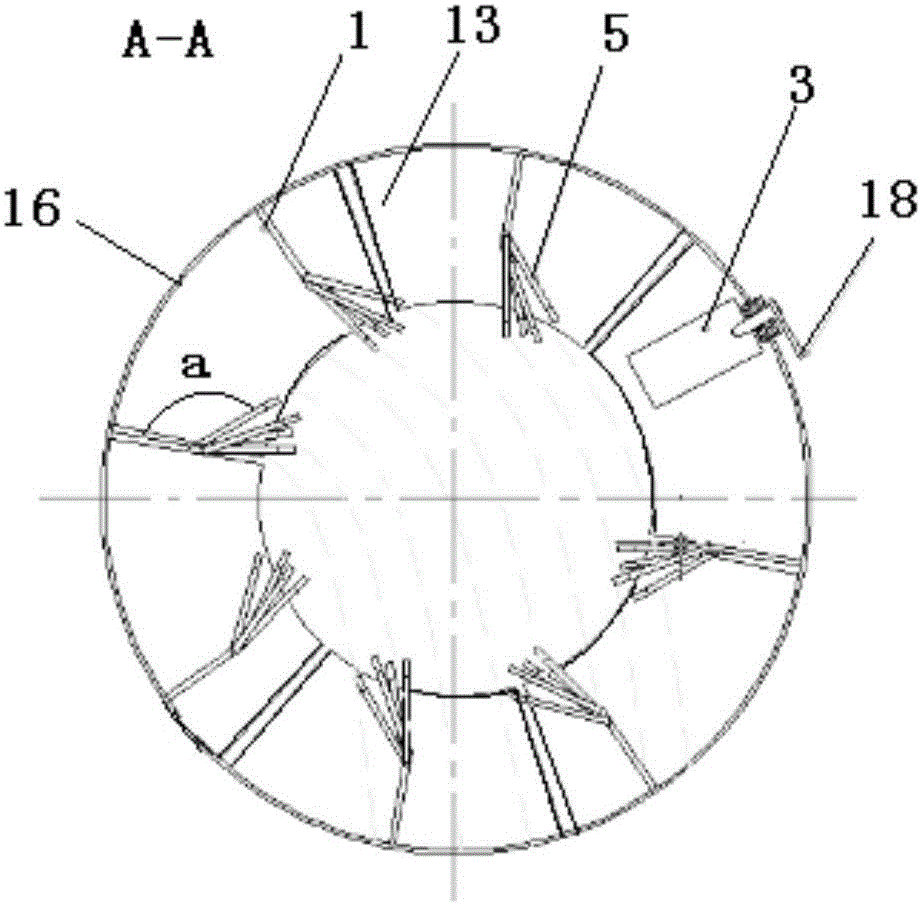

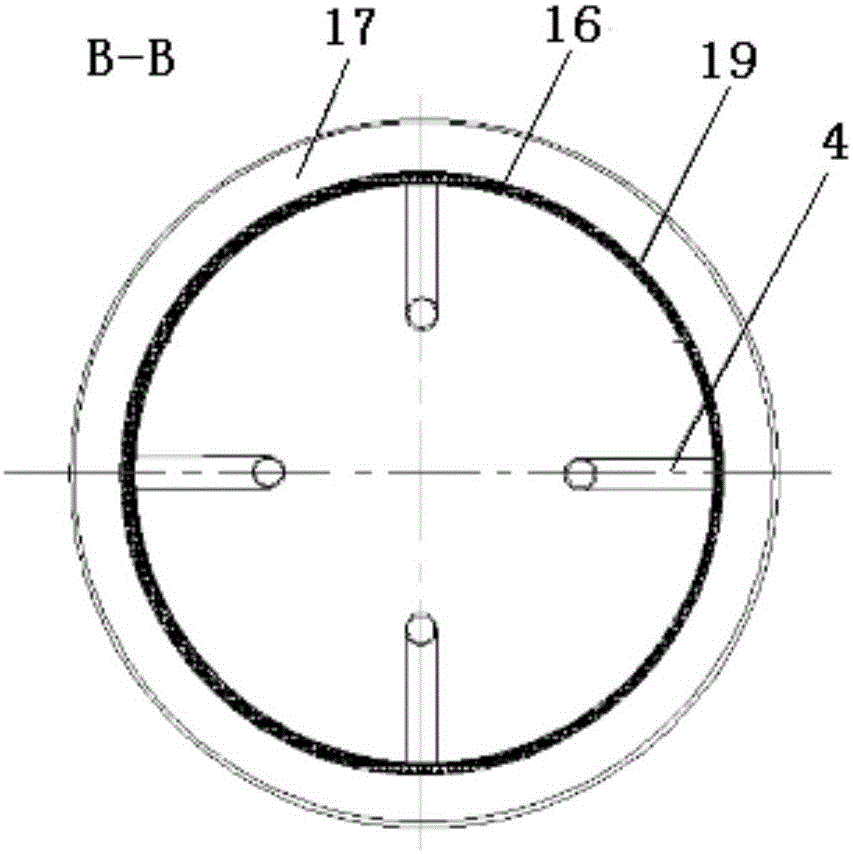

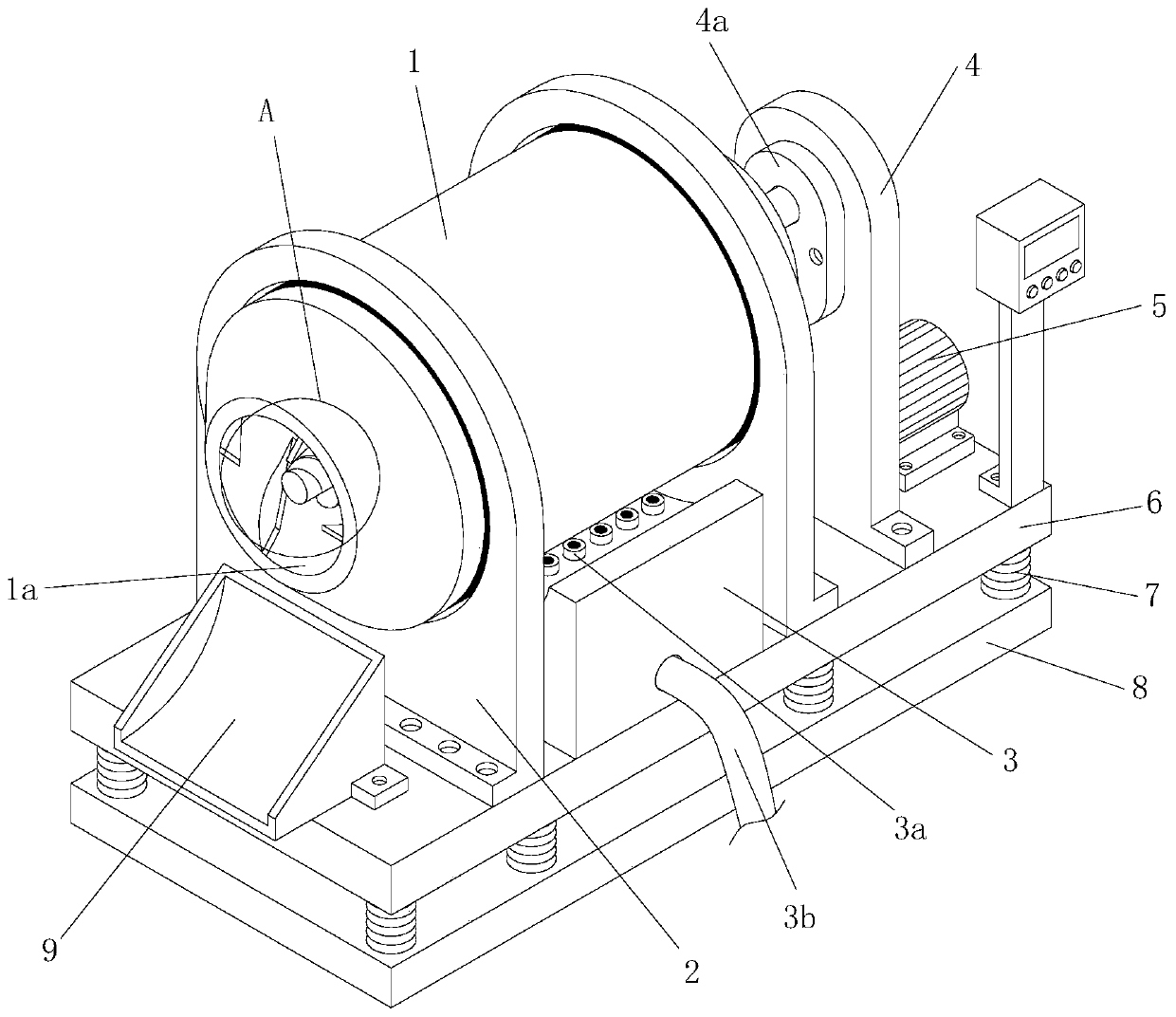

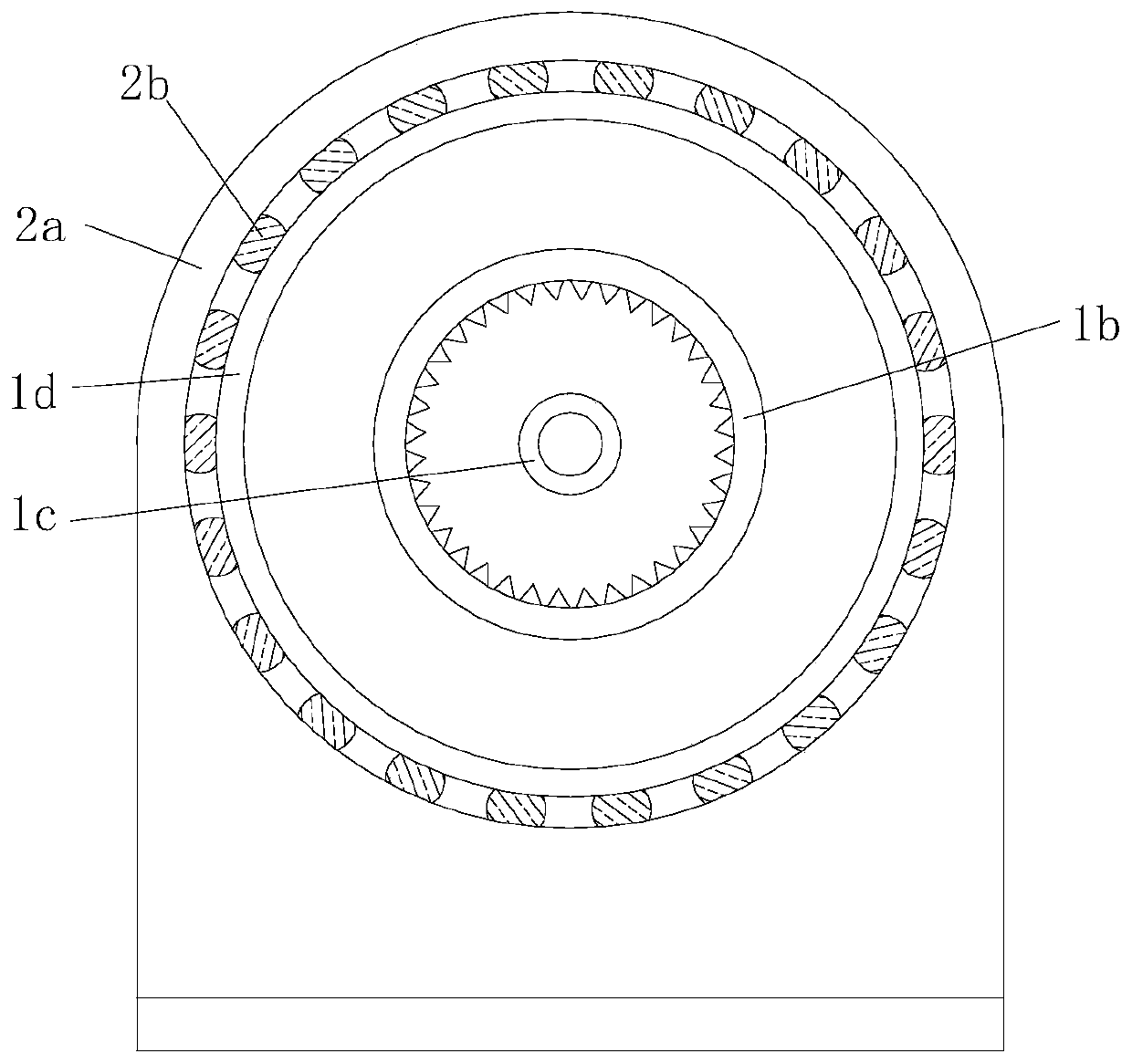

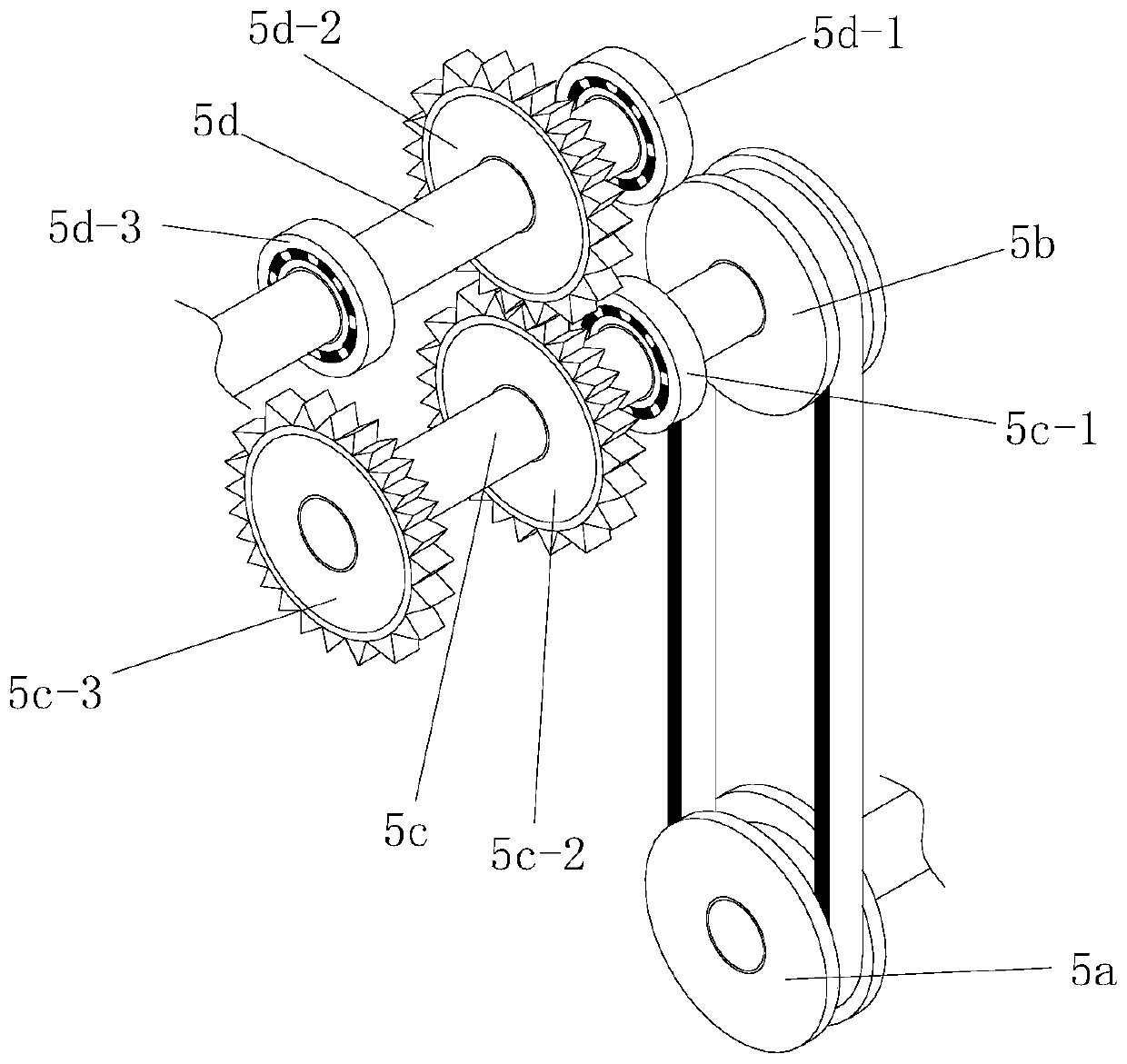

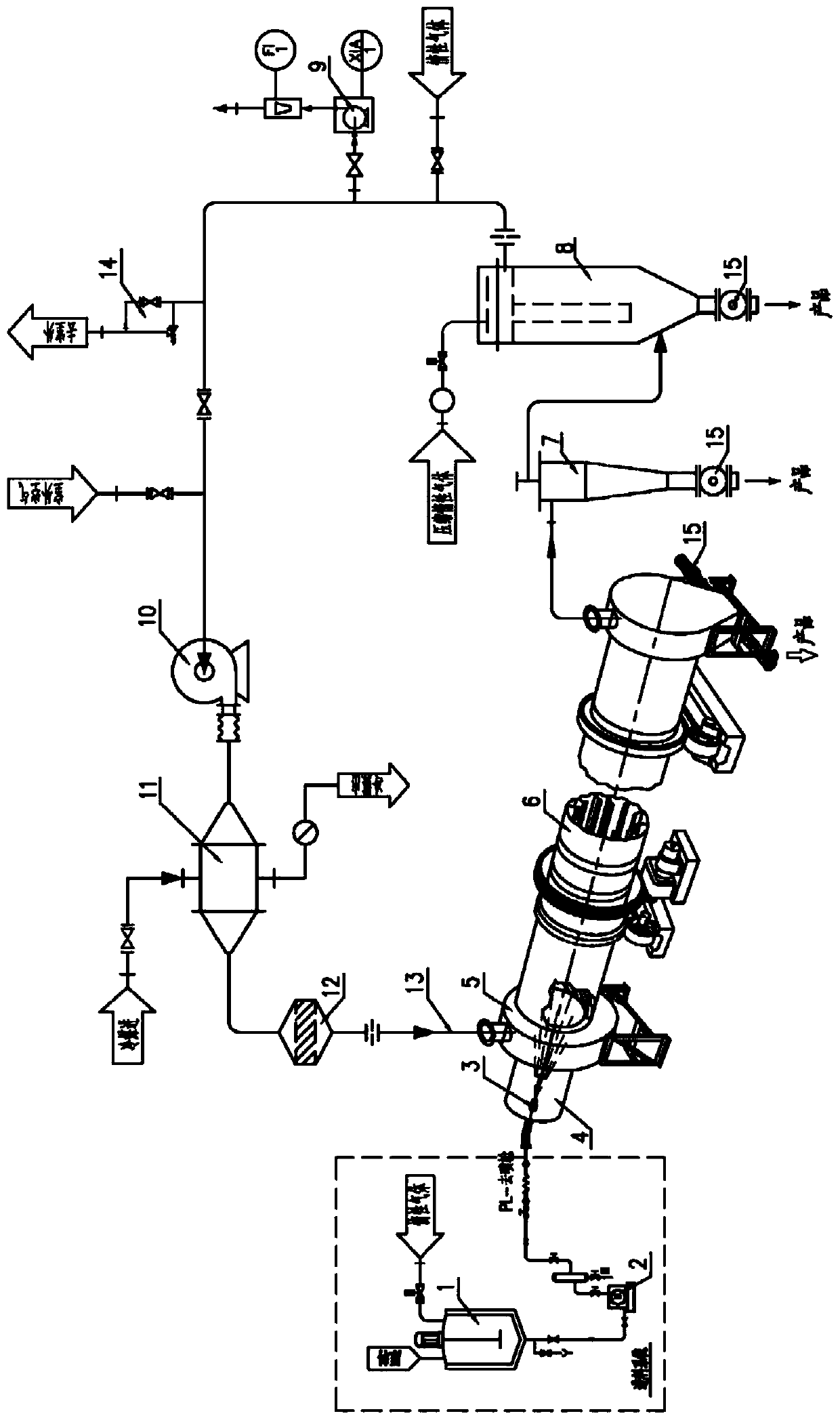

Rotary dryer suitable for garbage materials

PendingCN106500477AReal-time adjustment of residence timeEfficient dryingDrying gas arrangementsDrying solid materialsRetention timeLitter

The invention discloses a novel rotary dryer suitable for garbage materials. The novel rotary dryer suitable for the garbage materials comprises a barrel, a barrel driving device, a material inlet assembly and a material outlet assembly, wherein a plurality of elongated lifting plates, a plurality of trapezoidal lifting plates and a plurality of pushing lifting plates are arranged in the barrel; the elongated lifting plates are distributed uniformly along the circumference; the length direction of each elongated lifting plate is set in the axial direction of the barrel; a long side of each elongated lifting plate is welded with the inner side of the barrel; wide sides of the trapezoidal lifting plates are connected to the other long sides of the elongated lifting plates at intervals; the pushing lifting plates are arranged in the axial direction of the barrel at intervals; and an included angle is formed between the plane of each pushing lifting plate and the axial direction of the barrel. The lifting efficiency is improved, and the materials are raised fully; the materials are uniformly dispersed to a cross section of the rotating barrel, so that the materials are in full contact with smoke, and the heat transfer efficiency is improved; by the pushing lifting plates, the pushing angle is changed, the material advancing speed is also changed, the retention time is adjusted, and the materials are dried fully; and by a hot smoke supplementing device, the temperature of the materials in a middle rear part of the rotating barrel is increased, and therefore, the drying effect is improved.

Owner:SHENWU TECH GRP CO LTD

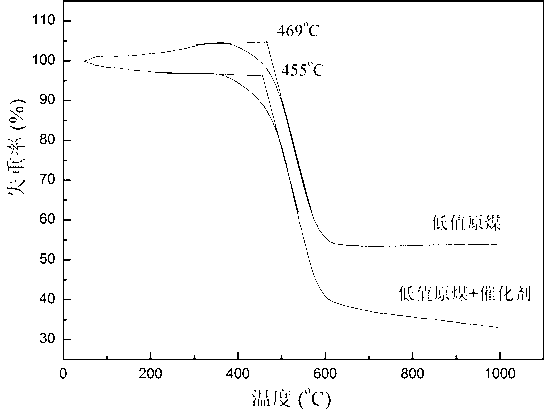

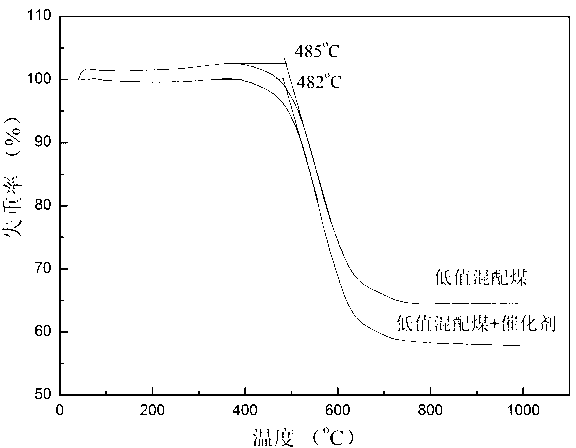

Combustion catalyst for low-heat value coal

InactiveCN103305313ALow ignition temperatureStable ignitionSolid fuelsAir quality improvementCombustionCLARITY

The invention provides a combustion catalyst for low-heat value coal. The catalyst comprises 20-100% of main active ingredients and the balance of binder, wherein the main active ingredients comprise Ca3Co4O9, Fe304, CeO2, and K2O in percentage by weight. The catalyst provided by the invention can be used for effectively reducing the initiation temperature of the low-heat value coal, the initiation temperature of the low-heat value coal can be reduced by 3-15 DEG C when the catalyst which accounts for 1-2% of the low-heat value coal is added, stable initiation of the low-heat value coal is achieved, the continuous and complete combustion of the low-heat value coal is promoted, the combustion efficiency and burning clarity of the low-heat value coal are improved, the utilization ratio of the coal is improved, and resource waste and air pollution are reduced.

Owner:河北博昶商贸股份有限公司

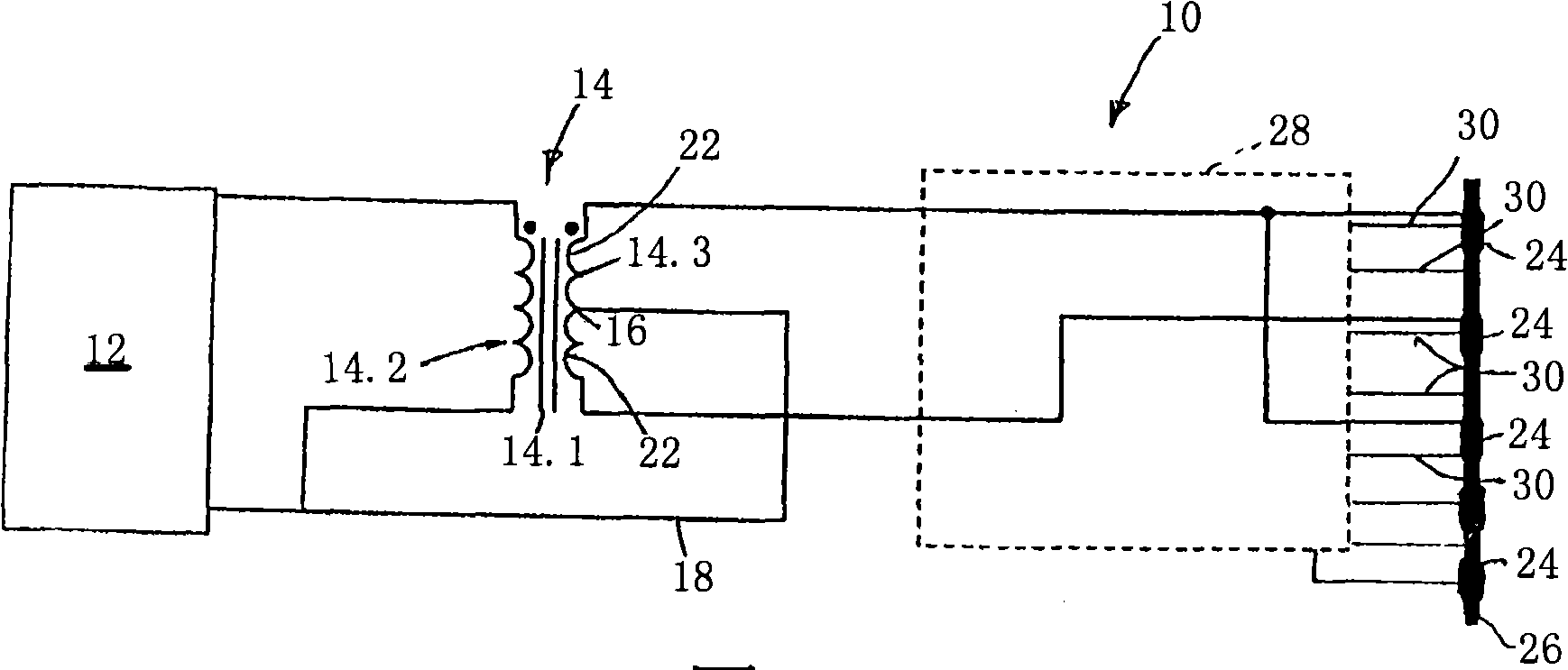

Heat treatment patients in vivo biological part

InactiveCN101288598AReduce scorchingSurgical instruments for heatingTherapeutic coolingTransformerEnergy supply

A system 10 for heating a site in a patient's body includes a transformer 14 having a primary winding 14.2 and a secondary winding 14.3 , the secondary winding 14.3 having at least one tap 16 to provide a patient reference and at least two sources 22 of radio frequency (RF) energy, the two sources 22 of RF energy being out of phase with each other. A group of electrodes 24 is connected to the sources 22 of RF energy provided by the secondary winding 14.3 to be simultaneously energised. The arrangement is such that there are more active electrodes 24 connected to one of the sources 22 of RF energy than the other of the sources 22 of RF energy with the energy supplied to one active electrode 24 being out of phase with the energy supplied to an adjacent active electrode 24.

Owner:CATHRX LTD

Electrical cable

InactiveCN1349652AEasy to crosslinkReduce scorchingPlastic/resin/waxes insulatorsThin material handlingElectrical conductorPolymer science

A cable comprising an electrical conductor with insulating and protecting layers surrounding the conductor is described. The cable is characterised in that at least one layer selected from said insulating and protecting layers consists of a crosslinked ethylene-alkyl (meth)acrylate-unsaturated silane terpolymer composition wherein the alkyl (meth)acrylate comonomer comprises more than 5 mole % and the terpolymer composition has a tensile modulus, determined according to ISO 527-2 (1 mm / min) of less than 100 MPa. Preferably, the crosslinked ethylene-alkyl (meth)acrylate polymer is a moisture curable ethylene-alkyl (meth)acrylate-vinyl trialkoxysilane terpolymer, wherein the trialkoxysilan termonomer comprises 0.2-5% by weight of the polymer composition. The polymer composition may include from 0 up to 50% by weight of a plasticiser, up to 60% by weight of a filler, and up to 10% by weight of an additive.

Owner:ボレアリステクノロジーオイ

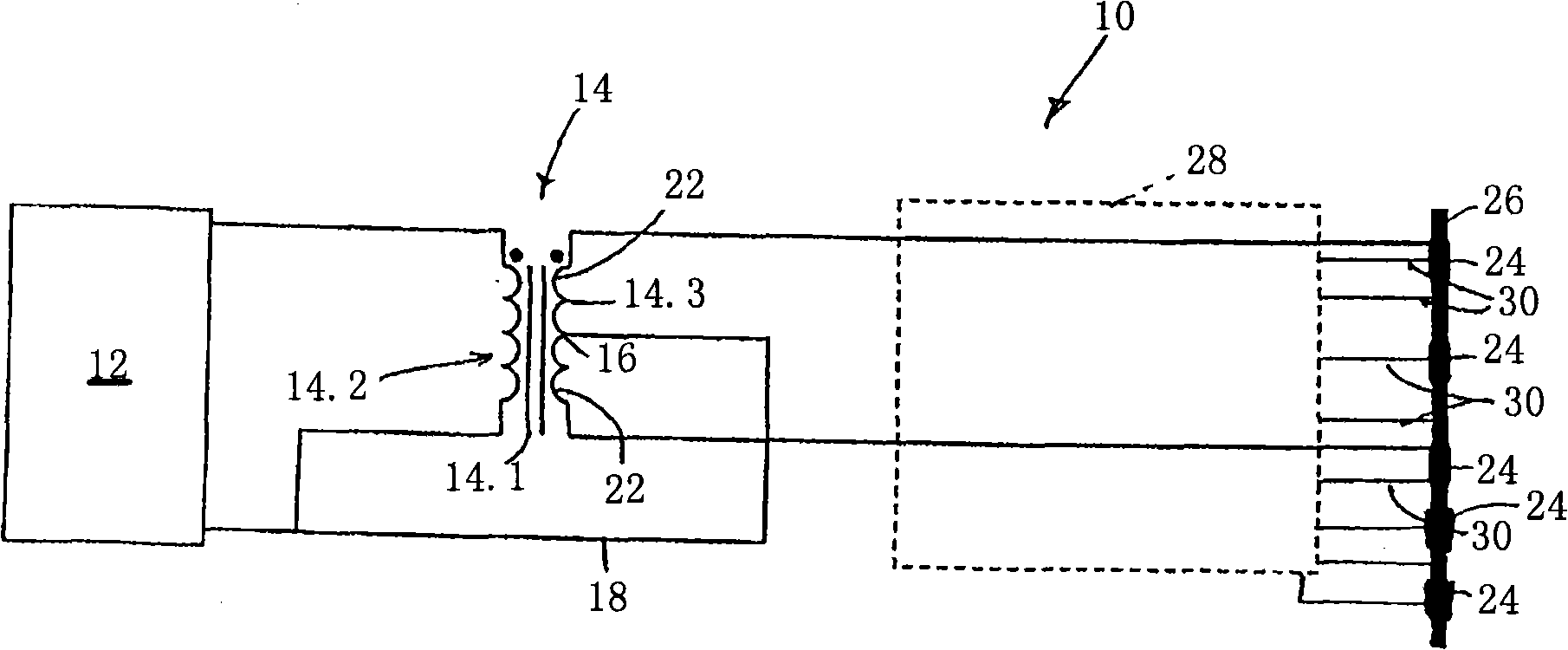

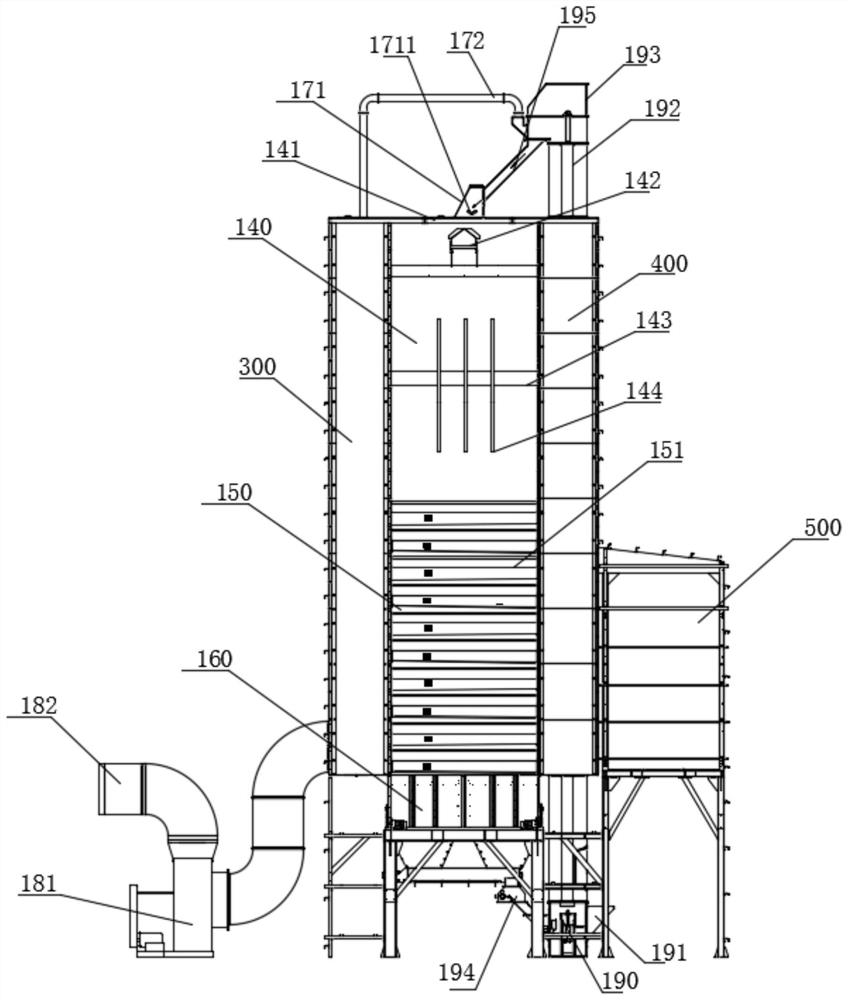

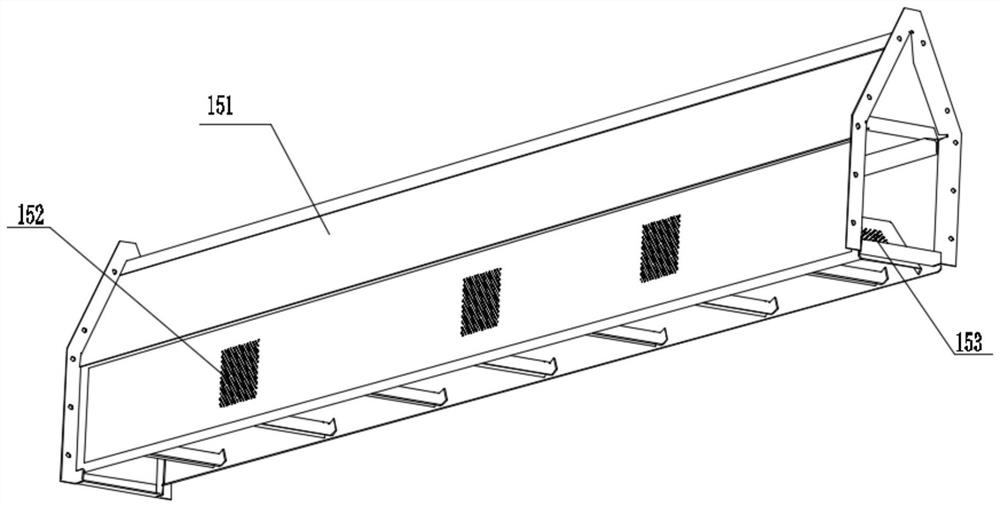

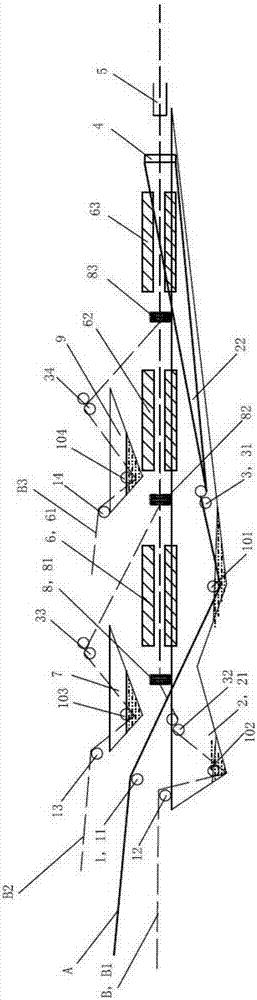

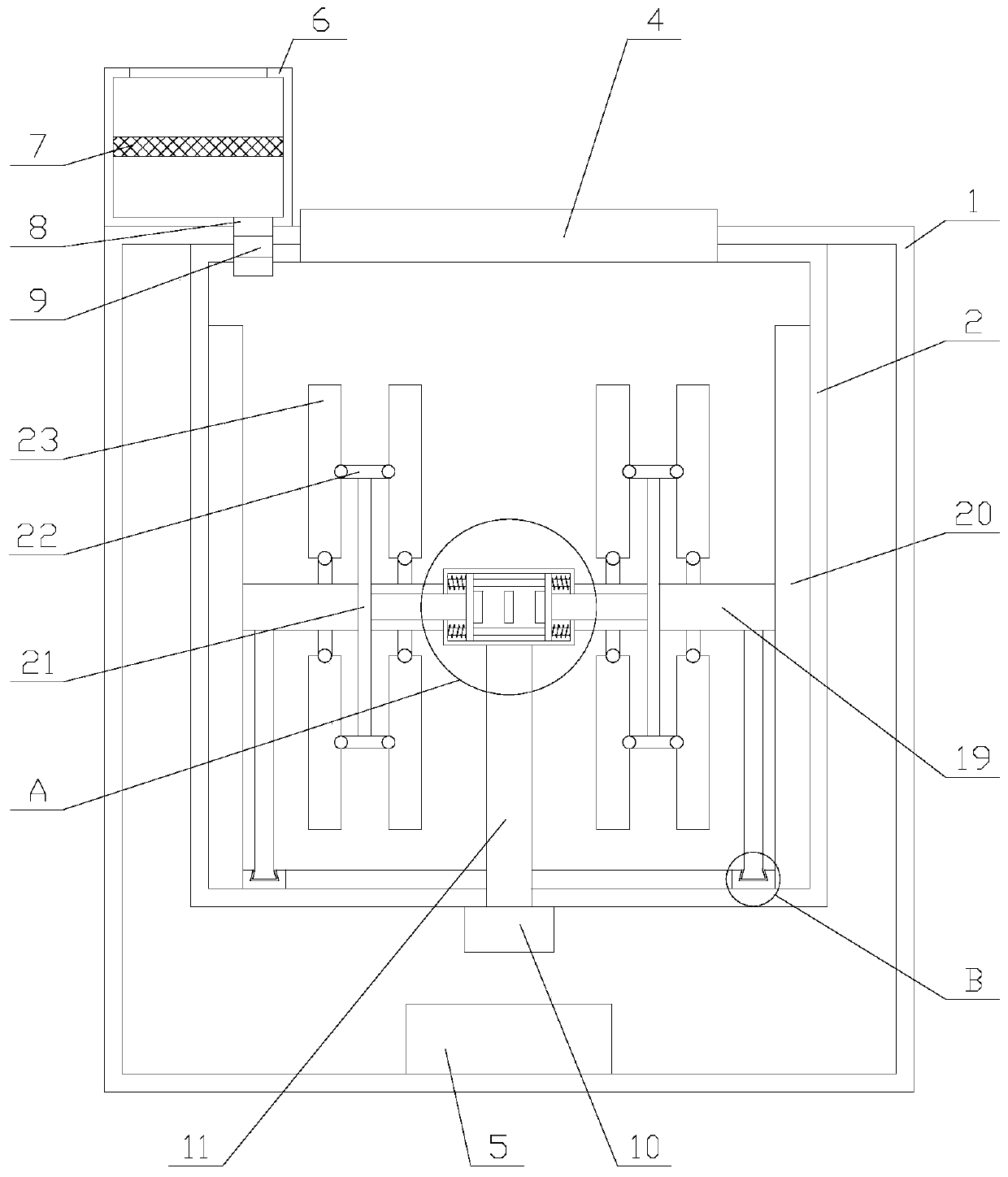

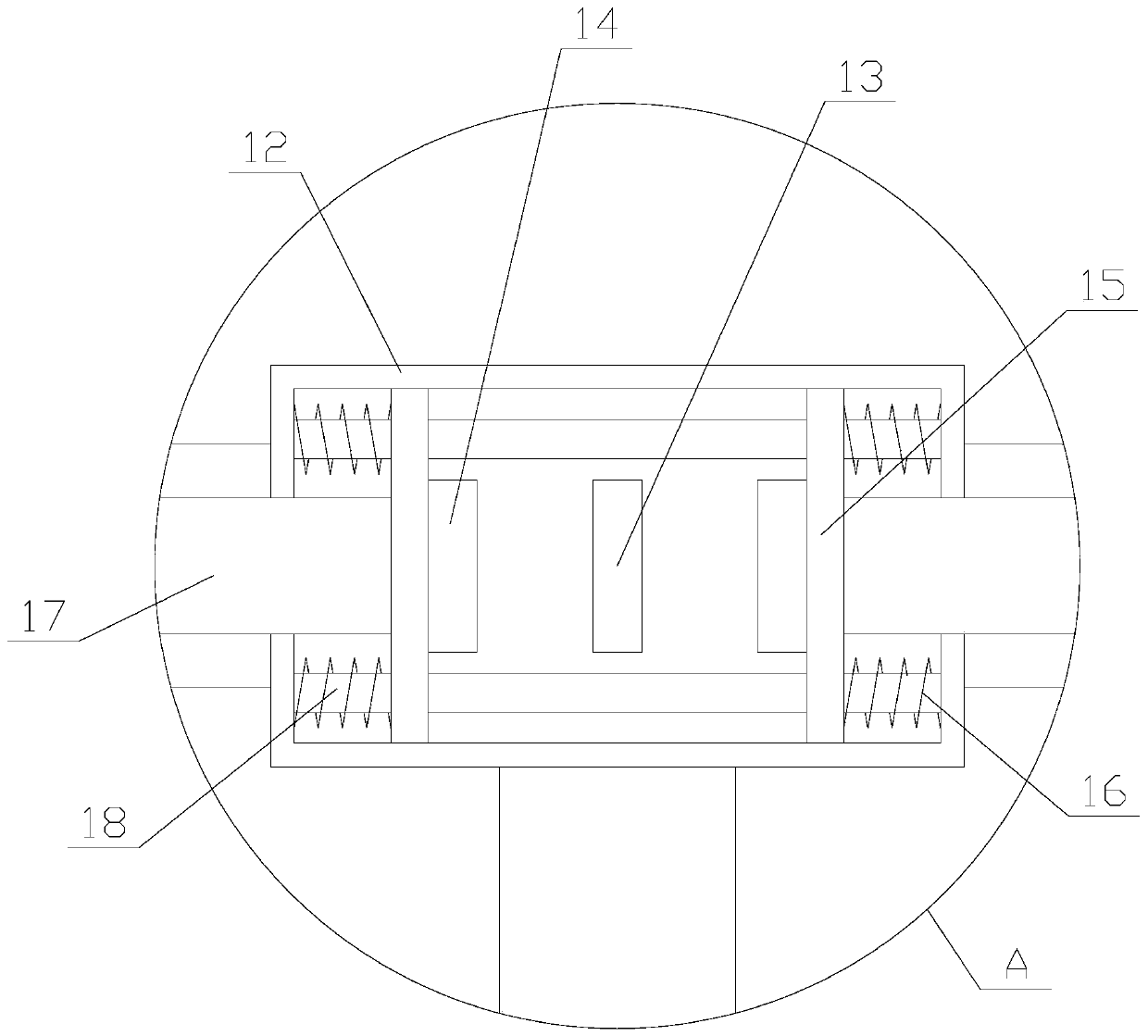

Grain drying process and drying equipment

InactiveCN111700110ALittle change in temperature differenceReduce scorchingDrying gas arrangementsSeed preservation by dryingMetallurgyAir heating

The invention discloses a grain drying process and drying equipment. The process comprises the steps of carrying out primary filtration, fine filtration, grain dispersion, grain tempering, grain drying, grain circulation and grain storage; the drying equipment comprises a drying machine, wherein a supporting base is fixedly installed at the lower end of the drying machine; the drying machine is divided into a tempering homogenizing section, a drying section and a discharging section from top to bottom, and the tempering homogenizing section and the drying section are consistent in height; whengrains are dried, the processes of windless tempering treatment, hot air heating and final tempering discharging are adopted, so that the temperature difference change of the grains is small, and thequality and value of the grains are improved; the height ratio of the tempering homogenizing section to the drying section is set to be 1: 1, so that the overall height of the drying machine can be greatly reduced, and therefore the produced finished product is reduced, and on the premise of ensuring the drying speed, the drying quality is improved.

Owner:安徽麦稻之星机械科技有限公司

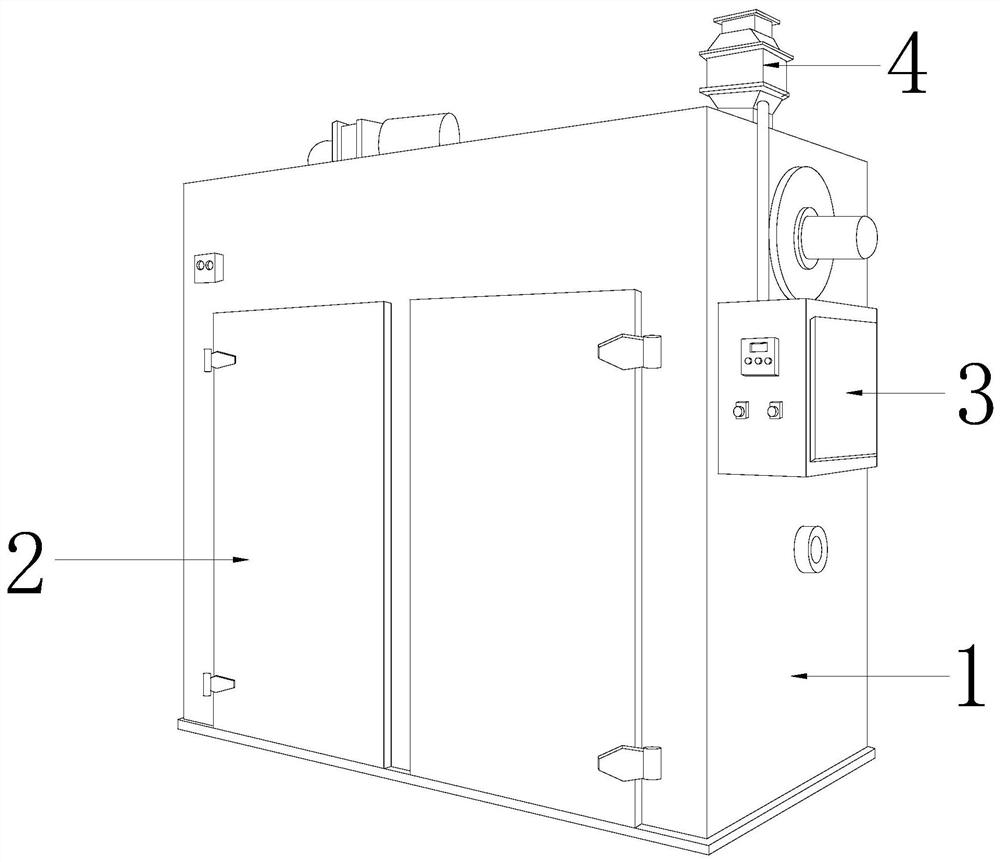

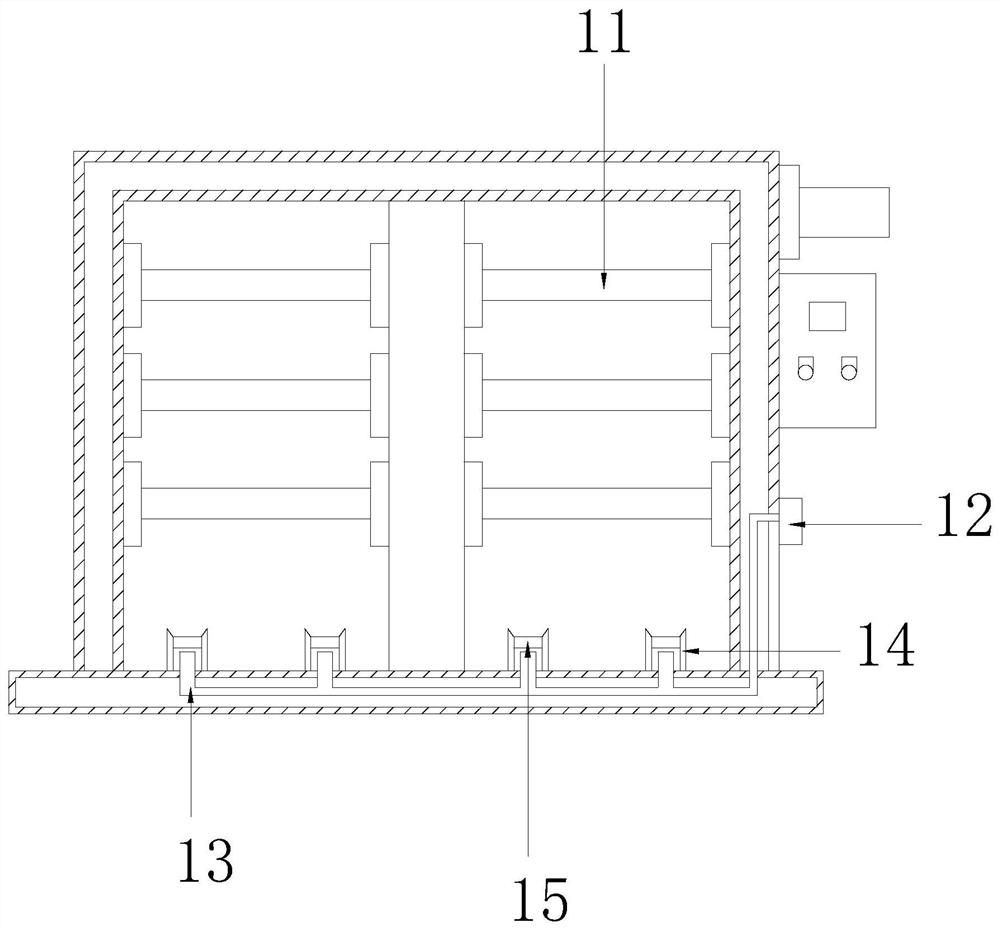

Wood processing dryer with sterilization function

InactiveCN112696892AIncrease the hot air diffusion areaAccelerateDrying gas arrangementsCleaning using toolsWood dryingStructural engineering

The invention discloses a wood processing dryer with a sterilization function. The wood processing dryer structurally comprises a machine body, a front door, a control box and a heater; the front door is hinged to the front face of the machine body; the control box is installed on the right side face of the machine body; and the heater is vertically fixed to the top of the right side of the machine body. Chippings on the outer wall of wood rub with a supporting frame to fall to the top of a dispersion net of an air injection pipe, a push plate of a removing mechanism makes contact with the dispersion net at the top of the air injection pipe, a scraper pushes and removes substances left at the top of the dispersion net, reduction of chipping substances which are burnt and solidified at the top of the dispersion net of the air injection pipe is facilitated, the hot air flow diffusion area of the air injection pipe is increased, the wood drying speed is further increased, due to continuous movement of the push plate, the substances in an accumulation cavity are prone to backflow due to vibration force, and the substances in the accumulation cavity are blocked through a rotating ring, so that backflow of the substances in the accumulation cavity is reduced, and the collection speed of the removed substances can be increased.

Owner:陆超林

Production method of high-dispersion high-thermal-stability insoluble sulfur

InactiveCN103318848AOvercome the disadvantage of poor adhesionUniform component performanceSulfur preparation/purificationSulfurThermal stability

The invention discloses a production method of high-dispersion high-thermal-stability insoluble sulfur. The method comprises the following steps: sulfur melting and heating: melting common sulfur at 145-155DEG C for sulfur melting, pumping the obtained melt to a heating tank, heating to 250-280DEG C, adding diethylhydroxylamine having a weight being 0.5-1% of the weight of sulfur, uniformly stirring, and heating to 490-550DEG C; and atomizing, quenching, curing, and cladding. The production method greatly improves the high-thermal-stability and the dispersibility of insoluble sulfur, and the insoluble sulfur obtained in the invention can completely satisfy the requirements of three-high insoluble sulfur by radial tires.

Owner:SHANGHAI JINGHAI ANHUI CHEM

Peroxide crosslinked semi-conductive shielding material for crosslinked cable conductor

The invention discloses a peroxide crosslinked semi-conductive shielding material for crosslinked cable conductors. The peroxide crosslinked semi-conductive shielding material for crosslinked cable conductors comprises the following raw materials in parts by weight: 50-60 parts of ethylene-vinyl acetate copolymer, 20-30 parts of ethylene propylene diene monomer, 30-40 parts of conductive carbon black, 1-3 parts of a crosslinker, 12-15 parts of dioctyl terephthalate, 4-6 parts of diformyl peroxide, 10-20 parts of a plasticizer, 1-5 parts of a flame retardant, 5-10 parts of an antioxidant and 2-10 parts of a stabilizer. The semi-conductive shielding material for cables has good tensile strength and tear resistance by using the ethylene-vinyl acetate copolymer as a main raw material; by adding the peroxide crosslinker, the scorch phenomenon of cables during use is reduced, and the safety and the reliability are improved.

Owner:高邮市金国电缆材料厂有限公司

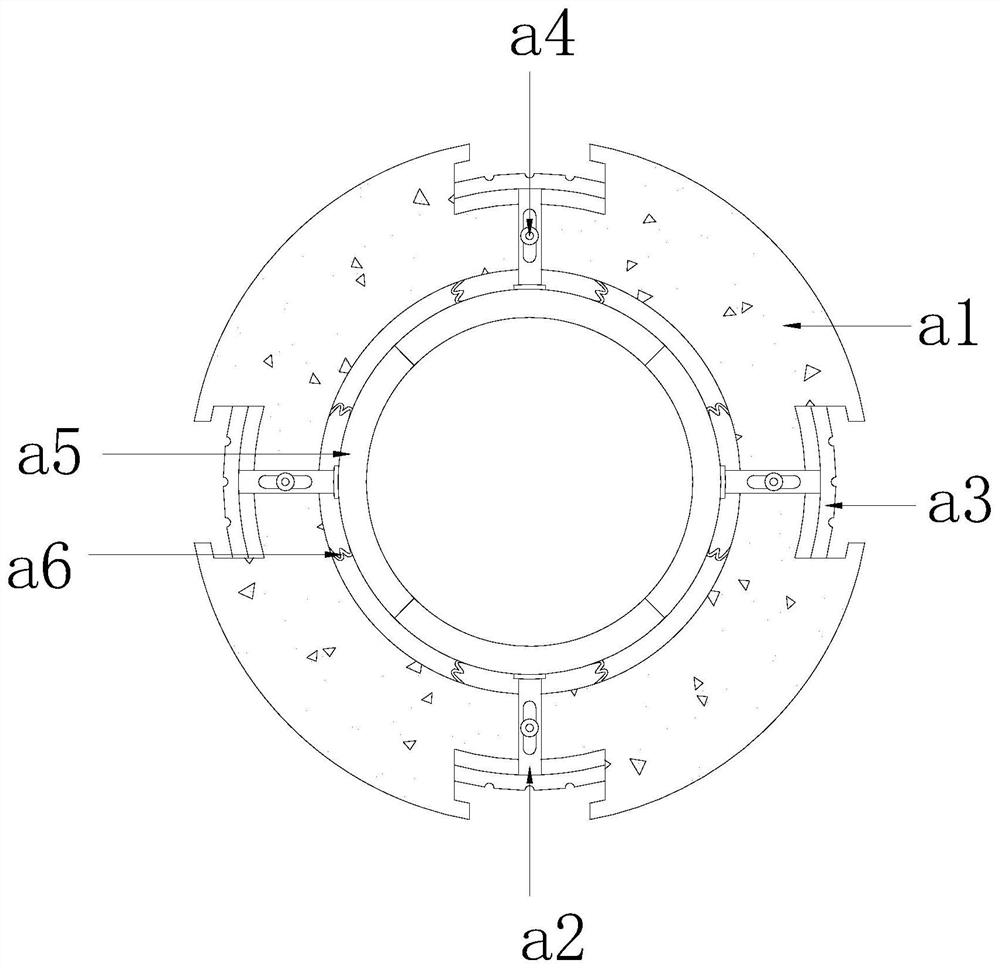

Food frying pan structure capable of realizing overturning of pan body through electric control

The invention provides a food frying pan structure capable of realizing overturning of a pan body through electric control. The food frying pan structure comprises a pot body, vertical supporting plates and a mounting plate, wherein the pot body is of a straight cylinder type; necking sections are symmetrically arranged at the two ends; annular inner rail grooves are formed in the upper half sections of the two vertical supporting plates respectively, and the two ends of the straight barrel section of the pot body are sleeved with the annular inner rail grooves, correspond to two annular outerrail grooves in the outer wall of the pot body and are rotationally connected through balls; a fire supply device is arranged at the lower end of the pot body; a driving mechanism is arranged on themounting plate; the driving mechanism comprises a gear motor; a platform plate is connected to the bottoms of the pot body, the two vertical supporting plates, the fire supply device, the mounting plate, the gear motor and a discharging guide groove body; a bottom plate is arranged at the lower end of the platform plate; and spring shock pads are installed at the positions, close to the peripheraledges, between the bottom plate and the platform plate one by one. By the above structure, food stir-frying efficiency is greatly improved, the waste of raw materials is reduced, and the production cost is saved.

Owner:ANHUI FOZILING FLOUR IND

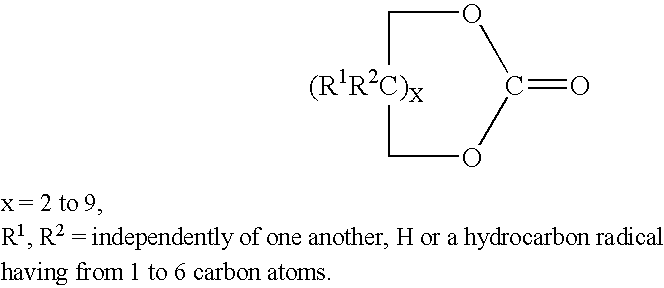

Method of using cyclic organic carbonates as additives in the production of polyurethane foams

The invention relates to the use of cyclic organic carbonates as additives in formulations for the production of polyurethane foams.

Owner:BURKHART GEORG +2

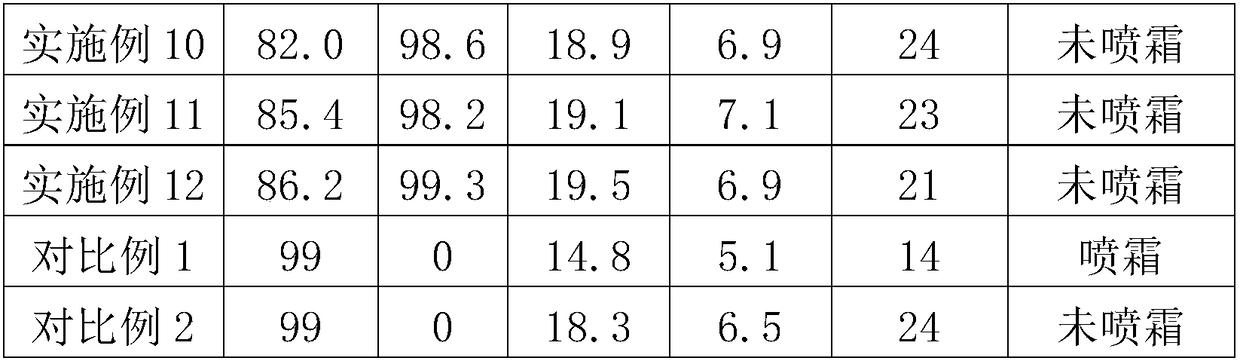

Preparation method of modified sulfur coated with two-component film forming agent

The invention relates to a preparation method of modified sulfur coated with a two-component film forming agent. The preparation method is characterized by comprising the following steps: successivelyadding various film forming agents in a stirring tank through a measuring tank for blending and adding an inorganic powder material suspension in the stirring tank for uniform mixing for later use; adding sulfur powder in a mixer in advance and then adding the mixed suspension in an accelerant powder according to the proportion requirements for uniform mixing; mixing the material by adopting themixer, then rolling through a roller, dispersing through a dispersing machine to obtain a mixed material, granulating by using an oscillating granulator, then conveying wet material grains in a dryerfor drying, crushing a dried product through a crusher, cooling, sieving and packaging to obtain a finished product. The preparation method provided by the invention has the advantages that the equipment requirements are simple, the cost is low, the safety is high, the preparation process is quick and efficient, the environment is friendly, no pollution exists, the release rate of sulfur is high at the sulfurization stage, no frost is sprayed, the processing safety performance of a rubber product is improved, and economic benefits are better.

Owner:安徽固瑞特新材料科技有限公司

Insoluble sulfur capable of prolonging storage time of rubber and preparation technique thereof

ActiveCN105621371AExtended storage timeImprove wear resistanceSulfur preparation/purificationDispersityPolymer science

The invention provides an insoluble sulfur capable of prolonging storage time of rubber and a preparation technique thereof, relating to the technical field of rubber product processing aids. The insoluble sulfur is prepared from common industrial sulfur powder, a light stabilizer, a vulcanization activator, a dispersing agent, an antistatic agent, a coupling agent, an accelerator, smectite, mica powder, an antioxidant, zinc stearate and lecithin. The production technique comprises the following steps: melting and liquefying, quenching, curing, pulverizing, extracting, drying and carrying out oil extension. The insoluble sulfur capable of prolonging storage time of rubber has the advantages of high quality, high heat stability, favorable dispersity, wear resistance, aging resistance and low cost, can not easily transfer when being used for rubber vulcanization, can tackify vulcanized rubber on the premise of avoiding blooming and reducing scorching, can enhance the aging resistance and wear resistance of the rubber product, prolongs the storage time of the rubber, and is safe to operate in the production process.

Owner:SHANGHAI JINGHAI ANHUI CHEM

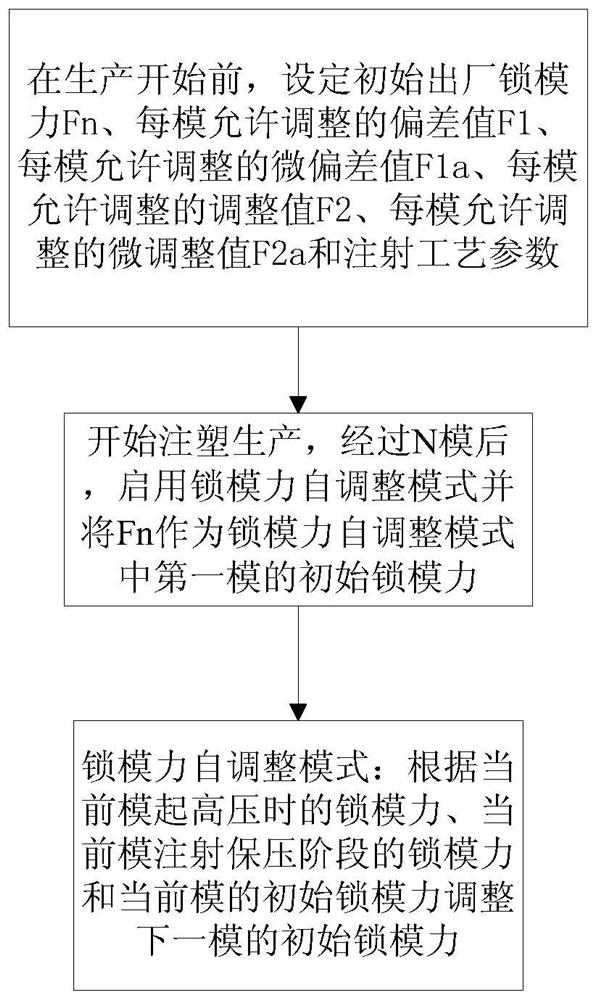

Self-adjusting method for mould clamping force of two-plate machine

ActiveCN112976519AReduce wearReduce the probability of scorching phenomenonManufacturing engineeringEnergy consumption

The invention discloses a self-adjusting method for mould clamping force of a two-plate machine. The self-adjusting method is characterized by comprising the following steps that 1, before production, setting initial delivery mould clamping force, a deviation value which is allowed to be adjusted by each mould, a micro-deviation value which is allowed to be adjusted by each mould, an adjusting value which is allowed to be adjusted by each mould, a micro-adjusting value which is allowed to be adjusted by each mould and injection process parameters are set according to the size of a mold, and the change of the mould clamping force of the mold in the injection molding production process is monitored in real time through a mould clamping force sensor; 2, after passing through N moulds, a mould clamping force self-adjusting mode is started; and 3, in the mould clamping force self-adjusting mode, the initial mould clamping force of the next mould is adjusted according to the mould clamping force when the current mould starts high pressure, the mould clamping force in the injection pressure maintaining stage of the current mould and the initial mould clamping force of the current mould. The self-adjusting method has the advantages that the initial mould locking force of the next mould is automatically adjusted by monitoring the mould locking force change of the current mould in real time through the mould locking force sensor, so that the wear of the mold is reduced, the probability that produced products are scorched is reduced, some unnecessary energy consumption in the production process is reduced, and the productivity is improved.

Owner:NINGBO SHUANGMA MASCH IND CO LTD

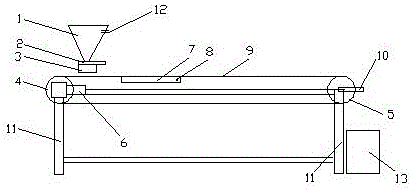

Crawler type continuous stir-frying machine for tartary buckwheat tea

The invention discloses a crawler type continuous stir-frying machine for tartary buckwheat tea. The crawler type continuous stir-frying machine comprises a feeder hopper, a feeder flat trough, an electromagnetic vibrator, a driving roller, a driven roller, a speed-adjustable motor, an electric heating plate, a temperature sensor, a net belt, a net belt tensioning mechanism, a support, a feed level sensor and a collector. The feeder flat trough is connected under the feeder hopper; the electromagnetic vibrator is arranged under the feeder flat trough; the driving roller and the driven roller support the net belt and are supported by the support; the driving roller is driven by the adjustable-speed motor; the net belt tensioning mechanism is arranged between the driven roller and the support; the collector is arranged under the driven roller; the electric heating plate is arranged on the support; the upper side of the electric heating plate is in closed contact with the net belt; the temperature sensor is arranged on the electric heating plate; and the feed level sensor is arranged on the feeder hopper.

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

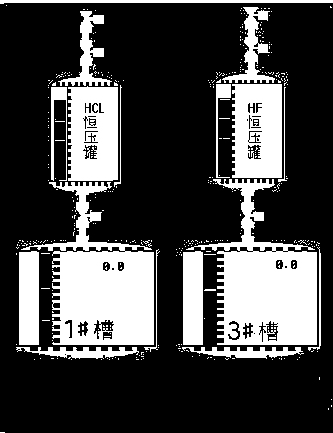

Acid adding method and device for stokehole cleaning machine

InactiveCN103658139AHigh precisionReduce acid concentration ratio errorSemiconductor/solid-state device manufacturingCleaning using liquidsAcid concentrationChemical waste

The invention discloses an acid adding method and device for a stokehole cleaning machine. The acid adding method and device has the advantages that by changing the flow type acid adding into the liquid level type acid adding, accuracy of acid prepared liquor amount is increased, acid concentration ratio error is reduced, the risks of silicon wafer burning and furnace tube and silicon wafer clamping tool pollution caused by unclean washing is reduced, and chemical waste is reduced, utilization rate of chemicals is increased. In addition, the method and device is widely applicable to various solution proportioning.

Owner:HEFEI HAREON SOLAR TECH

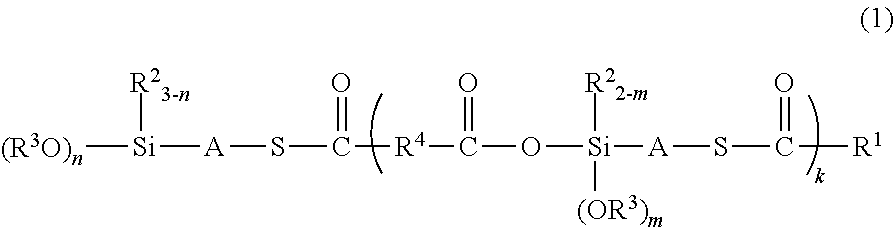

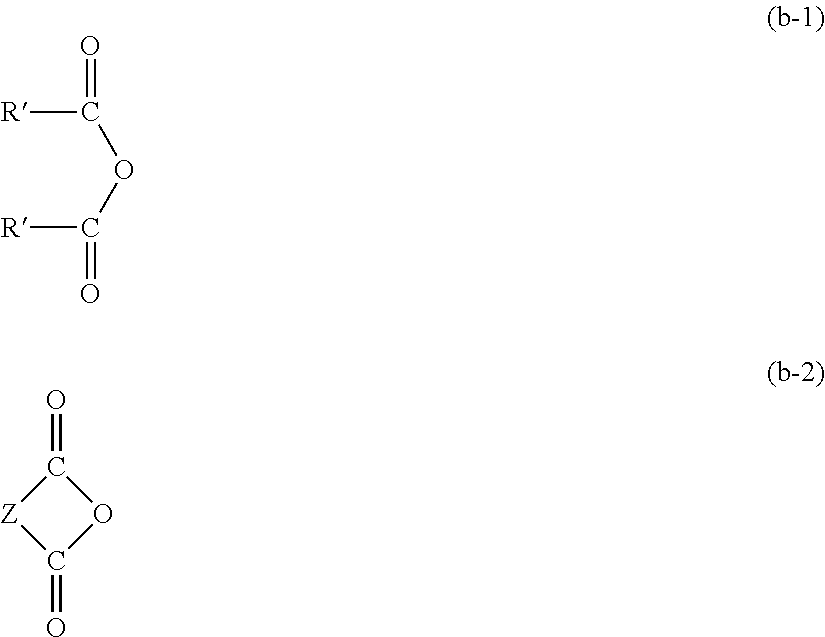

Method for producing thioester group-containing organosilicon compound, thioester group-containing organosilicon compound, compounding agent for rubber, rubber composition, and tire

ActiveUS20120296023A1Reduced byproductImprove production efficiencySilicon organic compoundsSpecial tyresPolymer scienceCarboxylic acid

A new method for producing a thioester group-containing organosilicon compound by a convenient reaction with dramatically improved workability generating reduced byproduct is provided. The method comprises reacting an organosilicon compound having a hydrolyzable silyl group and mercapto group with a carboxylic anhydride. Also provided are an organosilicon compound having a hydrolyzable silyl group, a thioester group, and carboxyl group in the same molecule capable of remarkably reducing hysteresis loss of the cured rubber composition; a compounding agent for rubber containing such organosilicon compound; a rubber composition prepared by blending such compounding agent for rubber; and a tire produced by using the cured rubber composition are also provided.

Owner:SHIN ETSU CHEM IND CO LTD

Cyanide-free alkaline copper plating electroplating solution for zinc alloy die castings and preparation method and electroplating method thereof

InactiveCN113151870ARemove serious threatReduce scorchingProcess efficiency improvementCopper platingCyanide

The invention discloses a cyanide-free alkaline copper plating electroplating solution for zinc alloy die castings and a preparation method and an electroplating method thereof. The cyanide-free alkaline copper plating electroplating solution is prepared from the following components of 5-50g / L of main salt, 5-30g / L of a compound adsorbent and 200-400g / L of a complexing composition. By adding the compound adsorbent to change the copper ion concentration in a double electrode layer on a cathode surface, the cathode interface copper ion potential can be effectively reduced, the copper ion discharging precipitation is inhibited, the 'zinc-copper replacement reaction' is completely inhibited in the alkaline plating solution, the complexing effect with the complexing composition is synergistic, the effect that 1 + 1 is greater than 2 is generated, the copper ion concentration in the double electrode layer is changed, and the copper ion potential is effectively reduced, so that copper ion discharging is more difficult; the 'zinc-copper replacement reaction' is completely inhibited in the alkaline plating solution, the technical problems that cyanide-free copper plating binding force of the zinc alloy die castings is poor and bubbling is prone to occurring are solved, and plating layers are bright and fine in crystal and firm in binding force.

Owner:张志梁

A smart energy large-scale composite core pultrusion process and device

The invention discloses a smart energy large-size composite core pultrusion process and device. The device comprises yarn dividing devices, a main resin dipping groove, resin extruding rollers, a yarn collecting device, a curing die, pre-curing dies, a first auxiliary resin dipping groove, resin scraping devices and a second auxiliary resin dipping groove. The main resin dipping groove comprises a first main resin dipping groove position and a second main resin dipping groove position; the pre-curing dies are arranged above the main resin dipping groove and comprise the first pre-curing die, the second pre-curing die and the third pre-curing die which are sequentially arranged; the resin scraping devices comprise the first resin scraping device, the second resin scraping device and the third resin scraping device and provided with inlets of the three pre-curing dies; and the smart energy large-size composite core pultrusion device comprises the main resin dipping groove with two groove positions and two auxiliary resin dipping grooves, most carbon fibers and all glass fibers are subject to resin dipping through the main resin dipping groove, a small part of carbon fibers are subject to resin dipping through the auxiliary resin dipping grooves, rein in the groove is not heated and is not prone to aging, and quality stability of a core stick is improved.

Owner:FAR EAST CABLE +2

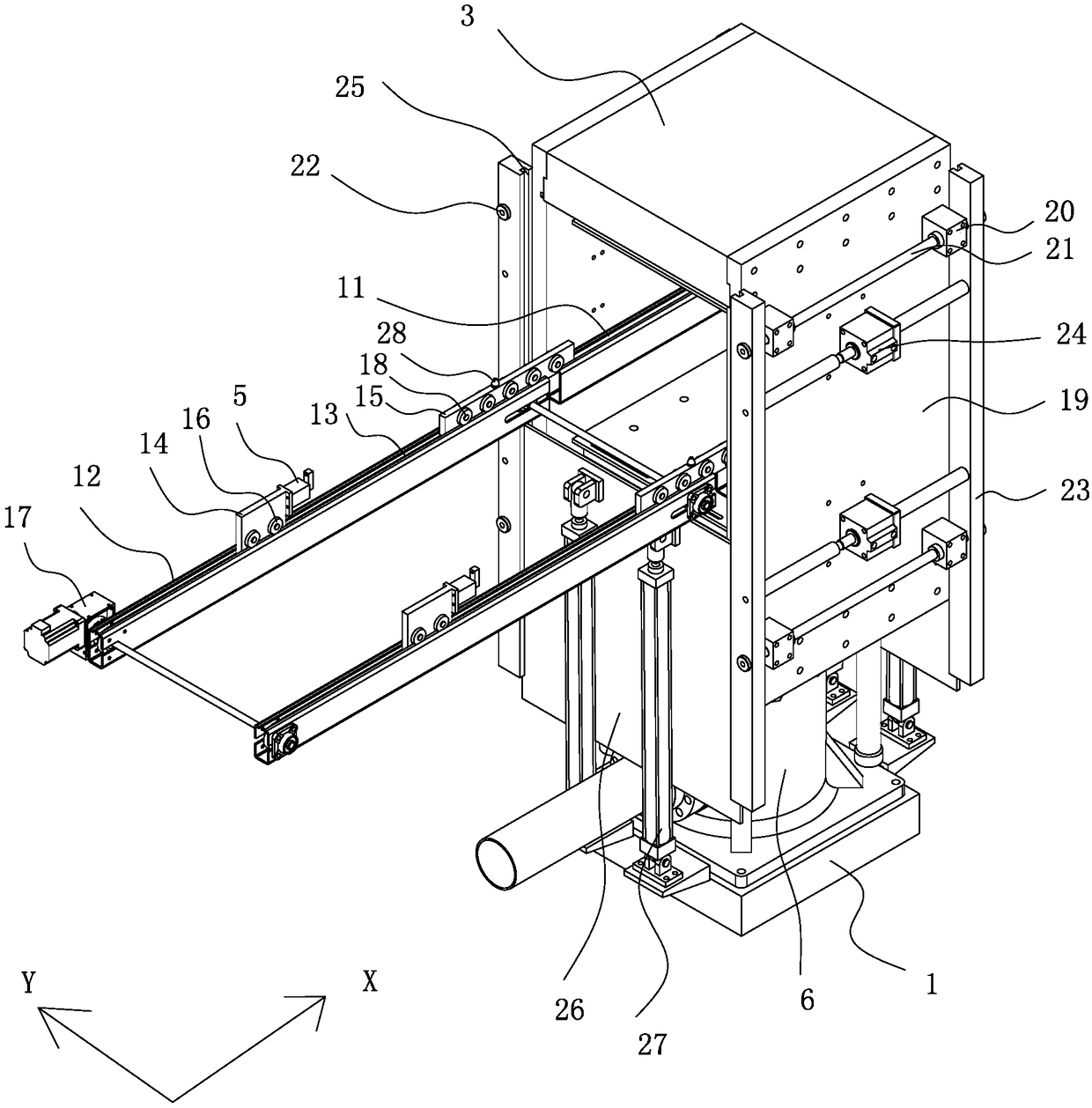

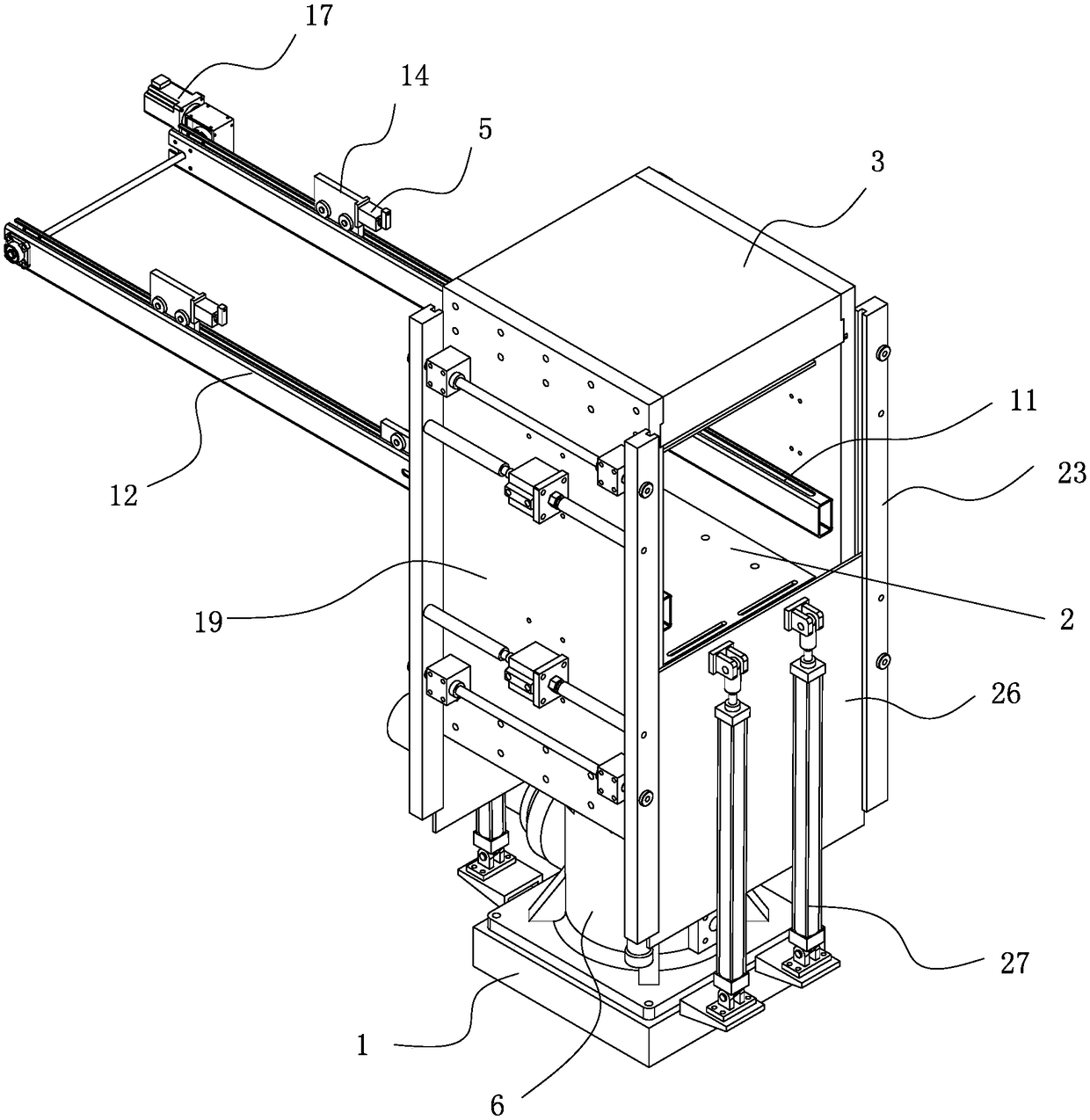

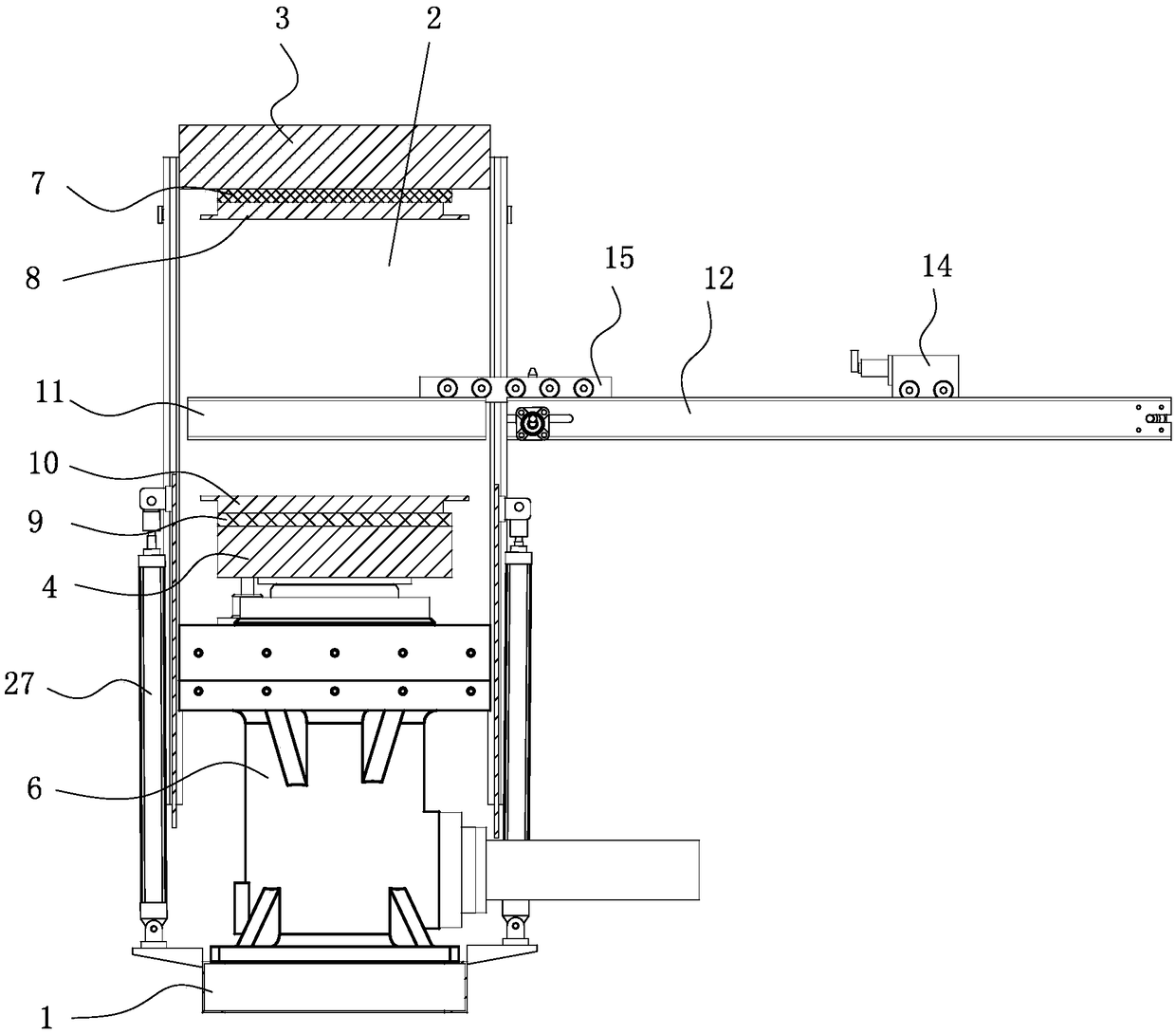

Fully-automatic vacuum bicolor one-time foaming forming machine

The invention relates to the field of foaming forming machines, in particular to a fully-automatic vacuum bicolor one-time foaming forming machine. According to the fully-automatic vacuum bicolor one-time foaming forming machine, the problem that in the prior art, vacuumizing difficulty is high, and consequently the product qualification rate is low is mainly solved. The fully-automatic vacuum bicolor one-time foaming forming machine comprises a rack and a heating station arranged on the rack. Side wall plates are fixedly arranged on the positions, on the two sides of the heating station, of the rack correspondingly. Guiding devices are arranged on the side wall plates in an extending mode in the two transverse directions. Side sliding plates are arranged at the two ends of the guiding devices correspondingly and provided with third driving devices for driving the side sliding plates to move. Side sliding grooves are formed in the positions, on the two side wall plates, of the oppositesurfaces of the side sliding plates correspondingly. A sealing lifting door is slidably arranged in the side sliding grooves. A fourth driving device is hinged between the rack and a sealing side sliding door.

Owner:JINJIANG BANGDA PLASTIC

Odorless automobile sealing strip and preparation method thereof

PendingCN112250952AFast vulcanizationIncrease the degree of cross-linkingPolymer scienceFoaming agent

The invention relates to an odorless automobile sealing strip is formed by compounding a dense rubber strip and a foamed rubber strip, and the dense rubber strip mainly comprises ethylene propylene diene monomer, reinforcing carbon black, environment-friendly oil, ground calcium carbonate, zinc oxide, stearic acid, a surfactant, bamboo fragrance, sulfur powder, an accelerant and a vulcanizing agent. The foamed rubber strip mainly comprises ethylene propylene diene monomer, reinforced carbon black environment-friendly oil, active calcium, zinc oxide, stearic acid, a processing aid, bamboo fragrance, sulfur powder, an accelerant, a vulcanizing agent, DTDM, DPTT and a foaming agent. According to the invention, ethylene propylene diene monomer (EPDM) is used as a main material, and a pluralityof added auxiliary materials and fragrance are interacted, so that the prepared automobile sealing strip is fragrant and free of pungent smell.

Owner:ZHEJIANG XIANTONG RUBBER & PLASTIC CO LTD

Full-automatic high-efficiency intelligent equipment for toasting urum

ActiveCN110326957AImprove the mixing effectReduce scorchingOther dairy technologyCooking vessel constructionsElectric machineryEngineering

The invention relates to a full-automatic high-efficiency intelligent equipment for toasting urum (skin on boiled milk); the equipment comprises a main body, a pot body, a control panel and a heatingdevice, and also comprises a stirring mechanism and a filtering mechanism; the stirring mechanism comprises a motor, a rotating rod, a fixed box and two stirring assemblies; each stirring assembly comprises a first connecting rod, a connecting shaft, a scraping plate and two stirring units; and the filtering mechanism comprises a filtering box, a filter screen and a feeding pipe. According to thefull-automatic efficient intelligent equipment for toasting urum, the materials in the pot body can be stirred through the stirring mechanism, so that the materials are uniformly heated; compared withthe existing stirring mechanism, the stirring mechanism provided by the invention is good in stirring effect, materials are prevented from being adhered to the inner wall of the pot body, and the probability of material burning is lowered; and impurities in the materials can be removed through the filtering mechanism, and compared with an existing filtering mechanism, the filtering mechanism is good in filtering effect, and the quality of produced urum is improved.

Owner:INNER MONGOLIA LICHENG IND CO LTD

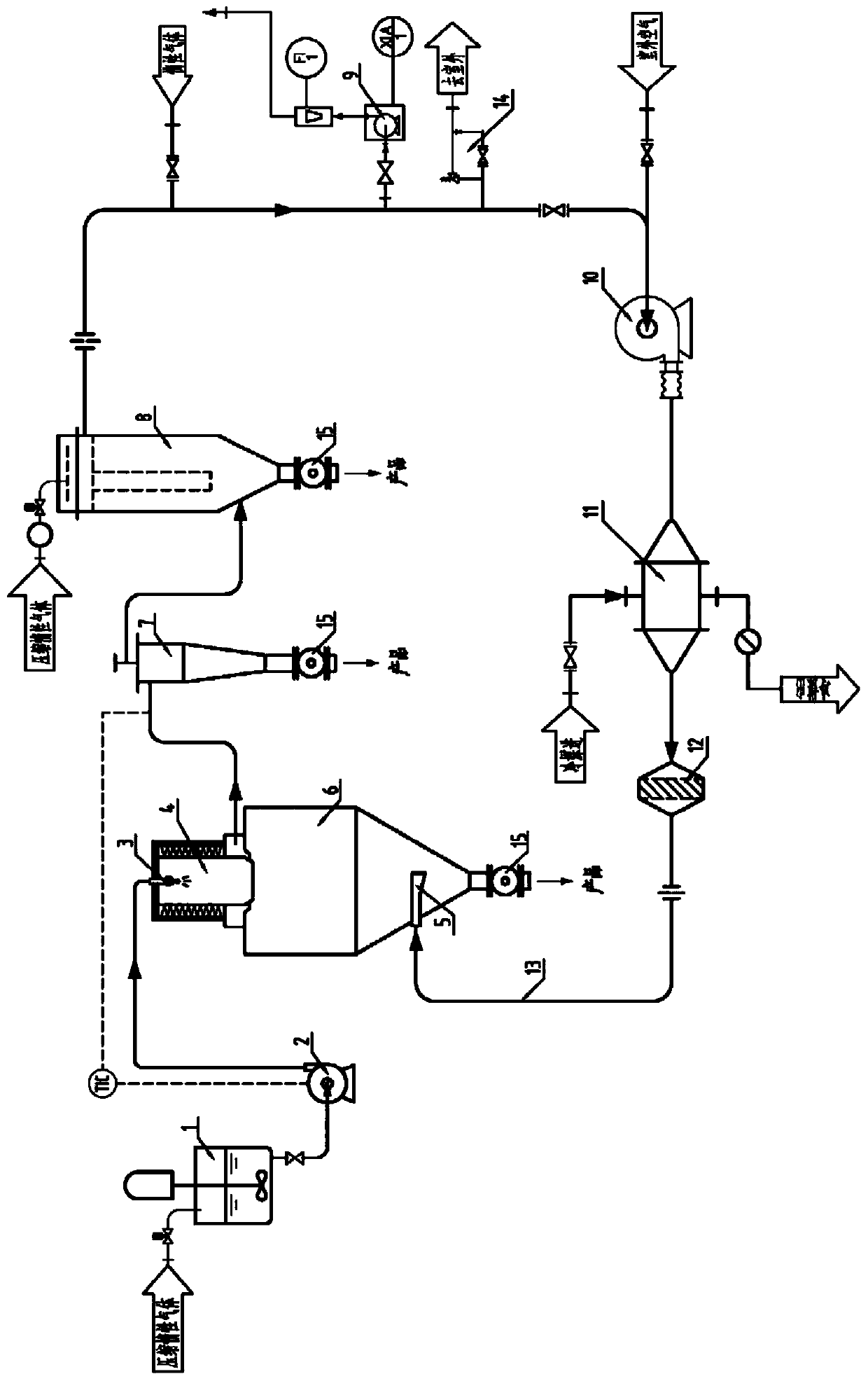

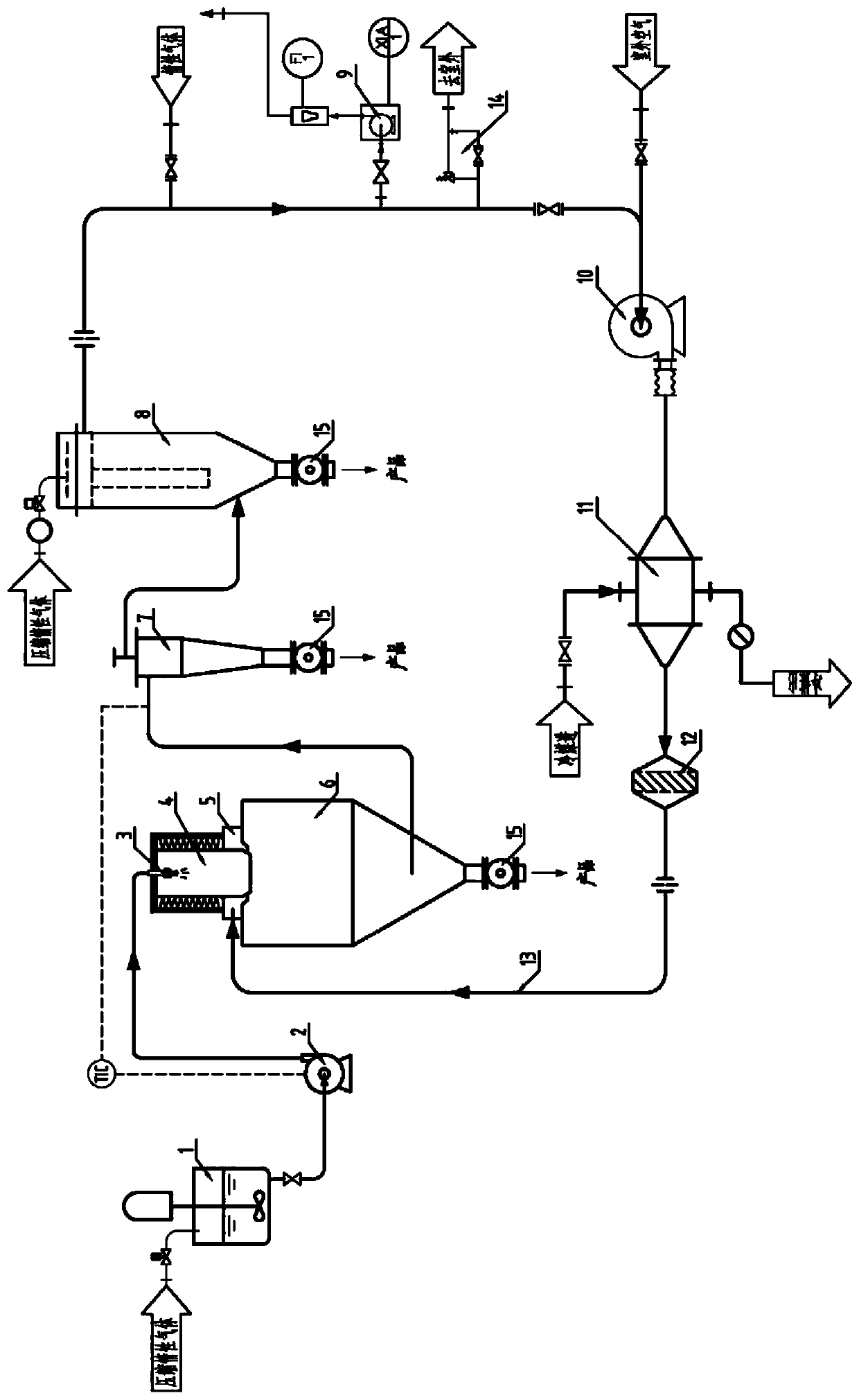

Spray reaction device for closed cycle preparation of insoluble sulfur

PendingCN111039263AImprove stabilitySuitable for large-scale industrializationSulfur preparation/purificationGas analysisPhysical chemistry

The invention discloses a spray reaction device for of insoluble sulfur, and relates to the technical field of preparation equipment of insoluble sulfur for rubber tires and rubber products. The sprayreaction device mainly comprises a melting system, a feeding system, a high-temperature reaction furnace, a cooling chamber, a separation system, a gas analysis system, a cooling system, a pressure balance system and a discharging system. According to the invention, inert gas is adopted to effectively reduce oxidation of sulfur and improve product quality; a quenching section process effectivelyrestrains the reverse reaction, so that the content of insoluble sulfur in a product is directly influenced; insoluble sulfur is obtained by adopting a low-temperature melting reaction method, so thatthe process is environment-friendly; and the spray reaction device can save resources and reduce cost, and has good market prospect.

Owner:江苏艾迪智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com