Acid adding method and device for stokehole cleaning machine

A technology of acid adding device and cleaning machine, which is applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., and can solve problems such as pollution of diffusion furnace tubes, dirty cleaning of silicon wafers, corrosion of silicon wafers, etc. , to achieve a wide range of applications, reduce silicon wafer scorching, and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

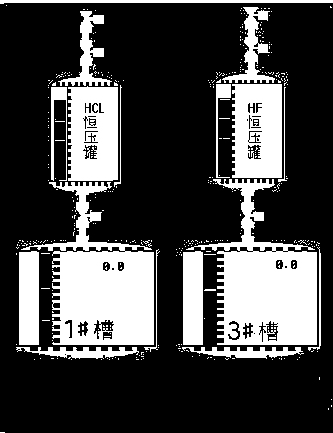

[0014] Such as figure 1 As shown, the acid adding device of the present invention includes a constant pressure tank for storing acid, a high liquid level sensor, a middle liquid level sensor and a cleaning tank; the high liquid level sensor and the middle liquid level sensor are located inside the constant pressure tank, and the constant pressure The surface of the tank is marked with a scale, which is convenient for adjusting the distance between the high liquid level sensor and the medium liquid level sensor. The constant pressure tank is connected with the cleaning tank through the acid adding pipeline.

[0015] Make the opening of the acid feeding pipeline moderate, and adjust the distance between the liquid level sensors so that the volume of acid required for the cleaning process is an integer multiple of the acid volume between the middle liquid level and the high liquid level. The level sensor automatically detects whether the liquid in the constant pressure tank reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com