Patents

Literature

674 results about "Acid concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid Concentration. The concentration of an acid is a measure of the amount of available acid ions dissolved in a solvent. Concentration can be measured in moles, parts per million or percentage. The concentration is a ratio of the solute to solvent content of a solution.

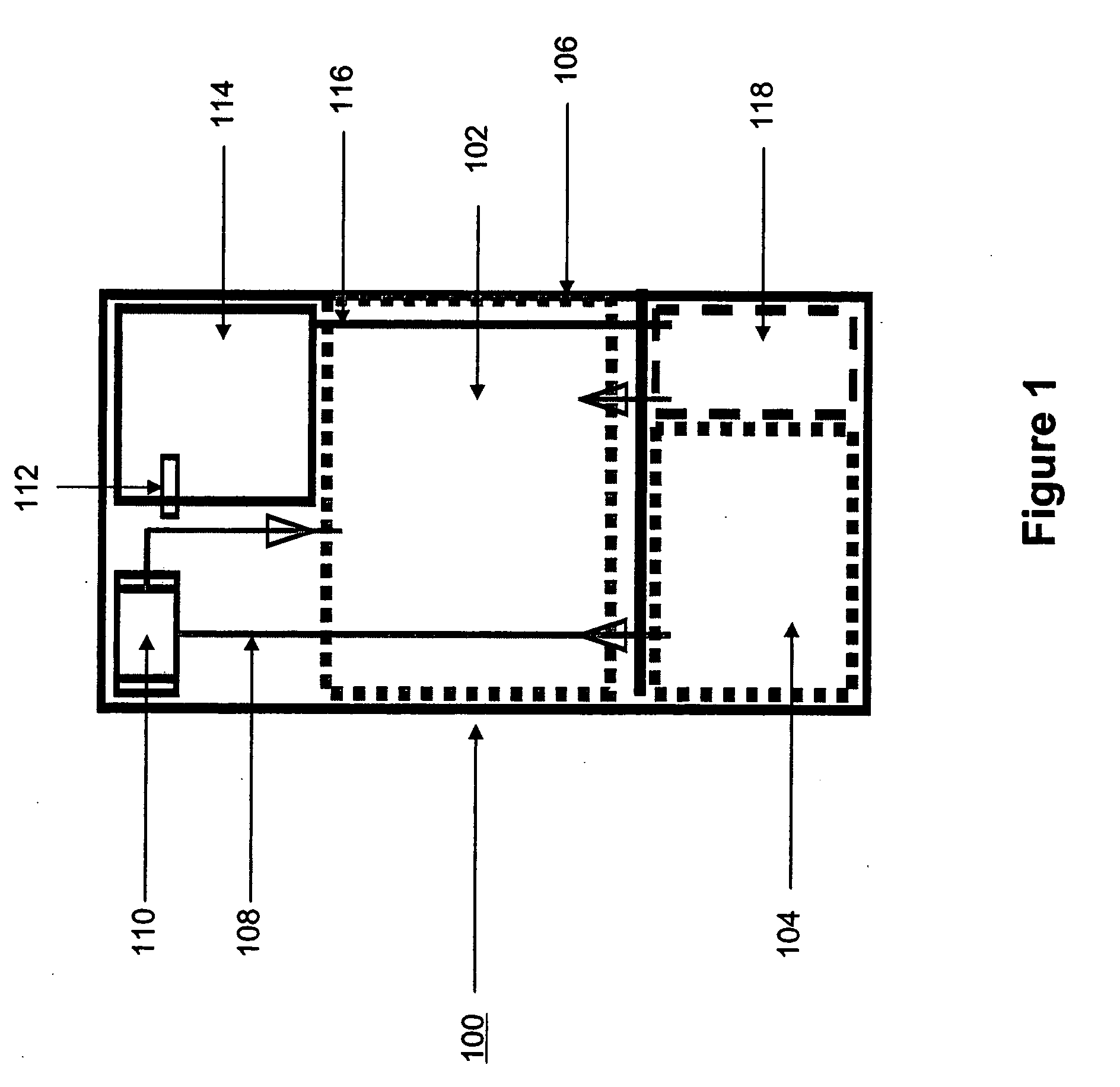

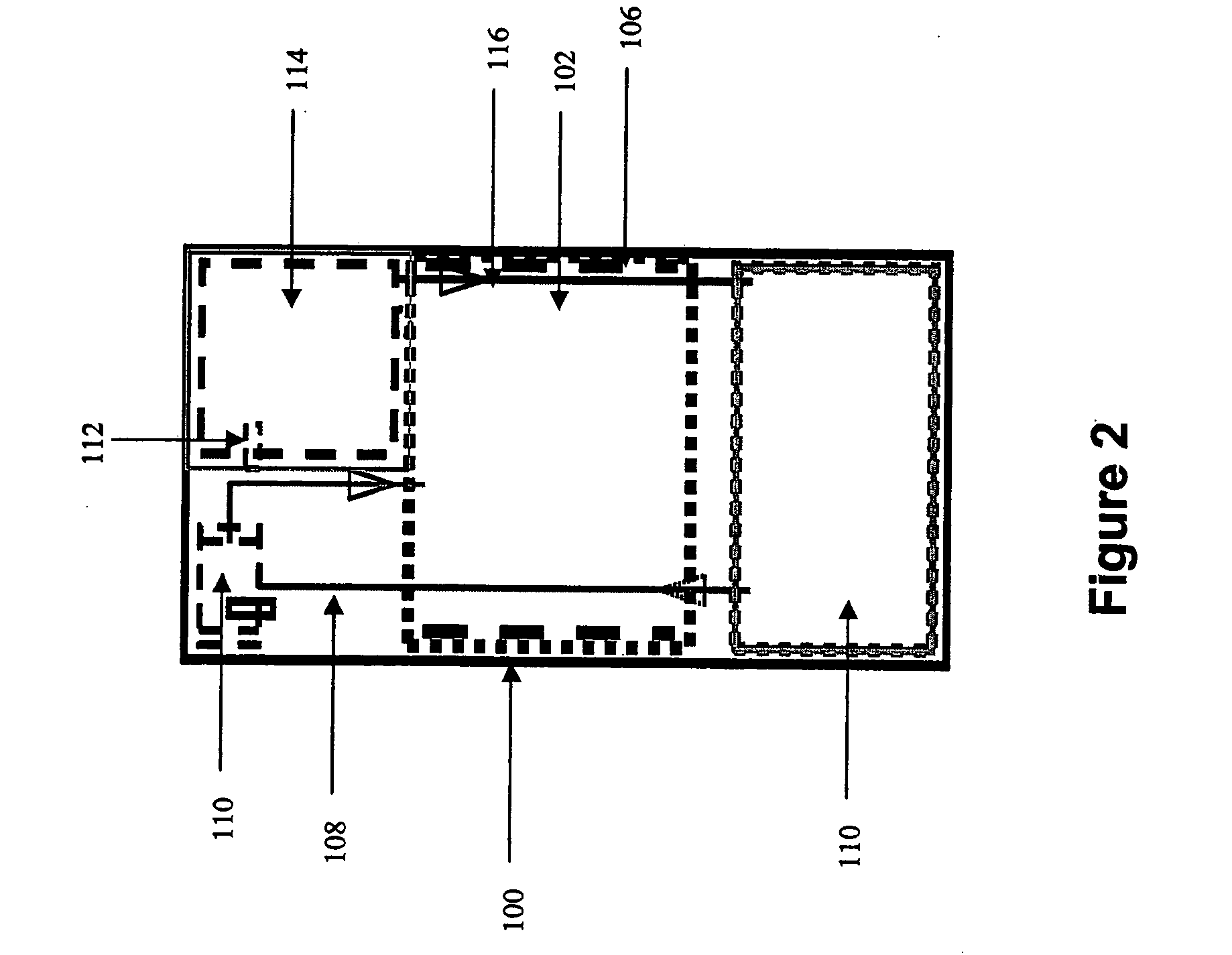

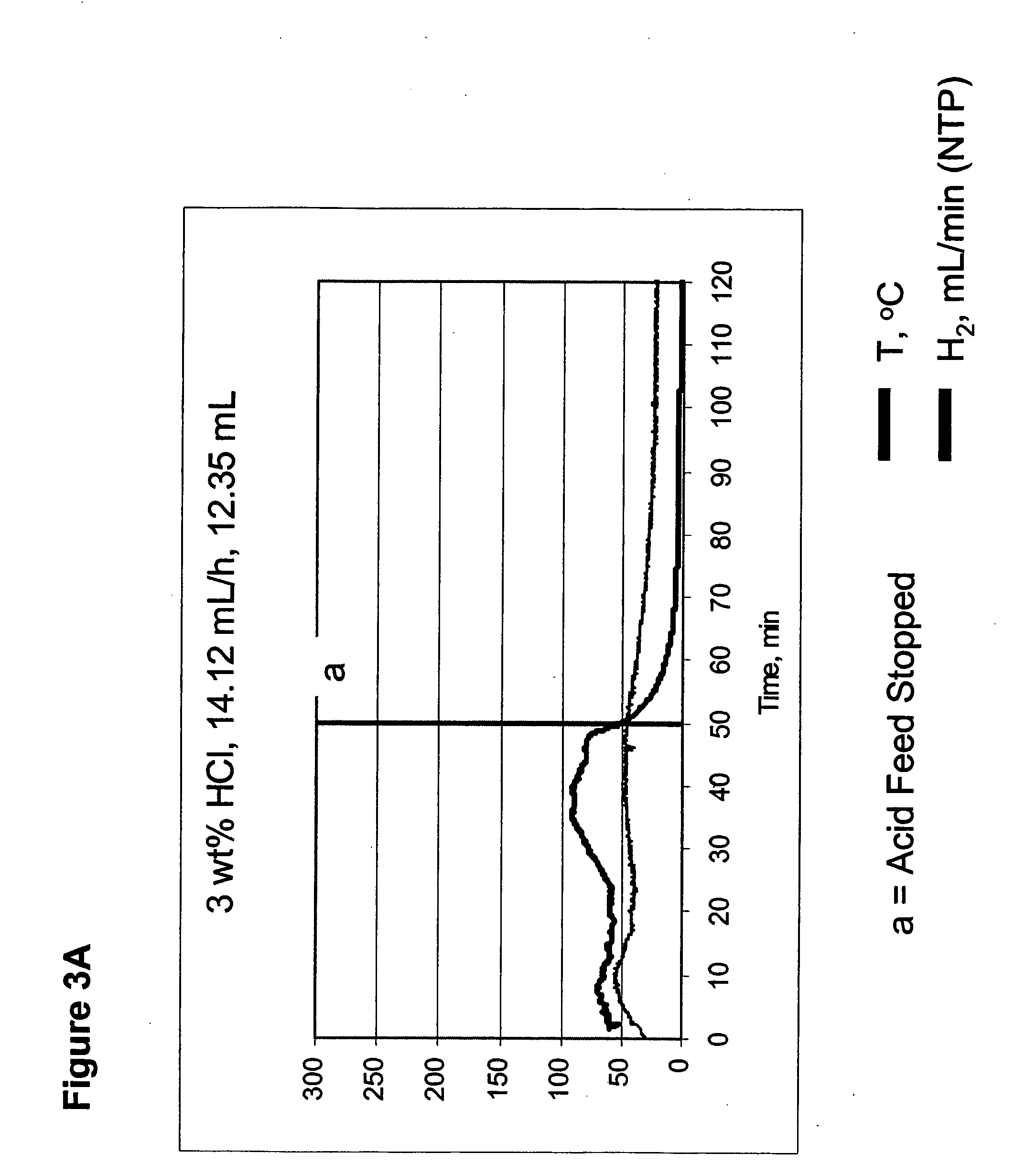

Systems and methods for hydrogen generation from solid hydrides

InactiveUS20050238573A1Regulate rateReactant parameters controlHydrogen productionO-Phosphoric AcidAlkaline earth metal

A system is disclosed for hydrogen generation based on hydrolysis of solid chemical hydrides with the capability of controlled startup and stop characteristics wherein regulation of acid concentration, acid feed rate, or a combination of both control the rate of hydrogen generation. The system comprises a first chamber for storing a solid chemical hydride and a second chamber for storing an acidic reagent. The solid chemical hydride is a solid metal borohydride having the general formula MBH4, where M is selected from the group consisting of alkali metal cations, alkaline earth metal cations, aluminum cation, zinc cation, and ammonium cation. The acidic reagent may comprise inorganic acids such as the mineral acids hydrochloric acid, sulfuric acid, and phosphoric acid, and organic acids such as acetic acid, formic acid, maleic acid, citric acid, and tartaric acid, or mixtures thereof.

Owner:MILLENNIUM CELL

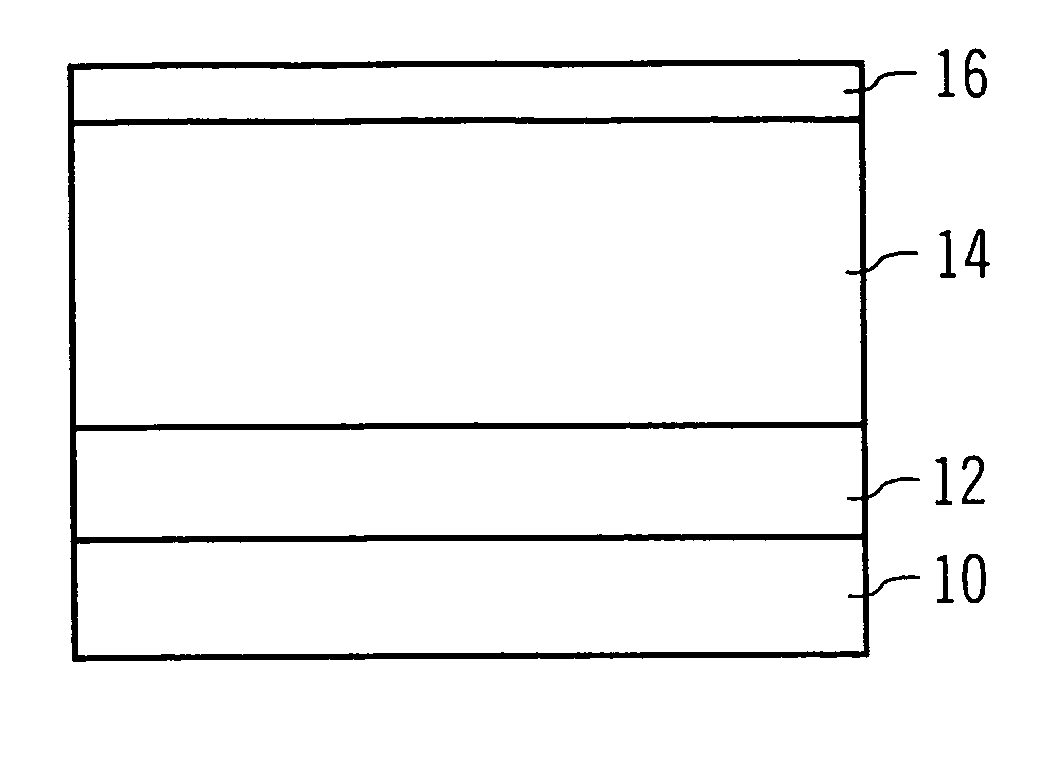

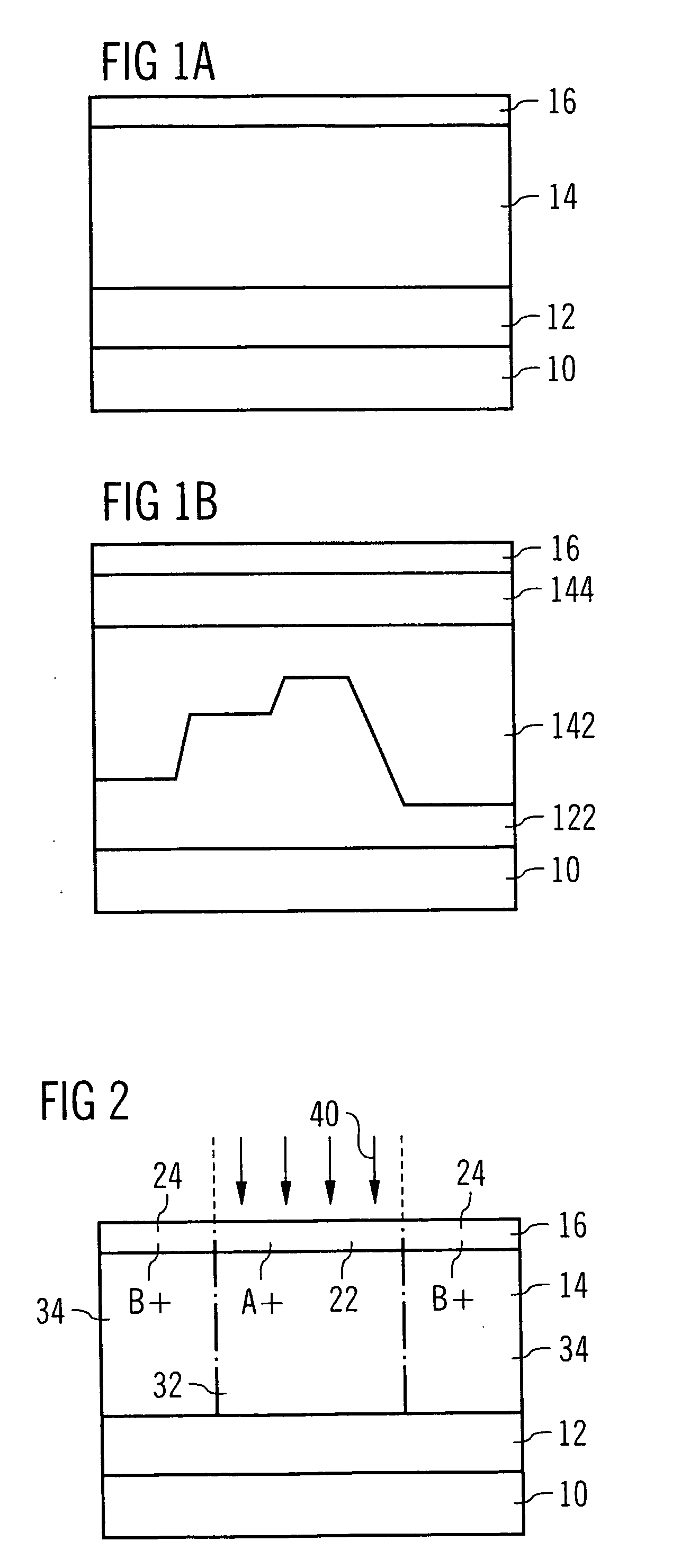

Method for removing threshold voltage adjusting layer with external acid diffusion process

Owner:ELPIS TECH INC

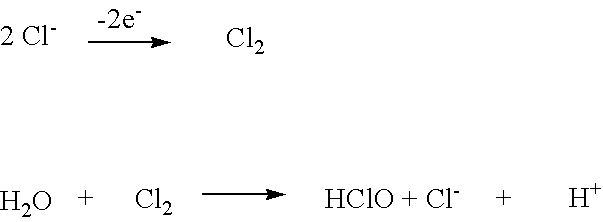

Physiologically balanced, ionized, acidic solution and methodology for use in wound healing

Described herein is a physiologically-balanced, acidic solution. Typically the solution is prepared by a chemical reactions or by the electrolysis of a solution comprising a mixture of an inorganic salt to form a physiologically balanced solution. This invention also relates to methods for use of the solutions, including a specialized bandage which may be used in combination with the solutions, or optionally with other topically applied materials. A mixture of inorganic salts and, optionally minerals, is used in order to mimic the electrolyte concentration and mixture of body fluid in an isotonic state. The solution typically comprises of one halide salt of lithium, sodium, potassium, calcium, and other cations. Typically the halide is fluoride, chloride, bromide, or iodide, and most typically chloride. A typical electrolyzed solution of the present invention has a pH within the range of about 2 to about 5, an oxidation reduction potential within the range of about +600 mV to about +1200 mV, and hypohalous acid concentration in the range of about 10 ppm to about 200 ppm. The solution has bactericidal, fungicidal, and sporicidal properties. The composition of the invention is nontoxic and has antibacterial properties, and is useful in any application in which antimicrobial properties are desirable.

Owner:NOVABAY PHARM INC

Pre-treatment of bales of feedstock

The present invention is directed to a method of pre-treating a lignocellulosic feedstock. The lignocellulosic feedstock comprises cereal straw, stover, or grass. One or more than one bale of lignocellulosic feedstock is conveyed into a pre-treatment reactor. Steam and acid are added to the bales and are maintained at a temperature, acid concentration, and for a time sufficient to hydrolyze hemicellulose to xylose and increase susceptibility of cellulose to digestion by cellulase enzymes, thus producing a pre-treated feedstock. The pre-treated feedstock is then removed from the pre-treatment reactor.

Owner:IOGEN ENERGY CORP

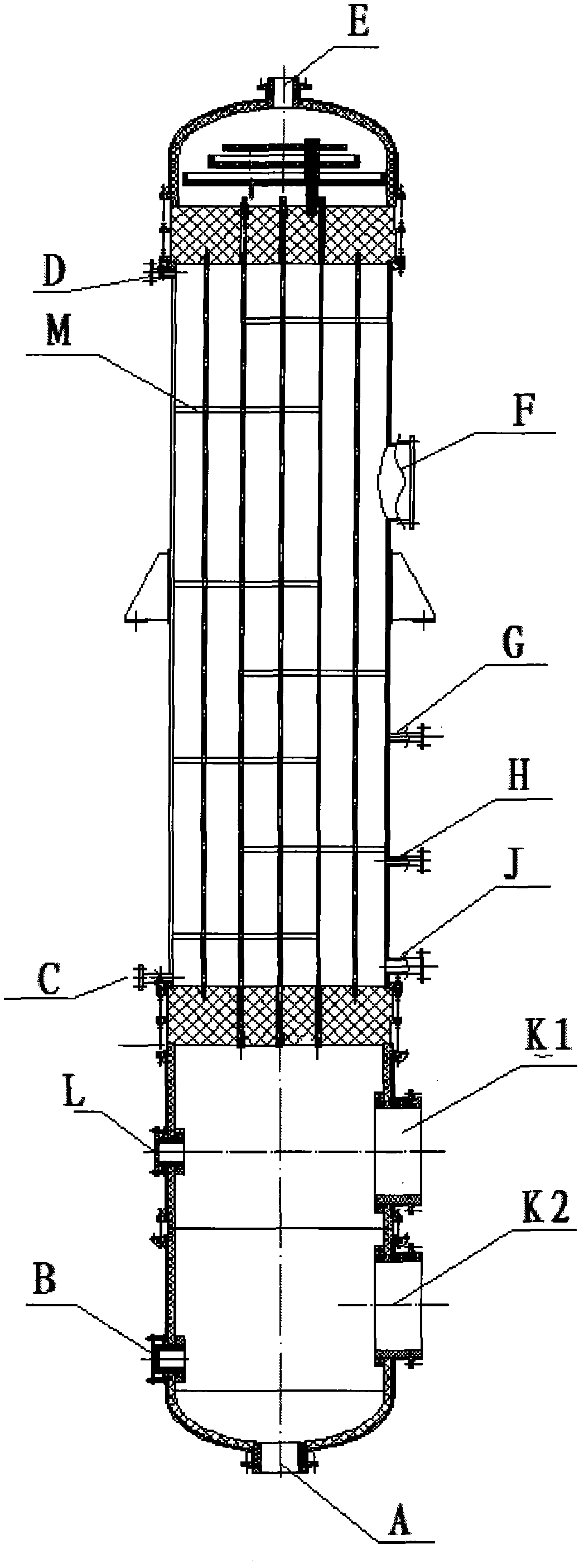

Descaling method of phospheric acid concentration heat exchanger

ActiveCN1724965AEfficient removalRemove completelyOrganic detergent compounding agentsSurface-active detergent compositionsHexamethylenetetraminePhosphoric acid

The invention discloses a method for decaling phosphoric acid concentration heat exchanger, namely a technique of adopting a washing-liquor composed of thin fluosilicic acid solution, organic phosphonic acid sustained-releasing agent and film forming matter and firstly washing the heat exchanger with water and then washing out the foul with the washing liquor. In the washing liquor, the fluosilicic acid is a 5%-20% thin acid, the organic phosphonic acid sustained-releasing agent includes amino tri- sub-methylene phosphoric acid, hydroxyl sub-ethyl di-phosphoric acid and hydroxyl-l, 1-subethyl di-phosphoric acid; the film forming matter includes nitrous phenylhydroxylamine ammonium salt and wuluotuopin as well as sodium molybdate. As using, adding in surface active agent alkyl sulphonate. The invention can make high efficiency and thorough decaling the graphite heat exchanger and simultaneously effectively control the corrosion of the washing liquor to the equipment and as compared with traditional washing methods, the invention improves the productivity of the equipment.

Owner:WENGFU (GRP) CO LTD +1

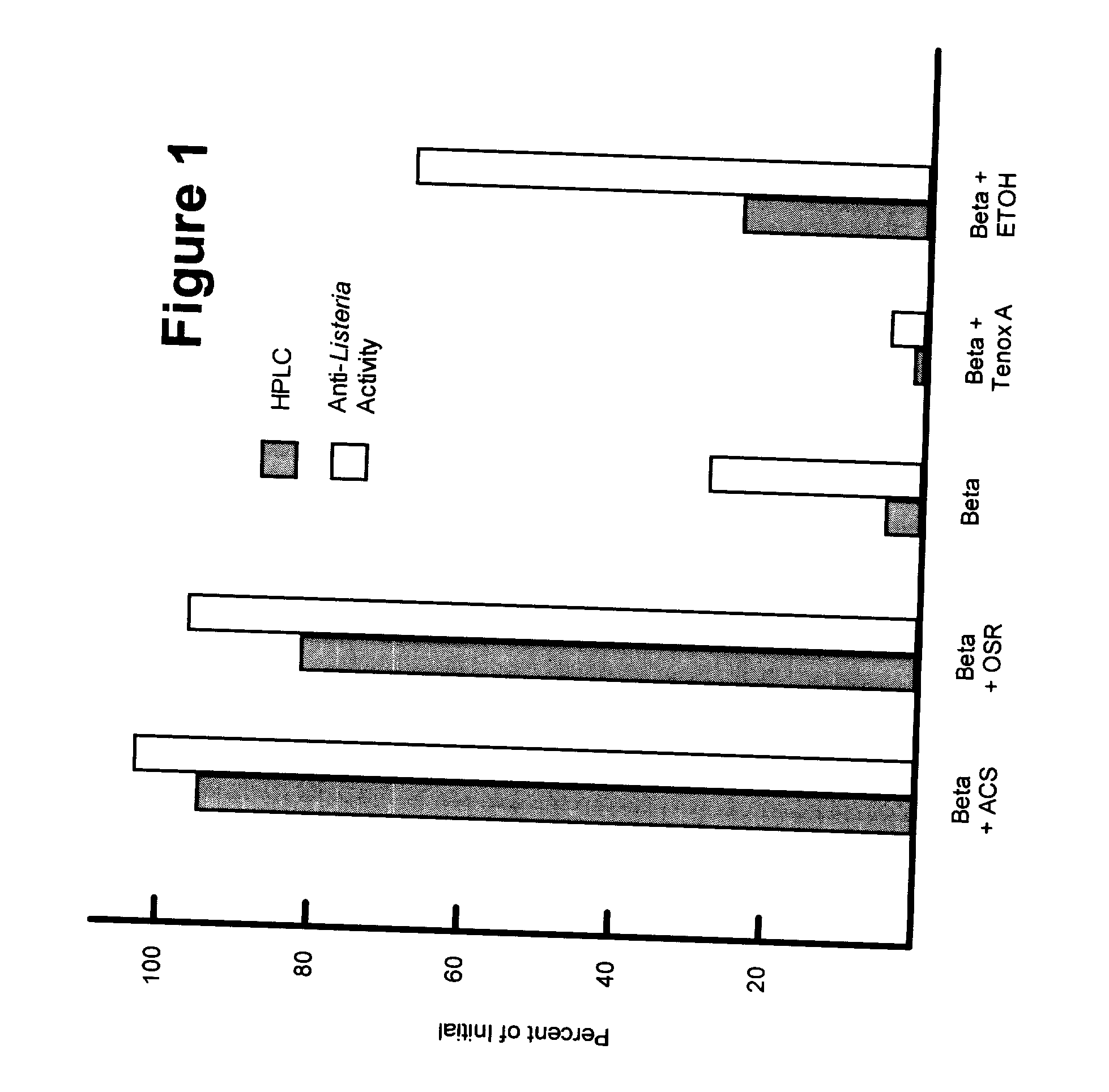

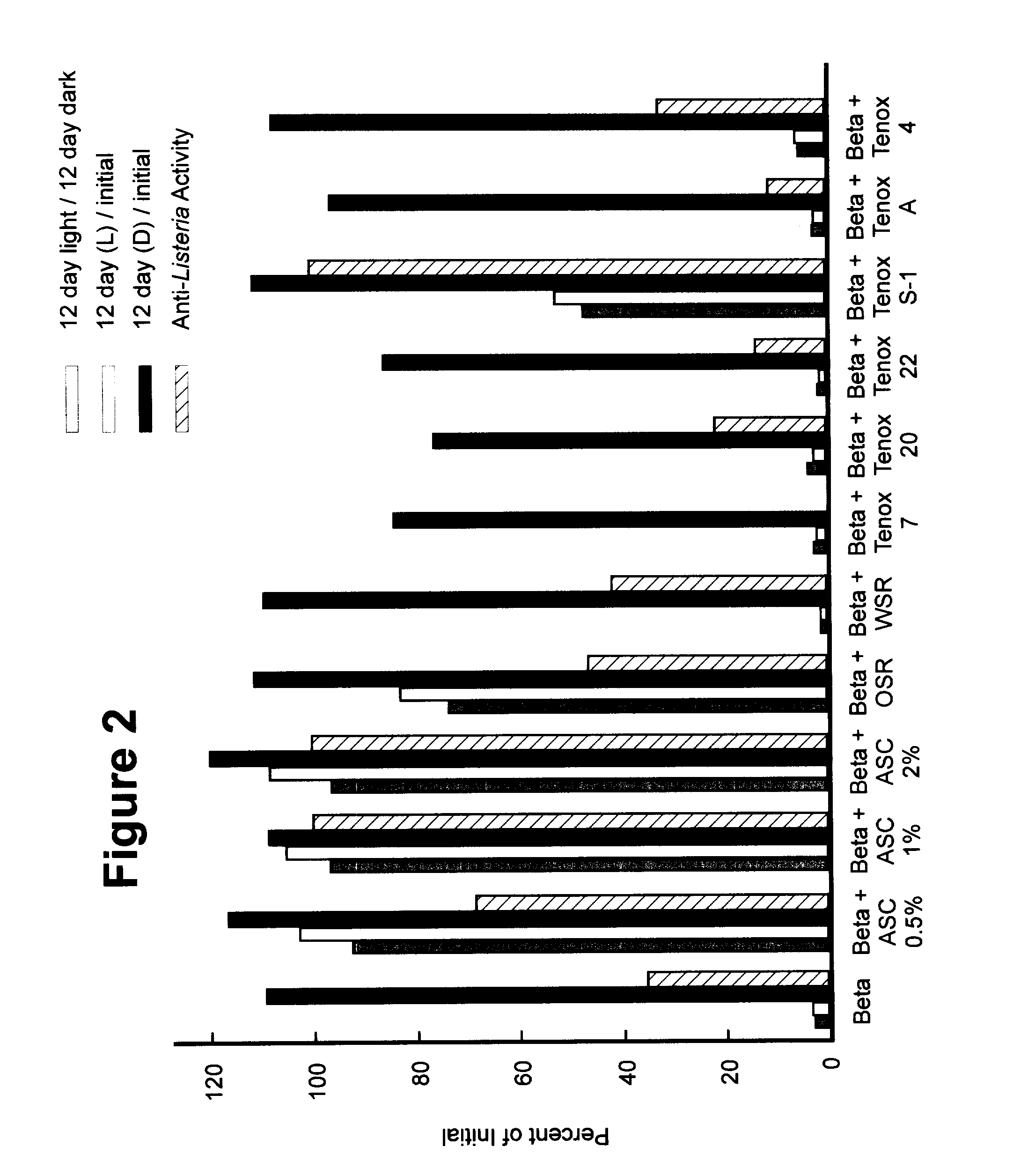

Hop beta acid compositions for use in food products

InactiveUS20040175480A1Easy to optimizeImprove stabilityMeat/fish preservation using chemicalsMeat/fish preservation using acidsFood gradeAlcohol

Hop beta acids are improved with respect to their antibacterial properties, especially their anti-Listeria properties. Enhancement in this regard is especially useful for the treatment of food products which are susceptible to bacterial contamination. This can be especially important when the hop beta acids are to be used in surface application onto the food products. The hop beta acids are rendered more effective by combining them with a food grade acid, a potassium ion source, and an optional antioxidant in a carrier solvent such as, for example, a food grade alcohols or a food grade glycol. The improved hop beta acid compositions of this invention provide increase stability, higher hop beta acid concentrations, and / or higher anti-Listeria activities.

Owner:KRAFT FOODS INC

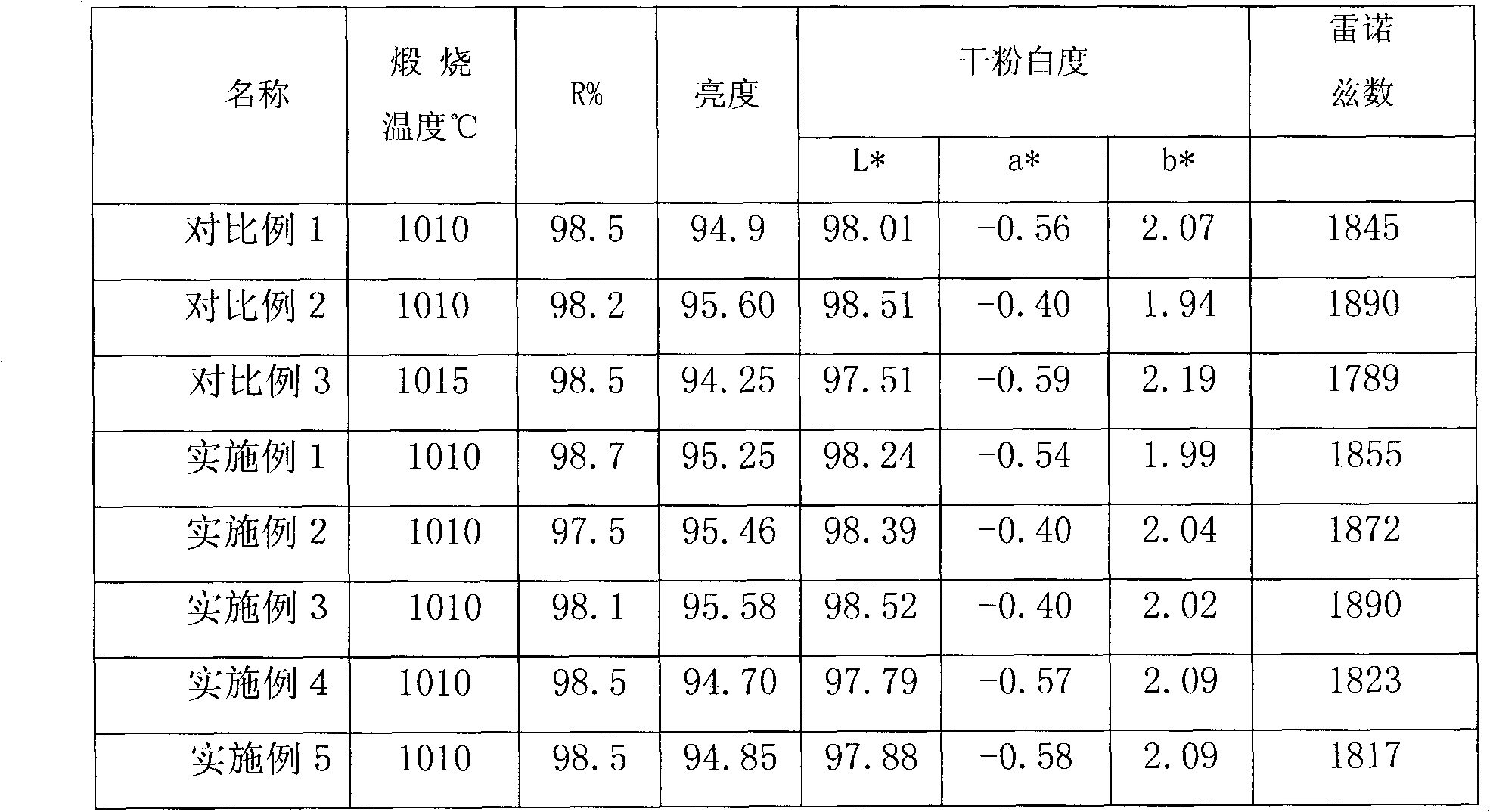

Method for preparing titanium pigment from novel-process-flow titanium slag and titanium concentrated ore through mixed acidolysis

ActiveCN101857269APigment performance is goodReduce dosageTitanium dioxideAcid concentrationTitanium

The invention discloses a method for preparing titanium pigment from novel-process-flow titanium slag and titanium concentrated ore through mixed acidolysis, which belongs to the technical field of titanium pigment production. The method of the invention comprises the following steps: adding the novel-process-flow titanium slag and concentrated sulfuric acid into the titanium concentrated ore; regulating the acid concentration to 82 to 86 percent; raising the temperature to 130 to 150 DEG C; curing solid mixtures generated in the reaction for 1.5 to 3 h at 160 to 220 DEG C; adding water for leaching; carrying out solid-liquid separation, and removing impurities; carrying out freezing crystallization concentration on obtained clear titanium liquid to obtain concentrated titanium liquid; and carrying out hydrolysis, washing, rinsing; salt treatment, calcination and post treatment on the concentrated titanium liquid to obtain the titanium pigment. When the technical scheme of the invention is adopted, the novel-process-flow titanium slag which has low price but is not applicable to the titanium pigment production is applied to the titanium pigment production on the basis of not changing the existing process and equipment for producing titanium pigment from titanium concentrated ore, titanium pigment products with good pigment performance are prepared, waste materials are changed into useful materials, and in addition, the consumption of reducing ferrous powder is saved, so the production cost is reduced.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

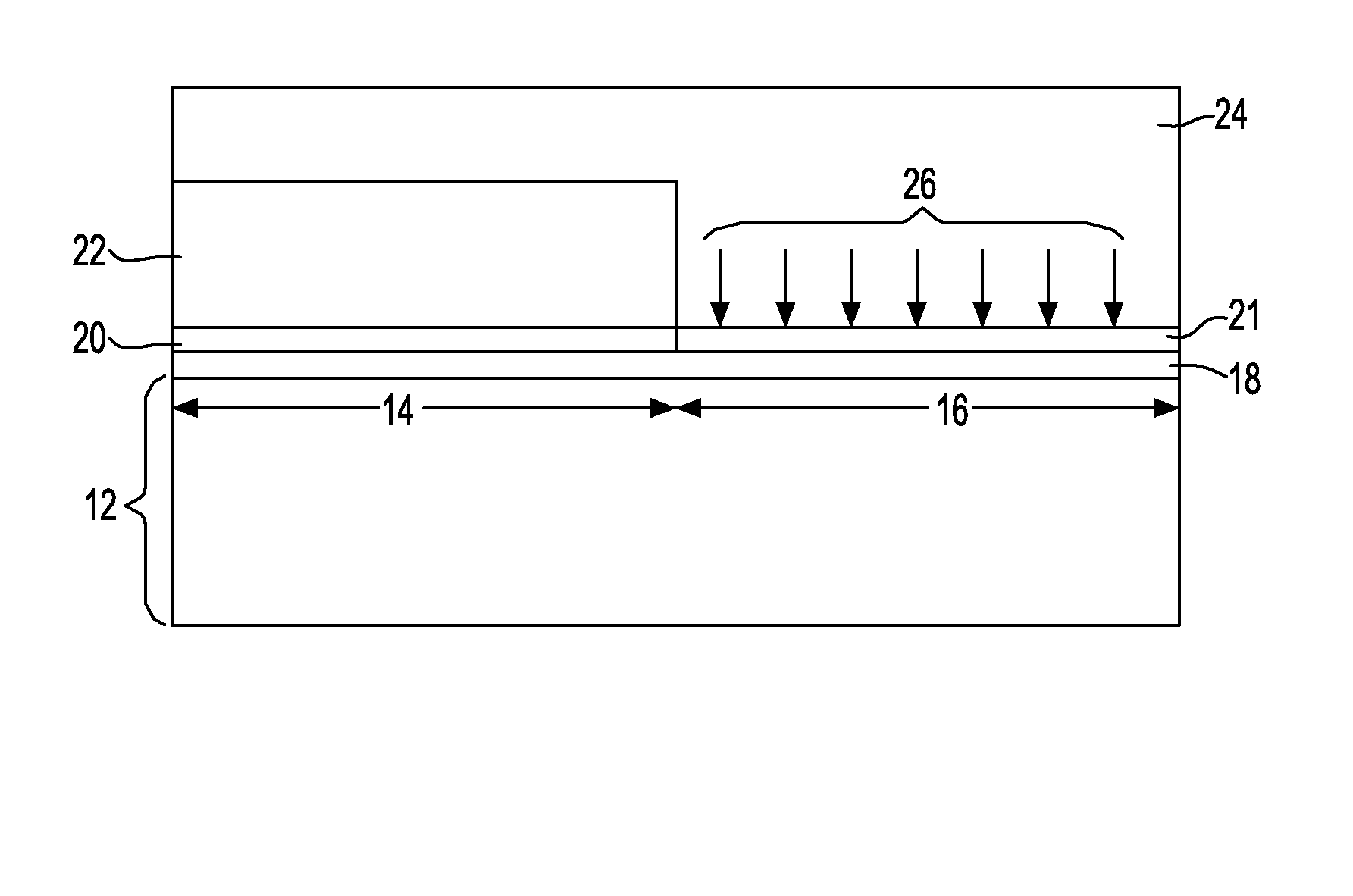

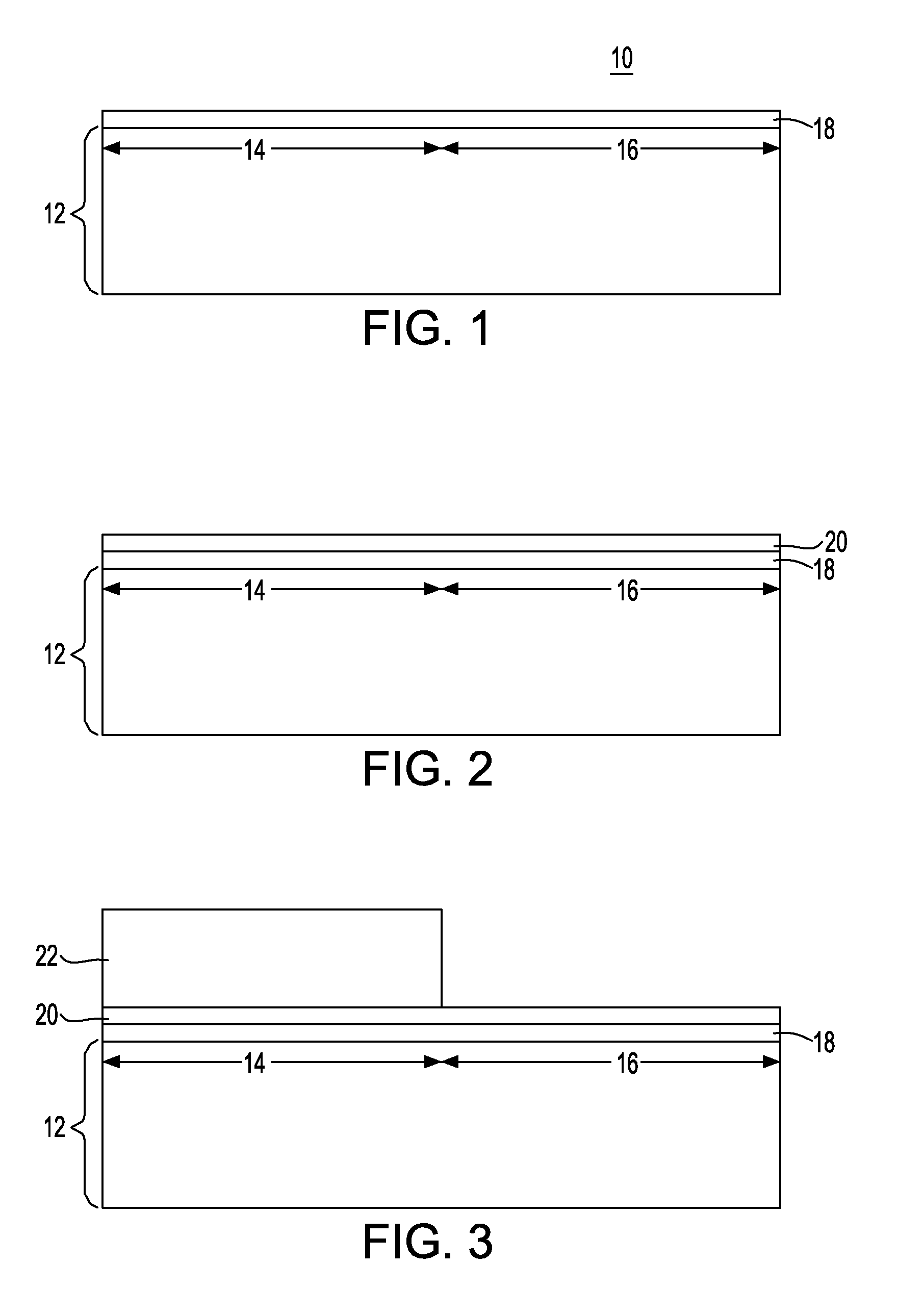

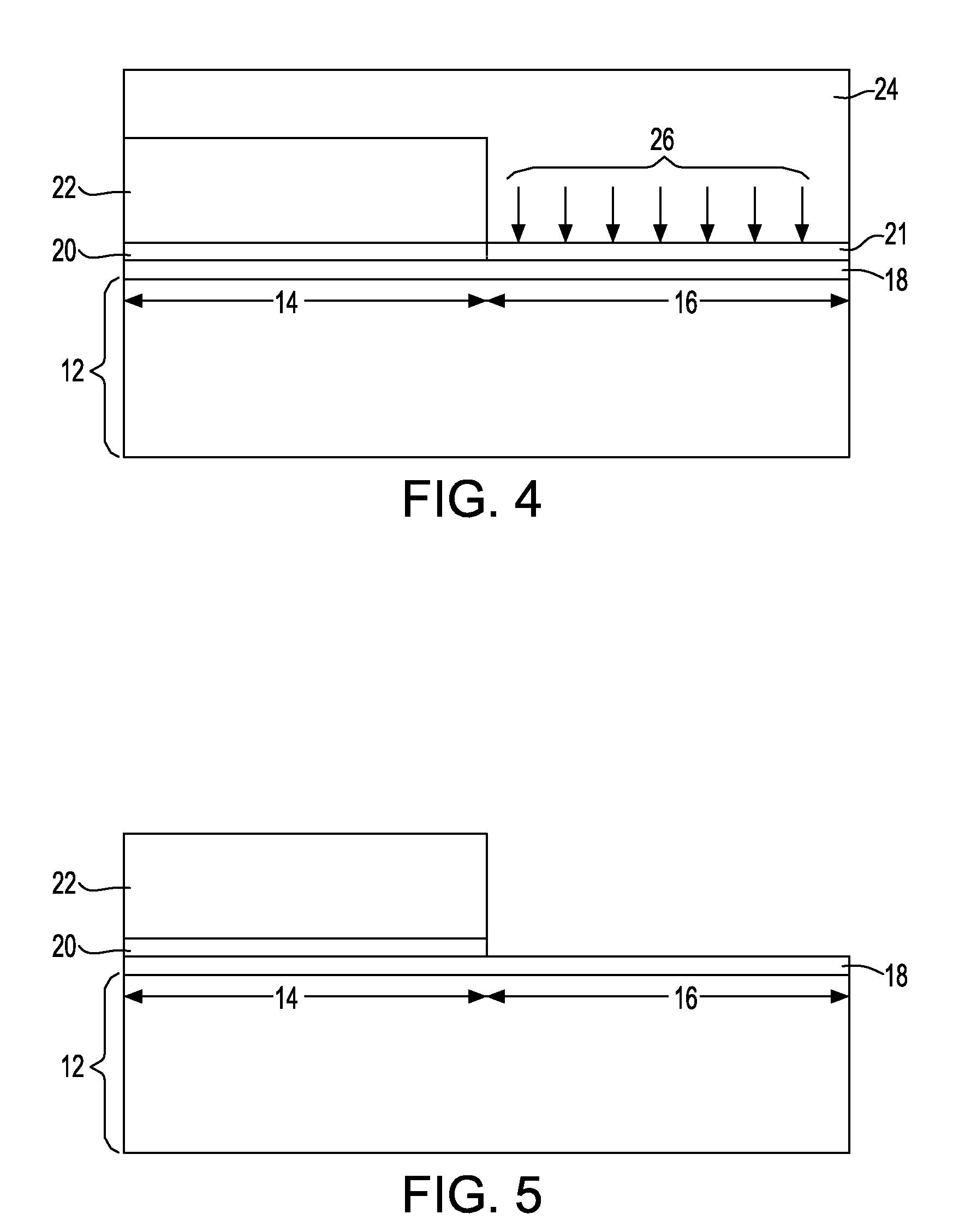

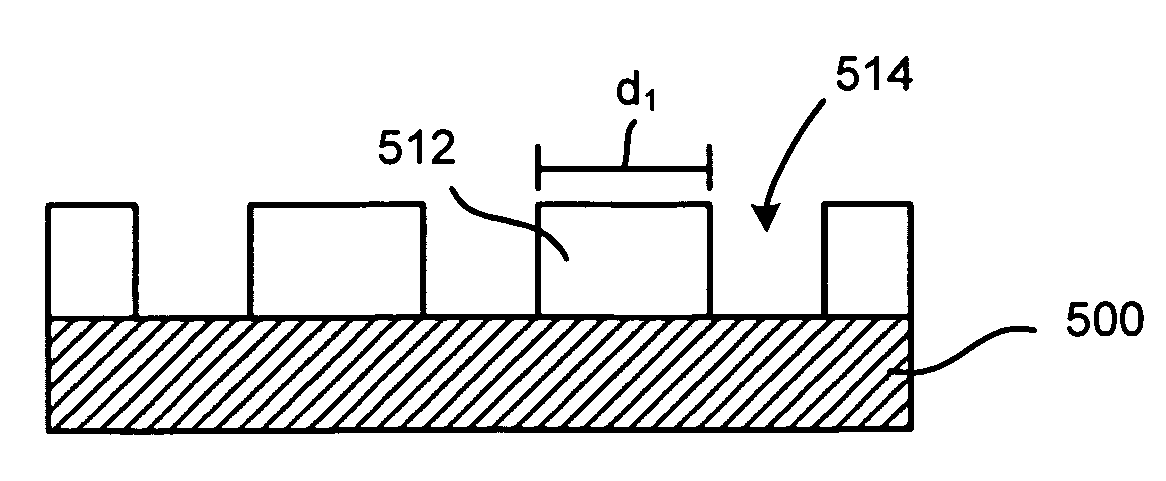

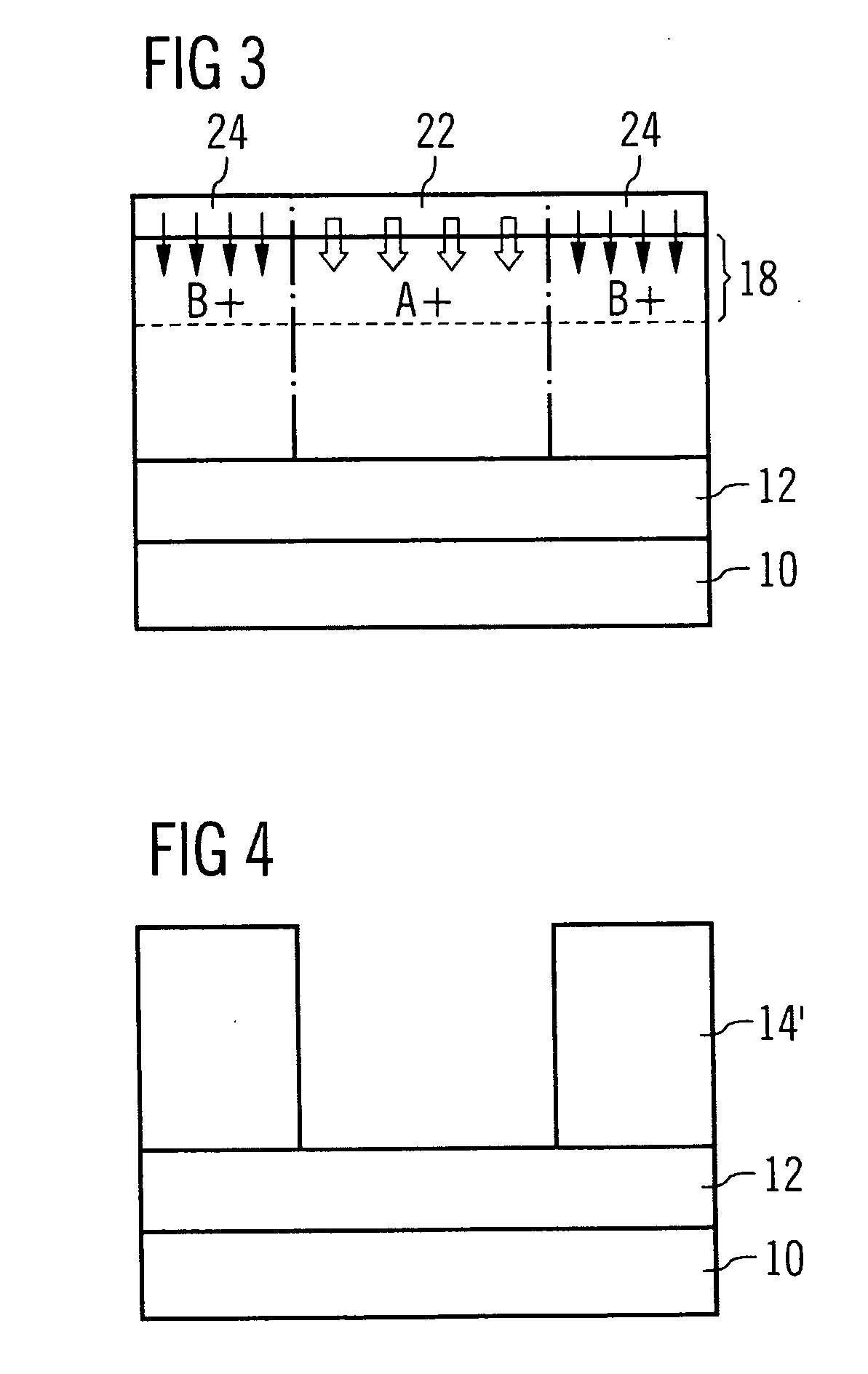

Method for reducing surface defects on patterned resist features

InactiveUS20090214985A1Reduce surface defectsSemiconductor/solid-state device manufacturingPhotosensitive material processingResistAcid concentration

A method is provided for post-processing lithographically patterned resists to reduce surface defects on a patterned resist feature. The method includes providing a substrate with a patterned resist feature containing surface defects with convex and concave regions, applying an acid solution to the patterned resist feature to form a surface acid layer on the patterned resist feature, heat-treating the patterned resist feature, where the heat-treating causes acid concentration in the convex regions and acid dispersion in the concave regions. The method further includes exposing the heat-treated patterned resist feature to a developing solution to preferentially remove resist material from the convex regions and form a trimmed patterned resist feature with reduced surface defects. According to one embodiment, the method further includes repeating the applying, heat-treating, and exposing at least once to further trim and reduce surface defects on the trimmed patterned resist feature.

Owner:TOKYO ELECTRON LTD

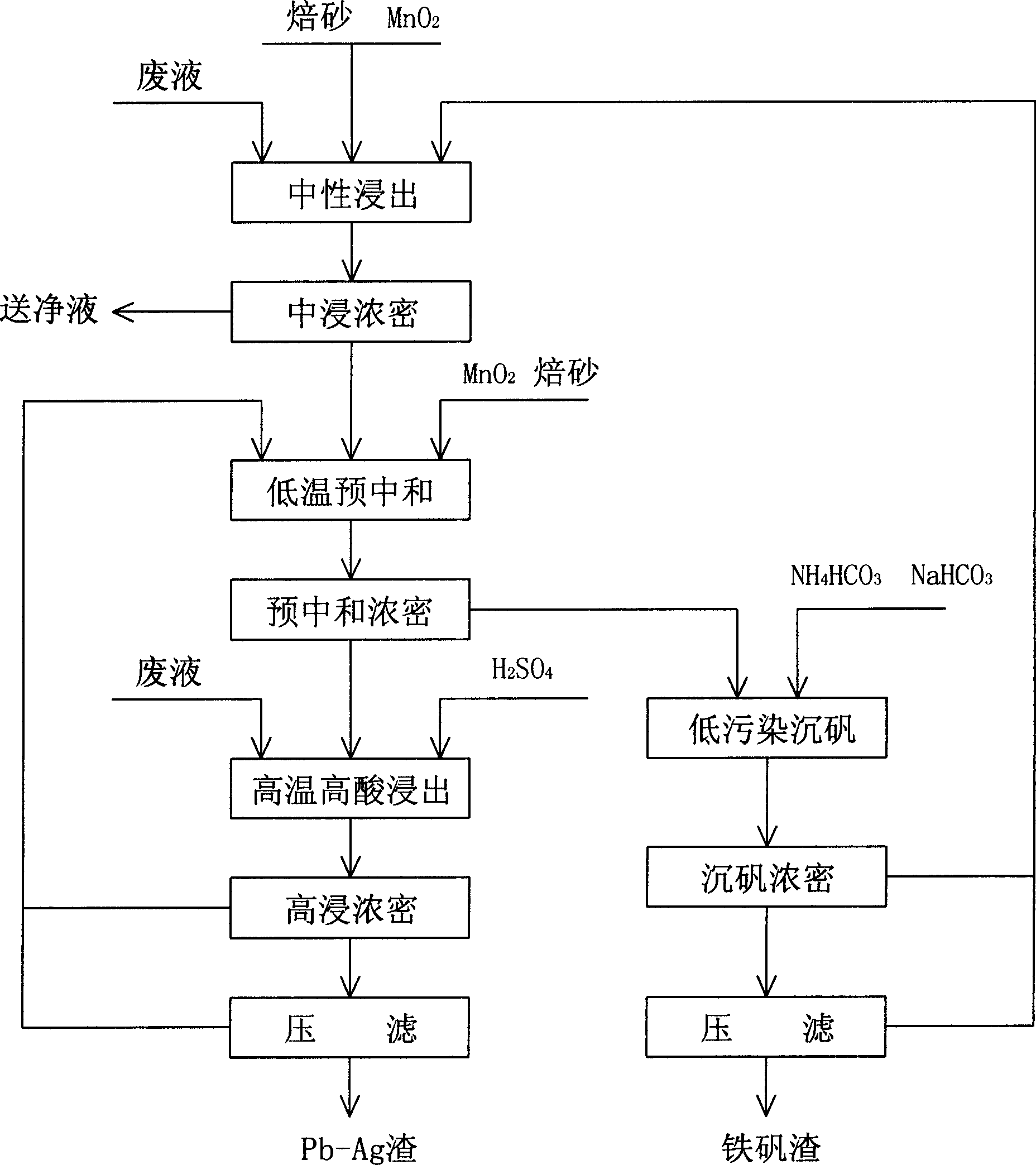

Low pollution vanadium settling iron-removing wet zinc smelting method

ActiveCN1900330AHigh recovery rateReduce consumptionProcess efficiency improvementAcid concentrationZinc smelting

The present invention discloses a kind of wet zinc smelting process, which includes four main technological steps of neutral leaching, low temperature pre-neutralizing, high temperature high acid concentration leaching, and low pollution vanadium settling and iron removing. Before low pollution vanadium settling and iron removing, the high temperature high acid concentration leaching step has iron leached at most, and the solution composition is regulated in the low temperature pre-neutralizing step for satisfactory iron removing effect during vanadium settling without need of adding neutralizing agent. The technological process is suitable for treating complicated zinc concentrate, and has raised metal recovering rate, strengthened impurity removing capacity, raised ultimate product quality, lowered material and power consumption and reduced pollution.

Owner:CHIFENG ZHONGSE ZINC IND CO LTD +1

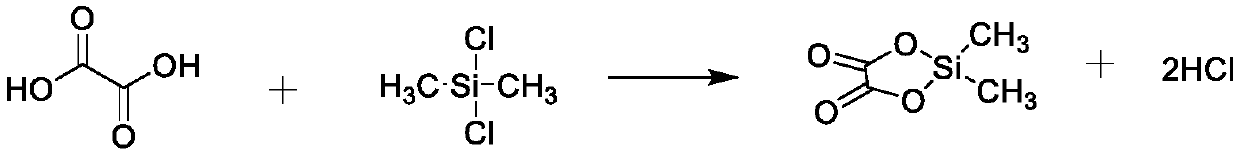

Preparation method of lithium difluorobisoxalate phosphate solution

The invention provides a preparation method of a lithium difluorobisoxalate phosphate solution. The preparation method of the lithium difluorobisoxalate phosphate solution comprises the following steps that (1) dichlorodimethylsilane and oxalic acid are reacted in the presence of a non-aqueous solvent to generate dimethyl silicon-based oxalate; and (2) lithium hexafluorophosphate is added into thereaction solution in the step (1), and reacting is carried out to obtain the lithium difluorobisoxalate phosphate solution. The preparation method is simple and practical, and industrial production can be achieved; the prepared lithium difluorobisoxalate phosphate solution can be directly used as an additive of a non-aqueous electrolyte battery; and the prepared lithium difluorobisoxalate phosphate solution has few chlorine compounds and free acids, wherein the chlorine compounds in terms of chlorine concentration are less than 5 mass ppm, and the free acids in terms of acid concentration converted from hydrofluoric acid are less than 200 mass ppm.

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

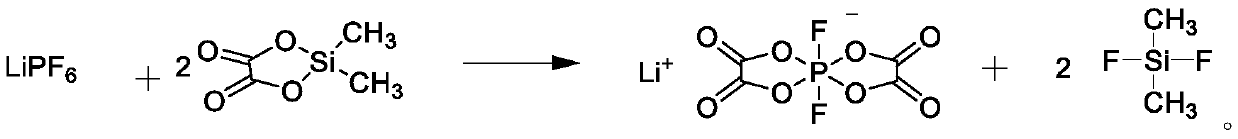

Method for comprehensively recovering Fe, Cu and Si from copper smelting slag

InactiveCN101555551AImprove resource utilizationImprove product added valueSilicaCalcium/strontium/barium chloridesSilicon dioxideMaterials science

The invention discloses a method for comprehensively recovering iron, copper and silicon dioxide from copper smelting slag. The method takes copper smelting slag as a raw material, and comprehensively recovers Fe, Cu and Si in copper slag by adopting wet chemistry metallurgical technology. A muriatic acid and an inorganic acid are mainly adopted for leaching the copper smelting slag, the leaching acid concentration, the solid to liquid ratio, the leaching temperature and the leaching time are selected according to the quality requirement of silicon dioxide products under certain conditions, and silicon dioxide is firstly separated through filtering and drying to prepare silica pigment; the leaching filtered liquid is counteracted, settled, filtered, dried and ground, and ferric oxide phase and copper-bearing phase are selectively separated by adopting a conventional mineral processing method.

Owner:KUNMING UNIV OF SCI & TECH

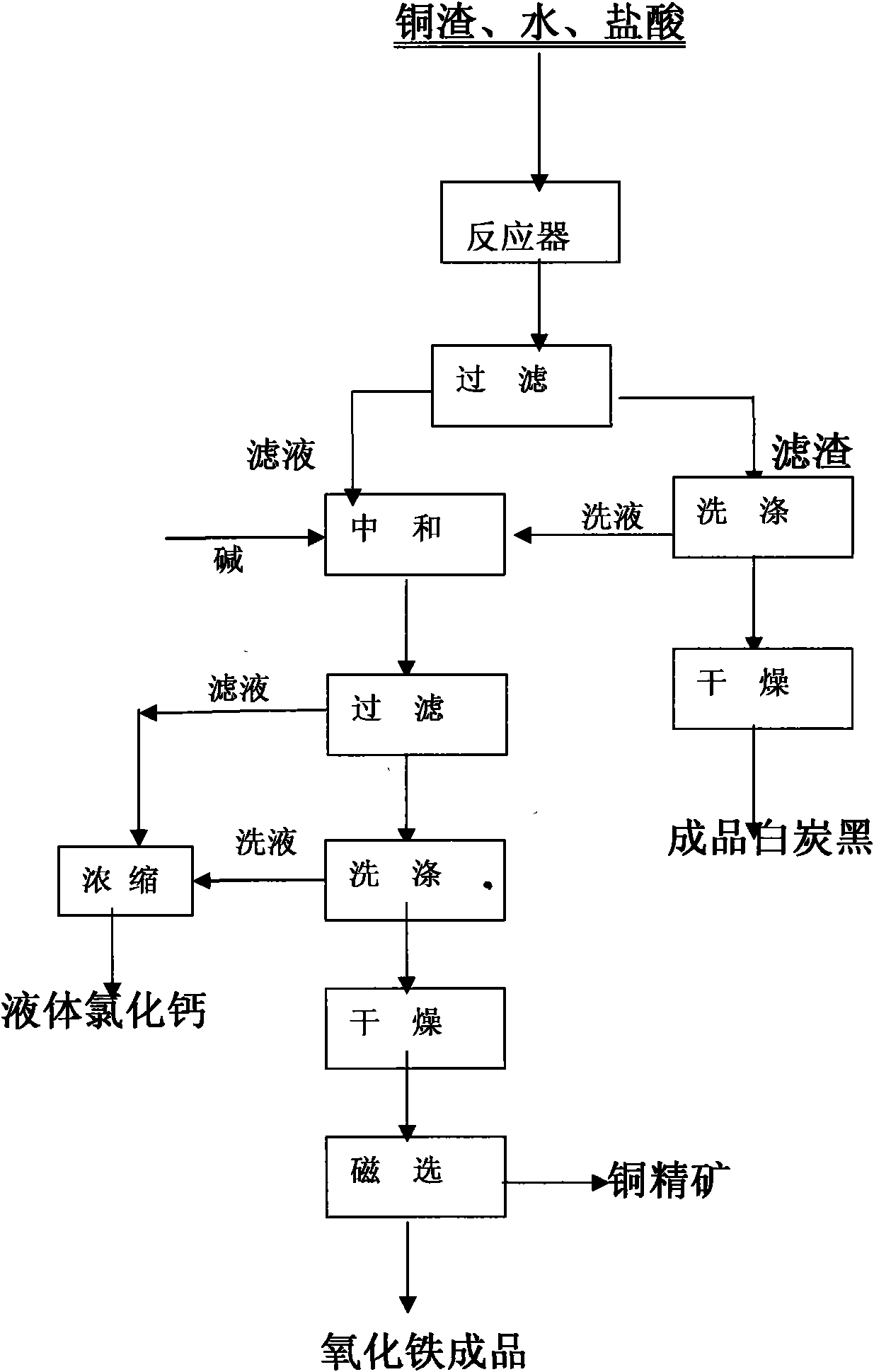

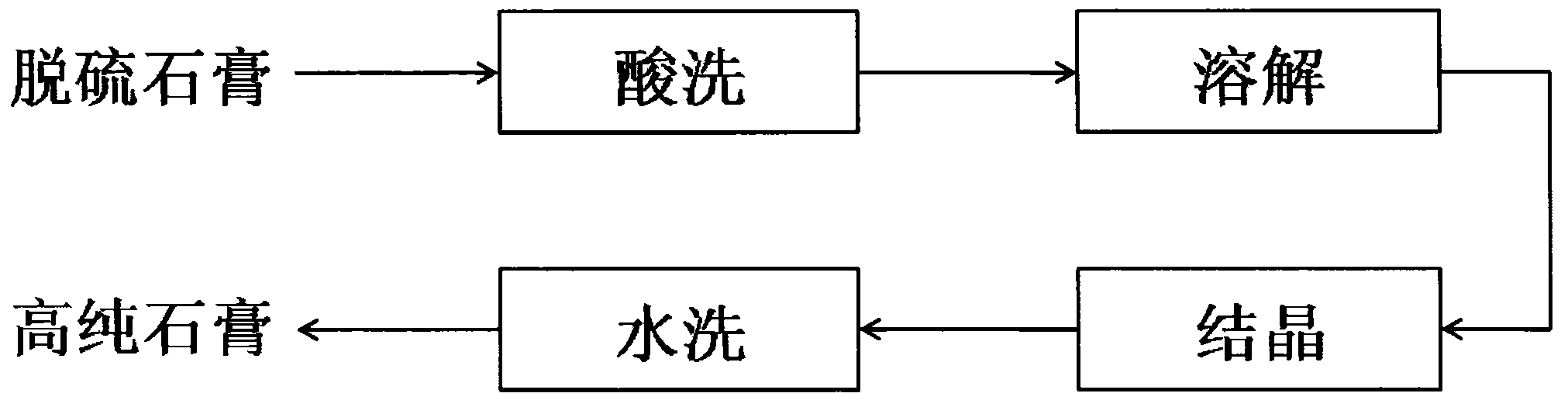

Method for recrystallizing and purifying desulphurized gypsum

InactiveCN101870494AHigh whitenessHigh purityCalcium/strontium/barium sulfatesSolubilityAcid washing

The invention provides a method for recrystallizing and purifying desulphurized gypsum, which mainly comprises the four steps of acid-washing, dissolution, crystallization and washing, and specifically comprises the following steps of: removing impurities, reacted with acids, in the desulphurized gypsum by the aid-washing, dissolving calcium sulphate in the desulphurized gypsum into the acid solution at a relatively higher temperature by utilizing the characteristic that the solubility of the calcium sulphate in the specific acid solution is remarkably changed with the temperature, performing solid-liquid separation to remove undissolved solid-phase impurities at the high temperature, performing cooling recrystallization and the solid-liquid separation on a liquid phase at a relatively lower temperature, and washing and drying a filter cake to obtain high-purity gypsum, wherein the liquid phase in the dissolution and recrystallization processes can be reused. Through the method provided by the invention, the gypsum with relatively higher purity and whiteness can be prepared by selecting a proper solid-to-liquid ratio, proper temperatures and proper acid concentration and performing dissolution and crystallization for a certain time, and the performance of the desulphurized gypsum is remarkably improved.

Owner:SHANGHAI UNIV

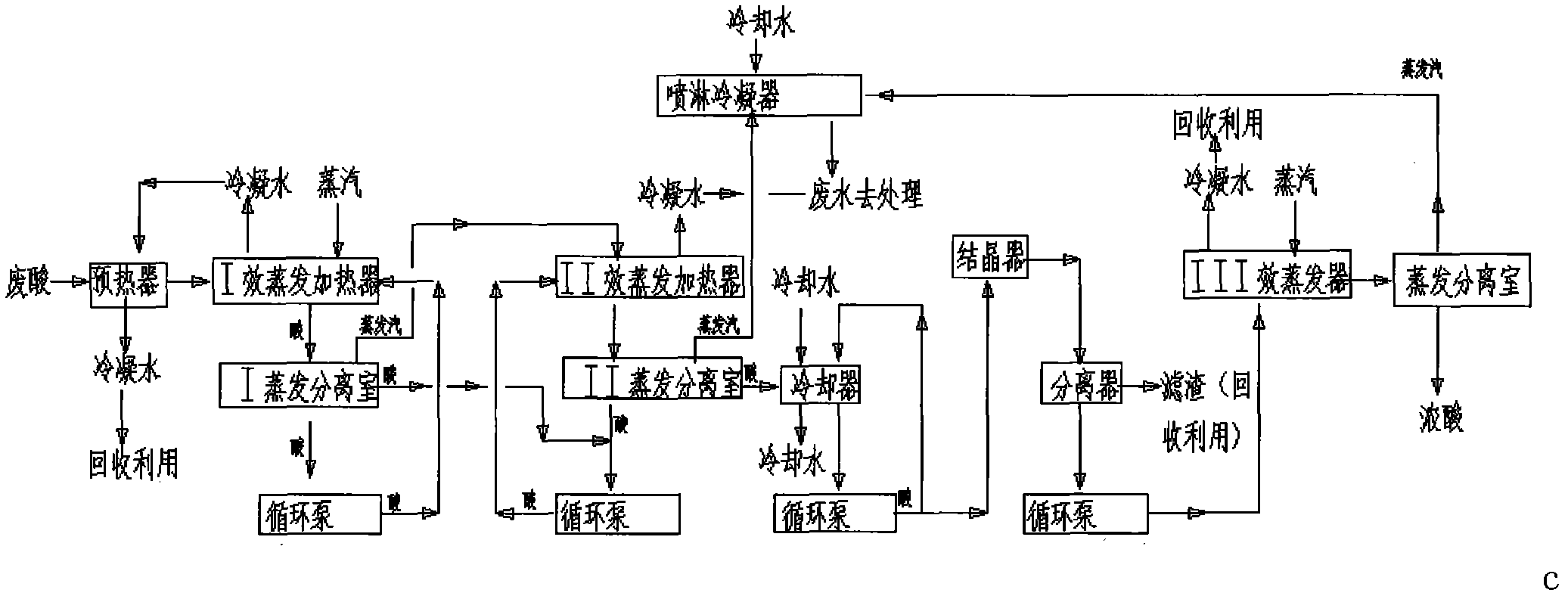

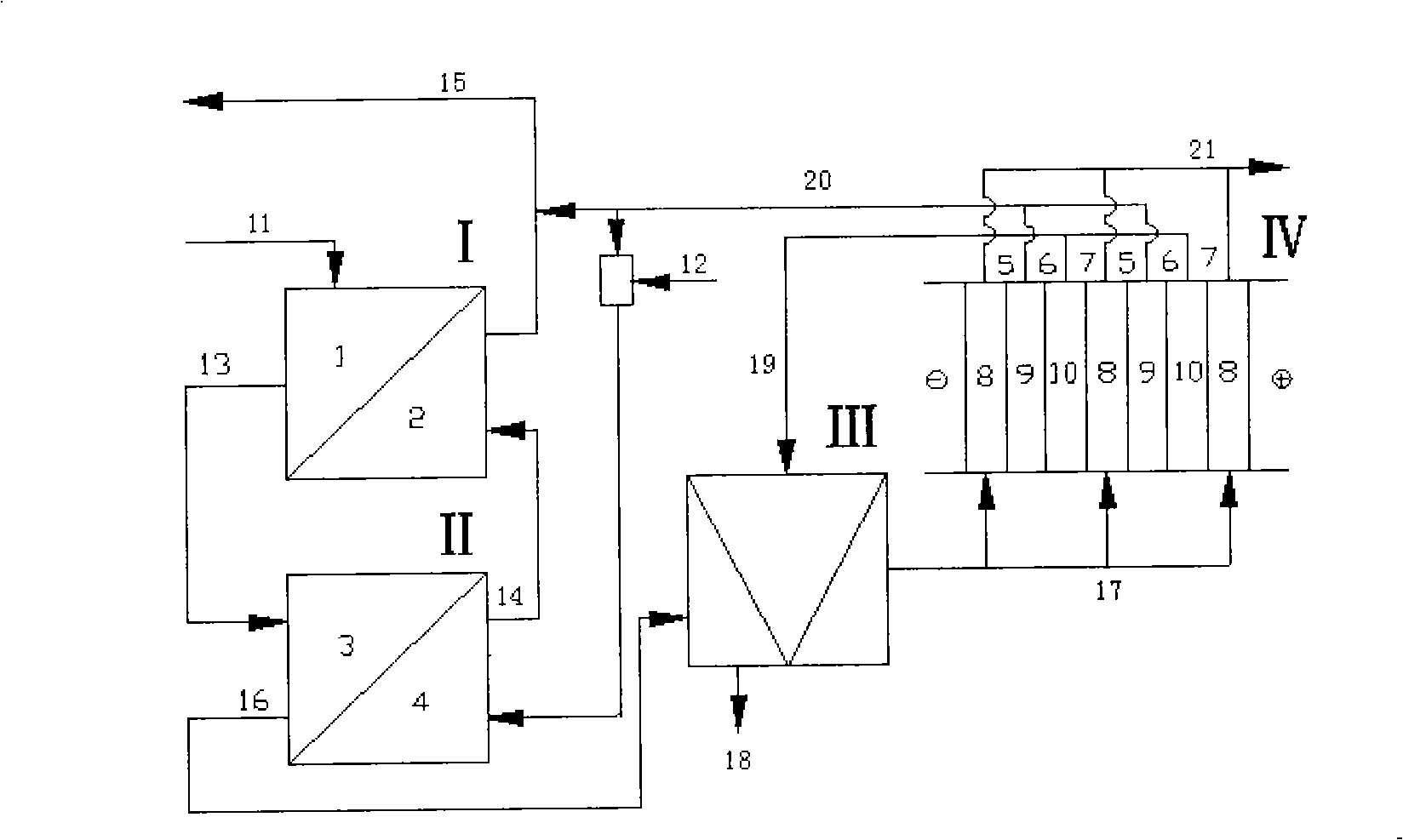

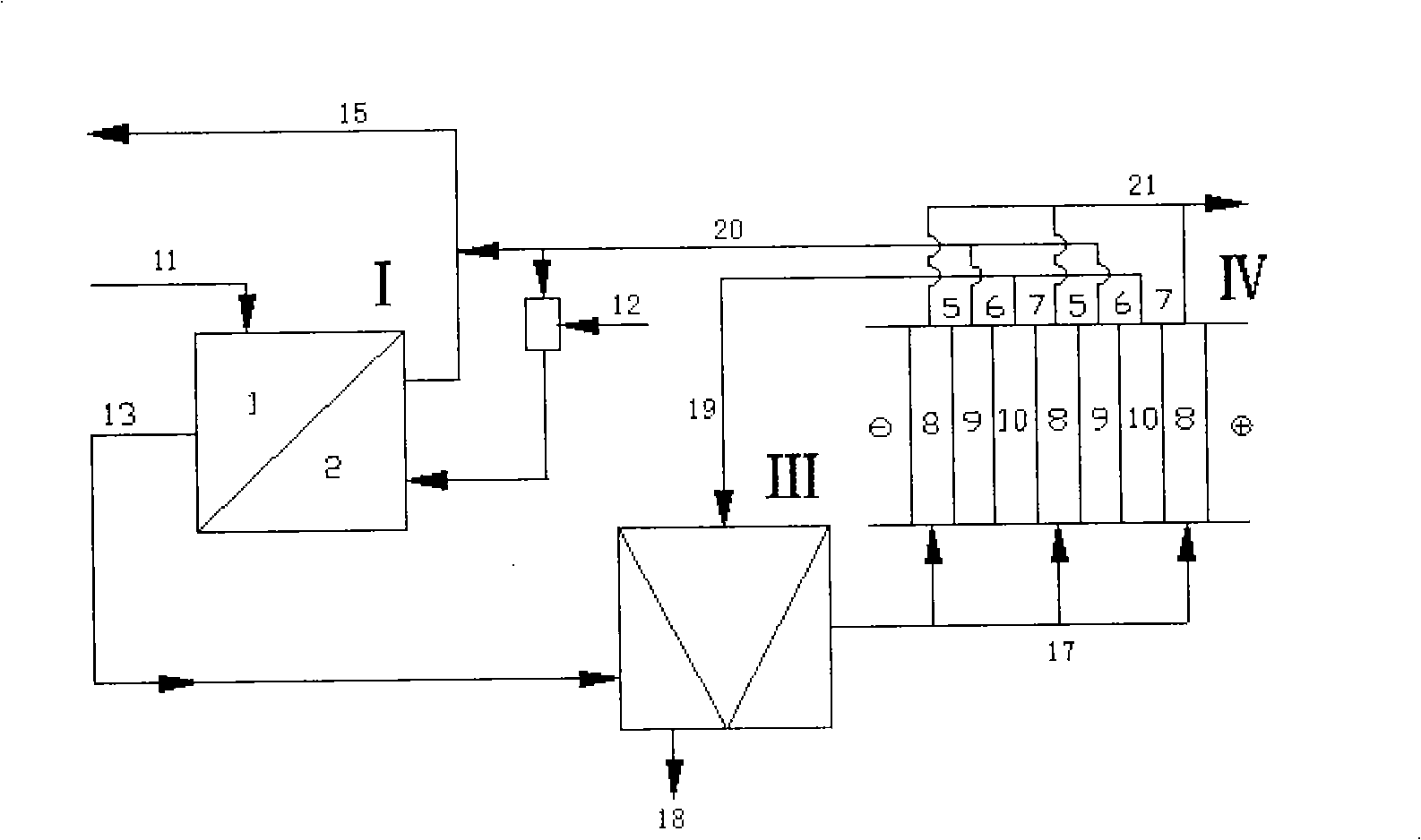

Waste acid concentration multistage treatment method

ActiveCN101935077ATake advantage ofReduce heat transfer areaMultistage water/sewage treatmentWater/sewage treatment by heatingSteam condensationSpray cooling

The invention relates to a waste acid concentration multistage treatment method which comprises the following steps of: heating 20-22% waste acid by a preheater, evaporating by a one-effect evaporation heater and a double-effect evaporation heater, cooling by a cooler and crystallizing by a crystallizer; heating by a triple-effect evaporation heater and separating by a separator to obtain 65% concentrated acid. The secondary steam part is used as a heat source part of the next stage heater and is condensed by spraying cooling water, wherein the one-effect evaporation heater and the double-effect evaporation heater are falling film graphite tube array evaporation heaters; the triple-effect evaporation heater is a floating head tube array graphite heat exchange. The water evaporation capability of the method is increased from 2.5 tons to 10 tons, and the stage number is 3 or more. A large amount of steam and cooling water is saved, and the pollution to the environment is reduced. The heat exchange area of equipment is reduced by 30%, and materials are saved and manufacturing cost is reduced correspondingly. The heat of steam is fully utilized, more than 35% of steam is saved, and more than 30% of cooling water can be saved. The condensed water part of the steam is used as the hear source part of the preheater and is recycled for other uses.

Owner:NANTONG JINGTONG GRAPHITE EQUIP

Anti-wear polyvinyl alcohol aldehyde acetal fiber and its preparing method and use

ActiveCN1900388AImprove spinnabilitySpinning head change rate is lowMonocomponent synthetic polymer artificial filamentWet spinning methodsFiberPolymer science

The present invention refers to wearability vinylon and preparation method and application. It is composed of 100 part by weight polyvinyl alcohol with degree of polymerization 1500-3000, alcoholysis degree 92-99 mol per cent, additive 2-6 part by weight, water 400-900 part by weight, adding to dissolution kettle, at temperature 90-120 degree centigrade, pressure 0.02-0.17 MPa, dissolution 6-10 hr, through filtering and debubbling to make spinning raw liquor; utilizing wet spinning, drawing-heat treating, aldehyde concentration 20-80 g / L, acid concentration 20-300 g / L, temperature 50-90 degree centigrade acetalation processing, to make wearability vinylon with linear density being 1.0-10 dtex, rupture strength 7-11 CN / dtex, elongation at break 10-30 per cent, softening temperature in water 110-120 degree centigrade, number of crimp 3.0-5.0 piece / 25 mm. Said short fiber pure spinning or mixed spinning with other fiber to make different count yarn, fabric used as tent gabe, Knapsack or training garment etc.

Owner:SOLDIER SYST RES CENT MILITARY SUPPLY EQUIP INST GENERAL LOGISTICS DEPT PLA +2

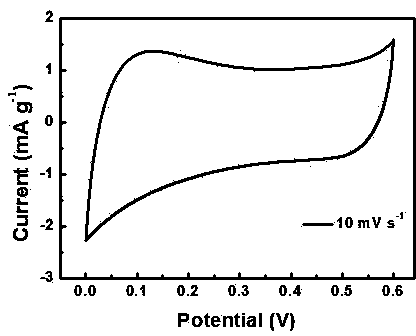

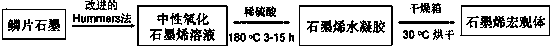

Preparation method of pore-adjustable graphene macroscopic bodies used for supercapacitor

The invention discloses a method for preparing graphene macroscopic bodies adopting different pore structures and used for a supercapacitor by adjusting sulphuric acid concentration. The method comprises the following steps in sequence: preparing a neutral oxidized graphene solution with the concentration of 4.5-8.8 mg / mL; adding a sulphuric acid solution into the neutral oxidized graphene solution, and mixing uniformly, wherein the volume of the sulphuric acid solution is two times of that of the neutral oxidized graphene solution, and the concentration of the sulphuric acid solution is 0.01-0.45 mol / L; placing a mixed solution in a reaction kettle to react for 3-15 hours at the temperature of 180 DEG C to obtain graphene hydrogel, and drying in a drying cabinet with the temperature of 30 DEG C to obtain the graphene macroscopic bodies. The obtained macroscopic bodies are used for electrode materials of the supercapacitor; the specific capacitance value of the obtained macroscopic bodies can reach 175-322 F / g under the electric current density of 100 mA / g.

Owner:LIAONING NORMAL UNIVERSITY

Method for extracting lithium from salt lake brine

ActiveCN104357676AEasy to operateReduce tributyl phosphate concentrationProcess efficiency improvementHigh concentrationKerosene

The invention provides a method for extracting lithium from salt lake brine. The method comprises the following steps: 1) preparing extract organic phases which comprise a composite extracting agent and a diluent, wherein the composite extracting agent is prepared by mixing tributyl phosphate with N,N-bis(2-ethylhexyl)-3-butanone acetamide according to a volume percent ratio of 50% to 50%; the diluent is sulfonated kerosene; 2) preparing an extract water phase which is an LiCl-MgCl2-H2O system; 3) adding HCl and FeCl3.6H2O to the extract water phase, wherein the ratio of amount of substances of iron and lithium is controlled to be 1.3 to 1, the acid concentration is 0.5mol / L, and the lithium concentration is 1-3g / L; 4) standing after fully mixing the extract water phase obtained in the step 3) with the extract organic phases obtained in the step 1) in a volume ratio of 1 to 2, and then separating a liquid phase. By adopting the method, the problems that the corrosivity of high-concentration tributyl phosphate towards extraction equipment is stronger and the dissolution loss of the extracting agent in water is serious in long-term operation are solved, and the lithium extraction efficiency of the prior art is achieved. The extraction method is simple and reliable to operate.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

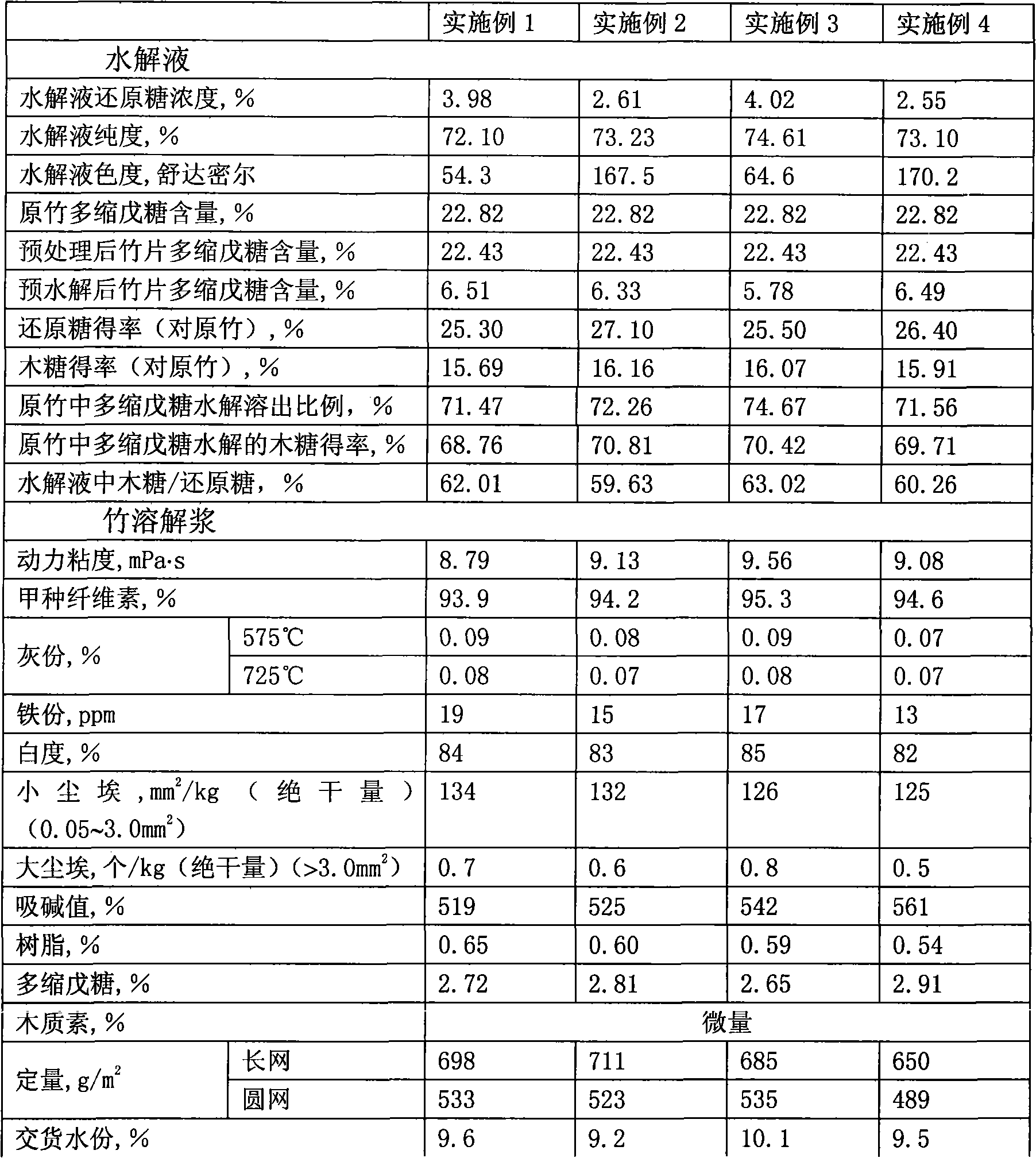

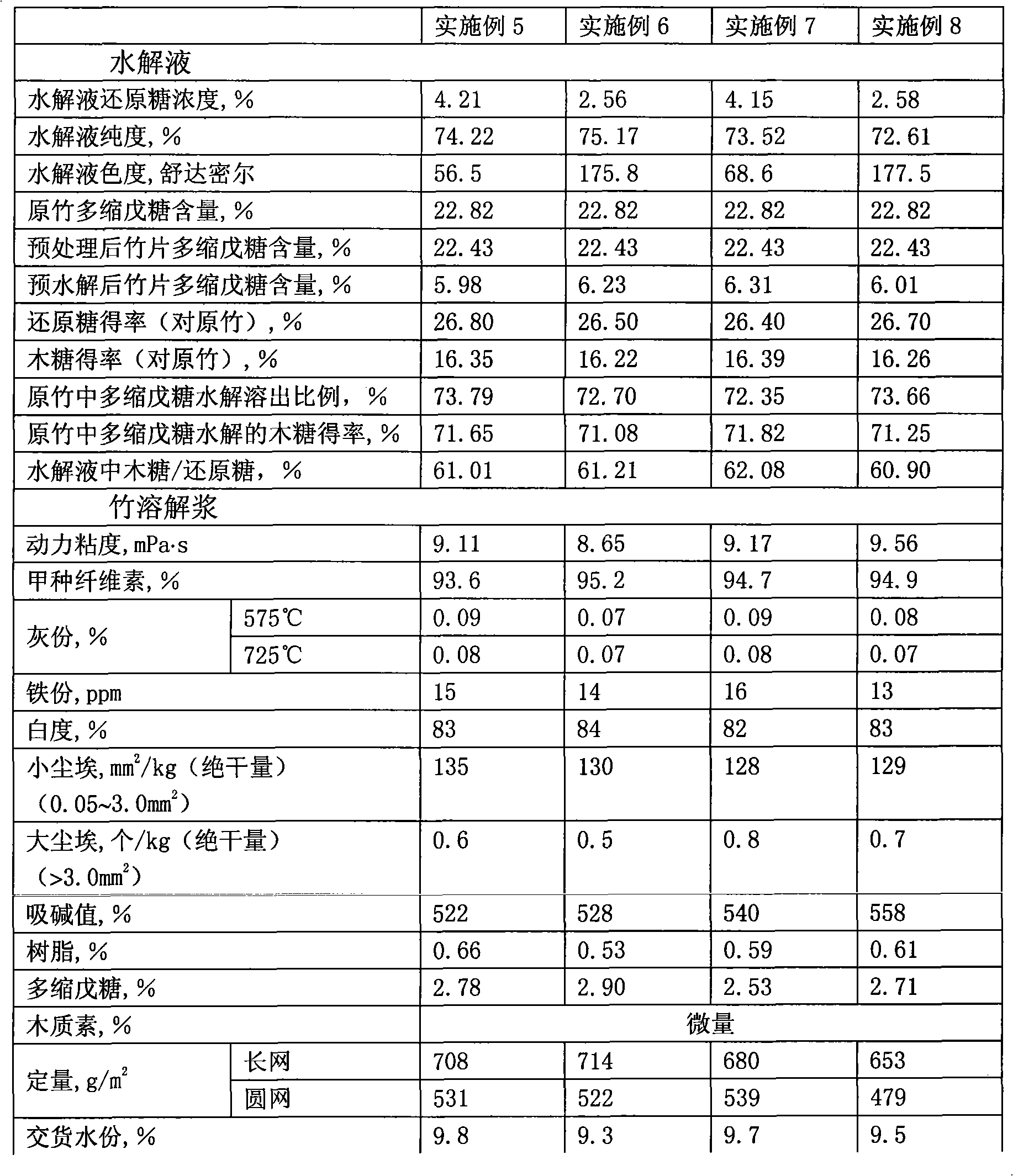

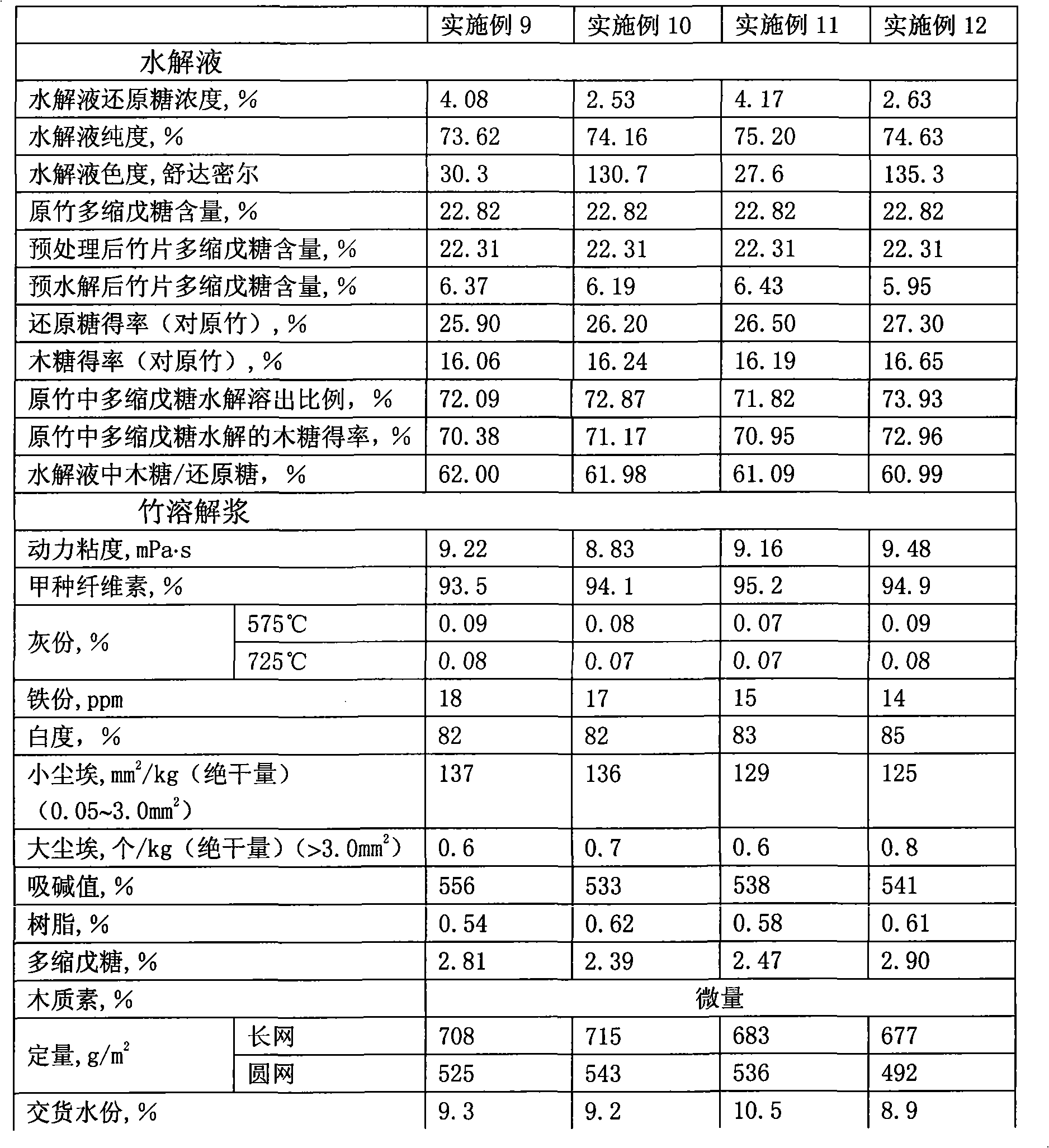

Method for preparing bamboo dissolving pulp by improved prehydrolysis alkaline process and product thereof

InactiveCN101514529AReasonable range of hydrolyzed reducing sugar concentrationReasonable range of purityPretreatment with acid reacting compoundsPulping with inorganic basesHydrolysatePerformance index

The invention relates to a method for preparing bamboo dissolving pulp by improved prehydrolysis alkaline process, which comprises the following steps of: bamboo material preparation, in which bamboo is made into bamboo sheets and bamboo threads, the bamboo sheets and threads are washed to remove impurities and dust; pretreatment, which is for removing more organic and nonorganic impurities, and in which the loss of pentosan is less than 2 percent; prehydrolysis, which is carried out at an acid concentration of sulphuric acid and hydrochloric acid of 0.1 to 10.0 weight percent, a temperature of between 80 and 14 DEG C and a liquor ratio of 1:4-15 for 30 to 400 minutes; and alkaline process. The method has the advantages that: the performance index of the bamboo dissolving pulp meets the requirements of viscose fibre pulp and the like; the improved prehydrolysis process allows the major part of pentosan in the bamboo to be hydrolyzed; the hydrolysate can be used as a raw material for xylose, xylitol, L-Arabinitol, ethanol and other products; the improved prehydrolysis process lays a good foundation for cooking and improving the reaction performance of the dissolving pulp; little production cost is added, the treatment load and cost of waste are reduced with the recovery of the products of the prehydrolysis, and the comprehensive cost is the lowest; and the comprehensive utilization of the components of biomass is realized during the pulping process of the dissolving pump.

Owner:上海士林纤维材料有限公司

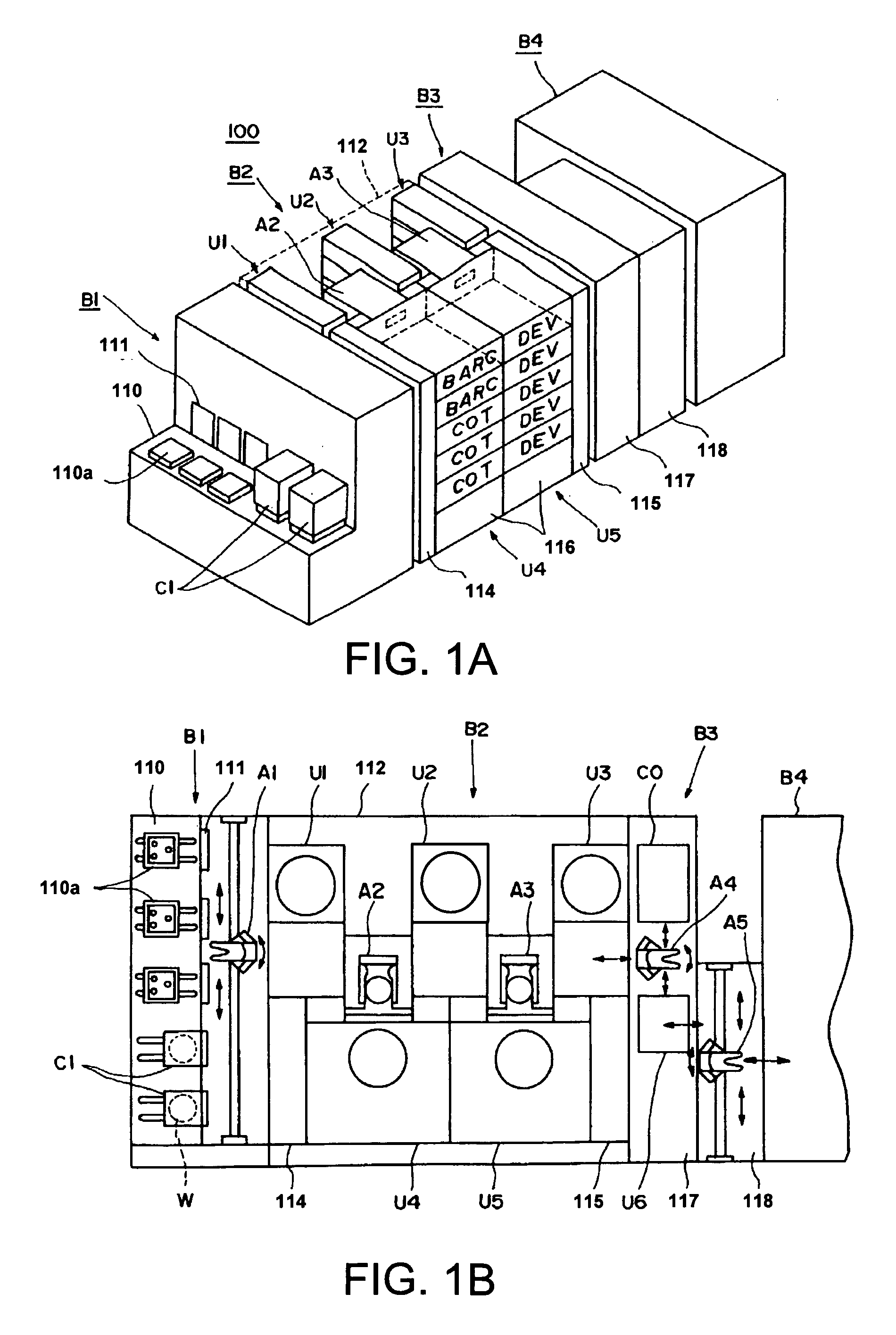

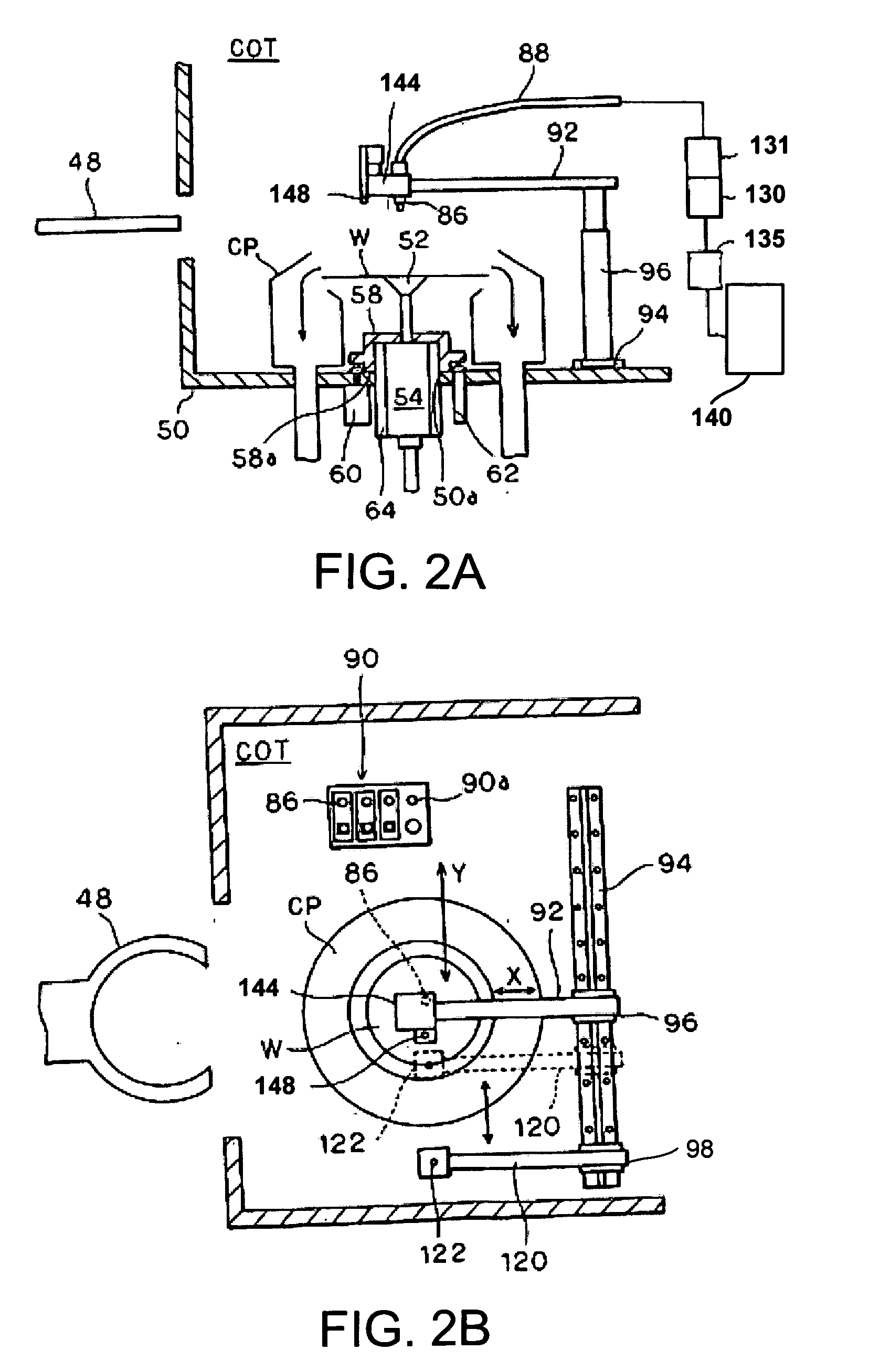

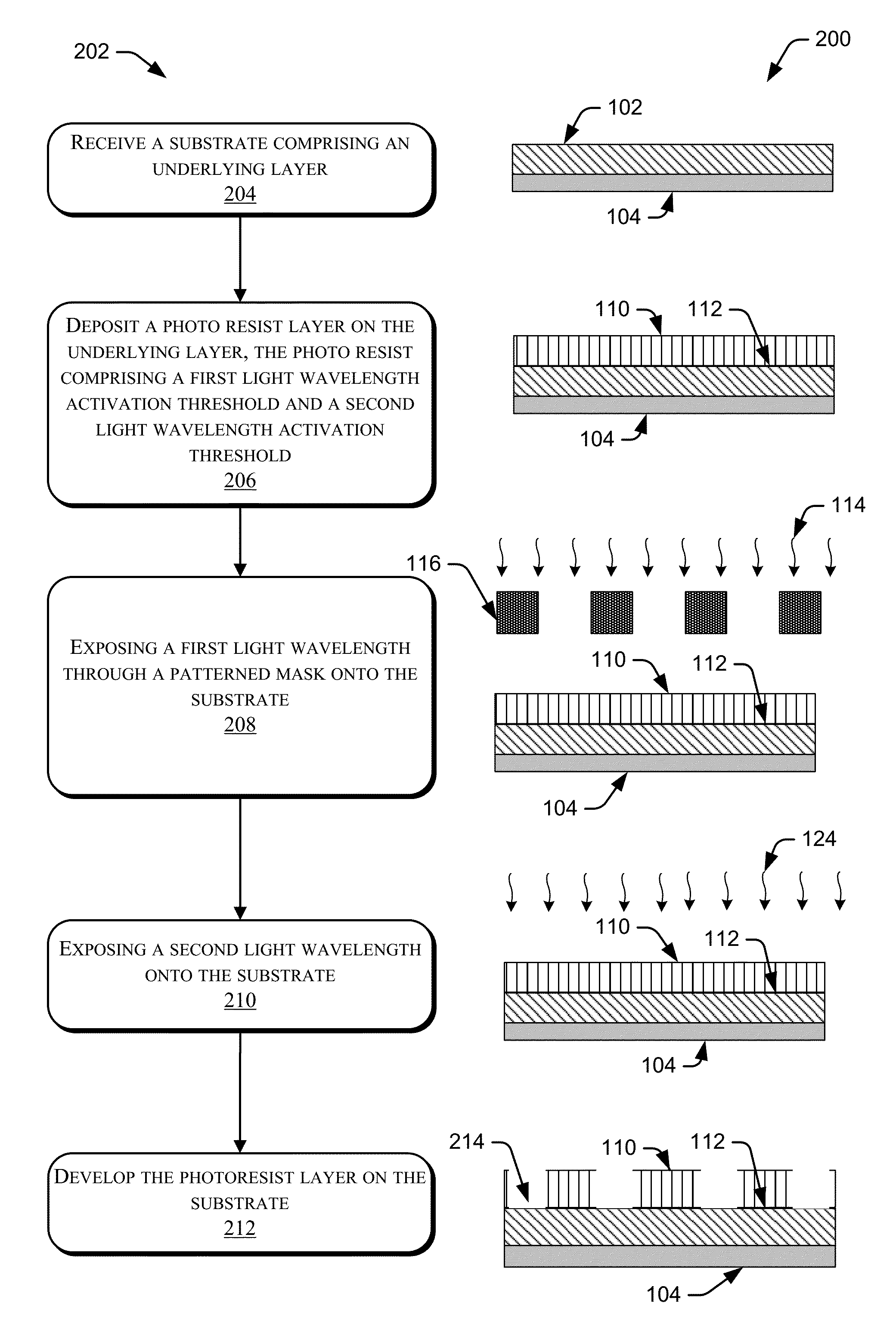

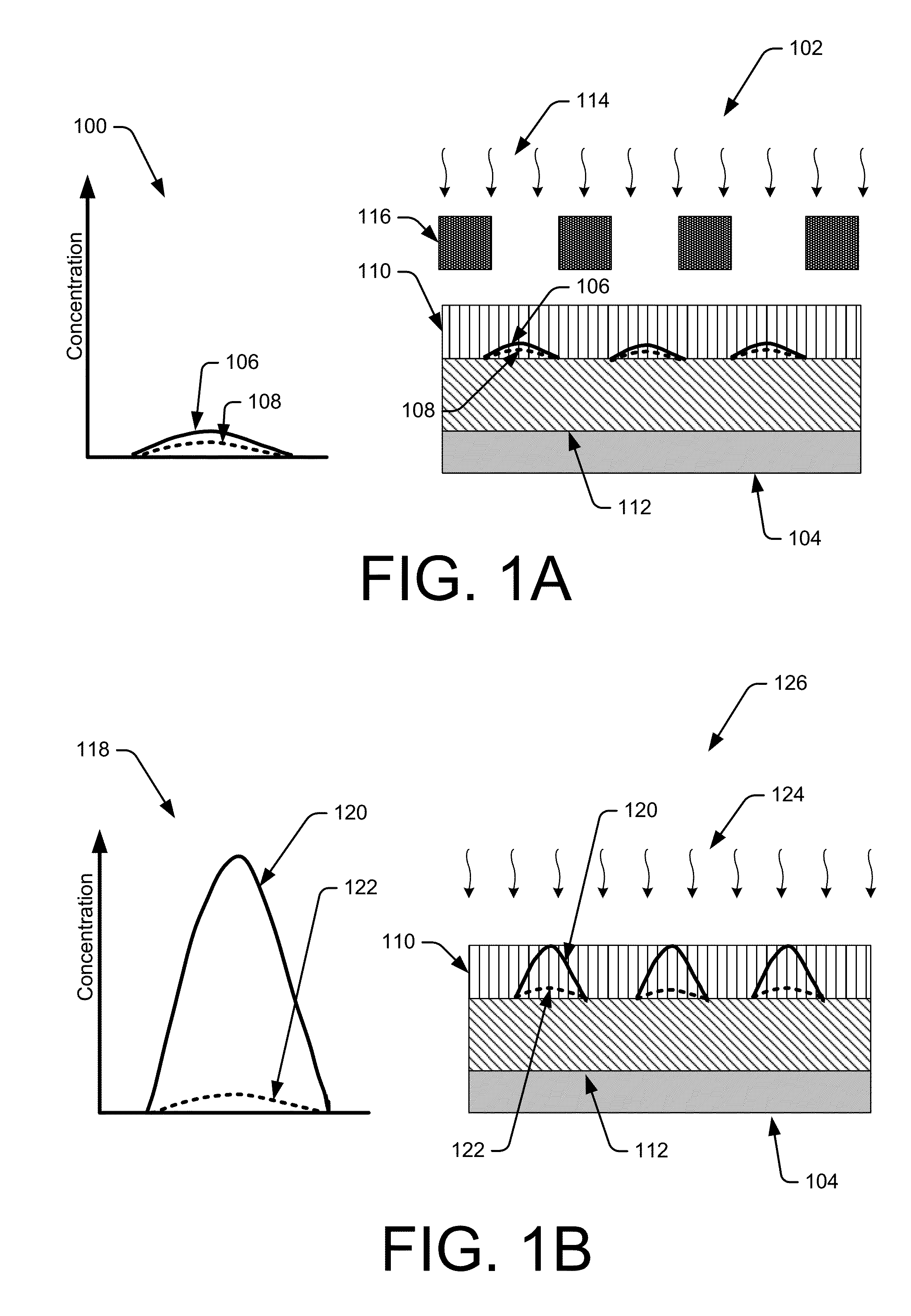

Methods and Techniques to use with Photosensitized Chemically Amplified Resist Chemicals and Processes

ActiveUS20150241783A1Prevent micro-bridgingPrevent scummingSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistGeneration rate

The disclosure herein describes methods for Photosensitized Chemically Amplified Resist Chemicals (PS-CAR) to pattern light sensitive films on a semiconductor substrate. In one embodiment, a two-step exposure process may generate higher acid concentration regions within a photoresist layer. The PS-CAR chemicals may include photoacid generators (PAGs) and photosensitizer elements that enhance the decomposition of the PAGs into acid. The first exposure may be a patterned EUV exposure that generates an initial amount of acid and photosensitizer. The second exposure may be a non-EUV flood exposure that excites the photosensitizer which increases the acid generation rate where the photosensitizer is located on the substrate. The distribution of energy during the exposures may be optimized by using certain characteristics (e.g., thickness, index of refraction, doping) of the photoresist layer, an underlying layer, and / or an overlying layer.

Owner:TOKYO ELECTRON LTD

Substrate for information recording medium, information reocrding medium and method for manufacturing same

InactiveUS20050162956A1Improve acid resistanceReduce torqueMagnetic materials for record carriersBase layers for recording layersVitrificationHeat resistance

A substrate for an information recording medium, which has high heat resistance and high acid resistance and is formed of a glass having a glass transition temperature (Tg) of 600° C. or higher and having an etching rate of 0.1 μm / minute or less with regard to a hydrosilicofluoric acid aqueous solution that is maintained at a temperature of 45° C. and has a hydrosilicofluoric acid concentration of 1.72% by weight, and an information recording medium having an information recording layer formed on the above substrate.

Owner:HOYA CORP

Photosensitive coating for enhancing a contrast of a photolithographic exposure

InactiveUS20070105043A1Reduce concentrationElectric discharge tubesPhotosensitive materialsResistX-ray

A photosensitive coating material for enhancing a contrast of a photolithographic exposure of a resist film formed on a substrate, including a base polymer, a solvent for facilitating deposition of the photosensitive coating material upon a surface adjacent to said resist film to form a film thereupon, an alkaline additive suited to diffuse into the adjacent resist for reducing or neutralizing an acid concentration formed locally therein, a photoactive component arranged to reduce or neutralize a concentration of the alkaline additives in portions of the photosensitive coating, which are exposed with optical light, UV- or X-ray radiation, electrons, charged particles, ion projection lithography.

Owner:QIMONDA

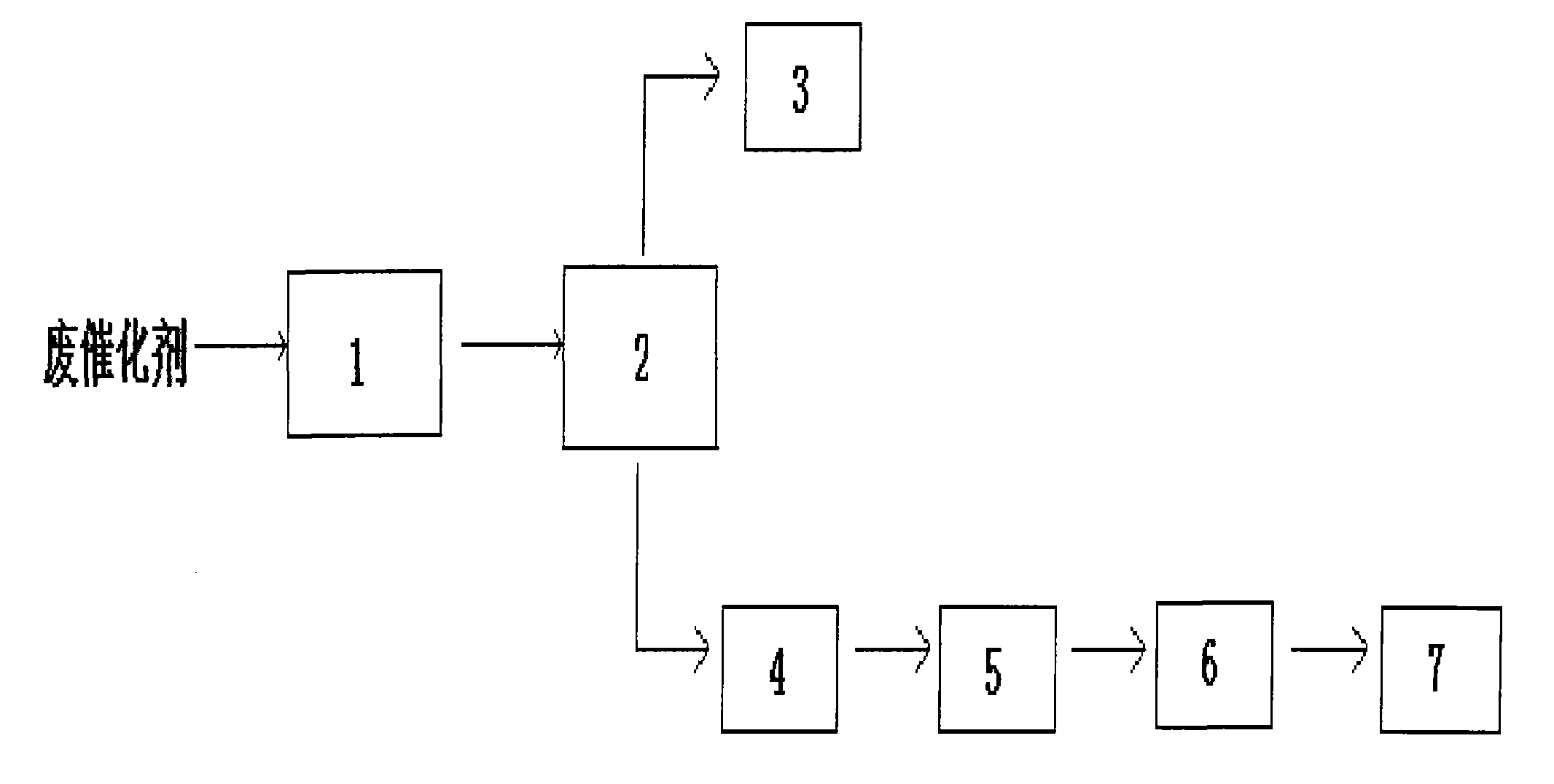

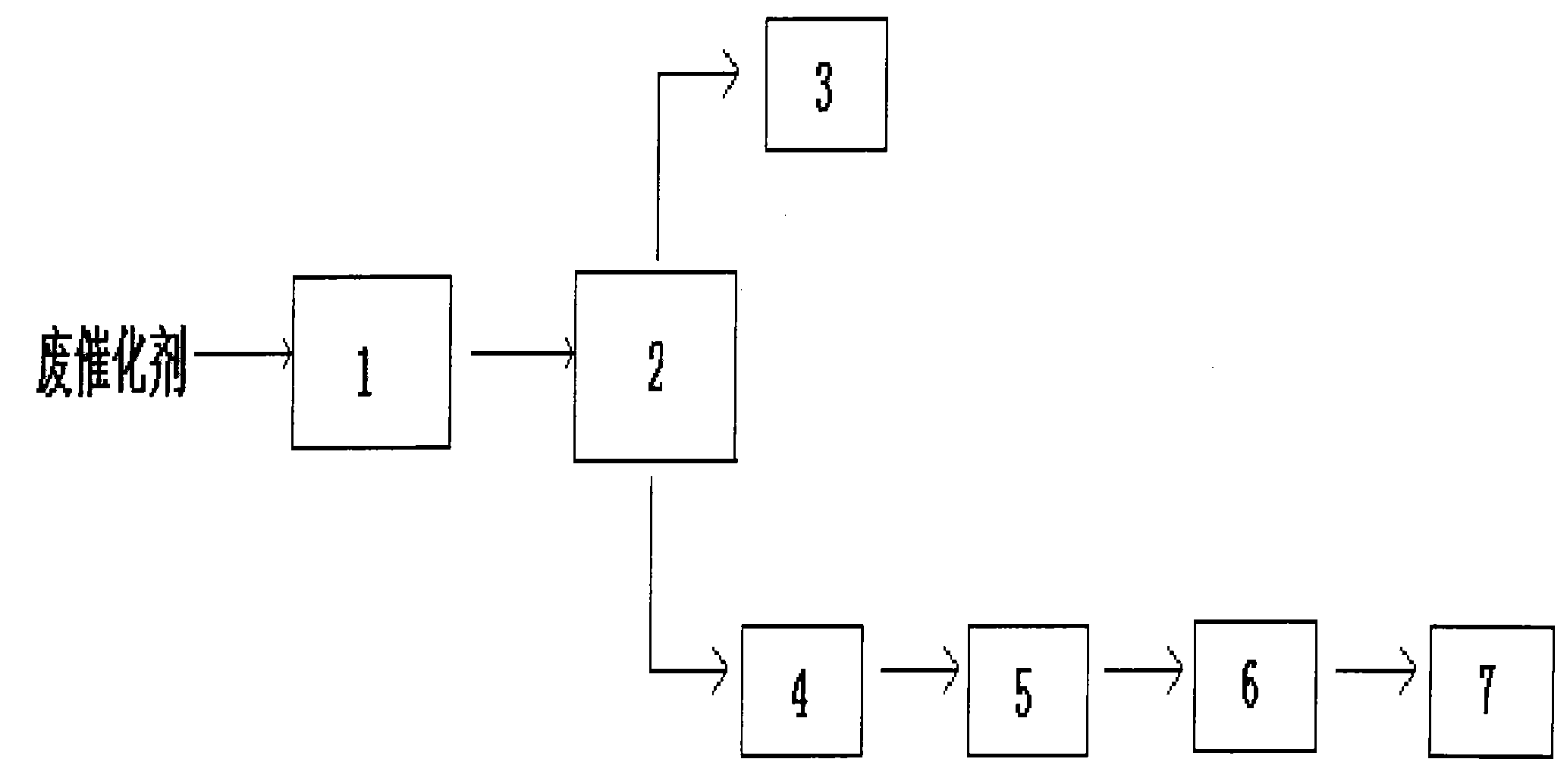

Method for recycling pure acid from metallic ion containing waste acid and regenerating alkali

ActiveCN101343039AHigh recovery rateReduce manufacturing costChlorine/hydrogen-chloride purificationSulfur-trioxide/sulfuric-acidFiltrationAcid concentration

Disclosed is a method which recovers pure acid from the waste acid contains metallic ion and reproduces alkaline, and belongs to the environmental protection field. The process steps include that: (a) the waste acid solution with the acid concentration 10%-40% is processed with the first level diffusion dialysis; (b) the residue after the step a is processed with the second level diffusion dialysis; the volume ratio of the first level (or the second level) waste acid (or the first level diffusion residue) in the first level (or the second level) diffusion dialysis groove residue and the acid recovery chamber collected solution is 1:0.5-1:3.0; the flow rate of the waste acid (or the first level diffusion residue) is enabled to be 0.2-0.6L / h; the flow rate of the acid recovery chamber collected solution is 0.1-1.8L / h; (c) the second residue after the step b is processed with neutralization and deposition; (d) the neutralized filtrate after the solid-liquid separation-filtration is fed to the three compartment electrodialysis groove middle chamber, the electrodialysis is processed for 1-3h under the voltage 5-15V to obtain the reproduction acid and reproduction alkaline. The method which recovers pure acid from the waste acid contains metallic ion and reproduces alkaline has the advantages of high acid recovery rate, low production cost and energy-consumption, less film pollution, saving water, reducing discharge and no secondary pollution.

Owner:HARBIN COSLIGHT STORAGE BATTERY

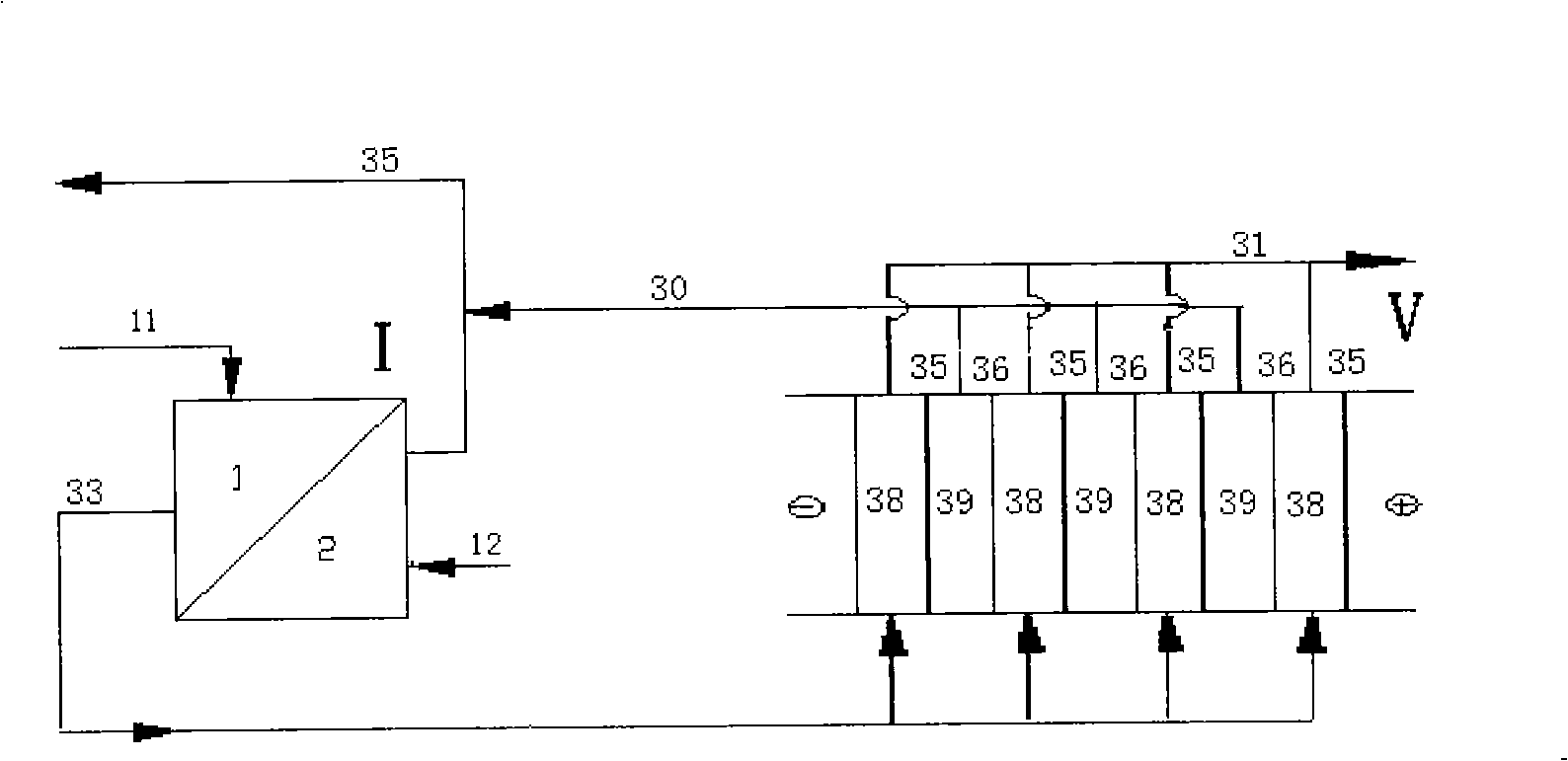

Regeneration method for heavy oil hydro-treating catalyst

InactiveCN102310005AEasy to recycleHigh recovery rateCatalyst regeneration/reactivationAcid concentrationFuel oil

The invention discloses a regeneration method for a heavy oil hydro-treating catalyst. The regeneration method comprises the following steps of: performing dry distillation, washing with an acidic solution, and performing roasting coke removal treatment, wherein the dry distillation temperature is 300 to 550 DEG C, the acidic solution is a hydrochloric acid-containing solution, the weight ratio of the washing acid to the catalyst is 5 to 50L / Kg, and the acid concentration is 0.1 to 0.5mol / L. Compared with the prior art, the regeneration method has the advantage of well recovering the service performance of an inactivated catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

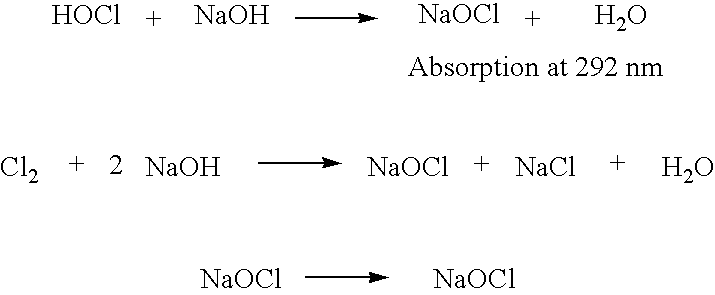

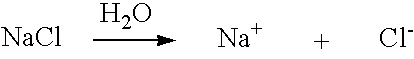

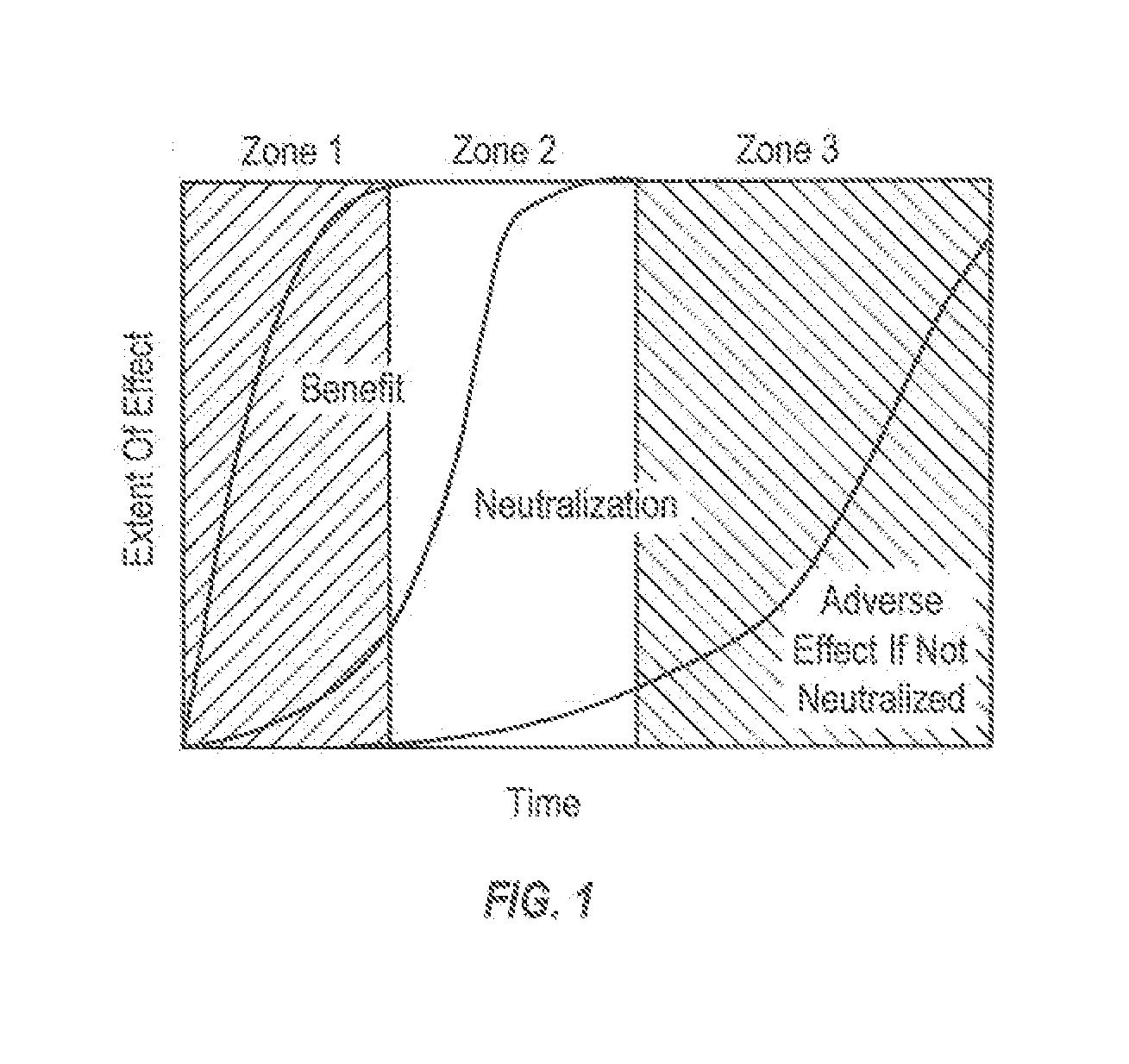

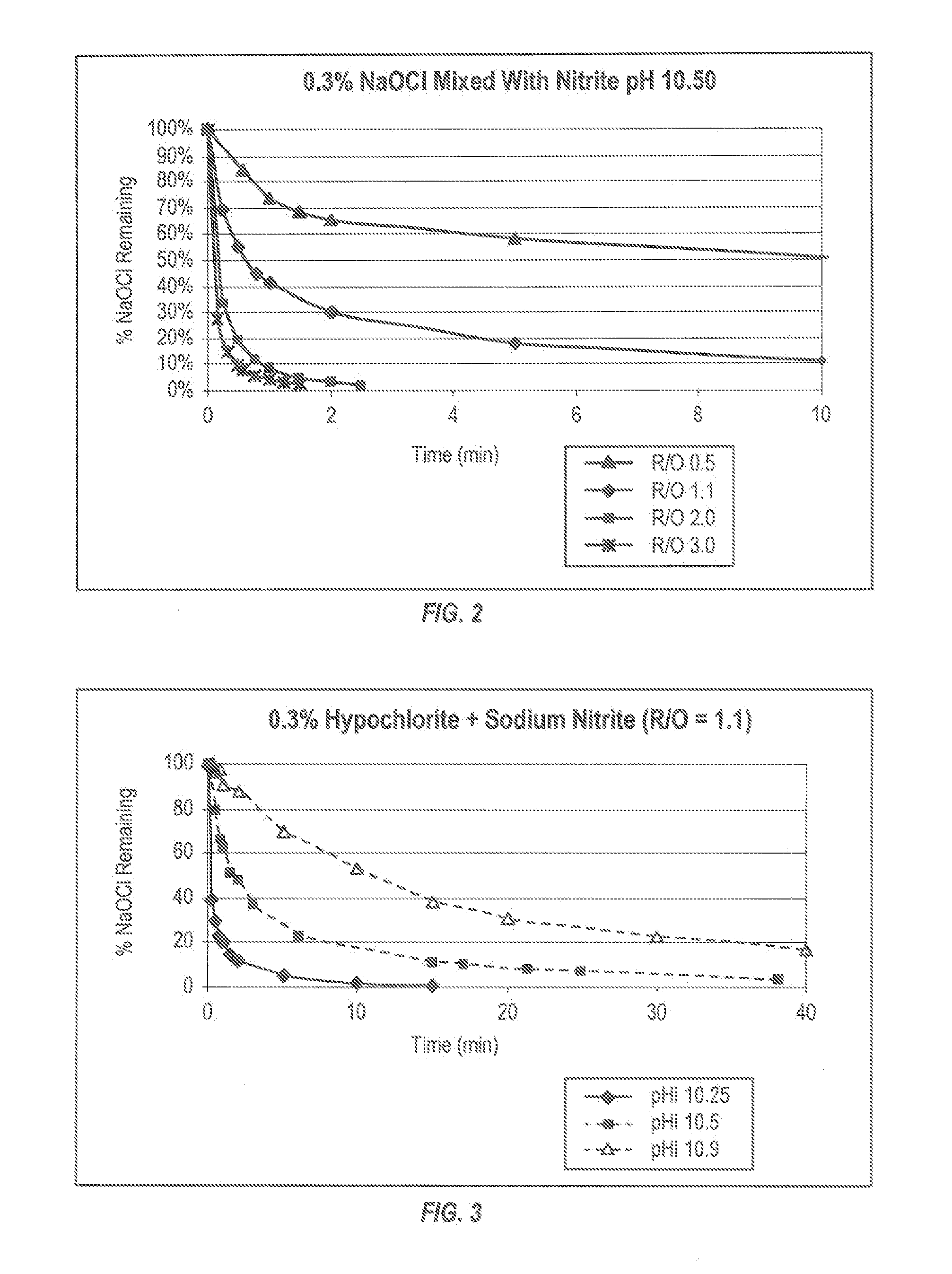

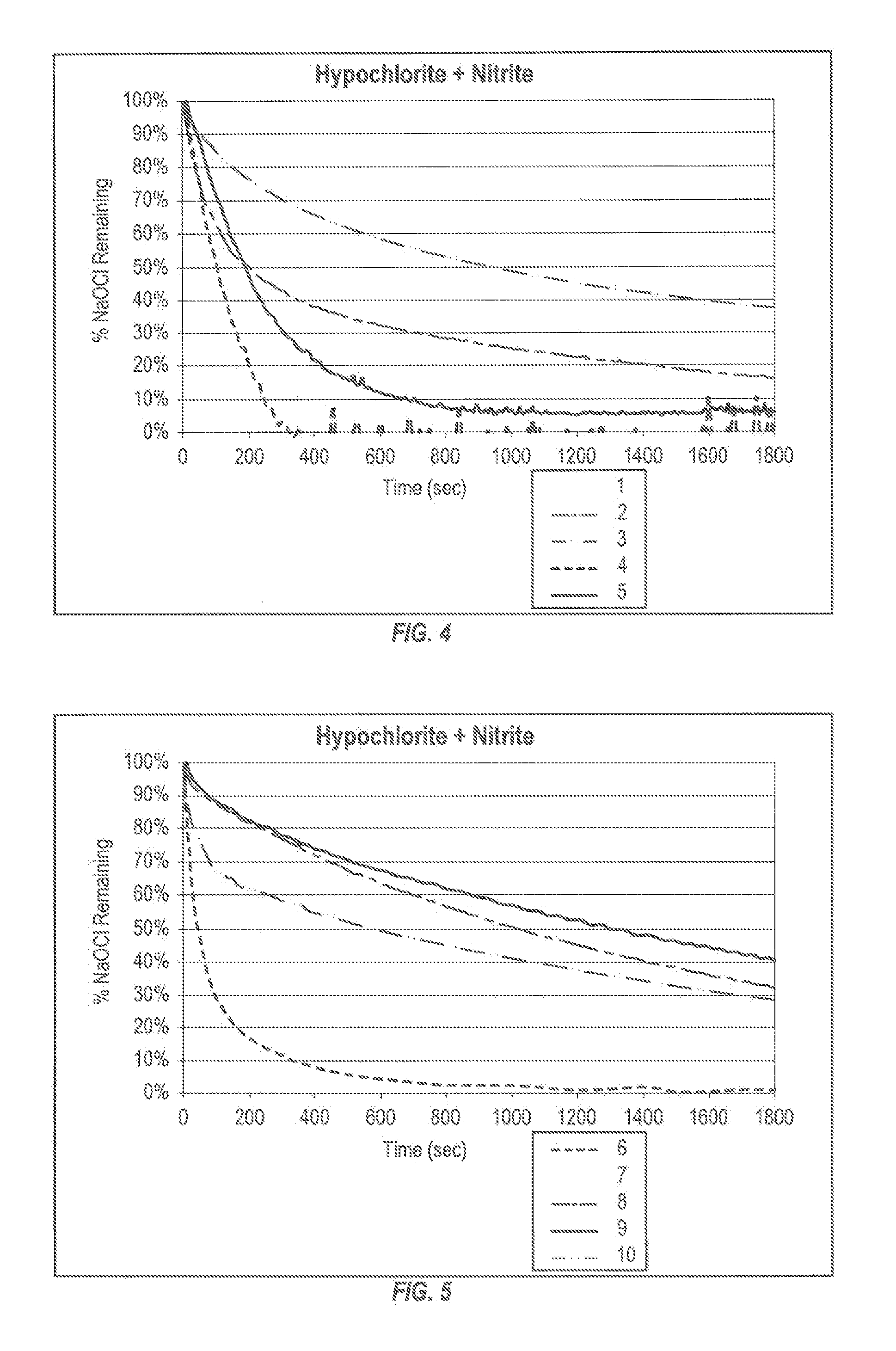

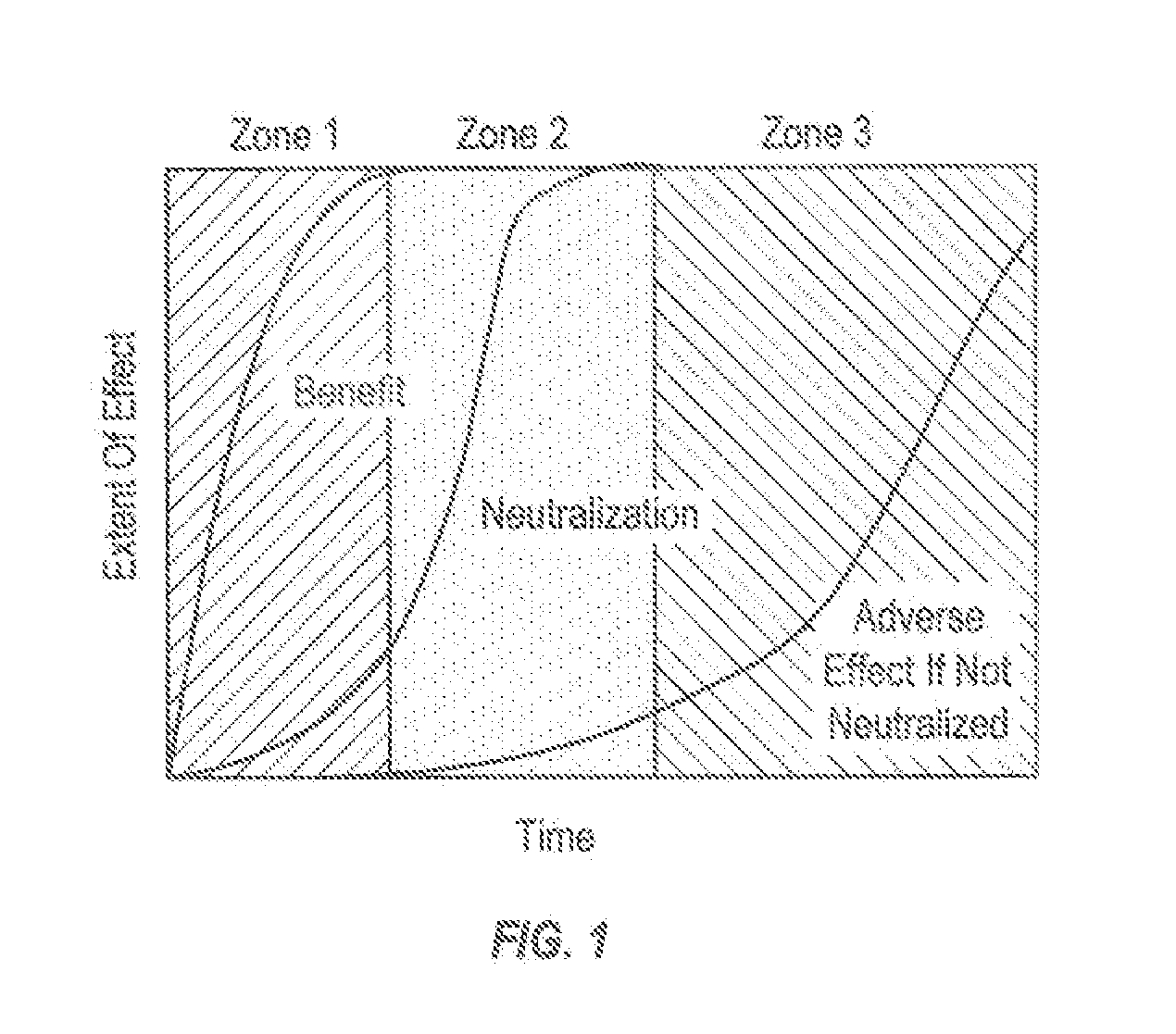

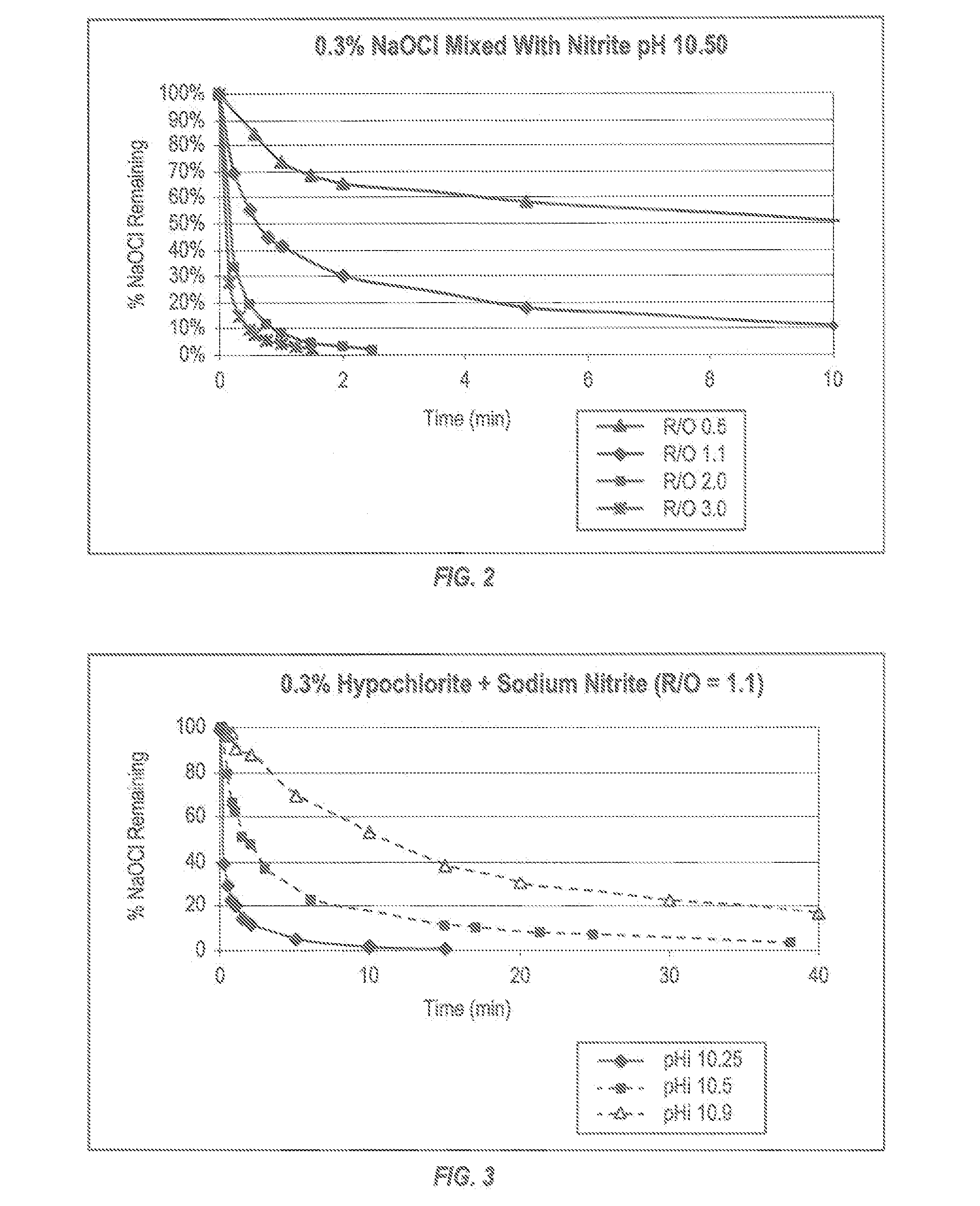

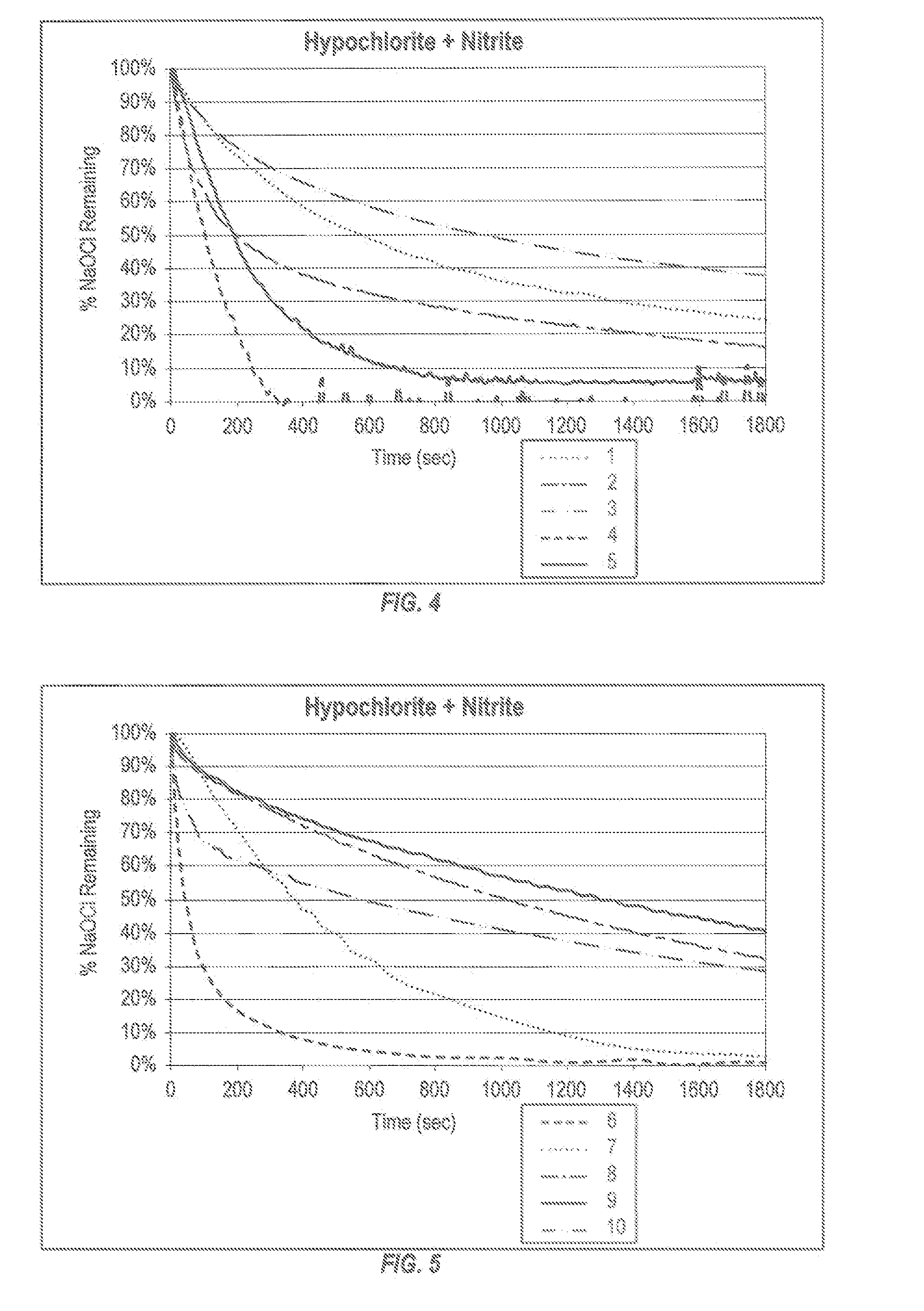

Targeted performance of hypohalite compositions thereof

InactiveUS20130216631A1Prevent and minimize negative side effectReduce oxidant concentrationInorganic/elemental detergent compounding agentsBiocideSodium chlorateHypochlorite

This invention relates to extend the benefits of using hypochlorite compounds such as sodium hypochlorite to clean and disinfect articles while reducing or eliminating the side effects of treating an article with a strong oxidant material. The invention relates to a single step process involving mixing of precursor compositions of a suitable hypohalite or hypohalous acid with a solution of a reducing agent. Optionally a buffer may be present in either or both precursor compositions, such that at time of use such active hypohalous acid concentration in the resulting aqueous mixture remains at a sufficient activity level to effect one or more desired benefits against a target substrate for a desired period of time. The oxidant is substantially consumed by reaction with the reducing agent after the time needed for achieving the desired benefit has passed.

Owner:THE CLOROX CO

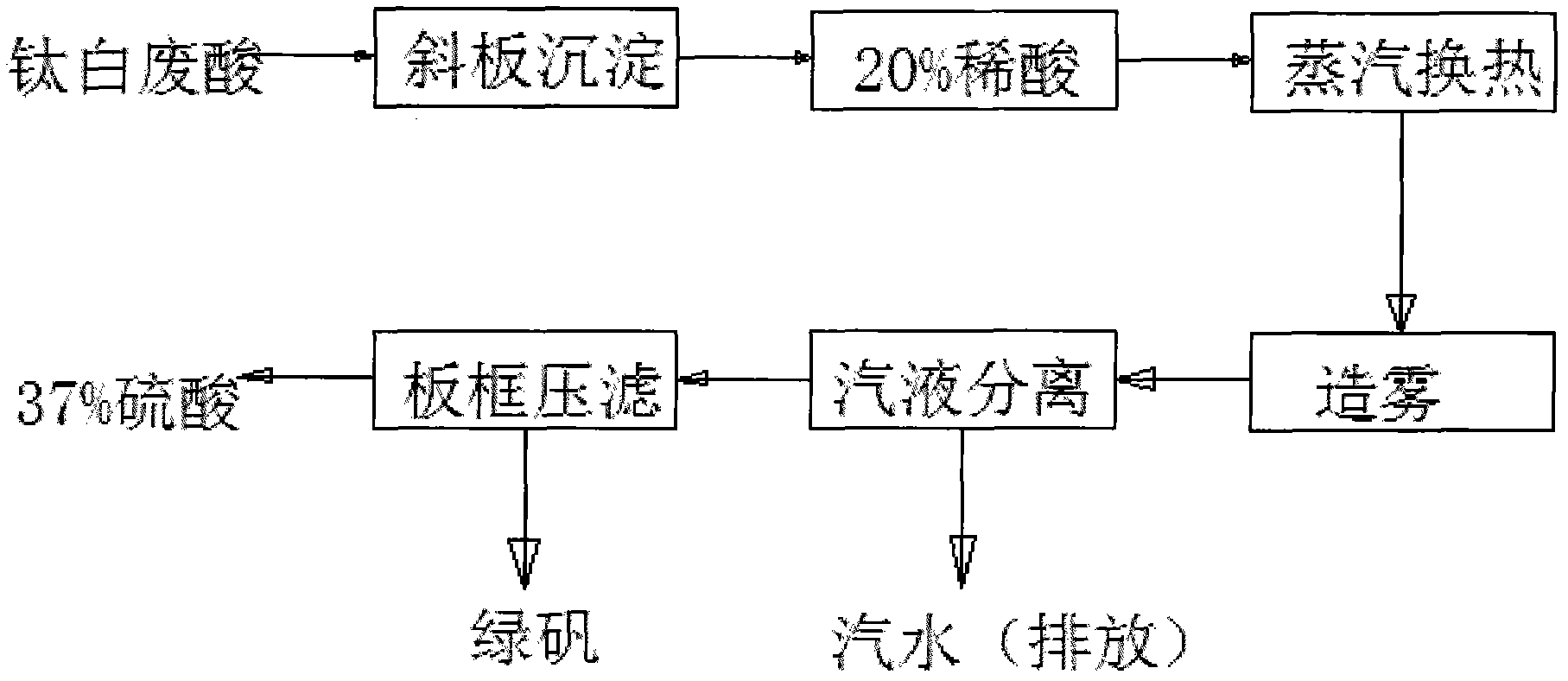

Process for recovering waste acid in producing titanium white powder by sulfuric acid method

InactiveCN1381398AImprove filtering effectInhibitionSulfur-trioxide/sulfuric-acidTitanium dioxideAcid concentrationWhite powder

A process for recovering the waste acid in producing titanium oxide powder by the sulfuric acid method features use of gas-liquid separation type non-volatile solution concentrating apparatus. It includes such steps as depositing the waste acid to receiver solid Ti, pre-concentrating at 50-60 deg.C until acid concentration is 40-50%, filtering, and concentrating at 65-75 deg.C until its concentration reaches more than 70%.

Owner:吉林市吉研高新技术开发公司 +1

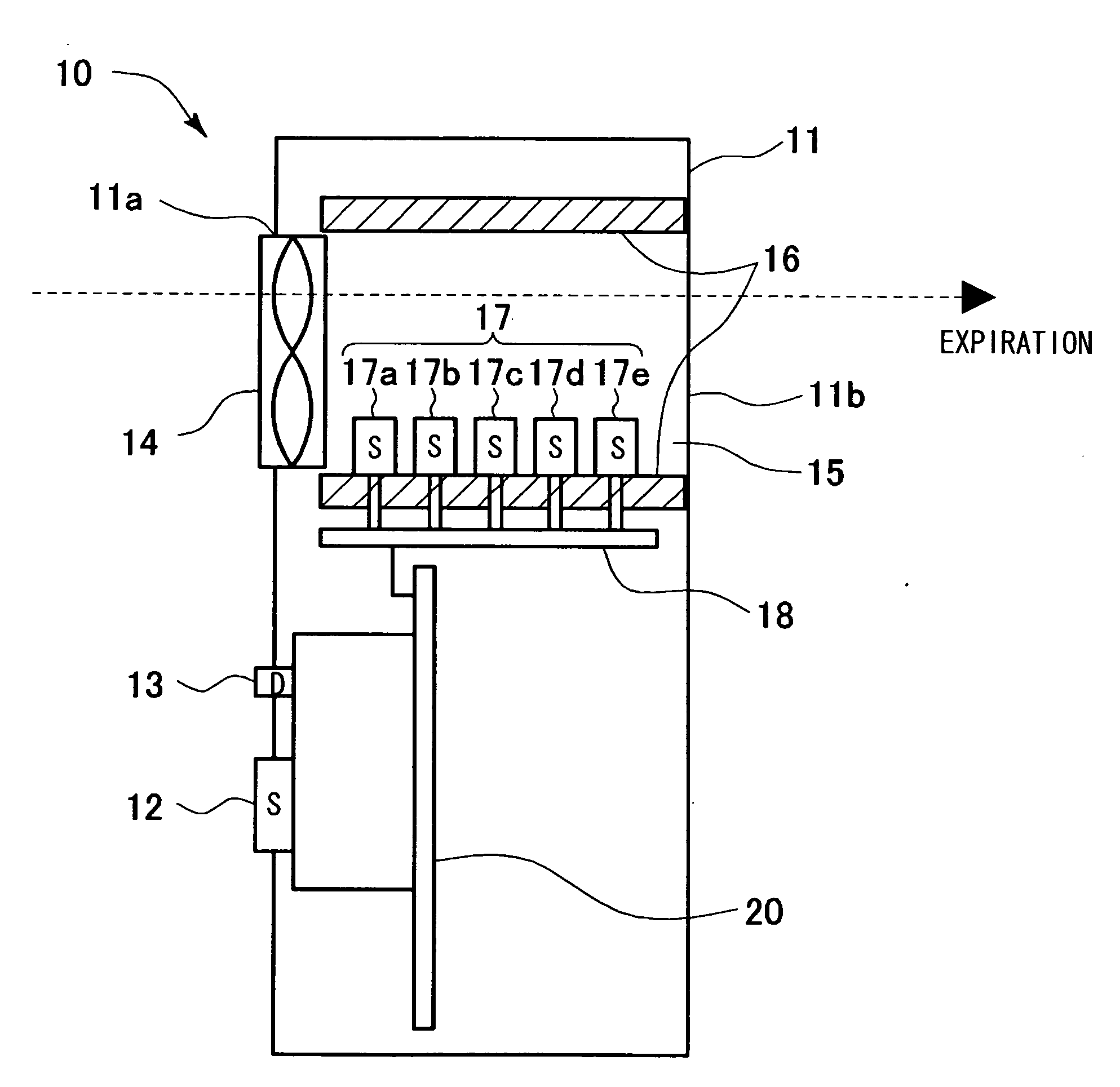

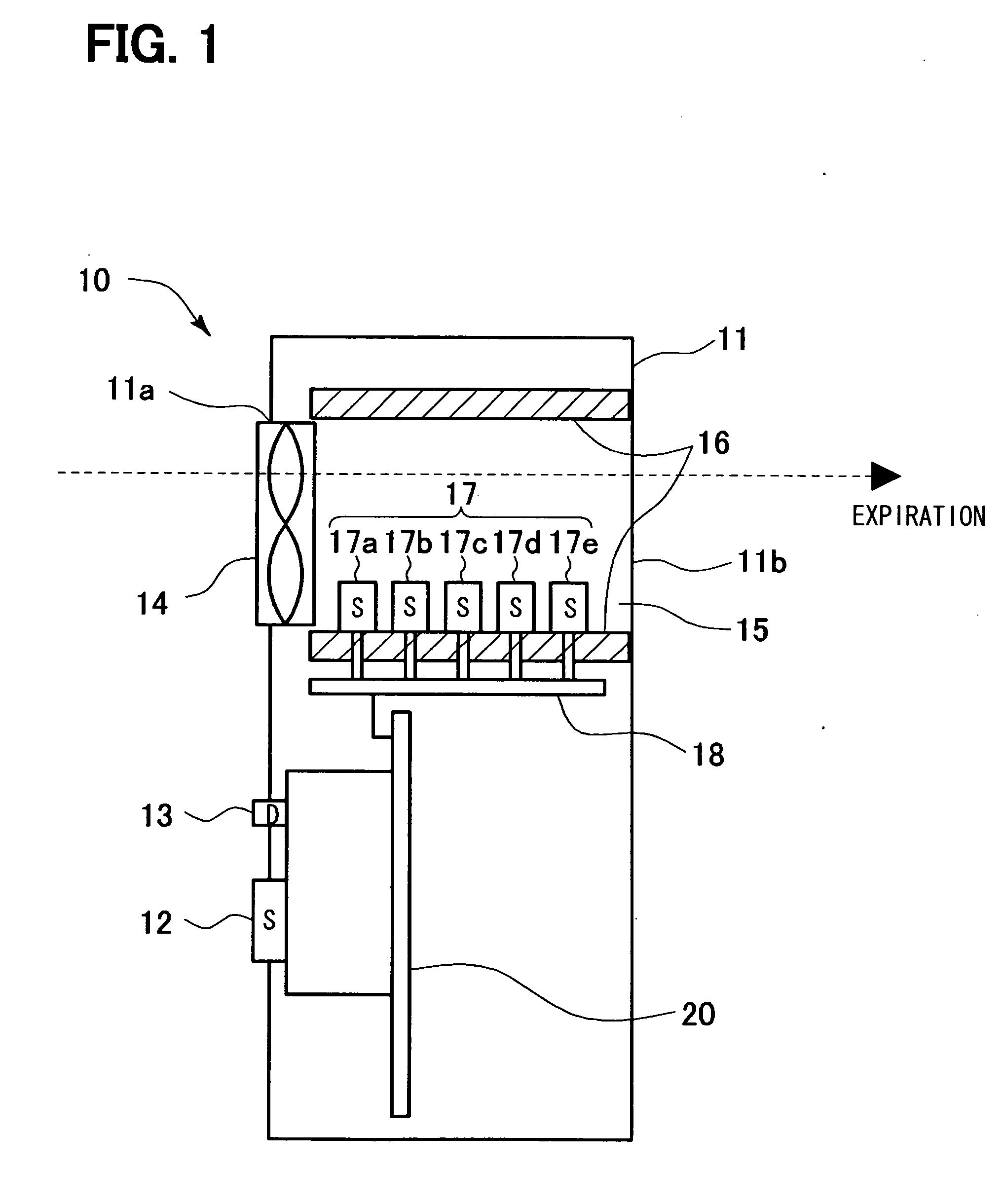

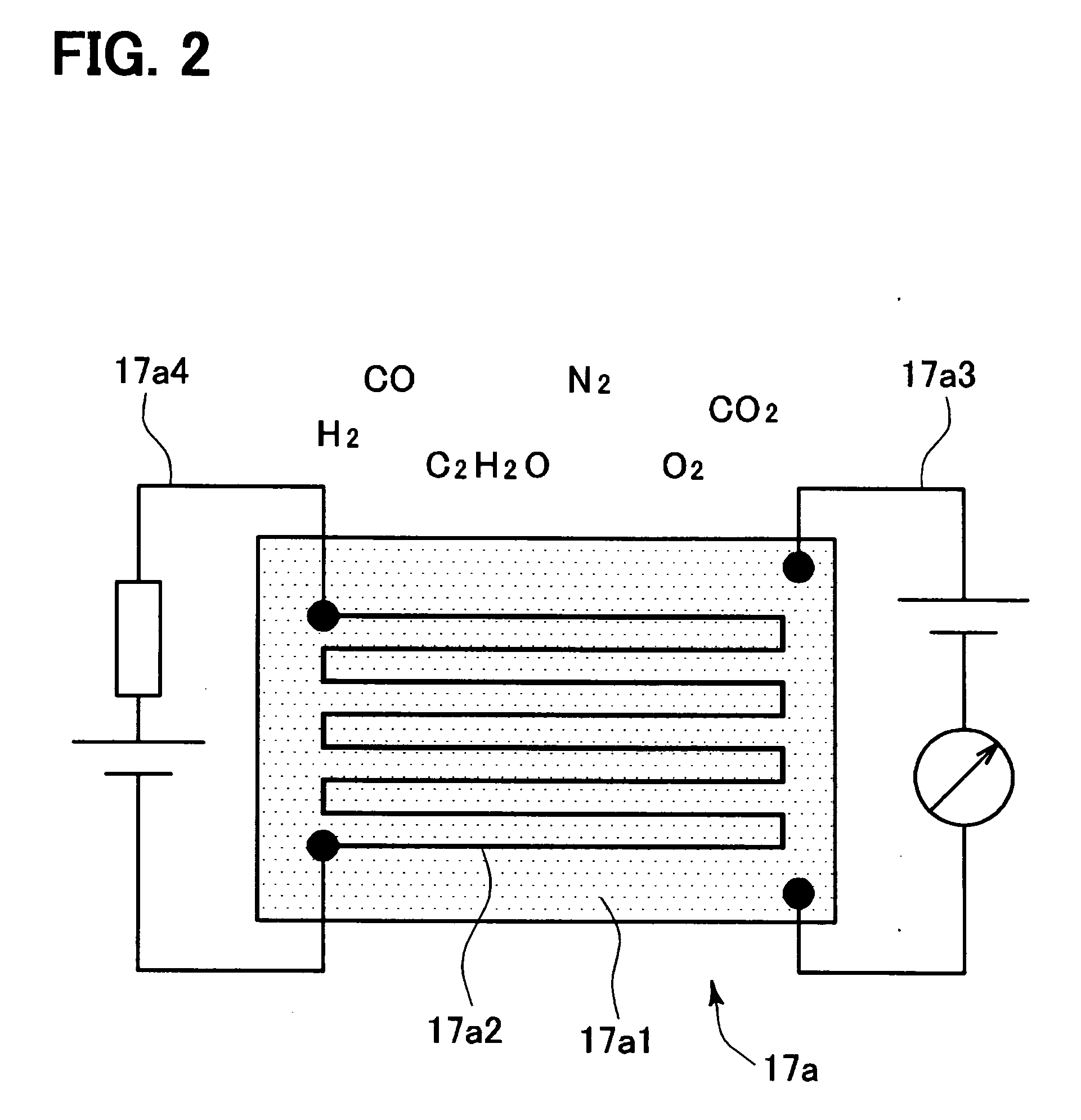

Alcohol concentration detecting device

An alcohol concentration detecting device for a vehicle includes an alcohol sensor to detect alcohol component contained in an expiration of an occupant of the vehicle, a gas sensor to detect gas components other than the alcohol component contained in the expiration, and a controller to calculate alcohol concentration based on detection value of the alcohol sensor. The controller corrects the calculated alcohol concentration based on detection value of the gas sensor. The alcohol sensor and the gas sensor are configured to further detect a state of air in a passenger compartment of the vehicle.

Owner:DENSO CORP

Targeted performance of hypohalite methods thereof

ActiveUS20130217610A1Reduce concentrationPrevent and minimize side effectInorganic/elemental detergent compounding agentsBiocideSide effectSodium chlorate

This invention relates to extend the benefits of using hypochlorite compounds such as sodium hypochlorite to clean and disinfect articles while reducing or eliminating the side effects of treating an article with a strong oxidant material. The invention relates to a single step process involving mixing of precursor compositions of a suitable hypohalite or hypohalous acid with a solution of a reducing agent. Optionally a buffer may be present in either or both precursor compositions, such that at time of use such active hypohalous acid concentration in the resulting aqueous mixture remains at a sufficient activity level to effect one or more desired benefits against a target substrate for a desired period of time. The oxidant is substantially consumed by reaction with the reducing agent after the time needed for achieving the desired benefit has passed.

Owner:THE CLOROX CO

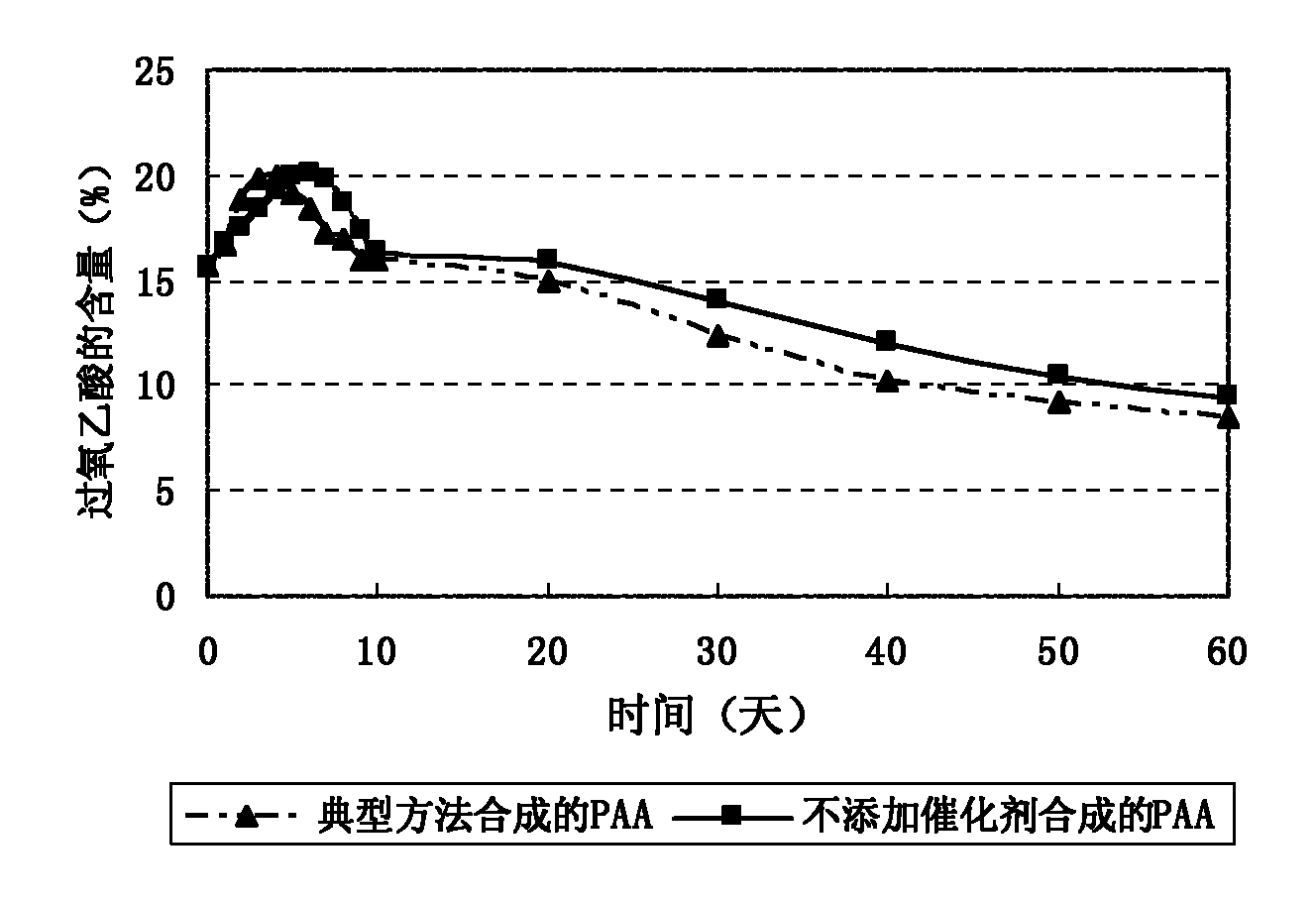

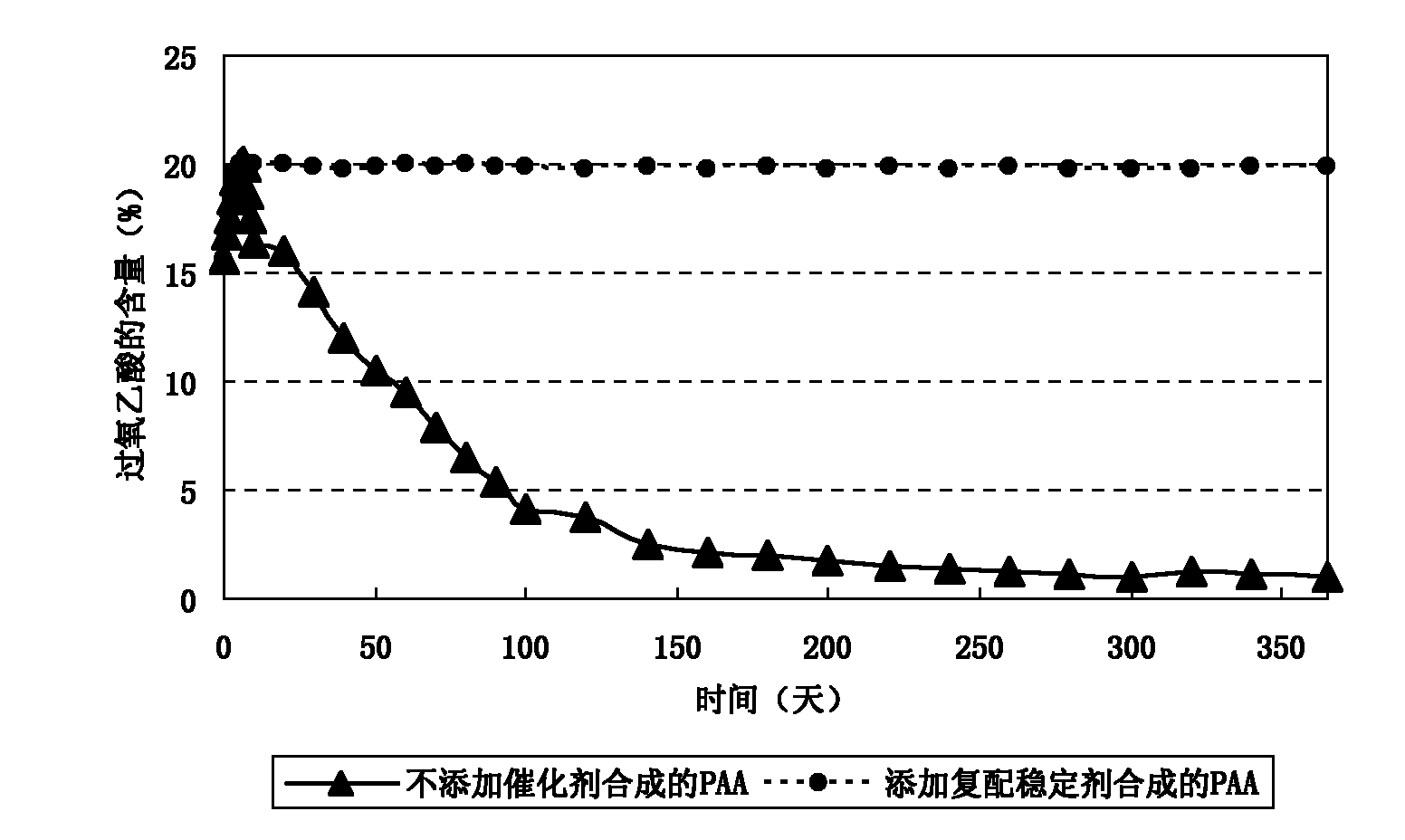

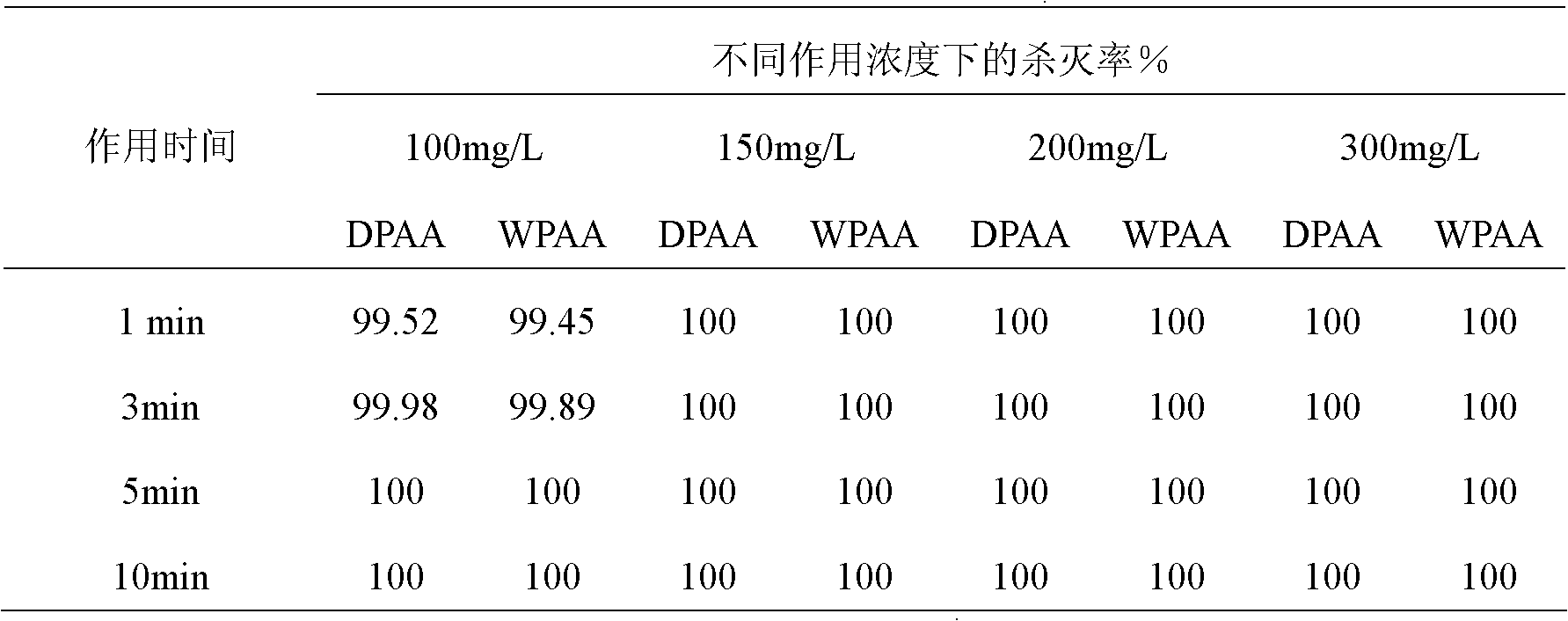

Stable peroxyacetic acid disinfectant

ActiveCN102090393AReduce decompositionImprove wettabilityBiocideDisinfectantsAcetic acidDisinfectant

The invention discloses a stable peroxyacetic acid disinfectant which relates to a disinfectant. The peroxyacetic acid disinfectant comprises the following raw materials in percentage by mass: 27-39 percent of hydrogen peroxide, 22-36 percent of acetic acid, 0.01-2 percent of compound stabilizer, 0.01-2 percent of surfactant and the balance of water. In the prepared peroxyacetic acid disinfectant, the concentration of the peroxyacetic acid is 15-20 g / 100g, the concentration of the hydrogen peroxide is 20-30 g / 100g, and the concentration of the acetic acid is 10-20 g / 100g. The peroxyacetic acid disinfectant has the characteristics of high peroxyacetic acid concentration, high stability, good disinfection and sterilization effects, simple production process, safety and the like.

Owner:GUANGDONG HUANKAI MICROBIAL SCI & TECH

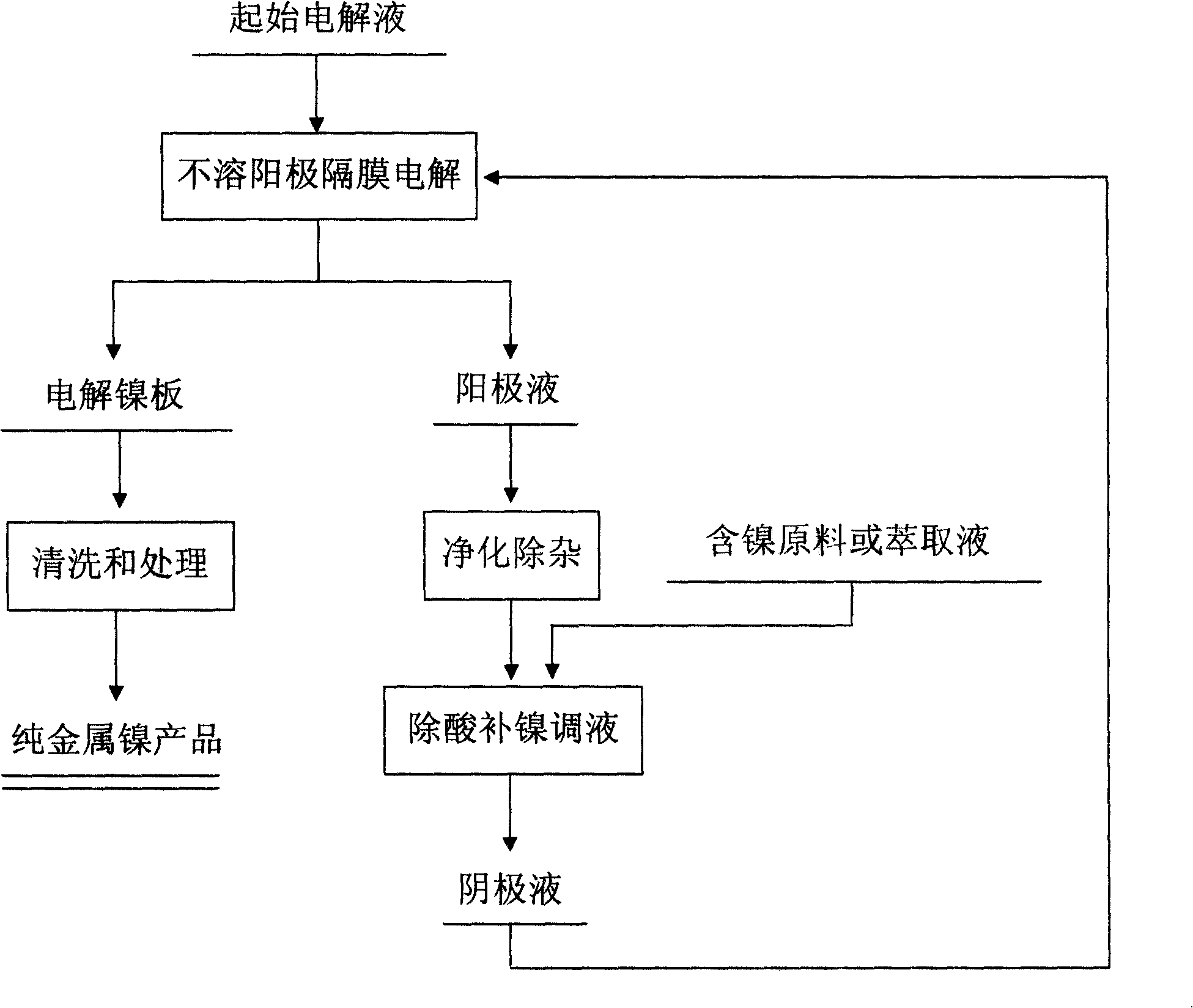

Method for producing electrolytic nickel using various nickel-containing raw material

InactiveCN101265589AAchieve balanceWide variety of sourcesPhotography auxillary processesSolventNickel ions

A method using various raw materials containing nickel to prepare electrolytic nickel is provided. The materials containing nickel obtained from various nickel smelting and nickel renewable resource recovery processes are taken as the raw materials, sulfate system electrolyte solution is adopted, pure metallic nickel is prepared by the method of insoluble anode diaphragm electrolysis; the acidity of the anolyte is adjusted by the direct neutralization method or the solvent extraction method in the electrolytic process, nickel ion is supplied, acid concentration is lowered, thereby changing into eligible catholyte, returning to the electrolytic process realizes the balance of nickel ion and acid concentration in the whole electrolytic process; the electrolyte system adopts falcial sulphate liquor, nickel sulphate, sodium sulphate, and boric acid are prepared into the catholyte which mainly contains: boric acid 1-25g / L, sodium sulphate70-150g / L, and nickel sulphate 50-120g / L, vitriol is added to adjust the pH value to about 2.0-2.5; the acidity of the anolyte is adjusted by the direct neutralization method or the solvent extraction method.

Owner:张建玲

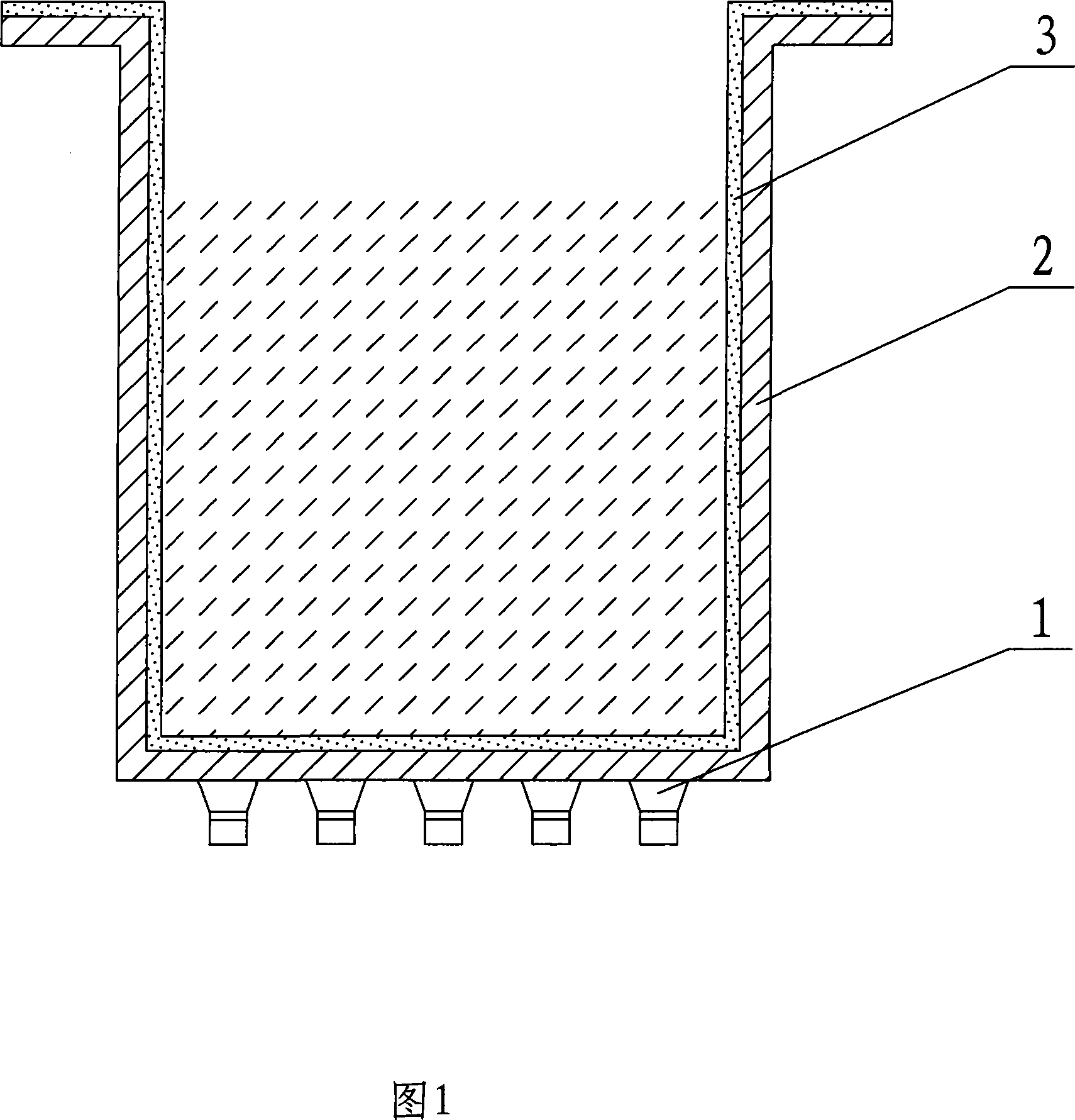

Ultrasonic cleaning groove and its processing method

InactiveCN101121170ALow acid concentrationReduce pollutionLiquid surface applicatorsFouling preventionAbrasive blastingUltrasonic sensor

The present invention discloses an ultrasonic cleaning tank comprising an ultrasonic transducer and a stainless steel reservoir; the reservoir wall thickness is between 1to 3 mm and the internal surface of the reservoir is blasted with grits; the internal surface of the reservoir with certain harshness is sprayed with a polytetrafluoroethylene layer and the polytetrafluoroethylene layer thickness is between 0.1 to 0.4 mm; the processing method is that the internal surface of the stainless steel reservoir is blasted with grits to make the surface harsh; after the internal surface is cleaned, at least twice polytetrafluoroethylene static sprayings are implemented on the internal surface of the reservoir; the coating of the cleaning tank surface is dense and the coating is closely combined with the reservoir to prevent the reservoir from being corroded by strong acid and have excellent abrasion resistant function; the ultrasonic conduction rate is high and the acid concentration of the cleaning liquid can be reduced which reduces the environmental pollution and effectively prolongs the service life of the cleaning device.

Owner:ZHANGJIAGANG ULTRASONIC & ELECTRIC

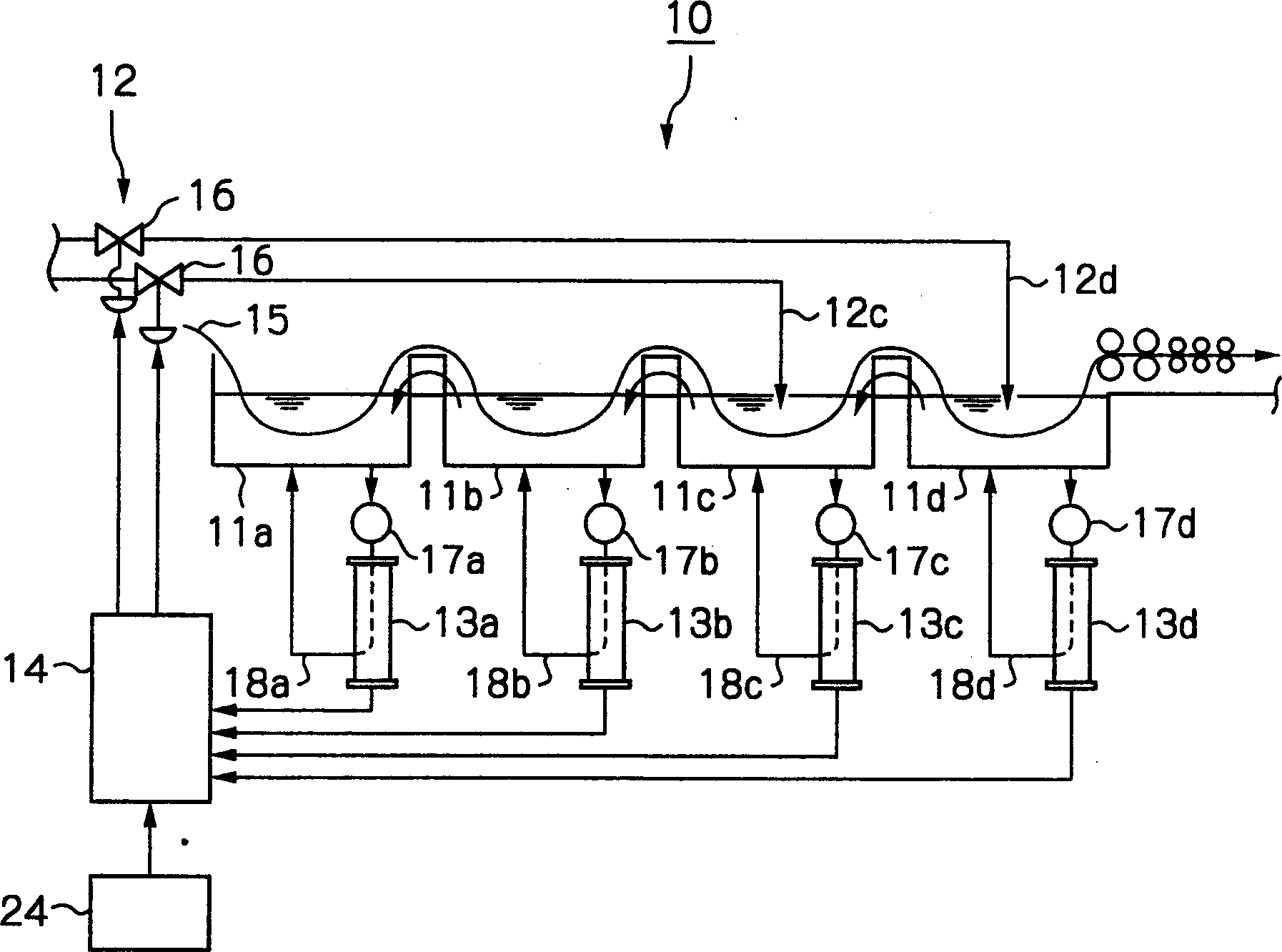

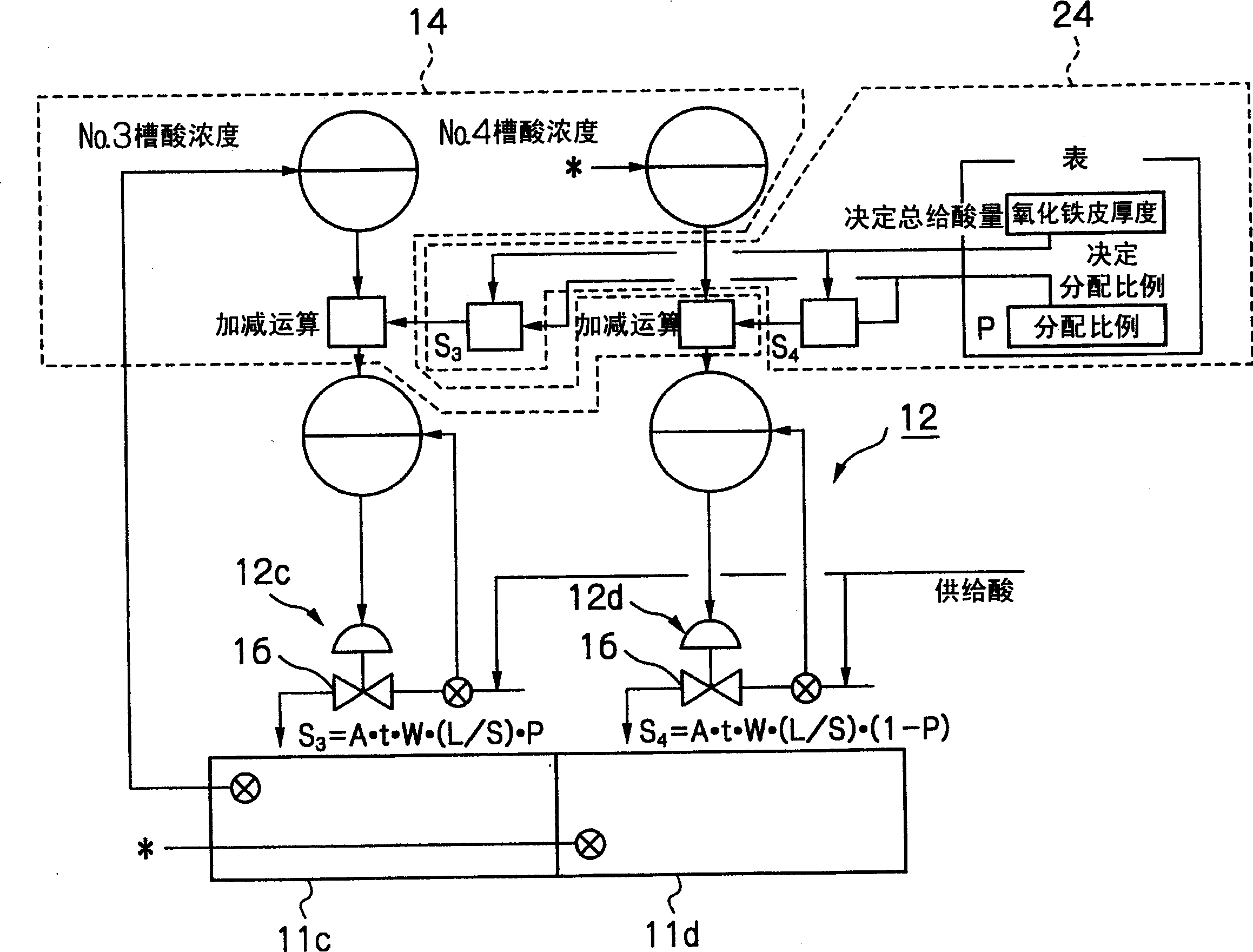

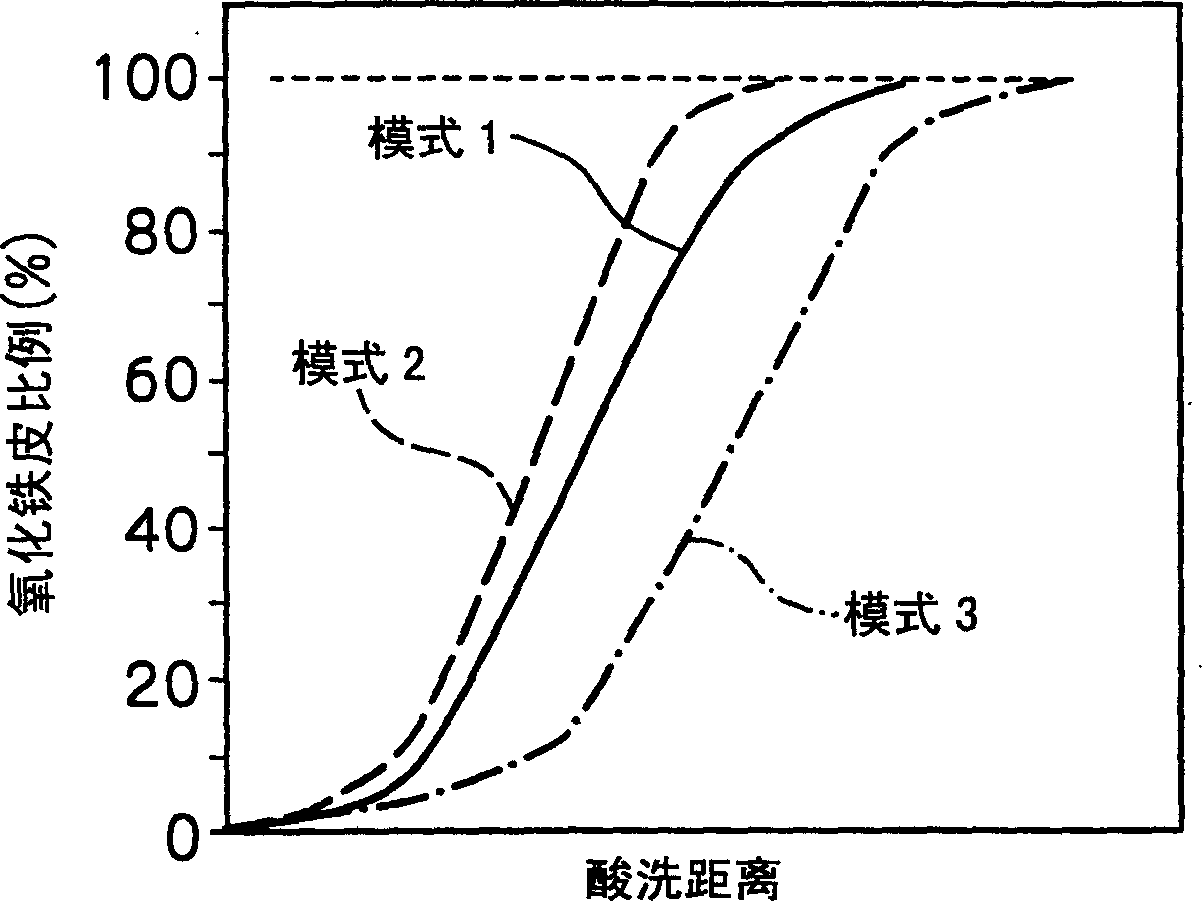

Continuous pickling method and continuous pickling device

InactiveCN1462321APrevent evaporationImprove pickling productivityWork treatment devicesMetal rolling arrangementsAcid concentrationEngineering

A pickling line control device (24) calculates forecast acid amounts consumed at pickling by pickling liquids stored in the third tank (11c) and the final tank (11d) of a continuous pickling device (10), determines respective acid liquid supply amounts to the third and final tanks (11c, 11d), and allows the an acid liquid supply system (12) to supply acid liquid. The acid concentrations of pickling liquids respectively stored in the acid liquid-supplied third and final tanks (11c, 11d) are continuously measured by acid concentration continuous measuring devices (13c, 13d), and acid liquid is supplied from the acid liquid supply system (12) to the third and final tanks (11c, 11d) based on the continuously measured values of measured acid concentrations so that the acid concentrations of pickling liquids stored in the third and final tanks (11c, 11d) match respective target values. Thereby, it is possible to increase, while restricting the acid concentration of pickling liquid from the final pickling tank to up to 12%, the acid concentrations of pickling liquids stored in the other pickling tanks.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com