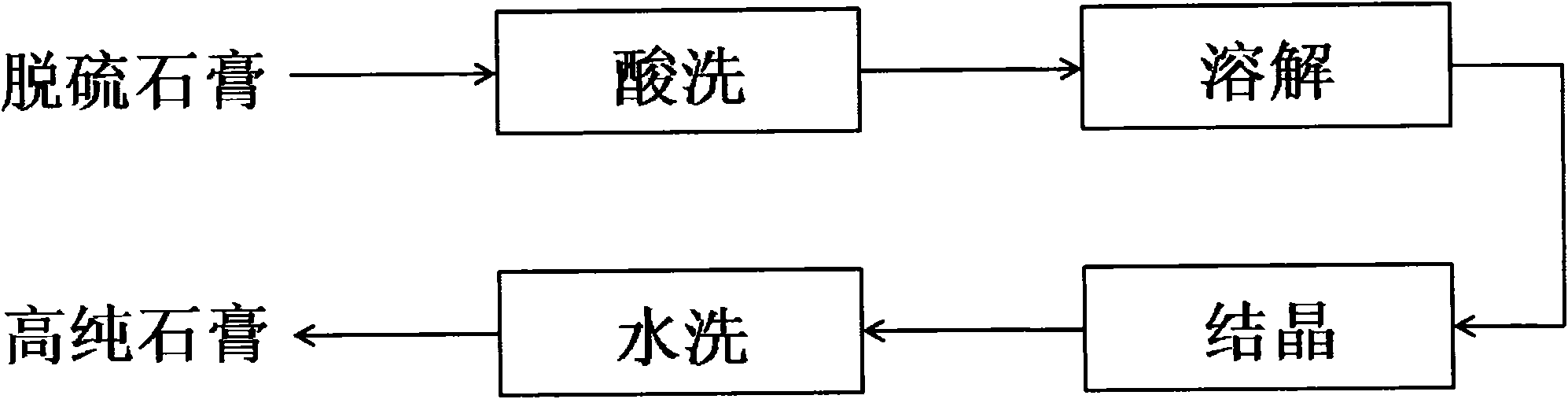

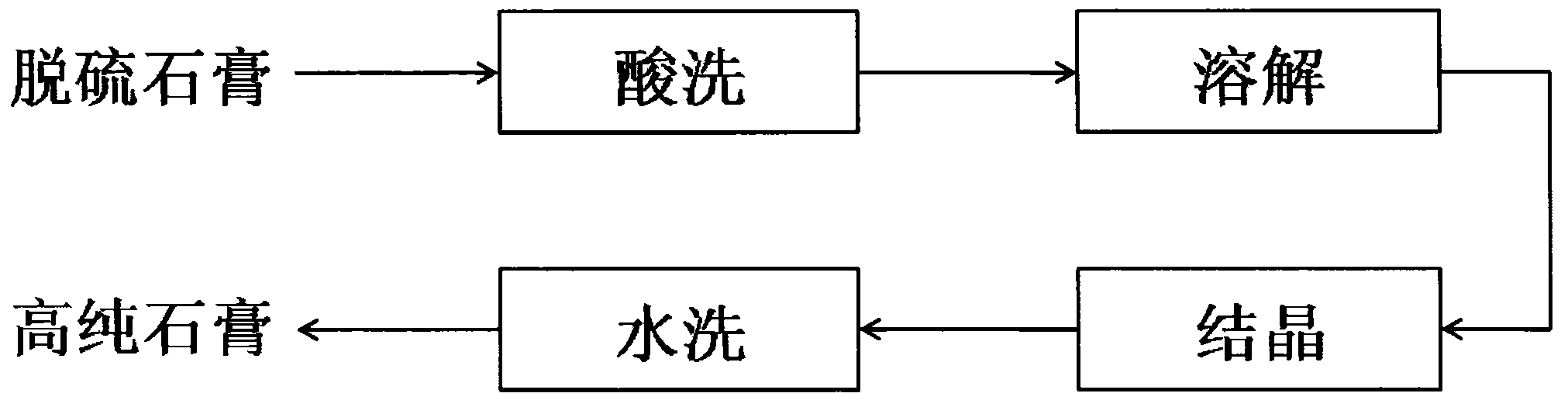

Method for recrystallizing and purifying desulphurized gypsum

A desulfurization gypsum and recrystallization technology, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of complex impurities, serious accumulation of desulfurization gypsum, low whiteness, etc., to reduce the burden on enterprises, good environmental benefits and social benefits , the effect of increasing corporate income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1: Crush the desulfurized gypsum from a coal-fired power plant, sieve it through an 80-mesh sieve, add 100.00 g of the crushed desulfurized gypsum to a 1000 mL beaker at the same time as 1000 mL of 1 mol / L nitric acid solution, and stir for 4 hours , to remove the impurities reacting with nitric acid in the raw material, then dry the filter cake in a 60°C blast drying oven for 12 hours, then crush it, weigh 35.00g of the above acid-washed and dried desulfurized gypsum, and mix it with 500mL, 2mol / L nitric acid Add the solution together into a 1000mL flask, immerse more than two-thirds of the volume in a 95°C constant temperature water bath, keep the temperature constant and stir for 4 hours. Put it into a 1000mL beaker, place it in a constant temperature water bath at 15°C for cooling and crystallization for 18h. After the crystallization is complete, filter with suction, transfer the filter cake to a 1000mL beaker for water washing, and then dry the filter cake...

Embodiment 2

[0014] Example 2: Recycle 500mL of the filtrate in Example 1, add 35.01g of acid-washed desulfurized gypsum into a 1000mL flask at the same time, then immerse more than two-thirds of the volume of the flask in a 95°C constant temperature water bath, keep the temperature constant and stir 4h. After the reaction is complete, suction filter while hot to remove solid residues not dissolved in the nitric acid solution, transfer the filtrate to a 1000mL beaker, and place it in a constant temperature water bath at 15°C for cooling and crystallization for 18h. After the crystallization is complete, filter with suction, transfer the filter cake to a 1000mL beaker for water washing, and then dry the filter cake in an oven at 60°C for 12 hours to obtain 15.55g of high-purity gypsum product. The whiteness after purification is 92.4%. The composition analysis of the product is shown in Table 1.

Embodiment 3

[0015] Example 3: Weigh 35.00 g of the recrystallized and purified desulfurized gypsum prepared in the steps of Example 1 to carry out secondary recrystallization and purification of desulfurized gypsum, and then add it to 1000 mL at the same time as the 2 mol / L nitric acid solution with a fixed volume of 500 mL in advance In the flask, more than two-thirds of the volume of the flask was immersed in a 95°C constant temperature water bath, and the temperature was kept constant and stirred for 4 hours. After the reaction was completed, suction filtered while it was hot, and the filtrate was transferred to a 1000mL beaker, and placed in a constant temperature water bath at 15°C for cooling and crystallization for 18h. After the crystallization is complete, filter with suction, transfer the filter cake to a 1000mL beaker for water washing, and then dry the filter cake in an oven at 60°C for 12 hours to obtain 17.42g of high-purity gypsum product. The whiteness of the primary recry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com