Method for preparing calcium sulfate crystal whiskers from desulfurized gypsum under normal pressure

A calcium sulfate whisker and desulfurization gypsum technology, which is applied in the field of calcium sulfate whisker preparation and modification, can solve the problems of poor product quality, large calcium salt consumption, high raw material prices, etc., achieve good economic benefits, simple preparation process, increase The effect of corporate earnings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

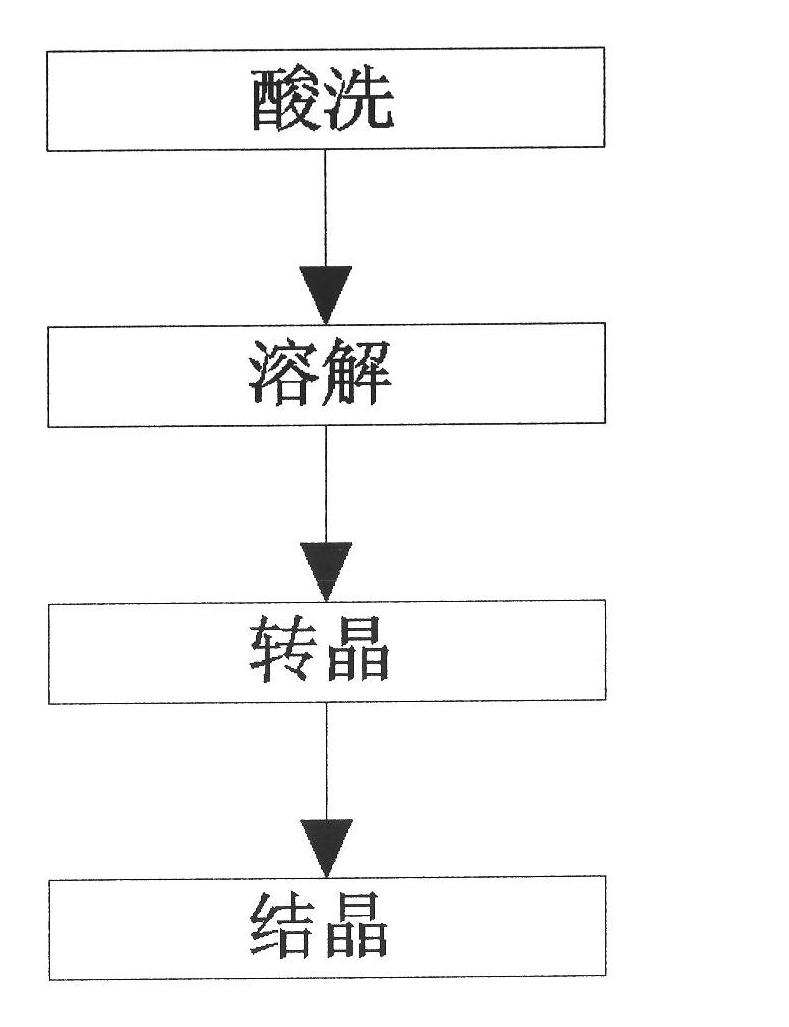

[0048] see Figure 1 to Figure 5 A method for preparing calcium sulfate whiskers from desulfurized gypsum under normal pressure provided in this embodiment comprises the following steps:

[0049] (1) Pickling: washing the desulfurized gypsum with excess inorganic acid dilute solution;

[0050] (2) Dissolving: mix the desulfurized gypsum after pickling with the acid solution, and keep stirring to dissolve the solid phase to obtain a mixed solution;

[0051] (3) crystal transformation: add a crystal transformation agent in the mixed solution, and carry out solid-liquid separation to remove solid-phase impurities to obtain a filtrate;

[0052] (4) Crystallization: the temperature of the filtrate is lowered, and after crystallization, the obtained filter cake is washed with water and dried to obtain calcium sulfate whiskers after solid-liquid separation.

[0053] Described step (1) specifically comprises the following steps:

[0054] (1.1) Prepare desulfurization gypsum;

[00...

Embodiment 2

[0077] The method for preparing calcium sulfate whiskers from desulfurized gypsum under normal pressure provided in this embodiment has the same basic steps as in Example 1, except that the following specific steps are different:

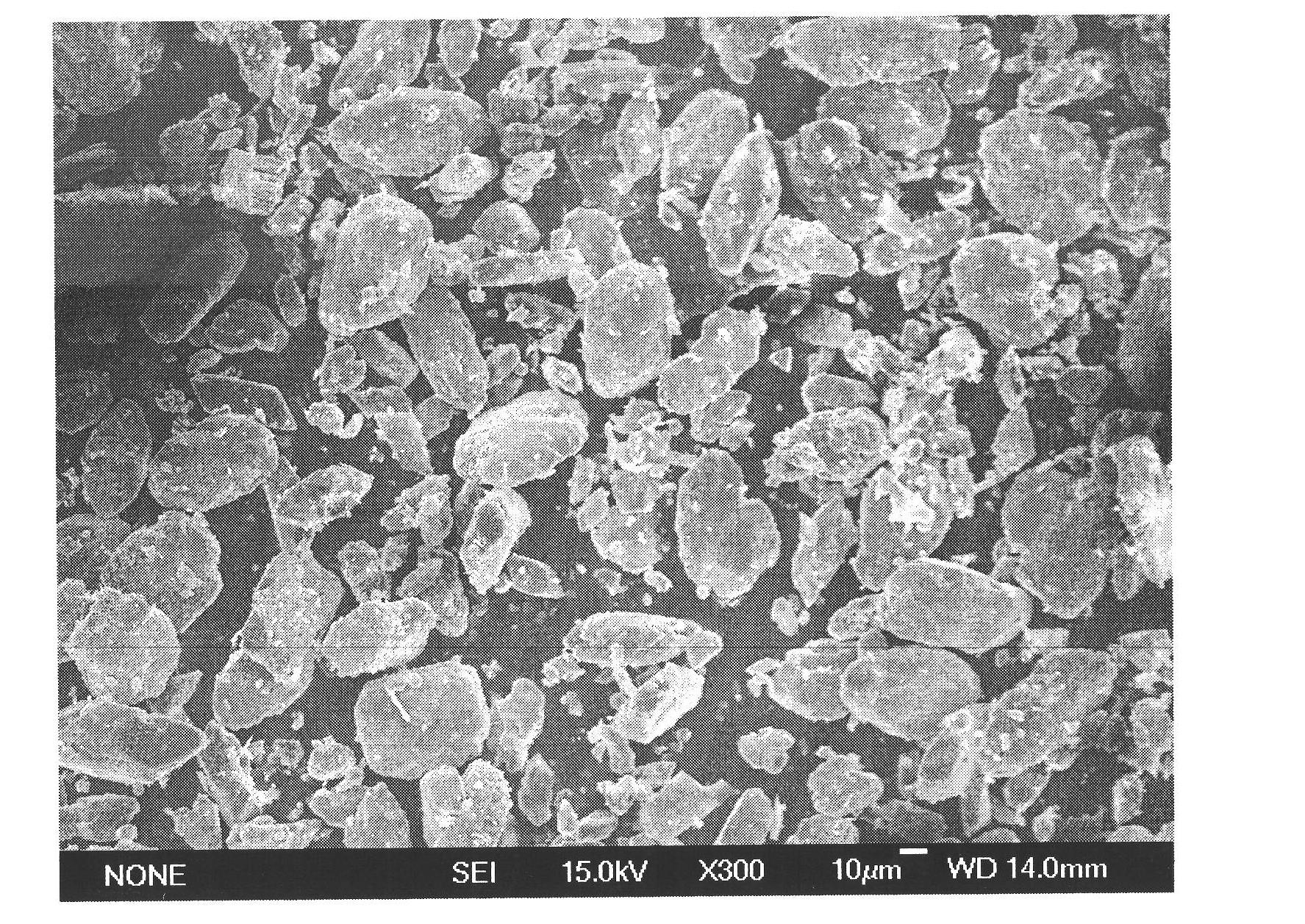

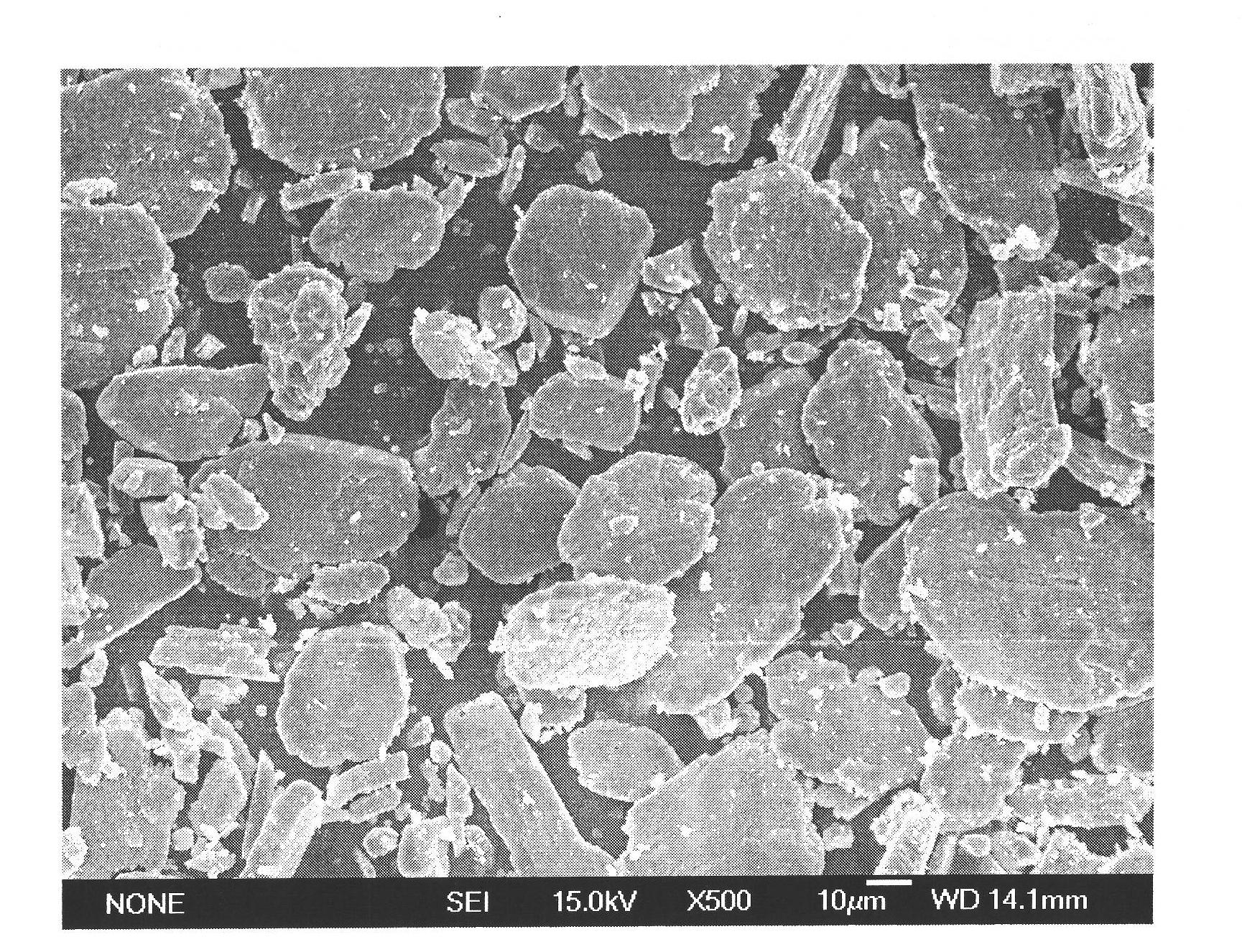

[0078] Crush the desulfurized gypsum from a coal-fired power plant, sieve it through an 80-mesh sieve, weigh 100.00 g of the crushed desulfurized gypsum, and then add it to a 1000 mL beaker at the same time as the 1000 mL 1mol / L nitric acid solution in advance, stir for 4 hours, remove Desulfurize the impurities in the gypsum raw material that react with the nitric acid solution to obtain a filter cake. The filter cake was then dried in a blast oven at 60° C. for 12 hours, and then crushed. Weigh 35.00 g of the above crushed filter cake, add it together with 500 mL, 2 mol / L nitric acid solution into a 1000 mL flask, then immerse more than two-thirds of the volume of the flask in a constant temperature oil bath at 100°C, And stirred for 1 hour, it w...

Embodiment 3

[0080] The method for preparing calcium sulfate whiskers under a kind of desulfurization gypsum normal pressure that present embodiment provides, its basic steps are identical with embodiment 2, and its difference is that its following specific steps are different:

[0081] Recycle 500mL of the filtrate in Example 2, add 35.01g of acid-washed desulfurized gypsum into a 1000mL flask at the same time, then immerse more than two-thirds of the volume of the flask in a 95°C constant temperature water bath, keep the temperature and stir for 1 hour , the solid phase was observed to dissolve, and when the solution was translucent, 3ml of silane coupling agent KH570 was added, kept at a constant temperature and stirred for 1 hour. A new round of filtrate was obtained, and then the filtrate was transferred to a 1000mL beaker and placed in a constant temperature water bath at 15°C for cooling and crystallization for 18 hours. Suction filtration is carried out after the crystallization is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com