Patents

Literature

601 results about "Whisker" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal whiskering is a phenomenon which occurs in electrical devices when metals form long whisker-like projections over time. Tin whiskers were noticed and documented in the vacuum tube era of electronics early in the 20th century in equipment that used pure, or almost pure, tin solder in their production. It was noticed that small metal hairs or tendrils grew between metal solder pads causing short circuits. Metal whiskers form in the presence of compressive stress. Zinc, cadmium, and even lead whiskers have been documented. Many techniques are used to mitigate the problem including changes to the annealing process (heating and cooling), addition of elements like copper and nickel, and the inclusion of conformal coatings. Traditionally, lead was added to slow down whisker growth in tin-based solders.

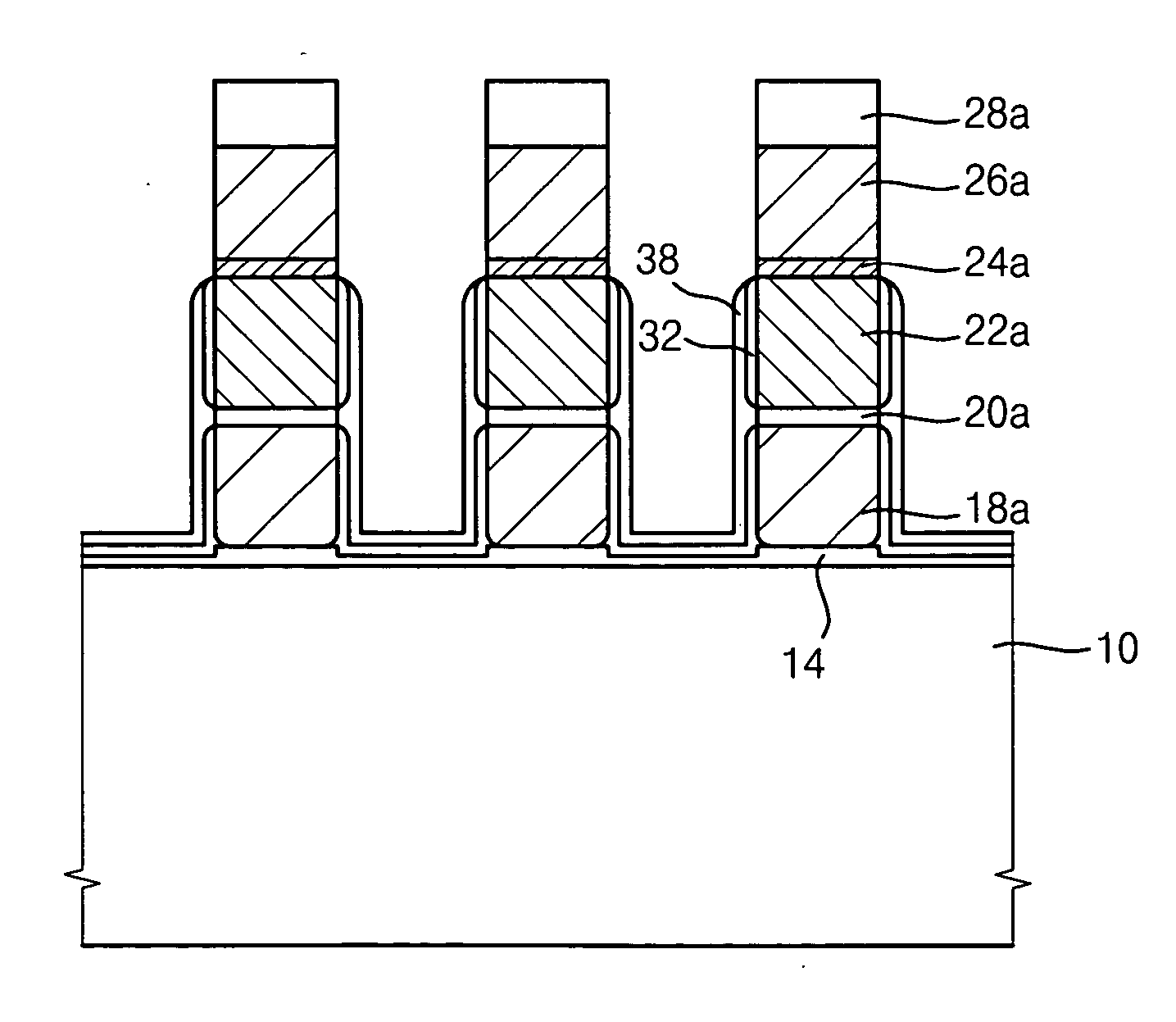

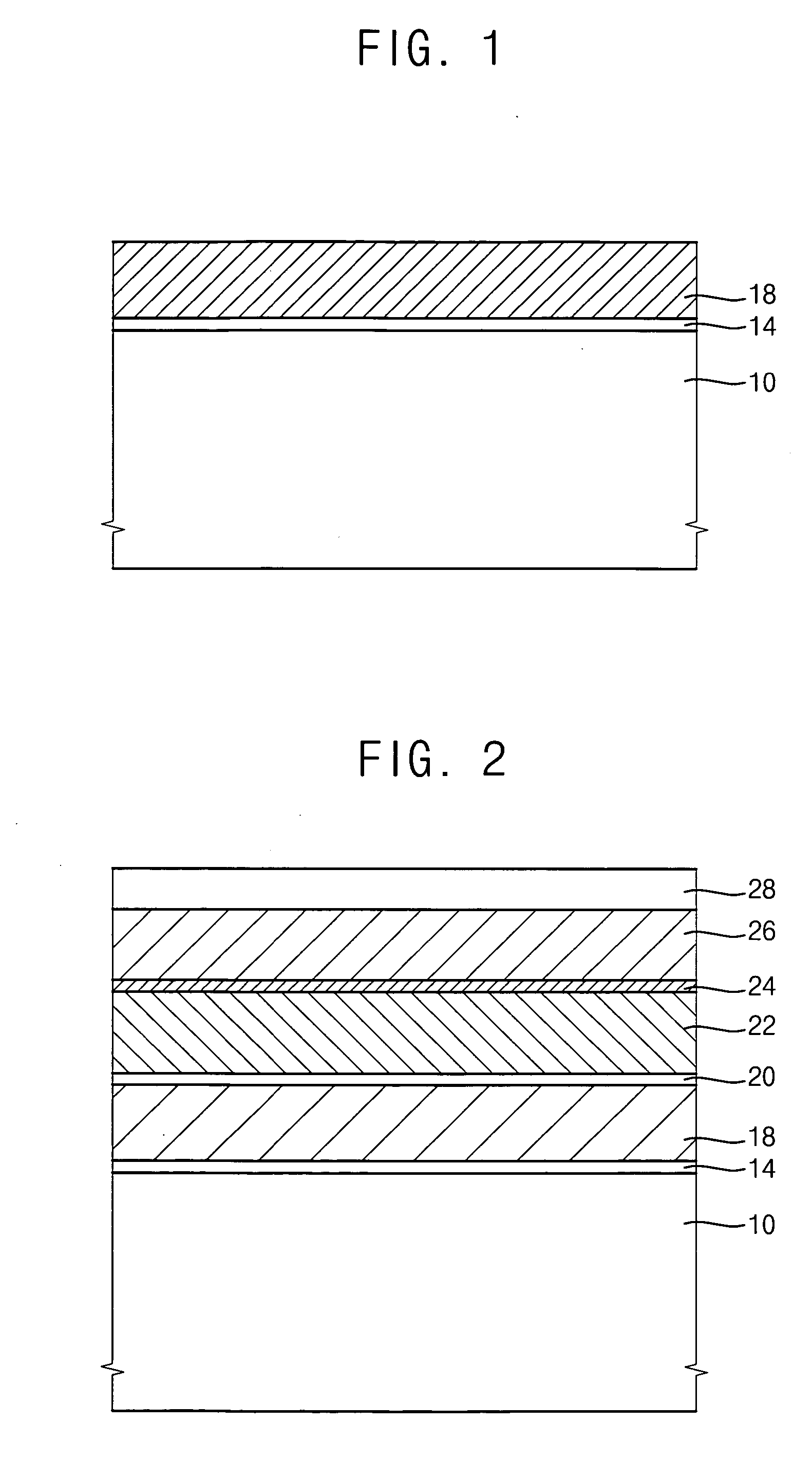

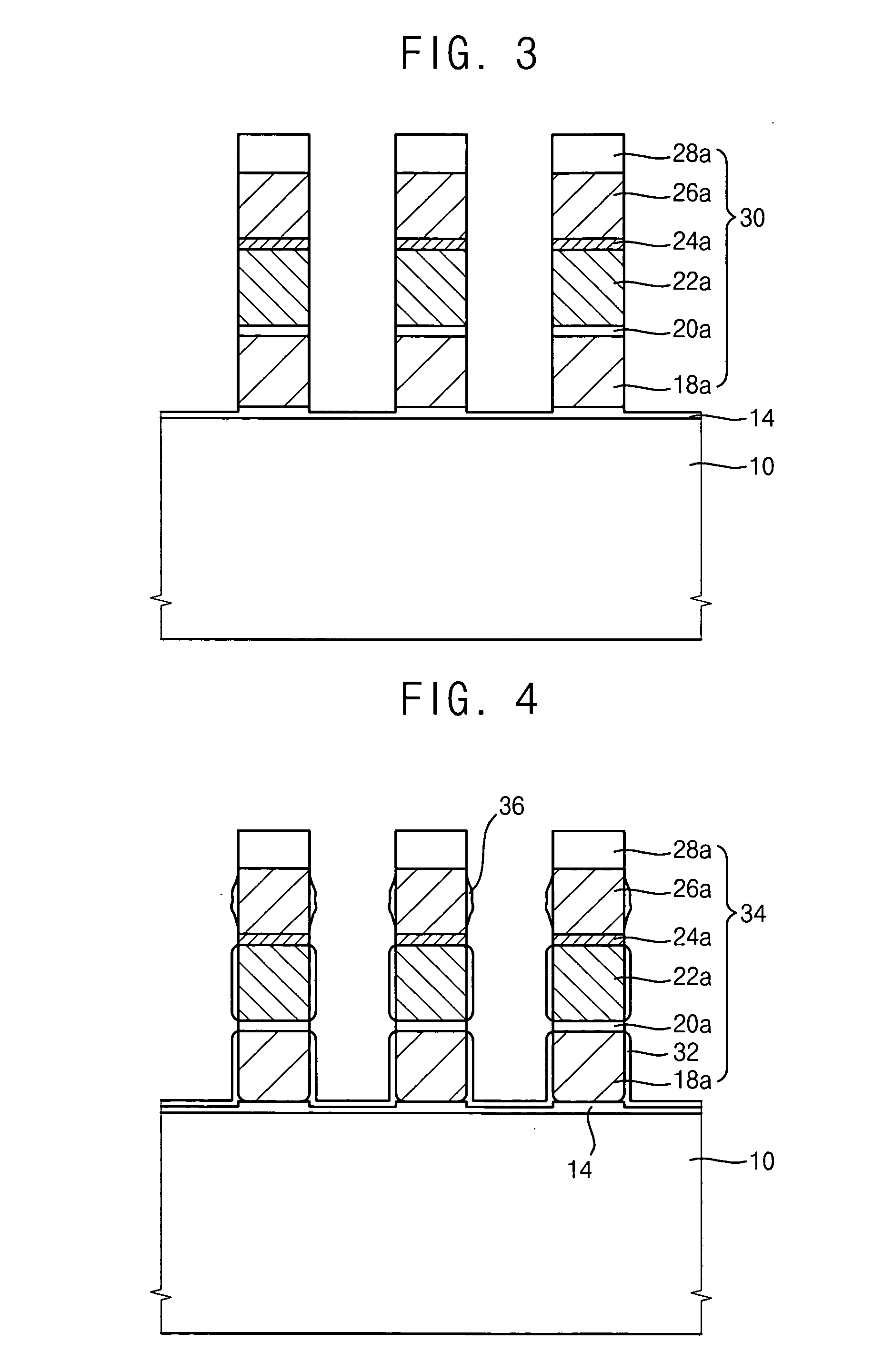

Method of forming a gate of a semiconductor device

ActiveUS20060110900A1Suppresses the generation of whiskersIncrease productionSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialEngineering

In a method for forming a gate in a semiconductor device, a first preliminary gate structure is formed on a substrate. The first preliminary gate structure includes a gate oxide layer, a polysilicon layer pattern and a tungsten layer pattern sequentially stacked on the substrate. A primary oxidation process is performed using oxygen radicals at a first temperature for adjusting a thickness of the gate oxide layer to form a second preliminary gate structure having tungsten oxide. The tungsten oxide is reduced to a tungsten material using a gas containing hydrogen to form a gate structure. The tungsten oxide may not be formed on the gate structure so that generation of the whiskers may be suppressed. Thus, a short between adjacent wirings may not be generated.

Owner:SAMSUNG ELECTRONICS CO LTD

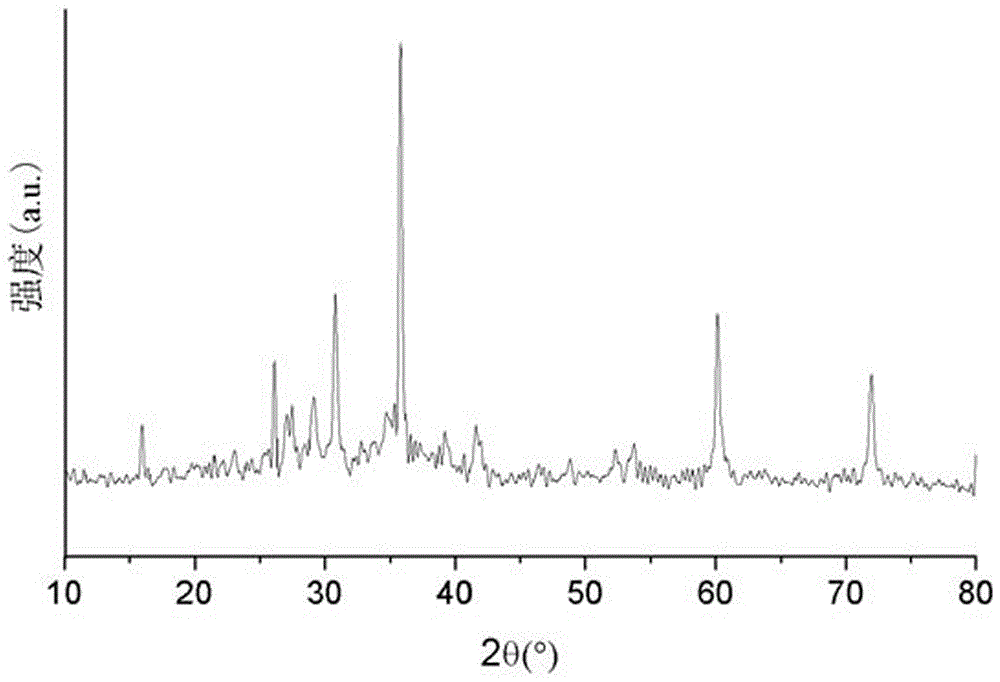

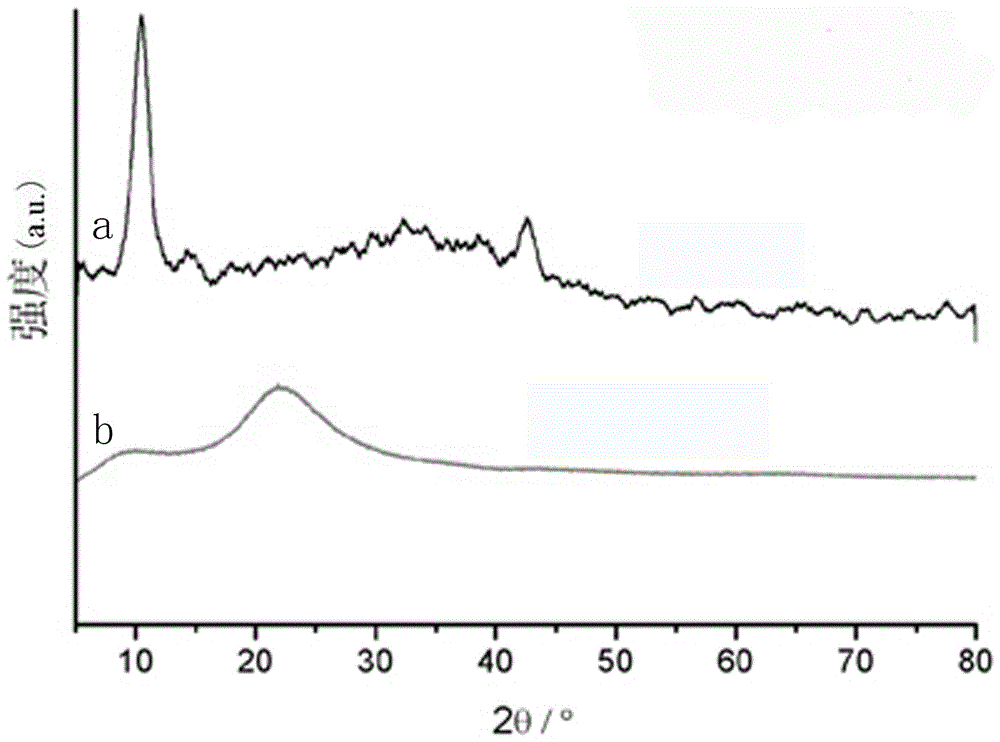

Method for preparing graphene toughened silicon carbide ceramic composite material

ActiveCN105801154AImprove mechanical propertiesEnhanced interface bindingCeramic compositeOxidation resistant

The invention belongs to the field of macromolecule inorganic chemistry, and in particular relates to a method for preparing a graphene toughened silicon carbide ceramic composite material. Specifically, the method comprises the following steps: by taking graphite oxide as a carbon source, wrapping the surface of reduced graphene oxide with a layer of SiO2 granules by using a hydrothermal method so as to form a good interface layer between graphene and SiC, uniformly dispersing, and implementing carbon thermal reduction reaction at the interface of graphene and SiO2 in the high-temperature sintering process so as to growth silicon carbide crystal whisker and granules in situ, thereby improving the interface strength and the oxidation resistance, achieving an interface intensification function, improving crack expansion resistance and further improving the fracture toughness of ceramic. The method aims at the defects that graphene is poor in dispersity and high-temperature oxidation resistance in a conventional graphene / silicon carbide composite material, in-situ growth, crack self-healing and toughness mechanisms are applied to a preparation technique of a graphene / silicon carbide material, and thus graphene toughened silicon carbide ceramic with excellent mechanical properties and interface binding properties can be prepared.

Owner:ZHONGYUAN ENGINEERING COLLEGE

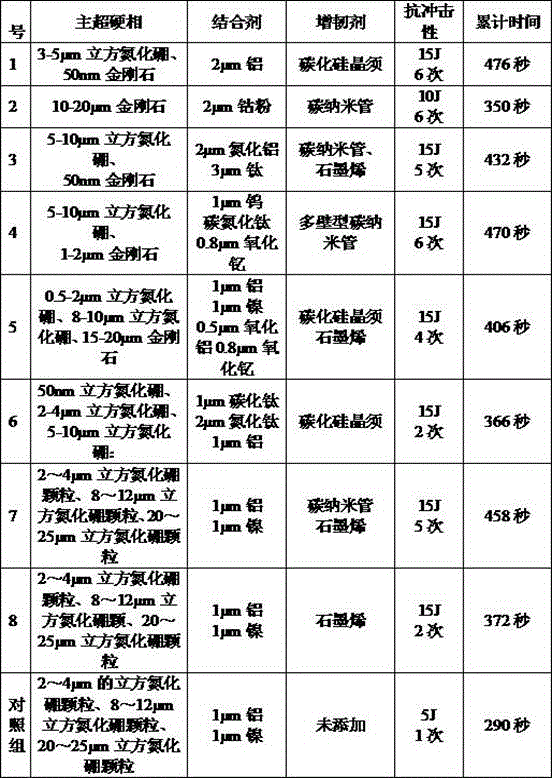

High-tenacity polycrystalline composite material, high-tenacity polycrystalline blade and preparation method of high-tenacity polycrystalline blade

InactiveCN105908041AImprove fracture toughnessImprove impact resistanceTurbinesOther manufacturing equipments/toolsCarbide siliconCarbon nanotube

Owner:FUNIK ULTRAHARD MATERIAL

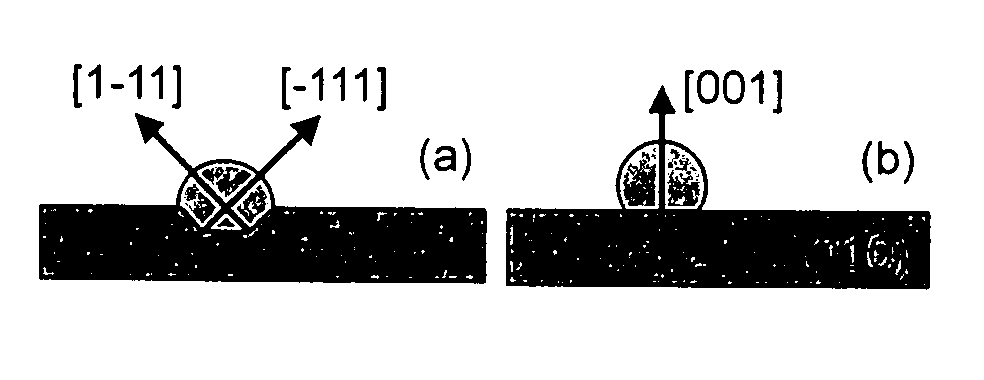

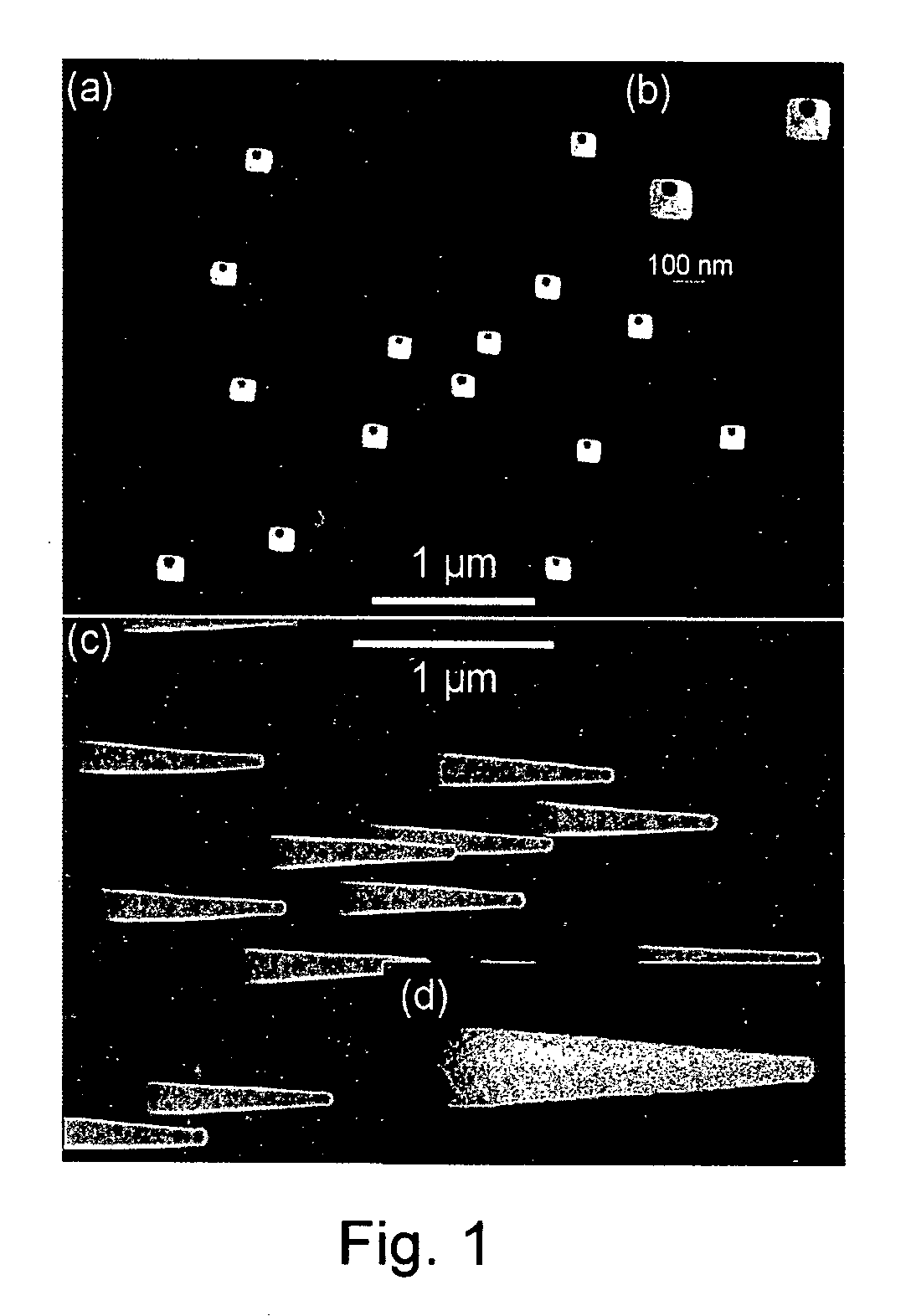

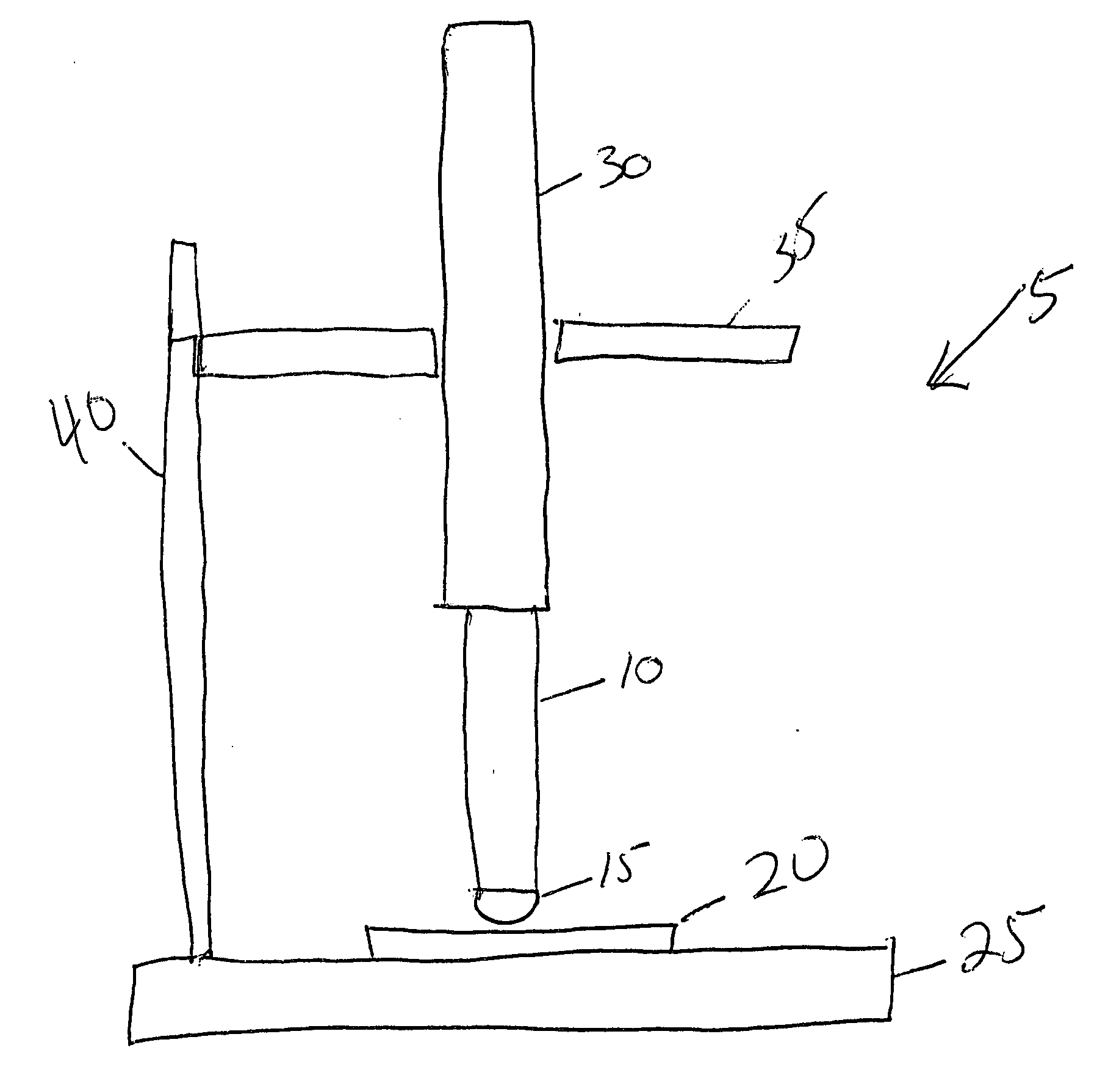

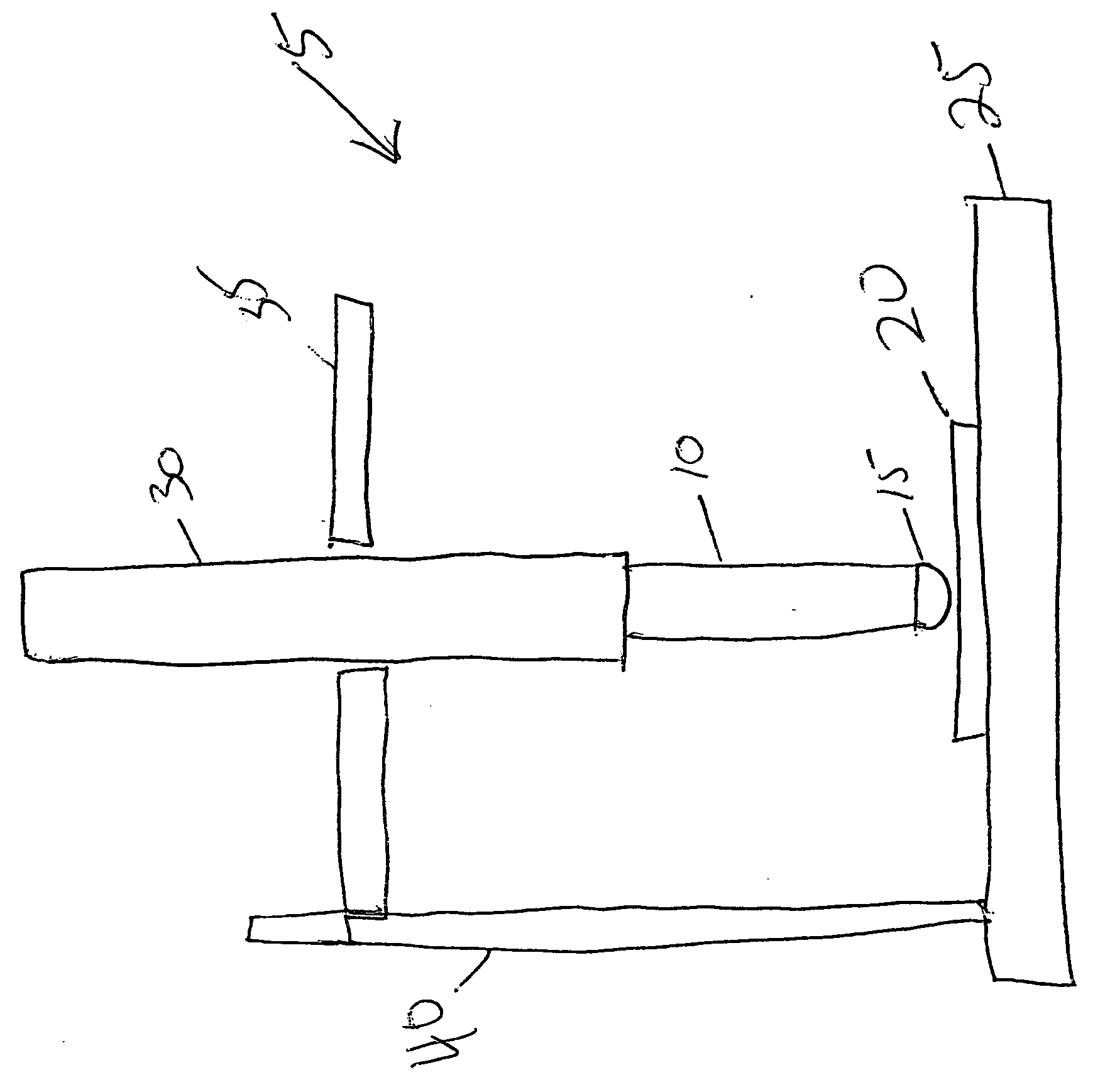

Directionally controlled growth of nanowhiskers

InactiveUS20060019470A1Well-defined surfaceReduce the temperatureMaterial nanotechnologyPolycrystalline material growthNanowireStacking fault

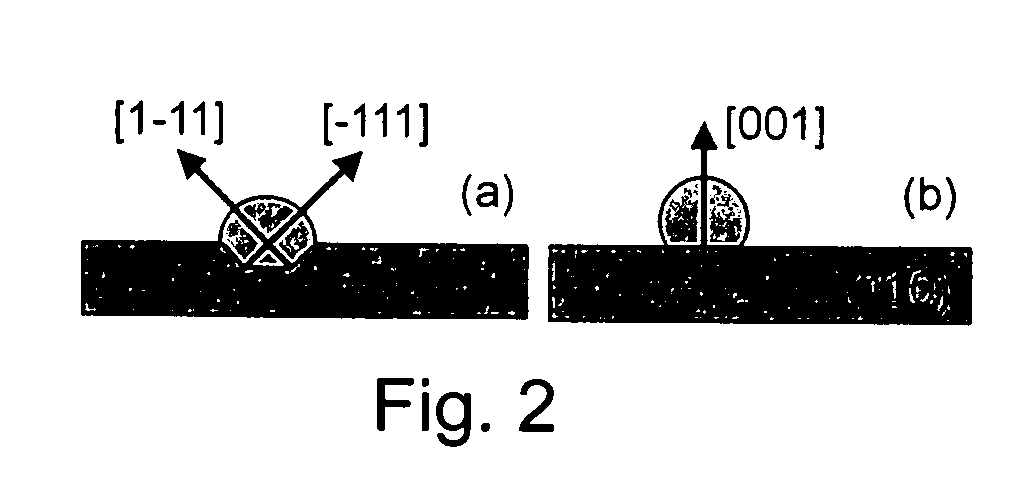

Nanowhiskers are grown in a non-preferential growth direction by regulation of nucleation conditions to inhibit growth in a preferential direction. In a preferred implementation, <001> III-V semiconductor nanowhiskers are grown on an (001) III-V semiconductor substrate surface by effectively inhibiting growth in the preferential <111>B direction. As one example, <001> InP nano-wires were grown by metal-organic vapor phase epitaxy directly on (001) InP substrates. Characterization by scanning electron microscopy and transmission electron microscopy revealed wires with nearly square cross sections and a perfect zincblende crystalline structure that is free of stacking faults.

Owner:QUNANO

Whisker reinforced aluminum oxide composite ceramic as well as preparation method and application thereof

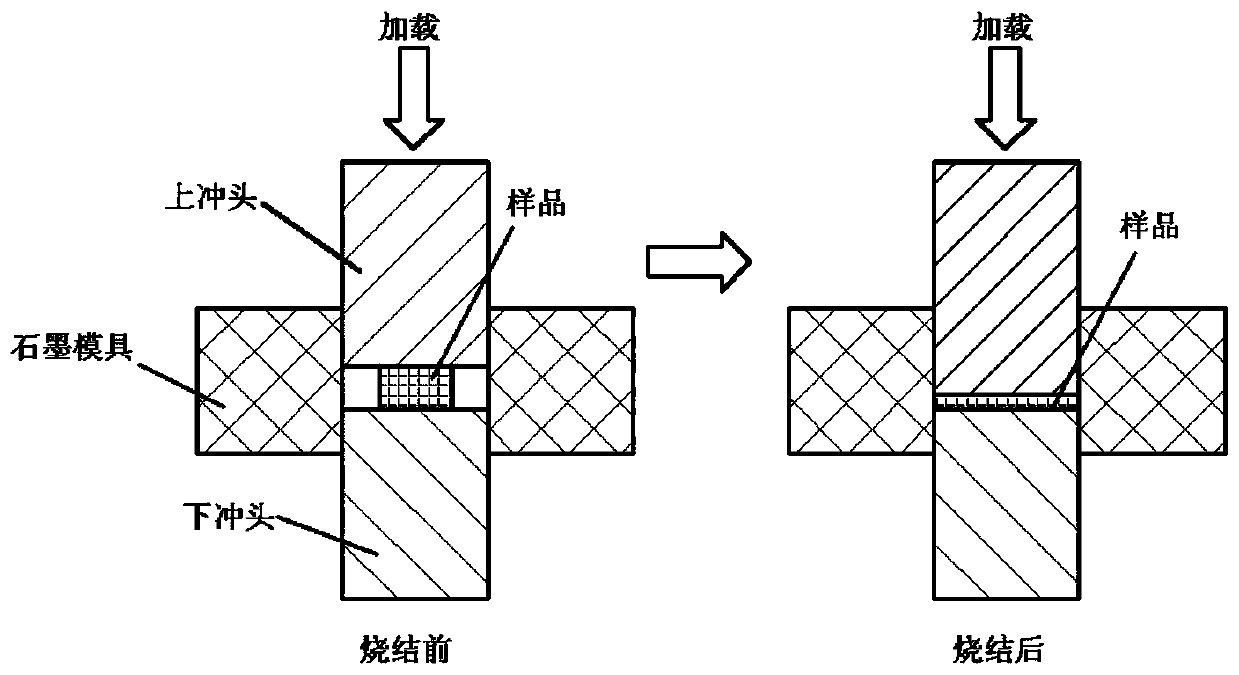

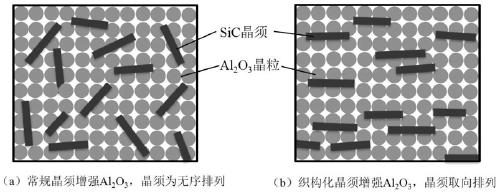

The invention relates to the technical field of ceramic materials, in particular to whisker reinforced aluminum oxide composite ceramic as well as a preparation method and application thereof. The composite ceramic is prepared from, by mass, 50-99.5 parts of aluminum oxide powder, 0.5-45 parts of whiskers, 0-20 parts of a sintering aid and 0-10 parts of a wear-resistant additive. The components are used as raw materials, a sample flows in a one-dimensional or two-dimensional direction in a mold by a hot-pressing flow sintering method, and the whiskers are directionally arranged to obtain the whisker-reinforced aluminum oxide composite ceramic. By texturing the whisker reinforced aluminum oxide composite ceramic, the toughness, strength, hardness and cutting performance of the aluminum oxide composite ceramic can be greatly improved. The whisker reinforced aluminum oxide composite ceramic prepared by the method is processed into a cutter which can be used for cutting a high-temperaturealloy at a high speed.

Owner:GUANGDONG UNIV OF TECH

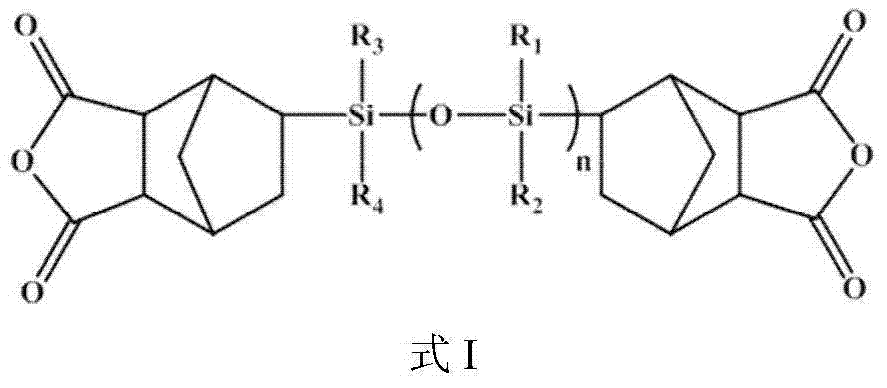

Novel electronic-grade polyimide film with low linear expansion coefficient and manufacturing method thereof

The invention relates to a manufacturing method of an electronic-grade polyimide film with low linear expansion coefficient. The method is characterized by comprising the steps that (1) the step-by-step condensation polymerization technology or the blending compounding technology is used for obtaining two or more polyamide acid glue solutions comprising rigid structures and soft structures at the same time and are different in rigidity and softness; (2) ultrafine inorganic whiskers, like zinc oxide whiskers, silicon carbide whiskers and zirconium tungstate whiskers, which are subjected to surface organic modification already and / or nanoparticle materials are smashed and cavitated through high-energy-density supersonic waves, and then the functional fillers are compounded with polybasic polyamide acid in an in-situ micro-nano mode; (3) the compounded glue solutions are subjected to filtration, vacuum defoamation, extrusion casting filming, chemical amidization or thermal amidization, infrared complete amidization, high-temperature thermal forming processing, corona processing and a reeling process, and therefore the electronic-grade polyimide film with the thickness being 7.5-125 micrometers, the linear expansion coefficient being 5-18ppm / DEG C, and good physical mechanical performance is obtained.

Owner:宏威高新材料有限公司 +1

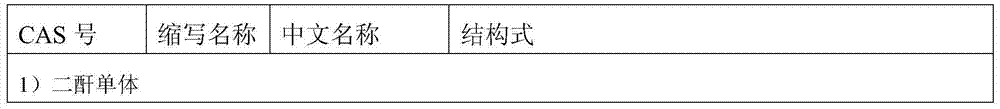

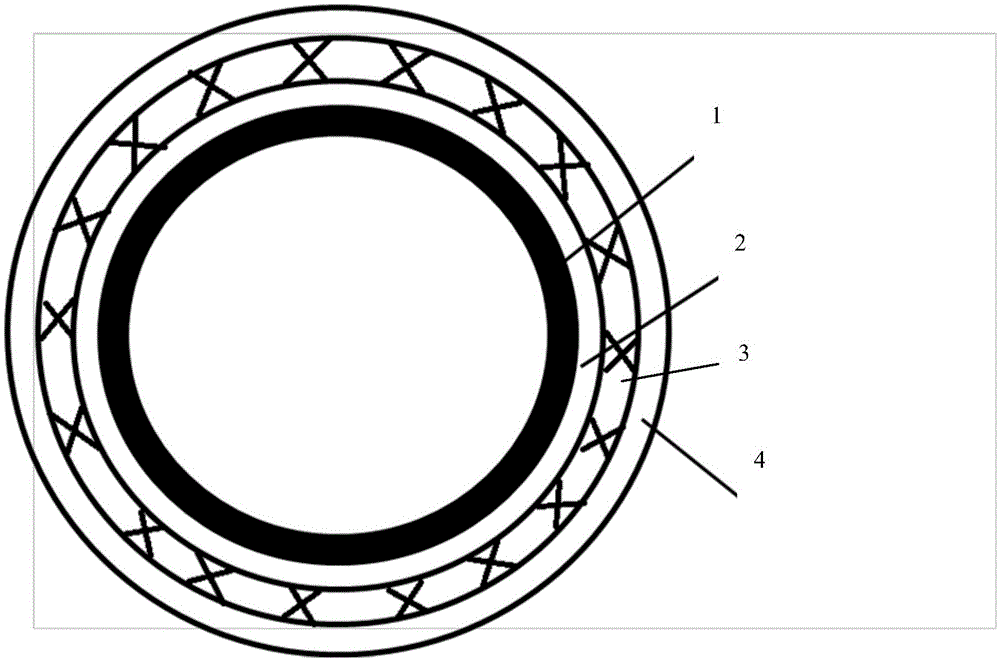

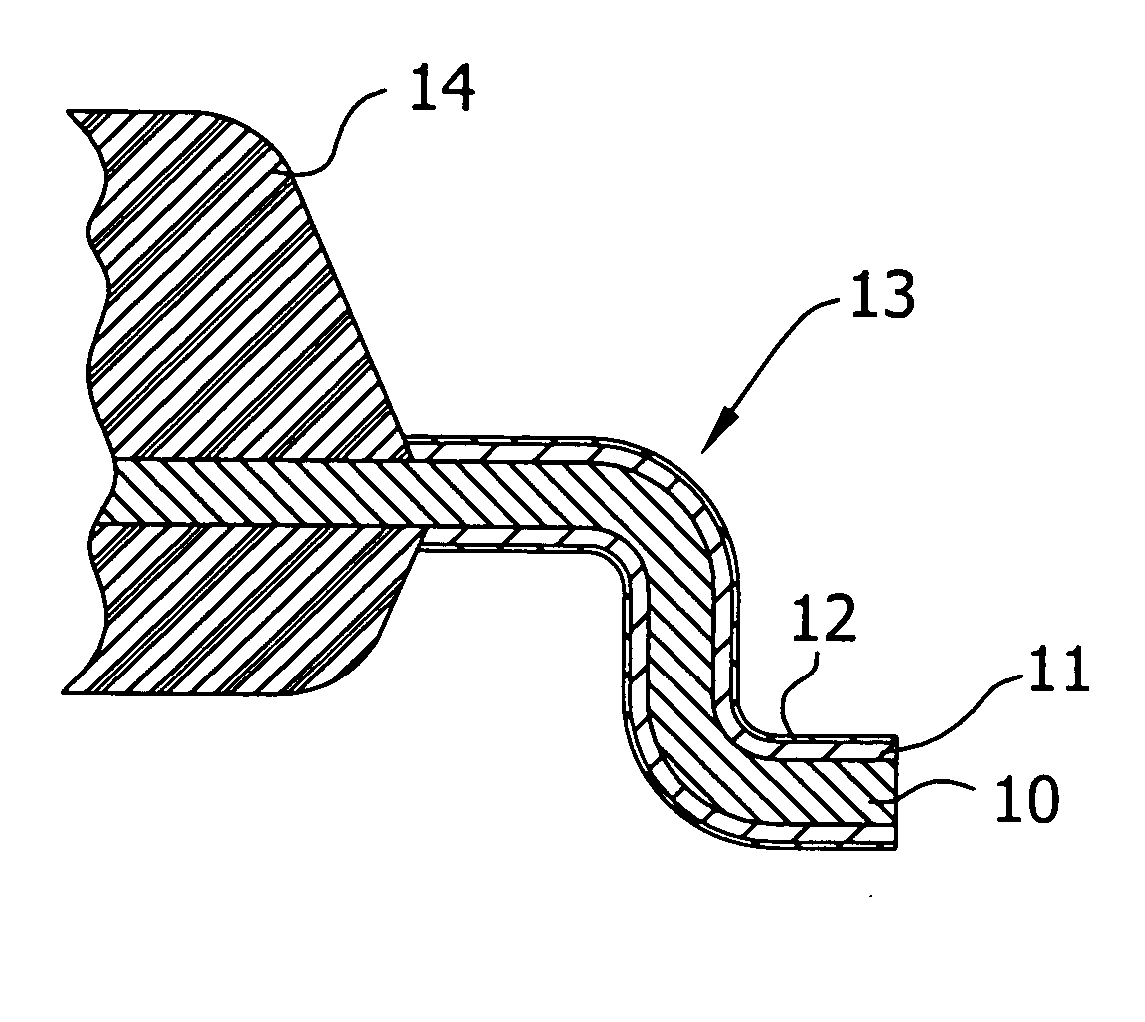

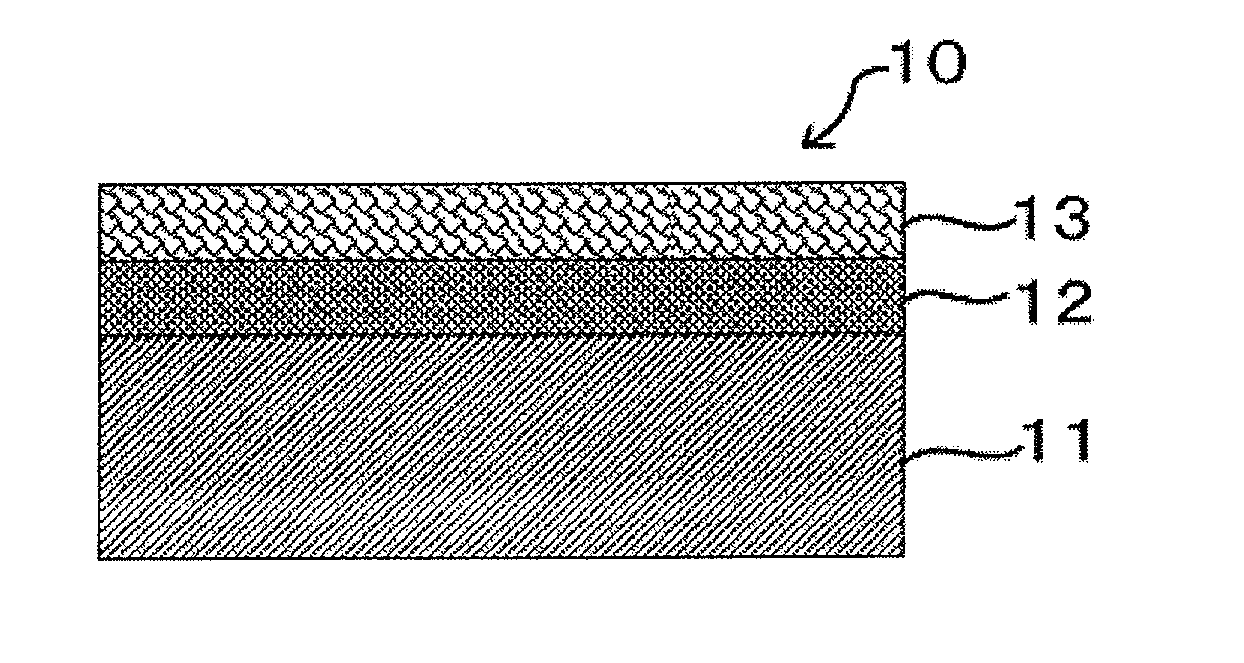

Multilayer structure of SiC/SiC (silicon carbide) composite cladding tube and preparation method thereof

ActiveCN103818056AHigh strengthHigh thermal conductivityCeramic layered productsCrack resistanceWhiskers

The invention discloses a multilayer structure of an SiC / SiC (silicon carbide) composite cladding tube and a preparation method of the multilayer structure. The multilayer structure of the SiC / SiC composite cladding tube is formed by alternately overlapping an SiC whisker toughening SiC composite layer and a continuous SiC fiber toughening SiC composite layer according to design needs. A three-layer overlapping structure takes the SiC whisker toughening SiC composite layer as an inner layer, a continuous SiC fiber toughening SiC composite material as a middle layer and a SiC whisker toughening SiC composite material as an outer layer; the multilayer structure can be formed by continuous alternate overlapping according to the design needs. The SiC whisker toughening SiC composite layer in the multilayer structure mainly plays a role of seal leakage prevention, meanwhile, the SiC whisker toughening SiC composite layer has high strength and toughness, the continuous SiC fiber toughening SiC composite layer plays a role of strength supporting, the multilayer structure of the SiC / SiC composite cladding tube has high crack resistance, high heat conductivity, high specific stiffness, high specific strength, excellent thermal shock and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

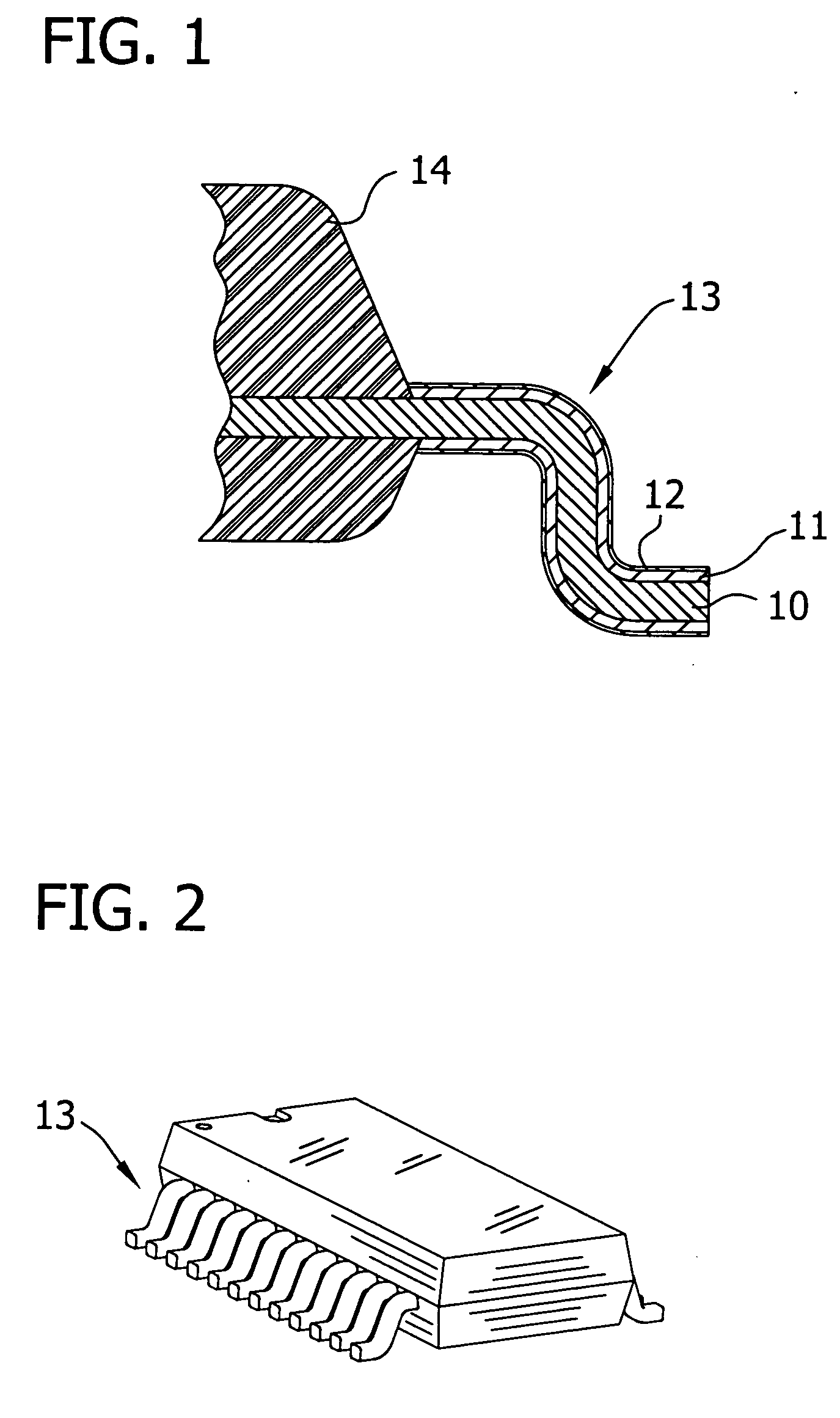

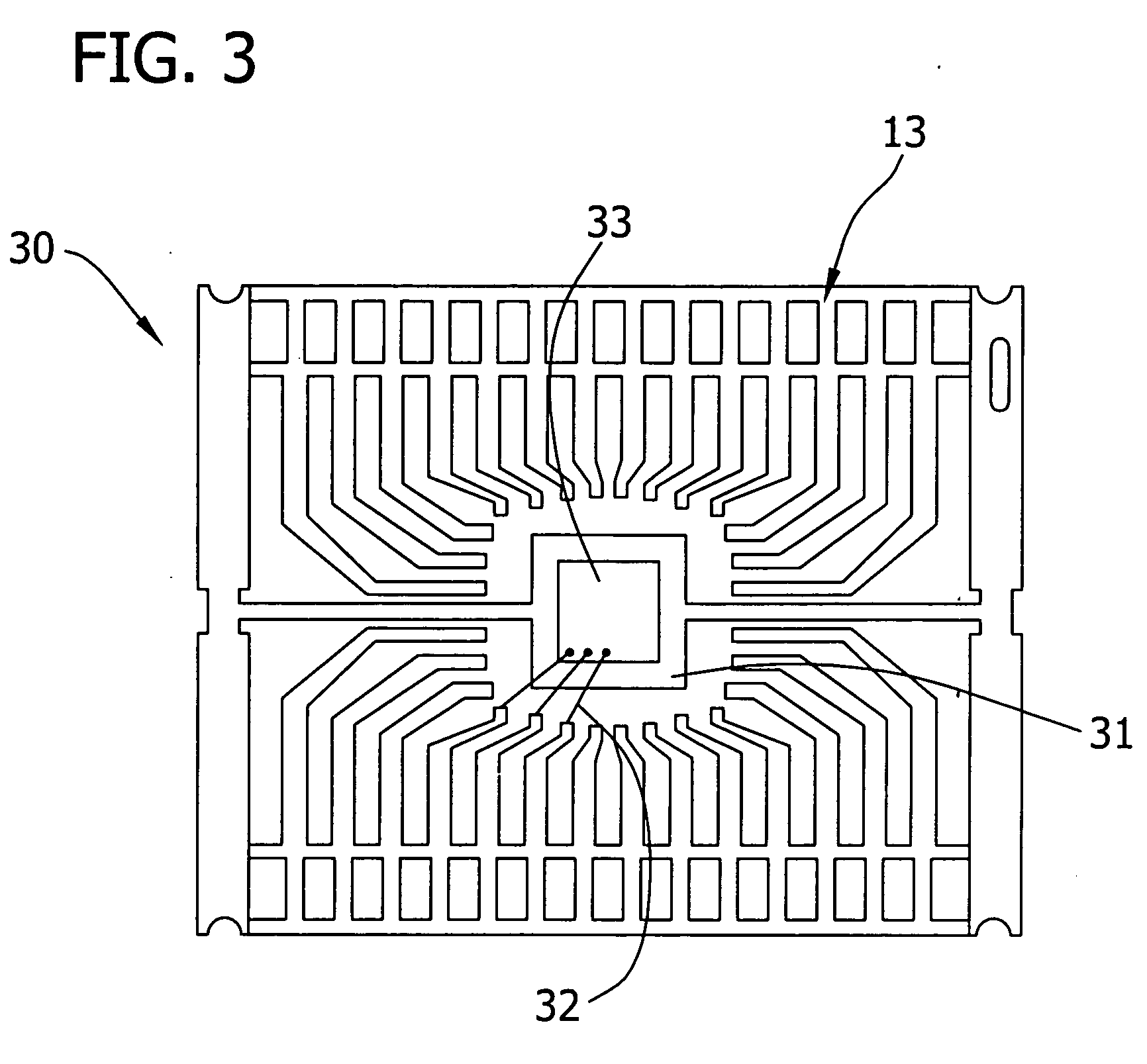

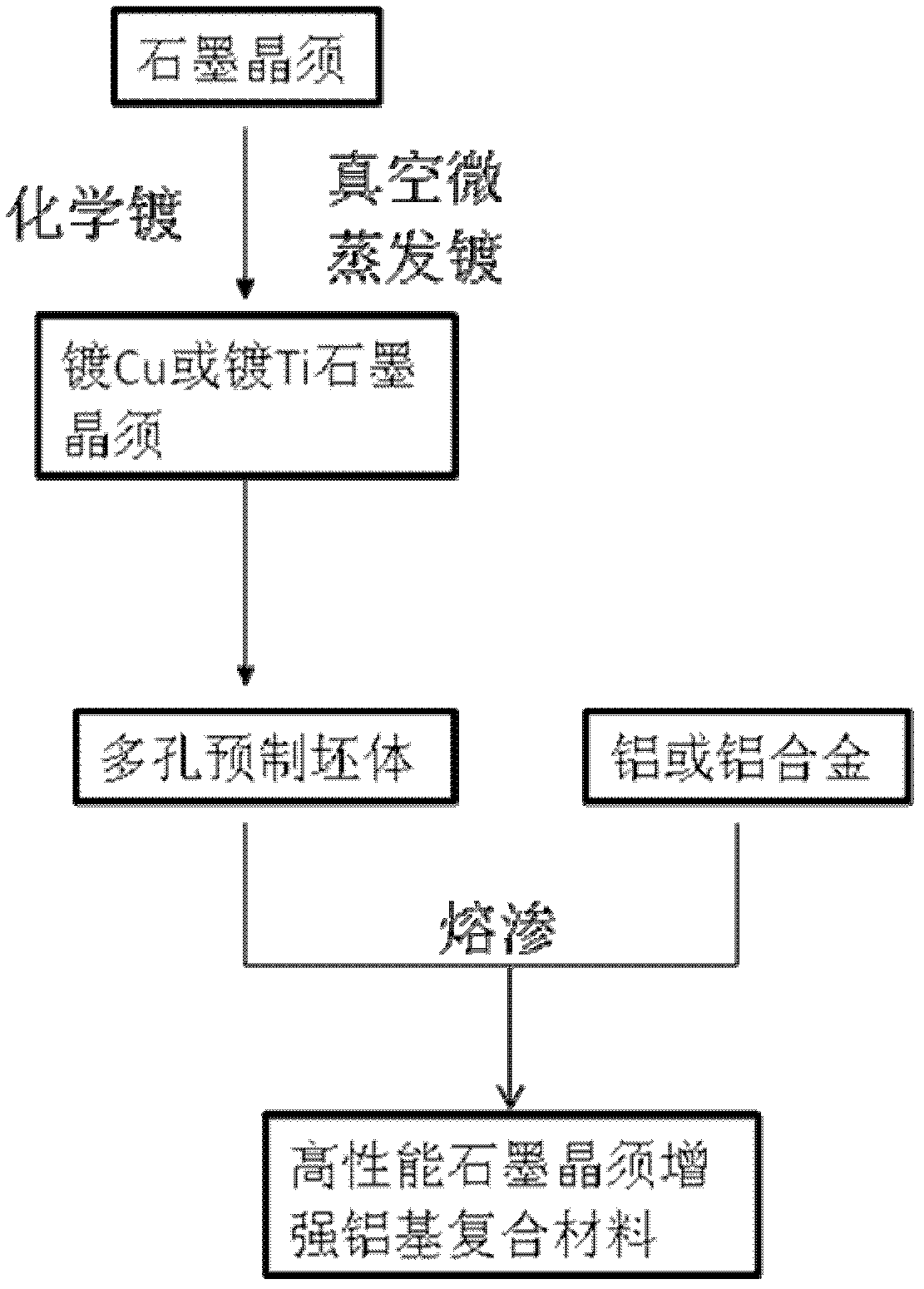

Tin-plated film and method for producing the same

InactiveUS20060016694A1Improve reliabilityHard to generate whiskerSemiconductor/solid-state device detailsSolid-state devicesTin platingThin membrane

The present invention has an object to provide a tin-plated film and a method for producing the same, capable of preventing whiskers from being generated and simultaneously preventing the surface of a substrate to be plated, which is not covered with a tin-plated film, from discoloring due to oxidation, by which prevention of whisker generation, suppression of whisker growth, and prevention of discoloring of a substrate to be plated are compatible with simplified operations ensuring excellent productivity. The method is provided with the steps of removing a part of a tin-plated film formed on copper or copper alloy; processing to prevent discoloring of the copper or copper alloy from which the tin-plated film is removed; and applying heat energy to the tin-plated film of the copper or copper alloy which is processed to prevent discoloring.

Owner:PANASONIC CORP

High-heat-conductivity high-toughness composite material and preparation method thereof

The invention discloses a high-heat-conductivity high-toughness composite material which is prepared from the following ingredients in parts by mass: 100 parts of matrix resin, 1-10 parts of a granular heat conductivity filler, 25-40 parts of a flake heat conductivity filler, 1-10 parts of a crystal whisker heat conductivity filler, 1-10 parts of a toughening agent and 0.1-0.5 part of a coupling agent. The invention further discloses a preparation method of the high-heat conductivity high-toughness composite material. A main body of a three-dimensional heat conductivity network is formed by graphite in the material; the crystal whisker heat conductivity filler penetrates through a resin layer and then is connected with graphite heat conductivity layers which are isolated by the resin; and the granular heat conductivity filler generates more mutual particle contact points. Thus, as the heat conductivity fillers of different shapes are effectively stacked, more heat conductivity paths are formed, and the heat conductivity property of the composite material is effectively improved; and meanwhile the granular heat conductivity filler and the crystal whisker heat conductivity filler have the toughening and enhancing functions on the composite material, so that the composite material has the advantages of high both heat conductivity and toughness.

Owner:HEFEI UNIV OF TECH

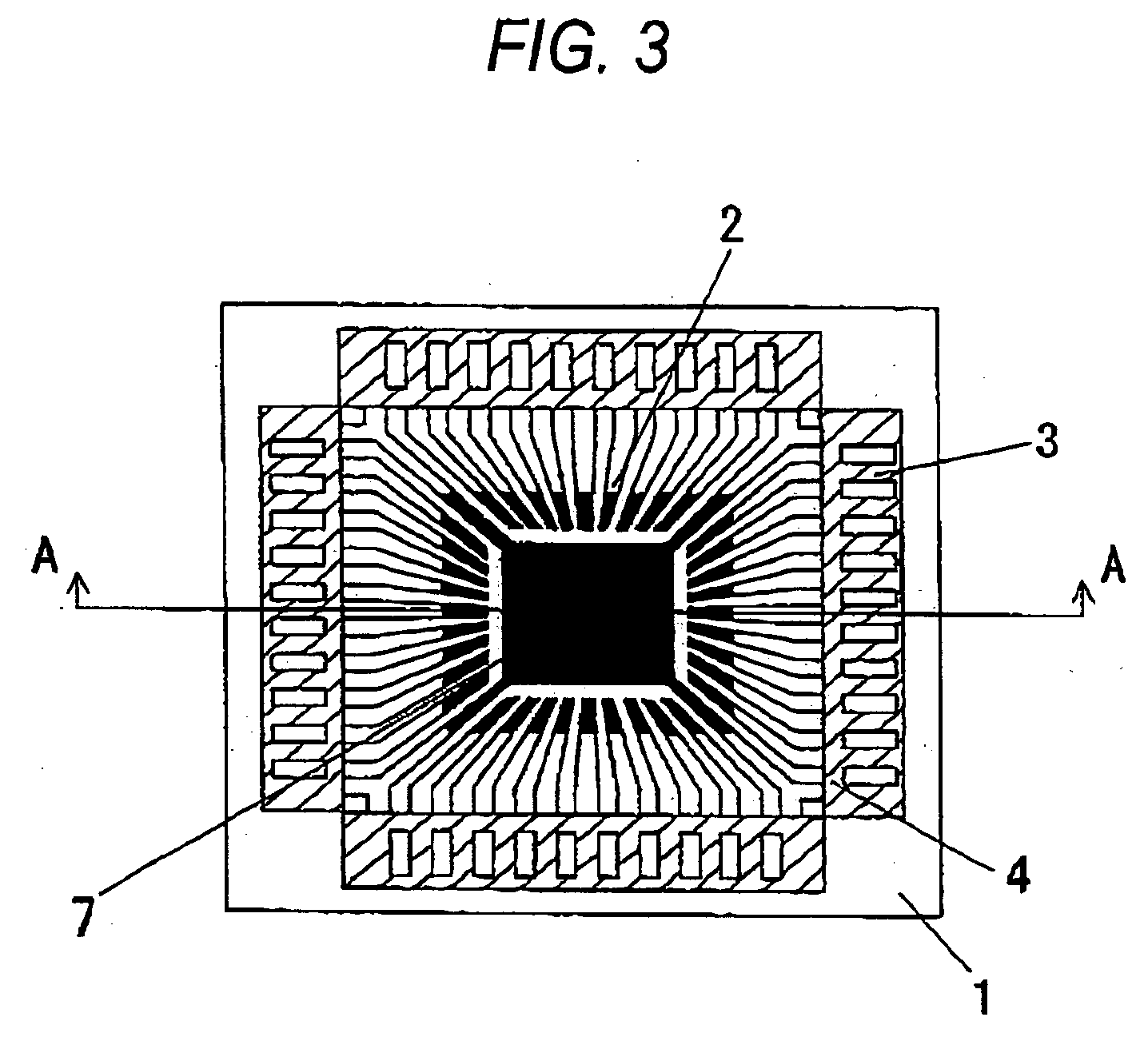

Tin-coated printed circuit boards with low tendency to whisker formation

ActiveUS7547479B2Thermometers using material expansion/contactionPrinted circuit aspectsTin platingEngineering

A coated article, which contains (i) at least one electrically non-conductive base layer, (ii) at least one layer of copper and / or a copper alloy, and (iii) a tin-containing layer, wherein the layer (ii) is positioned between the layer (i) and the layer (iii). The article is characterized in that the tin-containing layer (iii) contains at least one other metal.

Owner:ENTHONE GMBH

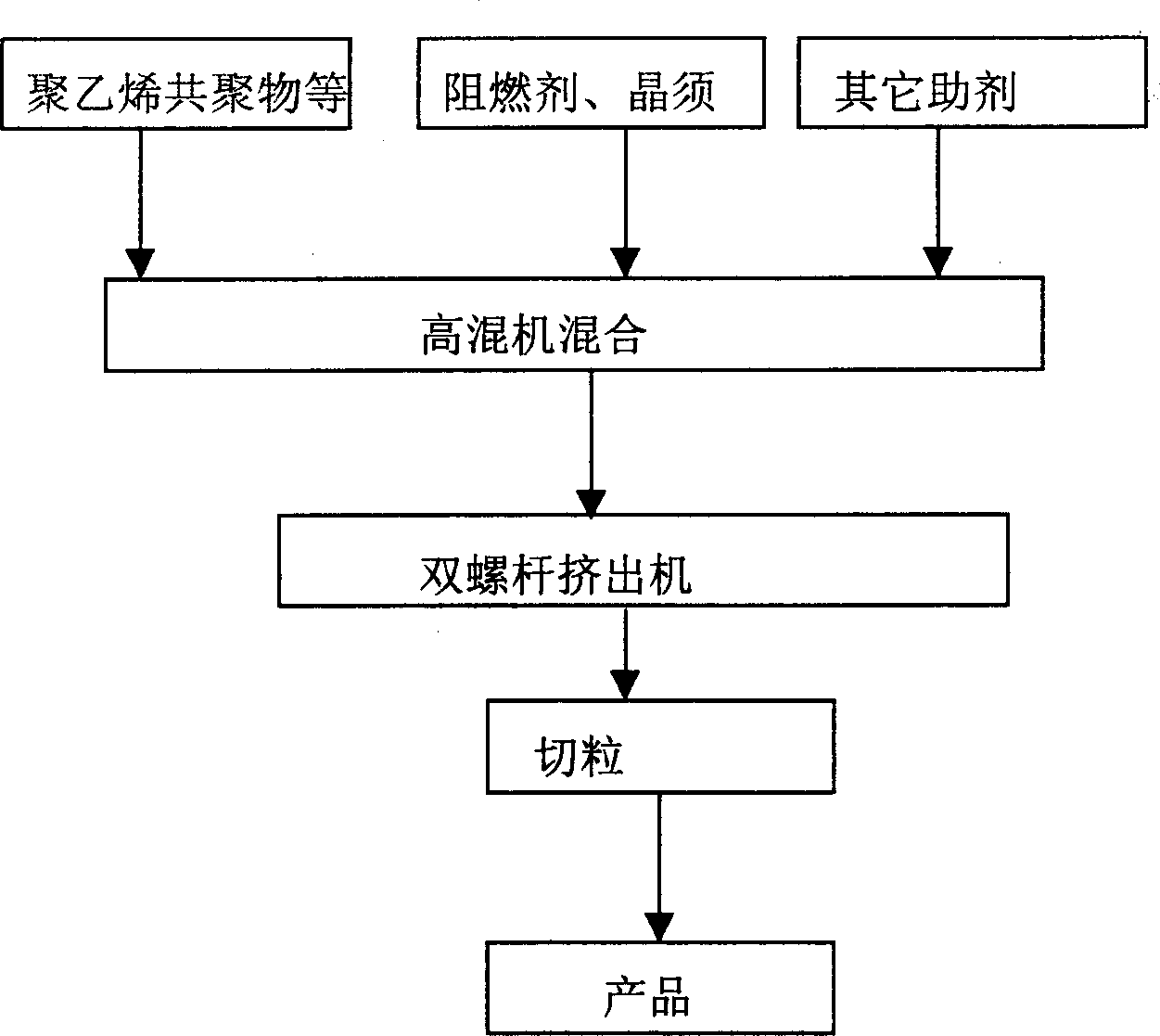

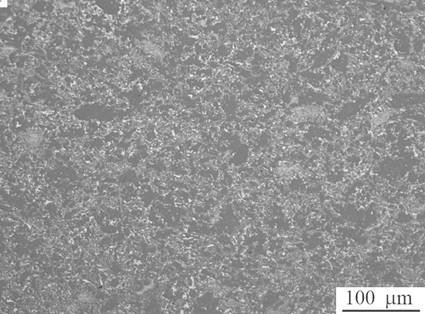

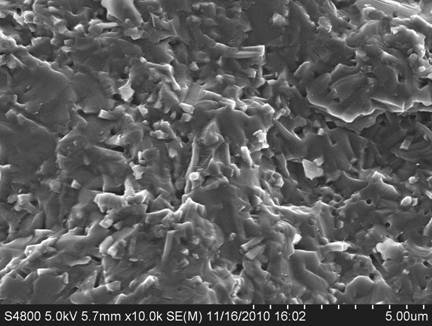

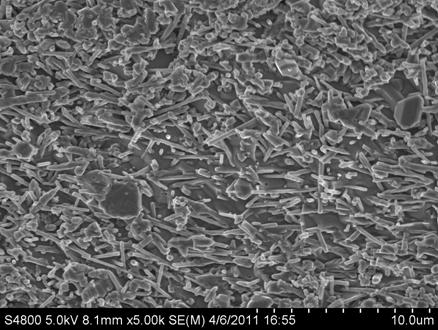

Thermoplastic non-halogen low fume fire resistant cable isolation material and processing tech. thereof

InactiveCN1787120AGood mechanical propertiesExcellent processing performanceRubber insulatorsPlastic/resin/waxes insulatorsInorganic crystalsMagnesium

The invention relates to a formula design for a thermoplastic halogen-free low-smoke flame-retardant cable insulating material and the manufacturing process thereof, concretely, using polyethene copolymer and / or modified ethylene-propylene rubber as a substrate, adding in halogen-free and nontoxic flame-retardant agent (nano magnesium hydroxide or aluminum hydroxide) and inorganic crystal whisker strengthening material as primary components, and adding in proper assistant, proportioning, mixing, plasticizing and making grains to make the insulating material. Its technical characters: not containing halogen, P, Al and other heavy metals; having god mechanical property, machining property and superior flame retardancy and having excellent thermal deforming, thermal ageing and thermal shock properties. The made cables have high safety and reliability. It is applied to the cables operating at 70 deg.C-105 deg.C long time, such as ship cables, cables for nuclear power plants, power and control cables for high-rise buildings, etc.

Owner:大连圣迈化学有限公司

SiC whisker reinforced SiC ceramic matrix composite and preparation method thereof

The invention belongs to the field of the preparation of ceramic matrix composites, and particularly relates to a SiC whisker reinforced SiC ceramic matrix composite and a preparation method thereof. The SiC whisker reinforced SiC ceramic matrix composite is prepared from a preform through a Si or Si alloy infiltration reaction, and the preform is prepared by compressing and molding a raw material comprising a rice hull SiC whiskerized product. By the method, the preparation process is simple, the temperature of the infiltration reaction is low, external pressure is not required, and the preform can be prepared into complicate shapes and can be used for preparing members with complicated shapes. A main composition phase SiC of the composite comes from rice hull, the raw material is rich, the cost is low, the manufacturing cost of the ceramic matrix composite can be remarkably reduced, the resource is saved and the environment is protected. The SiC ceramic matrix composite has good performance, SiC whiskers have the effect of strengthening materials, and the SiC whisker reinforced SiC ceramic matrix composite can be used for applicable occasions of SiC reaction sintering ceramic material products such as sliding bearings, corrosion-resistant and wear-resistant pipelines, valves and fan blades, military and civil body armors and the like.

Owner:ZHEJIANG UNIV

Composite coatings for whisker reduction

ActiveUS20090145765A1Increase corrosion resistanceDecreased coefficient of frictionElectrolytic coatingsCoupling contact membersWear resistantElectroplating

There is provided a method and composition for applying a wear resistant composite coating onto a metal surface of an electrical component. The method comprises contacting the metal surface with an electrolytic plating composition comprising (a) a source of tin ions and (b) non-metallic particles, and applying an external source of electrons to the electrolytic plating composition to thereby electrolytically deposit the composite coating onto the metal surface, wherein the composite coating comprises tin metal and the non-metallic particles.

Owner:MACDERMID ENTHONE INC

Preserving solderability and inhibiting whisker growth in tin surfaces of electronic components

InactiveUS20050249969A1Trend downSemiconductor/solid-state device detailsSolid-state devicesSolderabilityWhiskers

A method for reducing whisker formation and preserving solderability in tin coatings over metal features of electronic components. The tin coating has internal tensile stress and is between about 0.5 μm and about 4.0 μm in thickness. There is a nickel-phosphorus layer under the tin coating.

Owner:ENTHONE INC

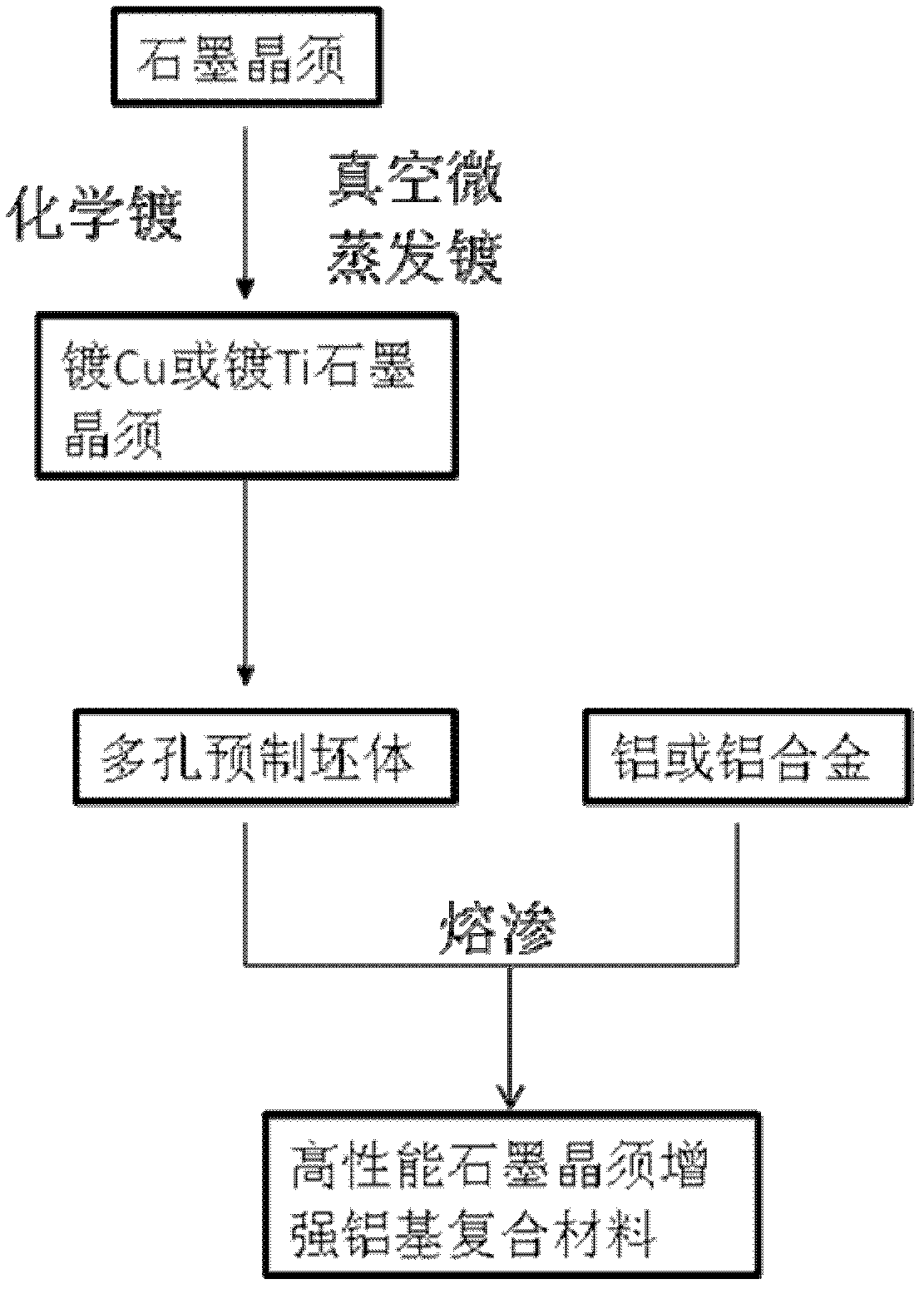

Method for preparing graphite whisker reinforced aluminum matrix composite material

InactiveCN102586703AHigh thermal conductivitySmall coefficient of thermal expansionThermal dilatationChemical plating

The invention discloses a method for preparing a graphite whisker reinforced aluminum matrix composite material. The composite material consists of plated high-reinforced-phase heat conducting graphite whiskers and matrix aluminum or aluminum alloy, wherein the volume fraction of the matrix aluminum or the aluminum alloy is 40%-65%, and the volume fraction of the plated graphite whiskers is 35%-60%. The production process comprises the steps of 1 adopting a chemical plating or vacuum salt bath plating method to plate copper or titanium on the surfaces of the graphite whiskers so as to form a plating layer with thickness of 0.1-1.5mum; 2 adding an appropriate amount of binder on the graphite whiskers with modified surfaces to perform die forming, and then adopting thermal degreasing to remove the binder and manufacture a porous prefabricated blank; and 3 stacking up the prefabricated blank and the aluminum or the aluminum alloy to perform vacuum pressure infiltration processing so as to finally obtain a graphite whisker-aluminum composite material part. The composite material prepared by means of the method has the advantages of being high in heat conductivity, low in thermal expansion coefficient, light in weight, high in densification, easy to process and the like.

Owner:UNIV OF SCI & TECH BEIJING

Whisker plasticizing tungsten carbide-cobalt base hard alloy material and its preparation process

The invention discloses a crystal whisker toughened tungsten carbide cobalt-base hard alloy material and the preparing method. It takes powder metallurgy technology, employs tungsten carbide- cobalt as base material, adds titanium carbide crystal whisker and prepares toughened tungsten carbide cobalt-base hard alloy material through a certain process. It is characterized in that: (1) employs powder metallurgy technology and prepares out product with different shapes. (2) the rigidity is high, compression strength and toughness are good, the titanium carbide crystal whisker increases toughness on basis of guranteeing strength of said alloy, and it aslo can be used to replace cobalt and as adhesive phase, to improve material performance. (3) the process is simplea nd cost is low. The hard alloy material can be used in mechanics, metallurgy, mine, first-order instrument and military, and uesd to prepare kinds of blade and drilling button, and new knife tool material.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

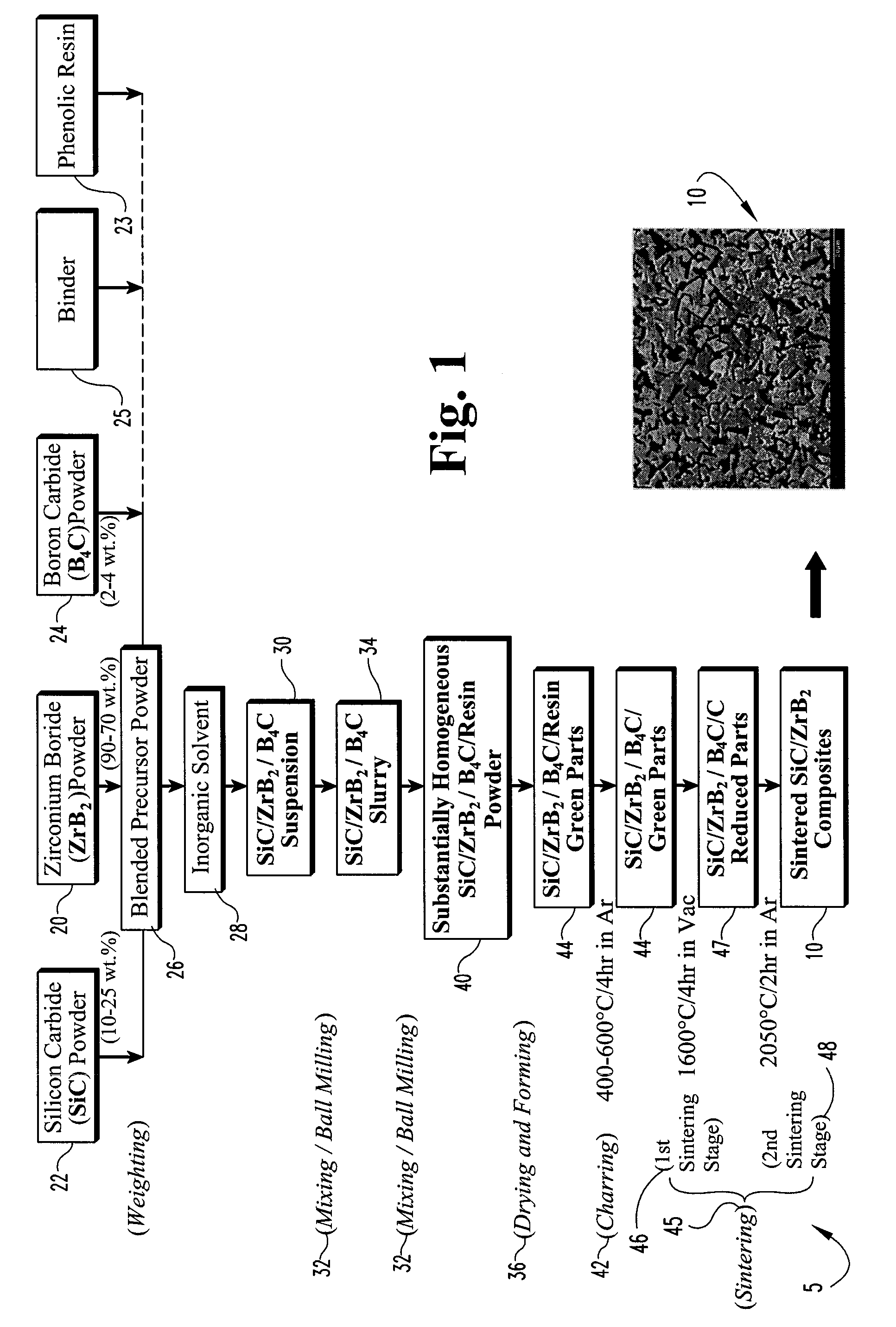

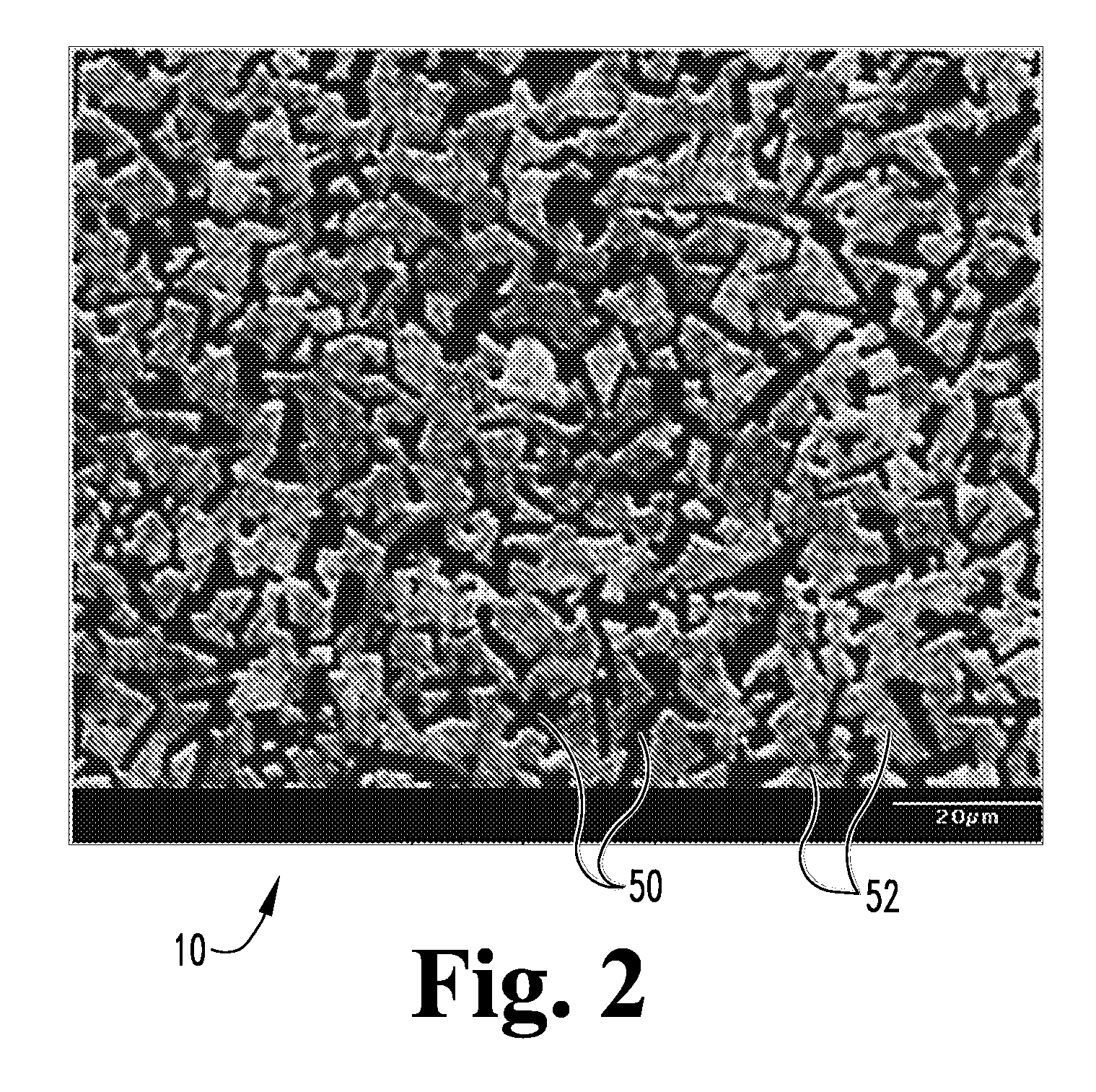

Pressurelessly sintered zirconium diboride/silicon carbide composite bodies and a method for producing the same

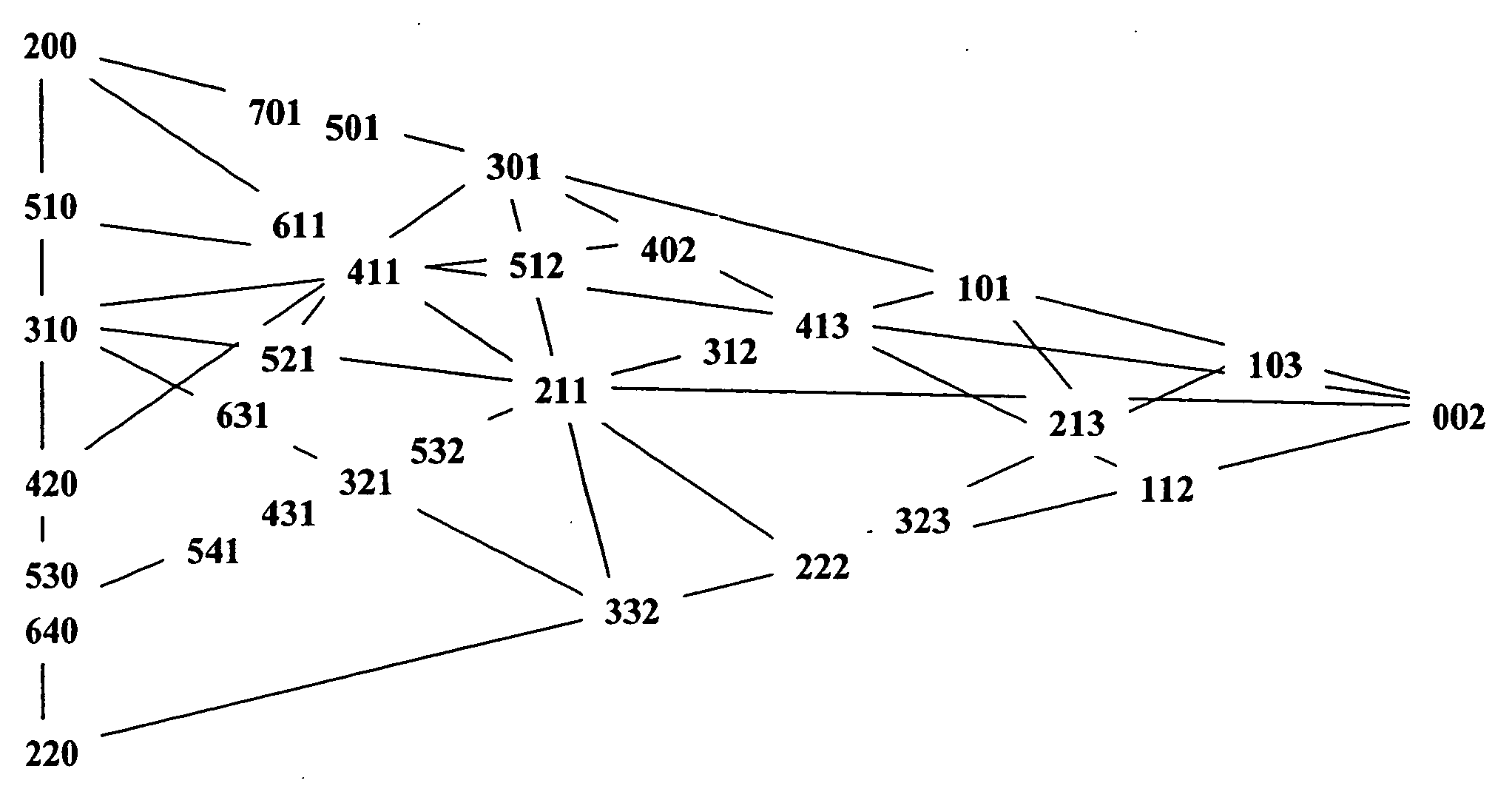

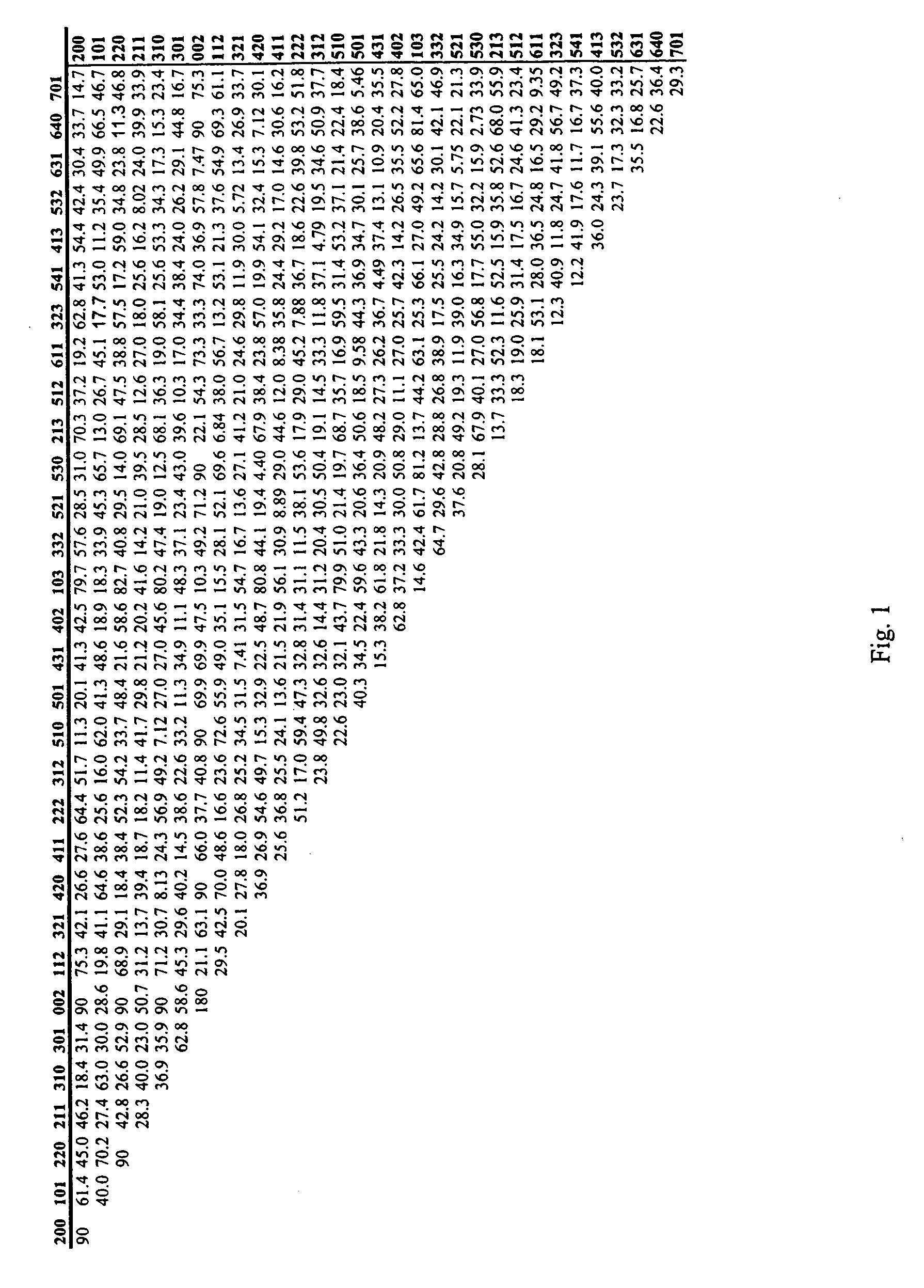

A method of sintering a ZrB2—SiC composite body at ambient pressures, including blending a first predetermined amount of ZrB2 powder with a second predetermined amount of SiC powder, wherein both powders are characterized by the presence of surface oxide impurities. Next the blended powders are mixed to yield a substantially homogeneous powder mixture and a portion of the substantially homogeneous powder mixture is formed into a green body. The body is fired to a first temperature, wherein substantially all surface oxide impurities are reduced and / or volatilized to substantially eliminate oxides from the green body, and the body is heated to a second temperature and sintered to yield a composite body of at least about 99 percent theoretical density and characterized by SiC whisker-like inclusions distributed substantially evenly in a ZrB2 matrix.

Owner:UNIVERSITY OF MISSOURI

Tin plating method

ActiveUS20060090819A1Reduce formationTendency increaseGlass/slag layered productsConductive pattern reinforcementTin platingWhiskers

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

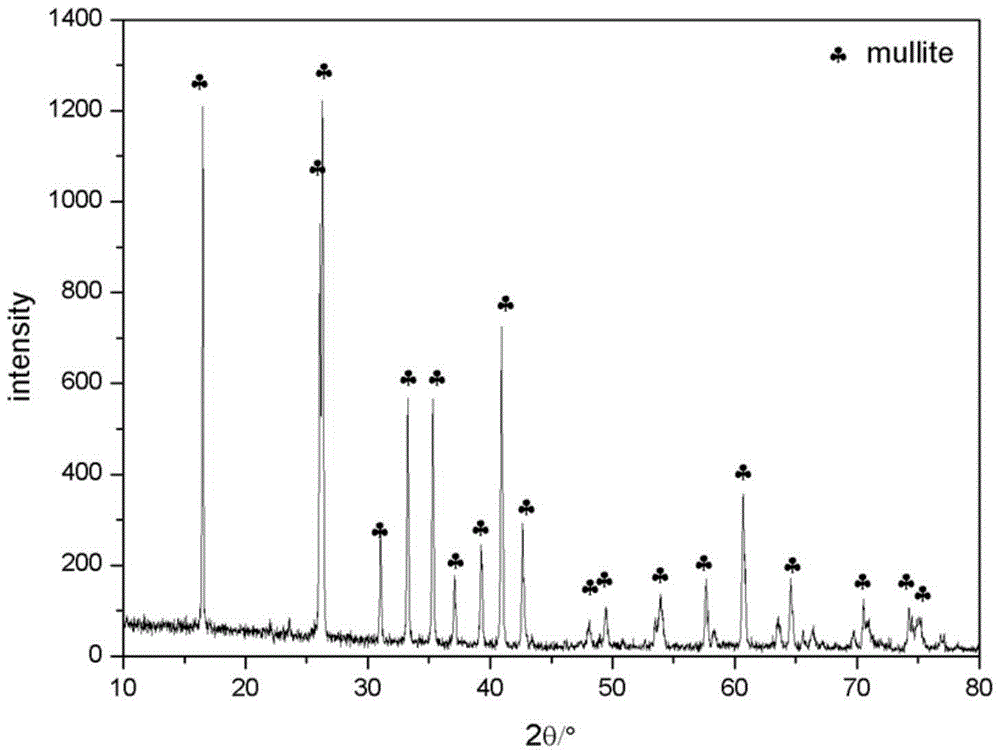

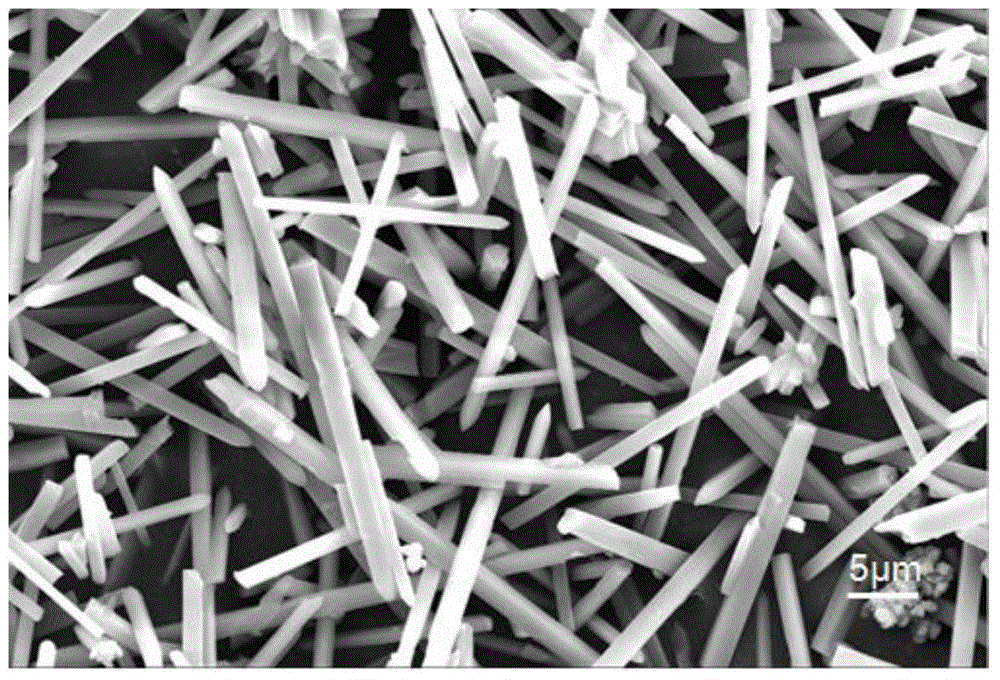

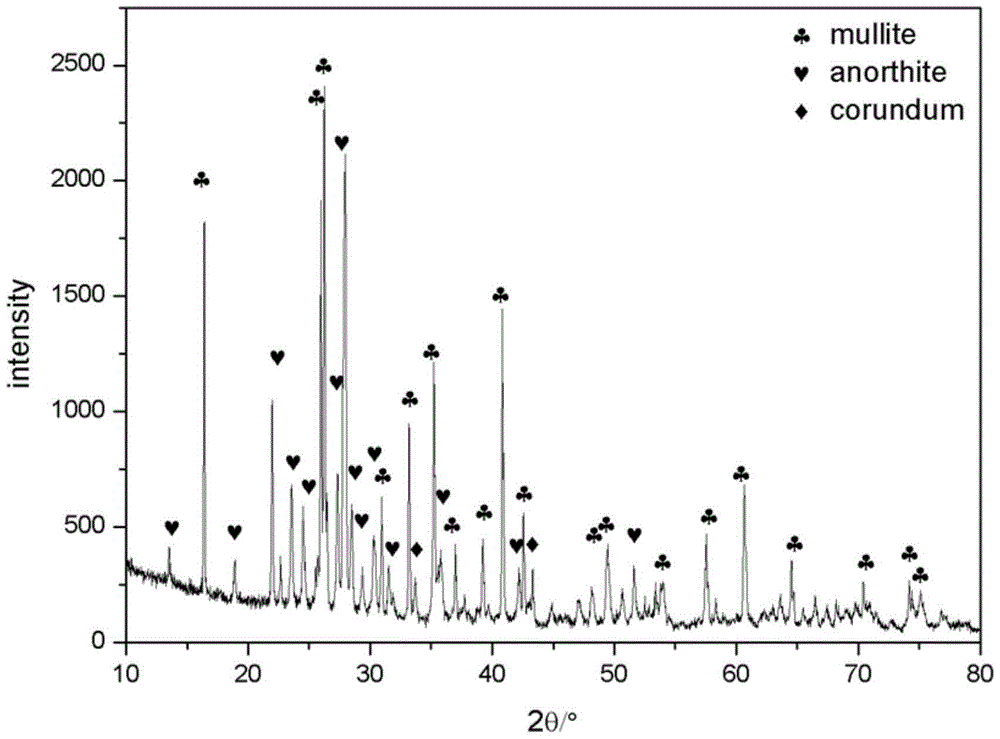

Mullite-whisker-reinforced anorthite porous ceramic and preparation method thereof

InactiveCN105198478ARaw materials are easy to getGood lookingCeramicwareSolid state reaction methodSilicon dioxide

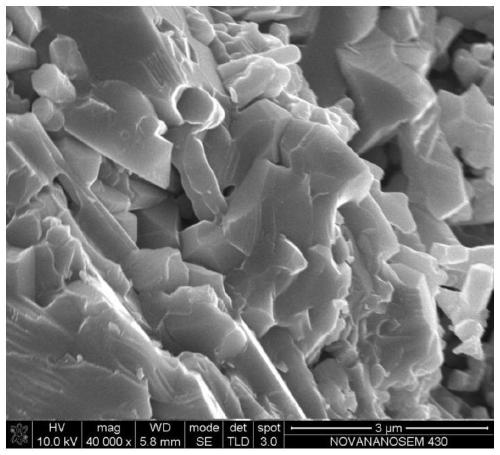

The invention provides a mullite-whisker-reinforced anorthite porous ceramic and a preparation method thereof. The preparation method comprises the following steps: preparing pure-phase high-length-diameter-ratio high-dispersibility mullite whisker by a solid reaction process, preparing a porous ceramic billet from the mullite whisker, alpha-aluminum oxide, silicon dioxide and calcium carbonate powder by a foam gelcasting process, and finally, sintering at 1450 DEG C for 5 hours to obtain the mullite-whisker-reinforced anorthite porous ceramic. The material prepared by the method has the advantages of high porosity, low thermal conductivity and high strength. The apparent porosity of the sample, in which the addition amount of the mullite whisker is 50 wt.%, is up to 90%; the room-temperature vacuum thermal conductivity is only 0.045 W / m.K; and the compression strength is up to 1.1 MPa. The research shows that the added mullite whisker inhibits the growth of the anorthite grains, and the high porosity, complicated pore structure and fine grains are main reasons for low thermal conductivity. The tight combination between the added whisker and base greatly enhances the strength of the material.

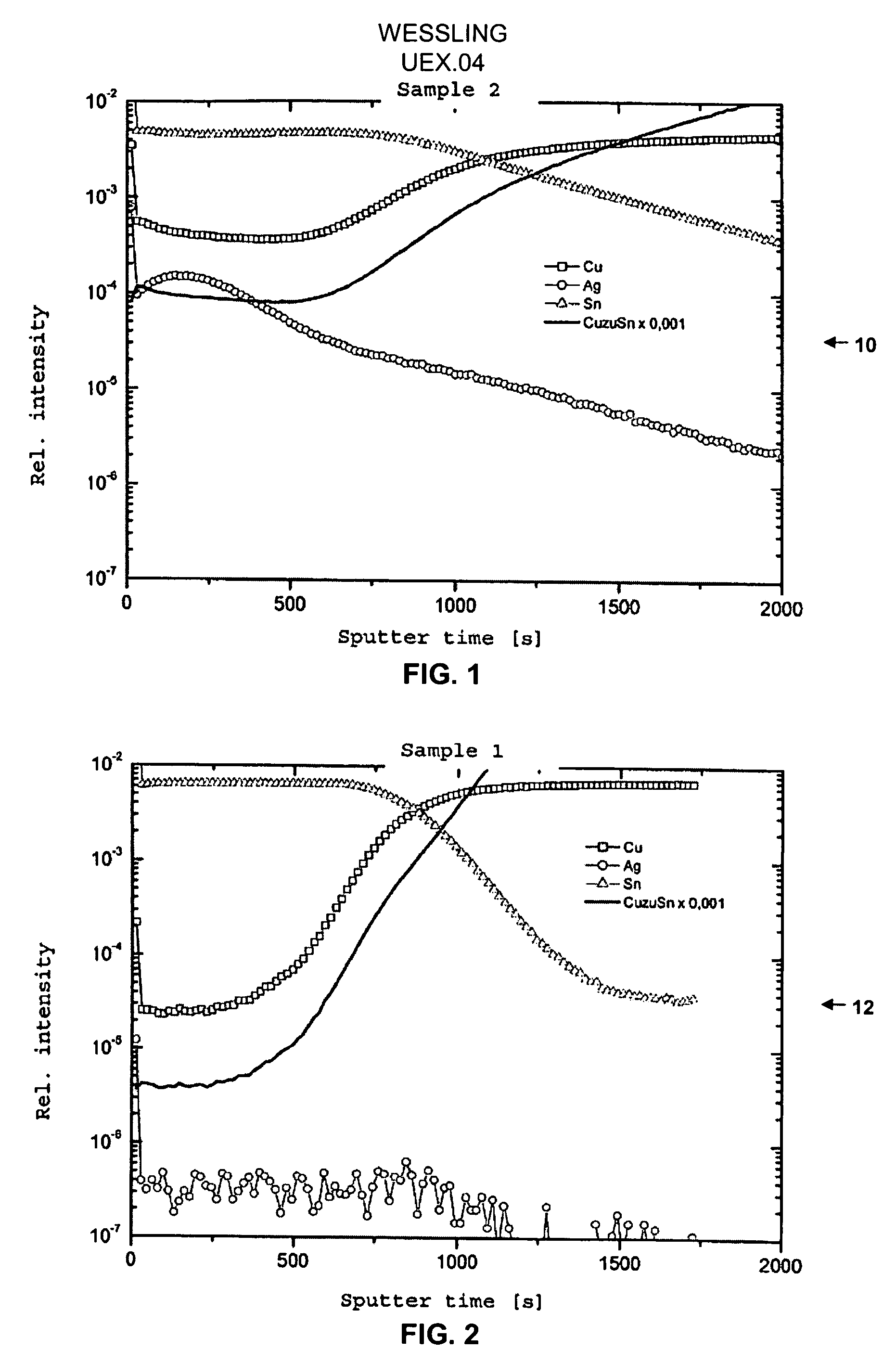

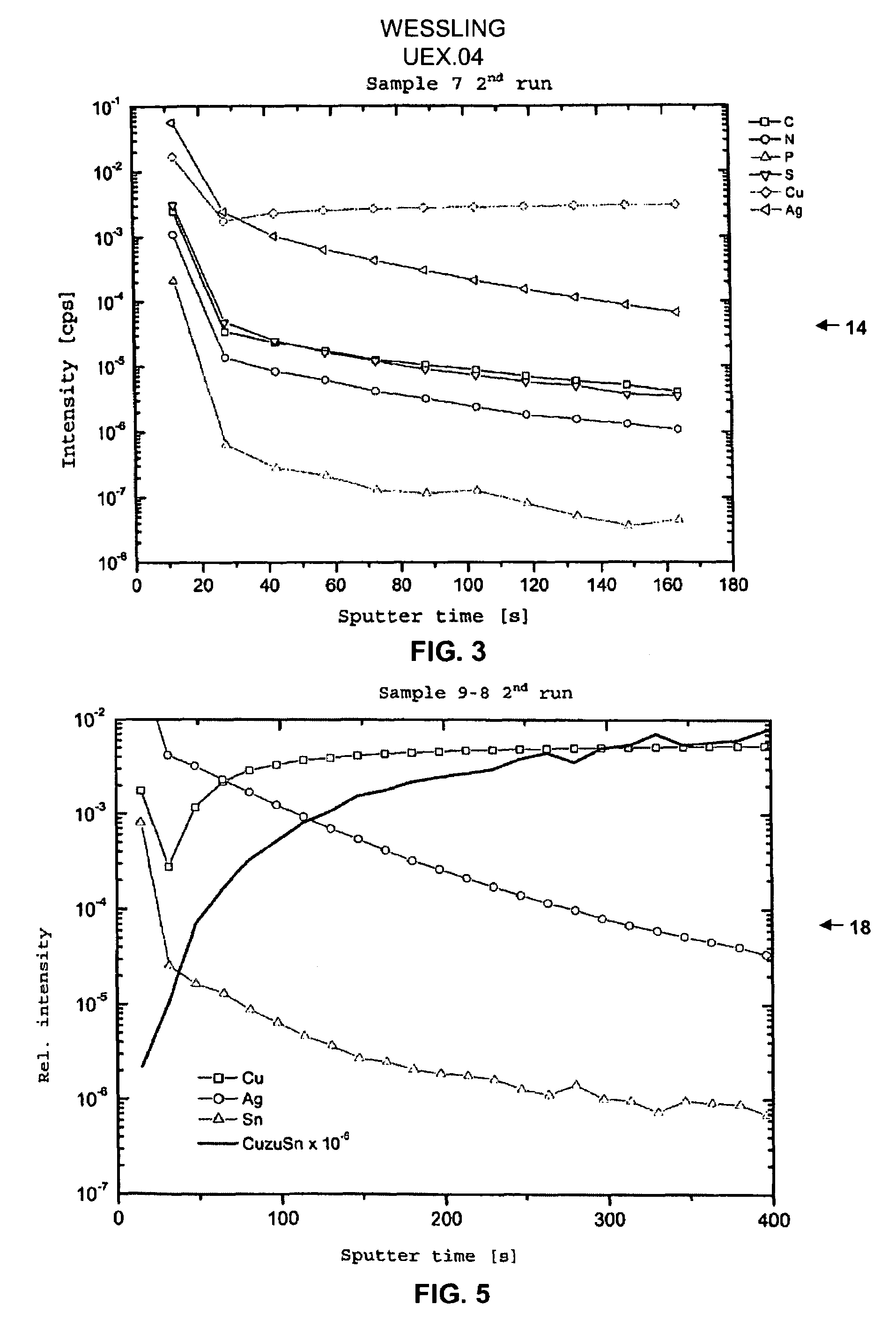

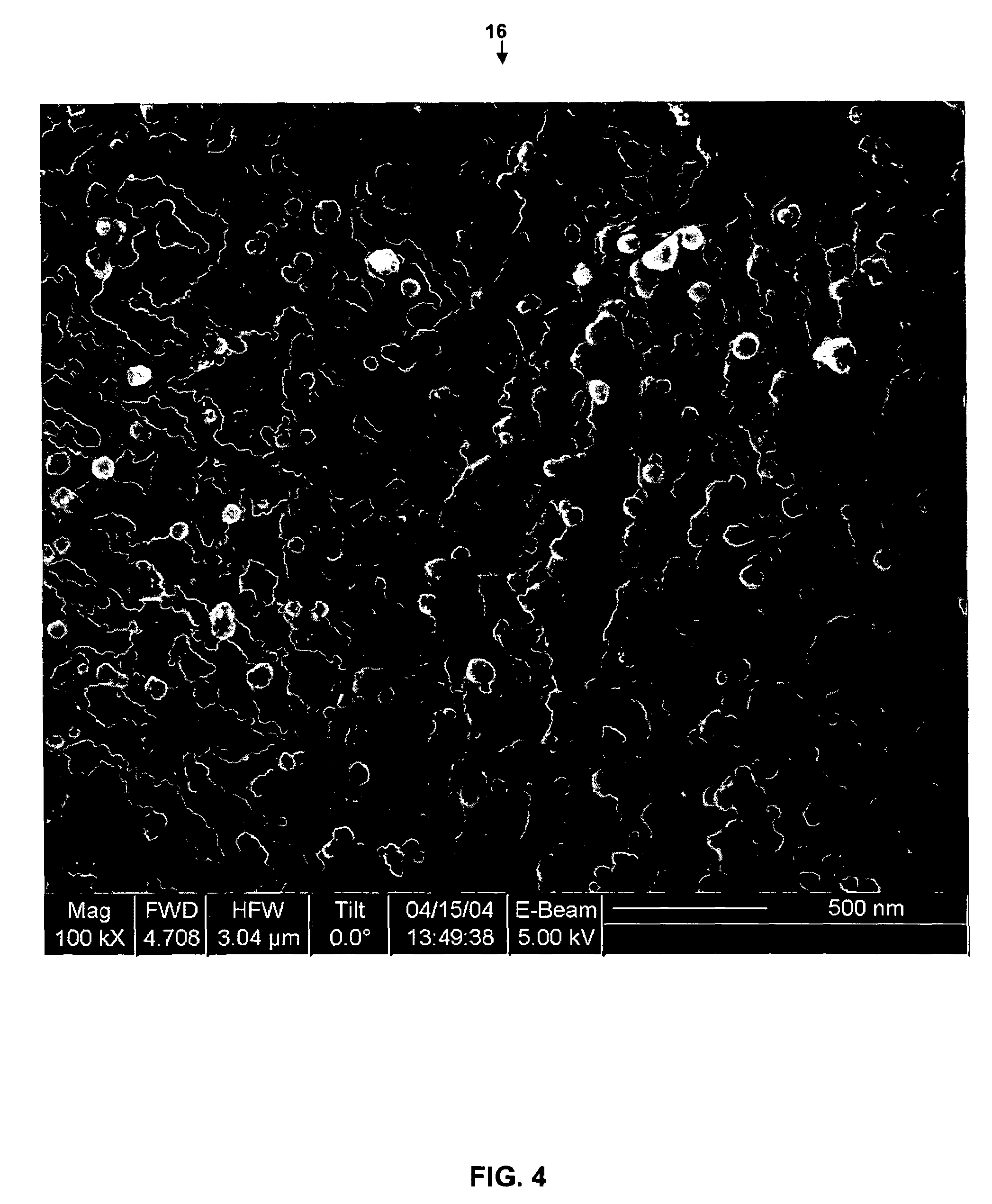

Silver barrier layers to minimize whisker growth in tin electrodeposits

InactiveUS20060292847A1Reduce formationHeavy loadSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSurface layerCompound (substance)

The invention relates to a method of reducing tin whisker formation in a plated substrate that includes a surface layer comprising tin. The method includes providing on electroplatable portions of the substrate (a) an underlayer comprising silver or (b) a barrier layer that passes a mechanical load test when the surface layer, after 48 hours of contact with a 1 mm hemispherical tip that carries a load of between 500 to 2000 g, exhibits no whiskers having a length of greater than 5 microns. The underlayer or barrier layer, whichever is present, is provided in a thickness sufficient to prevent formation of intermetallic compounds between the substrate and surface layer so that the surface layer exhibits reduced whisker formation compared to the same surface layer deposited directly upon the substrate. Typically, the underlayer or barrier layer includes 50 to 100% by weight silver or similar ductile material.

Owner:TECHNIC INC

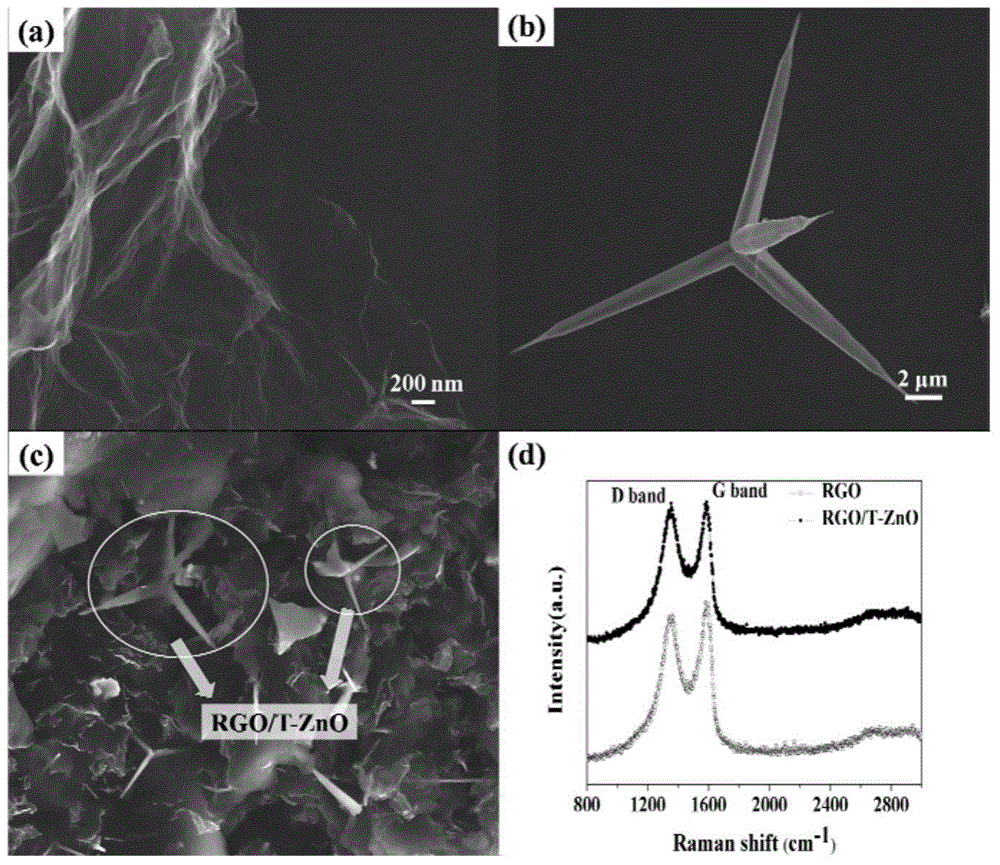

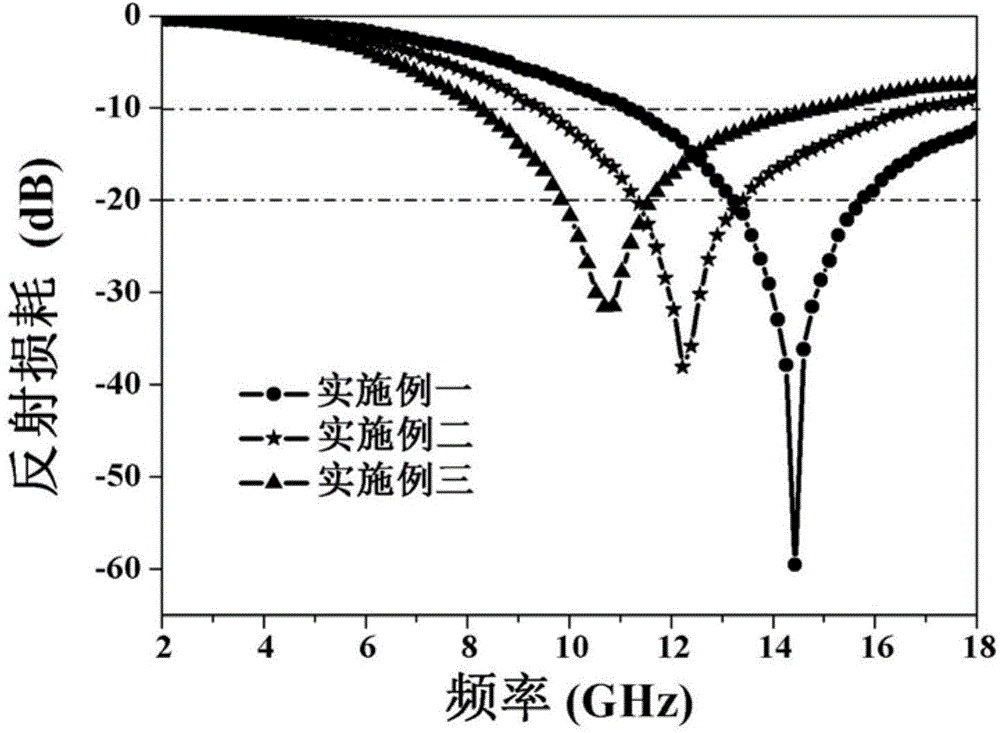

Compounded wave-absorbing material of grapheme/four-pin zinc oxide whisker and preparation method thereof

ActiveCN104099062AEasy to makeShort reaction timeOther chemical processesMicrowaveUltrasound treatment

The invention discloses a compounded wave-absorbing material of grapheme / four-pin zinc oxide whisker and a preparation method thereof, and belongs to the field of microwave absorption. Natural scale graphite is used as a raw material to prepare reduction-oxidation graphene; the obtained reduction-oxidation graphene is dispersed into an alcohol solution for ultrasound treatment for 3-5 h to obtain reduction-oxidation graphene dispersion liquid with the concentration of 0.3-0.6 mg / ml; adding four-pin zinc oxide whisker into the reduction-oxidation graphene dispersion liquid, wherein the mass fraction of graphene is 4-8% and the mass fraction of four-pin zinc oxide whisker is 8-12%; performing magnetic mixing for 30-40 min wherein the rotating speed is controlled at 400-600 rpm / min and the temperature is controlled within 20-40 DEG C; placing the mixed solution into a drying oven for drying, and keeping the temperature at 60-80 DEG C for 6-8 h, so as to obtain the compounded wave-absorbing material. The preparation process is simple, the prepared wave-absorbing material is excellent in wave-absorbing property, strong in wave-absorbing ability, wide in wave-absorbing frequency band, and strong in regulatory property; high absorption at different frequency can be realized by thickness adjustment.

Owner:UNIV OF SCI & TECH BEIJING

Special ceramic cutter material for wire-board or circuit board and preparation method thereof

InactiveCN101157554AImprove impact toughnessImprove wear resistanceTitanium carbideCeramic cutting tool

The invention discloses a ceramic cutting tool and the preparation method thereof special for a smashing line board or a circuit board, and belongs to the art of the smashing equipment. The ceramic cutting tool takes crystal whisker as the plasticizing material; tungsten carbide as the substrate material; titanium carbide as anti-friction agent; carbon as deoxidizing agent; and chromic compound, lanthanum oxide and cerium oxide as additive. The ingredients are evenly blended and directly molded by heat pressing. The raw material is not taken out until being fully mixed, and is then positioned into the sample heat pressing groove of a hot-press machine. The thermo-compression intensity of pressure is 10-40MPa, and the hot-press temperature ranges from 1,480 to 1,600DEG C. The flexible ceramic cutting tool of the invention is provided with good resilience, wearlessness, high rigidity and chemical stability. The technique of the cutting tool is quite simple and the production period is far shorter than the production period of the conventional preparation method that carries the compression molding of the evenly mixed raw materials first and then the sinter molding. The cutting tool material is fit for the cutting tool special for the making of a waste line board and the smashing equipment of the circuit board.

Owner:TSINGHUA UNIV

High-porosity mullite whisker porous ceramic tube and preparing method

The invention discloses a high-porosity porous ceramic tube formed by interlocking uniform mullite whiskers and a preparing method of the ceramic tube. Three types of powder including an aluminum source, a silicon source and a whisker growth catalyst are evenly mixed and then dispersed in an organic solution which is obtained by dissolving PESF and PVP in an NMP solvent, the liquid is mixed and ball-milled evenly and then placed in a die for extrusion phase conversion forming, and a ceramic tube blank is obtained. The blank is sintered at the temperature of 1300-1500 DEG C, the whiskers grow in situ and form an interlocked structure, and therefore the high-porosity mullite whisker porous ceramic tube with the porosity larger than 70% and the breaking strength larger than about 3 MPa is obtained. The mullite whisker porous ceramic tube can be applied in the fields of thermal insulation and preservation, noise reduction, catalyst carrier and gas-solid separation and the like.

Owner:QILU UNIV OF TECH

Fluororubber composition and molding articles

The invention discloses a fluororubber rubber composition and moulding product, which comprises the following parts: 100wt% fluororubber, 5-50wt% non-metal whisker and 0. 1-5wt% surface activator. The invention possesses high stretching strength and modulus, which improves heat resistance and abrasion resistance.

Owner:上海道氟实业有限公司

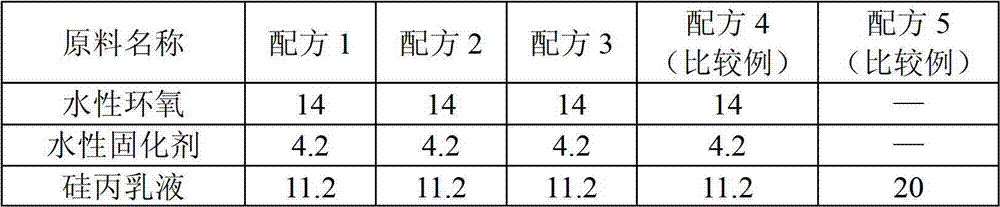

Water-based ultrathin expansion type formed steel construction fire retardant coating based on expansible graphite and crystal whisker system

ActiveCN103045047AHigh expansion ratioHigh strengthFireproof paintsEpoxy resin coatingsCarbon layerWater based

The invention discloses a coating for steel construction buildings and a preparation method thereof. The coating comprises the components in proportion ( by relative mass parts) as follows: 26-32 of film formation substances, 15-23 of a dehydration carbonizing catalyst, 8-15 of a carbonizing agent, 6-12 of a foaming agent, 2-5 of pigments and fillers, 2-5 of compound zinc phosphate, 1.5-5.5 of modified expansible graphite, 1.6-5.5 of crystal whisker, 0.9-1.2 of a film formation additive and 4.2-9.1 of a water-based curing agent. The expansible graphite and the crystal whisker system are utilized by the invention, the expansible graphite can greatly improve the expansion multiplying power of the water-based fire retardant coating and the strength of a crystal whicker strengthening carbon layer, the graphite flake falling is reduced, and thereby synergistically improving the fireproof performance.

Owner:XIAMEN UNIV +1

Silicon carbide whisker reinforced silicon nitride ceramic composite material and preparation method thereof

The invention provides a silicon carbide whisker reinforced silicon nitride ceramic composite material and a preparation method thereof. A matrix of the silicon carbide whisker reinforced silicon nitride ceramic composite material is silicon nitride ceramic; a reinforced material is silicon carbide whisker. The preparation method comprises the following steps: mixing the silicon carbide whisker with silicon powder and granulating, and then adding a sintering aid, a monomer crosslinking agent, a dispersing agent and pure water to be mixed to prepare a premix solution; adding an initiator and a catalyst into the premix solution, using aluminium oxide as a ball-milling medium to conduct ball mill for a period of time in a nylon tank, performing filtration and drying, sintering dried powder into a ceramic by adopting hot isostatic pressing, performing shape processing on the ceramic, and conducting nitridation on the ceramic finally. The silicon carbide whisker reinforced silicon nitride ceramic is improved in high-temperature strength, wear resistance, and abrasion resistance, so that silicon nitride ceramic can be more perfectly applied to wider field.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

High-temperature-resistant high-strength tough silicon nitride based wave-transparent composite material and preparation method thereof

ActiveCN107698271AEasy to processHigh forming precisionRadiating element housingsCeramicwareGas phaseBoron nitride

The invention relates to a high-temperature-resistant high-strength tough silicon nitride based wave-transparent composite material and a preparation method thereof. The preparation method comprises the following steps: preparing a porous Si3N4 whisker biscuit through gel casting, and performing drying and rubber discharging to obtain a porous Si3N4 preform; and preparing a boron nitride (BN) interface in the whisker preform through a chemical vapor infiltration (CVI) process, and preparing a multilayer alternate BN / Si3N4 matrix through the CVI process. In accordance with the design requirements for the structure and performance of a high-temperature wave-transparent antenna housing, the microstructure of each layer, the number of layers and the layer thickness of the multilayer alternateBN / Si3N4 matrix are regulated and controlled through CVI regulation and control to realize the regulation, control and optimization of the structure and performance of the composite material, therebyobtaining the high-temperature-resistant high-strength high-toughness Si3N4 based wave-transparent composite material which realizes broadband wave transmission and has excellent thermophysical properties.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

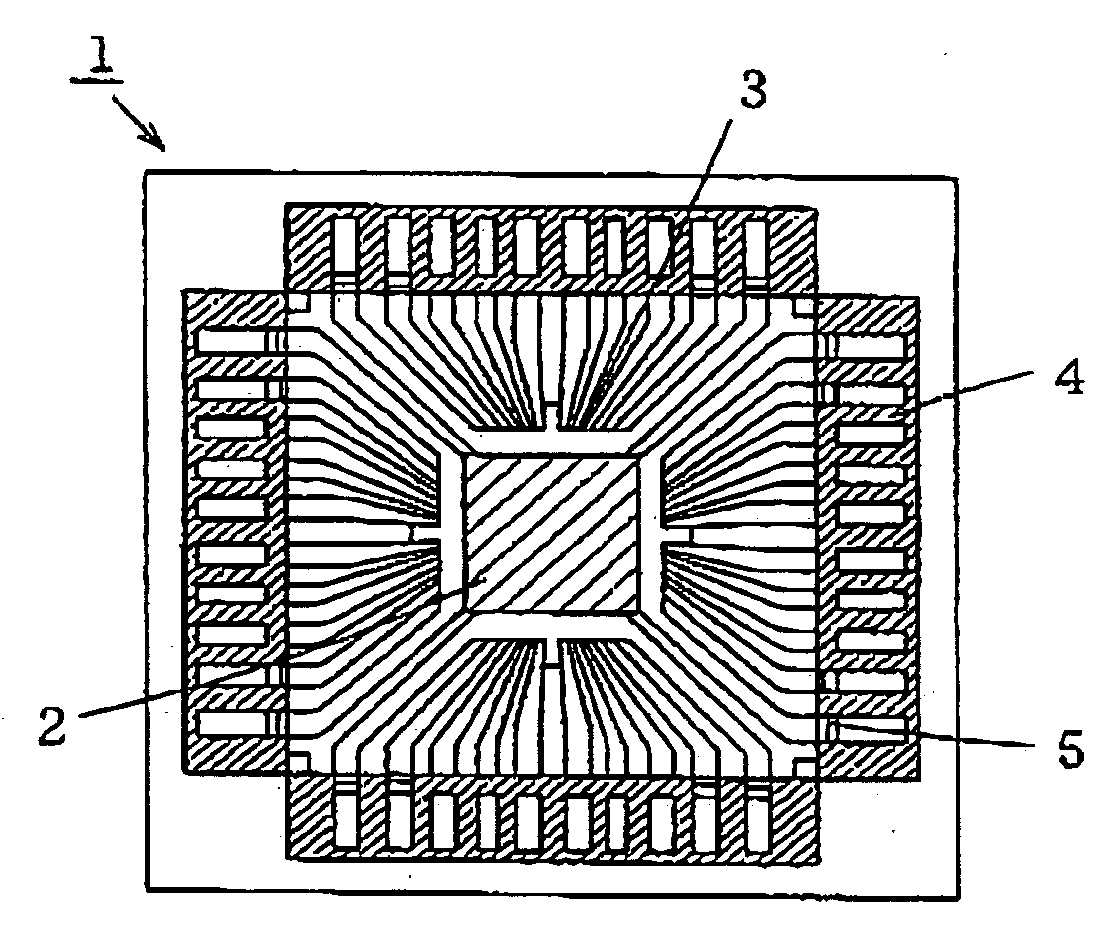

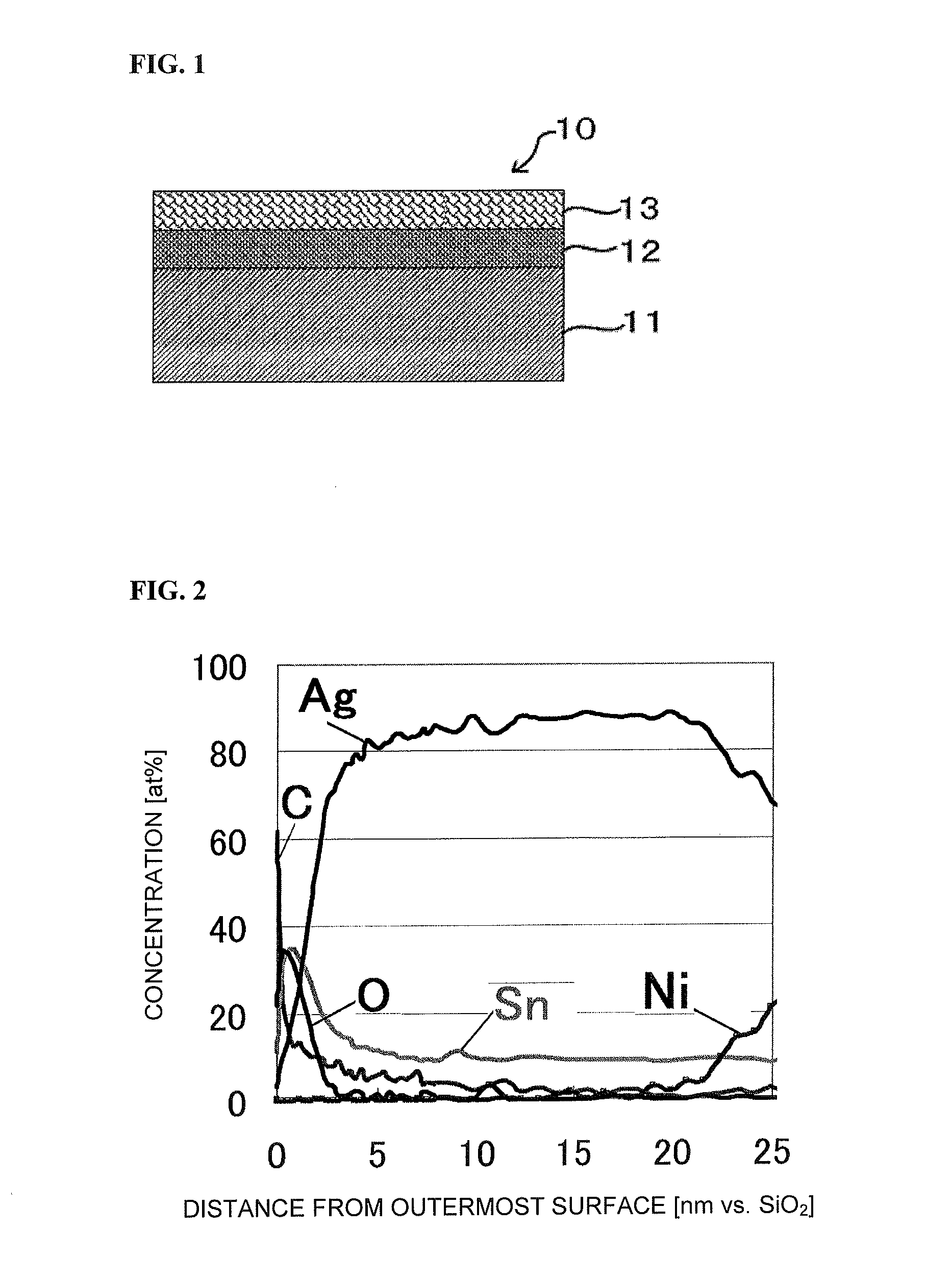

Metallic material for electronic components, and connector terminals, connectors and electronic components using same

ActiveUS20150047879A1Low degreeIncreased durabilityNon-insulated conductorsVacuum evaporation coatingMetallic materialsEngineering

The present invention provides a metallic material for electronic components having a low degree of whisker formation and a high durability, and connector terminals, connectors and electronic components using the metallic material. The metallic material for electronic components includes: a base material; on the base material, an lower layer constituted with one or two or more selected from the group consisting of Ni, Cr, Mn, Fe, Co and Cu; on the lower layer, an upper layer constituted with an alloy composed of one or both of Sn and In (constituent elements A) and one or two or more of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir (constituent elements B), wherein the thickness of the lower layer is 0.05 μm or more; the thickness of the upper layer is 0.005 μm or more and 0.6 μm or less; and in the upper layer, the relation between the ratio, the constituent elements A / (the constituent elements A+the constituent elements B) [mass %] (hereinafter, referred to as the proportion of Sn+In) and the plating thickness [μm] is given byplating thickness≦8.2×(proportion of Sn+In)−0.66 [herein, (the proportion of Sn+In)≧10 mass %].

Owner:JX NIPPON MINING& METALS CORP

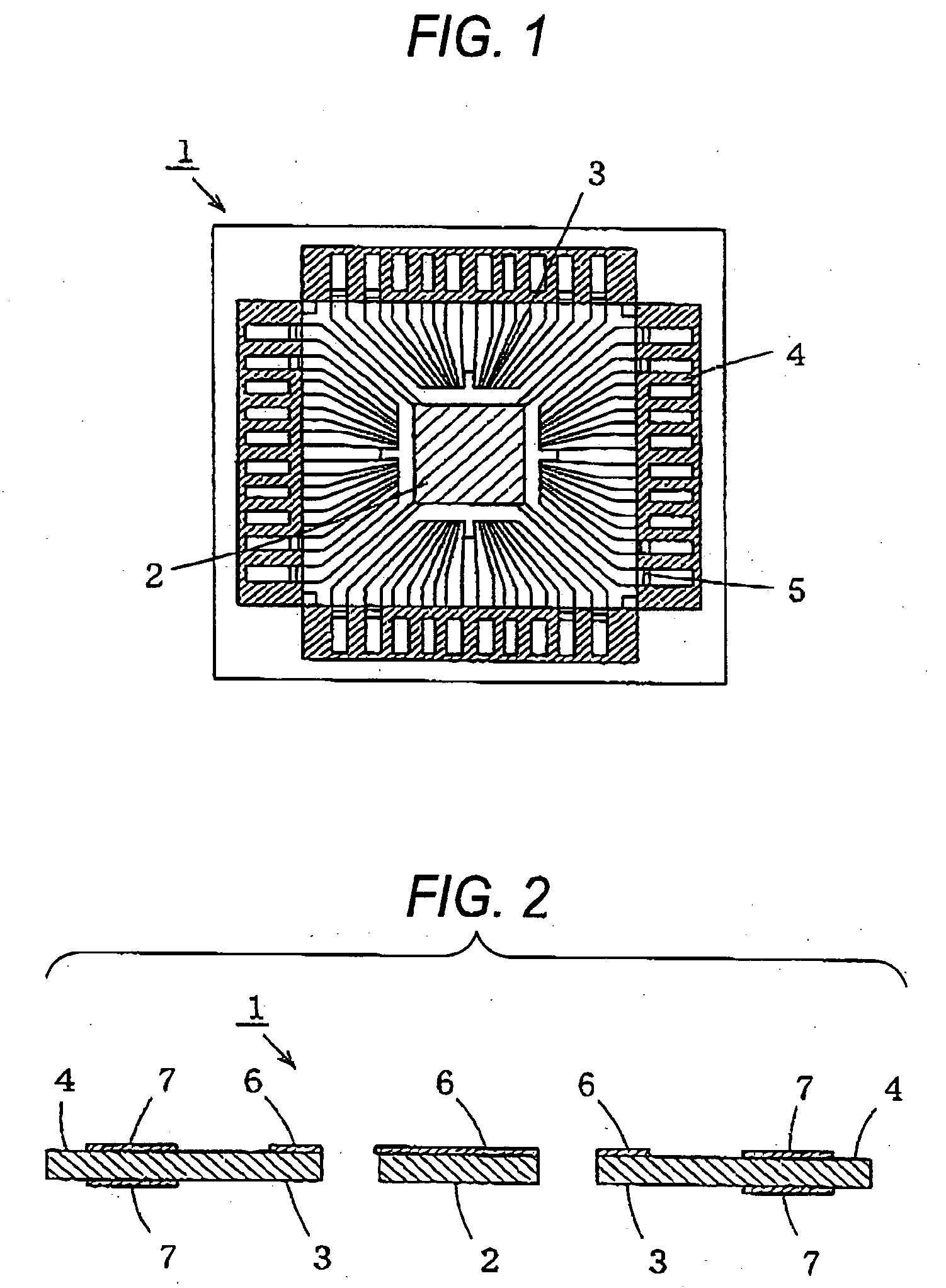

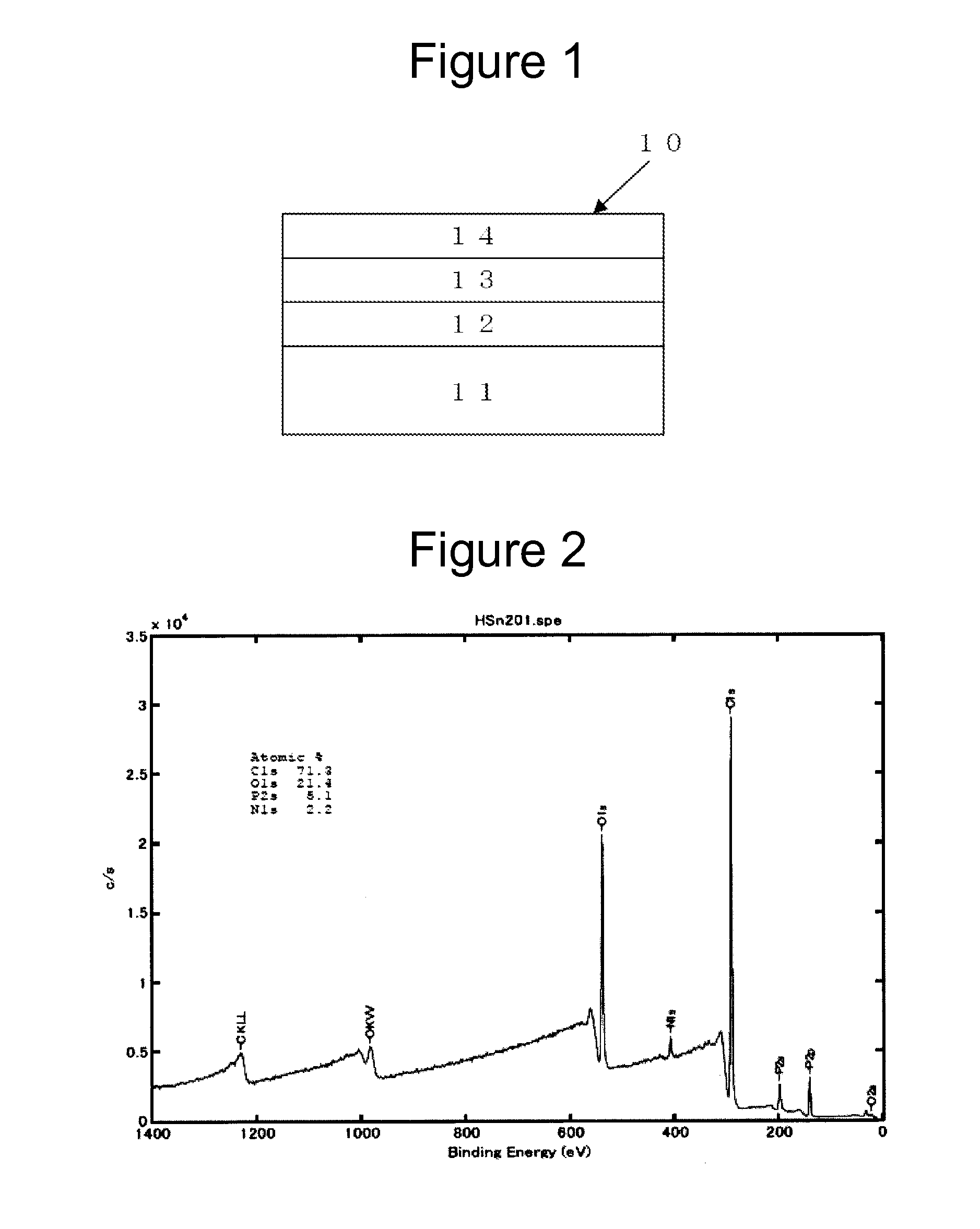

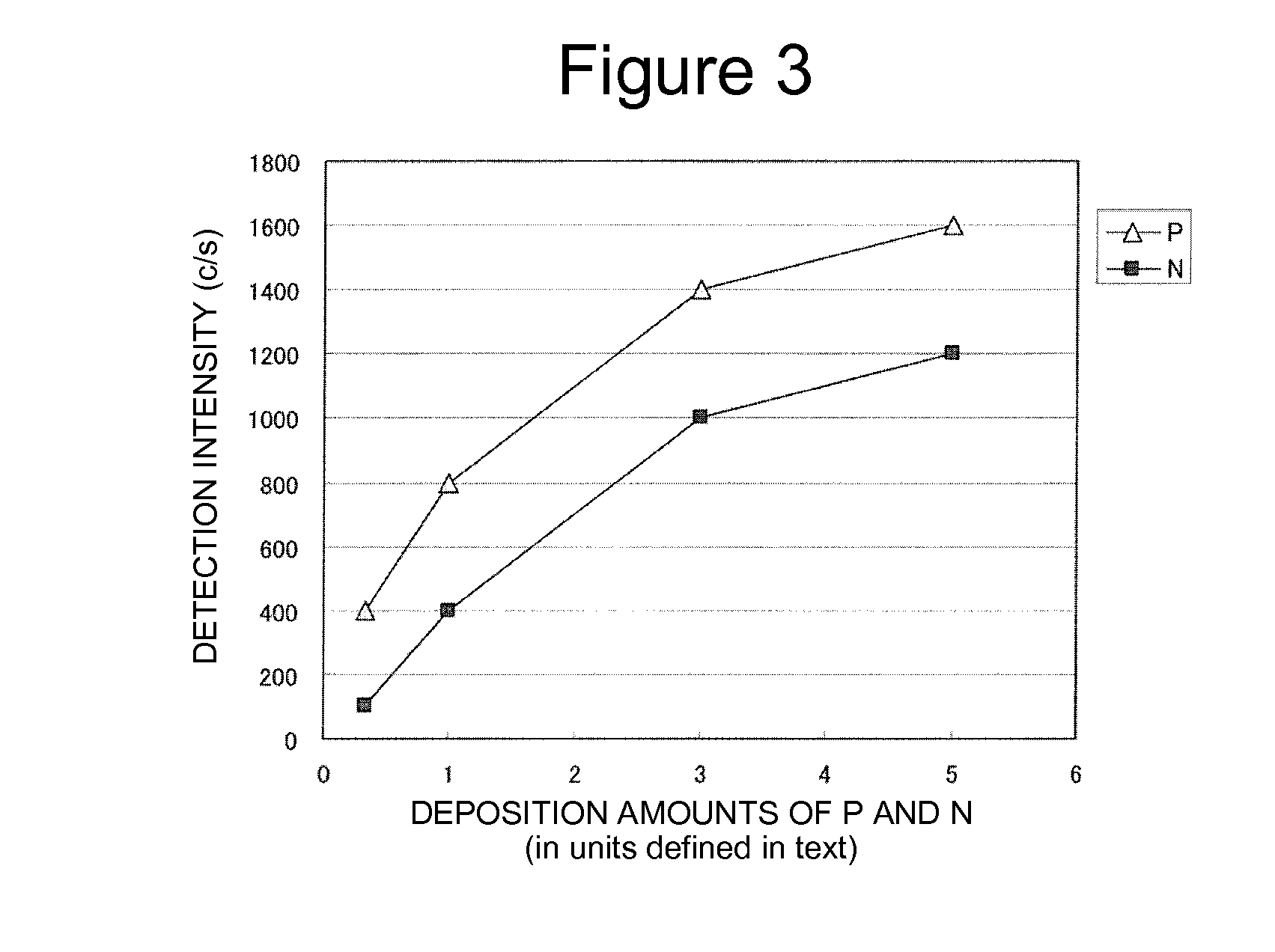

Metallic Material For Electronic Components And Method For Producing Same, And Connector Terminals, Connectors And Electronic Components Using Same

ActiveUS20150194746A1Low degreeIncreased durabilitySingle bars/rods/wires/strips conductorsPhosphatisationMetallic materialsOptoelectronics

The present invention provides metallic materials for electronic components, having low degree of whisker formation, low adhesive wear property and high durability, and connector terminals, connectors and electronic components using such metallic materials. The metallic material for electronic components includes: a base material; a lower layer formed on the base material, the lower layer being constituted with one or two or more selected from a constituent element group A, namely, the group consisting of Ni, Cr, Mn, Fe, Co and Cu; an intermediate layer formed on the lower layer, the intermediate layer being constituted with one or two or more selected from a constituent element group B, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir; and an upper layer formed on the intermediate layer, the upper layer being constituted with an alloy composed of one or two or more selected from the constituent element group B, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir and one or two selected from a constituent element group C, namely, the group consisting of Sn and In; wherein the thickness of the lower layer is 0.05 μm or more and less than 5.00 μm; the thickness of the intermediate layer is 0.01 μm or more and less than 0.50 μm; and the thickness of the upper layer is 0.02 μm or more and less than 0.80 μm.

Owner:JX NIPPON MINING& METALS CORP

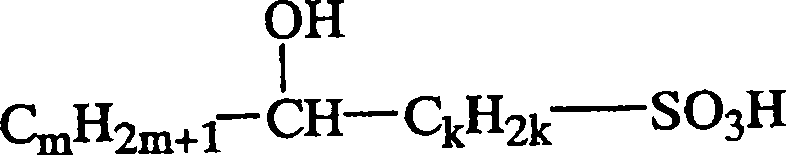

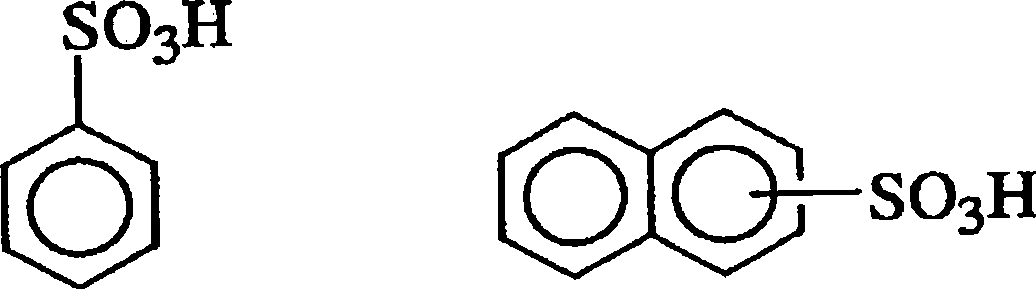

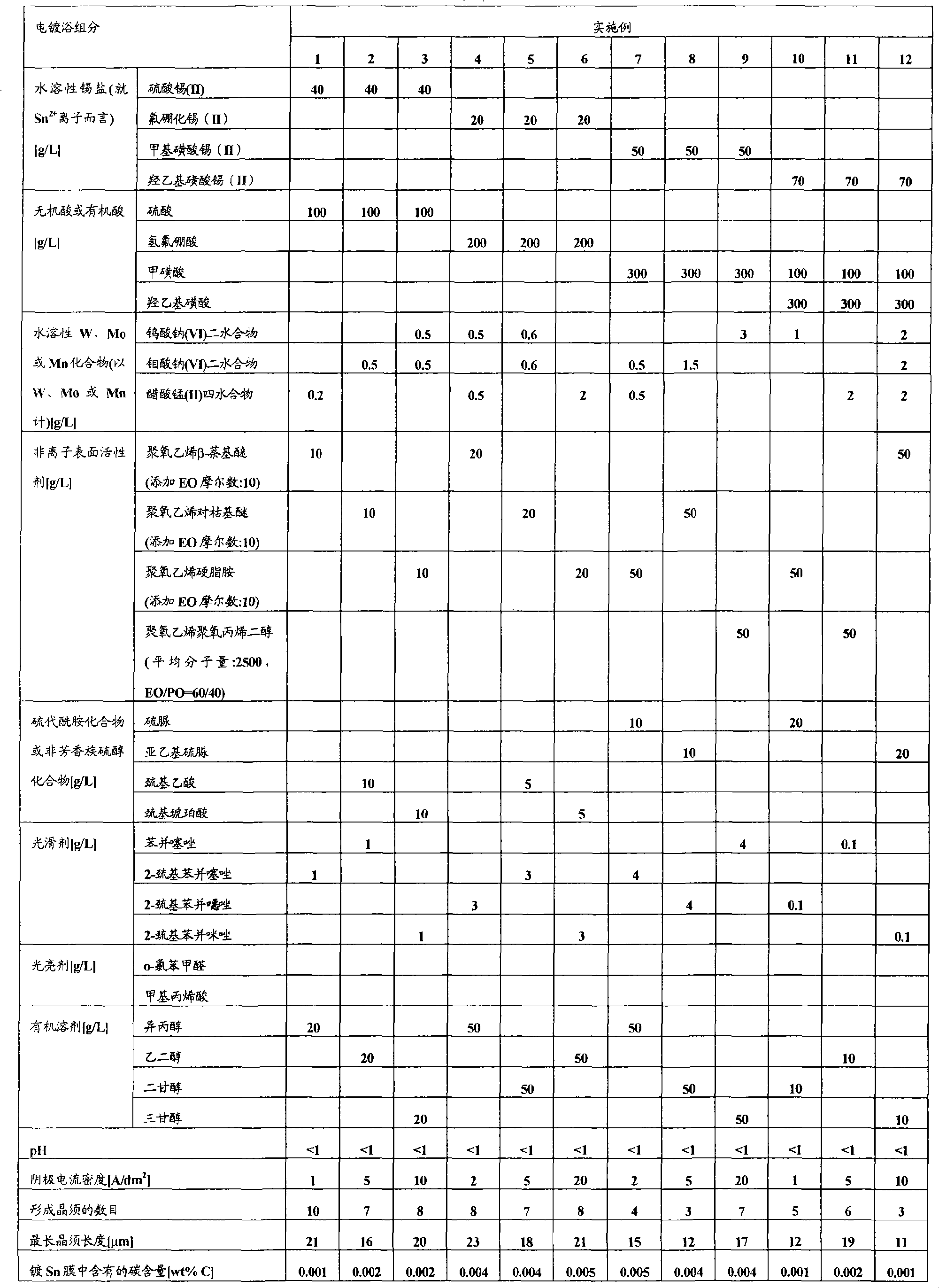

Tin electroplating bath, tin-plated coating film, tin electroplating method, and electronic device component

InactiveCN101421439ASemiconductor/solid-state device detailsSolid-state devicesCoated membraneOrganic acid

Disclosed is a tin electroplating bath containing a water-soluble tin salt, one or more substances selected from inorganic acids, organic acids and their water-soluble salts, and one or more substances selected from water-soluble tungsten salts, water-soluble molybdenum salts and water-soluble manganese salts. This tin electroplating bath enables to form a tin-plated coating film on components for electronic devices such as a chip component, crystal oscillator, bump, connector, lead frame, hoop member, semiconductor package and printed board, as a substitute for a tin-lead alloy plating material, while having high whisker suppressing effects.

Owner:C UYEMURA & CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com