Patents

Literature

431results about How to "Small coefficient of linear expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-transparent quartz crucible for polysilicon crystallization and manufacturing method thereof

InactiveCN101348324AHighlight substantive featuresSignificant progressGlass shaping apparatusSilicon compoundsCrack resistanceSlurry

The invention provides an opaque quartz crucible used in multicrystal silicon crystallization and a method for manufacturing the same. The crucible is of a regular square structure, and the compositions in mass ratio of the crucible are more than 99.7 Wt percent of silicon dioxide, less than 600ppm of aluminum oxide and less than 30ppm of ferric oxide. The method comprises the following steps: firstly, a raw material, i.e. high purity quartz is put into granulation equipment for wet method granulation, the grain size is controlled between 70 and 100mu m; then, slurry is fully stirred and then is fed into a gypsum mould under a pressure of between 2 and 3bar after being deposited for 24 to 48 hours; moreover, early grouting is assisted by slight vibration; the slurry is further settled for 5 to 8 hours, and is demoulded after fully dewatered; the slurry is dried inside a drier; and finally, a blank is put in a kiln for sintering so as to obtain the opaque quartz crucible. The proposal adopts grouting forming by a high-purity quartz material, and the sintered crucible has uniform inner structure; moreover, the crucible has excellent thermal shock stability and cracking resistance, and can meet the technological requirements for manufacturing multicrystal silicon cast ingots.

Owner:常熟华融太阳能新型材料有限公司

Lead-free glass powder, preparation method thereof, silver paste containing glass powder and crystal silicon solar cell manufactured by using silver paste

InactiveCN102126829AImprove adhesionStrong adhesionNon-conductive material with dispersed conductive materialSemiconductor devicesSilver pasteScreen printing

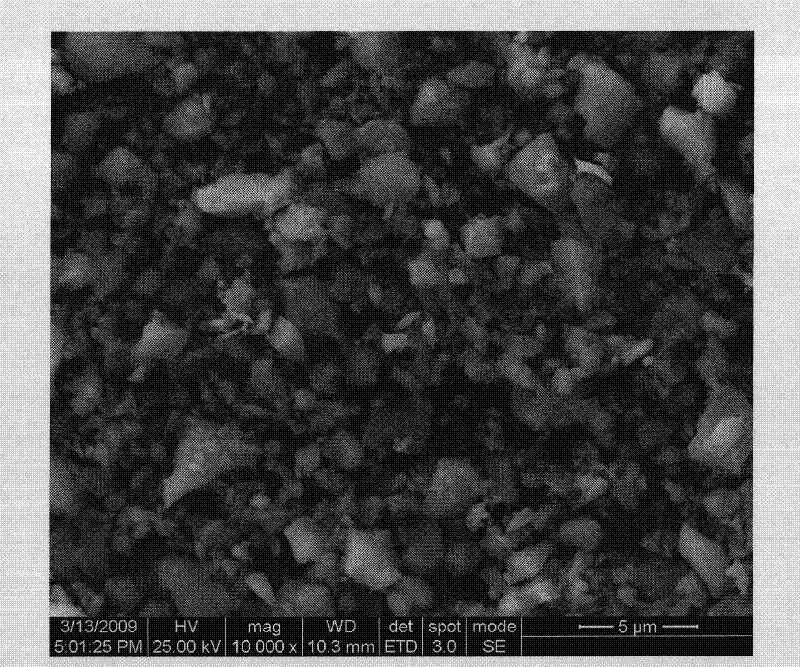

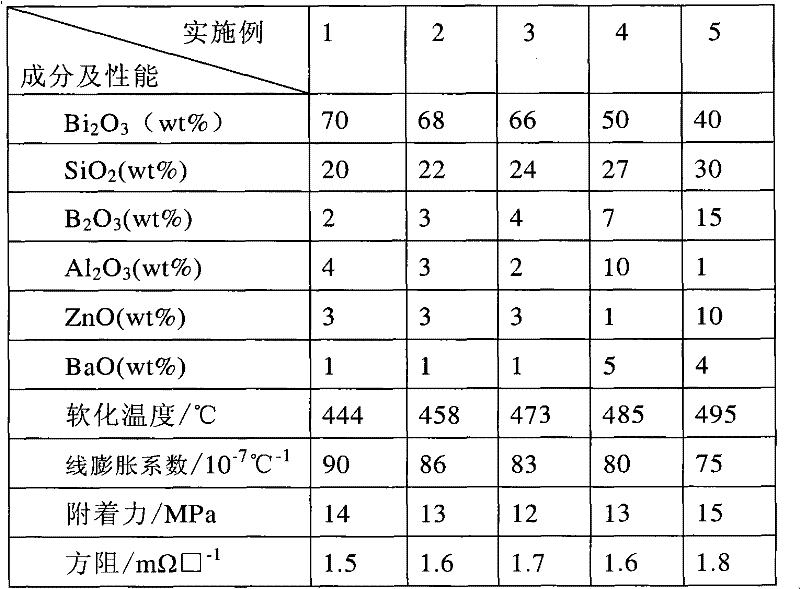

The invention discloses lead-free glass powder, a preparation method thereof, silver paste containing the glass powder and a crystal silicon solar cell manufactured by using the silver paste. The lead-free glass powder comprises the following components in percentage by weight: 20-30 percent of SiO2, 2-15 percent of B2O3, 40-70 percent of Bi2O3, 1-10 percent of ZnO, 1-10 percent of Al2O3 and 1-5 percent of BaO. The preparation method comprises the following steps of: (1) weighing the components for preparing a mixture; (2) putting the mixture into a crucible for melting; (3) performing water quenching on molten glass; (4) drying; (5) smashing the mixture into powder by planetary ball milling; and (6) screening. The needed silver paste is prepared from the lead-free glass powder, silver powder, an additive and an organic carrier. A solar panel front face electrode and a grid line are manufactured by performing screen printing and sintering on conductive silver paste on a cell substrate, so that the needed solar cell is obtained. The lead-free glass powder has low melting temperature, low softening temperature and low linear expansion factor.

Owner:湖南威能新材料科技有限公司

Exterior wall waterproofing heat-insulating decorating integrated material and preparation method thereof

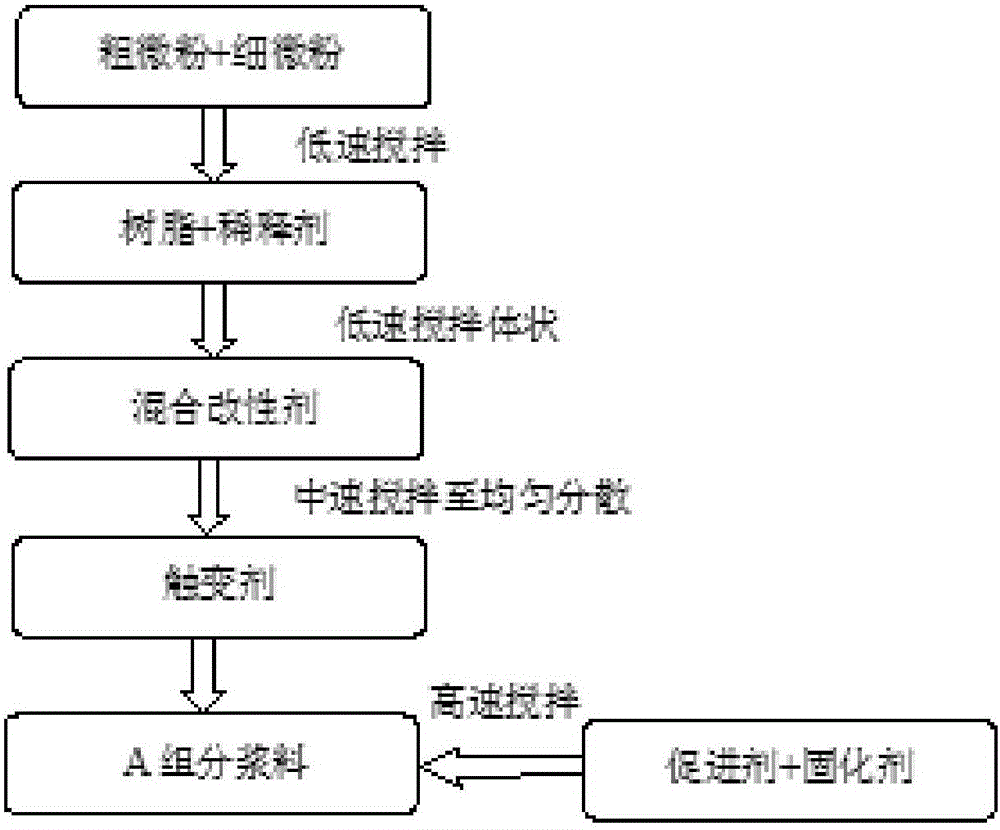

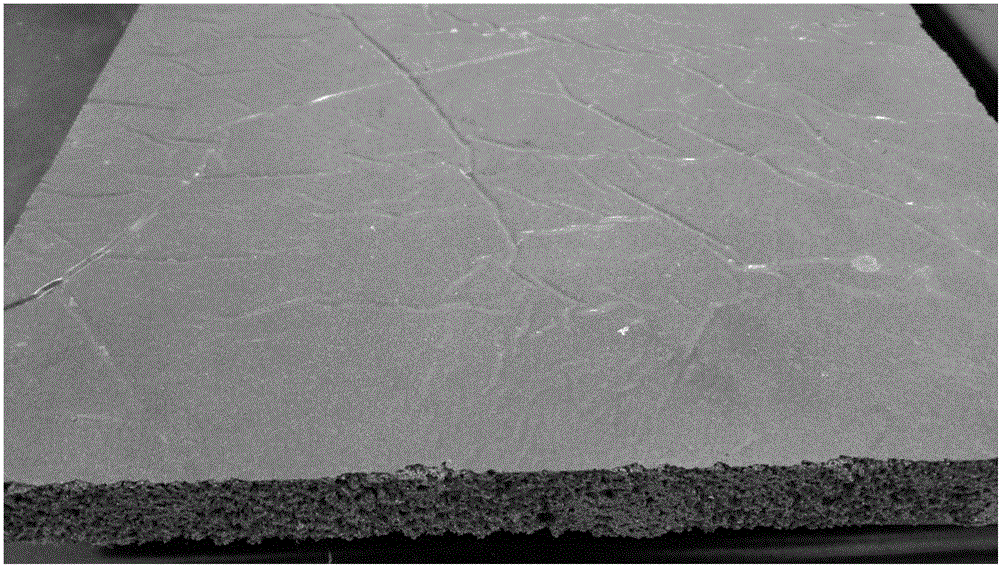

InactiveCN105694625AMeet various style requirements of high-end and high-end exterior finishesShort construction periodFireproof paintsAnti-corrosive paintsPolymer scienceSludge

The invention relates to an exterior wall waterproofing heat-insulating decorating integrated material and a preparation method thereof.The preparation method includes: using conventional resin like polyurea and polyurethane as raw materials, adding compound micropowder prepared from solid waste and sludge, and adding a mixed modifier and a thixotropic agent to prepare A-compound slurry; adding a promoter and a hardener, and performing spray coating, brush coating, roll coating and pouring methods to obtain the exterior wall waterproofing heat-insulating decorating integrated material.The material has the comprehensive advantages of good waterproof effect, high heat insulativity, high hardness, high hole closing rate, low density, good anti-seepage performance, high corrosion resistance, low linear expansion coefficient, high softening temperature, oxidization resistance, aging resistance, flame retardancy and firmness in binding with a substrate.When the material is used for building exterior walls, multiple times of leveling, waterproofing, heat insulating and decorating construction are not needed, on-site moisture-free operation and one-time forming can be realized, and the material is short in construction period, extremely low in cost and great in market prospect.

Owner:NANJING KAIBA ADVANCED MATERIALS CO LTD +1

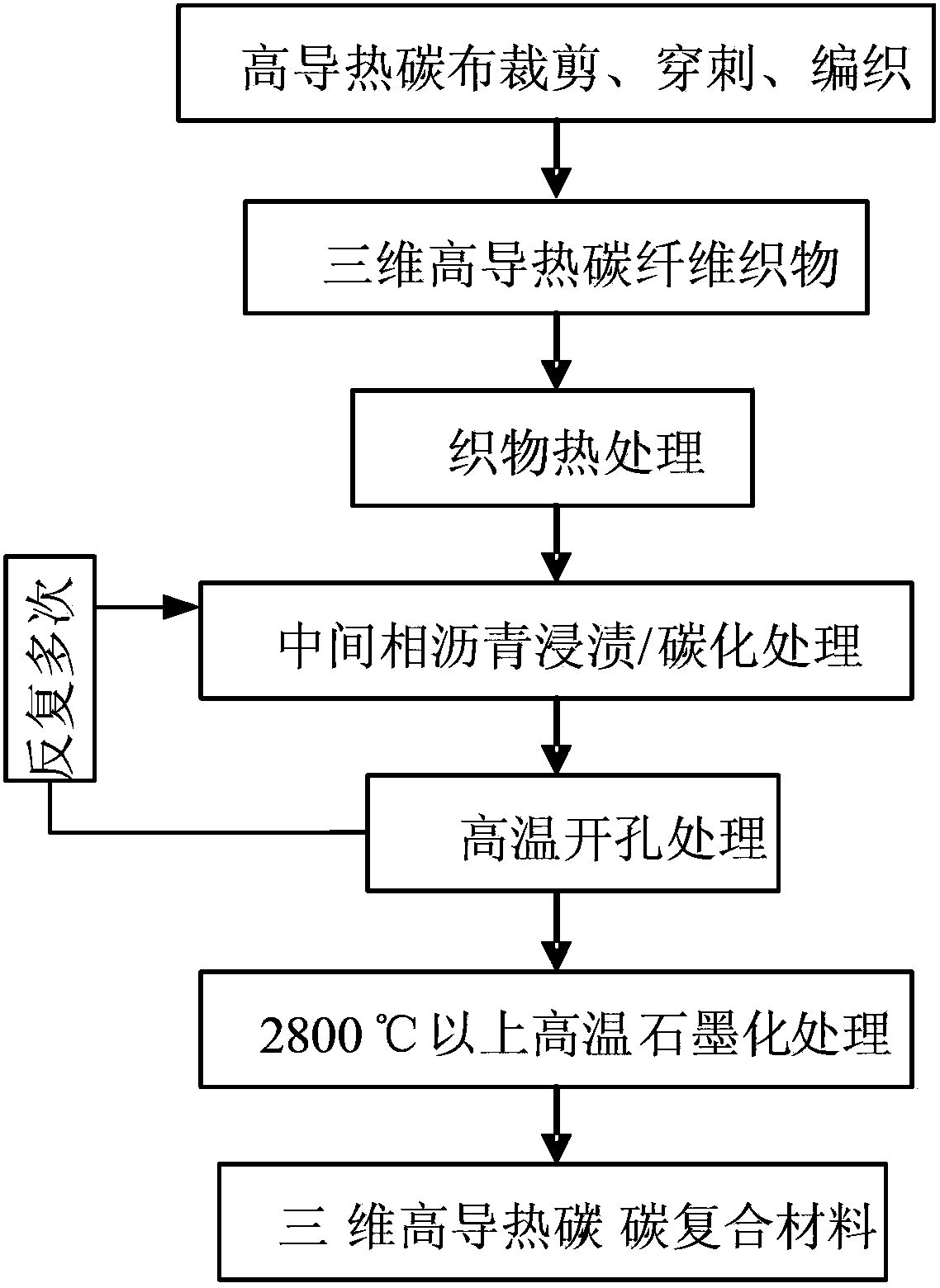

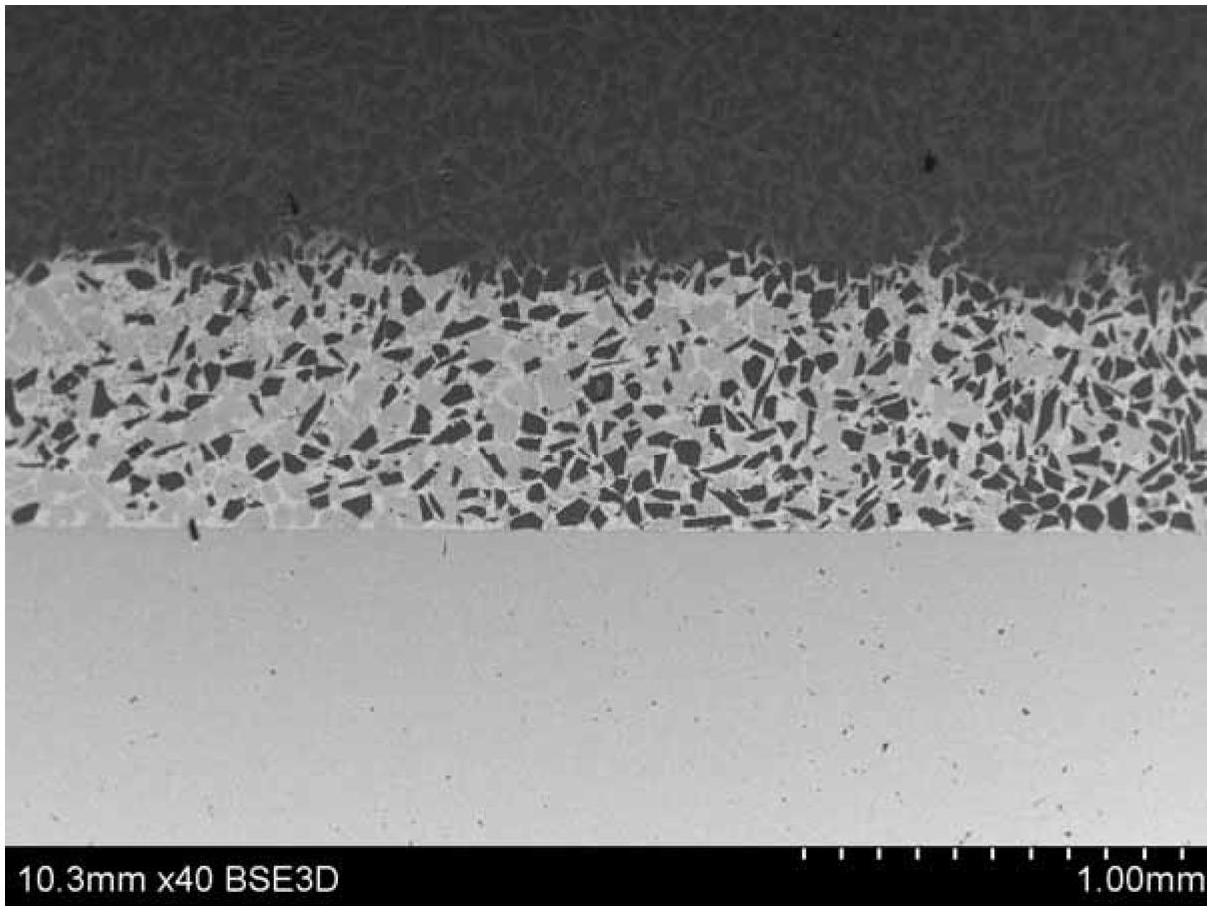

Three-dimensional mesophase pitch-based carbon/carbon composite material with high heat conductivity and preparation technology thereof

The invention relates to a three-dimensional mesophase pitch-based carbon / carbon composite material with high heat conductivity and a preparation technology thereof. The preparation technology comprises the following steps: firstly, by taking a mesophase pitch-based carbon fiber cloth with high heat conductivity as a reinforced body in the XY direction and a high-modulus carbon fiber as a reinforced fiber in the Z direction, preparing three-dimensional carbon fiber fabric with high heat conductivity by adopting a carbon cloth puncturing technology; secondly, by taking mesophase pitch as a precursor of matrix carbon, performing densifying treatment on the three-dimensional carbon fiber fabric with high heat conductivity by adopting a dipping / carbonizing technology; finally, performing graphitization treatment at a high temperature of 2800 DEG C above on the obtained materials, so as to obtain the three-dimensional mesophase pitch-based carbon / carbon composite material with high heat conductivity. Through the adoption of the technology method, the heat conductivity, modulus and dimensional stability of the carbon / carbon composite material are greatly improved, and the highest heat conductivity reaching 3600 w / mK of the material in the XY direction is increased by more than 5 times as compared with the common three-dimensional carbon / carbon composite material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Preparation method of fused silica refractory casting material unwetted by aluminum liquid

The invention belongs to the field of refractory materials and discloses a preparation method of a fused silica refractory casting material unwetted by an aluminum liquid, which comprises the following step of: enhancing a ground substance by adopting 10-20wt% of white alundum powder, 4-8wt% of calcium aluminate cement, 3-5wt% of hydrated alumina compound binding agent, 4-10wt% of silicon oxide micropowder and 3-6wt% of alumina micropowder, wherein 60-70wt% of fused silica is used as a main material, BaSO4 and Na3AlF6 is adopted as a compound aluminum liquid anti-wetting agent with the addition of 1-6wt%, and additional 0.12wt% of trimeric sodium phosphate and additional 0.03wt% of sodium hexametahposphate are adopted as dispensing agents. The casting material prepared by using the method has high strength, is unwetted by the aluminum liquid, has the highest use temperature of 1000 DEG C and can be used as the refractory materials, such as an aluminum flowing groove of an aluminum smelting furnace and the like.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Novel electronic-grade polyimide film with low linear expansion coefficient and manufacturing method thereof

The invention relates to a manufacturing method of an electronic-grade polyimide film with low linear expansion coefficient. The method is characterized by comprising the steps that (1) the step-by-step condensation polymerization technology or the blending compounding technology is used for obtaining two or more polyamide acid glue solutions comprising rigid structures and soft structures at the same time and are different in rigidity and softness; (2) ultrafine inorganic whiskers, like zinc oxide whiskers, silicon carbide whiskers and zirconium tungstate whiskers, which are subjected to surface organic modification already and / or nanoparticle materials are smashed and cavitated through high-energy-density supersonic waves, and then the functional fillers are compounded with polybasic polyamide acid in an in-situ micro-nano mode; (3) the compounded glue solutions are subjected to filtration, vacuum defoamation, extrusion casting filming, chemical amidization or thermal amidization, infrared complete amidization, high-temperature thermal forming processing, corona processing and a reeling process, and therefore the electronic-grade polyimide film with the thickness being 7.5-125 micrometers, the linear expansion coefficient being 5-18ppm / DEG C, and good physical mechanical performance is obtained.

Owner:宏威高新材料有限公司 +1

Preparation method of polyether imide flexible printed circuit substrate material

A process for preparing the polyether imide material as the base material of flexible printed circuit includes such steps as polycondensation between triphenyldiether tetrabasic acid bianhydride, biphenyl tetrabasic acid bianhydride, p-phenyldiamine and 3,3'-dimethyl-4,4'-diaminobibenzene, synthesizing polyamide, varnish, coating it on copper foil and high-temp. imidating. Its advantages are low expansibility and no curling.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Ultrasonic brazing method for high-volume-fraction silicon carbide particle enhanced aluminum-base composite and low-expansion alloy

ActiveCN102658411APromote wettingLow connection temperatureSoldering apparatusRoom temperatureMaterials science

The invention relates to an ultrasonic brazing method for an aluminum-base composite and low-expansion alloy, in particular to an ultrasonic brazing method for a high-volume-fraction silicon carbide particle enhanced aluminum-base composite and low-expansion alloy. The ultrasonic brazing method solves the problems that existing brazing methods for connection of the high-volume-fraction silicon carbide particle enhanced aluminum-base composite and the low-expansion alloy are complex in process and high in cost, connection temperature and joint residual stress. The method includes: firstly, cleaning to-be-brazed surfaces of the aluminum-base composite and the low-expansion alloy; secondly, coating a metal layer on the to-be-brazed surface of the low-expansion alloy; thirdly, lapping the to-be-brazed surfaces of the aluminum-base composite and the low-expansion alloy, wherein brazing materials are arranged on the lateral side of a lapping joint to form a to-be-brazed part; and fourthly, heating the to-be-brazed part, ultrasonically vibrating, heating, preserving heat, pressurizing at the joint while ultrasonically vibrating, and performing furnace cooling to the room temperature, so that ultrasonic brazing is completed. The ultrasonic brazing method is simple in process, low in cost, low in connection temperature and high in joint residual stress. The ultrasonic brazing method is used for the brazing field.

Owner:HARBIN INST OF TECH

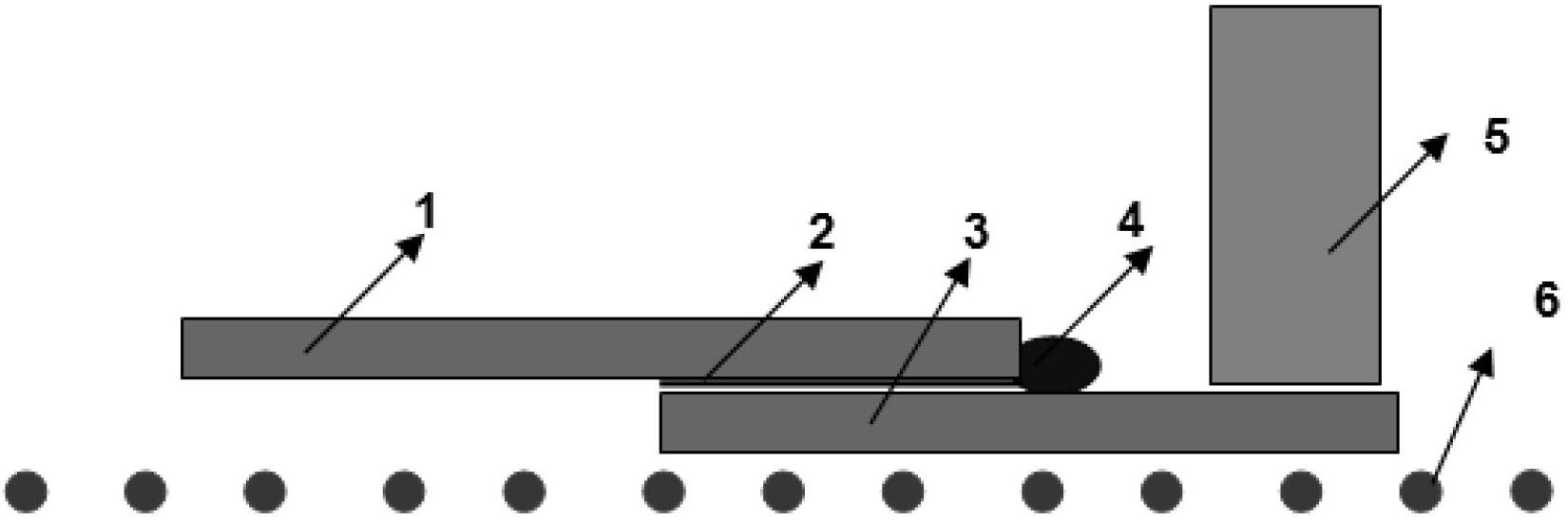

Aluminum piston manufacturing method

InactiveCN102943192AHigh temperature strengthImprove thermal fatigue resistancePlungersTrunk pistonsFiberPiston

The invention relates to an aluminum piston manufacturing method, which is characterized by comprising the following steps: (1) preparing an aluminum alloy for a piston; (2) carrying out a smelting treatment, wherein the prepared piston alloy is placed into a melting furnace to carry out melting, and the melted aluminum alloy liquid is subjected to primary refining, modification, refinement and secondary refining to provide a spare use for casting; (3) manufacturing an alumina ceramic short fiber preform; (4) preheating the alumina ceramic short fiber preform; (5) preheating a mold; (6) carrying out extrusion casting; (7) carrying out solidification piece taking; (8) carrying out a heat treatment on an aluminum piston blank; and (9) carrying out mechanical processing and a surface treatment on the aluminum piston blank to obtain the aluminum piston finished product. Compared to the aluminum piston in the prior art, the aluminum piston of the present invention has advantages of high strength and good ablation resistance.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

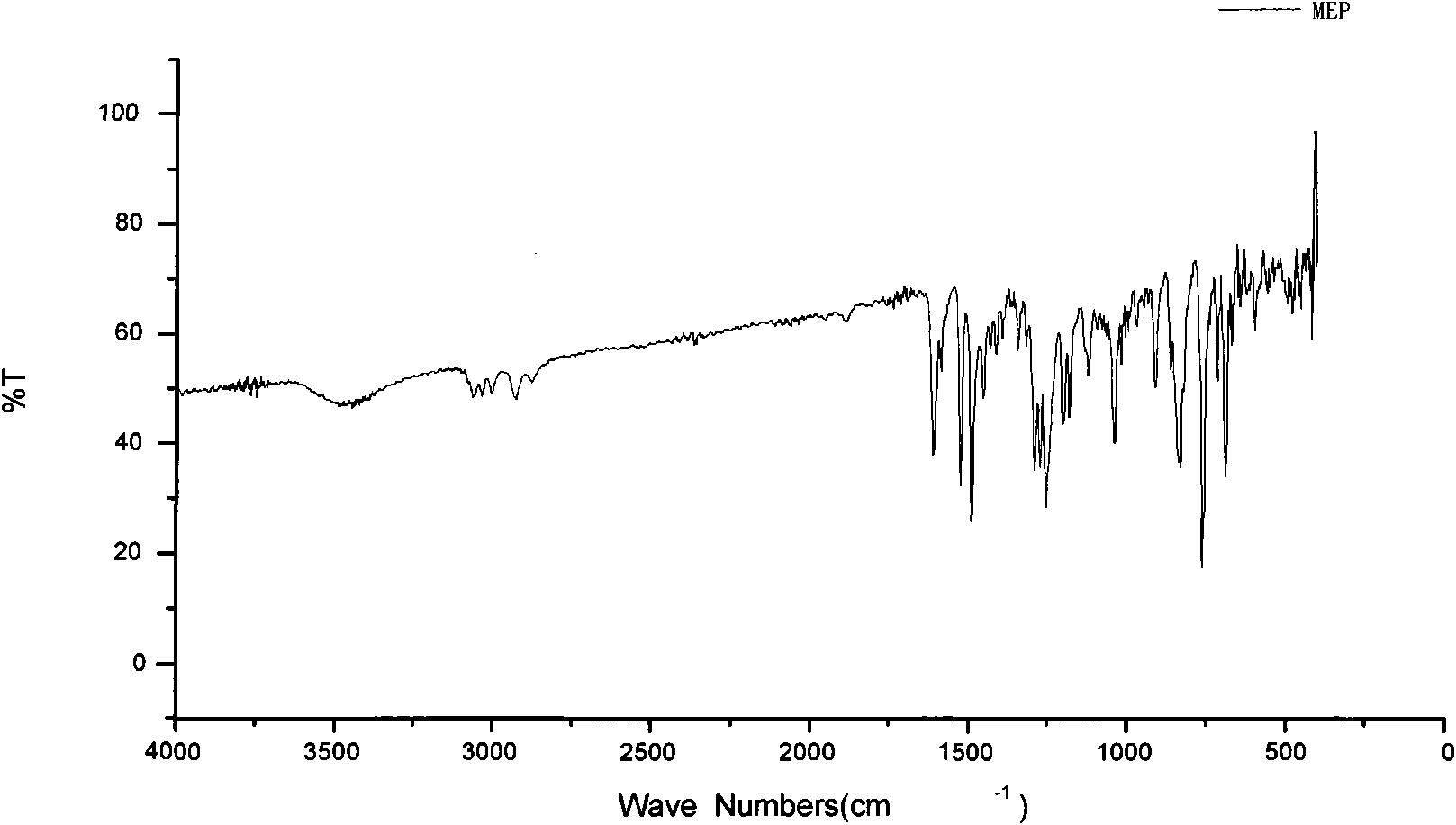

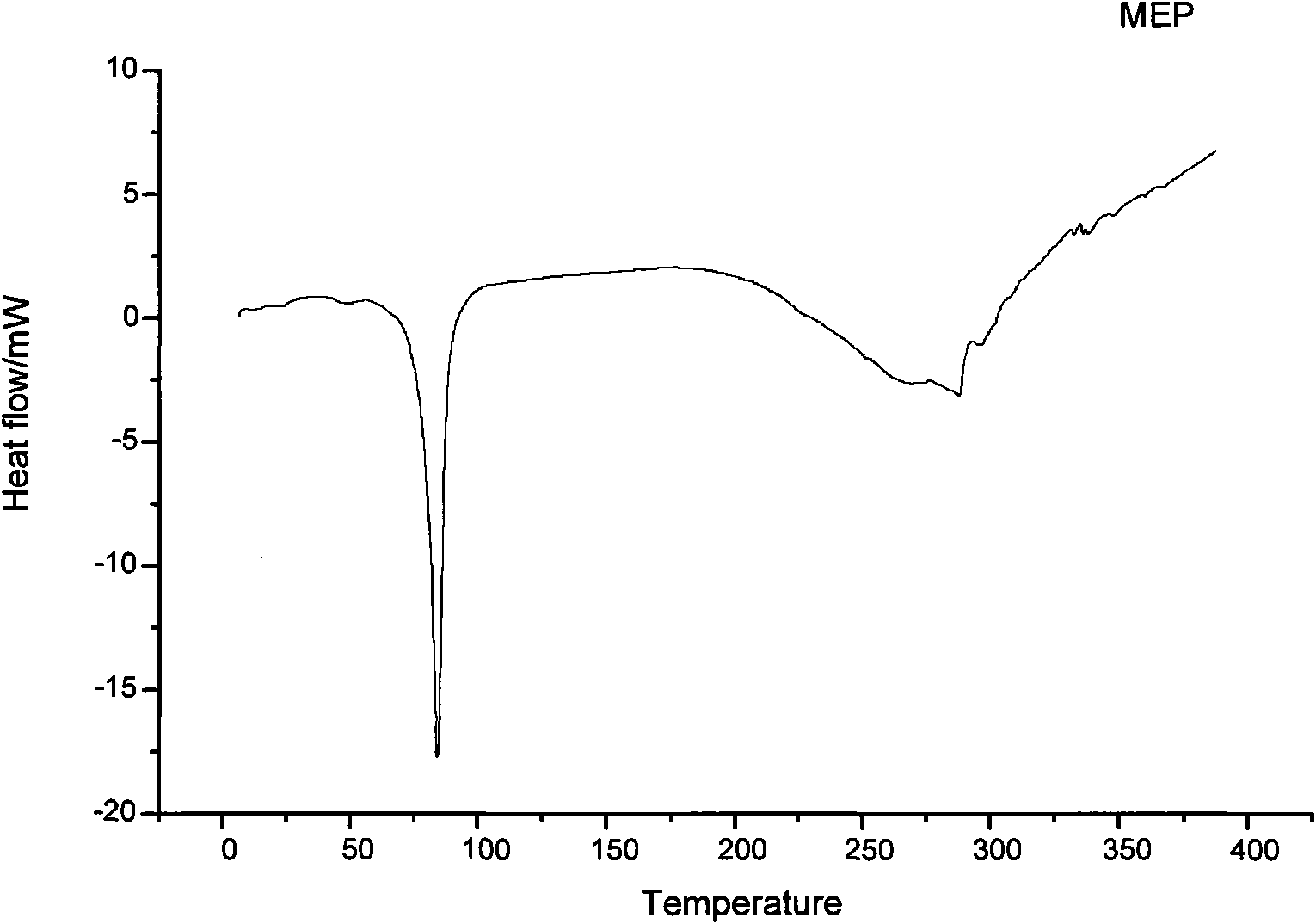

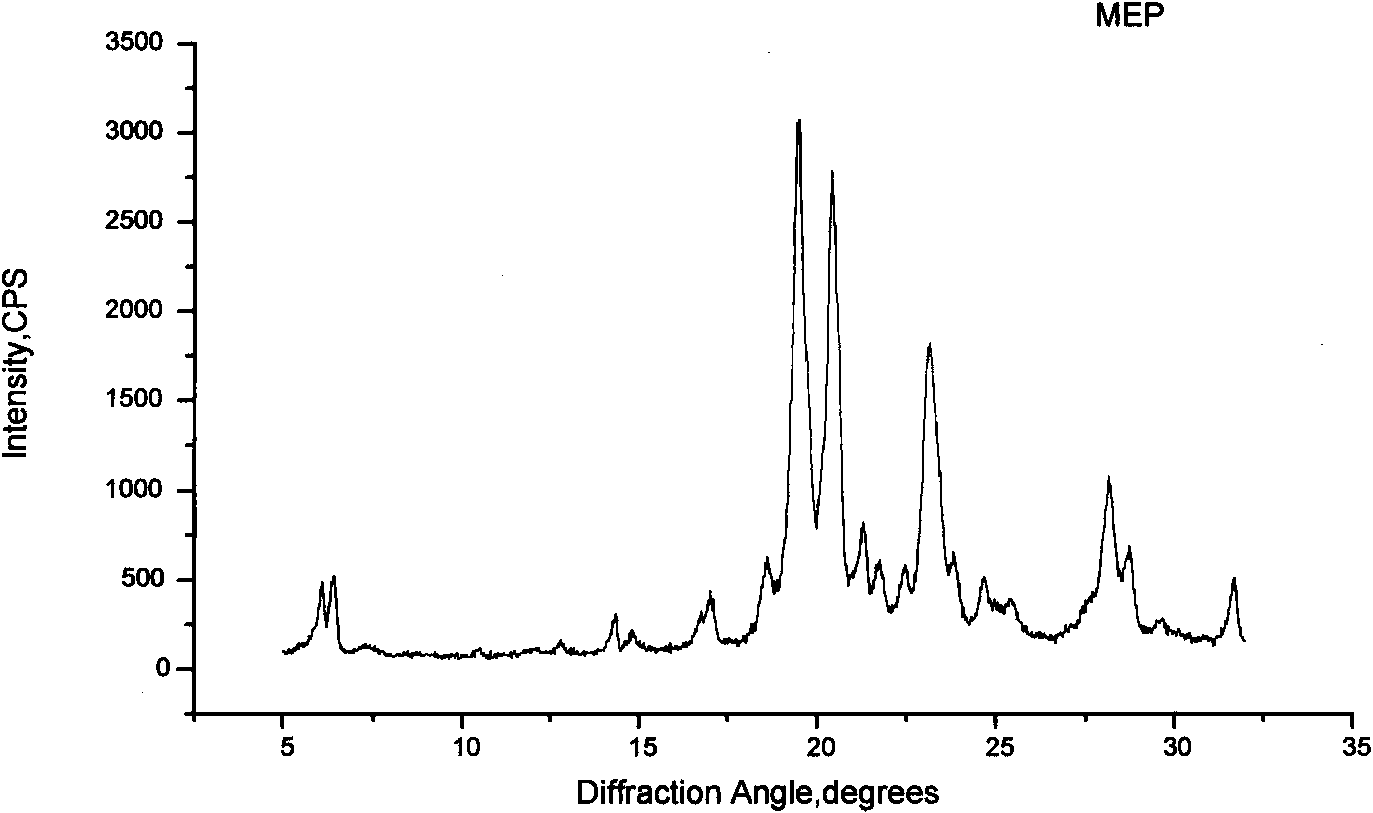

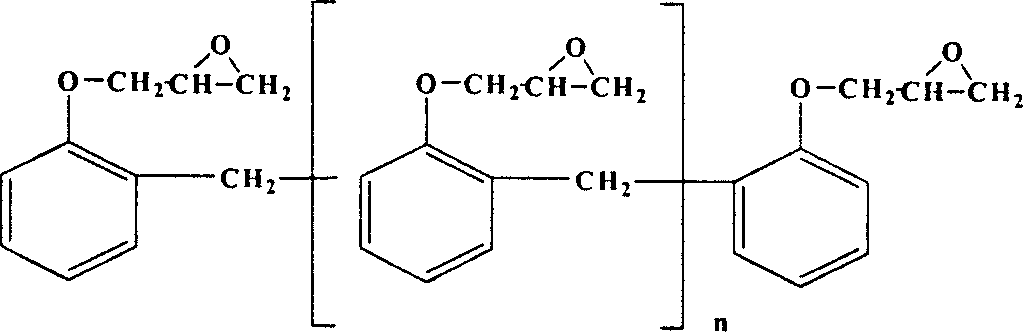

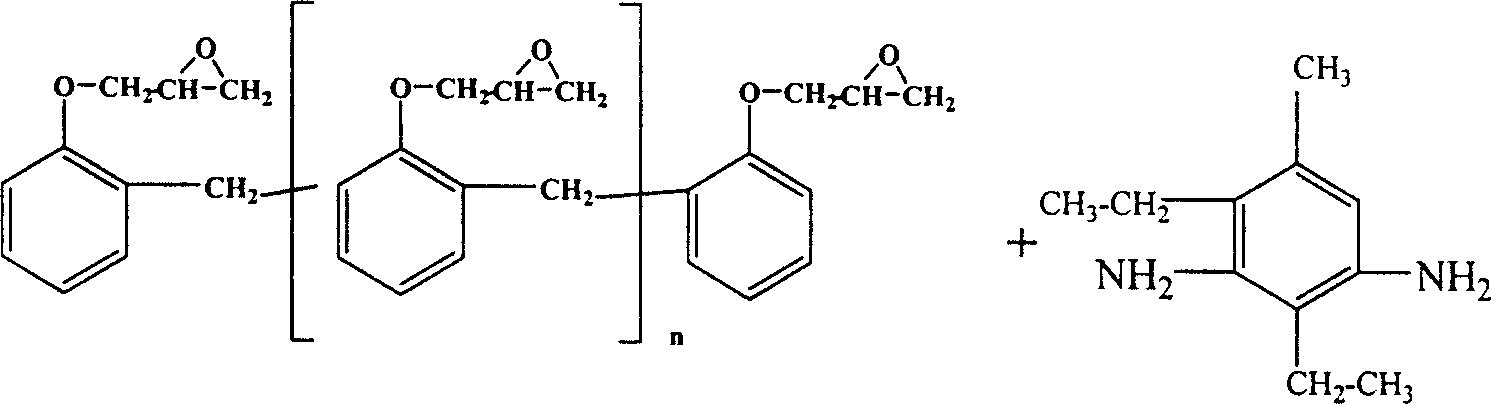

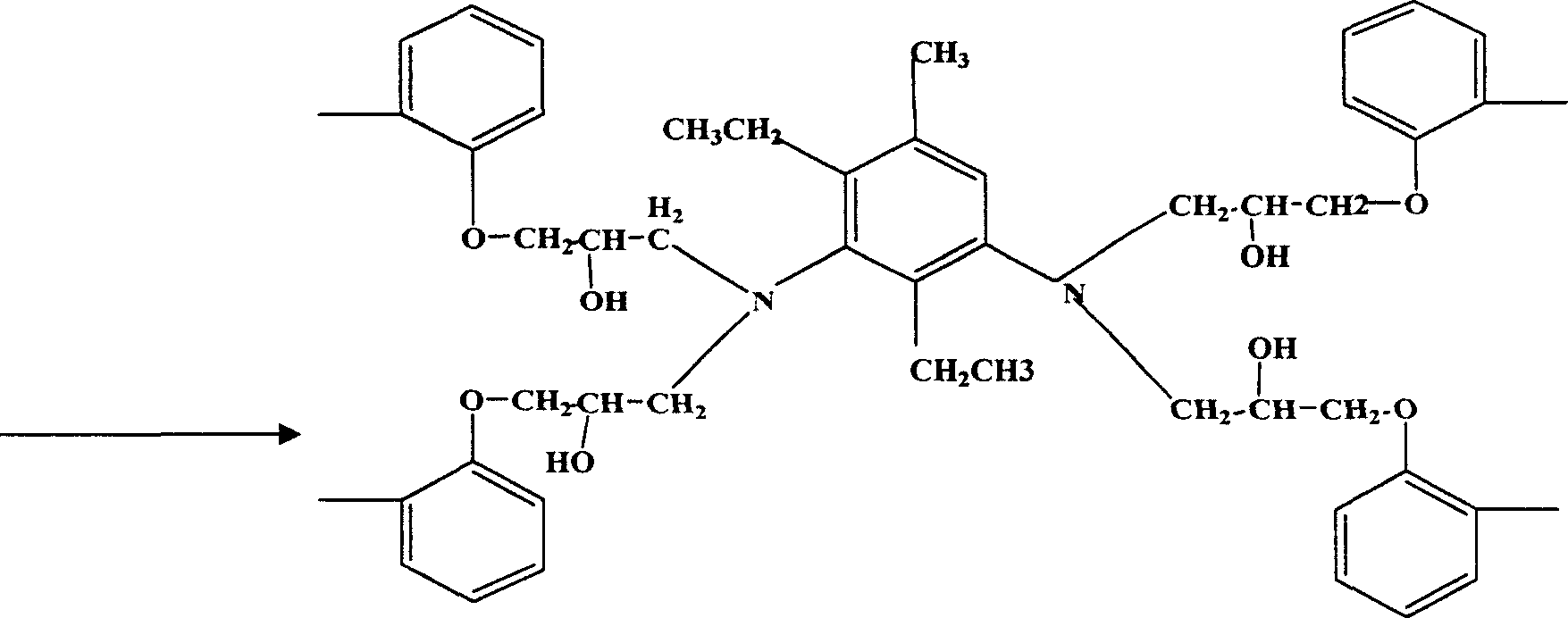

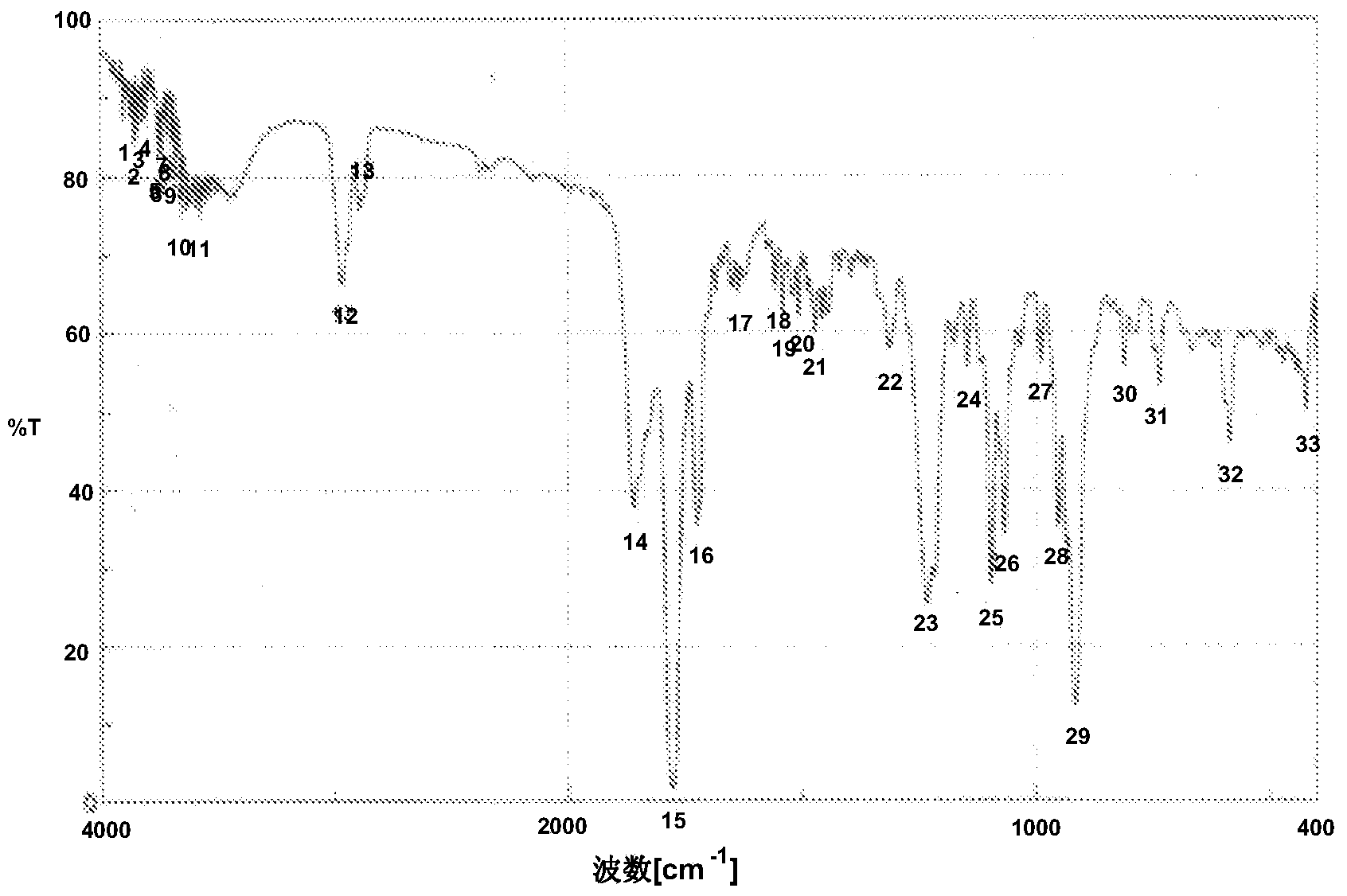

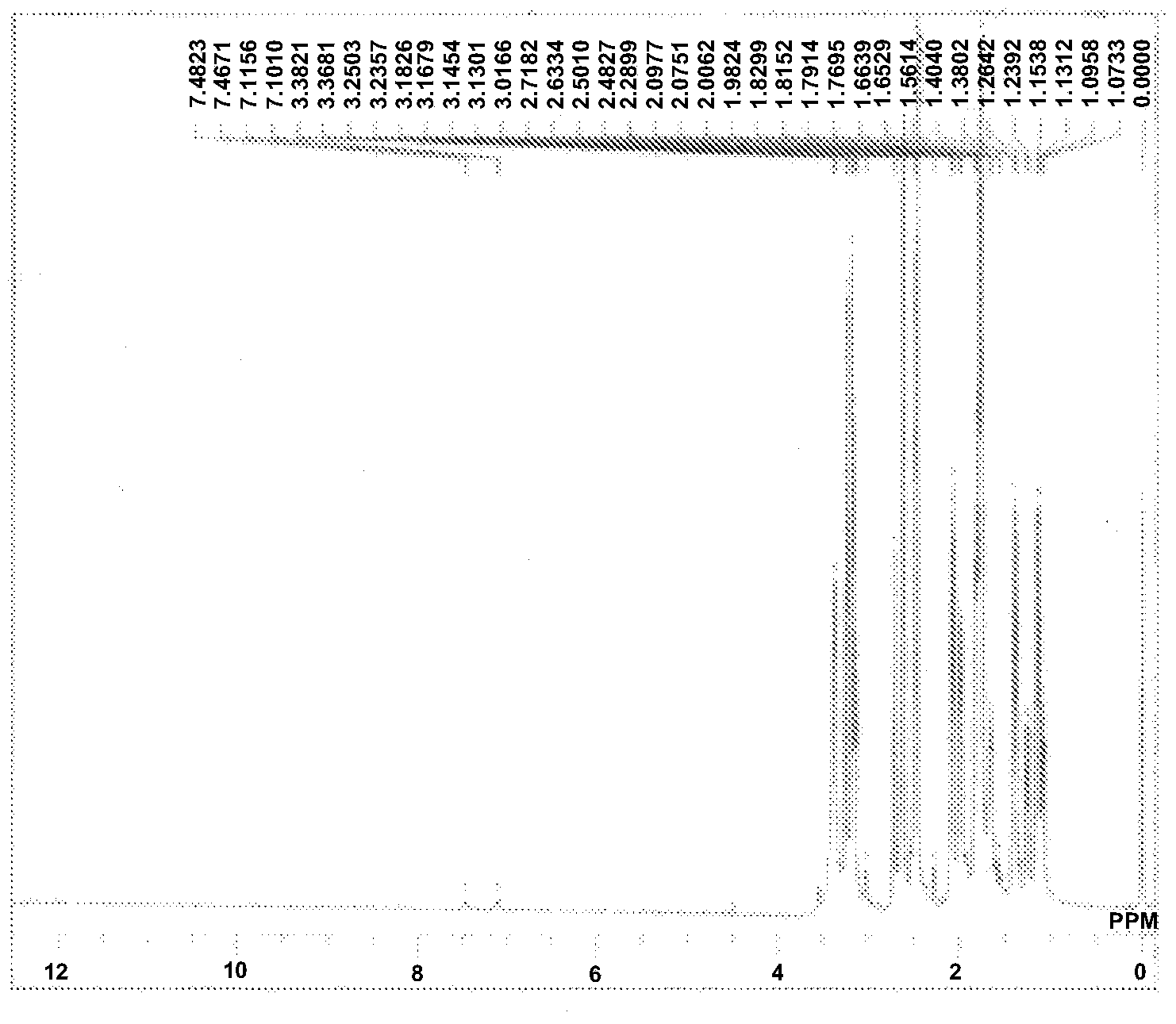

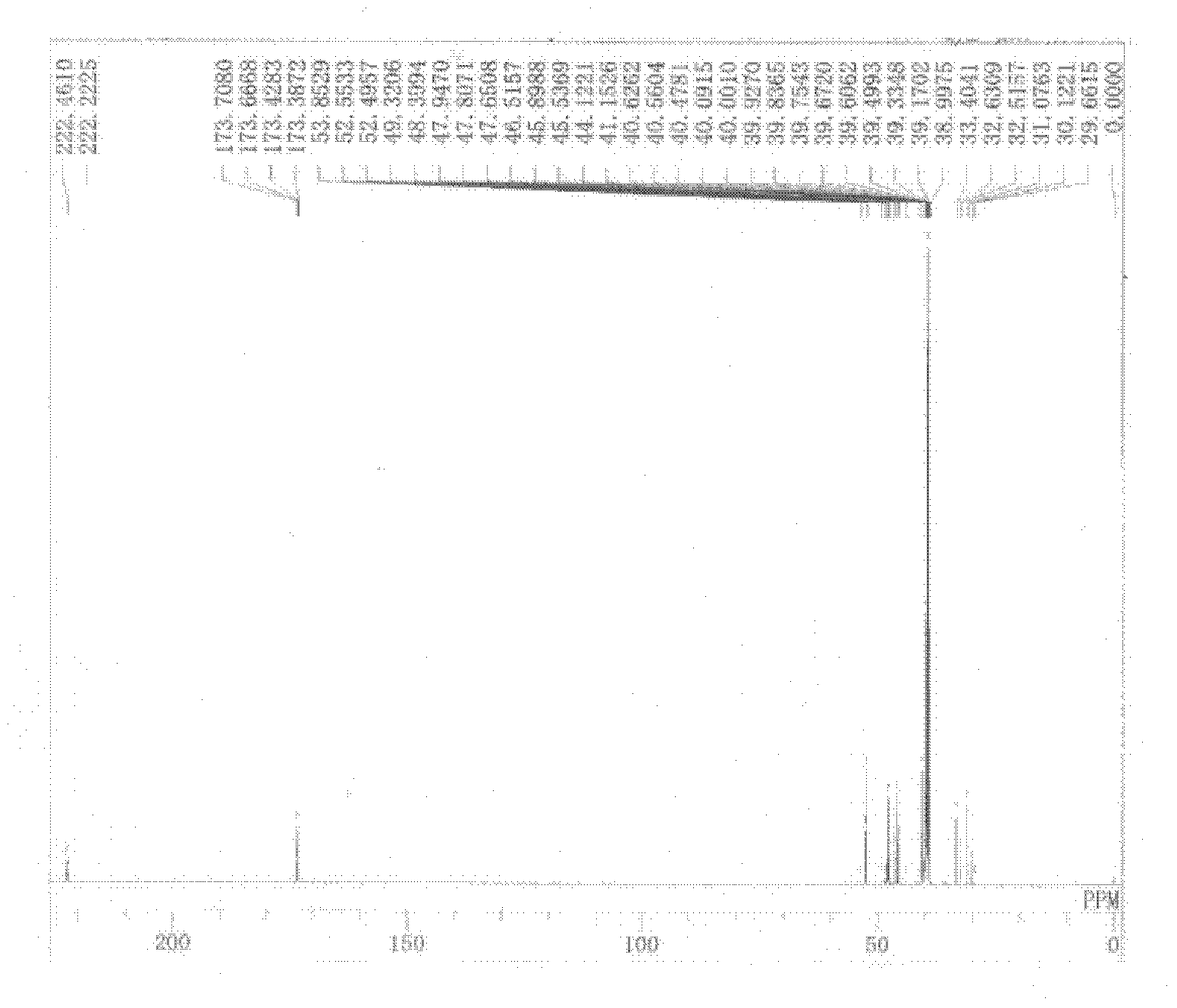

Preparing methods of liquid crystal epoxy resin oligomer and epoxy resin composition

InactiveCN101585821AReduce melt viscositySmall coefficient of linear expansionOrganic chemistryEpoxySide chain

The invention discloses a preparing method of liquid crystal epoxy resin oligomer and epoxy resin composition. The method comprises that: p-phenylphenol, epoxy chloropropane, phase transfer catalyst, sodium hydroxide and distilled water as raw materials are reacted to prepare the liquid crystal epoxy resin oligomer. The epoxy resin composition comprises: mixing the prepared liquid crystal epoxy resin oligomer and other raw materials based on weight proportionality: 10-30 parts of liquid crystal epoxy resin oligomers by weight, 10-30 parts of o-cresol-formaldehyde epoxy resins by weight, 5-25 parts of melamine modified linear phenol aldehyde resins by weight, 60-150 parts of spherical silicon micronized quartz powders by weight, 0.1-2 parts of curing accelerators by weight, 2-10 parts of flexibilizers by weight, 0.6-5 parts of resin acceptors by weight and 0.5-5 parts of lubricants by weight, which are mixed for smelting, crushed and demagnetizing to prepare the epoxy resin composition comprising side chain liquid crystal structure. The epoxy composition has good heat-resistant property and good physical mechanical property, is suitable for the encapsulations of large scale and grand scale integrated circuits.

Owner:GUANGDONG RONGTAI IND +1

Thermosetting plastic

The invention discloses a thermosetting plastic. The thermosetting plastic is characterized by comprising the following components in parts by weight: 60-95 parts of thermosetting resin, 5-40 parts of low-shrink additive, 150-300 parts of an inorganic mineral filler, 2-4 parts of an initiator, 0.6-1 part of calcium hydroxide micro powder, 2-6 parts of zinc stearate micro powder and 30-60 parts of glass fiber. In comparison with a conventional thermosetting plastic, the thermosetting plastic can be solidified more rapidly, high strength can be maintained within a wide temperature range, and the flame-retardant effect is good.

Owner:宁波华缘复合新材料有限公司

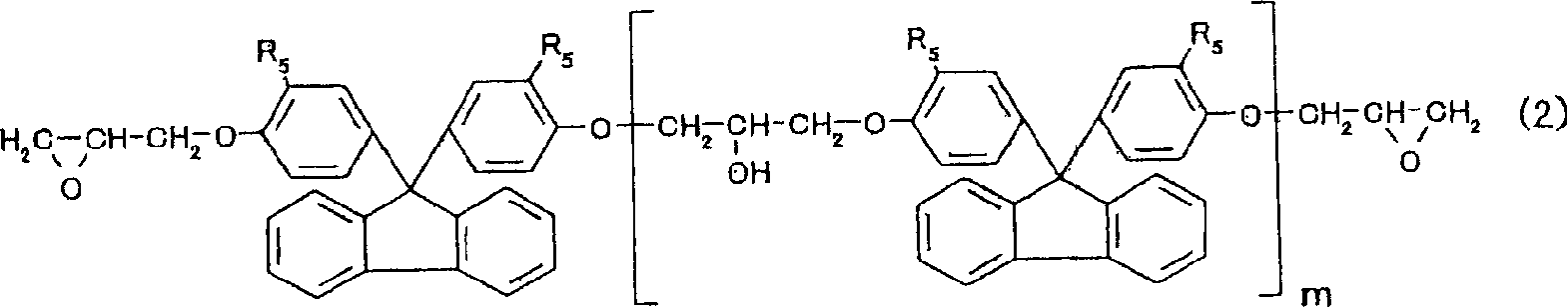

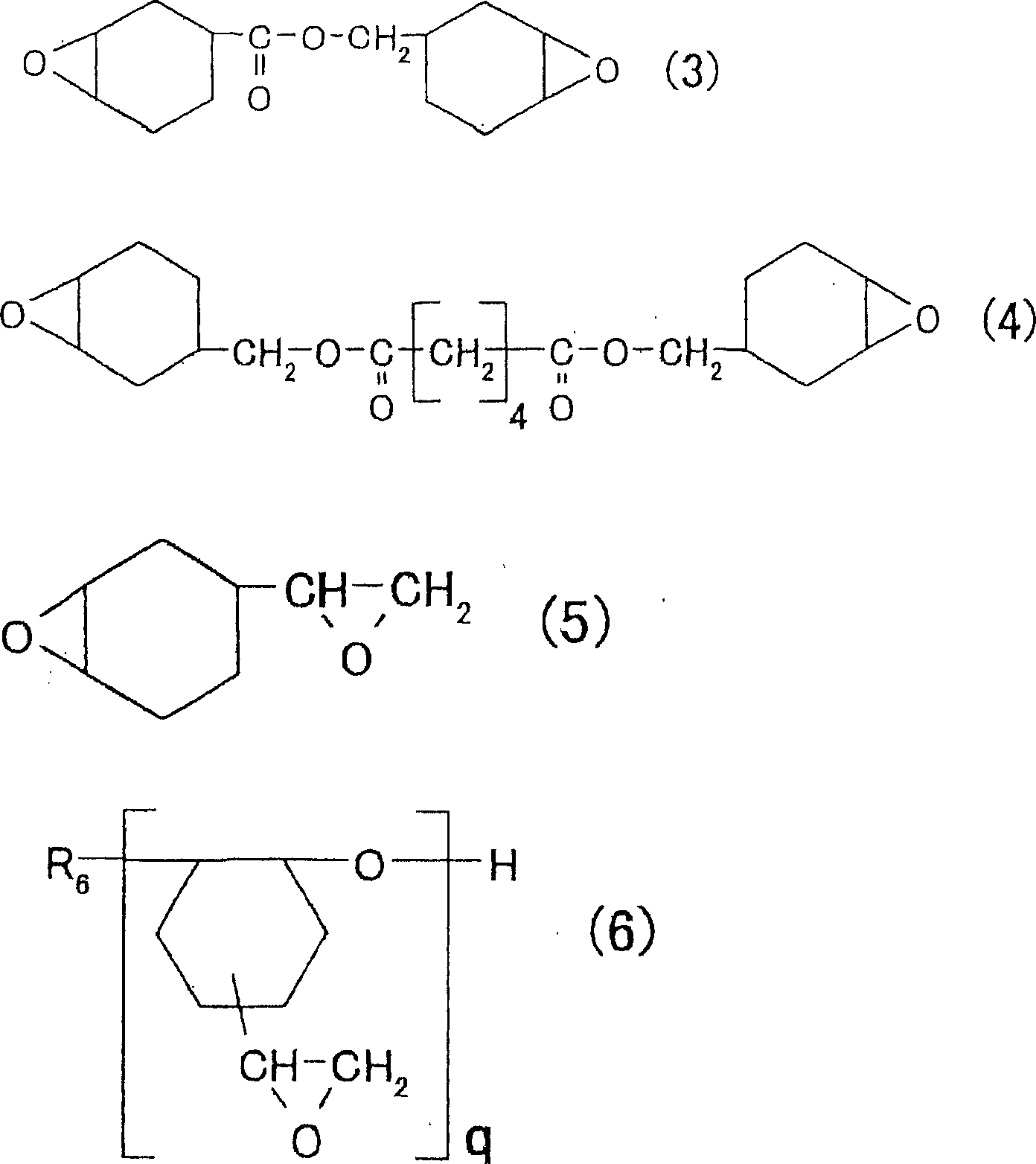

Transparent composite composition

InactiveCN1606597ALow transparencySmall coefficient of linear expansionThin material handlingNon-linear opticsEpoxyPolymer science

A transparent composite composition is provided which comprises an epoxy resin (a) and a glass filler (b) and in which the epoxy resin (a) comprises at least one epoxy resin whose refractive index after curing is lower than the refractive index of the glass filler (b) and at least one epoxy resin whose refractive index after curing is higher than the refractive index of the glass filler (b). The transparent composite composition of the invention has a low coefficient of linear expansion and is excellent in transparency, heat resistance and solvent resistance, among others and, therefore, is judiciously used, for example, in the form of liquid crystal display device substrates and organic EL device substrates (in particular of the active matrix type) and, further, transparent sheets, optical lenses, color filter substrates, solar cell substrates, touch panels, optical devices, optical waveguides, LED sealing materials and so forth.

Owner:SUMITOMO BAKELITE CO LTD

Ultra-high molecular weight polyethylene composition and process method for producing an ultra-high molecular weight polyethylene composition tubular product

ActiveCN104045901ASmall coefficient of linear expansionImprove mechanical propertiesRigid pipesPolymer scienceHigh density

The invention relates to an ultra-high molecular weight polyethylene composition with the advantages of low melt viscosity, good flowability and high mechanical strength and softening temperature and a process method for producing an ultra-high molecular weight polyethylene composition tubular product. The composition comprises the following components in parts by mass: 100 parts of ultra-high molecular weight polyethylene of which the viscosity-average molecular weight is 3000000-5000000, 0.5-10 parts of polyethylene wax of which the molecular weight is 1000-5000, 10-40 parts of high-density polyethylene of which the molecular weight is 100000-500000, 20-50 parts of ultra-high molecular weight polyethylene of which the molecular weight is 8 millions-11 millions, 0.5-3 parts of a lubricant, 1-10 parts of a filling enhancer, 0.5-2 parts of nucleating agent, and 0.1-2 parts of a compound antioxidant. According to the invention, problems of high viscosity, poor flowability and difficulty in processing of the ultra-high molecular weight polyethylene melt in the prior art solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified asphalt waterproof coiled material

ActiveCN104960267AImprove high temperature performanceImprove low temperature ductilitySynthetic resin layered productsConstructions elementsBituminous waterproofingAntioxidant

The invention relates to the field of waterproof building materials, in particular to a modified asphalt waterproof coiled material, and aims to solve the problems such that the common polymer waterproof coiled material is low in tensile performance and poor in environment friendliness and the common modified asphalt waterproof coiled material is short in life. The modified asphalt waterproof coiled material comprises modified asphalt, polypropylene fiber cloth and PE (polyethylene) film; the modified asphalt is synthetically made from, by weight, 40 to 50 parts of asphalt, 20 to 30 parts of high-density polyethylene, 15 to 30 parts of SBS (styrene butadiene styrene) rubber, 0.2 to 2 parts of stabilizer, 0.5 to 1 part of antioxidant, 0.1 to 2 parts of photo-stabilizer, and 10 to 20 parts of filler.

Owner:SICHUAN SHUYANG WATERPROOF MATERIAL

Modified epoxy resin adhesive used under low temperature

InactiveCN1670105ASmall coefficient of linear expansionImprove mechanical propertiesEpoxy resin adhesivesEpoxyThermal expansion

The invention relates to a modified epoxide resin adhesive agent used in low temperature and comprises in the weight proportion of modified epoxide resin of 50-80 shares, toughening agent of 50-20 shears and curing agent of 18-24 shears. The said modified epoxide resin is produced using TEOS as a precursor and original position introducing inorganic earth silicon particles in the weight proportion of 2-4 wt% in the bisphenol F epoxide resin by a sol-gel processing. The said toughening agent is low molecular weight epoxide resin, and the said curing agent is liquid aromaticamine. When it is used, mixing the said components homogeneously, spreading on the adhered substance by a vacuum pressure impregnation technology or directly, holding the temperature of 70-80 Deg. C for 24 h, then heating to the temperature of 130-140 Deg. C and holding for 12 h to make the adhesive agent cure completely. The said adhesive agent can be used in the temperature of -269-50 Deg. C and has higher tensile strength in low temperature, better impact flexibility, higher glass transition temperature and lower thermal-expansion coefficient.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

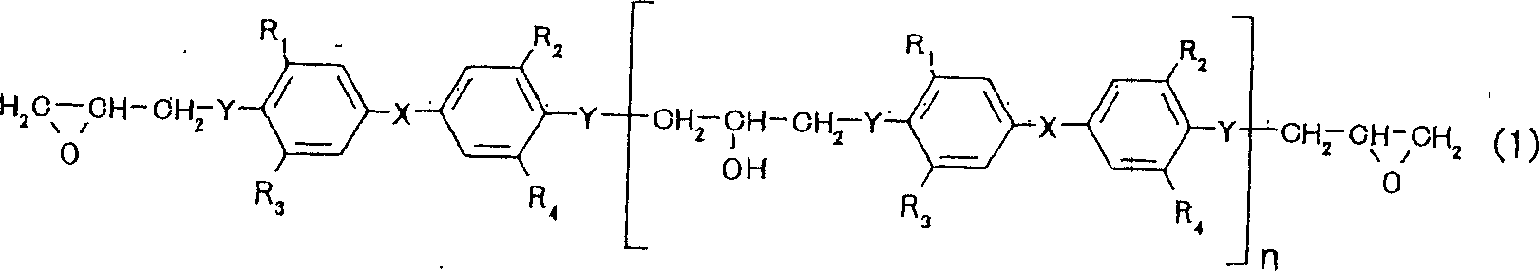

Transparent film, transparent conductive laminate, and touch panel, solar cell and display device, using same

ActiveCN103733274ASmall coefficient of linear expansionImprove thermal shock resistanceConductive layers on insulating-supportsThin material handlingDisplay deviceConductive materials

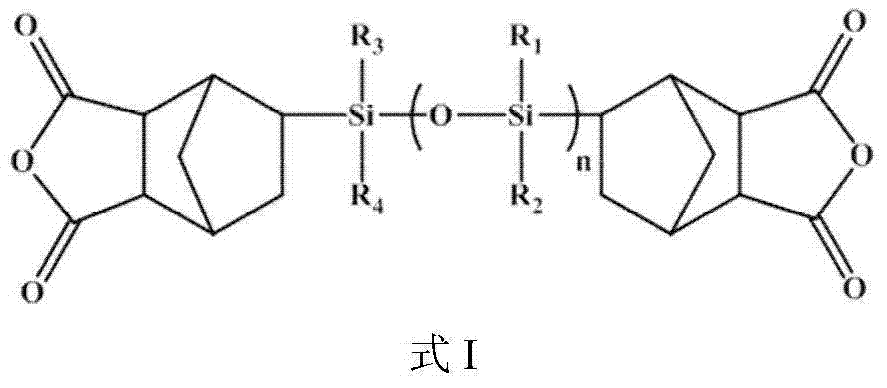

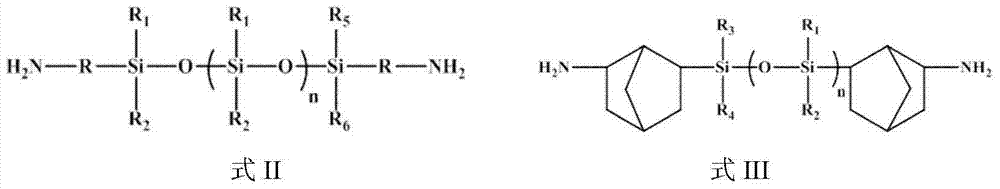

A transparent conductive laminate which is provided with both a substrate film that comprises a polyimide and a thin film that comprises a conductive material and that is laminated on the substrate film, wherein the polyimide comprises at least one kind of repeating units represented by general formula (1), has a glass transition temperature of 350 to 450 DEG C, and exhibits a coefficient of linear expansion of 30ppm / DEG C or less as determined by measuring the length change in a nitrogen atmosphere at a temperature rise rate of 5 DEG C / min within a temperature range of 50 to 200 DEG C. In general formula (1), R1, R2 and R3 are each independently one selected from the group consisting of a hydrogen atom, C1-10 alkyl and a fluorine atom; R4 is C6-40 aryl; and n is an integer of 0 to 12.

Owner:JX NIPPON OIL & ENERGY CORP

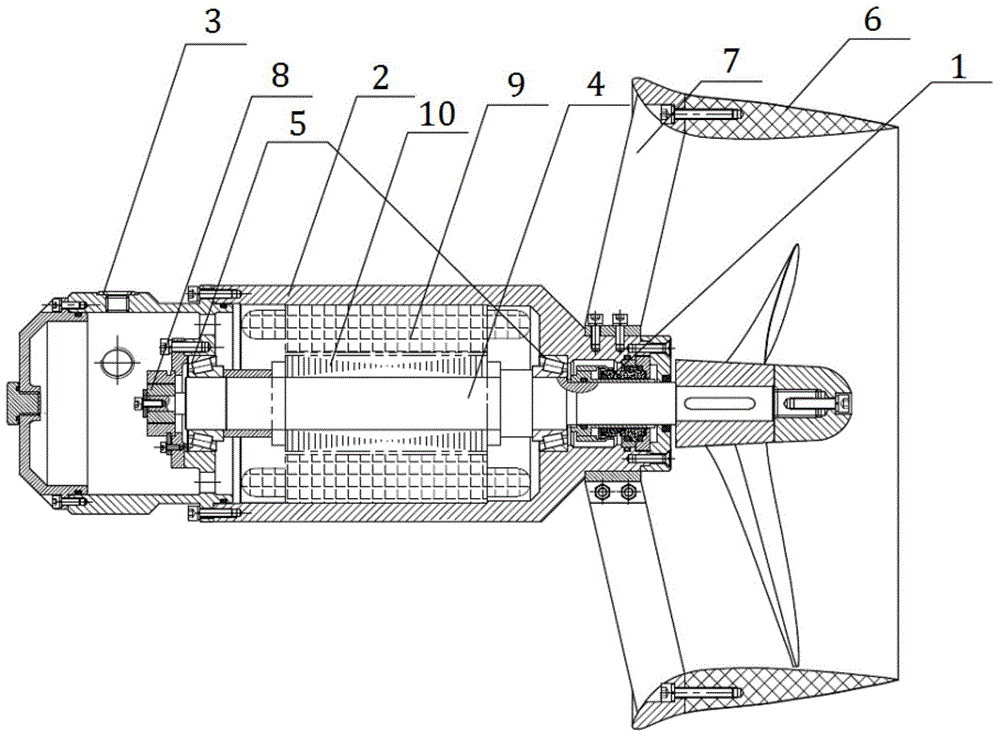

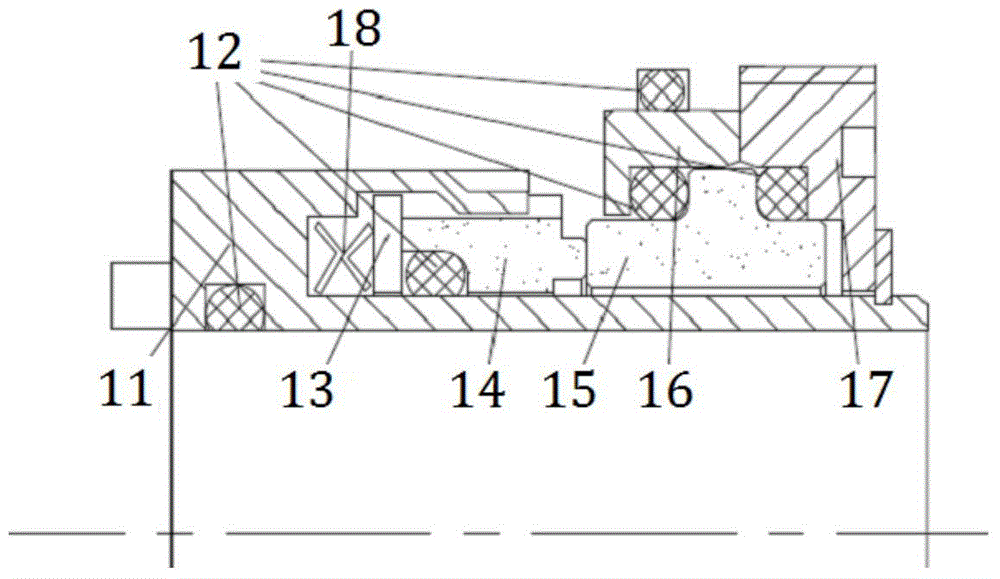

Full-sea-depth brushless direct-current electric propeller with rotary cartridge mechanical seal device

ActiveCN104443323AHigh hardnessSmall coefficient of linear expansionUnderwater vesselsUnderwater equipmentInterference fitWorking capacity

Provided is a full-sea-depth brushless direct-current electric propeller with a rotary cartridge mechanical seal device in the technical field of deep sea exploration. The full-sea-depth brushless direct-current electric propeller comprises the rotary cartridge mechanical seal device, a propeller shell, a guide pipe paddle, a brushless direct-current motor and a rotary transformer. The rotary cartridge mechanical seal device and a transmission shaft of the brushless direct-current motor are in axial sealing connection, the rotary transformer collects the rotating speed of the transmission shaft, and outputs rotating speed information through a transmission line of an electrohydraulic interface, the propeller shell and a stator of the brushless direct-current motor are assembled through interference fit, and the front end of the propeller shell and the guide pipe paddle are connected through a connecting support fixedly connected with a transitional flange. The rotary cartridge mechanical seal device is adopted, sealing materials are high in hardness and good in wear resisting performance, high temperature resisting performance and corrosion resisting performance, and the sealing structure is novel in structure, simple and reasonable in combination, small in size and good in sealing effect, so that the propeller has the work capacity within the full-sea-depth range of 0 m to 11,000 m.

Owner:SHANGHAI JIAO TONG UNIV

Molding compound for sheet tantalum capacitor

InactiveCN1546566AMeet the requirements of production molding process parametersImprove product qualityCapacitorsEpoxyCombustion

The invention discloses a molded plastic compound for sheet tantalum capacitor, which is an epoxy resin compound and belongs to the field of special-purpose plastic encapsulating material in electronic industry. The molded plastic uses epoxy resin as the main block resin and phenolic resins as curing agent, prepared by adding solidification accelerating agent, filling material, releasing agent, combustion inhibitor, coloring agent, coupling agent, toughening agent and modifier though the steps of disintegrating, mixing, pugging, cooling down, disintegrating, batch mixing, pre-forming and packaging.

Owner:WUXI RES & DESIGN INST OF CHEM IND

Composite investment casting refractory material and its production method

This invention discloses a composite wax mold casting fireproof material, with 30-300 micron particle diameter, which uses quartz, bauxite, or silicate fireproof material as core, coated by aluminum oxide coating, wherein the said silicate fireproof material is kaolinite fireproof material or grammite. The material is produced by mixing the 10-250 micron diameter quartz, bauxite, or silicate fireproof material granules with aluminium collosol at 0.5-1.5:1, and drying granulating. The said drying granulating is performed by heat drying and then by disintegration or spray drying. When this composite fireproof material is used for coating material, it can efficiently prevent the soluble ions leaching in the original fireproof granules, greatly improve the coating material stability, and fully guarantee the quality of the casting articles, which will make it to be a cheap and superior wax mold casting fireproof material.

Owner:ZHEJIANG YUDA CHEM IND

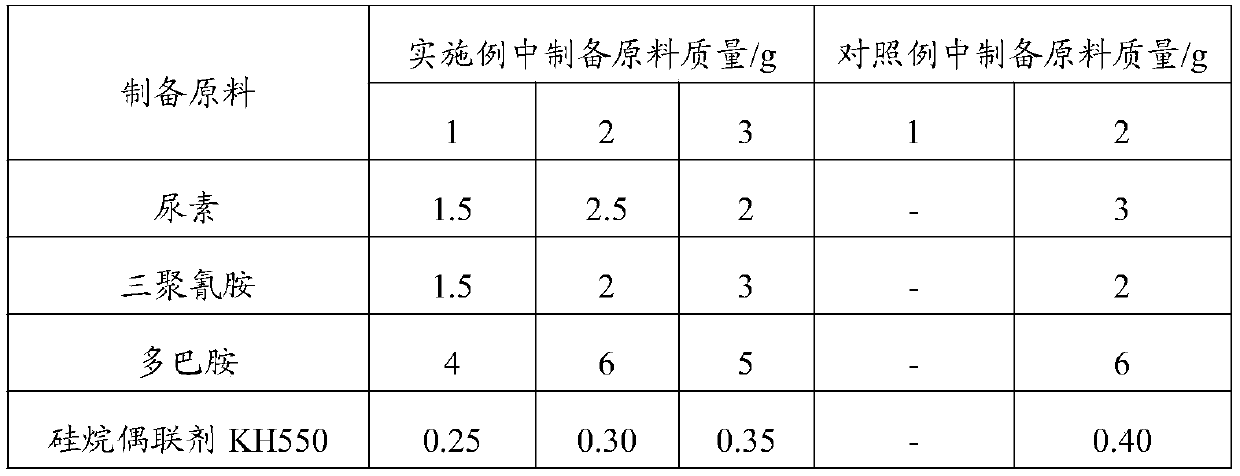

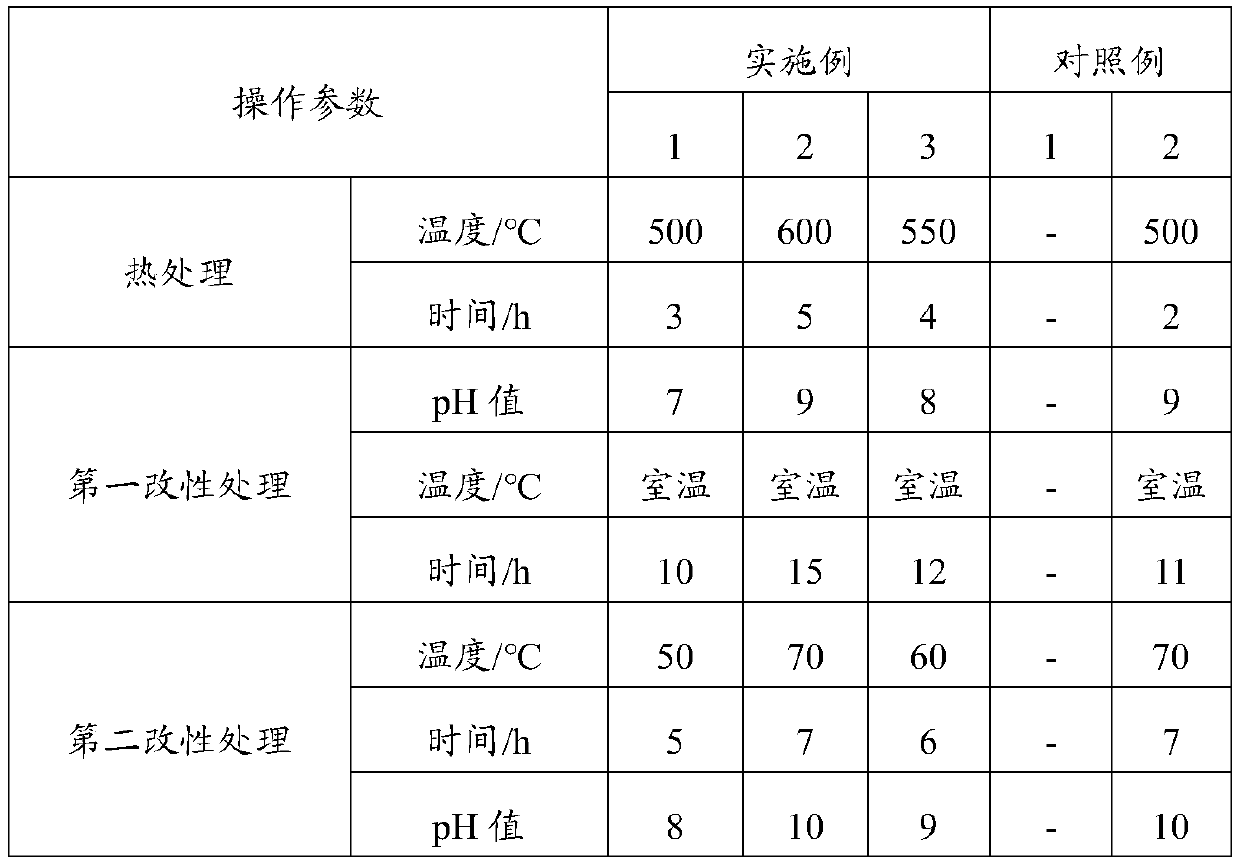

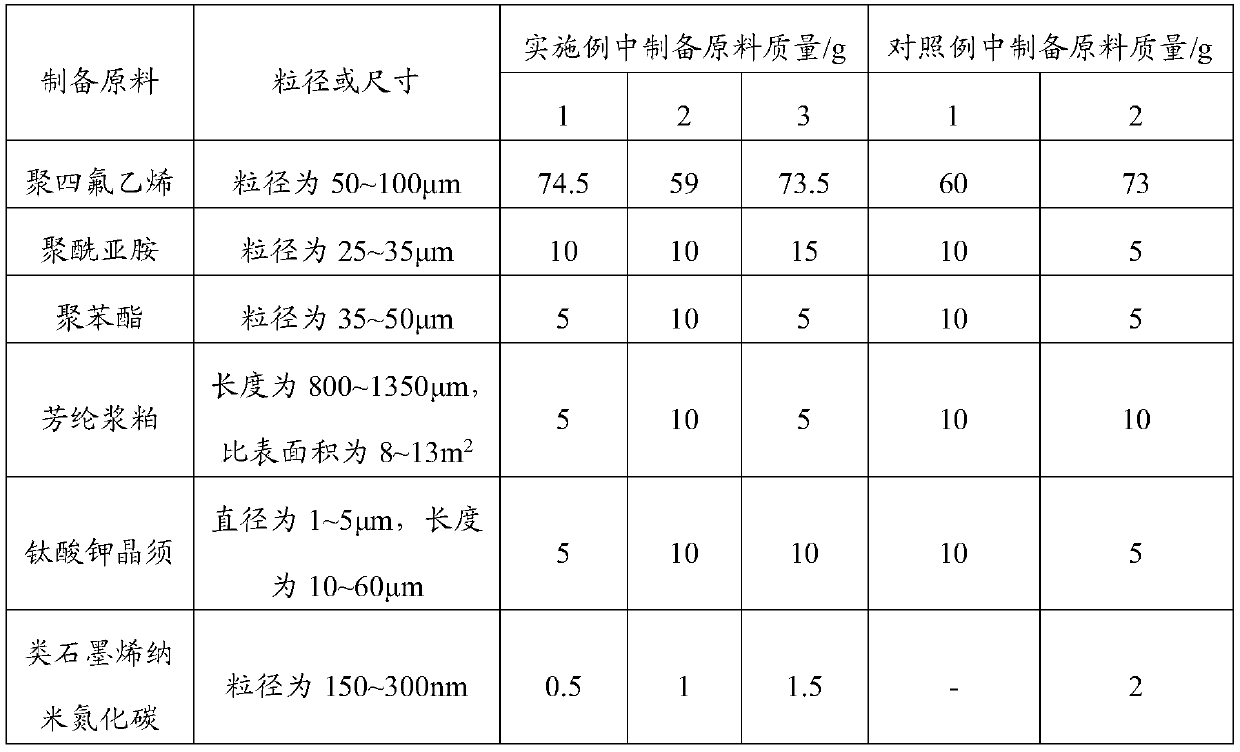

Graphene-like nano carbon nitride modified polytetrafluoroethylene friction material as well as preparation method and application thereof

ActiveCN109851962AStable coefficient of frictionHigh modulus of elasticityOther chemical processesAramidUltrasonic motor

The invention relates to the technical field of composites and specifically relates to a graphene-like nano carbon nitride modified polytetrafluoroethylene friction material as well as a preparation method and application thereof. The graphene-like nano carbon nitride modified polytetrafluoroethylene friction material provided by the invention comprises the following preparation raw materials in parts by mass: 50-80 parts of polytetrafluoroethylene, 5-15 parts of polyimide, 5-10 parts of polybenzoate, 5-20 parts of aramid pulp, 5-15 parts of potassium titanate whiskers and 0.5-1.3 parts of graphene-like nano carbon nitride. The graphene-like nano carbon nitride modified polytetrafluoroethylene friction material prepared by adopting the raw materials with the proportions also has relativelylow mass wear rate and relatively high conversion efficiency on the basis of stable friction coefficient and is capable of meeting the demand for the friction material in an ultrasonic motor.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

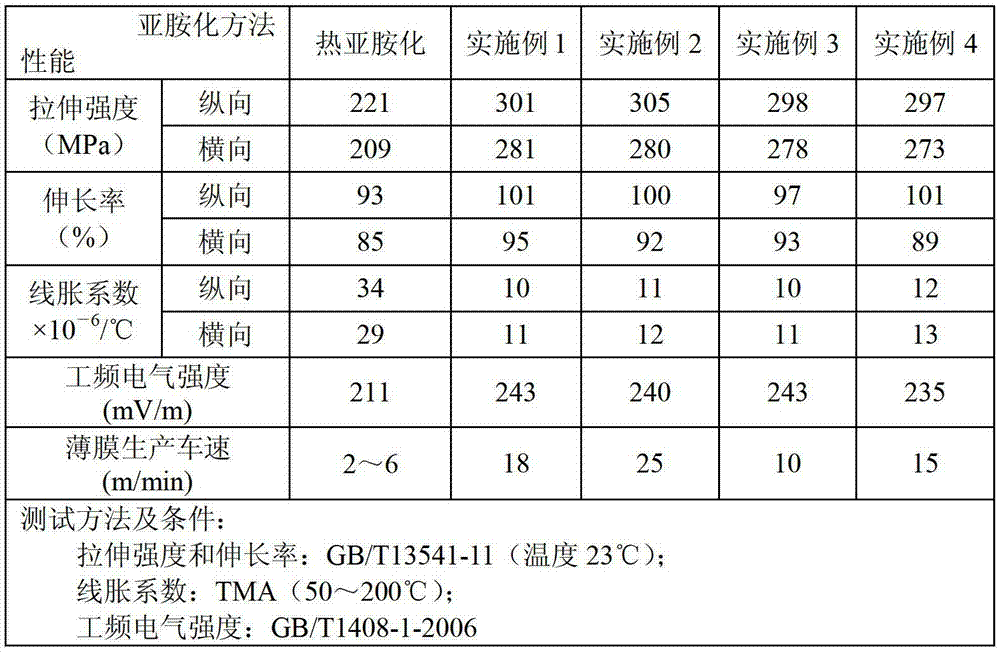

Method for preparing polyimide film by adopting chemical imidization in combined mode

ActiveCN103172891ASmall coefficient of linear expansionGood dimensional stabilityPolyamic acidMechanical property

The invention discloses a polyamic acid imidization catalyst composite and a method for preparing an electronic-grade polyimide film by adopting chemical imidization in a combined mode, and belongs to the technical field of the manufacture of electronic film insulating materials. The novel chemical imidization method of polyimide mainly comprises the following steps of: storing polyamic acid at a low temperature, and stretching to form a film in a casting way; and then producing high-quality electronic-grade polyimide film through a mixing type and bath type combined high-efficiency imidization method. Compared with a method firstly adopting thermal imidization, the method disclosed by the invention outstandingly improves the linear expansion coefficient, the mechanical property, and the like of the obtained polyimide film and is high in production efficiency, lower in preparation cost and suitable for large-scale chemical industrial production of the high-property polyimide film.

Owner:HUAWEI POLYIMIDE +1

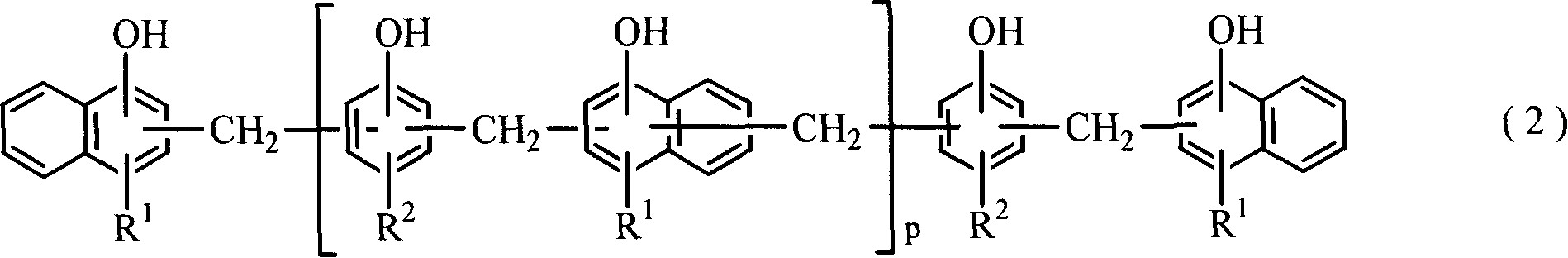

Polyimide, and alicyclic tetracarboxylic acid dianhydride for use in production of same

A polyimide which contains a repeating unit represented by general formula (1) and / or a repeating unit represented by general formula (2) [wherein R1, R2 and R3 independently represent a hydrogen atom or the like; R4 represents an aryl group having 6 to 40 carbon atoms; and n represents an integer of 0 to 12], wherein the ratio of the total amount of the repeating unit represented by general formula (1) and the repeating unit represented by general formula (2) to the total amount of all of repeating units is 90 mol% or more.

Owner:UBE IND LTD

Wear resistant heat preserving ceramic composite material

The invention relates to a wear-resistant heat preservation ceramic composite material which belongs to the field of materials and comprises primary materials and auxiliary materials according to weight percentage. The primary materials comprise corundum, chromic oxide, limestone, silicon dioxide, high alumina clay, silicate or calcium aluminate cement; the auxiliary materials comprise perlite powder, magnesia, quartz sand component, titanium oxide, dolomite, attapulgite, high temperature caking agent, composite strengthening agent, feldspar, and short carbon fiber component. The wear-resistant heat preservation ceramic composite material has the advantages of high intensity, being suitable for the strong eroding of various mediums, strong adhesive attraction, as well as excellent wear resistance and heat preservation performance. The wear-resistant heat preservation ceramic composite material has small coefficient of heat conduction, high melting point, and low linear expansibility. The integral performance is stable; the acid resistance, the alkali resistance and the erosion-proof capacity are strong; the density is small; a seamless integral wear-resistant heat preservation layer is formed after solidifying; the performance is extremely excellent; moreover, the wear-resistant heat preservation ceramic composite material is not easy to fall off, can effectively prolong the service lives of devices and pipelines, is convenient to be constructed, is used inside the pipelines, has the double effects of wear resistance and heat preservation, greatly reduces the production cost of enterprises, and improves the economic benefits thereof.

Owner:陈永祥

Modified inorganic nanoparticle toughening epoxy resin pouring sealant and preparation method thereof

InactiveCN104231993AFlame retardantImprove thermal conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyBound property

The invention relates to a modified inorganic nanoparticle toughening epoxy resin pouring sealant and a preparation method thereof. The epoxy resin pouring sealant consists of epoxy resin, a curing agent, an accelerant of the curing agent, an active diluent and polyaniline modified inorganic nanoparticles. The polyaniline has amino groups on the molecule chain, the boundary binding property of the inorganic nanoparticles and the epoxy resin can be improved, the dispersion of the inorganic nanoparticles in the epoxy resin is promoted, and meanwhile as the polyaniline has certain flame retardancy and a good heat conduction coefficient, the polyaniline modified inorganic nanoparticles can be toughened and at the same time the flame retardancy and the heat conduction property are improved, and multiple properties of a material are synchronously improved. The preparation method is simple in process and convenient to operate, an obtained pouring sealing material is low in toxicity and good in flowability, and the condensate of the pouring sealing material is very high in impact resistance, good in flame retardancy, low in linear expansion coefficient, high in heat conductivity and very suitable for sealing electronic devices in a pouring manner.

Owner:JIANGNAN UNIV +1

Resin-based composite material with controllable linear expansion coefficient and preparation method thereof

ActiveCN102337014ASmall coefficient of linear expansionEasy to produceCompression moldingFilling materials

The invention provides a resin-based composite material with a controllable linear expansion coefficient and a preparation method thereof. The composite material is characterized by mainly comprising the following components in parts by weight: 10 parts of unsaturated polyester resin, 2-30 parts of filling material, 2-20 parts of fiber, 1-5 parts of low shrinking agent, 0.6-2 parts of mould release agent and 0.2-1 parts of initiator, wherein the filling material and fiber are materials with negative expansion coefficients or low expansion coefficients. The preparation method comprises the following steps: evenly mixing 1-5 parts of low shrinking agent, 0.6-2 parts of mould release agent and 0.2-1.5 parts of initiator with 10 parts of unsaturated polyester resin; then adding 2-30 parts of filling material and 2-20 parts of fiber for evenly mixing again; and finally, carrying out compression molding at the temperature of 140-160 DEG C. The linear expansion coefficient of the material provided by the invention is adjustable within a range of (8-30)*10<-6> / DEG C, and the material provided by the invention has isotropy.

Owner:SHENZHEN XINTIAN TECH

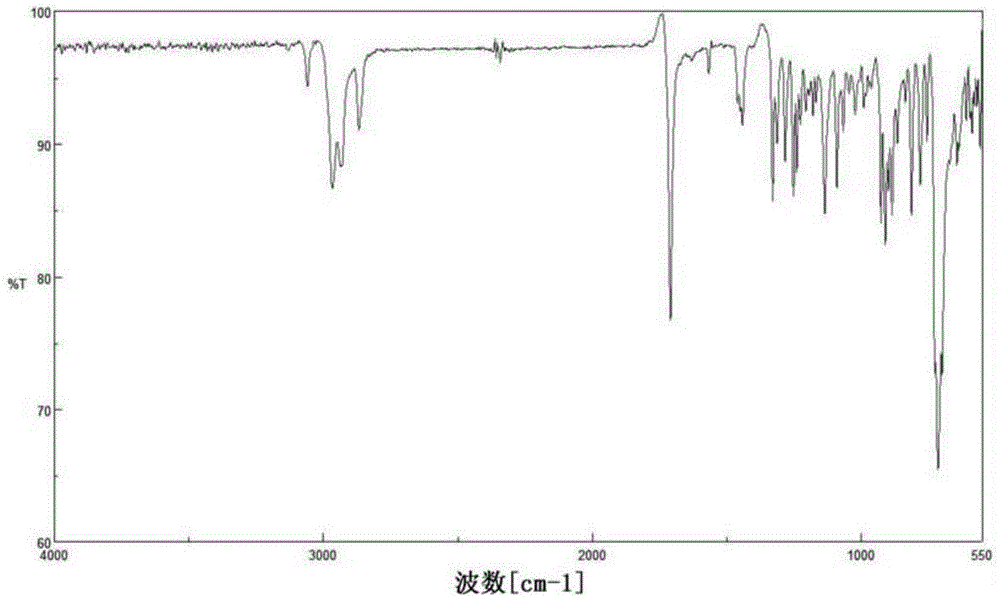

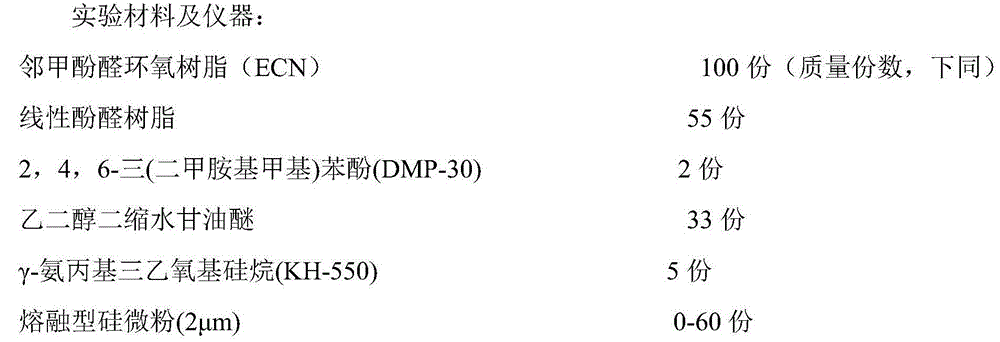

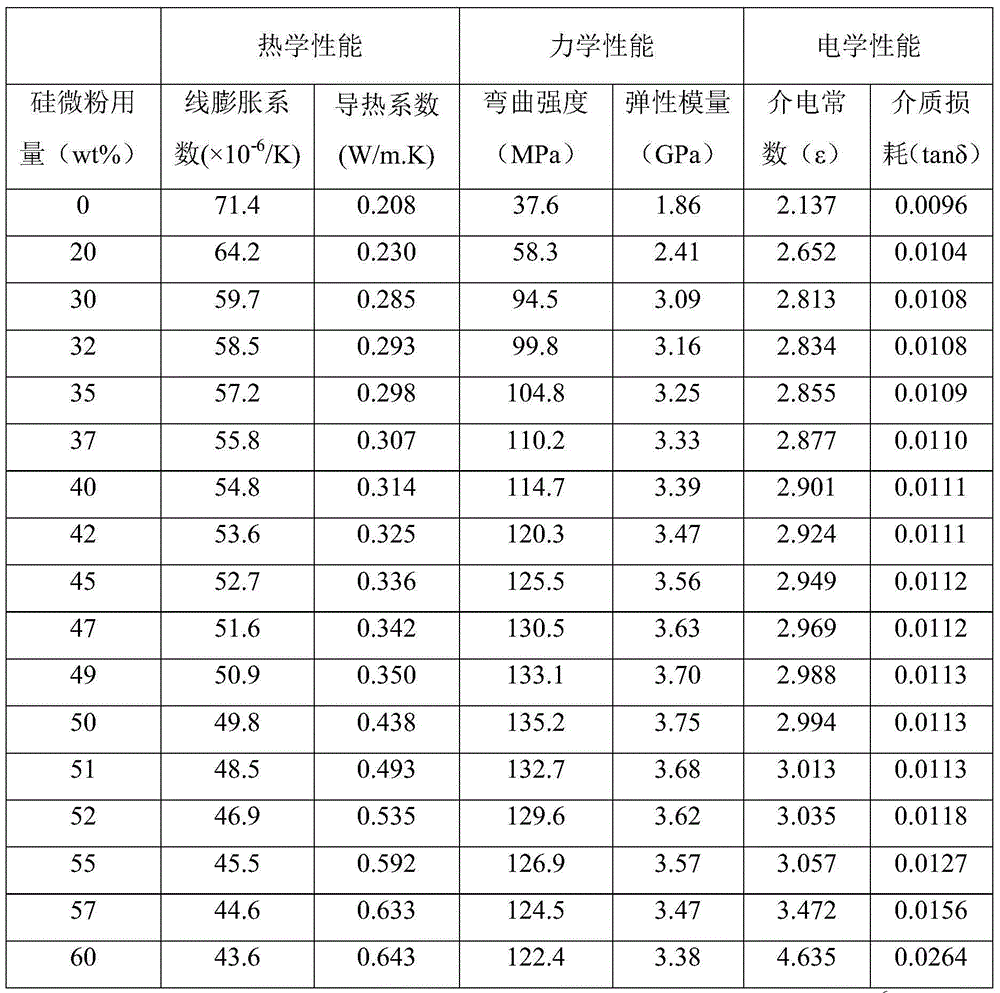

Epoxy molding compound and preparation method thereof

ActiveCN104672785ASmall coefficient of linear expansionImprove thermal conductivityMicroelectronicsSilane coupling

The invention discloses an epoxy molding compound and a preparation method thereof. The epoxy molding compound comprises the following components: epoxy resin, a coupling agent, a curing agent, a curing accelerator and filler, wherein the epoxy resin is o-cresol formaldehyde epoxy resin (ECN); a diluent is an epoxyactive diluent; the coupling agent is a silane coupling reagent; the curing agent is a latent curing agent; the curing accelerator is a latent curing accelerator; and the filler is silica powder. The thermal property, the mechanical property, the electric property and the like of the epoxy molding compound reach a balanced and relatively good level and can meet the requirements of the modern microelectronics packaging technology.

Owner:GUANGDONG DANBOND TECH

Manufacturing method of high thermal conductivity artificial graphite film

ActiveCN103889196ASmall coefficient of linear expansionHigh birefringenceCooling/ventilation/heating modificationsSolventDiamine

The invention relates to a manufacturing method of new nanometer materials, in particular to a manufacturing method of a high thermal conductivity artificial graphite film. The method comprises the steps that additive acid dianhydride, diamine compounds and organic polar solvent are polymerized in a reaction still to form a polyamide acid solution at certain temperature; the polyamide acid solution, imidize accelerant, a dehydrating agent, an end-capping reagent, a microwave heating material and a nanometer black liquor material are stirred in a stirred tank, are placed on a support to be in a film shape in a tape-casting mode and then are heated and dried in an oven, and polyimide films are obtained; the obtained polyimide films serve as raw materials, and are crossed, stacked, carbonized and graphitized, and finally the high thermal conductivity artificial graphite film is obtained. The manufacturing method is advanced in process, and the obtained graphite film has high thermal conductivity performance and good bending resistance.

Owner:中科悦达(上海)材料科技有限公司

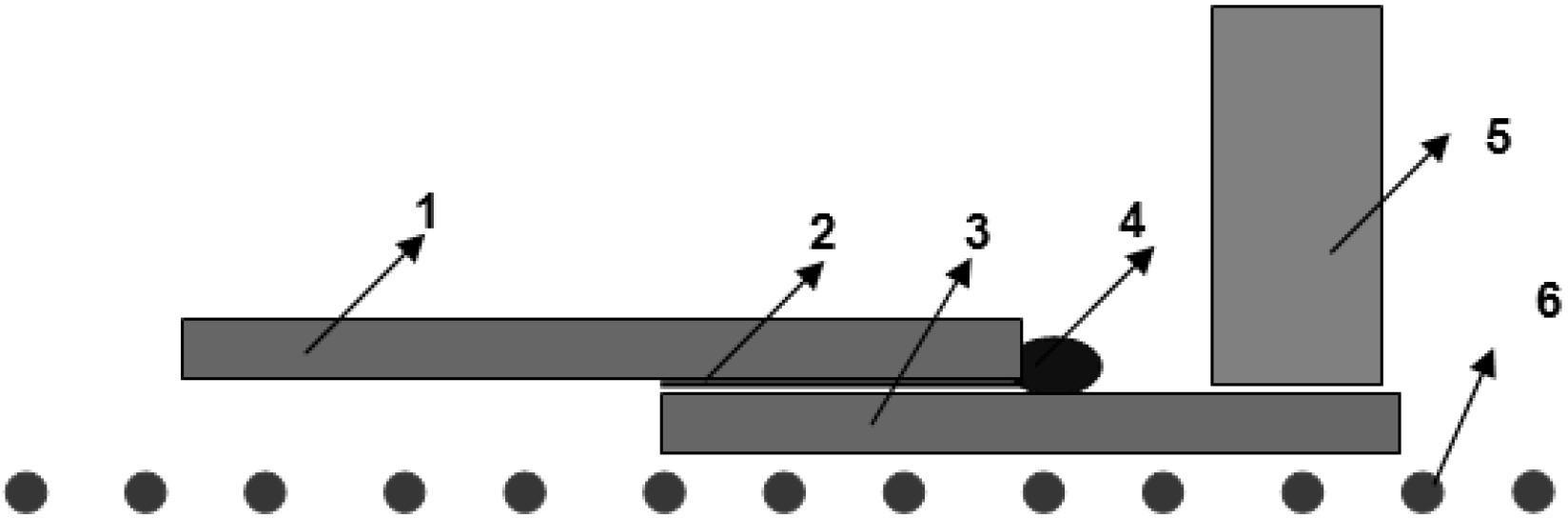

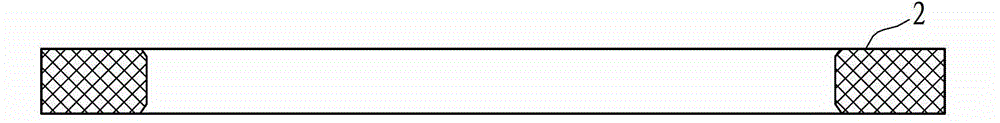

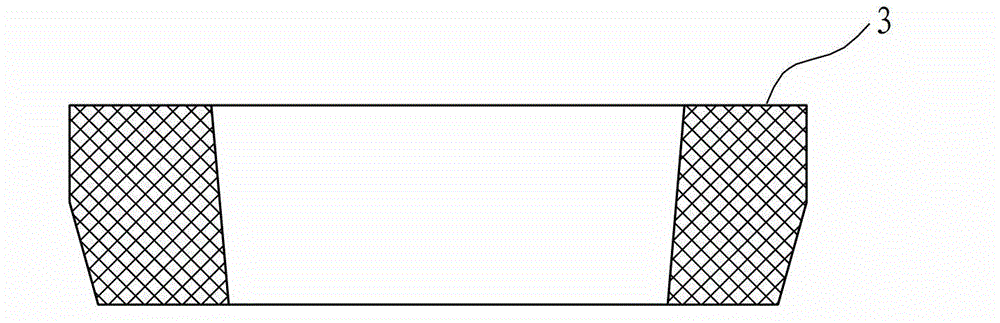

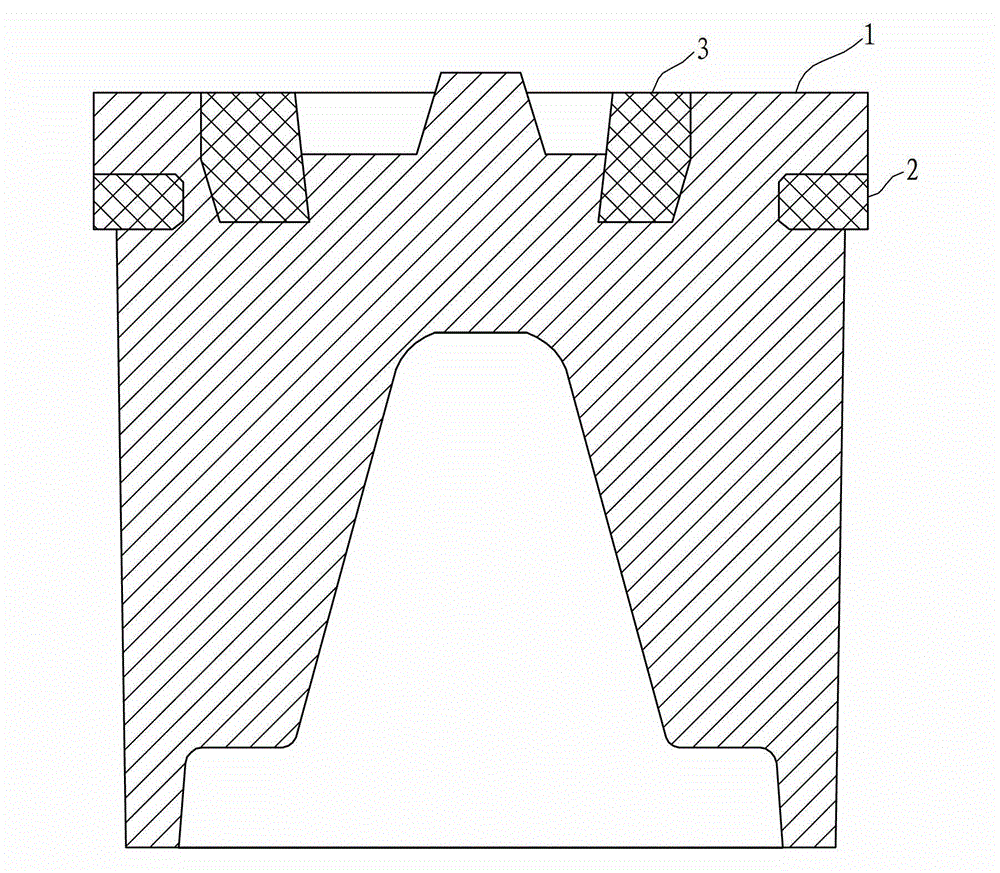

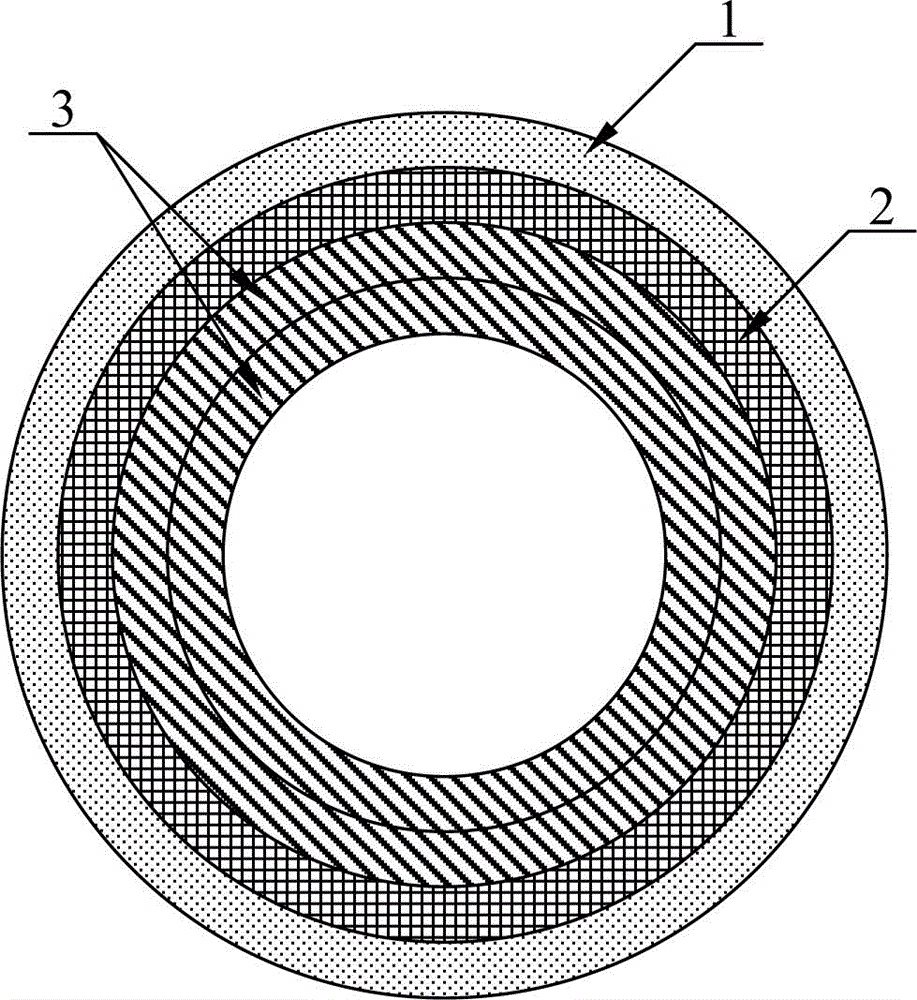

High-strength pipe made by thermoplastic continuous fiber prepreg tapes and manufacturing method and manufacturing equipment

ActiveCN105987237AImprove pressure resistanceImprove rigiditySynthetic resin layered productsLaminationFiberSurface layer

The invention relates to the tubing product field produced by substance in plastic or plastic state, in particular to a high-strength pipe made by thermoplastic continuous fiber prepreg tapes and a manufacturing method and manufacturing equipment.The high-strength pipe made by thermoplastic continuous fiber prepreg tapes comprises an inner layer pipe (1), a core layer (2) and a surface layer pipe (3), all of which are sequentially sleeved from the inside to the outside. The manufacturing method for high-strength pipe made by thermoplastic continuous fiber prepreg tapes is characterized by comprising following steps: heating, fusion, extrusion, cooling and cutting.The manufacturing equipment for high-strength pipe made by thermoplastic continuous fiber prepreg tapes is characterized by comprising an extruder and a co-extrusion composite die which are arranged in sequence. The high-strength pipe is overpressure resistant, highly-rigid and is low in expansion.

Owner:上海英泰塑胶股份有限公司

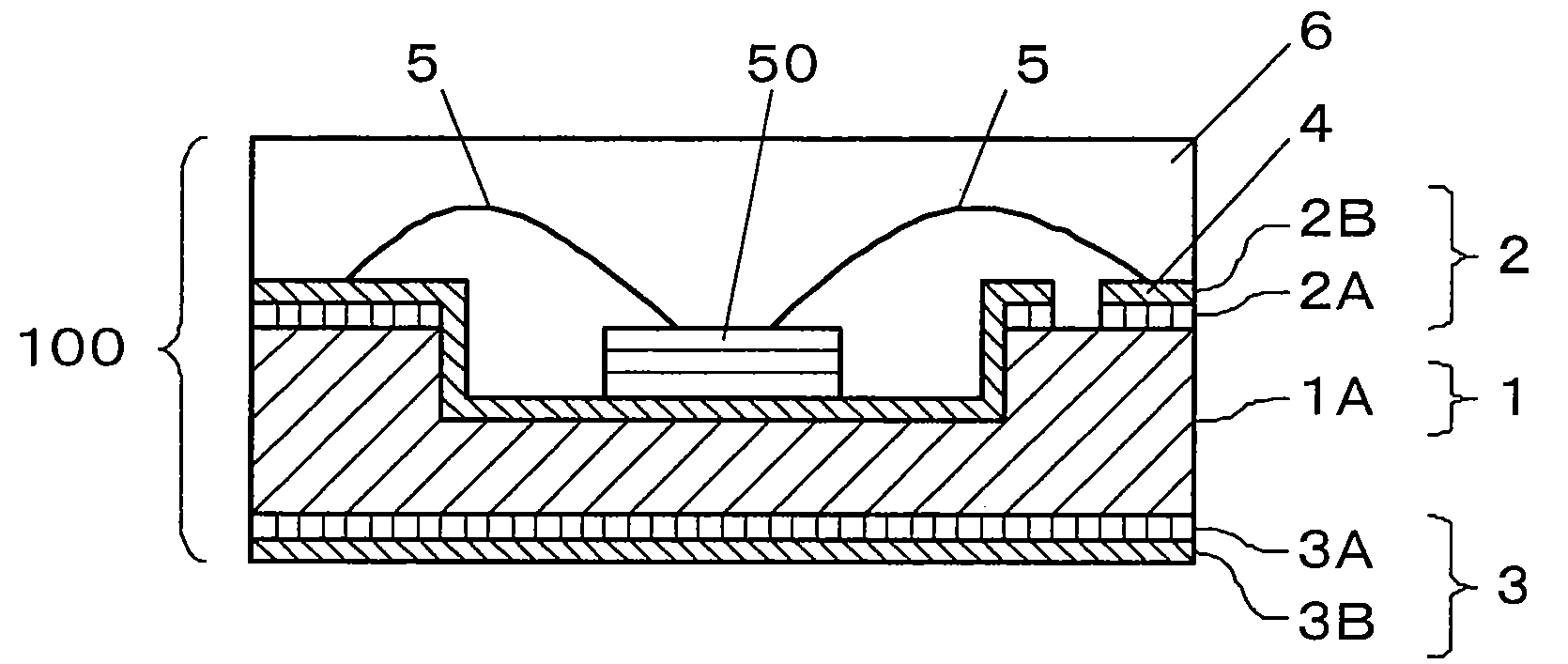

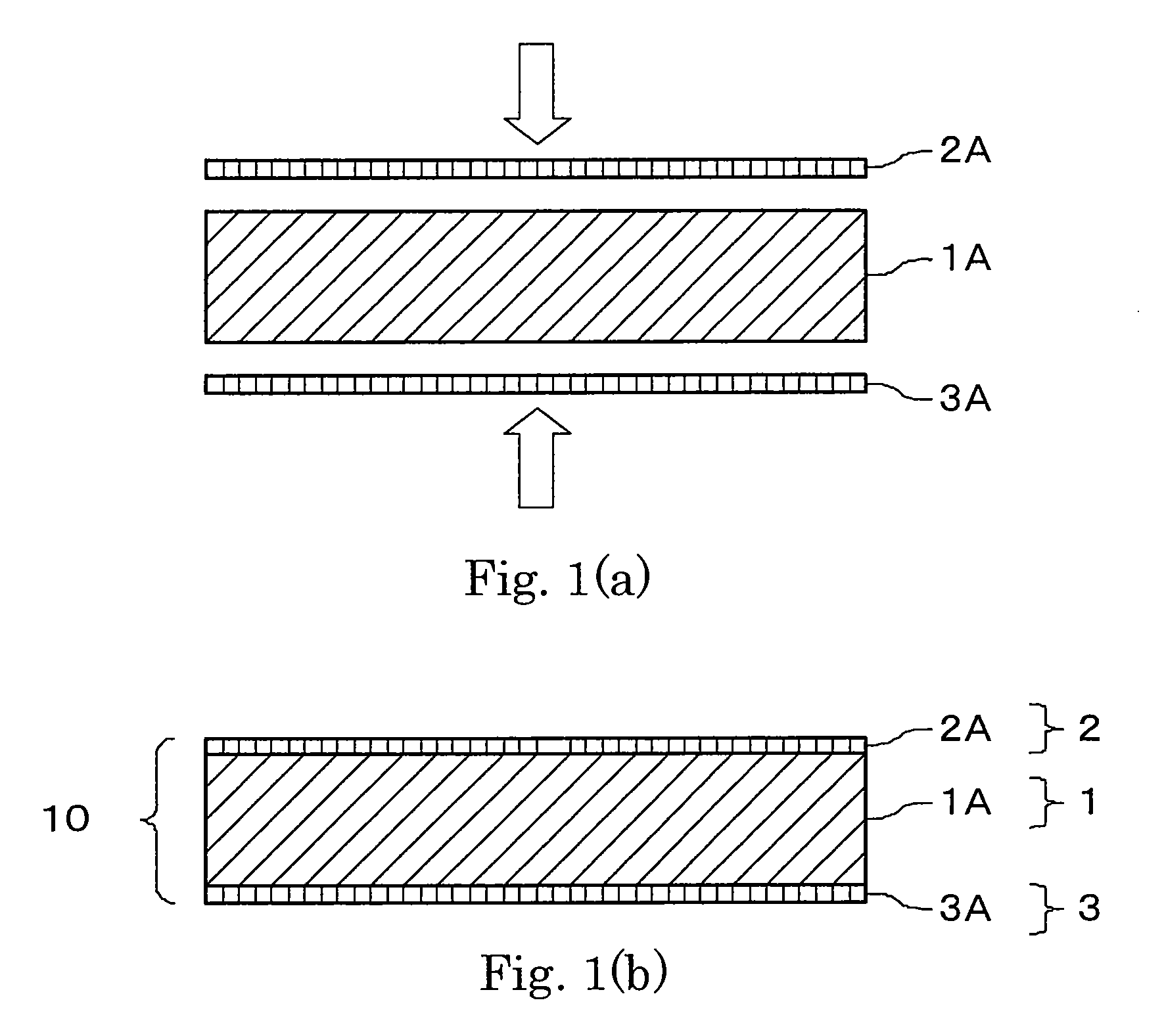

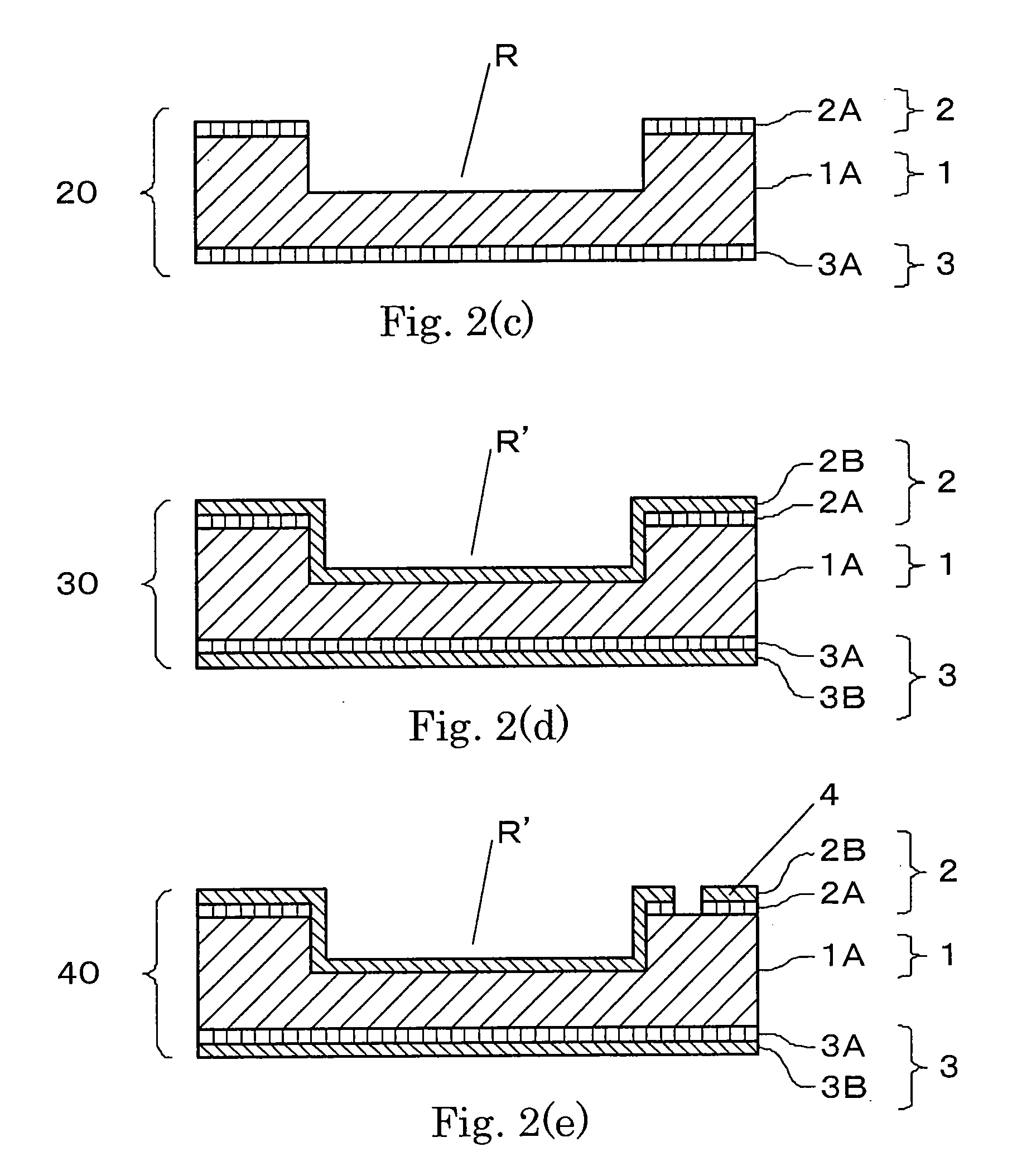

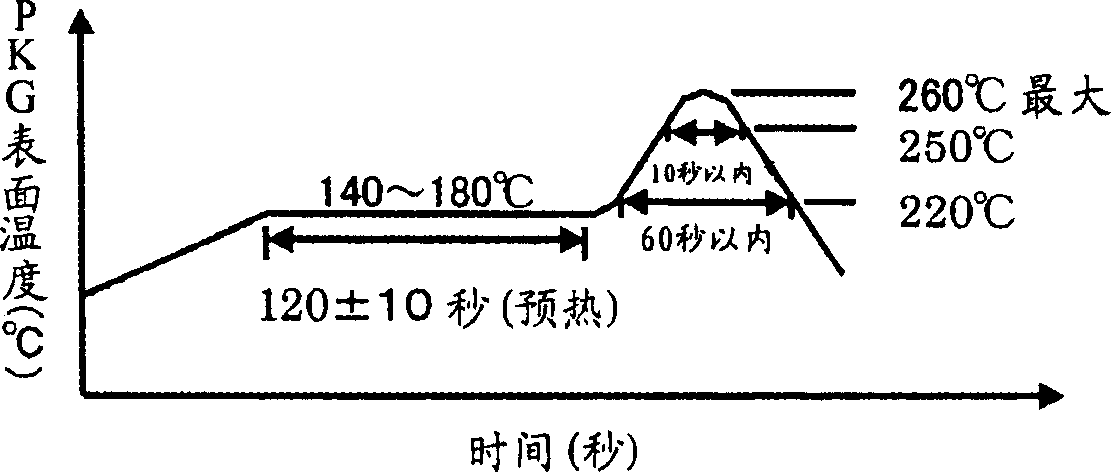

Substrate applicable in chip LED package

InactiveUS20100084167A1Small coefficient of linear expansionOvercome lack of heat resistancePrinted circuit aspectsSolid-state devicesPolyesterFiber

The present invention provides a substrate applicable in a chip LED package, the substrate having a conductive layer, an insulation layer and a heat-dissipation plate in this order, wherein the insulation layer comprises a liquid crystal polyester soluble in a solvent and a sheet comprising inorganic fibers and / or organic fibers. The substrate has a small linear expansion coefficient of the insulation layer in the surface direction and is extremely useful for production of a chip LED package while having a practical heat resistance.

Owner:SUMITOMO CHEM CO LTD

Semiconductor encapsulating epoxy resin composition and semiconductor device

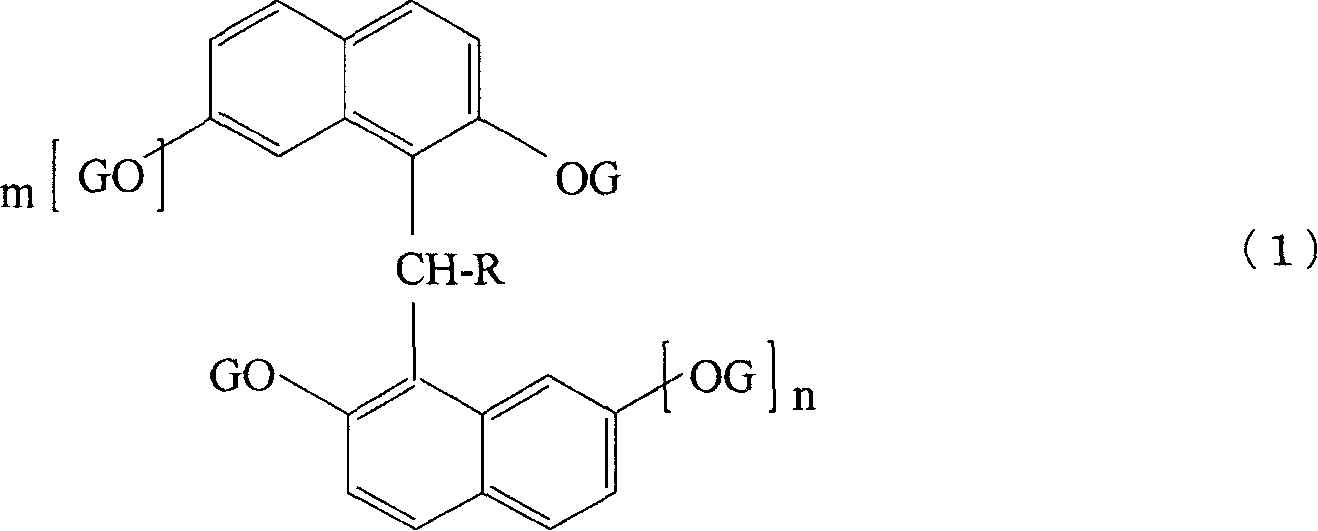

ActiveCN1854186AImprove liquiditySmall coefficient of linear expansionOther chemical processesSemiconductor/solid-state device detailsEpoxyDevice material

The present invention provides an epoxy resin composition, which is characterized in that it contains: (A) a naphthalene type epoxy resin represented by the following general formula (1), (m, n represent 0 or 1, R represents a hydrogen atom , an alkyl or phenyl group with 1 to 4 carbon atoms, G represents an organic group containing a glycidyl group, but in 100 parts by mass of the above general formula (1), the compound containing m=0 and n=0 is 35~ 85 mass parts, m=1, n=1 compound is 1 to 35 mass parts); (B) a phenolic resin curing agent having at least one substituted or unsubstituted naphthalene ring in one molecule; (C) inorganic matter filling agent and (D) at least one compound selected from rare earth oxides or hydrotalcite compounds. The epoxy resin composition of the present invention has good fluidity, small coefficient of linear expansion, high glass transition temperature, low hygroscopicity, and excellent lead-free solder crack resistance.

Owner:SHIN ETSU CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com