Patents

Literature

1923 results about "Linear expansion coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor device

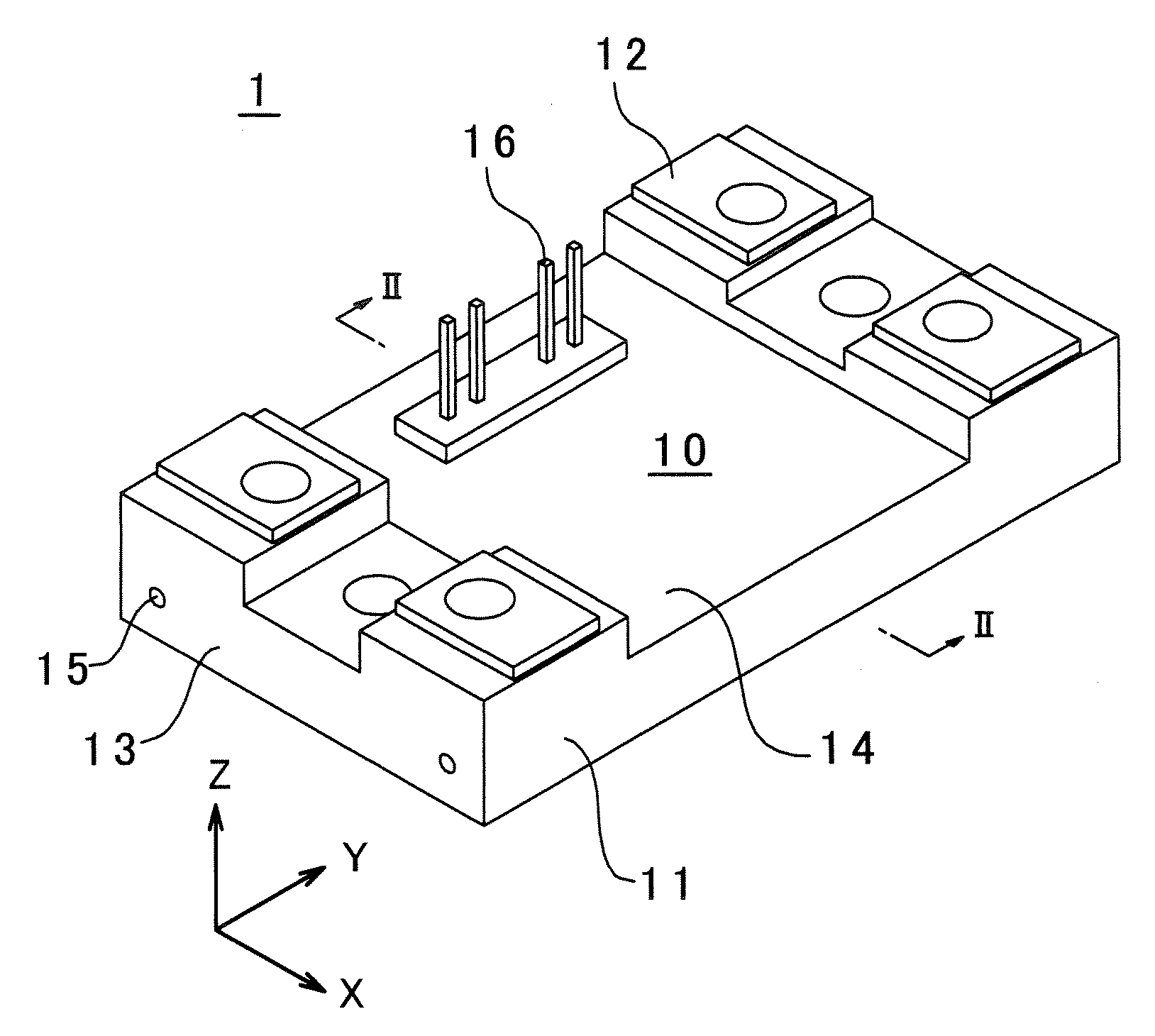

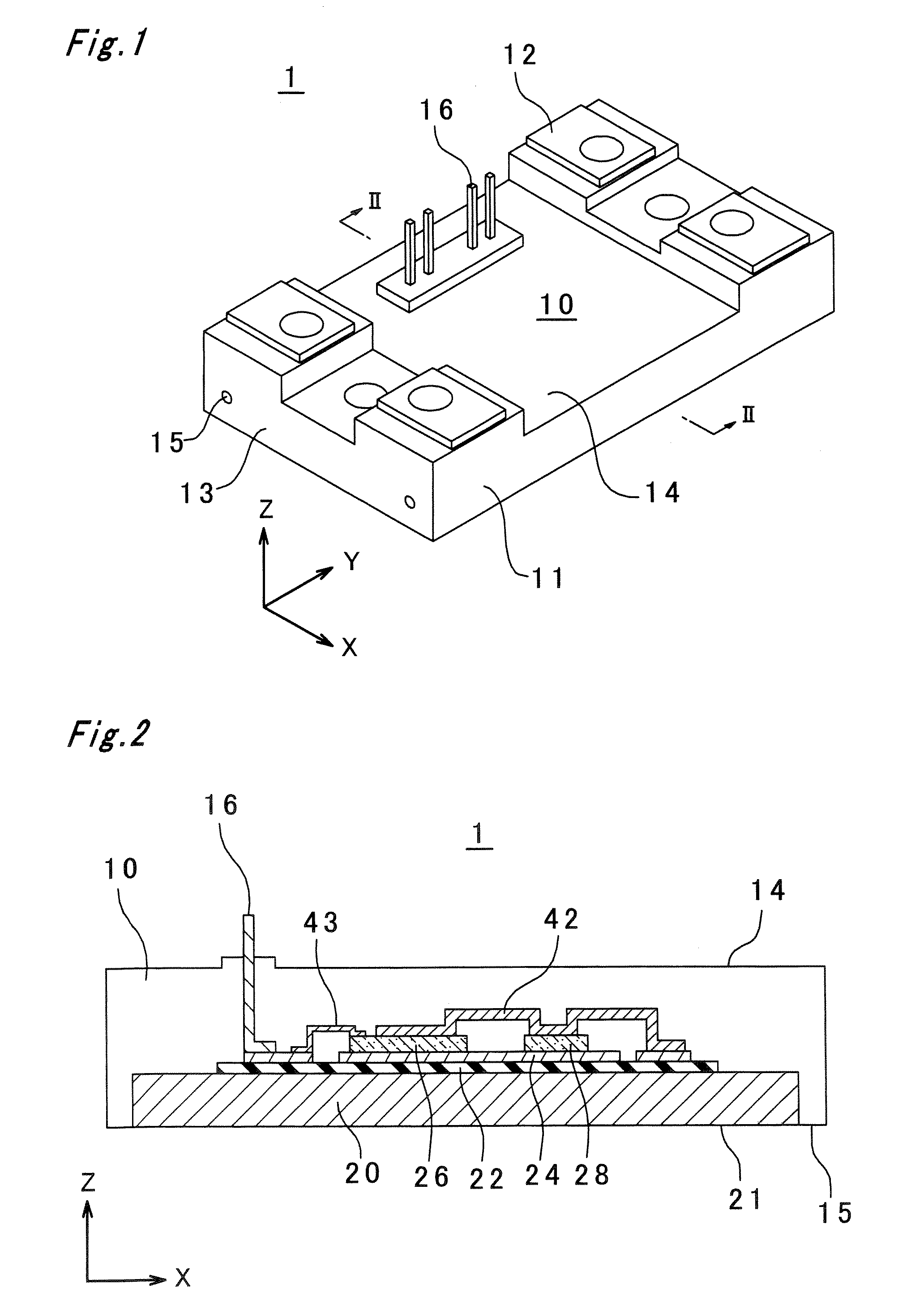

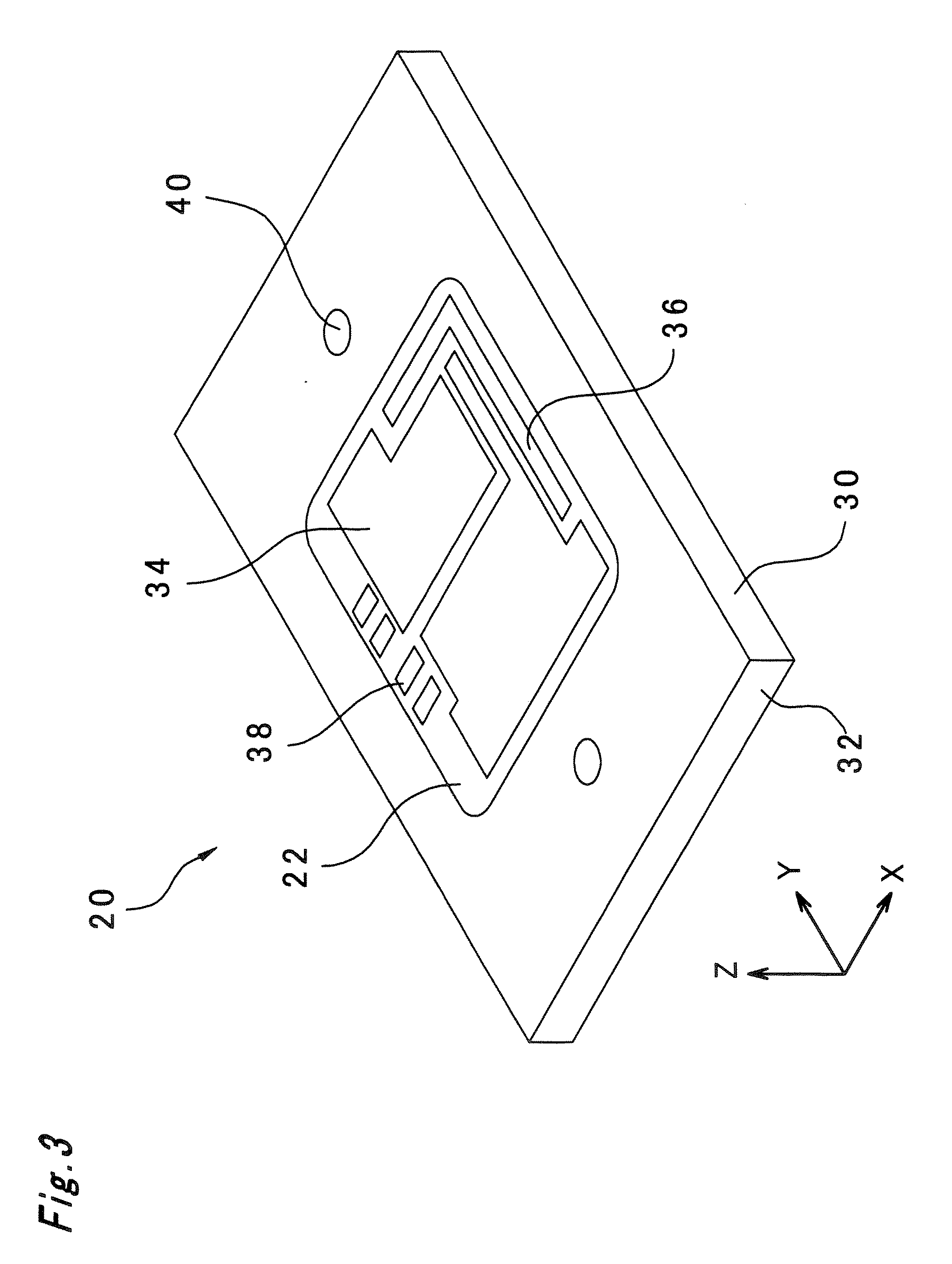

InactiveUS7119428B2Lower temperature riseEasy to operateSemiconductor/solid-state device detailsSolid-state devicesInterposerEngineering

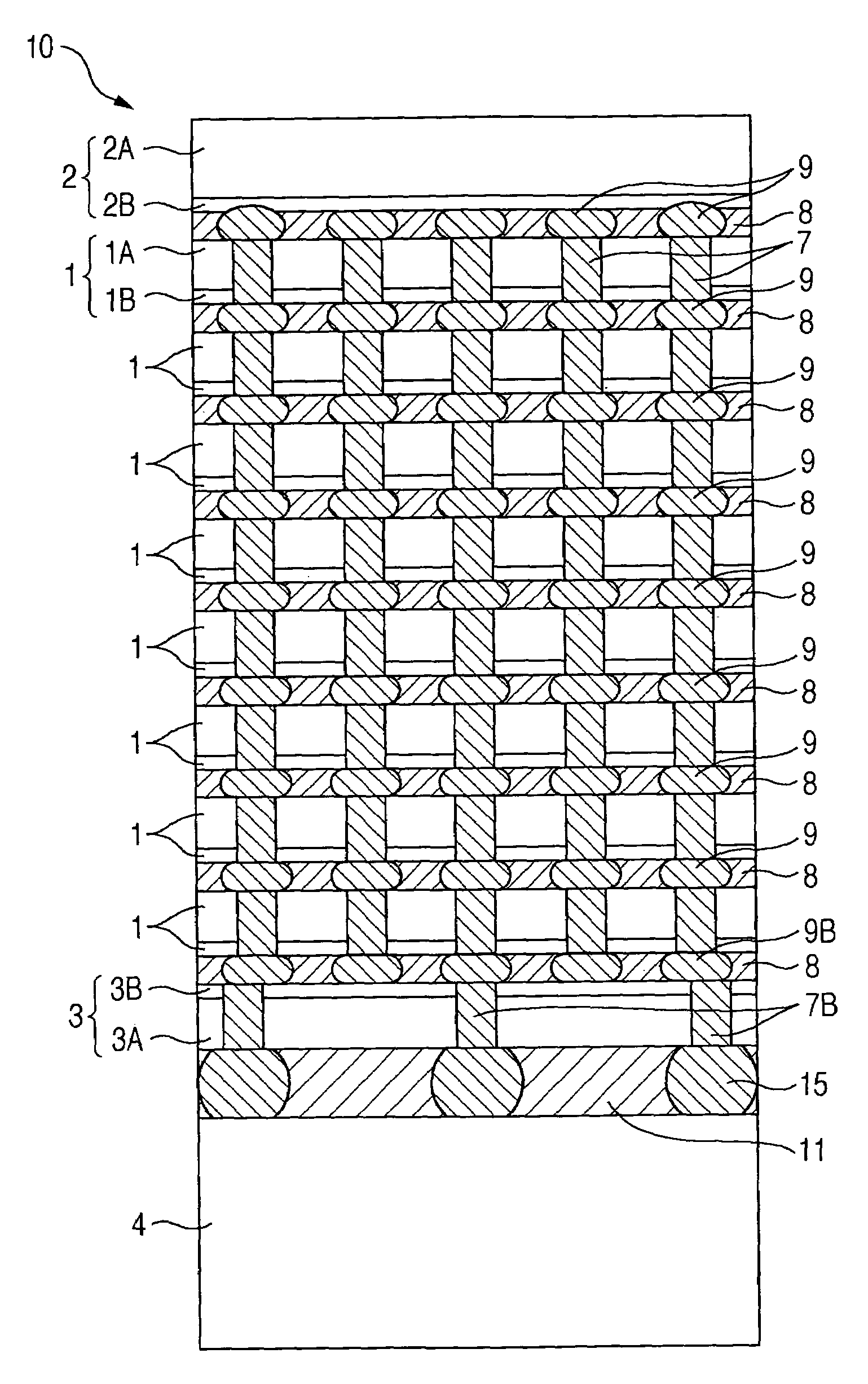

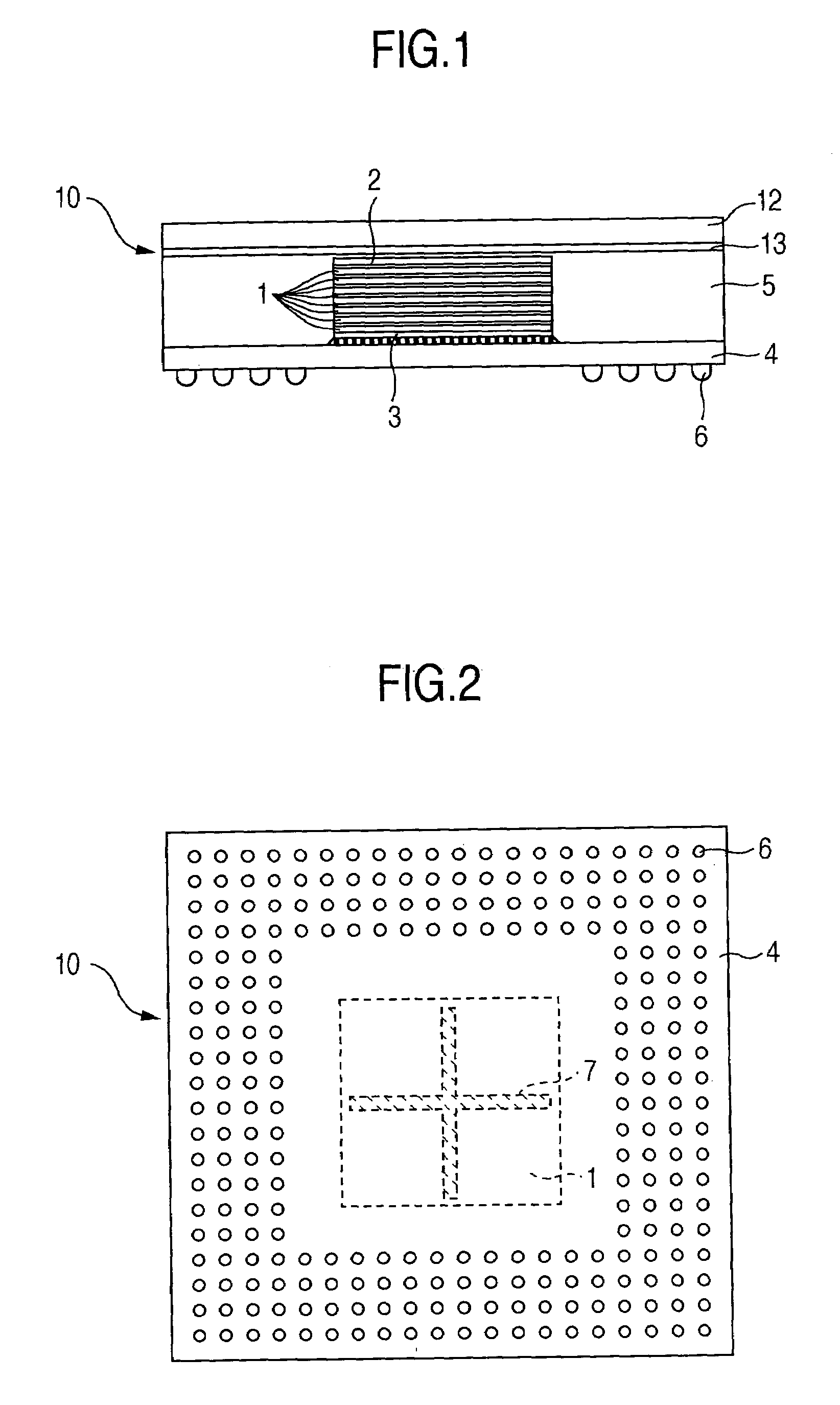

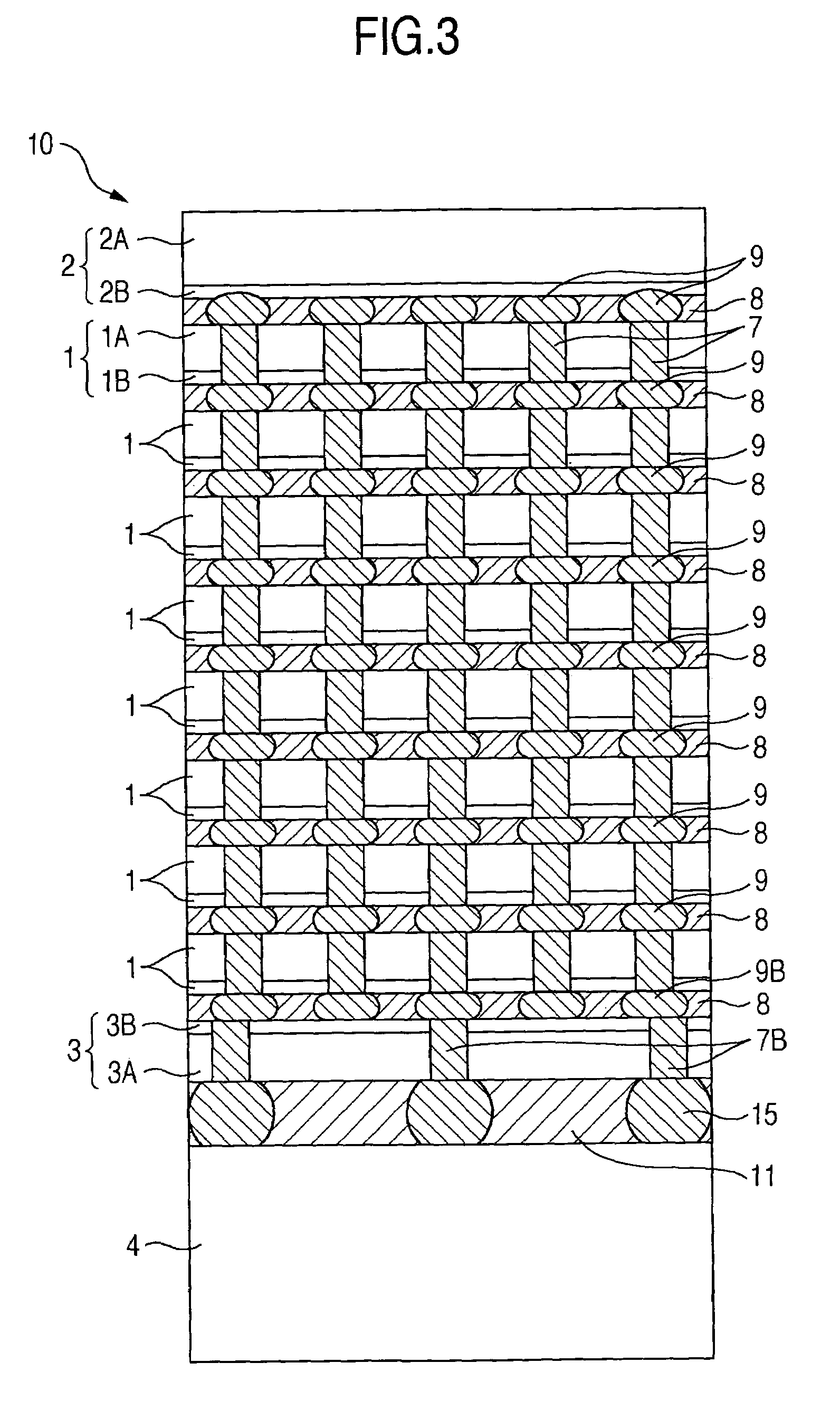

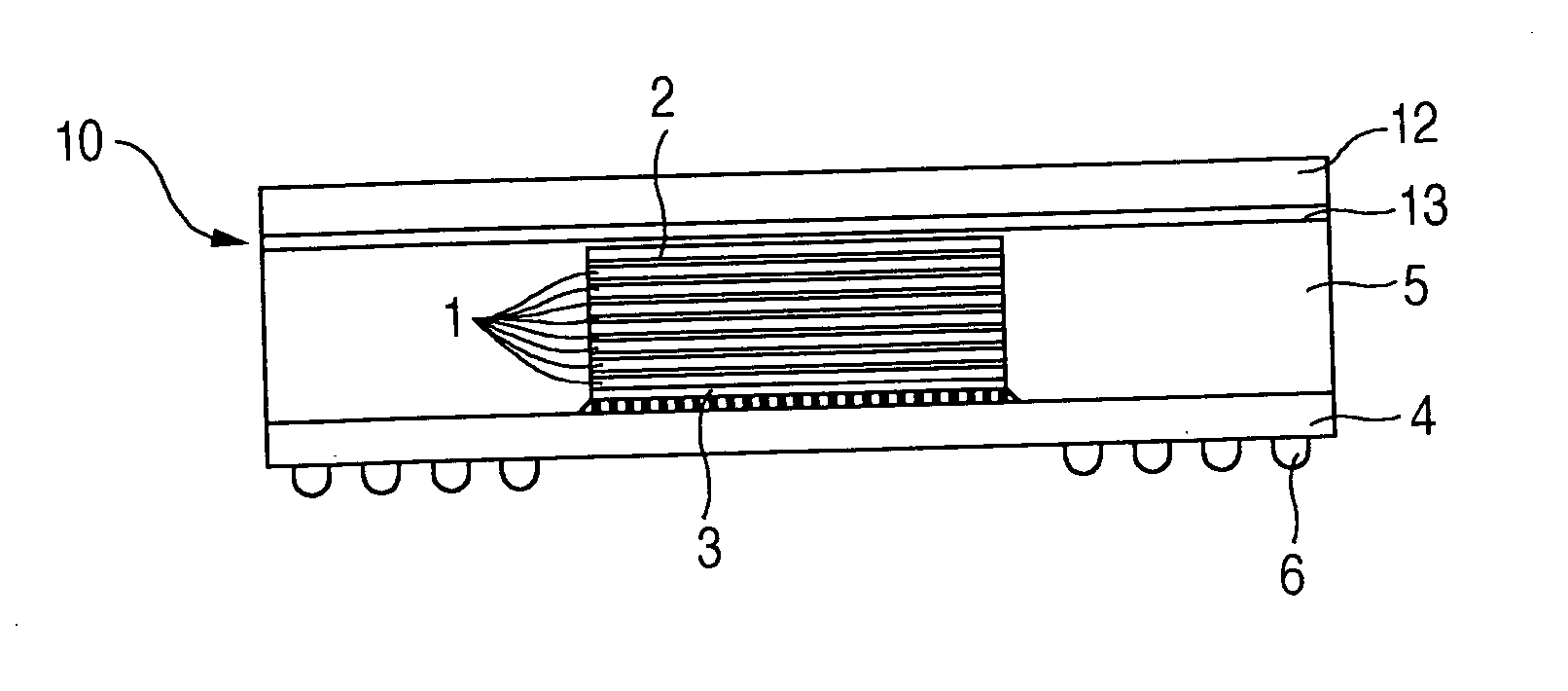

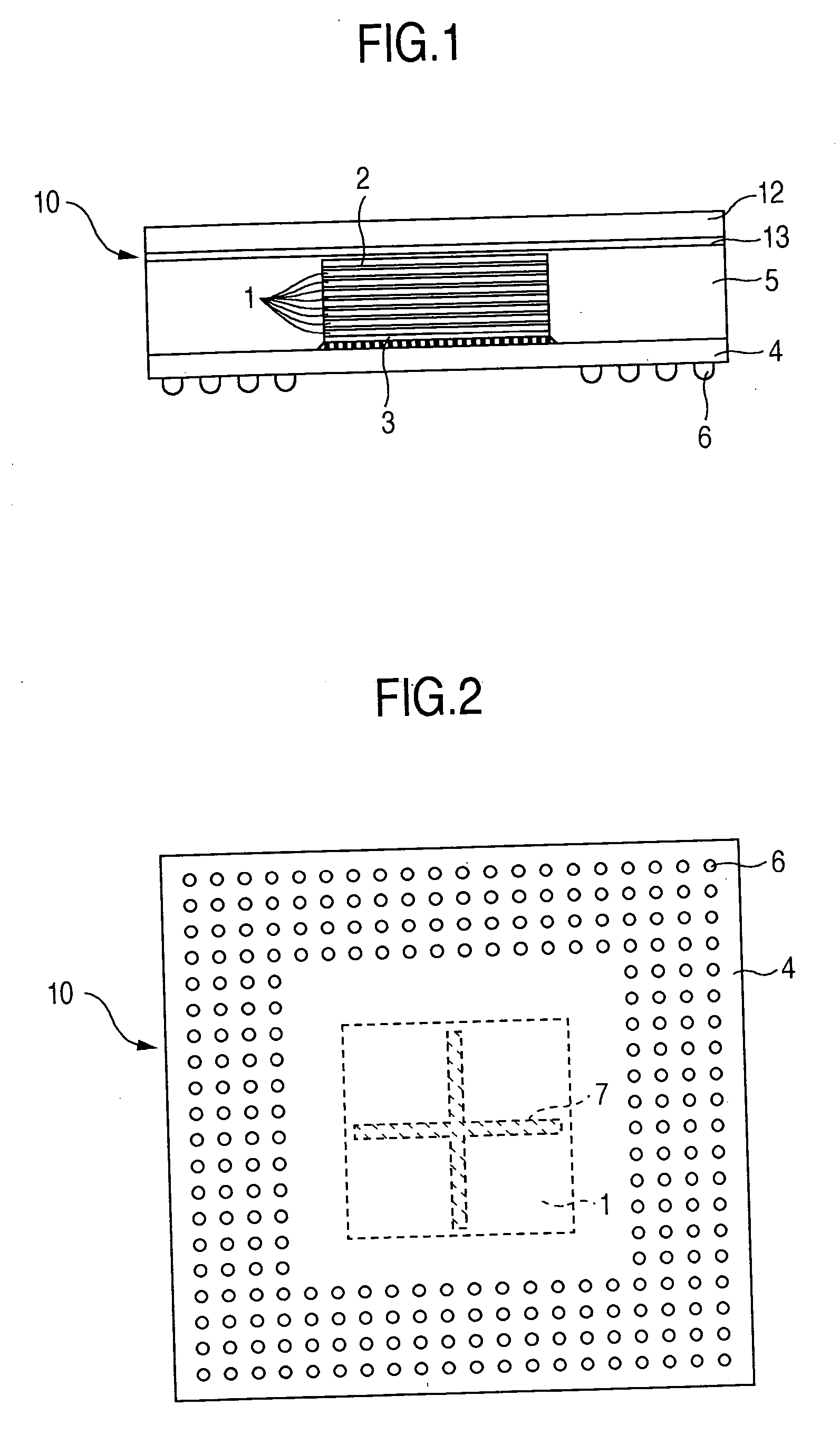

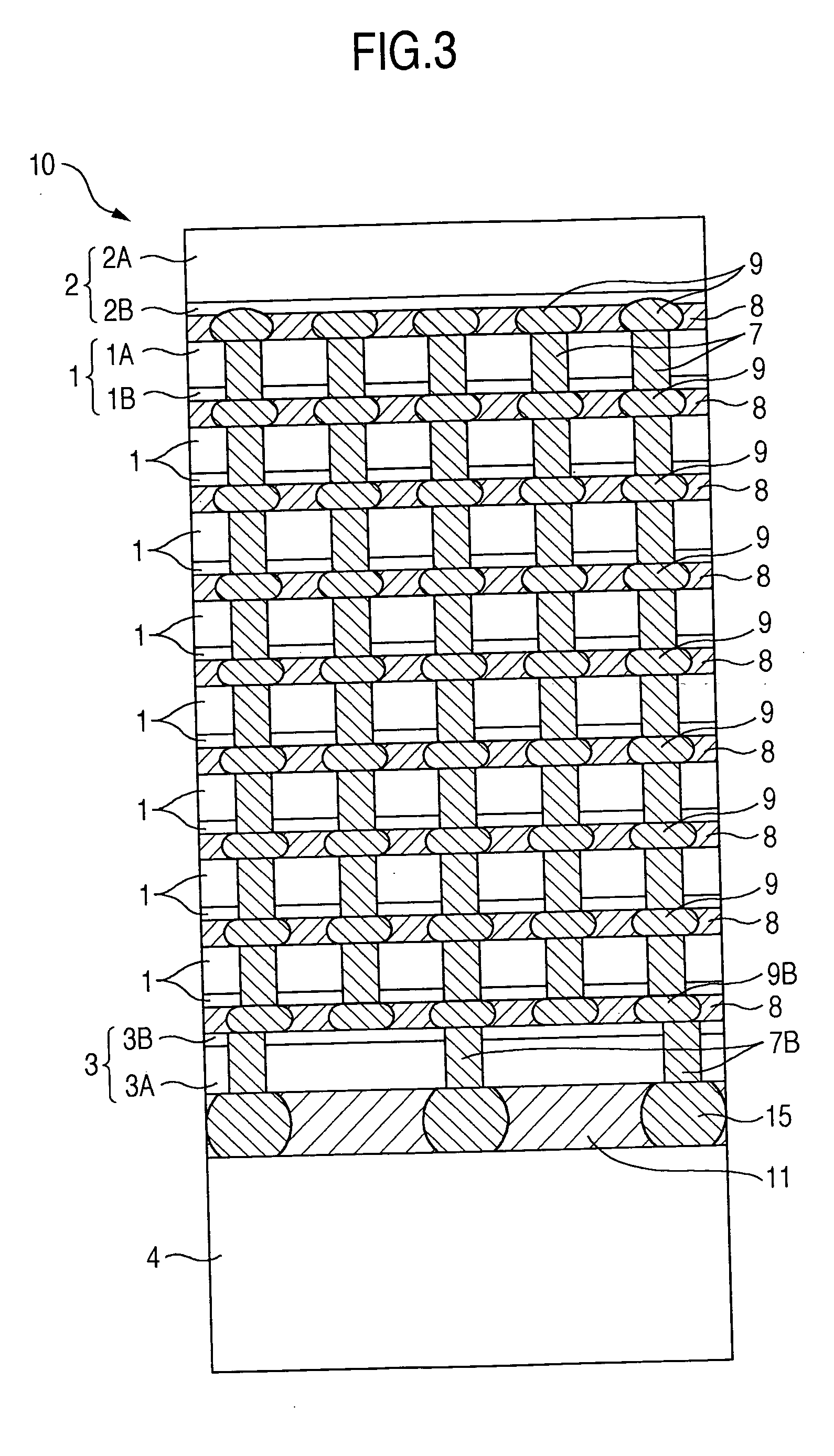

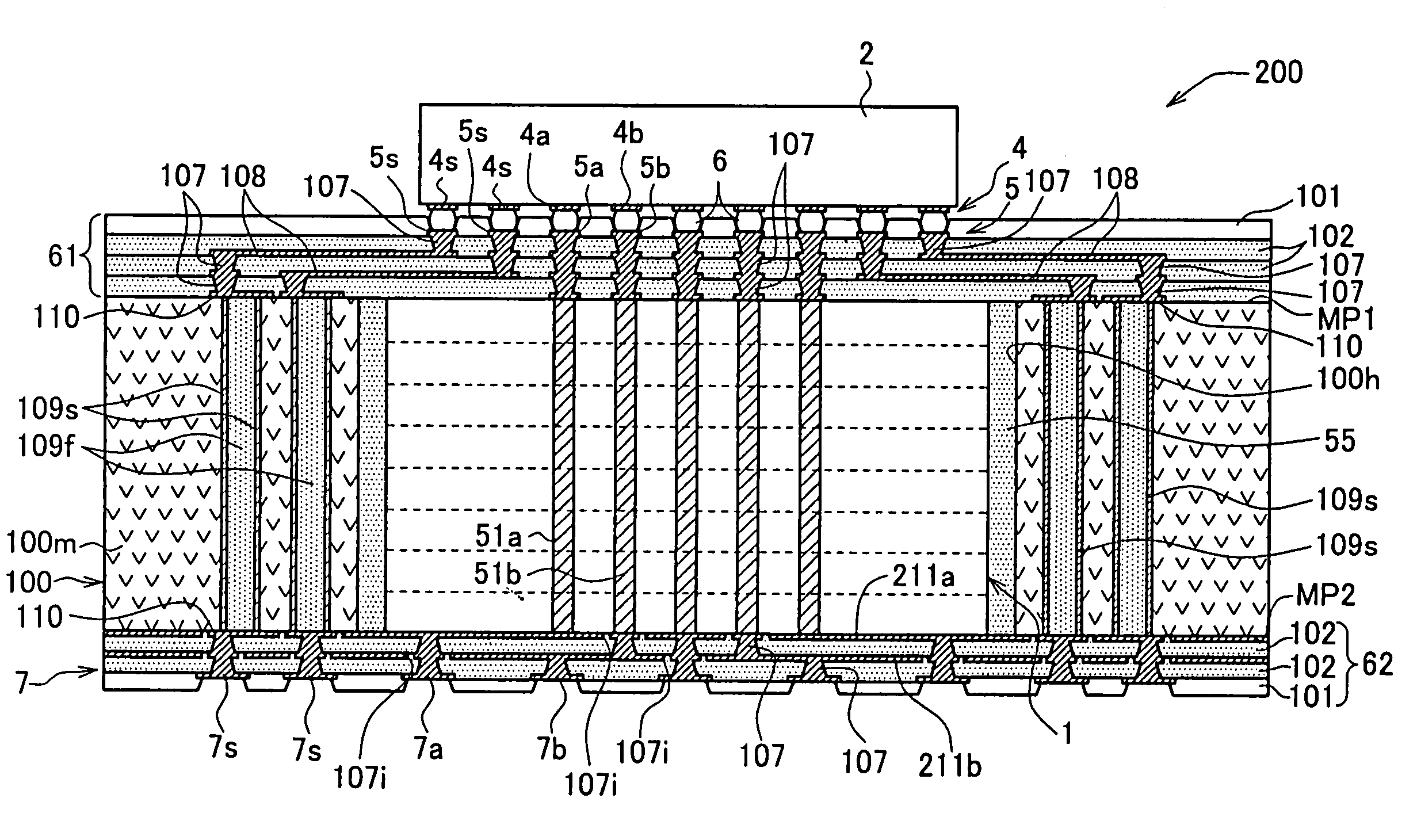

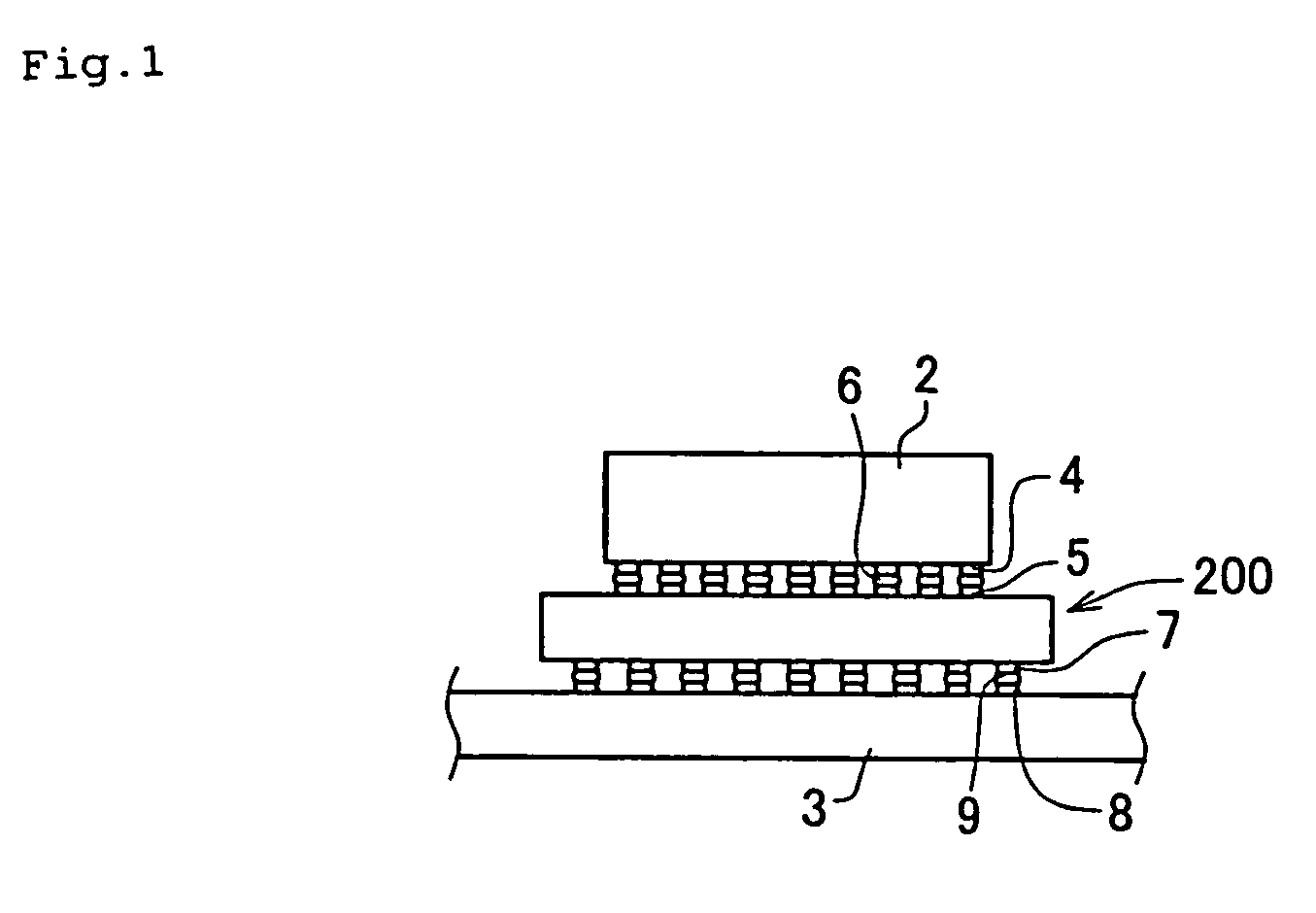

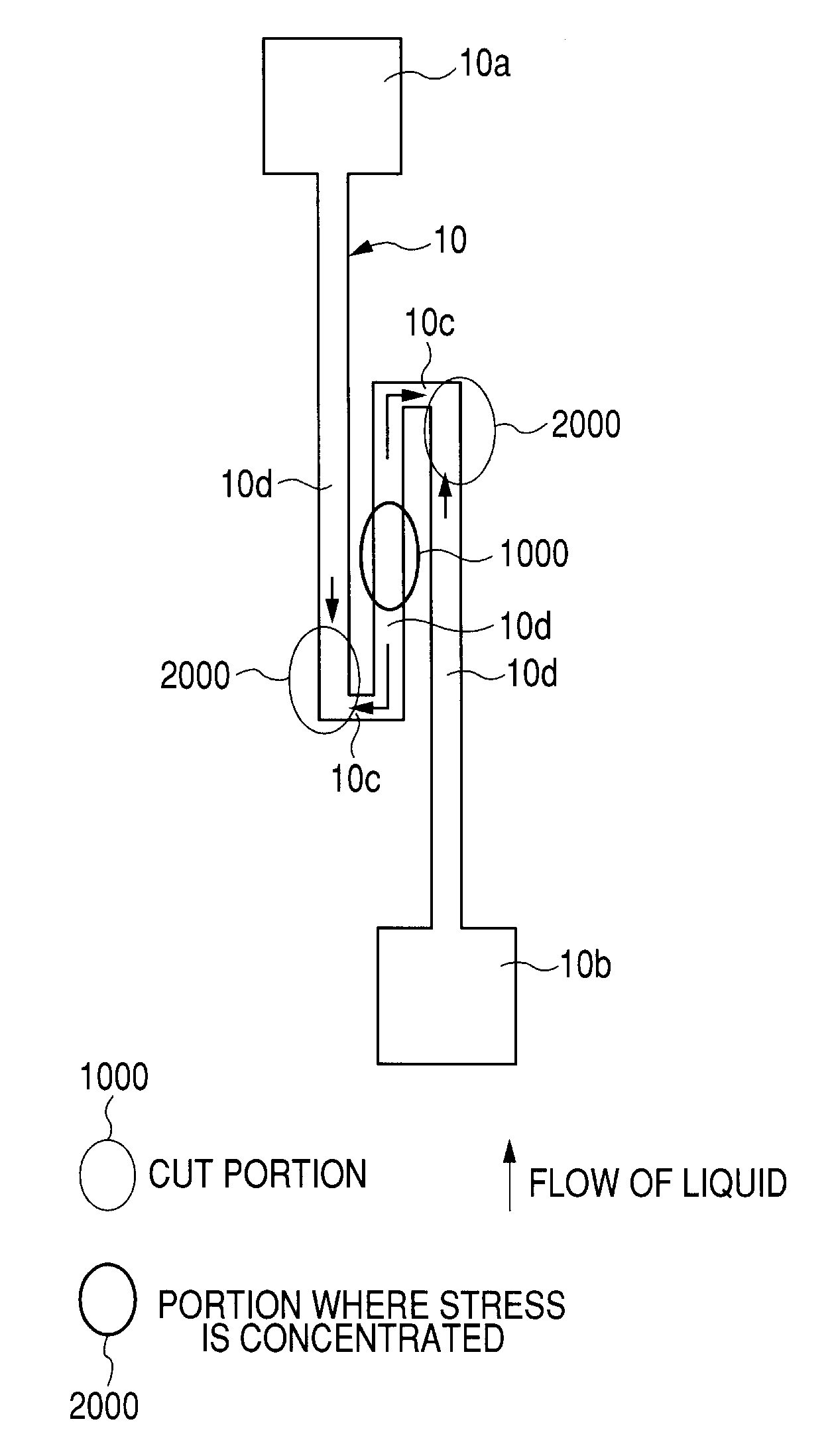

A semiconductor device capable of reducing a temperature increase during operation thereof is provided. In the semiconductor device, an interface chip is stacked on a plurality of stacked semiconductor elements. Both an “Si” interposer and a resin interposer are arranged under the plural semiconductor elements. The Si interposer is arranged between the resin interposer and the plural semiconductor elements. The Si interposer owns a thickness which is thicker than a thickness of a semiconductor element, and also has a linear expansion coefficient which is smaller than a linear expansion coefficient of the resin interposer, and further, is larger than, or equal to linear expansion coefficients of the plural semiconductor elements.

Owner:HITACHI LTD +1

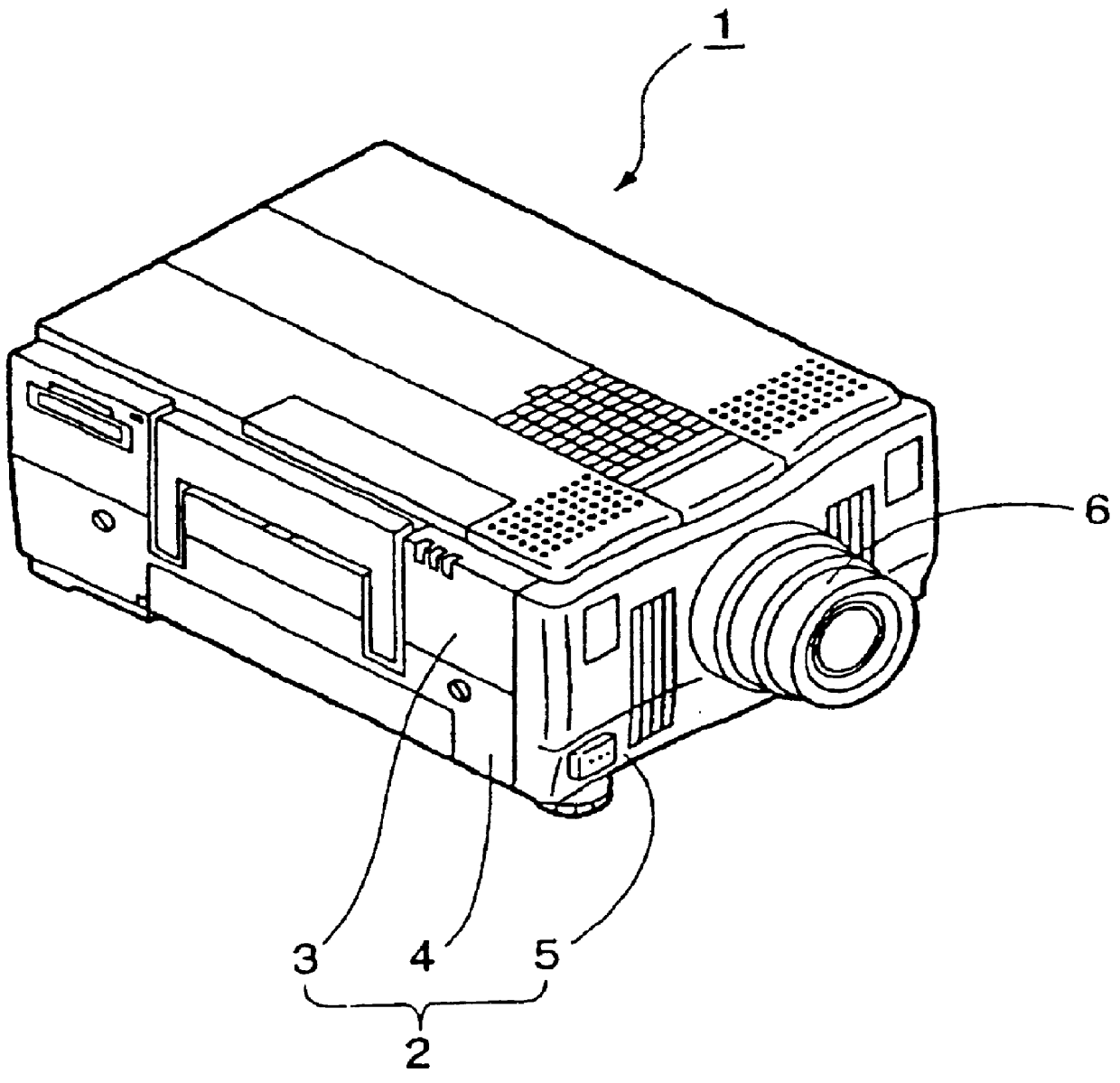

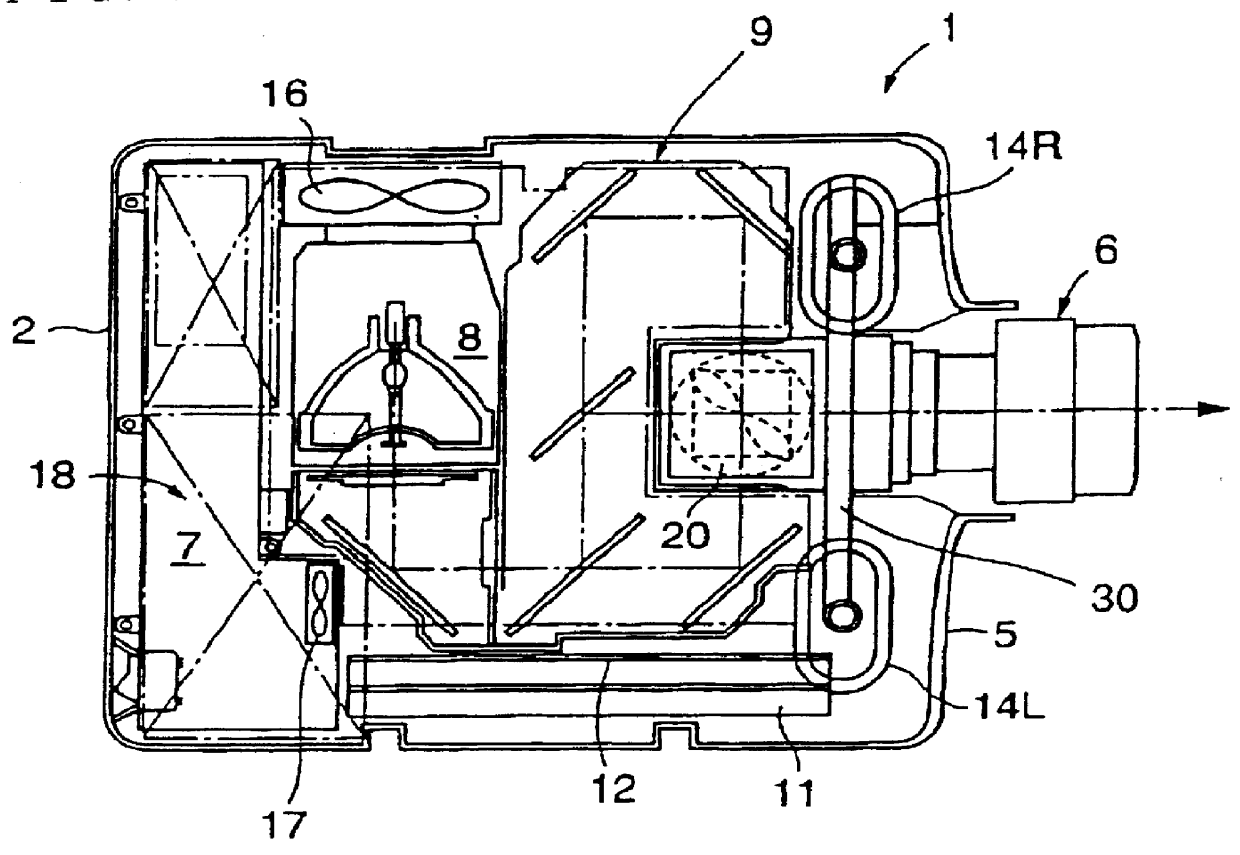

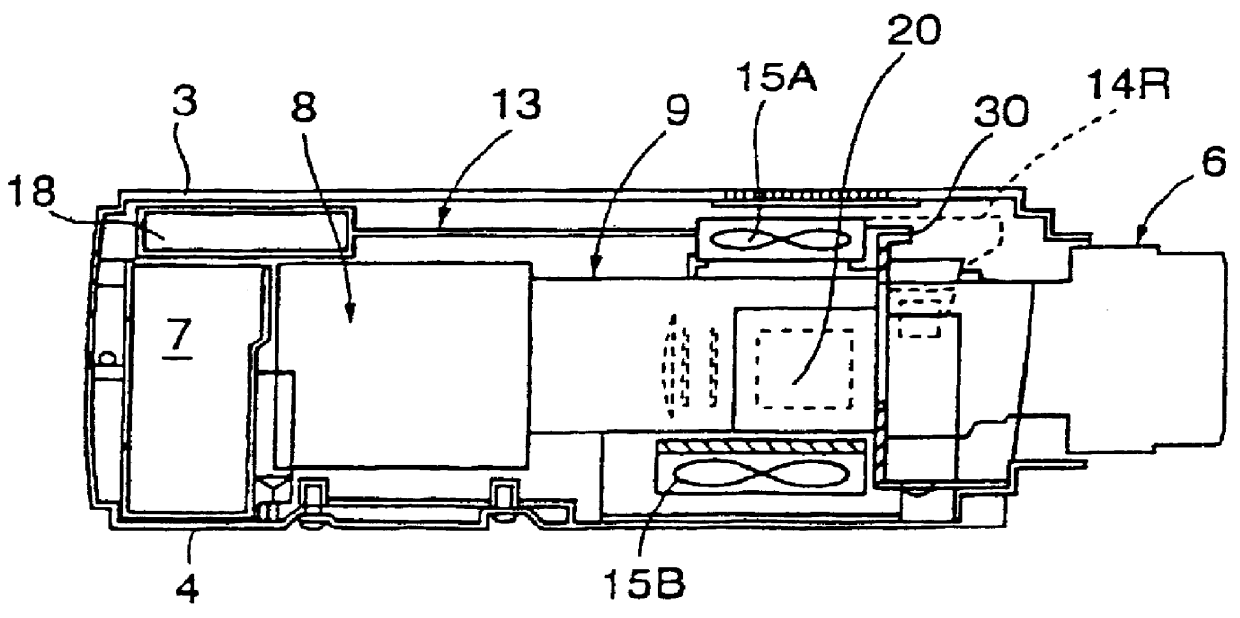

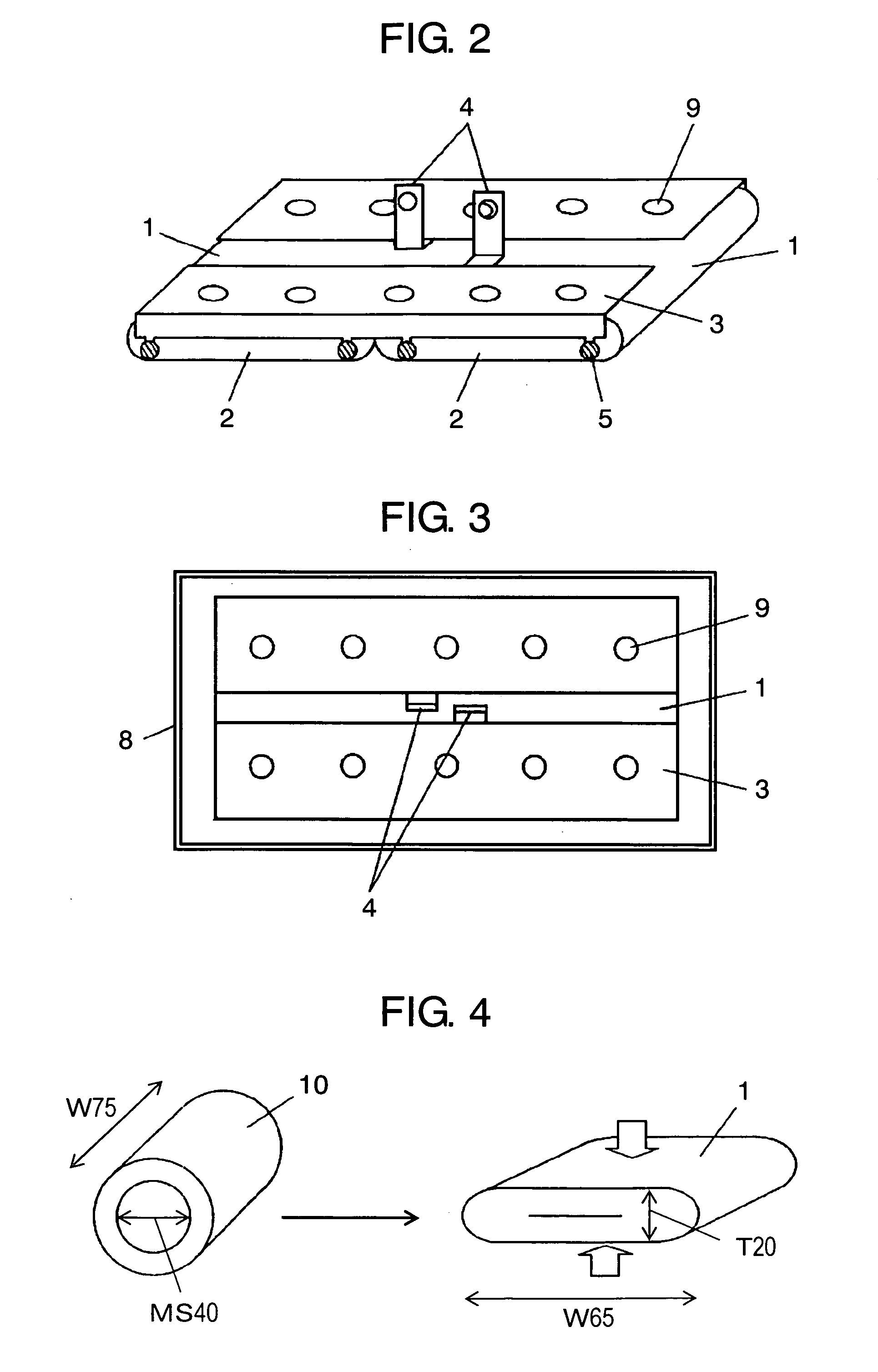

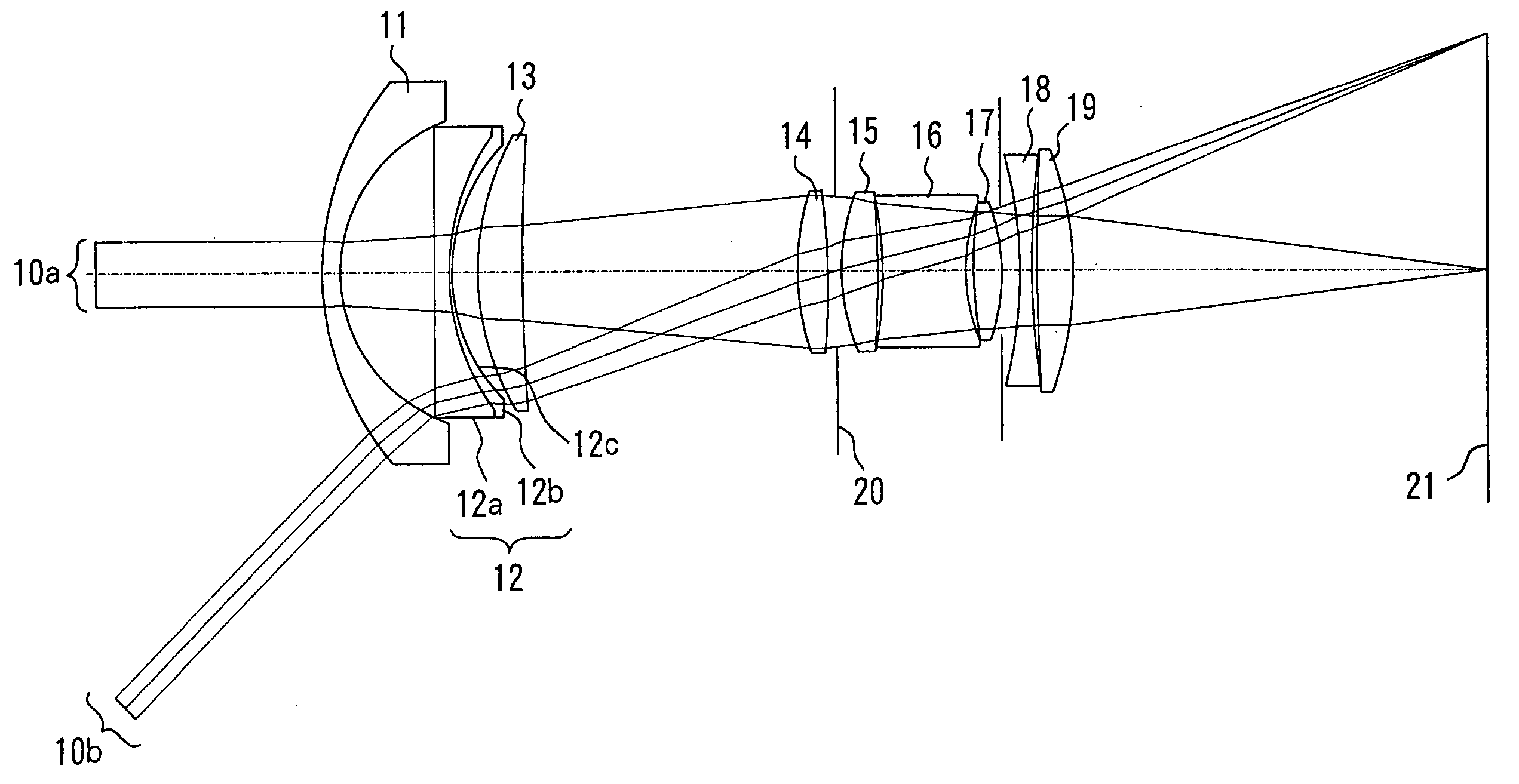

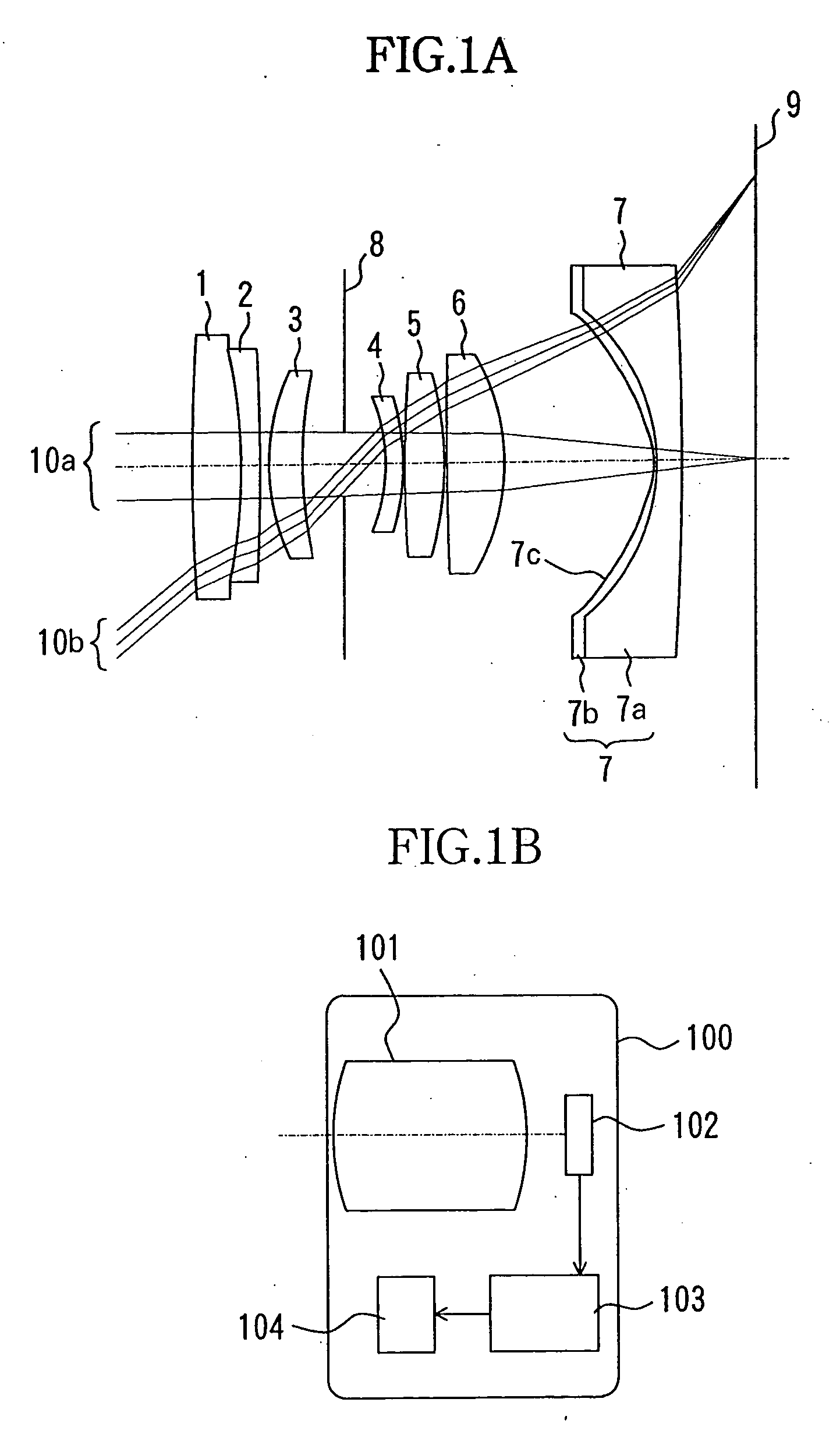

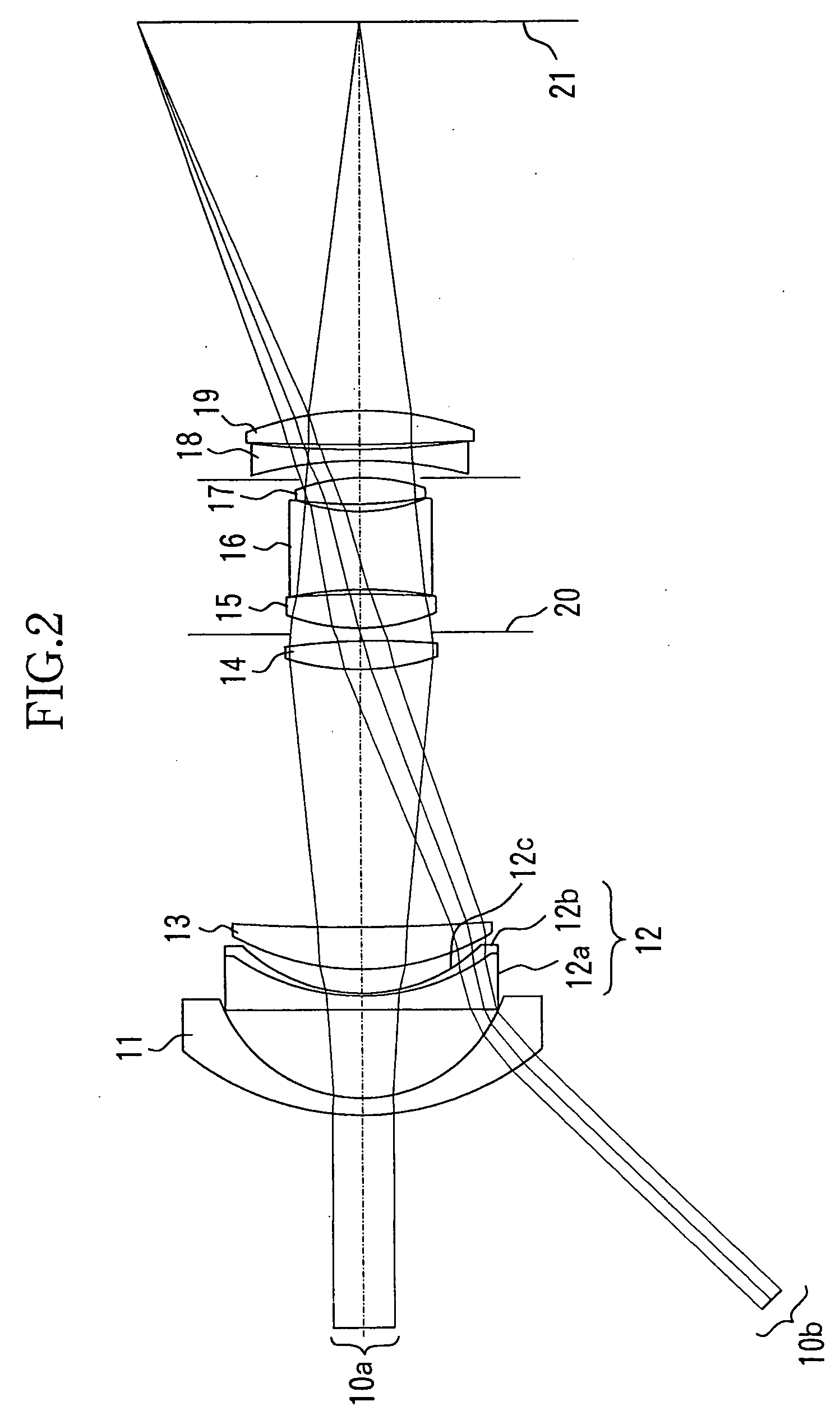

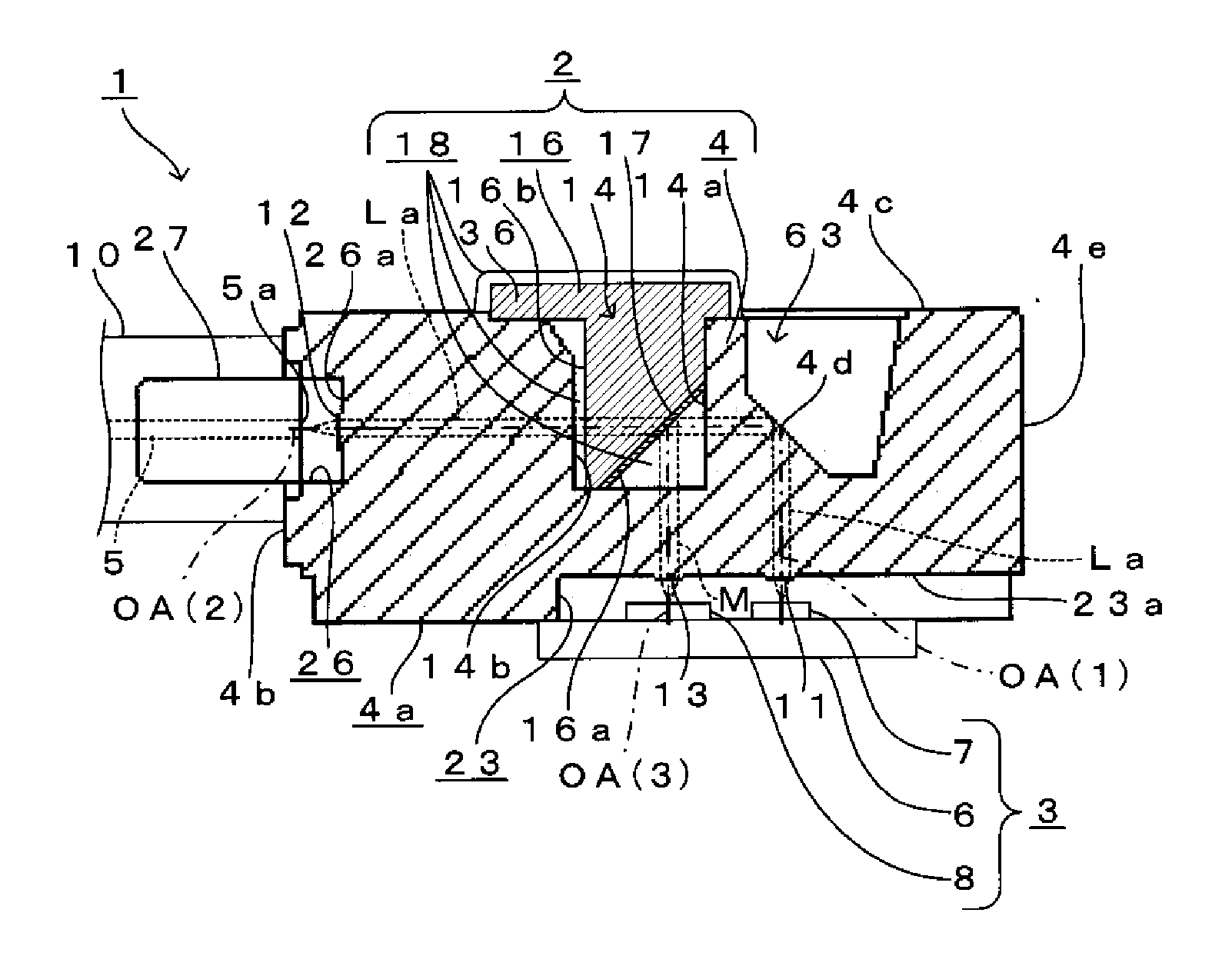

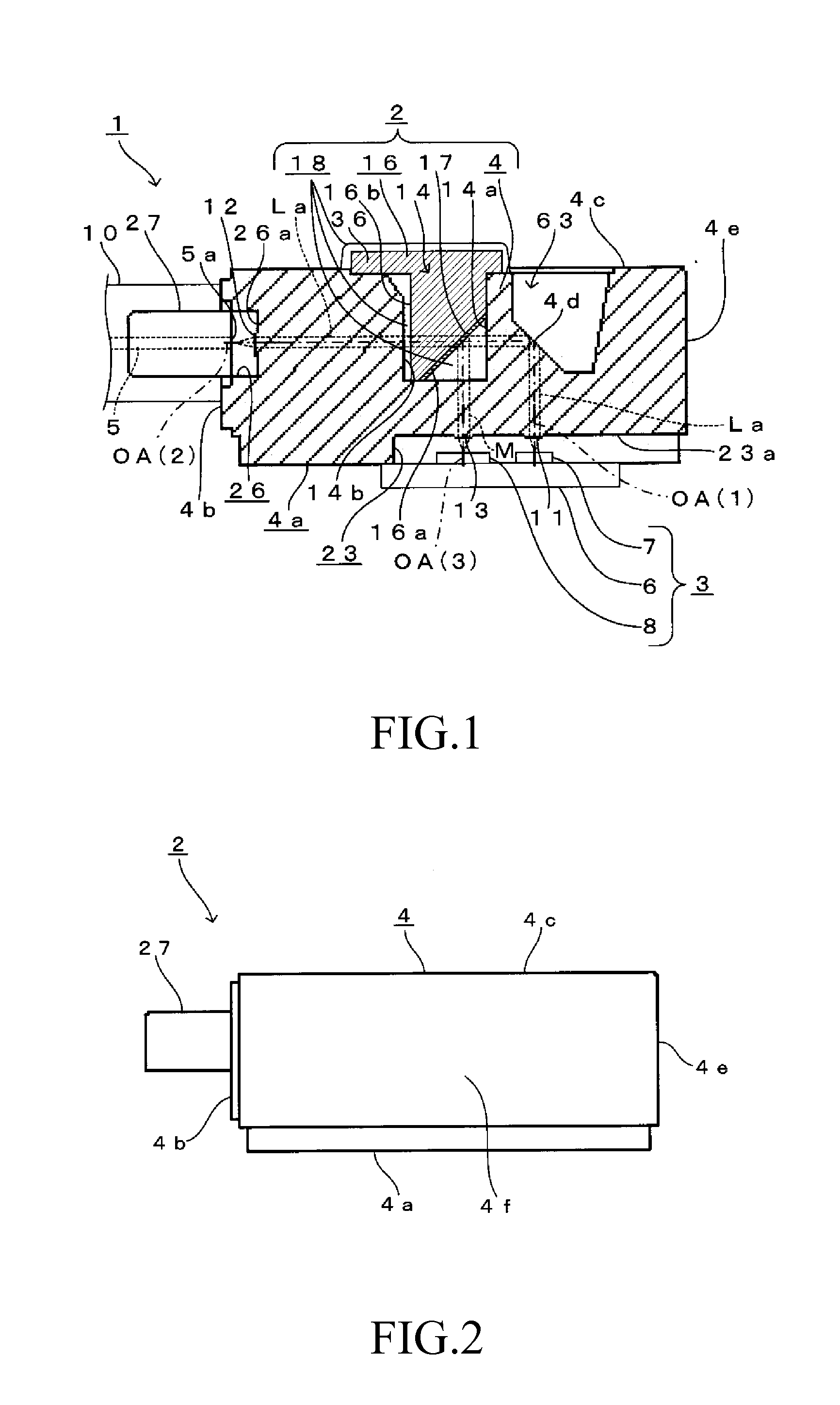

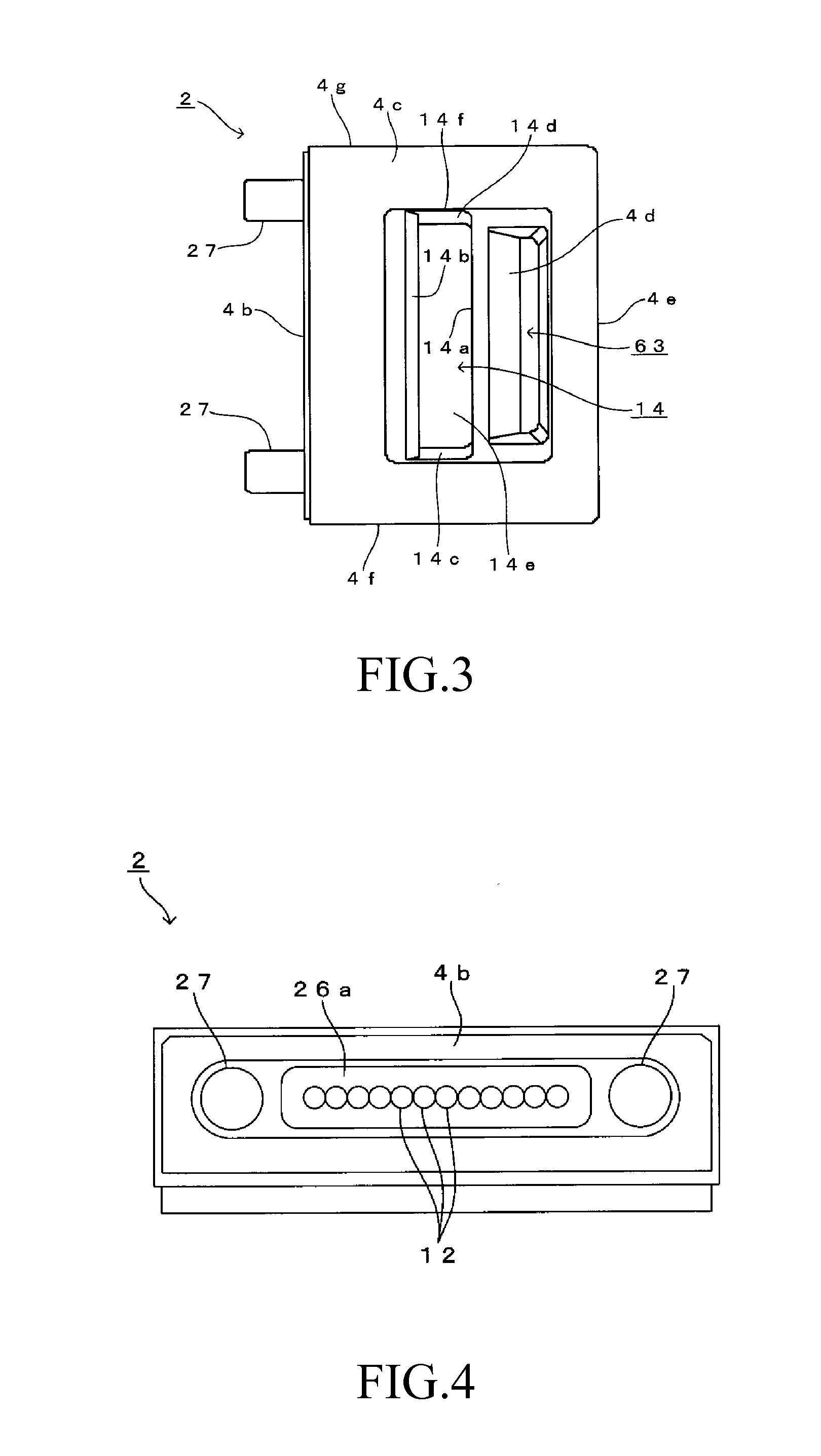

Projection display device

InactiveUS6056407APrevent intrusionEasy to replaceTelevision system detailsProjectorsLiquid-crystal displayFixed frame

PCT No. PCT / JP97 / 04652 Sec. 371 Date Aug. 12, 1998 Sec. 102(e) Date Aug. 12, 1998 PCT Filed Dec. 17, 1997 PCT Pub. No. WO98 / 27453 PCT Pub. Date Jun. 25, 1998A liquid crystal panel unit is provided on the light incident face of a prism combining body. The unit has a light valve frame plate for holding a liquid crystal panel and a fixing frame plate fixed onto the light incident face with an adhesive layer. The light valve frame plate is screwed onto the fixing frame plate with a medial frame therebetween. By using wedge members, by adjusting the position of the light valve frame plate on the light incident face, it is possible to precisely position and fix the liquid crystal panel which is held there so that it is possible to control the shifted amount of the pixel alignment and precisely adjust the focus. Thus, it is possible to easily improve the accuracy. Furthermore, the fixing frame plate and the light valve frame plate are composed of materials having linear expansion coefficients ranging from +E,fra 1 / 4+EE to four times that of the prism combining body and from +E,fra 1 / 5+EE to five times that of the fixing frame plate, respectively.

Owner:SEIKO EPSON CORP

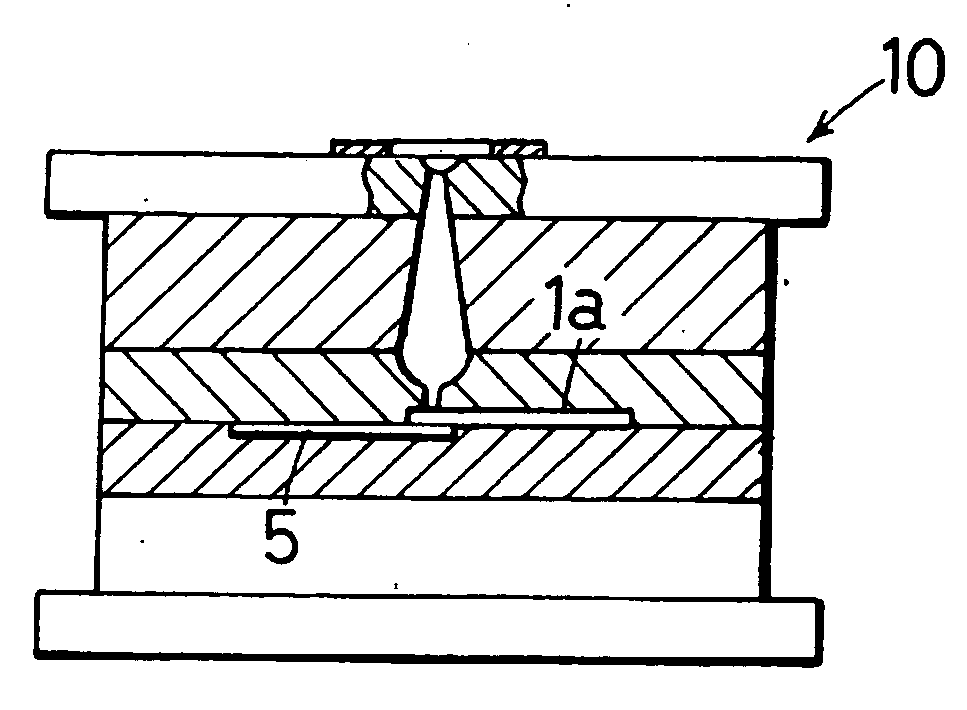

Composite of aluminum alloy and resin composition and process for producing the same

InactiveUS20060257624A1Mass productivityMold shrinkage factor should be smallSynthetic resin layered productsRecord information storagePolytetramethylene terephthalateHigh volume manufacturing

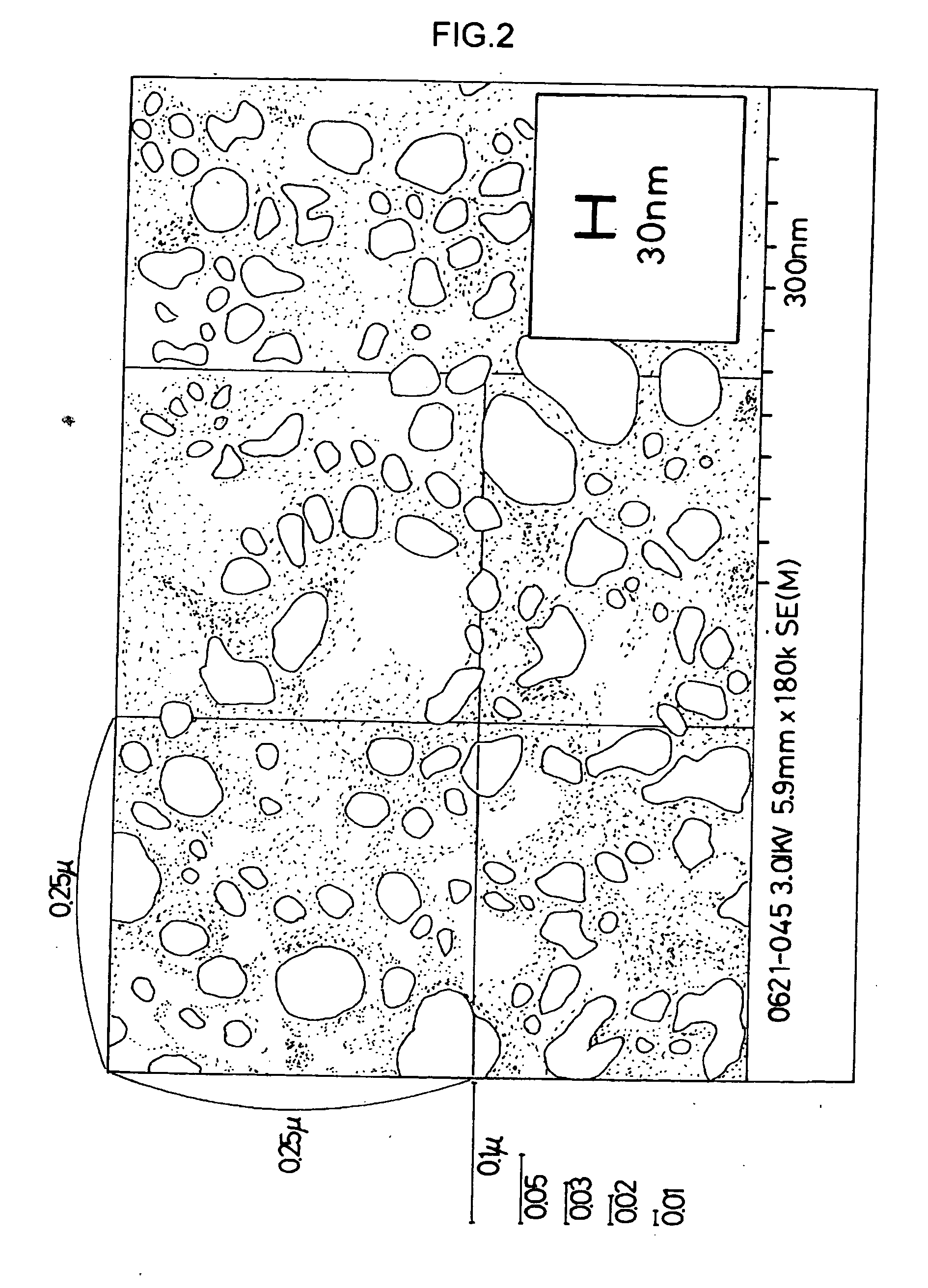

A composite characterized by comprising an aluminum alloy shaped item having a surface roughness of 5 to 50 μm or more, the surface provided with 1 μm or less fine depressions or protrusions, and a thermoplastic resin composition composed mainly of a polyphenylene sulfide or polybutylene terephthalate resin whose average of lengthwise and crosswise linear expansion coefficients is in the range of 2 to 4×10−5° C.−1, the thermoplastic resin composition penetrating and anchored in the depressions or protrusions. The thermoplastic resin composition is not easily detached from the aluminum alloy shaped item. Thus, in, for example, electronic equipments and household electrical appliances, the advantage of metallic cage body can be reconciled with the advantage of synthetic resin structure. This composite can ensure high production efficiency and is suitable for mass production. Further, morphology and structure designing thereof can be accomplished freely.

Owner:TAISEI PLAS CO LTD

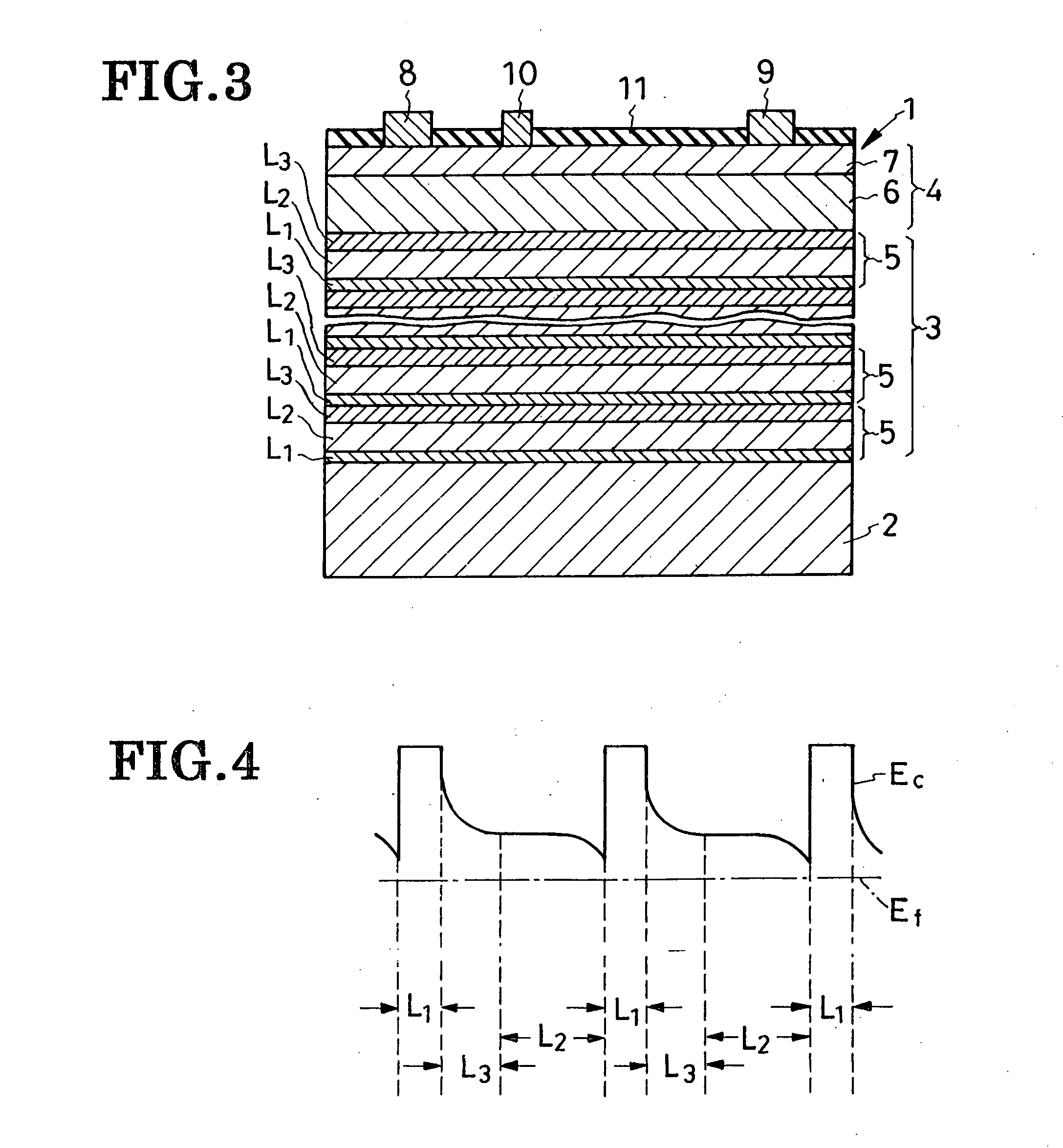

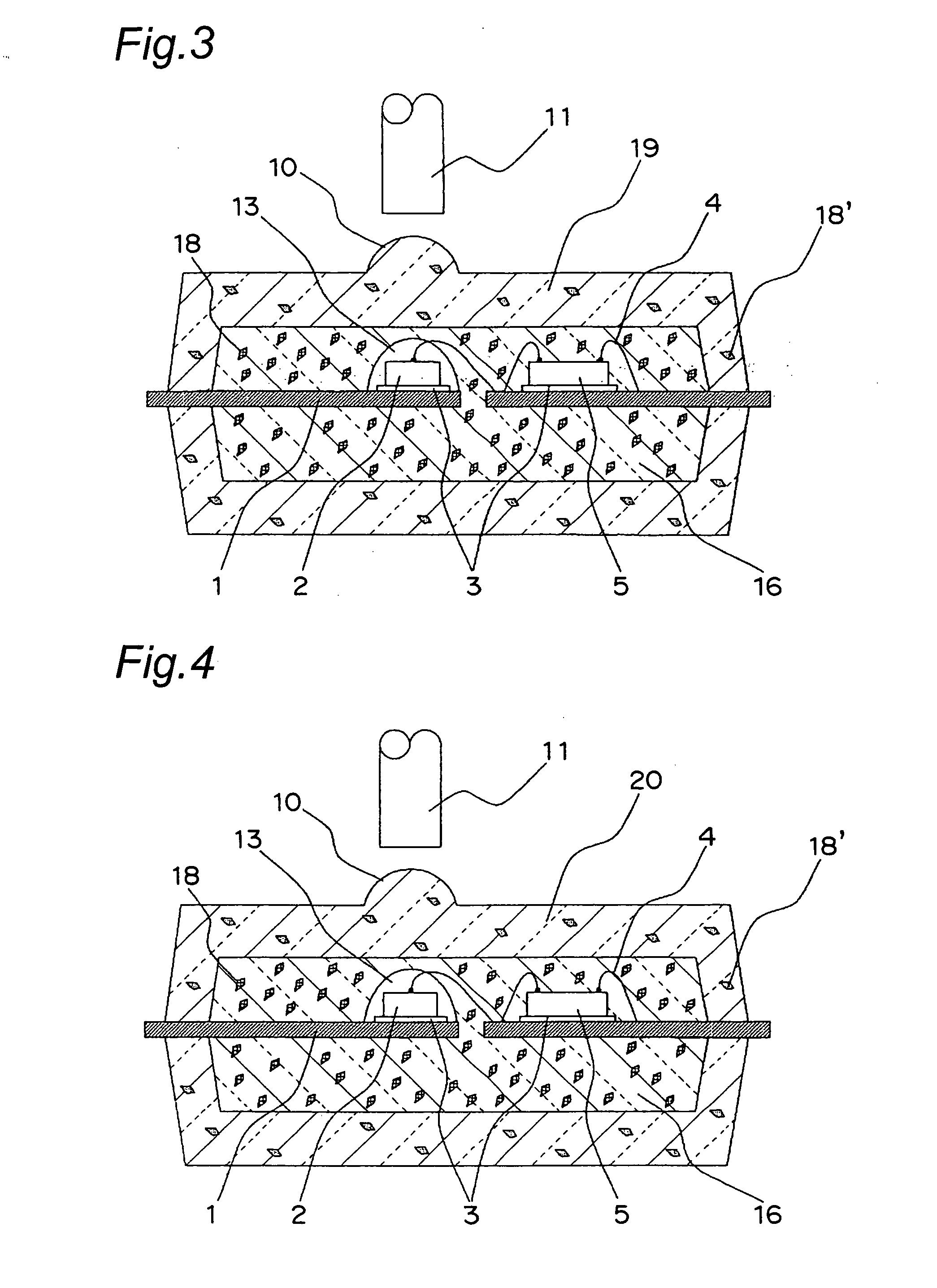

Semiconductor device

InactiveUS20050189639A1Lower temperature riseEasy to operateSemiconductor/solid-state device detailsSolid-state devicesDevice materialInterposer

A semiconductor device capable of reducing a temperature increase during operation thereof is provided. In the semiconductor device, an interface chip is stacked on a plurality of stacked semiconductor elements. Both an “Si” interposer and a resin interposer are arranged under the plural semiconductor elements. The Si interposer is arranged between the resin interposer and the plural semiconductor elements. The Si interposer owns a thickness which is thicker than a thickness of a semiconductor element, and also has a linear expansion coefficient which is smaller than a linear expansion coefficient of the resin interposer, and further, is larger than, or equal to linear expansion coefficients of the plural semiconductor elements.

Owner:HITACHI LTD +1

Intermediate substrate

ActiveUS6979890B2Reduce the overall heightReduce in quantitySemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductorPolymer

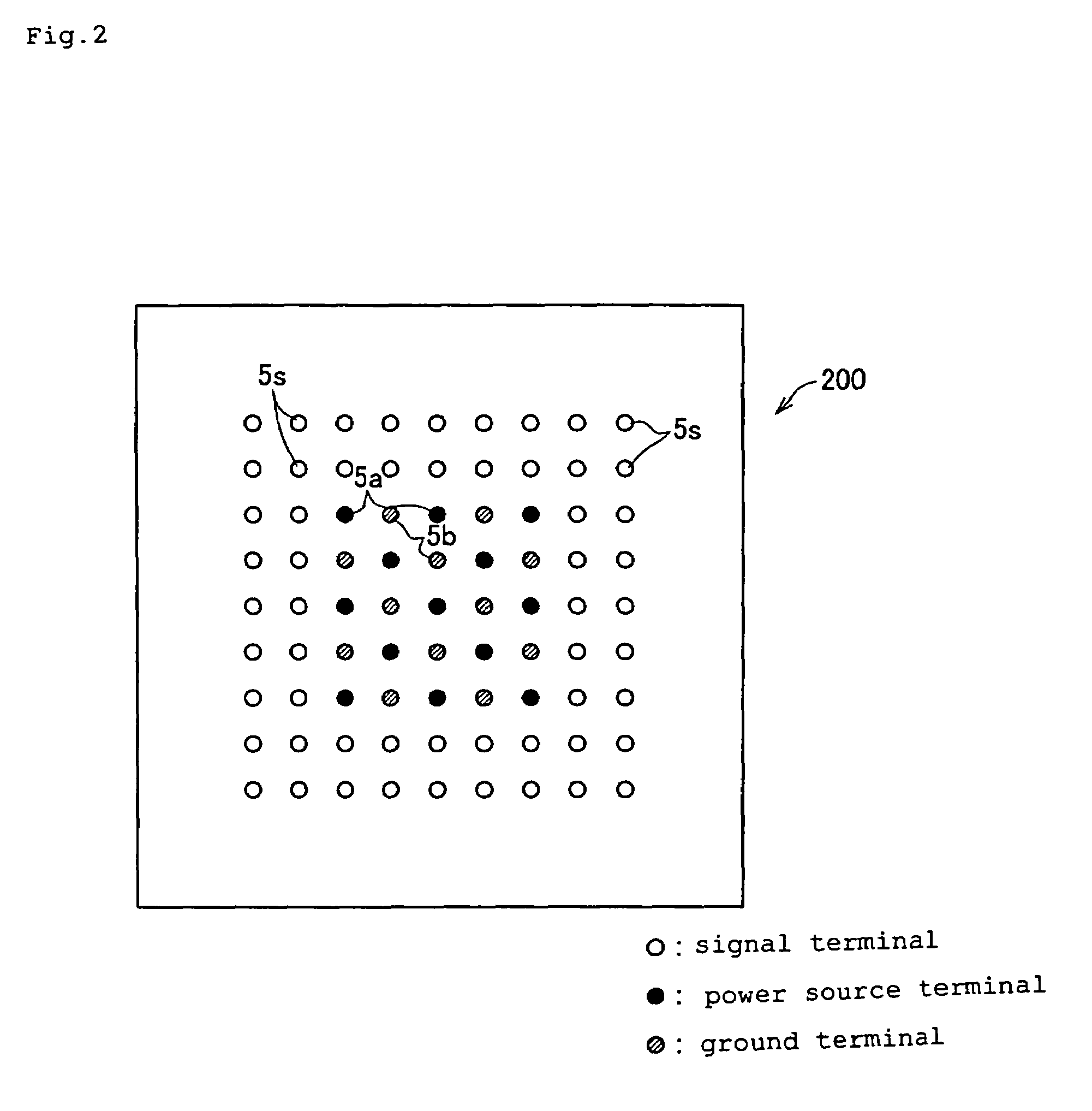

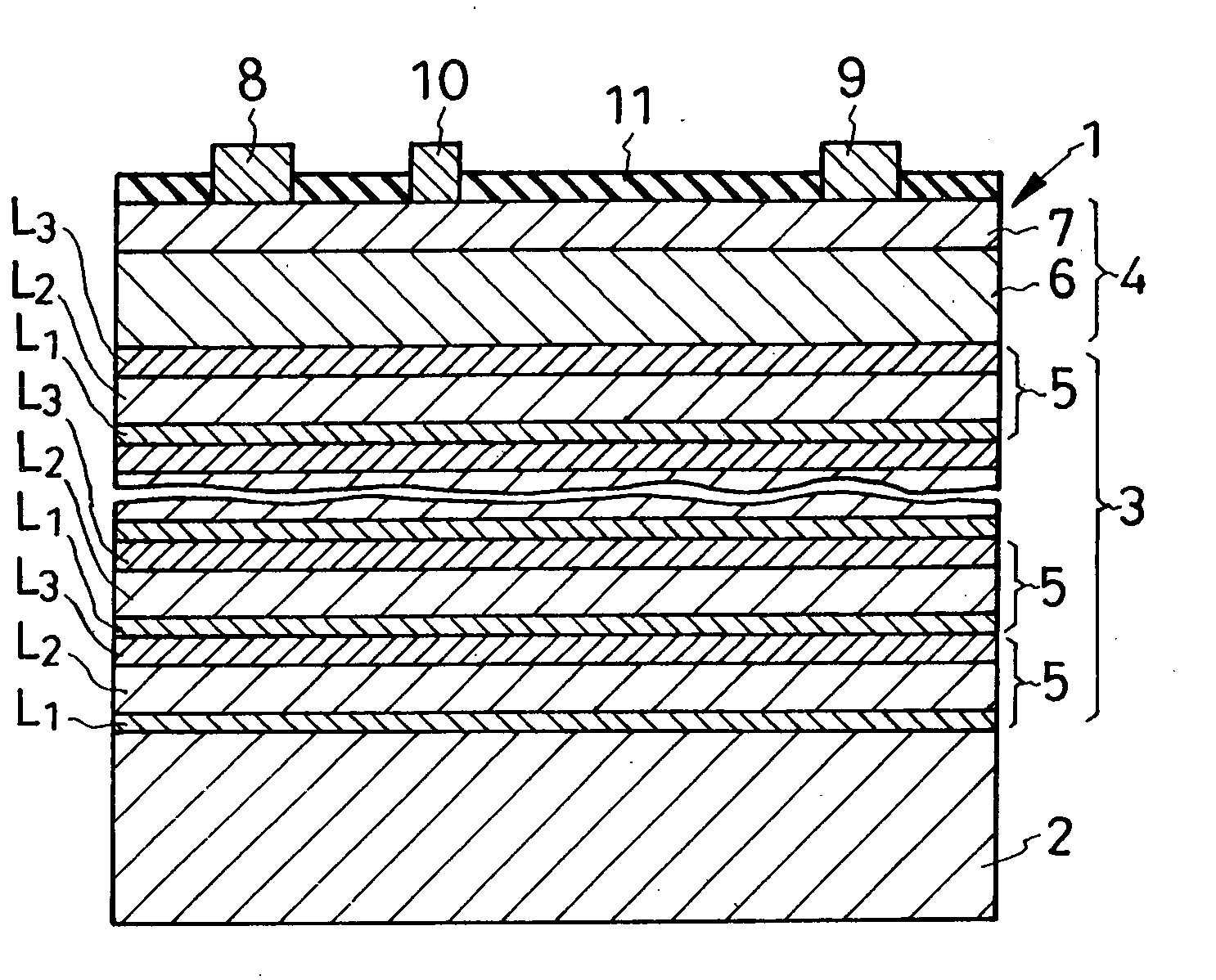

An intermediate substrate is provided which reduces the effect of the difference in the coefficients of linear expansion between the terminals of the substrate and those of a semiconductor integrated circuit device, and which thus lowers the likelihood of disconnection due to thermal stress. The intermediate substrate, which is a planar member made of a polymeric material, includes a substrate core including a main core body having formed therein a sub-core compartment, and a ceramic sub-core section accommodated in the compartment. A first terminal array on the first principal surface side includes two types of terminals, functioning either as power source terminals or ground terminals, and a signal terminal. The array occupies an area entirely included within an orthogonally projected region of the sub-core section projected onto a reference plane parallel to the planar surface of the substrate core.

Owner:NGK SPARK PLUG CO LTD

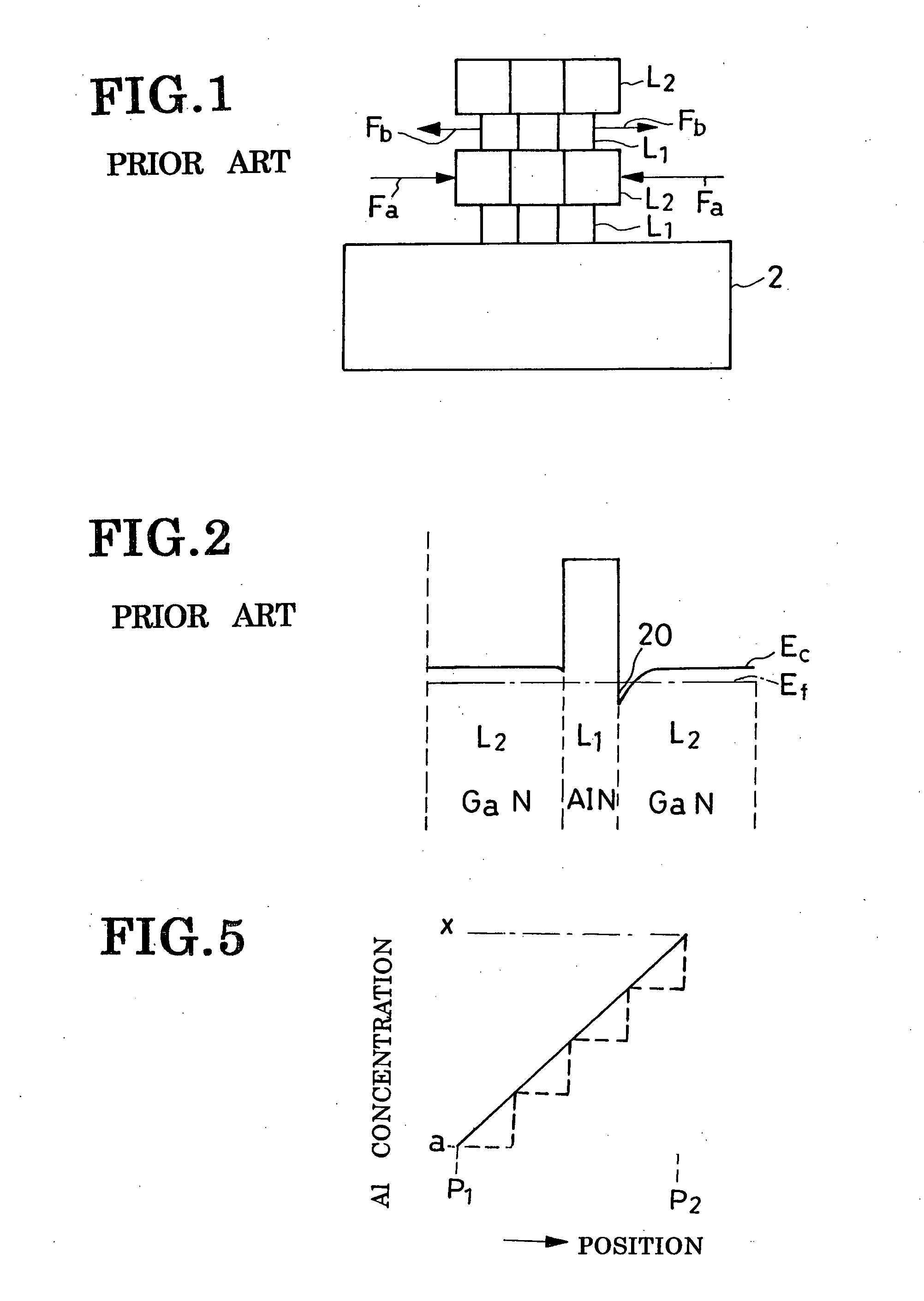

Nitride semiconductor substrate, method of fabrication thereof, and semiconductor element built thereon

ActiveUS20050110043A1Reduce the amount requiredLower resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesMESFETSilicon

A substrate system of the kind having a buffer region interposed between a silicon substrate proper and a nitride semiconductor region in order to make up for a difference in linear expansion coefficient therebetween. Electrodes are formed on the nitride semiconductor layer or layers in order to provide HEMTs or MESFETs. The buffer region is a lamination of a multiplicity of buffer layers each comprising a first, a second, and a third buffer sublayer of nitride semiconductors, in that order from the silicon substrate proper toward the nitride semiconductor region. The three sublayers of each buffer layer contain aluminum in varying proportions including zero. The aluminum proportion of the third buffer sublayer is either zero or intermediate that of the first buffer sublayer and that of the second. The low aluminum proportion of the third buffer sublayer serves to prevent two-dimensional electron gas from generating in the buffer region and hence to make this region sufficiently high in resistance to inhibit current leakage from the HEMTs or MESFETs.

Owner:SANKEN ELECTRIC CO LTD

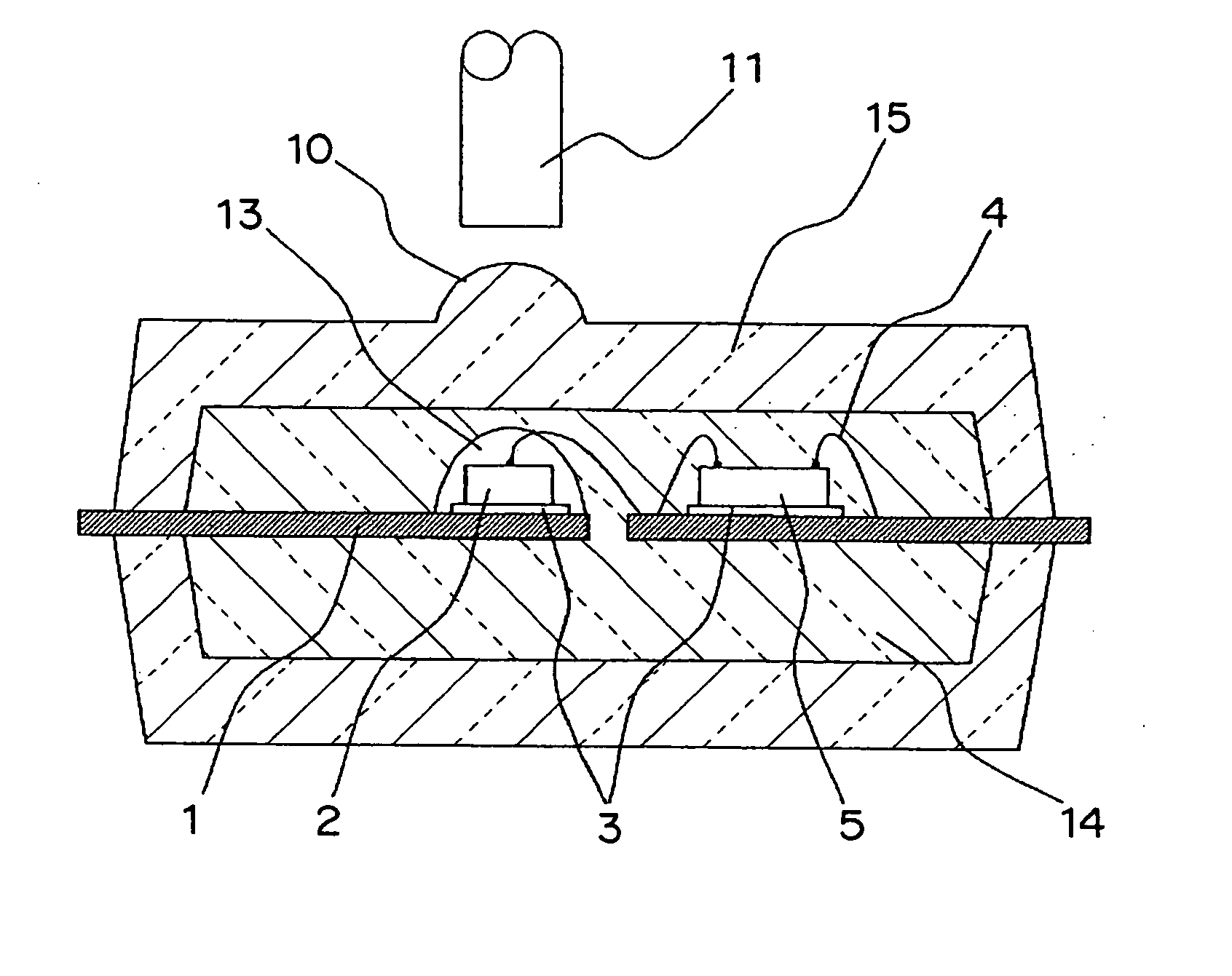

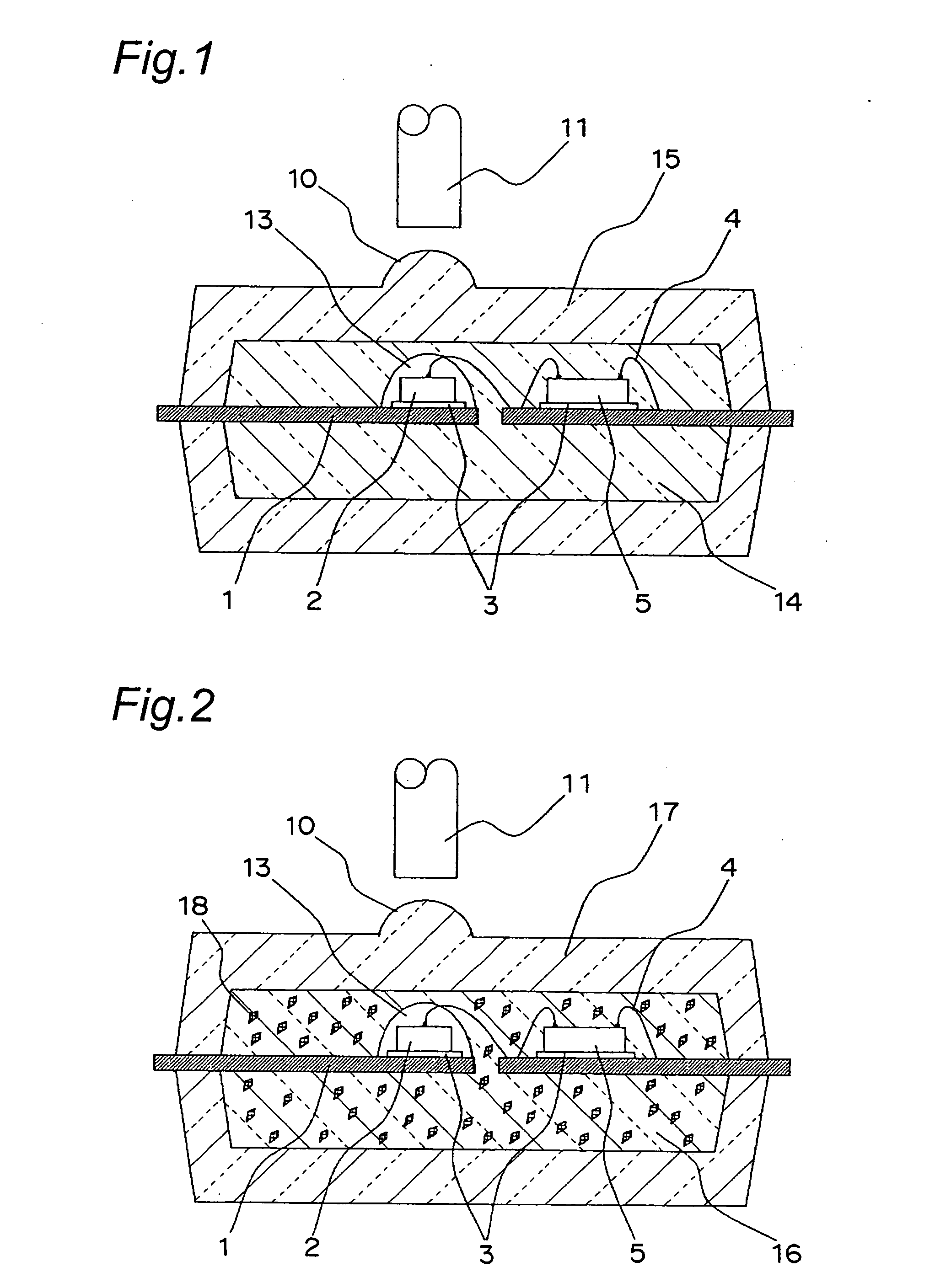

Optical semiconductor device, method for fabricating the same, lead frame and electronic equipment

InactiveUS20060054901A1Satisfactory optical transmission qualityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

An optical semiconductor element 2 is mounted on a lead frame 1, the optical semiconductor element 2 is encapsulated with a mold resin portion 14 of a first layer that has light permeability, and the mold resin portion 14 of the first layer is encapsulated with a mold resin portion 15 of a second layer that has light permeability. Then, a coefficient of linear expansion of the mold resin portion 14 of the first layer is made smaller than a coefficient of linear expansion of the mold resin portion 15 of the second layer.

Owner:SHARP KK

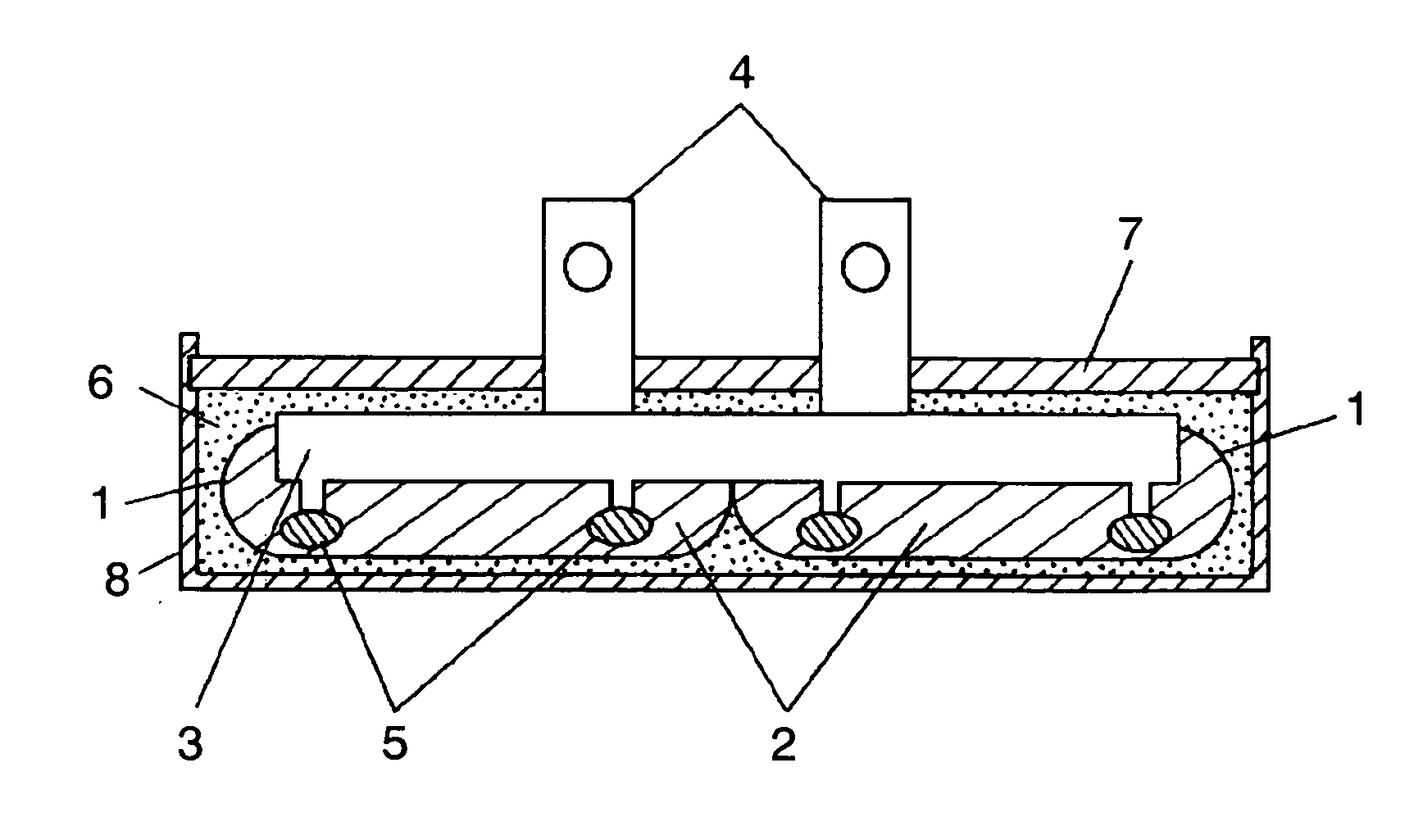

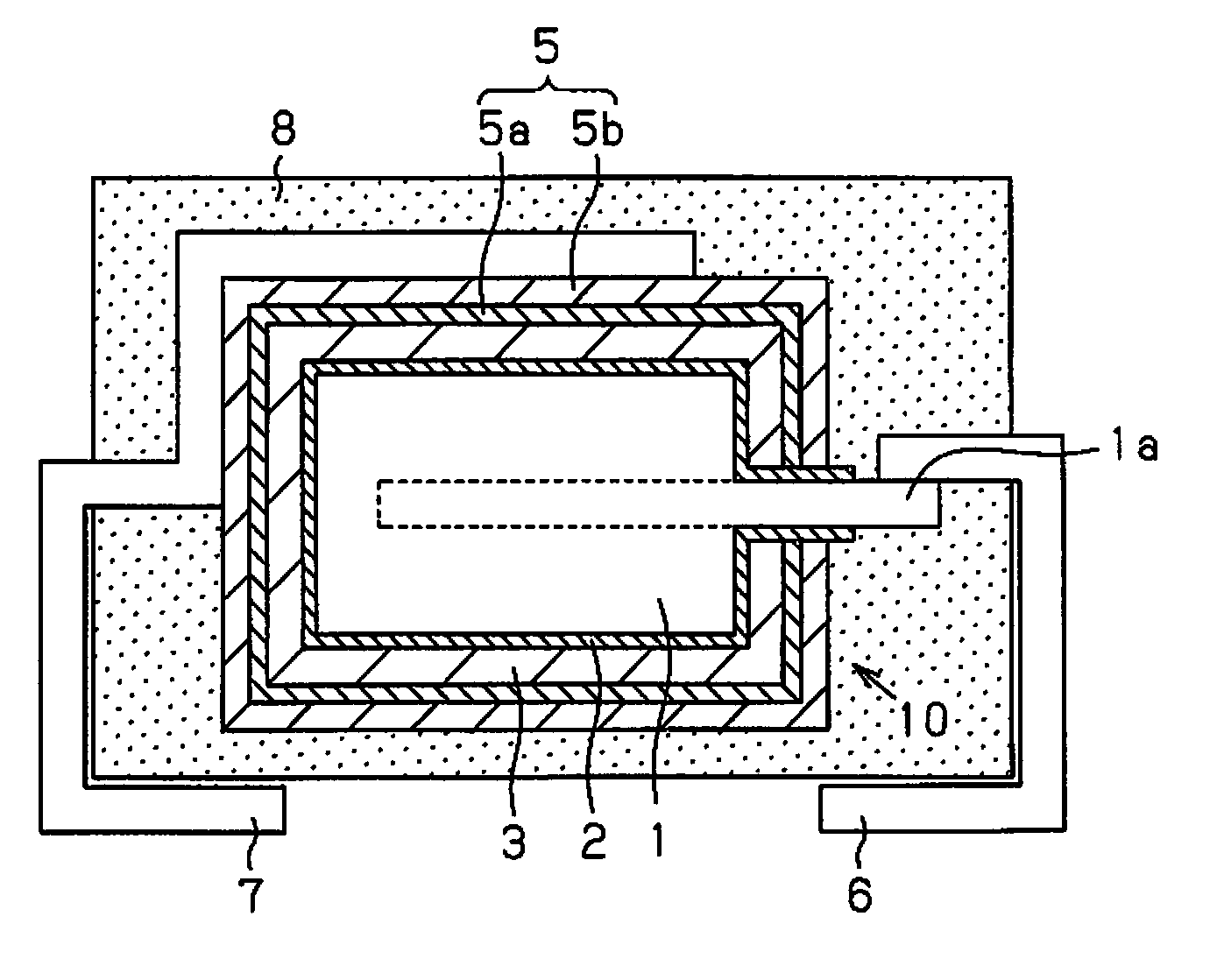

Film capacitor and method of manufacturing the same

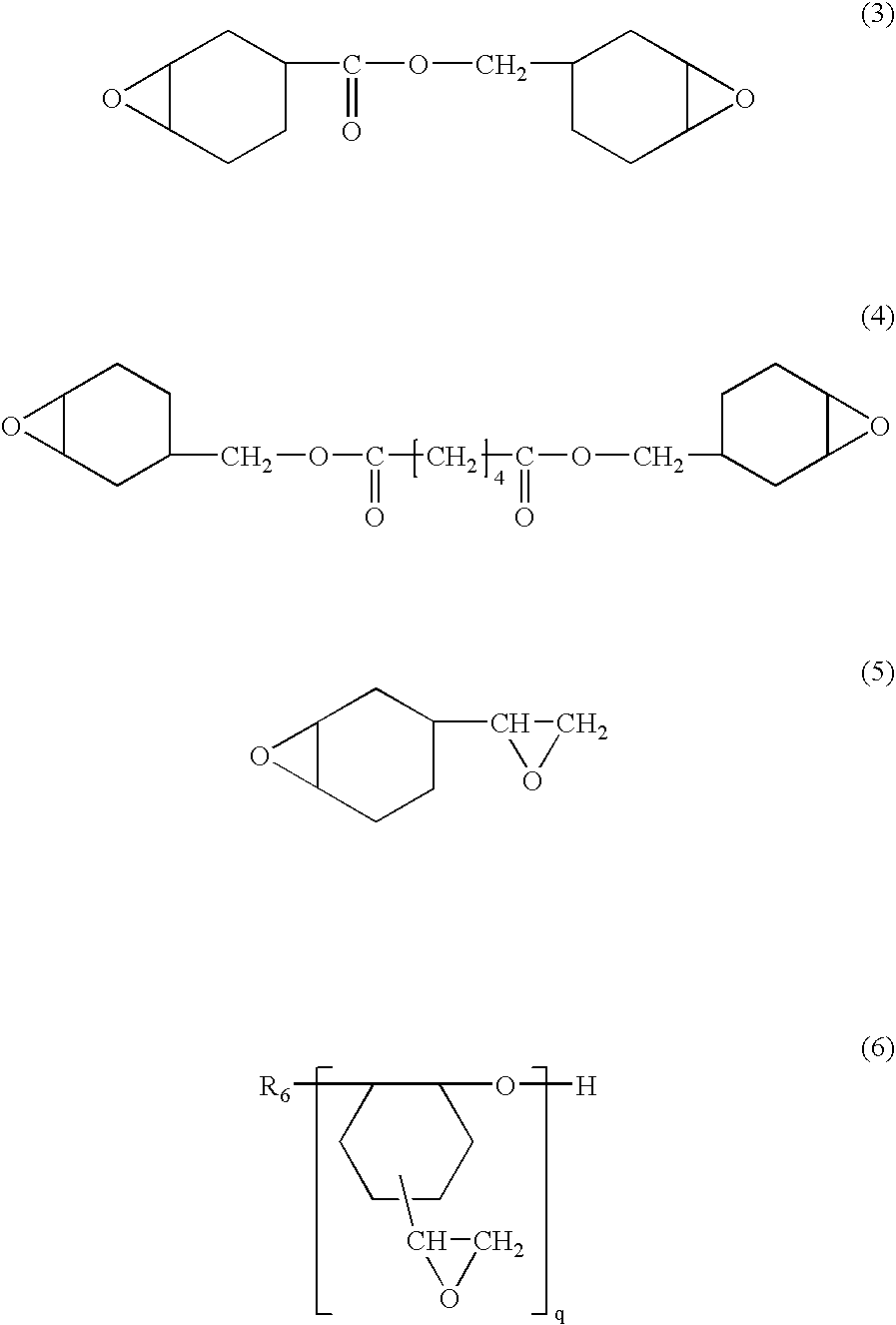

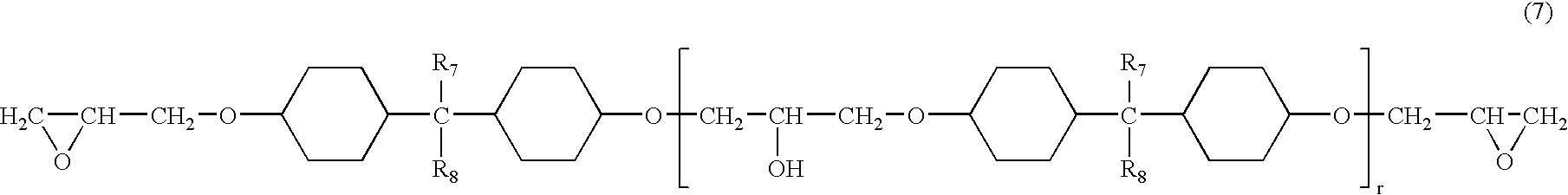

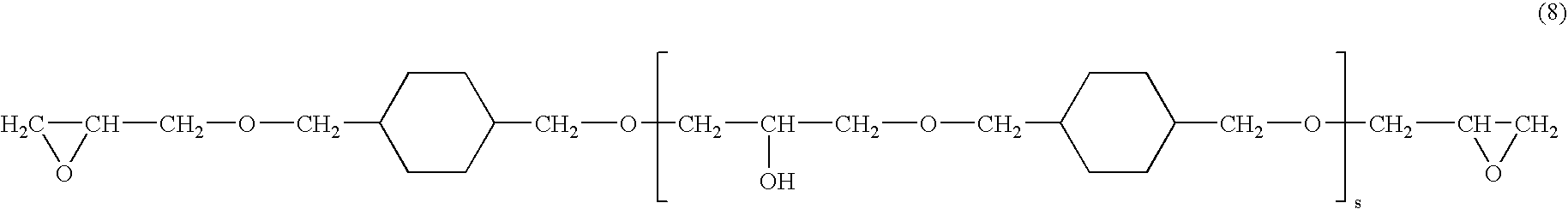

ActiveUS20060104006A1Improve moisture resistanceLow exothermic characteristicMultiple fixed capacitorsFixed capacitor dielectricEpoxyProduction rate

The invention provides a film capacitor and its manufacturing method suited to car-mount application, excellent in heat cycle tolerance and humidity resistance, and high in productivity, while maintaining low heat generation and low inductance characteristic. A film capacitor comprises a film capacitor element 1, a bus bar 3 as metal terminal connected to electrode 2 of this film capacitor element 1, and a case 8 for containing them, in which the film capacitor element 1 and bus bar 3 are packed within the case 8 by plural layers of epoxy resin compositions 6, 7, and the plural layers of epoxy resin compositions 6, 7 are formed in layers, and are composed so that the coefficient of linear expansion may be smallest in the epoxy resin composition 7 disposed in the uppermost layer, and therefore resin cracks can be prevented at the time of heat cycle, and a film capacitor of high reliability excellent inhumidity resistance is obtained.

Owner:PANASONIC CORP

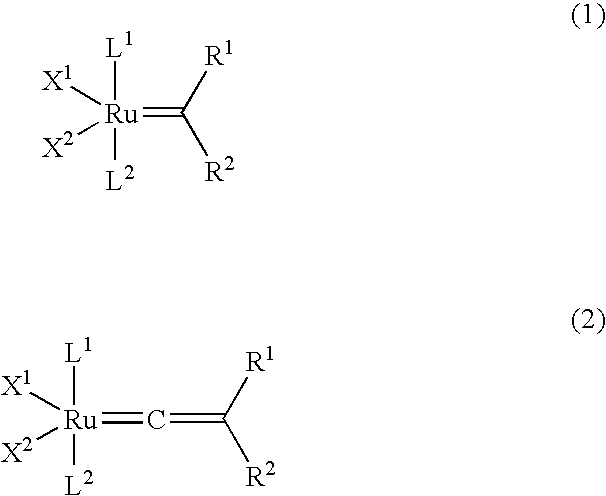

Polymerizable composition and formed article using the same

A polymerizable composition which comprises a cycloolefin monomer (A), a filler (B), a polymer (C) having a carboxyl group or a carboxylic acid anhydride group and having an acid value of 0.1 to 100 mgKOH / g, and a metathesis polymerization catalyst (D). The polymerizable composition comprises a cycloolefin monomer and a large amount of a filler, and has a low viscosity and is excellent in fluidity, and further can provide a molded product which is excellent in the lowness of dielectric constant, the lowness of dielectric loss tangent, the lowness of linear expansion coefficient, high heat resistance and adhesiveness, and further is free of bubble inclusion.

Owner:ZEON CORP

Resin composition

InactiveUS20050107497A1Improve barrier propertiesImprove moisture resistanceSpecial tyresRecord information storagePolymer scienceAdhesive belt

A resin composition, substrate material, sheet, laminated board, resin-bearing copper foil, copper-clad laminate, TAB tape, printed board, prepreg and adhesive sheet are provided which exhibit improved mechanical properties, dimensional stability, heat resistance and flame retardance, particularly high-temperature physical properties. A resin composition containing 100 parts by weight of a thermosetting resin and 0.1-65 parts by weight of an inorganic compound, the resin composition having a mean linear expansion coefficient (α2) of up to 17×10−3 [° C.−1] over the temperature range from a temperature 10° C. higher than a glass transition temperature of the resin composition to a temperature 50° C. higher than the glass transition temperature of the resin composition.

Owner:SEKISUI CHEM CO LTD

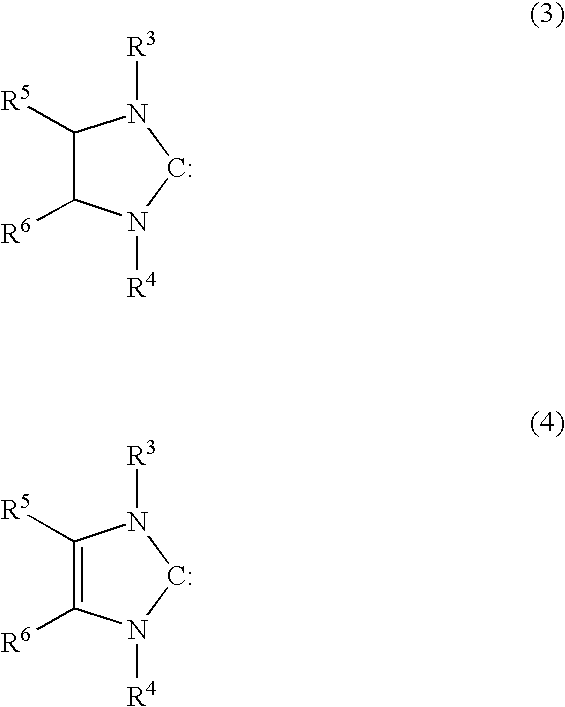

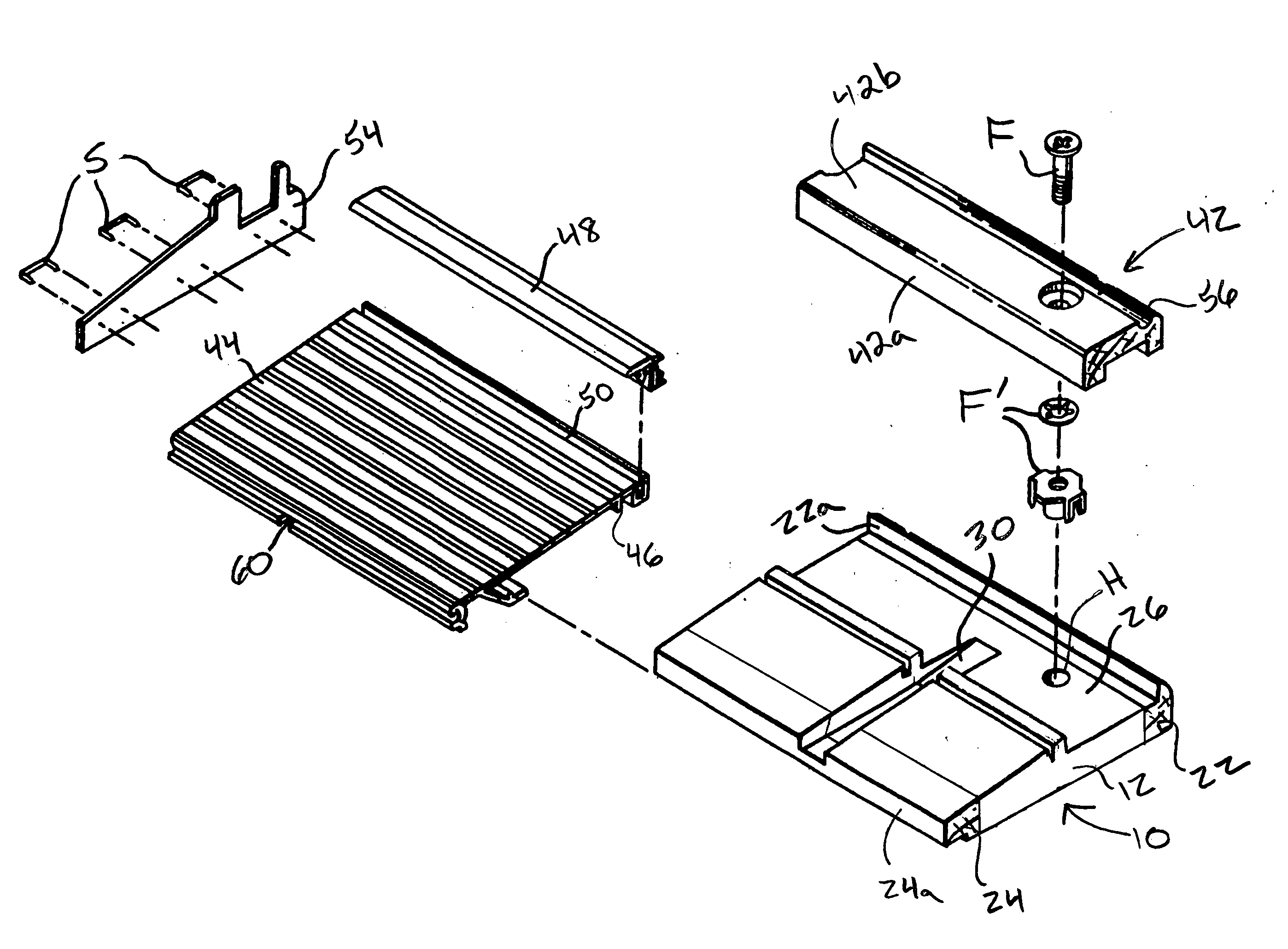

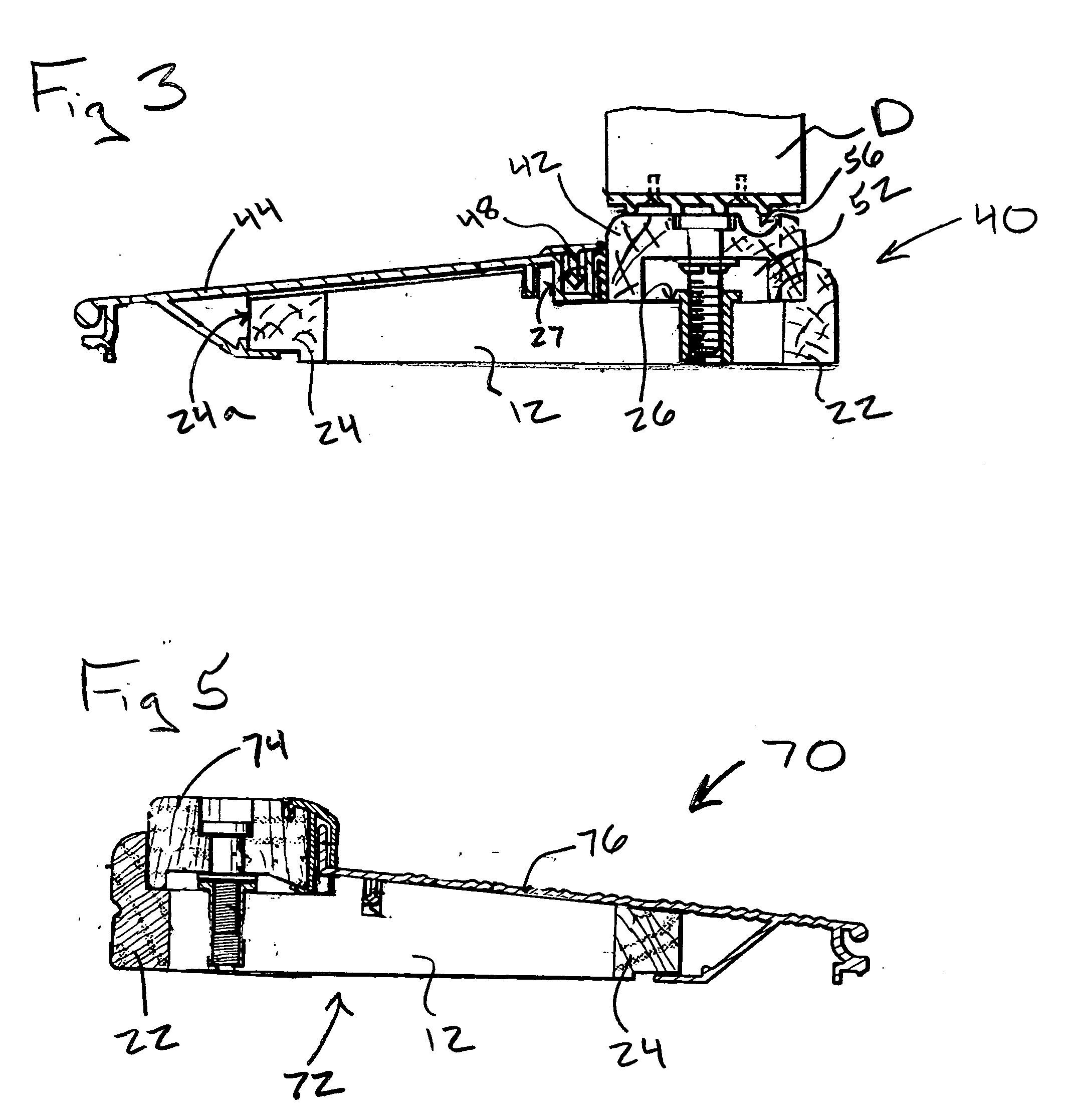

Banded door sill base and door sill assembly, and method of forming same

The present invention is directed to a banded doorsill base for disposition between a pair of doorjambs of a door frame. The doorsill base includes an elongate central portion formed from a polymeric material having a first coefficient of linear expansion, and first and second wooden strips bonded to and extending along opposite sides of the central portion for constraining the central portion and preventing linear expansion thereof. The first and second strips are formed from a material having a second coefficient of linear expansion less than the first coefficient. The first and second strips substantially prevent linear expansion of the central portion. The present invention also relates to a method of forming the banded doorsill base, and to a doorsill assembly having a banded doorsill base.

Owner:YOUNG ROBERT H

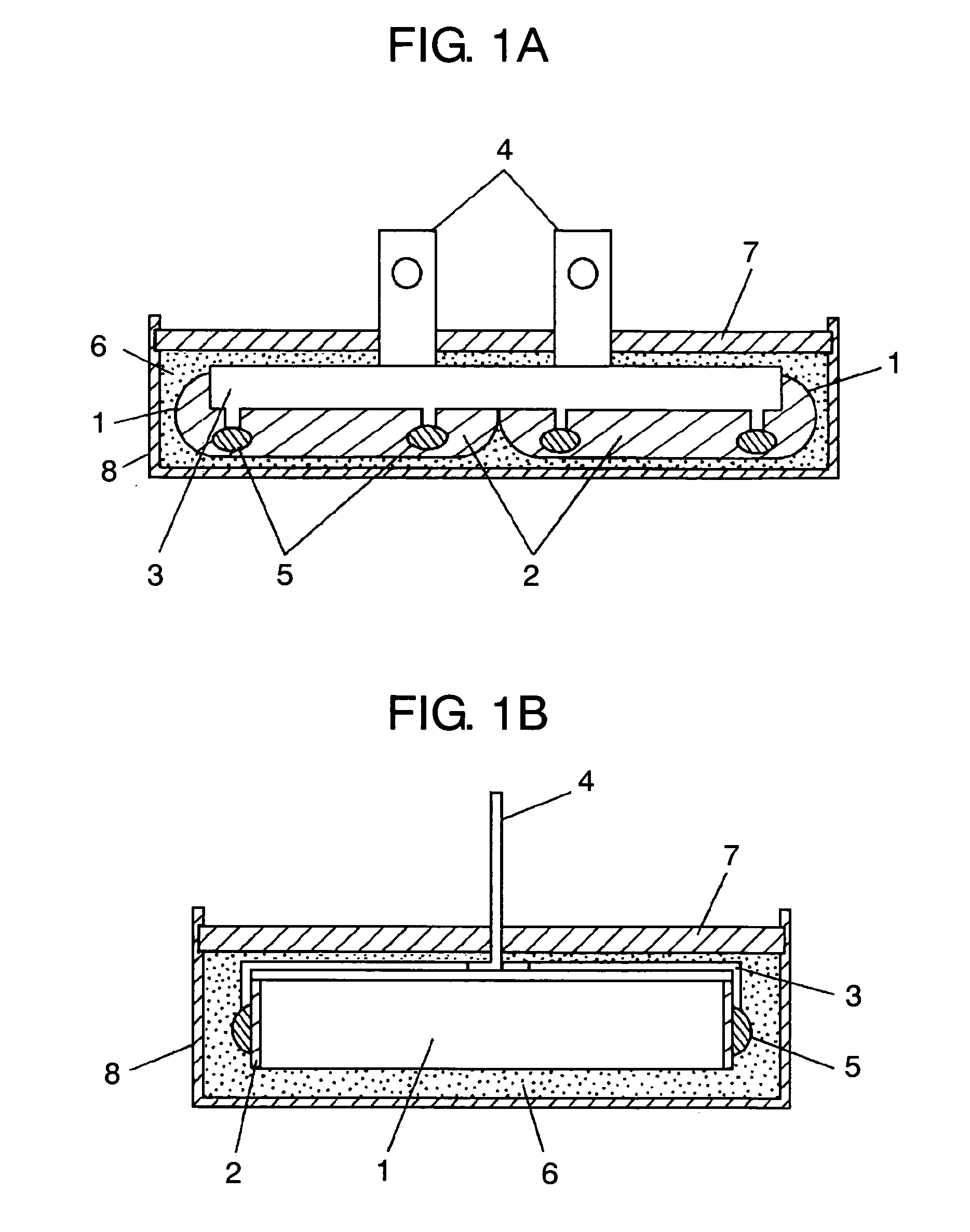

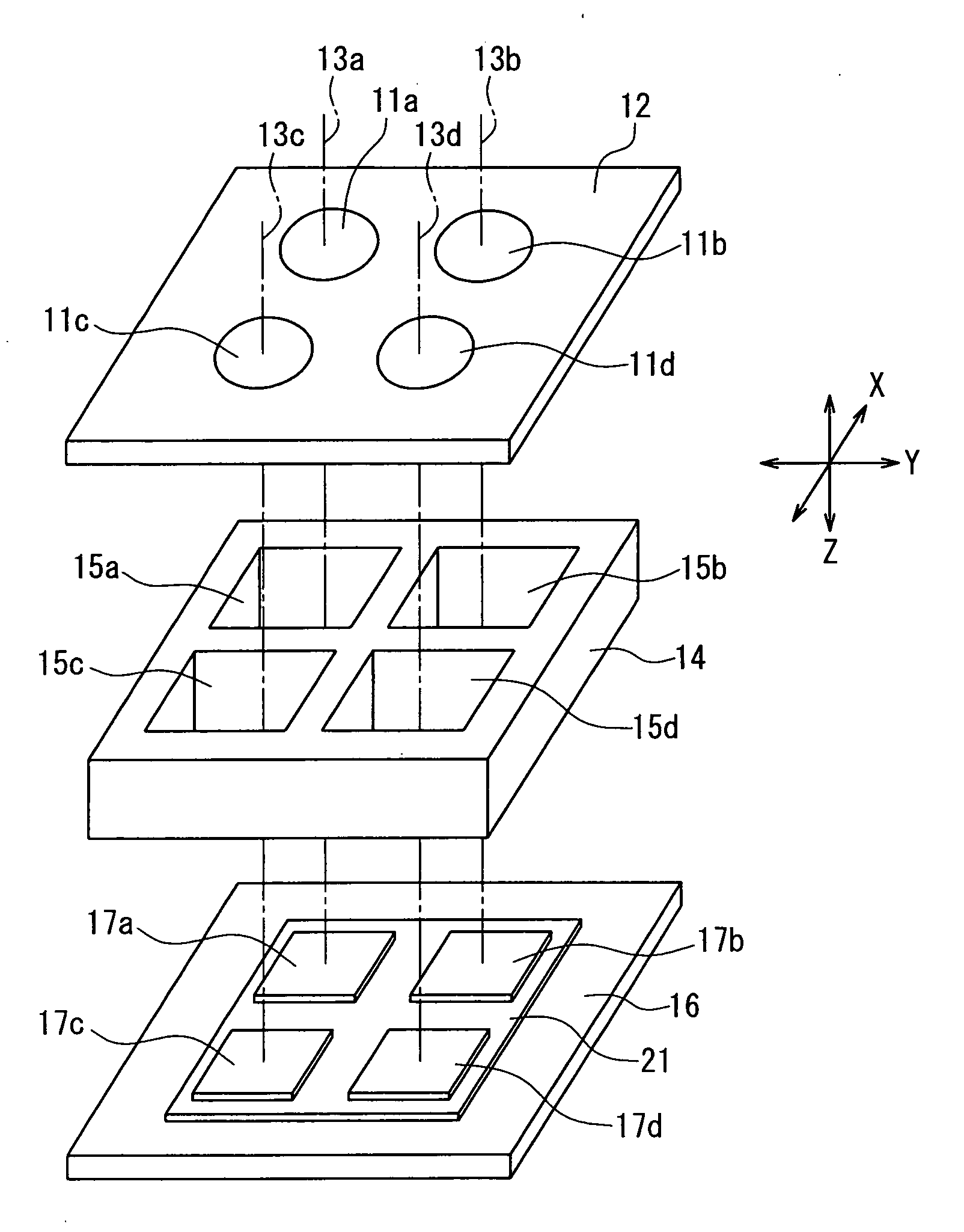

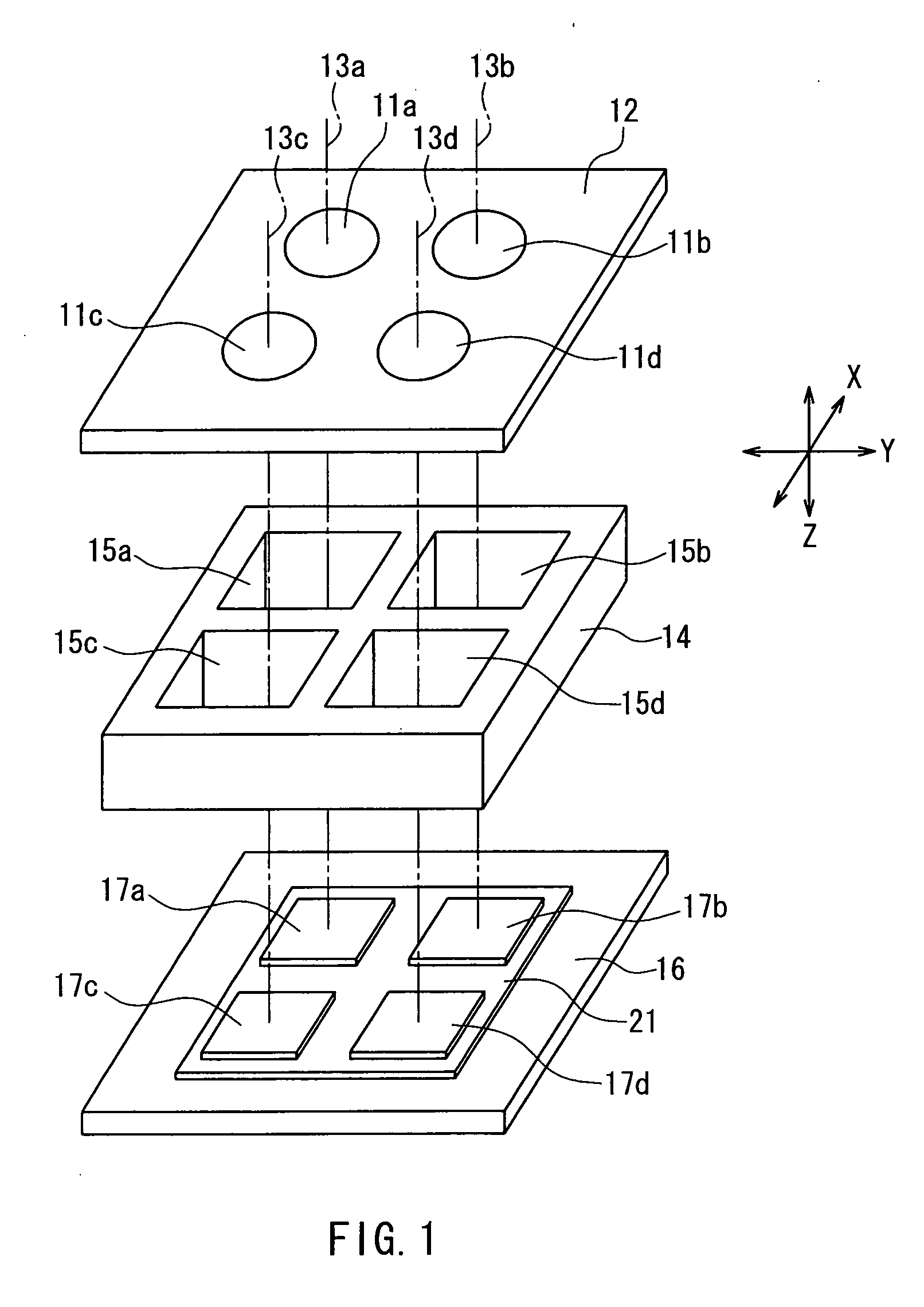

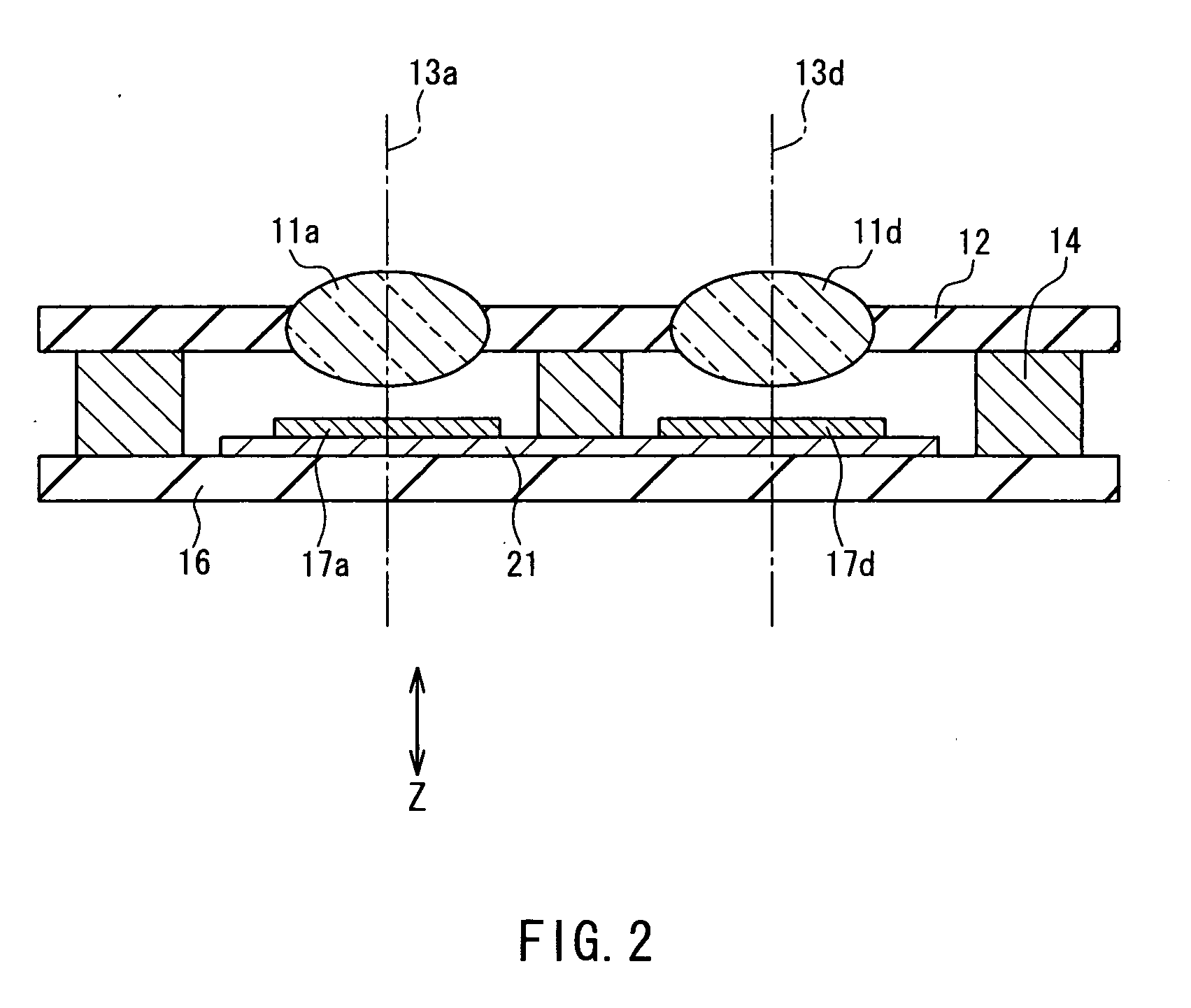

Camera module

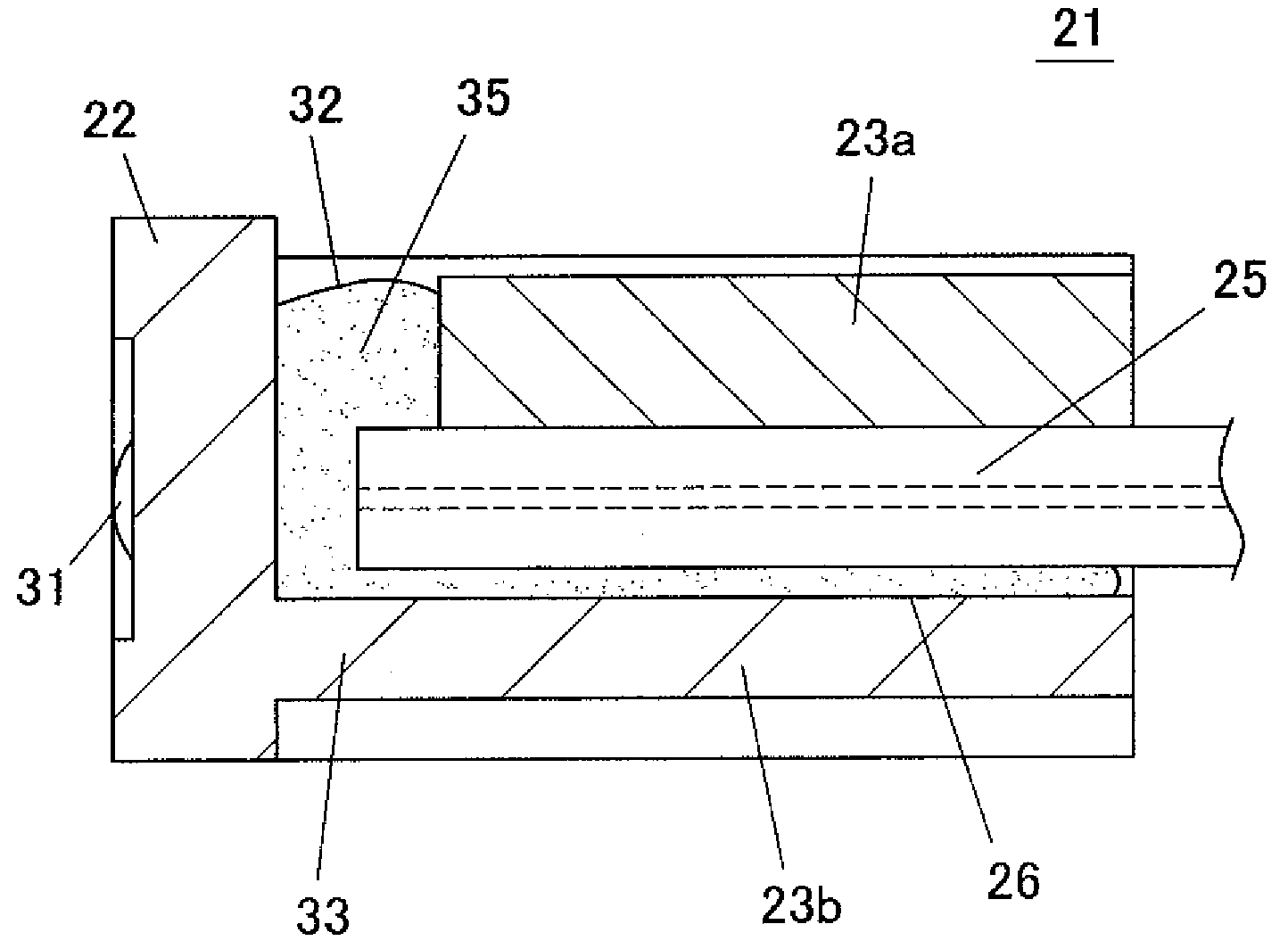

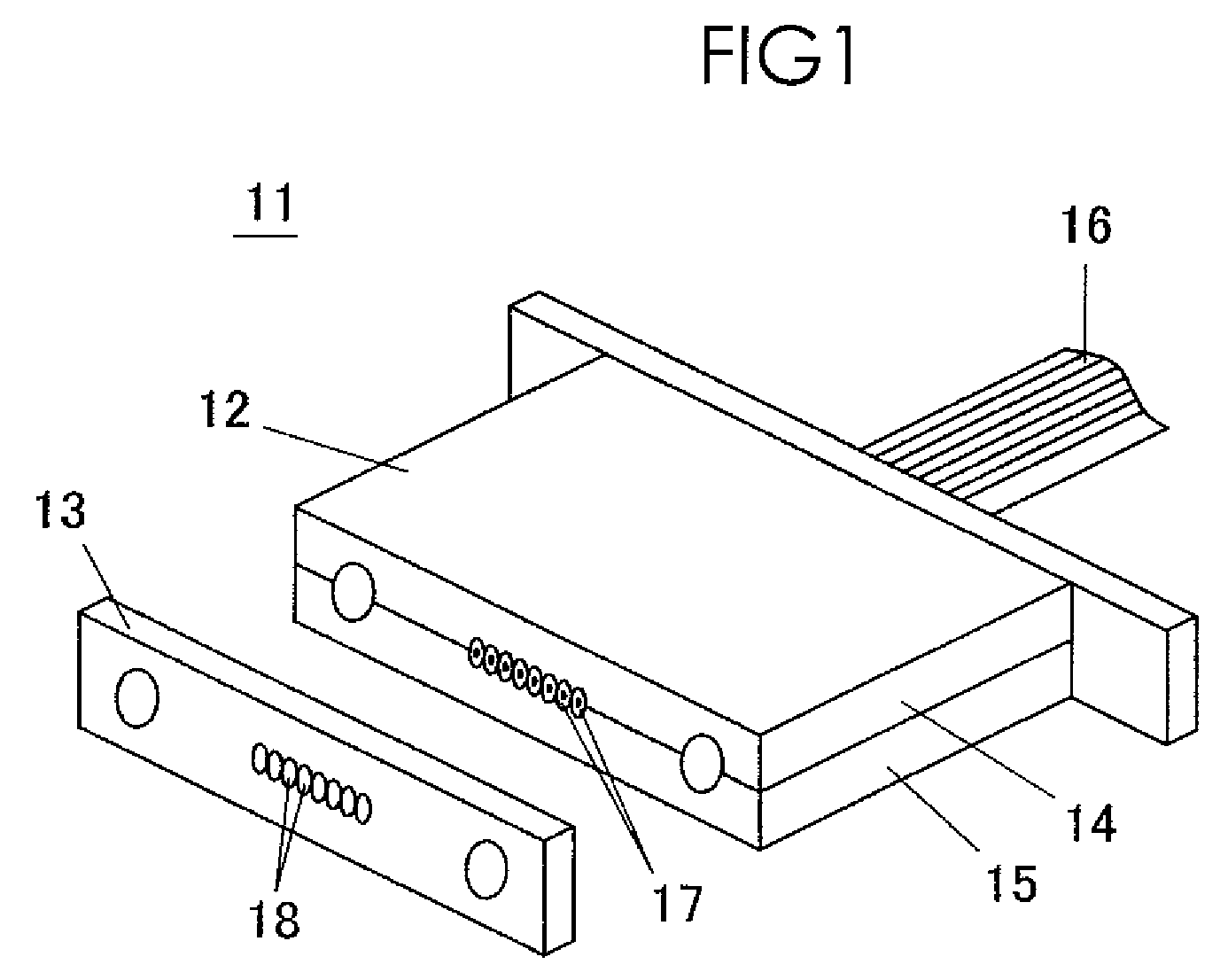

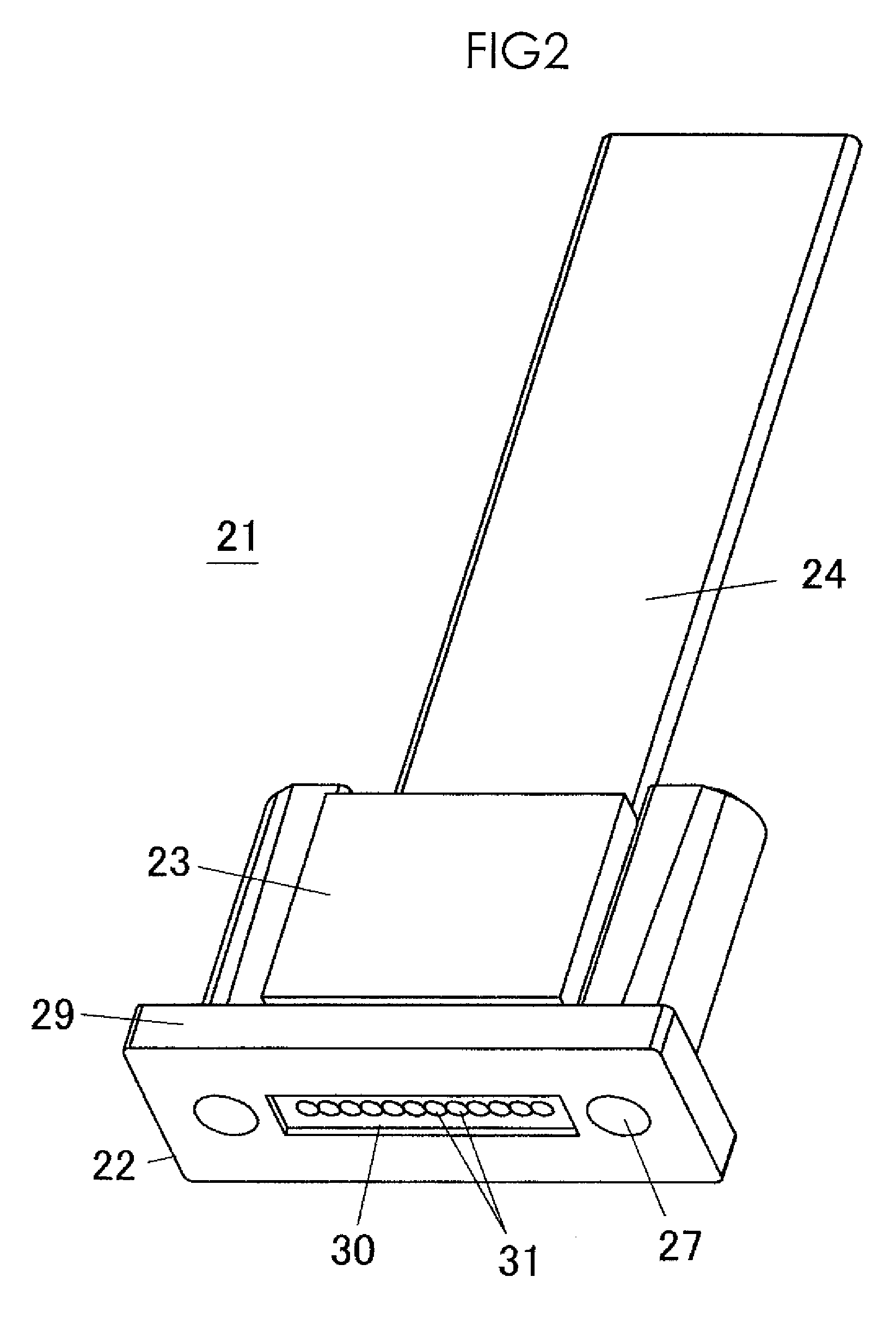

InactiveUS20070097249A1Increase production capacityQuality improvementTelevision system detailsTelevision system scanning detailsCamera moduleElectric signal

A plurality of single lenses (11a to 11d) form images of a subject in a plurality of imaging regions (17a to 17d), respectively, and electrical signals from the plurality of imaging regions are synthesized, whereby an image is obtained. The plurality of single lenses are held by a lens holder (12), and the plurality of imaging regions are held by an imaging device holder (16). The lens holder and the imaging device holder are disposed so as to be opposed to each other. The lens holder includes a member different from a member of the imaging device holder, and a linear expansion coefficient of a material of the lens holder is substantially equal to a linear expansion coefficient of a material of the imaging device holder. The materials of the lens holder and the imaging device holder are different from a material of the plurality of single lenses. Thereby, a high quality image can be obtained stably irrespective of a temperature change, and a distance to a subject can be measured accurately.

Owner:PANASONIC CORP

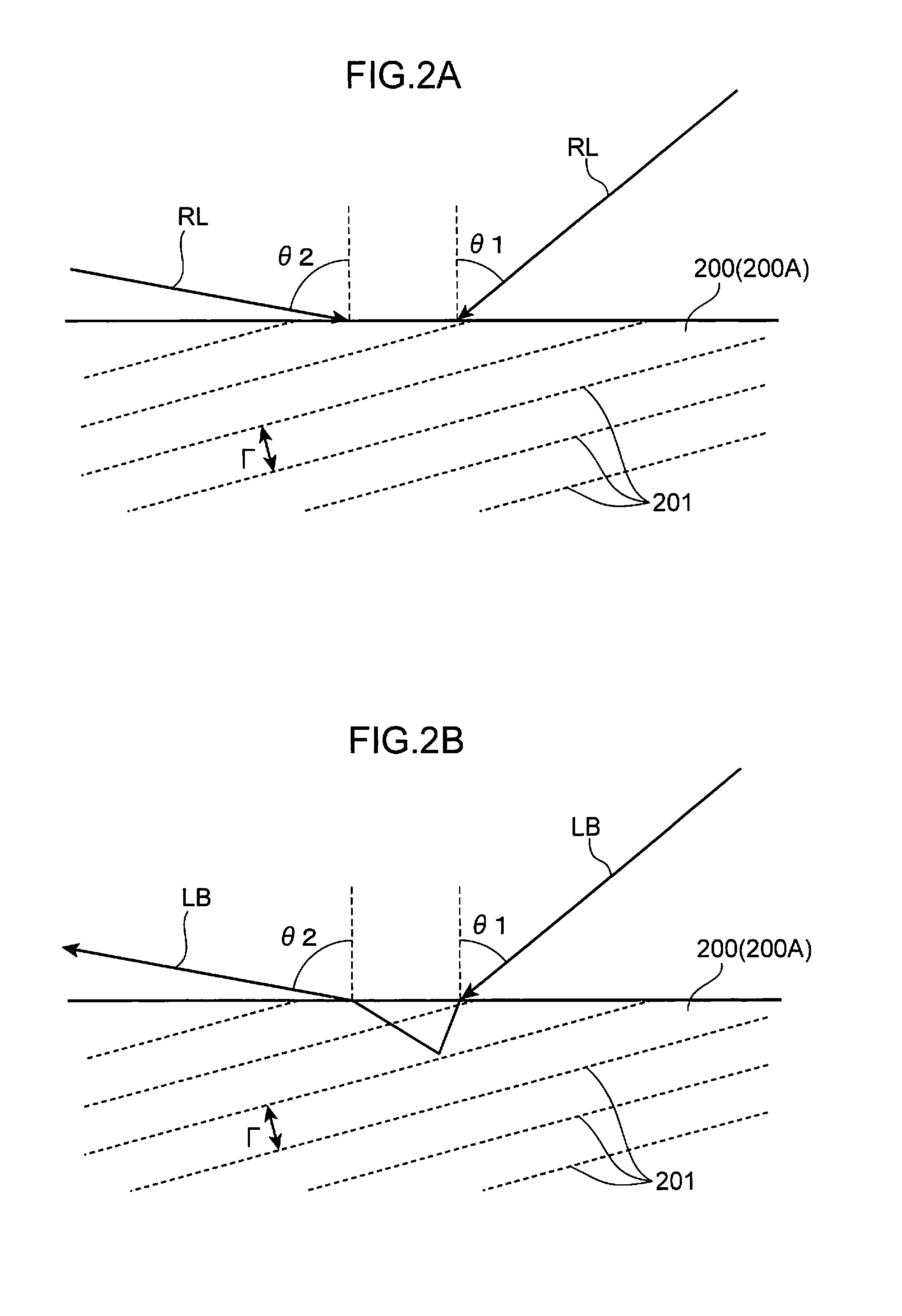

Optical element having minute periodic structure

ActiveUS20050036212A1Stable and favorable reflection suppressing effectDiffraction gratingsMountingsLength waveLinear expansion coefficient

An optical element is disclosed which is resistant to changes in environmental characteristics such as temperature and humidity and achieves a stable and favorable reflection suppressing effect. The optical element has a base member and a resin layer which is formed on the base member and has a linear expansion coefficient different from that of the base member. The resin layer has a minute periodic structure which has a period smaller than the wavelength of incident light on the optical element.

Owner:CANON KK

Liquid crystalline polymer composition and moldings

InactiveUS6063848AReducing anisotropy characteristicLow coefficient of linear expansion without deteriorating mechanical propertiesAlkaline-earth metal silicatesLiquid crystallineParticulates

PCT No. PCT / JP96 / 03880 Sec. 371 Date Sep. 8, 1997 Sec. 102(e) Date Sep. 8, 1997 PCT Filed Dec. 27, 1996 PCT Pub. No. WO97 / 24404 PCT Pub. Date Oct. 7, 1997The present invention provides a liquid crystal polymer composition wherein the low coefficient of linear expansion is attained without significantly deteriorating mechanical properties by incorporating plural fibrous fillers or a fibrous filler and a particulate filler with liquid crystal polymer in a specified ratio.

Owner:POLYPLASTICS CO LTD

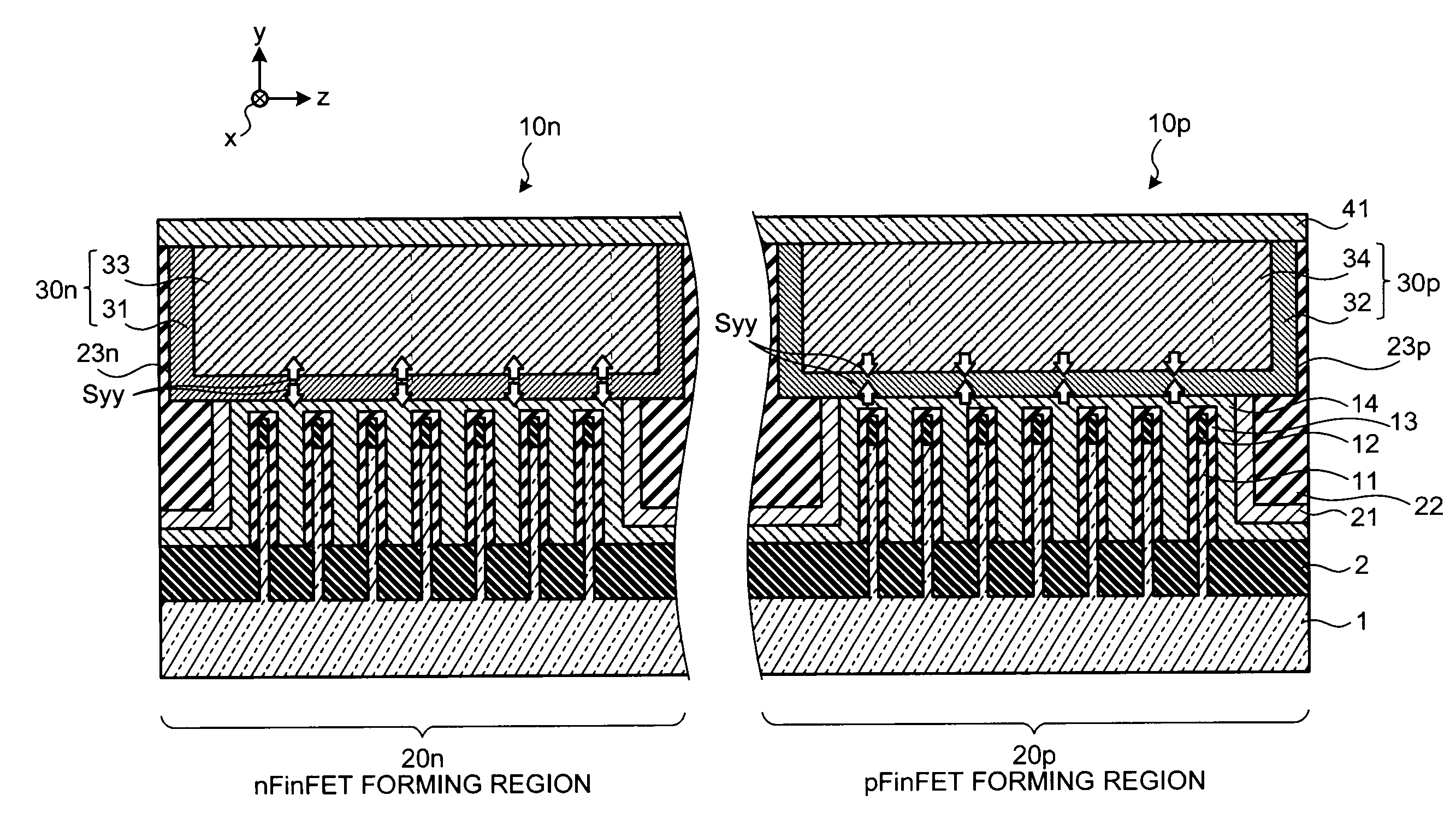

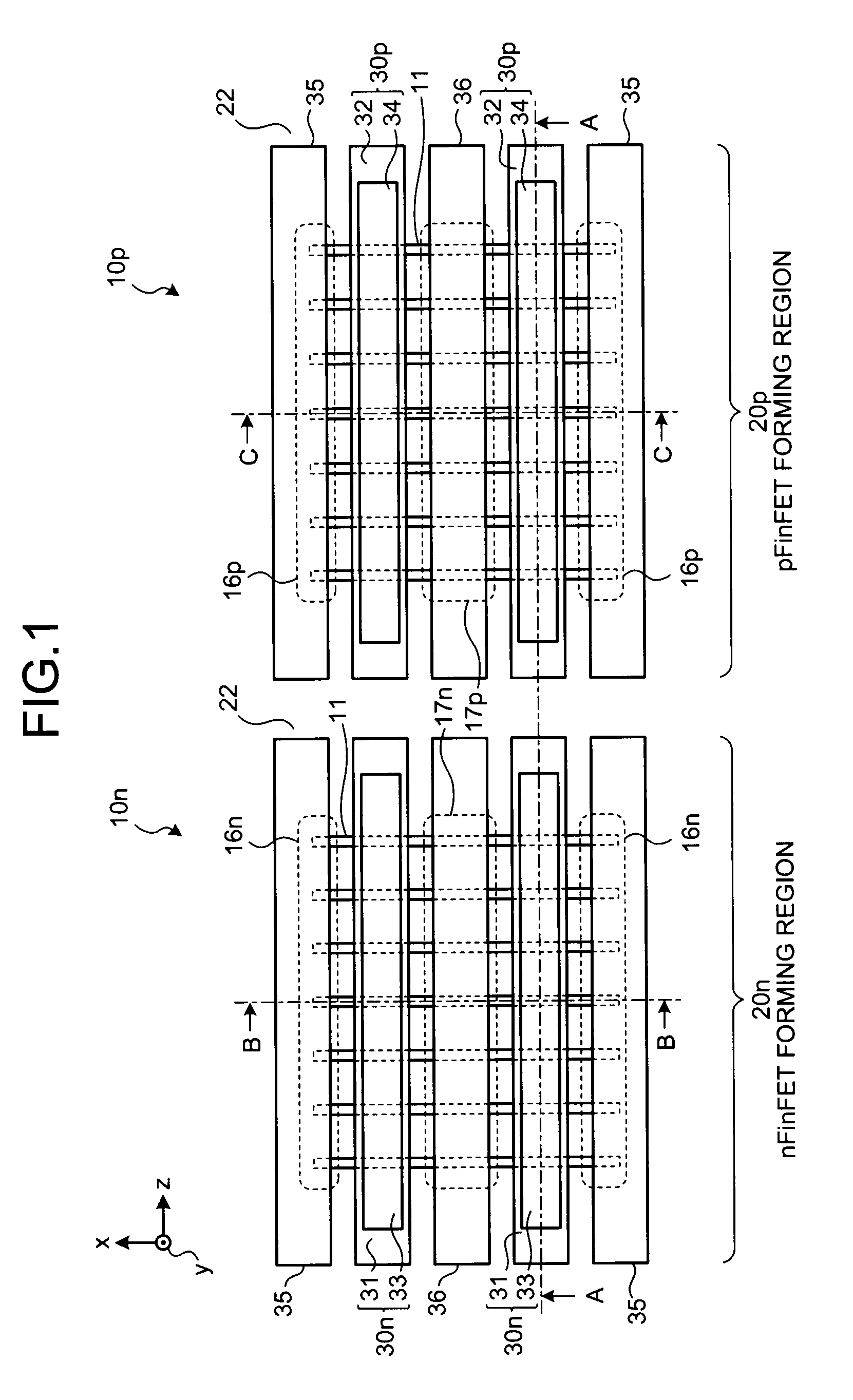

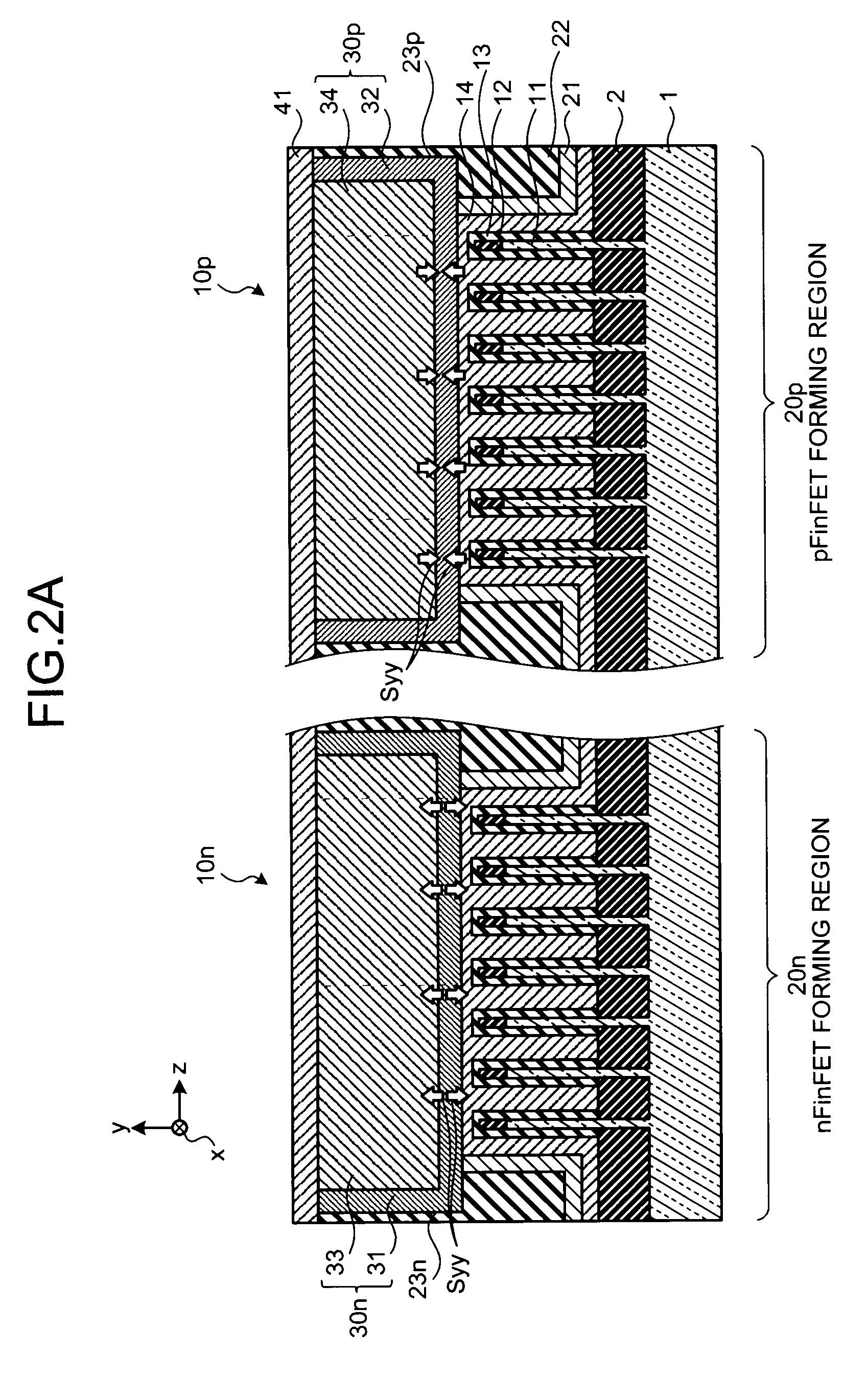

Semiconductor device and manufacturing method thereof

ActiveUS20090101982A1TransistorSemiconductor/solid-state device manufacturingDevice materialRoom temperature

A semiconductor device according to an embodiment of the present invention comprises: a semiconductor substrate; a first field-effect transistor formed on the semiconductor substrate, and including a fin constituted by a semiconductor layer having source and drain regions via a channel region in an extending direction, and a gate electrode formed on the channel region via an insulating film; a stress application layer formed on a top surface of the gate electrode, and formed by a conductive material of which a difference between linear expansion coefficients at a temperature of forming a stress application layer and a room temperature is different from a difference between linear expansion coefficients of the fin at the temperature of forming the stress application layer and the room temperature, and a plug layer formed on the stress application layer and above the fin, and made of a conductive material having larger Young's modulus than that of the fin.

Owner:KIOXIA CORP

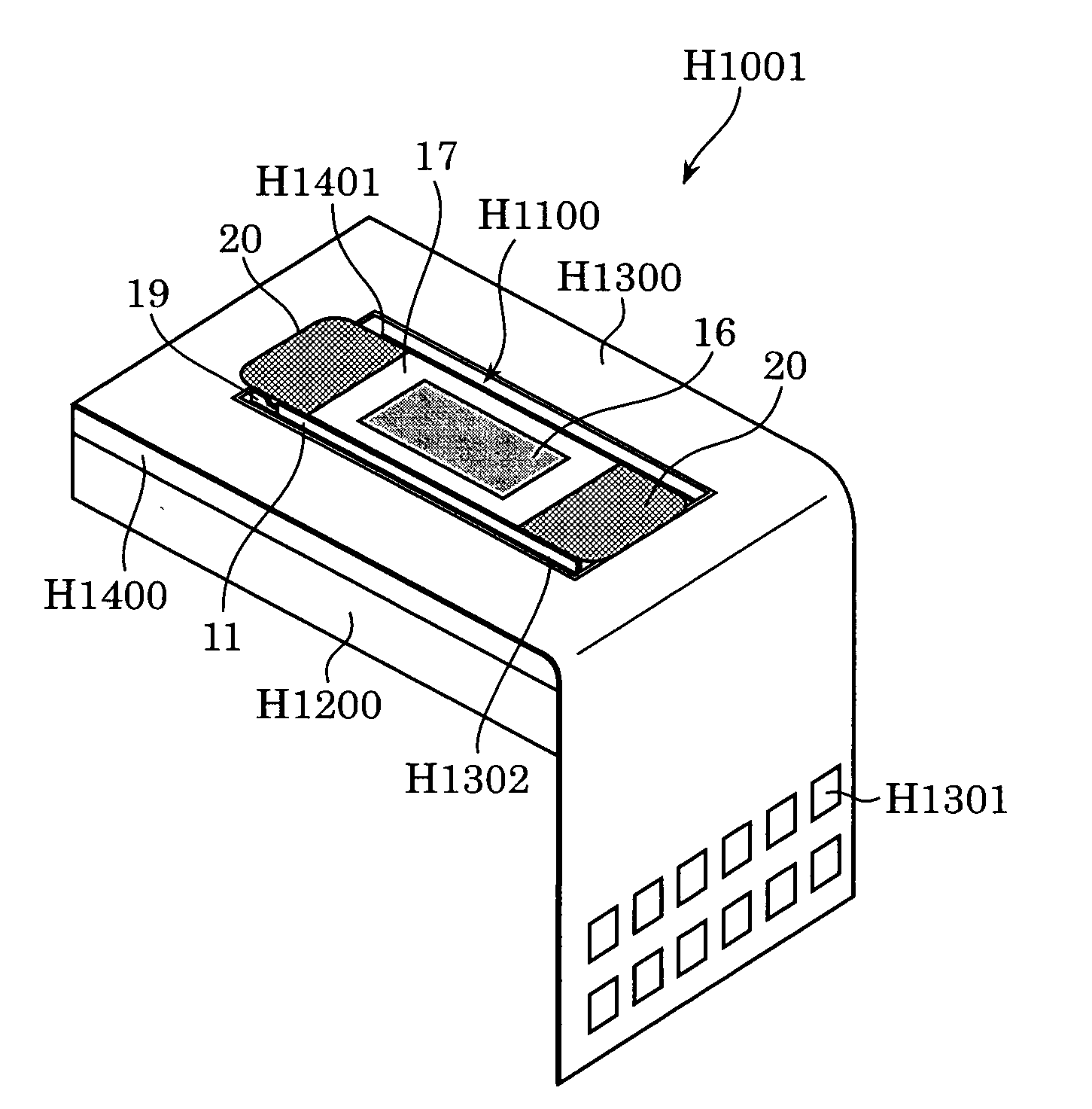

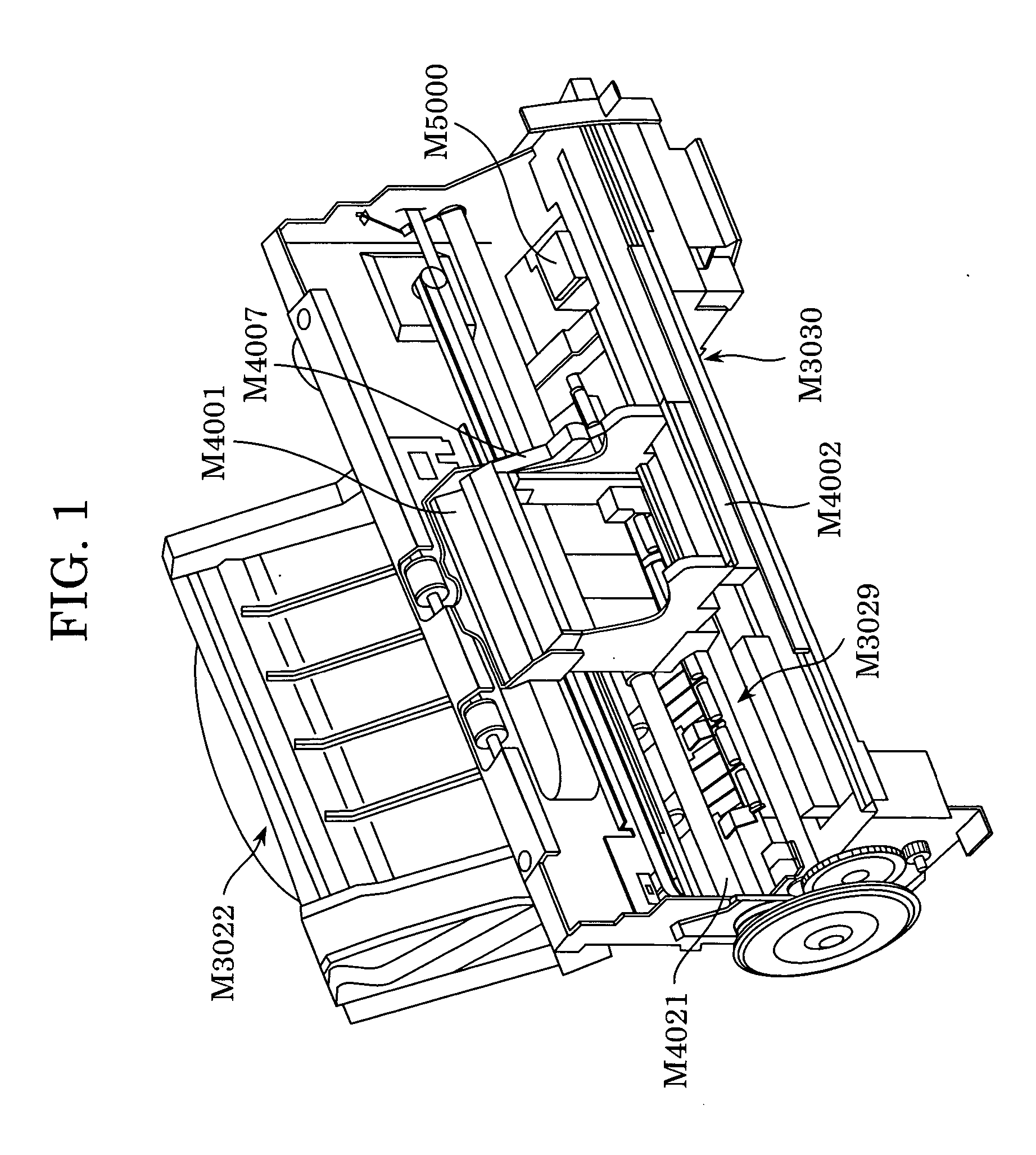

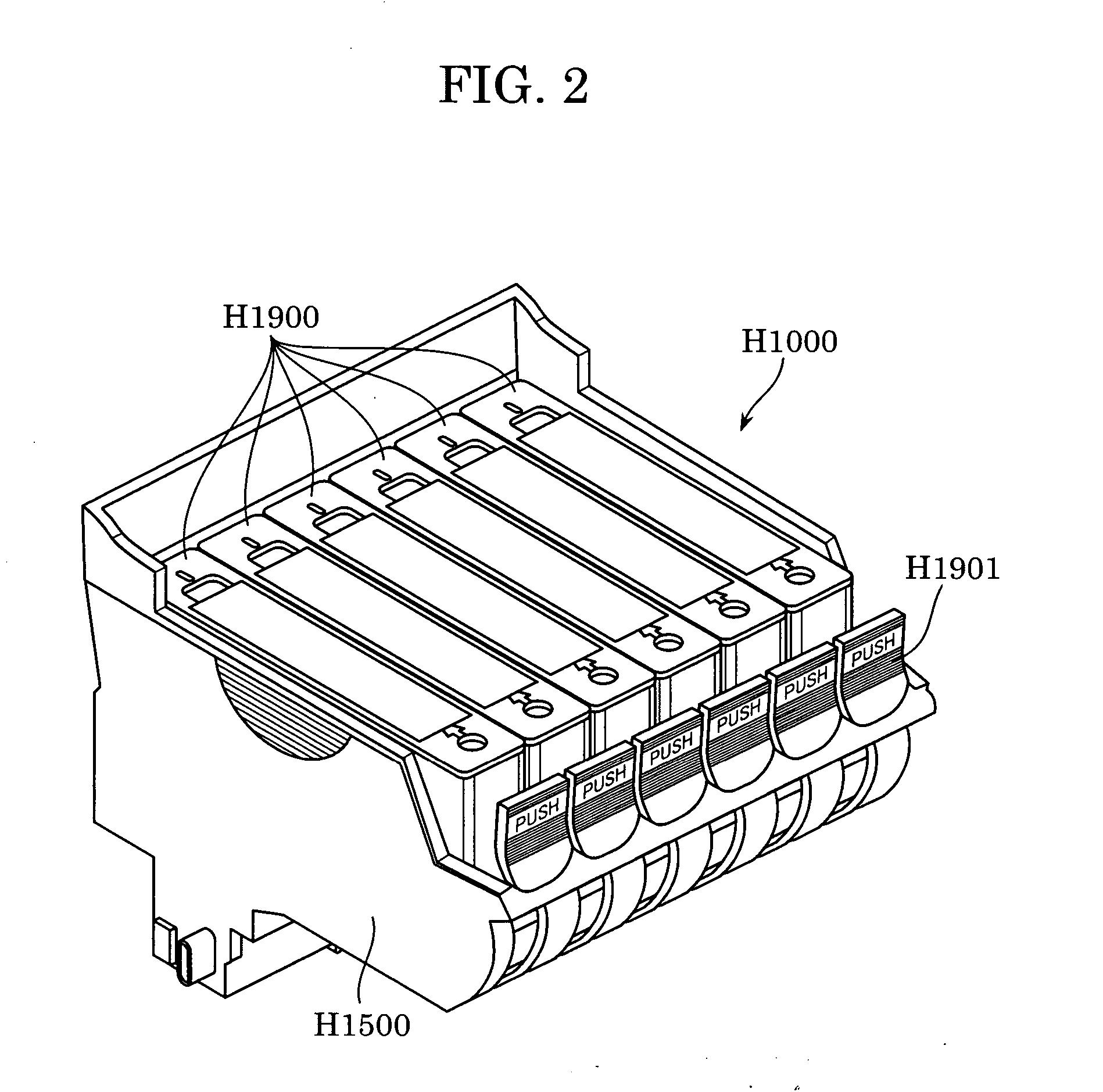

Ink jet head and ink jet printing apparatus having the head

An ink jet head has a head substrate including discharge elements for discharging ink, with an electric wiring board being electrically connected to the head substrate, in which the periphery of the head substrate is sealed with a first sealant, and an electric splice between the head substrate and the electric wiring board is sealed with a second sealant. The first and second sealants contain the same base resin and curing agent, and the second sealant shows higher hardness than the first sealant after curing. This ink jet head is free from problems such as cavities and fissures at the boundary of the two sealants caused by a difference in linear expansion coefficients.

Owner:CANON KK

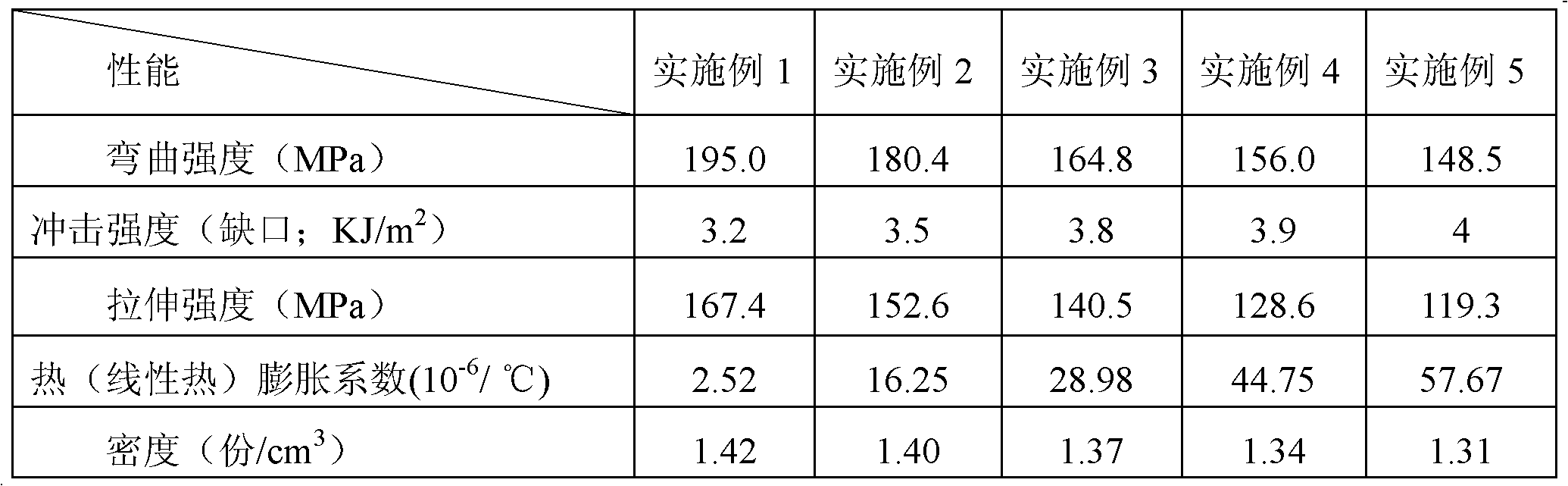

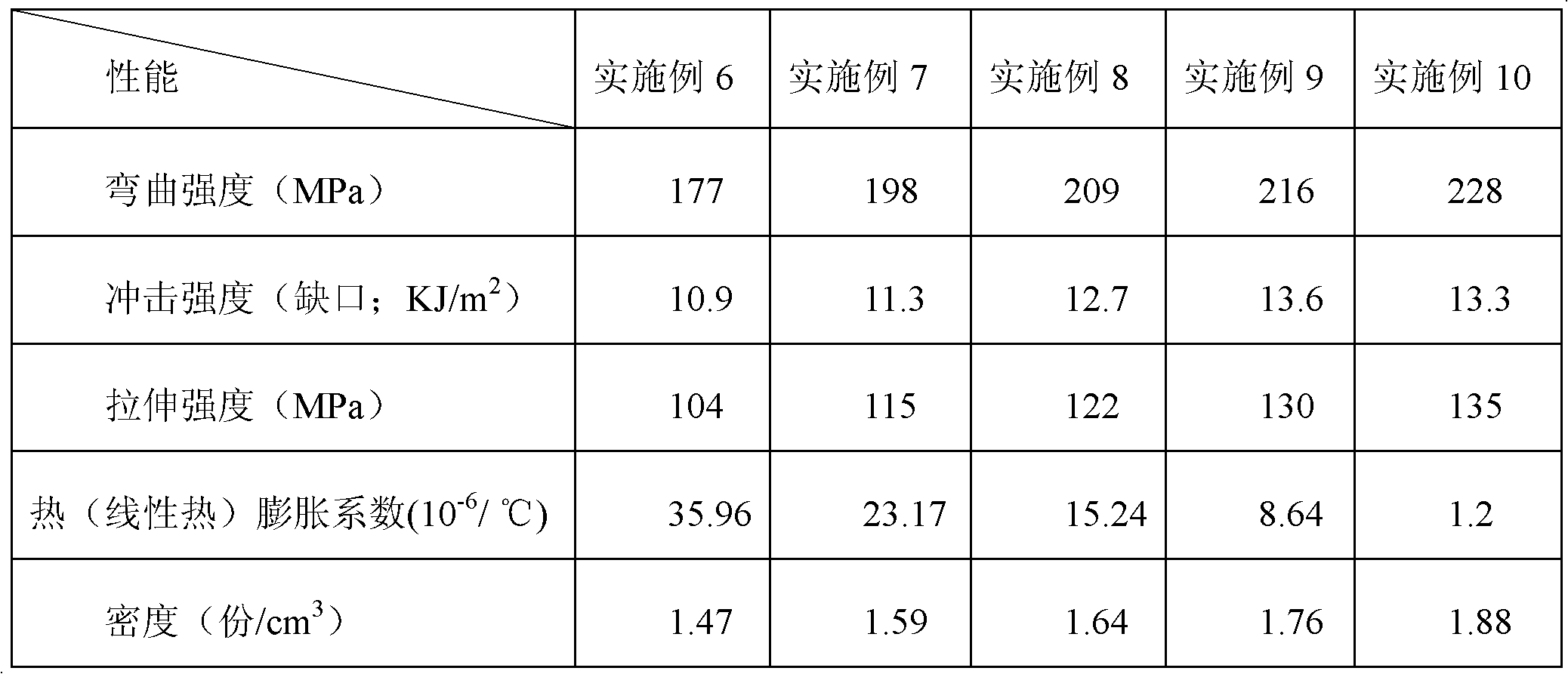

Low coefficient of thermal expansion thermoplastic resin composition, preparation method and application thereof

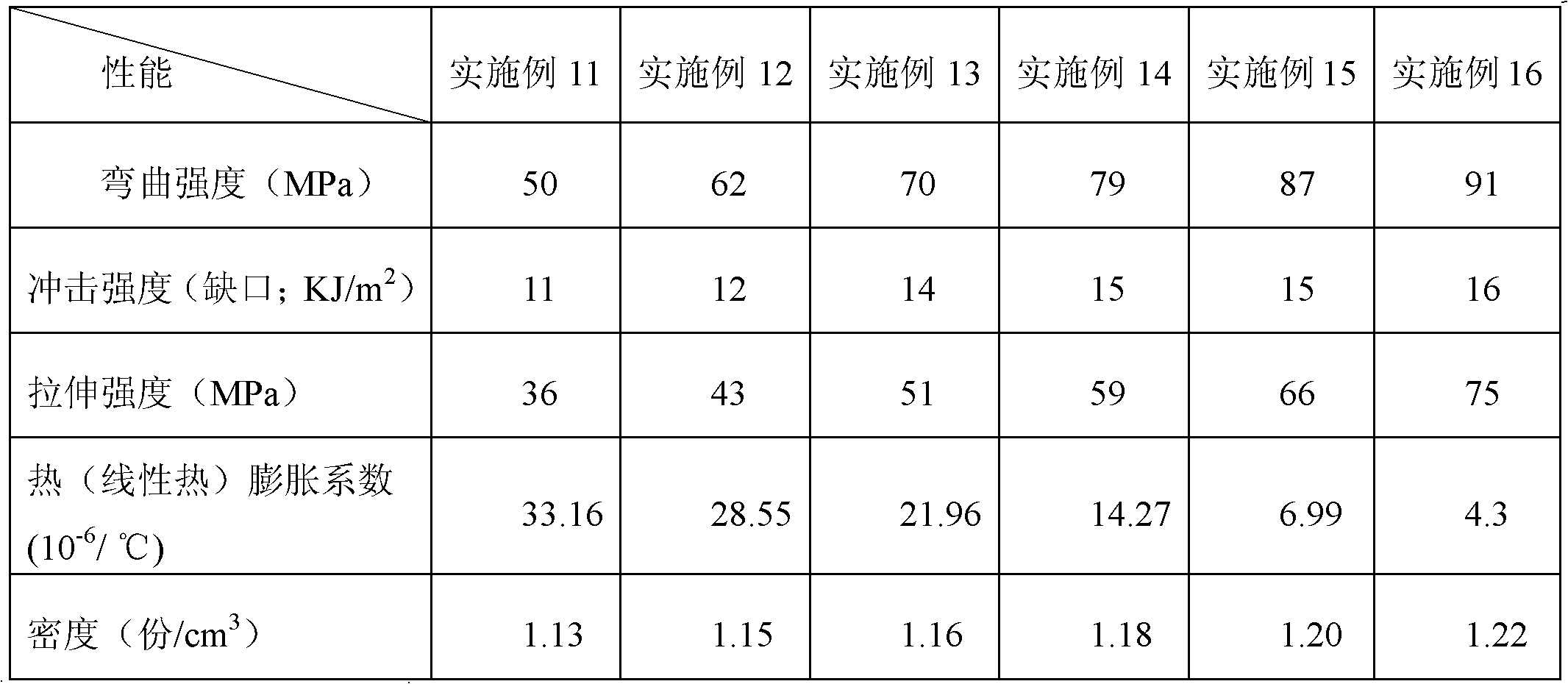

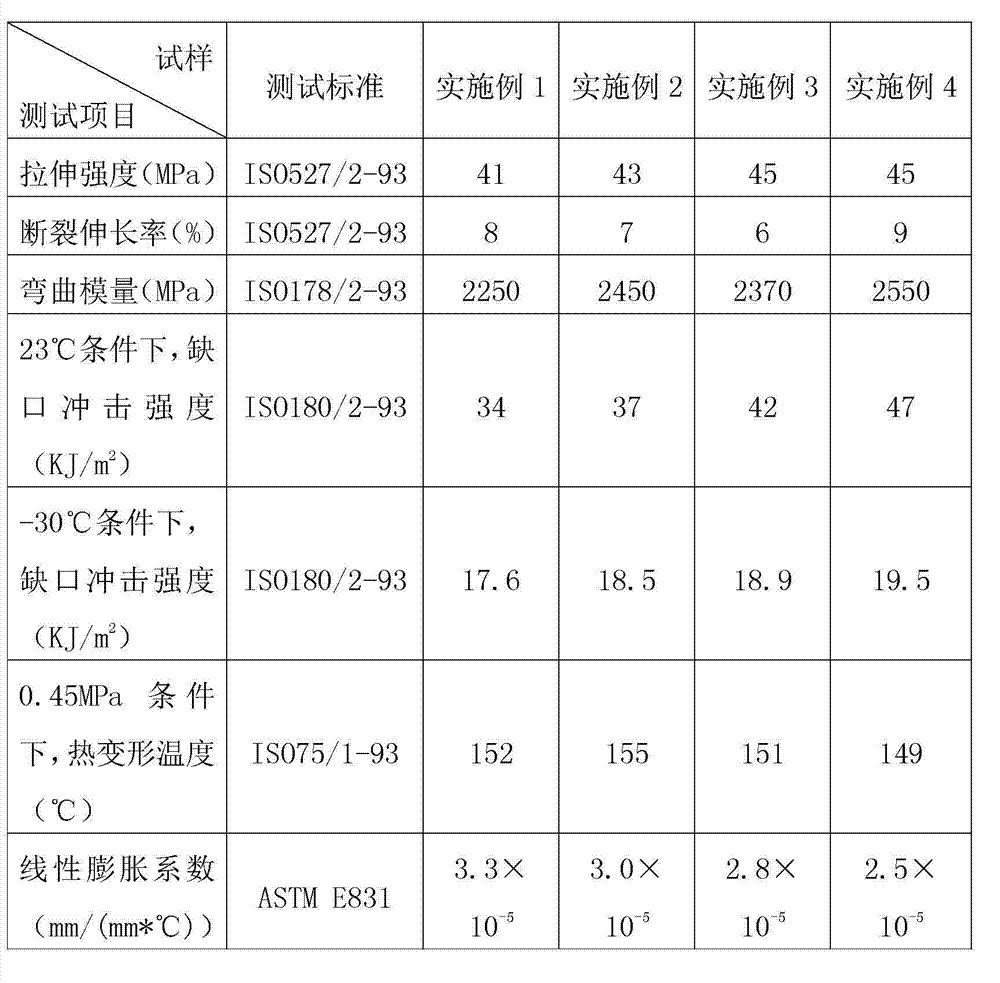

The invention belongs to the technical field of high polymer materials, and discloses low coefficient of thermal expansion thermoplastic resin composition, a preparation method and application of the low coefficient of thermal expansion thermoplastic resin composition. The resin composition is composed of, by weight, 340 to 900 parts of thermoplastic resin, 100 to 500 parts of carbon fibers, 0 to 5 parts of antioxygen, 0 to 5 parts of lubricating agent and 0 to 150 parts of flexibilizer. The preparation method comprises adding the 340 to 900 parts of the thermoplastic resin, the 0 to 5 parts of the antioxygen, 0 to 5 parts of the lubricating agent and the 0 to 150 parts of the flexibilizer to a high mixing machine to mix for 1 to 30 min, adding the mixture to a double-screw extruder, adding the 100 to 500 parts of the carbon fibers from the glass fiber feeding port or the side feeding port of the double-screw extruder to mix evenly, and carrying out extruding, dragging and prilling on mixed materials in the double-screw extruder to obtain the low coefficient of thermal expansion thermoplastic resin composition. The use of the low coefficient of thermal expansion thermoplastic resin composition applied to the fittings of a metal piece is provided. The thermoplastic resin is high in flexural modulus, tensile strength and impact strength, and low in linear expansion coefficient.

Owner:HEFEI GENIUS NEW MATERIALS

Optical transmission component and production method thereof

An aspect according to the invention provides a method of producing an optical transmission component in which peel-off and a bubble are not generated within a keeping temperature range in a bonding agent with which a space between an optical function portion and an end face of an optical transmission line is filled while a holder portion for holding the optical transmission line such as an optical fiber and the optical function portion such as a lens array are integrally molded. An optical function array is disposed across the space from a fiber holder, and the optical function array including lenses and a lower-side holder portion are integrally molded by a transparent resin. Fiber cores are placed in V-shape grooves of the lower-side holder portion, and an upper-side holder portion is put on the fiber cores. End faces of the fiber cores face the space, and the space is filled with the bonding agent. When a linear expansion coefficient of the bonding agent is smaller (or larger) than the linear expansion coefficient of the connection portion that connects the optical function array and the lower-side holder portion, the bonding agent is cured at an atmosphere temperature higher than an upper limit (or lower than a lower limit) of a keeping temperature of the optical transmission component.

Owner:MOLEX INC

Transparent composite composition

InactiveUS7132154B2Reduction factorImprove heat resistanceSynthetic resin layered productsGlass/slag layered productsEpoxyLiquid-crystal display

A transparent composite composition is provided which comprises an epoxy resin (a) and a glass filler (b) and in which the epoxy resin (a) comprises at least one epoxy resin whose refractive index after curing is lower than the refractive index of the glass filler (b) and at least one epoxy resin whose refractive index after curing is higher than the refractive index of the glass filler (b). The transparent composite composition of the invention has a low coefficient of linear expansion and is excellent in transparency, heat resistance and solvent resistance, among others and, therefore, is judiciously used, for example, in the form of liquid crystal display device substrates and organic EL device substrates (in particular of the active matrix type) and, further, transparent sheets, optical lenses, color filter substrates, solar cell substrates, touch panels, optical devices, optical waveguides, LED sealing materials and so forth.

Owner:SUMITOMO BAKELITE CO LTD

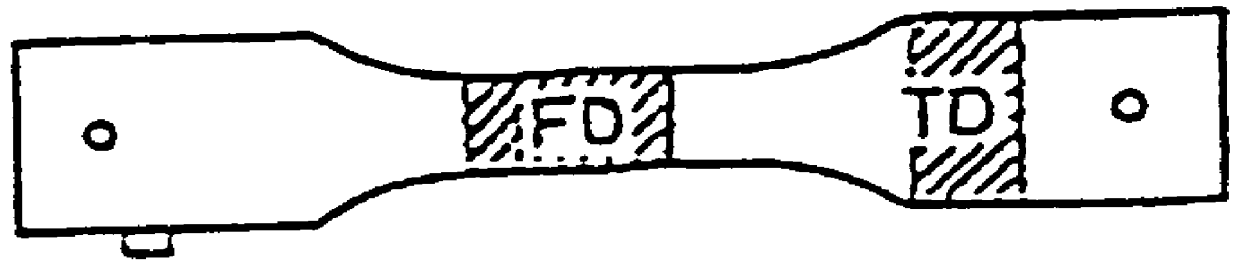

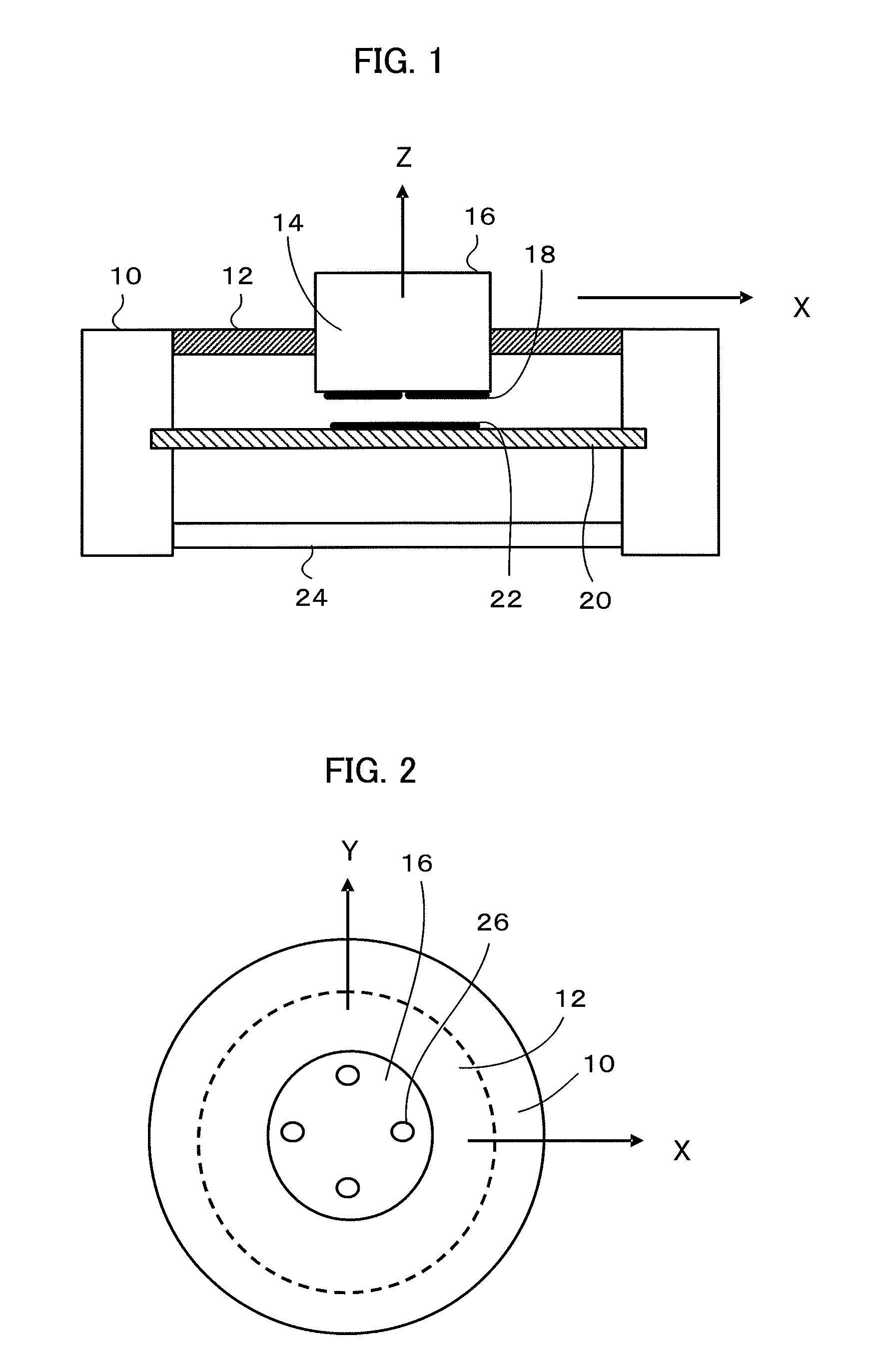

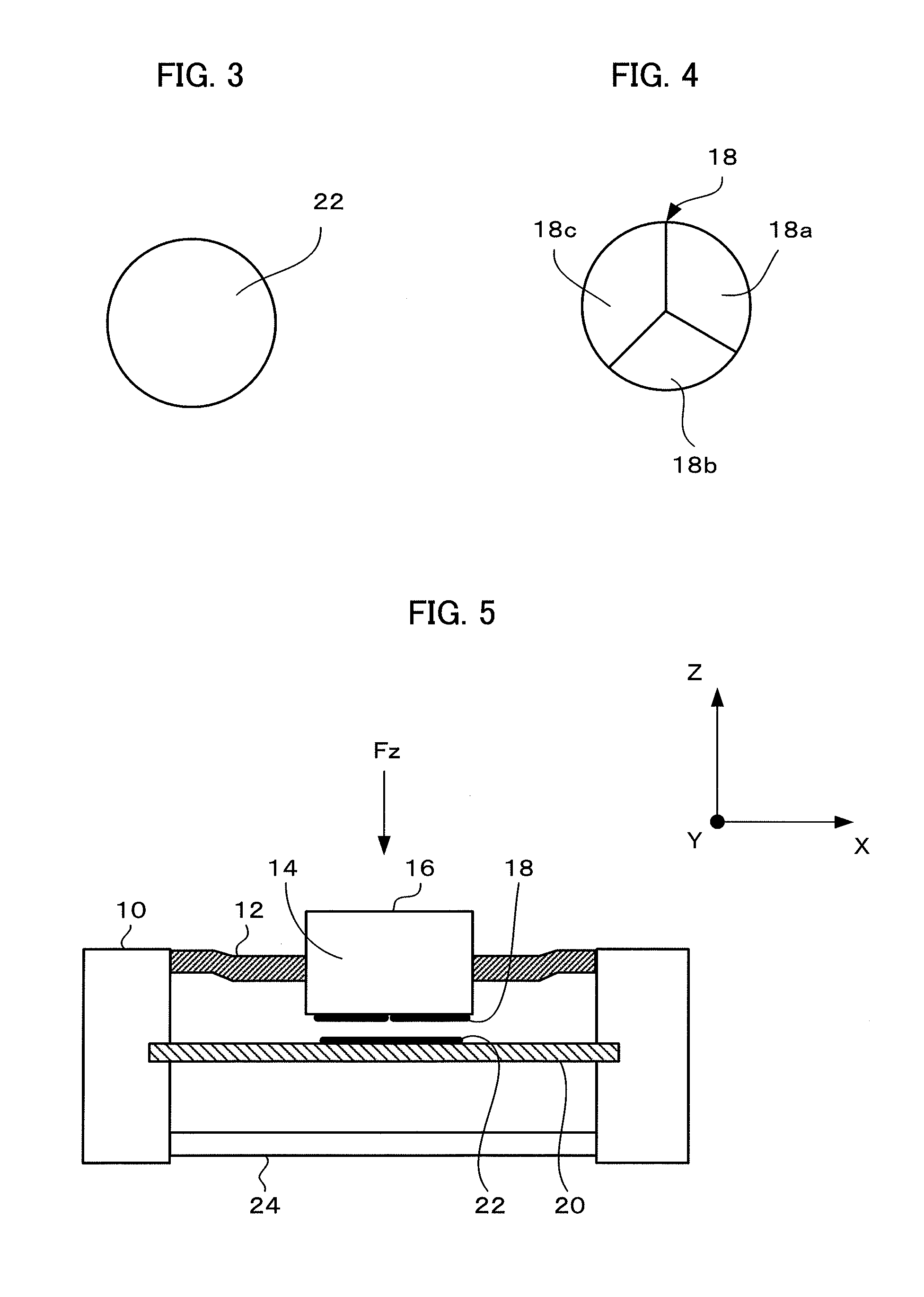

Capacitance-type force sensor

InactiveUS20120180575A1Simple structureReliable detectionForce measurementApparatus for force/torque/work measurementCapacitanceElectricity

A capacitance-type force sensor is provided with a fixed plate, a fixed portion on which the fixed plate is mounted, a load transmission portion, and an elastic portion through which the load transmission portion is mounted on the fixed portion. All these members are formed of materials having substantially equal coefficients of linear expansion. Further, a displacement electrode secured to the load transmission portion and / or a fixed electrode secured to the fixed plate is divided into three or more electrically independent electrodes such that the displacement and fixed electrodes form three or more capacitance elements.

Owner:FANUC CORP

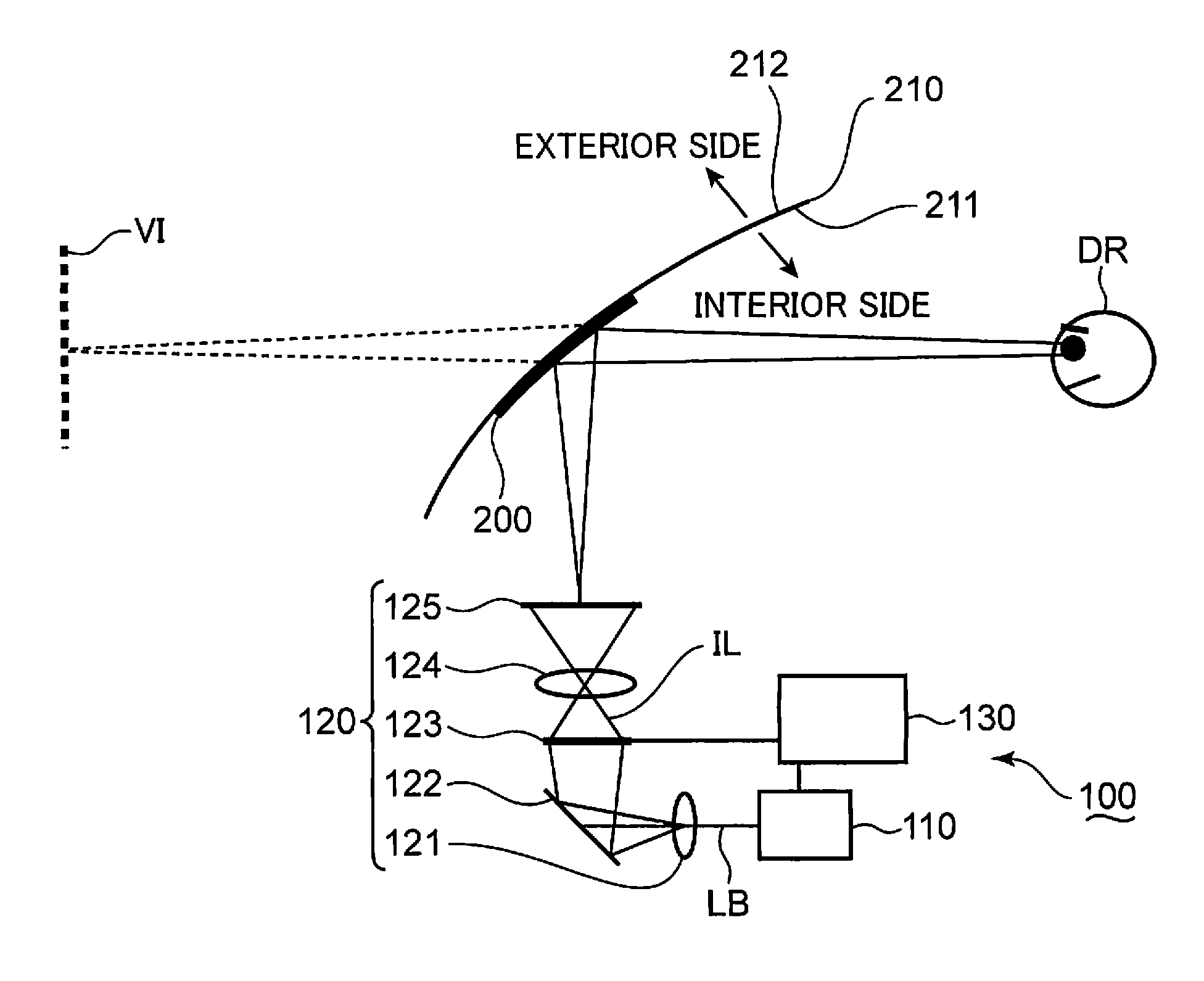

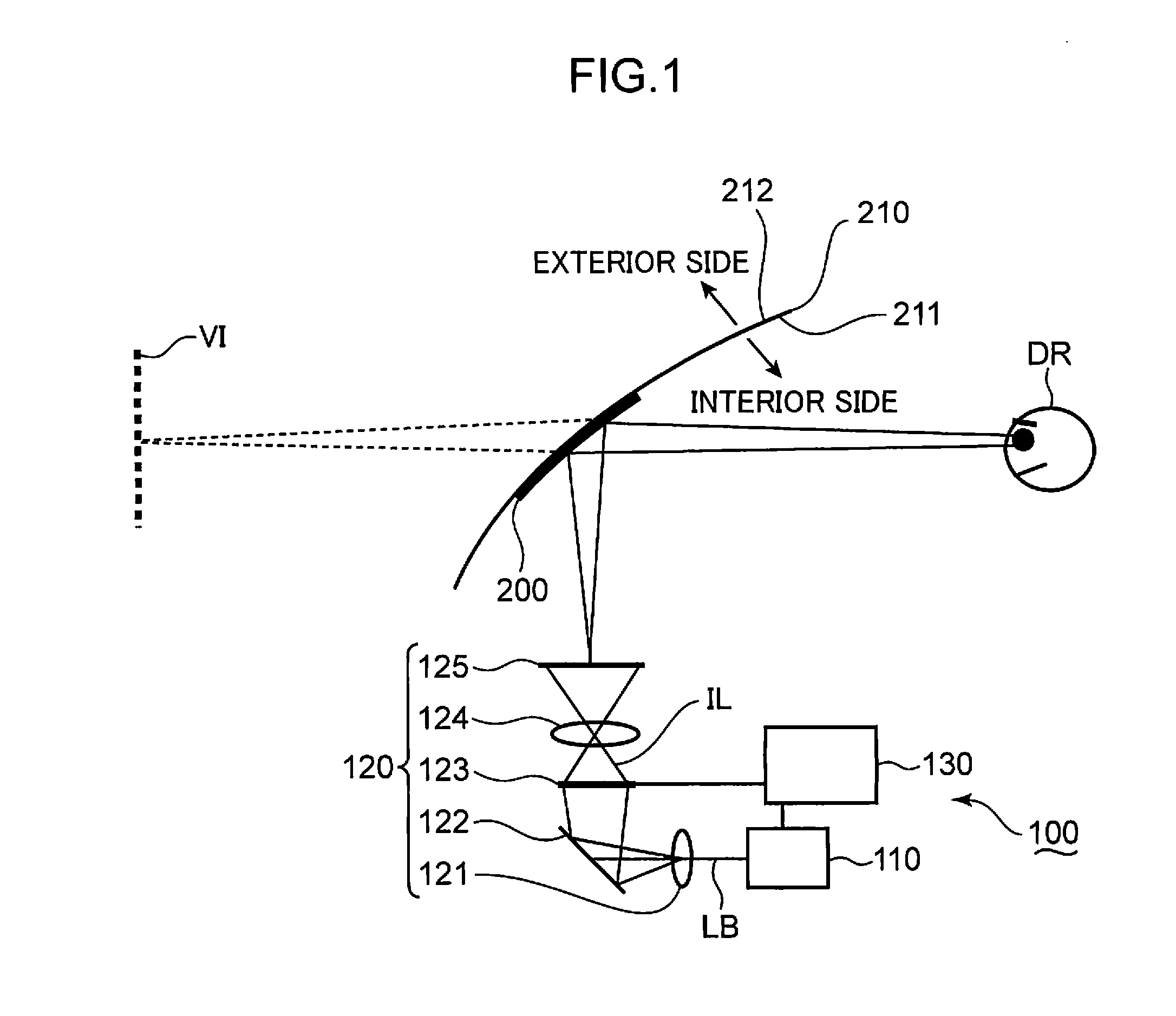

See-through display and head-up display

A see-through display including a light source for emitting light, a projection optical system for projecting the light emitted by the light source, and a volume hologram for deflecting the light projected by the projection optical system. The volume hologram has a linear expansion coefficient of α ( / ° C.) and interference fringes recorded with recording light having a wavelength of Λ (nm). The wavelength of the light emitted by the light source has a temperature dependency of K (nm / ° C.), and the wavelength Λ (nm) and the temperature dependency K (nm / ° C.) satisfy the relationship of 0≦K / Λ≦2α.

Owner:PANASONIC CORP

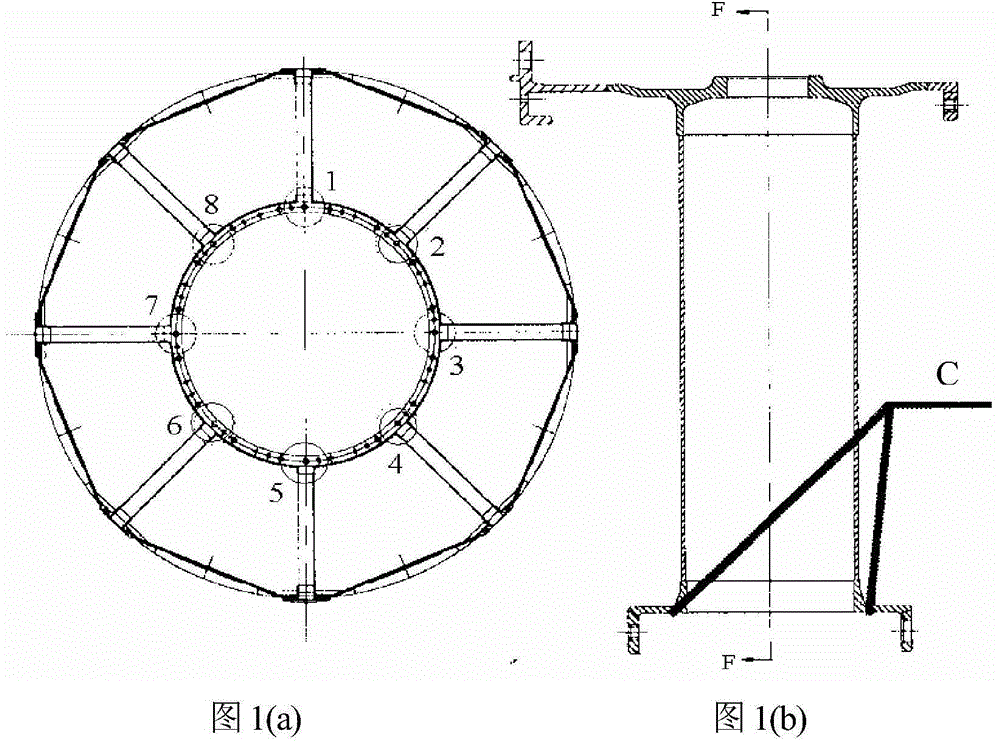

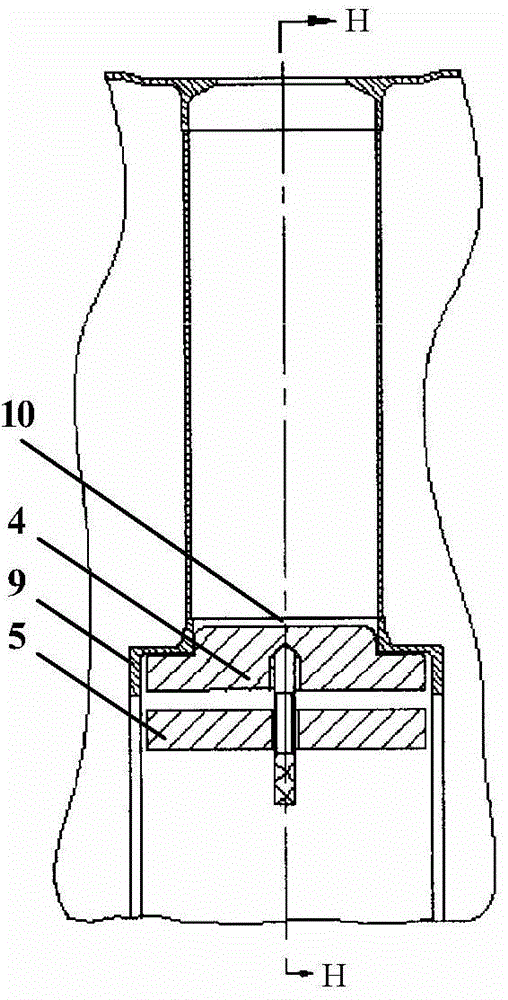

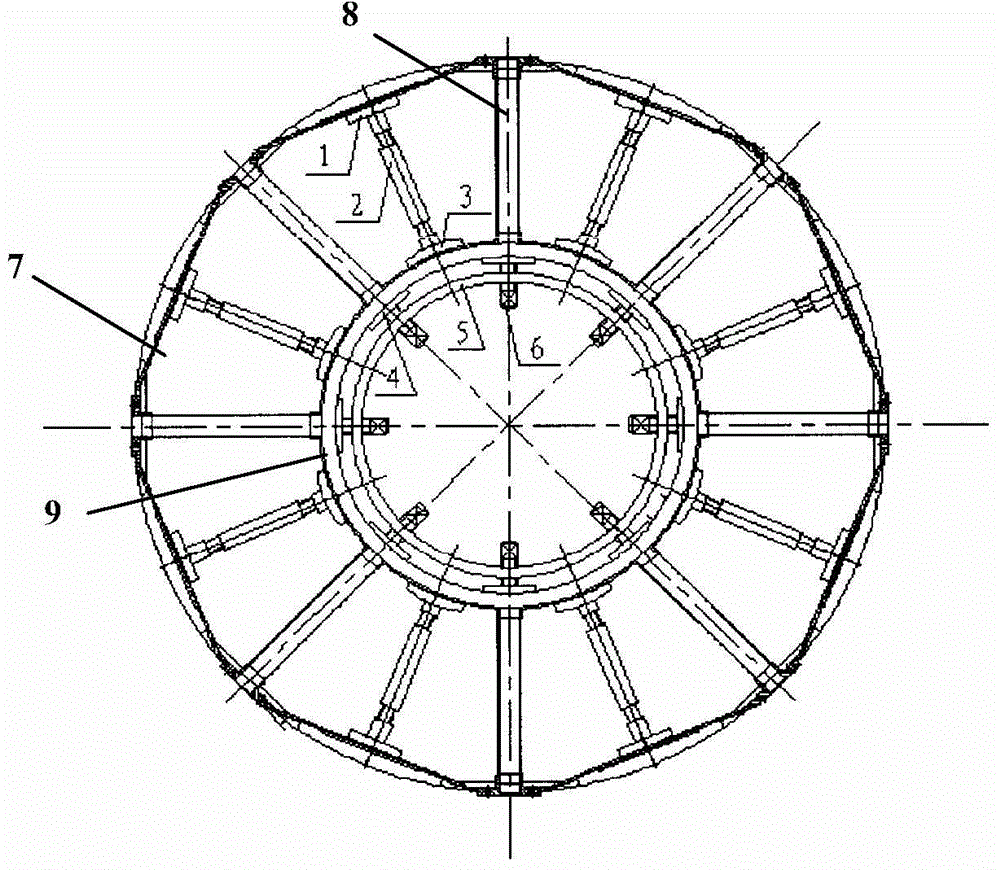

Method and tooling for controlling deformation of nickel-based ageing-strengthening high-temperature alloy casing welding assembly

ActiveCN103551770AAvoid fatigue crackingMeet reliabilityWelding/cutting auxillary devicesAuxillary welding devicesWelding residual stressElectron

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Lens array and optical module including the same

A lens array satisfies a+b+d1+e+ΔL≦W1 where:a: positional accuracy of first lens faces 11, b: positional accuracy of second lens faces 12, d1: positional accuracy of light-emitting elements 7, e: positional accuracy of optical fibers 5, ΔL=α×ΔT×L (α: coefficient of linear expansion of lens array main body 4; ΔT: temperature change in the lens array main body 4; and L: distance from a fixed position on a first surface 4a to a position of a lens face on the first surface 4a farthest from the fixed position),W1: a distance between attachment positions before and after movement, under a premise that a photovoltaic device 3 is moved from an attachment position at which optical coupling efficiency between the light-emitting elements 7 and fiber ends 5a indicates a maximum efficiency to an attachment position at which efficiency reduction equivalent to 2 dB is indicated.

Owner:ENPLAS CORP

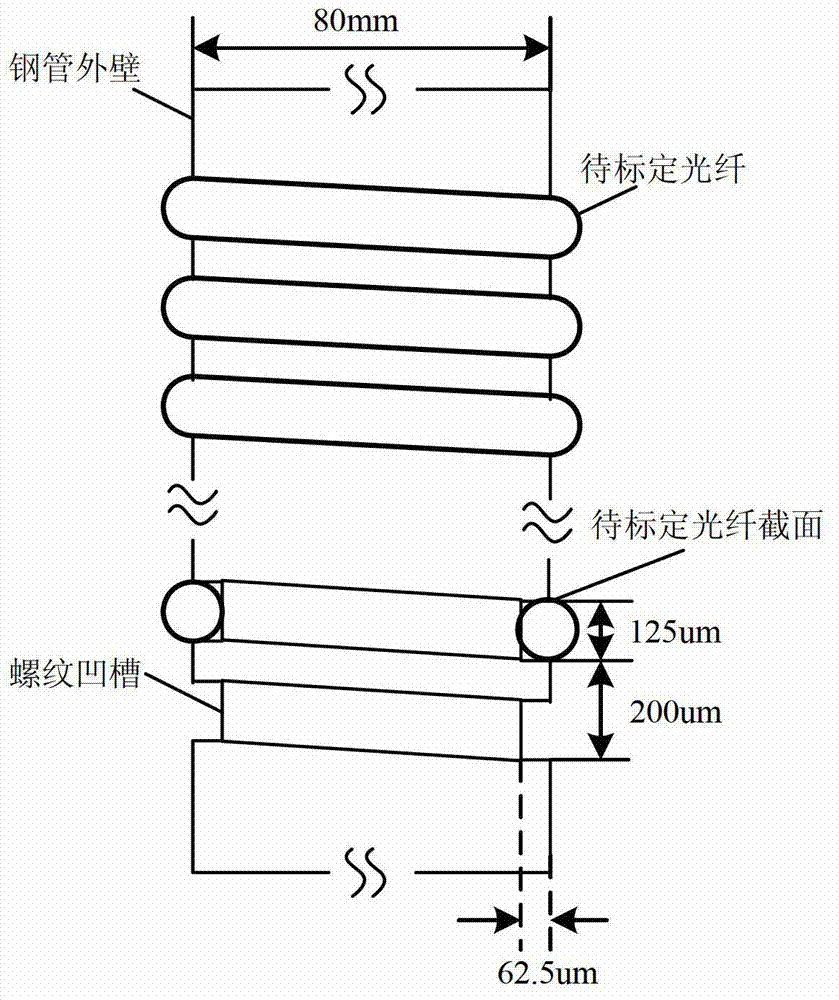

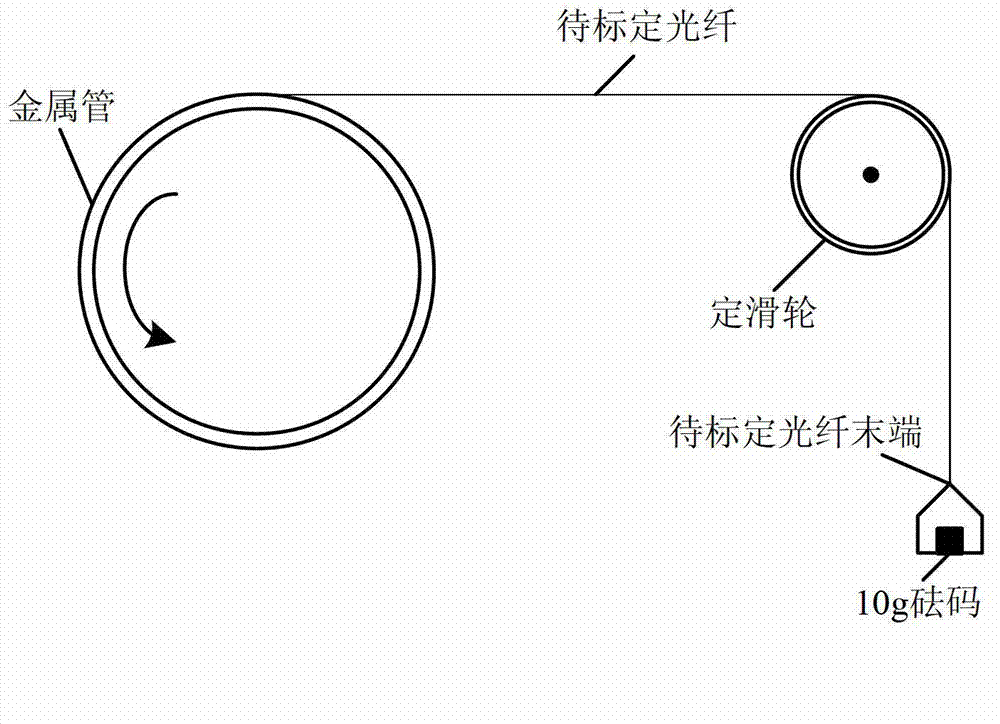

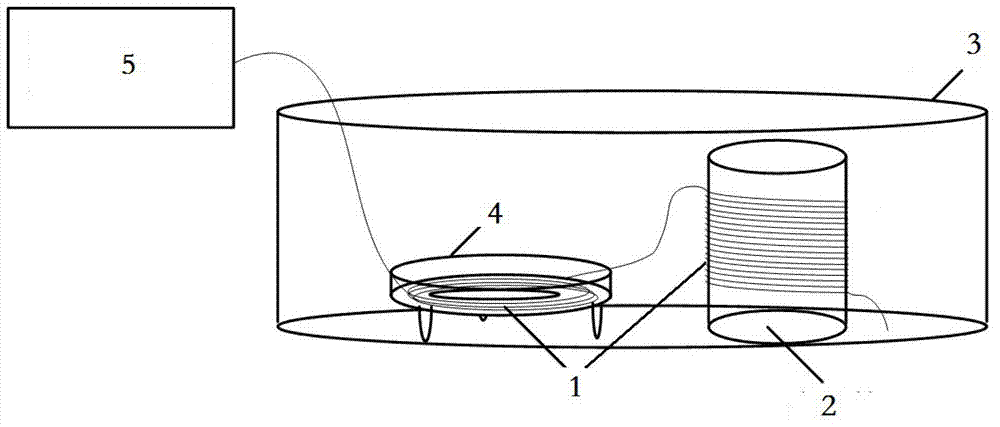

Optical fiber strain and temperature simultaneous calibration device and method based on Brillouin scattering

InactiveCN103115642AControl lengthEnsure consistencyMeasurement devicesPlastic optical fiberHigh strain

The invention belongs to the technical field of distribution-type optical fiber sensing measurement, in particular to an optical fiber strain and temperature simultaneous calibration device and a method based on Brillouin scattering. The optical fiber strain and temperature simultaneous calibration device comprises optical fiber Brillouin sensing measurement equipment, a shockproof support frame, a metal pipe and constant-temperature equipment. According to the method, the metal pipe with large and stable linear expansion coefficient is adopted to manufacture the strain calibration device, and the position of an optical fiber is accurately controlled by curving a thread on the outer wall of the metal pipe. Due to the characteristic that the optical fiber on the metal pipe bears strain and temperature at the same time, and the loose optical fiber only bears temperature, the temperature and the strain are calibrated simultaneously. The constant-temperature equipment is used for applying accurate and controllable strain and temperature on the optical fiber and the loose optical fiber on the metal pipe, and calibration of the strain of the optical fiber and temperature coefficient is carried out by means of detailed calibration steps. By means of the strain and temperature high-accuracy simultaneous calibration device and the method of the optical fiber Brillouin sensor, the problems of high strain calibration error and low efficiency of strain and temperature calibration are resolved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

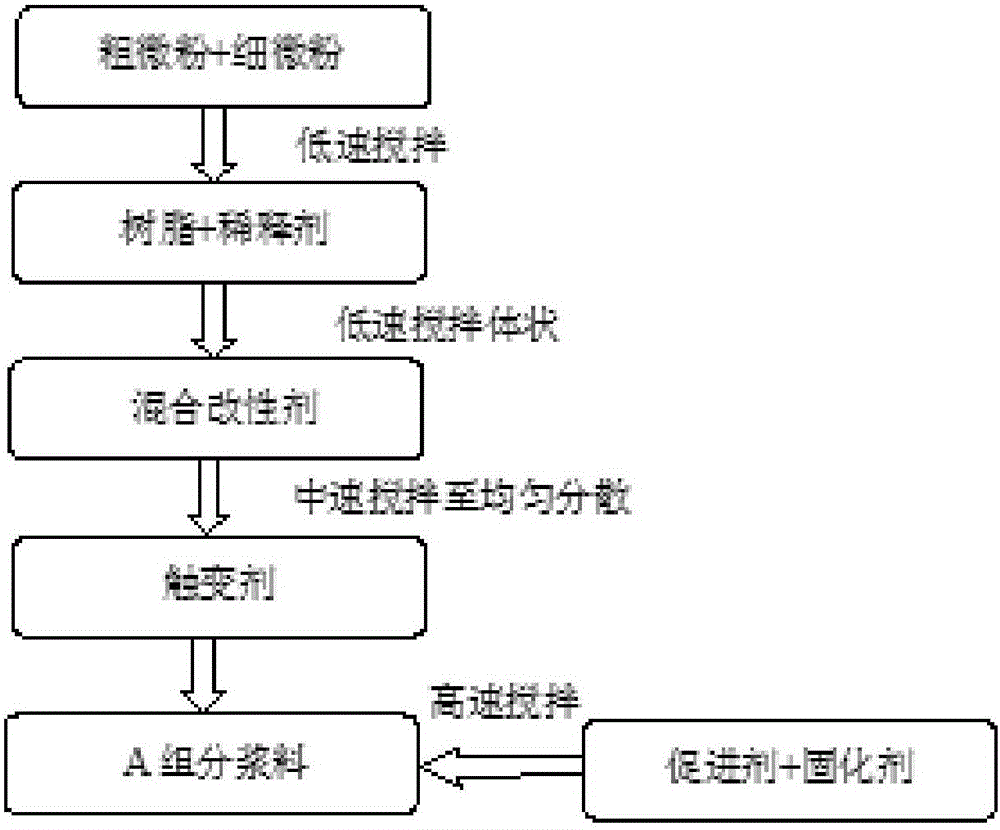

Exterior wall waterproofing heat-insulating decorating integrated material and preparation method thereof

InactiveCN105694625AMeet various style requirements of high-end and high-end exterior finishesShort construction periodFireproof paintsAnti-corrosive paintsPolymer scienceSludge

The invention relates to an exterior wall waterproofing heat-insulating decorating integrated material and a preparation method thereof.The preparation method includes: using conventional resin like polyurea and polyurethane as raw materials, adding compound micropowder prepared from solid waste and sludge, and adding a mixed modifier and a thixotropic agent to prepare A-compound slurry; adding a promoter and a hardener, and performing spray coating, brush coating, roll coating and pouring methods to obtain the exterior wall waterproofing heat-insulating decorating integrated material.The material has the comprehensive advantages of good waterproof effect, high heat insulativity, high hardness, high hole closing rate, low density, good anti-seepage performance, high corrosion resistance, low linear expansion coefficient, high softening temperature, oxidization resistance, aging resistance, flame retardancy and firmness in binding with a substrate.When the material is used for building exterior walls, multiple times of leveling, waterproofing, heat insulating and decorating construction are not needed, on-site moisture-free operation and one-time forming can be realized, and the material is short in construction period, extremely low in cost and great in market prospect.

Owner:NANJING KAIBA ADVANCED MATERIALS CO LTD +1

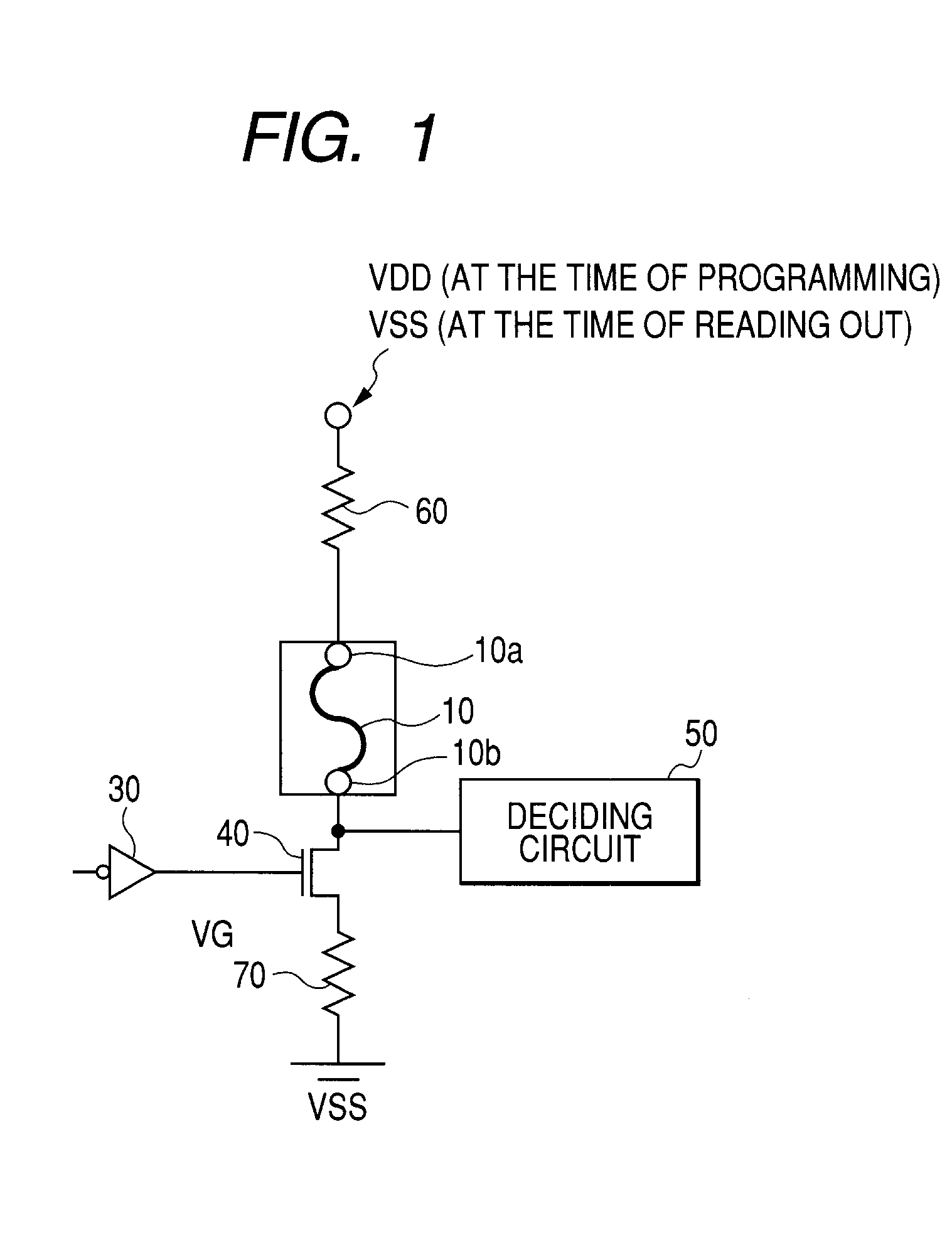

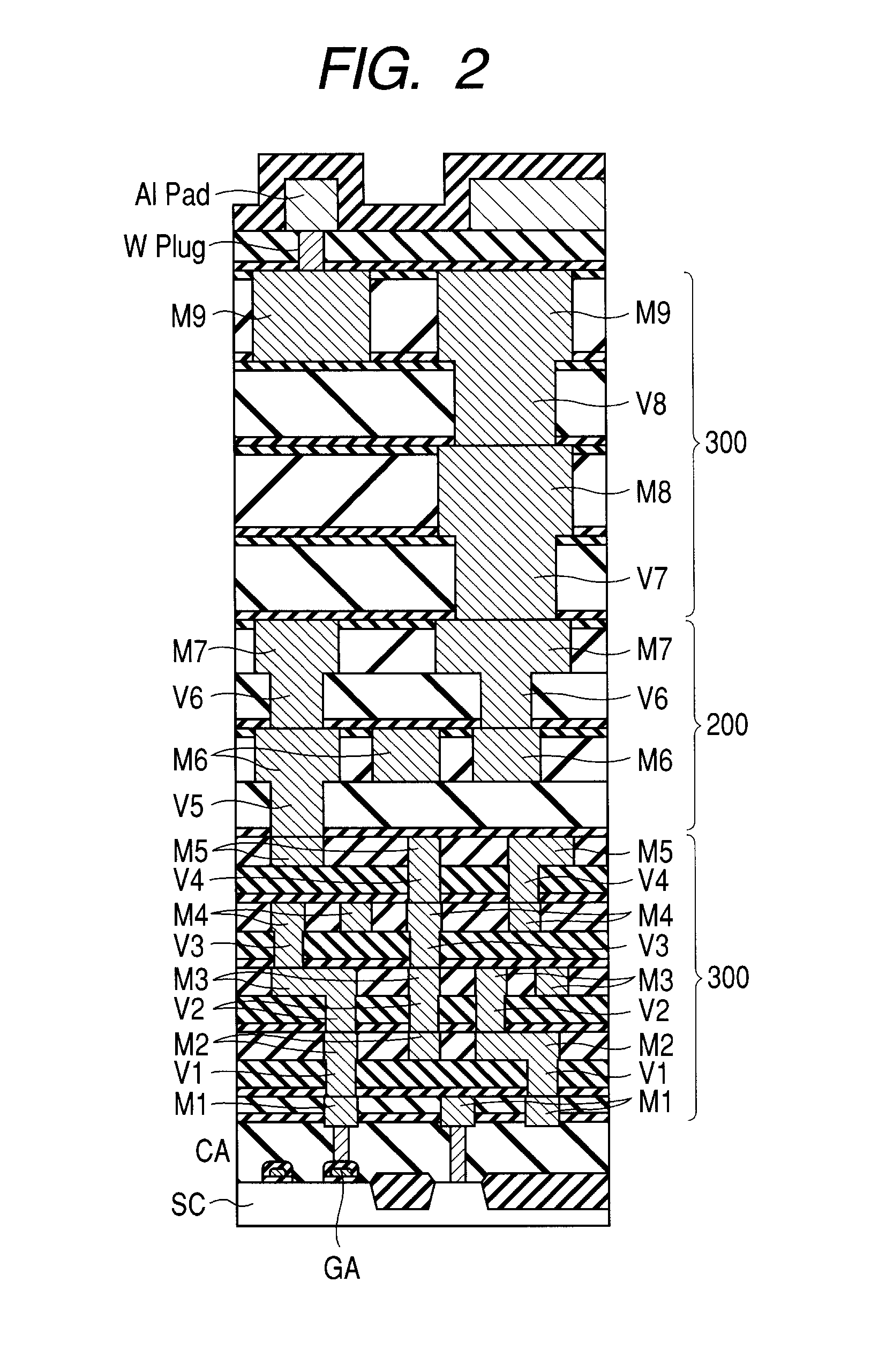

Semiconductor device and a method of increasing a resistance value of an electric fuse

ActiveUS20070210414A1Extension of timeAvoid damageSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceElectric fuses

Provided is a semiconductor device having an electric fuse structure which receives the supply of an electric current to be permitted to be cut without damaging portions around the fuse. An electric fuse is electrically connected between an electronic circuit and a redundant circuit as a spare of the electronic circuit. After these circuits are sealed with a resin, the fuse can be cut by receiving the supply of an electric current from the outside. The electric fuse is formed in a fine layer, and is made of a main wiring and a barrier film. The linear expansion coefficient of each of the main wiring and the barrier film is larger than that of each of the insulator layers. The melting point of each of the main wiring and the barrier film is lower than that of each of the insulator layers.

Owner:RENESAS ELECTRONICS CORP

Semiconductor device

ActiveUS20070138624A1Reduce warpageWarpage of the resin package can be reducedSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

One of the aspects of the present invention is to provide a semiconductor device, which includes a radiating plate, a wiring patterned layer on the radiating plate via an insulating layer, at least one semiconductor chip mounted on the wiring patterned layer. The semiconductor chip has a surface electrode. The semiconductor device further includes a conductive lead plate electrically connected with the surface electrode of the semiconductor chip, and a resin package of thermoplastic resin having anisotropic linear expansion coefficient varying based upon directions. The resin package covers the wiring patterned layer, the semiconductor chip, the conductive lead plate, and at least a portion of the radiating plate. The conductive lead plate extends in a direction which provides the resin package with the maximum linear expansion coefficient. In the semiconductor device so structured, the warpage of the resin package is reduced both in longitudinal and transverse directions.

Owner:MITSUBISHI ELECTRIC CORP

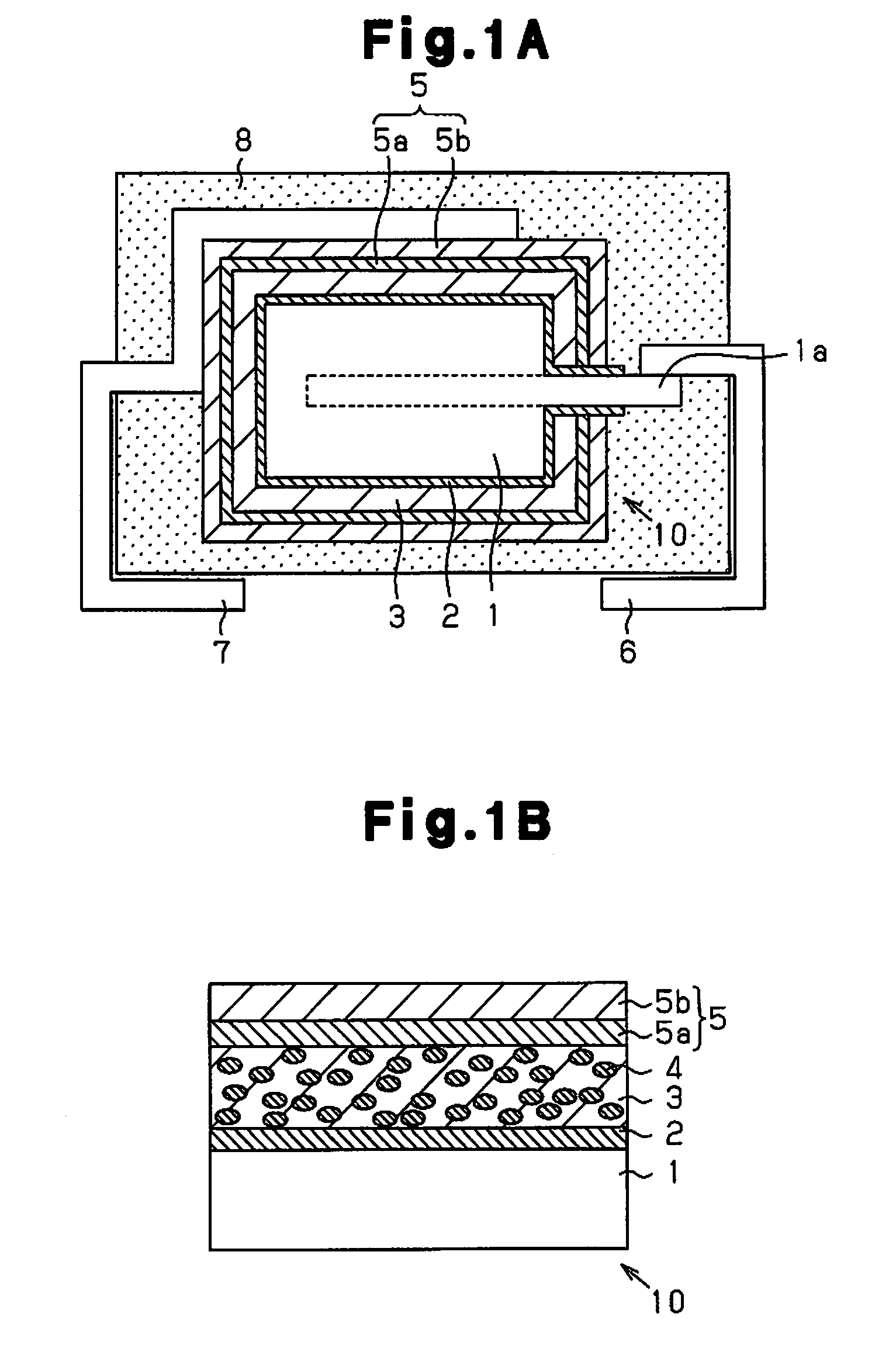

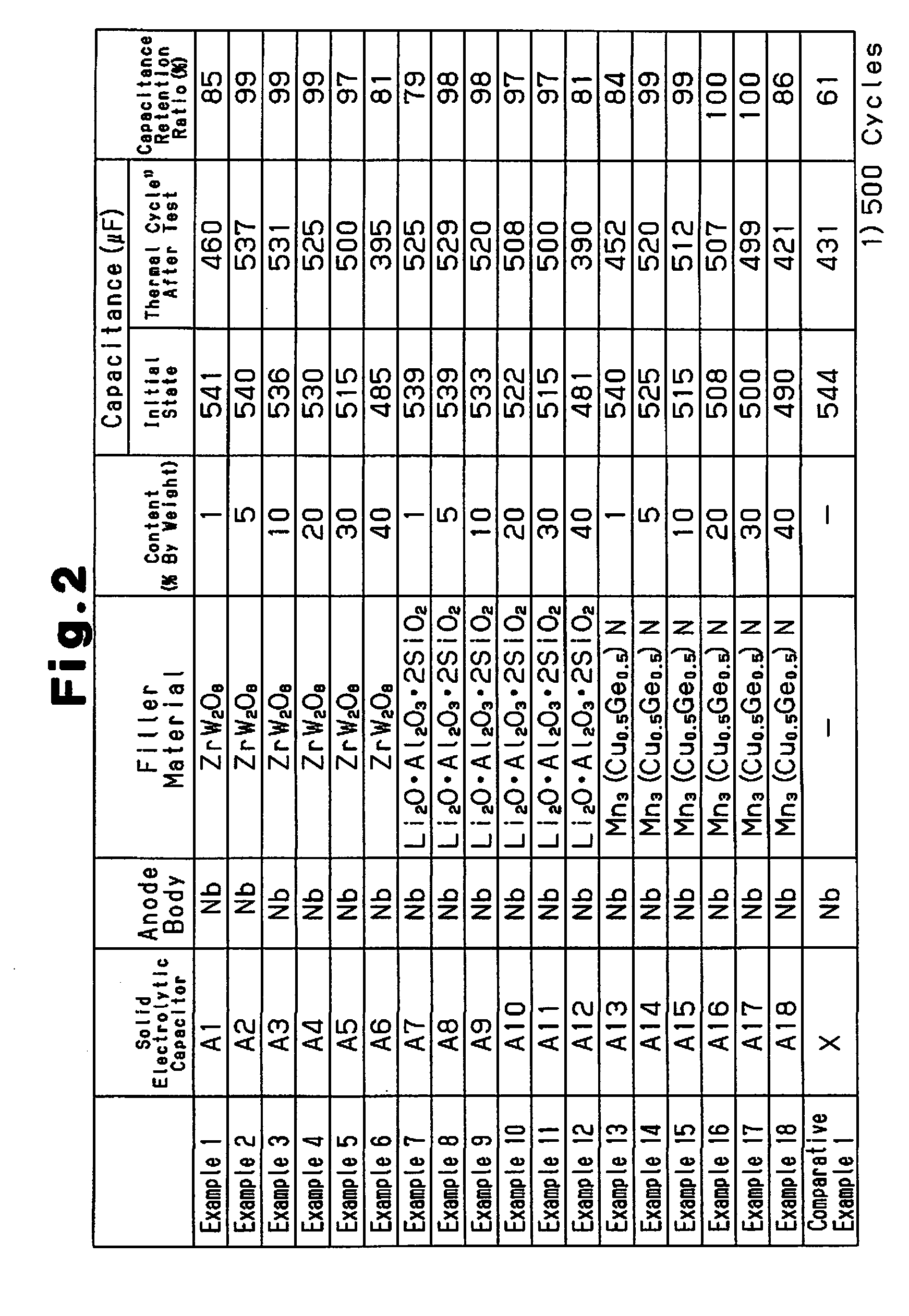

Solid electrolytic capacitor

InactiveUS20090231782A1Suppression capacitanceDuplicating/marking methodsActive material electrodesCapacitanceElectrolysis

A solid electrolytic capacitor that suppresses capacitance decrease caused by thermal loads. The solid electrolytic capacitor includes an anode body, a dielectric layer formed on a surface of the anode body, a conductive polymer layer formed on the dielectric layer, and a cathode layer formed on the conductive polymer layer. The conductive polymer layer contains a filler material having a negative linear expansion coefficient.

Owner:SANYO ELECTRIC CO LTD

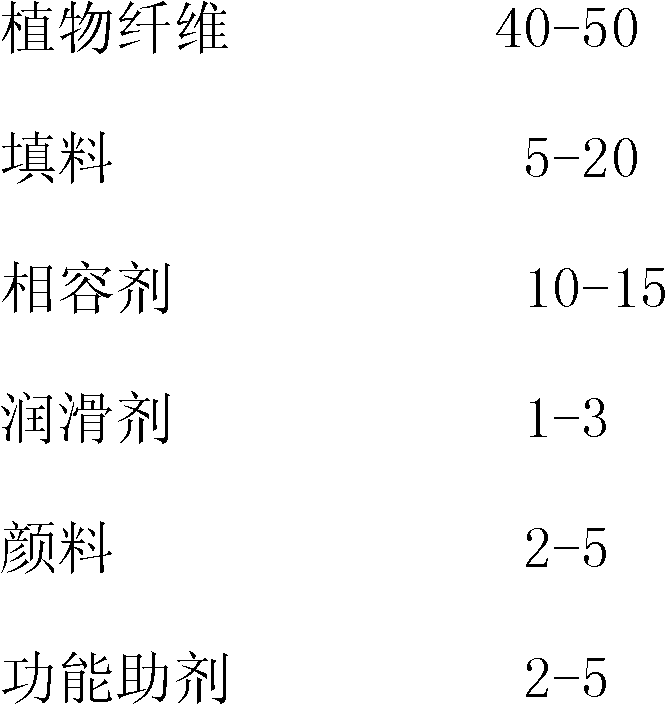

Low-temperature type wood-plastic floor and preparation technology thereof

The invention discloses a low-temperature type wood-plastic floor and a preparation technology thereof. The floor comprises substances of: plastic particles, plant fiber, a filling material, a compatibilizer, a lubricant, a pigment, and functional auxiliary agents. Compared with existing technologies, according to the invention, melted and modified plastic particles are adopted, the components are well formulated, and the mold of the product is improved. Under a temperature of -34 DEG C to 60 DEG C, the linear expansion coefficient of the prepared product is smaller than 5*10<-5>. When the product is processed through three times of freeze-thaw cycling tests according to ASTM D6109-10, the bending strength retention of the product is more than 97%.

Owner:HUANGSHAN HUASU NEW MATERIAL SCI & TECH CO LTD

Glass fiber reinforced polypropylene composite material for car radiator grid and preparation process thereof

The invention discloses a glass fiber reinforced polypropylene composite material for a car radiator grid and a preparation process thereof. The composite material comprises the following components in percentage by weight: 32-78% of polypropylene, 0-2% of a thermal stabilizer, 0-2% of an additive, 0-2% of an illumination stabilizer, 0-2% of a nucleating agent, 5-20% of a flexibilizer, 2-10% of a compatilizer and 15-30% of chopped glass fiber. Due to the adoption of the chopped glass fiber for filling, the rigidity and the heat resistance of the material are greatly improved, the linear expansion coefficient (CLTE) of the material can be also reduced, and the problems of size change and deformation of a workpiece due to rapid change of external environment temperature are solved. The prepared composite material is excellent in heat resistance, high in rigidity, excellent in size stability and weather resistance and high in impact resistance, and satisfactorily meets the demand of the car radiator grid.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com