Patents

Literature

1628results about "Multiple fixed capacitors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

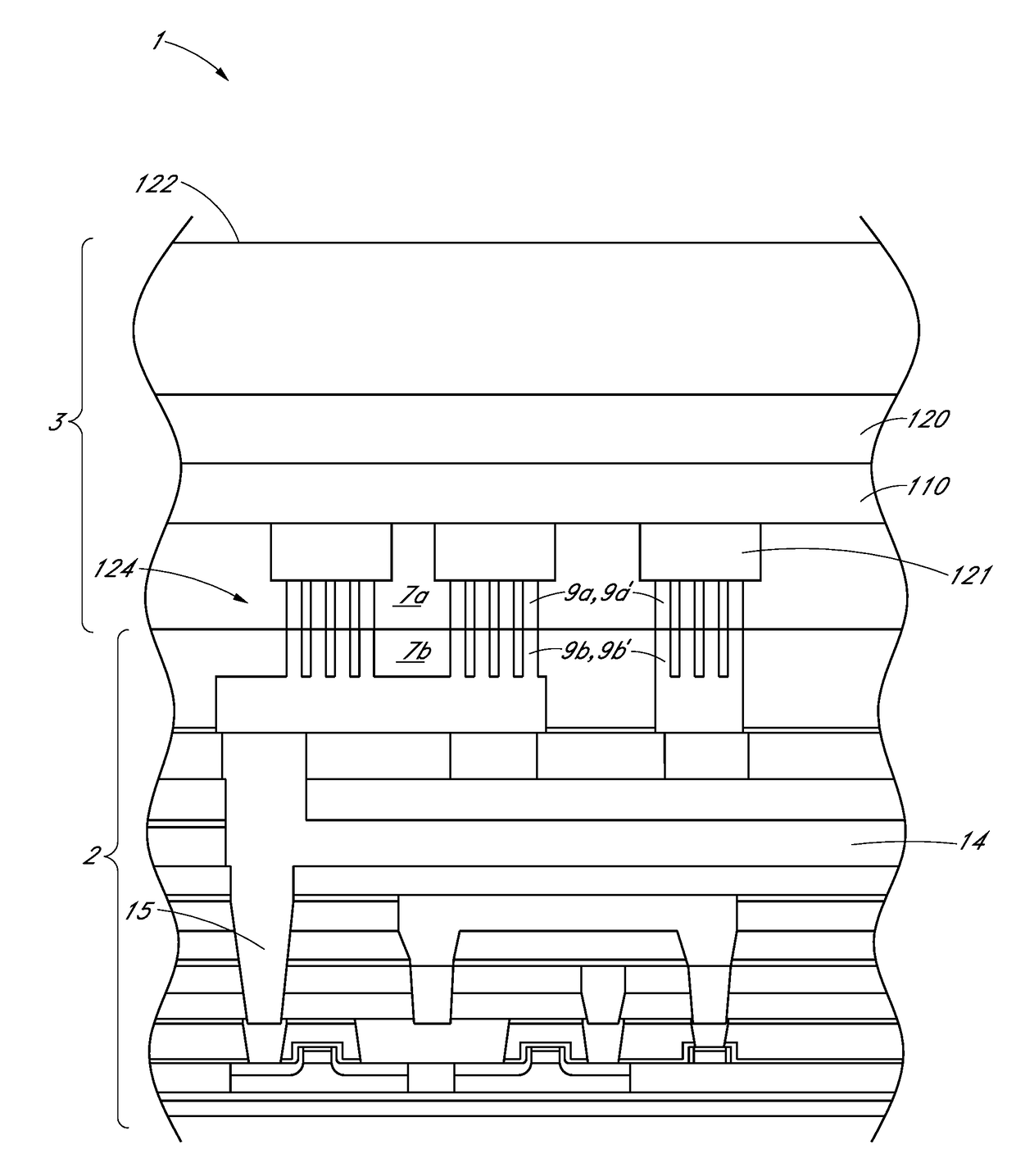

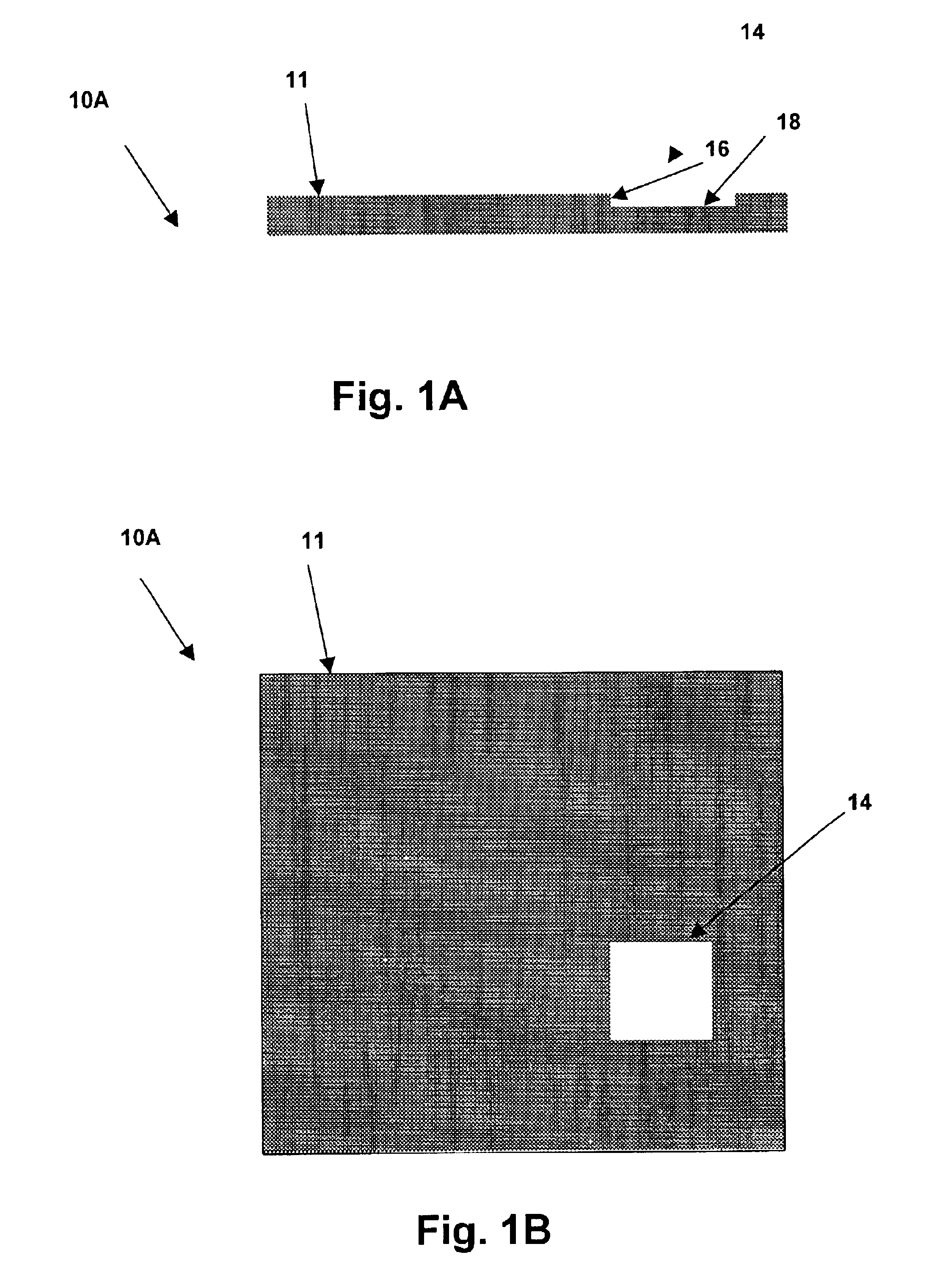

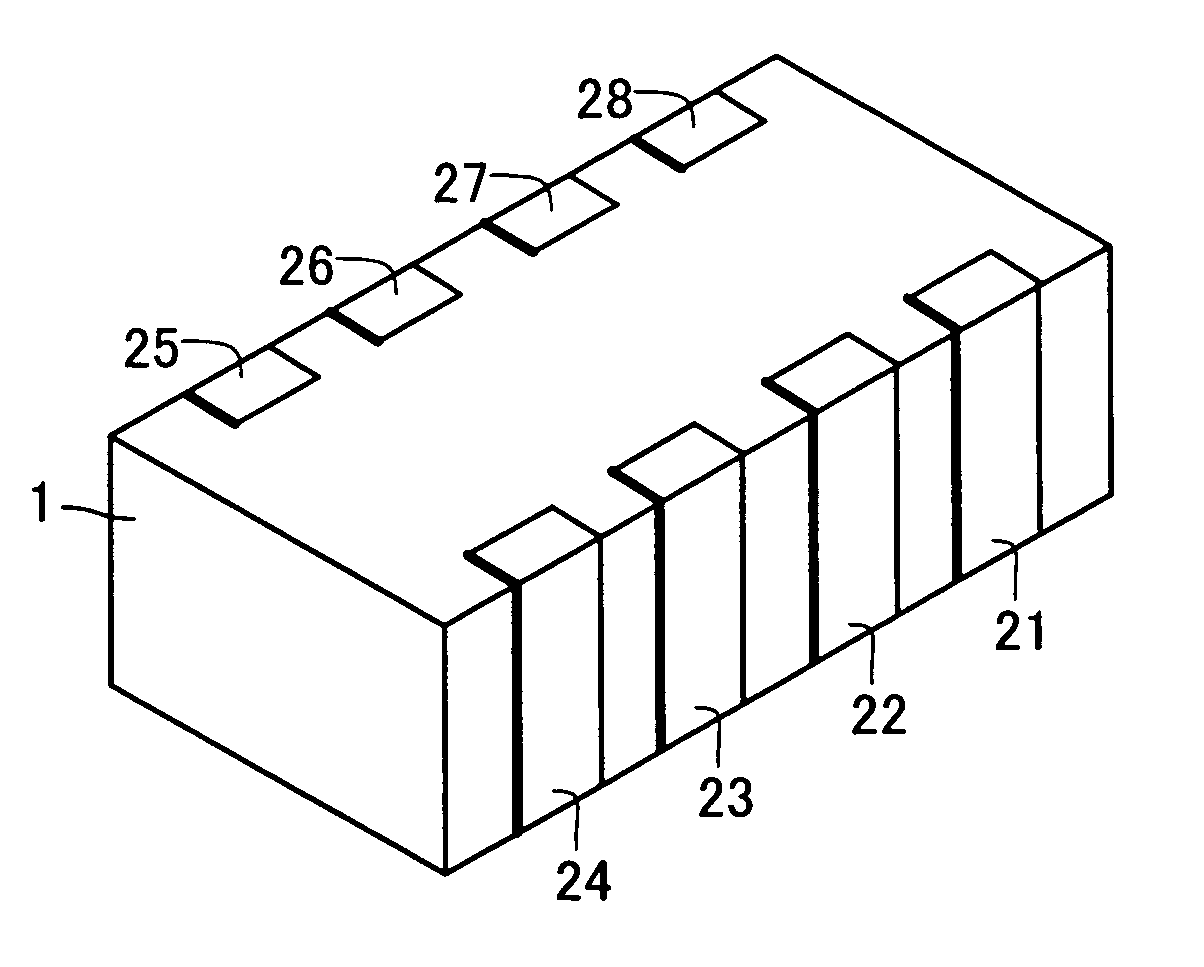

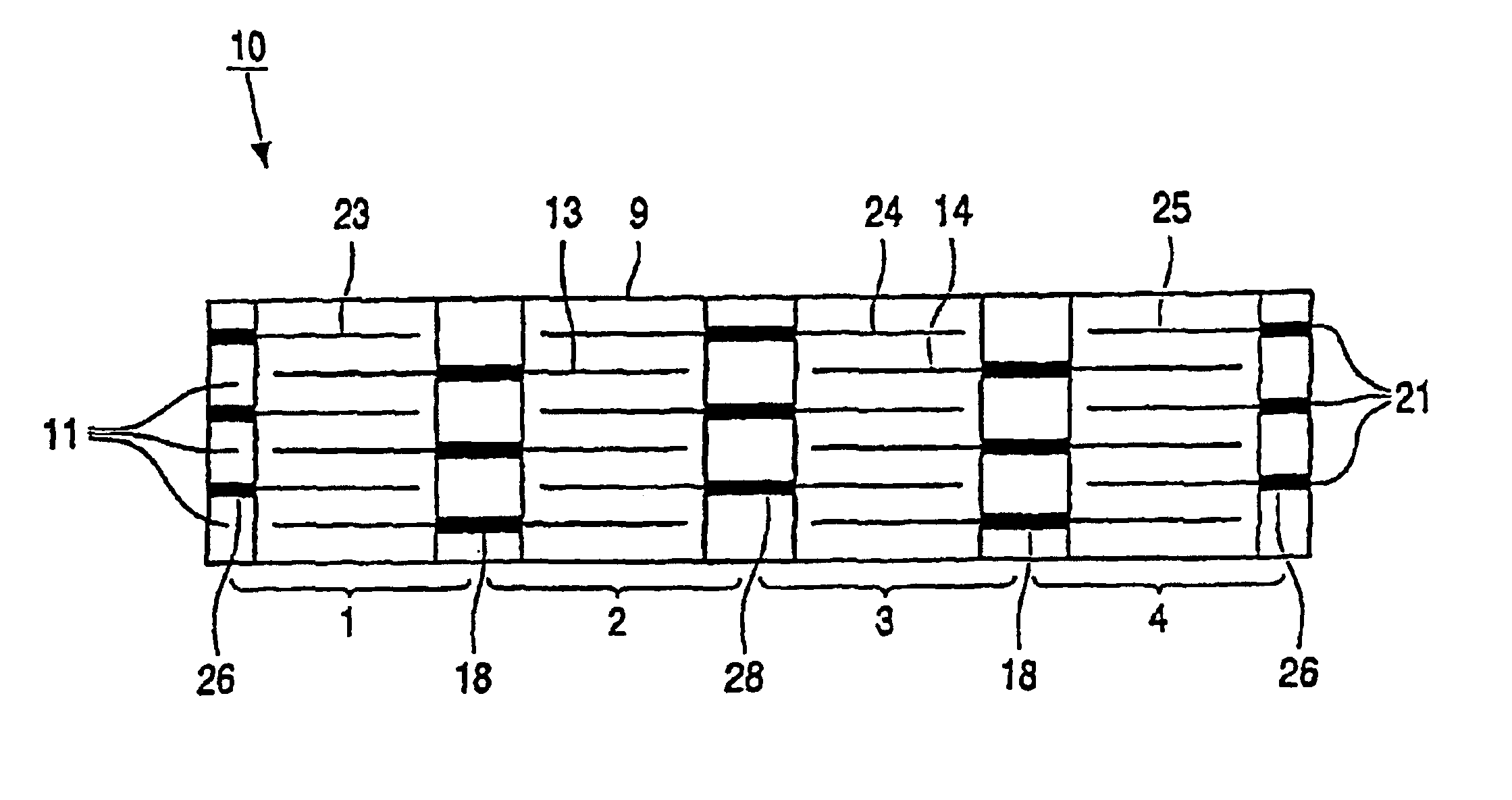

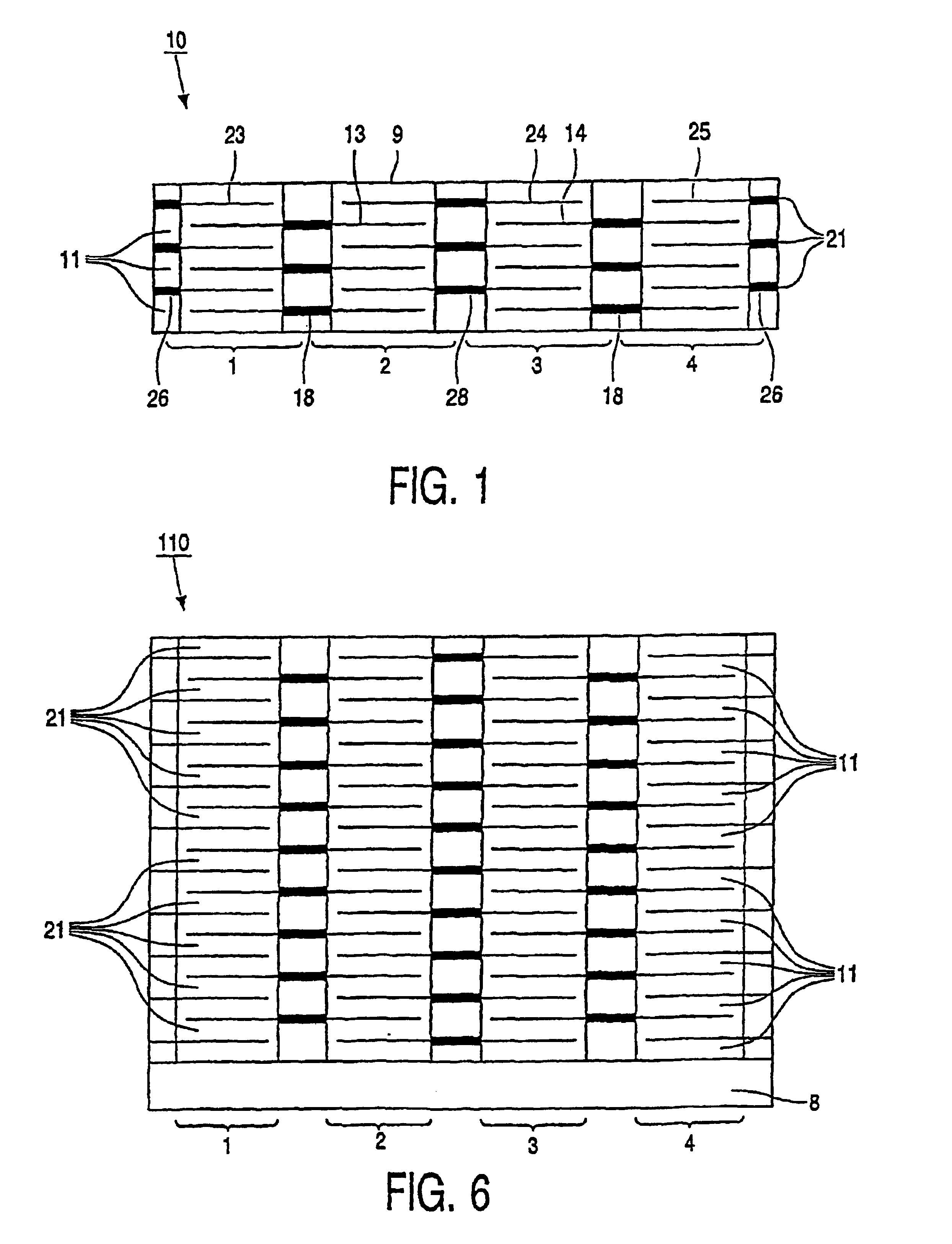

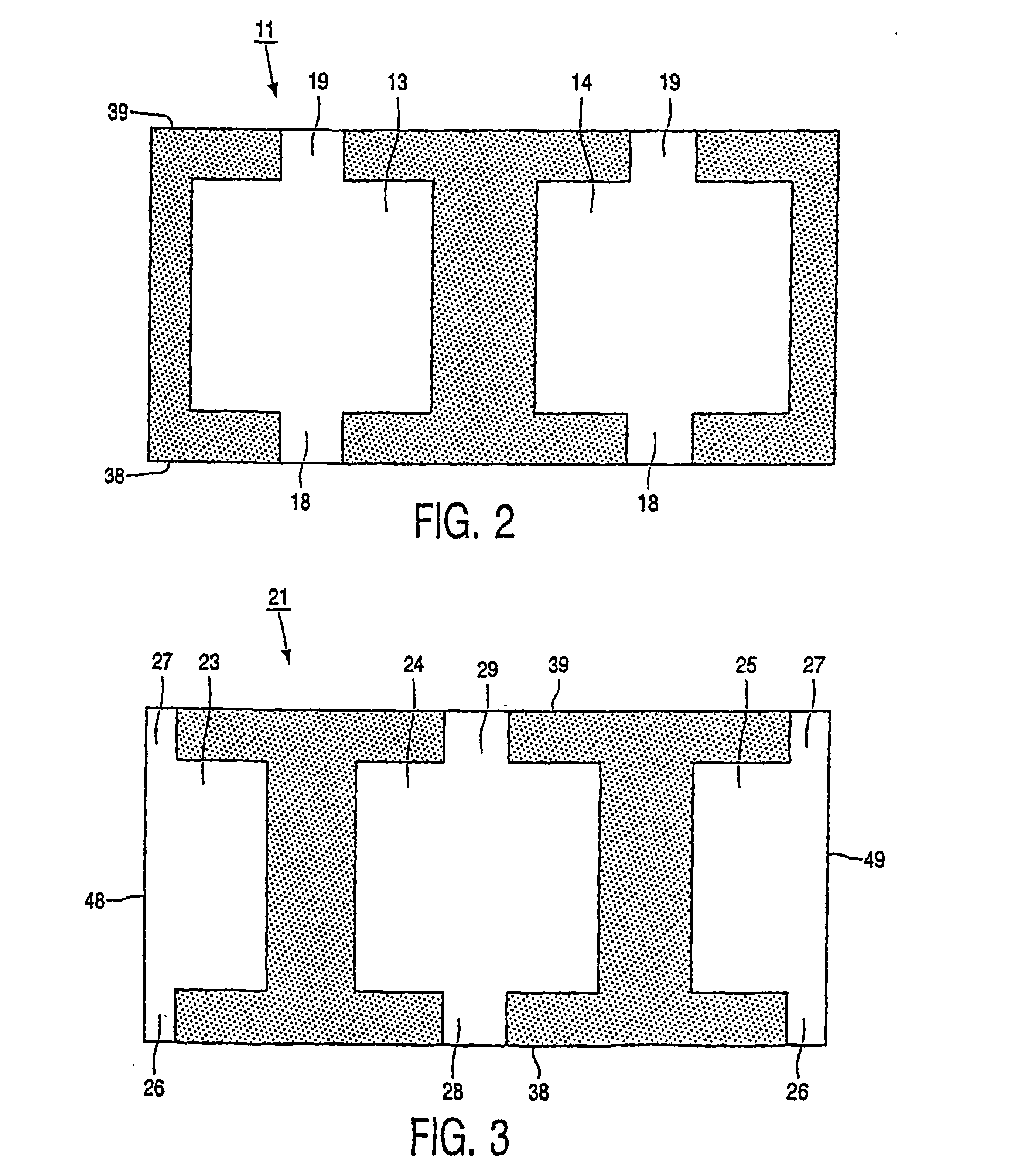

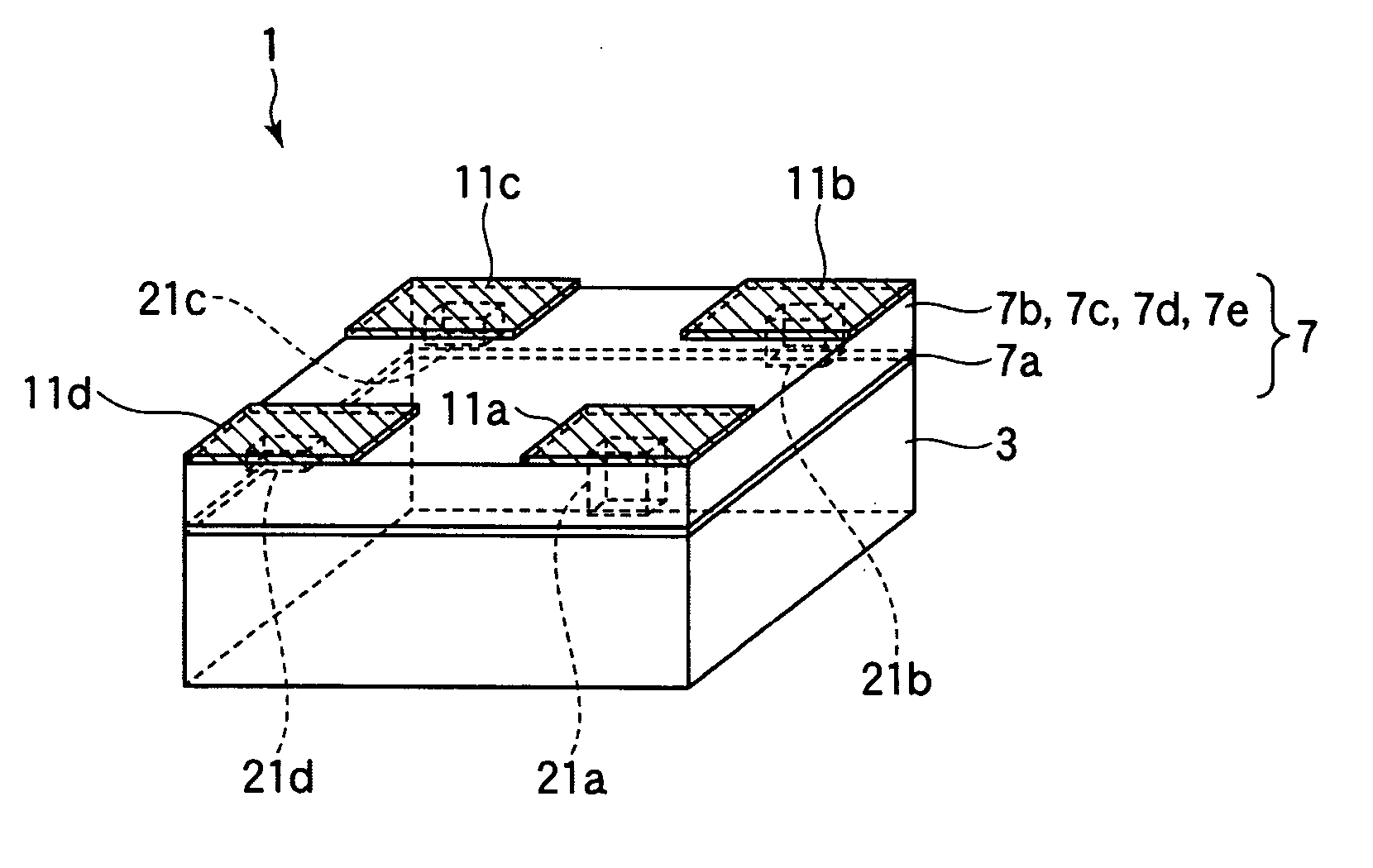

Plated terminations

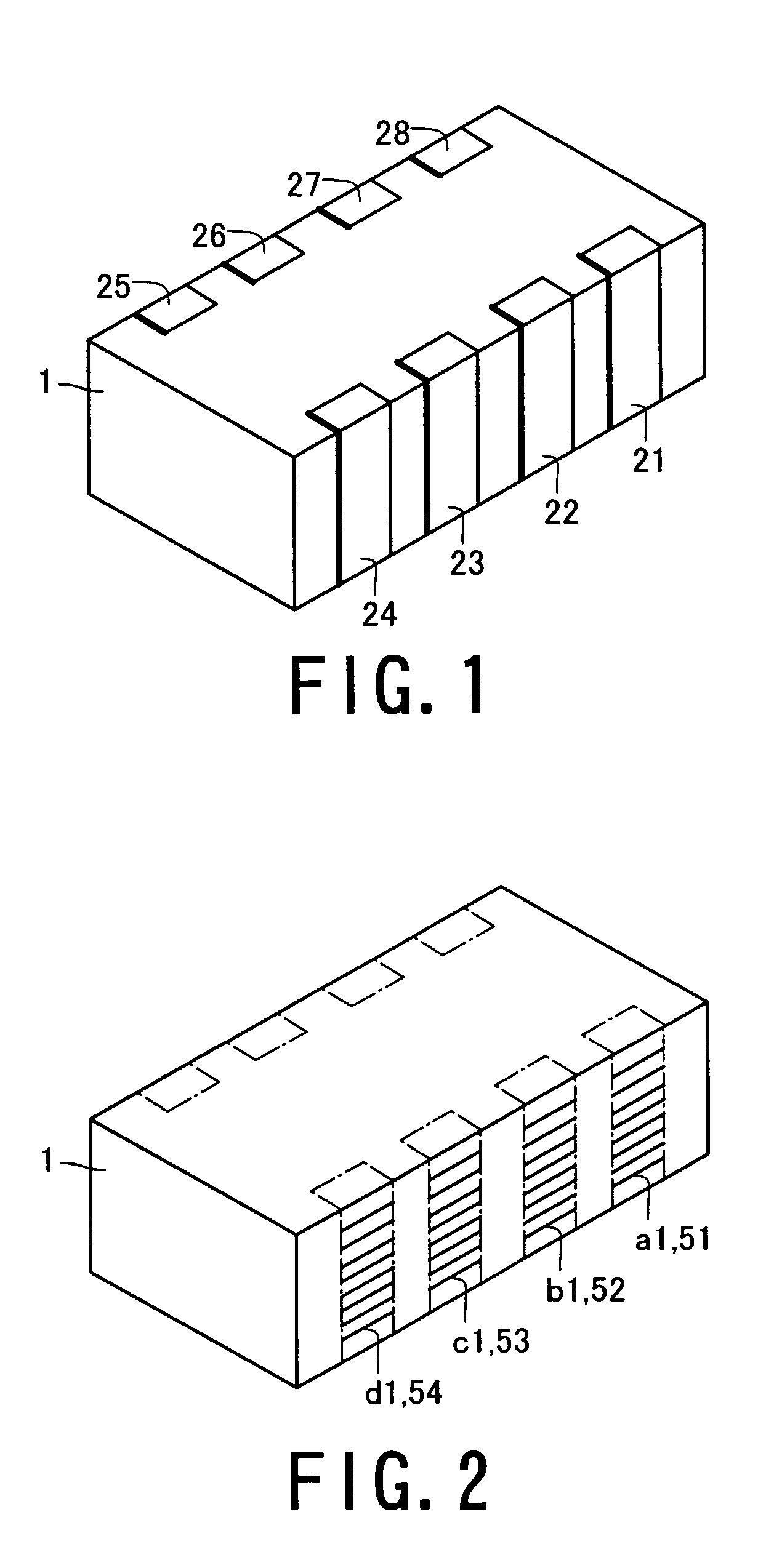

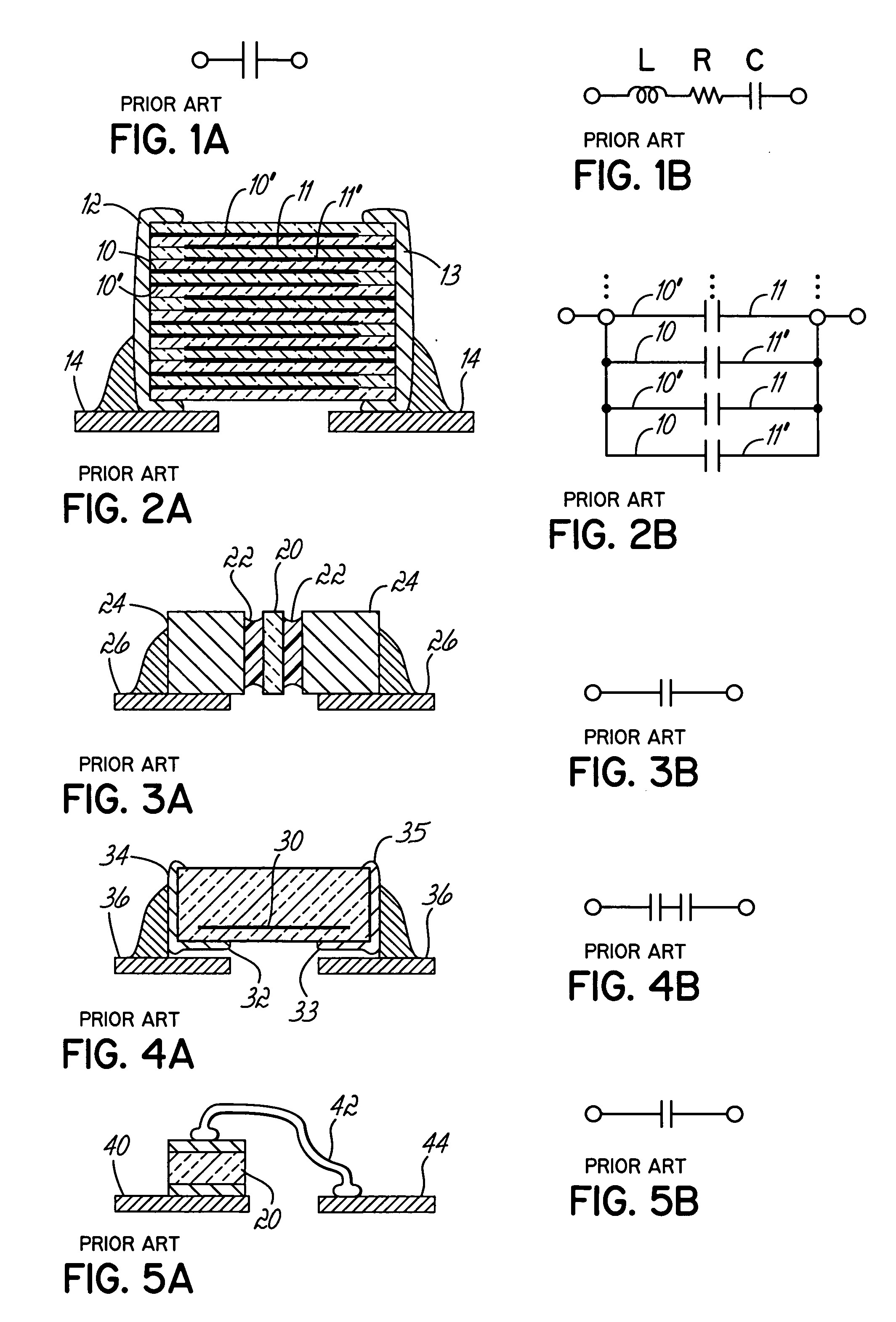

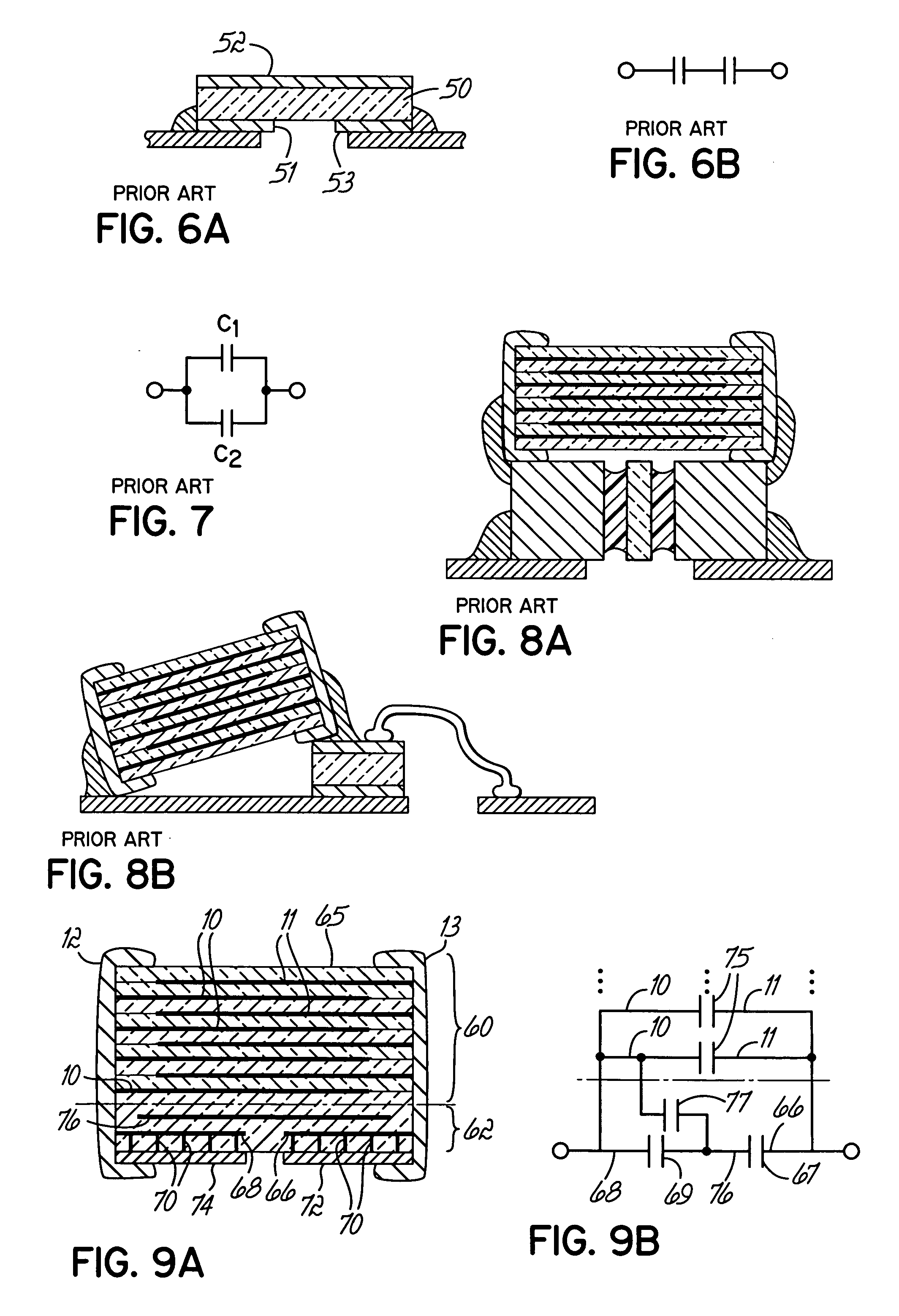

InactiveUS6960366B2Improved termination featureEliminate and greatly simplifyResistor terminals/electrodesFinal product manufactureTermination problemEngineering

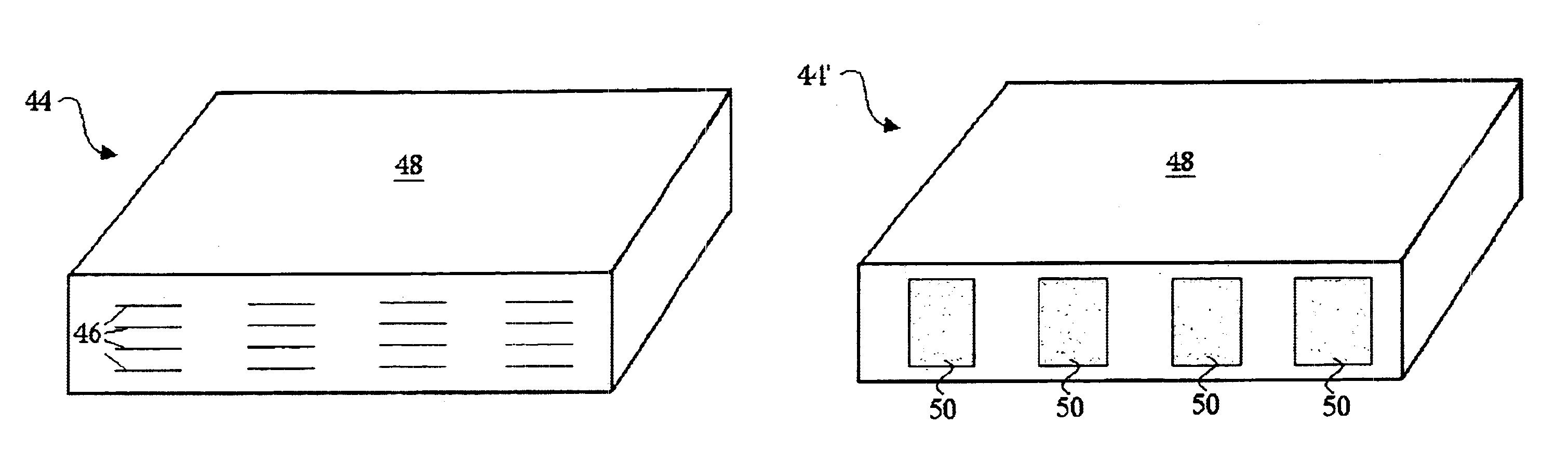

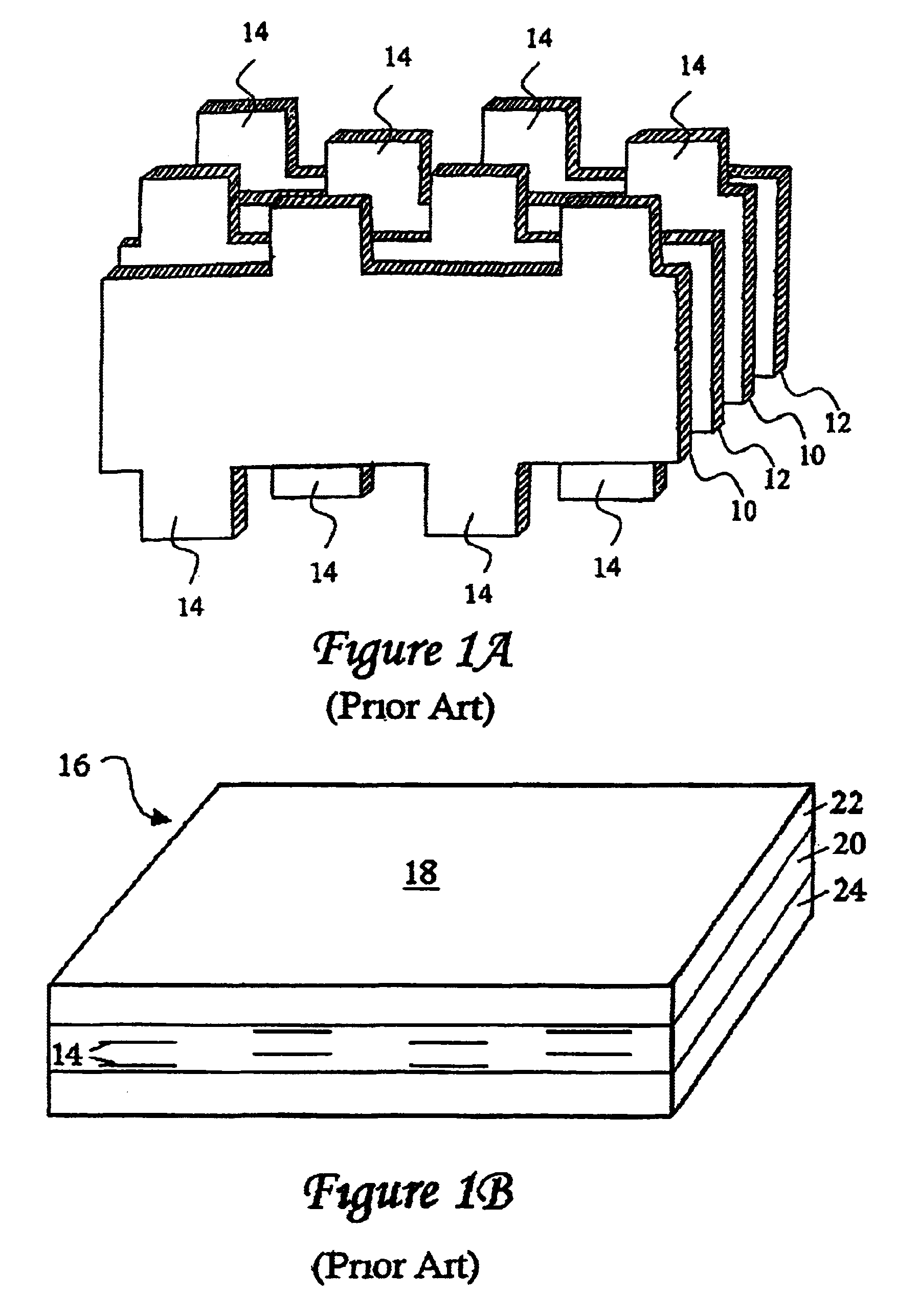

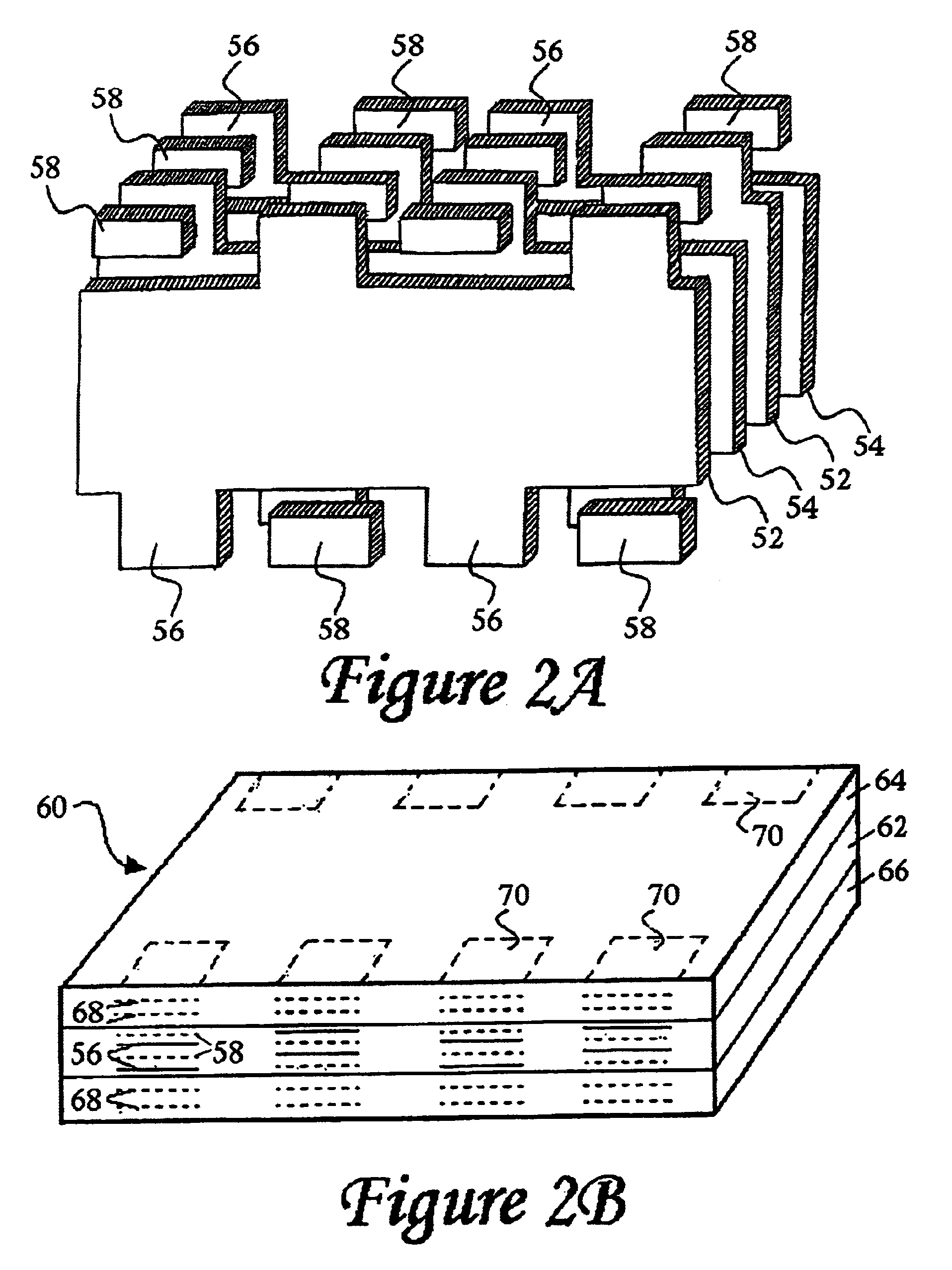

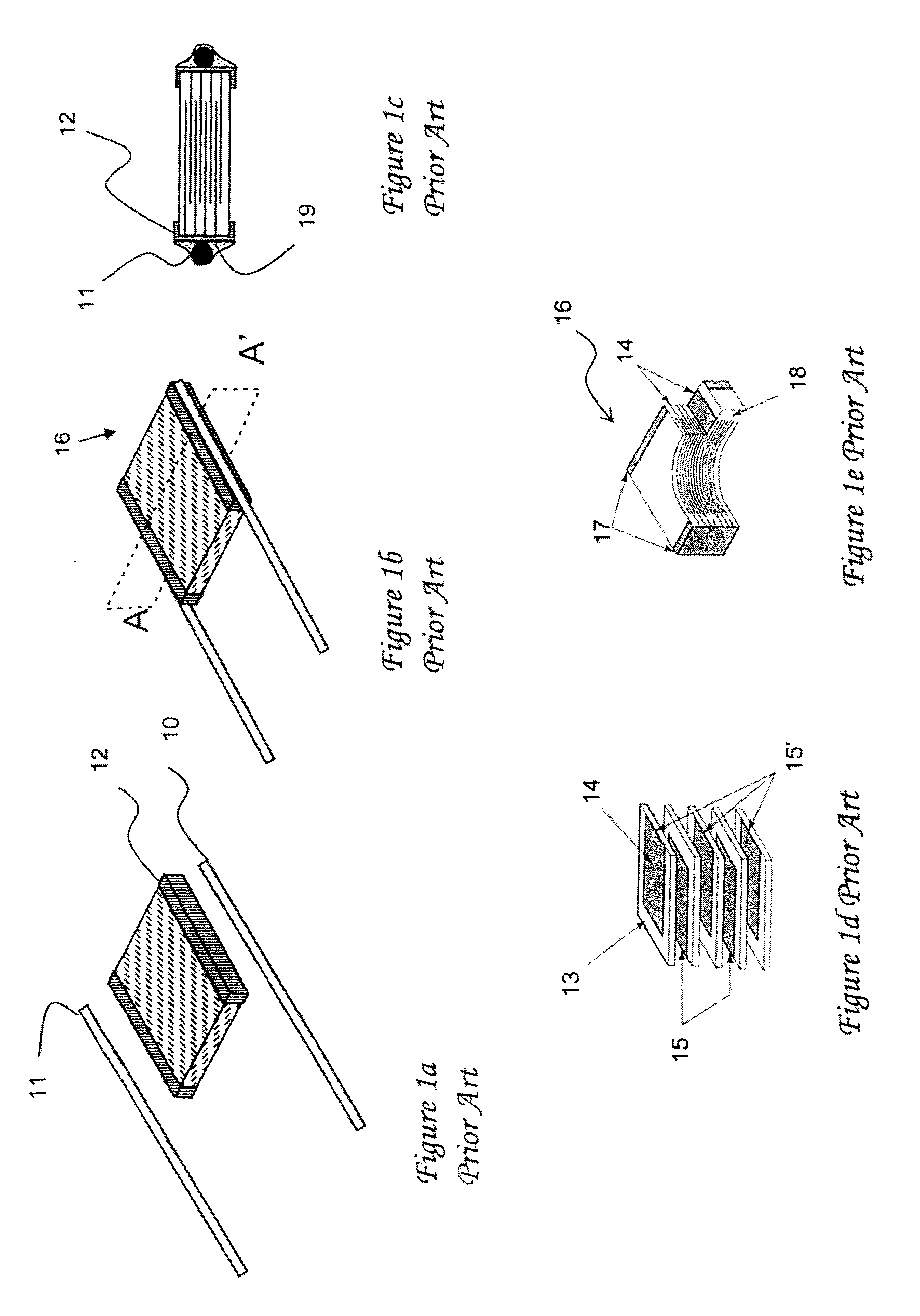

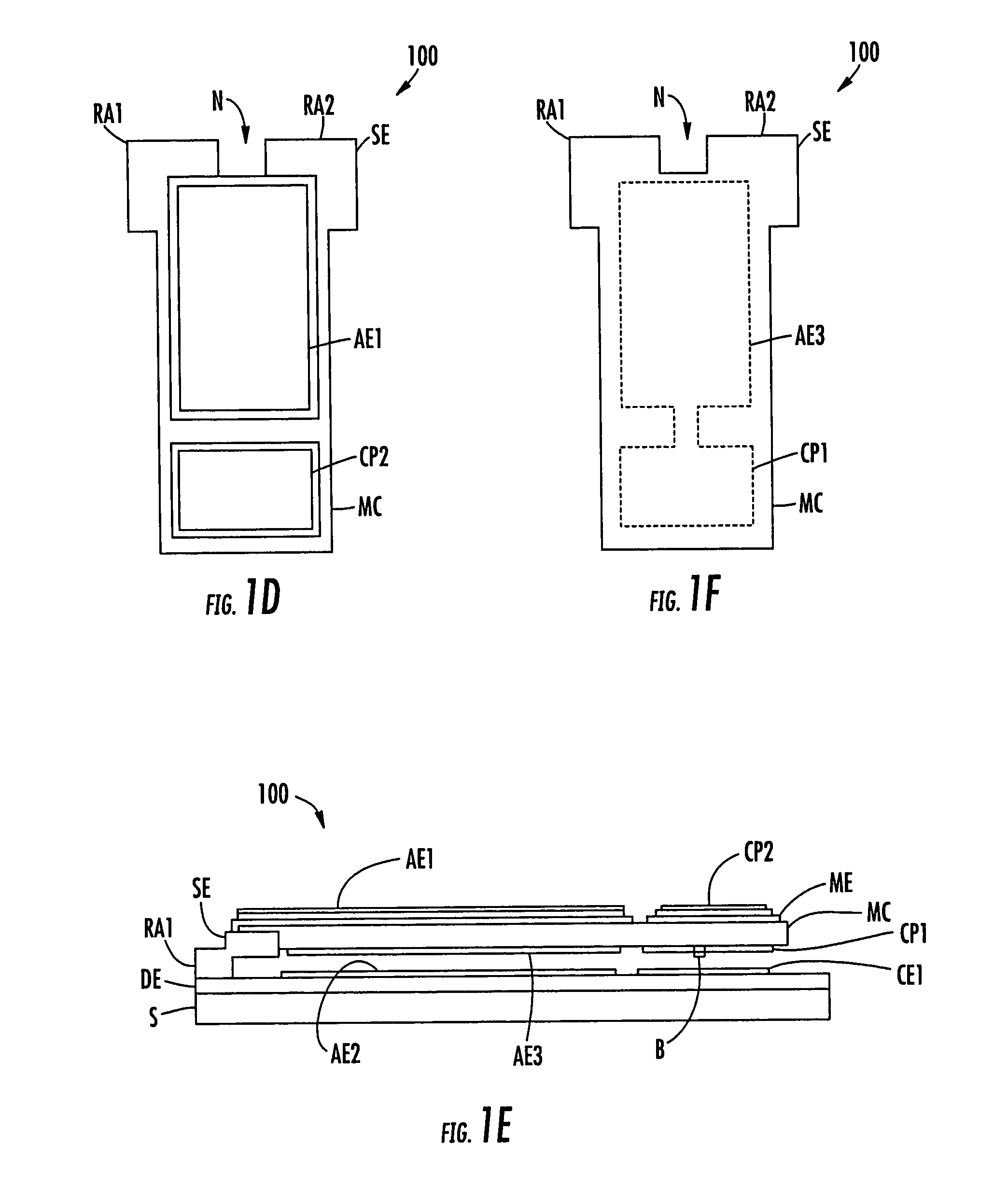

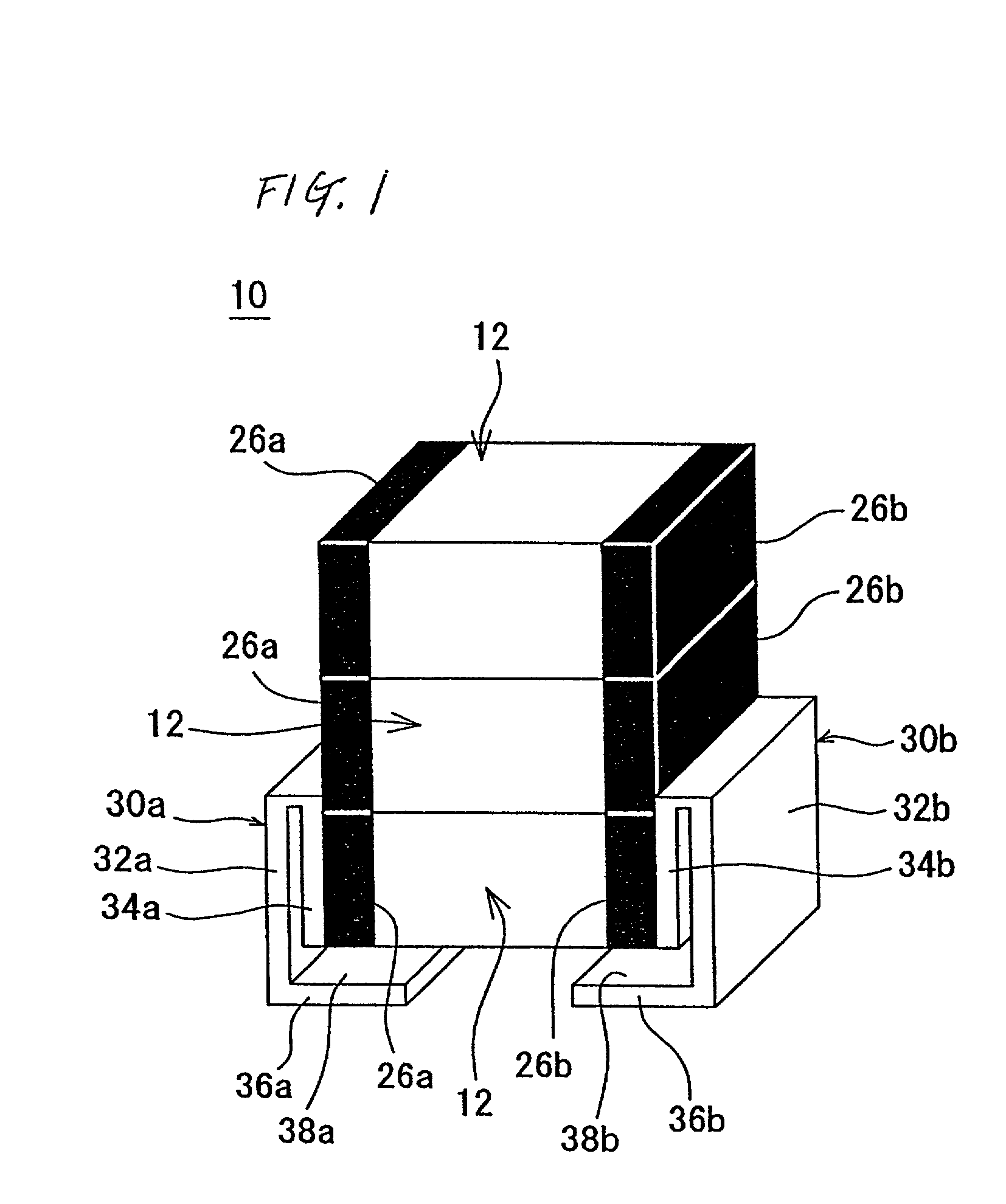

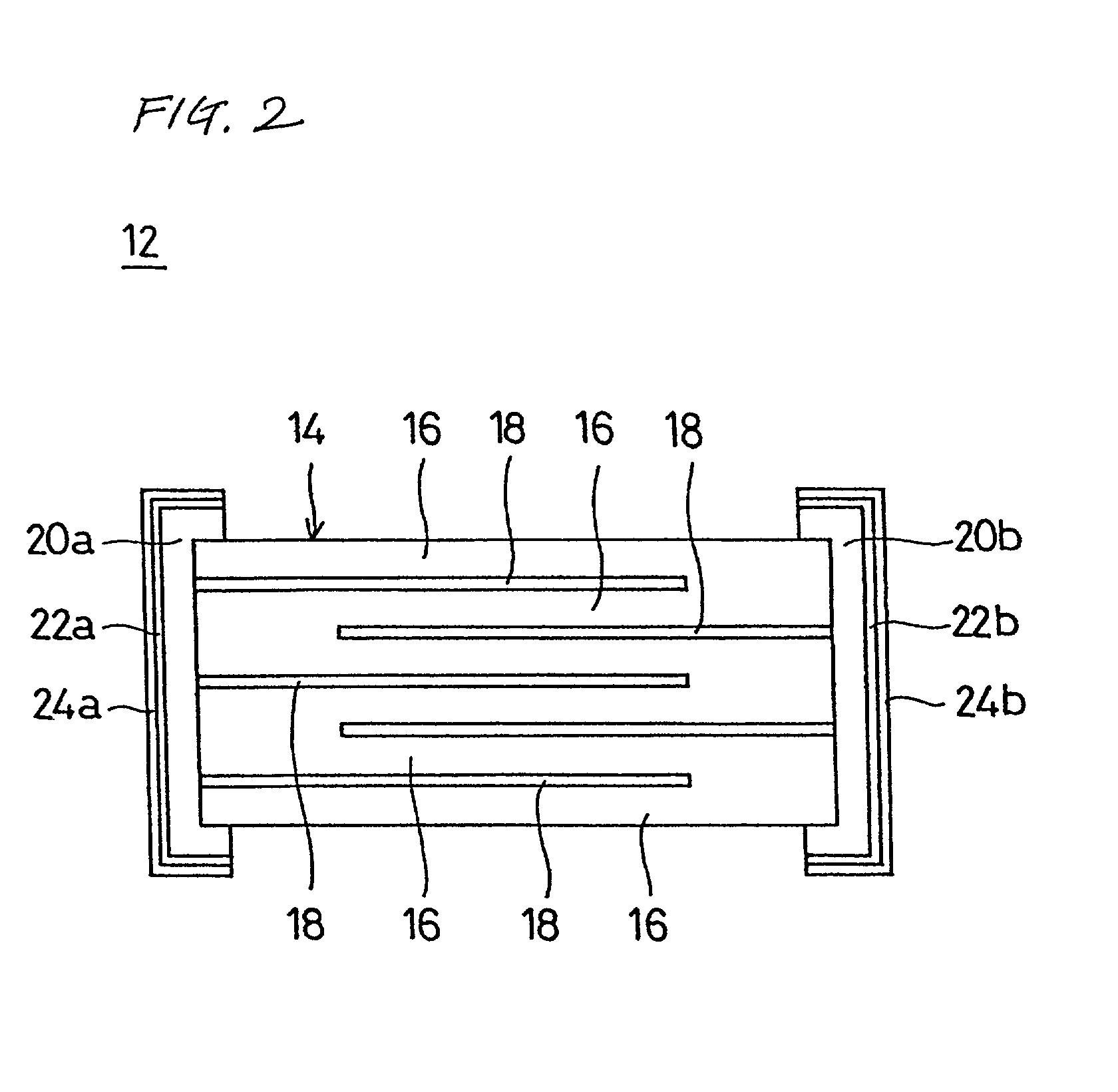

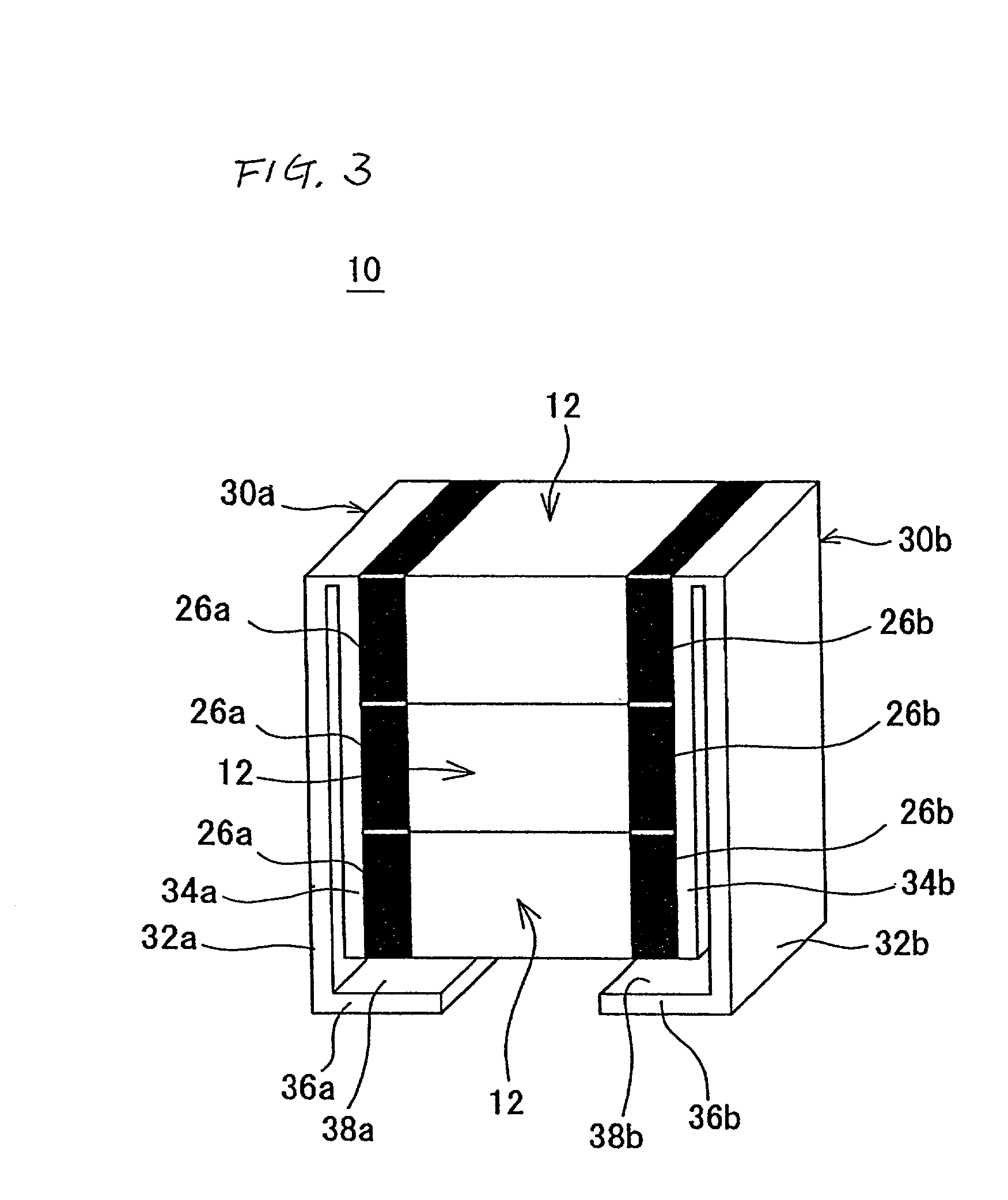

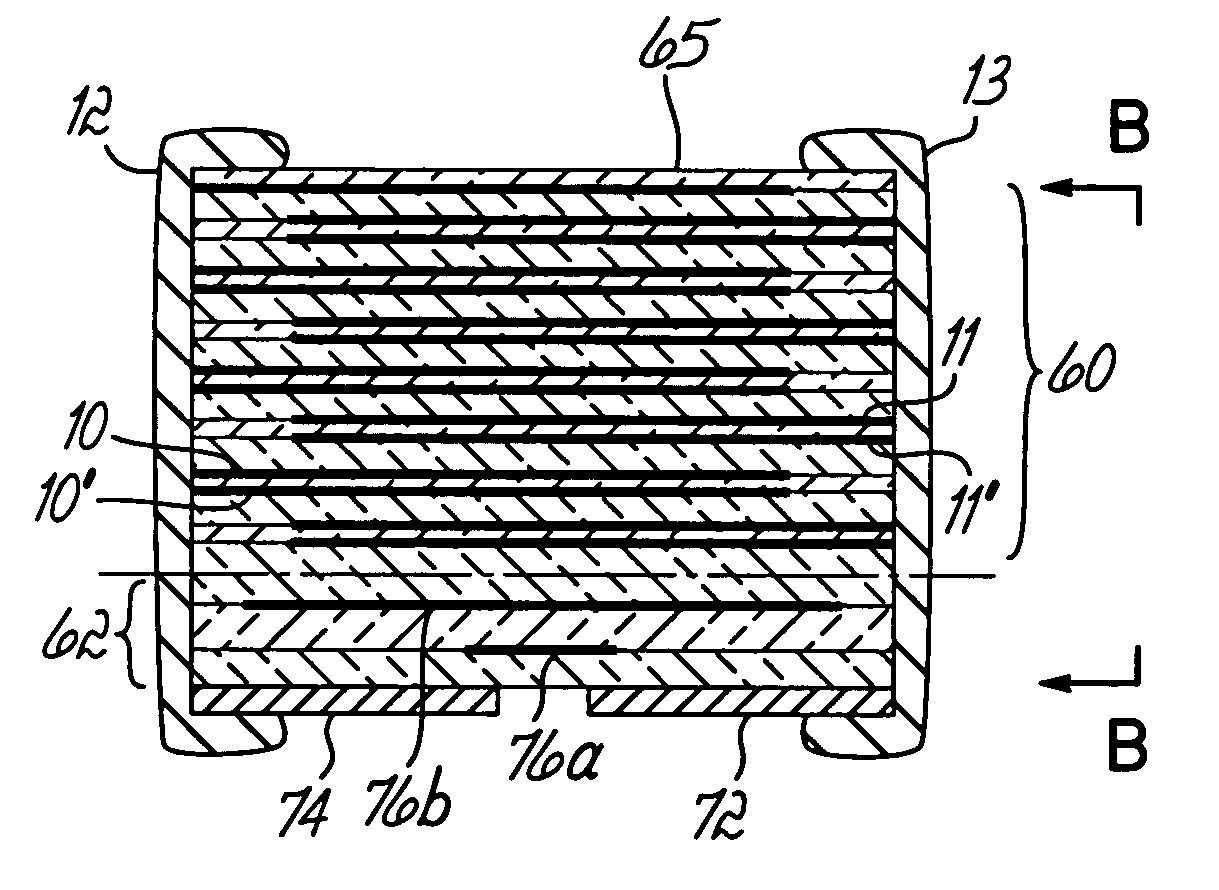

Improved termination features for multilayer electronic components are disclosed. Monolithic components are provided with plated terminations whereby the need for typical thick-film termination stripes is eliminated or greatly simplified. Such termination technology eliminates many typical termination problems and enables a higher number of terminations with finer pitch, which may be especially beneficial on smaller electronic components. The subject plated terminations are guided and anchored by exposed internal electrode tabs and additional anchor tab portions which may optionally extend to the cover layers of a multilayer component. Such anchor tabs may be positioned internally or externally relative to a chip structure to nucleate additional metallized plating material. External anchor tabs positioned on one or both of top and bottom surfaces of a monolithic structure can facilitate the formation of selective wrap-around plated terminations. The disclosed technology may be utilized with a plurality of monolithic multilayer components, including interdigitated capacitors, multilayer capacitor arrays, and integrated passive components. A variety of different plating techniques and termination materials may be employed in the formation of the subject self-determining plated terminations.

Owner:KYOCERA AVX COMPONENTS CORP

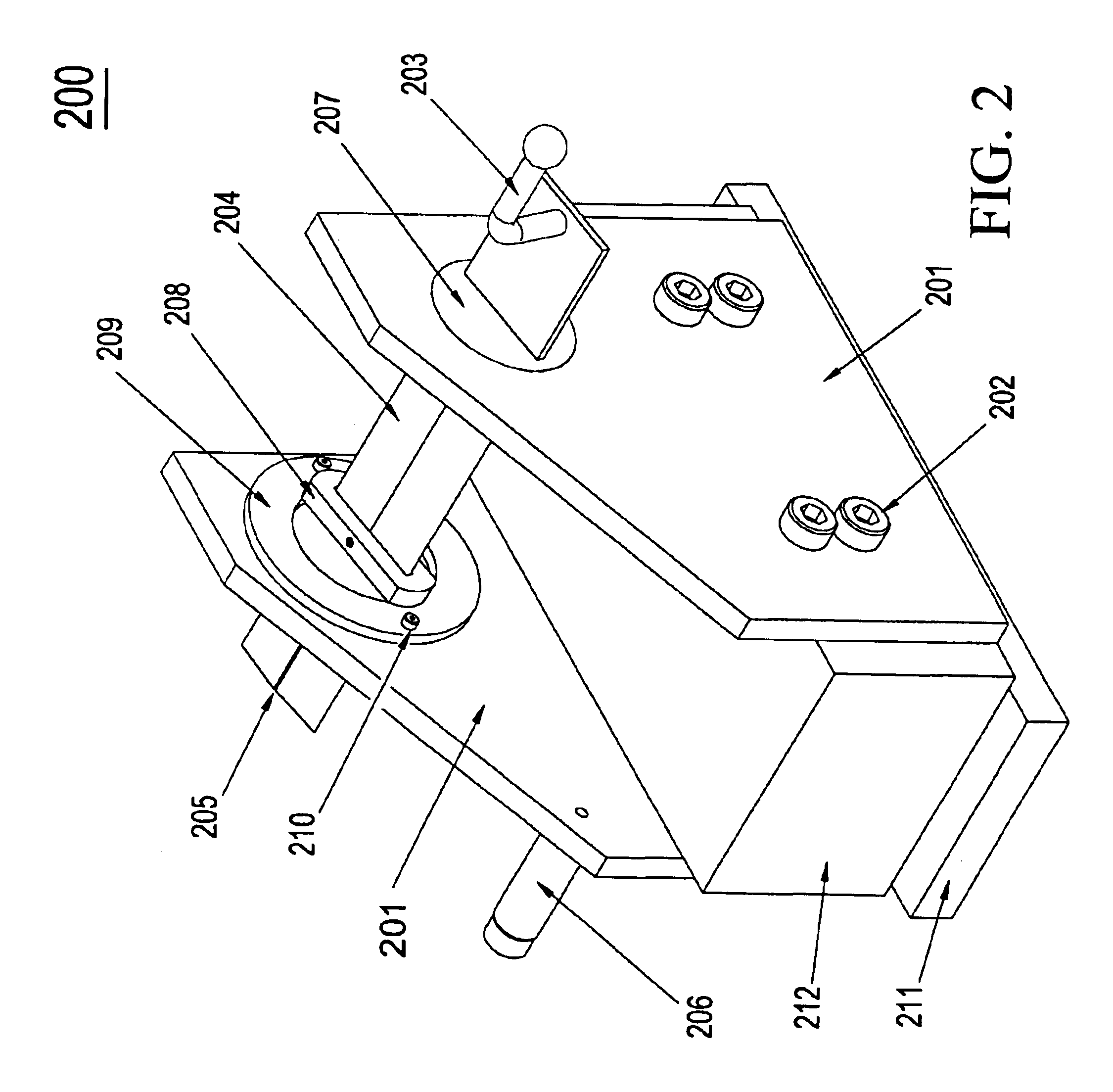

Supercapacitor with high energy density

InactiveUS6762926B1Sufficient energy densityLow costHybrid capacitor separatorsMultiple fixed capacitorsCapacitanceHigh energy

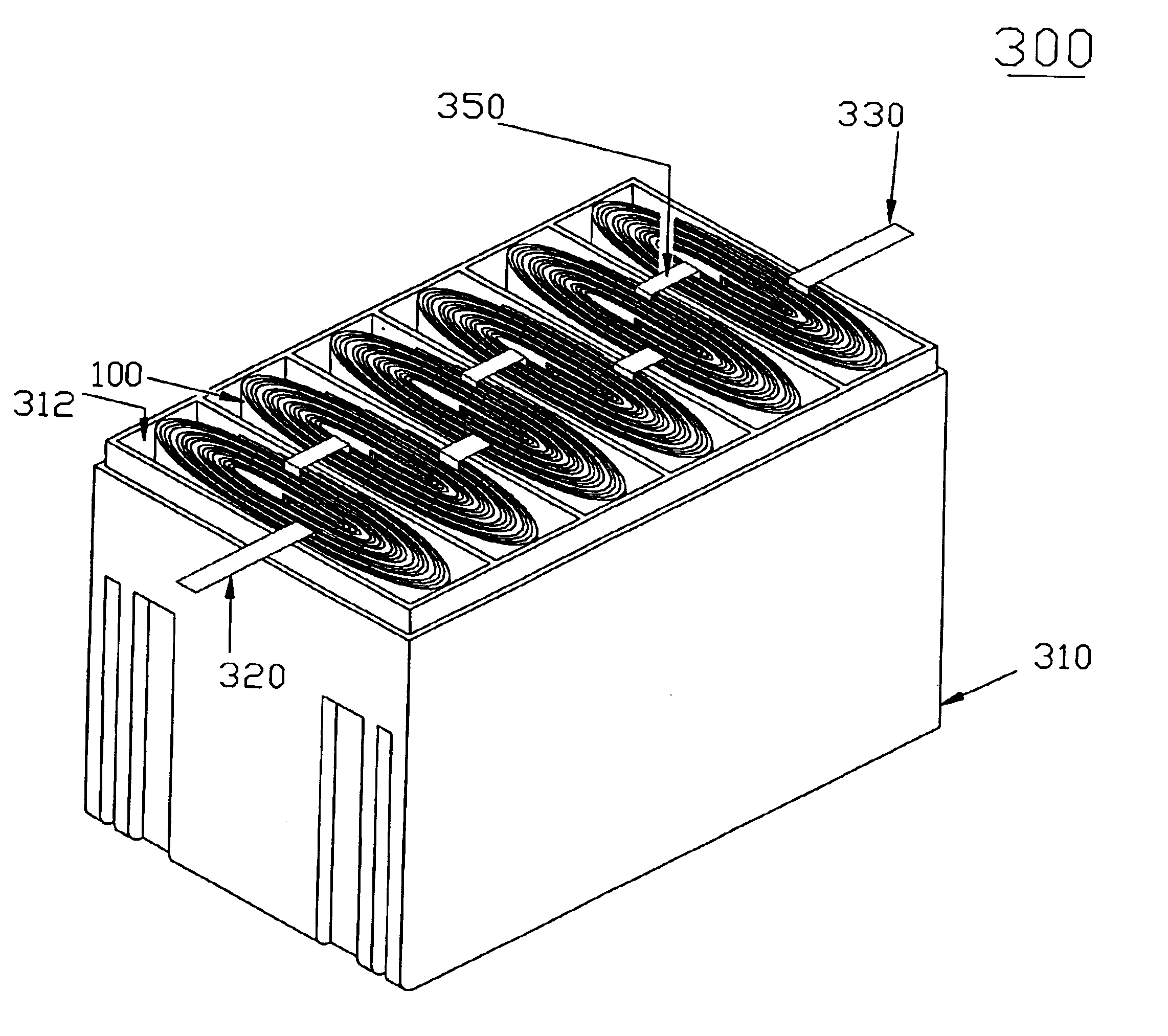

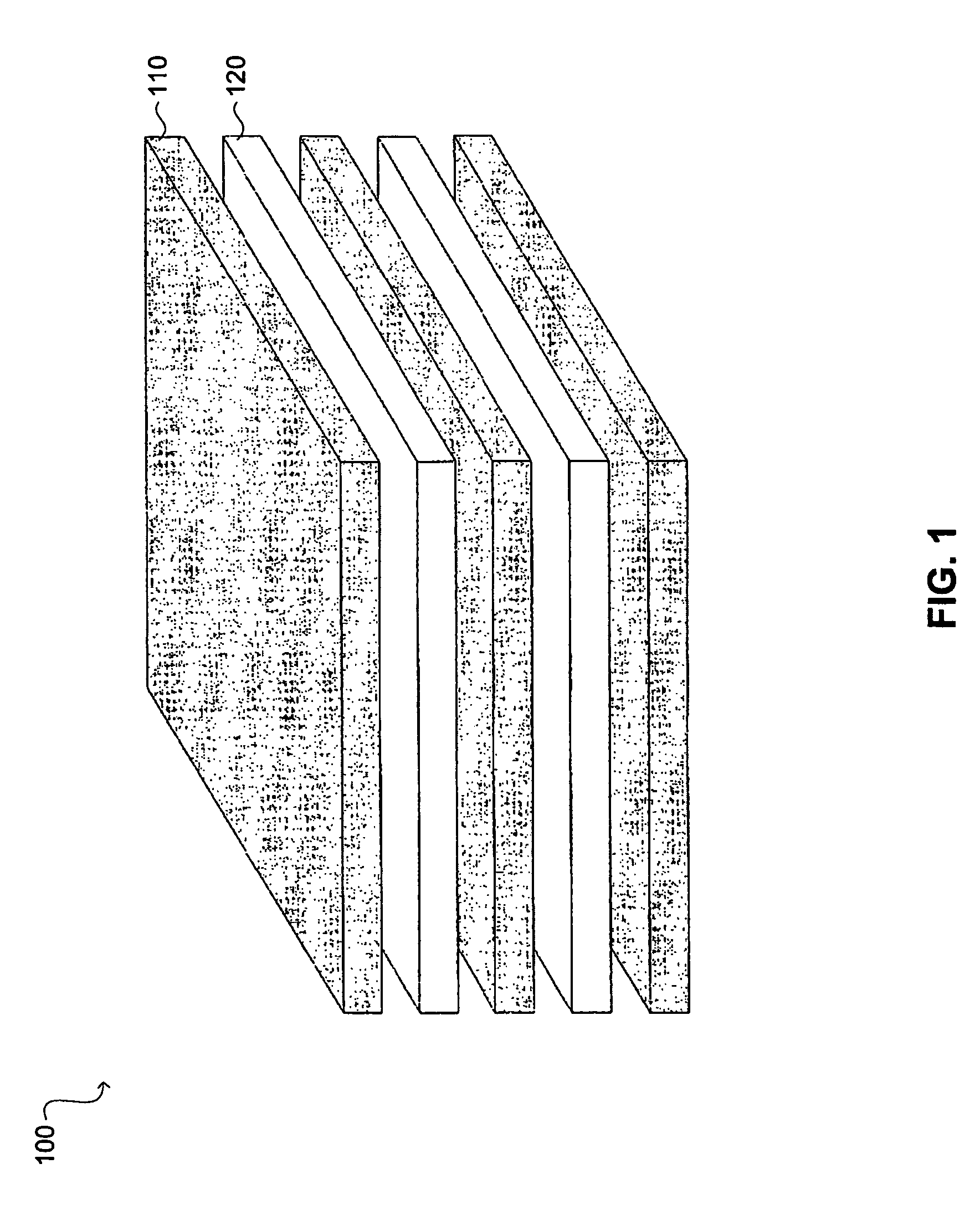

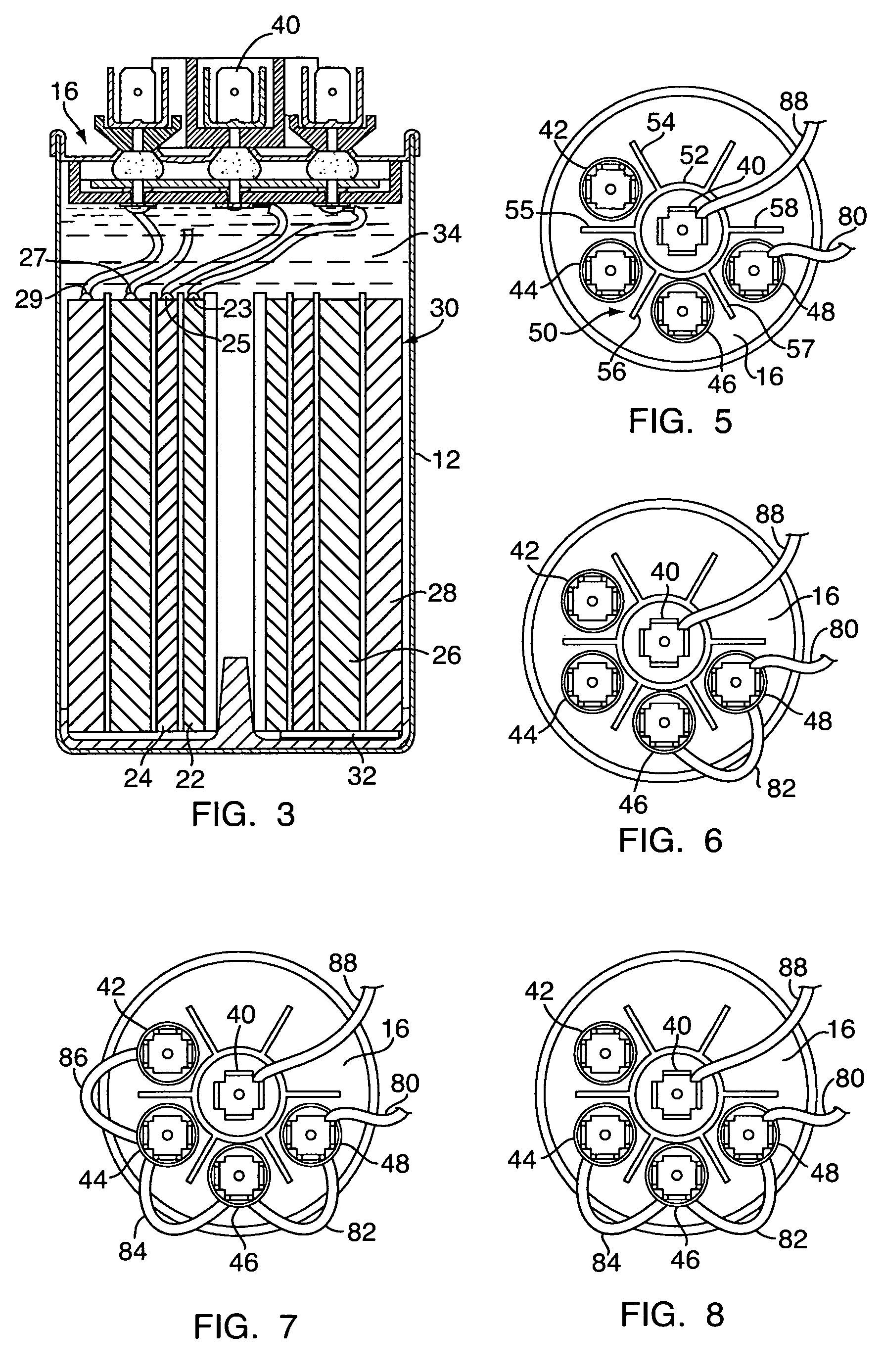

The energy content of supercapacitor is determined by its capacitance value and working voltage. To attain a high capacitance and a high voltage, several pieces of electrodes and separators are spirally wound with edge sealing to form a bipolar supercapacitor in cylindrical, oval or square configuration. While the winding operation effectively provides a large surface area for high capacitance, the bipolar packaging instantly imparts a unitary roll a minimum working voltage of 5V on using an organic electrolyte. The bipolar roll is a powerful building block for facilitating the assembly of supercapacitor modules. Using containers with multiple compartments, as many bipolar rolls can be connected in series, in parallel or in a combination of the two connections to fabricate integrated supercapacitors with high energy density as required by applications.

Owner:GAINIA INTELLECTUAL ASSET SERVICES

Capacitor for multiple replacement applications

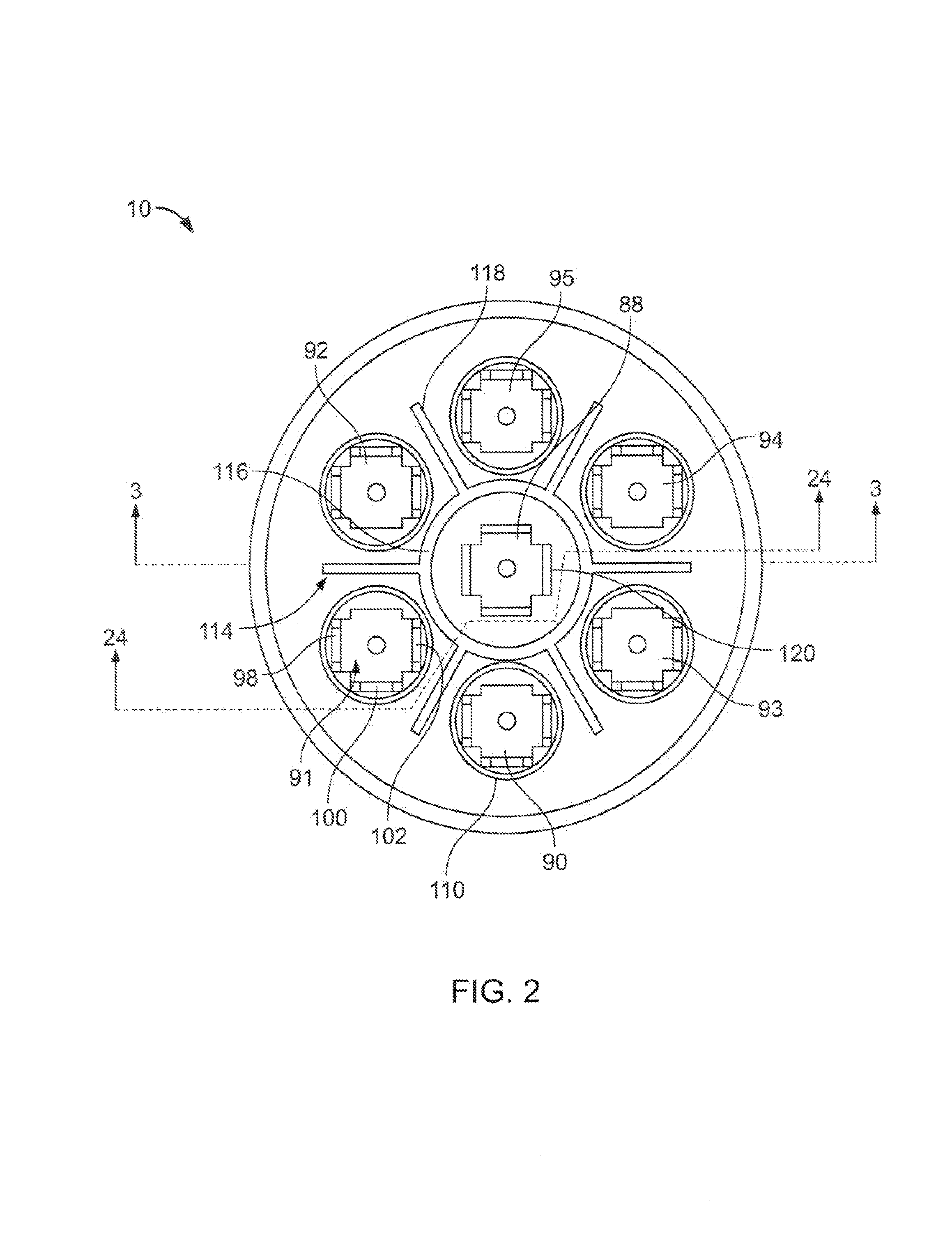

ActiveUS7203053B2Safely making and maintainingIncrease flexibilityMultiple fixed capacitorsElectrolytic capacitorsCapacitanceElectrical conductor

A capacitor provides a plurality of selectable capacitance values, by selective connection of six concentrically wound capacitor sections of a capacitive element each having a capacitance value. The capacitor sections each have a respective section element terminal at a first end of the capacitive element and the capacitor sections have a common element terminal at a second end of the capacitive element. A pressure interrupter cover assembly is sealingly secured to the open end a case for the element and has a deformable cover with a centrally mounted common cover terminal and a plurality of section cover terminals mounted at spaced apart locations. A conductor frangibly connects the common element terminal of the capacitive element to the common cover terminal and conductors respectively frangibly connect the capacitor section terminals to the section cover terminals. Deformation of the cover caused by failure of the capacitor element breaks at least some of the frangible connections sufficient to disconnect the capacitive element from an electric circuit in which it is connected. A cover insulation barrier mounted on the deformable cover, has a barrier cup substantially surrounding the common cover terminal and a plurality of barrier fins each extending radially outwardly from the barrier cup, and deployed between adjacent section cover.

Owner:AMRAD MFG LLC

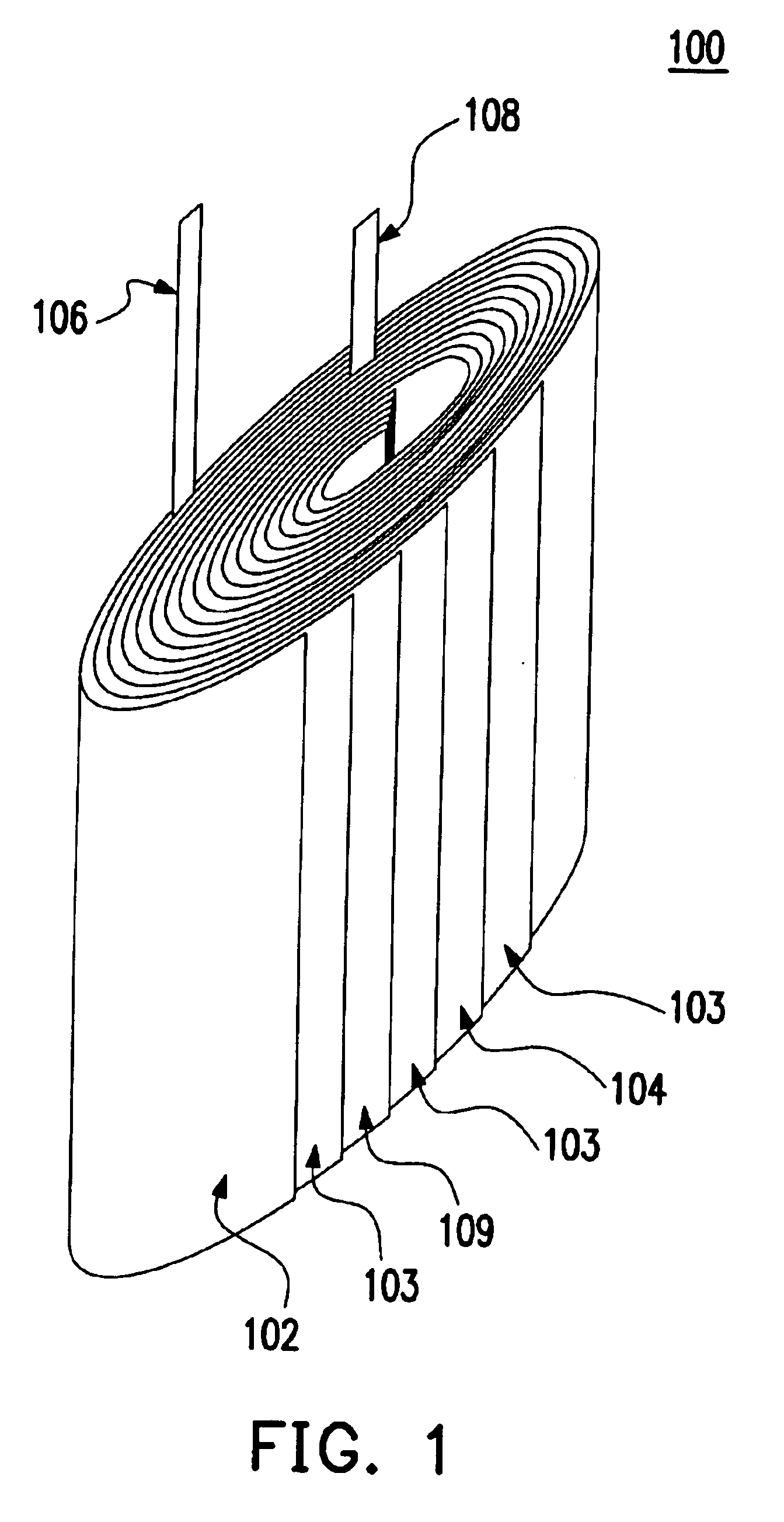

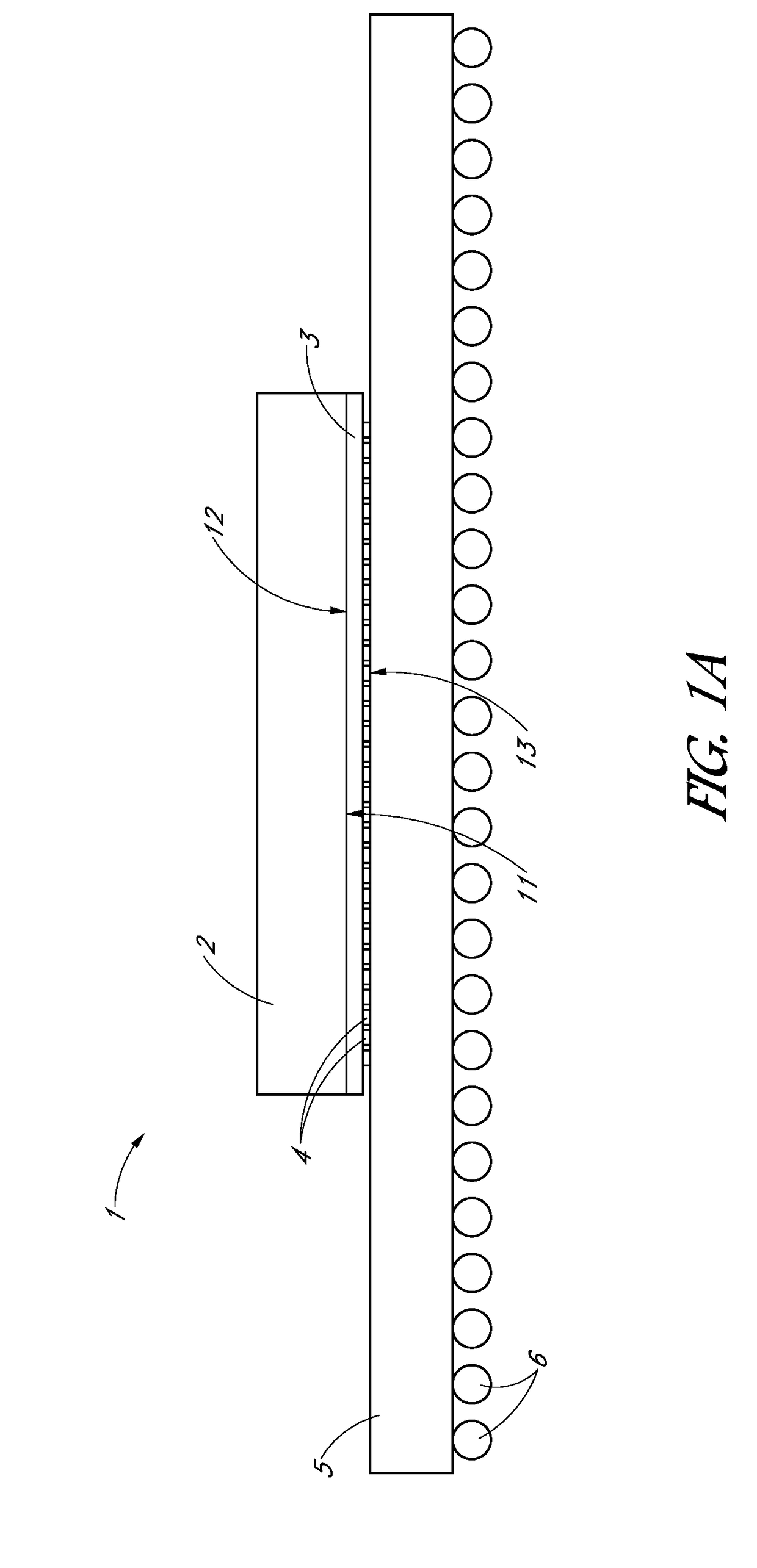

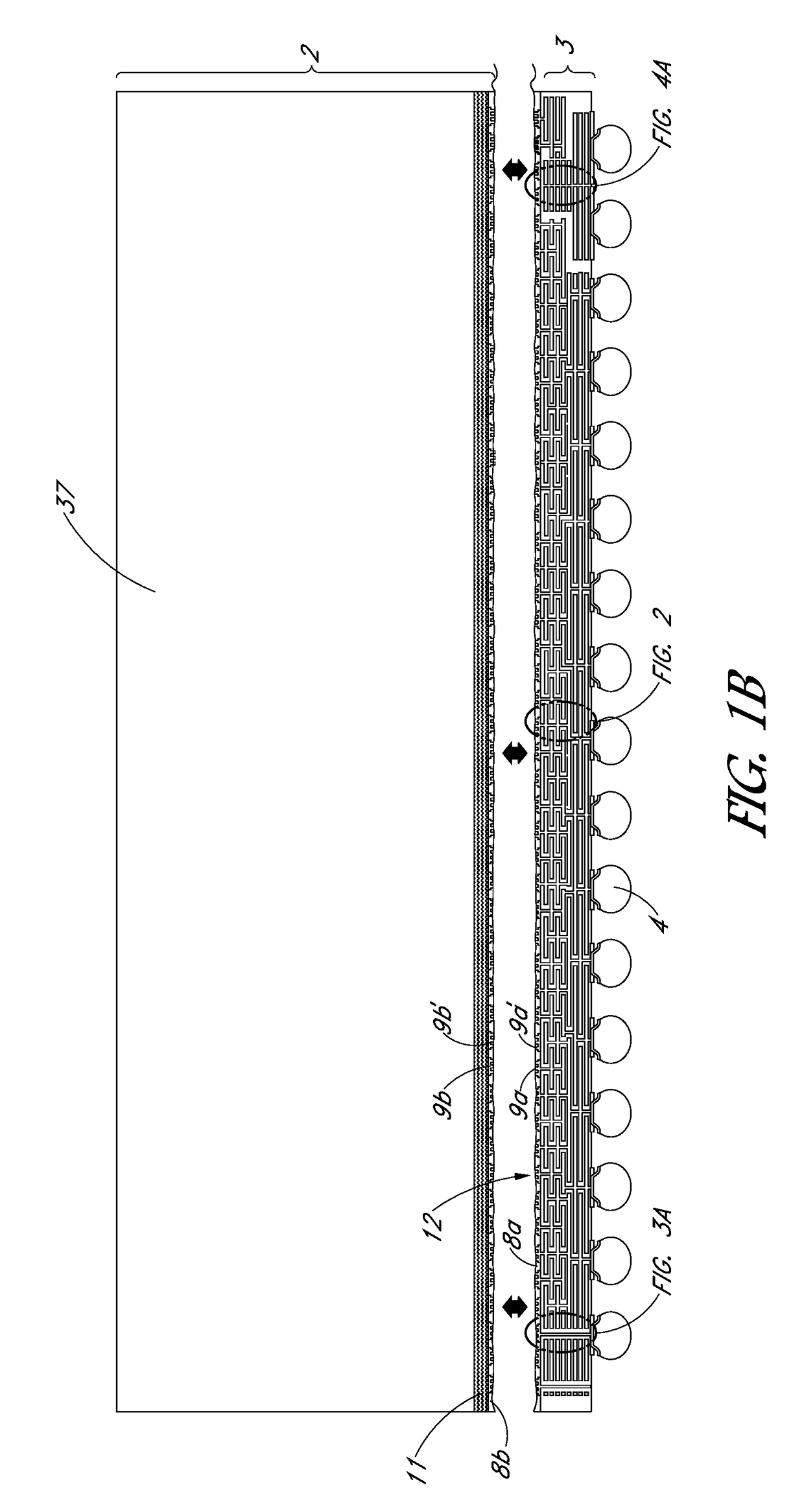

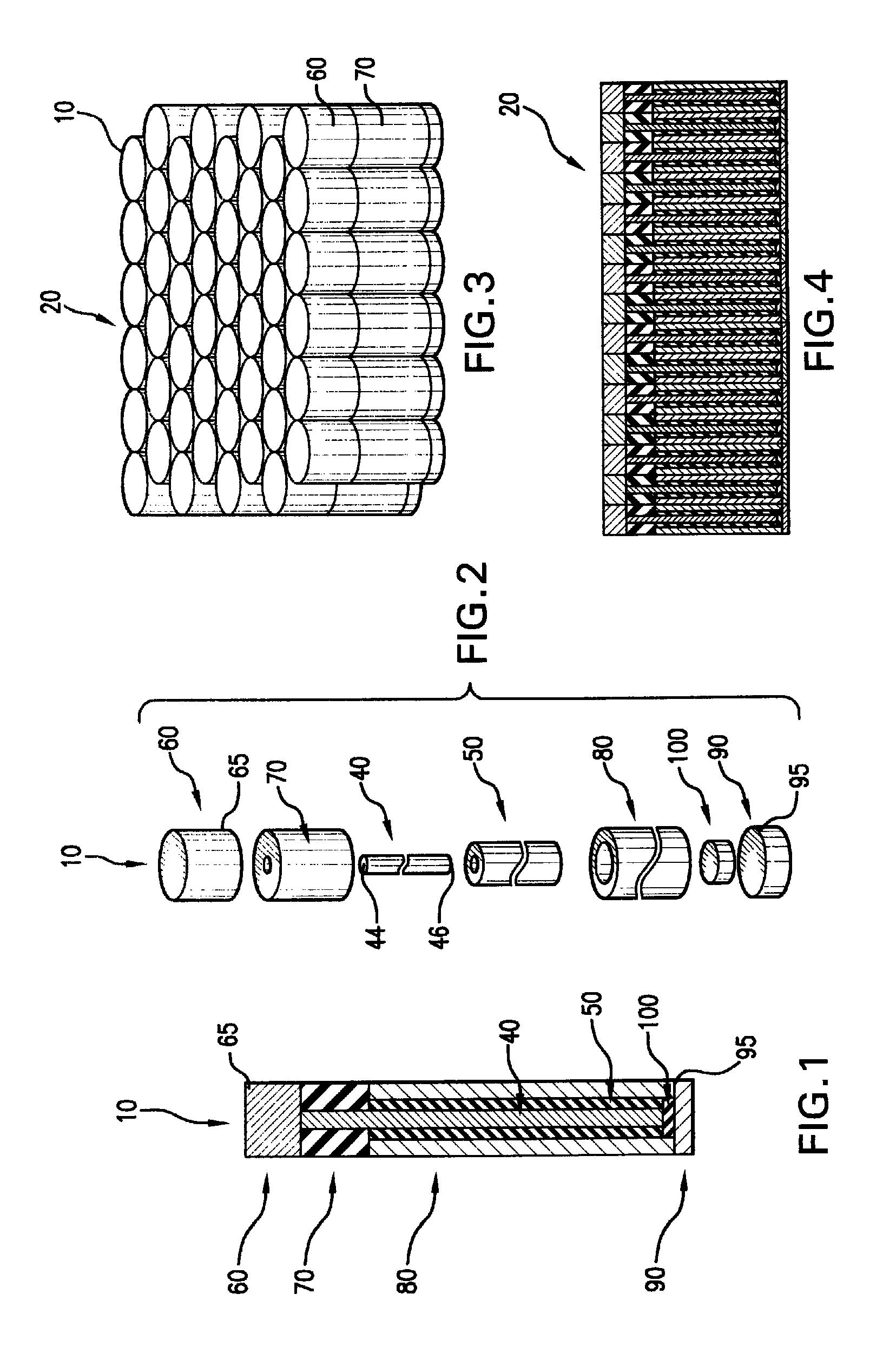

Low inductance, high rating capacitor devices

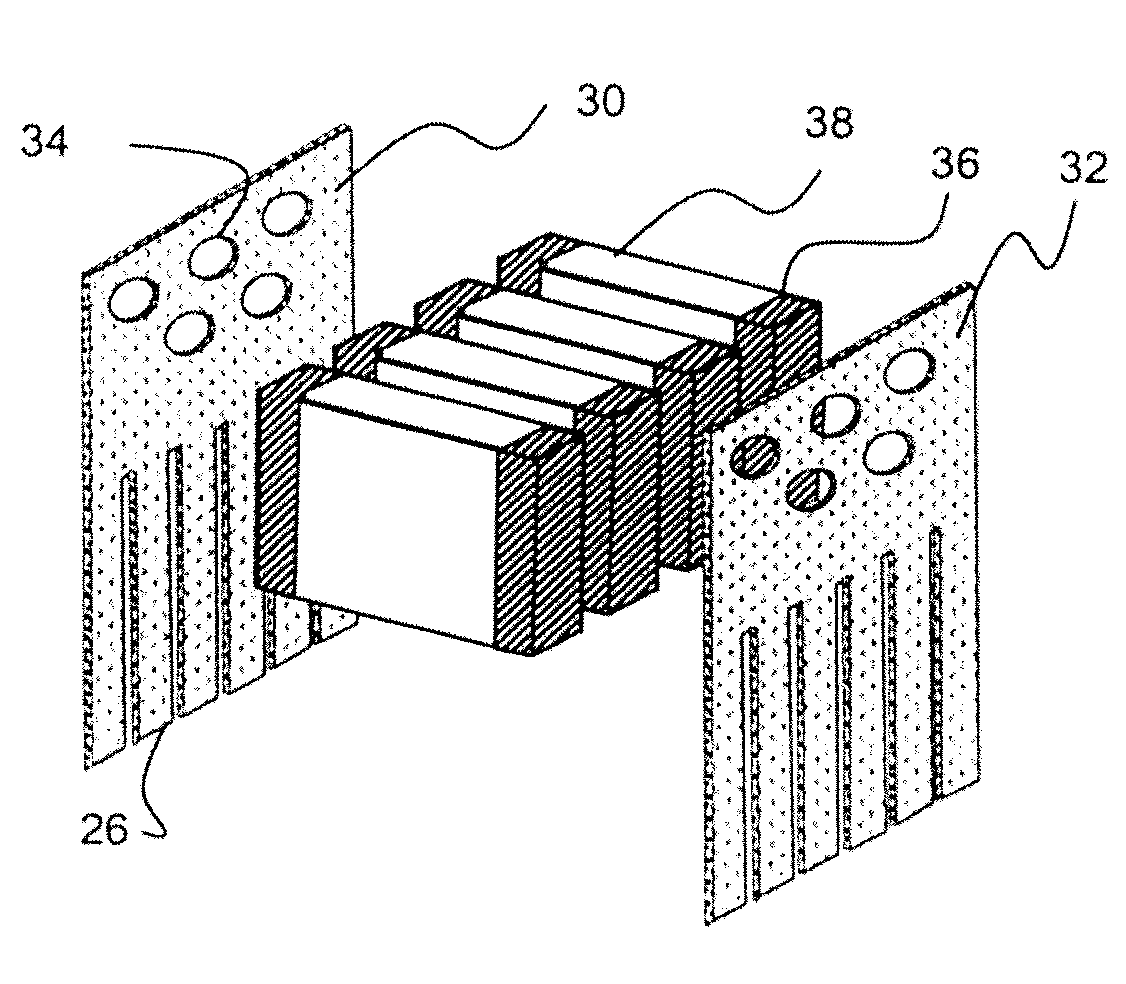

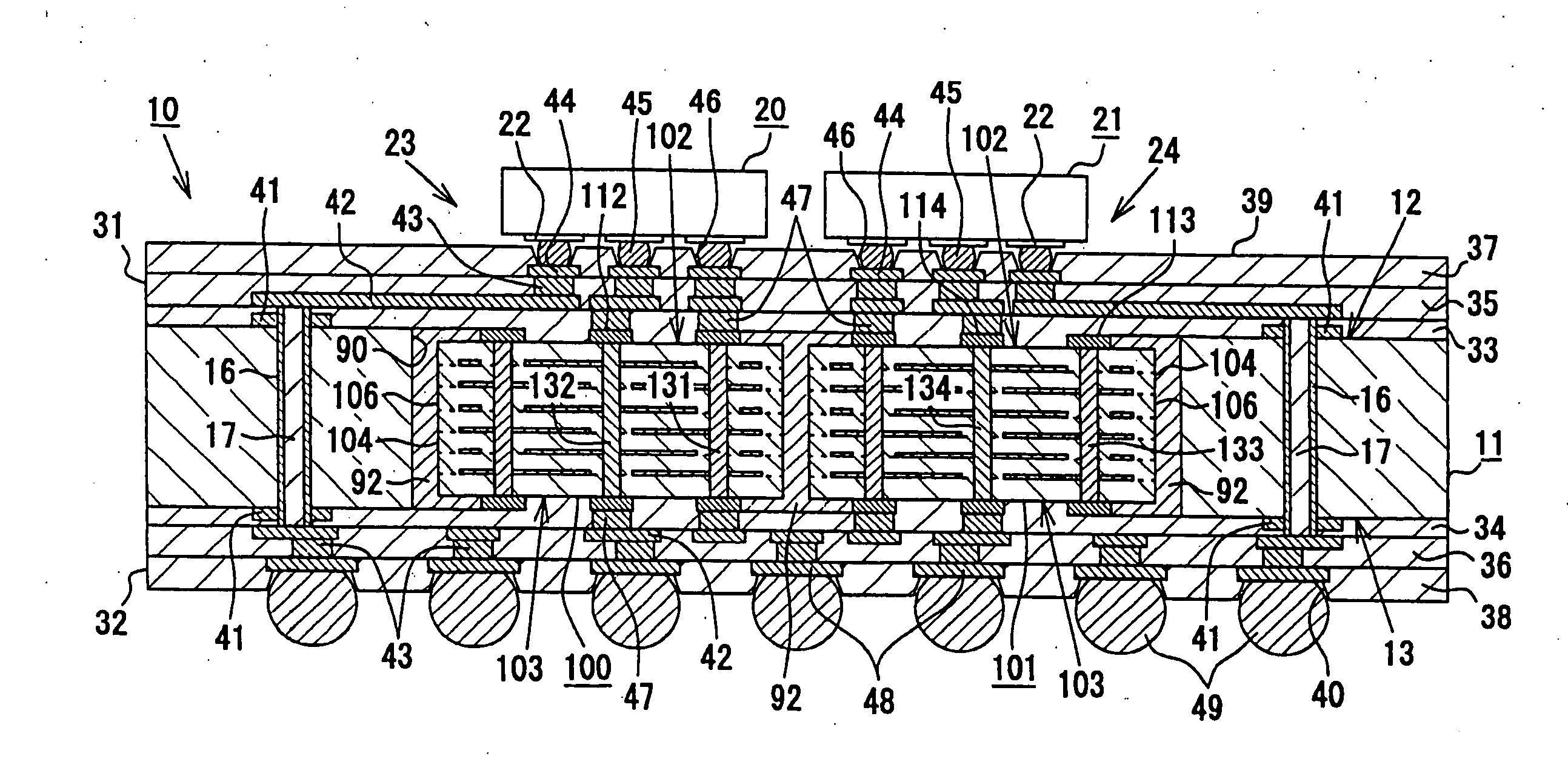

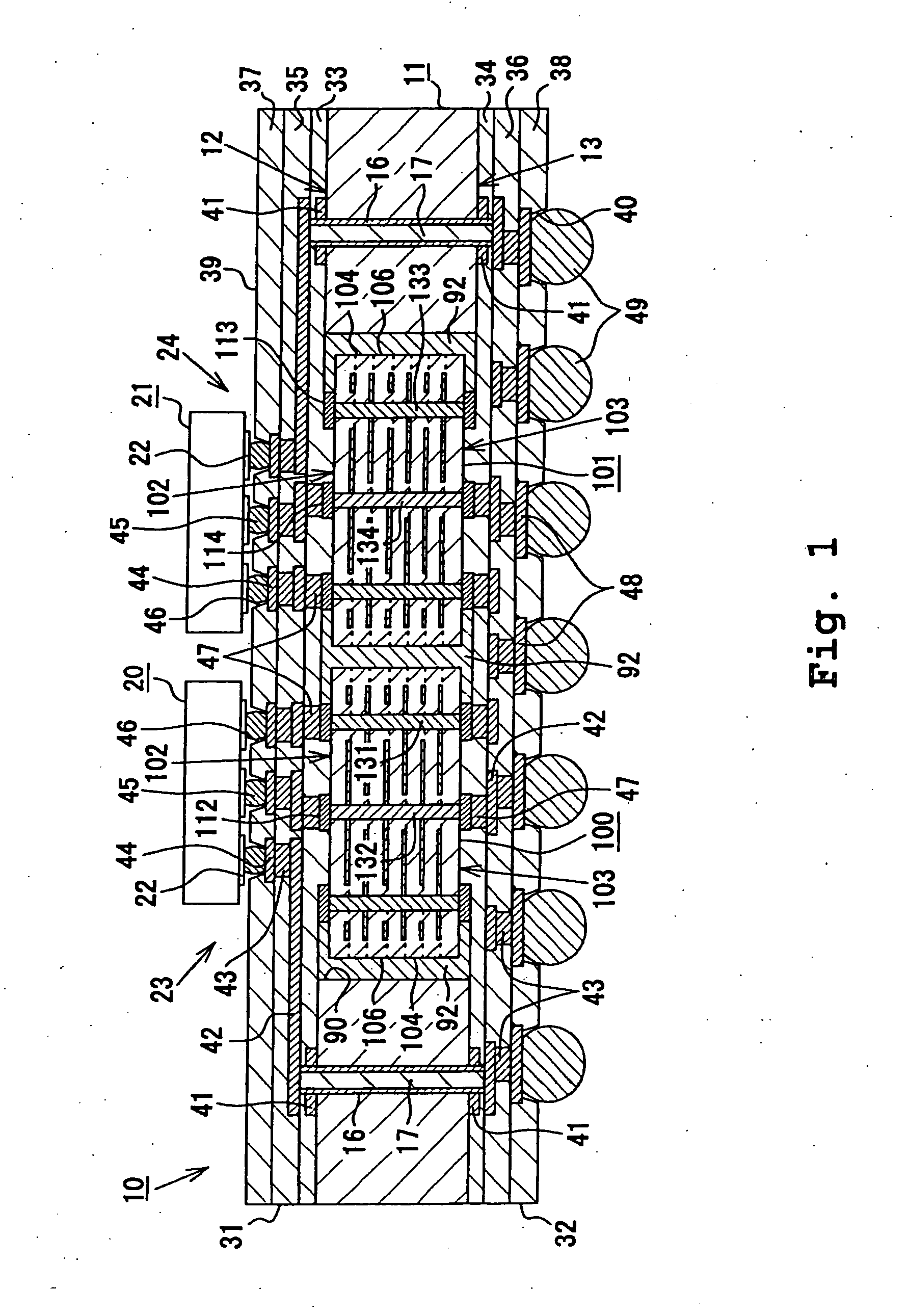

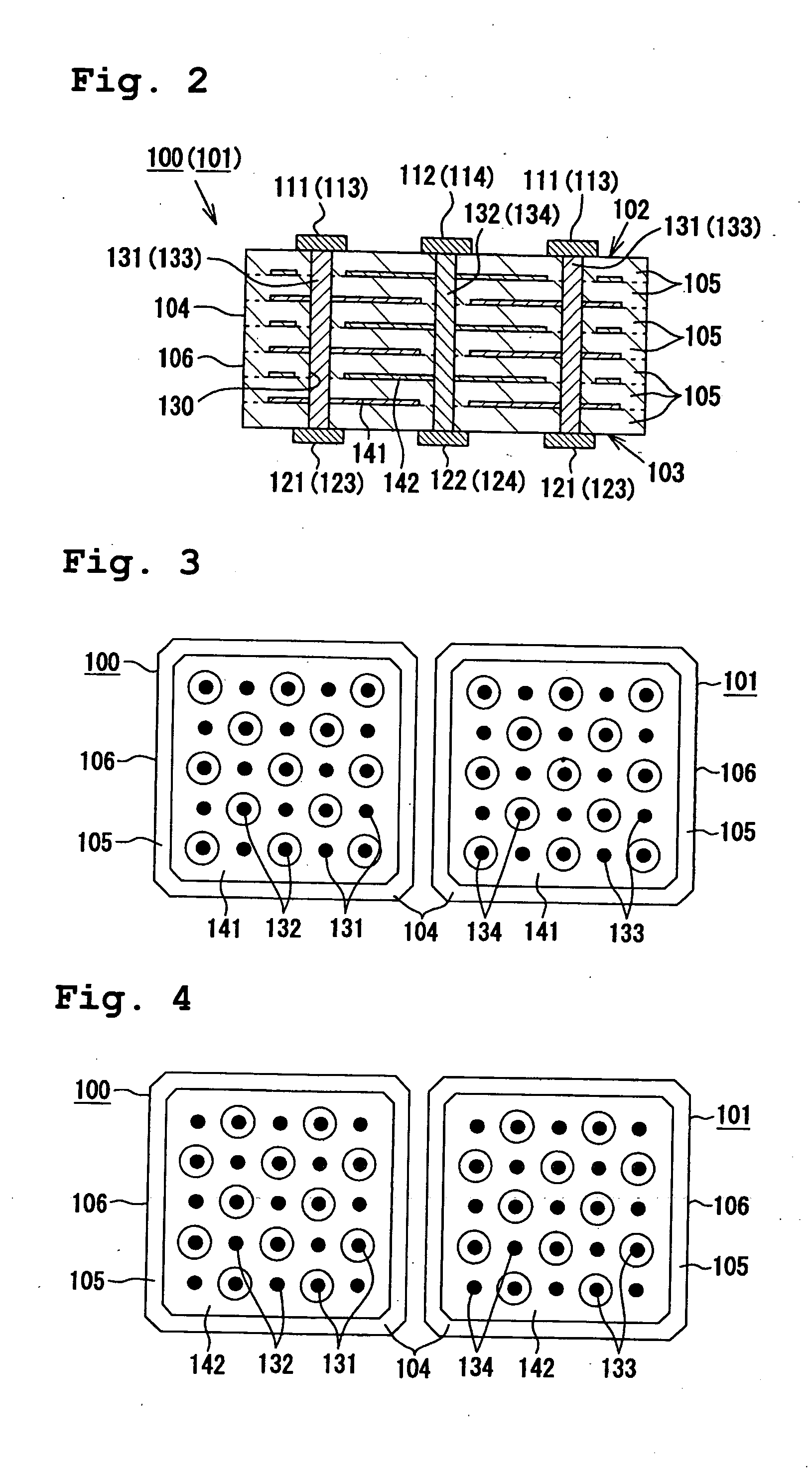

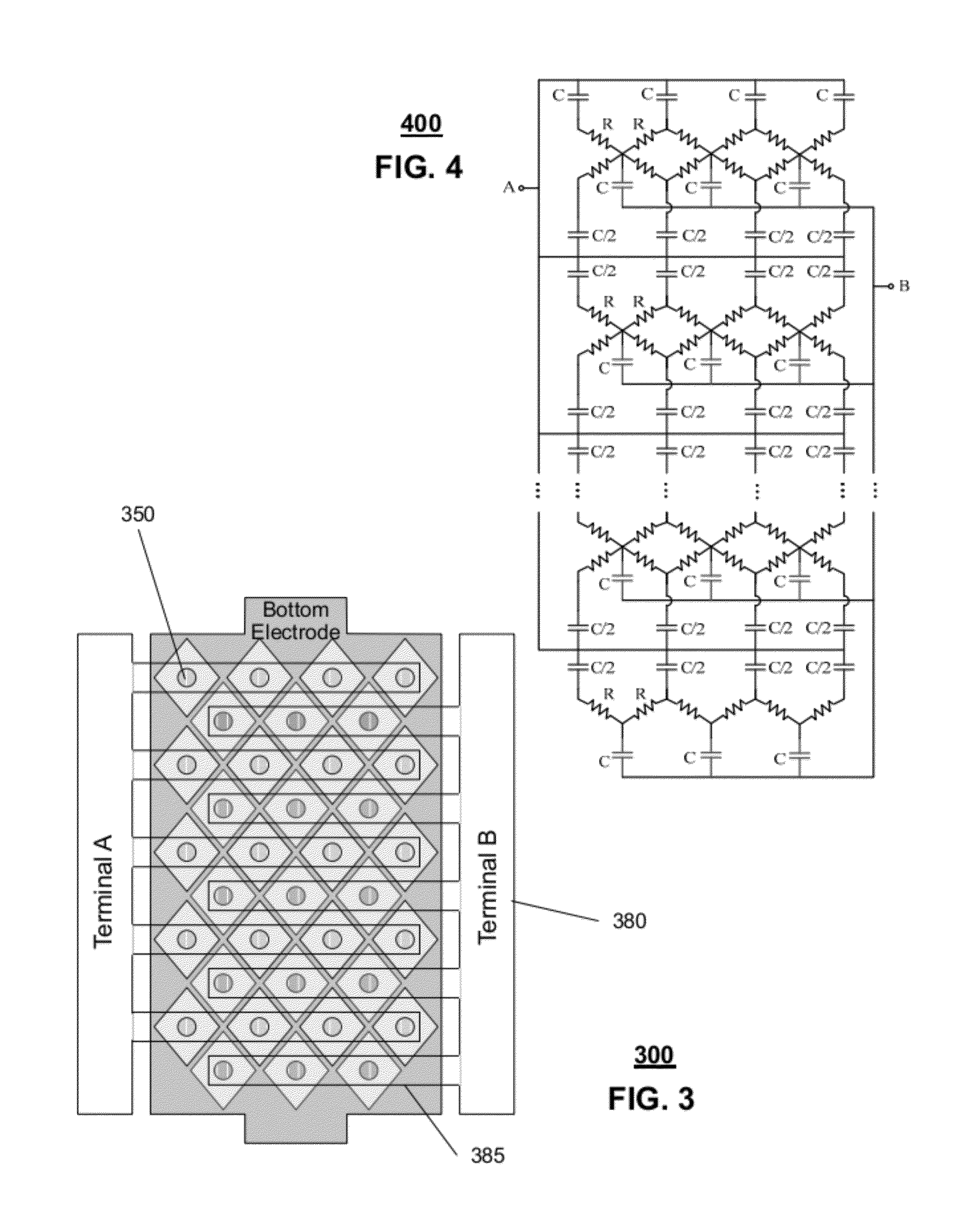

InactiveUS20090147440A1Reduce inductanceMultiple fixed capacitorsFinal product manufactureLow inductancePrinted circuit board

Methodologies and structures are disclosed for providing multilayer electronic devices having low inductance and high ratings, such as for capacitor devices for uses involving faster pulsing and higher currents. Plural layer devices are constructed for relatively lowered inductance by relatively altering typical orientation of capacitors such that their electrodes are placed into a vertical position relative to an associated circuit board. Optionally, individual leads may be formed so that the resulting structure can be used as an array. Internal electrodes may be arranged for reducing current loops for associated circuits on a circuit board, to correspondingly reduce the associated inductance of the circuit board mounted device. Leads associated with such devices may have added tab-like structures which serve to more precisely place the lead, to improve the lead to capacitor strength, and to promote lower resistance and inductance. Disclosed designs for reducing associated inductance may be practiced in conjunction with various electric devices, including capacitors, resistors, inductors, or varistors.

Owner:AVX CORP

Power capacitor

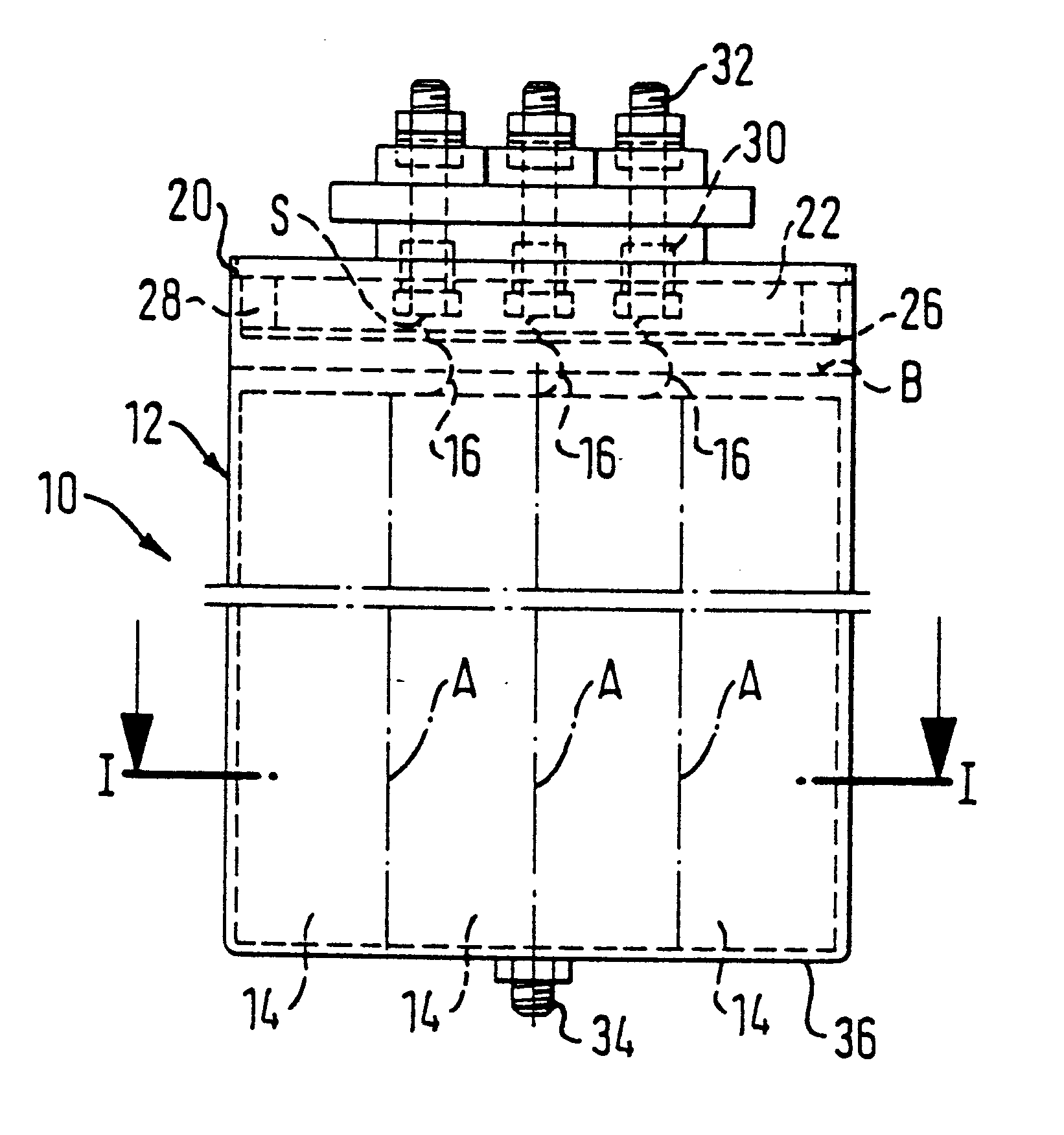

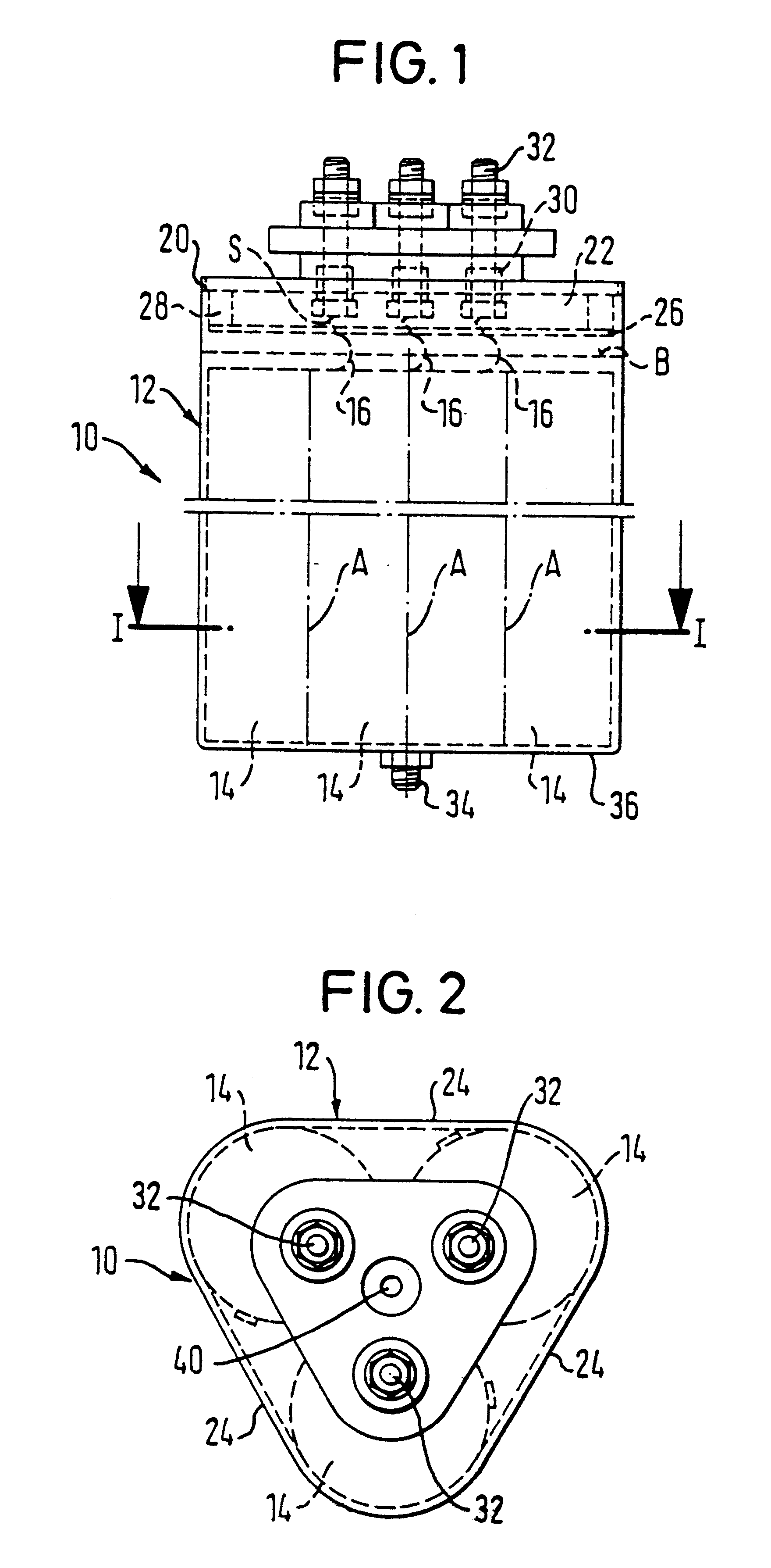

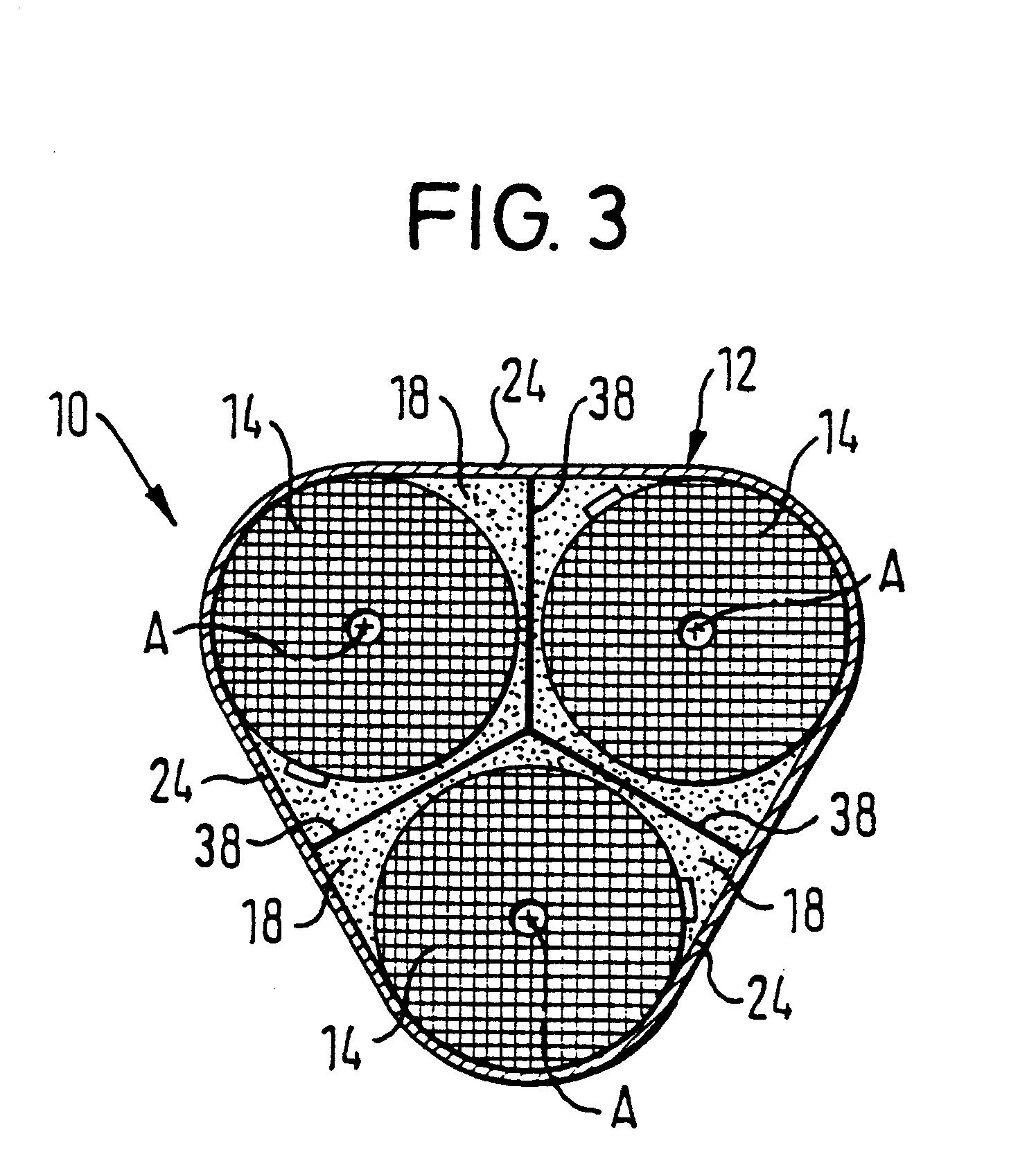

InactiveUS6212058B1Reduce construction heightImproved arrangeability in a rowMultiple fixed capacitorsWound capacitorsEngineeringCapacitor

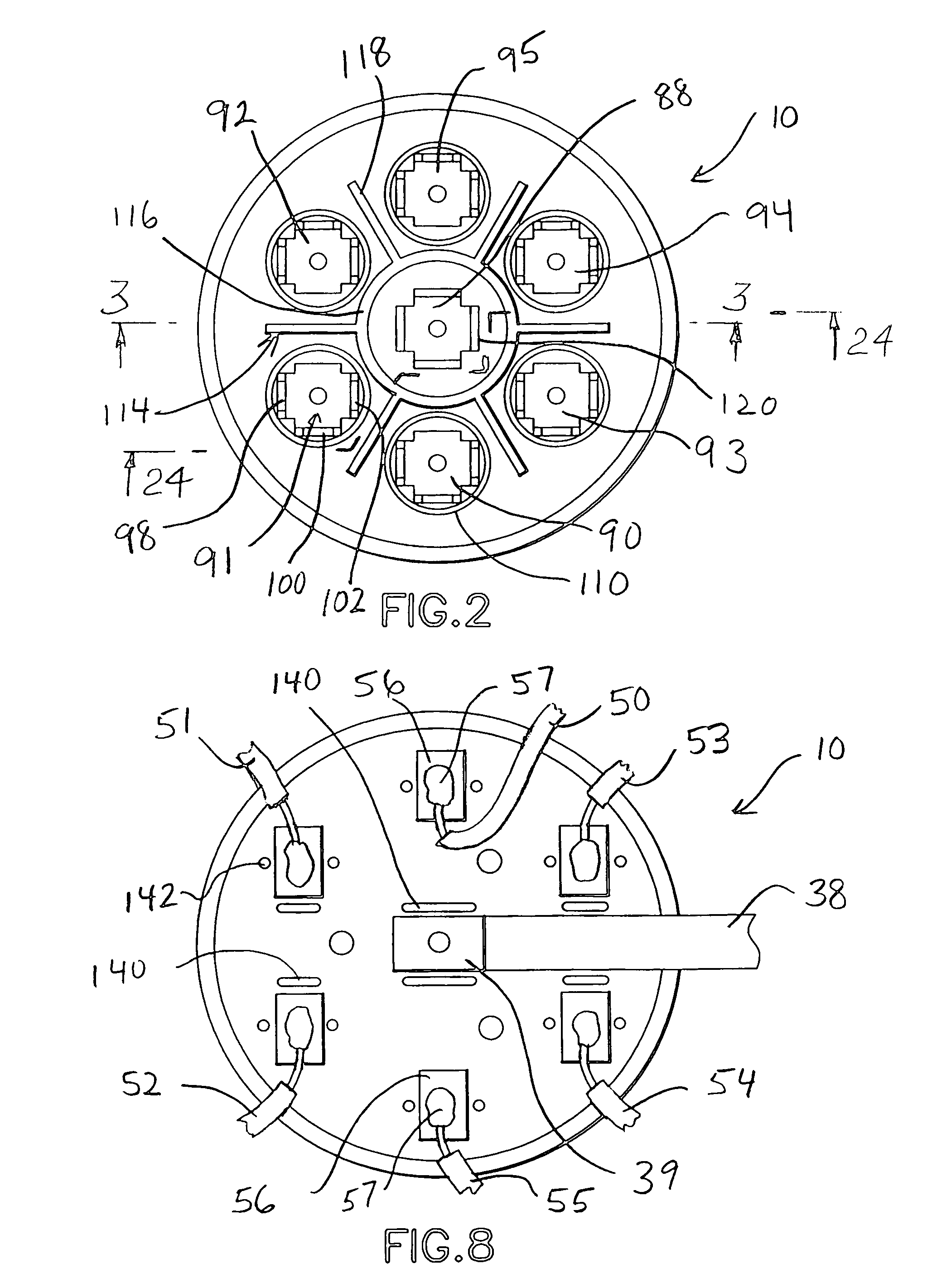

In a power capacitor with a plurality of round, wound elements accommodated in a common housing at least one wound element group consisting of three round, wound elements is accommodated in the housing, with the wound elements of the group being arranged in star-form alongside one another, with their axes parallel to one another. The housing has in cross-section in general the shape of a triangle having rounded corners, with a radius of curvature which corresponds at least substantially to the radius of the round, wound elements.

Owner:VISHAY ELECTRONICS

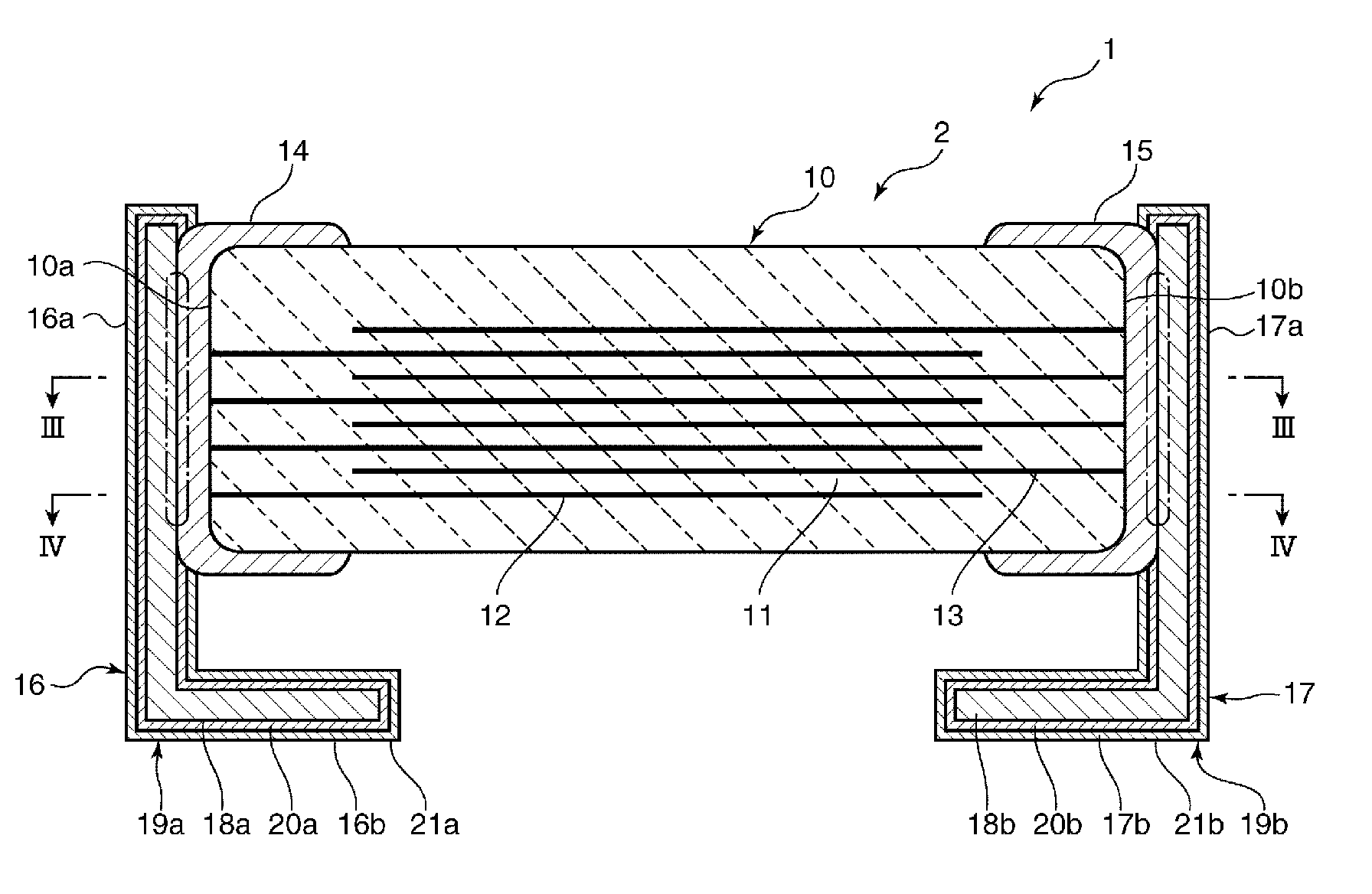

Capacitor for incorporation in wiring board, wiring board, method of manufacturing wiring board, and ceramic chip for embedment

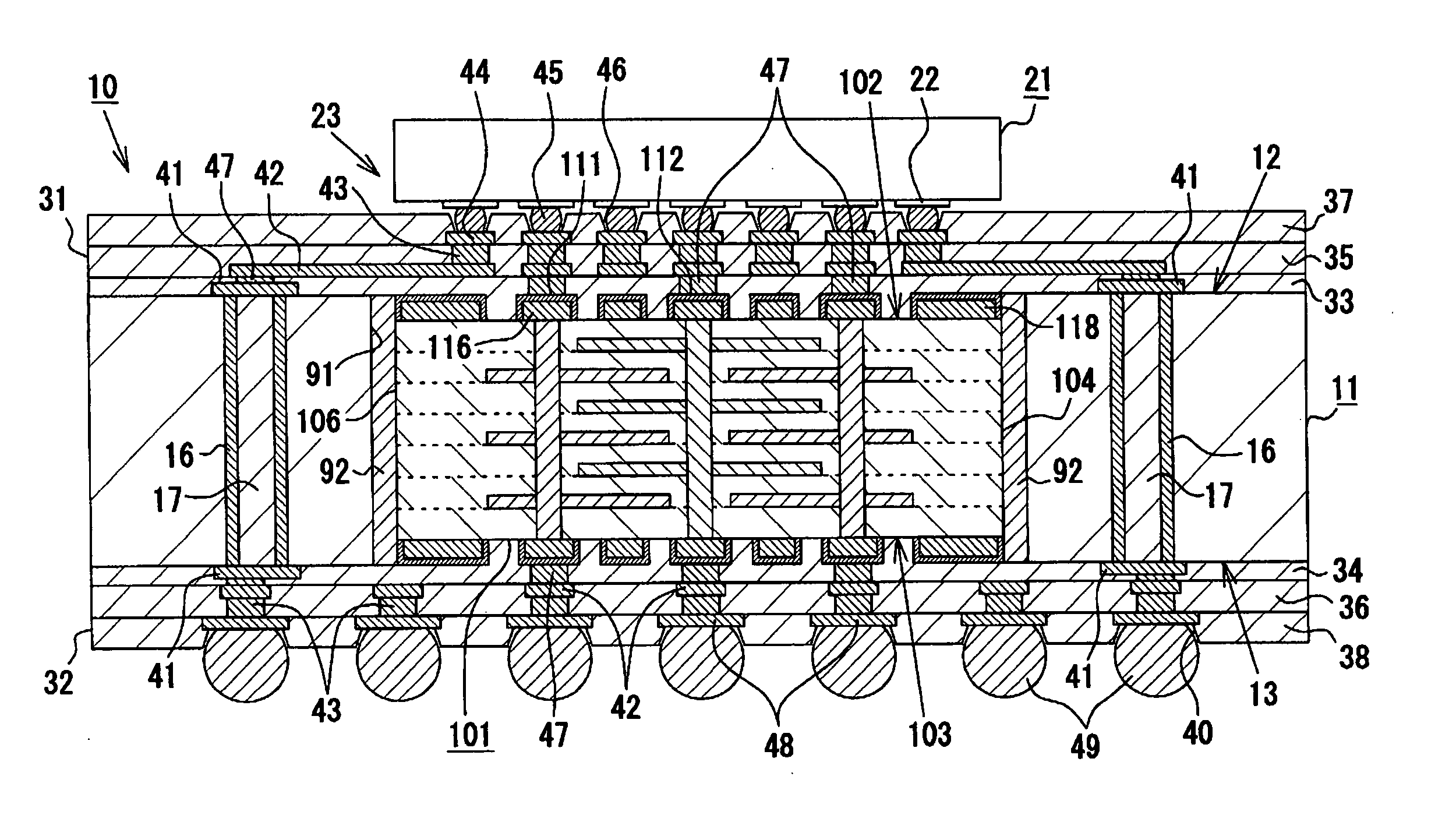

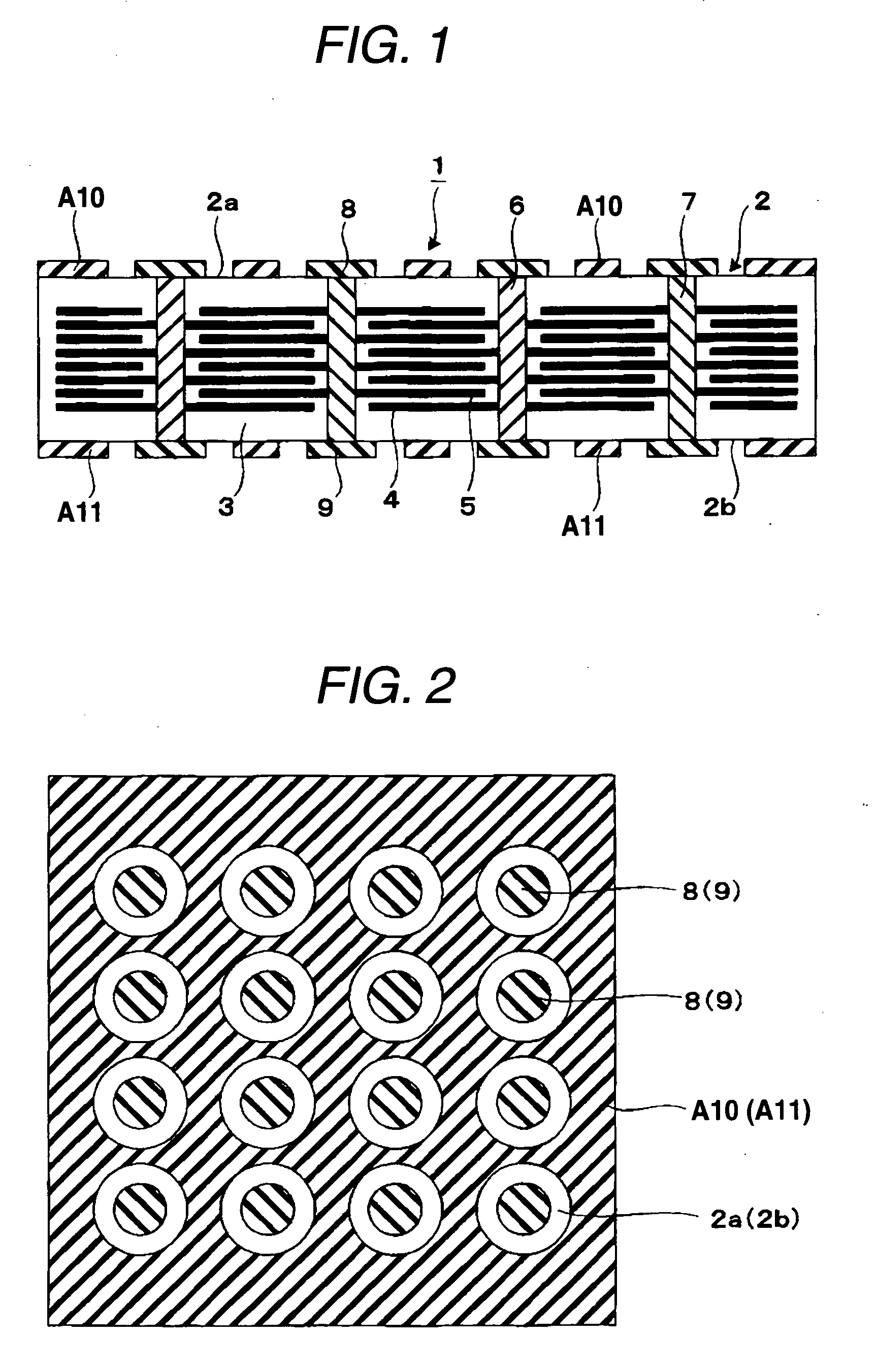

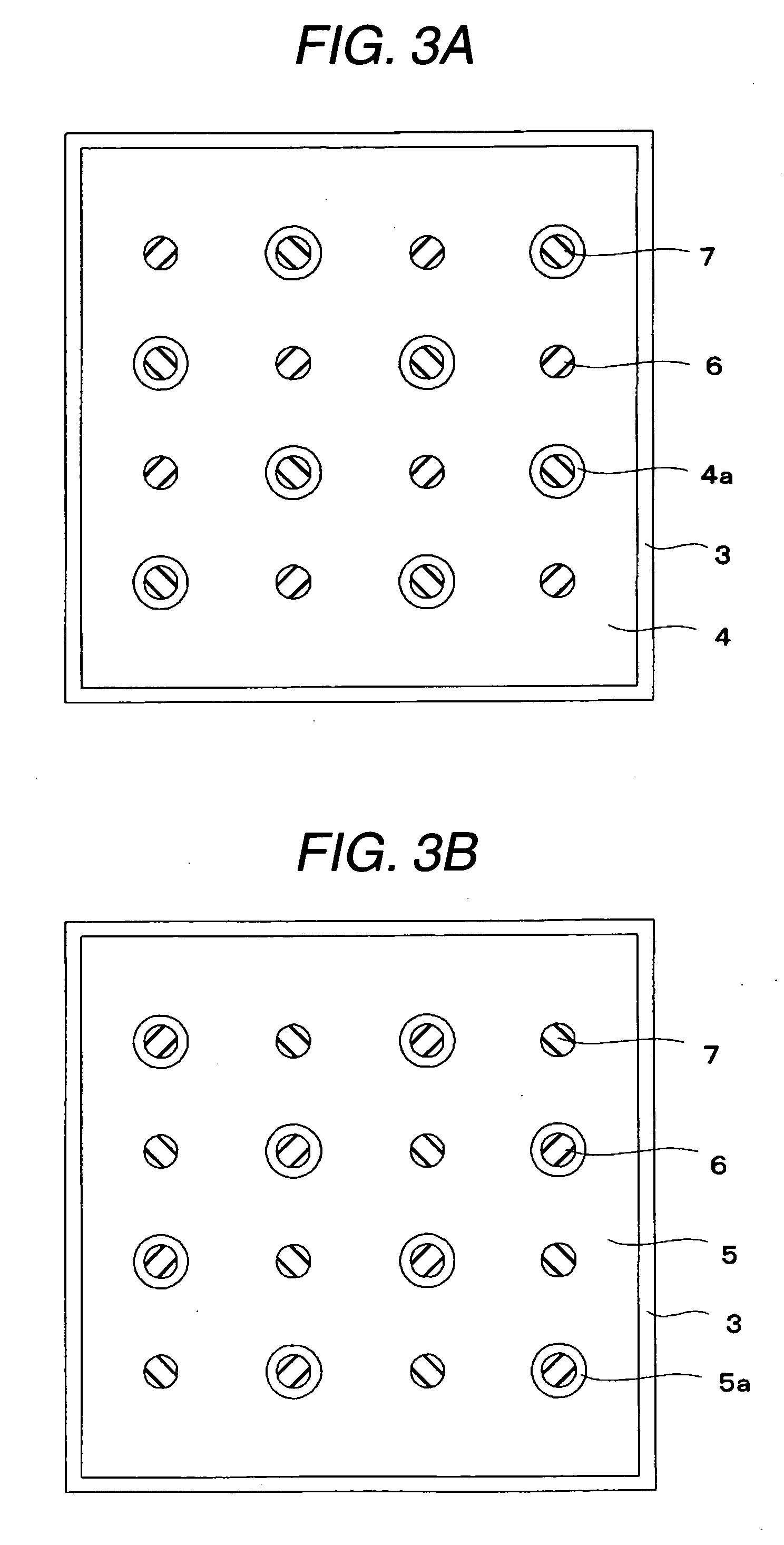

InactiveUS20070030628A1High bonding strengthImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDielectric layerCapacitor

A capacitor comprising: a capacitor body including a plurality of laminated dielectric layers, a plurality of inner electrode layers which are respectively disposed between mutually adjacent ones of the dielectric layers, a first main surface located in a laminated direction of the dielectric layers, and a second main surface opposite to the first main surface; a first outer electrode formed on the first main surface of the capacitor body and electrically connected to the inner electrode layers; a second outer electrode formed on the second main surface of the capacitor body and electrically connected to the inner electrode layers; a first dummy electrode formed on the first main surface of the capacitor body; and a second dummy electrode formed on the second main surface of the capacitor body.

Owner:NGK SPARK PLUG CO LTD

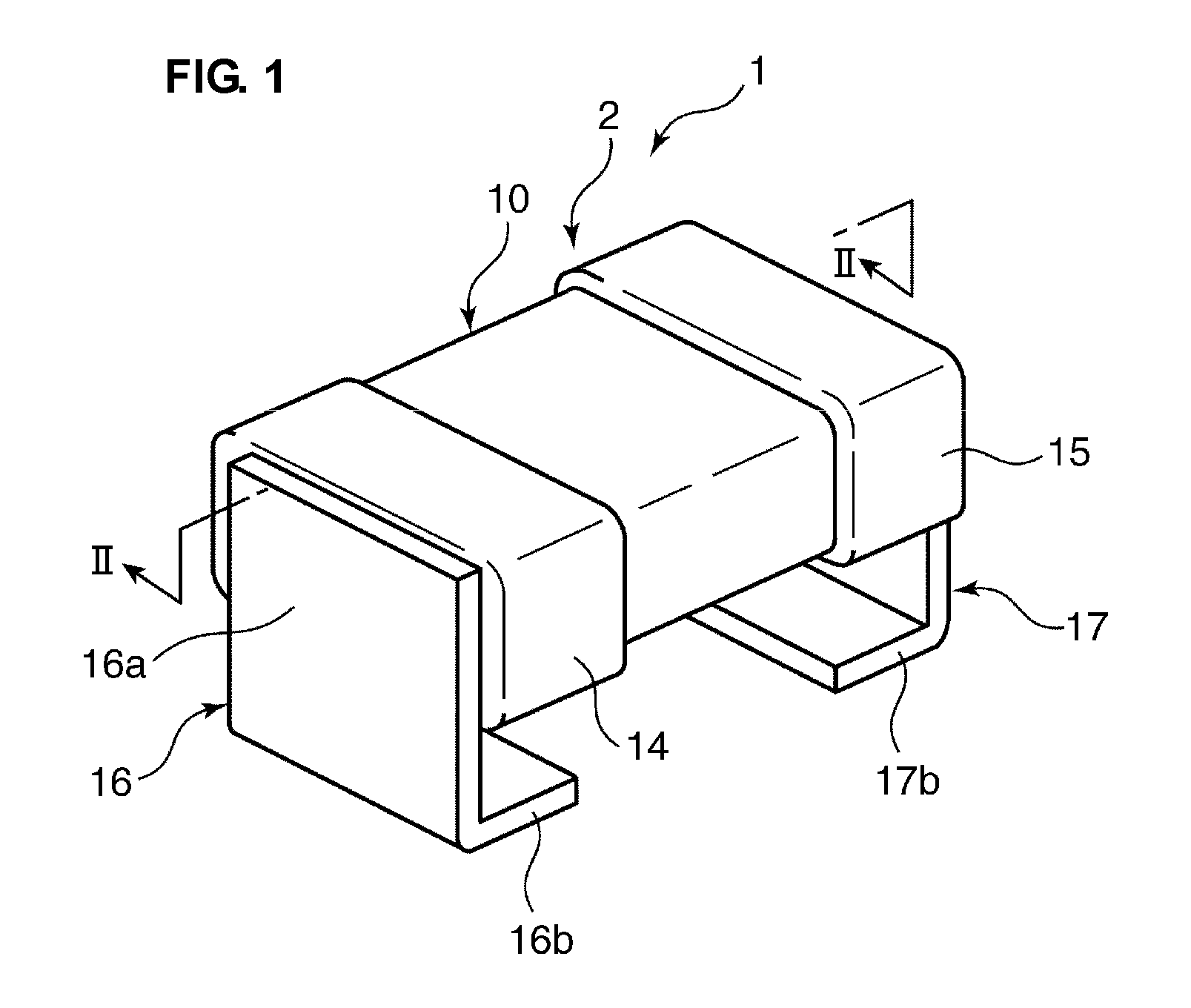

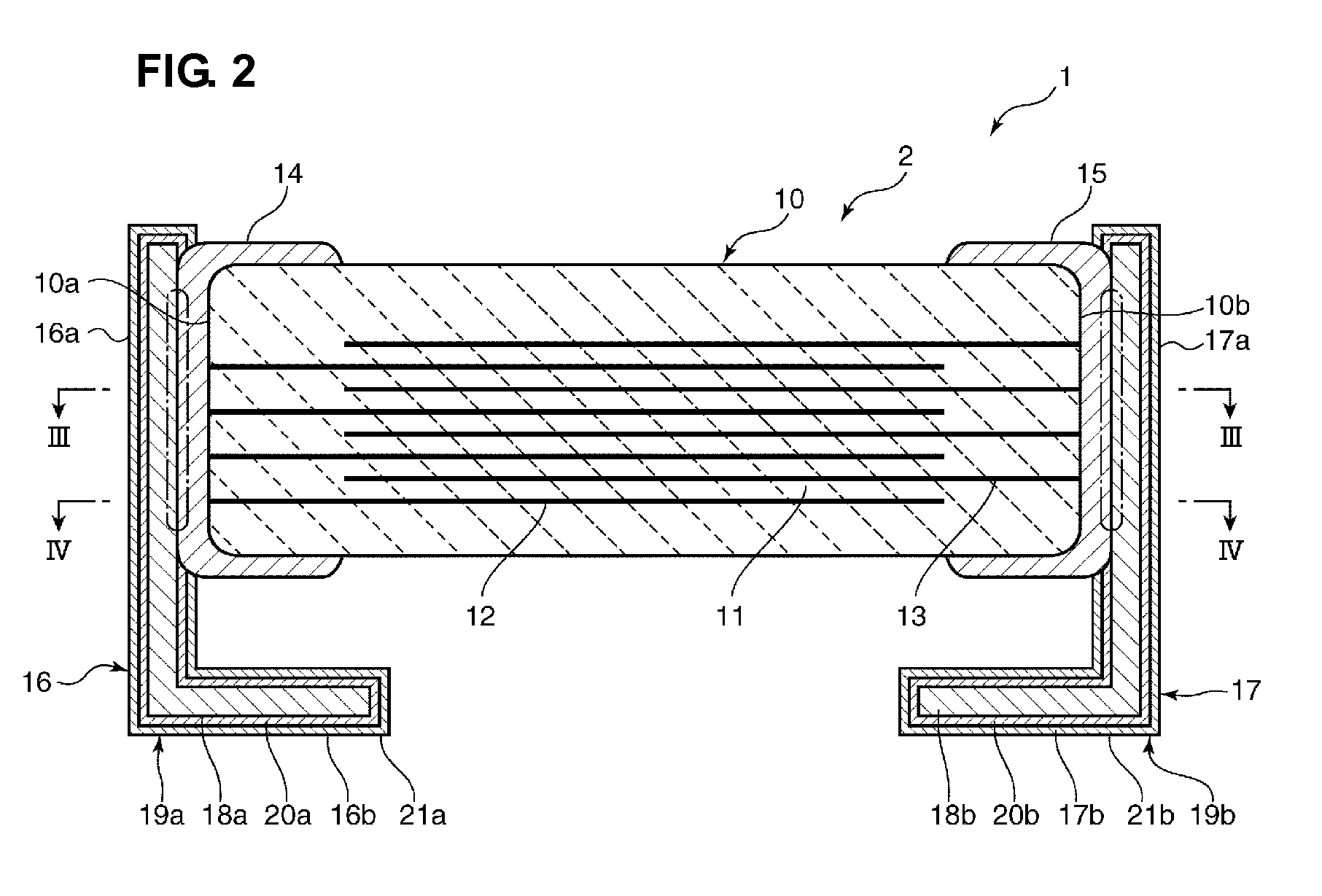

Laminated capacitor

A laminated capacitor that can be made small in size, that can prevent flashover, has excellent dielectric strength performance and a large capacitance is disclosed. Each gap between internal electrodes in the same plane is set at 2.7 to 20 times a thickness (element thickness) of a dielectric layer positioned between first and second internal electrode groups which face each other and a distance between an edge of the external terminal and an edge of the floating internal electrode closest to the external terminal among floating internal electrodes of the internal electrode group of the outermost layer is set at 0.4 mm to 1.4 mm.

Owner:MURATA MFG CO LTD

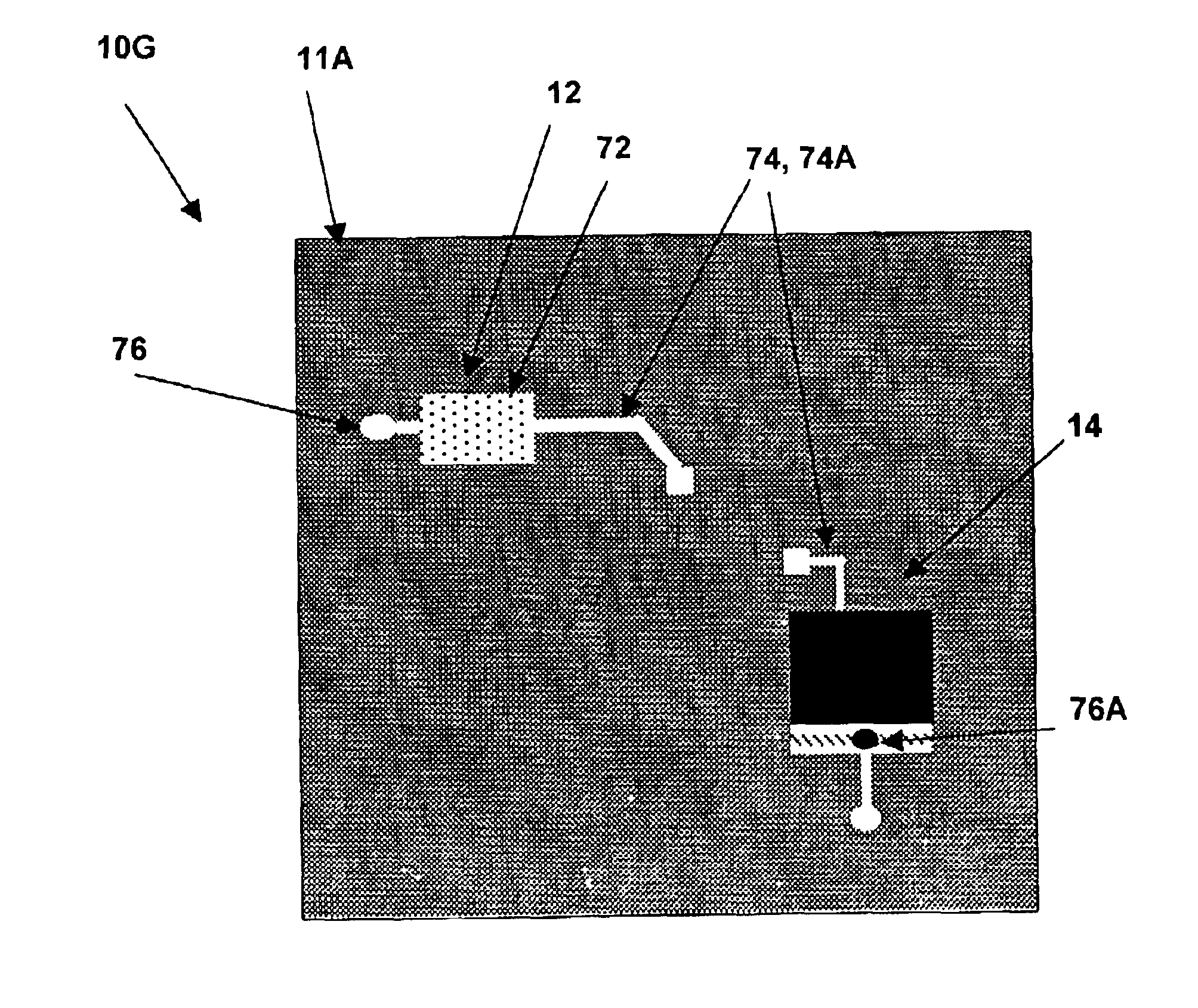

Bonded structures with integrated passive component

ActiveUS20180190580A1Multiple fixed capacitorsFixed capacitor dielectricEngineeringElectronic component

In various embodiments, a bonded structure is disclosed. The bonded structure can include an element and a passive electronic component having a first surface bonded to the element and a second surface opposite the first surface. The passive electronic component can comprise a first anode terminal bonded to a corresponding second anode terminal of the element and a first cathode terminal bonded to a corresponding second cathode terminal of the element. The first anode terminal and the first cathode terminal can be disposed on the first surface of the passive electronic component.

Owner:ADEIA SEMICON BONDING TECH INC

Integrated circuit substrate having embedded passive components and methods therefor

InactiveUS6987661B1Incremental costMultiple fixed capacitorsFixed capacitor dielectricConductive pasteConductive materials

An integrated circuit substrate having embdedded passive components provides a reduced cost and compact package for a die and one or more passive components. An insulating layer of the substrate is embossed or laser-ablated to generate apertures for insertion of a paste forming the body of the passive component. A resistive paste is used to form resistors and a dielectric paste is used for forming capacitors. A capacitor plate may be deposited at a bottom of the aperture by using a doped substrate material and activating only the bottom wall of the aperture, enabling plating of the bottom wall without depositing conductive material on the side walls of the aperture. Vias may be formed to the bottom plate by using a disjoint structure and conductive paste technology. Connection to the passive components may be made by conductive paste-filled channels forming conductive patterns on the substrate.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

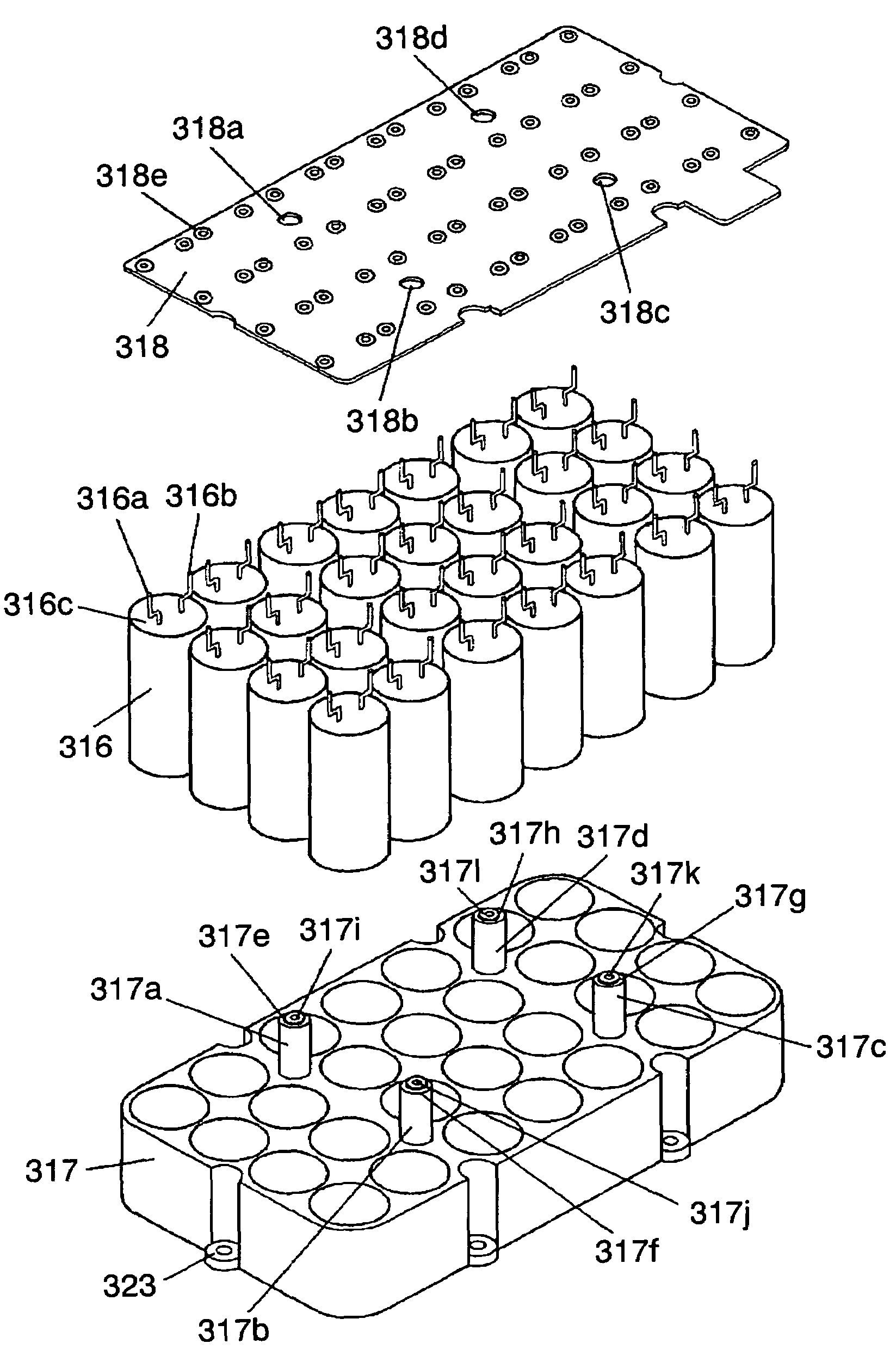

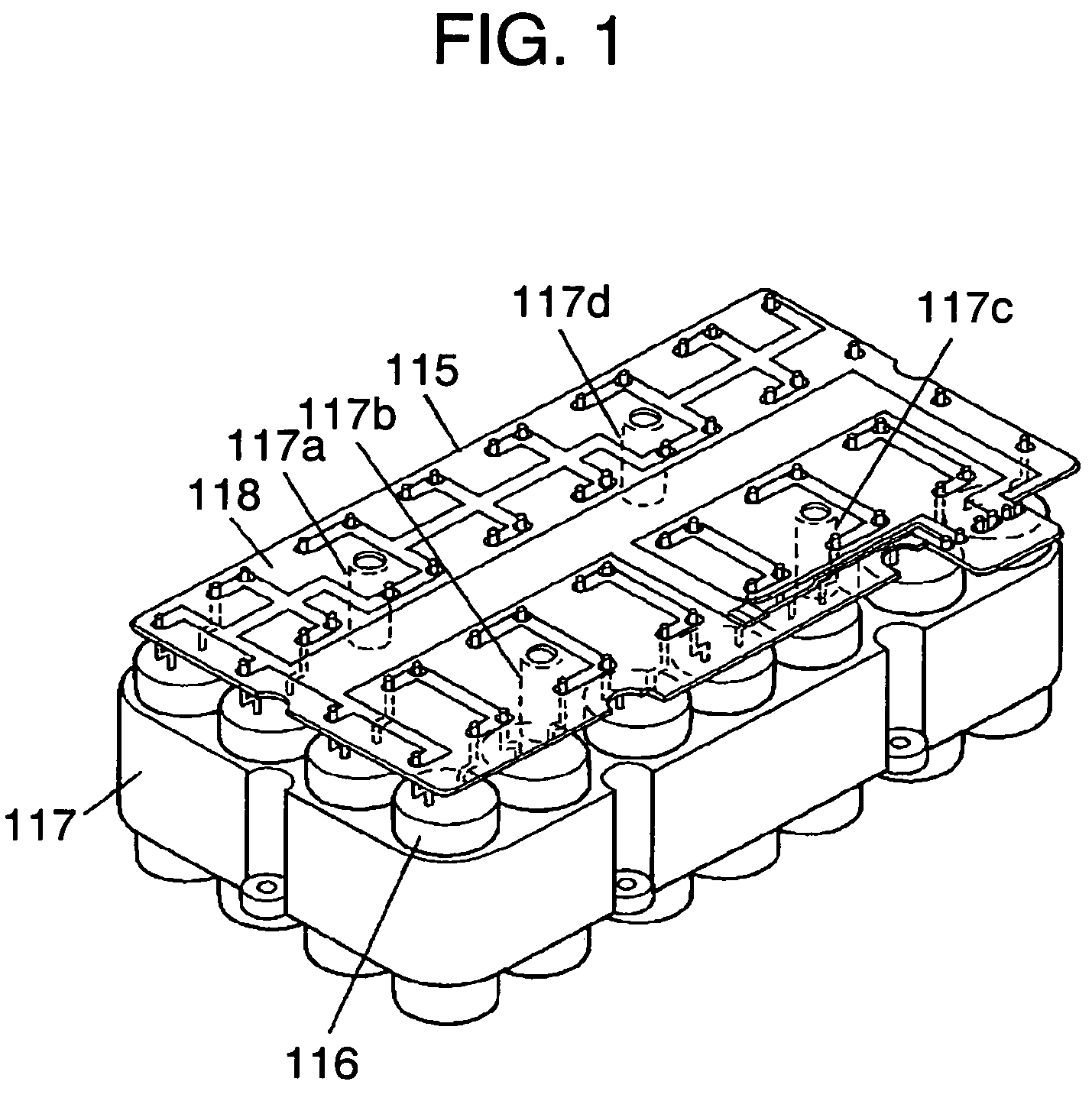

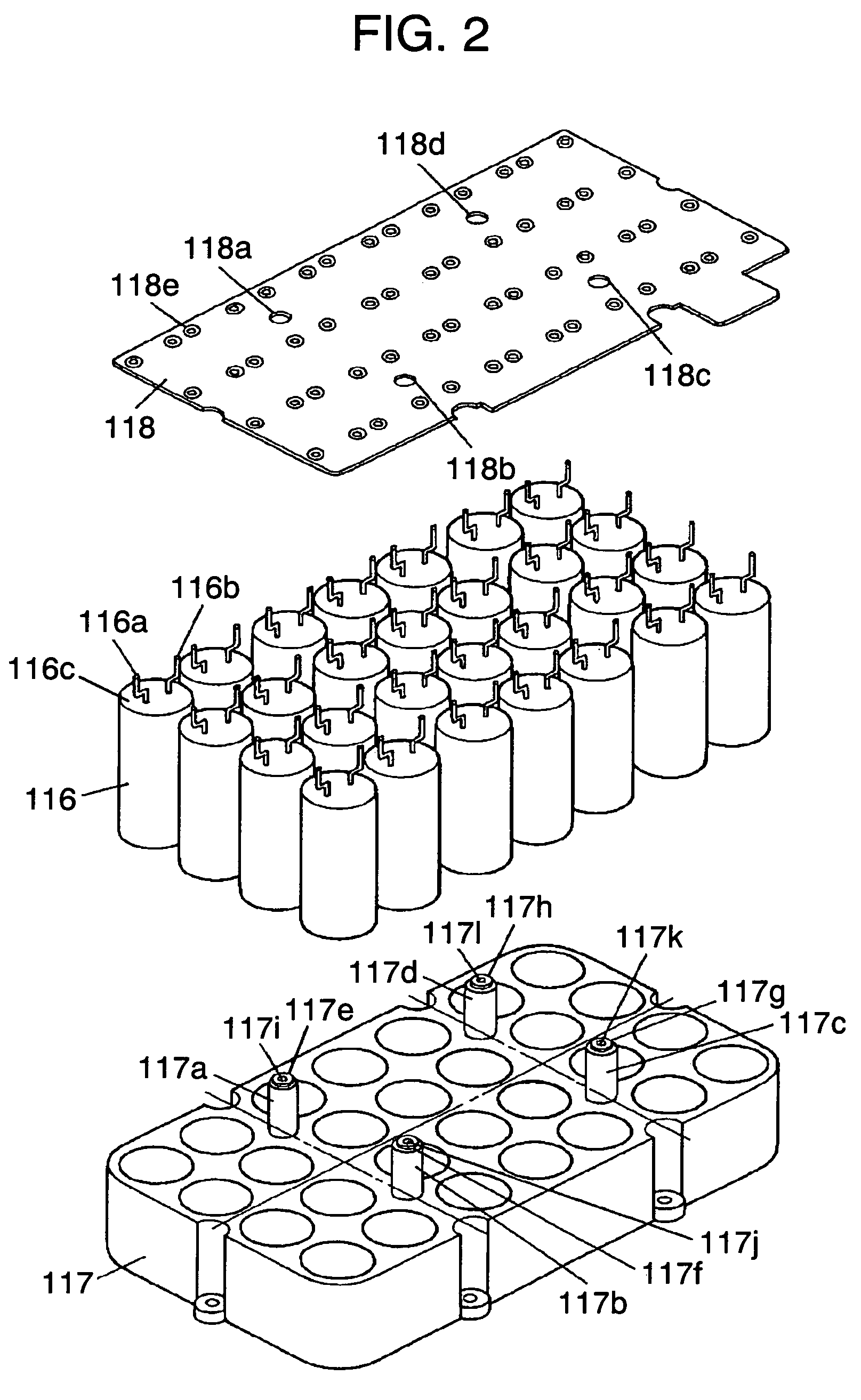

Capacitor unit

A capacitor unit is provided, which has a long lifetime and is free from maintenance when it is used as an emergency power supply of electronic control braking system, etc. and in which weight load is not applied to a circuit board, high reliability in use under harsh vibration conditions is achieved, and short-circuit defect does not occur even when an explosion-proof valve operates. The capacitor unit of the present invention includes a plurality of capacitors, a circuit board on which a circuit pattern for connecting the capacitors is formed, and a holder sandwiching and retaining the body parts of the capacitors.

Owner:PANASONIC CORP

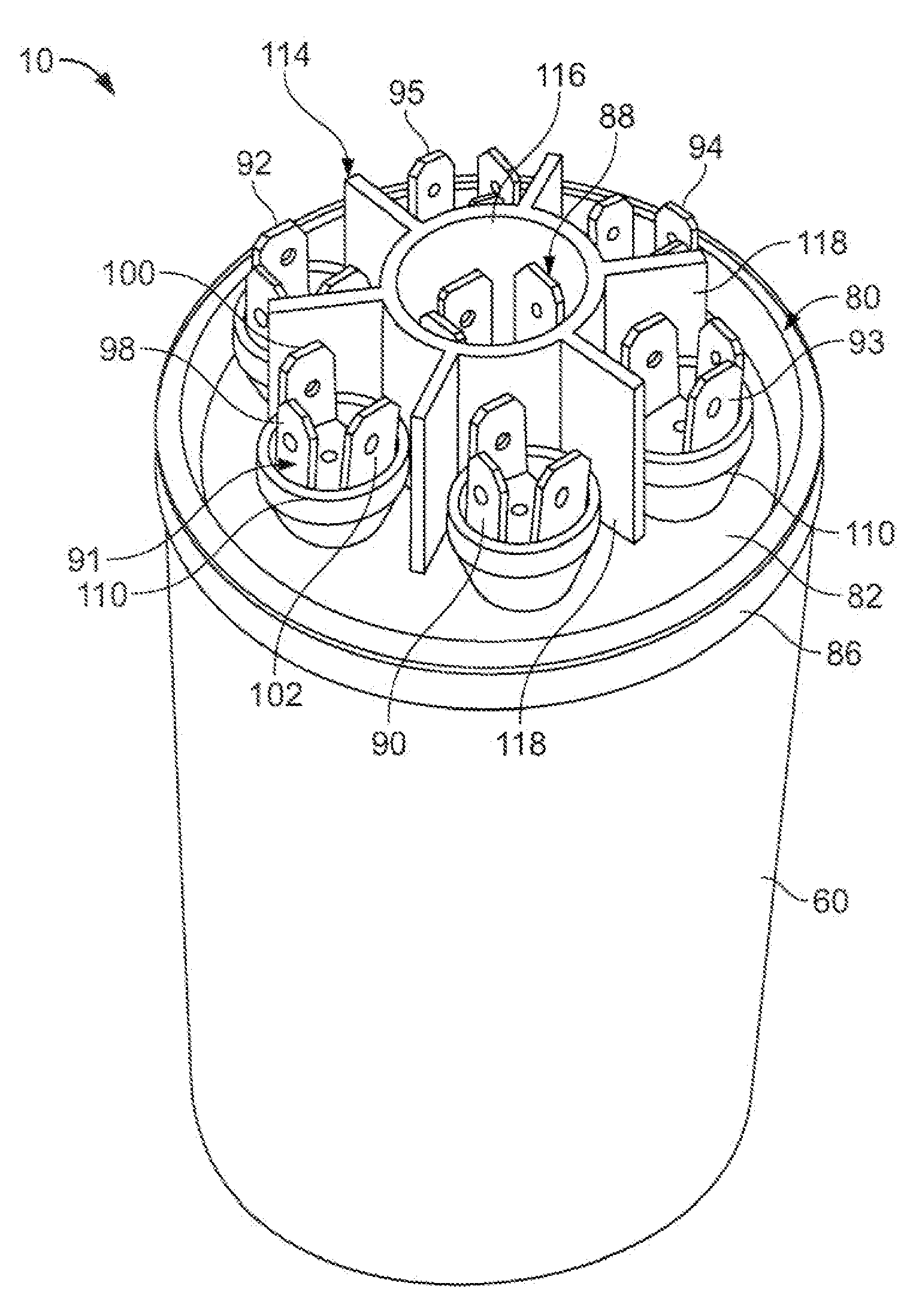

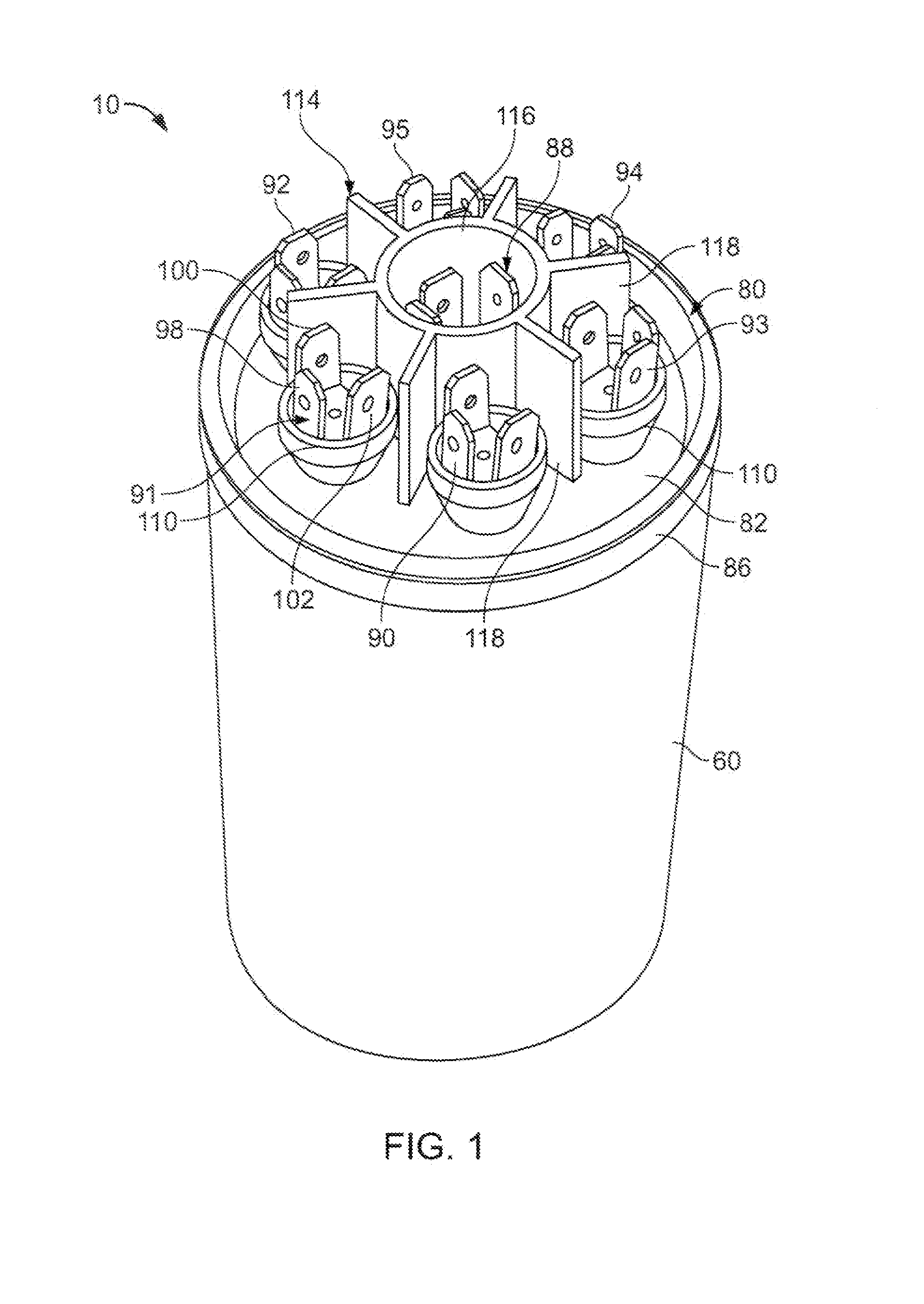

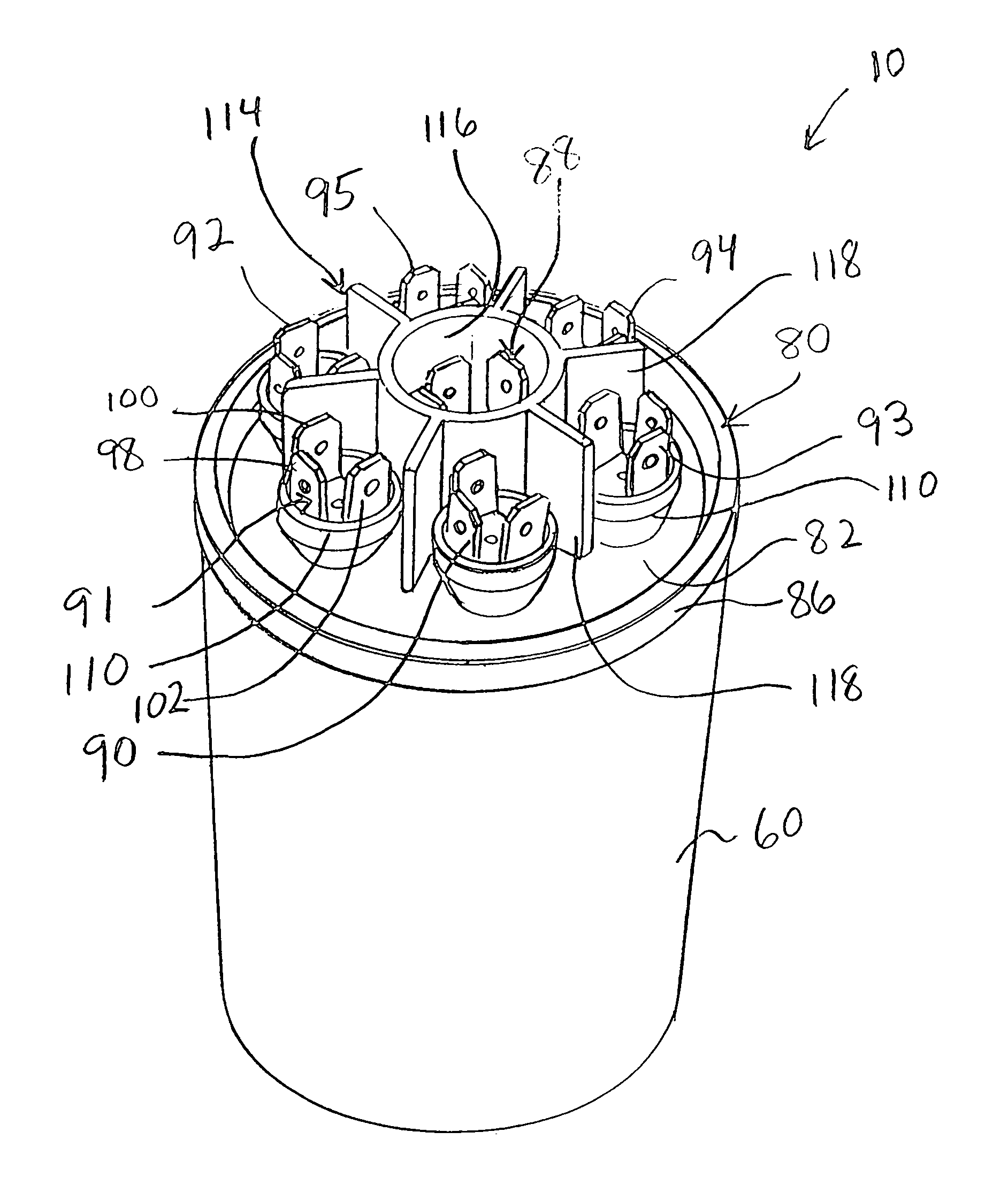

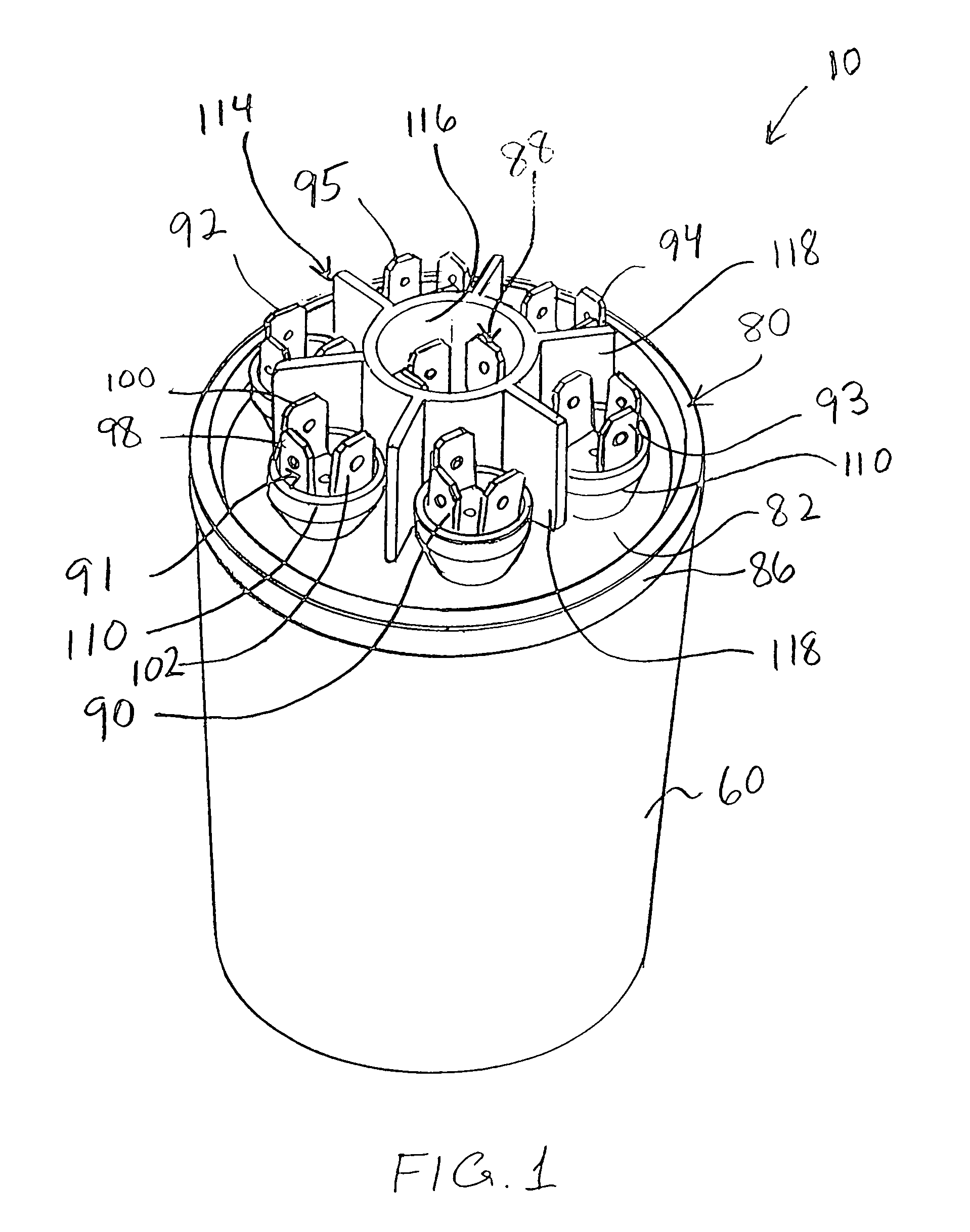

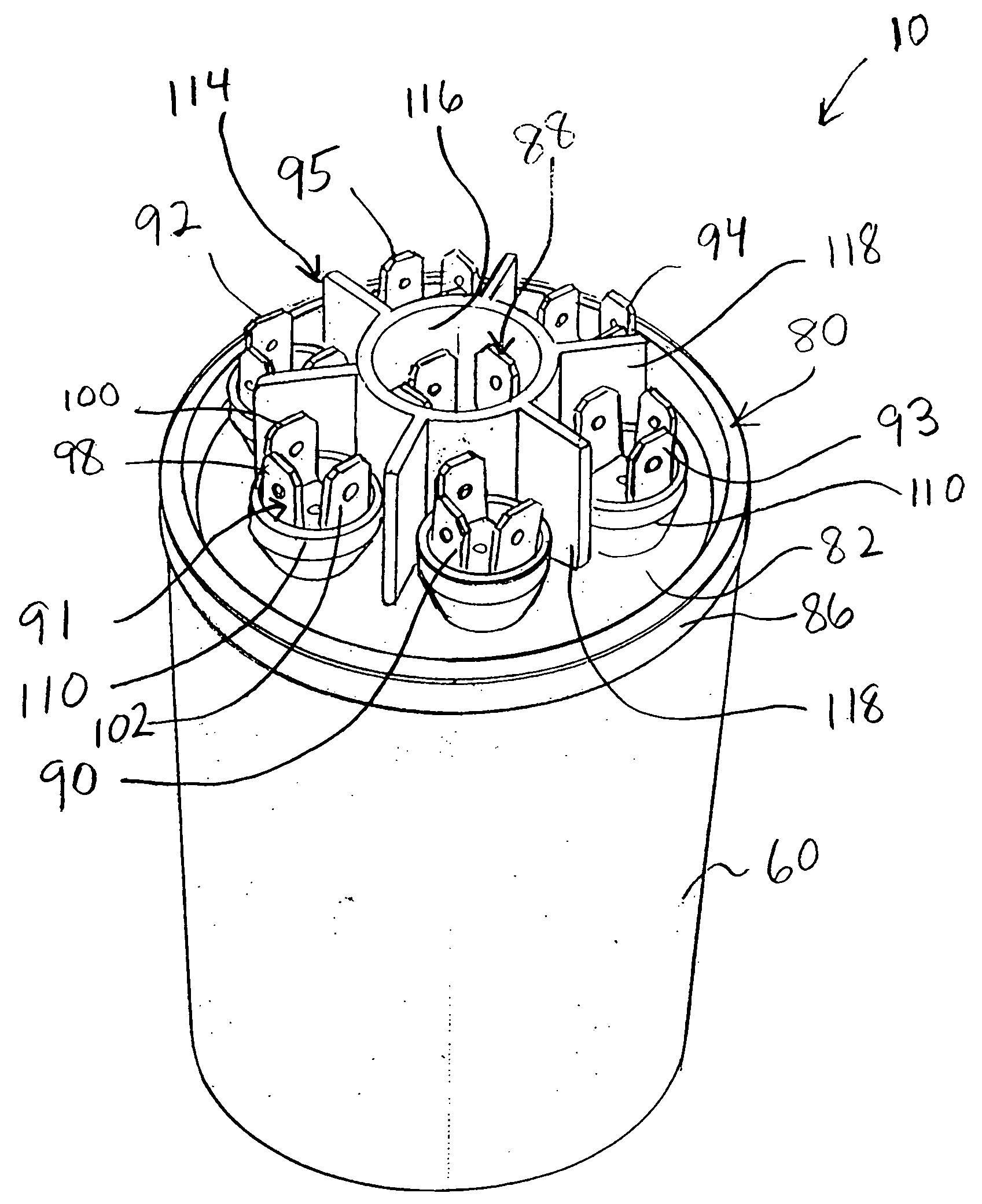

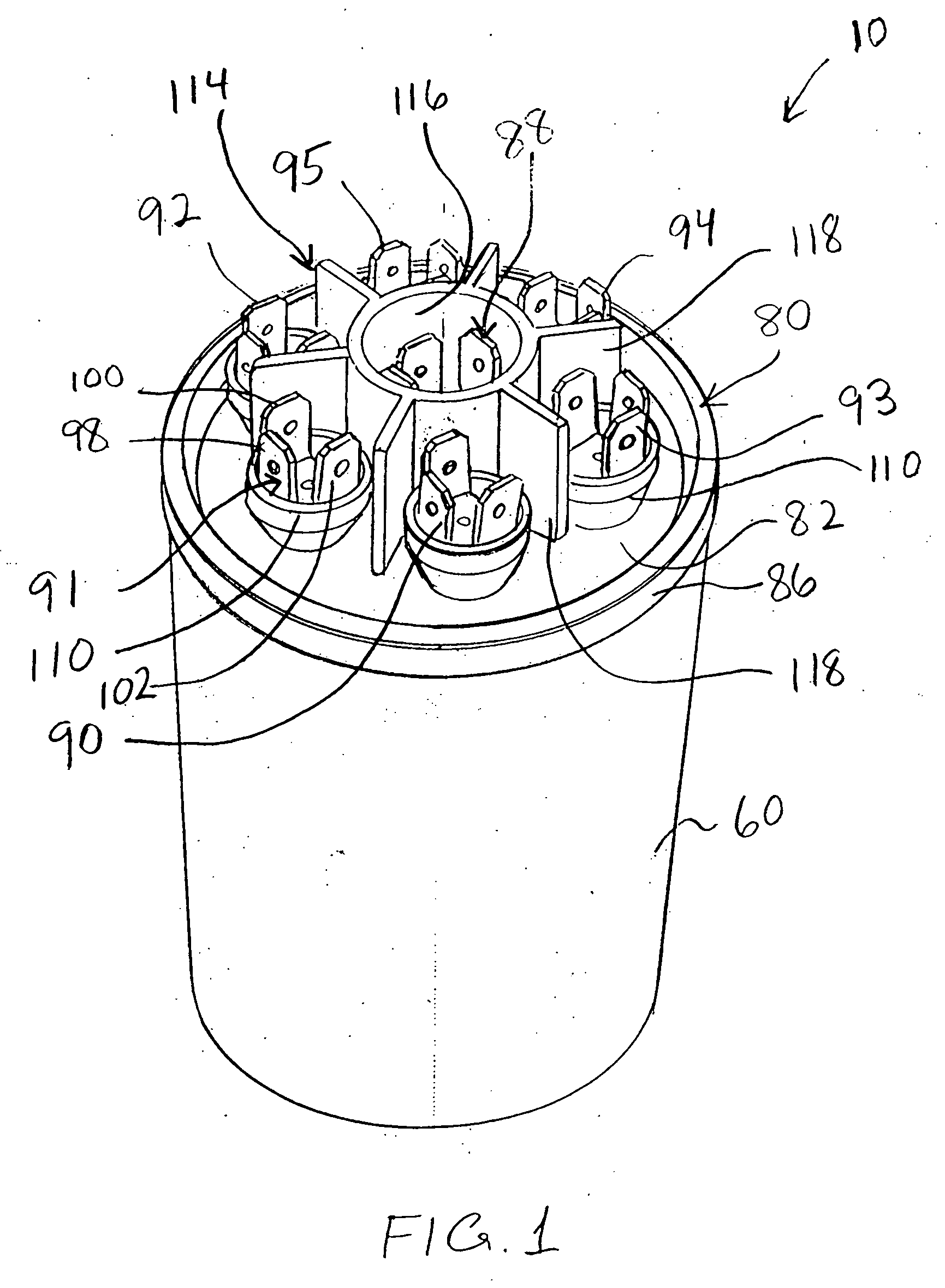

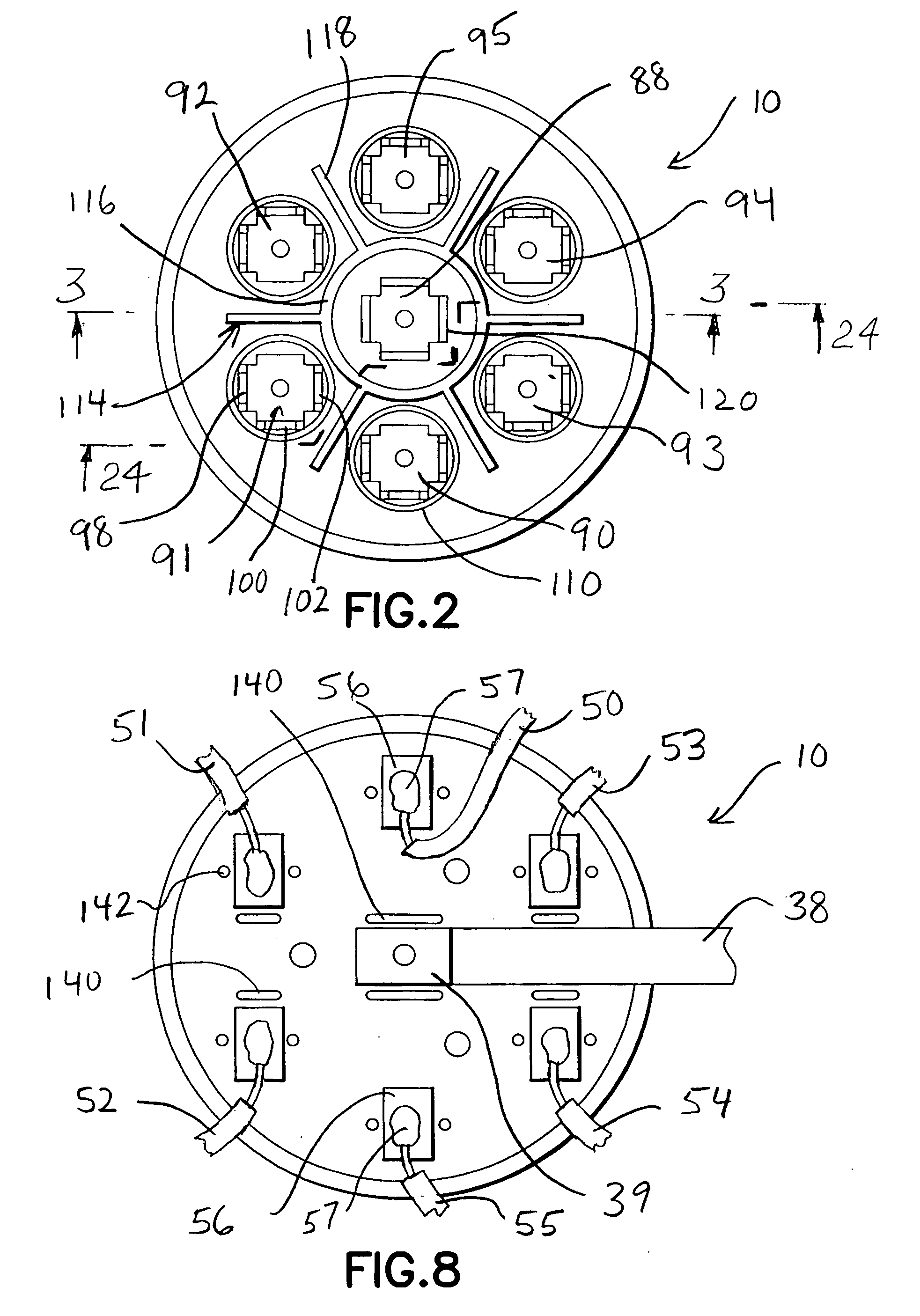

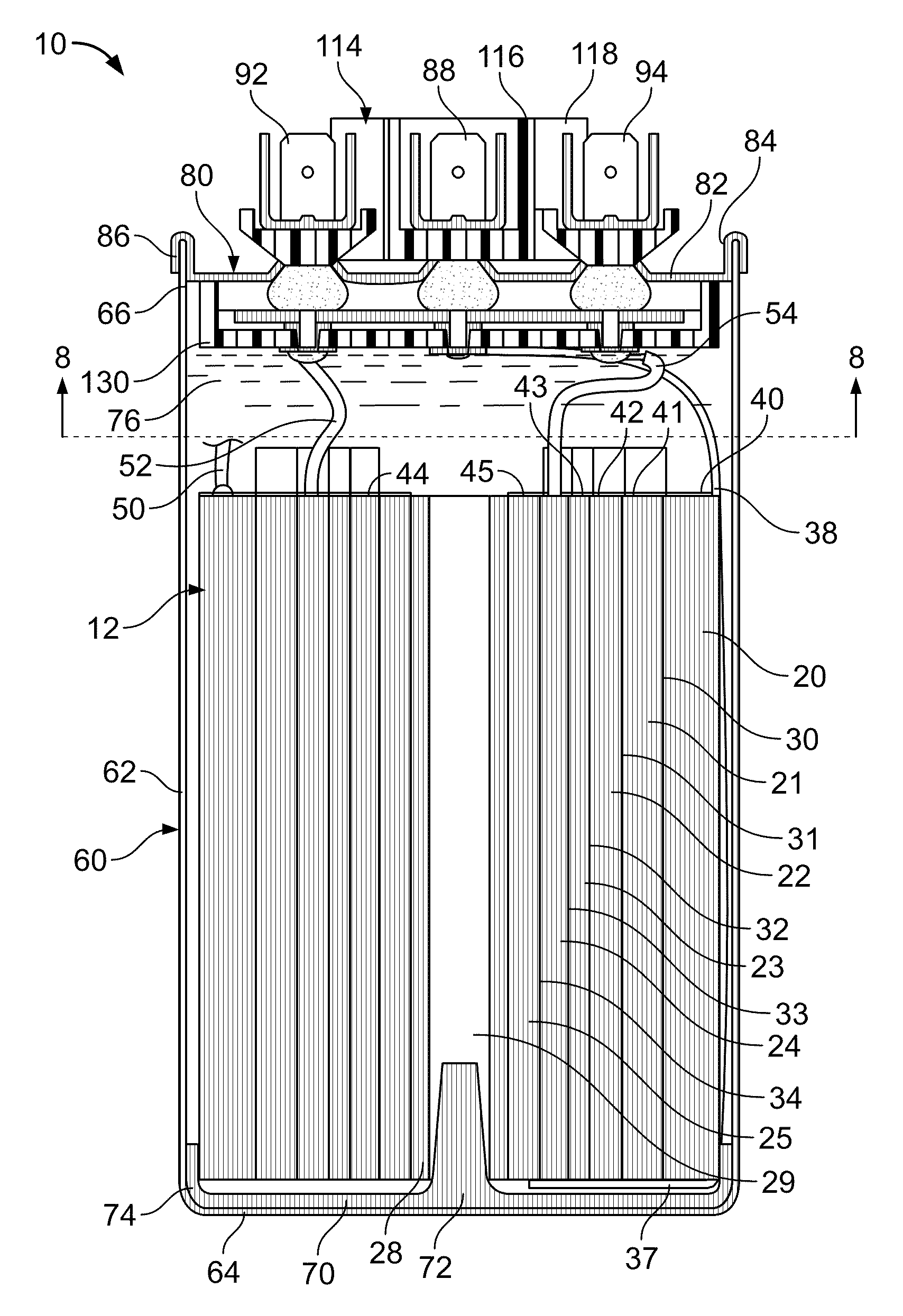

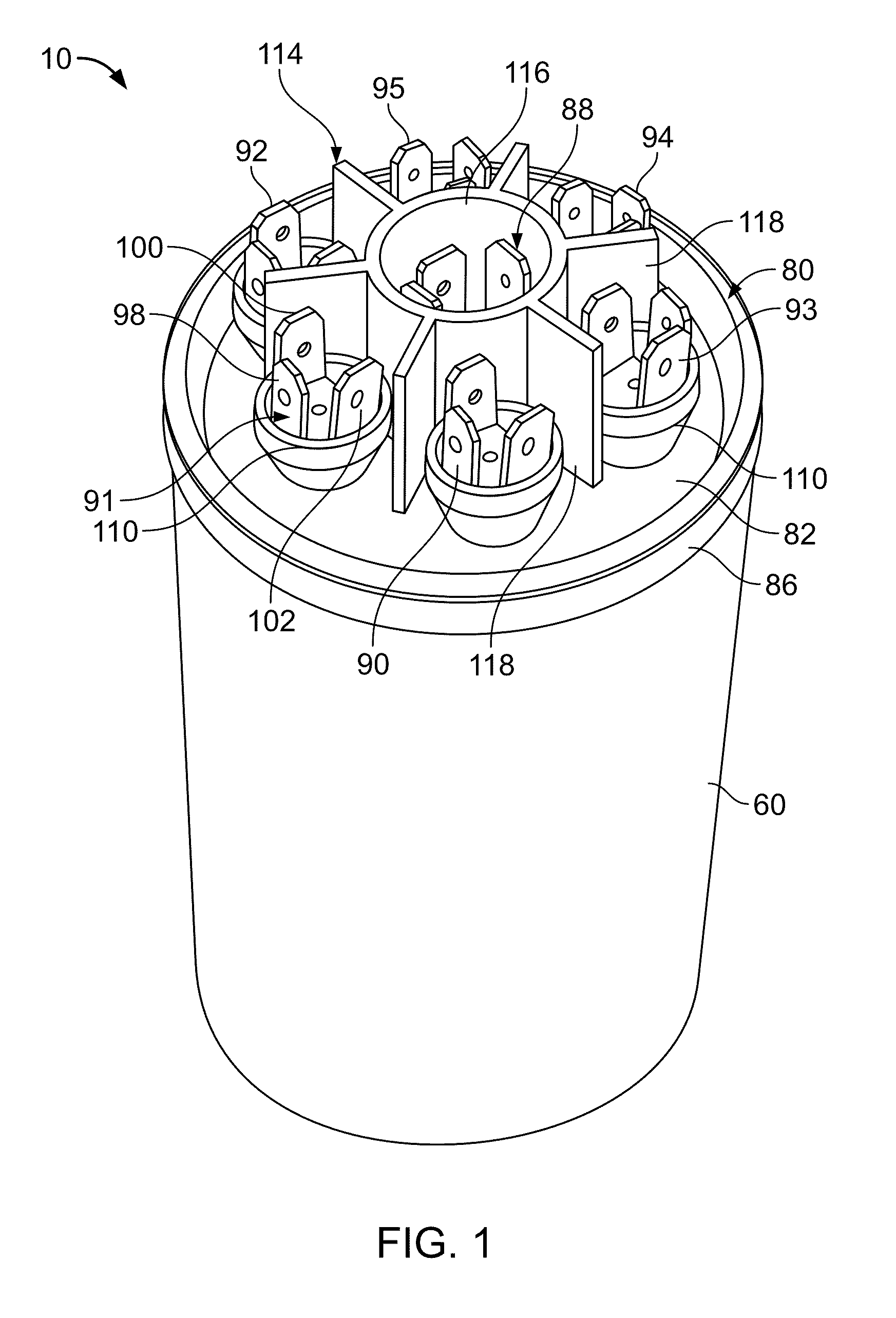

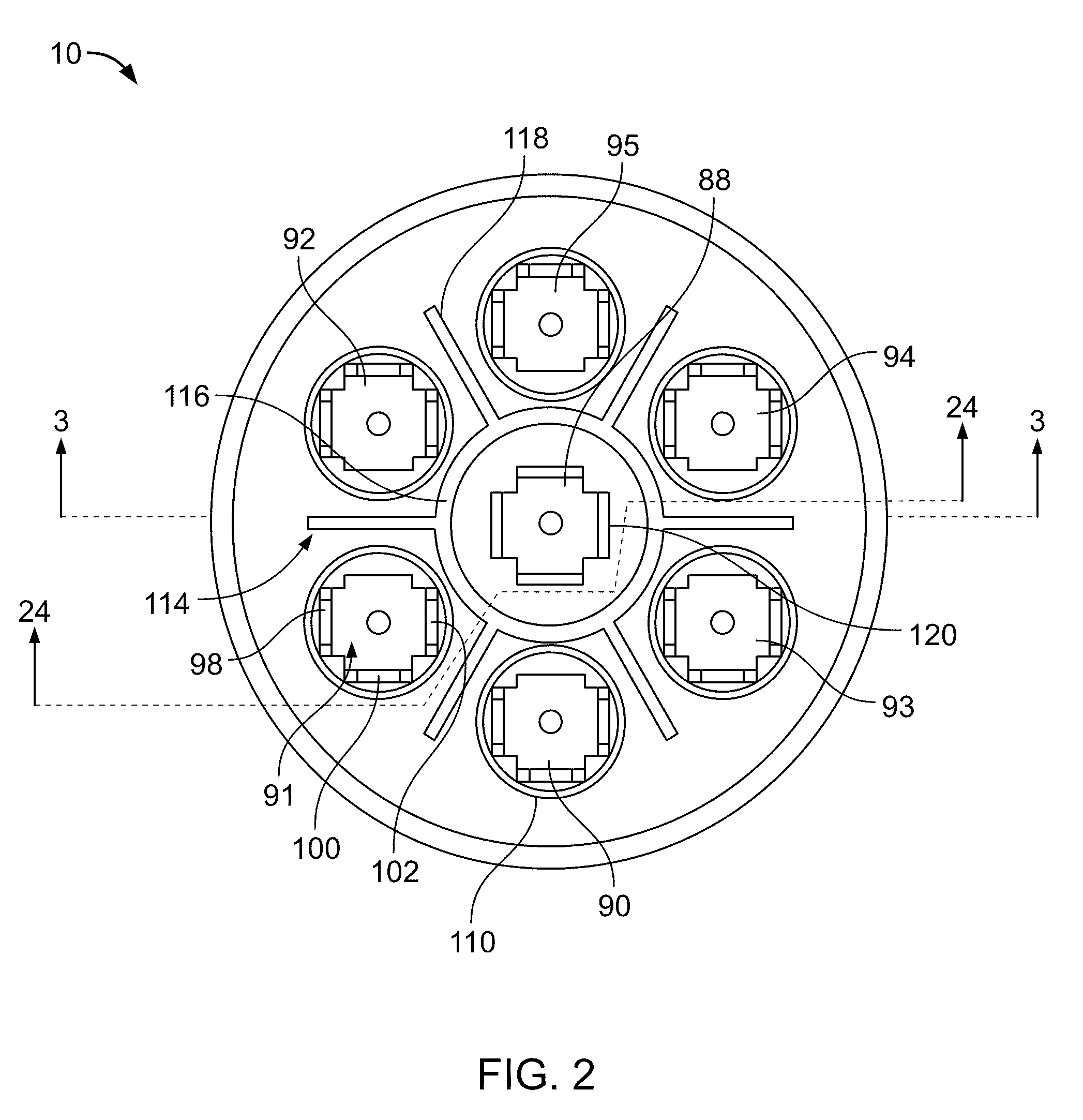

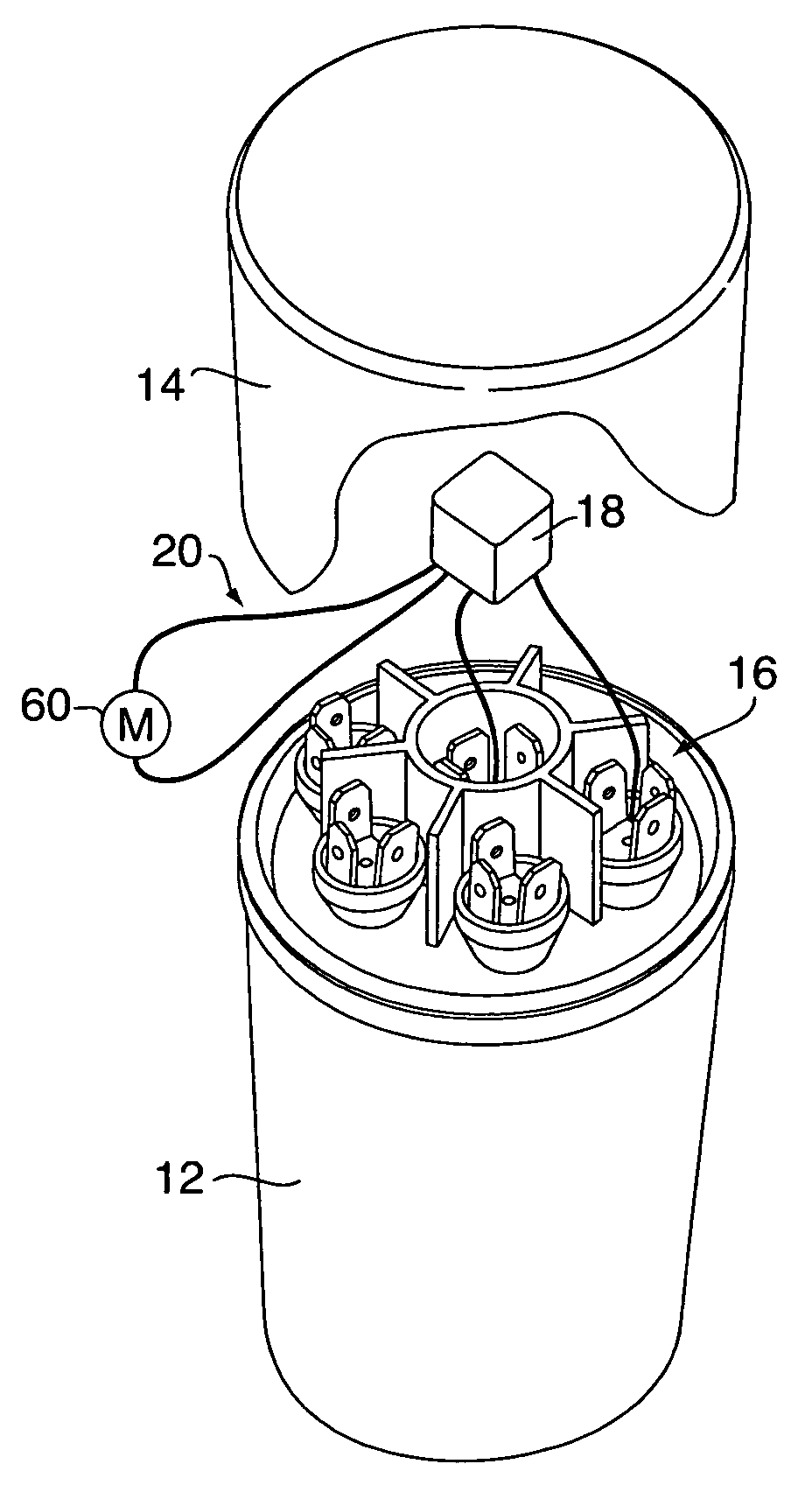

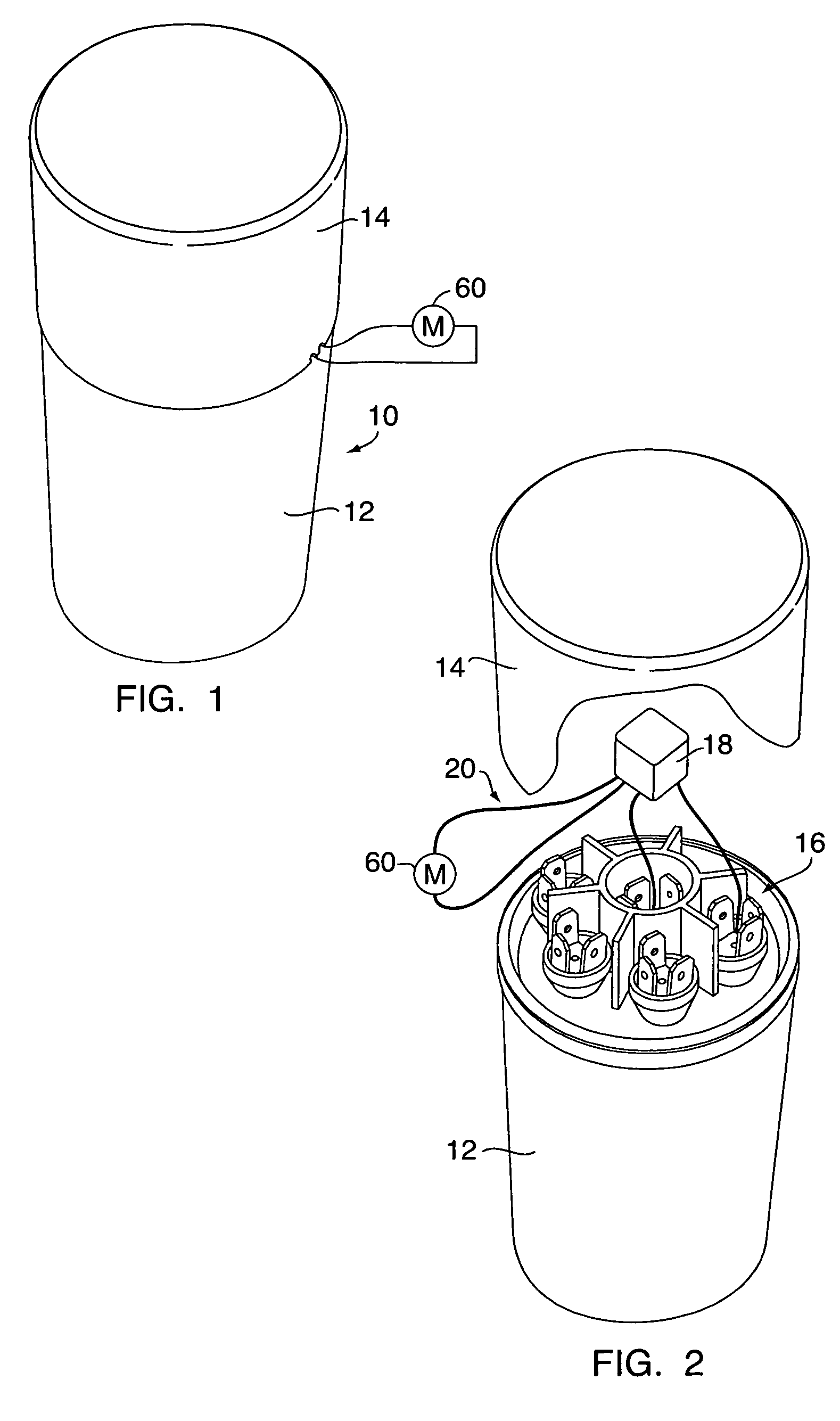

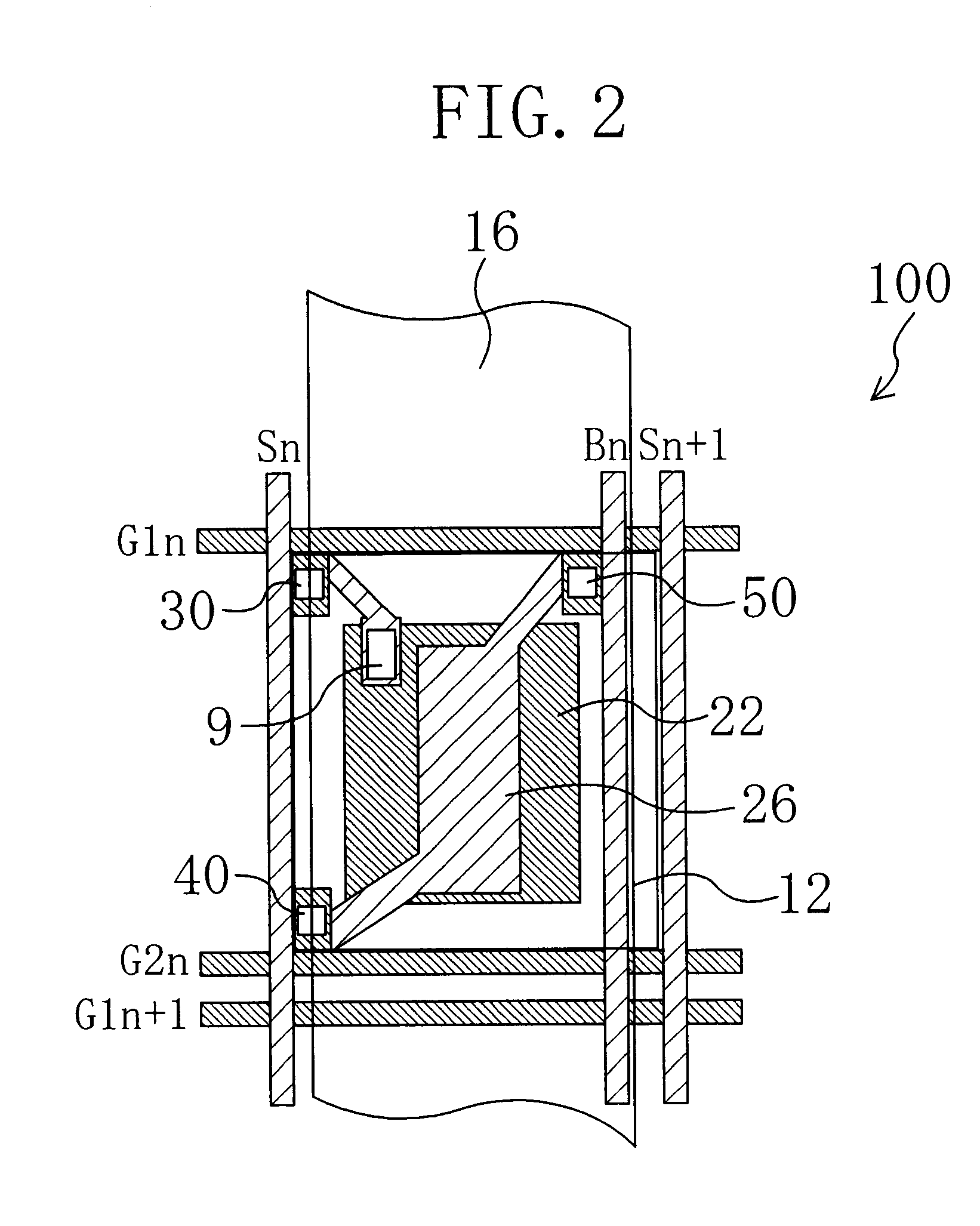

Capacitor with multiple elements for multiple replacement applications

ActiveUS7423861B2Safely making and maintainingIncrease flexibilityMultiple fixed capacitorsMechanically variable capacitor detailsCapacitanceElectrical conductor

A capacitor provides a plurality of selectable capacitance values, by selective connection of six capacitor sections of a capacitive element each having a capacitance value. The capacitor sections are provided in a plurality of wound cylindrical capacitive elements. Two vertically stacked wound cylindrical capacitance elements may each provide three capacitor sections. There may be six separately wound cylindrical capacitive elements each providing a capacitor section. The capacitor sections have a common element terminal. A pressure interrupter cover assembly is sealingly secured to the open end of case for the elements and has a deformable cover with a centrally mounted common cover terminal and a plurality of section cover terminals mounted at spaced apart locations. A conductor frangibly connects the common element terminal of the capacitor section to the common cover terminal and conductors respectively frangibly connect the capacitor section terminals to the section cover terminals. Deformation of the cover caused by failure of the capacitor element breaks at least some of the frangible connections sufficient to disconnect the capacitive element from an electric circuit in which it is connected. A cover insulation barrier mounted on the deformable cover, has a barrier cup substantially surrounding the common cover terminal and a plurality of barrier fins each extending radially outwardly from the barrier cup, and deployed between adjacent section cover terminals.

Owner:AMRAD MFG LLC

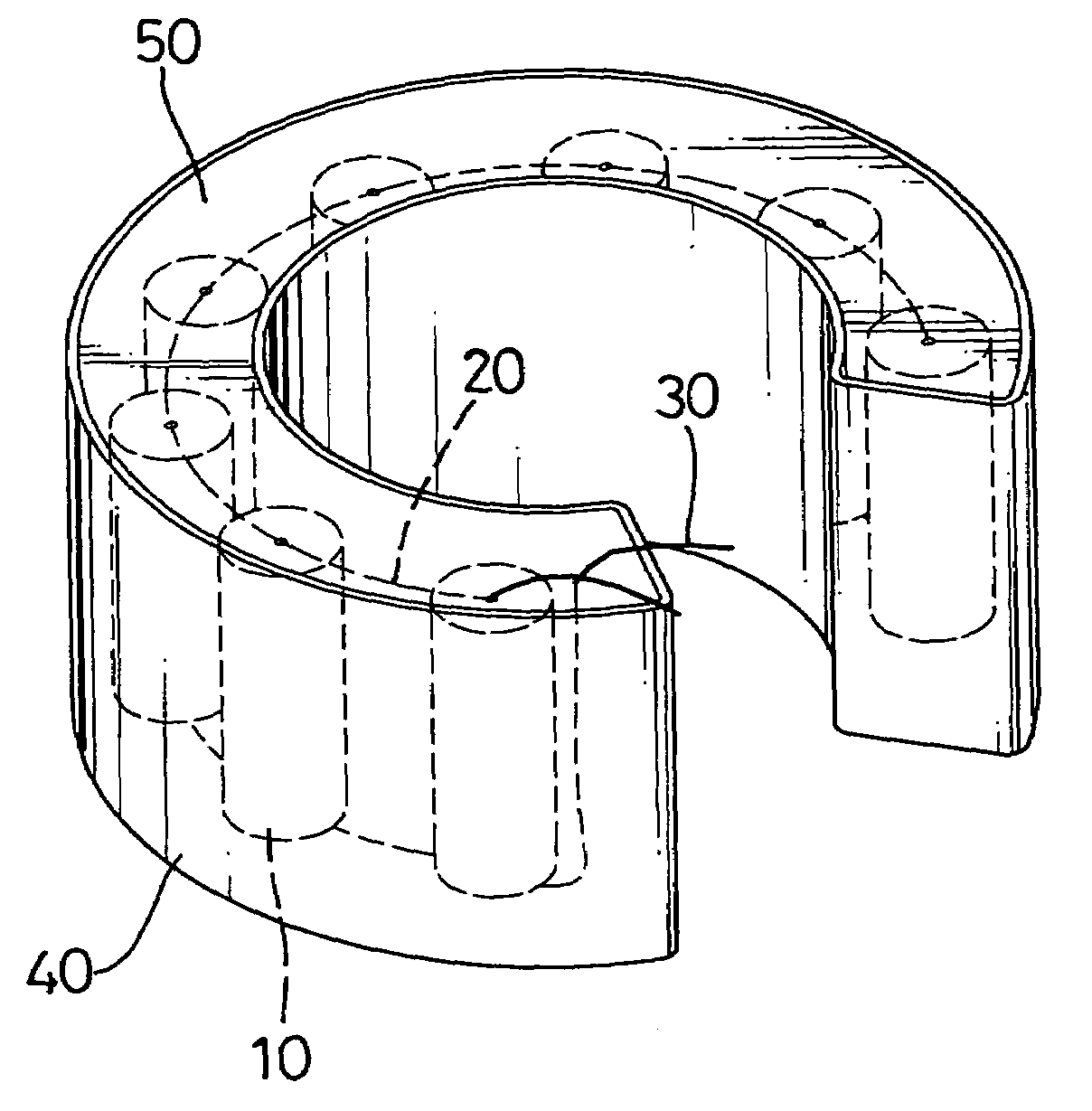

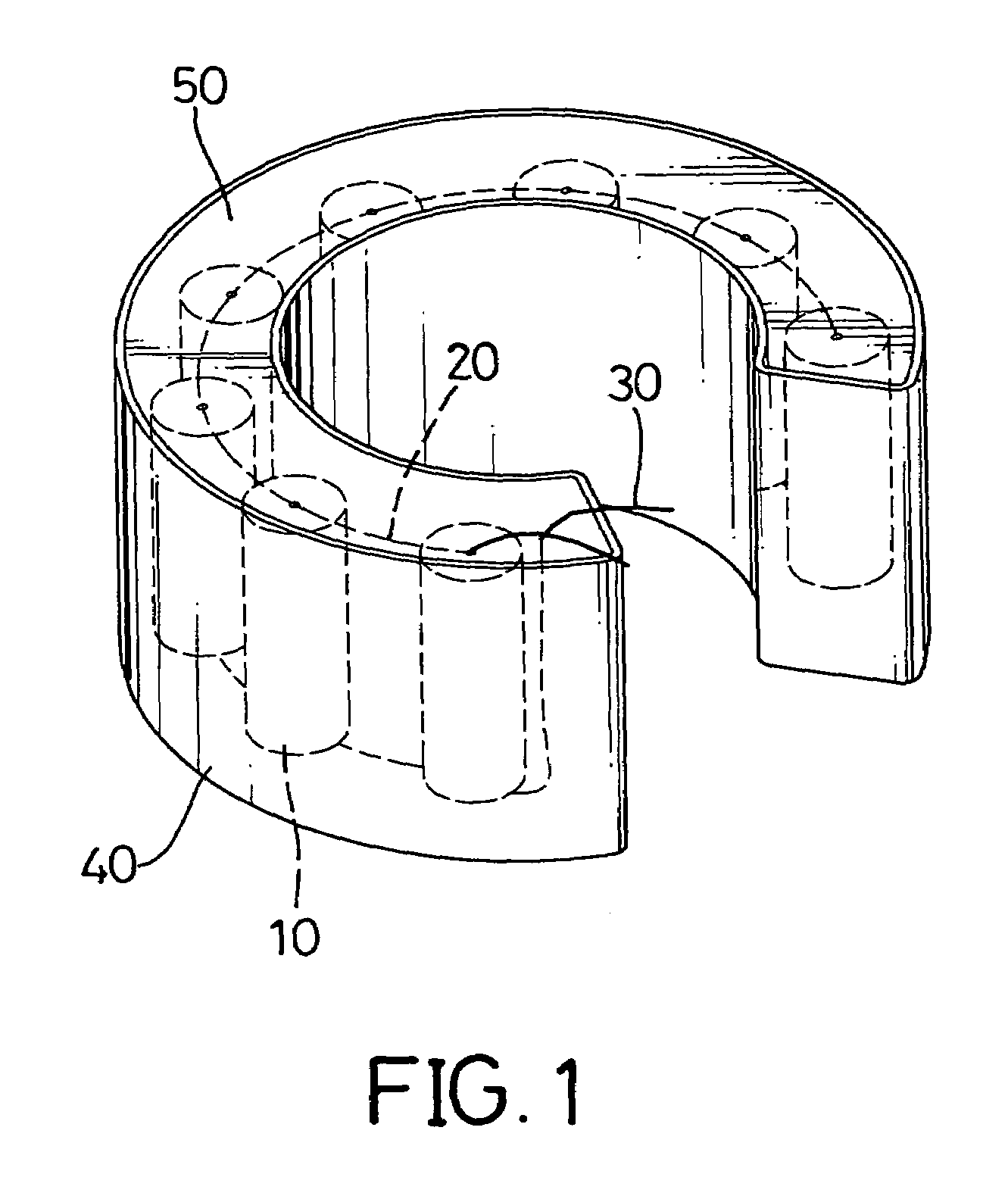

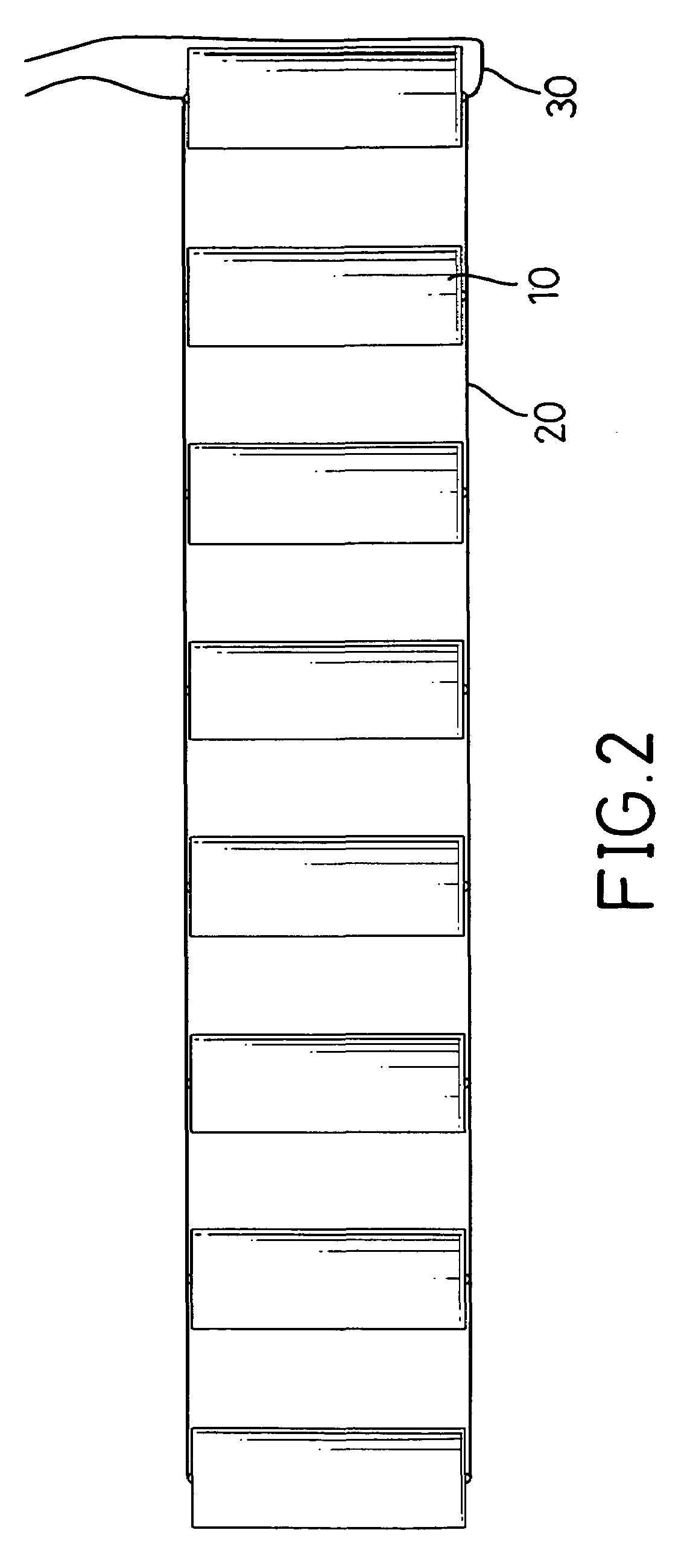

C-shaped combination capacitor assembly

InactiveUS7046498B1Simple processLess expensiveMultiple fixed capacitorsFixed capacitor electrodesCapacitorElectrical and Electronics engineering

A C-shaped combination capacitor assembly has a C-shaped shell, multiple capacitors, two conducting wires, two lead wires and encapsulant. The capacitors are mounted in the C-shaped shell. The conducting wires connect the capacitors in parallel. The two lead wires connect respectively to the conducting wires and protrude from the C-shaped shell. The encapsulant fills the C-shaped shell and covers and seals the capacitors, the conducting wires and the lead wires inside the C-shaped shell.

Owner:HUANG SHOU HSIUNG

Ceramic electronic component and method for manufacturing the same

ActiveUS20090296311A1Improve reliabilityIncrease resistanceMultiple fixed capacitorsFixed capacitor dielectricMetal particleElectronic component

A ceramic electronic component has a ceramic element assembly, external electrodes, and metal terminals. The external electrodes are arranged on the surface of the ceramic element assembly. The external electrodes contain a sintered metal. The metal terminals are electrically connected to the external electrodes, respectively. The external electrode and the metal terminal are directly diffusion-bonded by diffusion of metal in the metal terminals into the external electrodes. The above arrangement provides a ceramic electronic component having highly reliable metal particle bonding and a method for manufacturing the same.

Owner:MURATA MFG CO LTD

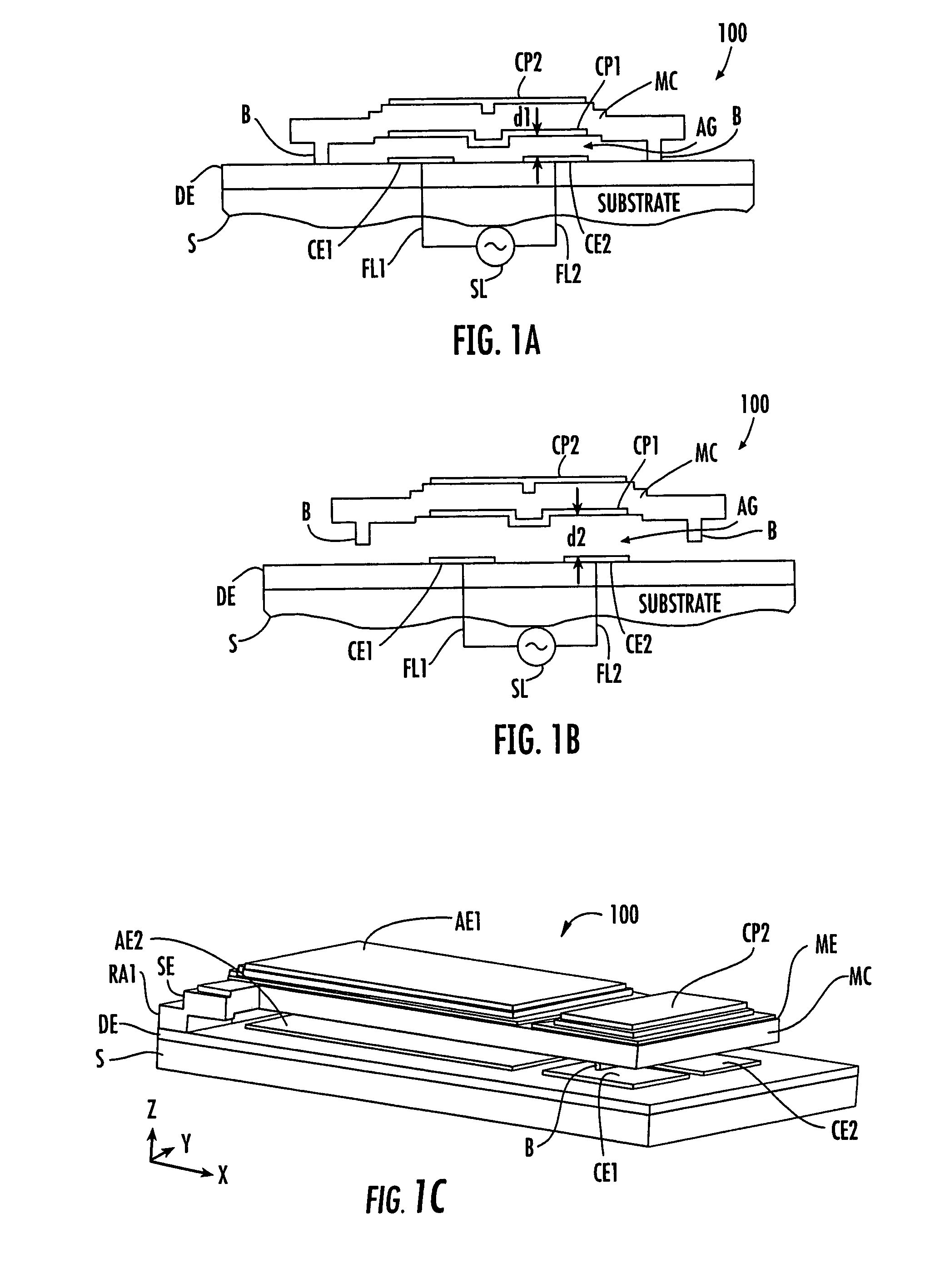

Micro-electro-mechanical system (MEMS) variable capacitors and actuation components and related methods

Micro-electro-mechanical system (MEMS) variable capacitors and actuation components and related methods are provided. A MEMS variable capacitor can include first and second feed lines extending substantially parallel to one another. Further, MEMS variable capacitors can include first and second capacitive plates being spaced apart from the first and second feed lines. The first and second capacitive plates can be separately movable with respect to at least one of the first and second feed lines for varying the capacitance between the first and second feed lines over a predetermined capacitance range.

Owner:AAC TECH PTE LTD

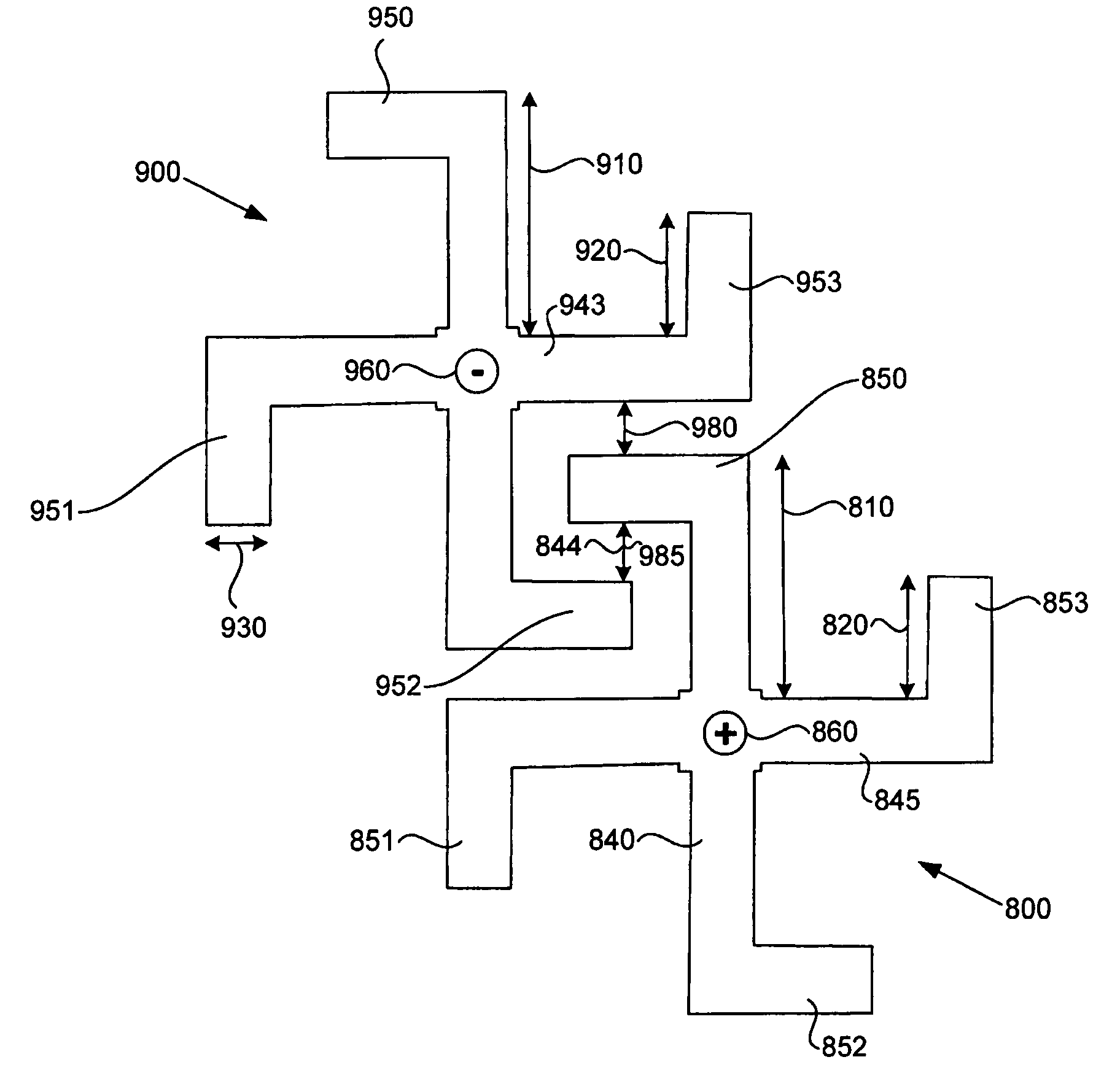

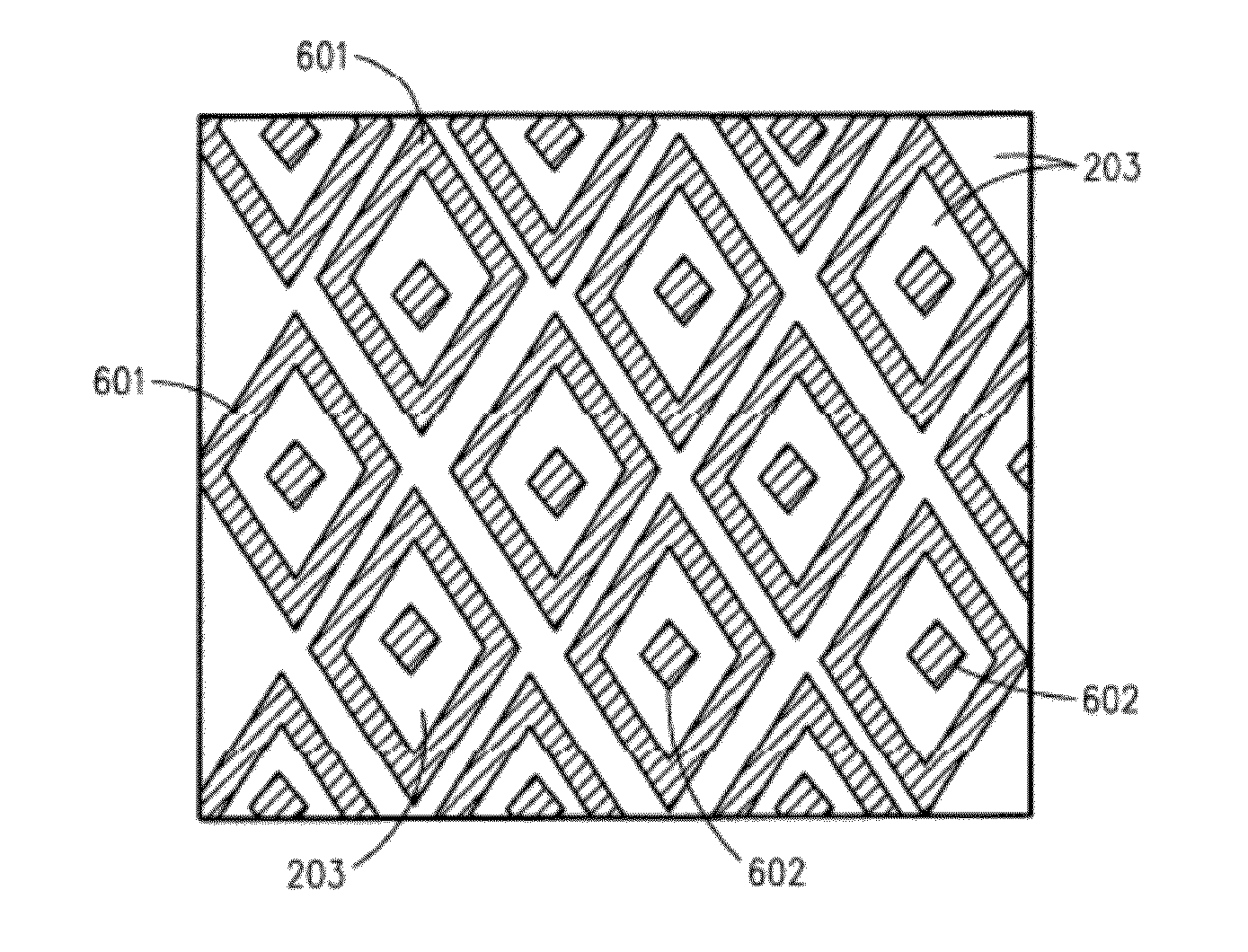

High density metal-to-metal maze capacitor with optimized capacitance matching

InactiveUS7009832B1Increase capacitance densityImproves capacitance capacitance matchingTransistorMultiple fixed capacitorsCapacitanceHigh density

A capacitor including a first and second component capacitor structure disposed on a substrate. A component capacitor structure includes an upright arm, a transverse arm, and a via. The upright arm has a top end and a bottom end that extend at substantially right angles to a central axis of the upright arm. The transverse arm has a left and right end that extend at substantially right angles to a central axis of the transverse arm. The upright arm and the transverse arm intersect to form a cross-like pattern and the top, bottom, left and right ends all extend in the same rotary direction. The via is electrically coupled to an area of intersection of the upright and transverse arms.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

Wiring board construction including embedded ceramic capacitors(s)

ActiveUS20070045815A1Small sizeMultiple fixed capacitorsCross-talk/noise/interference reductionCeramic capacitorEngineering

A wiring board includes a substrate core, ceramic capacitors and a built-up layer. The substrate core has a housing opening portion therein which opens at a core main surface. The ceramic capacitors are accommodated in the housing opening portion and oriented such that the core main surface and a capacitor main surface of each capacitor face the same way. The built-up layer includes semiconductor integrated circuit element mounting areas at various locations on a surface thereof. In the substrate core, each ceramic capacitor is respectively disposed in an area corresponding to each semiconductor integrated circuit element mounting area.

Owner:NGK SPARK PLUG CO LTD

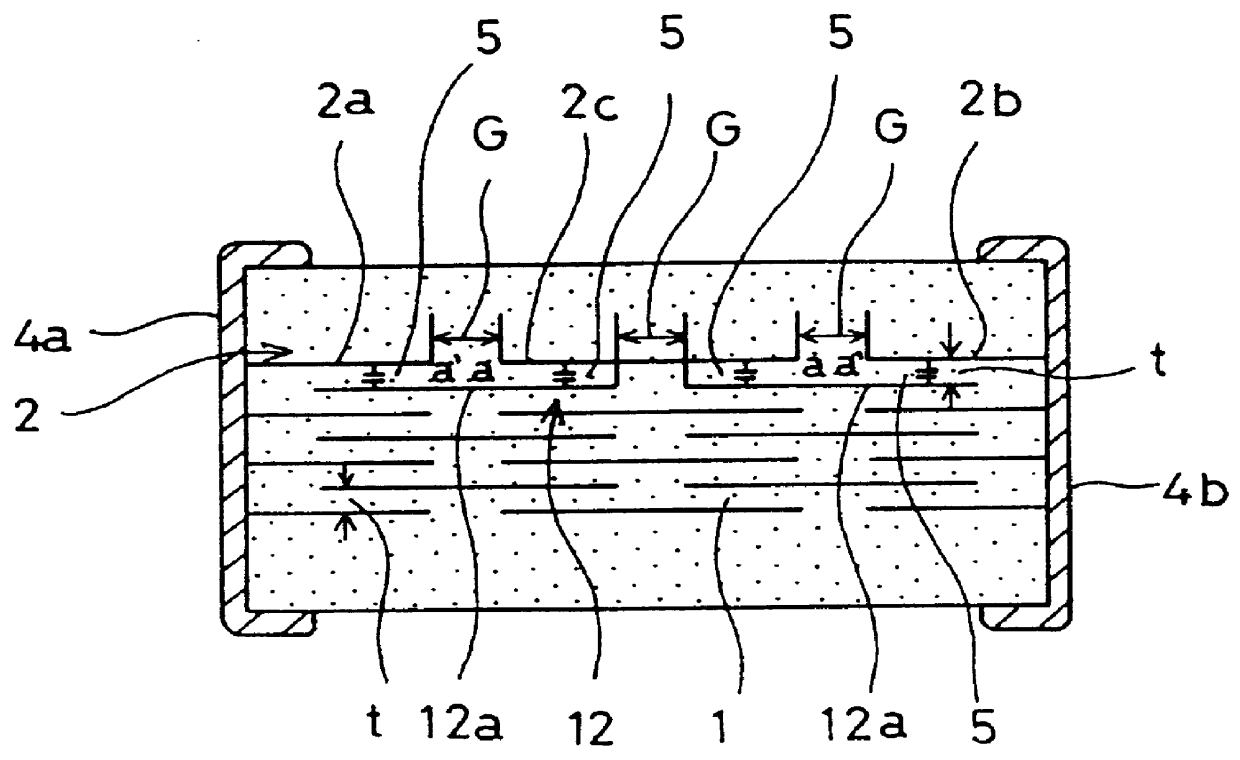

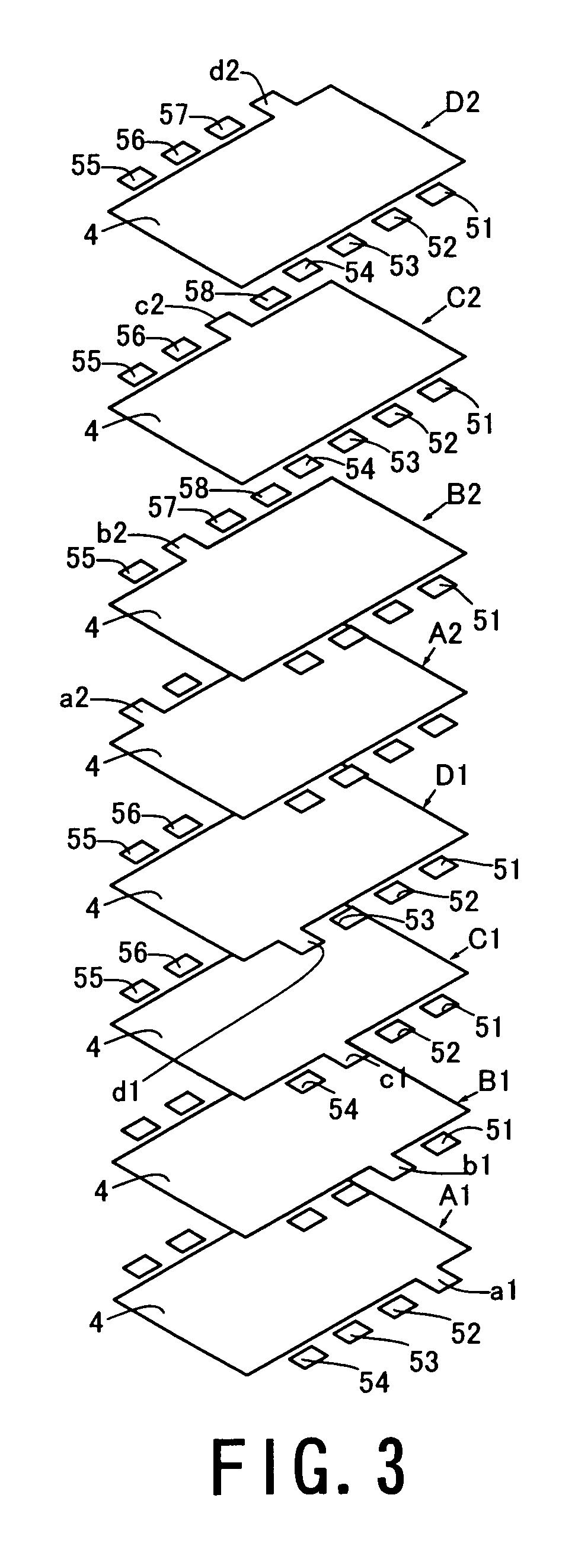

Laminated ceramic capacitor

ActiveUS7050288B2Reduce connectionsReducing occurrence of delaminationMultiple fixed capacitorsFixed capacitor electrodesCeramic capacitorEngineering

Internal electrodes A1 to D1 and A2 to D2 are laid in layers at spaces in the direction of thickness of a ceramic body 1. Lead electrodes a1 to d1 and a2 to d2 are led out to a side face to form lead portions. Dummy electrodes 51 to 58 have one-side ends led out to a side face to form lead portions in layers provided with the internal electrodes A1 to D1 and A2 to D2. The lead portion of a lead electrode a1 to d1 or a2 to d2 of each layer is superposed over the lead portion of a dummy electrode 51 to 58 belonging to another layer in the direction of thickness.

Owner:TDK CORPARATION

Capacitor for multiple replacement applications

ActiveUS20060227495A1Safely making and maintainingIncrease flexibilityMultiple fixed capacitorsFixed capacitor housing/encapsulationCapacitanceElectrical conductor

A capacitor provides a plurality of selectable capacitance values, by selective connection of six concentrically wound capacitor sections of a capacitive element each having a capacitance value. The capacitor sections each have a respective section element terminal at a first end of the capacitive element and the capacitor sections have a common element terminal at a second end of the capacitive element. A pressure interrupter cover assembly is sealingly secured to the open end a case for the element and has a deformable cover with a centrally mounted common cover terminal and a plurality of section cover terminals mounted at spaced apart locations. A conductor frangibly connects the common element terminal of the capacitive element to the common cover terminal and conductors respectively frangibly connect the capacitor section terminals to the section cover terminals. Deformation of the cover caused by failure of the capacitor element breaks at least some of the frangible connections sufficient to disconnect the capacitive element from an electric circuit in which it is connected. A cover insulation barrier mounted on the deformable cover, has a barrier cup substantially surrounding the common cover terminal and a plurality of barrier fins each extending radially outwardly from the barrier cup, and deployed between adjacent section cover.

Owner:AMRAD MFG LLC

Capacitor with multiple elements for multiple replacement applications

ActiveUS20090219665A1Safely making and maintainingIncrease flexibilityMultiple fixed capacitorsMechanically variable capacitor detailsCapacitanceElectrical conductor

Owner:AMRAD MFG LLC

Monolithic capacitor

InactiveUS20010007522A1Improve thermal shock resistancePrinted circuit assemblingMultiple fixed capacitorsCeramic capacitorMaterials science

A monolithic capacitor includes a plurality of monolithic ceramic capacitor elements provided with external electrodes at both ends thereof, solder layers arranged on the entire surfaces of the external electrodes of the monolithic ceramic capacitor elements, and metal terminals electrically connected to the external electrodes of the monolithic ceramic capacitor elements. The monolithic ceramic capacitor elements are joined to each other by the solder layers and are stacked on each other. The external electrodes of the monolithic ceramic capacitor elements are electrically connected to each other by the solder layers.

Owner:MURATA MFG CO LTD

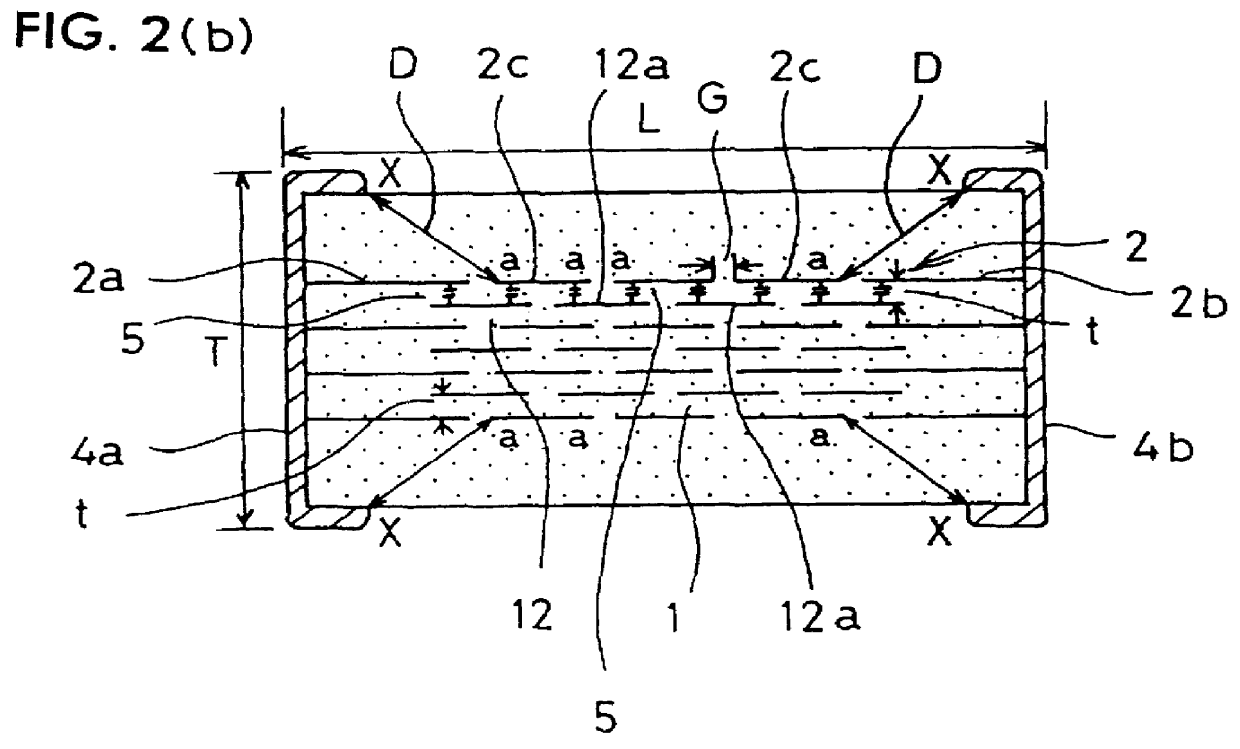

Film capacitor and method of manufacturing the same

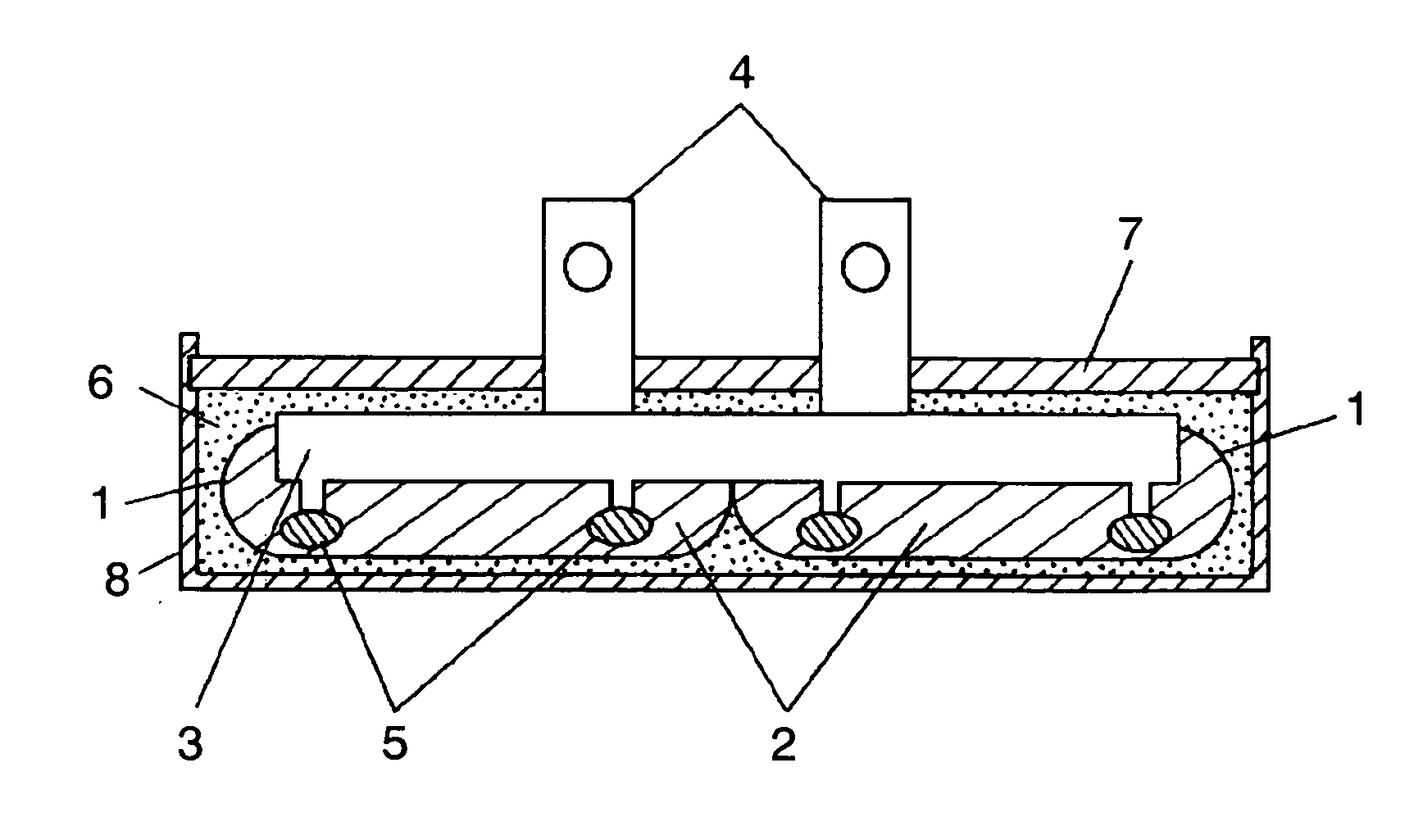

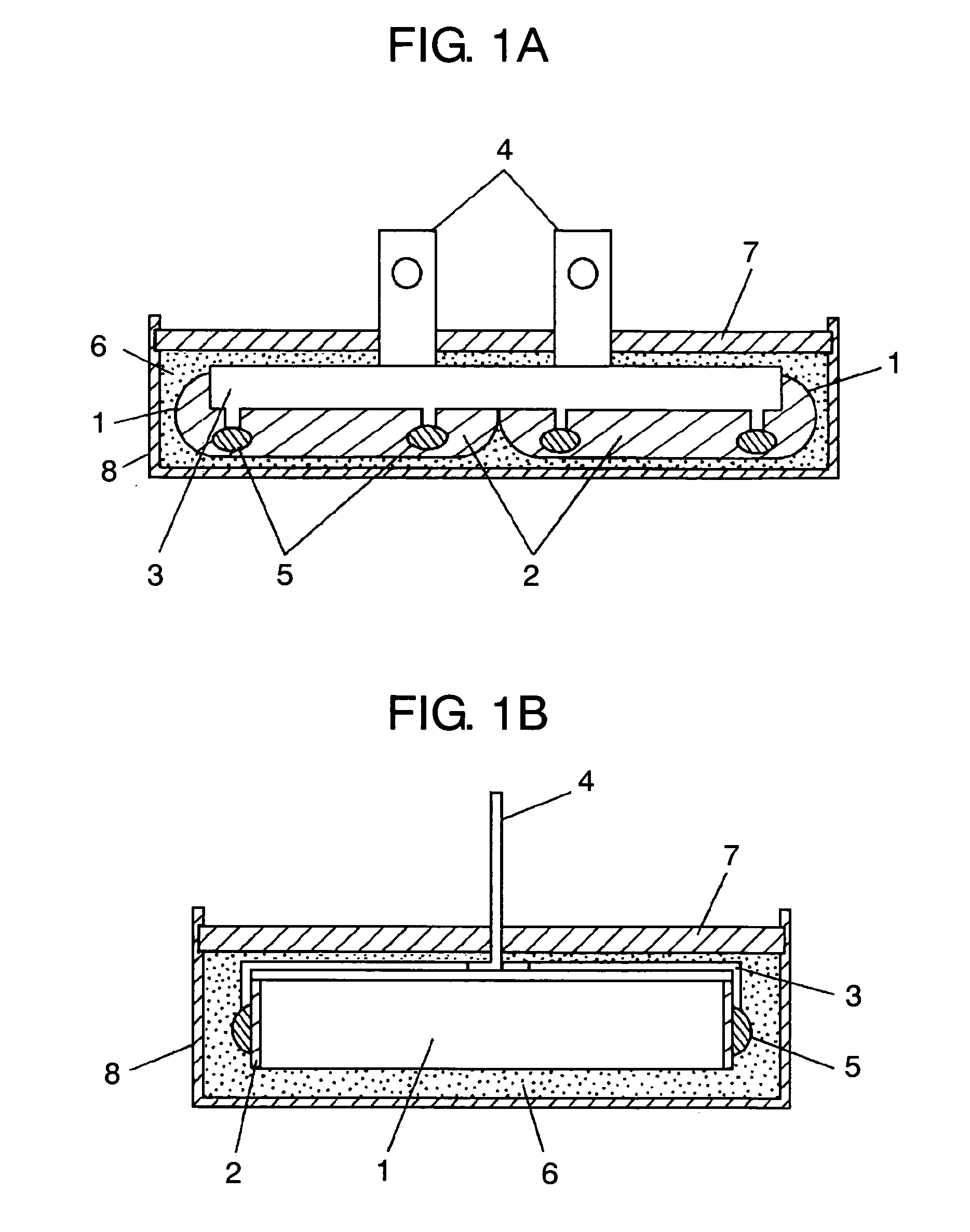

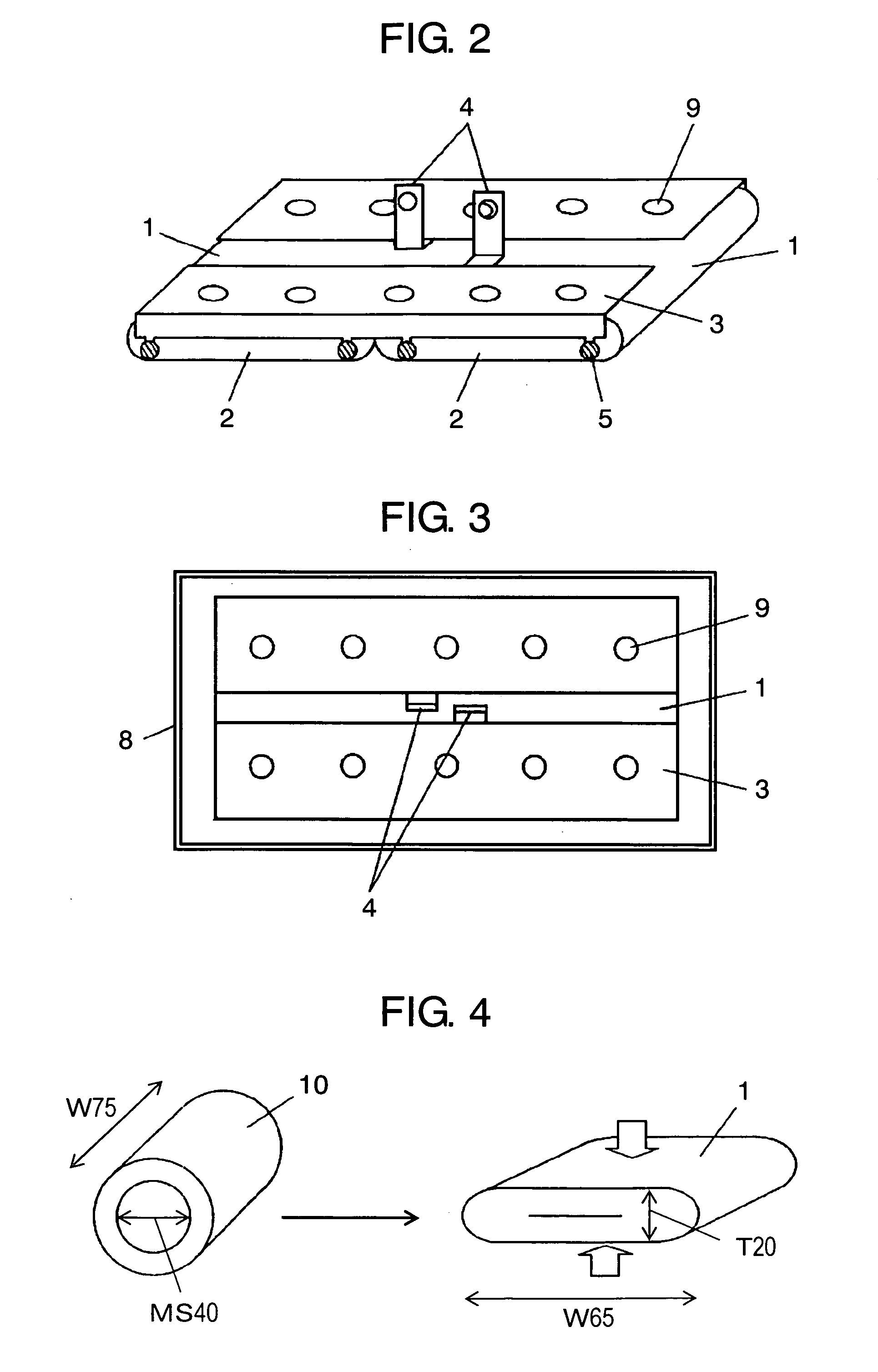

ActiveUS20060104006A1Improve moisture resistanceLow exothermic characteristicMultiple fixed capacitorsFixed capacitor dielectricEpoxyProduction rate

The invention provides a film capacitor and its manufacturing method suited to car-mount application, excellent in heat cycle tolerance and humidity resistance, and high in productivity, while maintaining low heat generation and low inductance characteristic. A film capacitor comprises a film capacitor element 1, a bus bar 3 as metal terminal connected to electrode 2 of this film capacitor element 1, and a case 8 for containing them, in which the film capacitor element 1 and bus bar 3 are packed within the case 8 by plural layers of epoxy resin compositions 6, 7, and the plural layers of epoxy resin compositions 6, 7 are formed in layers, and are composed so that the coefficient of linear expansion may be smallest in the epoxy resin composition 7 disposed in the uppermost layer, and therefore resin cracks can be prevented at the time of heat cycle, and a film capacitor of high reliability excellent inhumidity resistance is obtained.

Owner:PANASONIC CORP

Thin film capacitors

A system that incorporates teachings of the present disclosure may include, for example, a first solid electrode, a second electrode separated into subsections, and a dielectric medium separating the subsections from the first solid electrode, where the subsections of the second electrode include a first group of subsections and a second group of subsections, where the first group of subsections are connectable with a first terminal for receiving an input signal, and where the second group of subsections is connectable with a second terminal for providing an output signal. Other embodiments are disclosed.

Owner:NXP USA INC

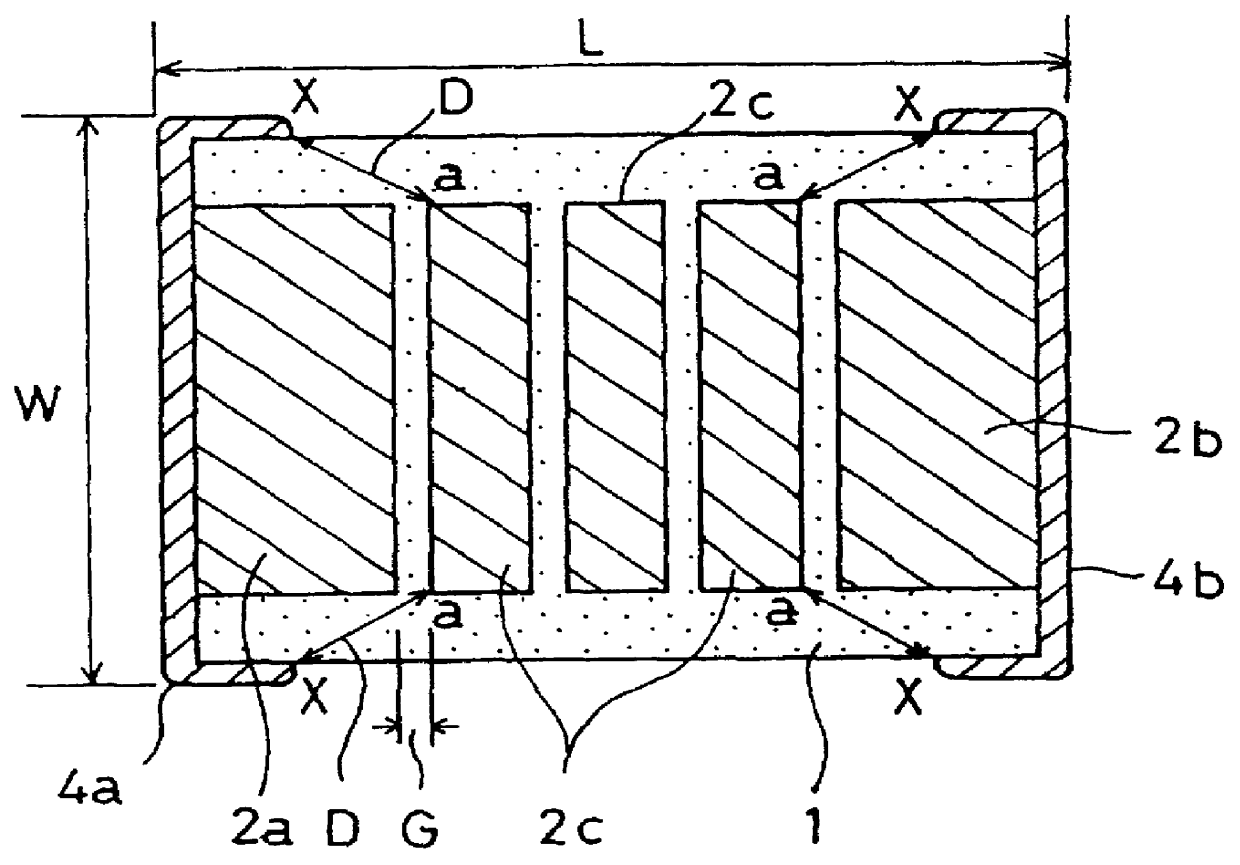

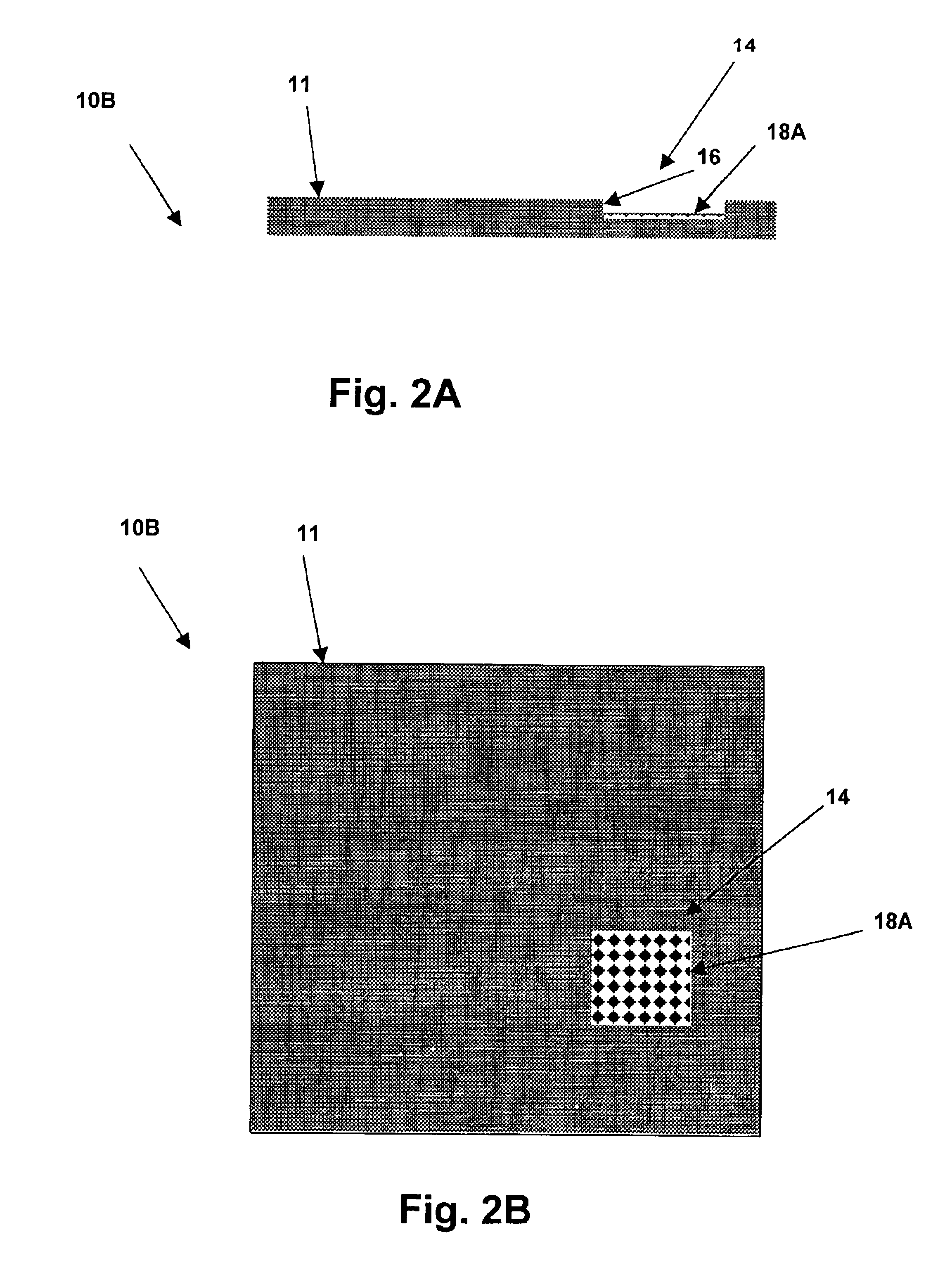

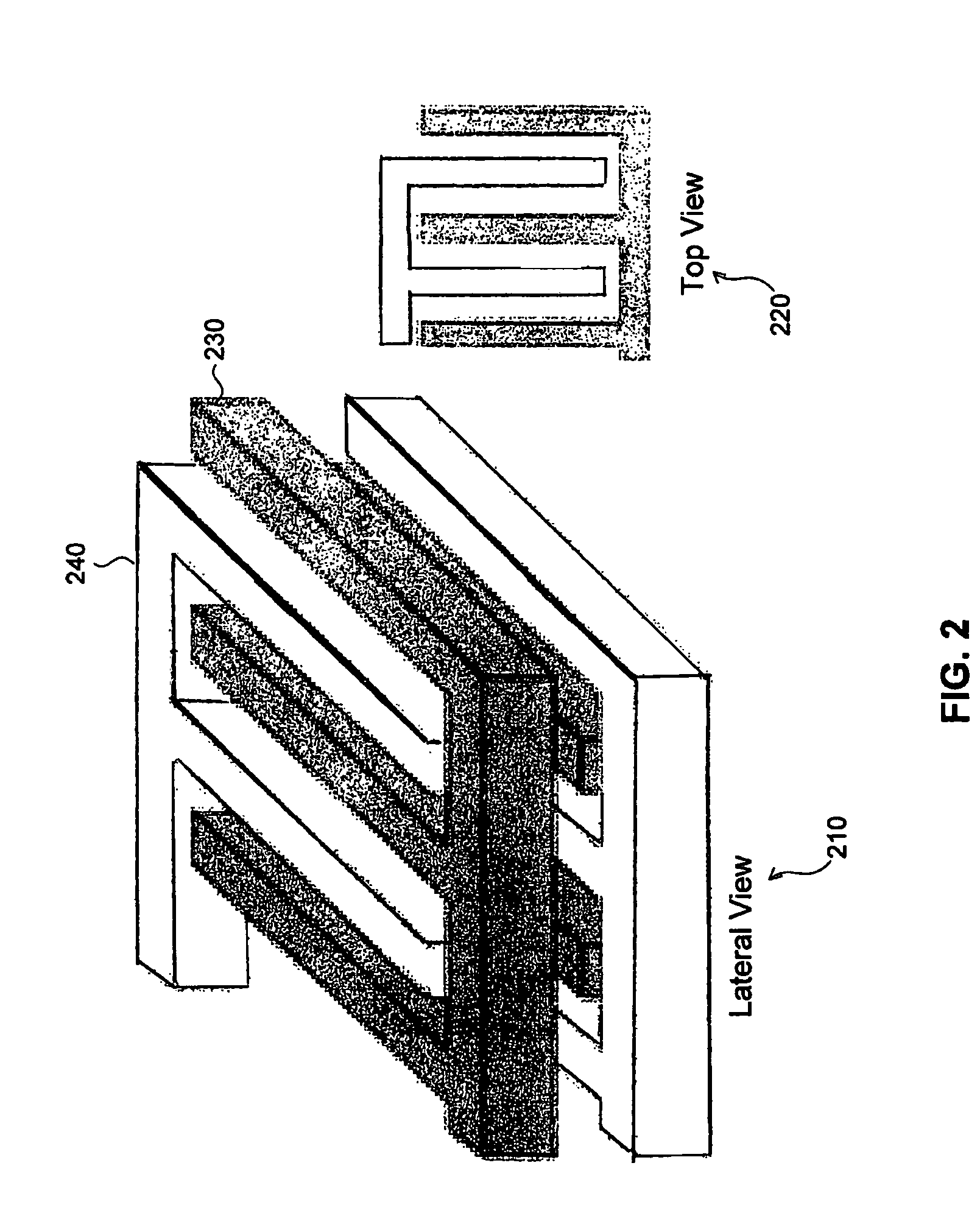

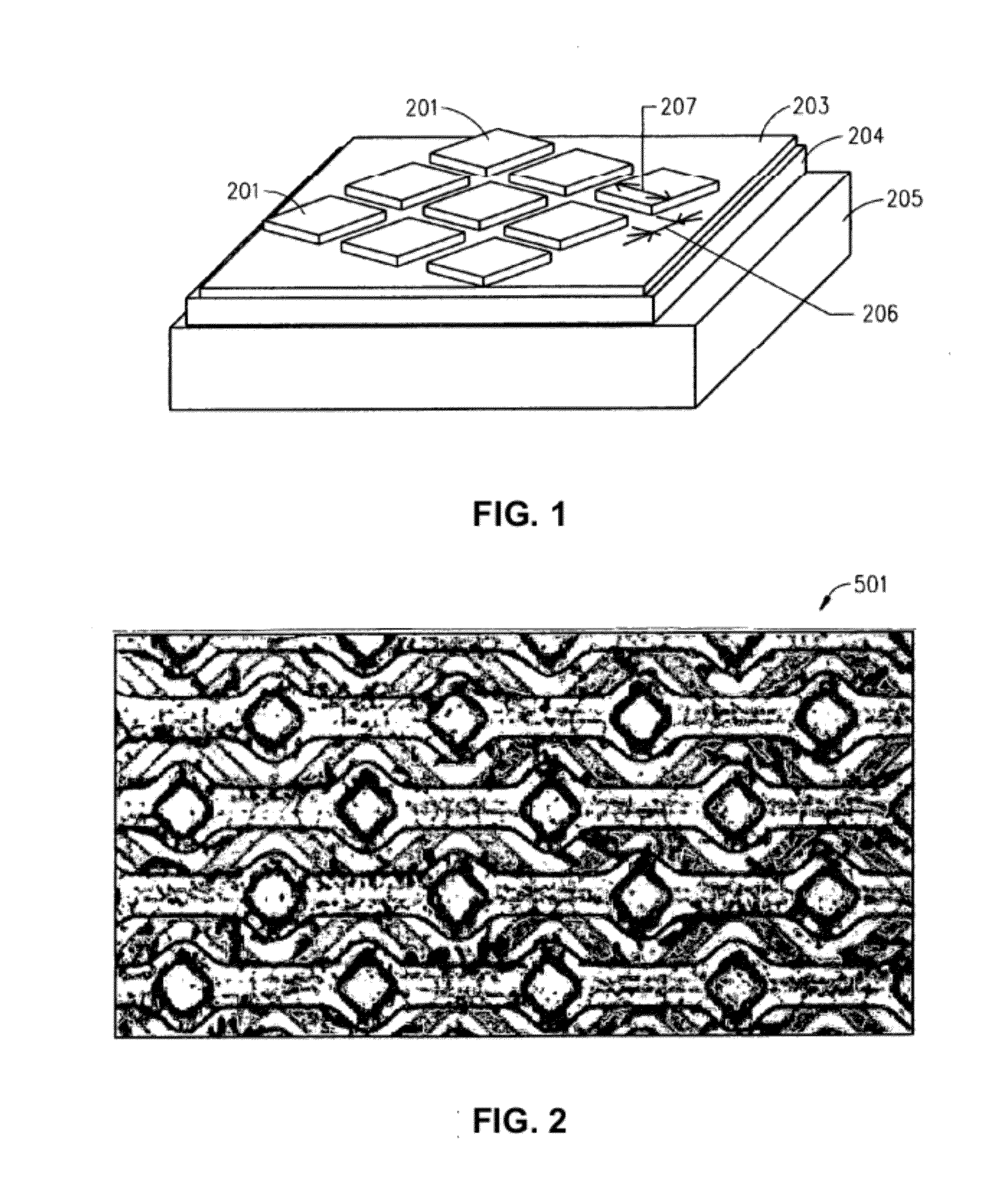

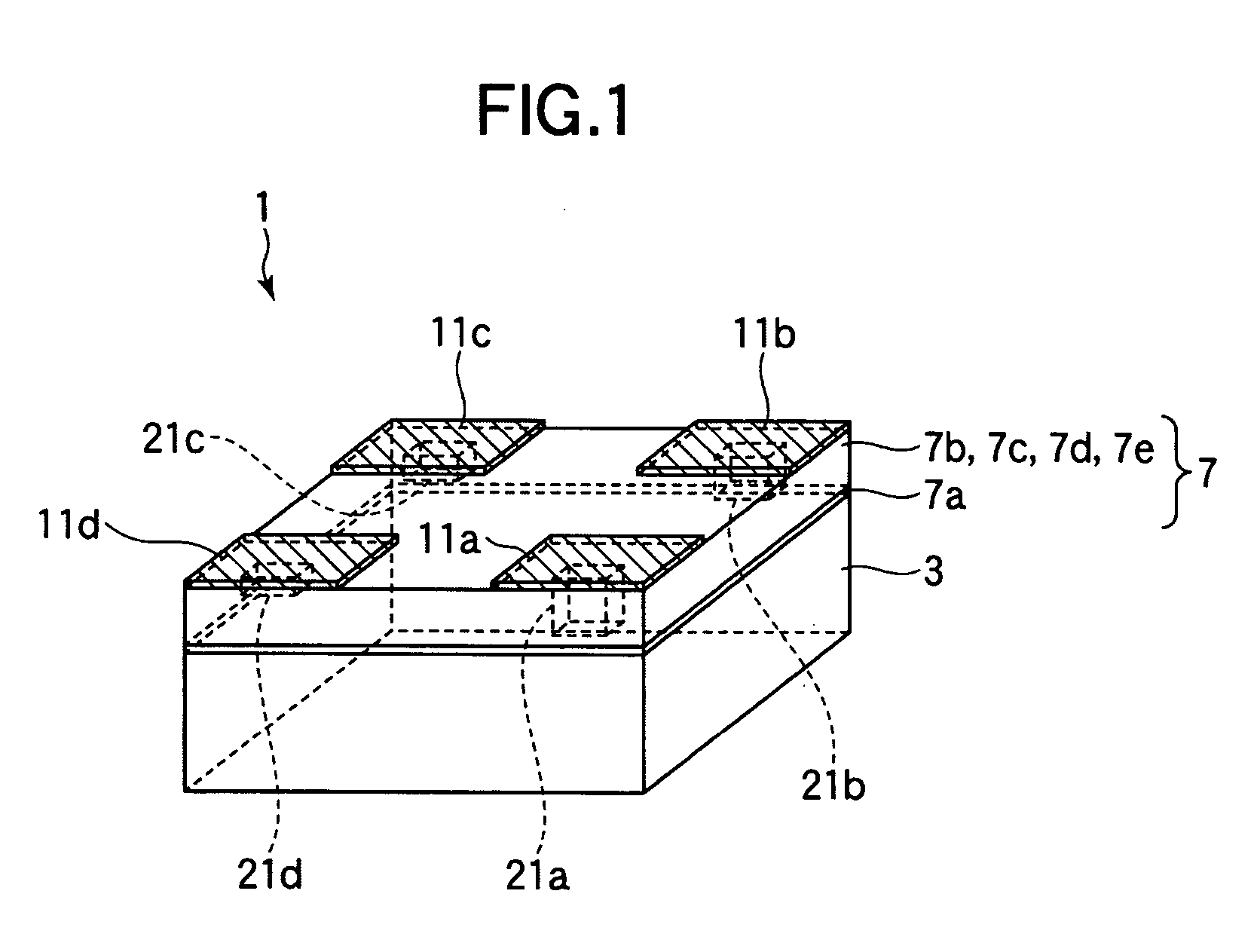

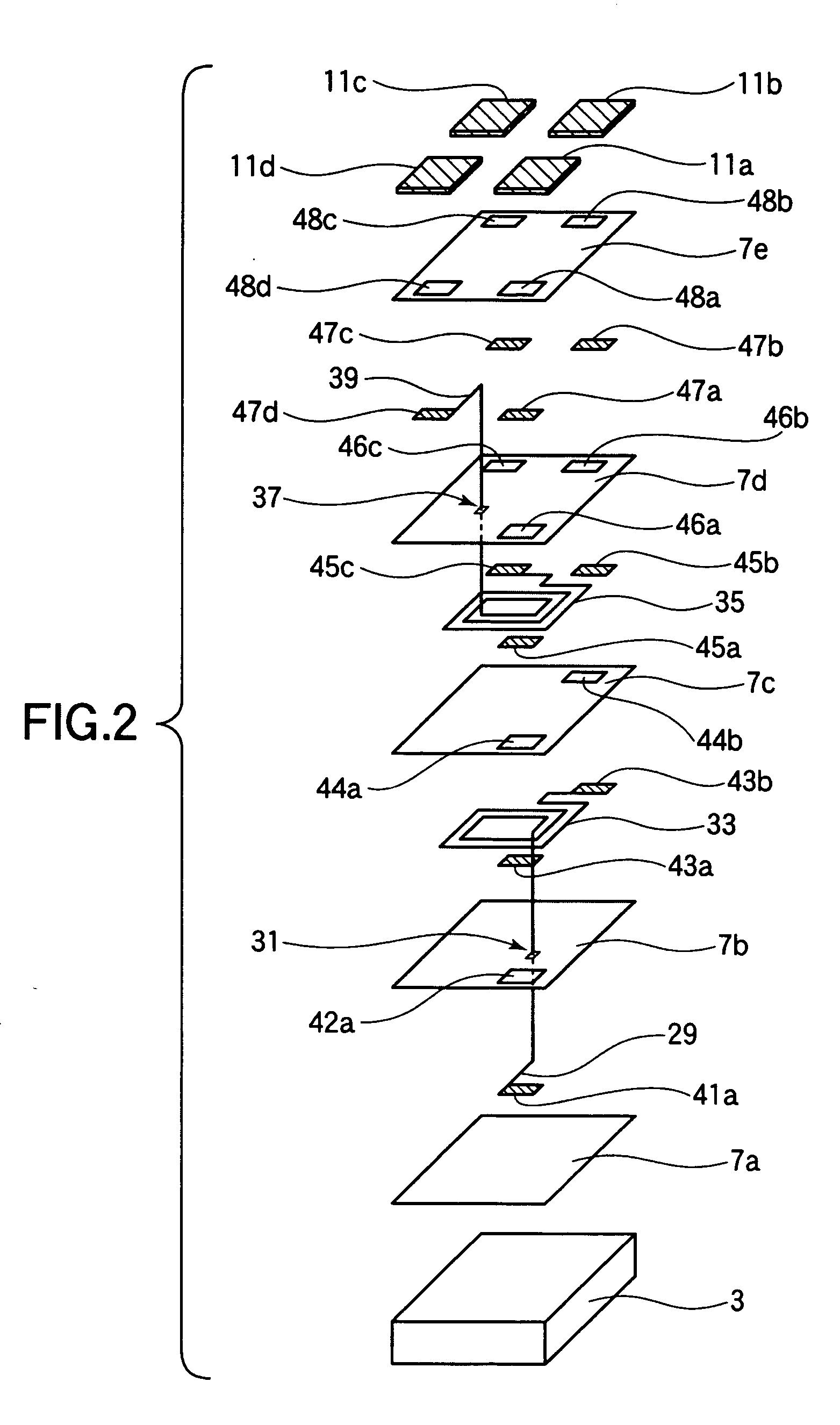

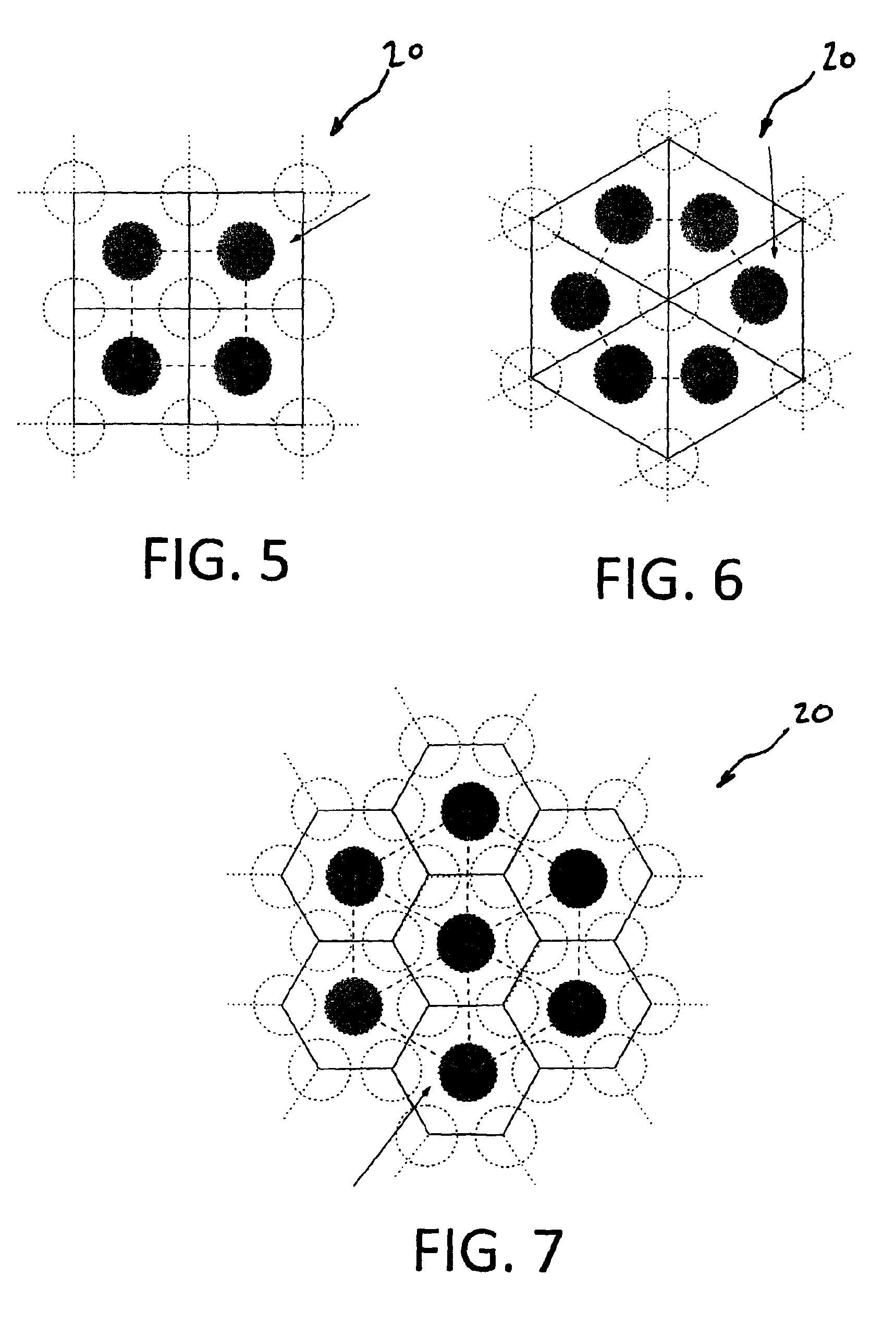

Ceramic multilayer capacitor array

InactiveUS6934145B2Easy to manufactureMultiple fixed capacitorsFixed capacitor dielectricCapacitanceDielectric plate

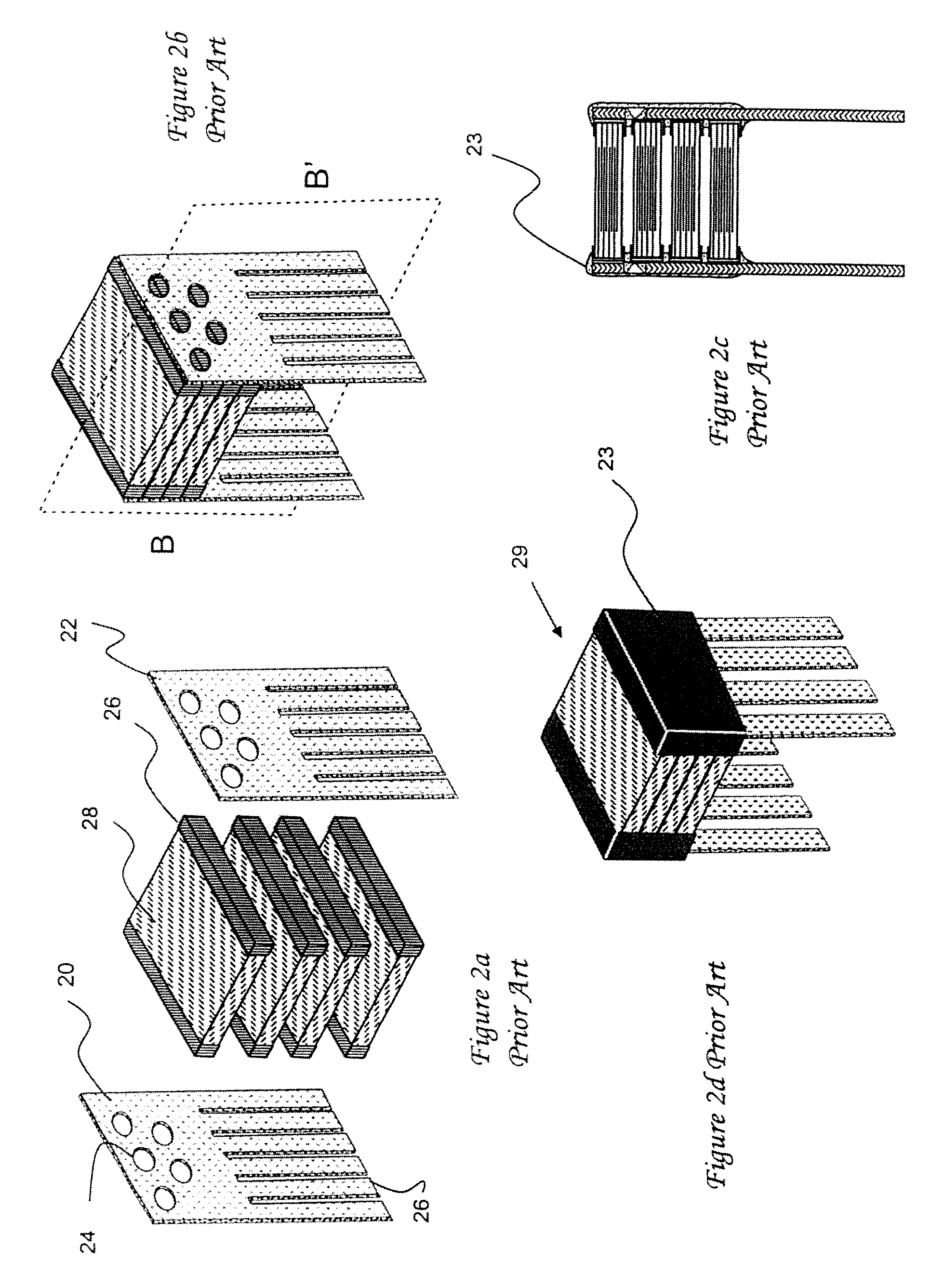

A ceramic multilayer capacitor array having a plurality of capacitors in a surface mount compatible package. The array is constructed from a plurality of first dielectric plates, each of which has a first pattern of electrodes, and a plurality of second dielectric plates, each of which has a second pattern of electrodes. The second pattern of electrodes is substantially identical to the first pattern of electrodes, and is shifted with respect to the first pattern of electrodes. Each of the electrodes has at least one tab portion, which extends to at least one of the side faces of the package. Perpendicularly projecting first and second plates, the tab portions of the electrodes in the first plates are free from the tab portions of the electrodes in the second plates.

Owner:PHYCOMP HLDG BV

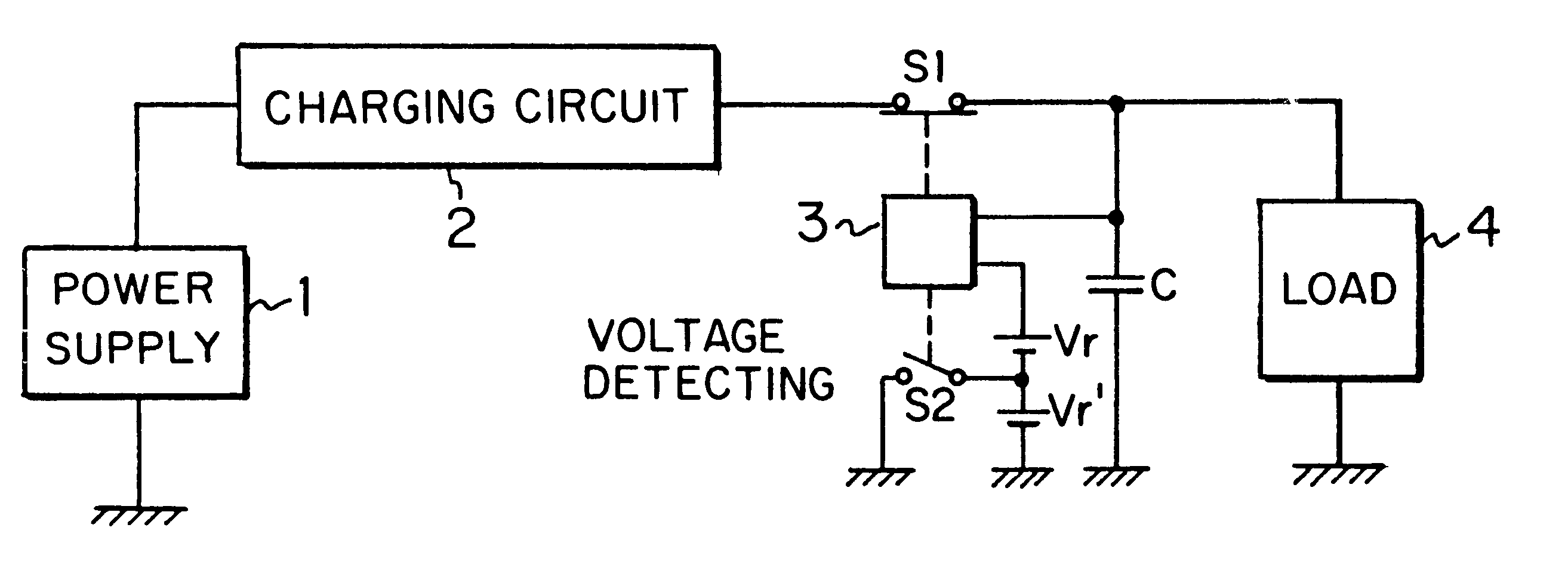

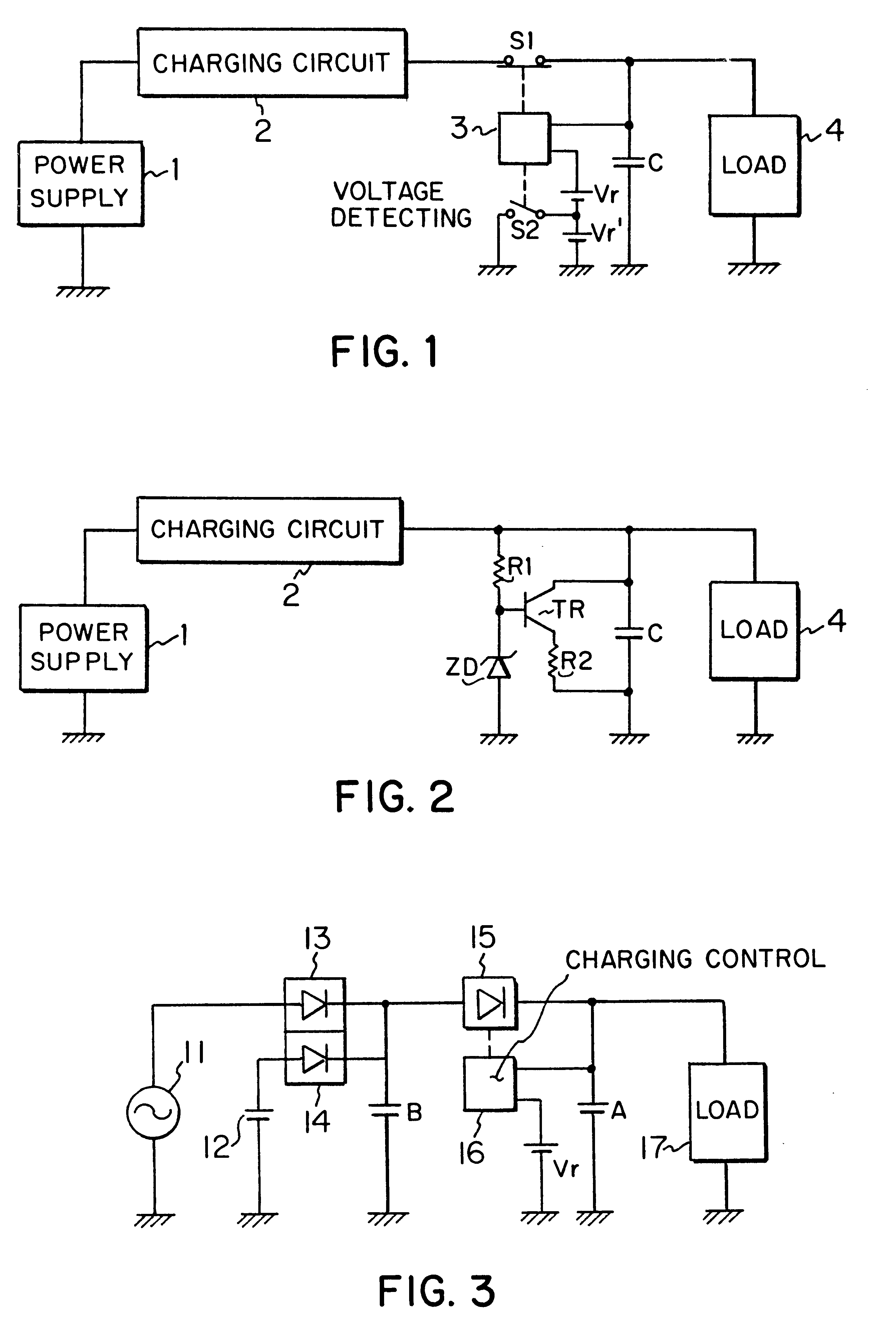

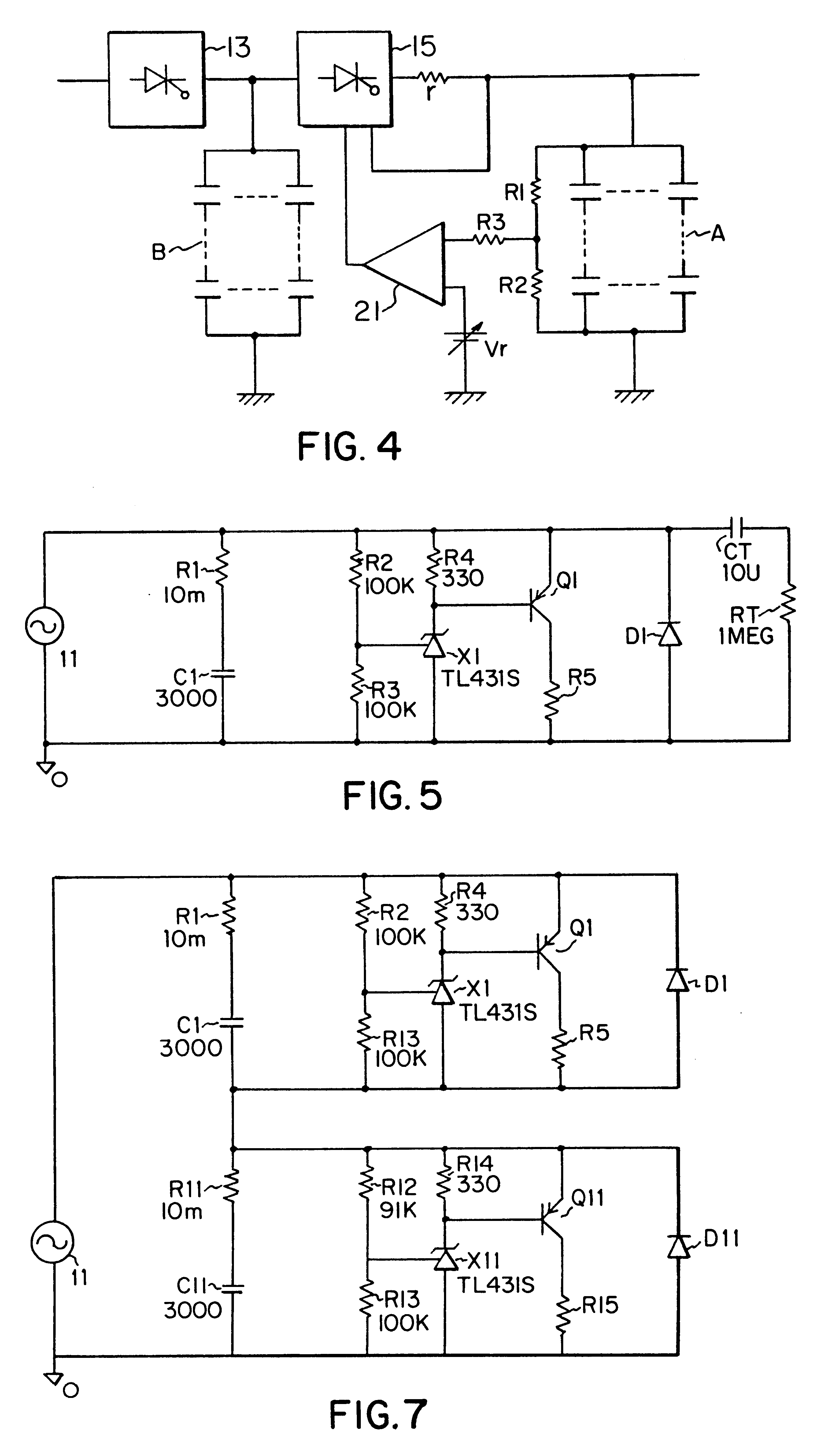

Storage capacitor power supply

InactiveUS6424156B1Fast chargingEffective electricalTesting dielectric strengthMultiple fixed capacitorsCapacitanceElectricity

A long-lived, lightweight, and quickly and precisely charged storage capacitor power supply capable of stably supplying electric power to a load. The power supply has a capacitor block consisting of capacitors connected in series, in parallel or in any combination of series and parallel. The power supply further includes a charging circuit for charging the block, a charging power supply connected with the block via the charging circuit, and a charge-limiting circuit. This charge-limiting circuit detects the voltage across the terminals of the block and limits charging of the block if the voltage reaches a given value. One embodiment of the invention further includes a charge-limiting circuit, a full charge-detecting circuit, and a residual electricity-detecting circuit connected in parallel with the block. The charge-limiting circuit senses that the voltage across the terminals of the block exceeds the given value and causes the charging current to bypass the block. The full charge-detecting circuit senses that the charge-limiting circuit is operated and determines that full charge is attained. The residual electricity-detecting circuit finds the residual electric power from the voltage across the terminals of the block. Another embodiment has a first and a second capacitor block. The voltage across the terminals of the first block is detected. The first block is charged from the second block until the detected voltage reaches a given voltage. The first block supplies electric power directly to the load.

Owner:NANTONG JIANGHAI CAPACITOR CO LTD +1

Electronic component and method of manufacturing the same

ActiveUS20070040163A1Reduce the overall heightLow costMultiple-port networksLayered productsElectrical conductorInsulation layer

The invention relates to a surface mount type electronic component mounted on a printed circuit board or hybrid IC (HIC) and a method of manufacturing the same and provides an electronic component which can be formed with a small size and a low height at a low cost and a method of manufacturing the same. A common mode choke coil as the electronic component has an overall shape in the form of rectangular parallelepiped that is provided by forming an insulation layer, a coil layer (not shown) formed with a coil conductor, and external electrodes electrically connected to the coil conductor in the order listed on a silicon substrate using thin film forming techniques. The external electrodes are formed to spread on a top surface (mounting surface) of the insulation layer.

Owner:TDK CORPARATION

Hard start kit for multiple replacement applications

ActiveUS8456795B2Single-phase induction motor startersMultiple fixed capacitorsCapacitanceHard start

A hard start capacitor replacement unit has a plurality of capacitors in a container sized to fit in existing hard start capacitor space. The capacitors are 4 metallized film capacitors wound in a single cylindrical capacitive element. The container has a common terminal and capacitors value terminals for the plurality of capacitors, which may be connected singly or in combination to provide a selected capacitance. An electronic or other relay connects the selected capacitance in parallel with a motor run capacitor. The hard start capacitor replacement unit is thereby adapted to replace a wide variety of hard start capacitors.

Owner:AMRAD MFG LLC

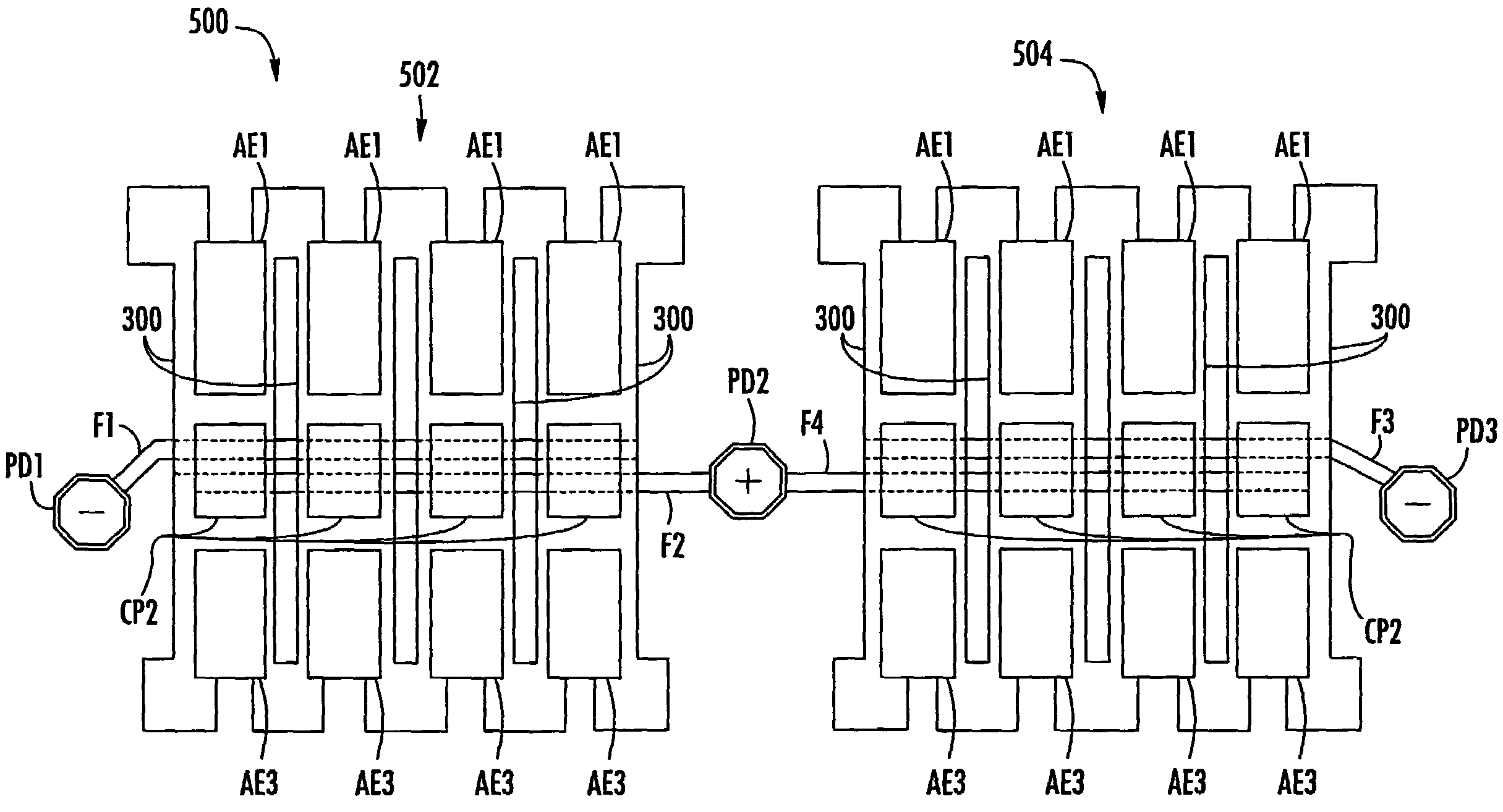

Integrated broadband ceramic capacitor array

InactiveUS6970341B1Effective wideband performanceImprove performanceMultiple fixed capacitorsFixed capacitor electrodesCeramic capacitorEngineering

A monolithic capacitor structure includes opposed and overlapping plates within a dielectric body, which are arranged to form a lower frequency, higher value capacitor. Other conductive structure is located either inside the dielectric body or on an external surface thereof and is effective to form a higher frequency, lower value capacitor in parallel with the lower frequency, higher value capacitor. The resulting array of combined series and parallel capacitors integral with the dielectric body provides effective wideband performance in an integrated, cost-effective structure.

Owner:DEVOE DANIEL +2

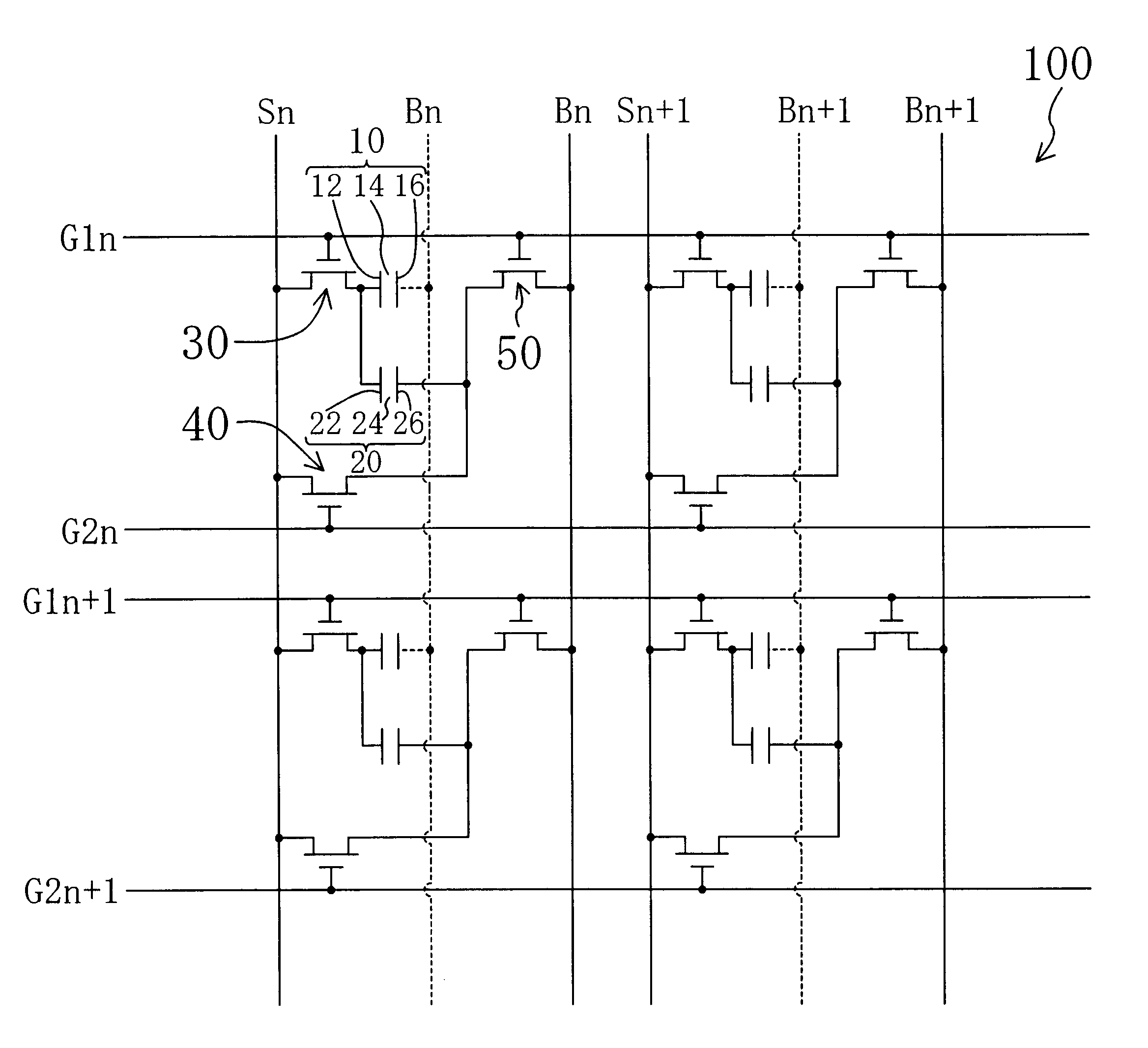

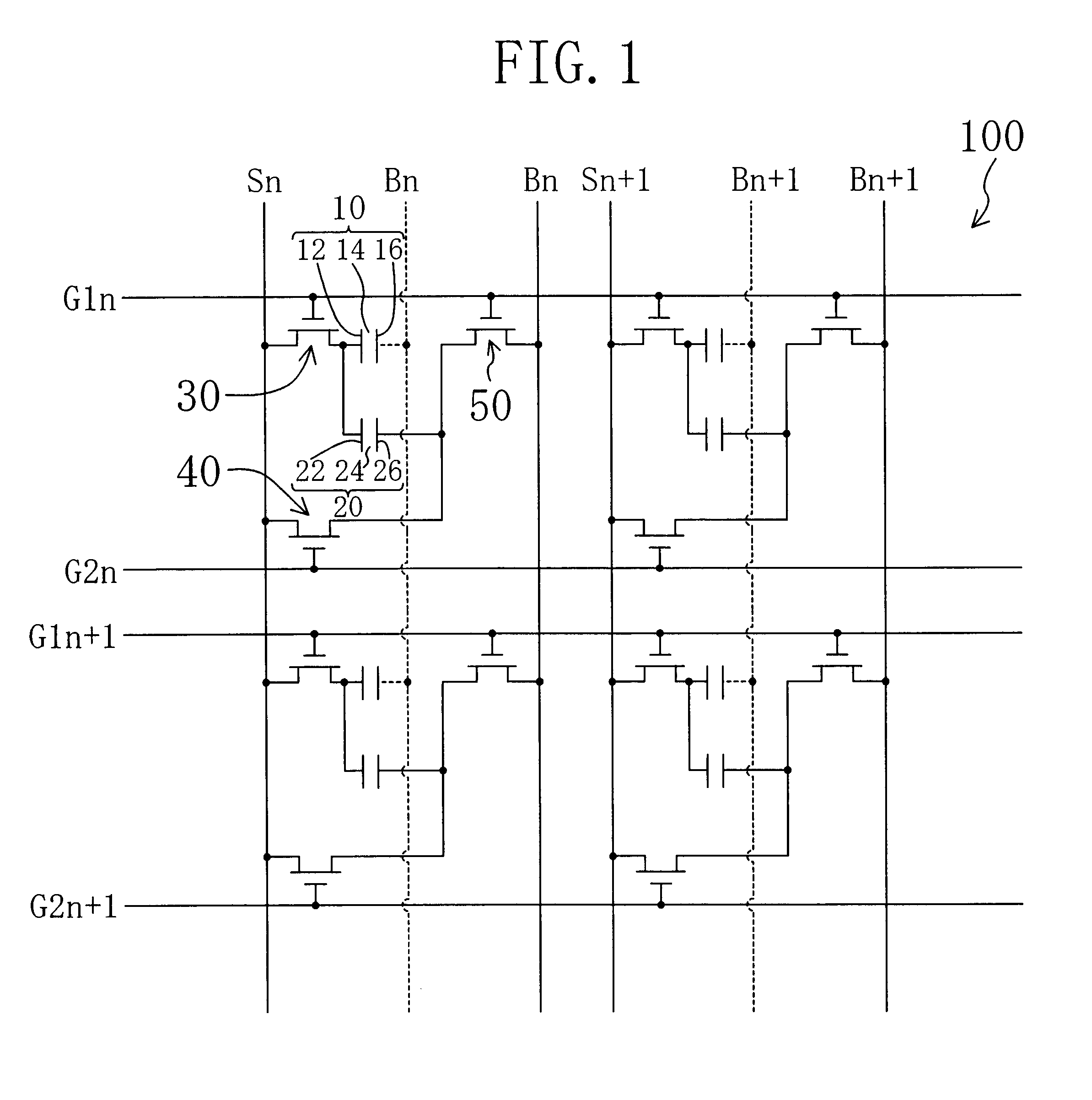

Electronic device and method for driving the same

InactiveUS6724359B2Television system detailsMultiple fixed capacitorsElectricityElectrical connection

An electronic device includes on a substrate: a plurality of first capacitors each including a first electrode and a second electrode opposing the first electrode via a first dielectric layer; a plurality of second capacitors each including a third electrode electrically connected to the first electrode and a fourth electrode opposing the third electrode via a second dielectric layer; a first line whose electrical connection to the first electrode and the third electrode is turned ON / OFF by a first switching element; a second line electrically connected to the second electrode at least temporarily; a third line whose electrical connection to the fourth electrode is turned ON / OFF by a second switching element; and a fourth line whose electrical connection to the fourth electrode is turned ON / OFF by a third switching element.

Owner:SHARP KK

Clad fiber capacitor and method of making same

A clad capacitor and method of manufacture includes assembling a preform comprising a ductile, electrically conductive fiber; a ductile, electrically insulating cladding positioned on the fiber; and a ductile, electrically conductive sleeve positioned over the cladding. One or more preforms are then bundled, heated and drawn along a longitudinal axis to decrease the diameter of the ductile components of the preform and fuse the preform into a unitized strand.

Owner:UT BATTELLE LLC

Popular searches

Transformers/inductances coils/windings/connections Semiconductor/solid-state device manufacturing Electrical connection printed elements Metallic pattern materials Printed element electric connection formation Semiconductor devices Varistors Fixed capacitor terminals Liquid/solution decomposition chemical coating Special surfaces

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com