Monolithic capacitor

a technology of monolithic capacitors and capacitors, applied in the field of monolithic capacitors, can solve problems such as the reduction of electrostatic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

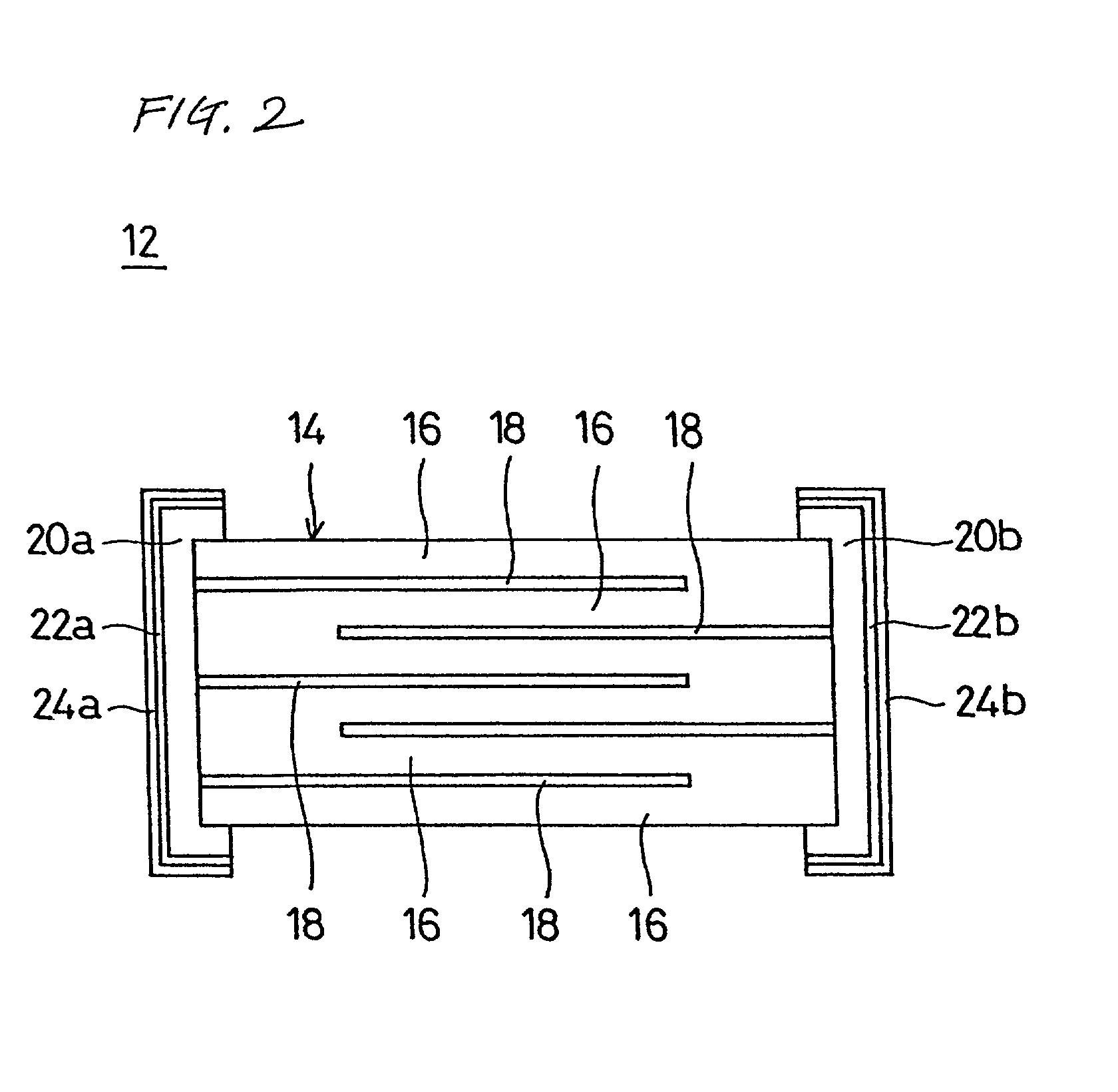

Embodiment Construction

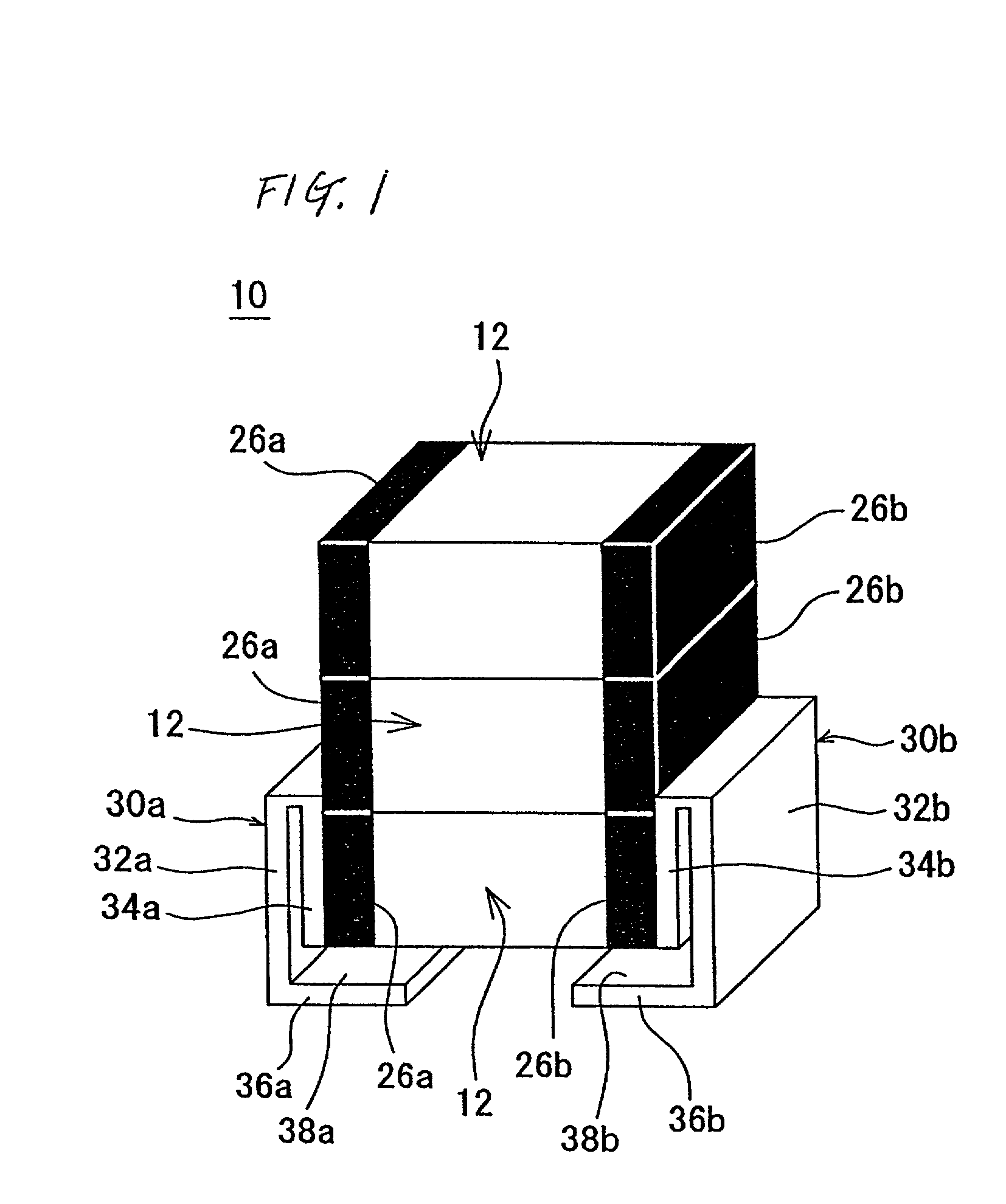

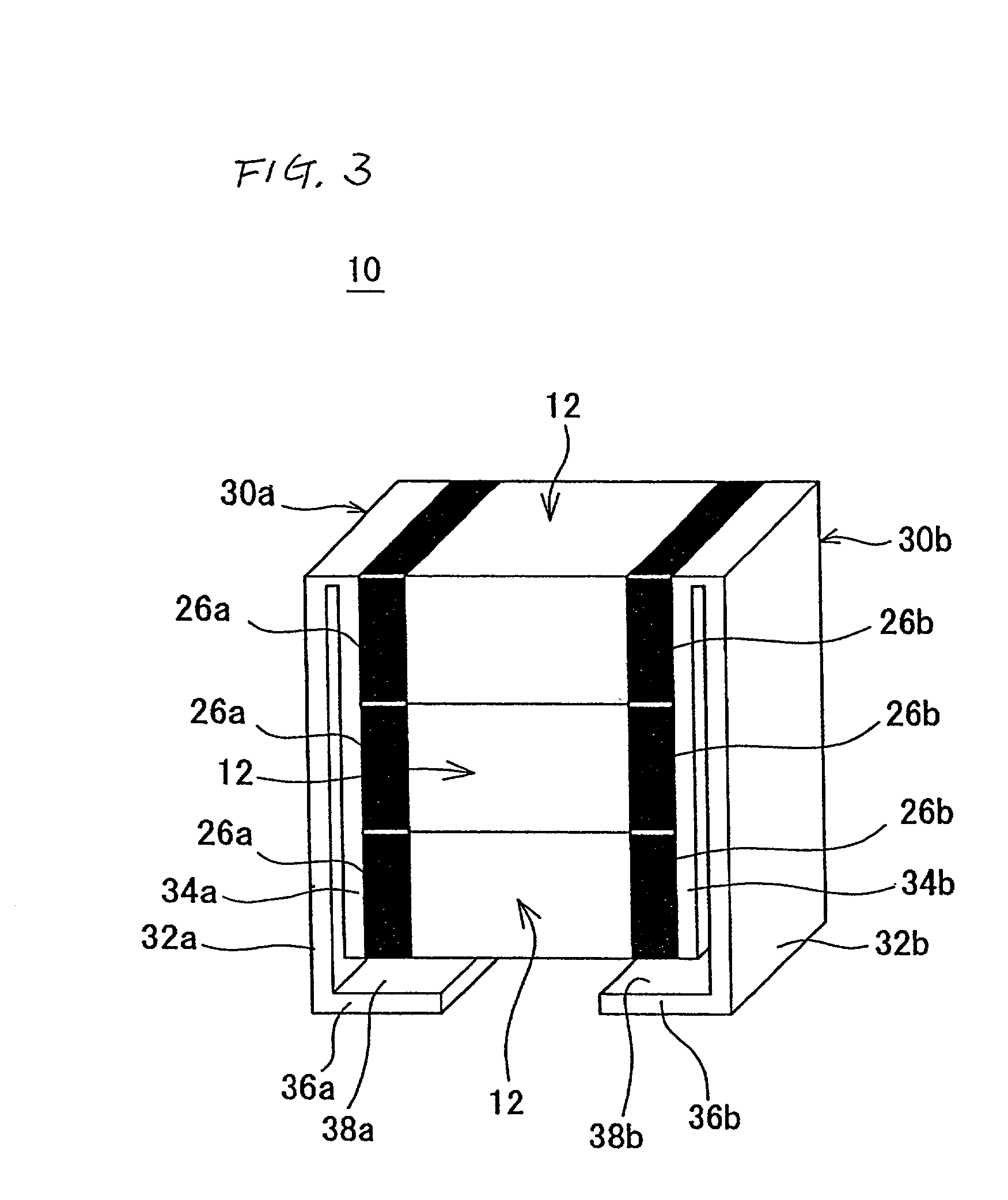

(FIG. 1) 2.5 Fe--Cr 0 / 36 0 / 36 Example 2 (FIG. 3) 7.0 Fe--Cr 0 / 36 0 / 36 Comparative 2.5 Fe--Cr 2 / 36 16 / 36 Example 1 (FIG. 4) Comparative 7.0 Fe--Cr 2 / 36 10 / 36 Example 2 (FIG. 6)

[0035] As is clear from Table 1, in Examples 1 and 2 constructed according to the first and second preferred embodiments of the present invention, in which solder layers were disposed on the entire surfaces of the external electrodes of the monolithic ceramic capacitor elements, the number of defects caused by thermal shock was zero. In contrast, in Comparative Examples 1 and 2 in which solder layers were partially formed on the surfaces of the external electrodes of the monolithic ceramic capacitor elements, defects occurred due to thermal shock.

[0036] This result occurred because when the external electrodes of the monolithic ceramic capacitor elements are partially connected by the solder layers, in the thermal shock cycle test, thermal stress is concentrated at the joints and cracks occur in the joints and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com