Patents

Literature

150results about How to "Improve cladding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

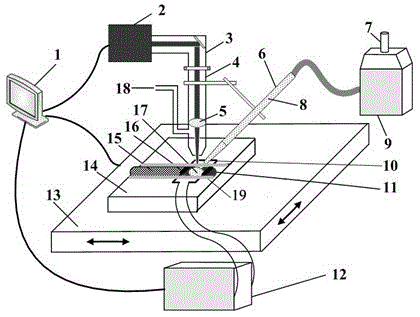

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

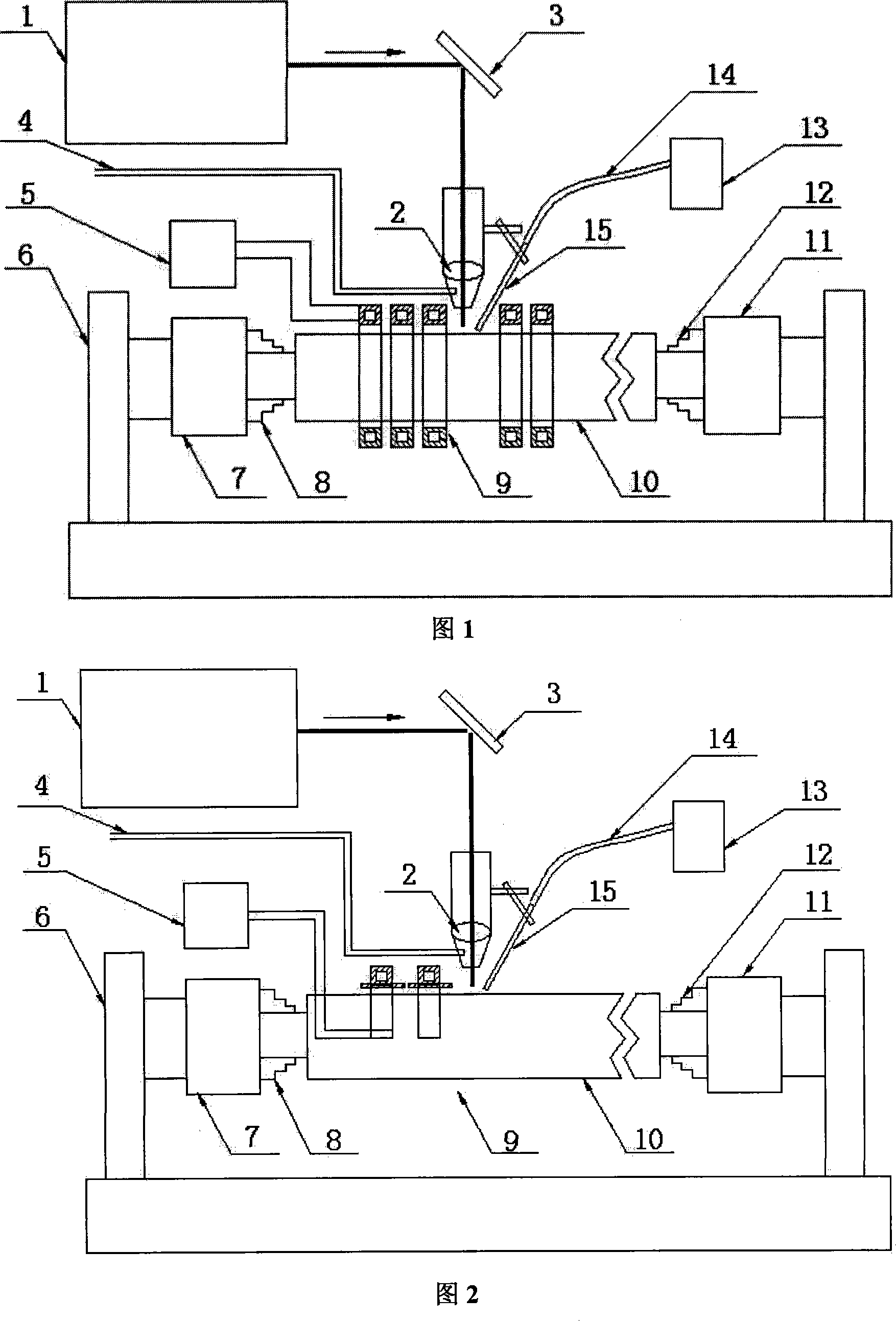

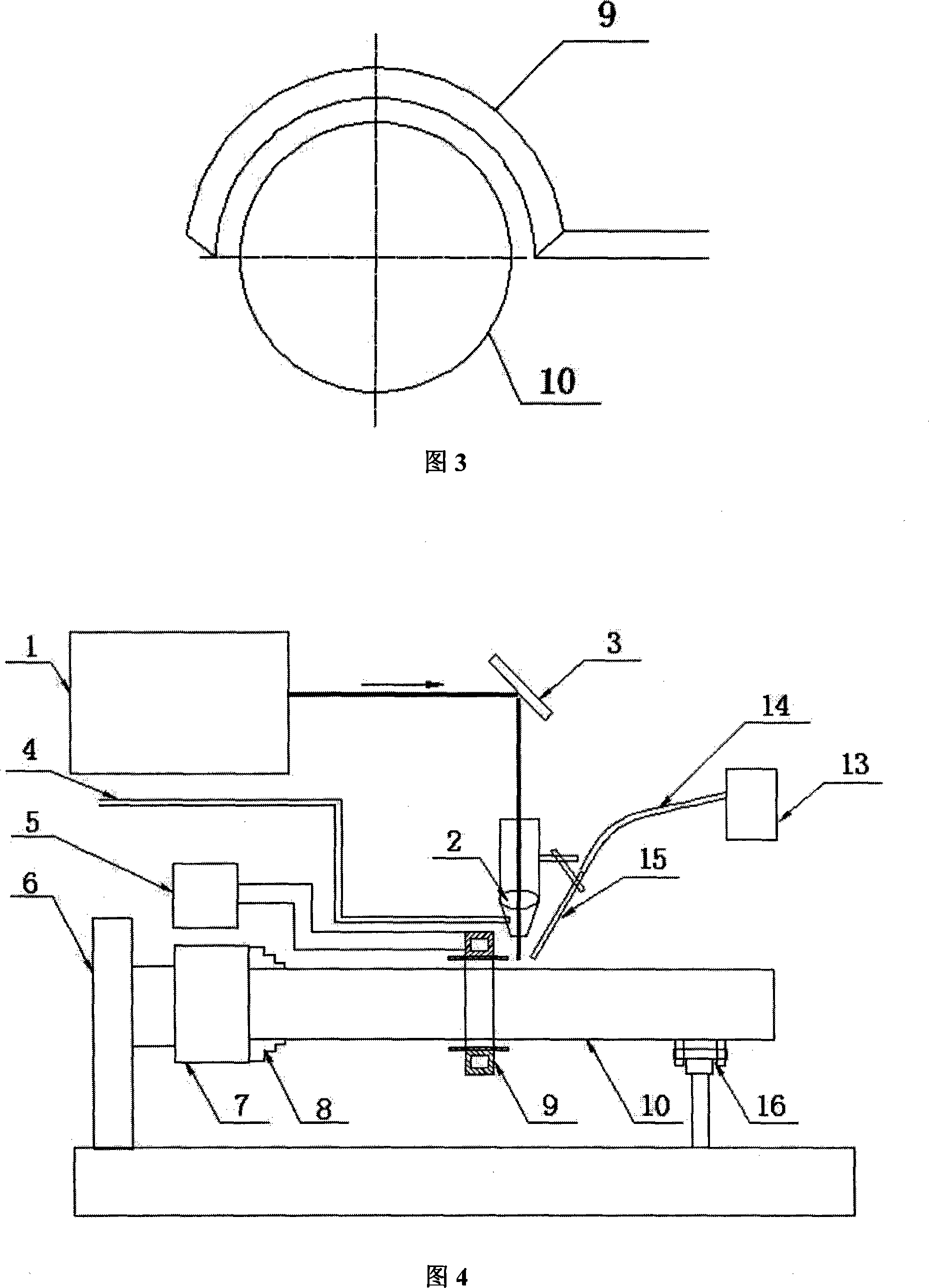

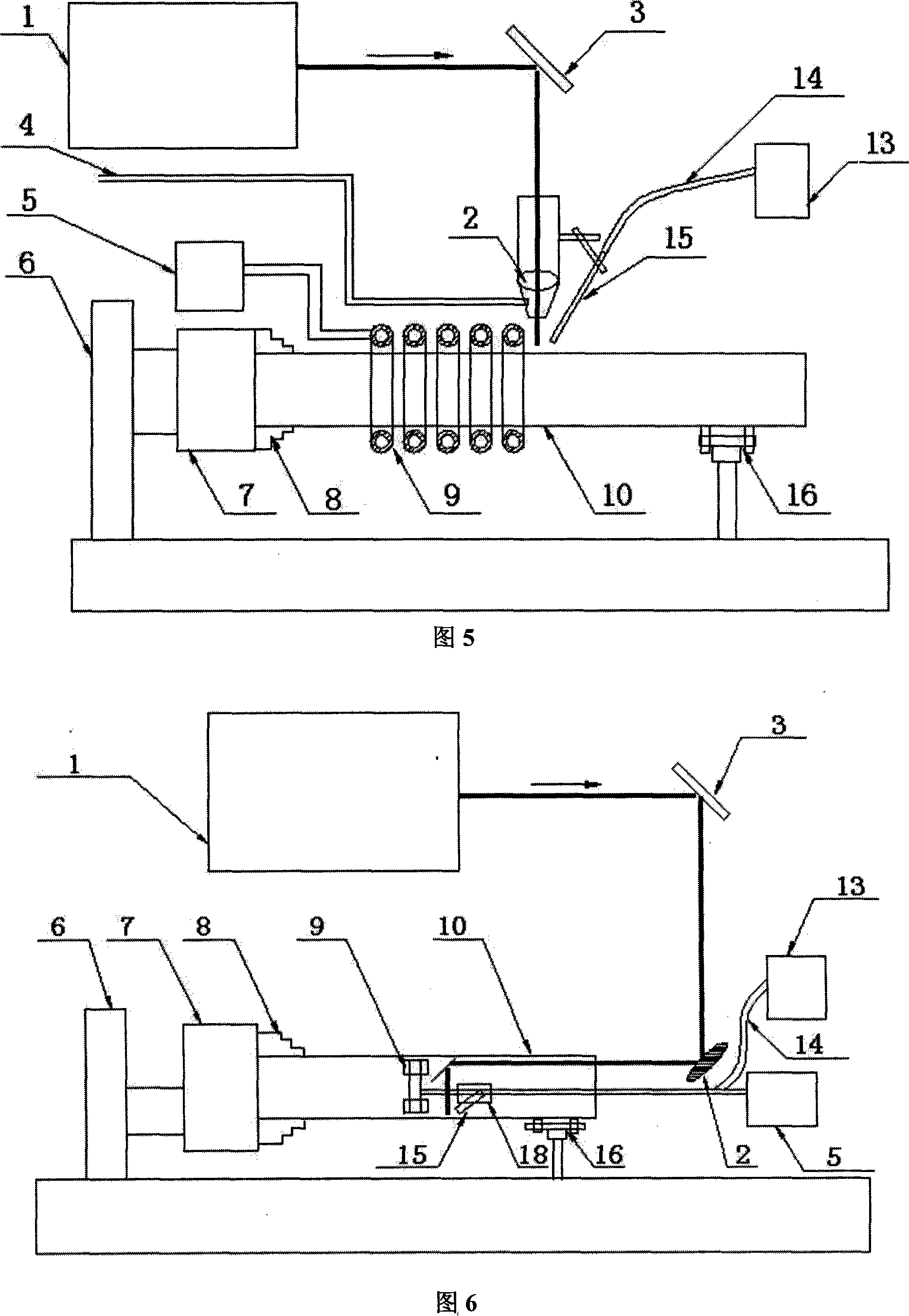

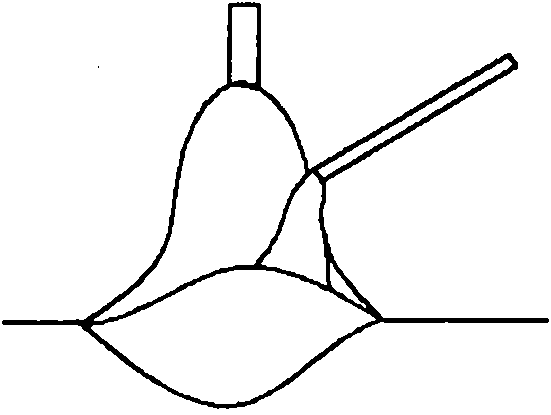

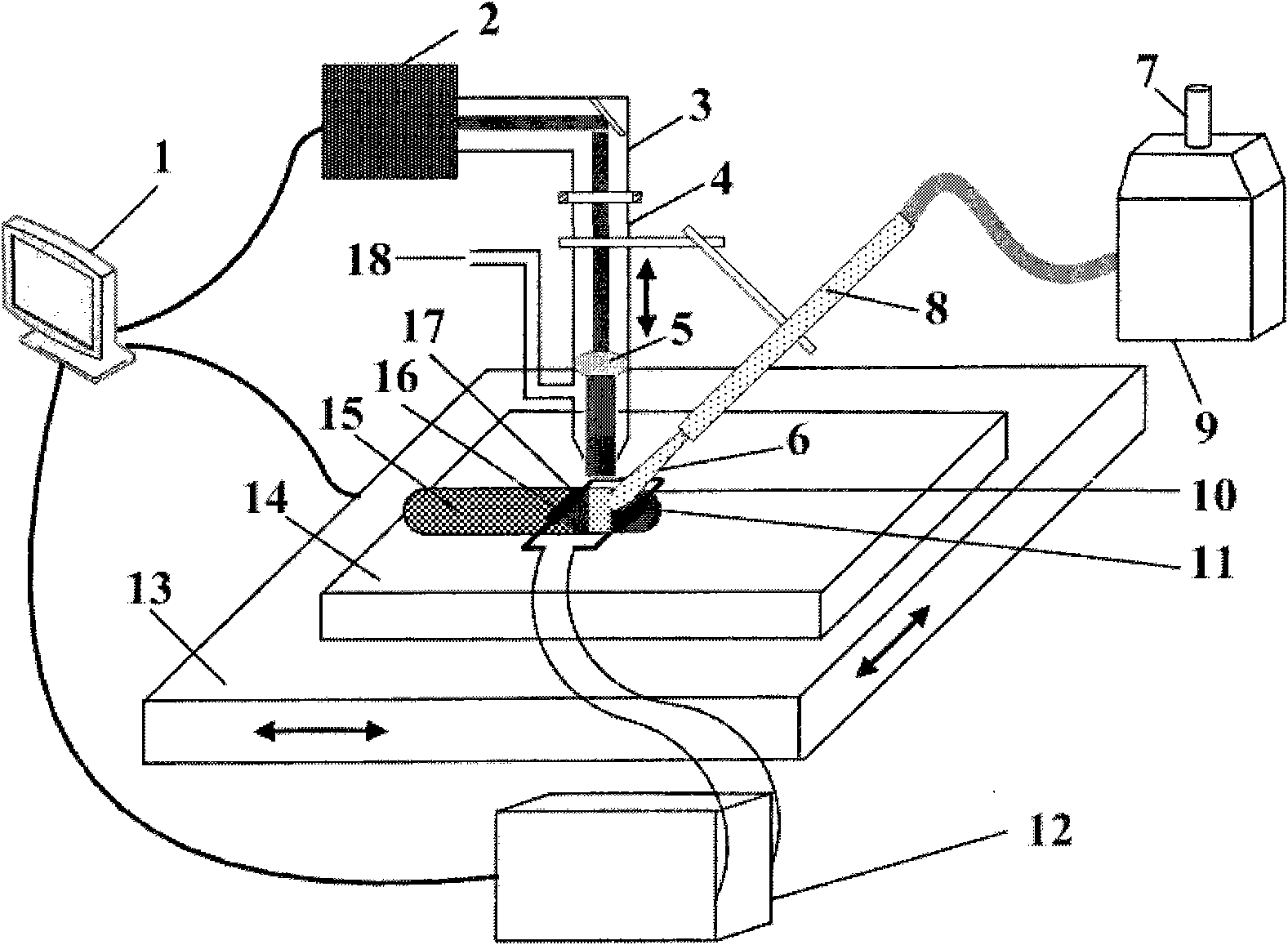

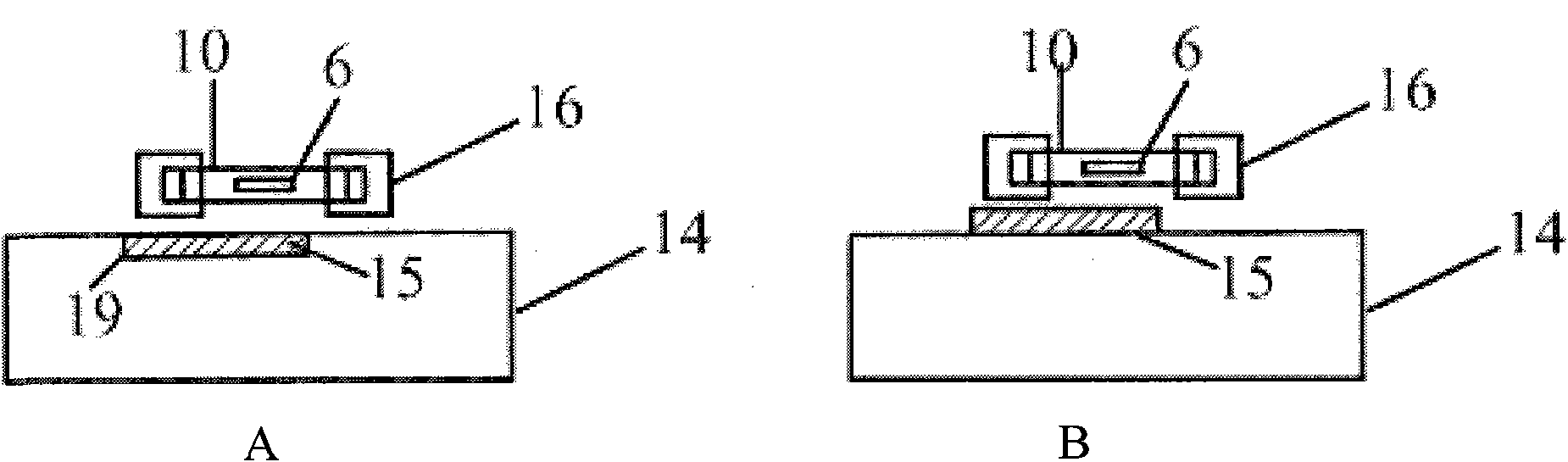

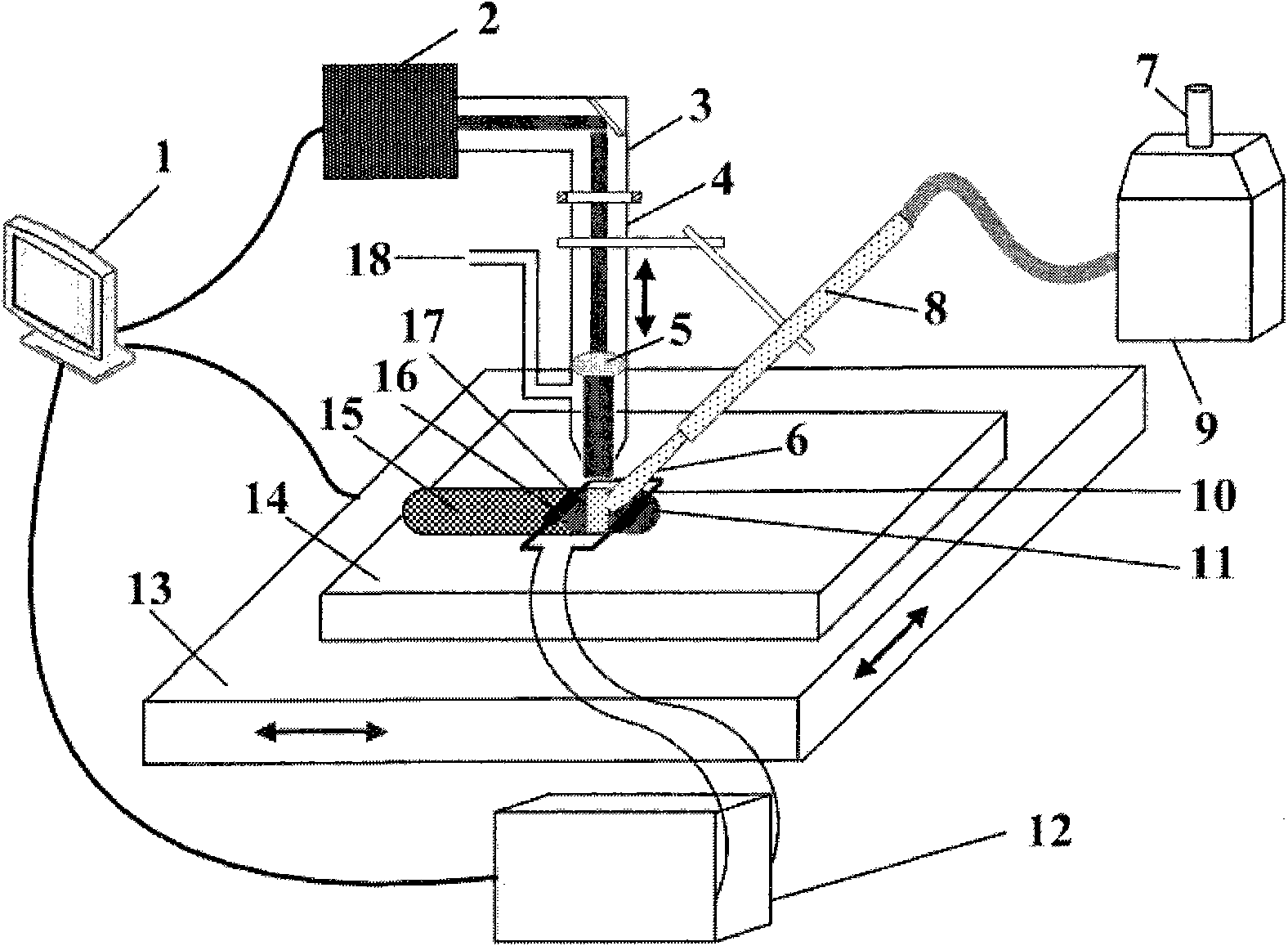

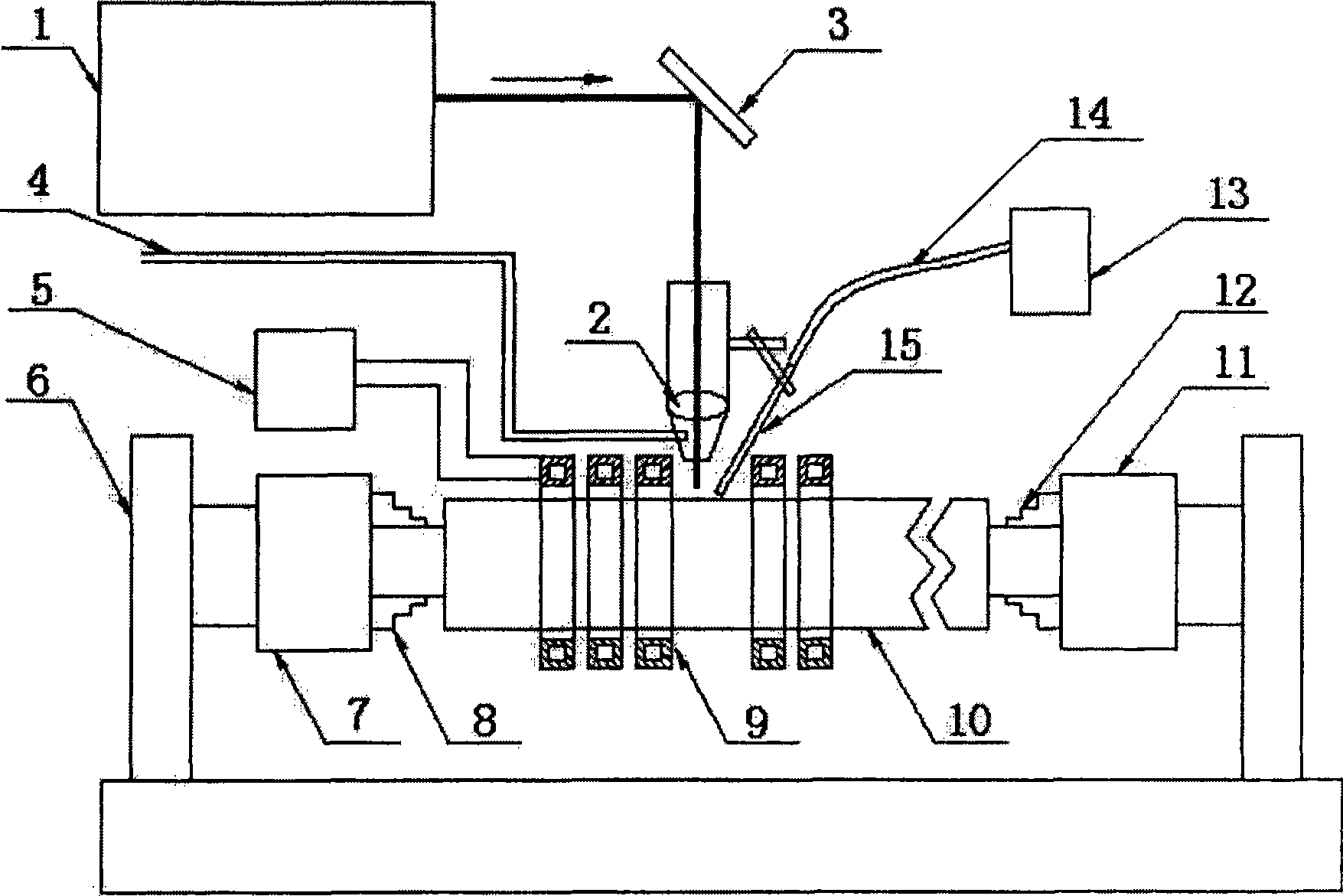

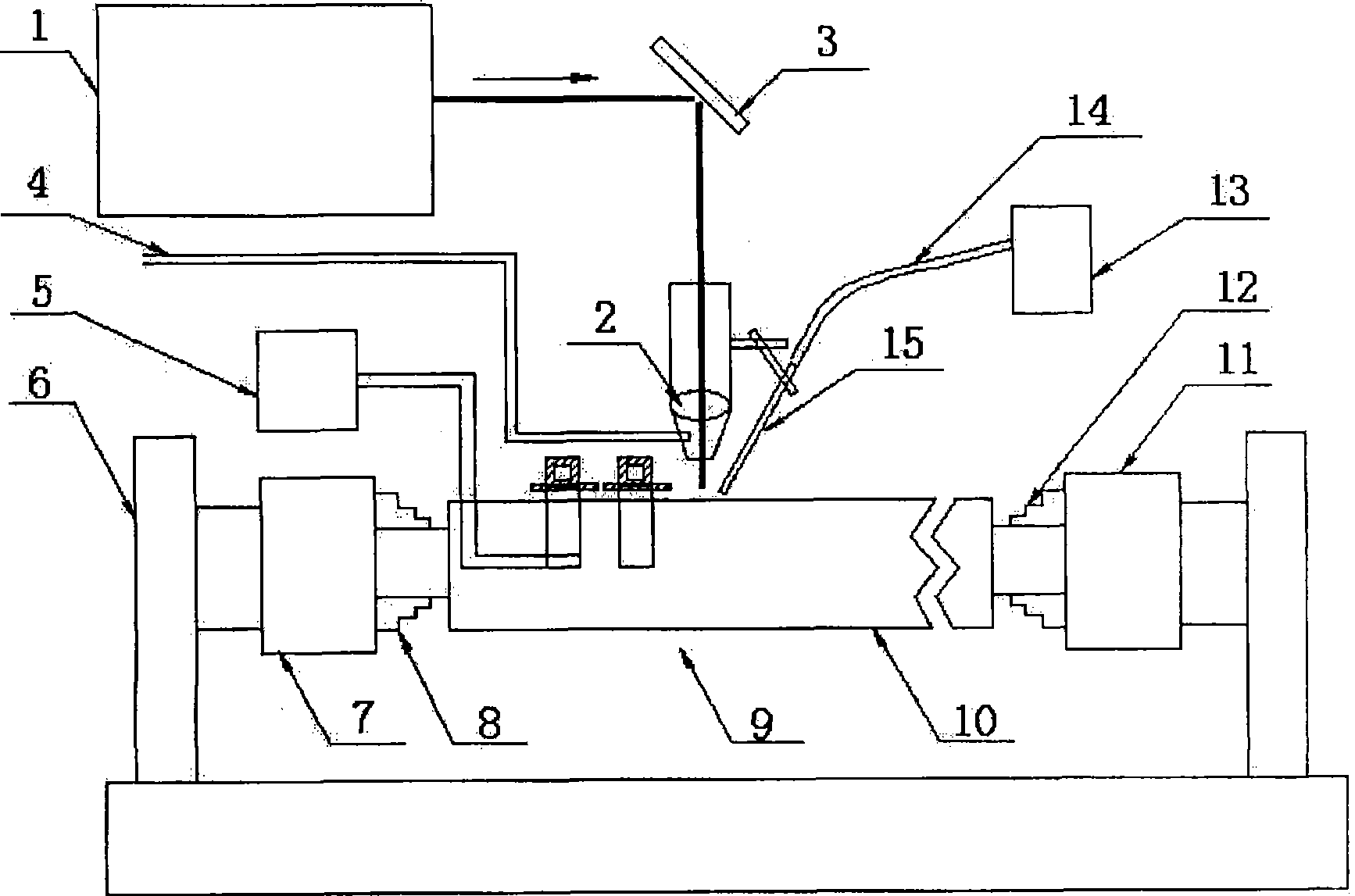

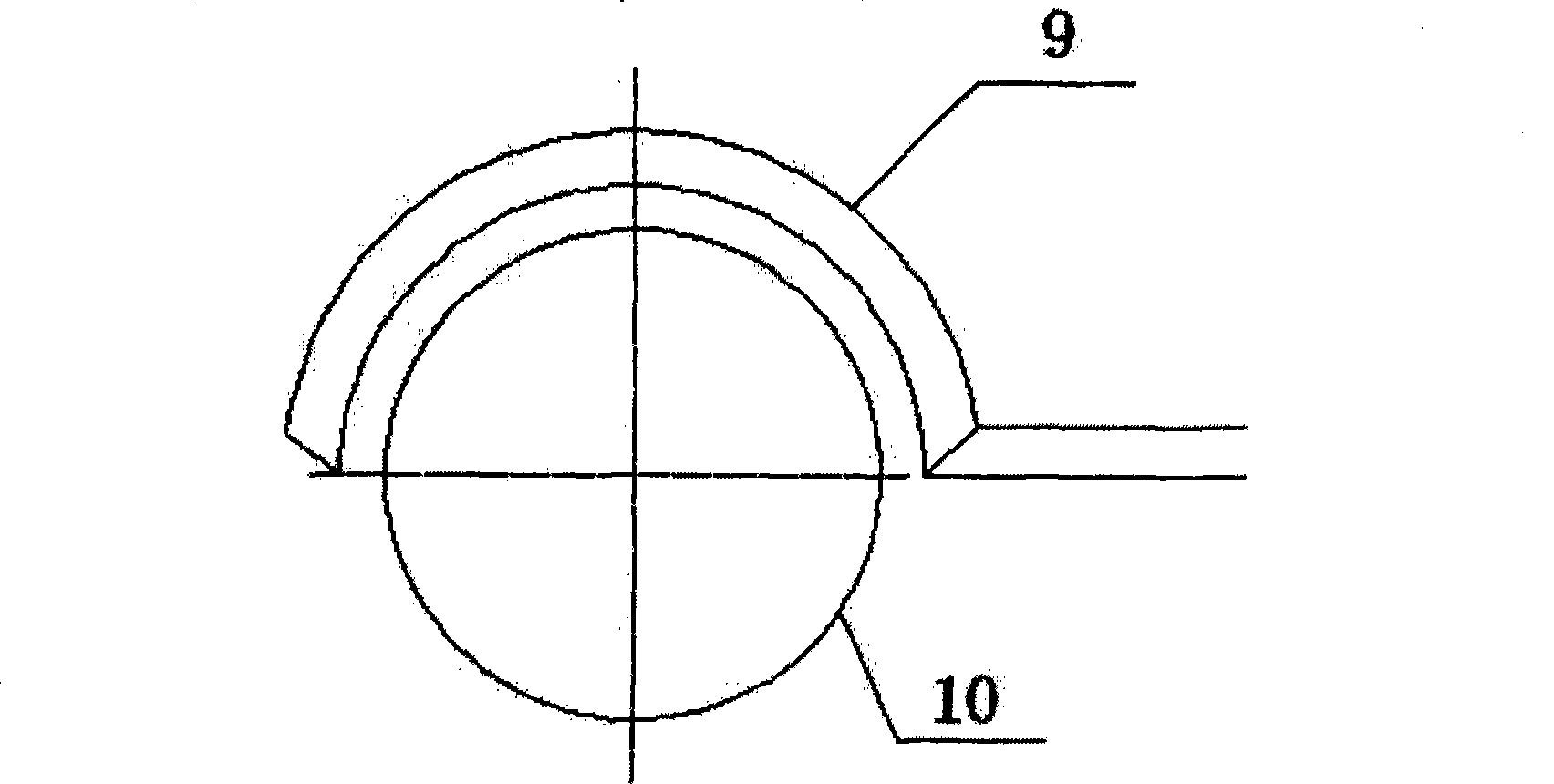

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

Method of laser induction composite cladding gradient function thermal barrier coating

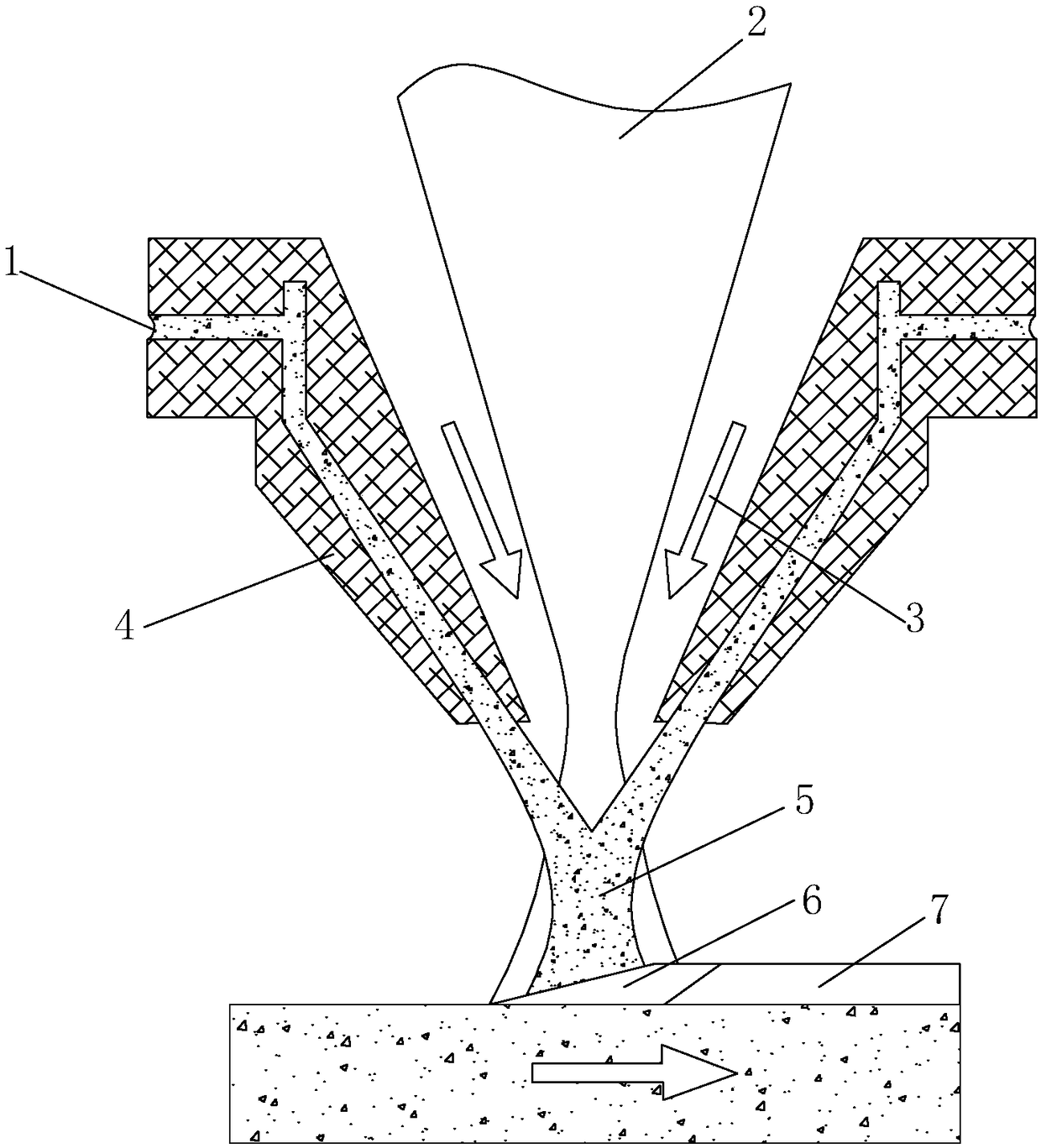

InactiveCN101748402AImprove cladding efficiencyImprove thermal shock resistanceMetallic material coating processesNumerical controlLaser scanning

The invention discloses a method of a laser induction composite cladding gradient function thermal barrier coating, which is characterized in that the methods and steps are as follows: (1) the surface of base material is provided with processing of rust removing, oil removing, cleaning and sand spraying; (2) meanwhile, the inert protective gas is blown into an induction heating zone through utilizing a copper pipe, which prevents the high-temperature oxidation; (3) a focused laser beam and a powder nozzle of an automatic double-hopper powder feeder are located in the induction heating zone, and the composition of the laser heat source and the induction heating source can be realized; (4) a numerical control machine is moved 70-30% of the laser spot diameter along the vertical direction of the laser scanning speed; (5) the mass percentage content of a ceramic phase in the composite powder is led to be increased by 0-90 wt.%; (6) steps (2)-(5) are repeated until the required thickness of the coating is achieved; otherwise, the work is ended. The advantages of the invention are as follows: (1) the size, the shape and the part needing to process of the base material are not limited; (2) for the gradient function thermal barrier coating, the content of the ceramic phase in the coating presents change of gradient and is controllable along the thickness direction of the coating; (3) the whole gradient function thermal barrier coating has no air hole and crack; (4) the service life is greatly increased.

Owner:NANCHANG HANGKONG UNIVERSITY

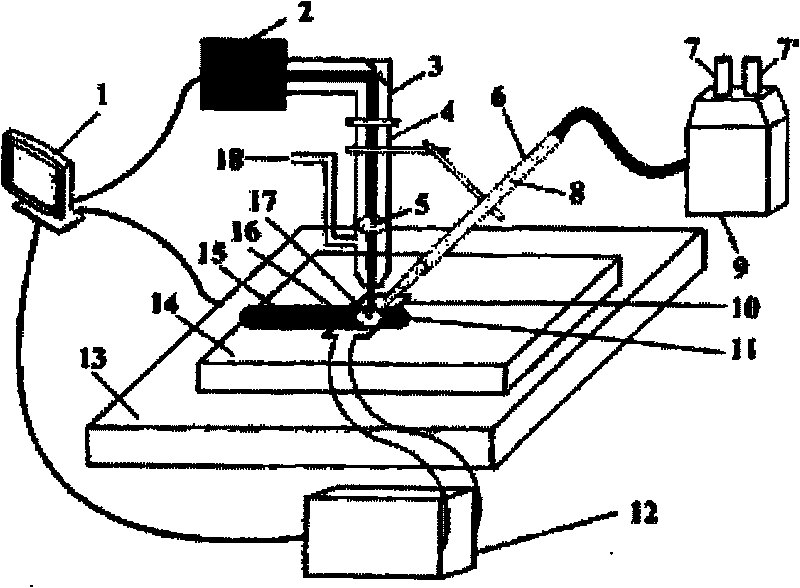

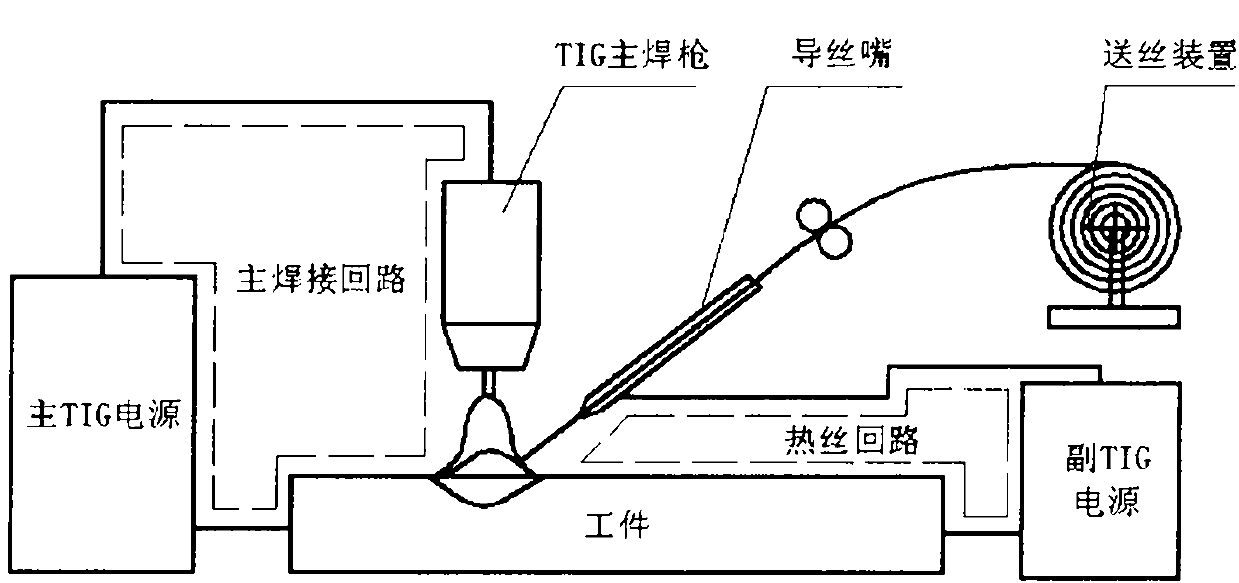

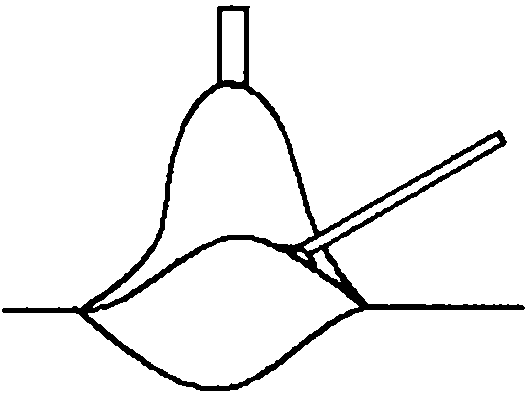

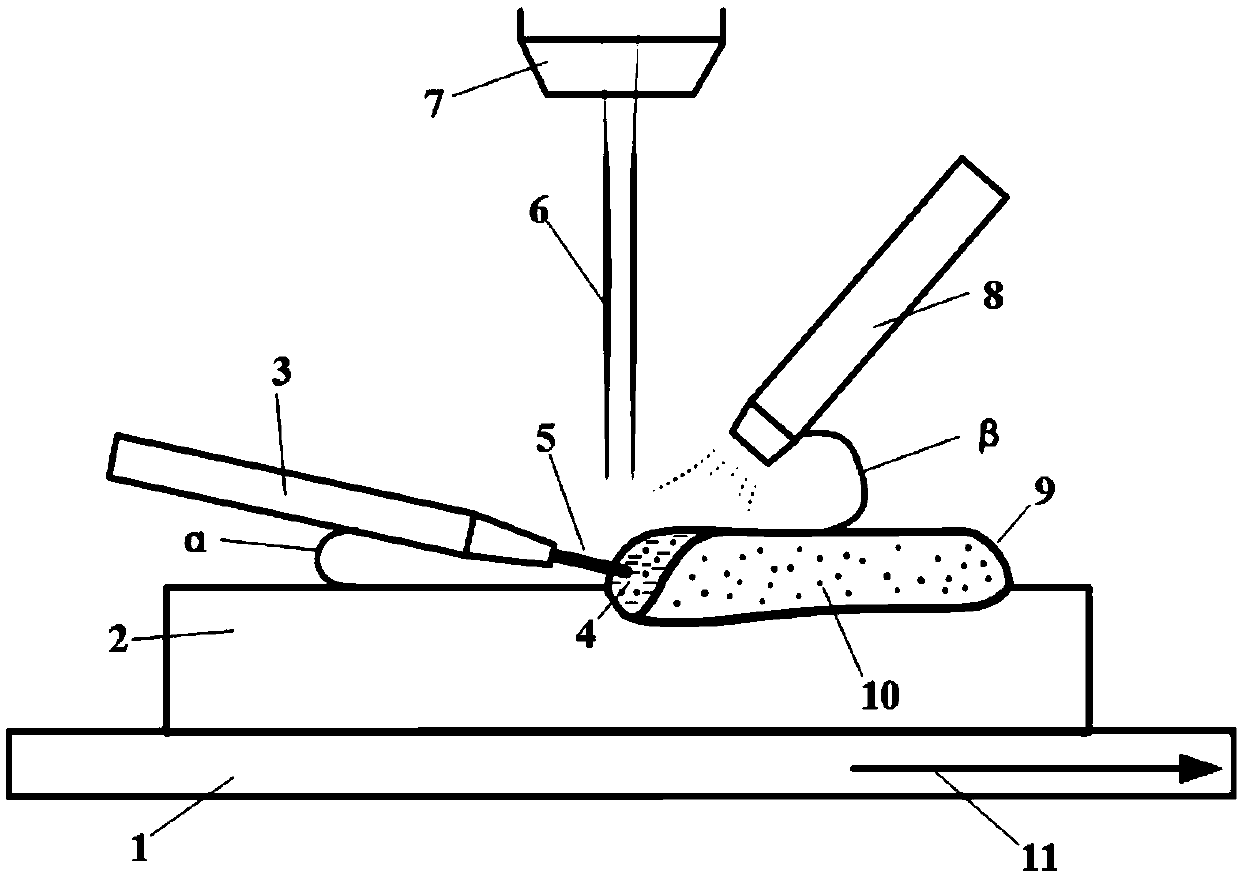

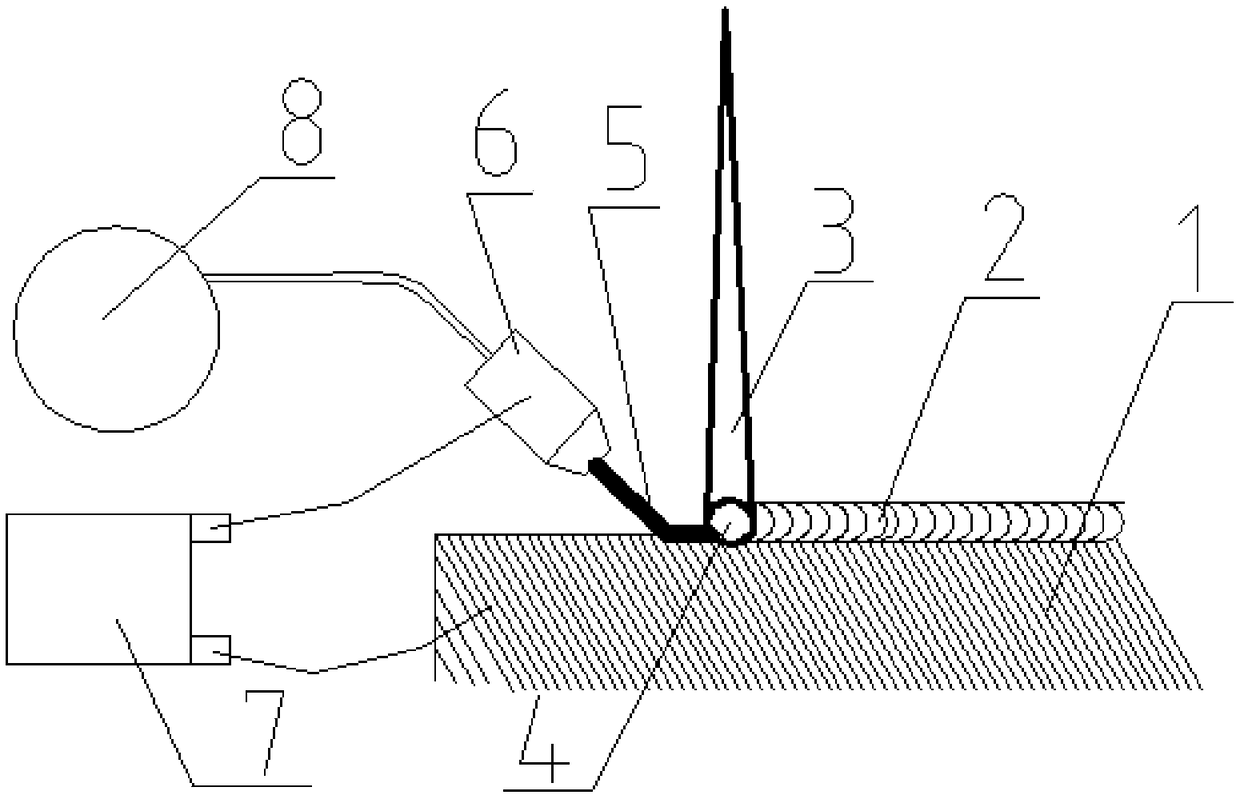

TIG (tungsten inert gas welding) power assistant double TIG (tungsten inert gas welding) compound heat source welding equipment and method

InactiveCN102000903AImprove cladding efficiencyExtended service lifeArc welding apparatusTungstenElectric arc

The invention provides a TIG (tungsten inert gas welding) power assistant double TIG (tungsten inert gas welding) compound heat source welding equipment and method, which heats up a welding wire through resistance heat or electric arc heat production at different-droplet transferring patterns to improve the welding wire cladding efficiency. The TIG power assistant double TIG compound heat source welding equipment consists of a main TIG power, a TIG main welding torch, a conducting wire nozzle, an assistant TIG power, a wire feed device and a work piece, wherein the main TIG power is connected with the TIG main welding torch and the work piece respectively, the main TIG power, the TIG main welding torch, a main welding arc and the work piece constitute a main welding loop; the welding method is that leading the assistant TIG power in a routine argon tungsten-arc welding system, connecting two electrodes of the assistant TIG power on the wire feed device and the work piece to form an electric conduction loop, and changing the size of the assistant TIG power electric current in the welding process to form the different-droplet transferring patterns. The invention has simple equipment, low cost, and is convenient to promote in the industrial production.

Owner:HARBIN INST OF TECH

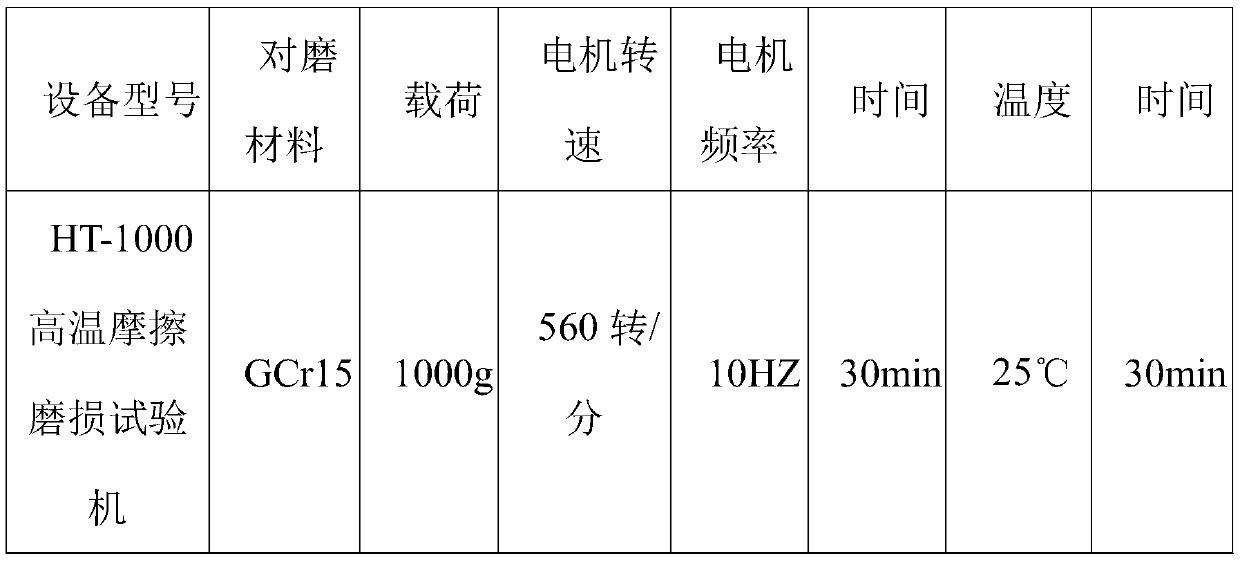

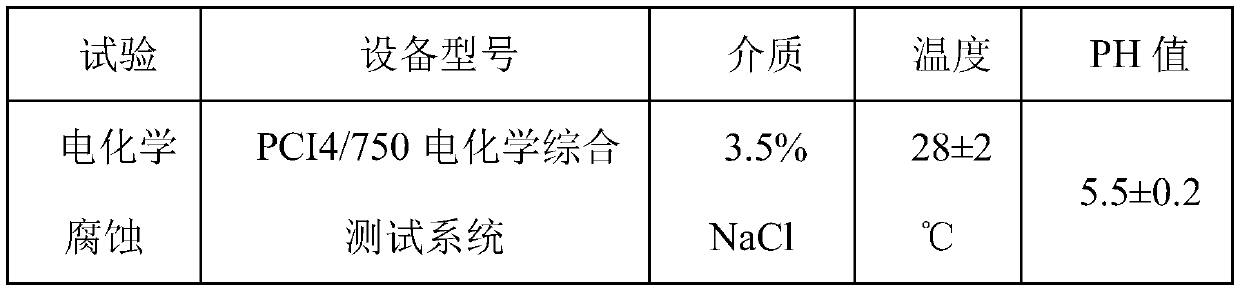

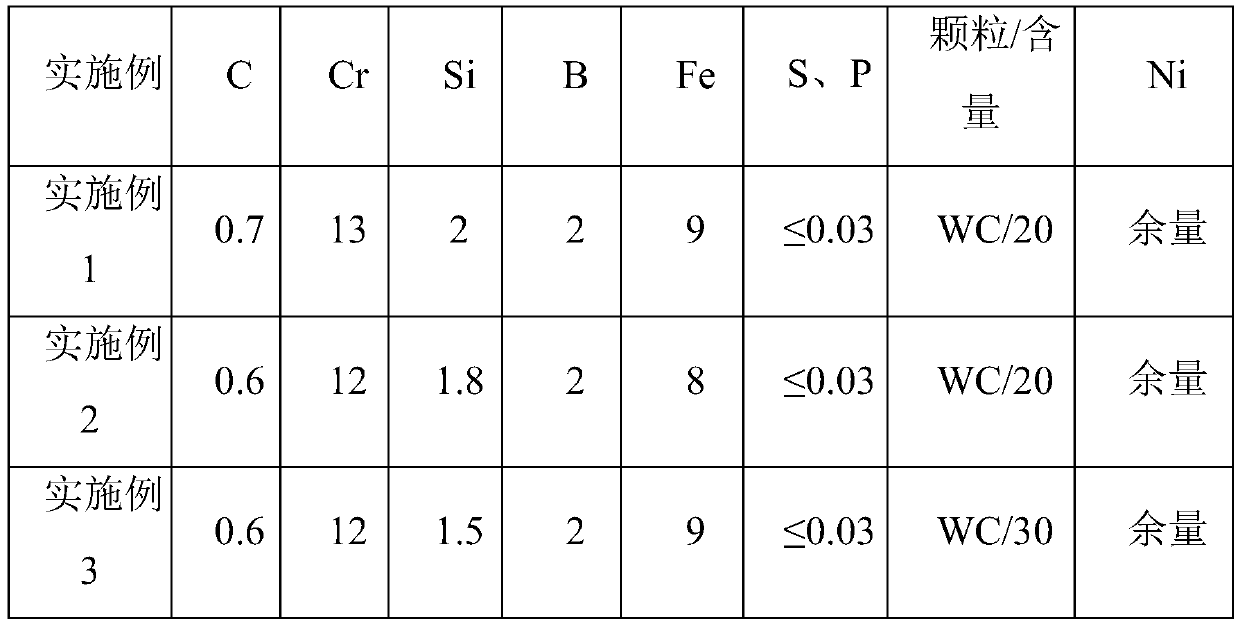

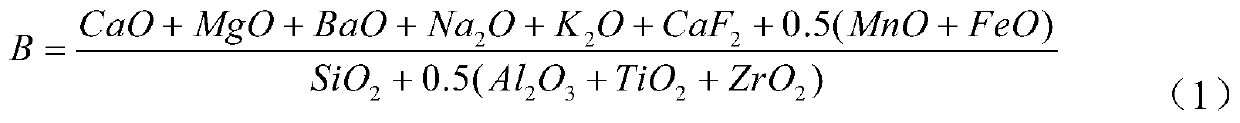

Preparation method of wear-resistant coating for high-accuracy roller piece

The invention relates to a preparation method of a wear-resistant coating for a high-accuracy roller piece. In the invention, a nickel-based (or cobalt-based) prefabricated layer is prepared by using a supersonic flame spraying process, and the prefabricated layer is treated by adopting an induction heating method, so that the bonding intensity between the coating and a substrate is enhanced. Thewear-resistant coating is prepared by adopting a composite surface treatment technology, so that a workpiece is prevented from being deformed in the machining process, the prepared coating is dense and crackless and has uniform hardness and high binding intensity, and the surface wear resistance and impact resistance of the workpiece are enhanced; and moreover, a preparation technology has the advantages of simple process, high cladding efficiency, low machining cost and the like. After machining, the binding intensity between the coating and the substrate is more than or equal to 70 MPa, andthe hardness of the coating can be up to HRB 55-70 by adjusting the adding amount of solid-phase wolfram carbide (WC) in spraying powder. The preparation method can be widely applied to the preparation of surface reinforced layers for industrial components with severe working conditions, such as high-frequency friction pairs, papermaking rollers, pumping rods, loops and the like.

Owner:BGRIMM ADVANCED MATERIALS SCI & TECH +1

Wide-band laser-induced hybrid cladding restoration and surface strengthening method for dies

InactiveCN102373468AImprove wear resistanceImprove corrosion resistanceMetallic material coating processesRepair timeLaser scanning

A wide-band laser-induced hybrid cladding repairing and surface strengthening method for dies is characterized in that a Ni based alloy powder for wide-band laser-induced hybrid cladding is used to repair damaged areas of dies or strengthen the surface of dies. By the adoption of a wide-band scanning system, different dies such as plastic die, hot work die, cold work die and the like can be repaired and undergo surface strengthening. The width of a single track laser-induced hybrid cladding layer reaches 20-30mm; the thickness of each track cladding can reaches 3mm; laser scan speed reaches 10m / min; the powder flow reaches 15kg / h; the powder utilization rate is 90%; the efficiency is raised by 5-10 times in comparison with simple laser cladding; repairing time is shortened by 30%; energy is saved by 10-40%; defects such as pores and crack in the coating are eliminated; wear resistance, corrosion resistance, antioxidation performance and fatigue resistance of dies are greatly raised; and the service life of dies can be increased by 3-10 times.

Owner:XIAOGAN KELONG INDAL

Open arc overlaying wire material with strong abrasive resistance for grinding roller and grinding disk

InactiveCN101658980AReduce splashFine particleWelding/cutting media/materialsSoldering mediaTitanium nitrideNanometre

The present invention provides an open arc overlaying wire material with strong abrasive resistance for a grinding roller and a grinding disk, which consists of a steel sheet and powder arranged in the steel sheet. A nano additive (A) is added into the powder, wherein the nano additive (A) can be one or any combination of three of nano TiN (titanium nitride), nano SiN (silicon nitride) and nano SiC (silicon carbide). The powder contains 3 to 5 weight percent of the nano additive (A). The nano additive (A) has the functions of strengthening dispersion of nano ceramic phases, improves cohesion strength, rupture strength and combination strength of a cladding layer material and has good high-temperature stability; and the nano additive (A) improves self lubricity of the material, improves theabrasive resistance of cladding layer metals and prolongs service life of the grinding roller and the grinding disk processed by overlaying. The service life of the grinding roller and the grinding disk processed by the overlaying is improved by 1.5 to 2 times than that processed by open arc overlaying; and the cladding efficiency is improved by 10 to 20 percent so as to save the overlaying wirematerial. The open arc overlaying wire material has light fume and less molten metal spatter in the process of overlaying, and a weld pass is smooth after the material is molded.

Owner:JIANGXI HENGDA HI TECH CO LTD

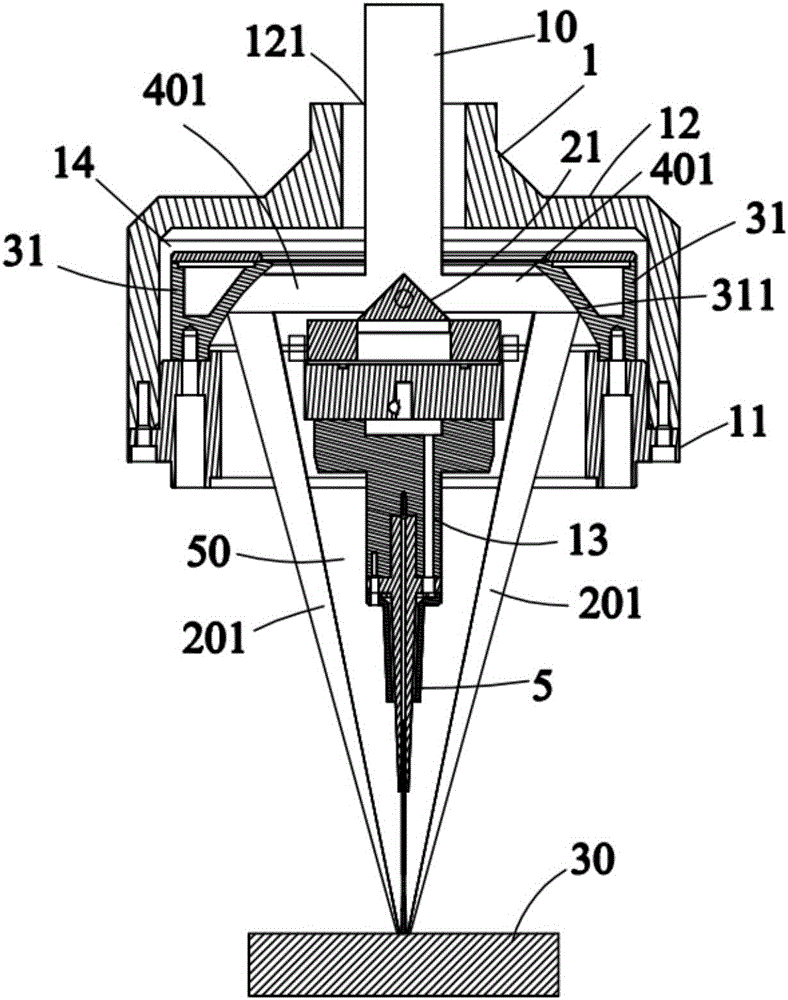

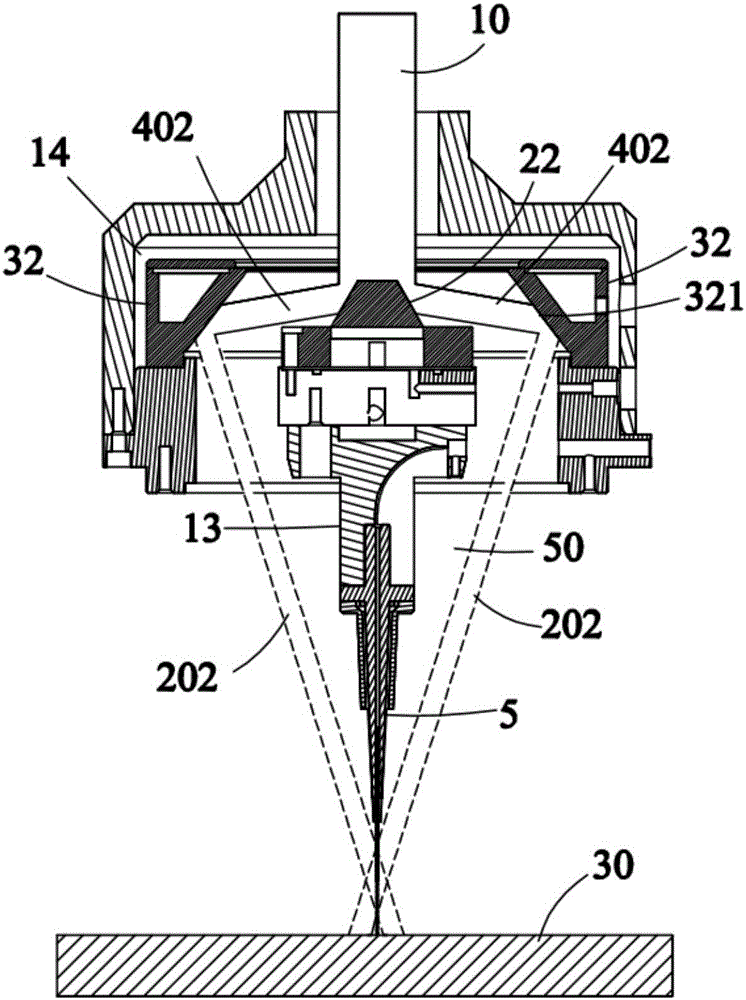

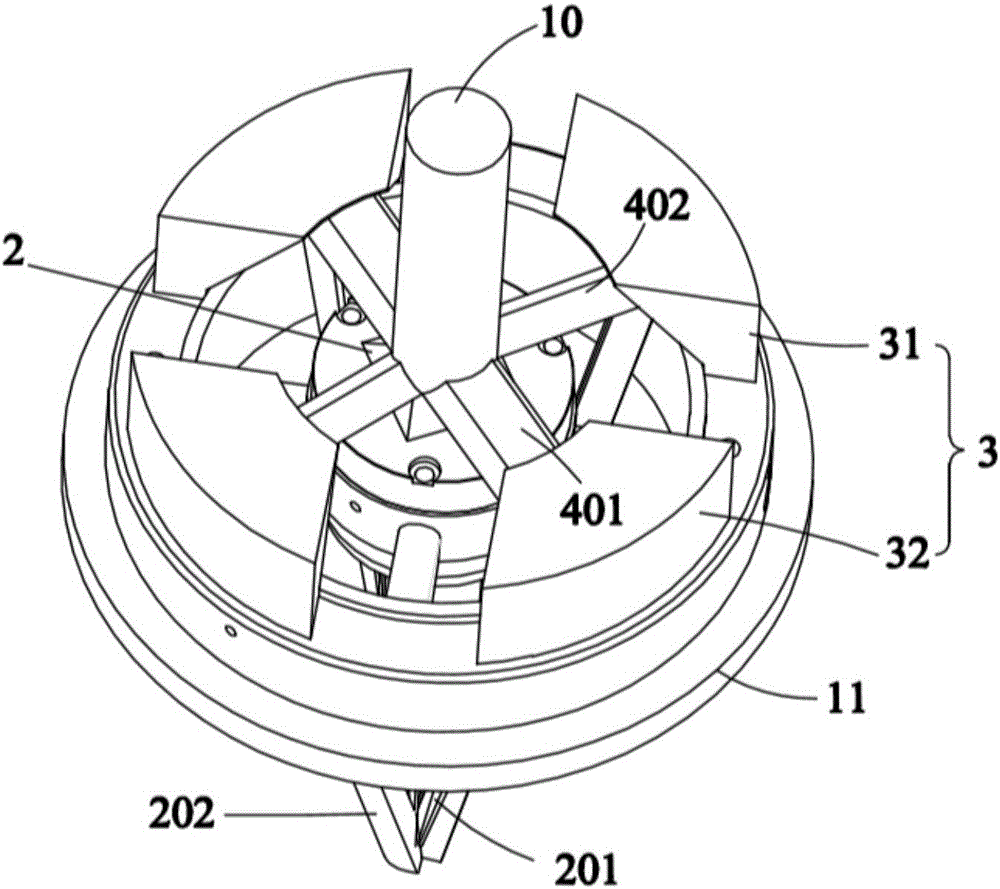

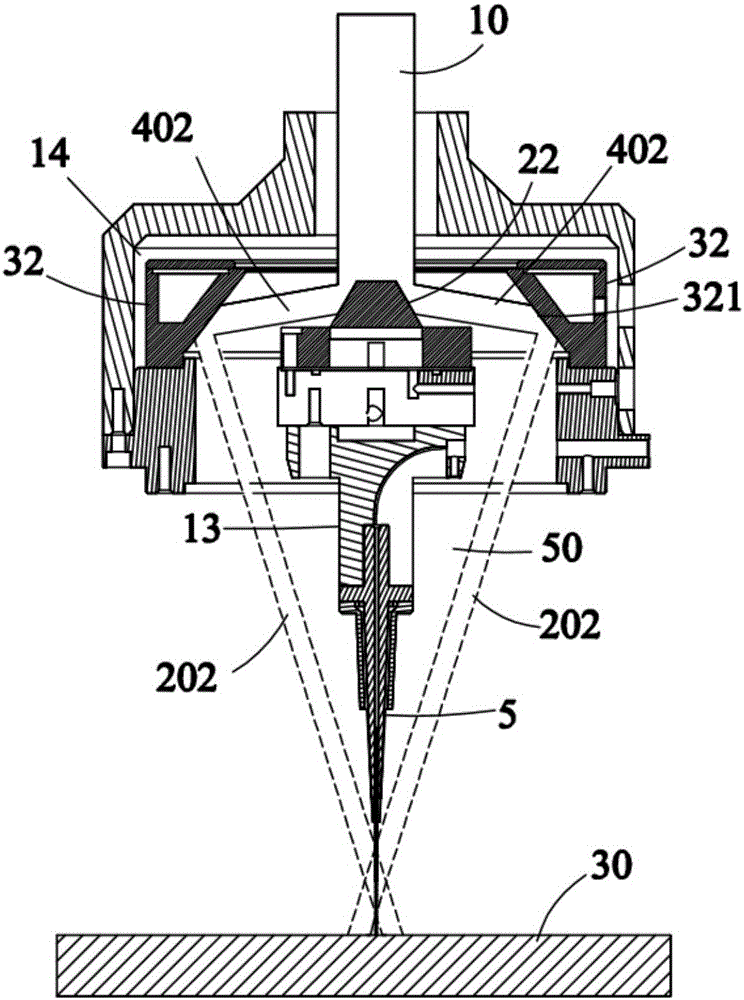

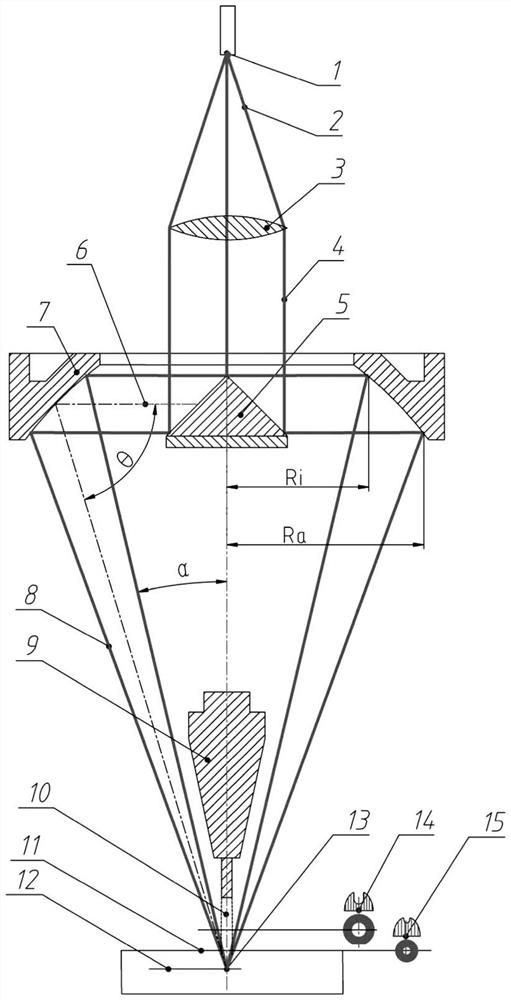

Multi-beam laser cladding device

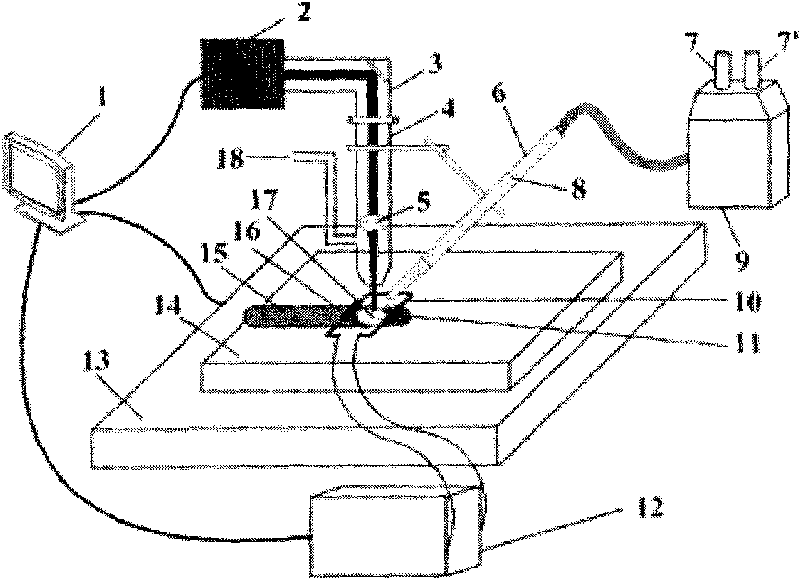

ActiveCN106583726AReduce thermal stressImprove cladding efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyBeam splitterLight beam

The invention relates to a multi-beam laser cladding device comprising a beam splitter and a reflecting-focusing assembly. The beam splitter comprises at least two first mirror surface portions and at least two second mirror surface portions, the first mirror surface portions and the second mirror surface portions are arranged alternately in the circumferential direction of the central axis of the beam splitter, part of incident beams are received and reflected by the first mirror surface portions so as to form first reflected beams, part of the incident beams are received and reflected by the second mirror surface portions so as to form second reflected beams, the first reflected beams and the second reflected beams are reflected in the circumferential direction of the central axis of the beam splitter, and the reflection angle of the first reflected beams is different from the reflection angle of the second reflected beams. The reflecting-focusing assembly comprises a reflecting-focusing lens and a reflector, the first reflected beams are reflected and focused by the reflecting-focusing lens so as to form cladding beams, and the second reflected beams are reflected by the reflector so as to form preheating beams.

Owner:SUZHOU ZHONGKE INNOVATION INST OF LASER INTELLIGENT MFG

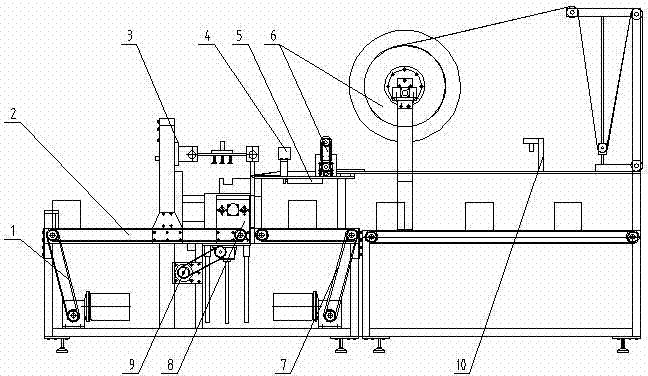

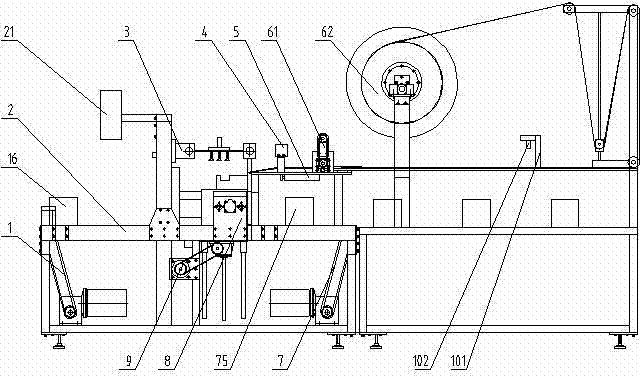

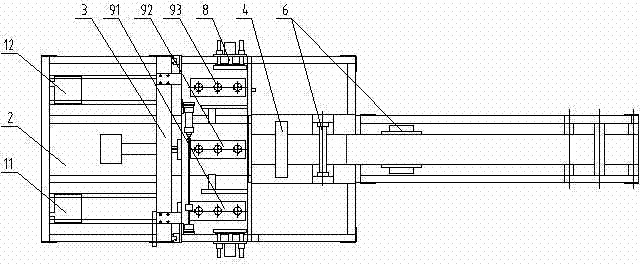

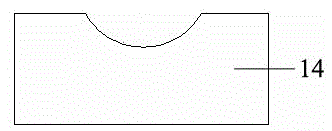

Novel full-automatic numerical control board packaging machine

InactiveCN103794823ASimple structureOverall small sizeFinal product manufactureLead-acid accumulators constructionNumerical controlSmall footprint

The invention relates to a novel full-automatic numerical control board packaging machine which comprises a pole plate conveying device, a pole plate finishing device, a pole plate lifting device, a pole plate absorbing device, a clapboard paper conveying device, a clapboard paper cutting device, a board packaging device, a pole plate group conveying device and a stand, wherein the pole plate conveying device is arranged at the left lower part of the stand; the tail end of the pole plate conveying device is provided with the pole plate finishing device; the pole plate lifting device is arranged under the stand; the pole plate absorbing device is arranged above the pole plate lifting device; the clapboard paper conveying device is arranged at the right upper part of the stand; the tail end of the clapboard paper conveying device is provided with the clapboard paper cutting device and the board packaging device; the pole plate group conveying device is arranged just under the clapboard paper conveying device. The novel full-automatic numerical control board packaging machine not only is simple in structure, compact in volume and small in occupied land area and improves the environment of a workplace, but also greatly improves the board packaging efficiency and the board packaging quality.

Owner:浏阳市联创机械设备制造厂

Laser-induction compounded cladding method for repairing continuous casting crystallizer

InactiveCN102909325AThickness is easy to controlLow dilution rateMetallic material coating processesAlloyCopper

A laser-induction compounded cladding method for repairing a continuous casting crystallizer is characterized by comprising the following steps: conducting deoiling, derusting, crack or scratch excavating, activating, and electronickelling or chemical nickel plating on a damaged part of the continuous casting crystallizer; then adopting laser-induction compounded cladding dedicated copper-base alloy powder to repair the damaged part of the continuous casting crystallizer, wherein the dedicated copper-base alloy powder comprises the following chemical constituents by weight percent: 7 to 9 percent of Ni, 8 to 12 percent of Sn, 5 to 15 percent of Al, 0.8 to 2 percent of Si and Cu in balancing amount. According to the invention, laser-induction compounded cladding repairing can be conducted on the damaged part of the continuous casting crystallizer under the condition that the cladding efficiency is improved by 1 to 5 times, so as to solve the problem that the conventional repairing coating of the continuous casting crystallizer is thin, easy to peel and low in thermal conductivity.

Owner:NANCHANG HANGKONG UNIVERSITY

Argon arc cladding material based on self-fused Fe-based alloy powder

InactiveCN103464928AHigh hardnessImprove wear resistanceMetallic material coating processesWelding/cutting media/materialsRare earthAlloy

An argon arc cladding material based on self-fused Fe-based alloy powder belongs to the technical field of material surfaces. The argon arc cladding material is characterized in that the cladding material comprises the following raw materials in percent by mass: 50-90% of self-fused Fe-based alloy powder, 5-15% of ferro-vanadium, 1-8% of ferro-molybdenum, 1-5% of graphite, 0-40% of WC and 1-3% of rare-earth alloy. The cladding material can be prepared into two forms: being arranged on the surface of a clean workpiece in a coating manner and flattened to form a coating with a thickness of 0.8-1.5mm; pressing into a film which is 0.8-1.5mm in thickness, 6-10mm in width and 50-100mm in length; air-drying at a room temperature for more than ten hours and then baking at a temperature of 120-200 DEC G for two hours for standby use. The argon arc cladding material has a low fusion point and is well formed and used for repairing the surfaces of steel workpieces and improving the hardness and the wear resistance of the surfaces. The surface hardness of a cladding layer reaches HRC51-62.

Owner:SHANDONG JIANZHU UNIV

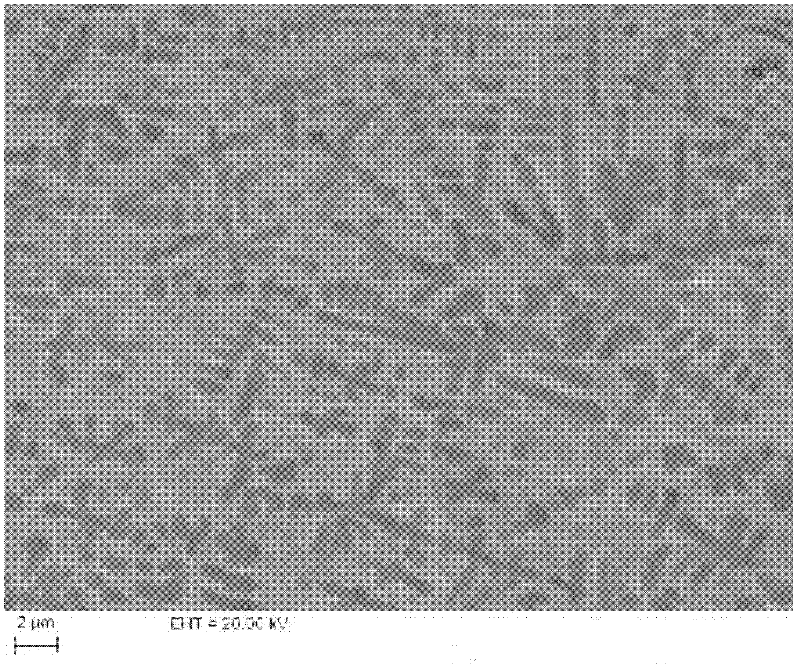

Method for preparing carbon nanotube-reinforced iron-rich porous composite material through laser-induction composite cladding

The invention provides a method for preparing a carbon nanotube-reinforced iron-rich porous composite material through laser-induction composite cladding. The method is characterized by comprising the following steps: (1) mixing copper alloy powder, ferroalloy powder and a carbon nanotube and adding the obtained mixture into an acrylic resin to prepare slurry; (2) uniformly mixing the slurry by using a planetary ball mill, carrying out drying and then carrying out grinding to obtain carbon nanotube uniformly-distributed Cu-Fe-based composite powder; and (3) preparing a carbon nanotube-reinforced Cu-Fe-based composite material on the surface of a substrate through laser-induction composite cladding and carrying out selective electrochemical corrosion in a nitric acid solution so as to obtain the high-strength porous iron-rich composite material with a three-dimensional structure. According to the invention, the carbon nanotube with a high-melting point is used to inhibit convection of molten Cu-Fe-based composite powder, reduce the movement speed and particle size of spherical Fe-rich particles and improve structural segregation and layering of the Cu-Fe-based composite material. Thus, the crack-free high-strength porous iron-rich composite material with uniformly distributed carbon nanotubes can be prepared under the conditions of high efficiency and low cost.

Owner:NANCHANG HANGKONG UNIVERSITY

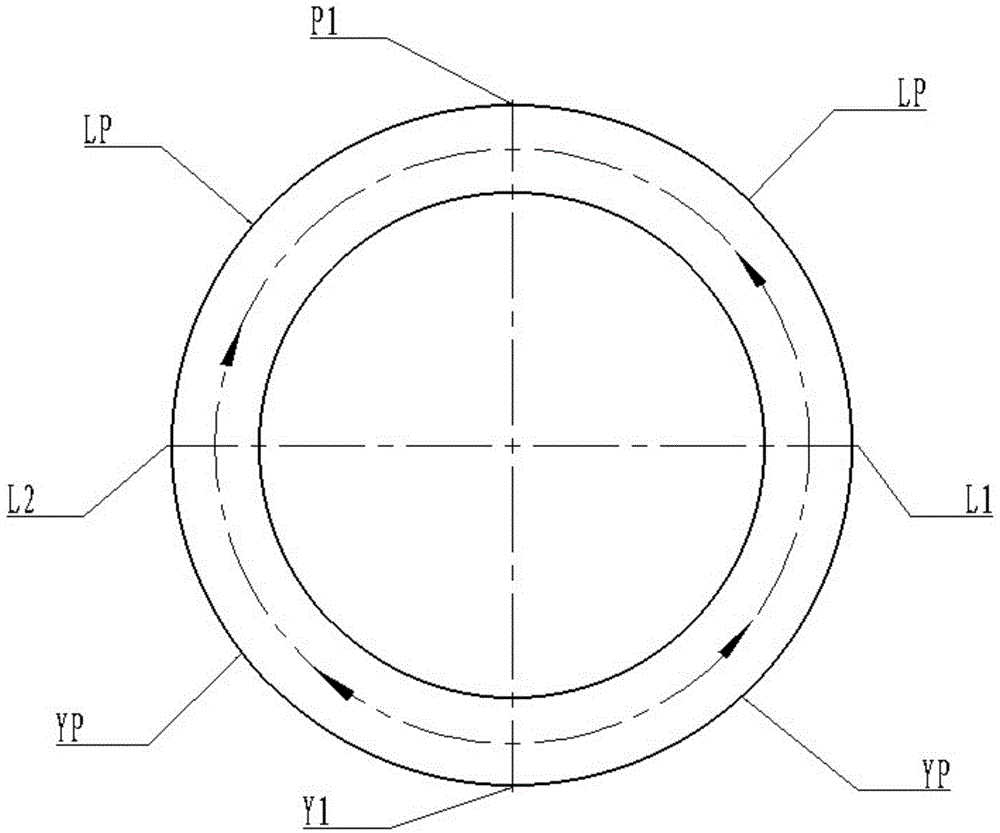

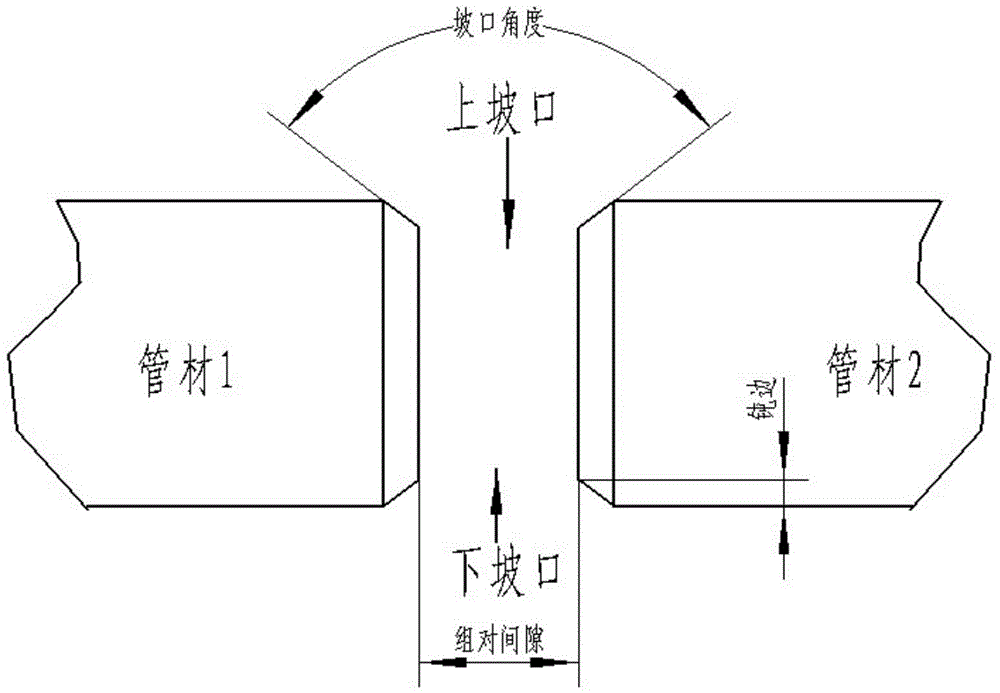

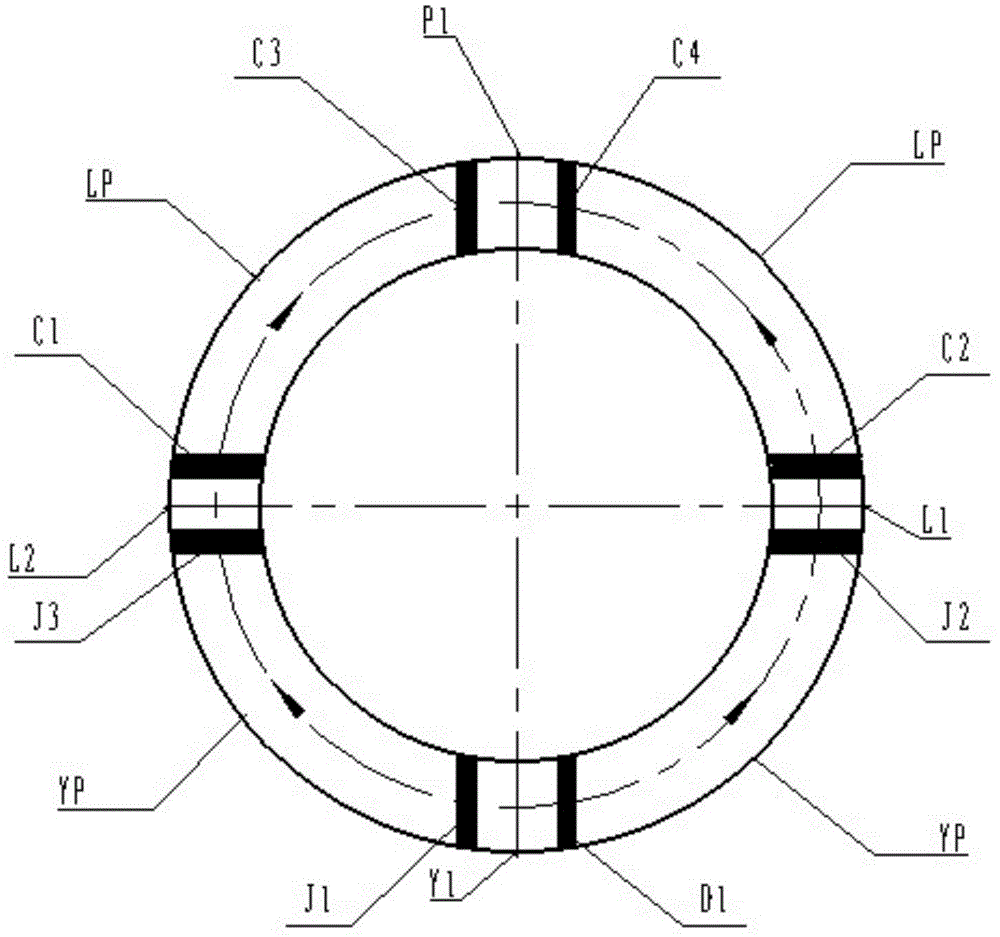

Pipeline welding method

ActiveCN104014909APrevent intrusionStrong penetrating powerArc welding apparatusPipeline systemsPower flowEngineering

The invention provides a pipeline welding method which comprises the following steps: carrying out pre-welding preparation, namely pairing all pipes according to a gap requirement and machining pipe grooves according to a groove angle requirement; choosing welding rods and electric currents, namely choosing proper welding rods and electric currents according to the diameters of the pipes, the thicknesses of pipe walls and welding skill proficiencies; carrying out backing welding by using argon arc welding; filling and welding cover surface by using electric covering surface large current interruption welding method. As the current interruption welding method controls welding sequences, welding current, welding rod angles, arc-starting points and arc-stopping points, the qualification rate of pipeline welding can be effectively increased.

Owner:CHINA HUAYE GROUP

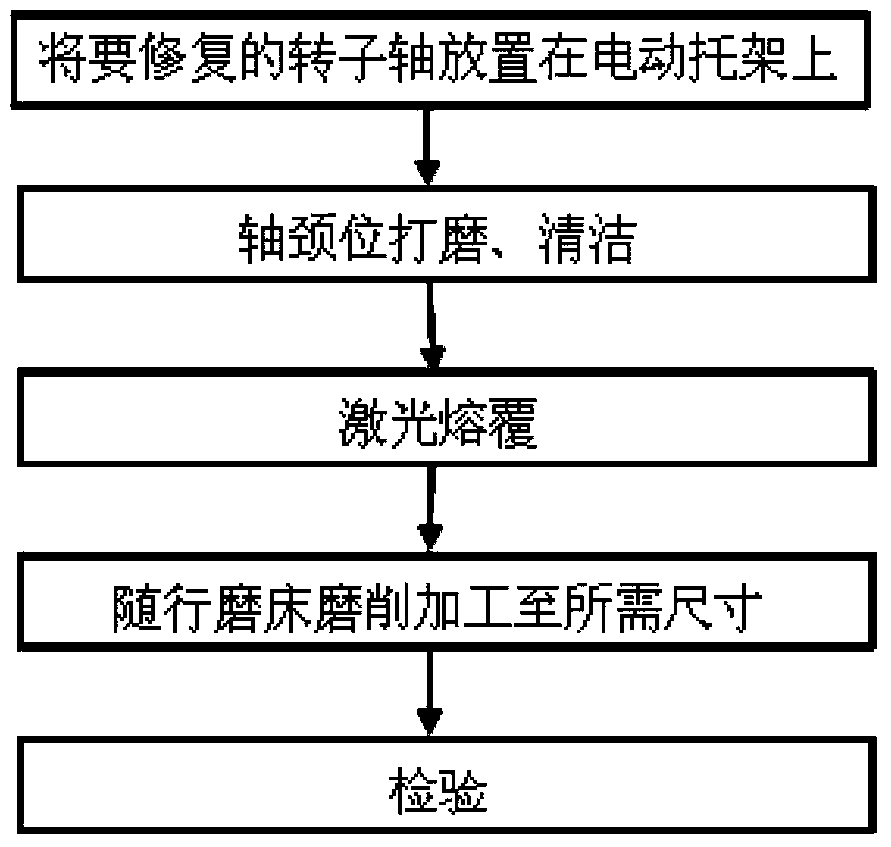

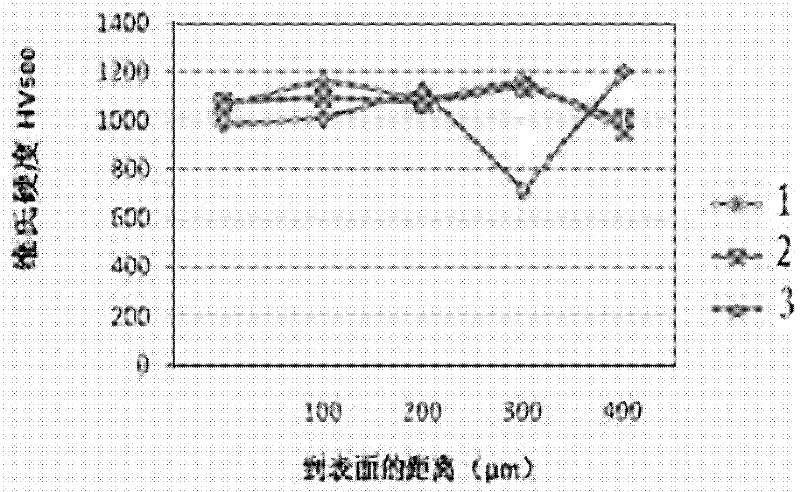

High speed rotating machinery axle laser cladding repair alloy powder and repair method

ActiveCN103352221AGood weldabilityImprove wear resistanceMetallic material coating processesLaser beam welding apparatusAlloyRepair method

The invention discloses a high speed rotating machinery axle laser cladding repair alloy powder and a repair method. The alloy powder is prepared with the following components by weight: 0.13 percent of C, 13 percent to 17 percent of Cr, 1.3 percent of Si, 4 percent to 6 percent of Ni, less than 0.03 percent of P, and the balancing percent being Fe. According to the method provided by the invention, alloy powder is obtained by strict screen of raw material and matching thereof, can restore the damage part size of the rotating shaft, and is wearproof, so as to enable the degree of wear proof of shaft neck after being repaired by the alloy powder to surpass the substrate, that is, for the degree of wearproof of the shaft neck, the service life of the repaired rotating shaft surpasses that of a newly produced rotating shaft; furthermore, corrosion resistance of the shaft neck of the repaired alloy powder is greatly increased, so as to enable the rotator shaft to be more wear-resisting in the next period, and the running of the unit to be more stable.

Owner:CHINA HUADIAN ENG +2

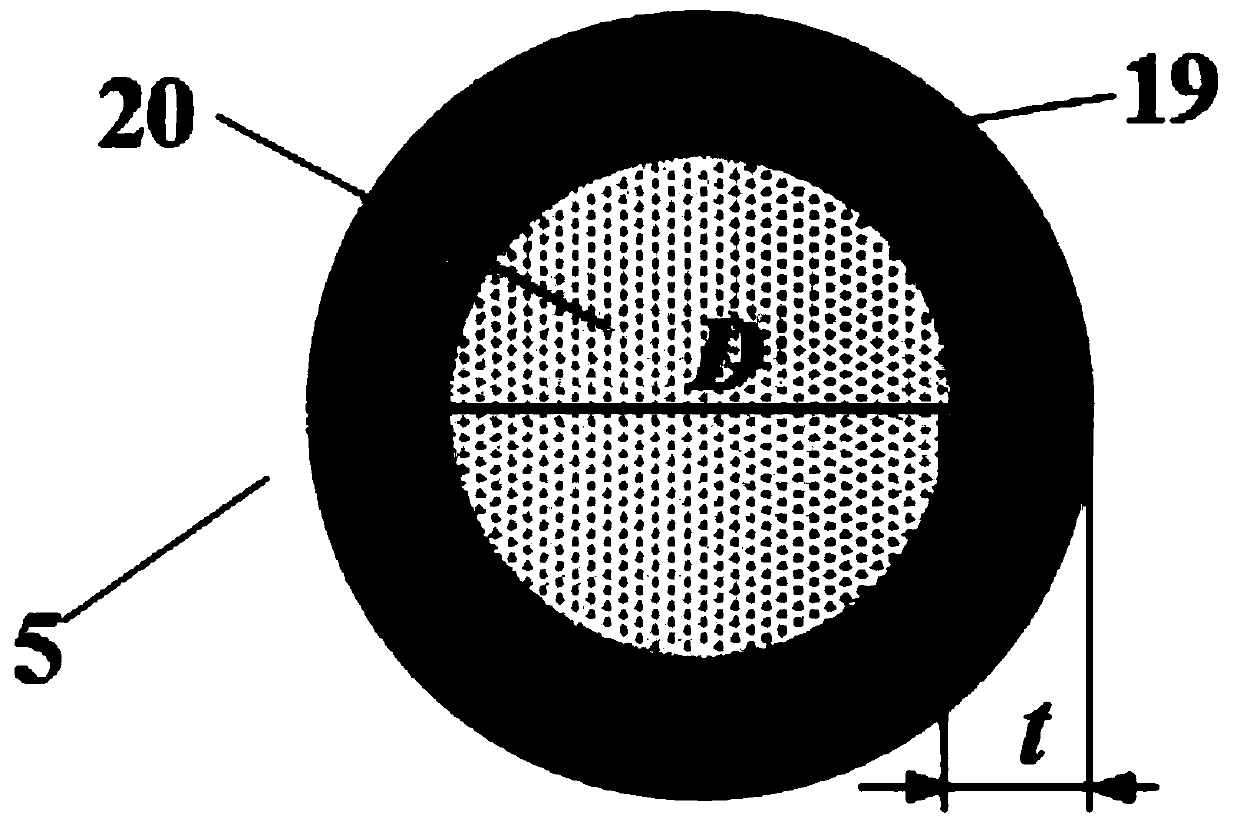

Laser melting deposition ceramic particle enhanced metal-base composite coating based on tubular powder core wire and machining method

InactiveCN110965060AEvenly distributedLow dilution rateMetallic material coating processesMachiningLaser

The invention discloses a laser melting deposition ceramic particle enhanced metal-base composite coating based on a tubular powder core wire and a machining method. A tubular metal layer serves as ametal base body, a filler serves as a ceramic particle enhancing phase, the advantages of the powder sending type and the advantages of the wire sending type are combined, and under the action of lasers, not only can the stable and smooth globular transfer process in the ceramic particle even distribution process be formed, but also the cladding efficiency, material utilization rate and automationdegree are high; and the continuous stable injection transition process can be realized through the wire. In addition, since the lasers are used as a heat source, heat input is precise and controllable, and the compact no-defect composite coating with low dilution rate and evenly distributed enhancing particles can be prepared.

Owner:TIANJIN UNIV

Powder material of high temperature erosion resistant cladding layer and preparation method of cladding layer

InactiveCN102268671AImprove bindingLow dilution rateMetallic material coating processesSurface engineeringGraphite

The invention relates to a powder material of a cladding layer with high temperature resistance and erosion resistance and a preparation method of the cladding layer, belonging to the technical field of surface engineering. The powder in the powder material comprises the following components by weight percent: 24-32% of pure titanium powder, 4.8-8% of graphite powder, 24-30% of chromium powder, 5-10% of molybdenum powder, 3-5% of titanium diboride powder, 1-3% of niobium carbide powder and the balance of nickel powder, wherein the weight ratio of pure titanium powder to graphite powder is 3.8-4. The preparation method of the cladding layer comprises the following steps: preparing mixed powder for cladding and preparing the cladding layer. The powder material has the advantages that the preparation cost is lower, the cladding layer has long life, the technology is easier and the powder material can be used to solve the preparation problem of the composite steel plate with high temperature erosion and corrosion resistance for the rocket launcher.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

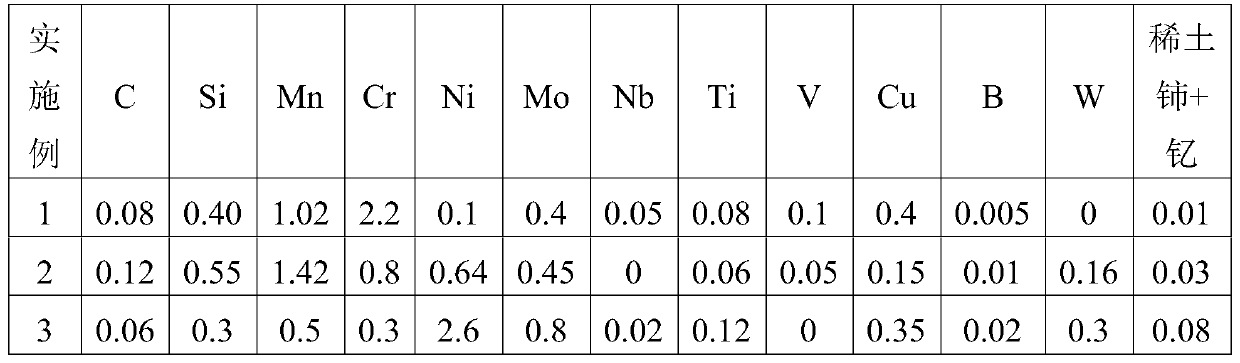

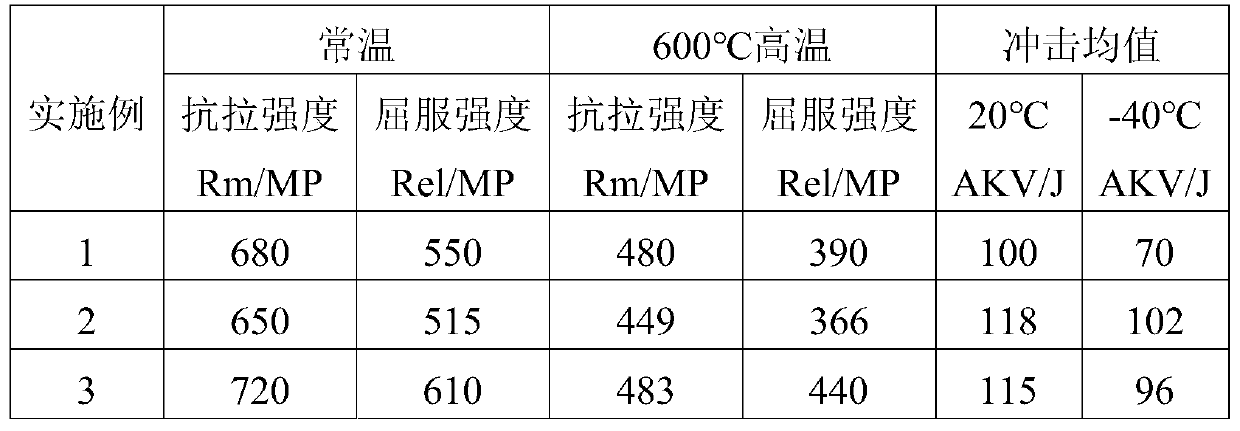

Flux-cored wire for additive manufacturing and preparation method of low-alloy high-strength steel

ActiveCN111360449AShorten the production cycleEasy to produceAdditive manufacturing apparatusArc welding apparatusRare-earth elementSheet steel

The invention discloses a flux-cored wire for additive manufacturing. The wire comprises a flux core and sheet steel. The flux core is composed of, by mass percent, 2.00%-3.83% of ferromanganese powder, 16.95%-20.85% of nickel powder, 8.35%-11.65% of chromium powder, 1.05%-3.00% of molybdenum powder, 0.90%-1.62% of ferrovanadium powder, 0.05%-0.10% of boron powder, 2.16%-10.82% of ferrotitanium powder, 0.5%-1.5% of ferrosilicon powder, 0.50%-1.00% of aluminum-magnesium powder, 0.80%-1.00% of rare earth elements and the balance being iron powder, wherein the sum of the mass percents of the components is 100%. The flux-cored wire is a wire used for arc additive manufacturing of low-alloy steel applied to a fan impeller. The invention further discloses a preparation method of low-alloy high-strength steel. The flux-cored wire has excellent comprehensive mechanical properties; and by the adoption of an additive manufacturing mode, the low-alloy high-strength steel can meet the requirementon the mechanical properties and is efficient and convenient to use.

Owner:XIAN UNIV OF TECH

Automatic powder feeding laser induction composite coating method and device

ActiveCN100503130CImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingNumerical controlSolid component

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

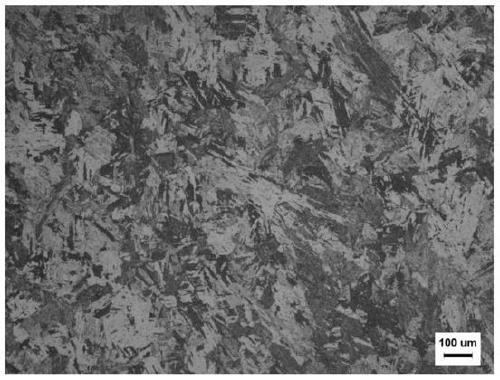

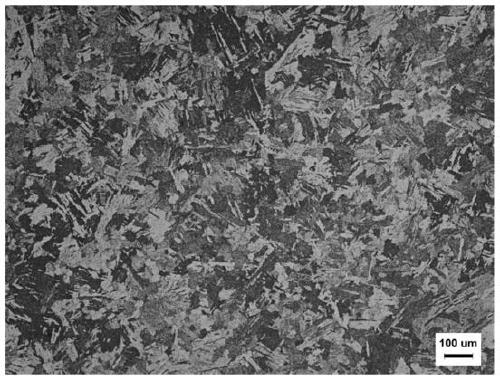

Iron-based alloy powder for laser cladding, and laser cladding method

PendingCN111945154AIncrease the dislocation densityImprove toughnessMetallic material coating processesCorrosion resistantIron based alloy

The invention discloses iron-based alloy powder for laser cladding, and a laser cladding method. The iron-based alloy powder is composed of the following components in percentage by mass: 0.1%-0.18% of C, 0.95%-1.07% of Si, 0.2045%-0.31% of Mn, 14.61%-16.242% of Cr, 2.51%-3.03% of Ni, 0.3%-0.41% of Mo, 0.075%-0.12% of V, 0.2%-0.23% of Nb, 0.045%-0.08% of N, 0.04%-0.08% of Cu, 0.4%-0.4998% of B, and the balance Fe. The laser cladding method is carried out on the basis of the iron-based alloy powder. According to the invention, through formula proportion optimization, reduction for the content of Cr element component in the iron-based alloy powder is realized while the hardness, wear resistance, corrosion resistance and welding performance of the iron-based alloy powder are not sacrificed atall and even improved, and then the cost is effectively reduced; and meanwhile, the hardness, wear resistance, corrosion resistance and welding performance of the iron-based alloy powder are improved, and the iron-based alloy powder has wide application and popularization prospects.

Owner:陕西陕北矿业有限责任公司 +2

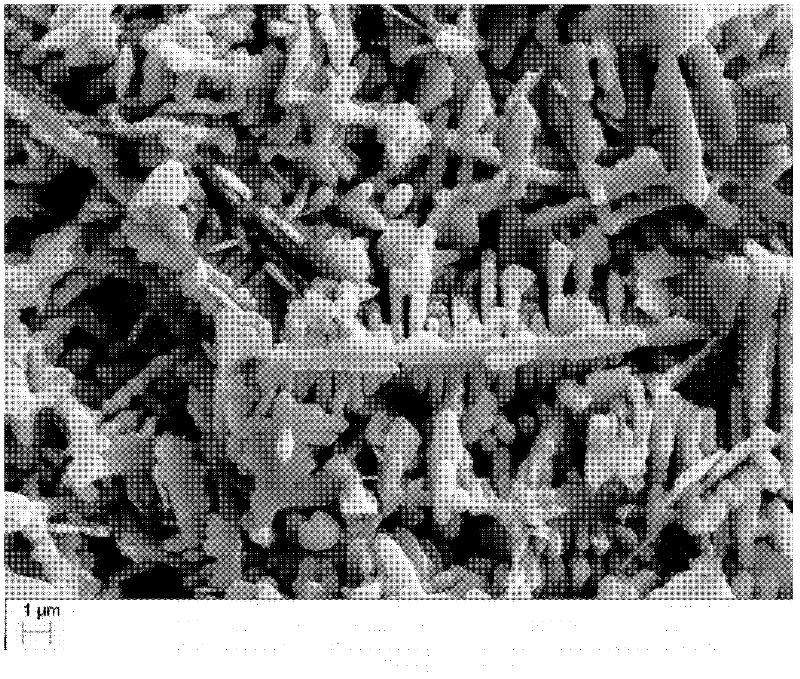

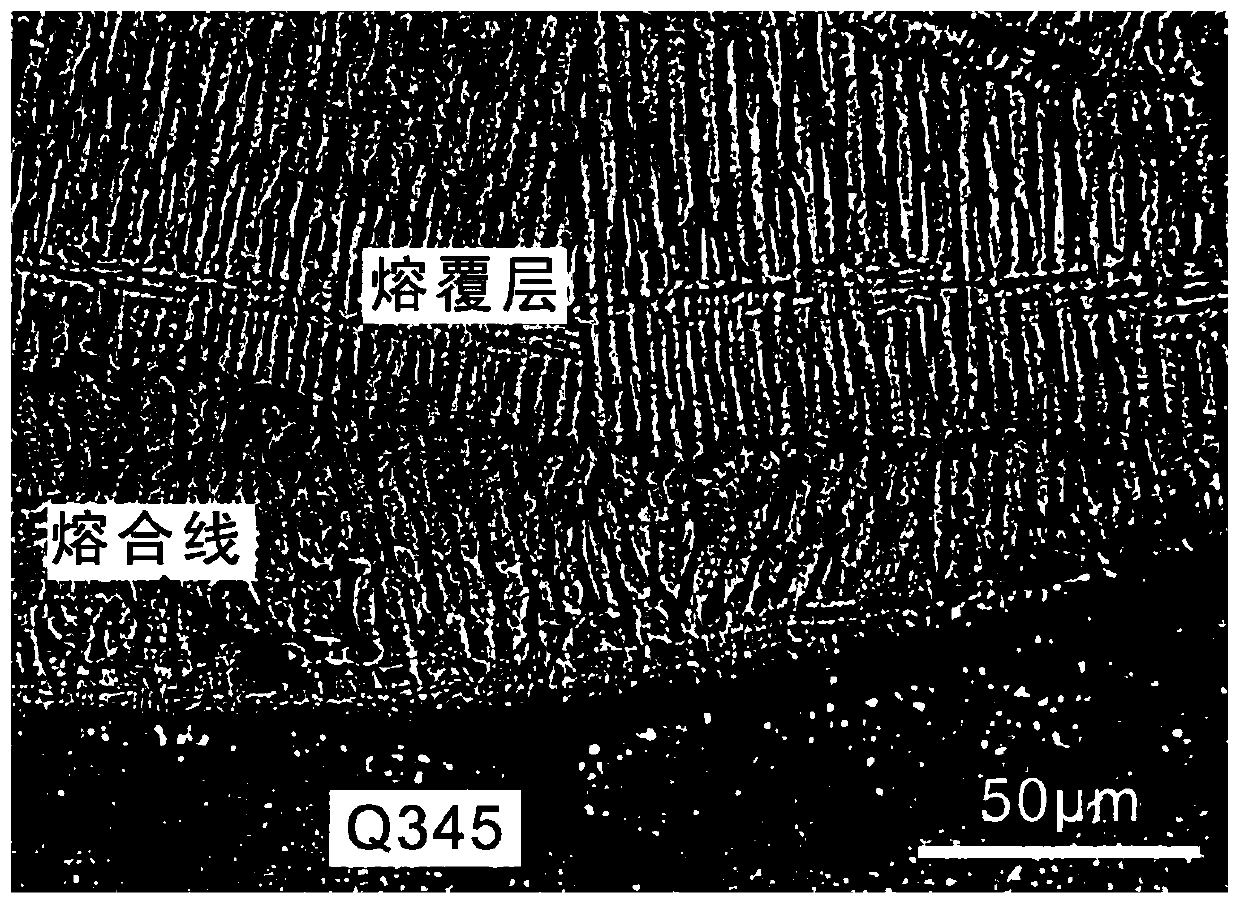

Preparation method for wear-resisting and anti-friction coating on vermicular graphite cast iron surface of cylinder head

InactiveCN109504966AReduce peelingReduce thermal stressMetallic material coating processesCast ironSurface finishing

The invention discloses a preparation method for a wear-resisting and anti-friction coating on a vermicular graphite cast iron surface of a cylinder head. The preparation method for the wear-resistingand anti-friction coating on the vermicular graphite cast iron surface comprises the following steps that firstly, vermicular graphite cast iron after surface treatment is subjected to moderate pre-heat treatment; then a Co-based alloy, Cr3C2 and MoS2 powder are mixed evenly and dried according to the proportion; the laser cladding technology is used to deposit the dried powder on the vermiculargraphite cast iron surface in the form of multi-channel overlap to form a Co-based composite coating; and finally, the Co-based composite coating is subjected to subsequent heat treatment to obtain awear-resisting and anti-friction cladding layer. The advantages are that the probability of peeling, separating and exfoliating can be greatly reduced by good metallurgical bonding, the damage to a matrix material is small, and the matrix deformation and strength loss are smaller; a vermicular graphite cast iron matrix is subjected to pre-heat treatment so that the thermal stress can be effectively reduced, and thus the crack initiation is controlled; the wear-resisting and anti-friction coating prepared is subjected to subsequent heat treatment, so that residual stress after laser cladding isreduced and eliminated, and cracks in the using process of the coating are avoided; the coating prepared has excellent performance, both wear-resisting and anti-friction performance; and the claddingefficiency is high.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Carbide-reinforced nickel-based welding wire for laser cladding and preparation method

ActiveCN113059294AImprove liquidityUniform compositionMetallic material coating processesWelding/cutting media/materialsFerrosiliconCarbide

The invention discloses a carbide-reinforced nickel-based welding wire for laser cladding. The carbide-reinforced nickel-based welding wire comprises a flux core and a welding scale, wherein the flux core is composed of the following components including, by mass, 0.5%-1.0% of C powder, 10.0%-30.0% of Cr powder, 5.0%-10.0% of ferrosilicon powder, 3.0%-9.0% of B powder, 5.0%-10.0% of ZrO2 powder, 1.0%-3.0% of Ce2O3 powder and the balance Ni powder, and the sum of the mass percentages of the components is 100%. The welding wire is specially used for a wire feeding laser cladding system, and a cladding layer using the flux-cored wire is high in hardness and good in wear resistance. The invention further discloses a preparation method of the ZrC and Ce2C3 reinforced nickel-based welding wire for laser cladding.

Owner:XIAN UNIV OF TECH

Repairing composite layer of amorphous/nanocrystalline cooling roller and preparation method of repairing composite layer

ActiveCN103895280AGood workmanshipInhibit sheddingElectrolytic coatingsMetallic material coating processesHigh power lasersHigh energy

The invention belongs to the technical field of material science, and particularly relates to a repairing composite layer of an amorphous / nanocrystalline cooling roller and a preparation method of the repairing composite layer. The composite layer consists of two layers, namely a copper-based alloy layer connected with base materials and a nickel-based alloy layer, wherein the copper-based alloy layer comprises the following components by weight percent: 7-9% of Ni, 8-12% of Sn, 5-15% of Co, 0.8-2% of Si and the balance being Cu; the nickel-based alloy layer comprises one of Ni-Co alloy, Ni-P alloy, Ni-Fe alloy and Ni-Cr alloy, and the weight content of Ni in alloy is 60-75%. The preparation method comprises the following steps of pretreating the surface of the cooling roller, electroplating the copper-based alloy layer and performing wide-strip cladding on the nickel-based alloy layer by a high-power laser. The prepared composite coating is uniform and compact, and excellent in wear resistance and heat resistance, and has the characteristics of high cladding efficiency and high energy absorptivity of the cooling roller to the laser beam.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

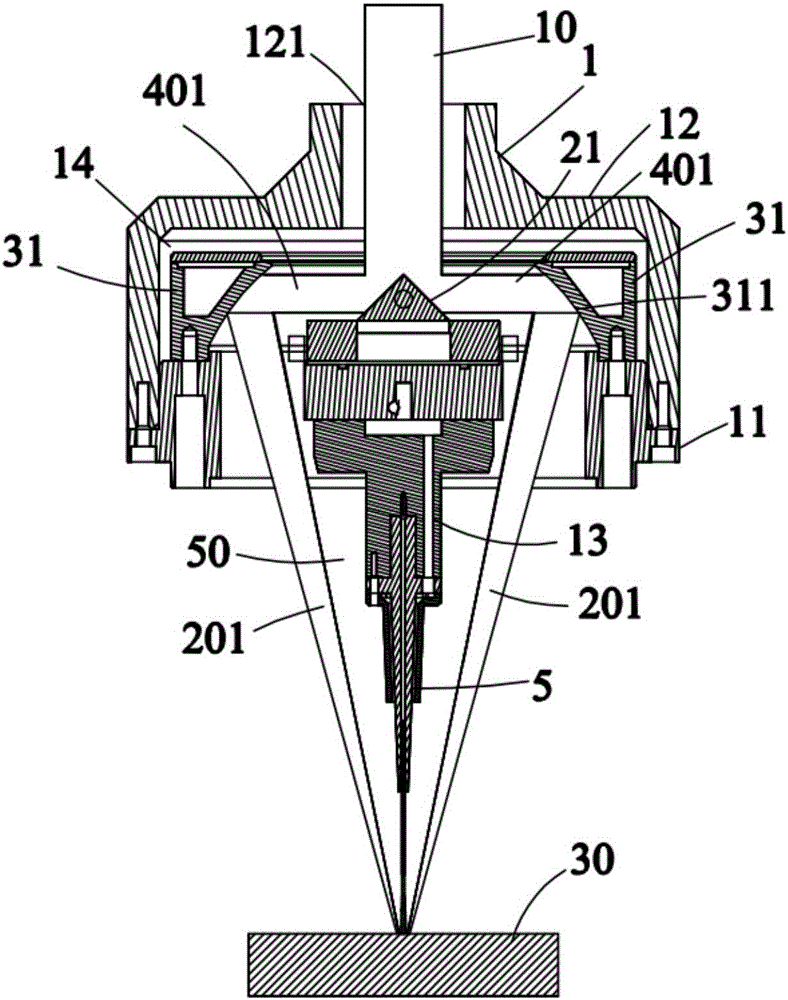

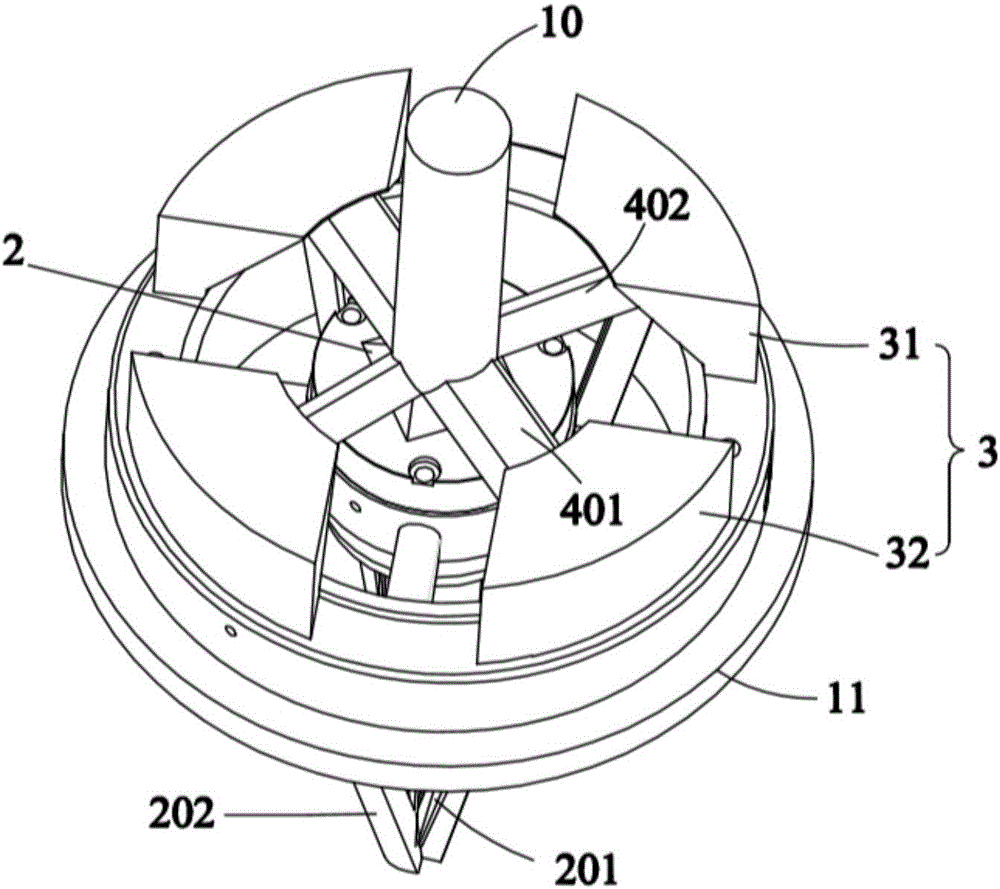

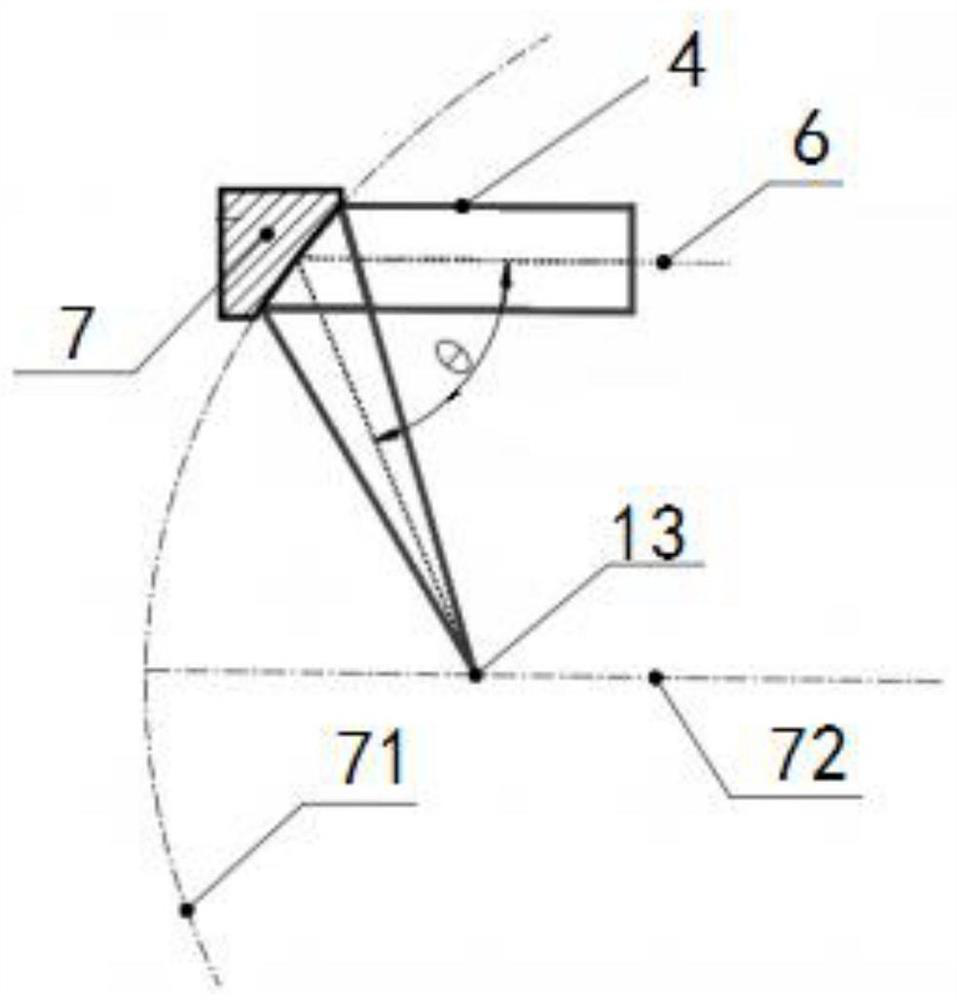

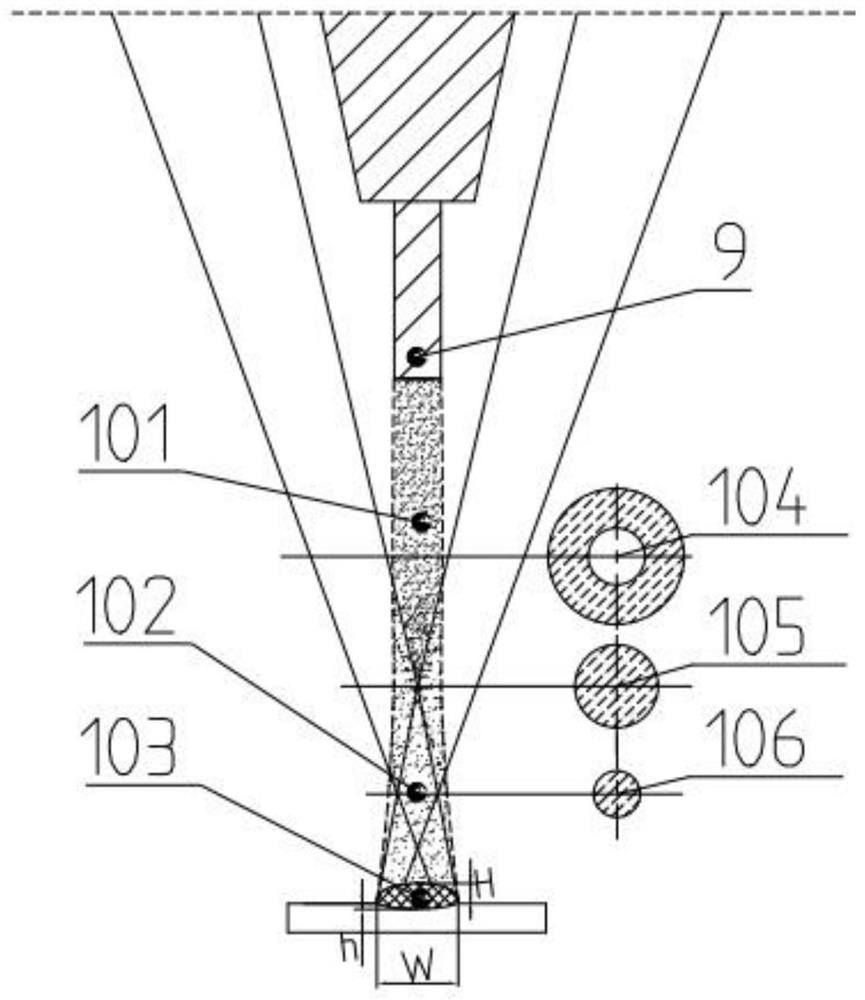

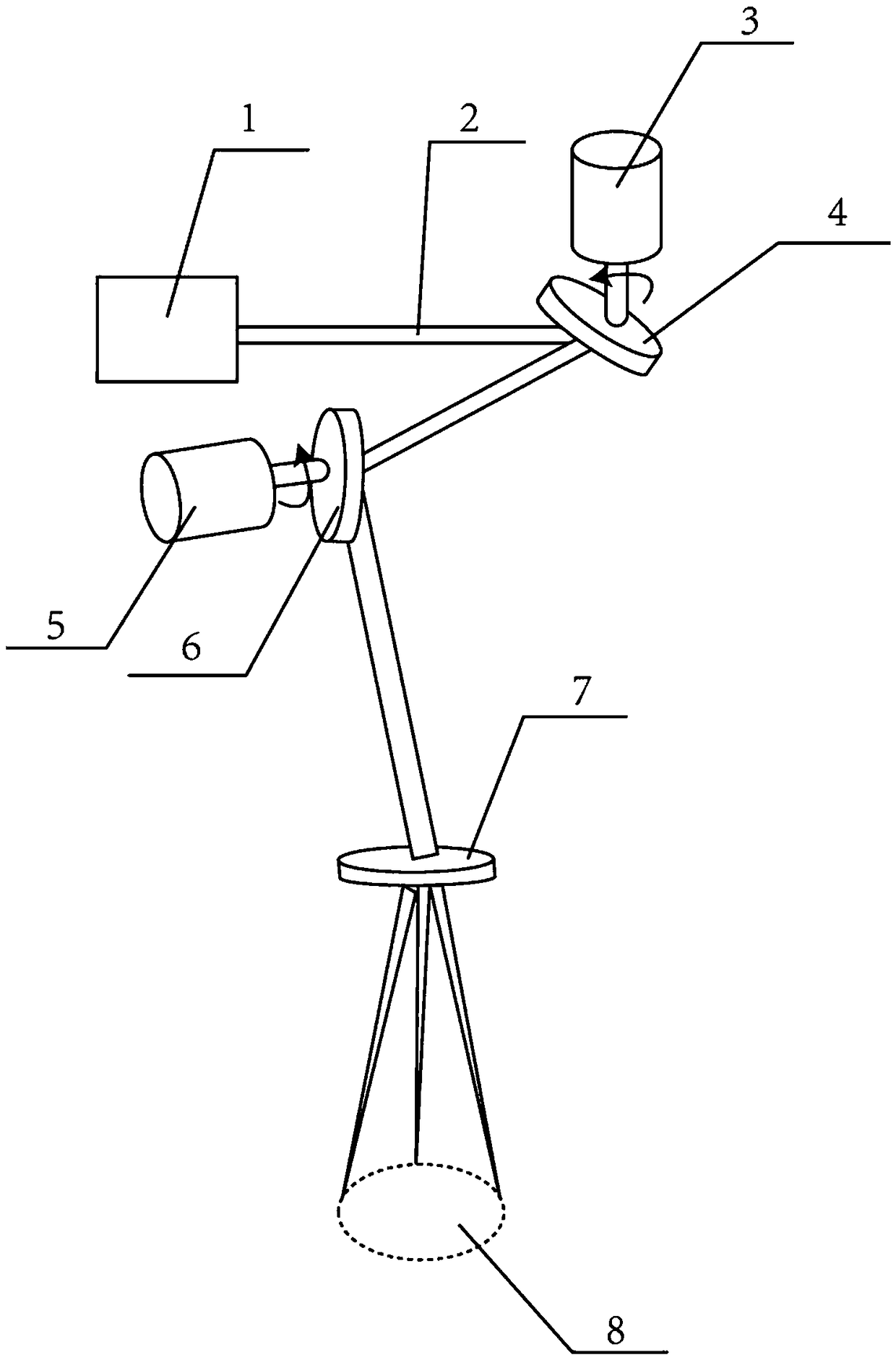

Laser multi-beam feeding cladding and preheating device

ActiveCN106757014ASmall sizeSimple structureMetallic material coating processesBeam splitterMolten bath

The invention relates to a laser multi-beam feeding cladding and preheating device used for converting an incident beam so as to clad a substrate with a clad material. The laser multi-beam feeding cladding and preheating device comprises a supporting frame, a beam splitter and a reflective focusing assembly, wherein the beam splitter and the reflective focusing assembly are arranged on the supporting frame. The incident beam is converted into a reflected beam by the beam splitter, and the reflected beam is reflected in the peripheral direction of the central axis of the beam splitter. The reflective focusing assembly comprises a reflective focusing face and a reflecting face, and the reflective focusing face and the reflecting face both face the beam splitter. The reflective focusing face conducts reflective focusing on part of the reflected beam to form a cladding beam, and the cladding beam conducts cladding on the clad material sprayed to the substrate so as to form a molten bath. The reflecting face reflects part of the reflected beam to form a preheating beam which preheats the clad material on the substrate and / or preheats and slowly cools the substrate. The supporting frame is staggered from the cladding beam and the preheating beam.

Owner:SUZHOU ZHONGKE INNOVATION INST OF LASER INTELLIGENT MFG

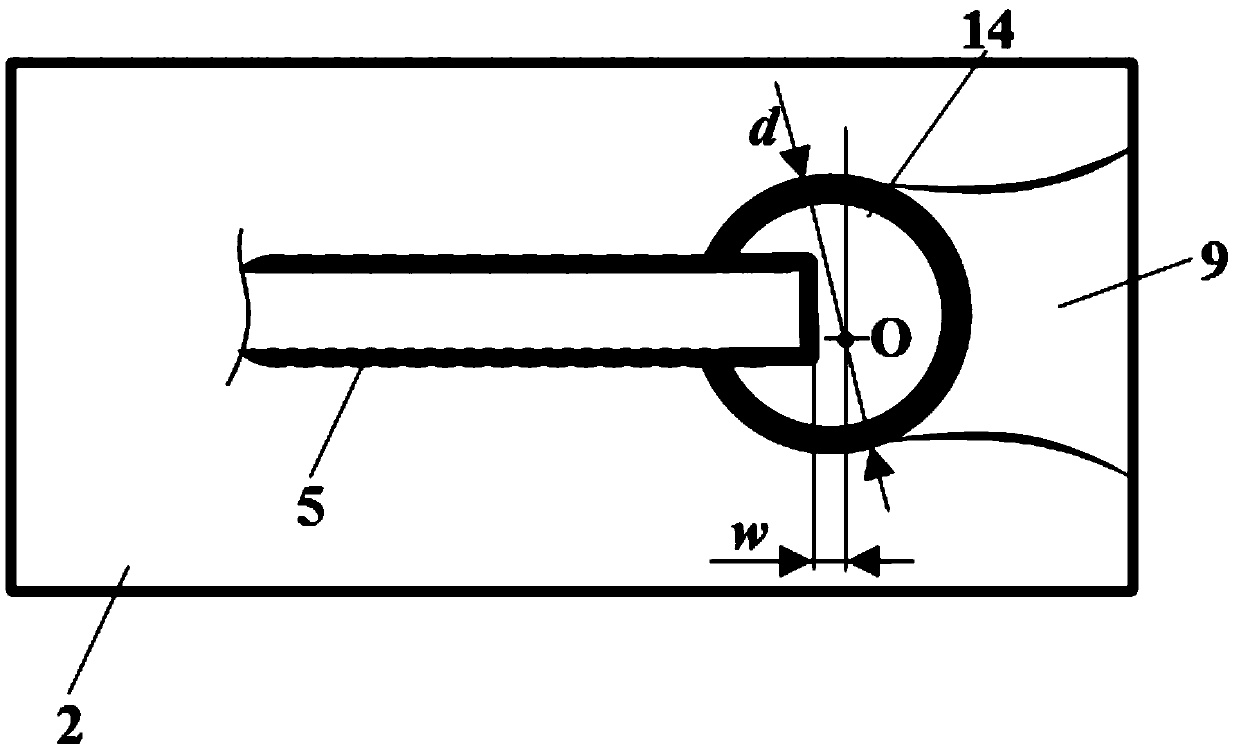

Iron-based welding wire for laser cladding and preparation method thereof

ActiveCN109940308AAdjust chemical costImprove cladding efficiencyWelding/cutting media/materialsSoldering mediaIron powderFerrosilicon

The invention discloses an iron-based welding wire for laser cladding. The iron-based welding wire comprises a flux core and a welding skin, wherein the flux core comprises the following components of, in percentage by mass, 1.7-6.5% of B powder, 1.3-4.0% of ferrosilicon powder, 2.6-5.5% of ferromanganese powder, 10-24% of Ni powder, 60-80% of Cr powder, and totaling 100%. The welding wire can realize high-hardness and high-wear-resistance cladding layers which are difficult to achieve by a solid welding wire. The invention also discloses a preparation method of the welding wire. The preparation method comprises the following steps of S1, weighing the powder according to the proportion; S2, carrying out heating treatment on the powder weighed in step 1, and then mixing; S3, wrapping the mixed powder prepared in step 2 in a low-carbon steel belt through a flux-cored wire drawing device; S4, reducing aperture of a mold in sequence after drawing of a first procedure is finished, and finally obtaining a flux-cored wire with diameter of 1.0-1.2 millimeters; and S5, drawing the flux-cored wire so as to wait for using.

Owner:XIAN UNIV OF TECH

High-efficient wire material laser cladding method

InactiveCN109434286AImprove cladding efficiencyIncreased cladding line speedLaser beam welding apparatusLaser beamsMelting point

The invention provides a wire material laser cladding method. The wire material laser cladding method comprises the following steps that one electrode of a wire material heating device is connected with a workpiece, the other electrode of the wire material heating device is connected with a conductive nozzle, the wire material penetrates through the conductive nozzle and then makes contact with the surface of the workpiece, a laser beam and the wire material are placed in a certain angle with the surface of the workpiece respectively, the wire material heating device is started, the wire material is preheated to a certain temperature, a laser is started, and a laser beam generated by the laser is focused on wire material on the surface the workpiece, the laser energy is absorbed by the wire material, then a molten pool is instantly formed on the surface of the workpiece, the melting pool is controlled to move on the surface of the workpiece according to a preset path and a preset speed, and the laser cladding is completed. According to the method, the initial temperature and the cladding linear speed of the wire material are increased, the temperature of the wire material is increased to be close to the melting point before the wire material enters the laser beam, the wire material can melt to form a molten pool on the surface of the workpiece only by relatively small laser energy and relatively short irradiation time of the laser beam, and the wire cladding efficiency and quality are obviously improved, therefore the method has a wide popularization and application prospect.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

Annular hollow offset-focus laser cladding device

PendingCN113102783AReduce areaUniform energy densityAdditive manufacturing apparatusIncreasing energy efficiencyLaser processingLight spot

The invention discloses an annular hollow offset-focus laser cladding device, and relates to the technical field of laser processing. The annular hollow offset-focus laser cladding device comprises a shell, a conical reflector, an annular off-axis parabolic focus lens, a nozzle and a powder spraying pipe, the top of the shell is provided with a light inlet, the conical reflector is arranged in the shell, and the conical reflector is arranged facing the light inlet; the annular off-axis parabolic focus lens and the conical reflector are oppositely and coaxially arranged; and the nozzle is installed below the conical reflector, the lower end of the nozzle is connected with the powder spraying pipe, the powder spraying pipe is coaxial with annular hollow offset-focus light formed after reflection of the annular off-axis parabolic focus lens, and a collimation protection gas sleeve is arranged on the periphery of the powder spraying pipe. The annular off-axis parabolic focus lens is used for horizontally shifting the focusing focus of the maternal parabola. According to the annular hollow offset-focus laser cladding device, the homogenization of the energy density of an annular light spot is realized, the coupling effect of a laser beam and powder is improved, the utilization rate of the metal powder is improved, and the cladding quality and appearance are improved.

Owner:SUZHOU UNIV

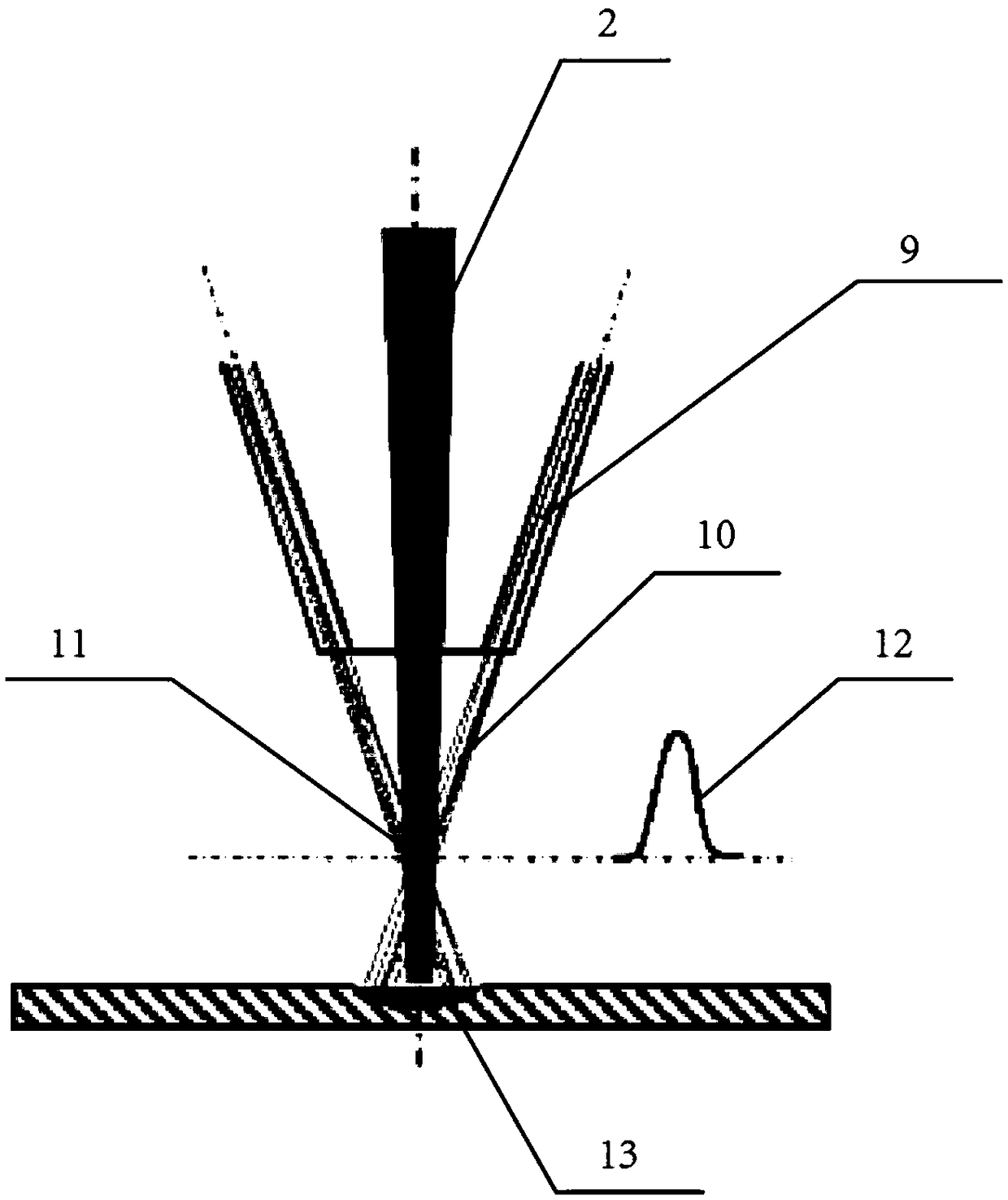

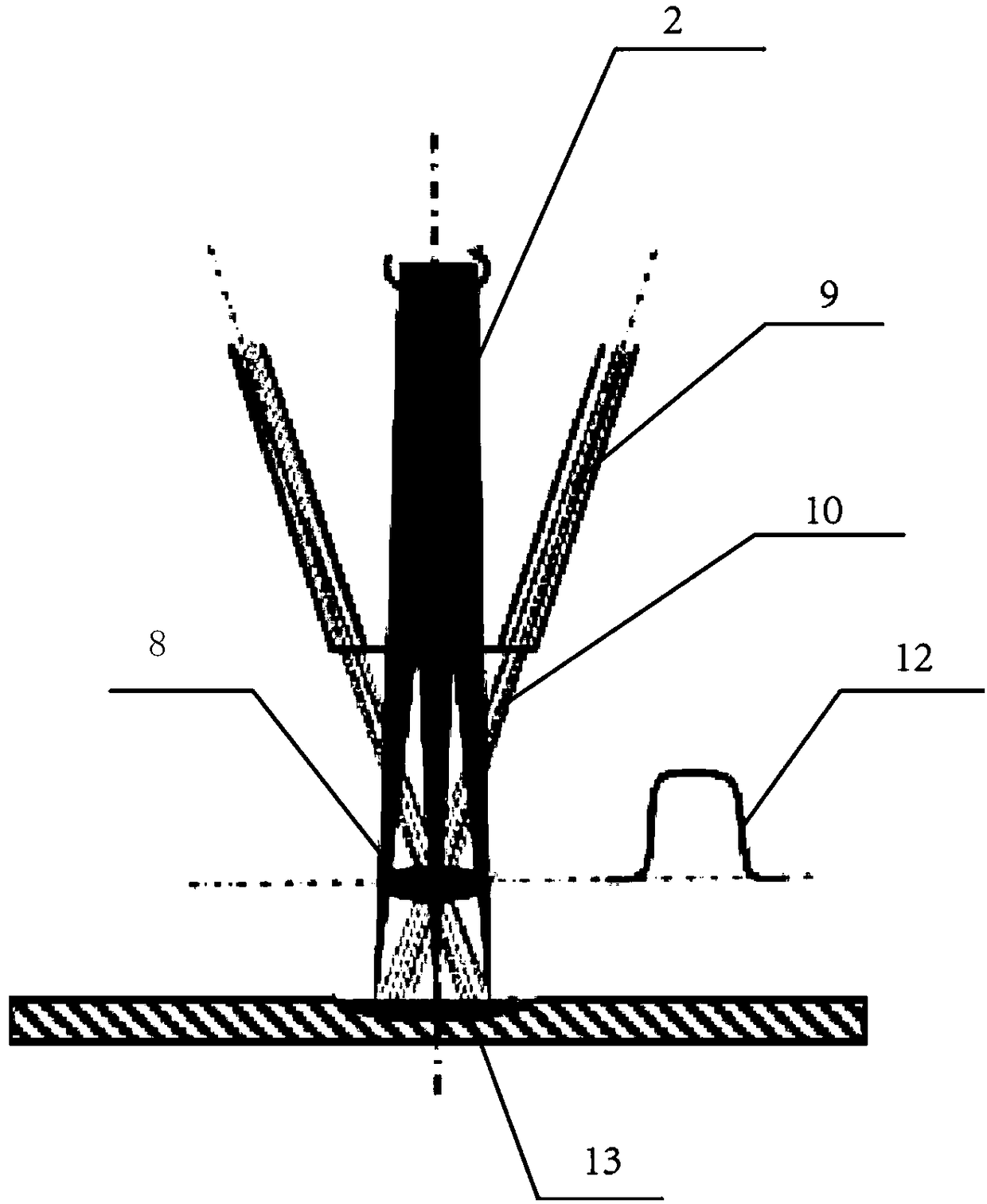

Rotating light beam ultra-high speed laser cladding method and device

ActiveCN108950545AIncrease profitImprove cladding efficiencyMetallic material coating processesUltra high speedLight beam

The invention provides a rotating light beam ultra-high speed laser cladding method and relates to an efficient laser cladding method. The rotating light beam ultra-high speed laser cladding method aims to solve the technical problems of low cladding speed and low efficiency of a prior laser cladding method. When laser cladding is carried out, optical elements are adopted to form a light beam rotating at a high speed according to a set path, and the light beam does uniform circular or elliptical circular motion on a workpiece to be clad. In the high-speed rotating process, a large-size light spot with approximately uniform energy density distribution is formed in space by the light beam, and therefore more powder is irradiated and heated by laser in this region, melts, falls into a moltenpool in a liquid or semi-solid form, and is cooled to form a cladding layer. Compared with a conventional laser cladding method, the method can greatly improve the powder feeding rate, and improve thecladding efficiency by 3-5 times. In addition, a larger molten pool is formed on the workpiece, and therefore the utilization rate of the powder is further improved.

Owner:ACUNITY TIANJIN CO LTD

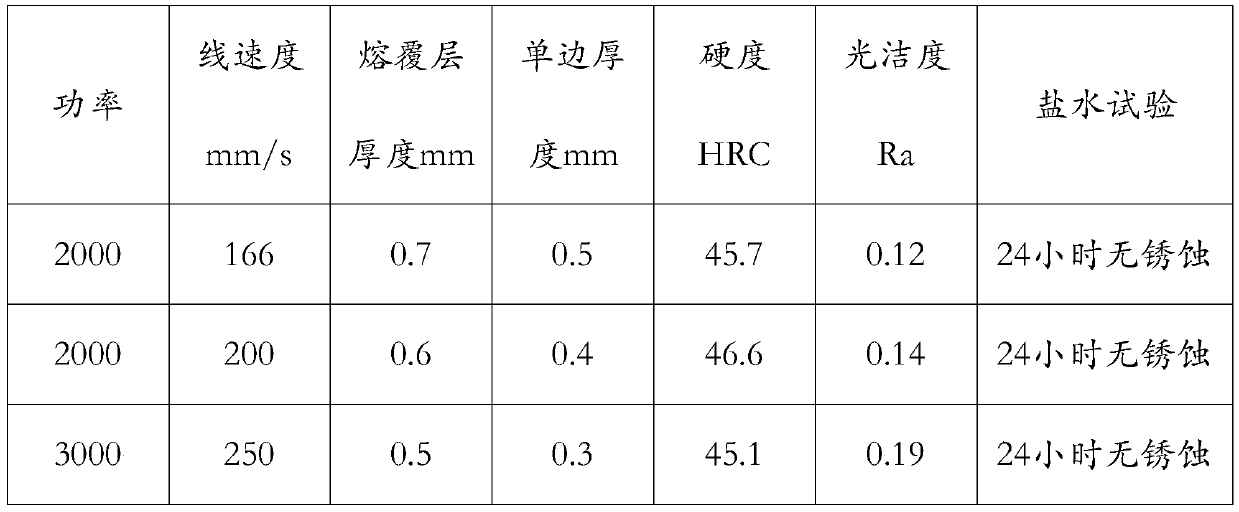

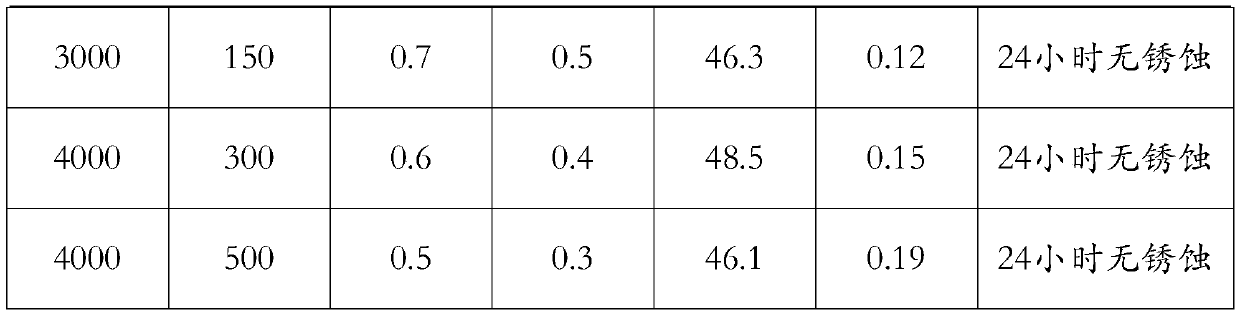

Titanium alloy petroleum drill rod wear-resistant belt and preparation method thereof

ActiveCN111139466AReduce dilutionImprove cladding efficiencyMetallic material coating processesUltra high speedTitanium

The invention discloses a titanium alloy petroleum drill rod wear-resistant belt and a preparation method thereof. A particle-reinforced titanium-based wear-resistant belt material layer is prepared on the surface of a titanium alloy matrix by adopting an ultrahigh-speed laser cladding method, and specifically, Ti6Al4V titanium alloy powder and B4C powder are selected to be mixed in proportion andsubjected to vacuum ball milling, a coating is prepared on a TA15 titanium alloy matrix through an ultra-high-speed laser cladding process, Ti and B4C generate TiB, TiC and other precipitated reinforcing phases in situ, the hardness and abrasion resistance of the cladding coating are improved, and meanwhile, Ti-based corrosion resistance is combined, the titanium alloy petroleum drill rod wear-resistant belt is applied to drilling of ultra-deep oil wells.

Owner:中机新材料研究院(郑州)有限公司

Ultra-high-speed laser cladding powder for repairing damaged water injection combination valve, and repairing method

InactiveCN110241411AExtended service lifeImprove wear resistanceMetallic material coating processesUltra high speedMetallurgy

The invention discloses a laser cladding powder which is prepared from the components in percentage by mass: 20.0 to 30.0 percent of WC reinforced particles, 9.0 to 13.0 percent of Cr, 7 to 9 percent of Fe, 1.0 to 2.0 percent of Si, 0.5 to 0.7 percent of C, 1.0 to 2.0 percent of B, and the balance Ni, wherein the sum of the mass percent of the components is 100 percent. The method for repairing the combination valve by adopting the laser cladding powder and an ultra-high-speed laser cladding technology is concretely implemented according to the following steps of (1) preparing the cladding powder; and vacuum sealing for standby use; (2) carrying out preprocessing on the surface of an ineffective oilfield water injection combination valve; and (3) determining a laser cladding technique and technological parameters according to the geometric dimension of the surface of the ineffective oilfield water injection combination valve.

Owner:XIAN UNVERSITY OF ARTS & SCI

High-weather-resistance fireproof steel welding alkaline flux-cored wire

InactiveCN110293332AImprove melting conditionImprove craftsmanshipArc welding apparatusWelding/cutting media/materialsRare earthRutile

The invention discloses a high-weather-resistance fireproof steel welding alkaline flux-cored wire. Flux-cored wire powder comprises components including, by weight percent, 18%-35% of magnesia, 5%-20% of fluorite, 3%-8% of barium fluoride, 6%-13% of zircon sand, 1%-7% of manganese ore, 5%-12% of rutile, 2%-5% of marble, 1%-3% of an aluminum-magnesium alloy, 0%-2% of sodium fluosilicate, 0%-1% oflithium fluoride, 0%-1% of lithium carbonate, 2%-5% of high carbon ferro-chrome, 0%-12% of micro-carbon ferro chrome, 0.3%-4% of copper powder, 0.2%-16% of nickel powder, 1.5%-4% of silicon iron, 1.8%-8% of manganese powder, 1.6%-5% of molybdenum powder, 1%-3% of ferrotitanium, 0.1%-1% of ferroboron, 0%-0.5% of ferroniobium, 0%-0.8% of ferrovanadium, 0%-2% of tungsten powder, 0.2%-3.2% of rare earth oxide, 0%-1% of graphite and the balance iron powder.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Laser cladding method of shaft and tube element

PendingCN110484910AHigh cladding line speedImprove cladding efficiencyPolishing machinesRevolution surface grinding machinesMaterial consumptionOptoelectronics

The invention discloses a laser cladding method of a shaft and tube element. The shaft and tube element comprises but is not limited to a column, a core rod and a boiler tube. The laser cladding method comprises the following steps: 1, carrying out machining or detecting before cladding; and 2, carrying out laser cladding. According to the laser cladding method, cladding linear velocity is higher,a cladding layer can be rapidly prepared within a short time, and the cladding efficiency is remarkably improved; and meanwhile, the heat effect is small, high-precision forming on the surface of a workpiece can be obtained, subsequent machining removal amount is reduced, machining programs are simplified, material consumption is reduced, and the machining efficiency is improved.

Owner:SHANDONG ENERGY HEAVY EQUIP GRP DAZU REMANUFACTURING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com