Preparation method for wear-resisting and anti-friction coating on vermicular graphite cast iron surface of cylinder head

A technology of vermicular graphite cast iron and anti-friction coating, which is applied in the coating, metal material coating process, etc., and can solve the problem of easy generation of hardened layer, increased crack tendency, and influence on the wear resistance and anti-friction performance of the cladding layer, etc. problems, to achieve the effect of controlling cracks, reducing residual stress, and eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (a) Derusting, degreasing and drying the surface of cylinder head vermicular graphite cast iron RuT300 (see Table 1 for chemical composition);

[0037] (b) Carrying out heat treatment in advance to the vermicular graphite cast iron after step (a), the preheating temperature is 200 DEG C;

[0038] (c) Co-based alloy, Cr 3 C 2 and MoS 2 The three powders are mechanically mixed and then dried, among which Cr 3 C 2 The mass percentage of powder is 10%, MoS 2 The mass percentage of the powder is 6%, and the rest is Co-based alloy powder Tribaloy800;

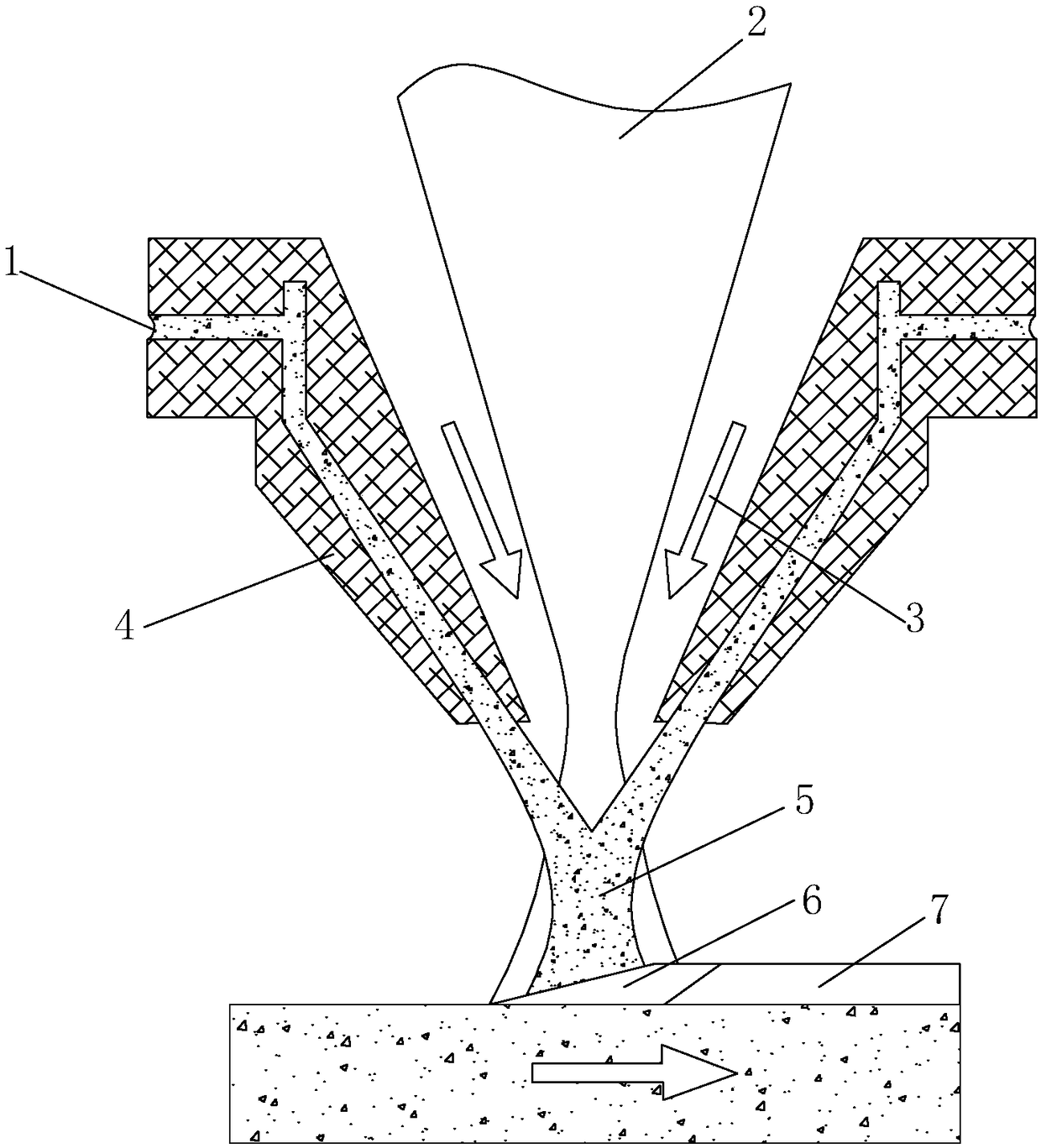

[0039] (d) using laser cladding technology, depositing the powder dried in step (c) on the surface of the preheated vermicular graphite cast iron in step (b), to obtain a wear-resistant and anti-friction coating with good bonding state and no cracks, By optimizing the process parameters, the coating thickness is controlled at about 1.2mm, the laser beam spot is a circular spot with a diameter of 3.5mm, the power is 2.0kW,...

Embodiment 2

[0049] (a) Derusting, degreasing and drying the surface of vermicular graphite cast iron RuT300 of the cylinder head;

[0050] (b) Carrying out heat treatment in advance to the compacted graphite cast iron after step (a), the preheating temperature is 250 DEG C;

[0051] (c) Co-based alloy, Cr 3 C 2 and MoS 2 The three powders are mechanically mixed and then dried, among which Cr 3 C 2 The mass percentage of powder is 12%, MoS 2 The mass percentage of the powder is 5%, and the rest is Co-based alloy powder Tribaloy400;

[0052] (d) using laser cladding technology, depositing the powder dried in step (c) on the surface of the preheated vermicular graphite cast iron in step (b), to obtain a wear-resistant and anti-friction coating with good bonding state and no cracks, By optimizing the process parameters, the coating thickness is controlled at about 1.3mm, the laser beam spot is a circular spot with a diameter of 5mm, the power is 2.2kW, the speed is 10mm / s, the powder fe...

Embodiment 3

[0056] (a) Derusting, degreasing and drying the surface of vermicular graphite cast iron RuT300 of the cylinder head;

[0057] (b) Carrying out heat treatment in advance to the vermicular graphite cast iron after step (a), the preheating temperature is 300 DEG C;

[0058] (c) Co-based alloy, Cr 3 C 2 and MoS 2 The three powders are mechanically mixed and then dried. Among them, Cr 3 C 2 The mass percentage of powder is 15%, MoS 2 The mass percentage of the powder is 4%, and the rest is Co-based alloy powder Stellite156;

[0059] (d) using laser cladding technology, depositing the powder dried in step (c) on the surface of the preheated vermicular graphite cast iron in step (b), to obtain a wear-resistant and anti-friction coating with good bonding state and no cracks; By optimizing the process parameters, the coating thickness is controlled at about 1.5mm, the light spot is a rectangular spot of 12mm×2mm, the power is 2.4kW, the speed is 12mm / s, the powder feeding amoun...

PUM

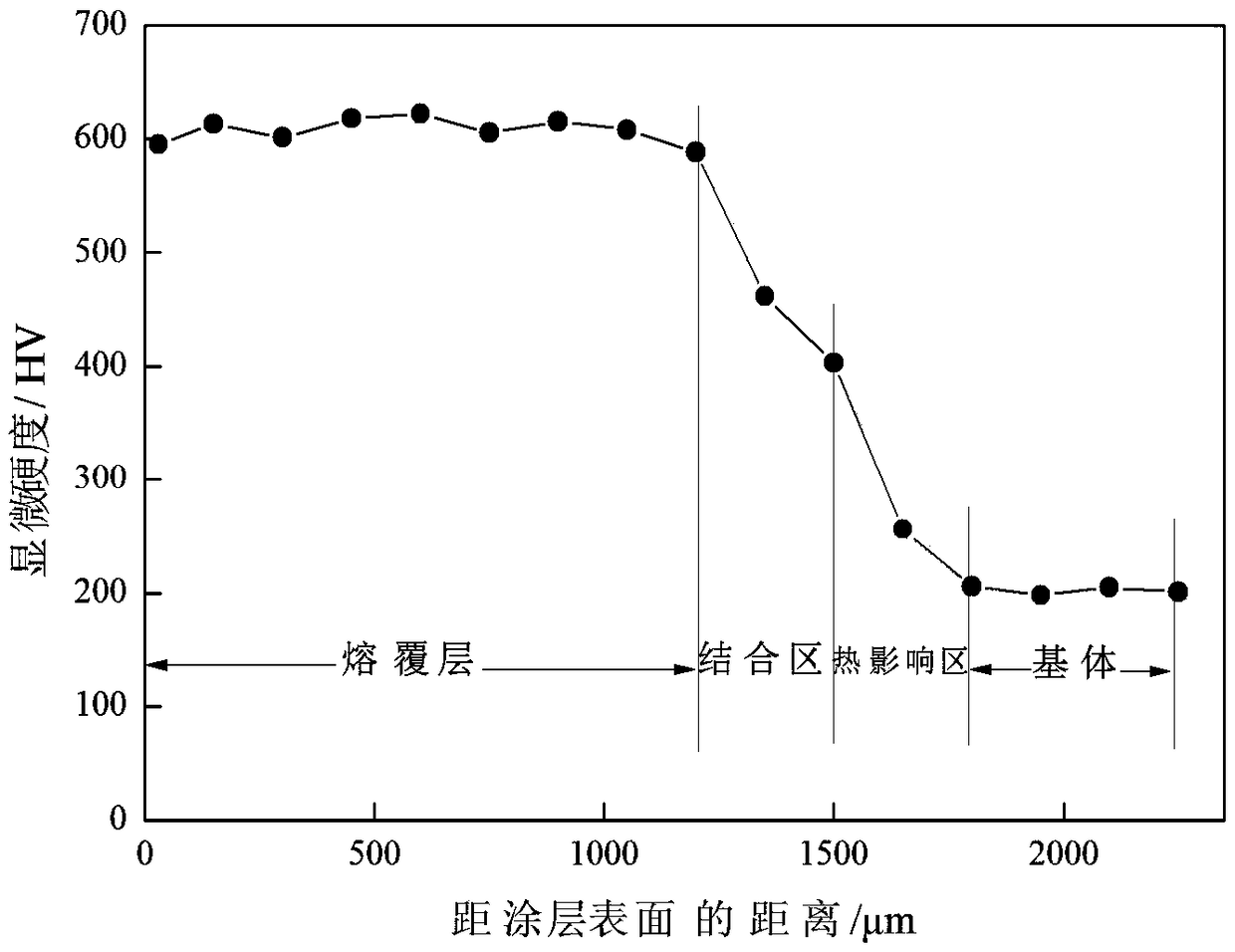

| Property | Measurement | Unit |

|---|---|---|

| Average microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com