Concrete spray steel mesh sandwich formwork cast-in-place shear wall construction method and shear wall

A construction method, concrete technology, applied to walls, building components, buildings, etc., can solve the problems of large amount of auxiliary construction, increase of secondary investment, increase of construction waste, etc., to reduce maintenance costs, increase internal bonding strength, and prolong life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

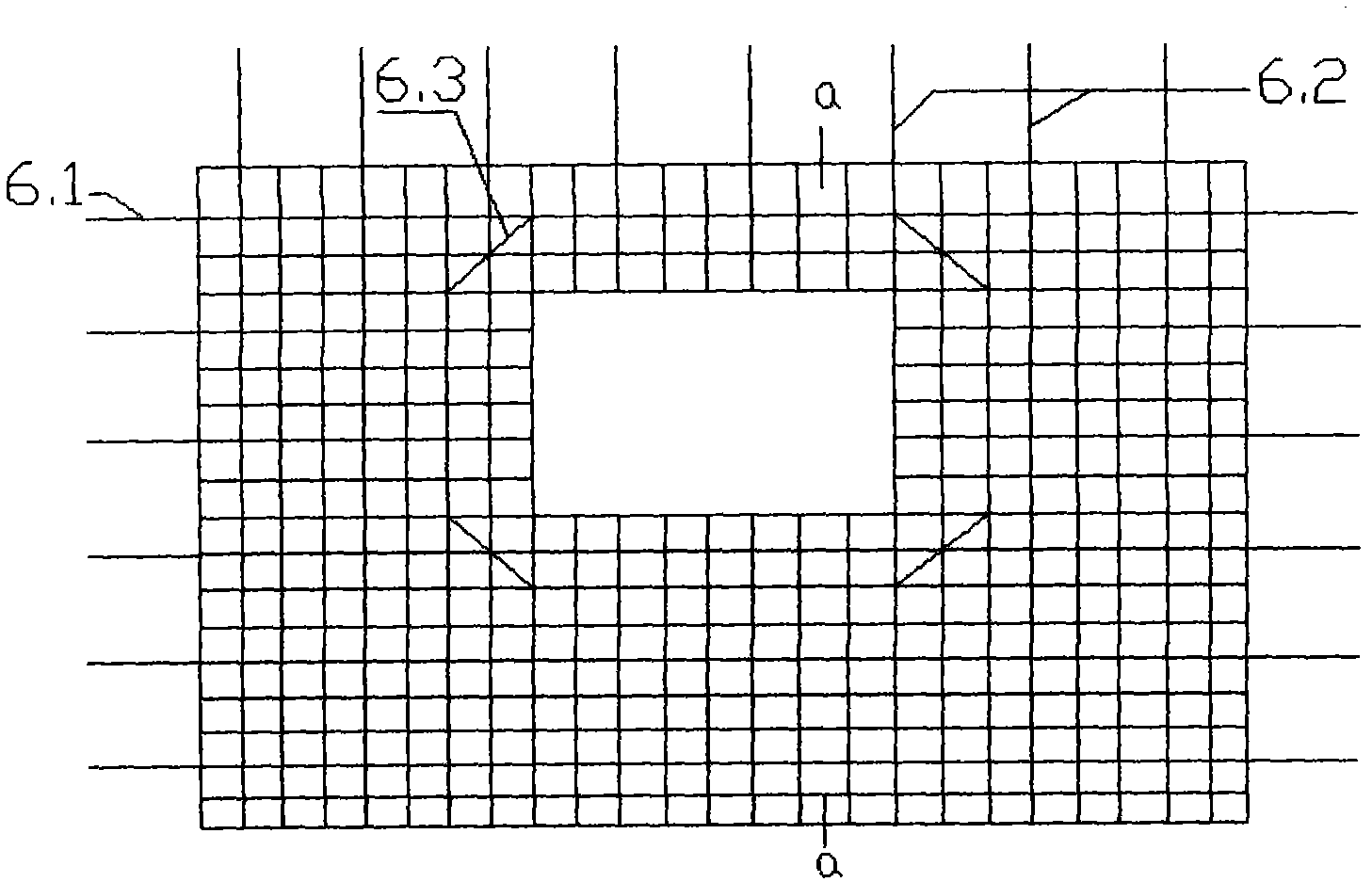

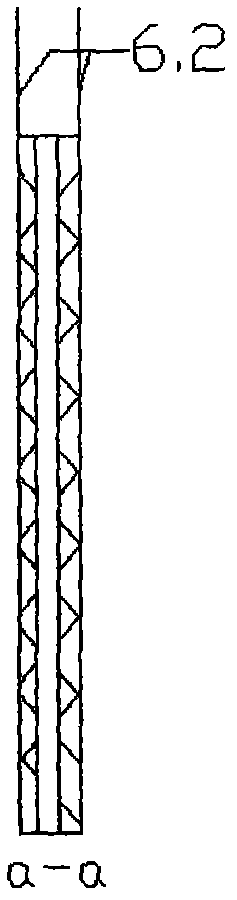

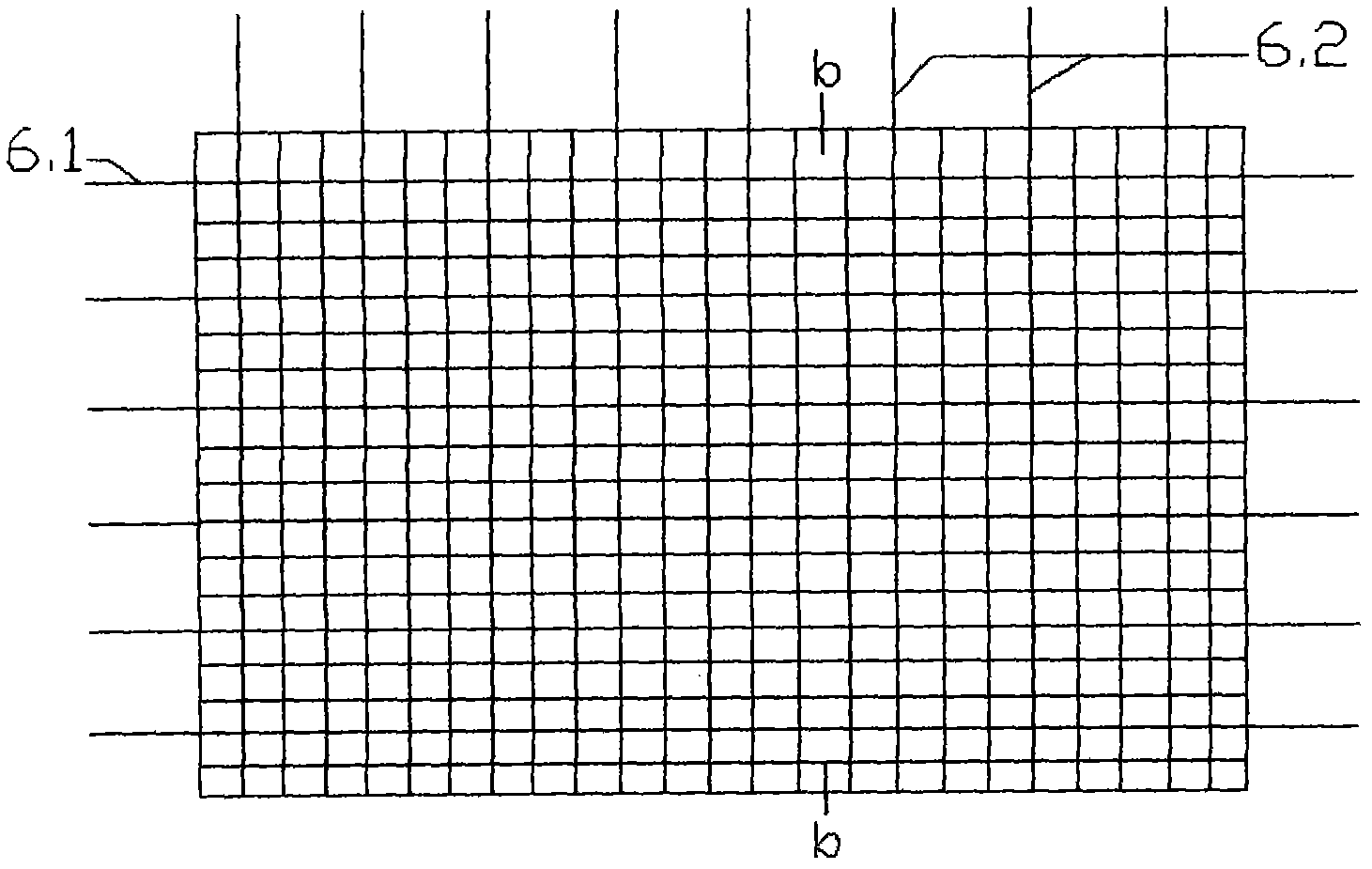

[0033] Combine below Figure 1-6 Illustrate construction method of the present invention with a kind of preferred construction scheme, comprise the following steps:

[0034] (1) Foundation construction: carry out foundation construction, and pre-embed the inner and outer formwork connecting steel bars 5 and the longitudinal anchor bars of the shear wall on the concrete foundation beam 11 .

[0035] (2) Install steel mesh sandwich light board:

[0036] (a) Install the matching inner and outer steel mesh sandwich light panels on the reserved formwork positions, the distance between them is determined by the thickness of the shear wall, and the outer steel mesh sandwich light panels whose height is the same as the floor height are installed first 2. Then install the inner steel mesh sandwich whose height is lower than the outer steel mesh sandwich light board by one ring beam or connecting beam height and width narrower than the outer steel mesh sandwich light board by two conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com