Non-stocker small-sized intelligent stereoscopic warehouse

A technology of three-dimensional warehouses and stackers, which is applied in the field of small intelligent three-dimensional warehouses without stackers, can solve the problems of large space occupation, inapplicability of forklifts, and high space utilization of automated three-dimensional warehouses, and achieve the goal of large space utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Describe the present invention below in conjunction with specific embodiment:

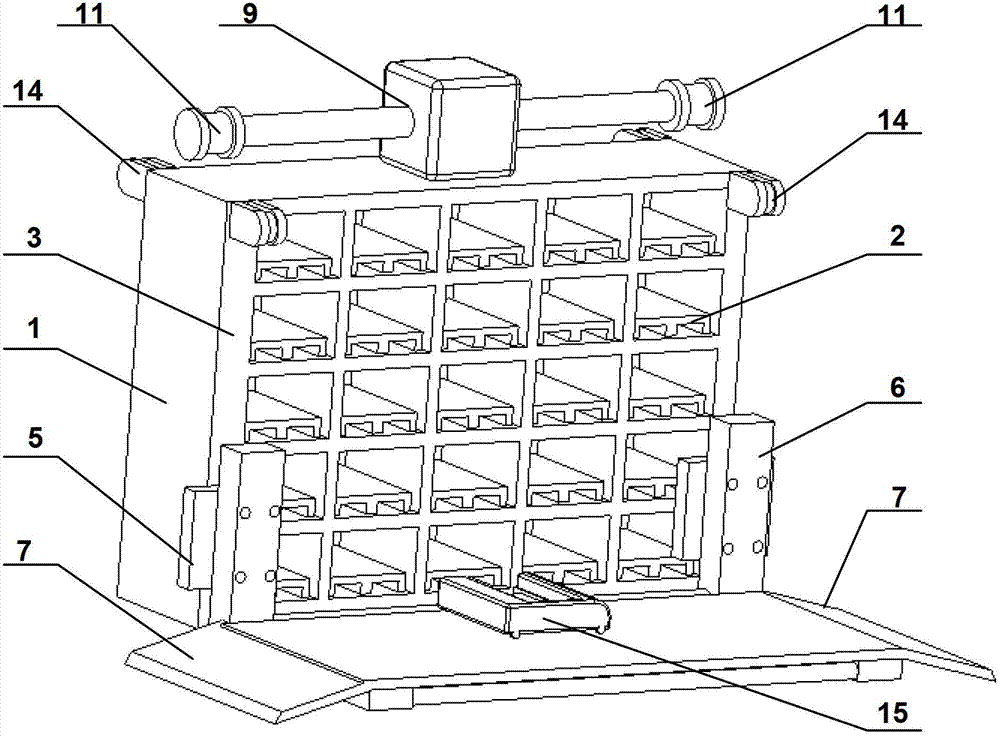

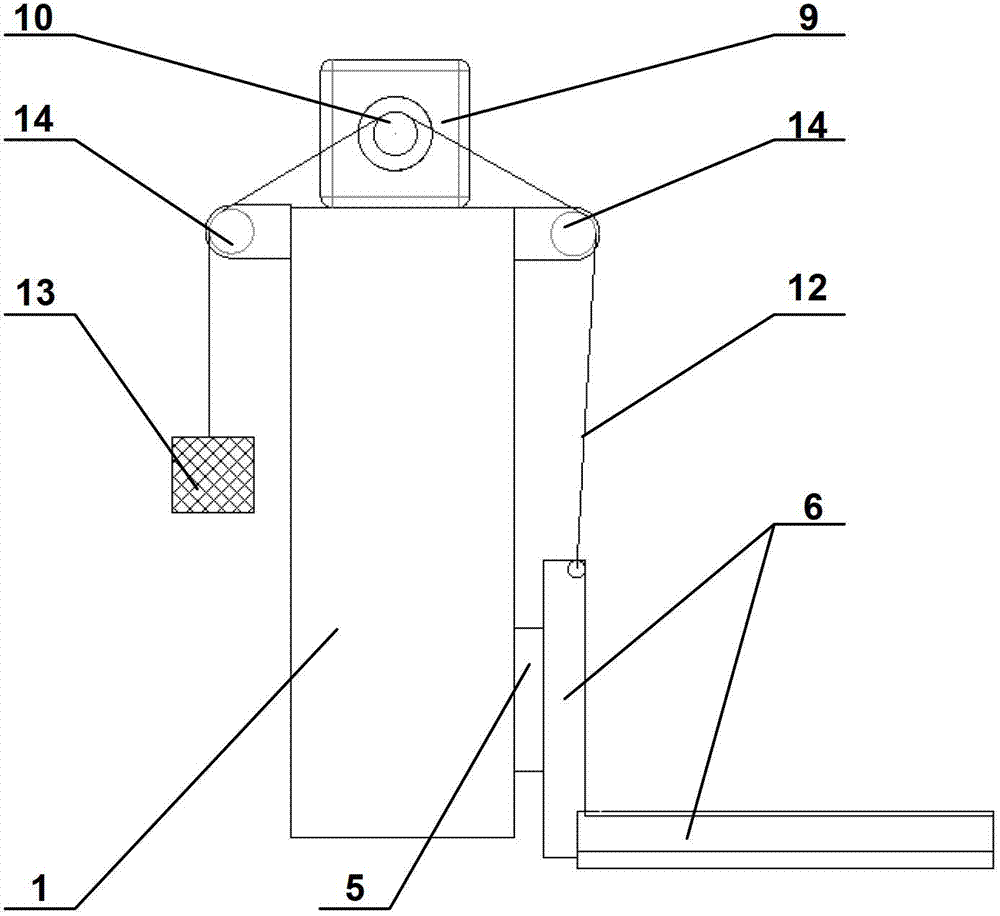

[0024] Refer to attached figure 1 , The non-stacker-type small-scale intelligent three-dimensional warehouse in this embodiment includes a shelf 1, a lifting platform, a transport trolley 15 and a lifting transmission system.

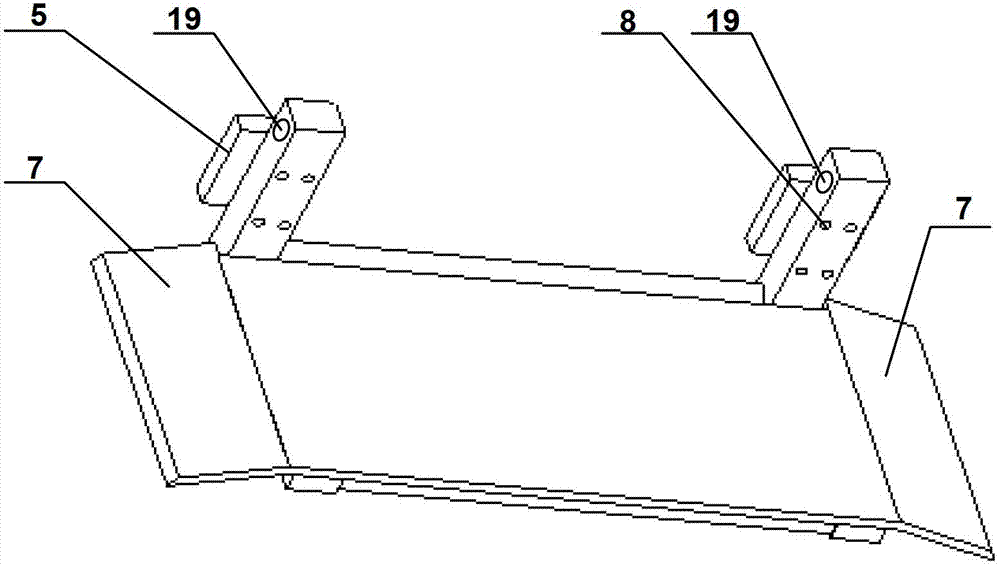

[0025] The shelf is a multi-layer combined shelf, which is flexible in combination and easy to load and unload. The distance between every two layers of boards can be adjusted up and down according to the height of the stored materials. The number of layers of the shelf can also be adjusted conveniently. number. A pallet 2 is placed in each compartment of the shelf, and materials are placed on the pallet; there are fork grooves on the underside of the pallet for extending into the fork, and the pallet can be taken out by the side double forks 16 of the transport trolley and placed on the transport trolley 15. Facilitate the transportation of materials.

[0026] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com