Patents

Literature

3347results about How to "Improve the level of intelligence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

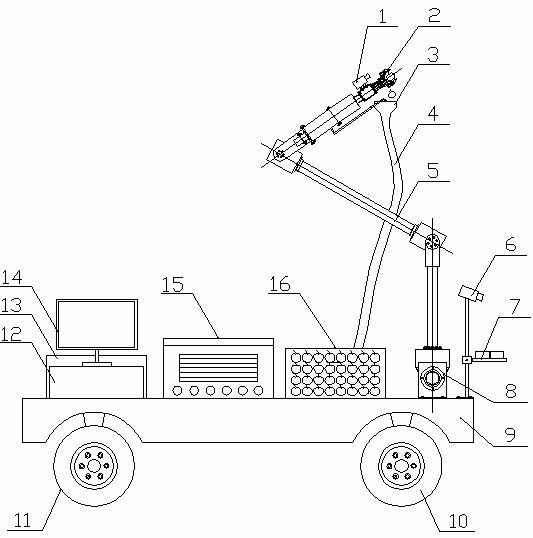

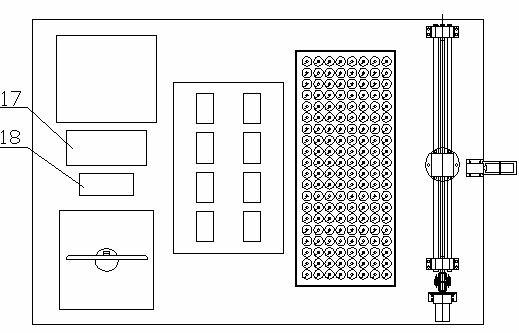

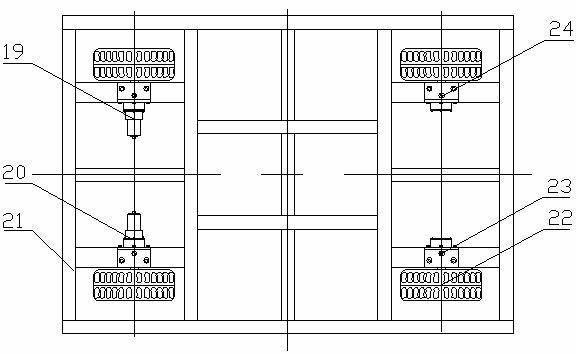

Wheel type mobile fruit picking robot and fruit picking method

InactiveCN102124866AReduce energy consumptionShorten speedProgramme-controlled manipulatorPicking devicesUltrasonic sensorData acquisition

Owner:NANJING AGRICULTURAL UNIVERSITY

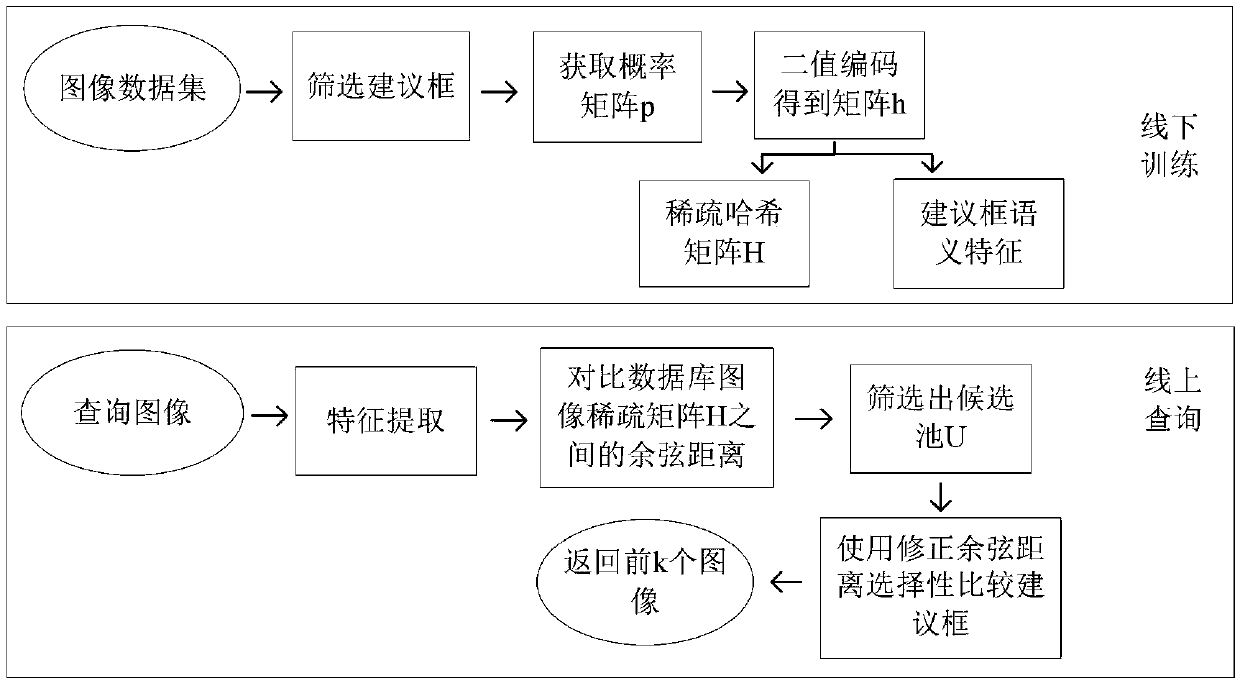

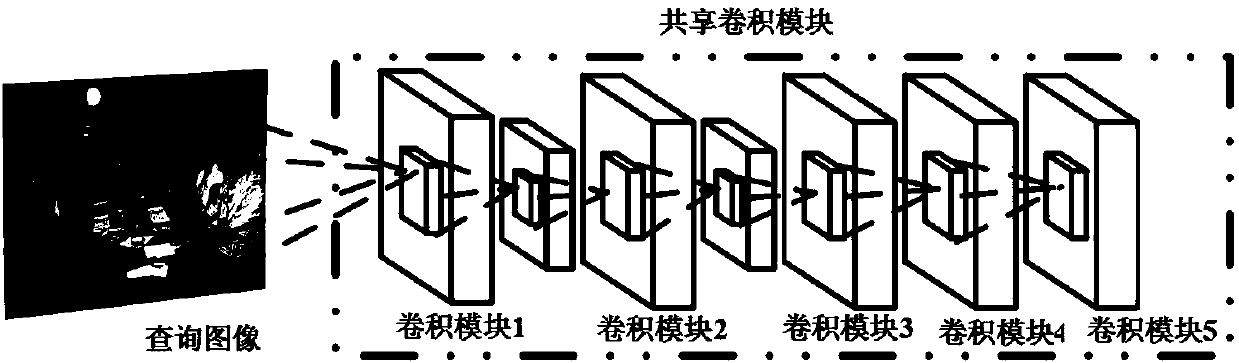

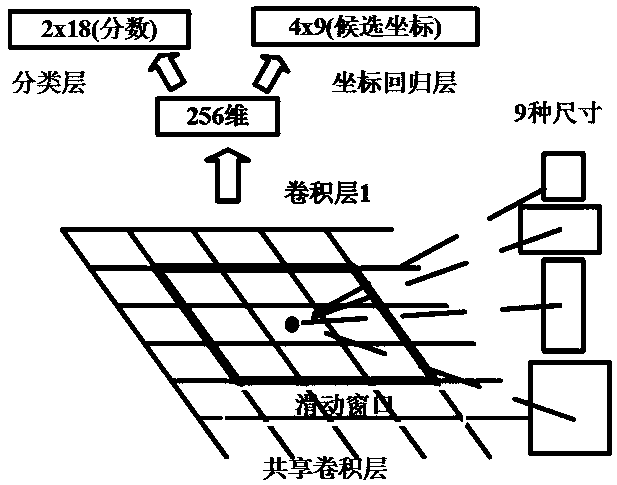

Multi-task layered image retrieval method based on depth self-coding convolution neural network

ActiveCN107679250ASearch results improvedSearch results are accurateCharacter and pattern recognitionNeural architecturesNerve networkImage retrieval

The invention discloses a multi-task layered image retrieval method based on a depth self-coding convolution neural network. The method is characterized by mainly comprising a multi-task end-to-end convolution neural network for deep learning and training recognition, a rapid visual segmentation detection and positioning method of a region-of-interest secondary screening module based on an RPN network, a coarse search of a full-graph sparse hash code, an area sensing semantic feature and matrix h accurate comparison and search based on the maximum response, and a region-of-interest selectivitycomparison algorithm. According to the method, the end-to-end training can be achieved, the interest region with higher quality can be automatically selected, the automation degree and the intelligent level of search by images can be effectively improved, and the image retrieval requirements of the big data age can be met by using little storage space at a high search speed.

Owner:ZHEJIANG UNIV OF TECH

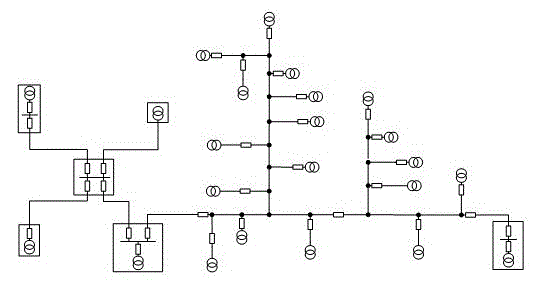

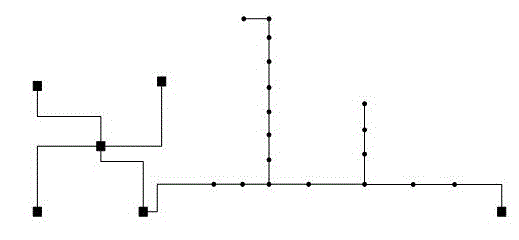

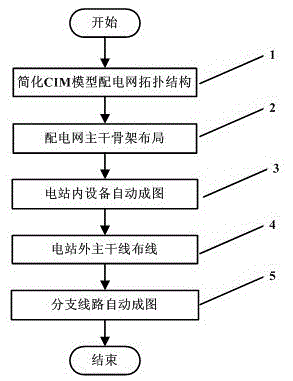

Automatic generation method used for single line diagram of distribution network and based on topological hierarchy

ActiveCN103150425ARealize automatic generationRealize a reasonable layoutSpecial data processing applicationsMassive gravityPower station

The invention discloses an automatic generation method used for a single line diagram of a distribution network and based on topological hierarchy. The method comprises the following steps: deleting related equipment in a topological structure of the distribution network, and simplifying the topological structure of the distribution network; acquiring key nodes of the topological structure of the distribution network, and generating a main framework of the topological structure of the distribution network; arranging the positions of the key nodes based on a gravitation-repulsion model, and obtaining a skeletal structure based on the gravitation-repulsion; describing the topological structure of the distribution network through an outgoing line-trunk line-T-shaped key node-branch line model of a power station; finishing the arrangement and the automatic mapping of the equipment in the power station on the basis of the topological structure of the equipment in the power station; and performing routing mapping without overlap or intersection on decibels of the trunk line and the branch line respectively. The automatic generation method achieves automatic generation of the single line diagram of the distribution network above a certain scale, and simultaneously, the generated single line diagram is clearer and more attractive through the routing algorithm without overlap or intersection.

Owner:SHANGHAI JIAO TONG UNIV

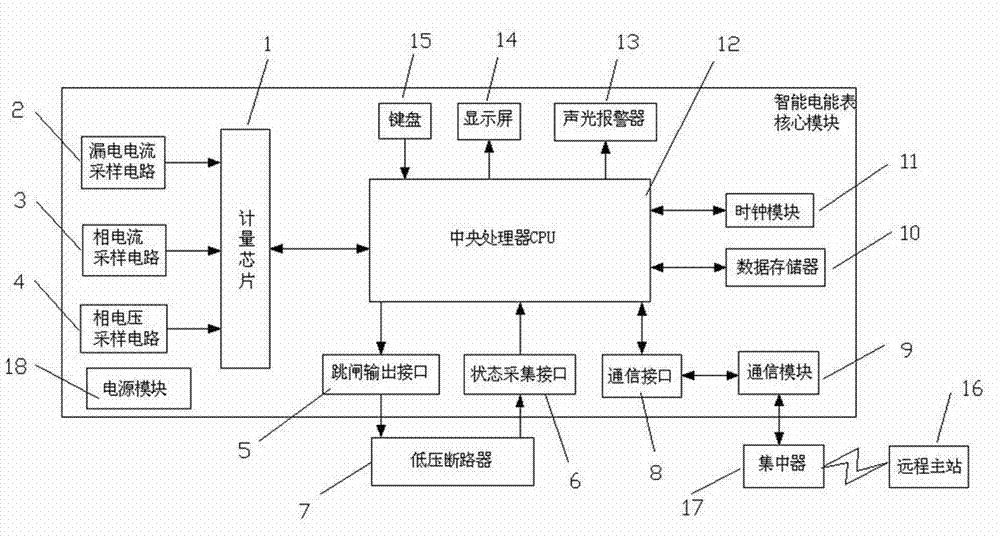

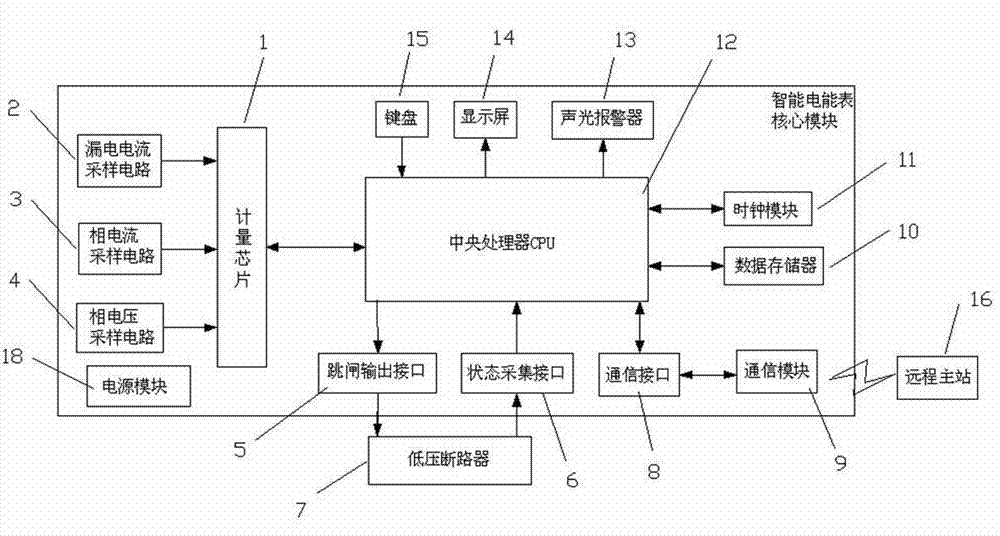

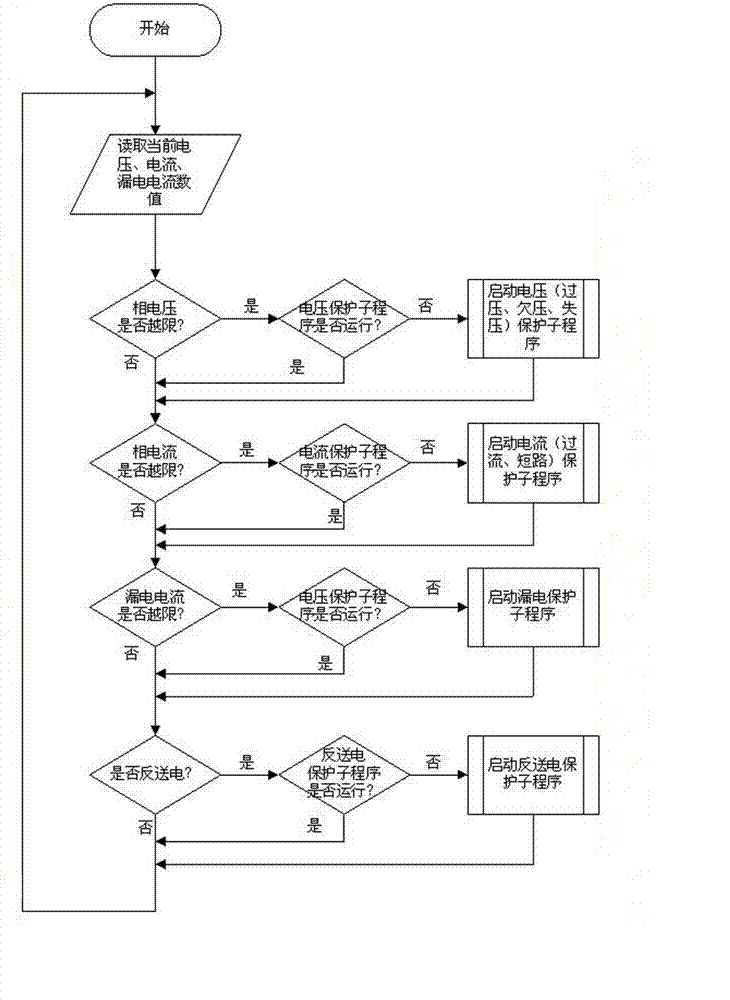

Smart electricity meter with function of monitoring and protecting power failure

InactiveCN102830255AImprove practicalityLow failure rateTime integral measurementPhase currentsHemt circuits

A smart electricity meter with a function of monitoring and protecting power failure comprises a metering chip, a leakage current sampling circuit, a phase current sampling circuit, a phase voltage sampling circuit, a CPU (central processing unit), a power module and a low voltage breaker. The leakage current sampling circuit is electrically connected with the metering chip which is mutually electrically connected with the CPU. The CPU is electrically connected with the low voltage breaker through a trip output port. The low voltage breaker is electrically connected with the CPU through a status acquisition interface. The invention further provides a power failure monitoring and controlling method of the smart electricity meter. The smart electricity meter has the advantages that the reliable power module for power failure protection and control is provided, various types of power failure warning and protection are provided, failure warning and failure protection for voltage, current, power and the like are achieved for power users, failure spots are prevented and isolated, economic loss and personal safety accidents due to failure of electric circuit equipment of the users are prevented and reduced, and reliability of low voltage grids is effectively improved.

Owner:王金泽

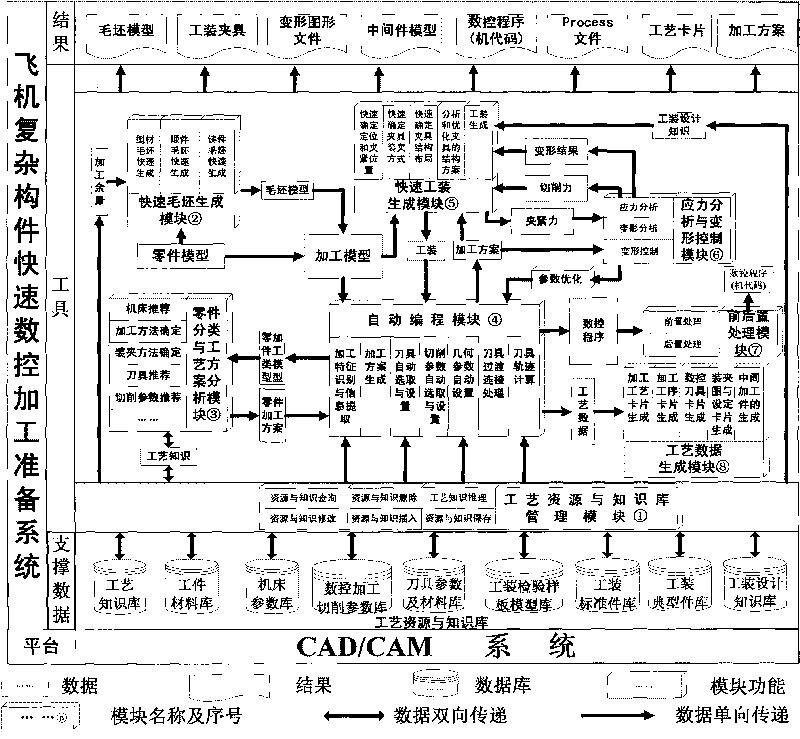

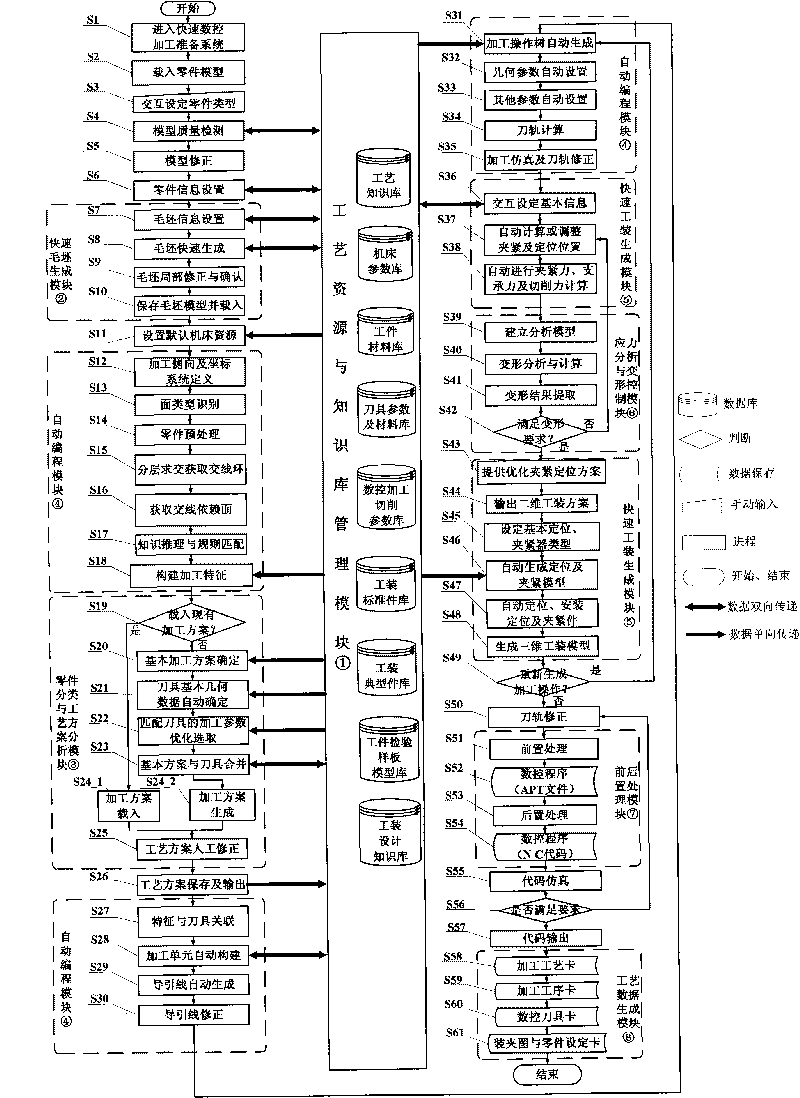

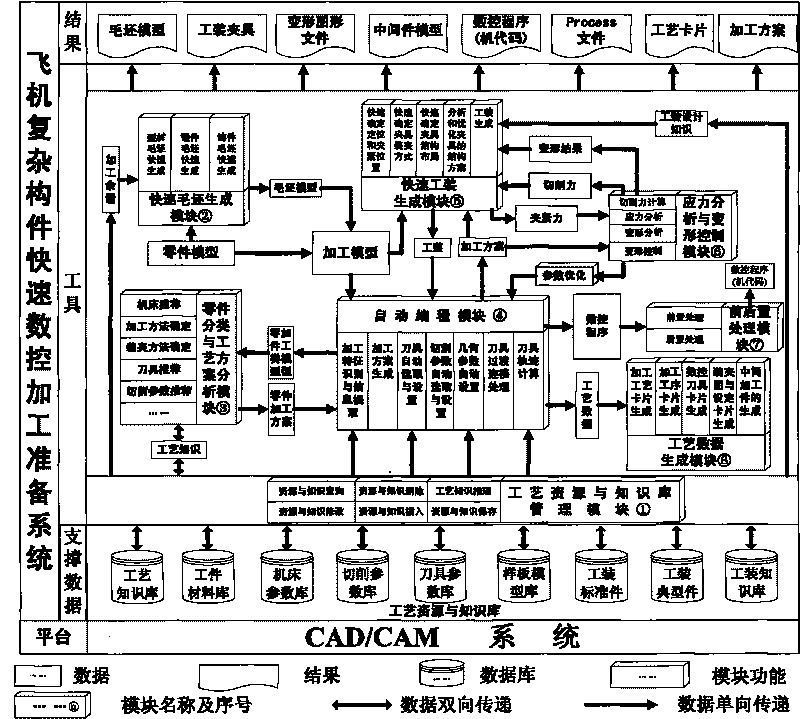

Preparation system of quick numerical control machining of complex parts of airplane and method

InactiveCN101763068ASolve problems such as unreasonable designIncrease specializationProgramme controlComputer controlNumerical controlProcess module

The invention discloses a preparation system of quick numerical control machining of complex parts of an airplane and a method. The system takes the existing CAD / CAM system as a platform, and comprises a technology resource and knowledge base management module, a quick blank generation module, a part classification and technical scheme analysis module, an automatic programming module, a quick tool generation module, a strain analysis and deformation control module, a front and rear process module and a technology data generation module. The system is built on the basis of a three-dimensional numeric part model, systematically and exactly embodies a specialized flow path for supporting the numerical control machining technology preparing and the programming of the complex parts of the airplane, can greatly reduce man-machine interaction operation required by preparing technology and programming, effectively solves the problems of the unstable programmed procedure and the unreasonable scheme design of the machining technology caused by the lack of the experience of process operators, and the like, can effectively control the deformation quantity during and after machining the parts, can obviously improve the efficiency and the quality of the numerical control machining preparing and the programming, and improves the professional level and the intelligence level of the CAD / CAM system.

Owner:SHENYANG AIRCRAFT CORP +1

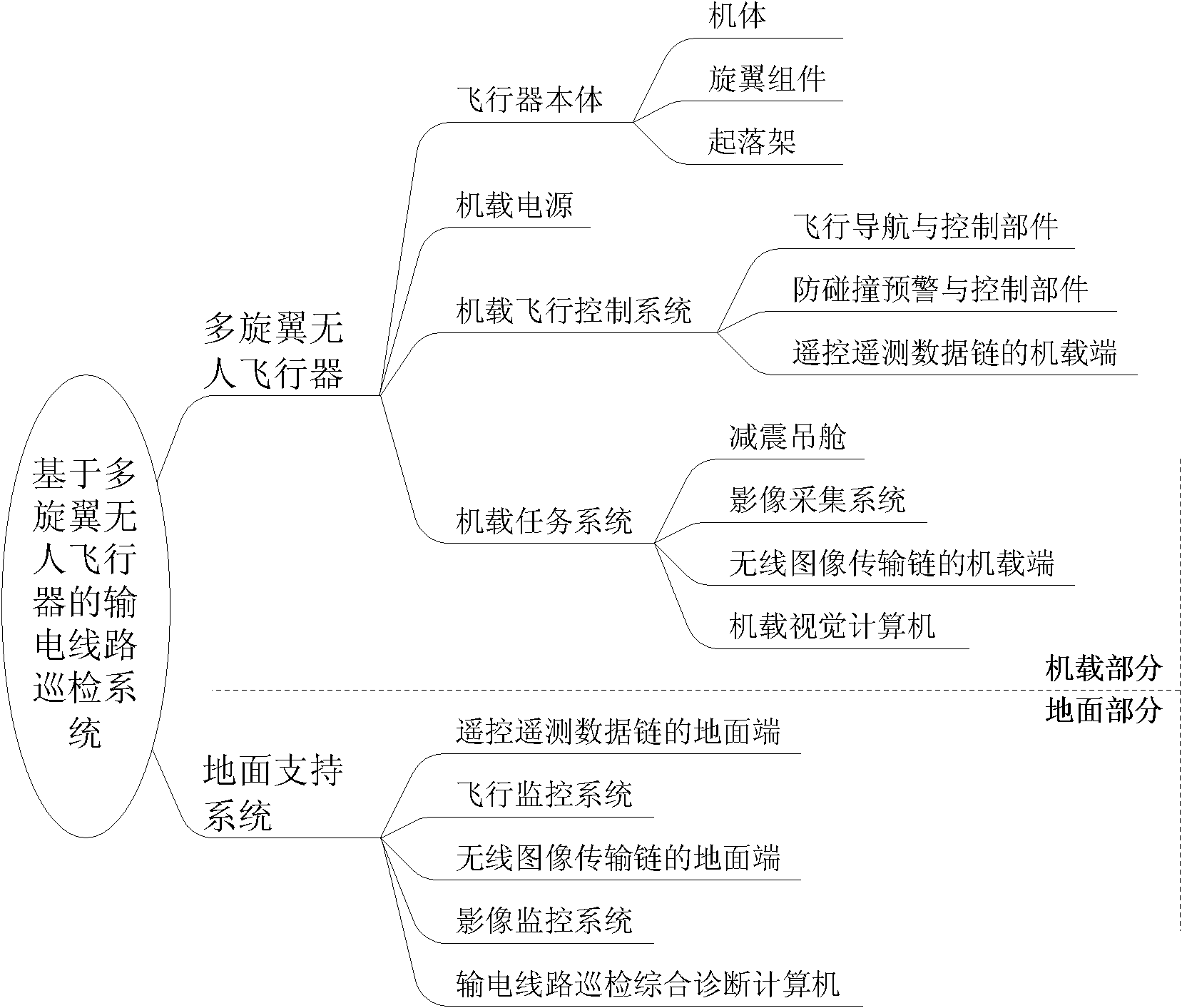

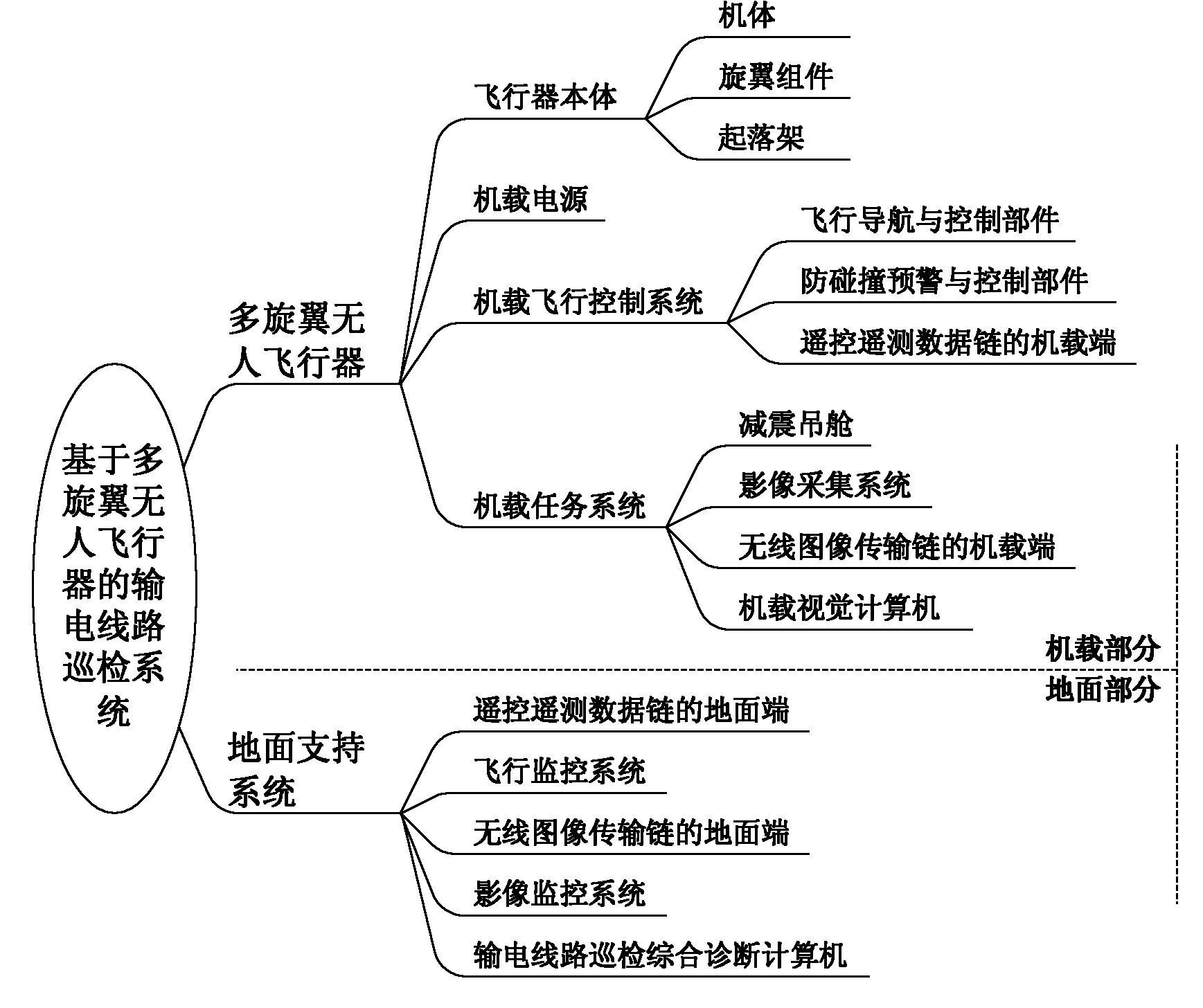

Transmission line inspection system based on multi-rotor unmanned aircraft

InactiveCN102183955AImprove mobilityPotentially less harmfulVehicle position/course/altitude controlPosition/direction controlNacelleWireless image transmission

The invention discloses a transmission line inspection system based on a multi-rotor unmanned aircraft, which comprises the multi-rotor unmanned aircraft and a ground support system, wherein the multi-rotor unmanned aircraft comprises an aircraft body, an airborne flight control system, an airborne task system and an airborne power supply for supplying power to all the electronic devices; the aircraft body comprises a body, an undercarriage fixedly connected below the body, and a plurality of rotor components which are symmetrically distributed on the periphery of the body; the airborne flight control system comprises a flight navigation and control part, a transmission line anti-collision warning and control part, and an airborne end used for remotely controlling a telemetry data chain; the airborne task system comprises a damping nacelle, an image acquiring device arranged on the damping nacelle, and the airborne end for a wireless image transmission chain; and the ground support system comprises a ground end for remotely controlling the telemetry data chain, a flight monitoring system, the ground end for a wireless image transmission chain, and an image monitoring system. The transmission line inspection system has a reasonable structure, is easily realized, and has high engineering application value.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

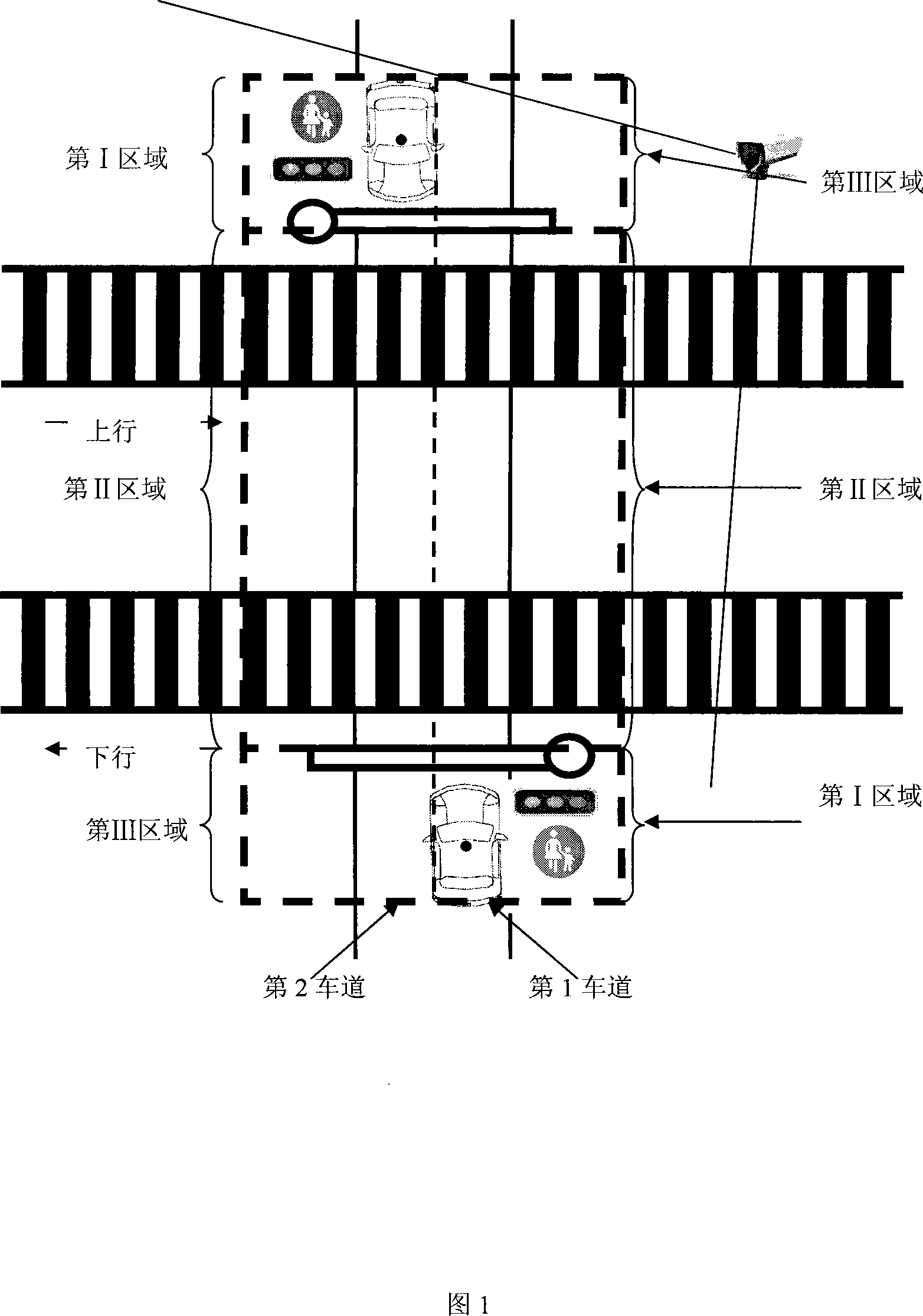

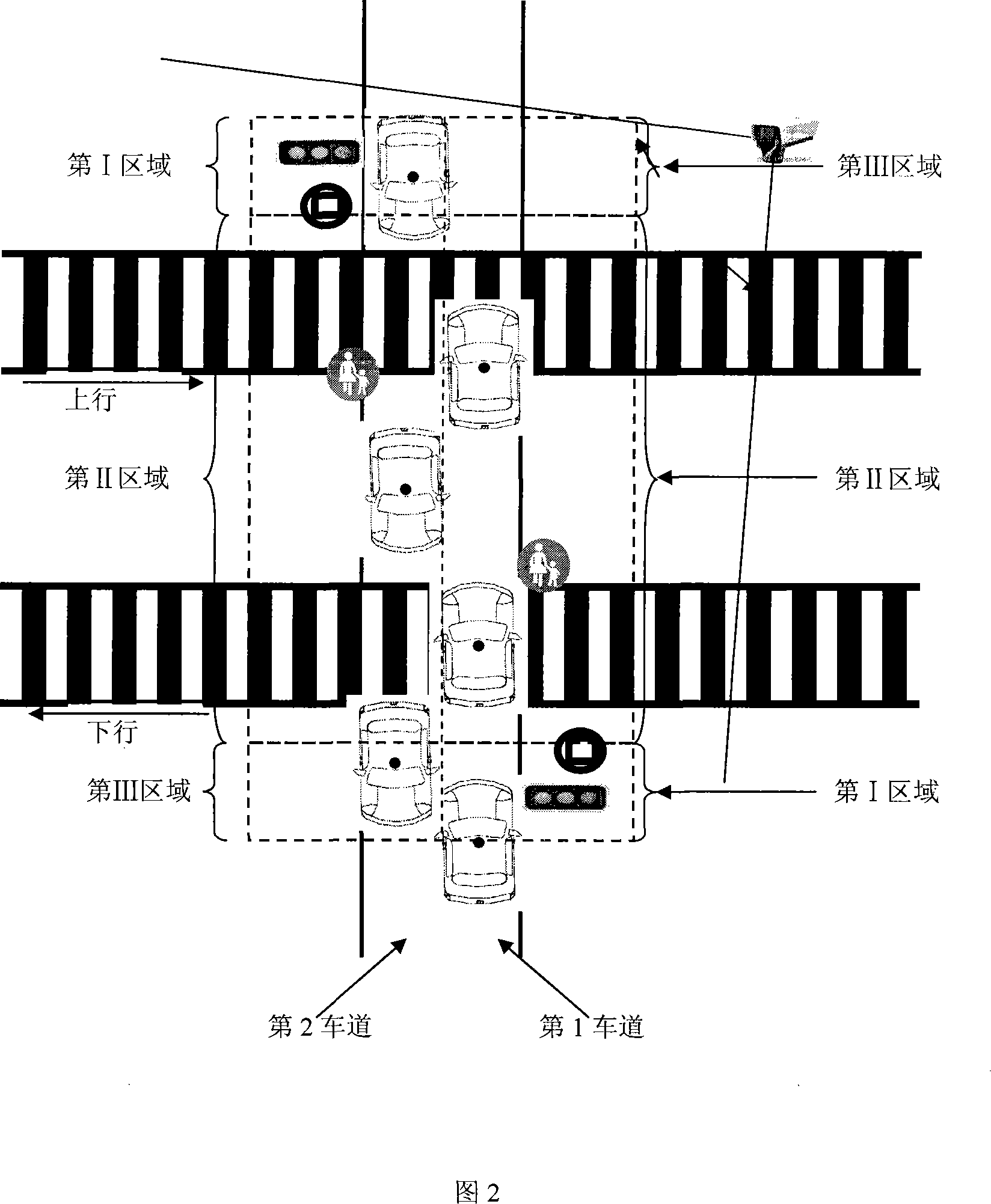

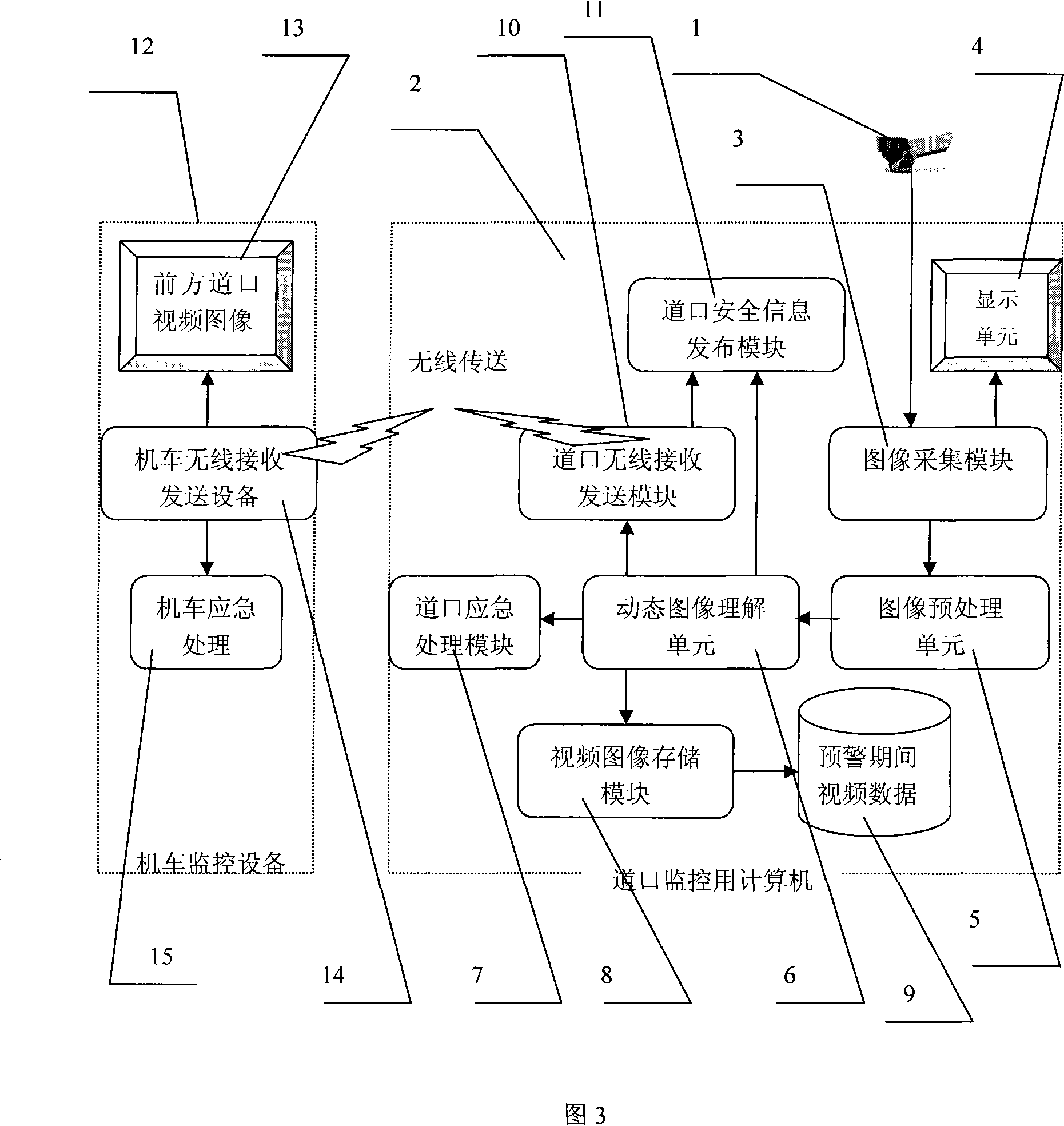

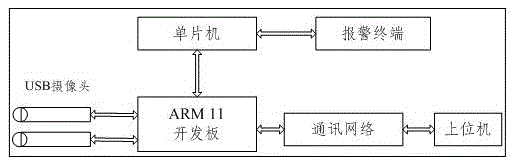

Intelligent video monitoring apparatus of railway crossing

InactiveCN101179710ANormative behaviorFacilitate law enforcementPicture signal generatorsClosed circuit television systemsVideo monitoringVideo sensors

The invention discloses an intelligent video monitor of railway crossing, which includes a video sensor that is arranged on the railway crossing and is capable of covering the traffic condition of the entire crossing as well as a monitoring computer that is used for monitoring the condition of the entire crossing and is capable of dynamic image understanding; wherein, the monitoring computer includes a video image collecting module, a displaying unit, an image pretreatment module, a railway crossing customizing module, a dynamic image understanding module used for analyzing the safety condition of the crossing, a video information saving module, a crossing wireless receiving and transmitting module and an issuing module of crossing safety information; wherein, the issuing module of crossing safety information is connected with a crossing displaying unit and an alarming sound playing unit; and the monitoring computer is connected with the wireless receiving and transmitting device. The invention has a high intelligence level and is capable of automatically judging various dangerous conditions or failures of the crossing through the image understanding technique and is also capable of mutual communication between the train driver and safety condition of the crossing as well as between the passengers and vehicles passing through the crossing and the train running condition through the wireless communication technique.

Owner:ZHEJIANG UNIV OF TECH

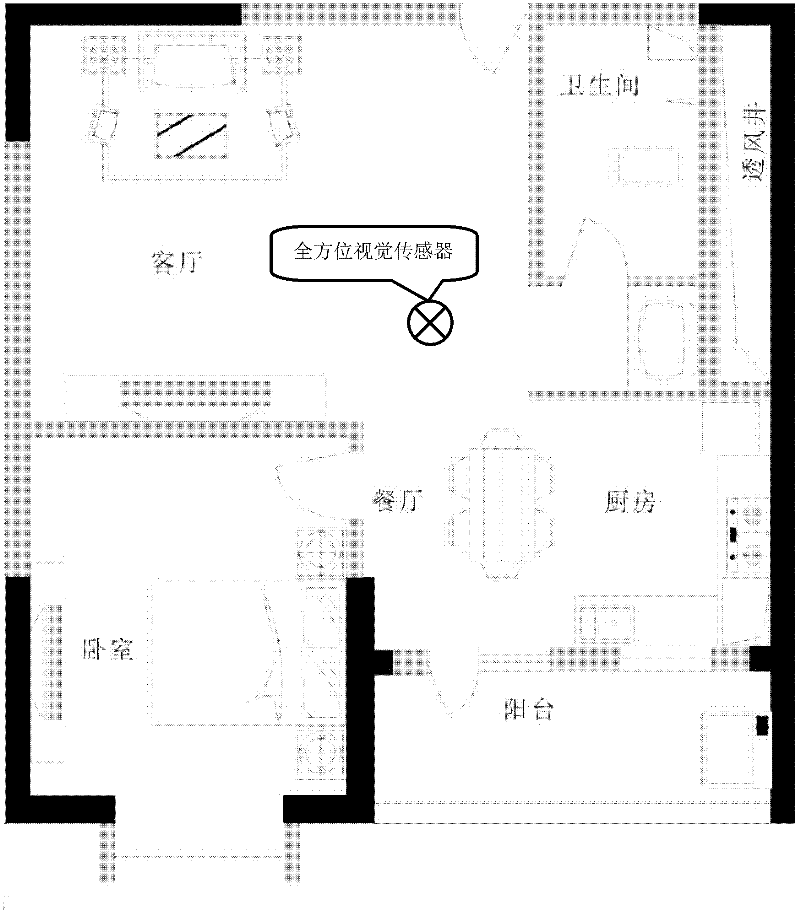

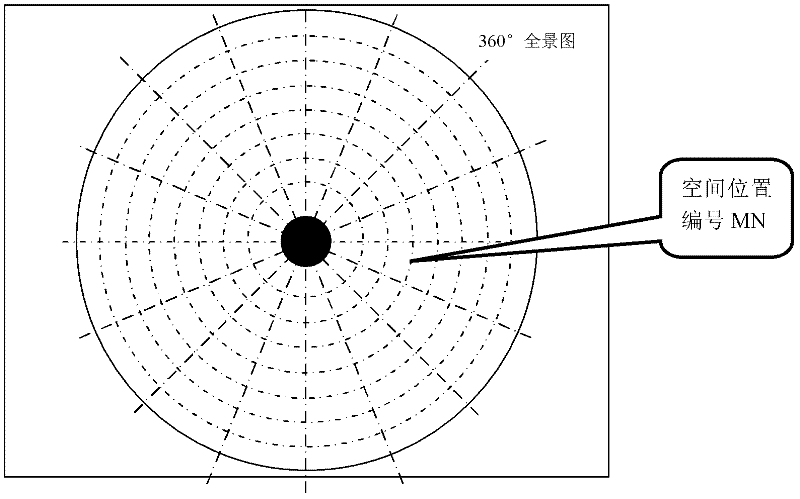

Safety monitoring system based on omnidirectional vision for old people living alone

ActiveCN102387345AImprove automationImprove the level of intelligenceCharacter and pattern recognitionClosed circuit television systemsOmnidirectional cameraSitting room

A safety monitoring system based on omnidirectional vision for old people living alone comprises an omnidirectional vision camera device and a microprocessor for analyzing, processing and determining activity quantity, postures, falling and daily behavior habits of the old people living alone according to full view images filmed by the omnidirectional vision camera device and relevant input information. The omnidirectional camera device is arranged above the middle of a living room of the old people living alone and can capture more than 80% daily activity video images of the old people. By means of computer vision, locating, tracking and identification of human bodies are conducted, and activity quantity, postures, movement behavior and daily life of the older people living alone are analyzed and determined. The safety monitoring system can not only automatically detect important matters of the older people within an indoor visual range such as falling and the like, but also can intelligently determine abnormal behaviors of the old people outside the visual range and when the old people go out, thereby providing a means of remote monitoring for the old people living alone.

Owner:ZHEJIANG UNIV OF TECH

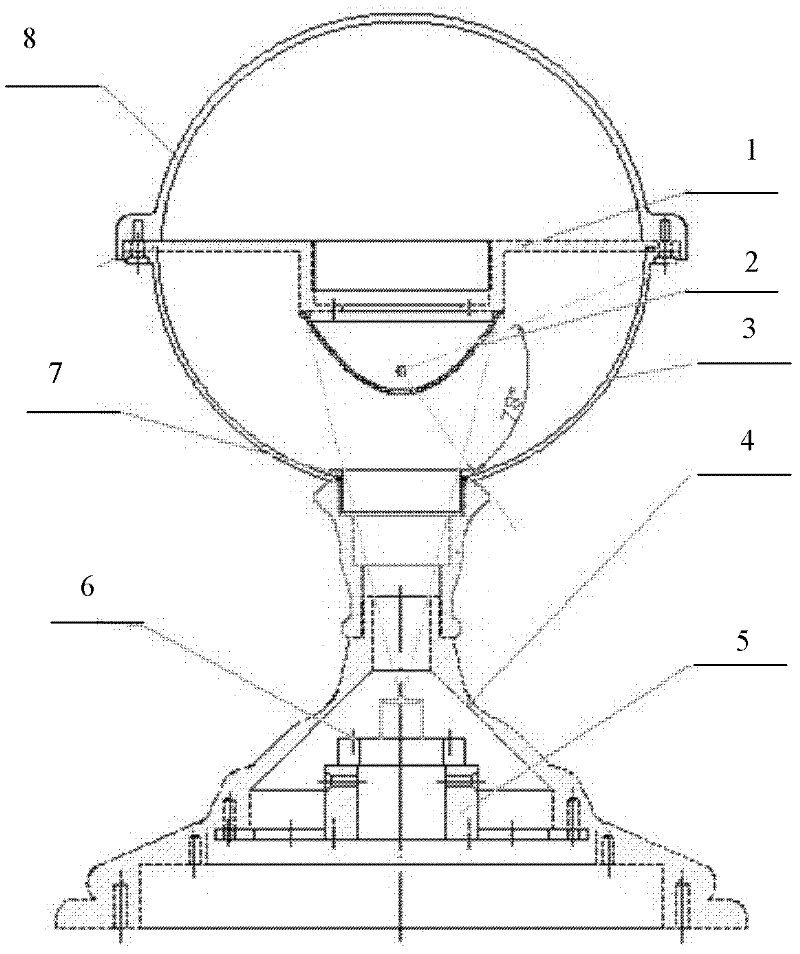

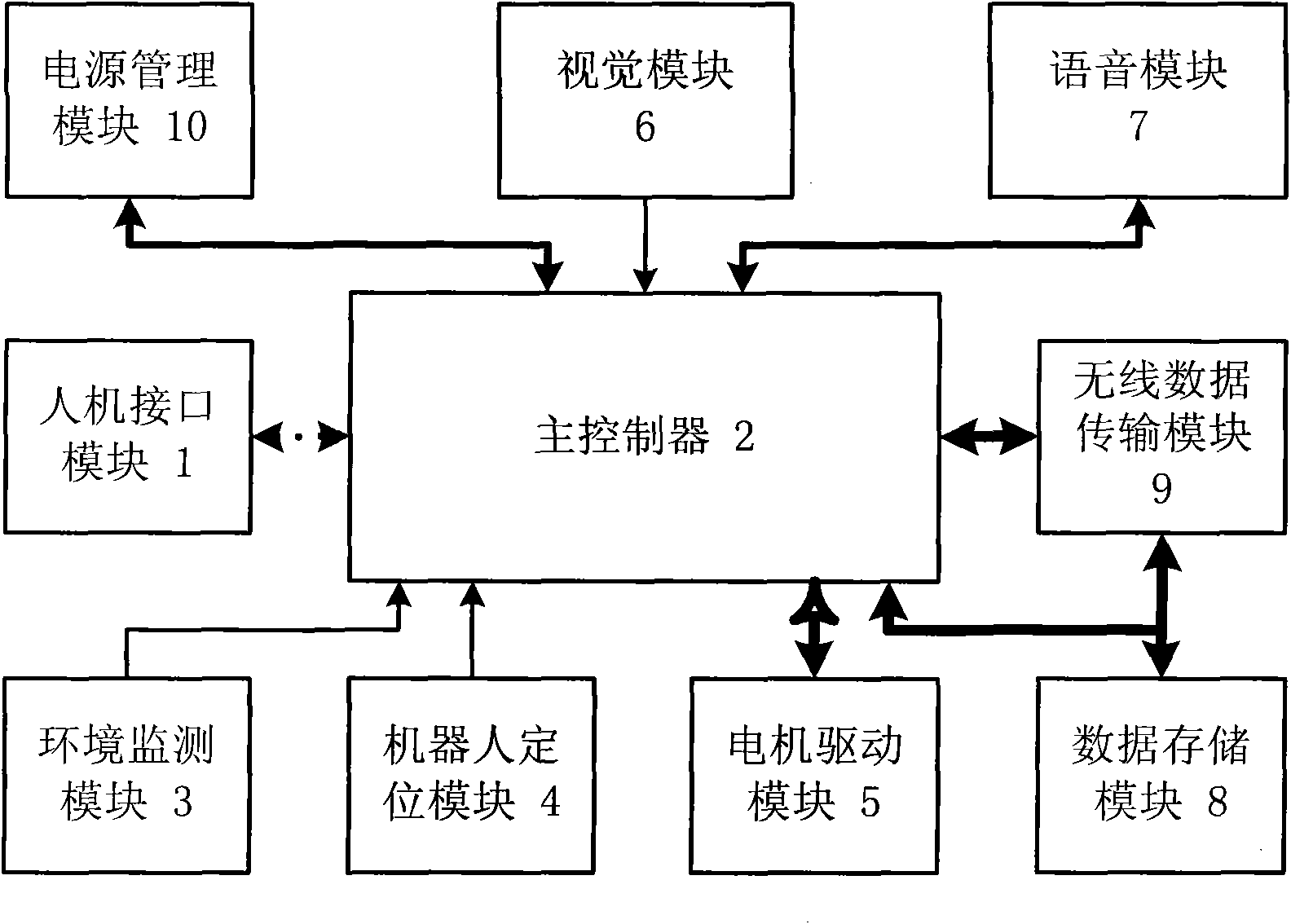

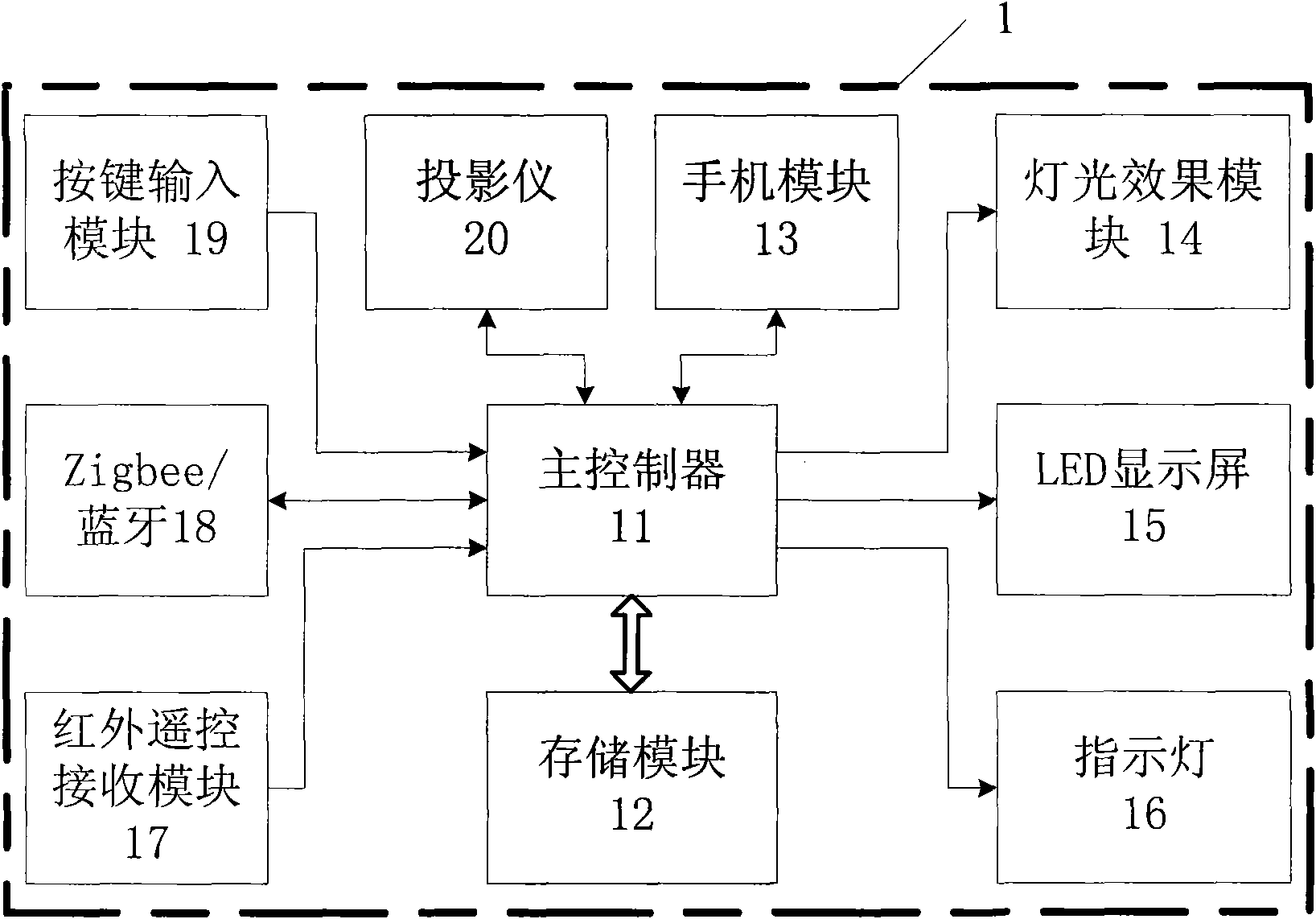

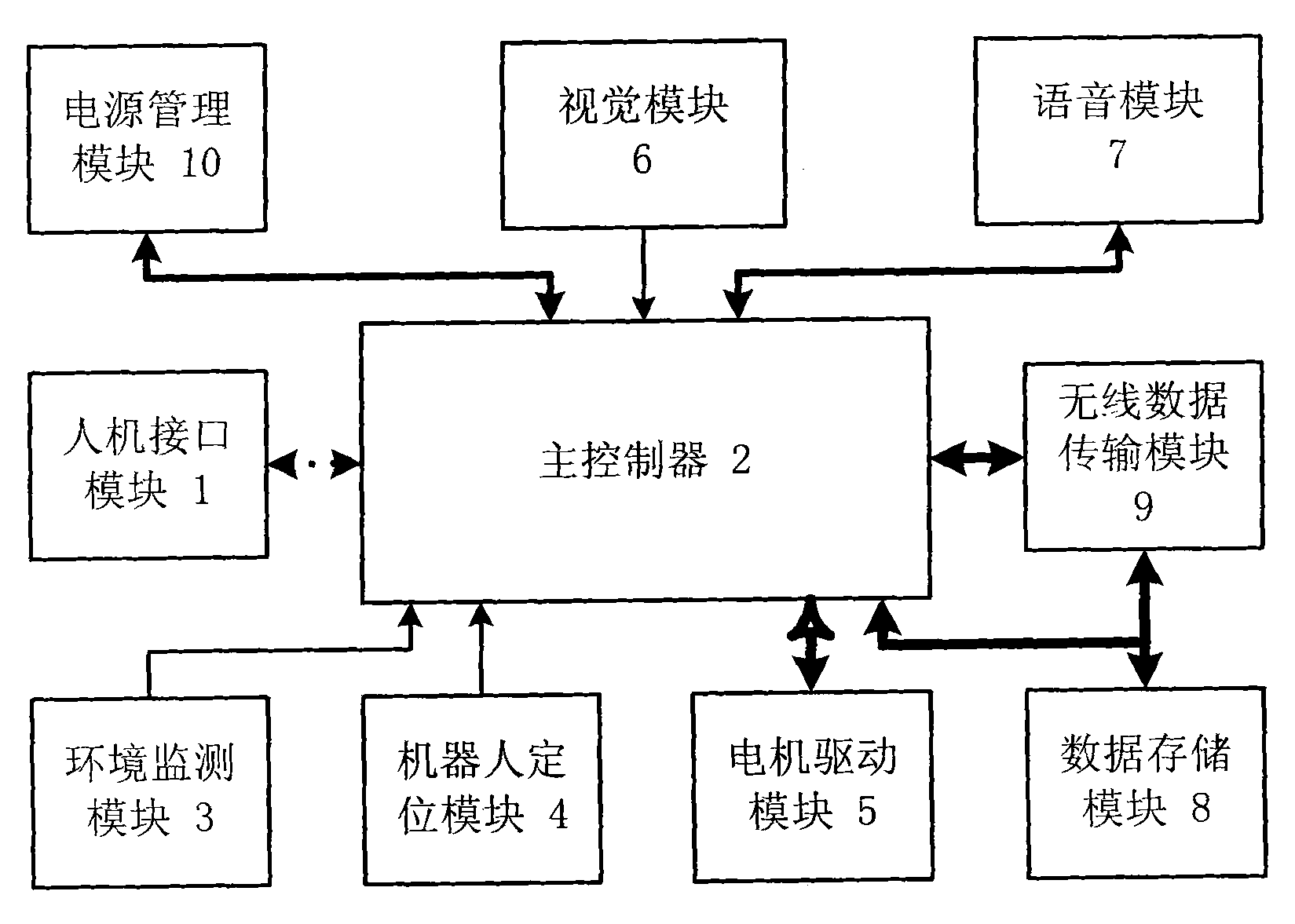

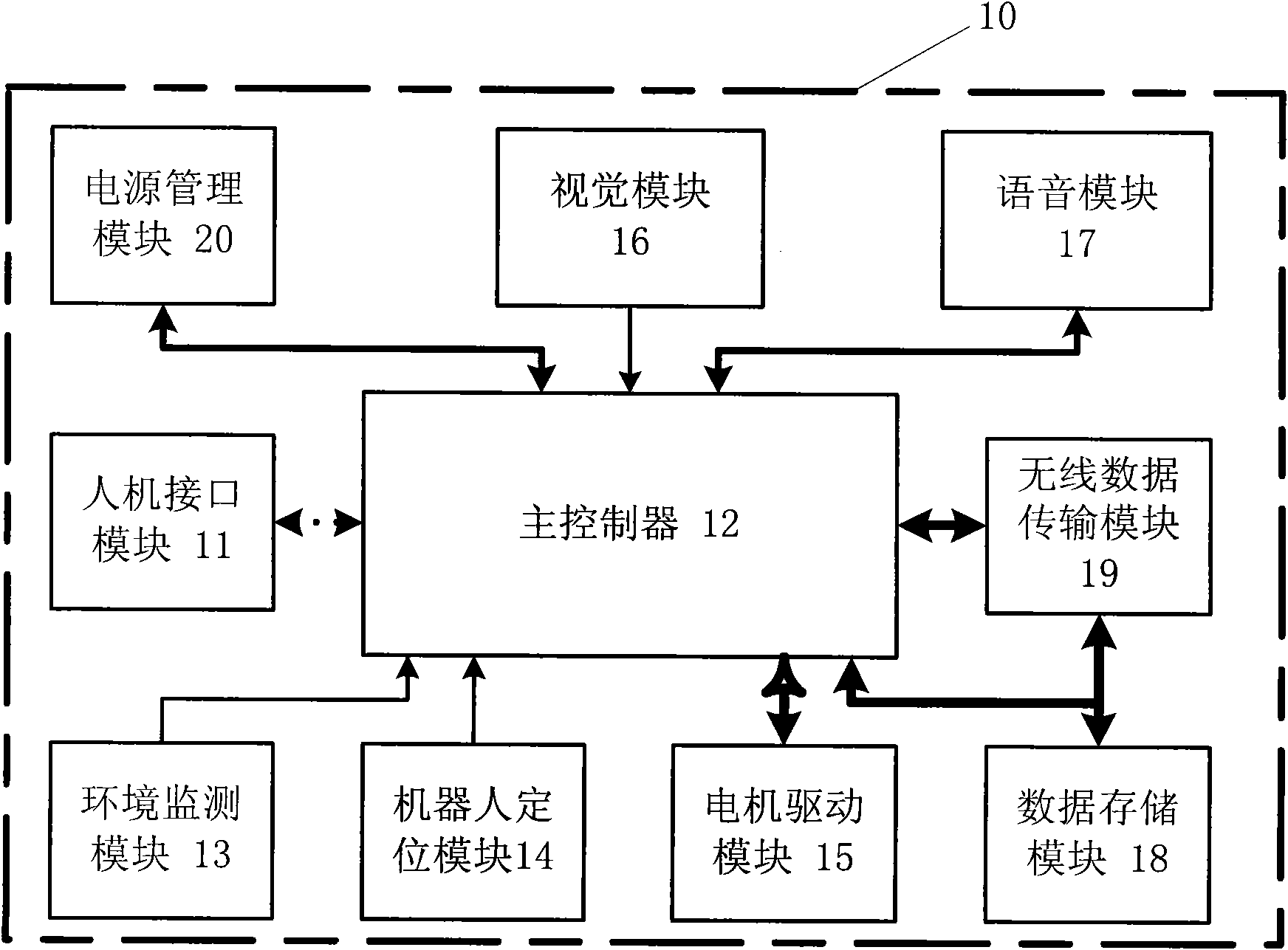

Intelligent robot

InactiveCN101947788AReal-time monitoringPrecise positioningProgramme-controlled manipulatorSupply managementRobot position

The invention relates to an intelligent robot. The intelligent robot comprises a man-machine interface module, a main controller, an environment monitoring module, a robot positioning module, a motor driving module, a vision module, a voice module, a data storage module, a wireless data transmission module and a power supply management module, wherein the man-machine interface module performs man-machine information exchange with a user and transmits the received data to the main controller; the environment monitoring module inputs the detected information to the main controller; the robot positioning module transmits external information to the main controller; the motor driving module is controlled by the main controller to perform servo control on a driving motor in the motor driving module; the vision module and the voice module transmits the acquired signals to the main controller; the main controller inputs various acquired signals into the data storage module and compares the signals with pre-called service data packets in the data storage module; the main controller controls the wireless data transmission module to perform information exchange with a server according to the preset fixed time; and the power supply management module supplies power to each module in the robot.

Owner:焦利民

Intelligent cooking machine and cooking method thereof

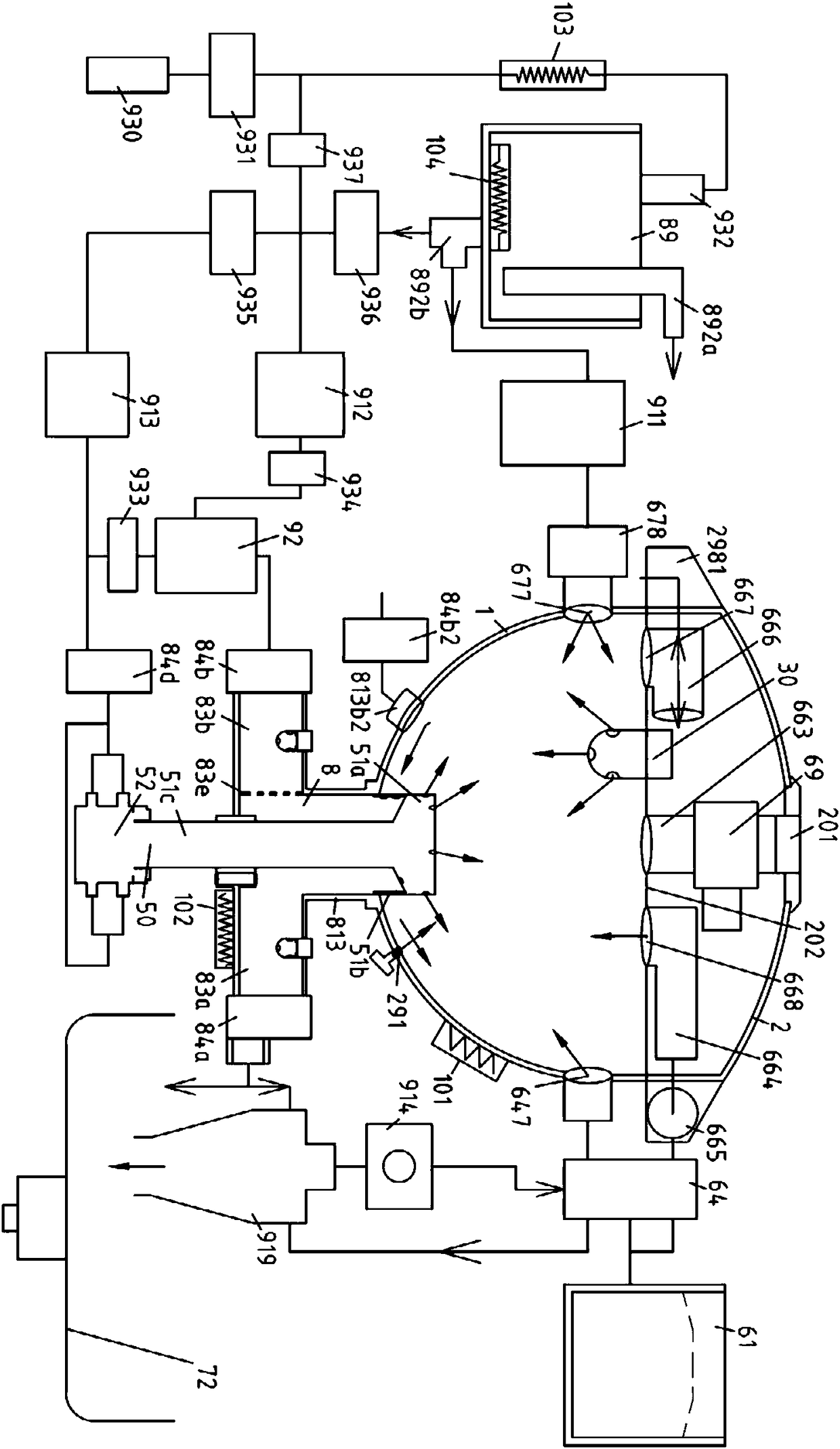

ActiveCN108113523AOvercome inherent flawsStir fry fullyCooking-vessel lids/coversBread-toastersIdentification deviceEngineering

The invention discloses an intelligent cooking machine and a cooking method thereof. The intelligent cooking machine comprises a novel stirrer used for stir-frying, and the problem of stir-frying of the intelligent cooking machine is solved better. The invention further discloses a stir-frying machine assembly frame which adapts the novel stirrer. The stir-frying machine assembly comprises a material inputting device, a dish containing device, a water containing device, a pot cover integrated system, and a bottom leakage injection device, and further comprises a manual button, an Internet of Things identification device and a network device. The novel cooking machine can be used as a stir-frying machine, and can also be used as other kitchen electric cooking machines such as a rice cooker,a soybean milk machine and a bread machine, and has a higher level of intelligence.

Owner:李亚锐

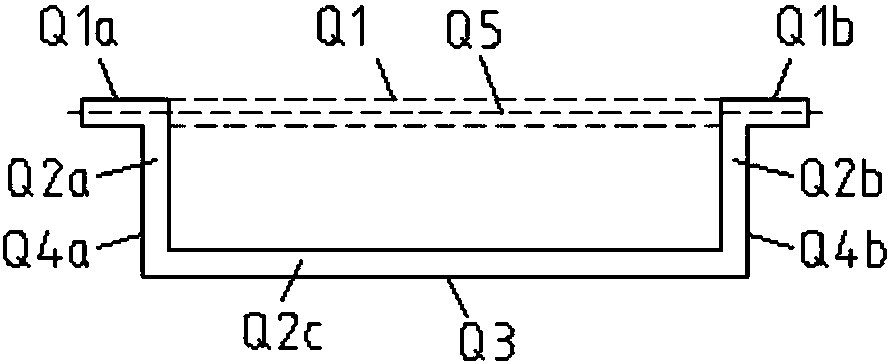

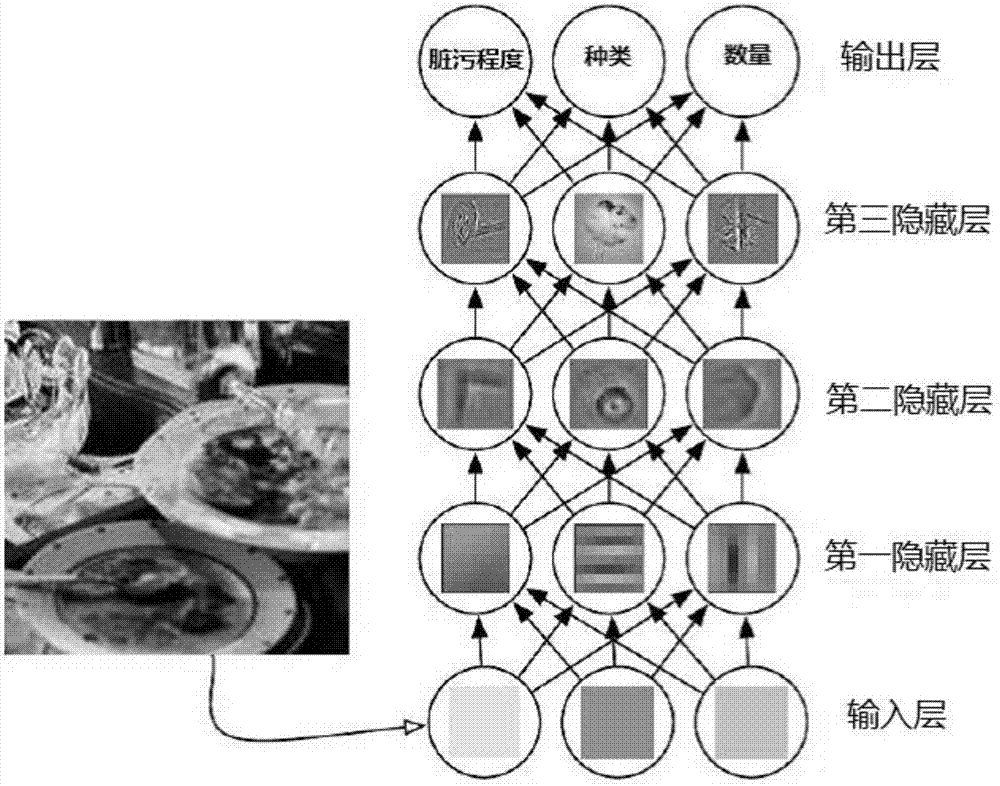

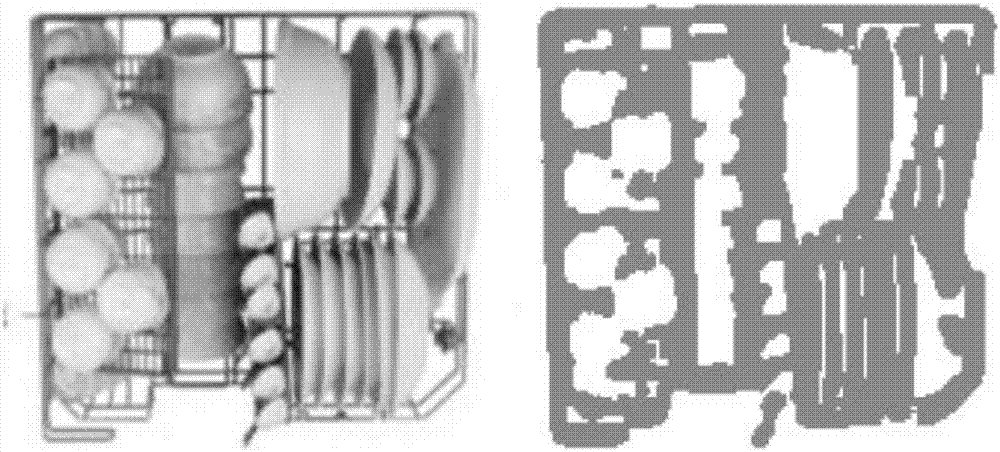

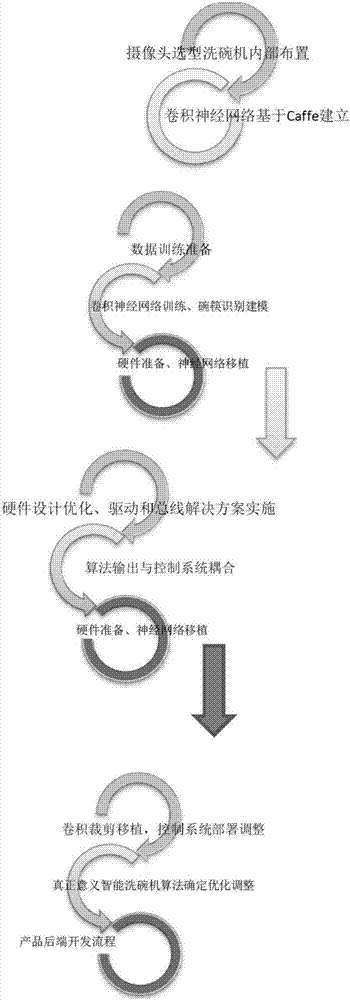

Washing control method and device of dish-washing machine and dish-washing machine

ActiveCN107485356AEasy to cleanImprove the level of intelligenceTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionComputer science

The embodiment of the invention provides a washing control method and device of a dish-washing machine and the dish-washing machine and belongs to the field of dish-washing machines. The washing control method comprises the steps that an image is shot in the dish-washing machine, wherein the image contains articles to be cleaned; the image is calculated to obtain the number, types and dirty situations of the articles to be cleaned in the image; the weight of the articles to be cleaned is detected; based on the number, types and dirty situations of the articles to be cleaned and the weight of the articles to be cleaned, washing parameters of the dish-washing machine are calculated; the dish-washing machine is controlled to run according to the washing parameters. By adopting the technical scheme of the embodiment, the intelligence level and washing effect of the dish-washing machine can be improved.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

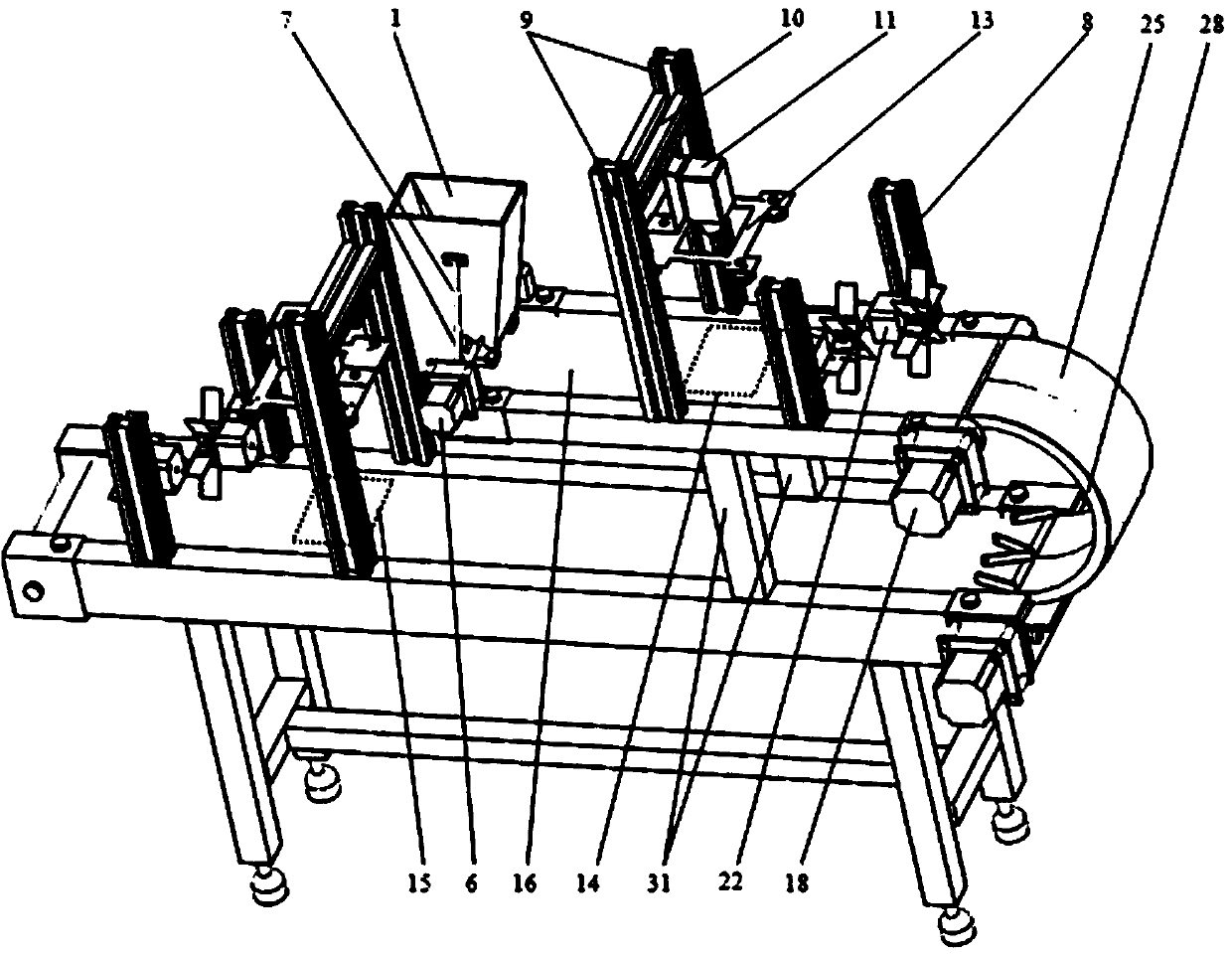

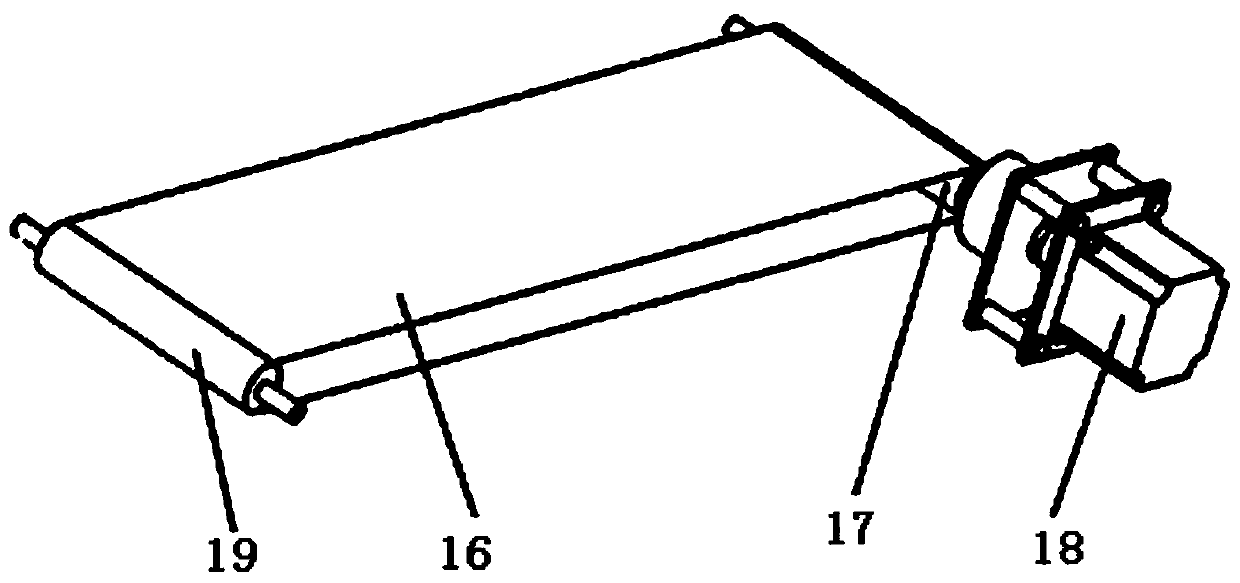

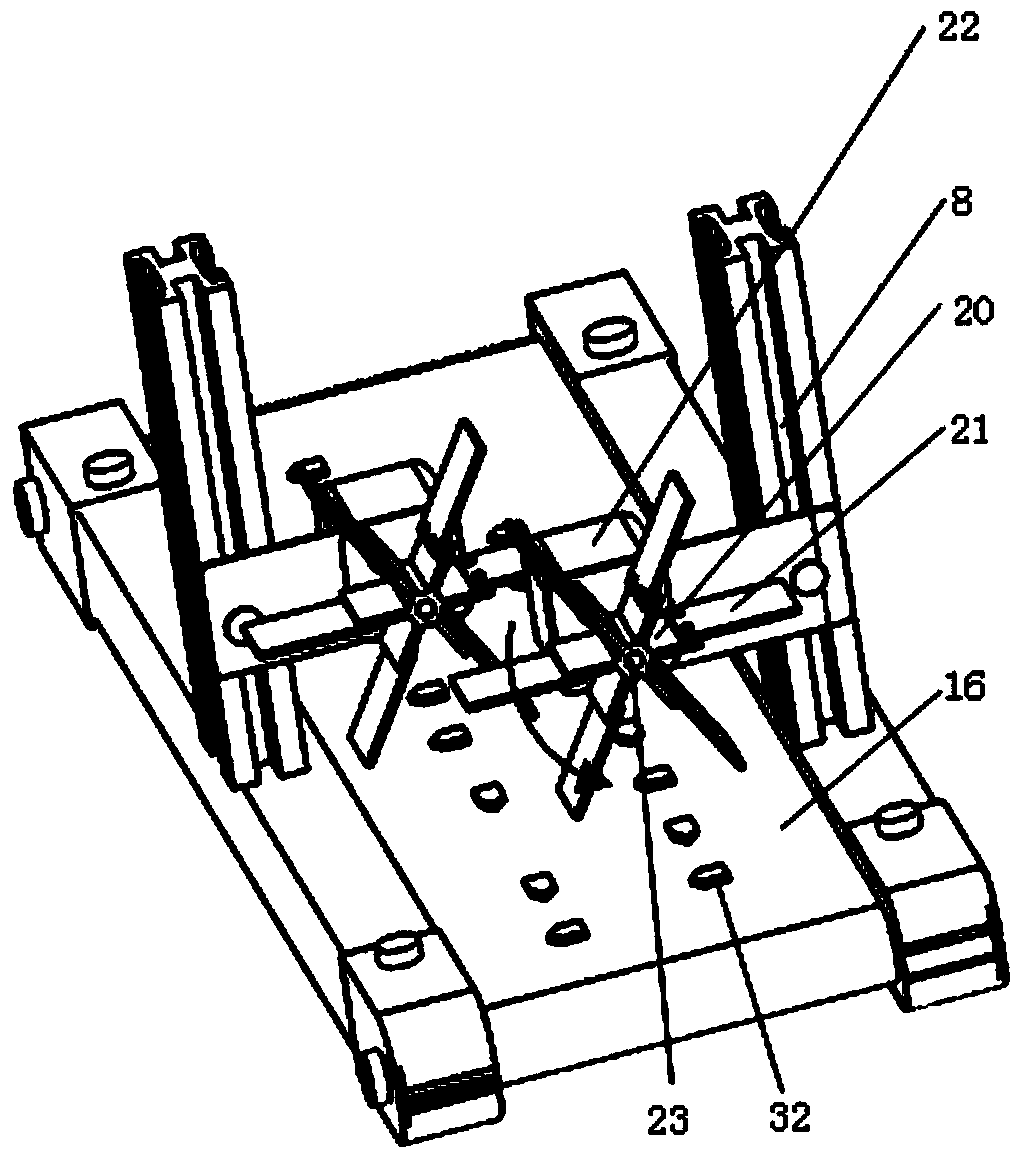

Corn-seed image carefully-choosing apparatus and usage method for apparatus

InactiveCN104084379AGuaranteed accuracyContinuous and even double row feedingSortingMachine visionImage detection

The invention relates to the technical field of visual inspection by using a machine, and concretely relates to an corn-seed image carefully-choosing apparatus and a usage method for the apparatus. The technical scheme is characterized in that the a practical efficient on-line carefully-choosing image detection algorithm for corn seeds is provided; a corn-seed turning-over mechanism is designed, which is capable of performing image detection determination on the front side and the reverse side of a corn seed and helps to guarantee accuracy of a detection result; an electromechanical sorting execution mechanism with simple structure is designed; and a novel double-row feeding mechanism is designed, which is capable of continuously uniformly performing double-row feeding on corn seeds. The corn-seed image carefully-choosing apparatus is simple in structure, precise and efficient, and is significant in guaranteeing enforcement of orientated precise sowing of corn, realizing careful choosing of corn seeds before sowing, promoting high quality, high yield and stable development of corn industry in our country and mechanization, automation and intelligentization level of agricultural-product detection.

Owner:CHINA AGRI UNIV

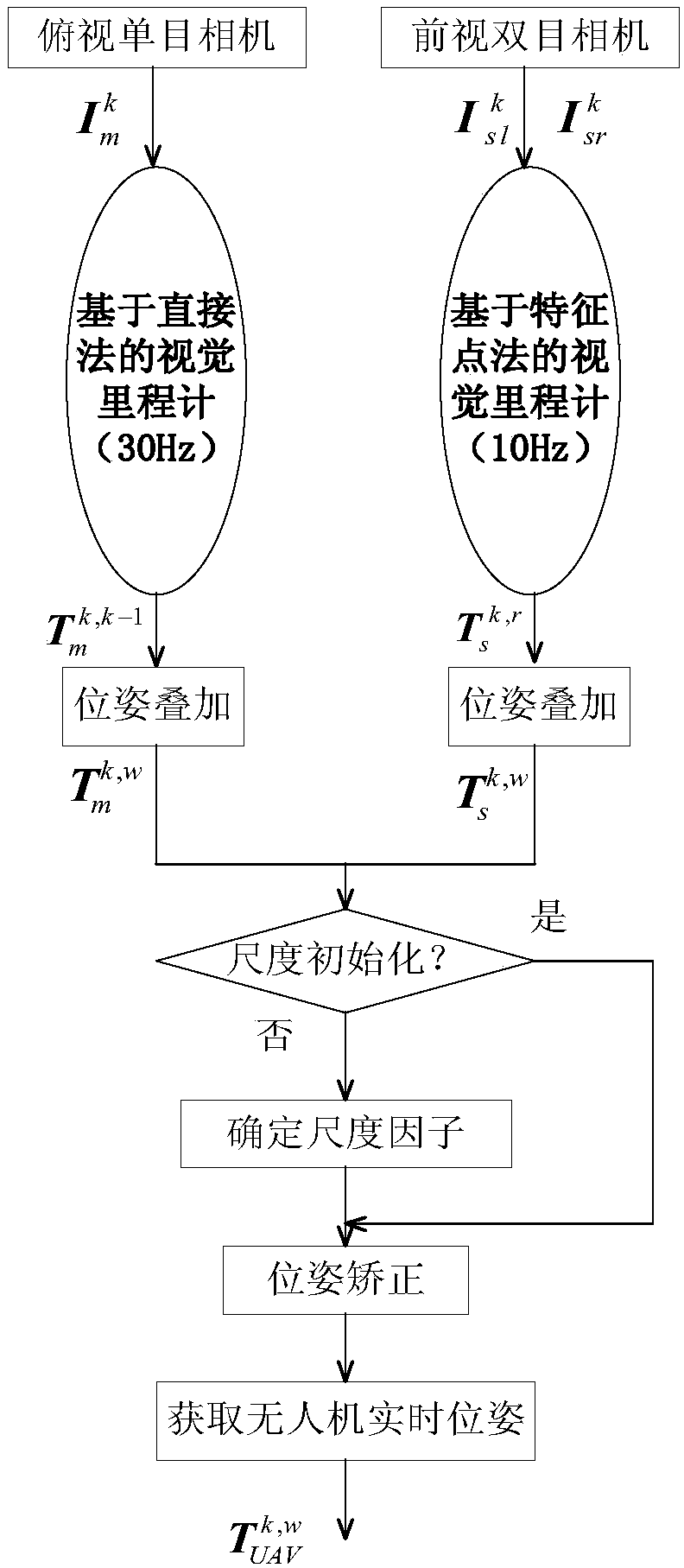

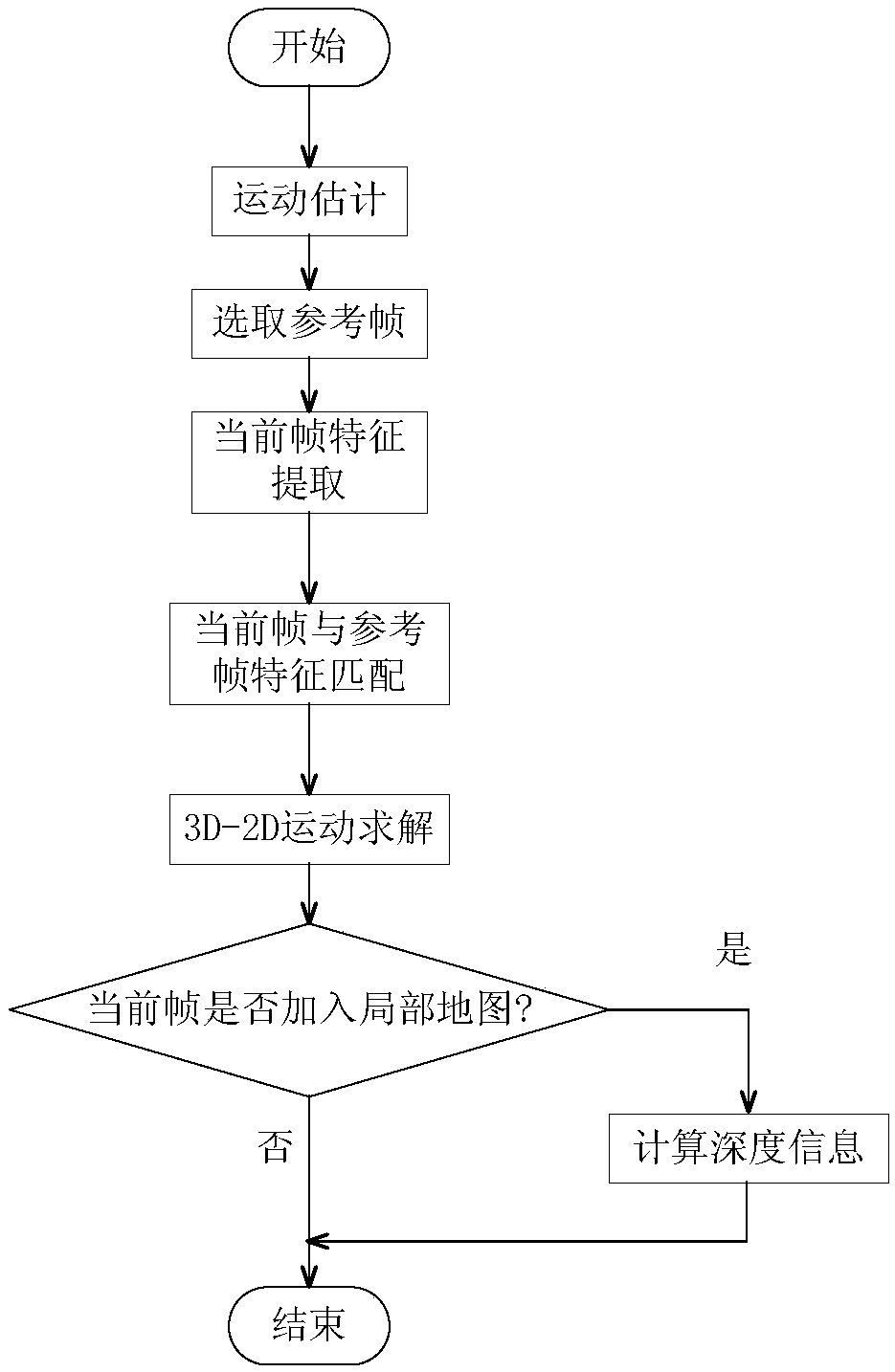

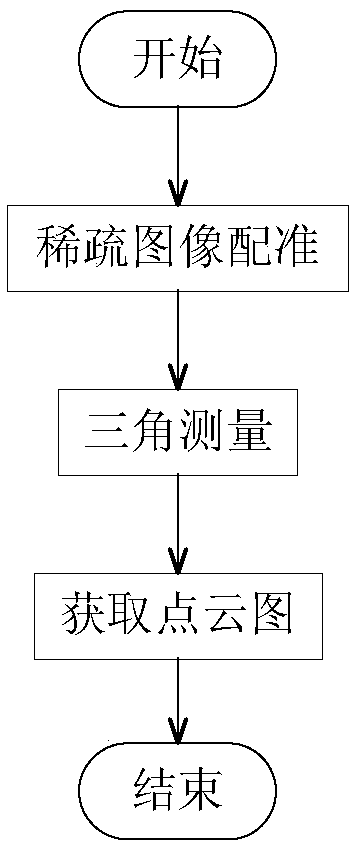

Simultaneous localization and mapping (SLAM) method for unmanned aerial vehicle based on mixed vision odometers and multi-scale map

ActiveCN109029417AReal-time accurate and reliable positioningShorten operation timeNavigational calculation instrumentsSimultaneous localization and mappingEnvironmental perception

The invention discloses a simultaneous localization and mapping (SLAM) method for an unmanned aerial vehicle based on mixed vision odometers and a multi-scale map, and belongs to the technical field of autonomous navigation of unmanned aerial vehicles. According to the SLAM method, an overlooking monocular camera, a foresight binocular camera and an airborne computer are carried on an unmanned aerial vehicle platform; the monocular camera is used for the visual odometer based on a direct method, and binocular camera is used for the visual odometer based on feature point method; the mixed visual odometers conduct information fusion on output of the two visual odometers to construct the local map for positioning, and the real-time posture of the unmanned aerial vehicle is obtained; then theposture is fed back to a flight control system to control the position of the unmanned aerial vehicle; and the airborne computer transmits the real-time posture and collected images to a ground station, the ground station plans the flight path in real time according to the constructed global map and sends waypoint information to the unmanned aerial vehicle, and thus autonomous flight of the unmanned aerial vehicle is achieved. Real-time posture estimation and environmental perception of the unmanned aerial vehicle under the non-GPS environment are achieved, and the intelligent level of the unmanned aerial vehicle is greatly increased.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

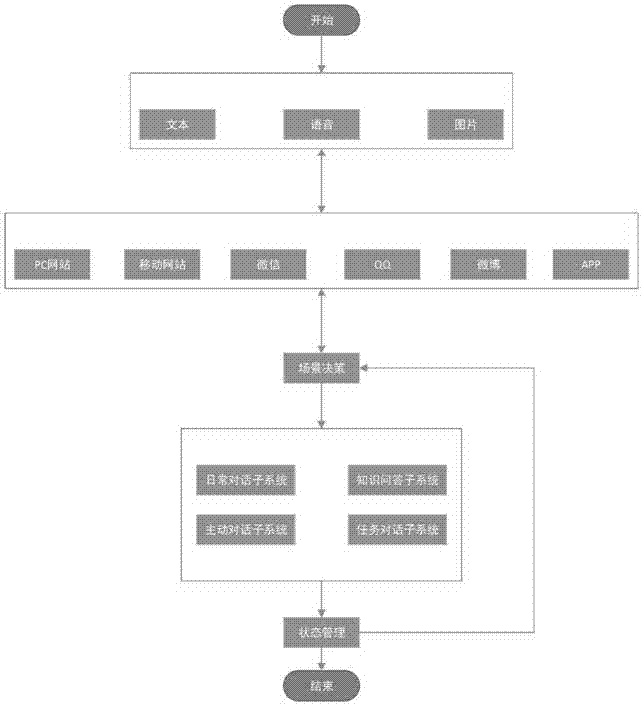

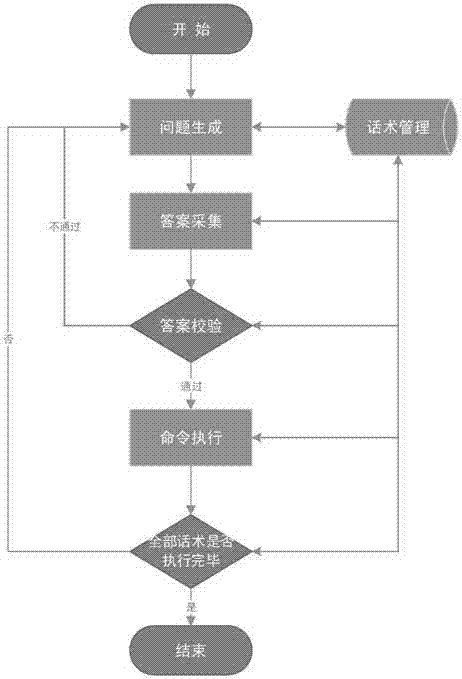

Conversation robot system

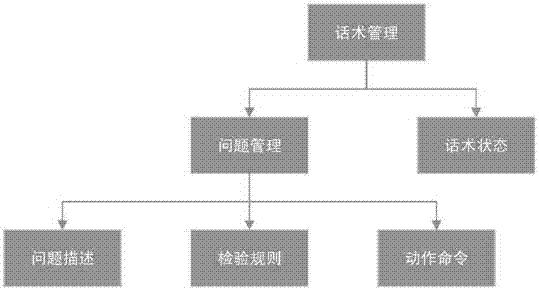

ActiveCN107133349AImprove the level of intelligenceImprove accuracySemantic analysisSpecial data processing applicationsRobotic systemsState management

The invention relates to a conversation robot system. The system comprises a multimedia processing module, a multi-channel access module, a scene decision module, a daily conversation subsystem, a question-answer subsystem, an active conversation system, a task conversation subsystem and a state management module. According to the system, besides the abilities of daily conversation, knowledge questioning and answering and task conversation, a conversation robot further can actively trigger a series of specific conversation skills according to specific scenes, chat with a user, collect and verify answers of the user and execute corresponding service commands.

Owner:北京无忧创新科技有限公司

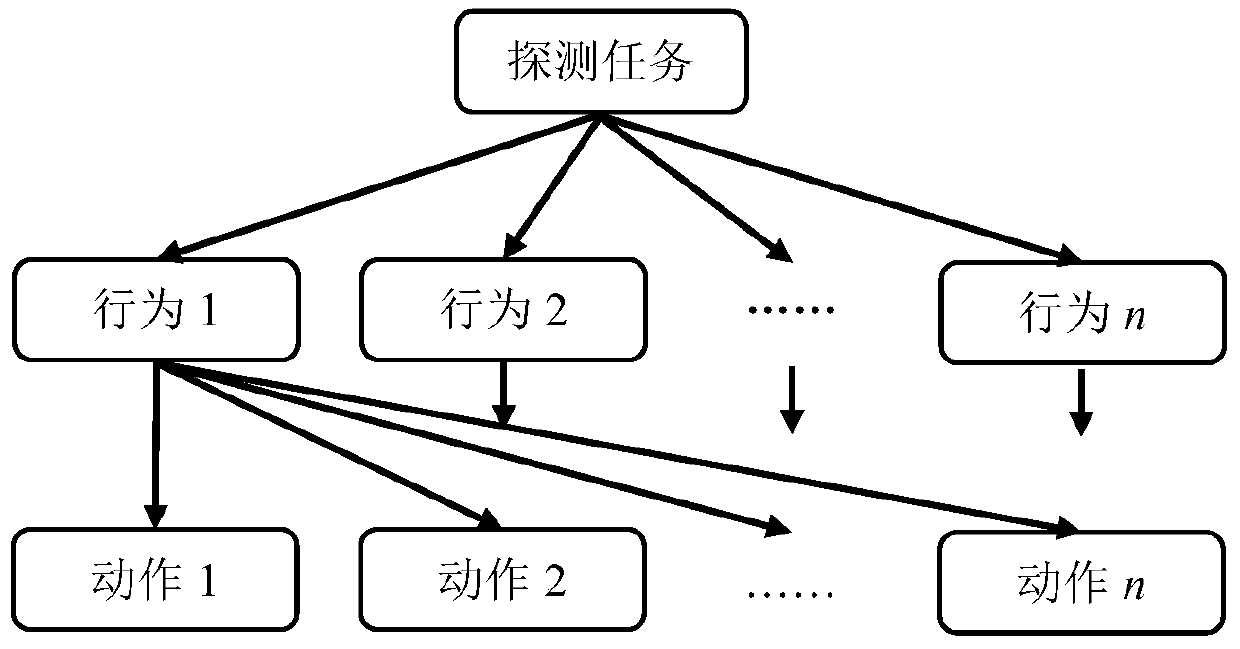

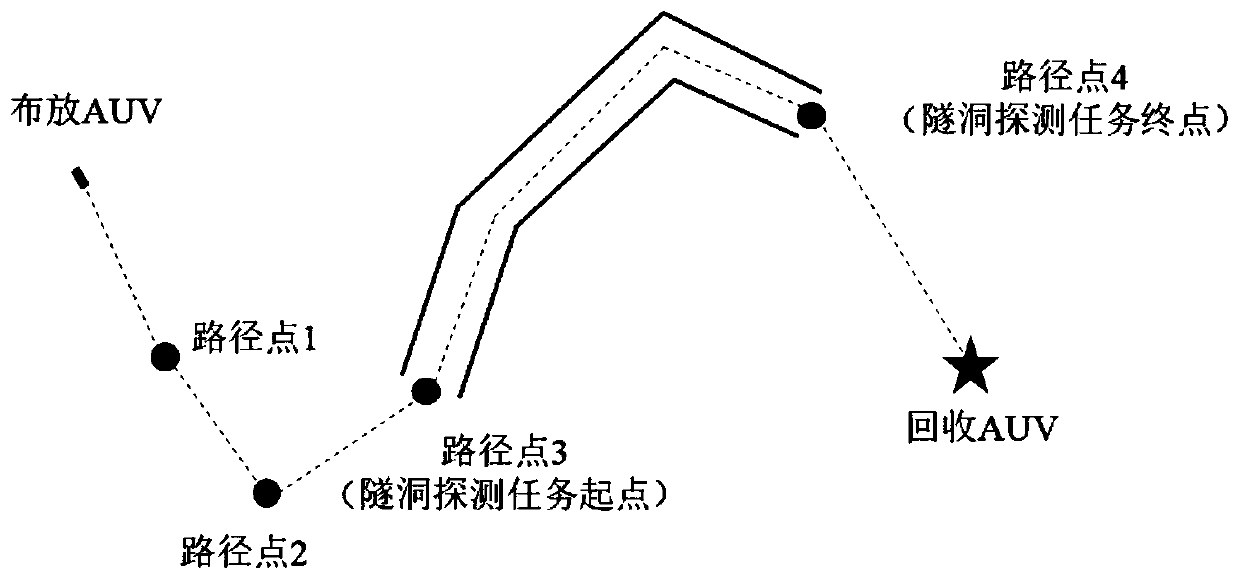

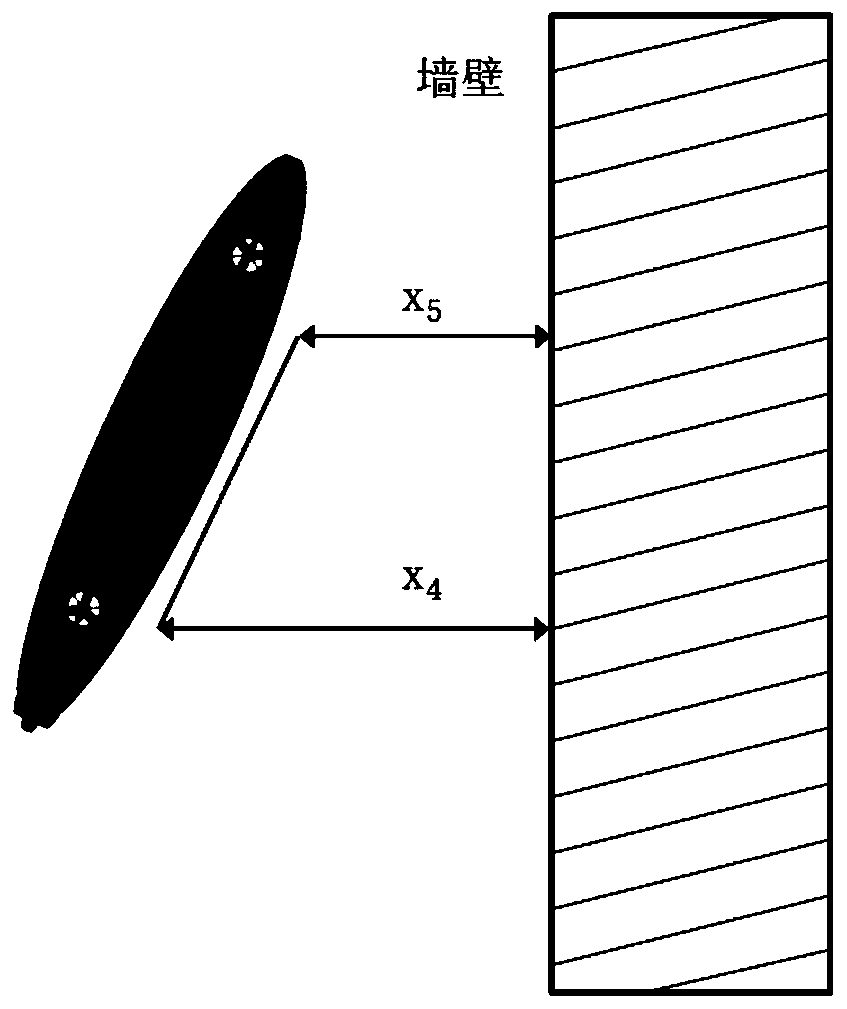

Reinforcement learning-based AUV behavior planning and motion control method

ActiveCN110333739ASolve the "curse of dimensionality" problemEasy to controlNeural architecturesPosition/course control in three dimensionsTask completionObstacle avoidance

The invention discloses a reinforcement learning-based AUV behavior planning and motion control method, which belongs to the technical field of underwater robots and aims at solving the problems of limited training experience and difficult application in a real environment as complex task planning by the AUV depends much on manual experience and a control method designed based on an intelligent algorithm needs an accurate environment mode. AUV tunnel detection is defined as a general task; behaviors corresponding to task completion comprise target trending, wall tracking and obstacle avoidance; a control instruction generated by the robot under water to complete the planned behavior is defined as an action; and when the AUV executes a tunnel detection task, a deep reinforcement learning DQN algorithm is used for real-time behavior planning, a corresponding deep learning behavior network is constructed, and planning of the tunnel detection task is completed. The AUV action network is trained by the DDPG method, the AUV is regarded as an environment model, and force-to-state mapping is obtained, thereby realizing the action control of the AUV.

Owner:HARBIN ENG UNIV

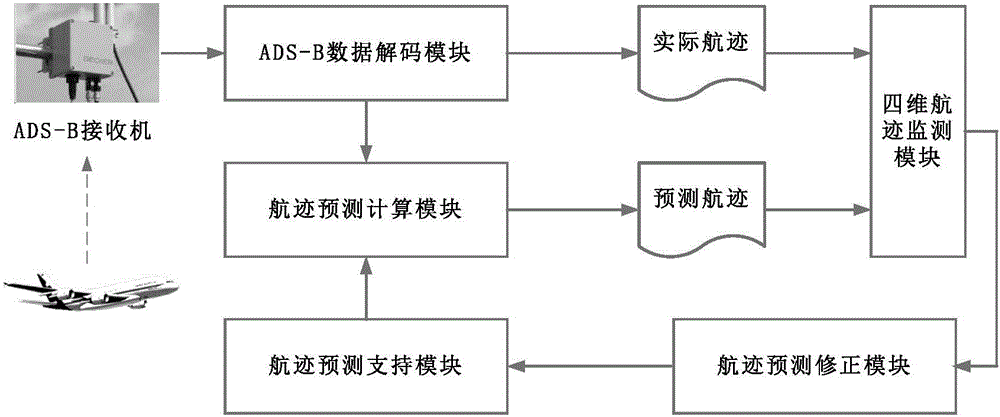

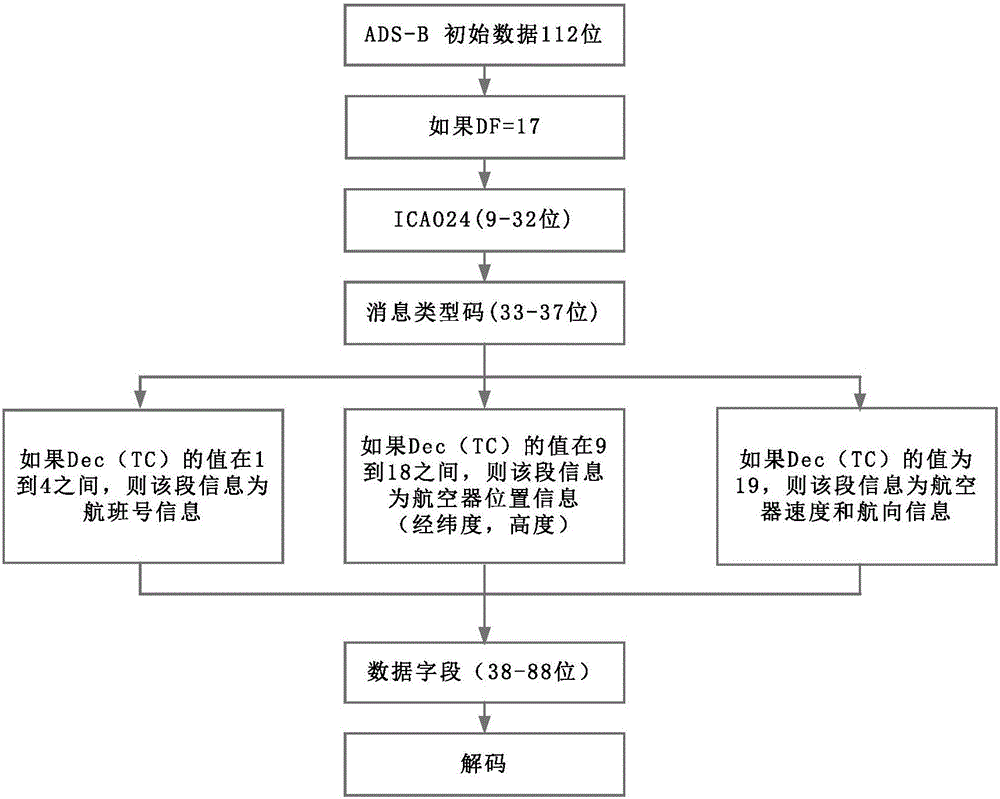

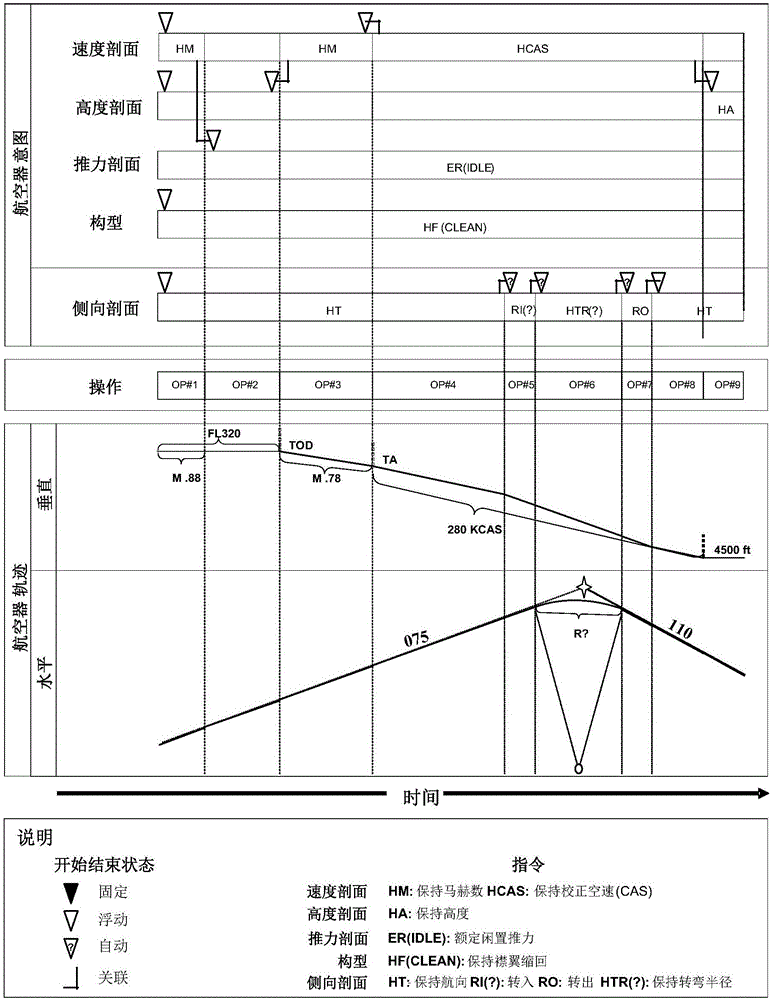

Four-dimensional flight track dynamic prediction method based on ADS-B information updating

The invention provides a four-dimensional flight track dynamic prediction method based on ADS-B information updating. By communicating with networks among ADS-B receivers, a ADS-B data decoding module is adopted to obtain real-time velocity information, height information, longitude information and latitude information of a flight, and consistency check is conducted on a predicted flight track and the real-time velocity, height, longitude and latitude of the flight, so that the dynamic, online and real-time flight track prediction capability is achieved. The method can provide important technical support for developing the automation and intellectualization of air traffic control and achieving the flight-track-based operation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

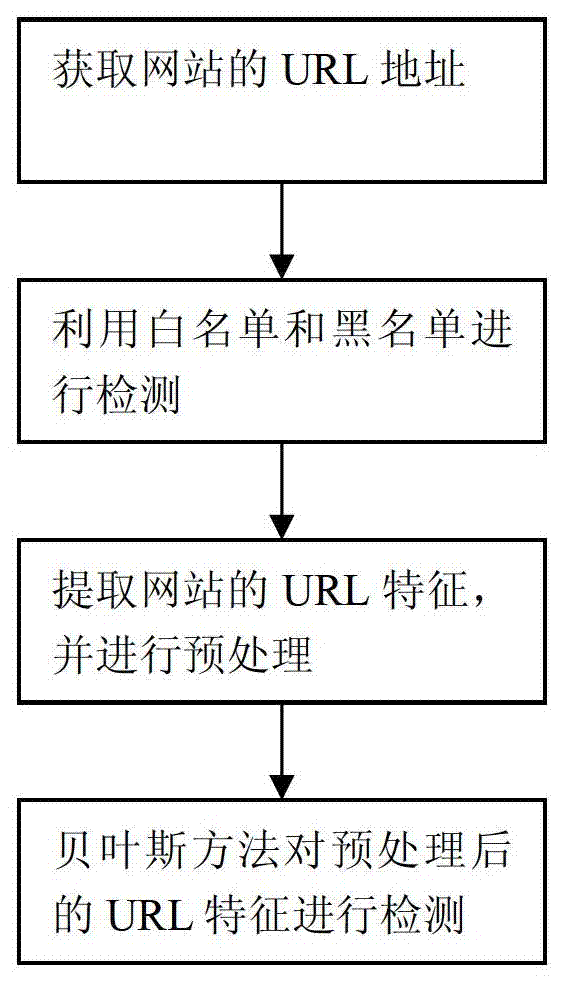

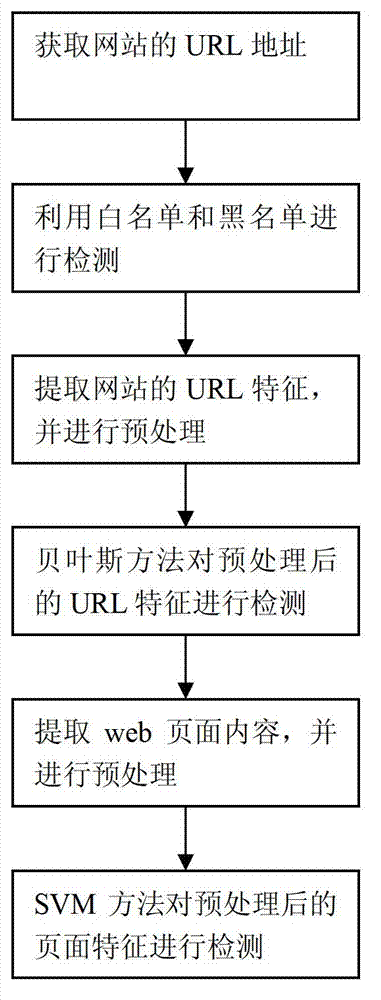

Real-time detection method and system of phishing website

InactiveCN102932348AEasy extractionMeet the requirements for rapid classificationData switching networksLeast squares support vector machineClient-side

The invention relates to a real-time detection method and system of a phishing website. The method comprises the following steps of: obtaining the URL (uniform resource locator) address of the current website; detecting the URL address of the website by use of a white list and a black list; extracting the URL features of the website URL not in the white list and the black list, and performing pretreatment; detecting the URL features after the pretreatment by a Bayesian method, and judging whether the website is a phishing website; if the website can not be clearly determined, determining the website to be a suspicious website; extracting the web page content of the suspicious website, and performing pretreatment; and detecting the page features after the pretreatment by a least square support vector machine method, and judging whether the website is a phishing website. The system consists of a system server and a system client, wherein the system server comprises a white list and black list module and the like; and the system client comprises a URL fingerprint list and the like. Compared with the prior art, the method and system provided by the invention improve the detection rate and the accuracy.

Owner:CHANGZHOU UNIV

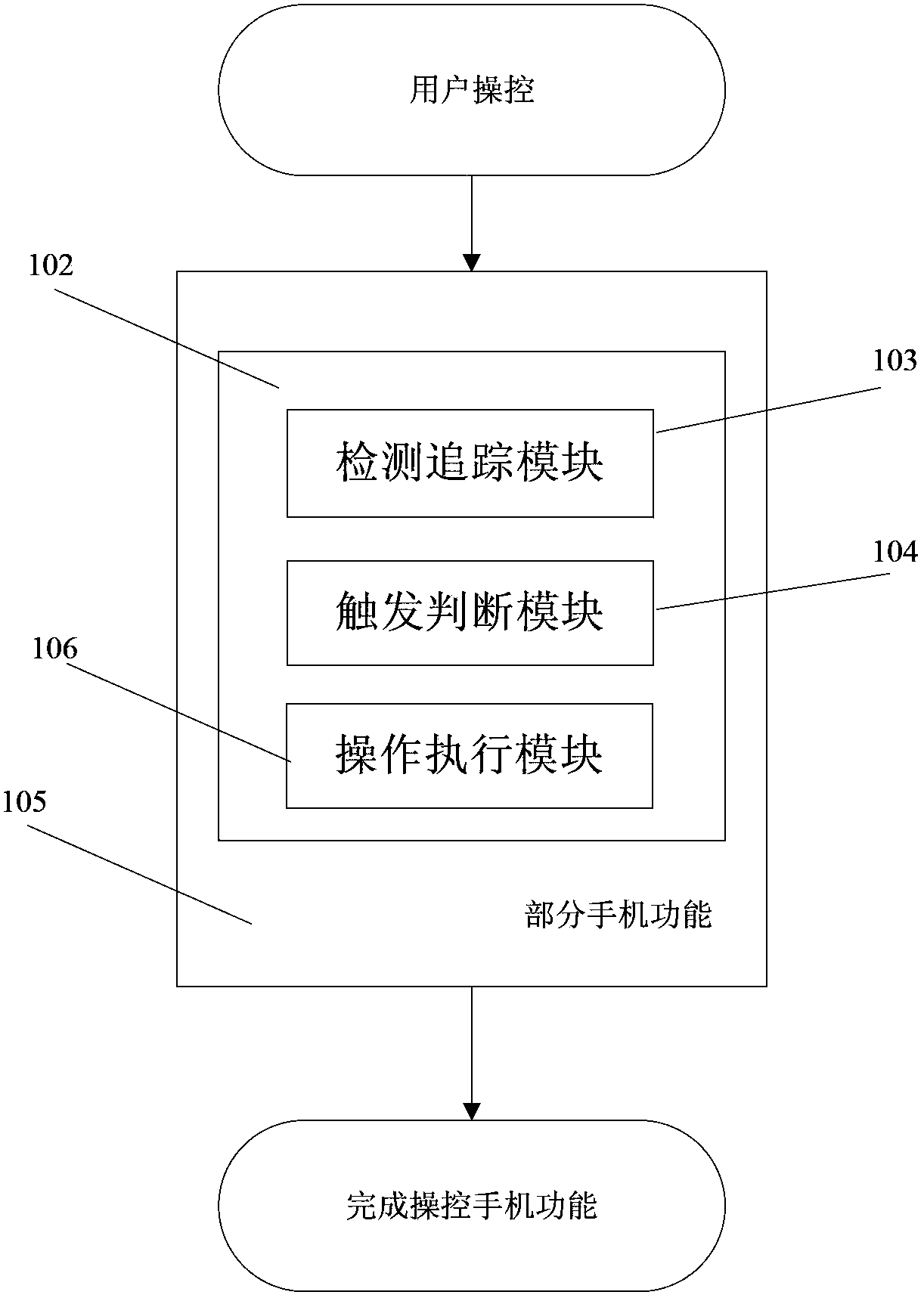

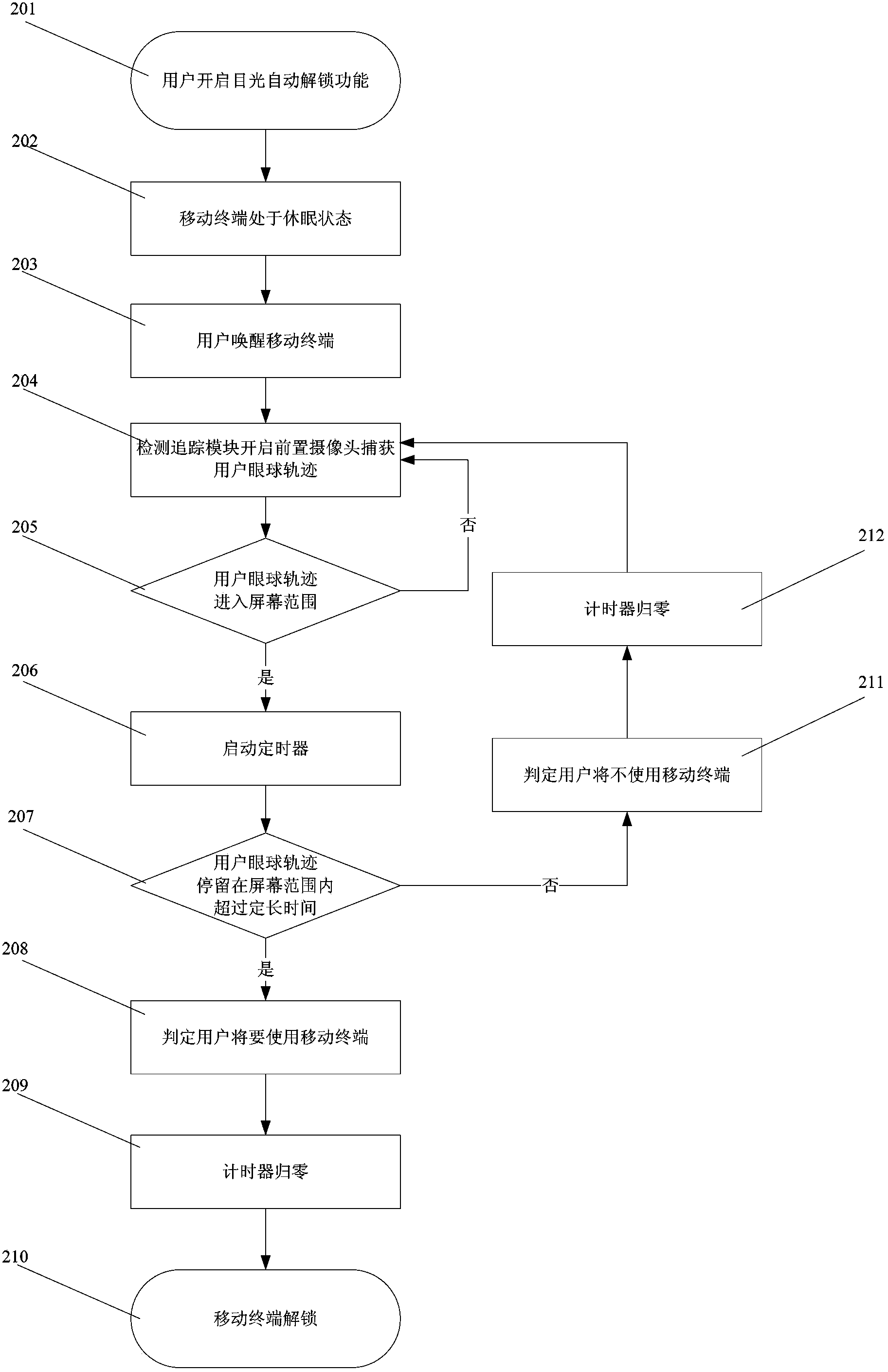

Mobile terminal and control method thereof

InactiveCN103699210AEasy to controlImprove operational efficiencyInput/output for user-computer interactionGraph readingTerminal equipmentComputer terminal

The invention discloses a control method of a mobile terminal. The control method comprises the steps that the mobile terminal detects and tracks the eyeball track of a user; whether a preset operation function is triggered or not is determined according to the tracked eyeball track; when the result is determined to be yes, the operation function which is triggered by the eyeball track is actuated. The invention also discloses the mobile terminal. The mobile terminal comprises a detection and tracking module which is used for detecting and tracking the eyeball track of the user, a trigger judging module which is used for determining whether the preset operation function is triggered or not according to the tracked eyeball track, and an operation actuation module which is used for actuating the operation function which is triggered by the eyeball track when the result is determined to be yes. According to the control method of the mobile terminal, the user can control the terminal equipment only by rotating the eyeballs.

Owner:BEIJING SAMSUNG TELECOM R&D CENT +1

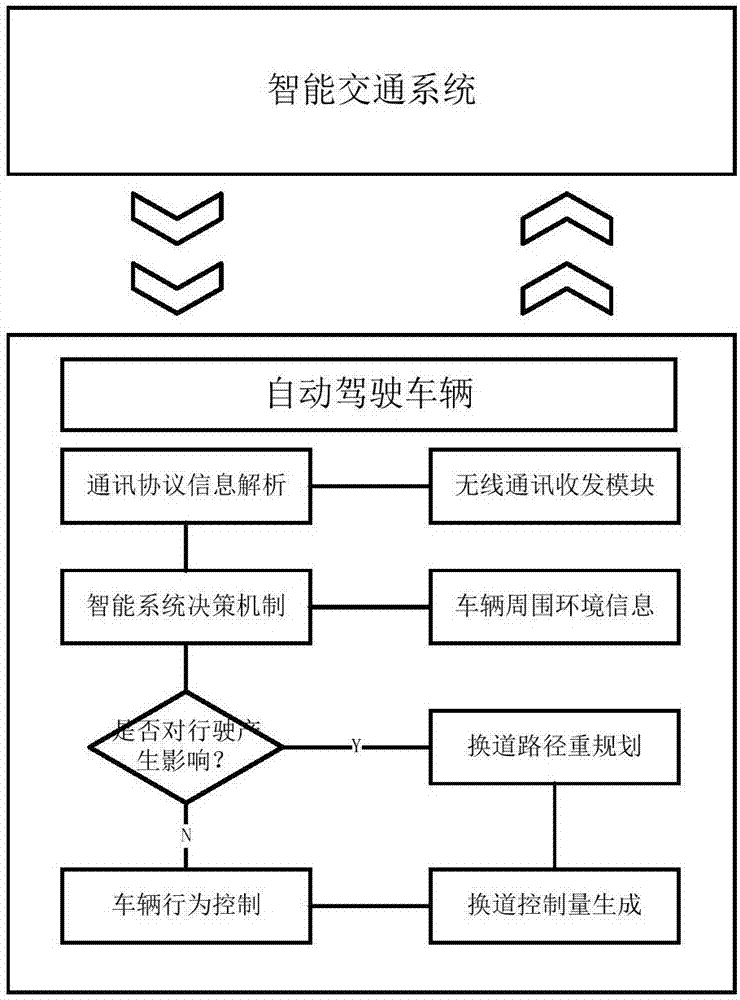

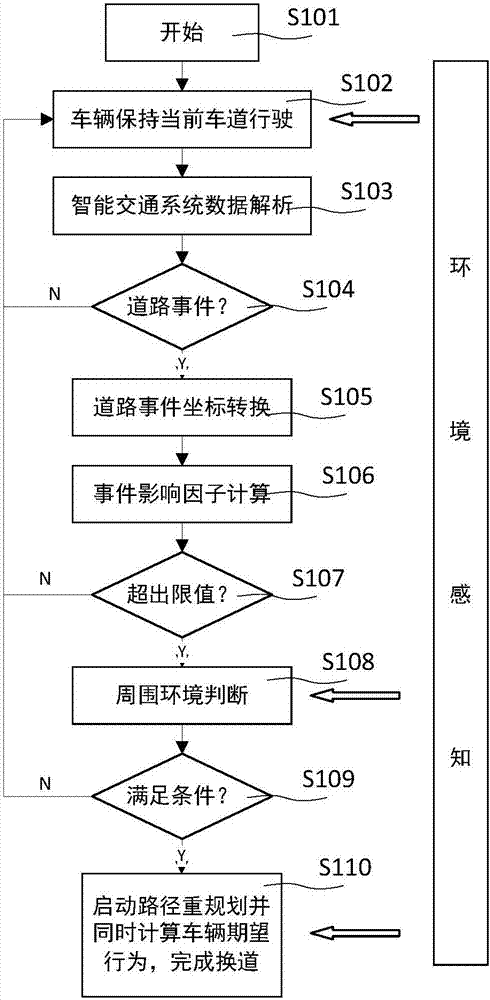

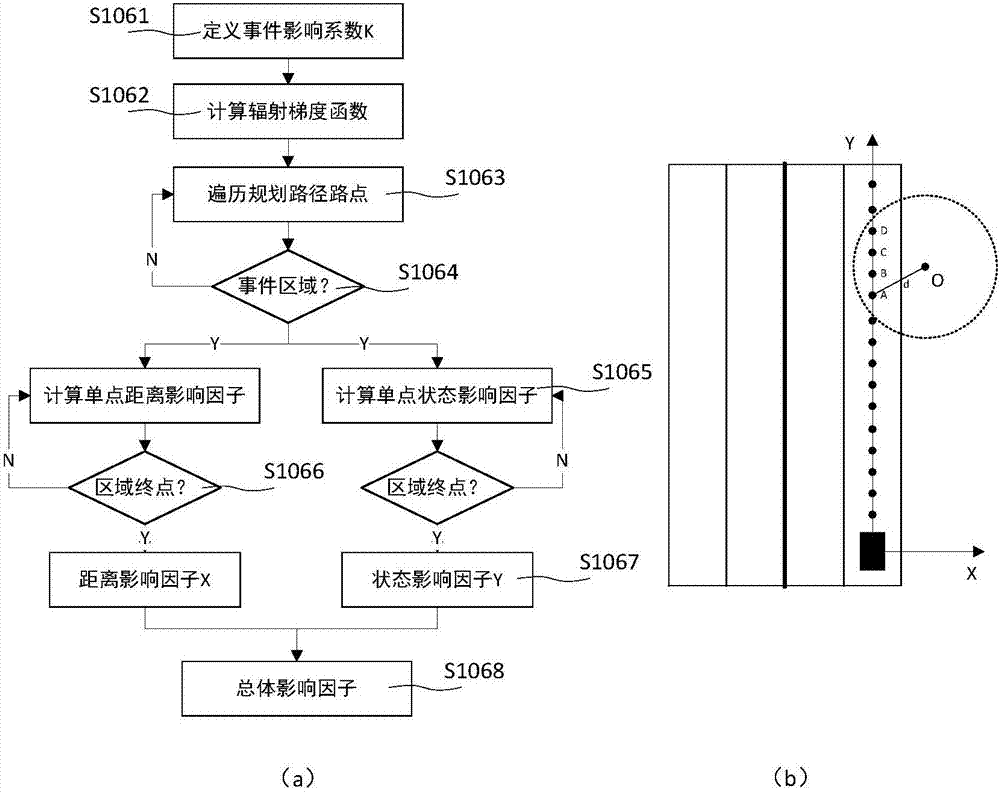

Intelligent traffic system-based intelligent vehicle lane changing decision-making method

ActiveCN106940933AIntelligent autonomous decision-making for changing lanesSmooth independent decision-making to change lanesArrangements for variable traffic instructionsAnti-collision systemsDecision takingBroadcast data

The invention relates to an intelligent traffic system-based intelligent vehicle lane changing decision-making method. The method comprises the following steps of firstly, parsing the received broadcast data of an intelligent traffic system by an intelligent driving system, and extracting the event information; secondly, completing the coordinate conversion of a road event by the intelligent driving system, and obtaining an event influence factor according to the event information; finally, according to the event overall influence factor and the judgment result that the current road environment allows the lane changing decision of a vehicle, allowing the lane changing path re-planning, simultaneously calculating the desired behavior of the vehicle and changing the lane of the vehicle. According to the technical scheme of the invention, according to the attribute of a road event ahead of the vehicle and the environmental information around the vehicle, the influence factor of the current vehicle driving road is calculated. Therefore, the necessity, the security and the reliability of the lane changing decision of an automatic driving vehicle are evaluated. Meanwhile, preparations are made in advance before the lane changing of the vehicle.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

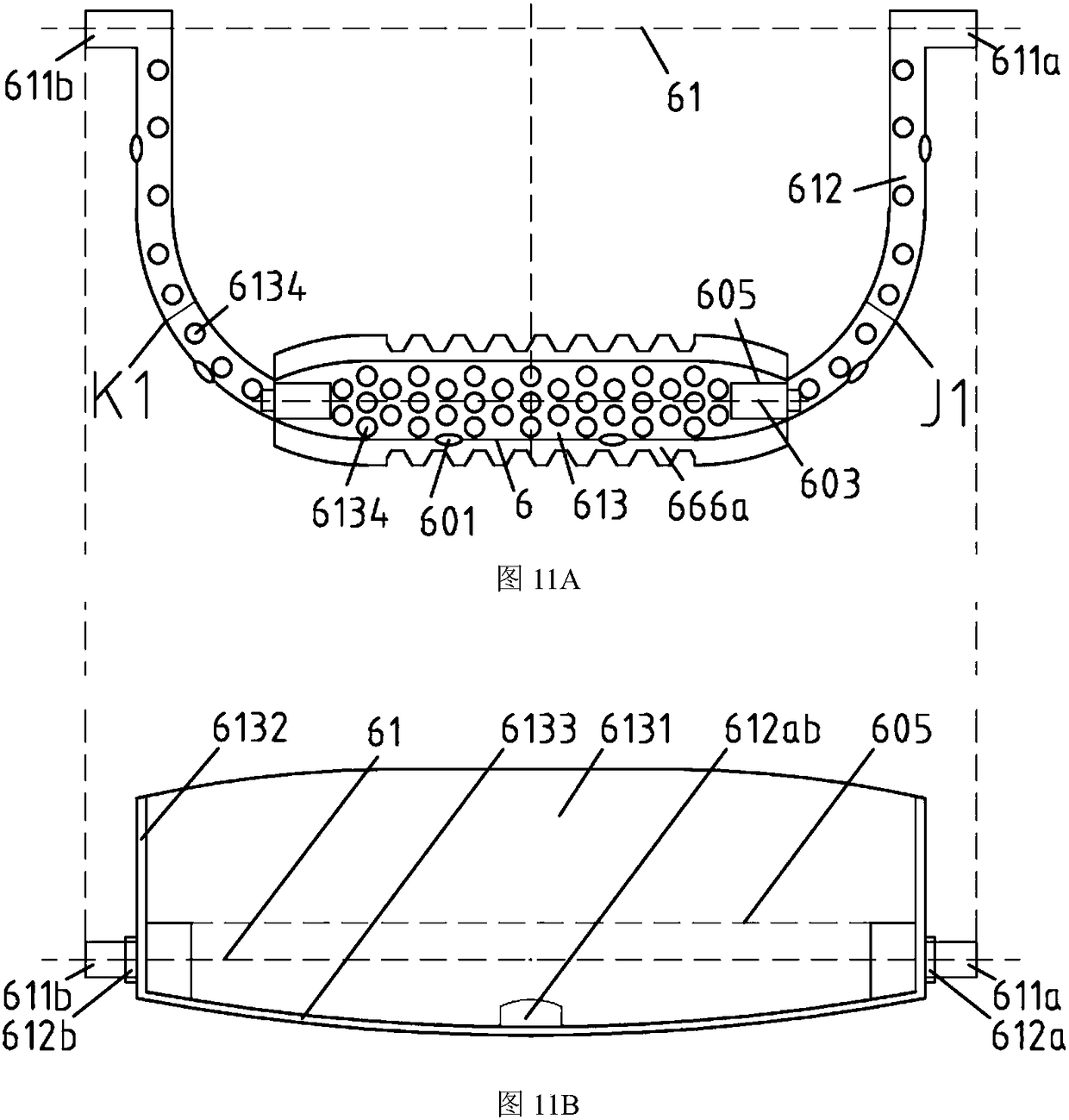

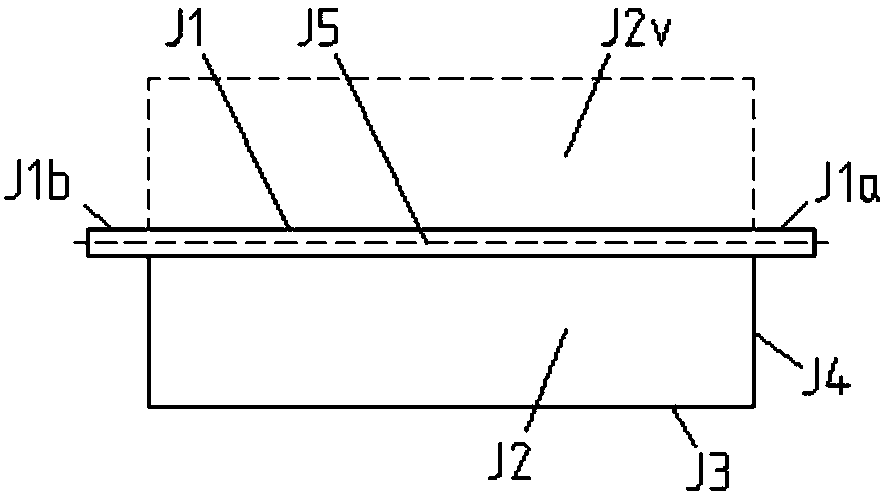

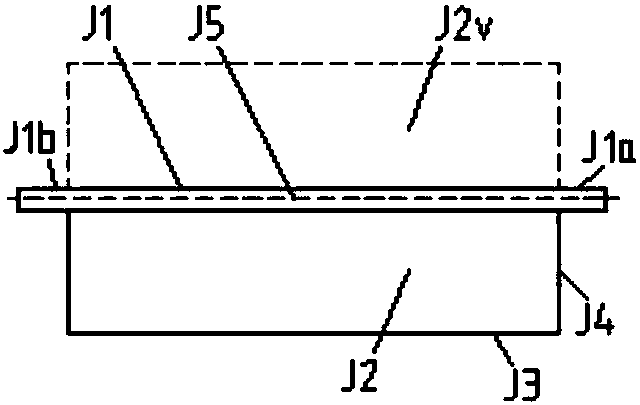

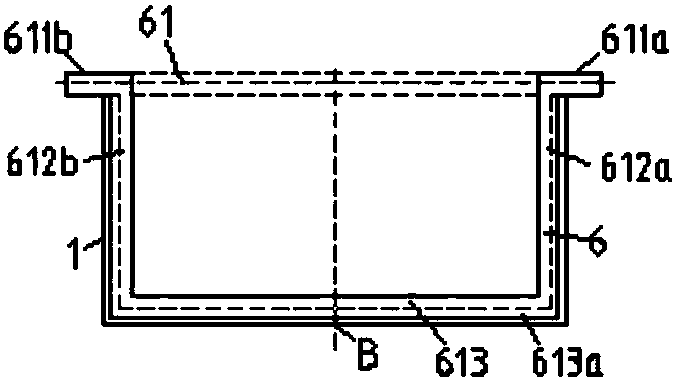

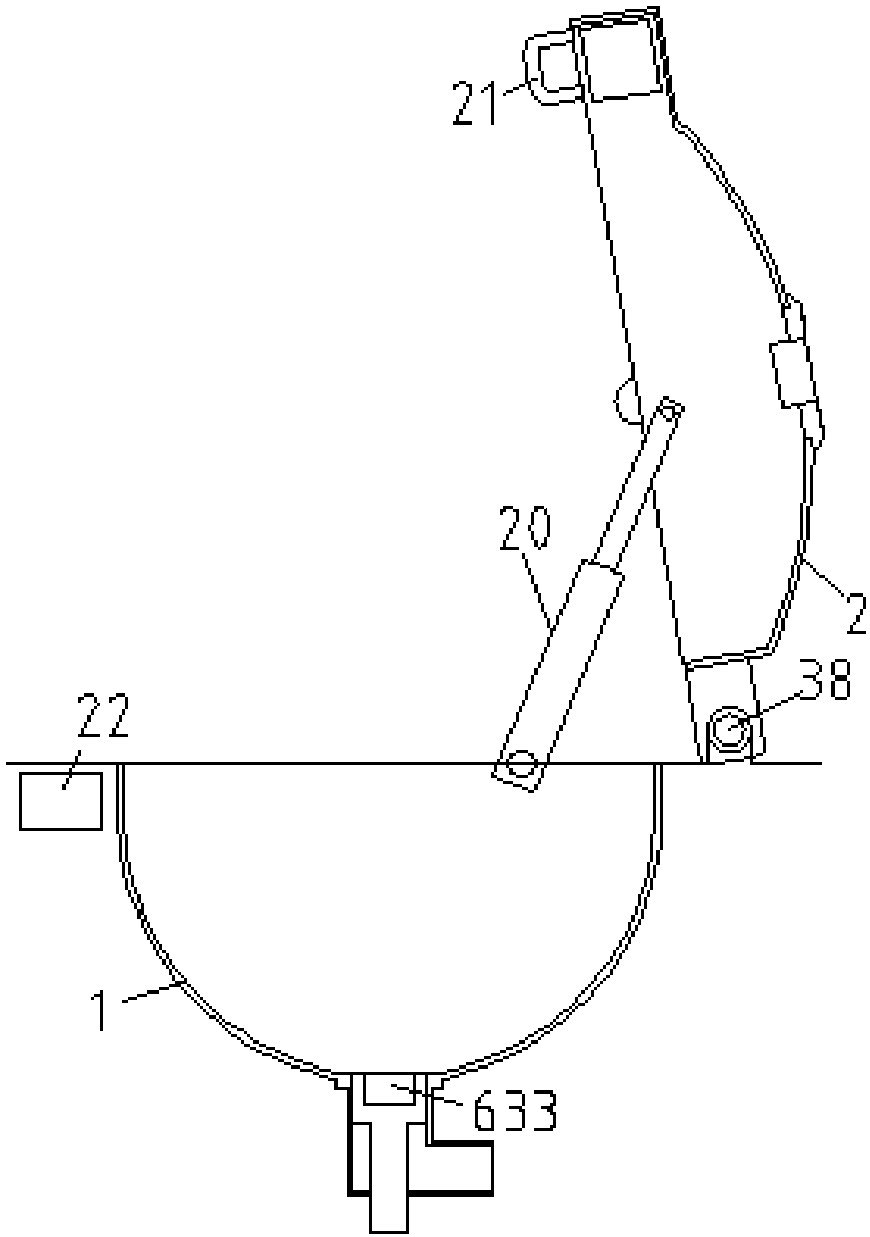

Stir-frying device of stirrer of intelligent cooker, cooker and cooking method thereof

ActiveCN109381032AOvercome inherent flawsStir fry fullyCooking vessel constructionsEngineeringCooking methods

The invention discloses a stir-frying device of a stirrer of an intelligent cooker, a cooker and a stir-frying cooking method thereof. The stir-frying device of the stirrer comprises a stirring turnersystem, wherein the stirring turner system comprises a stirring turner assisting module and a stirring turner, and the stirring turner assisting module assists the stirring turner to stir-fry foods in a pot body of the intelligent cooker. The stir-frying device enables the stirring turner to complete two or more independent movements. The pot body of the intelligent cooker comprises an envelopingplane formed by the movements of the stirring turner, and / or the stirring turner assisting module drives the stirring turner to stir-fry the foods in the pot body of the intelligent cooker by adopting a left-right stir-drying method or a deformable left-right stir-drying method. The stir-frying problem of the intelligent cooker is better solved.

Owner:李亚锐

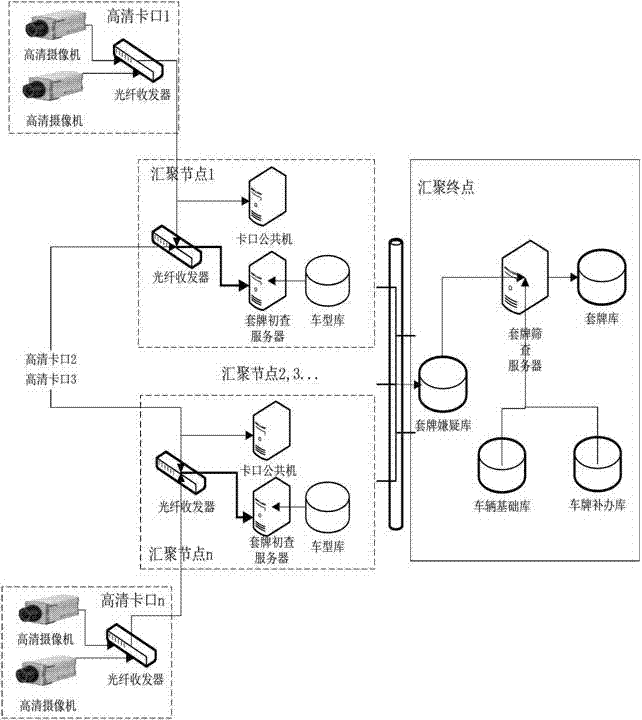

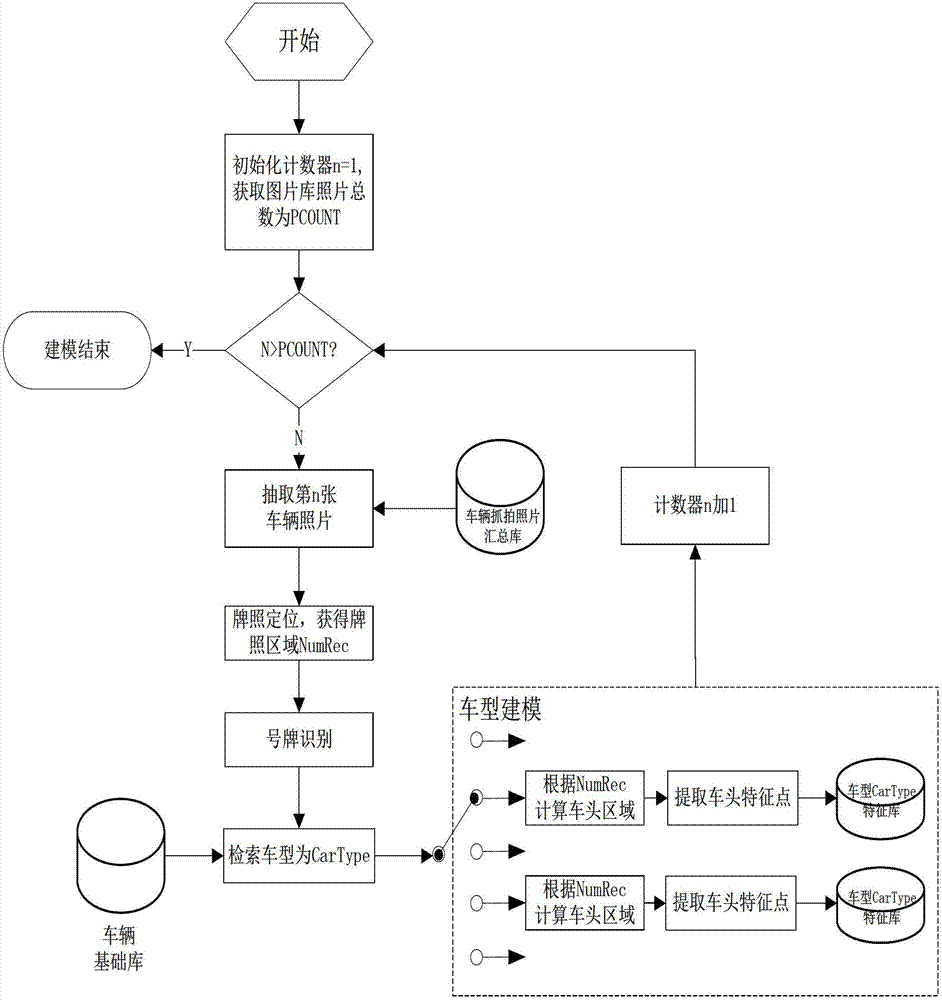

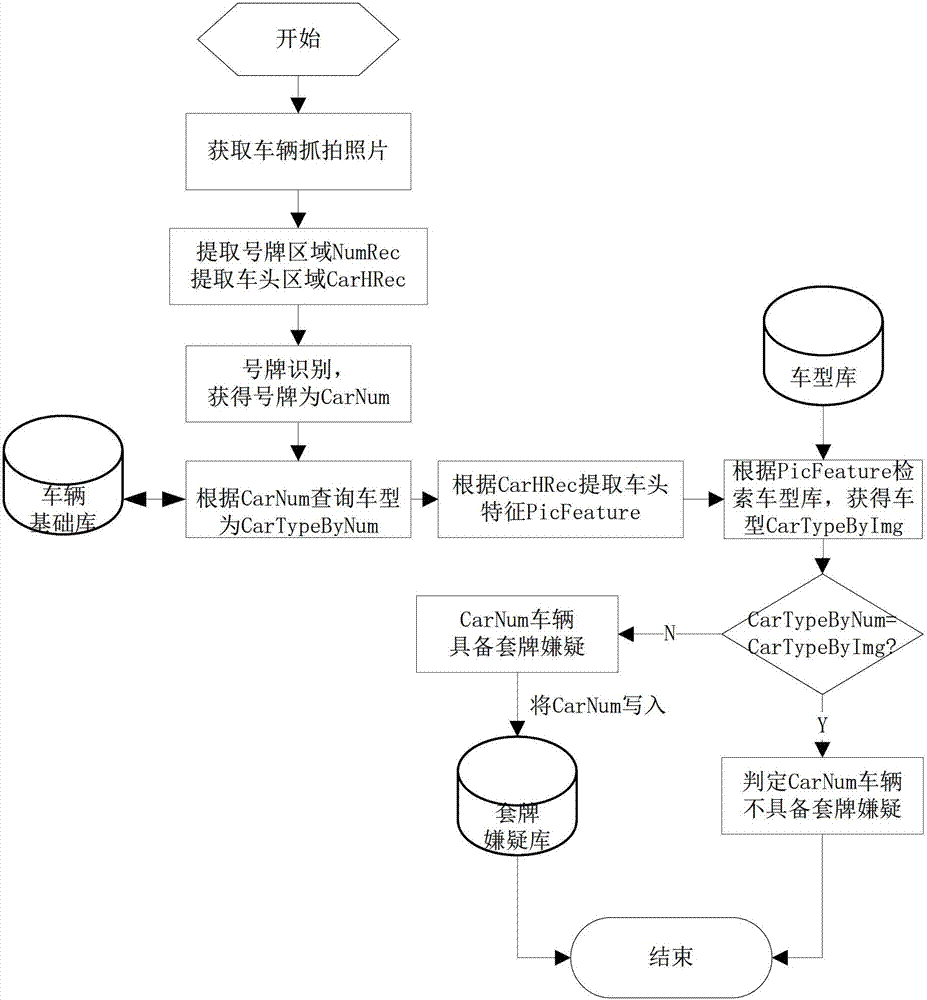

Image feature comparison based counterfeit vehicle registration plate identification method

ActiveCN103246876AImprove compatibilityImprove computing efficiencyRoad vehicles traffic controlCharacter and pattern recognitionPattern recognitionProcess module

The invention discloses an image feature comparison based counterfeit vehicle registration plate identification system which comprises a vehicle image acquisition module, a counterfeit registration plate pre-processing module and a counterfeit registration plate intensification identification module, and is characterized in that the vehicle image acquisition module is used for acquiring vehicle images and sending the images to the counterfeit registration plate pre-processing module; the counterfeit registration plate pre-processing module is provided with a vehicle type feature library and a vehicle basic library, and used for judging the type of the vehicle to be identified according to number plate area and vehicle head area, and for comparing the type with the vehicle type obtained from the vehicle type feature library through retrieval according to the vehicle number plate; when the vehicle type judged based on both the number plate area and the vehicle head area is not consistent with the vehicle type obtained from the vehicle type feature library through retrieval according to the vehicle number plate, the counterfeit registration plate pre-processing module takes the vehicle to be identified into the counterfeit registration plate suspicion library and transmits to the counterfeit registration plate intensification identification module for processing; the counterfeit registration plate intensification identification module judges whether the to-be-identified vehicle with the plate taken into the counterfeit registration plate suspicion library is the set of sign vehicle according to the vehicle number plate reissue condition, the intensity of license plate fuzzy coefficient of the to-be-identified vehicle image, and the intensity of the error clustering factor of license plate number.

Owner:SUZHOU XIANGYI NETWORK TECH

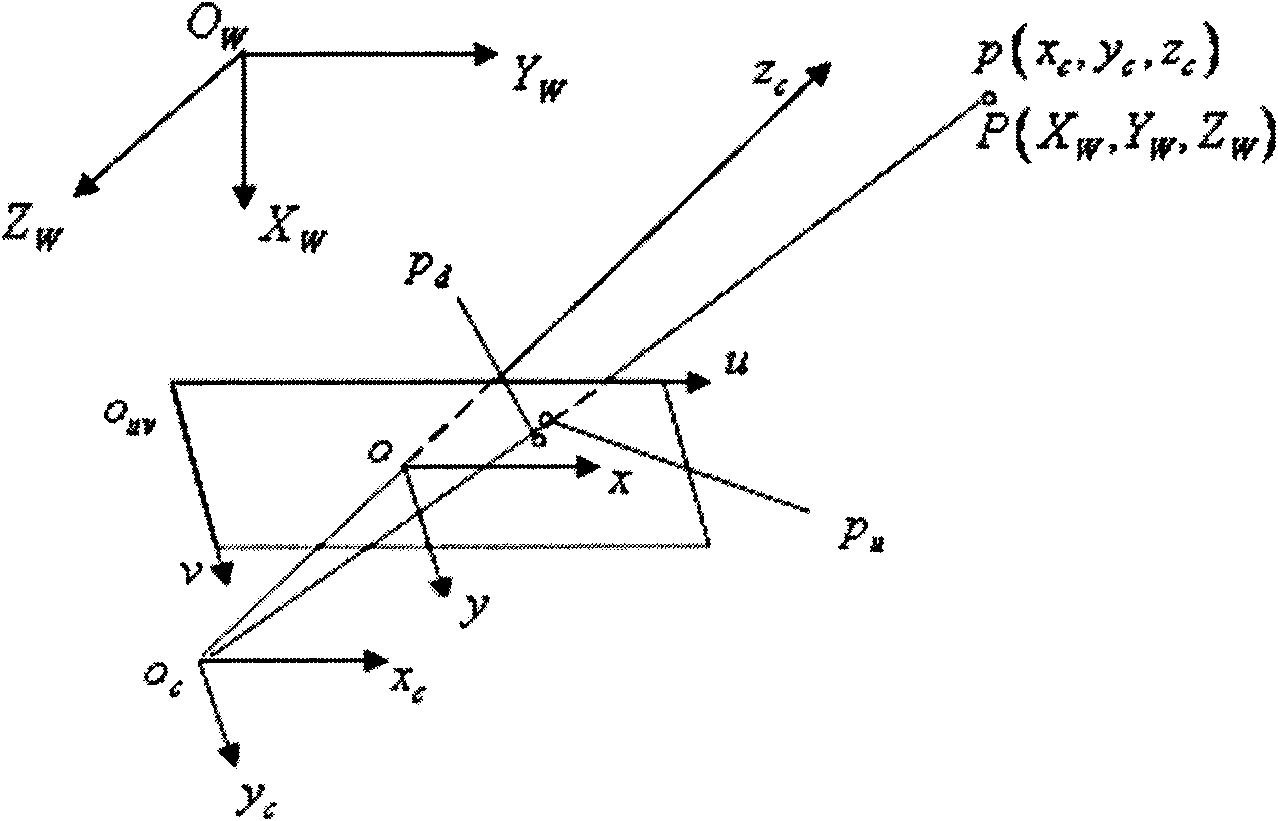

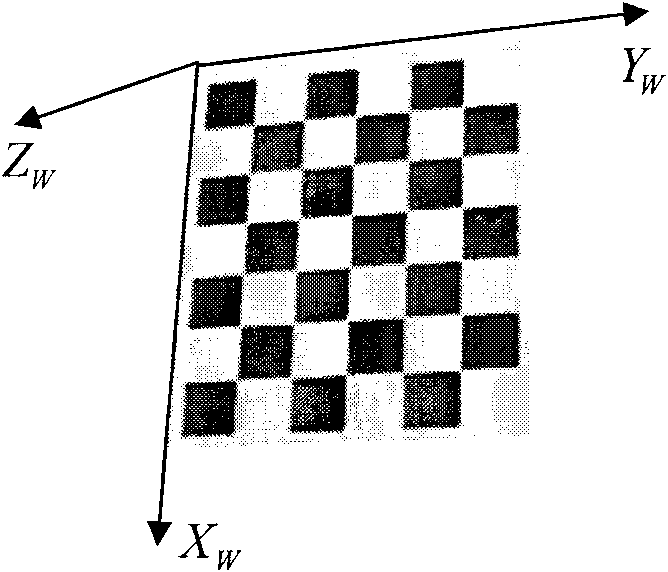

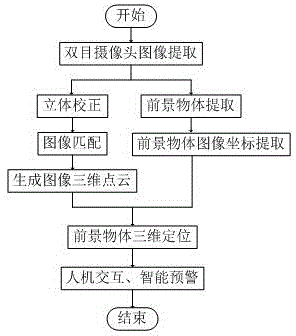

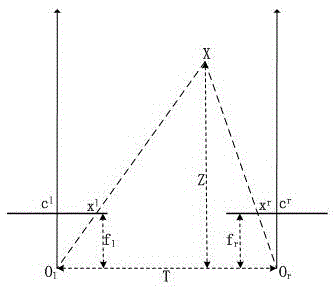

Vehicle intelligent method for automatically identifying road pit or obstruction

InactiveCN101549683AEnsure driving safetyReduce incidenceAutomatic initiationsCharacter and pattern recognitionInformation processingCyclic process

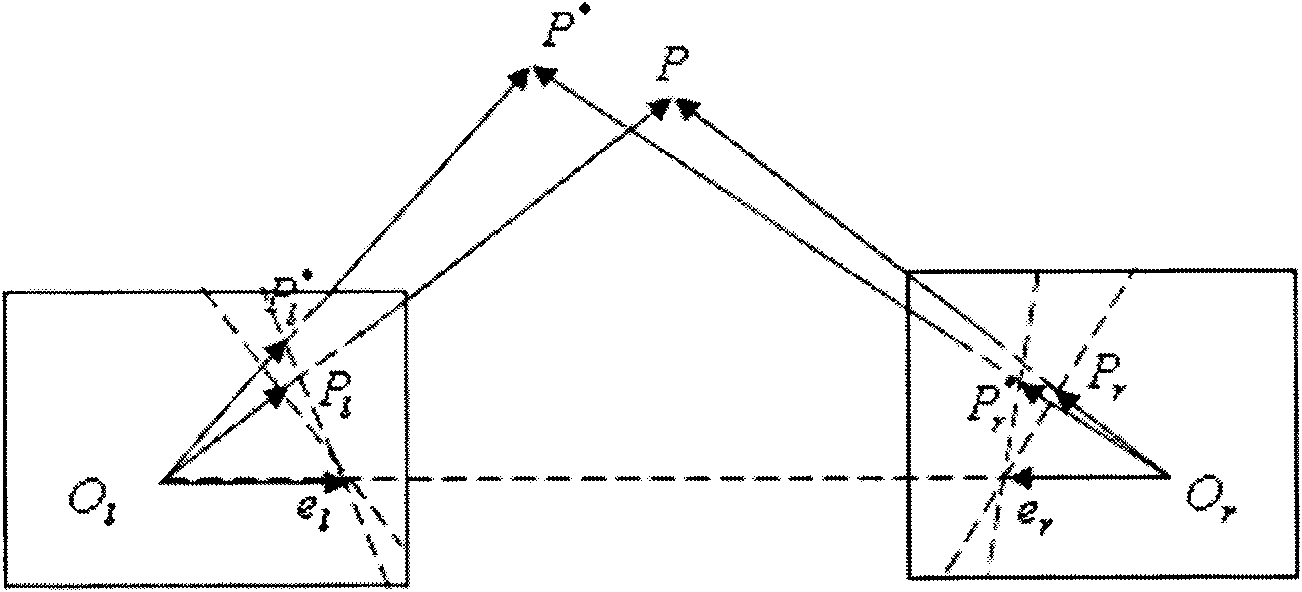

A vehicle intelligent method for automatically identifying road speed-limit sign in the technical field of information processing includes the following steps: step one, two pinhole cameras are respectively installed at the edge of the inner side of the vehicle front far-sight lamp; step two, the two pinhole cameras collect road surface scene images in real time, and the collected images are respectively transported to a signal processor; step three, the images are processed by eliminating image distortion; step four, aiming at corner points that already found out, the mutual matching of corner points is automatically realized in left and right views under the instruction of epipolar constraint; step five, the three-dimensional coordinate figure of object point is ensured; step six, pit or obstruction is identified; step seven, the vehicle driving is controlled; step eight, a cyclic process is carried out by repeating step two to step seven. The invention can further improve automatization and intelligentialization level on the aspect of guaranteeing the safety of vehicle driving without vehicle damages or traffic accidents due to pit or obstruction appearing on the road.

Owner:SHANGHAI JIAO TONG UNIV

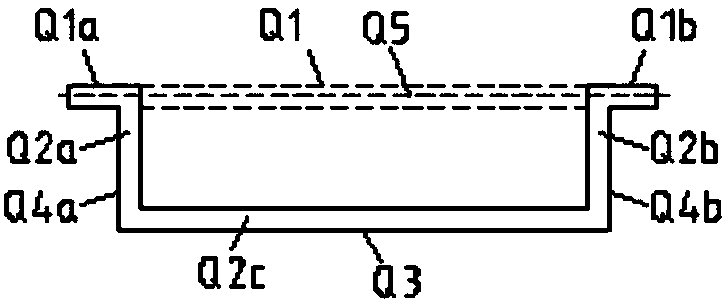

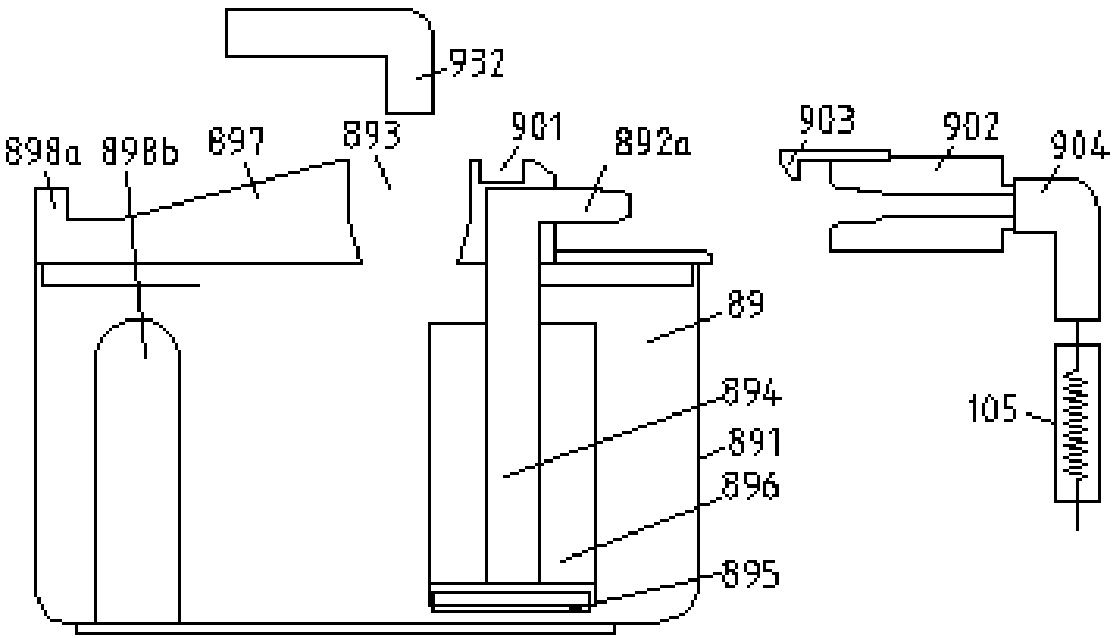

Intelligent rice cooker, integrated electric valve and filter screen pipe

ActiveCN108784446ATo achieve the purpose of saving waterCompact structureCooking-vessel lids/coversVessels with intergral heatingWater savingWater discharge

The invention discloses an intelligent rice cooker, an integrated electric valve and a filter screen pipe. The intelligent rice cooker comprises a bottom leakage spraying device, a water containing box and / or a feeding device; the feeding device comprises a worm rod and the filter screen pipe, the worm rod pushes rice grains to pass through the filter screen pipe, and a wind force, dust gravity and a centrifugal separator are used for removing dust in the rice grains; the rice cooker is provided with a filtering device for filtering rice washing water or cooker washing water discharged from the rice cooker for reuse; the rice cooker can achieve automatic addition of rice and water for cooking, and a rice cooker lid can be automatically opened or closed as needed. Through the technical scheme above, the intelligent rice cooker provided by the embodiment can save water in the processes of cooking rice and washing the cooker.

Owner:李亚锐

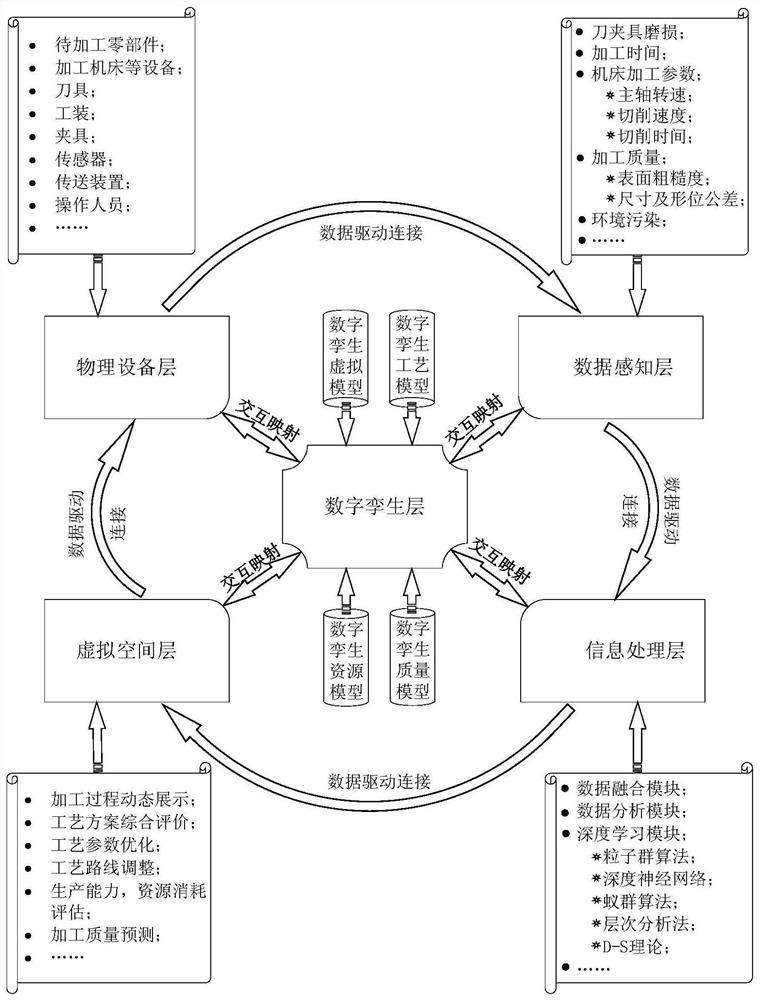

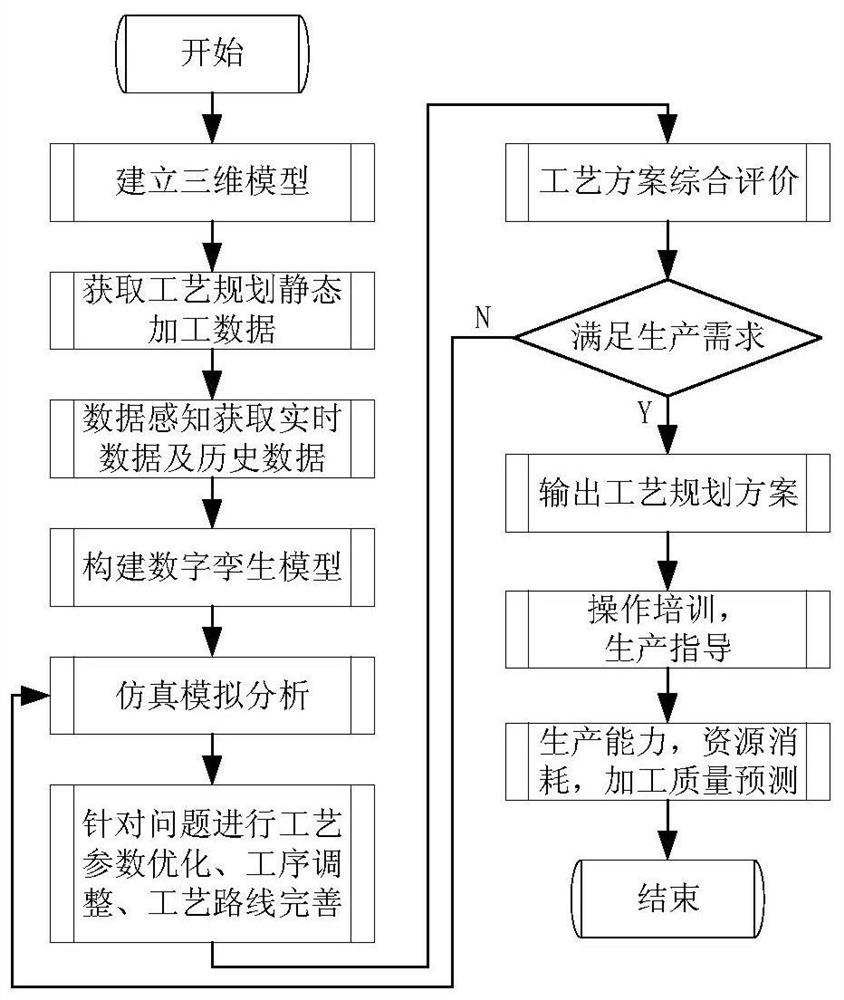

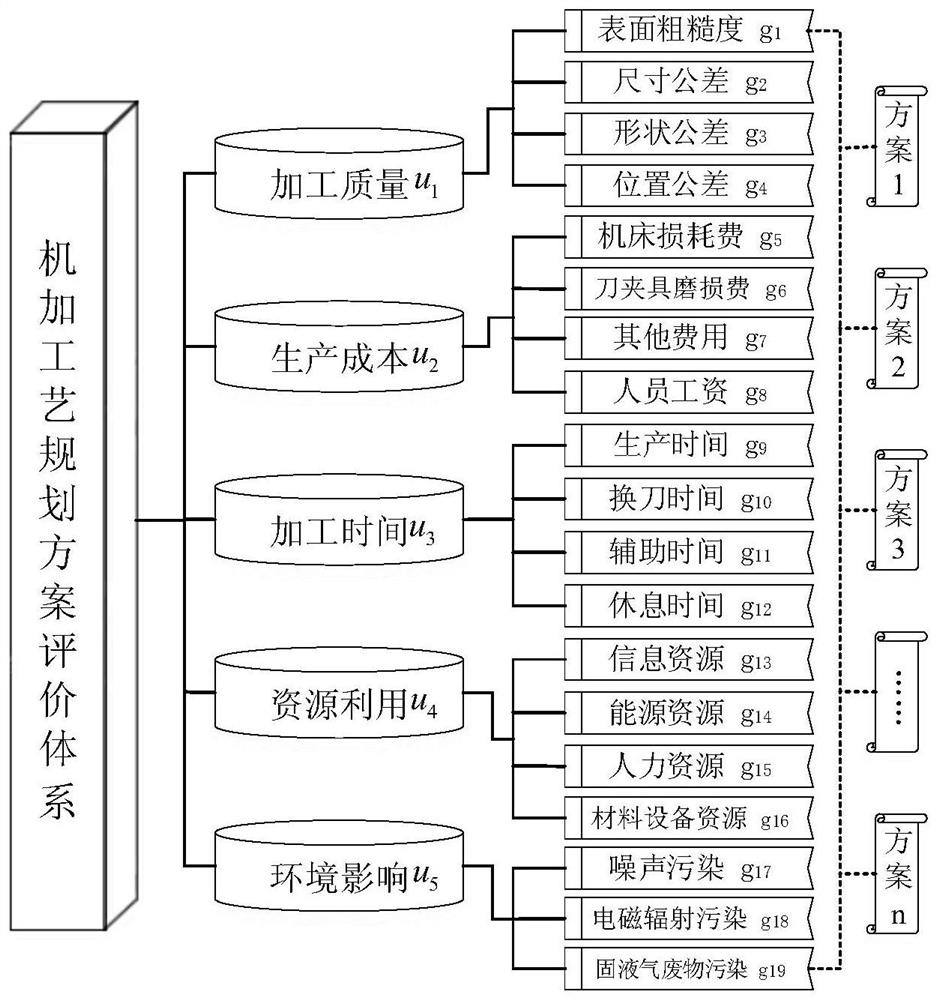

Multi-process planning comprehensive evaluation system and method based on digital twinning and deep learning

PendingCN111695734AOptimize schedulingEasy to controlForecastingDesign optimisation/simulationInformation processingVirtual space

The invention relates to a multi-process planning comprehensive evaluation system and method based on digital twinning and deep learning, and belongs to the field of process planning virtual simulation. The system comprises a physical equipment layer, a data sensing layer, an information processing layer, a virtual space layer and a digital twinning layer, the data sensing layer collects related real-time data and historical data of the physical equipment layer in the machining process and sends the data to the information processing layer for data fusion analysis and processing; meanwhile, the acquired data is transmitted to a virtual space layer, and a dynamic virtual model corresponding to the physical entity is constructed under the guidance of requirements of related models in a digital twinning layer; the digital twinning layer is used for leading the other layers together, carrying out virtual-real interaction feedback, fusion analysis and iterative optimization, and carrying out comprehensive evaluation analysis on different process schemes of the to-be-processed part, so that process parameter optimization and process route improvement are realized. According to the method, the flexibility and dynamic adaptability of process planning are improved, the resource utilization rate can be improved, the processing period is shortened, and the production cost is reduced.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI +1

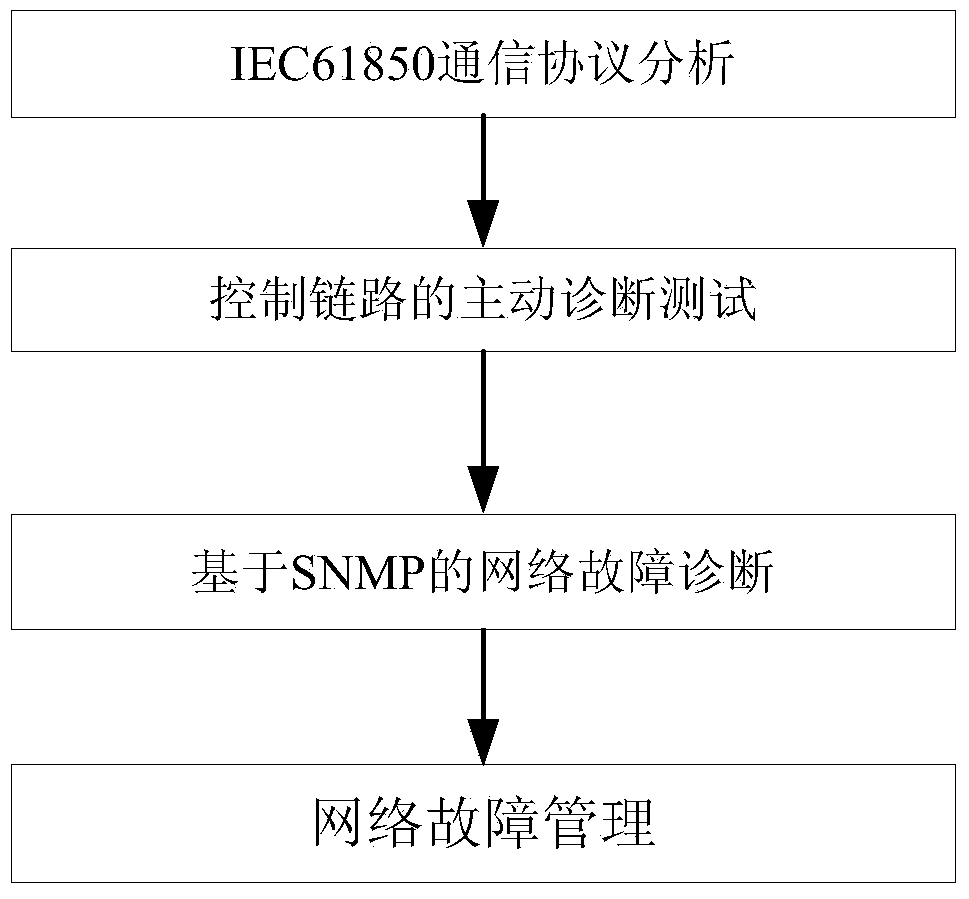

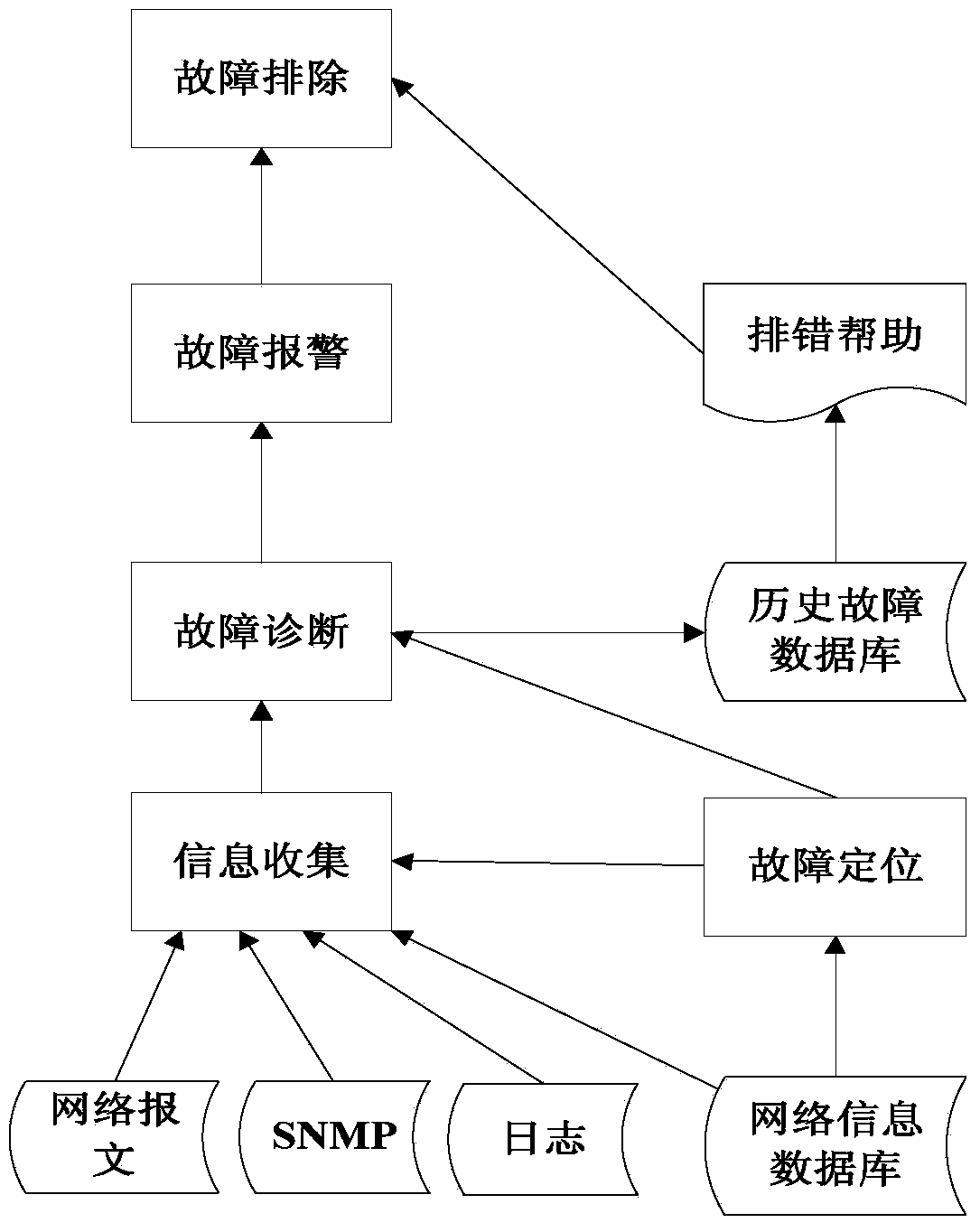

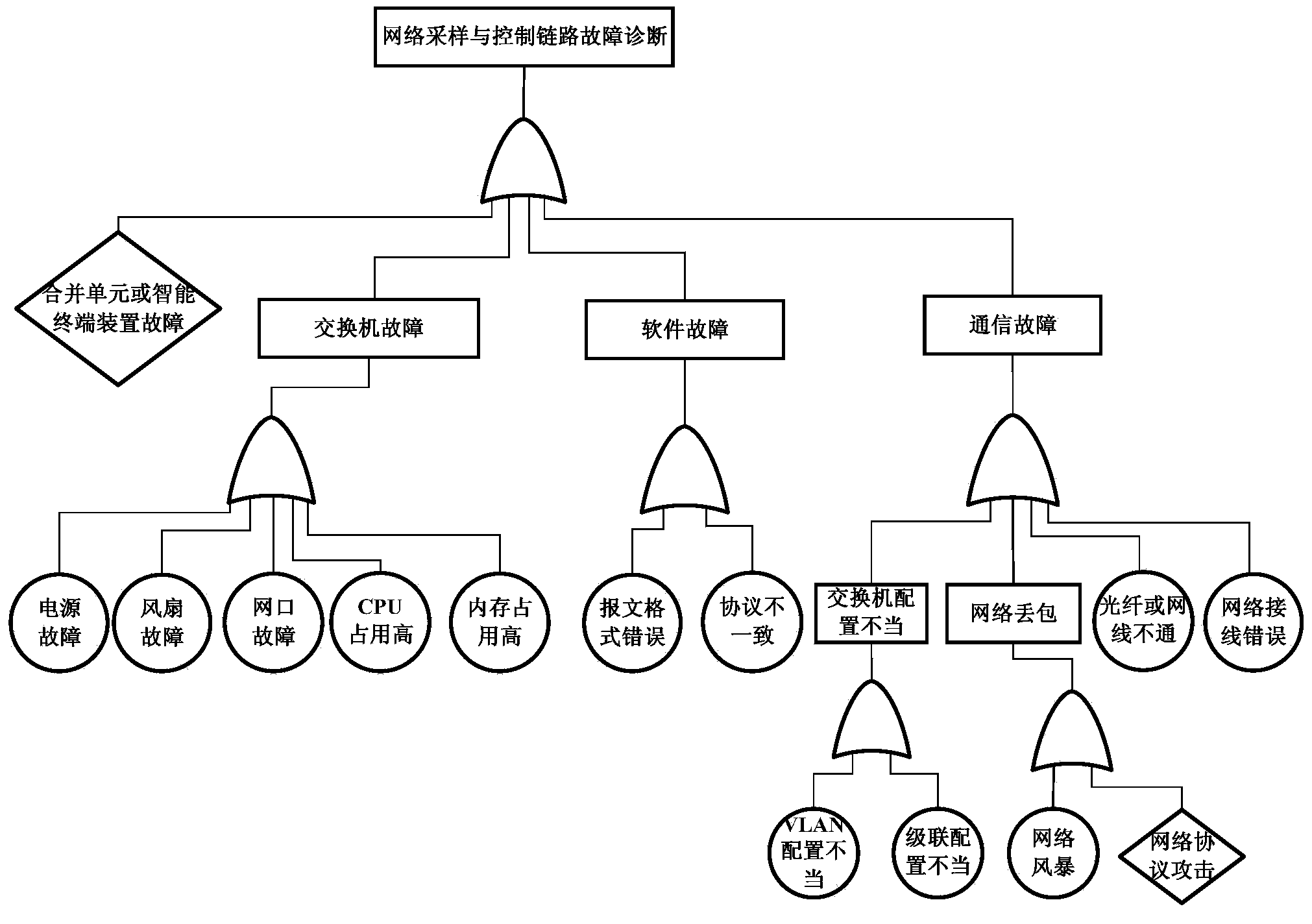

Self-diagnosis method of network sampling and control link of intelligent substation

ActiveCN103457791AImprove the level of intelligenceAvoid failureData switching networksInformation technology support systemSmart substationNetwork control

The invention provides a self-diagnosis method of a network sampling and control link of an intelligent substation. The method comprises the following steps of conducting IEC61850 communication protocol analysis; controlling an active diagnostic test of the link, and then finding out network faults; conducting network fault diagnosis based on an SNMP; conducting network fault management. The invention provides the self-diagnosis method of the network sampling and control link of the intelligent substation. The self-diagnosis method can timely find out various network faults of network operation, conduct positioning and eliminating on the faults, conduct management and recording on the network fault information, further ensure the reliability and safety of the application of network sampling and network control in the substation, and improve the intelligent level of the substation.

Owner:STATE GRID CORP OF CHINA +1

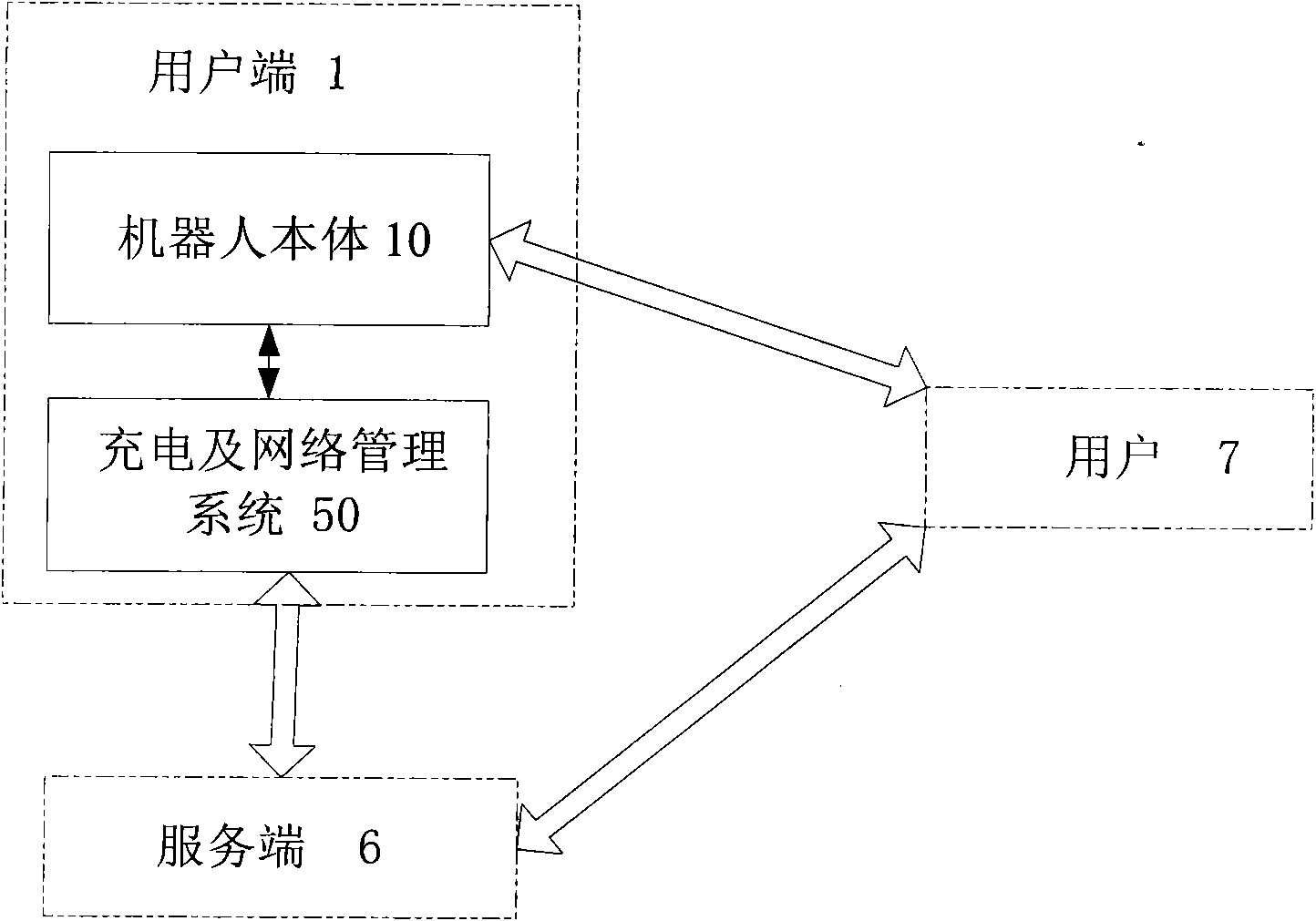

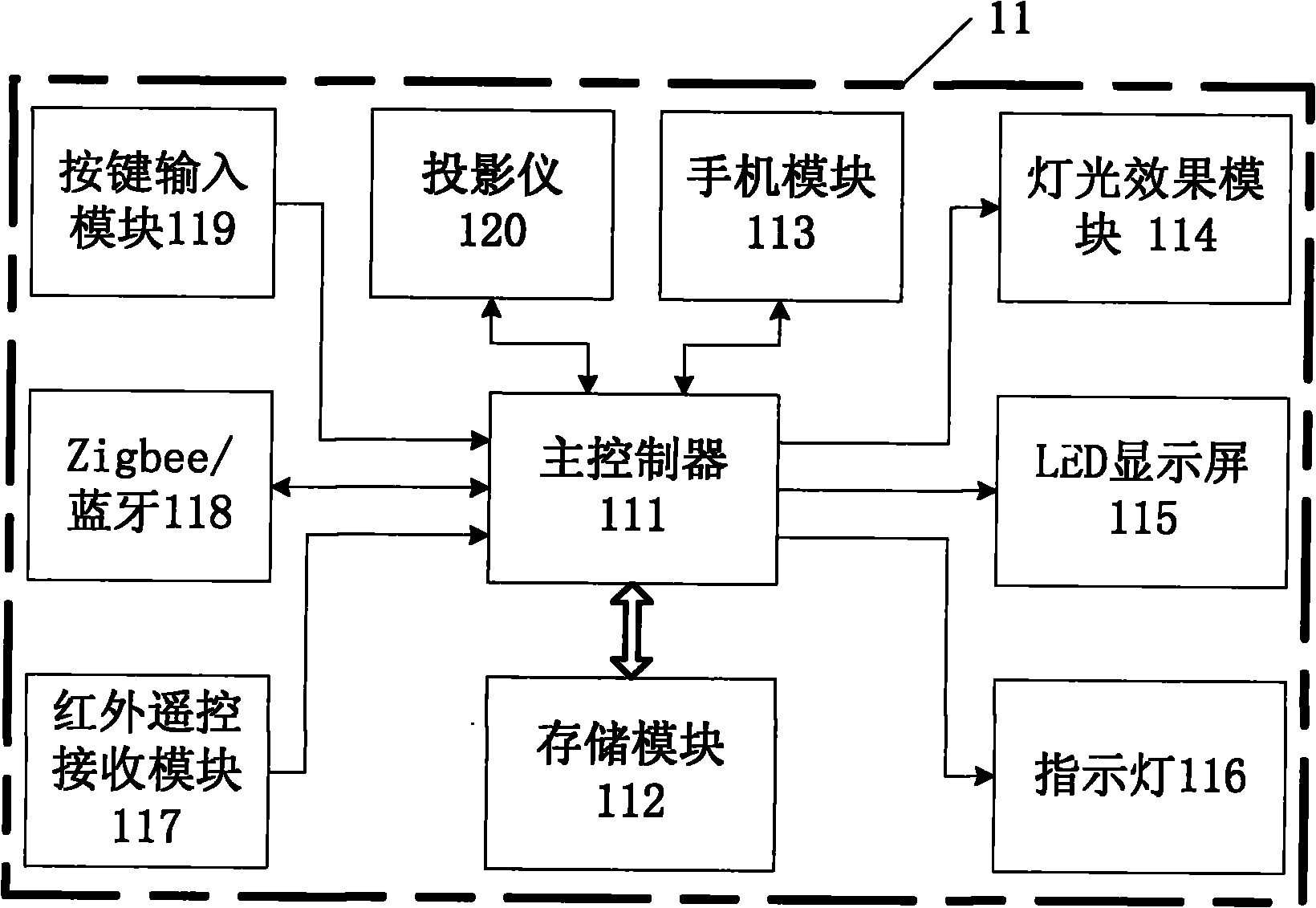

Household intelligent robot system

InactiveCN101927492AReal-time monitoringHigh degree of intelligenceProgramme-controlled manipulatorCrowdsNetwork management

The invention relates to a household intelligent robot system which comprises a user side, a server side and a user, wherein the user side comprises a robot body and a charging and network management system, the robot body comprises a man-machine interface module, a main controller, an environment monitoring module, a robot positioning module, a motor driving module, a vision module, a voice module, a data storage module, a wireless data transmission module and a power supply management module; the server side comprises a user service platform and a server side customized product server; the user can provide information support for customized service by using a computer to register information on the user service platform; and registration information of the user is collected to the server side customized product server via the user service platform, then a corresponding customized service data packet is generated after analysis and treatment, and the data packet is further sent to the user side via the server side customized product server. The household intelligent robot system can be applicable to the functions of various people groups, and has high degree of intelligence. The household intelligent robot system can be widely applied in the robot systems in various environments.

Owner:焦利民

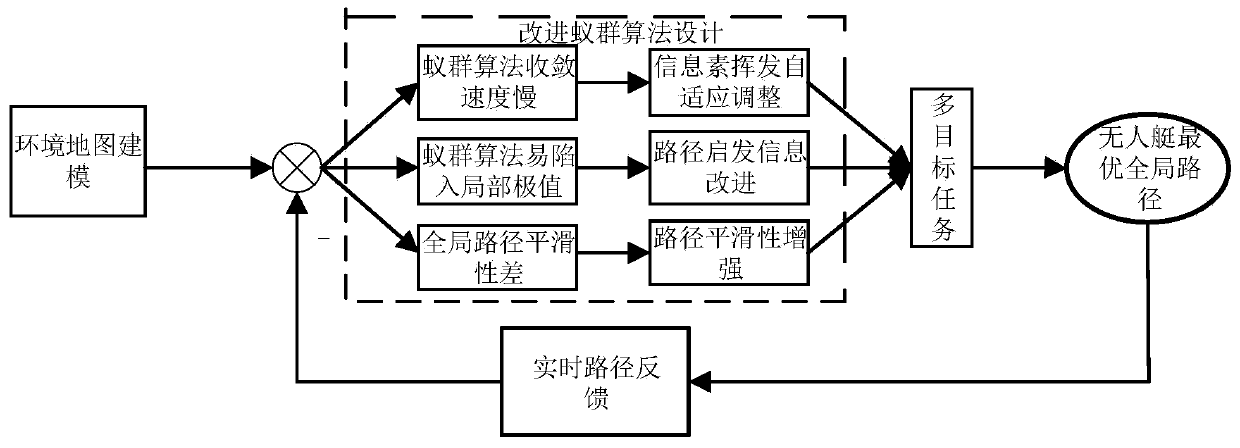

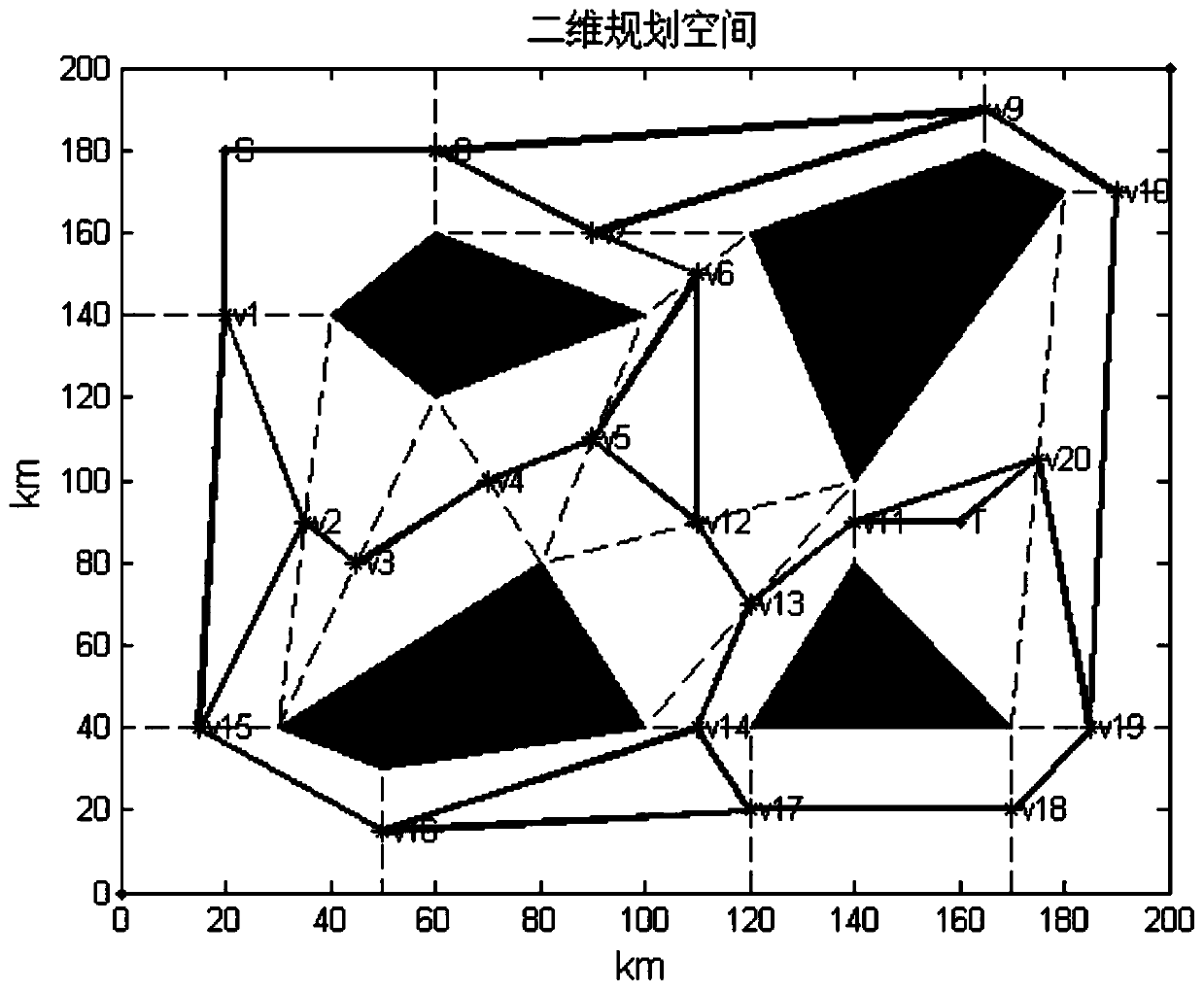

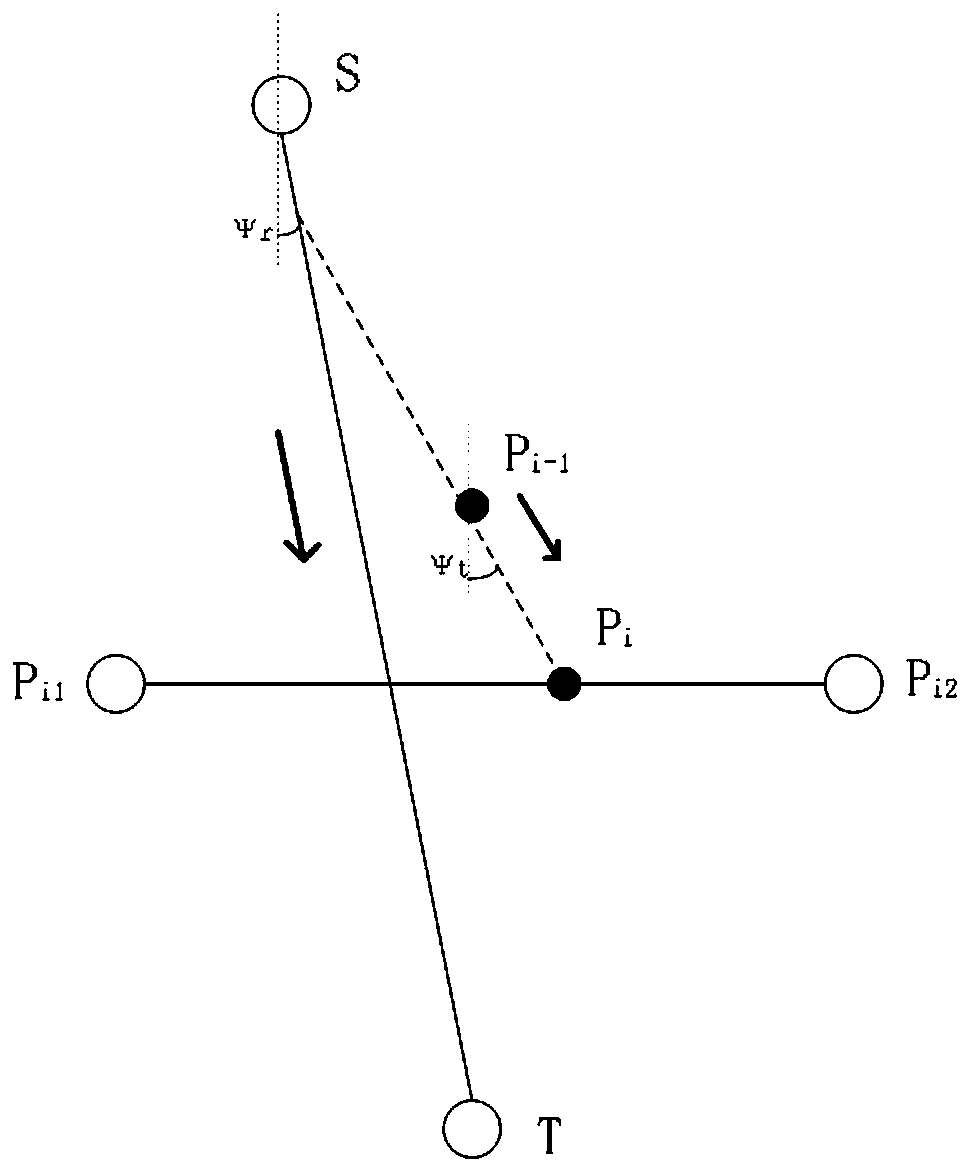

Unmanned ship global path multi-objective planning method based on improved ant colony algorithm

PendingCN111026126ALow volatility coefficientIncrease channeling effectPosition/course control in two dimensionsInformation strategiesMaritime navigation

The invention belongs to the field of unmanned ship global path planning and particularly relates to an unmanned ship global path multi-target planning method based on the improved ant colony algorithm. The method comprises steps of establishing a marine environment map model by utilizing a Maklink graph theory; improving a path heuristic information strategy to obtain a path average value; designing an ant pheromone volatilization adaptive adjustment strategy; designing a strategy combining local pheromone updating and global pheromone updating; improving the state transition probability of anext node searched by an ant colony through a heading angle deviation factor of an unmanned ship; and designing an evaluation function by integrating the requirements of the shortest global path length, the least optimization iteration times of the improved ant colony algorithm, the lowest path smoothing coefficient and the like. The method is advantaged in that multiple targets such as a globalpath distance of marine navigation of an unmanned surface vehicle, the iteration frequency of optimizing the global path by improving the ant colony algorithm and the smoothness coefficient of the planned global path are comprehensively considered, the optimal global path of marine navigation of the unmanned surface vehicle is finally planned, and the method has relatively high safety.

Owner:HARBIN ENG UNIV

Target object dynamic tracking and measurement positioning method

InactiveCN105550670ATo achieve the purpose of real-time early warningImprove the level of intelligenceImage enhancementImage analysisVideo monitoringPoint cloud

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

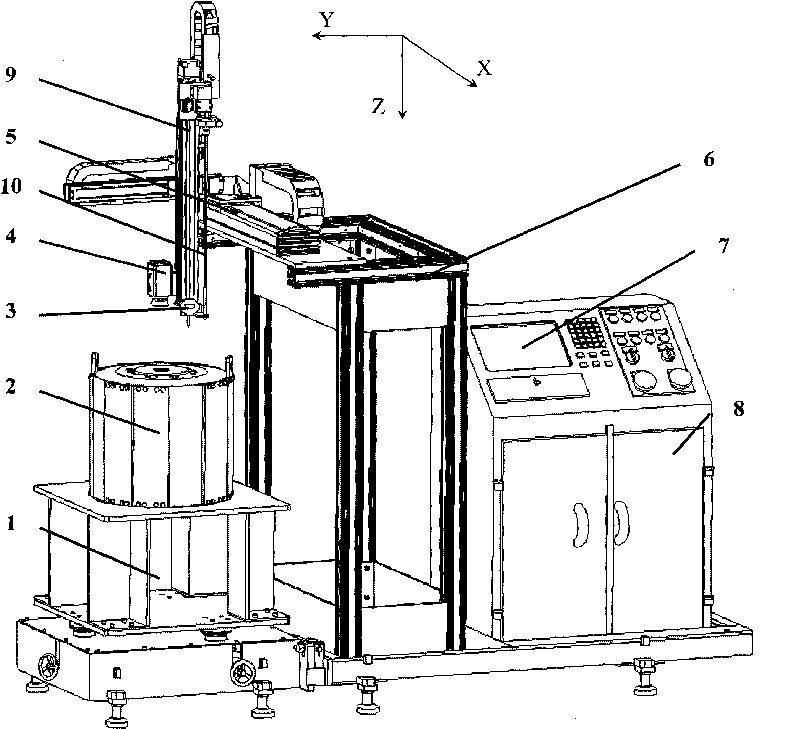

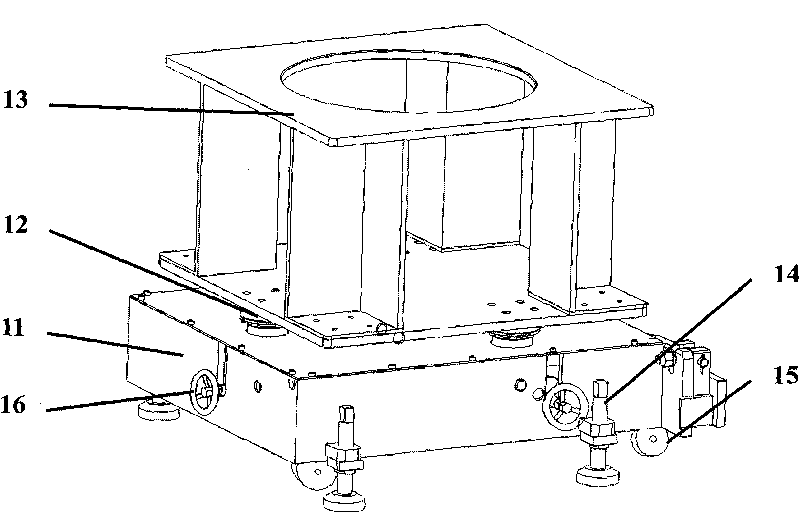

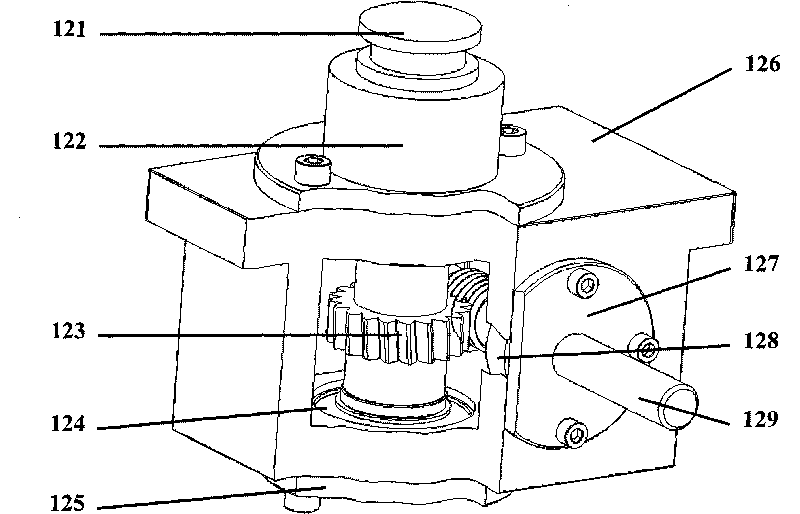

Magnetic field measuring device based on visual guiding robot

InactiveCN101702010AEasy to assembleEasy to carryMagnetic measurementsMeasurement deviceVision based

The invention relates to a magnetic field measuring device based on a visual guiding robot, which is characterized by comprising an adjustable workbench, a measuring system, a robot system and a control system which are matched with each other and have a modular design, wherein the adjustable workbench mainly consists of a base, there sets of adjusting mechanisms, a component placing table, foundation wheels and an adjustable support leg, and the gesture of the adjustable workbench can be adjusted by a hand wheel; the measuring system comprises a gesture measuring device of an object to be detected, a visual guiding positioning device and a magnetic field data collecting device; the gesture measuring device of the object to be detected mainly comprises a number dialgauge and a connecting rod; the visual guiding positioning device mainly comprises an integral camera and an image collecting card which are connected by cables; the magnetic data collecting device mainly comprises a multifunctional data collecting card, a teslameter and a Hall probe which are connected by cables; the robot system comprises a three-dimensional right angle coordinate robot; and the control system comprises an industrial personal computer and software.

Owner:HEBEI UNIV OF TECH

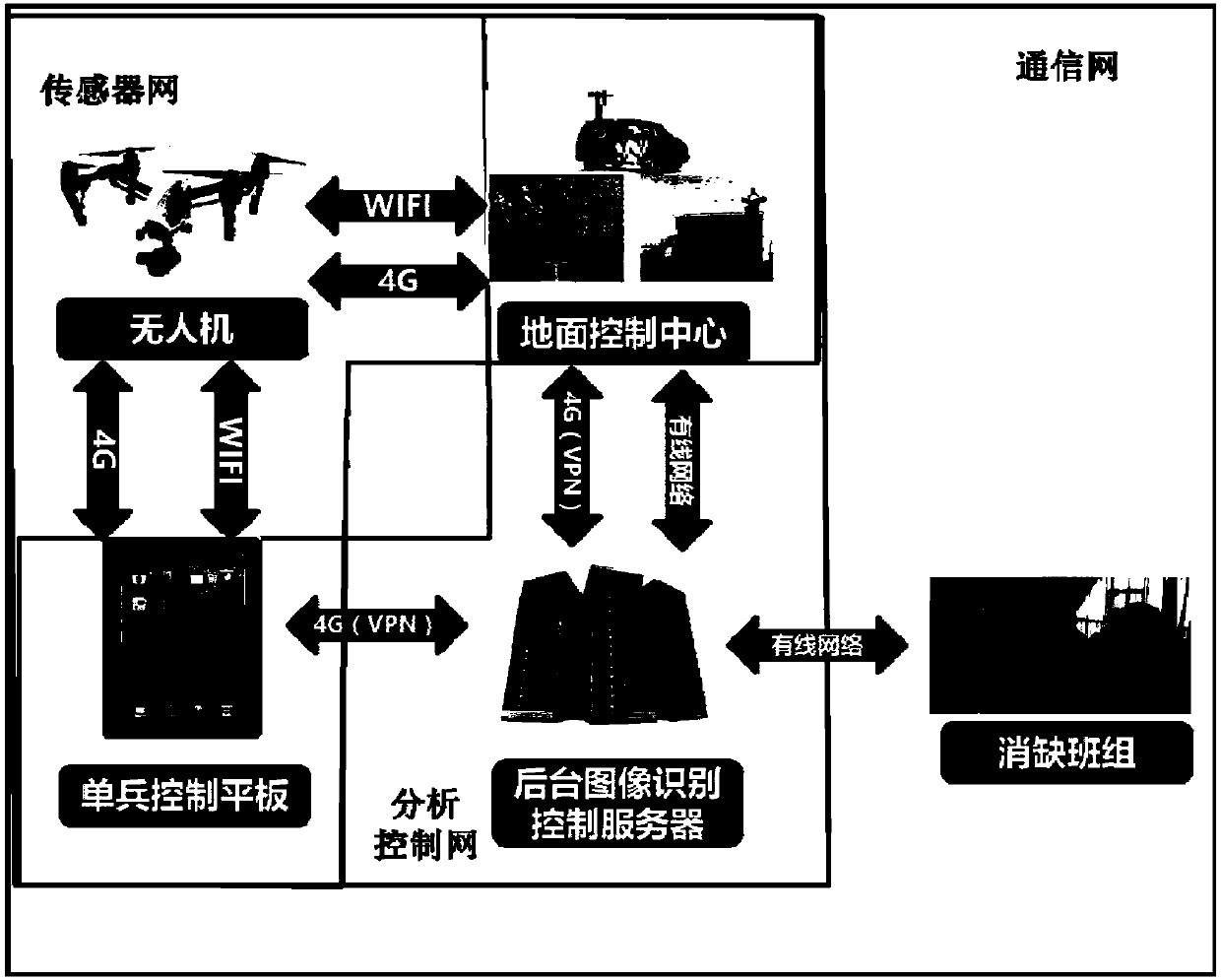

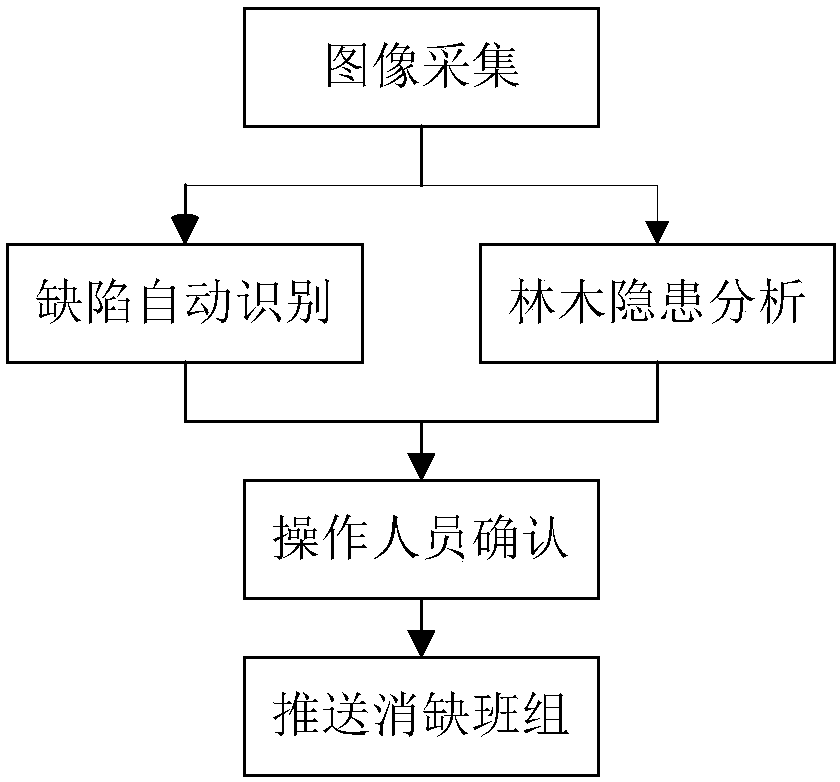

Artificial intelligence-based unmanned aerial vehicle power transmission line inspection system and method

ActiveCN108037770AImprove inspection efficiencyIncrease the level of automationTarget-seeking controlImaging analysisUncrewed vehicle

The invention discloses an artificial intelligence-based unmanned aerial vehicle power transmission line inspection system and a method. The system comprises an unmanned aerial vehicle, a background server and an unmanned aerial vehicle control platform. The unmanned aerial vehicle acquires a target image according to a preset control instruction and transmits the target image to the background server. The background server receives the target image, performs image analysis, and sends the analysis result to the unmanned aerial vehicle control platform. The image analysis comprises the steps ofdefect automatic identification and forest hidden danger analysis. The unmanned aerial vehicle control platform is used for receiving a control instruction of an operator about the unmanned aerial vehicle, and pushing the analysis result to a shortcoming-eliminating team / group according to a confirmation instruction of the analysis result. According to the invention, the automation level of the line inspection and shortcoming-eliminating operation is improved. The false alarm rate and the missing report rate of manual identification and treatment are reduced. The accuracy and the effectiveness of the analysis are improved.

Owner:JINING POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com