Preparation system of quick numerical control machining of complex parts of airplane and method

A technology for preparing systems and processing plans, applied in general control systems, control/regulation systems, computer control, etc., can solve the problem of prolonging the aircraft manufacturing cycle, affecting the machining quality and machining accuracy of parts, and the inability of post-processing programs to complete the numerical control system code. conversion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific implementation processes are provided, but the scope of protection of the present invention does not Limited to the following implementation examples.

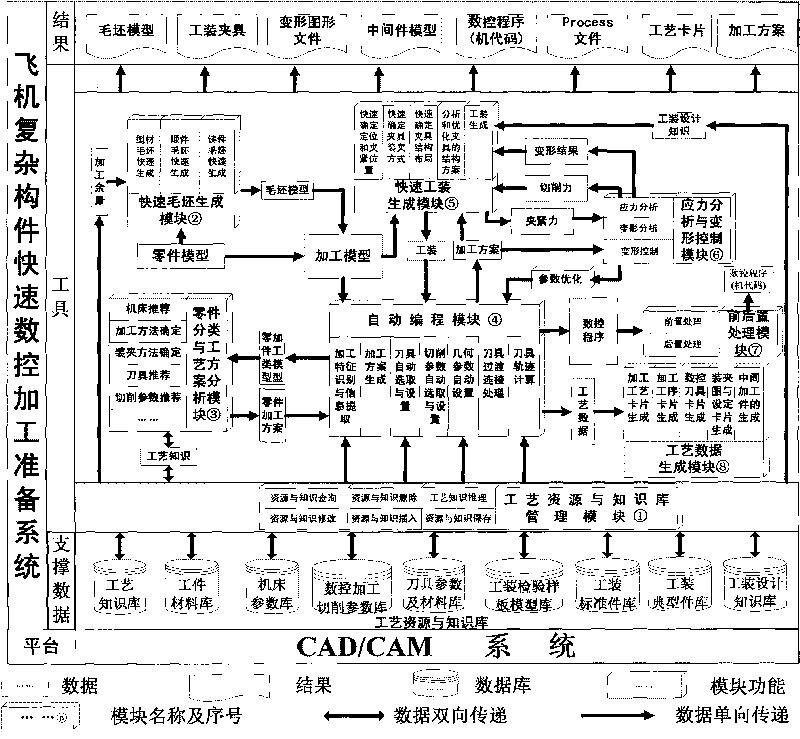

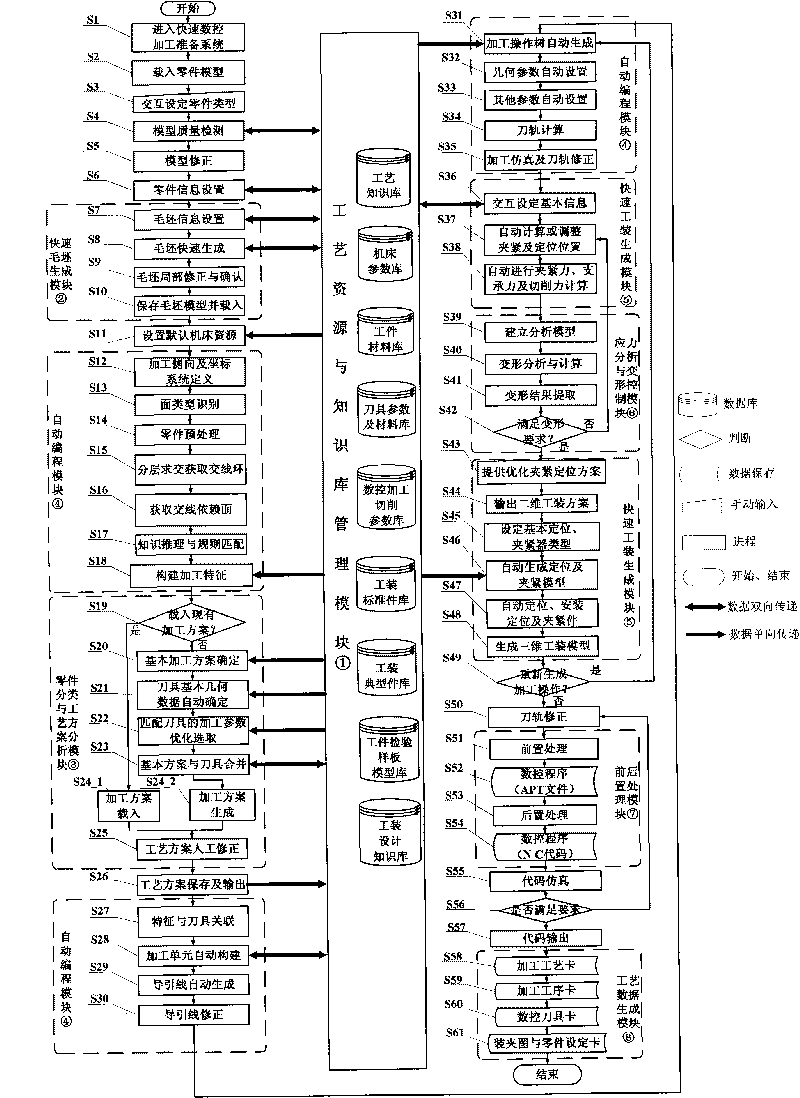

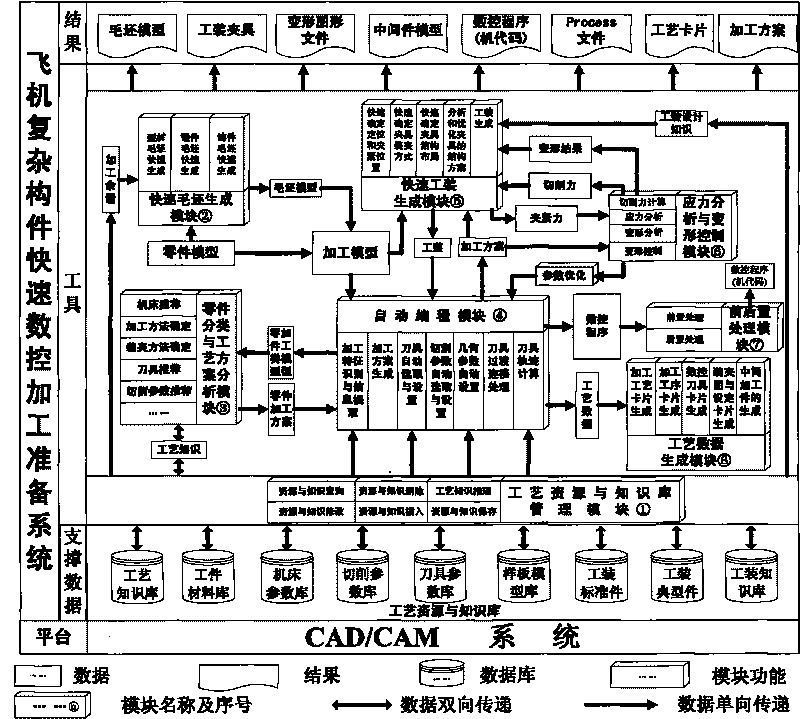

[0031] figure 1 It is a functional structure diagram of the rapid NC machining preparation system for aircraft complex components. This system is based on the "NC machining" module of the existing CAD / CAM system. Carry out and realize complete CNC machining on the 3D model from process plan planning, NC machining programming, machining deformation analysis, clamping configuration design, 3D modeling of blanks and semi-finished parts to clamping scheme, process optimization and fixture intelligent design The preparation process includes eight modules, spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com