Patents

Literature

1128 results about "Deformation control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

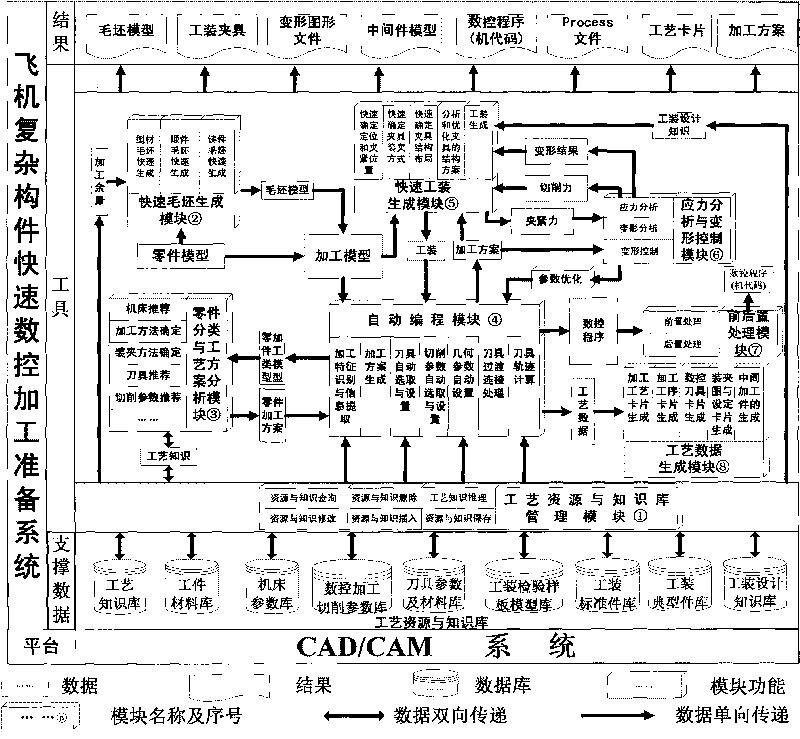

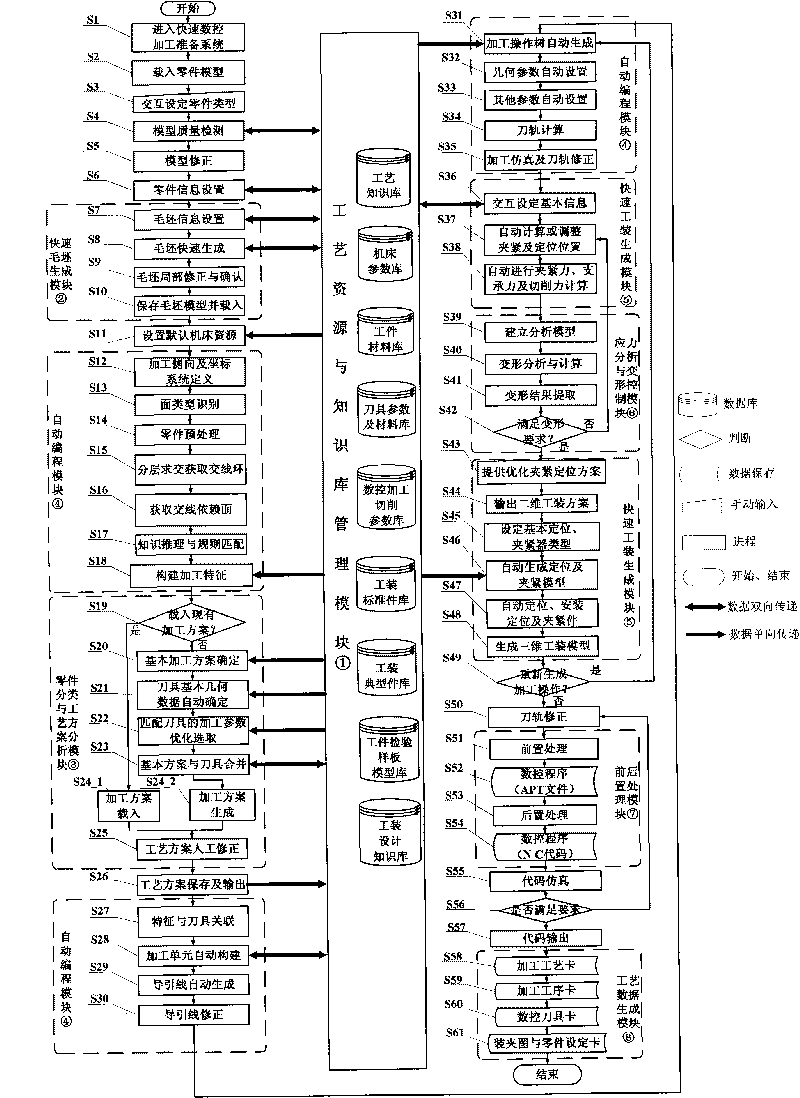

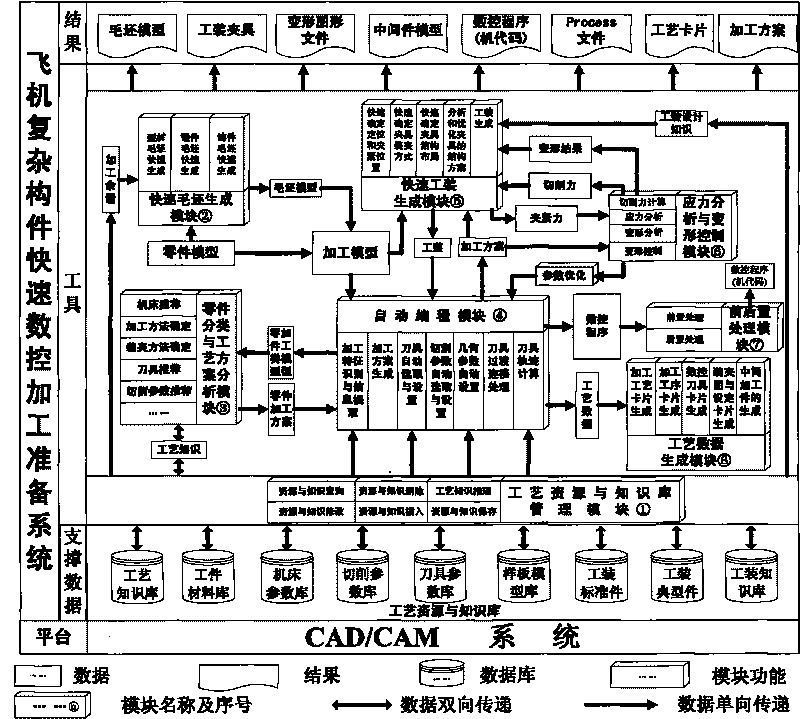

Preparation system of quick numerical control machining of complex parts of airplane and method

InactiveCN101763068ASolve problems such as unreasonable designIncrease specializationProgramme controlComputer controlNumerical controlProcess module

The invention discloses a preparation system of quick numerical control machining of complex parts of an airplane and a method. The system takes the existing CAD / CAM system as a platform, and comprises a technology resource and knowledge base management module, a quick blank generation module, a part classification and technical scheme analysis module, an automatic programming module, a quick tool generation module, a strain analysis and deformation control module, a front and rear process module and a technology data generation module. The system is built on the basis of a three-dimensional numeric part model, systematically and exactly embodies a specialized flow path for supporting the numerical control machining technology preparing and the programming of the complex parts of the airplane, can greatly reduce man-machine interaction operation required by preparing technology and programming, effectively solves the problems of the unstable programmed procedure and the unreasonable scheme design of the machining technology caused by the lack of the experience of process operators, and the like, can effectively control the deformation quantity during and after machining the parts, can obviously improve the efficiency and the quality of the numerical control machining preparing and the programming, and improves the professional level and the intelligence level of the CAD / CAM system.

Owner:SHENYANG AIRCRAFT CORP +1

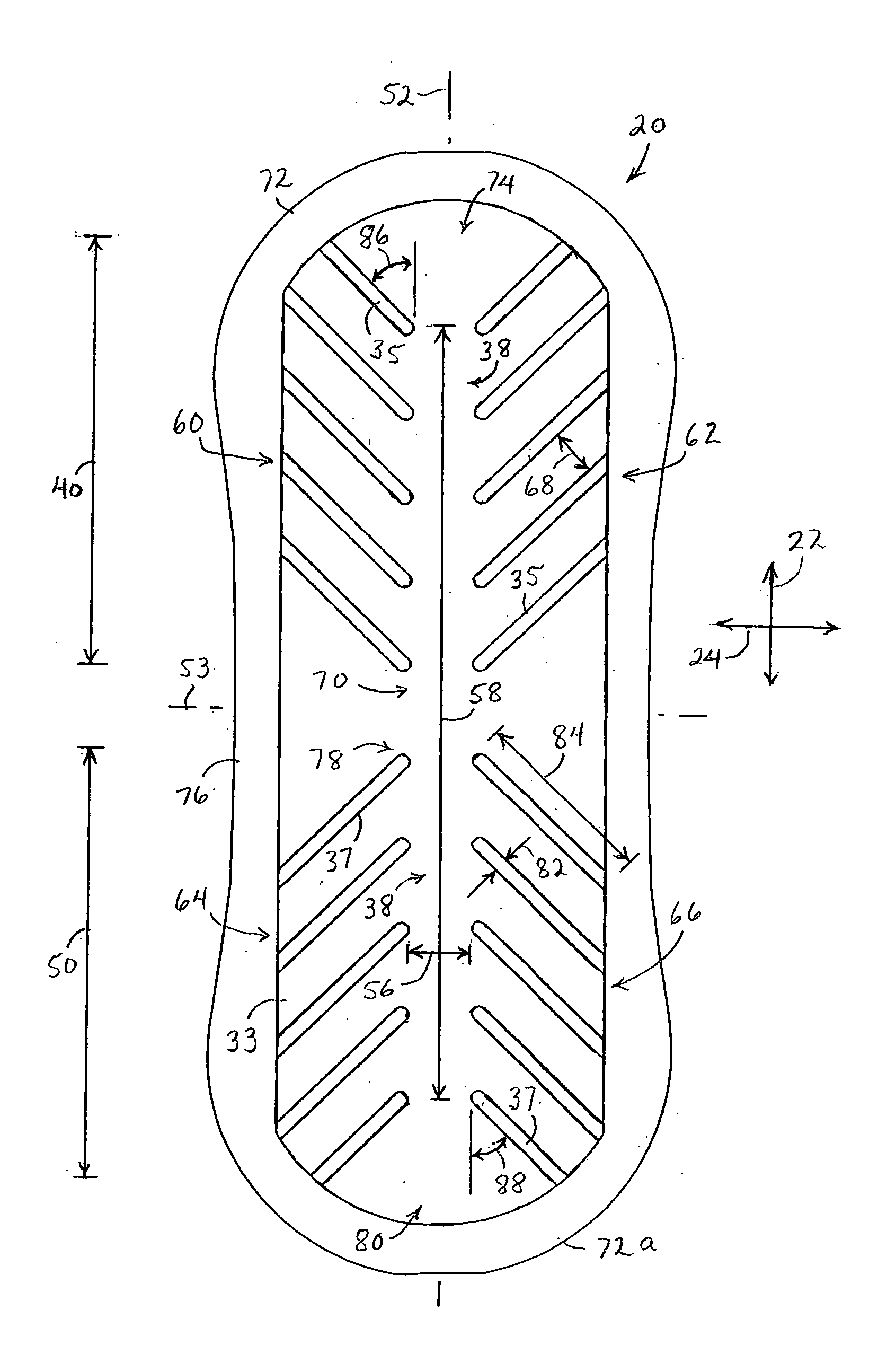

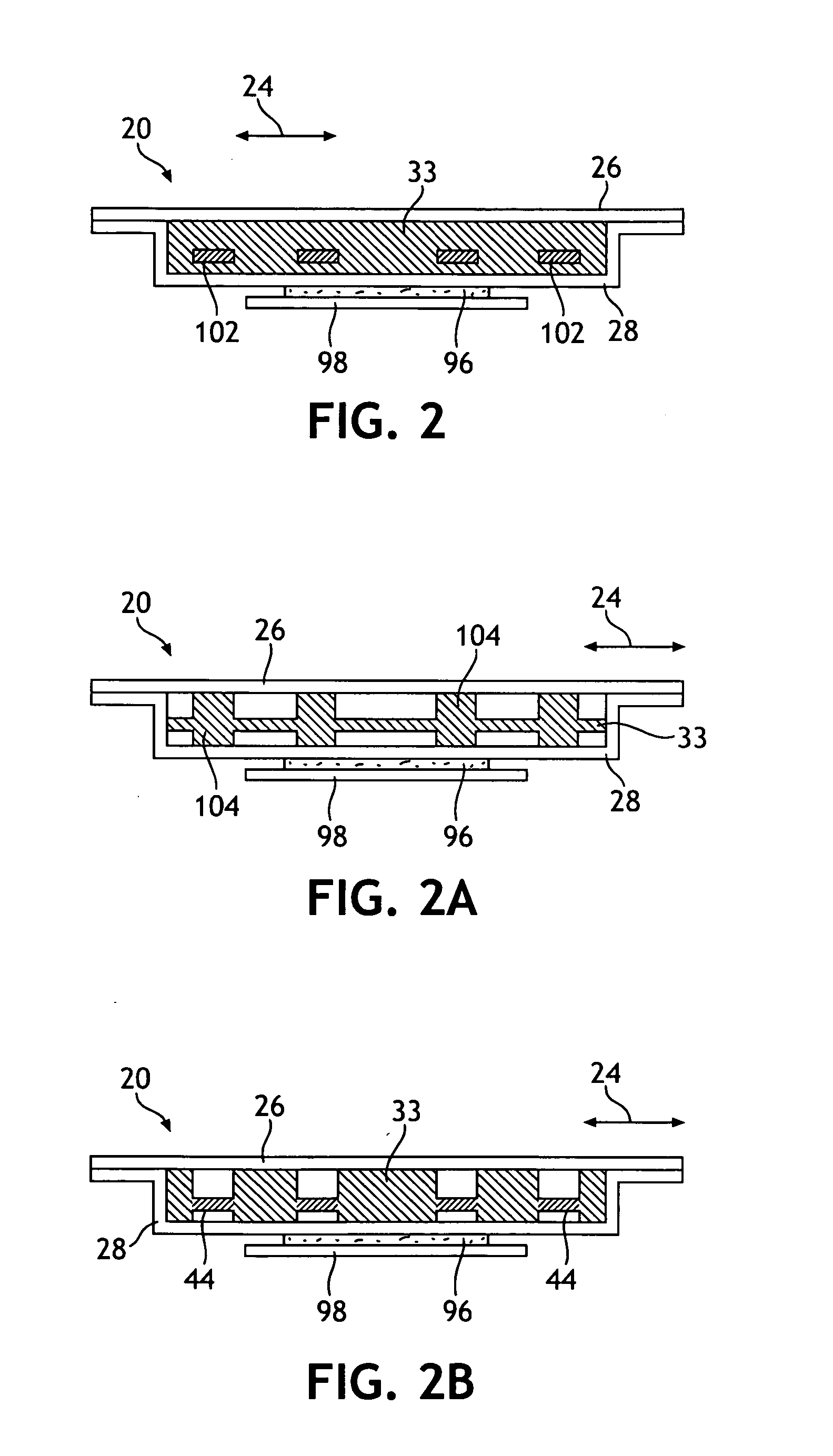

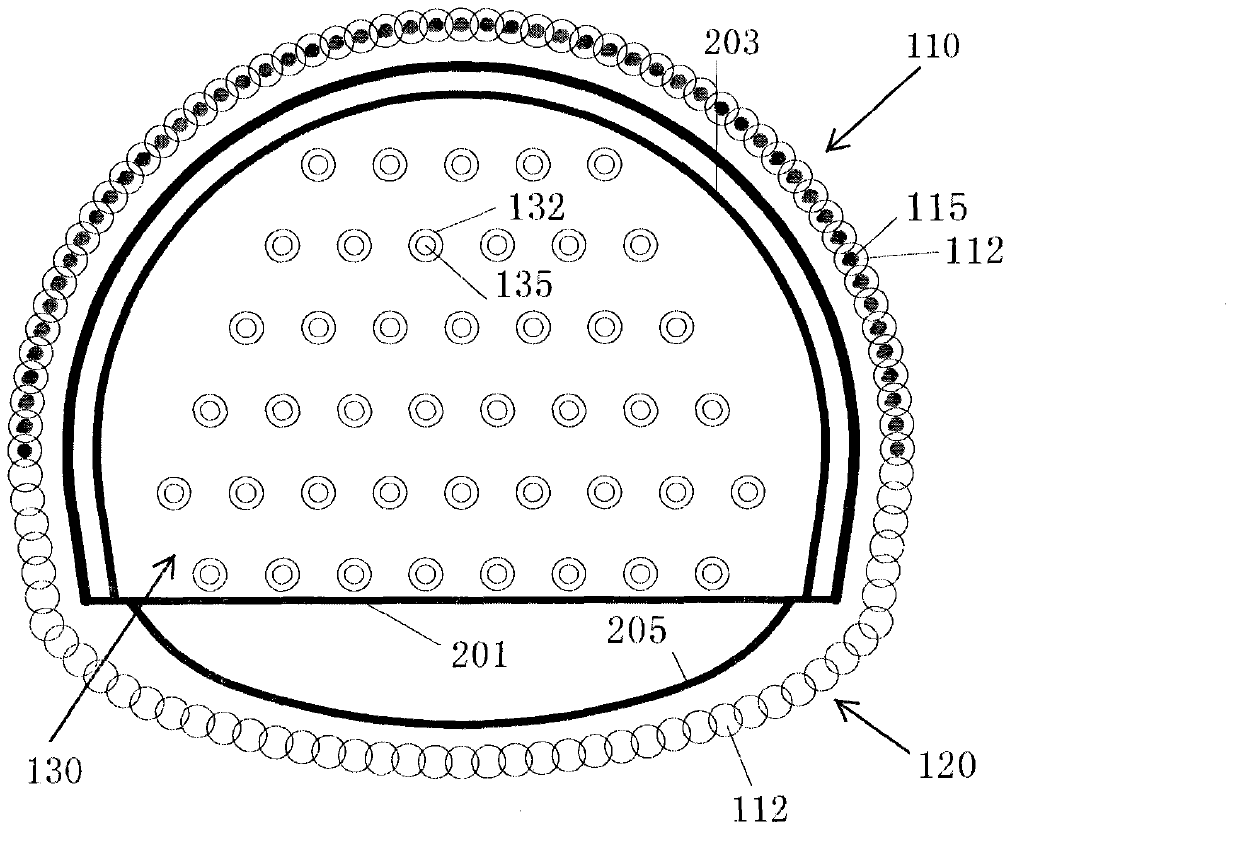

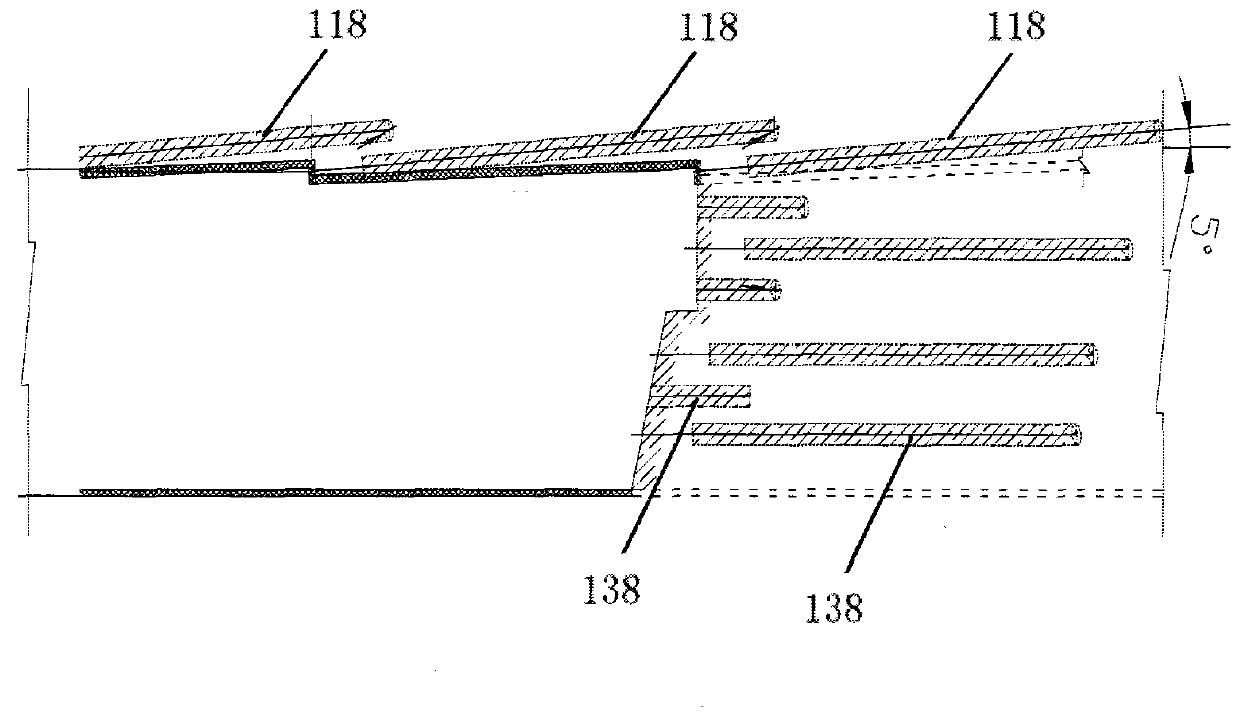

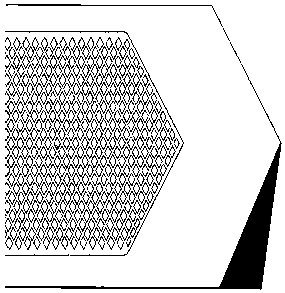

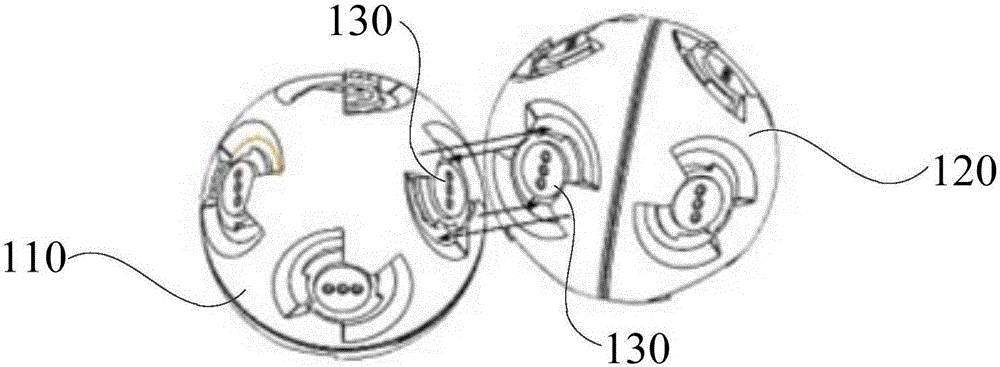

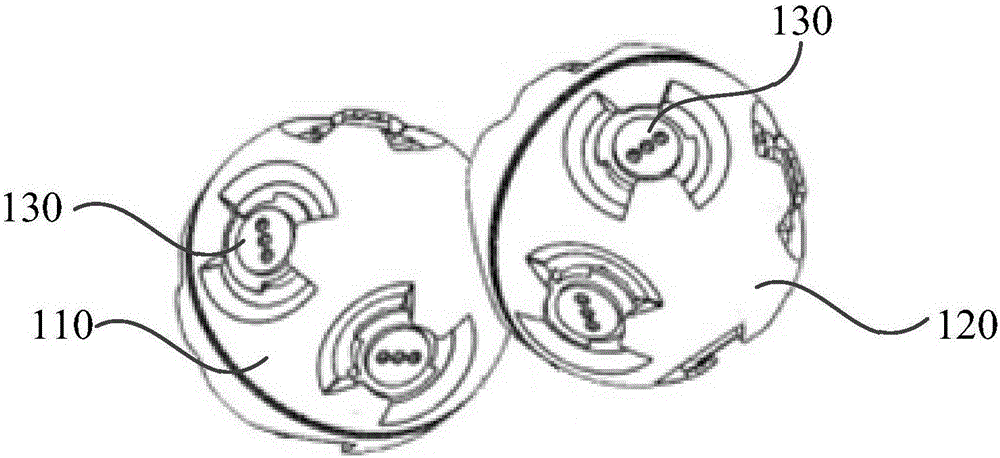

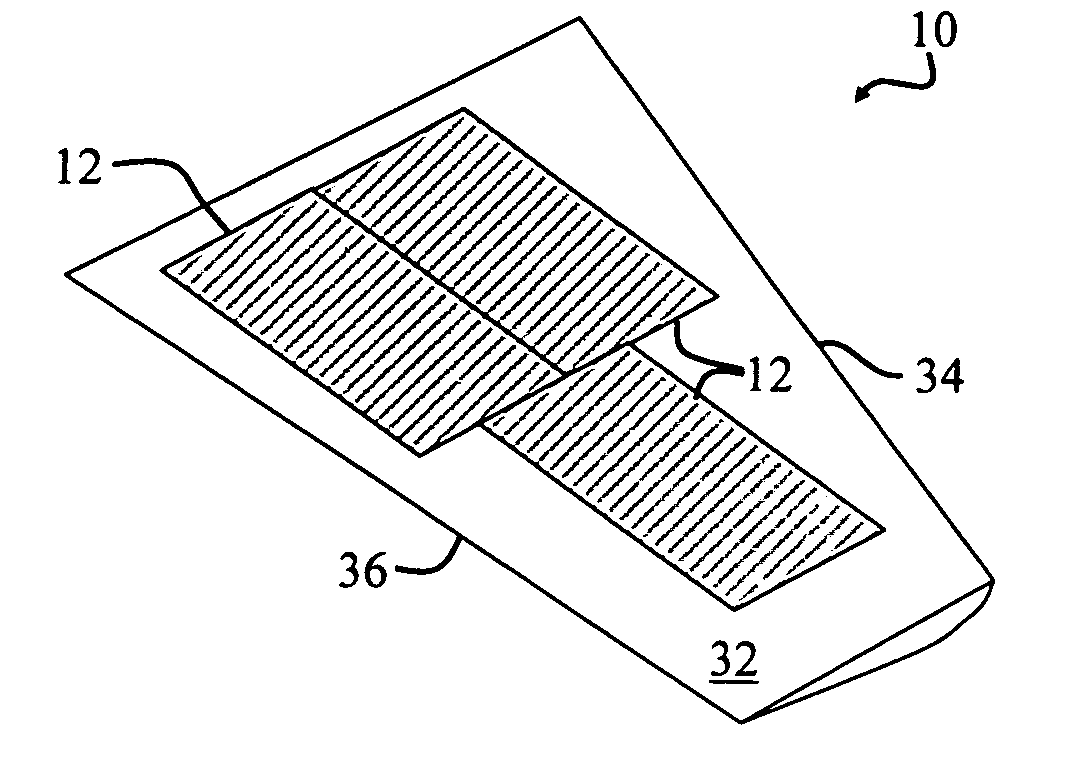

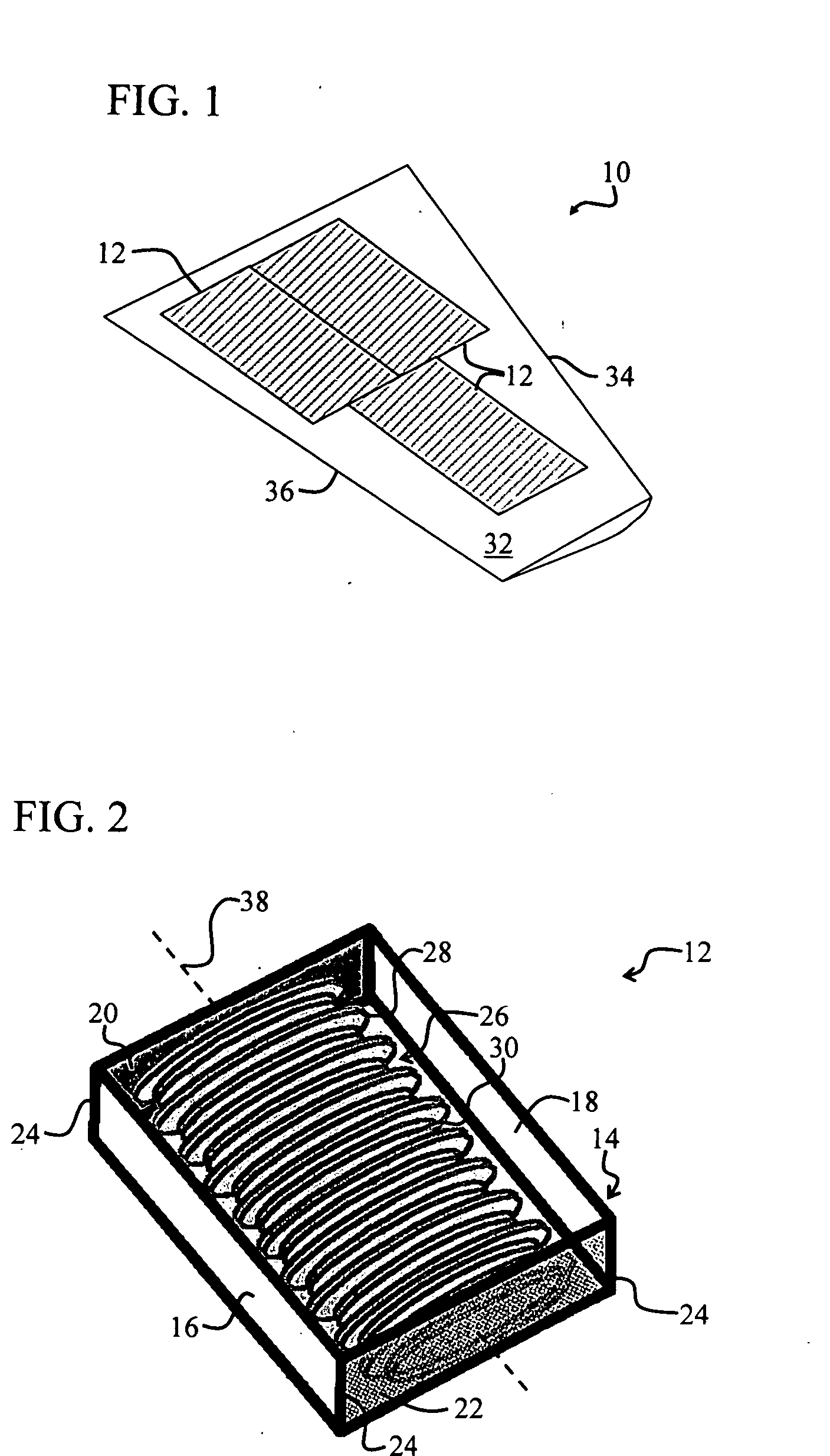

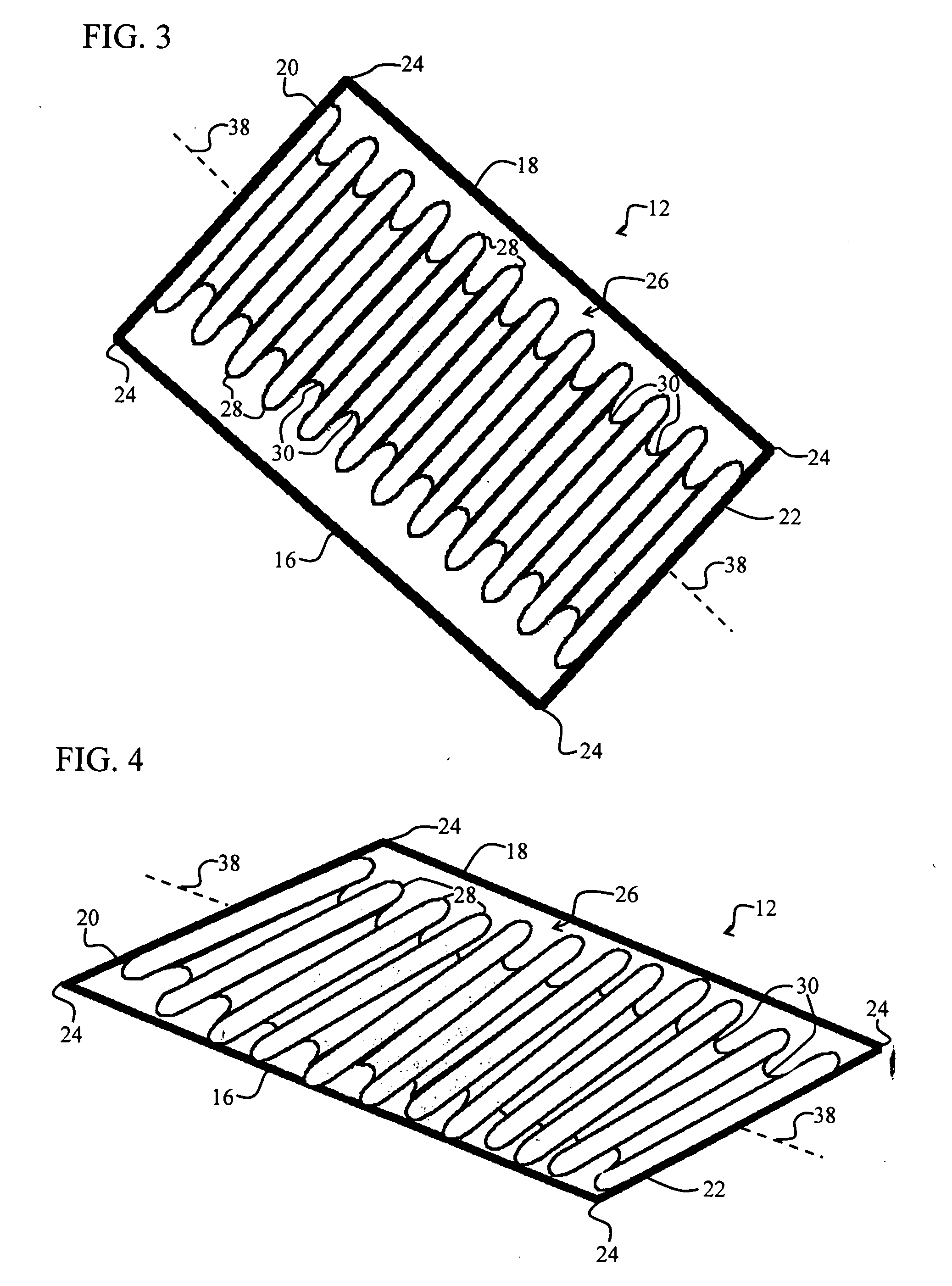

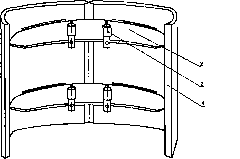

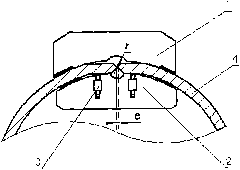

Embossed absorbent article

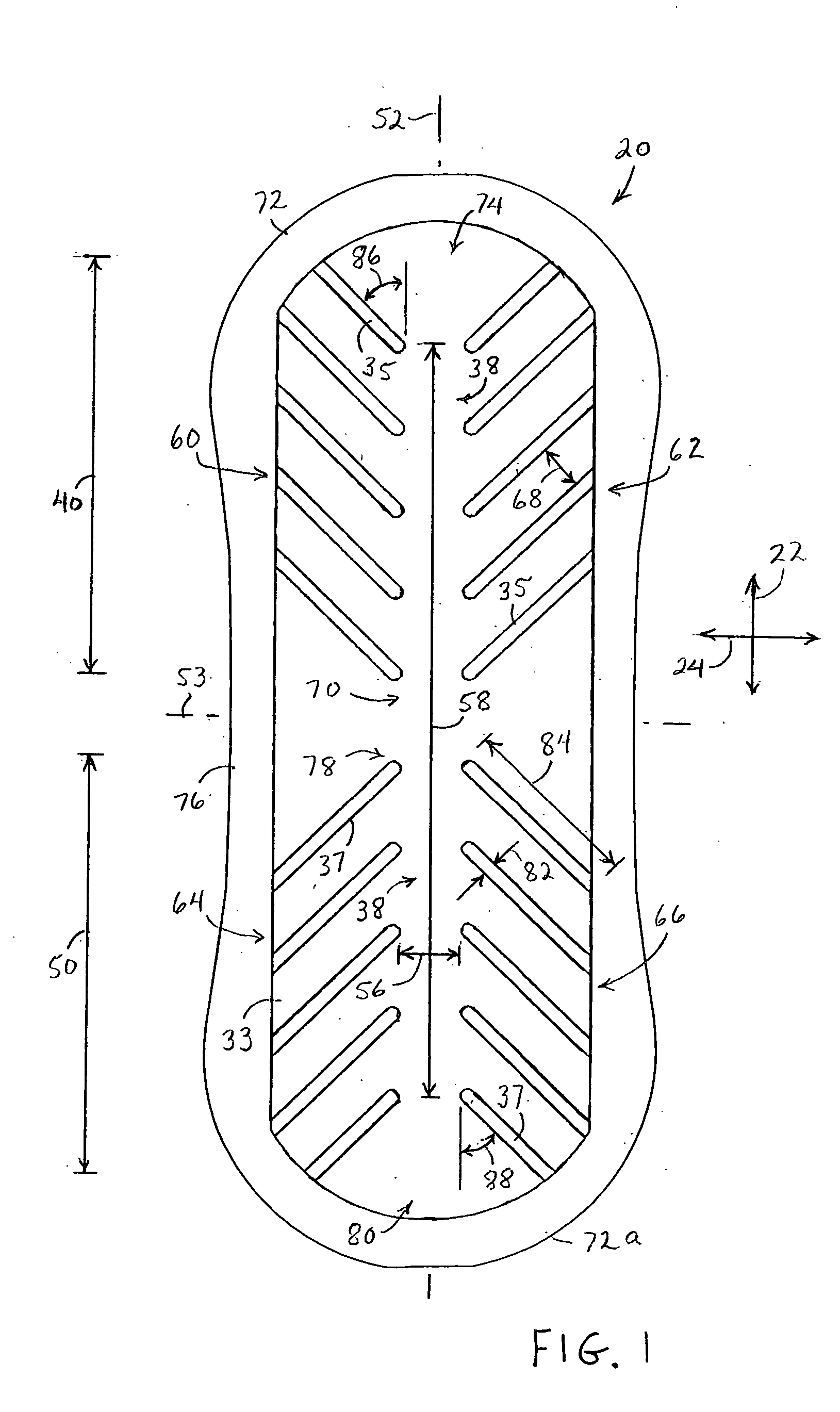

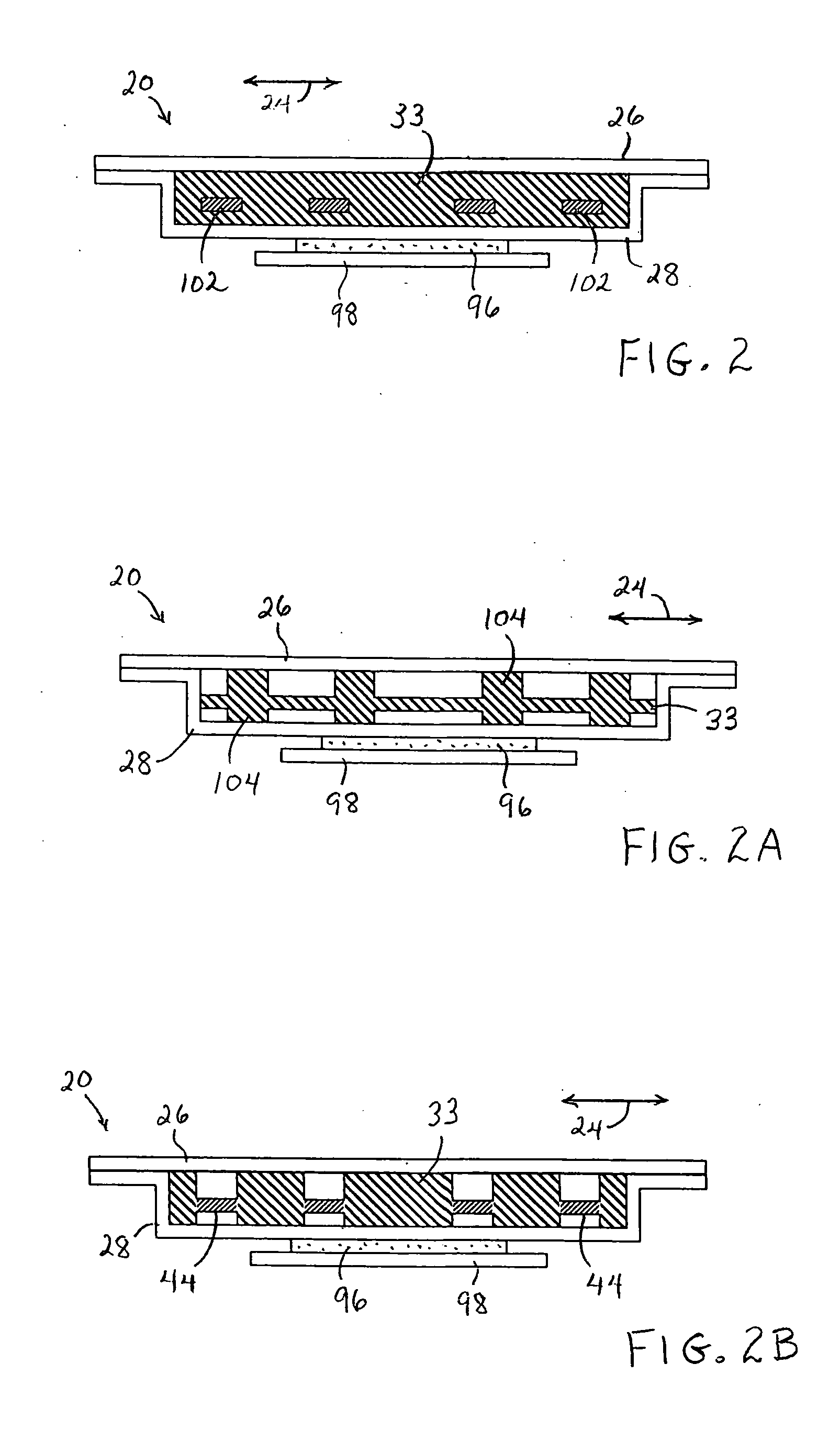

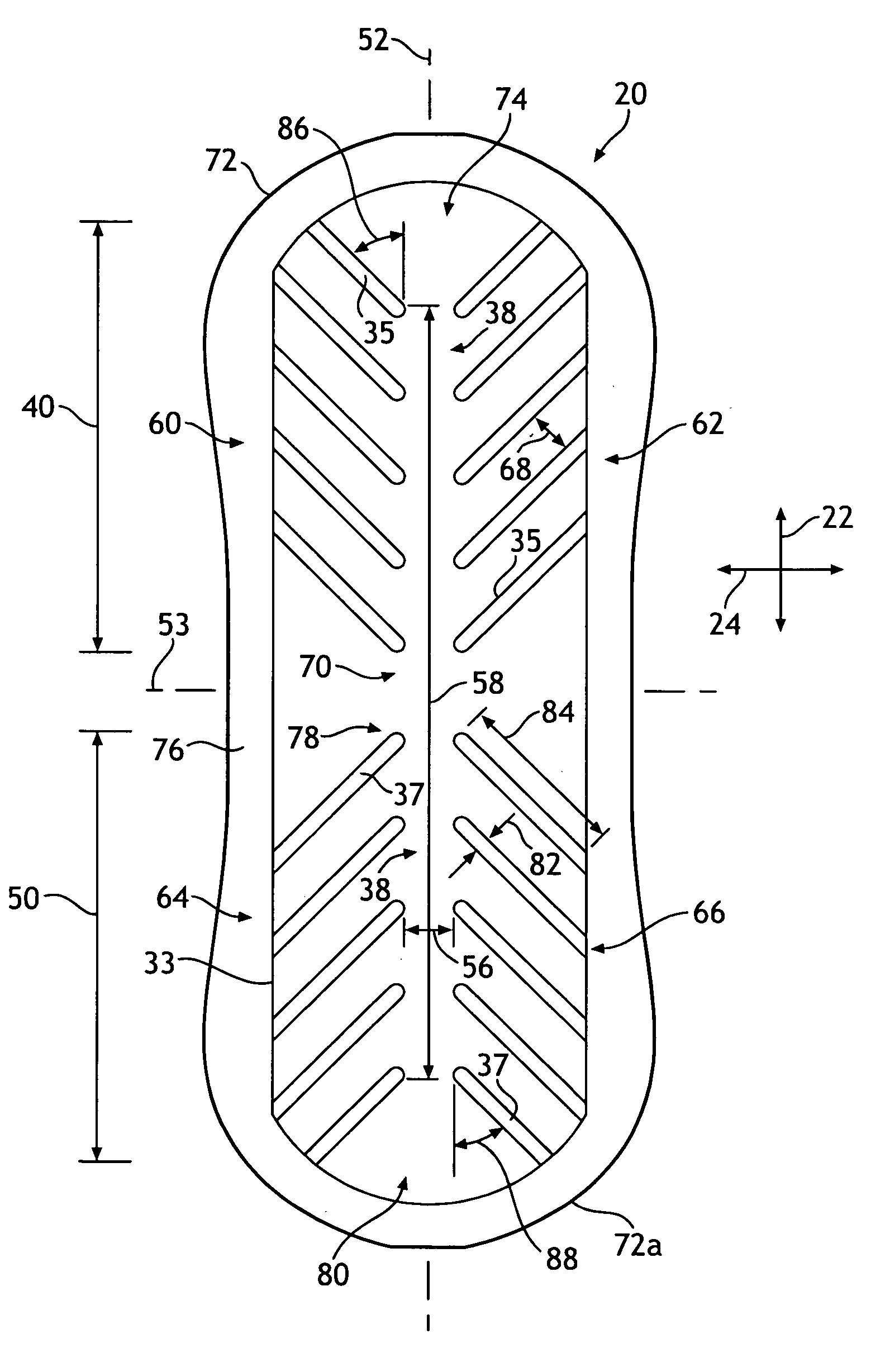

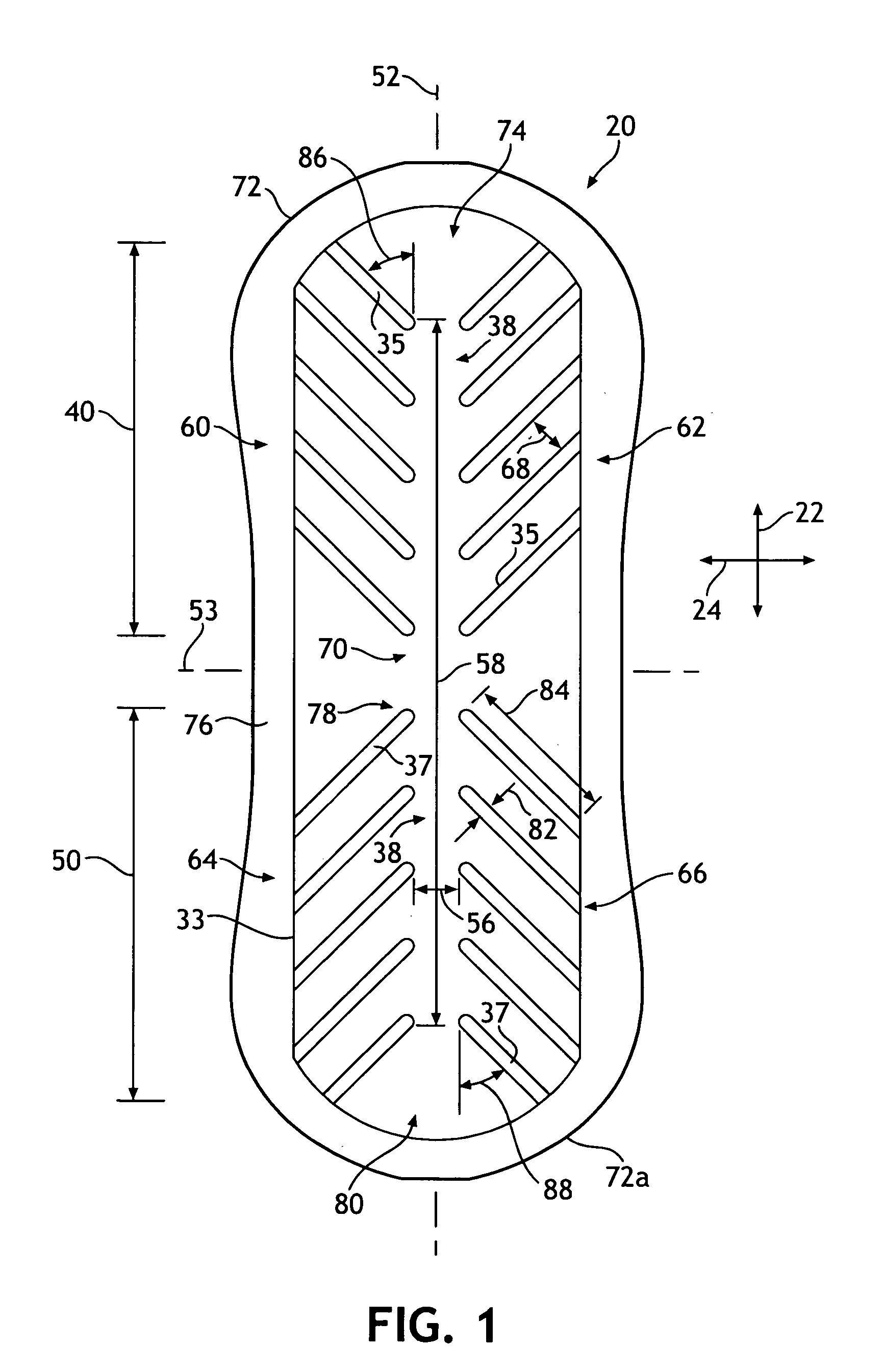

InactiveUS20050182374A1Avoid intersectionAdvantageously producedSanitary towelsBaby linensEngineeringDeformation control

An article (20) comprises a deformation-control member which can include an extending medial section (38), and a selected stiffened region (34). The stiffened region (34) can include a first array (40) of individual, stiffening elements (35), and at least a second array (50) of individual, stiffening elements (37). In particular features, each of the first and second arrays (40, 50) of stiffening elements can have a convergently arranged nose-end (70, 78), and a relatively divergently arranged tail-end (74, 80). In another feature, the first and second arrays (40, 50) of stiffening elements (35, 37) can be configured to substantially avoid intersecting in the medial section (38) of the deformation-control member. In a further feature, the second array (50) of stiffening elements (37) can have a counter-positioned configuration relative to the first array (40) of stiffening elements (35).

Owner:KIMBERLY-CLARK WORLDWIDE INC

Embossed absorbent article

InactiveUS7145054B2Advantageously producedBetter conformSanitary towelsBaby linensEngineeringDeformation control

An article (20) comprises a deformation-control member which can include an extending medial section (38), and a selected stiffened region (34). The stiffened region (34) can include a first array (40) of individual, stiffening elements (35), and at least a second array (50) of individual, stiffening elements (37). In particular features, each of the first and second arrays (40, 50) of stiffening elements can have a convergently arranged nose-end (70, 78), and a relatively divergently arranged tail-end (74, 80). In another feature, the first and second arrays (40, 50) of stiffening elements (35, 37) can be configured to substantially avoid intersecting in the medial section (38) of the deformation-control member. In a further feature, the second array (50) of stiffening elements (37) can have a counter-positioned configuration relative to the first array (40) of stiffening elements (35).

Owner:KIMBERLY-CLARK WORLDWIDE INC

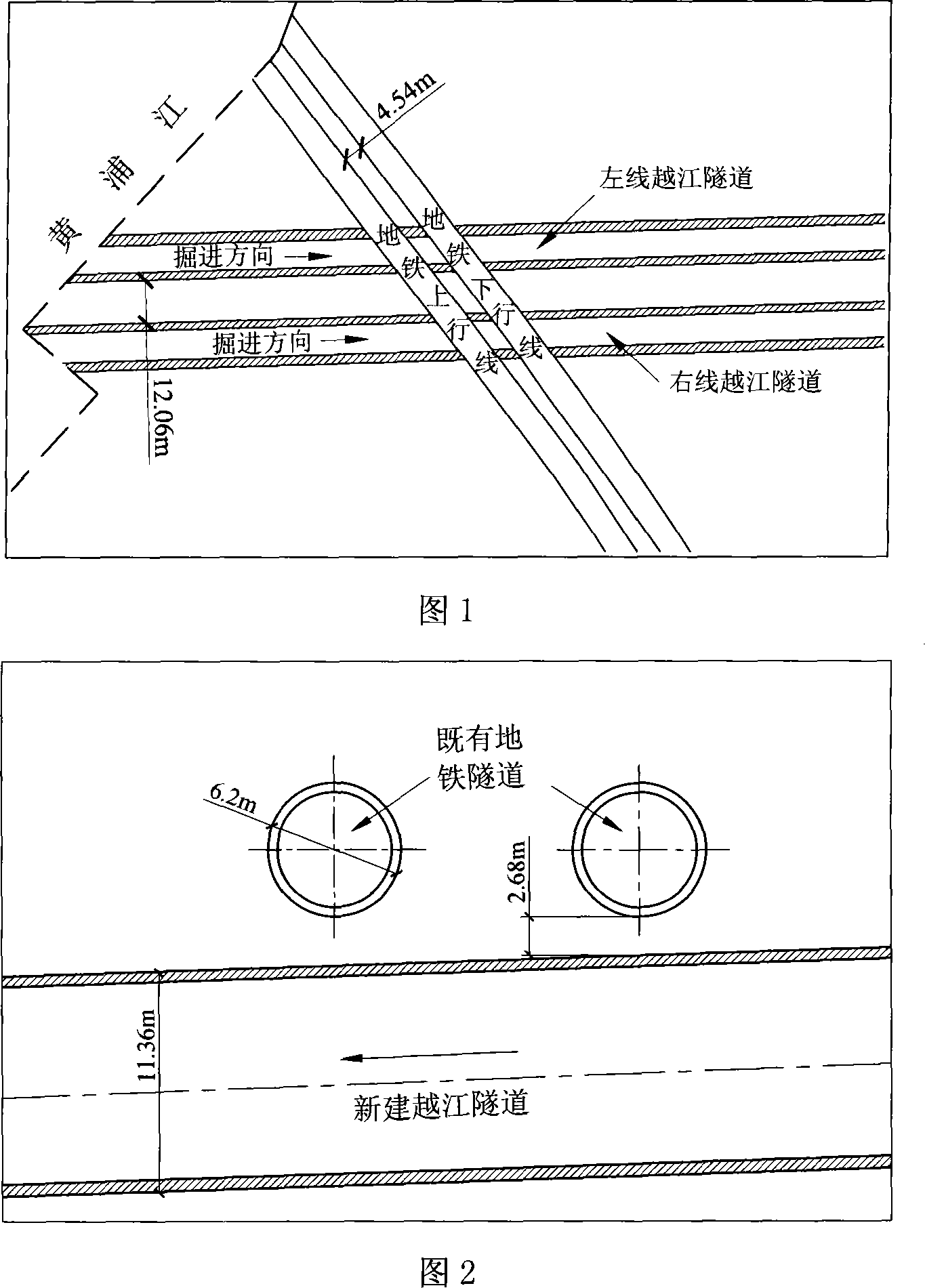

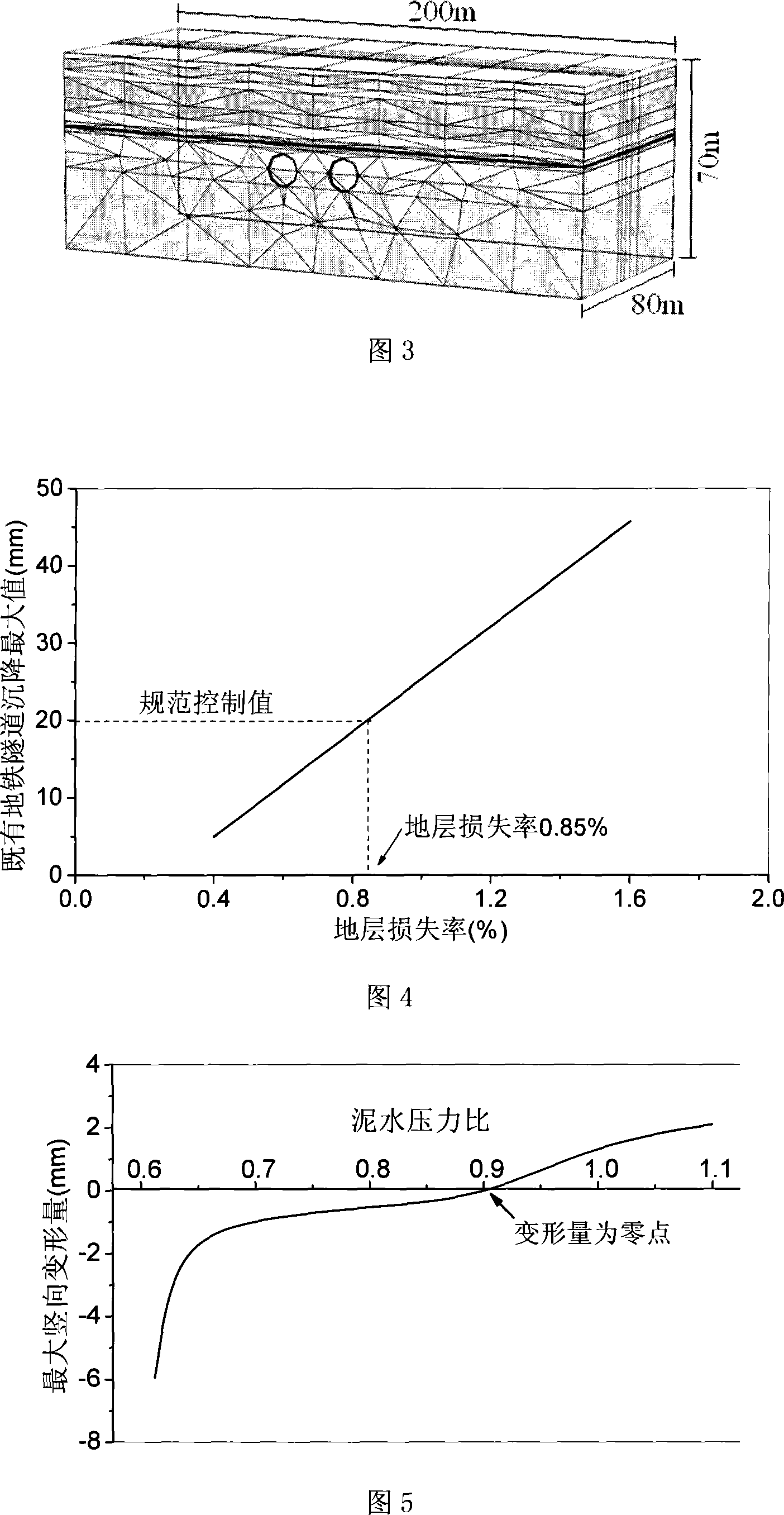

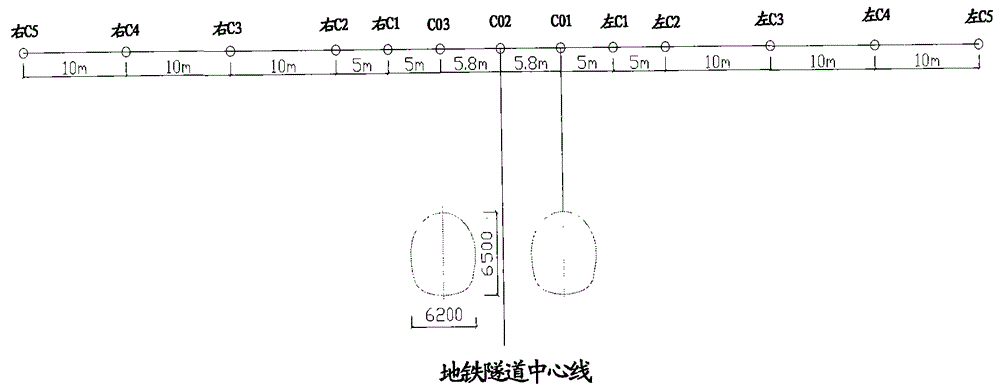

Large diameter tunneling close range down-traversing small diameter subway tunnel distortion control method

InactiveCN101215969AGuarantee smooth constructionEnsure safetyTunnelsUnderground tunnelFinite element method

The invention discloses a method for controlling distortion for deep large diameter shield tunnels to under-pass small diameter tunnels, which pertains to the technical field of tunnel engineering. According to the method, the control range of the stratum loss ratio of newly established tunnels and the optimum value of the support pressure of the shield cut surface are acquired by using the finite-element method; soil pressure in front of the shield cut surface is kept relatively balanced by setting the optimal value of the support pressure, and the support pressure fluctuation range of the cut surface is controlled to range from minus 10kPa to plus 10kPa; the stratum loss ratio of the newly established tunnels is controlled within the allowed range. According to the construction technique measures, a test propelling area is arranged before the shield reaches a cross position. In the area, construction is carried out according to the situation of the existing underground tunnels above; and construction parameters are controlled and regulated to adjust the support pressure, the propulsive velocity and the amount of the grout to be injected in time; the shield passes through the cross position in combination with the optimal values of the construction parameters of the test propelling area. The invention can not only ensure the construction of tunnels to be carried out safely and smoothly, but also minimize the influence of construction on ambient environment.

Owner:SHANGHAI JIAO TONG UNIV

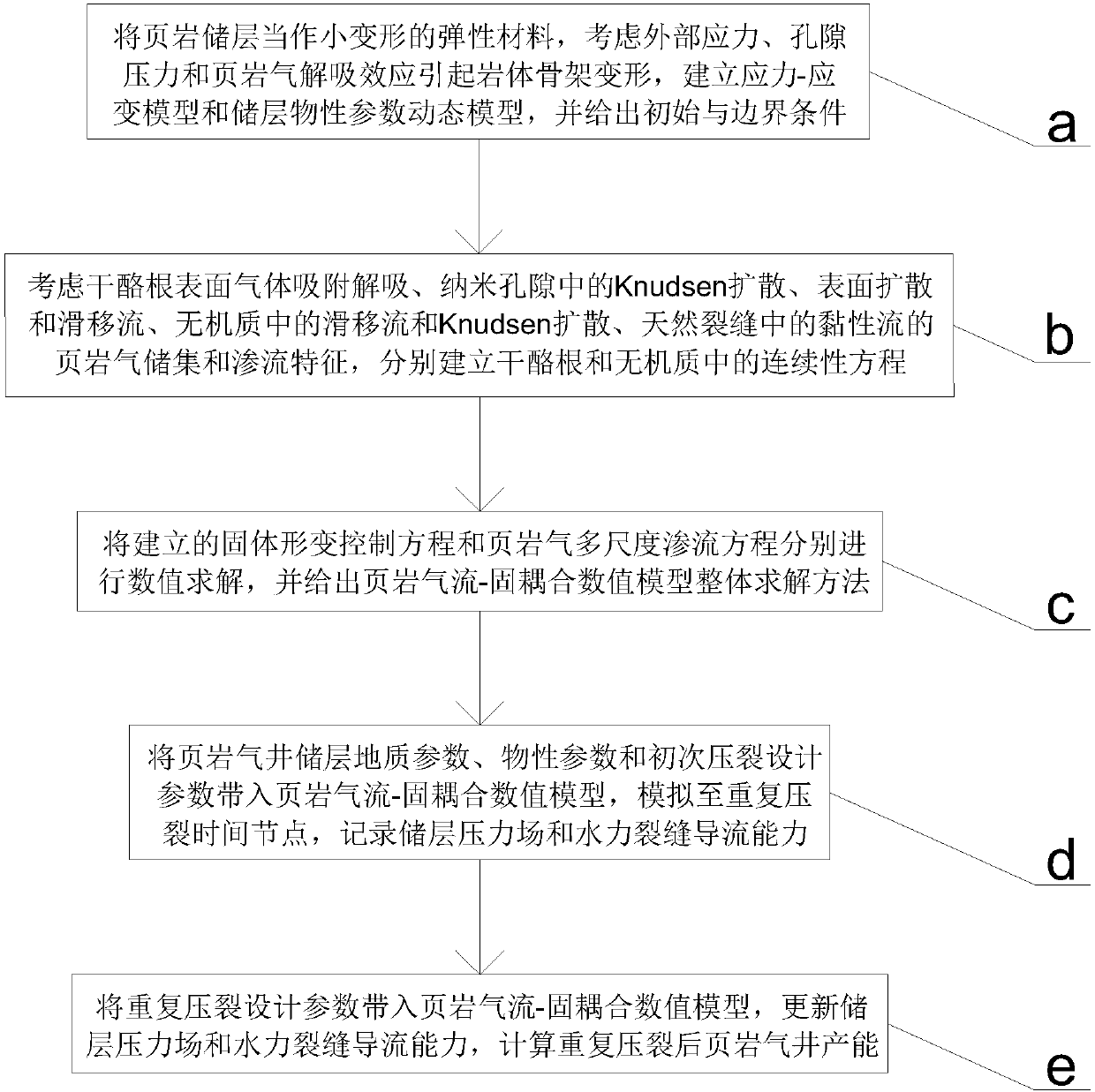

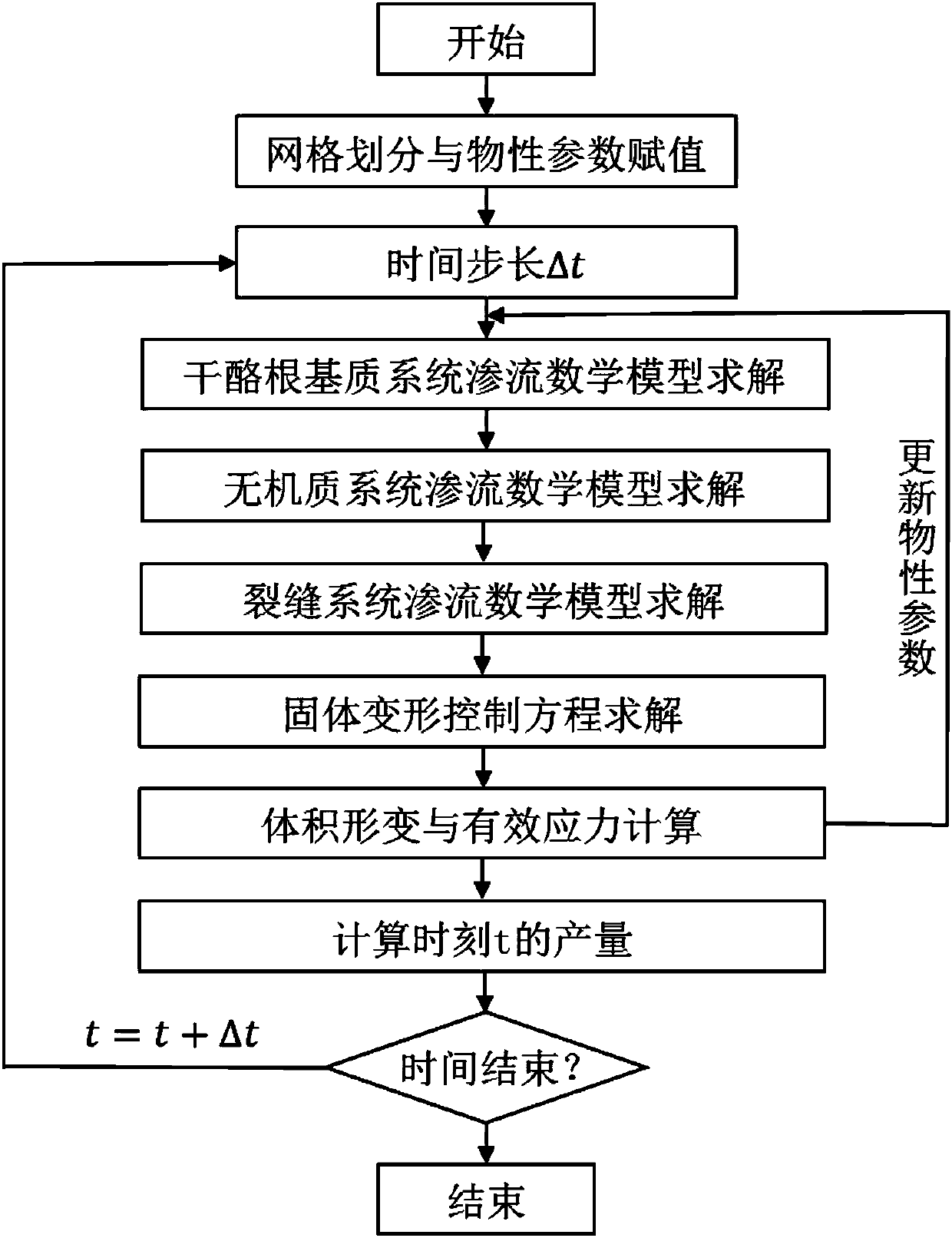

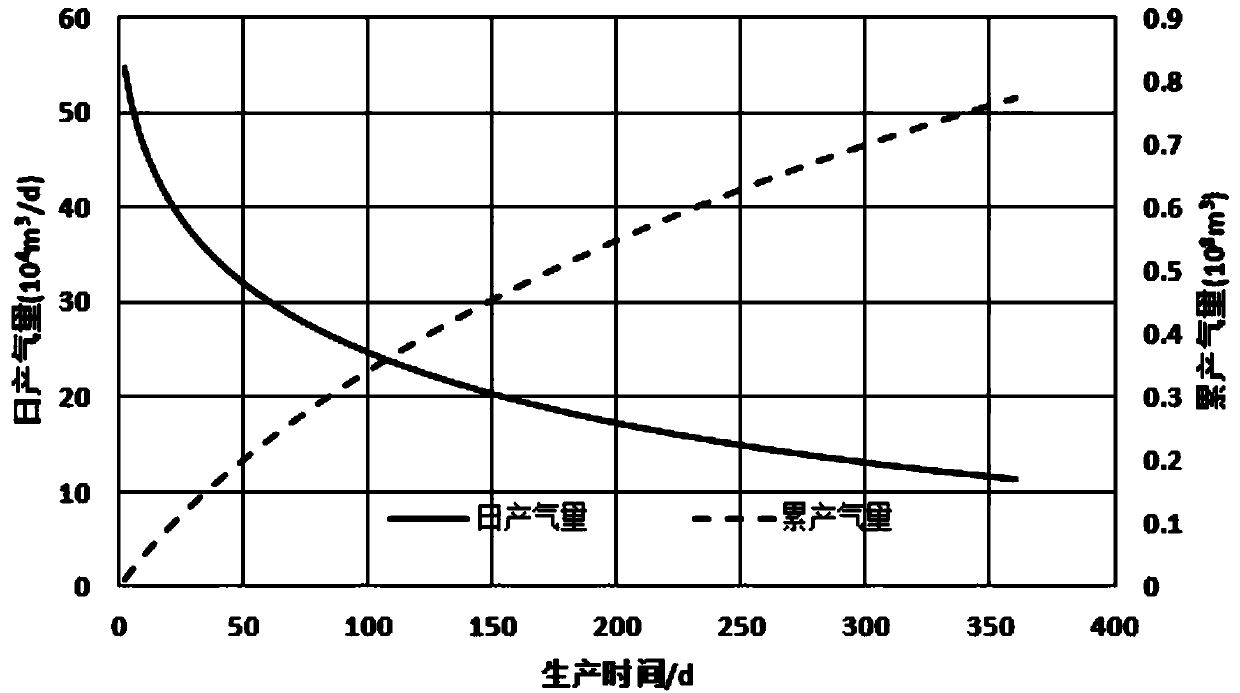

Shale gas horizontal well refracturing productivity calculation method

ActiveCN107622165ASolve the problem of inapplicable refracturing production capacity calculationFluid removalSpecial data processing applicationsKerogenDynamic models

The invention belongs to the technical field of unconventional oil gas production increasing transformation and particularly, relates to a shale gas horizontal well refracturing productivity calculation method. The method comprises the following steps of: by using a shale reservoir as an elastic material which is small in deformation, establishing a stress-strain model and a reservoir physical property parameter dynamic model; establishing a continuity equation in kerogen and an inorganic substance; respectively carrying out numerical solution on an established solid deformation control equation and shale gas multiscale seepage equation; bringing geological parameters, physical property parameters and primary fracturing design parameters of a shale gas well reservoir into a shale gas fluid-solid coupling numerical model, and recording a pressure field and hydraulic fracture flow conductivity of the reservoir; and bringing refracturing design parameters into the shale gas fluid-solid coupling numerical model, and calculating productivity of a shale gas well after refracturing. According to the method disclosed by the invention, seepage characteristics and stress-pressure field dynamic variations of the shale reservoir are considered, productivity and a recovery ratio of the shale reservoir after refracturing are predicted, and shale gas horizontal well refracturing optimizationdesign is guided.

Owner:SOUTHWEST PETROLEUM UNIV

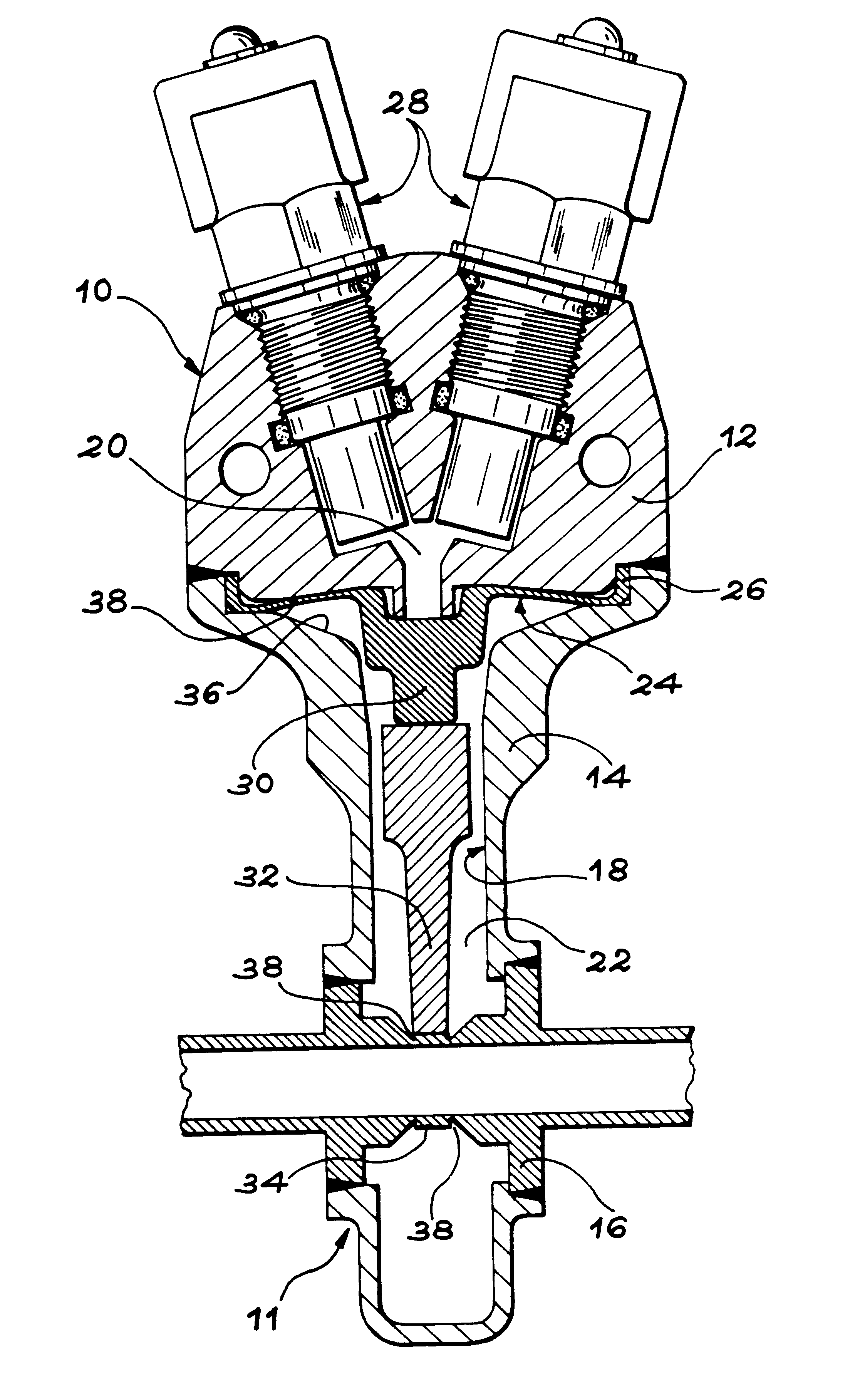

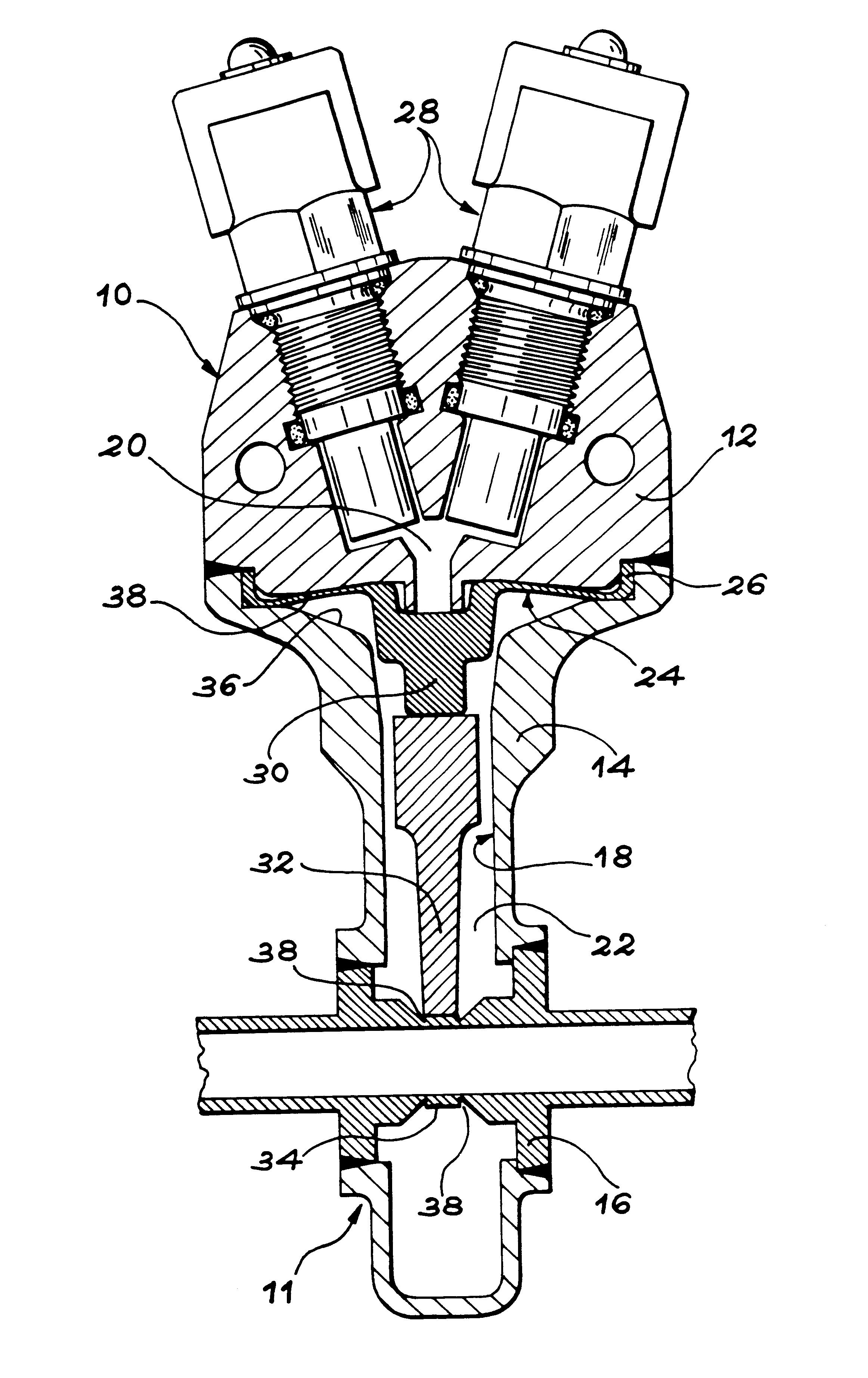

Pyrotechnic actuator with a deformable membrane

InactiveUS6397595B2Increase displacementIncreasing size and weightPyrotechnical actuatorsCombustion enginesCombustionActuator

A pyrotechnic actuator comprises a deformable membrane (24) separating a first chamber (20), which is able to receive pyrotechnic combustion gases, from a second chamber (22) containing a control member (32) displaceable by the membrane (24) during the operation of the actuator. In the inoperative state, the membrane (24) is prestressed counter to its deformation controlled by the intake of gases into the first chamber (20). In this way the functional travel is increased, which e.g. makes it possible to open or close a circuit with a larger cross-section without increasing the actuator size.

Owner:EADS LAUNCH VEHICLE

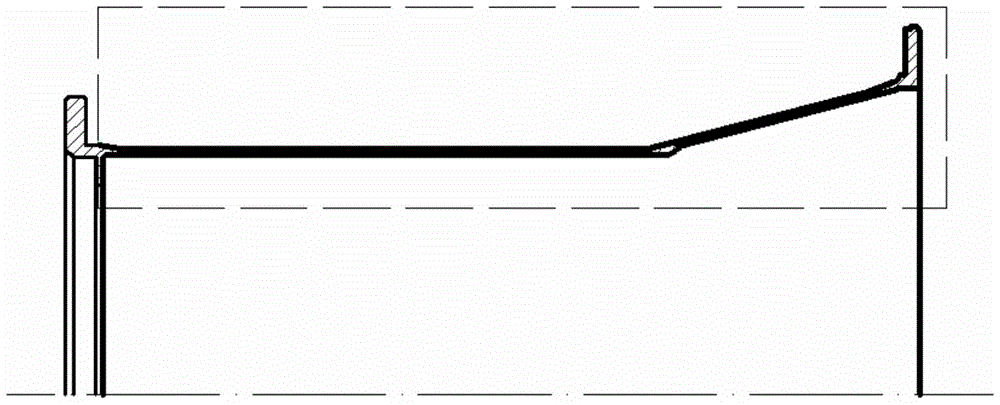

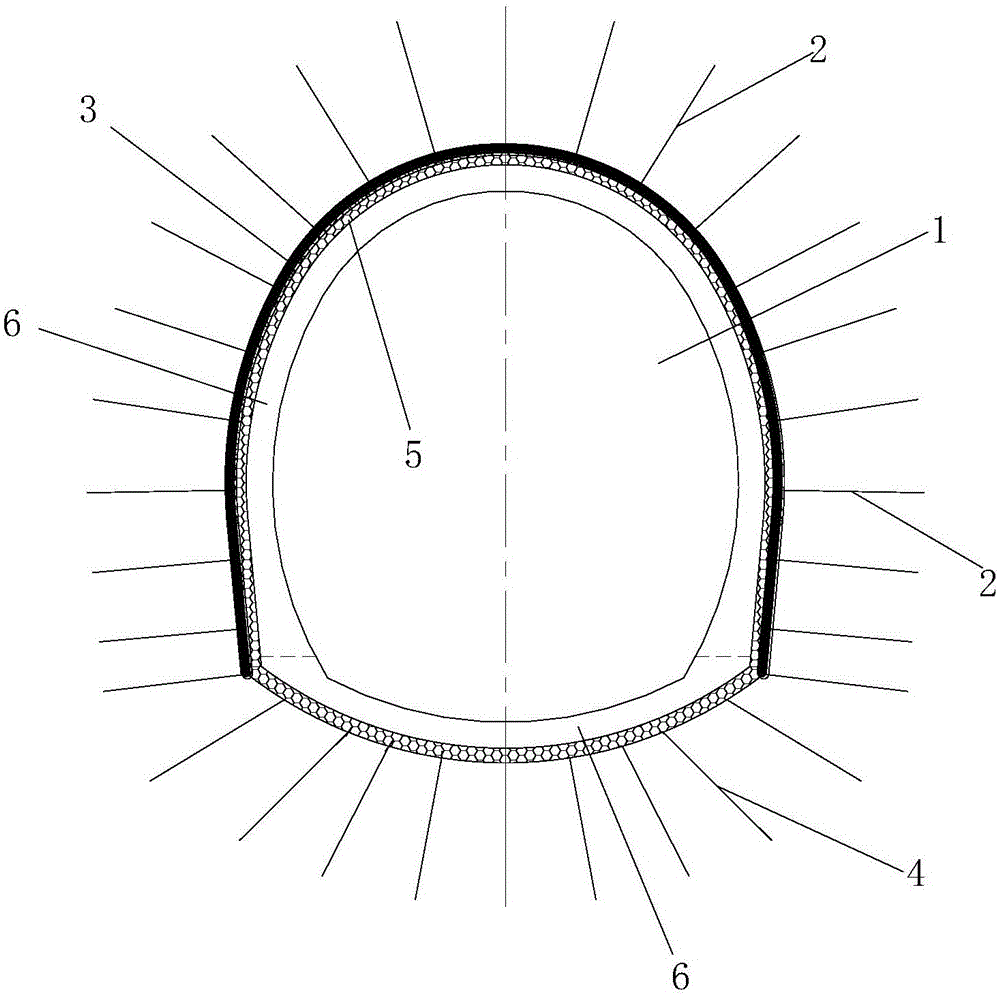

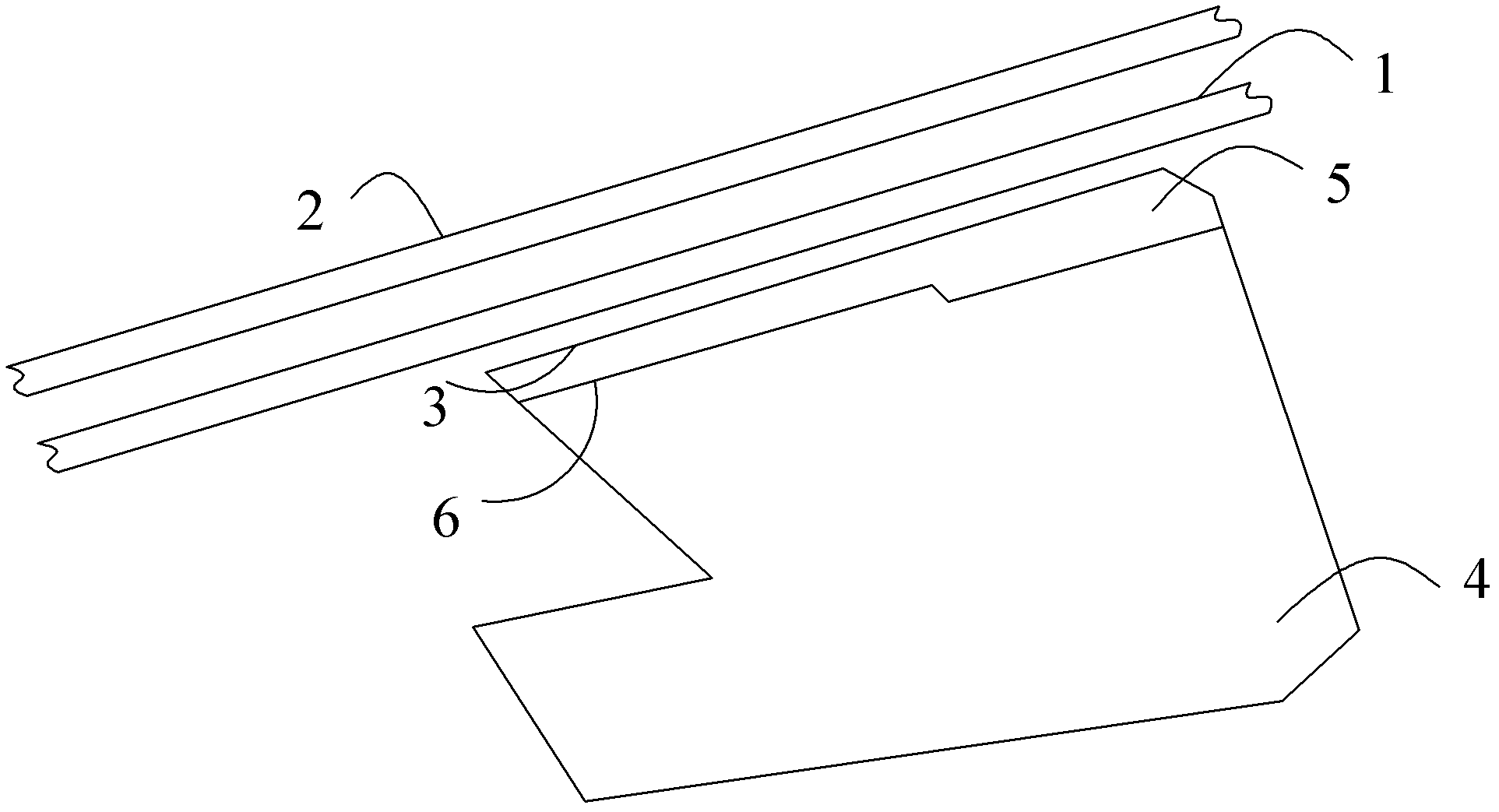

Construction method for deformation control via horizontal whirling jet grouting of long cantilever in soft-rock tunnel

InactiveCN103306687AImprove stabilityControl deformationUnderground chambersTunnel liningGlass fiberEngineering

The invention discloses a construction method for deformation control via the horizontal whirling jet grouting of a long cantilever in a soft-rock tunnel. The method comprises the following steps of: (1) drilling on the periphery of a dug outline, carrying out the whirling jet grouting while retreating a drill stem, and lowering a first profile component after the whirling jet grouting to form a first profile pile body; (2) repeating the step (1) to construct a first curtain system; (3) drilling on a tunnel face designed in a tunnel, carrying out the whirling jet grouting while retreating the drill stem, lowering a second profile component after the whirling jet grouting to form a second profile pile body; (4) repeating the step (3) to construct a second core earth reinforcing system; (5) carrying out the mechanical digging and initial supporting on a large section; (6) drilling in the arch springing position of middle and lower steps obliquely towards the lower direction of the tunnel at 30-45 degrees, lowering a third profile component to form a third profile pile body; and (7) repeating the step (6) to construct a locking whirling jet grouting pile stabilization system. According to the construction method, the advanced reinforcement of a horizontal whirling jet grouting pile with a highly strong tunnel outline, the binding and deforming effect of a tunnel face glass fiber anchor stem, and the anchoring of the locking whirling jet grouting pile are utilized, and the deformation of rock-soil is effectively controlled.

Owner:北京中铁瑞威基础工程有限公司

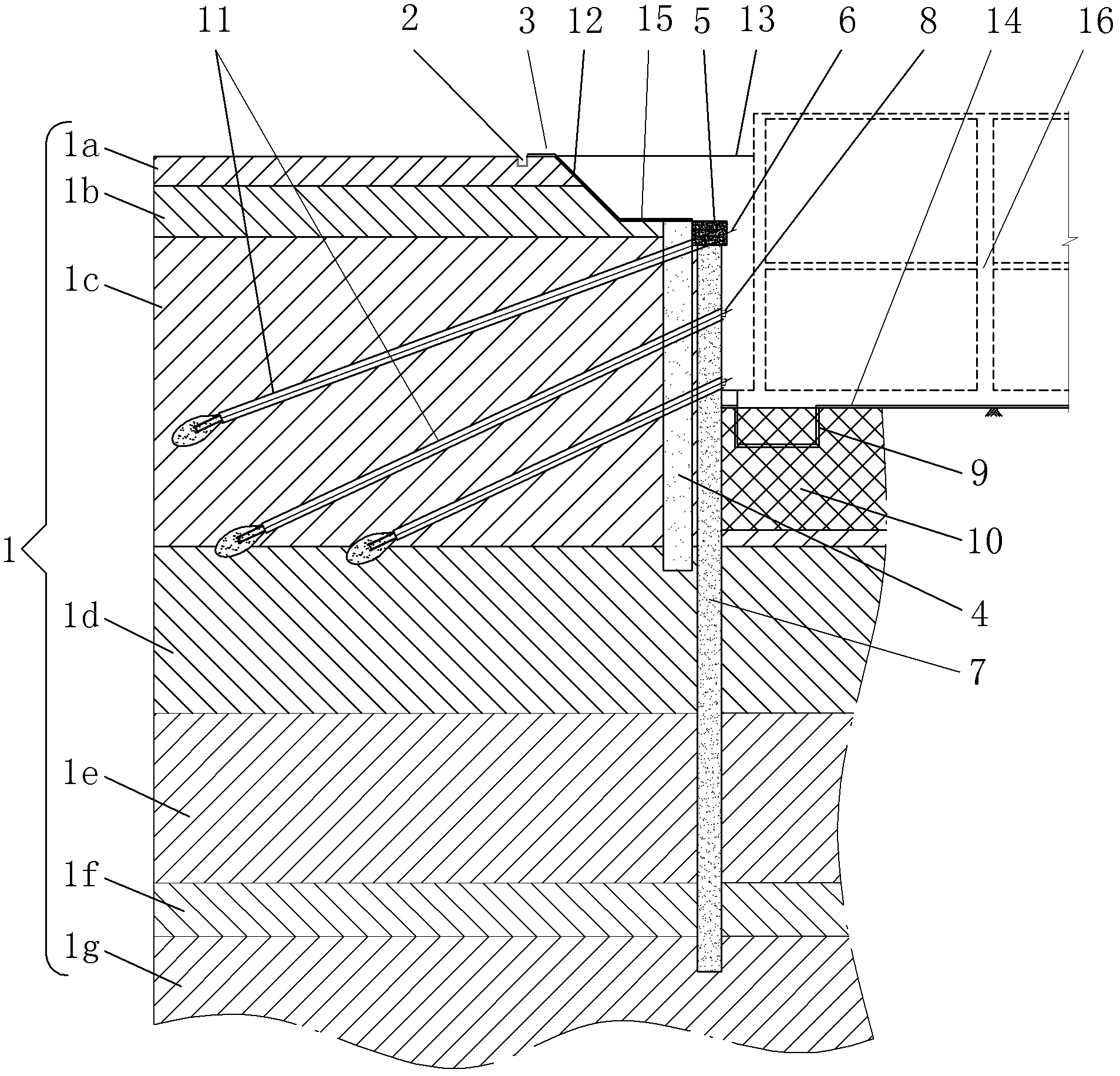

Foundation pit support construction method combining horizontal rotary jet-grouting soil bolting and bore concrete piles

ActiveCN102518135AOutstanding and Beneficial Technical EffectsControl deformation valueExcavationsBulkheads/pilesEngineeringDeformation control

The invention belongs to the technical field of foundation pit supporting for high-rise buildings, in particular to a foundation pit support construction method combining horizontal rotary jet-grouting soil bolting and bore concrete piles, which includes steps: firstly, constructing water-stop mixed piles and bored concrete piles according to a preset foundation pit; and secondly, performing soil excavation and soil bolting layer by layer and section by section. The foundation pit support construction method has the advantages that the foundation pit support constructed by the method is high in deformation control performance and stability and especially applicable to projections with high requirements on foundation pit deformation, and the method is applicable to mega-area foundation pit supporting in soft soil areas with failure of using internal support structures, limited slope reduction conditions and excavation depth limited within 15m, and meets the requirement that development and utilization of urban underground space continue to develop.

Owner:BIAOLI CONSTR GROUP

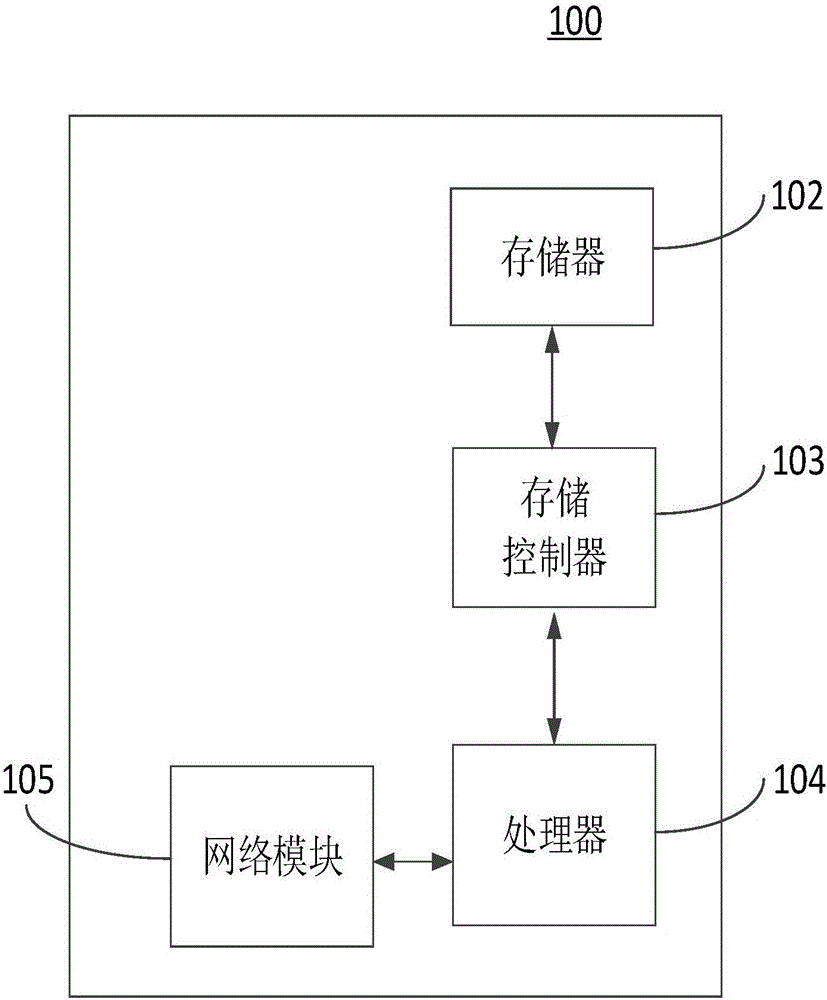

Information share method and mobile terminal

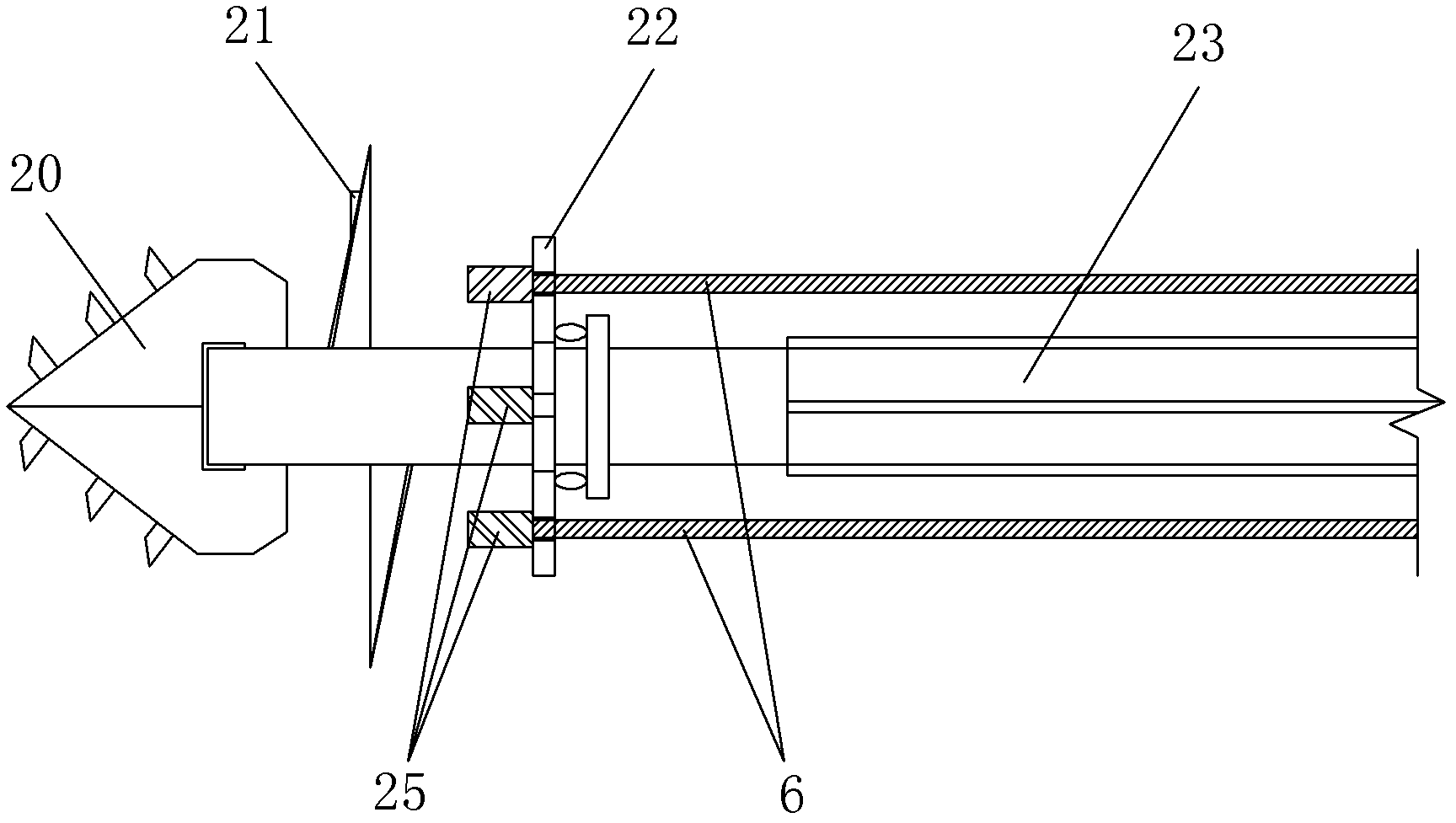

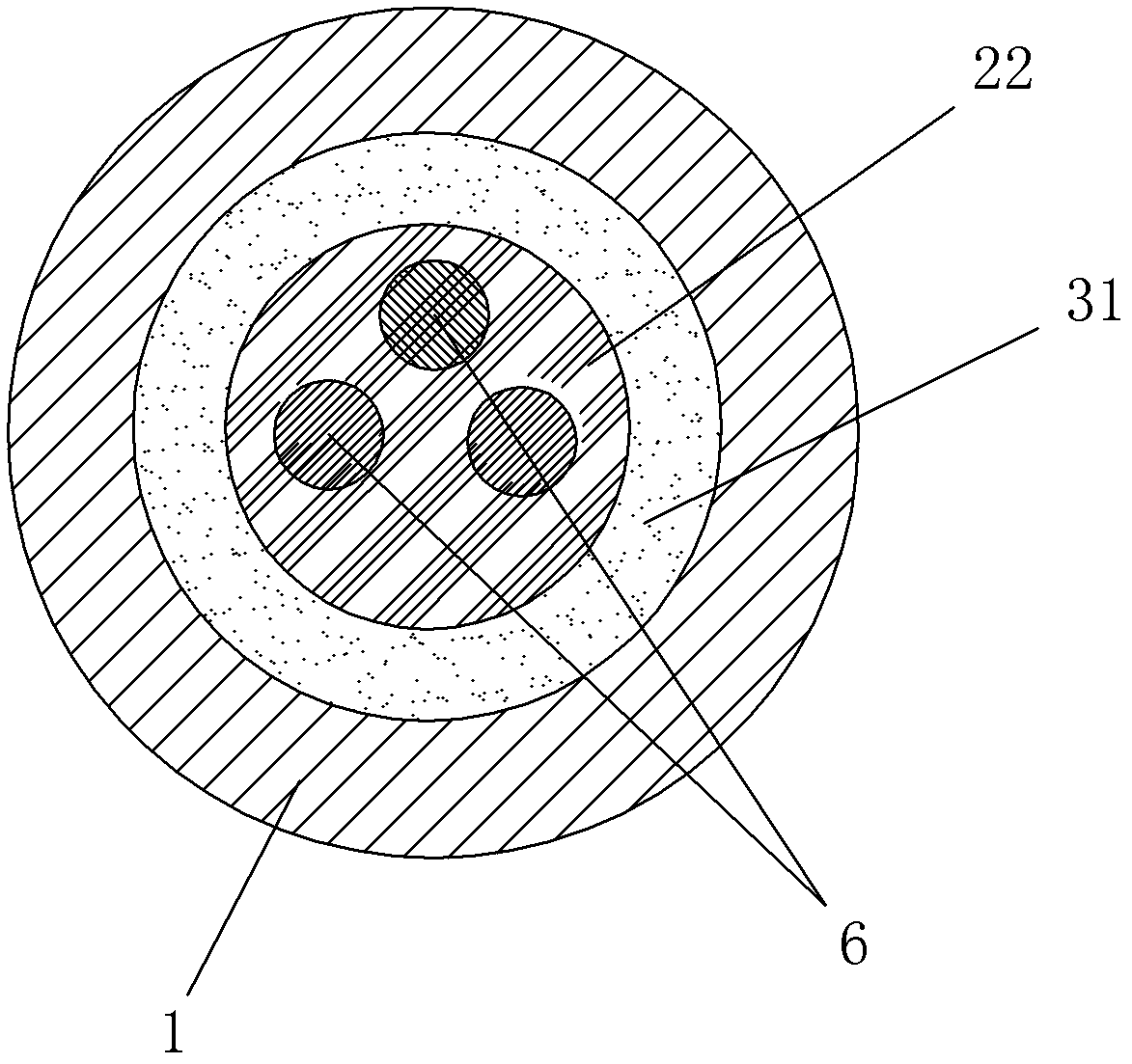

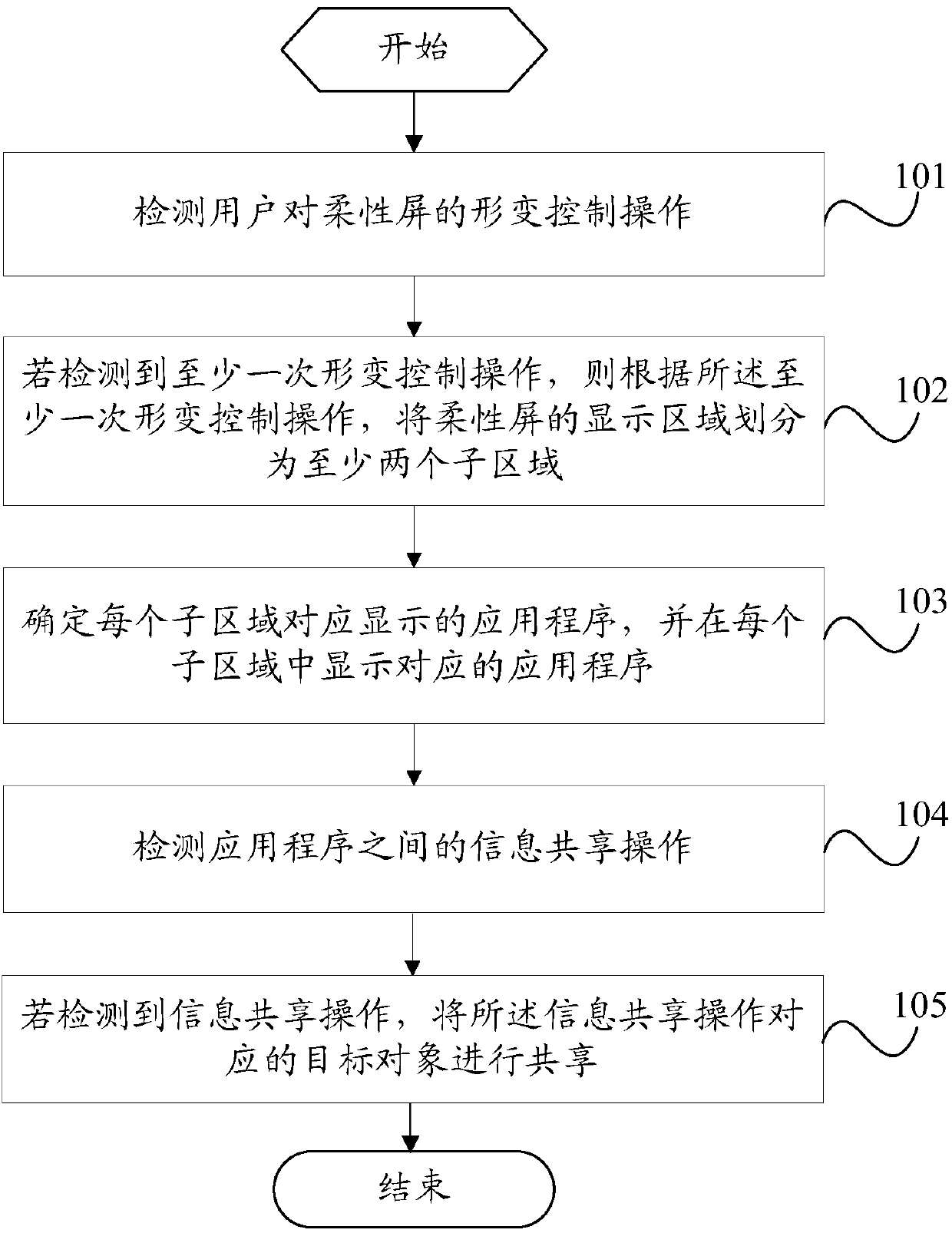

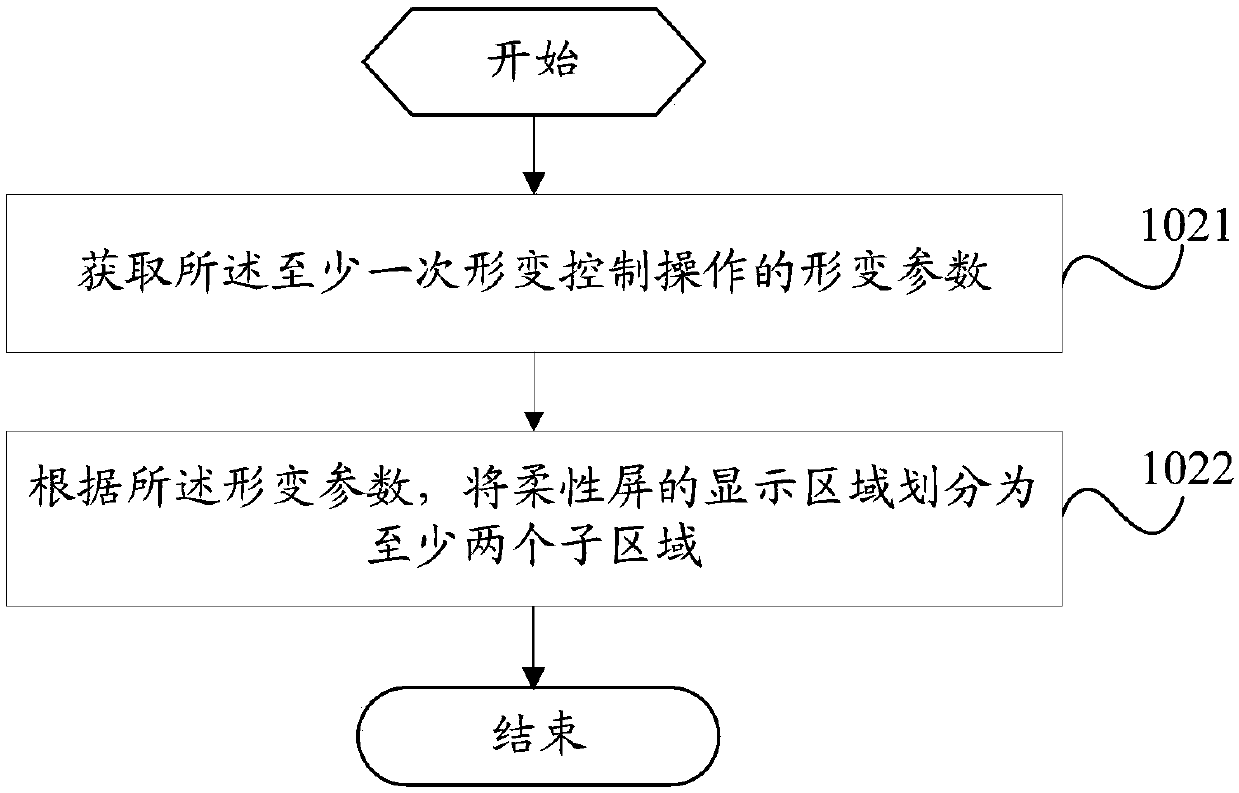

ActiveCN107632895ASolve the cumbersome operationAchieve sharingInterprogram communicationSpecific program execution arrangementsInformation sharingComputer terminal

The invention provides an information share method and a mobile terminal, relates to the field of communication, and aims at solving the problem that the operation is complex when content of another application program is selected in a process by using an application program. The method is applied to the mobile terminal with a flexible screen. The method comprises the following steps of: detectinga deformation control operation carried out on the flexible screen by a user; if at least one deformation control operation is detected, dividing a display area of the flexible screen into at least two sub-areas according to the at least one deformation control operation; determining an application program correspondingly displayed by each sub-area and displaying the corresponding application program in each sub-area; detecting an information share operation between the application programs; and if the information share operation is detected, sharing a target object corresponding to the information share operation, wherein the deformation control operation comprises a bending operation and a curling operation. According to the method, when content of another application is required, information share can be directly realized through an information share operation, so that the operation process is simplified.

Owner:VIVO MOBILE COMM CO LTD

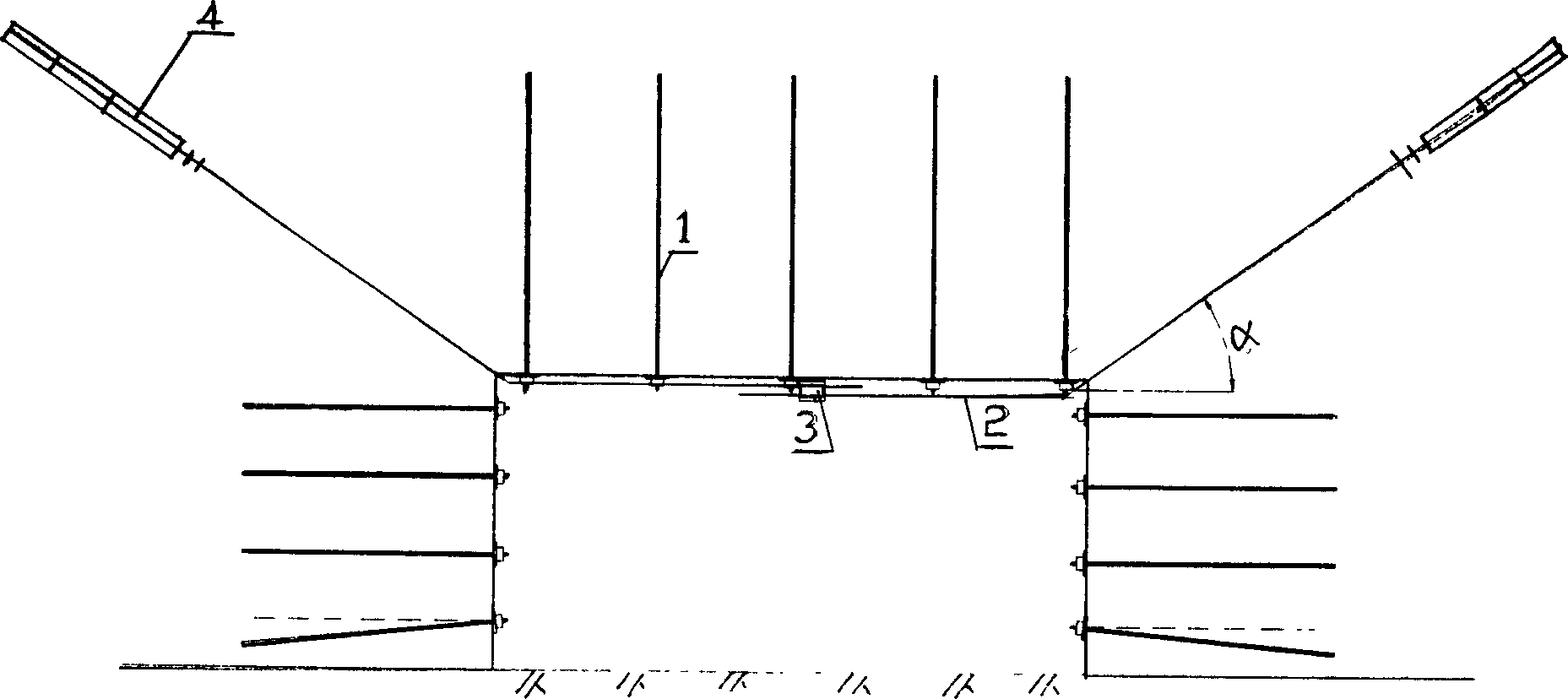

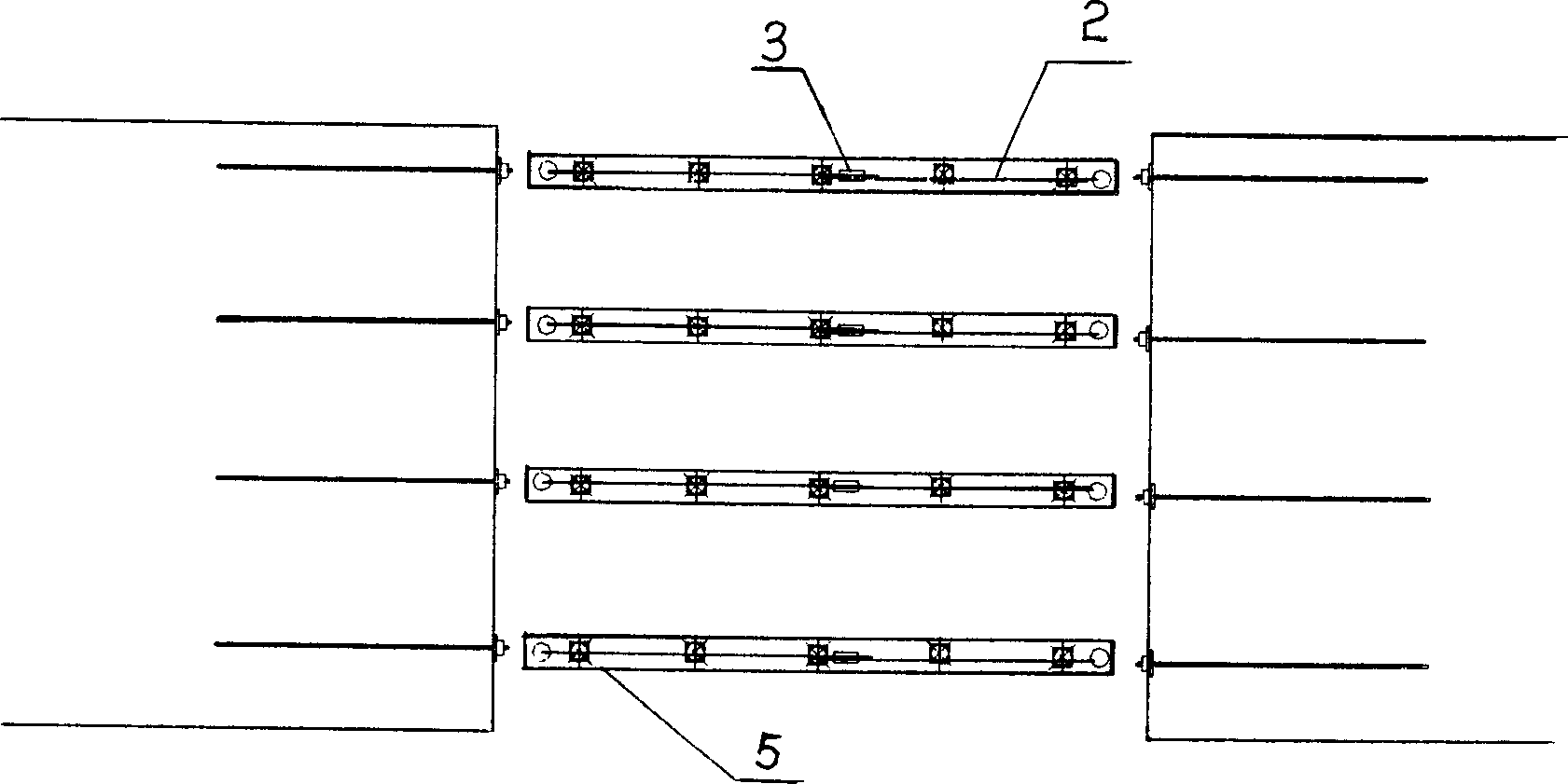

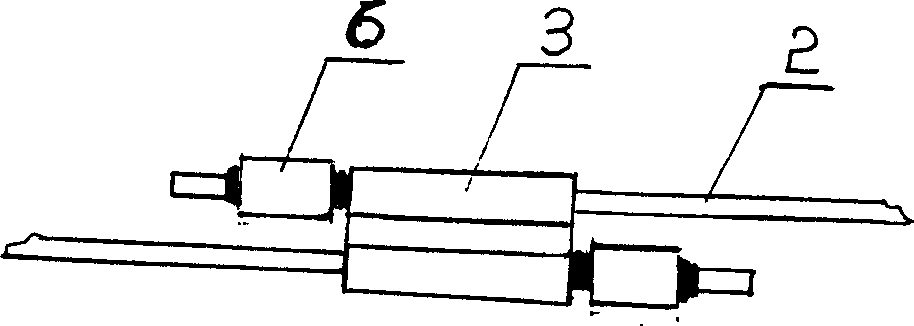

Truss supporting technology for ingredient top slope deformation control

InactiveCN1594834AReduce distortionSolve the problem of shear slip and cavingMine roof capsAnchoring boltsPull forceWhole body

A truss supporting technology for controlling ingredient top slope deformation is adapted for controlling the sinkage of wide span alley way top board separation layer, the top board and alley slope shear-slip breakaway or controlling the deformation of alley slope part. When using an anchor rod anchorage cable support for ingredient top board or alley slope part, plural trusses composed of two steel twist lines and double hole steel bushing coupler is set on the ingredient top board or alley slope part with spaces for support, each truss is shielded under the anchor solid, two steel twist lines are connected and locked by the coupler to form expansion and pull force to generate extrusion and protection function for the ally way top board or slope part. Not only the problem that the sinkage of the wide span alley way top board separation layer and the top board and alley slope shear-slip breakaway is solved, the top board is supported effectively, but also the displacement of the alley slope towards to alley inside is controlled, thereby the deformation of the alley slope is reduced, so the alley way can satisfy production requirement. In addition, the connection of the support whole body between the steel twist lines is adopted to change the limit of single anchorage cable support. The structure is simple, convenient in use and has broad practicability.

Owner:CHINA UNIV OF MINING & TECH

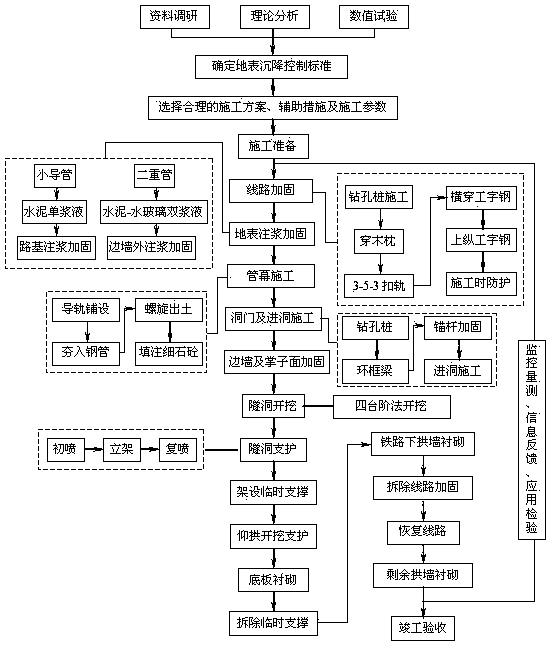

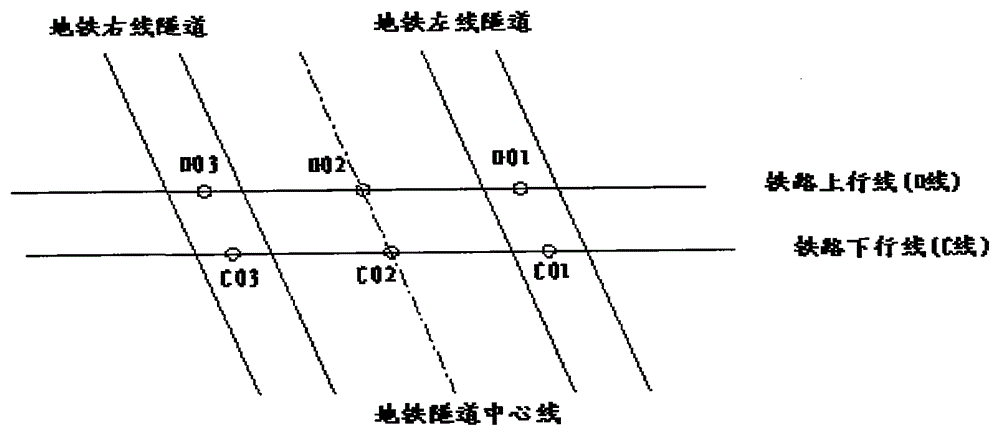

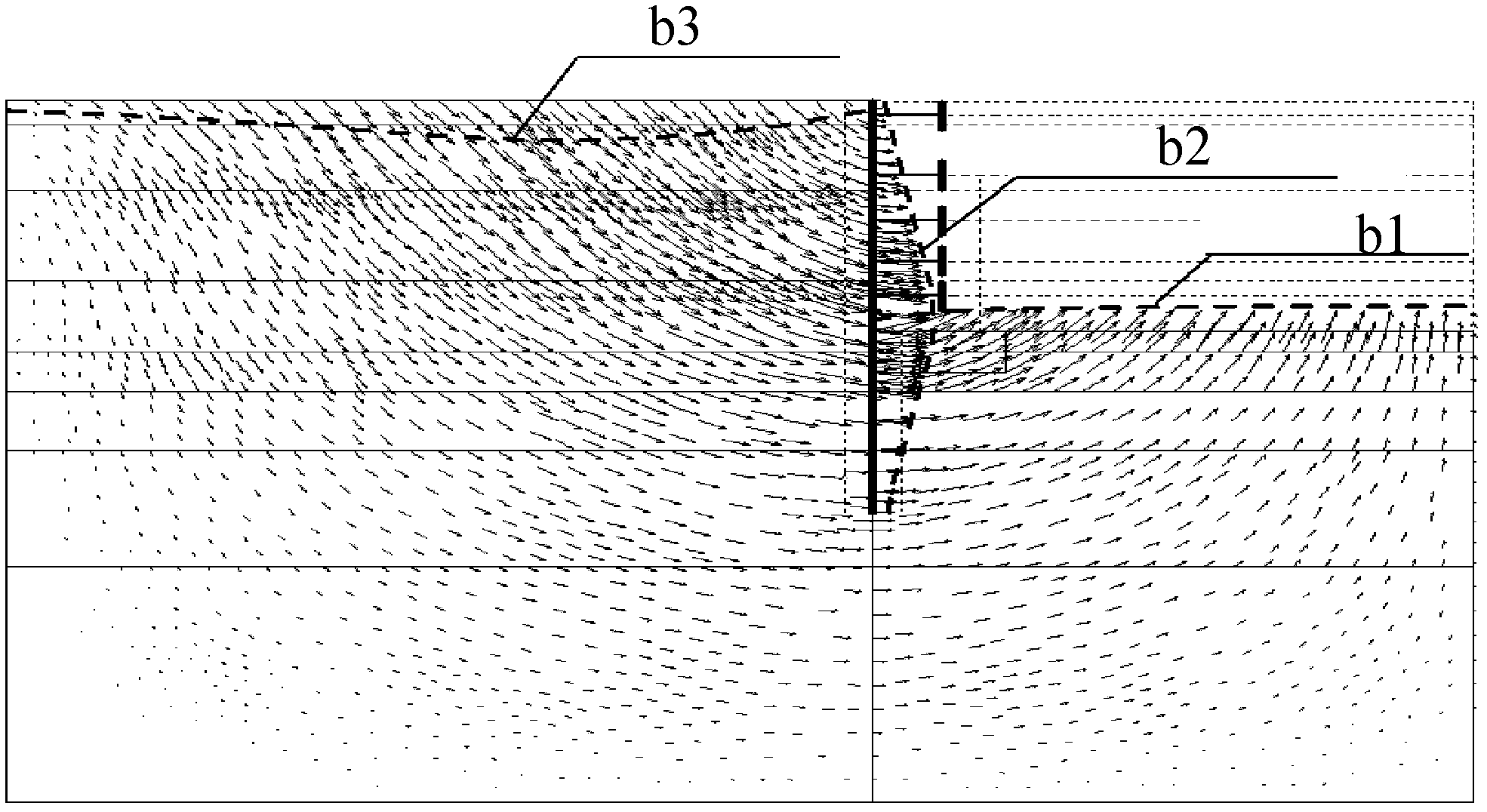

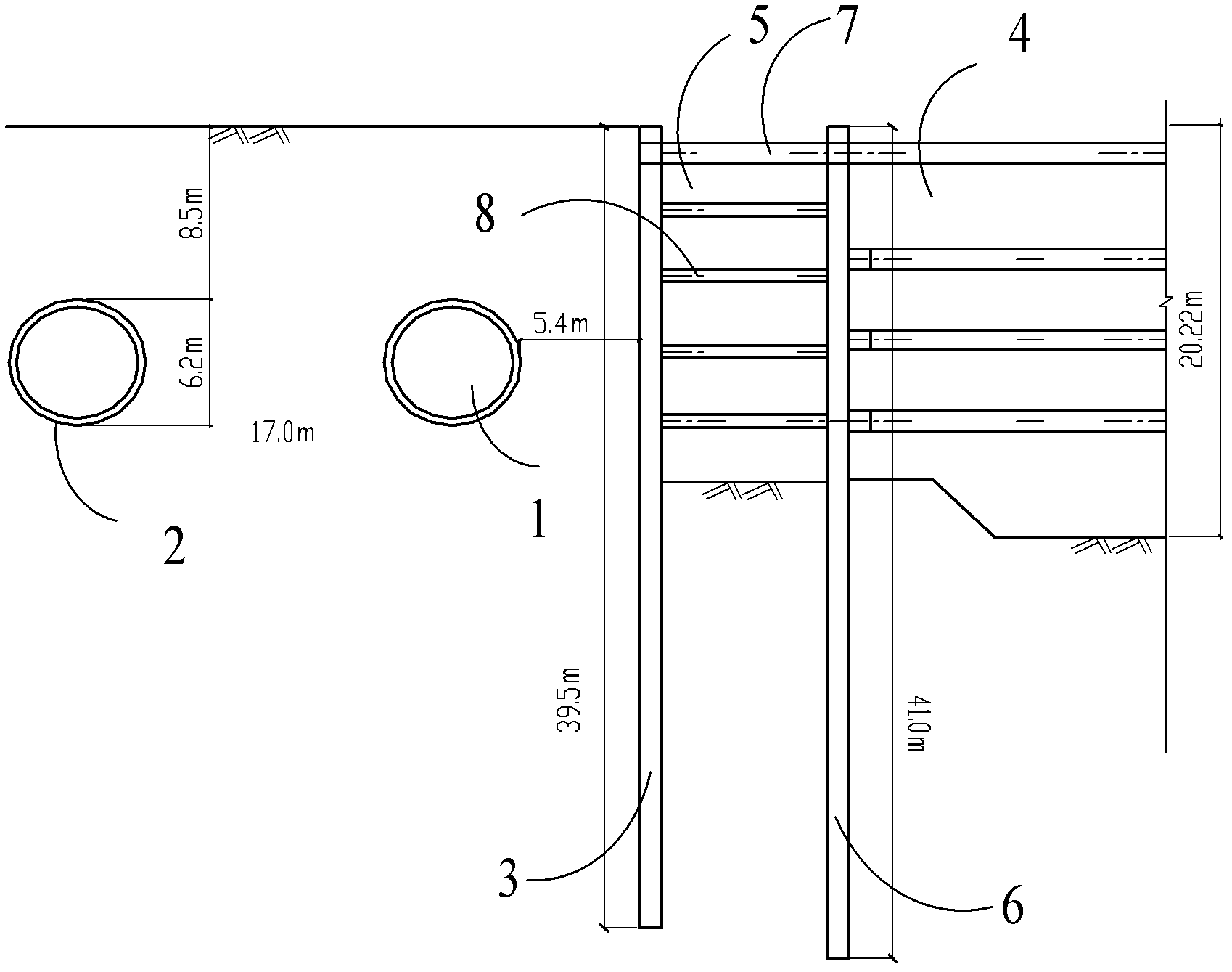

Underground excavation construction deformation control method for three-hole small clear distance tunnel underpass trunk railway

ActiveCN103375170AGuaranteed operational safetyReduce pollutionTunnelsTrackwayArchitectural engineering

The invention discloses an underground excavation construction deformation control method for a three-hole small clear distance tunnel underpass trunk railway, and belongs to the technical field of tunnel (hole) shallow buried soil stratum construction. Firstly, construction surface subsidence control standards are determined according to the requirement of an existing trunk railway for track smoothness; secondly, construction schemes and construction parameters of the three-hole tunnel are tested and determined by the aid of three-dimensional finite element static and dynamic numerical values. Construction includes the steps: reinforcing lines; grouting and reinforcing the earth surface; constructing an advanced tube screen; constructing a tunnel portal; constructing a tunnel crevasse; grouting and reinforcing side walls and tunnel faces; excavating the tunnel; supporting the tunnel; forming a secondary liner of the tunnel; recovering the lines, and monitoring measurement is performed in the whole construction process. Construction quality is strictly controlled according to a predetermined scheme and process in the construction process, the construction parameters are timely fed back and adjusted by the aid of an information construction technology, and operation safety of existing lines and structural stability of the tunnel are guaranteed.

Owner:中铁六局集团石家庄铁路建设有限公司 +1

Shape follow-up support deformation control method for selective laser melting forming of thin-walled part

ActiveCN108372298AEfficient additionAvoid complex and hard-to-remove problemsAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingDeformation control

The invention relates to a shape follow-up support deformation control method for selective laser melting forming of a thin-walled part. On the basis of existing selective laser melting forming support adding, the stress deformation behavior of the large thin-walled structural part in the forming process is analyzed and predicted, according to the molded surface structural characteristics, a design method that different shape follow-up supports are added at different positions is adopted, the problems such as cracking and deformation at the different positions such as the bottom in the selective laser melting forming process are solved through the method of supporting structure shape follow-up adding, the stability in the forming process is effectively improved, and the reliability of thequality of the formed structure part is guaranteed.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

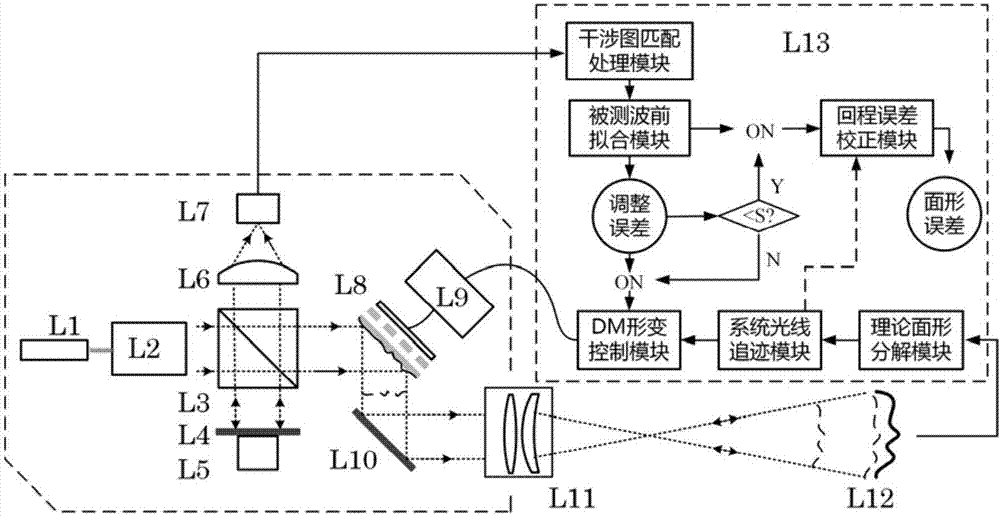

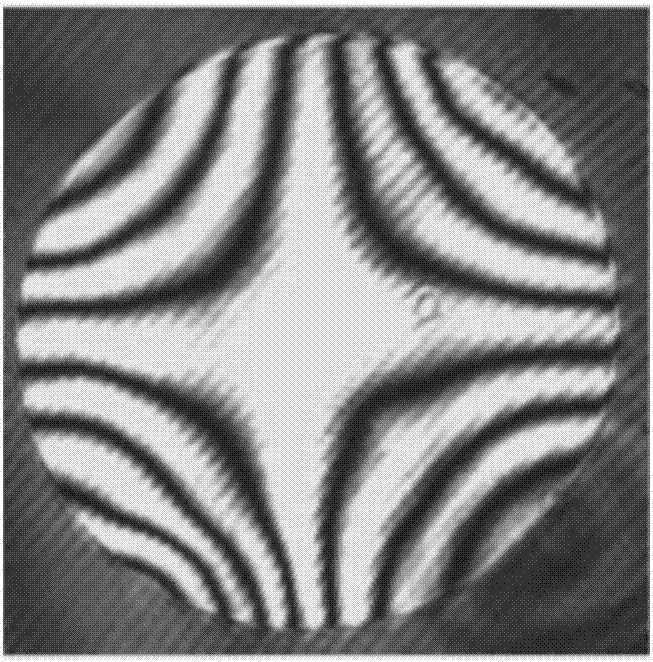

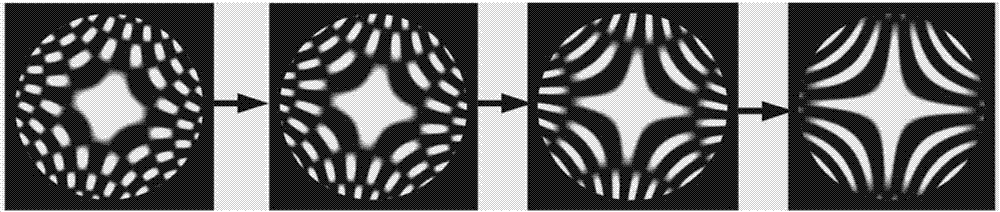

Adaptive non-zero digit interference detecting system for optical free curved surface

ActiveCN106918303AImplement non-zero bit detectionAchieving Adaptive CompensationUsing optical meansHysteresisBeam splitter

The invention discloses an adaptive non-zero digit interference detecting system for an optical free curved surface. The system comprises a free curved surface non-zero digit interference detecting system and an adaptive data processing and controlling system, wherein the free curved surface non-zero digit interference detecting system comprises a frequency stabilized laser, a collimating system, a beam splitter, a reference flat mirror, an imaging lens, a detector, a deformable reflector DM, a reflector and an aplanat. The adaptive data processing and controlling system comprises a system laser tracing module, a theoretical surface decomposition module, a DM deformation control module, an interferogram coupling processing module, a detected wavefront fitting module and a hysteresis error correction module. The adaptive non-zero digit interference detecting system can realize compensation for different Zernike low-order aberration by means of the continuous deformable reflector DM. Deformation of the deformable reflector is guided through the system laser tracing module, so that high-precision universal detection for a large-curvature changing free curved surface is realized.

Owner:ANHUI UNIVERSITY

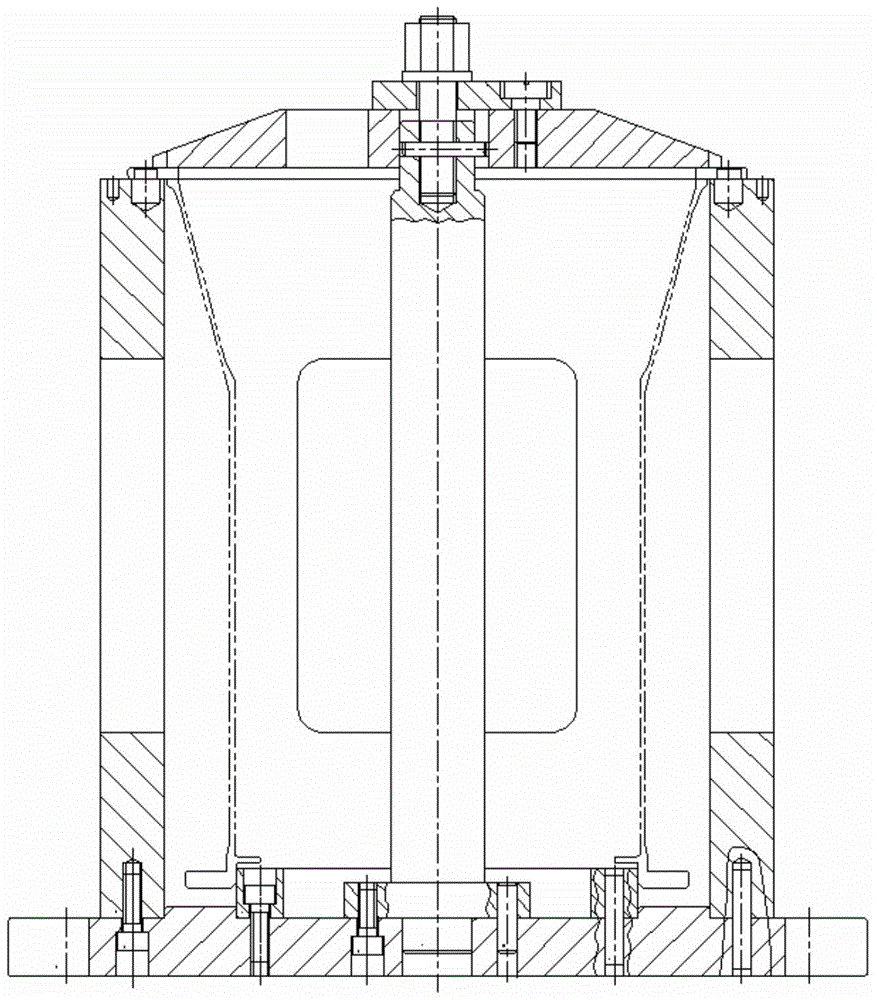

Machining method for deformation control of high-precision thin-wall cylinder shaft

InactiveCN106425286AHigh precision requirementsHigh hardnessWork clamping meansPositioning apparatusDeformation controlSuperalloy

The invention discloses a machining method for deformation control of a high-precision thin-wall cylinder shaft. A process scheme is determined: because a workpiece belongs to a thin-wall piece, the deformation control needs to be considered at the beginning of formulating a process route, the influence on deformation of the workpiece by machining stress in finish turning is controlled; an anti-deformation fixture structure is determined: a workpiece clamping mode is researched; a fixture clamping scheme is improved; a special anti-deformation fixture is used for finely turning inner and outer molded surfaces and machining a large end surface hole groove and a small end surface hole groove to solve the deformation problem caused in workpiece machining; the large end surface is axial reference of the whole workpiece to reach high precision requirement; and the small end surface is higher in technical condition requirement on the large end surface. The machining method has the following advantages: the technical difficulty of deformation of a high-temperature alloy thin-wall cylinder shaft is solved, a qualified workpiece is finally machined, the technical bottleneck of deformation of the high-temperature alloy thin-wall cylinder shaft is broken through, the workpiece design requirements are guaranteed, and the machining method can be popularized and applied in the same kind of workpieces to provide precious experiences for similar workpiece machining.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

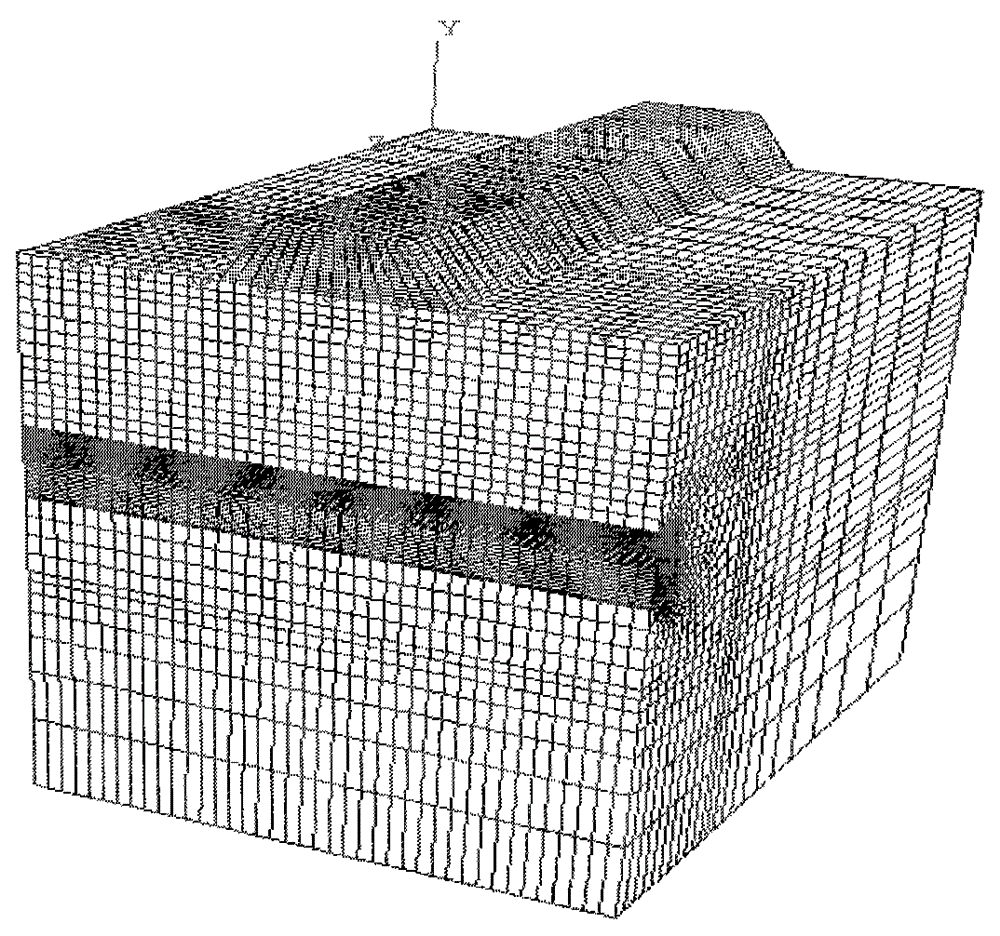

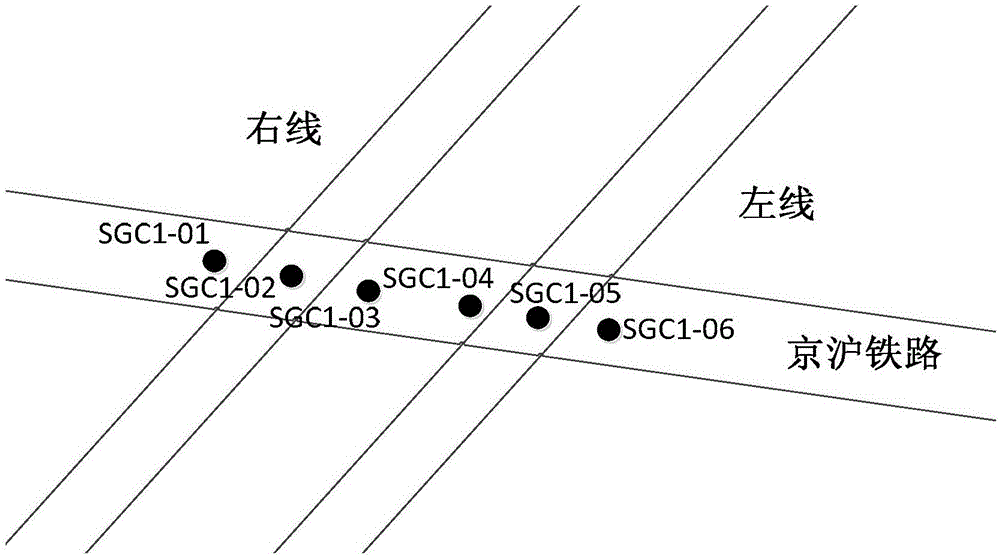

Settlement control method in process of enabling subway tunnel to penetrate through existing railway

InactiveCN105089698ASettlement control indicators are clear and intuitiveEasy to guide constructionMining devicesSpecial data processing applicationsEngineeringIndex system

The invention provides a settlement control method in a process of enabling a subway tunnel to penetrate through the existing railway. The settlement control method comprises the steps: establishing a line structure-subgrade-soil layer three-dimensional calculation model by utilizing a dynamic finite element theory to simulate and analyze deformation relations of a tunnel structure, a soil layer and a track foundation caused by subway tunnel construction at different tunnel burial depths in different excavation manners; by combining the existing subway tunnel under-through construction documents, summarizing and concluding deformation influence factors and a deformation influence rule to the existing line foundation, and an influence rule to track irregularity caused by tunnel excavation during subway tunnel under-through construction; based on correlation requirements on track static geometric dimensions and dynamic quality allowable deviation management in the existing railway deformation control index system, proposing a settlement control index in the process of enabling the subway tunnel to penetrate through the existing railway; if during construction, the real-time monitored subgrade settlement amount is over the settlement control index, giving out an alarm. The invention can relieve, eliminate and avoid adverse effects to the ground surface settlement of the crossed existing railway caused by subway construction, and provides a means to scientifically and reasonably developing safety evaluation of the subway tunnel construction.

Owner:中国铁道科学研究院集团有限公司城市轨道交通中心

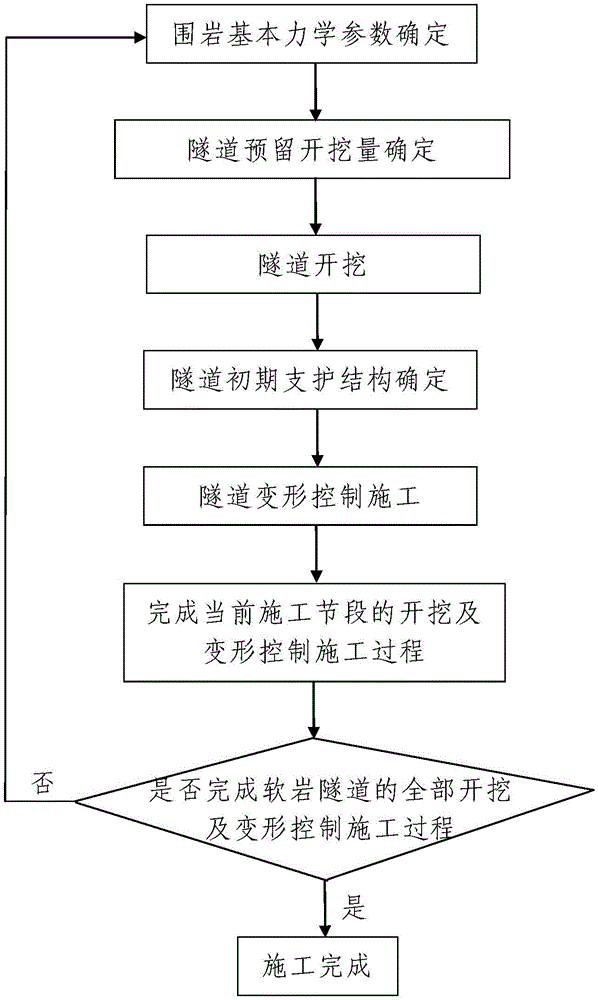

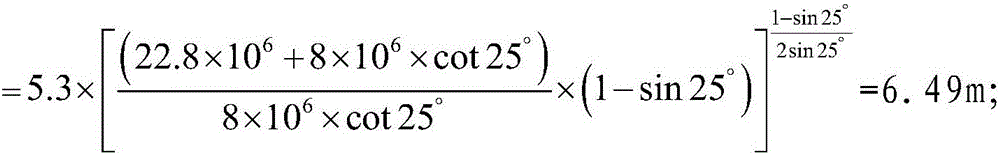

Soft rock tunnel deformation control method based on anchor rod force analysis

InactiveCN106499397AThe method steps are simpleEasy to implementUnderground chambersTunnel liningStructure of the EarthForce analysis

The invention discloses a soft rock tunnel deformation control method based on anchor rod force analysis. A soft rock tunnel is excavated and subjected to deformation control construction from back to front according to multiple segments, and when any segment is excavated and subjected to deformation control construction, the method includes the steps that 1, surrounding rock basic mechanical parameters are determined; 2, the tunnel reserved excavated volume is determined; 3, the tunnel is excavated; 4, a tunnel preliminary bracing structure is determined; 5, tunnel deformation control construction is carried out, wherein in the tunnel preliminary bracing construction process, a flexible mold bracing structure is constructed from back to front; 6, a next segment is excavated and subjected to deformation control construction; 7, the step 6 is repeated multiple times till the full excavation and deformation control construction process of the soft rock tunnel is completed. The soft rock tunnel deformation control method is reasonable in design, convenient to achieve and good in use effect, the reserved excavated volume is determined according to the surrounding rock deformation condition of the soft rock tunnel, the flexible mold bracing structure is adopted for carrying out full-section bracing on the tunnel, the flexible mold bracing structure and the tunnel preliminary bracing structure are in coordination deformation, and deformation of the soft rock tunnel can be effectively controlled.

Owner:XIAN UNIV OF SCI & TECH

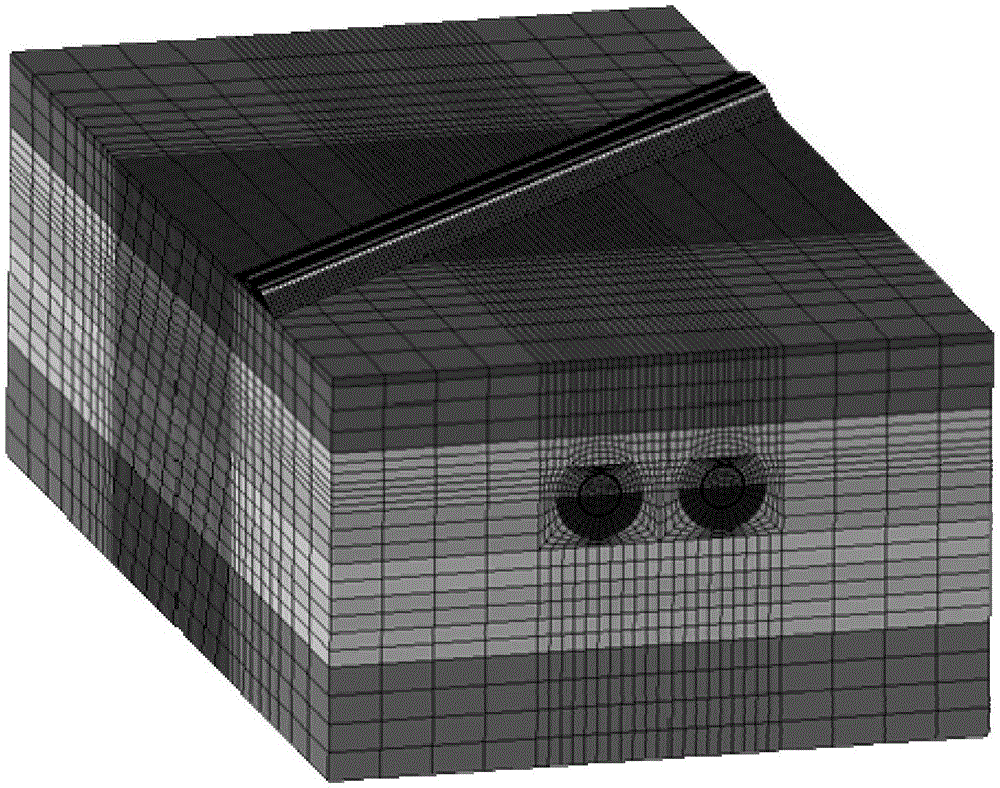

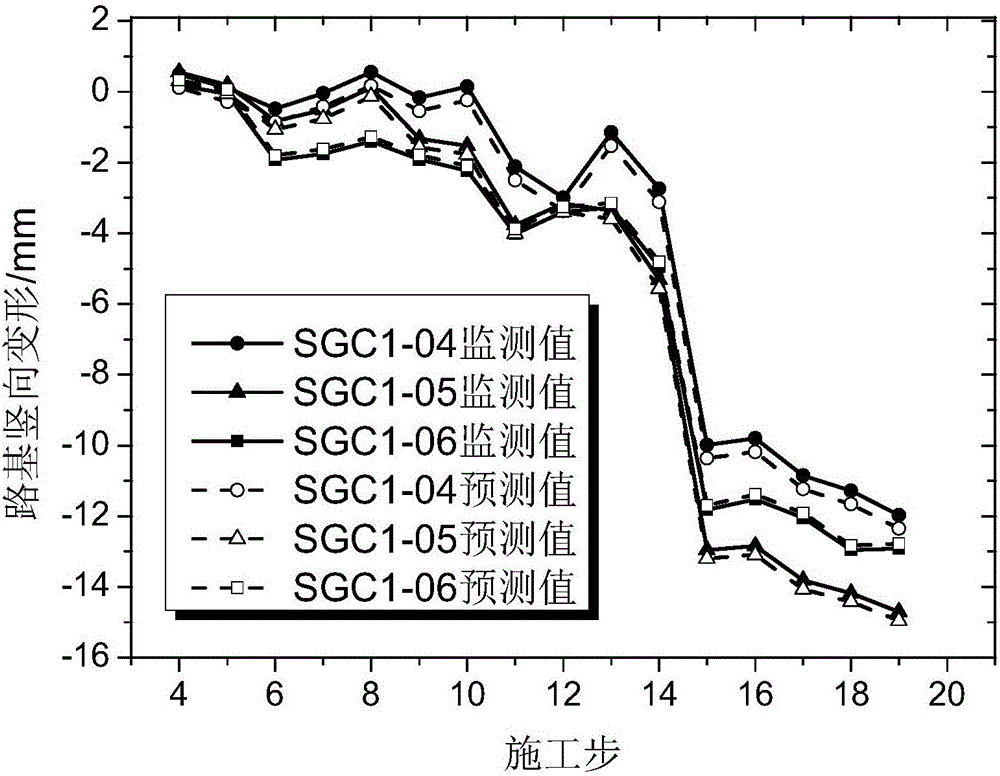

Settlement prediction method for metro tunnel shield undercrossing existing railway facilities

InactiveCN106649912AReduce adverse effectsEliminate and avoid adverse effectsGeometric CADForecastingMonitoring and controlDeformation control

The invention provides a settlement prediction method for metro tunnel shield undercrossing existing railway facilities. The method comprises the steps of using ABAQUS software in the finite element software to establish a three-dimensional calculation model of a soil-layer-subgrade-railway structure, calculating a vertical settlement displacement of the existing railway foundation and track, arrangingactual undercrossing construction materials of subway tunnel site including geological conditions, construction methods, section forms and dimensions, buried depth, settlement control indexes during construction and actually measured settlement data, combining the results of numerical analysis, summarizing the influence rules of deformation caused by the excavation work in the metro tunnel undercrossing construction to the existing railway foundation and track, making the comparison between the predicted value and the settlement control index stipulated in the existing railway deformation control index system in construction engineering, and based on the comparison results, adjusting shield parameters, excavation methods and excavation depth. The settlement prediction method for metro tunnel shield undercrossing existing railway facilities can in advance take corresponding reasonable shield parameters for tunnel excavation, and implement technical control measures of the settlement of surface facilities and settlement monitoring and control techniques.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +1

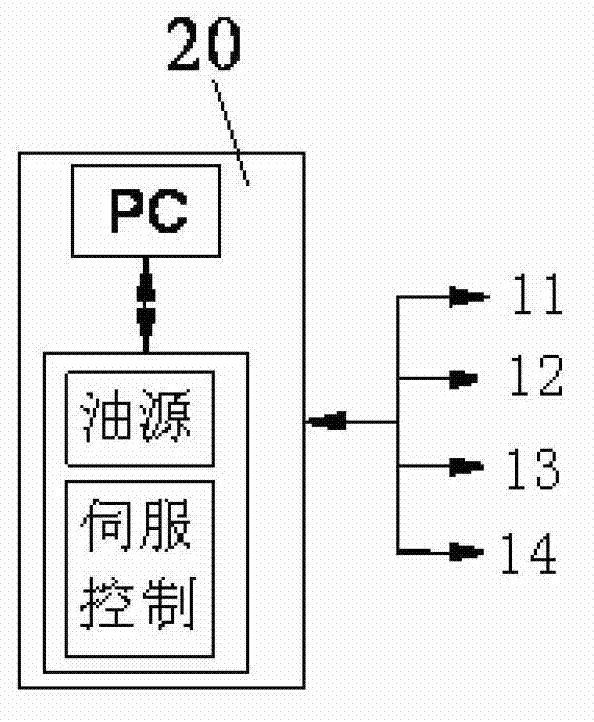

Design method for controlling deformation of deep foundation pit by using axial force servo system of steel support

InactiveCN102535479AMeet deformation control requirementsExcavationsAutomatic controlElement analysis

The invention discloses a design method for controlling the deformation of a deep foundation pit by using an axial force servo system of a steel support, comprising the following steps of: carrying out continuous medium finite-element analysis according to a deformation control value of a protected facility to obtain a lateral deformation control value of a space enclosing structure and an axial force control threshold value needing to be provided by a steel support; carrying out dynamic monitoring on the actual lateral deformation value of the space enclosing structure and the actual axial force output value of the steel support through detection elements and sending monitored results to an automatic control system; utilizing the automatic control system to carry out comparative analysis on the axial force control threshold value which is preset by advance computational analysis and the monitored results of all the detection elements; and controlling a hydraulic system to adjust support force of the steel support to the space enclosing structure. The design of the axial force of the steel support of the deep foundation pit is changed into an initiative pressurization regulating and controlling design from a passive stressed design so that the deformation of the space enclosing structure of the foundation pit is initiatively regulated and controlled according to control requirements of the deformation of the protected facility which is close to the deep foundation pit; and therefore, the protected facility which is close to the deep foundation pit is effectively protected.

Owner:同济大学建筑设计研究院(集团)有限公司轨道交通与地下工程设计分院 +1

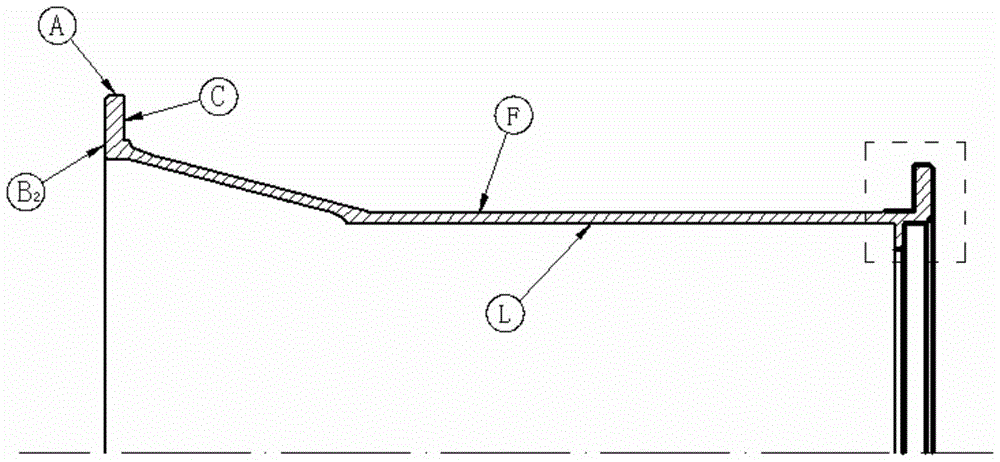

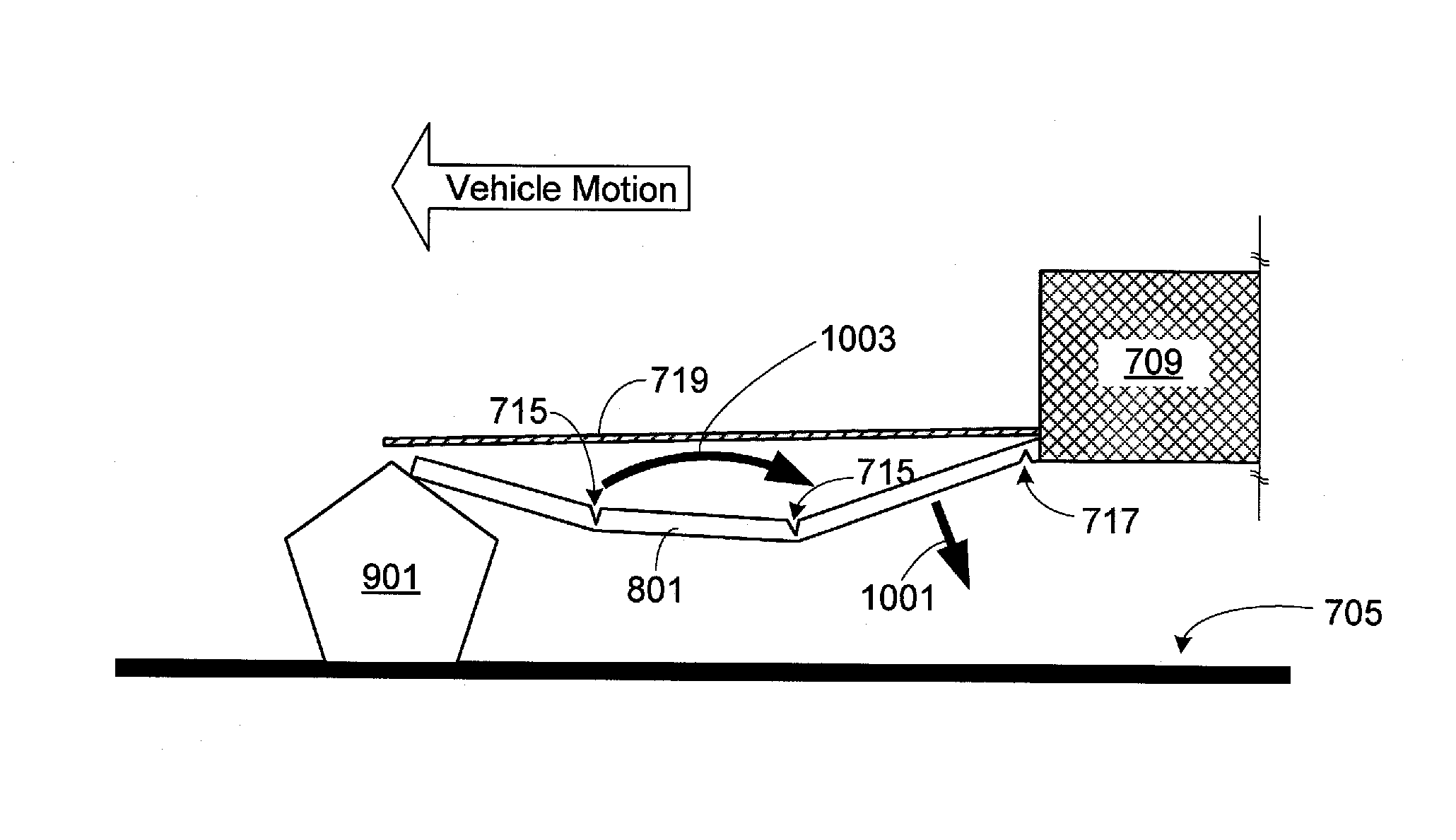

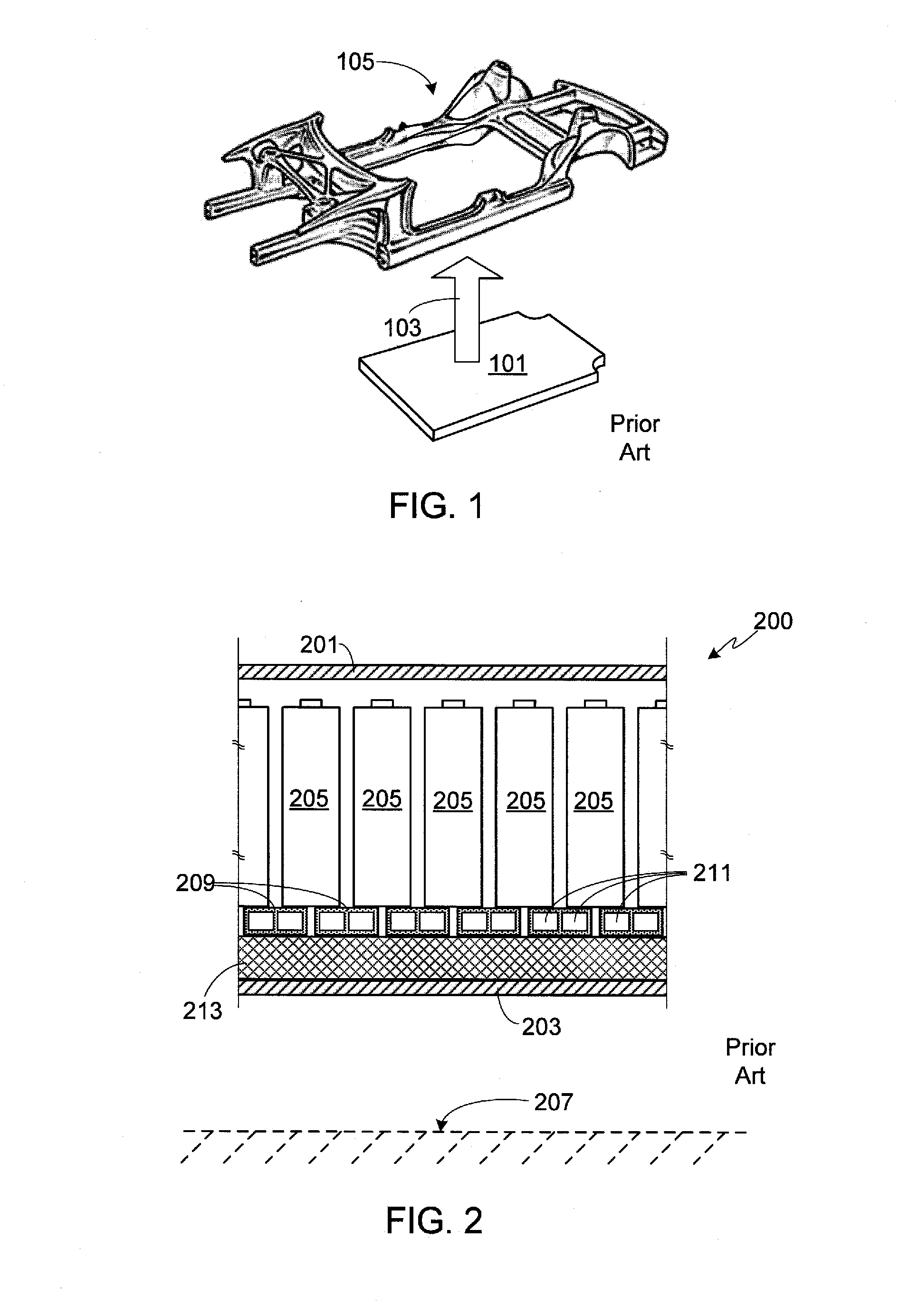

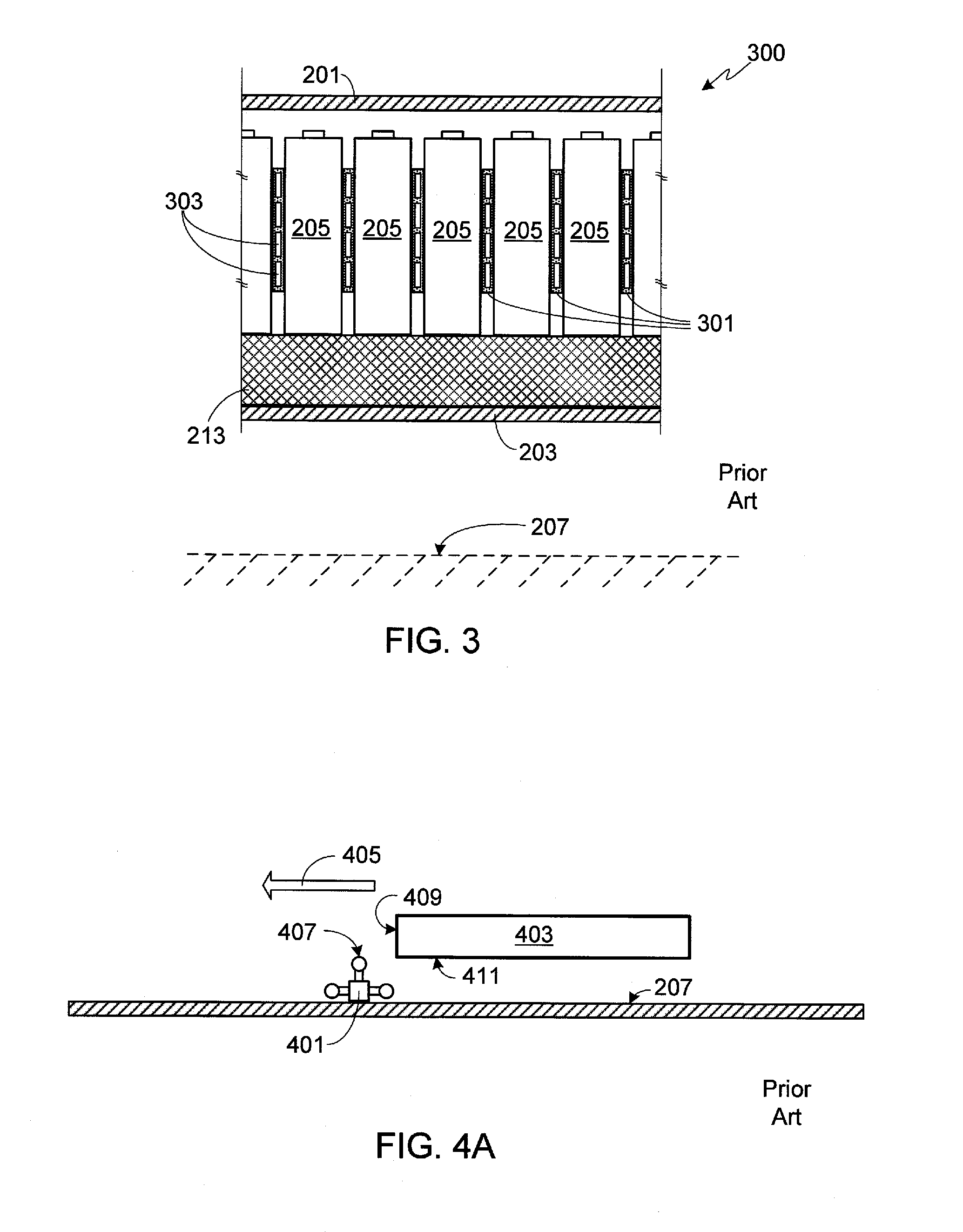

EV battery pack protection system utilizing an undercarriage debris trap

A battery pack protection system is provided for use with an electric vehicle in which the battery pack is mounted under the car. The system utilizes a debris capture plate mounted in front of the battery pack and positioned such that the leading edge of the mounted capture plate is positioned closer to the underlying road surface than the lowermost battery pack surface. Capture plate stiffeners, which are mounted to the capture plate, use deformation control features (e.g., notches) to promote a preconfigured pattern of capture plate deformation when a piece of debris impacts the plate's leading edge. The deformed capture plate then traps the debris and stops it from passing under the battery pack, thereby preventing the battery pack from possible debris impact damage.

Owner:ATIEVA USA INC

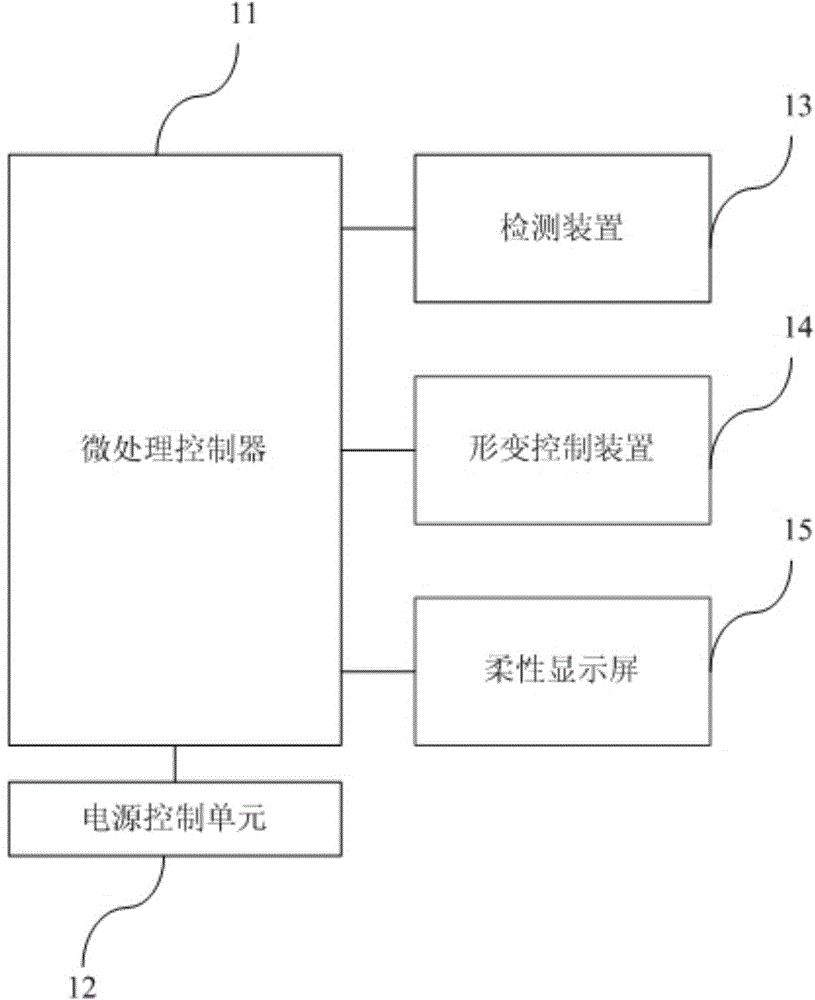

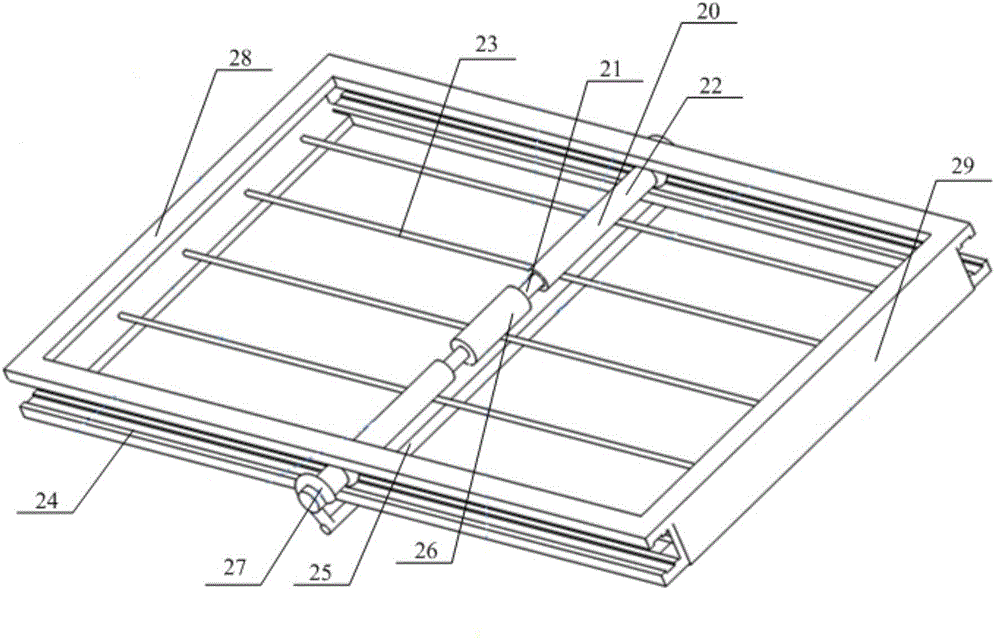

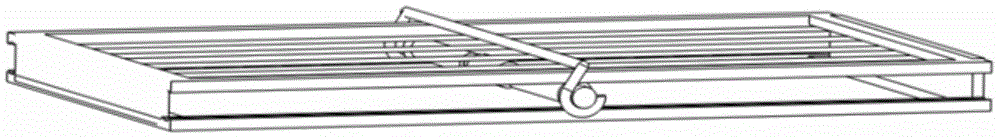

Mobile terminal which can automatically deform according to use state and method for achieving deformation of mobile terminal

ActiveCN104539764AMore convenientMore experienceTelephone set constructionsComputer terminalDeformation control

The invention discloses a mobile terminal which can automatically deform according to the use state and a method for achieving deformation of the mobile terminal. The mobile terminal comprises a micro-processing controller, a power control unit and a display screen. The power control unit and the display screen are in circuit connection with the micro-processing controller. The display screen is a flexible display screen. The mobile terminal further comprises a detection device, a display screen supporting device and a deformation control device. The flexible display screen is arranged on the display screen supporting device and controlled by the deformation control device. The deformation control device and the detection device are in circuit connection with the micro-processing controller. The mobile terminal can change the shape according to the environment where the mobile terminal is located or the operation state, when the mobile terminal plays videos, the mobile terminal deforms to be in the shape which is vertical, inclined and suitable for watching, and much convenience and more user experiences can be brought to users.

Owner:SHANGHAI MORUAN COMM TECH

Configuration control information processing method and device

ActiveCN106272550AImprove convenienceEasy to operateProgramme-controlled manipulatorCharacter and pattern recognitionInformation processingInformation control

The embodiment of the invention provides a configuration control information processing method and device and belongs to the field of computers. The method comprises the steps of acquiring the connecting information of a module to be matched, acquiring the connecting information of a target module and preset deformation control information corresponding to the connecting information of the target module, and matching the connecting information of the module to be matched with preset deformation conversion parameters to obtain current deformation control information; sending the current deformation control information to a modular robot corresponding to the connecting information of the module to be matched, so that the configuration of the modular robot corresponding to the connecting information of the module to be matched after deformation under the control of the current deformation control information can be identical with the configuration of a modular robot corresponding to the connecting information of a reference module after deformation under the control of the preset deformation control information. The operability and intelligence of a combined modular robot are improved, operation convenience is improved for users, and combination of the modular robot can be achieved with different interfaces when a module is damaged.

Owner:BEIJING KEYI TECH

Large-scale thin wall gear ring quenching deformation control method

ActiveCN101760602AAvoid deformationFurnace typesHeat treatment process controlDeformation controlHeating furnace

The invention discloses a large-scale thin wall gear ring quenching deformation control method, and after making a mould and regulating the mould, the large-scale thin wall gear ring quenching strain control is realized by using the following four steps of: A, putting the large-scale thin wall gear ring into a heating oven to heat to enable the inside diameter to swell, and then hanging and putting the mould into the inner hole of the large scale thin wall gear ring; B, hanging the heated large-scale thin wall gear ring and the mould out of the oven, then putting into the medium to quench and enable the inner hole of the large scale thin wall gear ring to contract and the support block of the mould to support the inner wall of the large scale thin wall gear ring; C, keeping the large-scale thin wall gear ring and the mould at a state of being quenched and molded, and hanging into the heating oven for low tempering; and D, hanging the large-scale thin wall gear ring and the mould out of the heating oven, cooling in the air and detaching the mould. By using the specially shaped mold in the process of quenching, the invention can effectively prevent the deformation after the large-scale thin wall gear ring is quenched.

Owner:CHONGQING GEARBOX

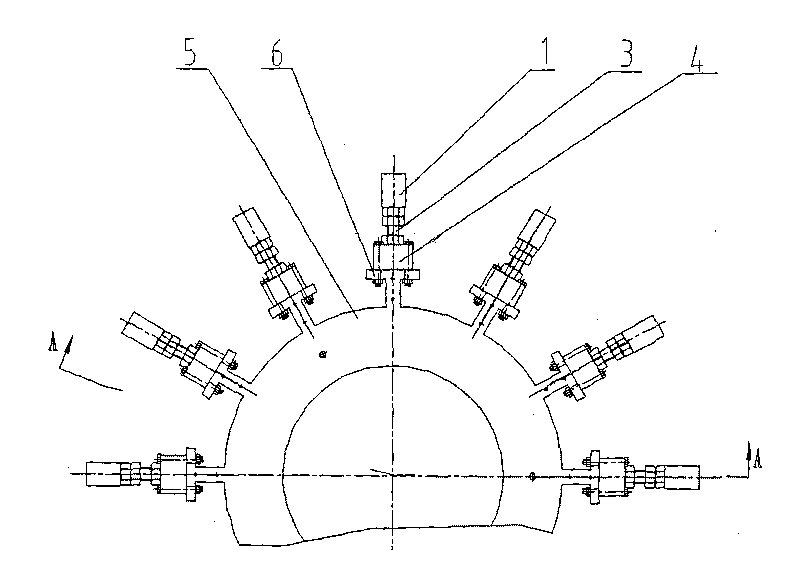

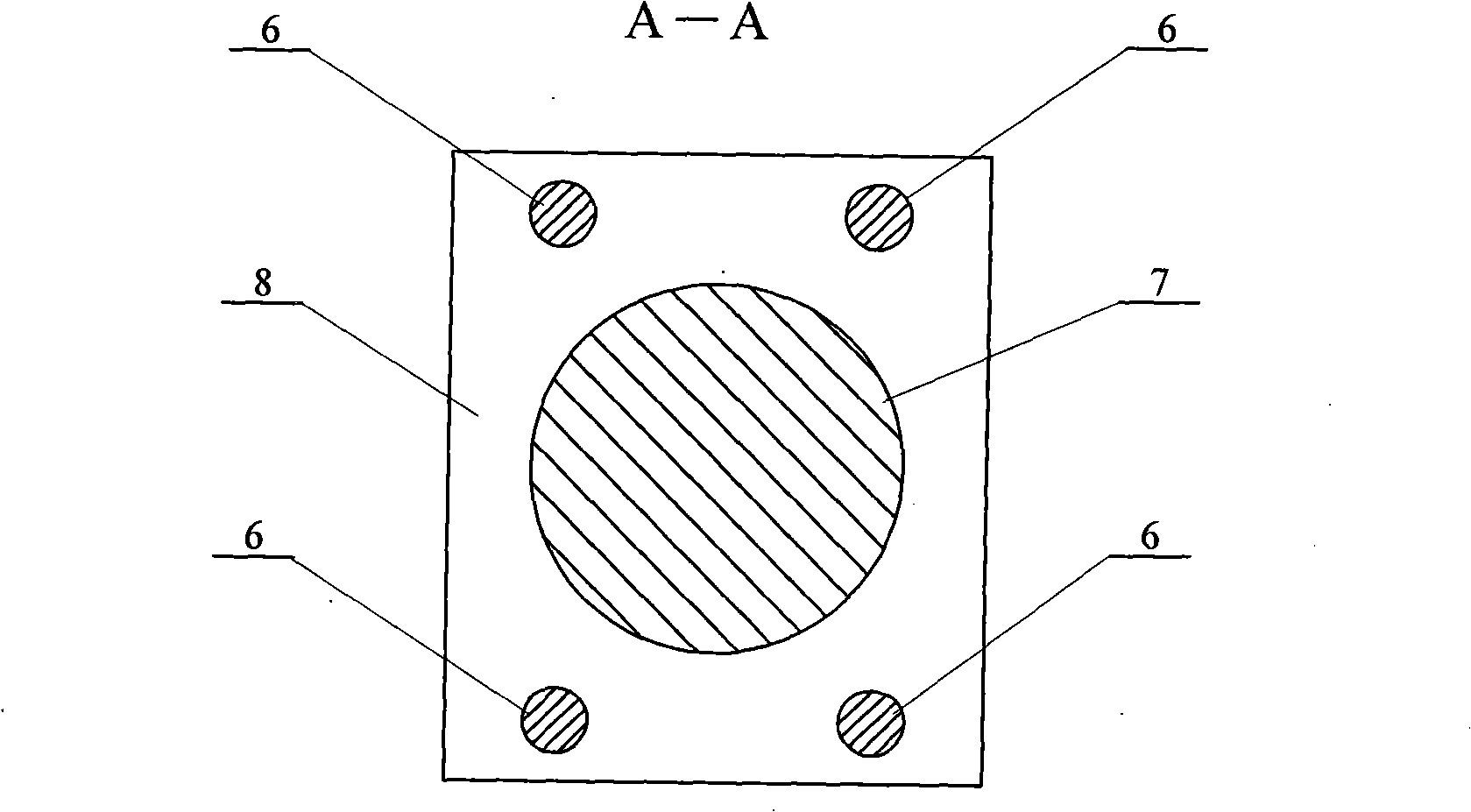

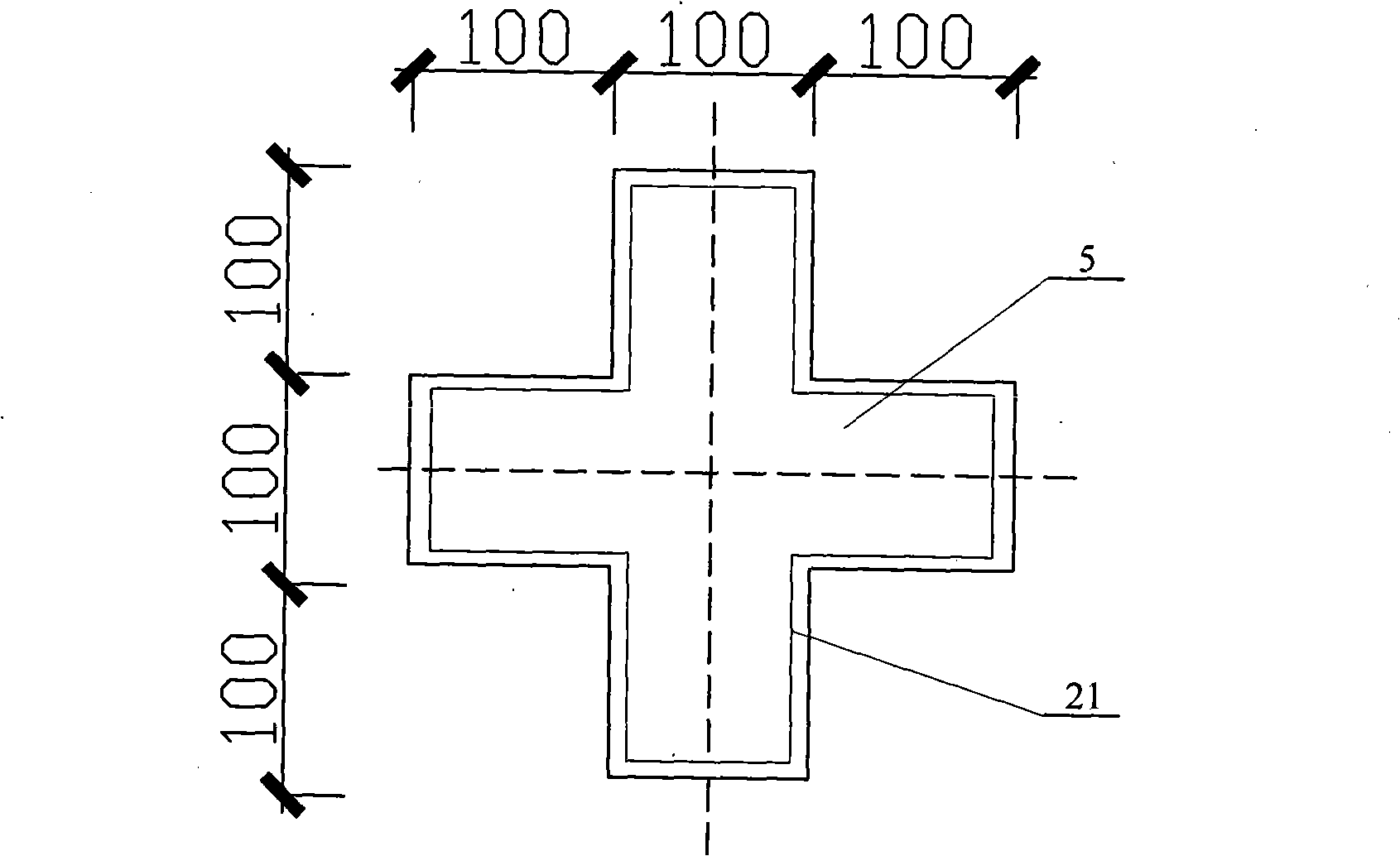

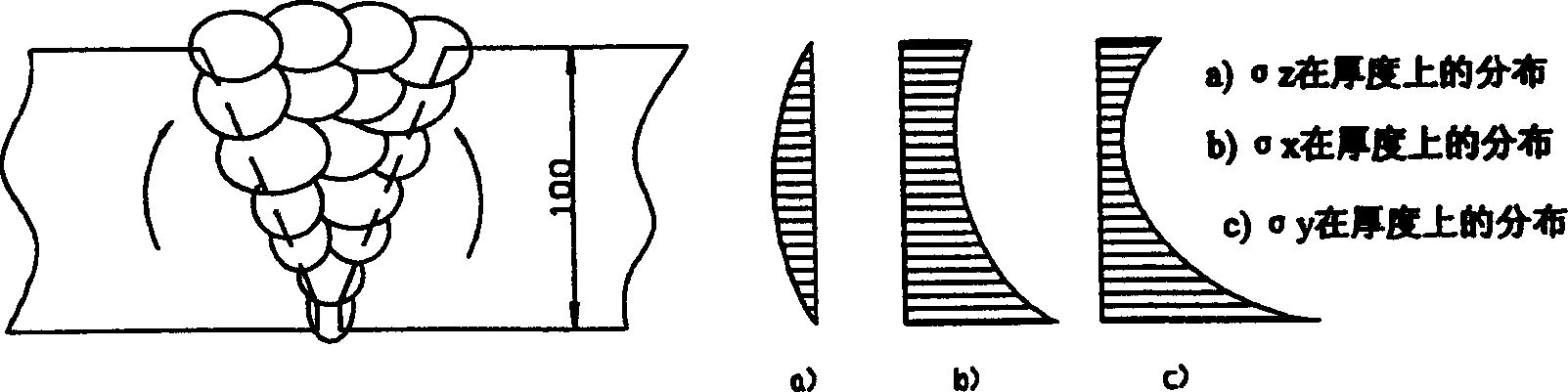

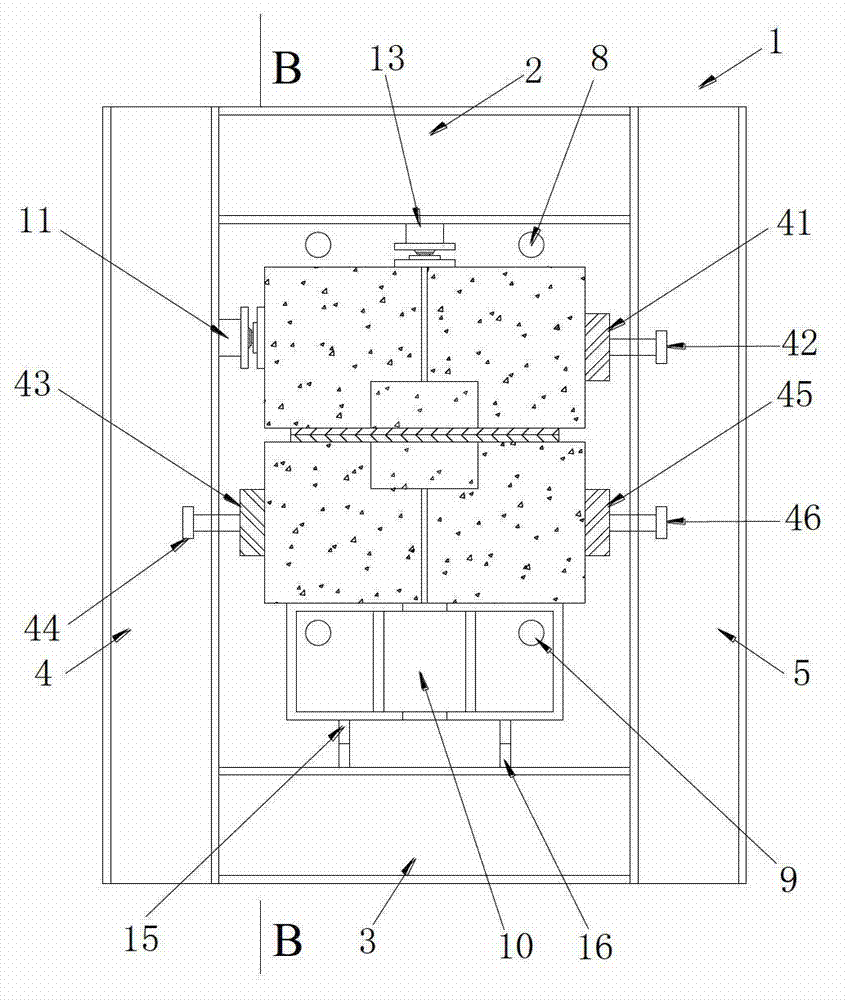

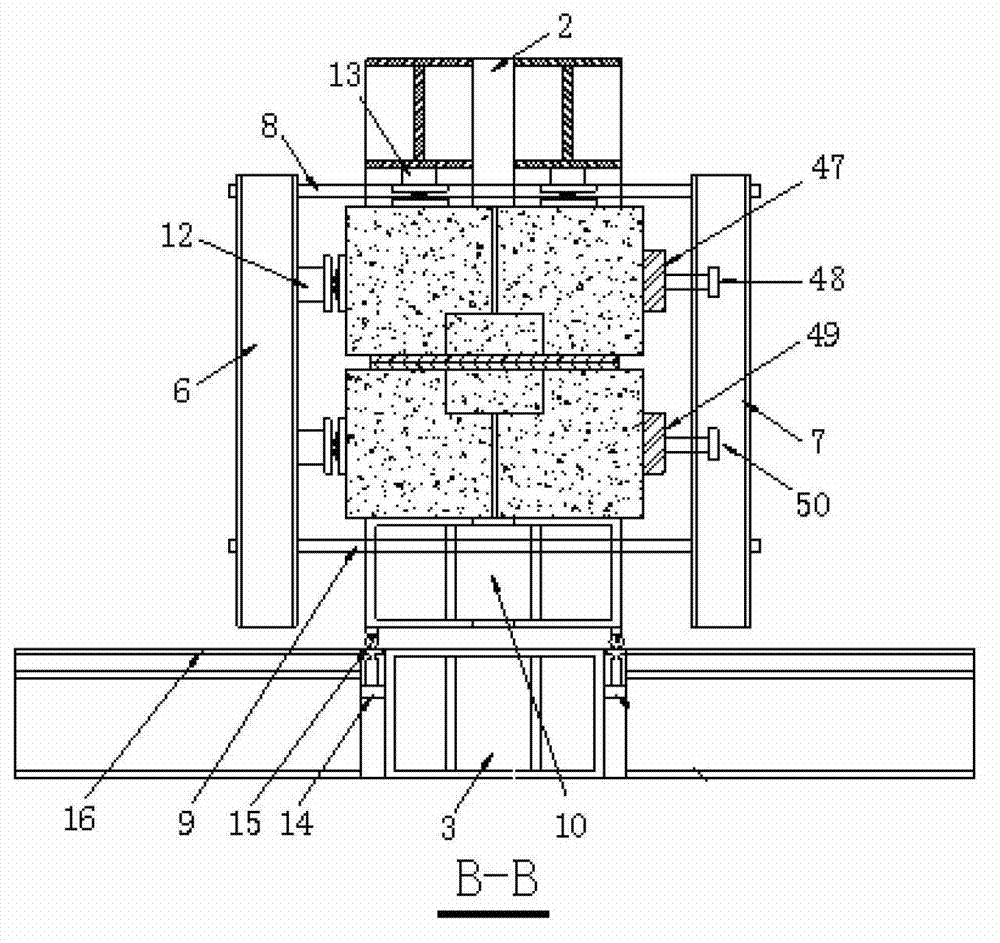

Concrete plane complicated applied force test device

InactiveCN101408489AEasy to disassembleEliminate uneven stressStructural/machines measurementStrength propertiesControl systemStructural engineering

The invention discloses a concrete plane complex stress test device, and relates to a concrete stress test device. The invention aims at solving the problem that when a concrete loading test is carried out by the existing multi-shaft testing loading equipment, the concrete transverse deformation is limited to result in friction, which causes a greater difference between the test result and the practical situation. In the device, a second vertical loader is fixed on the ground at the central position inside a reacting force frame, a first vertical loader is fixed on the underside of the central position of the reacting force frame beam, a first horizontal loader and a second horizontal loader are respectively fixed on the internal sides of a first steel plate and a second steel plate. The device can accomplish the concrete plane complex stress test which is a plane stress test of two-way stressing, two-way pulling, one-way stressing, one-way pulling, shear stressing and shear pulling. A hydraulic servo controls two mutually perpendicular loading directions by a control system and the loading speed and different two-way loading combinations can be adjusted automatically. The device can be used for a load control loading test and also for a deformation control loading test.

Owner:HARBIN INST OF TECH

Deformation control method for large structure piece welding

ActiveCN1554508AControl welding deformationMeet the design requirementsArc welding apparatusDeformation controlWelding deformation

The welding deformation controlling method for large structure member includes reserving shrinkage allowance of the part sizes and assembling sizes, separating large structure member into several parts to be welded together, welding after assembling of the members, integrally annealing to eliminate stress after welding, and arranging tensile ribs in the proper locations before transportation of the heat treated member. The welding adopts rich argon protection and arc welding to form bottom. The said process can control welding deformation of the large structure member effectively, shorten production period, lower labor strength and raise production efficiency.

Owner:DONGFANG TURBINE CO LTD

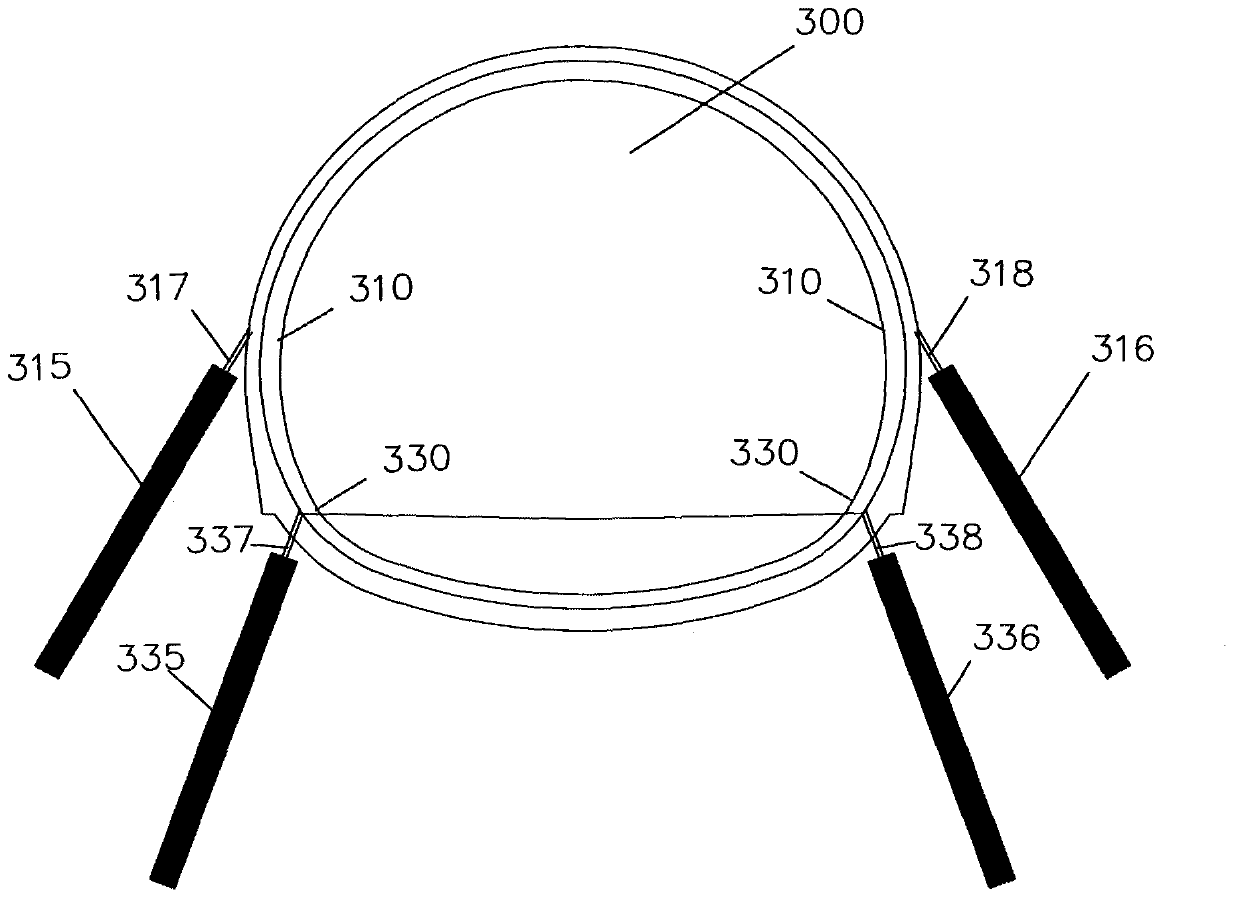

Deformation-control system and method

A system for selectively controlling deformation. The system includes a first mechanism for resisting deformation about an axis of an accompanying fluid foil. A second mechanism, in communication with the first mechanism, enables deformation along the axis and / or at an angle to the axis. In more a specific embodiment, the axis is a lengthwise axis of the fluid foil, which is a transformable airfoil, and the system includes a bellows device that is approximately concentric with the axis. The bellows device is supported by first base structure at one end and a second base structure at another end. The deformation at an angle to the first axis includes shear deformation or bending deformation. The deformation along the axis includes extension or strain deformation. The deformation about the axis includes torsion deformation.

Owner:COWAN DAVID L +1

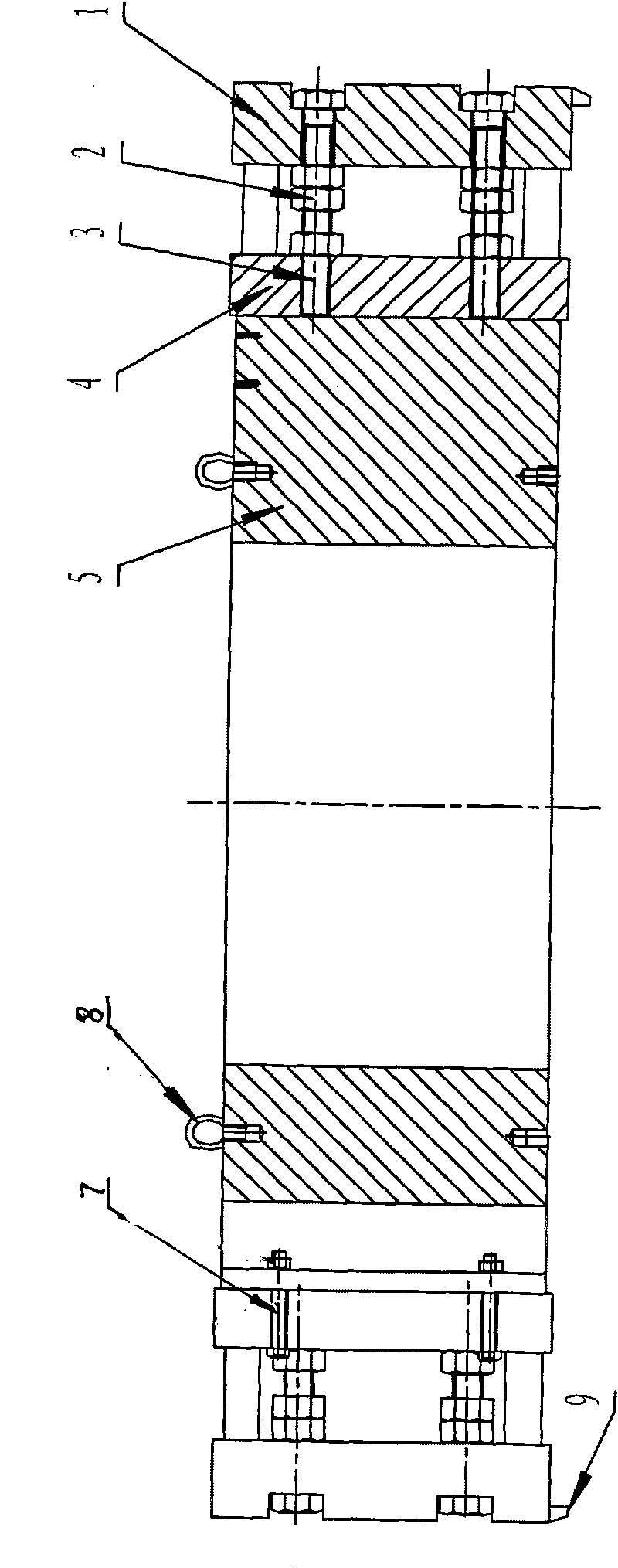

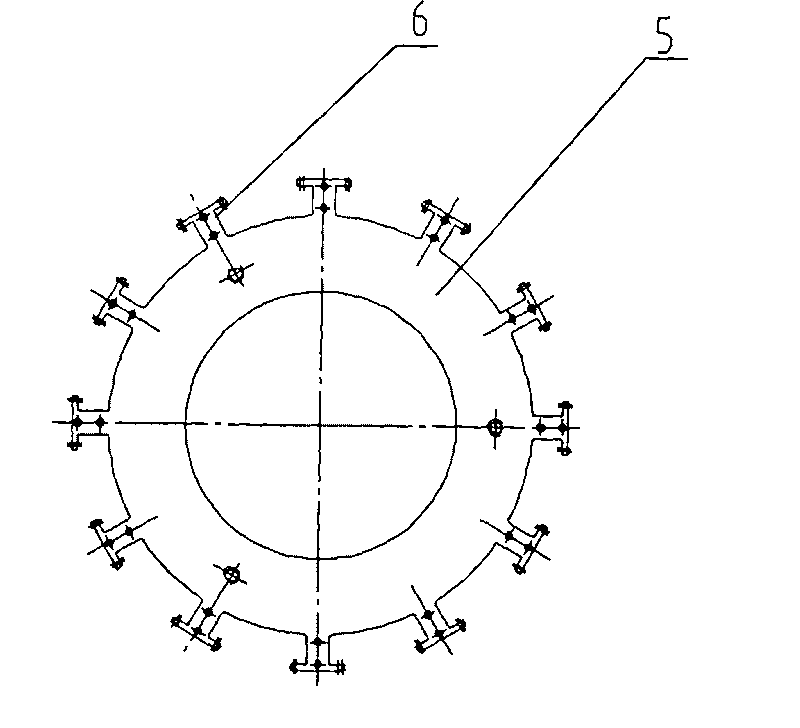

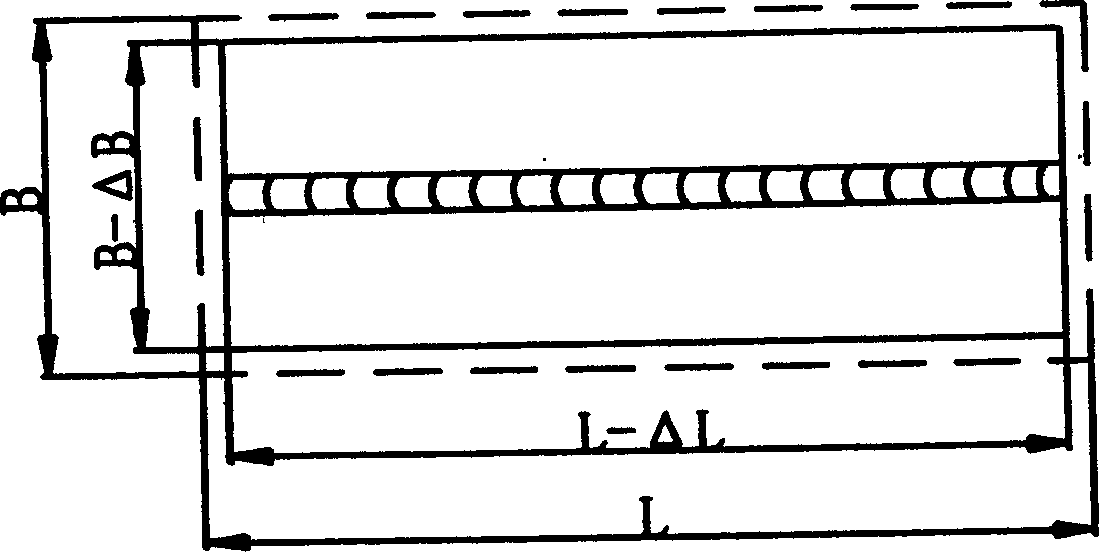

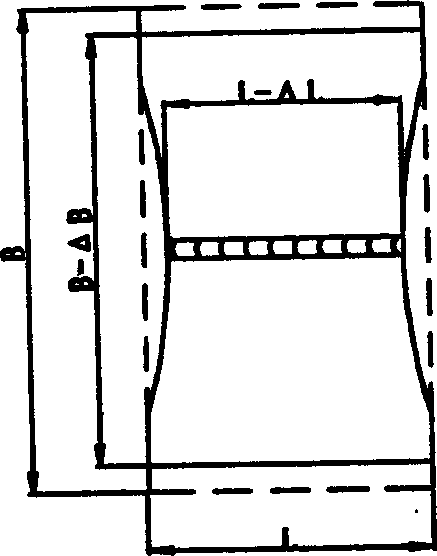

Welding deformation control aid of large-size stainless steel cylinder and welding deformation control method

ActiveCN101797671AAvoid mechanical propertiesAvoid thermal shaping processWelding/cutting auxillary devicesAuxillary welding devicesDirect observationFree state

The invention relates to a welding deformation control aid of a large-size stainless steel cylinder, comprising an inner arc flat panel, an outer arc flat panel and jack screws, wherein the inner arc flat panel and the outer arc flat panel are flat panels one side of which is an arc side, and the arc radiuses of the arc sides are the same as that of the cylinder; the jack screws are fixedly connected to both sides of points of the plat panels opposite to a longitudinal welding line of the cylinder; and the top ends of the jack screws face towards the arc sides of the plat panels. When in use, the assembly datum lines of the inner circumference and the outer circumference of the cylinder are drawn out on a welding platform, and the arc segment of the cylinder is hung on the platform and takes the places according to the datum lines; the lengths and the angles of a non-line length segment at both sides of the longitudinal line under a free state are measured, and the aid is selected according to the non-line lengths and the angles; the aid is spot welded on the cylinder, and the longitudinal line of the cylinder is alternately welded; and the welding order and the jack screws on the aid are adjusted according to the deformation condition of the longitudinal line. The invention has the advantages that the working procedures of mechanical shape correction and the hot shape correction after welding of the cylinder are avoided; the deformation in a welding process can be directly observed and regulated by taking technical measures; and the aid has simple structure and use method.

Owner:CHINA FIRST HEAVY IND +1

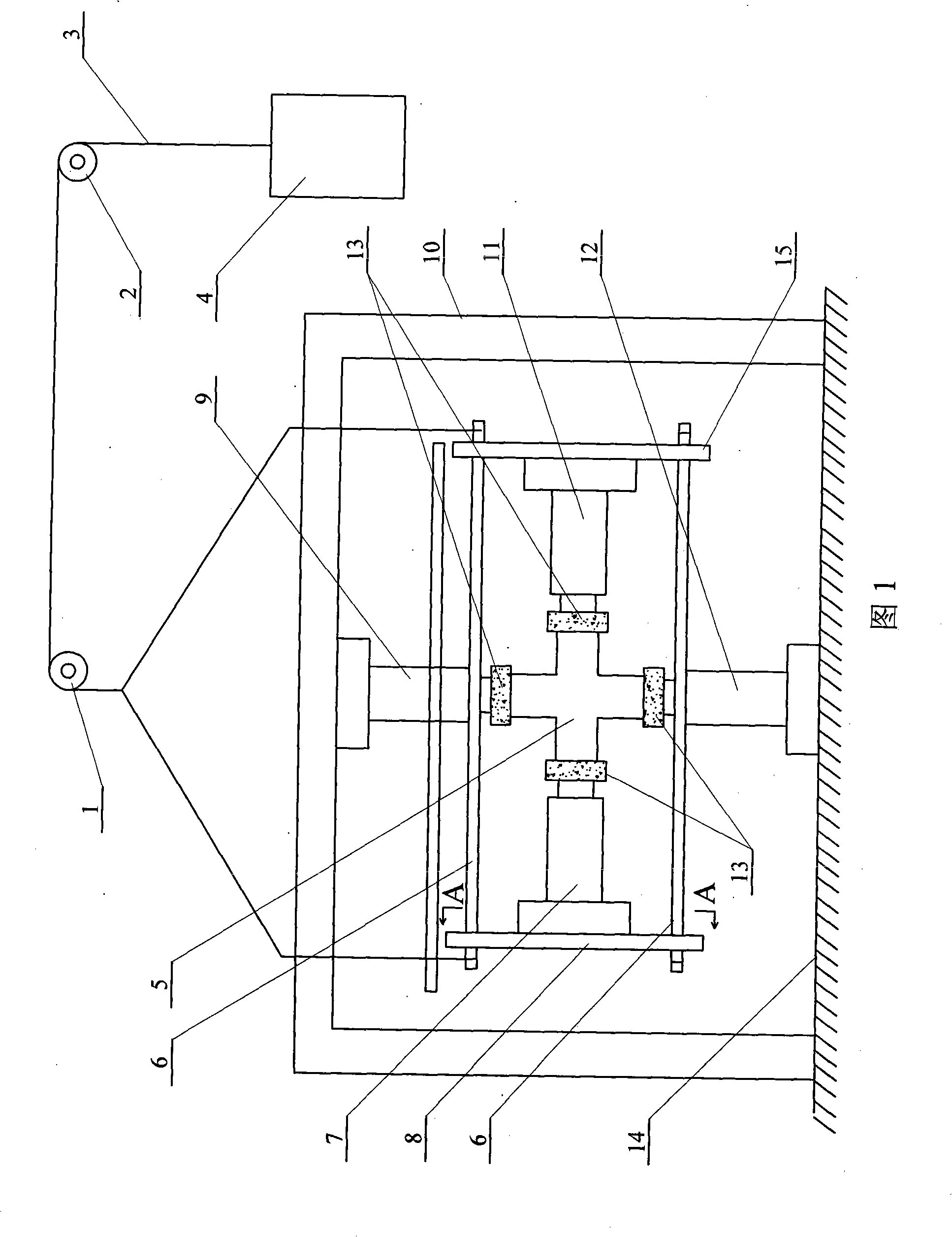

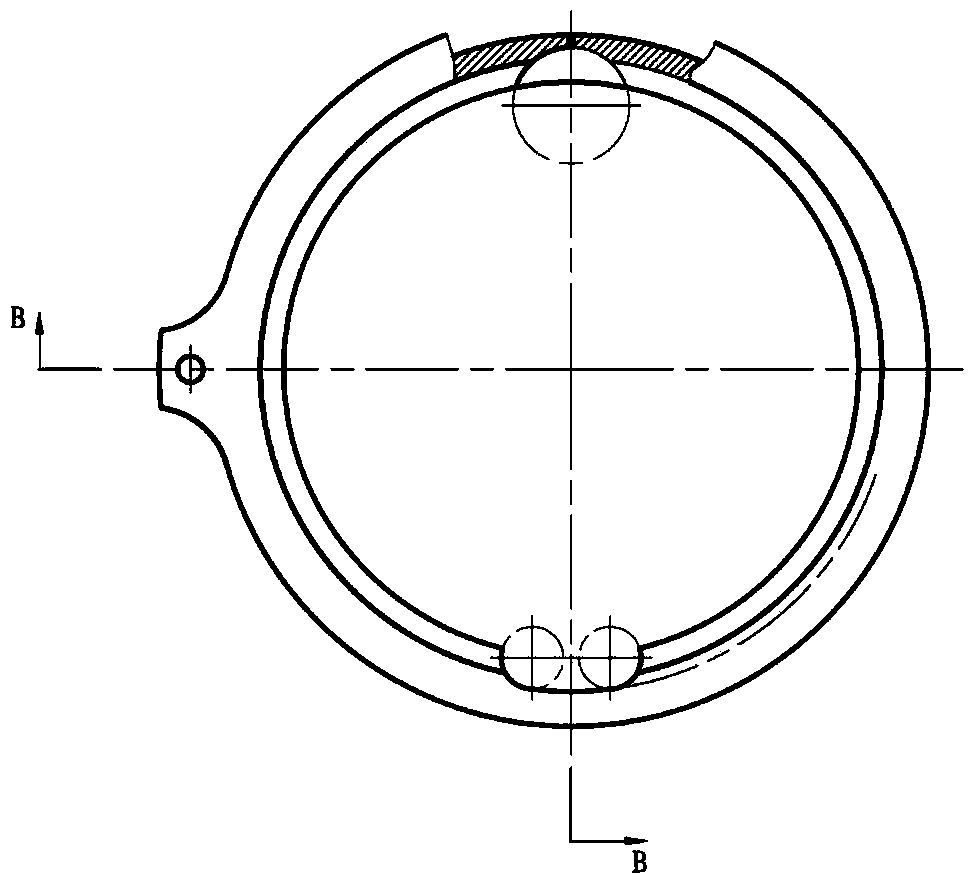

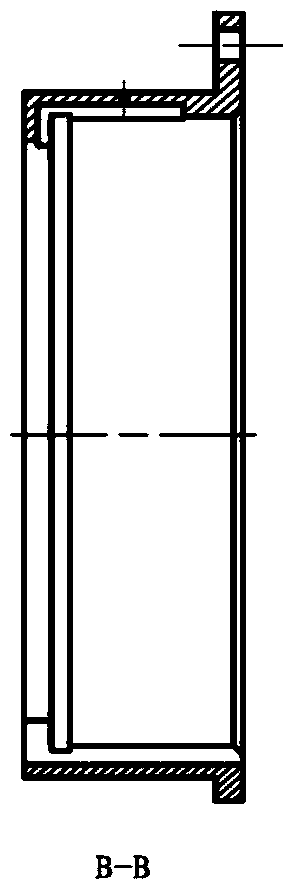

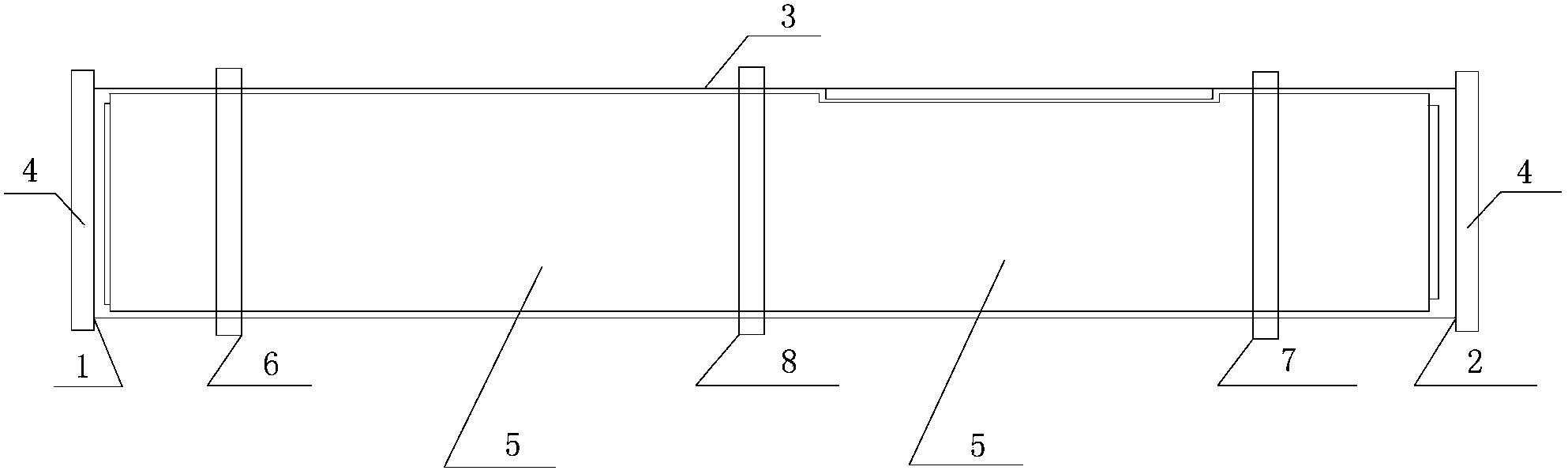

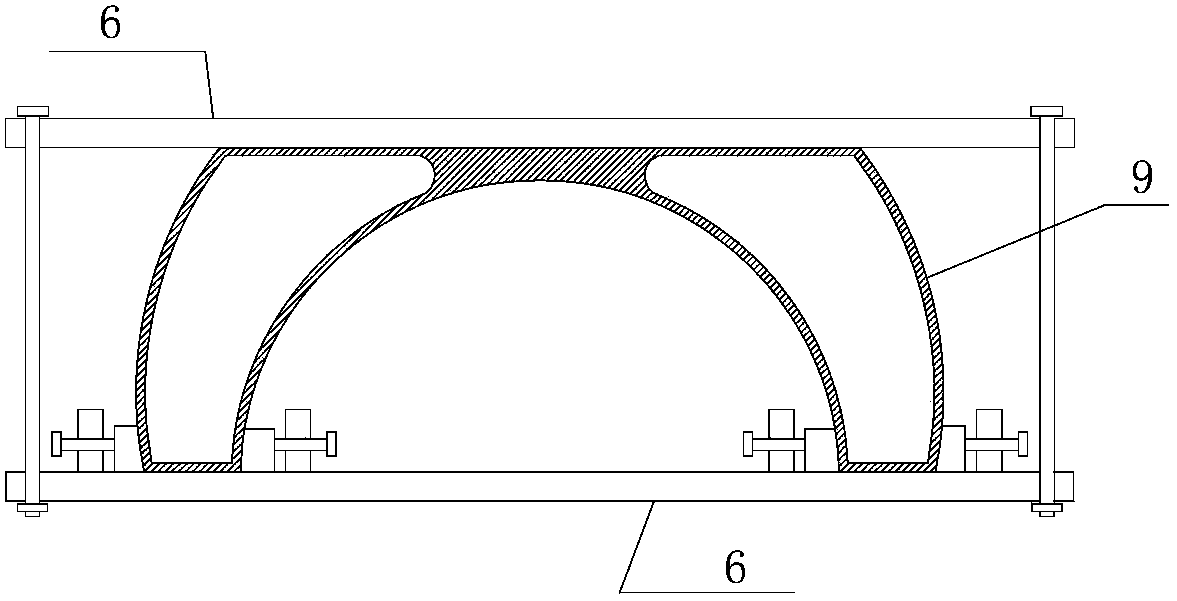

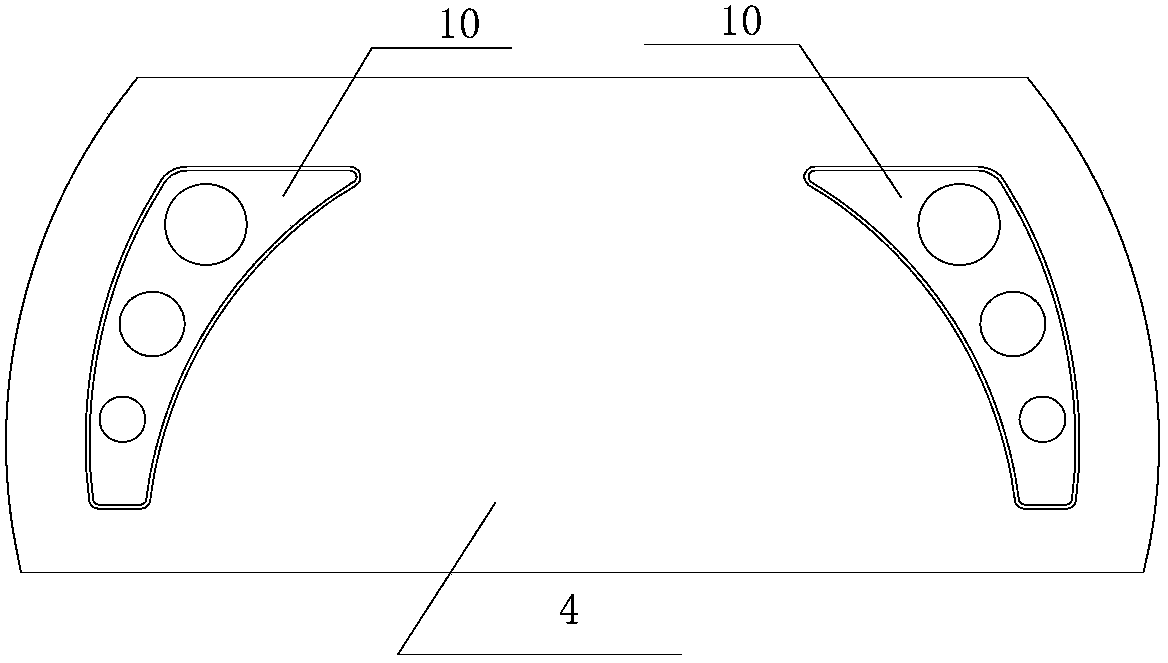

Waterproof ability testing system of three-directional loaded shield tunnel duct piece joint seam

InactiveCN102778337AMeet the requirements of loading conditionsImprove work efficiencyFluid-tightness measurement by detecting dimension changePilot systemData acquisition

The invention discloses a waterproof ability testing system of a three-directional loaded shield tunnel duct piece joint seam, belonging to the technical field of shield tunnels. The system comprises a self-balance frame subsystem, a load and deformation control subsystem, a testing piece conveying subsystem, an operating subsystem and a data acquisition subsystem, wherein the balance frame subsystem and the load and deformation control subsystem are connected by screw bolts; the balance frame subsystem and the testing piece conveying subsystem are connected by screw bolts; the load and deformation control subsystem and the operating subsystem are connected by leads; and the load and deformation control subsystem and the data acquisition subsystem are connected by leads. Through different combinations of the load and deformation control subsystem, the waterproof ability test to transverse seams, T-shaped seams and cross seams of shield tunnel duct pieces can be accomplished.

Owner:TONGJI UNIV

Machining deformation control method of bushing thin-wall part

ActiveCN104384825ASolve the processing stress problemReduce stressBearing componentsNumerical controlElement analysis

The invention provides a machining deformation control method of a bushing thin-wall part, and aims to provide a deformation control method for effectively controlling the machining deformation of an aluminum alloy thin-wall part, enabling the deformation in a controllable range and having stable and reliable quality. The method is realized through the following technical scheme: the stress finite element analysis and the stress strain state tendency analysis are performed by a finite element analysis model file and a simulation module; the meshing is performed by a partitioning second-order 20-node hexahedral unit to find out specific deformation areas and deflections; a smallest deformation scheme is selected to formulate a process machining scheme; and the heat treatment destressing is added after the semi-finishing for removing the machining stress deformation generated in the semi-finishing, and then, the finishing is performed for controlling the roundness of an outer circle and an inner hole within 0.02 mm. The inner hole and the outer circle are finished by the numerical control turning, so that the wall thickness difference is not bigger than 0.01; and a clamping part is cut off, and an end surface is machined, so that the total length is guaranteed. The method solves the machining difficulties of the bushing thin-wall part; and the pass percent can be improved above 90%.

Owner:PLA NO 5719 FACTORY

Heat treatment deformation control method of thin-wall saddle-shaped aluminum alloy casting

The invention discloses a heat treatment deformation control method of a thin-wall saddle-shaped aluminum alloy casting. The heat treatment deformation control method is suitable for large thin-wall casting aluminum alloy parts. According to the characteristics of the casting, a blocking disc and a clamp are arranged on the casting before heating, one end with a thicker wall is put into a furnace by a vertical placement way; thermal stress during heating can be reduced by heating in stages; in a solid melting stage, deformation during quenching can be reduced by adjustable tooling shape maintainance; in an aging stage a pretightening force is continued to be applied for maintainance of a tooling constraining force. The advantages of the heat treatment deformation control method are that: the heat treatment deformation control method uses an adjustable tooling shape maintainance method in heating, solid melting and aging stages to solve the heat treatment deformation control problem of the thin-wall casting aluminum alloy and avoid the problems of repeated deformation calibration and difficulties in shape, position and size control after solid melting. By application of the pretightening force before heating and after solid melting according to deformation rules, the purpose of precise deformation control can be achieved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Deformation control method when shield traverse building within short distance

The invention discloses a deformation control method when a shield traverses a building within a short distance. The deformation control method comprises the following steps of: firstly, analyzing effects of shield tunneling on a stratum and the building under the conditions of different support pressure ratios and different grouting effects by using a numerical analysis method, and putting forward an optimal support pressure ratio and demands on slurry property; secondly, reinforcing shielding excavation surface stability control, improving muck inside a pressure chamber into be at a liquid-plastic state by a muck conditioning mode, reducing fluctuation of pressure control, and controlling overexcavation by comparison of actual slag quality and theoretical slag quality; and finally, reinforcing wall grouting liquid performance control, and timely filling a shield tail gap without loss of slurry by adopting high-intensity slurry with thixotropy. In a shield tunneling process, security monitoring can be reinforced; a shield tunneling parameter can be timely adjusted, and the security of an adjacent building is ensured. According to the method, a large amount of stratum reinforcing expense is reduced, and an underground space is utilized relatively effectively.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com