Patents

Literature

285results about "Fluid-tightness measurement by detecting dimension change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

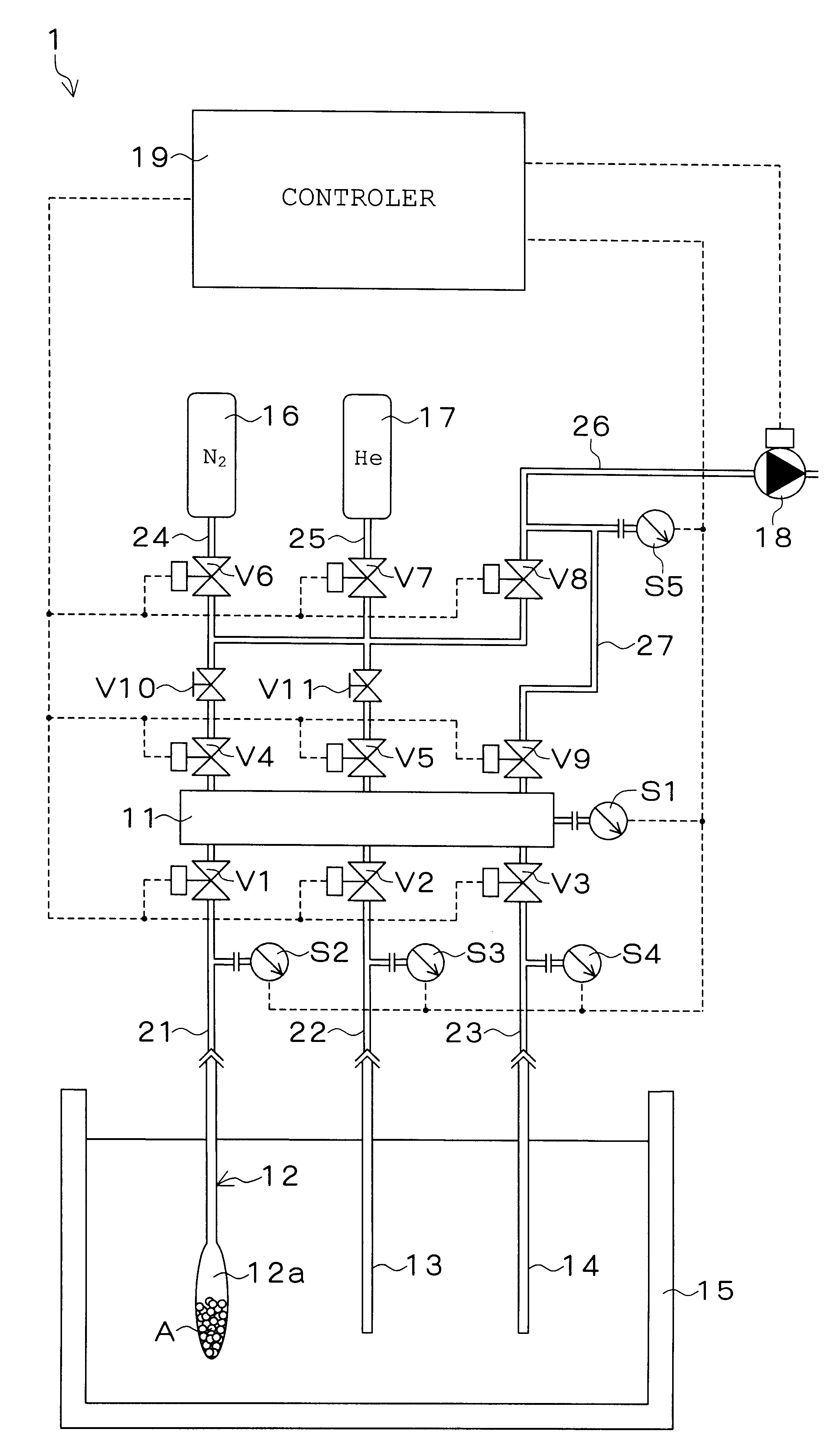

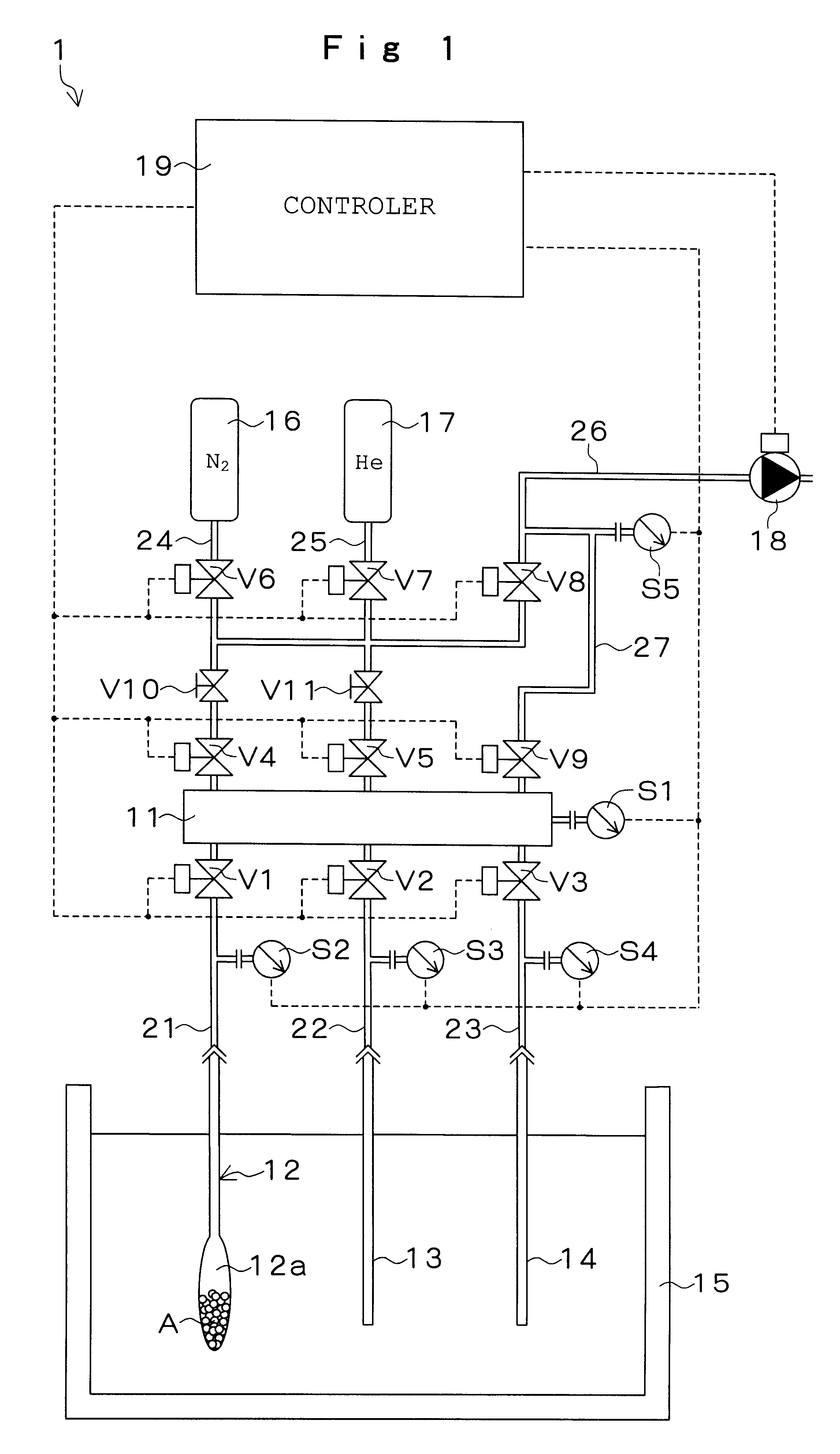

Method and apparatus for measuring amount of gas adsorption

InactiveUS6595036B1Initial dead volume of the sample cell can easily be correctedEasily and accurately determinedAnalysing fluids using sonic/ultrasonic/infrasonic wavesFluid-tightness measurement by detecting dimension changeChemical physicsDead volume

In a volumetric gas adsorption measuring method, an initial dead volume of the sample cell and an initial dead volume of a reference cell at the same time point are preliminarily determined. When the gas adsorption on the solid sample is to be measured, a change in the dead volume of the sample cell is calculated on the basis of an internal gas with the sample cell and reference cell immersed in a pressure of the reference cell measured at this time point cryogenic fluid temperature bath, the initial dead volume of the reference cell, and an initial gas pressure of the reference cell measured at a time point of the measurement of the initial dead volume of the reference cell. Then, the initial dead volume of the sample cell preliminarily measured is corrected on the basis of the change in the dead volume of the sample cell for the calculation of the amount of the gas adsorbed on the solid sample.

Owner:BEL JAPAN

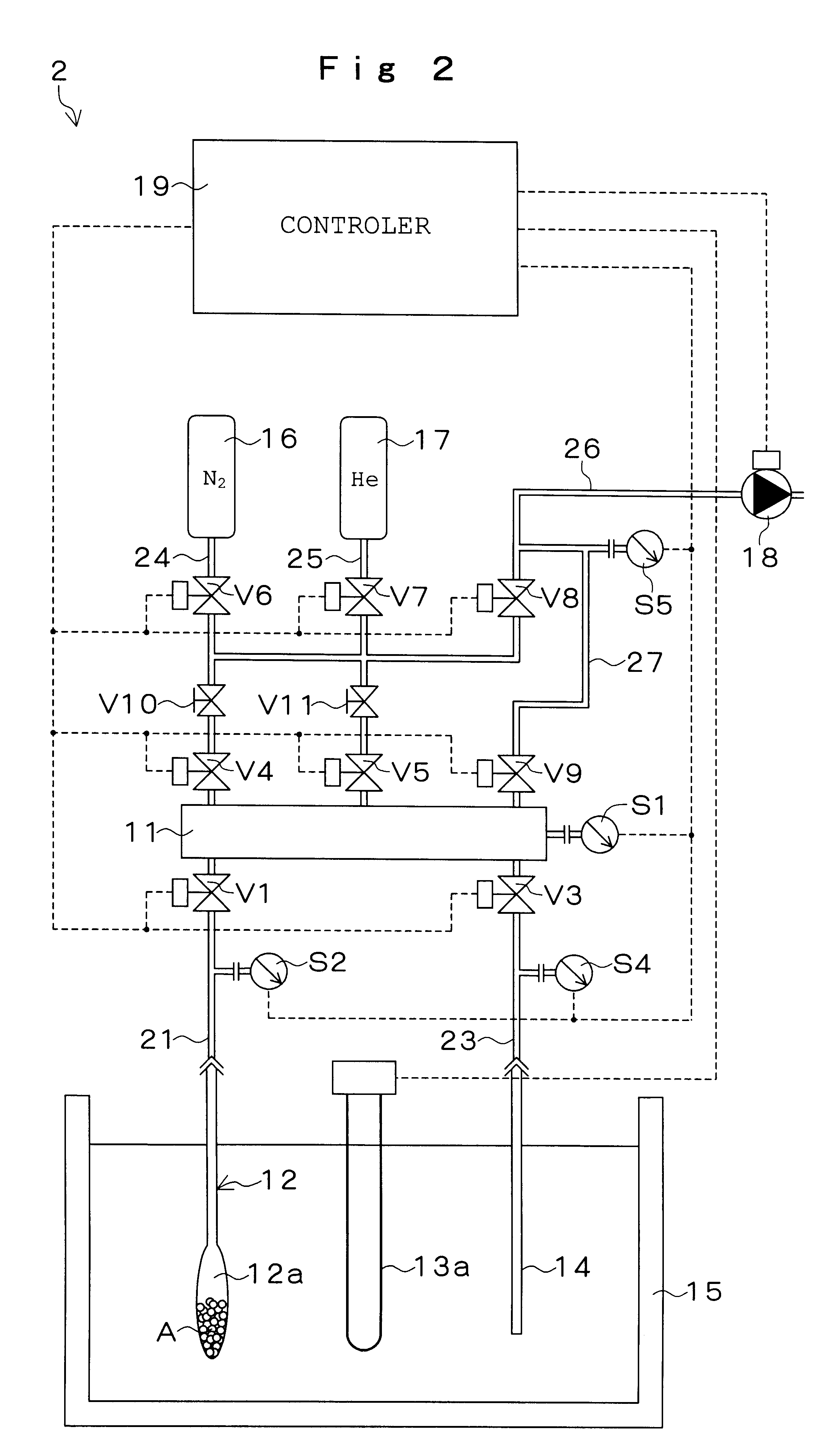

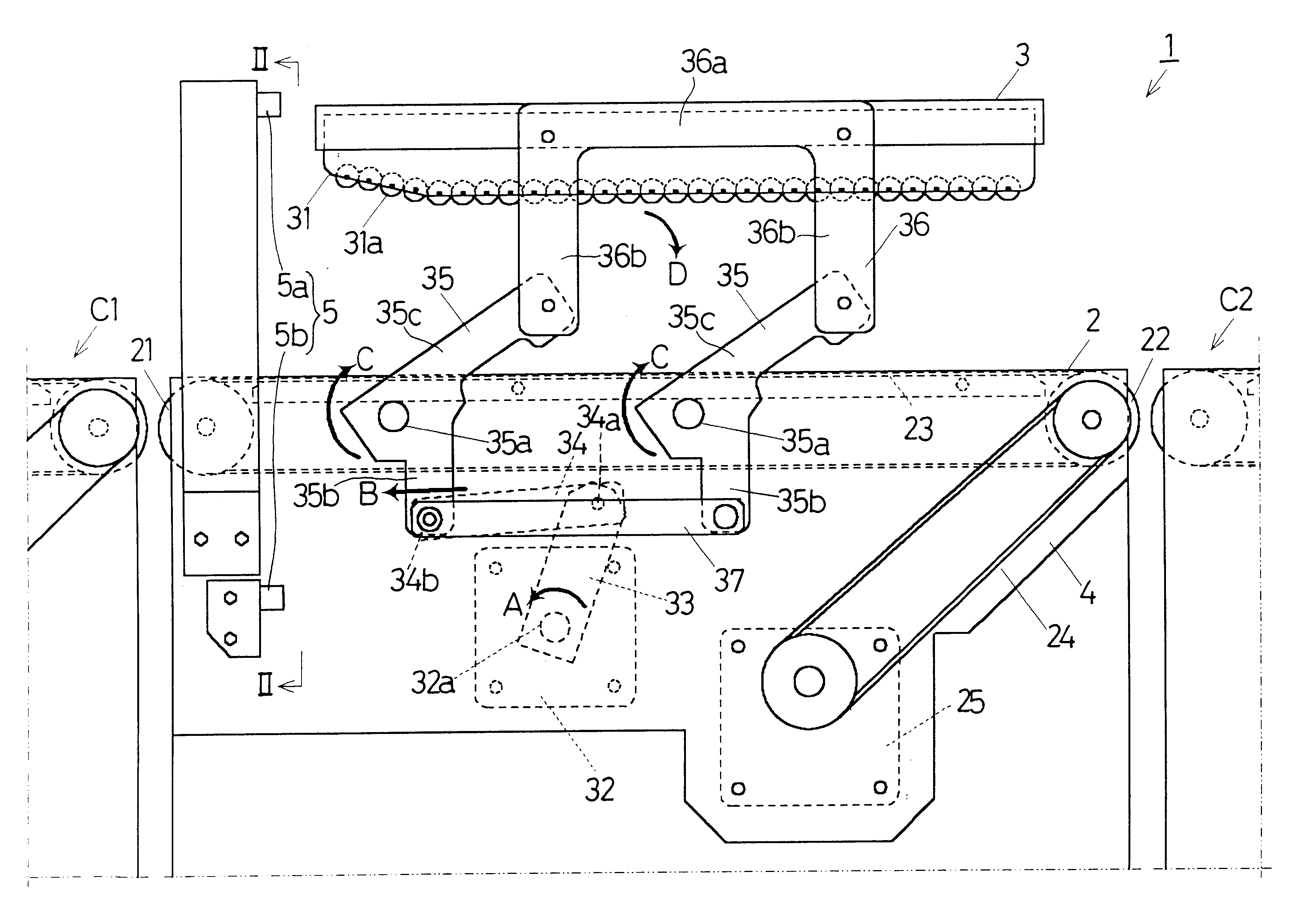

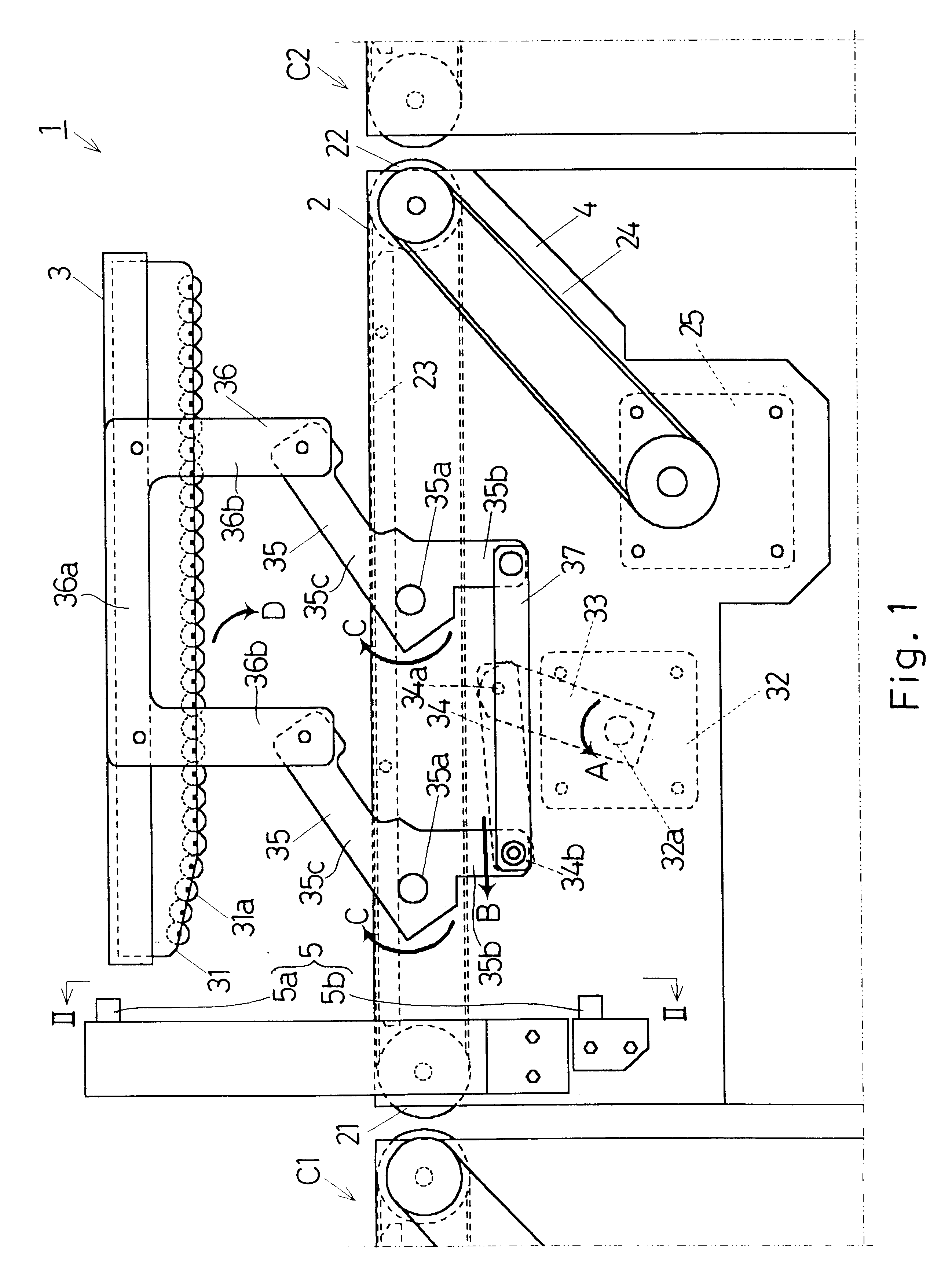

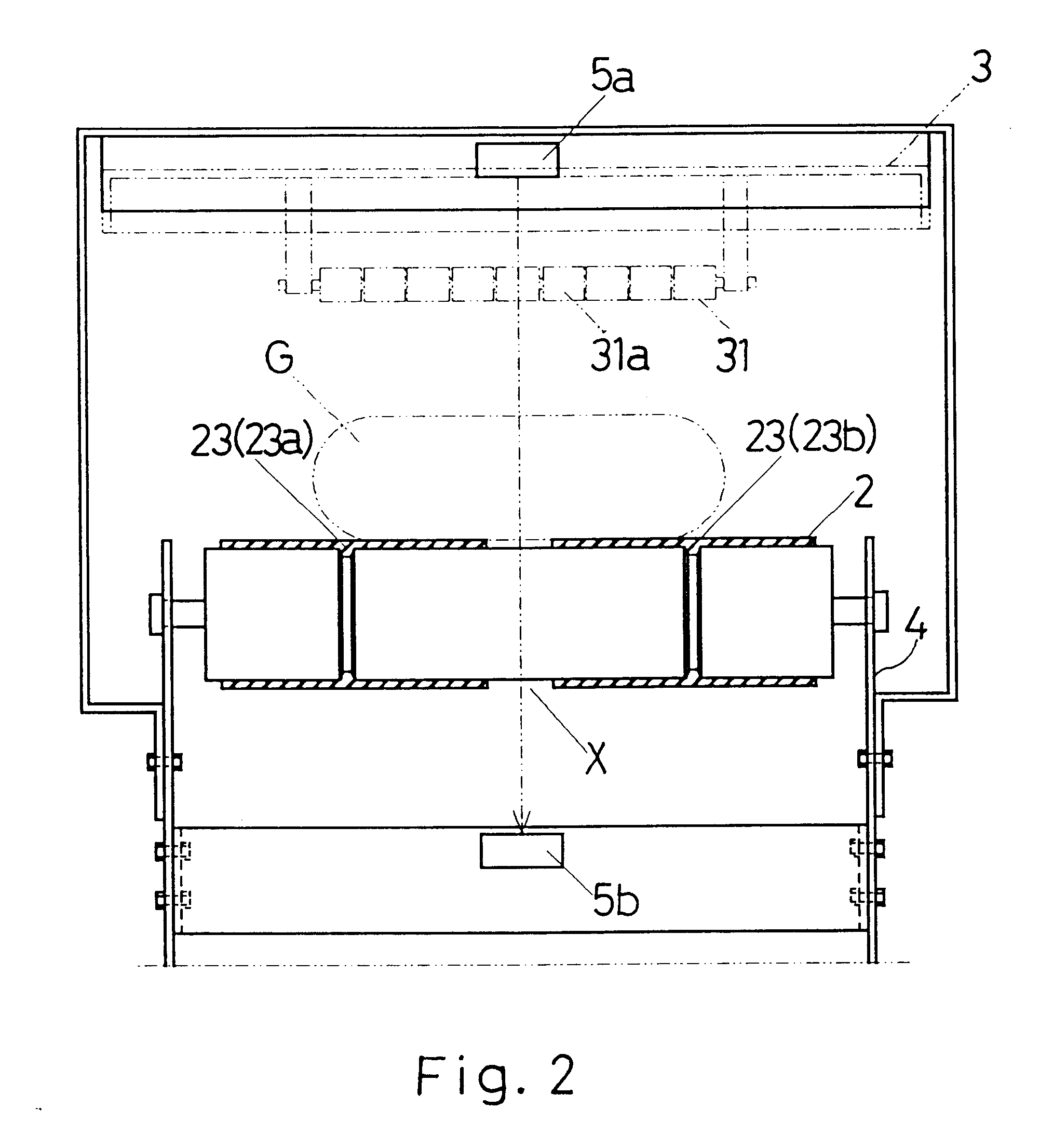

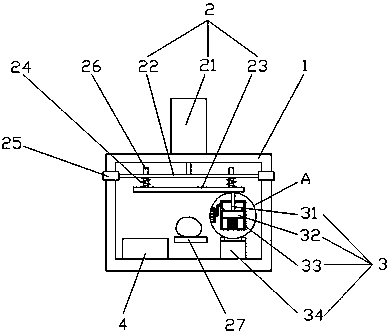

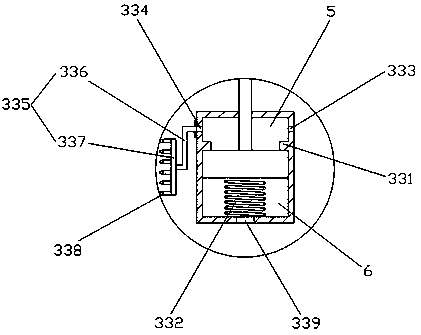

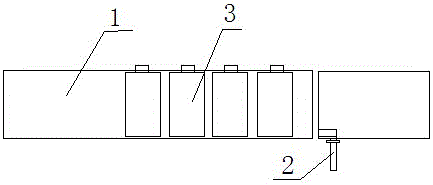

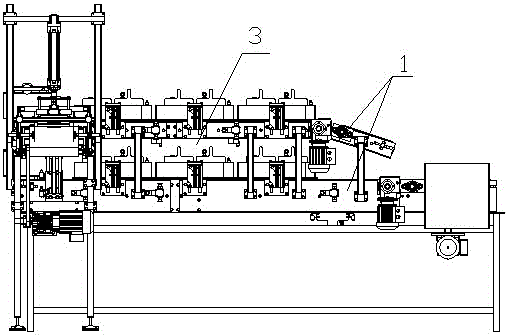

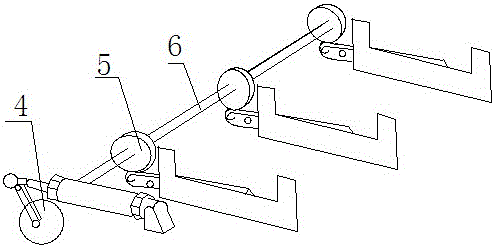

Seal inspecting machine

InactiveUS6474141B1Efficient executionInexpensive facilityMeasurement of fluid loss/gain rateFluid-tightness measurement by detecting dimension changeControl theoryElectric motor

A seal inspecting machine for inspecting bagged products to determine the presence or absence of a seal abnormality in each bagged product being transported by a transport conveyor 2 includes a presser unit 3 and a servo motor 32 for driving the presser unit 3 to sandwich the bagged product G between the presser unit 3 transport conveyor 2. The servo motor 32 itself has a capability of detecting a reactive force acting on the presser unit 3 or a displacement of the presser unit 3 that occurs as a result of contact with the bagged product, where any failure of the bagged product to exert a sufficient reactive force or displacement resistance is considered evidence of a seal abnormality being present in such bagged product. With this seal inspecting machine, seal check of the bagged products can be efficiently and inexpensively carried out.

Owner:ISHIDA CO LTD

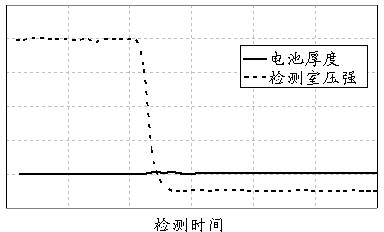

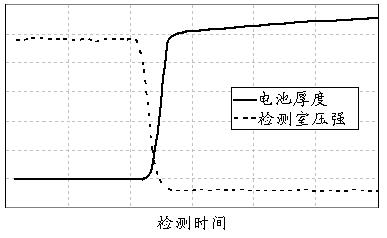

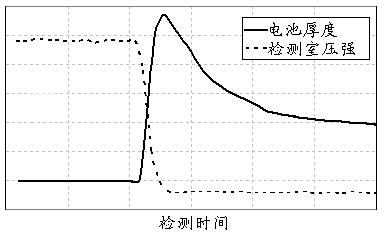

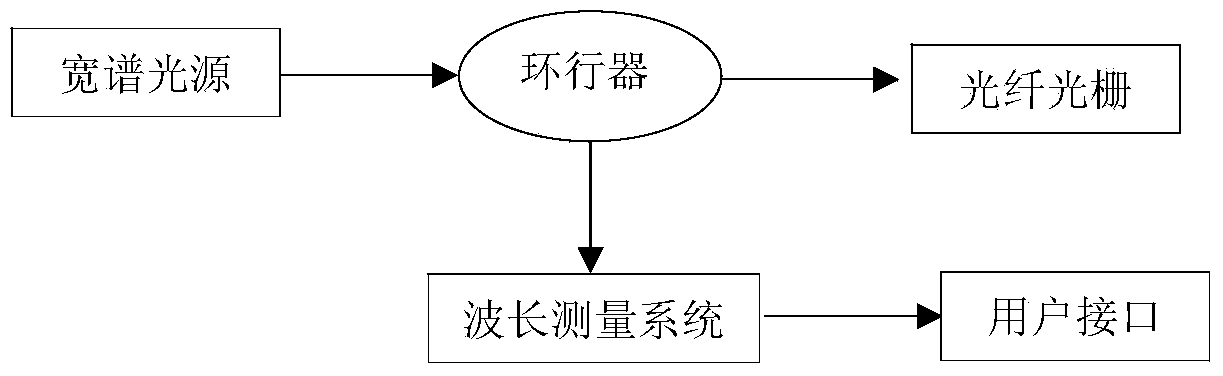

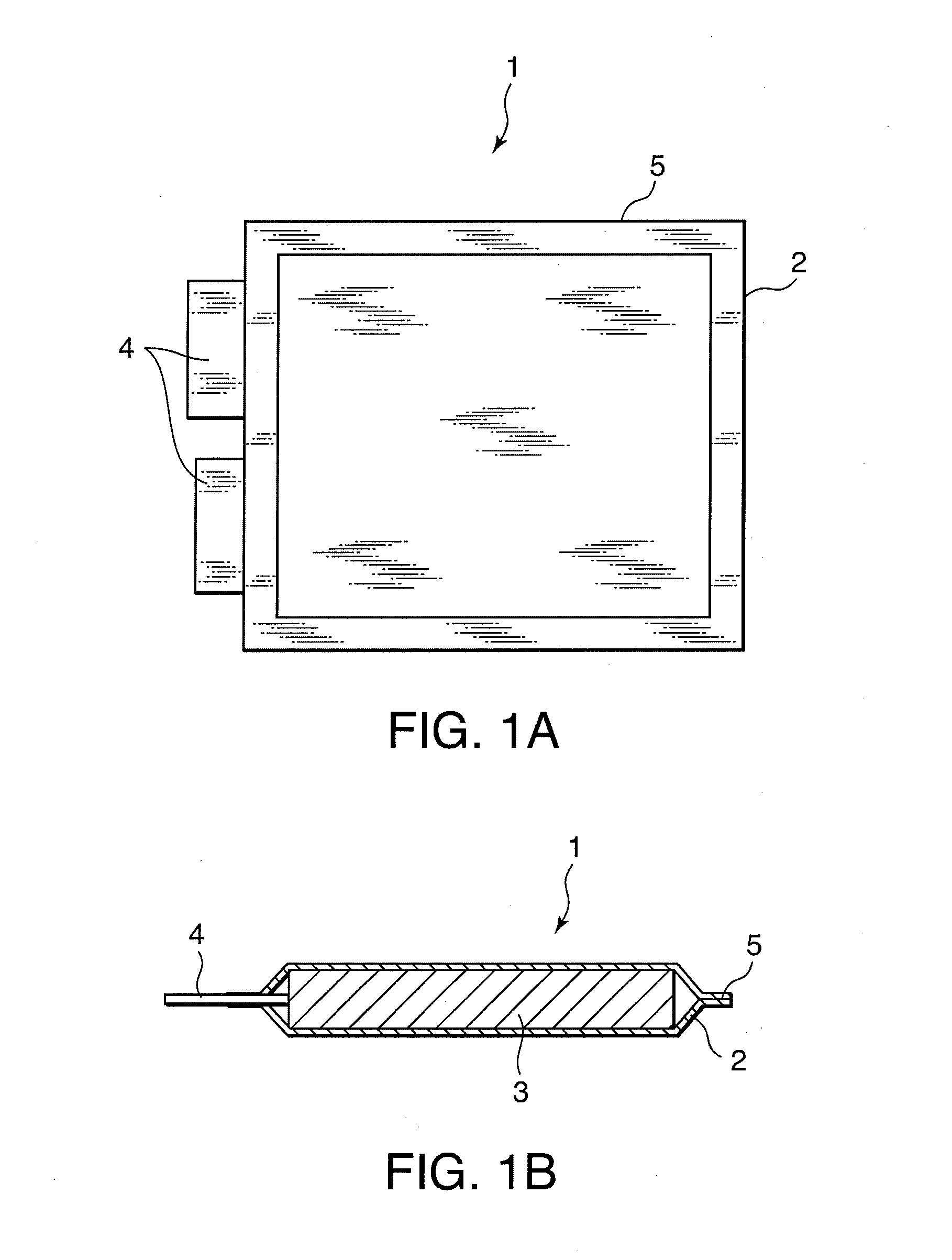

Flexible packaging article airtightness detection device and detection method

ActiveCN102269641AFast judgment of tightnessHigh sensitivityFluid-tightness measurement by detecting dimension changeUsing optical meansOptical measurementsEngineering

The invention discloses a device for detecting the tightness of a flexible packaged article, comprising: a detection chamber, a vacuuming device capable of evacuating the detection chamber, and a device for real-time and continuous detection of the thickness of the flexible packaging article in the detection chamber during the vacuuming process. Laser thickness measurement system, and identification system for automatic judgment of tightness. The device for detecting the tightness of the flexible package article of the present invention has the advantages of defect quantification, defect location, high sensitivity, and accurate detection of tiny air leakage. The sealing detection device adopts optical measurement system, software automatic recording and judgment integration technology, and is suitable for high-efficiency and automatic online continuous production detection. In addition, the invention also discloses a method for detecting the tightness of a flexible package.

Owner:DONGGUAN AMPEREX TECH +1

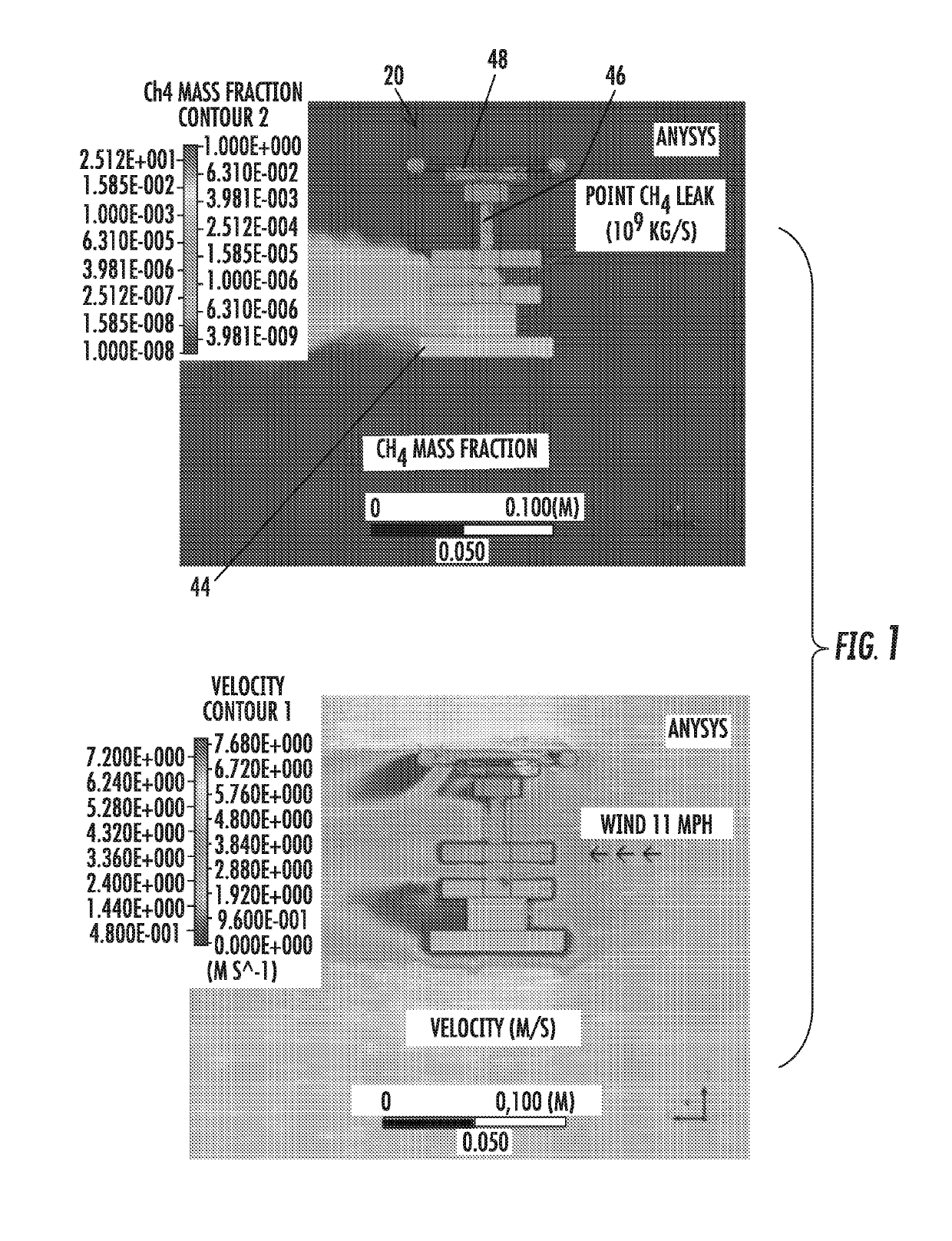

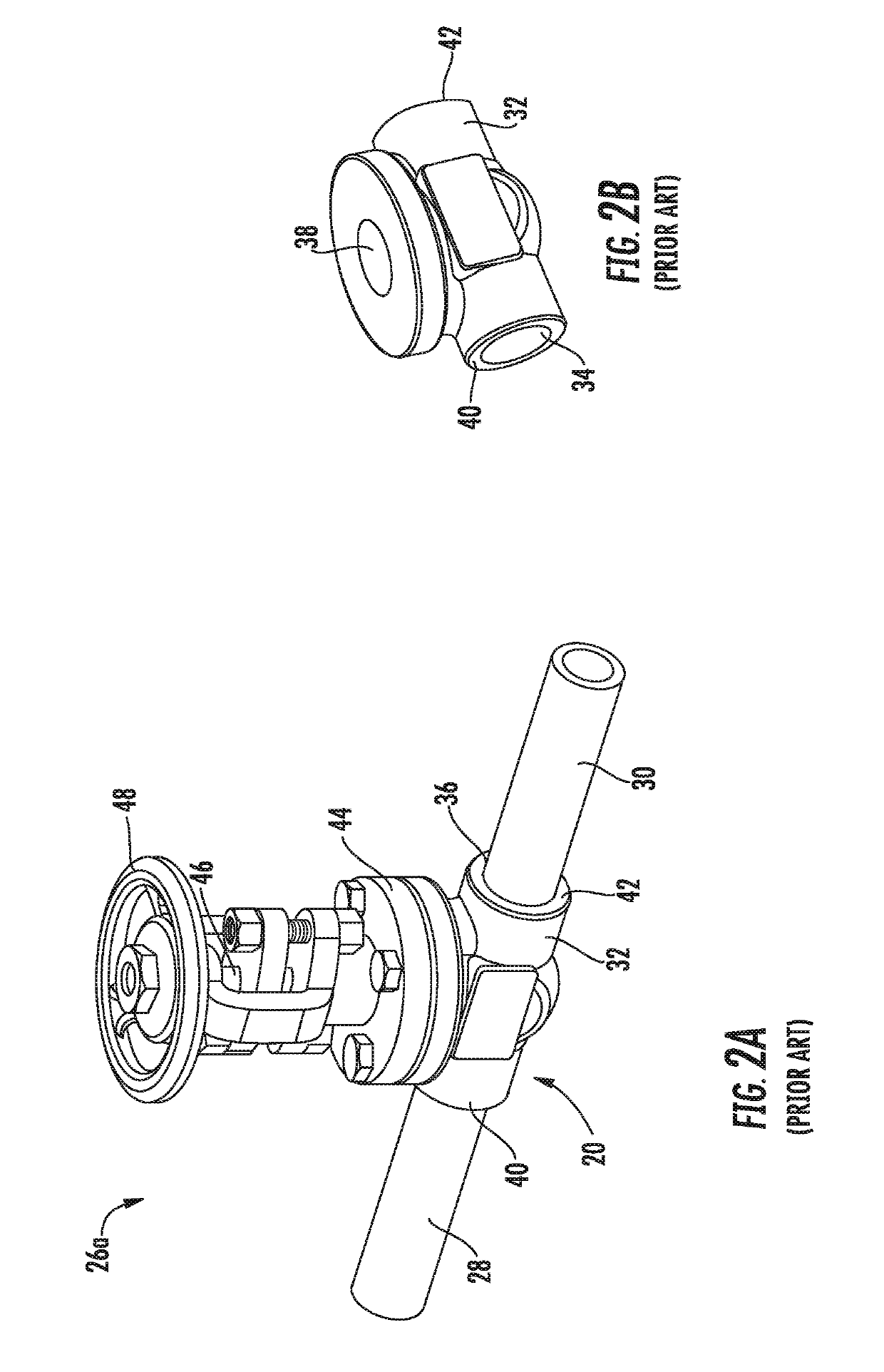

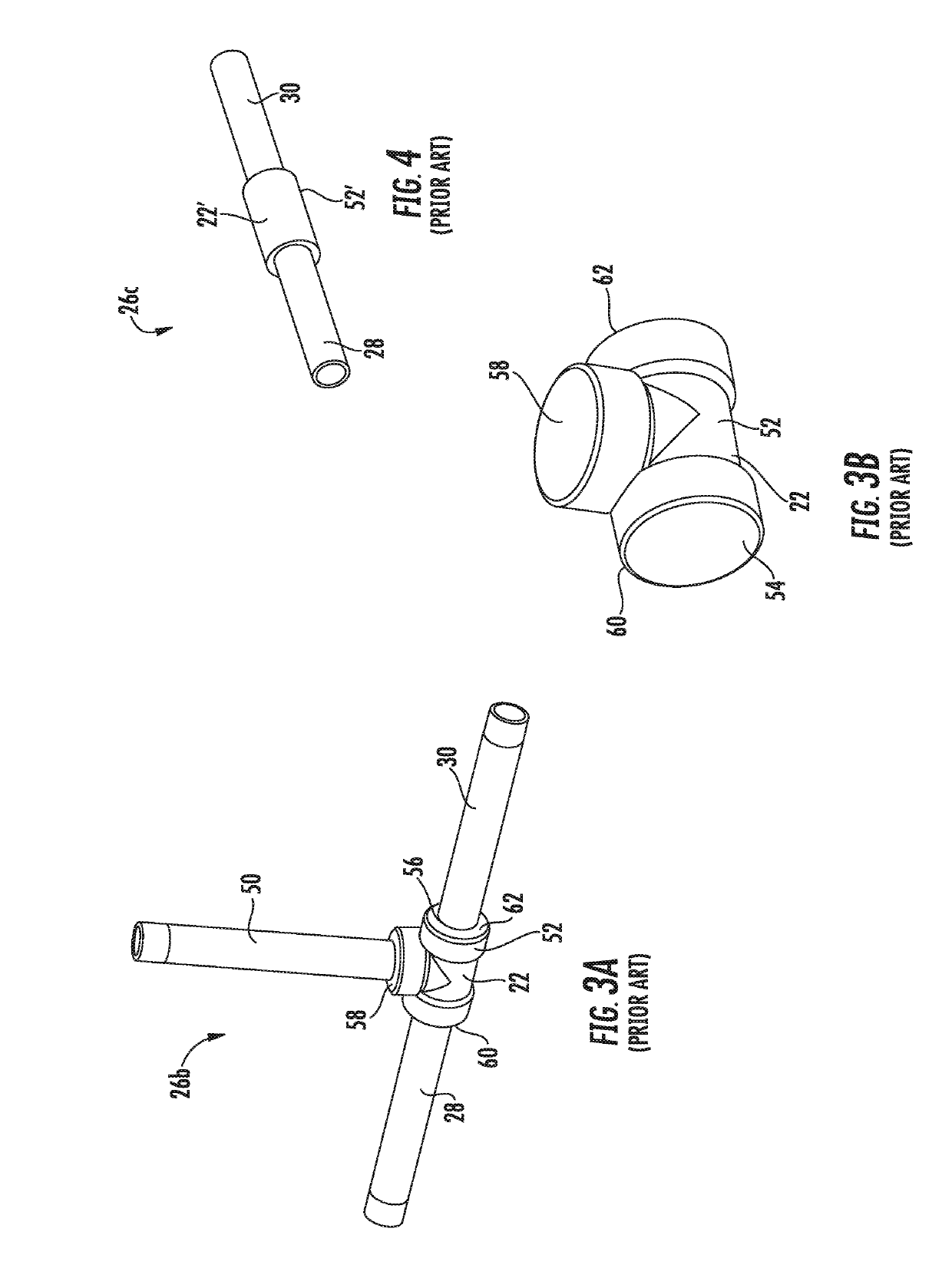

Leak sensor assemblies and systems utilizing same

InactiveUS20190094101A1Measurement of fluid loss/gain rateFluid-tightness measurement by detecting dimension changeEngineeringPiping

The present disclosure provides a leak sensor assembly which is configured to detect the leakage of gas from a component of a piping system. The leak sensor assembly includes a housing and at least one sensor. The housing is configured to be positioned proximate to the component and forms a pocket which allows gas leaked from the component to concentrate within the pocket in a generally uniform dispersion. The at lease one sensor is configured to detect the presence and concentration of gas within the pocket of the housing.

Owner:MOLEX INC

Method for detecting leakage of sealed object by using infrared imaging technique

InactiveCN1991324AQuick and accurate detectionFluid-tightness measurement by detecting dimension changeEngineeringImaging technique

A method for detecting the leakage of sealing object using the infrared imaging technique is disclosed that includes control device, infrared imaging technique, detection device and aerating device that characterized in that: the control device controls the valve to aerate the detected object and analytical judge automatically, and the control device collects the signal which is from the pressure sensor and temperature sensor by the inner analog / digital signal interface, and calculates the leakage amount, and at the same time the leaking point and leakage amount is determined by the pattern recognition and digital processing. The invention applies the infrared imaging technique for detecting the leakage of sealing object, and that can detect the leaking point and leakage amount quickly and accurately.

Owner:陈乃克

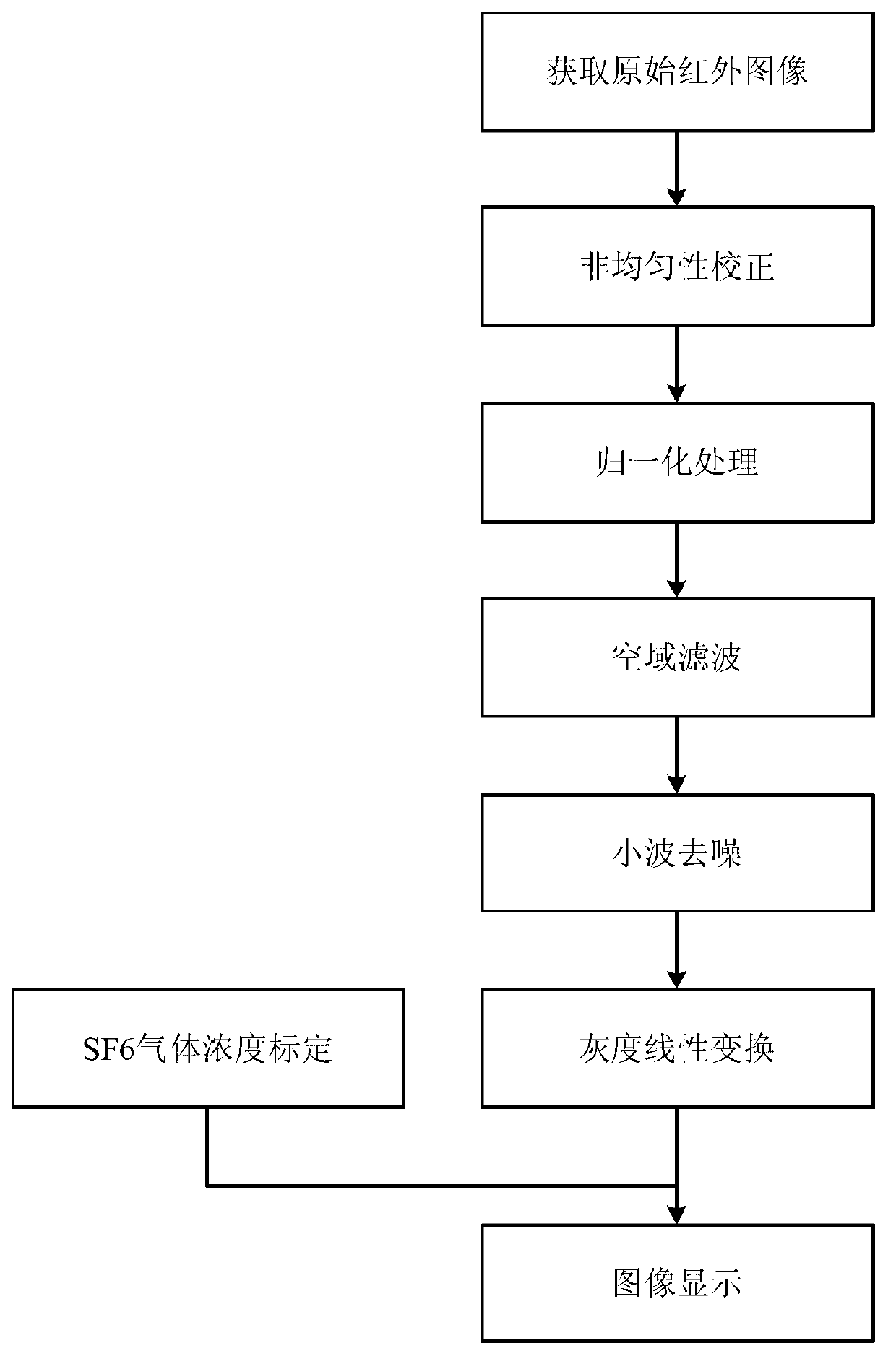

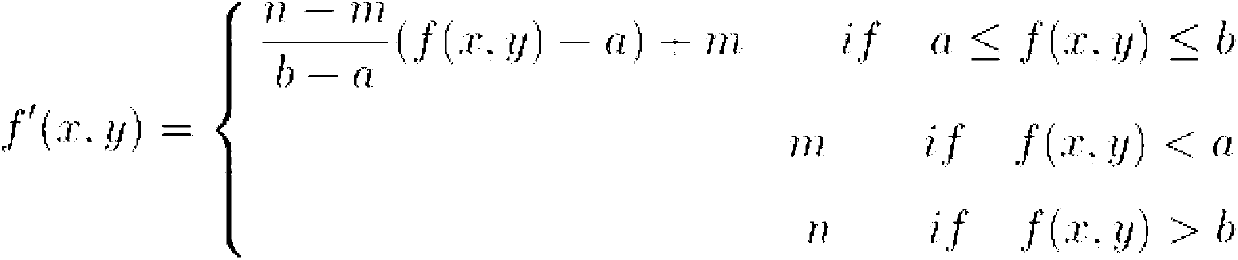

SF6 gas detection method based on infrared image processing

InactiveCN103217397AThe acquisition process is simple and convenientEasy accessFluid-tightness measurement by detecting dimension changeColor/spectral properties measurementsInfrared image processingReal time display

The invention discloses a SF6 gas detection method base on infrared image processing. The method comprises the steps of: S1, SF6 gas original infrared image is obtained with a passive infrared detection manner, and the original infrared image is subjected to non-uniformity correction, such that a corrected infrared image is obtained; S2, the corrected infrared image is subjected to normalization treatment, and the processed image is converted into a grayscale image; S3, the grayscale image is subjected to image filtering and grayscale linear transformation, such that a target image is obtained; and S4, the target image is subjected to real-time displaying. With the technical scheme provided by the invention, problems such as large infrared image noise and difficulty in real-time displaying in existing passive infrared SF6 gas leakage detection method can be solved.

Owner:JINCHENG POWER SUPPLY COMPANY OF STATE GRID SHANXI ELECTRIC POWER +2

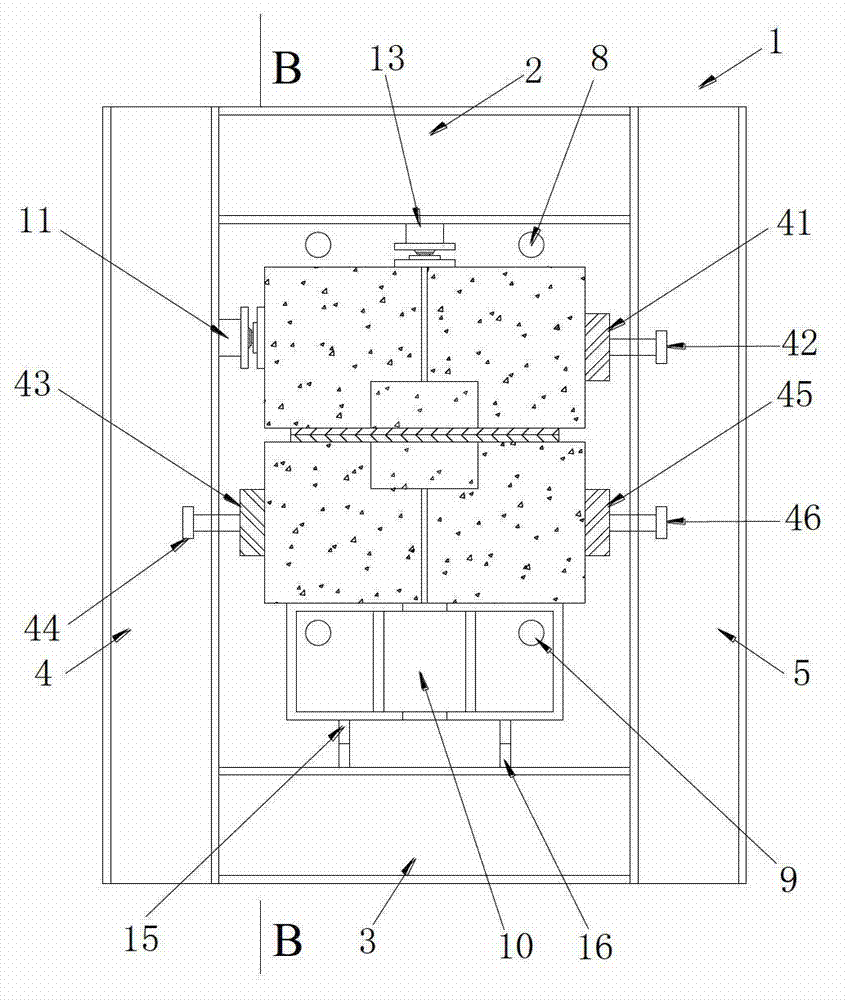

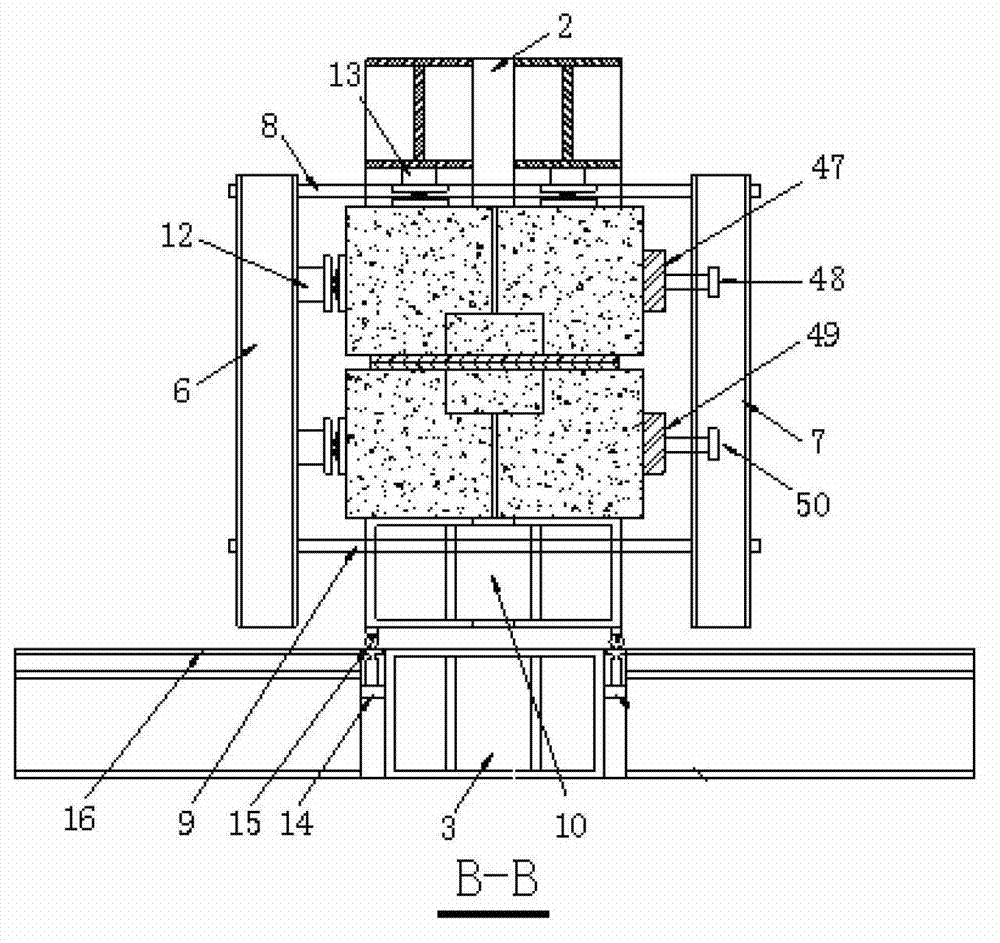

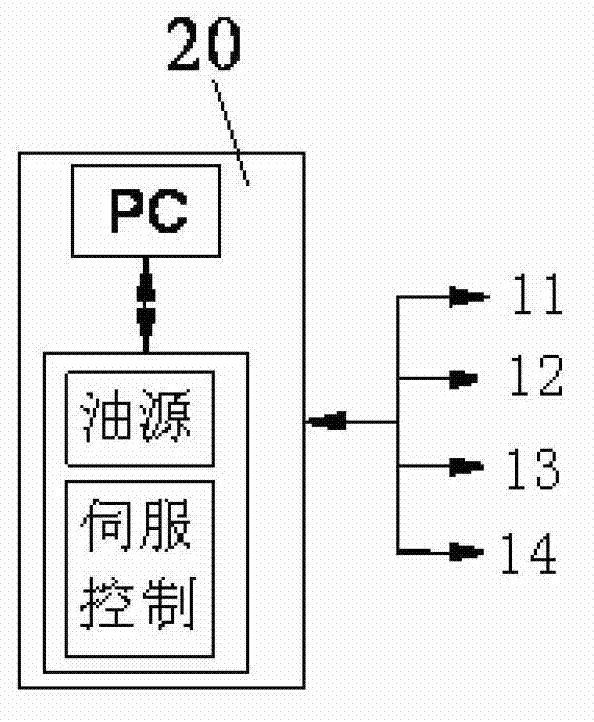

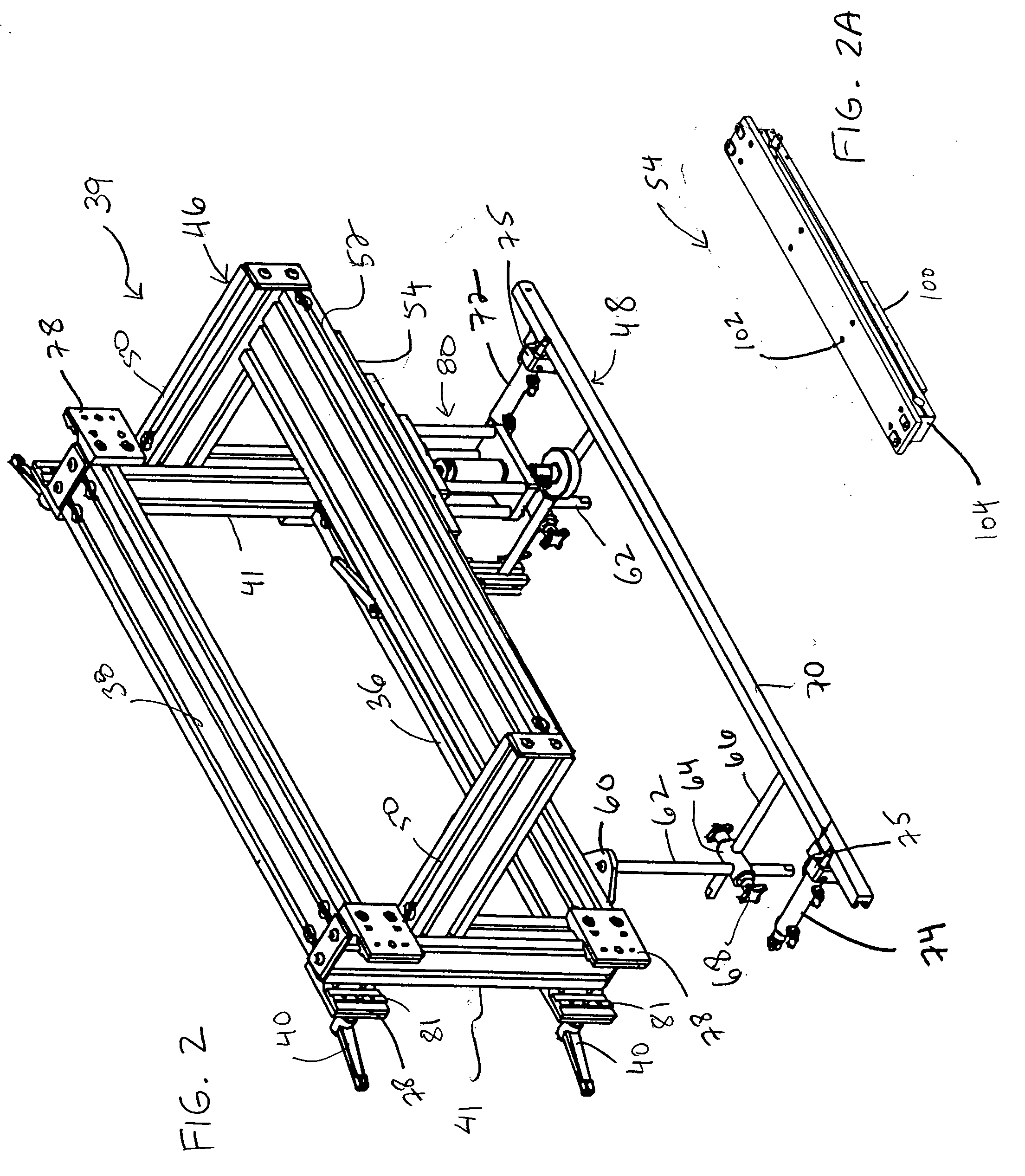

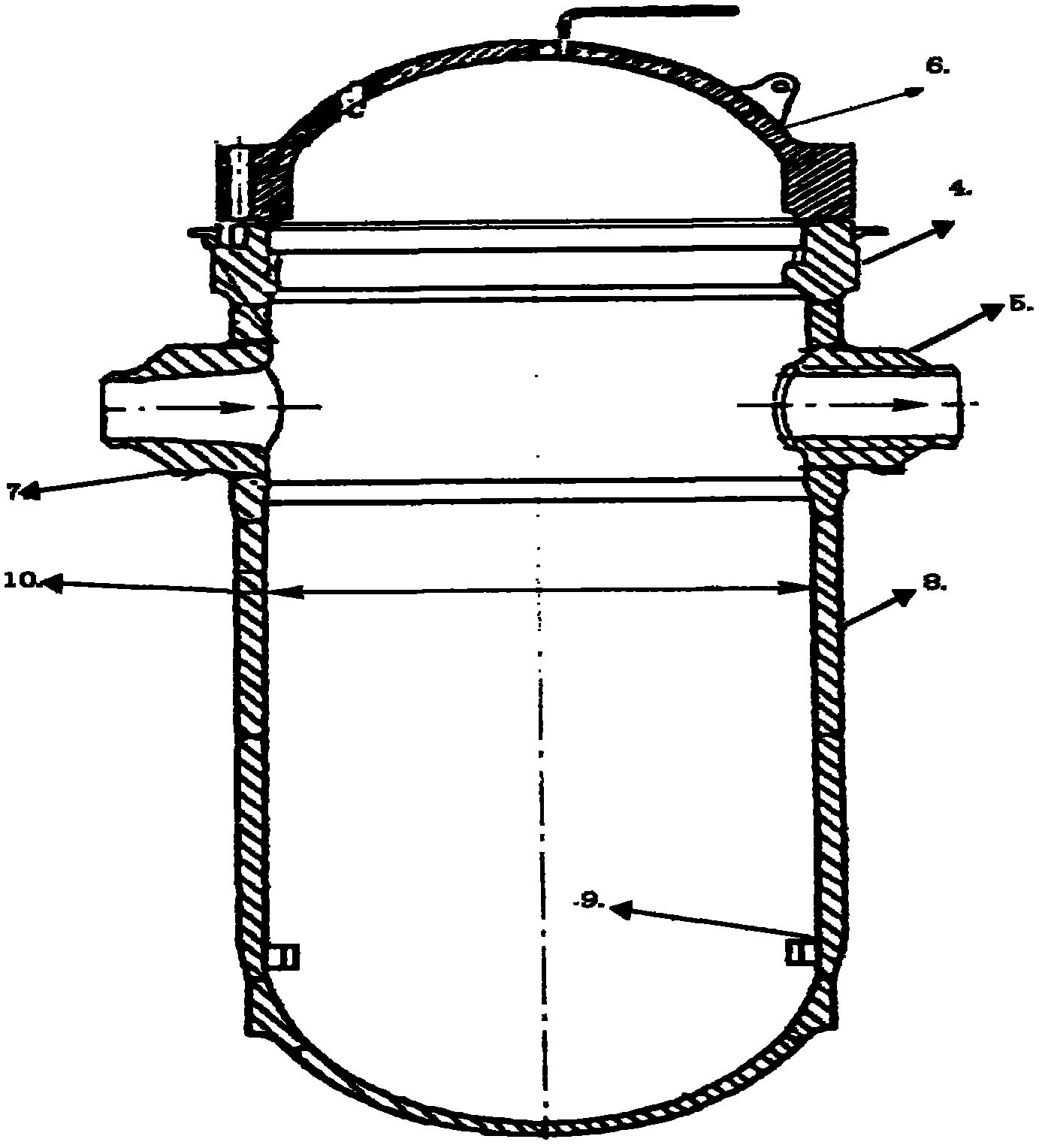

Waterproof ability testing system of three-directional loaded shield tunnel duct piece joint seam

InactiveCN102778337AMeet the requirements of loading conditionsImprove work efficiencyFluid-tightness measurement by detecting dimension changePilot systemData acquisition

The invention discloses a waterproof ability testing system of a three-directional loaded shield tunnel duct piece joint seam, belonging to the technical field of shield tunnels. The system comprises a self-balance frame subsystem, a load and deformation control subsystem, a testing piece conveying subsystem, an operating subsystem and a data acquisition subsystem, wherein the balance frame subsystem and the load and deformation control subsystem are connected by screw bolts; the balance frame subsystem and the testing piece conveying subsystem are connected by screw bolts; the load and deformation control subsystem and the operating subsystem are connected by leads; and the load and deformation control subsystem and the data acquisition subsystem are connected by leads. Through different combinations of the load and deformation control subsystem, the waterproof ability test to transverse seams, T-shaped seams and cross seams of shield tunnel duct pieces can be accomplished.

Owner:TONGJI UNIV

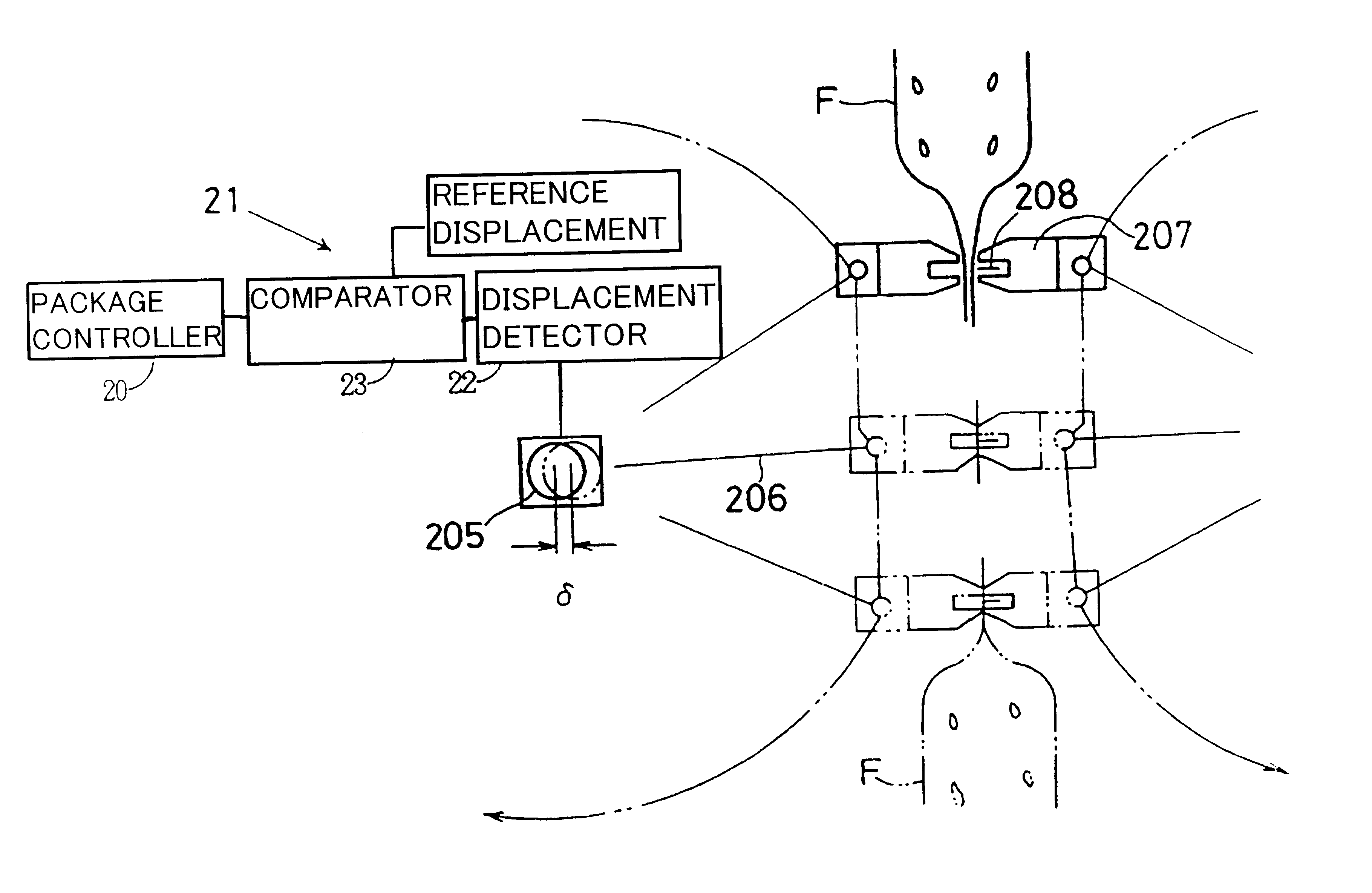

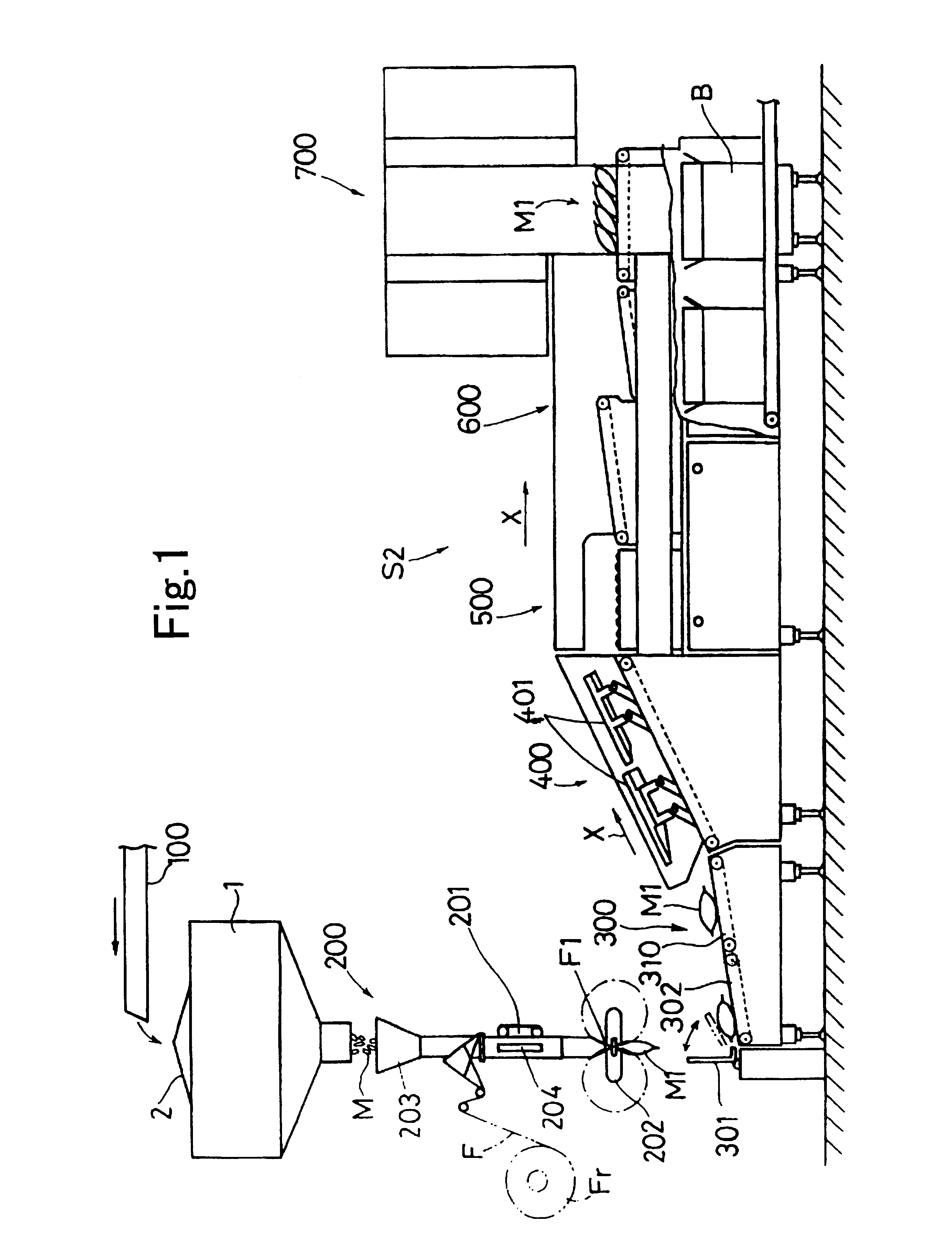

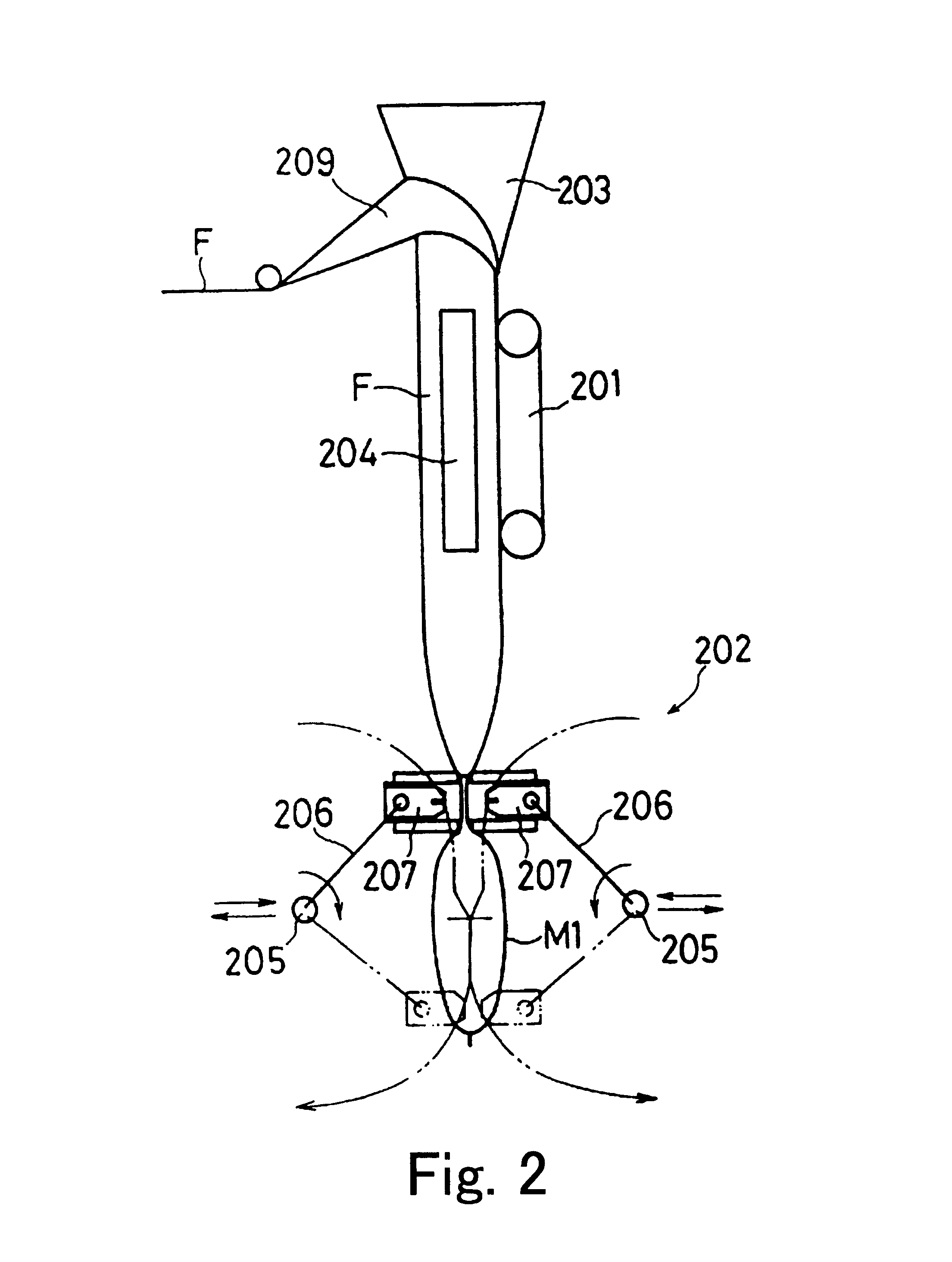

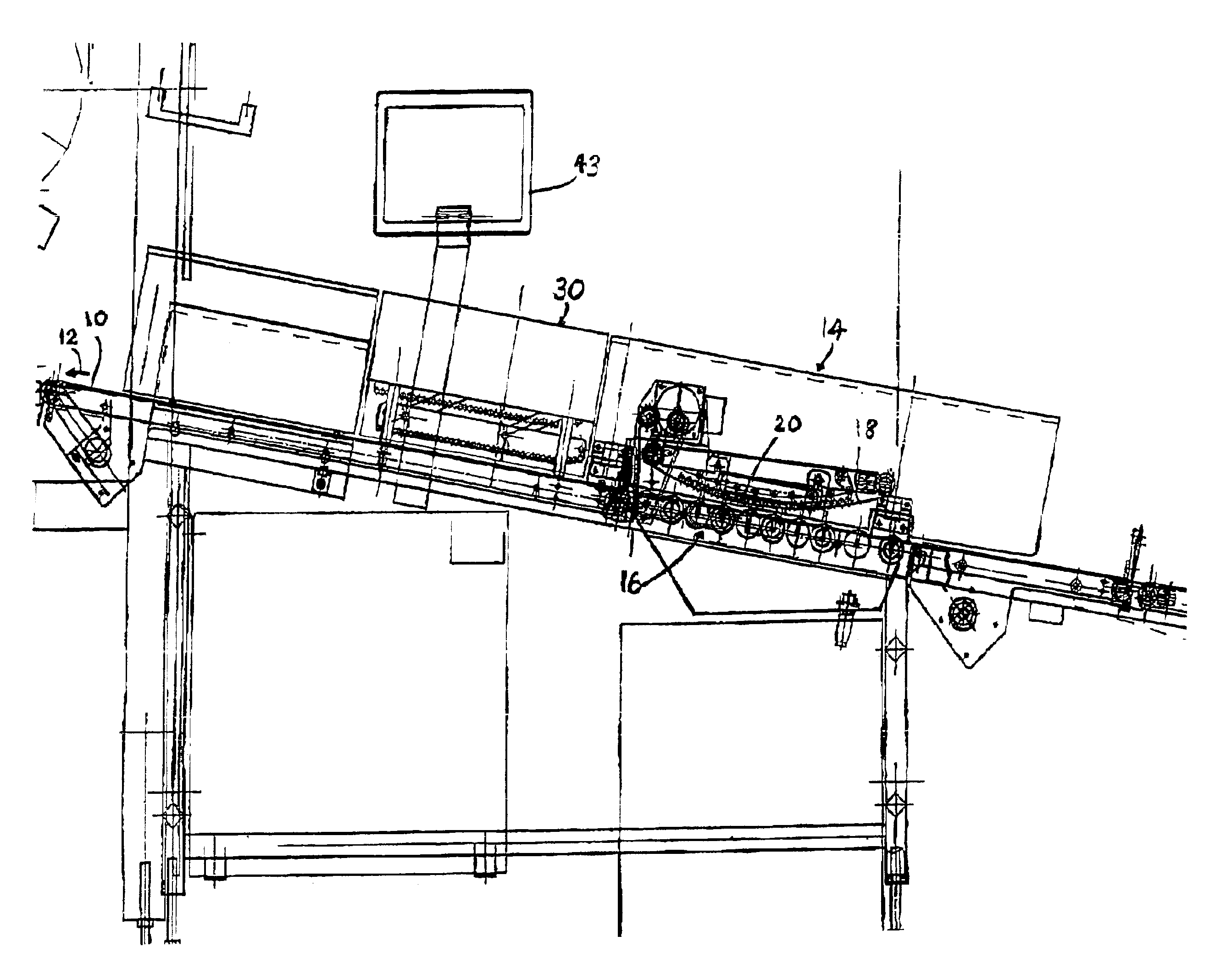

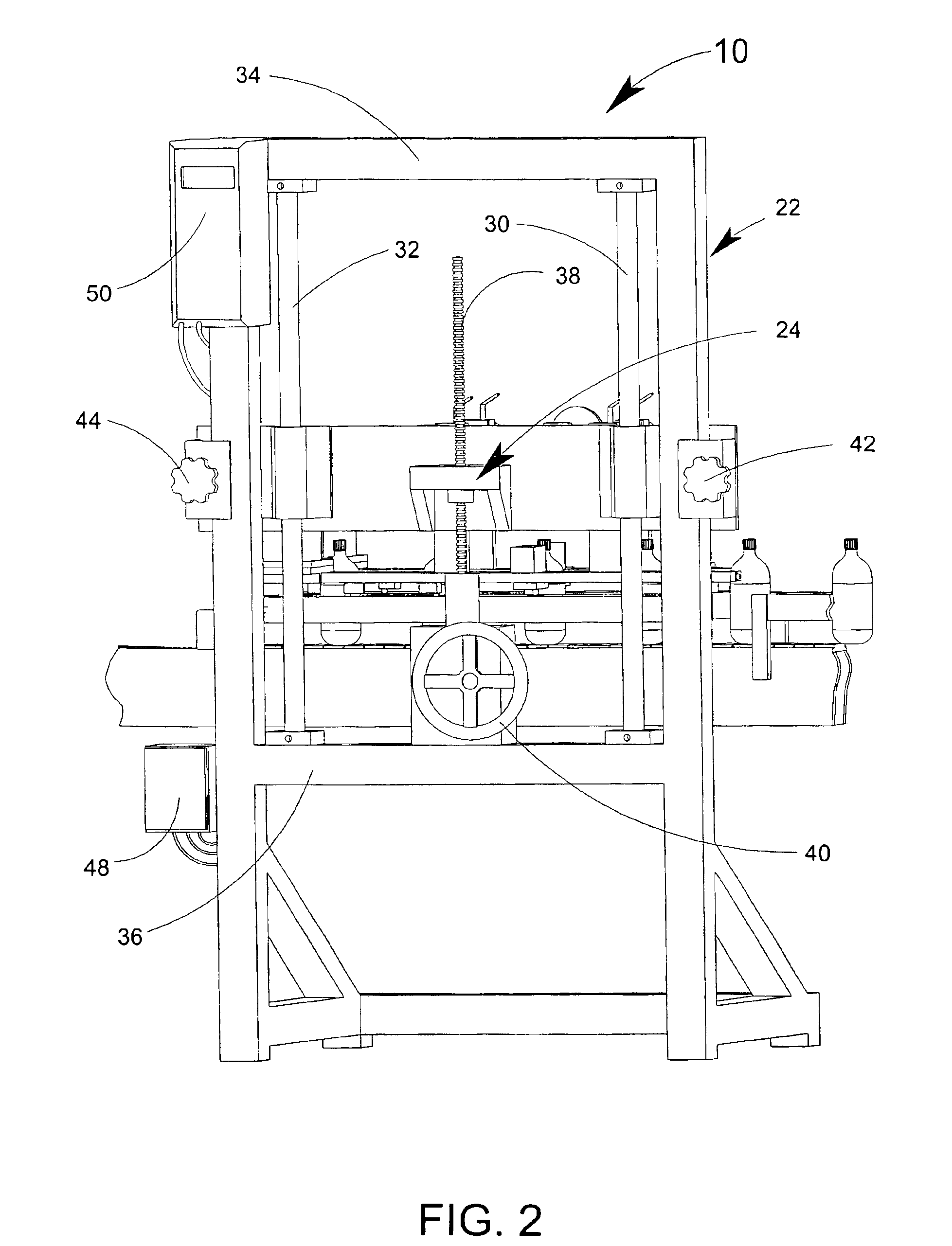

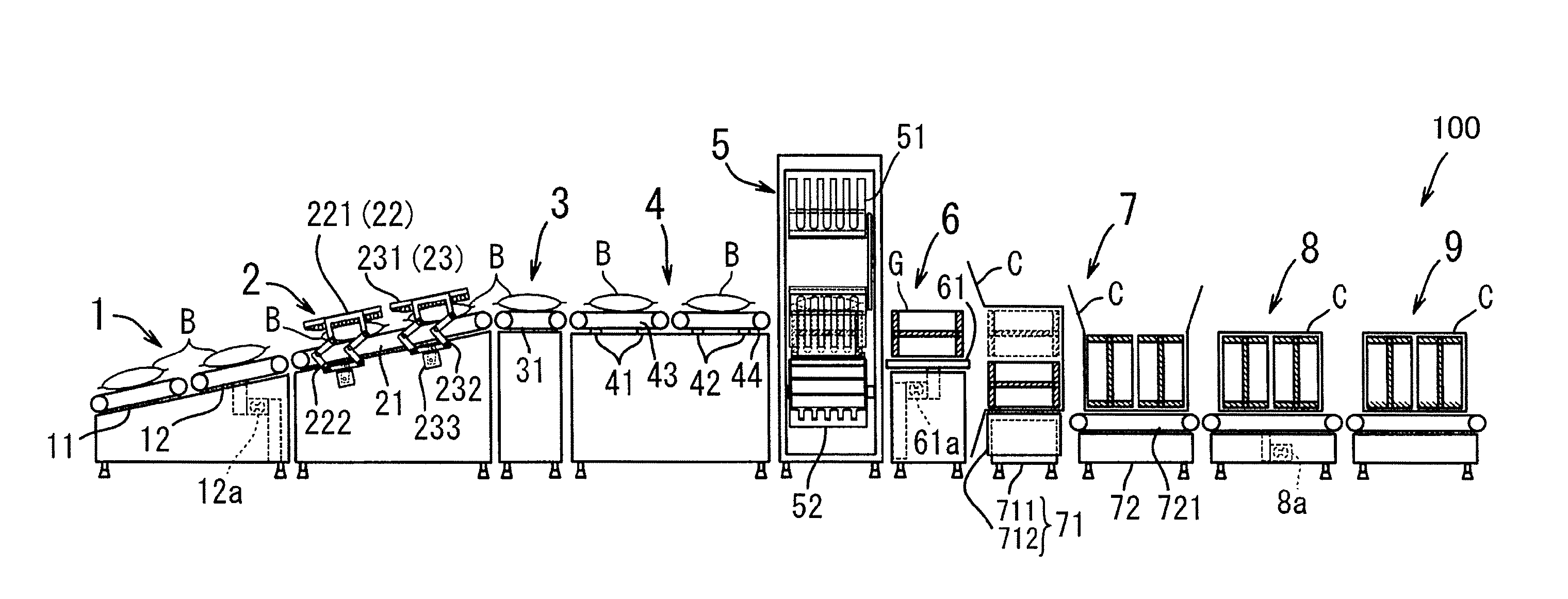

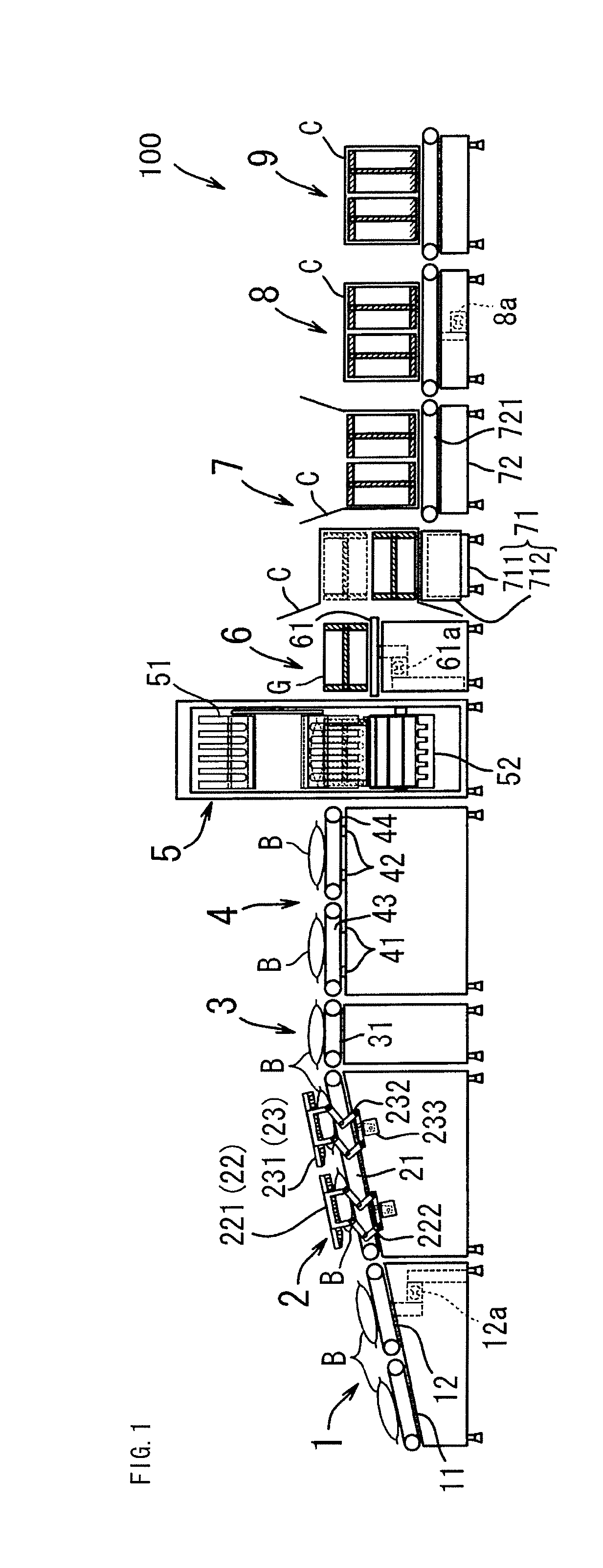

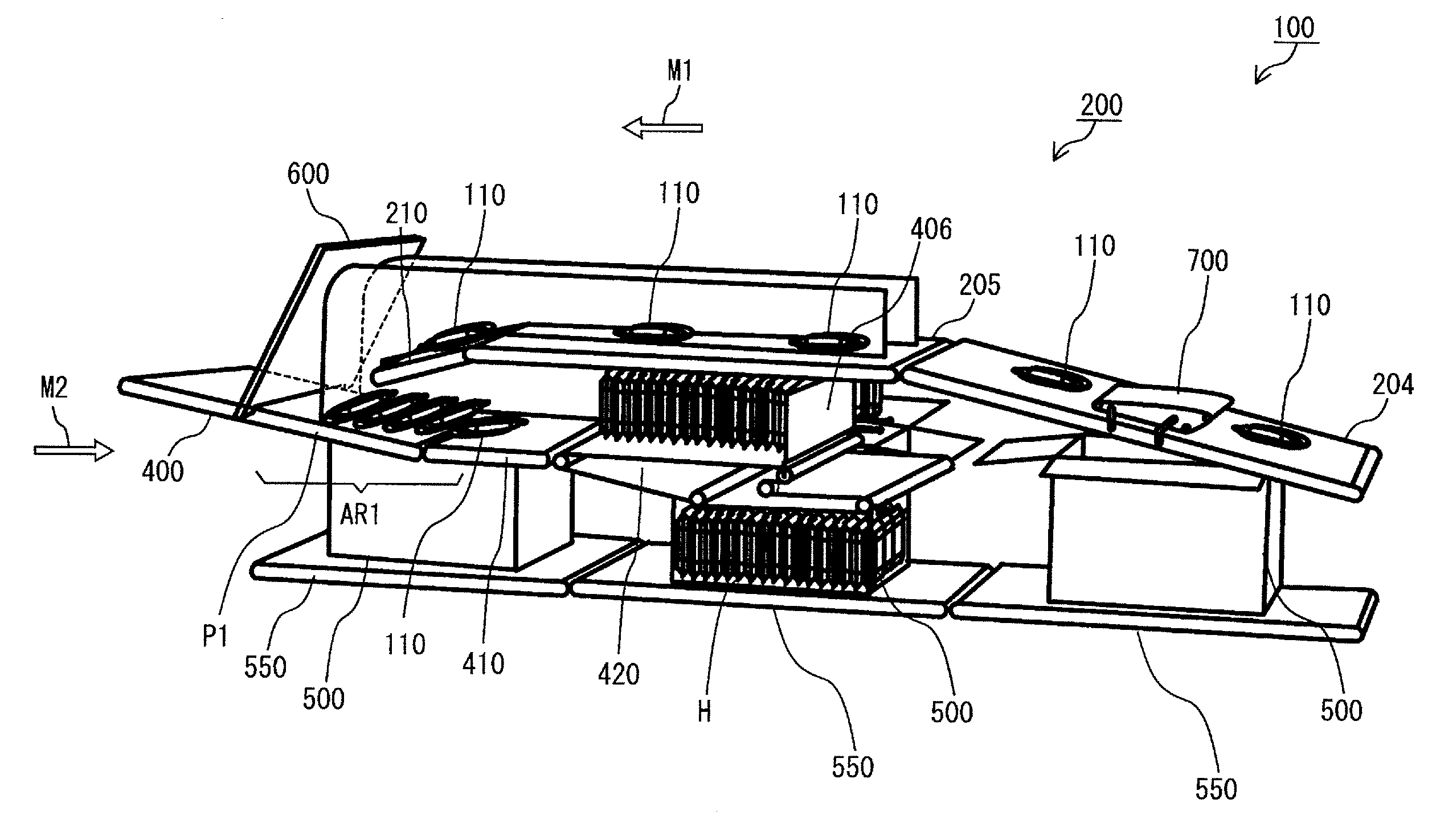

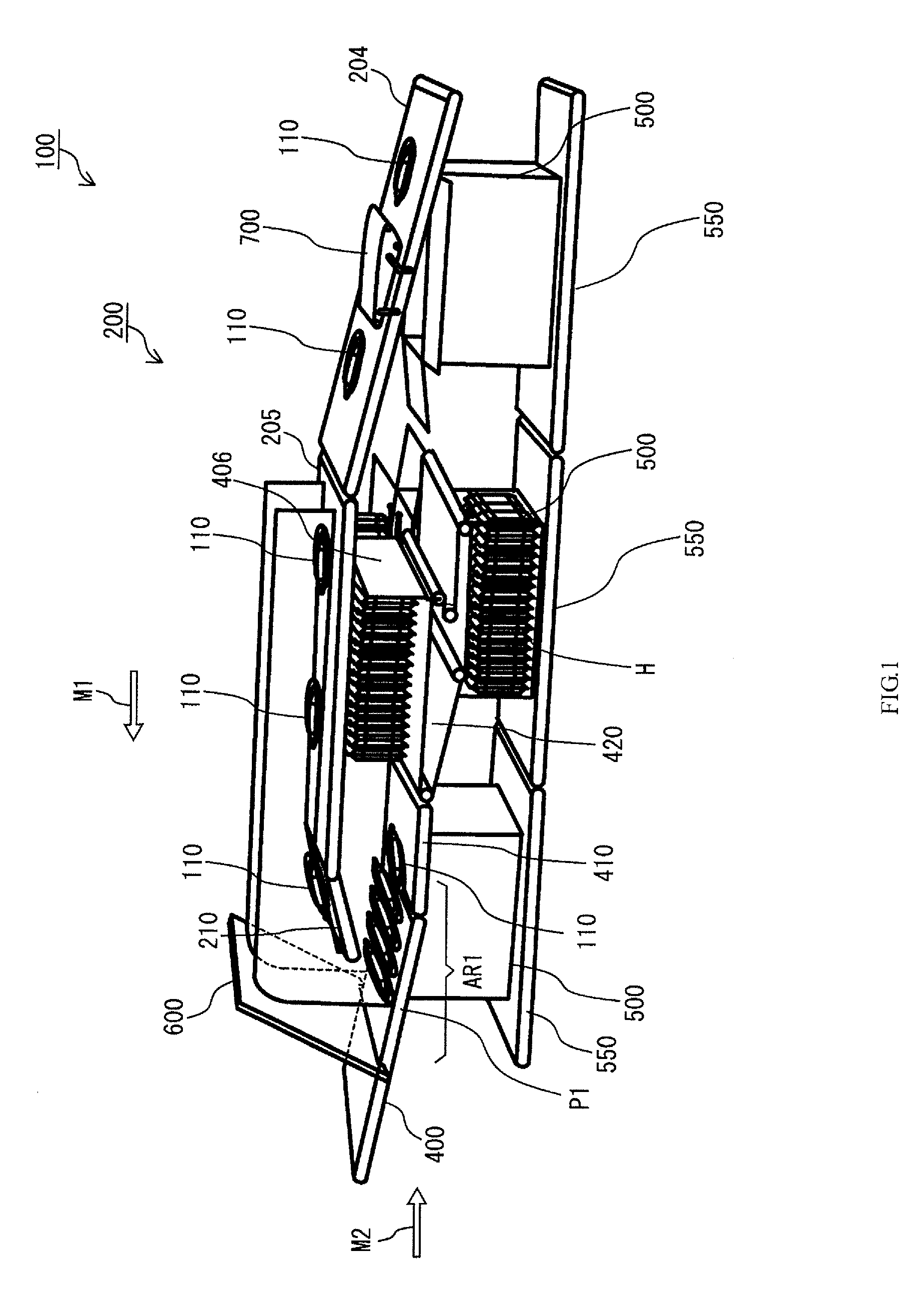

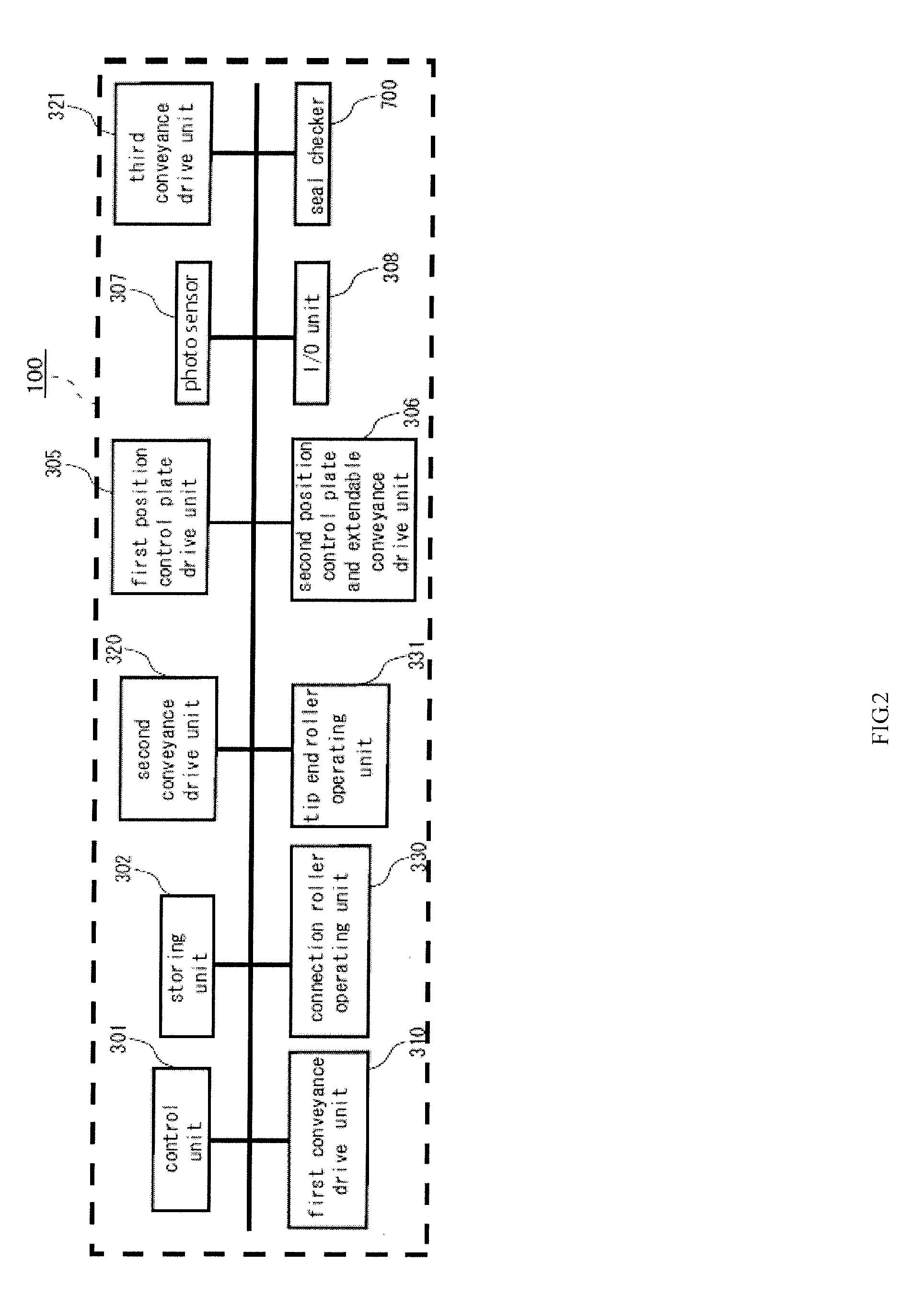

Automatic package inspecting system

InactiveUS6711874B1Low costProductivity of systemFluid-tightness measurement by detecting dimension changeWrapper twisting/gatheringHermetic packagingPackaging machine

A package inspecting system includes a packaging machine 200 including a vertical sealing device 201 for sealing opposite longitudinal side edges of a packaging material F, which extend in a direction conforming to a direction of flow of the packaging material F, together to render the packaging material F into a tubular form, and an end sealing device 202 for sealing an end of the tubular packaging material F after articles M have been filled in the tubular packaging material F, to thereby provide a bagged product M1, and a seal checker 400 for inspecting a sealing condition of the packaging material F of the bagged product M1. The package inspecting system also includes a bite detecting means 21 provided in the packaging machine 200 for detecting whether or not the articles M are bitten in the end of the packaging material F so that the presence or absence of an abnormal condition and a content of abnormality in each of the sealing devices 201, 202 can be diagnosed based on a result of detection, performed by the bite detecting means 21, and a result of inspection performed by the seal checker 400 with respect to the same bagged product M1.

Owner:ISHIDA CO LTD

Air leakage detection apparatus for gas packing food

ActiveCN108502275AIntuitive and reliable test resultsImprove efficiencyFluid-tightness measurement by detecting dimension changePackaging automatic controlInlet valveEngineering

The invention relates to the field of food detection equipment, in particular to an air leakage detection apparatus for gas packing food. The air leakage detection apparatus for the gas packing food comprises a rack, an ejection press device and a rejection device. The ejection press device comprises an electric actuator, an ejector rod and a press plate. The ejector rod and the press plate are connected through a plurality of buffer springs. A conveyer belt is arranged below the press plate. The rejection device comprises a vertical guide rod, a piston block, a piston cylinder and a limitingplatform. An inner chamber of the piston cylinder is divided into an upper chamber and a lower chamber by the piston block. A sliding hole for the guide rod to penetrate through is formed in the upperend of the piston cylinder. A limiting protrusion and a reset spring are arranged in the piston cylinder. The upper end of the piston block makes contact with the limiting protrusion. The lower end of the piston block makes contact with the reset spring. A one-way air inlet valve, a one-way air outlet valve and an air blowing pipe are arranged on the piston cylinder. The air blowing pipe communicates with the one-way air outlet valve. Both the one-way air inlet valve and the one-way air outlet valve communicate with the upper chamber. The air leakage detection apparatus for the gas packing food has the advantages that g automatic rejection of packaging bags with air leakage is achieved, detection results are visible and reliable, continuous detection can be carried out, and the efficiencyis greatly improved.

Owner:浙江金正检测有限公司

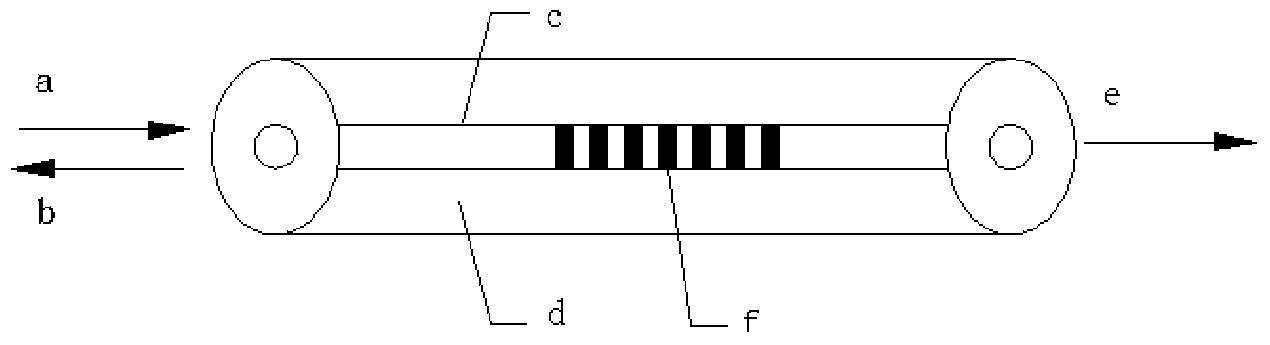

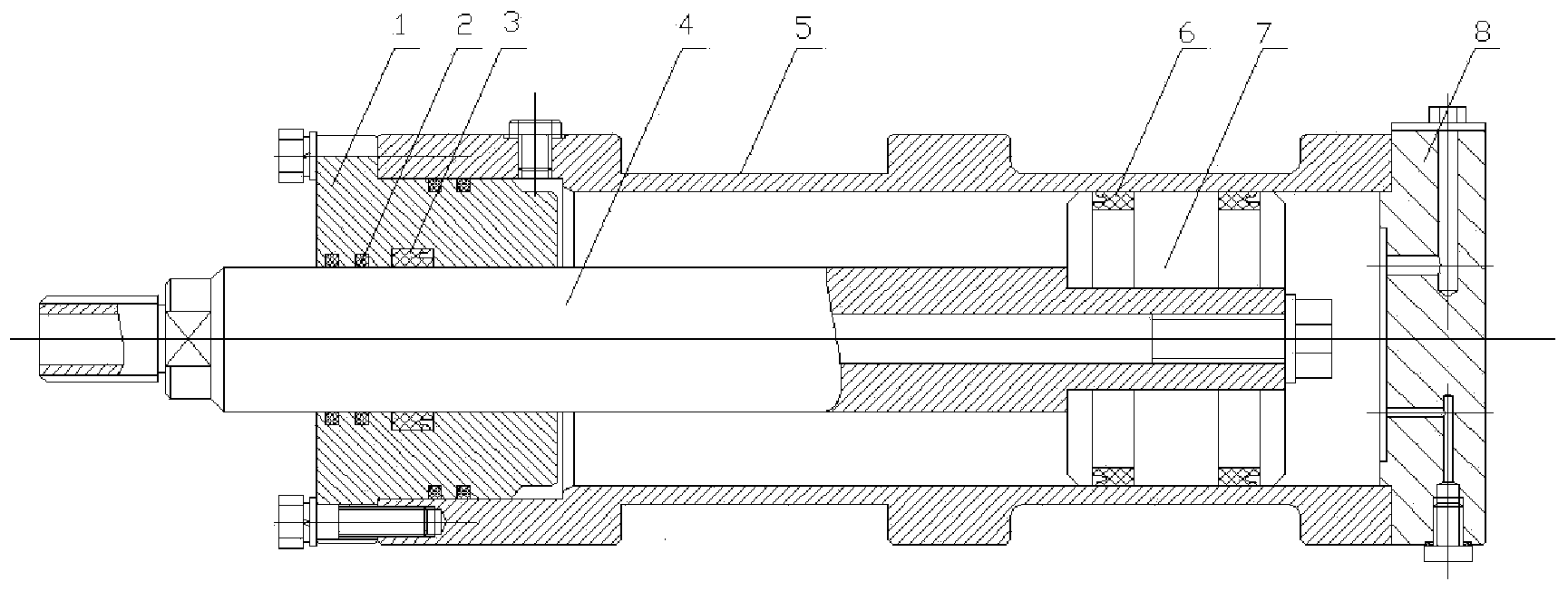

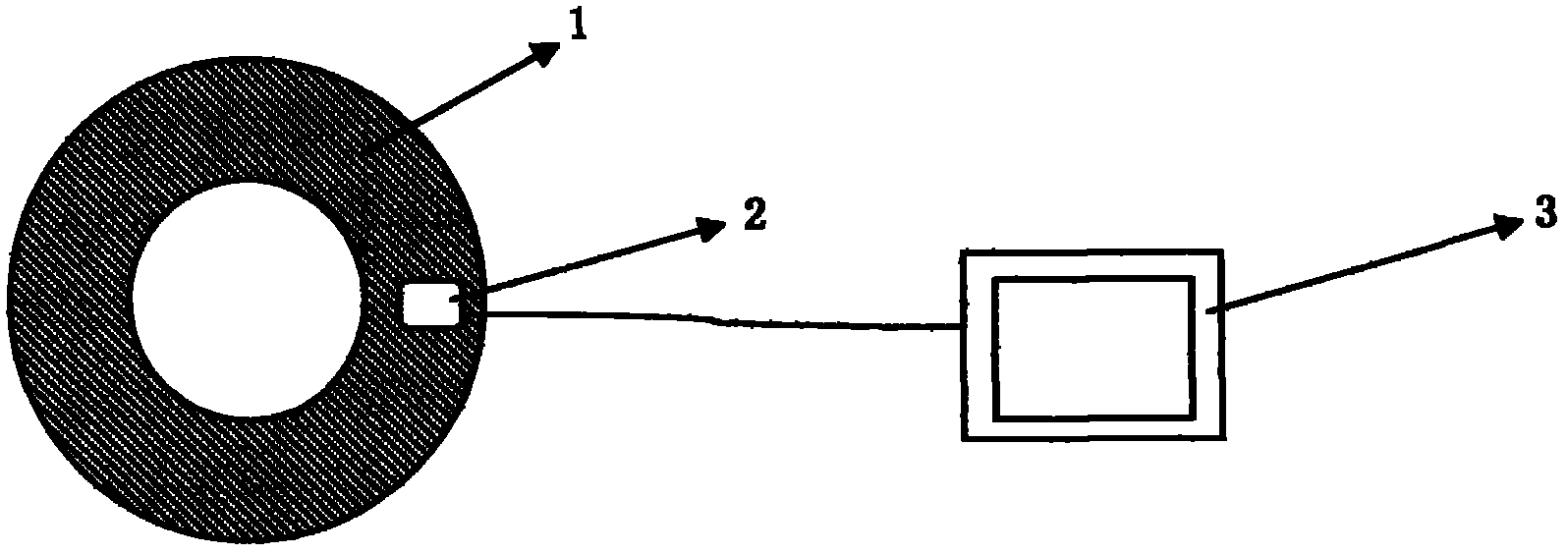

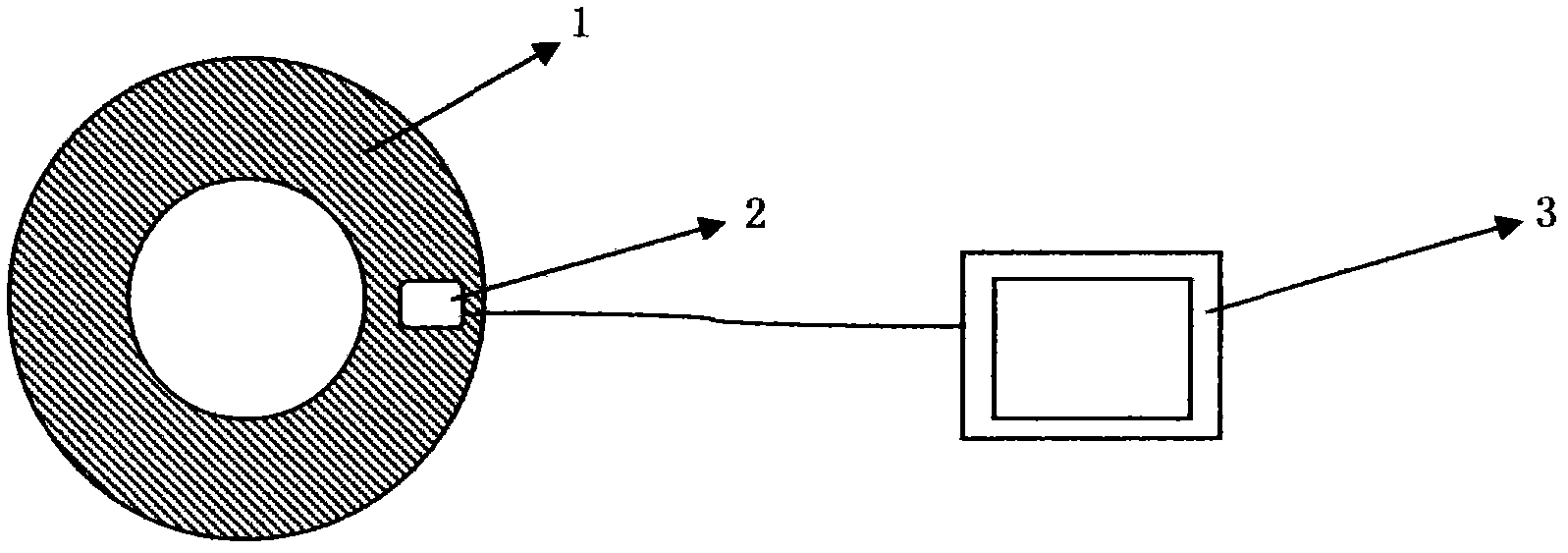

Fiber bragg grating sensing based hydraulic cylinder dynamic seal failure state monitoring method

ActiveCN103954413ARealize monitoringIncreased sensitivityFluid-tightness measurement by detecting dimension changeFiberHydraulic cylinder

The invention relates to a fiber bragg grating sensing based hydraulic cylinder dynamic seal failure state monitoring method. According to the method, the dynamic seal failure state of hydraulic cylinders is monitored timely through an optical fiber sensing technology, that is, fiber bragg grating strain transducers are laid at the bottoms and sides of hydraulic cylinder piston rod and piston dynamic seals, and a fiber bragg grating temperature transducer is lain in the hydraulic cylinder piston rod to monitor the dynamic seal state changes in the hydraulic cylinder timely. Strain and temperature change data of the hydraulic cylinder dynamic seal working surface are acquired and analyzed in real time through a hydraulic cylinder dynamic seal failure state monitoring system, and the hydraulic cylinder dynamic seal failure state is determined accurately through the comparison of the actual strain value and the standard value of the dynamic seal working surface of the hydraulic cylinder. The method has the advantages of being capable of achieving point measuring and multi-point distributive monitoring when the dynamic seal state changes are monitored during the working of the hydraulic cylinder, good in sensitiveness, high in accuracy and capable of preventing leakage failures effectively and preventing environmental pollution.

Owner:WUHAN UNIV OF TECH

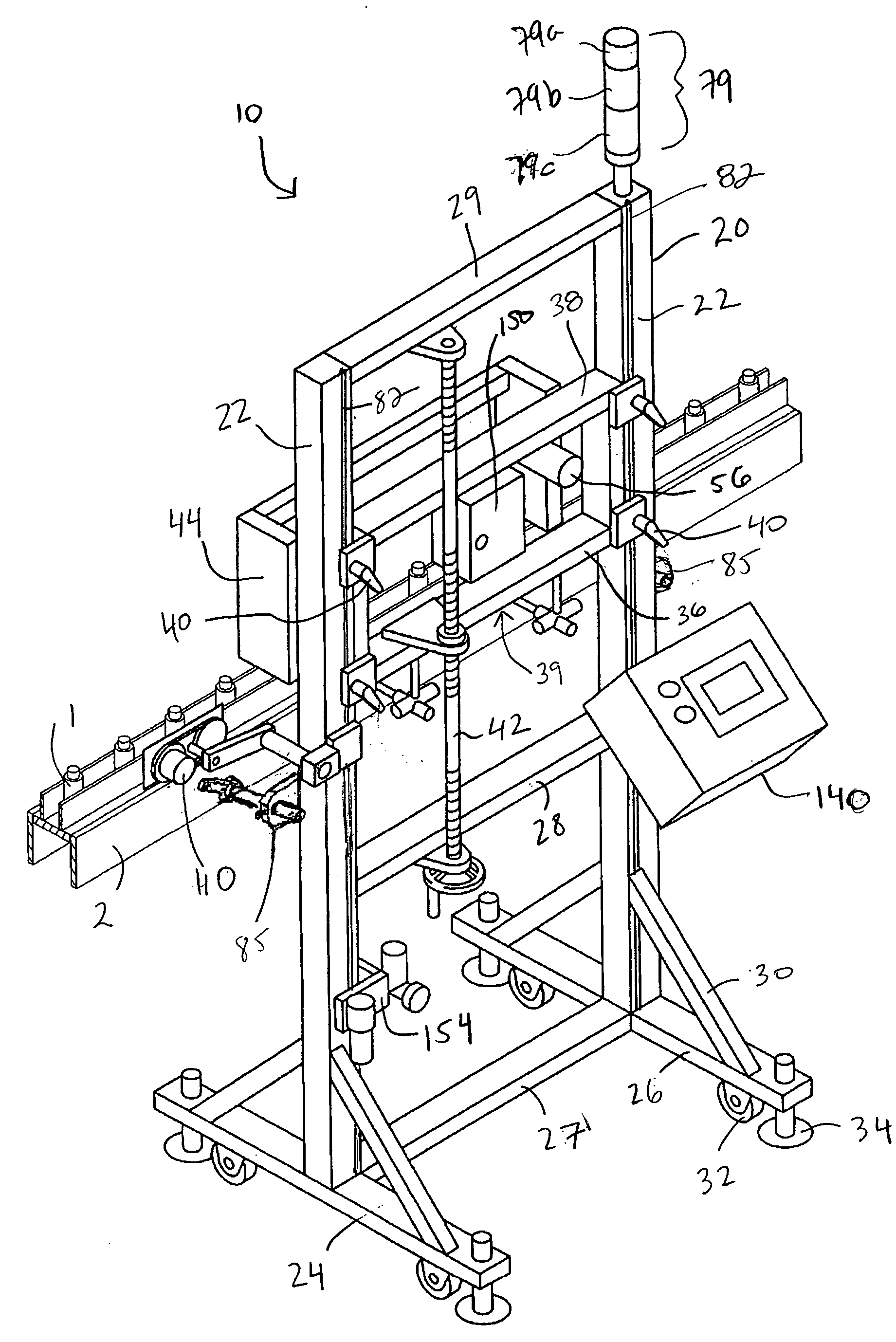

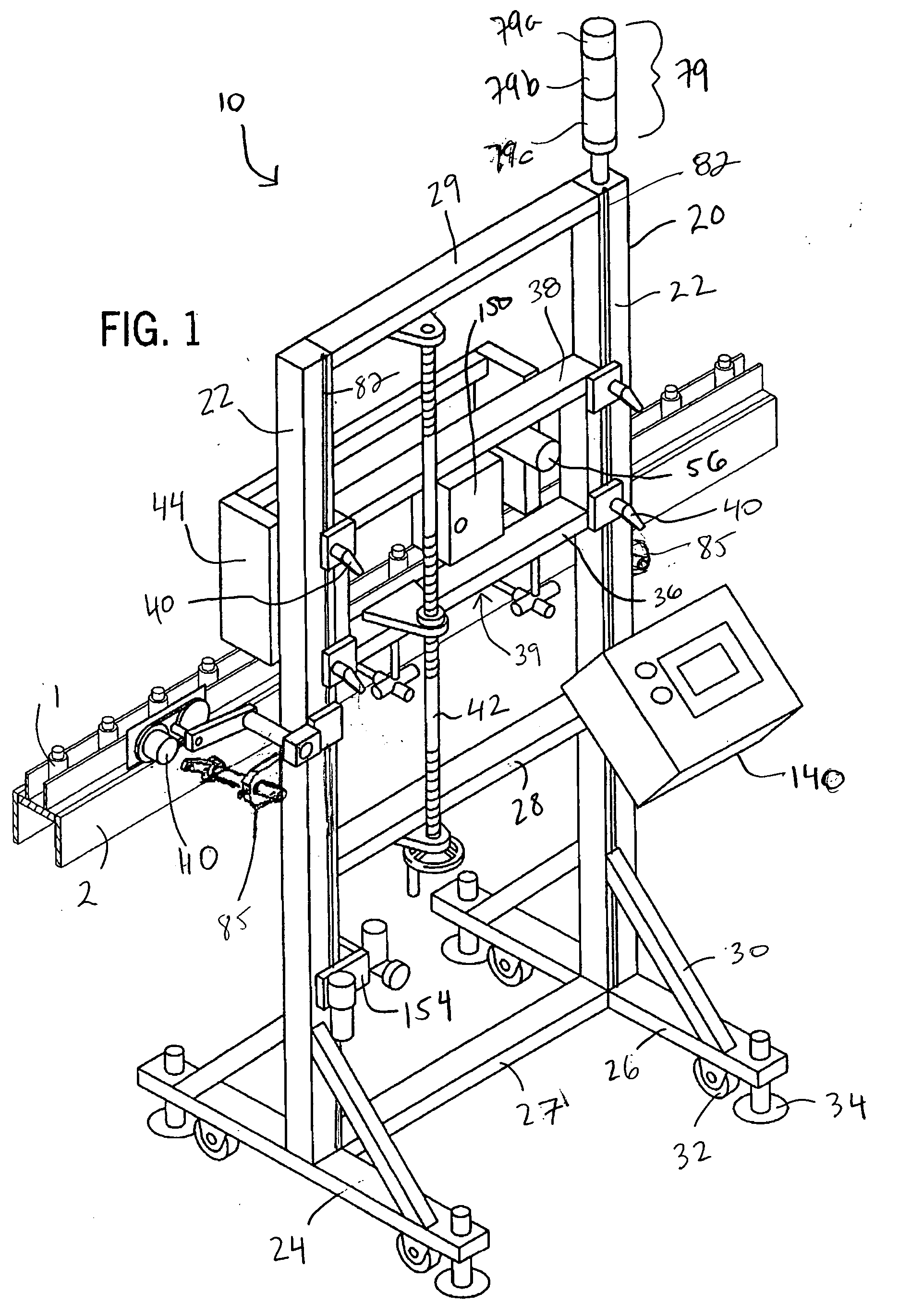

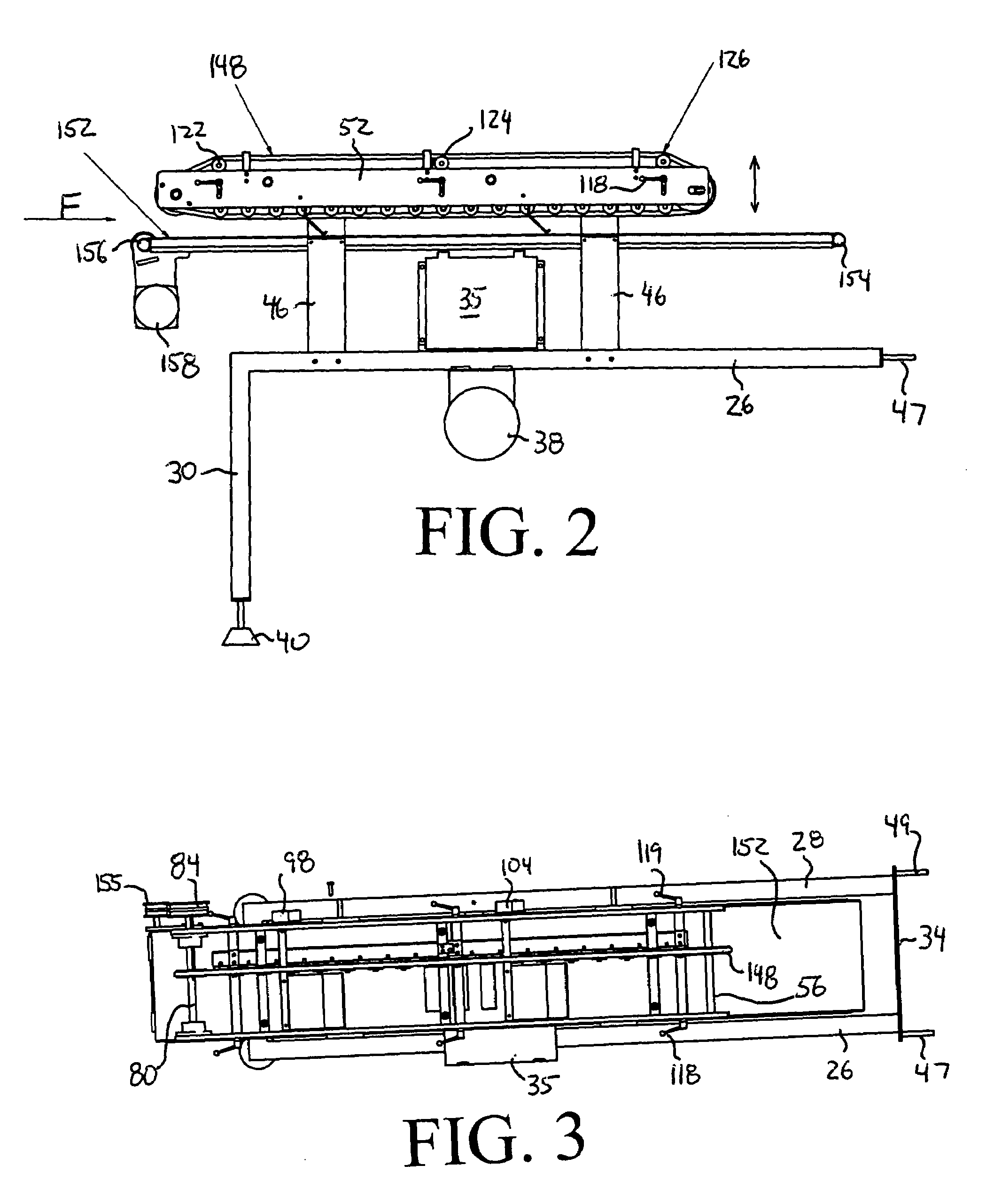

Package handling apparatus detecting package height

InactiveUS6941796B2Faster and efficient and more adaptableMeasurement of fluid loss/gain rateFluid-tightness measurement by detecting dimension changeMotor driveBall screw

An apparatus to test integrity of a seal of a package. The apparatus includes a height detector detecting a height of the package, a test portion determining the integrity of the seal based upon a position of the test portion as a function of time when contacting the package, and a mover moving the test portion into an initial position of contact with the package based upon the detected height. The test portion includes a test head contacting the package, and the mover includes a servo motor driving the test head, and a ball screw linking the servo motor and the test head.

Owner:ISHIDA CO LTD

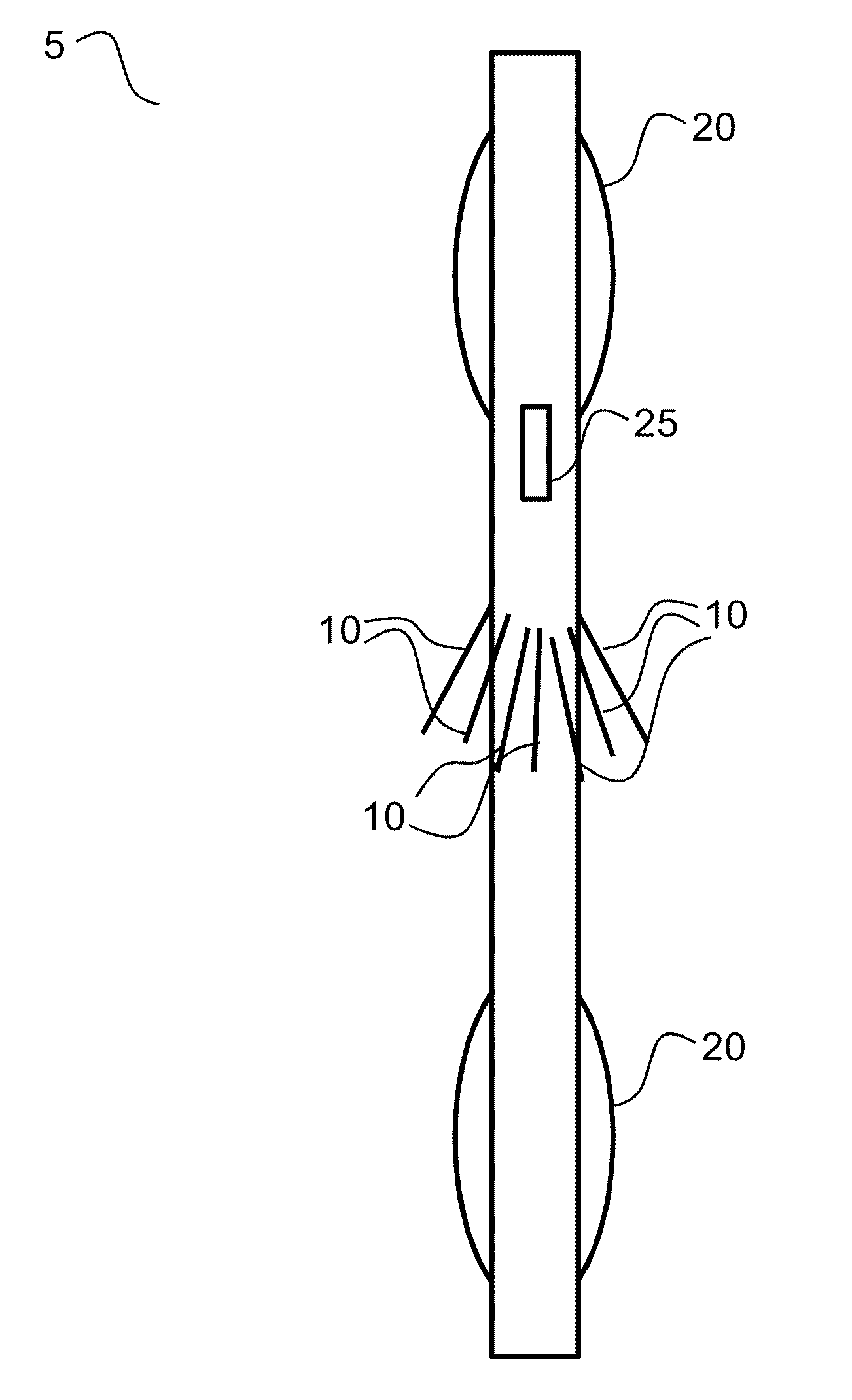

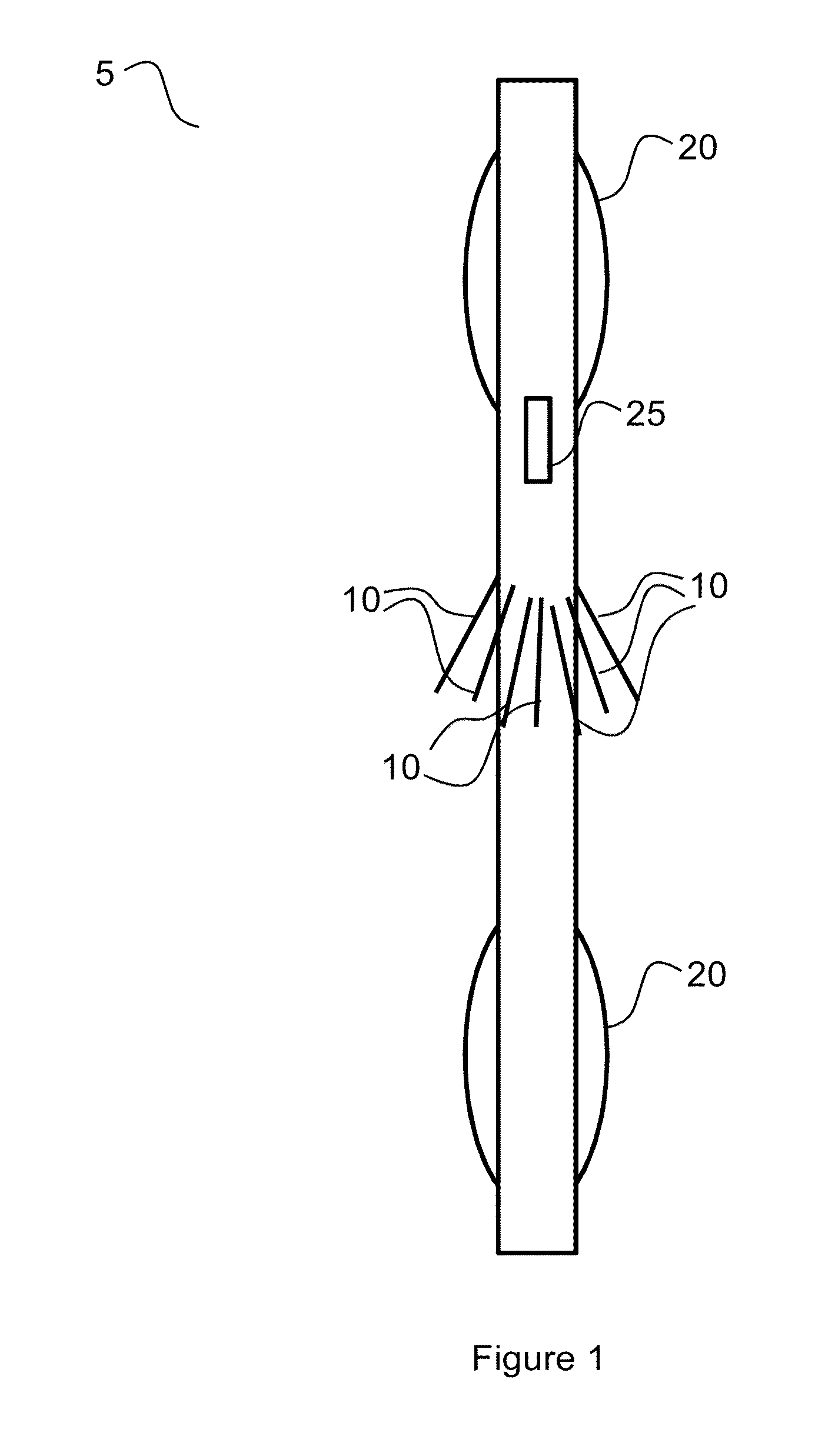

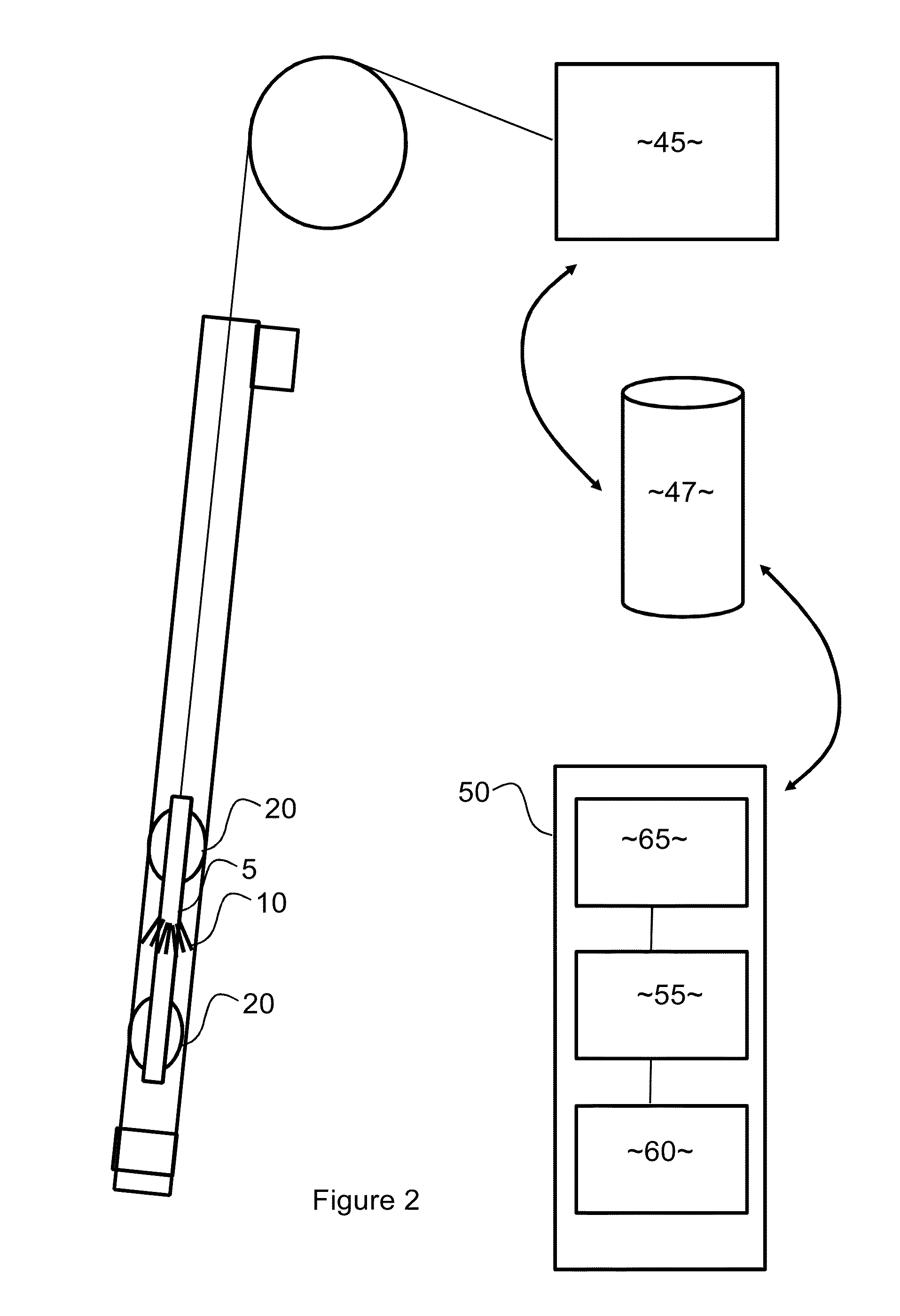

System and method for determining deformed pipe geometry

ActiveUS20150285607A1Raise the possibilitySurely and accurately determineFluid-tightness measurement by detecting dimension changeFeeler-pin gaugesMeasurement pointEngineering

A method and associated system for determining geometry of a deformed pipe or conduit or wellbore, the method comprising: collecting, determining and / or receiving measurement data indicative of a plurality of radii of the pipe or conduit using equipment centred in the pipe at two or more points a known distance from the measurement point but not at the measurement point itself; selecting a deformation type and / or deformation model; processing the measurement data to determine one or more geometrical properties of the pipe or conduit, the geometrical properties being indicative of, or associated with, one or more deformations, shapes or profiles of at least part of the pipe or conduit; and guiding and / or constraining at least a part of the processing of the measurement data using the selected deformation type or model and / or fitting the selected deformation model to the measurement data.

Owner:E V OFFSHORE

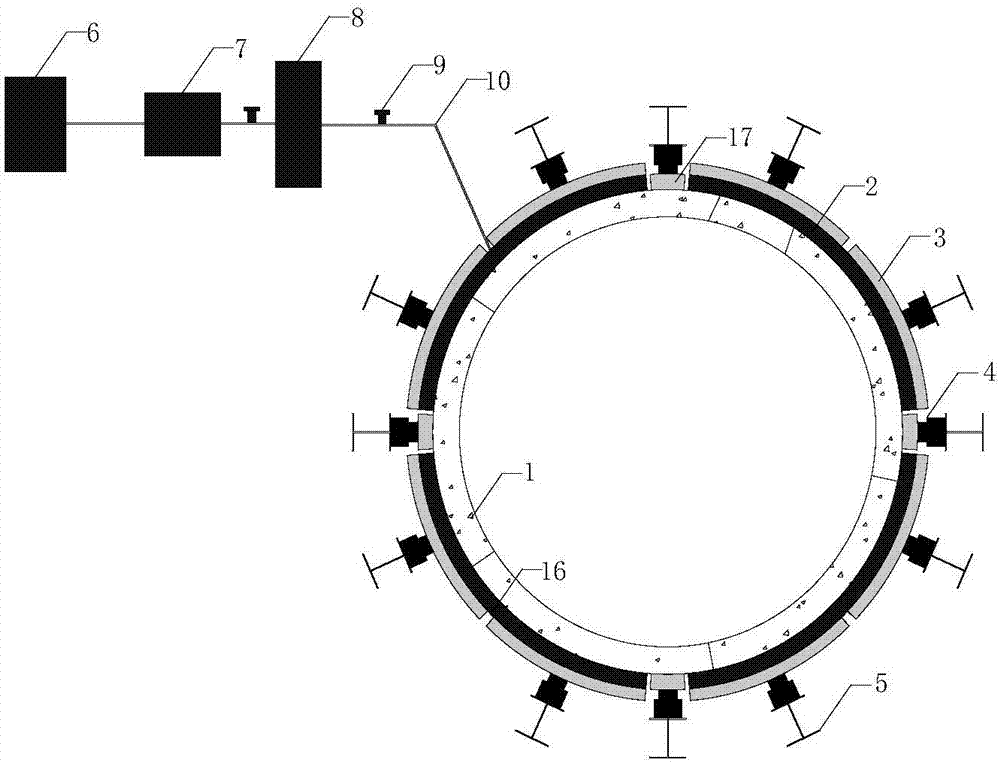

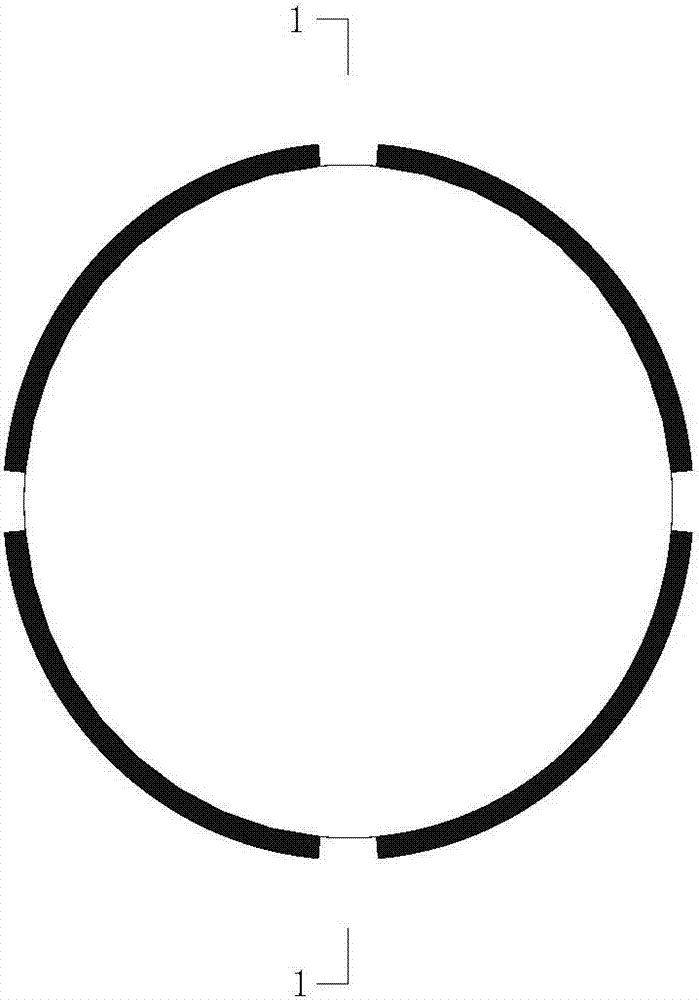

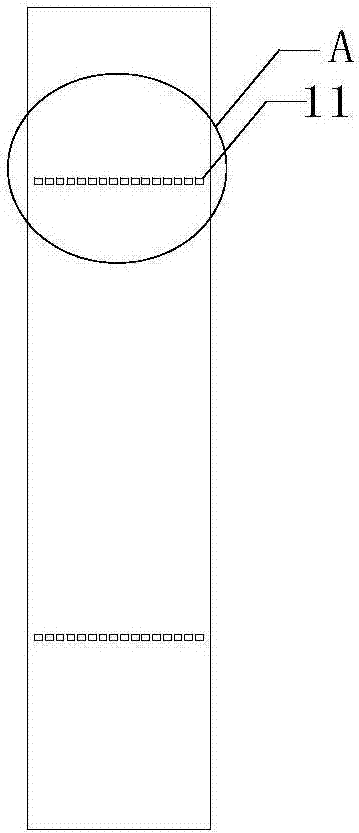

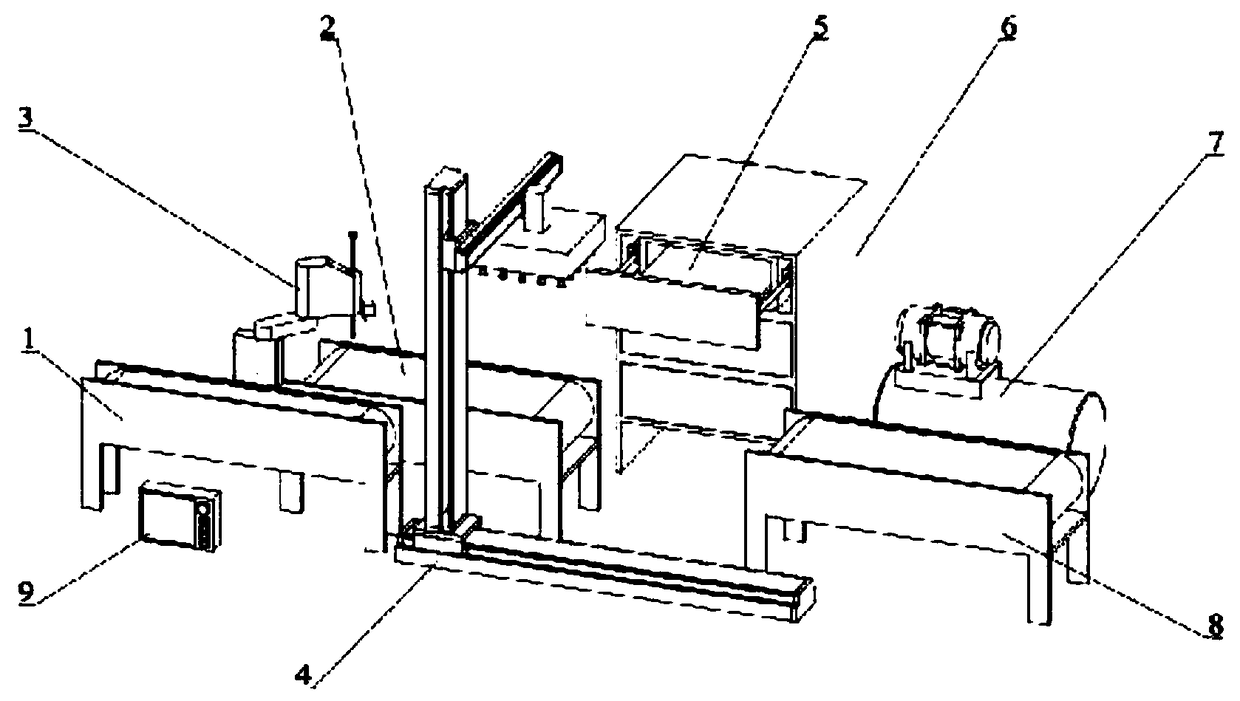

Shield tunnel pipe ring impermeability performance testing method with simulation of water and soil loading effects

PendingCN106885661AFluid-tightness measurement by detecting dimension changeStructural engineeringWater leak

The invention relates to a shield tunnel pipe ring impermeability performance testing method with simulation of water and soil loading effects. Employed devices comprise a water pressure loading system, multiple hydraulic jacks 4 and a water bag 2 which is fixed to the outside of a pipe ring. According to each joint position of the pipe ring, multiple rows of holes 11 are arranged at the inner layer of the water bag. The testing method comprises a step of allowing the water bag 2 on the pipe ring, a step of arranging a bearing plate and a hydraulic jack, a step of allowing the water pressure loading system to inject water to each sub water bag of the water bag 2 through different water pipes 10, stopping water injection when a pressure water with a scale is filled with water with a certain depth, and recording a scale value at that time to be an initial reading, a step of controlling the hydraulic jacks 4 to add pressure to the water bag to simulate water and soil load borne by a shield tunnel, and recording a pressure water tank scale value in the time of maintaining the load, and a step of using a laser displacement sensor to measure the opening amount of a segment joint.

Owner:TIANJIN UNIV

Fast detecting method for sealing performance of closed flexible package bag

InactiveCN1719218AEasy to operateThe detection process is fastMeasurement of fluid loss/gain rateFluid-tightness measurement by detecting dimension changeMechanical engineeringConstant pressure

The present invention discloses a sealability quick detection method of closed flexible package bag. Said method includes the following steps: placing the completely-closed flexible package bag sample and closed flexible package bag to be detected into a container, closing the container cover, air-inflating said container to reach the rated pressure of package bag and retaining the constant pressure for a certain time, finally quickly opening said sealing cover of container and observing the volume change of two package bags so as to obtain the sealability of the detected package bag.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

Indirect contact container measurement

ActiveUS6918285B2Eliminating container structuralEliminating aesthetic damageDetection of fluid at leakage pointMeasurement of fluid loss/gain rateInternal pressureProduction line

Apparatus and methods for in-line testing of the internal pressure of flexible containers traveling along a production line at high speeds. The apparatus inspects semi-rigid plastic and thin-walled liquid filled containers by analyzing the output from a load cell that indirectly measures the reaction force applied to a container through the intermediary of a load cell roller that, in turn, supports a flexible belt that directly contacts containers while moving them through an inspection station without interrupting the flow of the production line. Containers are contacted only by a flexible portion of a conveyor belt to minimize structural and aesthetic damage to them that might otherwise occur during the inspection process.

Owner:TELEDYNE INSTR INC

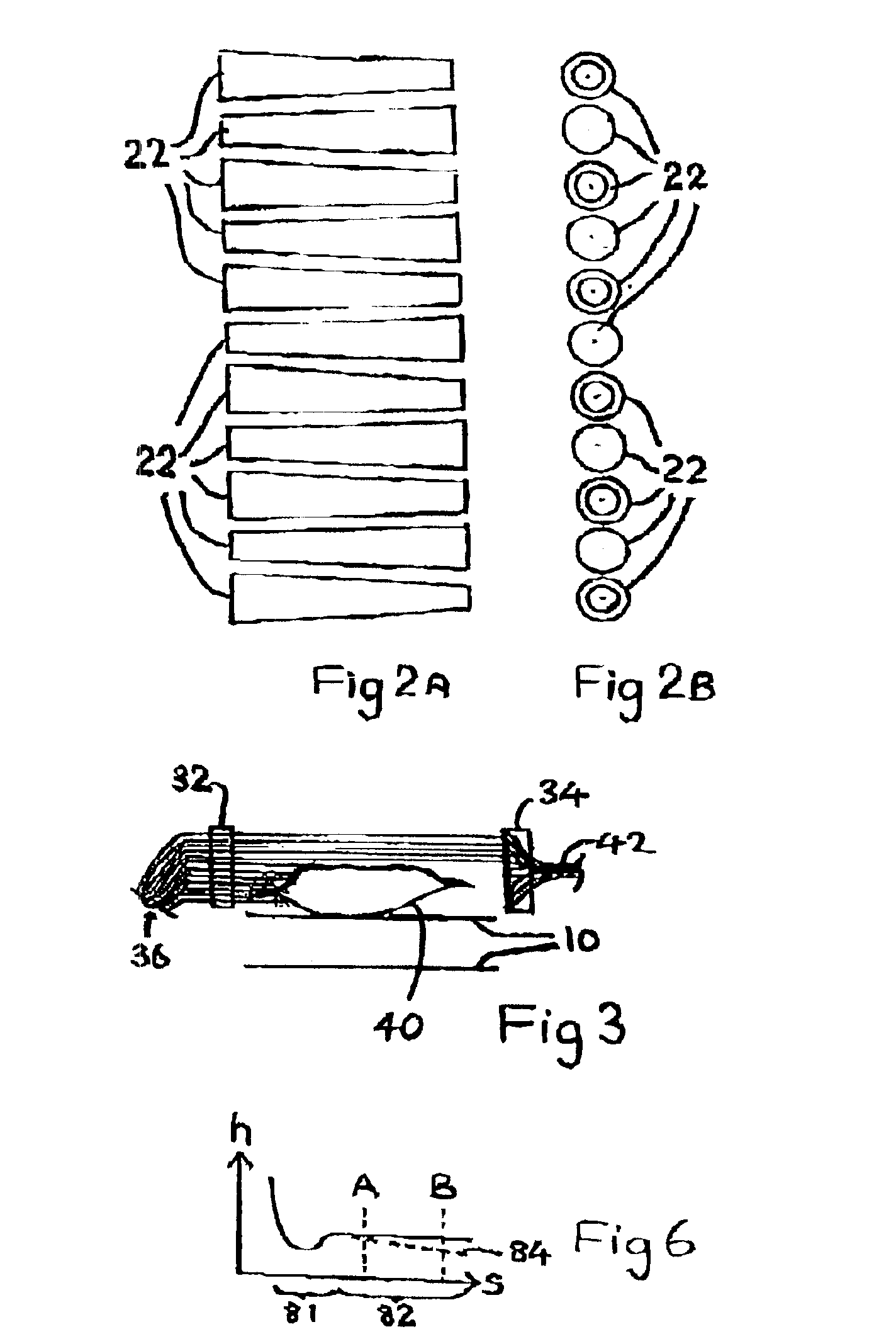

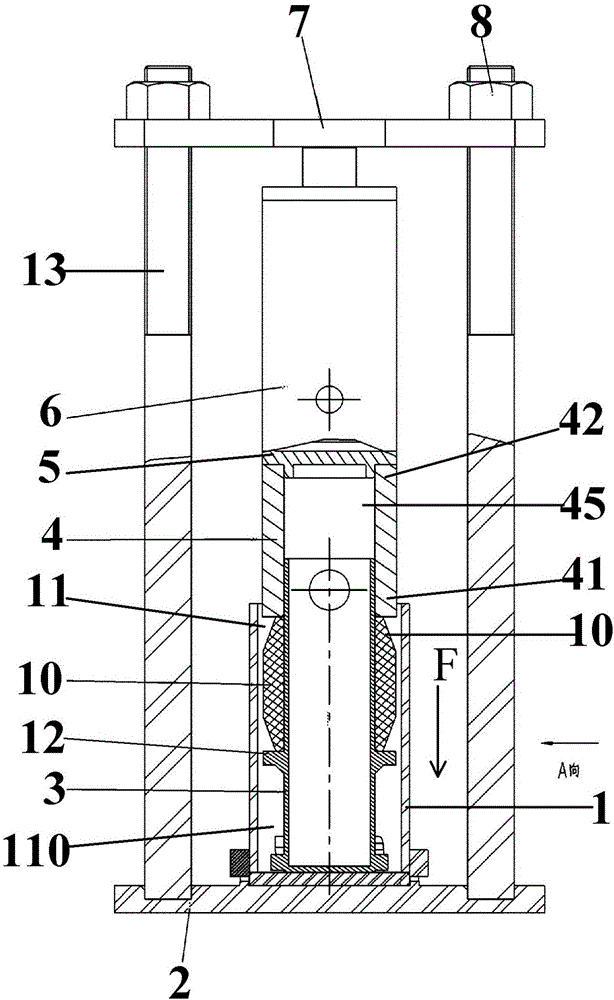

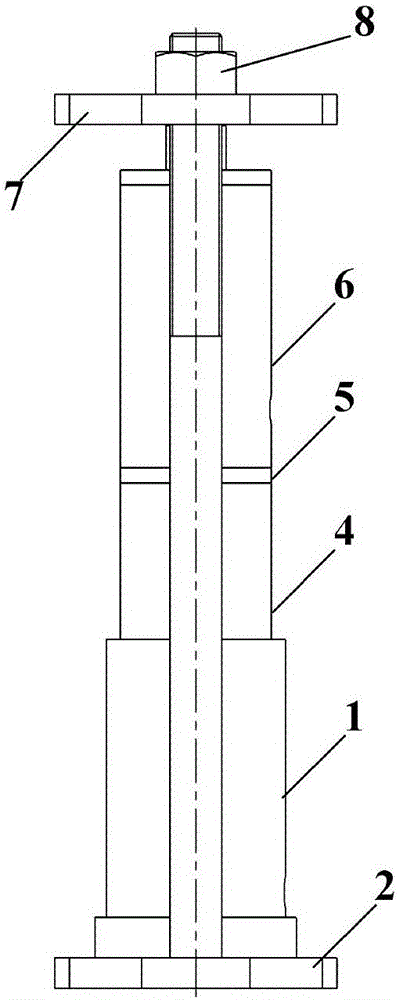

Self-tightening sealing pressure test tool for high-pressure steel tube

ActiveCN102607956ATo achieve the role of tight sealGuaranteed tightnessDetection of fluid at leakage pointFluid-tightness measurement by detecting dimension changeEngineeringHigh pressure

The invention relates to a self-tightening sealing pressure test tool for a high-pressure steel tube, which comprises a hollow draw bar, wherein one end of the hollow draw bar is provided with a water injection channel, the other end of the hollow draw bar is communicated with a tube cavity of the high-pressure steel tube, and a nut, an ejection block, a first sealing assembly, a second sealing assembly and a gland are arranged outside the hollow draw bar in sequence; and the nut is in screwed connection with the hollow draw bar, the inner end surface of the nut butts against the outer end surface of the ejection block, the outer circumference side of the inner end surface of the ejection block butts against the end surface of a tube head of the high-pressure steel tube, the inner circumference side of the inner end surface of the ejection block butts against one end of the first sealing assembly, the other end of the first sealing assembly butts against one end of the second sealing assembly, the other end of the second sealing assembly butts against one end surface of the gland, and the other end surface of the gland butts against the hollow draw bar. When being used, the test tool is clamped in the tube cavity of the high-pressure steel tube and locked, and the self-tightening sealing pressure test tool is tightly sealed due to additional arrangement of the first sealing assembly and the second sealing assembly. Compared with the prior art, the self-tightening sealing pressure test tool disclosed by the invention has the characteristics of good sealing effect, simple structure, convenience for manufacturing and operation and convenience for assembly and disassembly.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

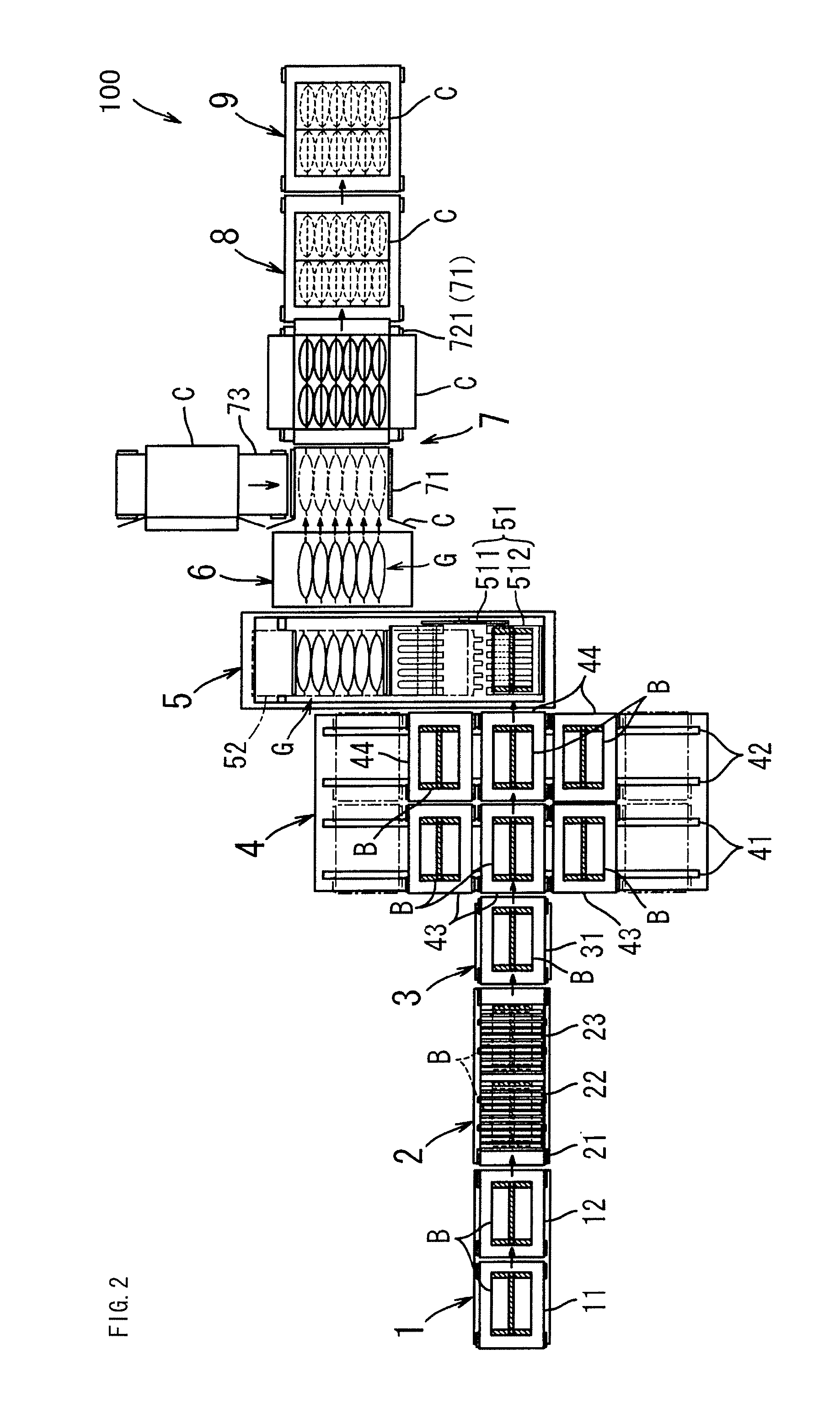

Boxing device and packaging device

InactiveUS20100115886A1Accurately determineIncrease production capacityFluid-tightness measurement by detecting dimension changeMaterial check-weighingBiomedical engineeringWeight measure

Owner:ISHIDA CO LTD

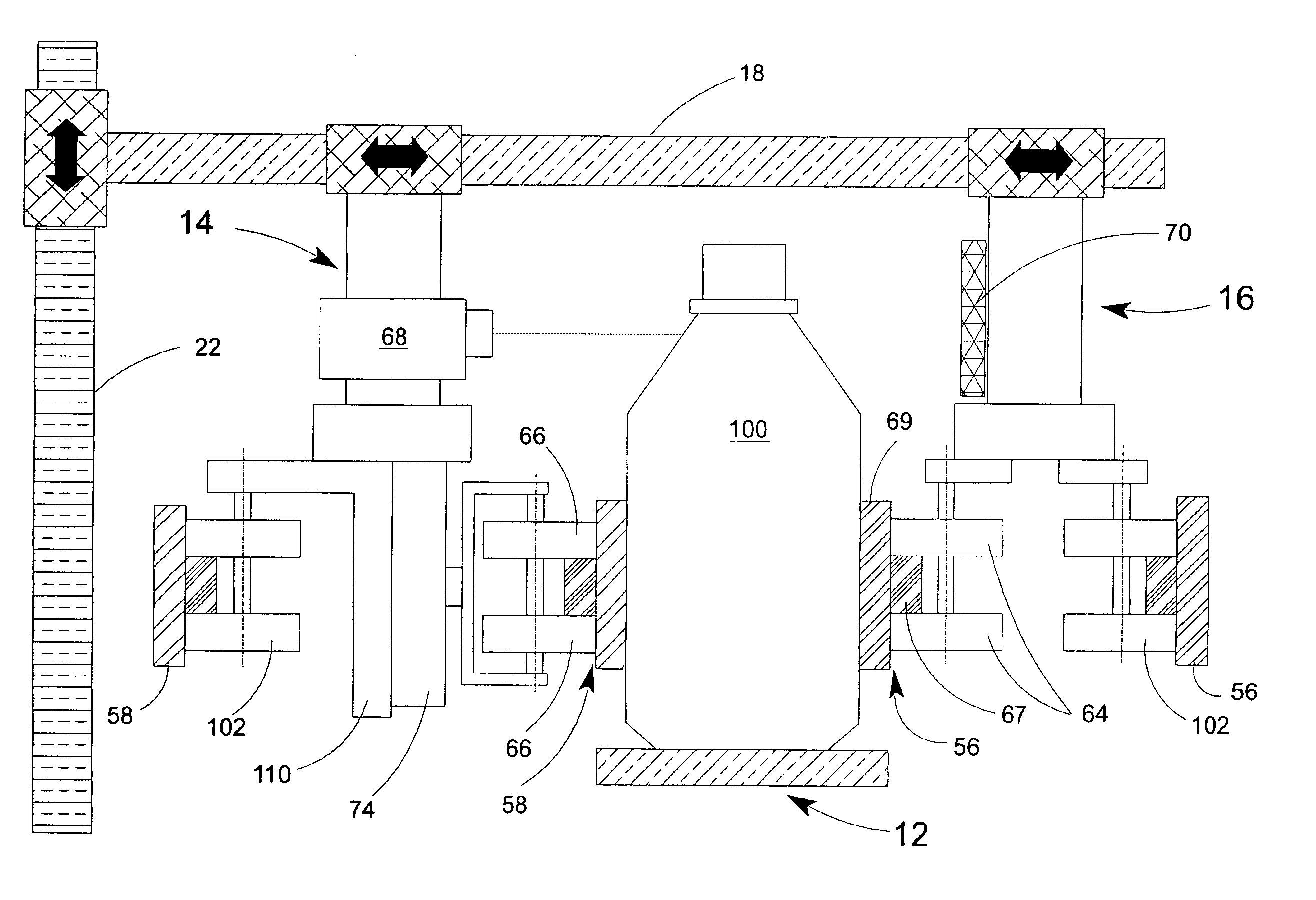

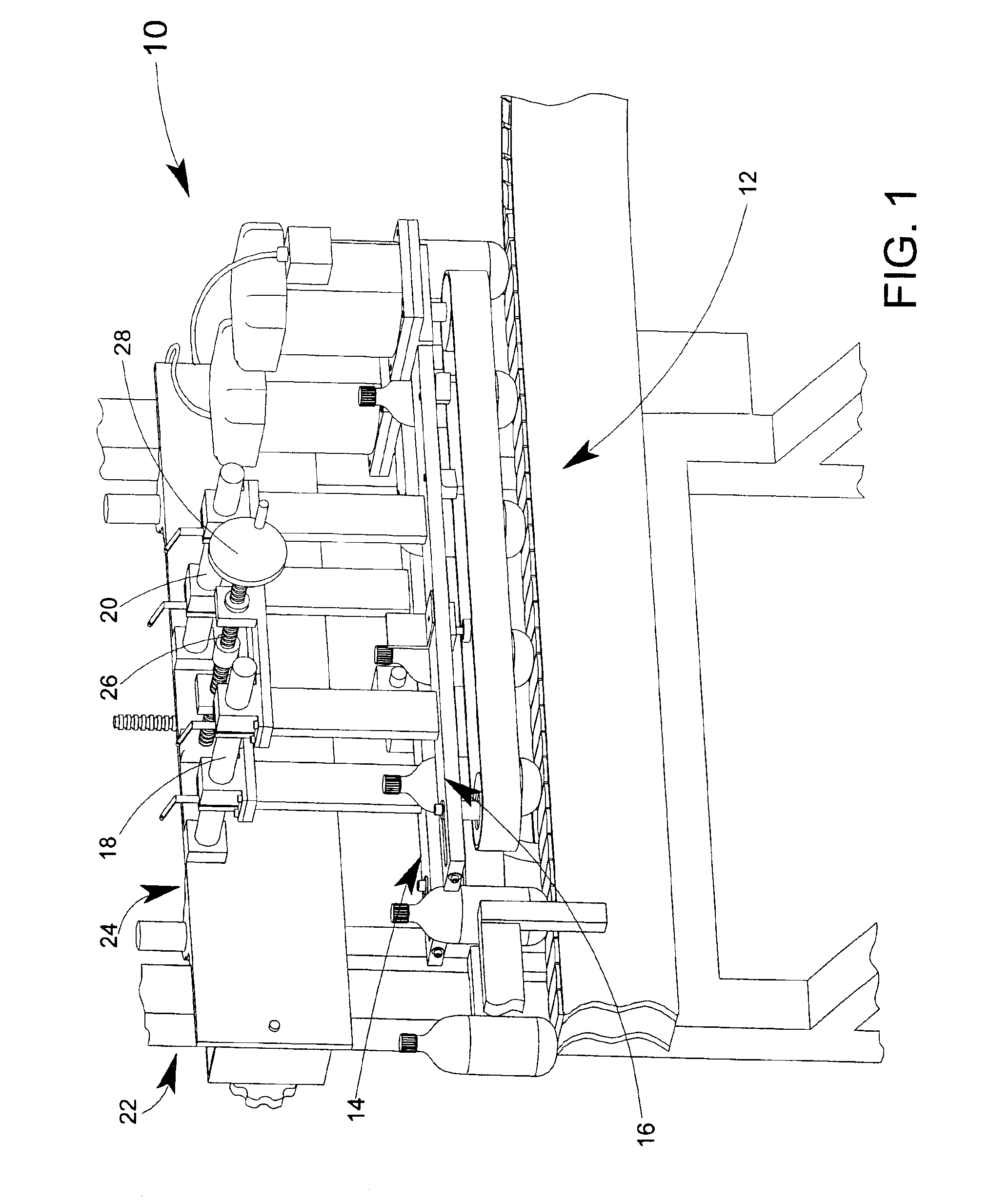

Container leak detection apparatus and method

An apparatus and method for testing a container as to leakage and defects. The apparatus is especially useful for testing plastic bottles because it does not contact one or more of the bottle sides during testing. A frame with the test components may be adjusted so that the apparatus will fit many different conveyor configurations and container sizes. A container is moved along by a conveyor, where it is sensed by a photo-eye to initiate testing. The test probe makes contact with the container opening, and travels with the container during testing. The test probe introduces air into the container and detects the maximum pressure and pressure decay. If the pressures are not within an acceptable range, the container is ejected from the conveyor.

Owner:GENERAL ELECTRIC CAPITAL AS AGENT

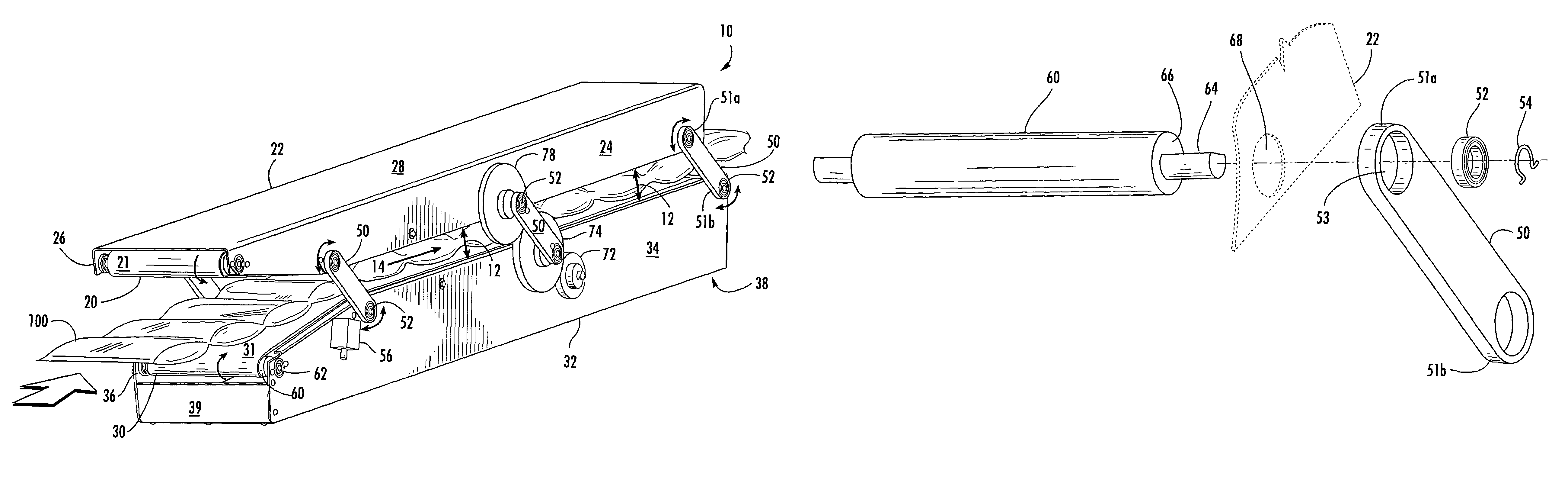

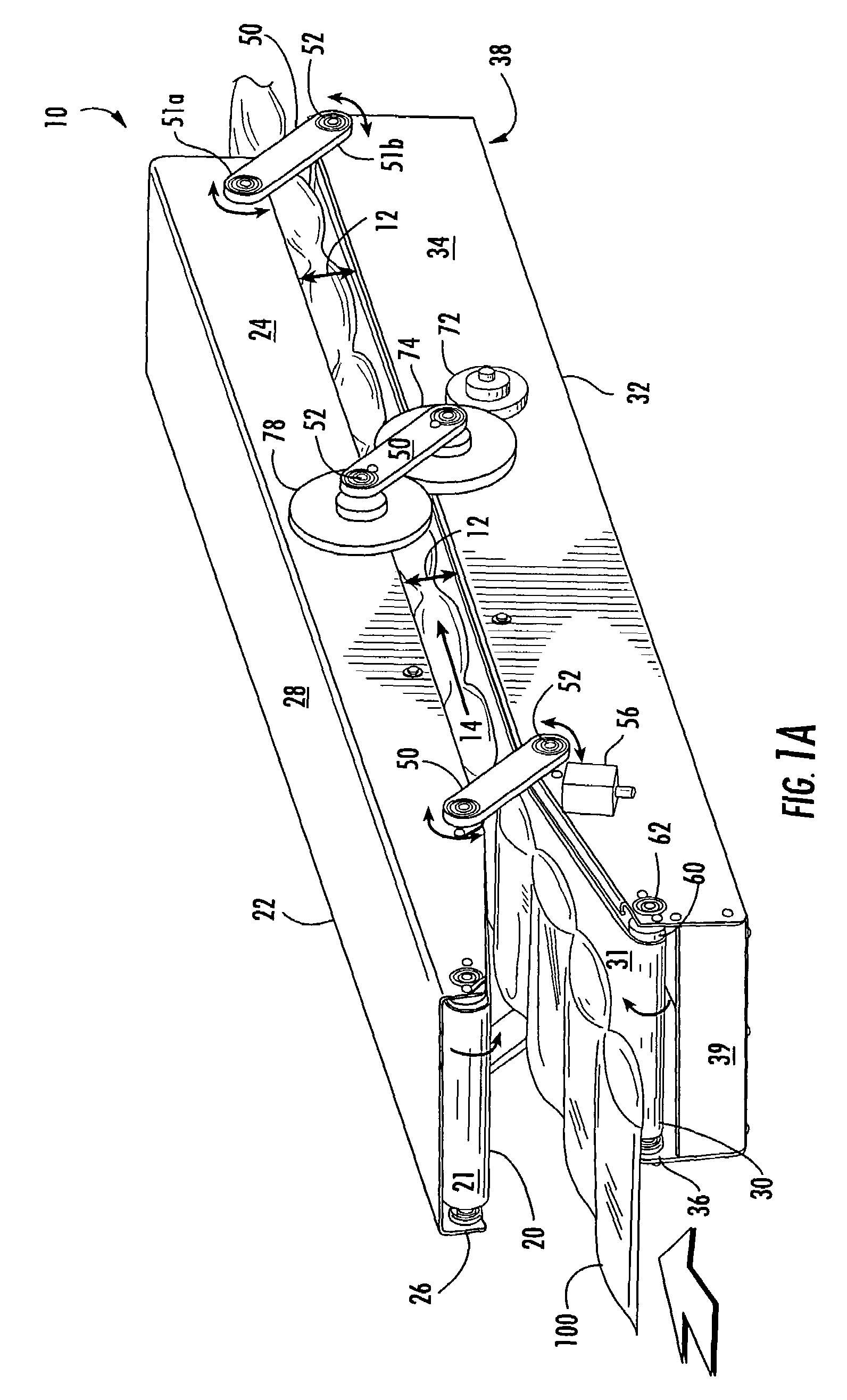

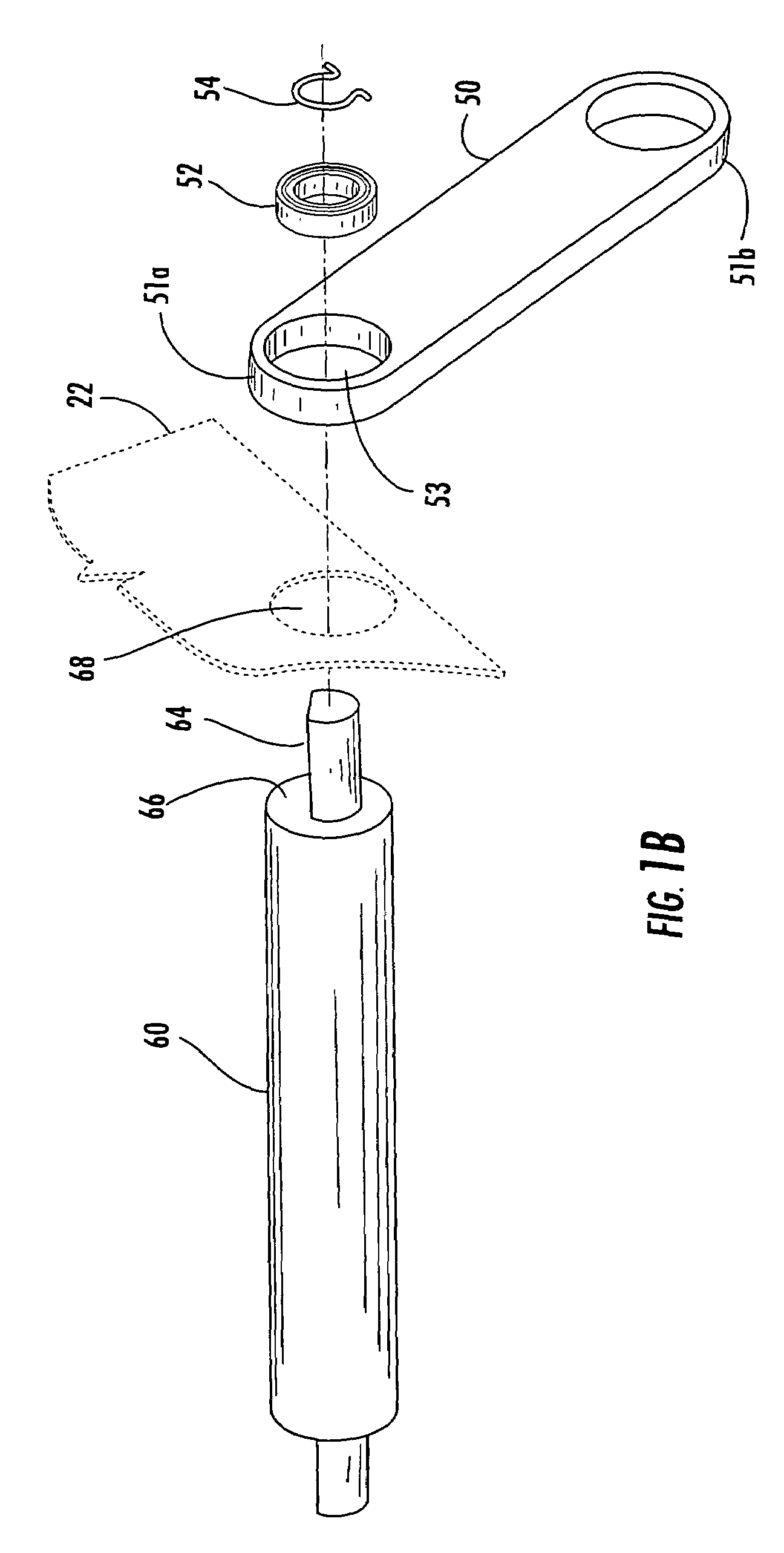

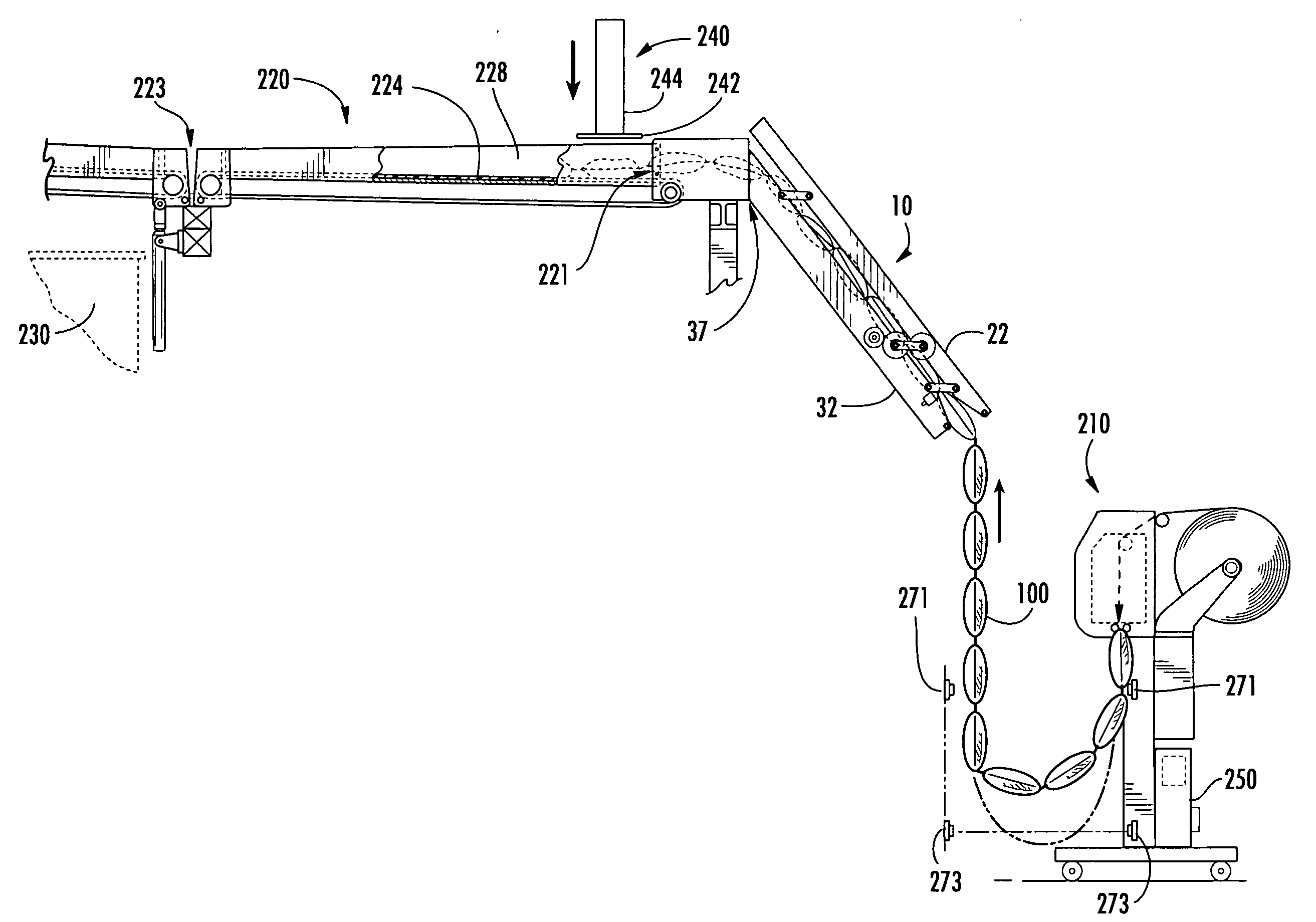

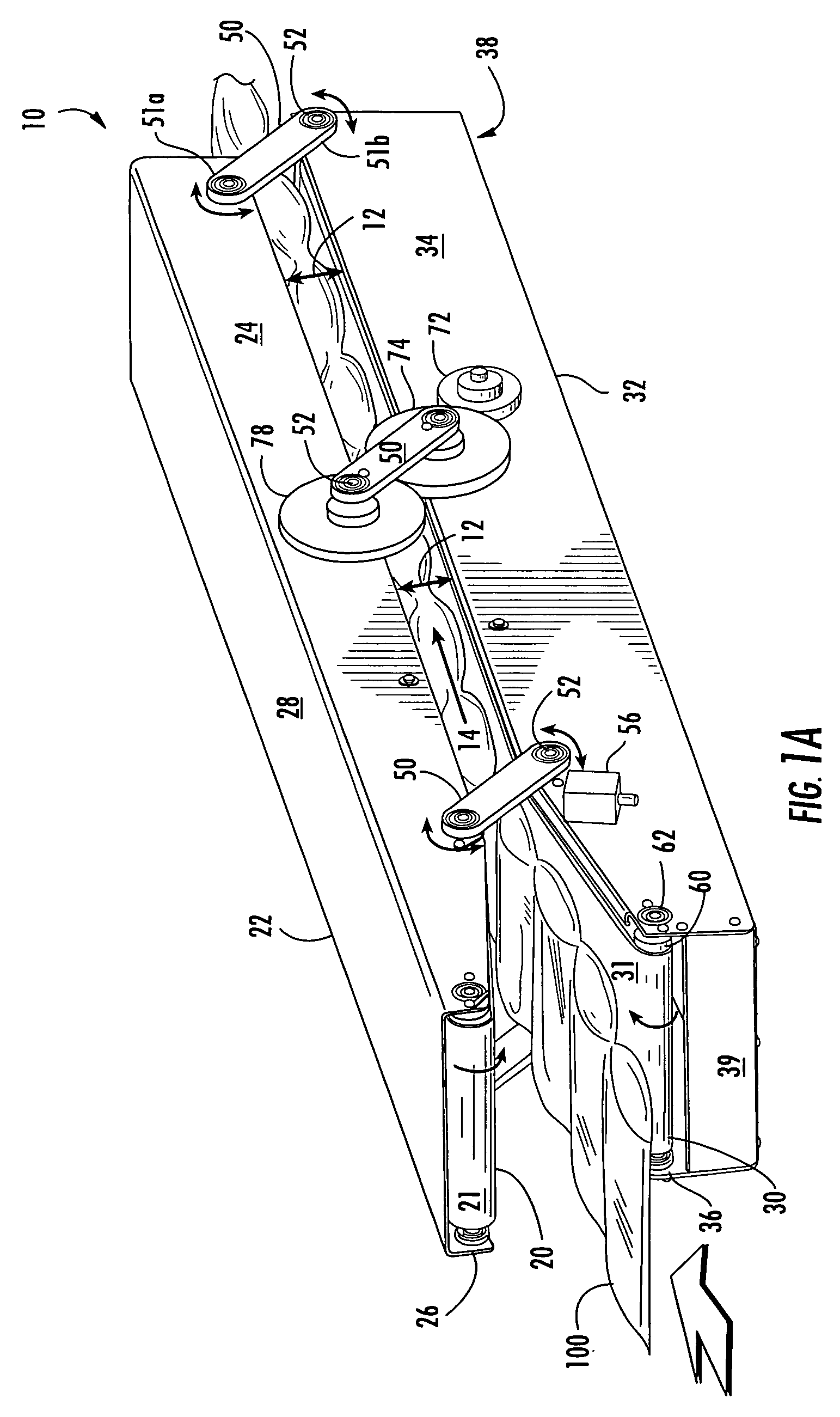

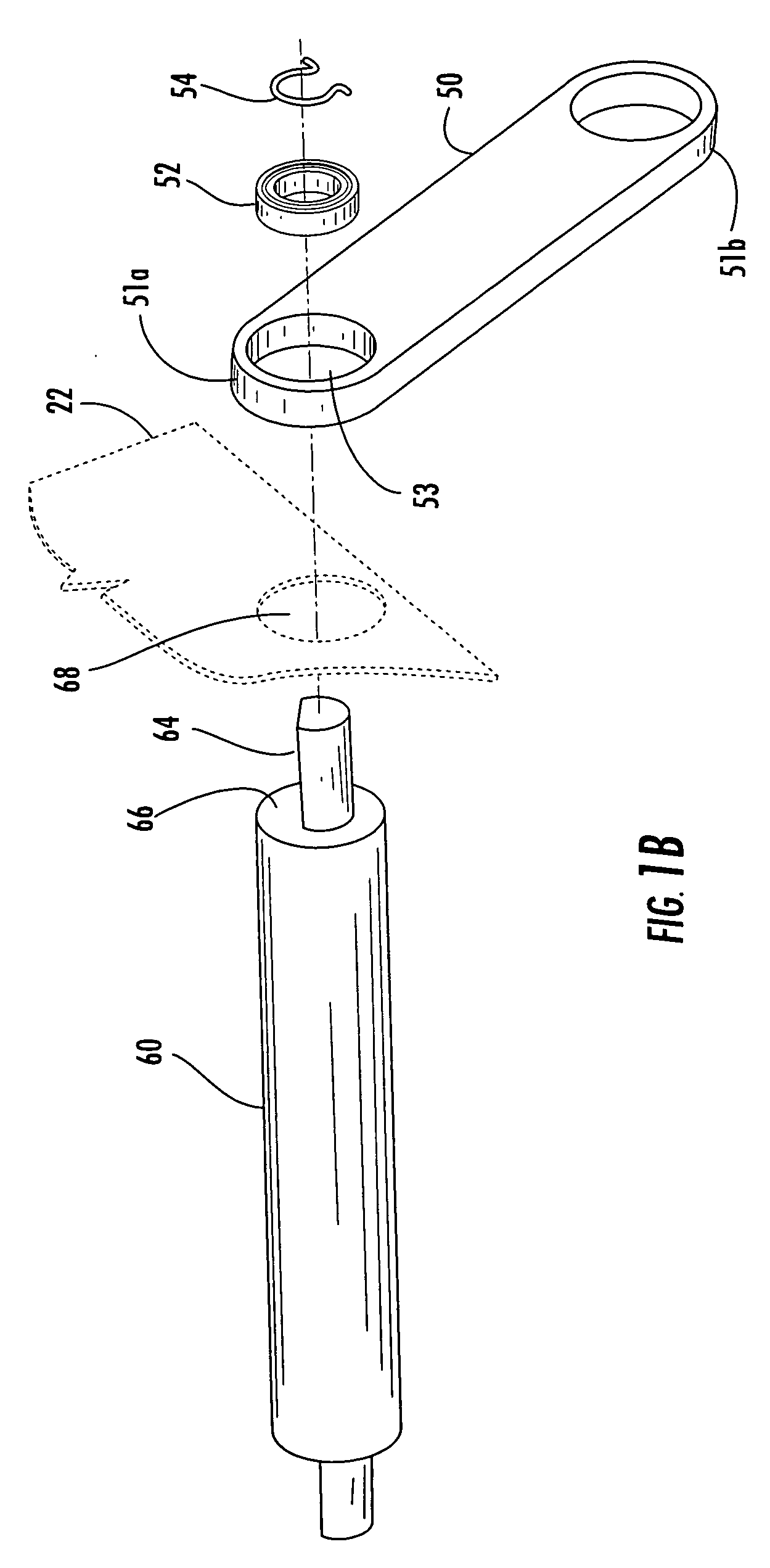

Apparatus and system for detecting under-filled cushions

InactiveUS7231749B2Reduce the overall heightPrecise processCapsFluid-tightness measurement by detecting dimension changeCushionLeather belt

Owner:SEALED AIR U S

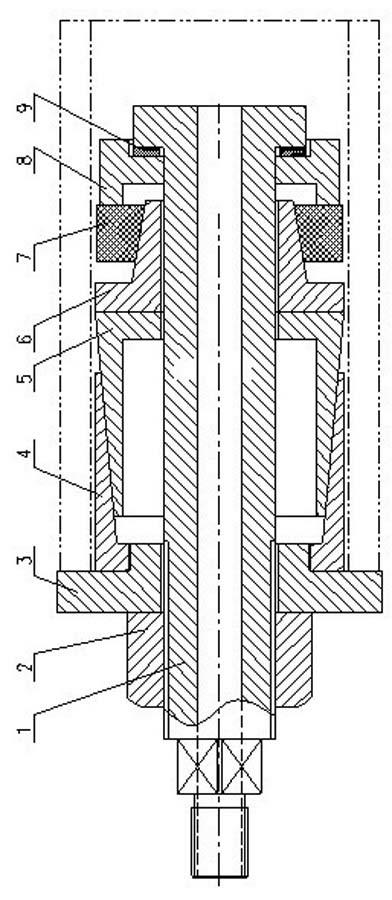

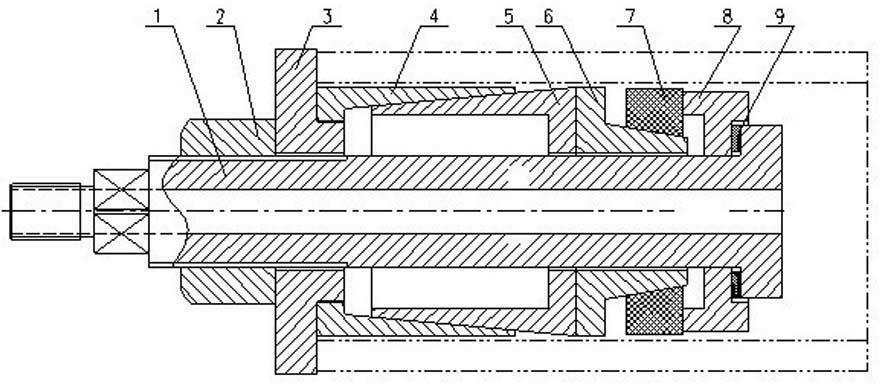

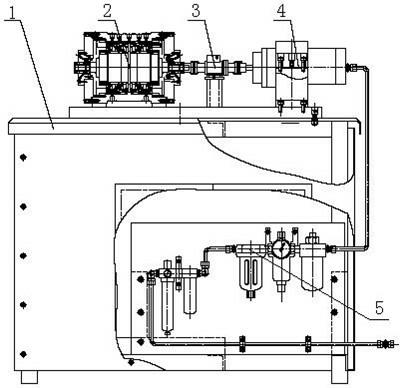

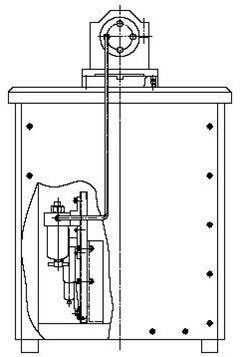

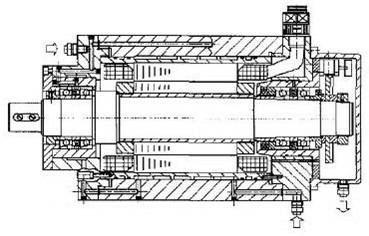

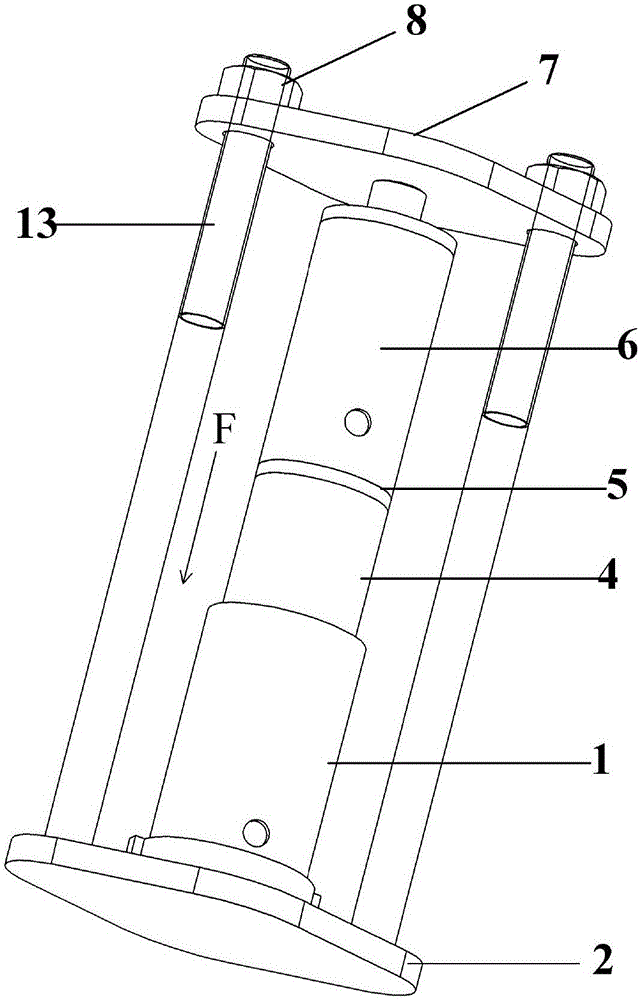

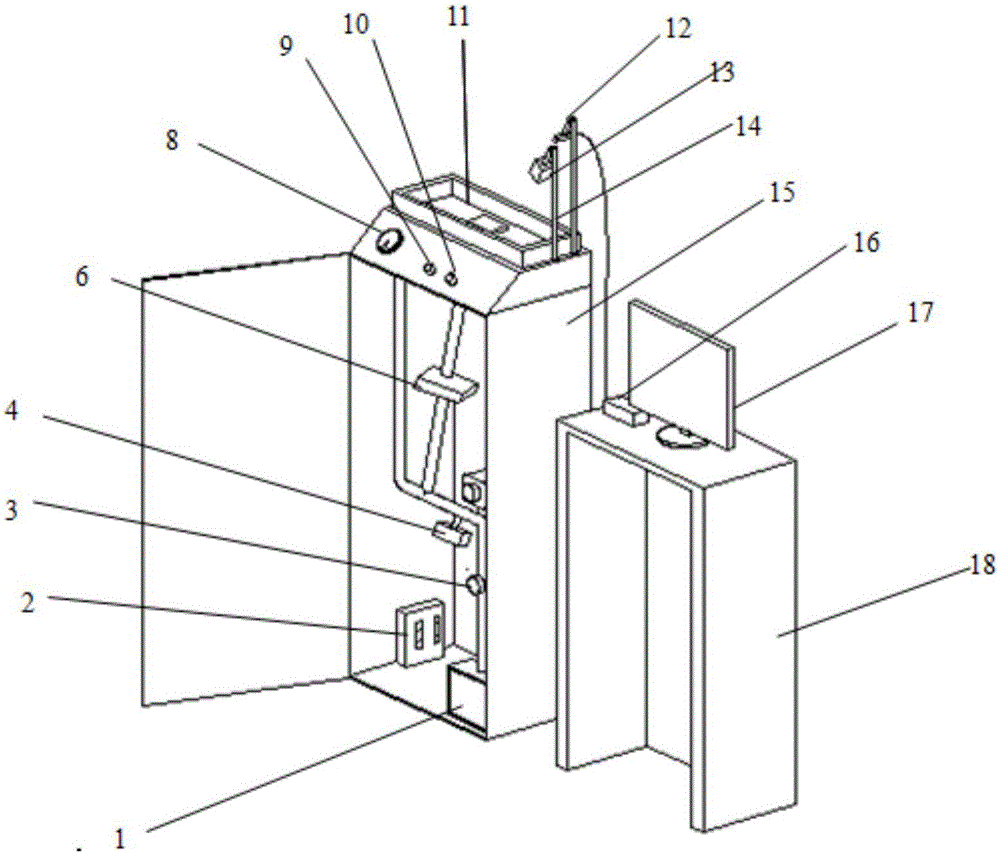

Contact high-speed mechanical seal testing device

InactiveCN102680175AIncrease test difficultyShorten the test cycleMeasurement of fluid loss/gain rateFluid-tightness measurement by detecting dimension changeElectricityContact high

The invention discloses a contact high-speed mechanical seal testing device which comprises a bench, a main test chamber, a high-speed torque gauge coupler, a drive motorized spindle, and a cooling and lubricating liquid supply system, wherein the main test chamber, the high-speed torque gauge coupler and the drive motorized spindle are mounted on the bench; the cooling and lubricating liquid supply system is mounted in the bench; the main test chamber and the drive motorized spindle are connected through the high-speed torque gauge coupler; and the drive motorized spindle is connected with the cooling and lubricating liquid supply system. The contact high-speed mechanical seal testing device can perform rotational speed and pressure tests within a greater range, tests performance of mechanical seal at a superspeed, increases mechanical seal test difficulty, and shortens cycles of tests and research and development.

Owner:DALIAN HUAYANG SEALS

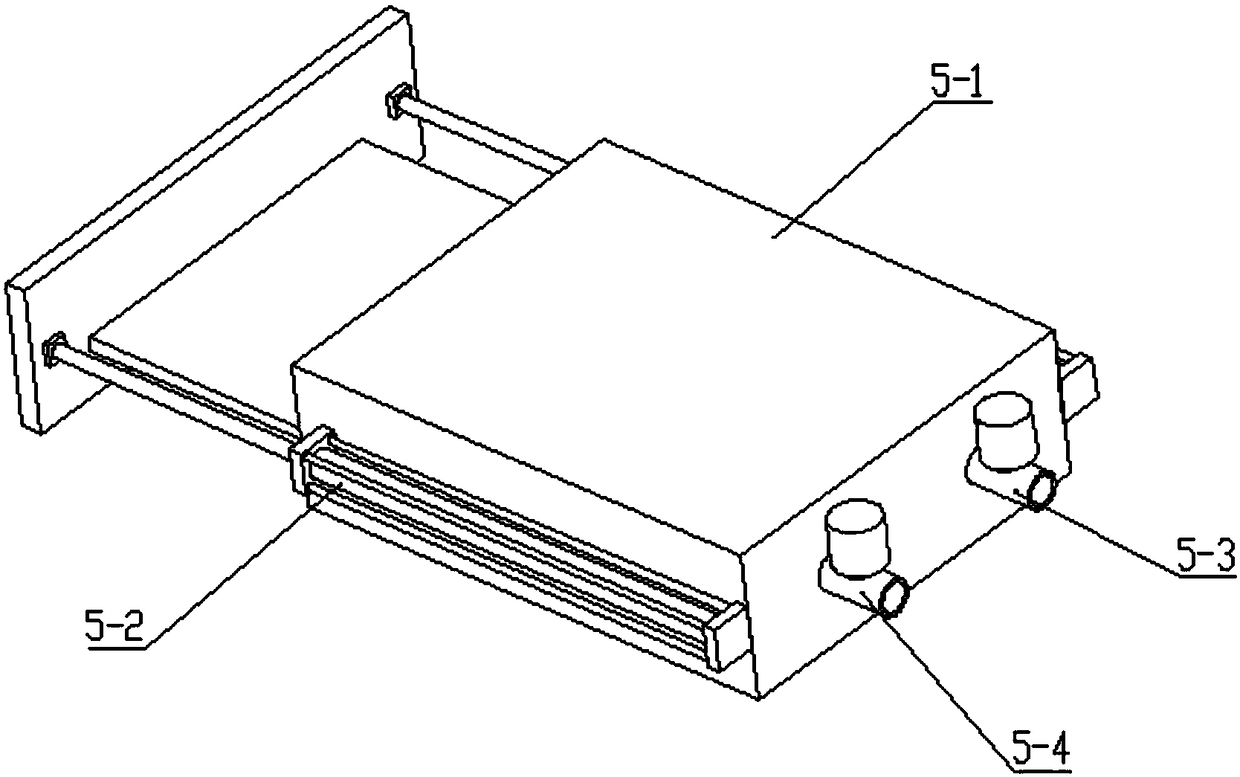

Sealing online detection system for small size flexible packaging bag

PendingCN109506858ARealize leak detectionMeet the testing requirementsFluid-tightness measurement by detecting dimension changeMaterial analysisControl systemEngineering

The invention discloses a sealing online detection system for a small size flexible packaging bag. The system comprises a first, second and third conveyor belts respectively used for conveying a packaging bag to be inspected, a packaging bag to be inspected placed in an array and a qualified packaging bag, a first and second gripping mechanisms of a mechanical arm with a machine vision system, a sealed compartment, a frame, an air pressure source for vacuuming or pressurizing the sealed compartment and a controller; the sealed compartment is composed of a drawer-shaped compartment body, an aircylinder driving the compartment body, an air pressure sensor for measuring the air pressure in the compartment body, first and second air valves, a light source and a camera and is mounted on the frame, and a closed container is formed when the compartment body and the first and second air valves are closed; when the compartment body is closed, the first air valve connected to the air pressure source controls the connecting and the disconnecting of the air pressure source, and the second air valve controls the connecting and disconnecting of the compartment body with the atmosphere; a camerais used for photographing the packaging bag in the compartment; the controller detects an air pressure value and the setting of a pressing protecting time and the processing and display of the data,and controls the system to achieve the automatic detection of the packaging bag. The system automatically performs the sealing inspection of the packaging bag on a production packaging line, and has high detection efficiency and automation.

Owner:福建好日子食品有限公司

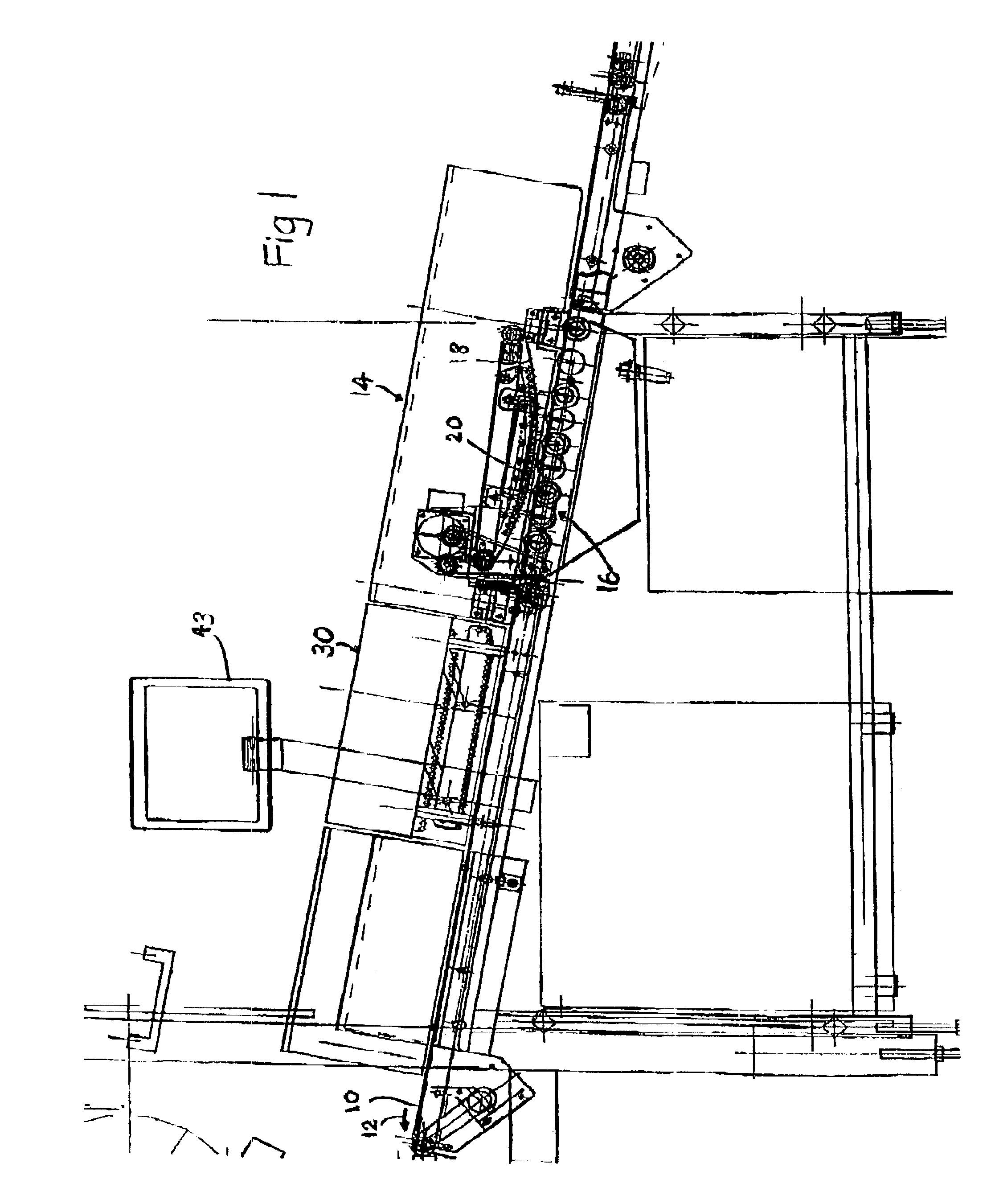

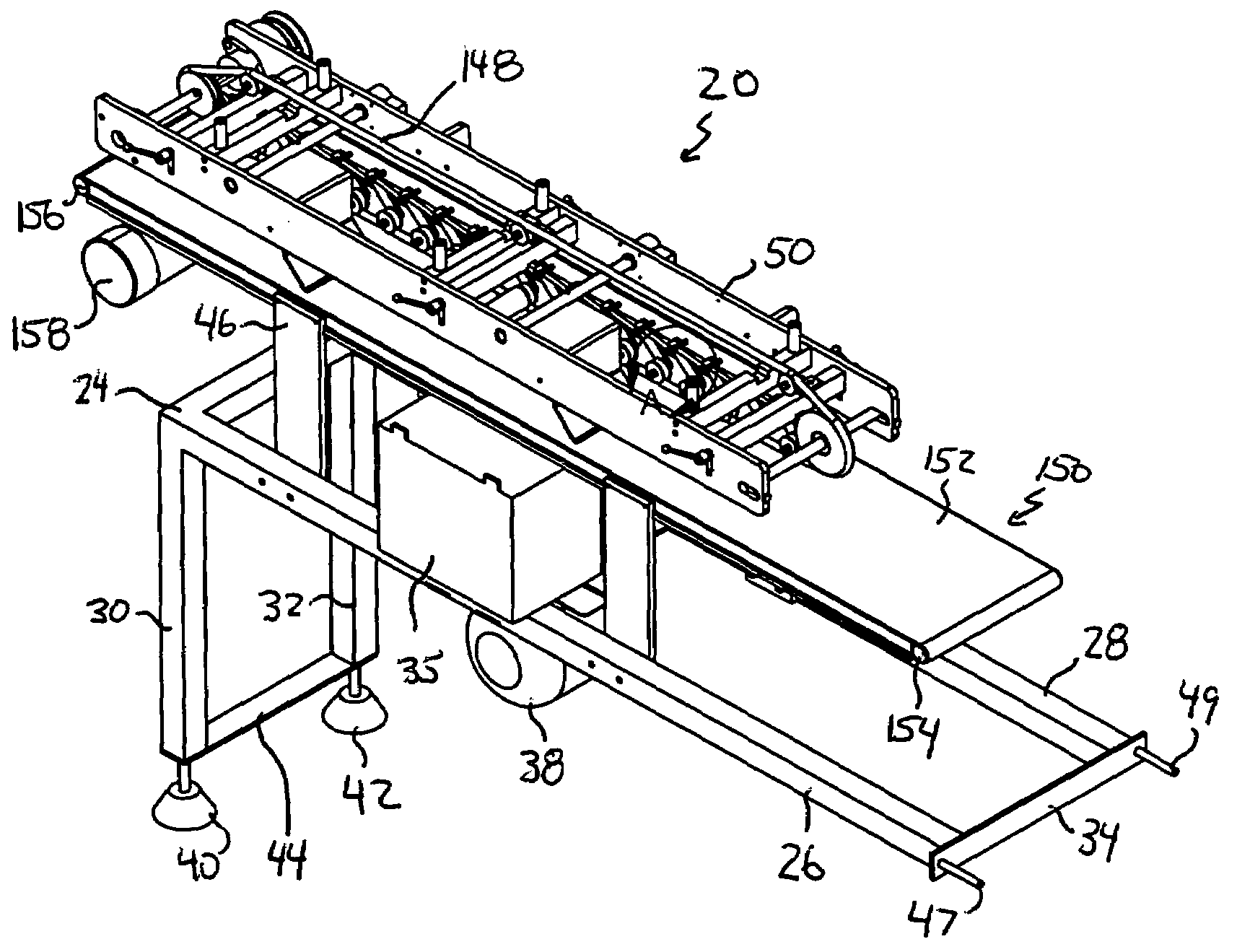

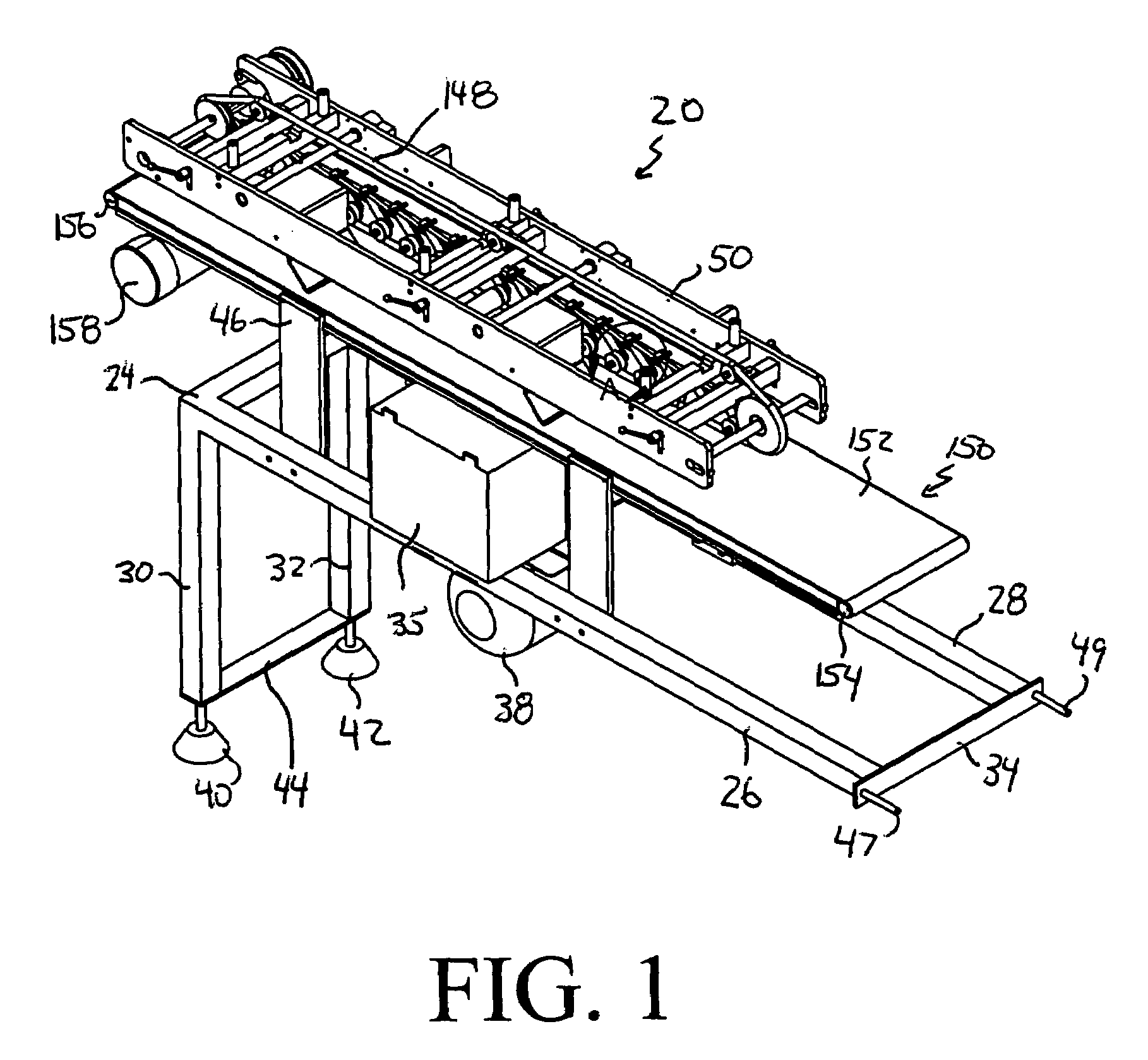

Apparatus and system for detecting under-filled cushions

InactiveUS20060042190A1Reduce the overall heightPrecise processCapsFluid-tightness measurement by detecting dimension changeEngineeringCushion

The invention is an under-filled cushion detector that is capable of conveying a string of packaging cushions and detecting whether the string of packaging cushions may be under-filled. The detector includes an upper driven belt that is movably suspended above a lower belt. The belts cooperate together to define a longitudinal cushion pathway between the belts. The distance between the upper and lower belts may vary depending upon the thickness of the string of packaging cushions. If a string of under-filled cushions travels between the upper and lower belts, the upper belt can move downwardly in the direction of the lower belt. A switch stops the upper and lower belts if the height of the cushion pathway decreases below a predetermined threshold. The detector can be used in a system for manufacturing and transporting packaging cushions to a desired location.

Owner:SEALED AIR U S

Intelligent controlled sealing gasket

InactiveCN102080726AEngine sealsFluid-tightness measurement by detecting dimension changeEngineeringStress relaxation

The invention relates to an intelligent controlled sealing gasket. In the sealing gasket, the temperature, pressure and deformation of the gasket are measured by a sensor, the data is transmitted to a computer by the sensor, and the computer can know important performance parameters such as compressibility, resiliency and ratios of creep relaxation and stress relaxation at any time by analyzing the data, so that the sealing gasket is in the monitoring state at any time to make the conclusion whether the design requirement is met or not, and can predict what kind of leakage states the gasket lies and whether the design requirement still can be met within a period of time in future or not by analysis.

Owner:NINGBO TIANSHENG SEALING PACKING

Sealing ring sealing performance detection apparatus

PendingCN106644318AGuaranteed pressureGuaranteed reliabilityFluid-tightness measurement by detecting dimension changeMaterial strength using tensile/compressive forcesHigh pressureMechanical engineering

Owner:TIANDING SEALING TECH BEIJING CO LTD

Package seal inspecting apparatus, and method for inspecting package seals

InactiveUS7107823B1Improve versatilityDetection of fluid at leakage pointMeasurement of fluid loss/gain rateSize measurementProcess engineering

A package inspection apparatus is provided, and includes a conveyor for transporting a package, a pressure unit for applying a compressive force to the package, a tracer movable over the upper surface of the package for measuring package attributes along a dimension of the package, and a processor. According to some embodiments, the processor determines a trace area of the package from the package measurement attributes. According to certain embodiments, the measured package attributes are compared to a running average, and if the package is within predetermined tolerances, the package measurement attributes are averaged into the running average. Also provided is a related method.

Owner:CPOR

Detecting system for sealing property of aluminum foil blister package

ActiveCN105910777AFully automatedAutomation hasFluid-tightness measurement by detecting dimension changeOptical measurementsData treatment

The invention relates to a detecting system for sealing property of an aluminum foil blister package. The detecting system comprises a vacuum air path system, an optical measuring system and a data collecting processing system, wherein the vacuum air path system comprises a sealing cavity, a vacuum pump, a pressure-relieving valve, a reversing valve and a pressure sensor; the reversing valve is respectively connected with the sealing cavity, the vacuum pump and the pressure-relieving valve through the pipelines; the pressure sensor is also mounted on a pipeline which is directly communicated with the sealing cavity; the bottom in the sealing cavity is used for loading a to-be-detected aluminum plastic bubble cap; the top surface of the sealing cavity is provided with a window sealed with a transparent material; the optical measuring system comprises a light source, a light source controller, an image sensor and a bracket; the light source and the image sensor are mounted on the same side of the sealing cavity through the bracket; included angles between the irradiating direction of the light source as well as the shooting direction of the image sensor and the inner bottom of the sealing cavity are 45-60 degrees; the light source controller is connected with the light source and is used for controlling the luminance of the light source; a data processing system comprises a computer connected with the image sensor.

Owner:天津河北工业大学科技园发展有限公司

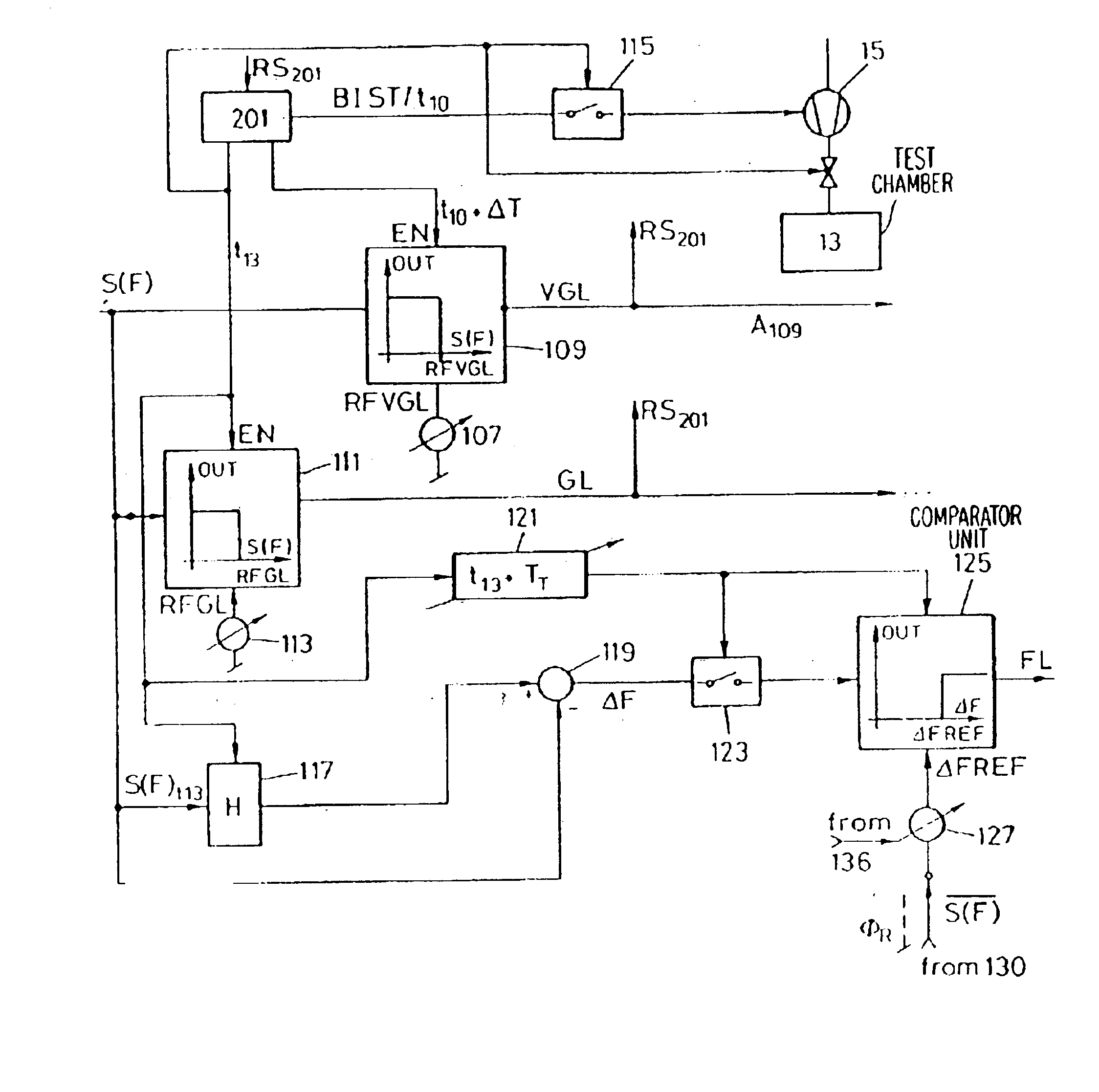

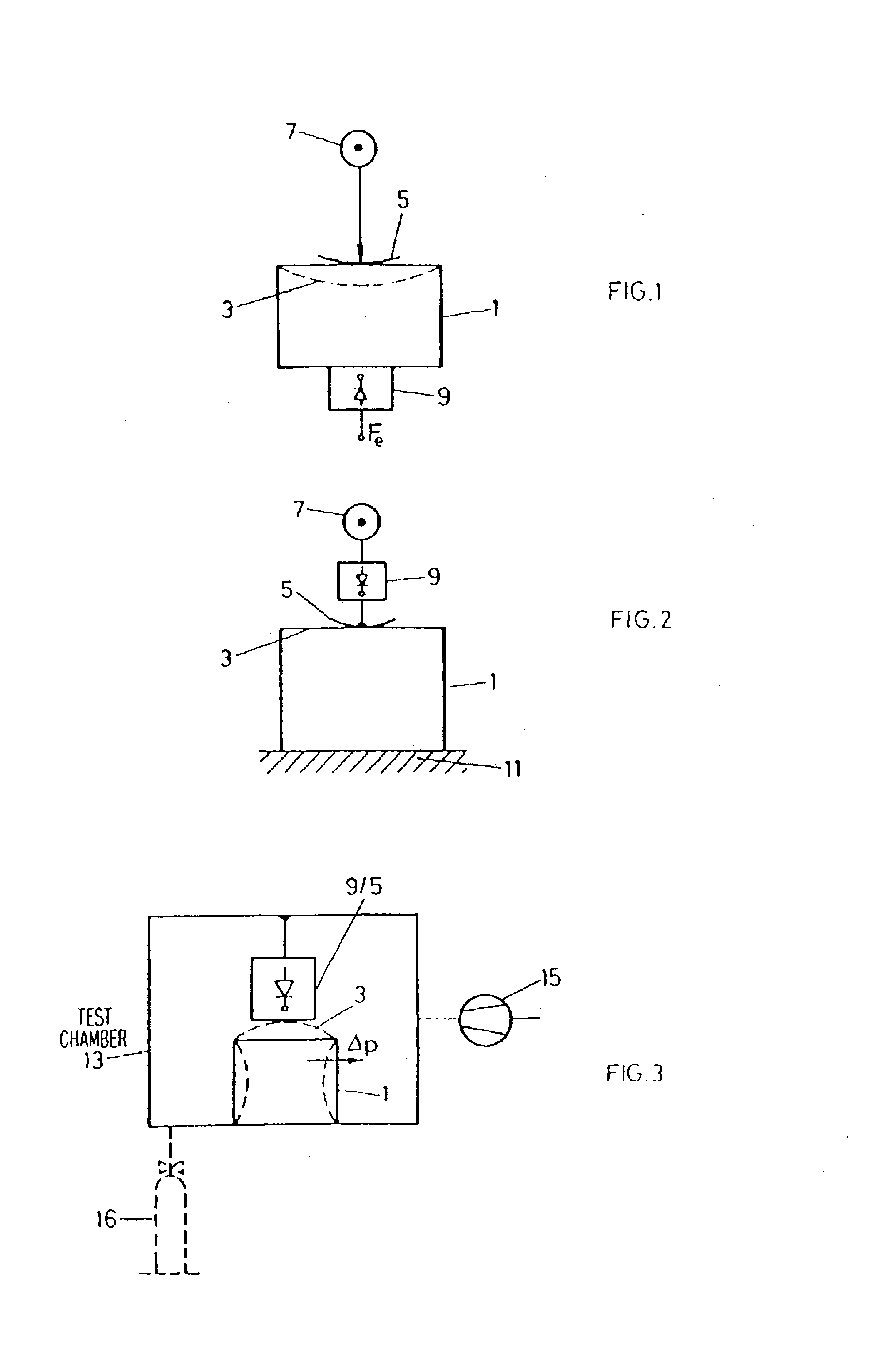

Method and apparatus for leak testing closed containers

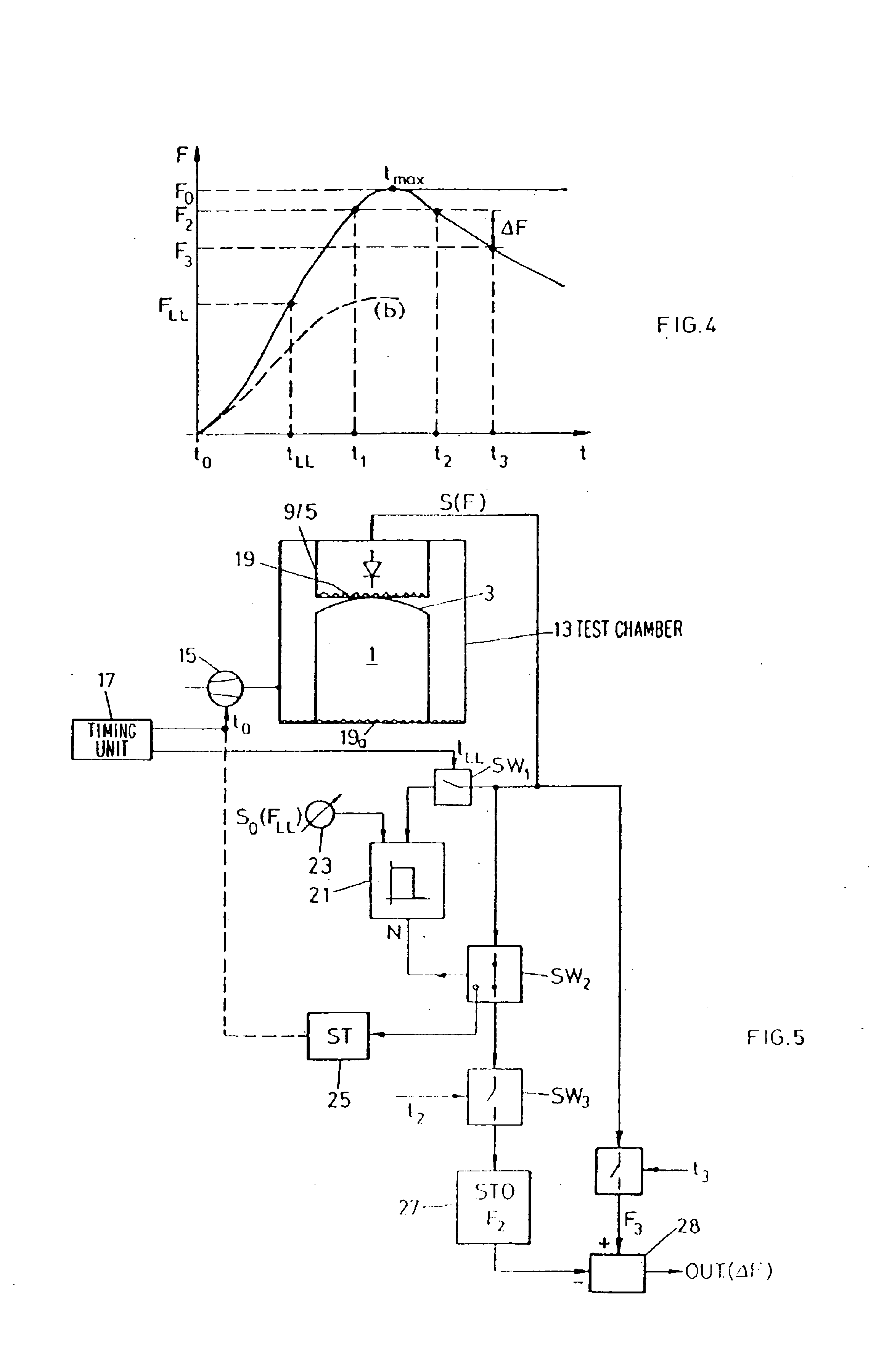

InactiveUS6840087B2Easy to monitorReduce reaction forceDetection of fluid at leakage pointMeasurement of fluid loss/gain rateElectricityDifferential signaling

Leak testing a closed container with at least one flexible wall area is performed with the method and apparatus wherein a biasing arrangement compresses or expands the container under test. A biasing force is monitored with a force detector applicable to the wall of the container. The force detector generates an electric output first biasing force signal at a first po9int in time which is stored for comparison with the monitored biasing force signal at a second subsequent point in time to generate a different signal as a leak indicative signal. A difference signal is generated at the first point in time from the first force measuring signal stored and the first force measuring signal. This latter difference signal is stored as a zero offset signal which is used to compensate zero offset of the generated difference signal.

Owner:WILCO AG

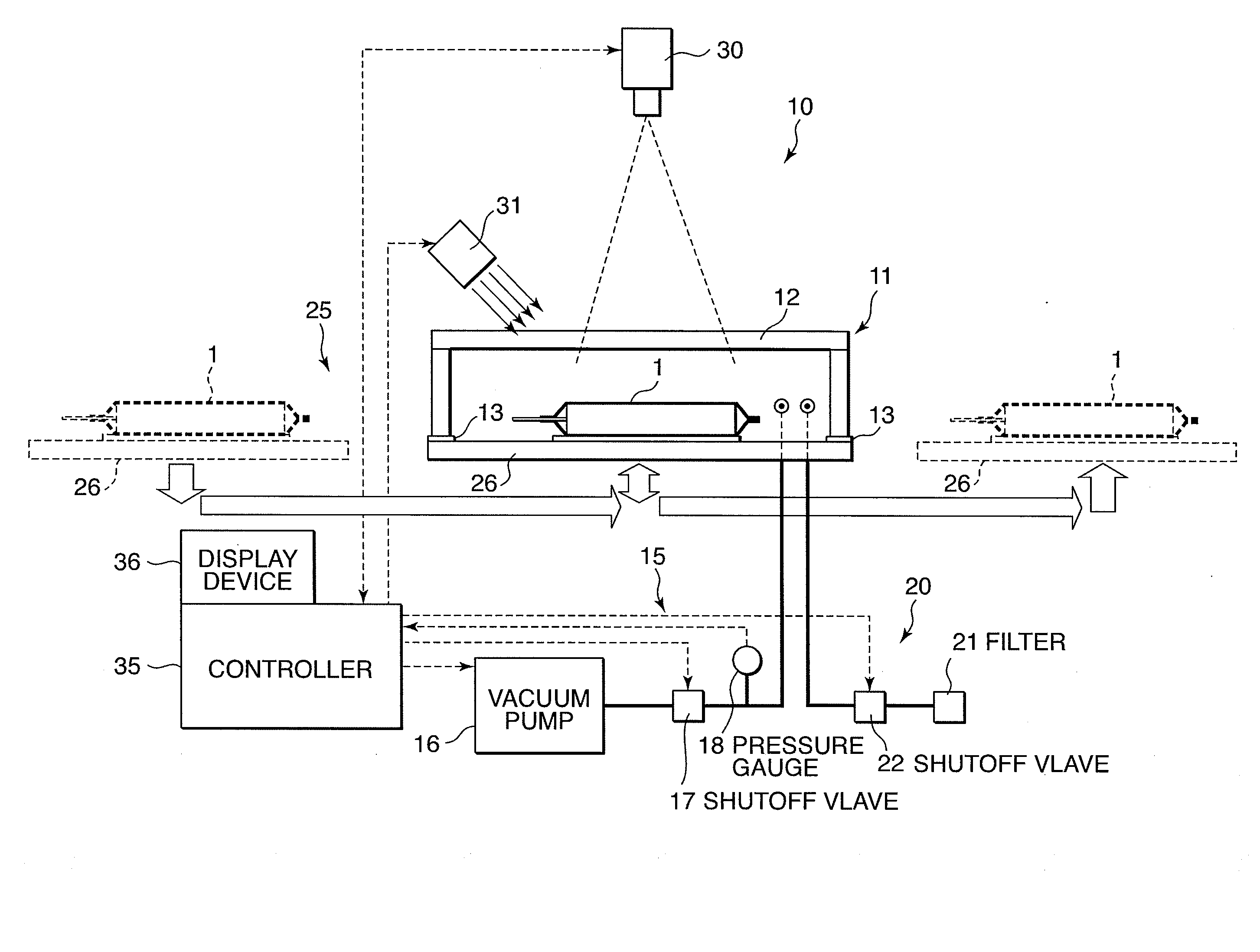

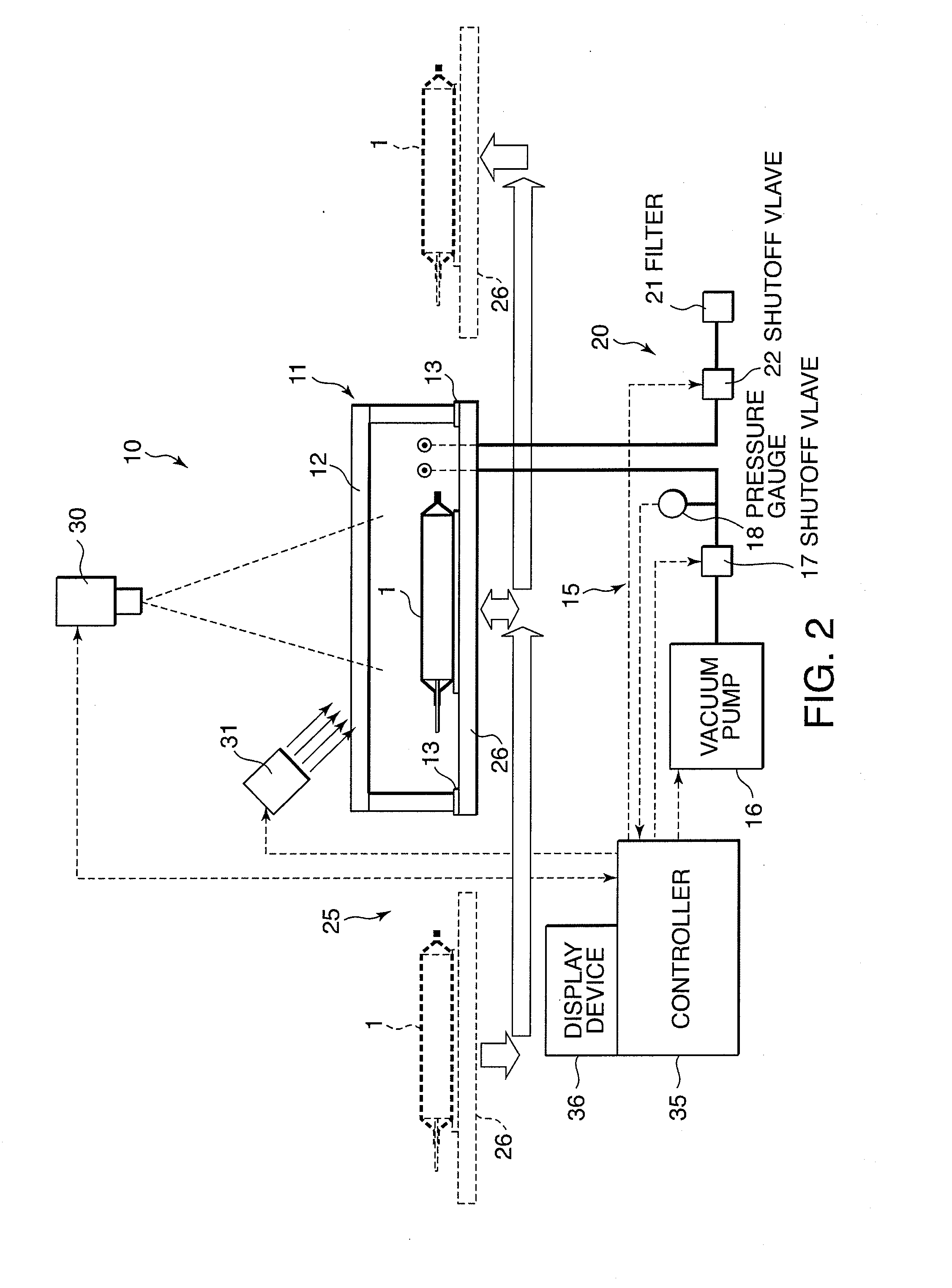

Airtightness inspection method and airtightness inspection apparatus for sealed battery

ActiveUS20130141571A1Improve accuracyInspection is accurateMeasurement of fluid loss/gain rateFluid-tightness measurement by detecting dimension changeEngineeringCcd camera

A soft packaged sealed battery is contained in an airtight container. The airtight container is decompressed and images of the surface shape of the sealed battery in the airtight container before and after decompression are captured by a CCD camera or the like. Whether or not airtightness of the sealed battery is maintained is determined based on a change in the captured images, e.g. a change in the surface shape appearing as luminance differences of pixels. By this determination method, highly accurate airtightness determination is realized by eliminating the influence of invisible fine creases on a sealed battery surface.

Owner:ENVISION AESC JAPAN LTD

Packing bag leakage detection device and method

InactiveCN105712070ARemove in timeSmall footprintFluid-tightness measurement by detecting dimension changeControl devices for conveyorsEngineeringConveyor belt

Packaging bag leakage detection equipment, the entire equipment is supported by a support frame, and also includes a conveyor belt, a rejection mechanism, and a detection mechanism. The conveyor belt, the rejection mechanism, and the detection mechanism are respectively connected by computer control, and the detection mechanism and the rejection mechanism are connected by the conveyor belt. The detection mechanism also includes a vacuum pump and a sensor connected to it. The invention can quickly and accurately detect the leakage of the packaging bags, and promptly remove unqualified packaging bags; the device of the invention occupies less space, has high detection accuracy and high detection efficiency.

Owner:SHANDONG MINGJIA TECH

Case packer

ActiveUS20110023422A1Measurement of fluid loss/gain rateFluid-tightness measurement by detecting dimension changeMechanical engineeringControl unit

A case packer is adapted to convey a plurality of packages and to pack the plurality of conveyed packages in a box. The case packer includes a first conveying unit, a detector, a second conveying unit and a control unit. The first conveying unit is configured and arranged to convey the packages. The detector is configured and arranged to detect a thickness of at least one of the packages. The second conveying unit includes an accumulating portion where the packages are accumulated with the packages being partially overlaid on one another. The second conveying unit is configured and arranged to convey the packages overlaid in the accumulating portion. The control unit is configured to adjust operation of the second conveying unit based on a detected value from the detector.

Owner:ISHIDA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com