Patents

Literature

2019 results about "Test probe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A test probe is a physical device used to connect electronic test equipment to a device under test (DUT). Test probes range from very simple, robust devices to complex probes that are sophisticated, expensive, and fragile. Specific types include test prods, oscilloscope probes and current probes. A test probe is often supplied as a test lead, which includes the probe, cable and terminating connector.

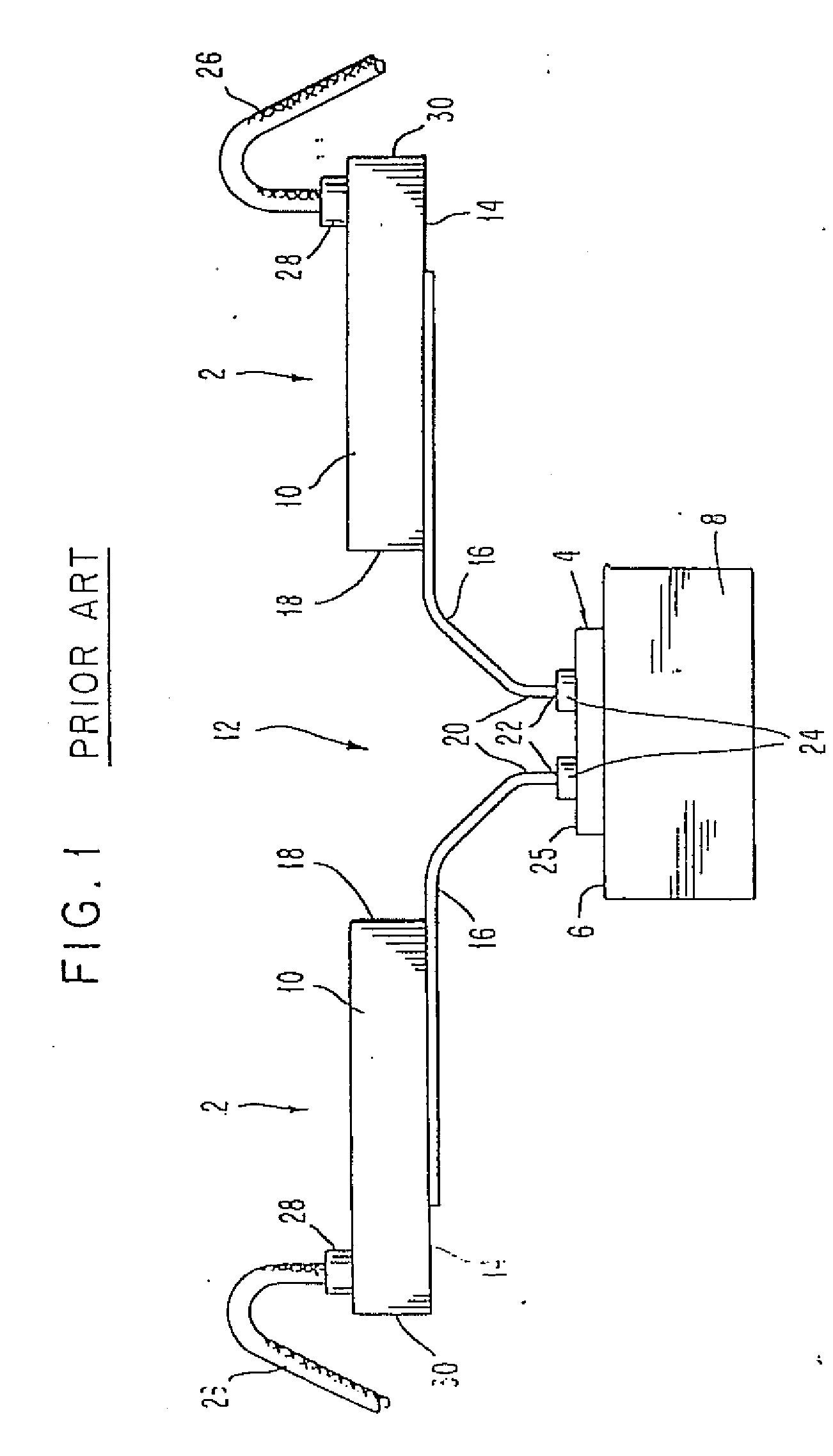

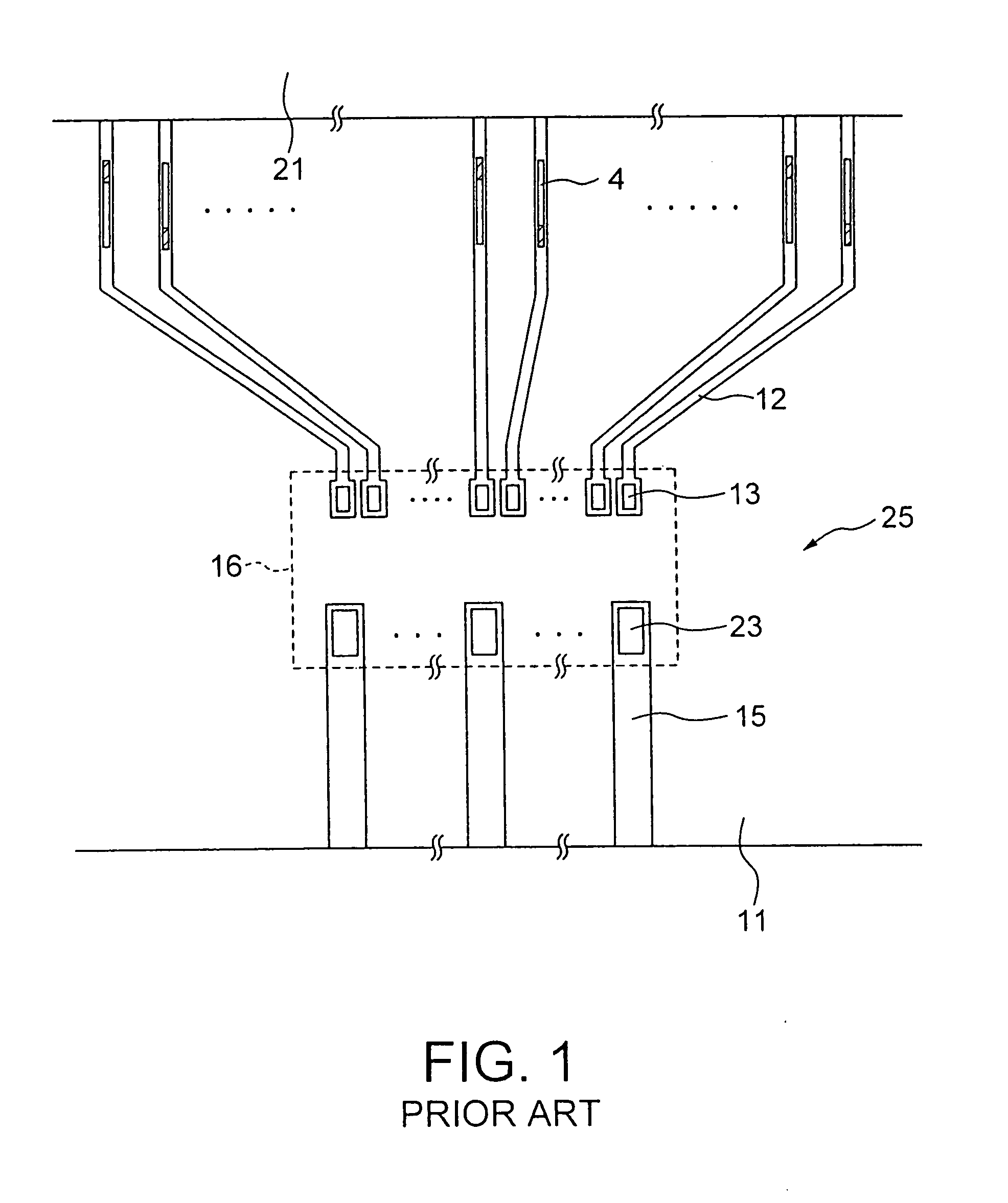

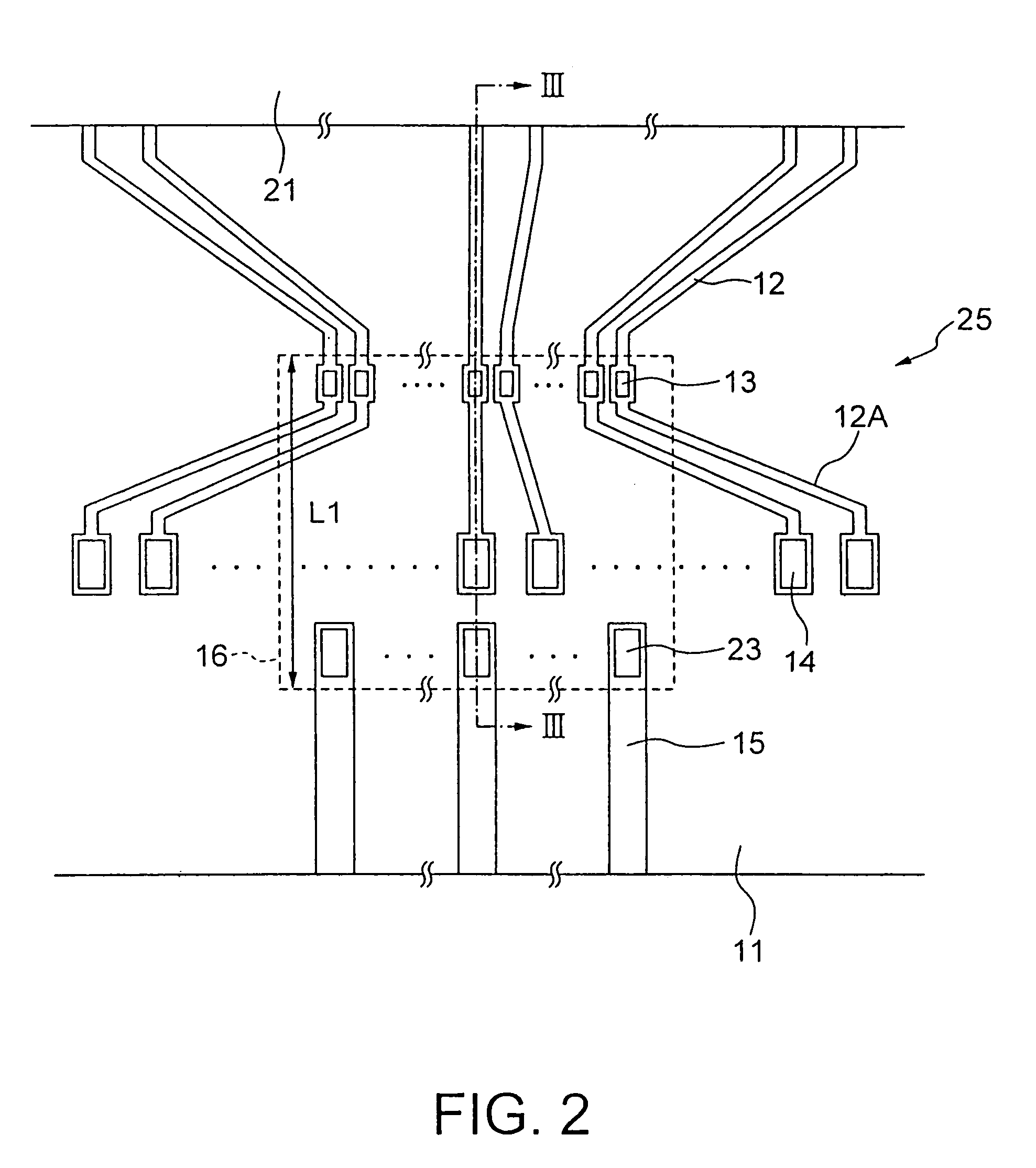

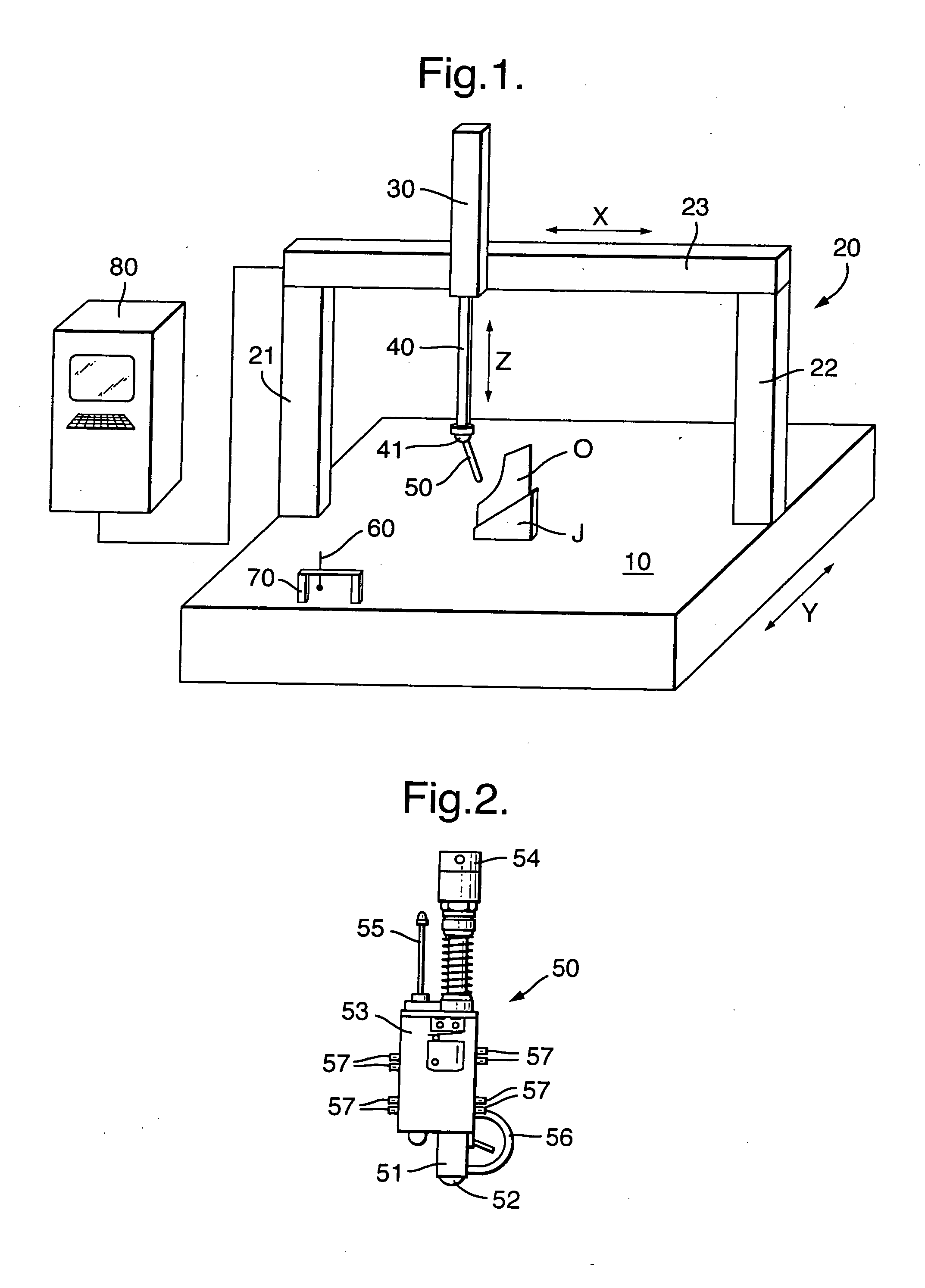

Apparatus and method for the testing of circuit boards, and test probe for this apparatus and this method

InactiveUS7015711B2Improve reliabilityLess calibration timeMeasurement leads/probesPrinted circuit testingTest probeTest point

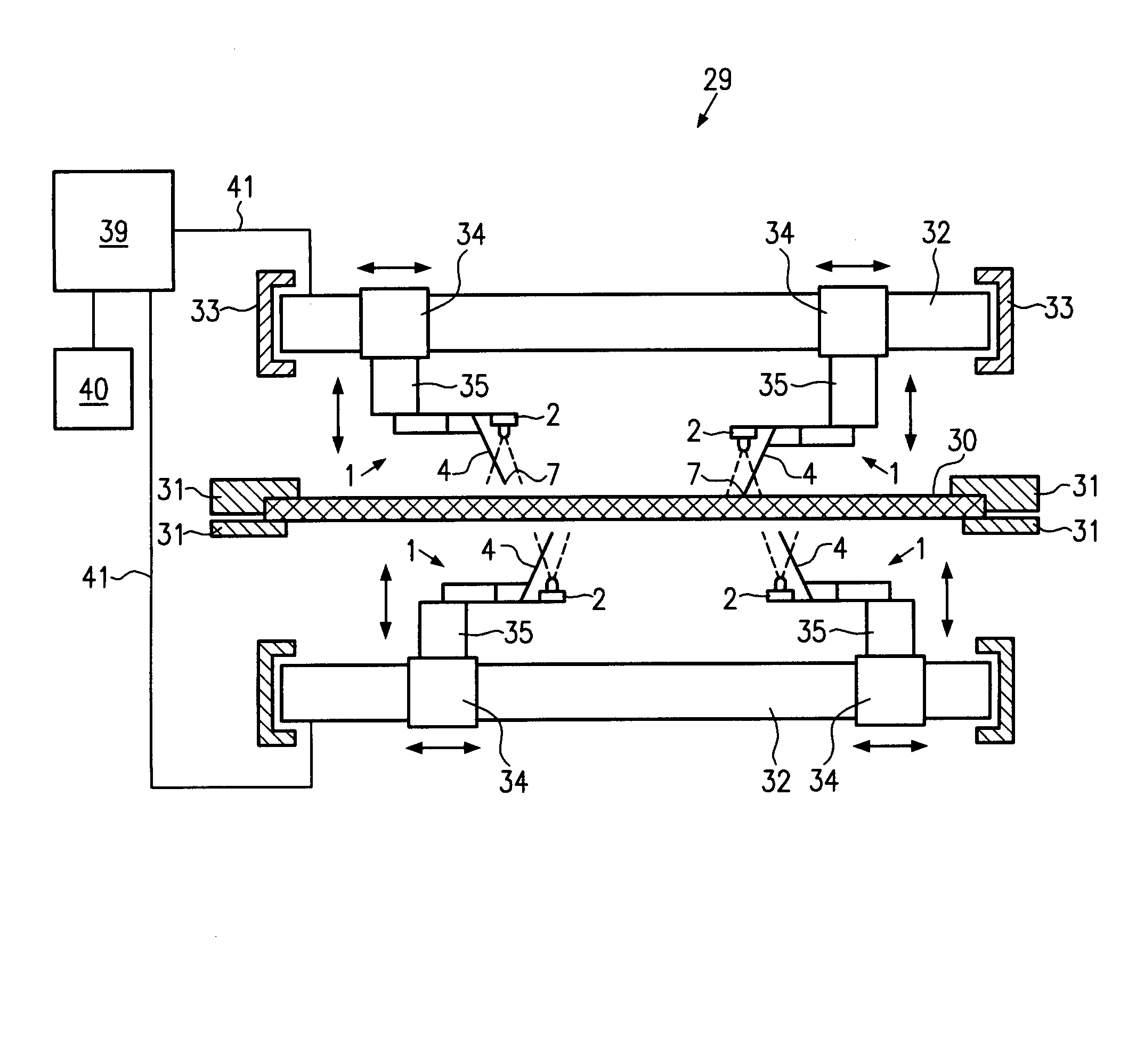

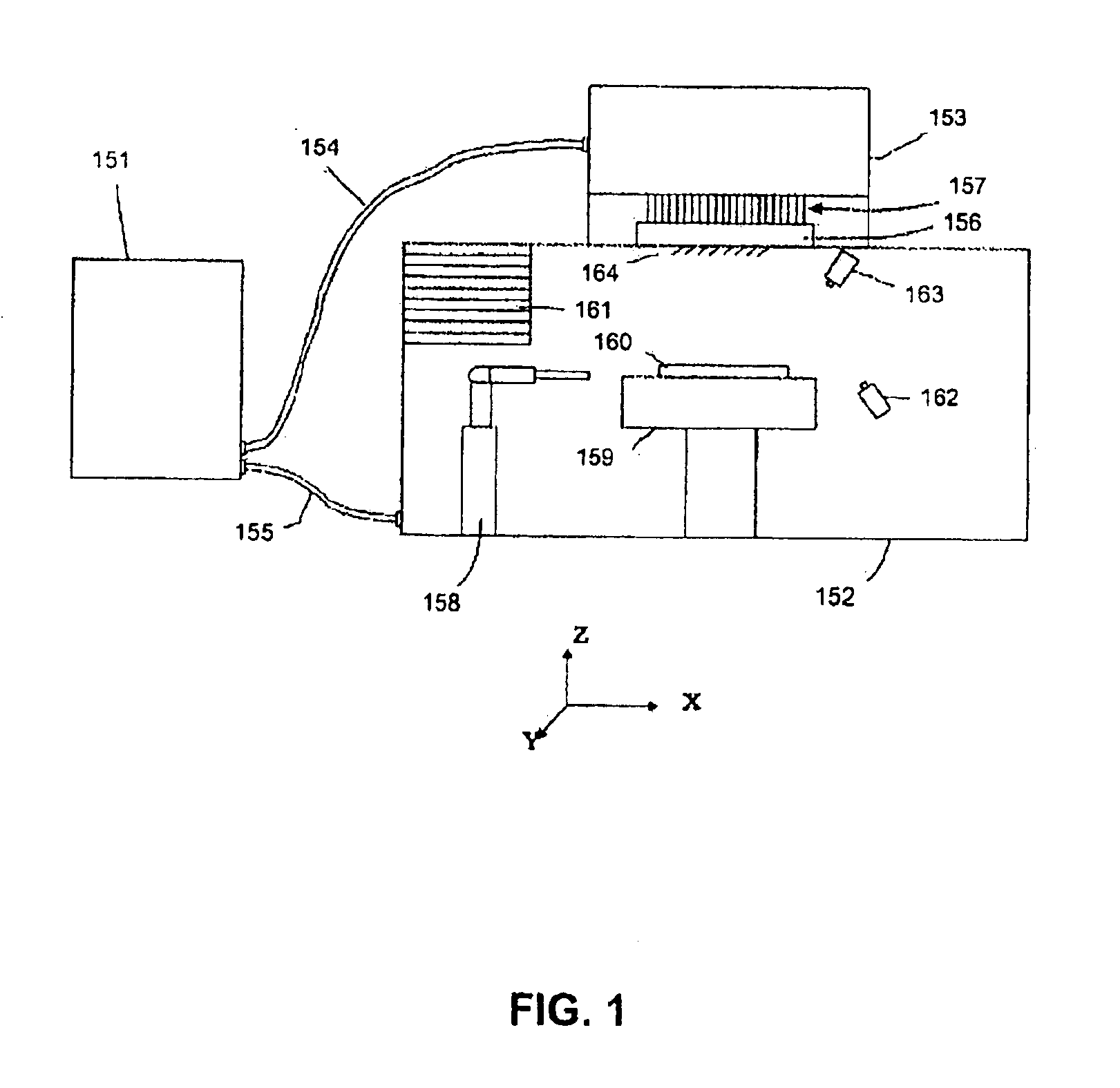

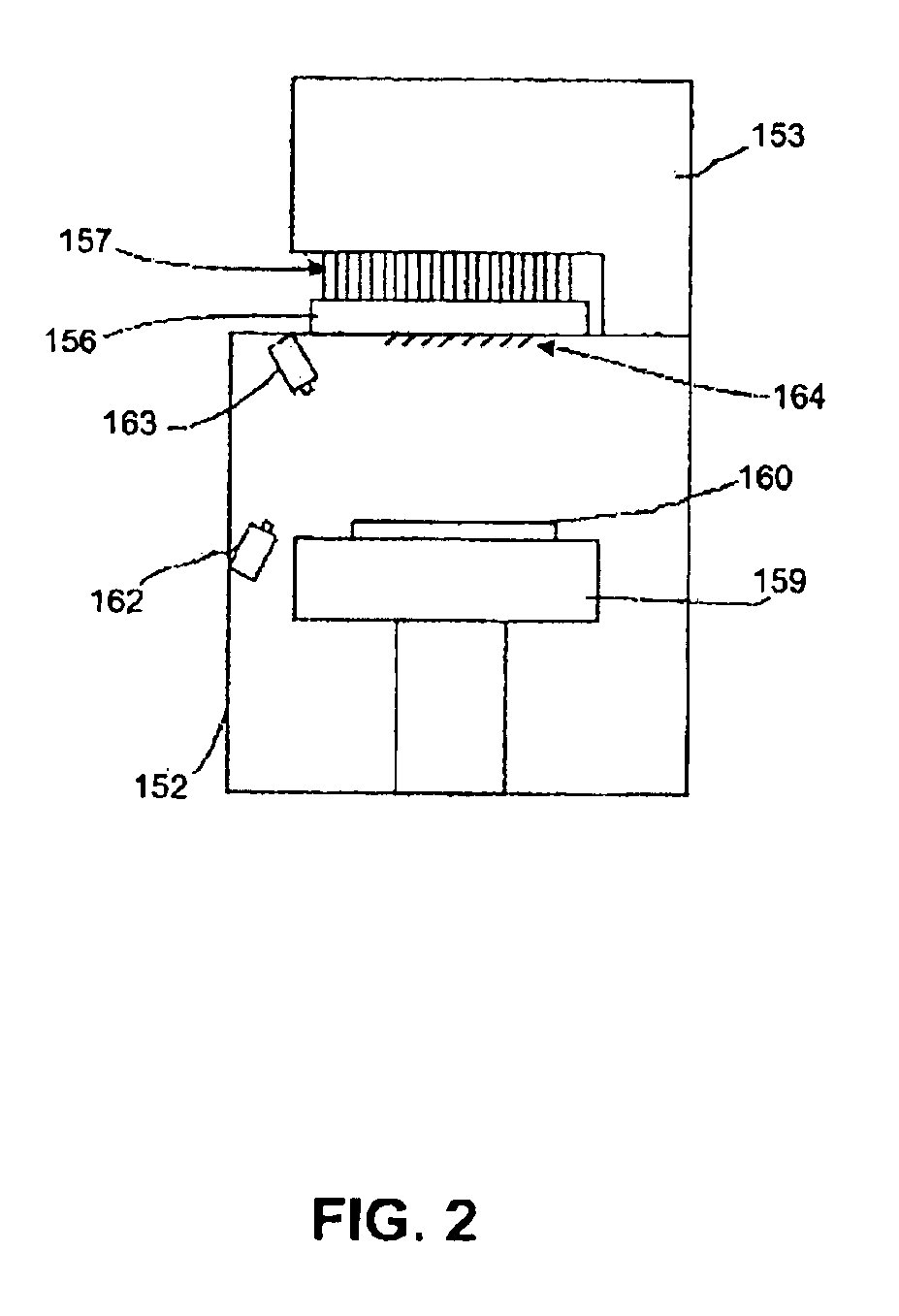

An apparatus and a method for the testing of circuit boards, together with a test probe for this apparatus and this method, in which the contact tips of a test finger of a finger tester are monitored during the testing process by an optical detection device and their movement, at least when approaching a part of the circuit board test points of a circuit board to be tested, is corrected on the basis of the result determined by the optical detection device in such a way that the contact tip makes reliable contact with the circuit board test point concerned. The correction data hereby obtained may be used in the calculation of calibration data.

Owner:ATG TEST SYST

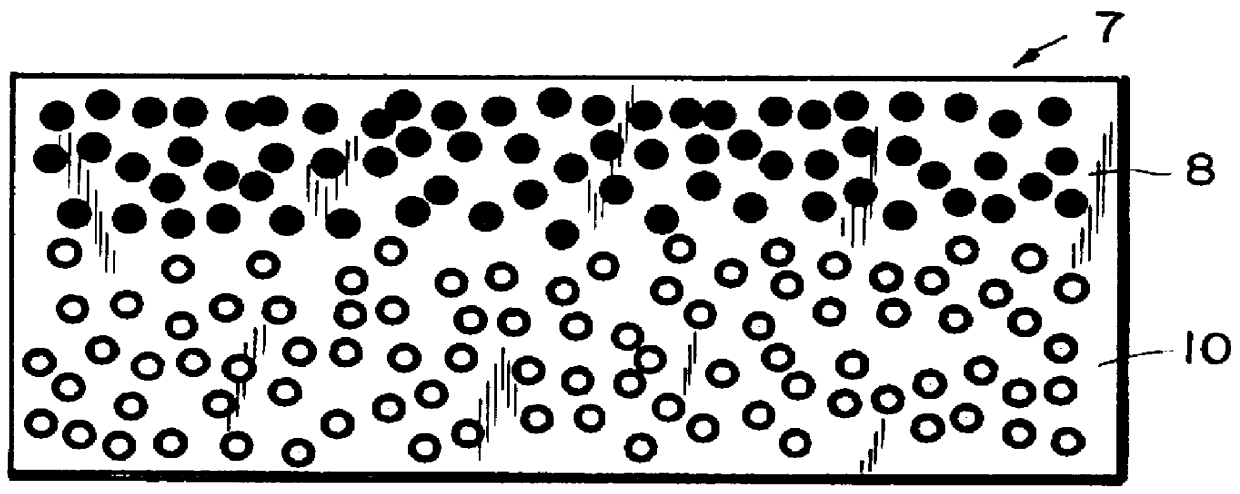

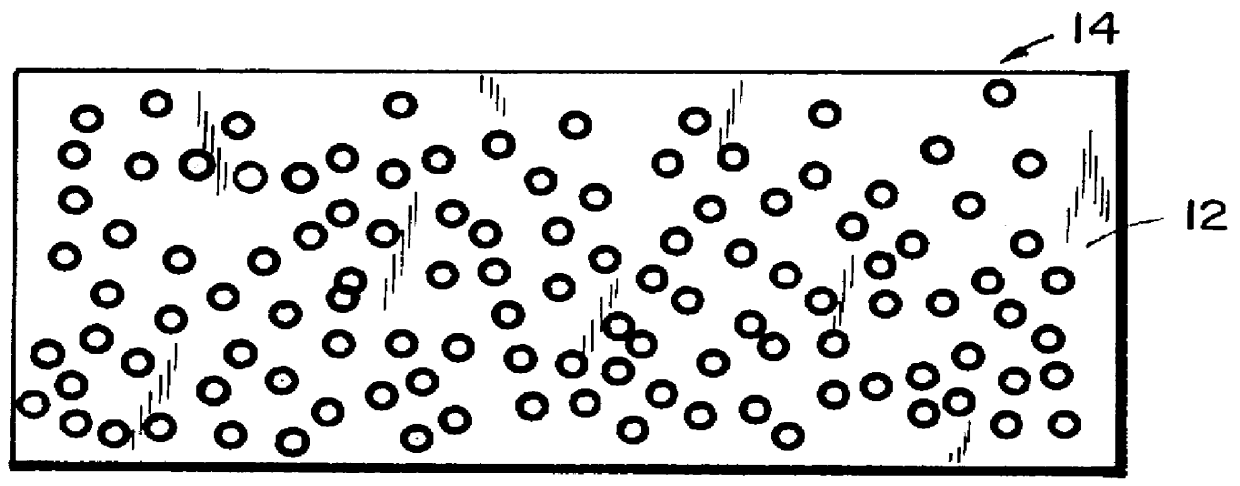

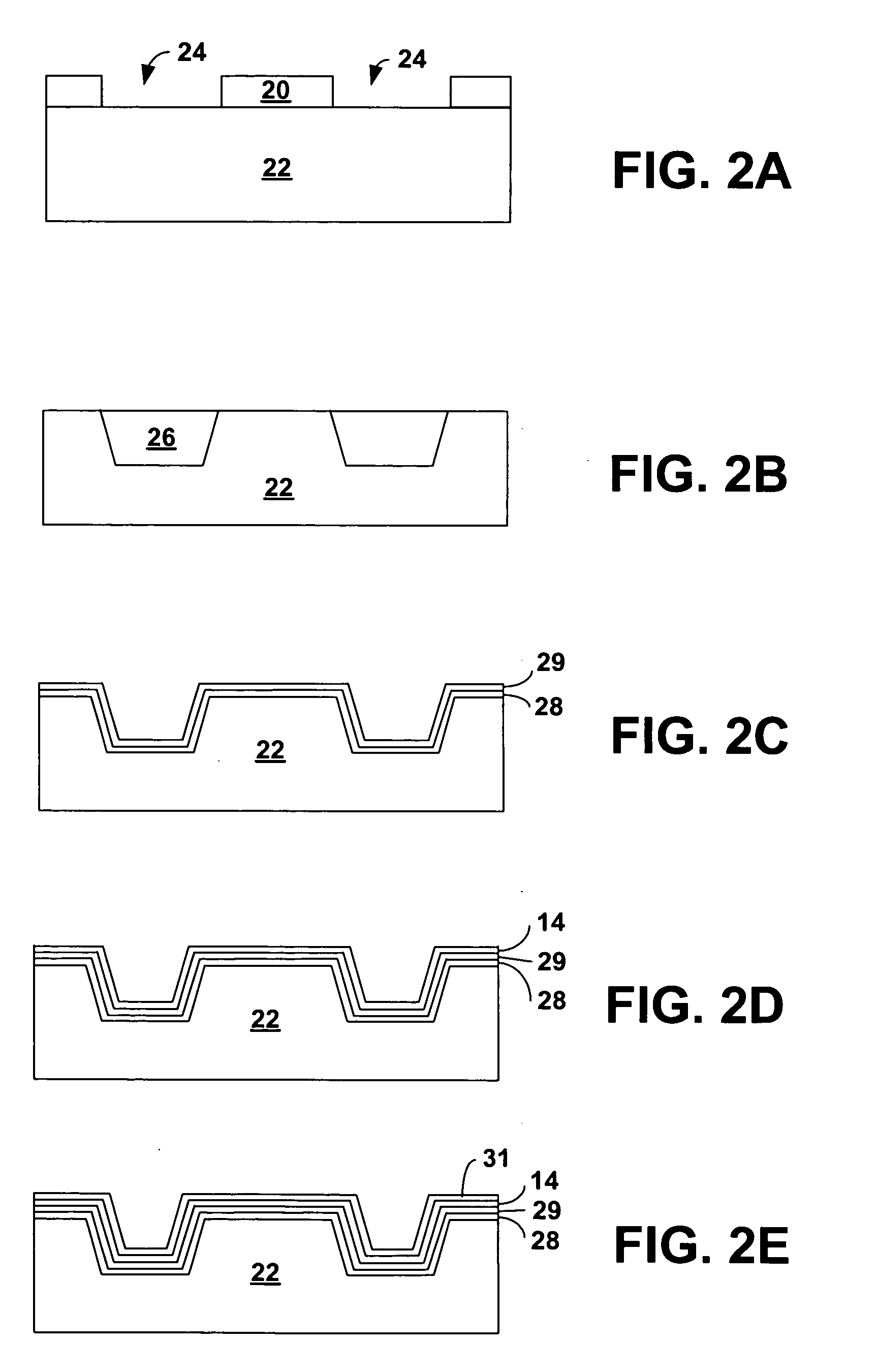

Foamed elastomers for wafer probing applications and interposer connectors

InactiveUS6054651AEasy to optimizeSimple structurePlastic/resin/waxes insulatorsInsulated cablesElastomerEngineering

The present invention is directed to a new foamed elastomer composition including elastomer, hollow fillers, and reinforced fillers for supporting the conducting wires in the test probes for wafer level testing and burn in and interposer connector applications. The thermally stable elastomer resin is mixed with hollow fillers and reinforced fillers before filling into the probe or connector mold with an array of elongated conducting wires, then is crosslinked by a crosslinking agent and a catalyst. The use of compressible hollow fillers to foam the elastomer has been successful to enhance the compliance and resilience, and to reduce the thermal expansion, density, and dielectric constant of the elastomer.

Owner:GLOBALFOUNDRIES INC

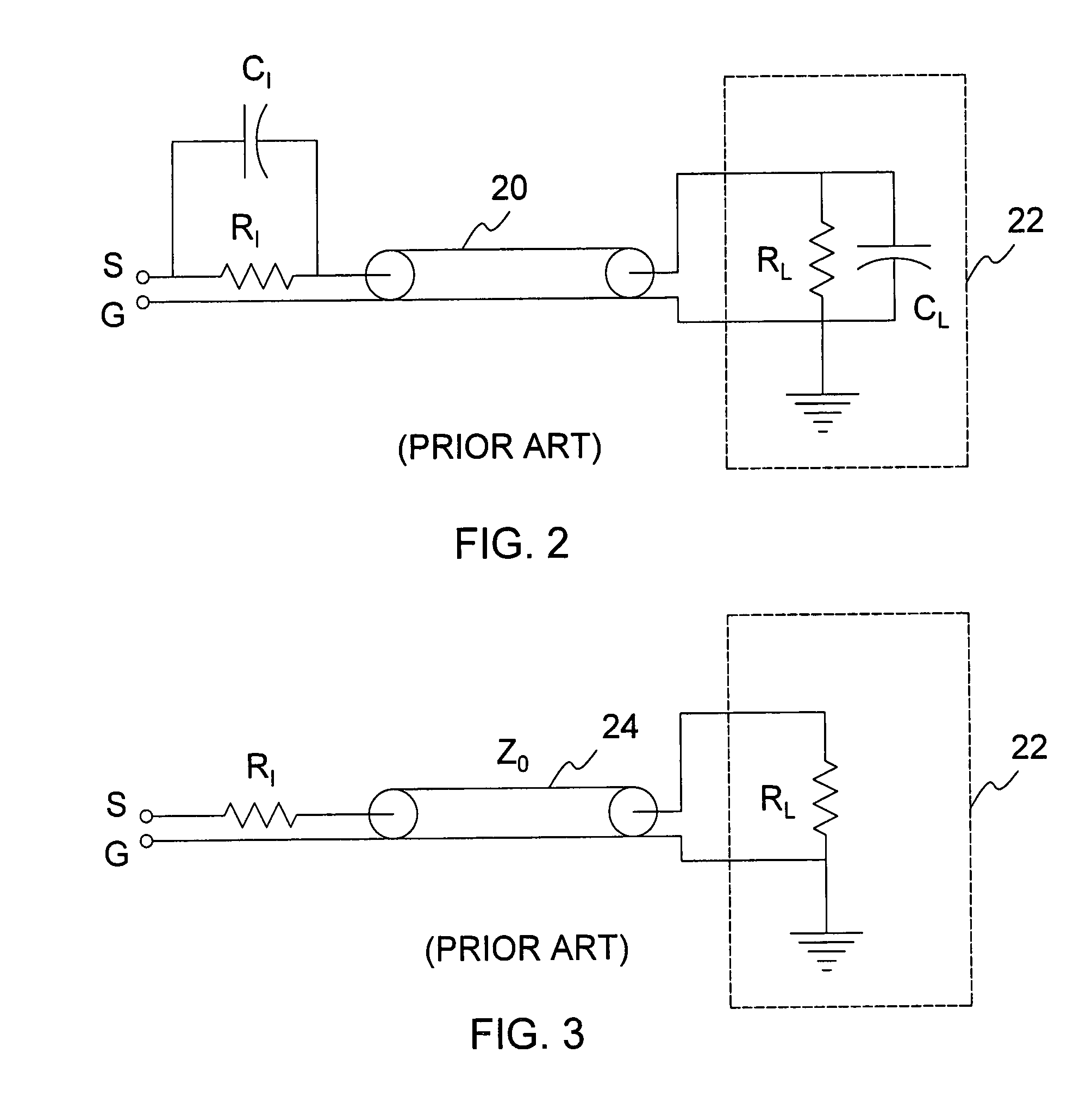

Transmission line input structure test probe

InactiveUS7019544B1Resistance/reactance/impedenceElectrical measurement instrument detailsDifferential signalingCharacteristic impedance

A differential electrical test probe tip for sensing a plurality of electric signals and generating a differential signal including an elongate common substrate having a two signal test points at one end and a differential amplifier at the second end. Two transmission lines are on the common substrate, each connecting a respective signal test point a signal input of the differential amplifier. The characteristic impedances of the two transmission lines are substantially equal. In one preferred embodiment, the common substrate is a flexible substrate. In one preferred embodiment an over-mold, which may have gaps therein, at least partially encloses the common substrate, the first transmission line, and the second transmission line.

Owner:TELEDYNE LECROY

AC coupled parameteric test probe

InactiveUS20070296435A1Increase signal couplingSemiconductor/solid-state device testing/measurementMeasurement leads/probesElectricityCoupling parameter

A probe for contacting and testing ICs on a semiconductor device includes a dielectric insulating material tip. The dielectric tip does not contaminate the surface being probed unlike metal probe tips. A contact scrub is further not required with signals being capacitively or inductively coupled from the probe tip to the IC. Testing can be performed during early fabrication steps of the wafer without the need for applying a metalization layer to the wafer to form bond pads. Testing can be performed by inductively coupling an AC signal to the probe tip, with coupling enhanced by including a magnetic material in the dielectric probe tip. Using an AC test signal enables testing of ICs without requiring separate power and ground connections.

Owner:FORMFACTOR INC

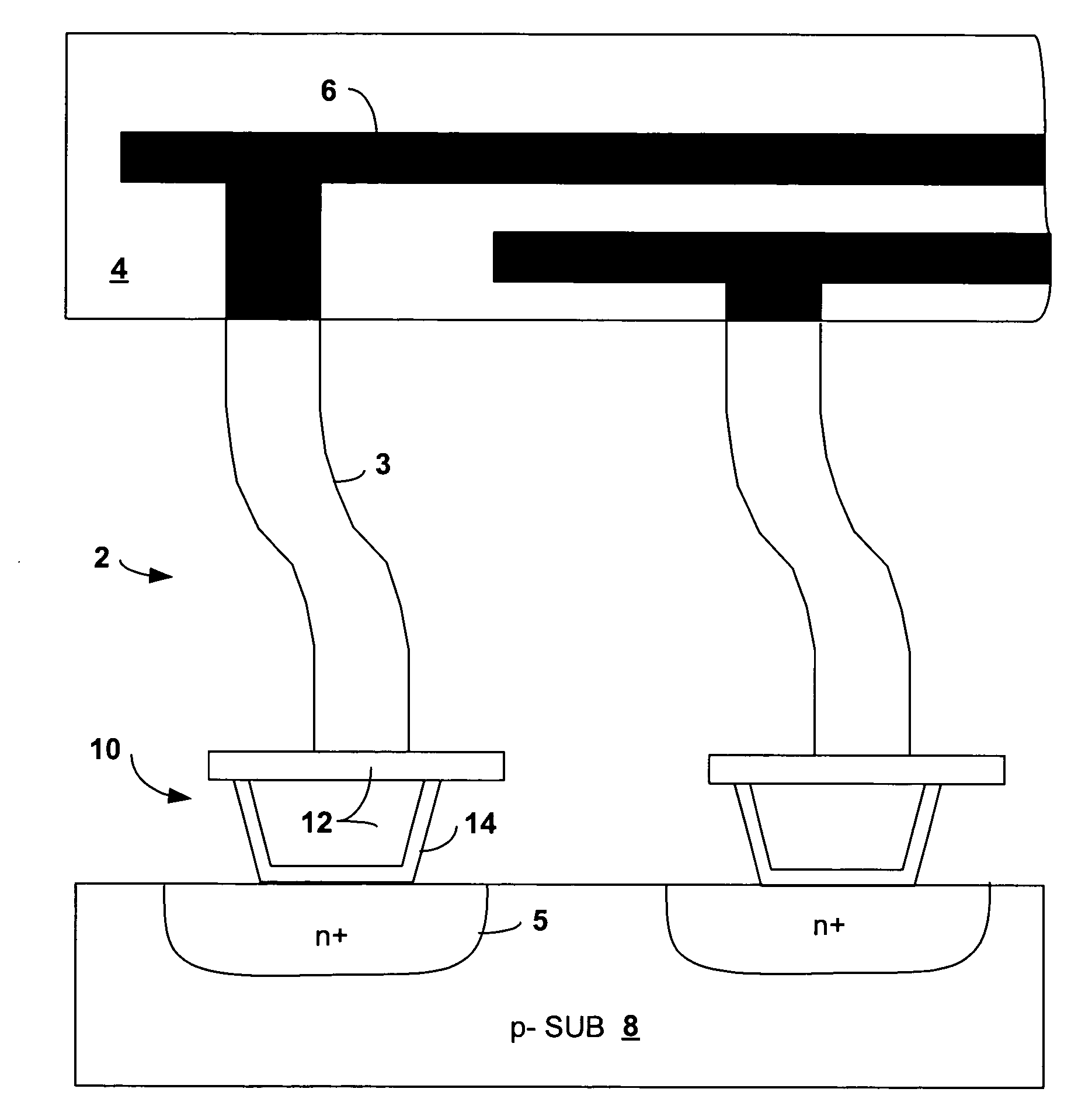

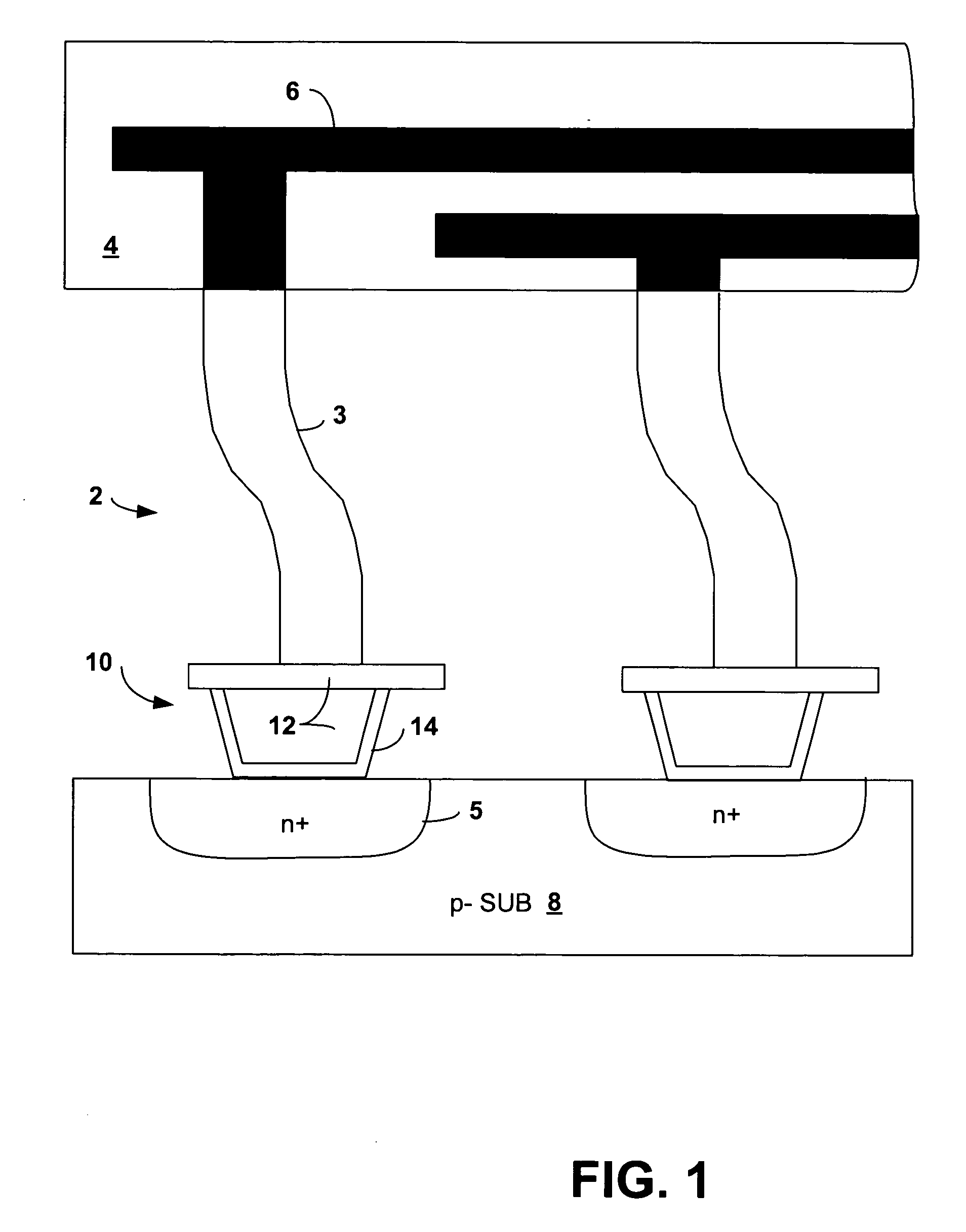

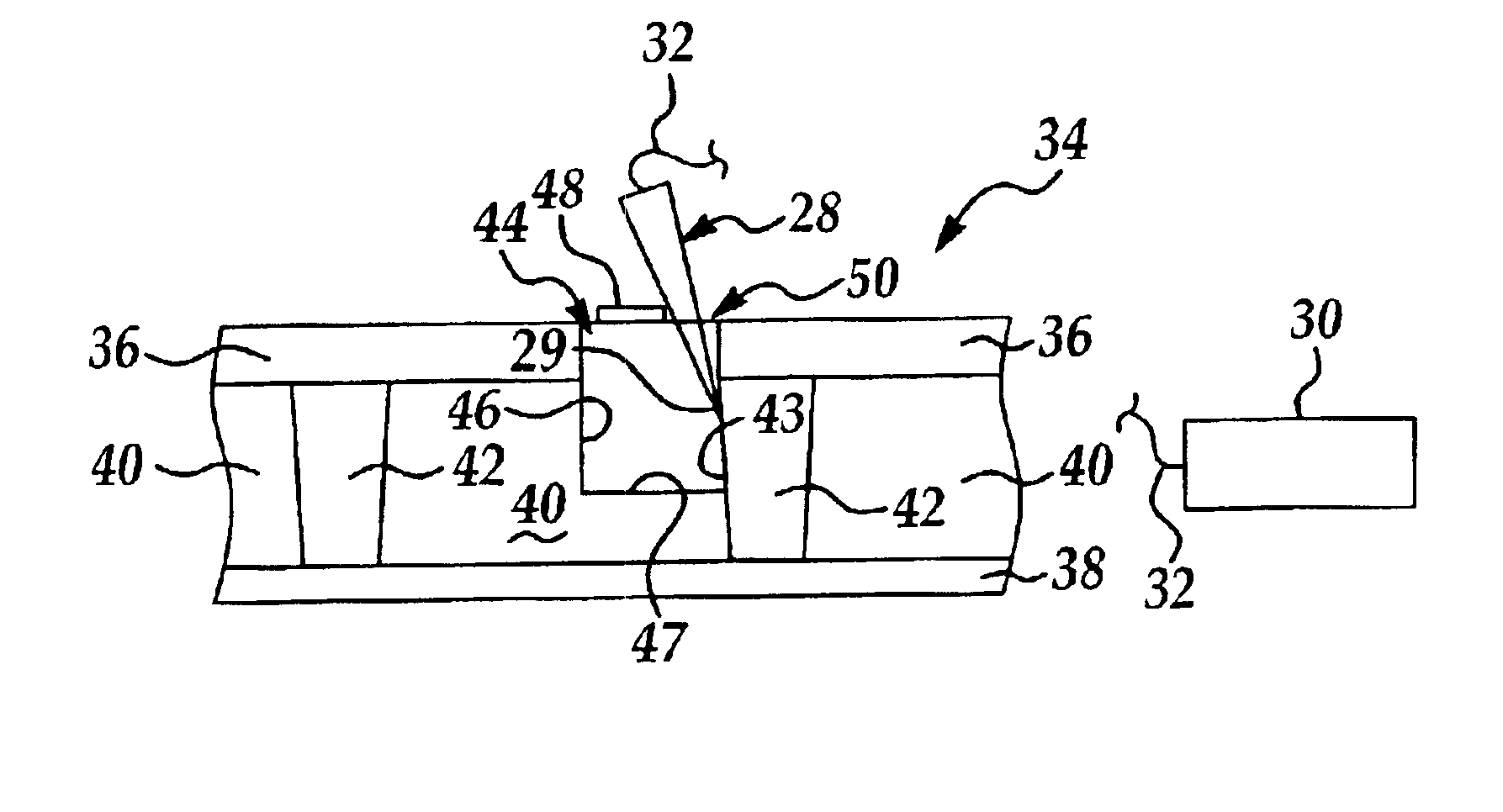

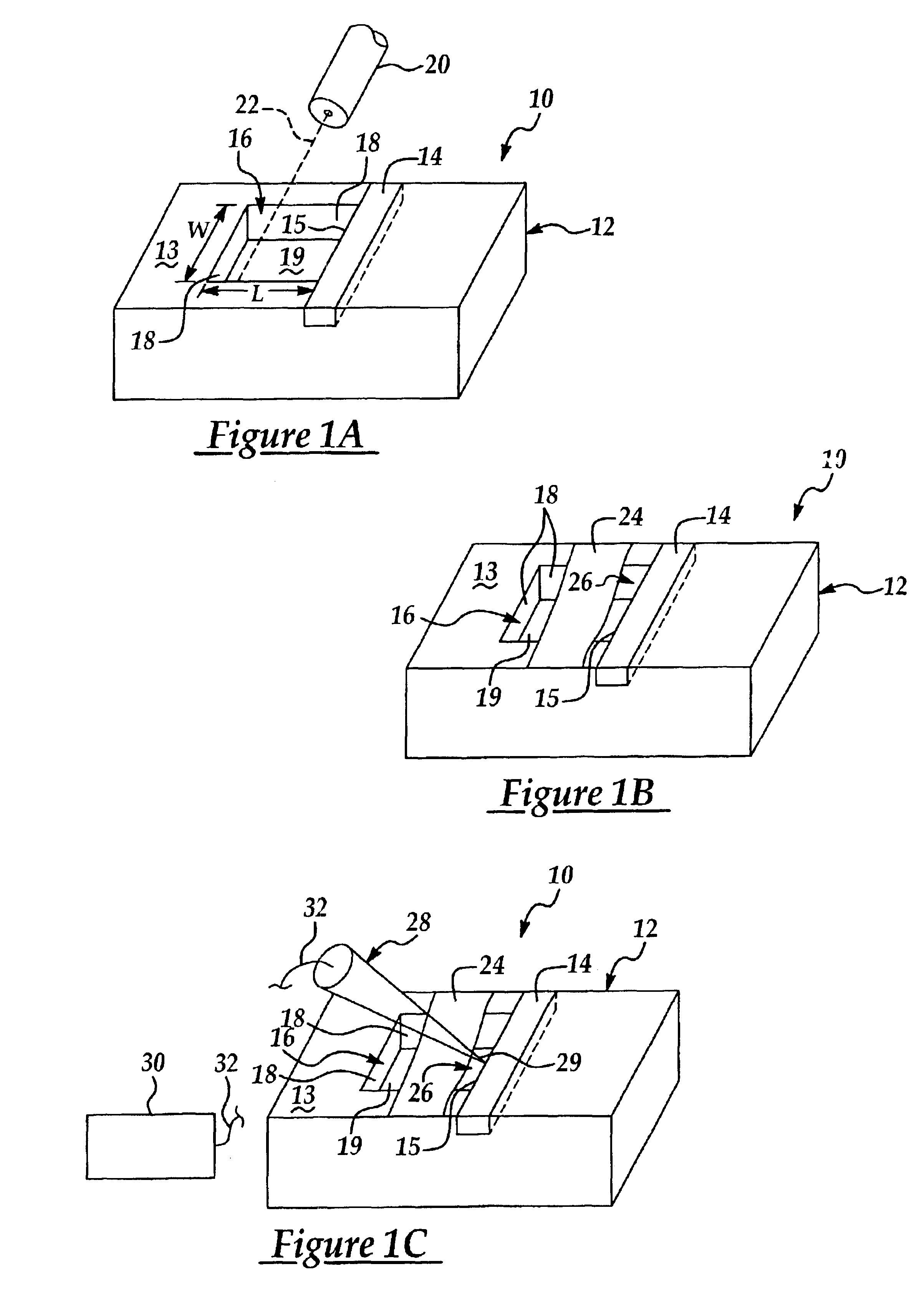

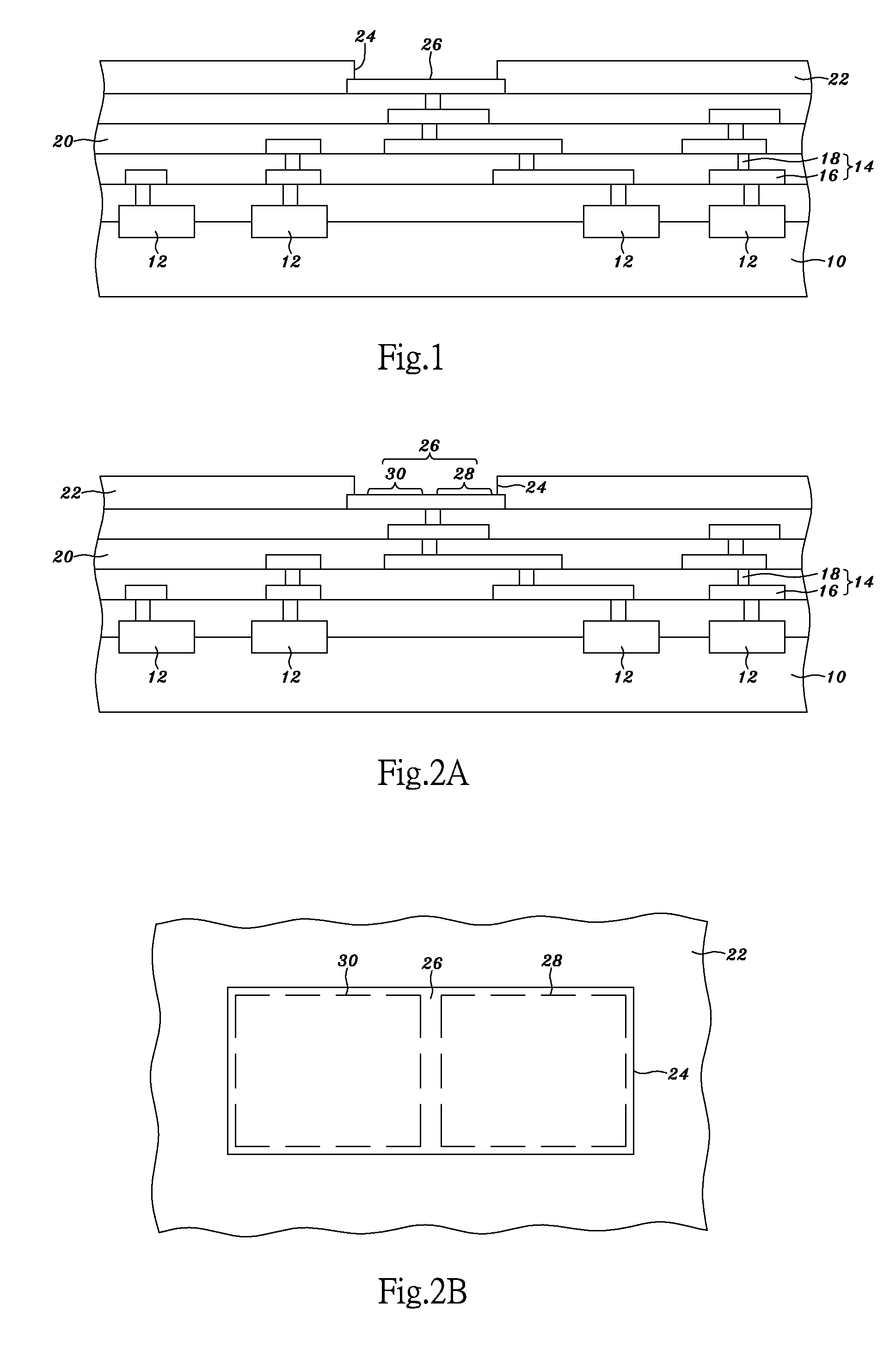

Probing of device elements

InactiveUS6902941B2Reduce contact resistanceAvoid Particle ContaminationSemiconductor/solid-state device testing/measurementElectronic circuit testingDielectricElectricity

A new and improved method for the probing of integrated circuits (ICs) and is particularly suitable for probing various elements of an IC for failure analysis or other electrical testing and / or measurement of the IC. The method includes providing a probe access trench in the IMD (intermetal dielectric) or other substrate adjacent to the circuit element to be tested and then providing direct electrical contact between the test probe and the sidewall of the element through the trench, during the testing process. Such direct electrical contact between the test probe and the sidewall of the element prevents excessively high contact resistance which may otherwise occur in the use of a probing pad between the test probe and the element.

Owner:TAIWAN SEMICON MFG CO LTD

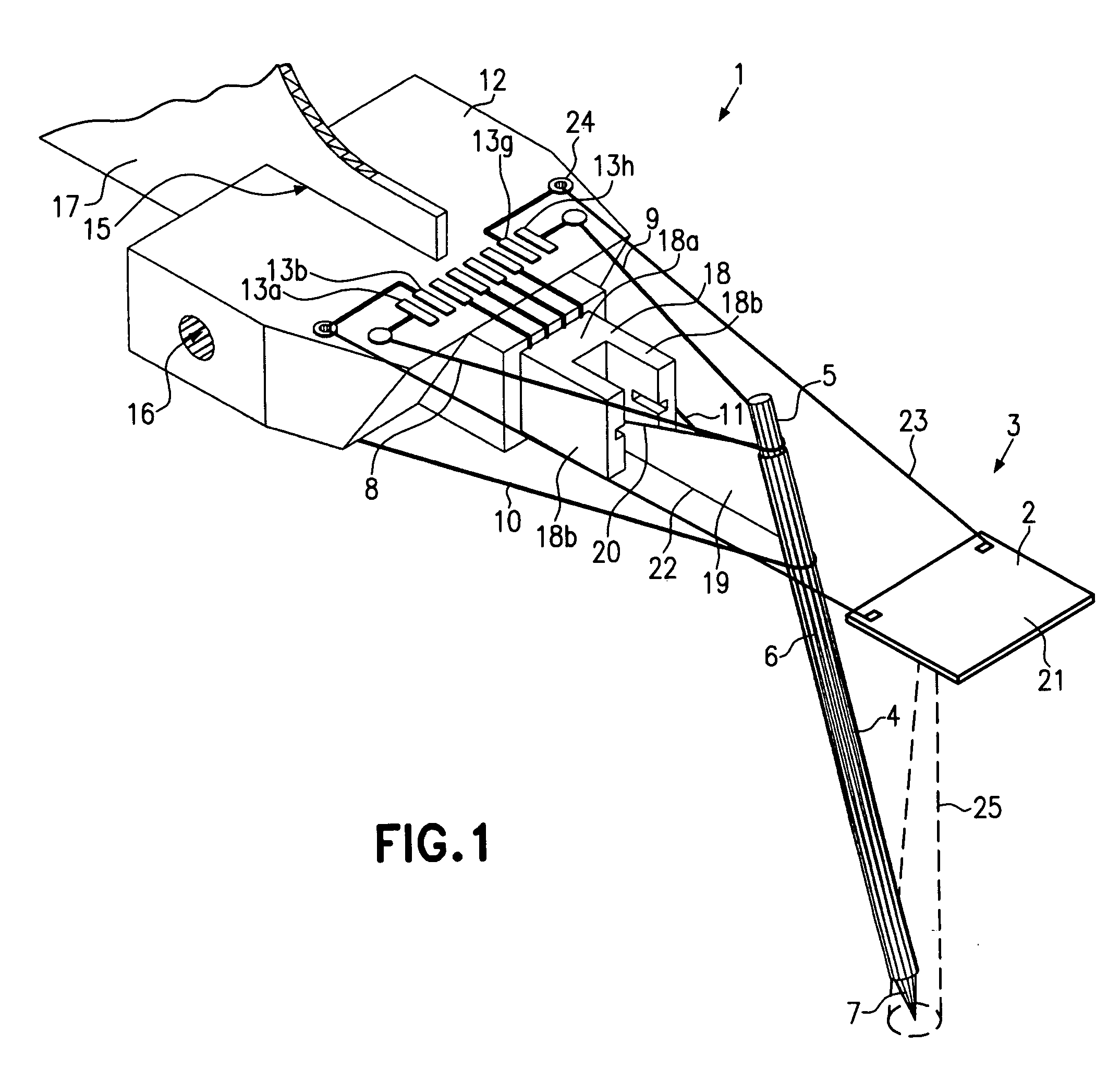

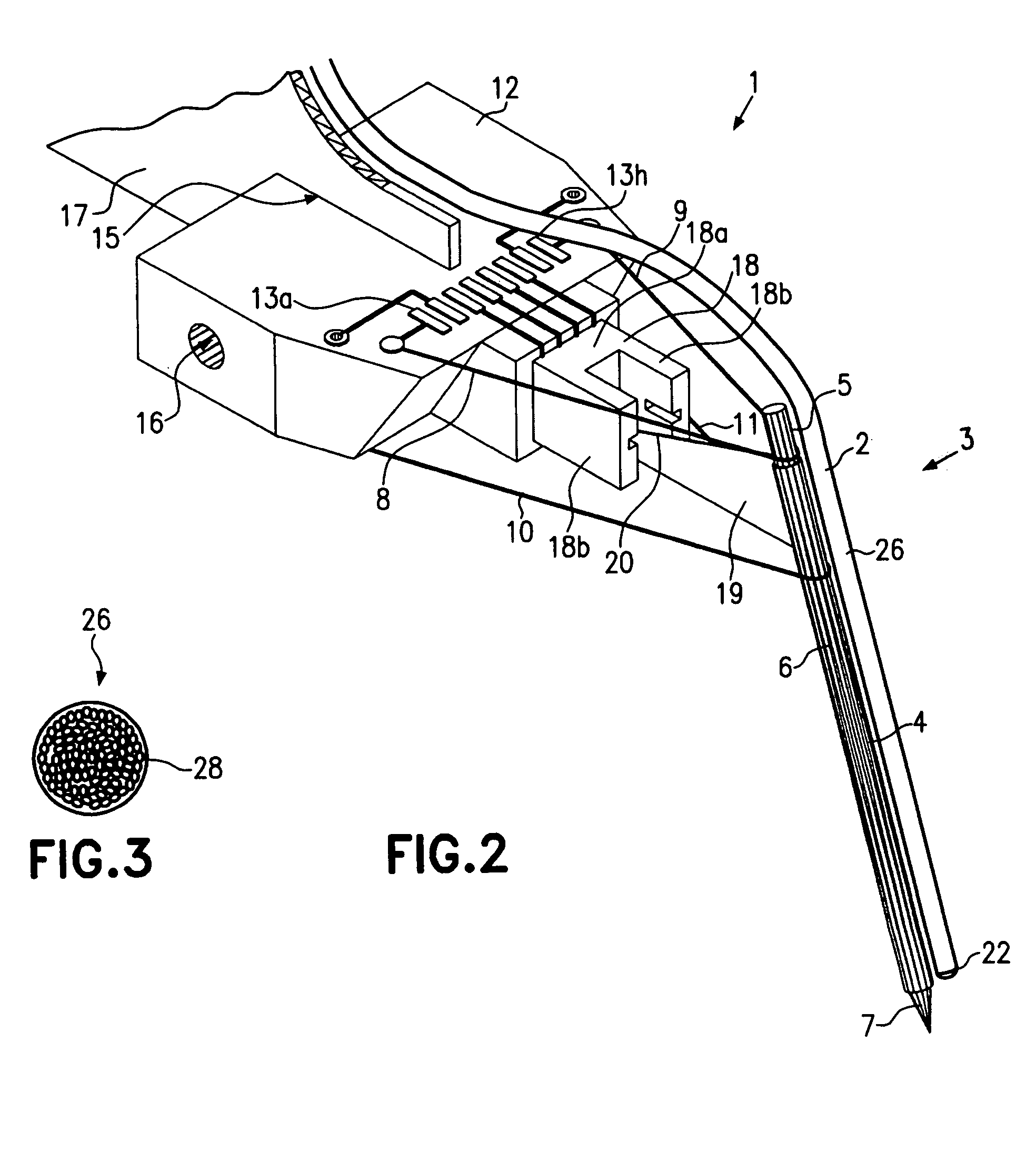

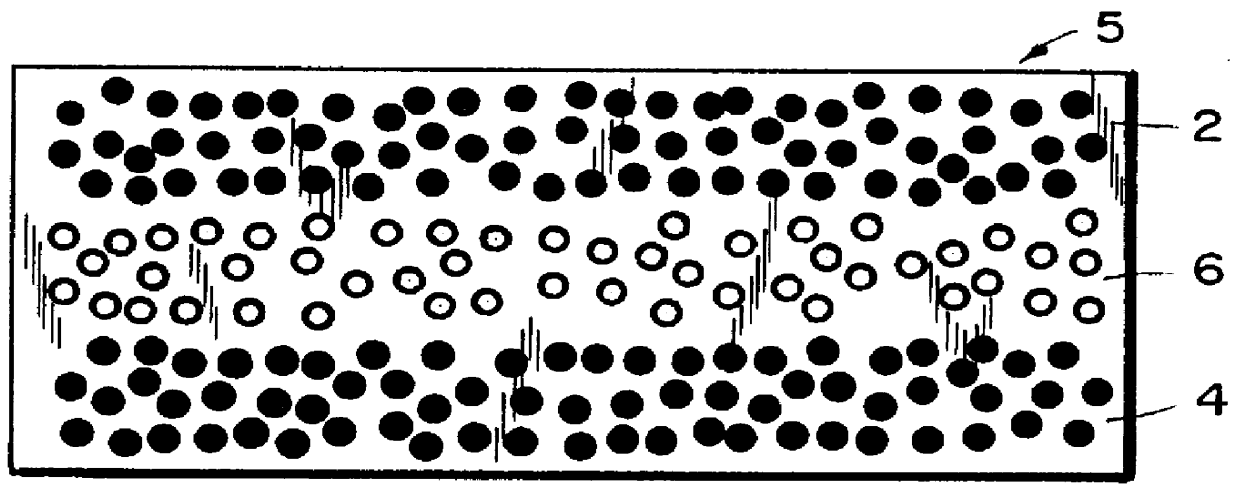

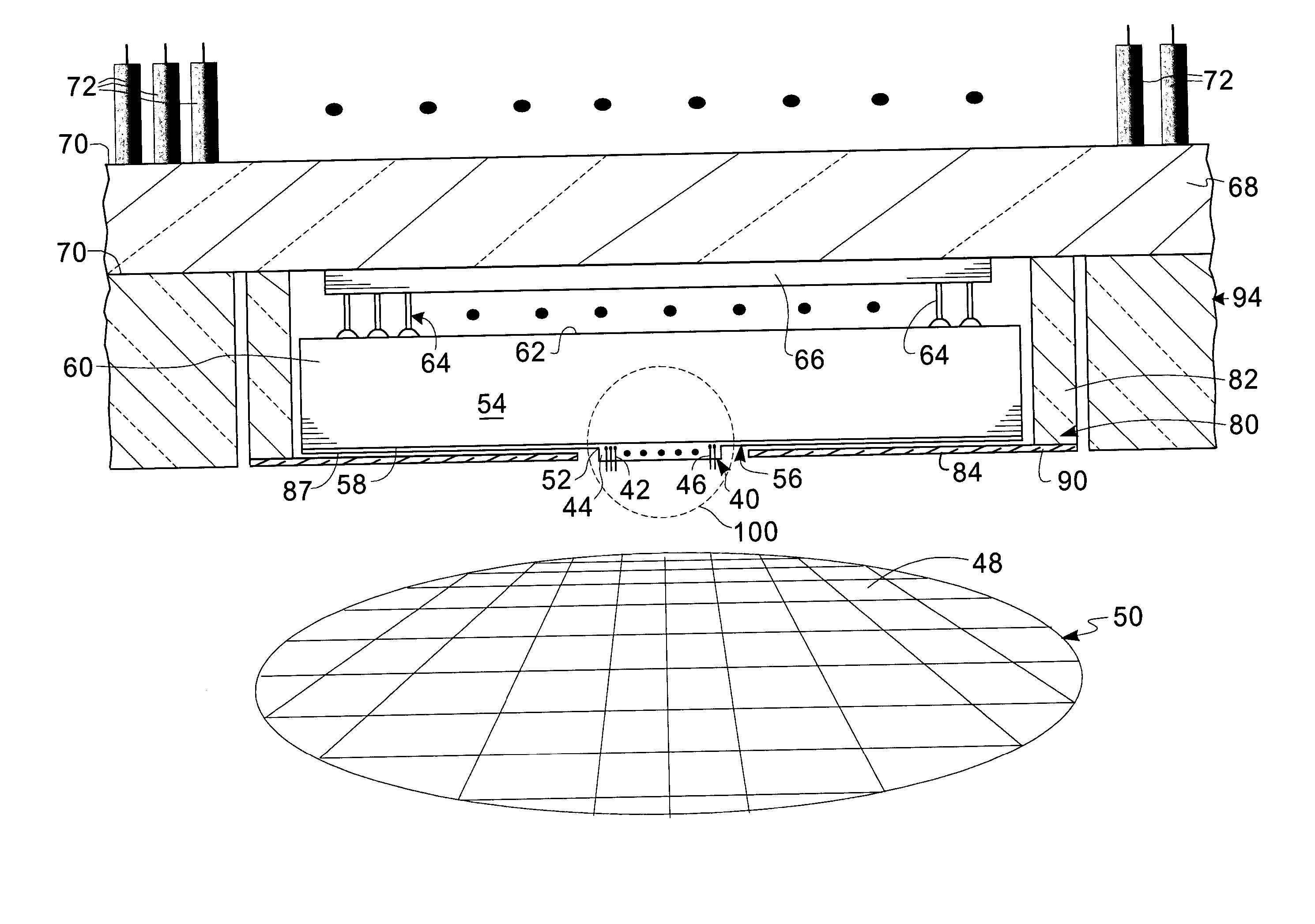

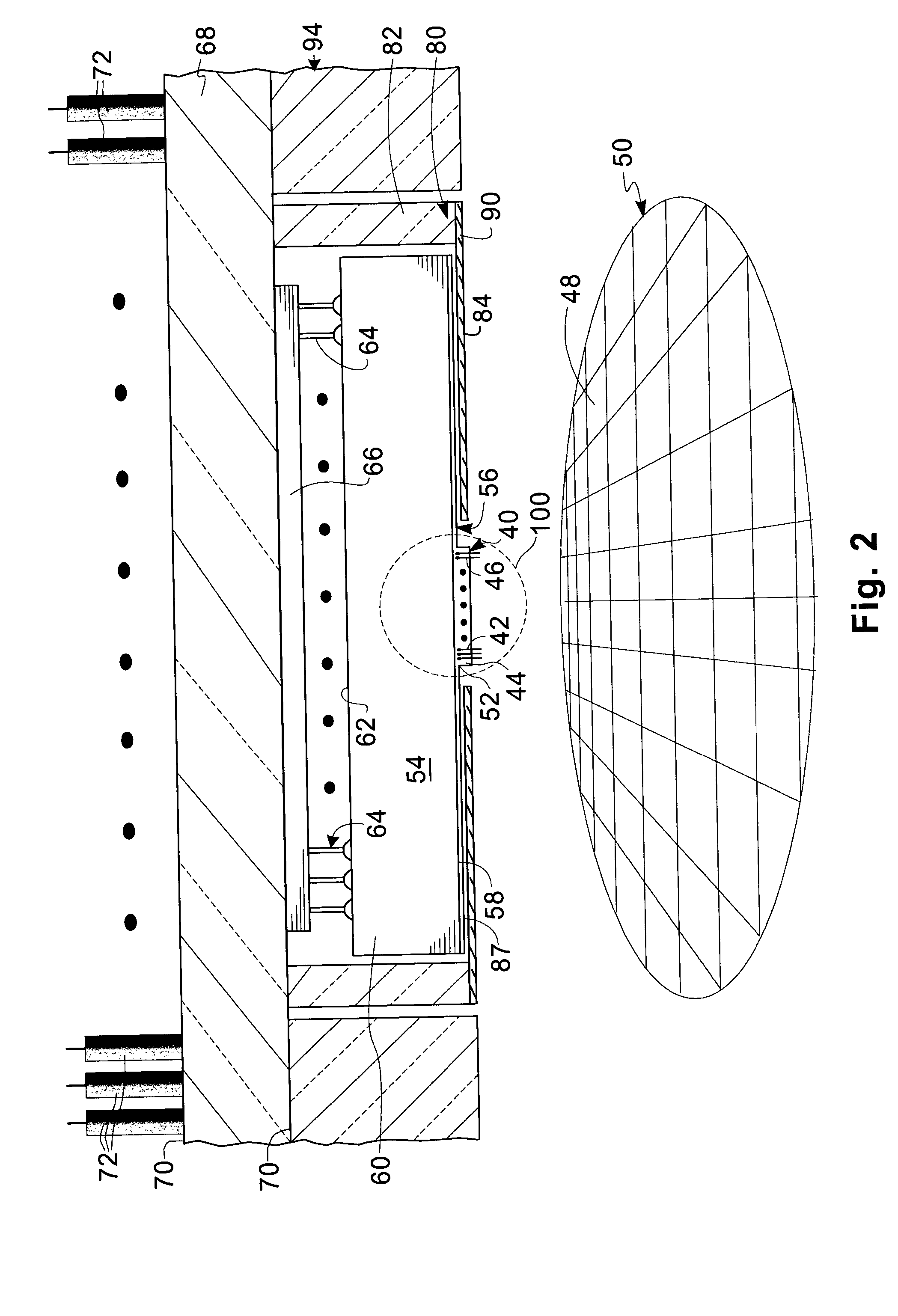

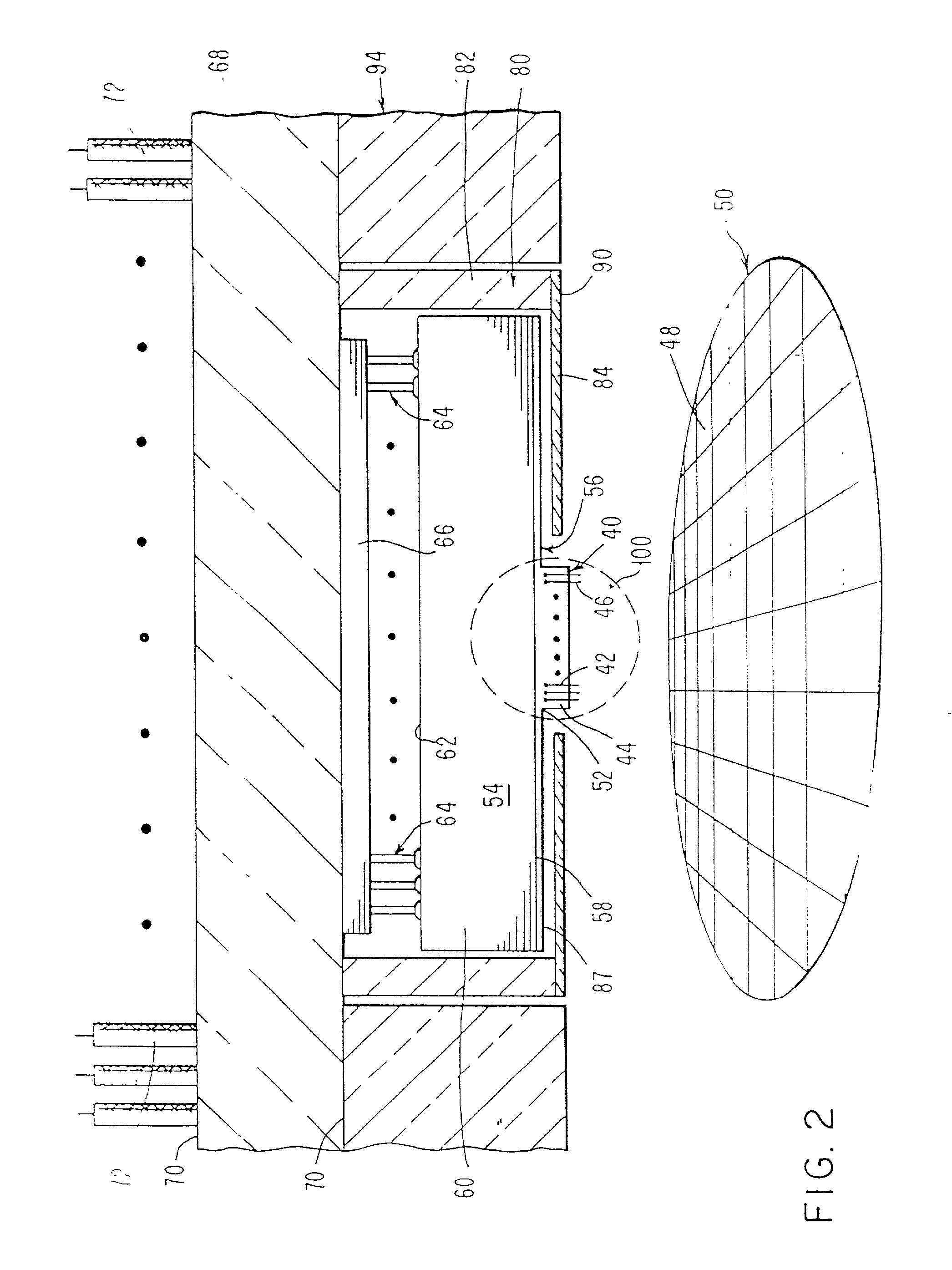

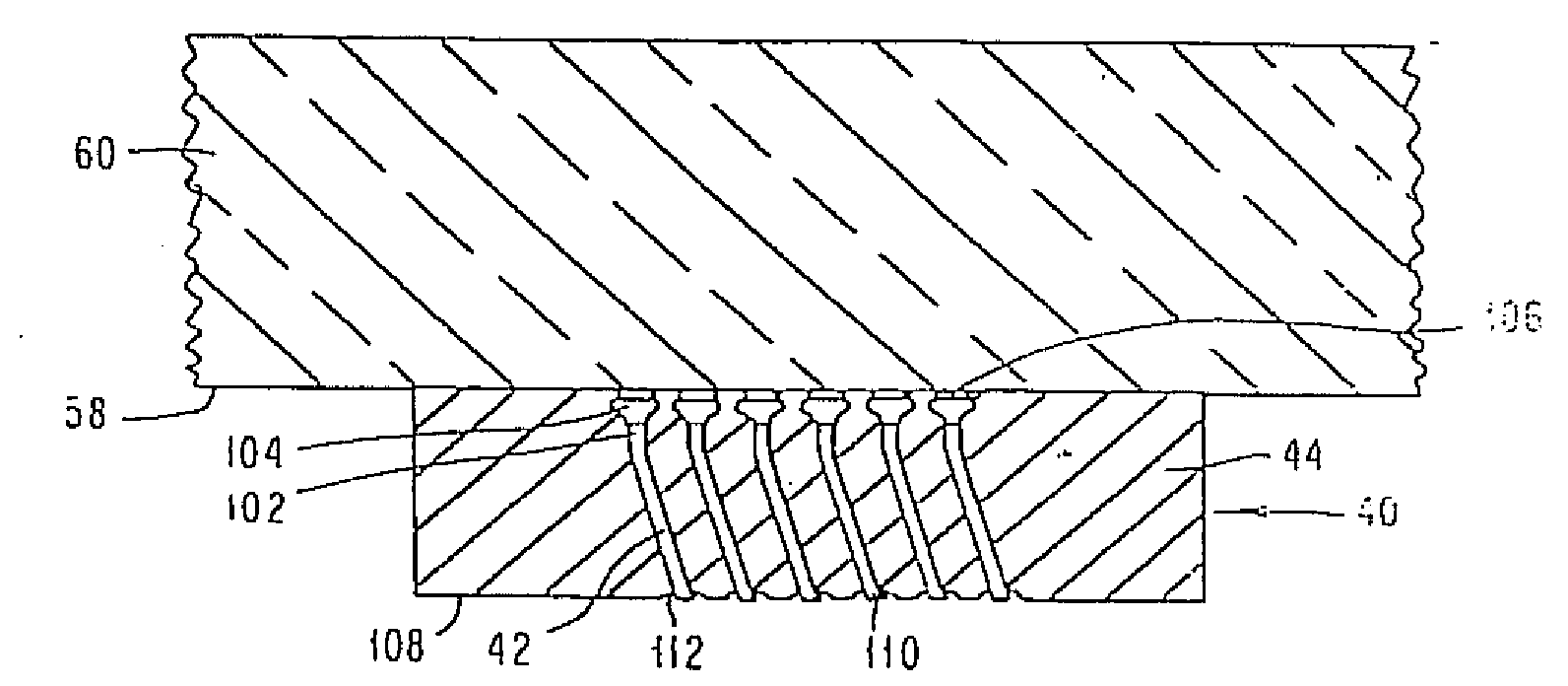

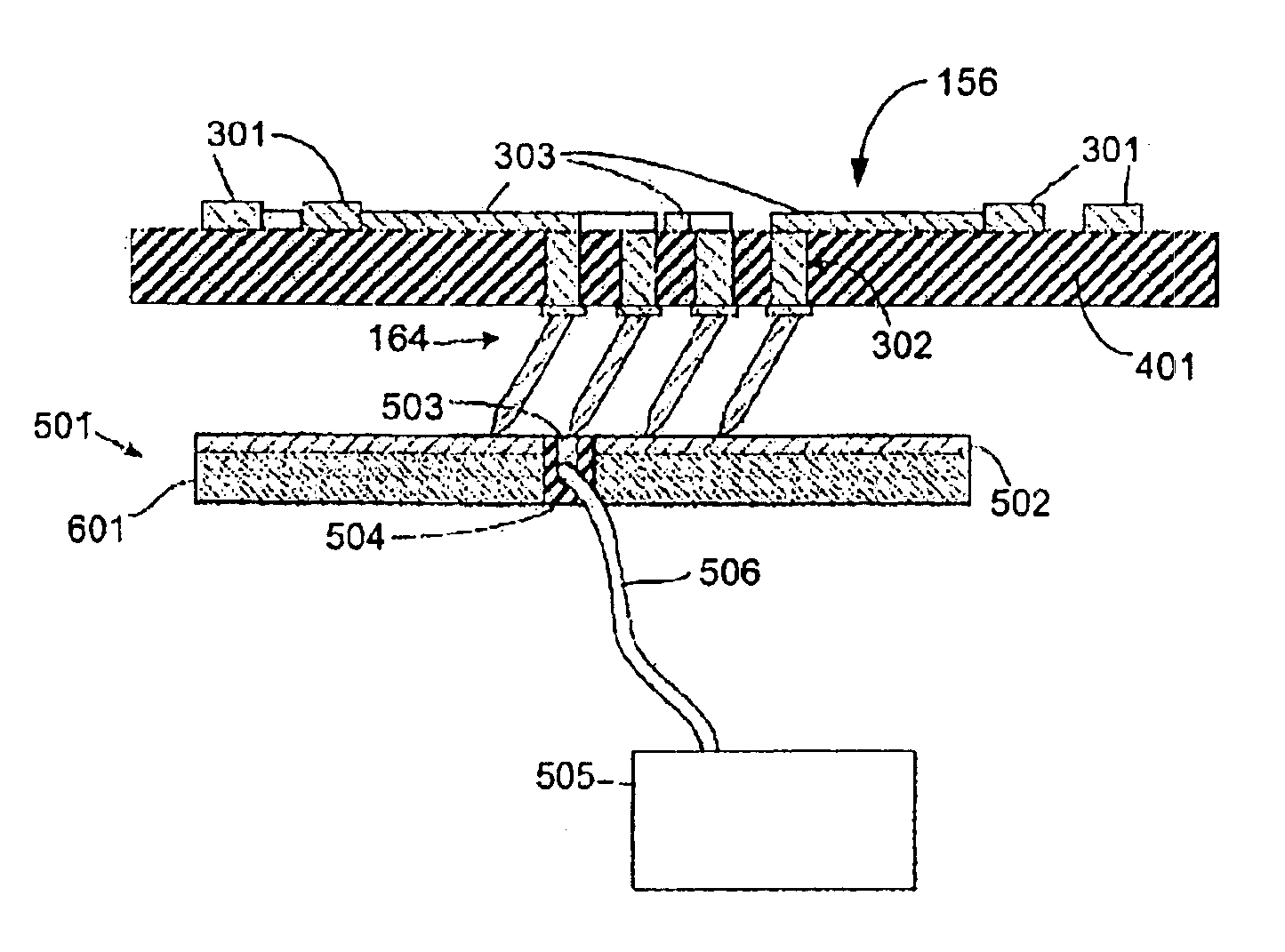

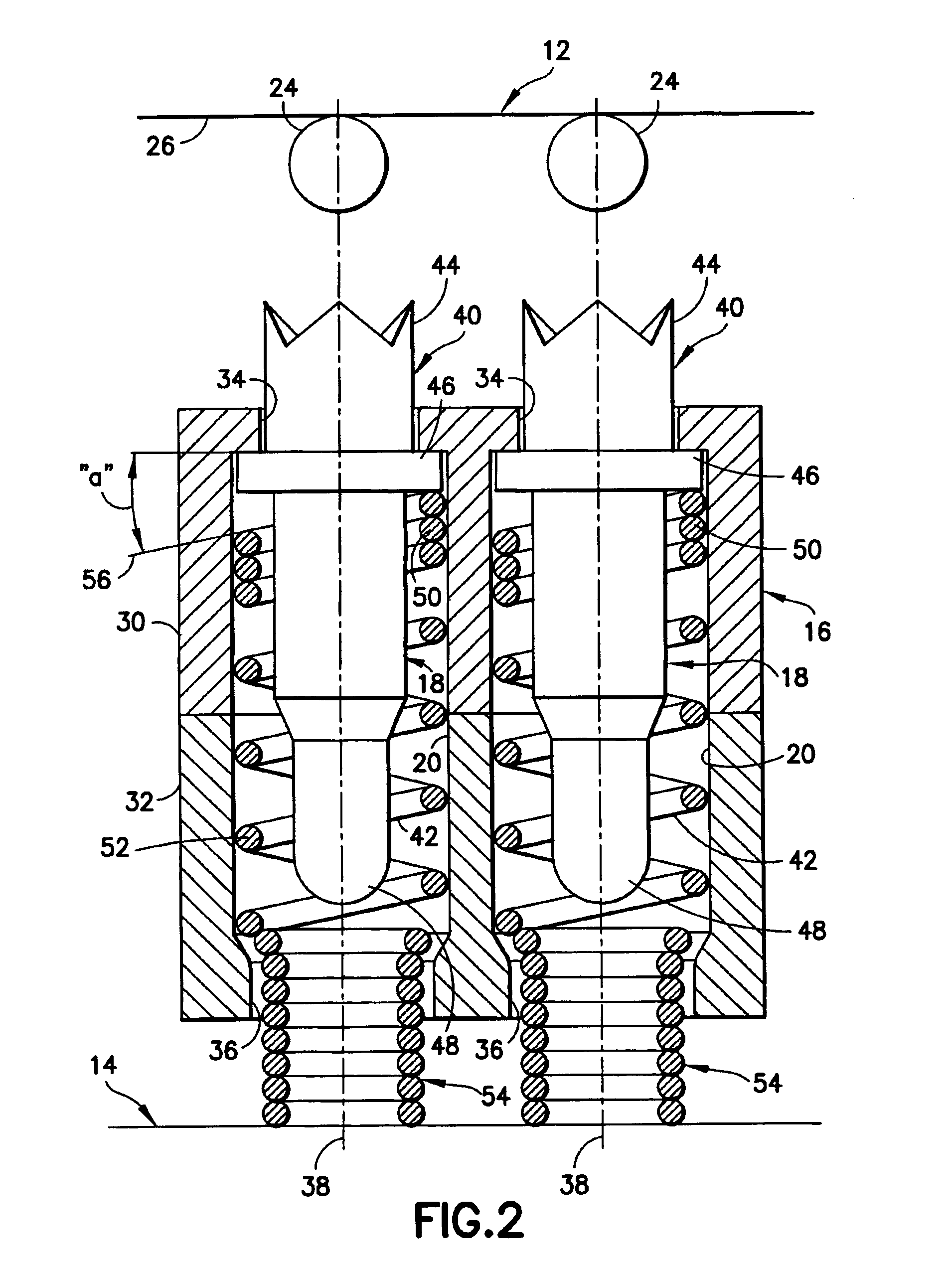

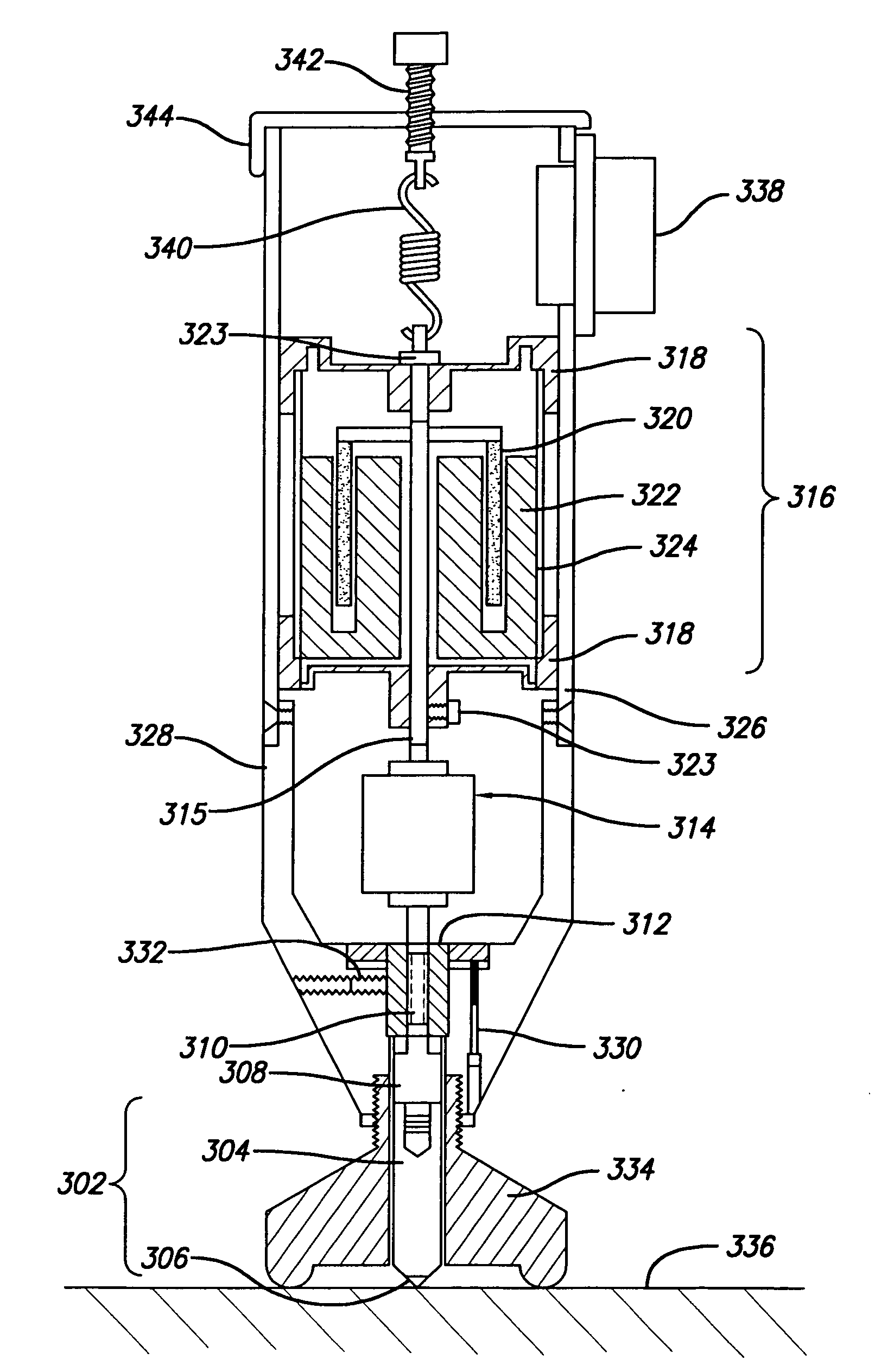

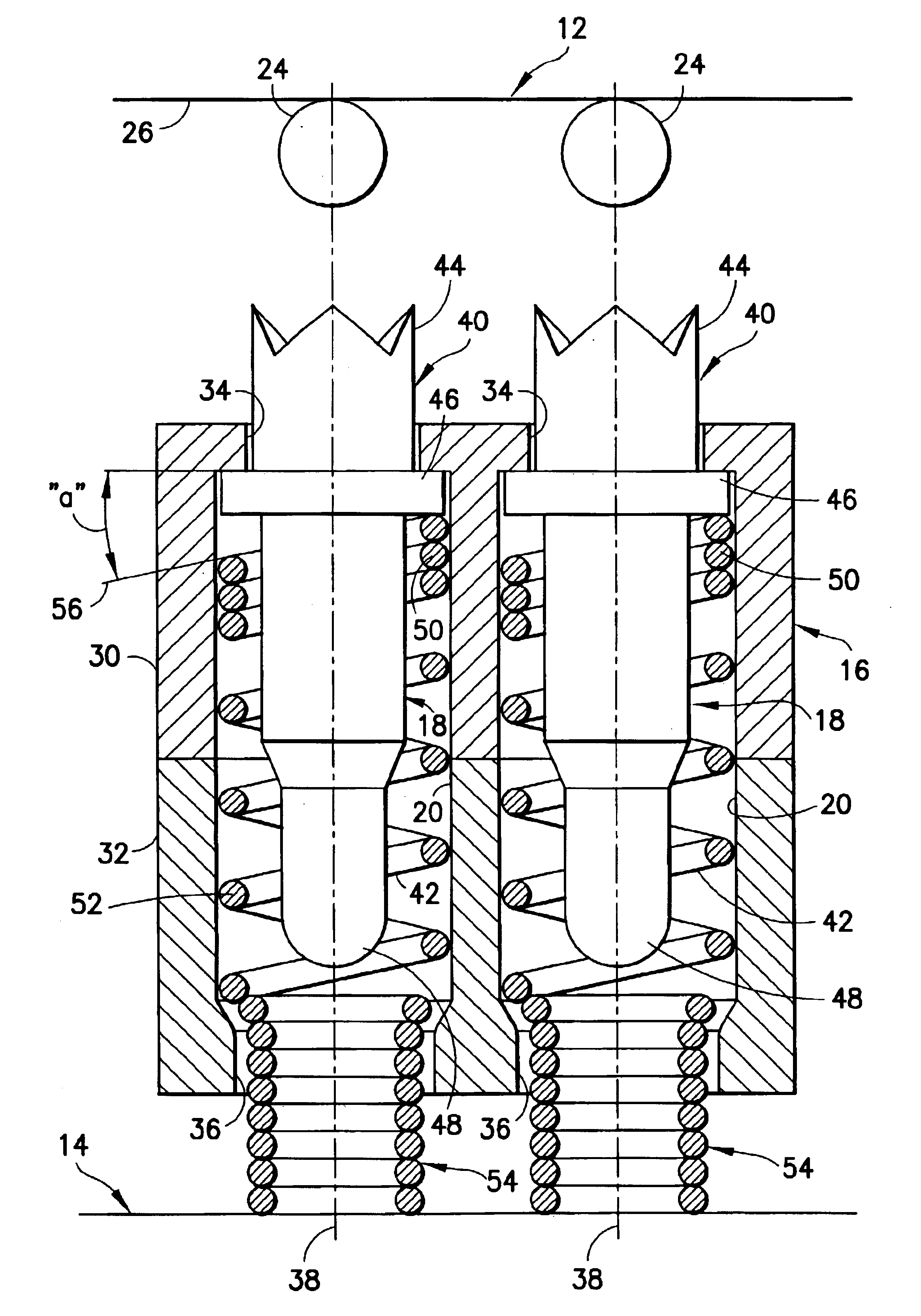

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20050062492A1High performance functional testingHigh-temperature burnElectrical measurement instrument detailsManufacture of electrical instrumentsConvertersContact pad

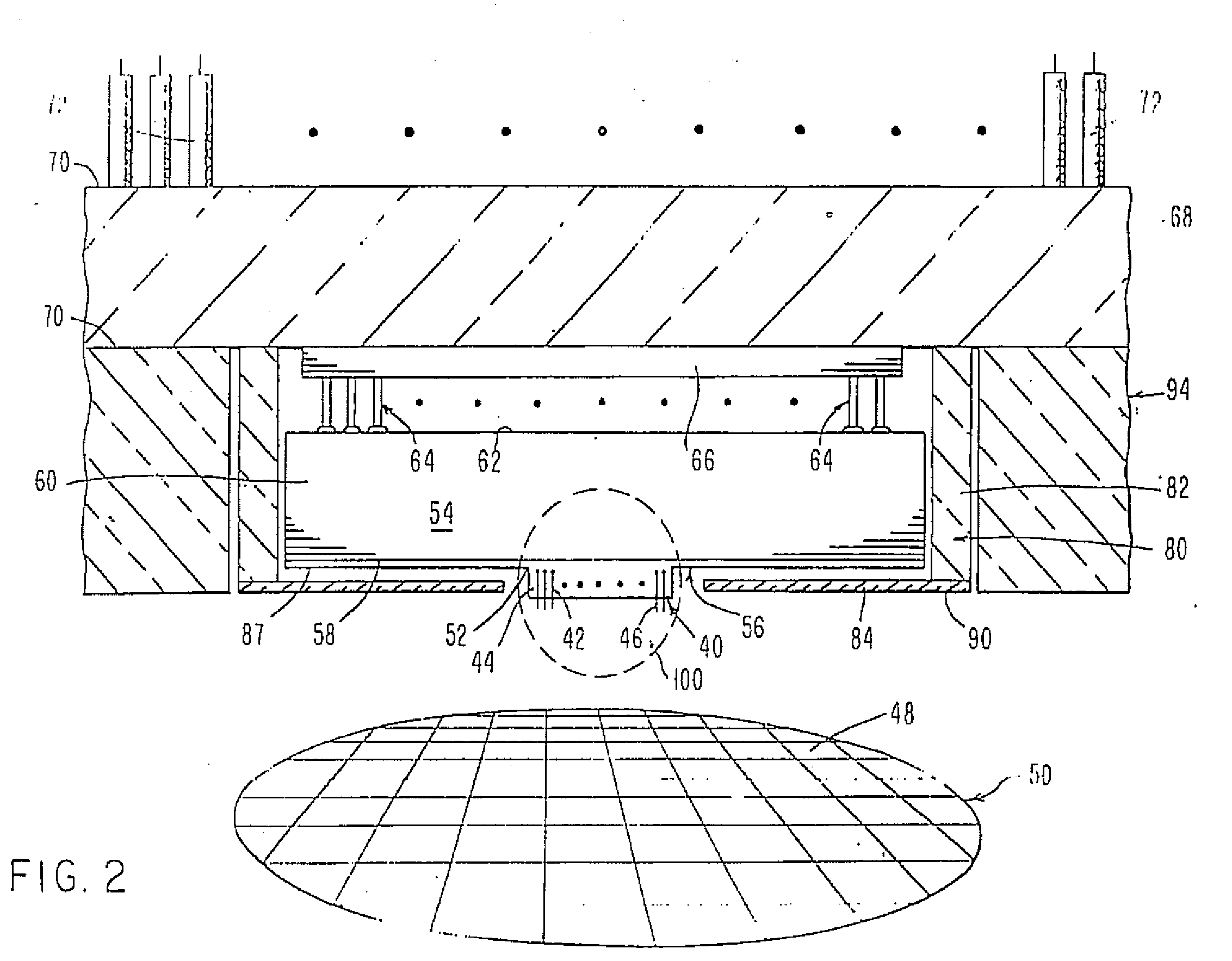

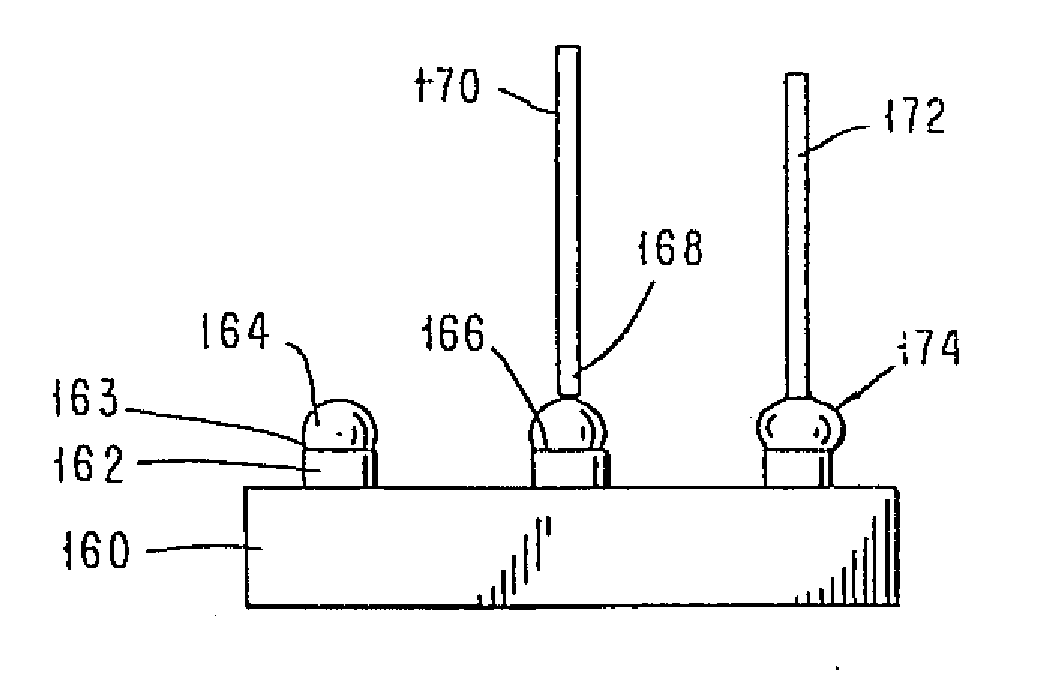

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer. Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed in the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20070271781A9High performance functional testingHigh-temperature burnElectrically conductive connectionsElectronic circuit testingElastomerElectricity

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer. Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed ion the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20080106291A1High performance functional testingHigh temperature burn in applicationsElectronic circuit testingElectrical measurement instrument detailsElastomerElectricity

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer forms or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer. Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed in the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer. The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20080048697A1High performance functional testingHigh temperature burn in applicationsElectrical measurement instrument detailsManufacture of electrical instrumentsElastomerContact pad

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed in the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20080047741A1High performance functional testingHigh temperature burn in applicationsElectrical measurement instrument detailsElectrical testingElastomerContact pad

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer. Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed in the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20080048690A1High performance functional testingHigh temperature burn in applicationsElectrical measurement instrument detailsManufacture of electrical instrumentsElastomerContact pad

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed in the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20080048691A1High performance functional testingHigh temperature burn in applicationsElectrical measurement instrument detailsElectrical testingElastomerContact pad

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed in the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20080100316A1High performance functional testingHigh temperature burn in applicationsManufacture of electrical instrumentsMeasurement leads/probesElastomerContact pad

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed in the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

Apparatus and method for electromechanical testing and validation of probe cards

InactiveUS6911814B2Electrical measurement instrument detailsFault location by increasing destruction at faultProbe cardEngineering

A method of testing a probe card includes the step of positioning the probe card in a prober over a verification wafer that is placed on a stage. The probe card is brought in contact with a contact region on the verification wafer. The verification wafer includes a shorting plane surrounding the contact region. A test signal is sent through the verification wafer to the probe card. A response signal from the probe card is received and analyzed.

Owner:FORMFACTOR INC

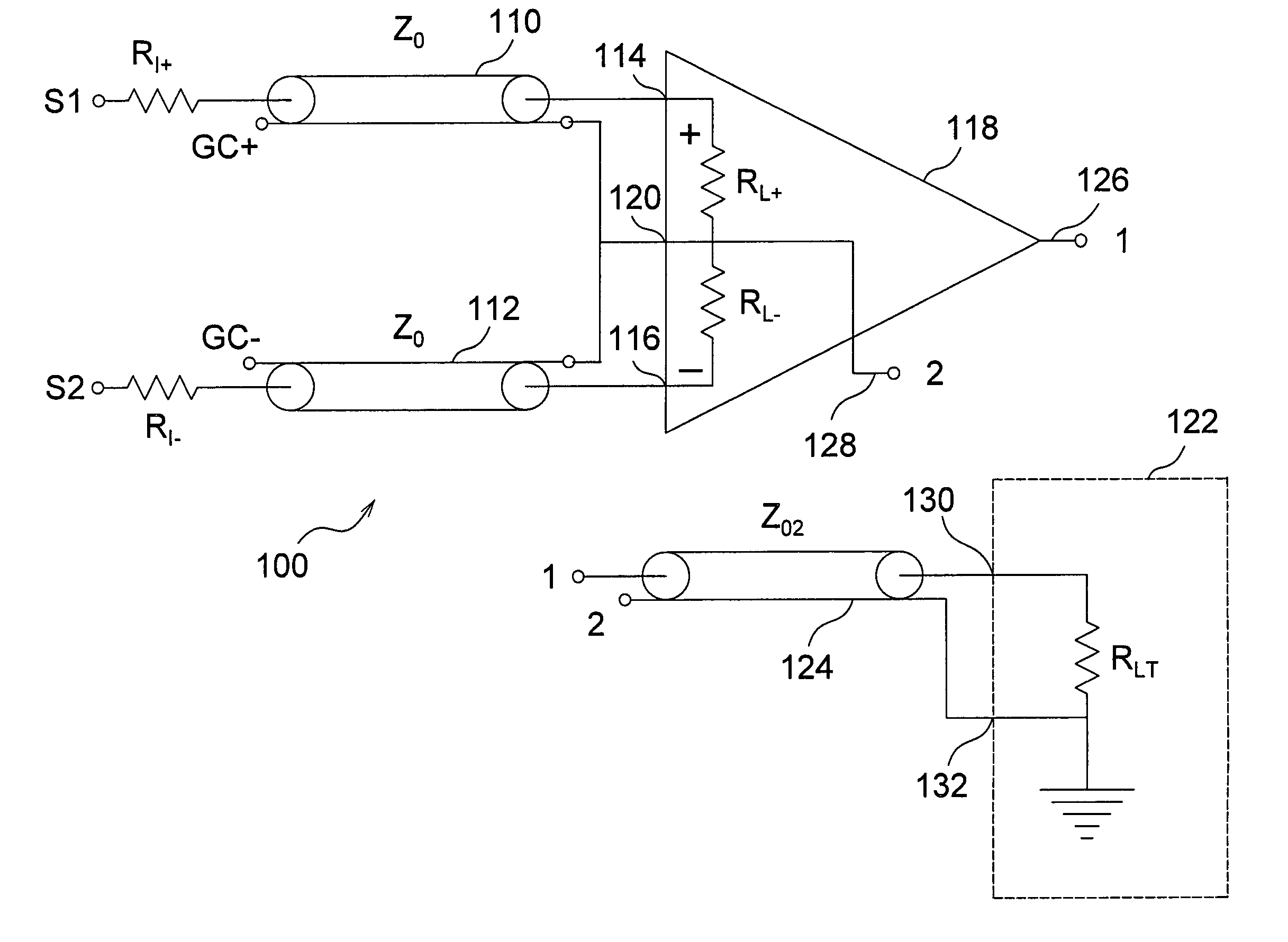

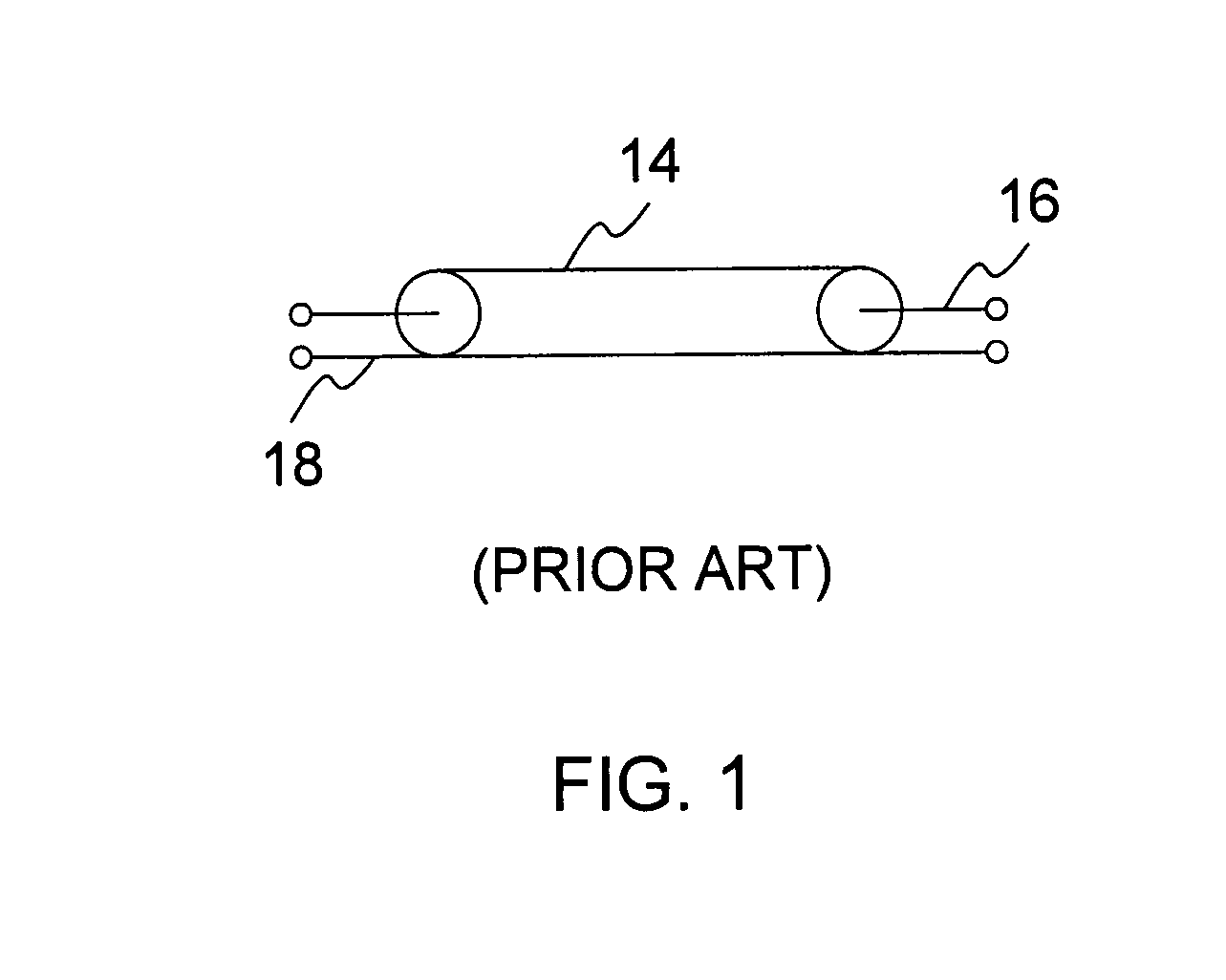

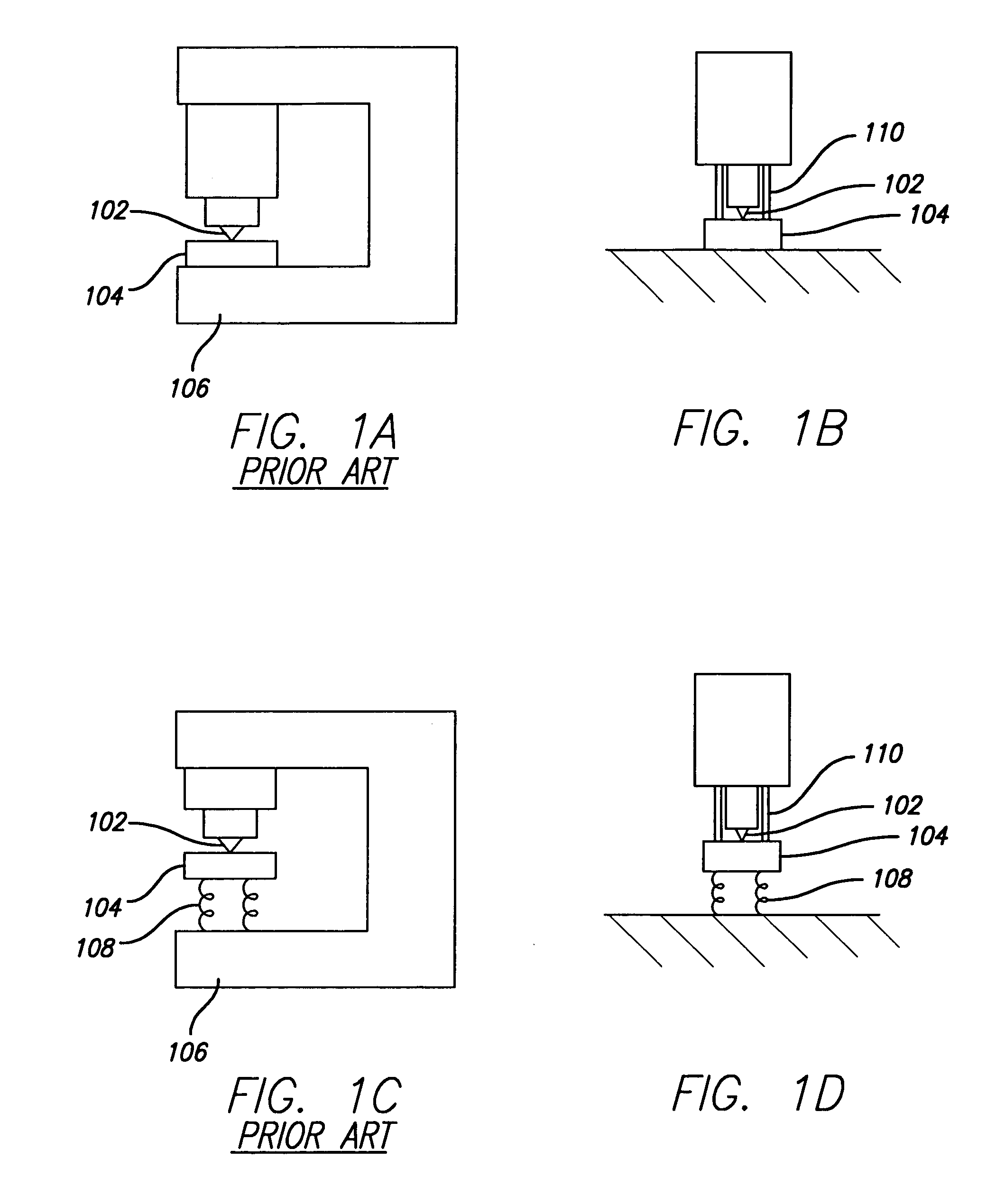

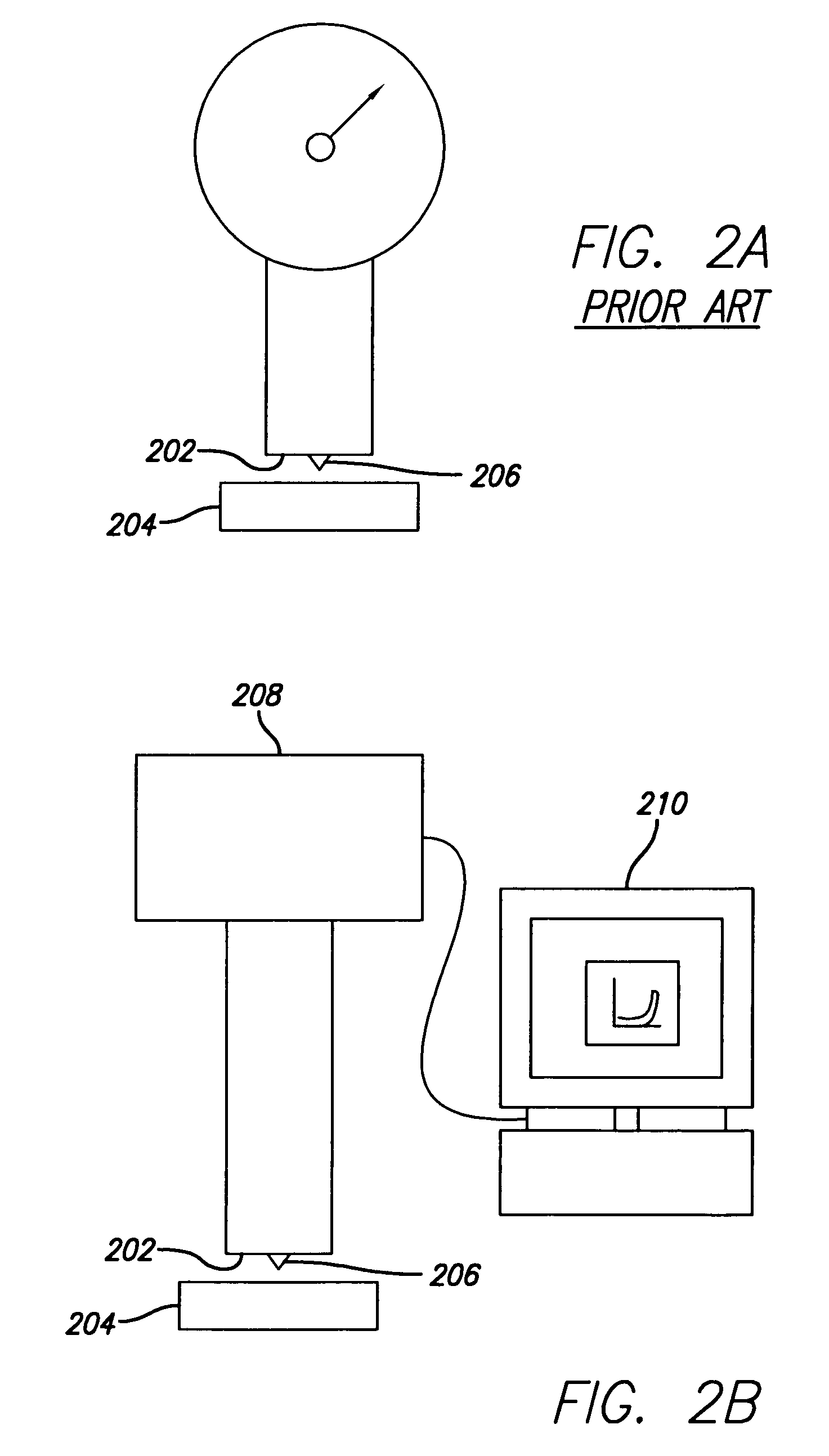

Self-calibrating electrical test probe

InactiveUS6870359B1Easy to understandElectronic circuit testingElectrical measurement instrument detailsEngineeringCalibration test

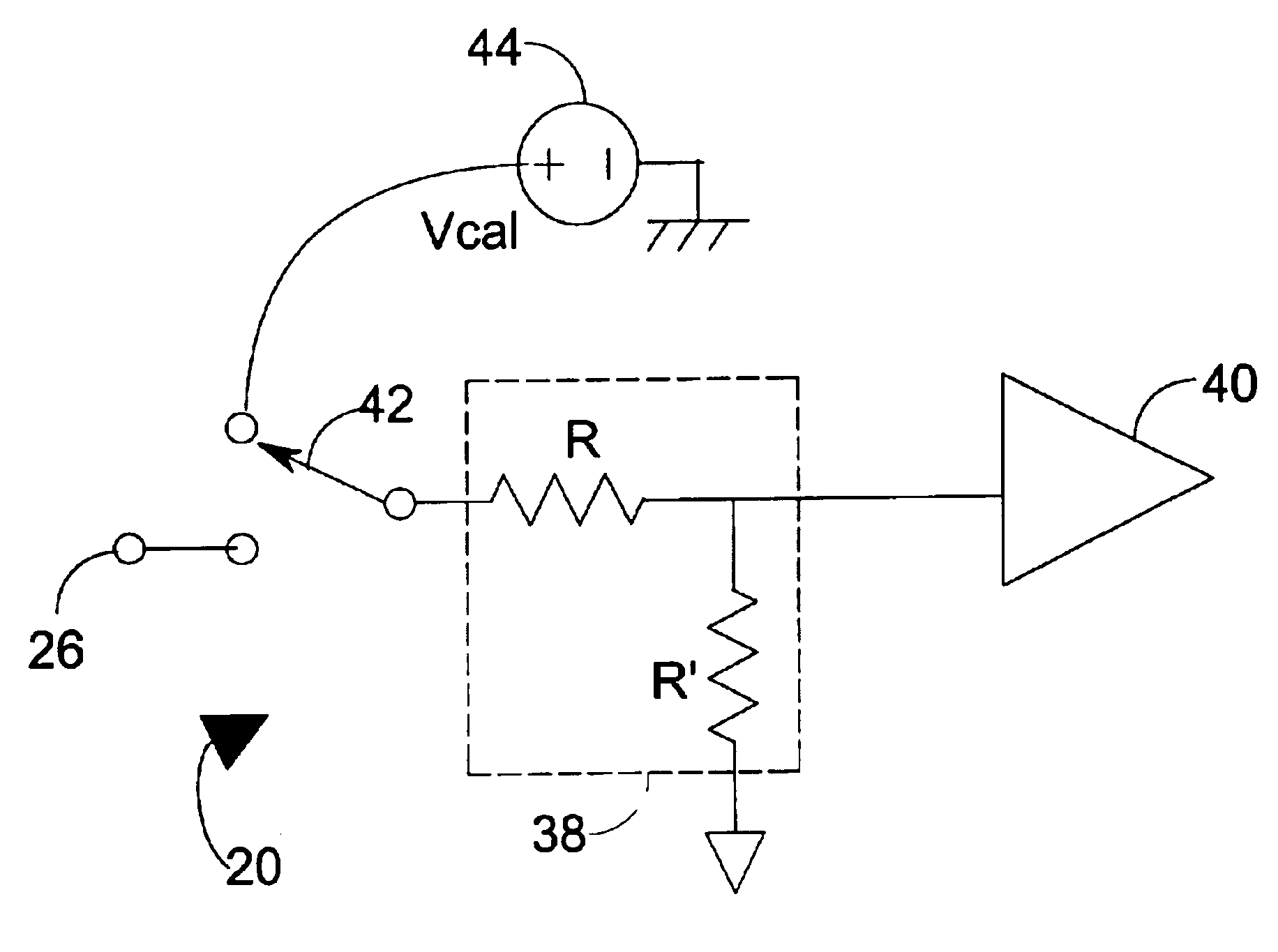

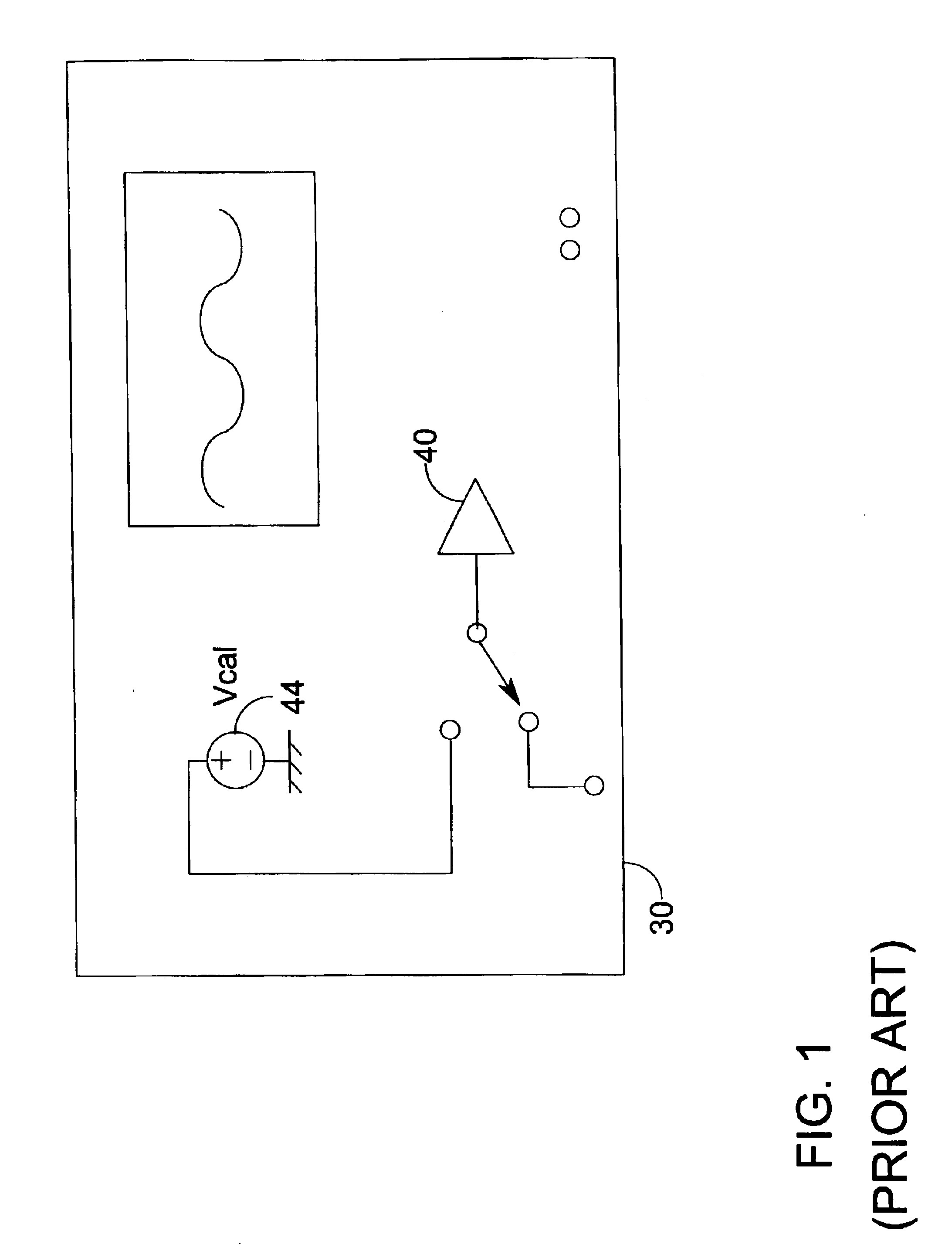

A self-calibrating test probe system of the present invention does not require probing head removal and replacement. Using the system of the present invention, the test probe and / or the entire system (including a testing instrument) may be calibrated or may self-calibrate while the probing head remains connected to an electrical component under test. The self-calibrating electrical testing probe system includes calibration circuitry including at least one input resistor, at least one relay, and at least one known calibration reference signal. If the test probe is an active test probe, the calibration circuitry may also include at least one amplifier. Each relay has a first position that provides signal access to a testing signal from an electrical component under test and a second position that provides signal access to the known calibration reference signal. Using the present invention, the error of the test probe and / or system is determined and compensated. Exemplary methods by which error compensation may be provided includes, for example, amplifying the testing signal, creating a correction table of correction values and adding an appropriate value from the correction table, or mathematically compensating.

Owner:TELEDYNE LECROY

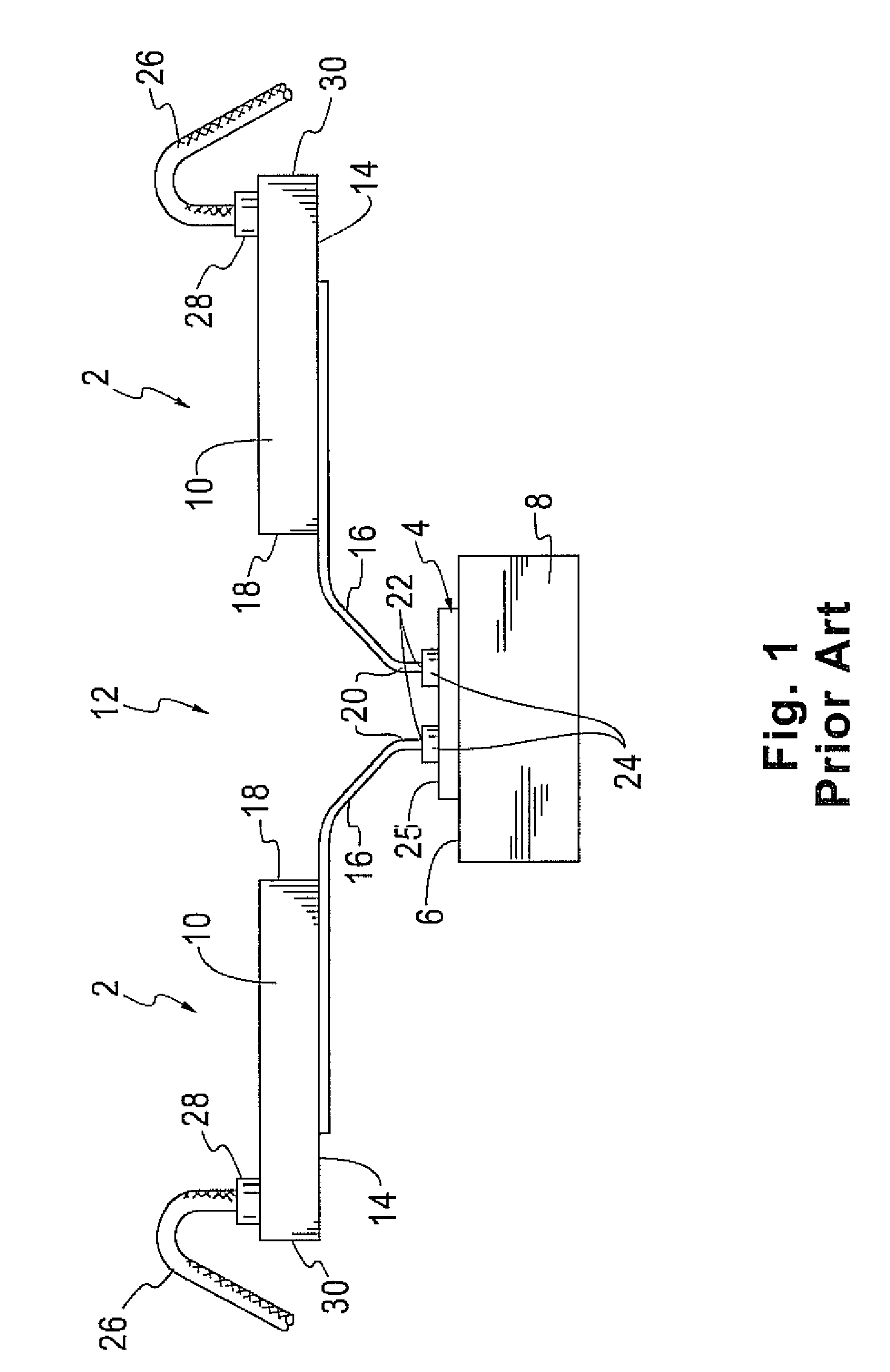

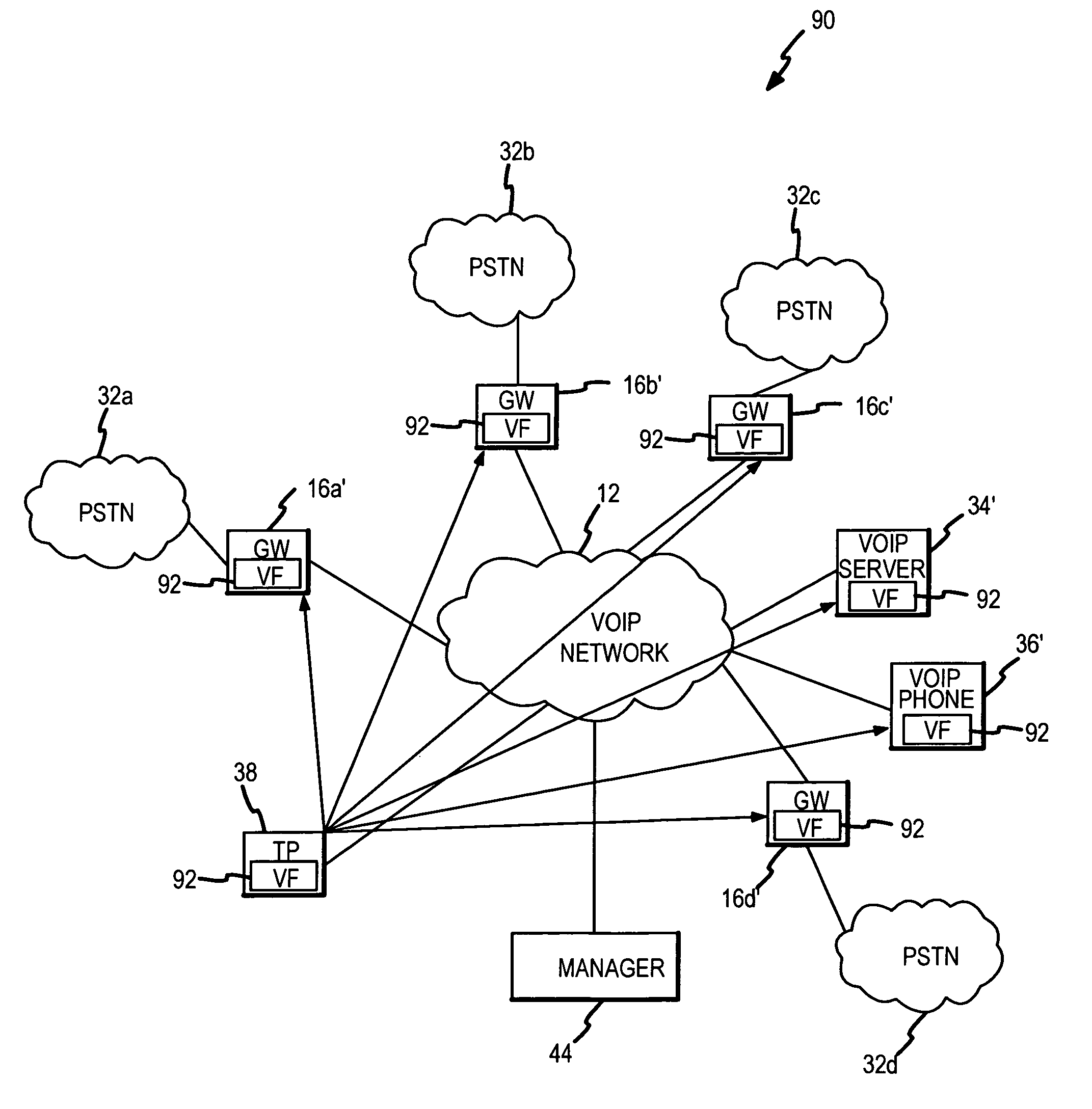

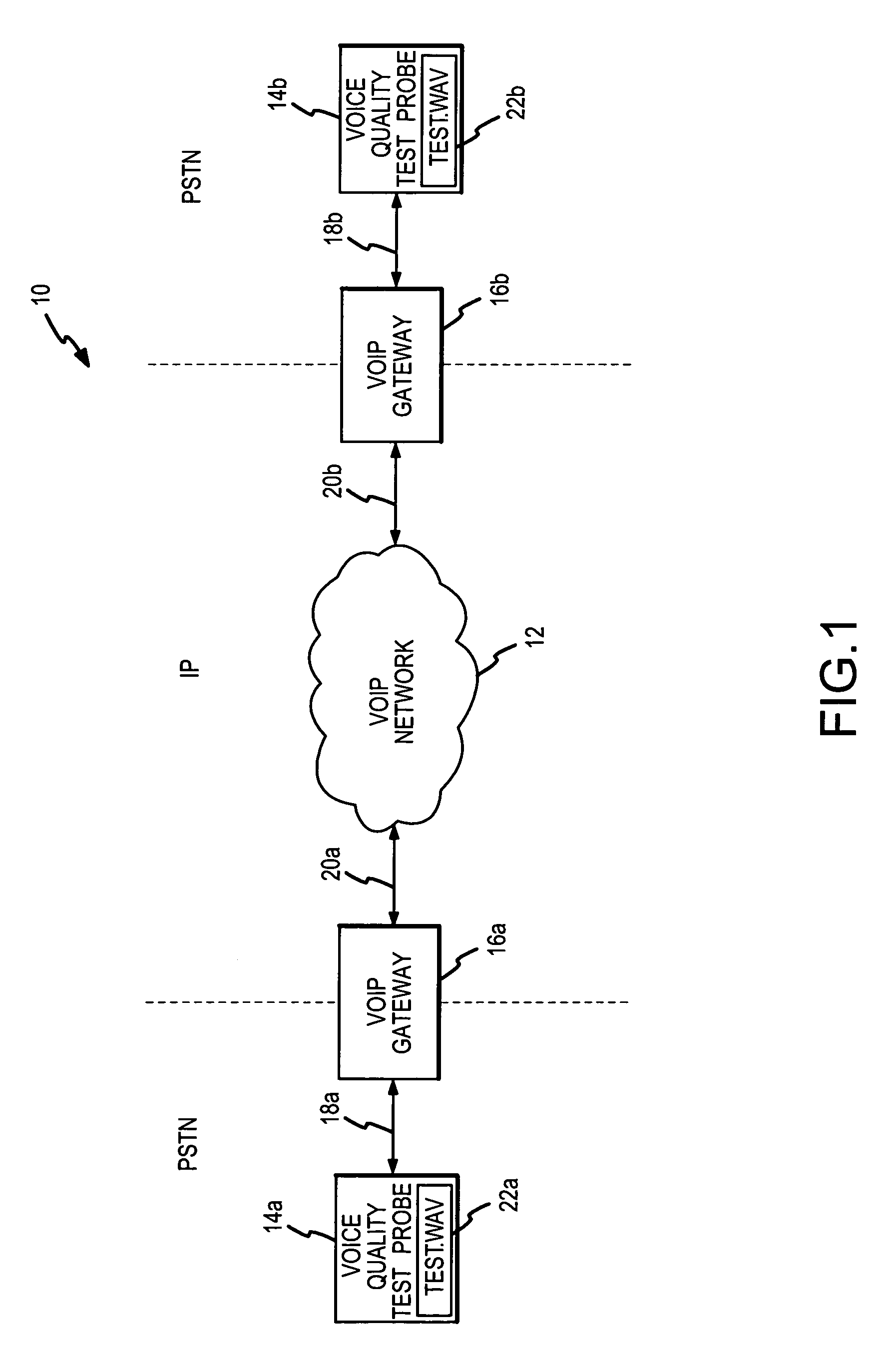

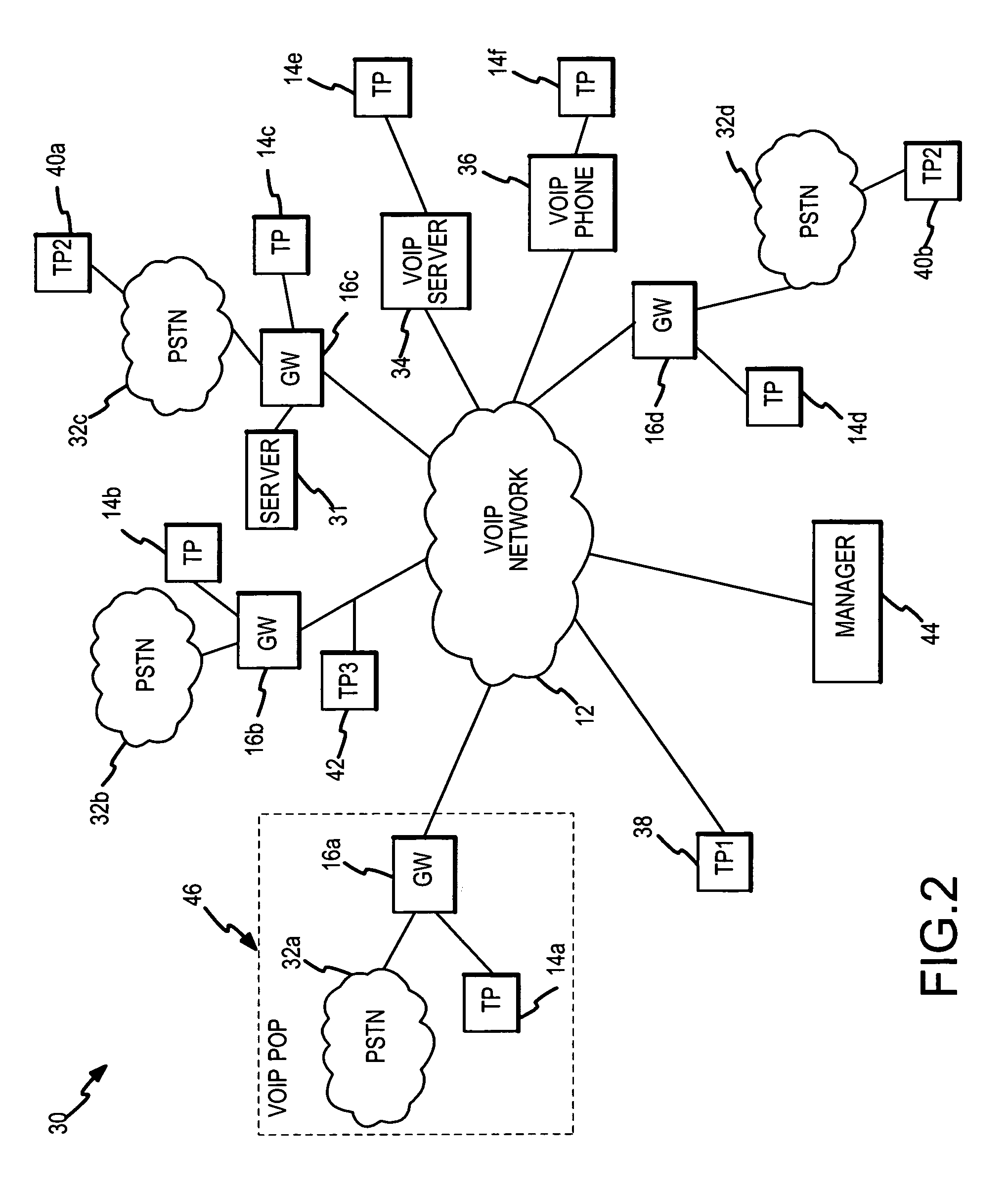

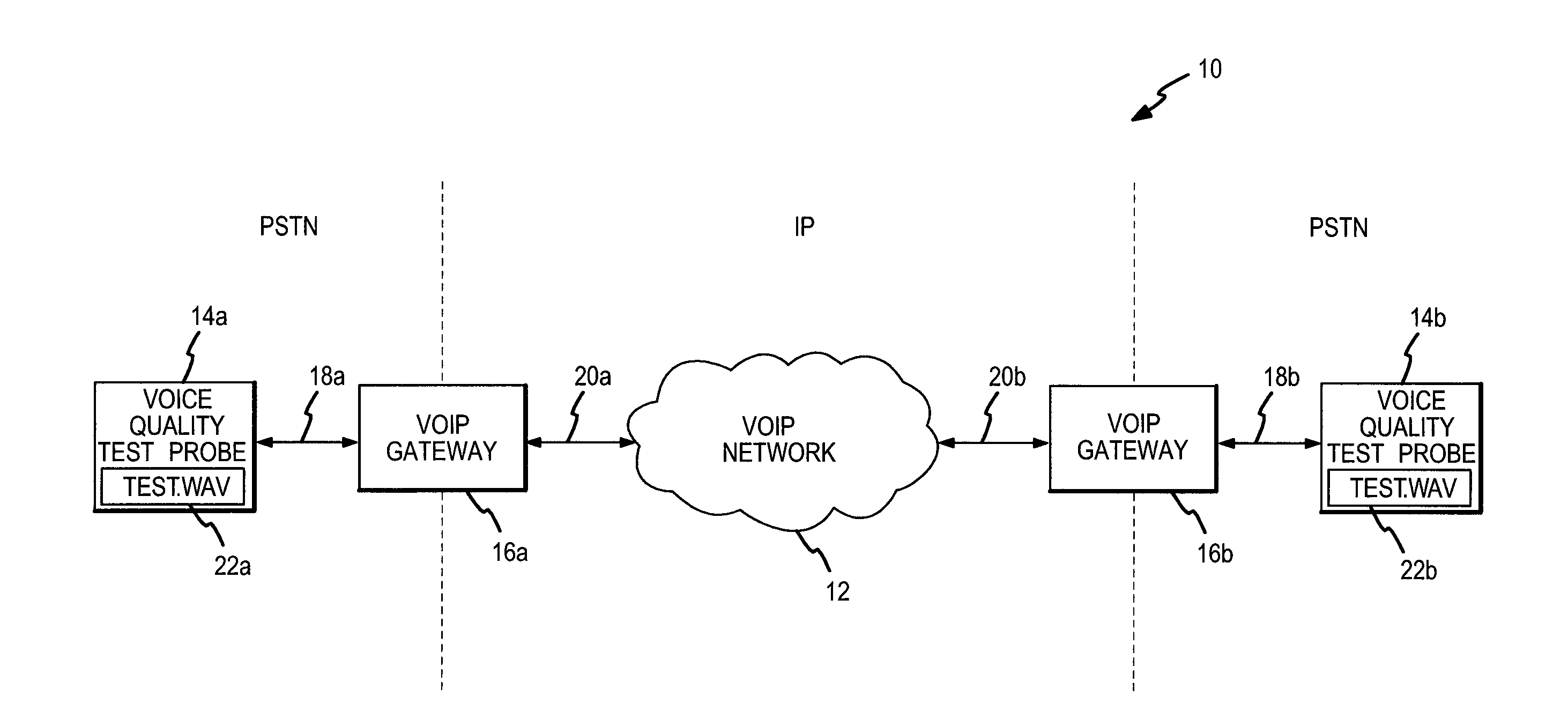

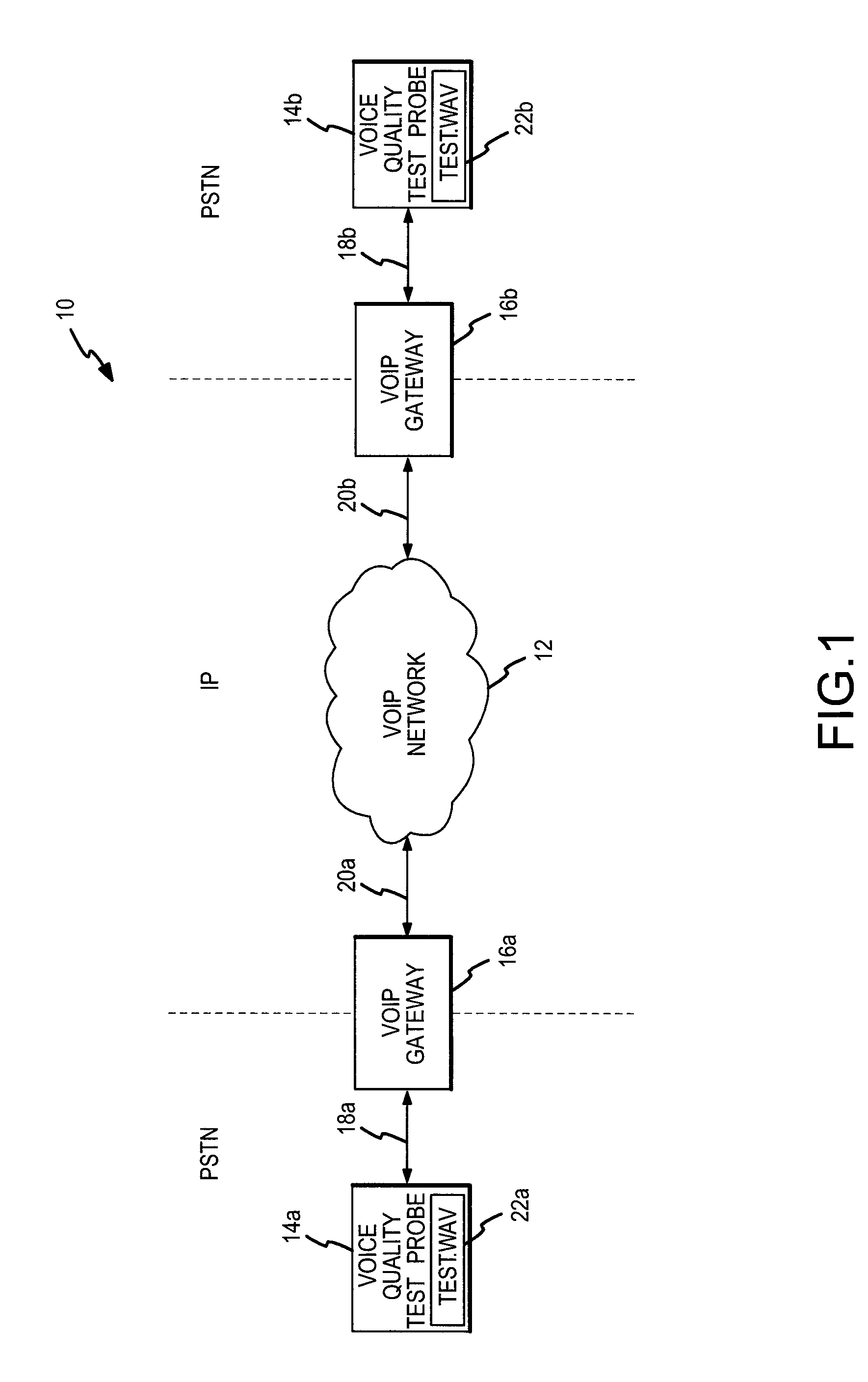

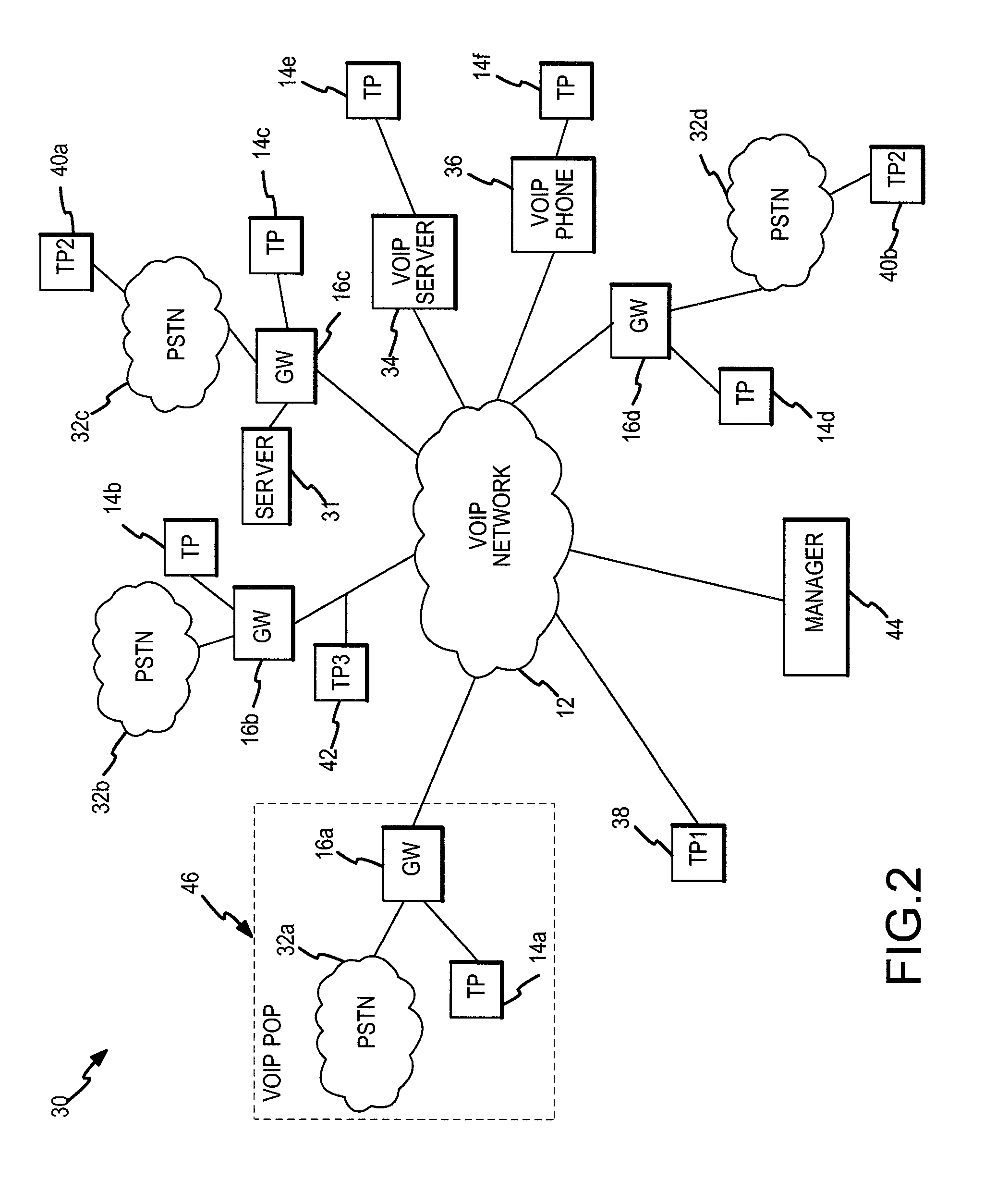

Service level agreements based on objective voice quality testing for voice over IP (VOIP) networks

ActiveUS7173910B2Telephone data network interconnectionsError preventionService-level agreementComputer network

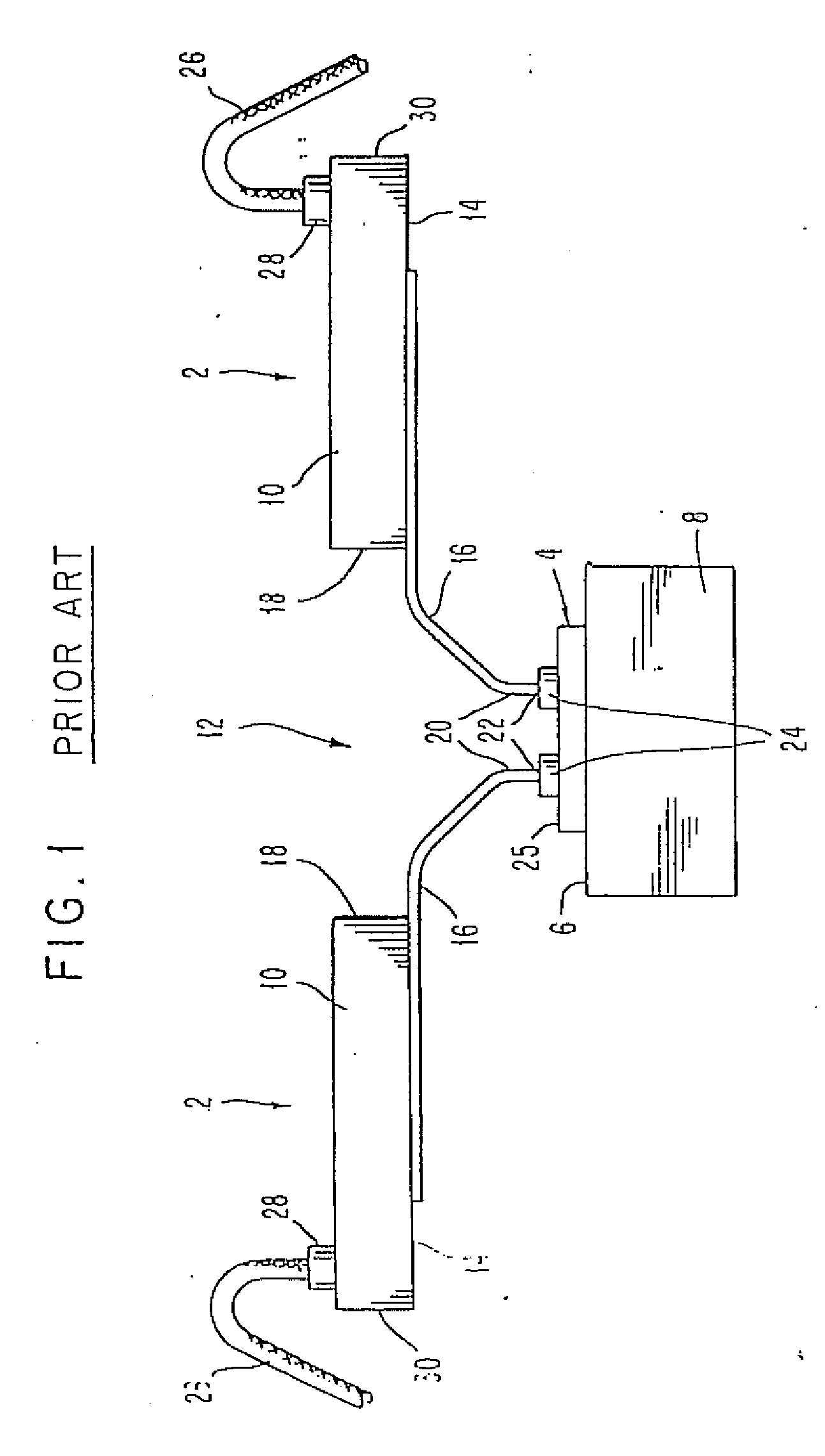

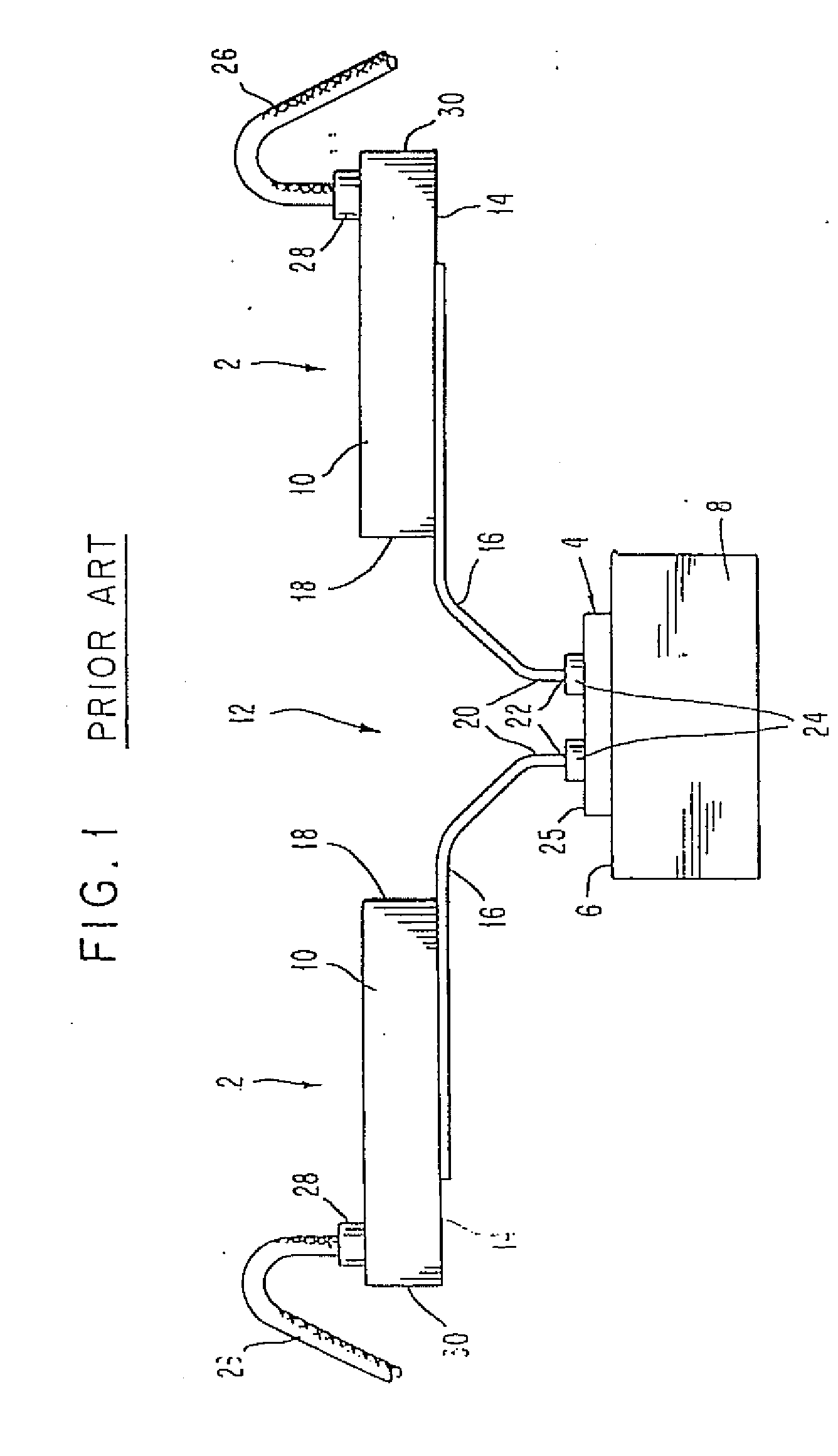

An objective, service-level specific voice call listening quality test scheme for a Voice Over IP (VOIP) network is presented. Test probes are deployed along the border of the VOIP network. Each test probe is capable of placing calls over the VOIP network to the other test probes at different levels of service and measuring call quality using an objective measurement algorithm such as PAMS or PSQM. The measurement results are collected on an ongoing basis to obtain information on the VOIP network's voice call quality. The information is compared to thresholds to measure performance against Service Level Agreement guarantees.

Owner:LEVEL 3 COMM LLC

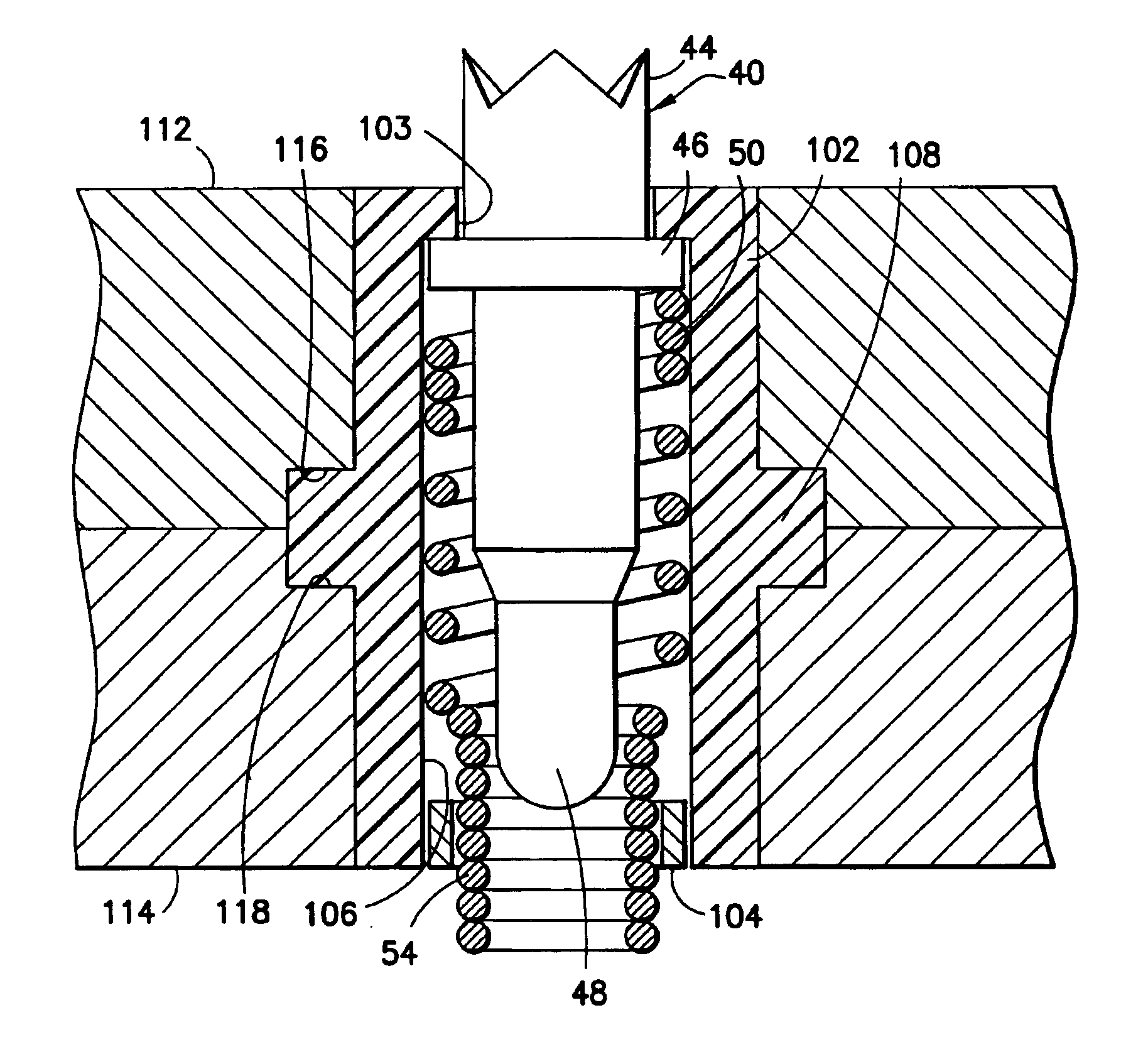

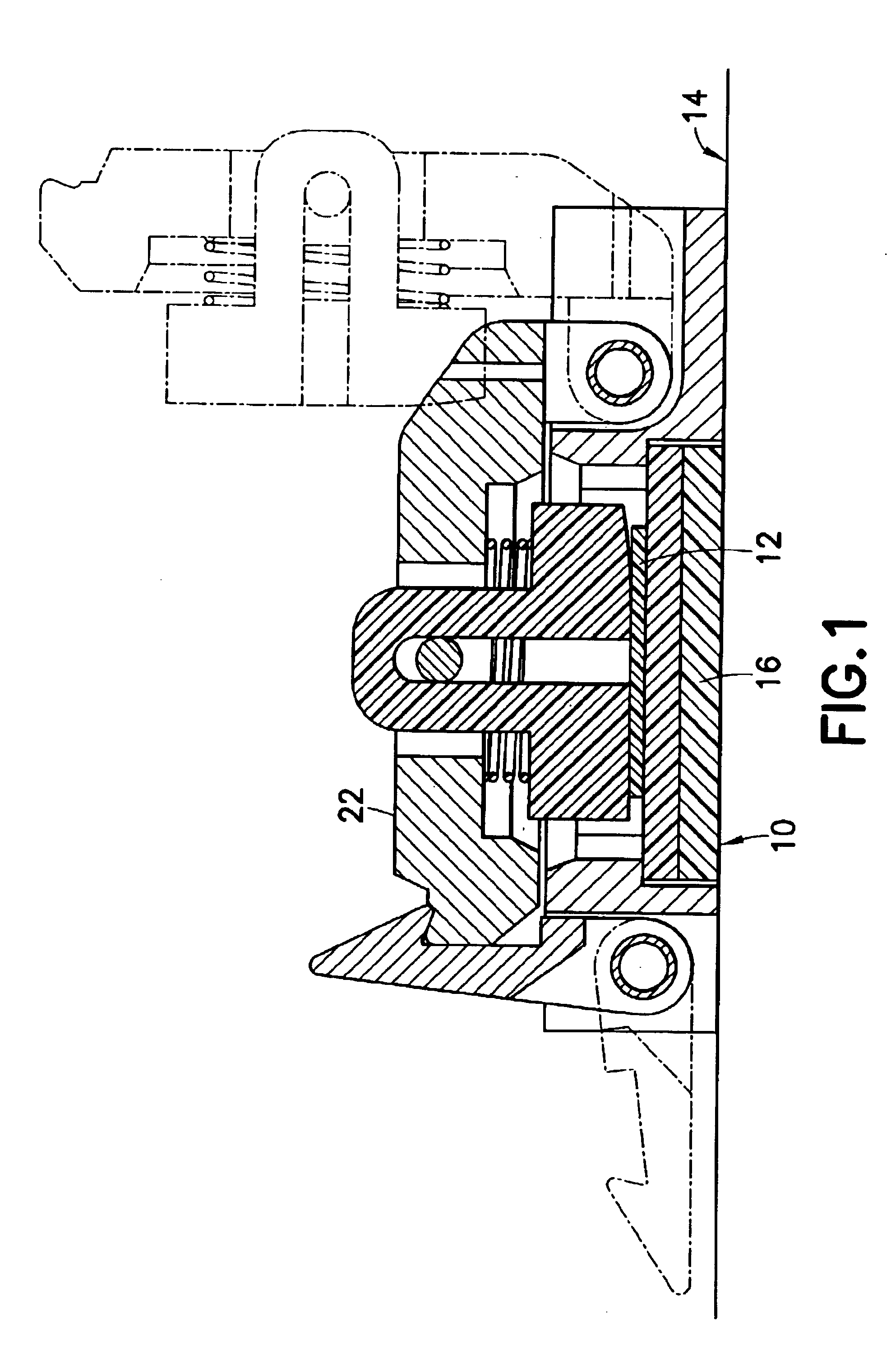

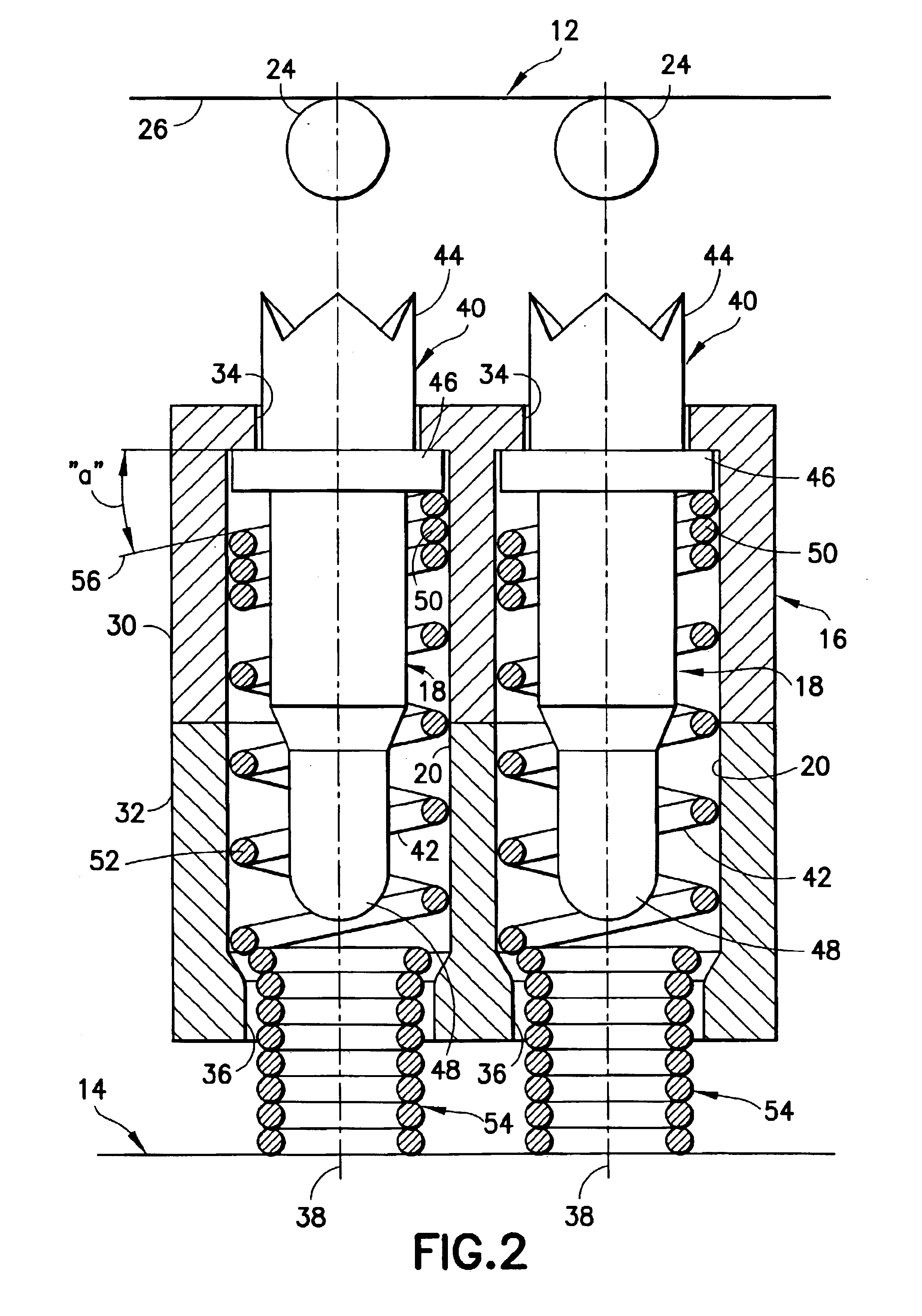

Shielded integrated circuit probe

InactiveUS6937045B2Reliable electrical connectionLow insertion force parameterCoupling contact membersMeasurement instrument housingElectricityElectrical resistance and conductance

A test probe consists of an elongated screw machine contact biased by a helical spring and mounted in a through hole of a non-conductive substrate. One end of the contact includes a crown for engaging a solder ball lead of an IC package, and the contact includes an intermediate collar which maintains the contact within the through hole. The helical spring is disposed about the contact, with one end thereof engaging the lower end of the collar. The other end of the helical spring has contiguous coils and is of a reduced diameter so as to extend beyond the lower end of the non-conductive substrate to make electrical contact with a printed circuit board. When the test probe is compressed between the IC package and the printed circuit board, the inherent twisting of the helical spring causes the contact to tilt and make electrical contact with the contiguous coils, thereby establishing a direct electrical path between the IC package and the printed circuit board, with minimum resistance and minimum inductance. In an alternate embodiment, each probe is disposed within a dielectric housing which, in turn, is disposed in a through hole in a conductive substrate to effectively shield the probe from electrical interference.

Owner:ARIES ELECTRONICS

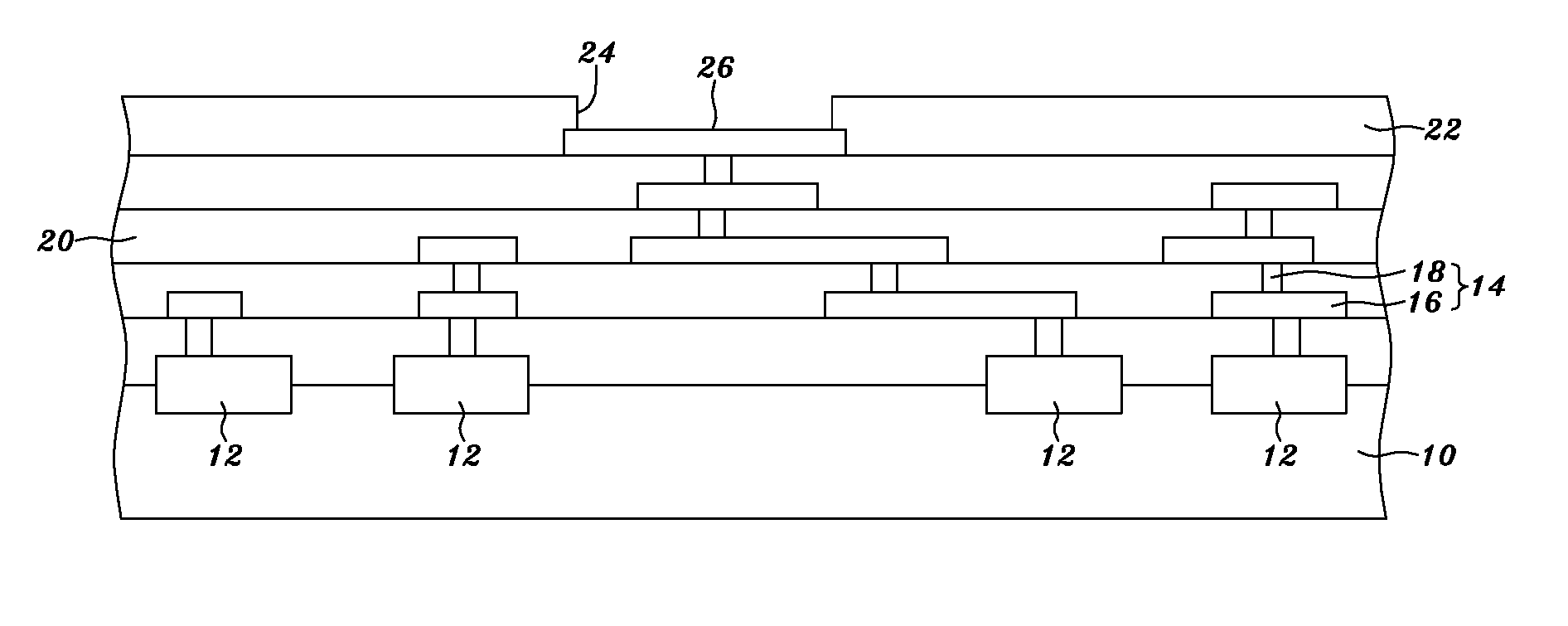

Semiconductor chip

ActiveUS20070164279A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSemiconductor chipElectrical testing

A semiconductor chip comprises a metal pad exposed by an opening in a passivation layer, wherein the metal pad has a testing area and a bond area. During a step of testing, a testing probe contacts with the testing area for electrical testing. After the step of testing, a polymer layer is formed on the testing area with a probe mark created by the testing probe. Alternatively, a semiconductor chip comprises a testing pad and a bond pad respectively exposed by two openings in a passivation layer, wherein the testing pad is connected to the bond pad. During a step of testing, a testing probe contacts with the testing pad for electrical testing. After the step of testing, a polymer layer is formed on the testing pad with a probe mark created by the testing probe.

Owner:QUALCOMM INC

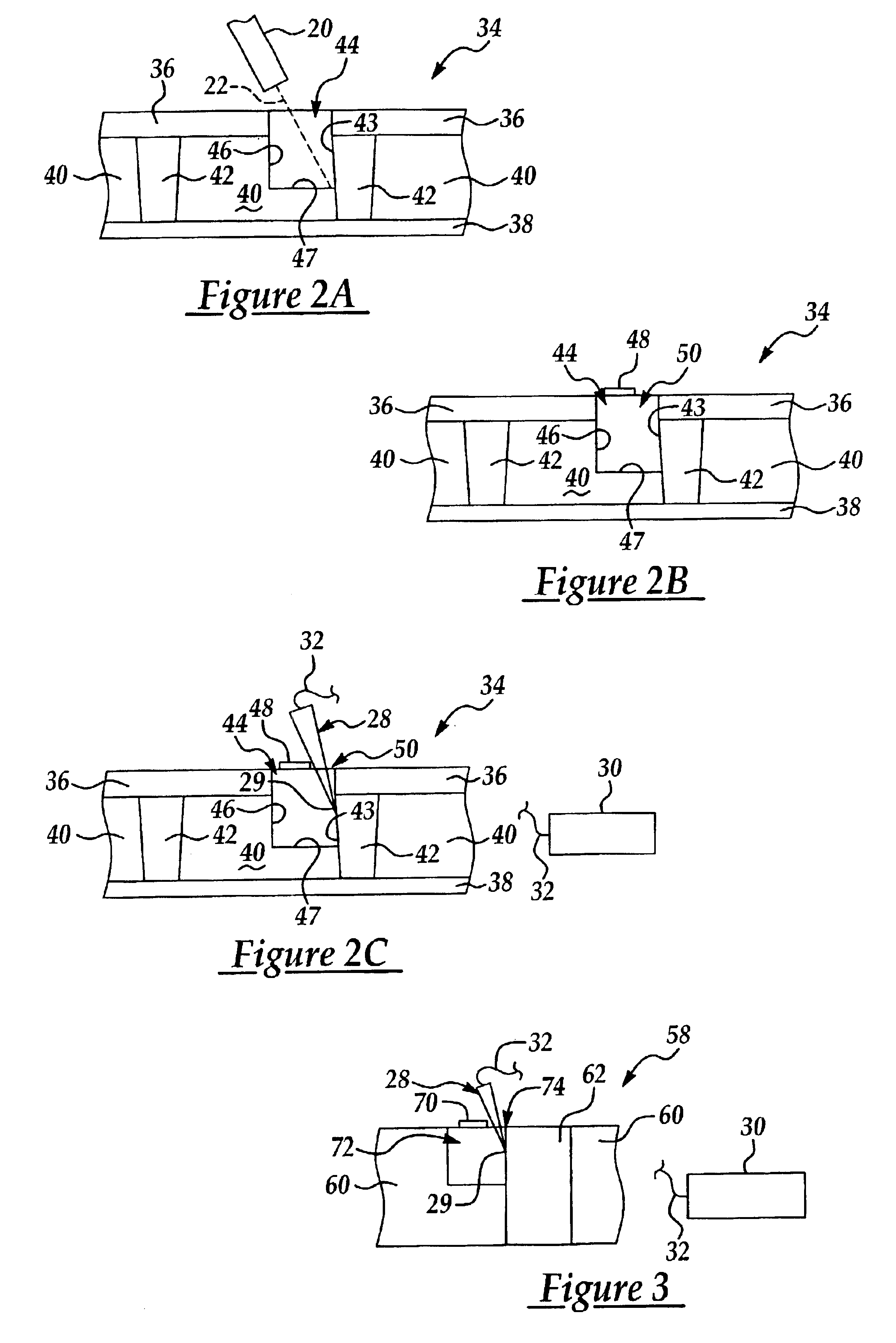

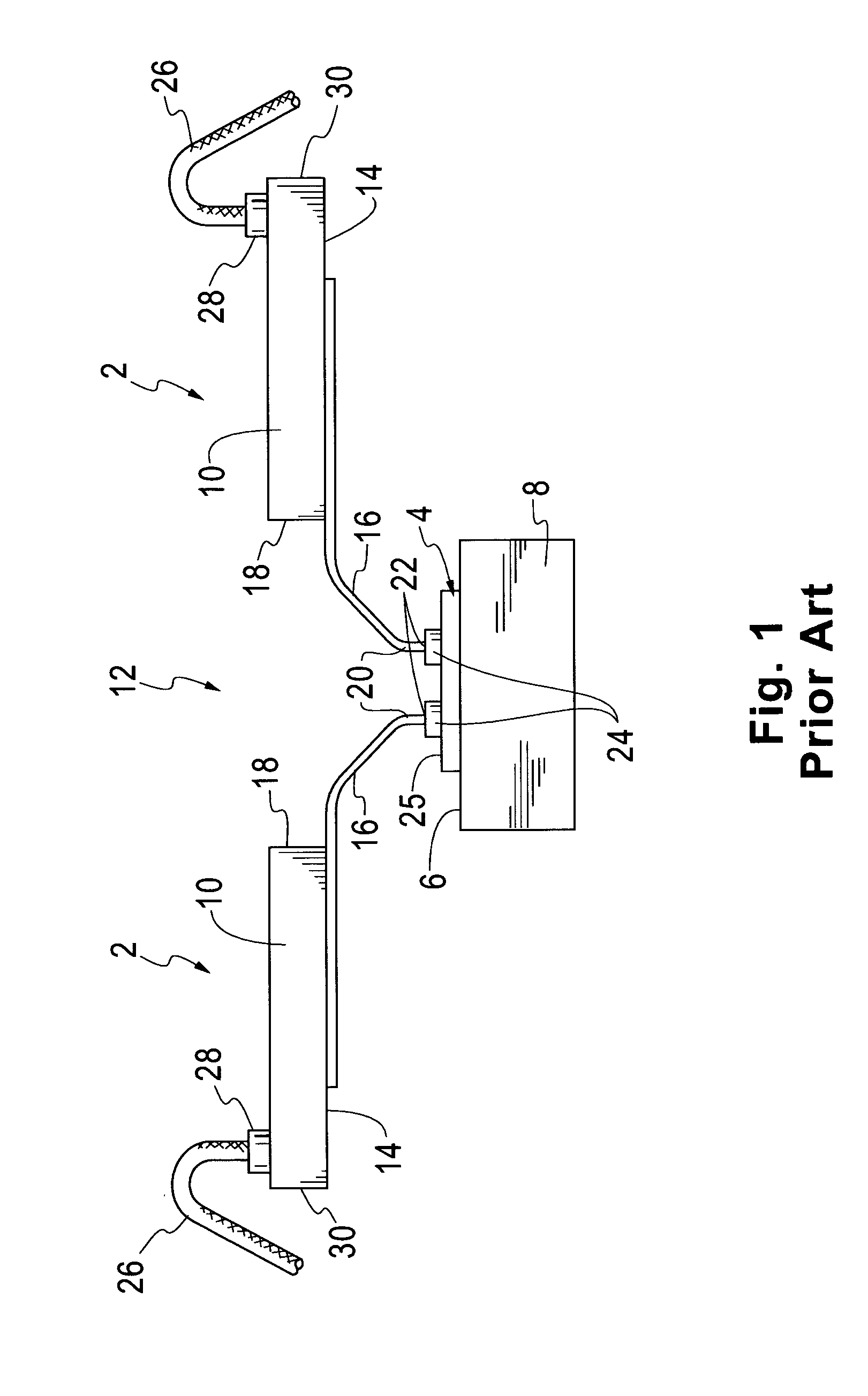

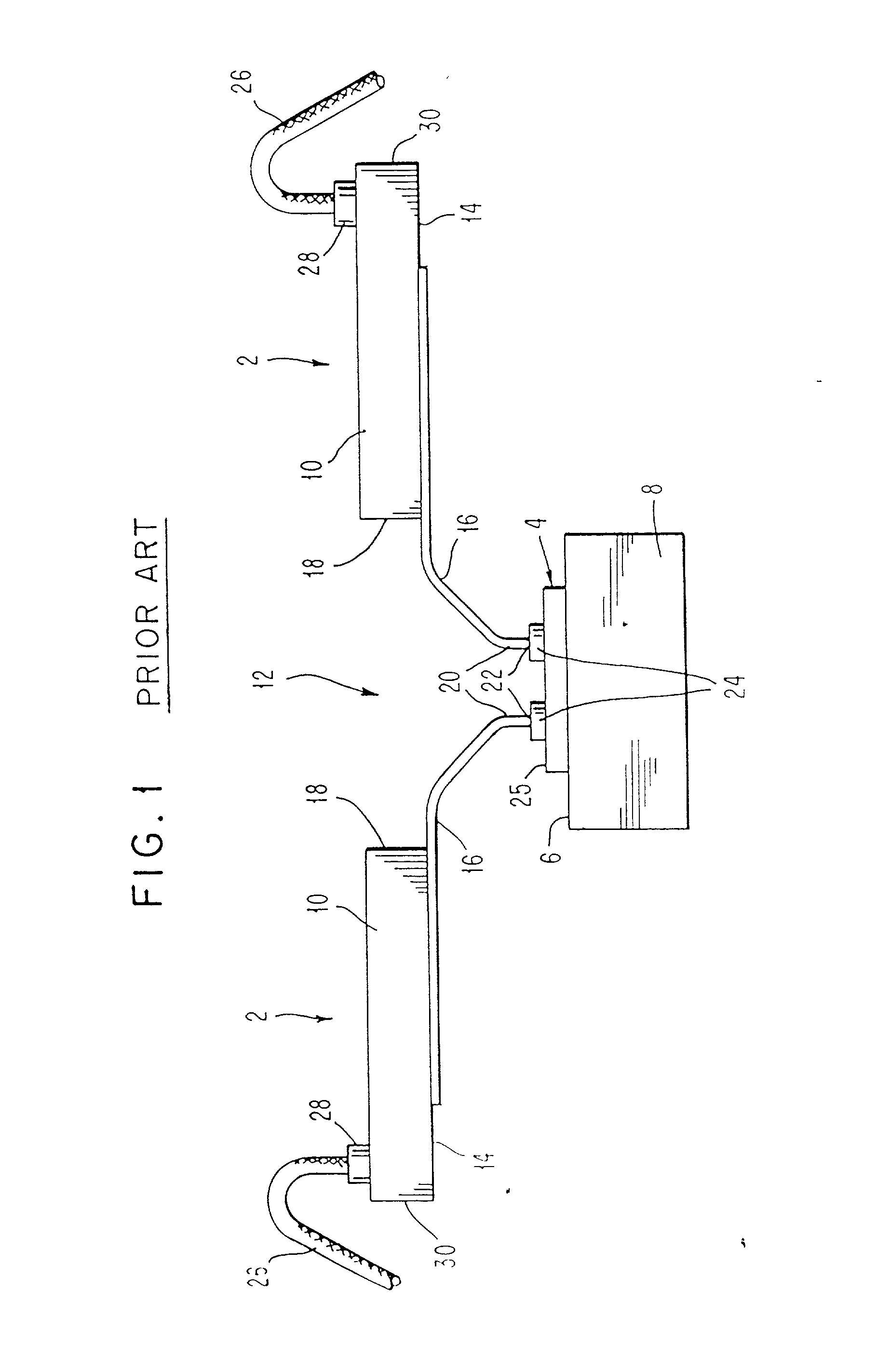

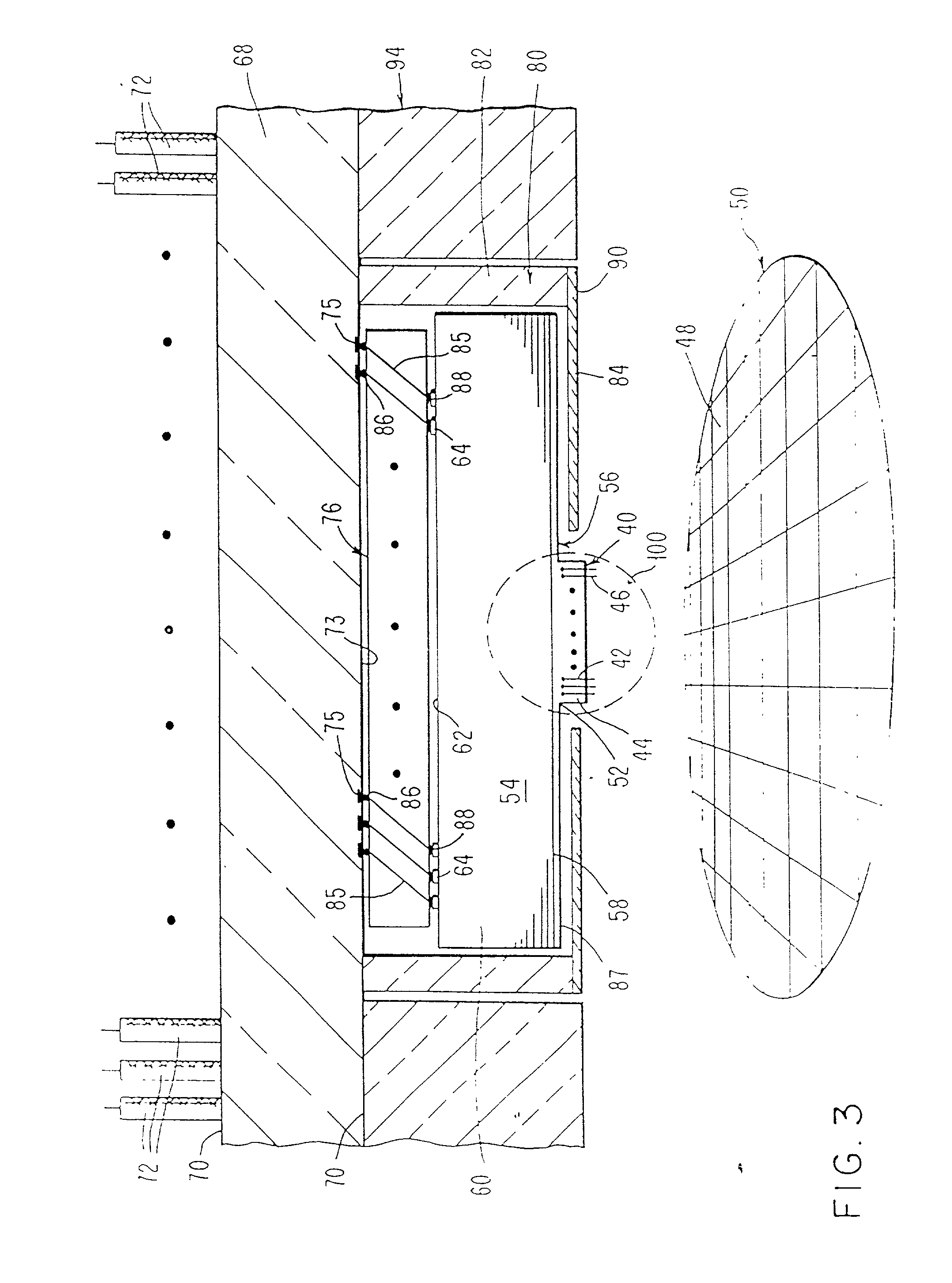

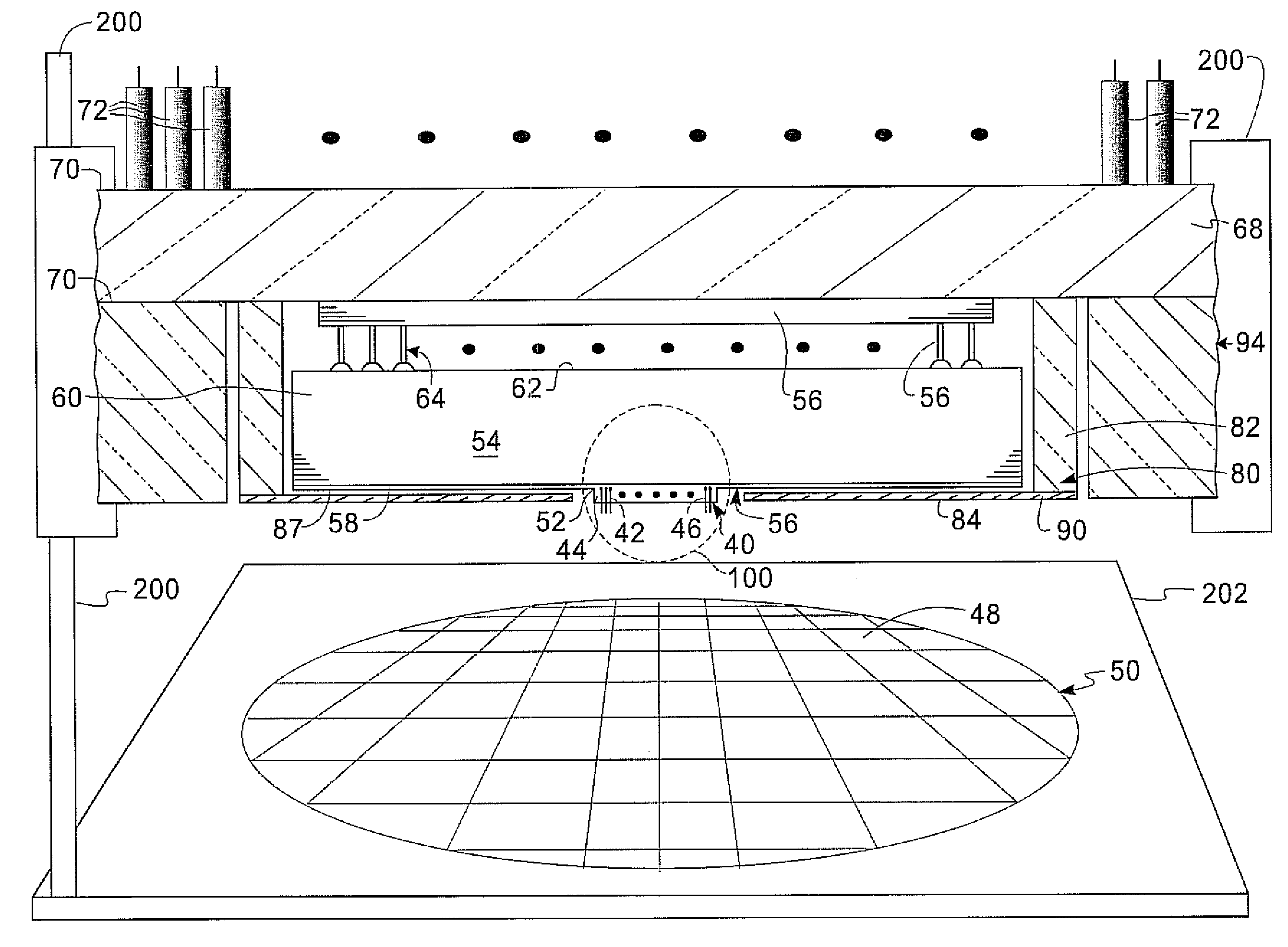

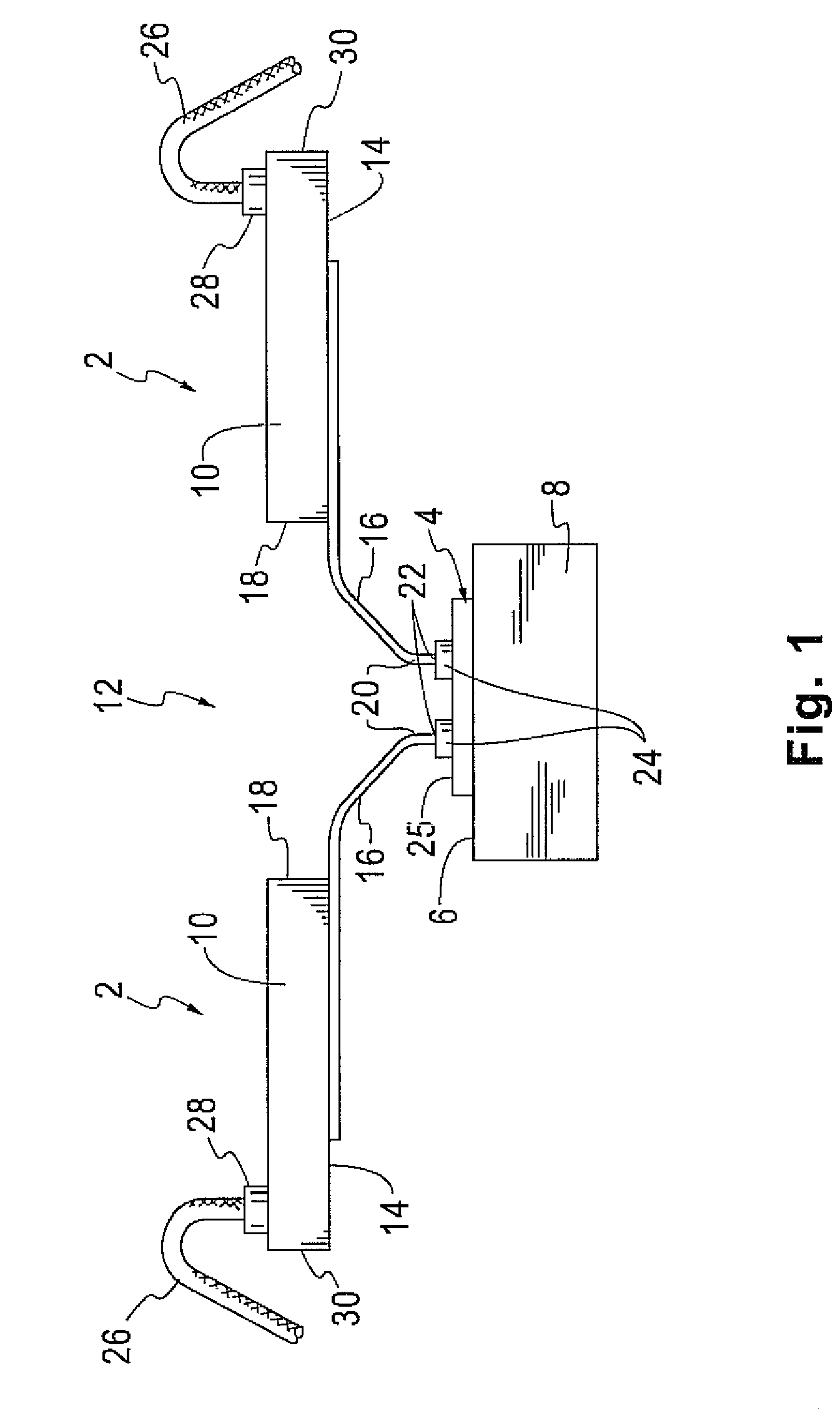

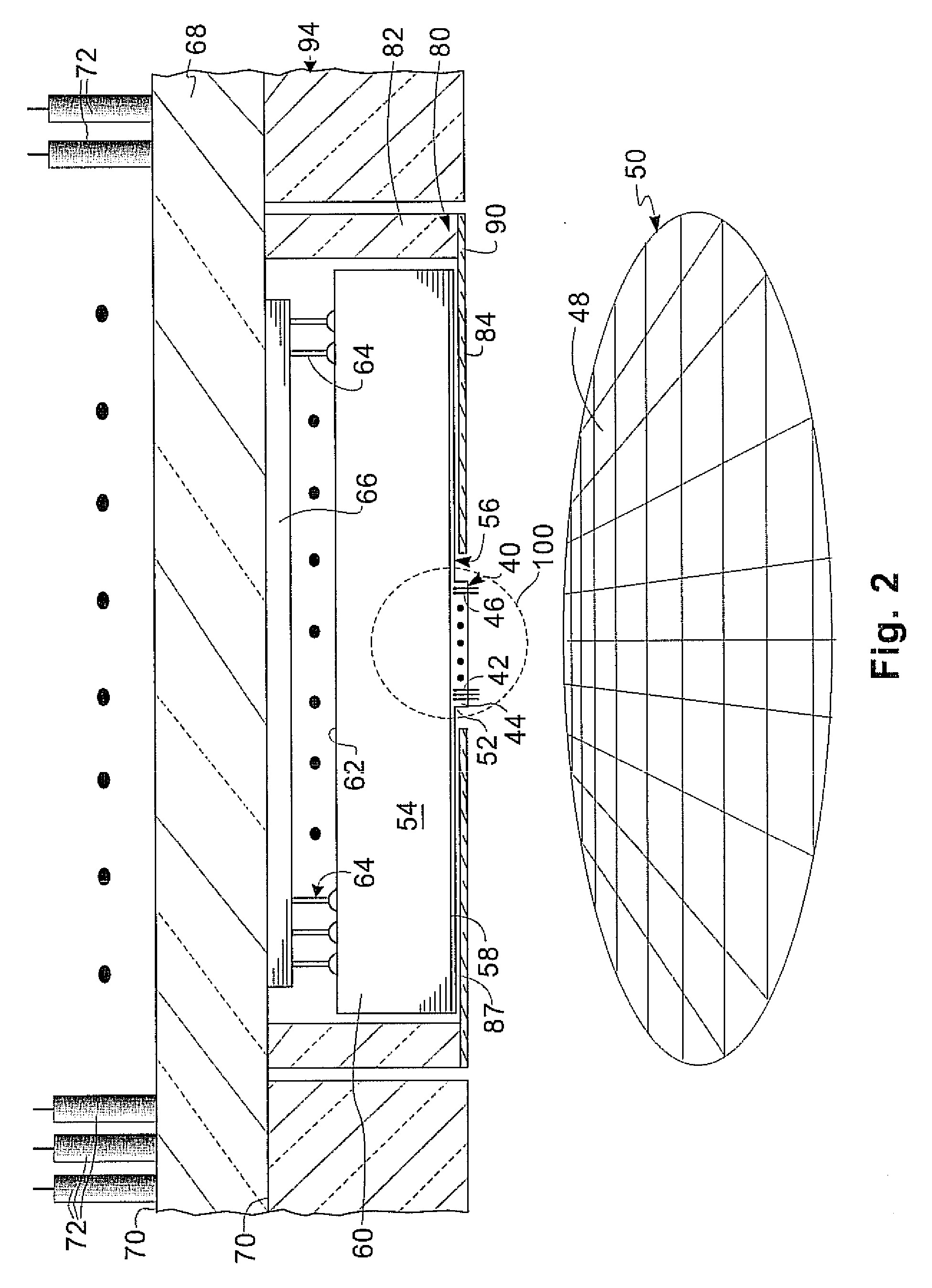

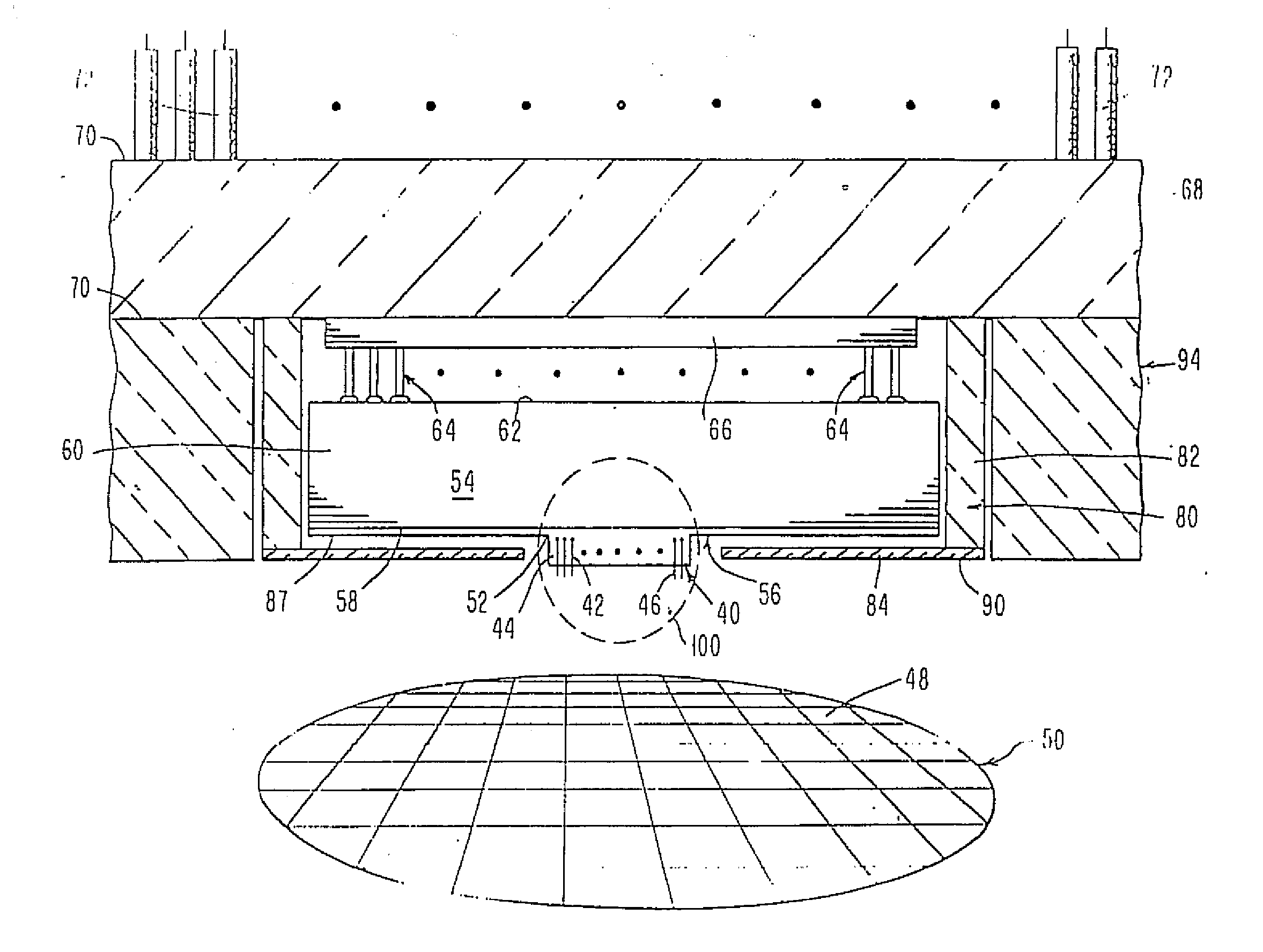

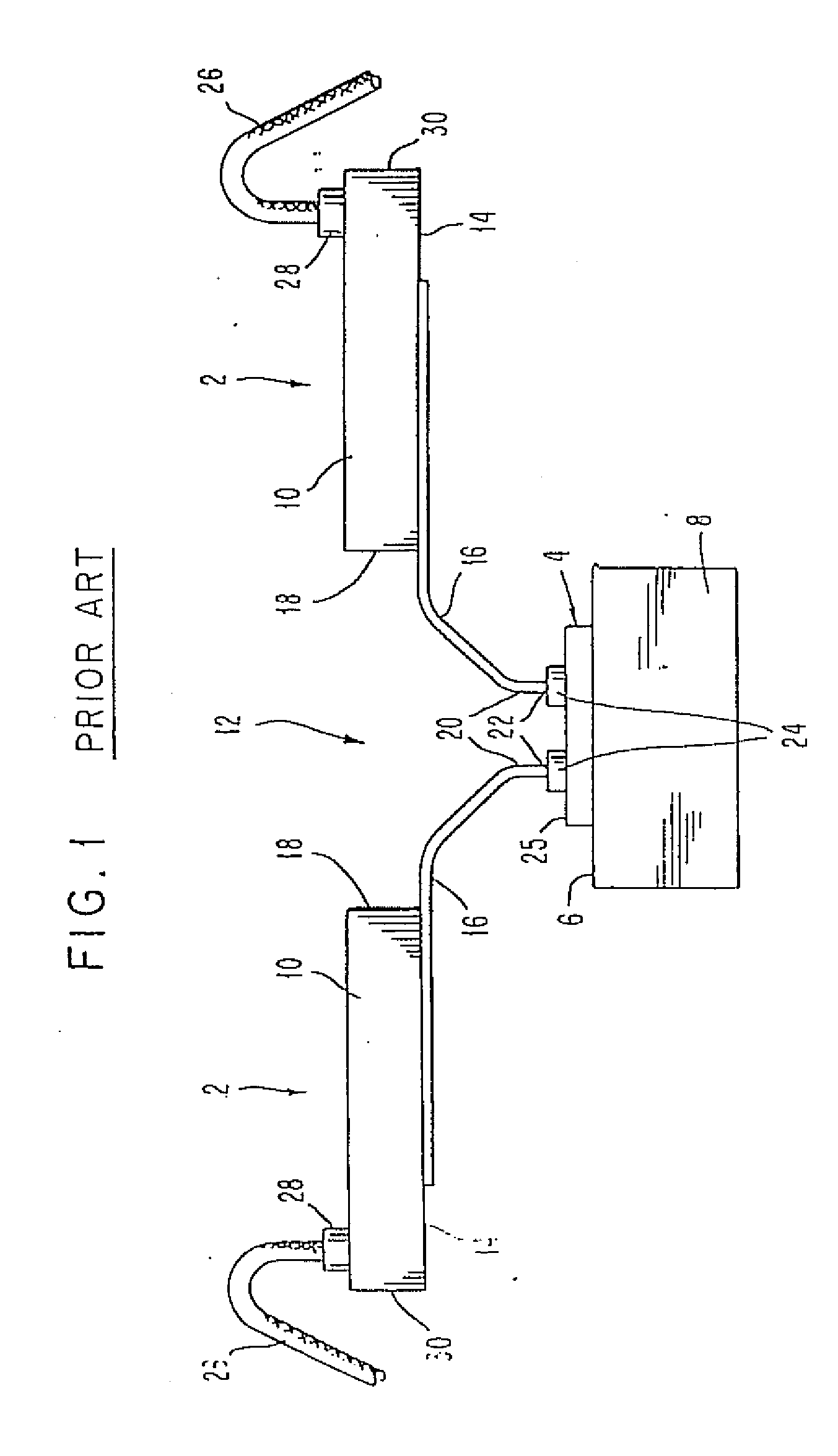

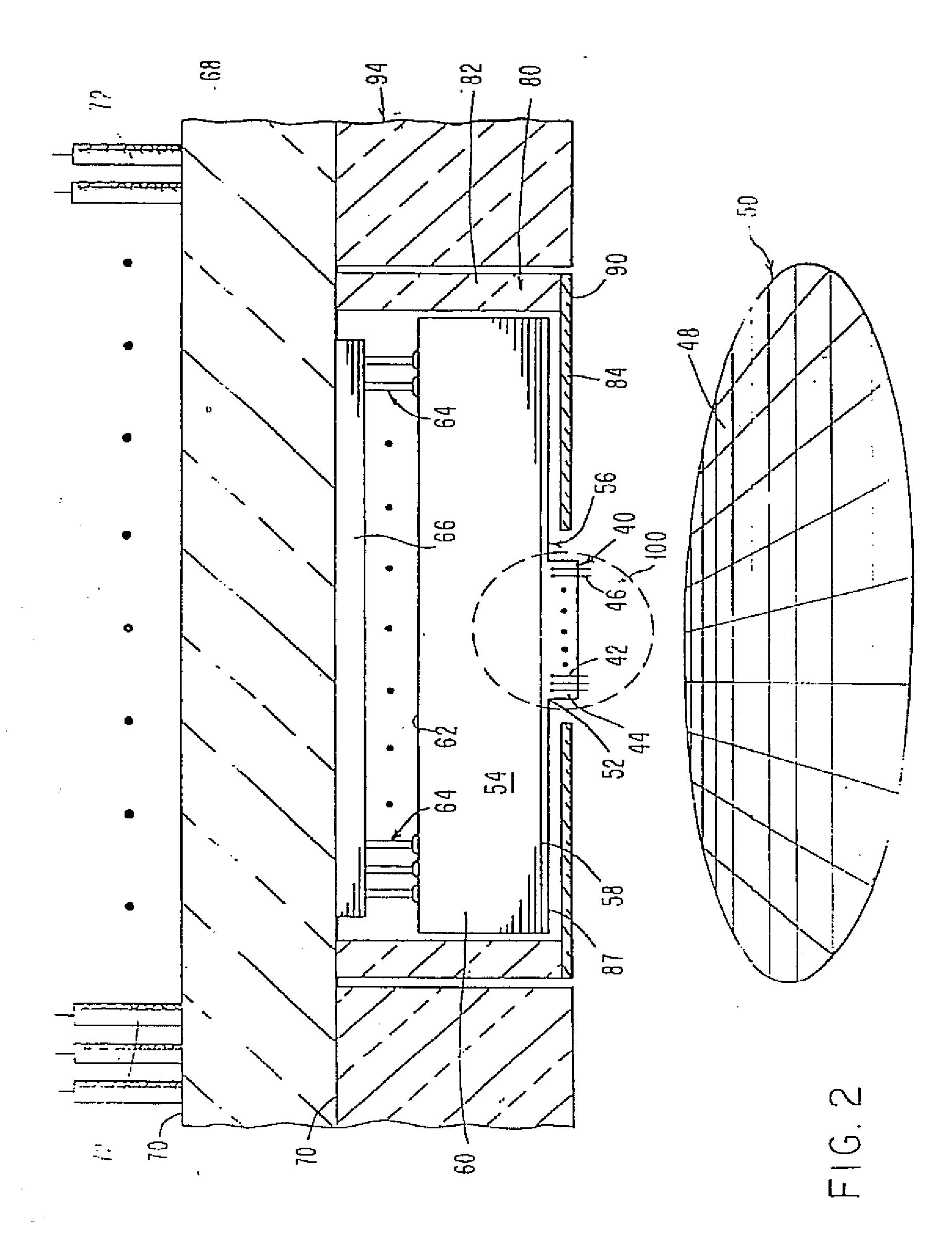

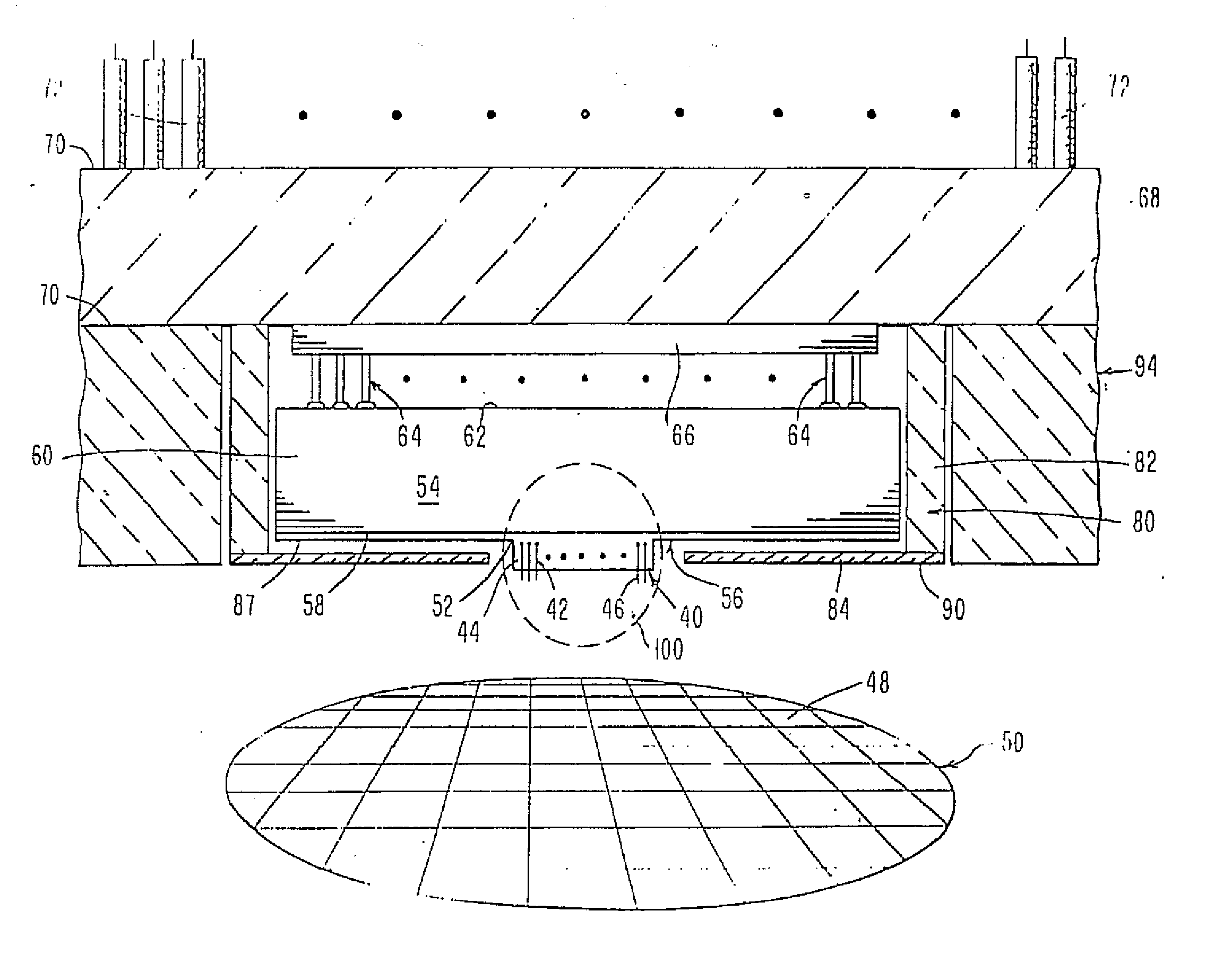

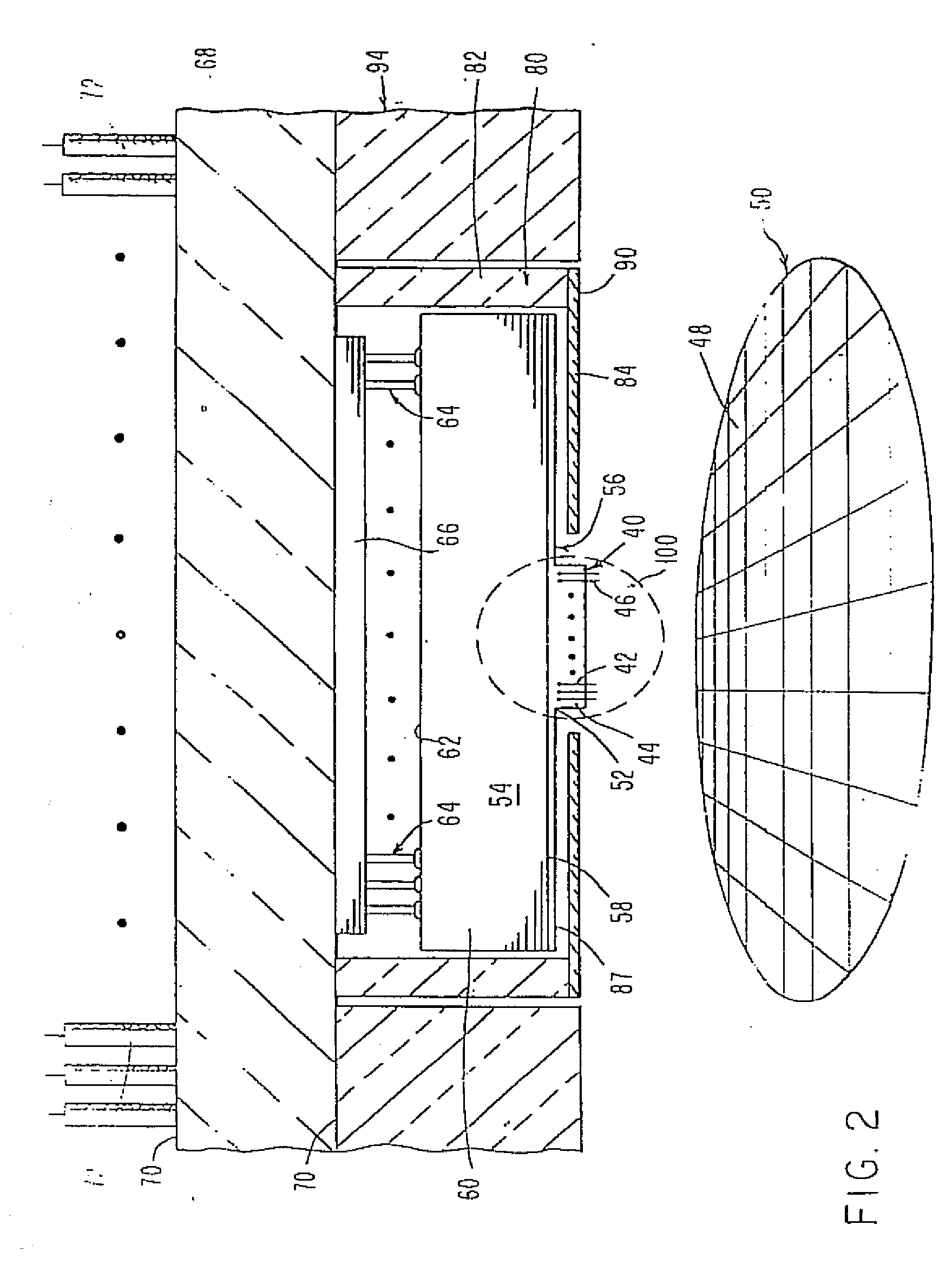

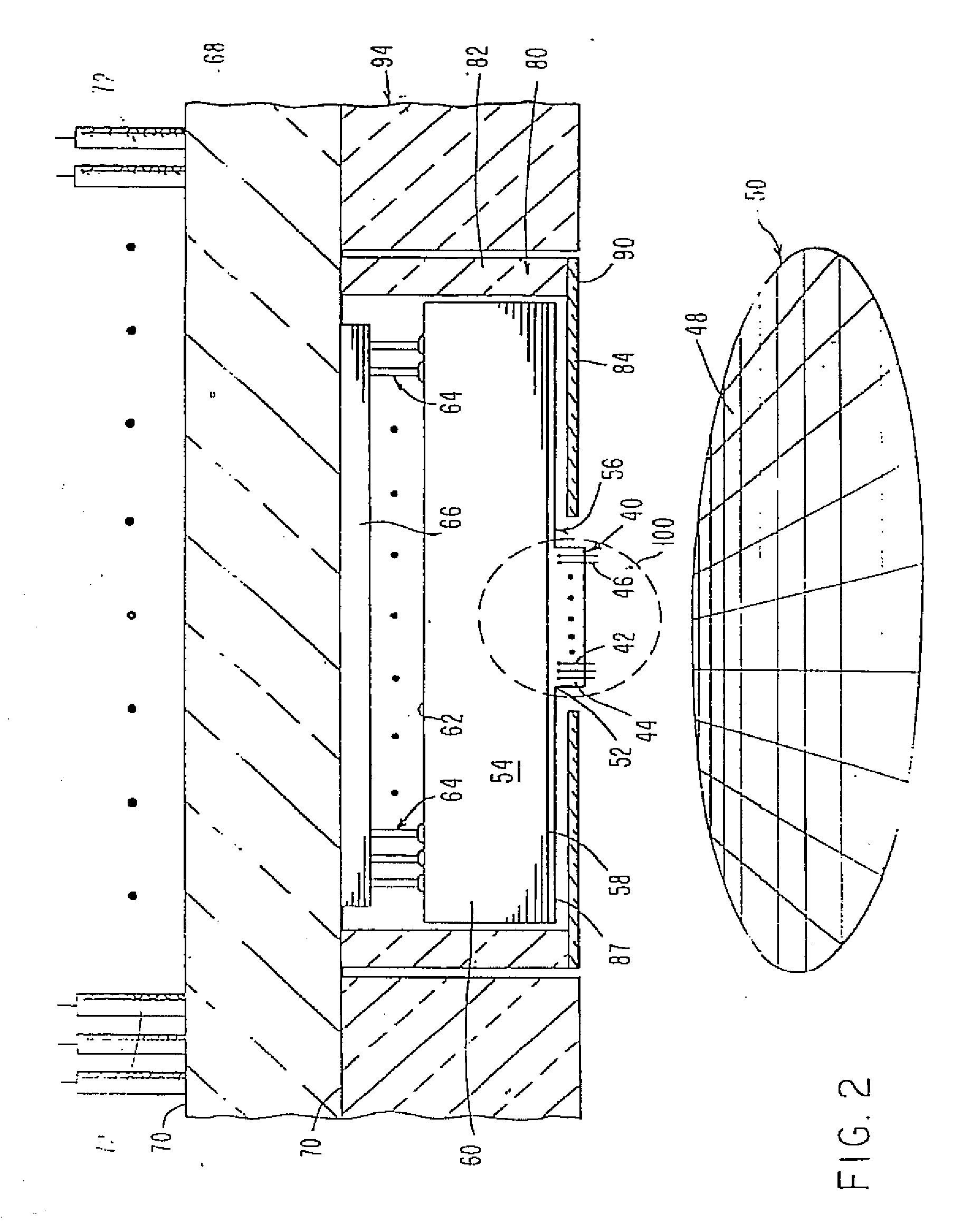

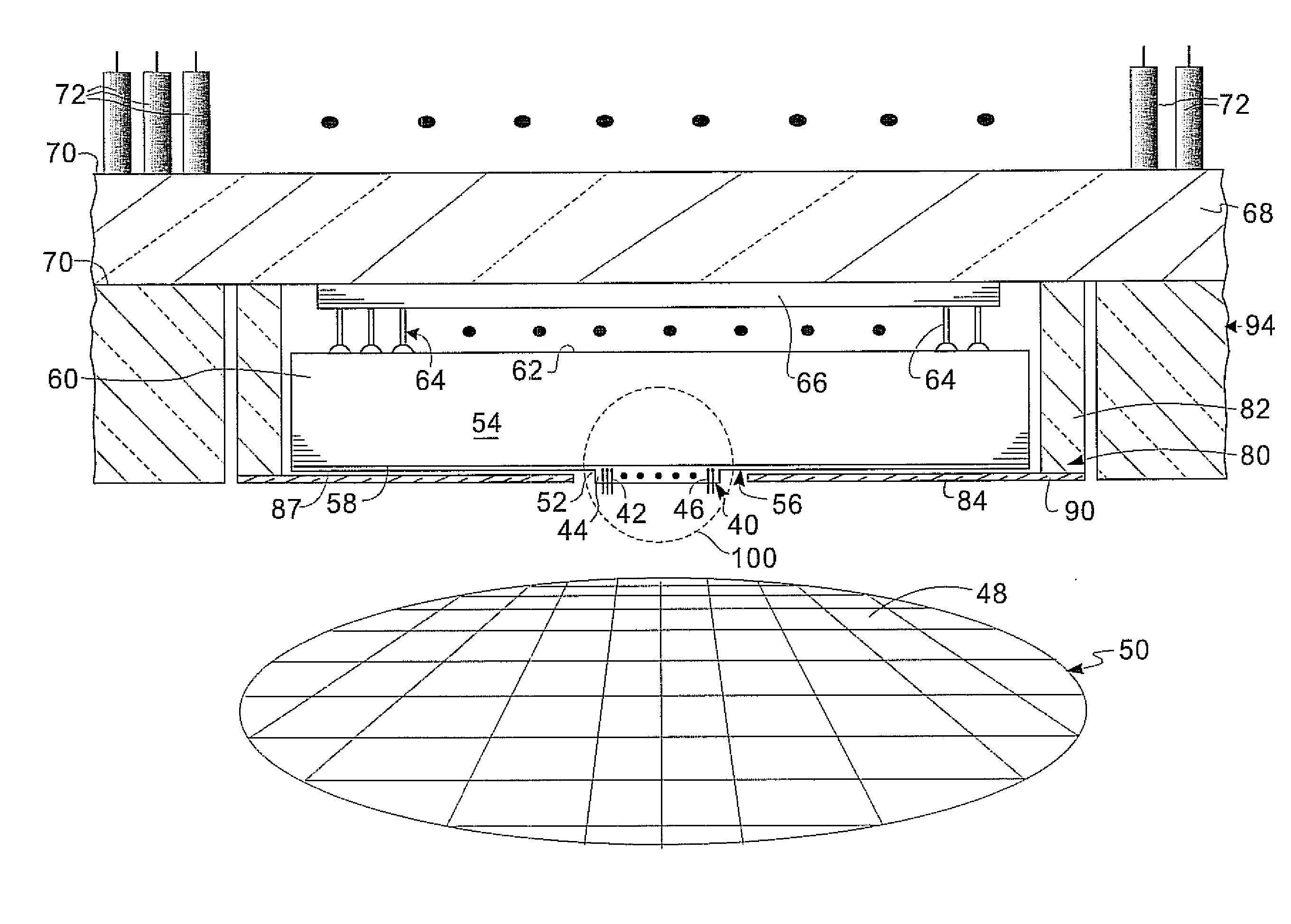

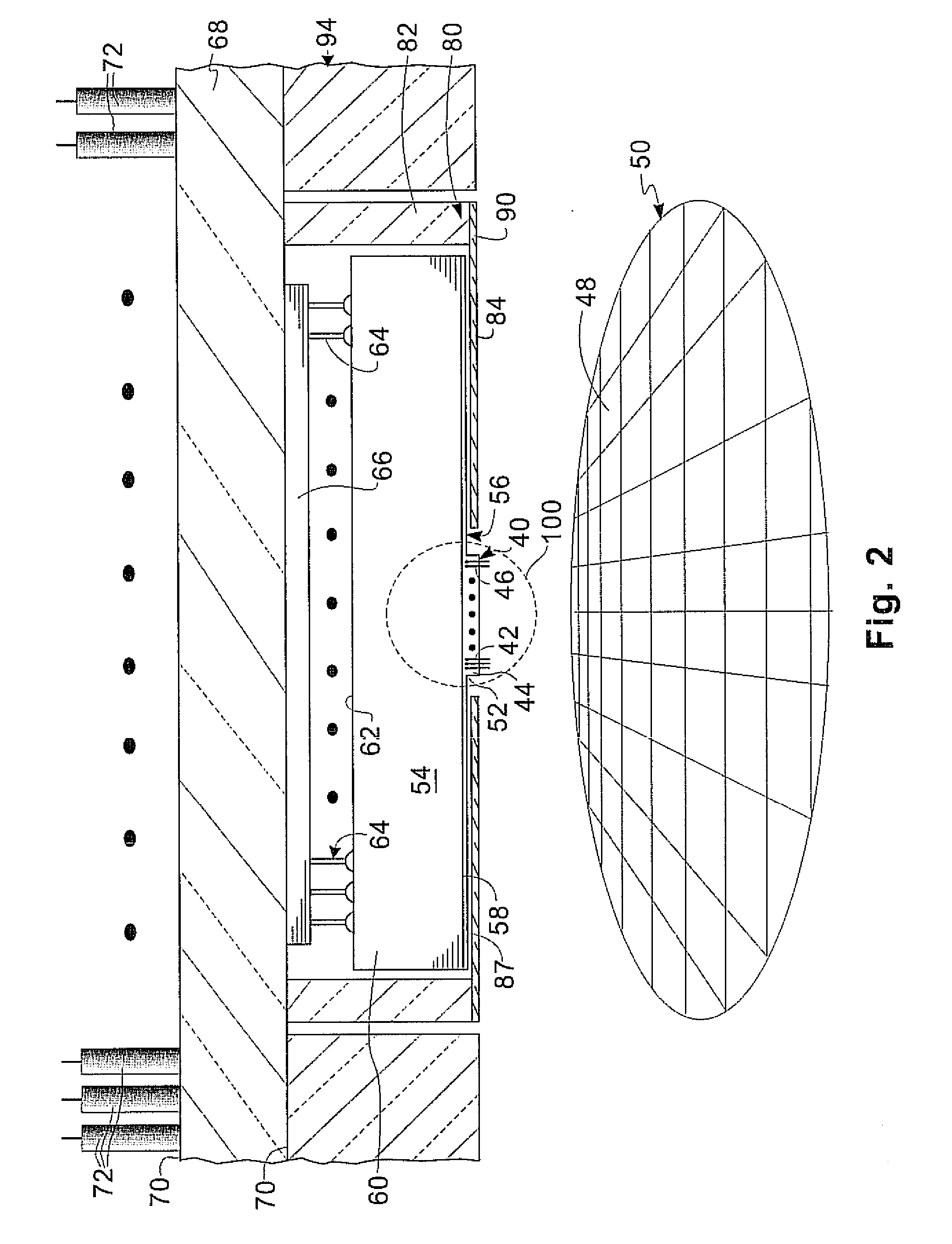

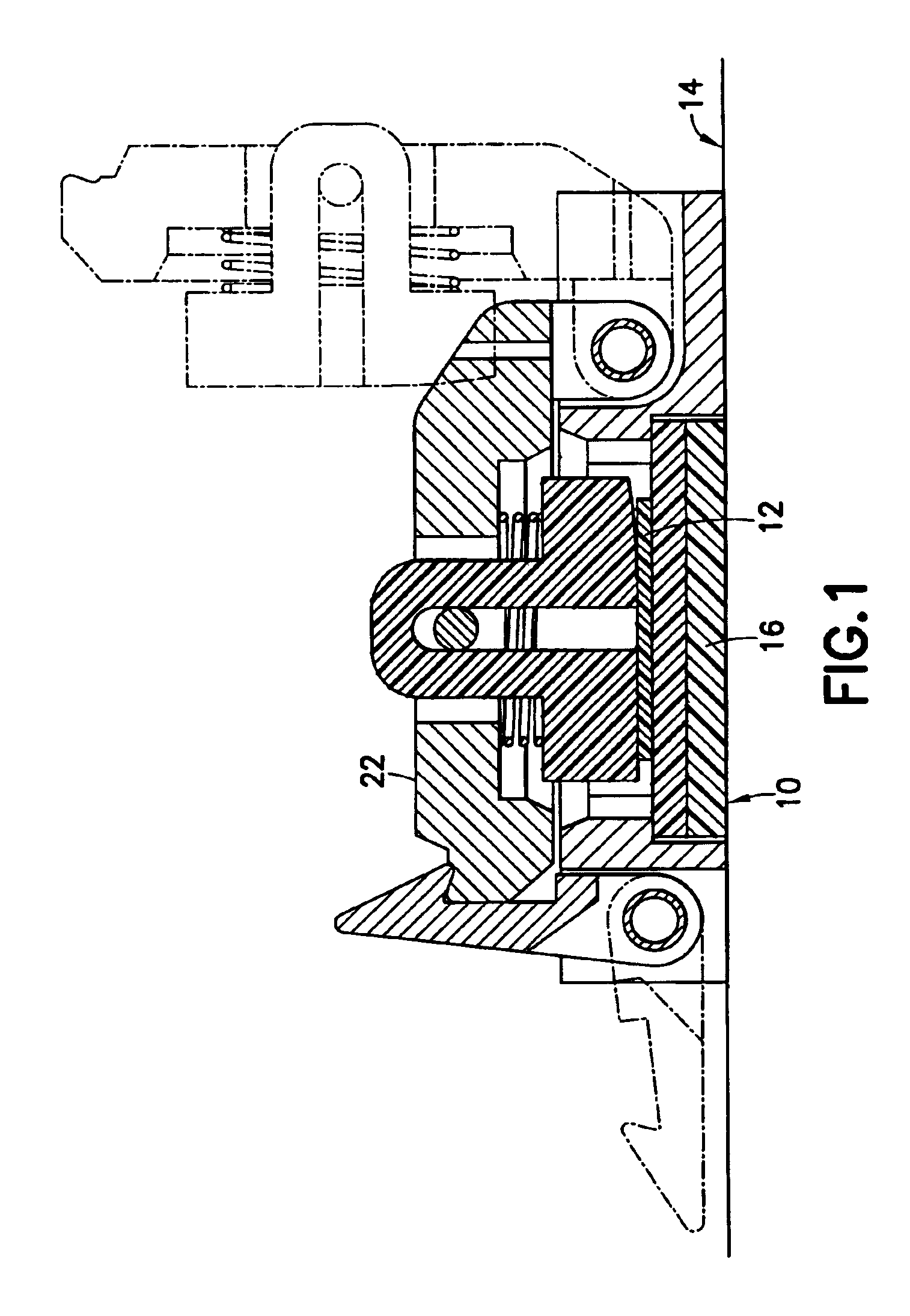

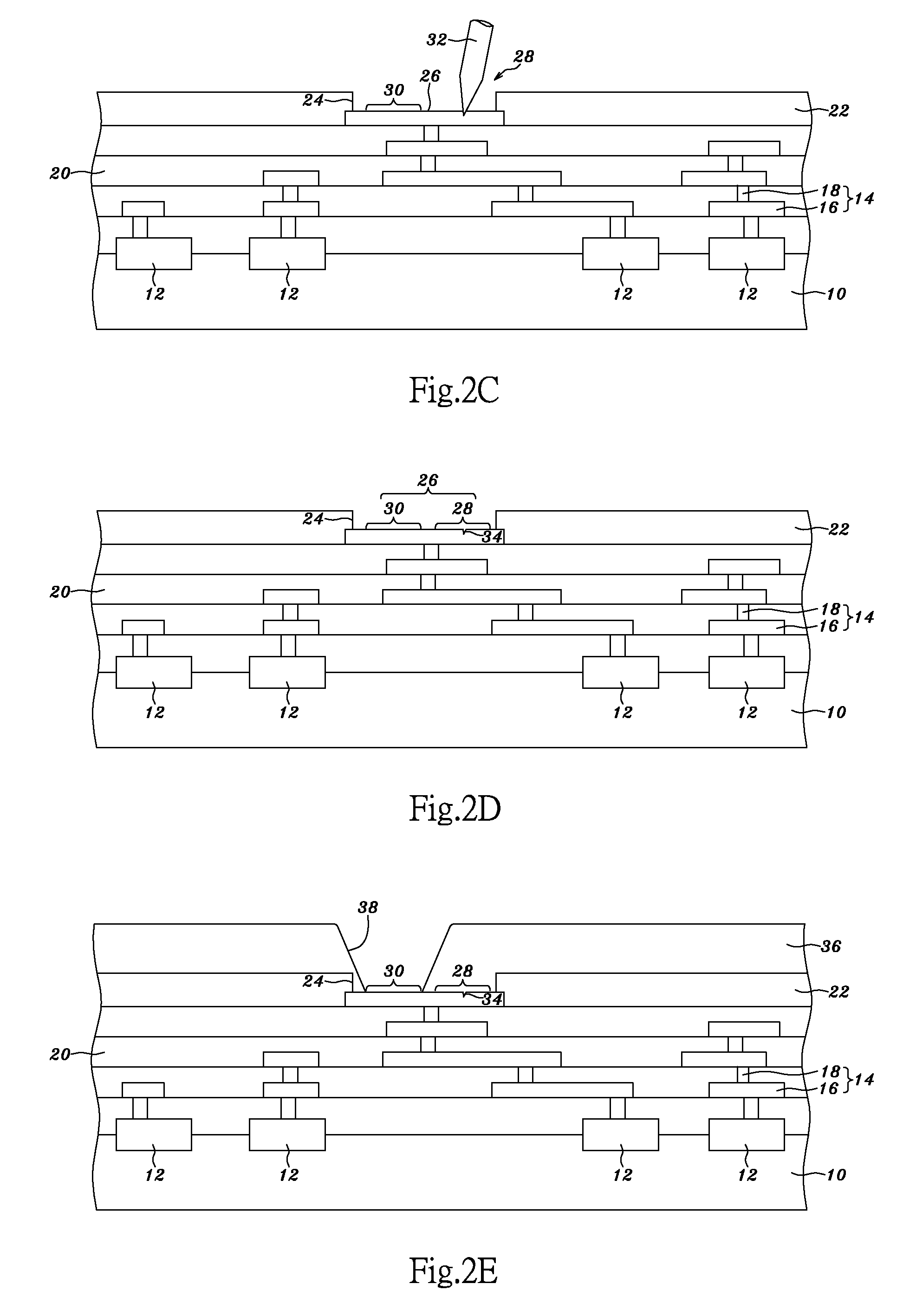

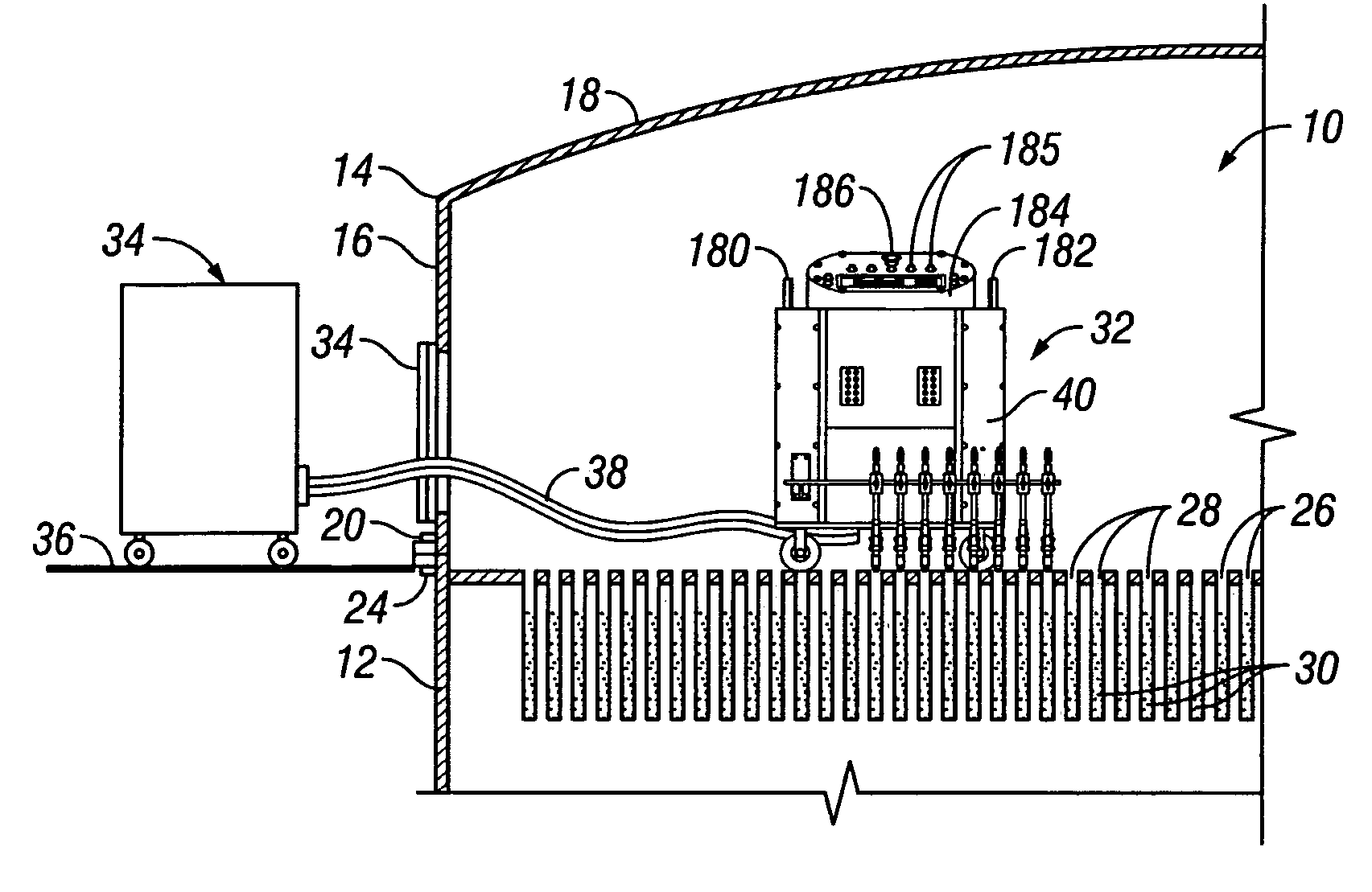

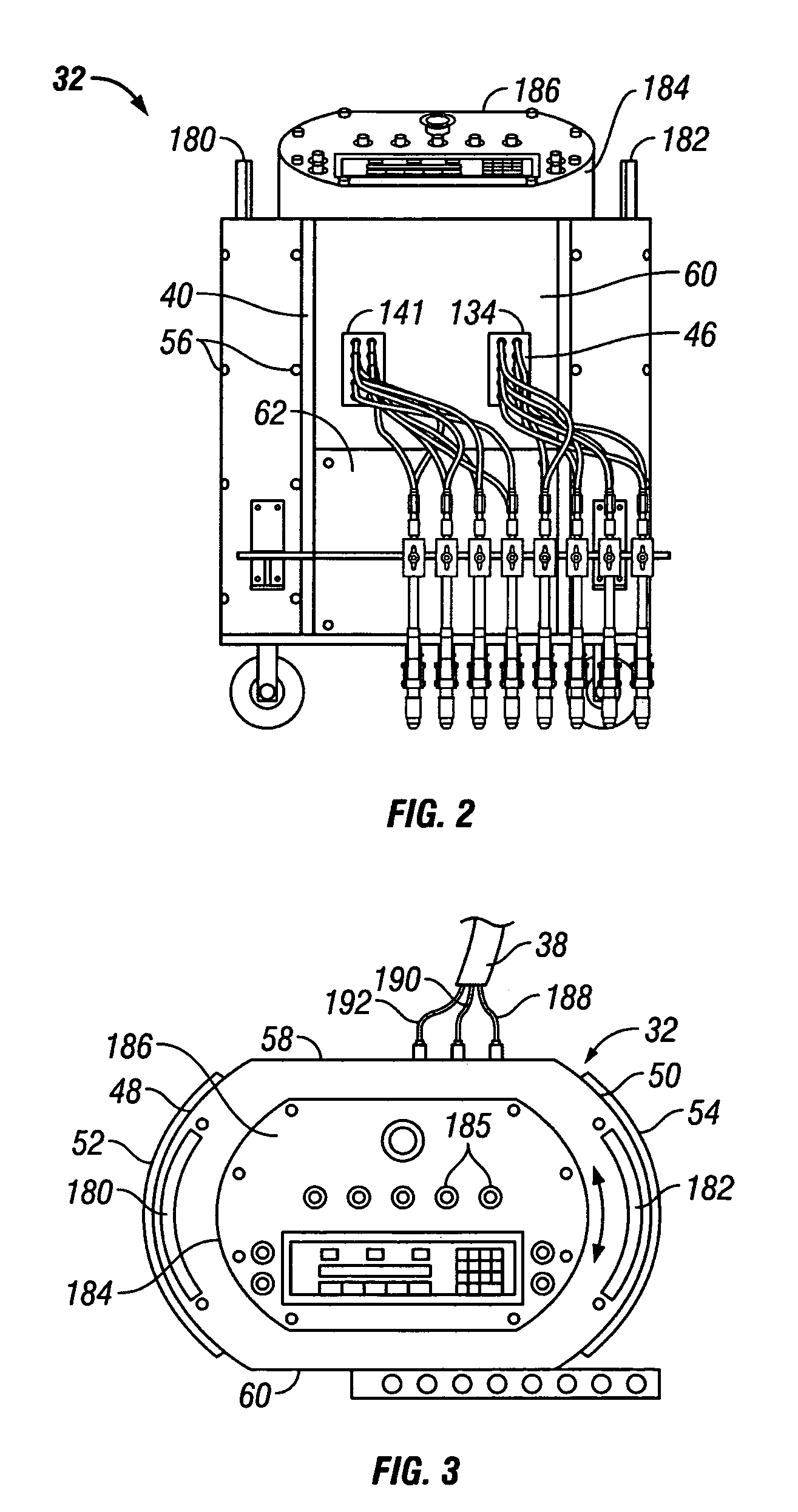

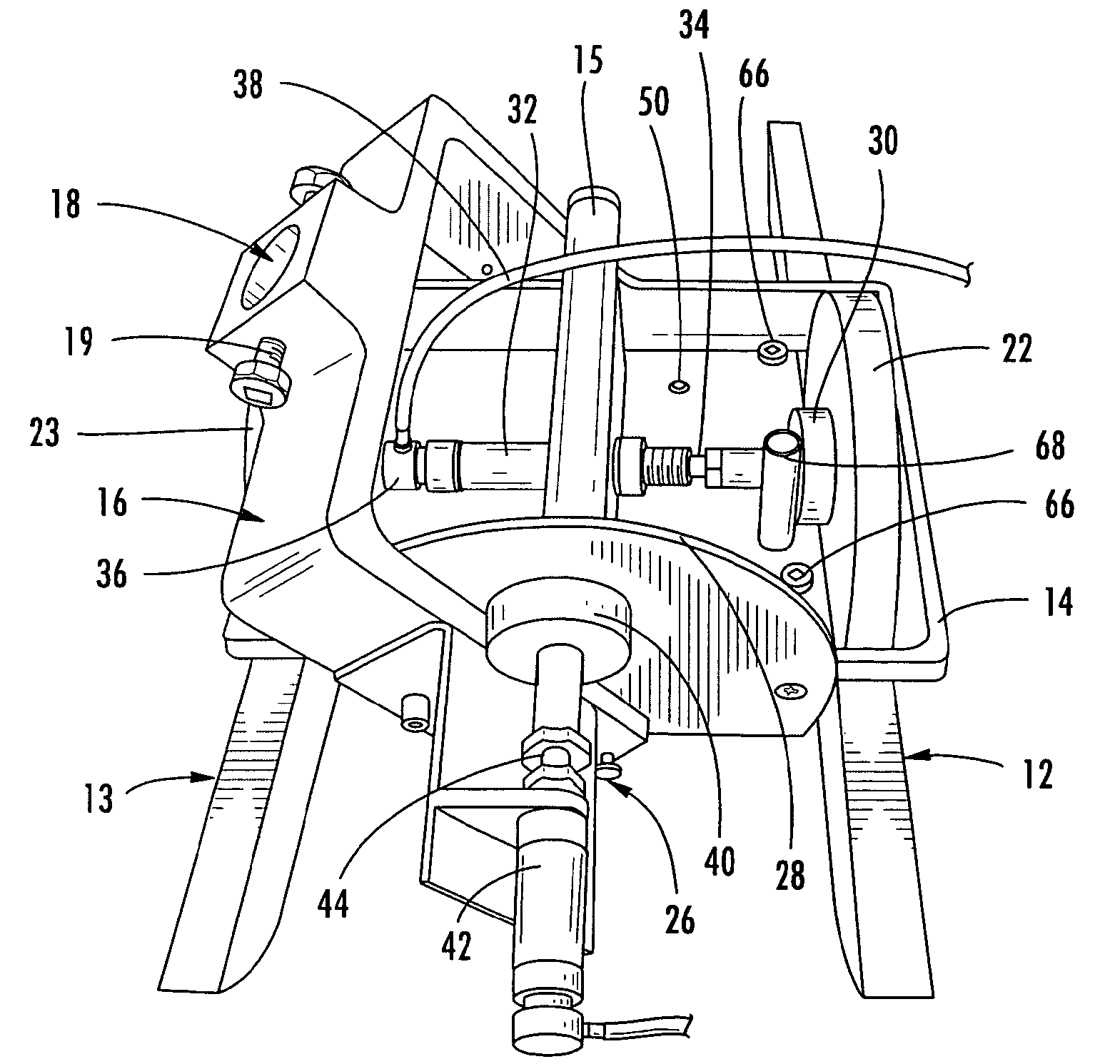

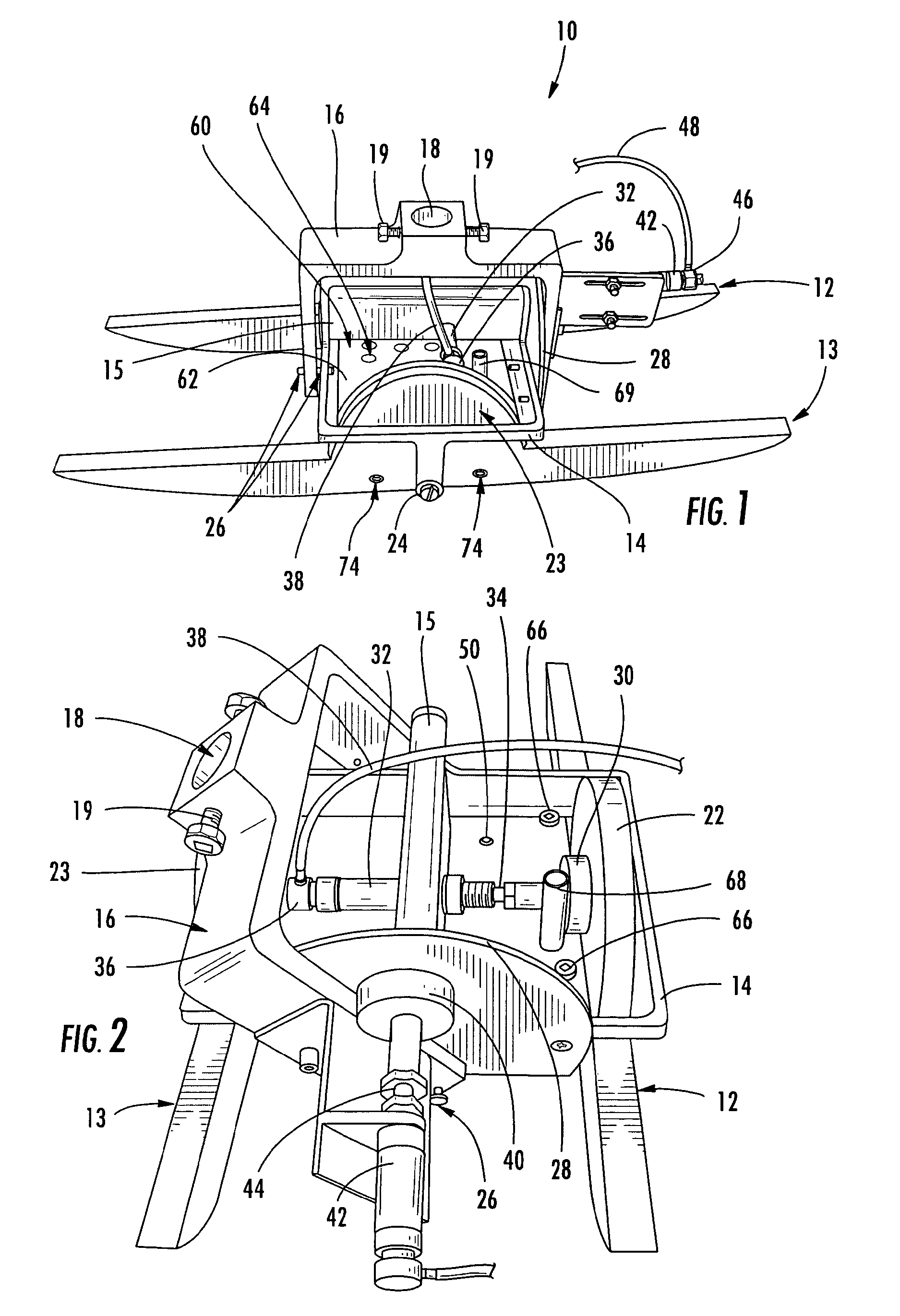

Method and apparatus for differential pressure testing of catalytic reactor tubes

ActiveUS6981422B1Efficient testingMinimizes servicing timeProcess control/regulationMaterial strength using tensile/compressive forcesDifferential pressureEngineering

A multi-tube differential pressure (Delta P) testing system for testing catalyst filled tubes of tube and shell type catalytic reactors has at least one mobile test unit for movement on the upper tube sheet of a catalytic reactor. An array of test probes is mounted to the mobile test unit and is selectively positionable in sealed gas pressure communicating engagement within the upper ends of selected reactor tubes. A pressure testing gas delivery system is interconnected with the test probes and selectively communicates pressurized gas to the testing tubes at a blow-down pressure or selected test pressure determined by restricted orifices. A differential pressure measurement system measures the back-pressure resulting from application of test pressure to individual reactor tubes and having a computer receiving electronic back-pressure measurement data and producing an electronic and / or visual record correlated with a reactor tube numerical sequence and identifying the resulting back-pressure of each reactor tube of the multi-tube test. The testing system is capable of selectively electronically counting in normal sequence and in inverted sequence to accommodate test unit orientation and incorporates a separate manually positioned testing wand to accommodate tube positions of the reactor that cannot be readily accessed by one or more of the array of test probes.

Owner:WINDLASS METALWORKS

Service Level Agreements Based on Objective Voice Quality Testing for Voice Over IP (VOIP) Networks

InactiveUS20070127391A1Telephone data network interconnectionsError preventionService-level agreementComputer network

An objective, service-level specific voice call listening quality test scheme for a Voice Over IP (VOIP) network is presented. Test probes are deployed along the border of the VOIP network. Each test probe is capable of placing calls over the VOIP network to the other test probes at different levels of service and measuring call quality using an objective measurement algorithm such as PAMS or PSQM. The measurement results are collected on an ongoing basis to obtain information on the VOIP network's voice call quality. The information is compared to thresholds to measure performance against Service Level Agreement guarantees.

Owner:LEVEL 3 COMM LLC

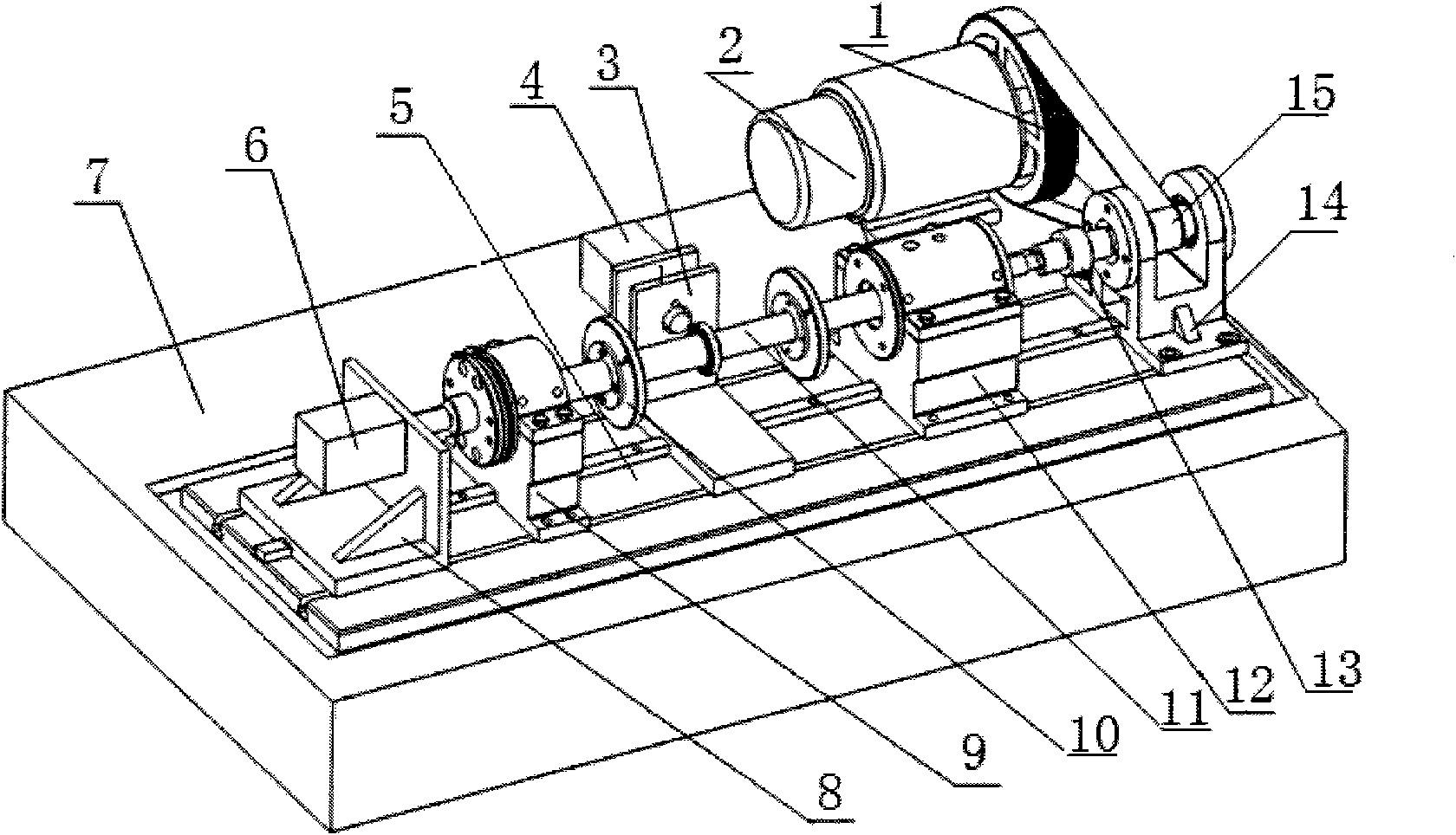

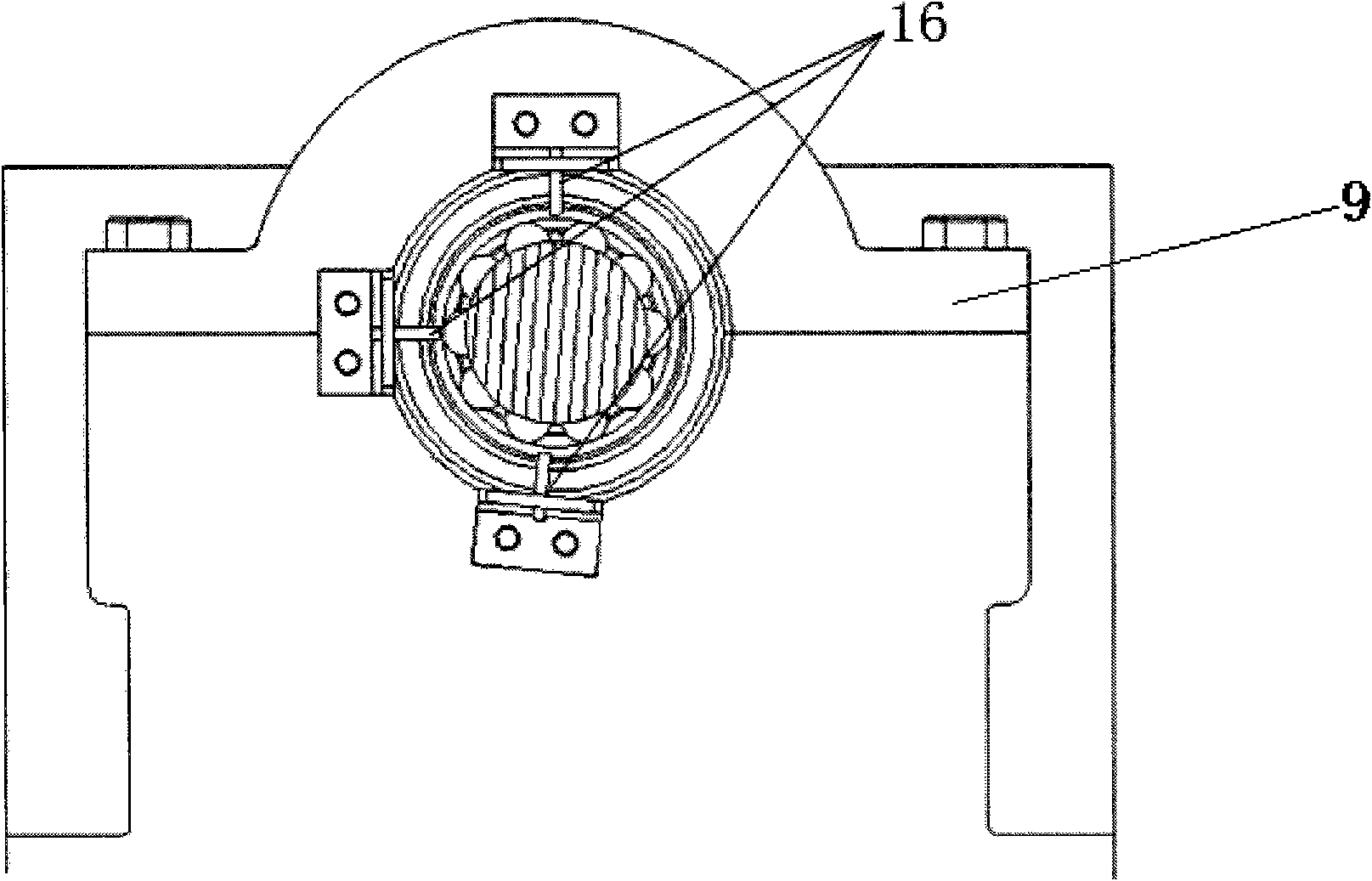

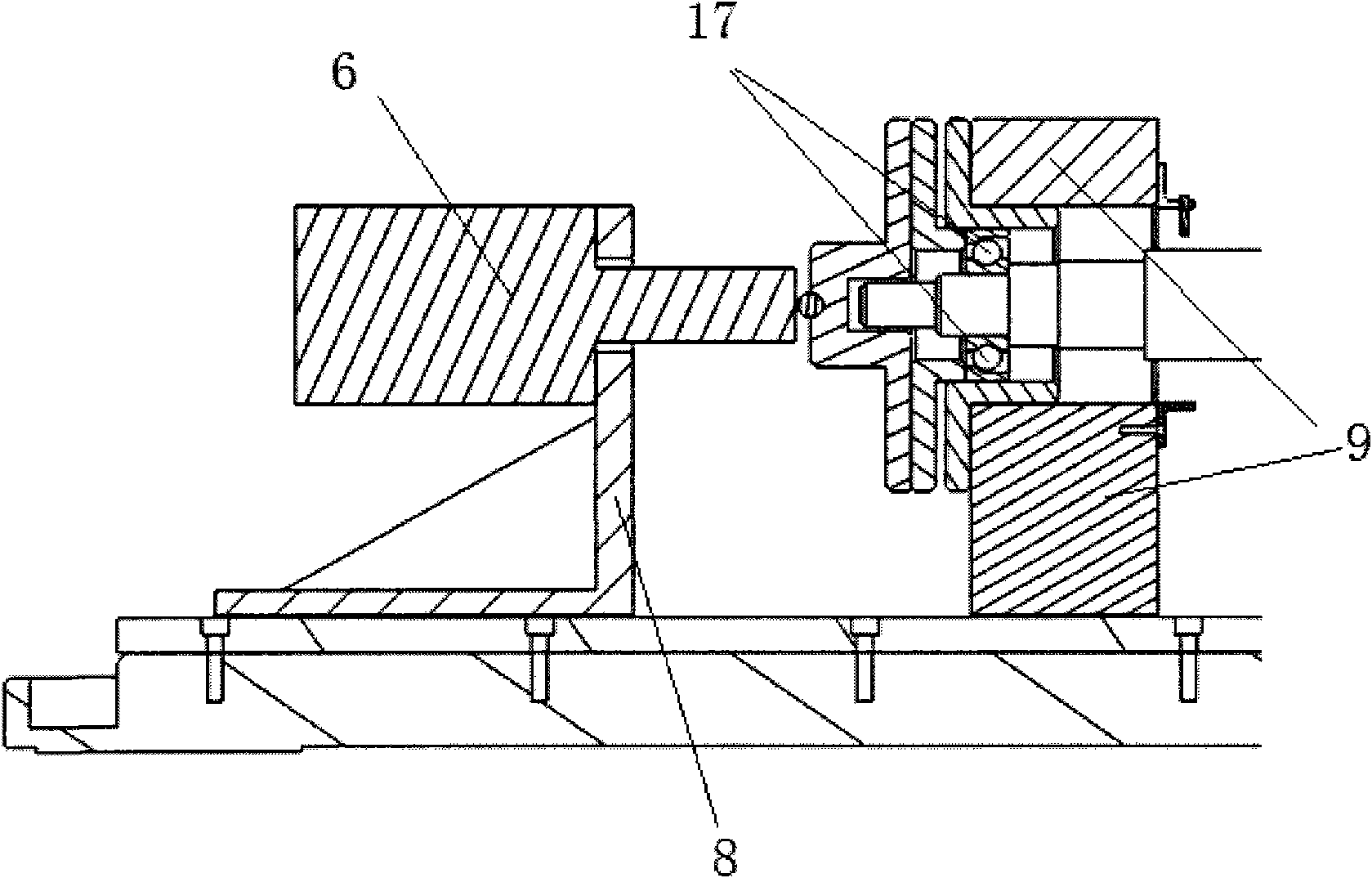

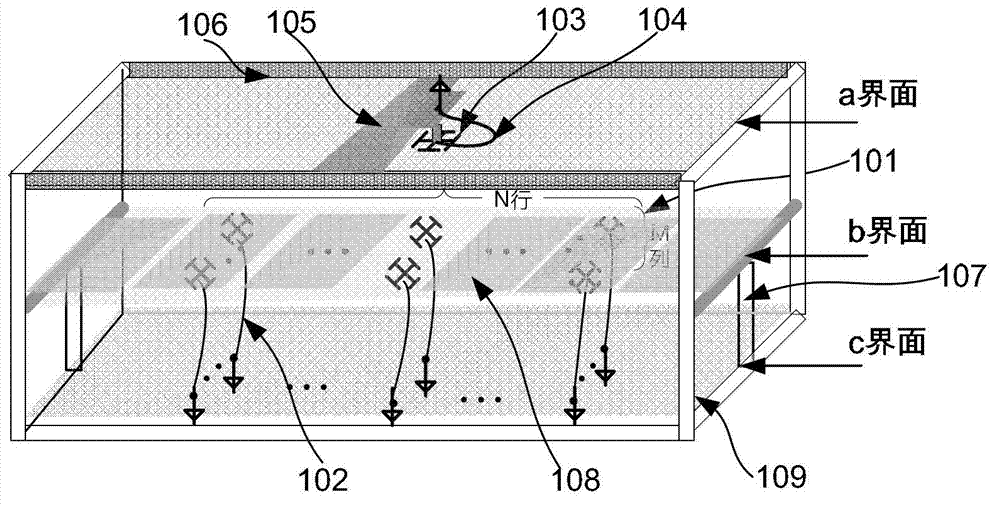

Comprehensive test experiment device for dynamic and static properties of rolling bearing-main shaft system

InactiveCN101936810AImprove utilization efficiencyThe test data is close toMachine bearings testingEngineeringSingle type

A comprehensive test experiment device for dynamic and static properties of a rolling bearing-main shaft system comprises a main shaft in which the front end is installed on a front end bearing support saddle; the end surface of the front end bearing support saddle is provided with three laser displacement sensor test probes; the front end bearing support saddle is internally provided with an experiment bearing; load is carried out through a radial load hydraulic tank and an axial load hydraulic tank; the back end of the main shaft is assembled on a back end bearing support saddle, and the back end bearing support saddle is configured to be paired angle contact bearings, and both an integrated monitoring ring and a pre-tightening push block are installed between the angle contact bearings to realize self-adapting pre-tightening of the bearing; the main shaft is provided with an eccentric quality shock excitation disk for applying bearing shock excitation; and the main shaft is driven by a variable-frequency electric motor. The comprehensive test experiment device for dynamic and static properties of a rolling bearing-main shaft system is used for detecting the influence on the dynamic and static properties of multiple types of bearings and the main shaft system, thereby overcoming the defect that the existing rolling bearing-main shaft experiment platform has the characteristics of single-type tested bearing, too low integration degree and rough single processing, being capable of carrying multiple experimental researches, and improving the flexibility of the rolling bearing-main shaft experiment platform.

Owner:SHENJI GRP KUNMING MACHINE TOOL +1

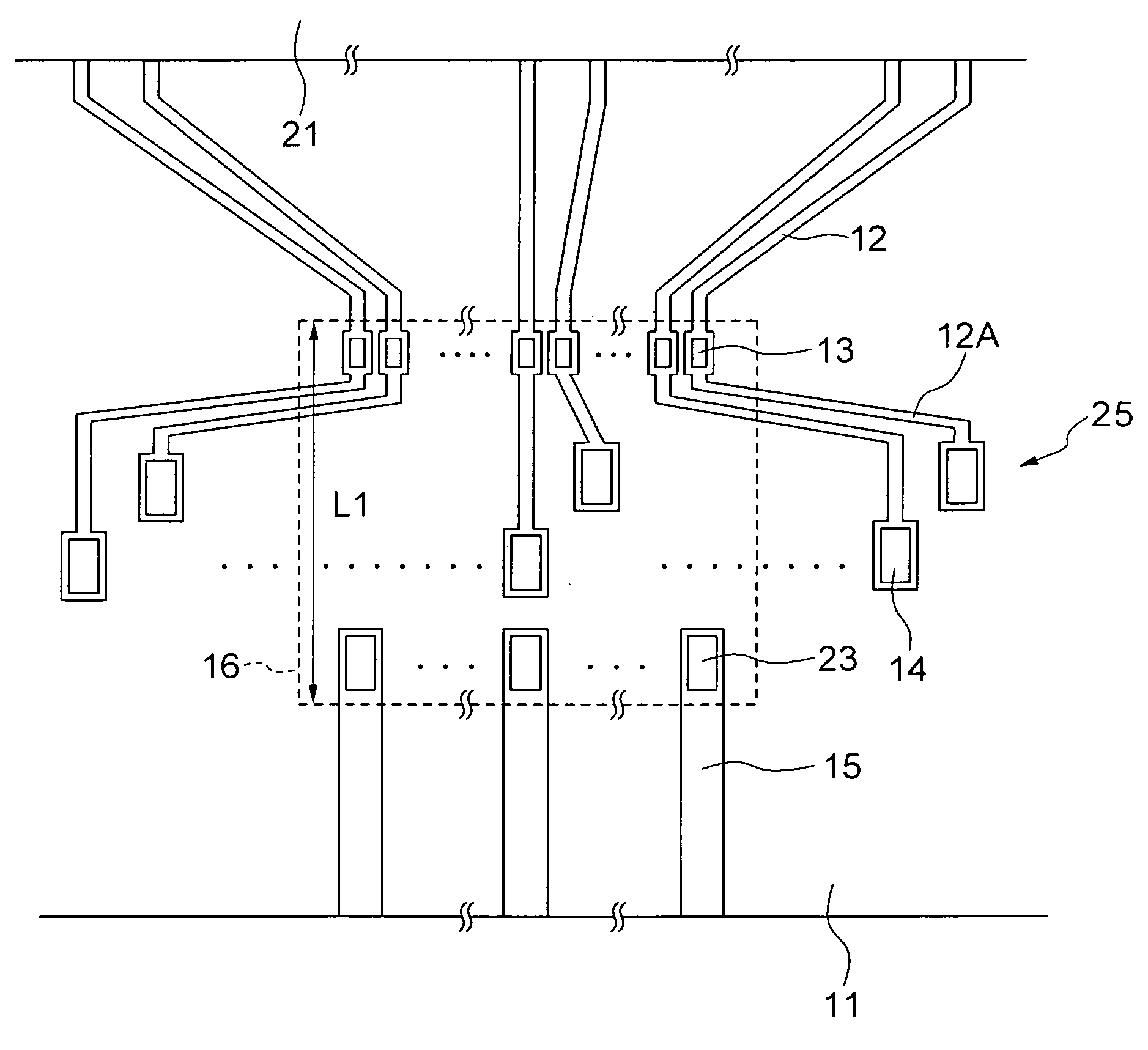

LCD device having test contact pads

InactiveUS6930744B1Safe test operationGuaranteed uptimeNon-linear opticsIndividual semiconductor device testingContact padSemiconductor chip

To make the test probe not directly in contact with the electrode pads for the semiconductor chip mounting, without using an advanced technology for making the pitch of electrode pads narrower, and remove the chip mounting failures such as scratching of electrode pads caused by testing, adherence of impurity particles, electrical corrosion.The electrode pads 13 formed on the distal ends of the external leads 5 for press-connecting the input electrodes 12 of the semiconductor chip 6 are disposed at both sides (shown as L1) of the semiconductor chip 6. The terminal-electrode leads 2 from the electrode pads 3 pass under the semiconductor chip 6 while keeping a pitch of the electrode pads 3. The test electrode pads 4 are disposed in alternate arrangement on the distal ends of terminal-electrode leads 2. The test electrode pads 4 may be disposed in alternate arrangement in three steps or more of multiple steps.

Owner:VISTA PEAK VENTURES LLC

Multiple-frequency ultrasonic test probe, inspection system, and inspection method

ActiveUS20070227250A1Improve efficiencyIncrease speedAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationCatheterMultiple frequency

Owner:THE BOEING CO

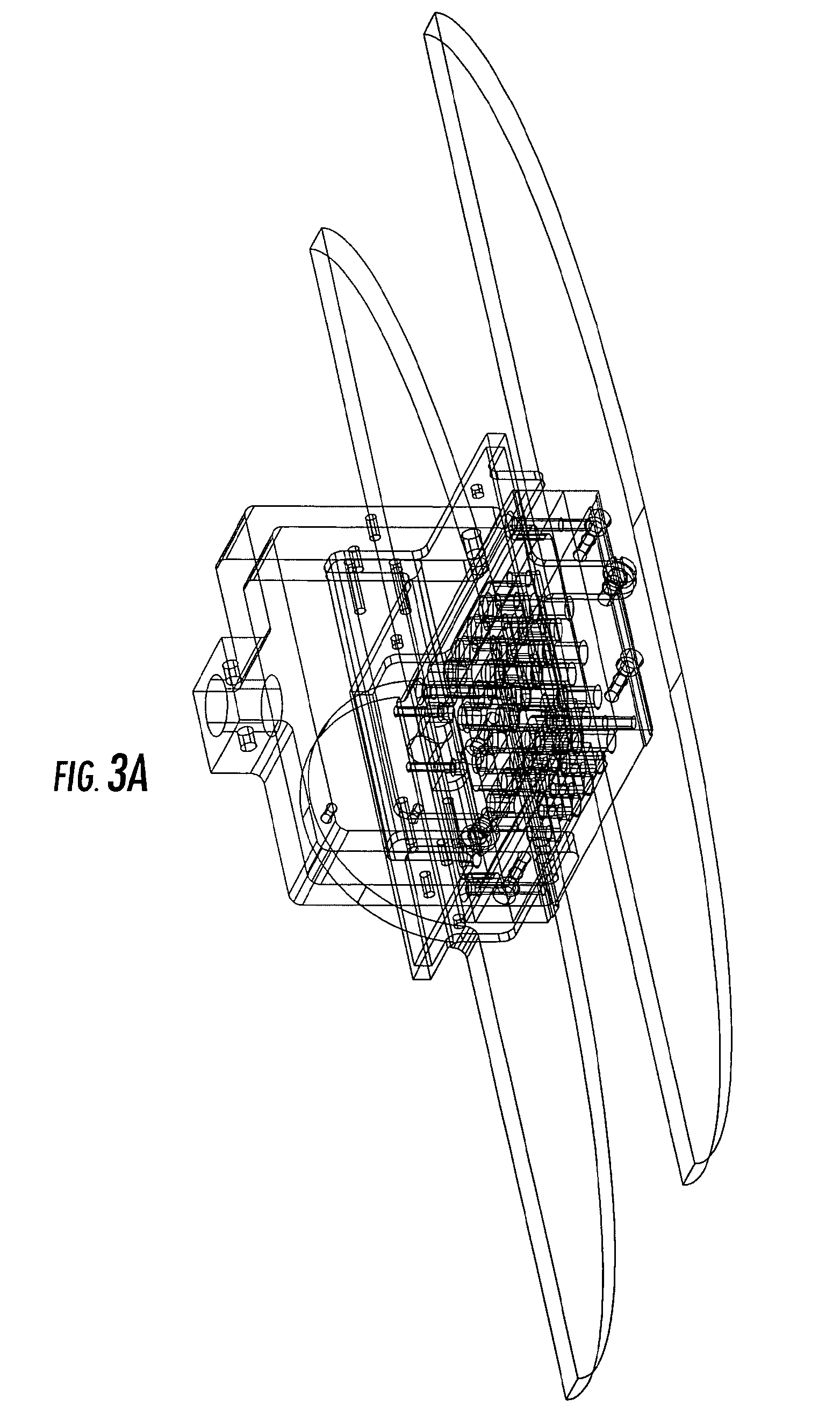

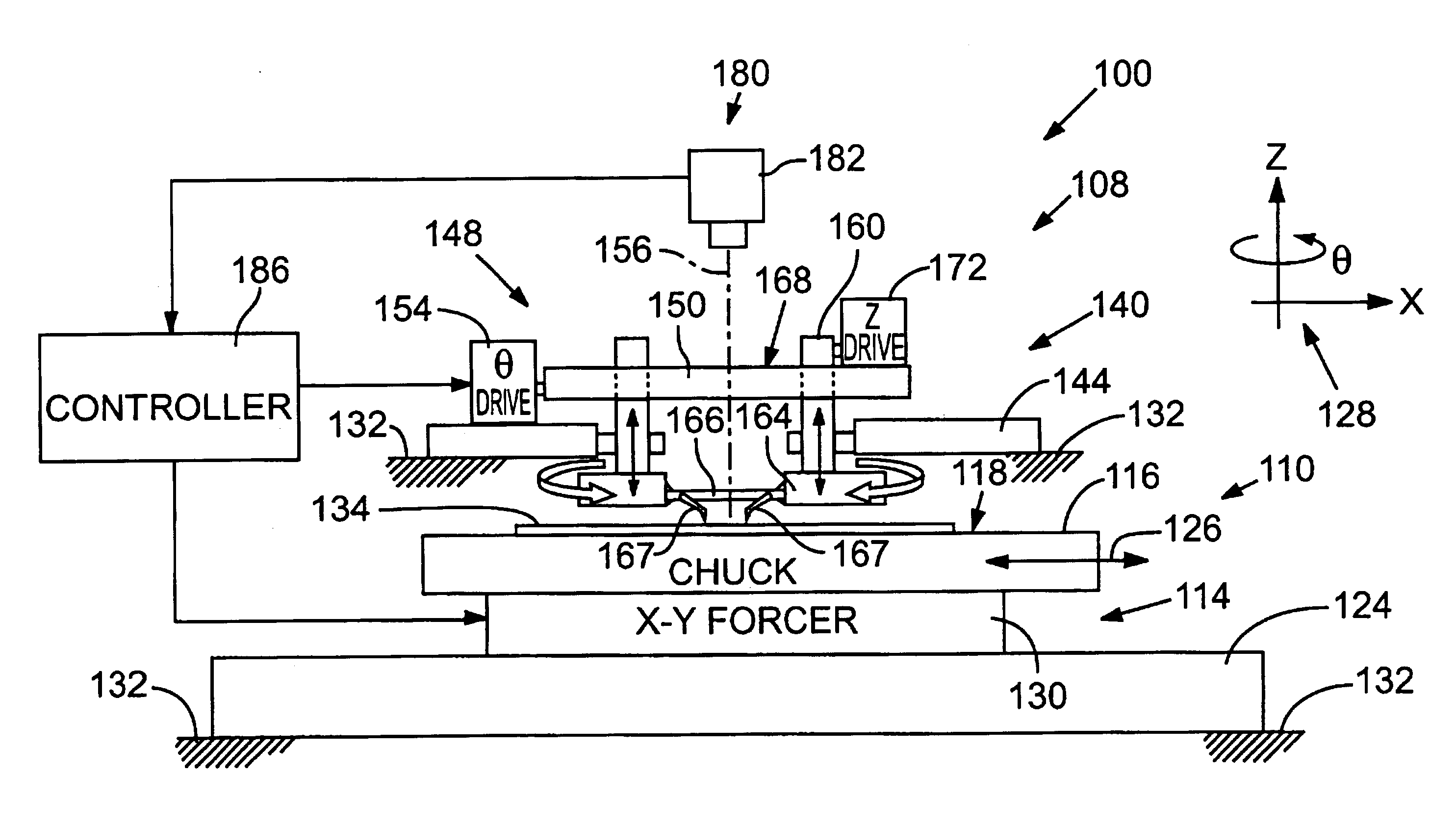

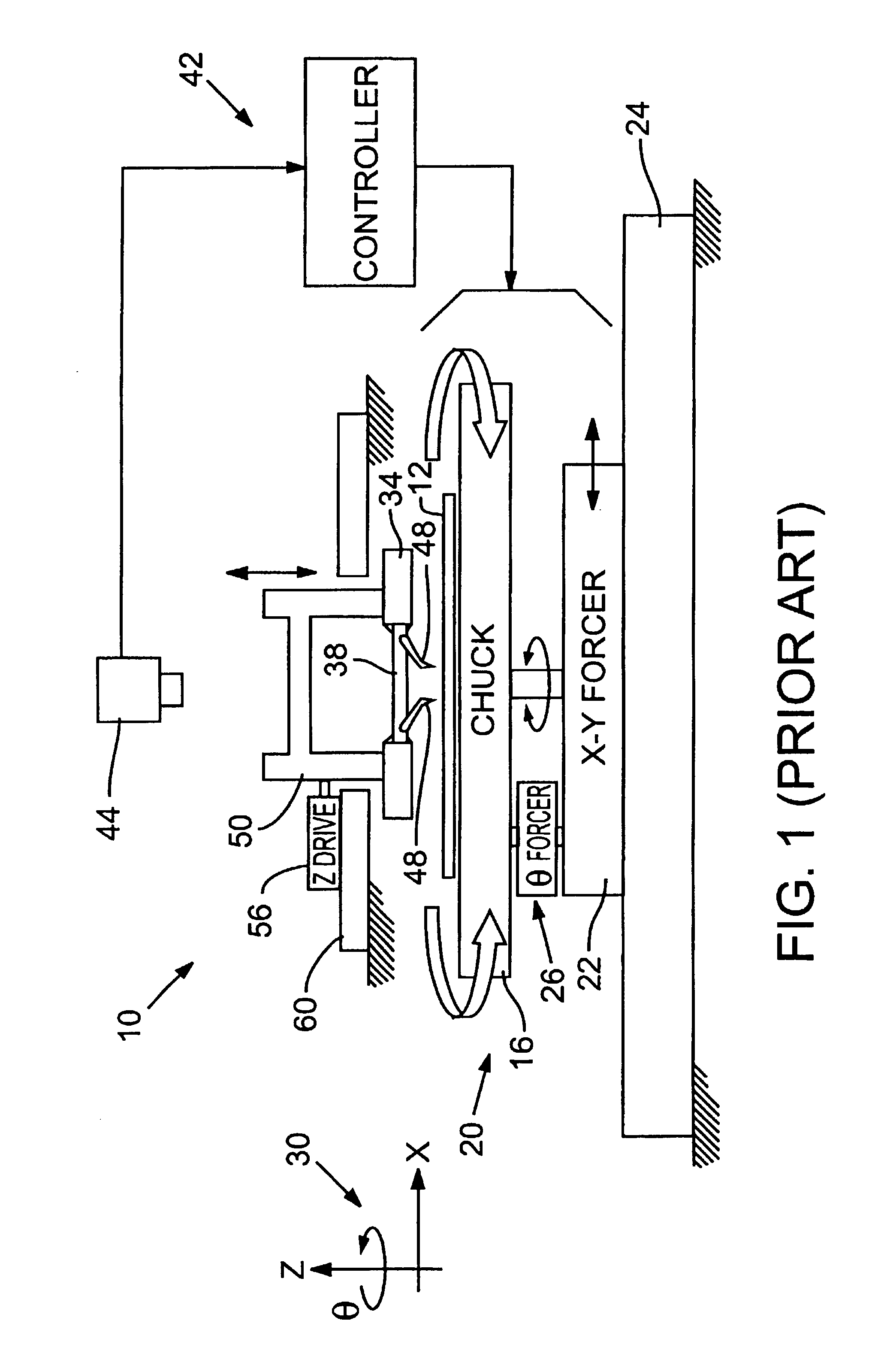

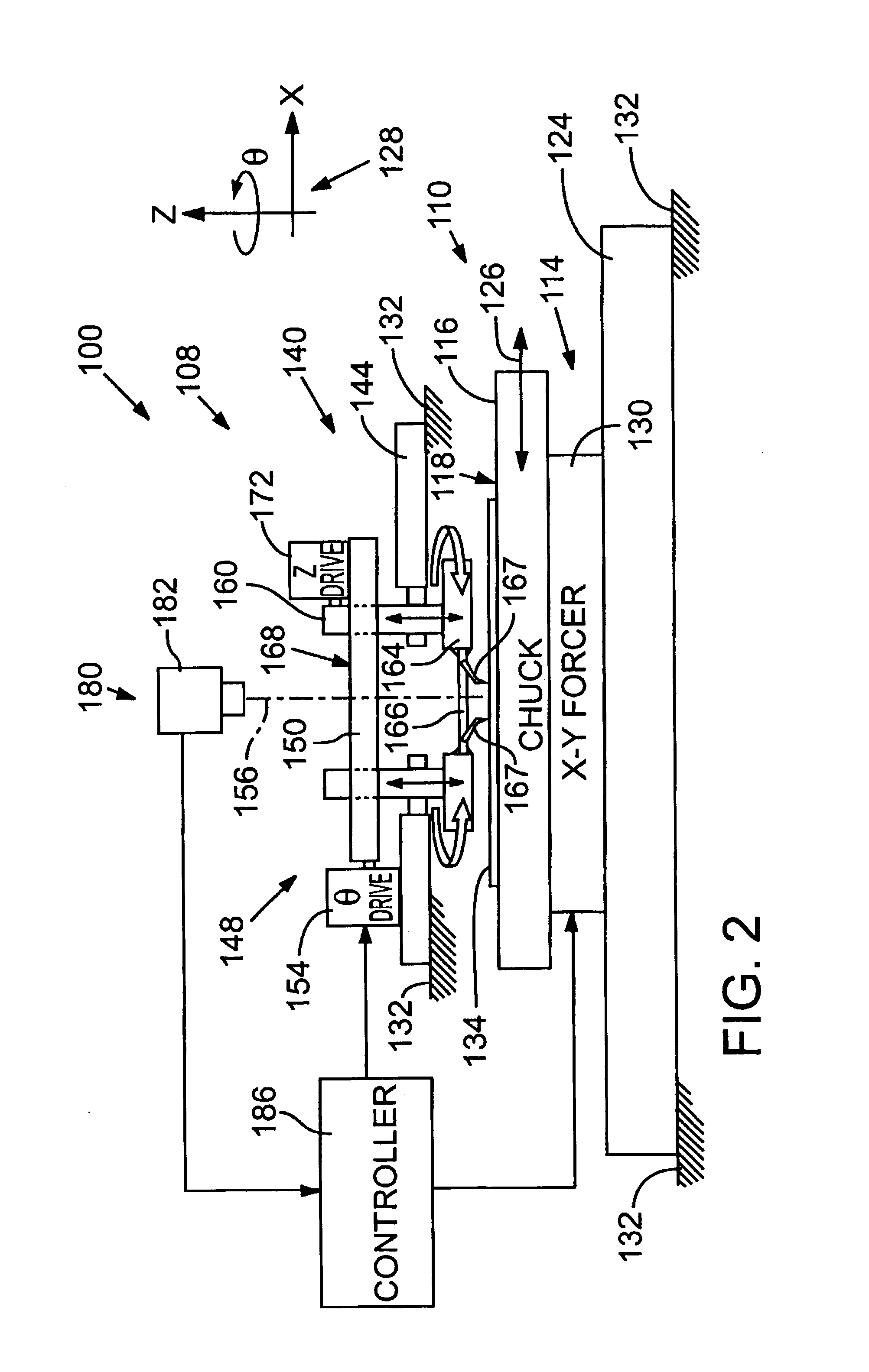

Test probe alignment apparatus

InactiveUS7119566B2Easy to participateAvoid vibrationSemiconductor/solid-state device testing/measurementMeasurement leads/probesRotary stageProbe card

A test probe alignment apparatus includes a rotatable θ stage that is decoupled from a workpiece positioning stage so that the workpiece positioning stage can move a workpiece in an X-Y plane without moving the θ stage, thereby inhibiting vibration in and inertia of the workpiece positioning stage, and improving the speed and accuracy of workpiece movements. The θ stage is driven for rotation about an axis substantially perpendicular to the X-Y plane. The rotatable stage supports a carriage adapted for holding a probe card. The carriage rotates in concert with the θ stage to thereby align the probe card relative to the workpiece. A Z-stage is operatively engaged with the carriage for moving the carriage along the axis of rotation relative to the workpiece. A computer processor performs coordinate transformations on preprogrammed movement vectors, to adjust for angular misalignment of the workpiece as measured by a position sensor.

Owner:ELECTRO SCI IND INC

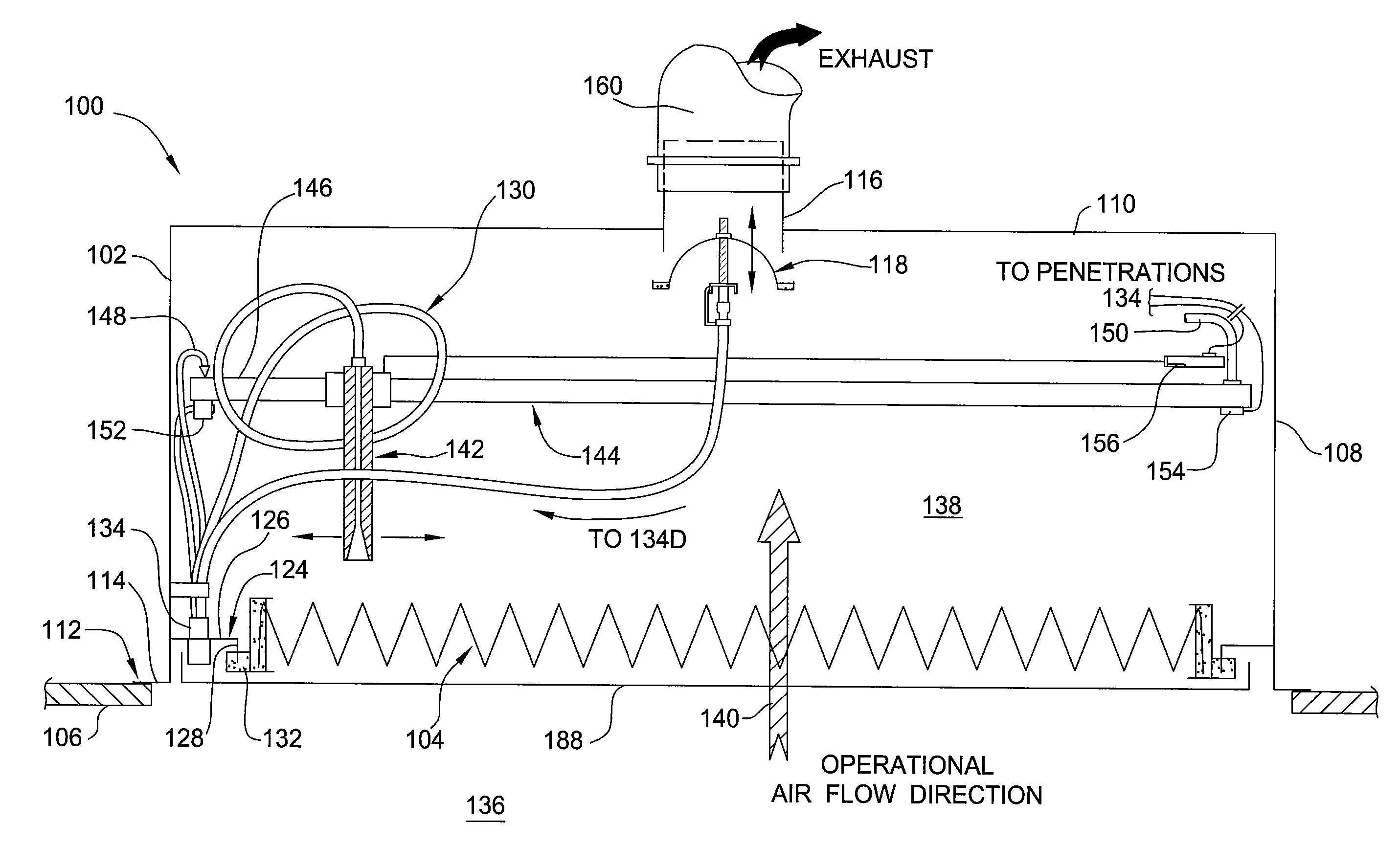

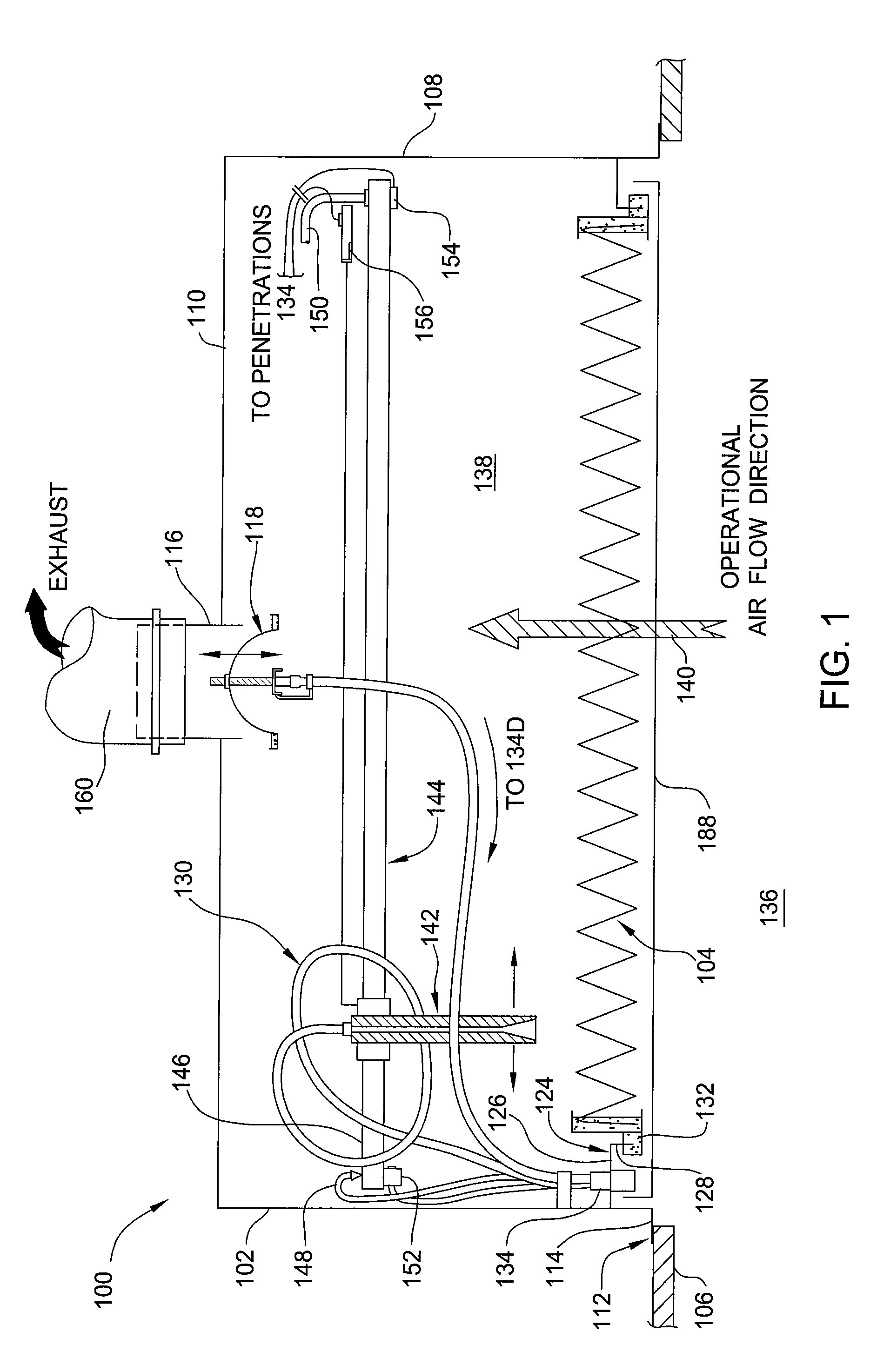

Exhaust filter module with mechanically positionable scan probe

Embodiments of the invention generally provide a filter module having a mechanically positionable test probe disposed therein and a method for testing a filter. In one embodiment, a filter module includes a housing adapted to receive a filter element. A sample probe suitable for leak testing the filter element is disposed in the interior volume of the housing. The sample probe may be moved to scan the filter by an actuator. In another embodiment, a method for testing a filter includes challenging a room side of a filter element disposed in a housing with a test aerosol, moving a probe disposed within the housing to obtain samples for testing and determining if the samples exceed a predefined leak criteria.

Owner:CAMFIL USA

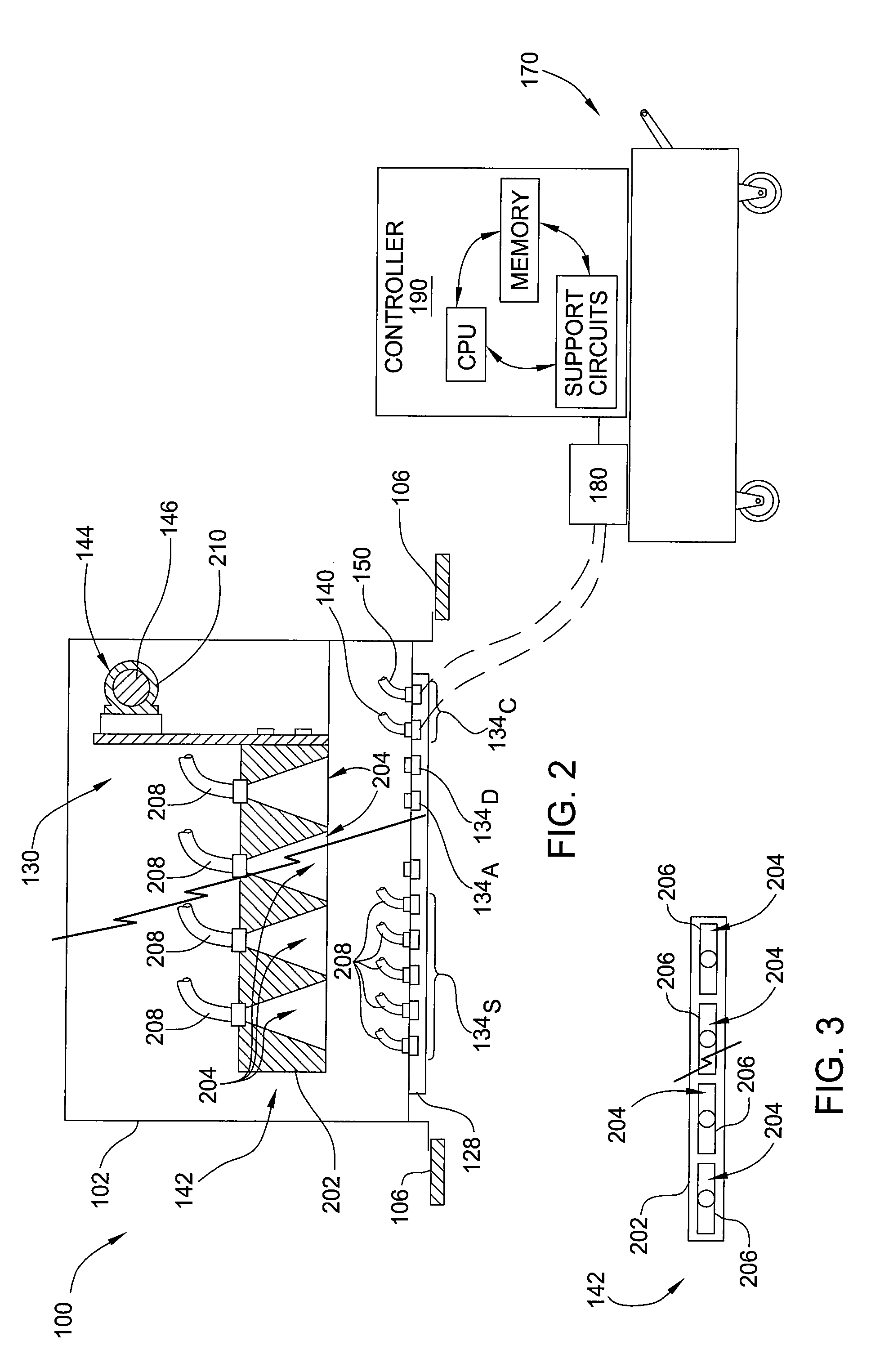

Apparatus for Measuring Wall Thicknesses of Objects

ActiveUS20090178482A1Correct misalignmentMultiple-port networksAnalysing solids using sonic/ultrasonic/infrasonic wavesTransducerUltrasonic testing

An apparatus for measuring wall thicknesses of objects, comprises: a coordinate measuring machine comprising a probe holder and an object support, the coordinate measuring machine being configured to provide relative movement between the probe holder and the object support in three dimensions; and an ultrasonic test probe which is held by the probe holder. The coordinate measuring machine brings the transducer of the ultrasonic test probe into contact with a position on a surface of an object at the object support so that the probe can measure an object wall thickness at the probe contact position.

Owner:ROLLS ROYCE PLC

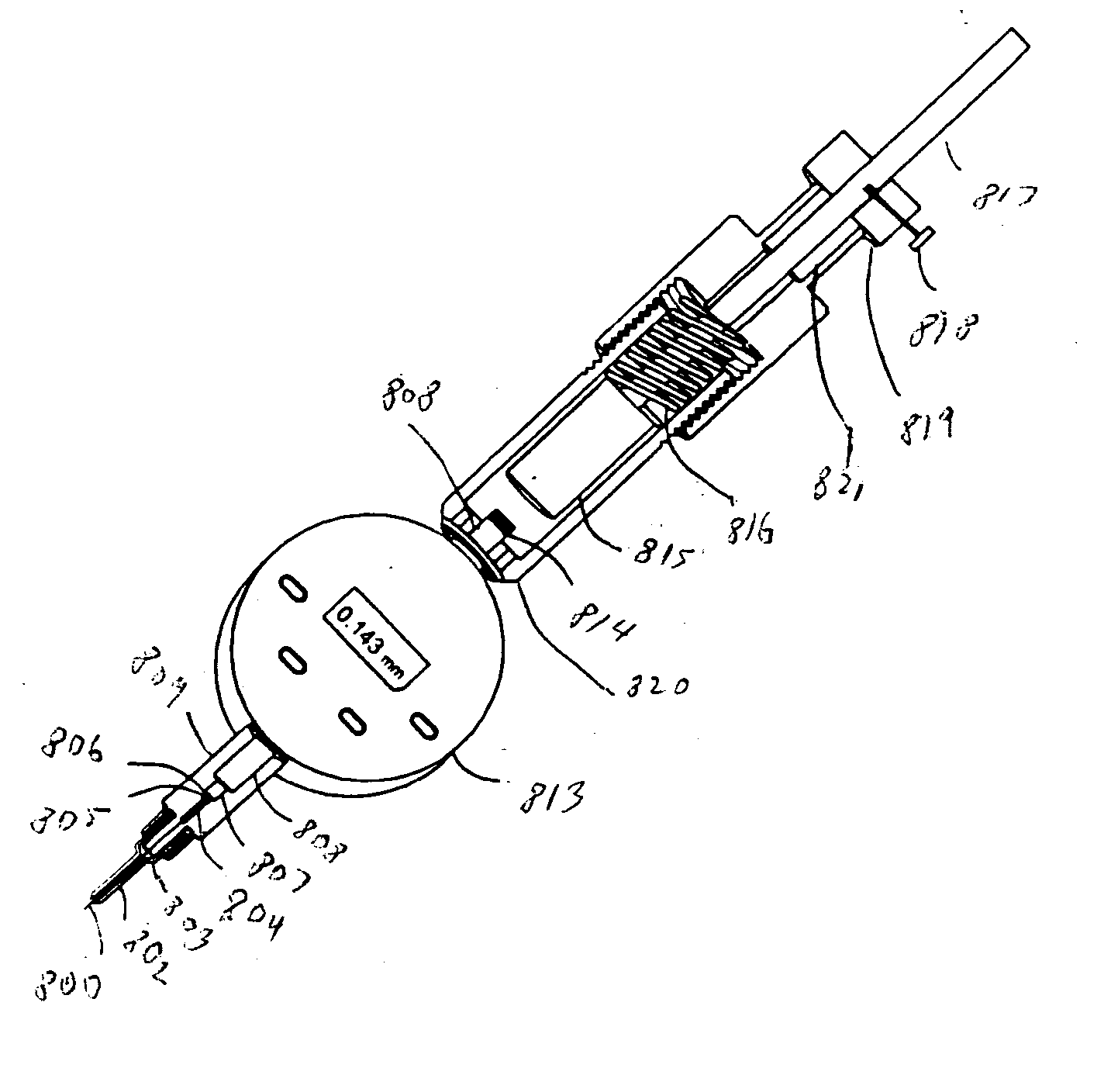

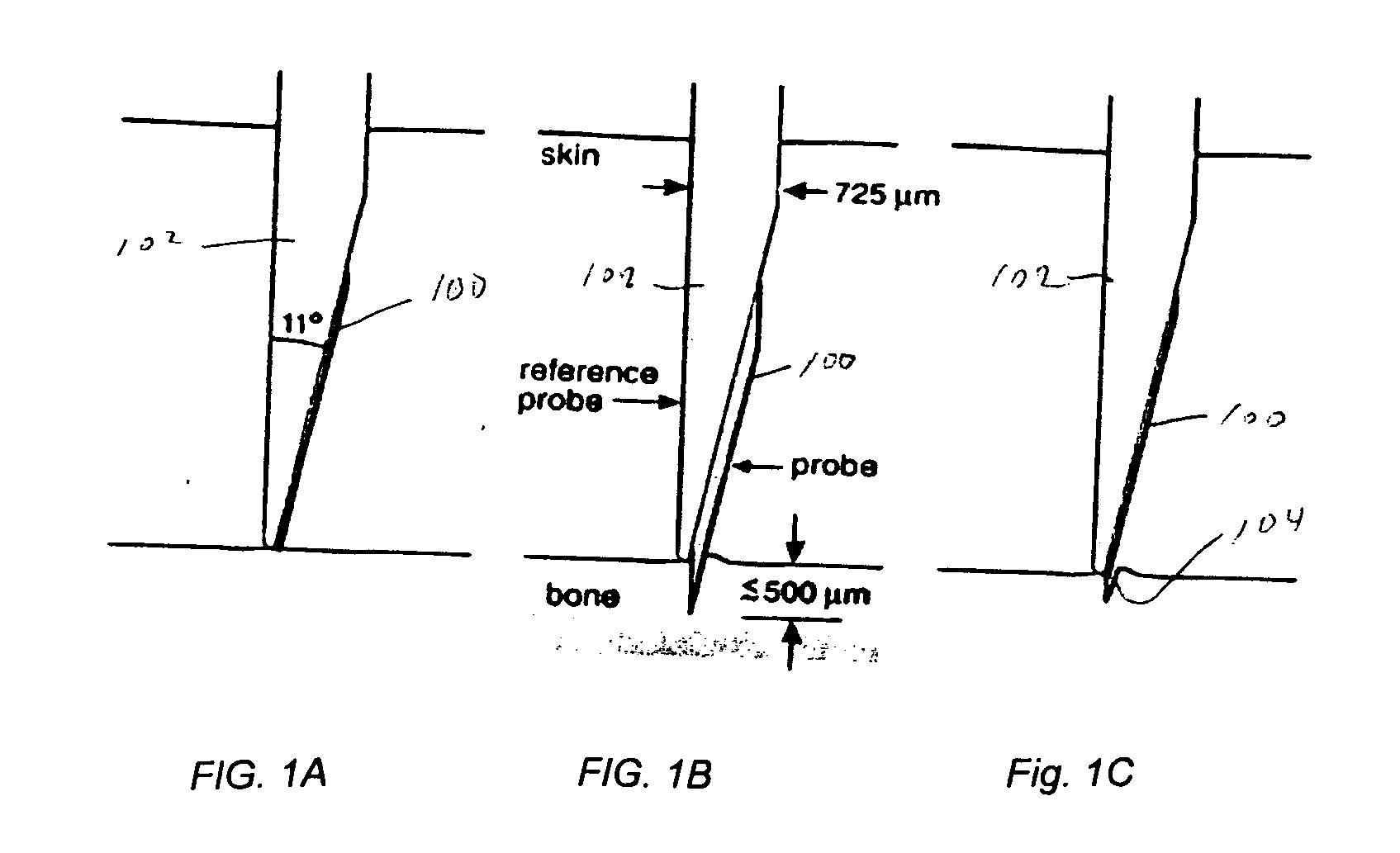

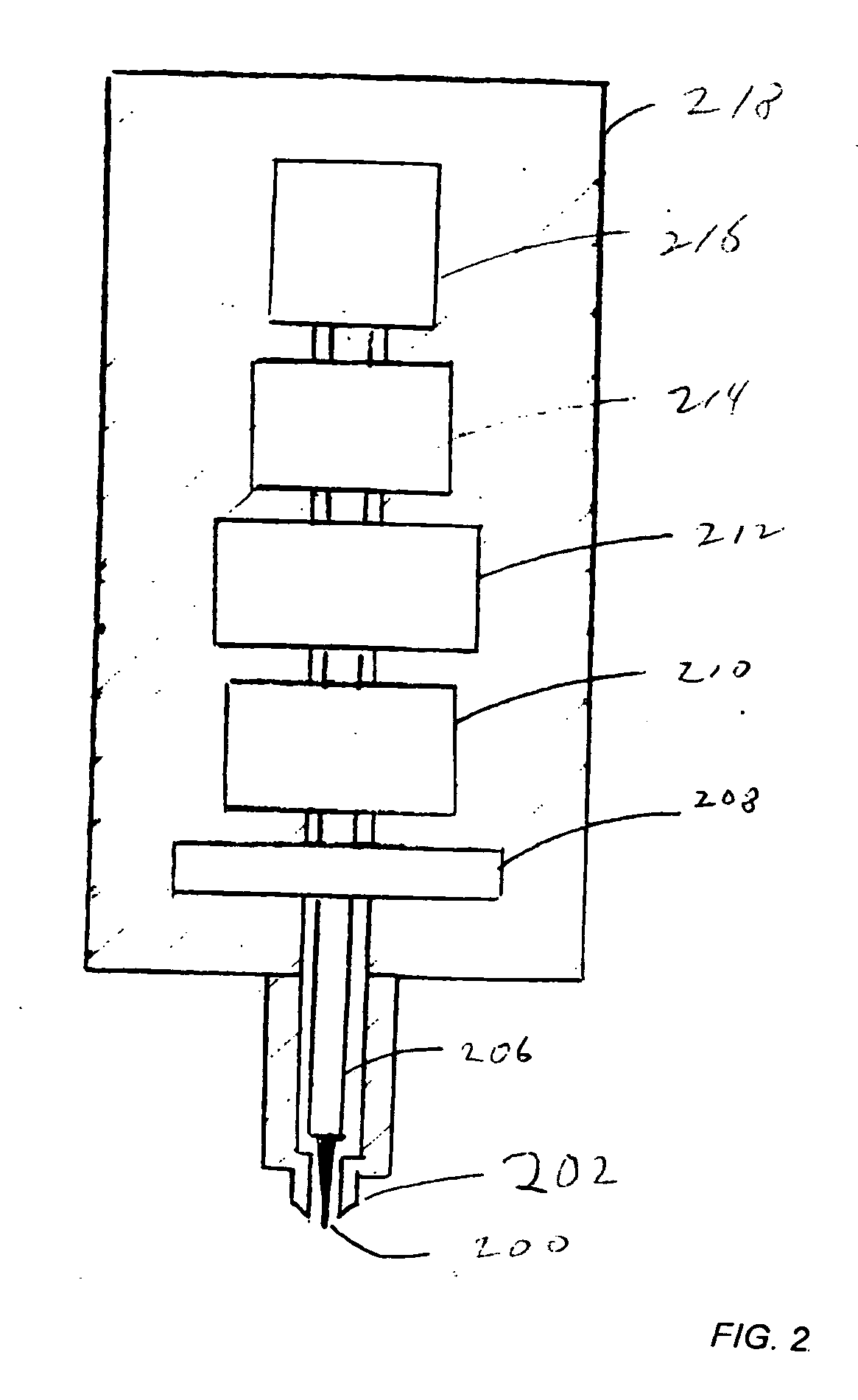

Methods and instruments for materials testing

ActiveUS20090056427A1Improve abilitiesIncreases ease and speedDiagnostics using pressureSurgeryMaterials testingHand held

Methods and instruments for characterizing a material, such as the properties of bone in a living human subject, using a test probe constructed for insertion into the material and a reference probe aligned with the test probe in a housing. The housing is hand held or placed so that the reference probe contacts the surface of the material under pressure applied either by hand or by the weight of the housing. The test probe is inserted into the material to indent the material while maintaining the reference probe substantially under the hand pressure or weight of the housing allowing evaluation of a property of the material related to indentation of the material by the probe. Force can be generated by a voice coil in a magnet structure to the end of which the test probe is connected and supported in the magnet structure by a flexure, opposing flexures, a linear translation stage, or a linear bearing. Optionally, a measurement unit containing the test probe and reference probe is connected to a base unit with a wireless connection, allowing in the field material testing.

Owner:RGT UNIV OF CALIFORNIA

Methods and instruments for assessing bone fracture risk

ActiveUS20070276292A1Quick and inexpensive testRisk of fracturePerson identificationSensorsHealth riskFracture risk

Methods and instruments for assessing bone, for example fracture risk, in a subject in which a test probe is inserted through the skin of the subject so that the test probe contacts the subject's bone and the resistance of the test bone to microscopic fracture by the test probe is determined. Macroscopic bone fracture risk is assessed by measuring the resistance of the bone to microscopic fractures caused by the test probe. The microscopic fractures are so small that they pose negligible health risks. The instrument may also be useful in characterizing other materials, especially if it is necessary to penetrate a layer to get to the material to be characterized.

Owner:RGT UNIV OF CALIFORNIA

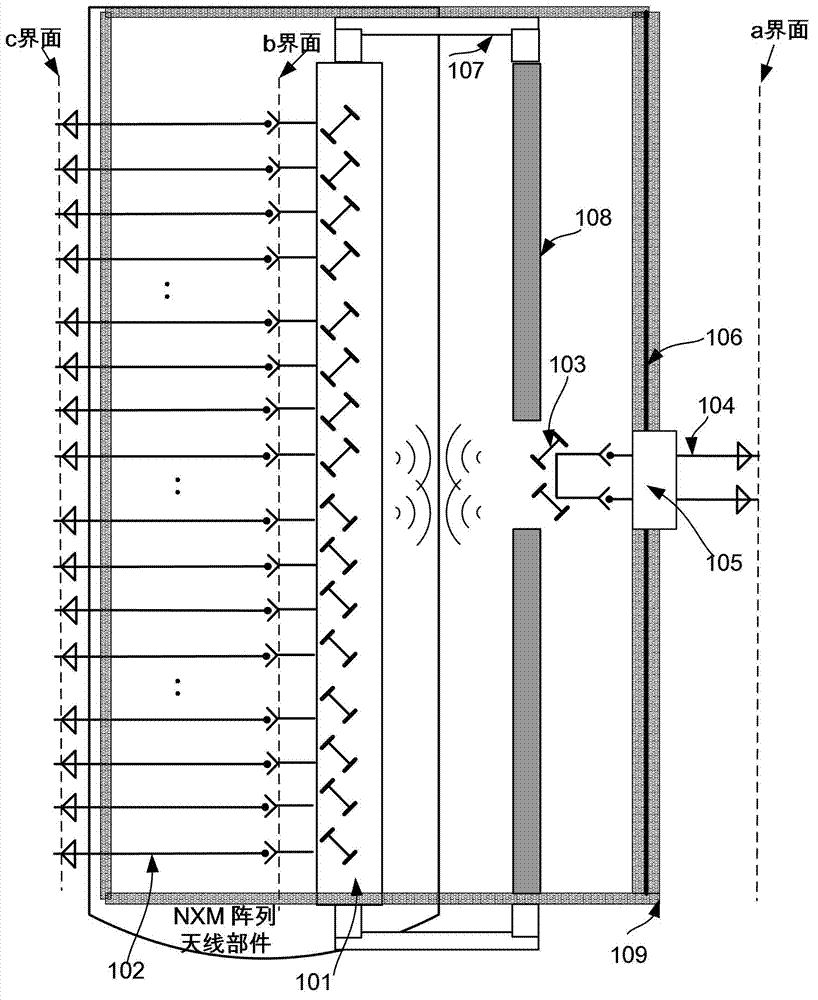

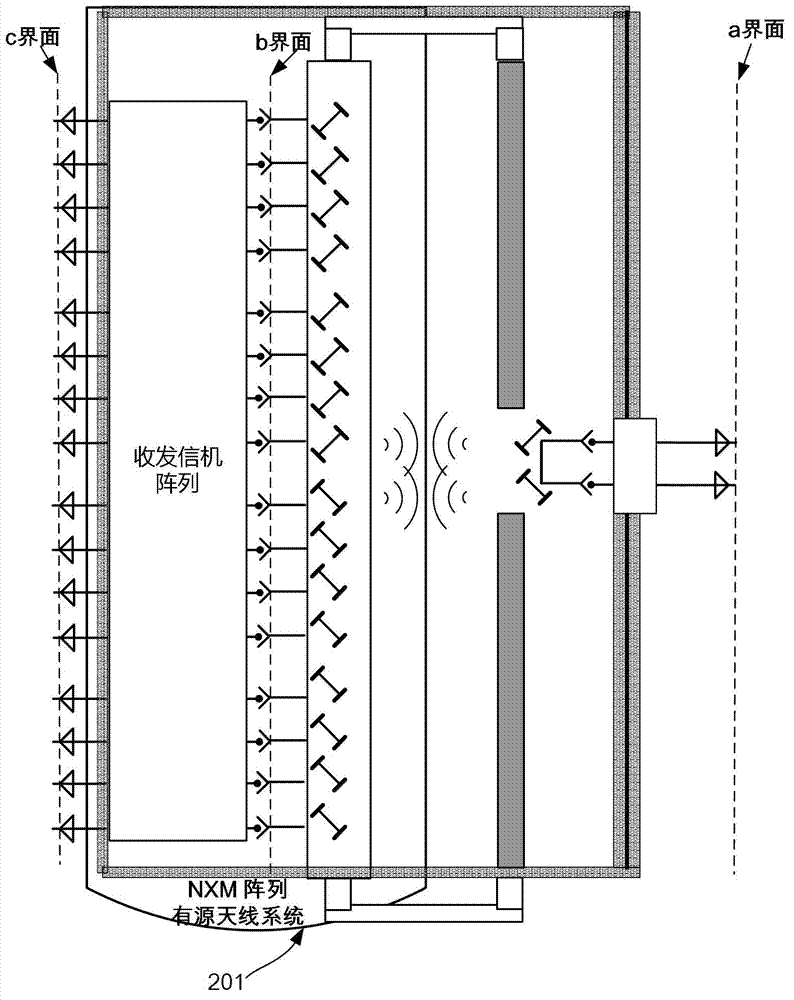

Method and device for testing radio frequency index and wireless index of active antenna system

ActiveCN102830298AImprove test efficiencyReduce testing costsTransmitters monitoringElectrical testingTest efficiencyIndex test

The invention discloses a method and a device for testing a radio frequency index and a wireless index of an active antenna system. A probe-type test hood based on a near field coupling mode is adopted to test the radio frequency index of the tested active antenna system. The method comprises test hood single body calibration, test hood environment calibration, radio frequency index test, putting the tested active antenna system into the test hood, wherein the test environment is the same as the calibration environment, and carrying out radio frequency test on the tested active antenna system through a radio frequency port of a test probe after compensating the test environment according to the calibrated calibration result. The invention provides the comprehensive testing method at the same time. A space radio frequency (OTA) test is respectively adopted to test spatial characteristic of the active antenna system; and the near field coupling mode is adopted to test the radio frequency index of the active antenna system. The advantages of two testing methods are fully combined, and the defects and problems of the two testing methods are overcome and solved, thereby optimizing the test efficiency and the test cost.

Owner:ZTE CORP

Integrated circuit test probe

InactiveUS6844749B2Reliable electrical connectionLow insertion force parameterElectric discharge tubesCoupling contact membersCoil springSolder ball

A test probe consists of an elongated screw machine contact biased by a helical spring and mounted in a through hole of a non-conductive substrate. One end of the contact includes a crown for engaging a solder ball lead of an IC package, and the contact includes an intermediate collar which maintains the contact within the through hole. The helical spring is disposed about the contact, with one end thereof engaging the lower end of the collar. The other end of the helical spring has contiguous coils and is of a reduced diameter so as to extend beyond the lower end of the non-conductive substrate to make electrical contact with a printed circuit board. When the test probe is compressed between the IC package and the printed circuit board, the inherent twisting of the helical spring causes the contact to tilt and make electrical contact with the contiguous coils, thereby establishing a direct electrical path between the IC package and the printed circuit board, with minimum resistance and minimum inductance.

Owner:ARIES ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com