Patents

Literature

387 results about "Hand pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

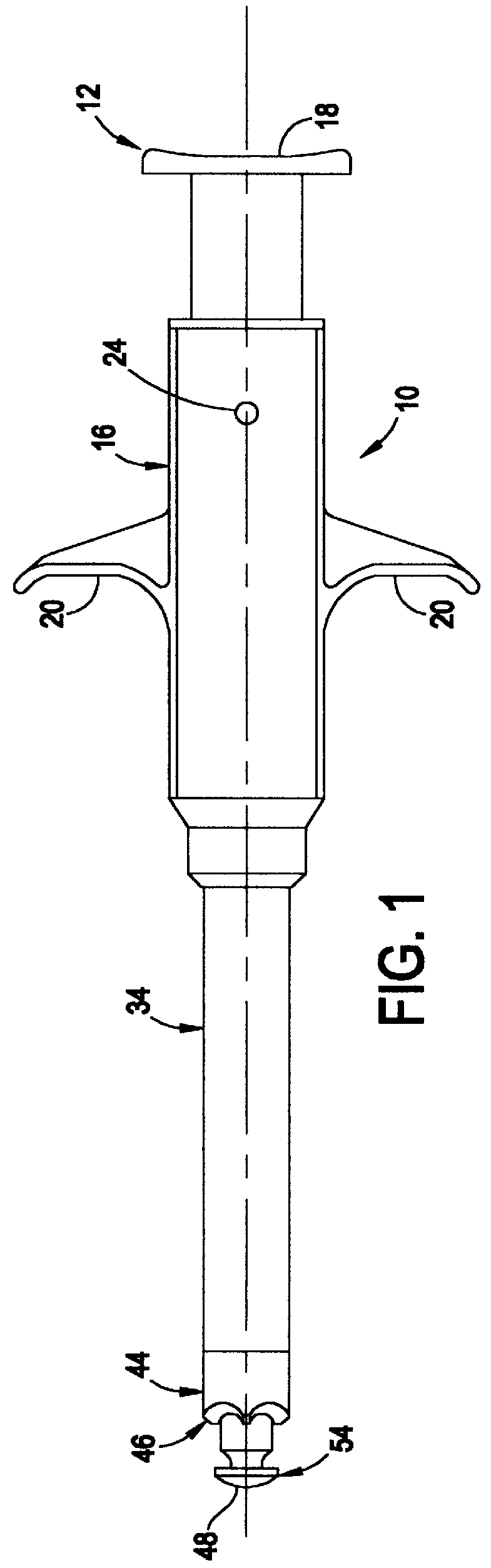

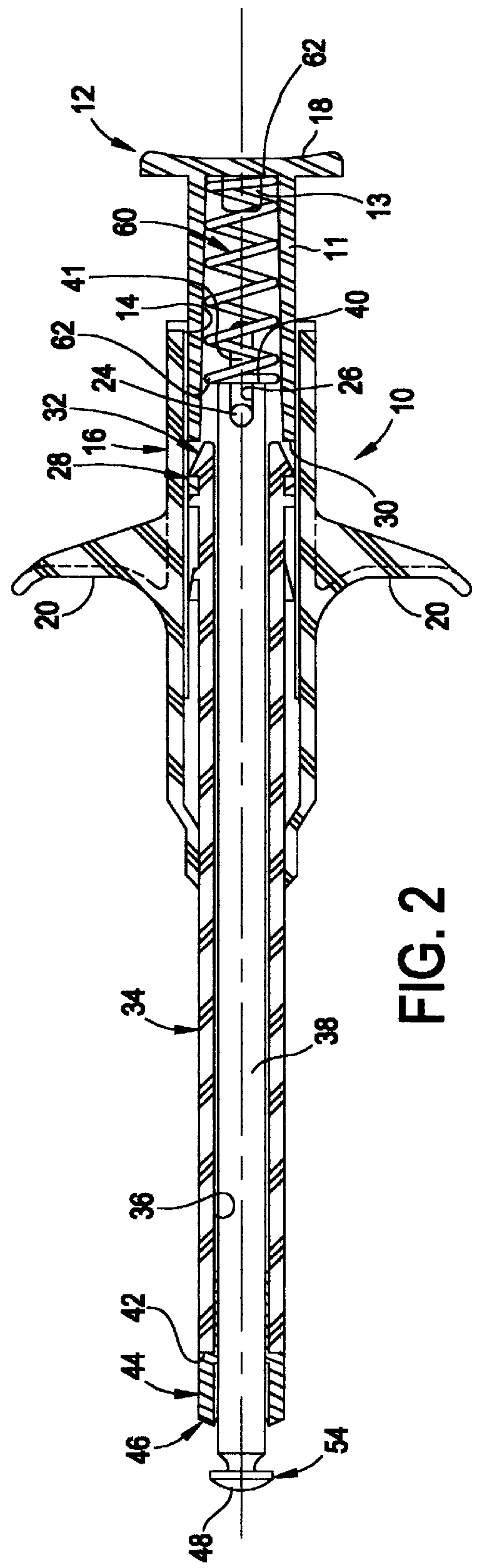

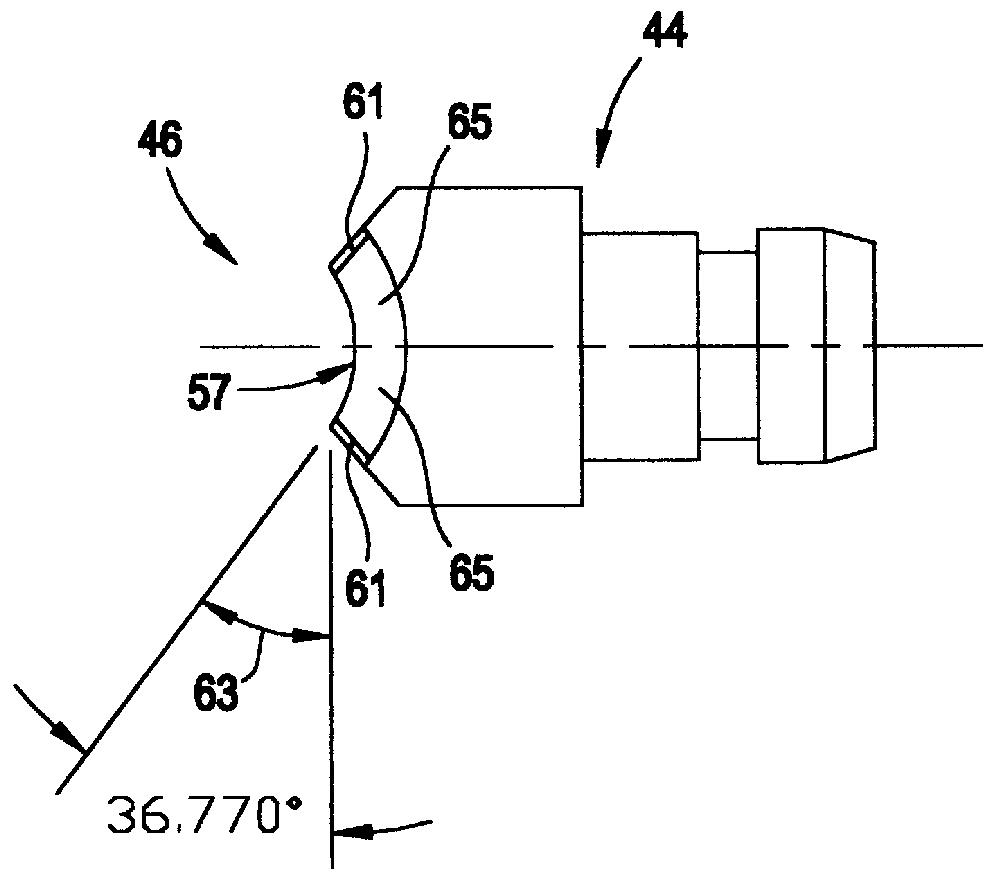

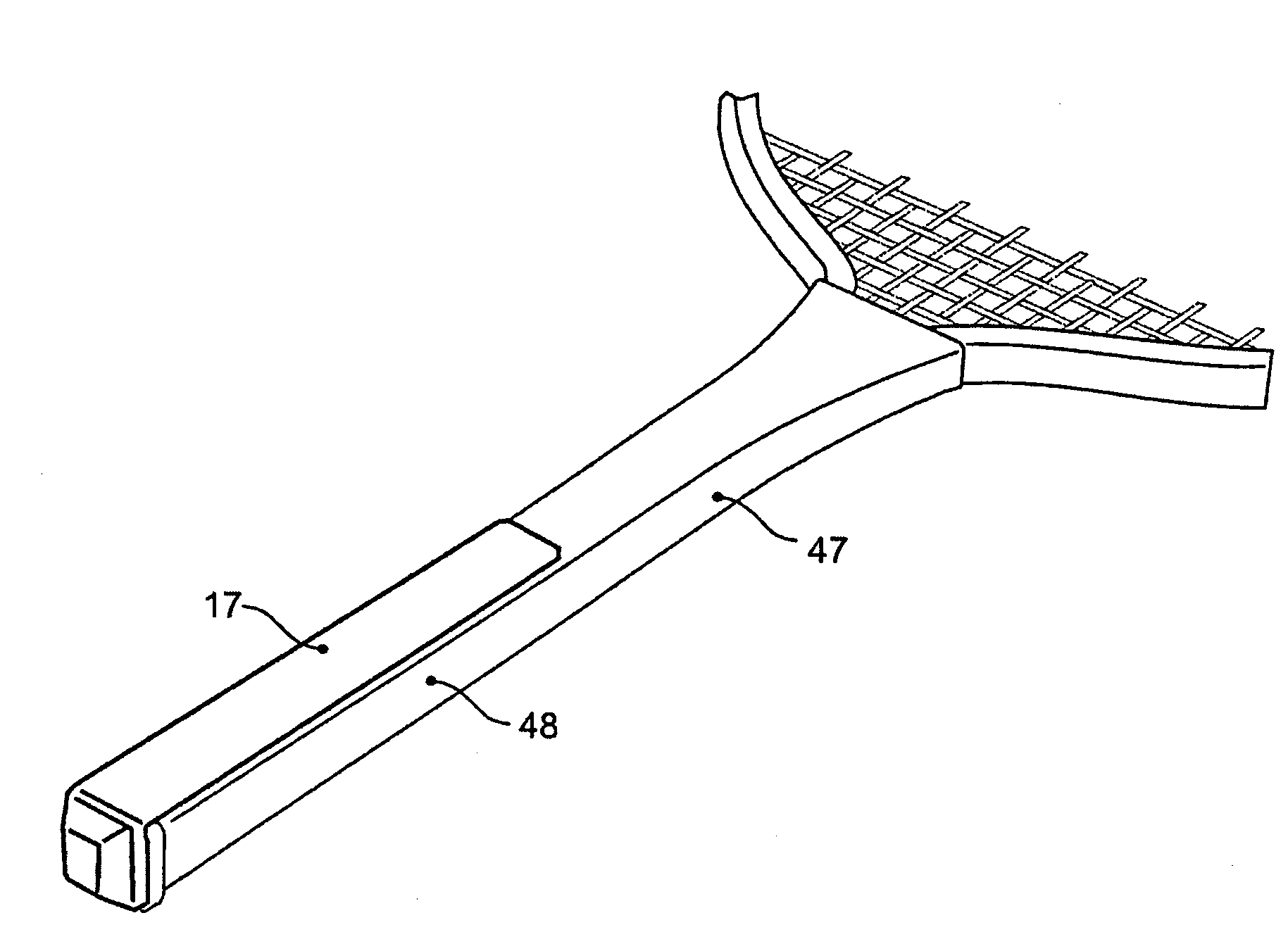

Medical punch with high shear angle cutting edges

InactiveUS6080176AClean and accurate cutReduce wearSurgical needlesExcision instrumentsEngineeringHand pressure

A medical punch having a plurality of cutting edges. The fact that the medical punch has a plurality of cutting edges provides, for example, that the medical punch can be used to achieve a clean and accurate cut, and provides that an excessive amount of hand pressure need not be employed to effect the cut.

Owner:ATRION MEDICAL PRODS

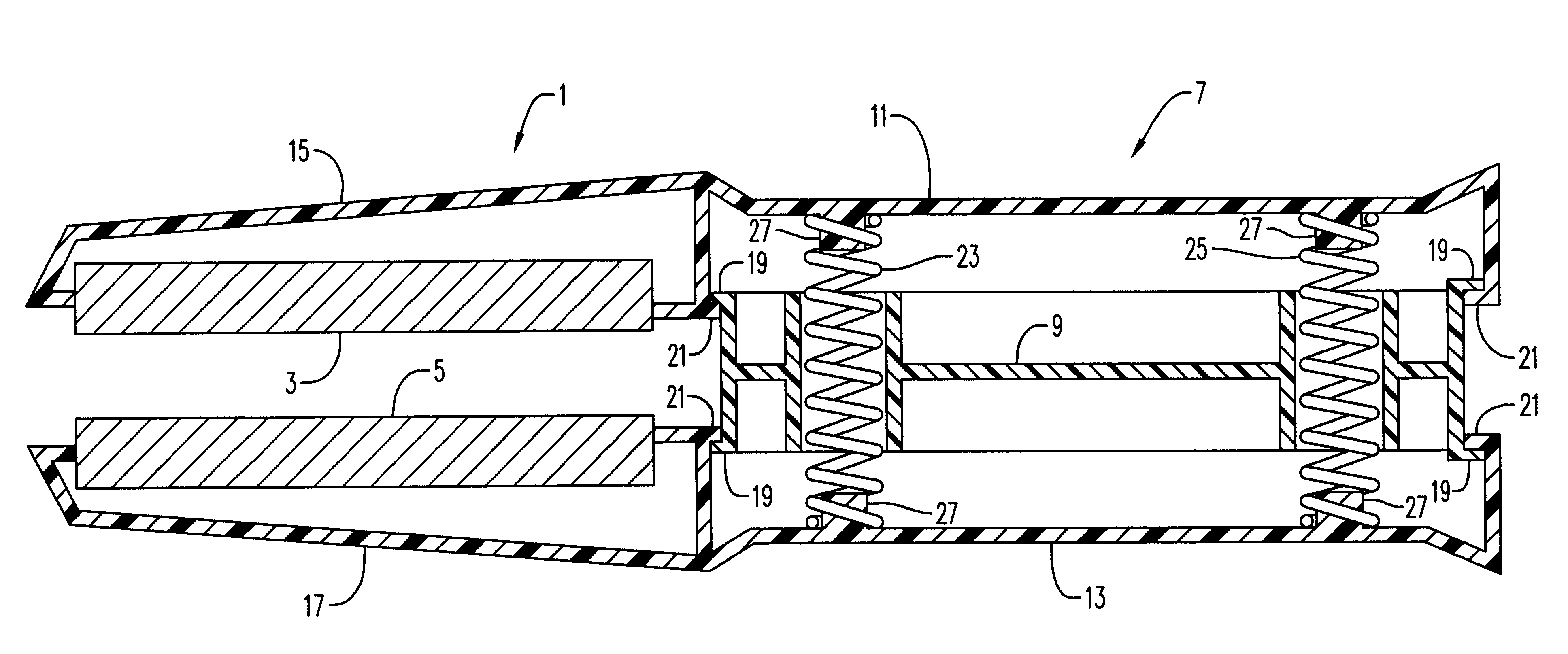

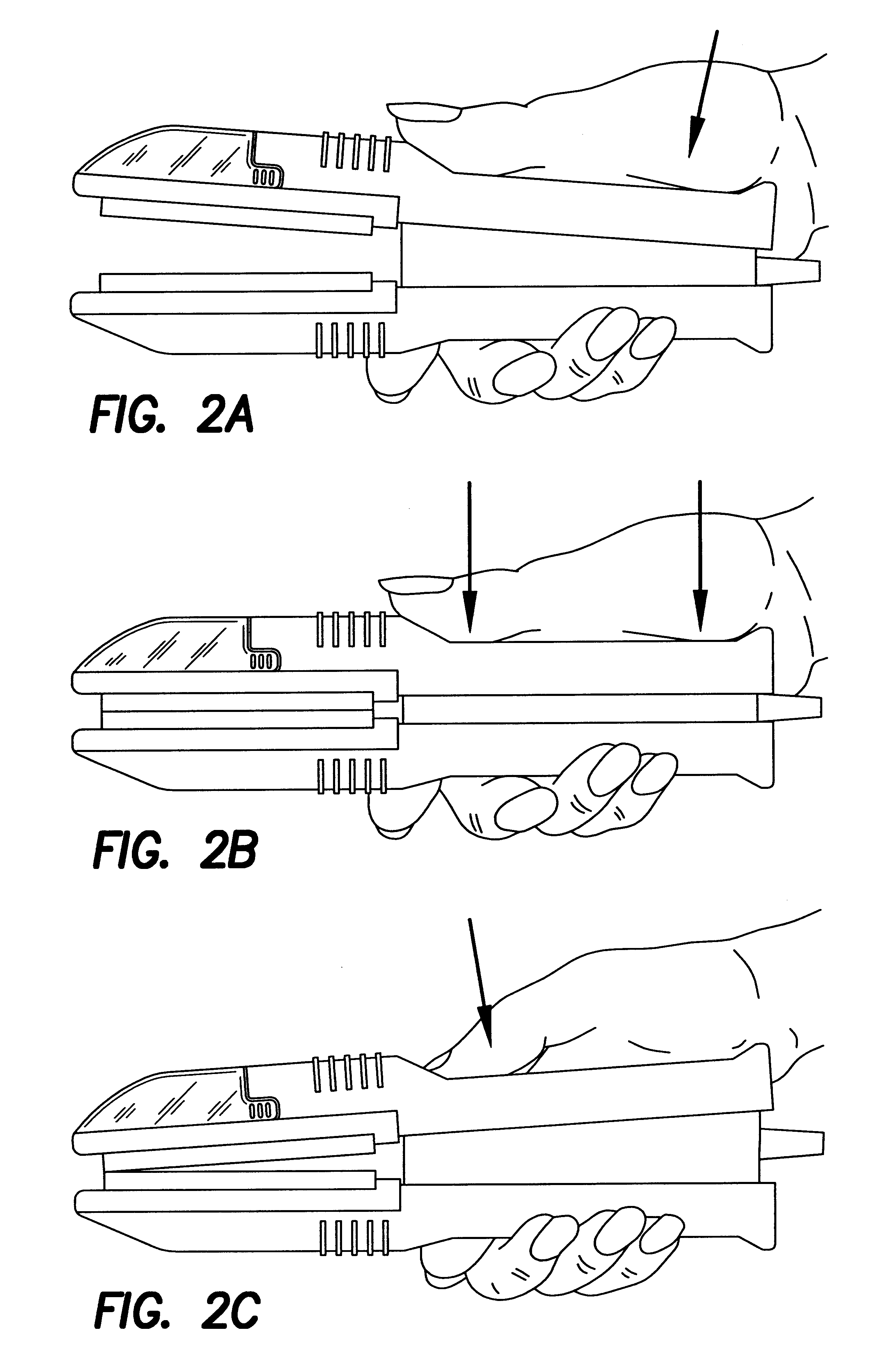

Hair styling tongs with biased handles

Hairdressing tongs have a pair of arms extending from handles. Each arm has a heating pad affixed thereto. The handles have opposed openings. A central element is positioned between the handles and fitted within the openings such that the central element is slidable toward the handles. The central element has guide openings. Springs are positioned in the guide openings for biasing apart the handles. The springs enable hand pressure to move the handles and arms together from a completely open position to a completely closed position and, in absence of the hand pressure, to maintain the handles and arms in relatively parallel configuration, biased against stops of the central element.

Owner:CONAIR CORP

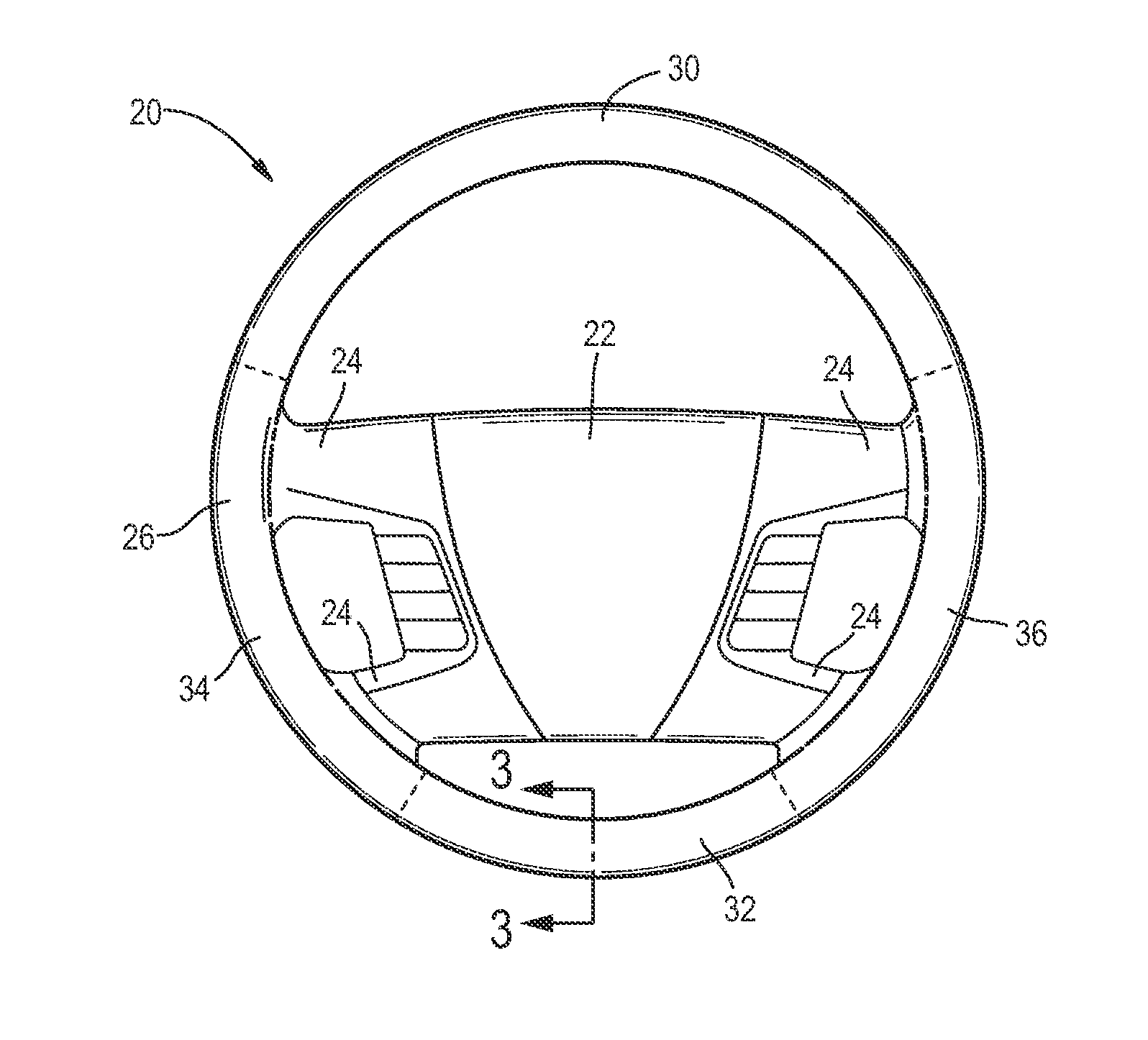

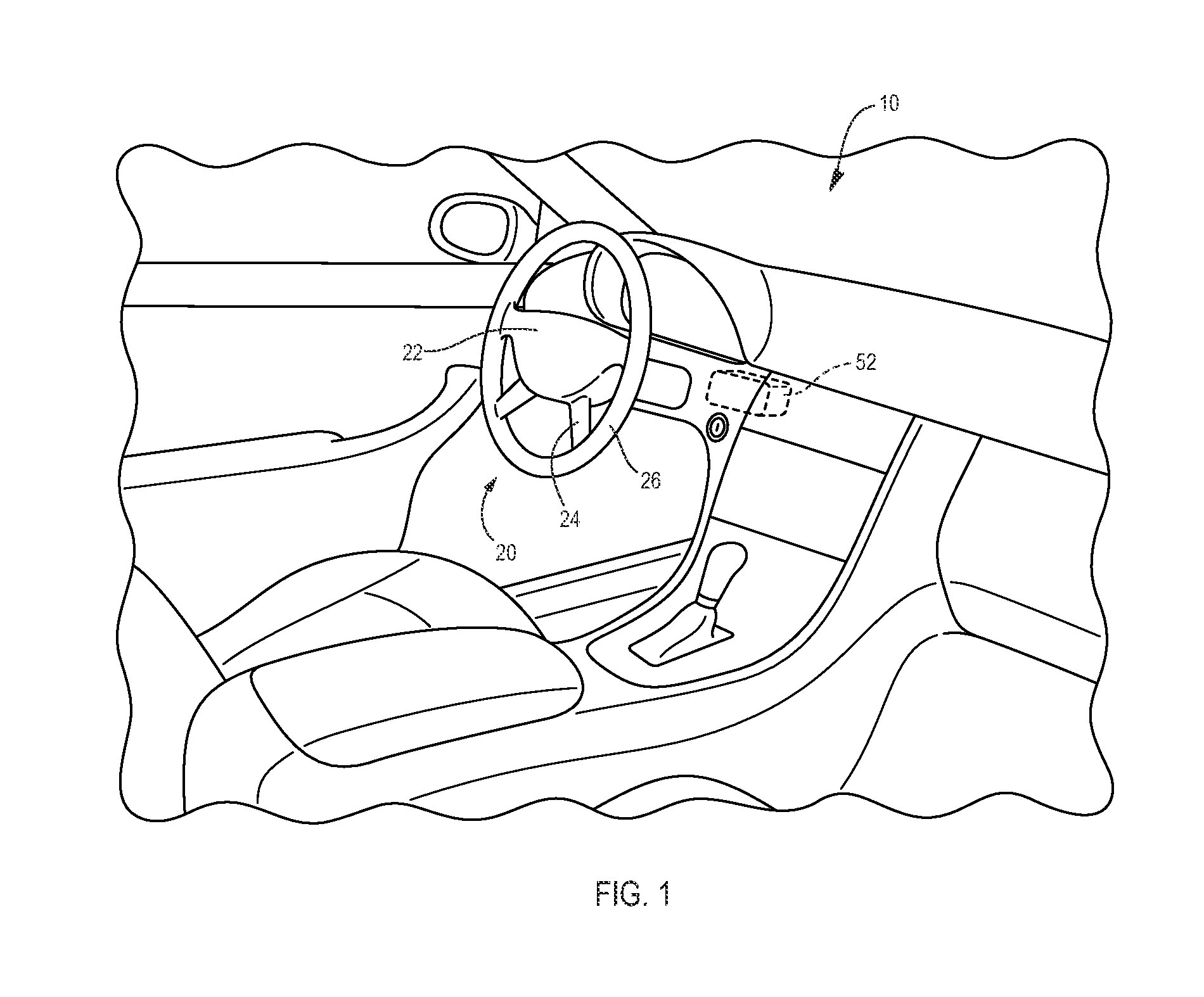

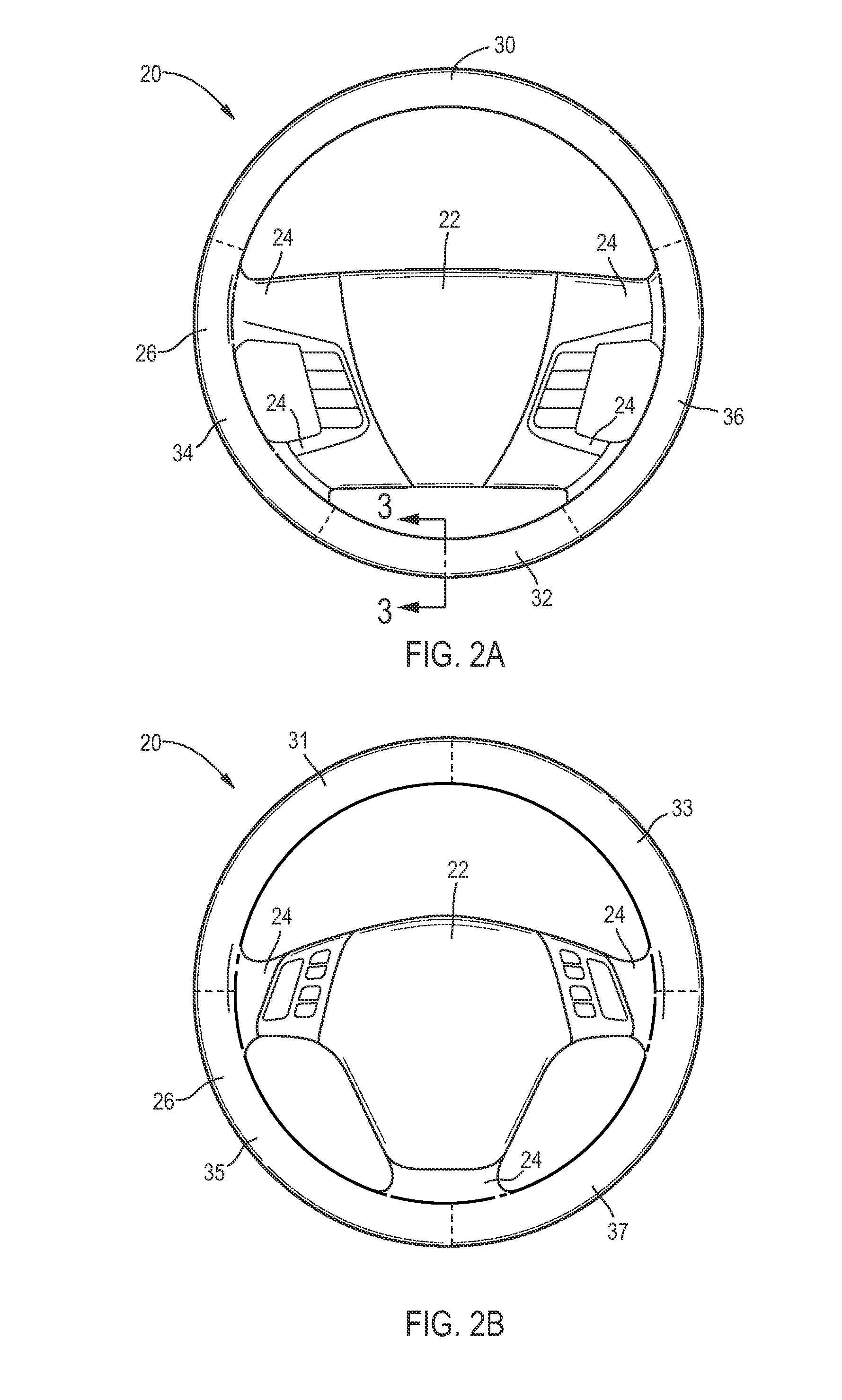

Steering wheel with hand pressure sensing

The invention relates to a vehicle safety system includes a steering wheel, a plurality of pressure sensitive sensors located in the steering wheel, and a control unit. The pressure sensitive sensors can be located in different regions of the steering wheel. The pressure sensitive sensors can determine if a driver's hand is pressing upon a respective region of the steering wheel associated with one or more of the plurality of pressure sensitive sensors. The control unit can be configured or programmed to determine if at least one of the driver's hands is pressing upon a region of the steering wheel for a predetermined amount of time.

Owner:JOYSON SAFETY SYST ACQUISITION LLC

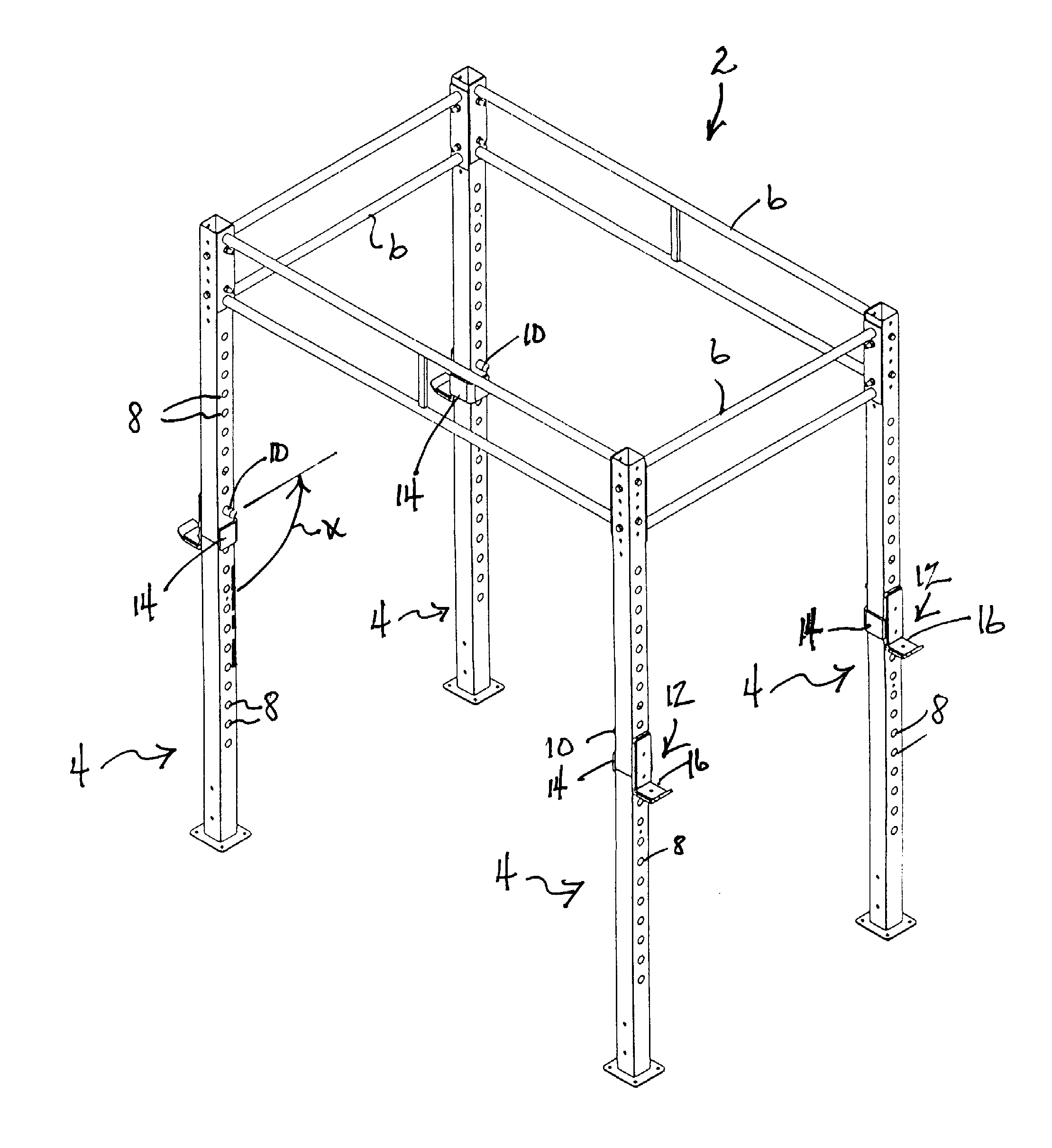

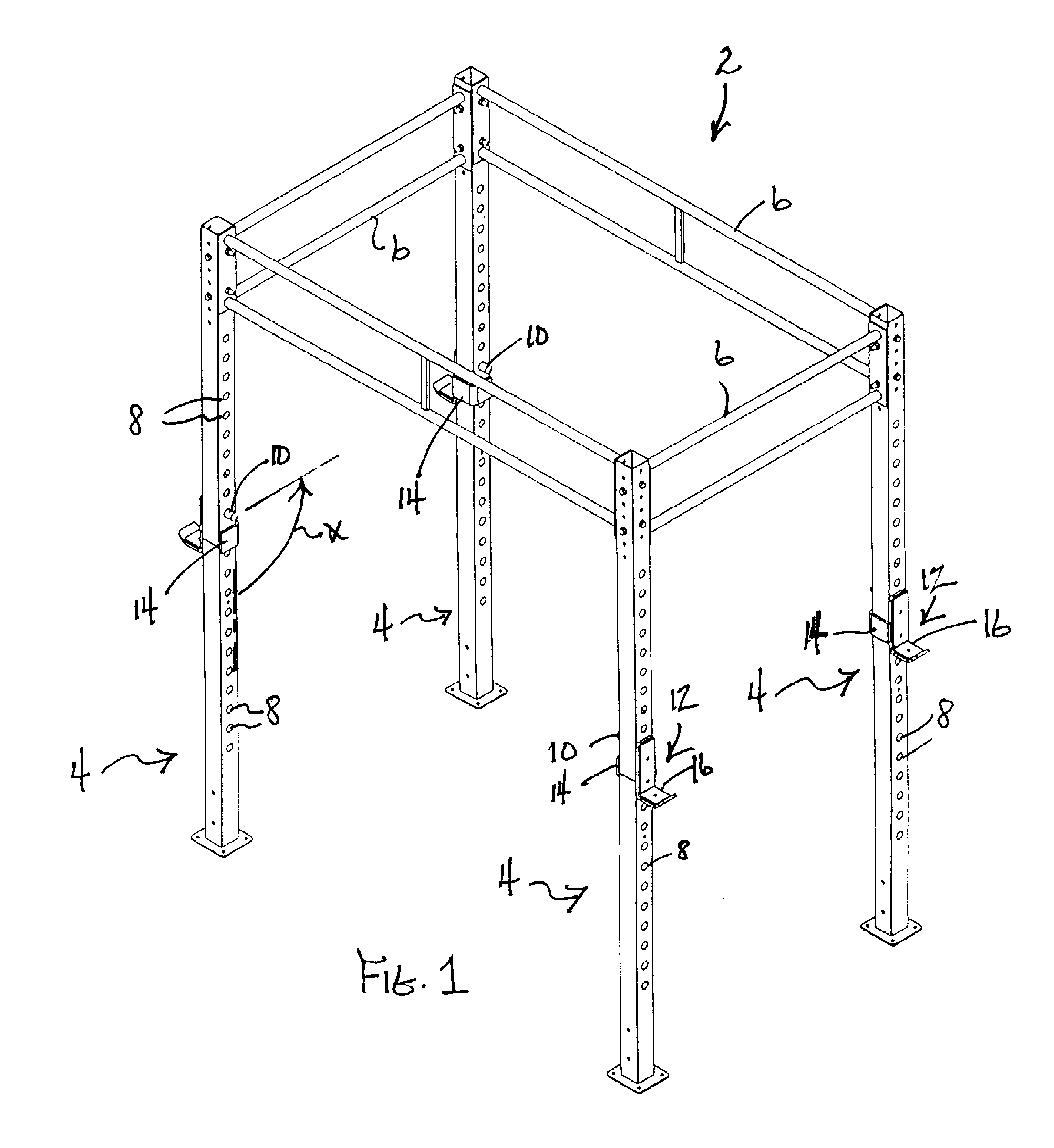

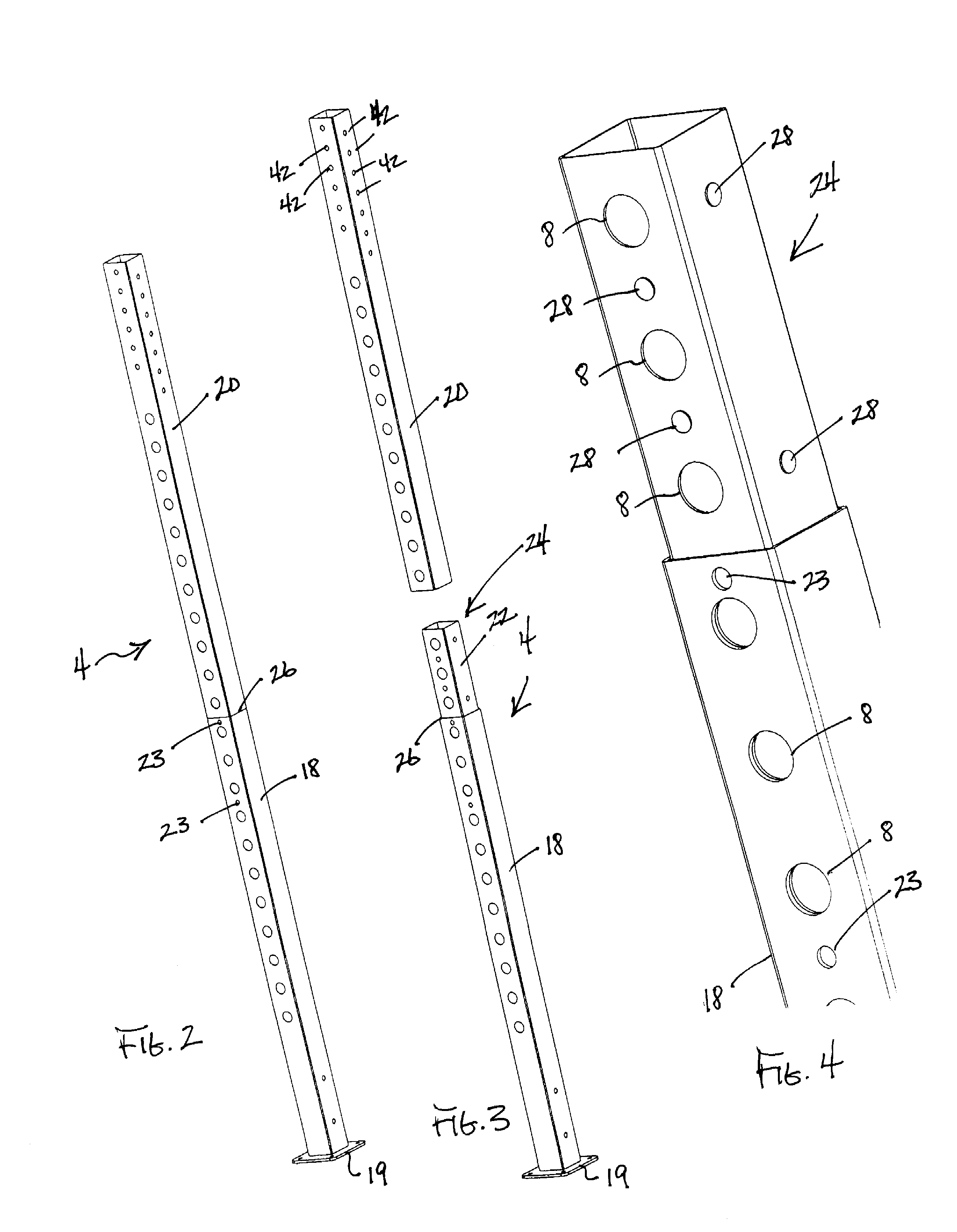

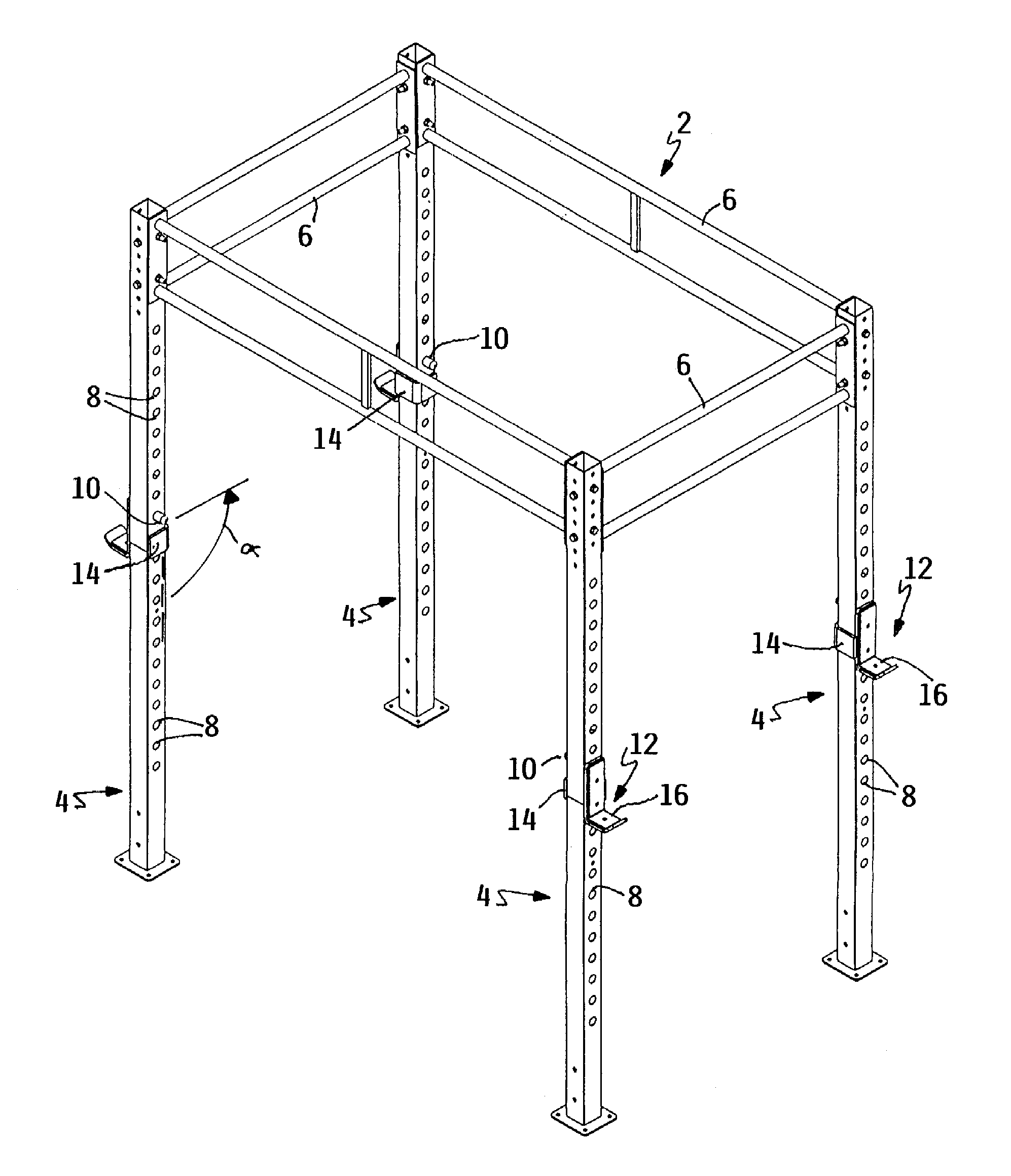

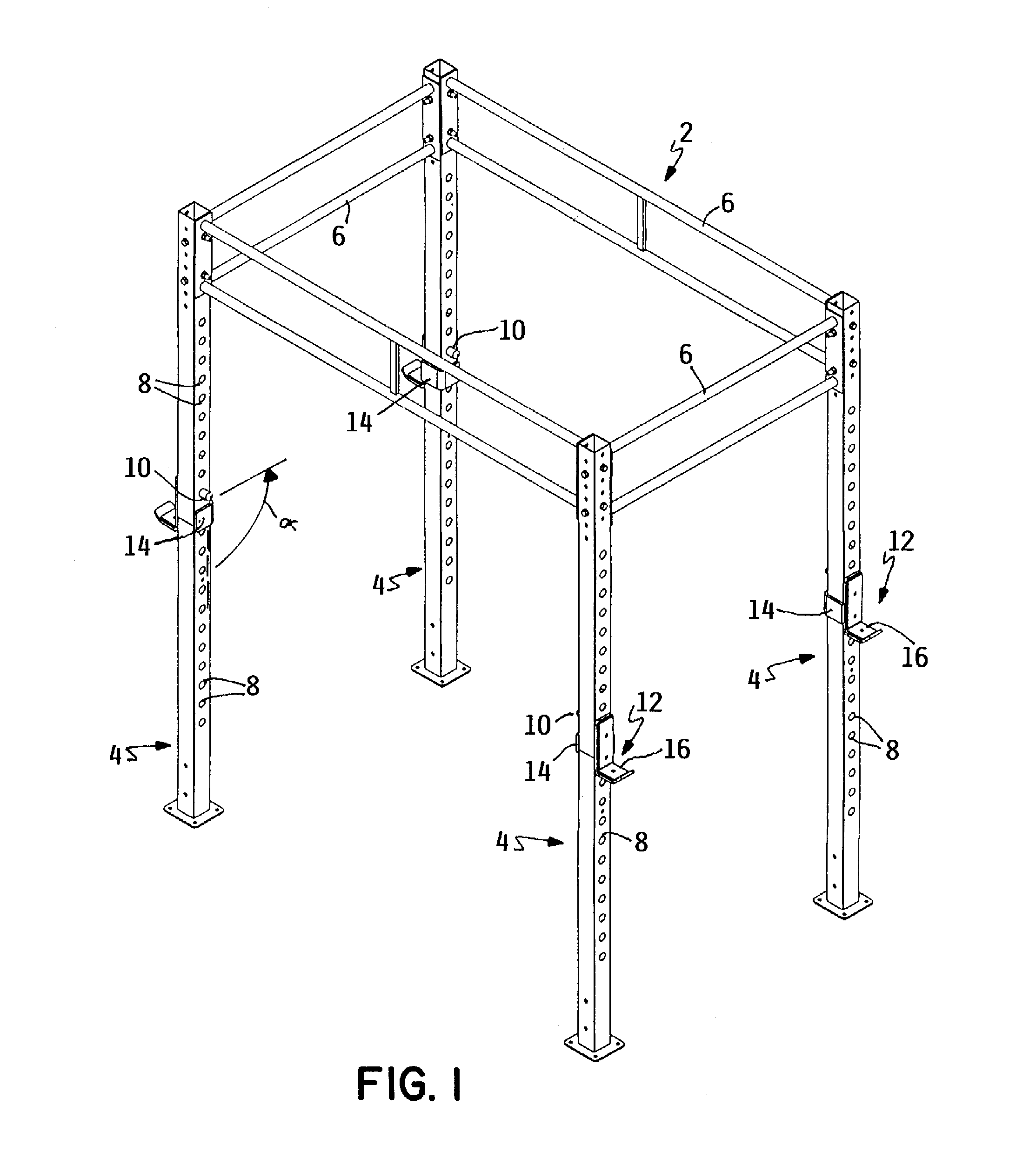

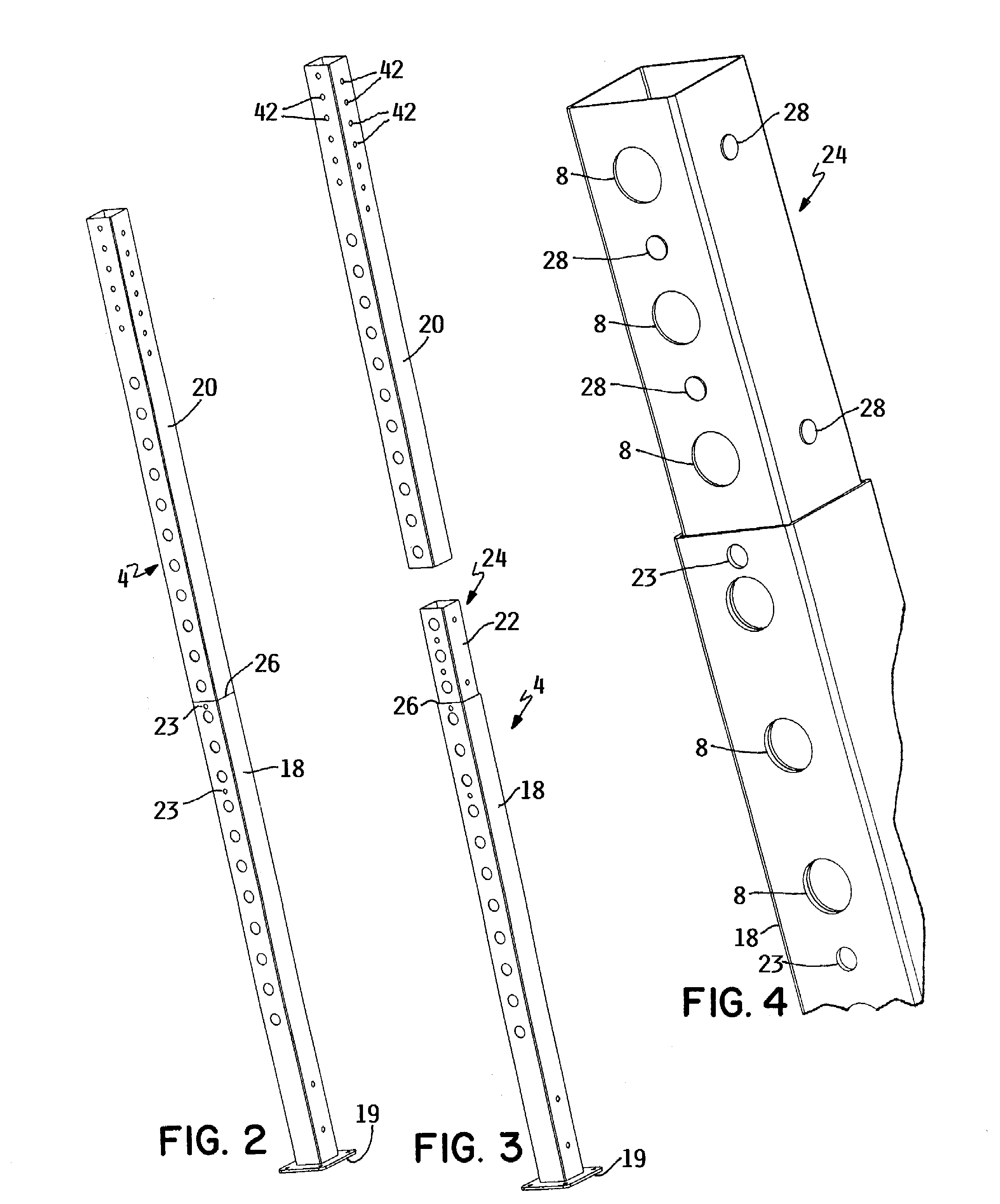

Exercise equipment frame having sectional structural members

An exercise equipment frame, such as a power cage, is formed from uprights that comprise at least two sections that are telescopically interfit with one another. The sections have an interference fit between them when the telescopic interconnection is made that is tight enough to require the use of a tool that enables leverage greater than that achievable by the hand pressure of a user. The sections may be of substantially equal length to one another when forming the main uprights of the frame to allow packaging of the sections when disassembled in a carton of more regular dimensions. The sections may also be unequal length to allow coupling of a frame extension to the top of a completed power cage type frame.

Owner:POWERBLOCK HLDG

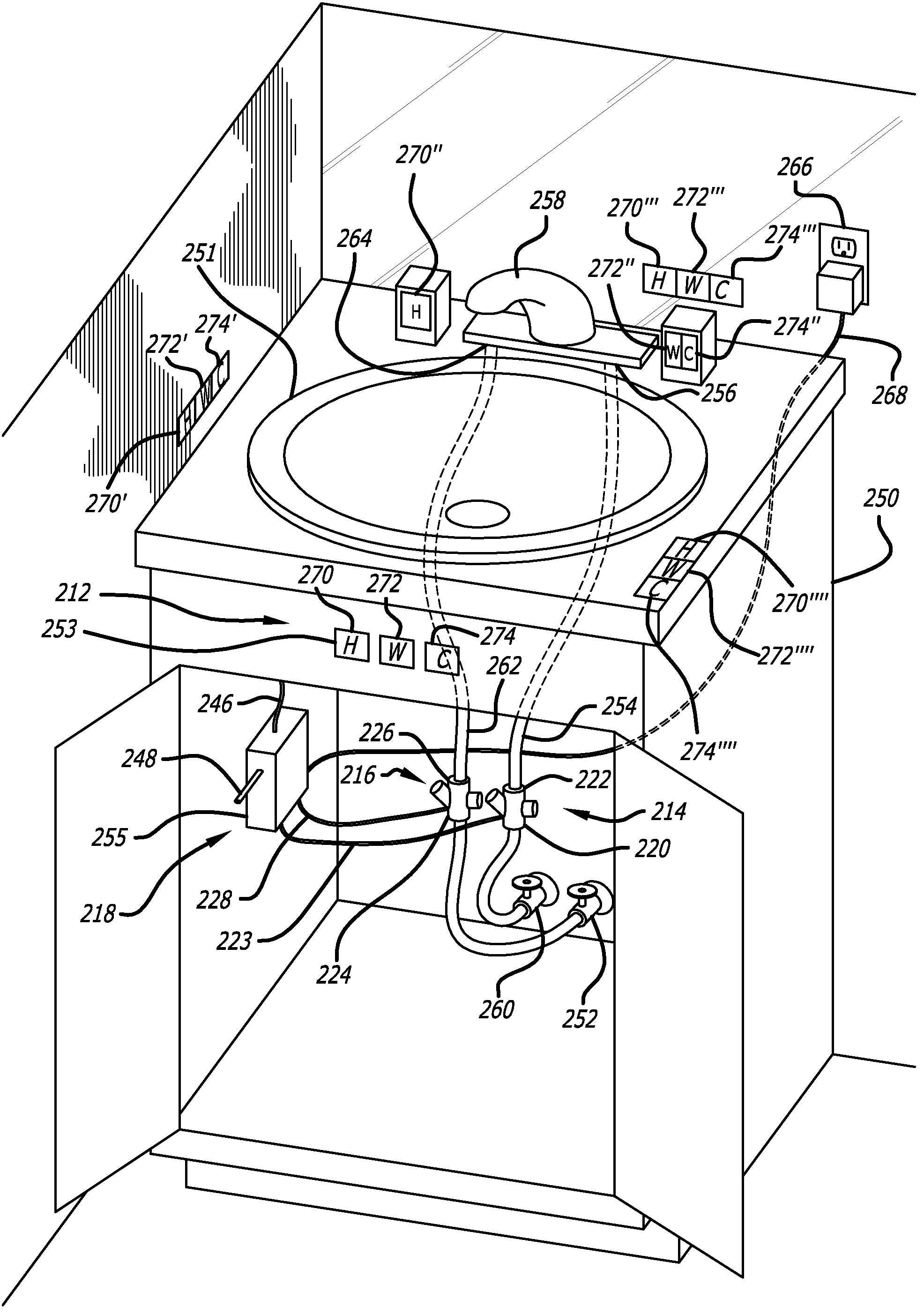

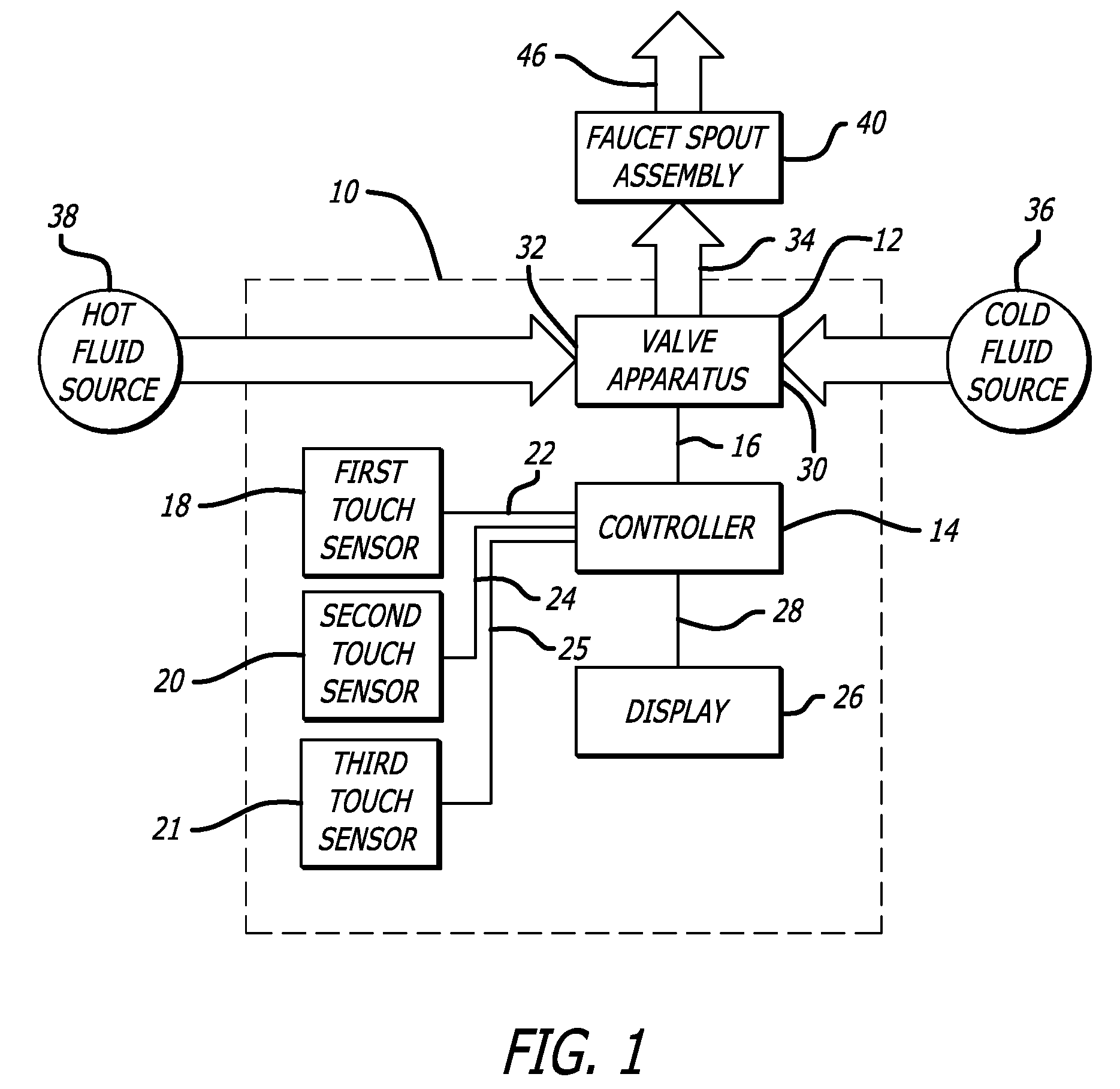

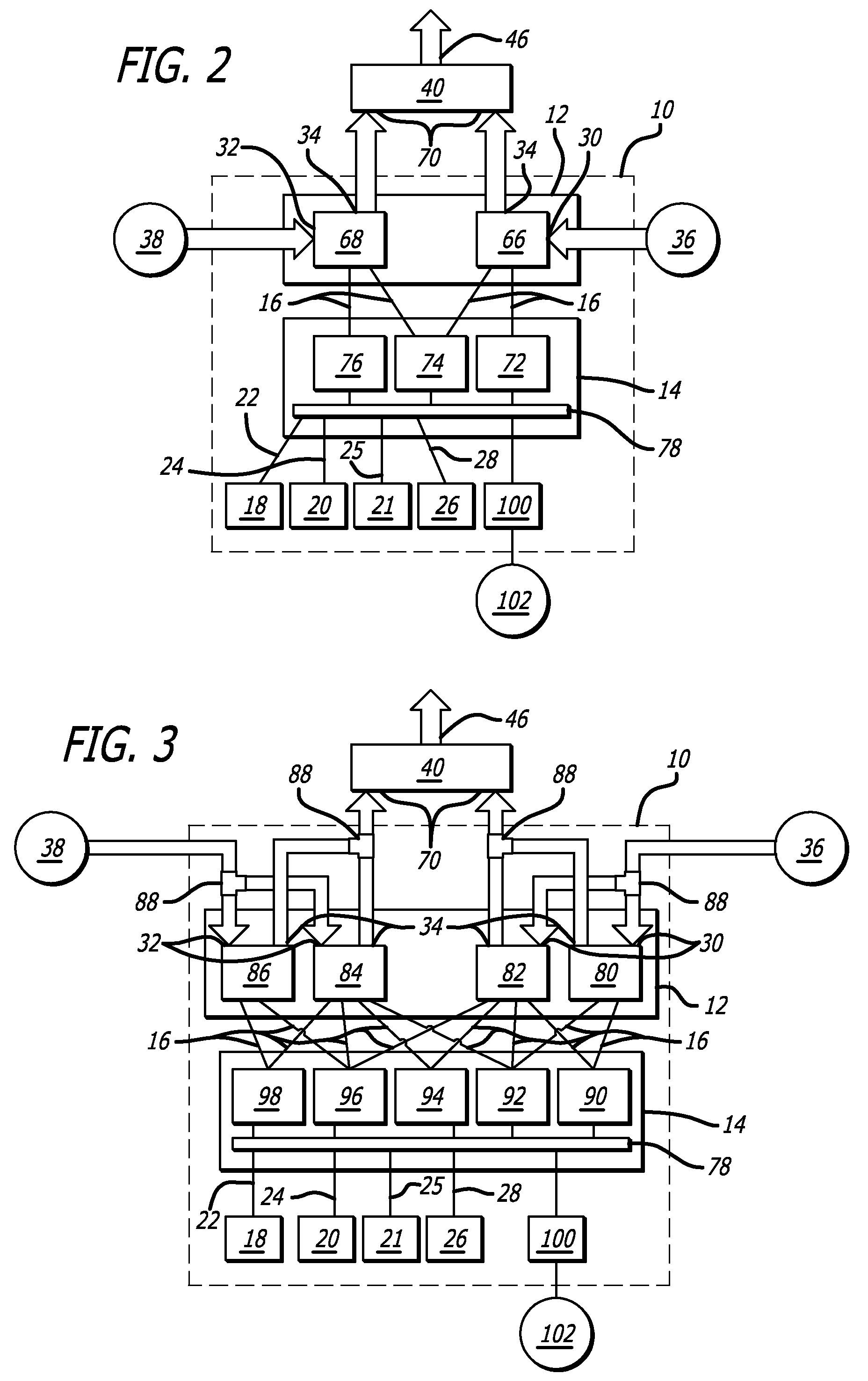

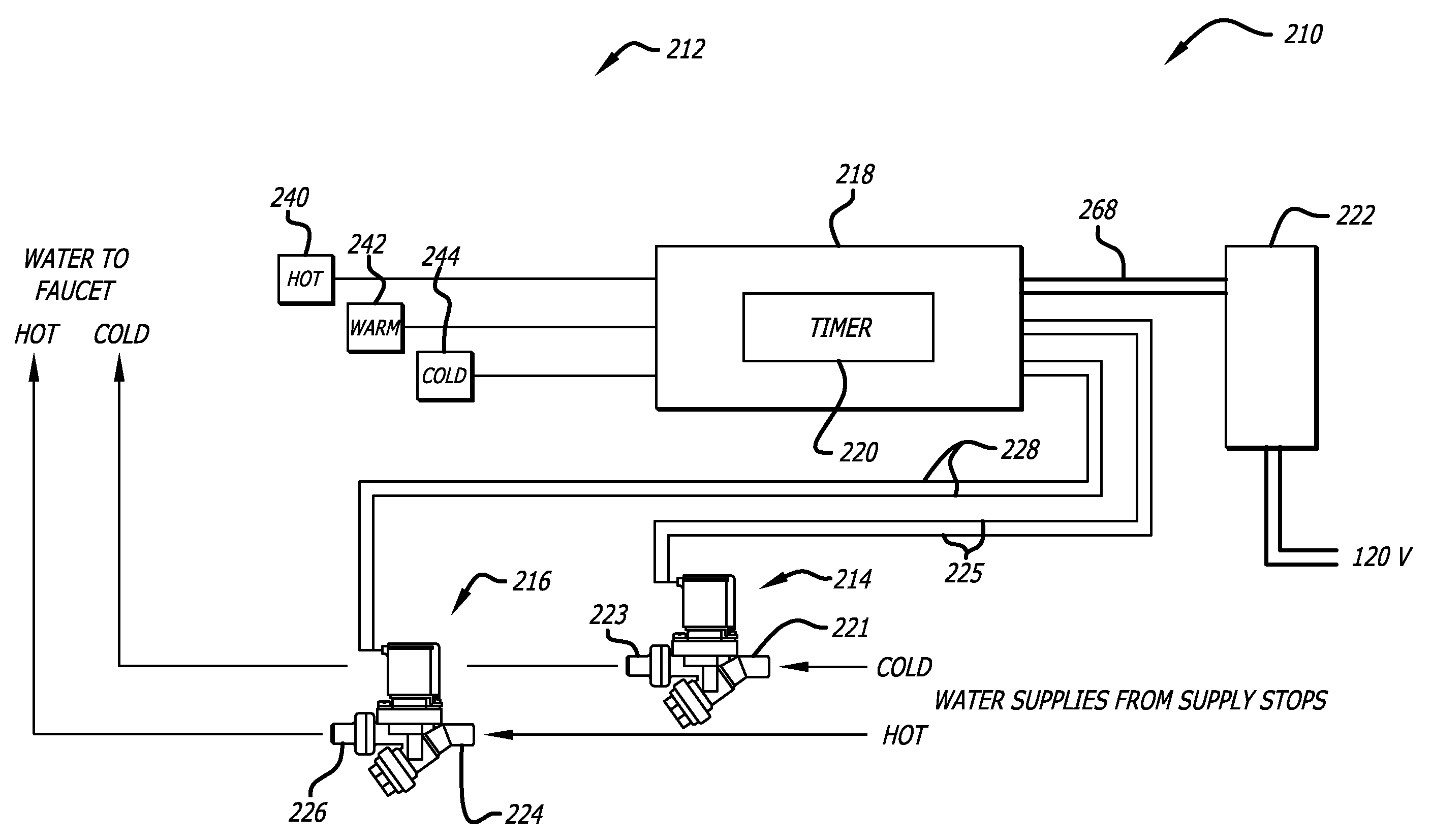

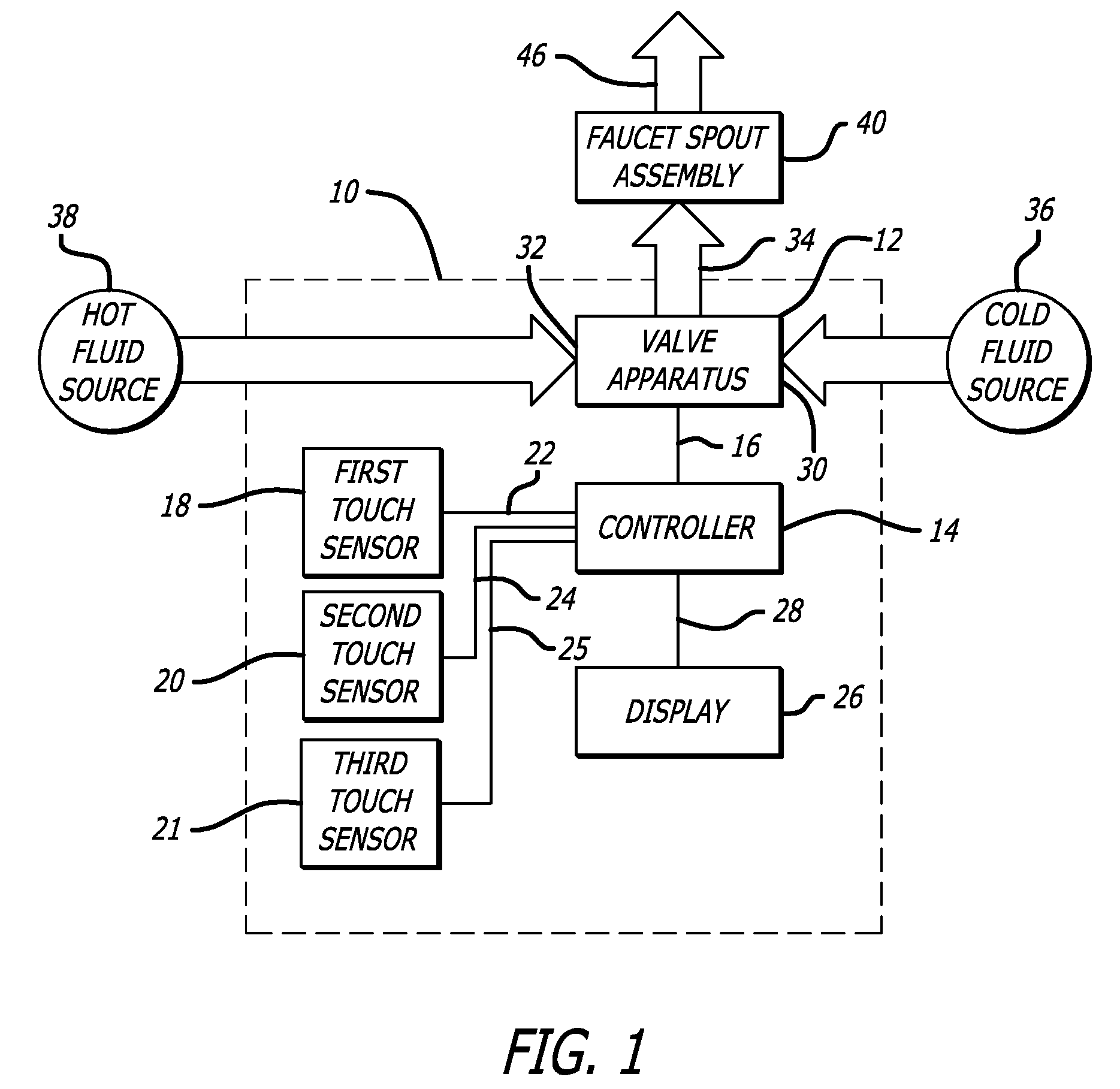

Faucet control system and method

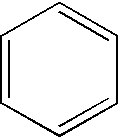

ActiveUS7766026B2Operating means/releasing devices for valvesServomotor componentsControl systemWarm water

A faucet control system comprises a valve apparatus, sensors or a touch panel to be activated by a user, and a controller that controls the valve apparatus. A first sensor may start fluid flow and a second sensor may alter the proportion of fluids delivered from two fluid sources. Alternatively, a first sensor may initiate hot water flow, a second sensor may initiate cold water flow, and a third sensor may initiate flow of a mixture of hot and cold water to create a warm water flow. The sensors may be activated without being touched and may include infrared sensing elements. The touch panel may be activated with hand pressure and may include electrically conductive sheets. Alternatively, hot, cold and / or warm touch sensors may be provided separately. The touch panel may have a first portion for allowing fluid flow from a cold fluid source, a second portion for allowing fluid flow from the cold fluid source and a hot fluid source, and a third portion for allowing fluid flow from the hot fluid source. The controller may include an adjustable timer so that fluid flow can be stopped automatically after a selected period of time. Other systems include a one sensor system, a two sensor system, a three sensor system and a five sensor system. In the five sensor system, one sensor activates hot water flow, another sensor activates cold water flow, and three sensors activate various levels of warm water flow.

Owner:BOEY KUM F

Exercise equipment frame having sectional structural members

An exercise equipment frame, such as a power cage, is formed from uprights that comprise at least two sections that are telescopically interfit with one another. The sections have an interference fit between them when the telescopic interconnection is made that is tight enough to require the use of a tool that enables leverage greater than that achievable by the hand pressure of a user. The sections may be of substantially equal length to one another when forming the main uprights of the frame to allow packaging of the sections when disassembled in a carton of more regular dimensions. The sections may also be unequal length to allow coupling of a frame extension to the top of a completed power cage type frame.

Owner:POWERBLOCK HLDG

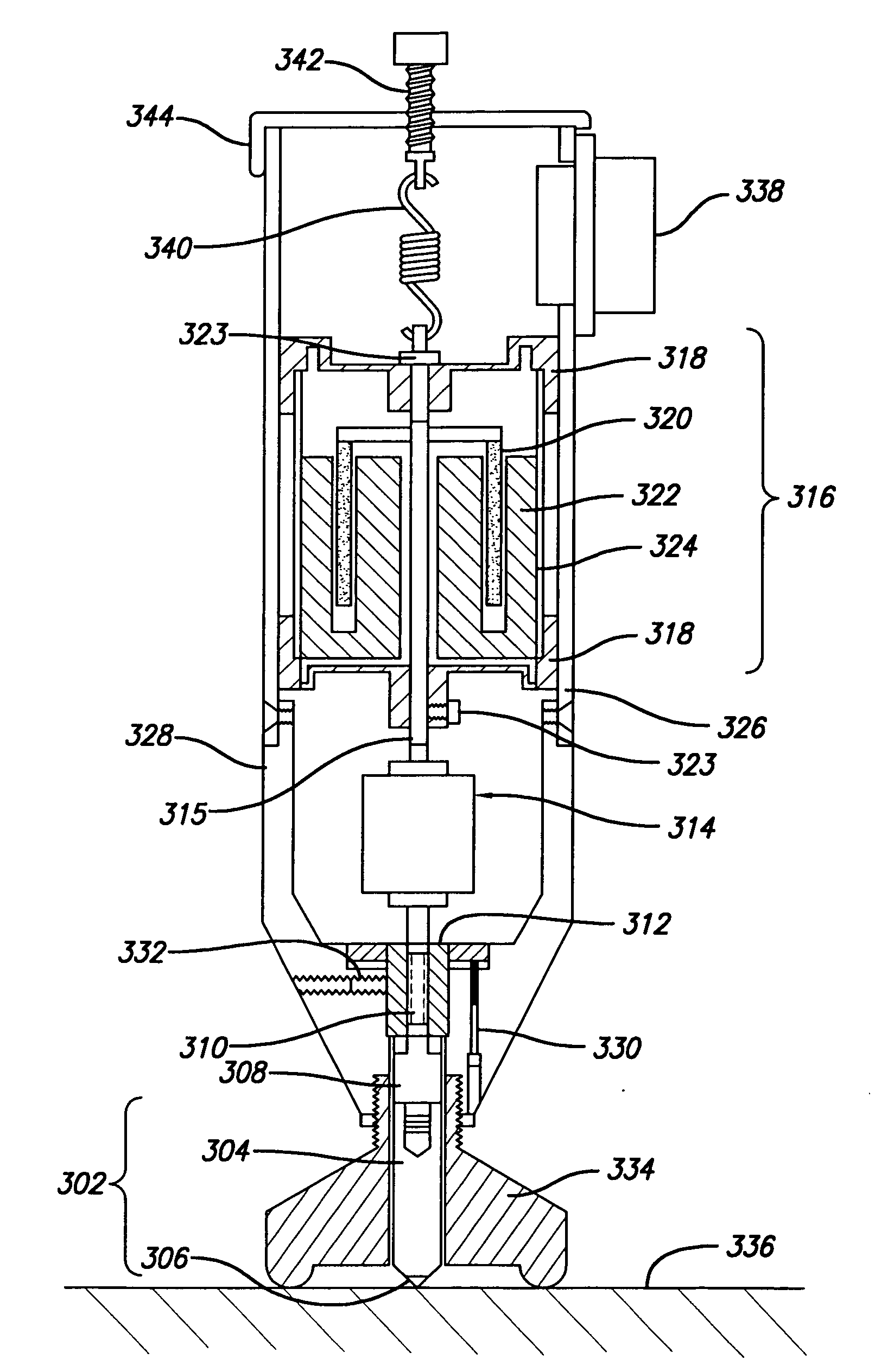

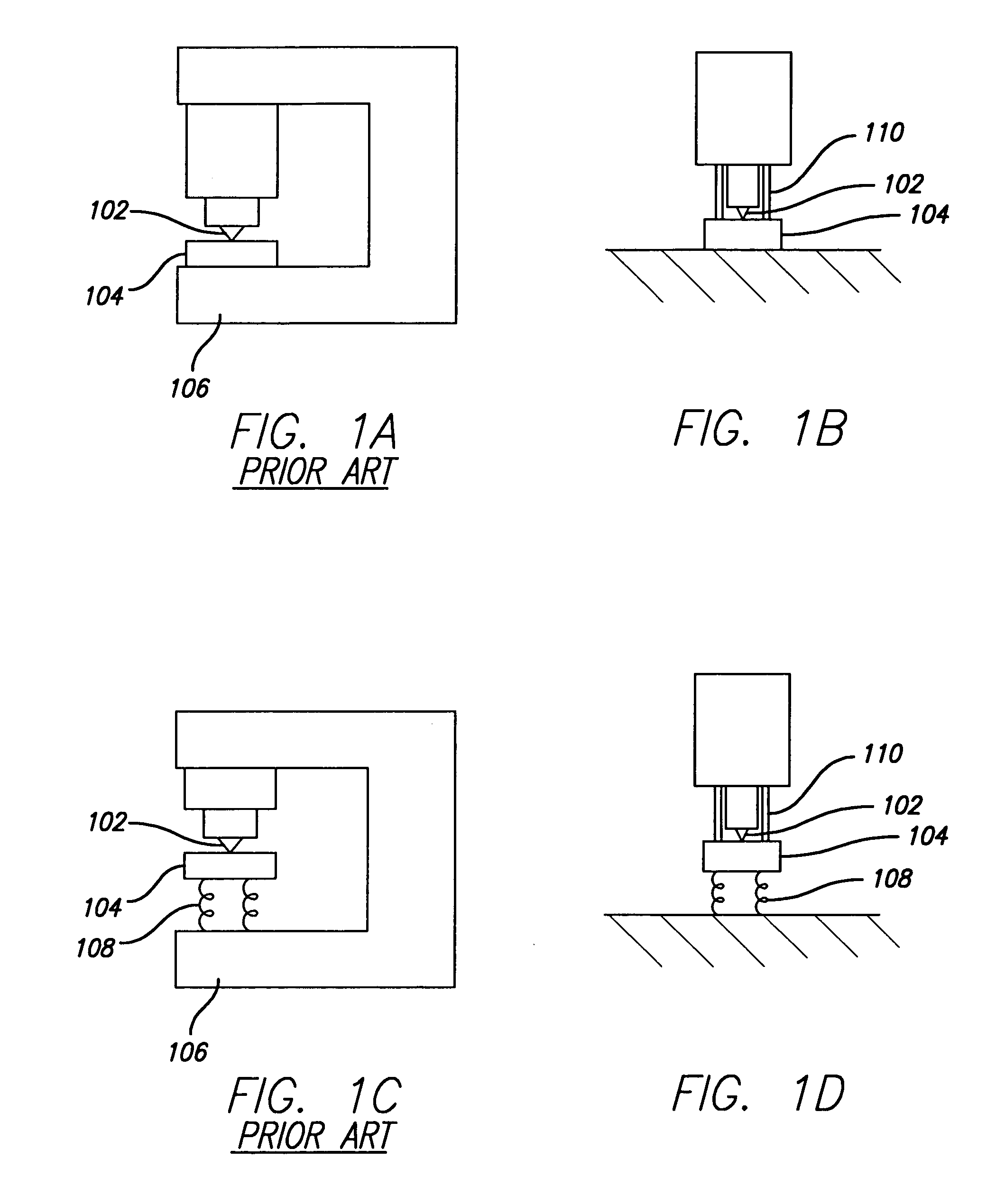

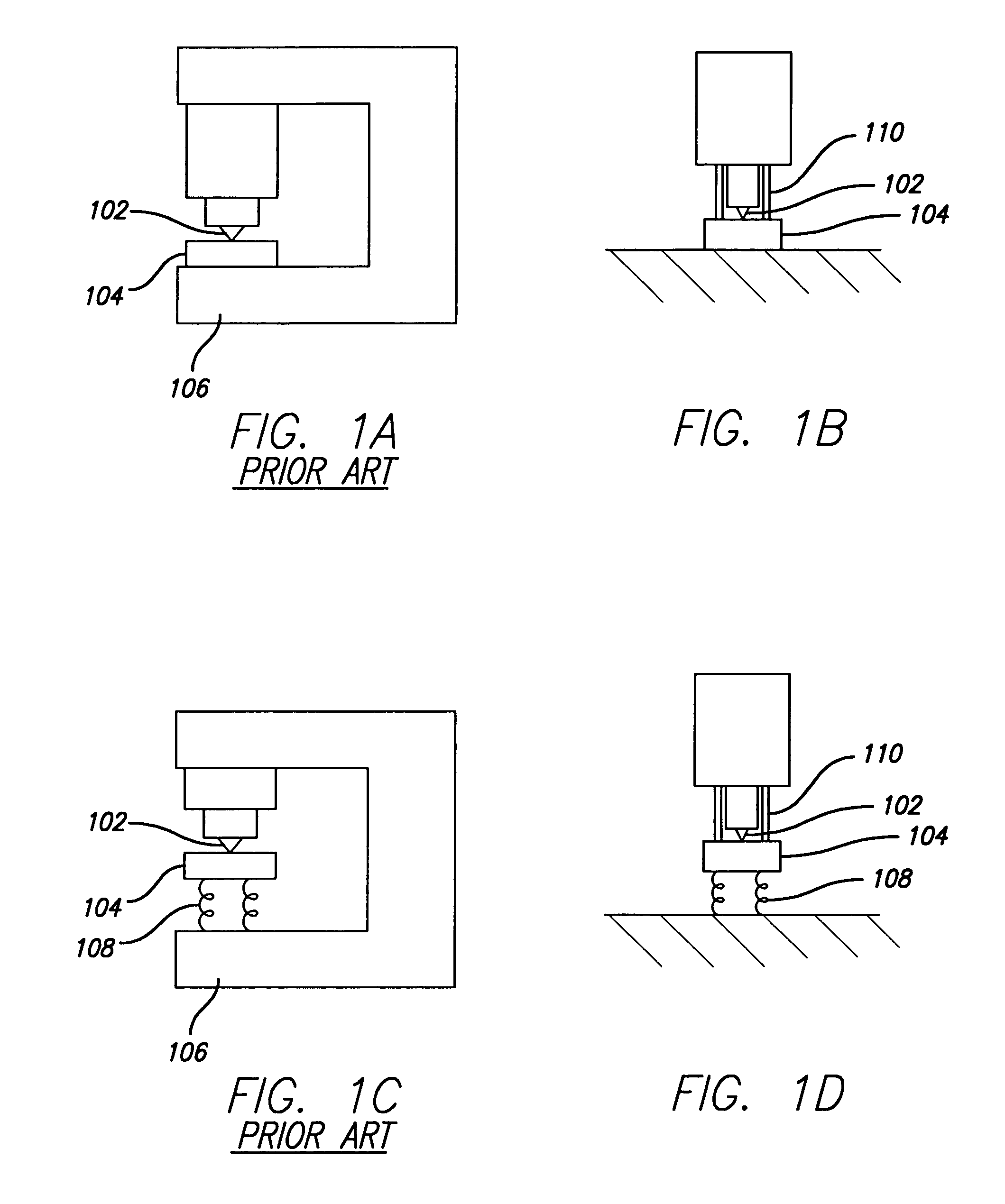

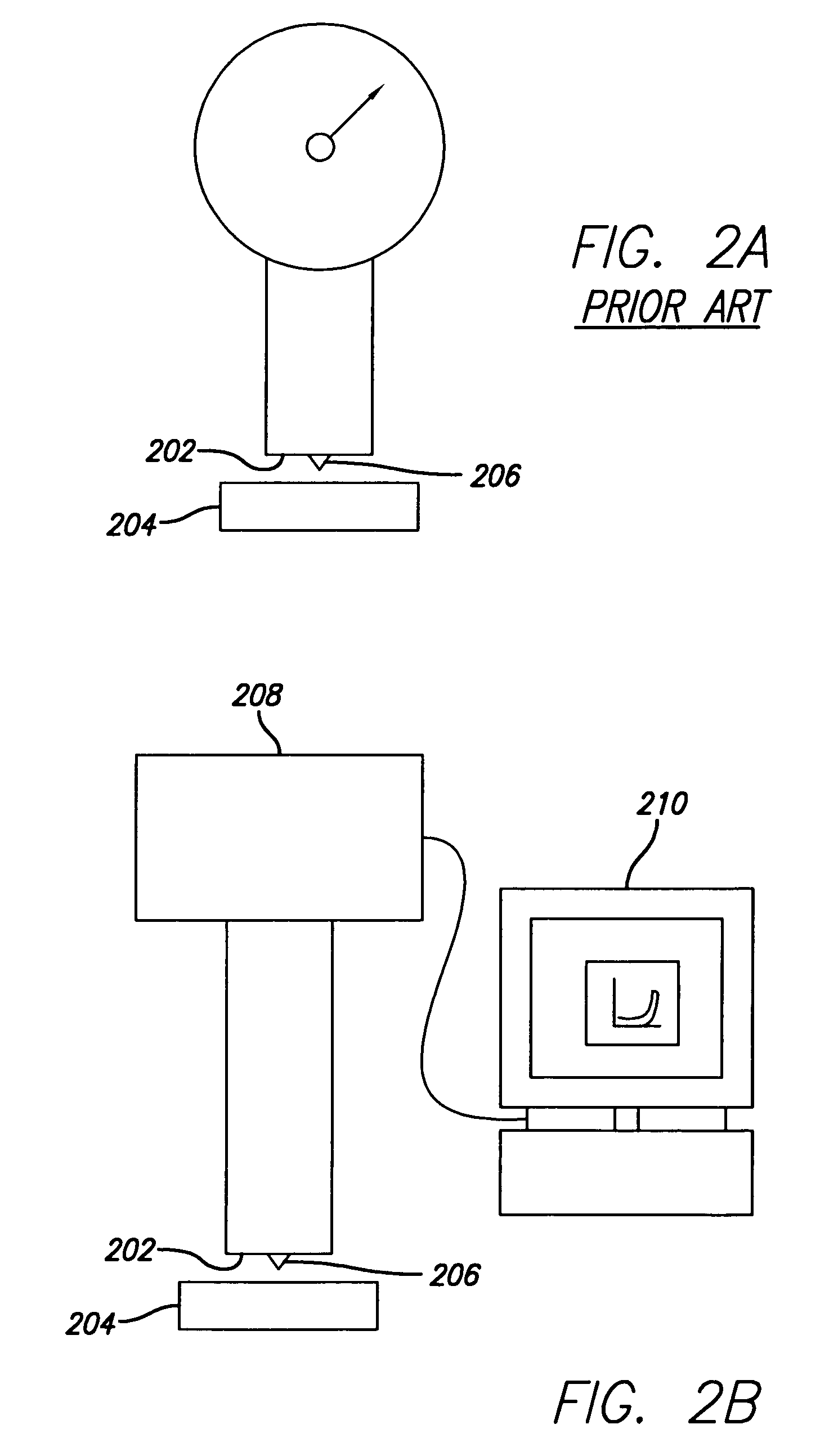

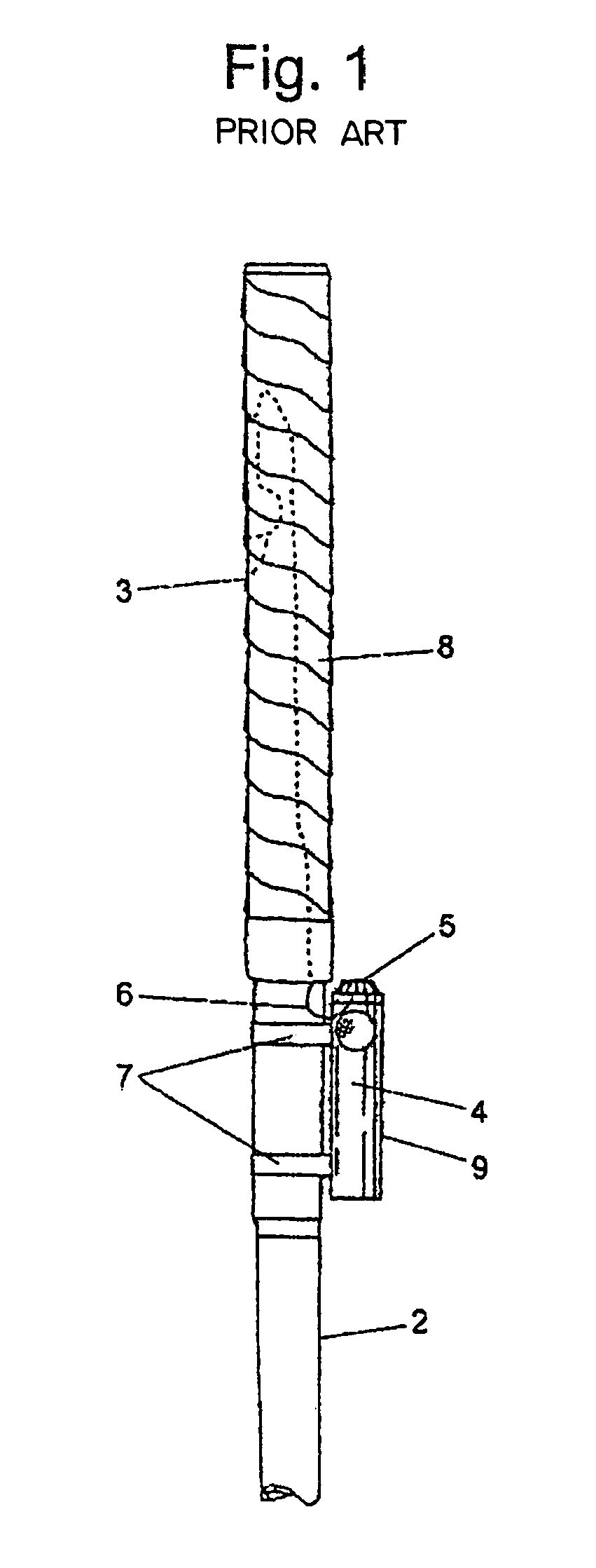

Methods and instruments for materials testing

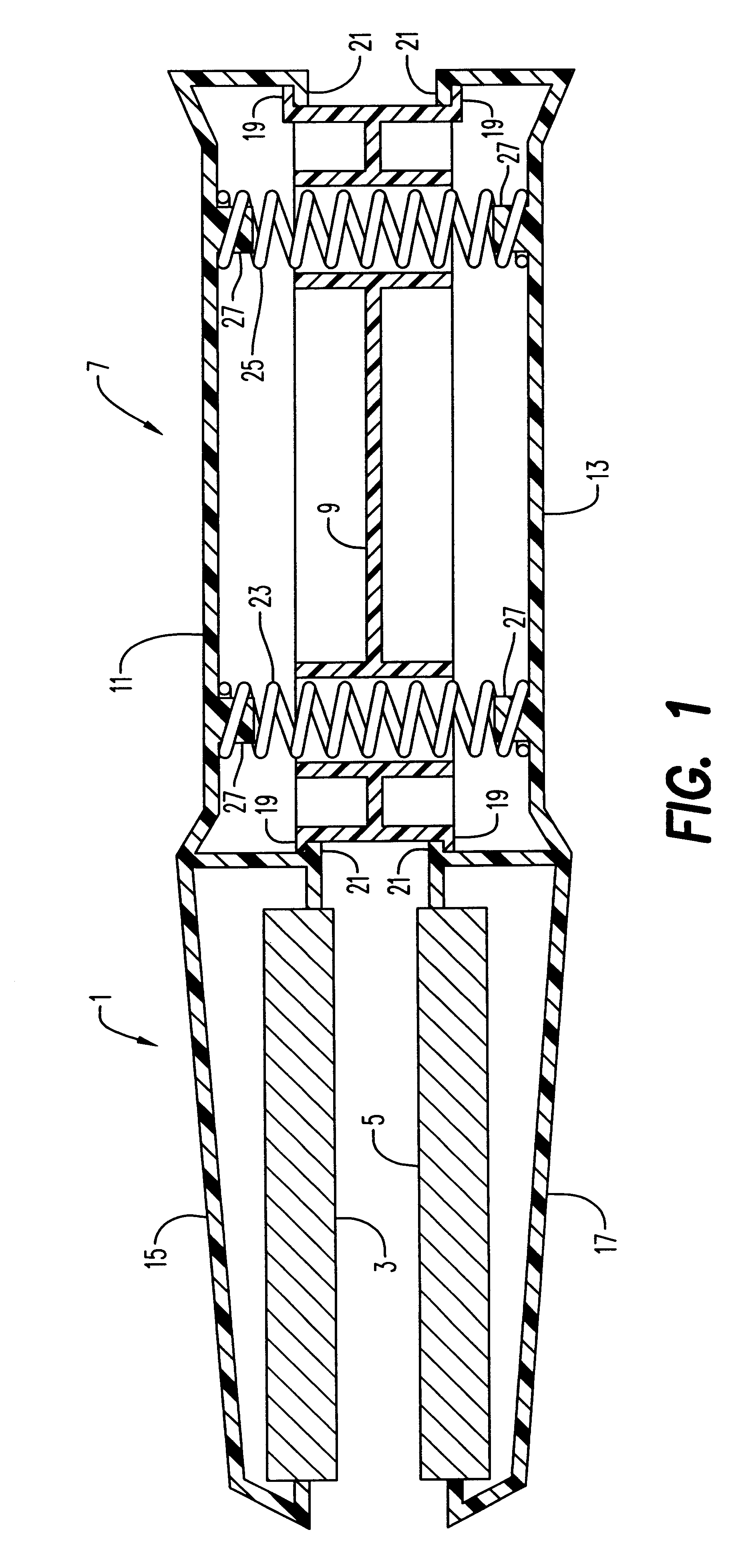

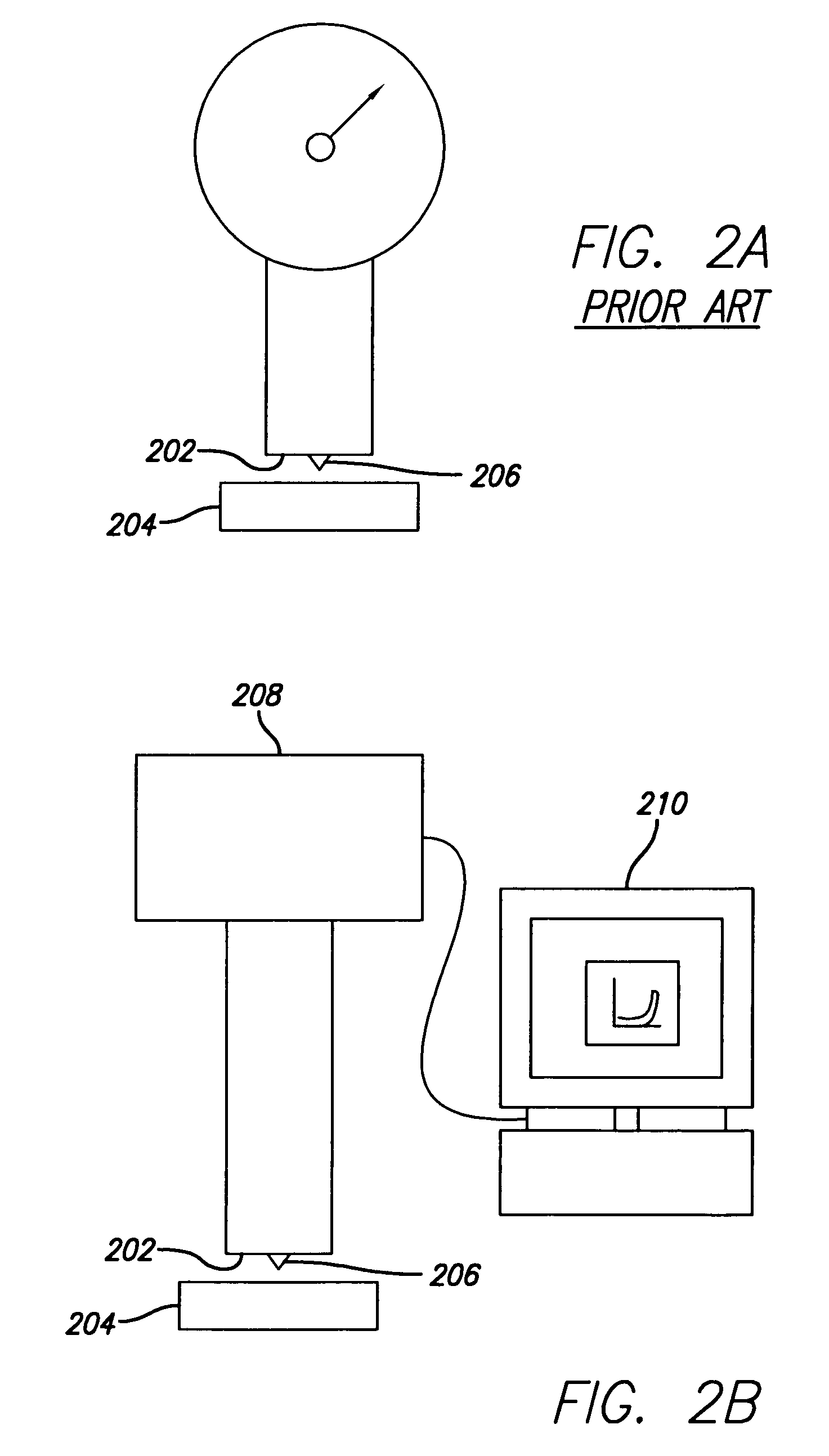

ActiveUS20090056427A1Improve abilitiesIncreases ease and speedDiagnostics using pressureSurgeryMaterials testingHand held

Methods and instruments for characterizing a material, such as the properties of bone in a living human subject, using a test probe constructed for insertion into the material and a reference probe aligned with the test probe in a housing. The housing is hand held or placed so that the reference probe contacts the surface of the material under pressure applied either by hand or by the weight of the housing. The test probe is inserted into the material to indent the material while maintaining the reference probe substantially under the hand pressure or weight of the housing allowing evaluation of a property of the material related to indentation of the material by the probe. Force can be generated by a voice coil in a magnet structure to the end of which the test probe is connected and supported in the magnet structure by a flexure, opposing flexures, a linear translation stage, or a linear bearing. Optionally, a measurement unit containing the test probe and reference probe is connected to a base unit with a wireless connection, allowing in the field material testing.

Owner:RGT UNIV OF CALIFORNIA

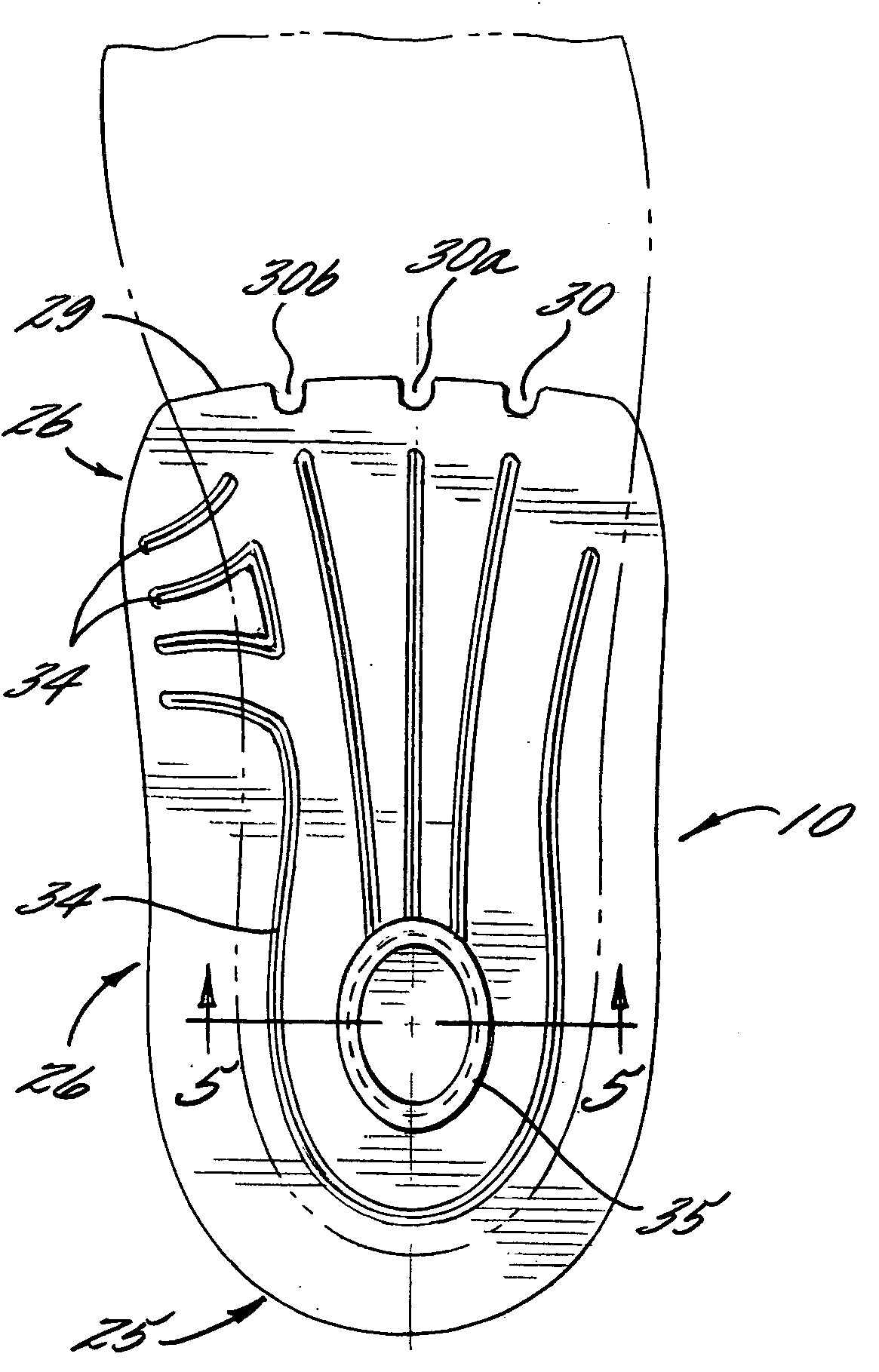

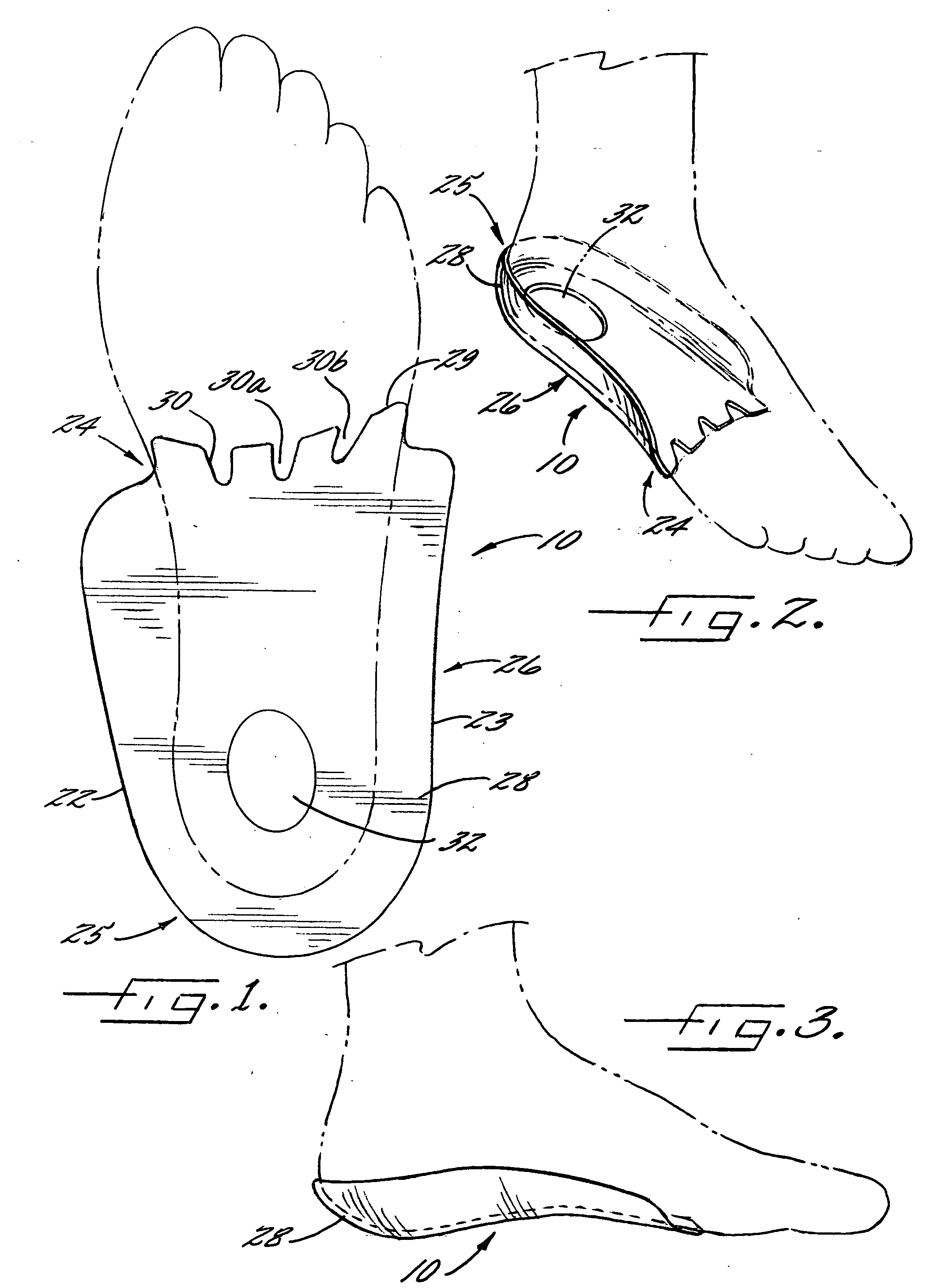

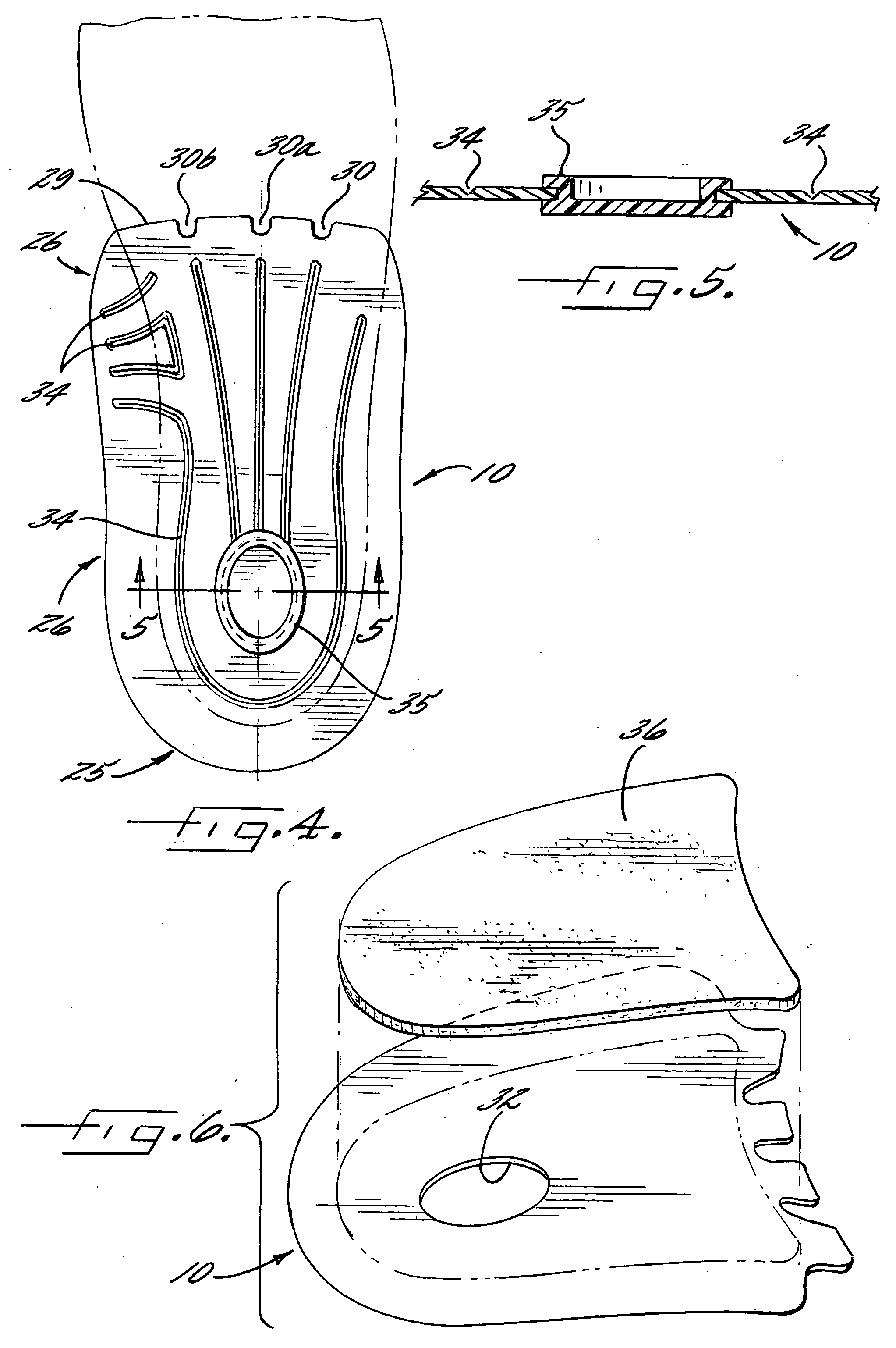

Molded foot support

InactiveUS20060086004A1Improve comfortCorrects the accommodative function of the footSolesInsolesPhysical medicine and rehabilitationFoot soles

There is provided a foot support conforming to a user's foot. The foot support includes a supportive member defining a front portion, a rear portion and an arch portion for engagement against the foot plantar arch. The rear portion has a concave periphery formed for partial resting abutment of the person's heel. The supportive member is fabricated from thermoplastic material formed to shape in a custom application. Preferred materials are thermoplastic materials providing easily formable shapes that soften or react at a low temperature between and are capable of being molded and shaped with hand pressure to the bottom of the foot while the foot is in a non-weight bearing position. Subsequently the thermoplastic material hardens retaining the molded shape. In a second embodiment, a footbed assembly having a cushioning top layer overlaying the upper surface of the molded supportive member is provided. The invention also contemplates a method for custom forming the supportive member.

Owner:BANYAN LICENSING

Composition and method for road-film removal

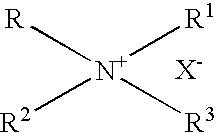

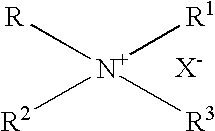

InactiveUS6864220B2Cationic surface-active compoundsOrganic detergent compounding agentsOrganic acidHydrotrope

A concentrate and a ready-to-use or diluted formulation for an aqueous vehicle cleaner can remove a wide range of different types of traffic film using either low pressure application, hand pressure application, water jet spray apparatus, clean-in-place systems or other manual or mechanical washing systems. The compositions may comprise, for example, one or more solutions that each or collectively contain or comprises:a) at least one anionic surfactant;b) at least one poly[oxyalkylene] ammonium cationic surfactant; andc) an alkaline agent.Optional additional ingredients may comprise at least one polycarboxylic acid chelating agent (preferably an aminocarboxylic acid chelating agent), at least one non-ionic or amphoteric surfactant, at least one hydrotrope, inorganic and / or organic acids and at least one silicate. The alkaline agent may provide a pH (when the finished product is diluted to 0.5 to 5% by weight in water) will be between about 9 to 13. The concentrate may be provided as a one-part or two part solution. Certain formulations have been found to be shelf stable as one-part concentrate or ready-to-use solutions, even with significantly different properties amongst the components. The compositions of the invention are also used in cleaning processes for surfaces, especially vehicle surfaces in car wash systems. The compositions are used in such processes where there are single or multiple liquid application steps.

Owner:ZEP IP HLDG LLC

Lightweight, portable, collapsible, pressurized fluid delivery system for on demand use by hikers, runners, bikers, or other applications where periodic hydration is necessary

InactiveUS20060144862A1Avoid insufficient lengthEasy accessTravelling sacksTravelling carriersStopcockEngineering

A system which applies pressure to a flexible, collapsible container of liquid stored within a flexible backpack. The system has an inflatable bladder of similar size and shape as the collapsible container of water upon which pressure is to be exerted. A tube permanently attached to the fluid container, having a valve at the opposite end for release of pressurized fluid when opened. A valve mechanism which can be opened by squeezing with the teeth when positioned in the user's mouth, or by digital pressure when held on the hand. A tube of permanently attached to the inflatable bladder through which air or other gas may pass providing means to inflate the bladder. The tubes being of sufficient length to extend beyond the confines of the backpack containing the liquid chambers extending to with easy reach of the person wearing the backpack. A stopcock or other valve connection providing means to control airflow into and out of the inflatable bladder. A pressure ball which provides means of forcing air into the bladder by repeated hand pressure on the ball.

Owner:REICHERT LUCAS +1

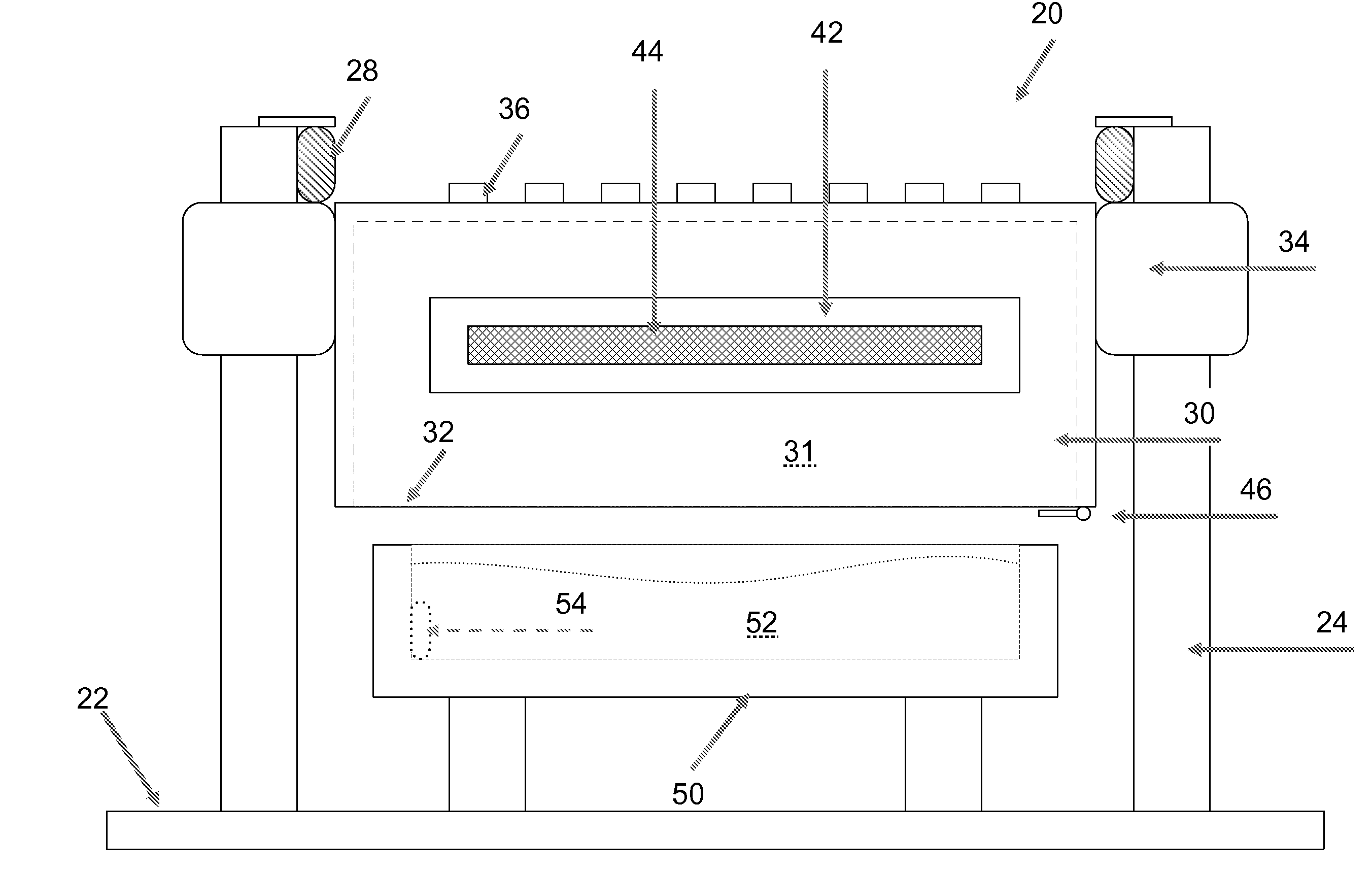

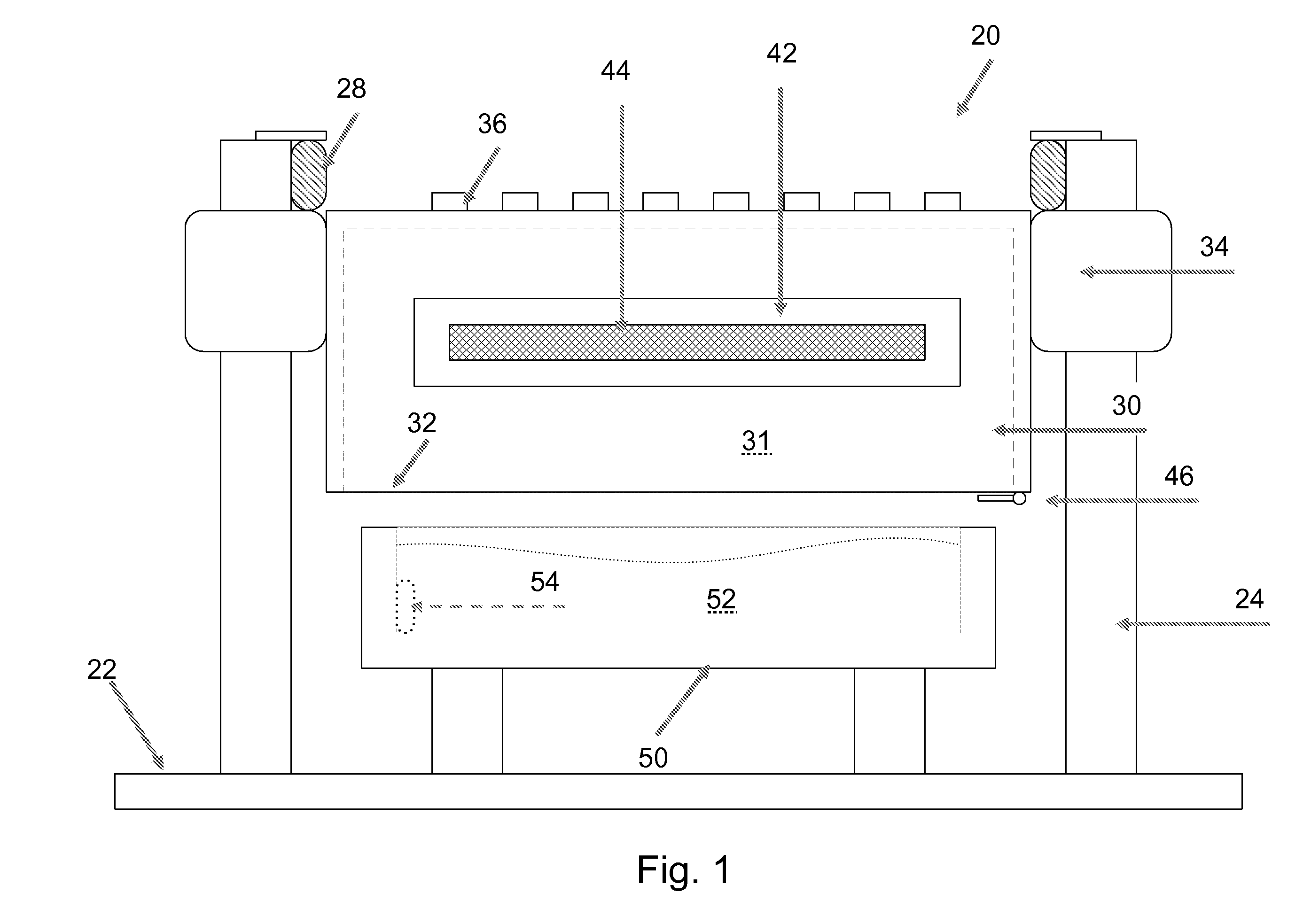

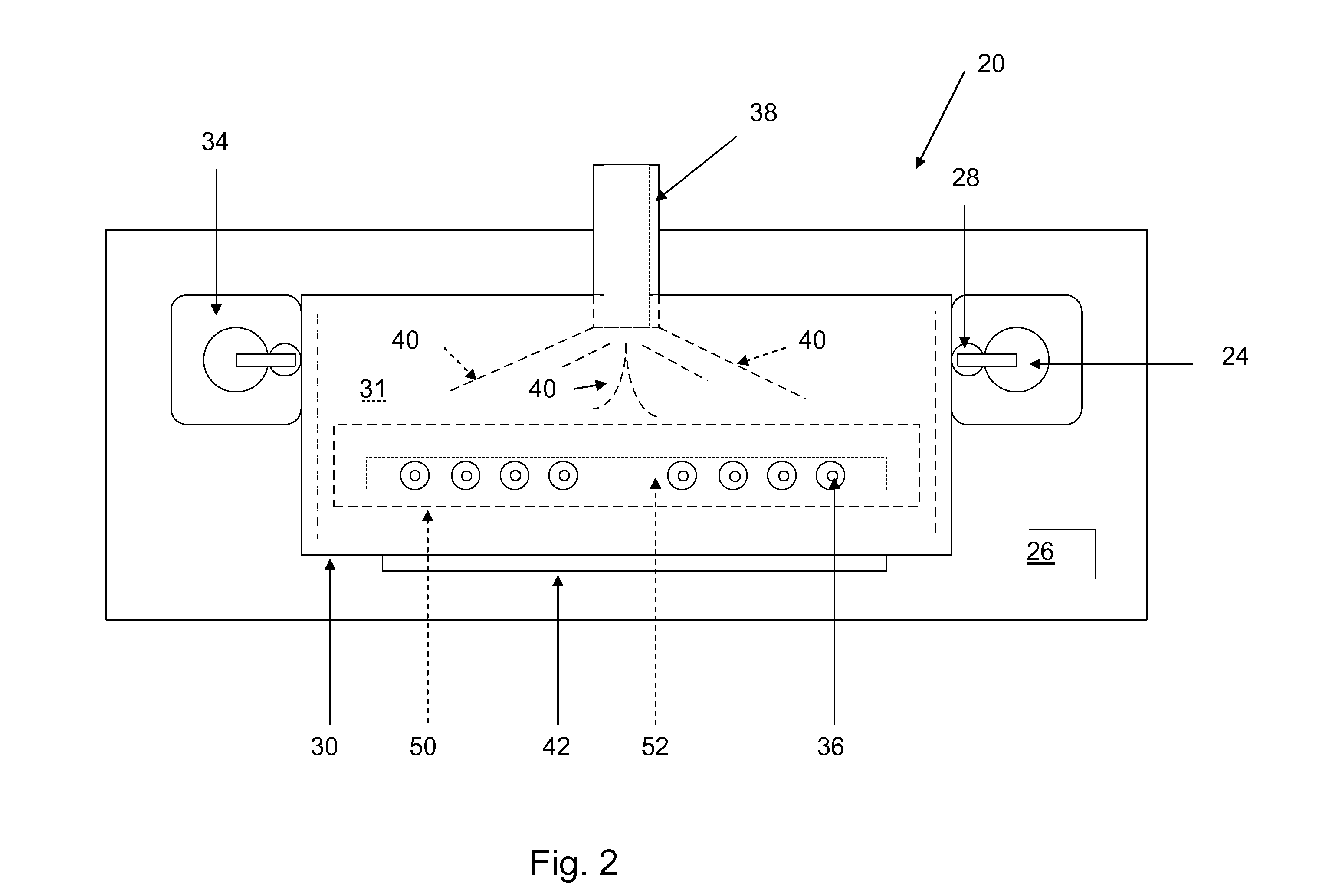

Medical and dental tool cleaning device

An apparatus for cleaning of dental instruments and medical instruments. The apparatus includes a body for holding such instruments that is biased apart from an immersion tank. The retained instruments can be lowered into the immersion tank by hand operation. After the hand pressure is removed, the instruments are biased to pull out of the immersion bath. The instruments are then blown dry by pressurized gas.

Owner:CIAMPAGLIA OSCAR

Composition and method for road-film removal

InactiveUS20020128169A1Improved metal protectionCationic surface-active compoundsOrganic detergent compounding agentsOrganic acidHydrotrope

A concentrate and a ready-to-use or diluted formulation for an aqueous vehicle cleaner can remove a wide range of different types of traffic film using either low pressure application, hand pressure application, water jet spray apparatus, clean-in-place systems or other manual or mechanical washing systems. The compositions may comprise, for example, one or more solutions that each or collectively contain or comprises: a) at least one anionic surfactant; b) at least one poly[oxyalkylene] ammonium cationic surfactant; and c) an alkaline agent. Optional additional ingredients may comprise at least one polycarboxylic acid chelating agent (preferably an aminocarboxylic acid chelating agent), at least one non-ionic or amphoteric surfactant, at least one hydrotrope, inorganic and / or organic acids and at least one silicate. The alkaline agent may provide a pH (when the finished product is diluted to 0.5 to 5% by weight in water) will be between about 9 to 13. The concentrate may be provided as a one-part or two part solution. Certain formulations have been found to be shelf stable as one-part concentrate or ready-to-use solutions, even with significantly different properties amongst the components. The compositions of the invention are also used in cleaning processes for surfaces, especially vehicle surfaces in car wash systems. The compositions are used in such processes where there are single or multiple liquid application steps.

Owner:ZEP IP HLDG LLC

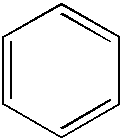

Methods and instruments for materials testing

ActiveUS7966866B2Improve abilitiesIncreases ease and speedDiagnostics using pressureSurgeryMaterials testingHand held

Methods and instruments for characterizing a material, such as the properties of bone in a living human subject, using a test probe constructed for insertion into the material and a reference probe aligned with the test probe in a housing. The housing is hand held or placed so that the reference probe contacts the surface of the material under pressure applied either by hand or by the weight of the housing. The test probe is inserted into the material to indent the material while maintaining the reference probe substantially under the hand pressure or weight of the housing allowing evaluation of a property of the material related to indentation of the material by the probe. Force can be generated by a voice coil in a magnet structure to the end of which the test probe is connected and supported in the magnet structure by a flexure, opposing flexures, a linear translation stage, or a linear bearing. Optionally, a measurement unit containing the test probe and reference probe is connected to a base unit with a wireless connection, allowing in the field material testing.

Owner:RGT UNIV OF CALIFORNIA

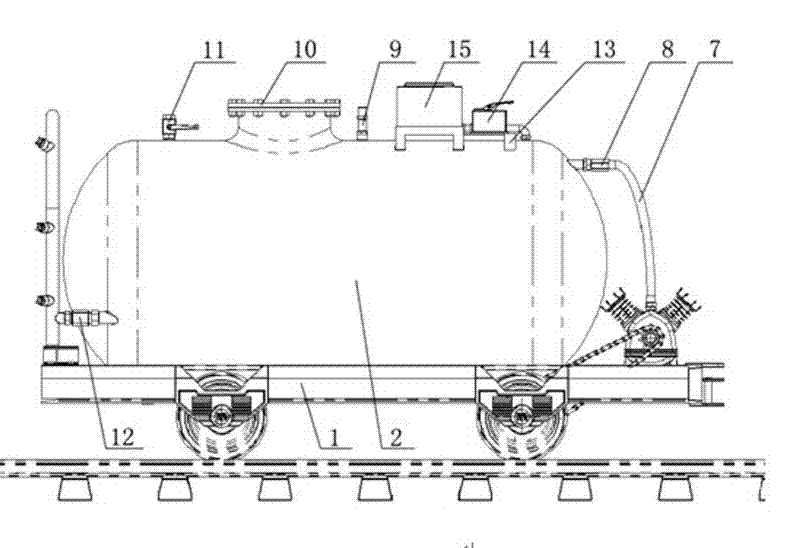

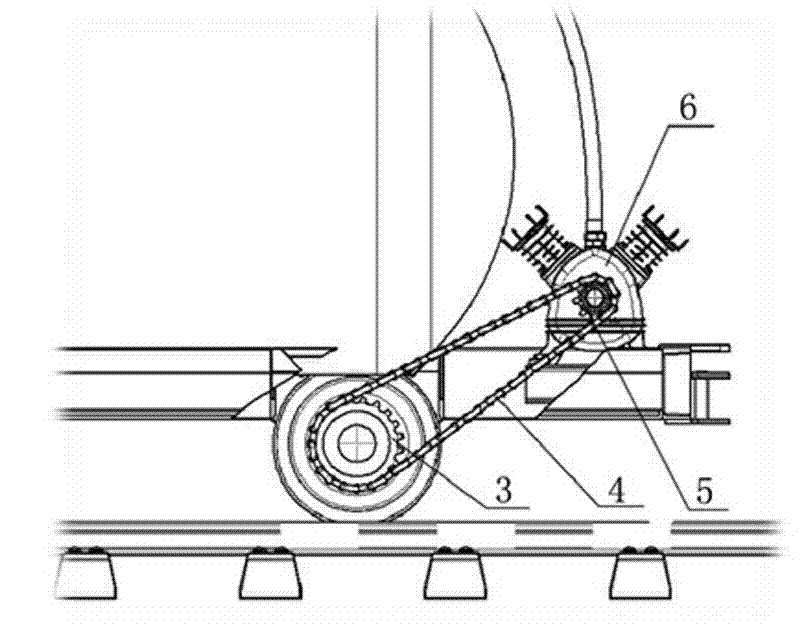

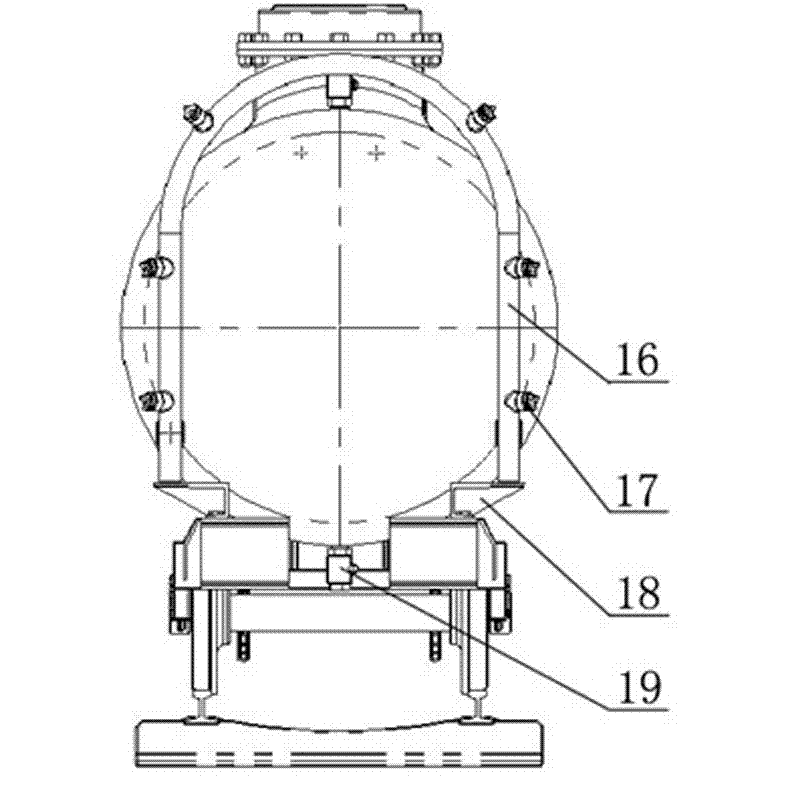

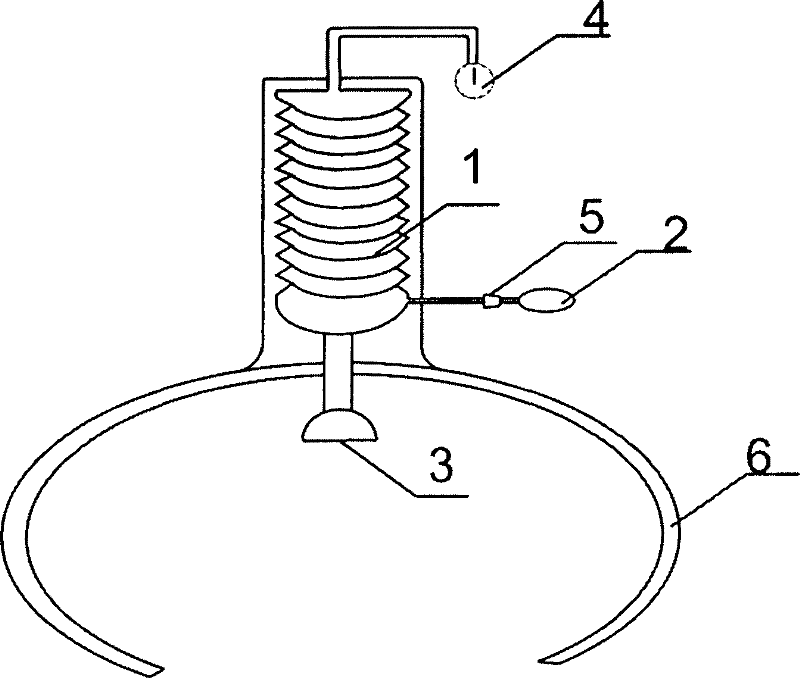

Passive and automatically pressurized mobile washing device for coal mine underground railway lane

InactiveCN102230390AFully automatedGuaranteed cleanlinessDust removalFire preventionWater storage tankDust control

The invention discloses a passive and automatically pressurized mobile washing device for a coal mine underground railway lane. The passive and automatically pressurized mobile washing device comprises a water storage box and an air compressor which are fixed on a plate trailer; the air compressor is linked with a plate trailer axle belt mechanism, and is communicated with the water storage box; the water storage box is communicated with a medicament box, a hand pump and a back pressure pump; the other end of the hand pump is communicated with the medicament box; and the other end of the back pressure valve is communicated with a spraying water pipe. The air compressor is linked with a plate trailer axle, so that an external power supply is avoided, and passive and automatic pressurization is realized. The water storage box is arranged on the plate trailer for supplying water automatically, so the full-process automation for washing the railway lane is realized. The medicament box is arranged in the water storage box for adding a curing agent or a fire retardant into water, so that the dust removal of the railway lane is more safe, reliable and fast.

Owner:TAIYUAN UNIV OF TECH

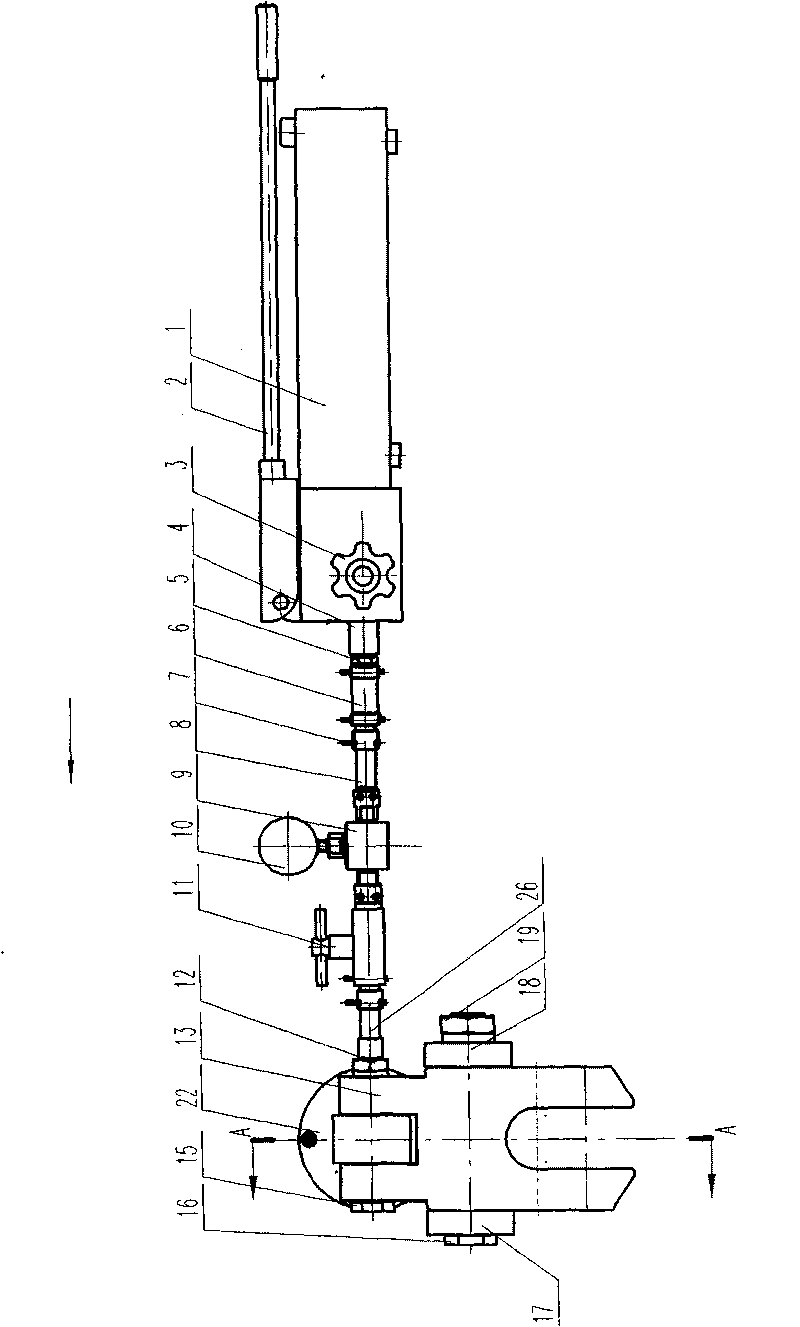

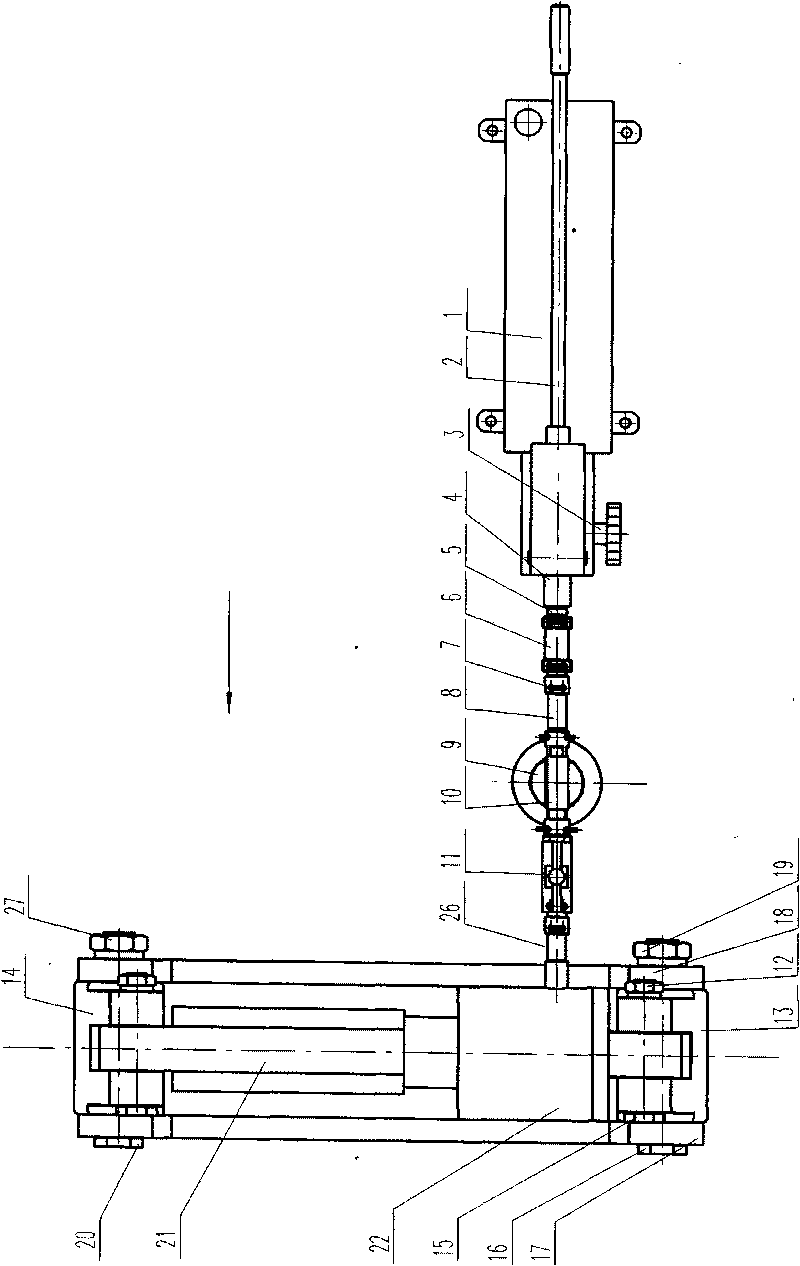

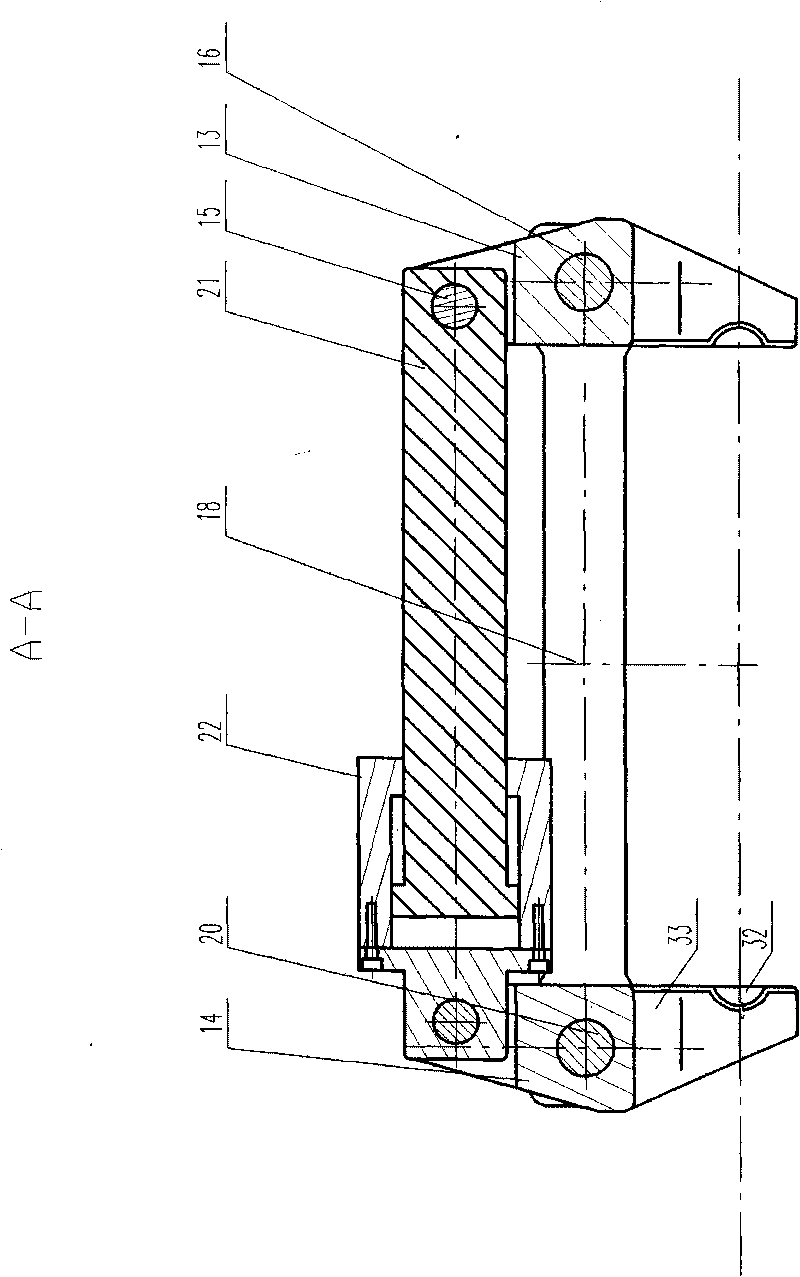

Device for measuring tension of scraper conveyer chain

The invention relates to a device for measuring the tension of a scraper conveyer chain, mainly comprising a high-pressure pump, a hand compression rod, an unloading valve, a stop valve, a tension meter, a blocking chain block, a telescopic oil cylinder and an oil cylinder piston rod. With the combination of the hydraulic drive, the tension meter and the blocking chain block of the device for measuring the tension of the scraper conveyer chain, the tension of the scraper conveyer chain under the coal mine is measured immediately on the spot, the measured pretension and the static tension are contrasted, compared and are optimized to finally determine the reasonable pretension and the reasonable static tension, the tensioning degree of the scraper conveyer chain is guided and debugged with the pretension and the advantage and the disadvantages of tensioning state of the scraper conveyer chain are appraised with the static tension so that the scraper conveyer chain can be in the reasonable tensioning state to suffer from less accident and have long service life. The device has reasonable and advanced design, compact structure, convenient carrying, mounting and detecting and is safe, stable and reliable, thereby being very ideal.

Owner:山西煤矿机械制造股份有限公司

Flexible compression unit for on demand, portable, collapsible fluid delivery systems

InactiveUS20060144863A1Avoid insufficient lengthEasy accessTravelling sacksTravelling carriersStopcockEngineering

A system which applies pressure to a flexible, collapsible container of liquid stored within a flexible backpack. The system has an inflatable bladder of similar size and shape as the collapsible container of water upon which pressure is to be exerted. A tube of permanently attached to the inflatable bladder through which air or other gas may pass providing means to inflate the bladder. The tube being of sufficient length to extend beyond the confines of the backpack containing the liquid chamber extending to with easy reach of the person wearing the backpack. A stopcock or other valve connection providing means to control airflow into and out of the inflatable bladder. A pressure ball which provides means of forcing air into the bladder by repeated hand pressure on the ball.

Owner:REICHERT LUCAS +1

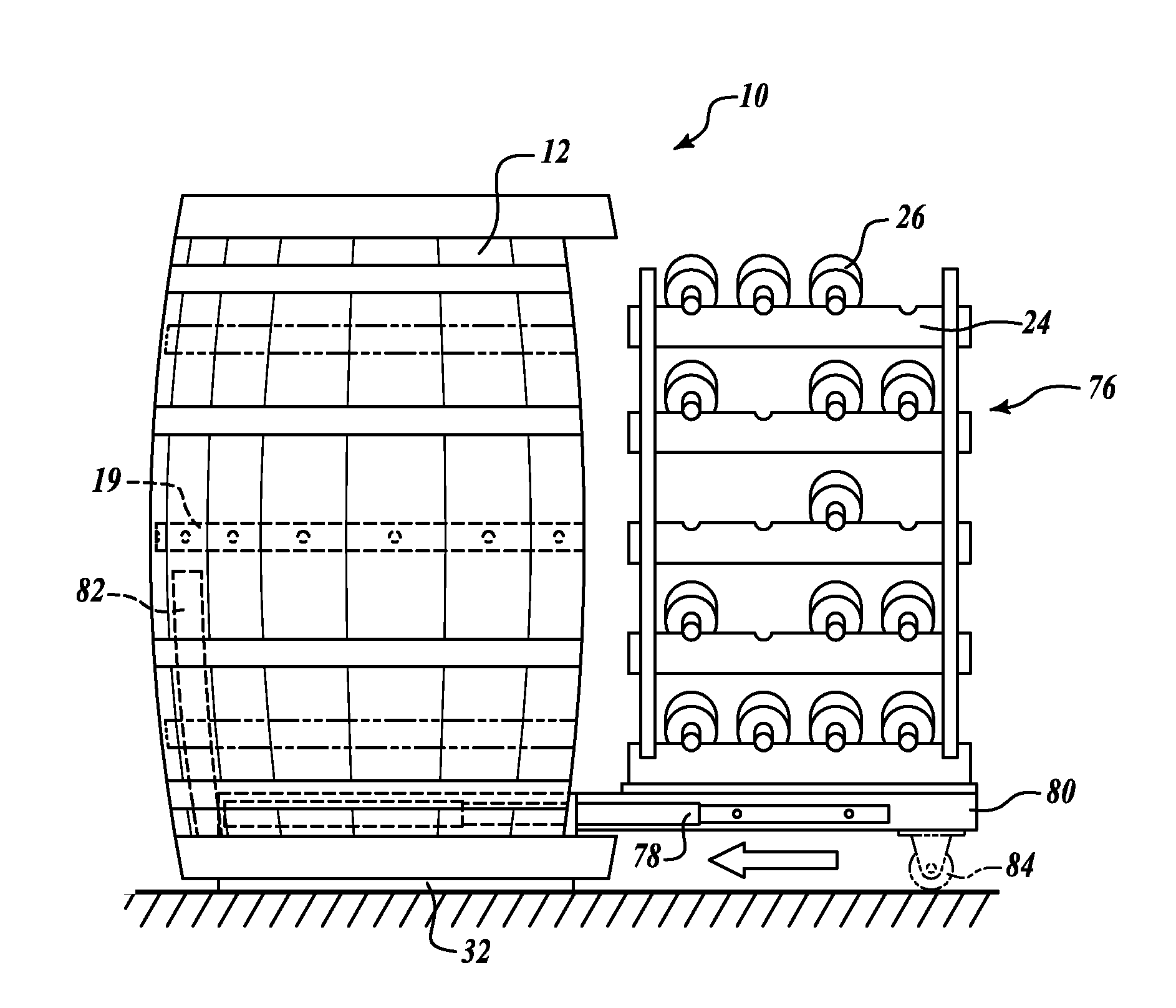

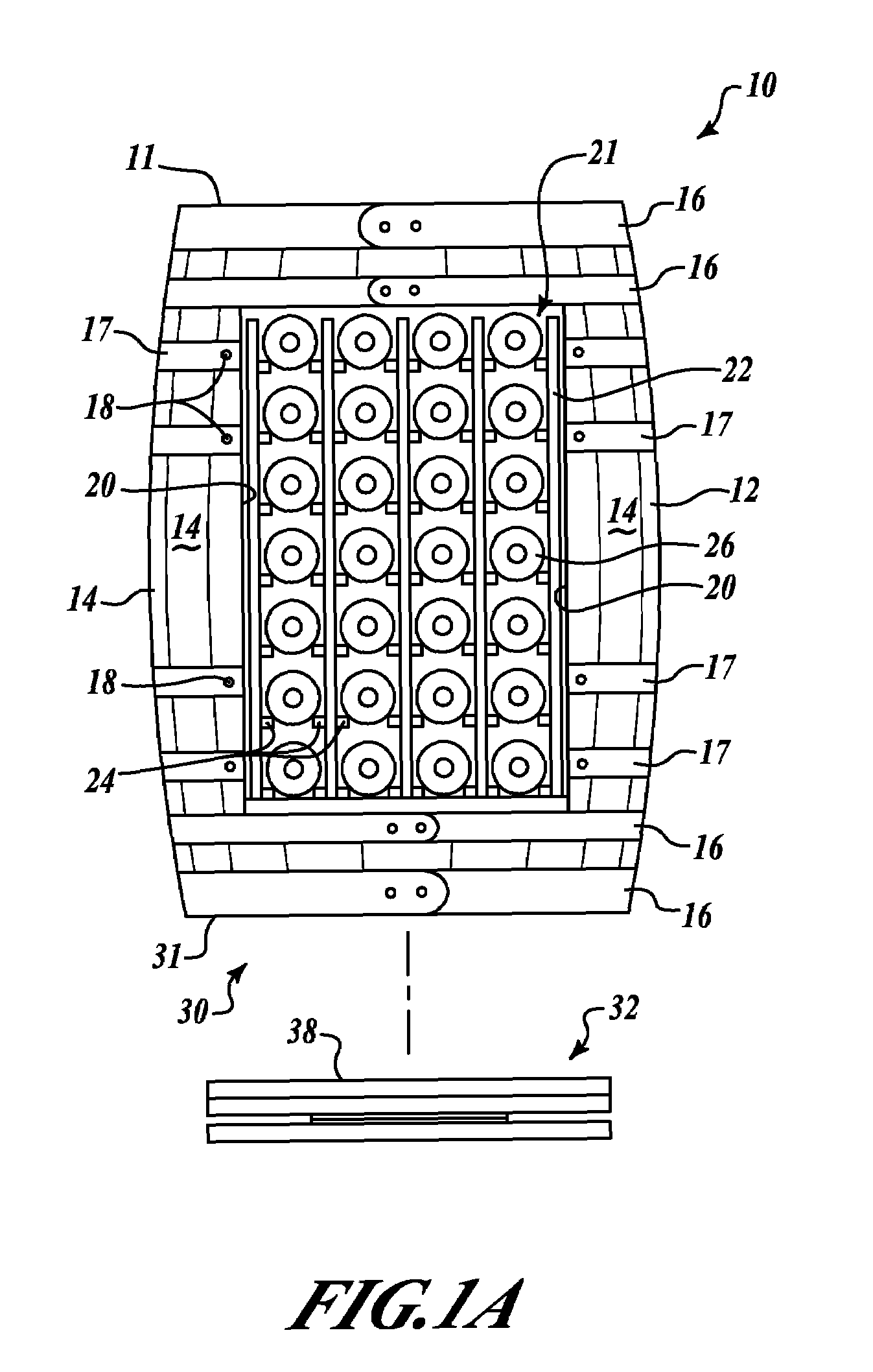

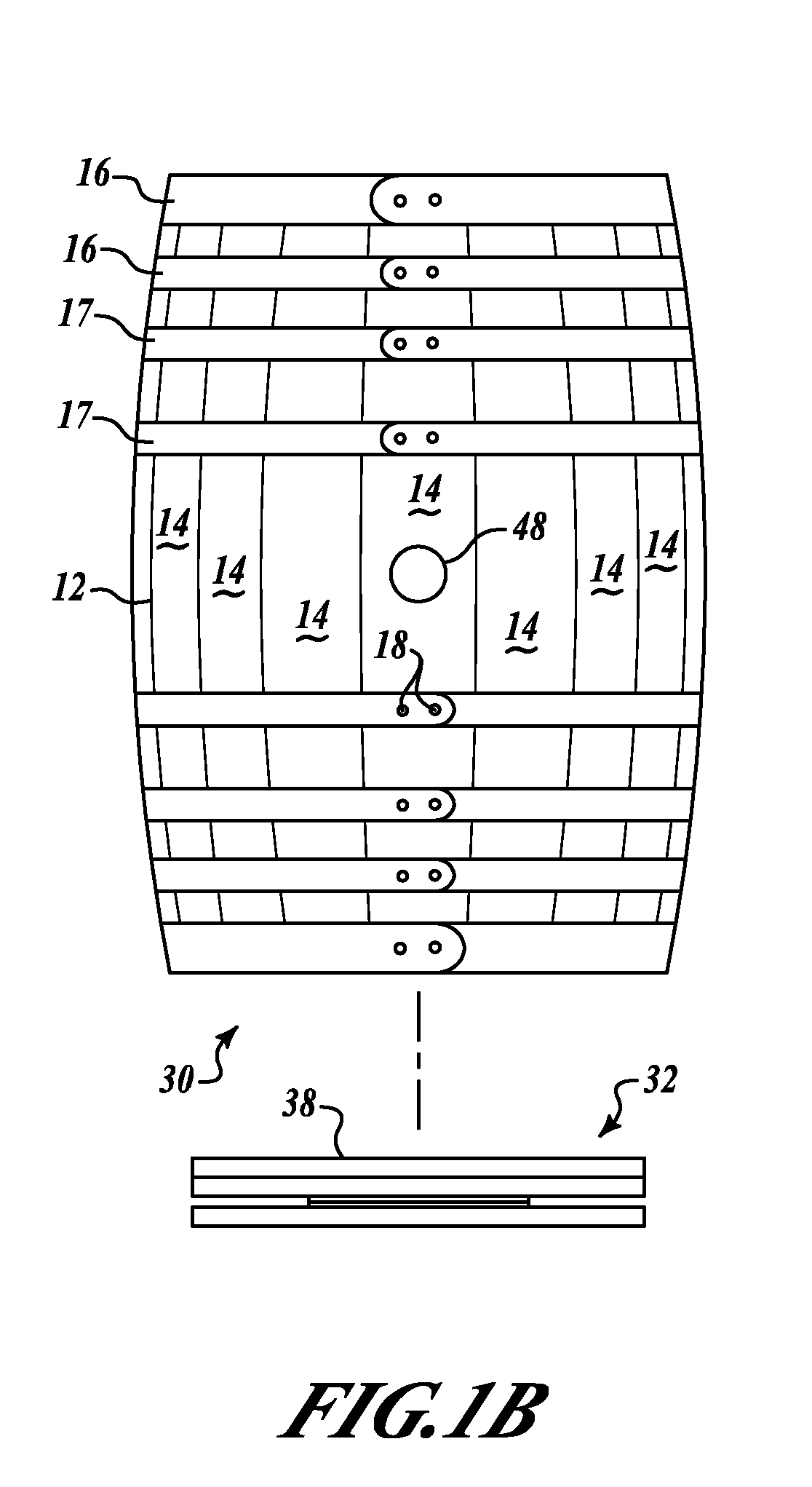

Rotating barrel storage system

Storage units of standard, new or used wood stave barrels, mounted on end on a rotating platform and having a side opening cut-out to the interior for access to shelving, drawers, wine racks or other storage devices fitted in the interior. The barrel is mounted on and secured to a rotatable platform that includes a turntable mechanism, the platform being specifically sized to fit inside the base recess of the barrel, so that it is hidden by the barrel lip, yet holds the barrel sufficiently off the ground to clear carpeting or other irregular flooring such as slate, brick or tile pavers, that might otherwise interfere with its rotation. The platform includes friction sliders so that the barrel rotates under hand pressure but does not spin freely. Selected feet or spacer disks are used to provide minimum needed clearance so the barrel appears to float just above the flooring surface.

Owner:MCNULTY JOHN M

Hand pressure abatement apparatus for use with a power tool

A power tool user pressure abatement system may include a soft, cushioning material configurable to a tool such as a power tool, including a power drill, such that the material remains in position between the tool and a user's contacting hand, thereby minimizing impact forces and pressures imparted during tool use. In at least one embodiment, a unitary piece of cushioning material such as neoprene may be cut or slit appropriately in order to facilitate quick placement of the material onto the tool, retention of the material in an effective position during tool use, and quick removal thereof. Associated methods are also disclosed.

Owner:ROBINSON JOSH M

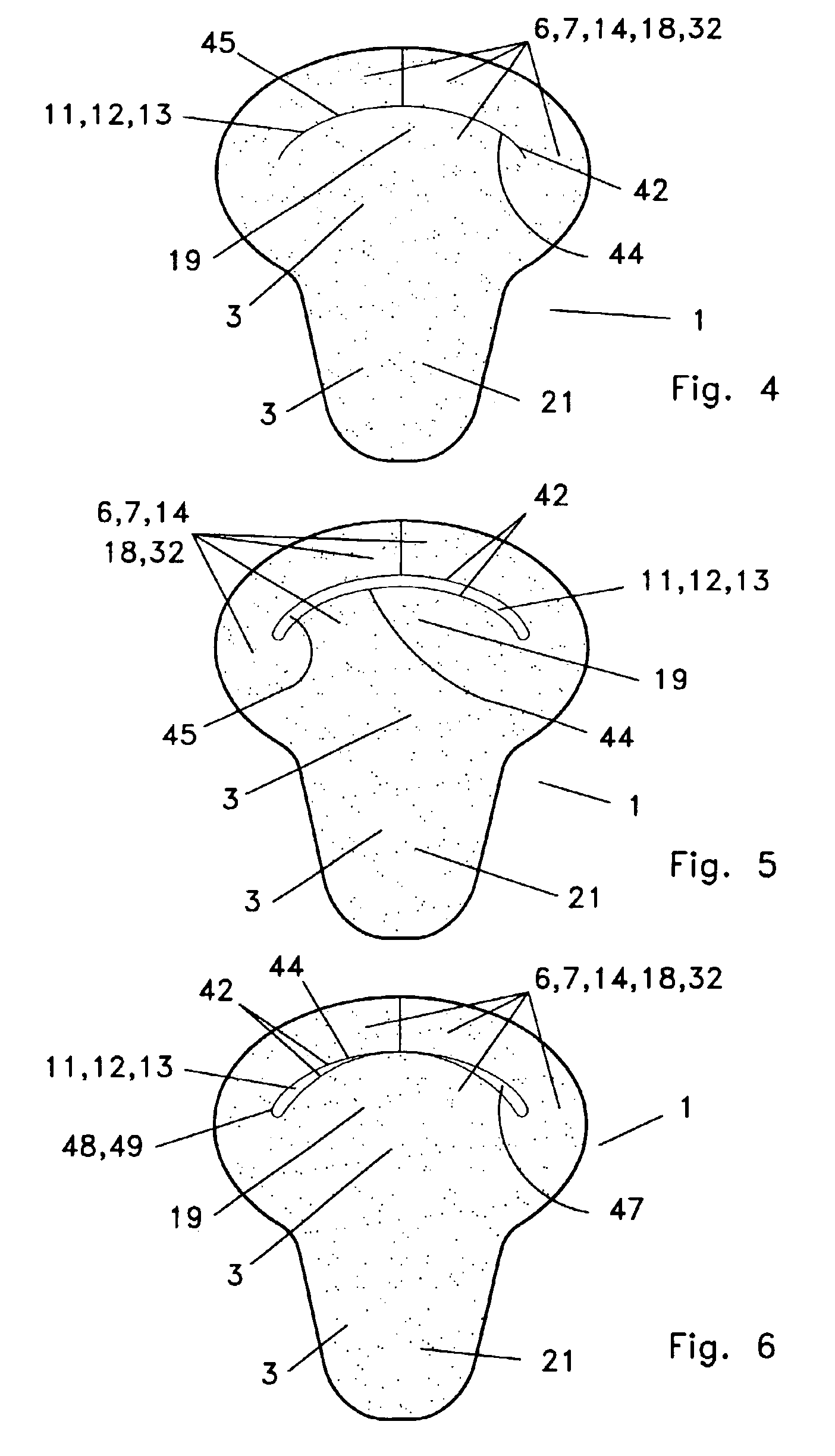

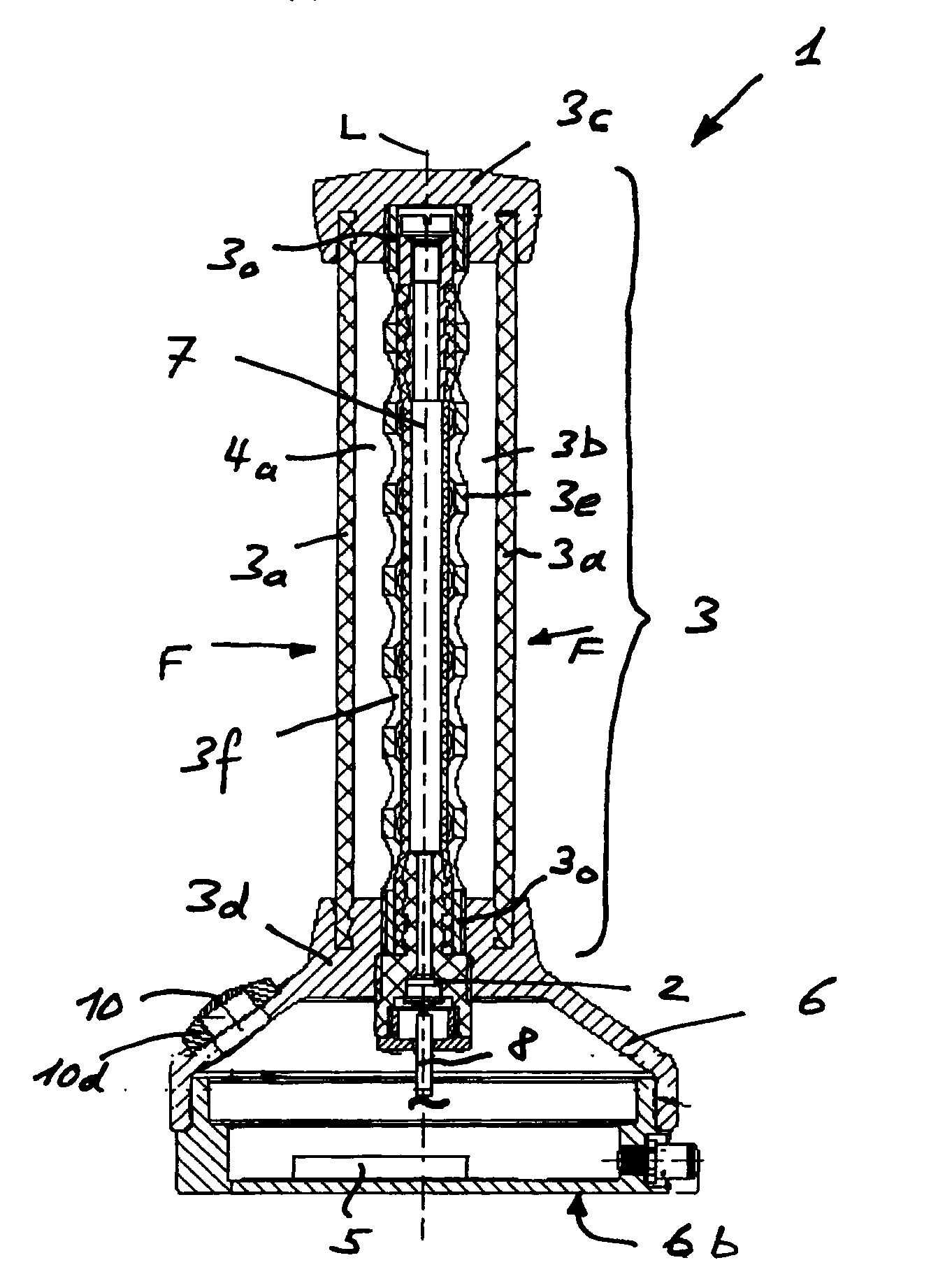

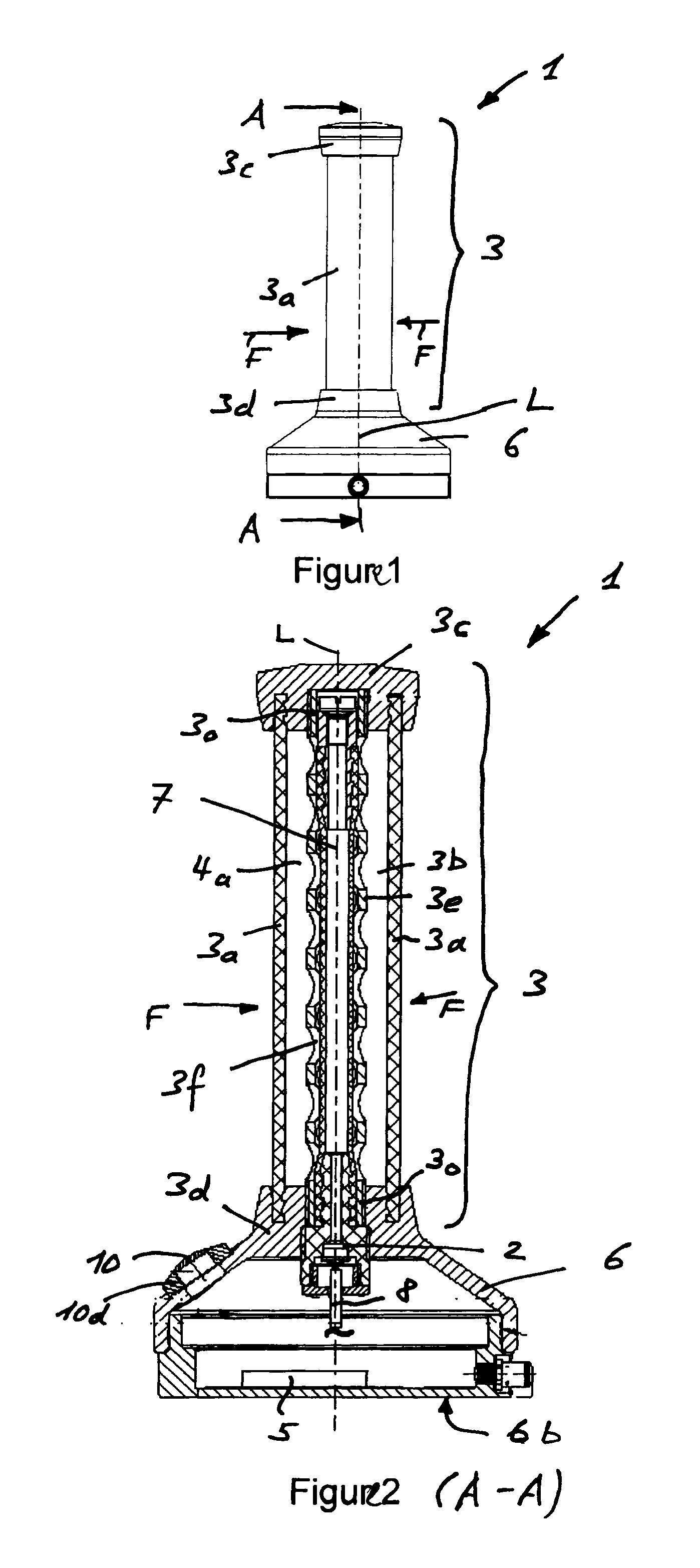

Apparatus and method for detecting the hand force of the hand pressure

ActiveUS20130023799A1Pain generationReliable strengthPerson identificationSensorsInterior spaceEngineering

An apparatus for detecting hand force or hand pressure includes a longitudinally extending hollow body having an upper fixed end part, a lower fixed end part and a longitudinally extending spacer element that keeps the upper end part and the lower end part mutually spaced apart. The hollow body includes a flexible outer cover which connects the upper end part to the lower end part such that a closed inner space is formed within which the spacer element is also arranged. The outer cover is can be at least partly surrounded by a hand, and the inner space of the hollow body contains a gel, elastic multicomponent or liquid material which acts as a pressure transmitter. A pressure measuring apparatus extends at least partly in the inner space in the longitudinal direction to transmit the pressure from the outer cover via the pressure transmitter to the pressure measuring apparatus.

Owner:MSYS

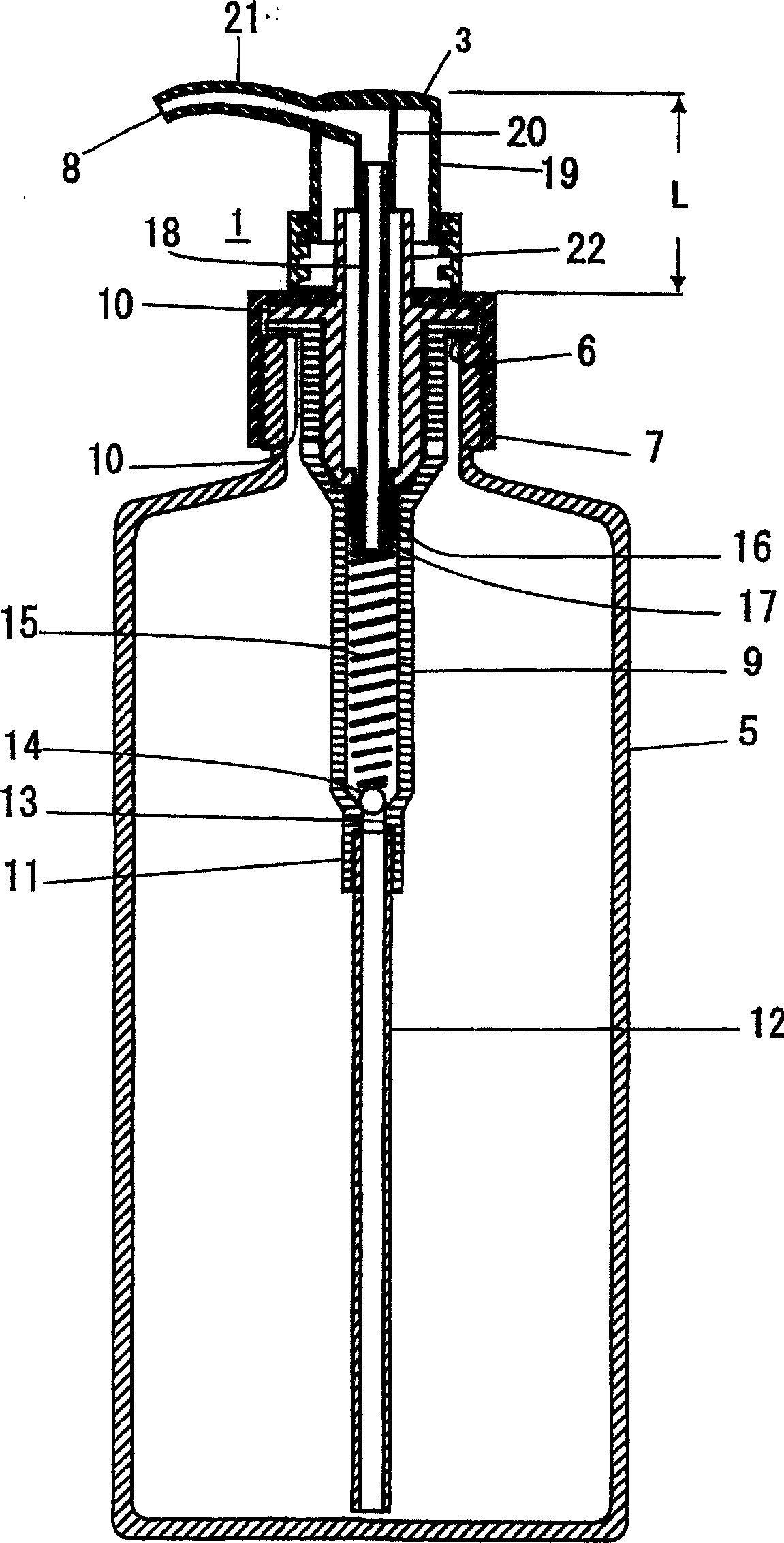

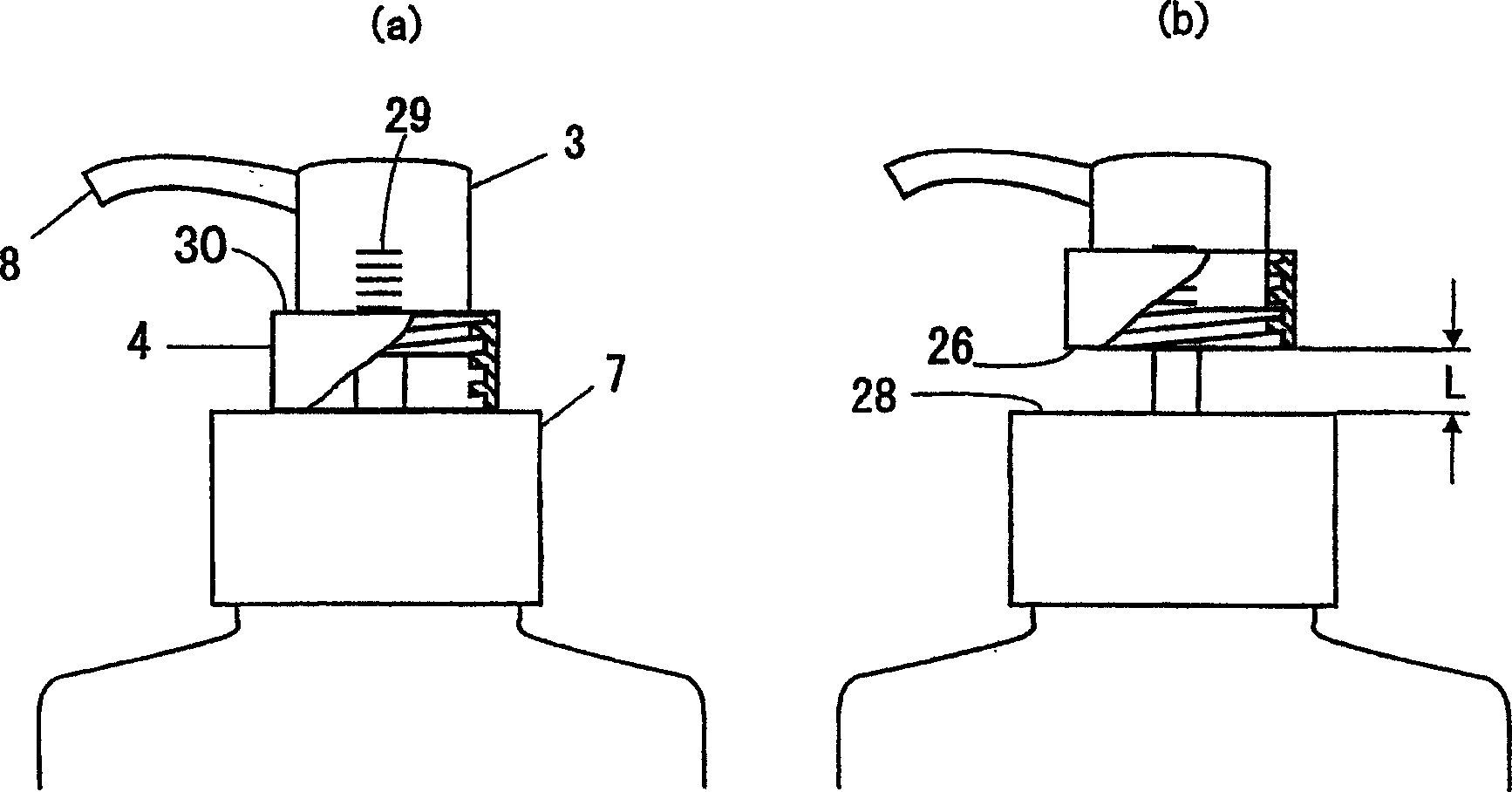

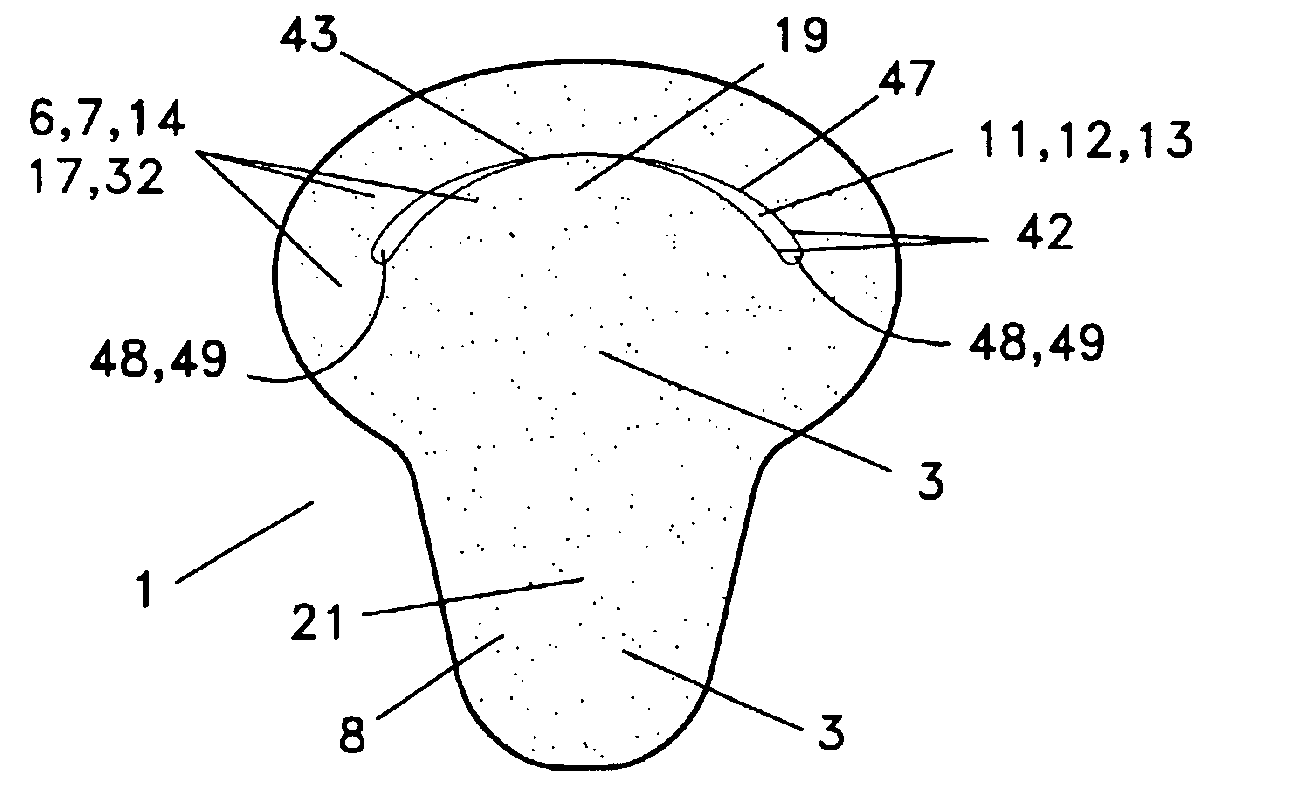

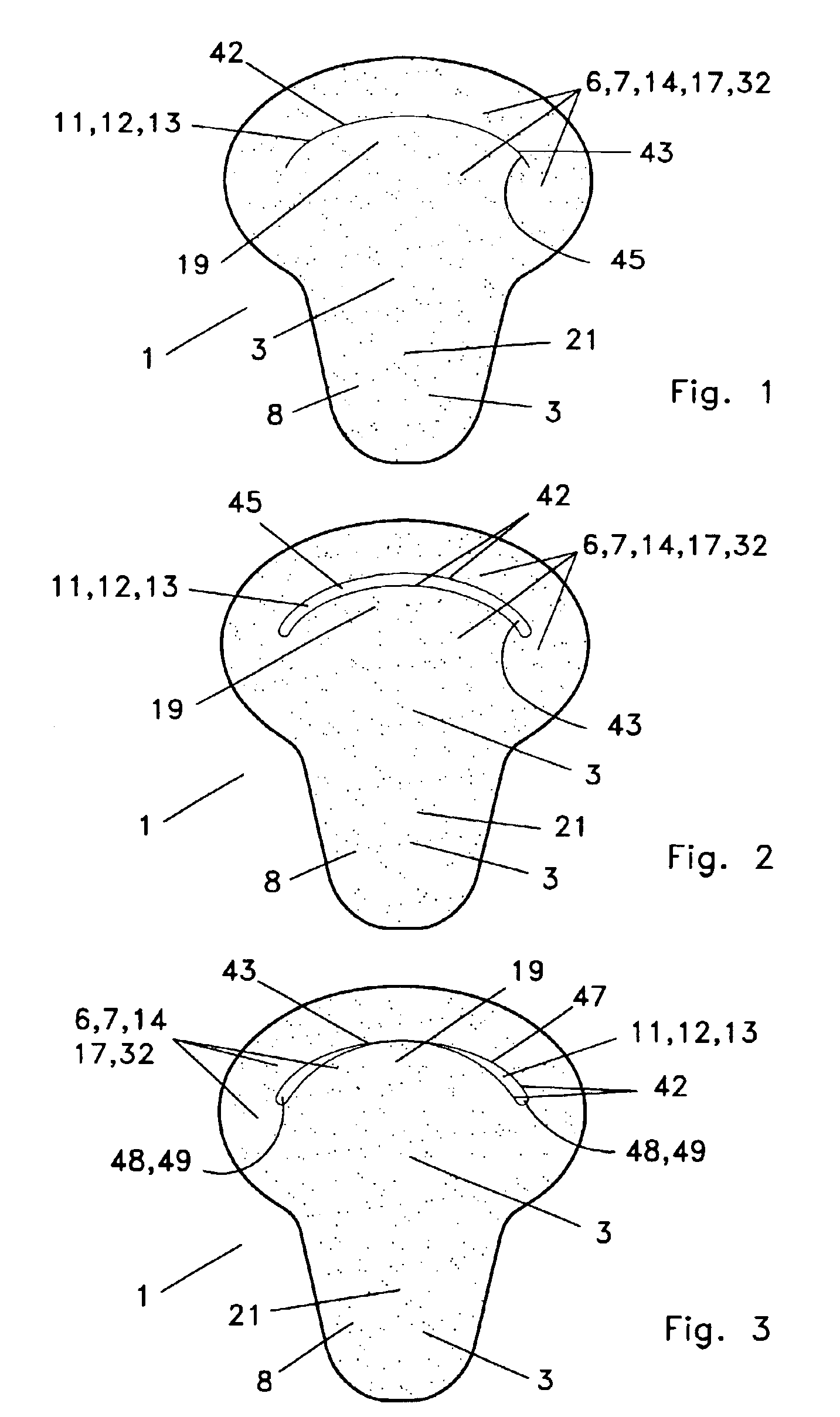

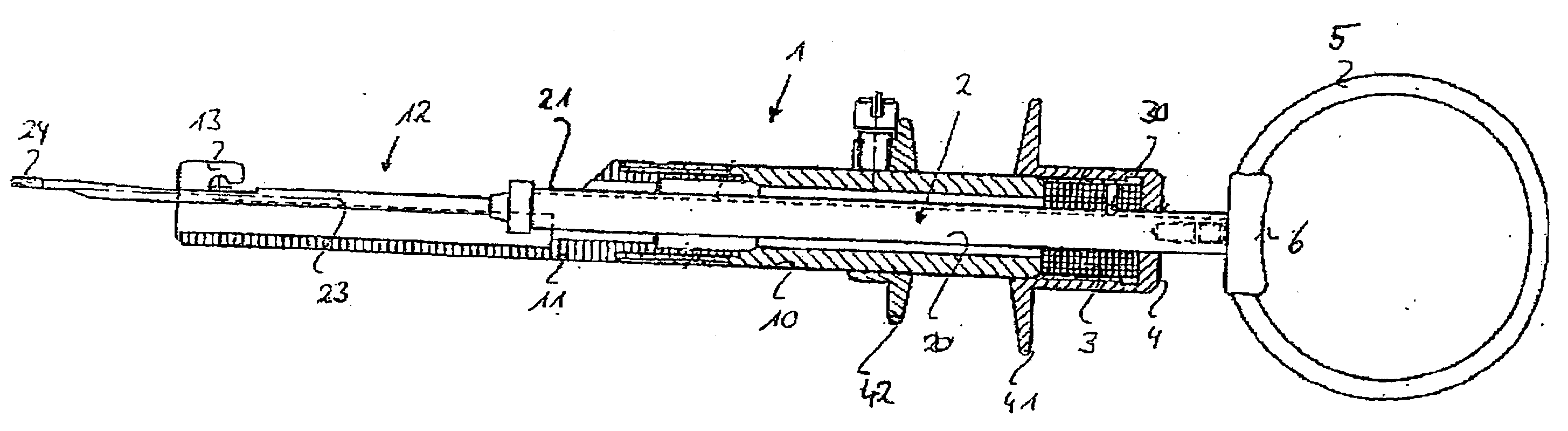

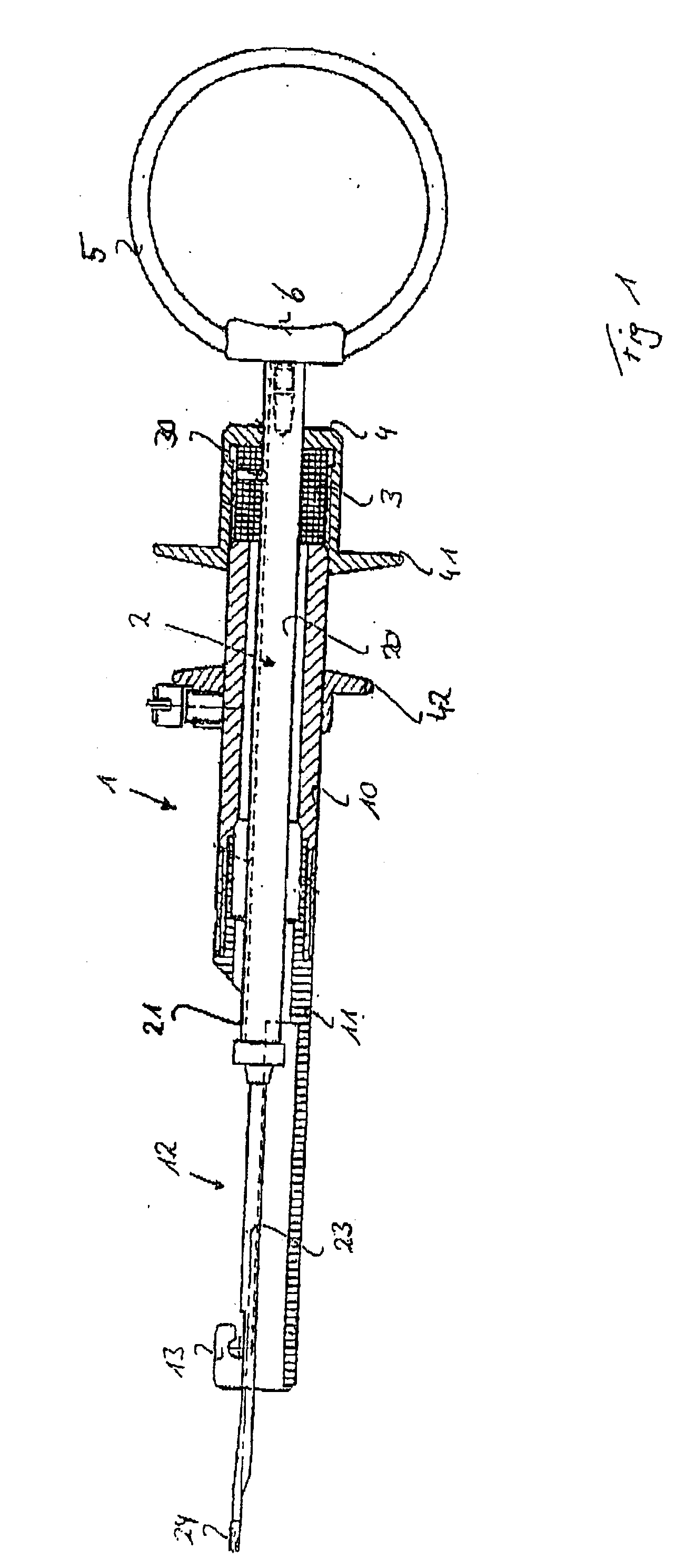

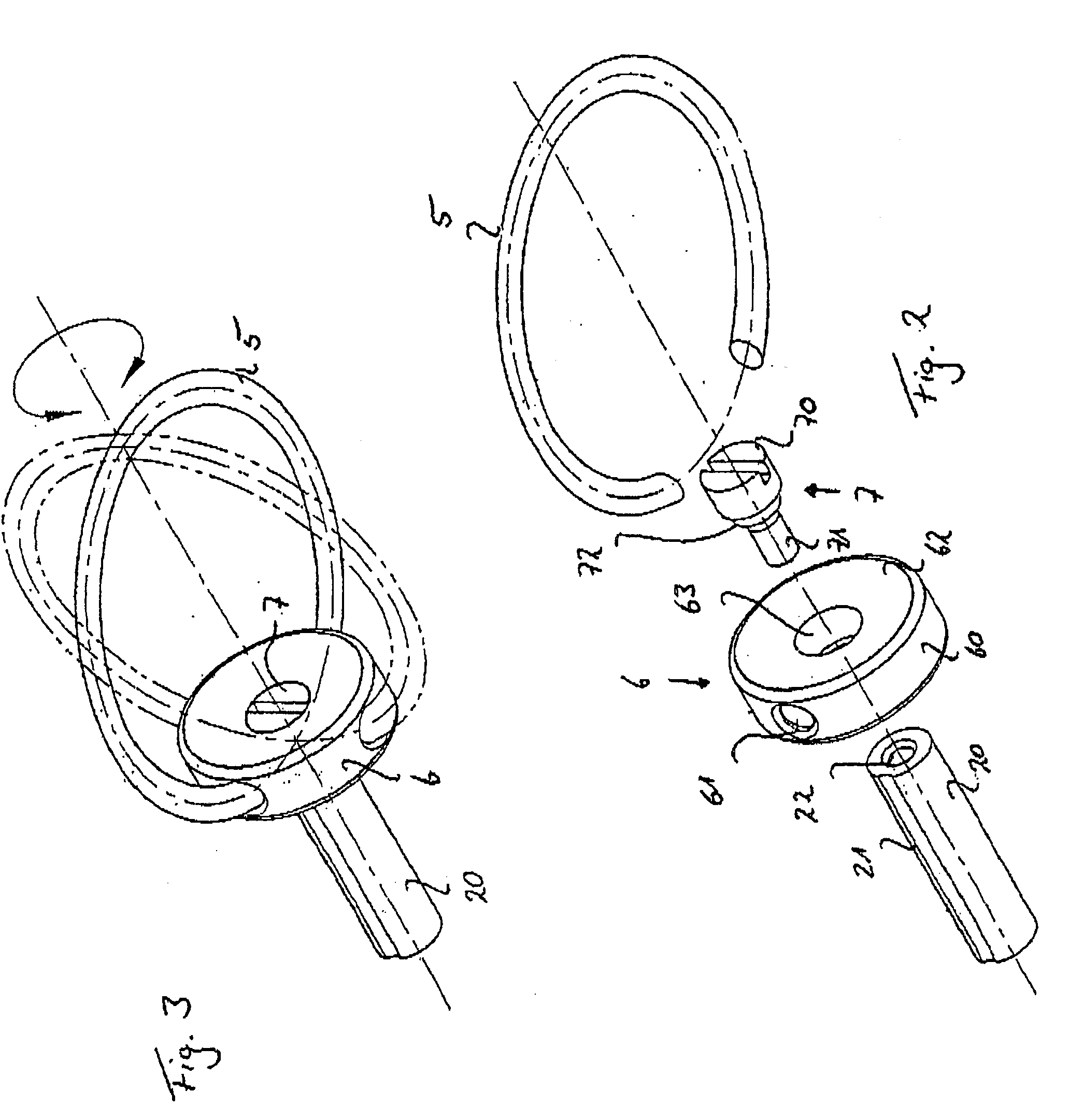

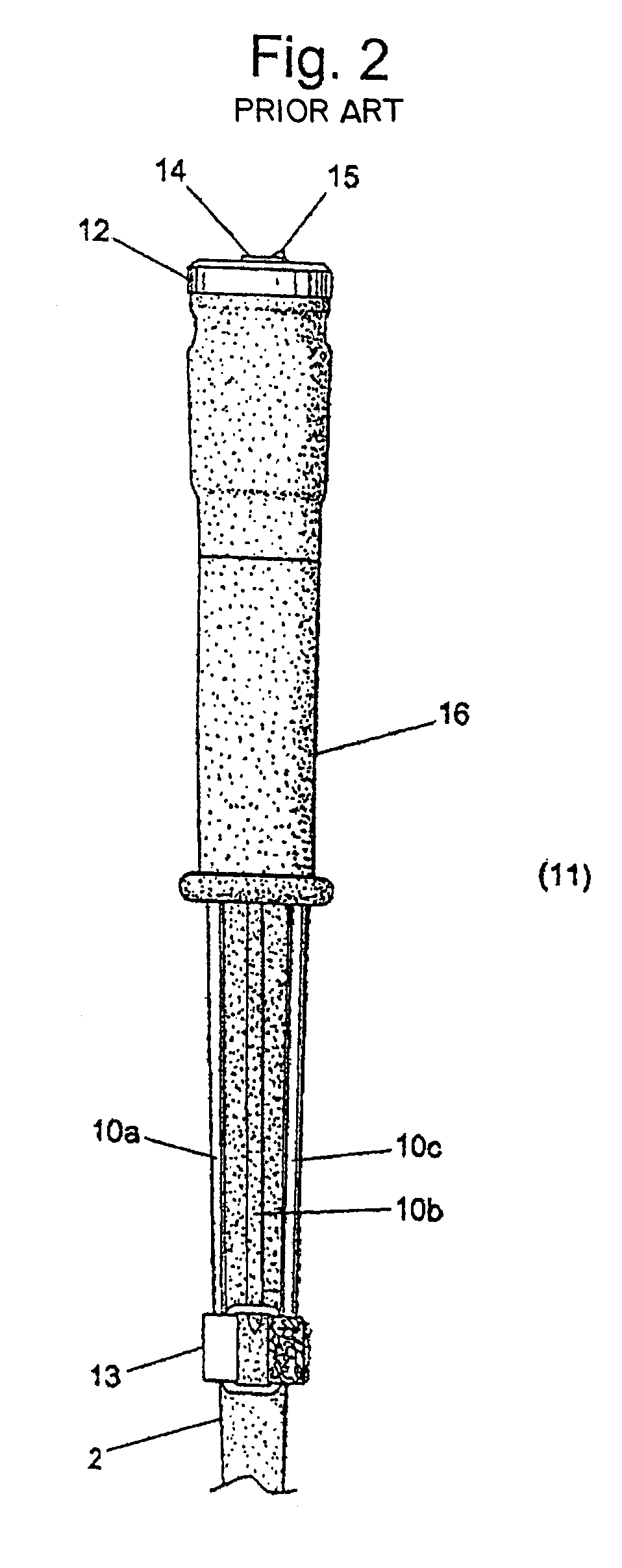

Injector with finger ring

A hand-operated injector for inserting a lens into an. eye has a grip body (1) with a lens holder (13) for holding a lens, and a plunger (2) arranged displaceably in the grip body (1) for guided insertion of the lens into the eye. An actuating means (5, 6) for displacing the plunger (2) relative to the grip body (1) is arranged on the plunger (2), which actuating means (5, 6) is rotatable relative to the plunger (2). The injector can thus be rotated through any desired angle, without having to substantially change the position of the hand pressing on the plunger (2), in particular the position of the thumb.

Owner:ASICO +1

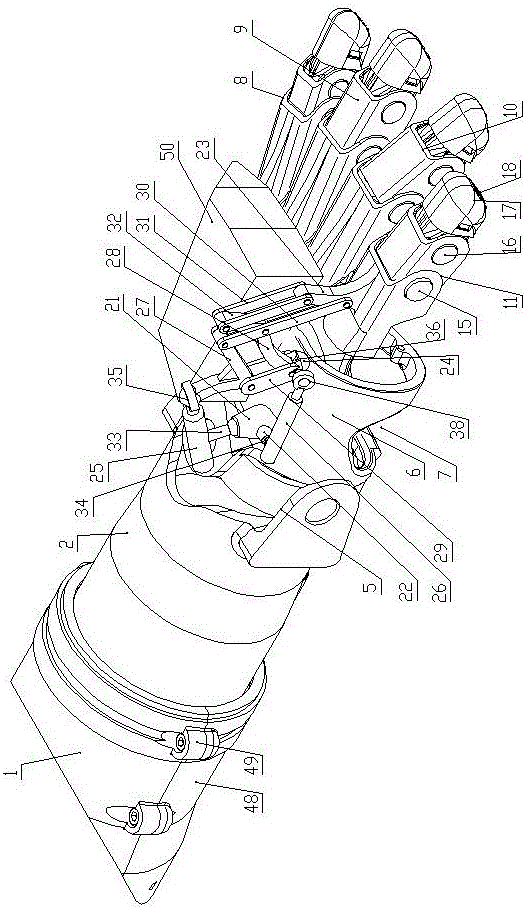

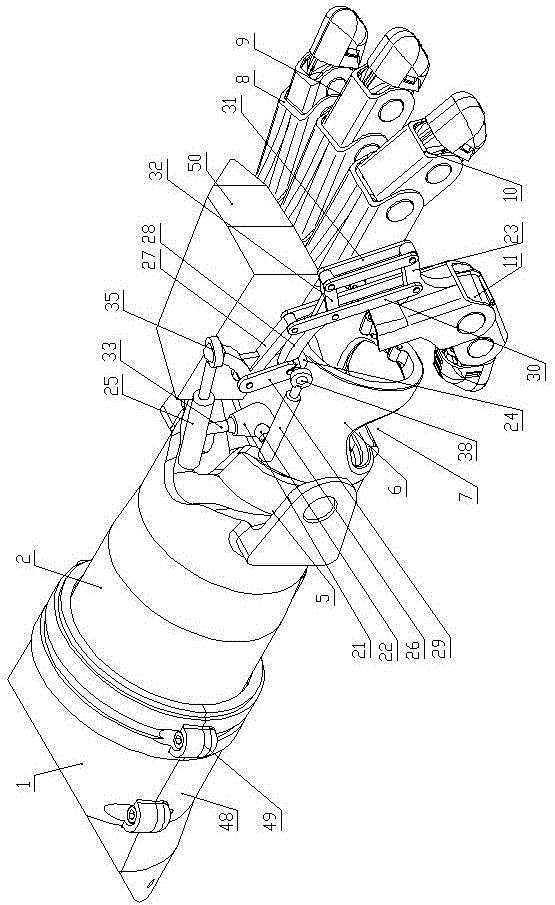

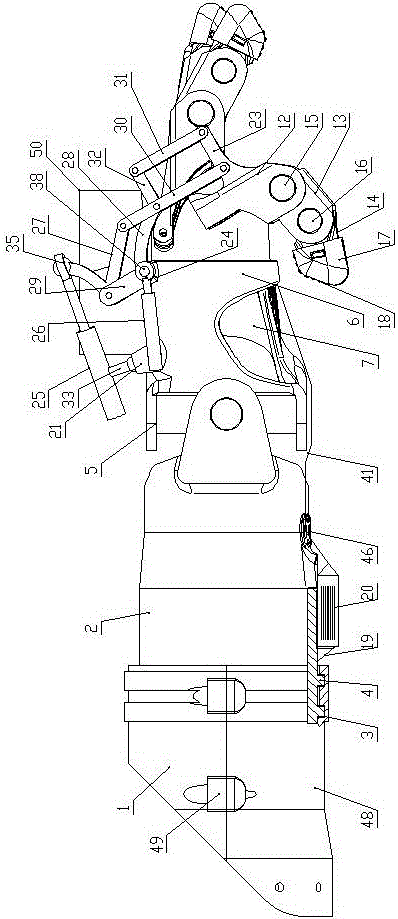

Four-finger exoskeleton bending and grabbing power mechanism of hand pressure reduction machine exoskeleton device

InactiveCN106112987ARealize activitiesCompact structureProgramme-controlled manipulatorJointsLittle fingerEngineering

The invention discloses a four-finger exoskeleton bending and grabbing power mechanism of a hand pressure reduction machine exoskeleton device. The four-finger exoskeleton bending and grabbing power mechanism comprises a palm containing barrel and a minitype pneumatic muscle tendon. A thumb stretching opening is formed in the left side or the right side of the bottom of the palm containing barrel. A little finger exoskeleton assembly, a ring finger exoskeleton assembly, a middle finger exoskeleton assembly and an index finger exoskeleton assembly which are located on the front side of the palm containing barrel are in transmission connection with the top of the palm containing barrel side by side through single-drive multi-rod mechanisms correspondingly. A knuckle bending, pulling and fastening mechanism is arranged between each of third knuckle sleeves of the little finger exoskeleton assembly, the ring finger exoskeleton assembly, the middle finger exoskeleton assembly and the index finger exoskeleton assembly and the minitype pneumatic muscle tendon. The four-finger exoskeleton bending and grabbing power mechanism is specially designed for a transport worker, and force of the hand of the transport worker is fully relieved; and the weight of carried weights is greatly improved, and the efficiency of cargo handling is improved. In addition, the four-finger exoskeleton bending and grabbing power mechanism can be used for medical apparatus and instruments, and better and more comprehensive rehabilitation of the hand and the wrist of a patient is facilitated.

Owner:HUANGHE S & T COLLEGE

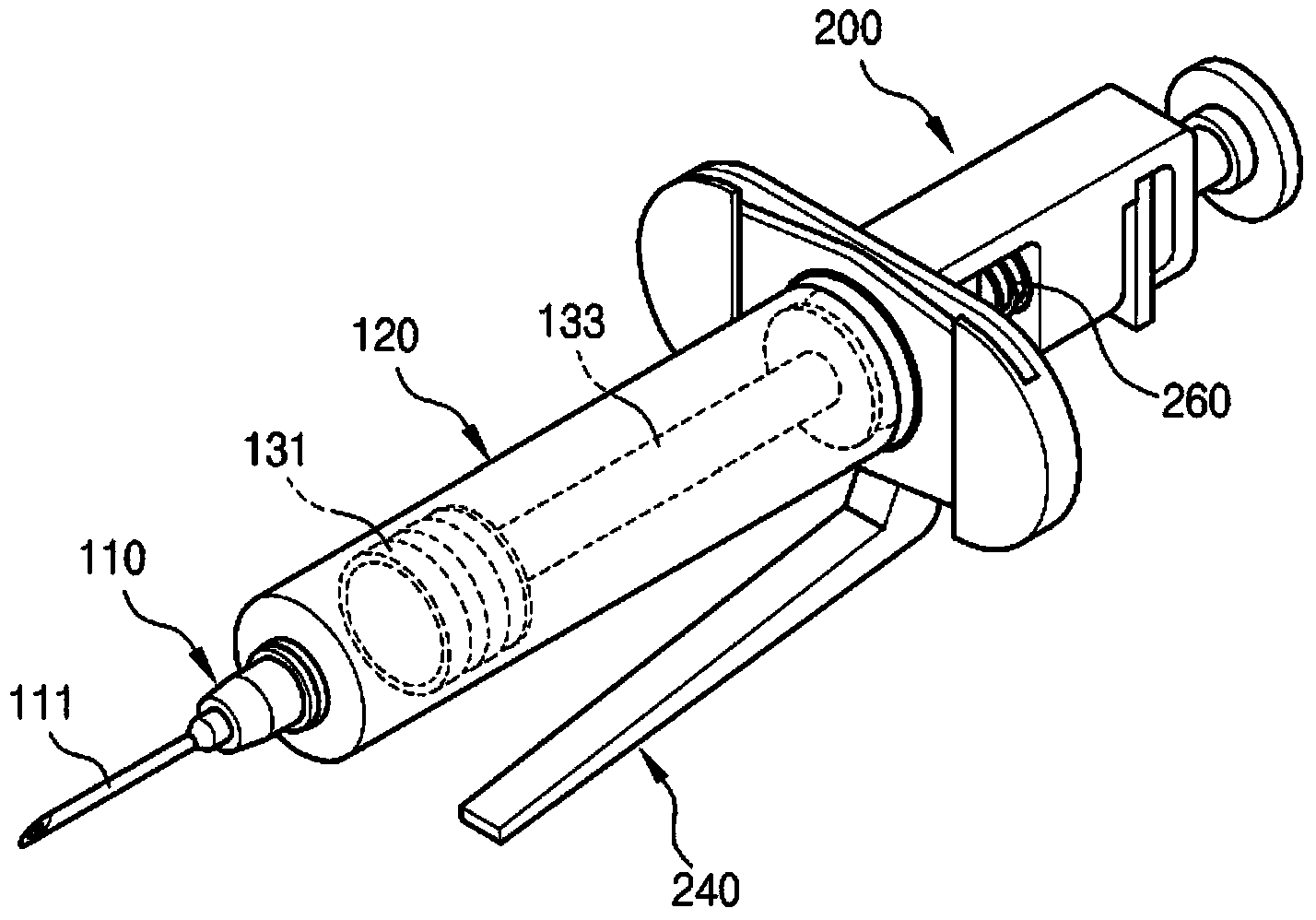

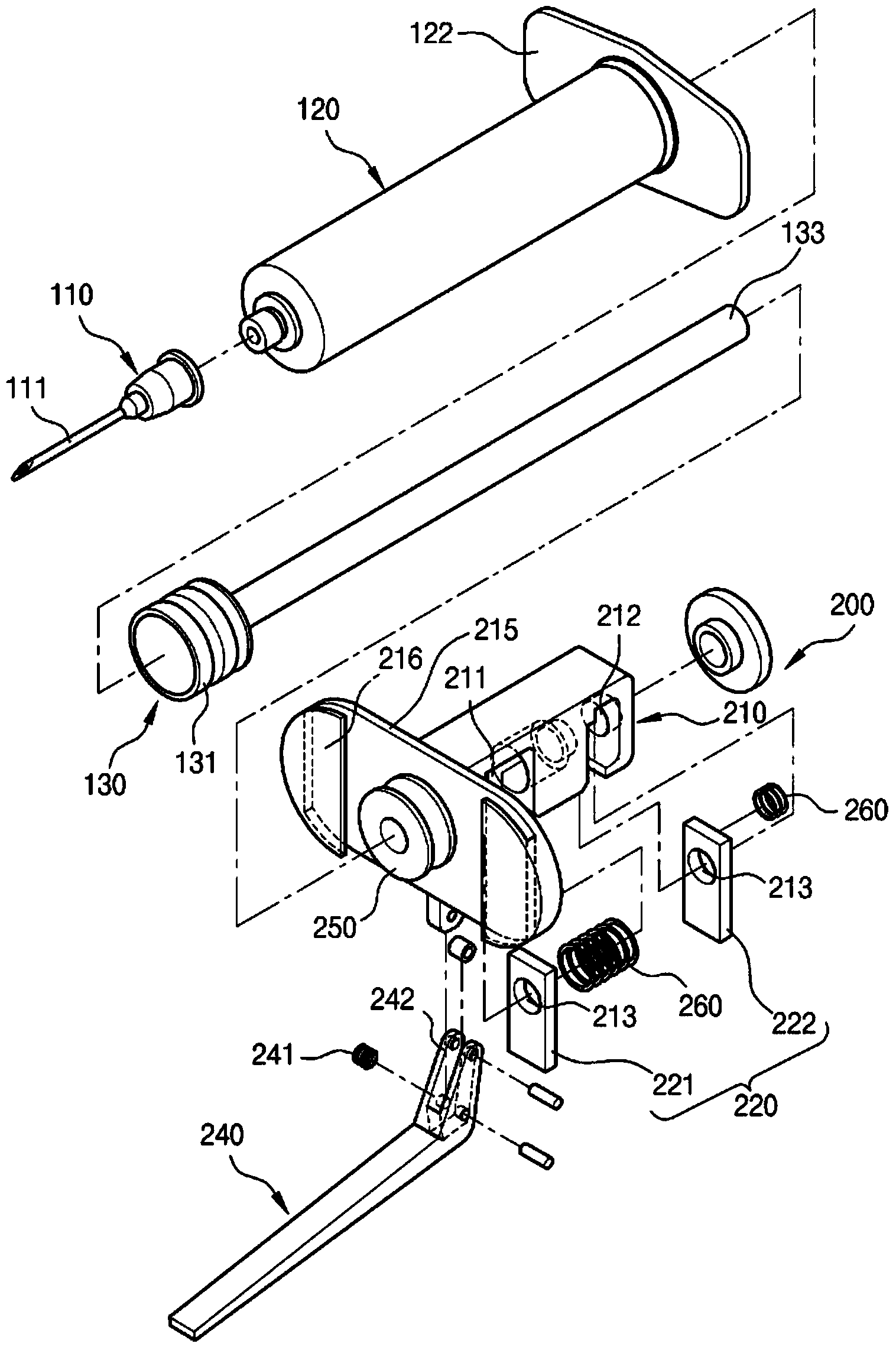

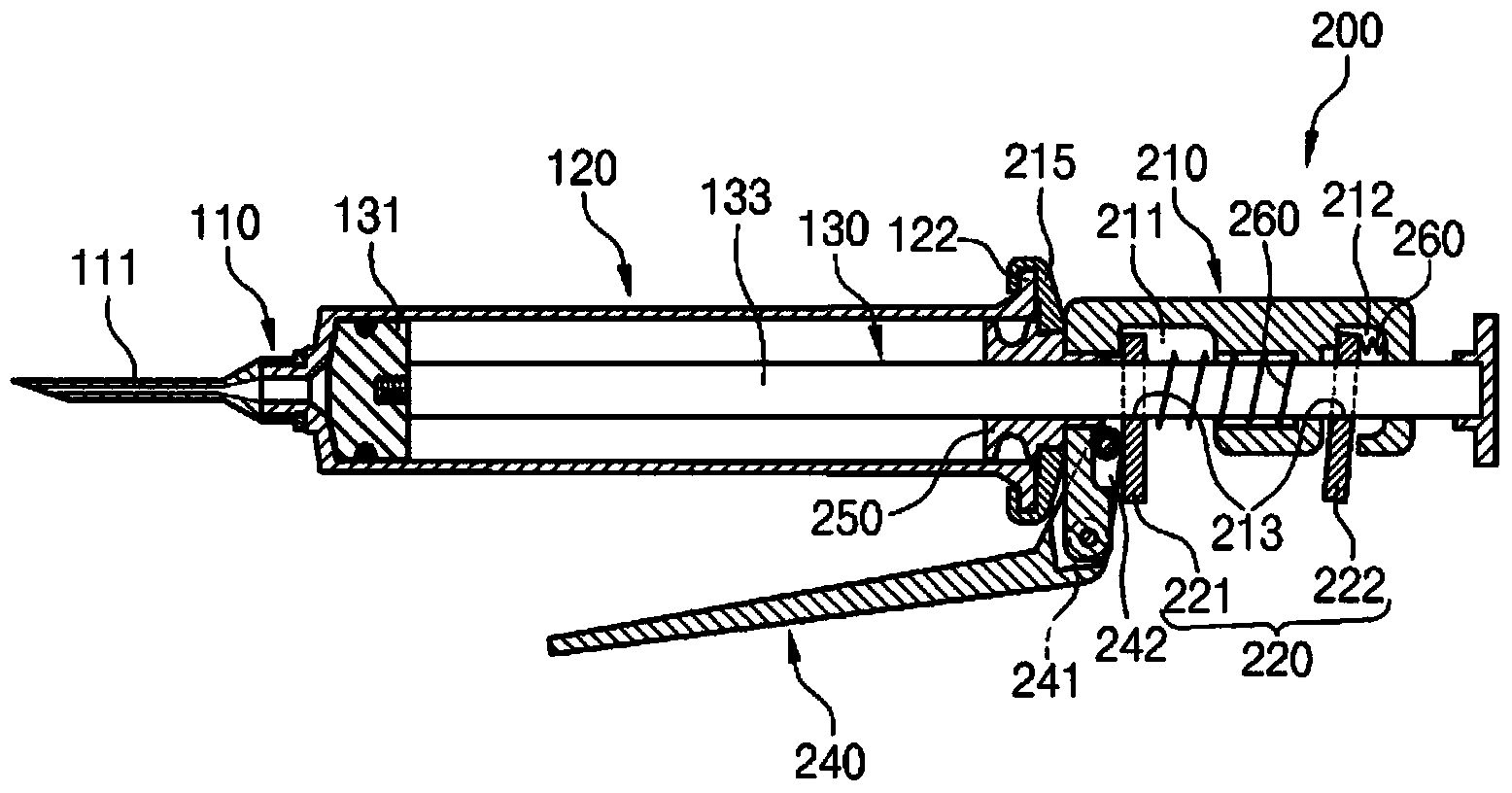

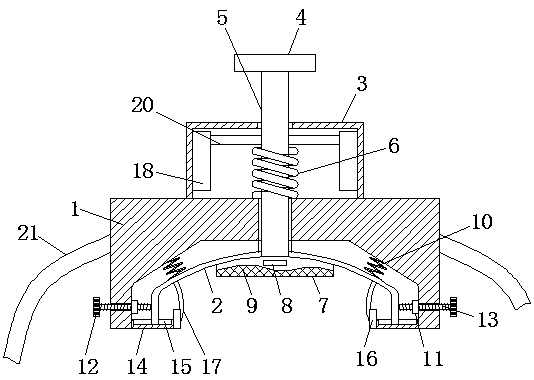

Syringe pressure generating and pressure displaying device

ActiveCN103648557AEasy extractionImprove extraction efficiencyInfusion syringesVaccination/ovulation diagnosticsLinear motionEngineering

The syringe pressure generating and pressure displaying device of the present invention is constituted in such a way that an auxiliary device is detachably joined to a cylinder flange while a rod bar is provided in the auxiliary device so as to pass therethough, and hand pressure on a lever that is hinge connected to the auxiliary device so as to be disposed horizontally in line with the syringe creates a rotational motion acting due to leverage, whereupon said rotational motion is converted to a linear motion via a motion-converting means, and the rod bar and a piston are moved with increased force.

Owner:李喜永

Hand pressure sensor warning device

InactiveUS7362231B2Drawback can be obviatedNew featureForce measurementBall sportsHand heldMembrane switch

An ergonomic lightweight hand pressure sensor-warning device for use with hand held objects like sport devices, steering devices, writing devices or computer devices, as well as the method for its assembly. This new hand pressure sensor warning device is designed as a relatively thin plaster / band-aid to attach the device onto the outside surface of the handgrips of hand held devices like a golf club, making the attachment to and detachment from the hand held device very simple and user-friendly. The device contains an electrical membrane switch, an electrical indicator with an alarm device and a streamlined oblong housing element which contains the principal components in a compact unit. Due to its low manufacturing costs, the warning device is also highly attractive as a commercial advertising product and as a corporate gift or premium product. The unintended and unexpected detachment of the device during a golf swing is practically impossible.

Owner:BOS ARIE CORNELIS

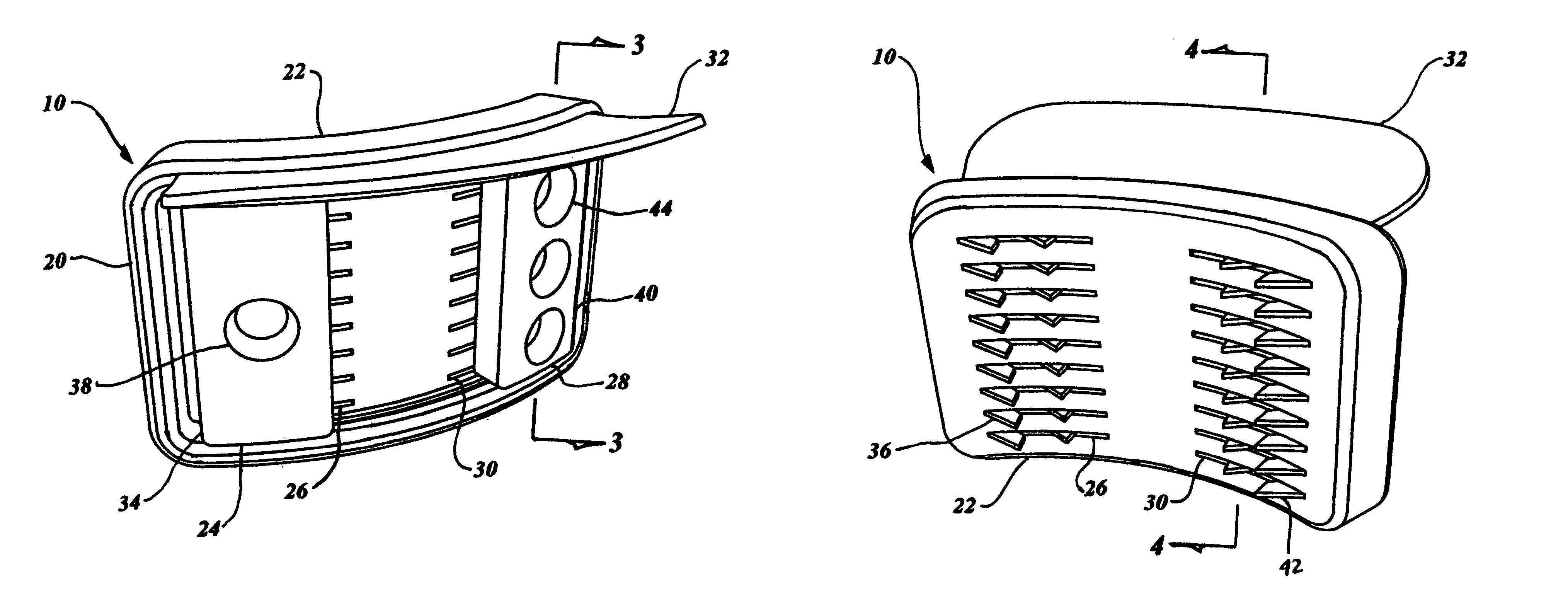

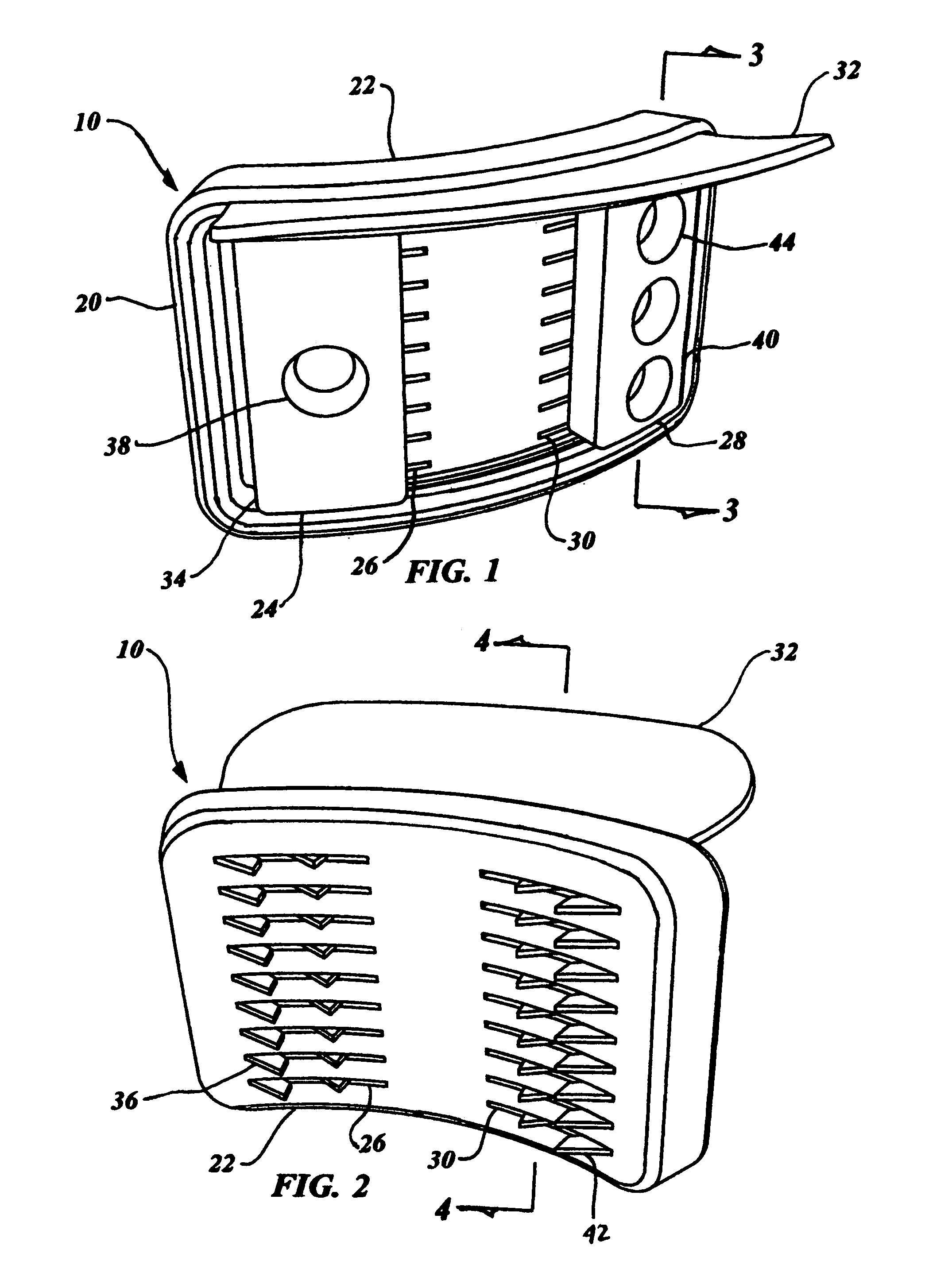

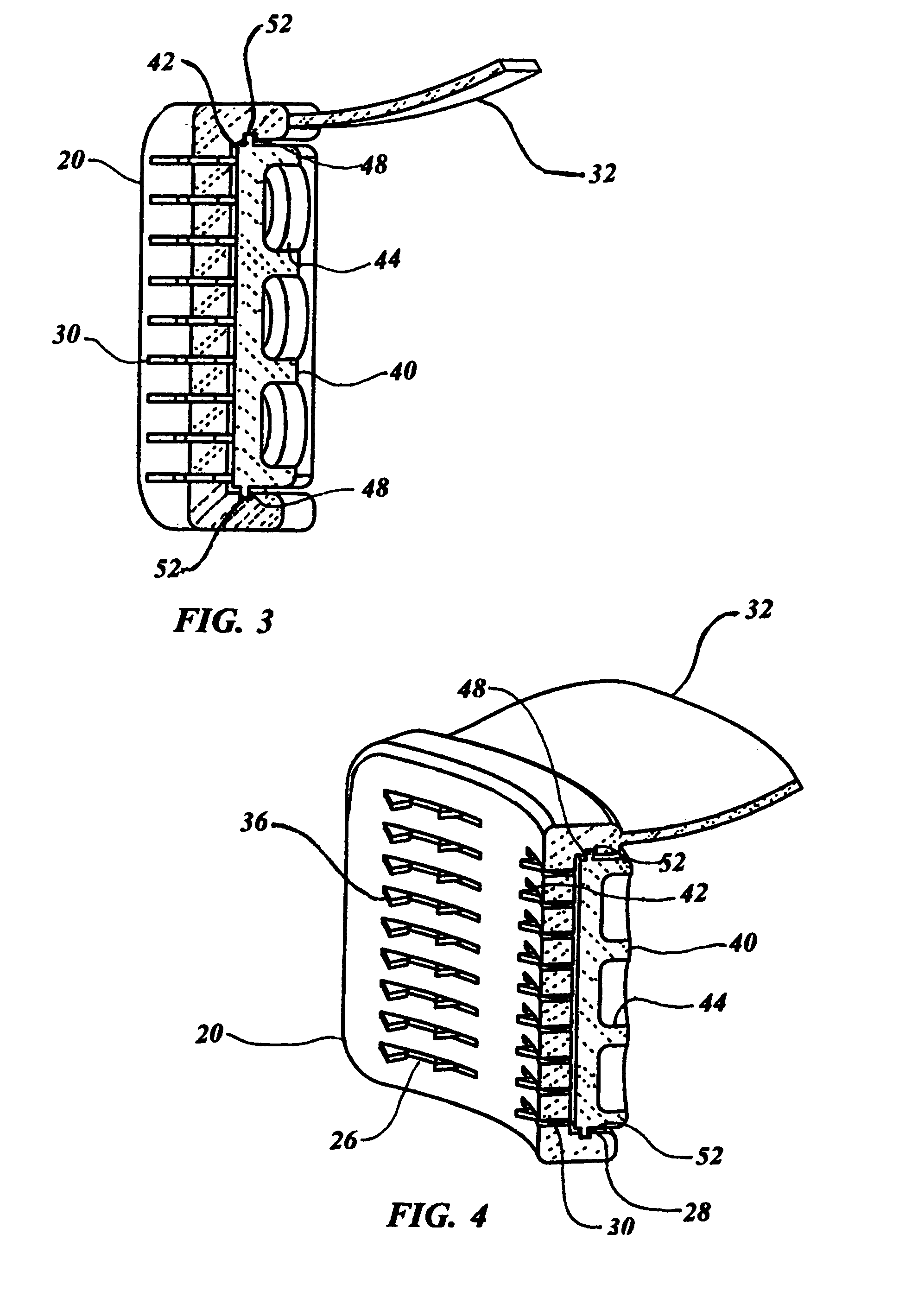

Fruit and vegetable gripper

InactiveUS7547006B1Easy to handlePrevent slippingDough dividingPositioning apparatusEngineeringHand pressure

A fruit and vegetable gripper (10) consisting of a resilient body (20) having a curved concave gripping surface (22) containing a number of slots (26), with a cutting shield (32) integrally formed within the body. A first insert (34) and a second insert (40) snap into the body, with each insert including gripping barbs (36) and (42) that penetrate the slots. When the gripper is manually held, the first insert gripping barbs (36) and second insert gripping barbs (42) are extended by hand pressure when a fruit or a vegetable is held, thereby achieving a positive non-slip grip.

Owner:LOCKWOOD TIM

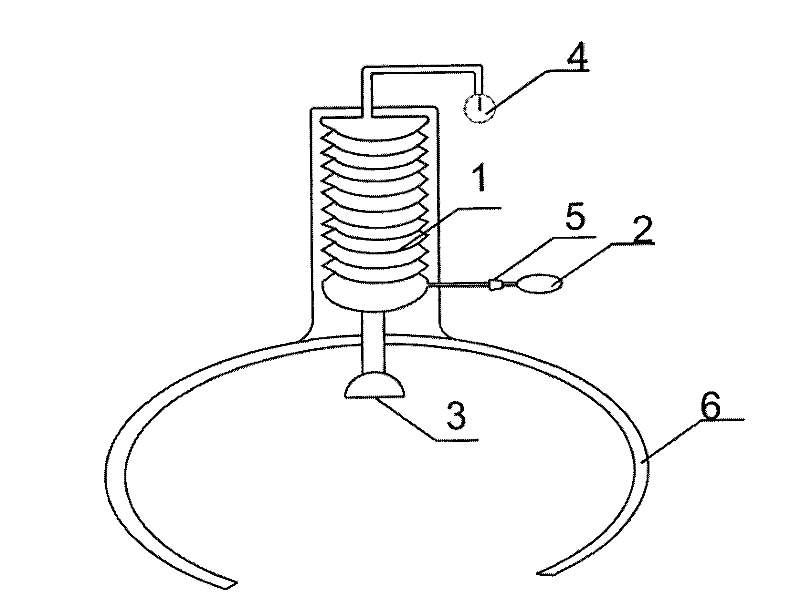

Compression hemostasis device capable of preventing haemorrhage after arteriopuncture and venipuncture

The invention discloses a compression hemostasis device capable of preventing haemorrhage after arteriopuncture and venipuncture. The compression hemostasis device disclosed by the invention comprises an inflation air sac, a hand pressure aerator and a compression device, wherein the hand pressure aerator is communicated with the inflation air sac; and the upper part of the compression device is of a hollow tubular shape and is communicated with the inflation air sac, and the lower part is of an upside-down bowl shape. Compared with the prior art, the compression hemostasis device disclosed by the invention has the following beneficial effects that: 1, a surgery doctor can autonomously adjust pressure for hemostasis according to the practical situation of a patient, a stable hemostasis pressure is provided for the patient, labour intensity of a doctor is greatly alleviated, and success rate of postoperation hemostasis on the patient is improved; and 2, the compression hemostasis device is convenient to use and is healthy.

Owner:谢维玲

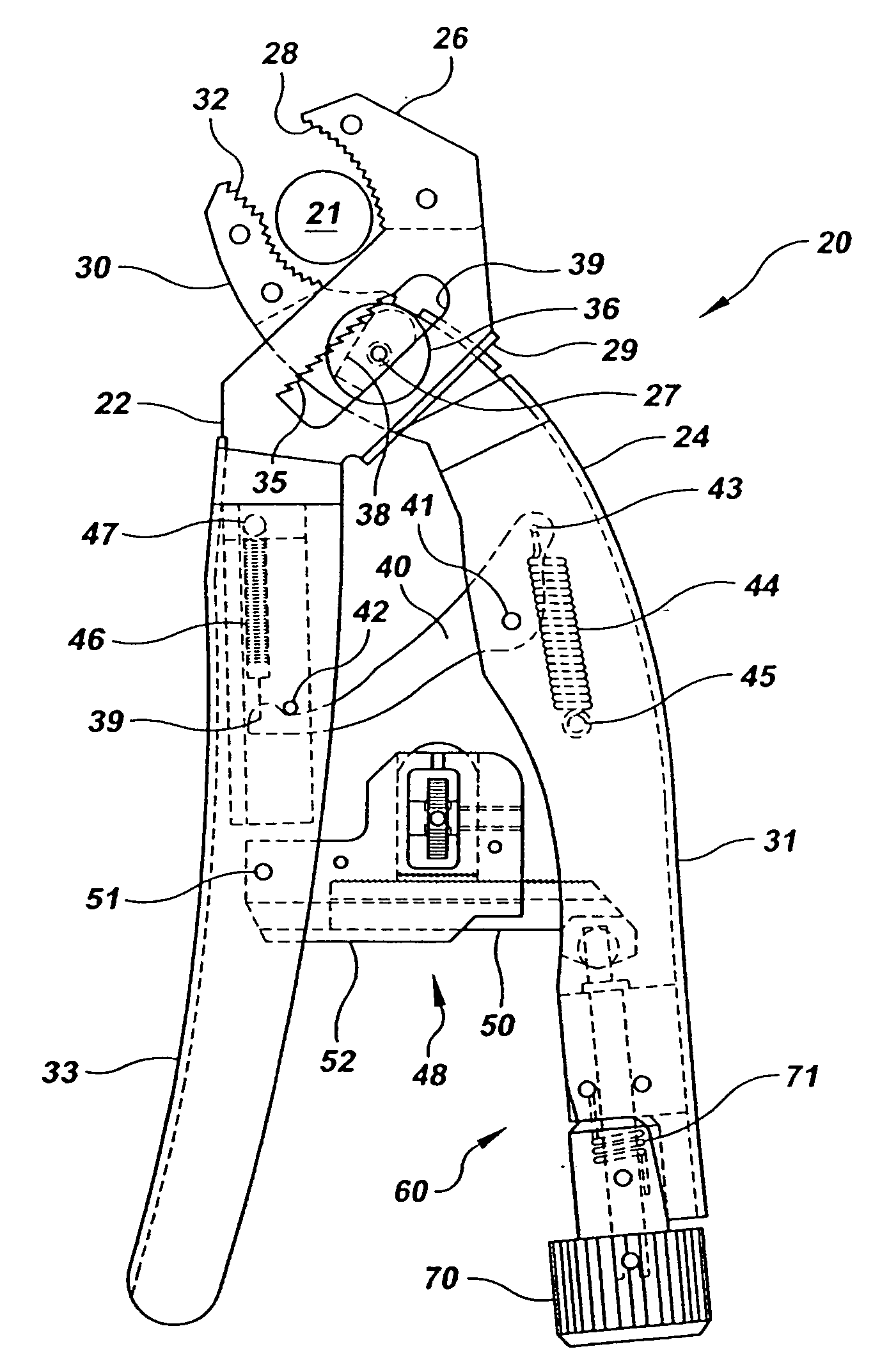

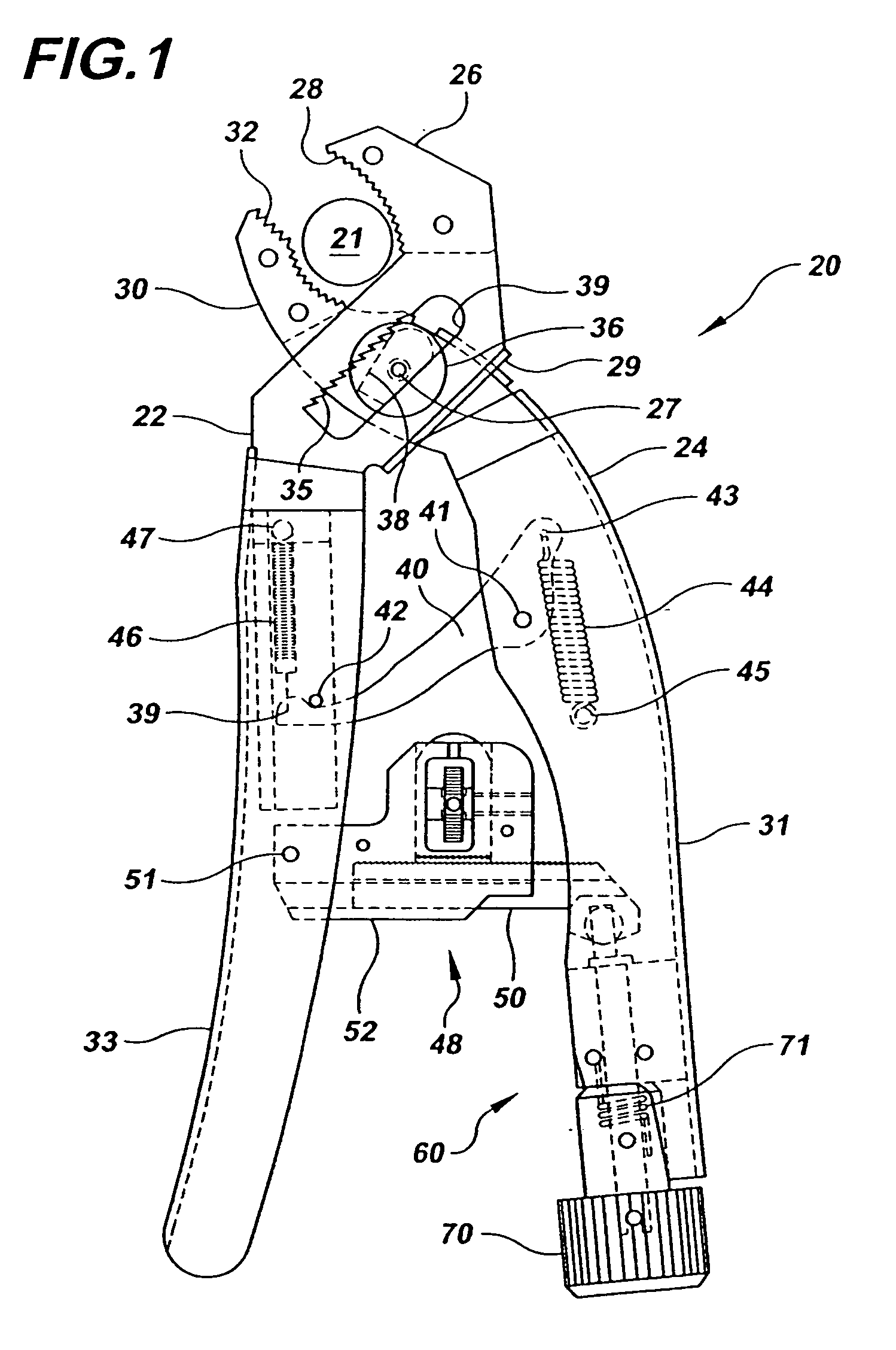

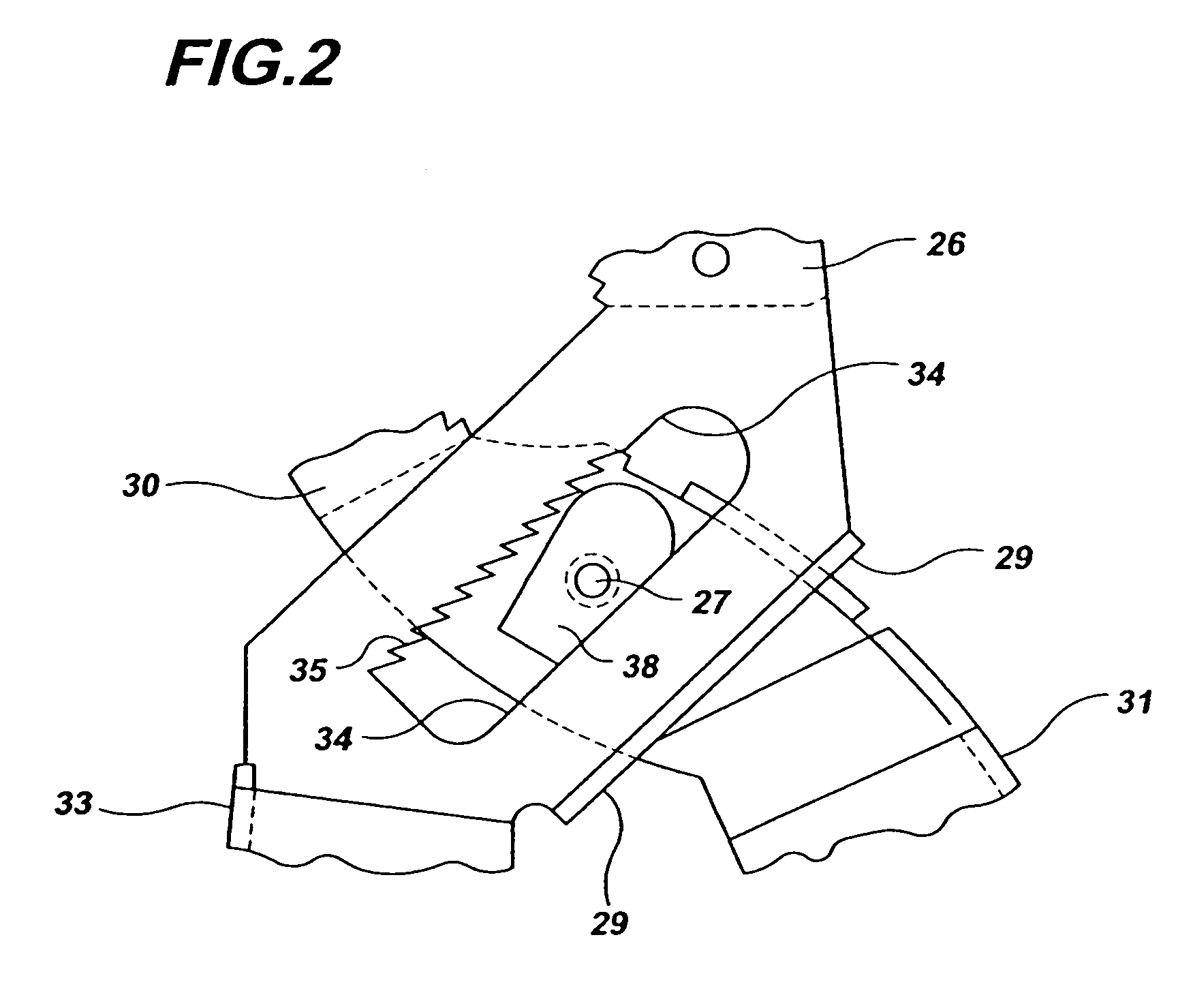

Self-adjusting, locking pliers with grip ping force adjustment

InactiveUS20060137497A1Increased torsional strengthReduce distancePliersLocking mechanismEngineering

Self-adjusting pliers include first and second elongated members each having at one end a jaw portion and at the other end a handle portion, with the elongated members pivotally connected at a position intermediate the jaw and handle portions such that upon positioning the jaw portions on a workpiece and squeezing the handle portions toward each other, the jaws adjust to thickness of the workpiece as they grip the workpiece. The pliers further include a ratchet locking mechanism between the handle portions, the locking mechanism adapted to releasably secure the handle portions upon squeezing of the handle portions toward each other and gripping of the workpiece by the jaw portions to prevent the handle portions from moving apart. A cam operated adjustor is connected to the locking mechanism to increase pressure of the jaw portions about the workpiece, after securing, by hand pressure alone.

Owner:SMITHVILLE LLC

Novel hemostatic device for cardiology

The invention discloses a novel hemostatic device for cardiology. The device comprises a fixing block, the inner cavity of the fixing block is provided with an elastic fixing ring, the top of the fixing block is fixedly connected with a fixing frame, the top of the fixing frame is provided with a pressing plate, a pressing rod is fixedly connected to the bottom of the pressing plate, and the bottom of the pressing rod sequentially penetrates the fixing frame and the fixing block and extends to the inside of the fixing block to be fixedly connected with the inner wall of the elastic fixing ring. By means of the fixing block, the elastic fixing ring, the fixing frame, the pressing plate, the pressing rod, a buffer spring, a pressing head, a pressure sensor, aseptic absorbent cotton, a connecting spring, a fixed shaft, an adjusting knob and a threaded rod, the hemostatic device can be firmly fixed on the surface of a patient to facilitate operation conducted by a medical worker. At the same time, the problems of bleeding and subcutaneous hematoma of the patient and physical and mental fatigue of the medical worker caused by the fact that the hands of the medical worker are prone to excessive fatigue after long-time pressing and may exert force unevenly are solved.

Owner:赵志勇

Production method of low-carbon high-chromium steel

The invention provides a production method of low-carbon high-chromium steel. The method comprises the following steps: the converter tapping carbon content is controlled to 0.15-0.25wt% and the tapping temperature is controlled to 1660-1670 DEG C, and balanced steel is tapped; 1.2-3kg of small active lime particles are added in each ton of steel after tapping; the Ruhrstahl & Hereaeus (RH) furnace adopts high lance height hand pressure control, the lance height and the oxygen flow are adjusted dynamically at any time according to the carbon content of steel, the waste gas flow is controlled to no more than 3000Nm<3> / h, the stepped pressure-reducing way is adopted, and the molten steel liquid level of the vacuum chamber is always controlled to be below the boundary of the bottom groove and the middle groove; when the RH furnace performs light treatment to reduce the carbon content of steel to 0.10wt%, the pressure is adjusted, the oxygen lance adopts a low lance height and the lance height is lowered to the optimum decarburization location; and fluorite and aluminum powder are added in the low frequency (LF) furnace to reduce chromium in slag. By adopting the production method of low-carbon high-chromium steel, the carbon content can be reduced to below 0.01% and the chromium content is no less than 5%, thus the RH furnace can be used to produce pure and qualified low-carbon high-chromium steel.

Owner:ANGANG STEEL CO LTD

Faucet control system and method

ActiveUS20080163942A1Avoid flowOperating means/releasing devices for valvesServomotor componentsWarm waterStarting fluid

A faucet control system comprises a valve apparatus, sensors or a touch panel to be activated by a user, and a controller that controls the valve apparatus. A first sensor may start fluid flow and a second sensor may alter the proportion of fluids delivered from two fluid sources. Alternatively, a first sensor may initiate hot water flow, a second sensor may initiate cold water flow, and a third sensor may initiate flow of a mixture of hot and cold water to create a warm water flow. The sensors may be activated without being touched and may include infrared sensing elements. The touch panel may be activated with hand pressure and may include electrically conductive sheets. Alternatively, hot, cold and / or warm touch sensors may be provided separately. The touch panel may have a first portion for allowing fluid flow from a cold fluid source, a second portion for allowing fluid flow from the cold fluid source and a hot fluid source, and a third portion for allowing fluid flow from the hot fluid source. The controller may include an adjustable timer so that fluid flow can be stopped automatically after a selected period of time. Other systems include a one sensor system, a two sensor system, a three sensor system and a five sensor system. In the five sensor system, one sensor activates hot water flow, another sensor activates cold water flow, and three sensors activate various levels of warm water flow.

Owner:BOEY KUM F

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com