Patents

Literature

117 results about "Shear angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Angle of shear. [′aŋ·gəl əv ′shēr] (geology) The angle between the planes of maximum shear which is bisected by the axis of greatest compression.

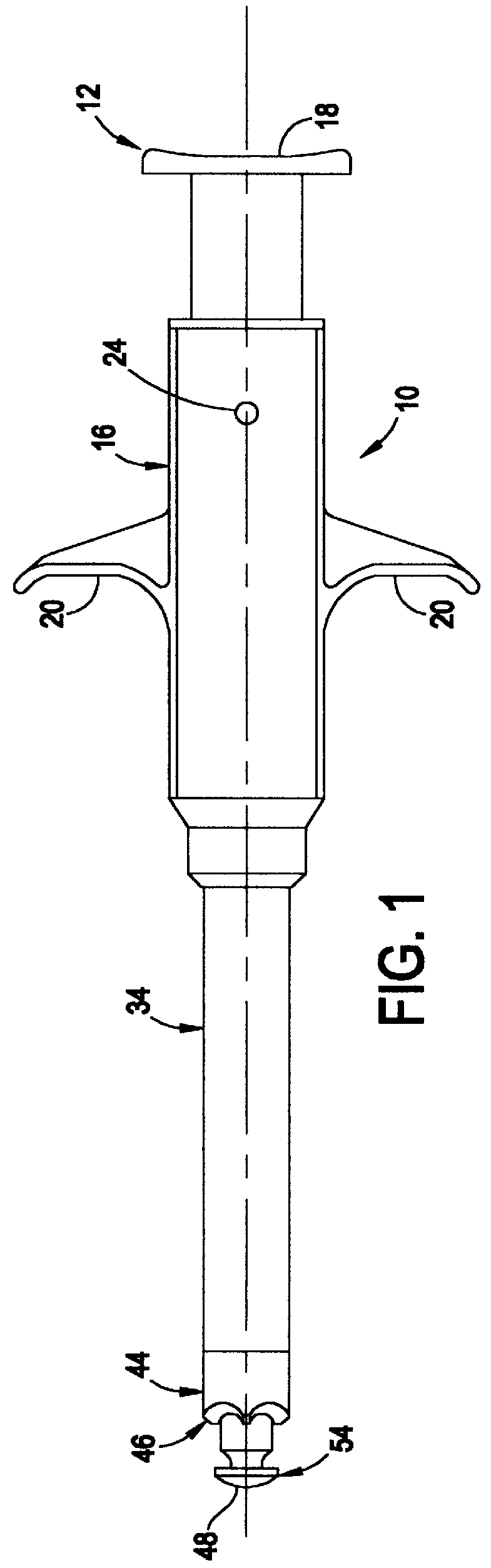

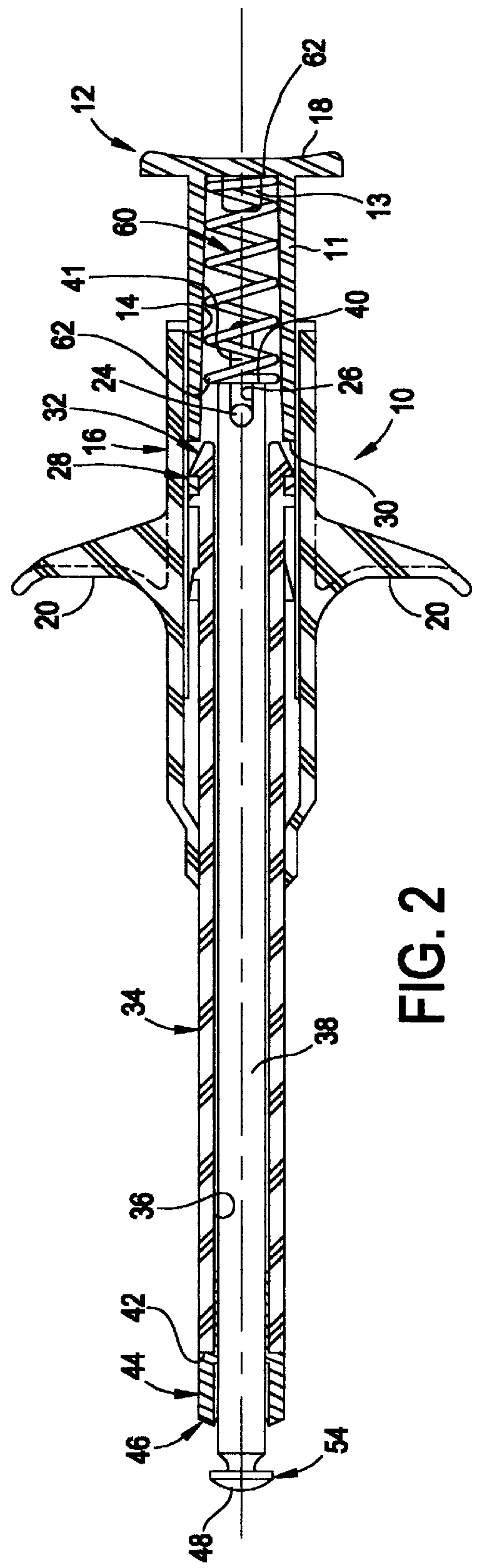

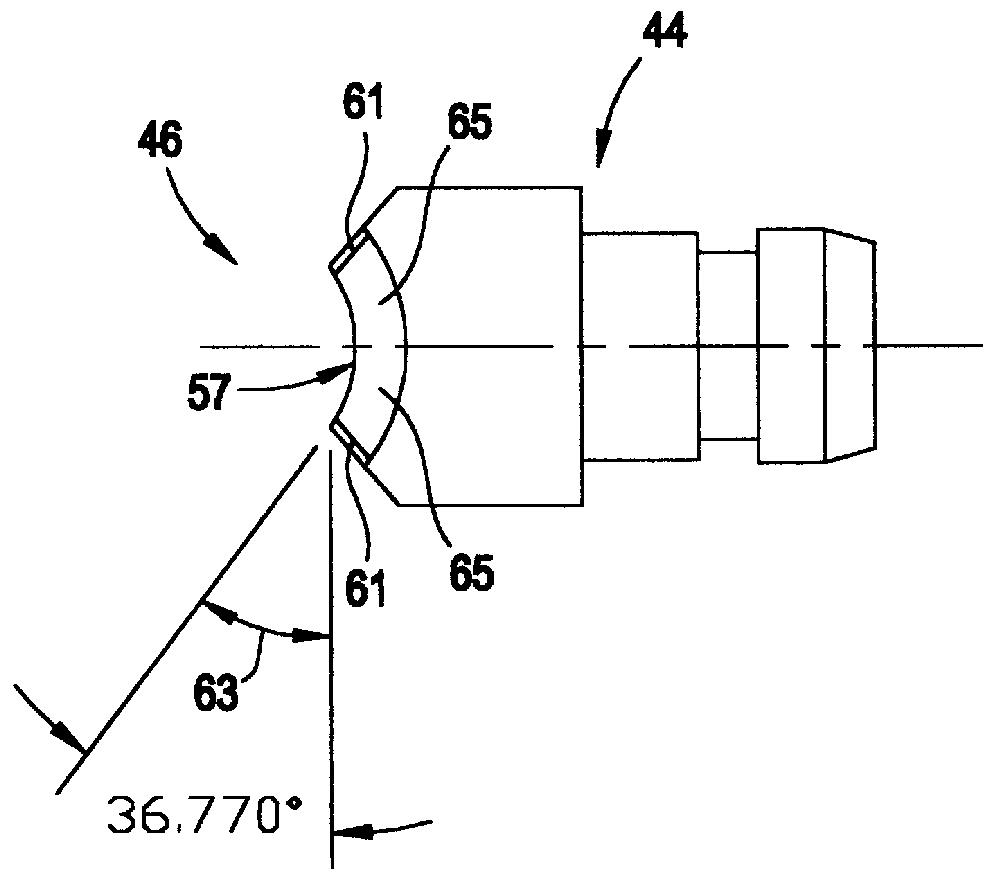

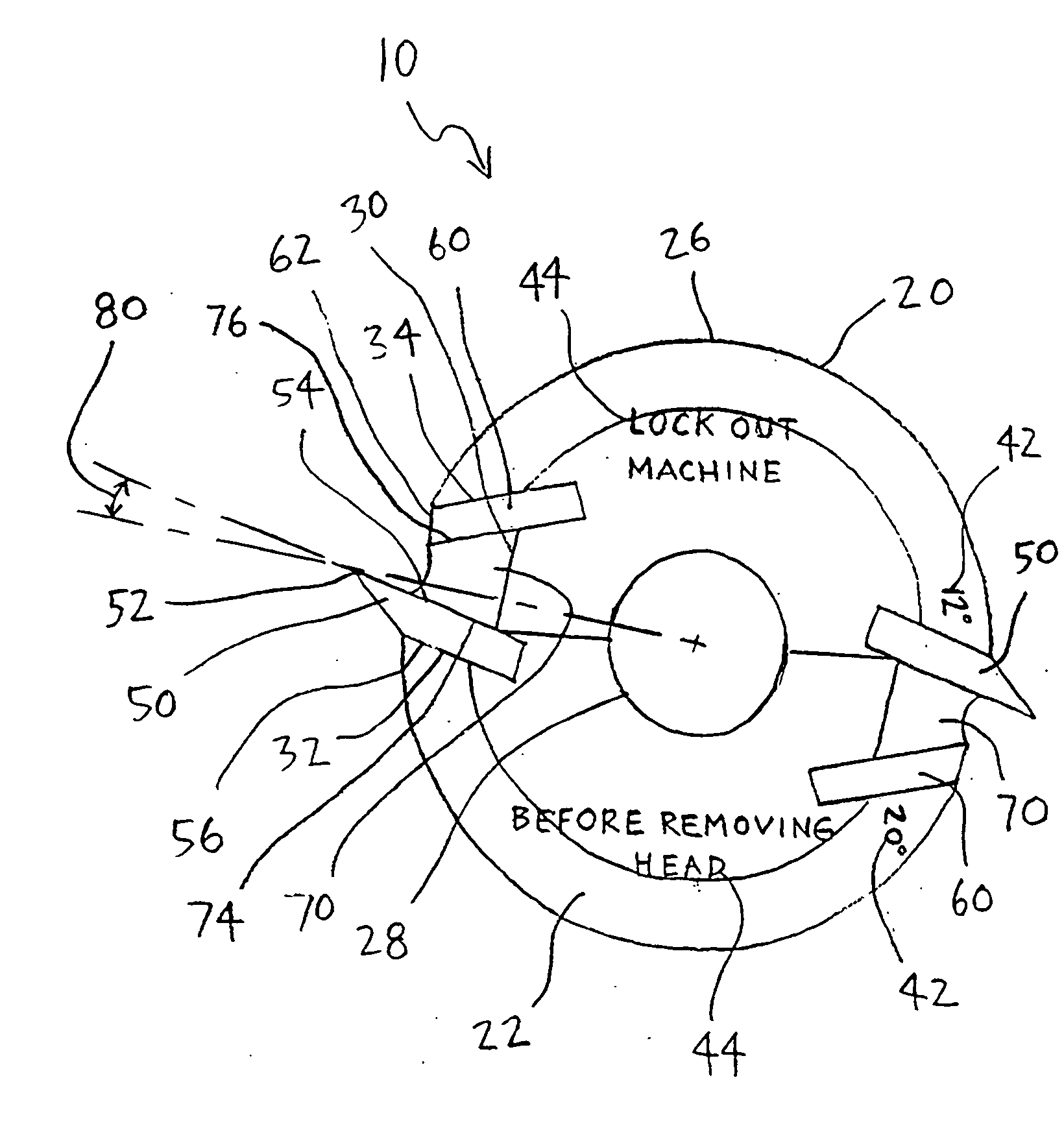

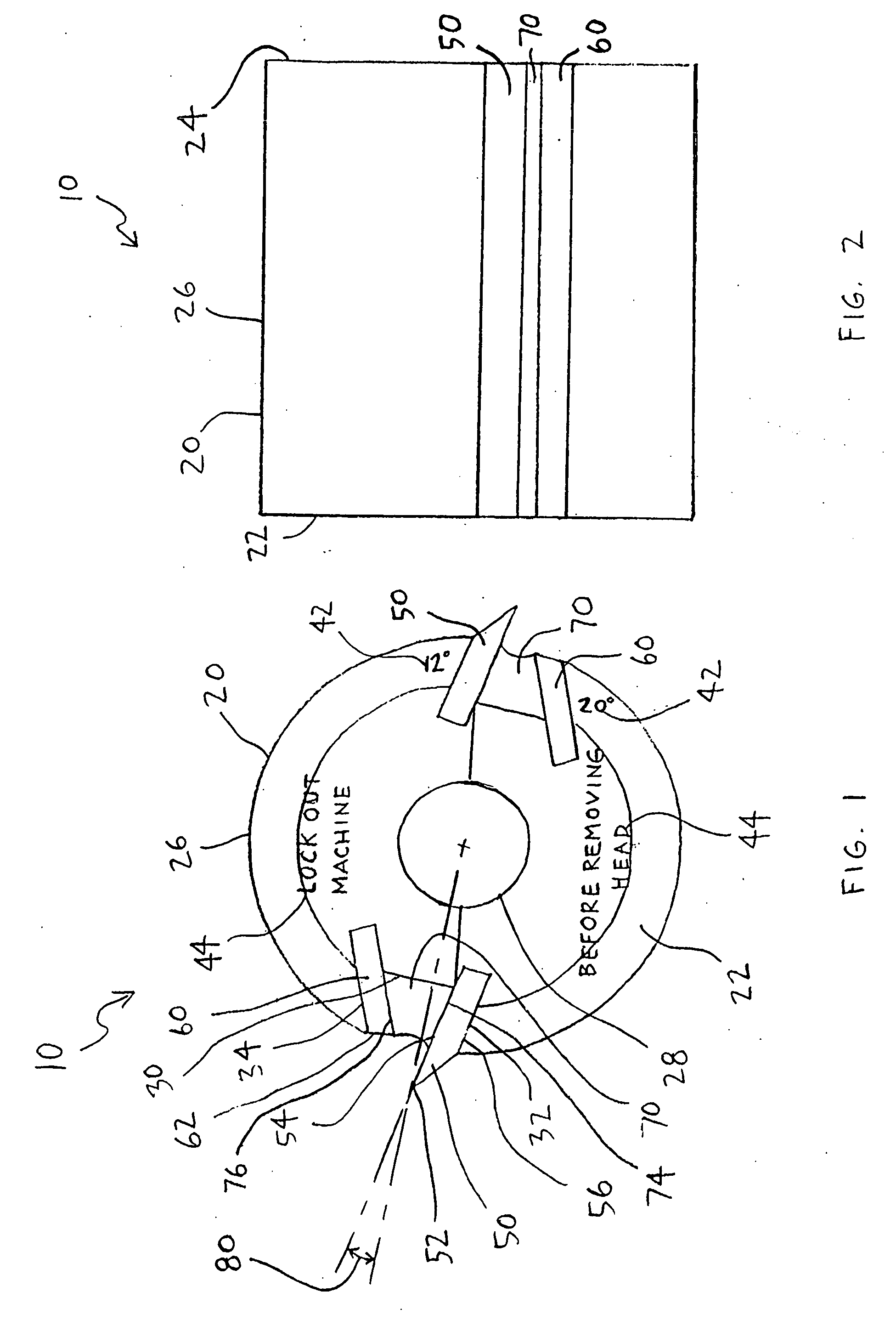

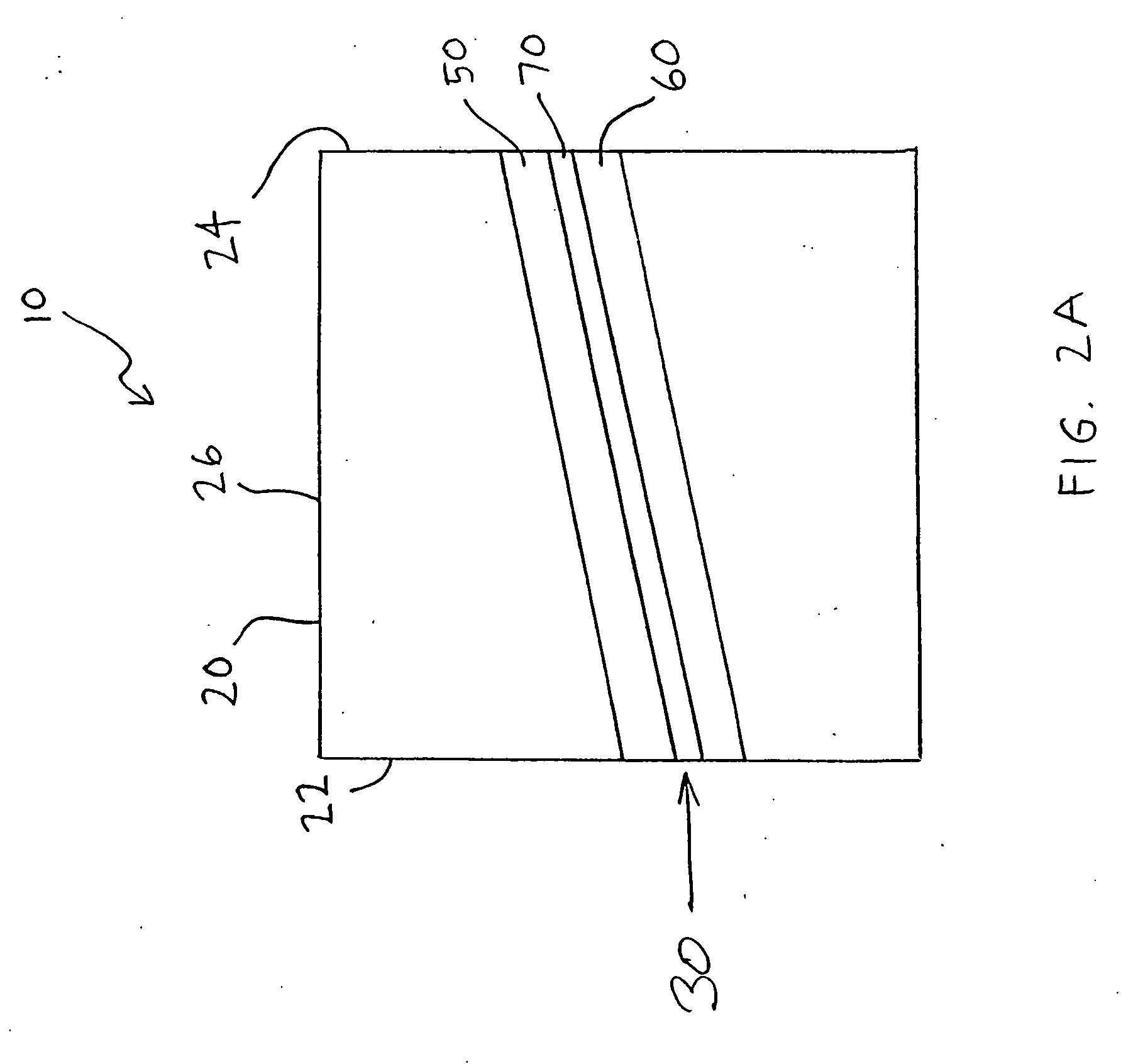

Medical punch with high shear angle cutting edges

InactiveUS6080176AClean and accurate cutReduce wearSurgical needlesExcision instrumentsEngineeringHand pressure

A medical punch having a plurality of cutting edges. The fact that the medical punch has a plurality of cutting edges provides, for example, that the medical punch can be used to achieve a clean and accurate cut, and provides that an excessive amount of hand pressure need not be employed to effect the cut.

Owner:ATRION MEDICAL PRODS

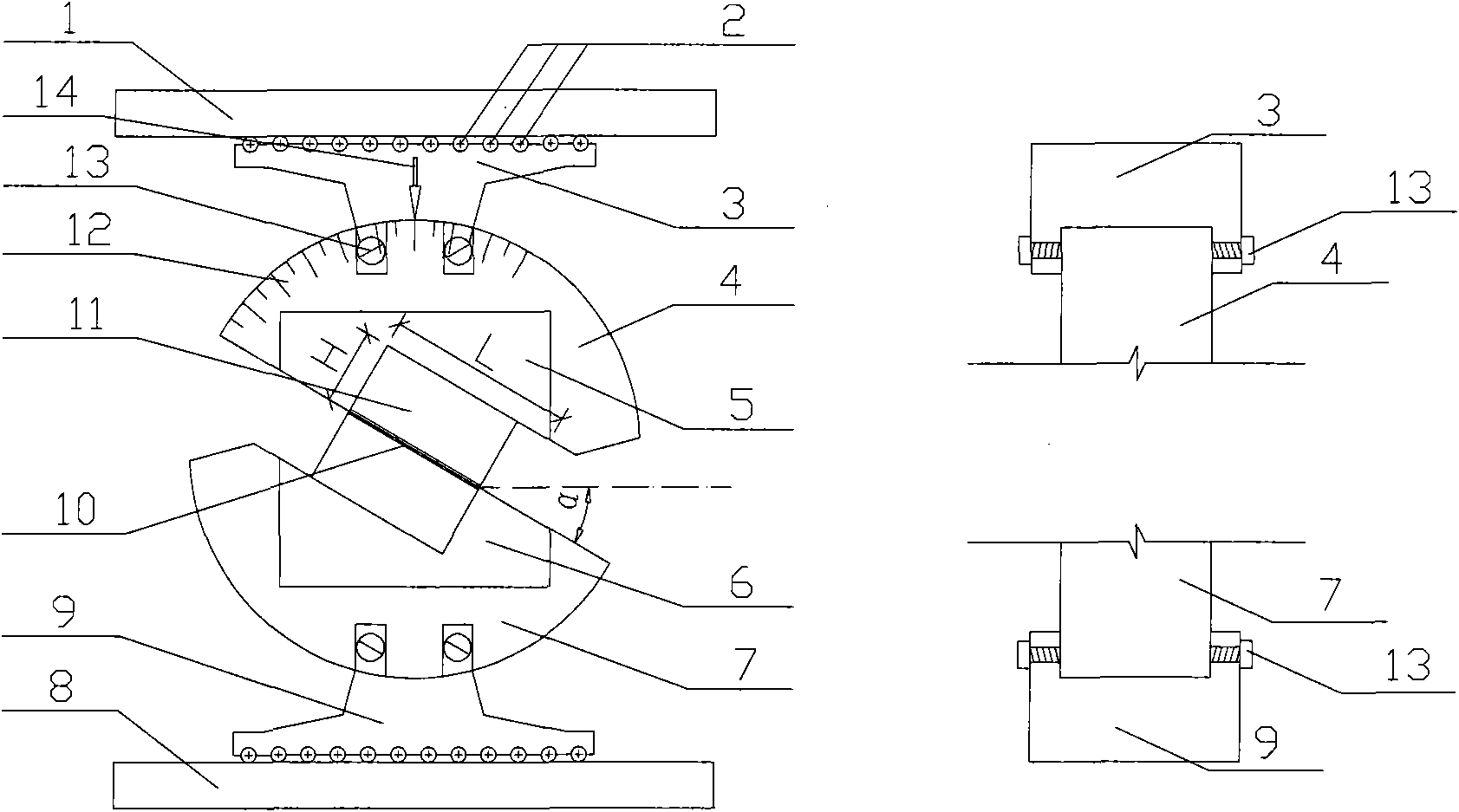

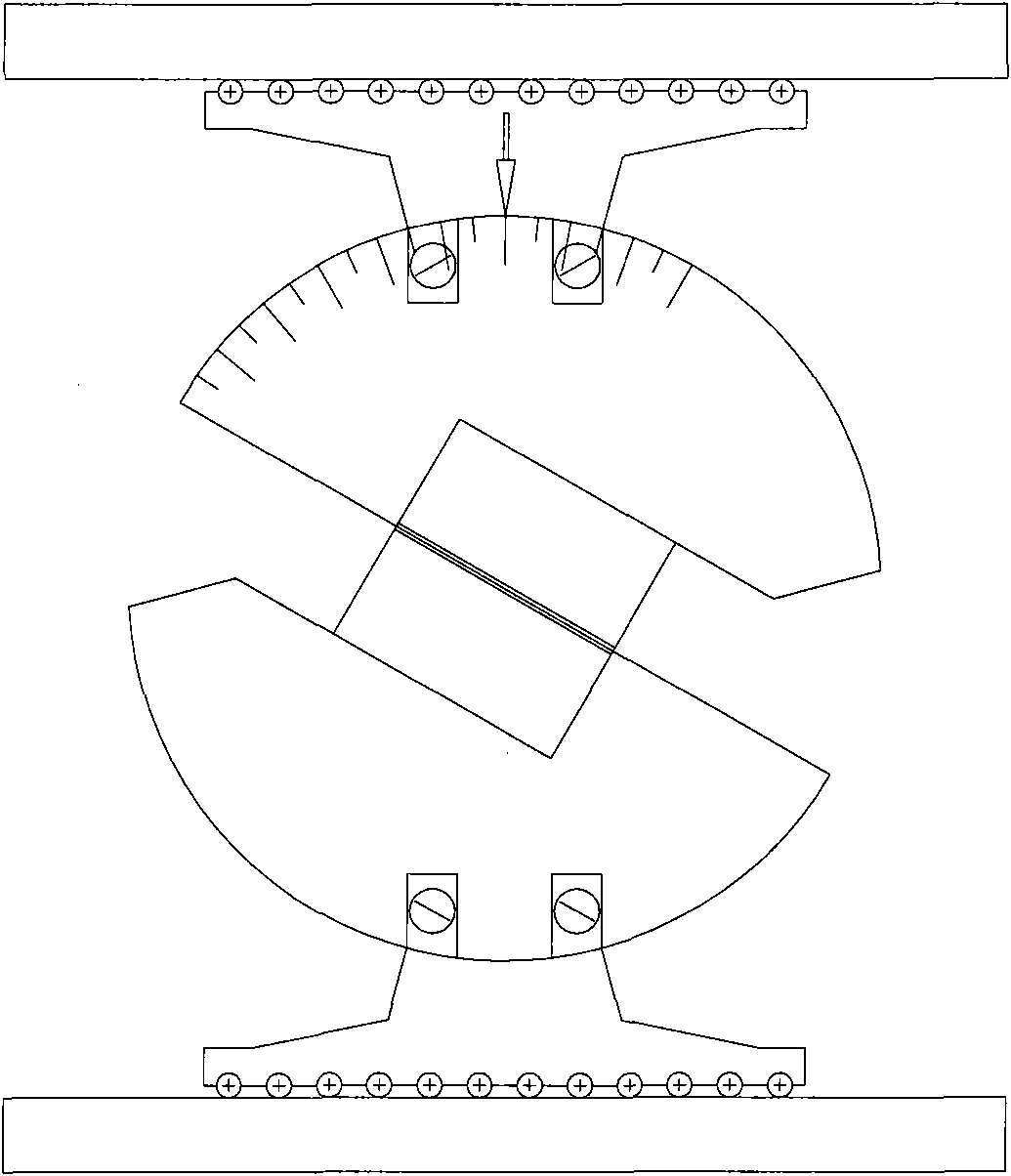

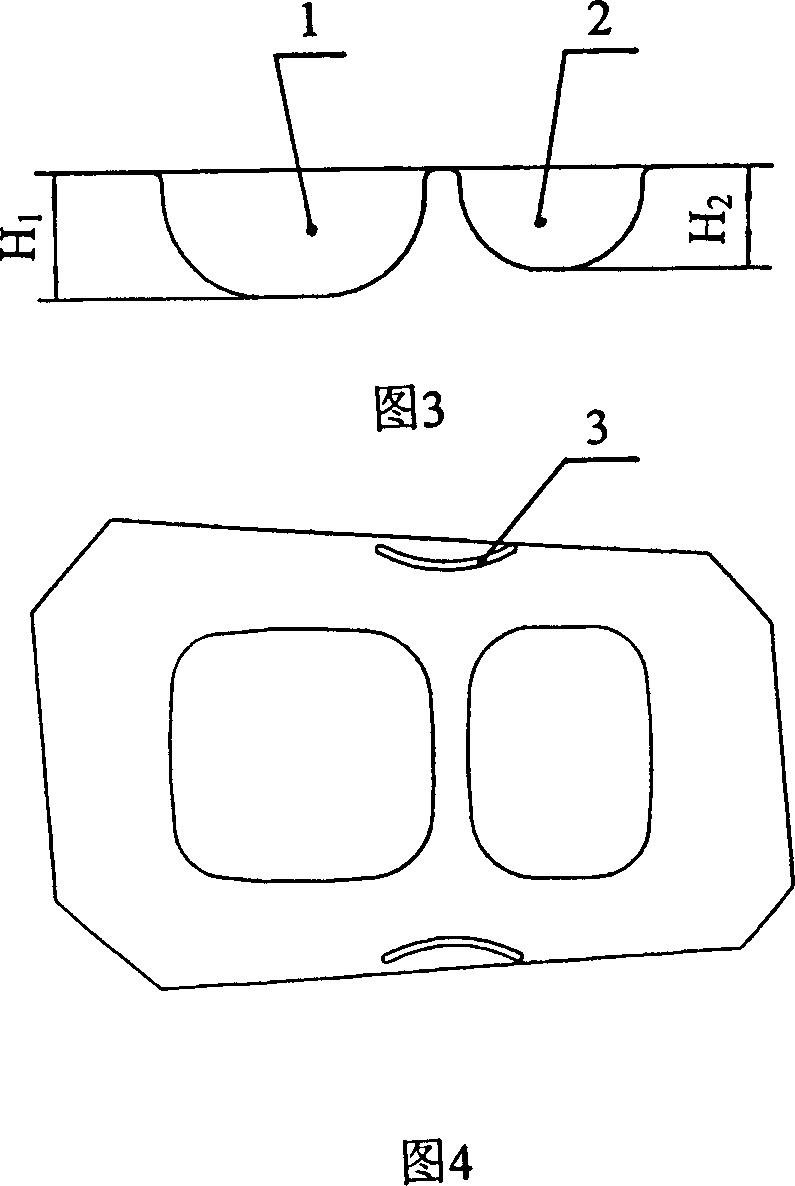

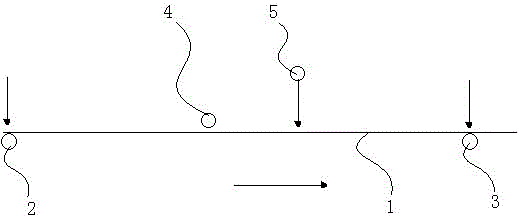

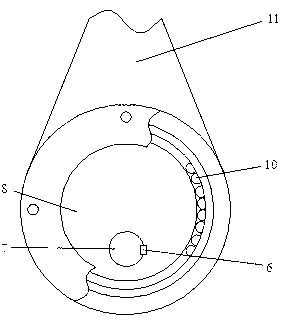

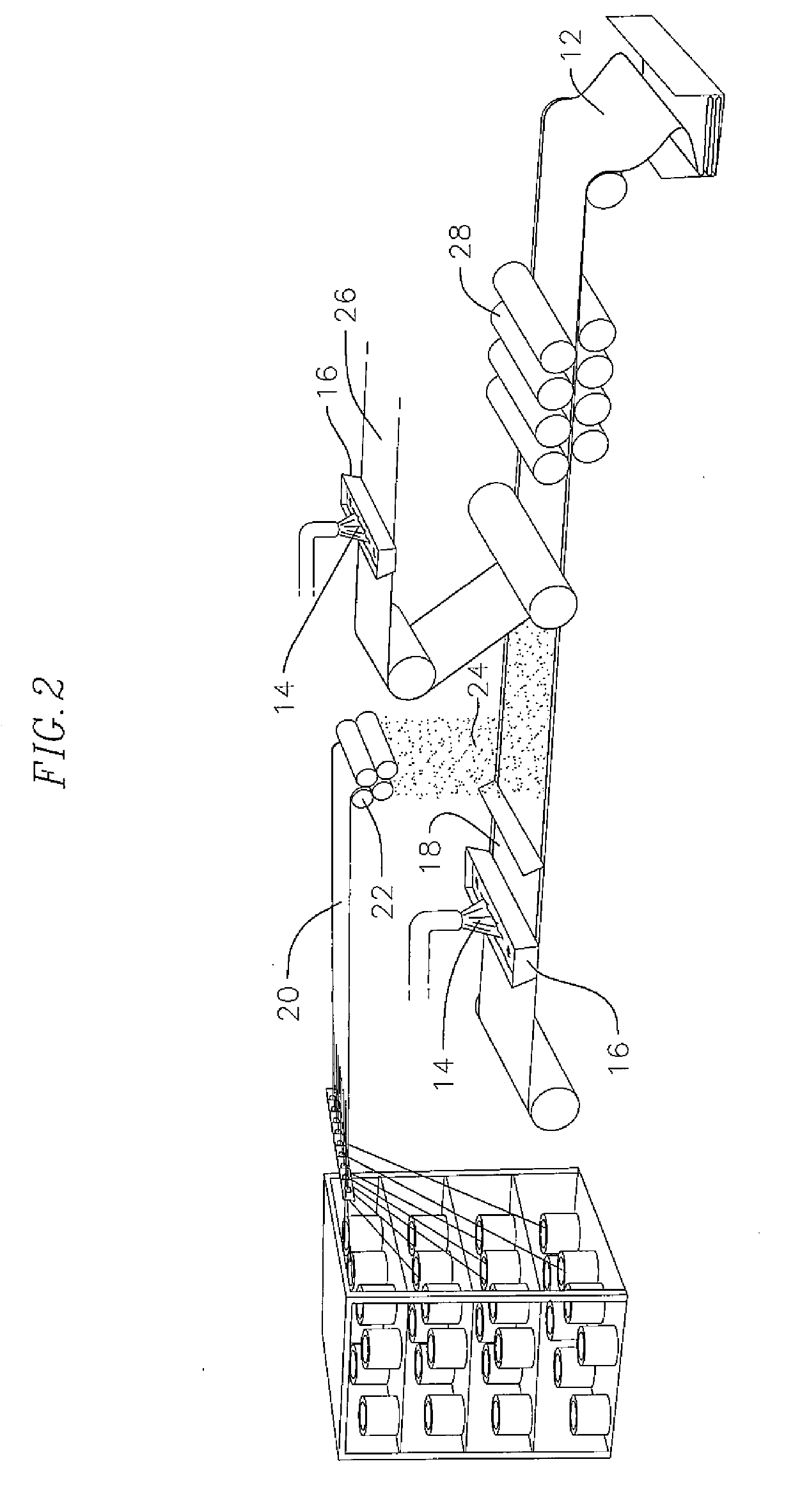

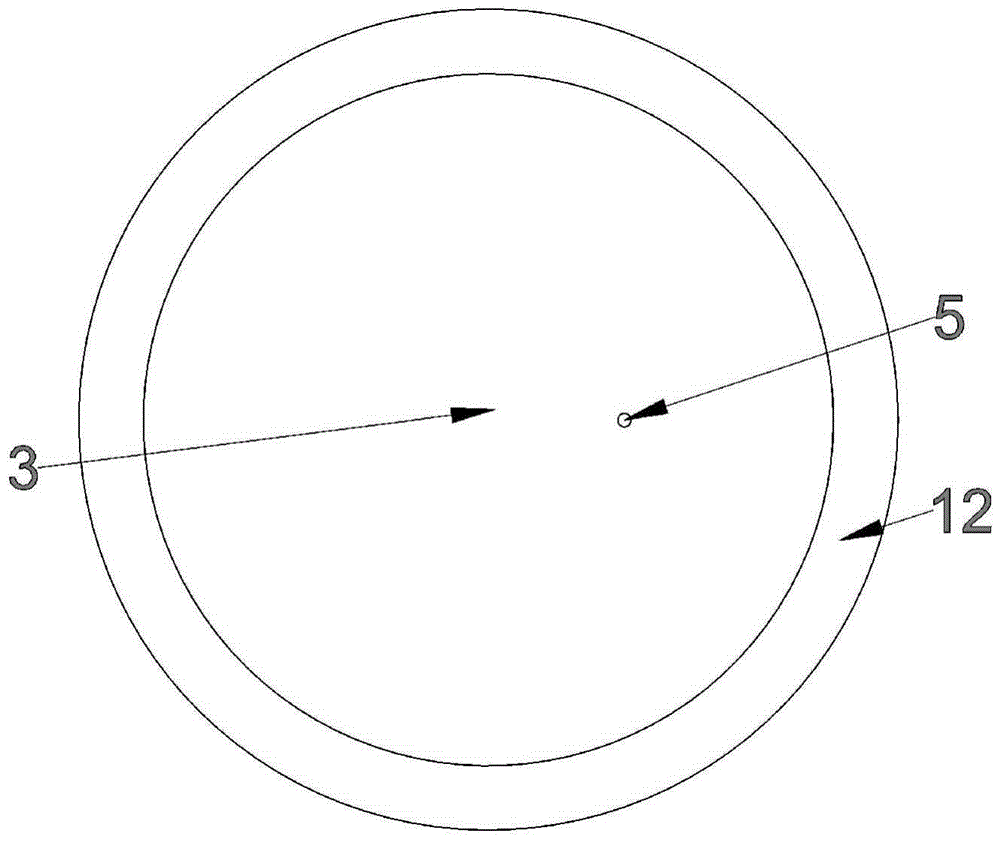

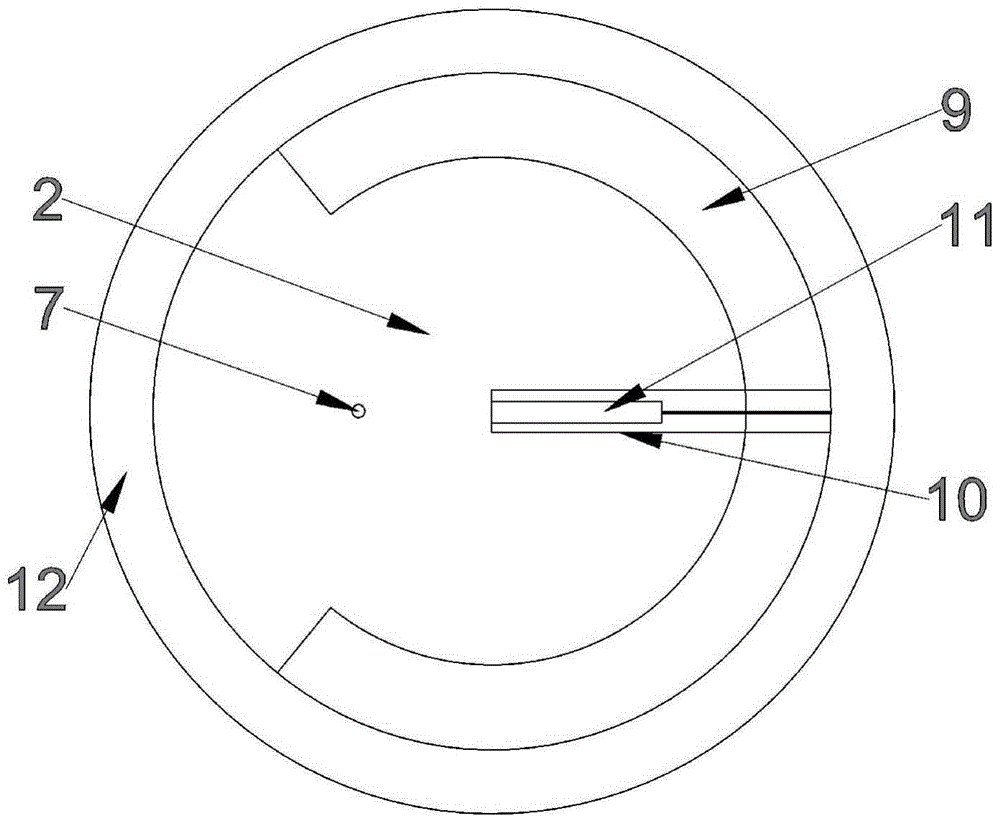

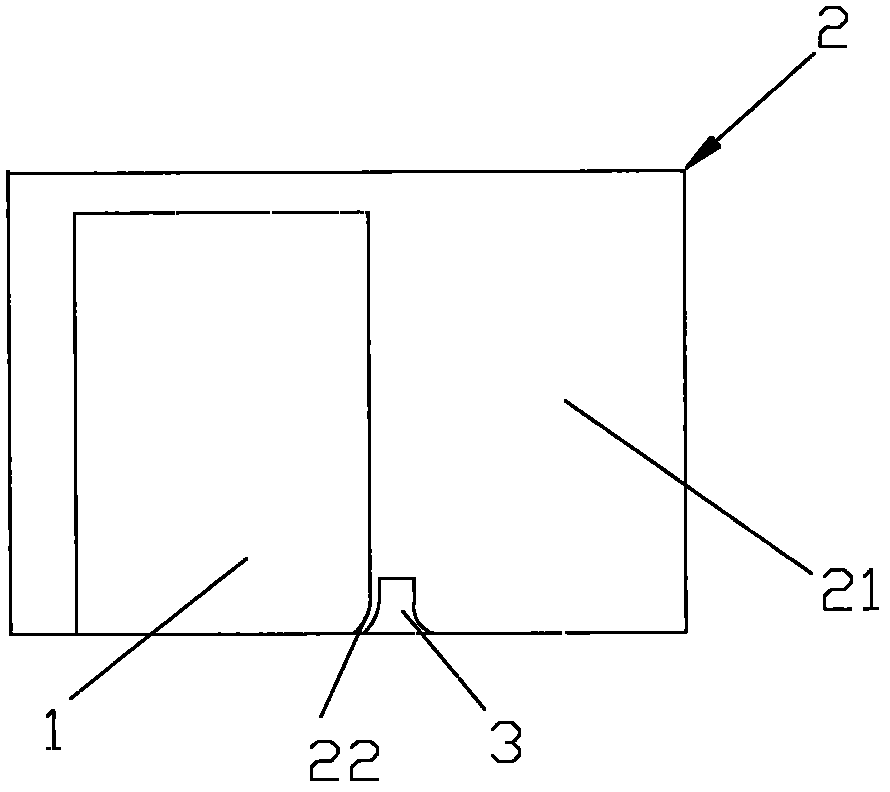

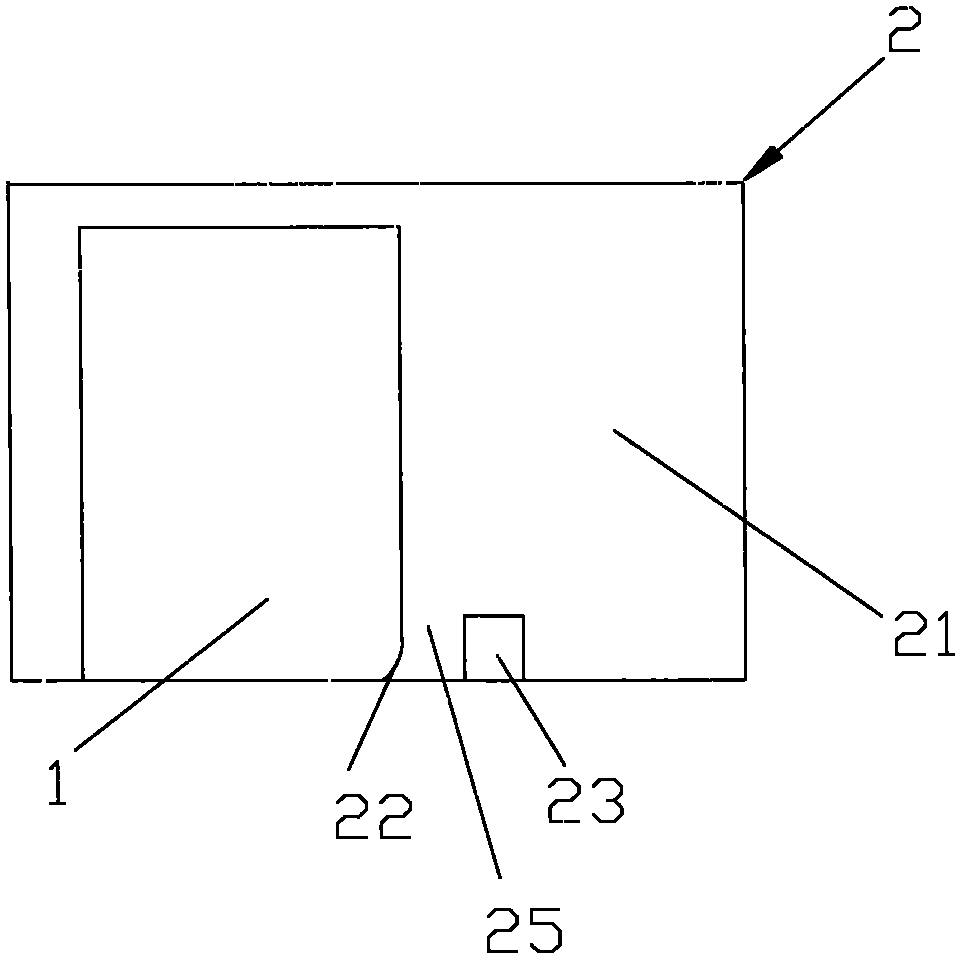

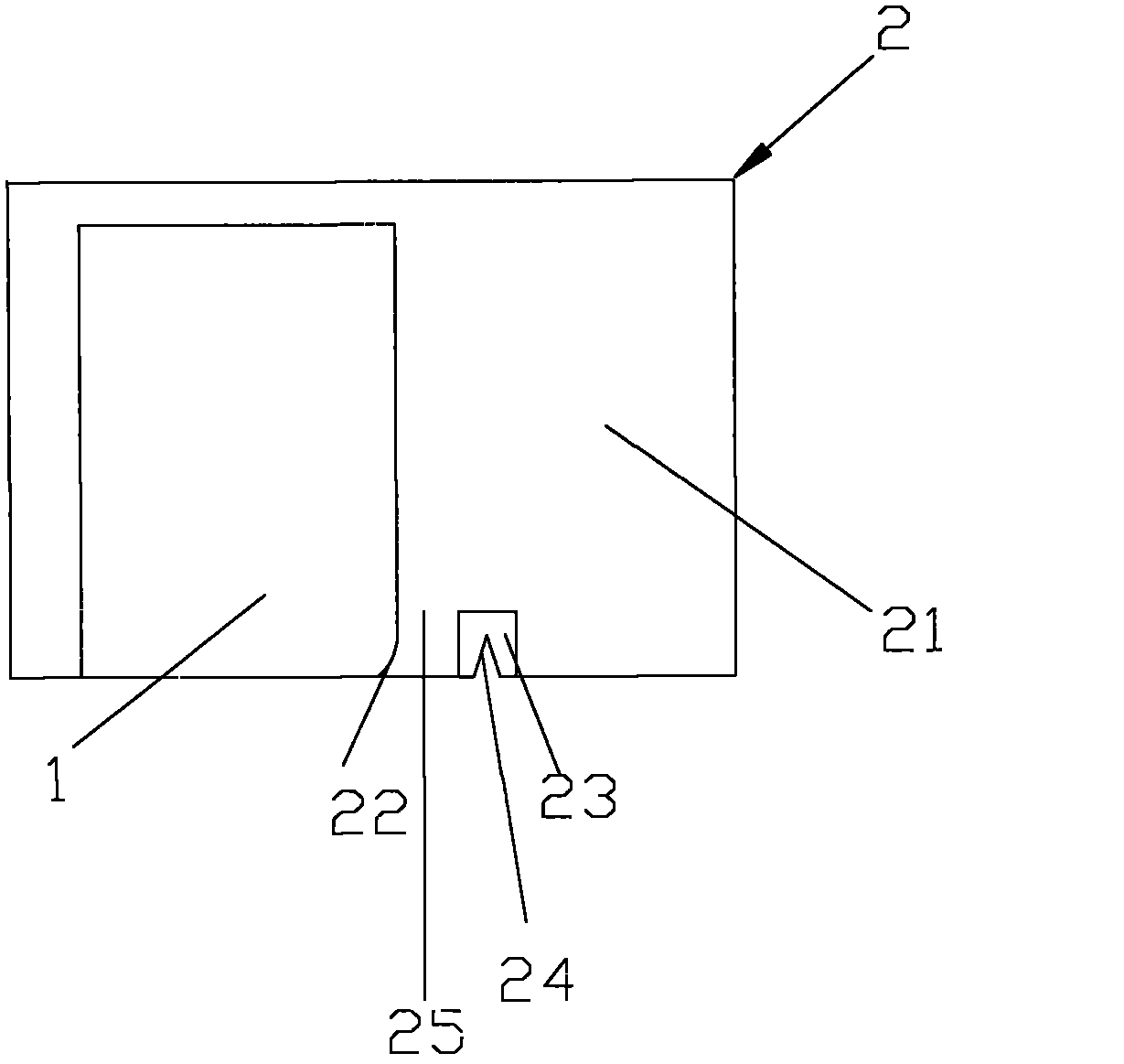

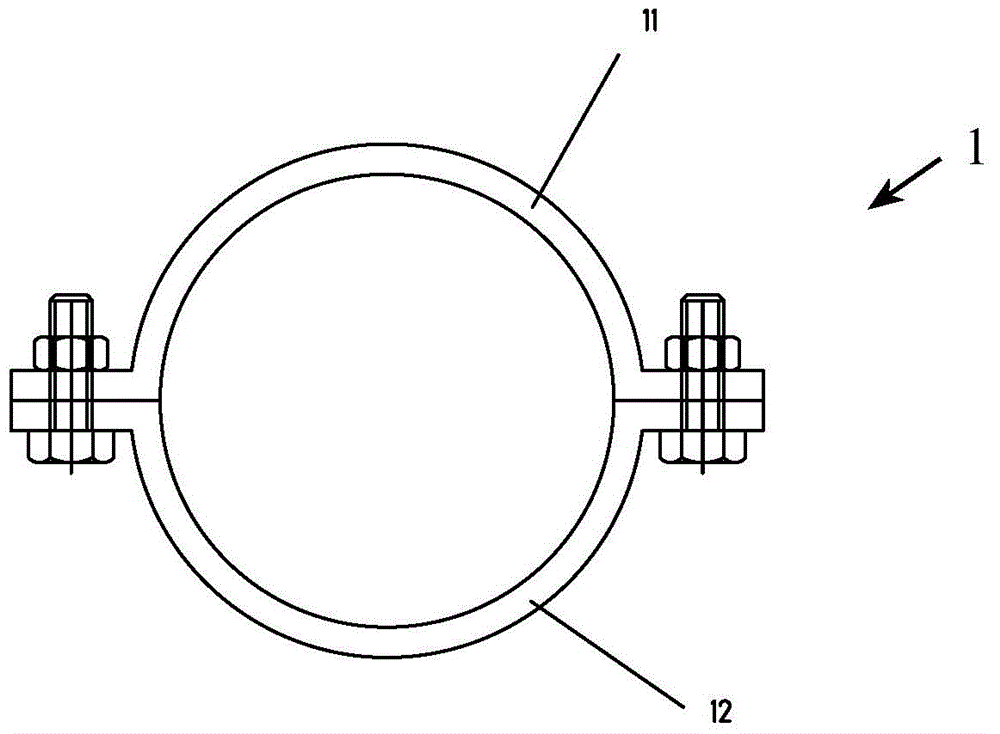

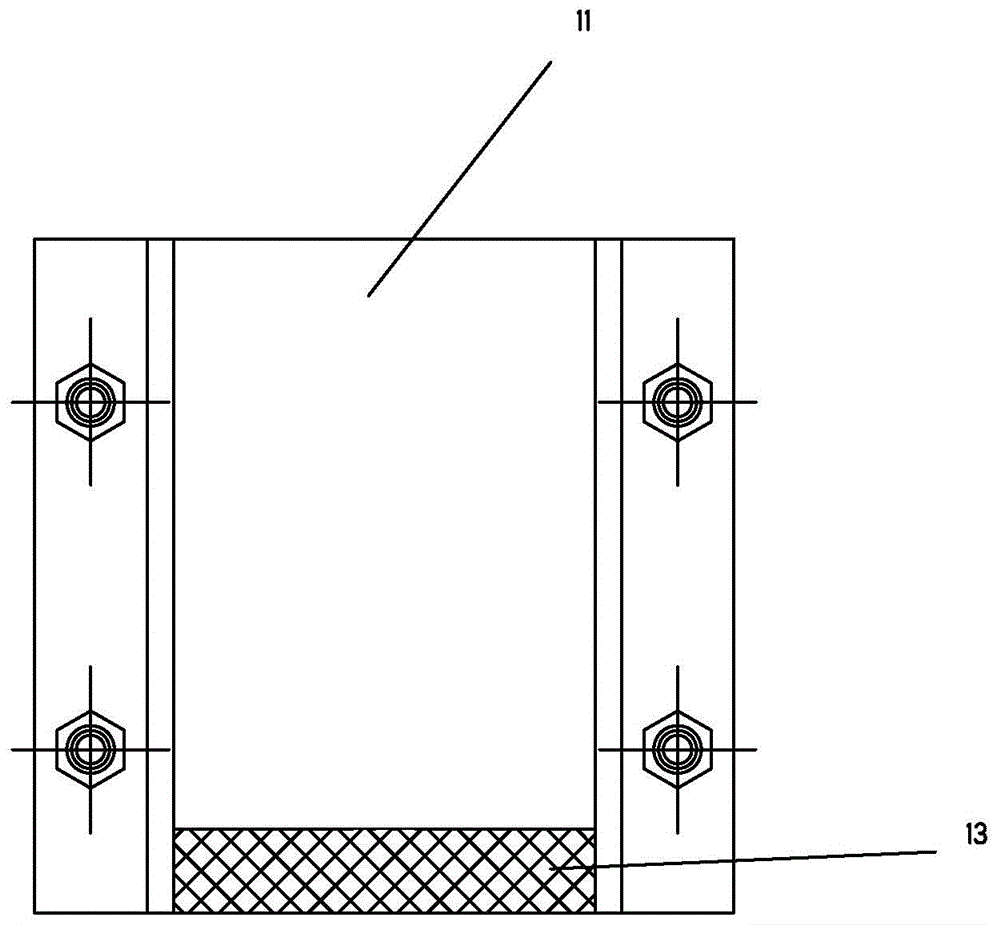

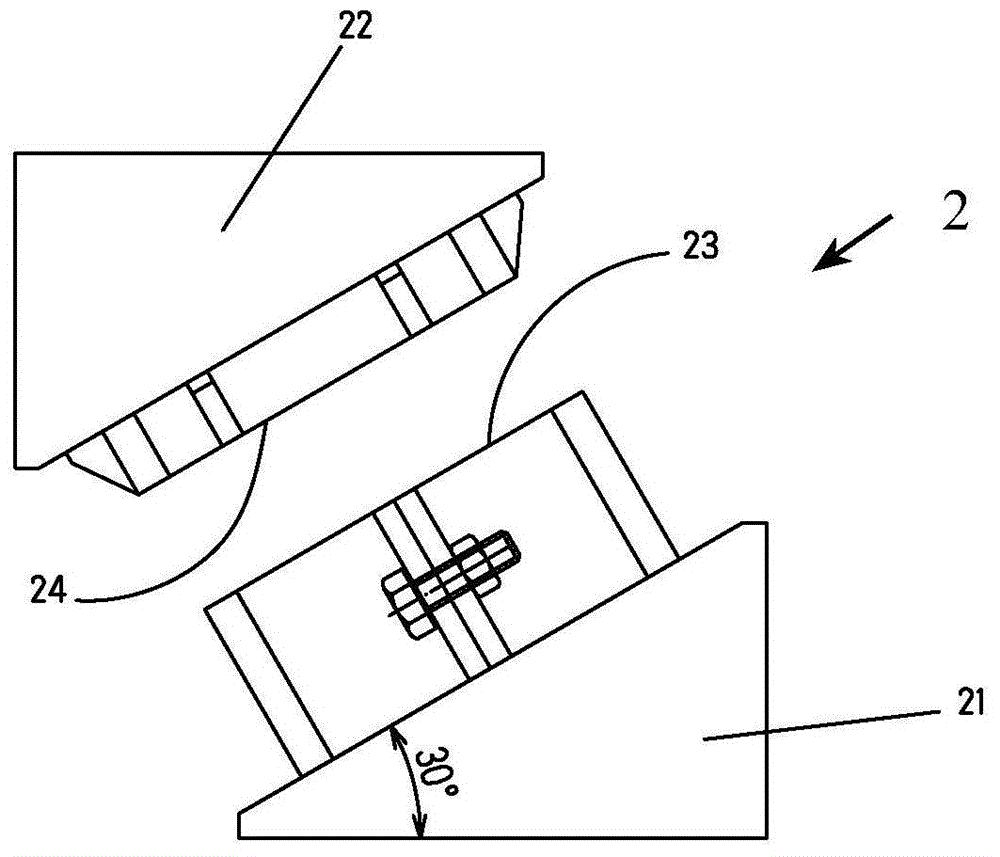

Pavement structure and testing device for bridge deck pavement bonding interface shearing-resistance characteristic

InactiveCN101620054AEffective simulationRational engineering designMaterial strength using steady shearing forcesStress conditionsBridge deck

The invention relates to a pavement structure and a testing device for bridge deck pavement bonding interface shearing-resistance characteristic, which are based on mechanics principle and indoor test, effectively simulate road surface and simulate stress conditions, can realize continuous change with 0-80 degrees of shearing angle, meet needs of different working conditions and are suitable for the design and research of the pavement structure, the indoor test and engineering test. The testing device comprises an upper part and a lower part, each part comprises a bearing board, a rolling shaft, an arc base, a semi-circular clamp, an internal collet and a clamp fixing device. The whole device also comprises an angle dial scale and an angle pointer and other attached parts which are used for indicating the size of the angle. A square testing piece is arranged in the internal collet, the semi-circular clamp and the base can rotate relatively, after the shearing angle is set, the clamp and the base are fixed by the clamp fixing device. The horizontal surface of the other side of the base is contacted with the bearing board in a rolling way by the rolling shaft, so as to lead the device loading to generate vertical displacement and to move horizontally at the same time.

Owner:张磊

Integral stretching technology of double (three)-tank stainless steel water tanks

The invention is a stainless steel double-tanked (three-tanked) water tank stretching technique, including the working procedures such as batching, shearing angle, first stretching, shearing side, washing, annealing, second stretching, cutting side, punching hole, surface processing, etc. The water tank made by the working procedures forms a through structure without welding, reducing production cost and avoiding the problems of water leakage and of affecting fastness, thus heightening the whole quality and service life of the water tank.

Owner:ZHEJIANG FRANTA

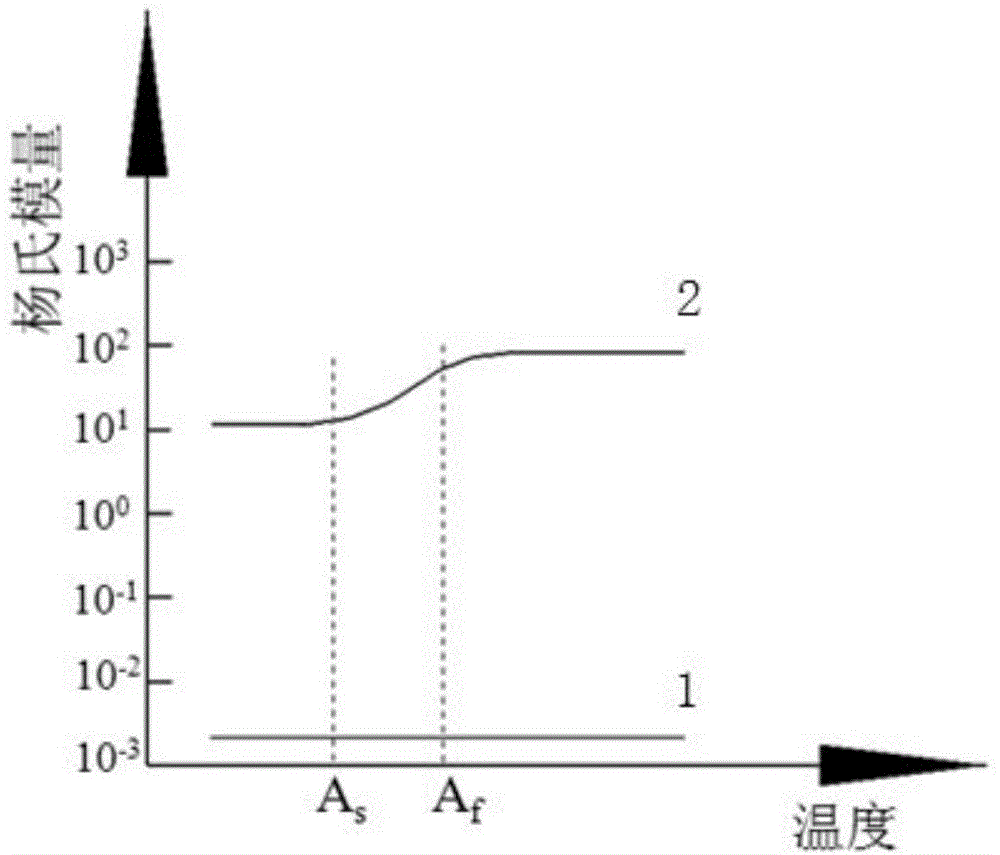

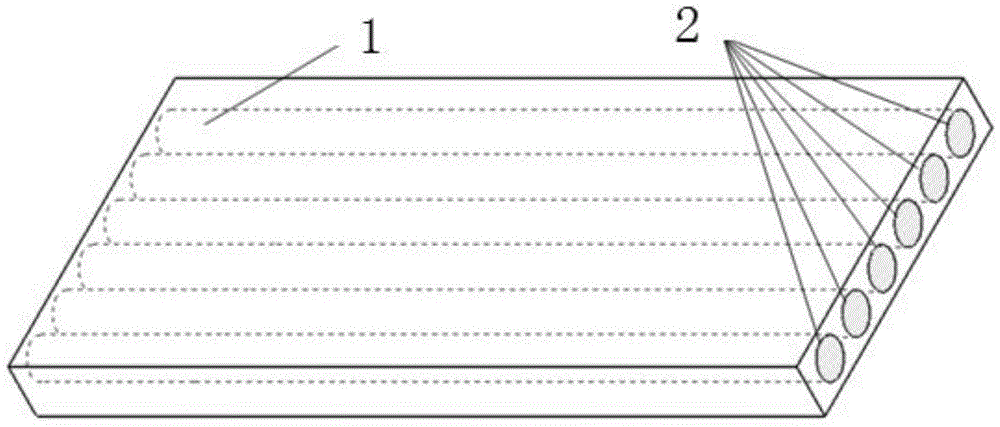

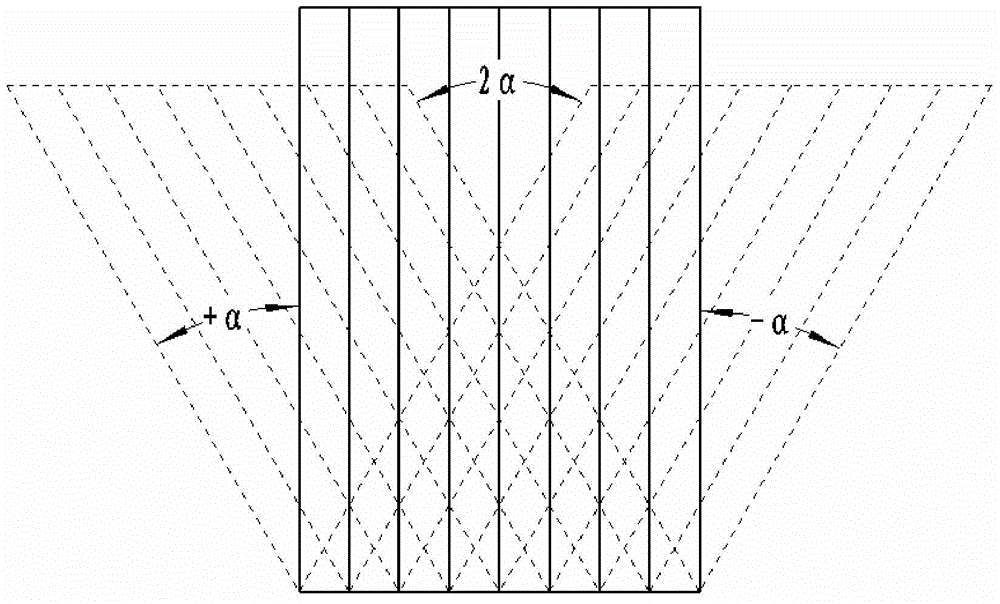

Shape memory alloy fiber and super-elastic body compound deformation skin

InactiveCN104816815AGood in-plane deformation propertiesCompatible with in-plane deformabilityFuselage bulkheadsIn planeAviation

The invention relates to a shape memory alloy fiber and super-elastic body compound deformation skin, belonging to the technical field of aviation, and aiming at solving the problems that the existing deformation skin has a single function and is poor in deformation performance. The shape memory alloy fiber and super-elastic body compound deformation skin comprises a super-elastic body base body and shape memory alloy fibers, wherein the shape memory alloy fibers are arranged in the super-elastic body base body in parallel in a curing way. The multifunctional deformation skin has in-plane deformation capability, out-plane deformation capability and variable rigidity characteristic, is capable of realizing the in-plane deformation with the shearing angle being + / -20 degrees and hardly has large wrinkles; the out-plane deformation can be transformed into a T-shaped curved surface state from a plane state. Furthermore, due to the excitation of heat energy, in the martensite phase and austenite phase transformation process of shape memory alloy, the compound skin system can obtain the variable rigidity characteristic.

Owner:HARBIN INST OF TECH

Hydraulic shearing machine

InactiveCN102000870ASimple structureImprove versatilityShearing machinesReducerPulp and paper industry

The invention relates to a hydraulic shearing machine which comprises a base, wherein a bracket is fixed on the base; the bracket is provided with two isolated mounting plates; a shearing tool is arranged between the two mounting plates; each mounting plate is provided with a cambered sliding hole; the shearing tool is arranged on the sliding holes through an axis pin and can rotate along the sliding holes; the shearing tool is connected with an angle adjuster; the bracket is provided with an elongated height adjustment hole; and the mounting plates are installed on the bracket through the height adjustment hole. The shearing tool is assembled on the mounting plates, the shear angle of the shearing tool can be adjusted by using a hand wheel, and the height of the shearing tool can be adjusted through a turbine worm reducer. The invention has the advantages of simple structure and favorable universality, and can be used for shearing corrugated boards with different arching radians.

Owner:WUXI GUANGCAI MACHINERY MFG

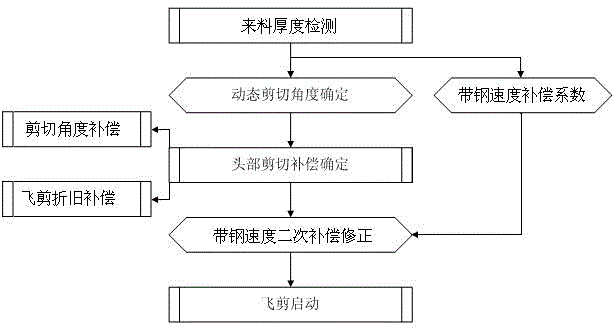

Control method for dynamic shearing displacements of flying shear of hot continuous rolling mill

ActiveCN104950802AAchieve high precision shear controlProgramme controlComputer controlStrip steelControl theory

The invention discloses a control method for the dynamic shearing displacements of a flying shear of a hot continuous rolling mill. The control method comprises the following steps: setting a standard roll speed and initial head shearing lengths, and obtaining the thicknesses of strip steels through measurements; calculating according to the standard roll speed and through an experimental combination with an actual roll speed during actual working to obtain the velocity compensation factors of the strip steels; obtaining a primary shearing compensation quantity; carrying out a secondary amendment on the primary shearing compensation quantity by virtue of the velocity compensation factors of the strip steels, and finally obtaining actual head shearing displacements. According to the control method disclosed by the invention, the shearing displacements are compensated by combining with the changes of the shearing angles of the strip steels with different thicknesses during the shearing of the flying shear and the depreciation condition of the flying shear, and then a compensation result is secondarily amended according to the characteristics of the strip steels during a shearing process and by virtue of the velocity factors, thus realizing high-accuracy shearing control.

Owner:BAOSHAN IRON & STEEL CO LTD

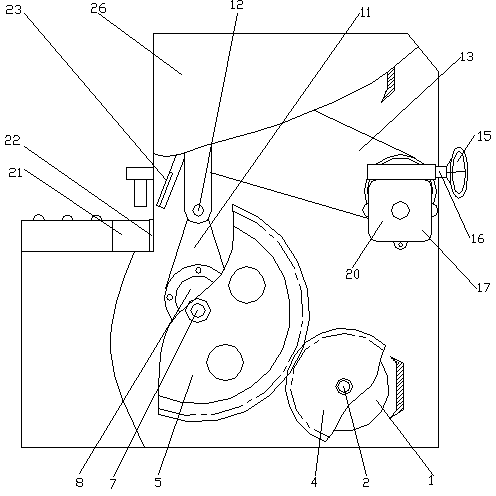

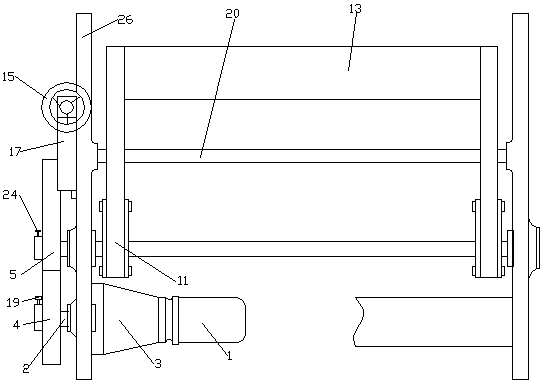

Novel plate shearer based on optimized crank-rocker mechanism

ActiveCN103240456ARealize continuous adjustmentExtended service lifeShearing machinesDrive shaftAgricultural engineering

The invention discloses a novel plate shearer based on an optimized crank-rocker mechanism. The novel plate shearer based on the optimized crank-rocker mechanism comprises a main shaft of the plate shearer, an upper knife rest and a plate shearer wall plate; the novel plate shearer based on the optimized crank-rocker mechanism further comprises an actuating device, a transmission device, and a blade gap adjusting mechanism; and the actuating device comprises a switched reluctance speed regulation motor and a transmission shaft, the switched reluctance speed regulation motor is connected with the transmission shaft, the transmission device is connected with the actuating device, and the blade gap adjusting mechanism is connected with the upper knife rest. The novel plate shearer based on the optimized crank-rocker mechanism can accurately adjust the blade gap, namely, can continuously adjust the shear angle so as to guarantee the accuracy of processing; and meanwhile enables the actuating device of the plate shearer to achieve stepping speed regulation so that the shearing efficiency is improved. Besides, the transmission mode of the novel plate shearer based on the optimized crank-rocker mechanism is stable, the transmission ratio is accurate, the working is reliable, the working efficiency is high, the service life is long, and the applicable ranges of power, speed and size are wide.

Owner:安徽金大进重工机床有限公司

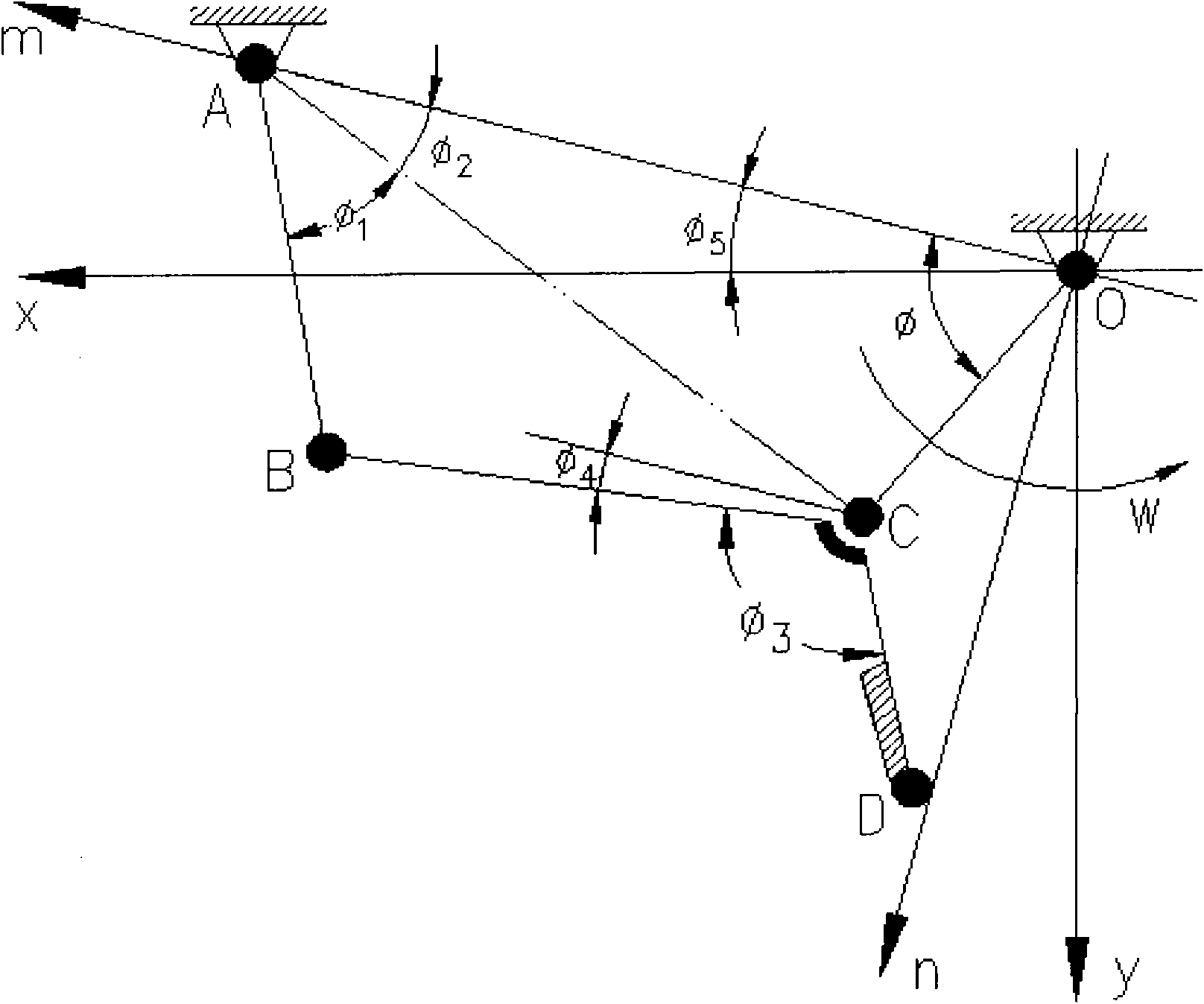

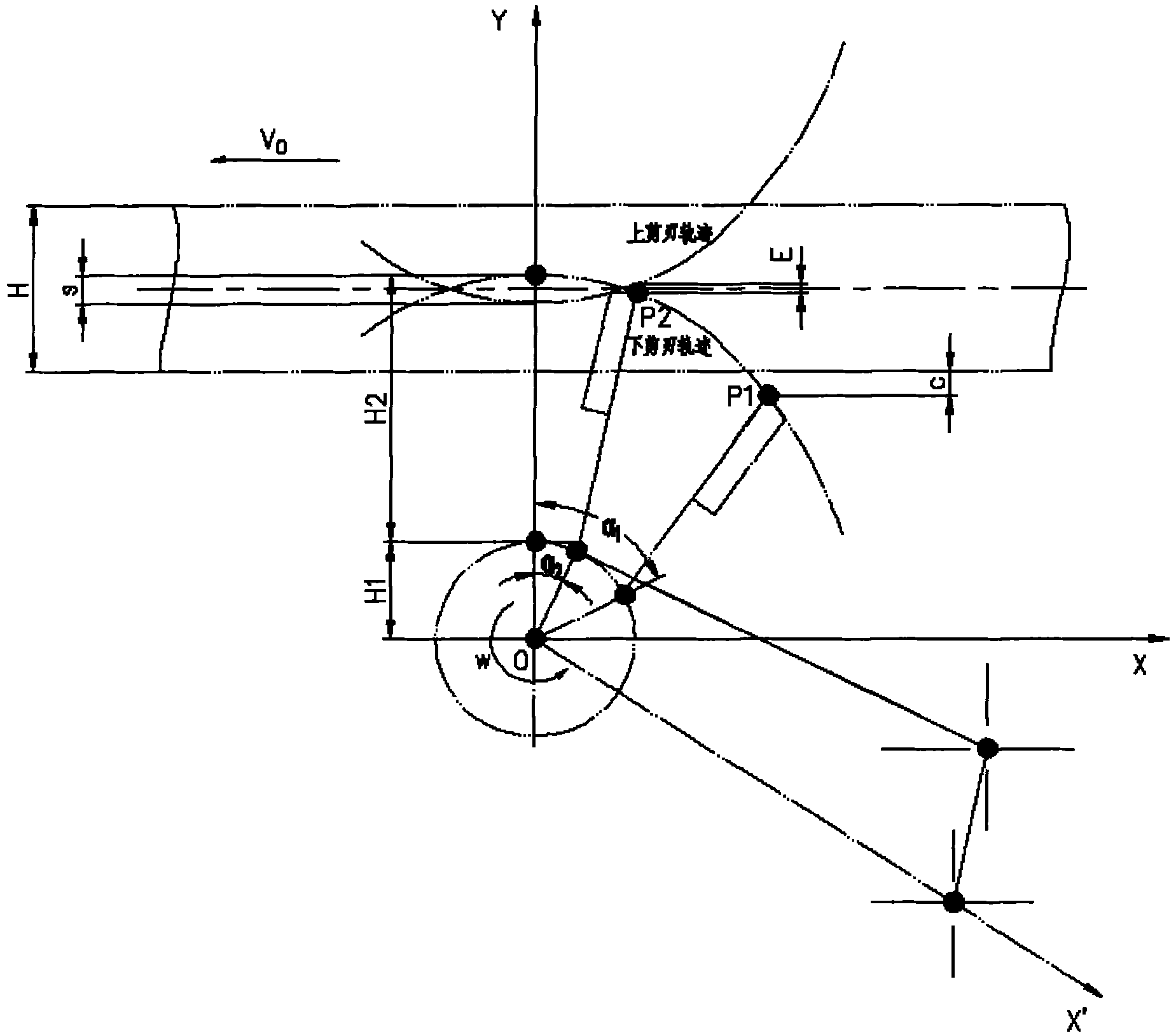

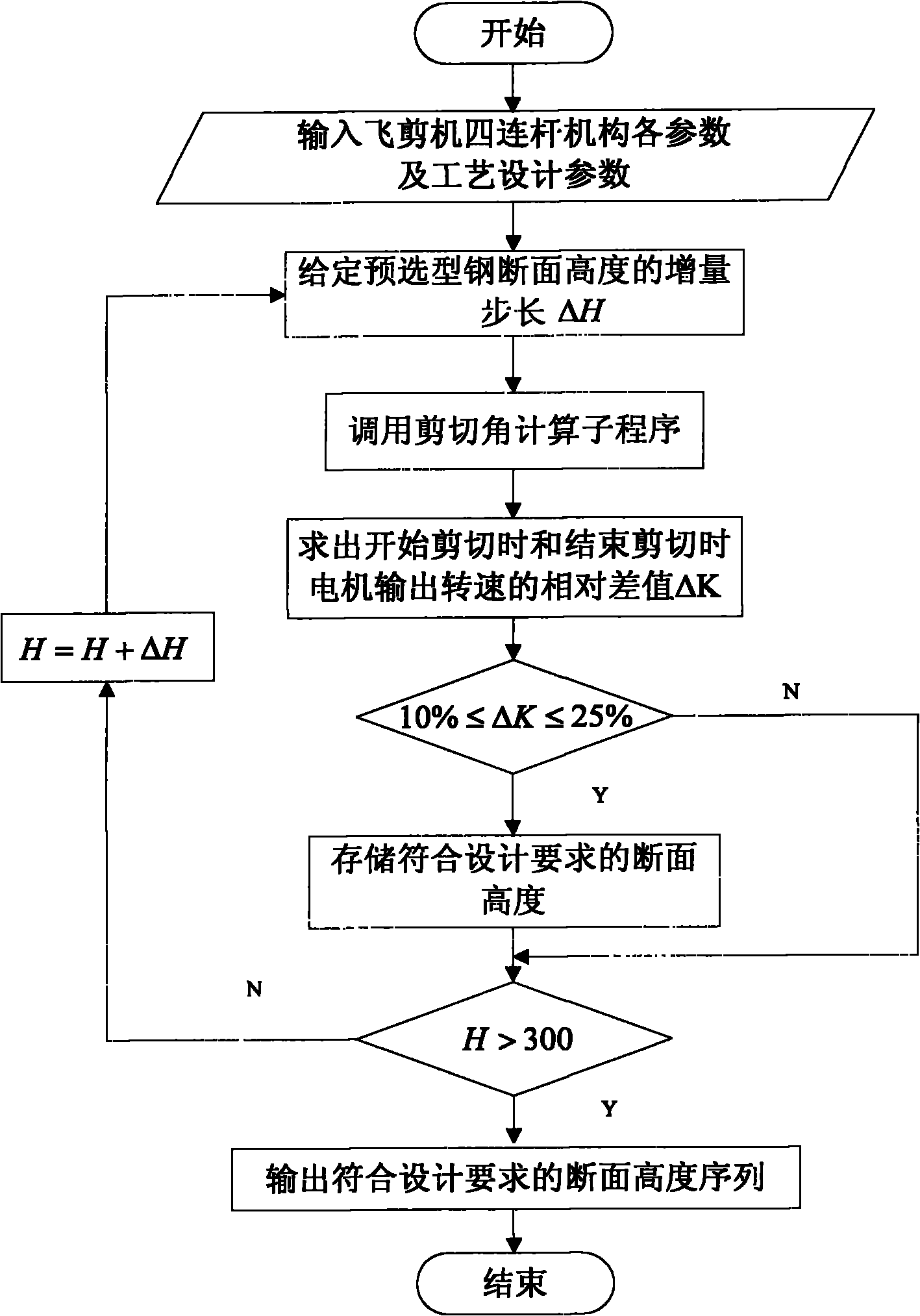

Method for designing section height sequence of structural steel sheared by hot rolling flying shears

InactiveCN102063531ATruly reflect the principles of the designUnderstand job characteristicsAerodynamics improvementSpecial data processing applicationsEngineeringDesign values

The invention relates to the technical field of metallurgical hot rolling process, and particularly discloses a method for designing a section height sequence of structural steel sheared by hot rolling flying shears, which comprises the following steps of: calculating a space trace curve of shearing blades; calculating theoretical coordinate values of the shearing blades; calculating a shear angle; performing translation on the output rotating speed of a motor, and the like; and finally determining judgment criterion for the selection of the motor and the rotating speed in systematic checking calculation to be that a relative difference between the output rotating speeds of the motor before and after the shearing may be not more than 25 percent and not less than 10 percent, determining that the designed section heights of the structural steel meet design requirements after the motor and the rotating speed reach the judgment criterion in a given section height designing range of the structural steel, and sequentially recording the designing values to obtain the section height sequence of the structural steel sheared by the hot rolling flying shears. The method can be used as an advantageous supplementary design for the design of a crank-link mechanism of the flying shears, and has the advantages of high universality, adaptability, high speed, high calculation accuracy and the like.

Owner:WISDRI ENG & RES INC LTD

Rotatable cutting tool

InactiveUS20050127220A1Multi-purpose machinesProfiling/shaping machinesMechanical engineeringShear angle

There is provided a rotatable cutting tool for supporting at least one knife in at least two alternate angular cutting configurations. The cutting tool includes a body that defines at least one cavity extending generally in a longitudinal direction of the body. Each cavity is configured to support one of the knives at predetermined hook and shear angles, and each cavity can be configured to provide a different hook and / or shear angle.

Owner:MOLDER SERVICES

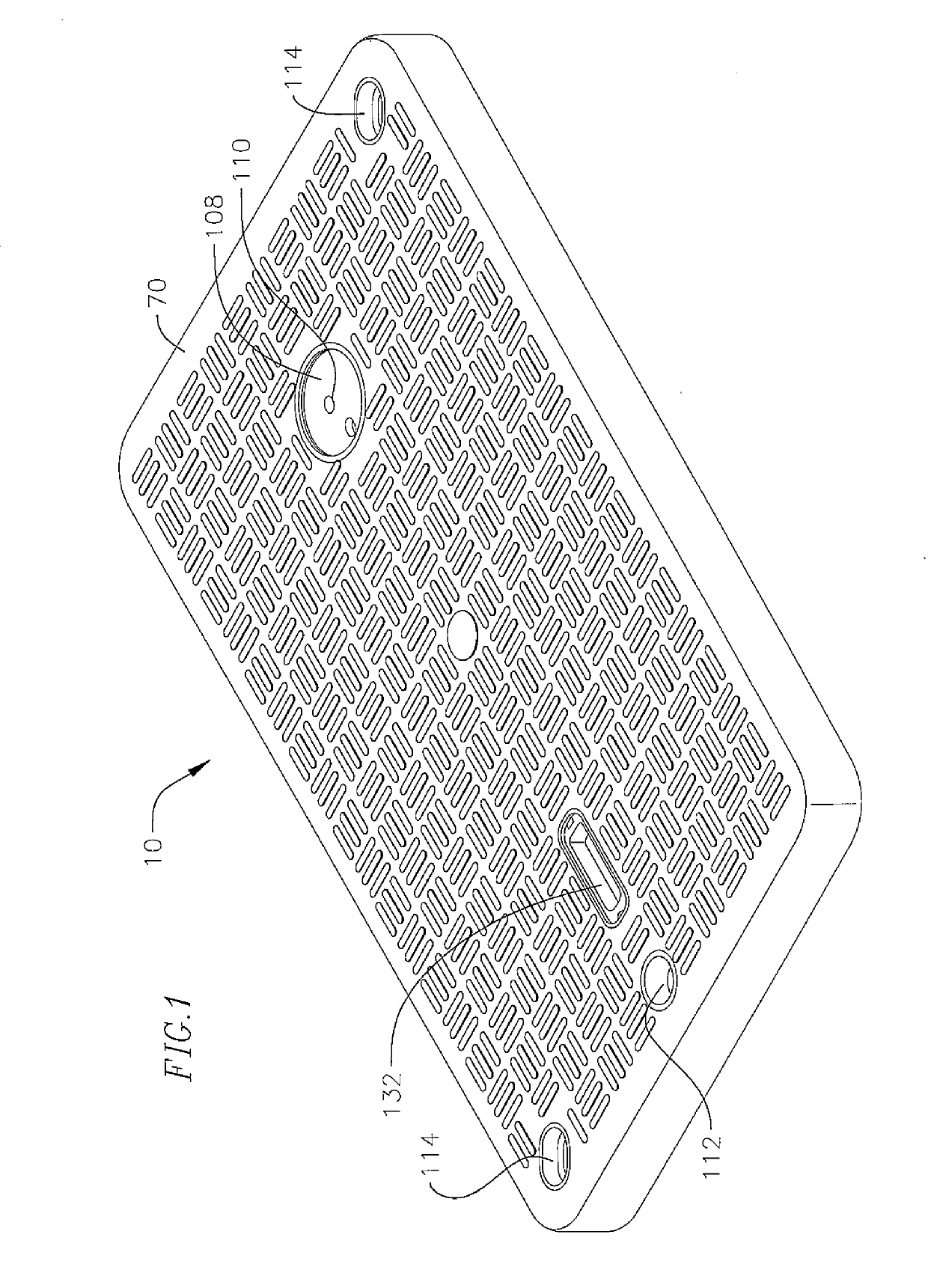

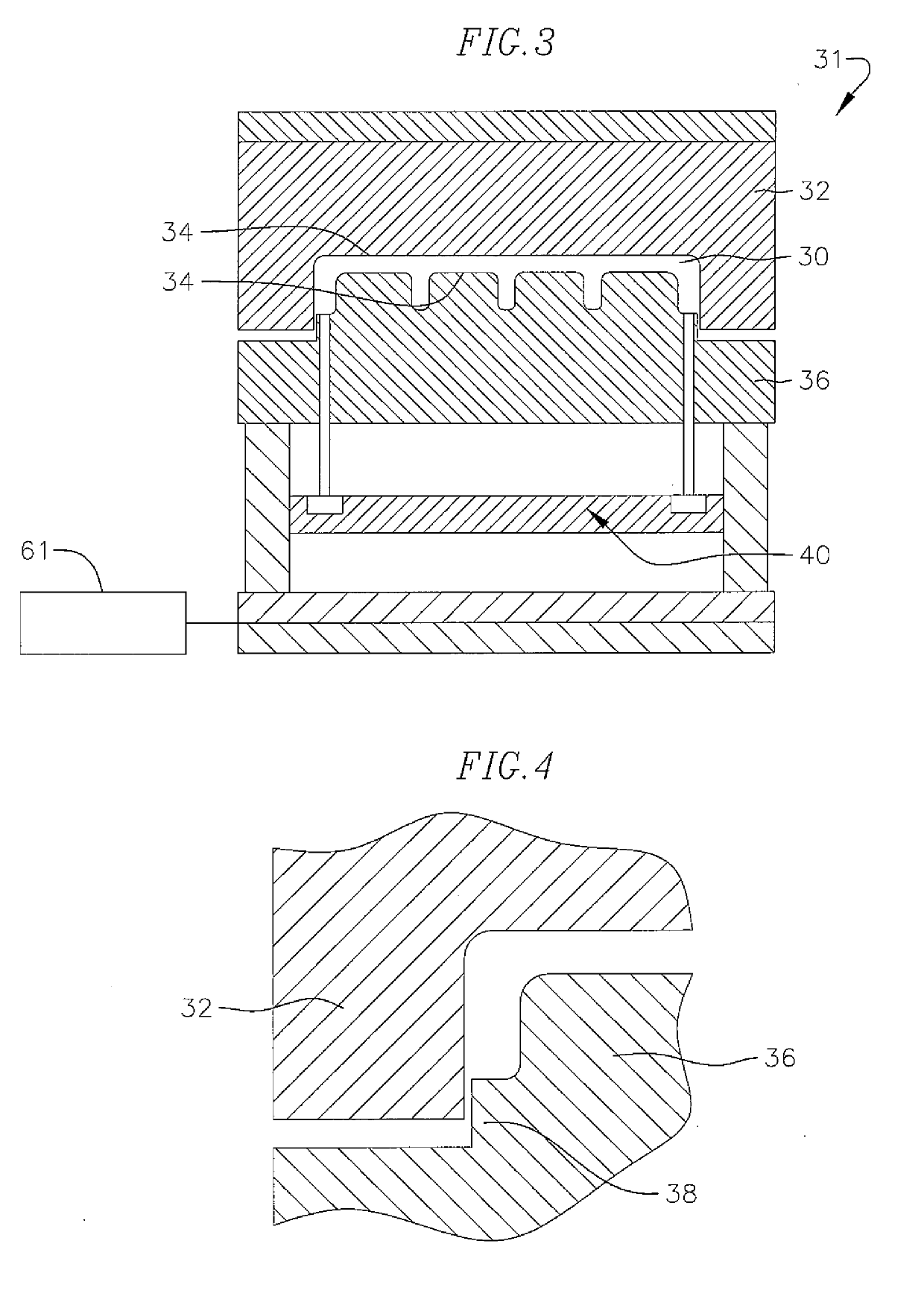

Method of manufacturing a thermoset polymer utility vault lid

ActiveUS20190176375A1Reduce weightHigh strengthArtificial islandsLamination ancillary operationsPolyesterFiber-reinforced composite

A method of manufacturing a fiber reinforced composite material lid for an utility vault including mixing an unsaturated polyester thermosetting matrix in to a resin paste, compounding the resin paste into a fiber reinforced composite material, maturing the compounded fiber reinforced composite material, cutting the matured compound into a charge pattern, molding the charge pattern in a mold cavity of a heated mold under low pressure to form the lid and cooling and machining the lid. The mold includes a cavity die and a core die having a shear angle for interfacing the core die within the cavity die and a steam pot for heating the cavity die and the core die, wherein the lid is molded between the cavity die and the core die and removed from the mold by a lid ejection mechanism.

Owner:CHANNELL COMML CORP +1

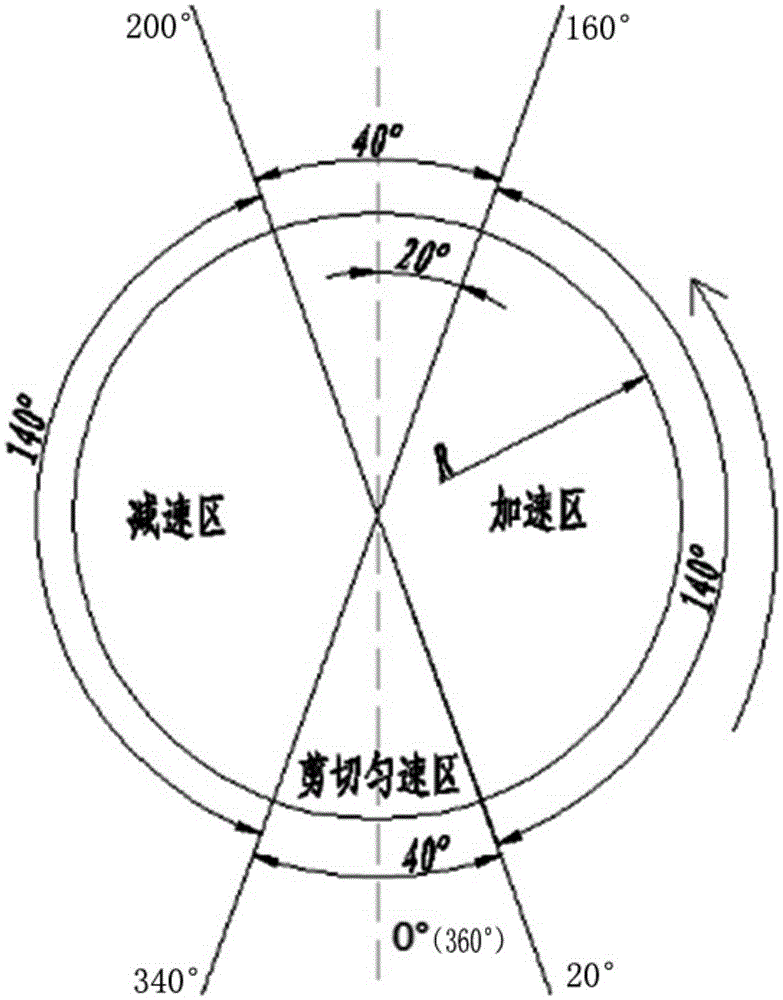

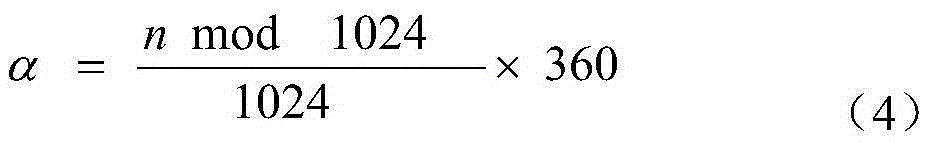

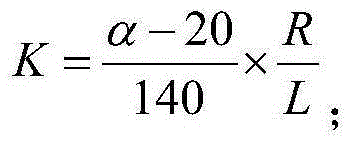

Flying shear control method

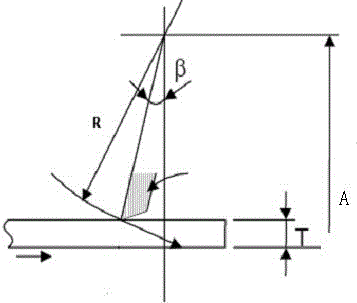

ActiveCN105382331AImprove cutting accuracyImproved shear control stabilityShearing control devicesEngineeringGreek letter alpha

The invention relates to a flying shear control method. When shearing is conducted continuously, the overall speed of rolling meets the equation that V=Vb+VC, wherein Vb=Vm*(1+Vm%), and Vc=Vm*K; the shear blade angle is alpha, when a shear blade is at the lowest point, the alpha is 0 degree, the addition speed coefficient K and the alpha meet equations that when alpha is greater than 340 degrees and smaller than or equal to 360 degrees, and alpha is greater than 0 degree and smaller than or equal to 20 degrees, K is equal to 0; when alpha is greater than 20 degrees and smaller than or equal to 160 degrees: K= , when alpha is greater than 160 degrees and smaller than or equal to 200 degrees: K= , when alpha is greater than 200 degrees and smaller than or equal to 340 degrees: K= , wherein R is the diameter of a roller, and L is the shearing length. The flying shear control method has the advantages that the shearing precision of band steel is improved, the shearing angle and torque are calculated precisely, accordingly, the shearing precision can be controlled, model calculating is completed, and the stability of shearing control is improved. The shearing angle is divided according to intervals, so that the addition speed coefficient K is evaluated precisely, and accordingly the shearing precision is improved.

Owner:DALIAN HUAYELIAN AUTOMATION

Sheet metal part stamping and welding technology

ActiveCN109648267ASolve the quality problem of excessive cracksAvoid wrinkling and even cracking problemsEngineeringMachining

The invention relates to the technical field of machining of sheet metal parts, in particular to a sheet metal part stamping and welding technology. The technology comprises the steps of drawing forming, shaping treatment, design of a shear angle and a V-shaped notch, secondary drawing of a convex hull, bending and burr pressing, side push flattening and welding. Compared with the prior art, the side stamping work procedure performed after bending is omitted, the entire stamping work procedure is greatly simplified, the production efficiency is improved, the problems that bent corners are likely to be wrinkled and cracked and cracks of joints of the four corners of a formed product are too large are solved, the product appearance quality is ensured, and the product has the quite good market competitiveness.

Owner:DONGGUAN HAOSHUN PRECISION TECH CO LTD

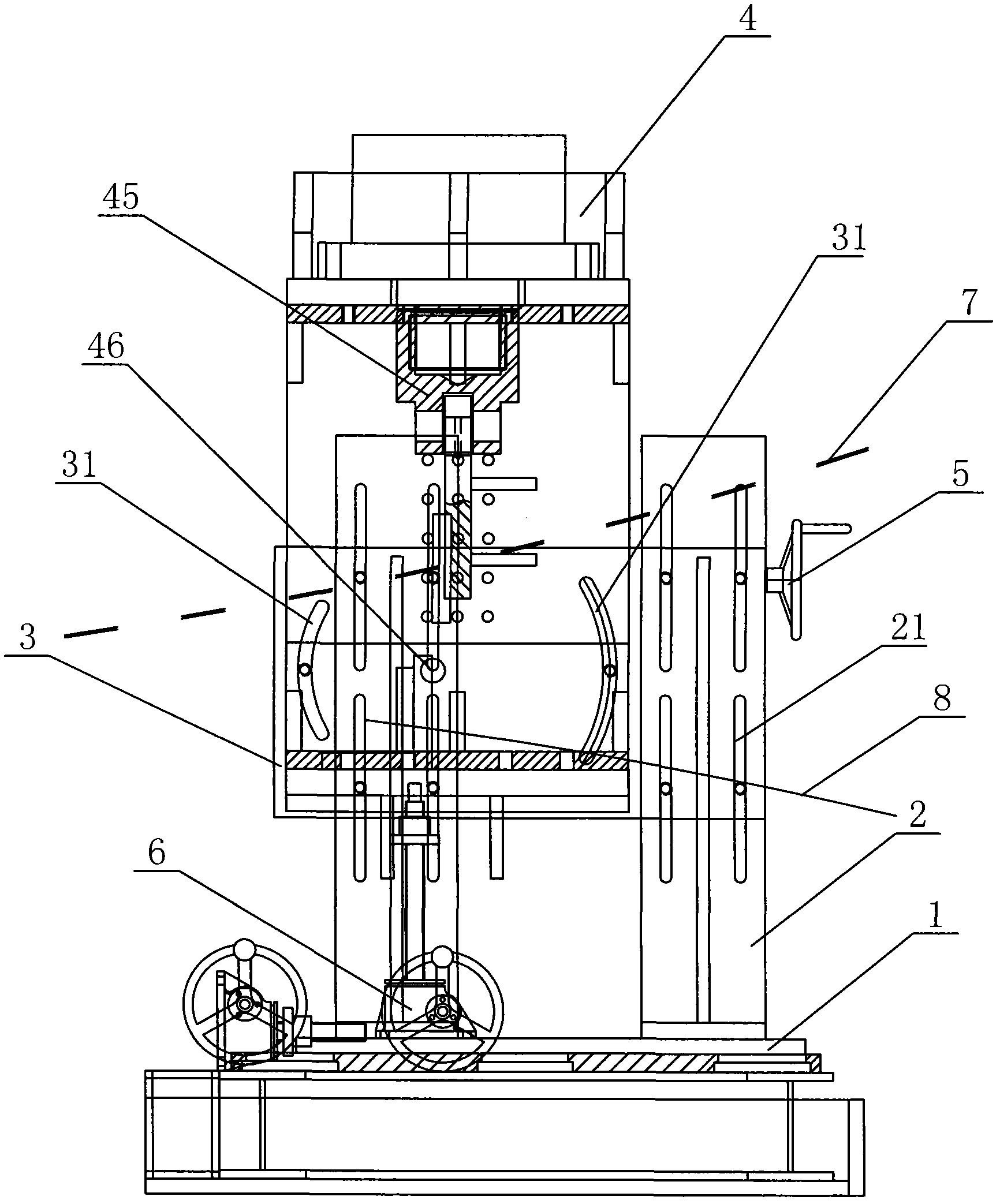

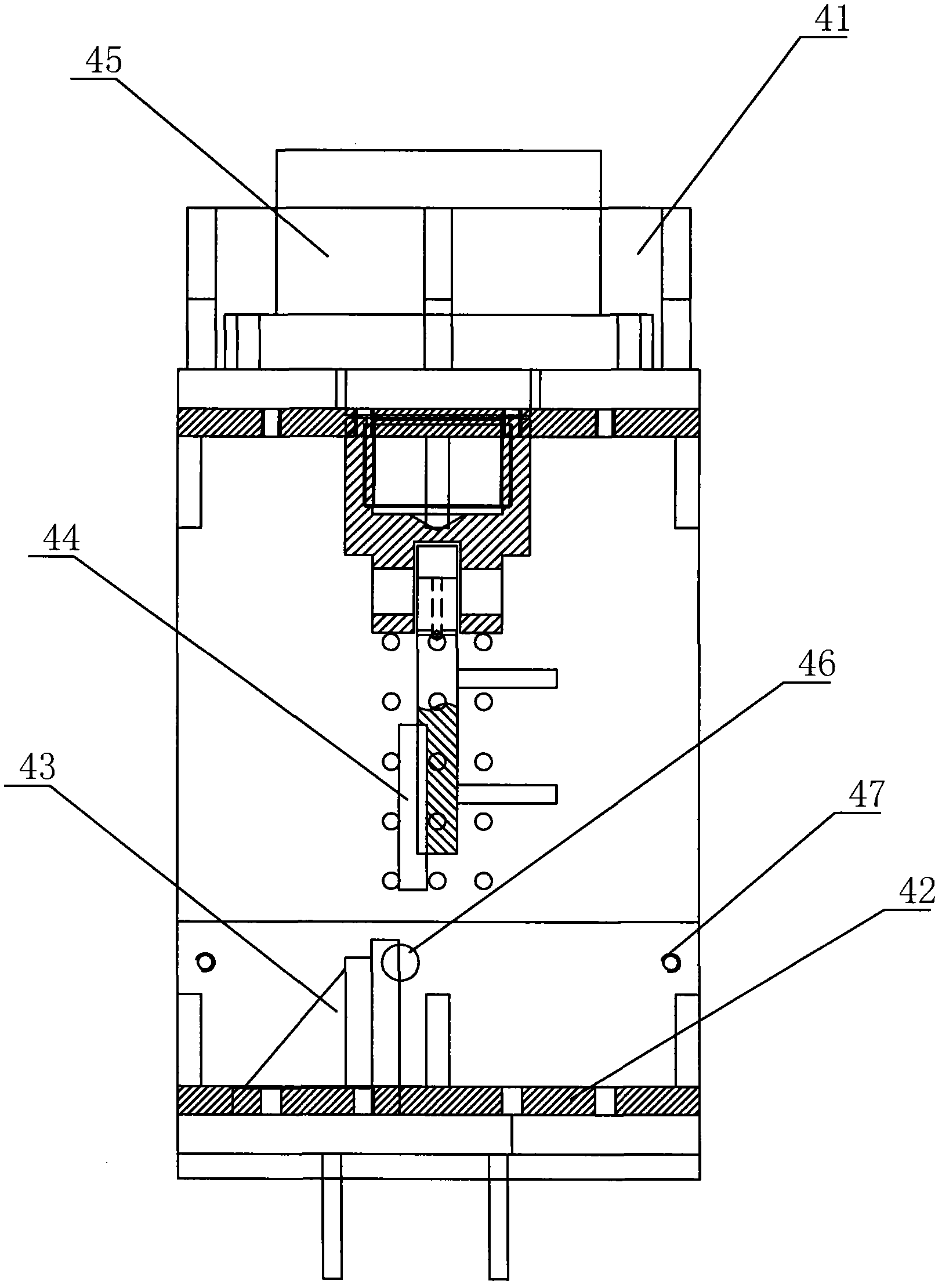

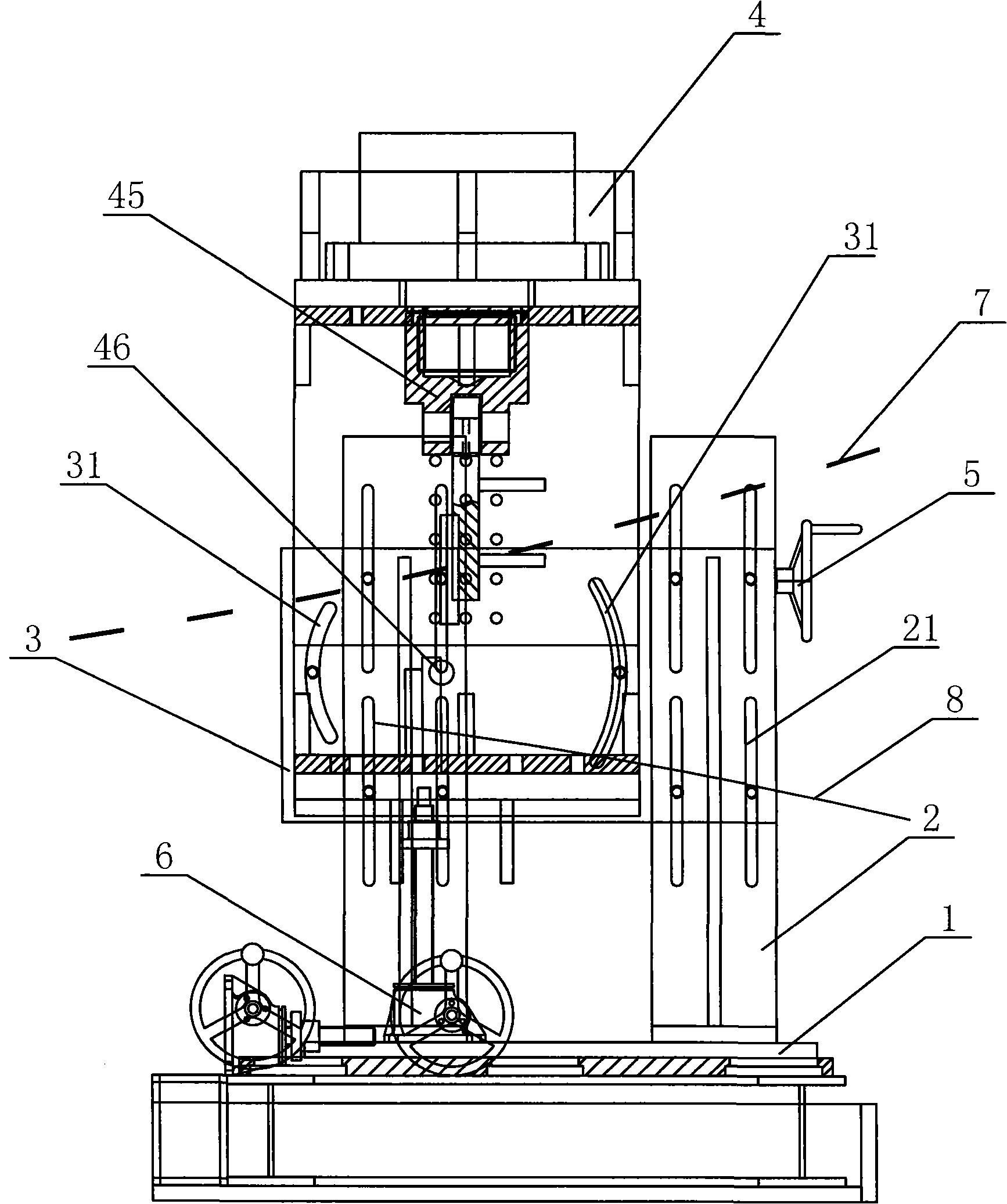

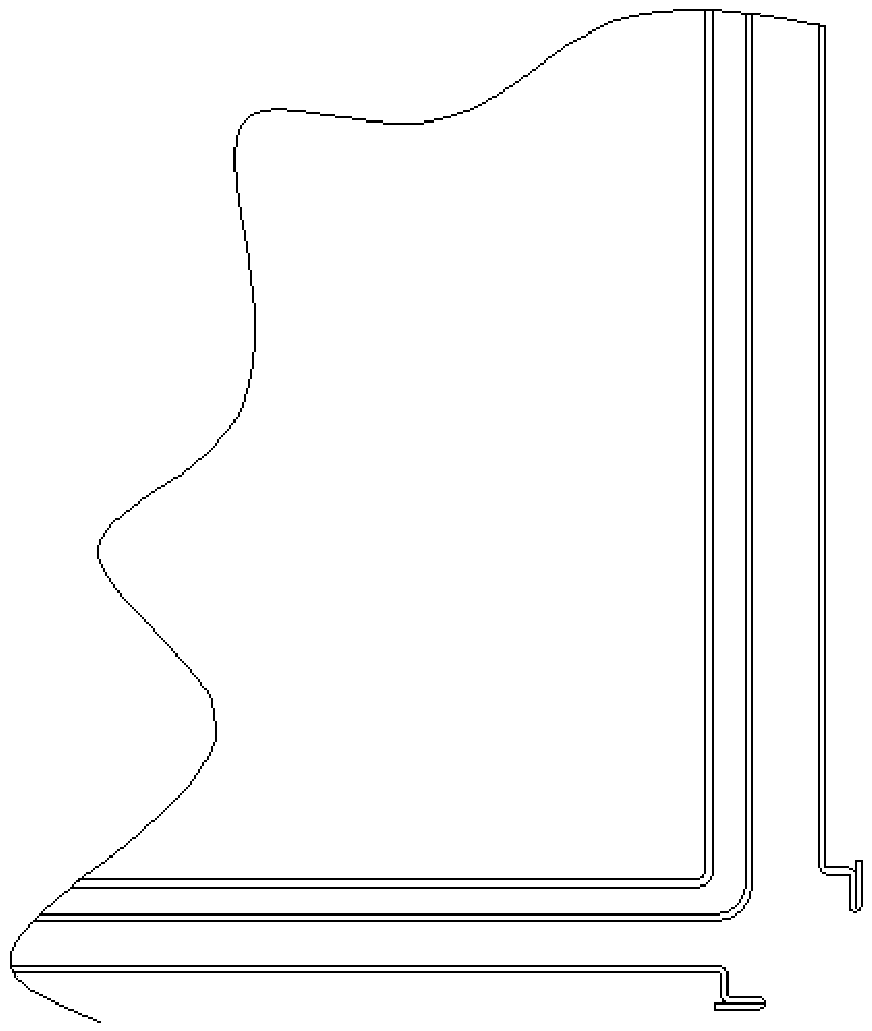

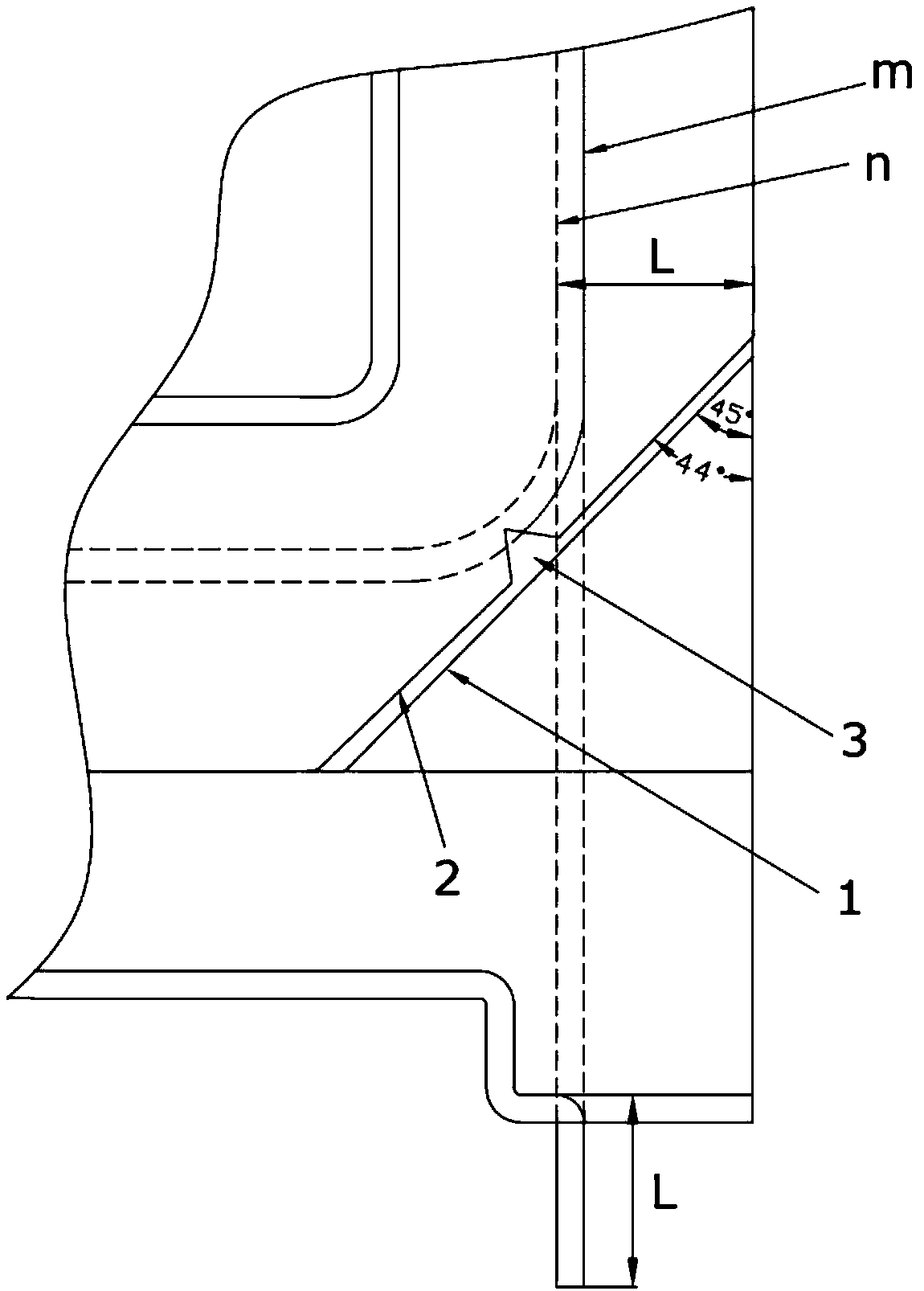

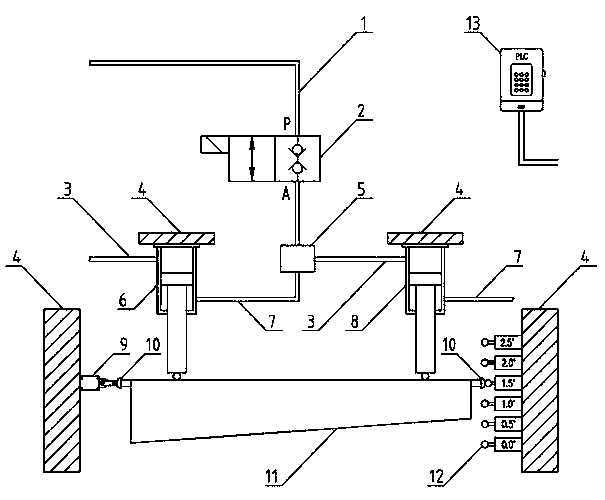

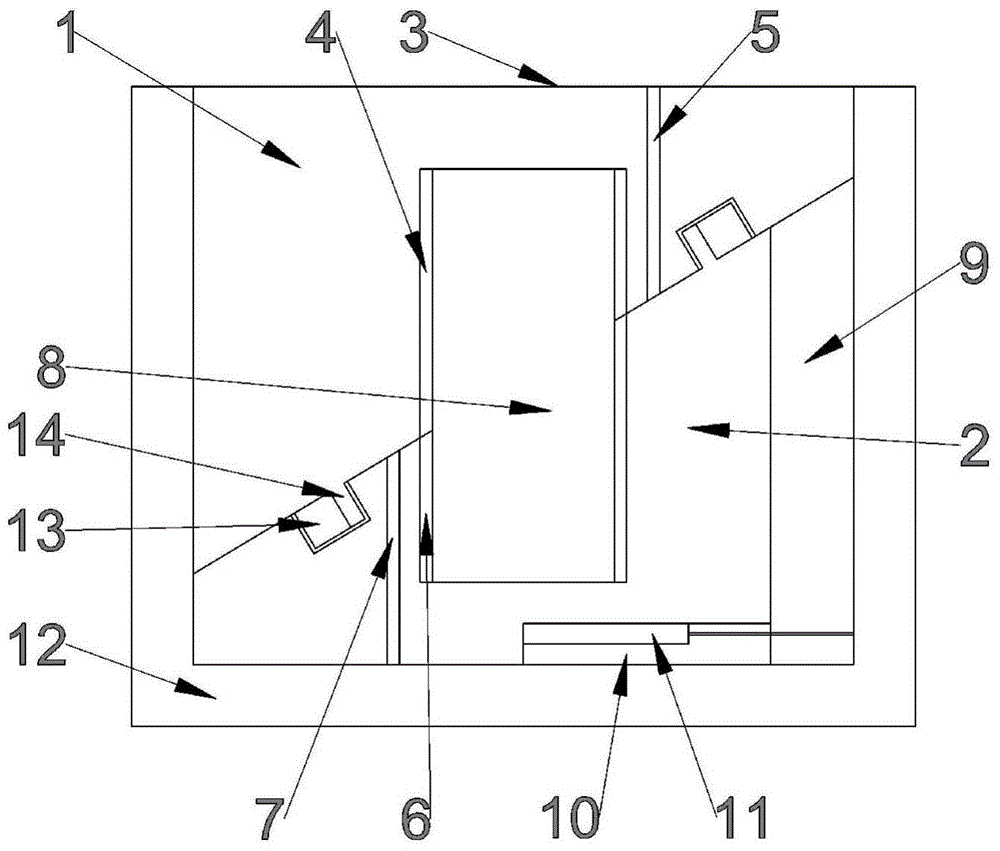

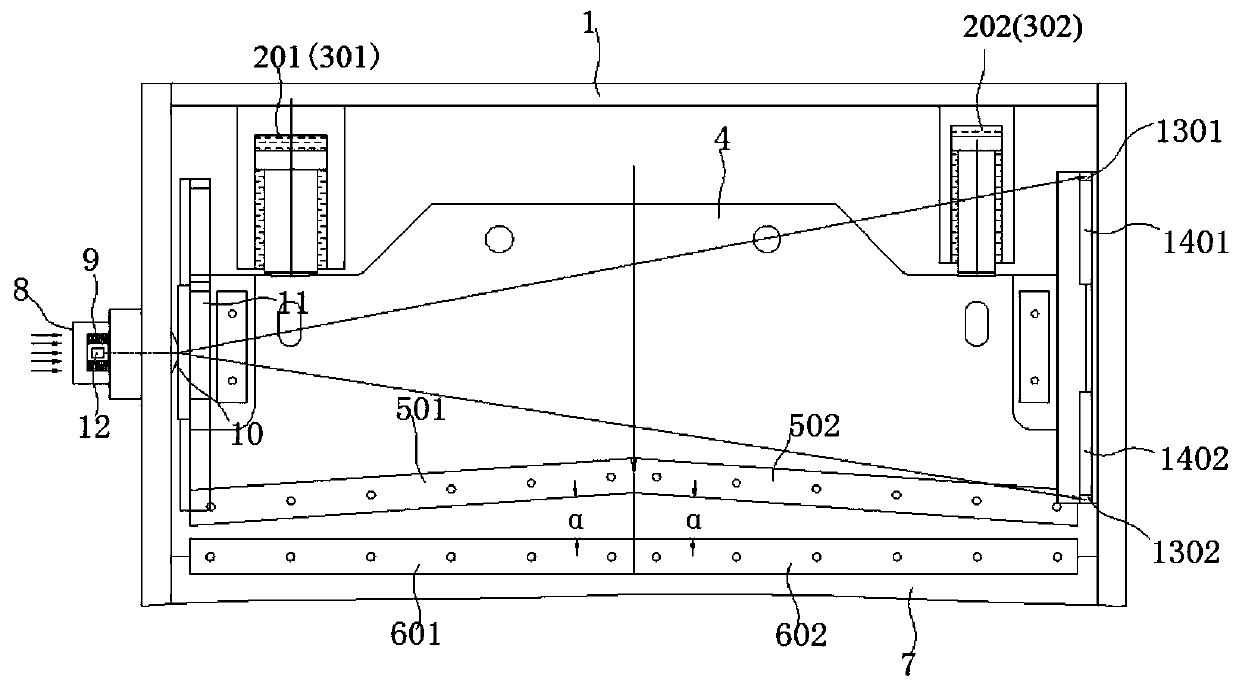

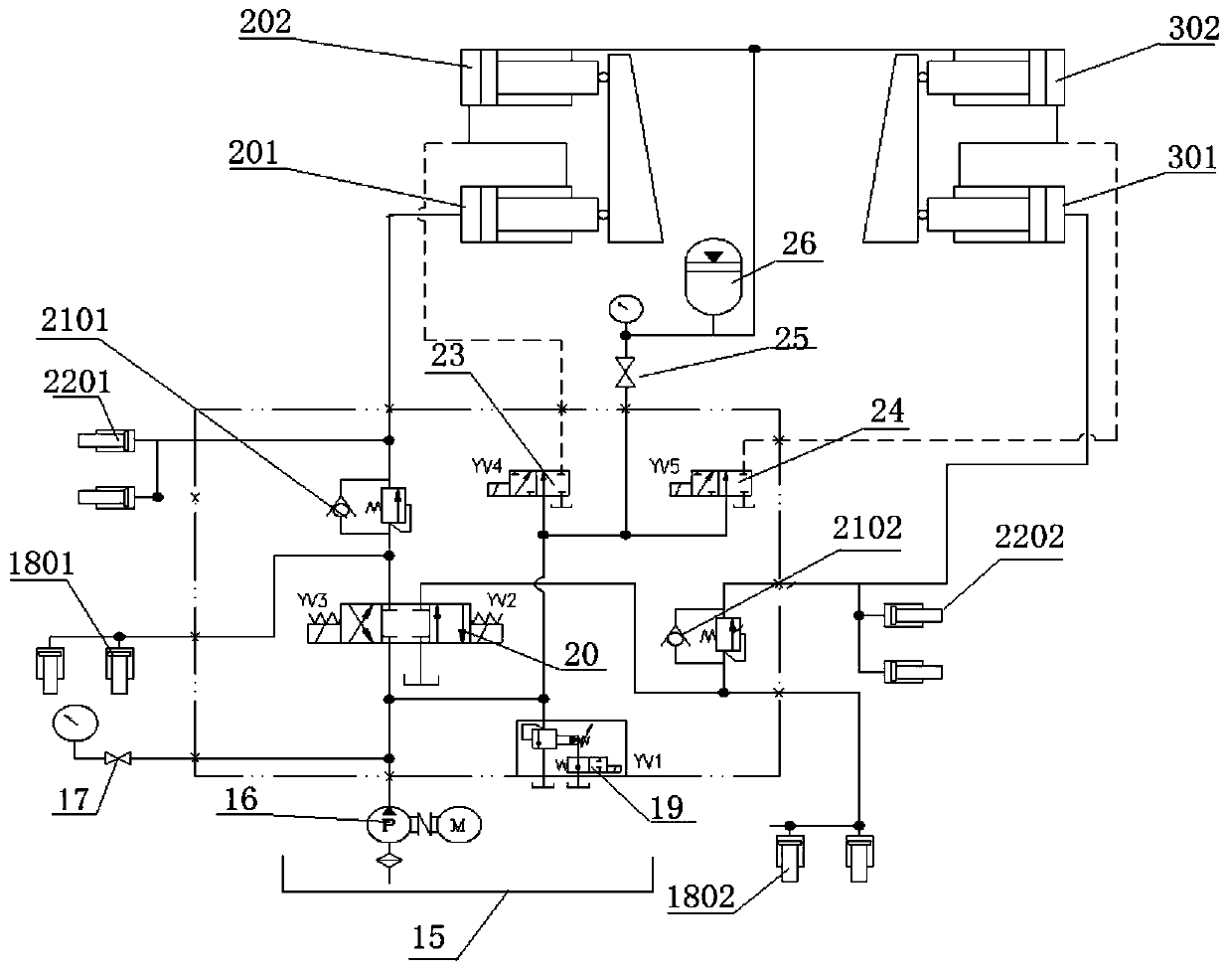

Automatic detection hydraulic adjusting device of shear angle of plate shearing machine

InactiveCN103658808AAccurate realizationRealize regulationShearing machinesShearing control devicesMagnetic valvePetroleum engineering

The invention relates to an improvement of an adjusting device of the switch blade shear angle of a hydraulic plate shearing machine, and discloses an automatic detection hydraulic adjusting device of the shear angle of a plate shearing machine. The automatic detection hydraulic adjusting device is provided with a machine frame, a left oil cylinder, a right oil cylinder, a tool rest and a controller. The left oil cylinder is communicated with an upper cavity oil pipe and the right oil cylinder is communicated with a lower cavity oil pipe. The automatic detection hydraulic adjusting device is characterized in that both the lower cavity oil pipe communicated with the left oil cylinder and the upper cavity oil pipe communicated with the right oil cylinder are communicated with an electro-magnetic valve through a three-way valve, and the input end of the electro-magnetic valve is communicated with an oil conveying adjusting pipe; a travel switch is installed at the position, located on the left side of the tool rest, of the machine frame, a trigger wheel is arranged on the travel switch, a detection switch group is installed at the position, located on the right side of the tool rest, of the machine frame and a plurality of trigger wheels are arranged on the detection switch group. The automatic detection hydraulic adjusting device solves the problem that the shear angle is prone to being changed and plate shearing quality is poor due to the fact that in the existing adjusting device of the shear angle of the hydraulic plate shearing machine, leakage occurs in a hydraulic oil system, and mainly serves as the improvement of the existing adjusting device of the shear angle of the plate shearing machine.

Owner:HUANGSHI HUAXIN MACHINERY EQUIP

Rock seepage-stress coupling shear rheological test box

The invention discloses a rock seepage-stress coupling shear rheological test box. The rock seepage-stress coupling shear rheological test box comprises an upper test box body and a lower test box body, wherein a slope serves as a contact face. The upper test box body and the lower test box body are arranged in a sealed sleeve, and a rock sample penetrates through the contact face to be fixedly clamped in a hollow cylindrical barrel formed between the upper test box body and the lower test box body; the upper test box body and the lower test box body are each provided with a water seepage hole led to the contact face from the upper surface and the lower surface, and a strainmeter is installed at the bottom of the lower test box body. Axial pressure is applied to the upper test box body and transmitted to the lower test box body, the contact face, namely, the slope serves as a shear face, the water seepage holes can apply seepage pressure to the shear face to achieve the seepage-stress coupling effect, the seepage-stress coupling shear flow variable is converted by measuring horizontal deformation of the lower test box body and the shear angle of the contact face, and reference value is achieved for quantitatively researching the shear rheological property of rock under the seepage-stress coupling condition.

Owner:HOHAI UNIV

Gate type plate shearing machine

ActiveCN104551208AMeet shear requirementsGuaranteed not to tiltServomotorsShearing machine accessoriesBall bearingEngineering

The invention relates to a gate type plate shearing machine. The gate type plate shearing machine comprises a lathe bed, a material supporting mechanism and a shearing mechanism, wherein the left end of a tool post is connected with the lower end of a piston rod of a left oil cylinder, the right end of the tool post is connected with the lower end of a piston rod of a right oil cylinder, cylinder blocks of the left oil cylinder and the right oil cylinder are respectively fixed on the lathe bed, the lower ends of the piston rods of the left oil cylinder and the right oil cylinder are respectively screwed with connection rods through threads, a connection rod hole is formed in the lower end of each connection rod, the axis of each connection rod hole is vertical to the axis of each piston rod and vertical to a plane where the tool post is located, a ball bearing is installed in each connection rod hole, sliding shafts are respectively installed in inner holes of the ball bearings, the sliding shafts, the ball bearings and the lower ends of the connection rods are all located in installation holes of the tool post, two ends of each sliding shaft are respectively supported in two sliding holes of a sliding shaft seat, flange covers respectively stretched out towards the periphery are arranged on the outer end faces of the sliding shaft seats, and the flange covers are respectively connected onto the tool post. The gate type plate shearing machine can achieve adjustments of intervals of tool edges and shearing angles of the tool post, and transmits torque of the oil cylinders.

Owner:江苏扬力液压装备有限公司

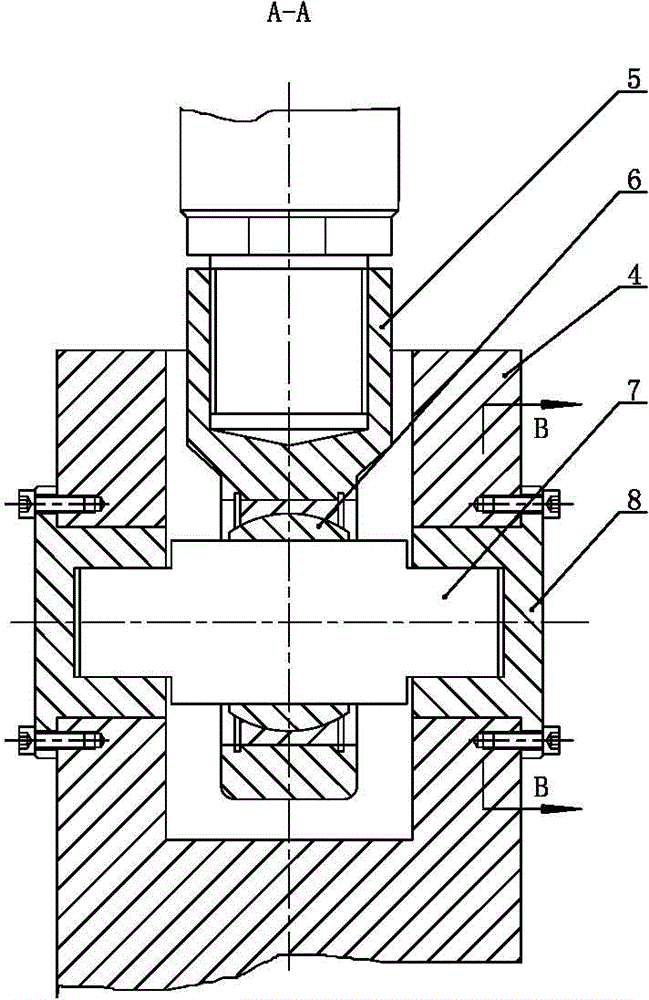

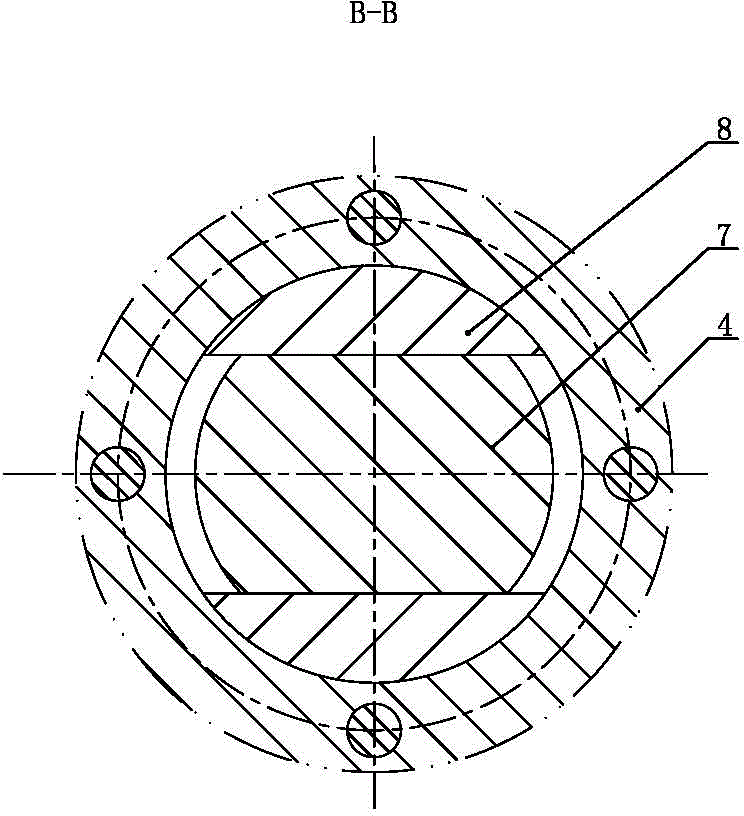

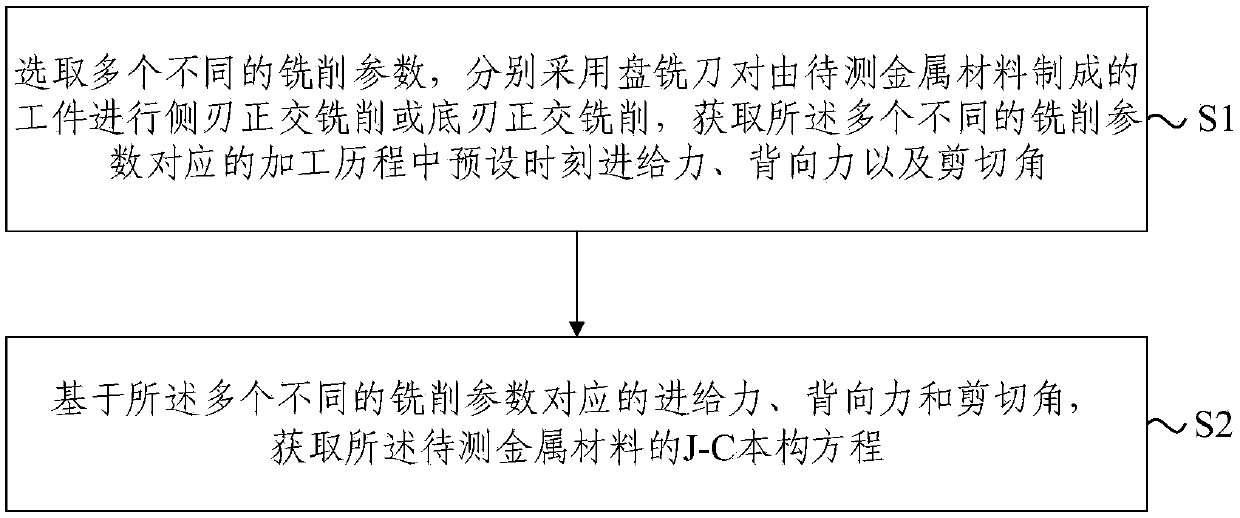

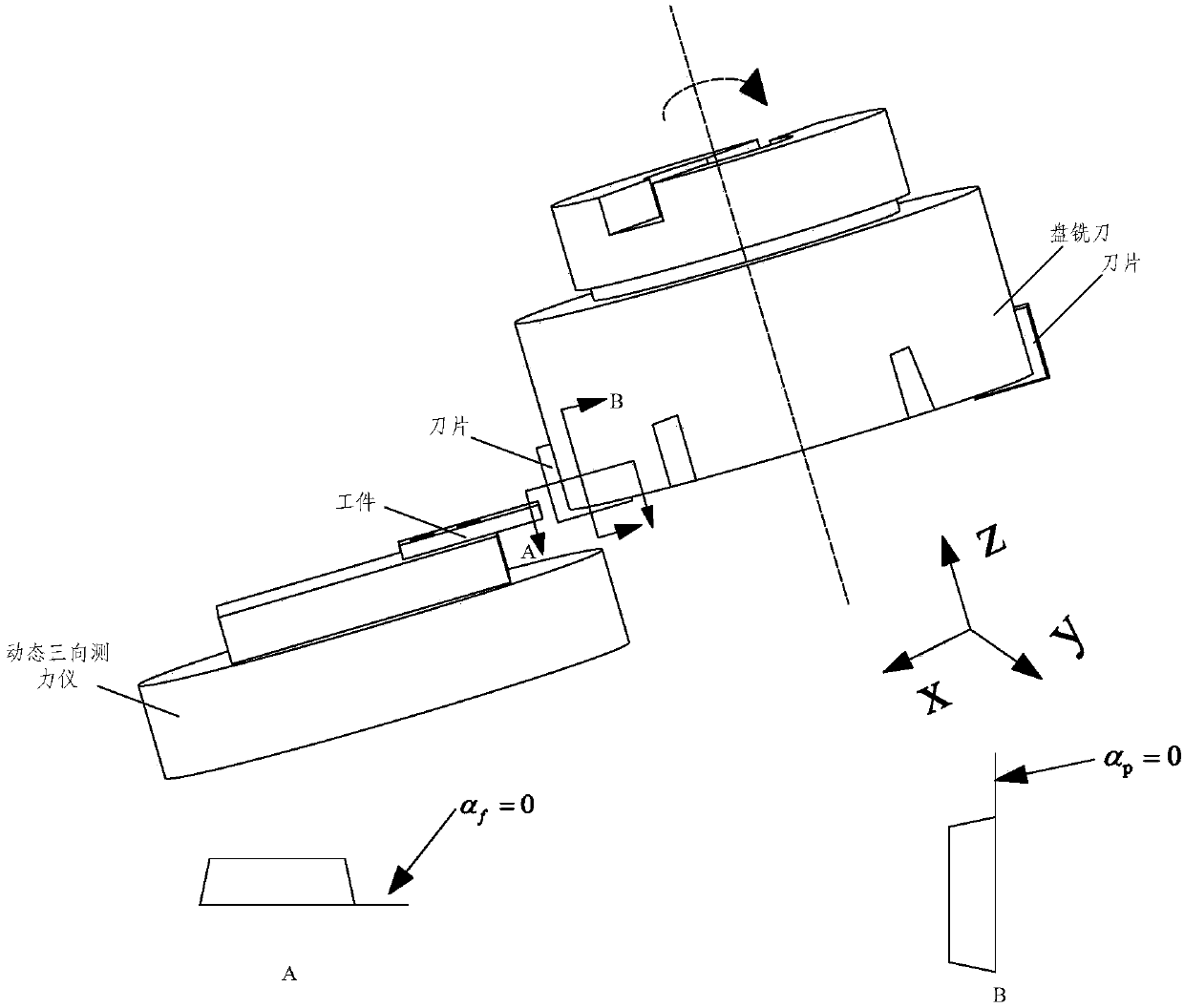

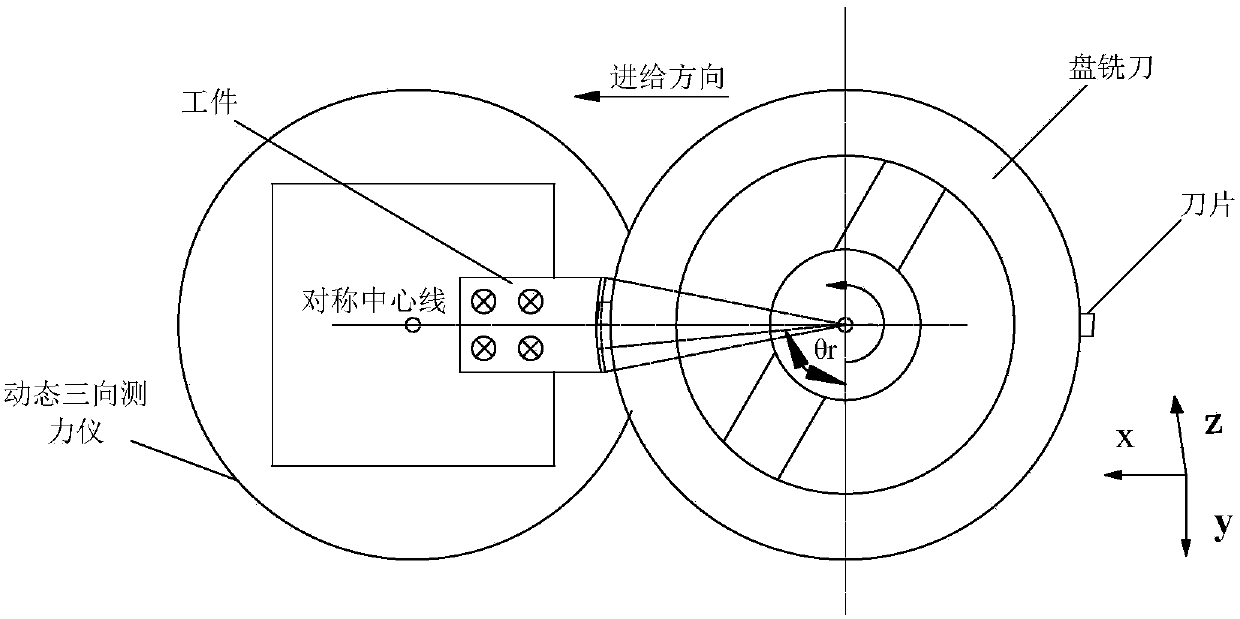

Metal material J-C constitutive equation acquisition method based on orthogonal milling experiment

ActiveCN107832484AThe J-C constitutive equation is accurateEasy accessDesign optimisation/simulationForce sensorsFeeding forceMechanical models

The invention provides a metal material J-C constitutive equation acquisition method based on an orthogonal milling experiment. Side edge orthogonal milling or bottom edge orthogonal milling is carried out on a workpiece made of a to-be-tested metal material, and the feeding force Ff, the back force Ft and the shear angle phi c which correspond to multiple different milling parameters at a presetmoment in the machining process are obtained; on the basis of the feeding force Ff, the back force Ft and the shear angle phi c which correspond to the different milling parameters, a J-C constitutiveequation of the to-be-tested metal material is obtained. By constructing the special orthogonal milling experiment, a mechanical model in the cutting process is stable and simple, the feeding force Ff, the back force Ft and the shear angle phi c can be obtained more easily, and then the J-C constitutive equation of the to-be-tested metal material can be obtained more easily.

Owner:BEIHANG UNIV

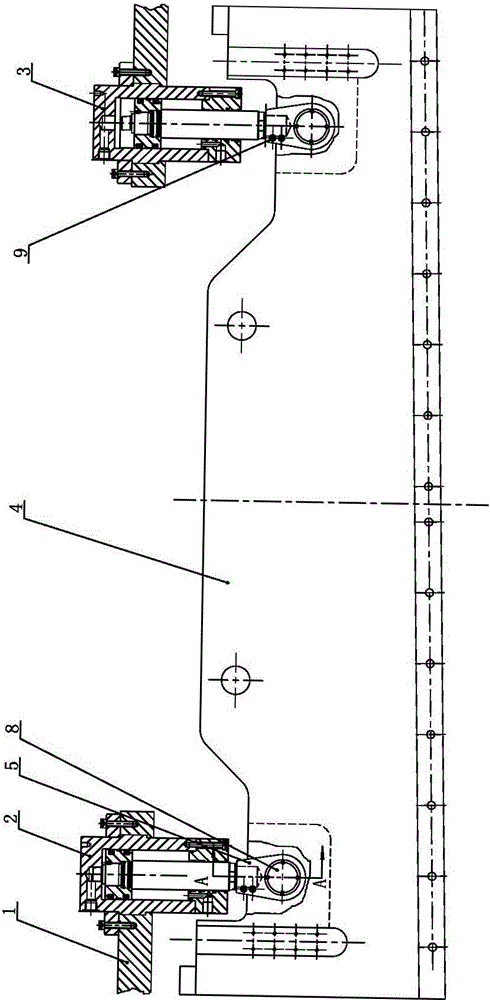

Horizontal plate shearing machine capable of automatically adjusting shearing angle and shearing angle adjusting control method for horizontal plate shearing machine

PendingCN109848474AGuaranteed fixed effectImprove stabilityShearing machinesShearing machine accessoriesShear angleInductor

The invention discloses a horizontal plate shearing machine capable of automatically adjusting a shearing angle and a shearing angle adjusting control method for the horizontal plate shearing machineand belongs to the technical field of forging machine tools. The horizontal plate shearing machine capable of automatically adjusting the shearing angle comprises a rack, a knife rest and a workbench;the rack is internally provided with the knife rest and the workbench which are distributed in a horizontal direction; the workbench is provided with a static knife; the knife rest is provided with amoving knife matched with the static knife; the left side of the rack is provided with a side supporting point; the side supporting point is connected with a rolling wheel through a disc spring; theleft side of the knife rest is correspondingly provided with a guide rail plate; the position, on the inner wall of the rack, of the right side of the knife rest is provided with a first laminating plate and a second laminating plate; and the side supporting point, the first laminating plate and the second laminating plate are provided with a first inductor, a second inductor and a third inductorrespectively. According to the technical scheme of the invention, the shearing angle of the horizontal plate shearing machine can be automatically adjusted, so that the shearing angle is ensured to befixed.

Owner:ANHUI DONGHAI MACHINE MFG CO LTD

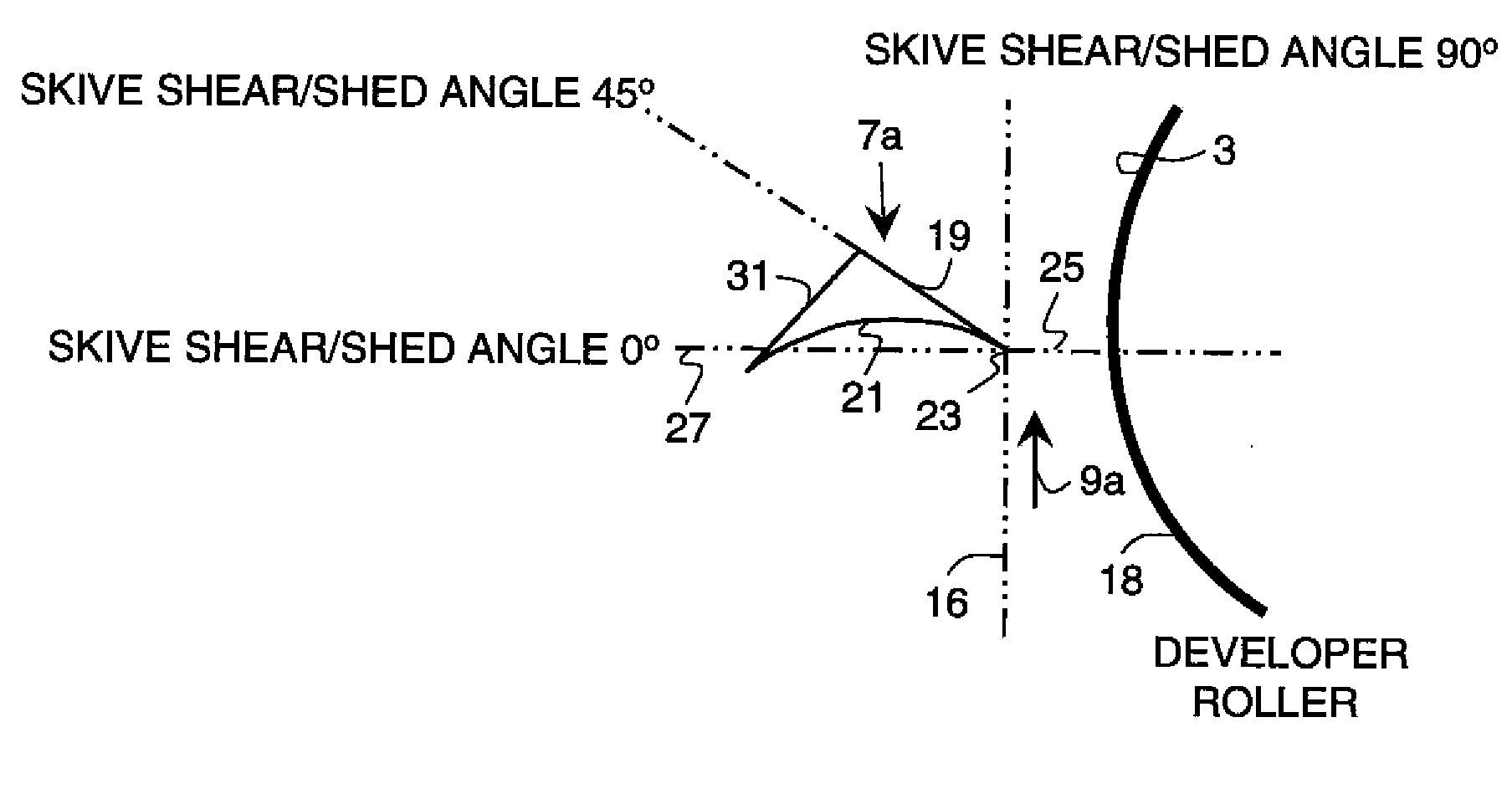

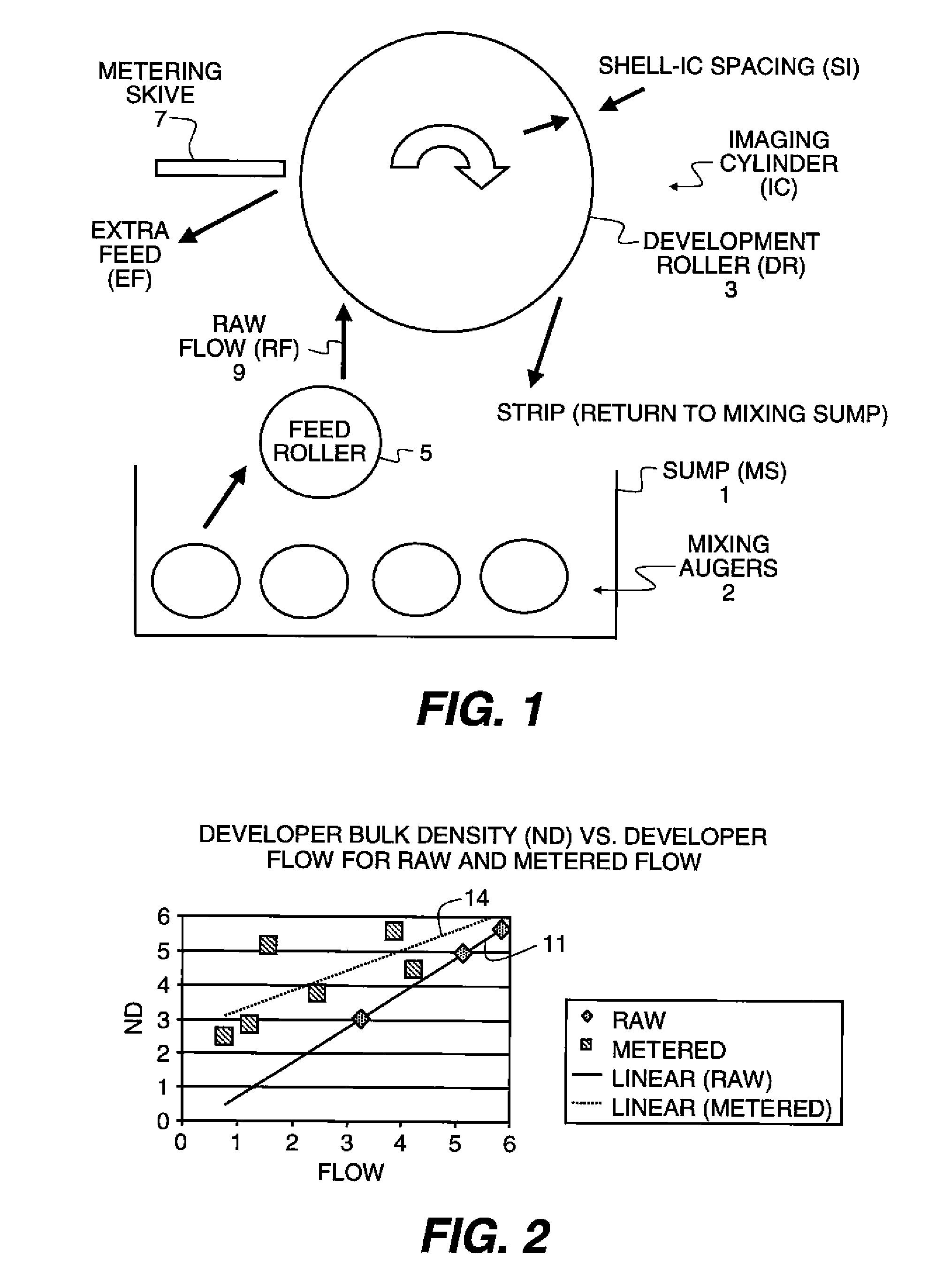

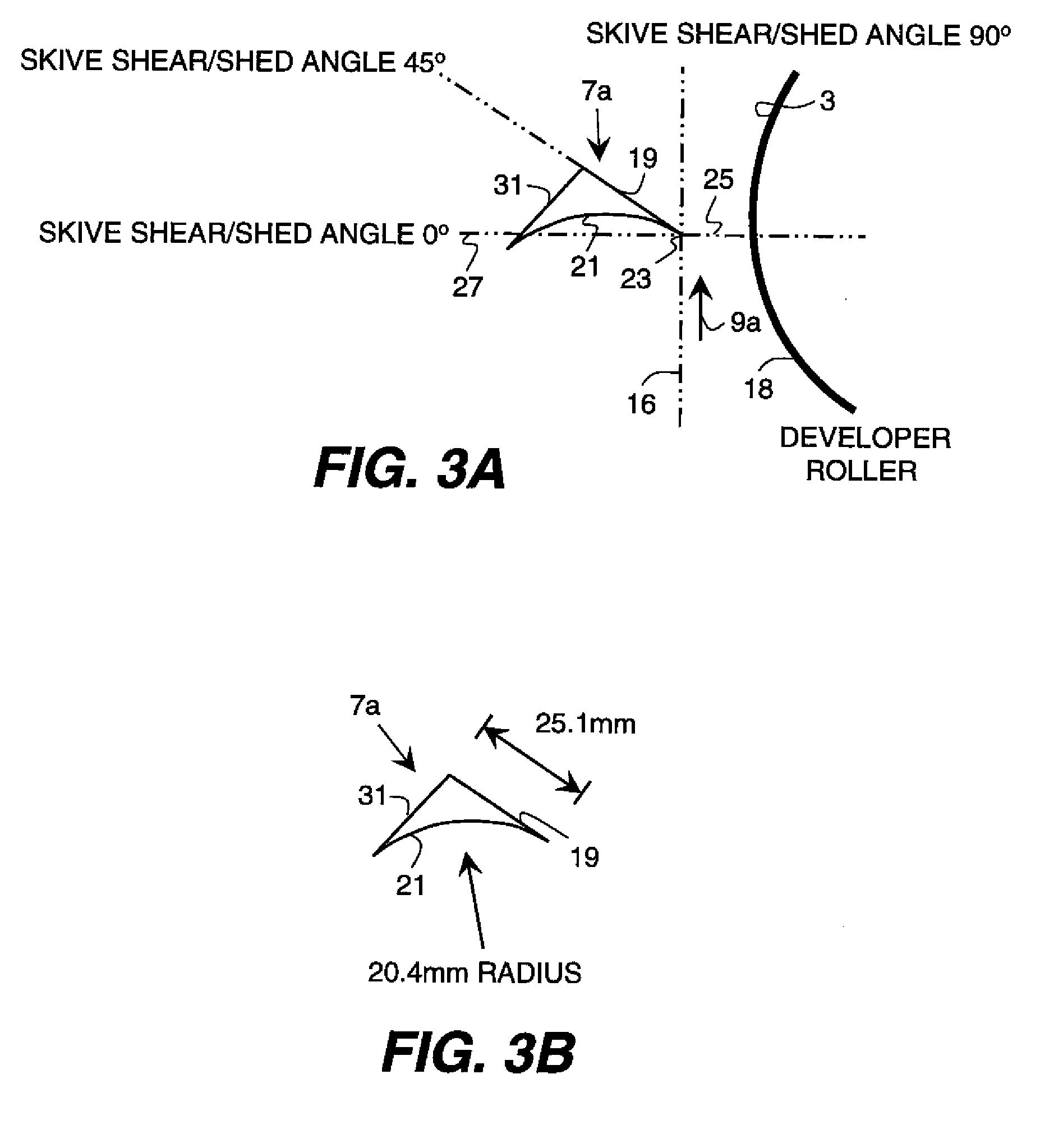

Metering skive for a developer roller

InactiveUS20100158580A1Minimize compressionPromote sheddingElectrographic process apparatusMechanical engineeringShear angle

Owner:EASTMAN KODAK CO

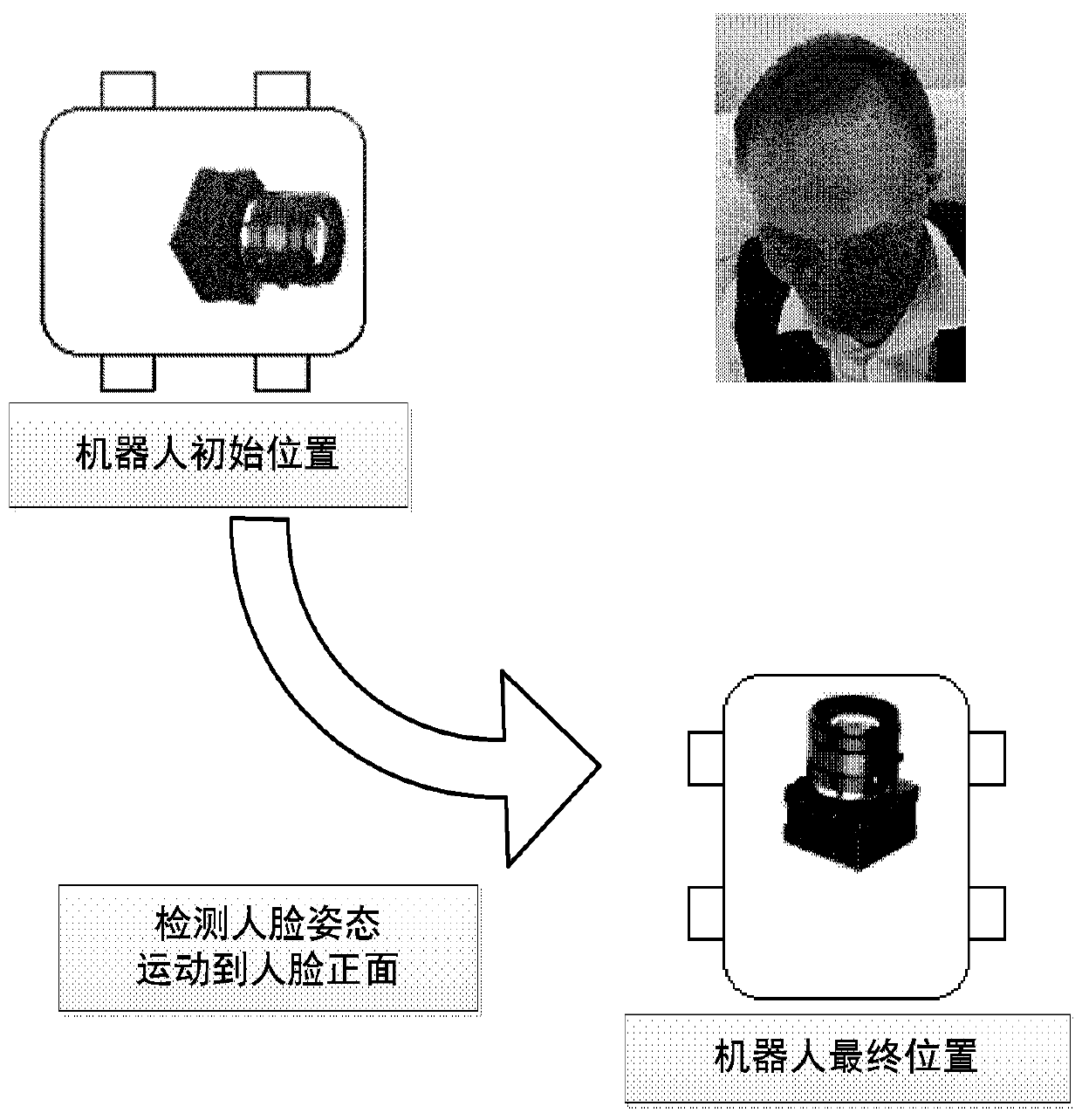

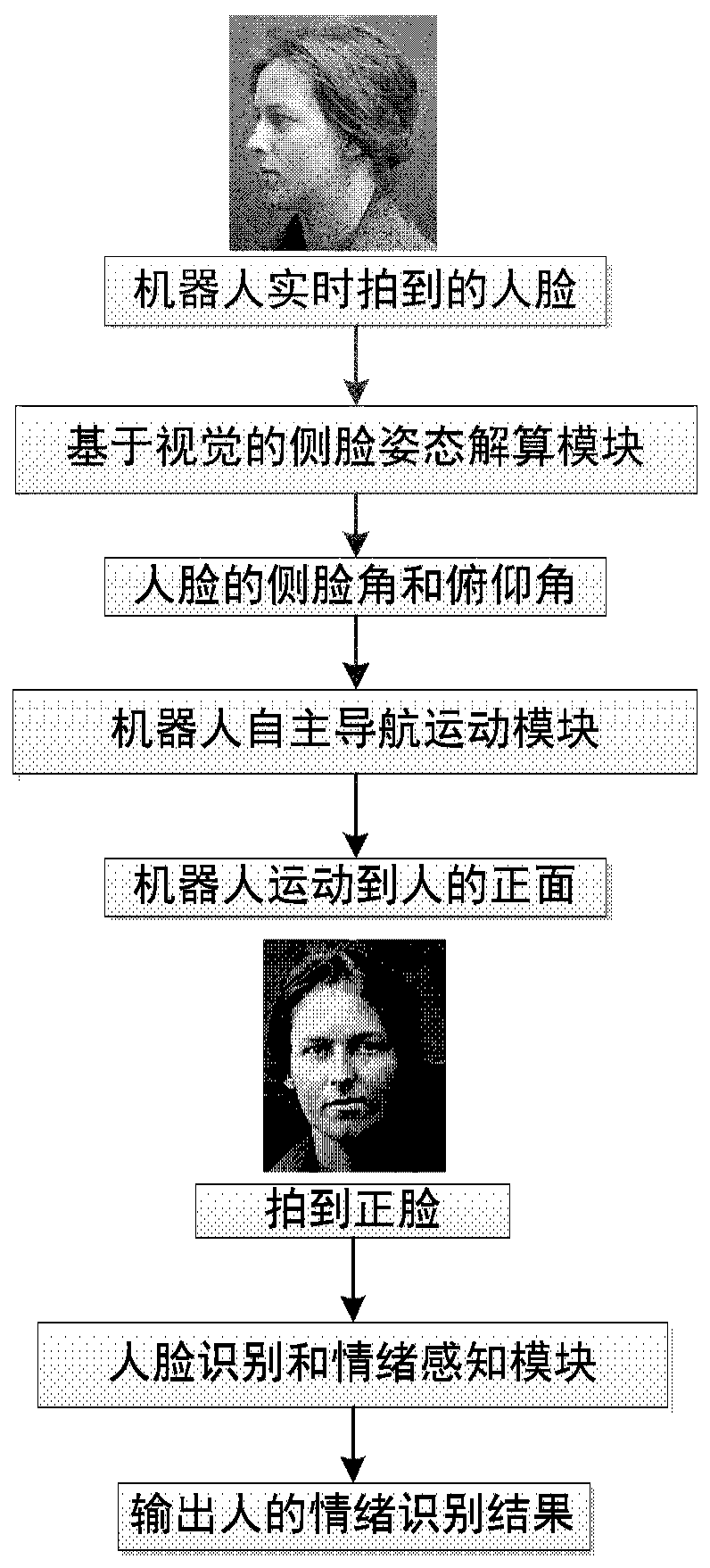

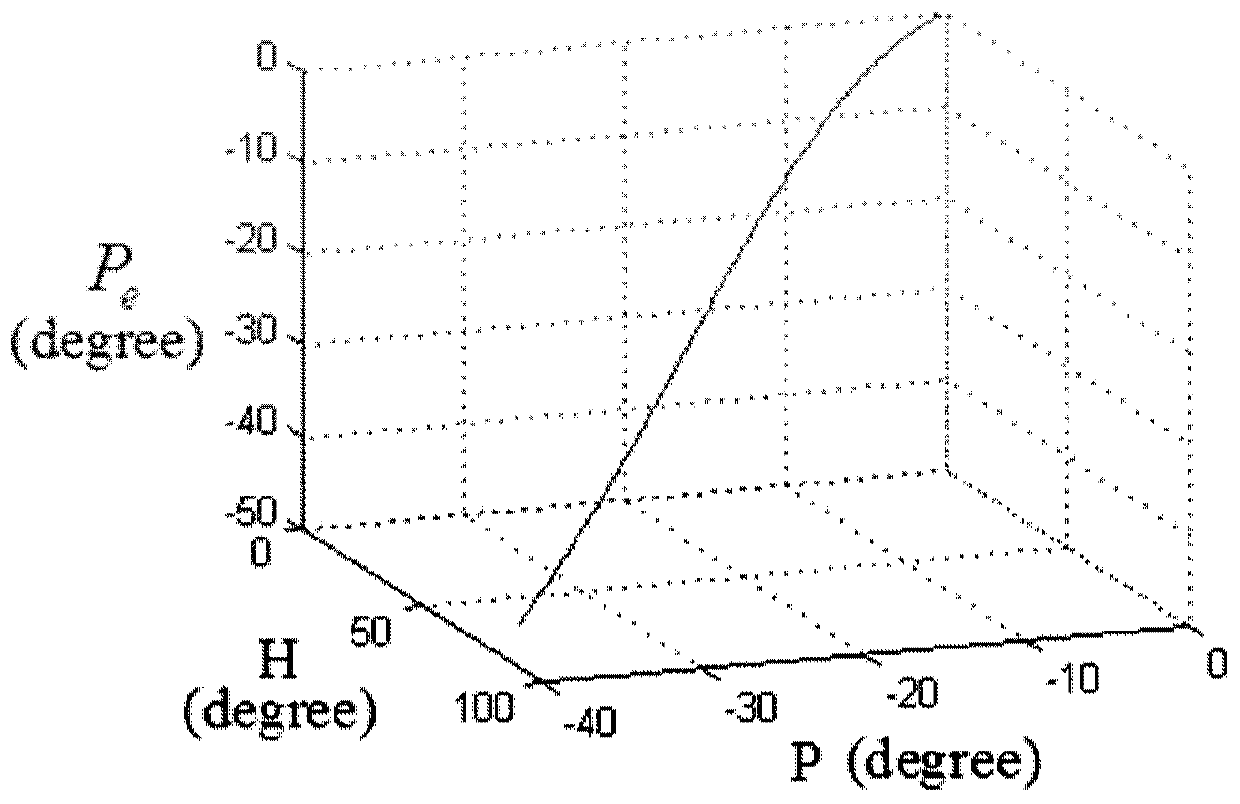

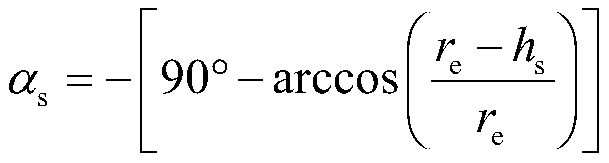

A vision-based side face posture resolving method and an emotion perception autonomous service robot

ActiveCN109886173ACharacter and pattern recognitionEmotion perceptionPhysical medicine and rehabilitation

The invention discloses a vision-based side face posture resolving method and an emotion perception autonomous service robot, wherein the side face posture resolving method is used for acquiring an attitude angle of a face image detected in a current state relative to a face in a front face state in real time, and comprises the following specific steps of constructing an attitude change model of aface area; constructing a shearing angle model of the face; and constructing an attitude angle resolving model based on shear angle elimination. The emotion perception autonomous service robot comprises an acquisition module which is provided with the side face posture resolving method in advance; a navigation module used for controlling the robot to move to a place over against the human face tocollect a front face image of the human face according to the human face attitude angle obtained by the collection module; and a face recognition and emotion sensing module used for finally realizingthe identity recognition and emotion detection. According to the vision-based side face posture resolving method and the emotion perception autonomous service robot provided by the invention, the problem that the identity and emotion of a person cannot be identified during side face is solved.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

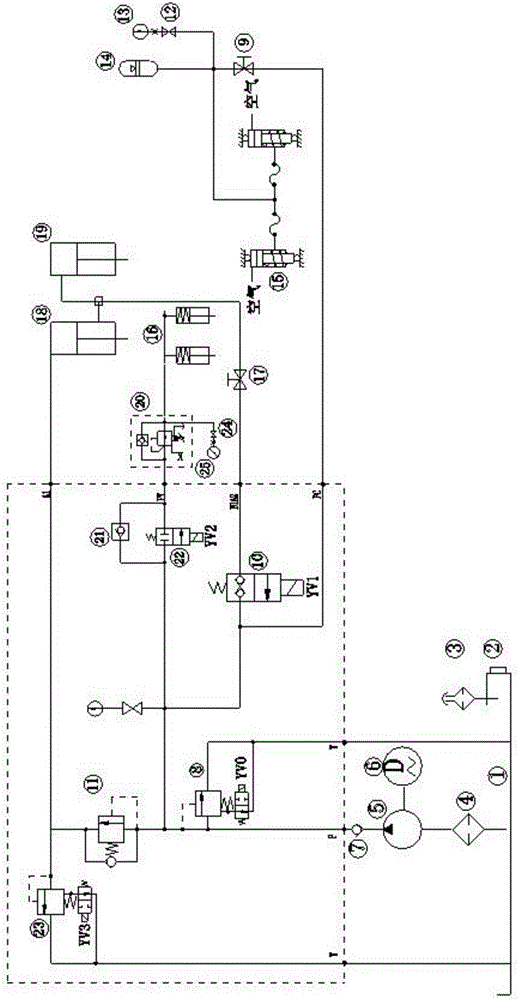

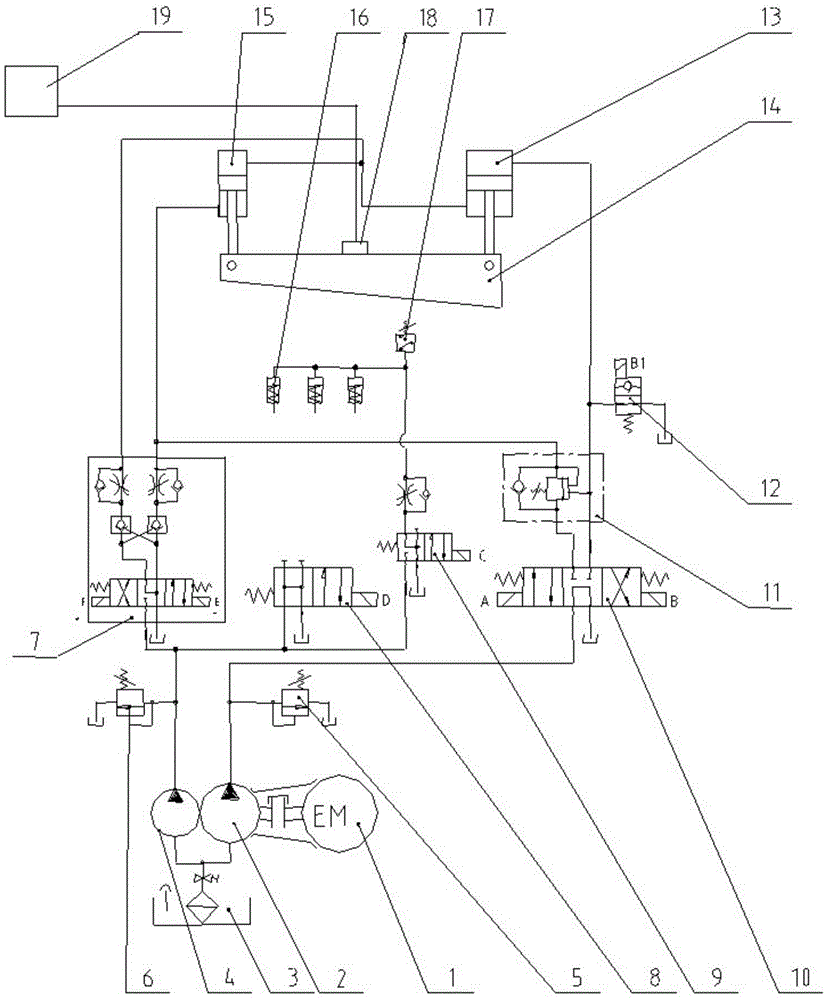

Control method of guillotine shear hydraulic system

ActiveCN106270722ALow costReduce layoutFluid-pressure actuator safetyFluid-pressure actuator testingCharge controlRisk stroke

The invention discloses a control method of a guillotine shear hydraulic system and belongs to the technical field of hydraulic machines. The control method controls the hydraulic system to finish system unloading stand-by state control of a plate shear, material preloading control, shearing control, return stroke control, tool rest shear angle decrease or increase control, energy accumulator charging control and oil cylinder charging control through sequential control of an electromagnetic relief valve I, a switching valve, a two-position two-way electromagnetic valve and an electromagnetic relief valve II in combination with a check valve I and a check valve II. Compared with the existing hydraulic system, the guillotine shear hydraulic system has the advantages that the the structure greatly simplified and the production cost is reduced. The control method enables the system to operate stably and can meet various working operation requirements. The material pressing action can be controlled independently and the pressure is controllable, and it is convenient to overhaul and maintain.

Owner:安徽省华夏机床制造有限公司

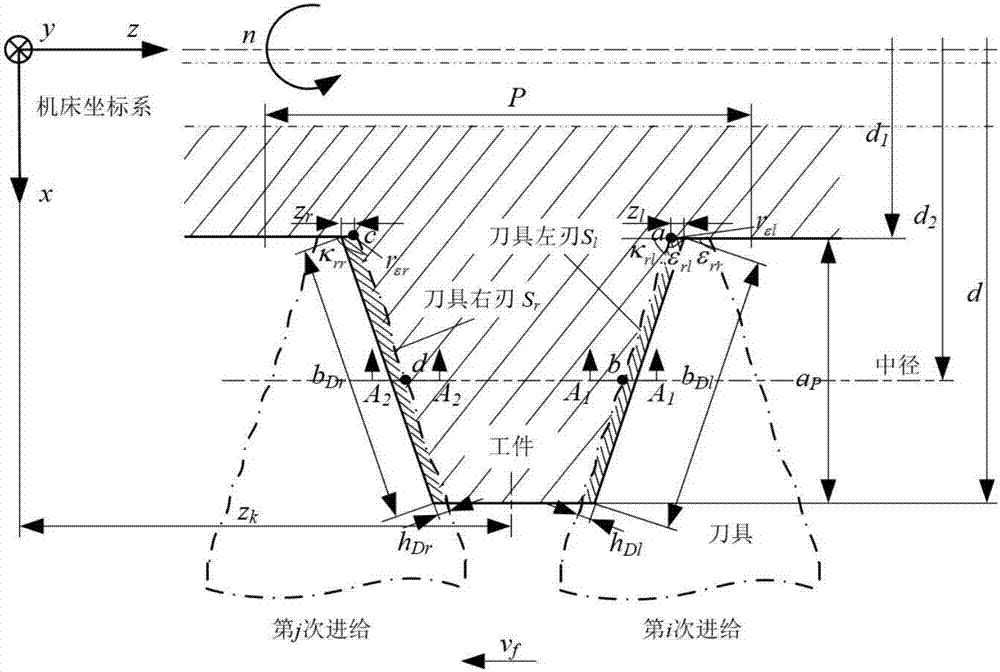

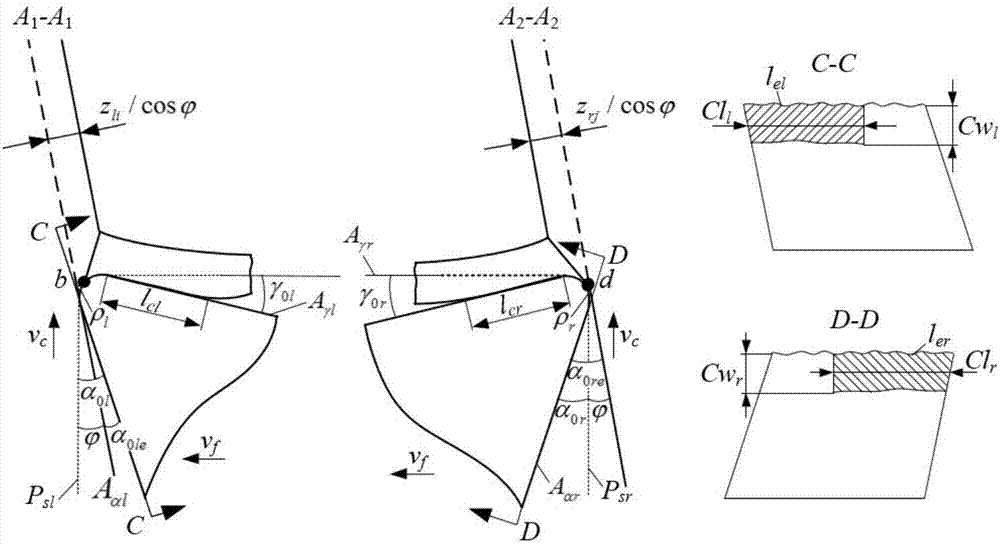

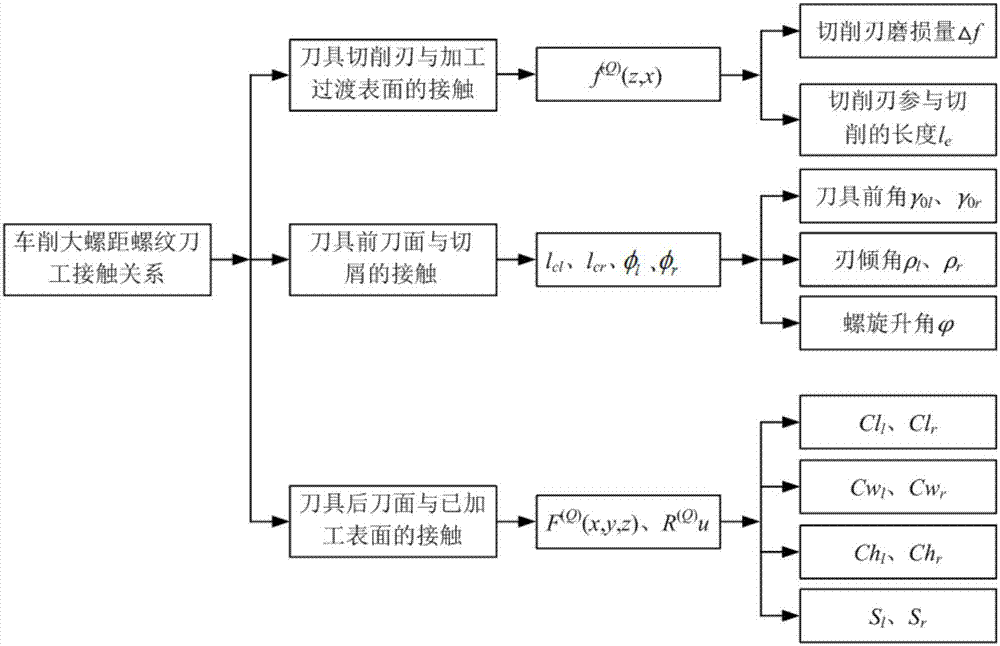

Method for calculating and testing difference of cuttingbehaviors of tool-workpiece interfaces of left and right cutting edges

The invention relates to a method for calculating and testing the difference of cutting behaviors of tool-workpiece interfaces of left and right cutting edges, and aims at solving the problem that the existing testing method cannot comprehensively disclose the difference of thecutting behaviors of a cutting large-pitch trapezoid external threaded cutter. The method comprises the following steps: determining the hierarchical structure and the characteristic variable of a tool-workpiece contact relation of a cutting large-pitch thread; calculating and analyzing the tool-workpiece contact length and the tool-workpiece contact width of the left and right edges; establishing left and right edge cutter force tolerance models; using a deformation coefficient and relative slippage calculation method, a shear angle and frictional angle calculation method, and a cutting behavior difference experiment testing method of the left and right cutting edges of the cutter to disclose the states of cuttings of the left and right edges in the cutting, the abrasions of the left and right edges, and the difference of the dynamic cutting behaviors of the left and right edges. The method discloses the states of cuttings of the left and right edges in the cutting, the abrasions of the left and right edges, and the difference of the dynamic cutting behaviors of the left and right edges, so that effective evidences are provided for improving the quality of the machined surface.

Owner:HARBIN UNIV OF SCI & TECH

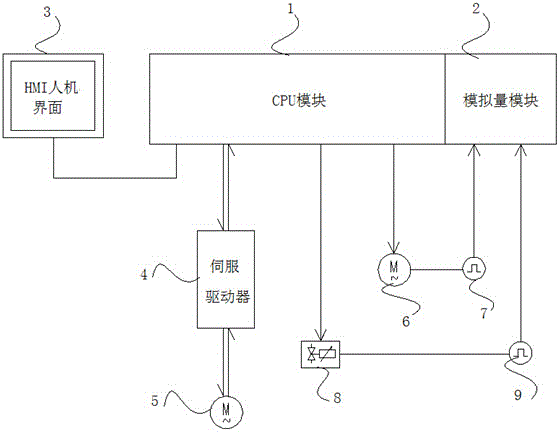

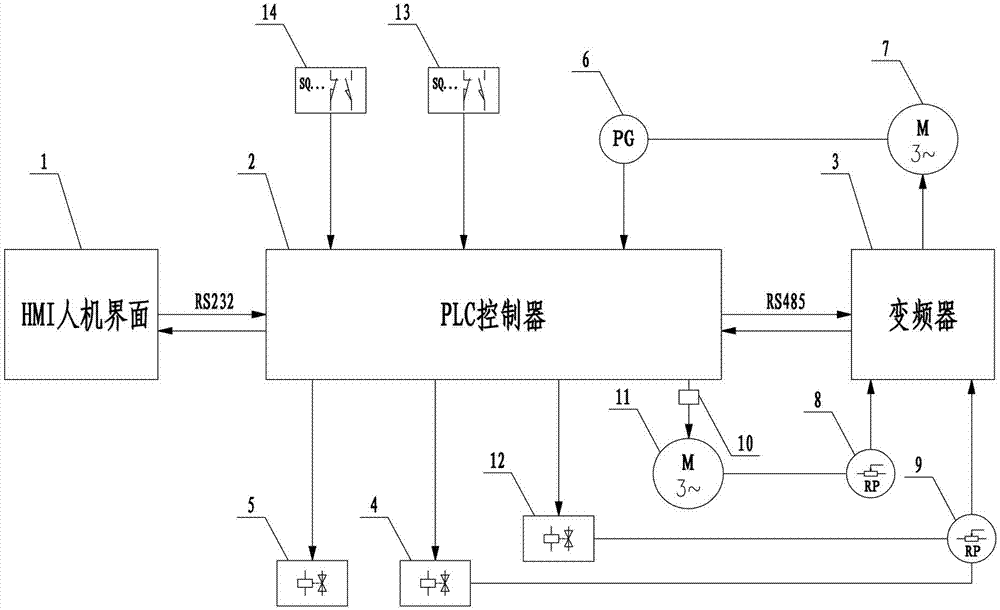

Electric control system of numerical-control plate shearing machine

InactiveCN104536362ARealize intelligent controlEasy to operateProgramme control in sequence/logic controllersNumerical controlSolenoid valve

The invention discloses an electric control system of a numerical-control plate shearing machine, relating to the technical field of numerical-control plate shearing machines. The electric control system comprises a CPU module, an analog module and an HMI; a high-speed counting port of the CPU module is connected with a servo driver, the input end of a cutting-edge gap adjusting motor and the input end of a solenoid valve; the servo driver is connected with a servo motor; the servo motor is connected with a back stopper; the output end of the cutting-edge gap adjusting motor is connected with the input end of a linear displacement sensor; the output end of the linear displacement sensor is connected with the analog module; the output end of the solenoid valve is connected with the input end of a stay wire rotating potentiometer; and the output end of the stay wire rotating potentiometer is connected with the analog module. The electric control system can accurately control the back stopper, the cutting-edge gap, the cutting-edge shear angle and the shearing stroke of the numerical-control plate shearing machine, intelligent control is realized by combining the HMI technology, and the electric control system also has the advantages of being easy to operate and maintain and proper in the price.

Owner:TIANSHUI METALFORMING MACHINE TOOL GROUP

Double-pump plate shearing machine and control method thereof

ActiveCN105598522AImprove machining accuracyEasy to operateShearing machinesMetal working apparatusControl systemFuel tank

The invention discloses a double-pump plate shearing machine and a control method thereof, and belongs to the field of a plate shearing machine. The double-pump plate shearing machine comprises a tool rest, an oil pump motor, a main oil pump, an oil tank, a main oil cylinder, an auxiliary oil cylinder, a pressing oil cylinder, a pressure switch, a pressing oil pump, a main overflow valve, a pressing overflow valve, a combined three-position four-way reversing valve, a two-position four-way reversing valve I, a two-position four-way reversing valve II, a three-position four-way reversing valve, a one-way sequence valve and an electromagnetic ball valve, wherein a tilt angle sensor is arranged on the tool rest; the tilt angle sensor is connected with an external control system; the oil tank is connected with the main oil pump and the pressing oil pump; the oil pump motor is connected with the main oil pump and the pressing oil pump. The double-pump plate shearing machine has the advantages of large pressing force of the plate shearing machine, high shearing angle regulation accuracy and high automation degree.

Owner:马鞍山市中亚机床制造有限公司

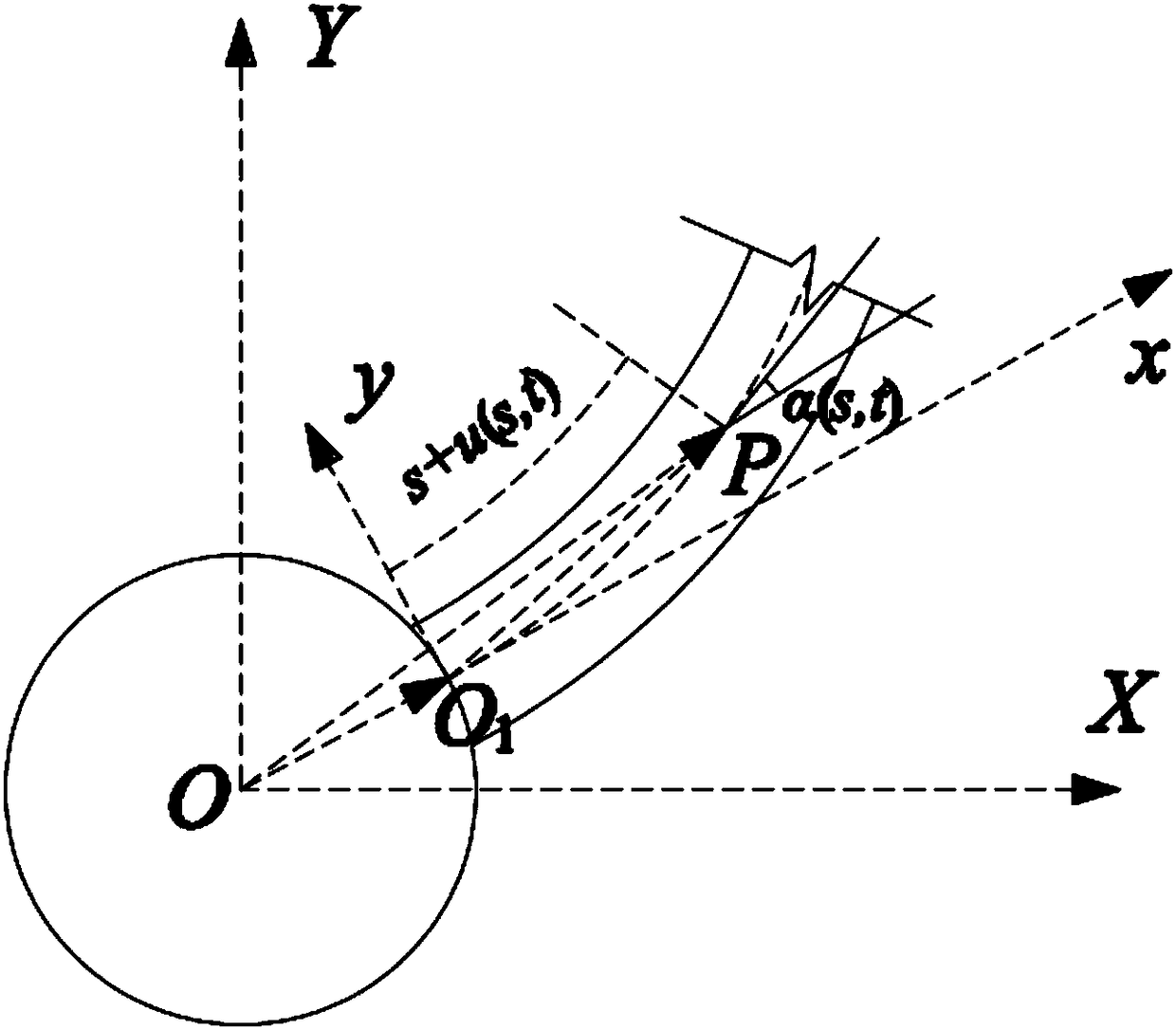

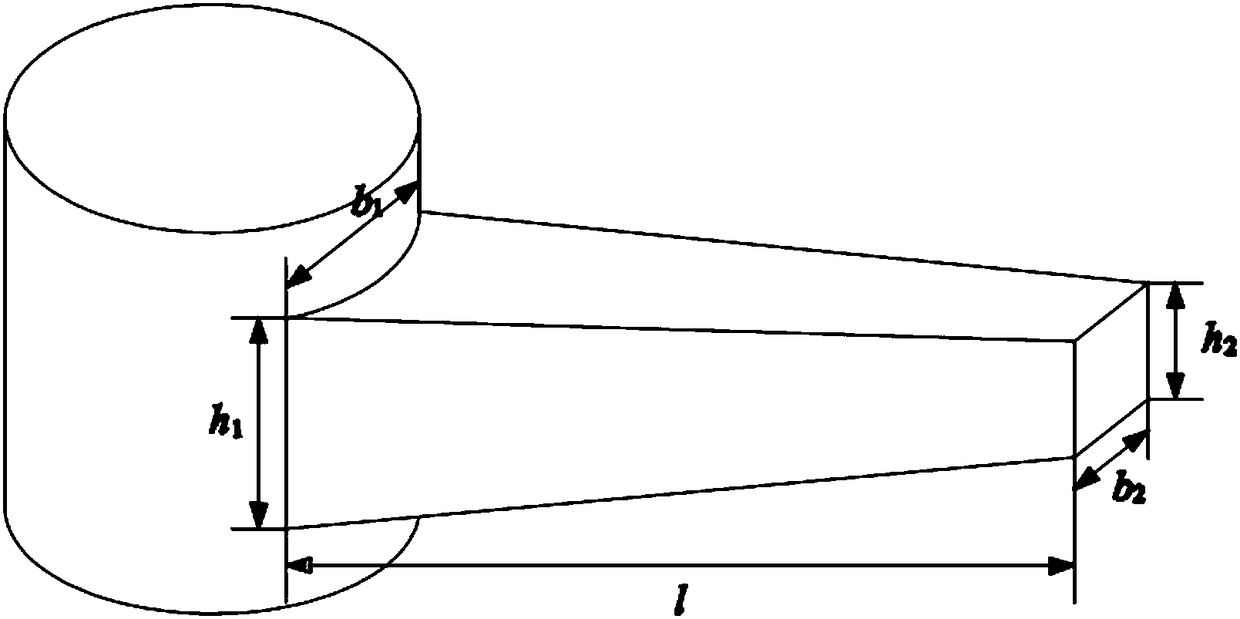

Method for calculating dynamic response at tail ends of central rigid body-FGM tapered beam systems

ActiveCN108388699AImprove calculation accuracyImprove computing efficiencyGeometric CADDesign optimisation/simulationTensile strainDynamic models

The invention discloses a method for calculating dynamic response at tail ends of central rigid body-FGM tapered beam systems. The method comprises the following steps of: describing a geometric displacement relationship of a flexible FGM beam by using an arc length coordinate, and respectively describing transverse bending, longitudinal tensile deformation and a shear angle of the flexible beam by using a dip angle and a tensile strain variable; discretizing a deformation field by adoption of an assumed mode method, and carrying out equation deduction by using a second-type Lagrange equationso as to obtain a rigid-flexible coupled dynamic model of a central rigid body-FGM tapered beam system; compiling an FGM beam tail end response calculation program by using C++, and obtaining a changevalue of the beam system tail end response along with a large-scale rotation time through reading parameters such as geometric parameters, function gradient functions and material components of the central rigid body-FGM tapered beam system. By adoption of the method, the calculation precision and efficiency are relatively high.

Owner:NANJING UNIV OF SCI & TECH

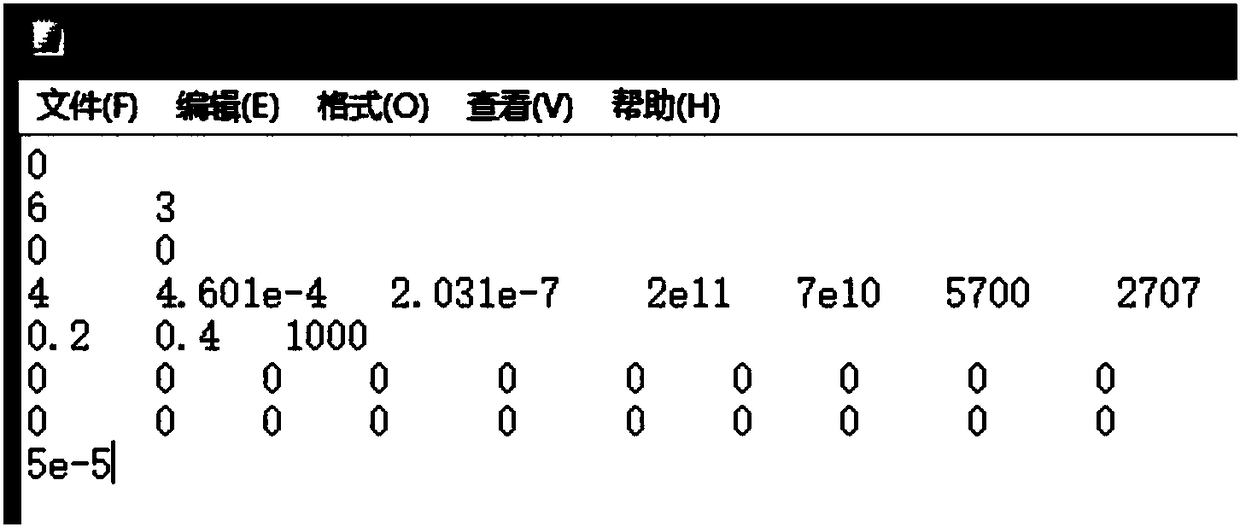

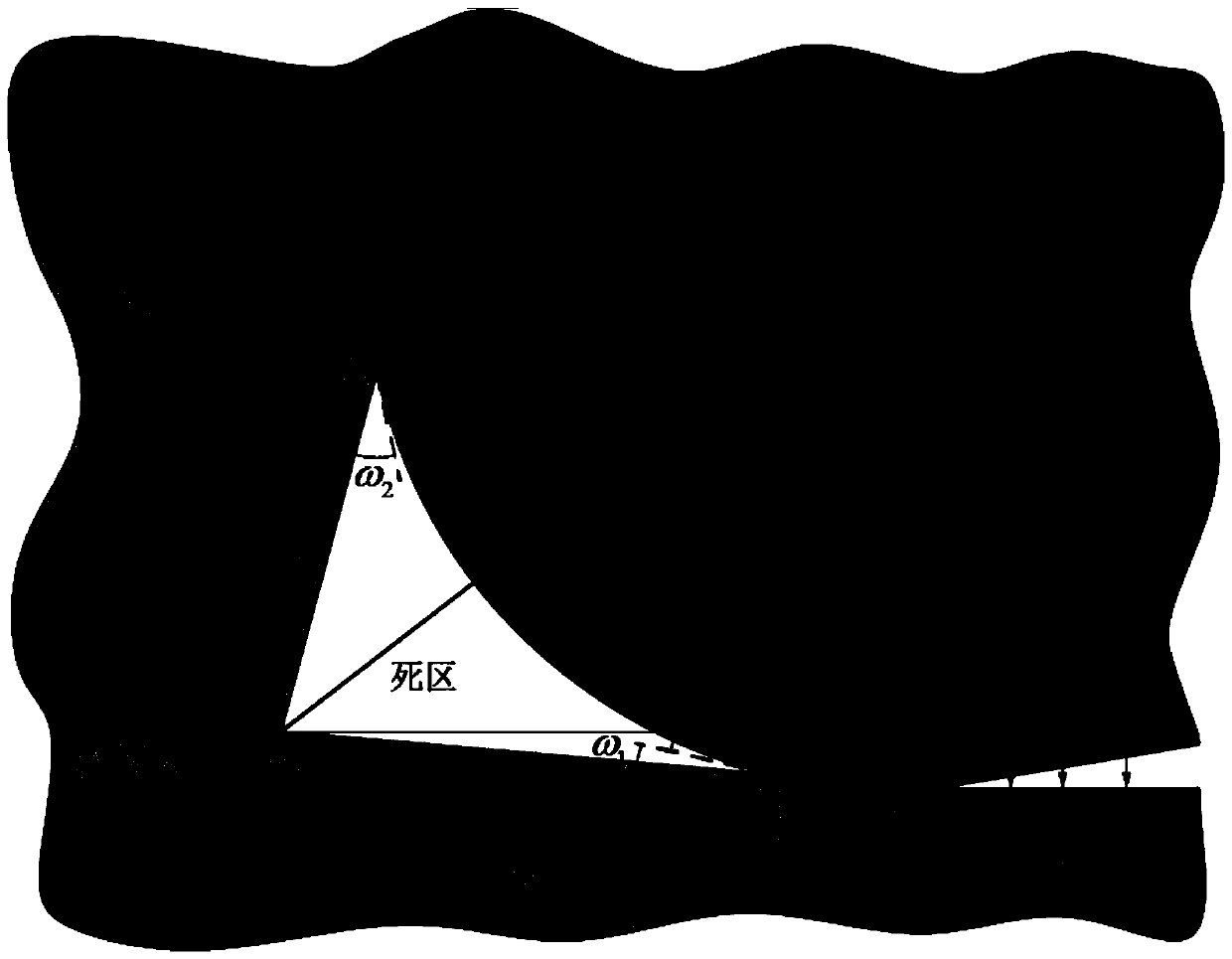

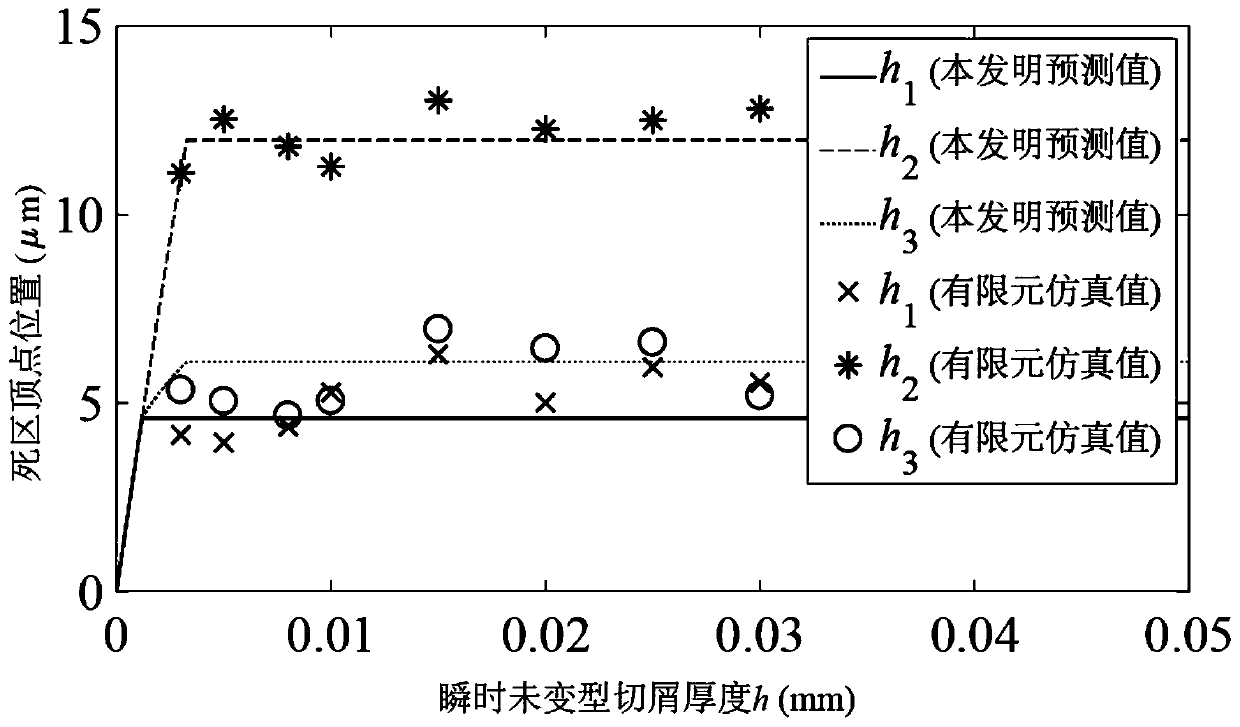

Method for predicting metal cutting tool nose dead zone morphology through considering metal slippage

ActiveCN110472308AReasonable theoretical explanationGet rid of the interference of human factorsSpecial data processing applicationsSlip linePredictive methods

The invention relates to a method for calculating the dead zone morphology by using the metal slip line theory complete theory. The method comprises the following steps: firstly, determining the radius of a blunt circle of a tool nose of a used tool through measurement; and then front angles and friction angles of all positions on the blunt circle of the tool nose need to be calculated, and then shearing angles of all the positions, namely the shearing direction of metal, are obtained. And obtaining the friction coefficient of each position by using the friction angle, and further solving theincluded angle between the metal slip line and the plastic boundary, namely the included angle between the boundary line of the dead zone and the blunt circle of the tool nose; the metal shearing direction is collinear with the boundary line of the dead zone, so that the positions of the vertexes S1 and S2 of the dead zone on the blunt circle of the tool nose can be solved. And after judging whether the vertexes S1 and S2 exist or not, deriving and solving the position of the vertex S3 through a geometrical relationship by utilizing the positions of the vertexes S1 and S2 and the included angle between the boundary line of the dead zone at the two points and the blunt circle of the tool nose, so as to completely determine the morphology of the dead zone of the tool nose. According to the method, the complete morphology of the dead zone of the tool nose can be predicted through complete theoretical calculation without any factors needing to be given manually.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

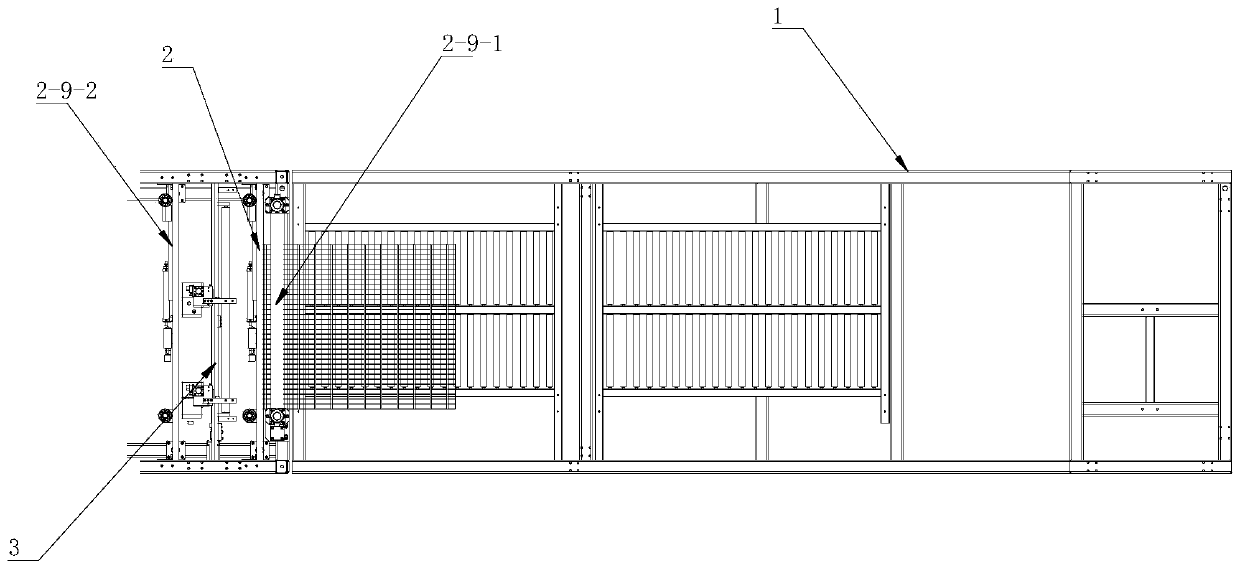

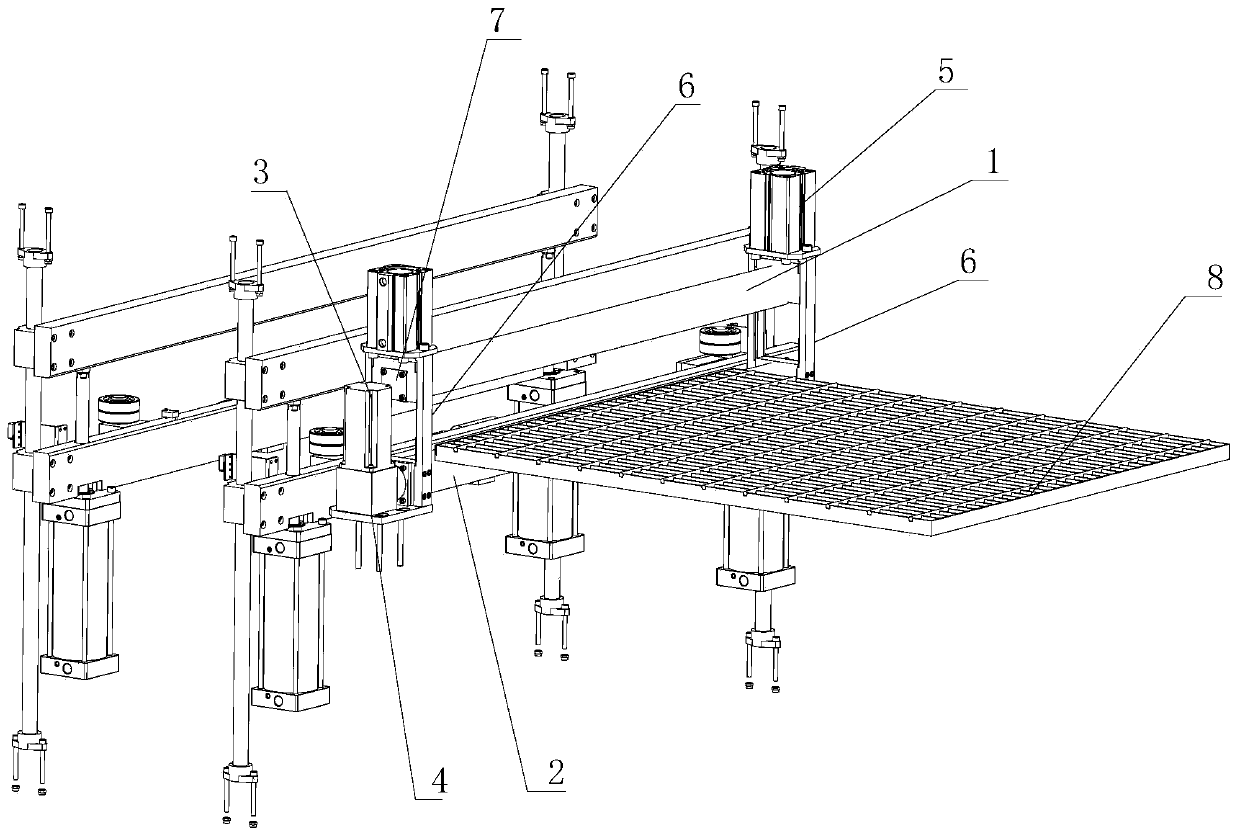

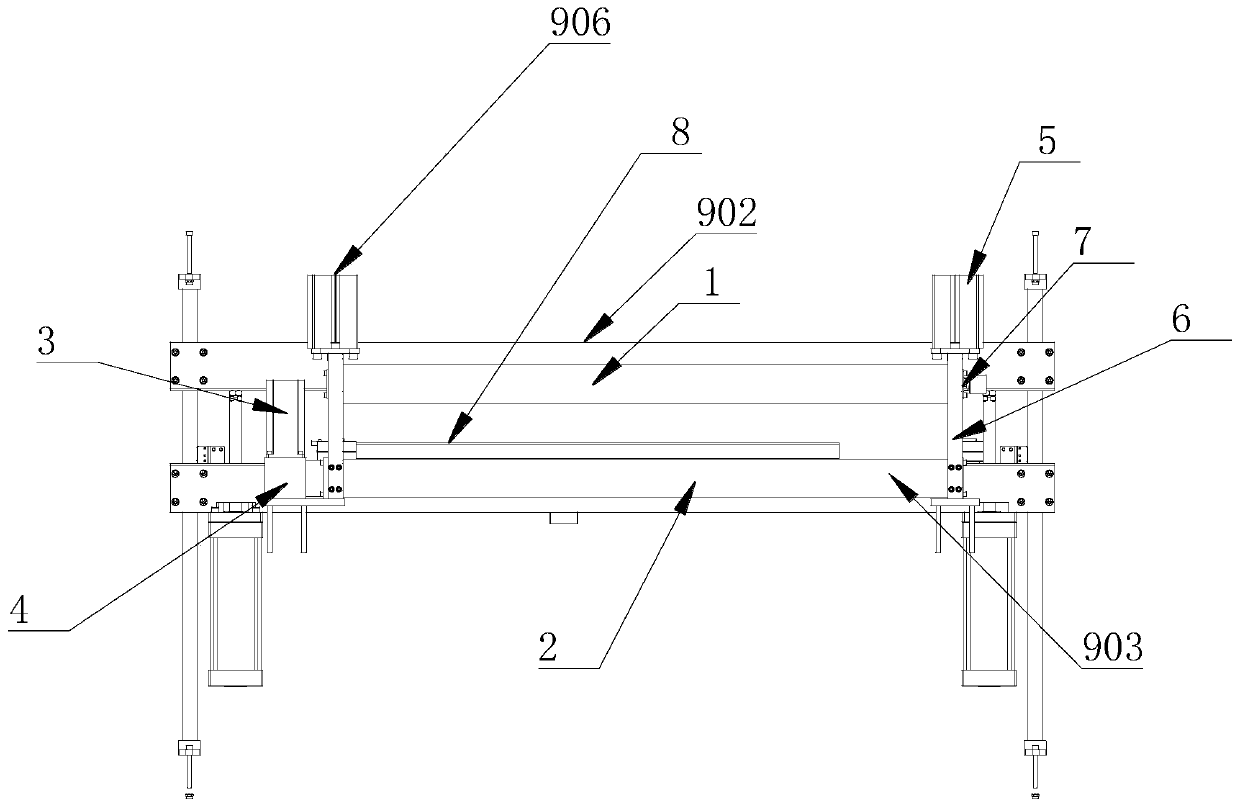

Automatic shearing system, automatic shearing method and automatic production line for steel grid plate as well as manufacturing method

PendingCN110142448AImprove shear efficiencyImprove quality and efficiencyMetal-working feeding devicesShearing machinesProduction lineHydraulic cylinder

The invention discloses an automatic shearing system, an automatic shearing method and an automatic production line for a steel grid plate as well as a manufacturing method. The automatic shearing system comprises a pedestal, wherein a feeding mechanism and a shearing device are mounted on the pedestal; the shearing device comprises a shearing mechanism; the shearing mechanism comprises a mountingplate; an upper shearing head and a lower shearing head which are symmetrical mutually are fixedly mounted on the mounting plate; slot holes are symmetrically formed in the upper shearing head and the lower shearing head; a fixed blade and a movable blade are mounted in the slot holes of the upper shearing head to form shearing angles; the upper shearing head is movably mounted on the mounting plate, and is driven by a Z-direction transmission mechanism to move on the mounting plate; and the shearing mechanism further comprises a power mechanism for pushing the movable blade to move. The automatic shearing system meets shearing requirements of steel grid plates of different models by changing telescopic distance of piston rods of hydraulic cylinders, greatly improves production efficiency, greatly increases a material utilization rate of the steel grid plate, and effectively improves production environment.

Owner:冯艳

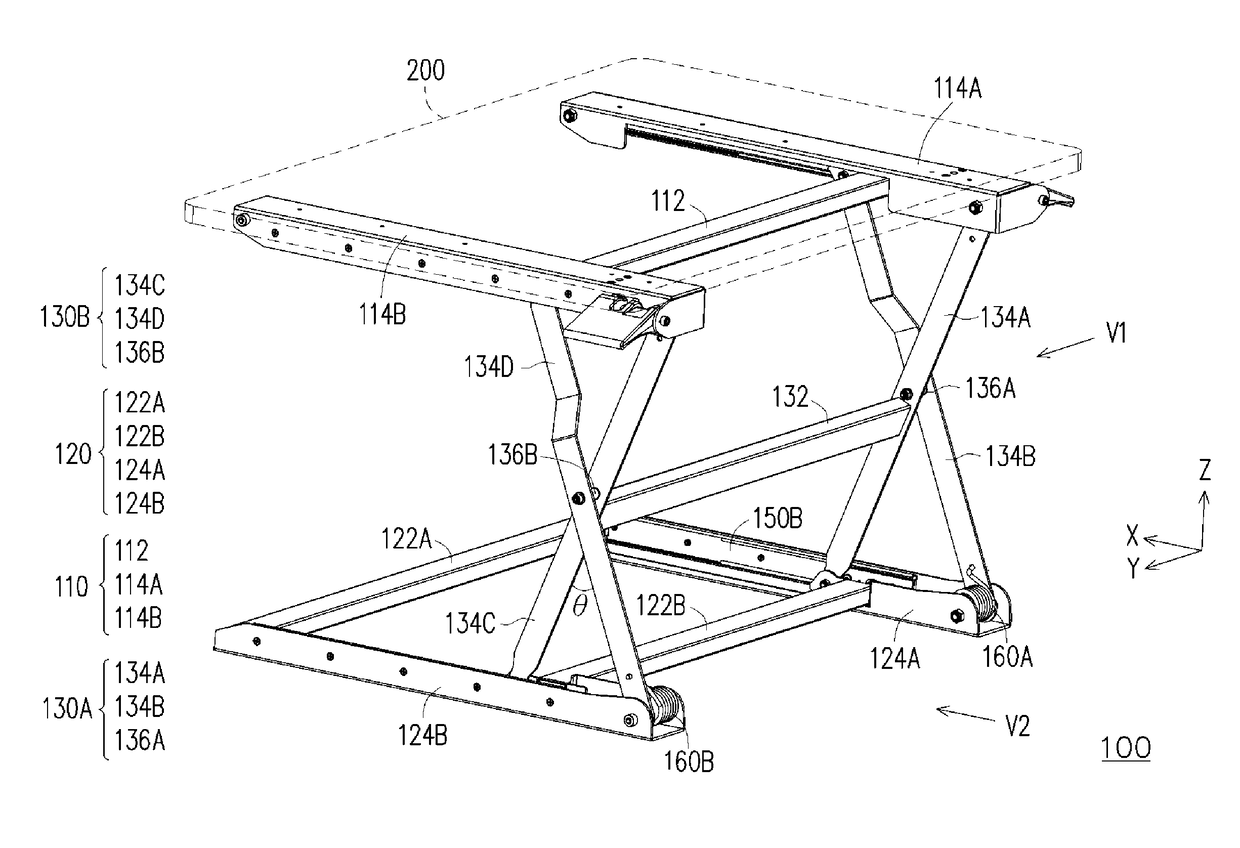

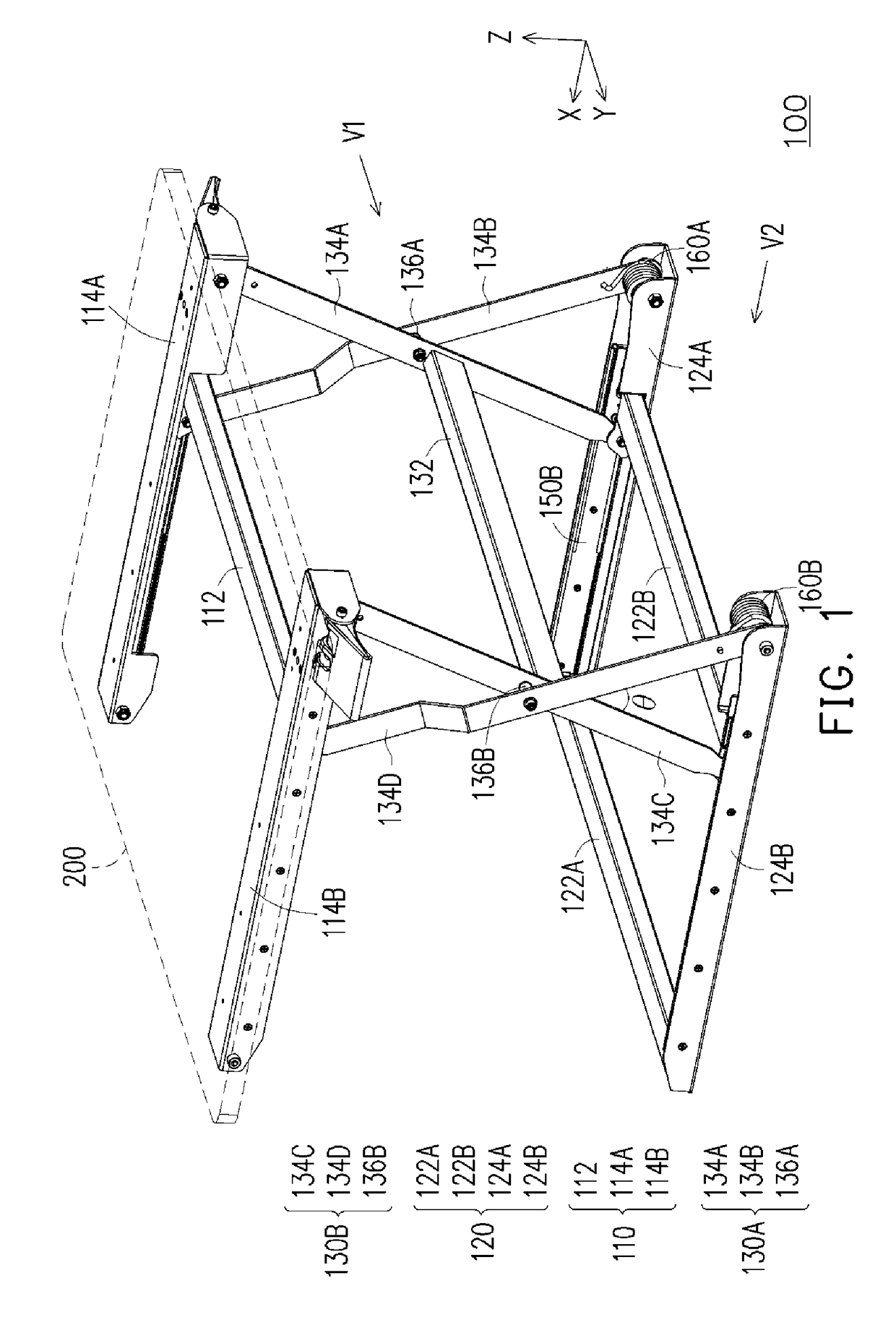

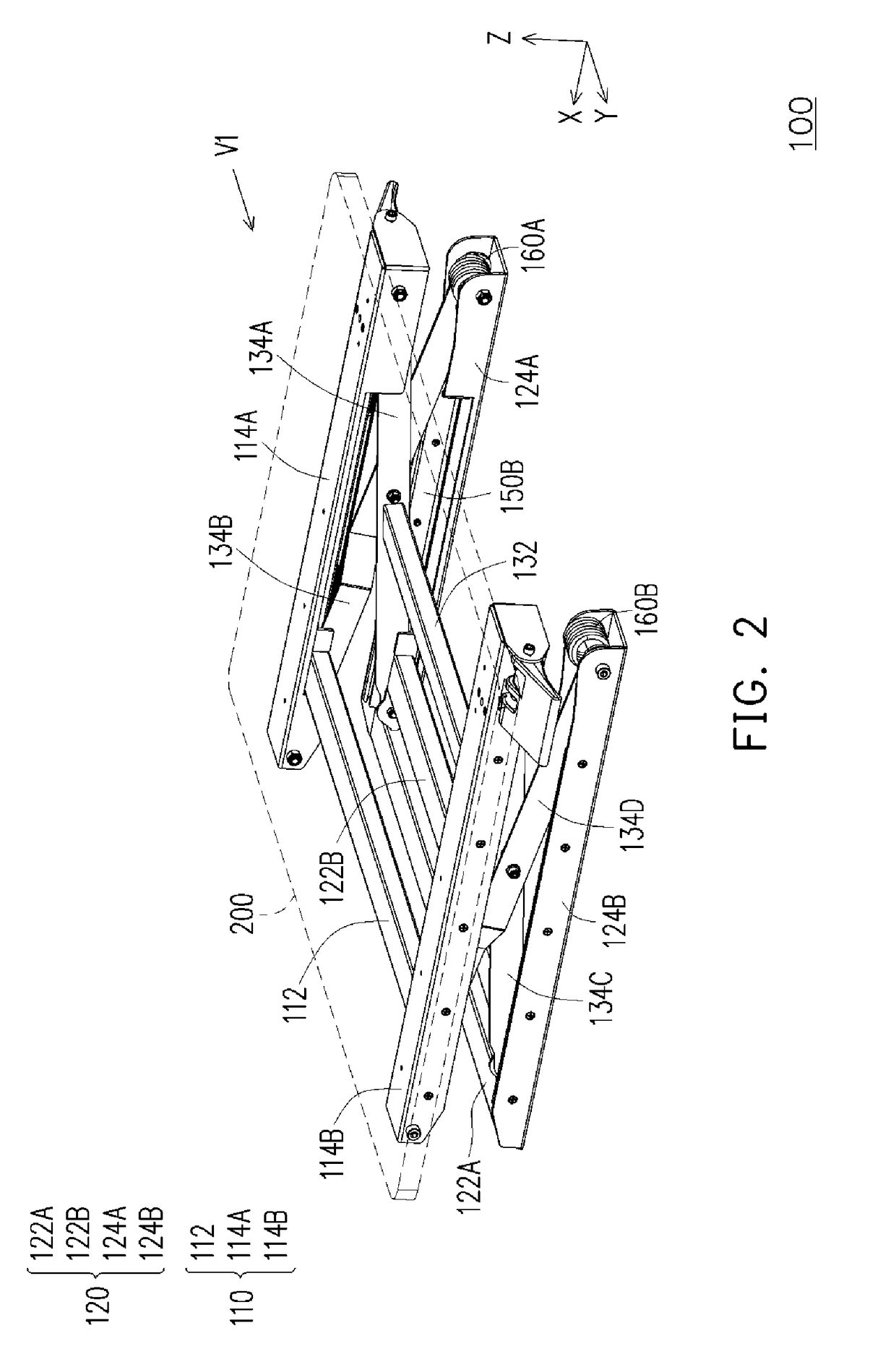

Lifting mechanism for desk

A lifting mechanism for desk including a first bracket, a second bracket, and at least one cross-arm assembly is provided. The cross-arm assembly has at least three connecting ends for connecting the first bracket and the second bracket respectively. The cross-arm assembly rotates about a first axis to change a shear angle thereof, and drives the first and the second brackets to move close to or away from each other relatively in a second axis.

Owner:HUANG MING HSIEN

Hydraulic brake-type numerical control shearing machine electric control system

InactiveCN106933192AMeet diverse processing needsReduce procurement costsNumerical controlFrequency changerNumerical control

Owner:HUANGSHI HUAXIN MACHINERY EQUIP

Method for preventing lithium ion battery corner from being damaged during flexible package

ActiveCN102709600AImprove performanceFinal product manufactureElectrolyte accumulators manufactureStress concentrationElectrical battery

The invention belongs to the technical field of lithium ion batteries and in particular relates to a method for preventing a lithium ion battery corner from being damaged during flexible package. The method includes performing corner prepackaging process at a corner where an air bag intersects with a cell to form a corner prepackaging area; performing air bag bottom packaging process on the air bag on the right side of the corner prepackaging area to form an air bag bottom packaging area; and setting a shear angle in the air bag bottom packaging area. Compared with the prior art, a stress concentration area can be produced artificially through angle shearing at the position far from the corner on the air bag, the air bag is bent firstly in the stress concentration area when the air bag needs to be bent during a production process of cell post-treatment, therefore corner damage in the intersection area of the air bag with the cell is avoided, and possibility of the corner damage is reduced.

Owner:NINGDE AMPEREX TECH

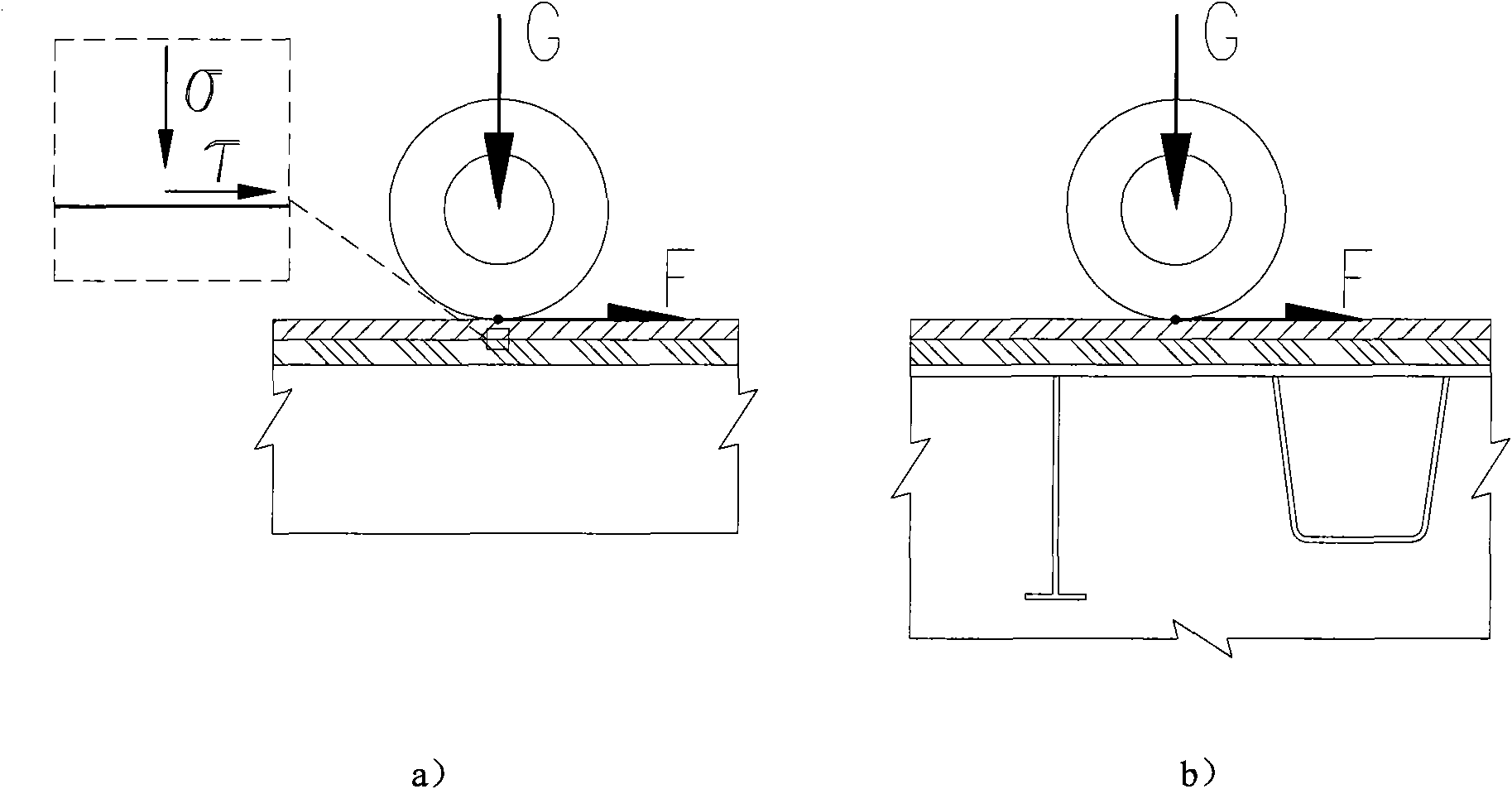

Method for determining material composition for asphalt pavement interlayer treatment measures

ActiveCN104655500AImprove the rationality of composition designImprove design rationalityMaterial strength using steady shearing forcesThermal insulationShear angle

The invention discloses a method for determining material composition for asphalt pavement interlayer treatment measures. The method comprises the following steps: test-piece molding step: after test-pieces to be measured undergo thermal insulation for 5-6 h, the test-pieces are put into a shear test mold, and angle of the shear test mold is selected according to ratio of vertical load to horizontal load; after the test-pieces continuously undergo thermal insulation for 30 min, the shear test mold containing the test-pieces is put into a shear test machine for a shear measuring test; the maximum force sensed by a sensor in the shear test machine and the maximum displacement value when the maximum force is reached are recorded, and shear strength is calculated according to shear angle and shear area; the calculated shear strength is recorded into a table; and after all the test-pieces are measured and shear strength of all the test-pieces is recorded, the maximum shear strength is selected from the table. Cementing agent spraying amount, ballast grain sizes and ballast greval corresponding to the maximum shear strength are the determined material composition for asphalt pavement interlayer treatment measures.

Owner:CHINA ACAD OF TRANSPORTATION SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com