Hydraulic shearing machine

A shearing machine, hydraulic technology, applied in shearing device, shearing machine equipment, metal processing equipment and other directions, to achieve the effect of simple structure and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

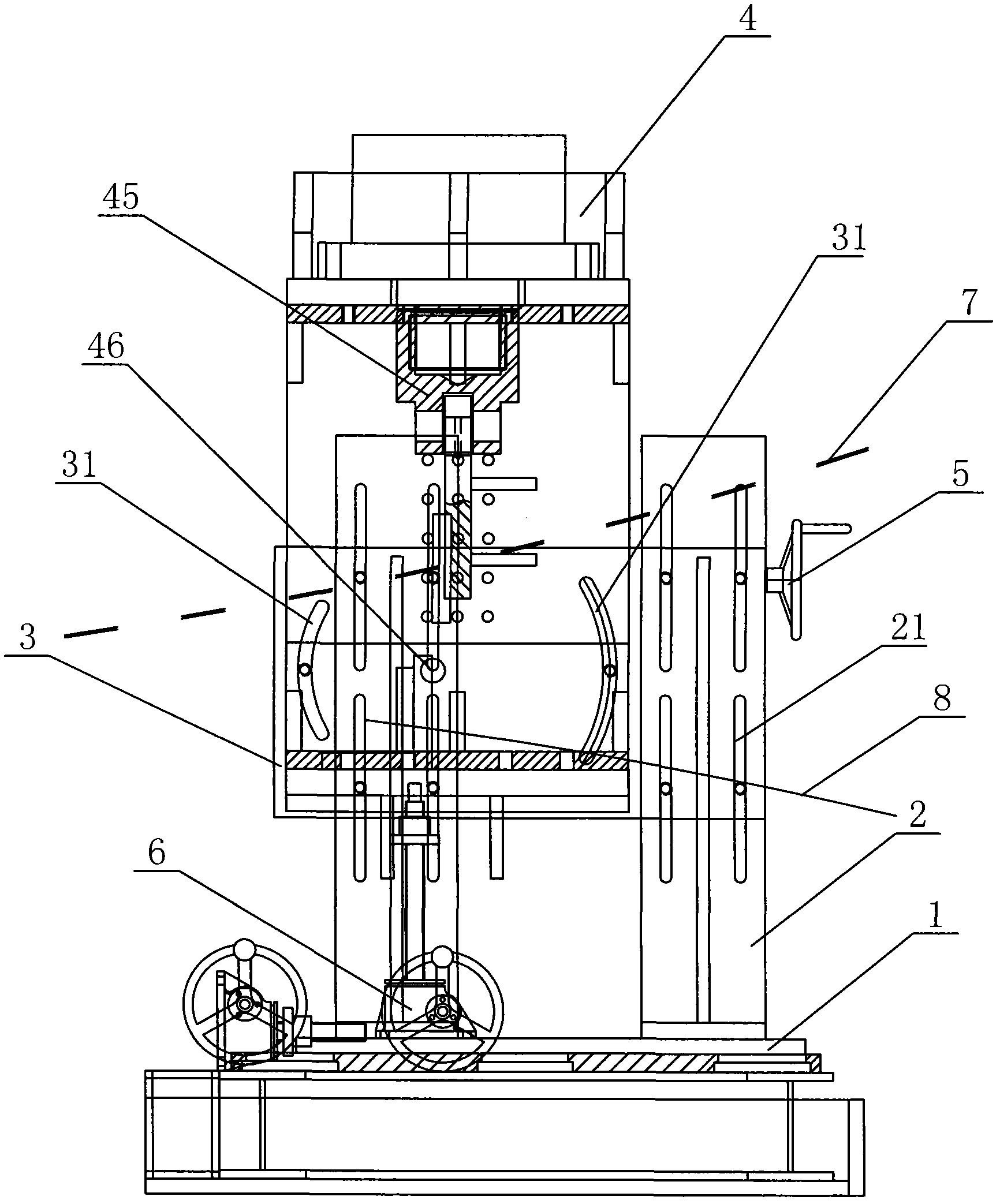

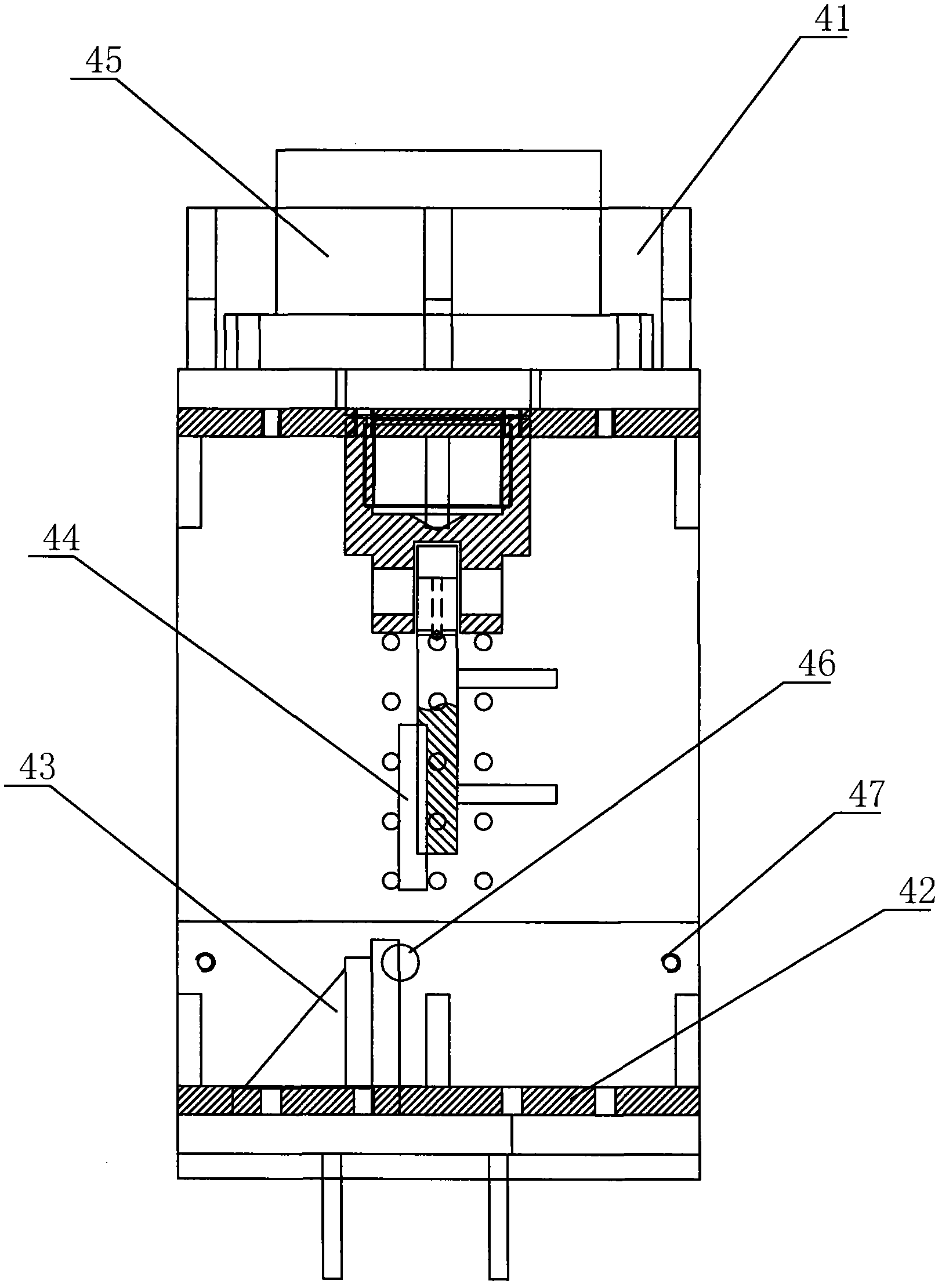

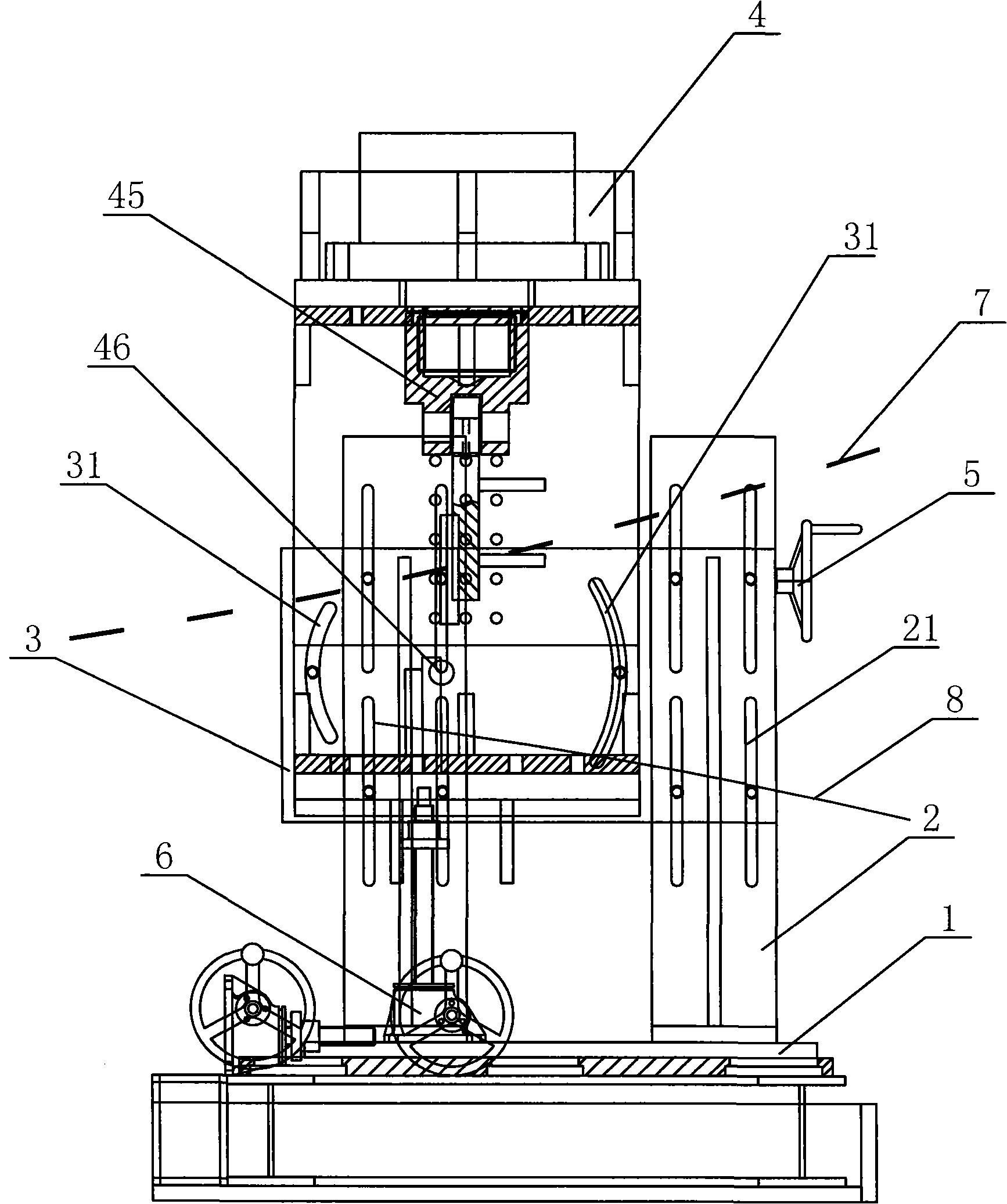

[0014] Please refer to figure 1 and figure 2 as shown, figure 1 It is a structural schematic diagram of a hydraulic shearing machine of the present invention; figure 2 It is a structural schematic diagram of the shearing tool of the hydraulic shearing machine of the present invention.

[0015] In this embodiment, a hydraulic shearing machine includes a base 1 on which two brackets 2 spaced apart are fixed, and the bracket 2 is equipped with two mounting plates 3 spaced apart, And the two brackets 2 are provided with elongated height adjustment holes 21, the mounting plate 3 is installed on the bracket 2 through the height adjustment holes 21, and the height adjustment of the mounting plate 3 is connected by a worm gear reducer. Runner 6, rotating height adjustment runner 6 can adjust the setting height of mounting plate 3, and between described two mounting plates 3, shearing cutter 4 is installed, and described shearing cutter 4 comprises knife rest 41, and described kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com