Electric control system of numerical-control plate shearing machine

An electrical control system and shearing machine technology, applied in the direction of electrical program control, general control system, control/regulation system, etc., can solve the problems of long maintenance cycle, long supply cycle, inability to meet, etc., and achieve easy maintenance and easy maintenance. Operation, affordable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

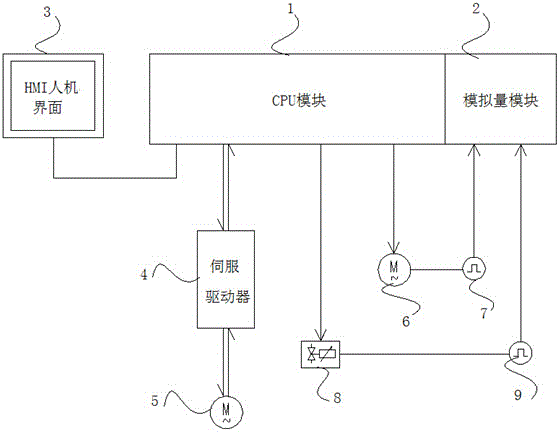

[0016] like figure 1 A kind of electric control system of numerical control shearing machine shown, its programmable logic controller PLC comprises CPU module 1, analog quantity module 2, HMI man-machine interface 3, the high-speed counting port of CPU module 1 is connected with servo drive 4, cutting edge respectively The input end of the gap adjustment motor 6 and the input end of the solenoid valve 8 are connected, and the CPU module 1 has a high-speed counting function and a high-speed pulse output function;

[0017] The servo driver 4 is connected to the servo motor 5, and the servo motor 5 is connected to the backgauge; the CPU module 1 sends a high-speed pulse signal with an appropriate duty ratio to the servo driver 4, and the servo encoder in the servo driver 4 converts the gear ratio to The displacement signal is sent to the servo motor 5, and the servo moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com