Soybean milk maker with large milk capacity range and control method thereof

A capacity range and control method technology, applied in dairy products, food preparation, beverage preparation devices, etc., can solve the problems of inconvenient use for consumers, undercooked soybean milk, insufficient crushing, etc., and achieve the effect of expanding the range of water level capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

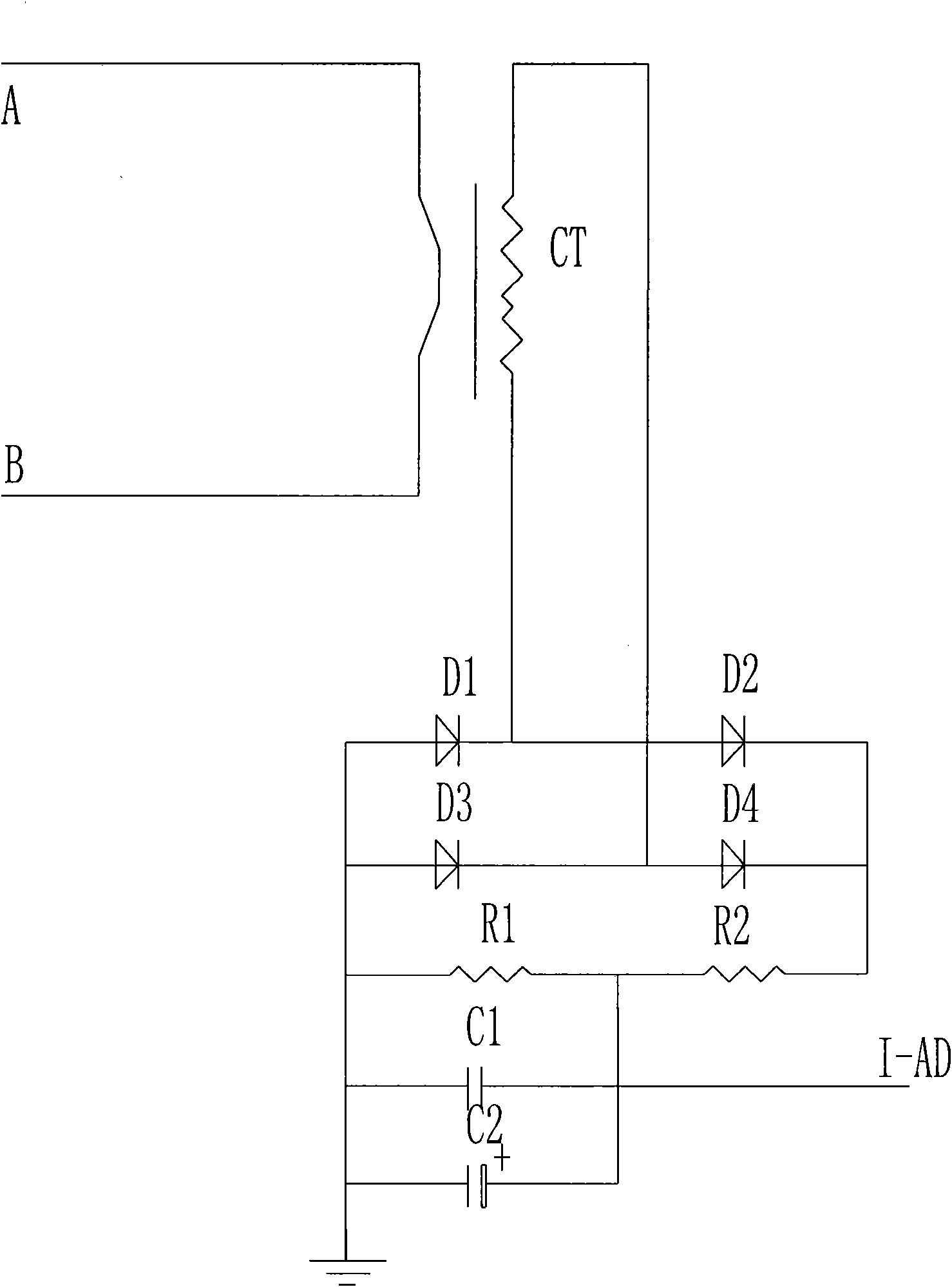

[0030] A soybean milk machine with a large pulping capacity range, including a heating device, a crushing device, a temperature sensing device, an overflow prevention device, and a device capable of judging the pulping capacity according to the temperature change parameters measured by the temperature sensing device, and then setting the heating The control device of the working program of the device or the crushing device; the control device is respectively connected with the heating device, the crushing device, the temperature sensing device and the overflow prevention device.

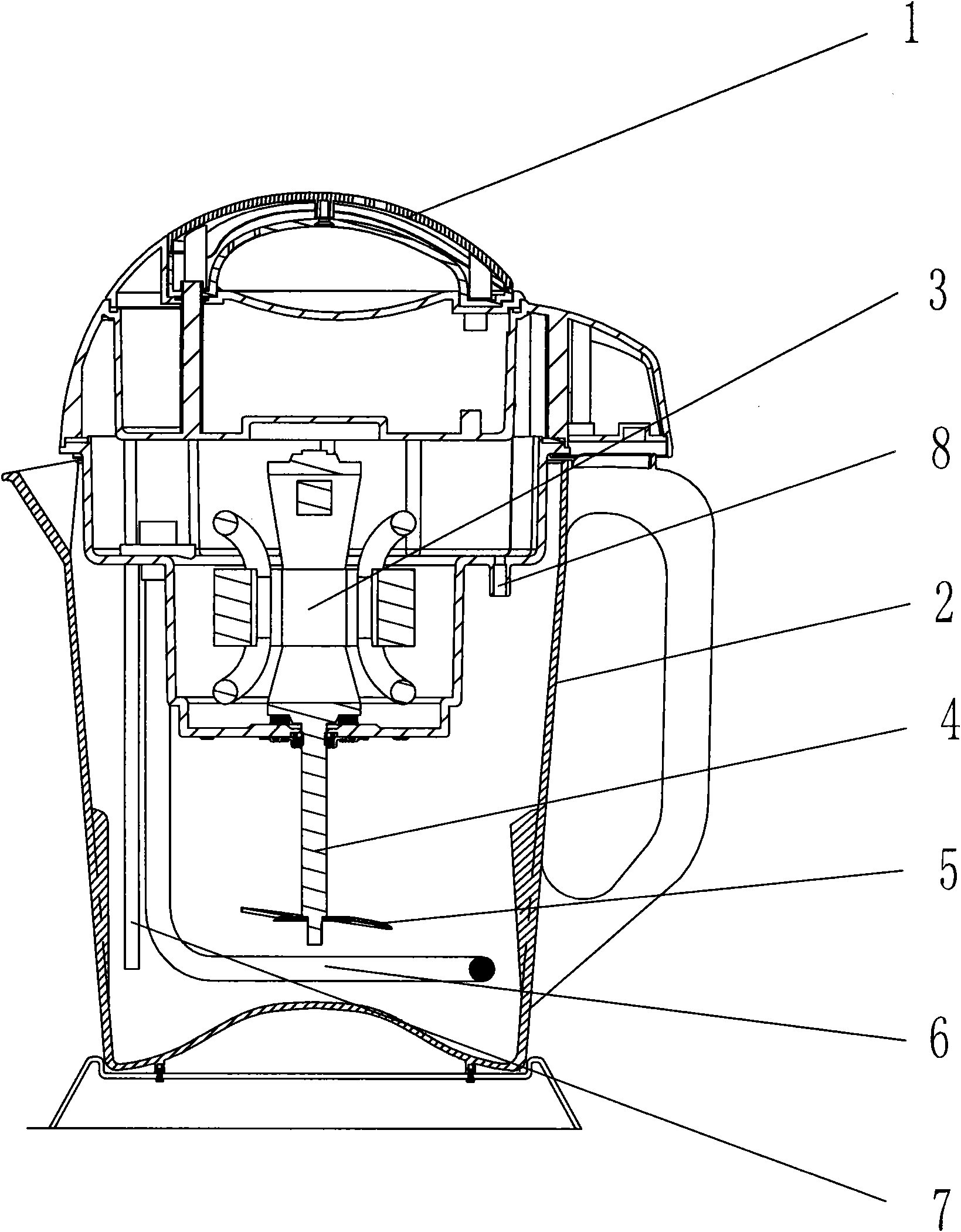

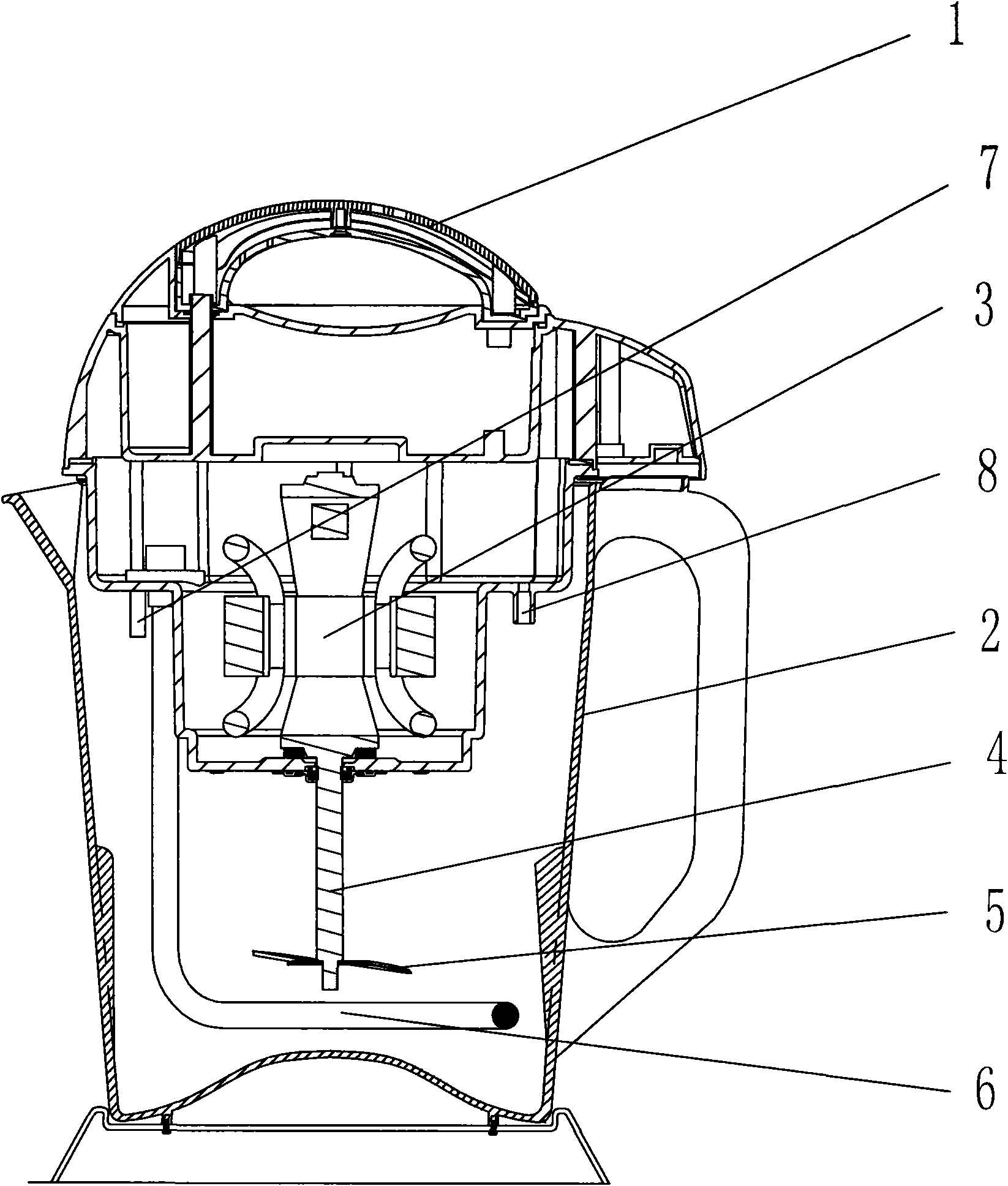

[0031] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention, which consists of two parts: a machine head 1 and a cup body 2 (pulping container). The heating device is a heat pipe 6 extending downward from the machine head 1. The provided cutter head 5, the rotating shaft 4 of the cutter head 5 is connected with the motor 3, the anti-overflow device adopts the anti-ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com