Patents

Literature

3644 results about "Cooking process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The cooking process involves using a variety of methods and tools to prepare a set of ingredients so that they are digestible and have flavour. The process uses a form of scientific method and so the quantities of different ingredients and the conditions in which the food is prepared influence the resulting product.

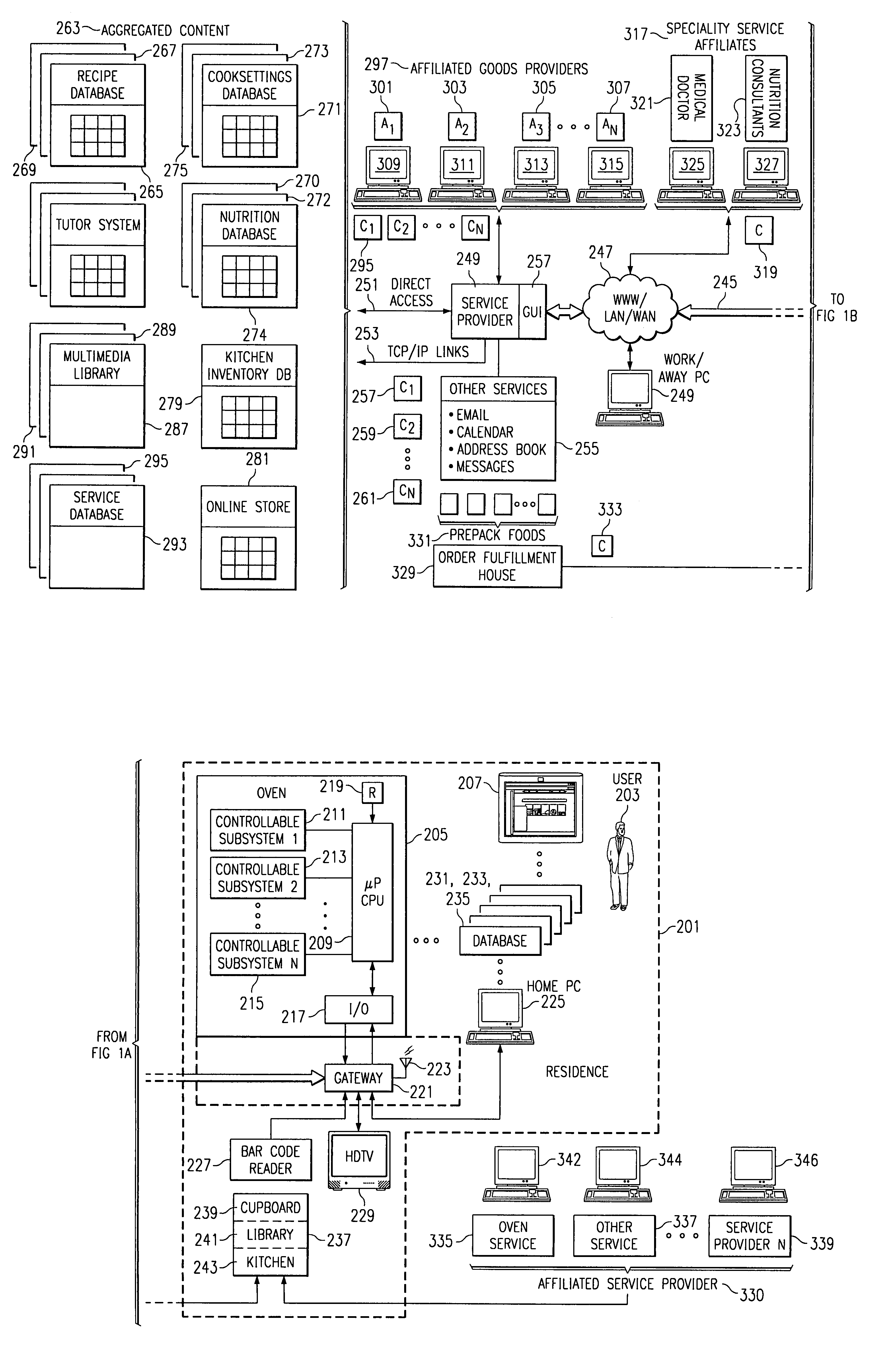

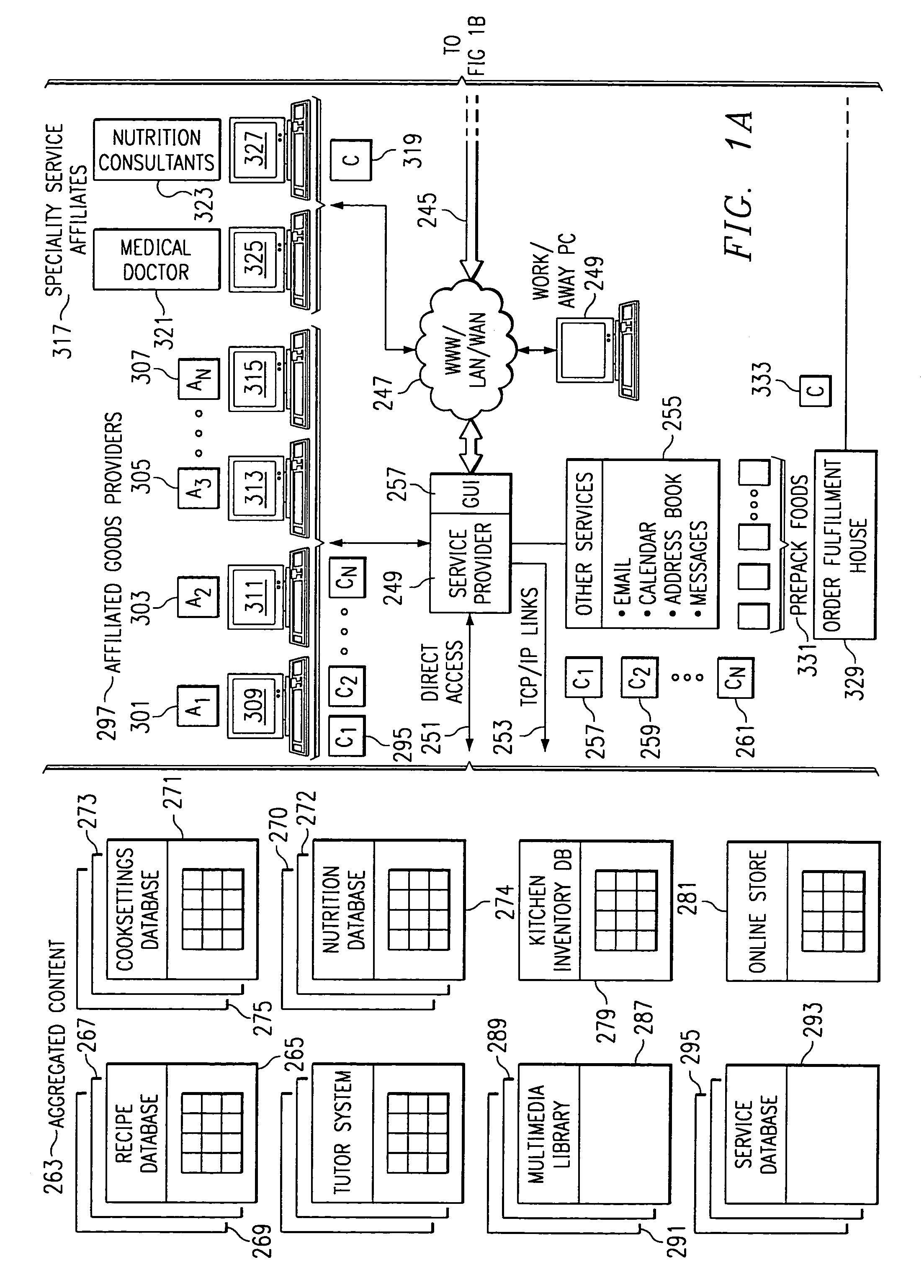

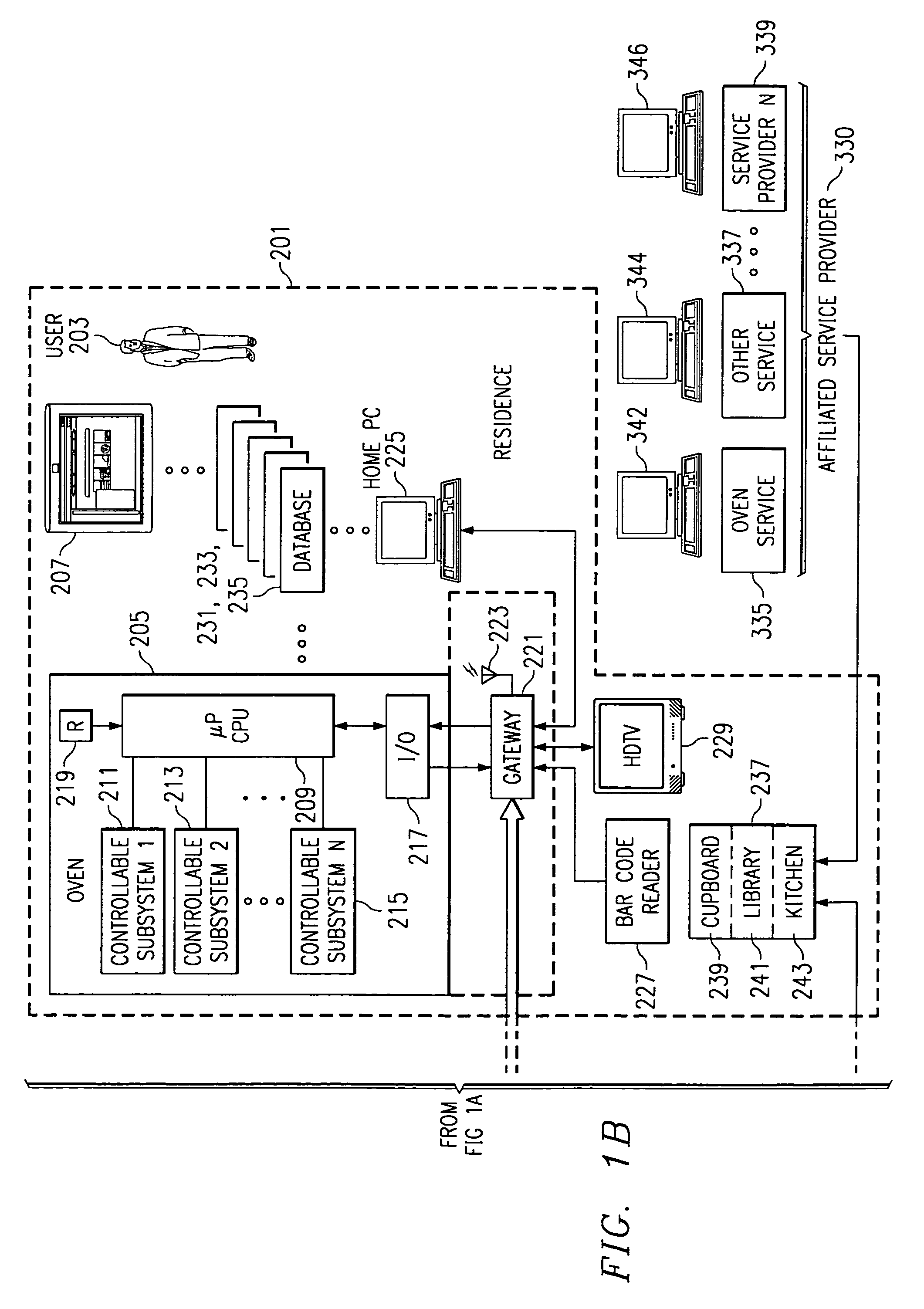

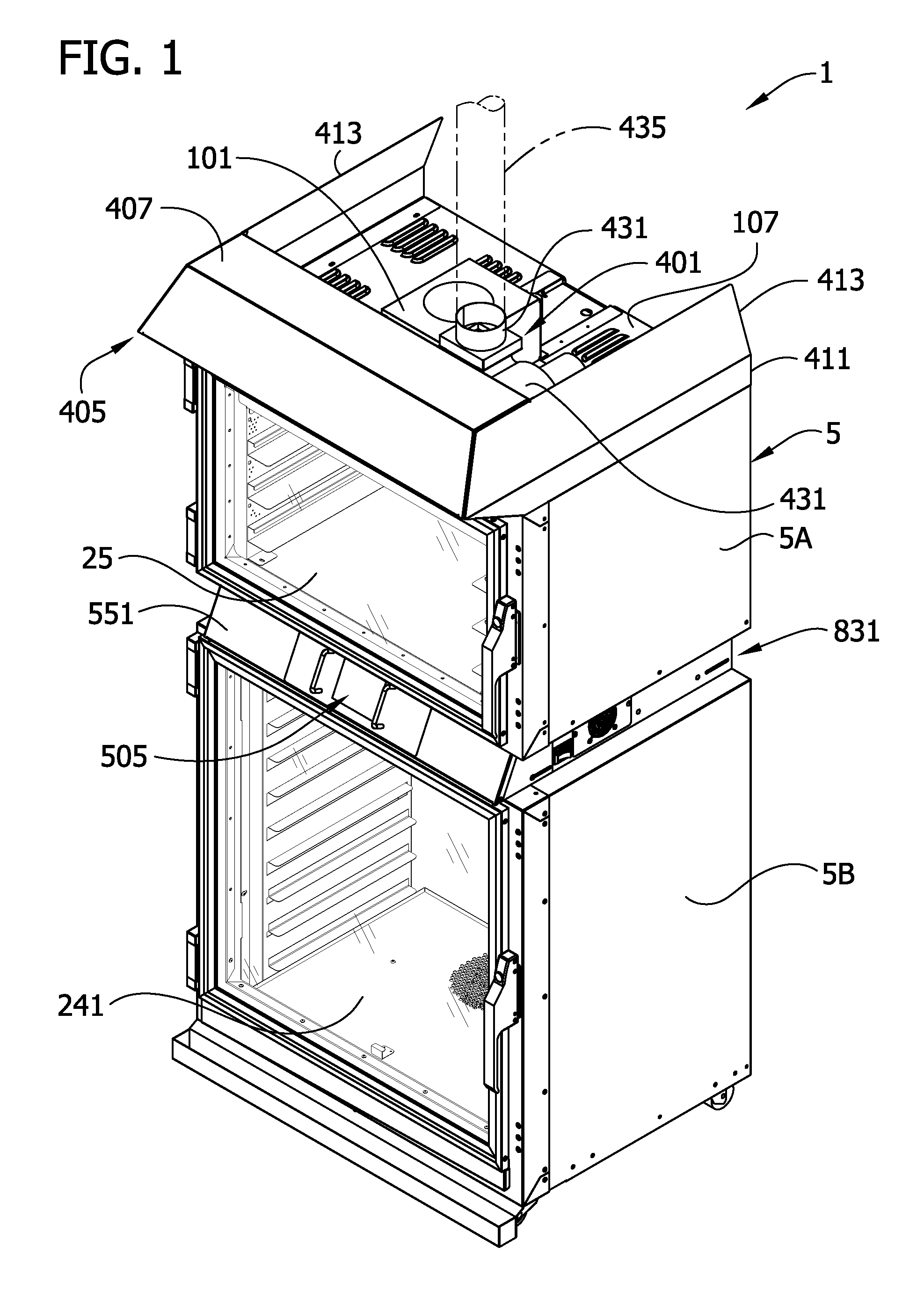

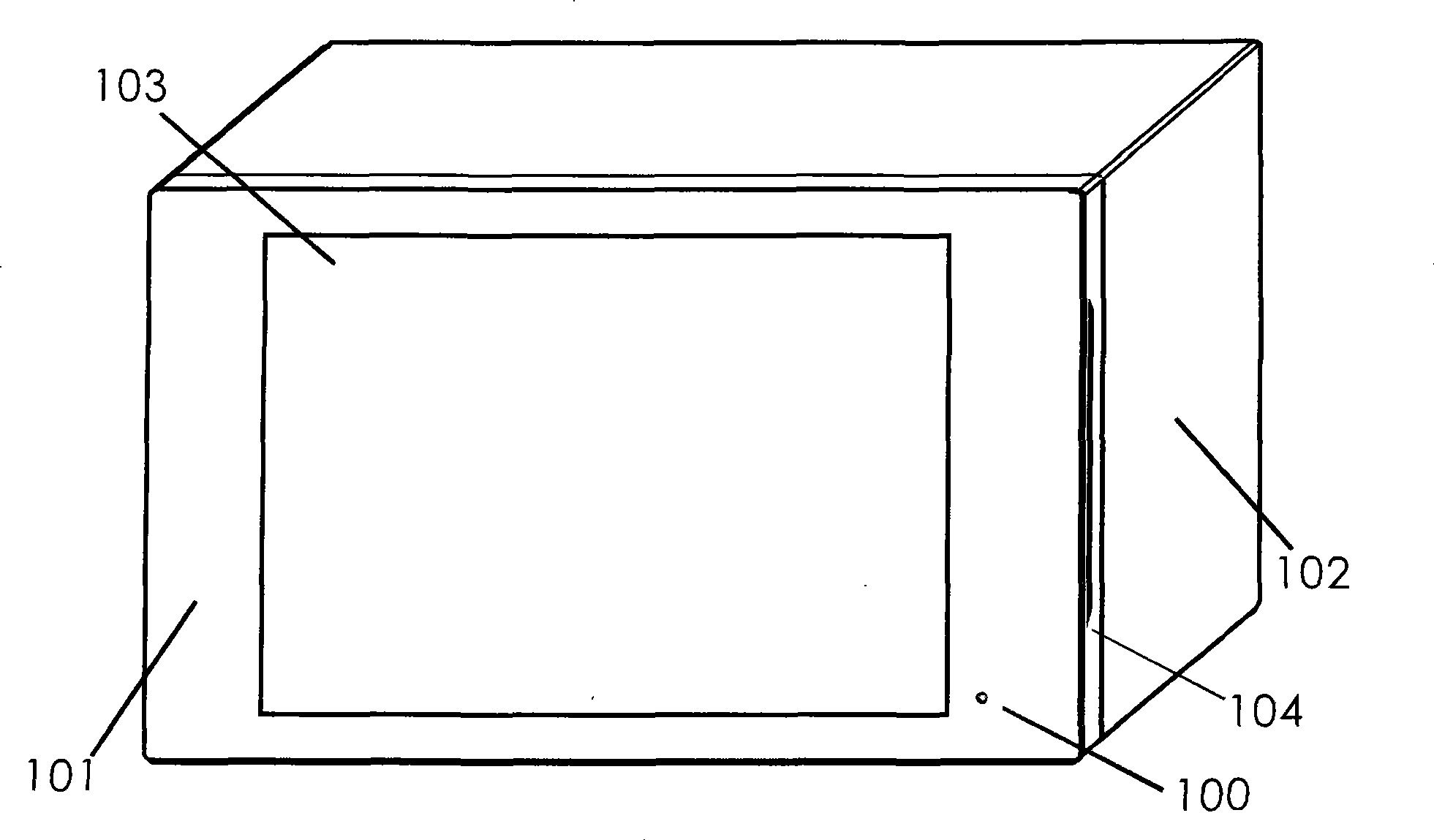

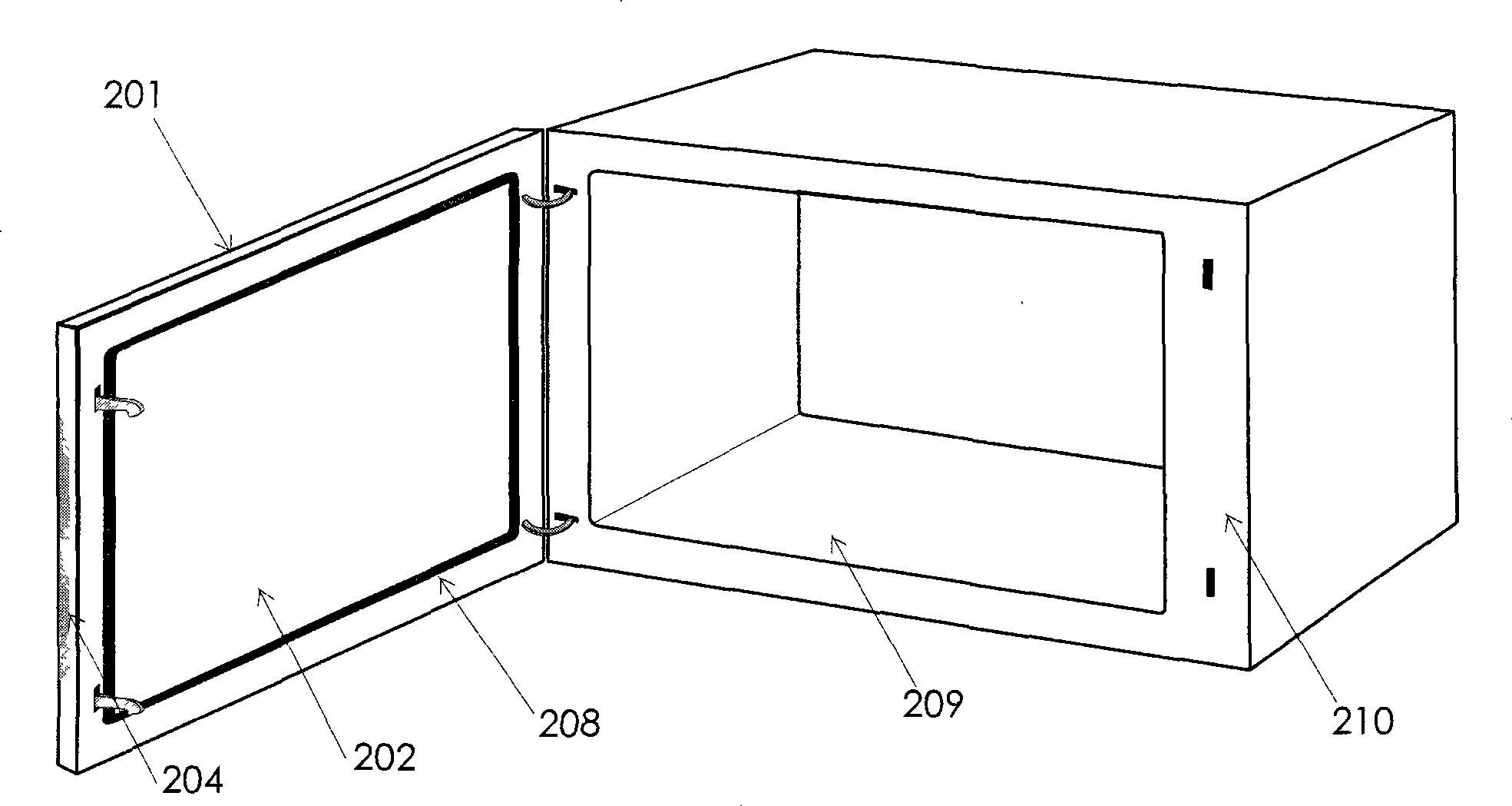

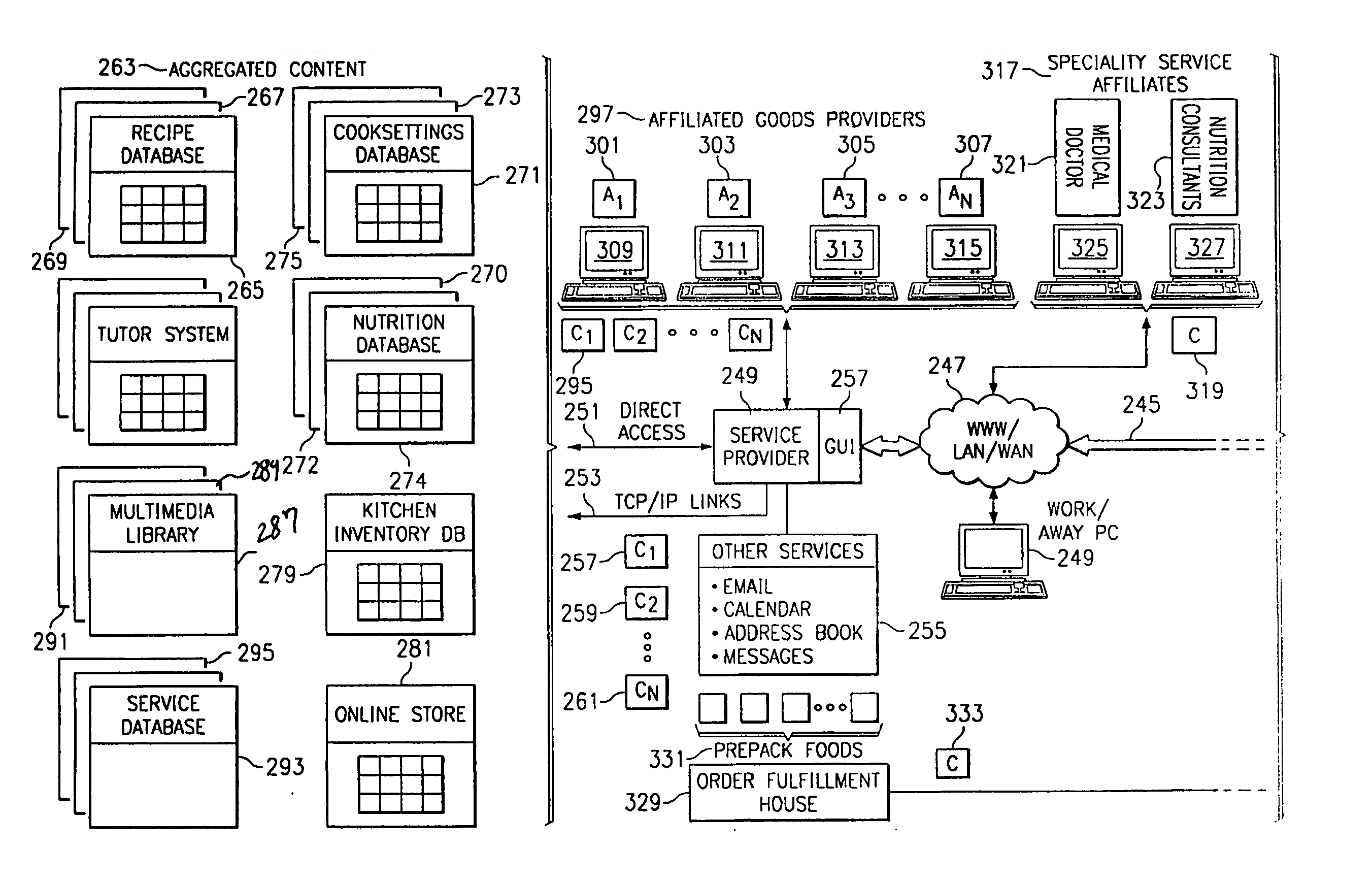

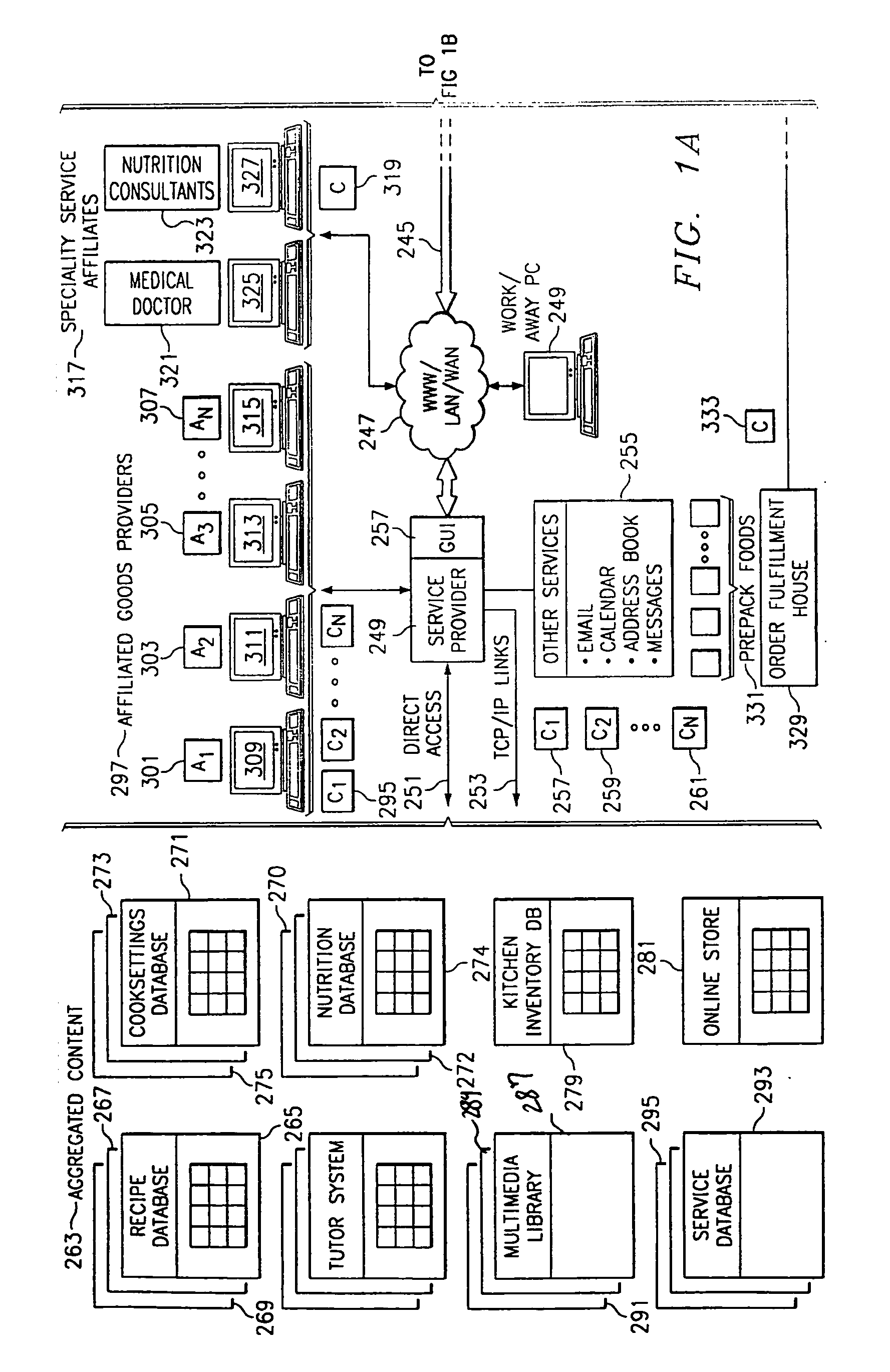

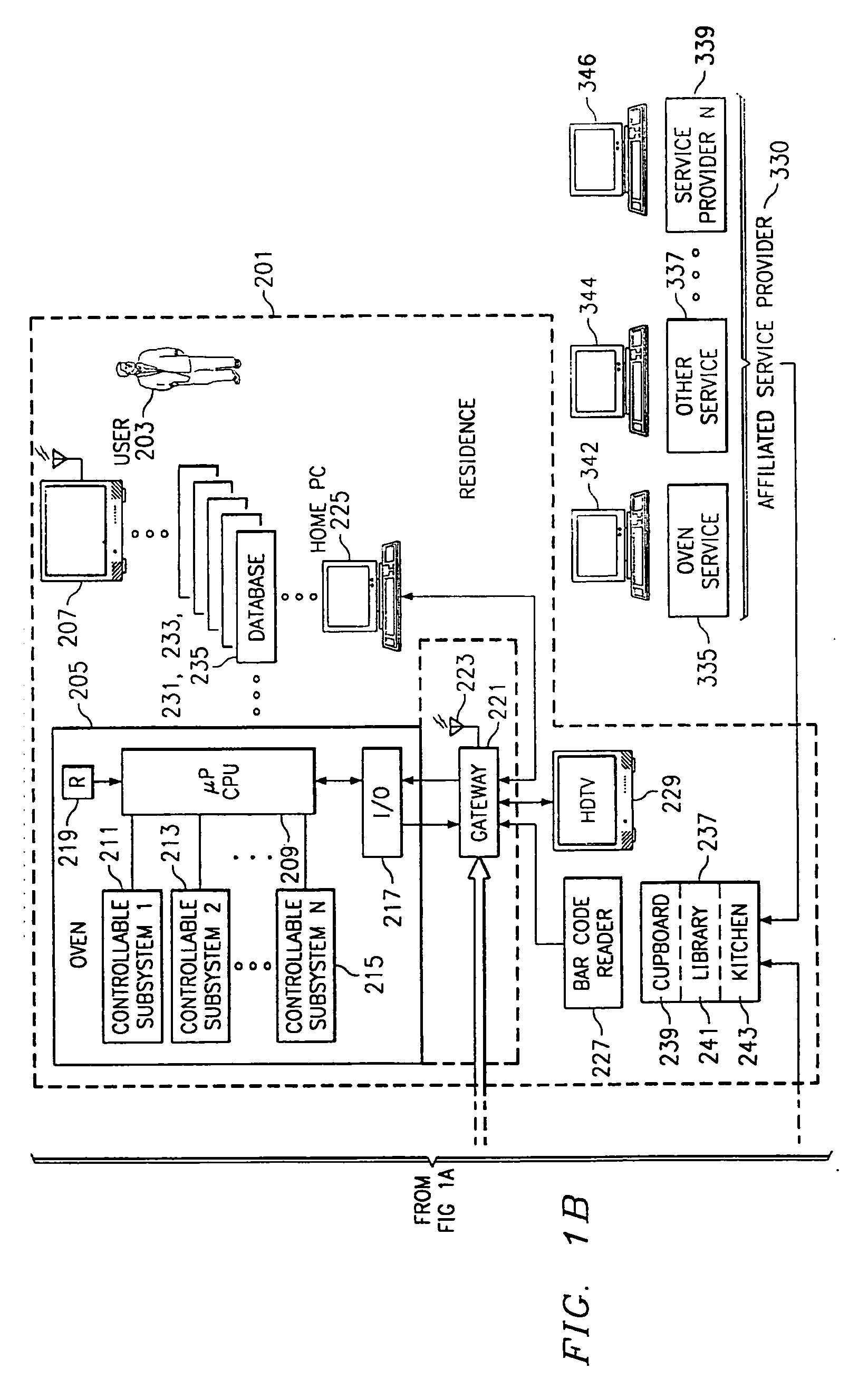

Rapid cooking oven with broadband communication capability to increase ease of use

An improved oven for use in a residence is described. The oven includes a cooking chamber, a programmable controller for executing program instructions, memory media for recording executable program instructions, and at least one controllable cooking system under control of the programmable controller, which provides a data-processing-controlled high speed cooking process which may be applied to food placed in the oven chamber. A plurality of cooking programs are recorded in the memory media of the oven. These define a plurality of high speed cooking routines available for use with the oven. A gateway server is communicatively coupled to the programmable controller. It manages the communication of digital content which is at least in-part related to operation and utilization of the improved oven. A broadband communication channel extends from a source of digital content, which is external to the residence, to the residence. The broadband communication channel delivers particular digital content related to the oven through the gateway server for distribution within the residence, including distribution to the programmable controller of the oven in order to facilitate cooking operations utilizing the oven.

Owner:TURBOCHEF TECH INC

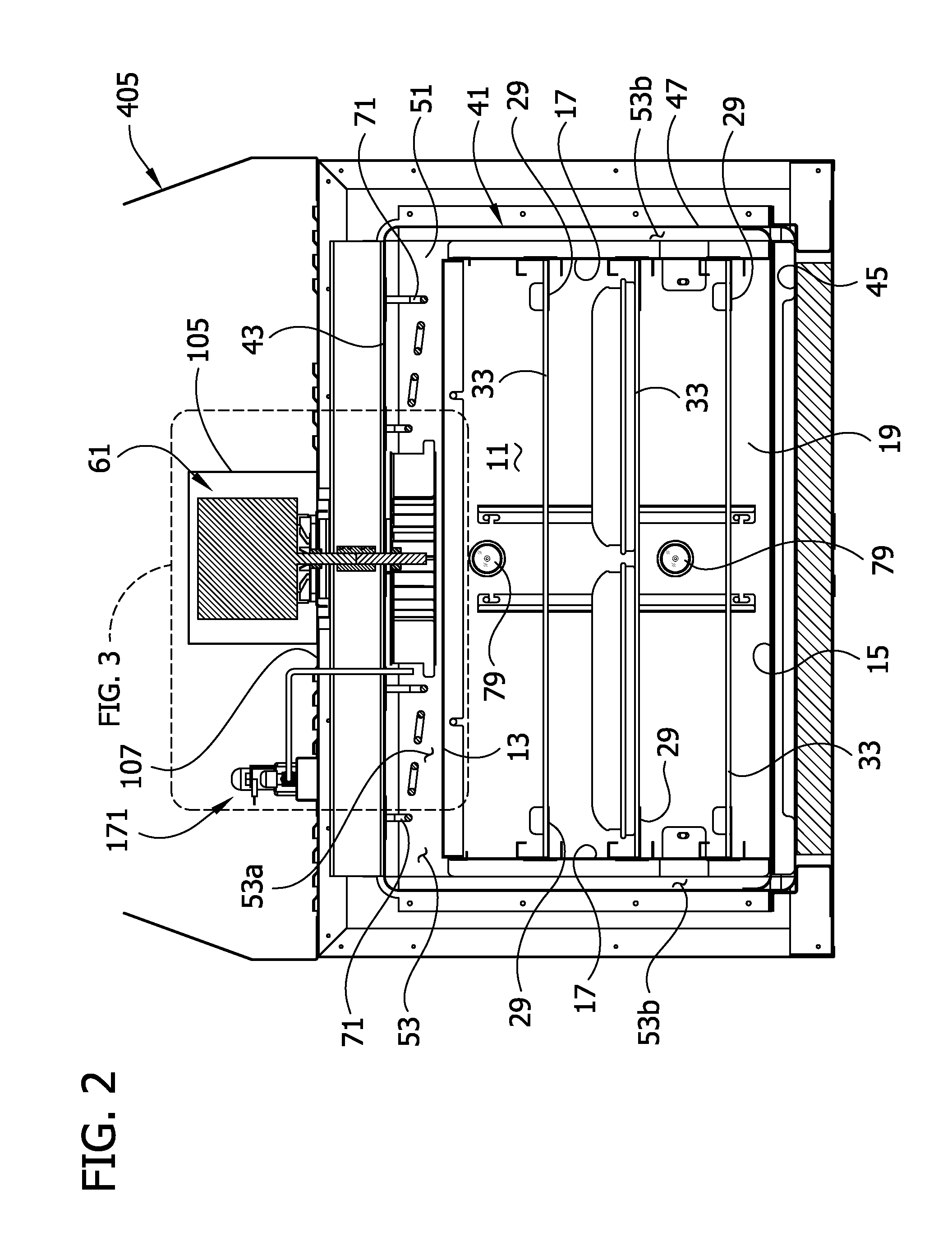

Convection oven

ActiveUS8378265B2Easy accessSelf-cleaning stoves/rangesElectrical heating fuelImpellerLiquid-crystal display

Owner:DUKE MANUFACTURING COMPANY

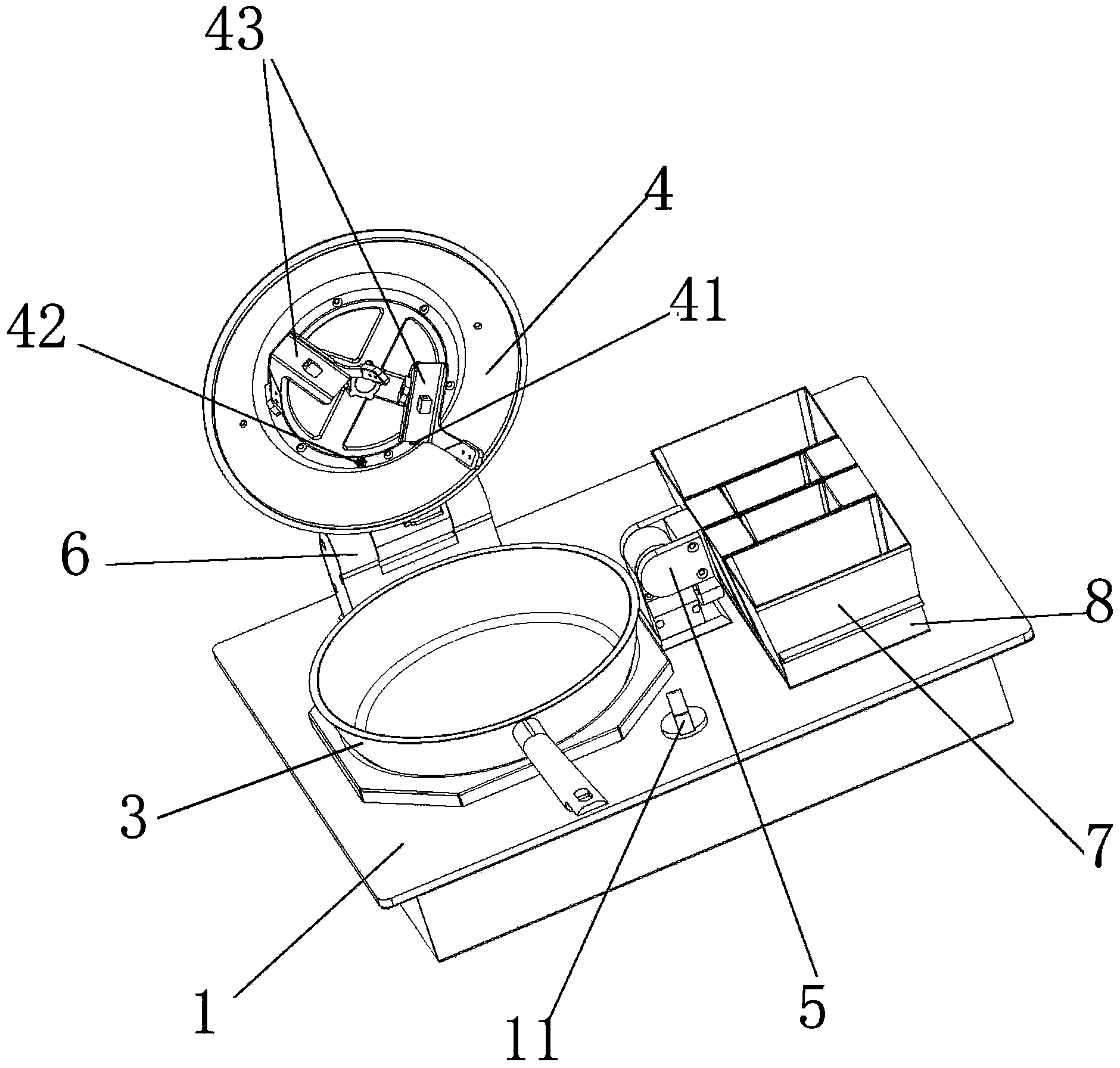

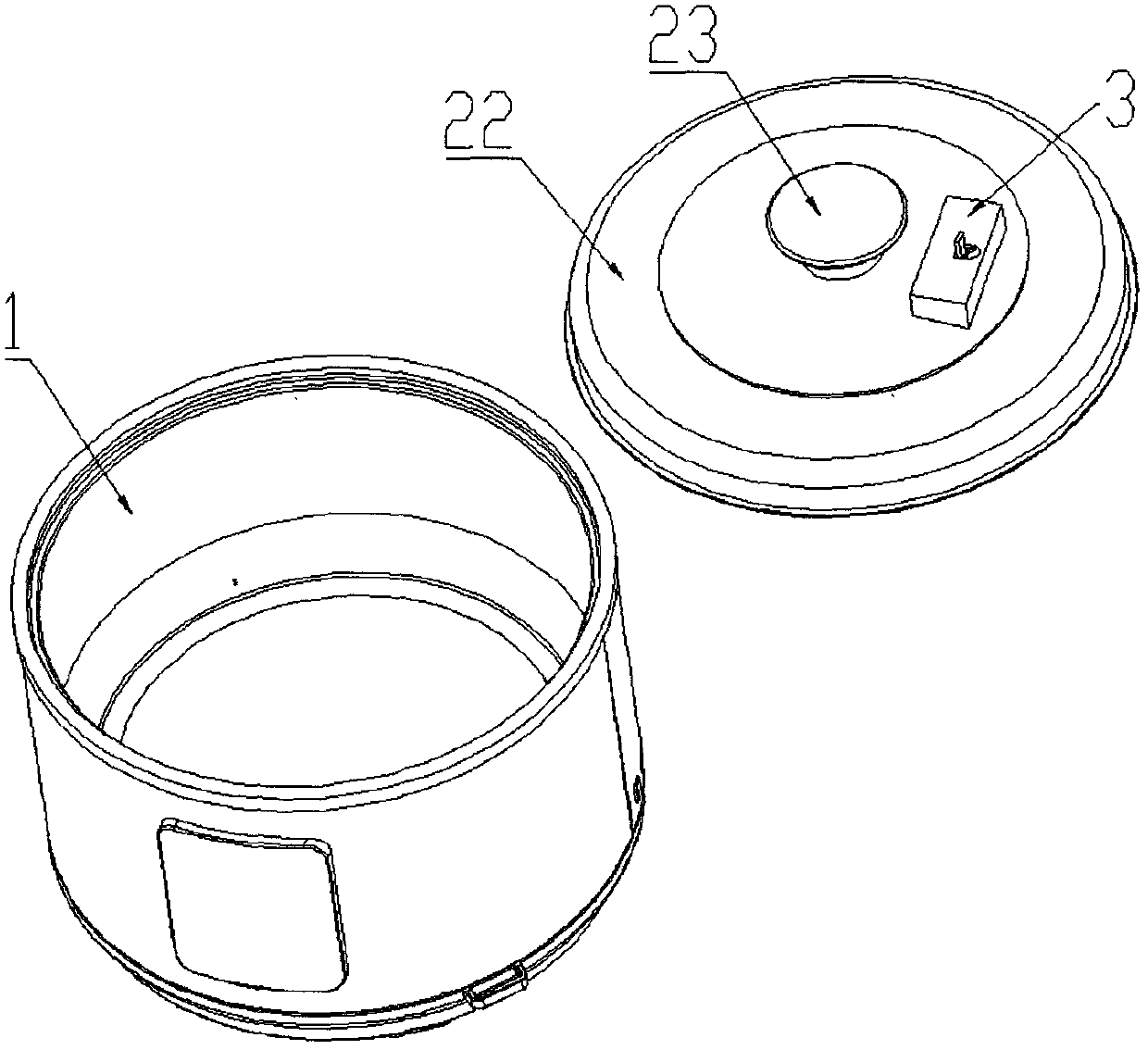

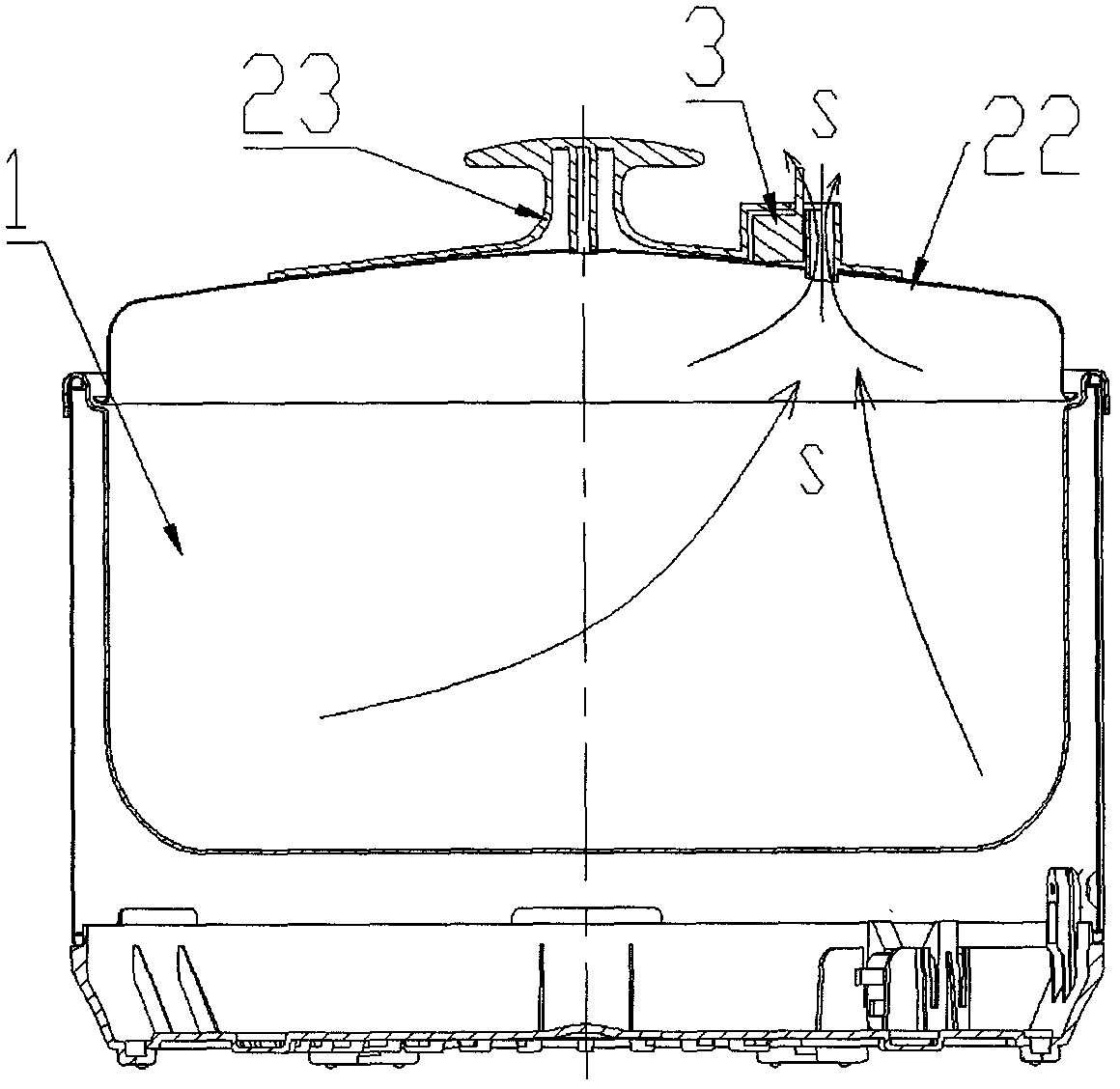

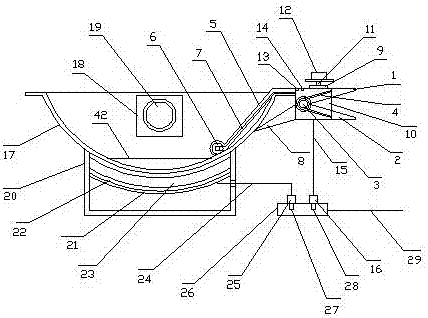

Intelligent cooking equipment

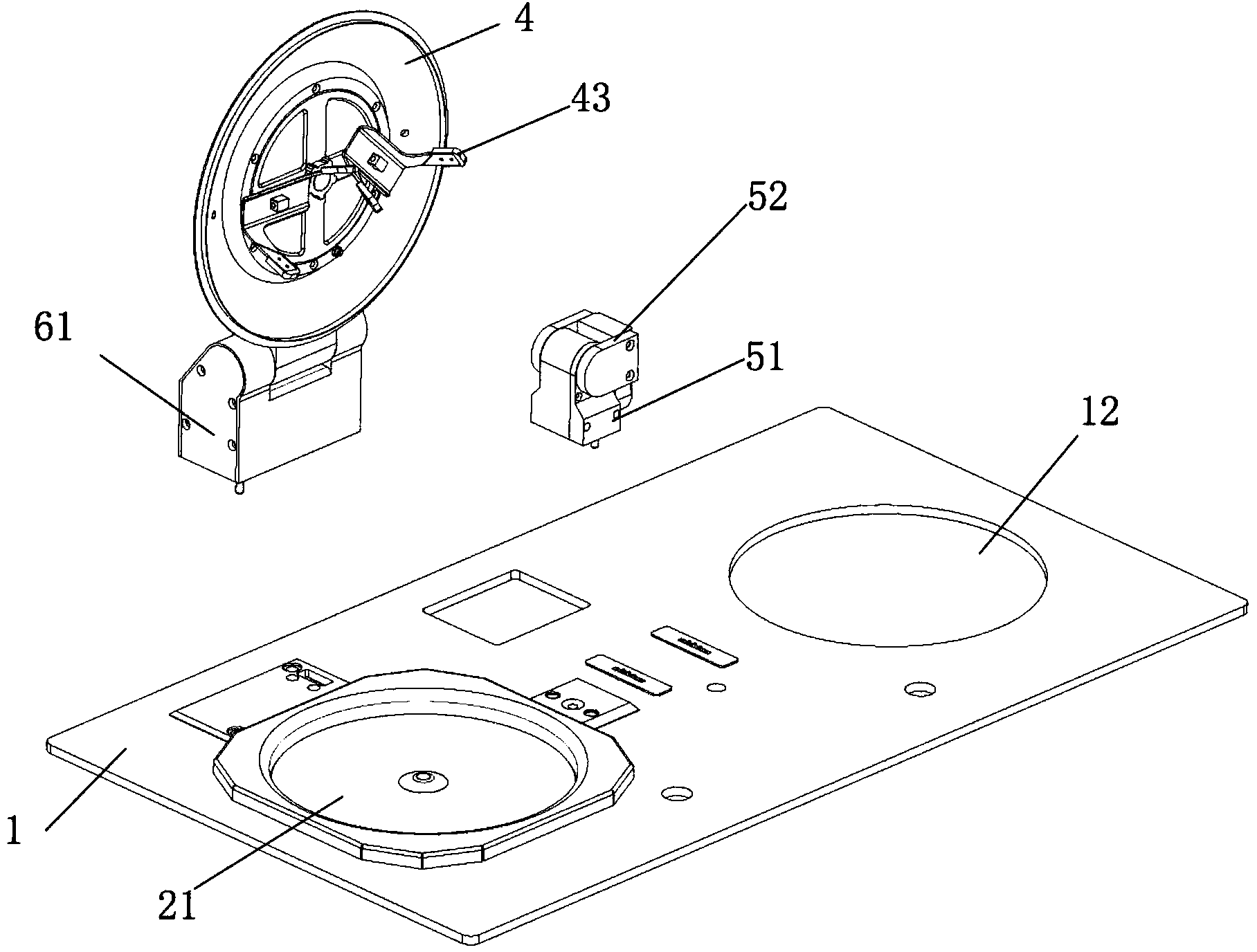

InactiveCN103892696ACompact structureReduce volumeCooking-vessel lids/coversFood materialEngineering

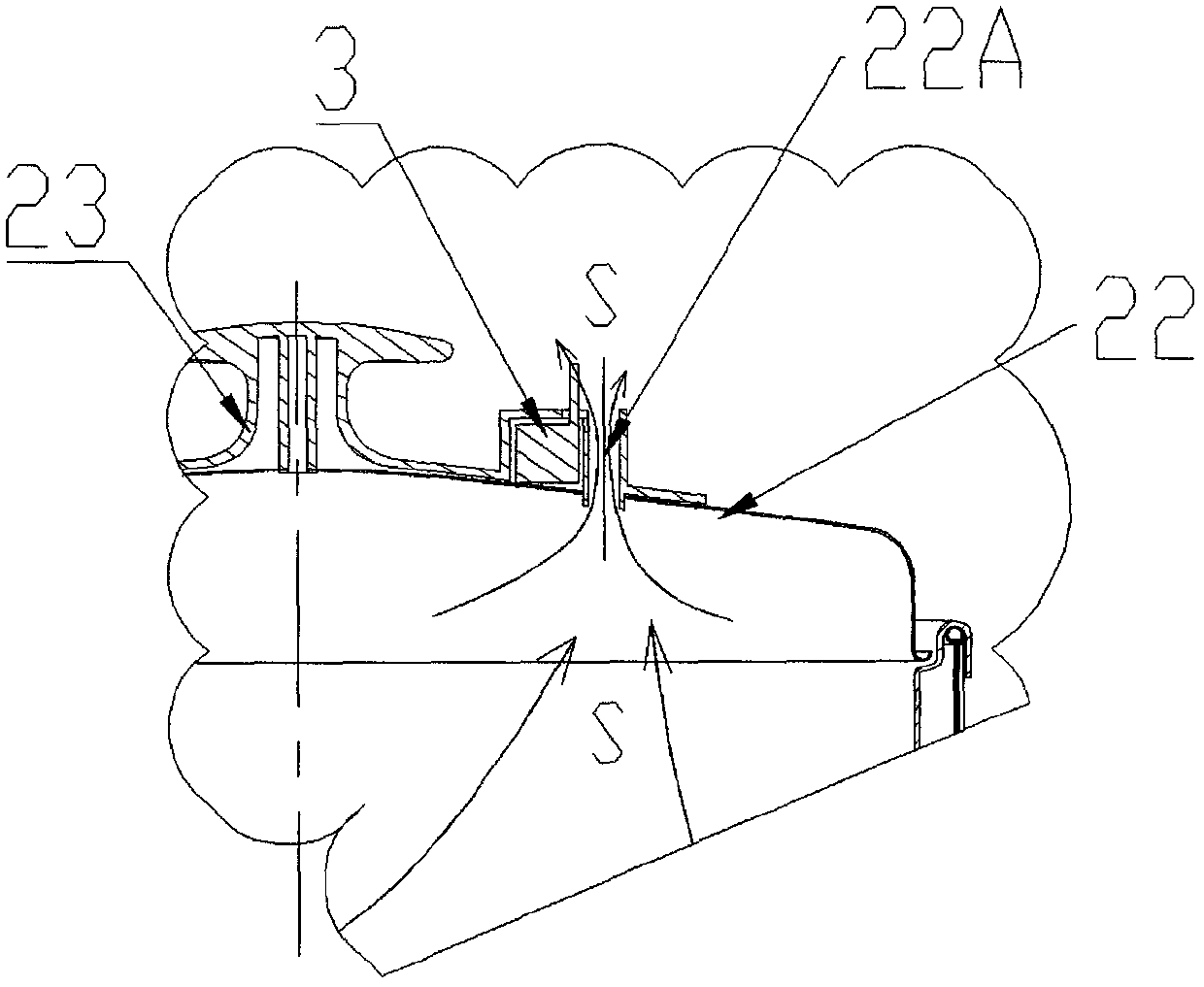

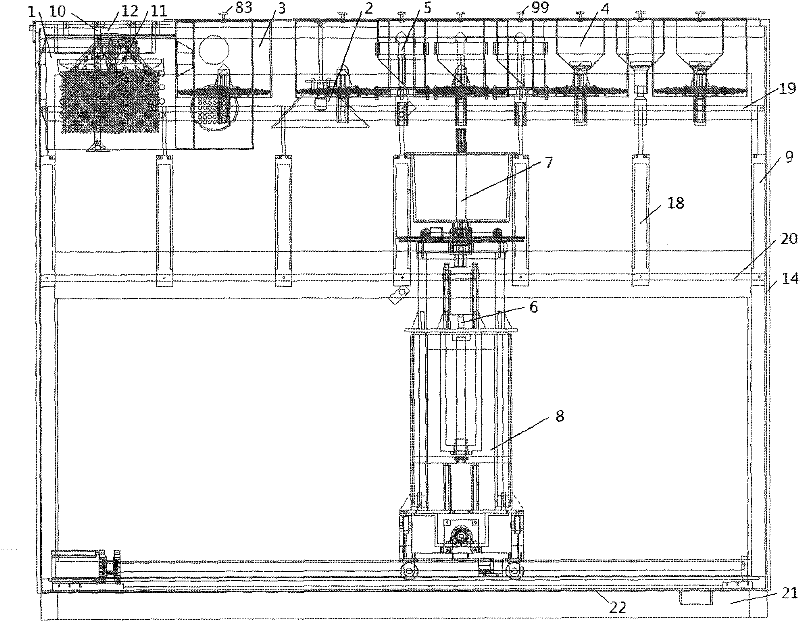

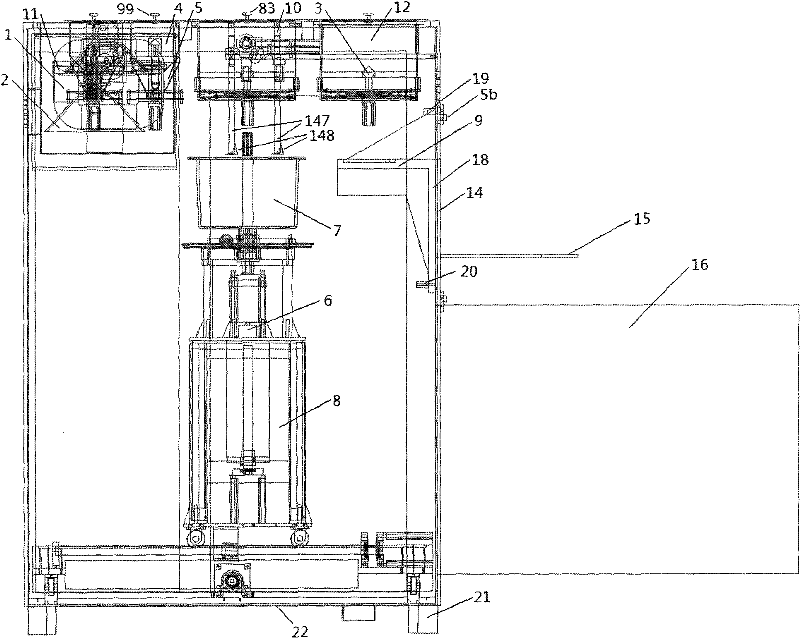

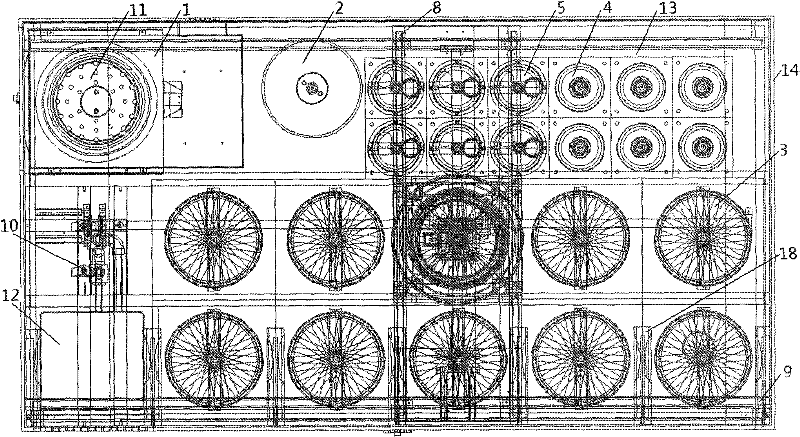

The invention discloses intelligent cooking equipment. The intelligent cooking equipment comprises a cooking bench (1), a heating mechanism (2), a pot body (3), a pot cover (4) arranged at the upper end of the pot body (3) and a control mechanism, and is characterized in that a feeding mechanism (5) is arranged on one side of the pot body (3), the feeding mechanism (5) is controlled through the control mechanism to be turned so as to feed cooking materials into the pot body, the pot cover (4) is fixedly connected with a pot cover driving mechanism (6), and the pot cover driving mechanism (6) is controlled through the control mechanism to be turned so as to open and close the pot cover. The intelligent cooking equipment achieves automatic cooking, food materials and seasoning are added according to appointed sequences in the cooking process, and the cooking process completely simulates an artificial cooking process, and high-quality dishes can be cooked.

Owner:SUZHOU WESTON HOME AUTOMATION

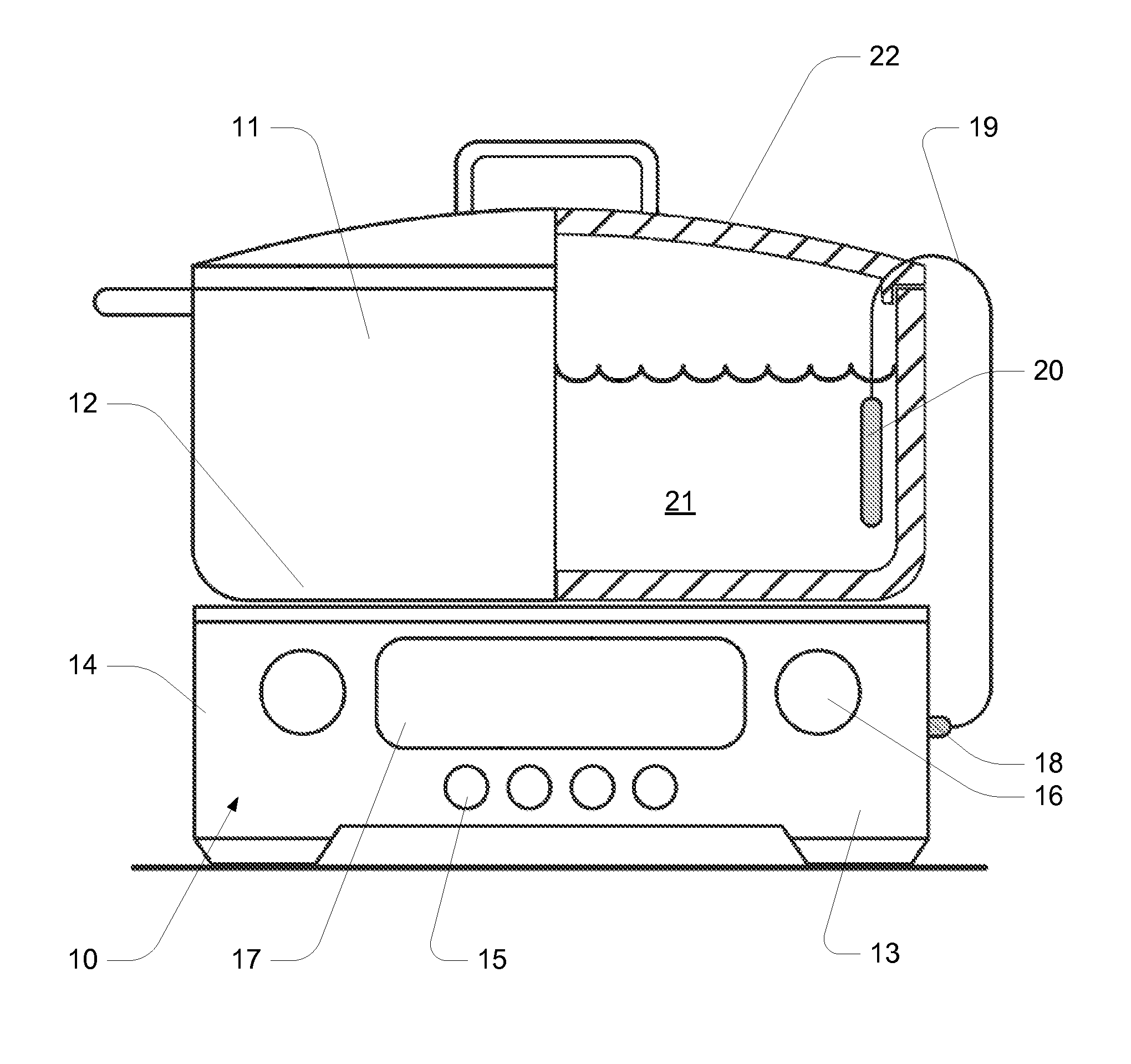

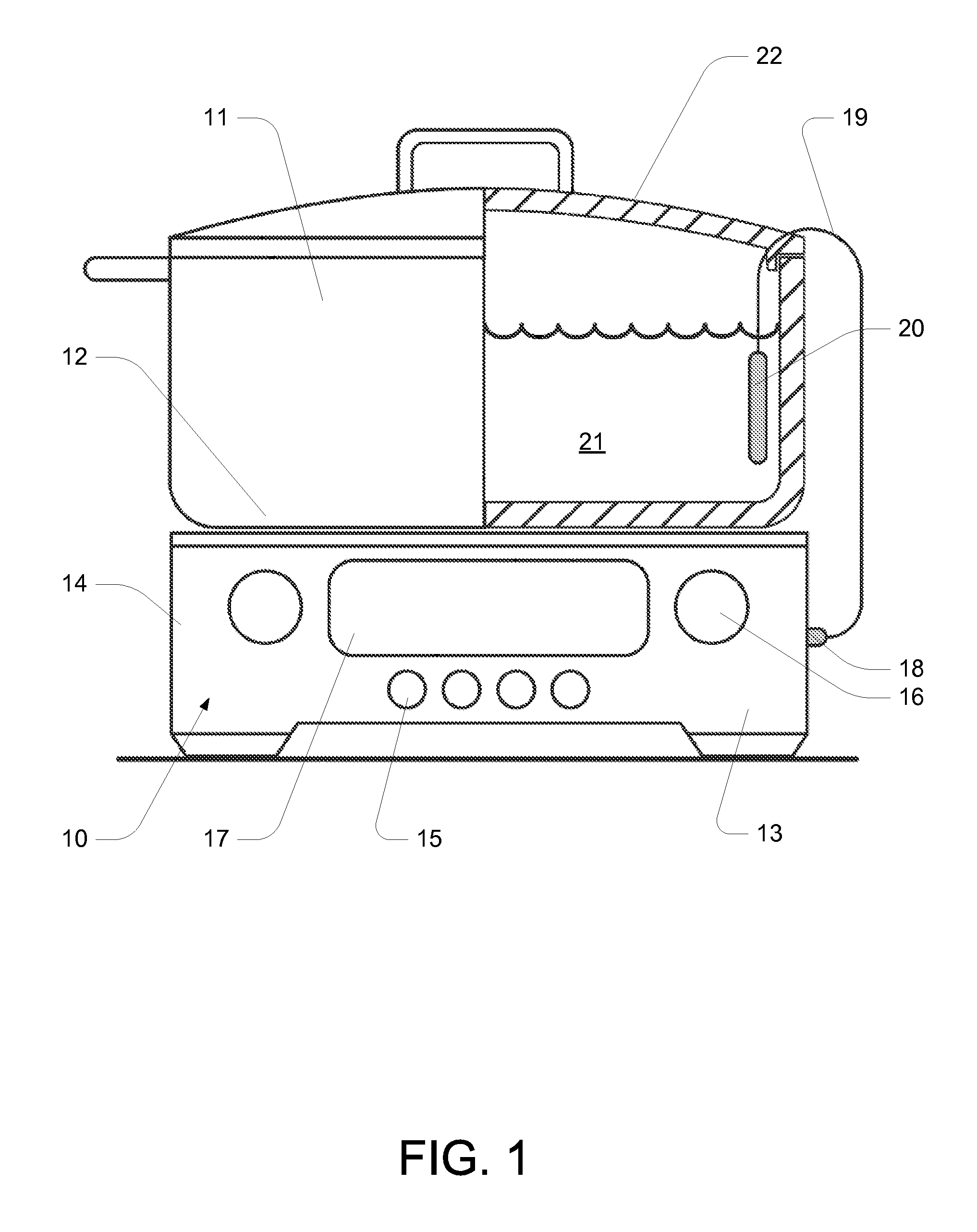

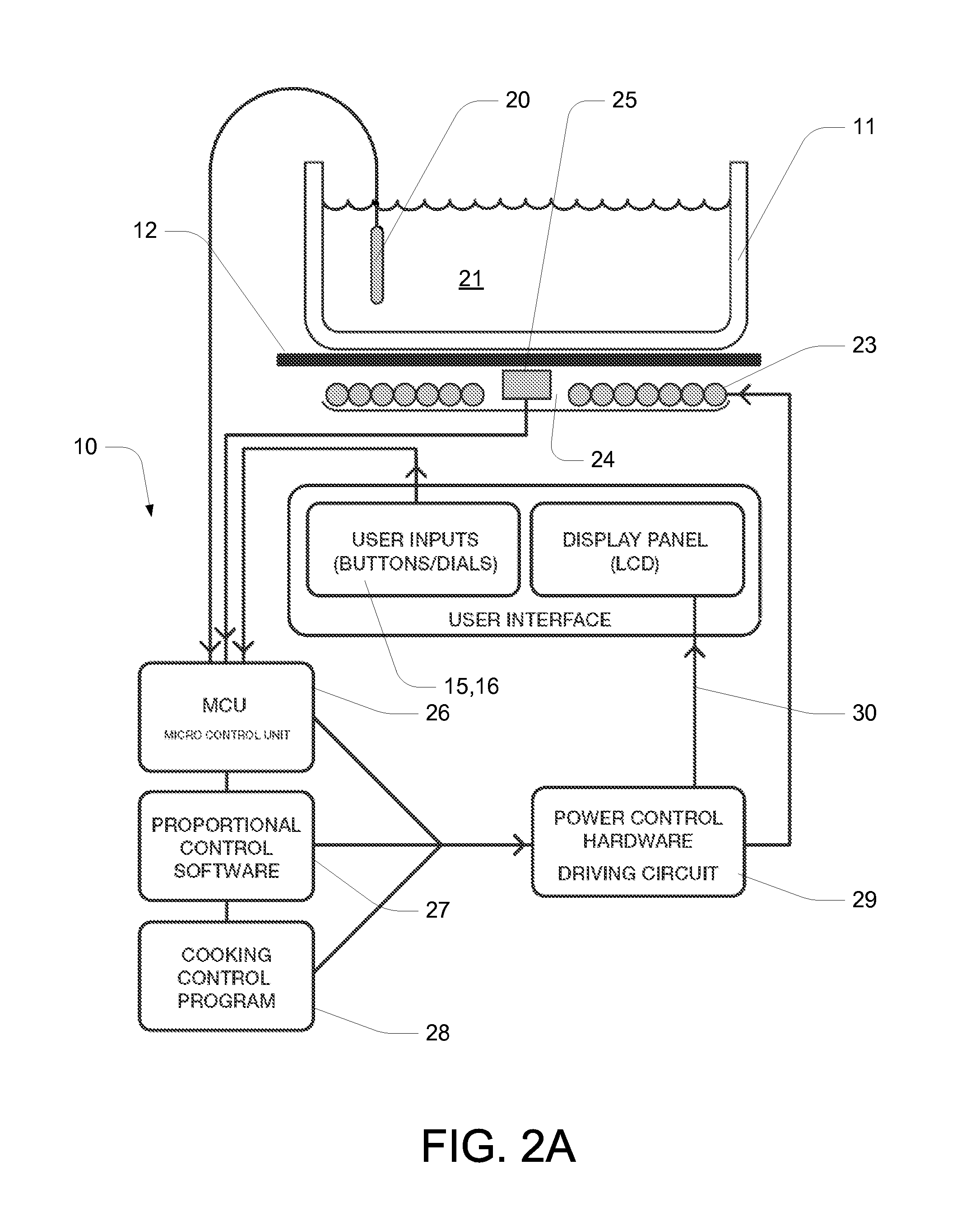

Multi cooker

ActiveUS9191998B2Automation easeEase predictabilityBoiling over preventionWater-bath cooking vesselsTemperature controlEngineering

Owner:BREVILLE HLDG PTY LTD

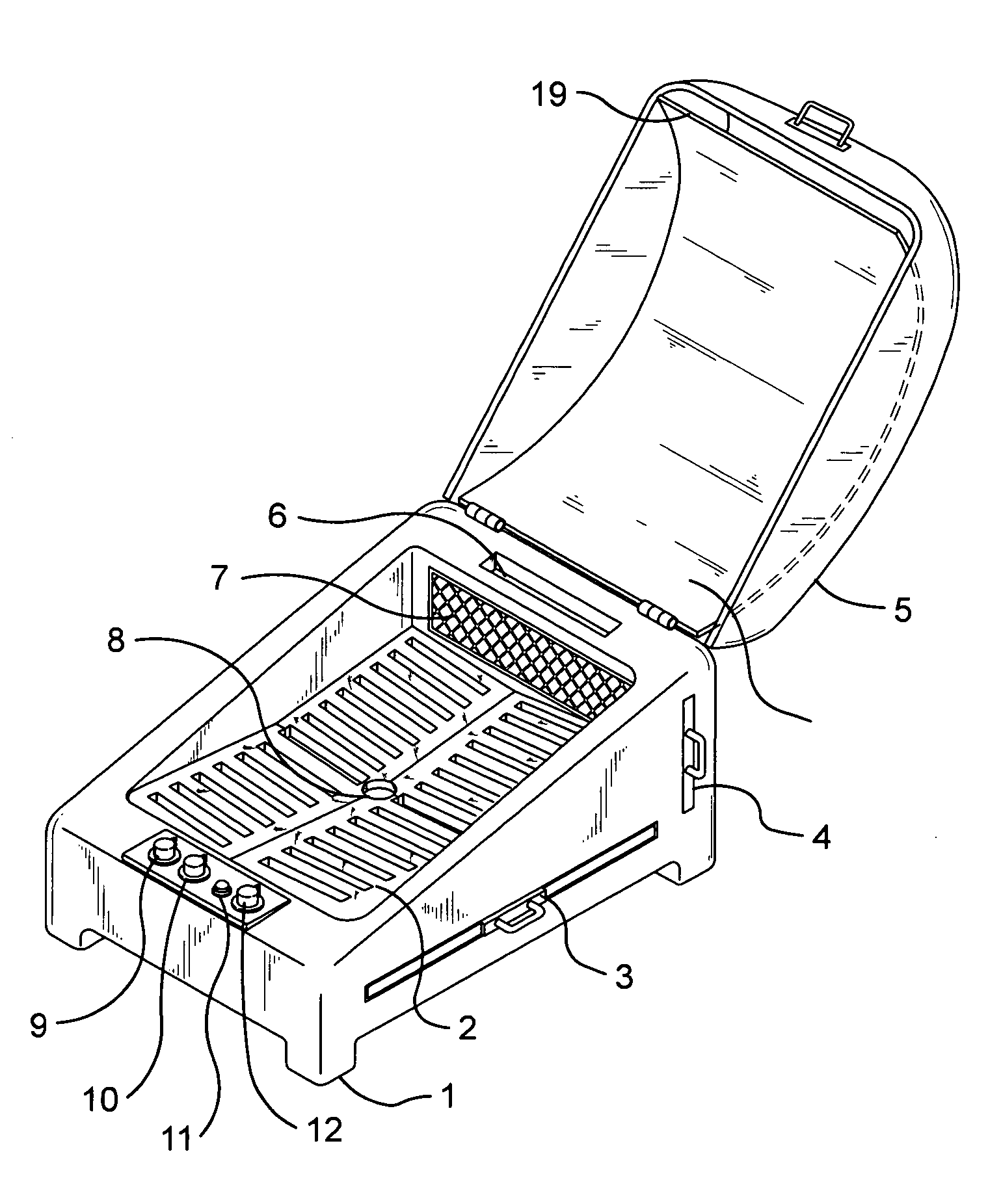

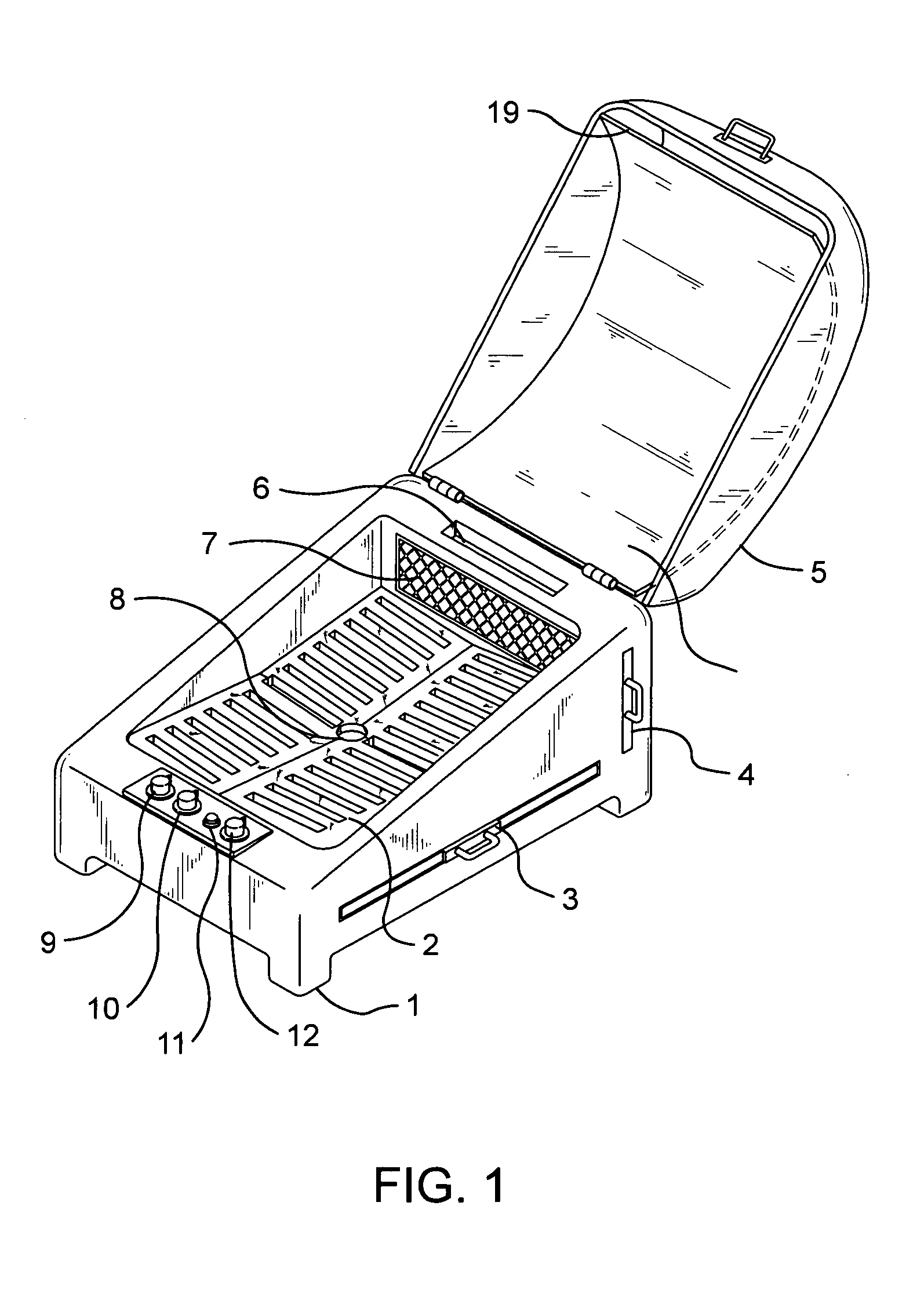

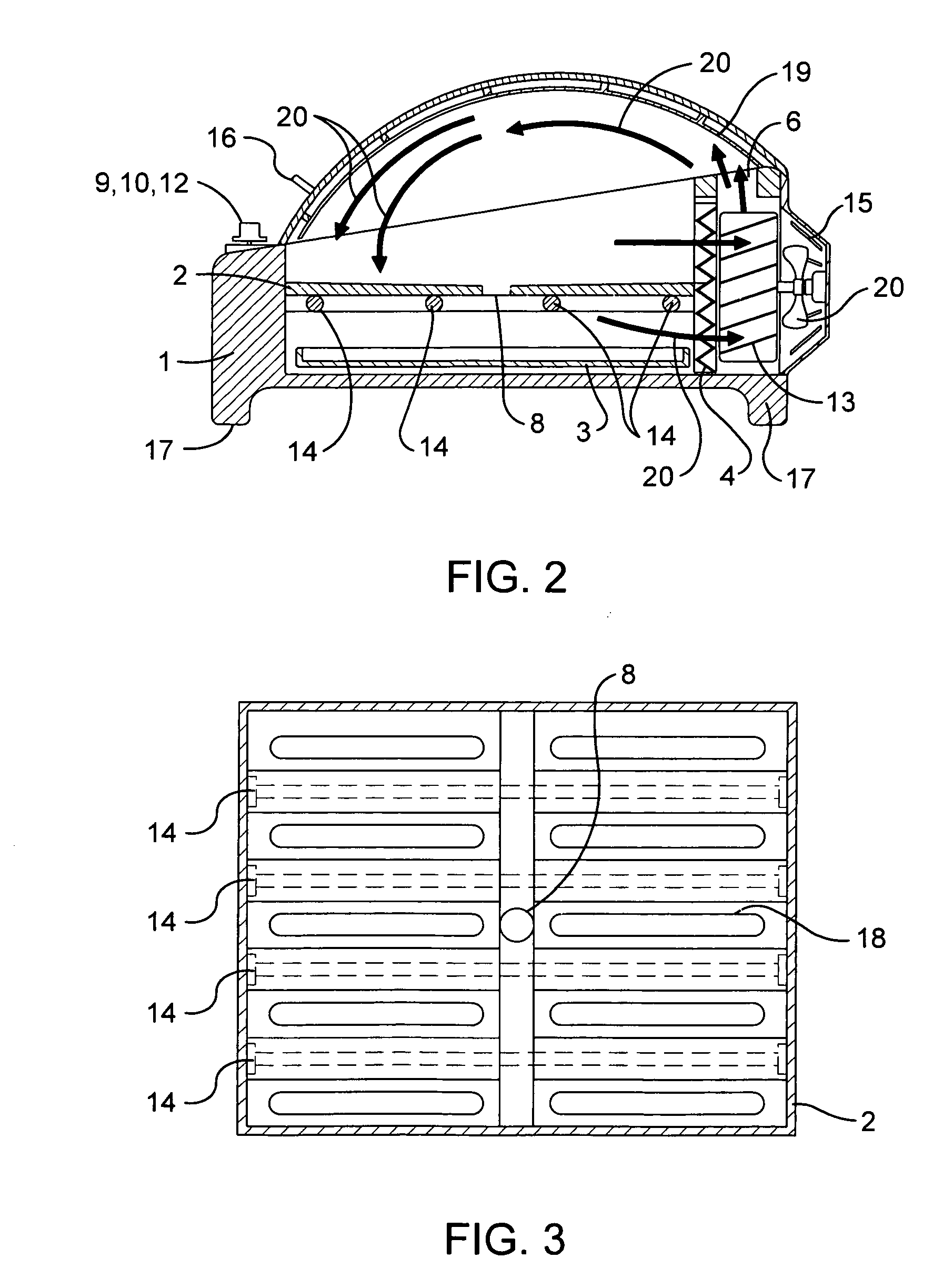

Convection grill

A portable electric grill for that has utilizes an electric fan to draw smoke and cooking odors through a filter then redirects and circulates the cleaner hot air around food to create convection heating thereby improve and making faster the cooking process. The grill can be used for indoor or outdoor use. It has a removable lid that when in the down position it provides the circulation of the hot air throughout the grill. It has a removable grill plate that either sits on top of heating elements or has heating elements imbedded in the grill plate. The grill plate is used for searing various foods and then allowing the convection air to cook the foods throughout. It has controls for regulating temperature, cooking time and fan speed. It has a pull-out grease tray to catch and dispose of drippings from cooking food. The filter is removable for cleaning.

Owner:JONES EDWARD MICHAEL

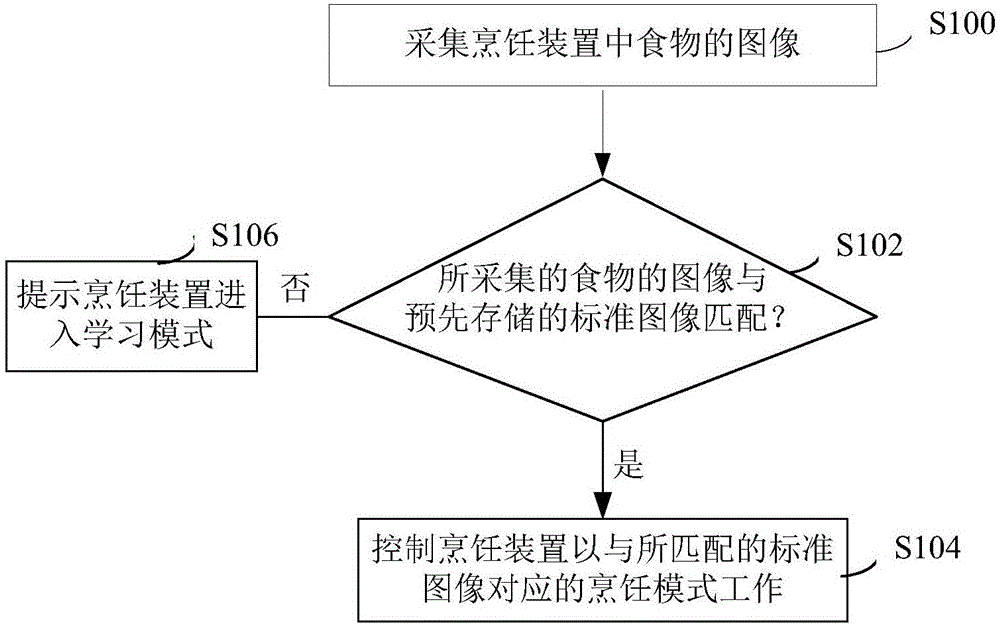

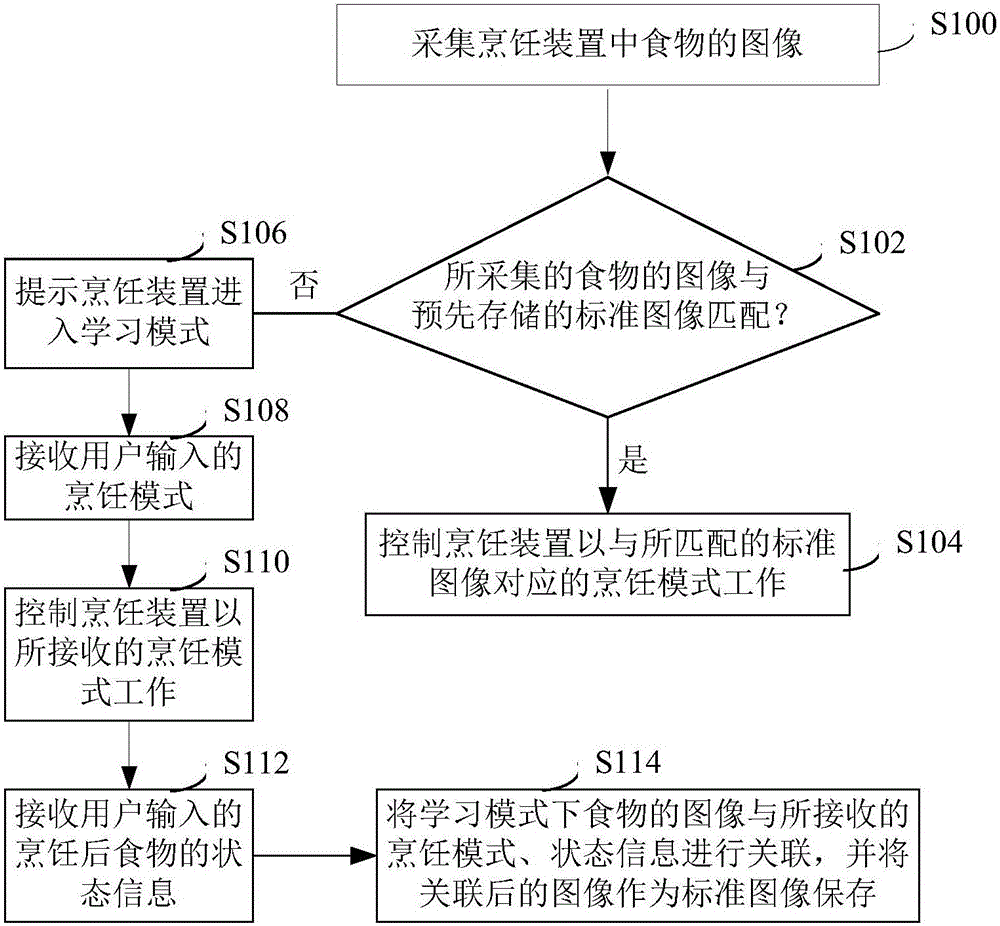

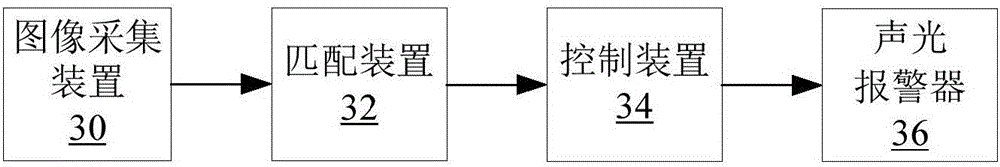

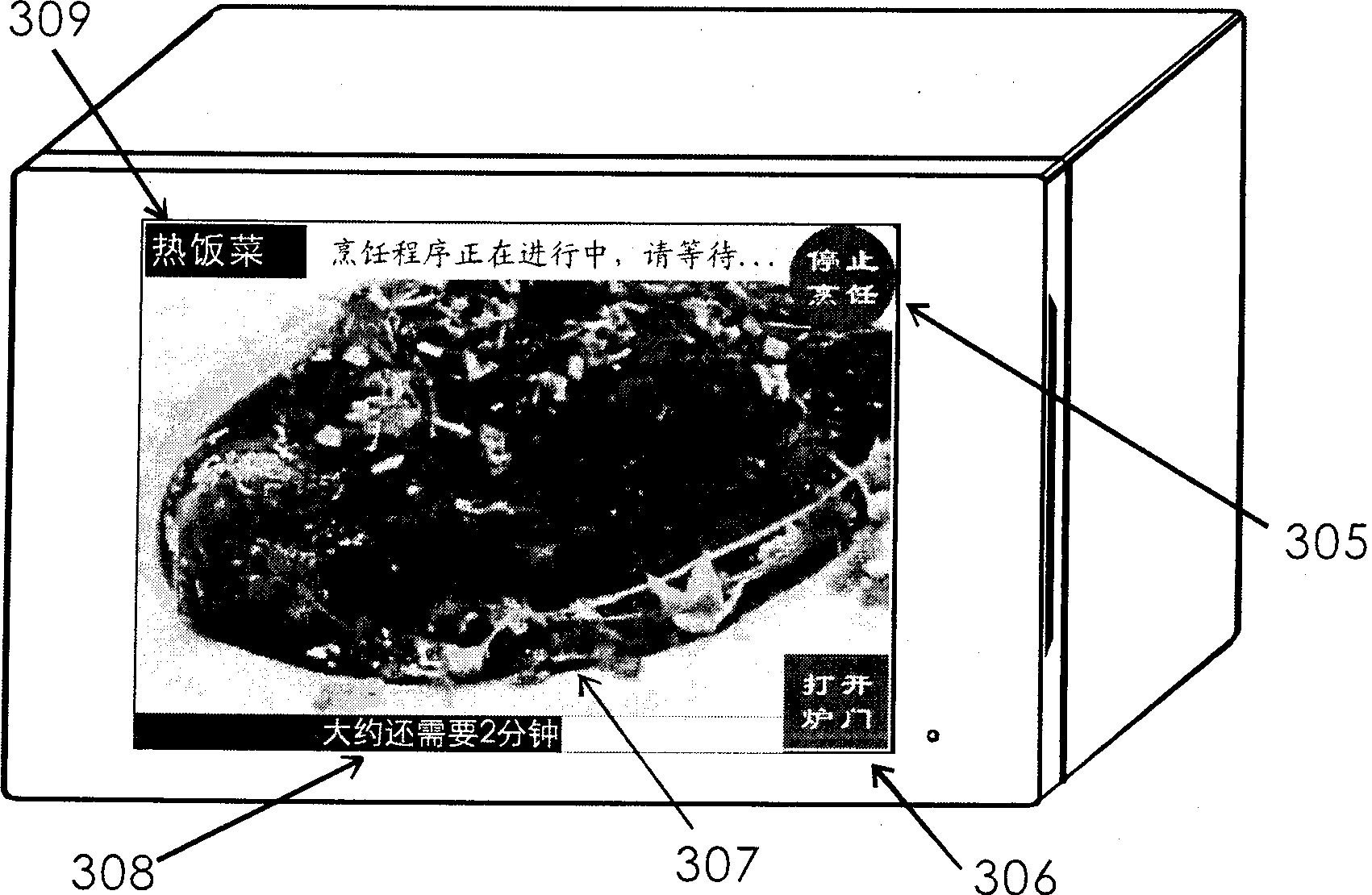

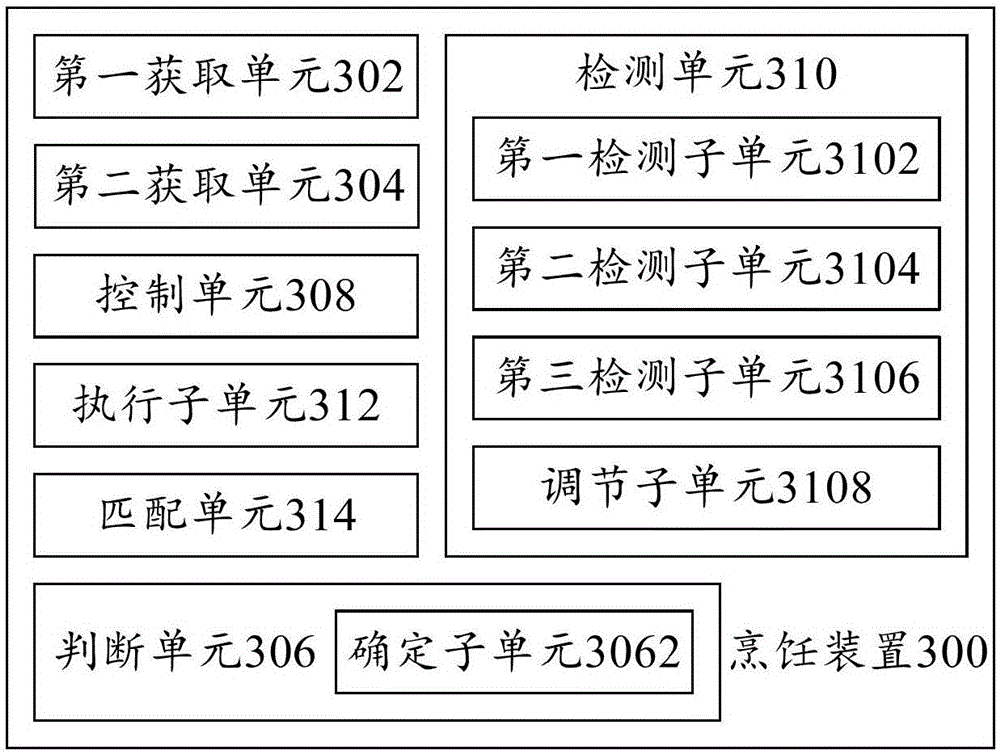

Cooking control method and equipment and cooking device

ActiveCN106037448AControl the cooking processProgramme controlComputer controlEngineeringCooking methods

The invention relates to the field of food cooking, and discloses a cooking method and equipment and a cooking device. The method comprises the steps that an image of food in the cooking device is collected; the collected food image is matched with pre-stored standard images, and different standard images correspond to different cooing modes; under the situation that the collected food image is matched with any one of the pre-stored standard images, the cooking device is controlled to work in the cooking mode corresponding to the matched standard image; under the situation that the collected food image is not matched with all the standard images in the pre-stored standard images, the cooking device is prompted to enter a learning mode. Therefore, different cooking modes can be adopted for different food, and the cooking process of the food can be more accurately controlled.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

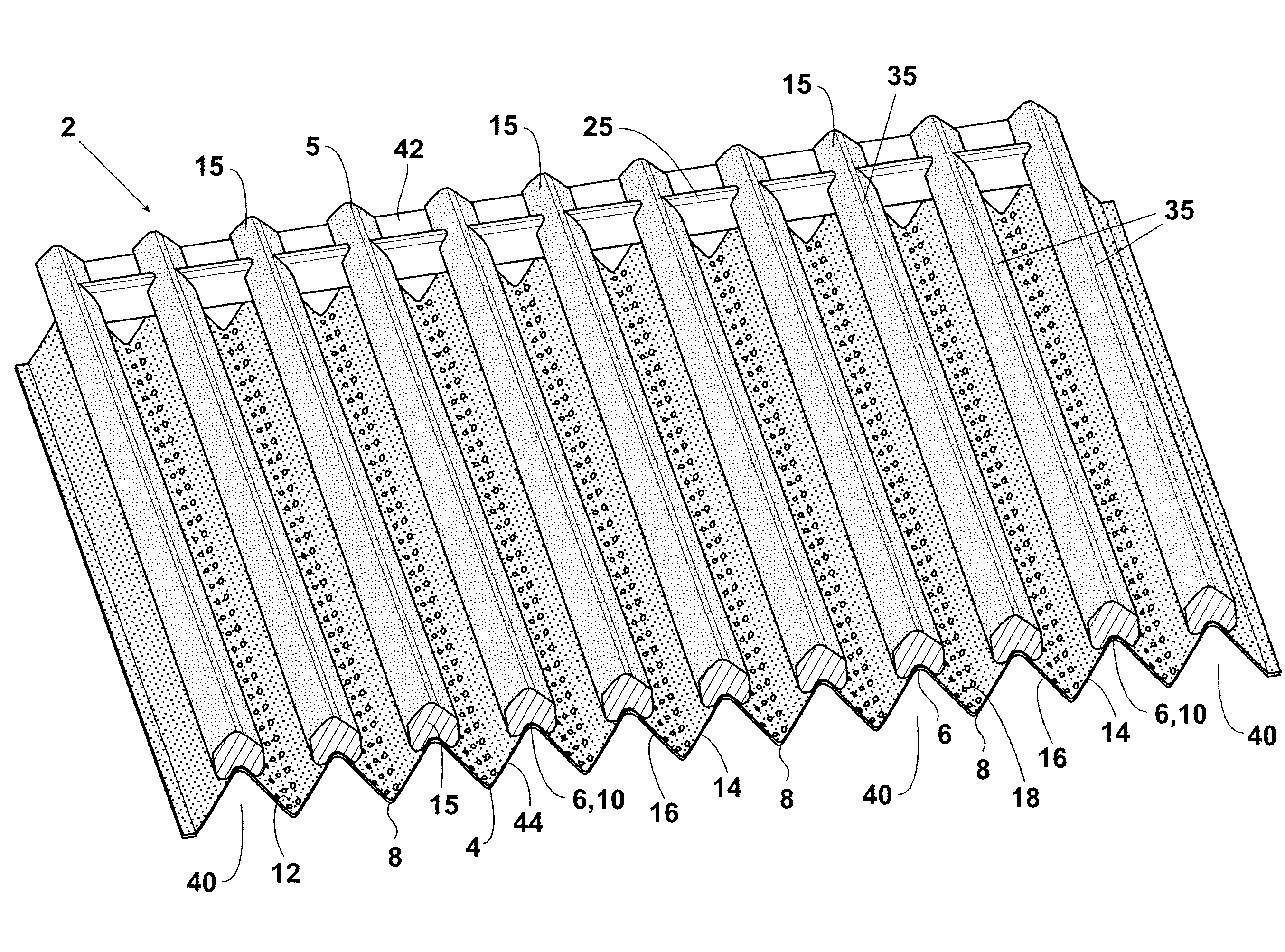

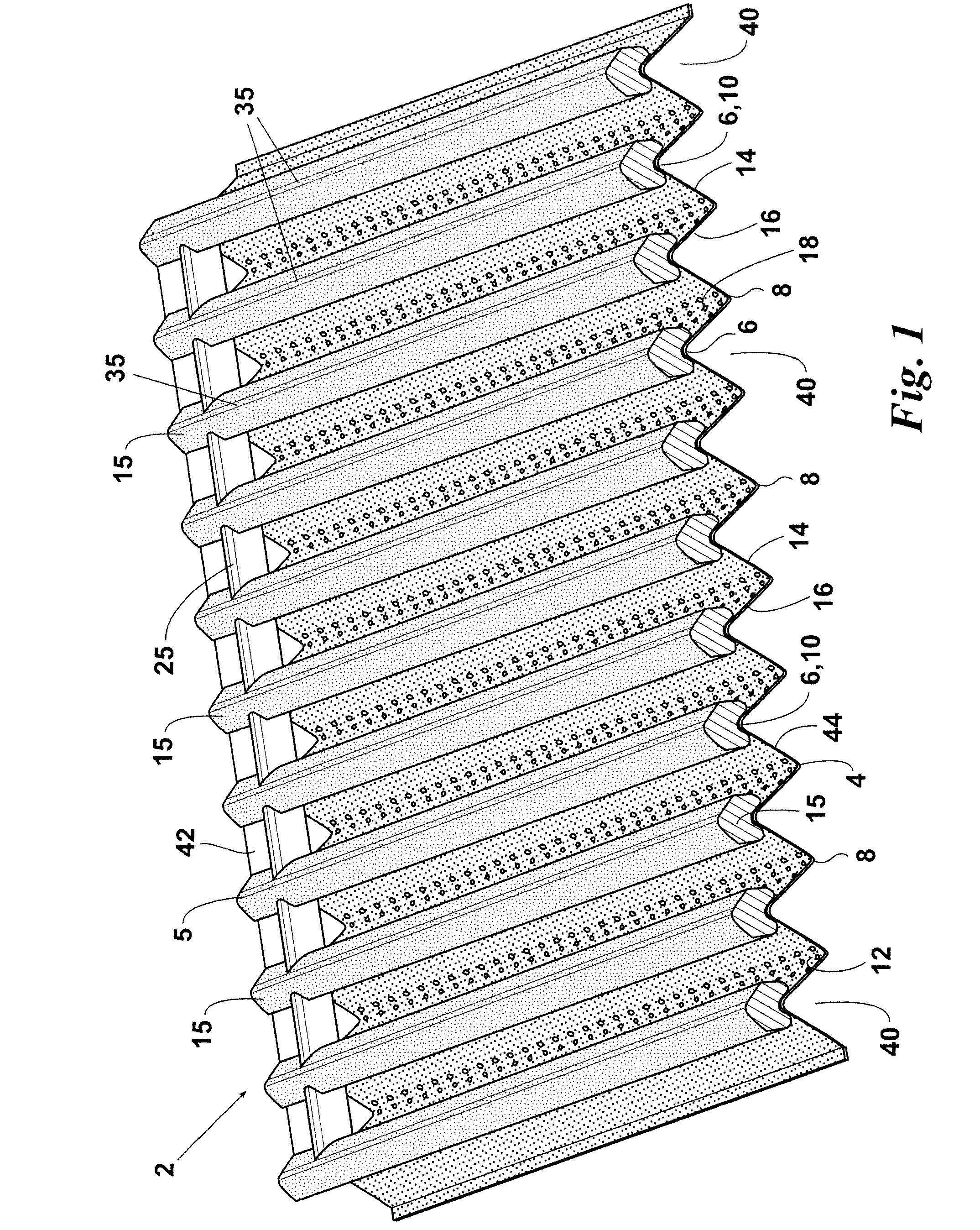

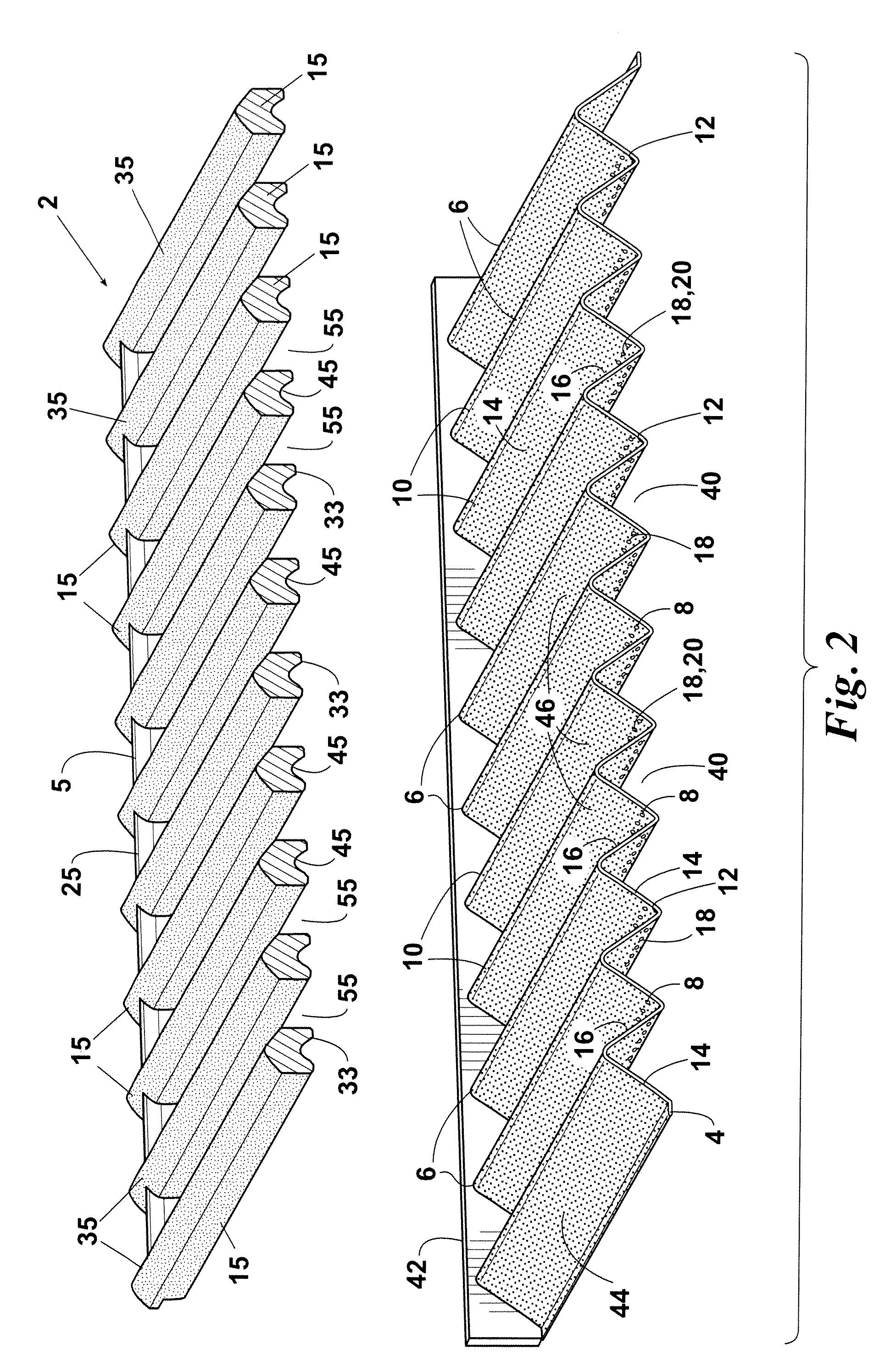

Cooking grate assembly and cooking apparatus

ActiveUS20120222665A1Reduces and eliminates occurrenceRust-free cookingDomestic stoves or rangesSolid bar grateEngineeringFood contact

A grate assembly for cooking food products and a grilling apparatus which uses the grate assembly for supporting the food during cooking. The grate assembly comprises: (a) a lower grate element having a series of parallel peak structures with valleys therebetween and (b) an upper grate element having a series of parallel food support ribs which are sized and spaced such that each rib will be positioned over the top of a corresponding peak structure. The upper food contacting surfaces of the ribs will remain substantially rust-free at atmospheric and cooking conditions.

Owner:W C BRADLEY CO

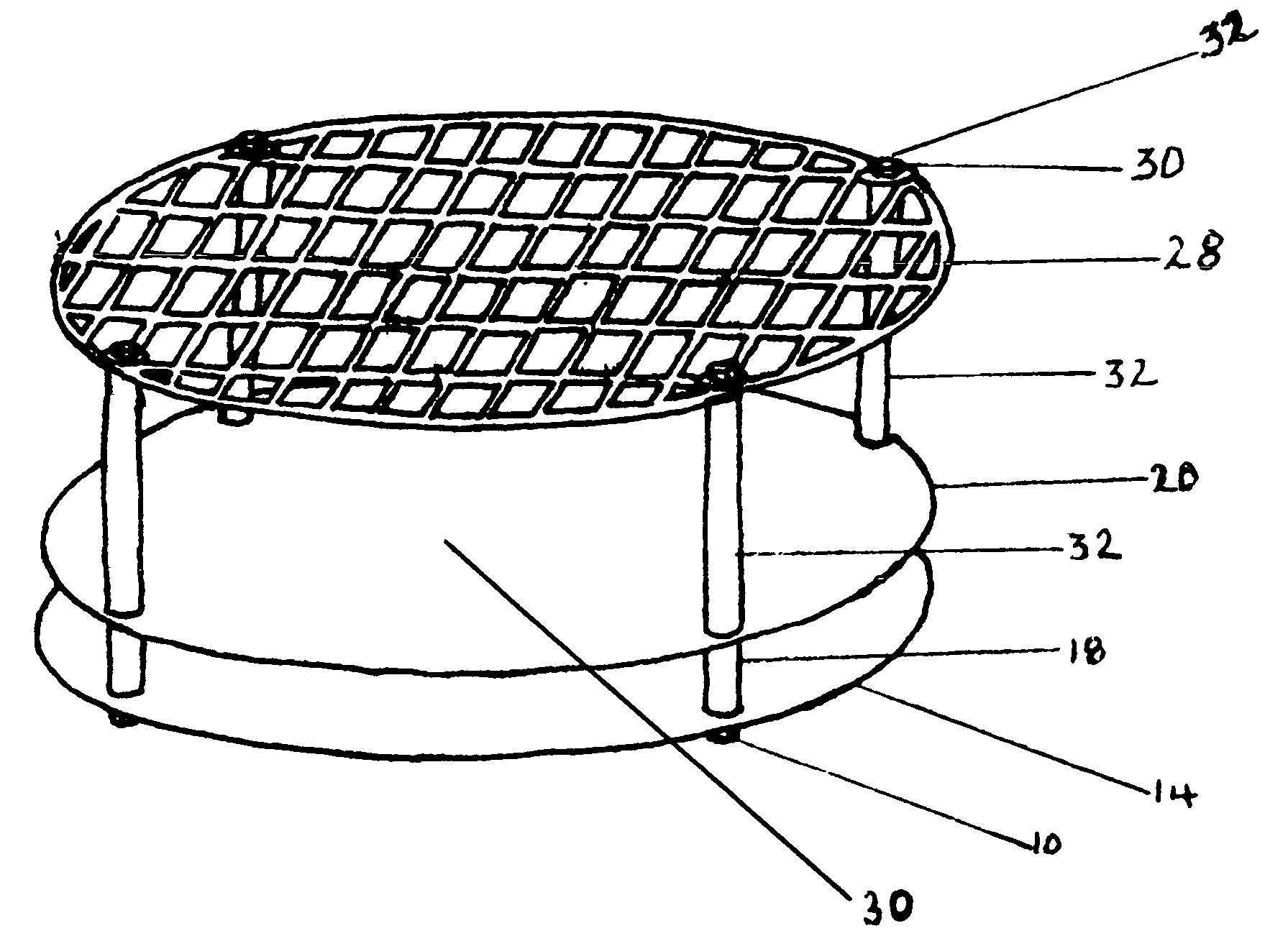

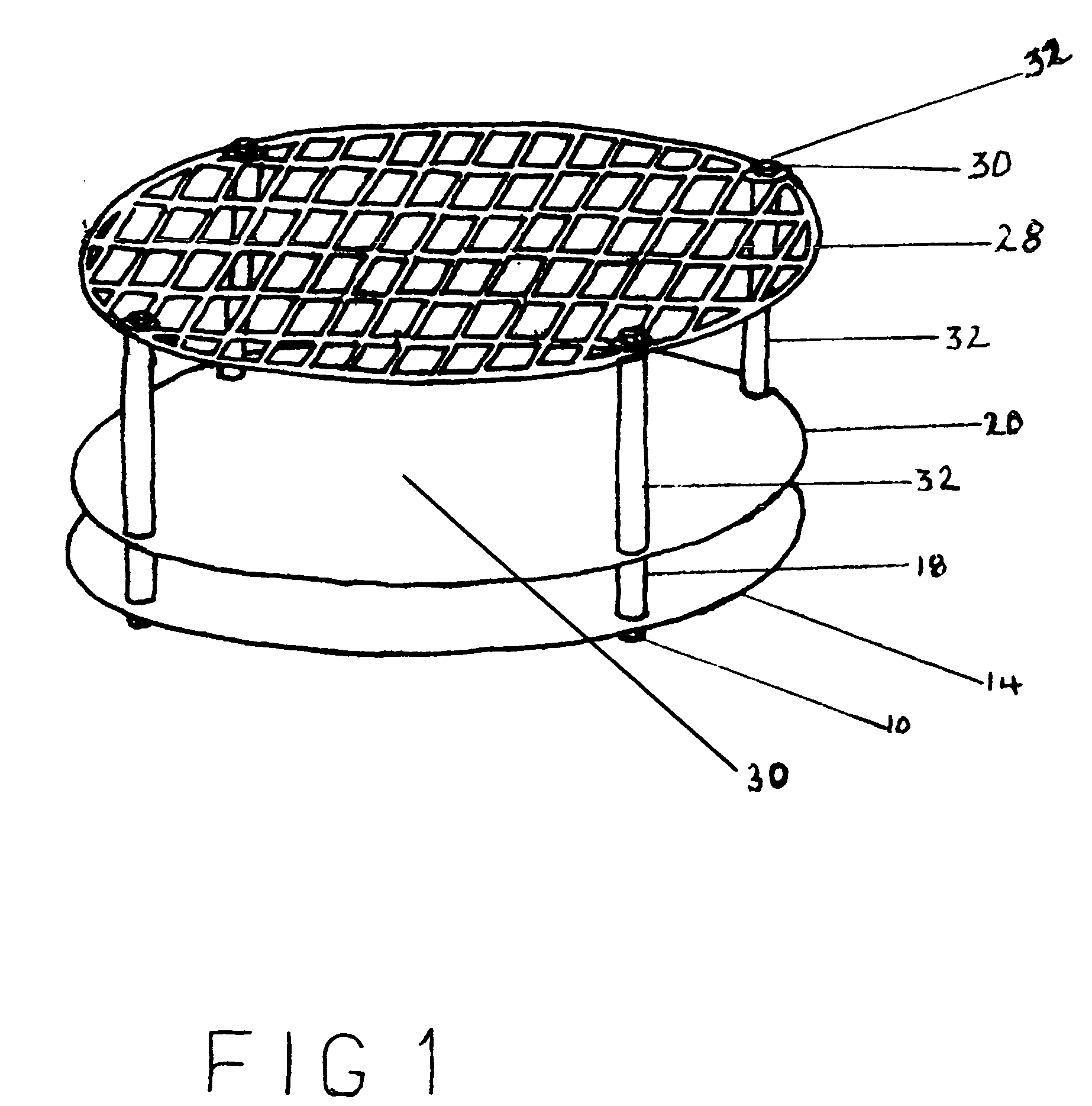

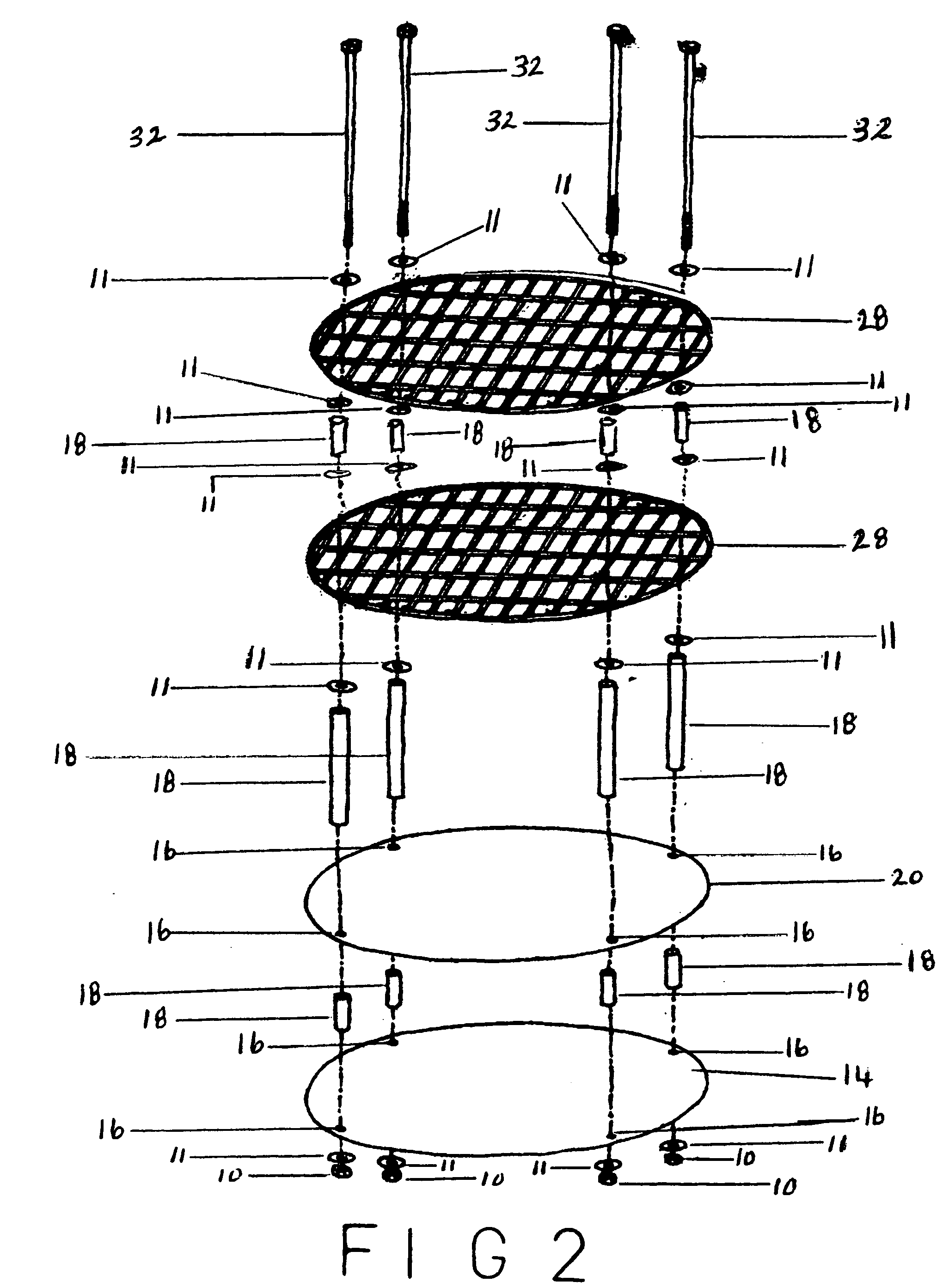

Multiple bottom outdoor grill accessory

InactiveUS20050039612A1Effective waySimple methodRoasters/grillsFood preparationEngineeringMechanical engineering

An apparatus comprised of a base plate, a heat diffuser plate and cooking surface, plate, with or without handles and situated an adequate distance, one above the other, to be used with existing conventional outdoor grill. Plurality spacers located intermittently around the plates provide support and separation. The apparatus is placed directly onto the existing grill and is of sufficient and variant size to hold food for cooking and to fit with an existing grill. This grill accessory is constructed of materials which are not subject to easy degradation by heat produced by outdoor grills and is designed with fixed or removable plates. A variation being an independent outdoor grill that embodies the multiple bottom grill accessory as an intrinsic part of its structure. The multiple bottom grill accessory converts the outdoor grill cooking process to the likes of an oven, thus cooking foods not normally cooked on a grill in a healthier manner.

Owner:DENNY SEAN PATRICK

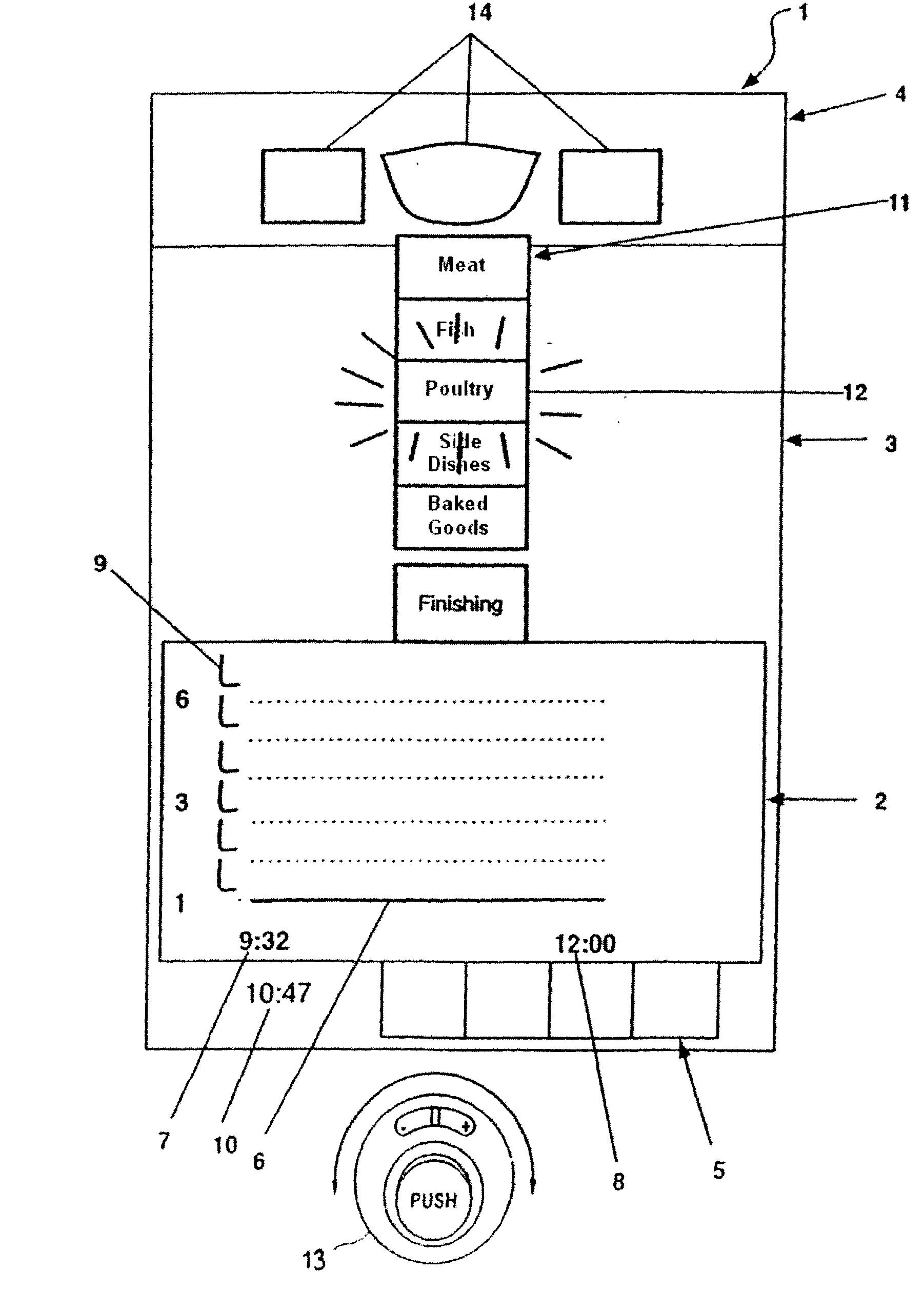

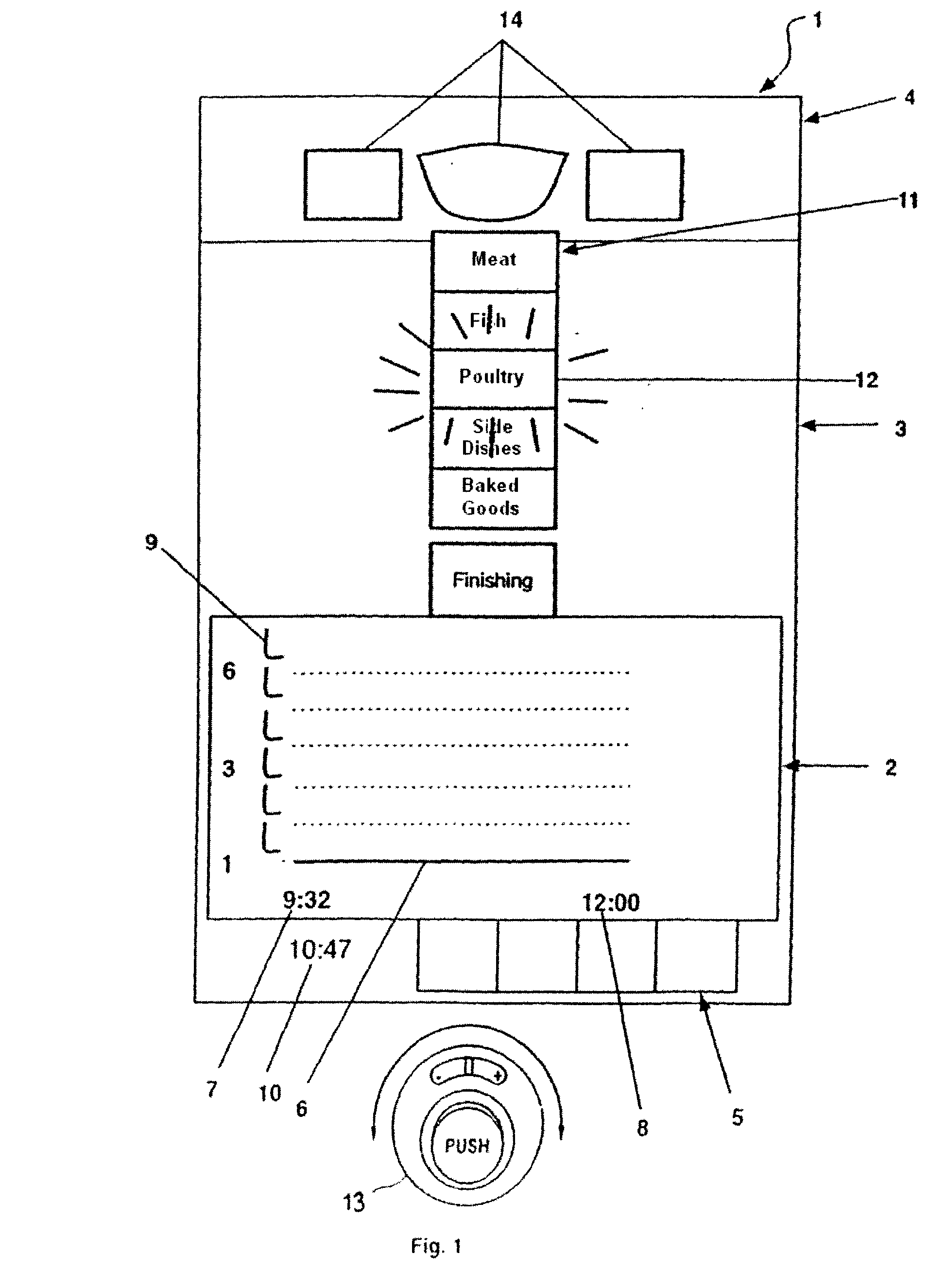

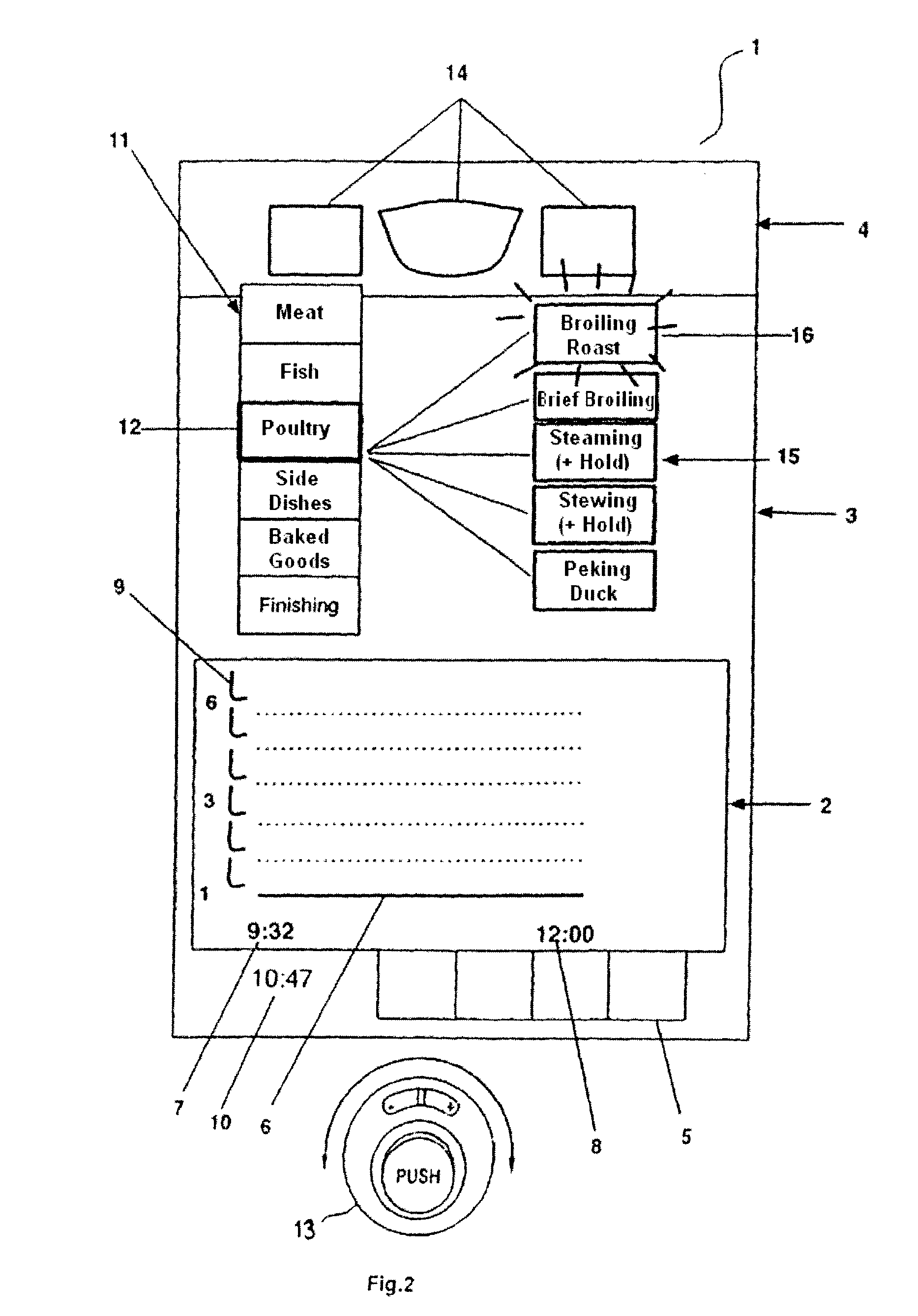

Method for selecting and arranging program representatives and a cooking device therefor

InactiveUS20120003364A1Easy to operateDomestic stoves or rangesLighting and heating apparatusDisplay deviceCooking process

A method for selecting and arranging program representatives and a cooking device therefor including displaying program representatives on a display device, where the programs are for a cooking device, selecting program representatives via an input device, where the display device is connected to the input device and a control or regulating device, and storing the programs on a storage device, where the control or regulating device is connected to the storage device, the cooking device, or provided by the cooking device, and to the display device to display a program representative as a virtual token on a virtual token board on the display device. The method also includes placing the virtual token on an area of the virtual token board through various means, which enables a representation of a cooking process through the virtual token board to determine when and how to cook and item using the cooking device.

Owner:RATIONAL AG

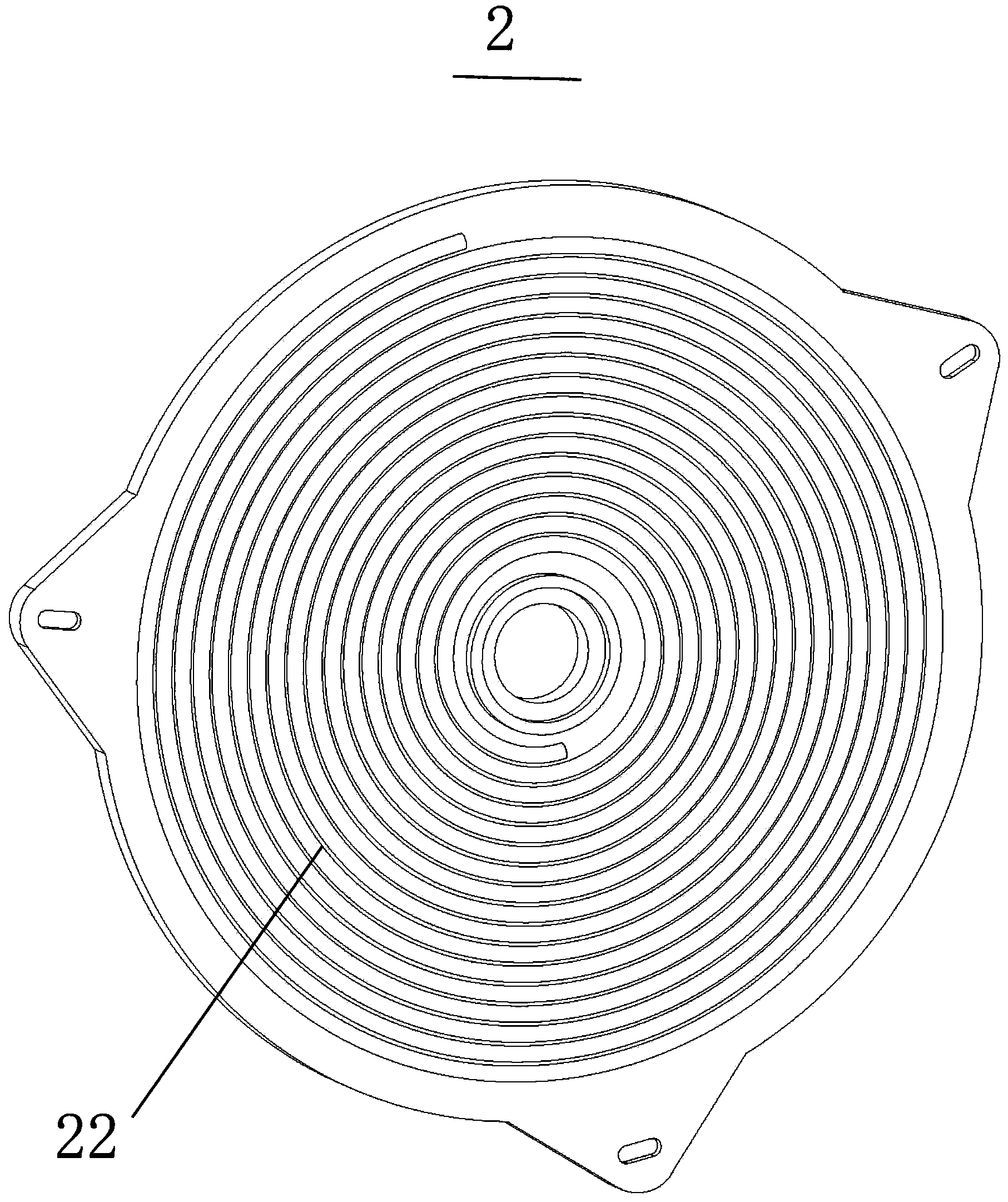

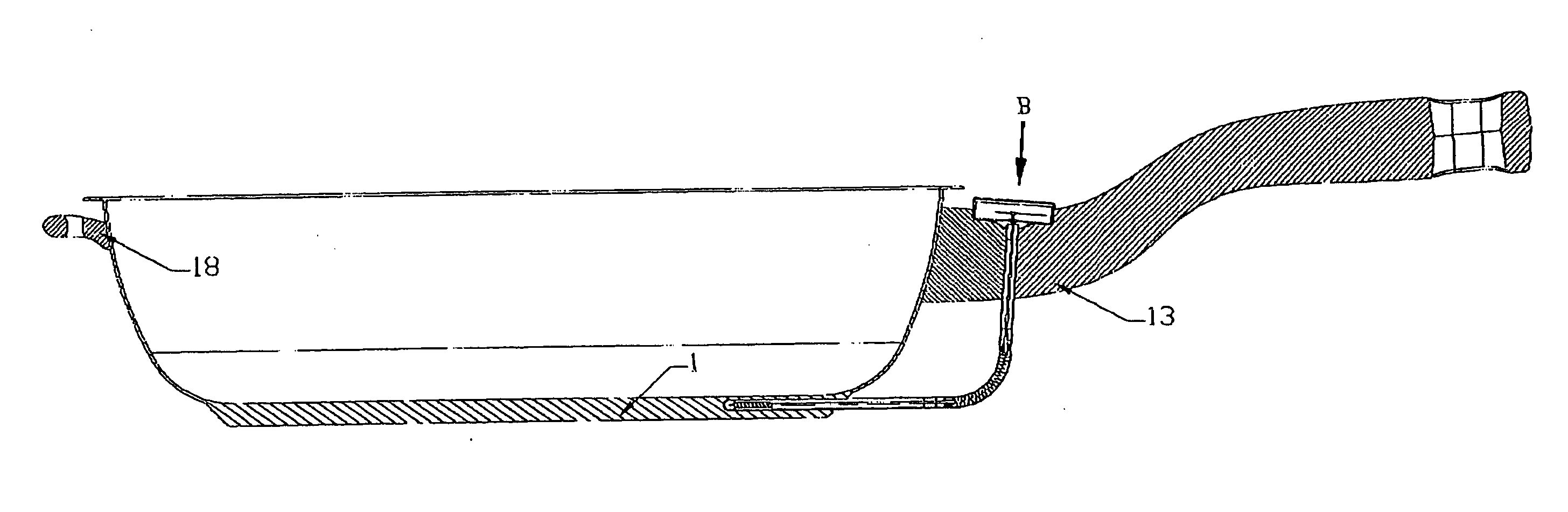

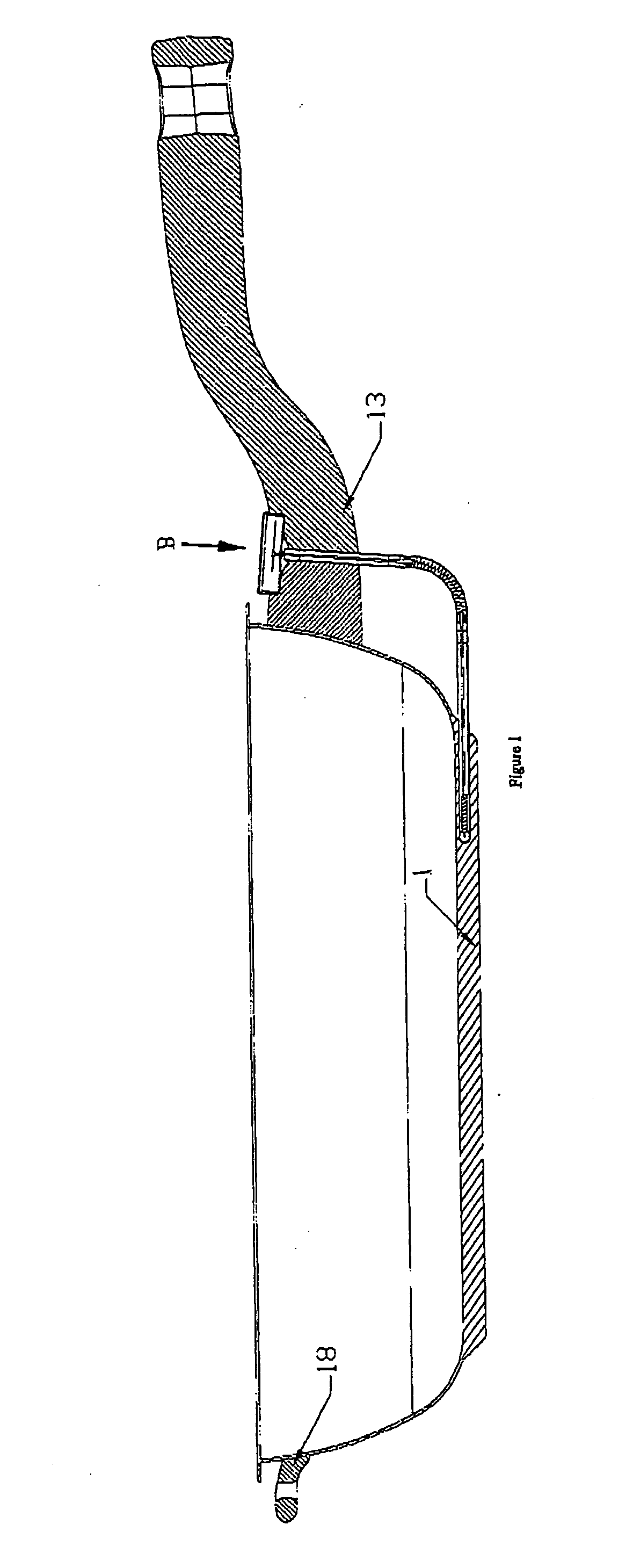

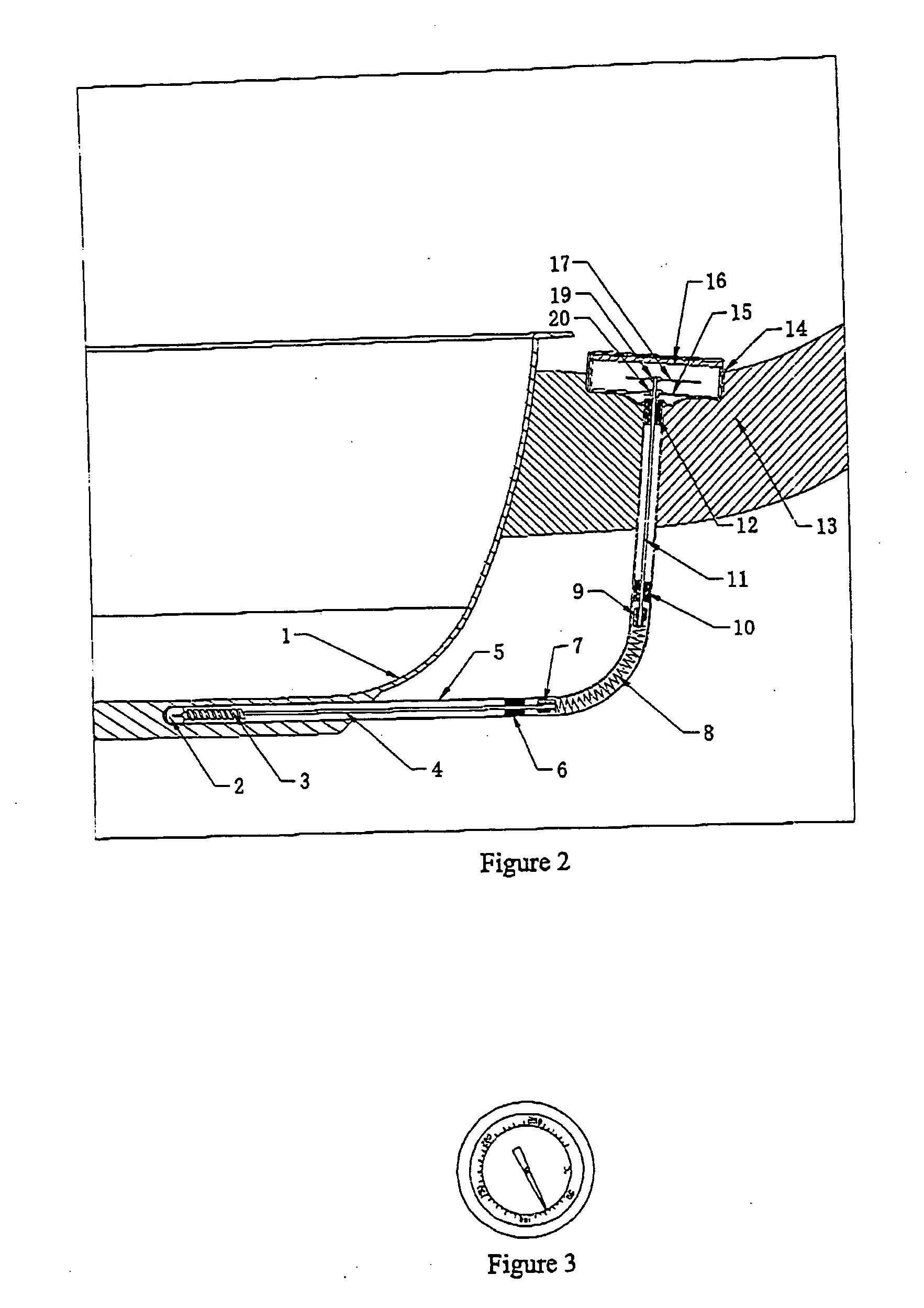

Pan with temperature displaying

InactiveUS20070095215A1Simple structureEasy to useThermometer detailsFrying pansBiochemical engineeringCooking process

The invention discloses a pan with temperature displaying including a pan body and a handle, a temperature-sensing bimetal element being provided in the bottom of the pan body, a display means being provided in the handle, and the temperature-sensing bimetal element being connected with the display means. The invention can rapidly and precisely indicate the temperature of the pan bottom of the pan so that the user can control the cooking level during cooking. The pan according to the invention is of a simple structure, is convenient to use and is easy to popularize.

Owner:MINGLE DEV (SHENZHEN) CO LTD

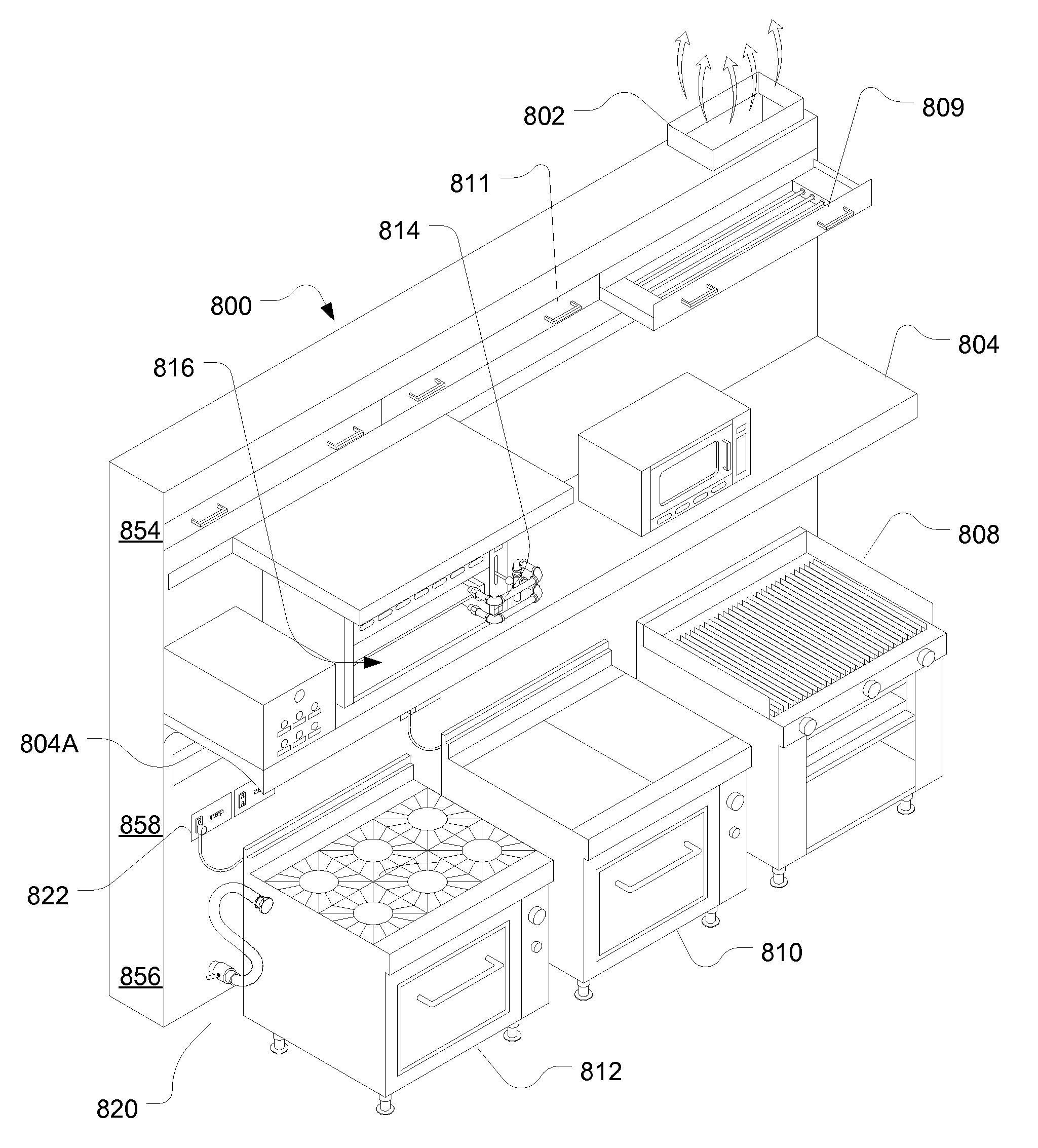

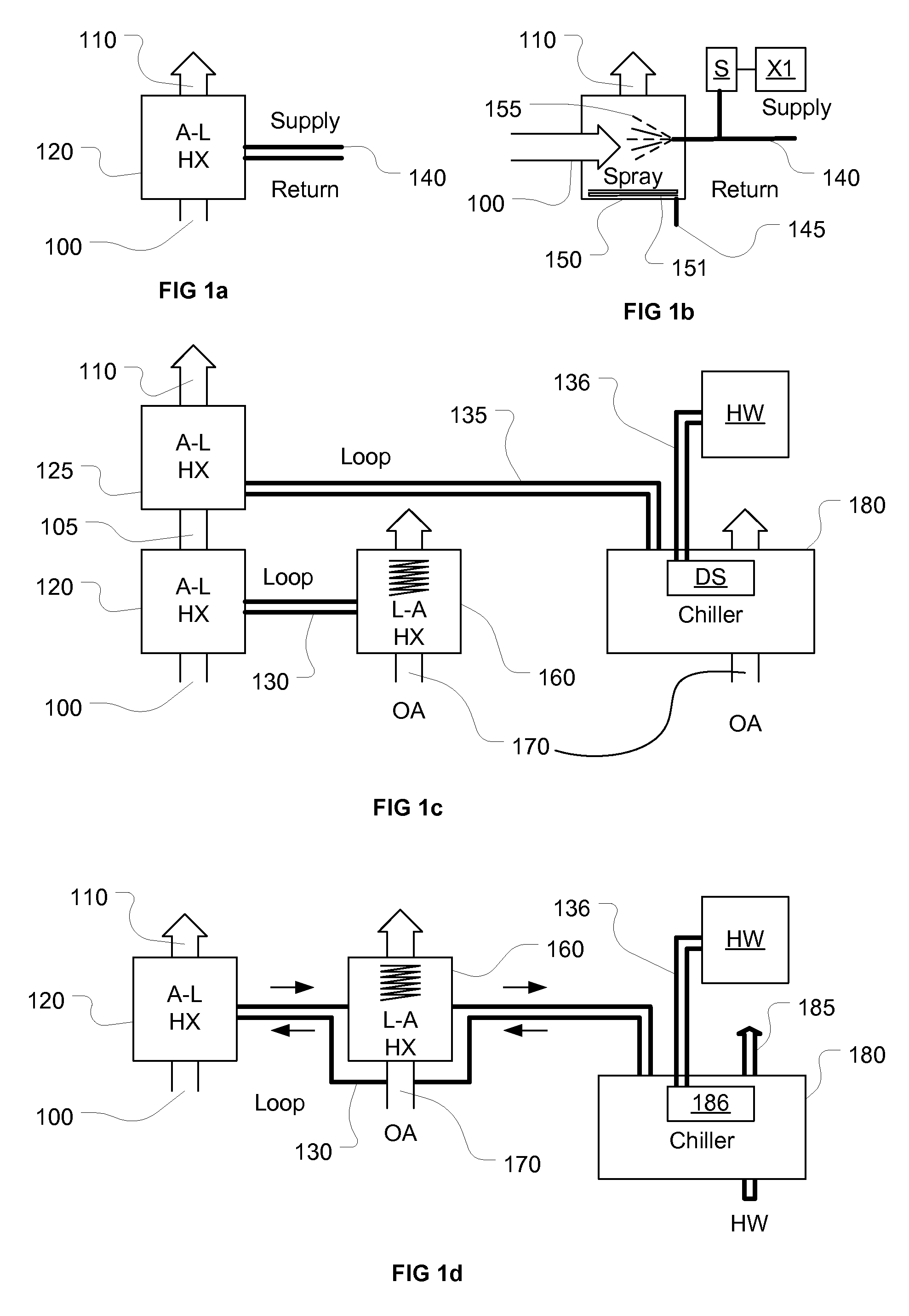

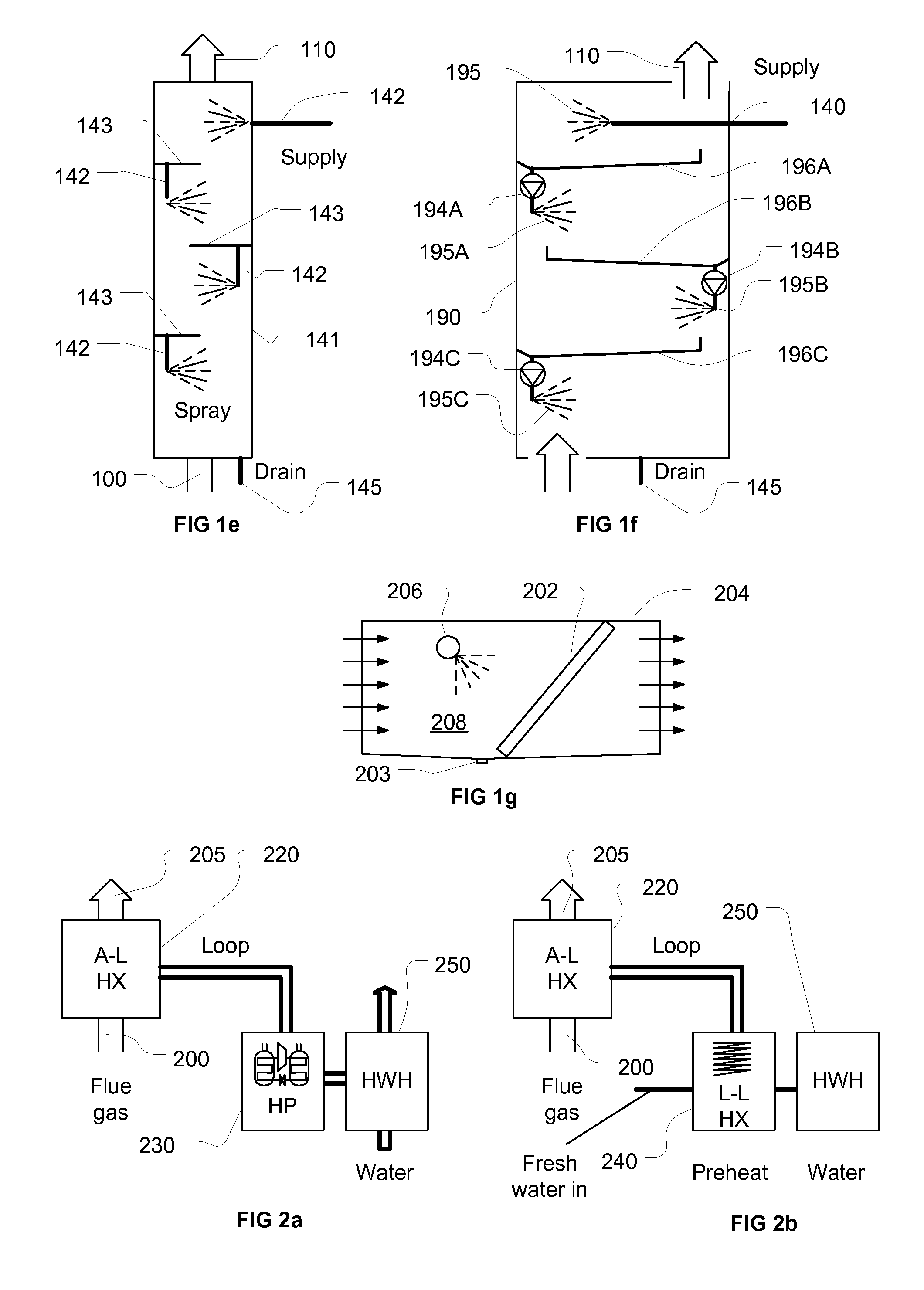

Recirculating exhaust system

ActiveUS20090264060A1Reduce net energy lossDomestic stoves or rangesRecuperative heat exchangersModularityEngineering

Systems, devices and methods provide energy recover, modular systems to build and revise commercial kitchen services, closed circuit exhaust, and high efficiency capture and containment of fumes from cooking processes.

Owner:HALTON GROUP LTD

Smart pan

InactiveCN107048976AReduce firepowerAvoid spillingBoiling over preventionWarming devicesAutomatic controlControl signal

The invention belongs to the field of pans, and particularly discloses a smart pan comprising a pan body, a handle, a thermocouple and a pan controller. The thermocouple is assembled to the bottom of the pan body, and the pan controller is disposed within the handle. The pan controller acquires the corresponding cooking program, the cooking program is configured with the set value of the pan temperature associated with time, the measured value of the pan temperature based on thermocouple detection and the set value of the pan temperature obtained from the cooking program are processed to generate a control signal for manipulating a heating unit for heating the smart pan and changing the strength of heating power of the heating unit, the measured value of the pan temperature is enabled to reach the set value of the pan temperature till the cooking program is totally executed by the pan controller, and food cooking is finished. Throughout the cooking process, the smart pan manipulates the heating unit based on the acquired cooking program, the temperature of the smart pan is controlled automatically, food cooking is completed without user participation, and users can make delicious food either with or without cooking skills.

Owner:李明守

Programmed control stove capable of displaying video cooking course and management control method thereof

InactiveCN101387414APrevent overflowPrevent drynessDomestic stoves or rangesLighting and heating apparatusAutomatic controlProcess engineering

Owner:郭恒勋

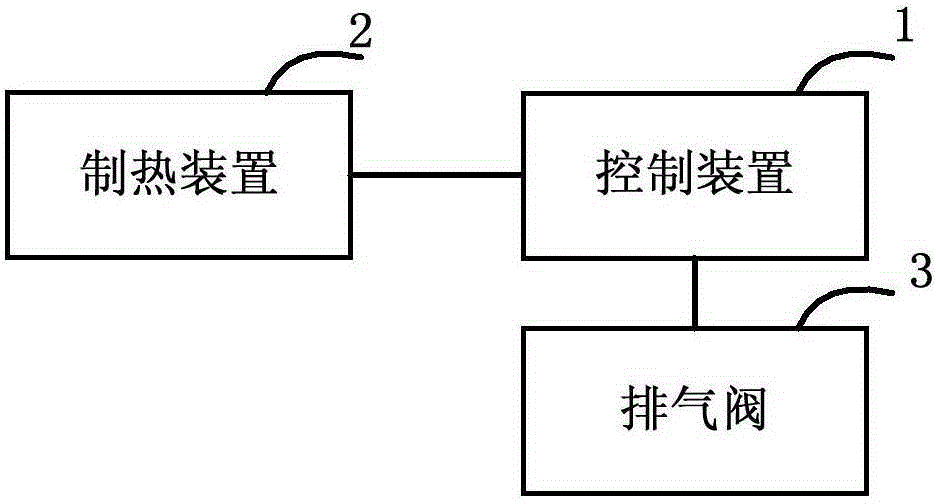

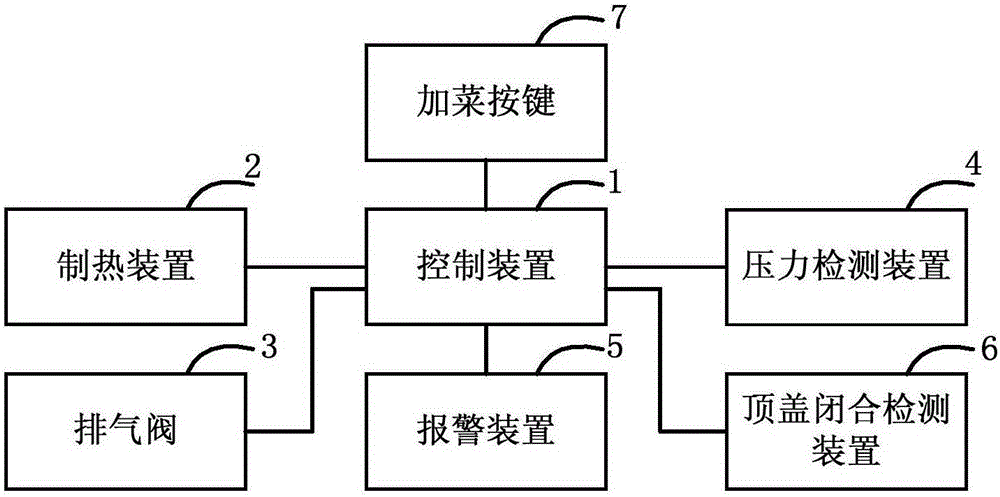

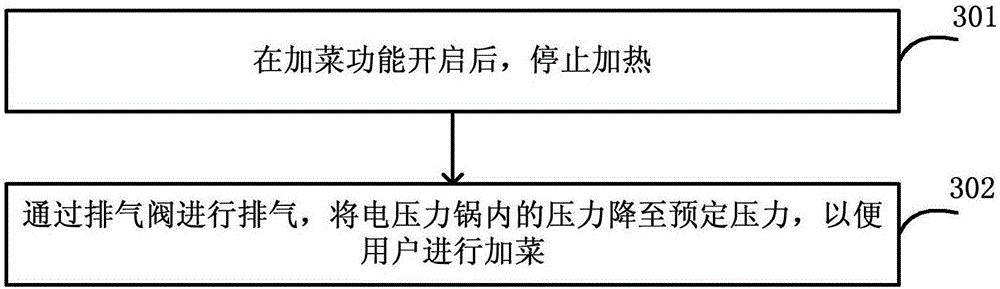

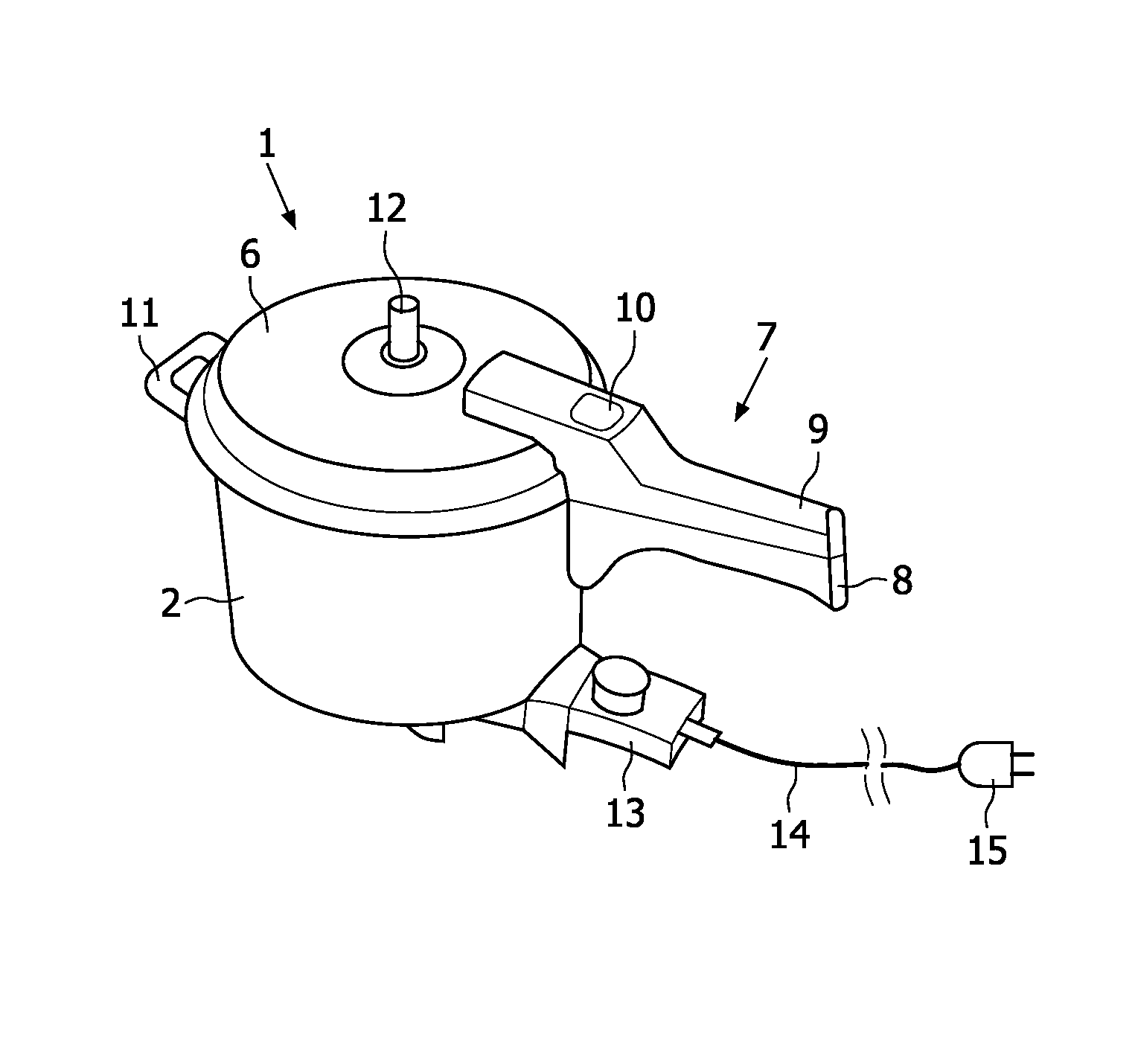

Electric pressure cooker and control method thereof

ActiveCN105231811AAdding vegetables is safe and convenientImprove experiencePressure-cookersExhaust valveEngineering

The invention discloses an electric pressure cooker and a control method thereof, and relates to the field of control. After the vegetable adding function is started, a control device indicates a heating device to stop heating and indicates an exhaust valve to exhaust air, the pressure in the electric pressure cooker is reduced to the predetermined pressure accordingly, and a user can add vegetables conveniently. As the heating device and the exhaust valve are controlled, the user can safely and conveniently add the vegetables at any time in the cooking process, and the user experiences are improved.

Owner:GREE ELECTRIC APPLIANCES INC

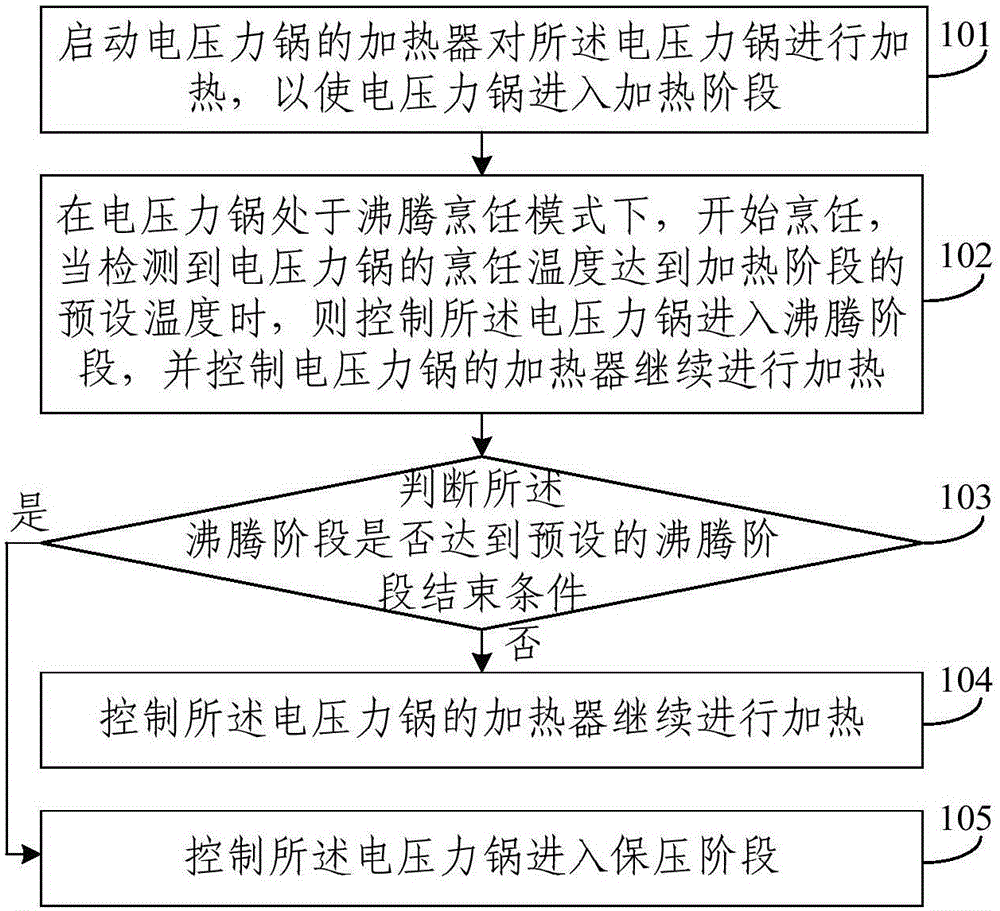

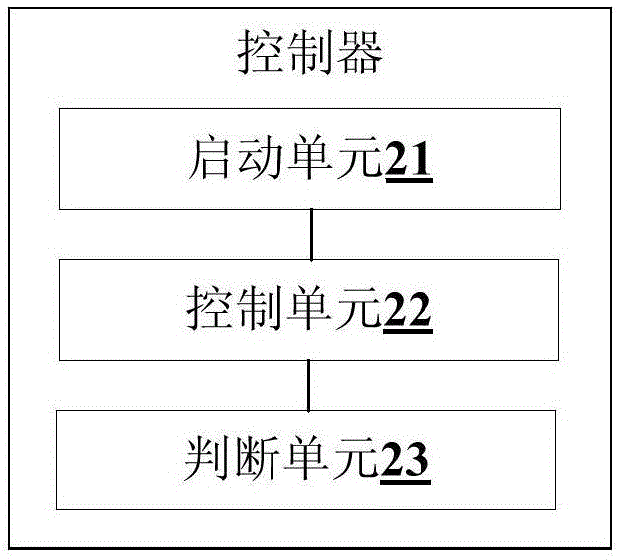

Electronic pressure cooker control method, controller and electronic pressure cooker

ActiveCN105105626AIncreased boiling phaseFully boiledPressure-cookersCooking processPressure controlled method

The invention discloses an electronic pressure cooker control method, a controller and an electronic pressure cooker, wherein the electronic pressure cooker control method comprises: starting a heater of the electronic pressure cooker to heat the electronic pressure cooker so as to make the electronic pressure cooker enter into a heating stage; beginning to cook when the electronic pressure cooker is under a boiling cooking mode; when the cooking temperature of the electronic pressure cooker reaches at the preset temperature of the heating stage, the electronic pressure cooker is controlled into a boiling stage and the heater of the electronic pressure cooker is controlled to continuously heat; judging whether the boiling stage meets the preset finish conditions of the boiling stage or not; if the boiling stage doesn't meet the preset finish conditions of the boiling stage, the heater of the electronic pressure cooker is controlled to continuously heat; and if the boiling stage meets the preset finish conditions of the boiling stage, the electronic pressure cooker is controlled into a pressure maintaining stage. By adopting the electronic pressure control method, the controller and the electronic pressure cooker disclosed by the invention, before the electronic pressure cooker enters the pressure maintaining stage, the boiling stage is increased, thus the problem that the existing electronic pressure cooker is not boiling or is not boiling enough during the cooking process is solved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

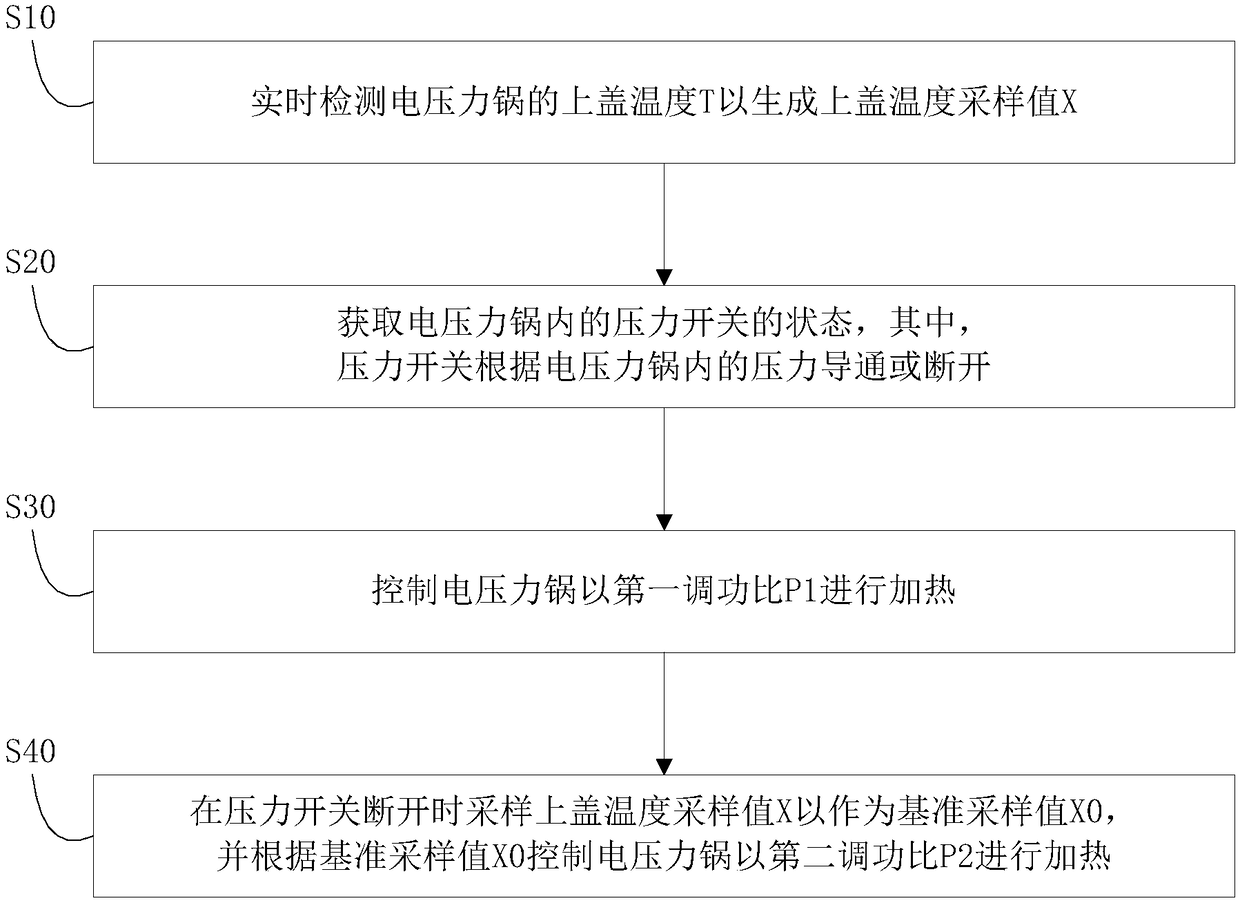

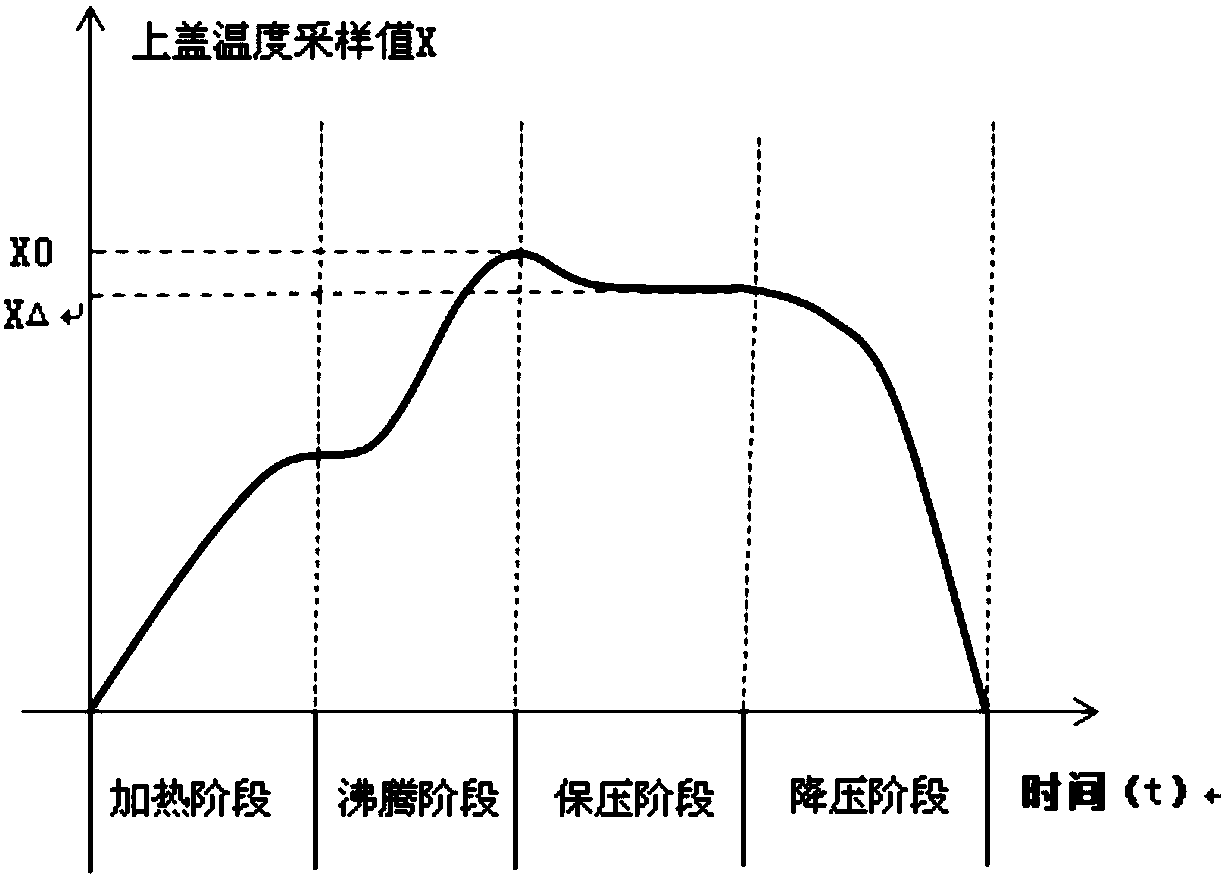

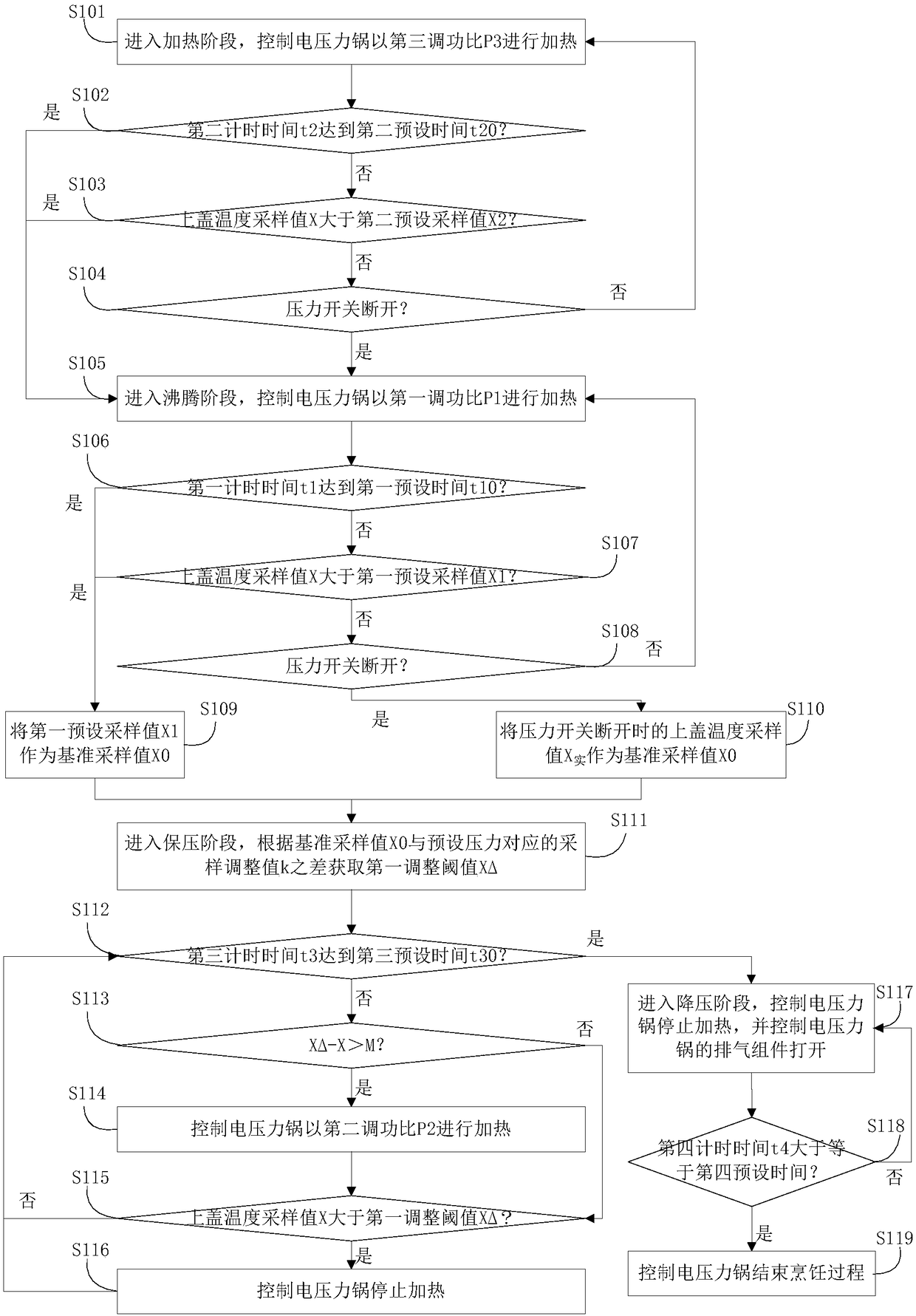

Electric pressure cooker, as well as cooking control method and cooking control device thereof

ActiveCN108402889AAvoid issues like overflowImprove experiencePressure-cookersWorking environmentEngineering

The invention discloses an electric pressure cooker, as well as a cooking control method and cooking control device thereof. The method comprises the following steps: detecting upper cover temperatureof the electric pressure cooker in real time so as to generate an upper cover temperature sampled value; acquiring the states of a pressure switch in the electric pressure cooker, wherein the pressure switch gets connected or disconnected in accordance with pressure in the electric pressure cooker; controlling the electric pressure cooker to conduct heating by a first power adjusting ratio; and sampling the upper cover temperature sampled value when the pressure switch is disconnected to serve as a standard sampled value, and controlling the electric pressure cooker to conduct heating by a second power adjusting ratio in accordance with the standard sampled value; therefore cooking processes of the electric pressure cooker can be controlled in accordance with the states of the pressure switch, so that the product (the electric pressure cooker) can adapt to working environments of different altitudes, such problems as spillover and the like of the electric pressure cooker caused by pressing deviation can be prevented, a cooking effect can be improved, product competitiveness can be improved and user experience can be improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Cooking device with image detection sensor

ActiveUS20180317692A1Avoid problemsCompact structureDomestic stoves or rangesLighting and heating apparatusImage detectionEngineering

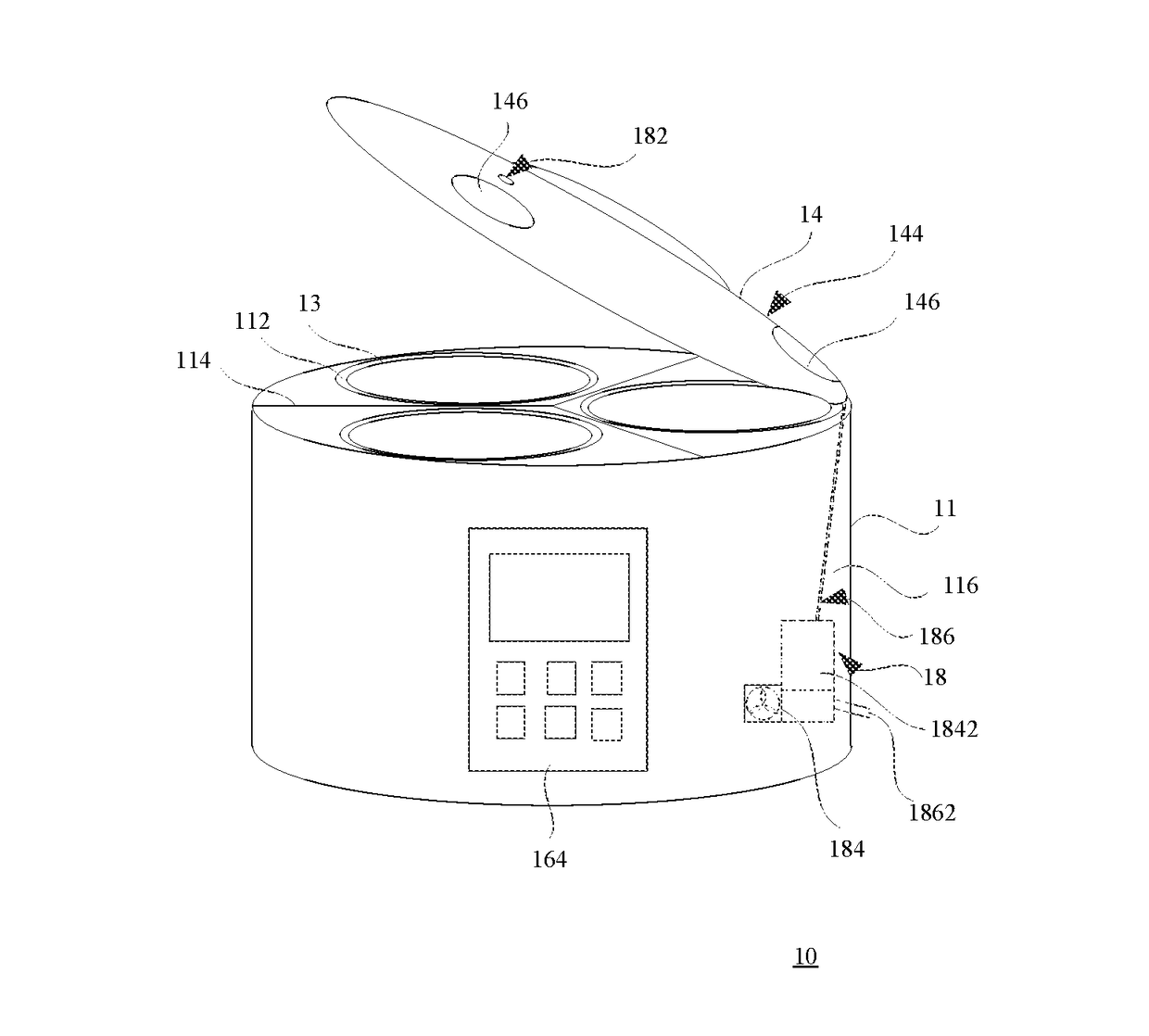

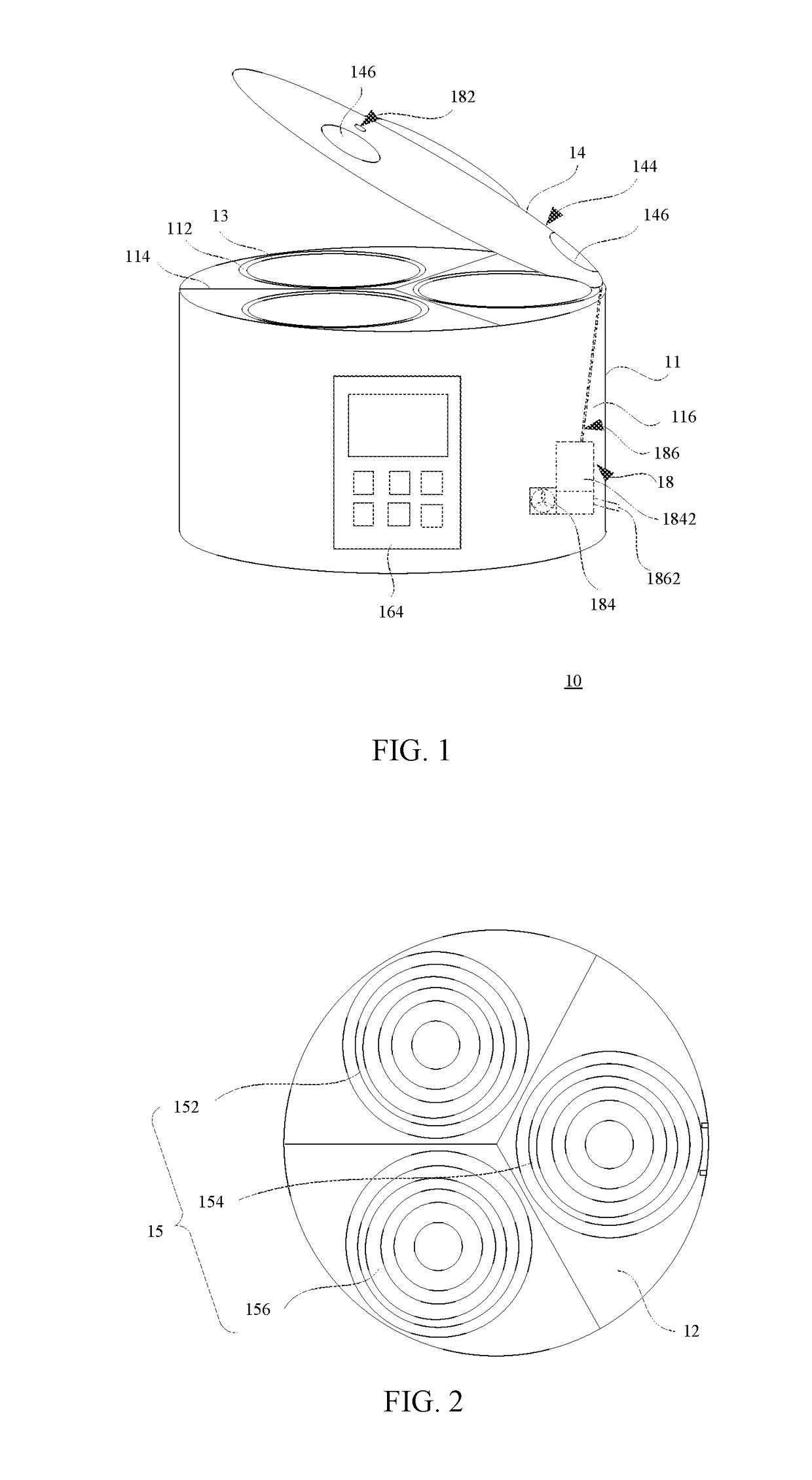

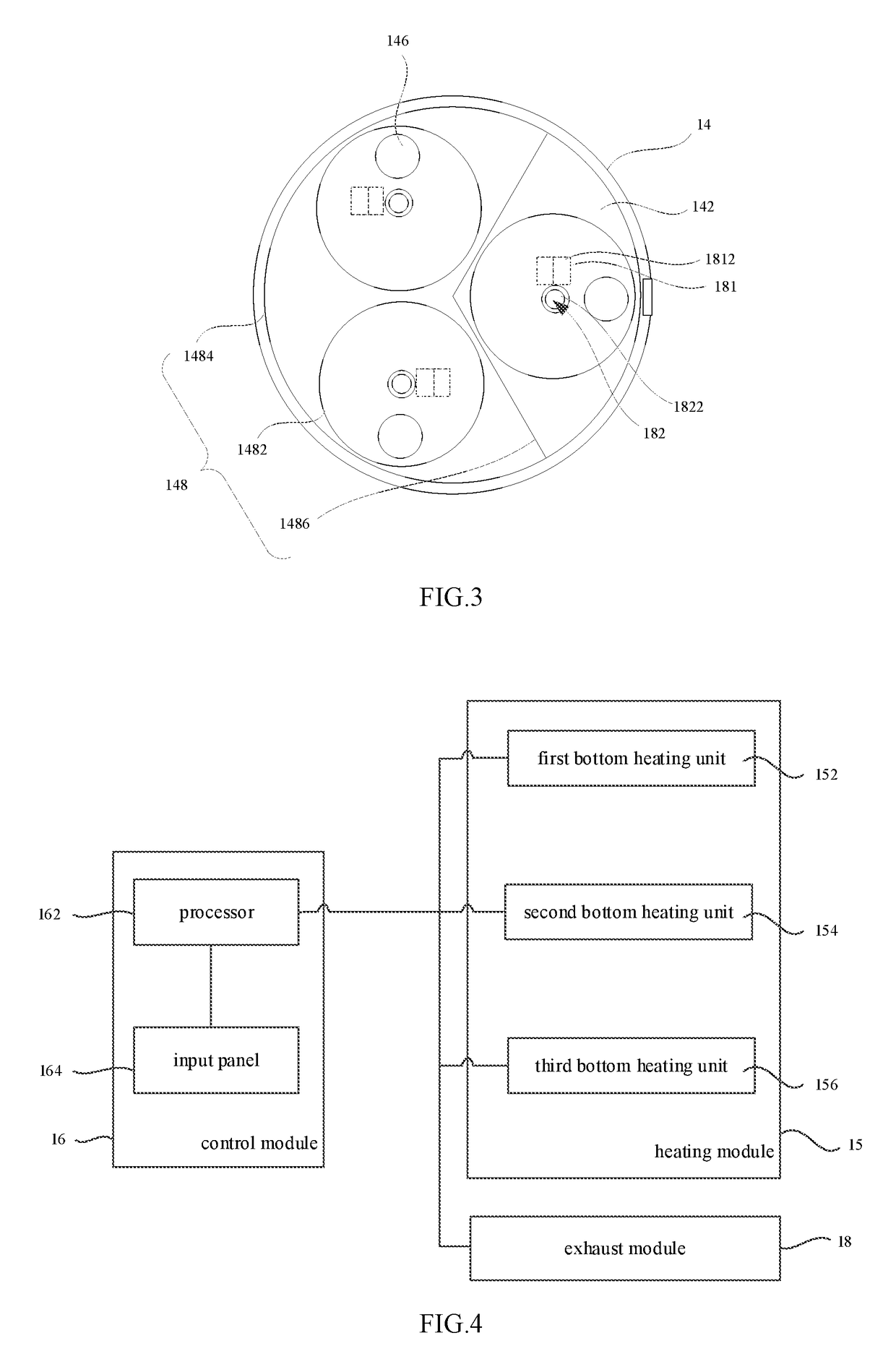

A cooking device includes a base, a housing, a lid, a detection module, a control module and an exhaust module. The detection module includes an image detection sensor arranged on the lid and configured to take an image of a cooking process. The control module includes a processor connected with the detection module and arranged in the base or the housing, and a wireless unit configured to perform information interaction with a portable electronic device to transmit cooking parameters including the image out of the cooking device. The exhaust module includes an air-filled element, an air-extraction element, an inlet passage and an exhaust passage. The inlet passage is disposed on the lid, the air-filled element is disposed on the inlet passage, the air-extraction element is disposed on the exhaust passage and used to exhaust fog or oil fume generated in the at least one inner pot

Owner:SHENZHEN ZEZHI INTPROP CO LTD

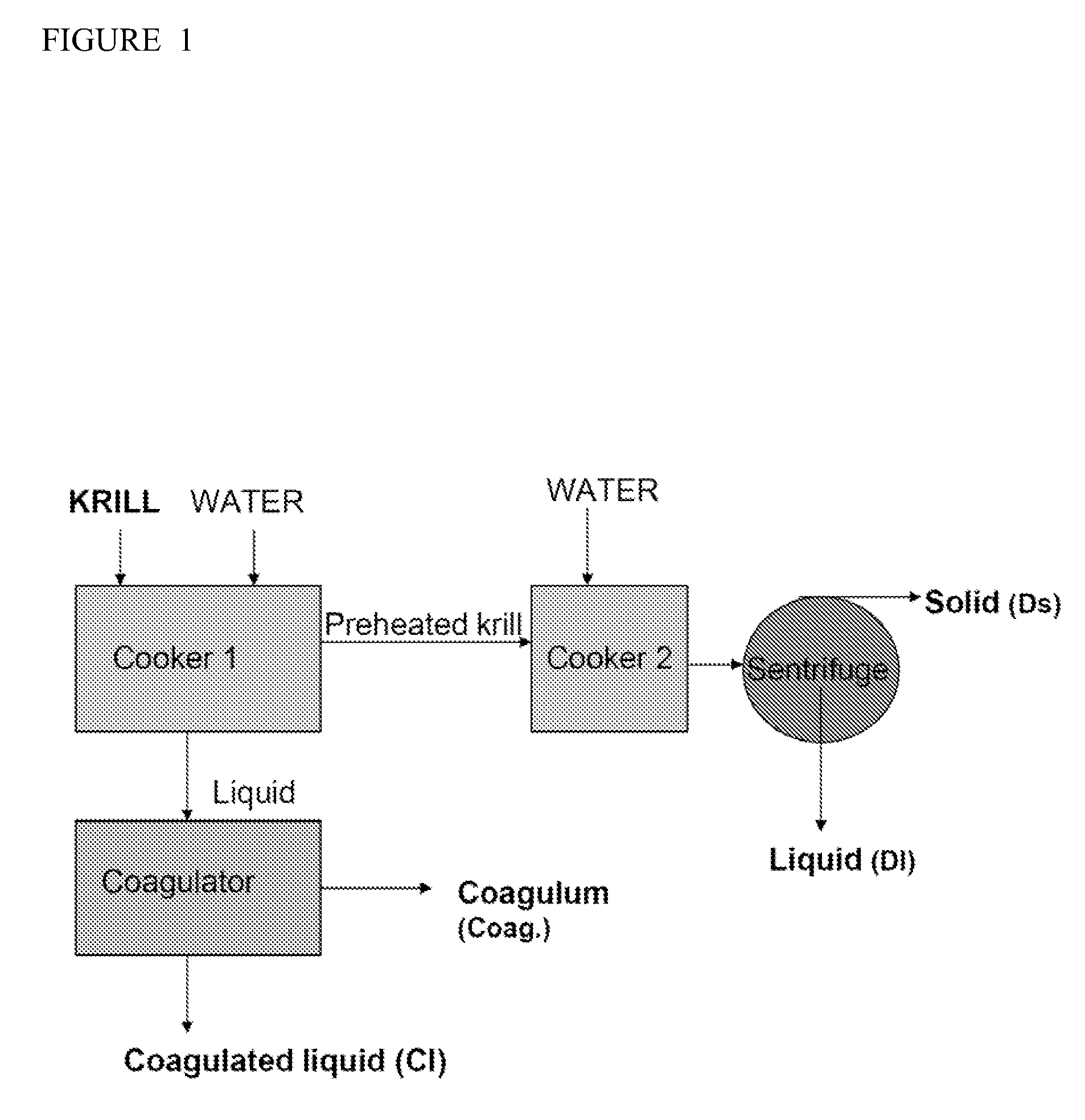

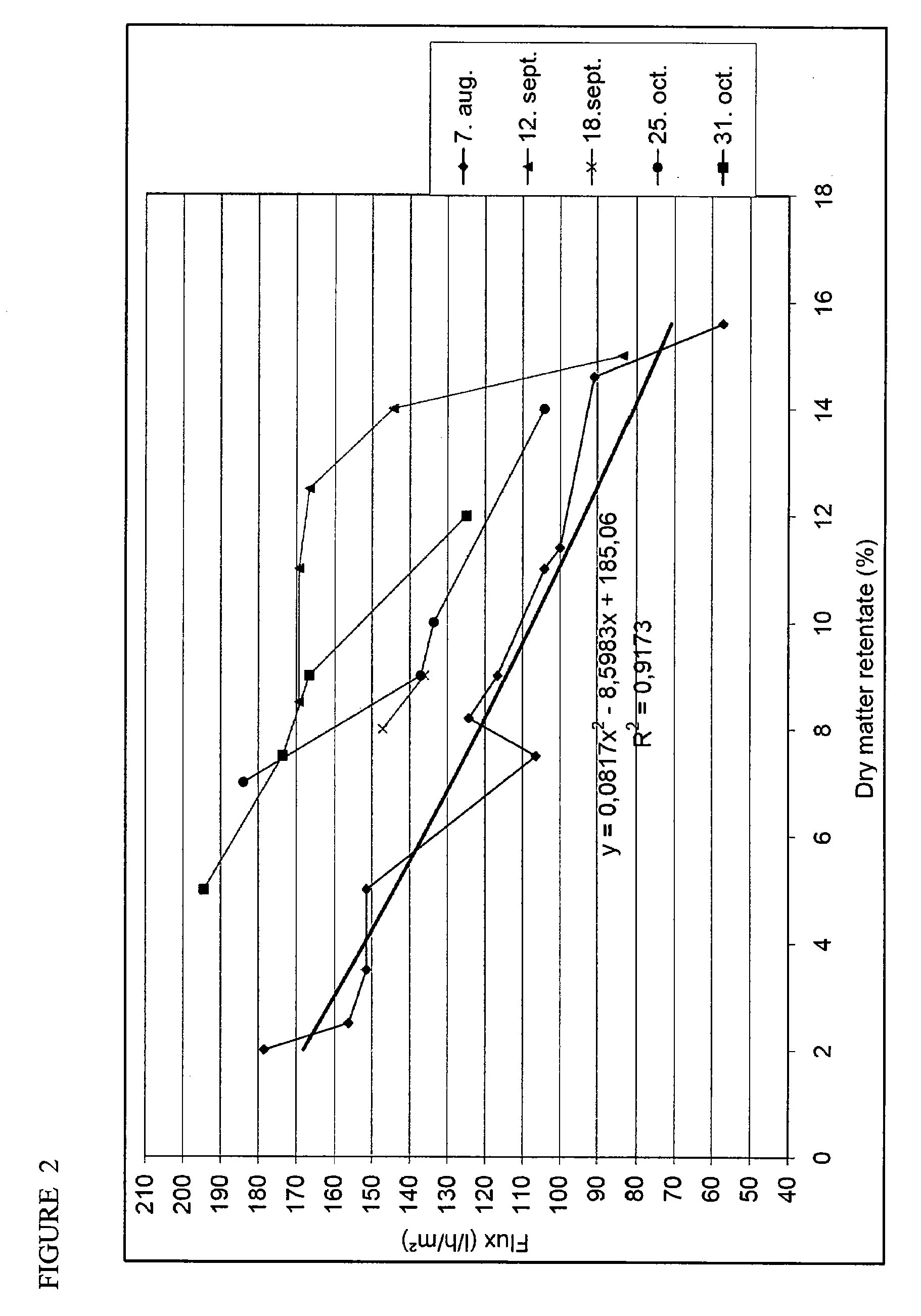

Method for making krill meal

InactiveUS20090061067A1Organic active ingredientsEdible oils/fats ingredientsAstaxanthinPhospholipid

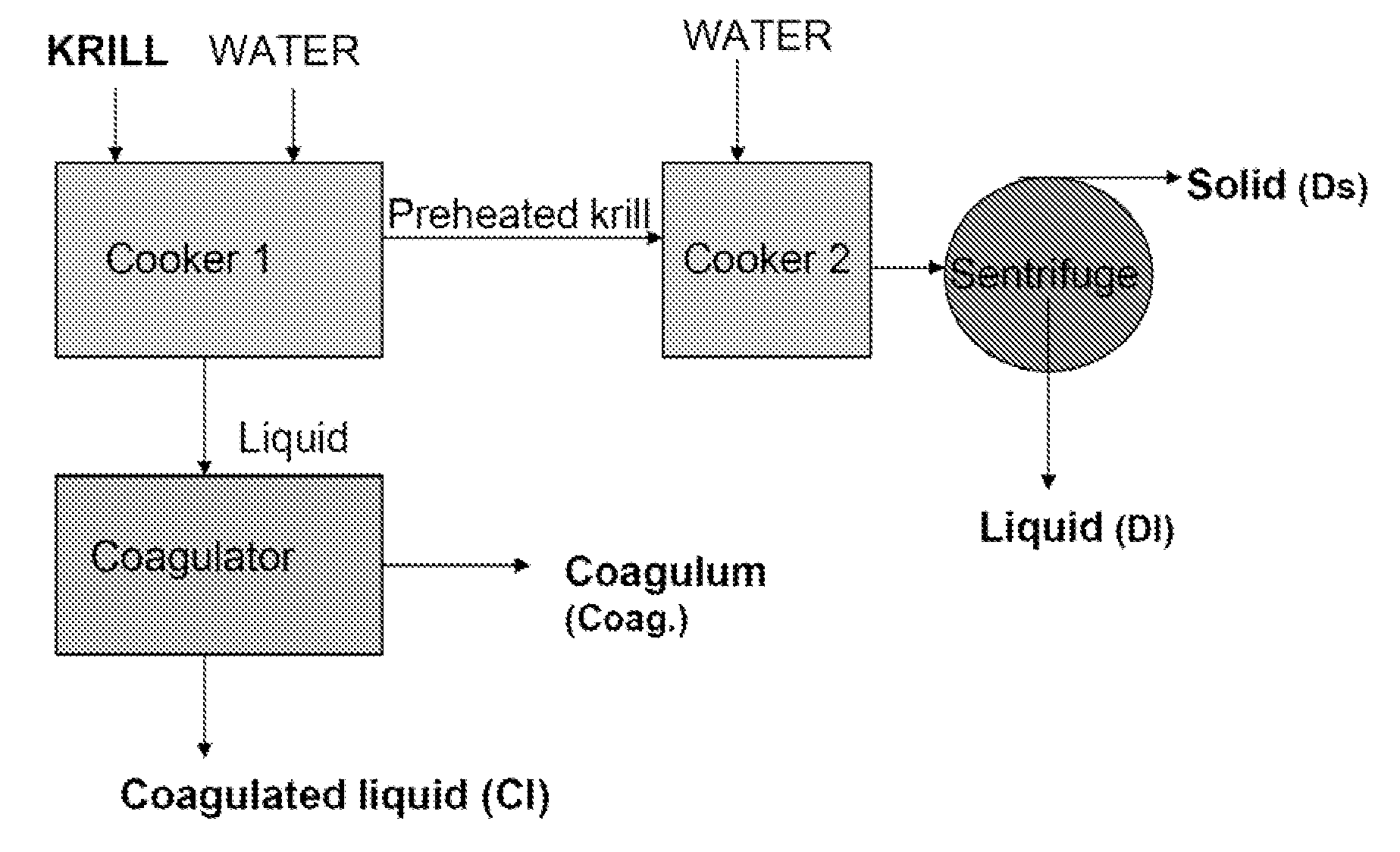

A new method for krill meal production has been developed using a two step cooking process. In the first step the proteins and phospholipids are removed from the krill and precipitated as a coagulum. In the second stage the krill without phospholipids are cooked. Following this, residual fat and astaxanthin are removed from the krill using mechanical separation methods. A novel krill meal product with superior nutritional and technical properties is prepared.

Owner:AKER BIOMARINE ANTARCTIC

Electric heating cooking utensil with wireless steam detection device

The invention discloses an electric heating cooking appliance with a wireless steam detection device, which is a detection device for detecting the temperature, humidity, flow velocity and flow data signals of the steam flowing into the atmosphere through the pot cover in different boiling states of the liquid with wireless transmission and reception. On the pot lid of the electric cooking appliance that is detachable from the pot body or utensils and has no signal transmission wires, this effectively solves the problem that the pot lid and the pot body or utensils can be separated. The electrothermal liquid heating appliance is susceptible to product structure, heating method, and material changes , use environment, operation method, aging deformation, commercial pots of different specifications, etc., especially the changes in altitude, which cause existing problems such as electric rice cookers, electric pressure cookers, electric steamers, and electric stew pots. It has realized the intelligent judgment, adjustment and control of the cooking process when the electric heating stoves such as induction cooker, electric ceramic stove, health pot, electric tea set, and light-wave oven are performing the function of "steaming, cooking, and stewing".

Owner:谢勇

Intelligent fully automatic cooking robot

InactiveCN102273912AShorten the timeImprove qualityProgramme control in sequence/logic controllersWarming devicesAutomatic controlMicrowave oven

The intelligent fully automatic cooking robot involved in the present invention adopts the intelligent automatic control technology of mechanical and electrical integration, software and hardware combination, conducts intelligent automatic cooking based on microwave ovens and other stoves, and places multiple liquid and solid ingredient boxes and vegetable boxes on the panel , according to the prompts of the intelligent automatic cooking controller, after placing the prepared dishes, in the case of unattended, at any time according to the requirements of the person at the specified time for accurate and precise cooking, one intelligent automatic completion of one or more Cooking dishes, people can enjoy a delicious meal when they go home from work; the invention adopts the concept of a manipulator, which has a simple and efficient structure, small size, and is easy to use. Environmental protection requirements; used at home can save people a lot of time for cooking, so that people can live a higher quality of life or perform more creative work, and use it in commercial operations can reduce labor and save costs.

Owner:洪家平

Semiautomatic electrothermal cooking pot

ActiveCN106943002ADetermined by degree of maturitySimple structureElectric heatingVessels with intergral heatingTemperature controlFood material

The invention discloses a semiautomatic electrothermal cooking pot, comprising a clip-type temperature controller, a stainless steel pot, an electric cooker and a power socket board, wherein the clip-type temperature controller is provided with a clip bracket; the front end of the clip bracket is provided with a temperature control switch; the left end of the temperature control switch is communicated with a capillary tube; the left end of the capillary tube is communicated with a temperature sensing head; the temperature sensing head is tightly clung to the lower right end of the stainless steel pot; a clip opening of the clip bracket is supported at the right end of the stainless steel pot. The pot disclosed by the invention has the advantages that a water level line at the bottom of the stainless steel pot is a sauce-reducing water level line during a cooking process; different water adding amount in the pot is controlled according to different food materials and cooking requirements, the water adding amount is in direct proportion to cooking time, the cooking time depends on the water adding amount, the cooking degree of cooked food depends on the cooking time, and the sauce-reducing degree of the cooked food depends on different pot bottom temperatures; the cooked food can reach an expected effect by means of flexibly and expertly mastering the water adding amount and the different pot bottom temperatures; after cooking, the electric cooker powers off automatically, the situation that the food is scorched due to oblivion is prevented, and the effects of saving time, labor and worry are achieved.

Owner:临沂威尔森新型材料有限公司

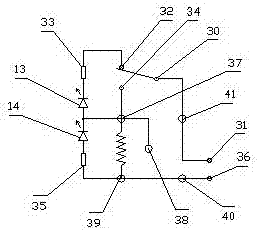

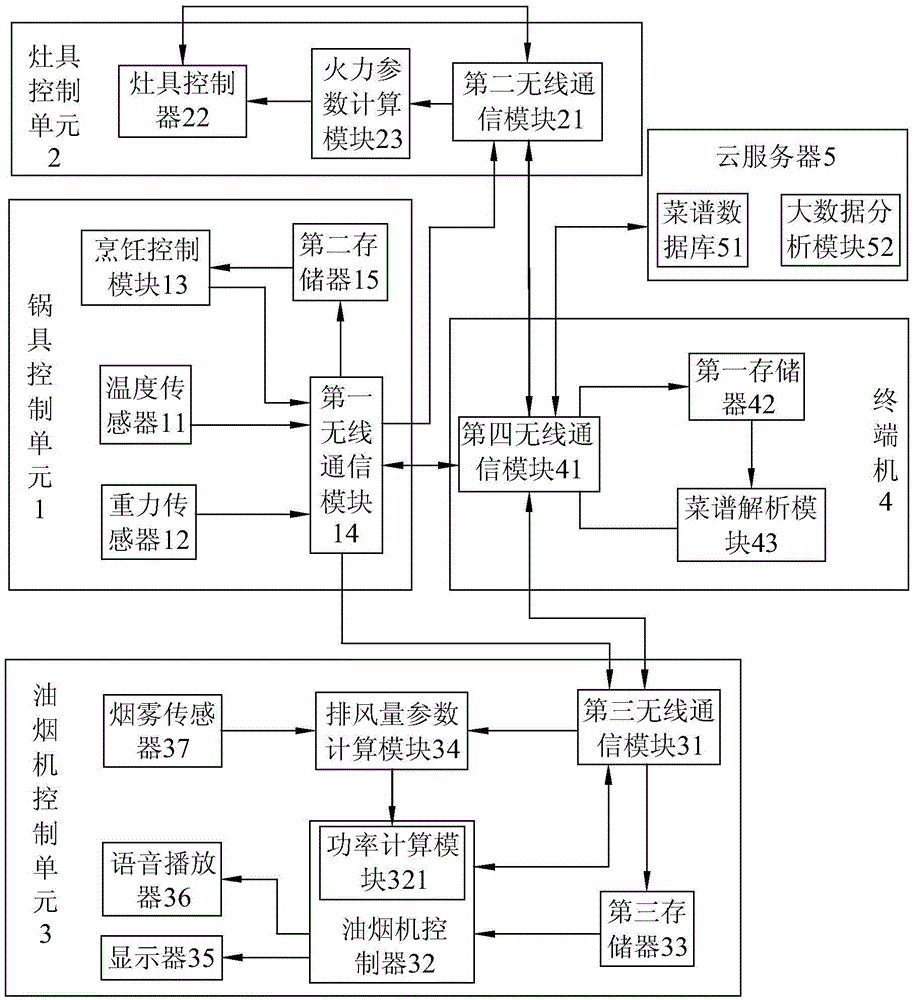

Intelligent cooking system and method

ActiveCN105652680AEnable direct communicationFine-tuning of firepowerComputer controlProgramme total factory controlControl engineeringControl cell

The invention relates to an intelligent cooking system. The intelligent cooking system comprises a pot control unit, a stove control unit and a range hood control unit, and the stove control unit and the range hood control unit are in communication with the pot control unit respectively. The intelligent cooking system further comprises a terminal and a cloud server. The terminal is in wireless communication with the pot control unit, the stove control unit, the range hood control unit and the cloud server. The invention further relates to an intelligent cooling method. The terminal can download cookbook data in the cloud server and transmit the date to the pot control unit so that cooking can be controlled. In the cooling process, the pot control unit can detect the weight of food placed in a pot and can also detect the heating temperature of the pot so that weight data and temperature data can be transmitted to the stove control unit and the range hood control unit, the fire power and the exhaust air rate can be flexibly and autonomously adjusted in real time, and the system can adapt to different food quantities. Meanwhile the terminal can be used for fine adjusting the fire power of a stove and the work power of a draught fan so that control over cooking can be more accurate.

Owner:ZHEJIANG AICHEN GRP CO LTD

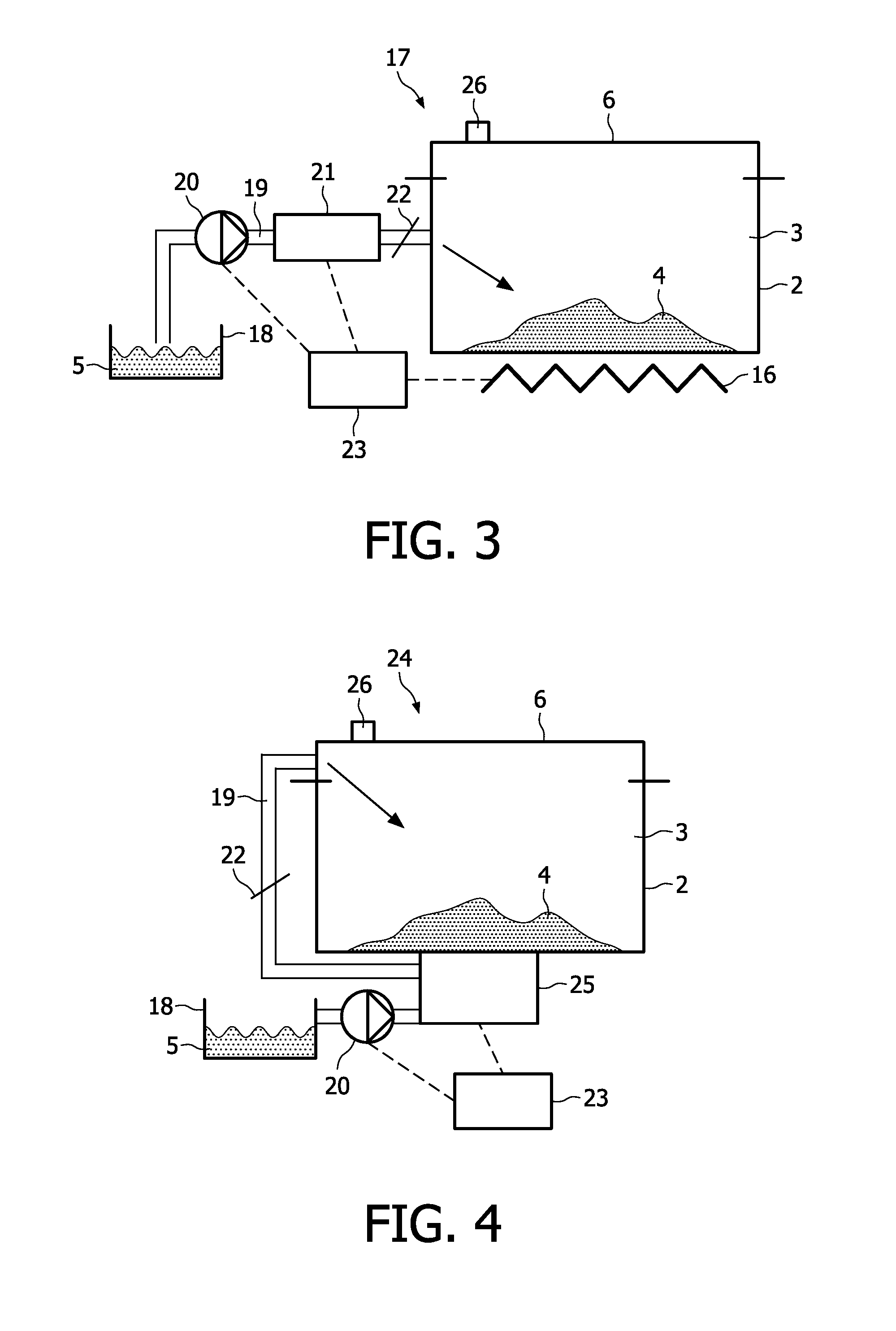

Method and device for cooking food such as rice

InactiveUS9295354B2Shorten the timeBoiling over preventionBeverage vesselsProcess engineeringCooking process

A device for cooking food such as rice is configured to perform a cooking process which is performed by heating the food under the influence of boiling water during a period of time. The device includes a controller for controlling an operation of the device. The controller is configured o operate components of the device in such a way that a total quantity of water to be used in the cooking process is gradually supplied to the food. The supply of a major portion of the total quantity of the water is performed when the cooking process is already taking place. In one embodiment, the cooking process is initiated by evaporating a relatively small portion of the total quantity of the water to steam, supplying this steam to the food, and allowing this steam to condense on the food.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

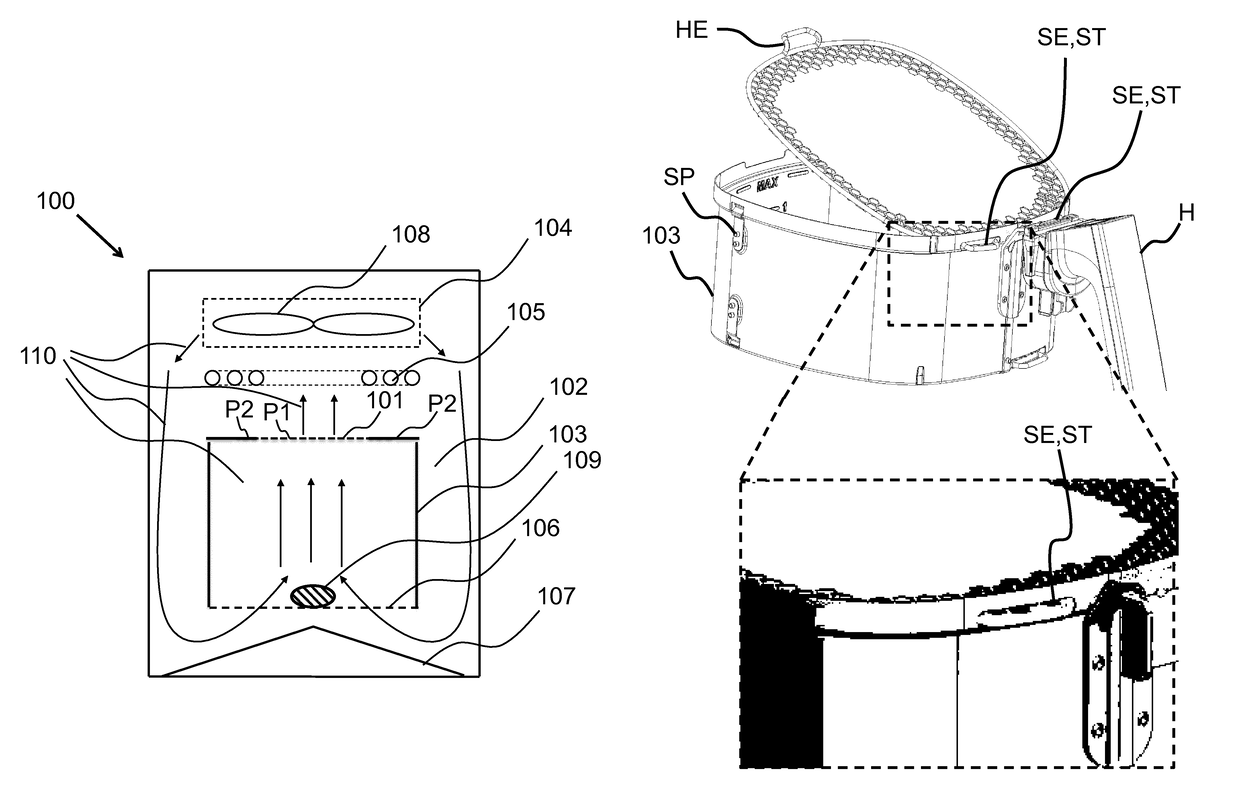

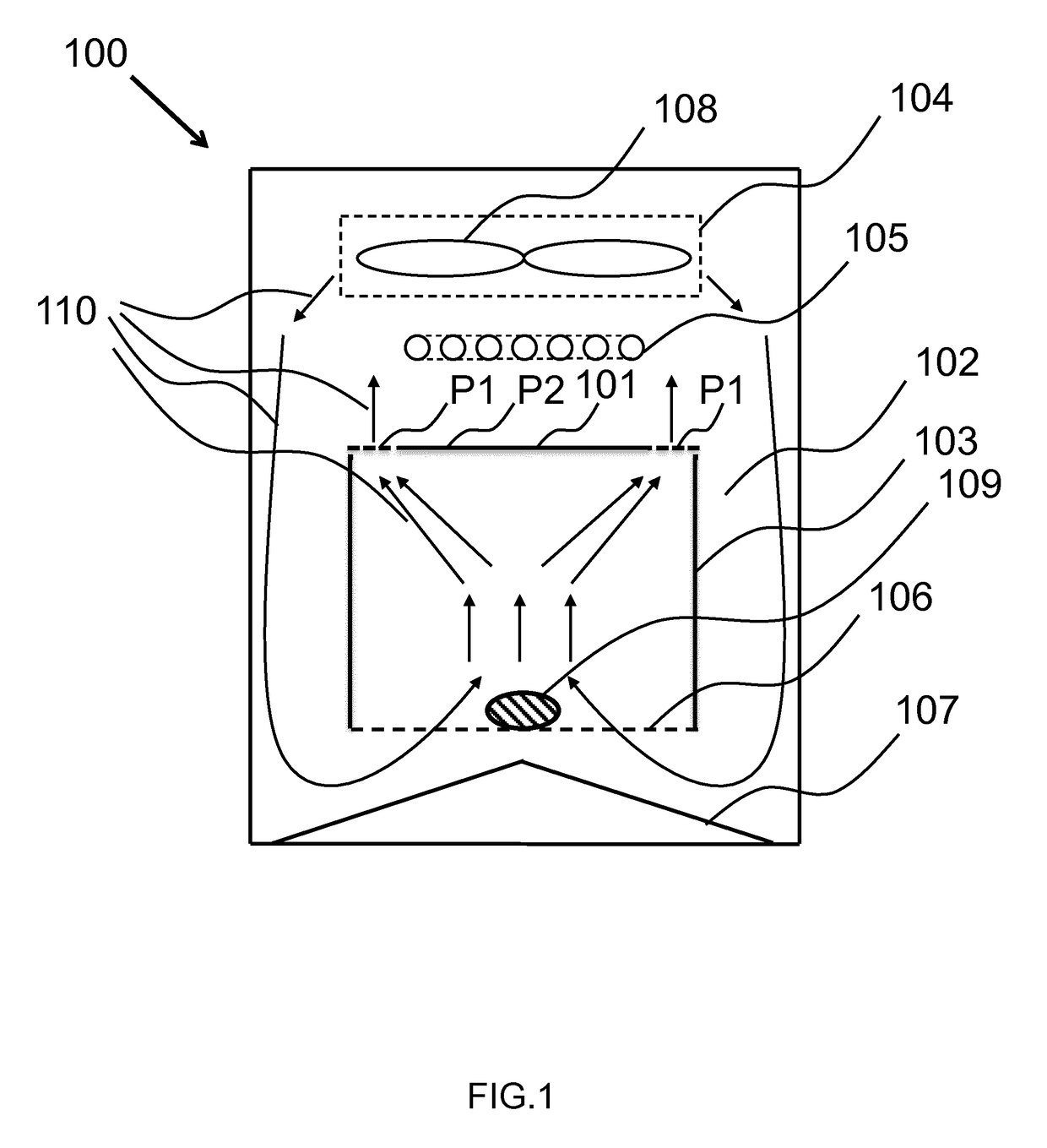

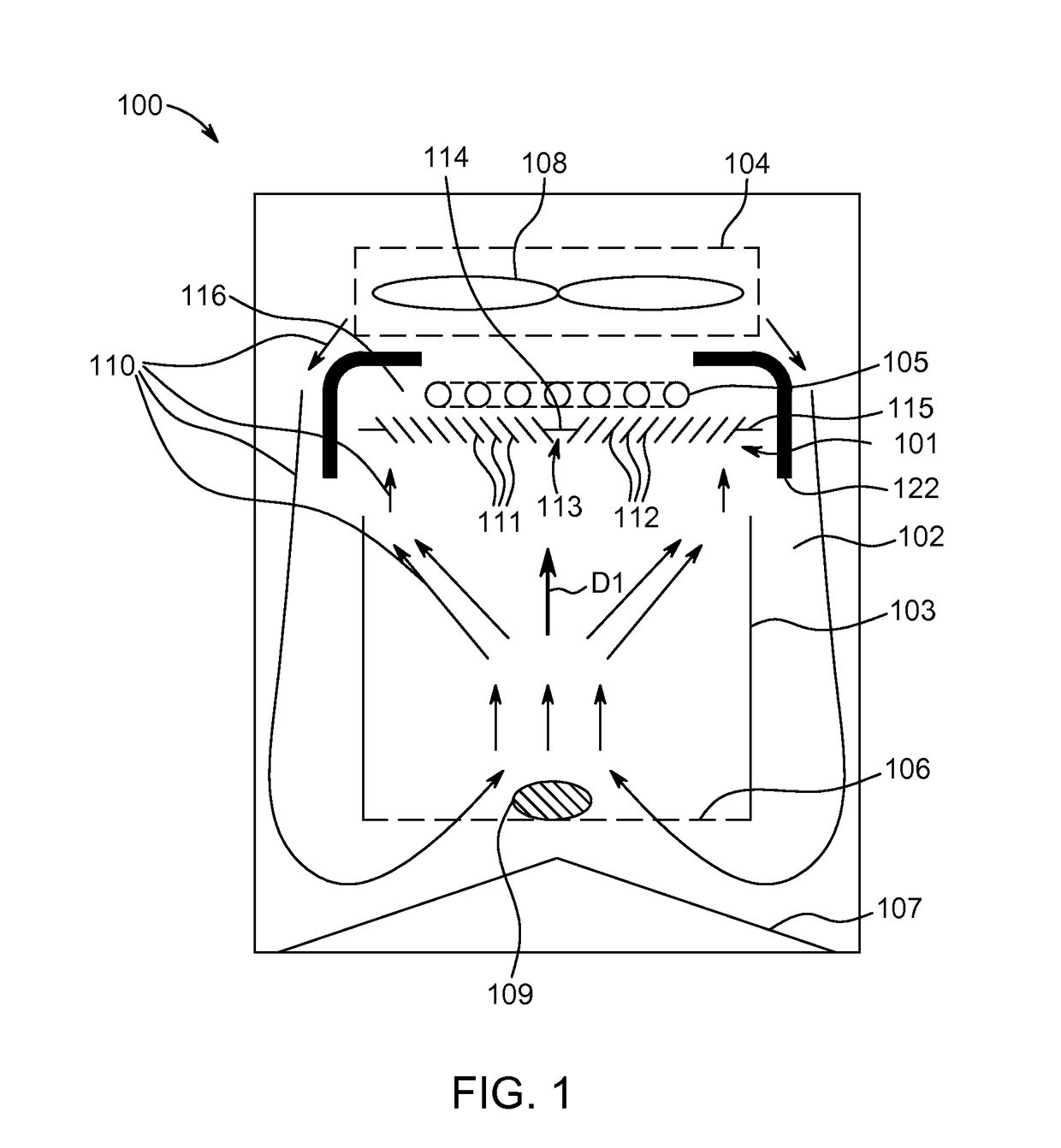

Lid for reducing fumes in an air-based fryer

ActiveUS9854941B2Reduce the amount requiredCooking-vessel materialsDomestic stoves or rangesThermodynamicsCooking process

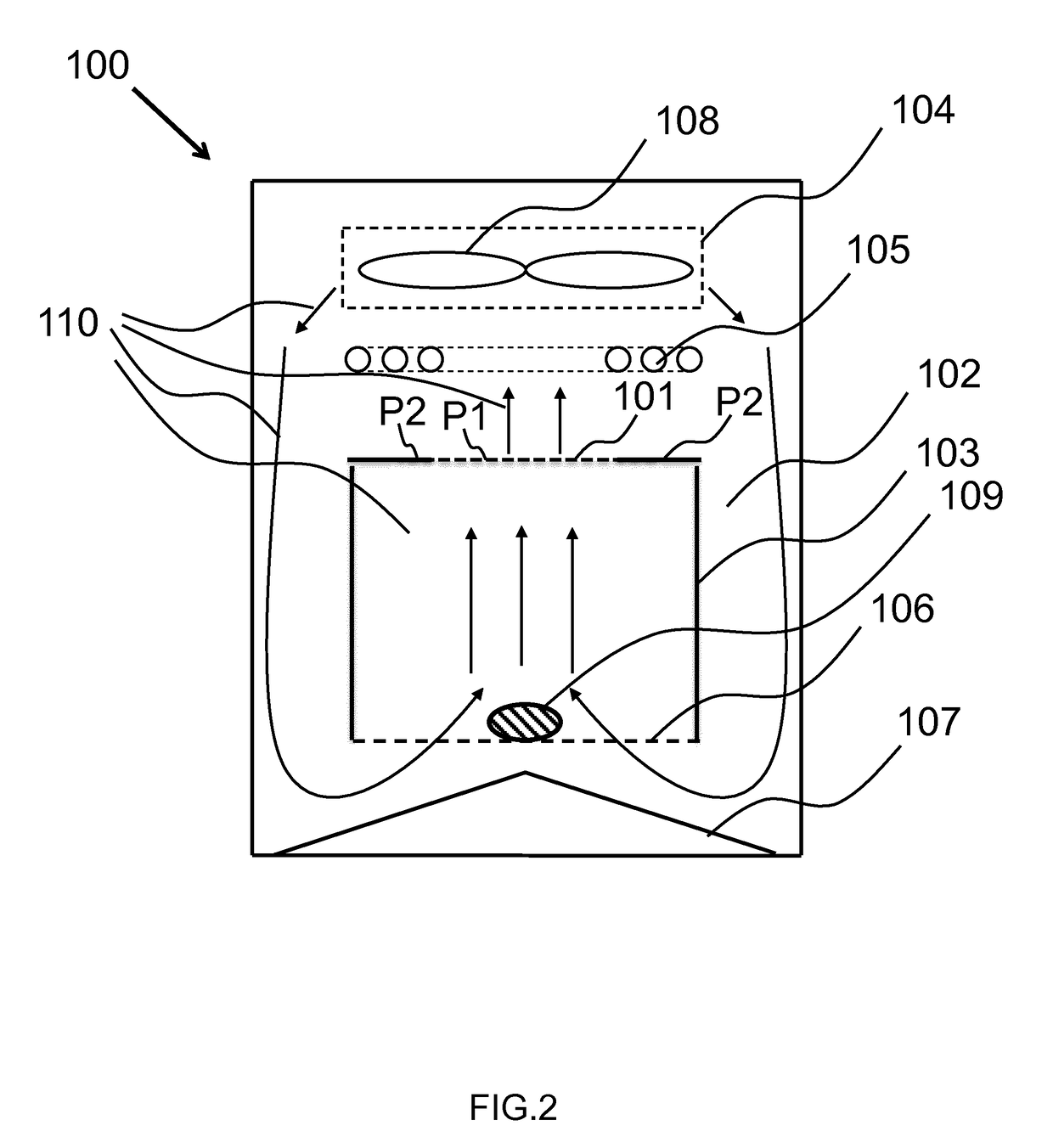

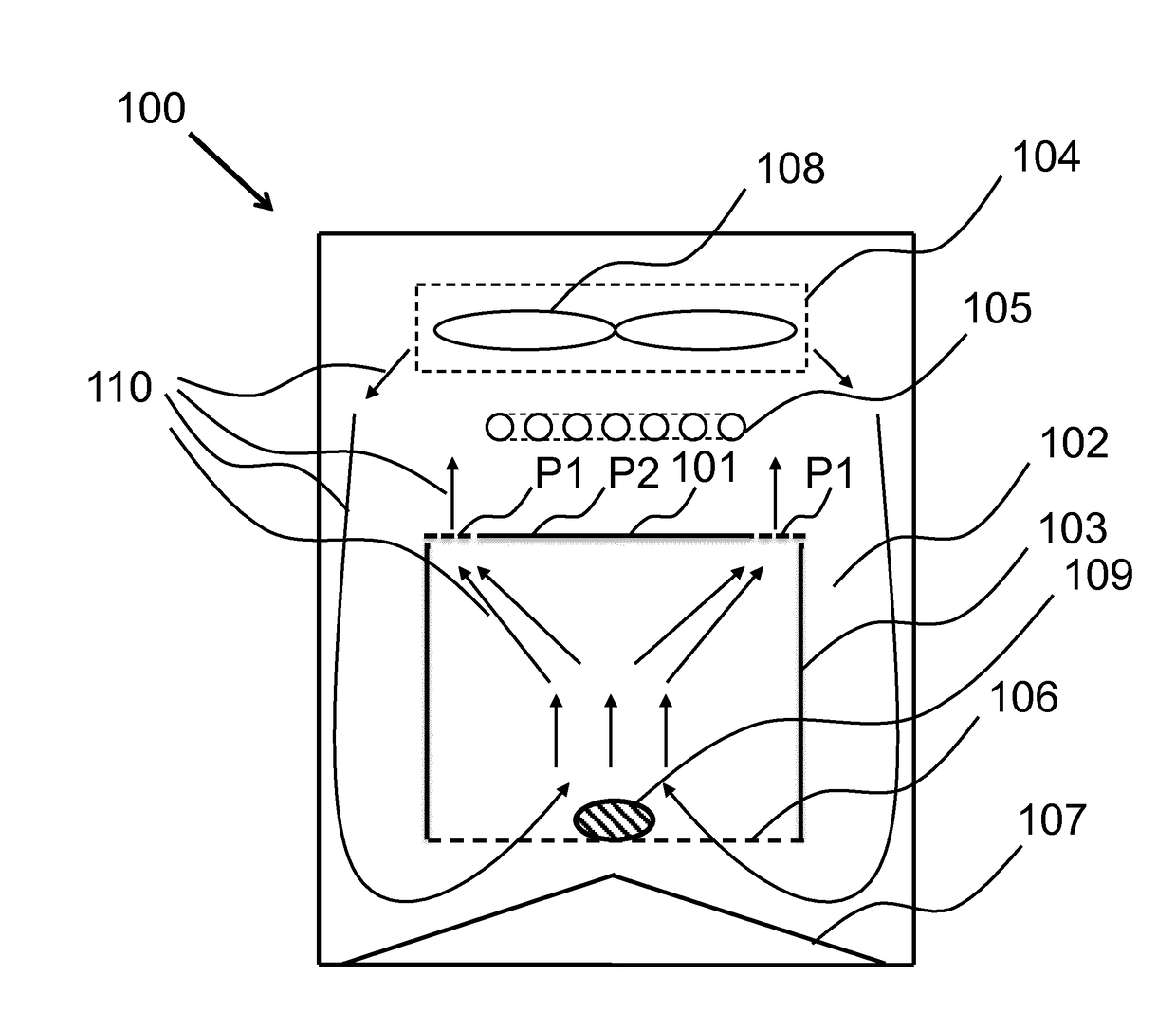

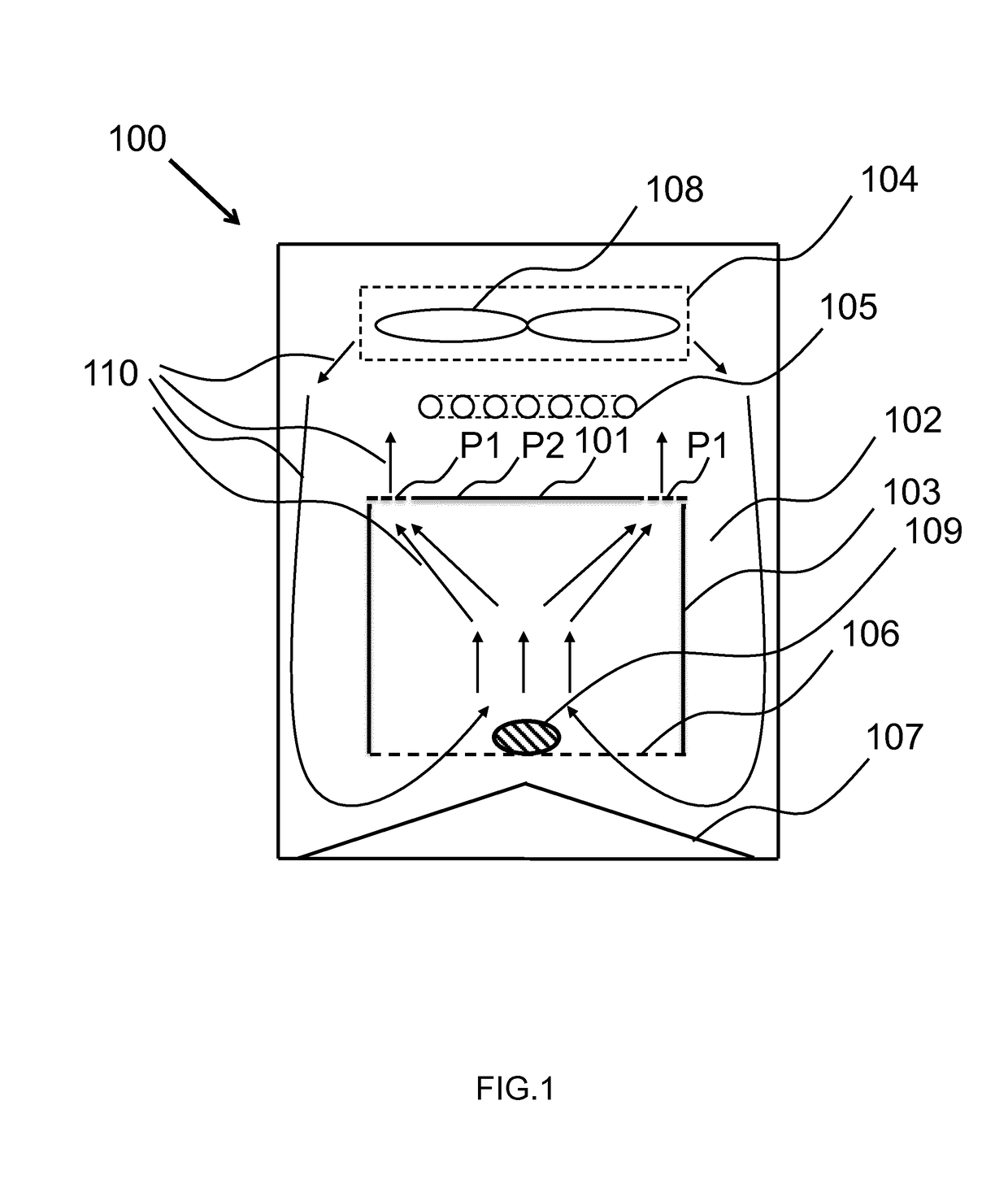

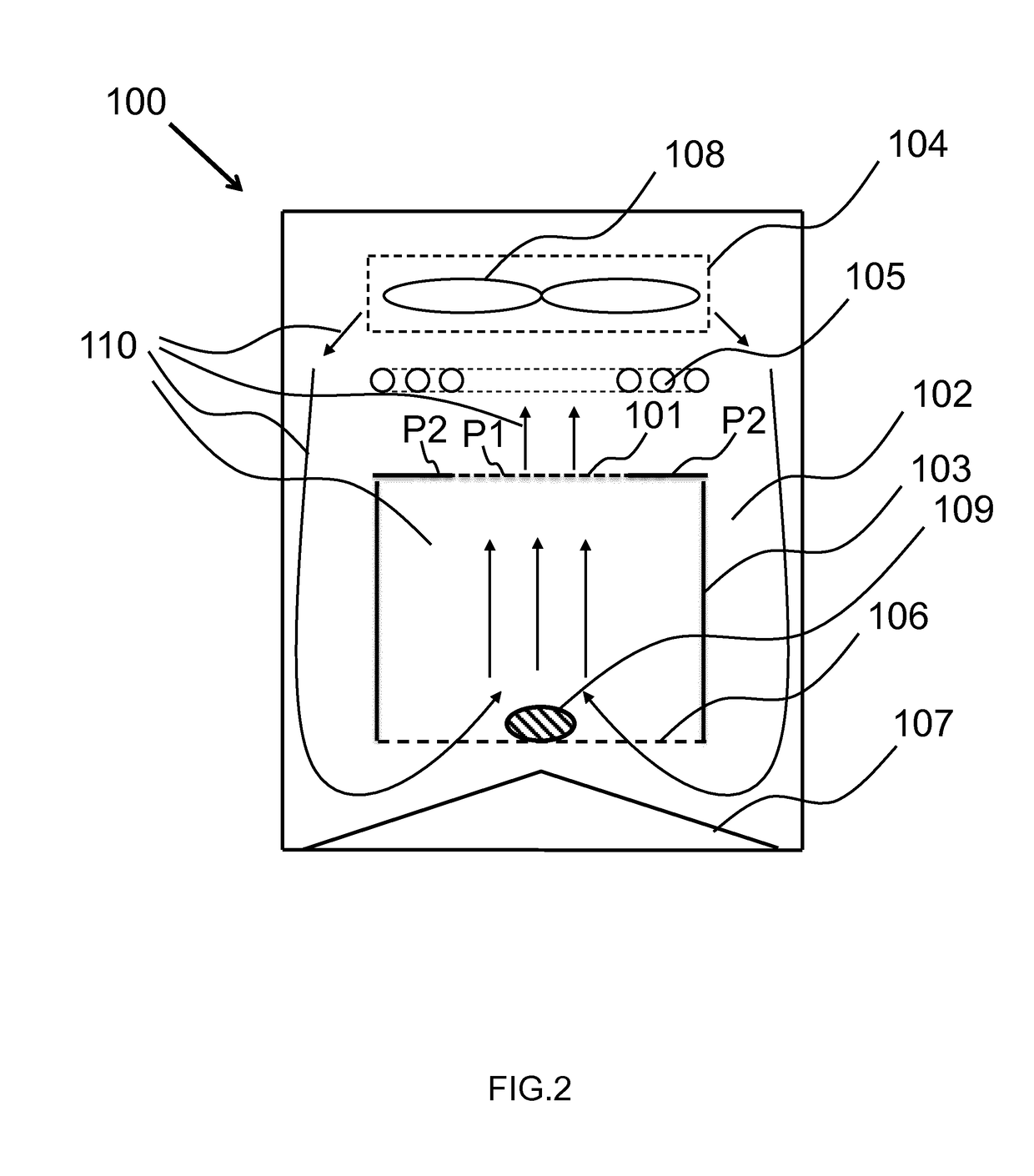

The invention relates to an air-based flyer apparatus (100) for preparing food. The apparatus comprises a food preparation chamber (102), a food basket (103) placed in said food preparation chamber (102), a system (104) for circulating an upward flow of hot air inside said food basket (103), a heating element (105) placed above said food basket (103) to generate said hot air, a lid (101) placed below the heating element for covering the food basket. The lid (101) comprises a first part (P1) being air-permeable, and a second part (P2) facing said heating element (105) being air-impermeable. The invention allows reducing fumes generated by an air-based flyer during cooking process.

Owner:VERSUNI HLDG BV

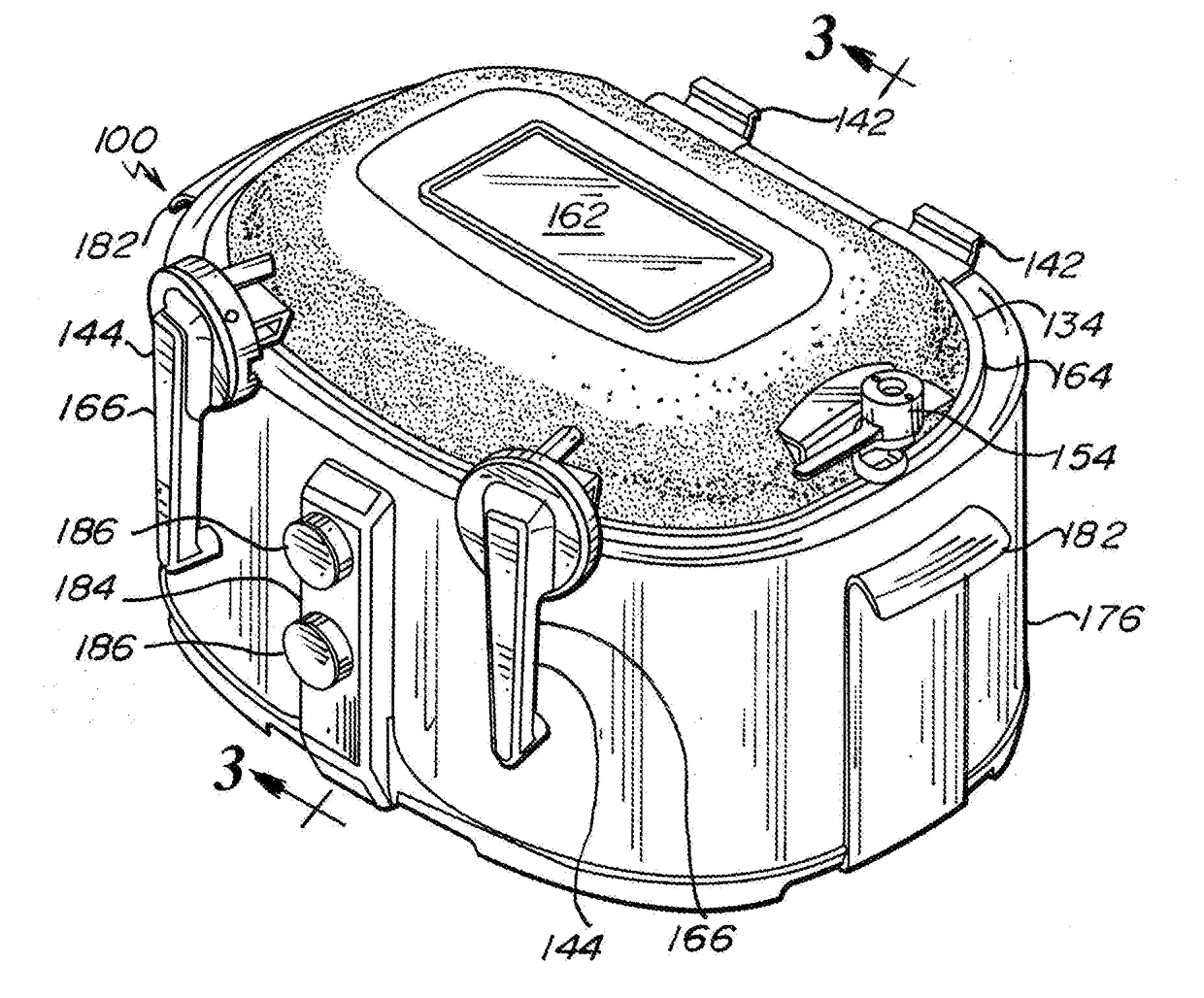

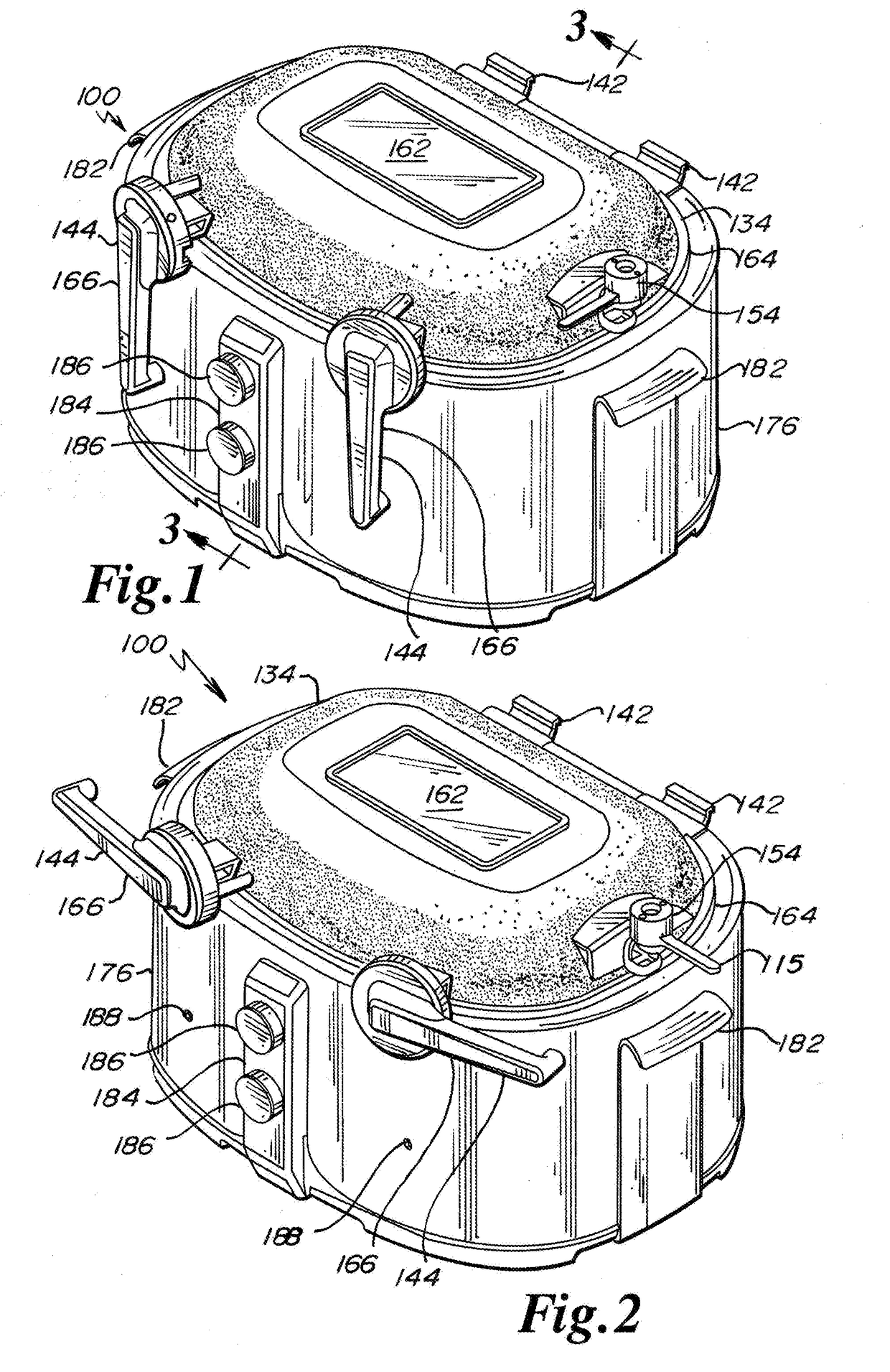

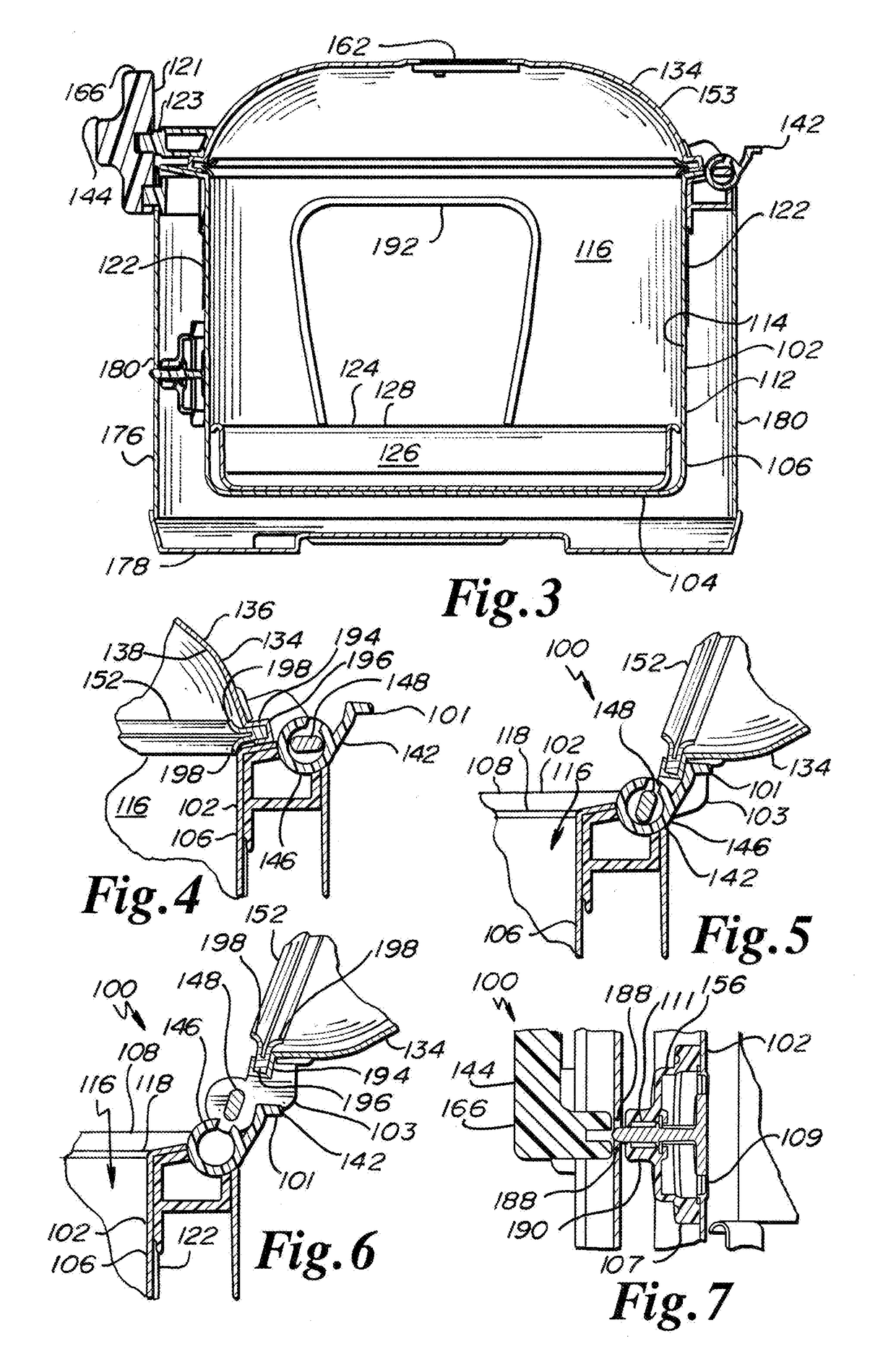

Rapid cooking oven with broadband communication capability to increase ease of use

An improved oven for use in a residence is described. The oven includes a cooking chamber, a programmable controller for executing program instructions, memory media for recording executable program instructions, and at least one controllable cooking system under control of the programmable controller, which provides a data-processing-controlled high speed cooking process which may be applied to food placed in the oven chamber. A plurality of cooking programs are recorded in the memory media of the oven. These define a plurality of high speed cooking routines available for use with the oven. A gateway server is communicatively coupled to the programmable controller. It manages the communication of digital content which is at least in-part related to operation and utilization of the improved oven. A broadband communication channel extends from a source of digital content, which is external to the residence, to the residence. The broadband communication channel delivers particular digital content related to the oven through the gateway server for distribution within the residence, including distribution to the programmable controller of the oven in order to facilitate cooking operations utilizing the oven.

Owner:TURBOCHEF TECH INC

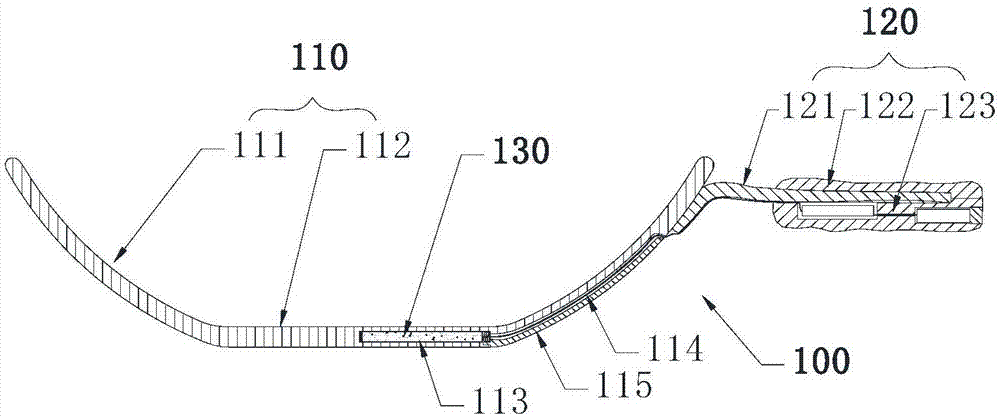

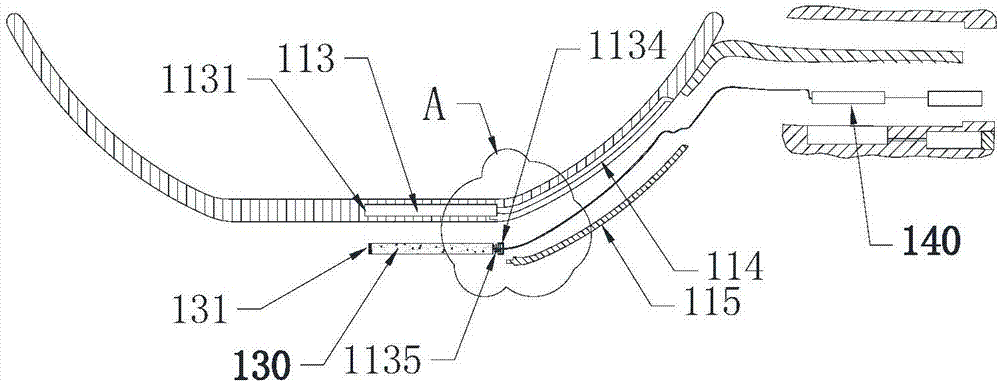

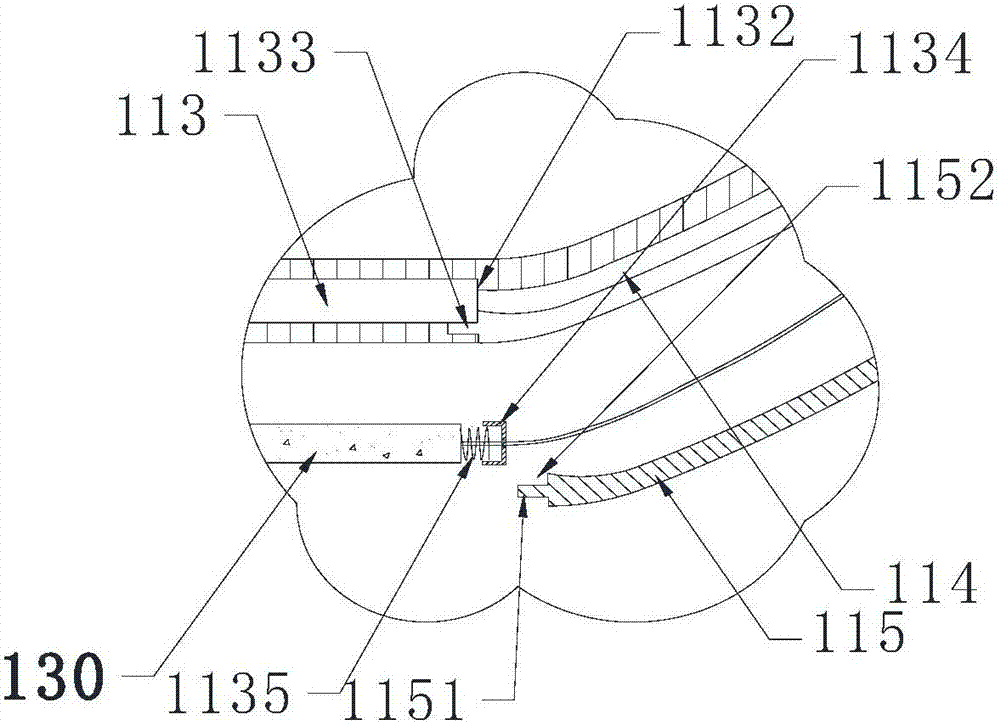

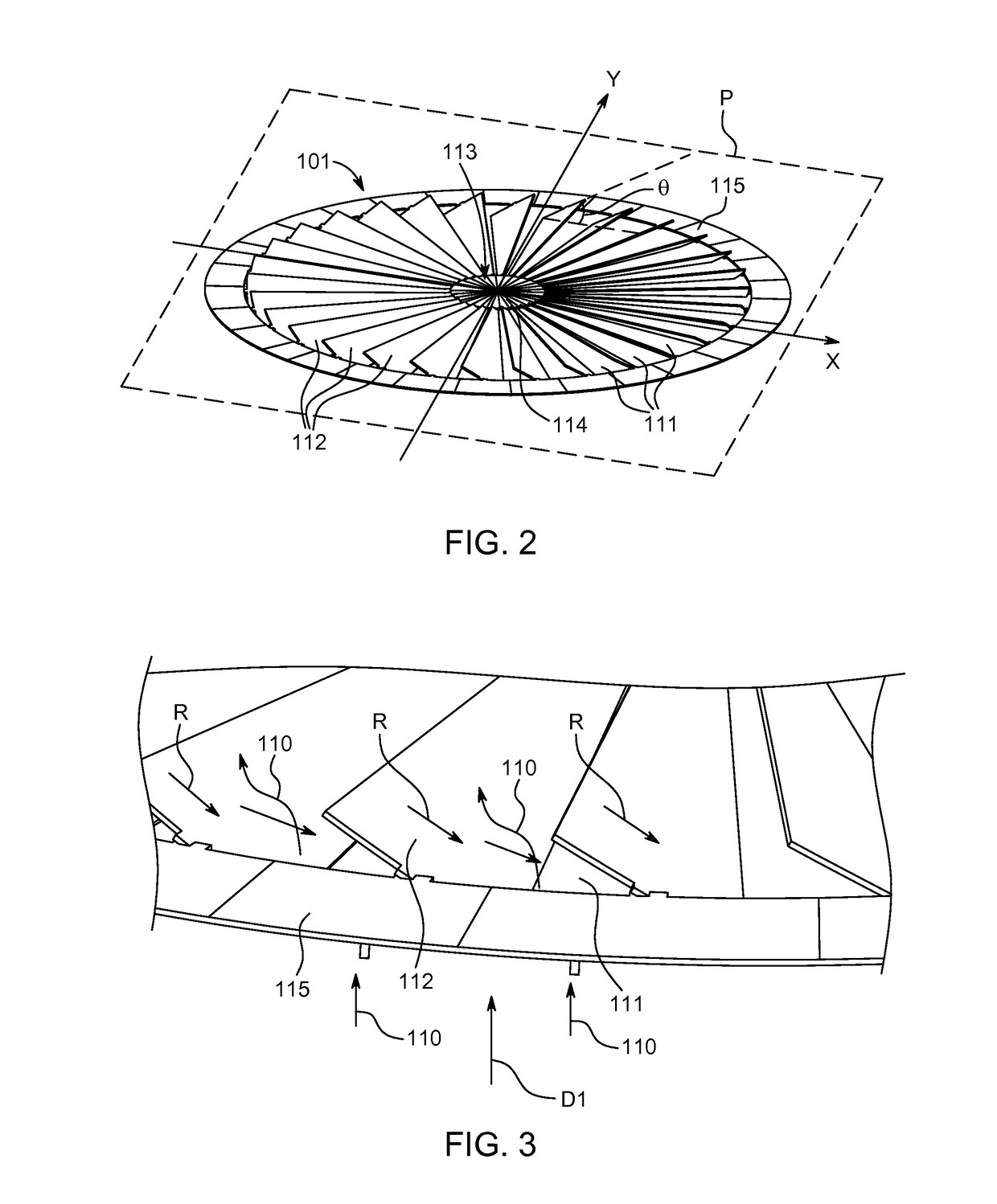

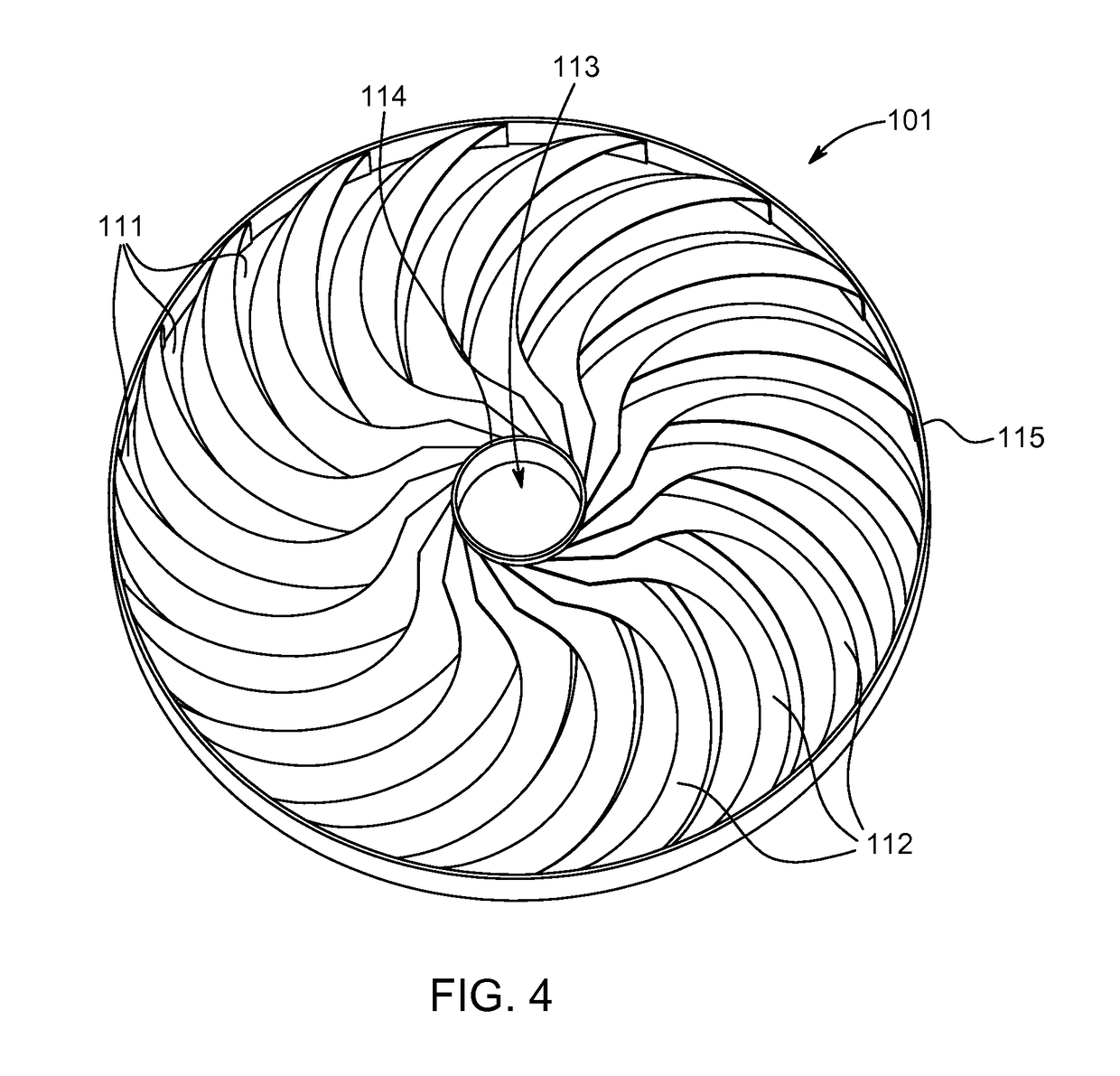

Shield for air-based fryer apparatus

The invention relates to a air-based fryer apparatus (100) including a shield (101) for use in a cooking apparatus (100) having a food preparation chamber (102) to receive a food support (103), a system (104) for circulating a flow of hot air inside the food preparation chamber (102) and a heating element (105) to heat at least the circulated air. The shield (101) is configured to be disposed between the heating element (105) and the food support (103). The shield (101) comprises a plurality of inclined surfaces (112) and a plurality of apertures (111) between the inclined surfaces (112) through which the flow of hot air can pass, wherein the inclined surfaces (112) are adapted to block a direct line of sight through the apertures (11) in the shield (101) from the heating element (105) to the food support (103) to prevent air flowing from the food support (103) to the heating element (105) through the apertures without being defelected by the inclined surfaces. The invention allows, among various advantages, reducing fumes generated by an air-based fryer during cooking process.

Owner:KONINKLJIJKE PHILIPS NV

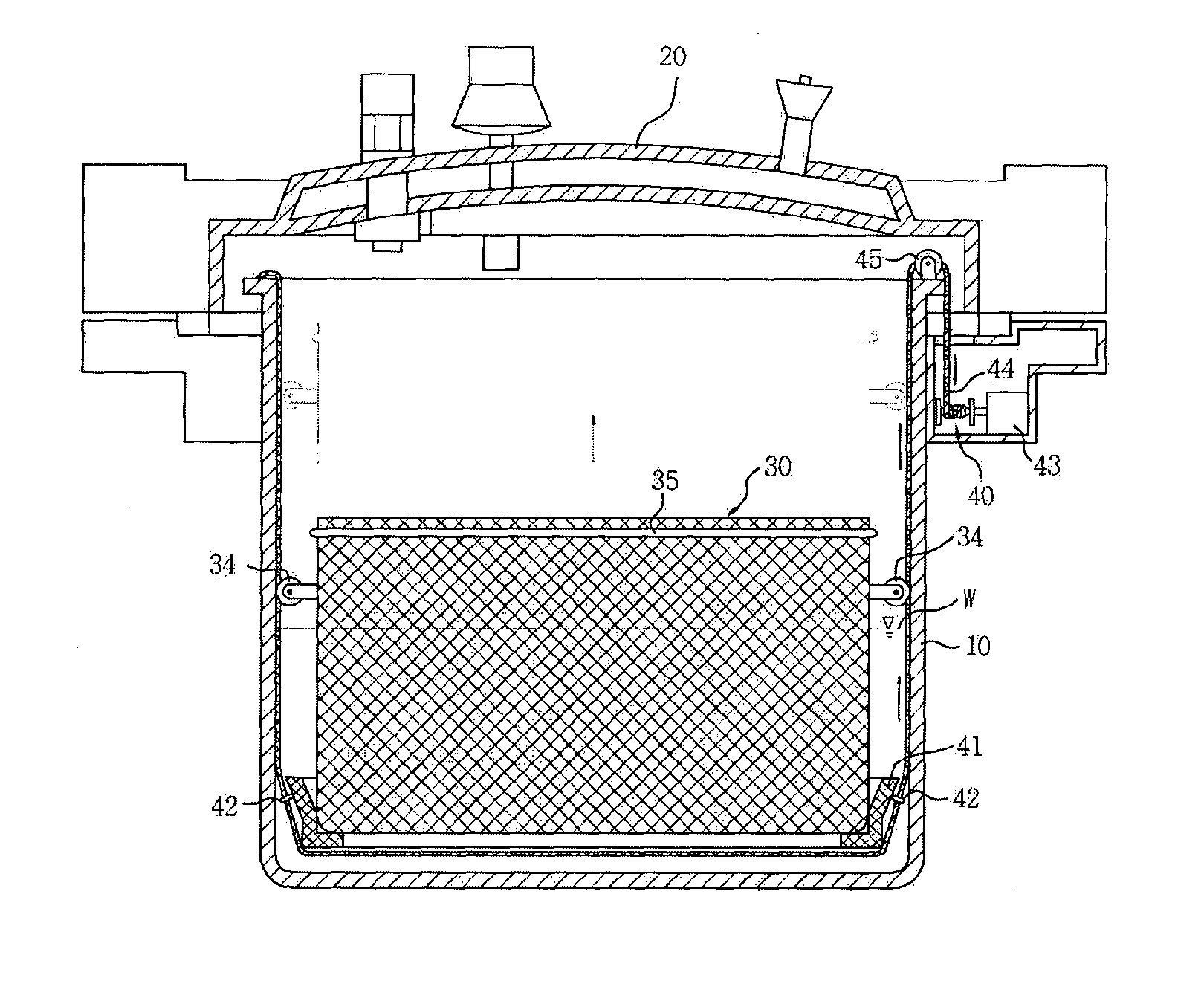

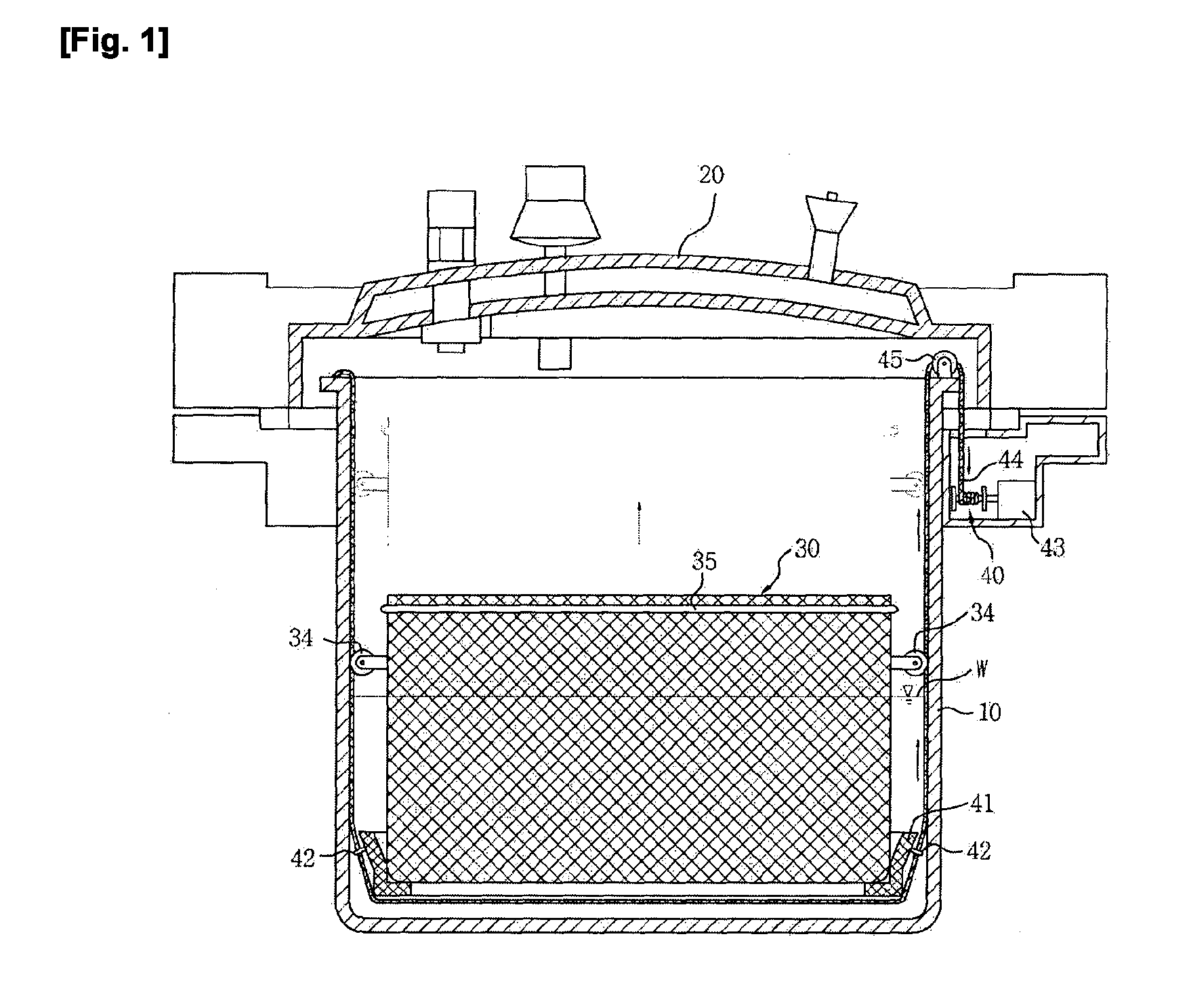

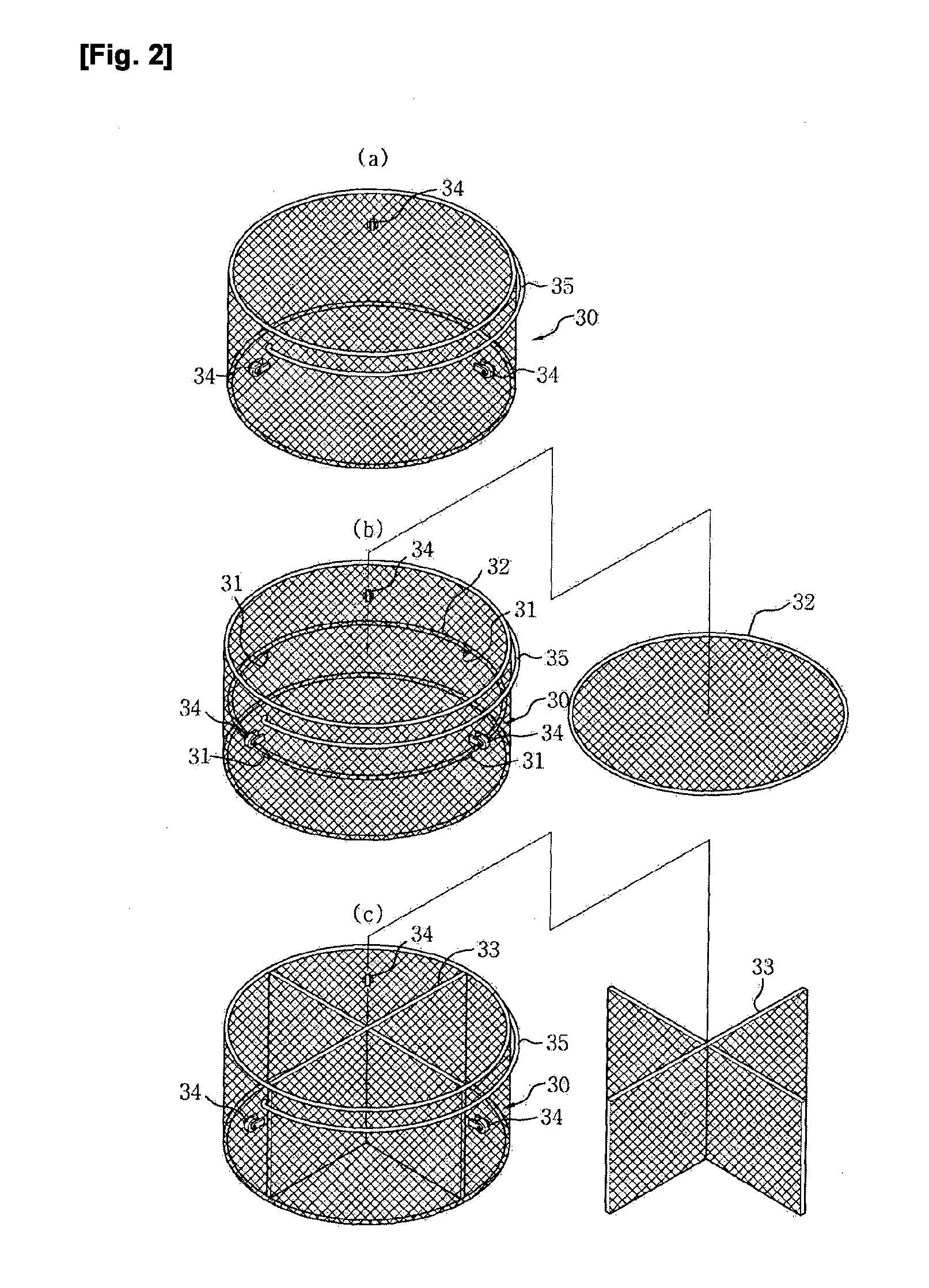

Pressure cooker for cooking noodles

The present invention relates to a pressure cooker for cooking noodles, wherein a cooking container capable of cooking noodles is formed into a net shape inside a main body of the pressure cooker and a lifting means capable of lifting the cooking container is provided, thereby allowing noodles to be evenly cooked through and enabling cooking of high quality noodles with taut and excellent texture through a dual cooking process comprising the following steps: putting noodles in the cooking container, boiling the noodles, and then lifting the cooking container to the surface of the water using the lifting means to steam the noodles at a high temperature and at a high pressure.

Owner:LEE KEUN YOUNG

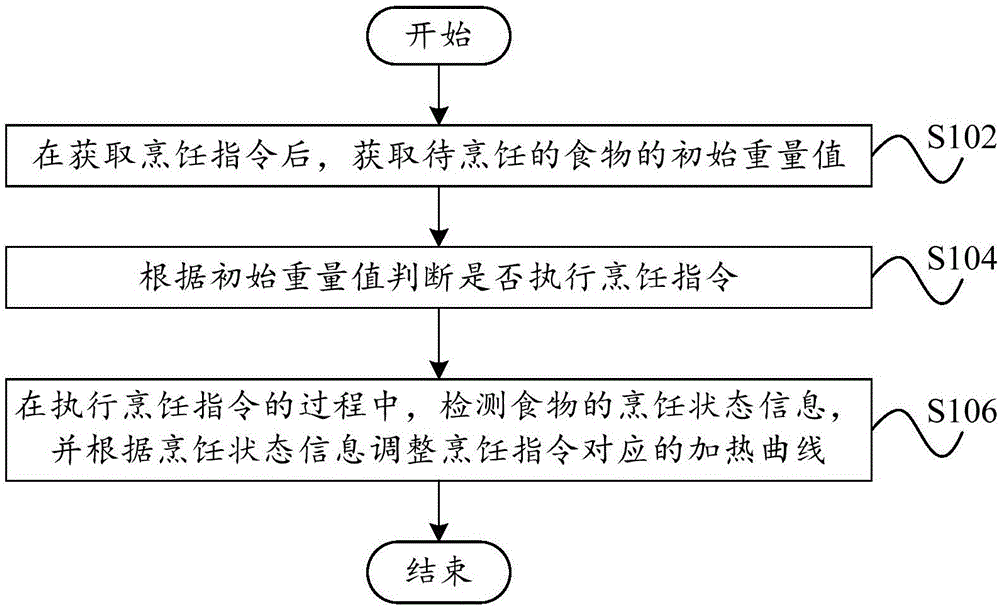

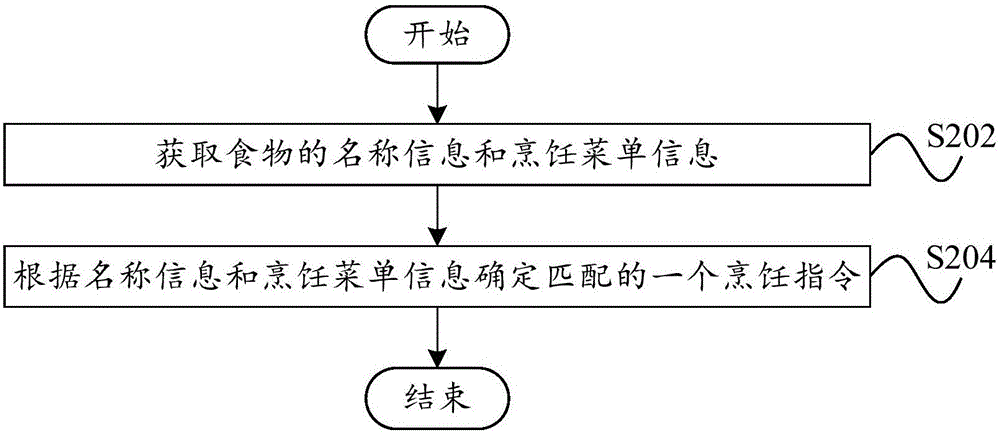

Cooking method, cooking apparatus, and cooking utensil

InactiveCN106802584AImprove cooking efficiencyImprove user experienceProgramme control in sequence/logic controllersVessels with intergral heatingPower parameterProcess engineering

The invention provides a cooking method, a cooking apparatus, and a cooking utensil. The cooking method comprises: obtaining an initial weight value of to-be-cooked food after obtaining a cooking instruction; determining whether to execute the cooking instruction according to the initial weight value; and detecting cooking state information of the food in the process of executing the cooking instruction, and adjusting a heating curve corresponding to the cooking instruction according to the cooking state information, wherein the heating curve comprises a cooking time parameter and a cooking power parameter. According to the technical scheme, in the cooking beginning stage and the cooking process, the cooking state of the cooked food is detected, the effect of preventing no-load cooking of the cooking utensil is realized, and the cooking effect of the cooking utensil is improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

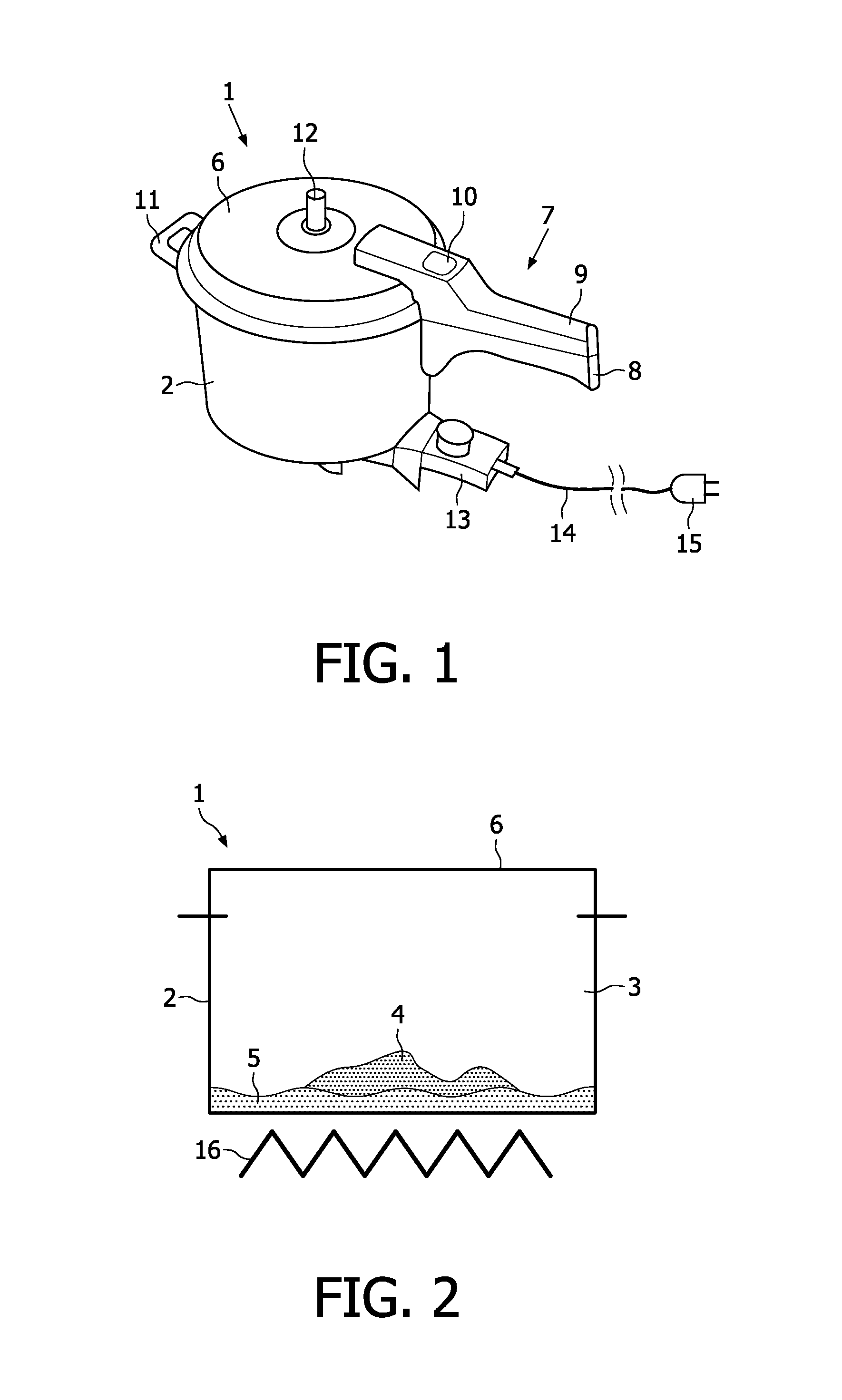

Pressure cooking appliance

An oval shaped countertop kitchen appliance having a cooking chamber that defines a cavity. The cooking chamber has a rim defining an opening to the cavity. An electric heating element is disposed proximate the cavity to heat the cavity. A pan retaining foodstuff therein has a generally hollow interior and a rim defining an opening for accessing the interior thereof. The pan is sized and shaped to fit within the cavity of the cooking chamber. A lid is sized and shaped to at least partially cover the cooking chamber rim when placed on the cooking chamber rim. At least one hinge and one latch are mounted to one of the exterior surface of the side wall of the cooking chamber and the lid. A pressure seal is present in the interface of the lid and the cooking chamber rim. Said pressure seal is compressed when latching mechanism is in its latched position. Pressure regulating valve communicates between the cooking chamber cavity and the outside, to limit the pressure built up within the cooking chamber as foodstuff is heated by said electric heater and emits steam during the cooking process. Said cooking pressure is set at a predetermined level. Temperature in the cooking chamber is controllable by the user as is the duration of the cooking cycle.

Owner:GLUCKSMAN DOV Z

Lid for reducing fumes in an air-based fryer

ActiveUS20170065127A1Reduce the amount requiredCooking-vessel materialsDomestic stoves or rangesEngineeringCooking process

The invention relates to an air-based flyer apparatus (100) for preparing food. The apparatus comprises a food preparation chamber (102), a food basket (103) placed in said food preparation chamber (102), a system (104) for circulating an upward flow of hot air inside said food basket (103), a heating element (105) placed above said food basket (103) to generate said hot air, a lid (101) placed below the heating element for covering the food basket. The lid (101) comprises a first part (P1) being air-permeable, and a second part (P2) facing said heating element (105) being air-impermeable. The invention allows reducing fumes generated by an air-based flyer during cooking process.

Owner:KONINKLJIJKE PHILIPS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com