Patents

Literature

7363 results about "Convection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Convection is the heat transfer due to the bulk movement of molecules within fluids such as gases and liquids, including molten rock (rheid). Convection includes sub-mechanisms of advection (directional bulk-flow transfer of heat), and diffusion (non-directional transfer of energy or mass particles along a concentration gradient).

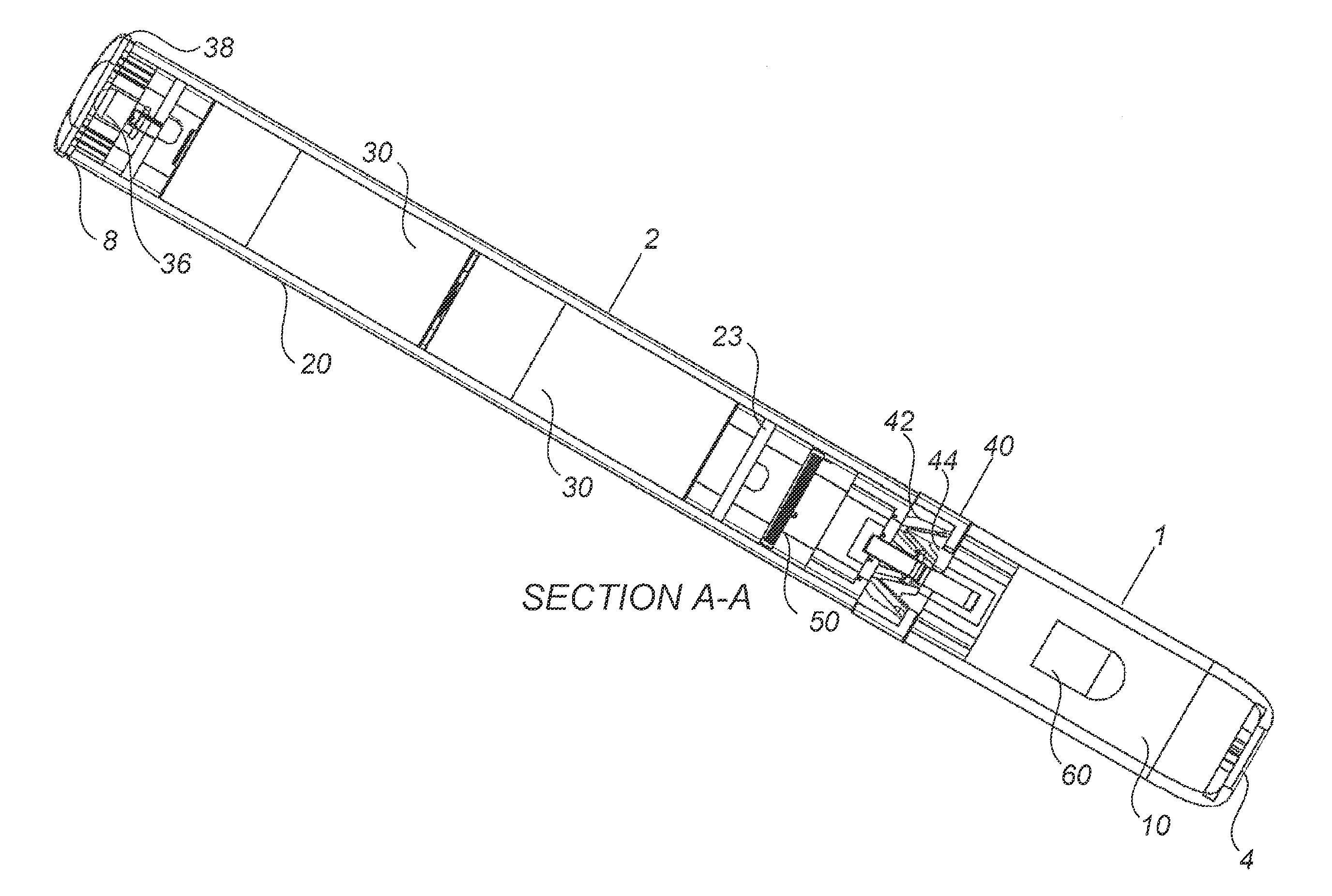

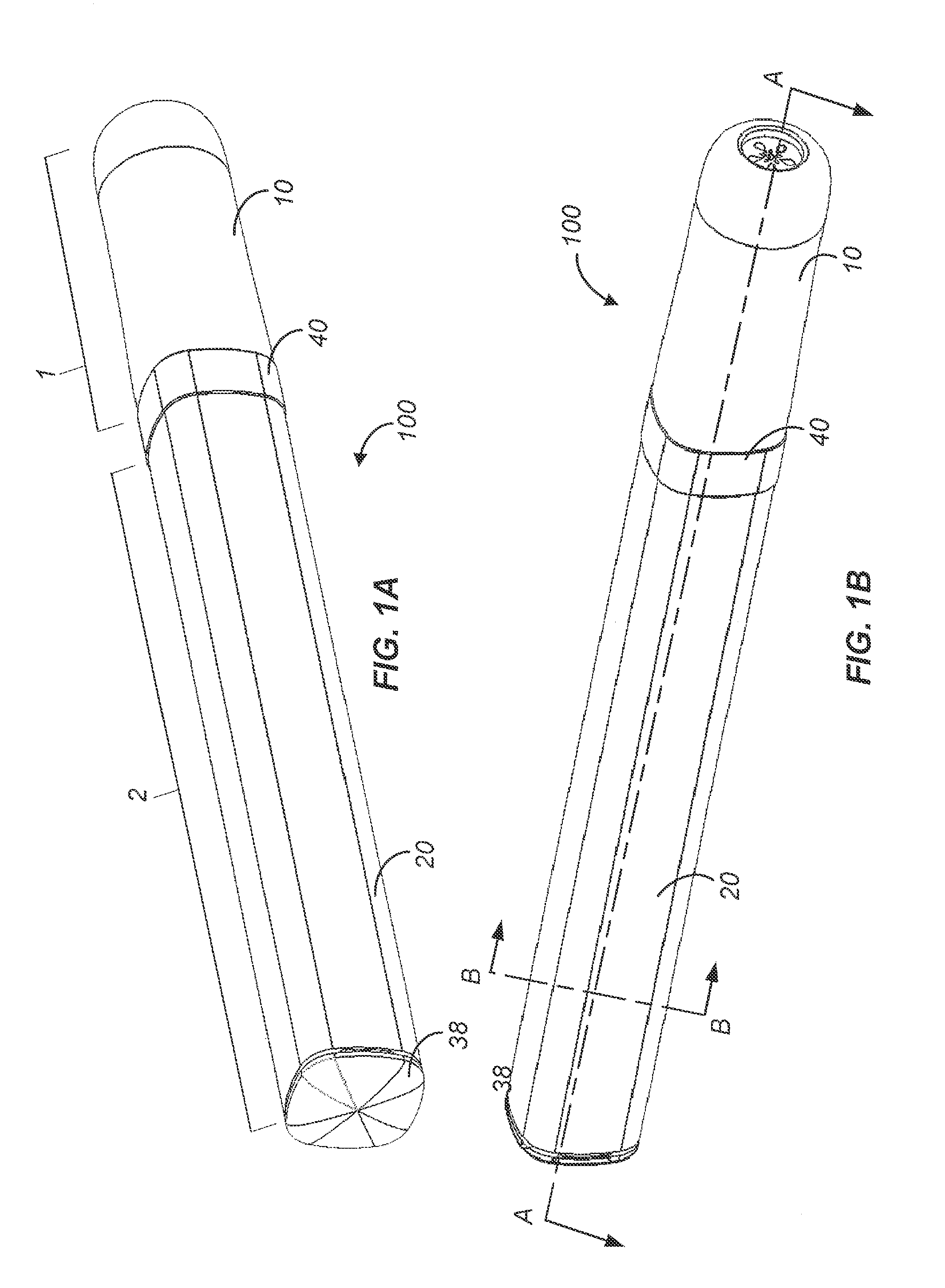

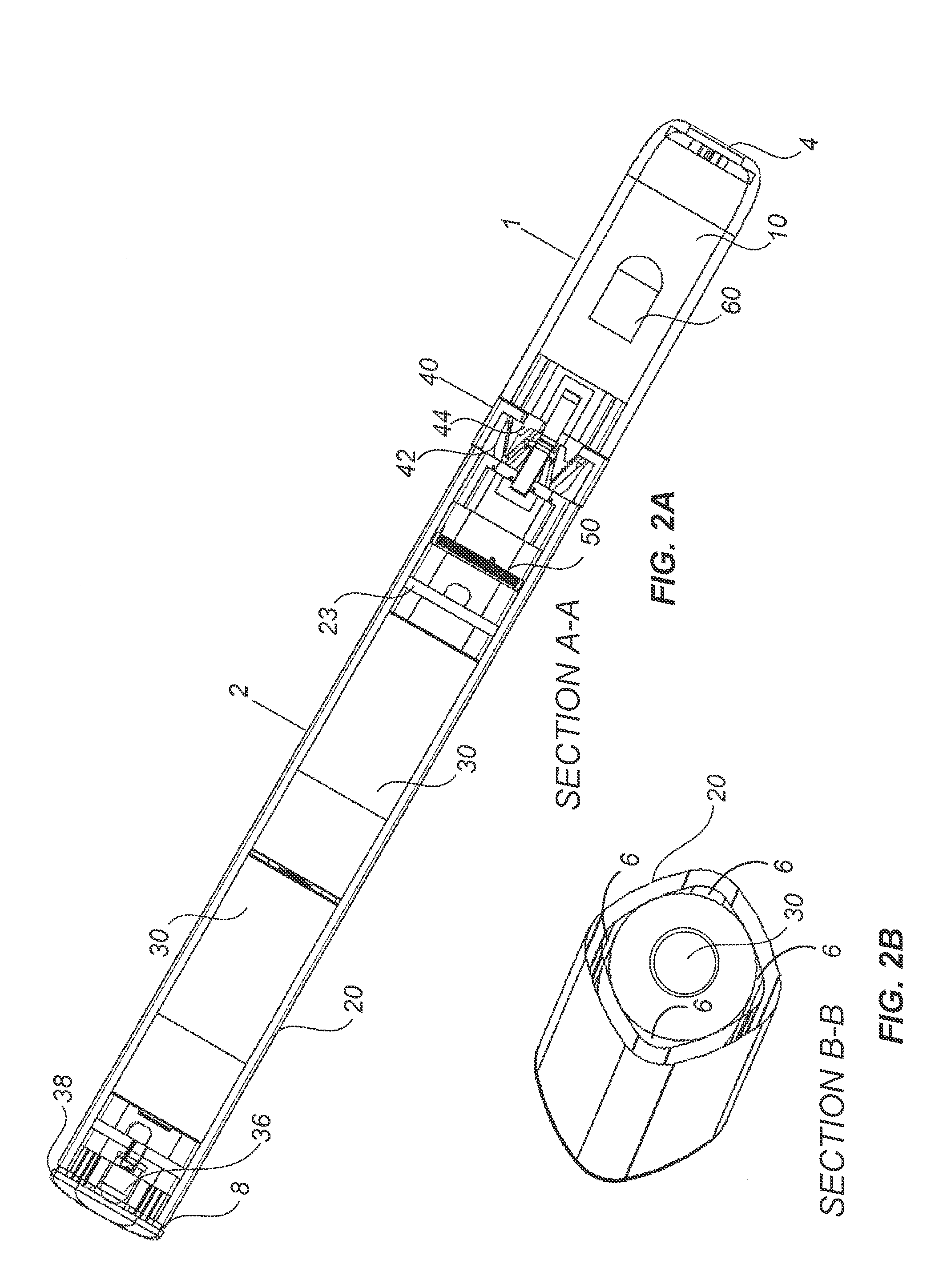

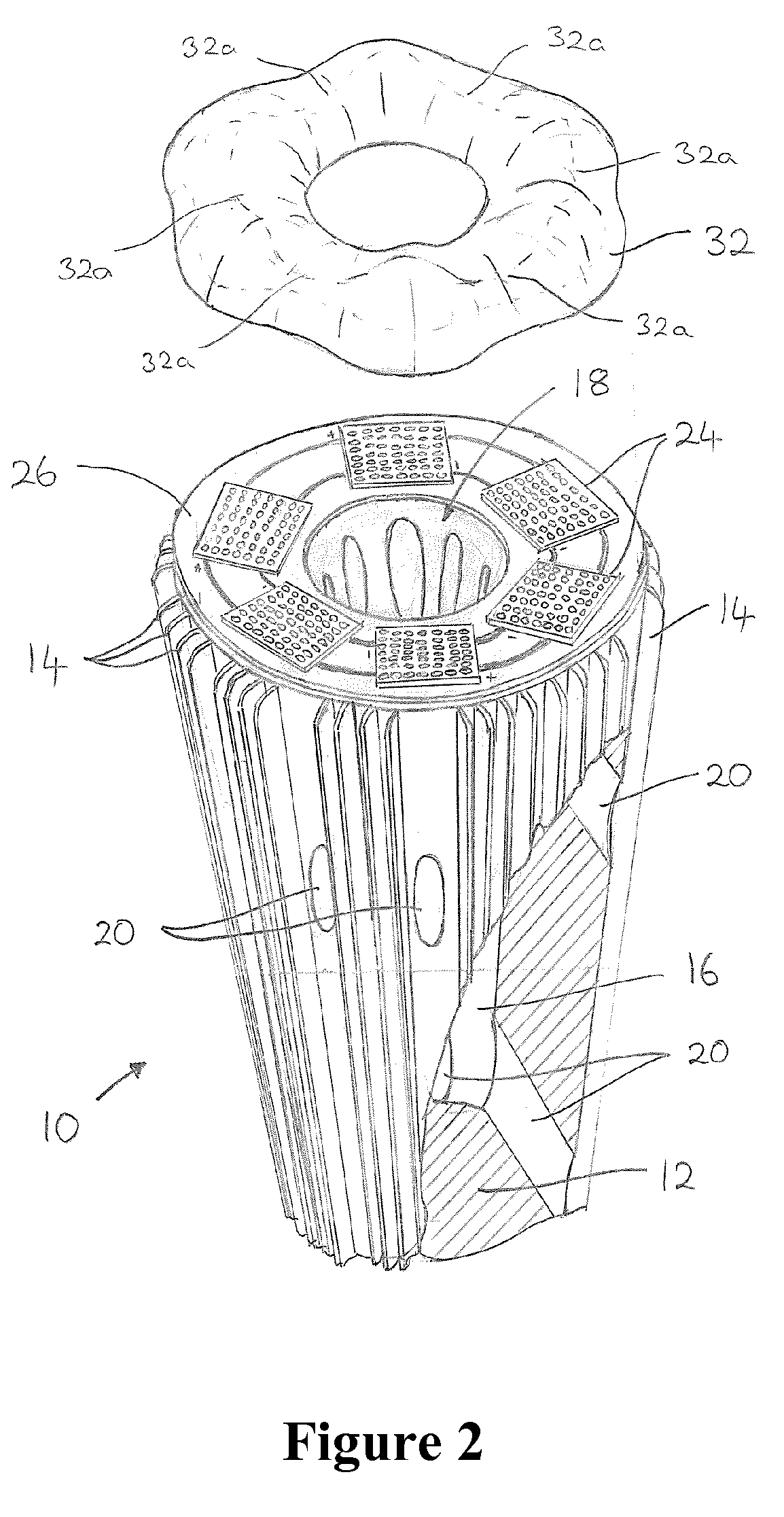

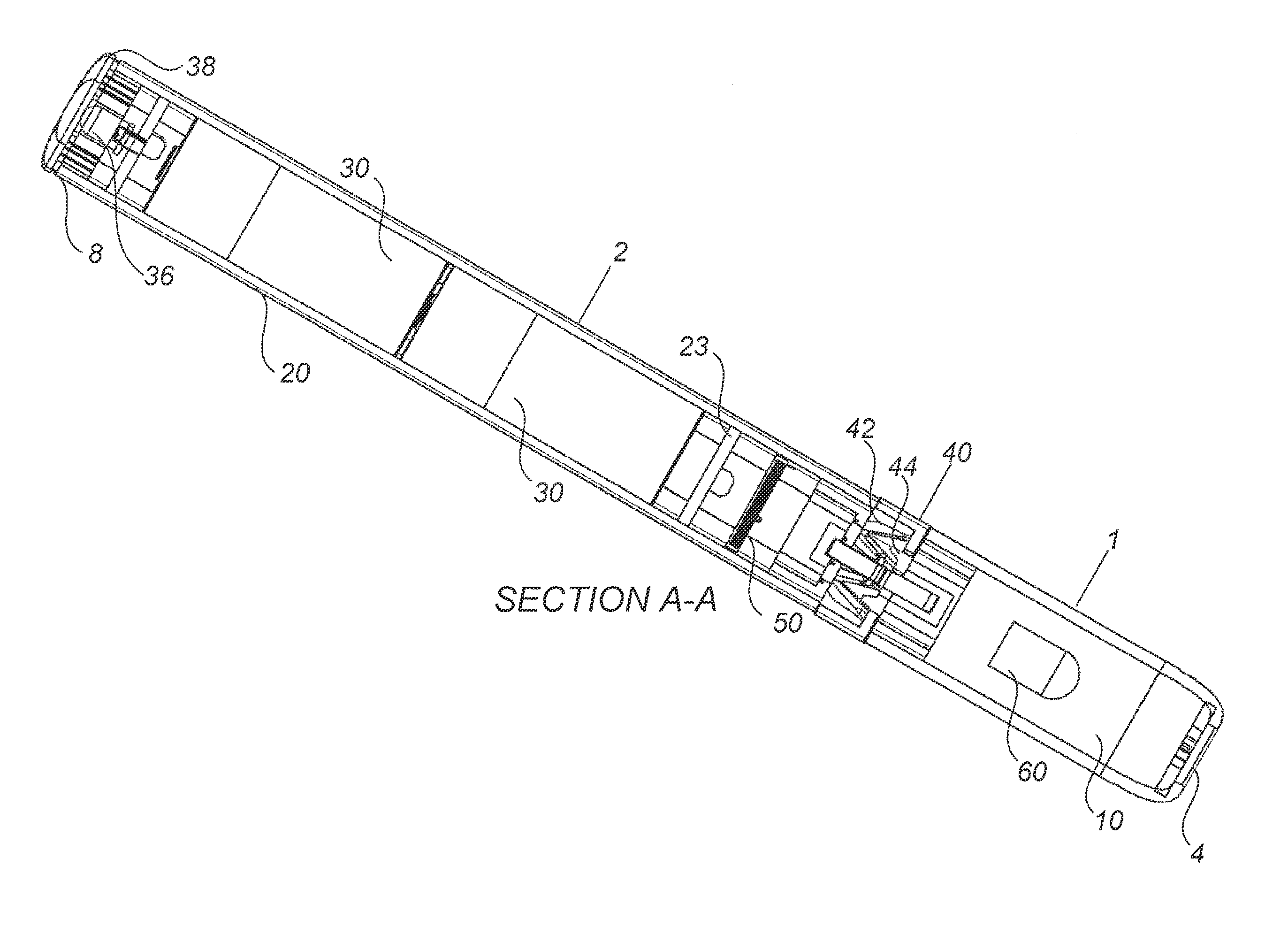

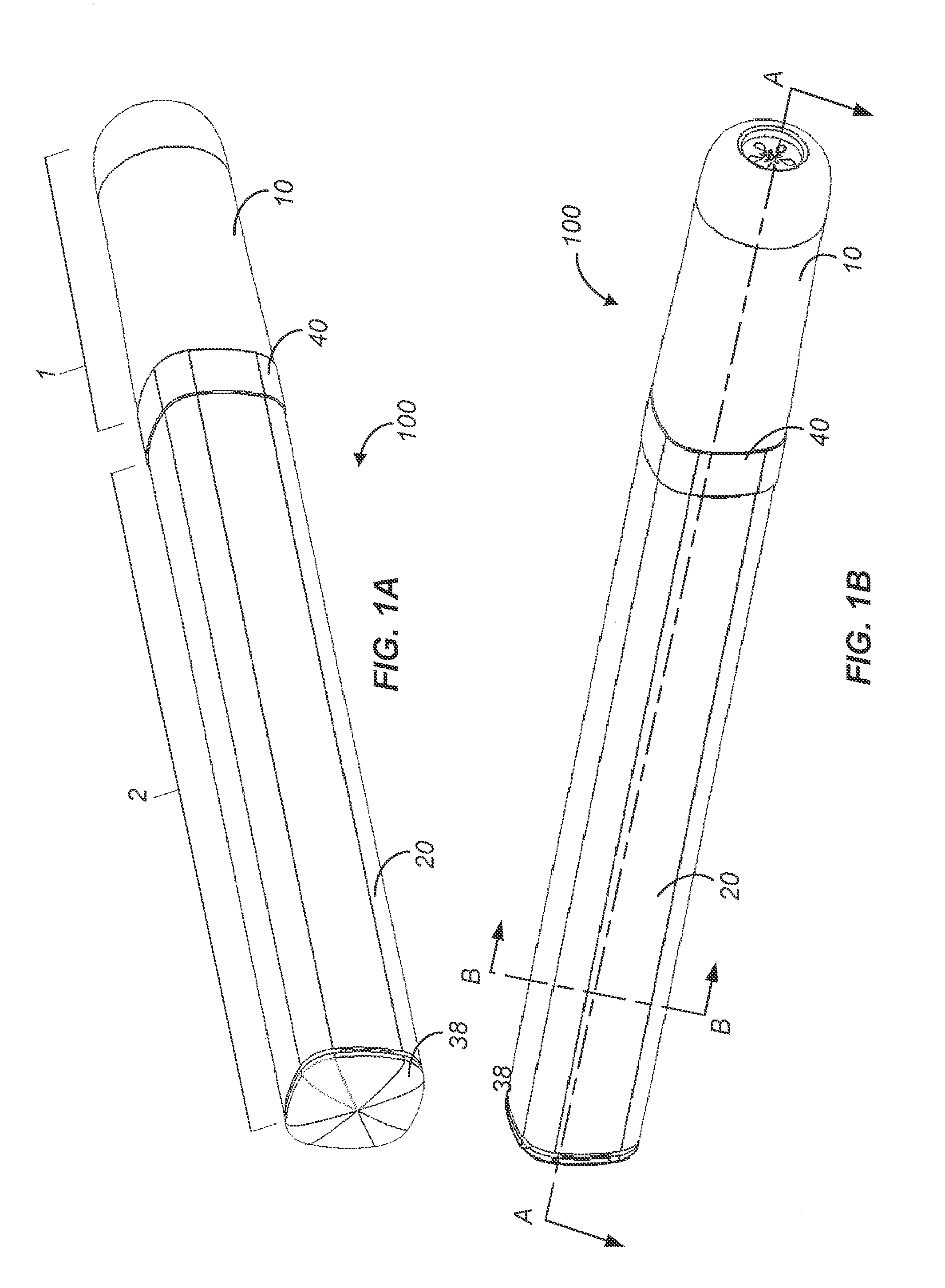

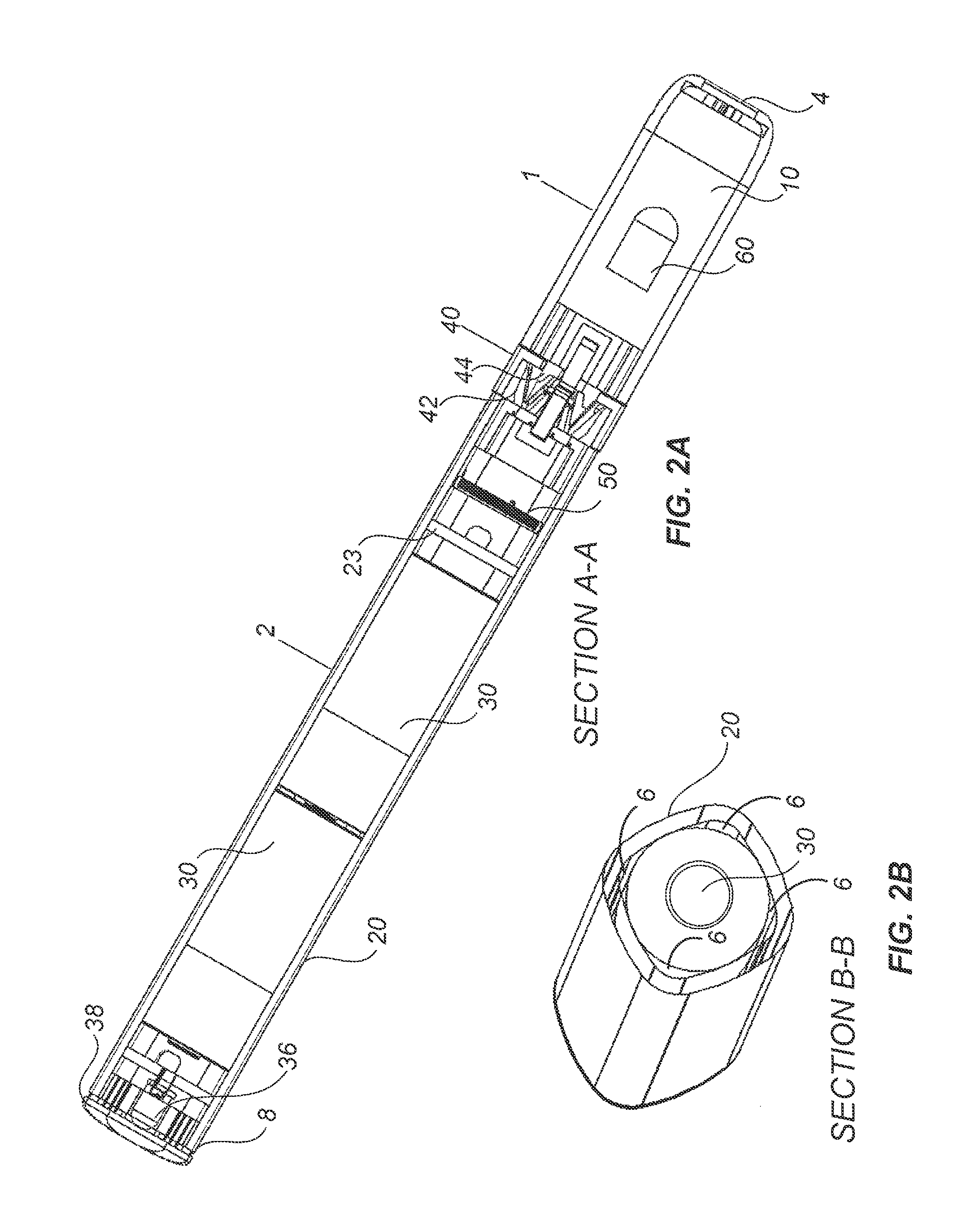

Electronic vaporizing device and methods for use

InactiveUS20130298905A1Increase heatImproved vaporizing capabilityTobacco devicesInhalatorsCelluloseBrick

Devices and methods for vaporizing active ingredients of a selected substance for inhalation using a portable vaporization device are provided herein. In certain aspects, the device includes a portable power source, a heating portion, an inhalation sensor, a temperature sensor, a distal light source, and a grinding portion. In response to an inhalation by a user, the power source energizes a heating element of the heating portion so as to heat air flow to a desired vaporization temperature within a few seconds of detecting inhalation, using convection and radiative heating. The device may include a receptacle for receiving a cartridge containing a pre-prepared substance, such as a liquid, gel, powder, or solid brick, and a grinding portion to allow a user to grind intact portions of cellulose-based material into smaller pieces to facilitate vaporization by manually rotating portions of the device relative to each other.

Owner:UPTOKE

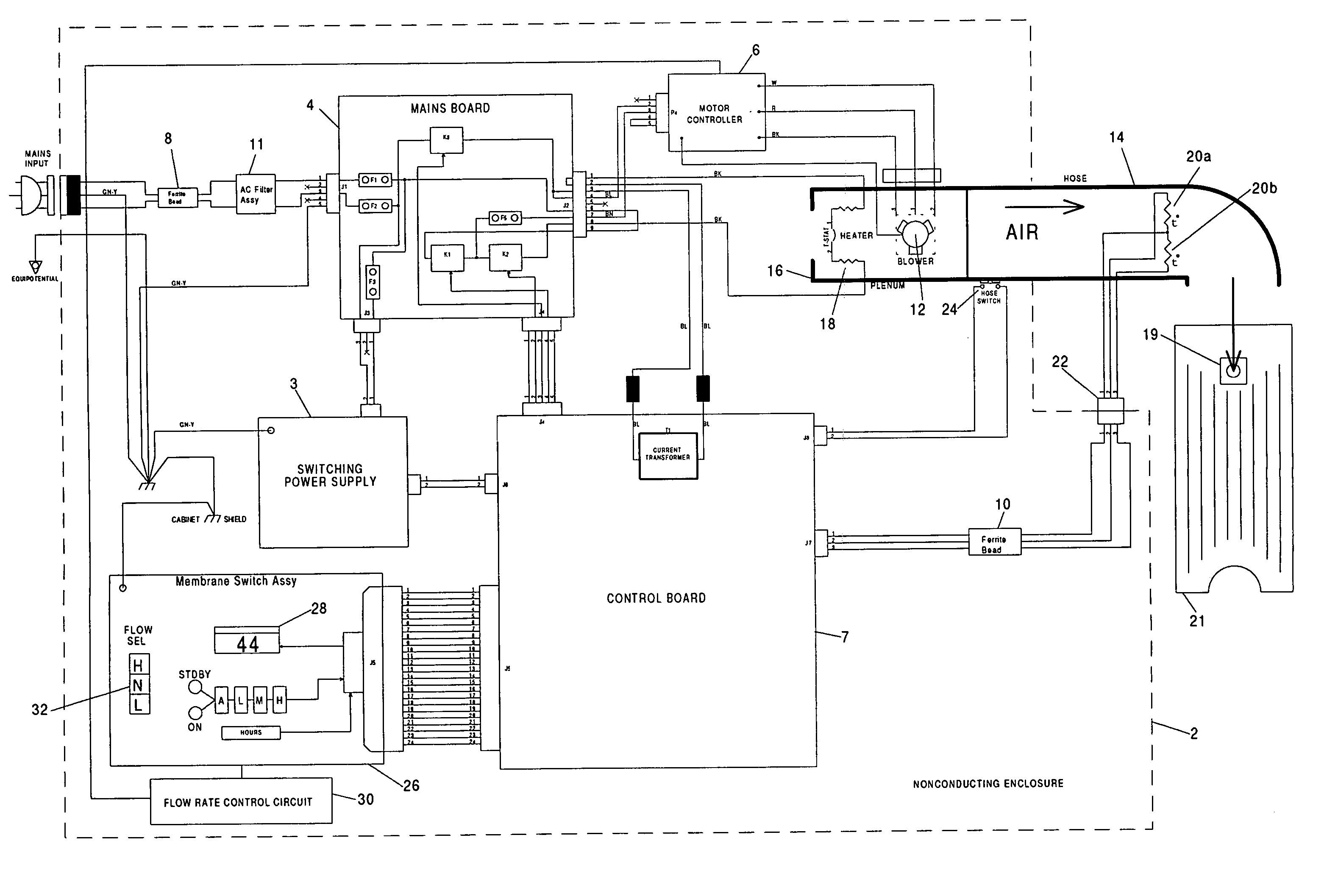

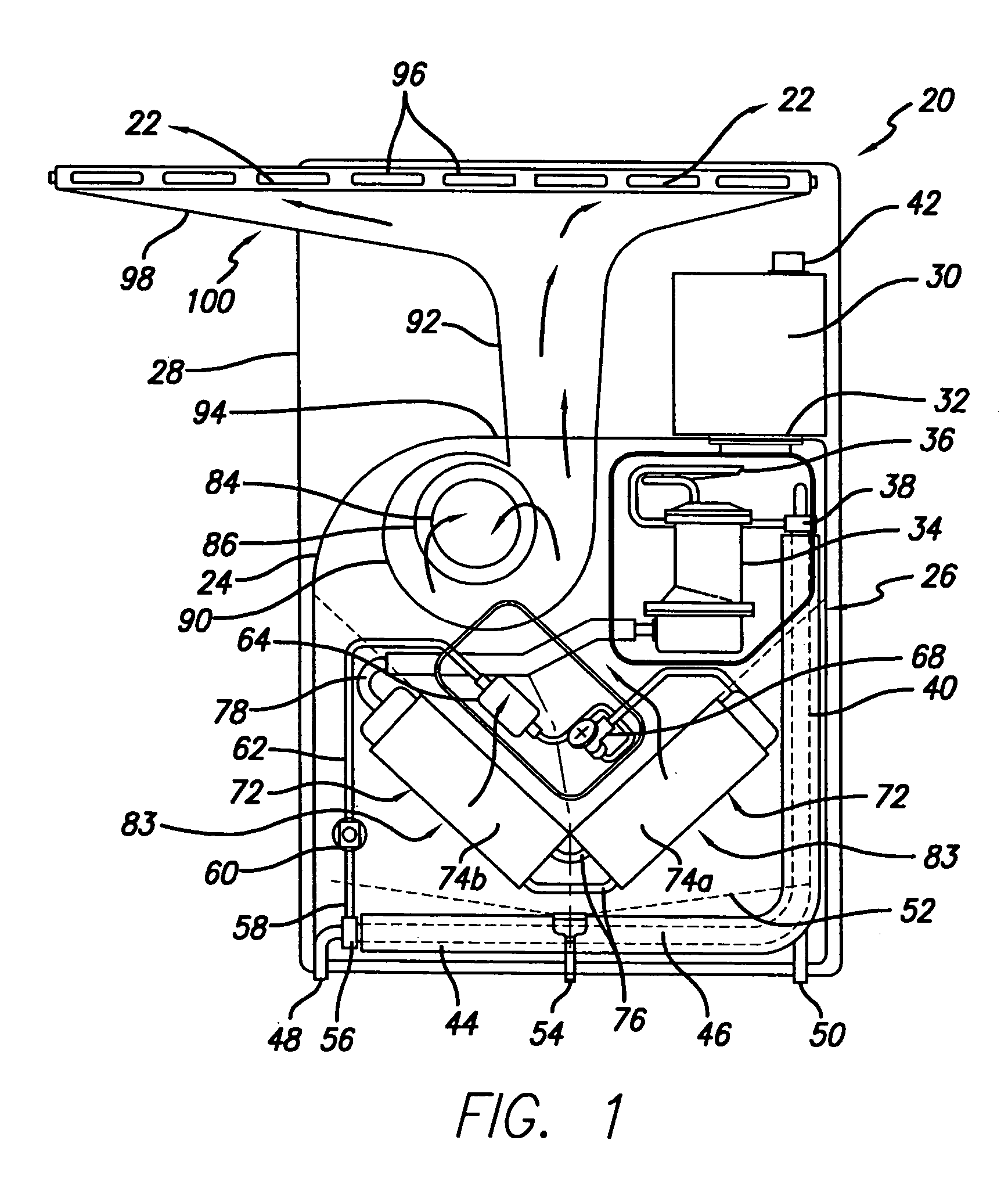

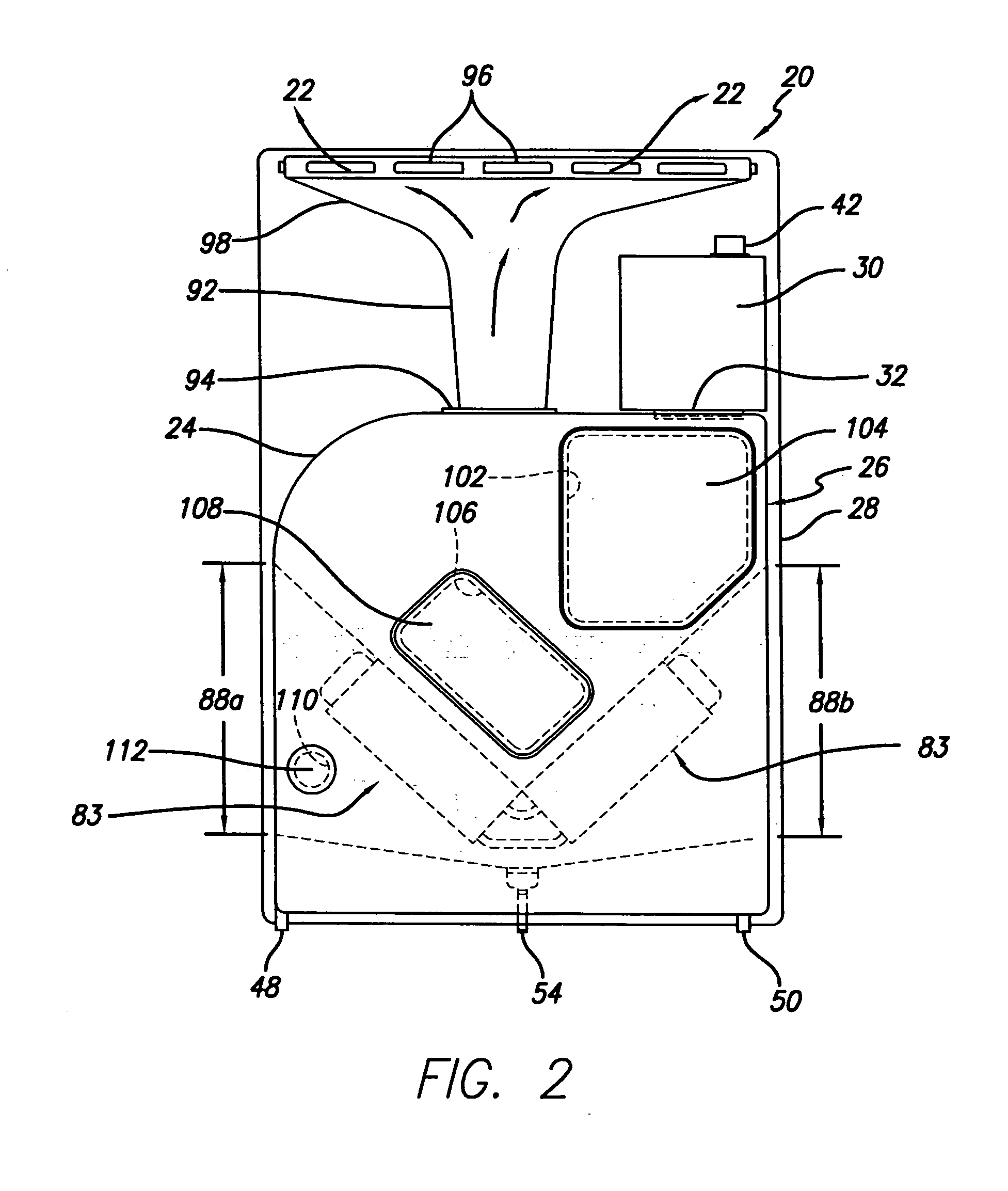

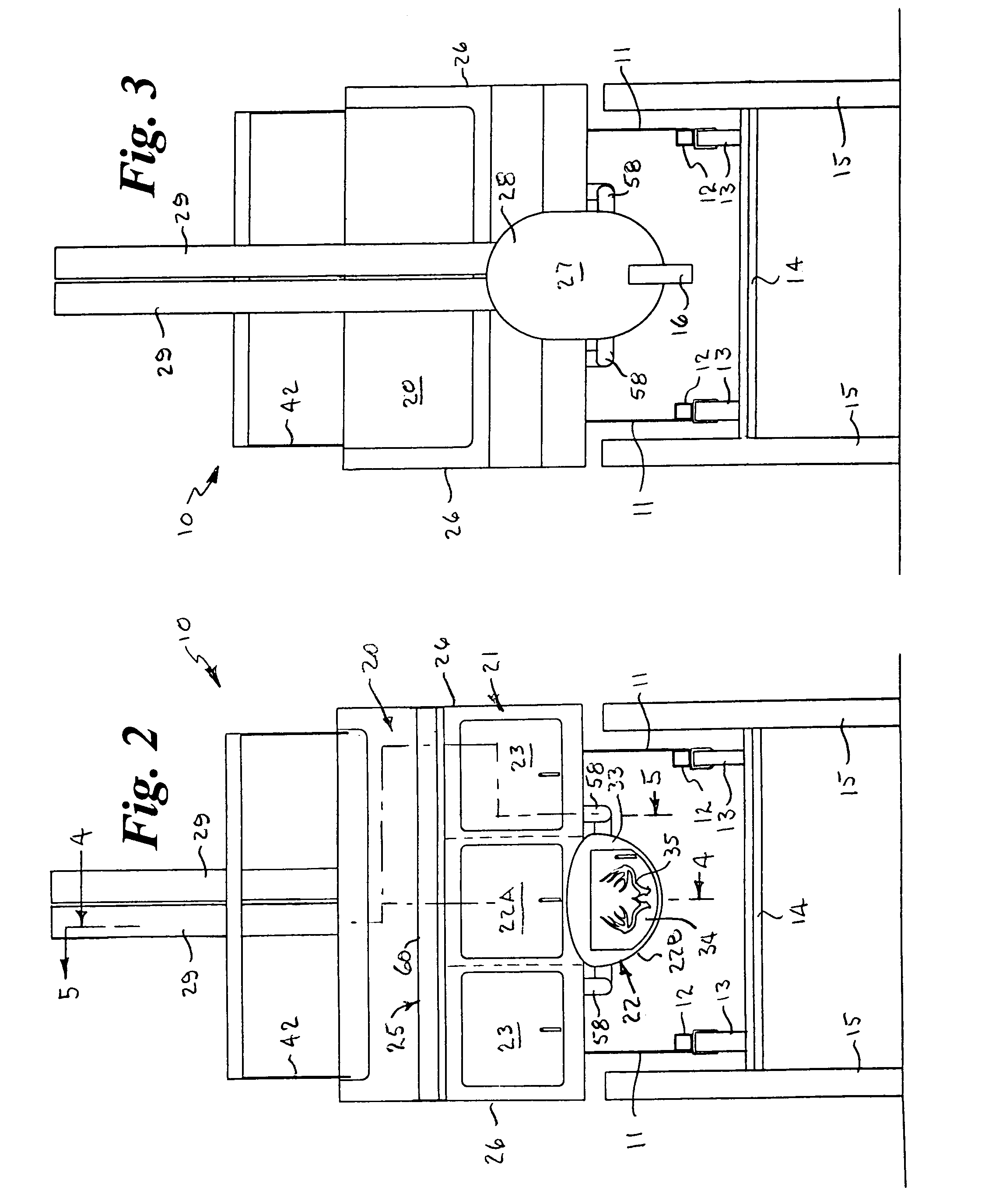

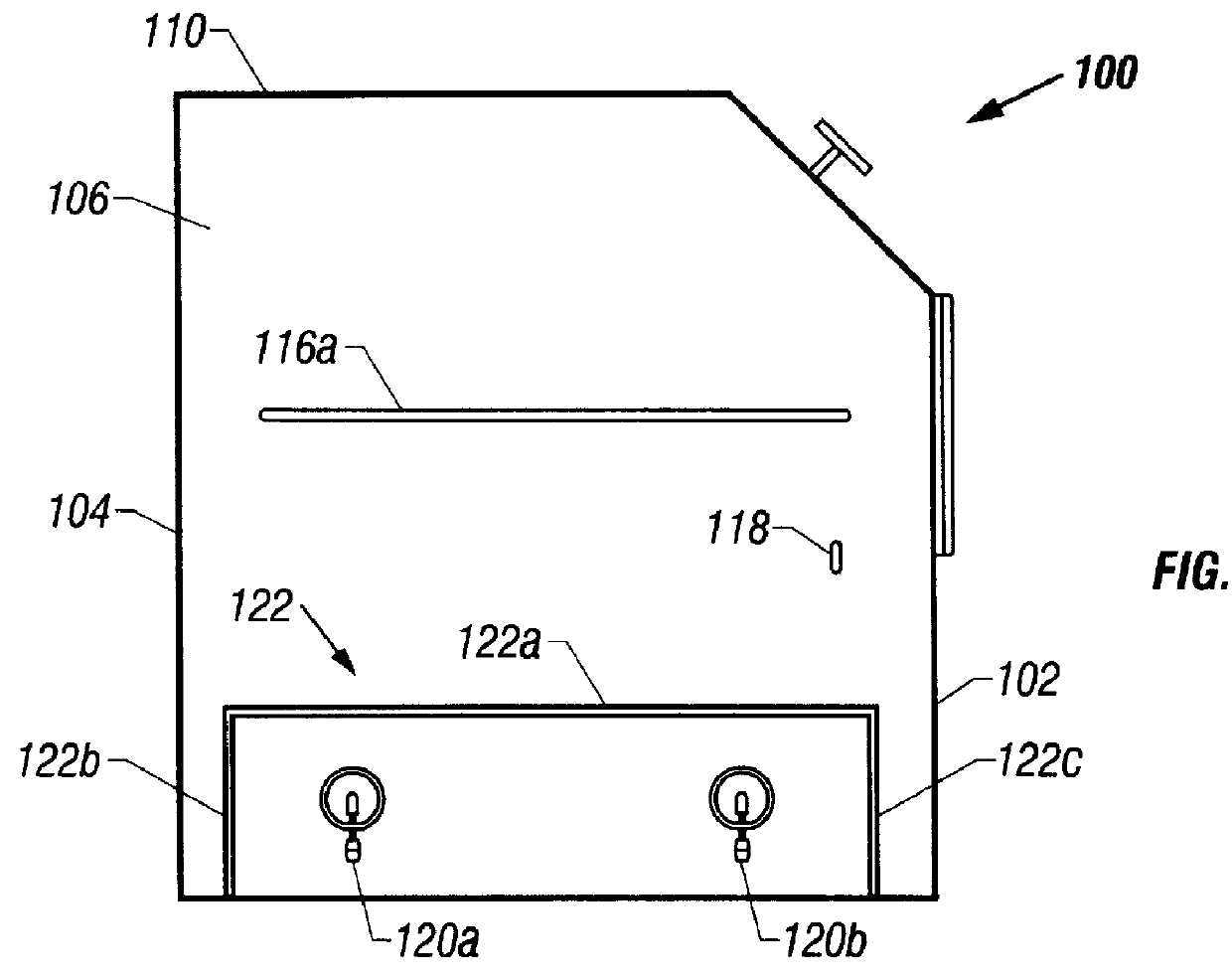

System for providing actuated optimal inflation to multiple temperature regulated blankets and method therefor

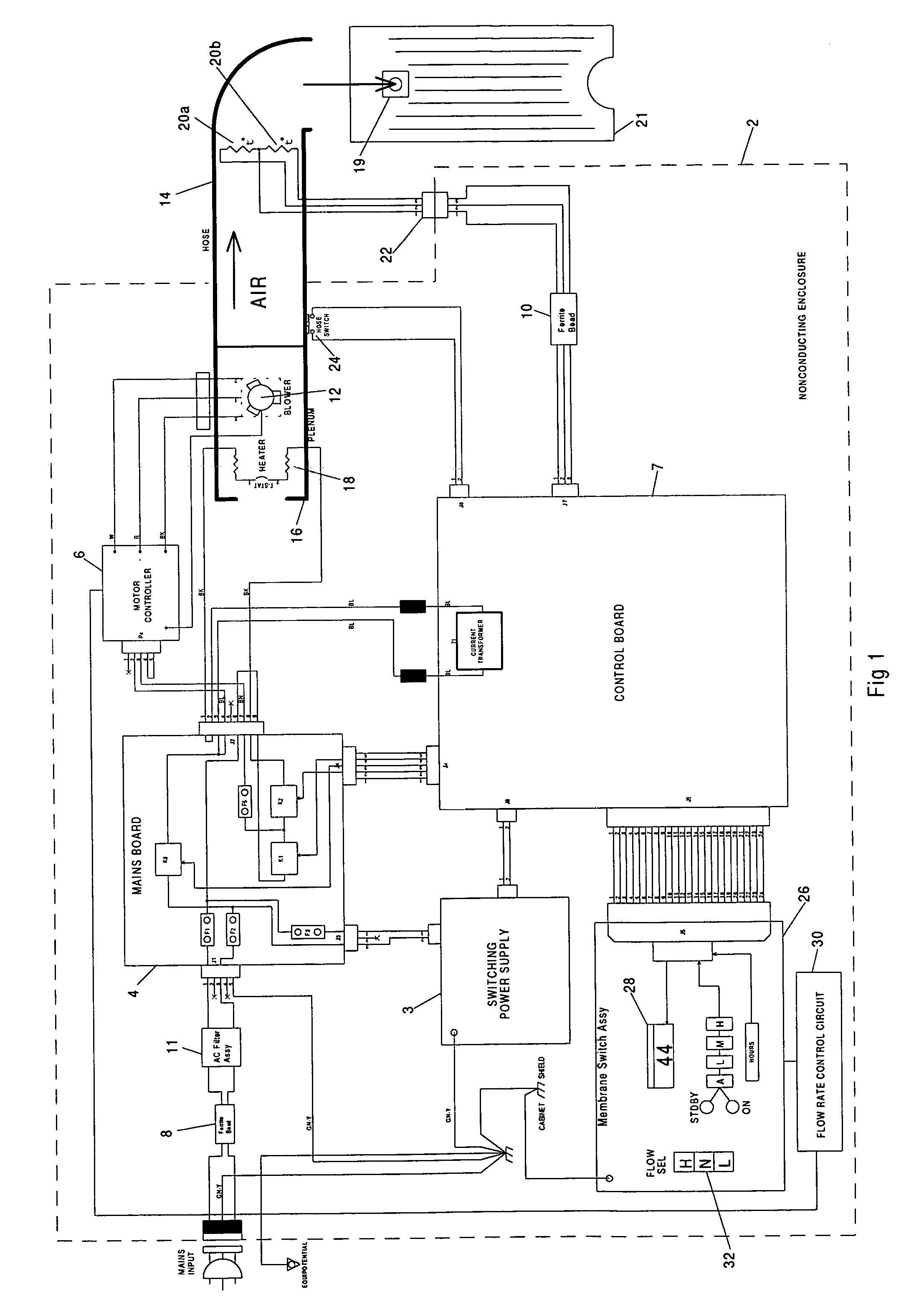

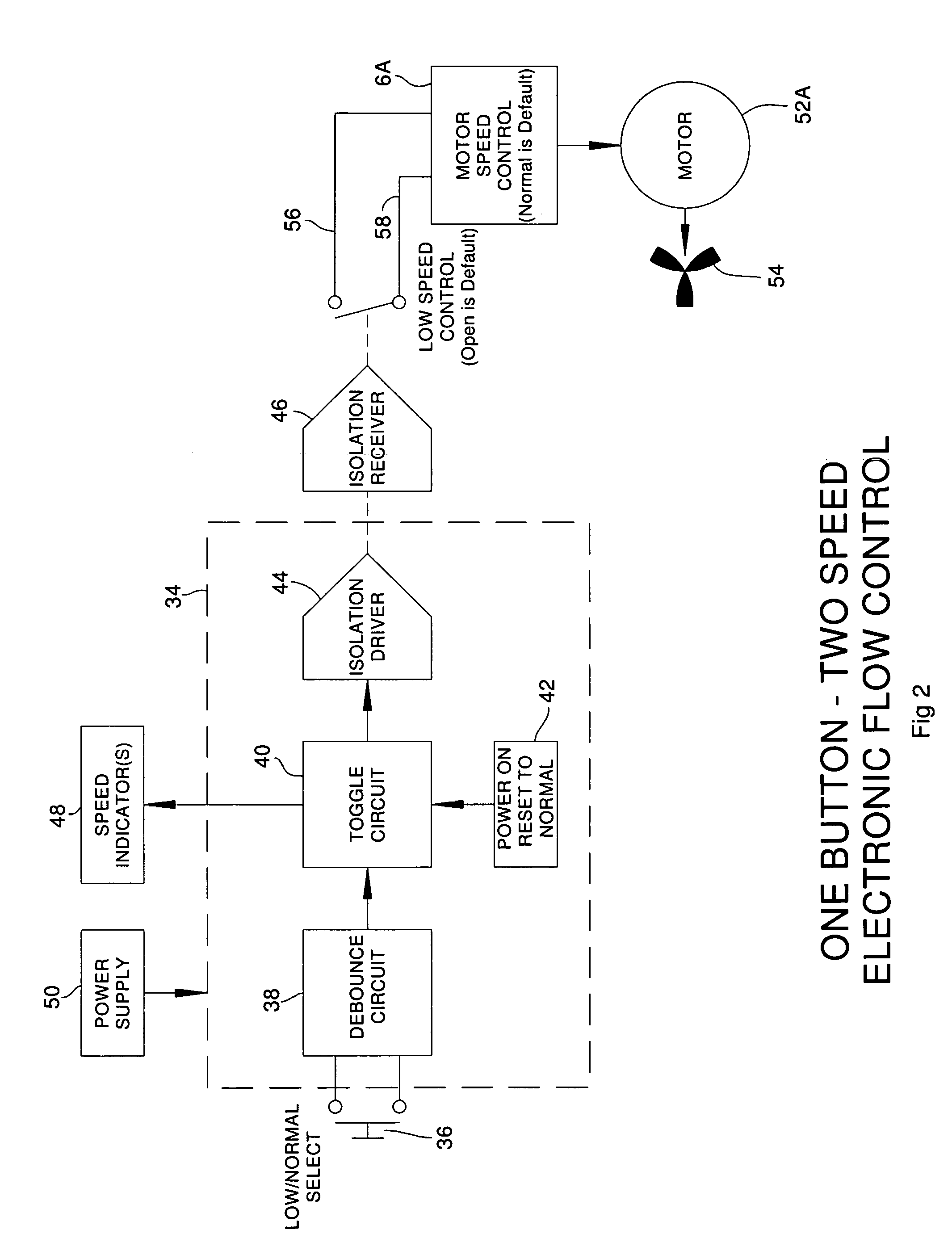

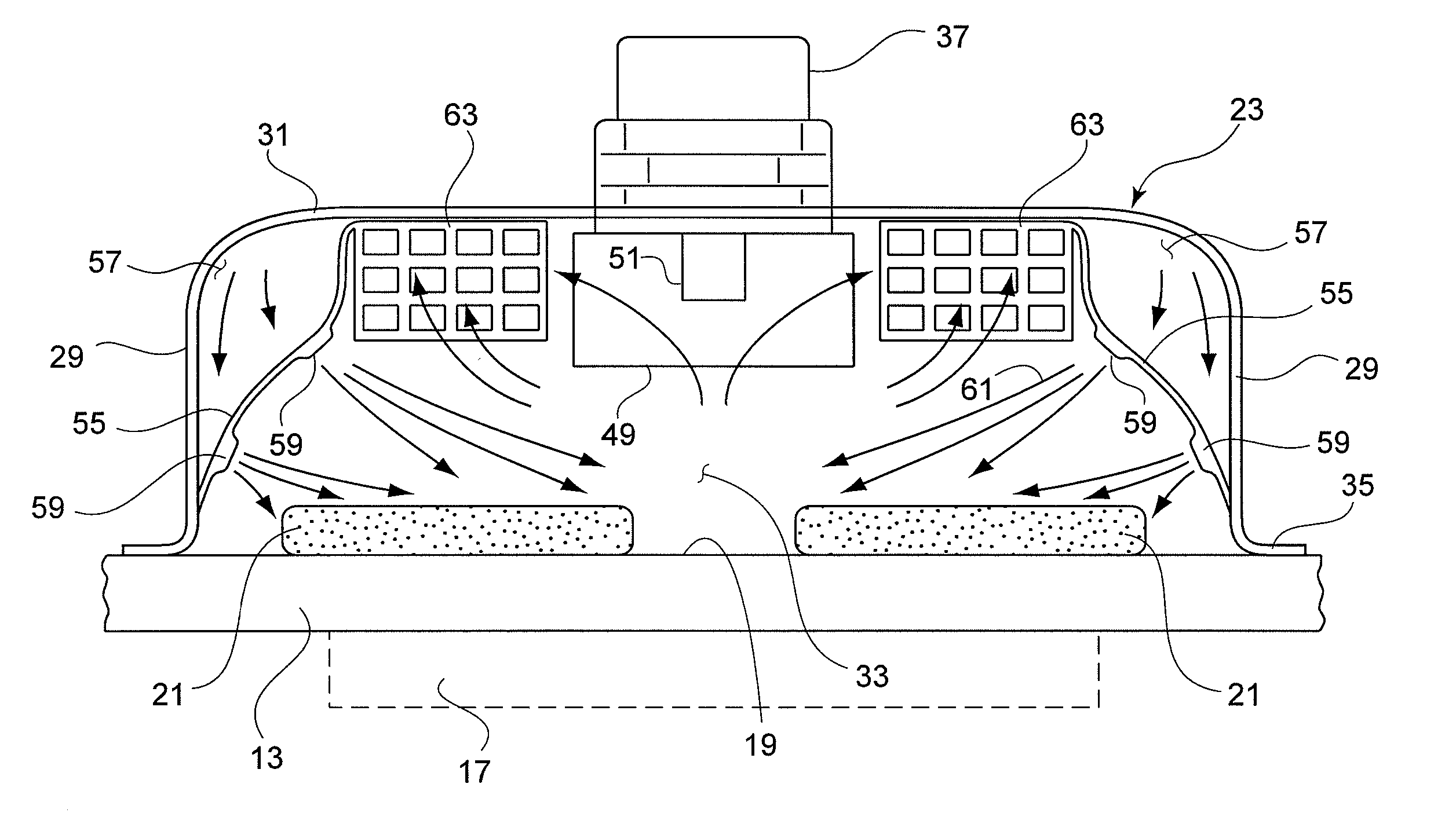

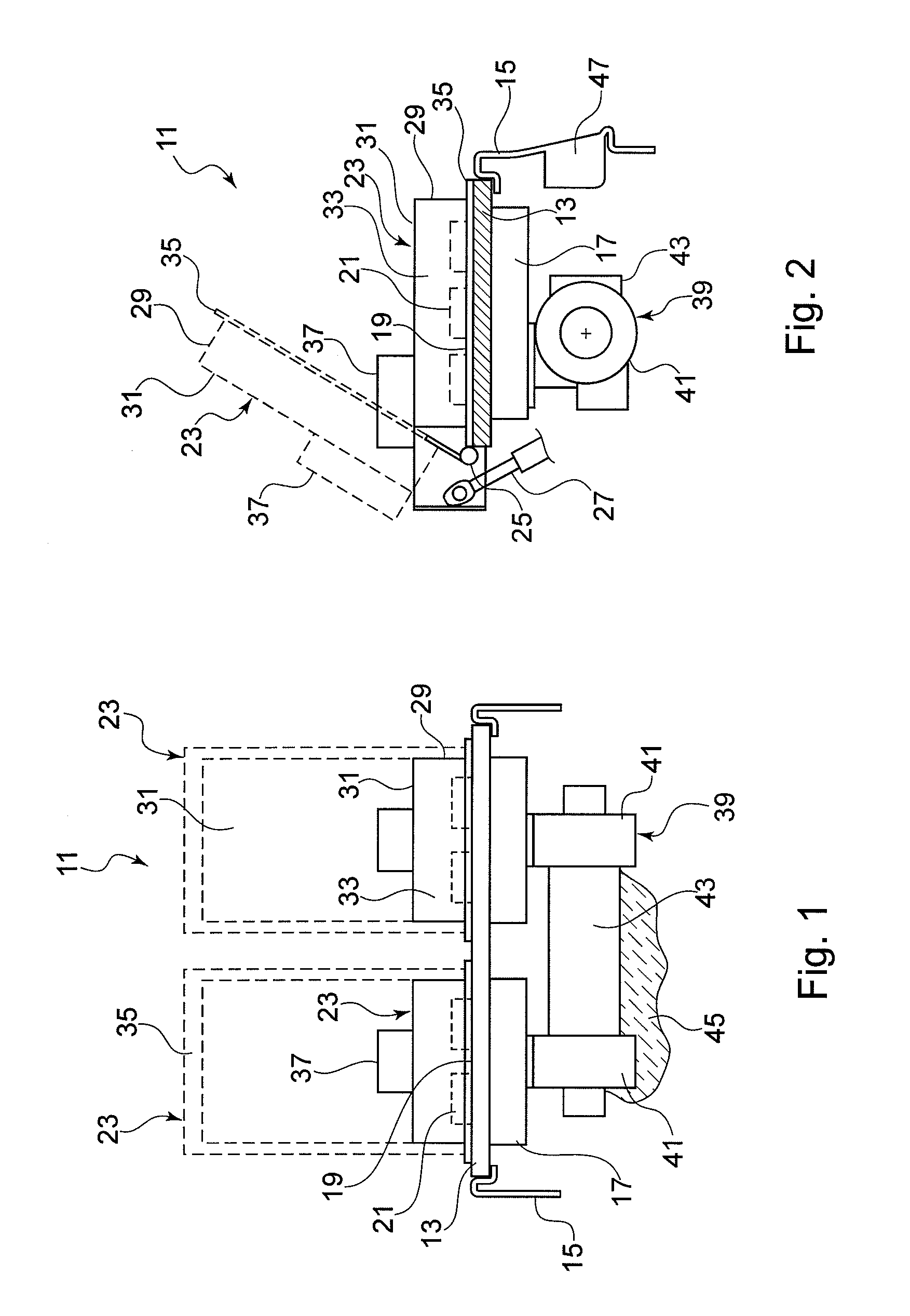

A convective warmer to which blankets of different dimensions may be connected is capable of providing air to the various blankets at flow rates that optimally inflate those blankets to achieve the optimal clinical result for the patients covered by those blankets. The blanket connected to the warmer may range from a full size adult warming blanket to a pediatric warming blanket. The convection warmer may have multiple fixed air flow rates each selectable by a user, via switch(es) either electronically or mechanically. For the electronic selection of a given flow rate, a motor adaptable to rotate a different speeds is used. To vary the flow rate mechanically, a valve is controlled to vary the amount of air that may pass to the blanket. Instead of different fixed flow rates, variable air flow rates, selectable by the user, may be used. Also, a feedback circuit that maintains the pressure sensed at the outlet of the warmer to a preset pressure may be used to eliminate the need for user intervention.

Owner:SMITHS MEDICAL ASD INC

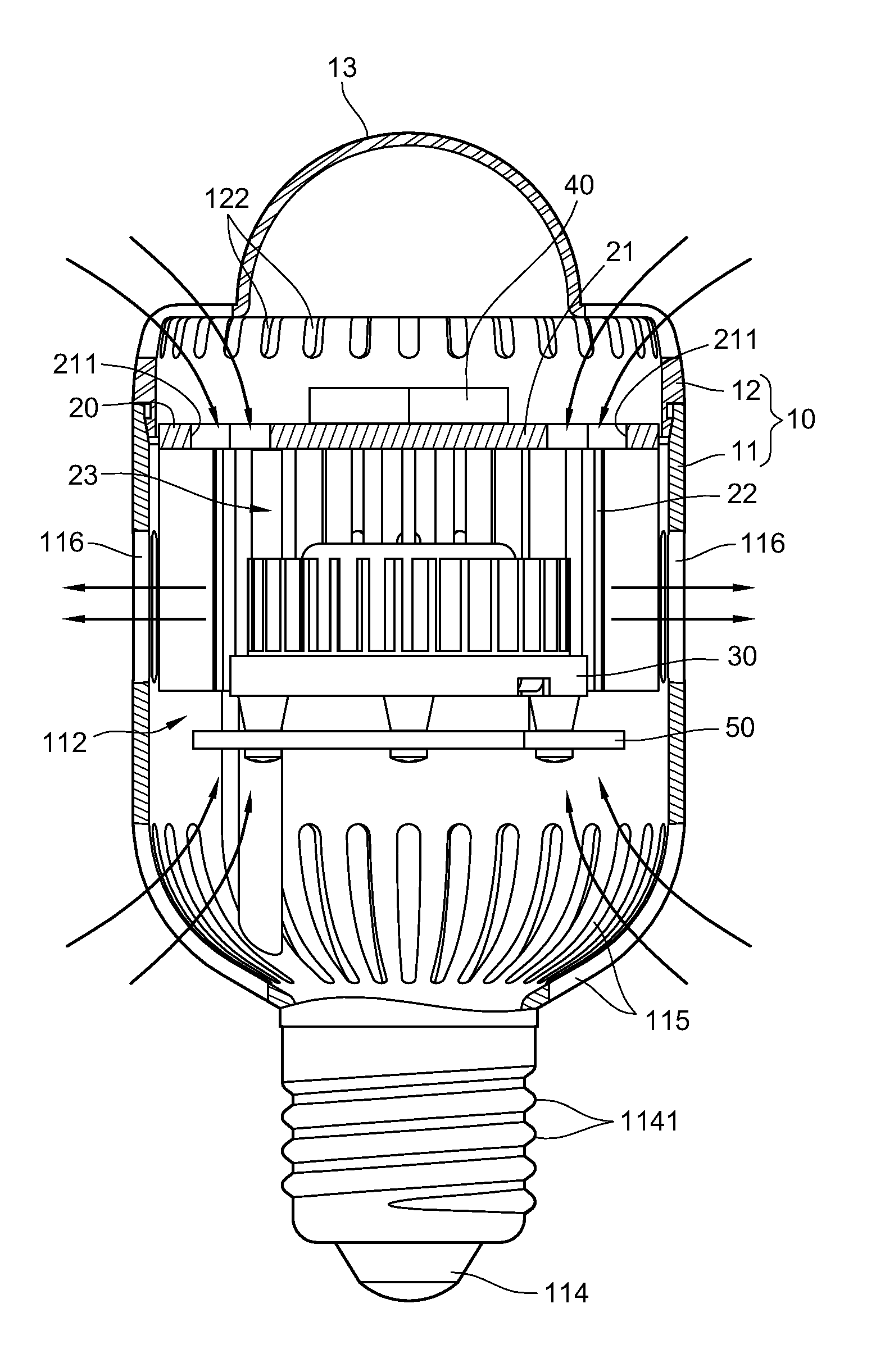

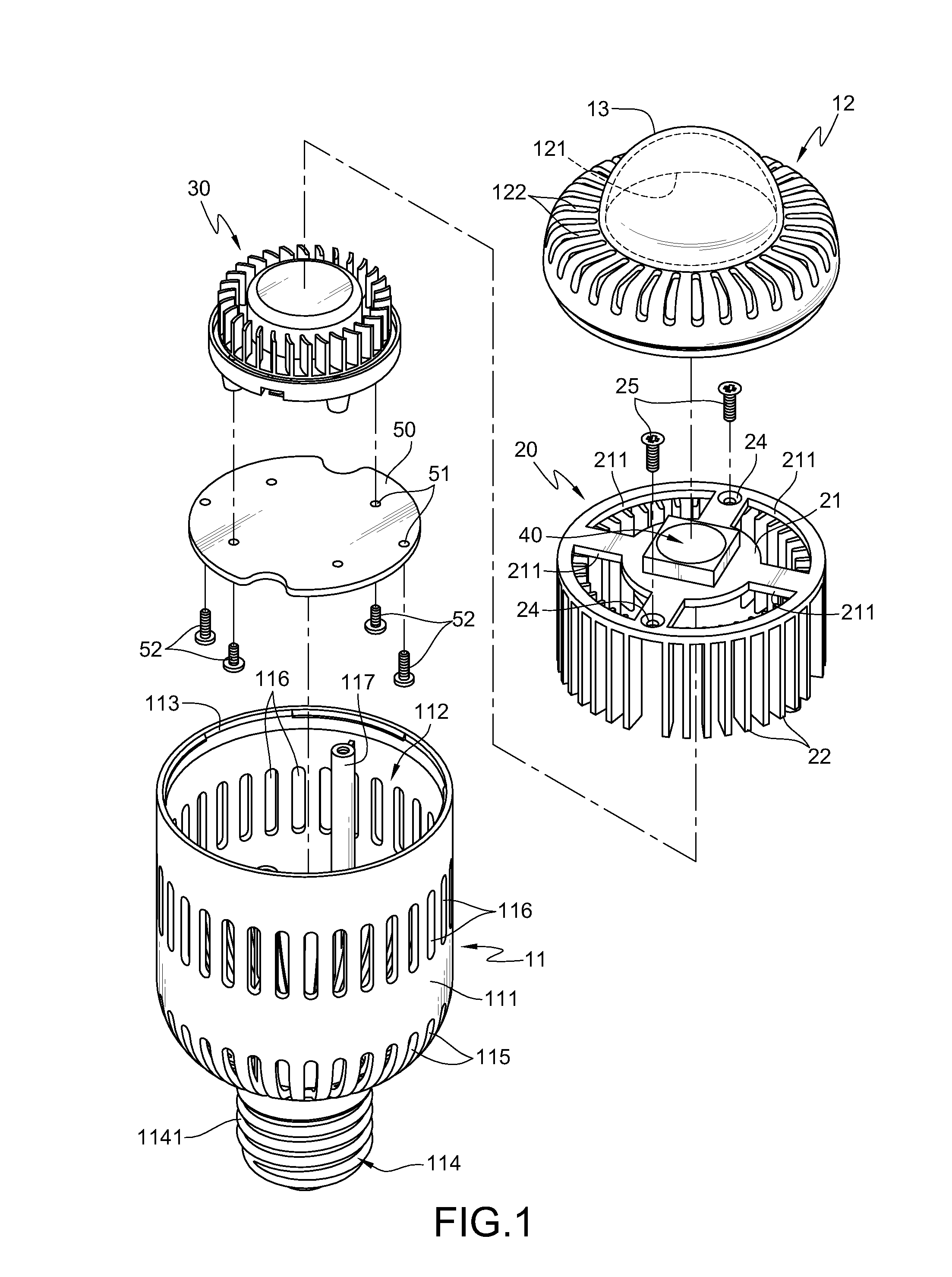

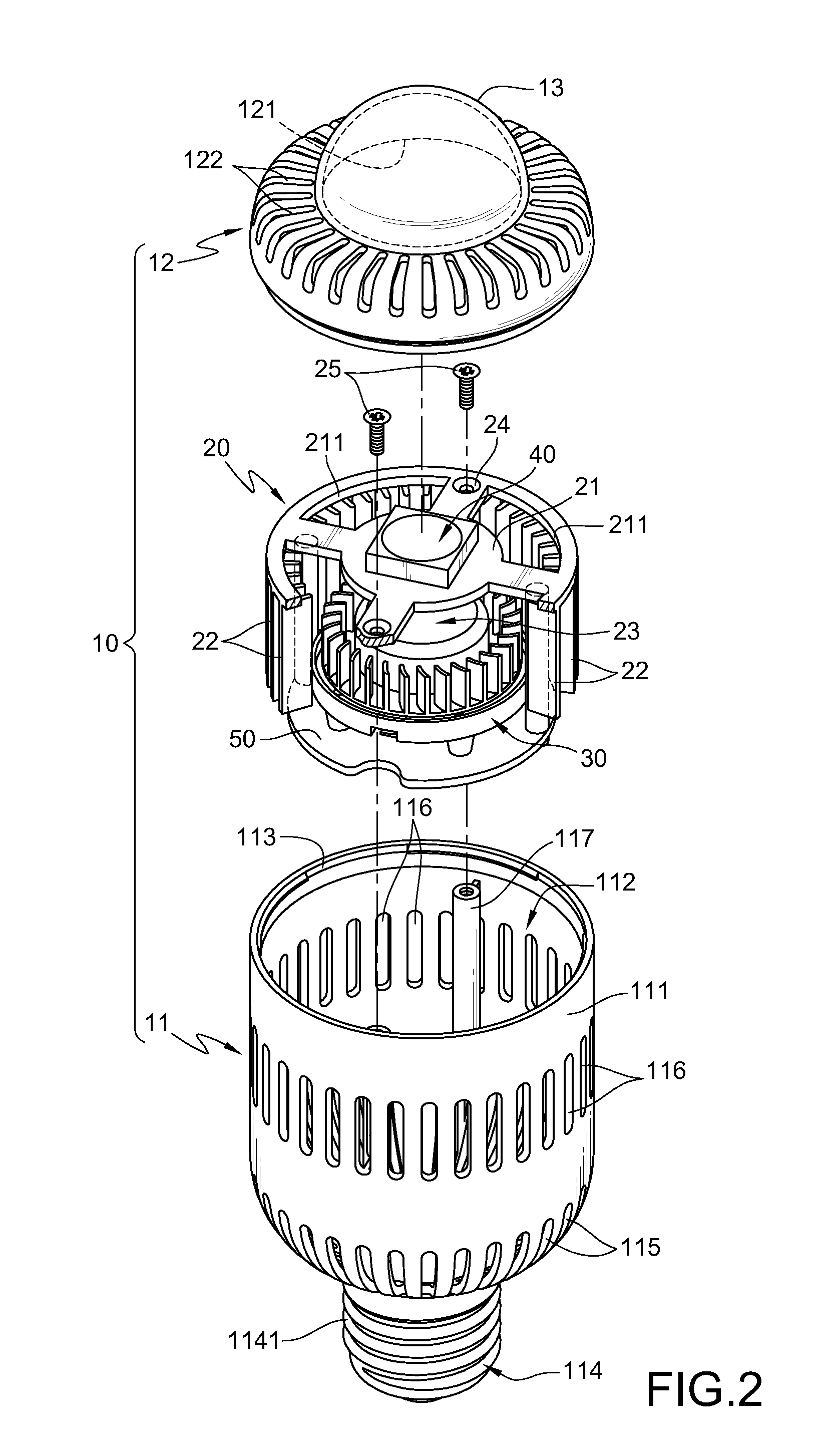

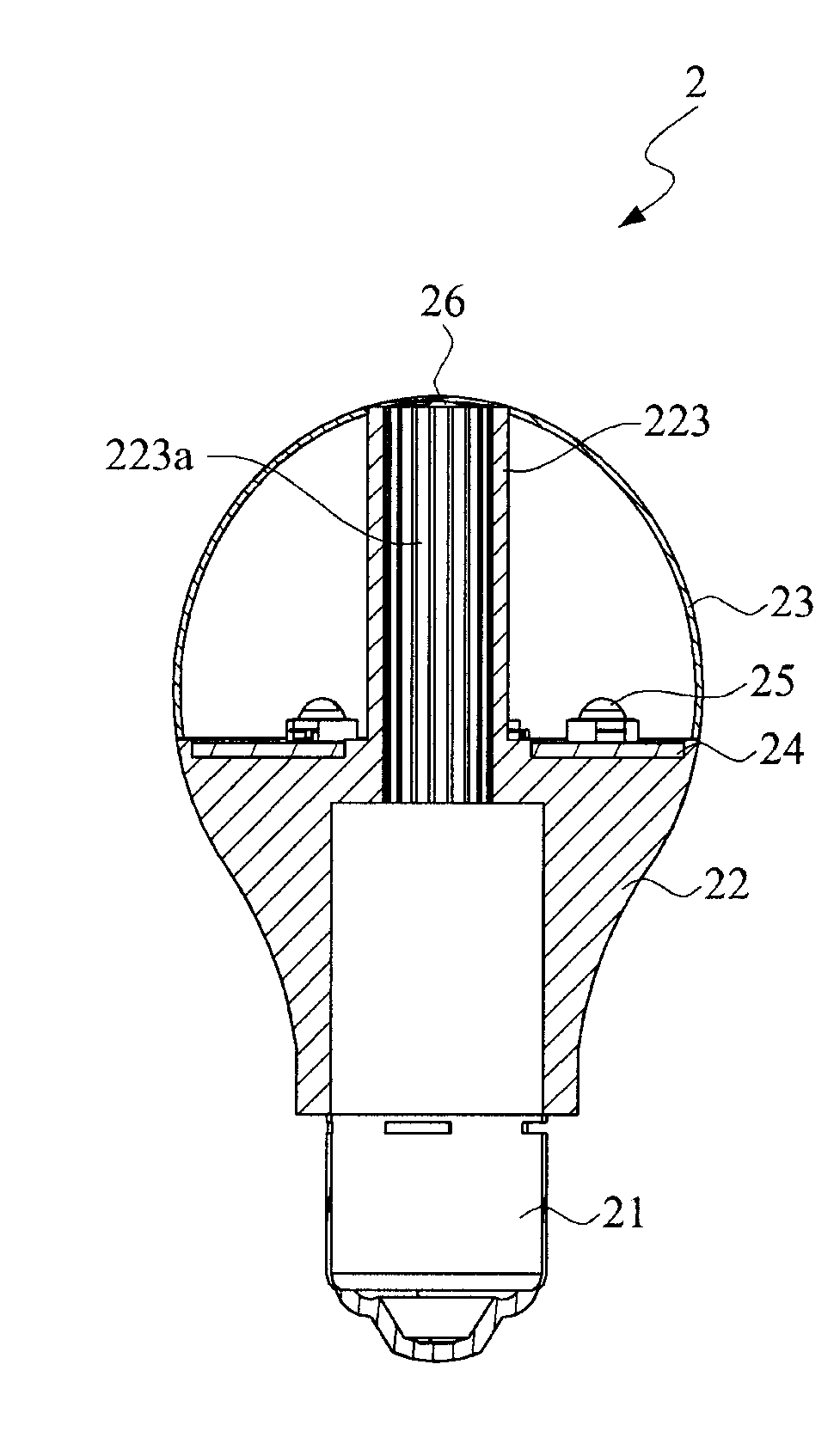

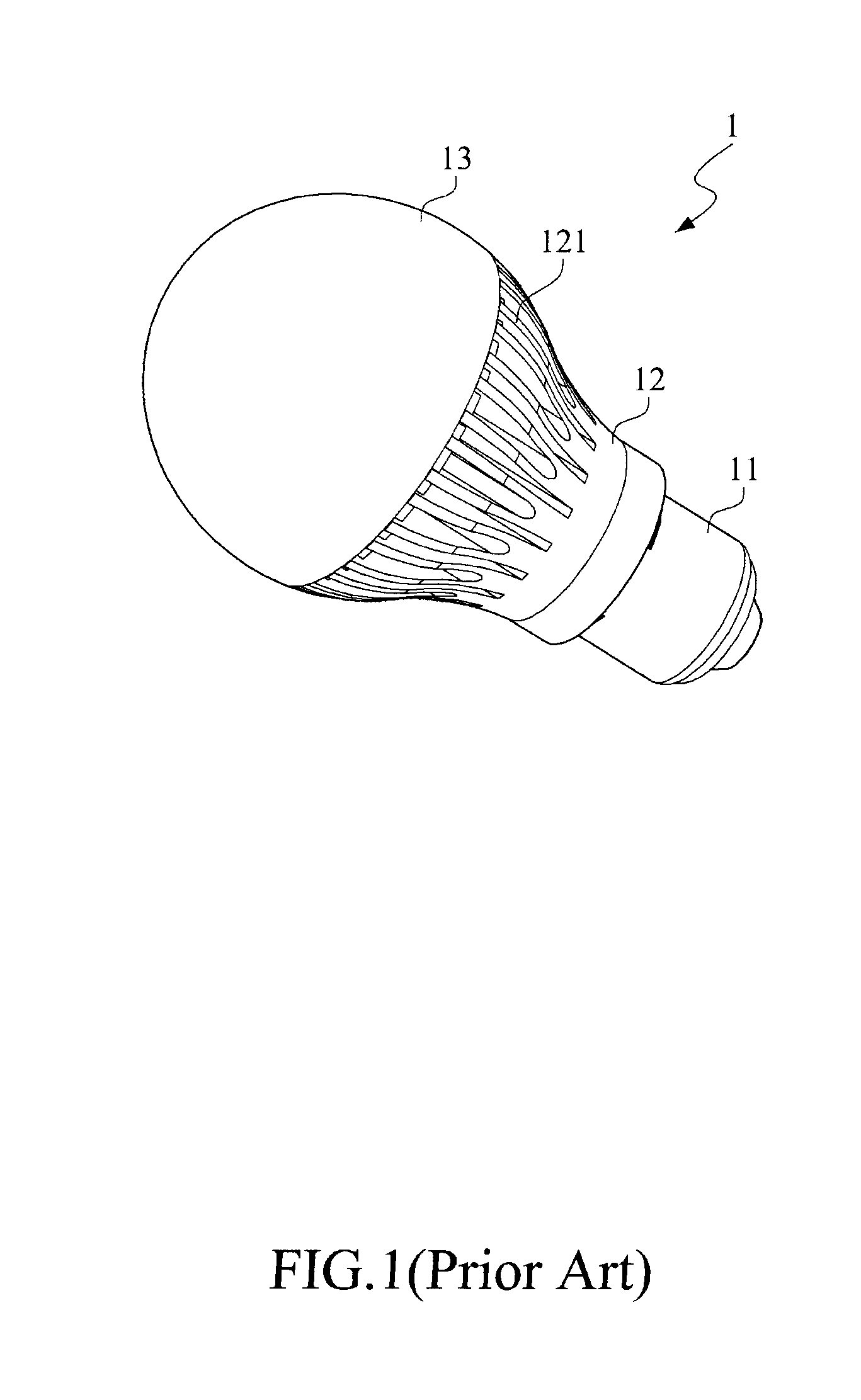

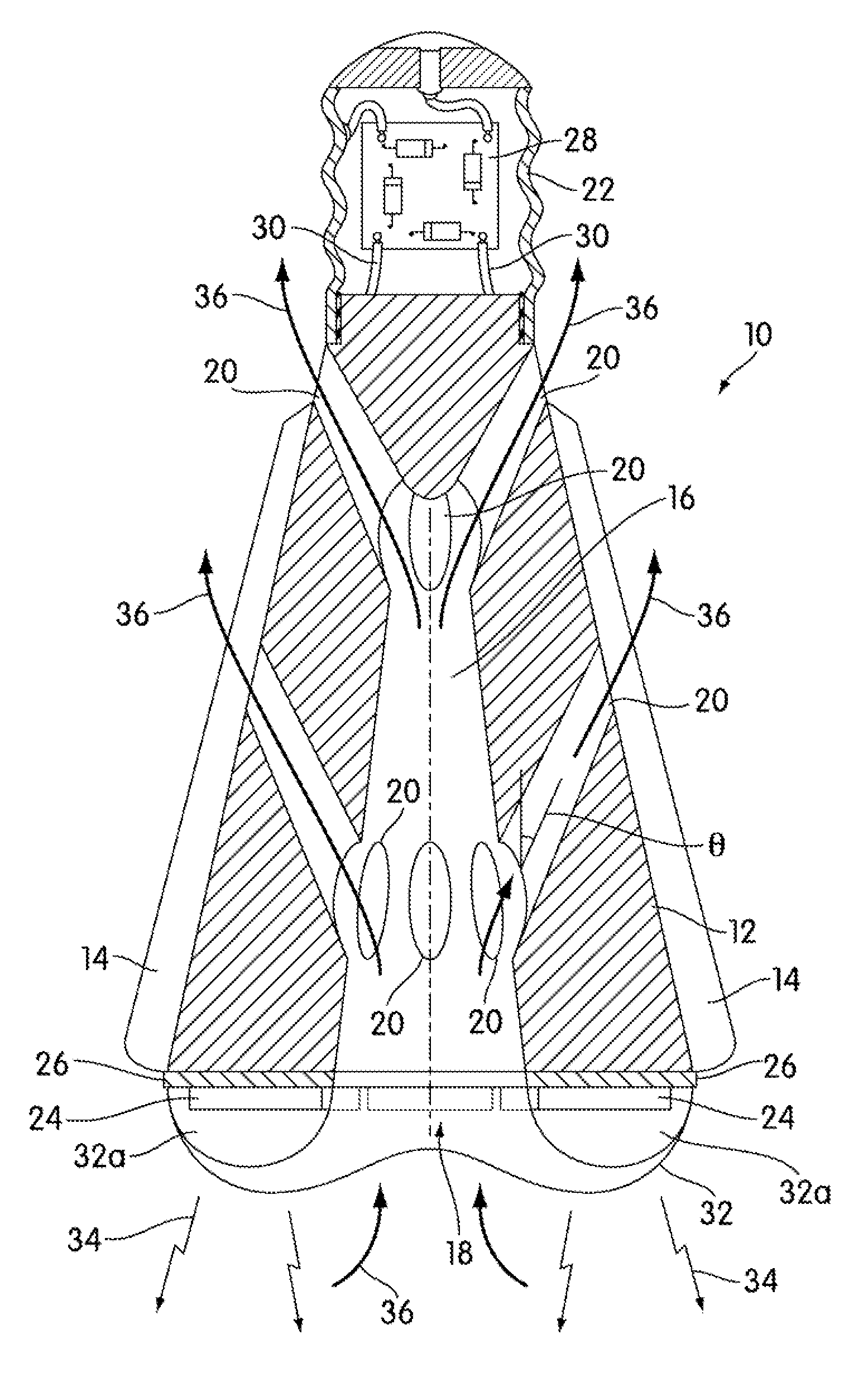

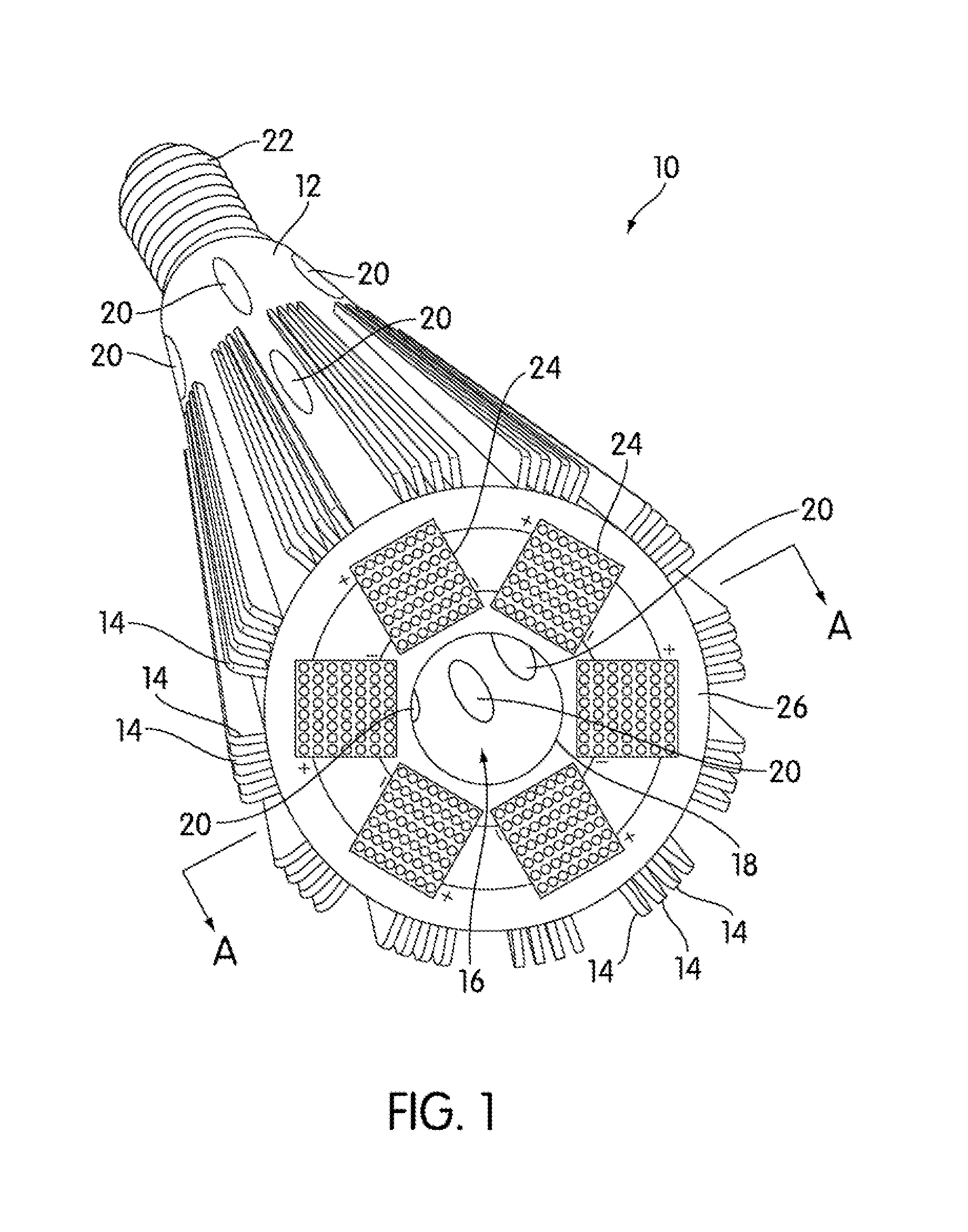

Light emitting diode (LED) lighting device

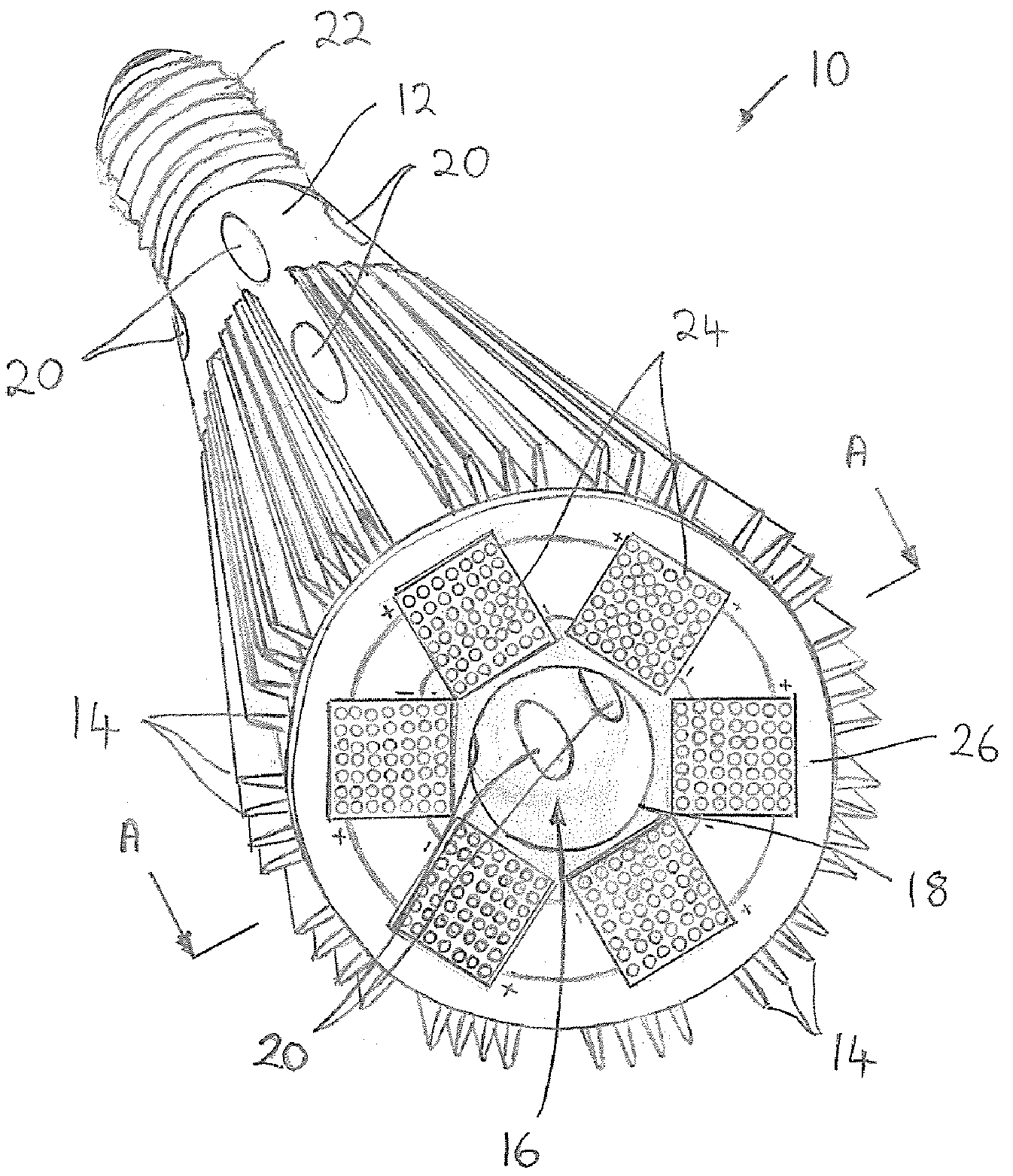

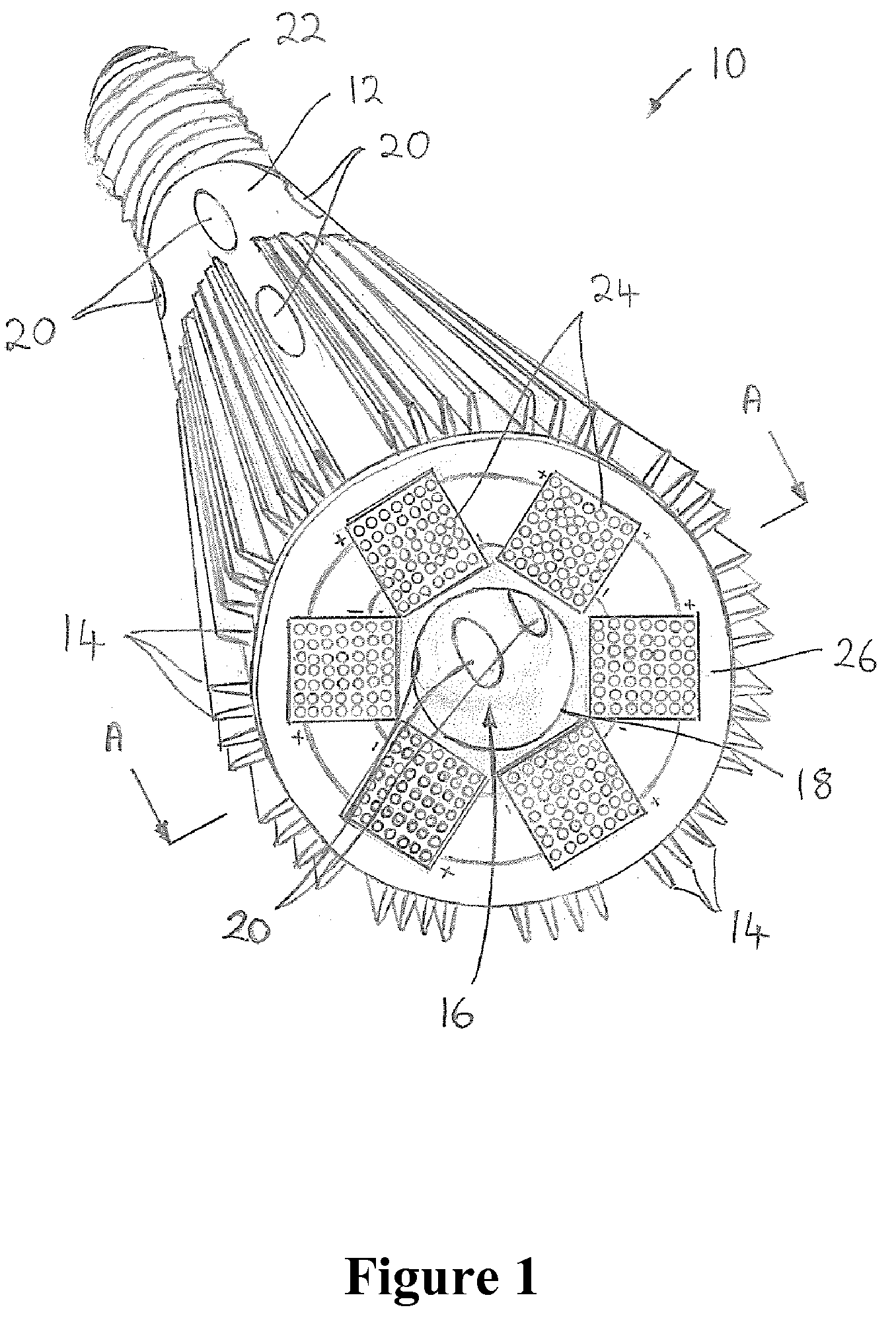

ActiveUS20100060130A1Increase air flowHigh trafficPoint-like light sourceElectric discharge tubesEffect lightEngineering

An LED lighting device comprises: a thermally conducting body having an at least one opening that connects with a cavity within the body and a plurality of LEDs mounted in thermal communication with a face of the body and positioned around the opening. One or more passages pass through the body from the cavity to an outer surface of the body and are configured such that in operation air moves through the cavity by thermal convection thereby to provide cooling of the body. Each passage is configured in a direction that extends in a direction at an angle of about 45° to a line that is parallel with the axis of the body toward the outer surface of the body away from the face. The body can be configured such that its outer surface has a form factor resembling an incandescent light bulb or halogen reflector lamp.

Owner:BX LED LLC

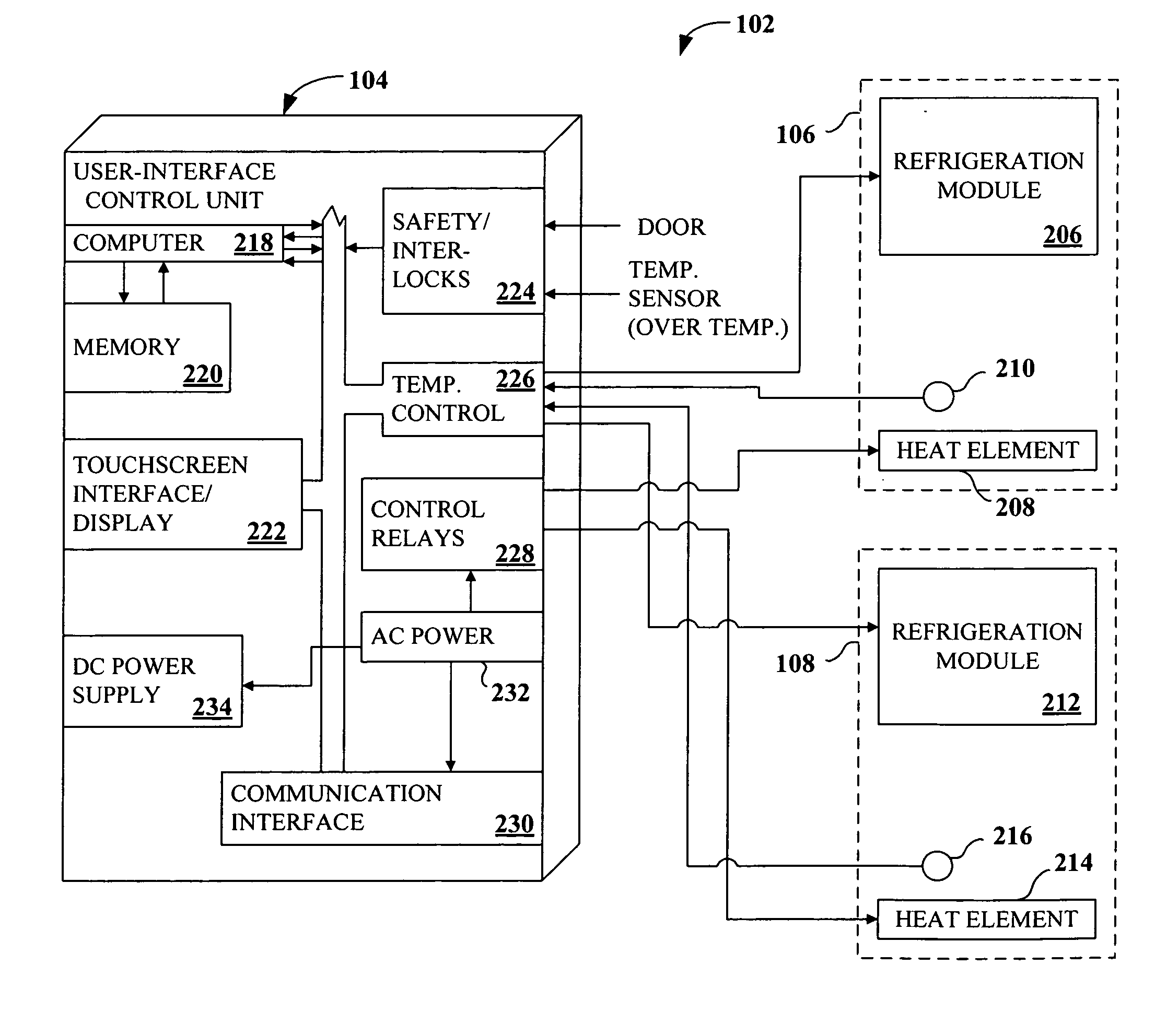

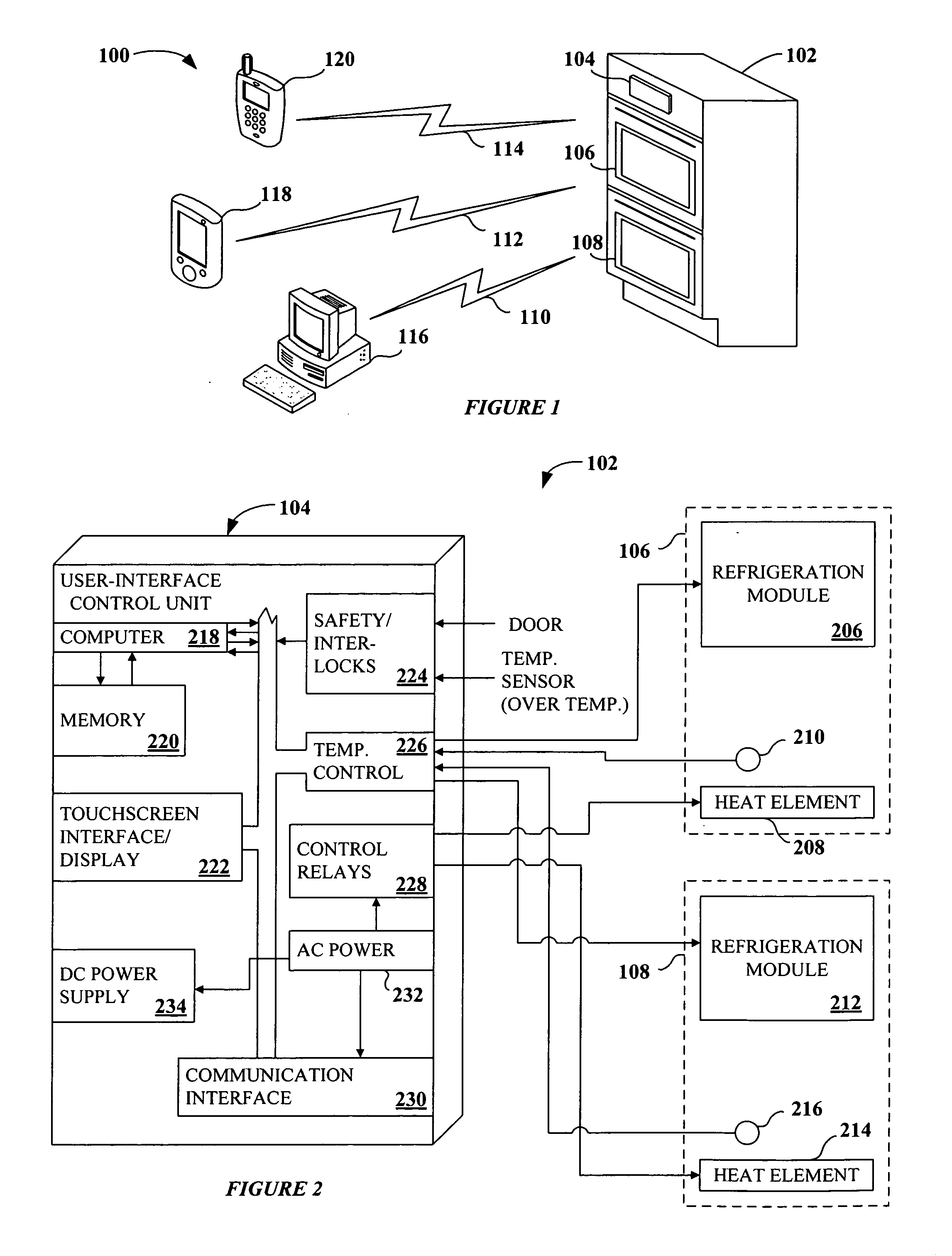

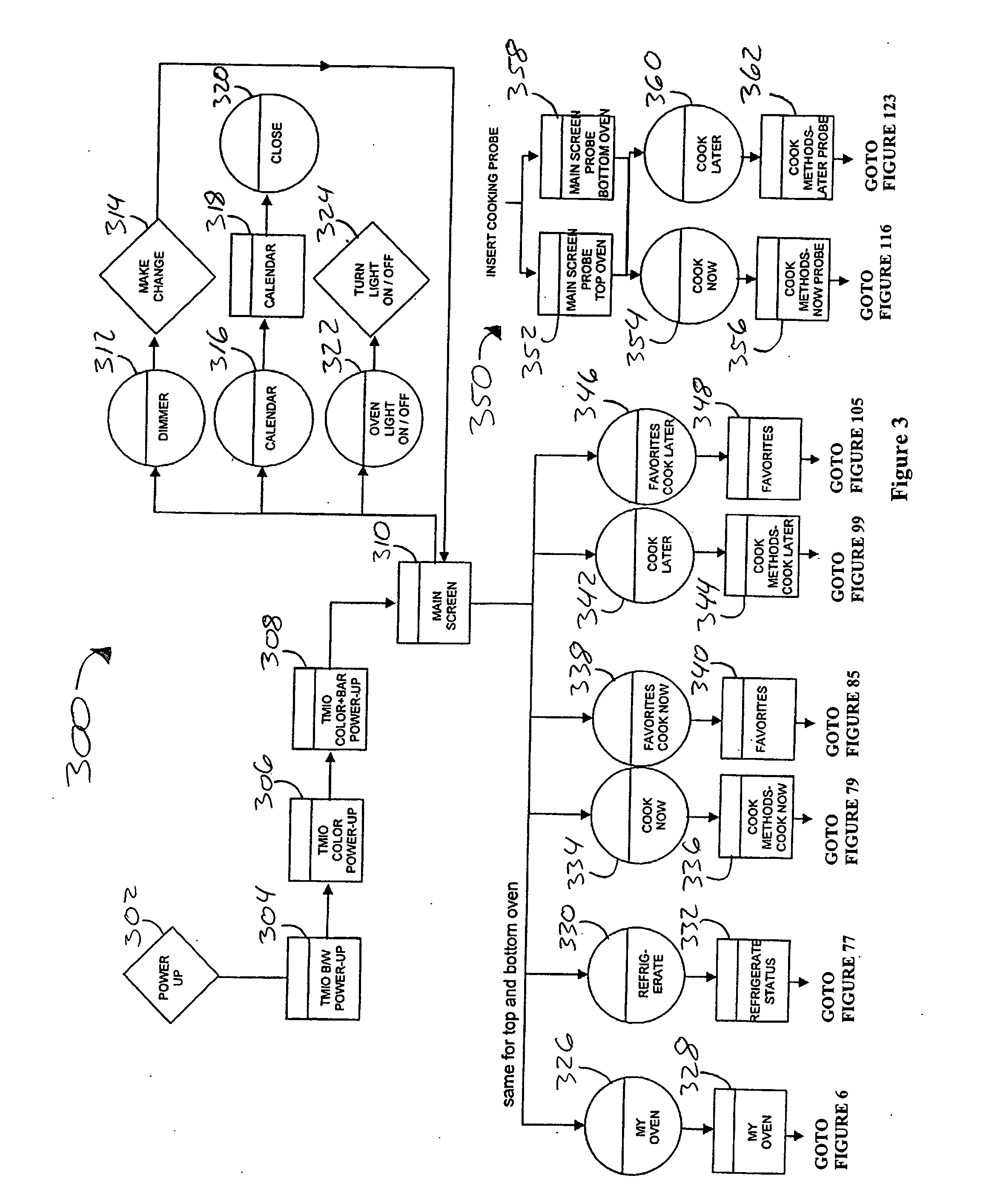

Method and control interface for food preparation on a cooking appliance

InactiveUS20070158335A1Domestic stoves or rangesBoiling over preventionGraphical user interfaceThe Internet

A graphical user interface adapted to enable a user to direct and control a cooking appliance. The graphical user interface generally enables a plurality of cooking appliance operations through associated layers of screens, such as a refrigerate operation, a cook now operation, a cook later operation, etc., and a plurality of cook settings, such as a bake setting, a roast setting, a broil setting, a warm setting, a convection bake setting, a convection roast setting, a convection broil setting, a convection defrost setting, etc. The graphical user interface is adapted to be integrated with and accessible through one or more of the cooking appliance, a handheld device, an Internet-accessible computer, etc.

Owner:VIKING RANGE

Electronic vaporizing device and methods for use

Devices and methods for vaporizing active ingredients of a selected substance for inhalation using a portable vaporization device are provided herein. In certain aspects, the device includes a portable power source, a heating portion, an inhalation sensor, a temperature sensor, a distal light source, and a grinding portion. In response to an inhalation by a user, the power source energizes a heating element of the heating portion so as to heat air flow to a desired vaporization temperature within a few seconds of detecting inhalation, using convection and radiative heating. The device may include a receptacle for receiving a cartridge containing a pre-prepared substance, such as a liquid, gel, powder, or solid brick, and a grinding portion to allow a user to grind intact portions of cellulose-based material into smaller pieces to facilitate vaporization by manually rotating portions of the device relative to each other.

Owner:UPTOKE LLC

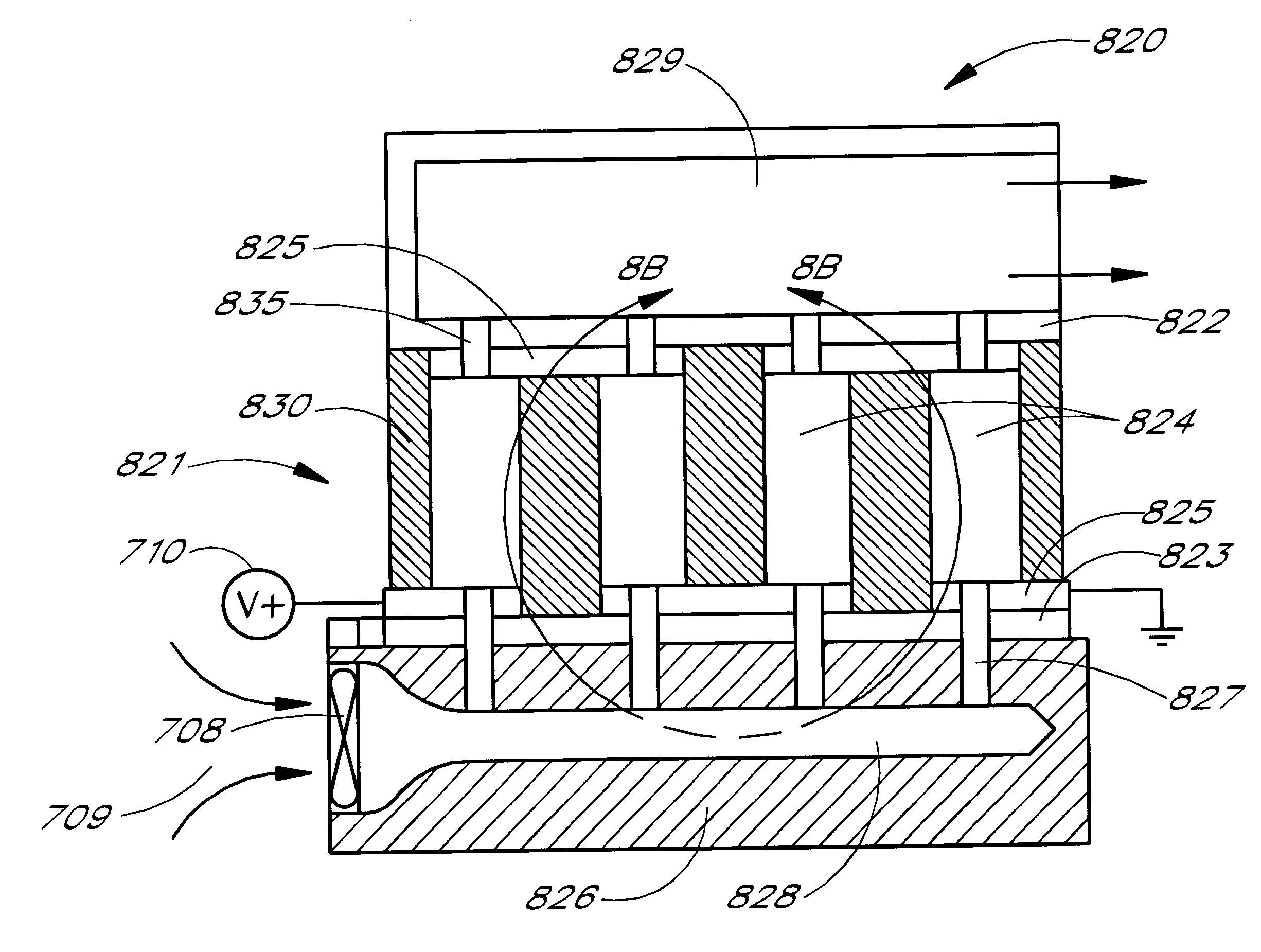

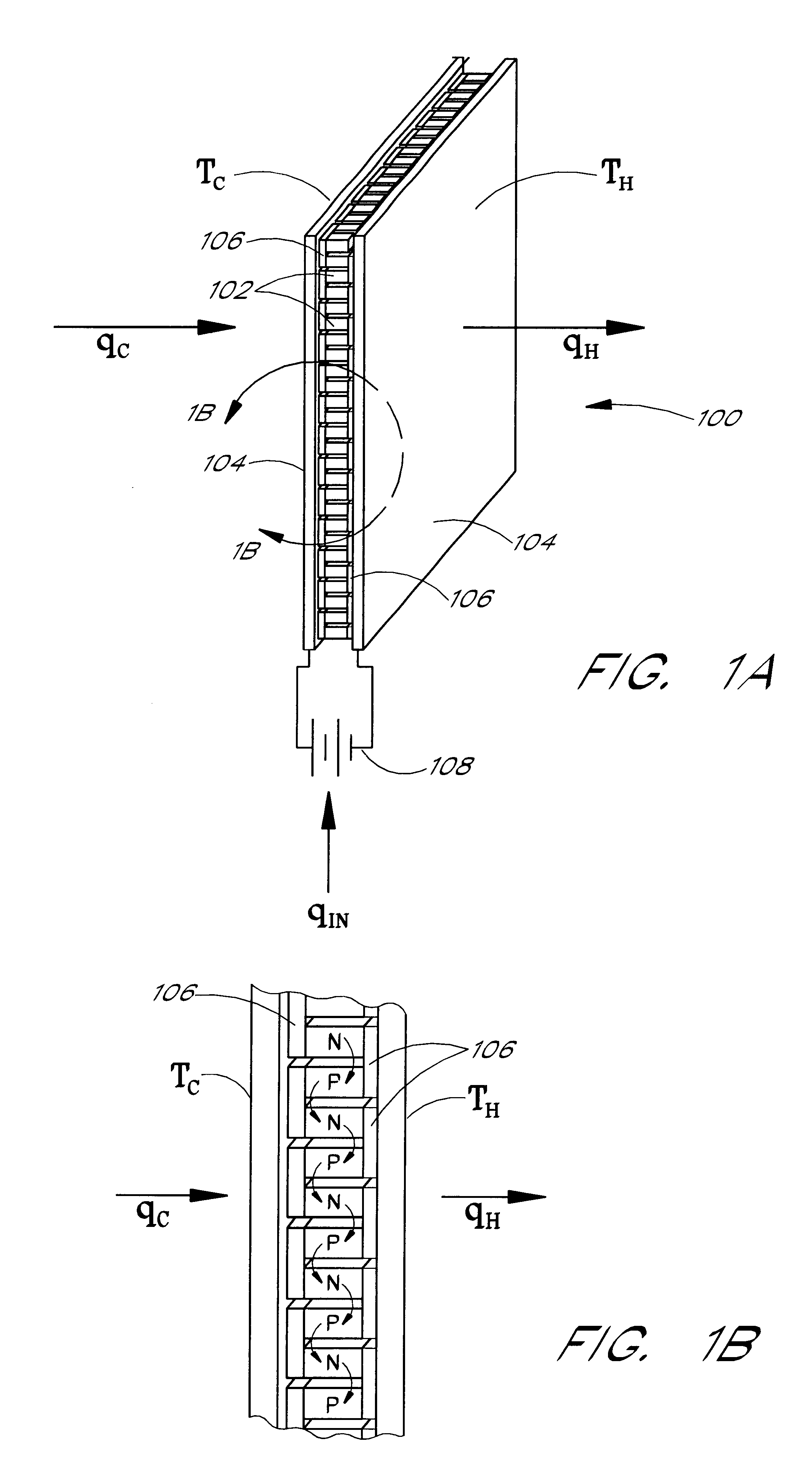

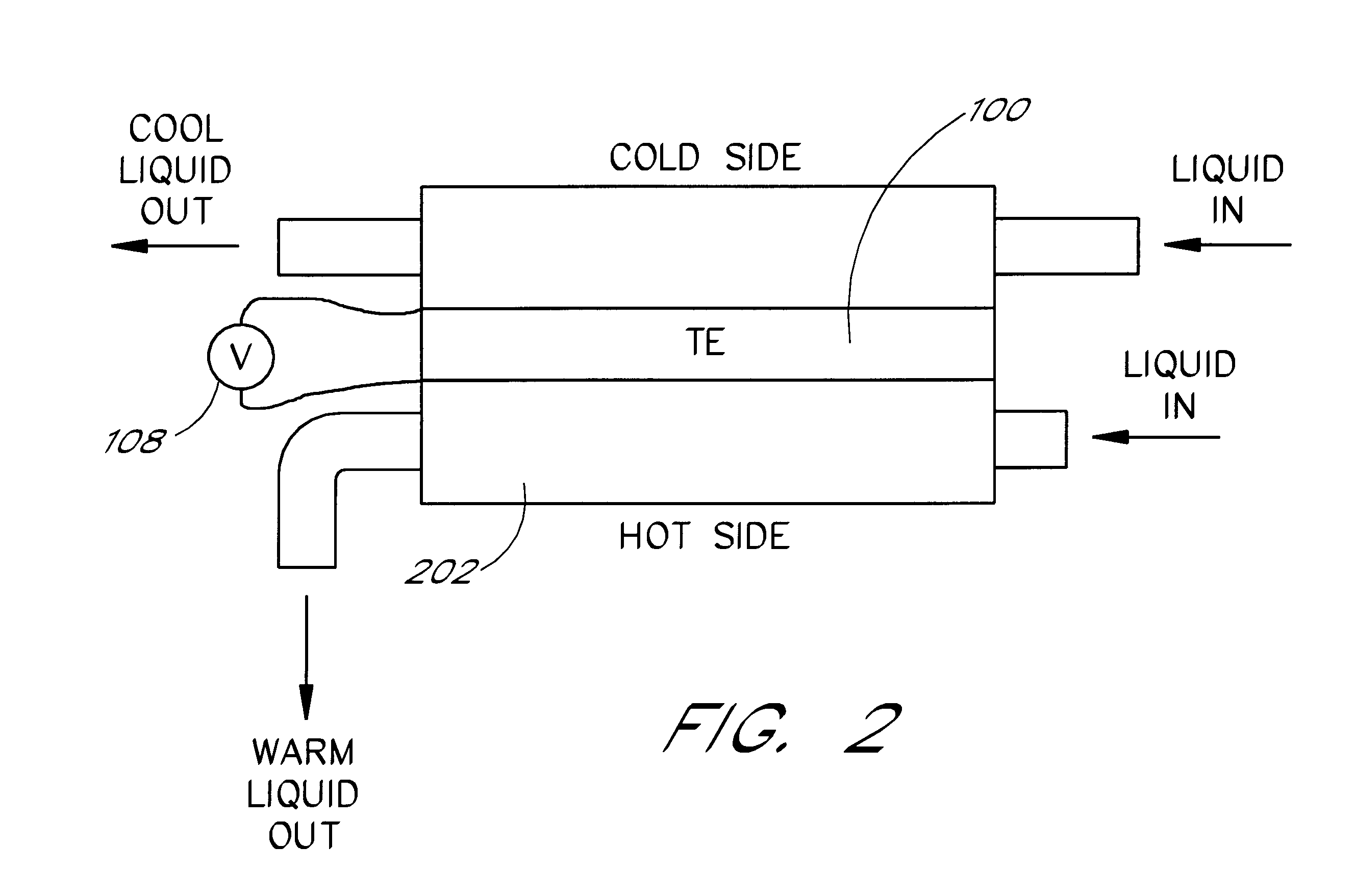

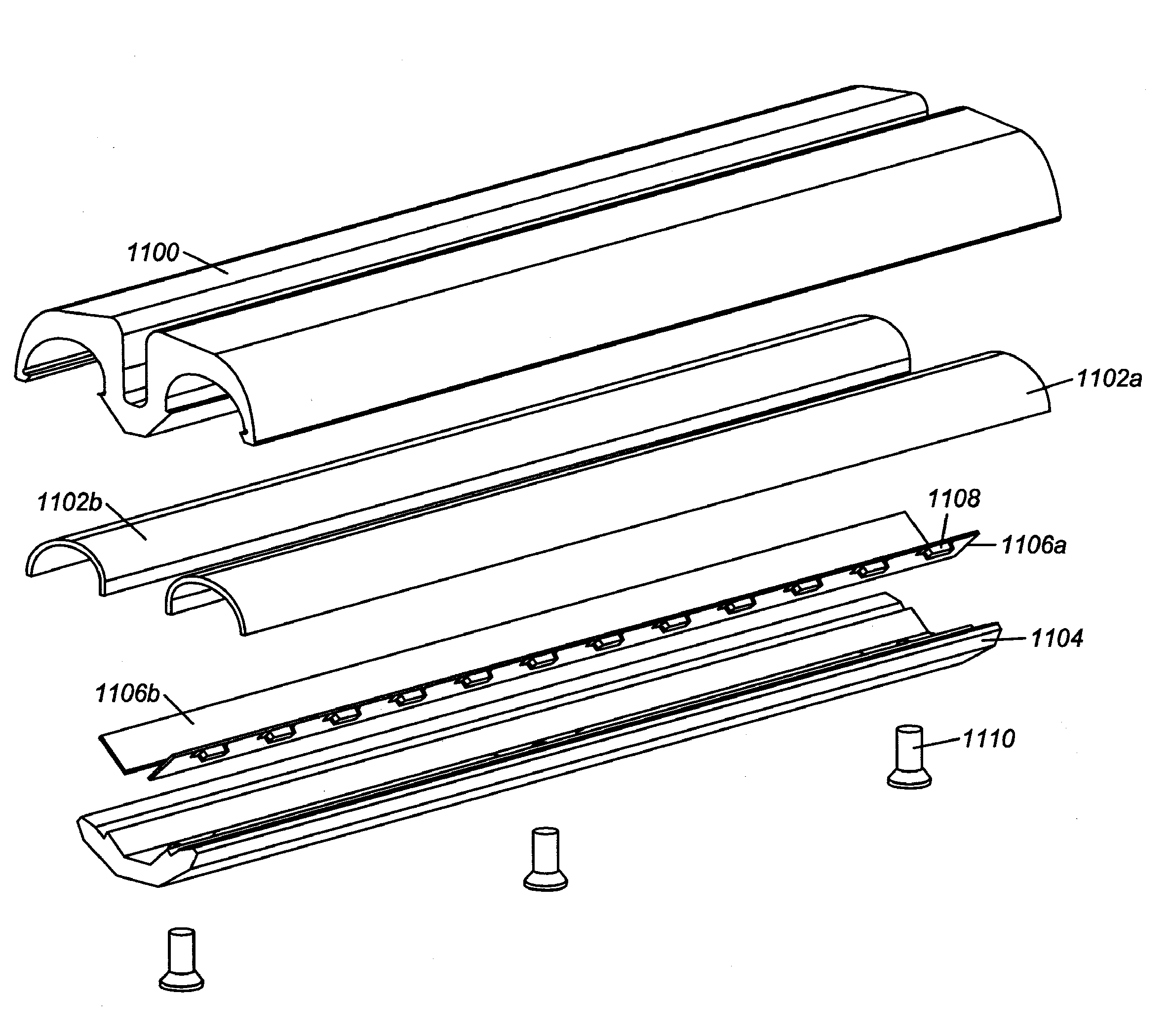

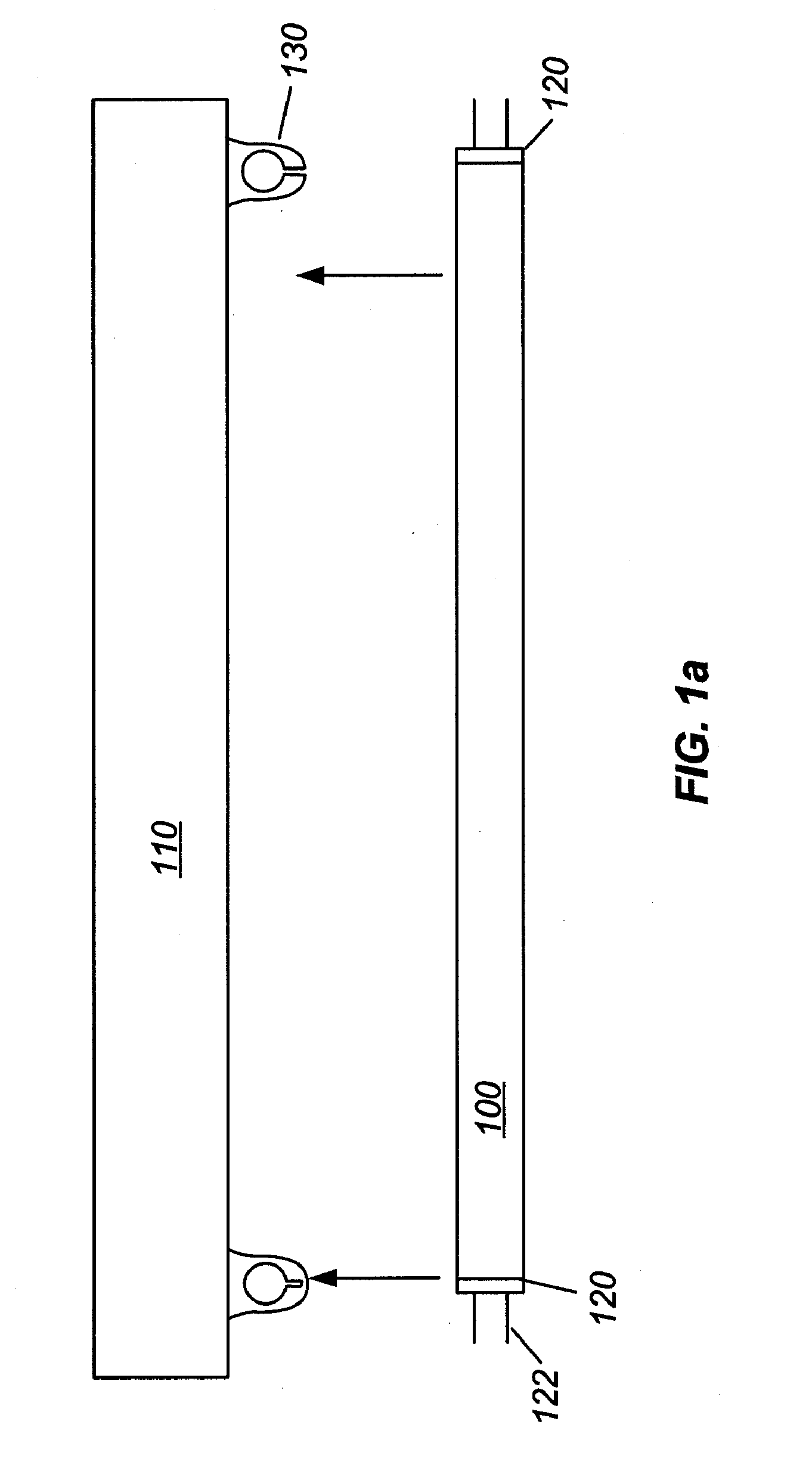

Efficiency thermoelectrics utilizing convective heat flow

InactiveUS6672076B2Thermoelectric device with peltier/seeback effectBoilers/analysersThermoelectric materialsHeat flow

An improved efficiency thermoelectric system is disclosed wherein convection is actively facilitated through a thermoelectric array. Thermoelectrics are commonly used for cooling and heating applications. Thermal power is convected through a thermoelectric array toward at least one side of the thermoelectric array, which leads to increased efficiency. Several different configurations are disclosed to provide convective thermal power transport, using a convective medium. In addition, a control system is disclosed which responds to one or more inputs to make adjustments to the thermoelectric system.

Owner:BSST INC +1

Lighting unit with heat-dissipating chimney

ActiveUS20110199769A1Avoid problemsLighting support devicesPoint-like light sourceLight equipmentEffect light

The invention provides systems and methods for providing illumination. A lighting unit may have a support structure, and one or more light emitting elements supported by a circuit board contacting the support structure. A first optical element and a second optical element may be provided. A remote luminescent material may be provided on one or more optical elements. Light emitting elements configured to excite the luminescent material such as highly efficient light emitting diodes may be directed towards the luminescent material. The support structure may be a heat dissipating element, which may conduct heat from a heat source to a surface of the support structure. The heat dissipating element may have a passageway permitting the formation of a convection path to dissipate heat from the support structure. Such lighting units may be used to replace conventional fluorescent light tubes or other lighting devices, or may be provided as standalone lighting units.

Owner:SATCO PRODS

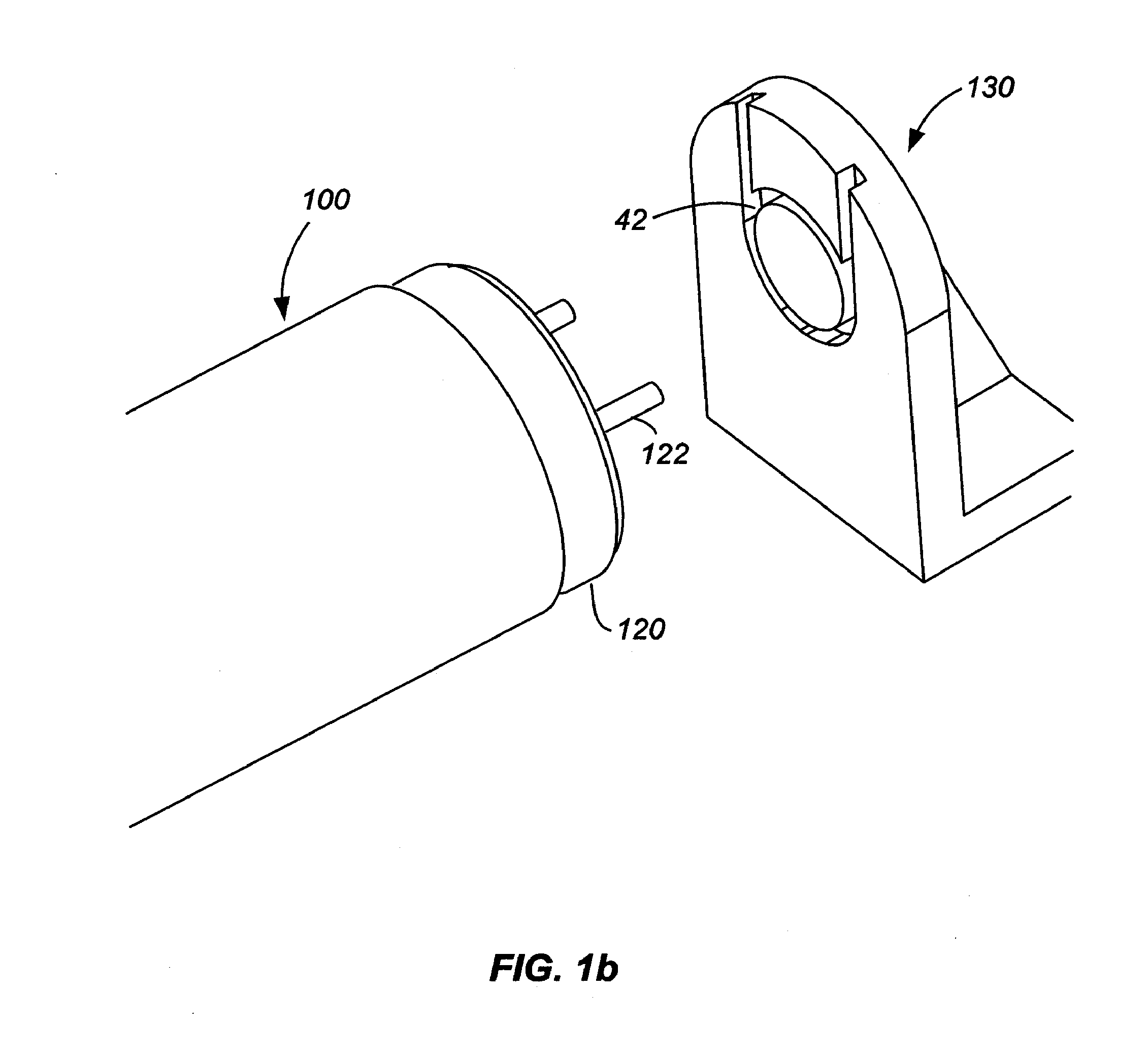

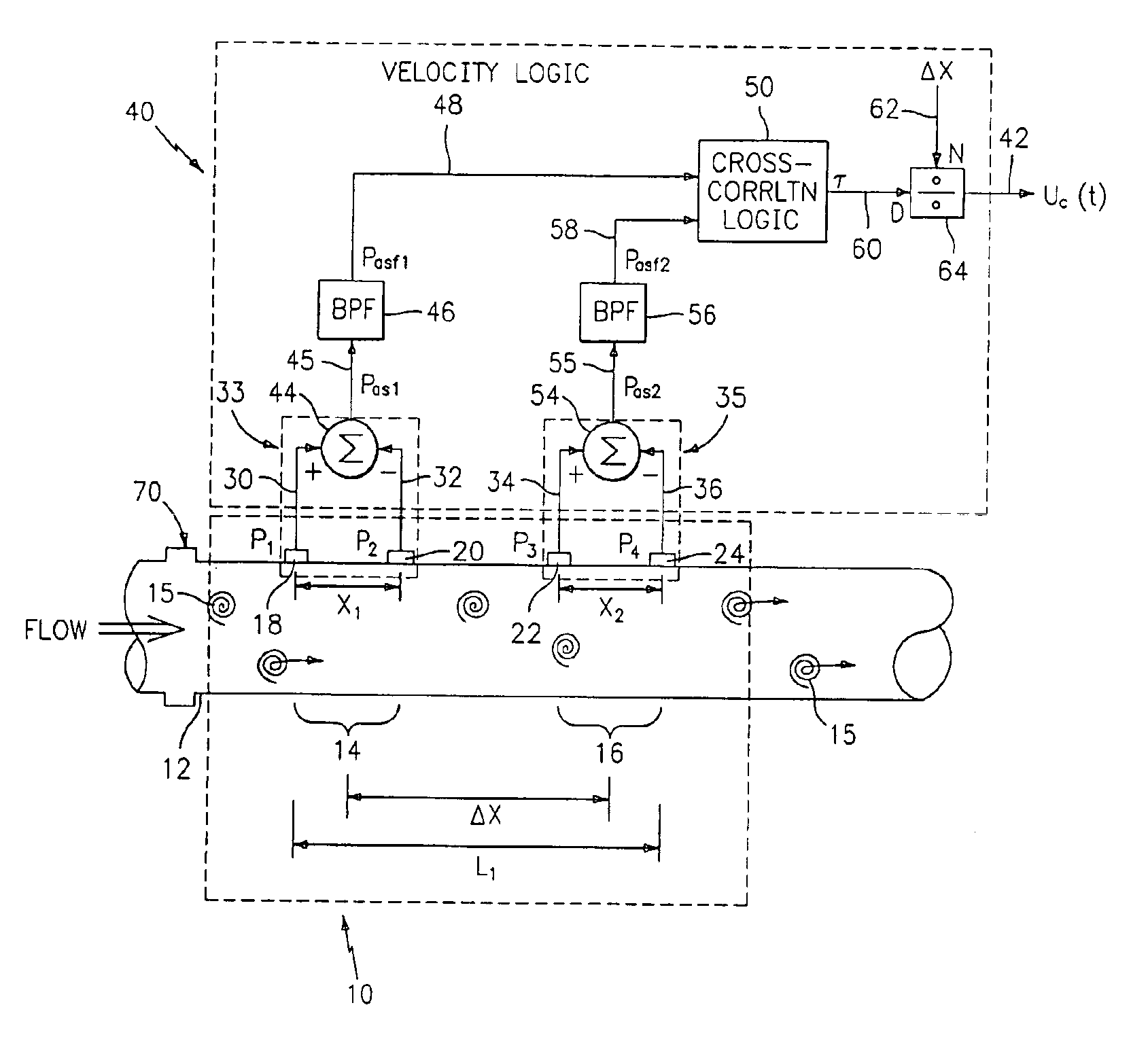

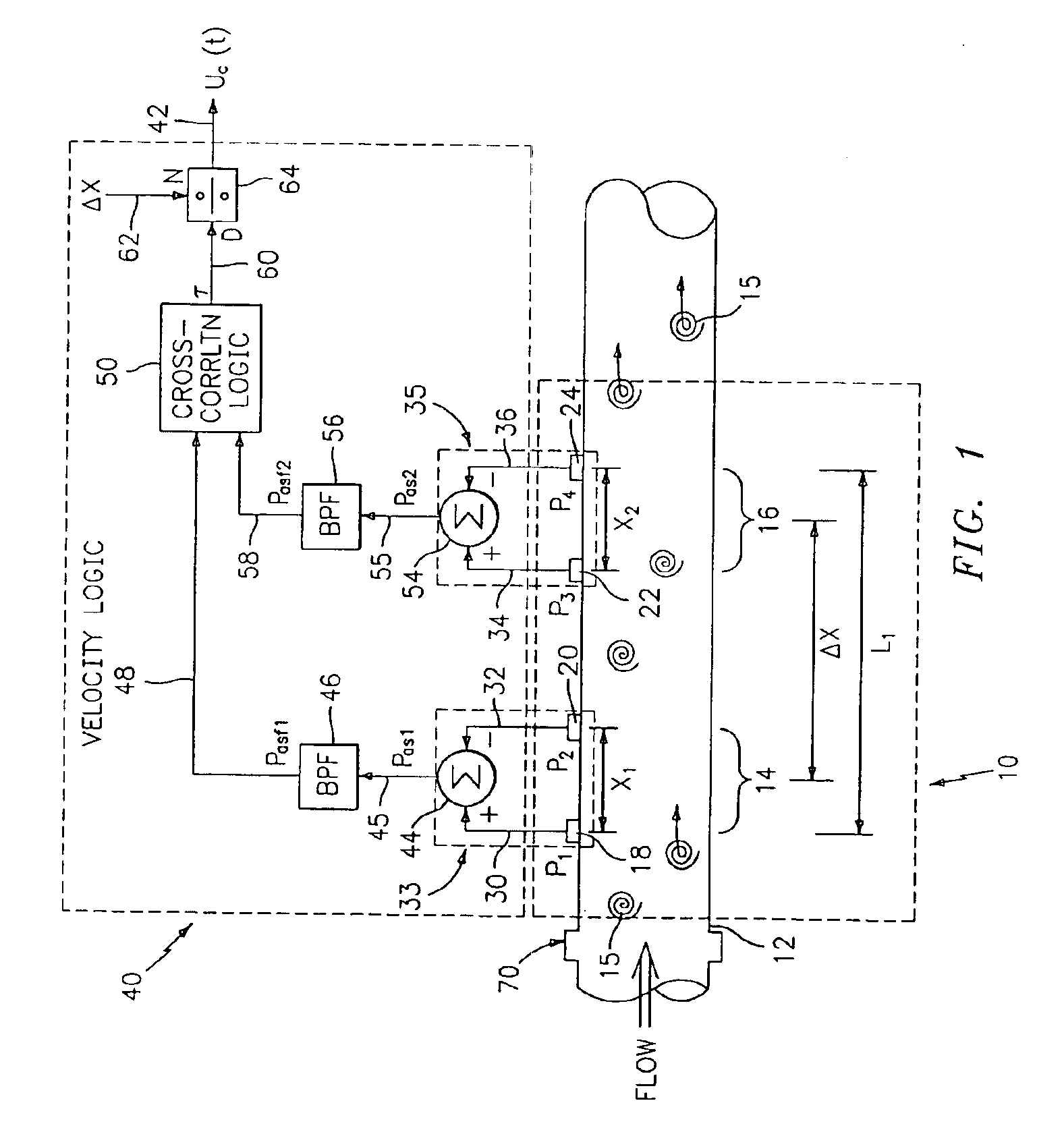

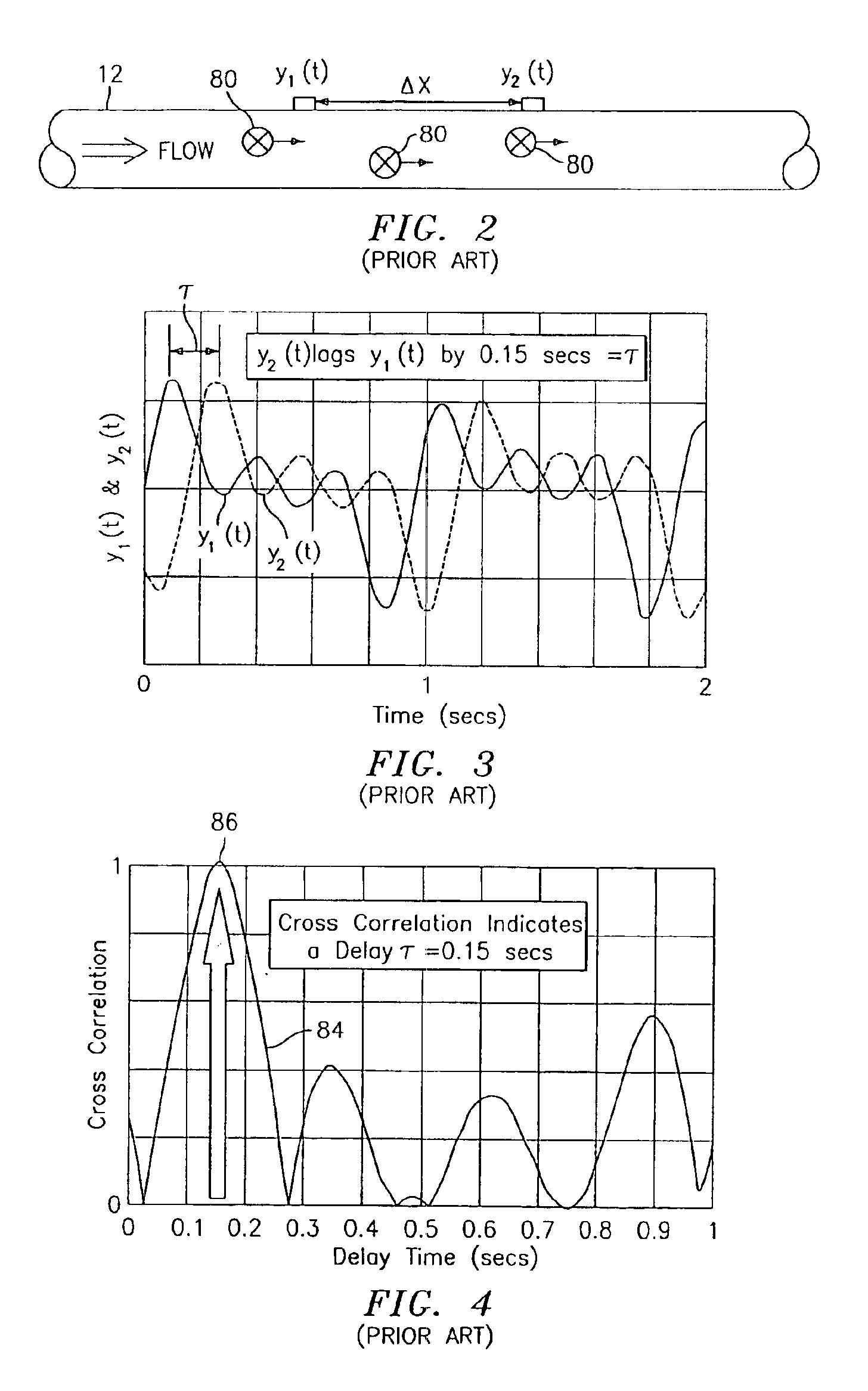

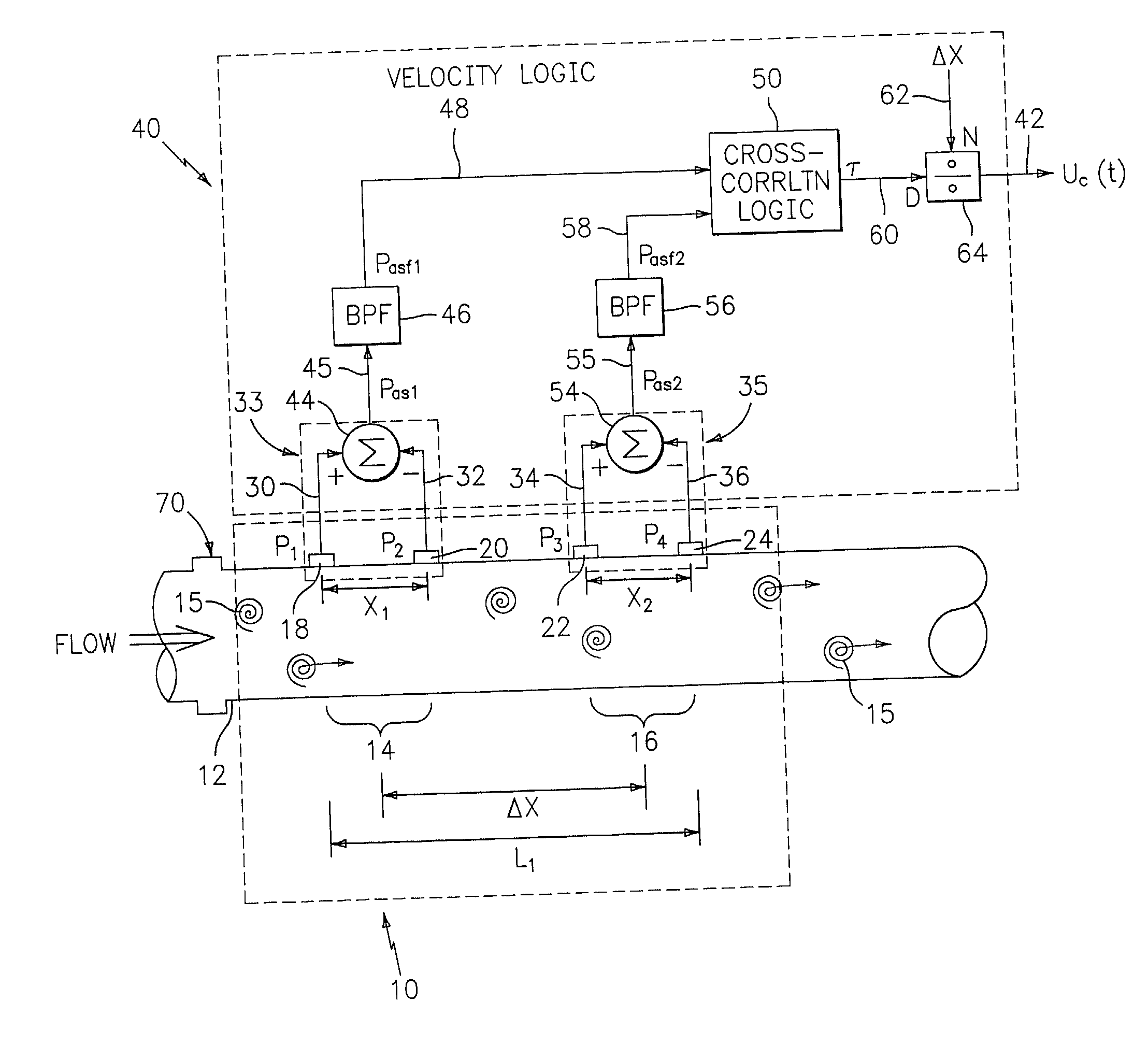

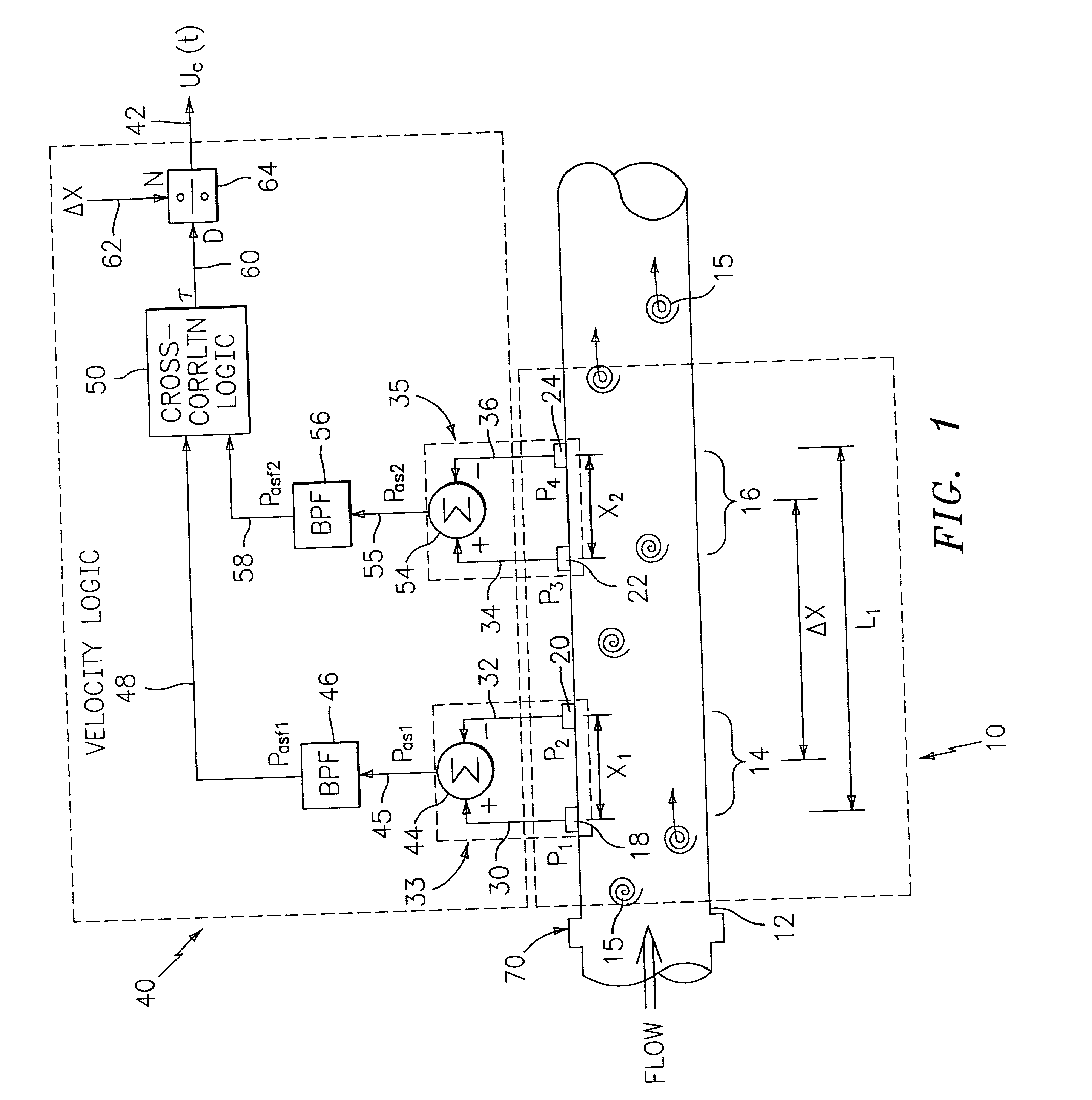

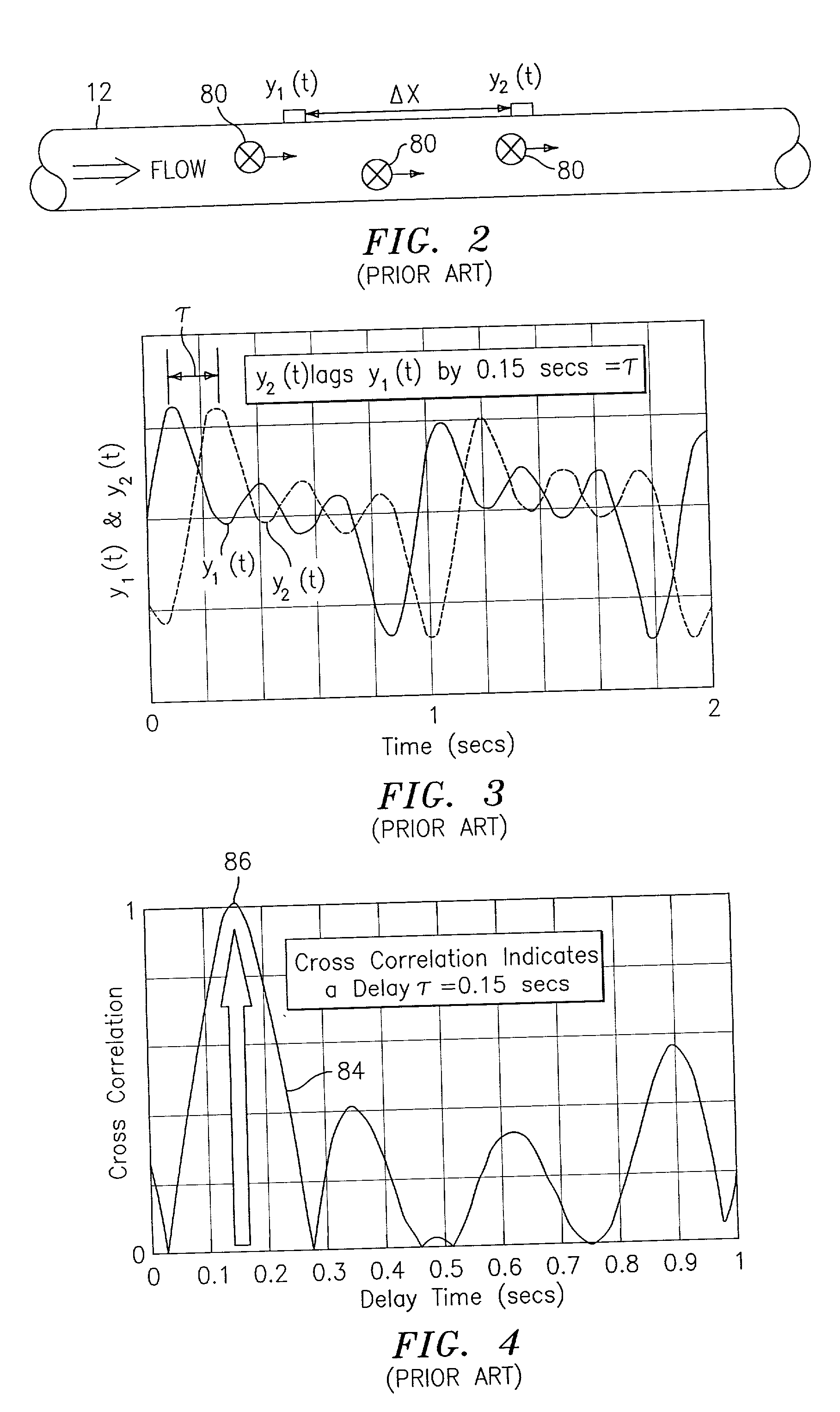

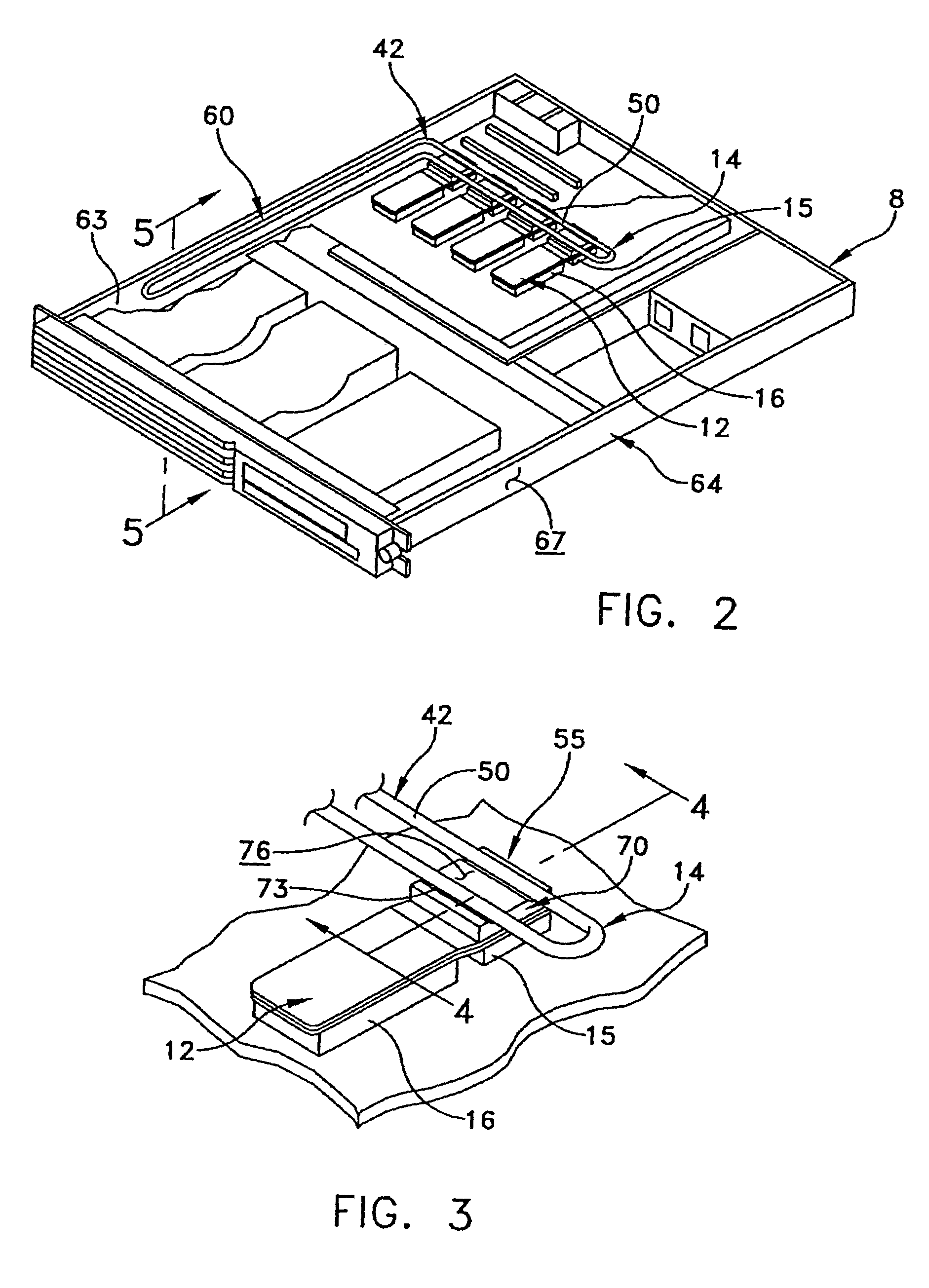

Flow rate measurement for industrial sensing applications using unsteady pressures

Flow rate measurement system includes two measurement regions 14,16 located an average axial distance ΔX apart along the pipe 12, the first measurement region 14 having two unsteady pressure sensors 18,20, located a distance X1 apart, and the second measurement region 16, having two other unsteady pressure sensors 22,24, located a distance X2 apart, each capable of measuring the unsteady pressure in the pipe 12. Signals from each pair of pressure sensors 18,20 and 22,24 are differenced by summers 44,54, respectively, to form spatial wavelength filters 33,35, respectively. Each spatial filter 33,35 filters out acoustic pressure disturbances Pacoustic and other long wavelength pressure disturbances in the pipe 12 and passes short-wavelength low-frequency vortical pressure disturbances Pvortical associated with the vortical flow field 15. The spatial filters 33,35 provide signals Pas1,Pas2 to band pass filters 46,56 that filter out high frequency signals. The Pvortical -dominated filtered signals Pasf1,Pasf2 from the two regions 14,16 are cross-correlated by Cross-Correlation Logic 50 to determine a time delay τ between the two sensing locations 14,16 which is divided into the distance ΔX to obtain a convection velocity Uc(t) that is related to an average flow rate of the fluid (i.e., one or more liquids and / or gases) flowing in the pipe 12. The invention may also be configured to detect the velocity of any desired inhomogeneous pressure field in the flow. The invention may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

Differential thermopile heat flux transducer

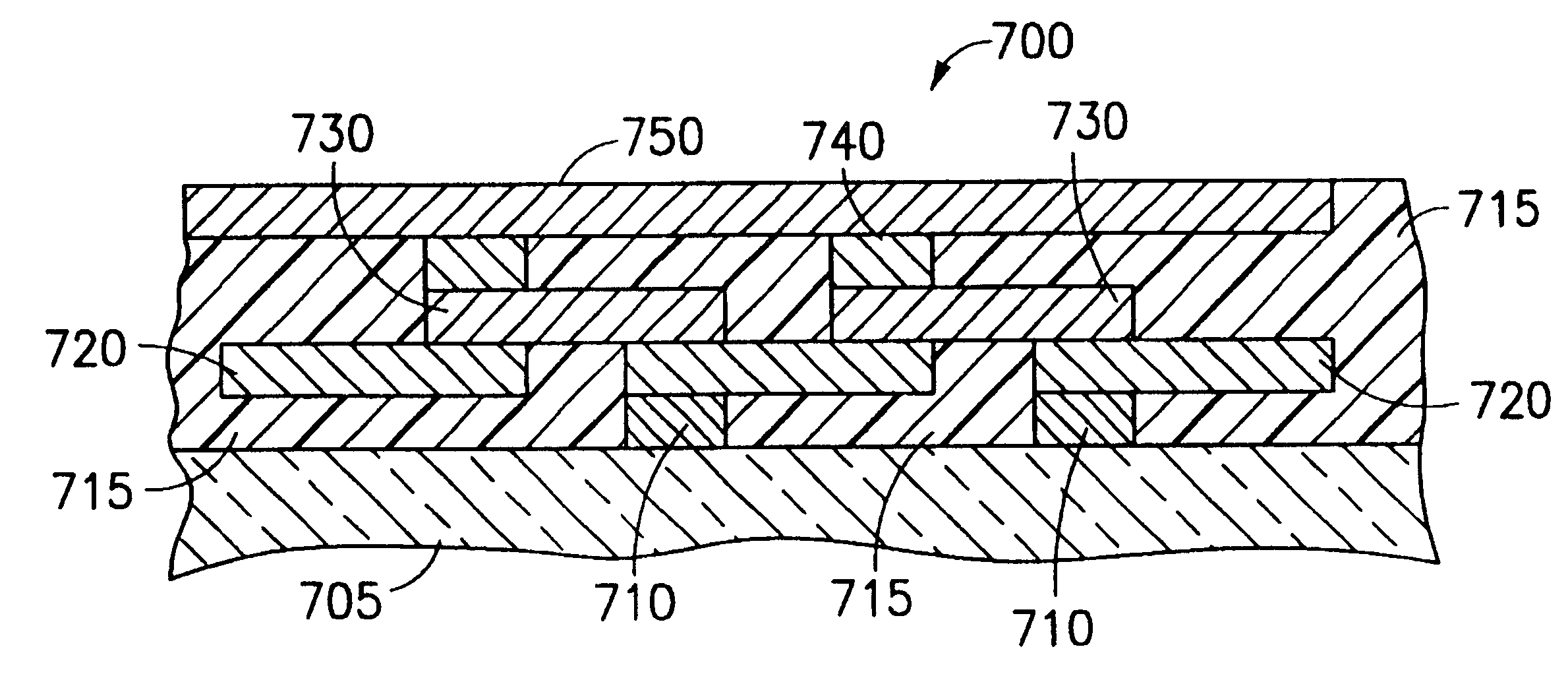

InactiveUS6278051B1Thermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentHeat flowThermopile

A thin sensor for heat flux and temperature, designed for adhesive attachment to a surface, is manufactured on a flexible insulated metallic substrate. The sensor exhibits a combination of high sensitivity for heat flux and low resistance to the flow of heat. These characteristics enable it to measure heat flux at surface boundaries with improved accuracy over conventional heat flux transducers because the temperature drop produced by the sensor is very small. The response by the sensor to radiation, convection and conduction are equal. As such, the sensor can be calibrated in one mode of heat transfer and used for measurement in other modes. The high sensitivity of the sensor makes it ideal for measuring heat flow through insulating materials, and well adapted to instrumenting heat flow in buildings, detecting fires at an early stage, or remotely measuring the temperature of string and web products in industrial processing.

Owner:VATELL CORP

Flow rate measurement for industrial sensing applications using unsteady pressures

Flow rate measurement system includes two measurement regions 14,16 located an average axial distance .DELTA.X apart along the pipe 12, the first measurement region 14 having two unsteady pressure sensors 18,20, located a distance X.sub.1 apart, and the second measurement region 16, having two other unsteady pressure sensors 22,24, located a distance X.sub.2 apart, each capable of measuring the unsteady pressure in the pipe 12. Signals from each pair of pressure sensors 18,20 and 22,24 are differenced by summers 44,54, respectively, to form spatial wavelength filters 33,35, respectively. Each spatial filter 33,35 filters out acoustic pressure disturbances P.sub.acoustic and other long wavelength pressure disturbances in the pipe 12 and passes short-wavelength low-frequency vortical pressure disturbances P.sub.vortical associated with the vortical flow field 15. The spatial filters 33,35 provide signals P.sub.as1,P.sub.as2 to band pass filters 46,56 that filter out high frequency signals. The P.sub.vortical -dominated filtered signals P.sub.asf1,P.sub.asf2 from the two regions 14,16 are cross-correlated by Cross-Correlation Logic 50 to determine a time delay .tau. between the two sensing locations 14,16 which is divided into the distance .DELTA.X to obtain a convection velocity U.sub.c(t) that is related to an average flow rate of the fluid (i.e., one or more liquids and / or gases) flowing in the pipe 12. The invention may also be configured to detect the velocity of any desired inhomogeneous pressure field in the flow. The invention may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

Lamp structure

InactiveUS20110037368A1Good effectCancel noisePoint-like light sourceElectric discharge tubesEngineeringConvection

A lamp structure includes a lamp housing. A plurality of air intake holes is respectively opened on two opposite sides of the lamp housing, and a plurality of vent holes is opened between the plurality of air intake holes on the two sides. A heat sink and a light-emitting element disposed on the heat sink are disposed inside the lamp housing. The heat sink is surrounded by a plurality of heat dissipation fins to form an accommodation chamber for accommodating a fan. When activated, the fan intakes an airflow respectively through the plurality of air intake holes on two sides of the lamp housing, blows the airflow to the plurality of heat dissipation fins, and ventilates the hot air through the vent holes, thereby realizing a double circulatory heat convection exchange effect.

Owner:RISUN EXPANSE

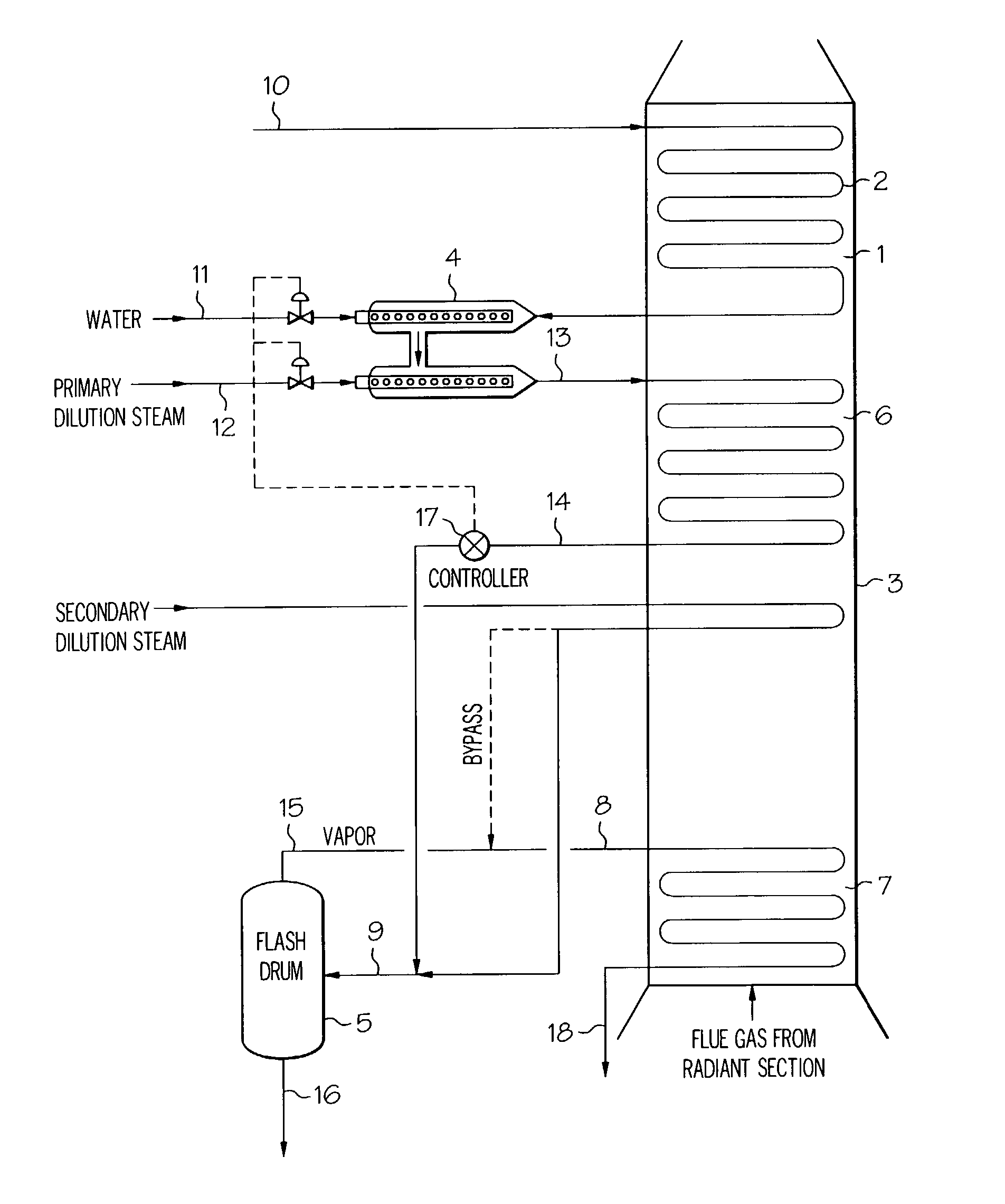

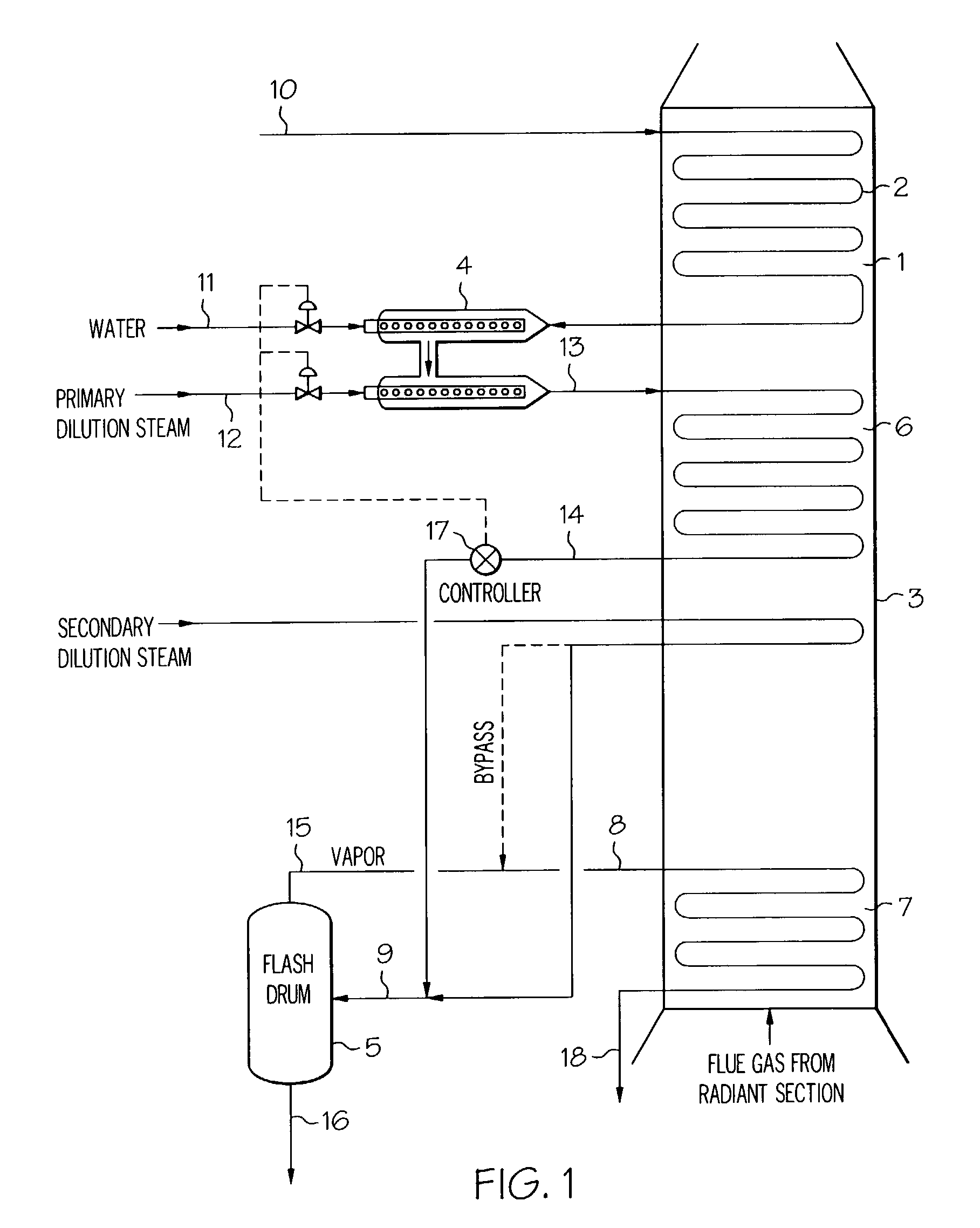

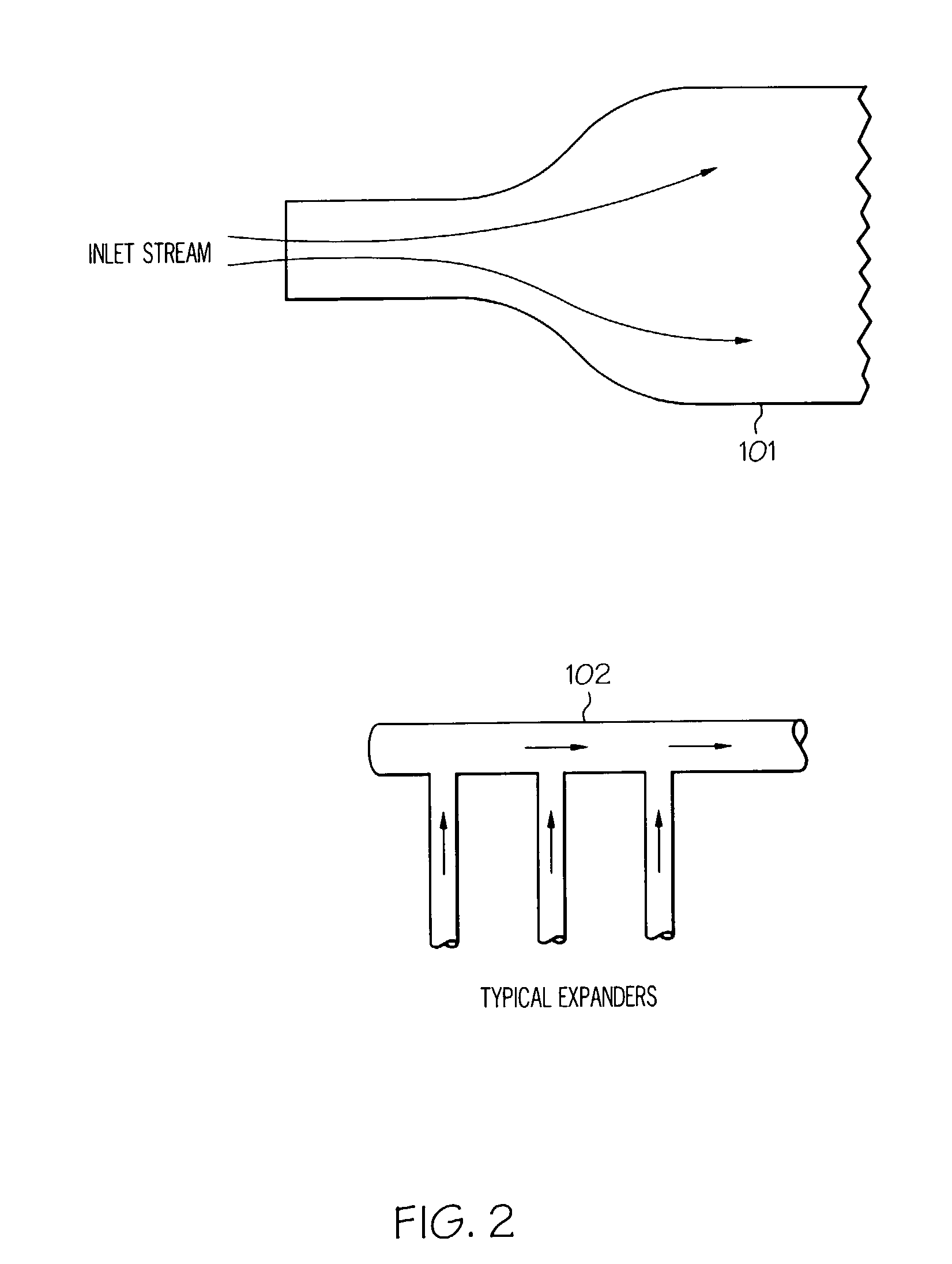

Converting mist flow to annular flow in thermal cracking application

ActiveUS7097758B2Reduce flow rateShorten speedThermal non-catalytic crackingHydrocarbon oil cracking processGas phaseEngineering

A process to increase the non-volatile removal efficiency in a flash drum in the steam cracking system. The gas flow from the convection section is converted from mist flow to annular flow before entering the flash drum to increase the removal efficiency. The conversion of gas flow from mist flow to annular flow is accomplished by subjecting the gas flow first to at least one expander and then to bends of various degrees and force the flow to change directions at least once. The change of gas flow from mist to annular helps coalesce fine liquid droplets and thus being removed from the vapor phase.

Owner:EXXONMOBIL CHEM PAT INC

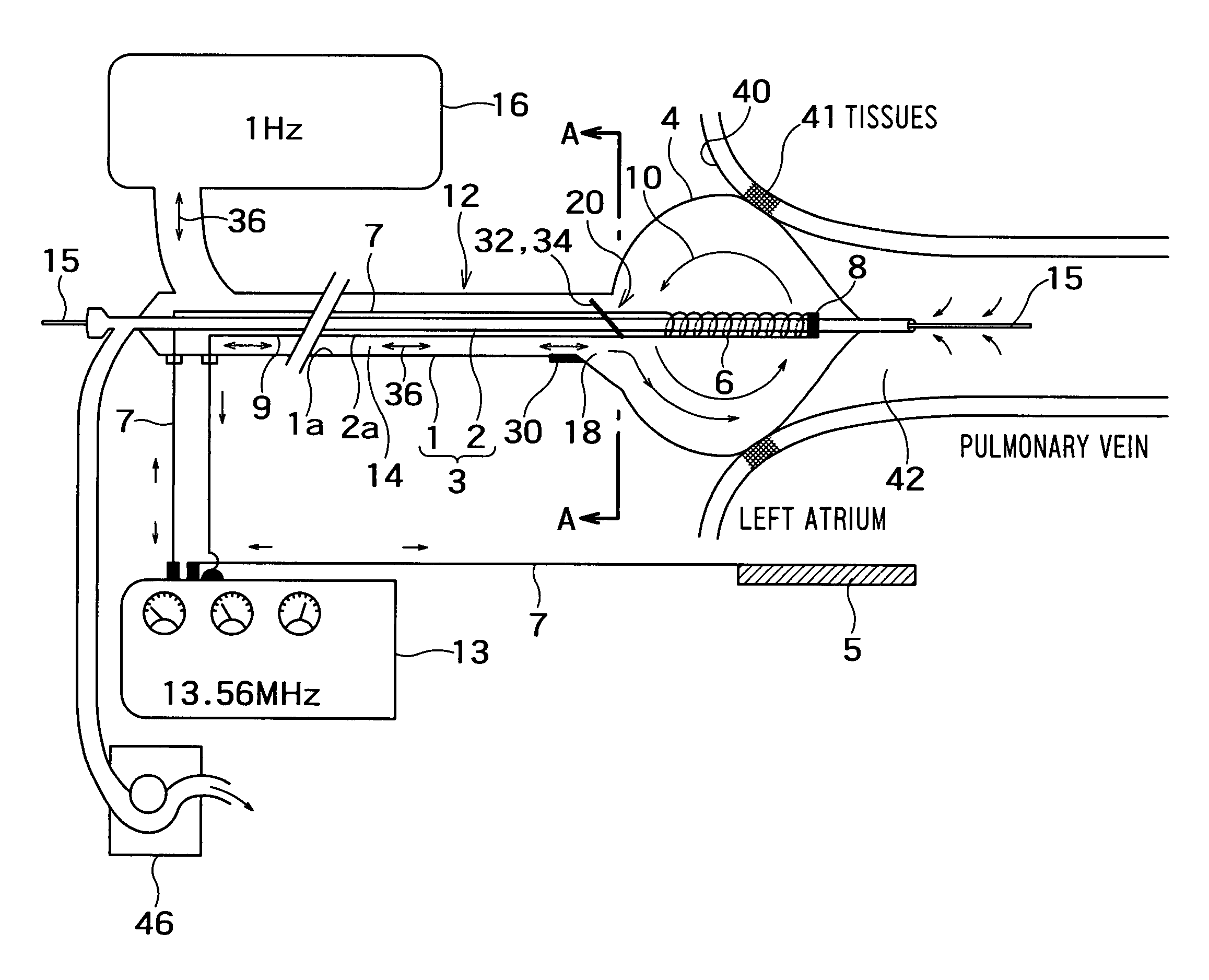

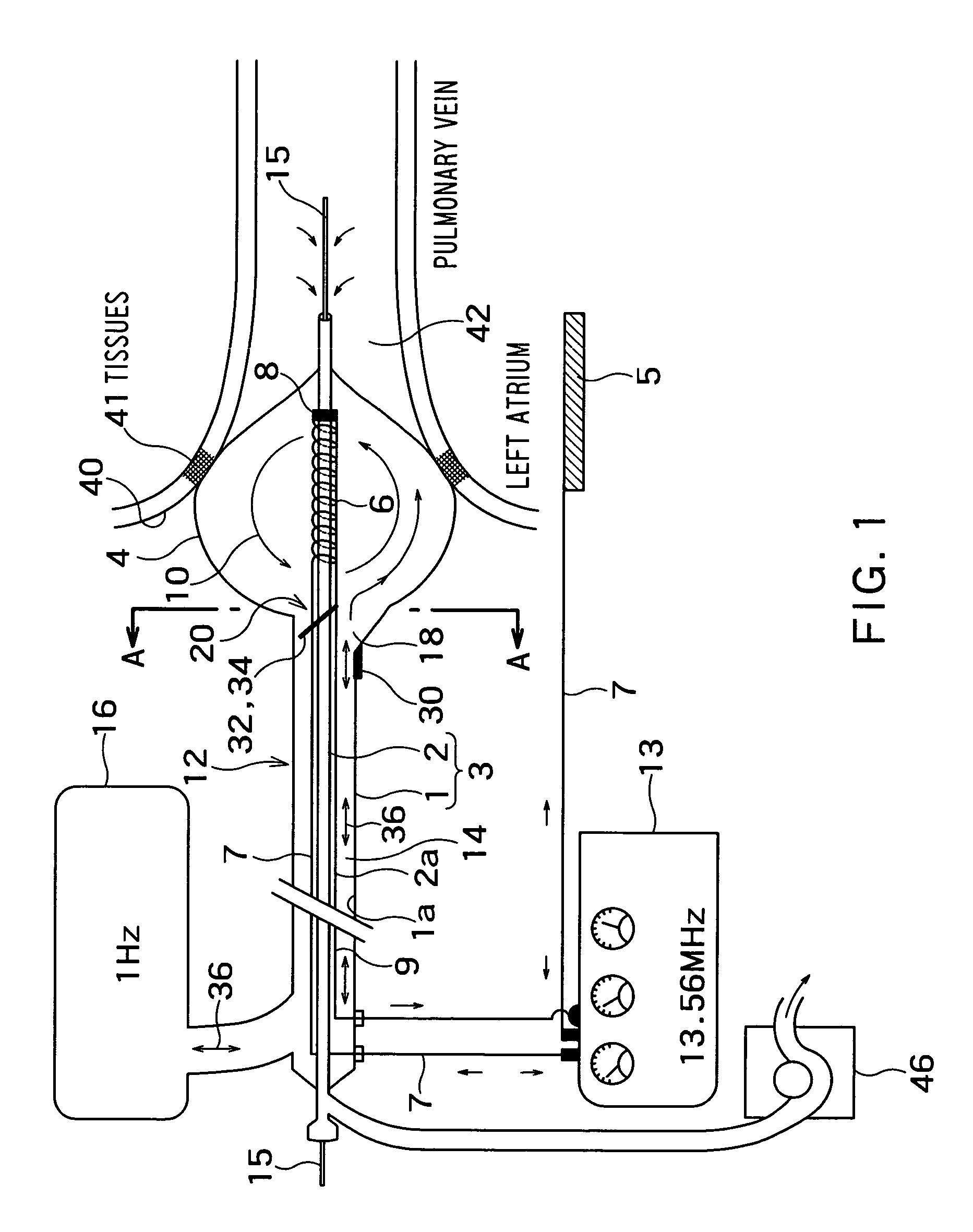

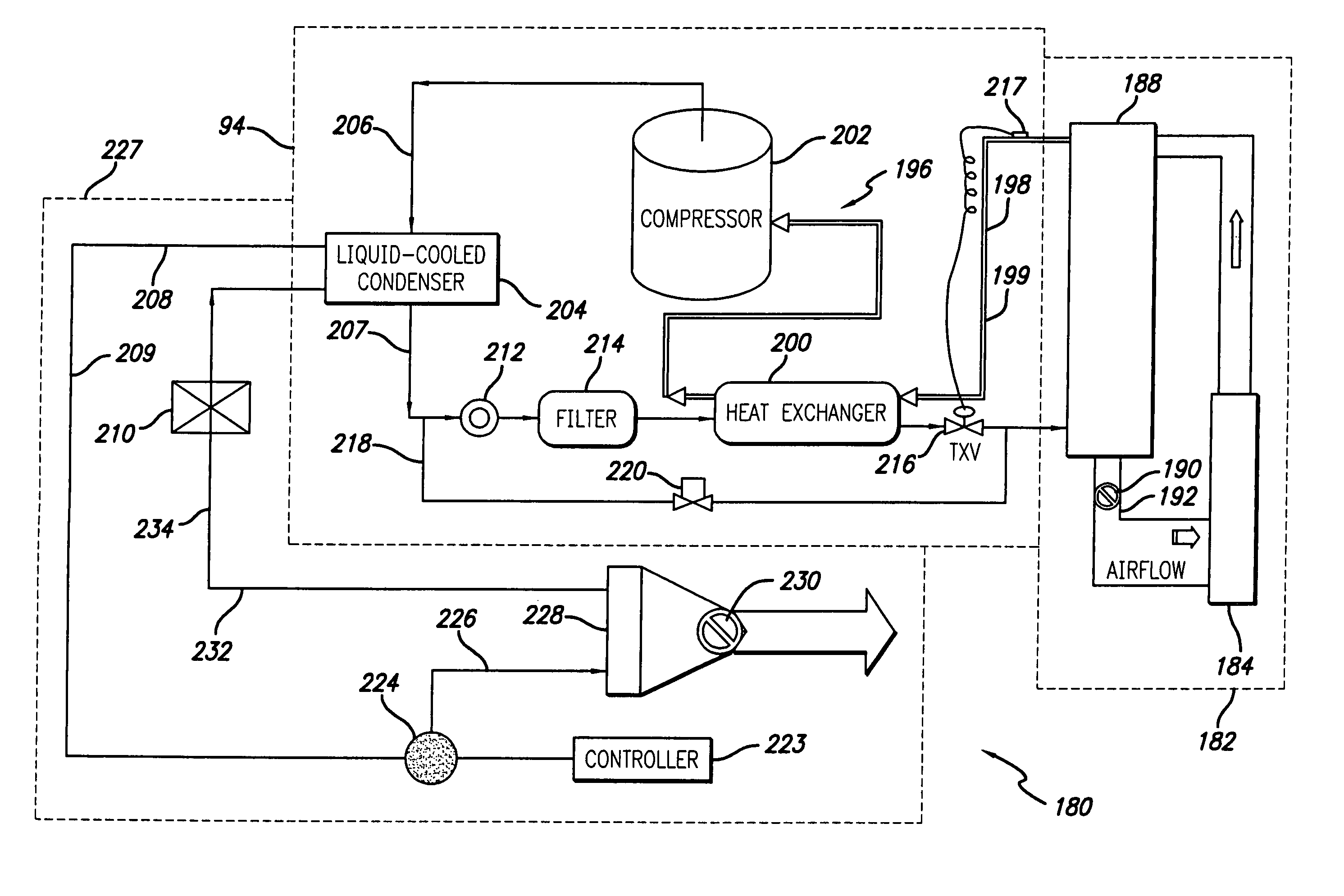

Radio-frequency thermal balloon catheter

ActiveUS8231617B2Reduce temperature differenceHeating evenlyStentsMulti-lumen catheterVertical planeMedicine

A radio-frequency thermal balloon catheter includes a catheter tube including an outer tube and an inner tube, a balloon connected to an end part of the outer tube and an end part of the inner tube, and capable of coming into contact with a target diseased part when inflated, a radio-frequency electrode placed in the wall of the balloon or inside the balloon to transmit radio-frequency current, a lead wire electrically connected to the radio-frequency electrode, a temperature sensor capable of measuring temperature inside the balloon, and a swirling current producing means for making a fluid contained in the balloon swirl in a vertical plane in the balloon so as to reduce an upper-lower temperature difference between an upper part and a lower part of the interior of the balloon due to convection of the fluid to naught.

Owner:JAPAN ELECTEL

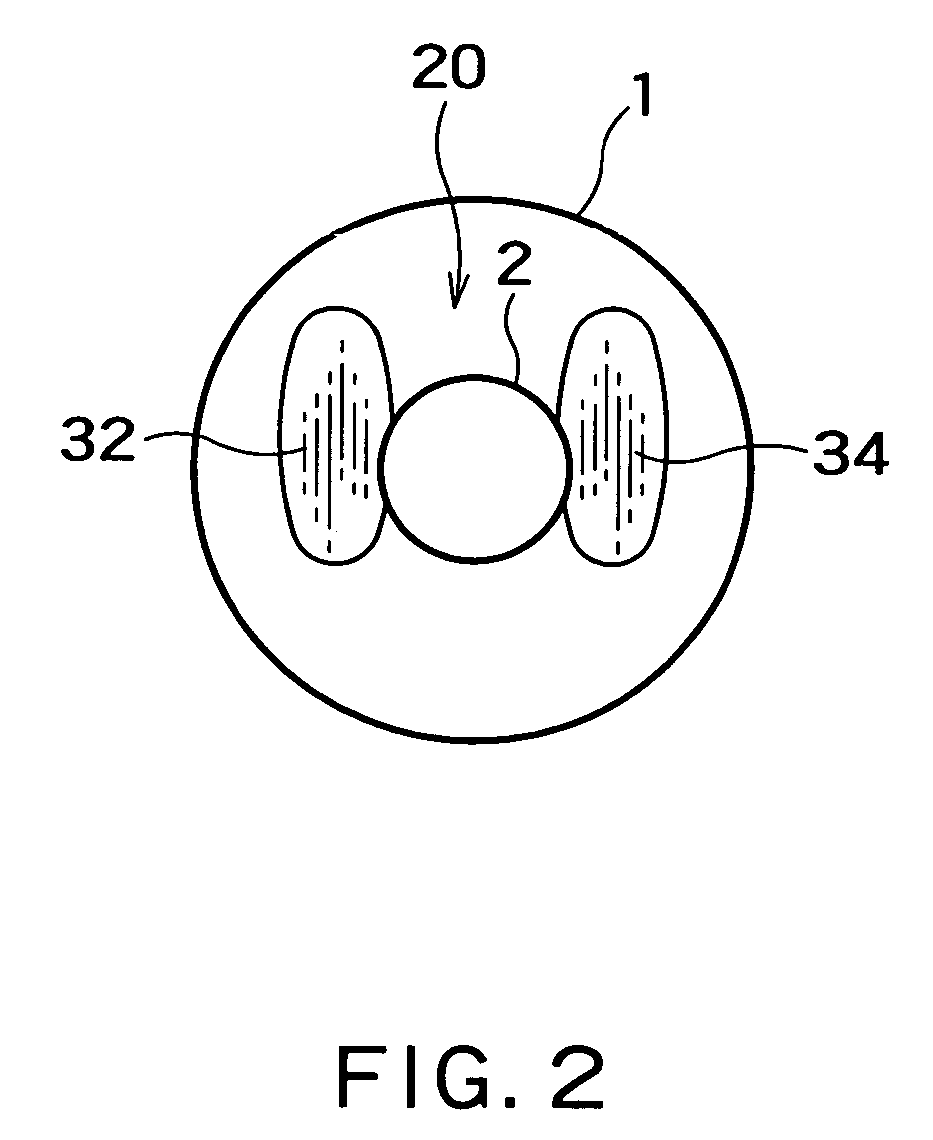

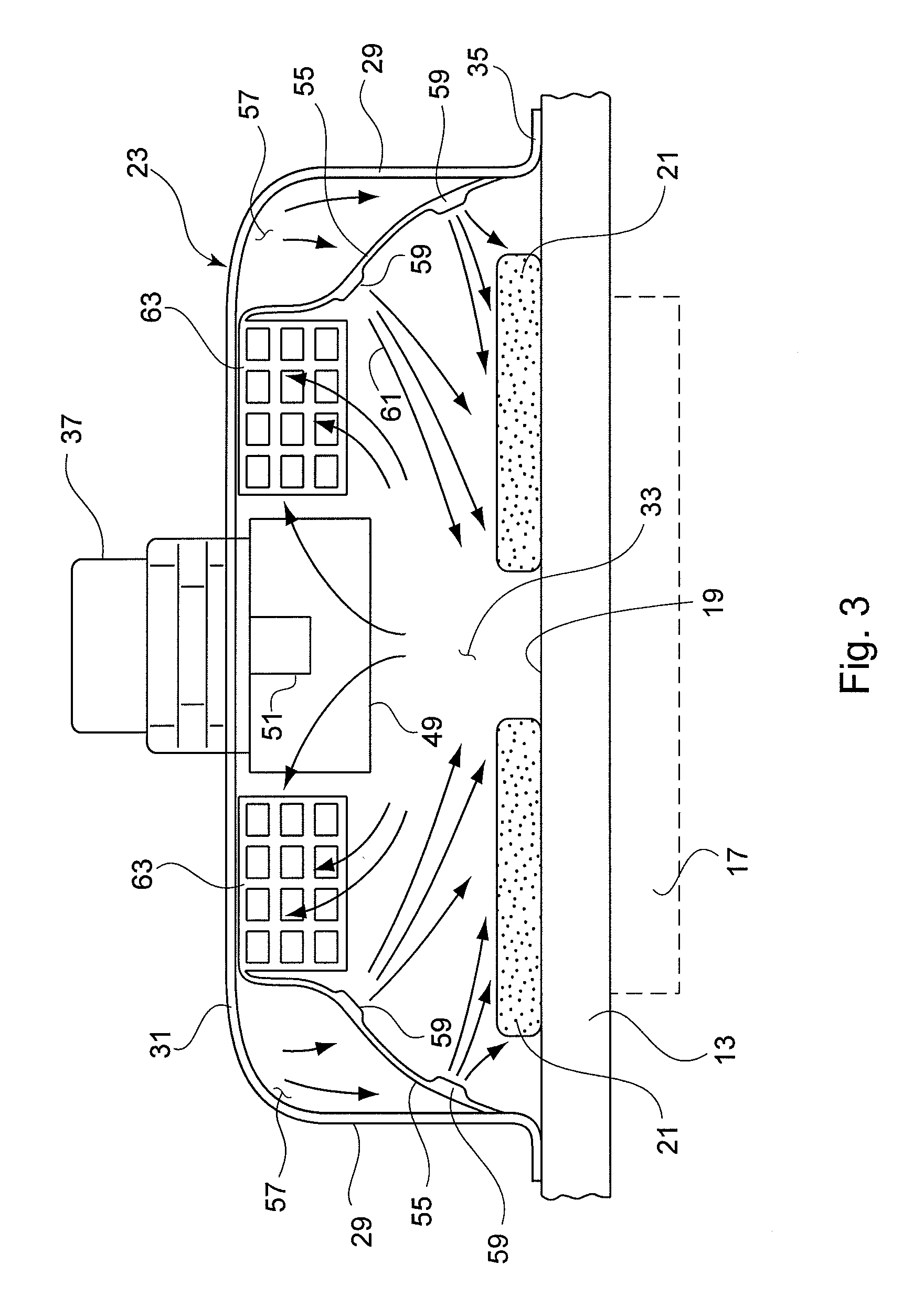

Cooling system for a commercial aircraft galley

In the improved cooling system for a commercial aircraft galley, heat is transferred from a galley food cart by a point-of-use heat exchange system to a liquid cooled condenser. Liquid coolant for the liquid cooled condenser is circulated in a liquid coolant loop to a heat exchanger expelling heat for cooling the liquid coolant. The liquid coolant may be water or a mixture of water and glycol. A flow of cooling air from a heat exchanger cooled by the liquid cooled condenser is cycled through an air over system, through an air through system, or from a thermal convection air cooling system providing at least one cooled galley food cart surface to provide cooling. Heat may be transferred from a plurality of galley food carts to the circulating liquid coolant.

Owner:BE INTPROP

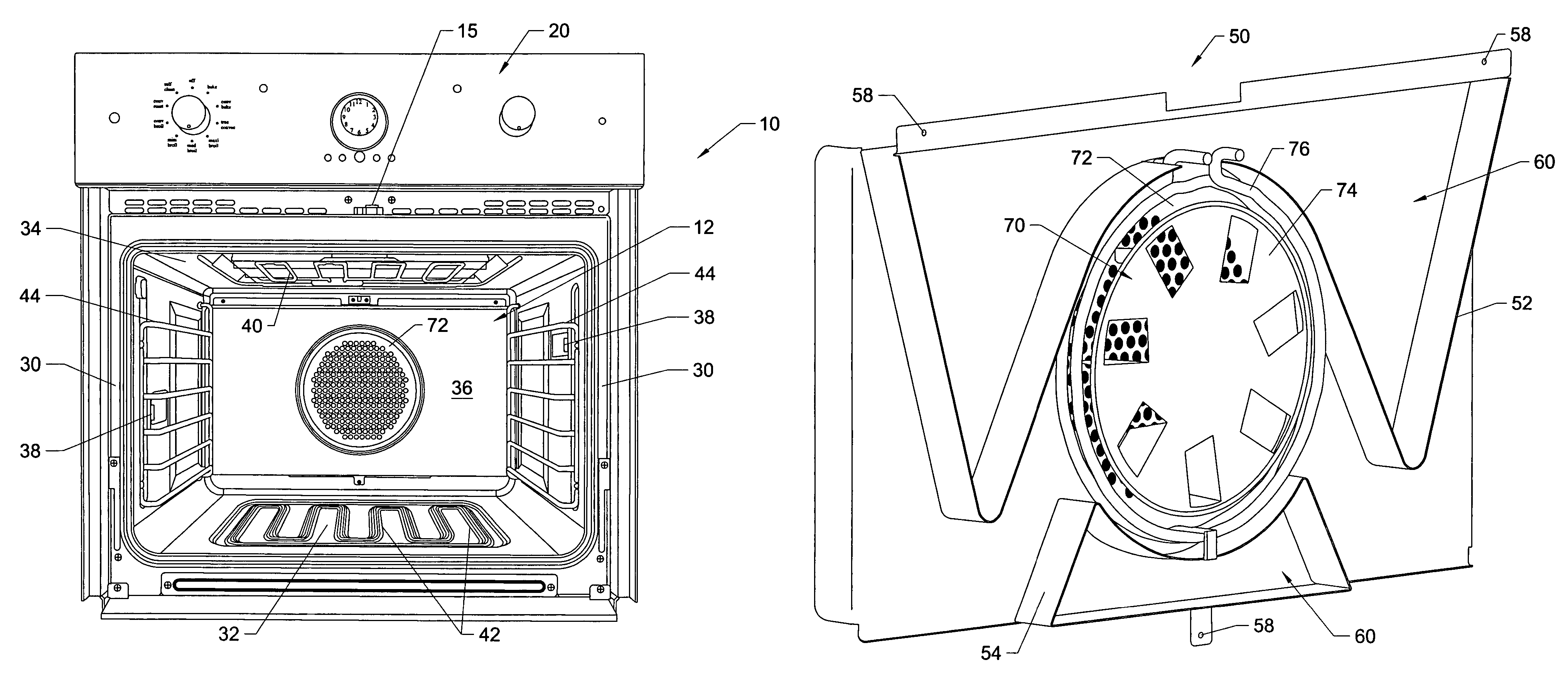

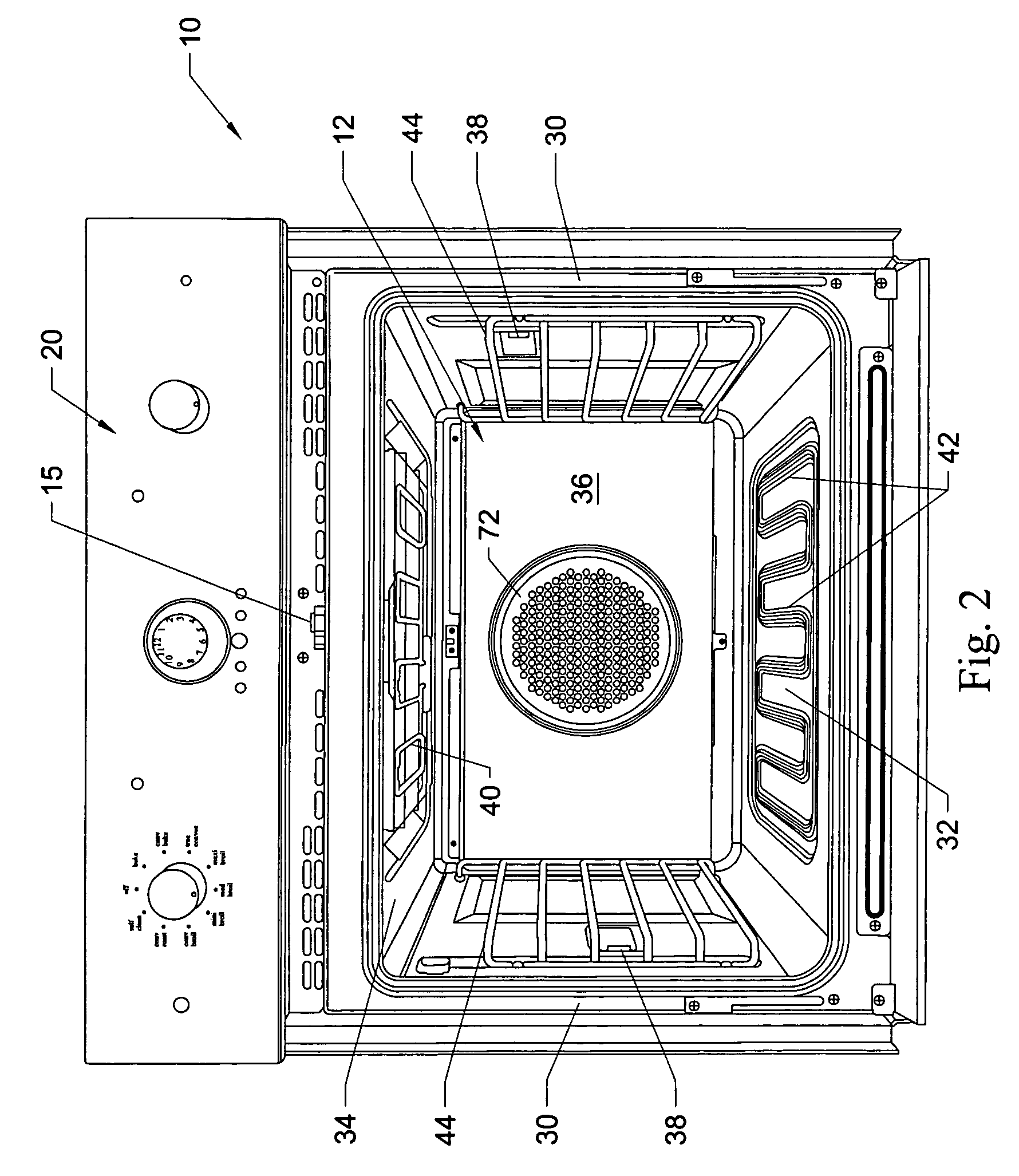

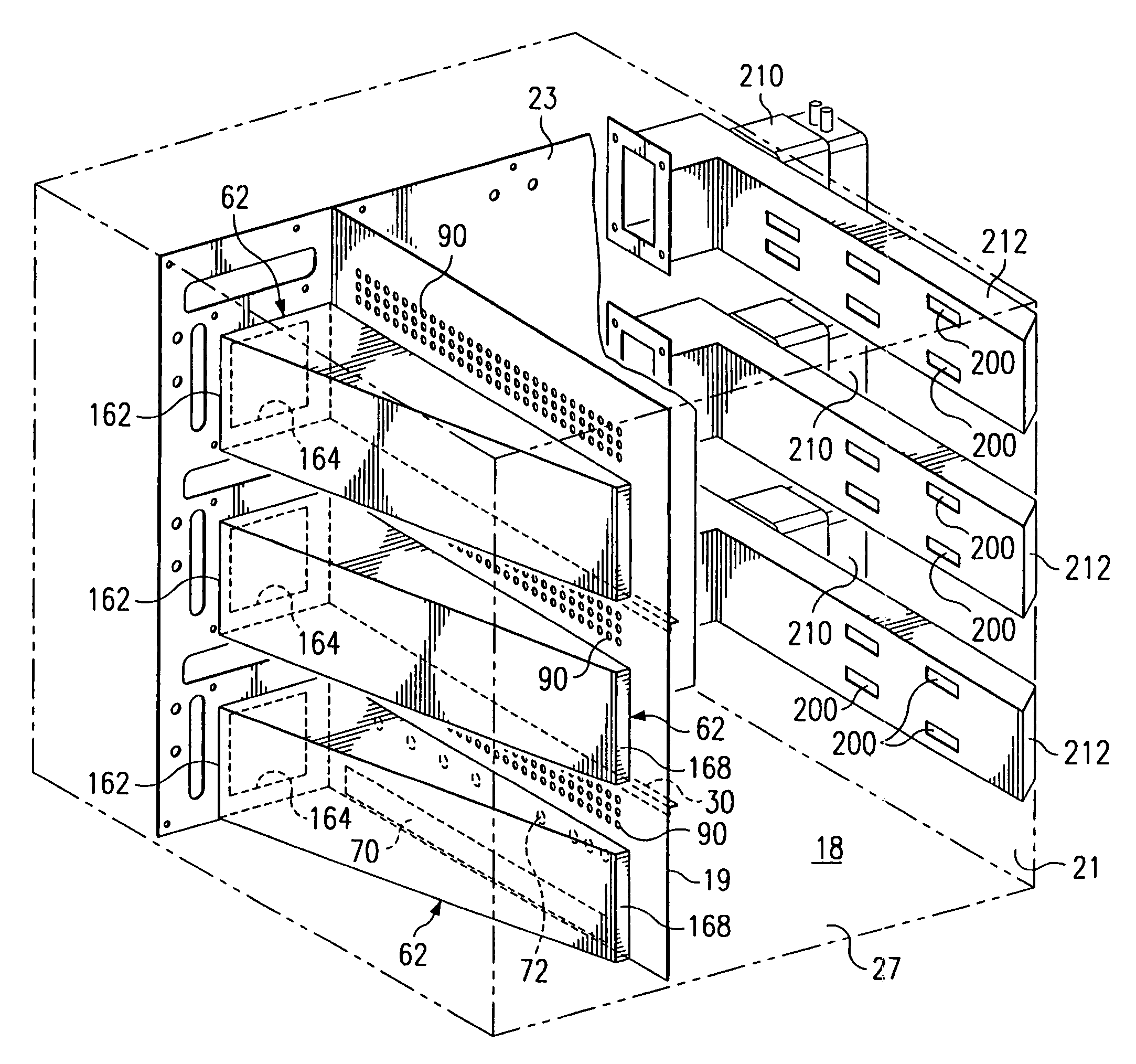

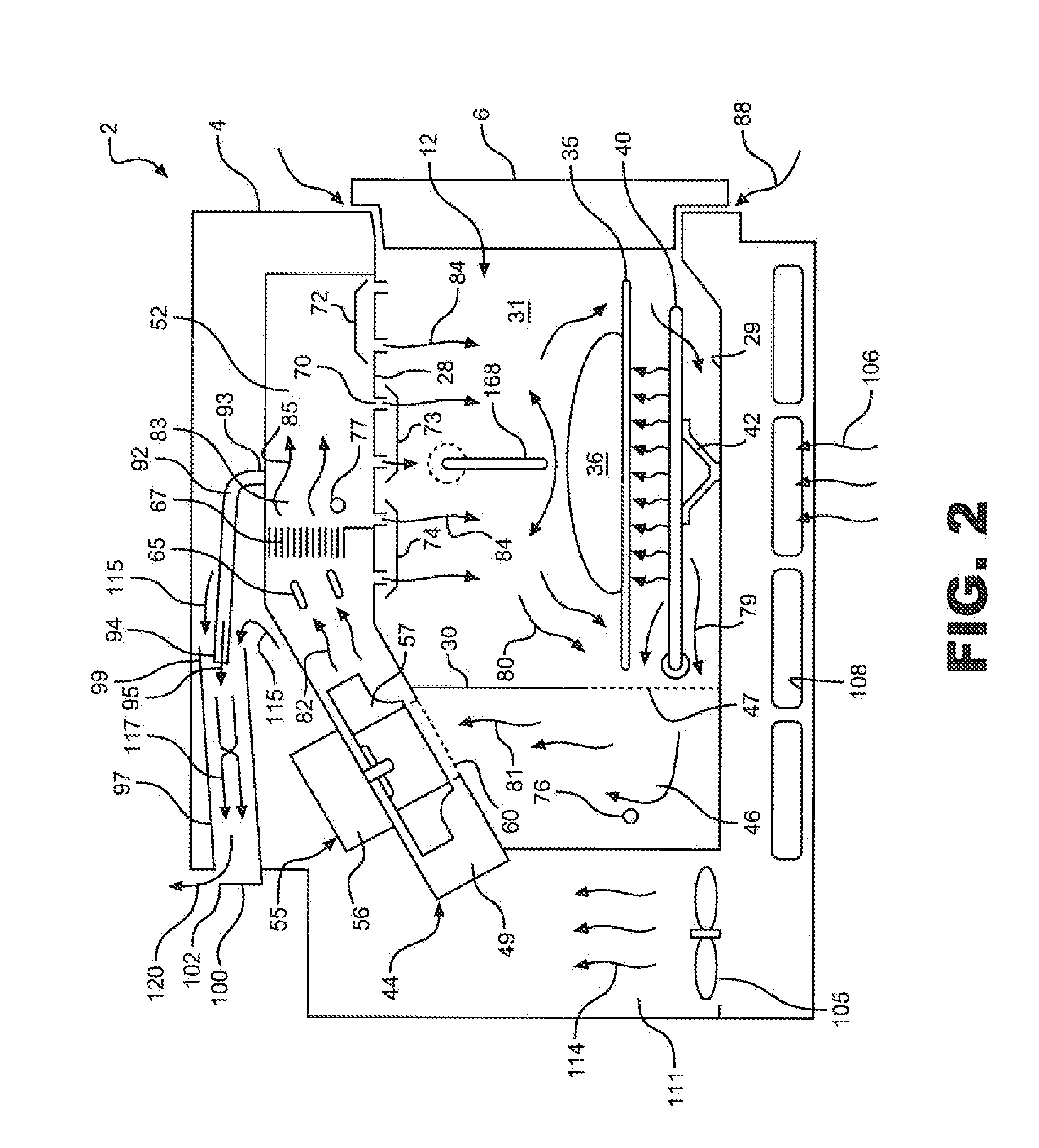

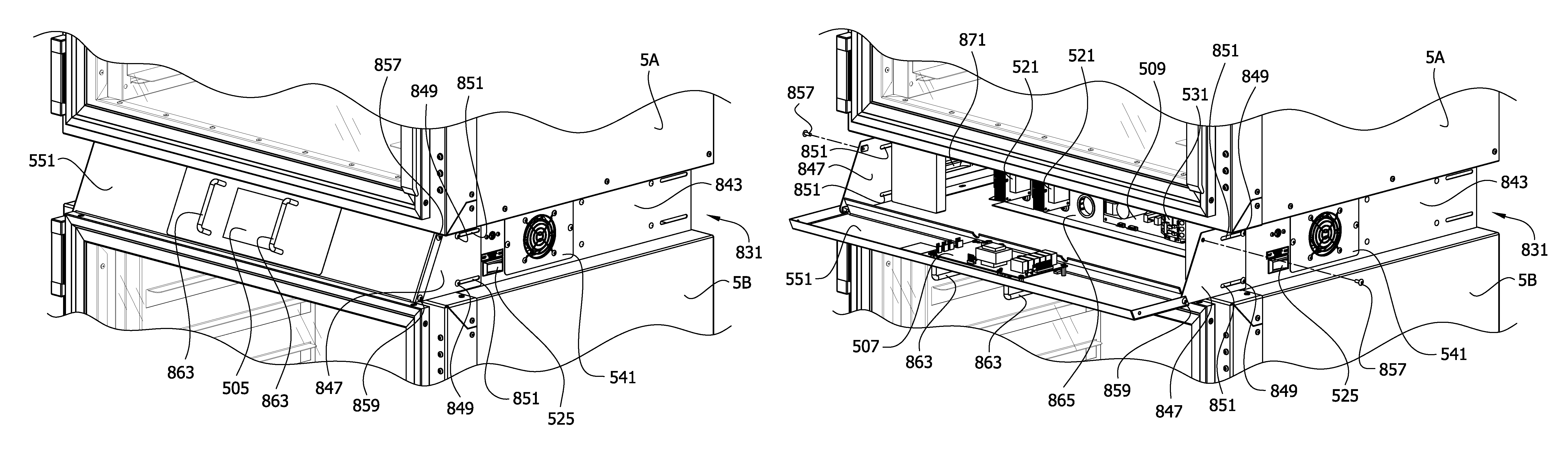

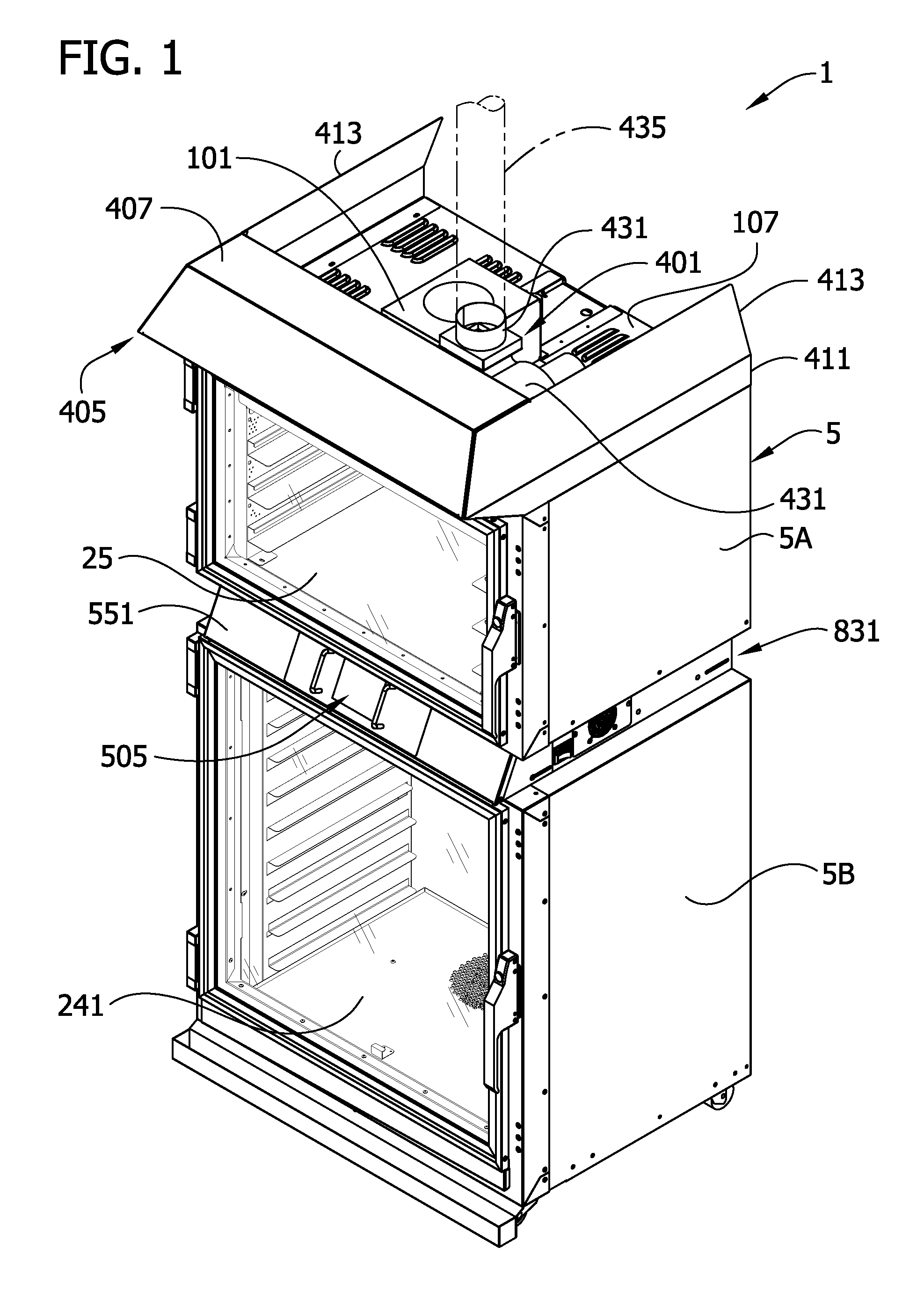

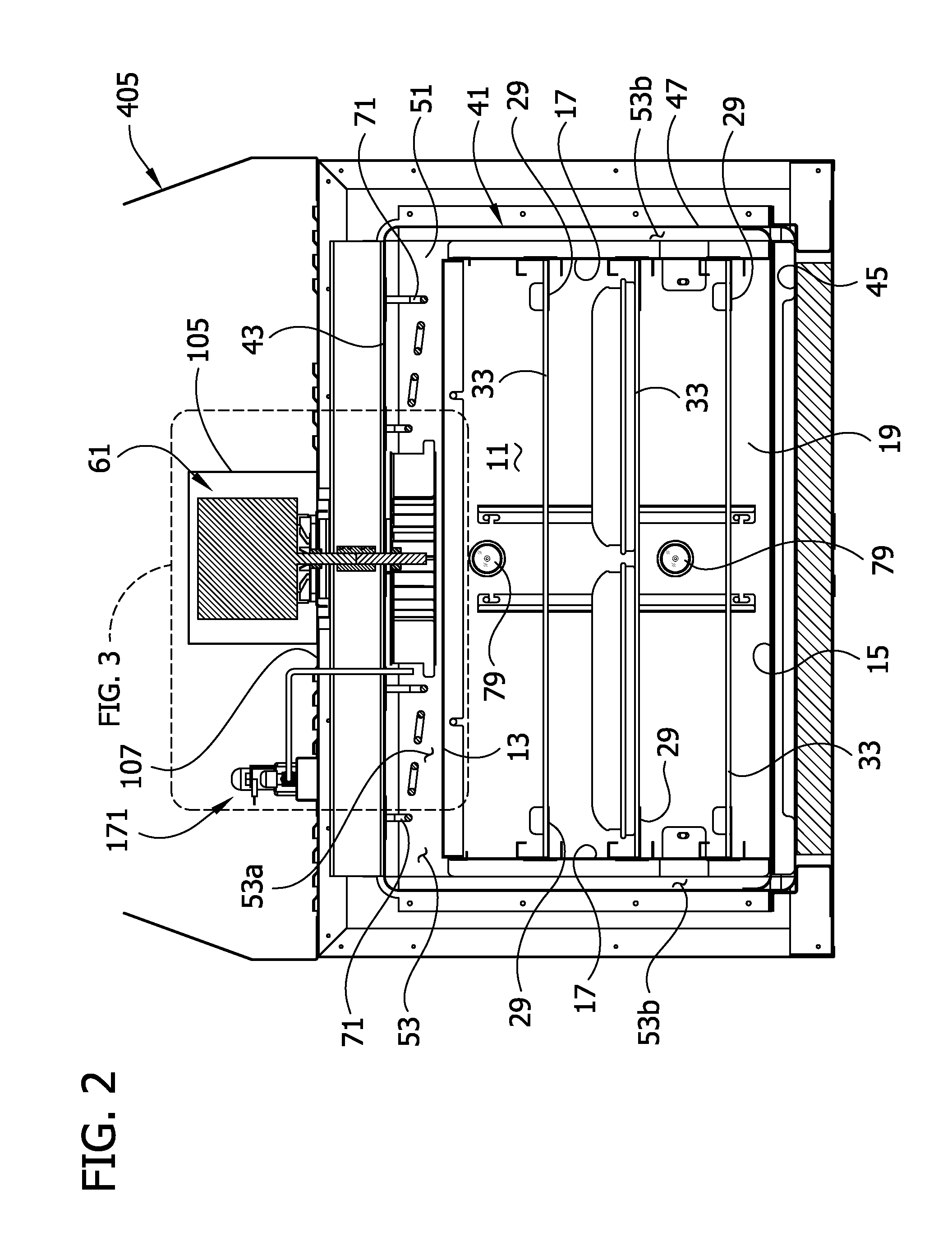

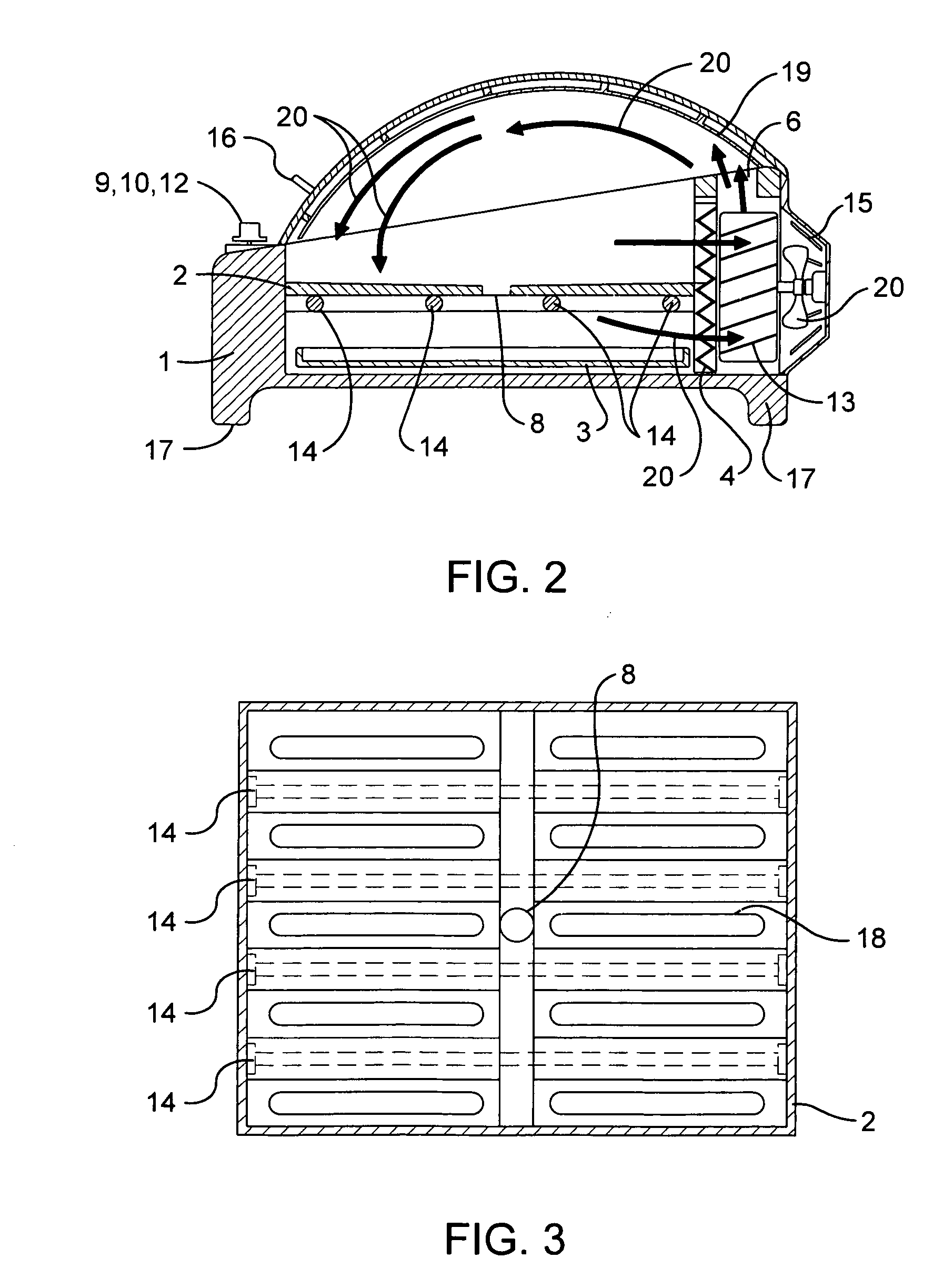

Multi-mode convection oven with flow control baffles

InactiveUS7468495B2Cook food accurately and evenlyEven air distributionAir-treating devicesDomestic stoves or rangesControl systemEngineering

An airflow control system for an oven having an oven cavity and a fan having a first operating mode for generating a first flow of air and a second operating mode for generating a second flow of air is provided. A baffle is included adjacent the fan to direct the first flow of air to a first region of the cavity in the first operating mode and to direct the second flow of air to a second region of the cavity in the second operating mode. A method of controlling airflow in an oven having an oven cavity is also detailed. The method can include different modes of operation, with different clockwise and counterclockwise rotational times for the fan, with different heating elements energized, or a combination of both, depending upon the food to be cooked in the oven.

Owner:VIKING RANGE

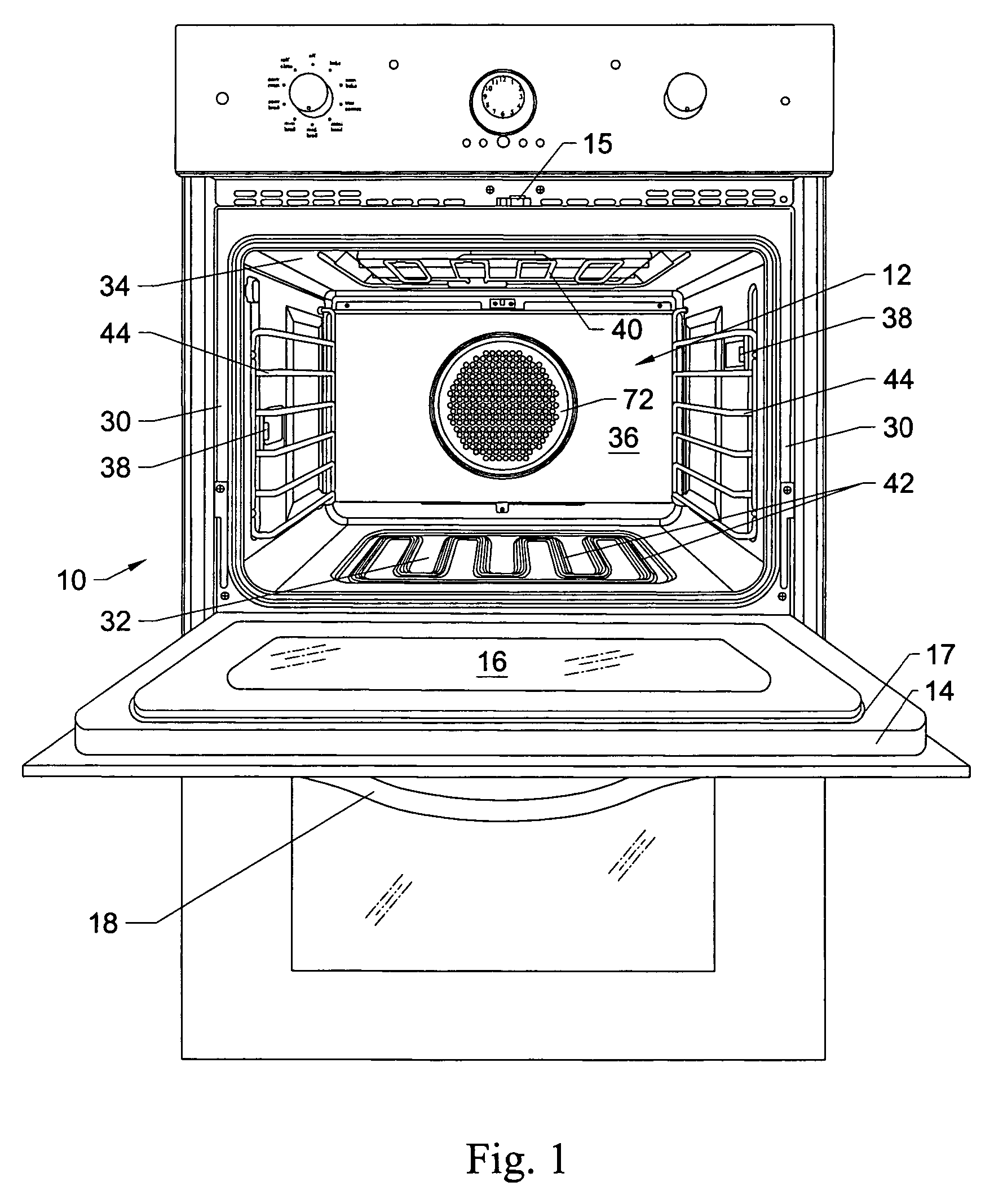

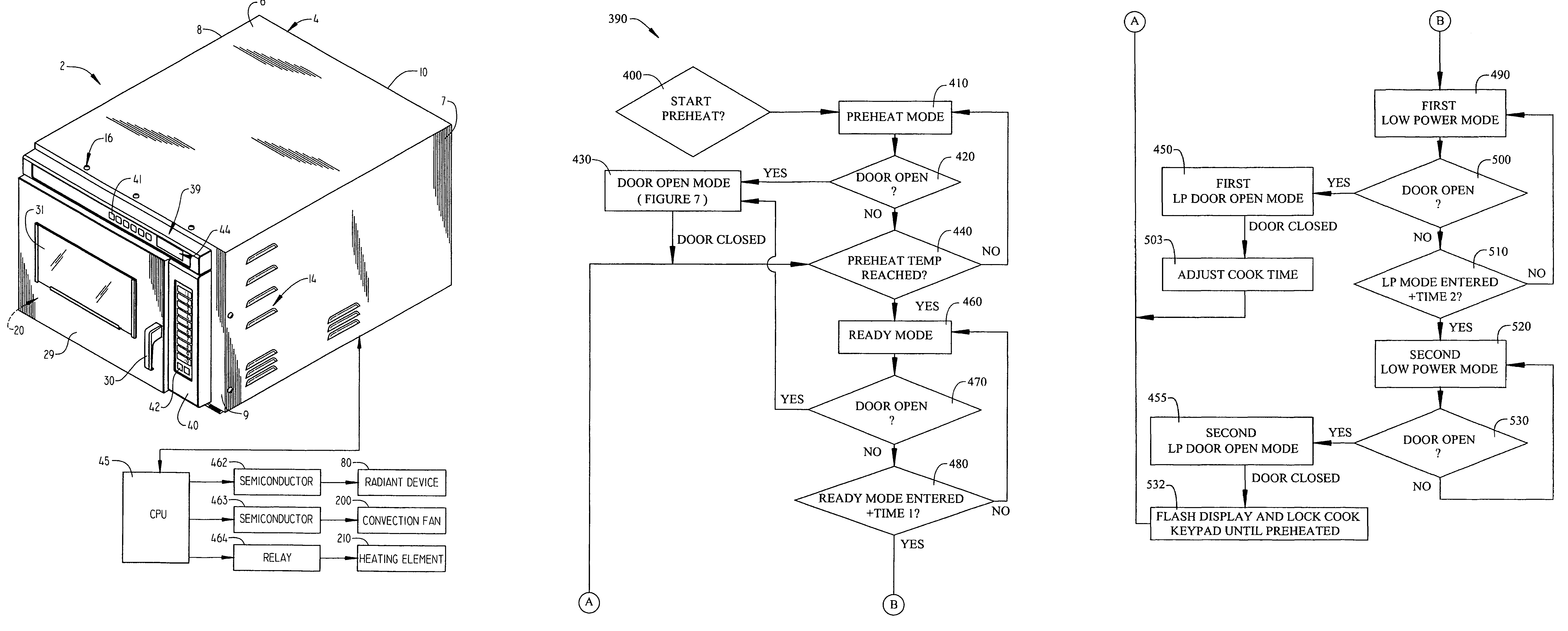

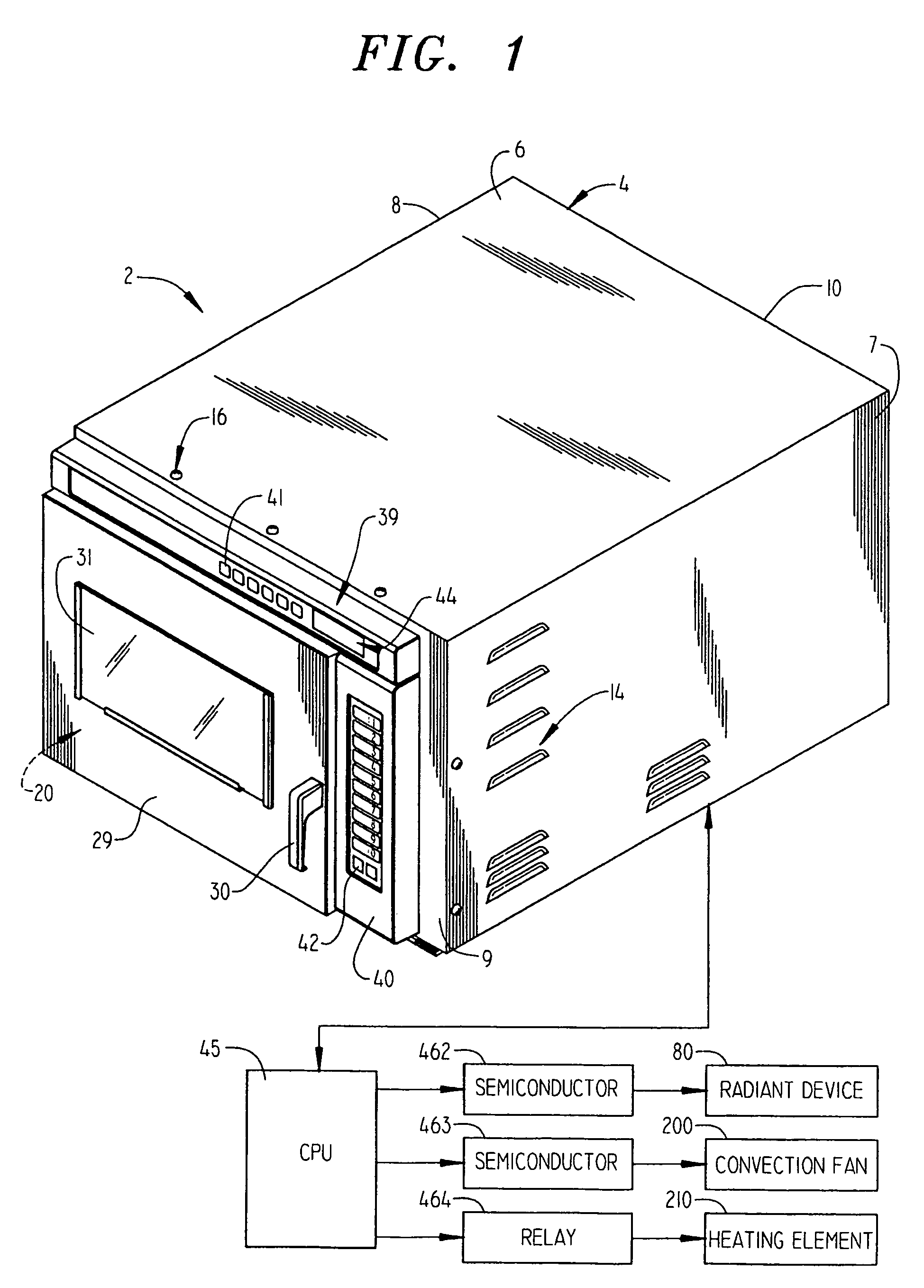

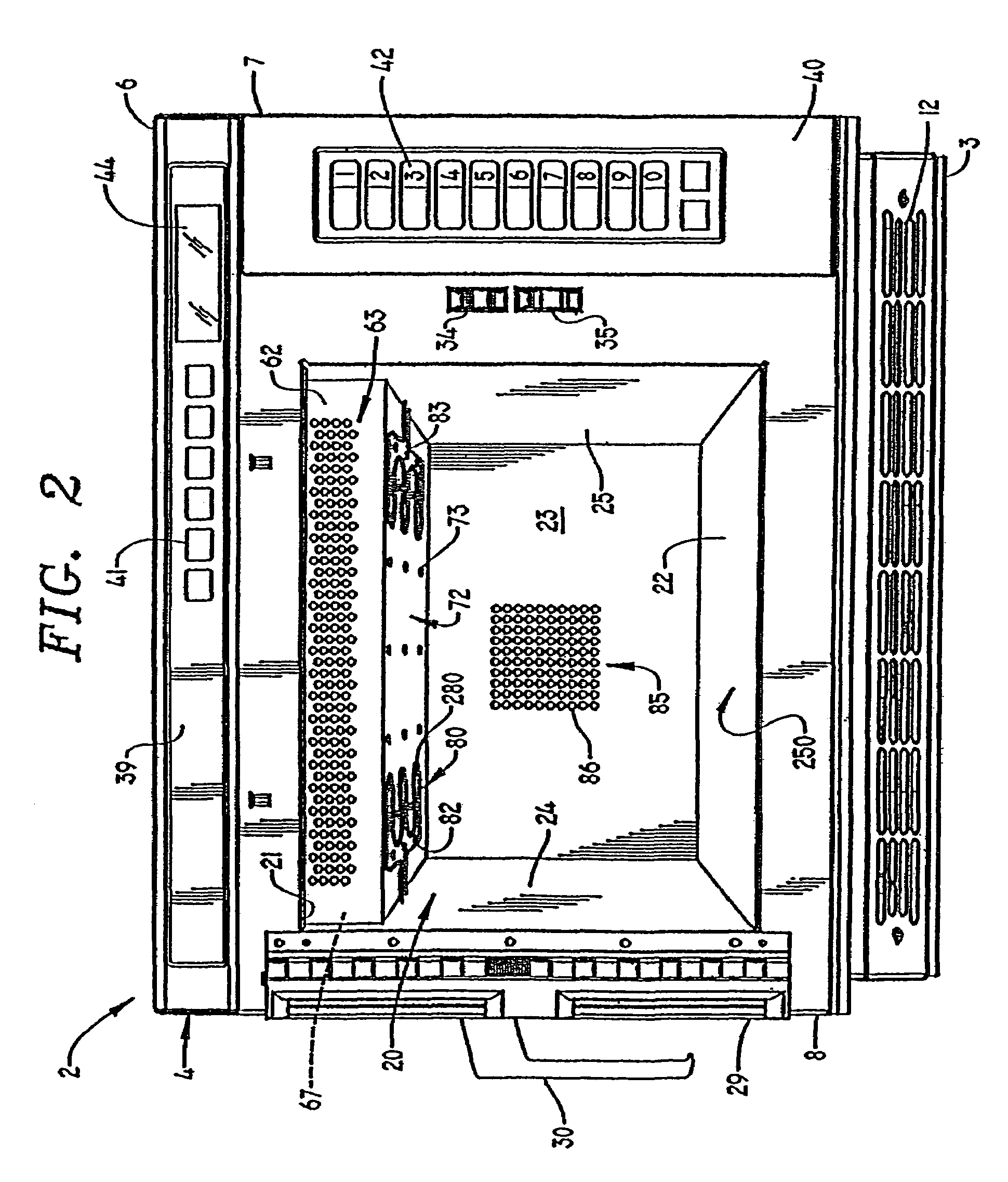

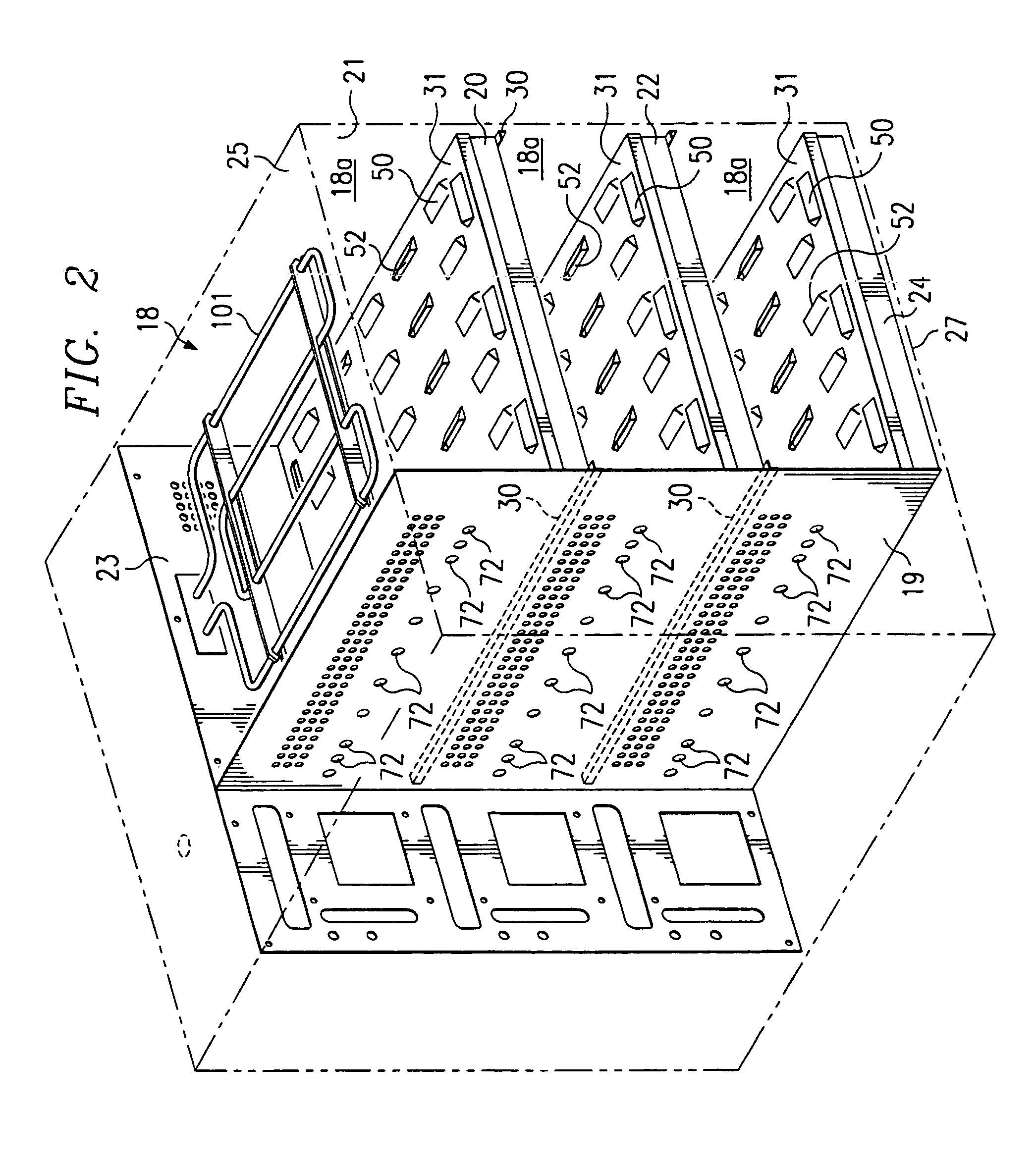

Operational modes for a cooking appliance employing combination cooking technology

A cooking appliance includes a controller for establishing a plurality of operating modes for heating an oven cavity. Specifically, the controller establishes one of a pre-heat mode, a ready mode, a first low power mode and a second low power mode for controlling a temperature of the oven cavity. Upon selecting a temperature for the oven cavity, the controller operates a radiant heating device, a convection fan and a convection heating device at full power to establish the selected temperature. After the selected temperature is achieved, the controller switches to a ready mode and reduces heat output of both the radiant heating device and the convection heating device, while also reducing fan speed. After respective periods of time in which a door of the appliance is not opened, the controller switches to first and second low power modes to conserve energy.

Owner:ACP OF DELAWARE

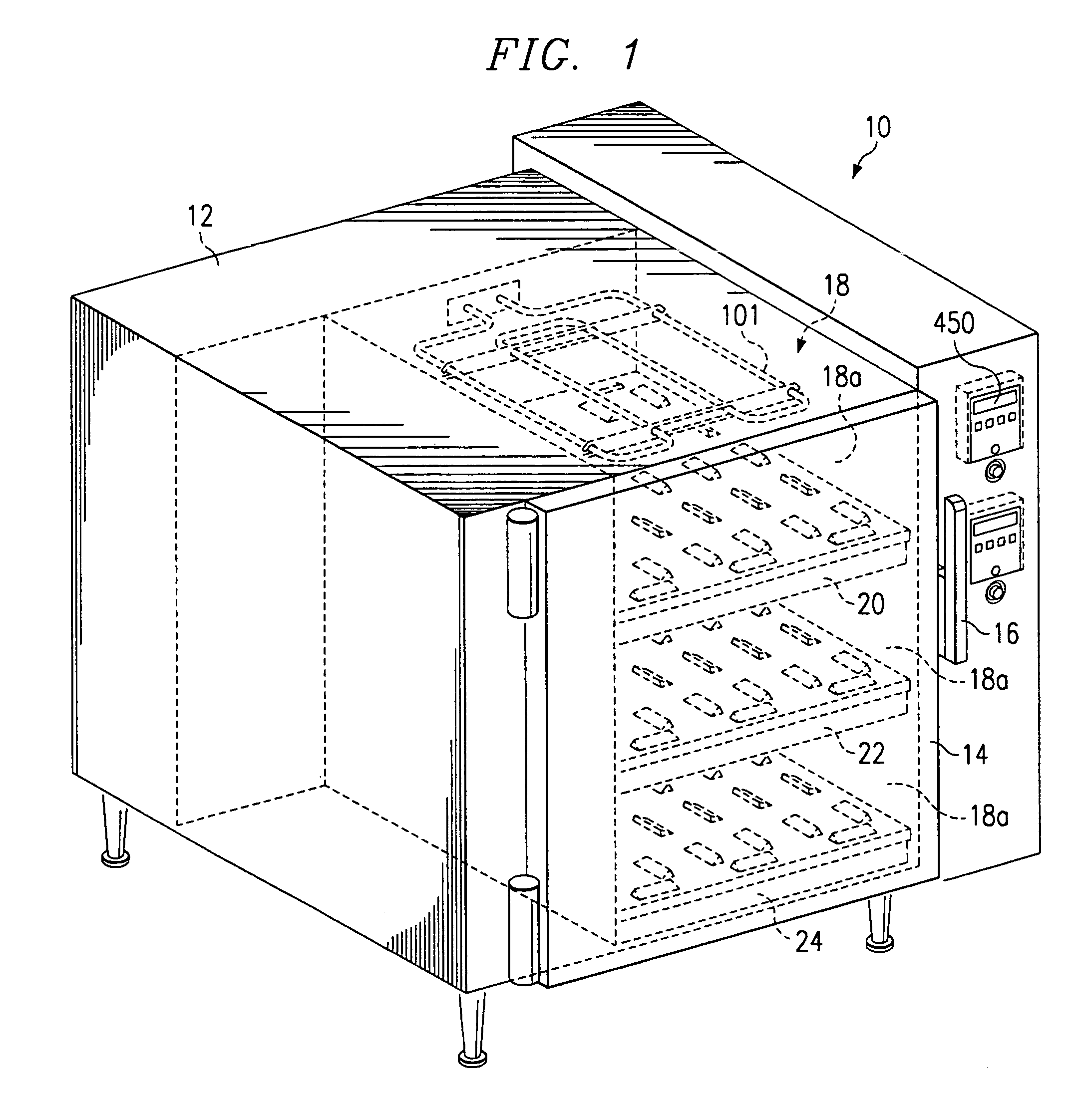

Multi-shelved convection microwave oven

An oven, is provided that includes multiple heat transfer means, including convection and microwave heat transfer means. The oven includes a cooking chamber, a blower and at least a shelf disposed within the cooking chamber. The shelf is designed to act as a food support as well as a conduit through which heated air passes into the cooking chamber. The microwave heating means comprises a microwave source and wave guide through which microwaves travel. The wave guide includes a plurality of openings through which microwaves can pass into said cooking chamber. In the preferred embodiment, the openings in the wave guide are positioned to correspond with the predetermined minima or maxima for the microwave wavelength propagating within the wave guide. An electric heating element may also be disposed within the cooking chamber to provide an alternative heating source.

Owner:ENERSYST DEV CENT

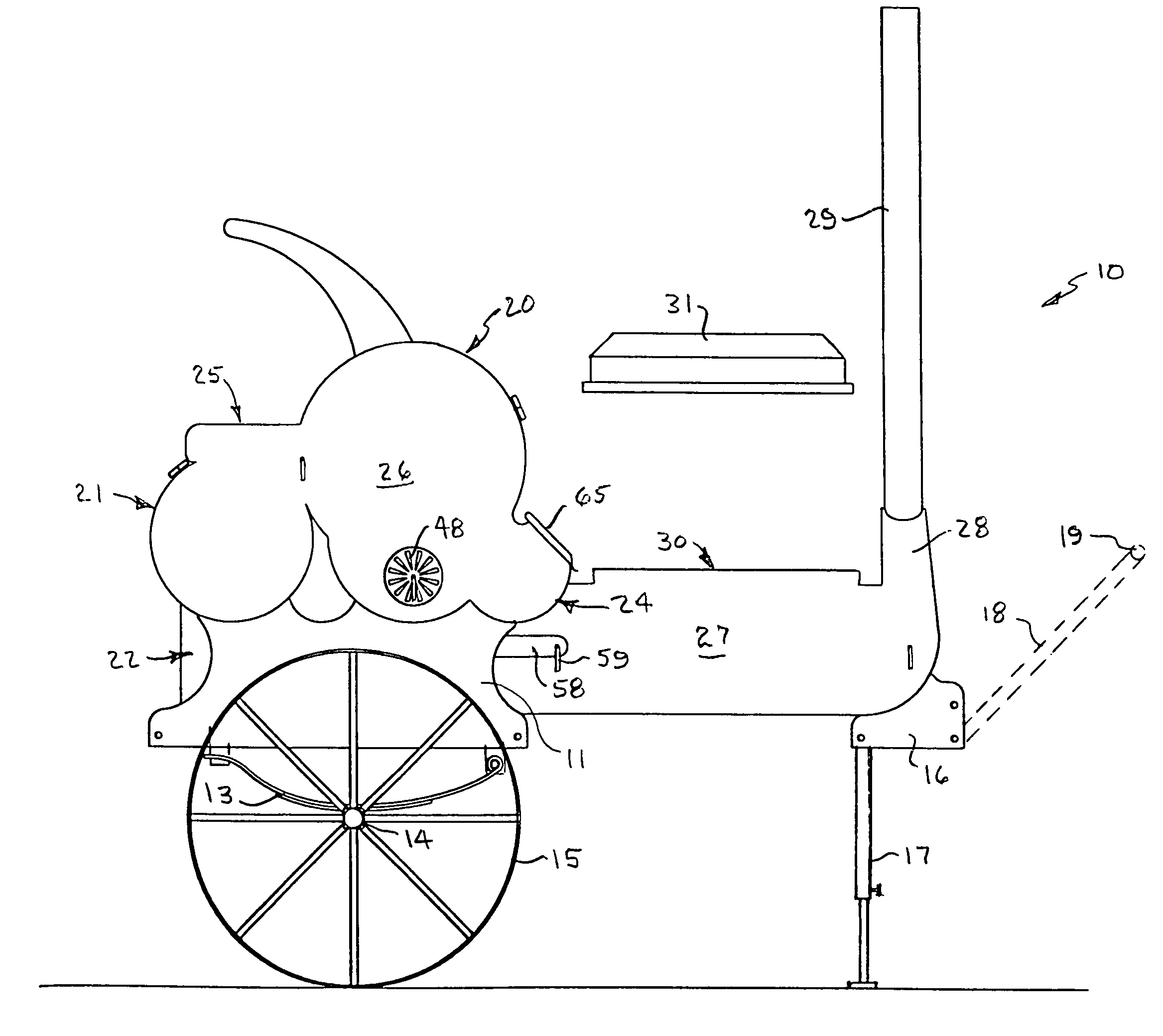

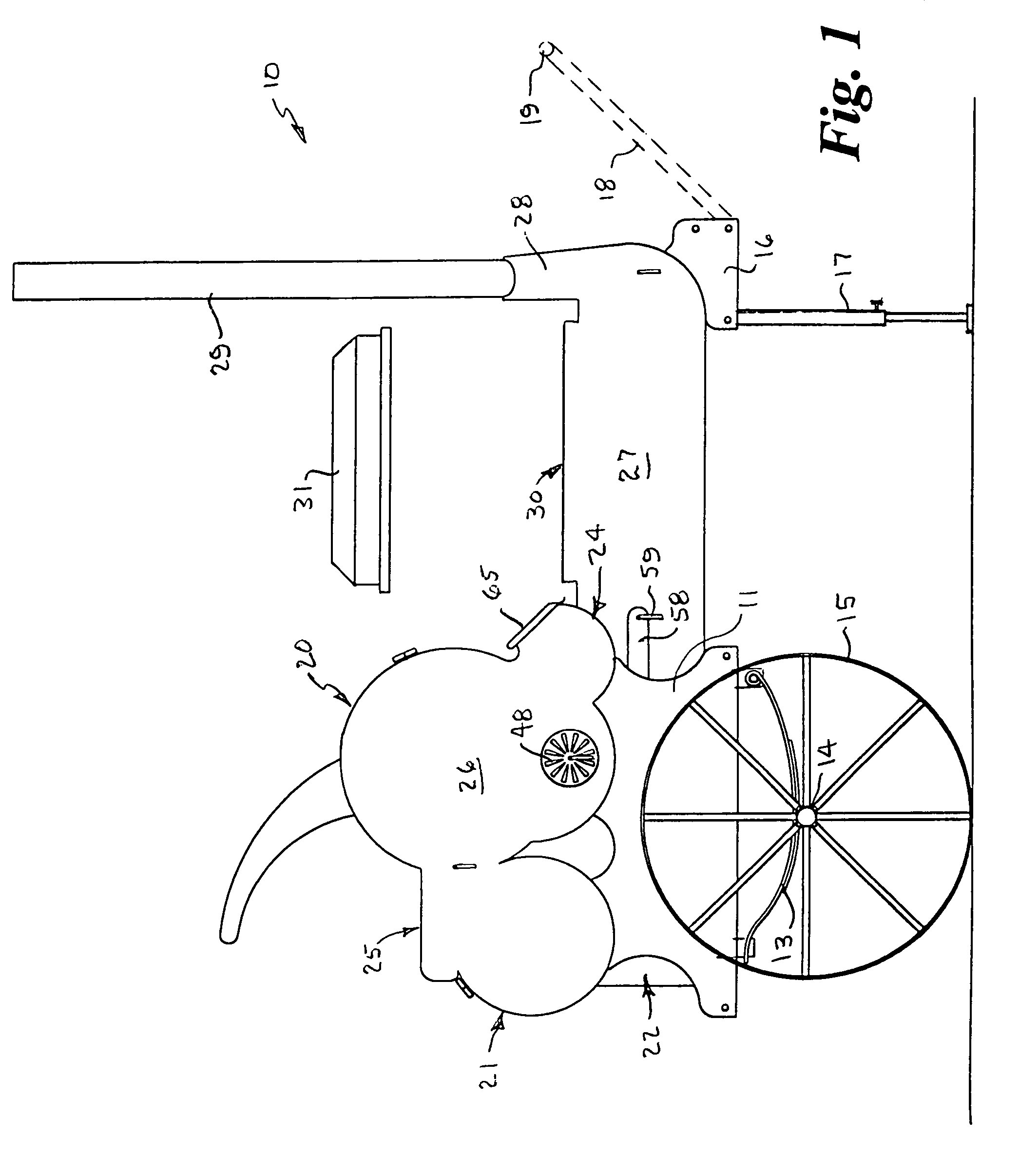

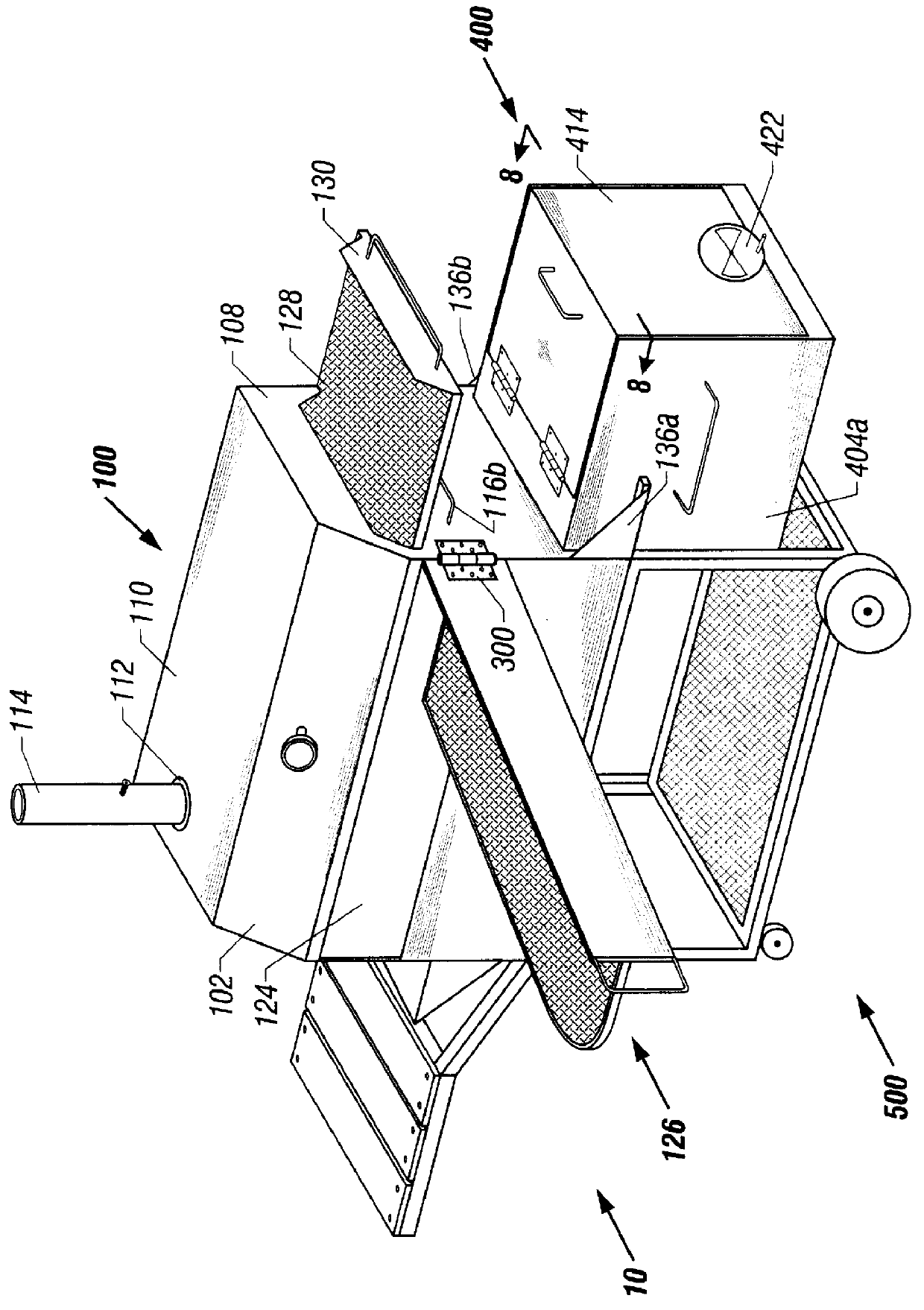

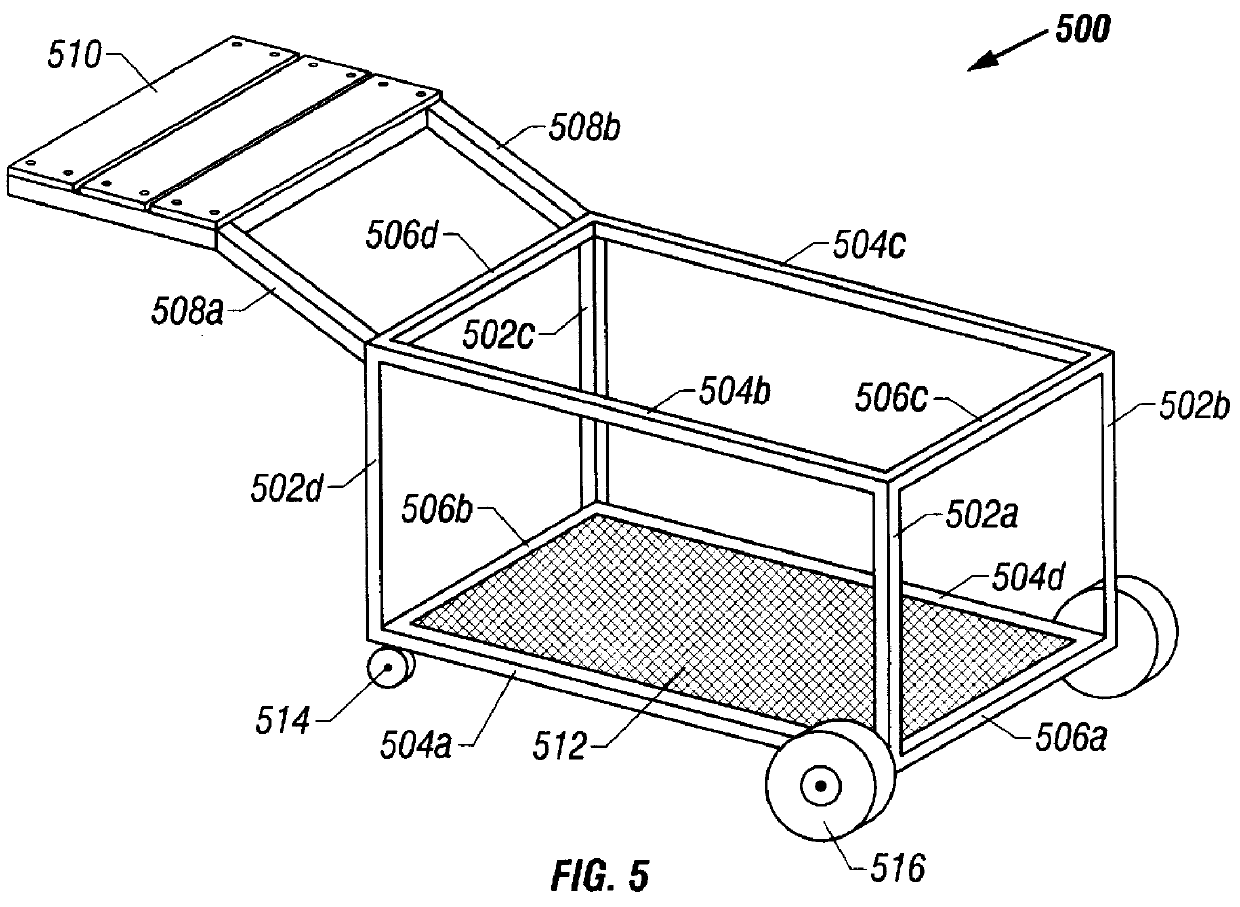

Outdoor multi-method cooker

InactiveUS7156087B1Lighting and heating apparatusStove/ranges for heating waterCombustionDifferential pressure

An outdoor multi-method cooker for preparing a wide variety of different foods at the same time using selective convection, radiant, or conduction cooking operations with or without smoke, or combinations thereof, using a single heat source. The cooker has a horizontal central longitudinal chamber with a firebox at one end and a pair of stacks at the opposed end, a main oven, a pair of lateral smokeless ovens, a warming compartment, and a griddle above the firebox, all disposed transversely on the longitudinal chamber in parallel spaced relation, and a steam table along the upper portion of the longitudinal chamber. The cooker operates on the principle of equalization of natural differential pressures caused by rising warmer air, similar to the draw created by the upper portion of a fireplace, for drafting hot gases or smoke laden hot gases from the combustion source and selectively routing it through passageways into and around the various components.

Owner:CHURCHILL III ALBERT B +1

Temperature Control for Cooking Appliance Including Combination Heating System

A combination cooking appliance controls a radiant heating element provided in an oven cavity and a convection heating element provided in an air plenum with a regulating system which receives signals from multiple temperature sensors. More specifically, the appliance includes a first temperature sensor provided in an air return plenum portion for controlling the radiant heating element and a second temperature sensor arranged in a discharge air plenum portion, preferably downstream of a catalyst, for controlling the convection heating element. The heating elements are independently controlled based on the sensed temperatures to establish a desired oven cavity temperature, while accommodating for temperature fluctuations due to the incoming fresh air stream.

Owner:ACP

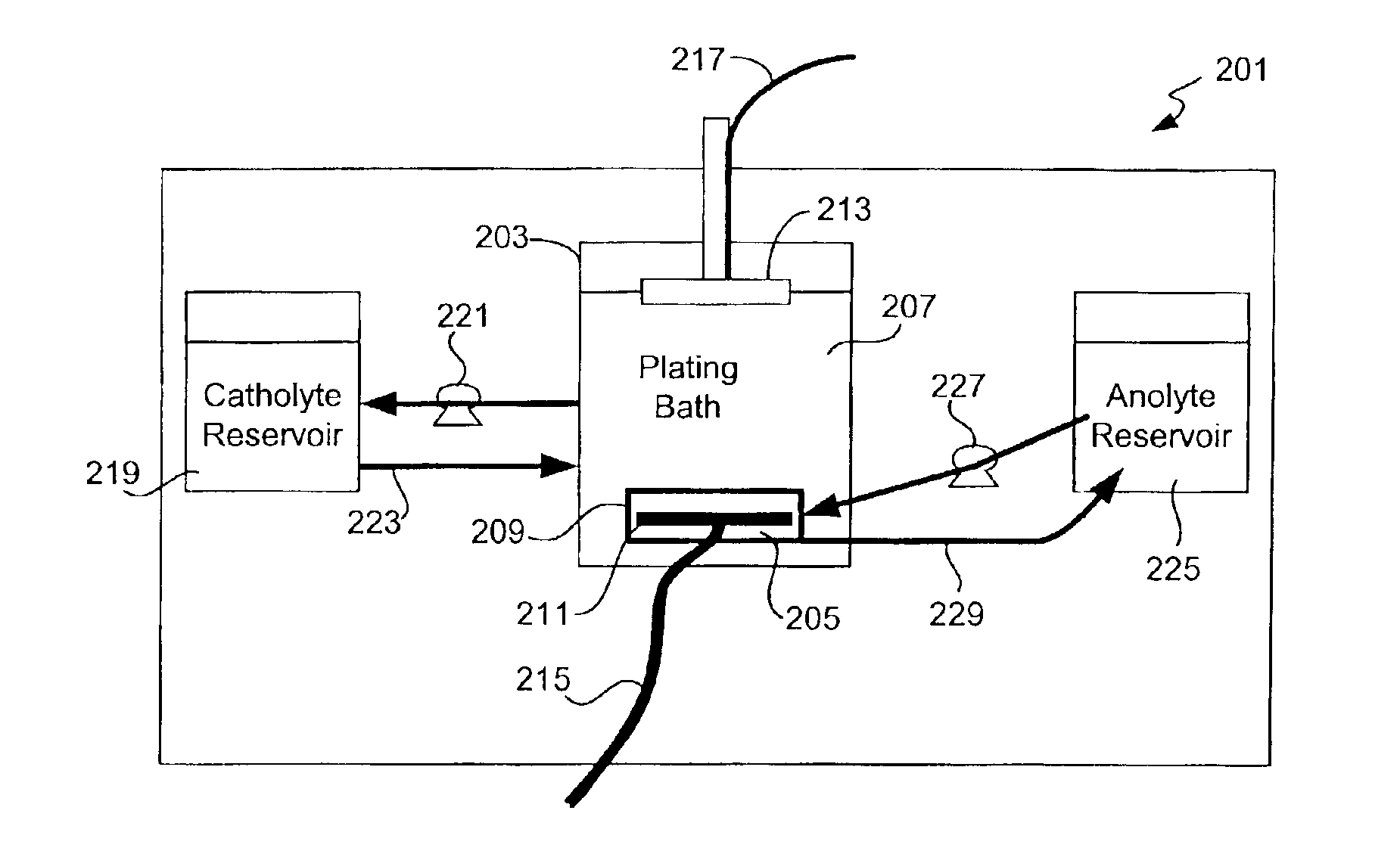

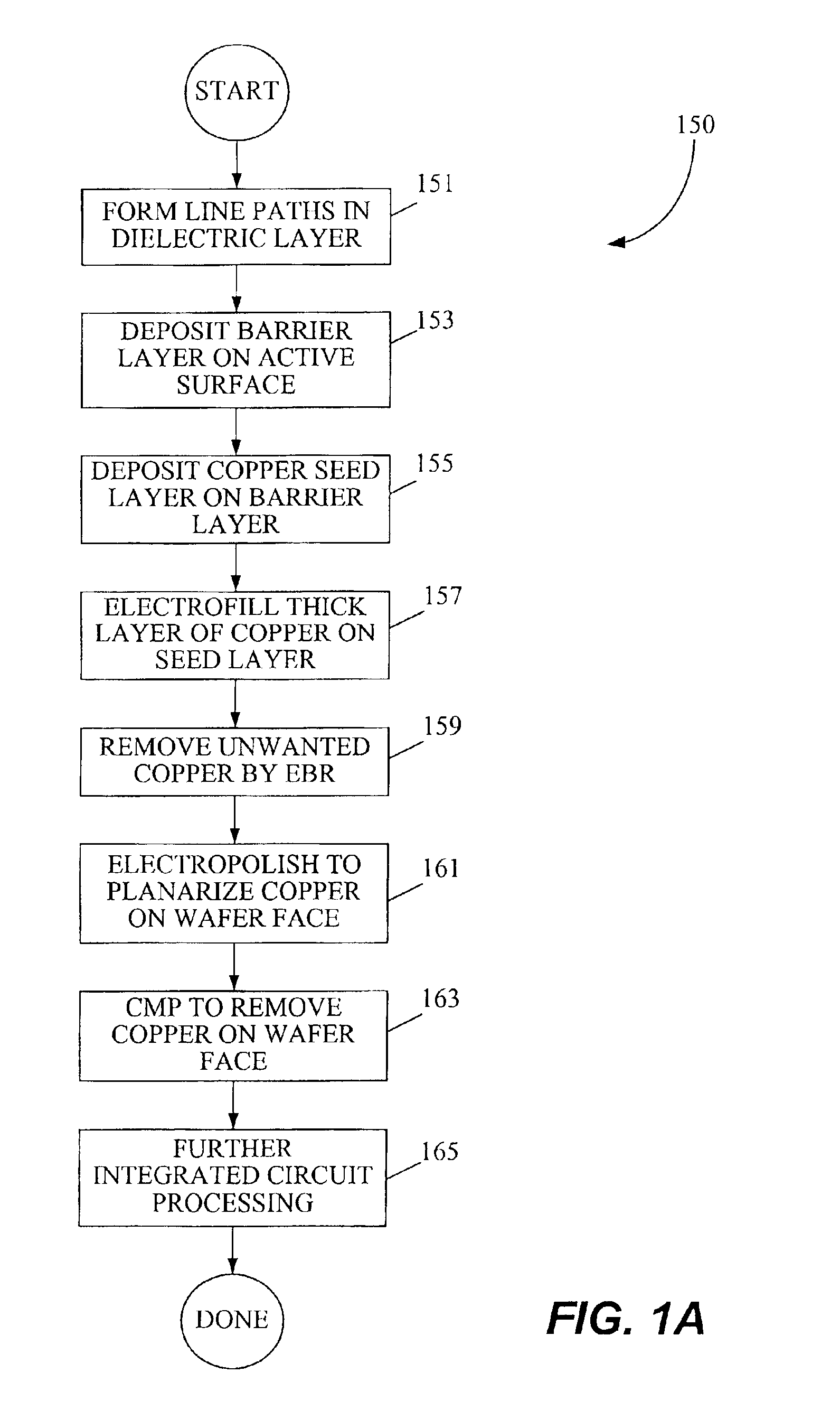

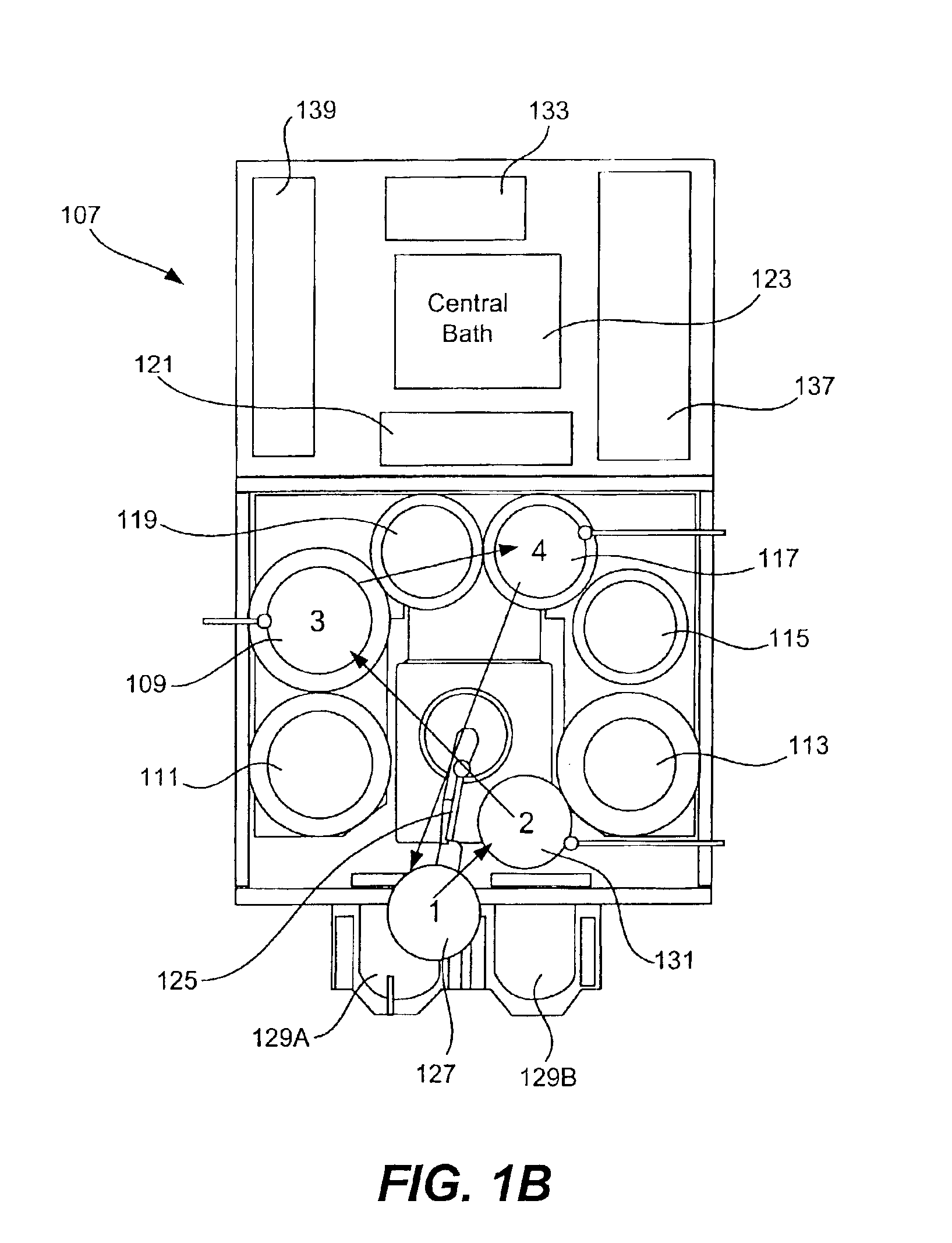

Copper electroplating method and apparatus

An electroplating apparatus prevents anode-mediated degradation of electrolyte additives by creating a mechanism for maintaining separate anolyte and catholyte and preventing mixing thereof within a plating chamber. The separation is accomplished by interposing a porous chemical transport barrier between the anode and cathode. The transport barrier limits the chemical transport (via diffusion and / or convection) of all species but allows migration of ionic species (and hence passage of current) during application of sufficiently large electric fields within electrolyte.

Owner:NOVELLUS SYSTEMS

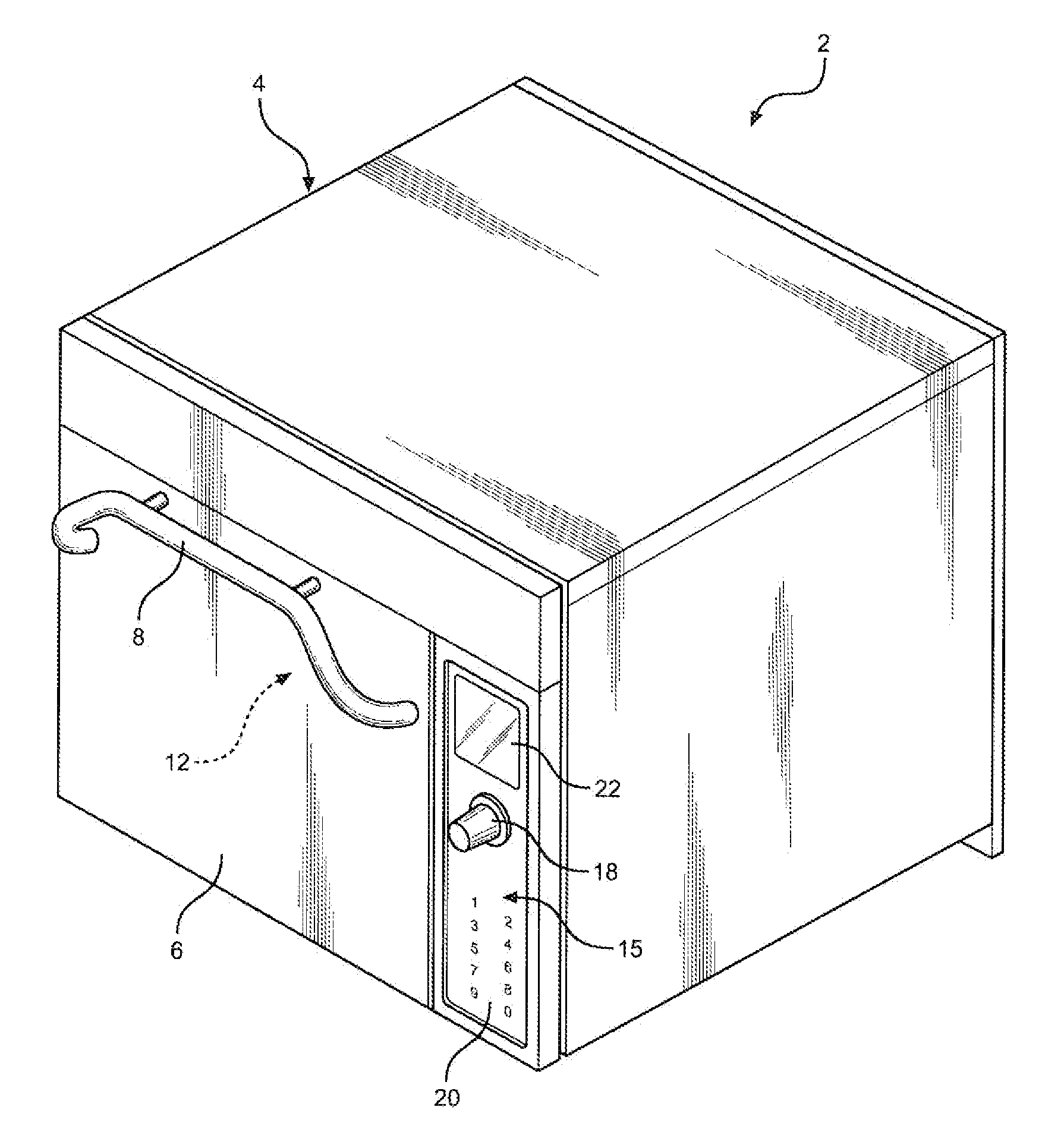

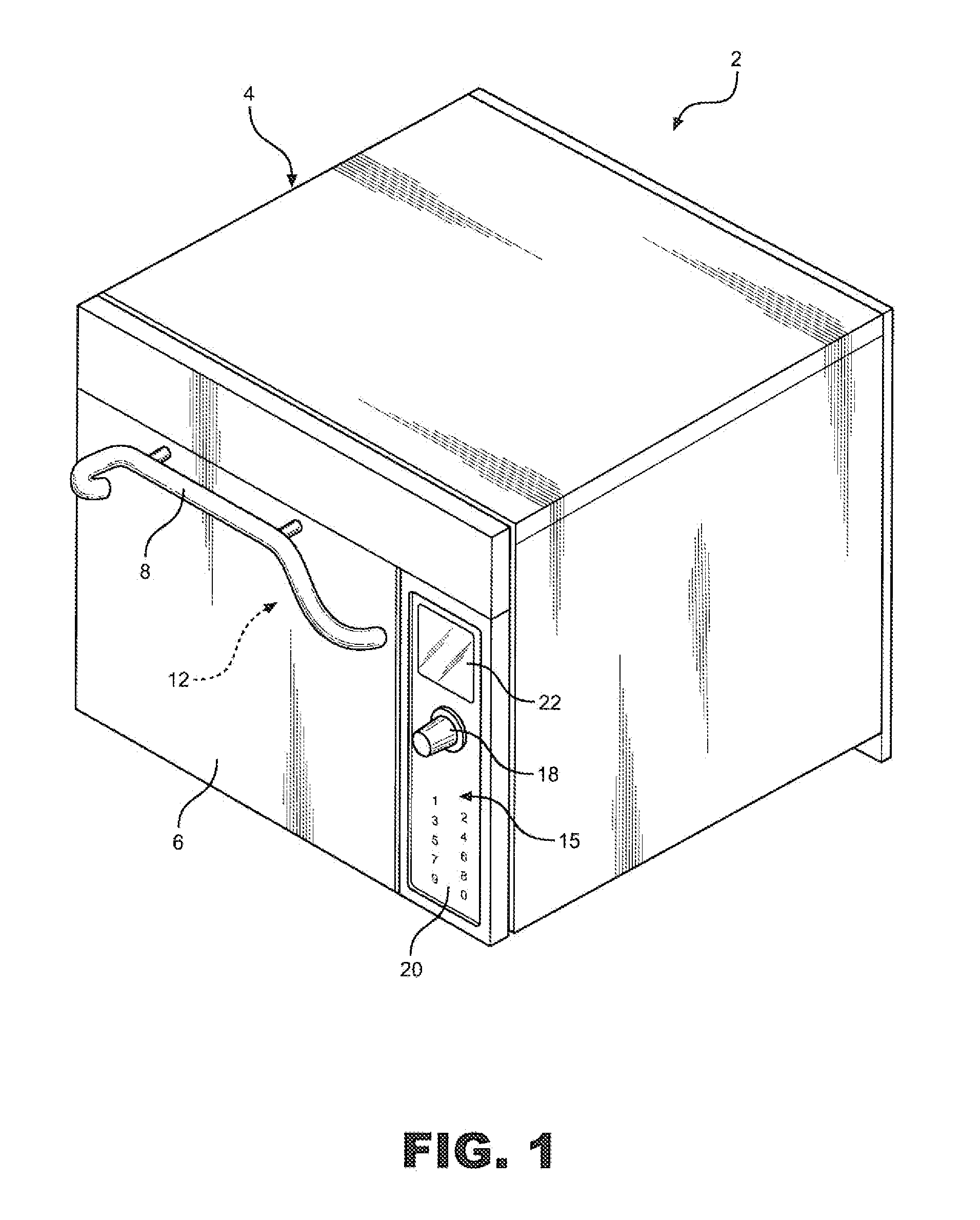

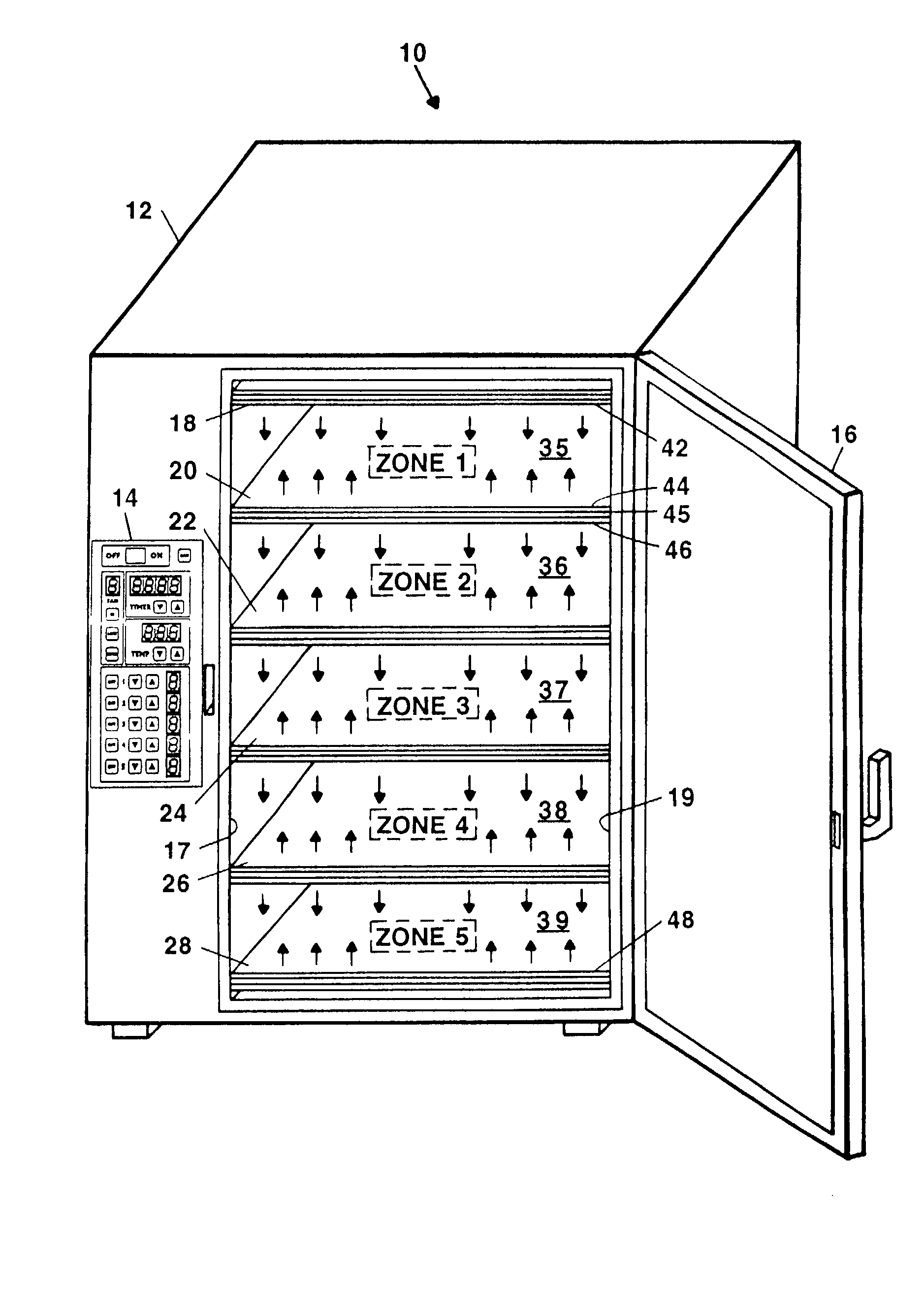

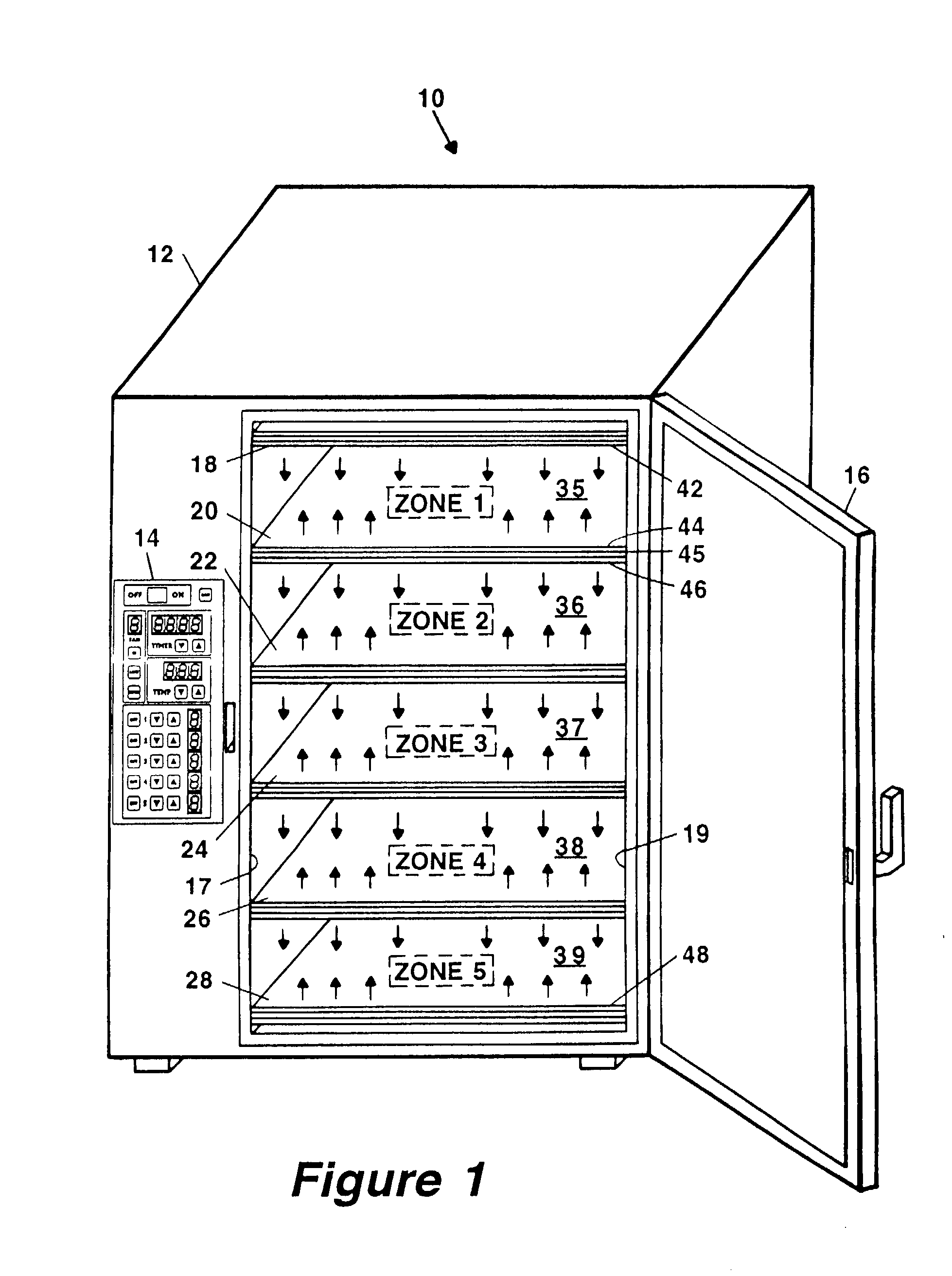

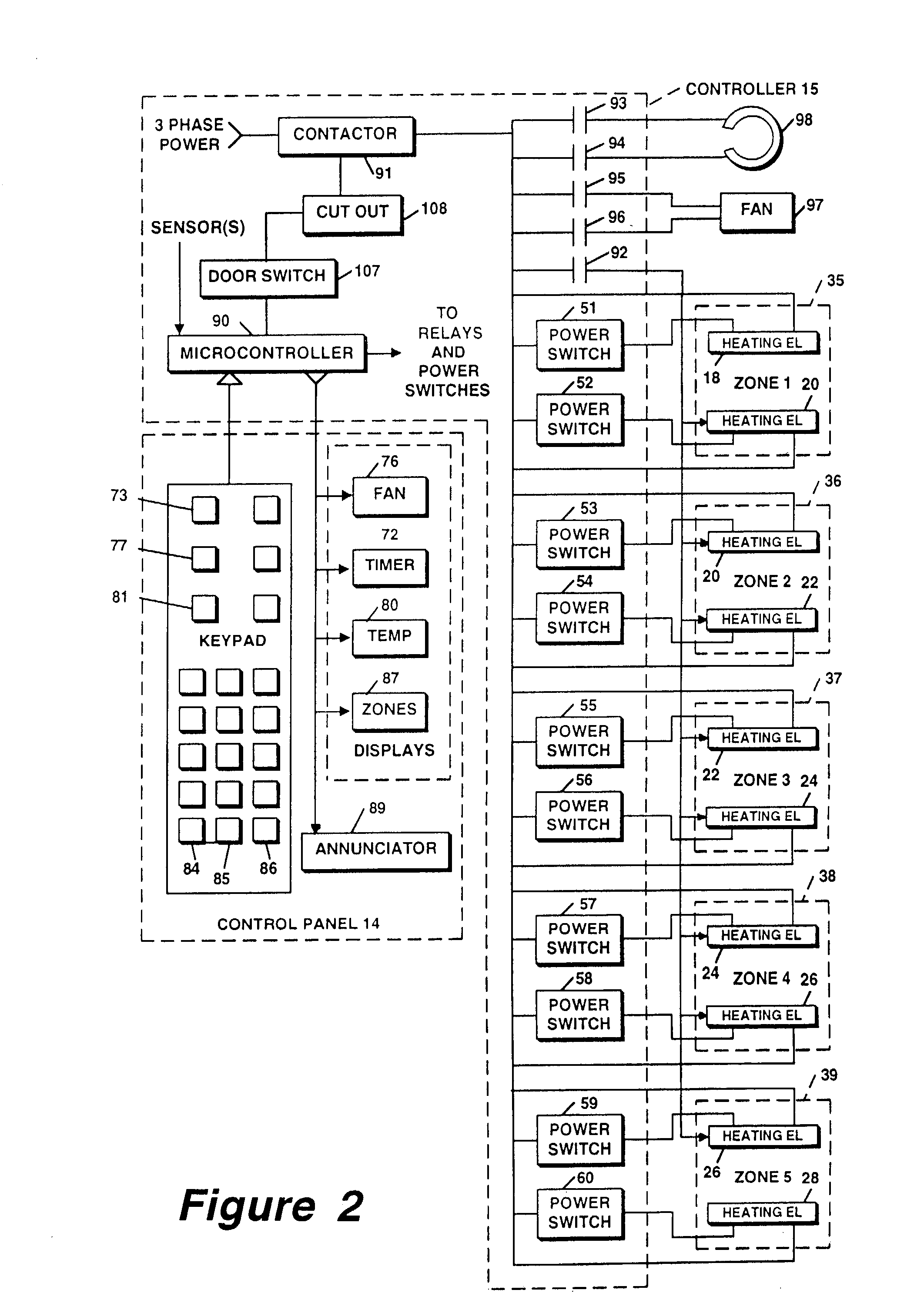

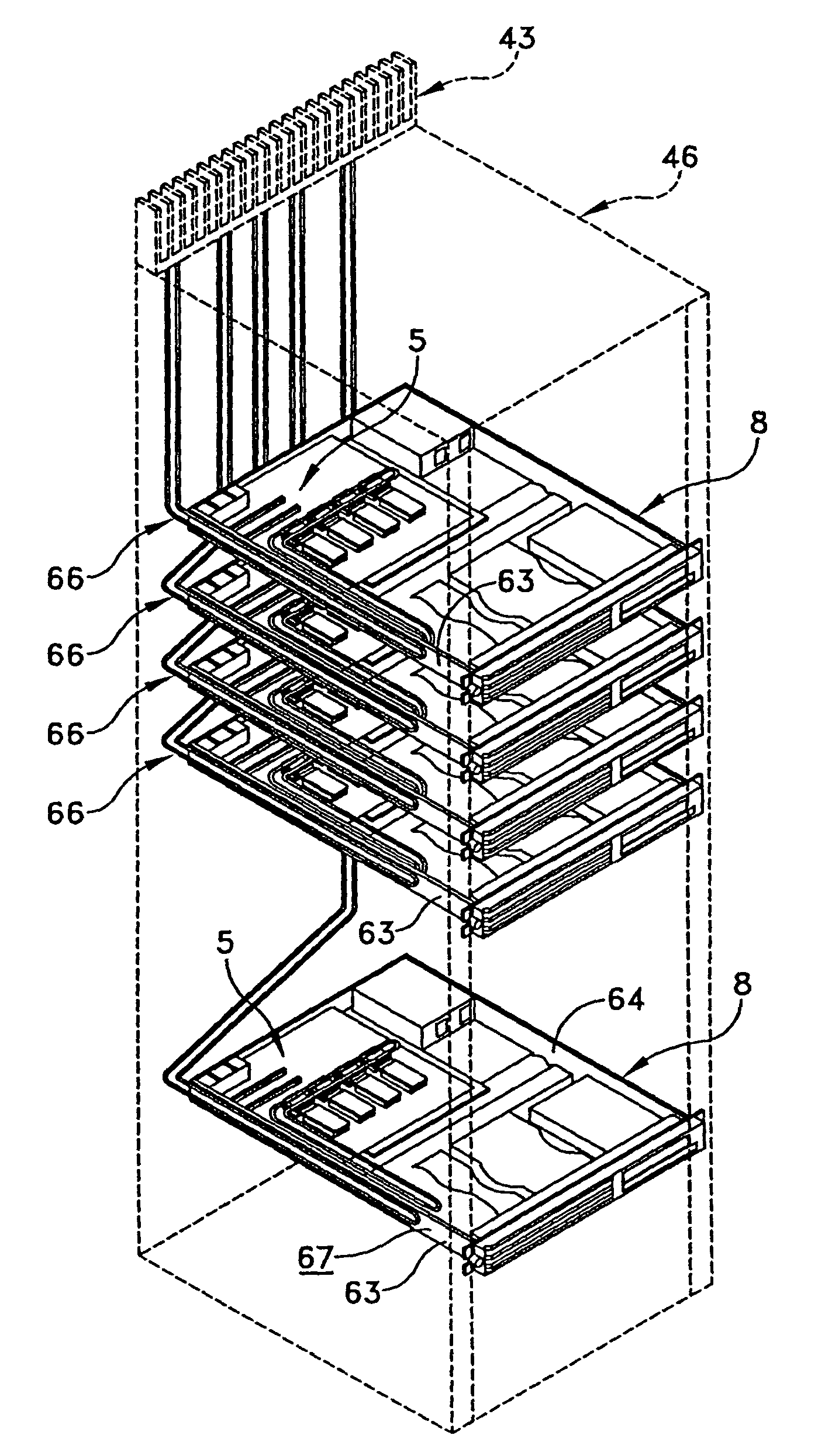

Convection oven

ActiveUS8378265B2Easy accessSelf-cleaning stoves/rangesElectrical heating fuelImpellerLiquid-crystal display

Owner:DUKE MANUFACTURING COMPANY

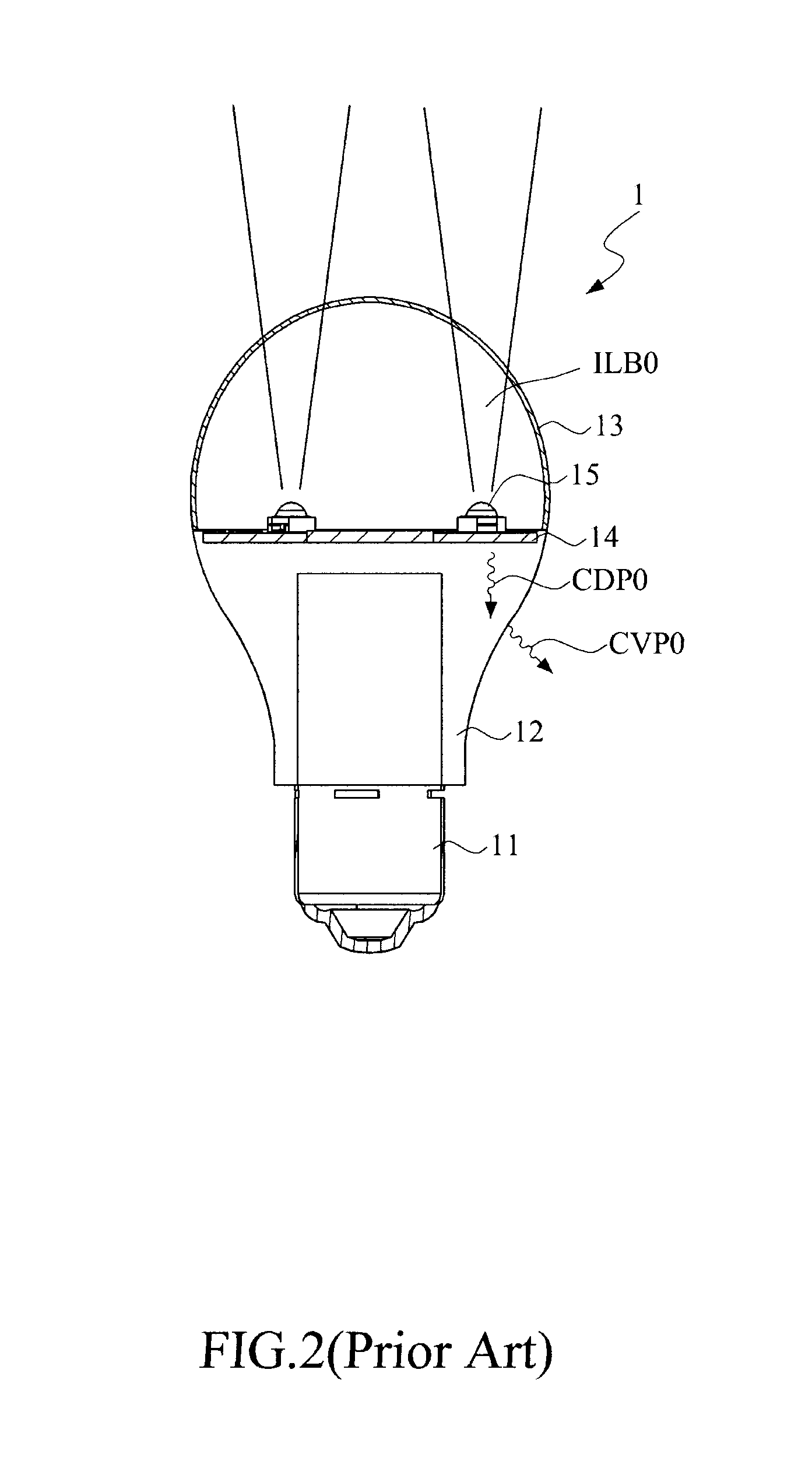

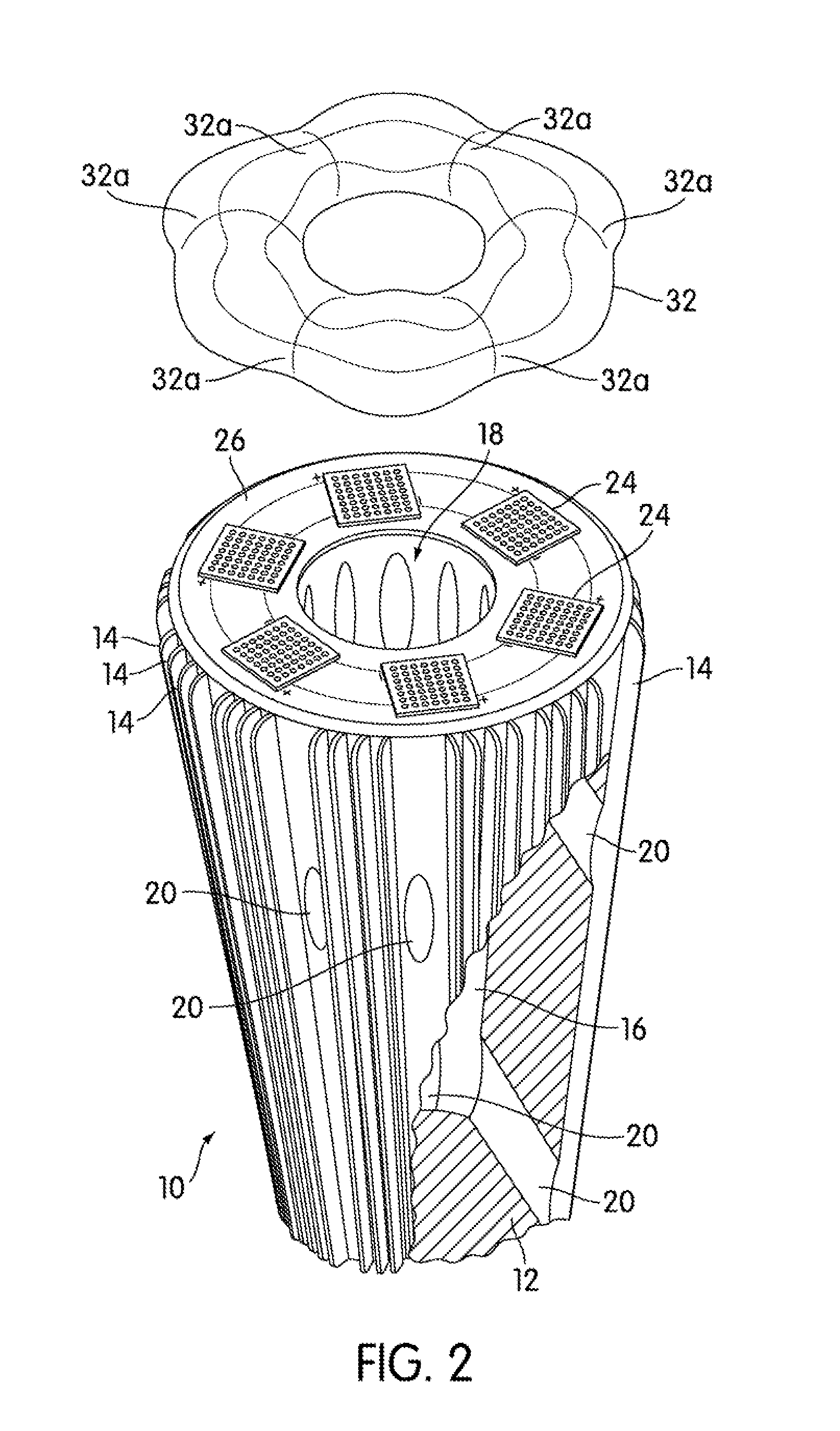

Light emitting diode bulb

InactiveUS20100073944A1Improve heating efficiencyImprove work efficiencyPoint-like light sourceElongate light sourcesLight beamEngineering

A light emitting diode (LED) light bulb comprising a heat dissipation module, a circuit board, at least one LED light source and a light-transmissible packaging shell is disclosed in the present invention. The heat dissipation module comprises a heat dissipation base and a heat convection tube extended from the heat dissipation base. The circuit board is assembled to the heat dissipation module. The LED light source is arranged on the circuit board, and releases heat energy when projecting at least one illumination light beam. The light-transmissible packaging shell is assembled to the heat dissipation module to package the LED light source, and formed with a heat dissipation opening. The heat convection tube is extended to the heat dissipation opening to communicate with external environment, so that a heat convection action is progressed between the heat convection tube and external environment to dissipate heat energy.

Owner:EDISON-OPTO

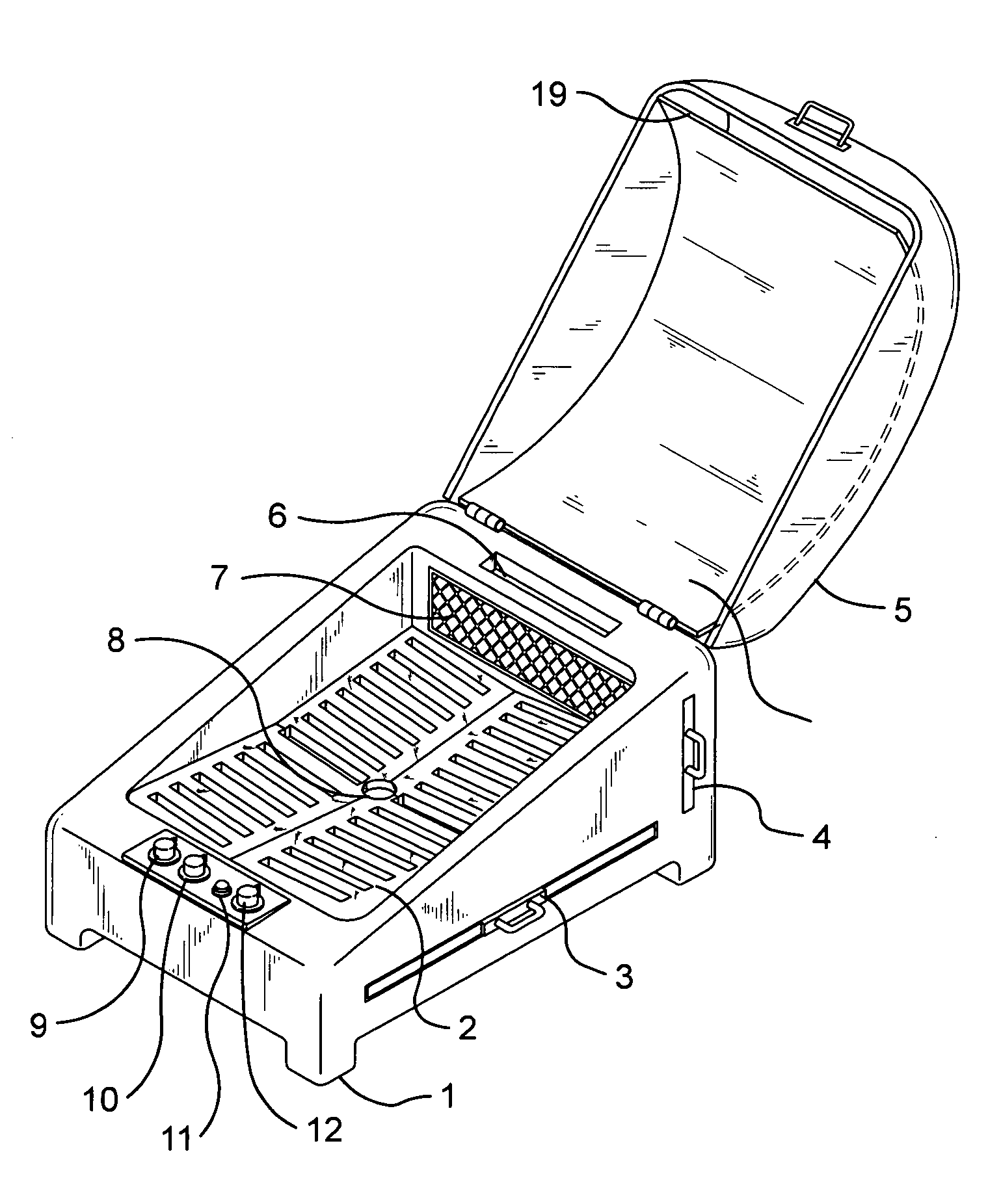

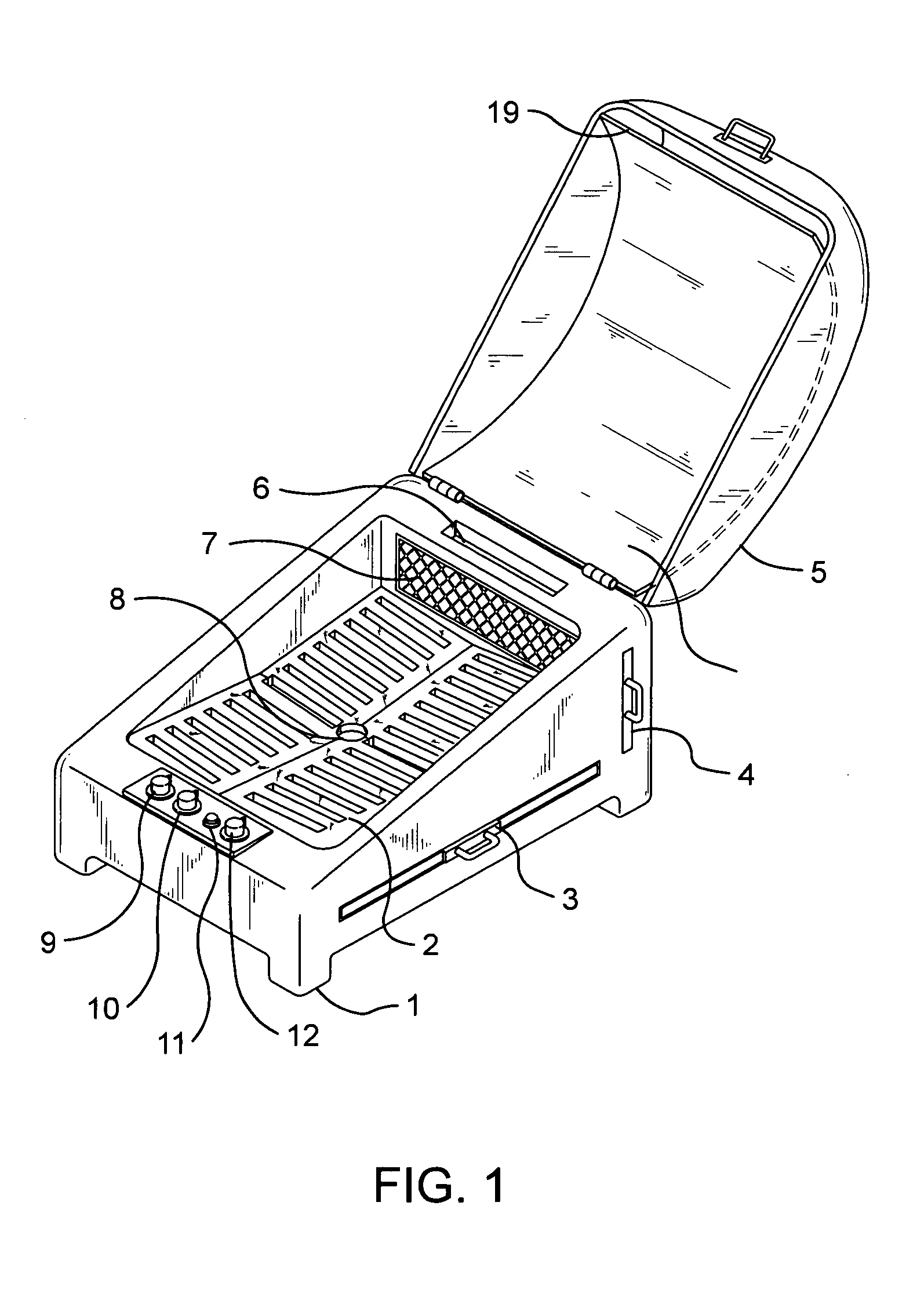

Convection grill

A portable electric grill for that has utilizes an electric fan to draw smoke and cooking odors through a filter then redirects and circulates the cleaner hot air around food to create convection heating thereby improve and making faster the cooking process. The grill can be used for indoor or outdoor use. It has a removable lid that when in the down position it provides the circulation of the hot air throughout the grill. It has a removable grill plate that either sits on top of heating elements or has heating elements imbedded in the grill plate. The grill plate is used for searing various foods and then allowing the convection air to cook the foods throughout. It has controls for regulating temperature, cooking time and fan speed. It has a pull-out grease tray to catch and dispose of drippings from cooking food. The filter is removable for cleaning.

Owner:JONES EDWARD MICHAEL

Light emitting diode (LED) lighting device

ActiveUS8143769B2Increase air flowHigh trafficPoint-like light sourceElectric discharge tubesEffect lightEngineering

An LED lighting device comprises: a thermally conducting body having an at least one opening that connects with a cavity within the body and a plurality of LEDs mounted in thermal communication with a face of the body and positioned around the opening. One or more passages pass through the body from the cavity to an outer surface of the body and are configured such that in operation air moves through the cavity by thermal convection thereby to provide cooling of the body. Each passage is configured in a direction that extends in a direction at an angle of about 45° to a line that is parallel with the axis of the body toward the outer surface of the body away from the face. The body can be configured such that its outer surface has a form factor resembling an incandescent light bulb or halogen reflector lamp.

Owner:BX LED LLC

Modular outdoor grill with a pivotal food supporting rack

InactiveUS6039039AConvenient inspectionEasily manipulatedDomestic stoves or rangesMeat/fish preservationCombustion chamberMechanical engineering

A modular outdoor grill for cooking over a bed of combustible fuel or by means of convection heating from an externally mounted firebox. The modular grill comprises a housing with an outwardly, horizontally pivotal food-supporting tray, a vertically extending standard for supporting said housing, and either a horizontally reciprocating fuel-supporting grate or an externally mounted firebox.

Owner:PINA JR AMADO

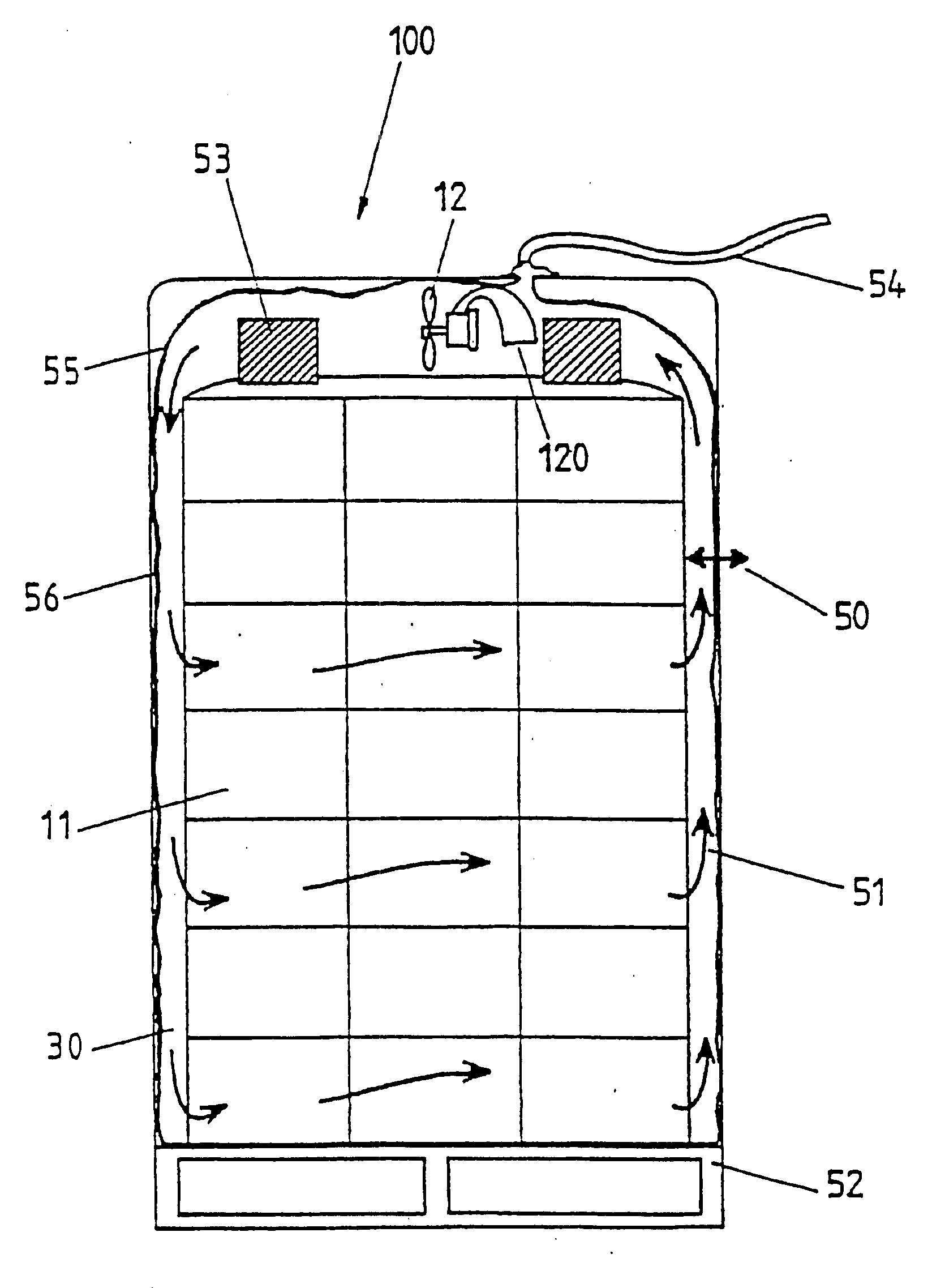

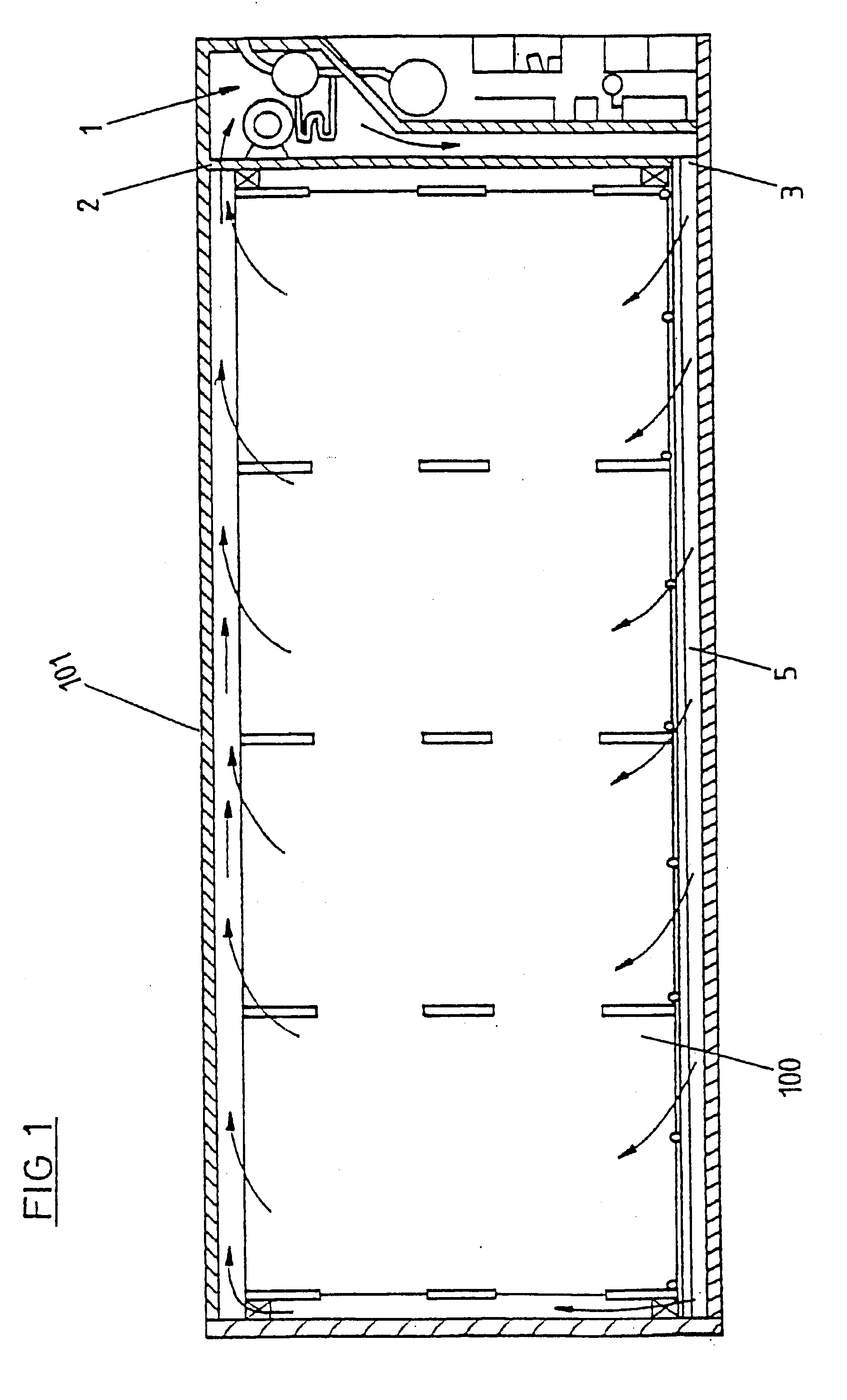

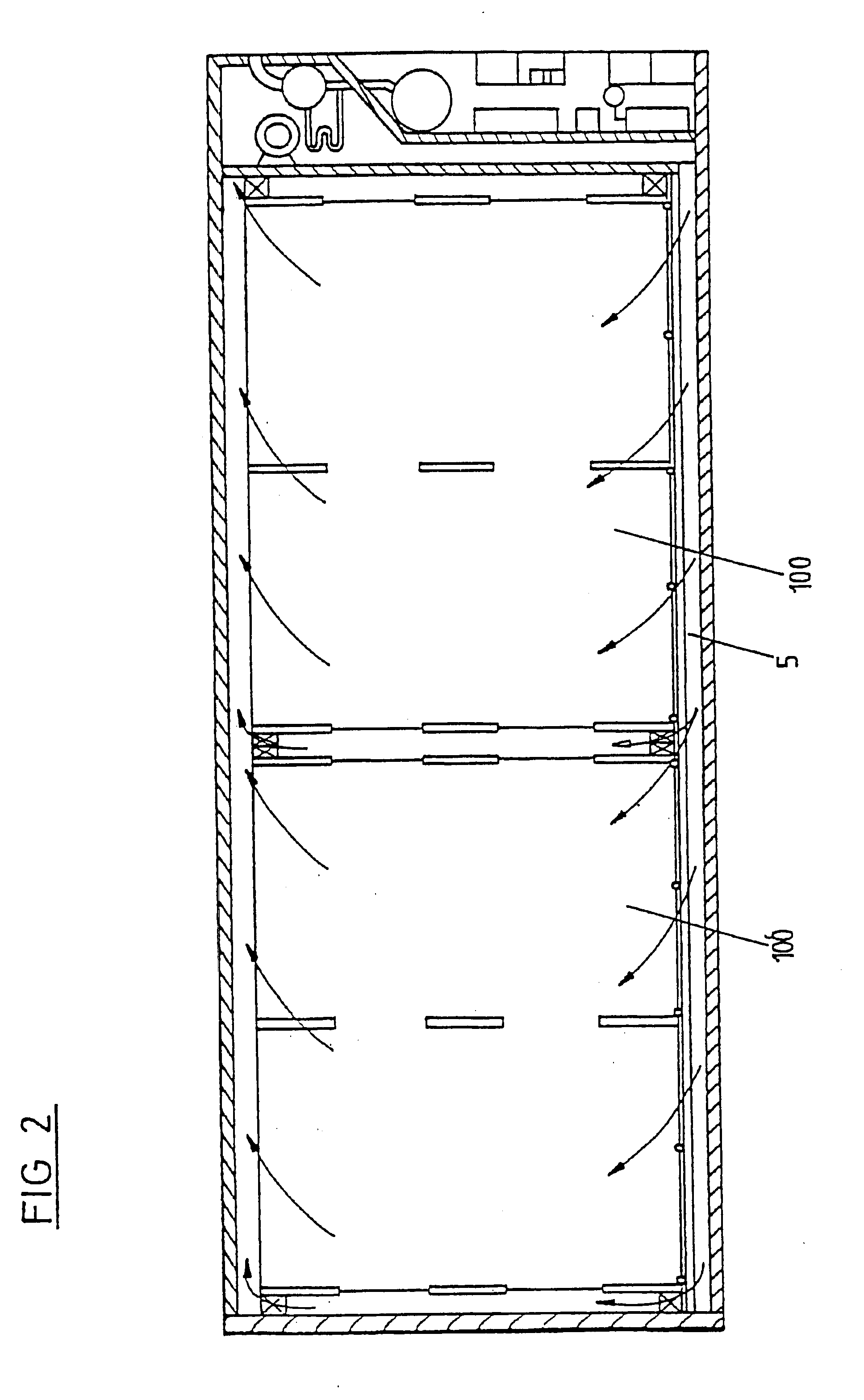

Method of transporting or storing perishable produce

InactiveUS6615908B1Convenient infusionIncrease humiditySpace heating and ventilationOperation mode of machinesGas compositionProduct gas

The invention allows cool rooms or sea containers designed for frozen goods to handle produce requiring more precisely controlled temperatures and conditions, e.g., vegetables and fruits requiring temperatures in the chilling range and often also needing control or modification of the atmosphere. Each load of produce (100) (e.g. of pallet size) is held in the sea container or cool room but is sealed from the air of the refrigerated environment by, for example, a plastics bag (56). The atmosphere within the bag is then circulated by a fan (12) (or by convection currents from a heating element) so as to pass through the load and around it via ducts (30) provided adjacent the bag (56). Heat exchange (50) between the circulating gas and the refrigerated environment, via the plastics film, serves to cool the load. However, if cooling is excessive a heating element can be used to raise the temperature of the circulating atmosphere. Gas composition of the atmosphere can be controlled by scrubbing, flushing, etc. via pipes from a central unit or at each load individually or by choosing semi-permeable plastic for the sealing bags.

Owner:TRANSPHERE SYST

Griddle

ActiveUS20080105136A1Reduce cooking timeAir-treating devicesMilk preservationProcess engineeringInternal heating

A high-speed griddle for cooking food products has a griddle platen having a cook surface for receiving food products thereon, and heating means are provided for heating the platen. A clamshell cover is configured for sealing contact with the cook surface of the platen, the cook surface and cover cooperating to enclose a cook volume. An electromagnetic energy source is configured for emitting energy into the cook volume, the energy source emitting energy of a frequency selected to cause internal heating of food products within the cook volume. In addition, a convection air system is configured to provide a flow of heated air into the cook volume. The heated platen, electromagnetic energy source, and convection air system cooperate to rapidly cook food products within the cook volume.

Owner:TURBOCHEF TECH INC

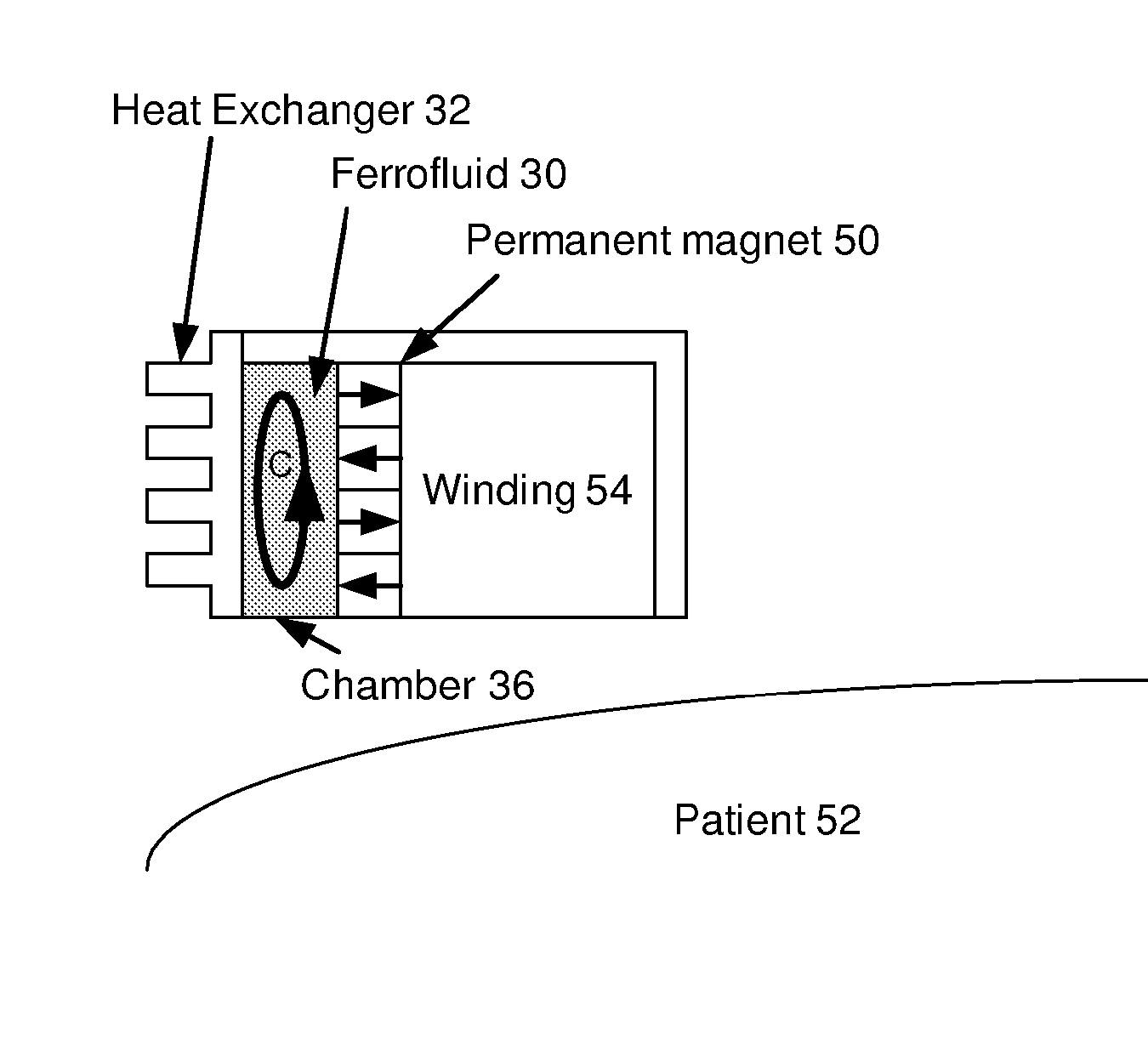

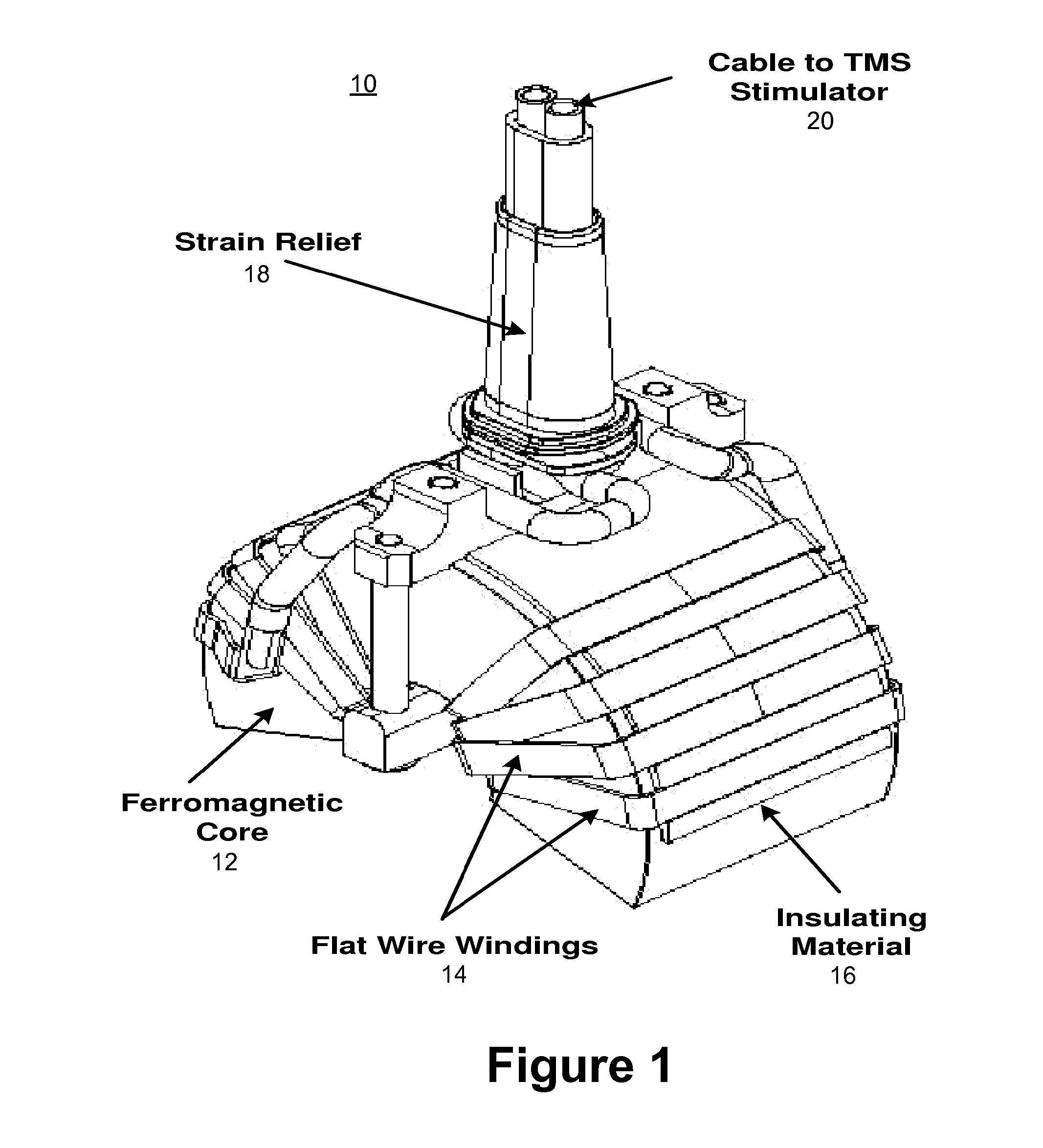

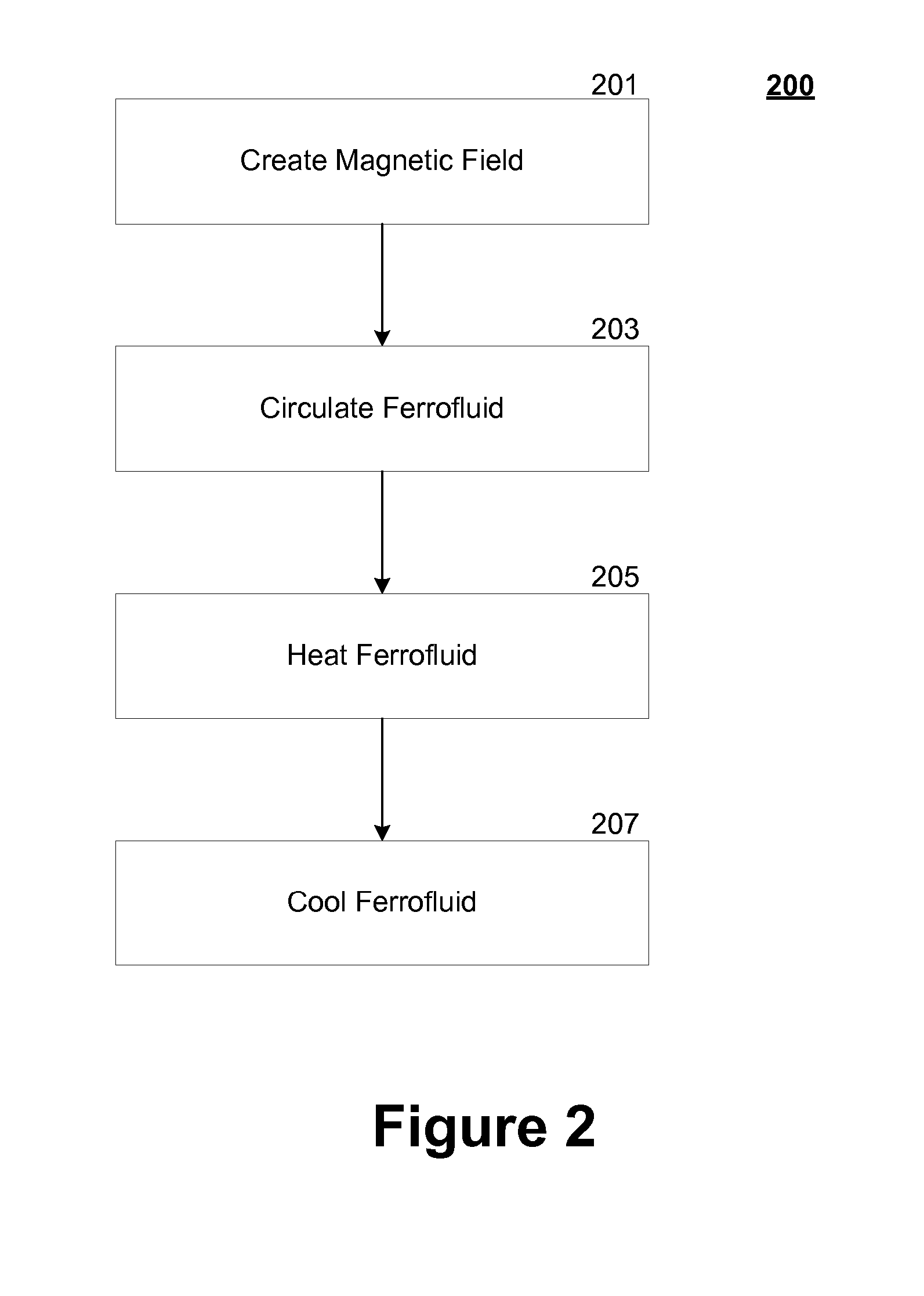

Ferrofluidic cooling and acoustical noise reduction in magnetic stimulators

A ferrofluid chamber has a housing that is adapted to be coupled to a component that generates a magnetic field. A ferrofluid may disposed within the housing for cooling the component via convection of the ferrofluid that is induced by the magnetic field.

Owner:NEURONETICS

Multiple panel oven having individual controls for combined conductive and radiant heating panels

A multiple panel cooking oven having individual controls for combined conductive and radiant heating. Each panel comprises an upper heating element for conductive heating and a lower heating element for radiant heating to obtain uniform baking within a zone between panels in the oven. A control panel having displays and keypads interfaces with a processor which provides control signals for adjusting the temperature of the heating elements of the panels. Cooking energy efficiency is increased through the use of radiative and conductive heat transfer, to reduce bake times by significantly increasing heat transfer to the food products. Independent cook zones allow preparation of multiple products simultaneously under different cooking conditions. The oven, in one embodiment may include a convection heating mode of operation. In an alternative embodiment no convection mode is provided and the sole source of heat is provided by the conductive / radiant panels.

Owner:TIAX LLC

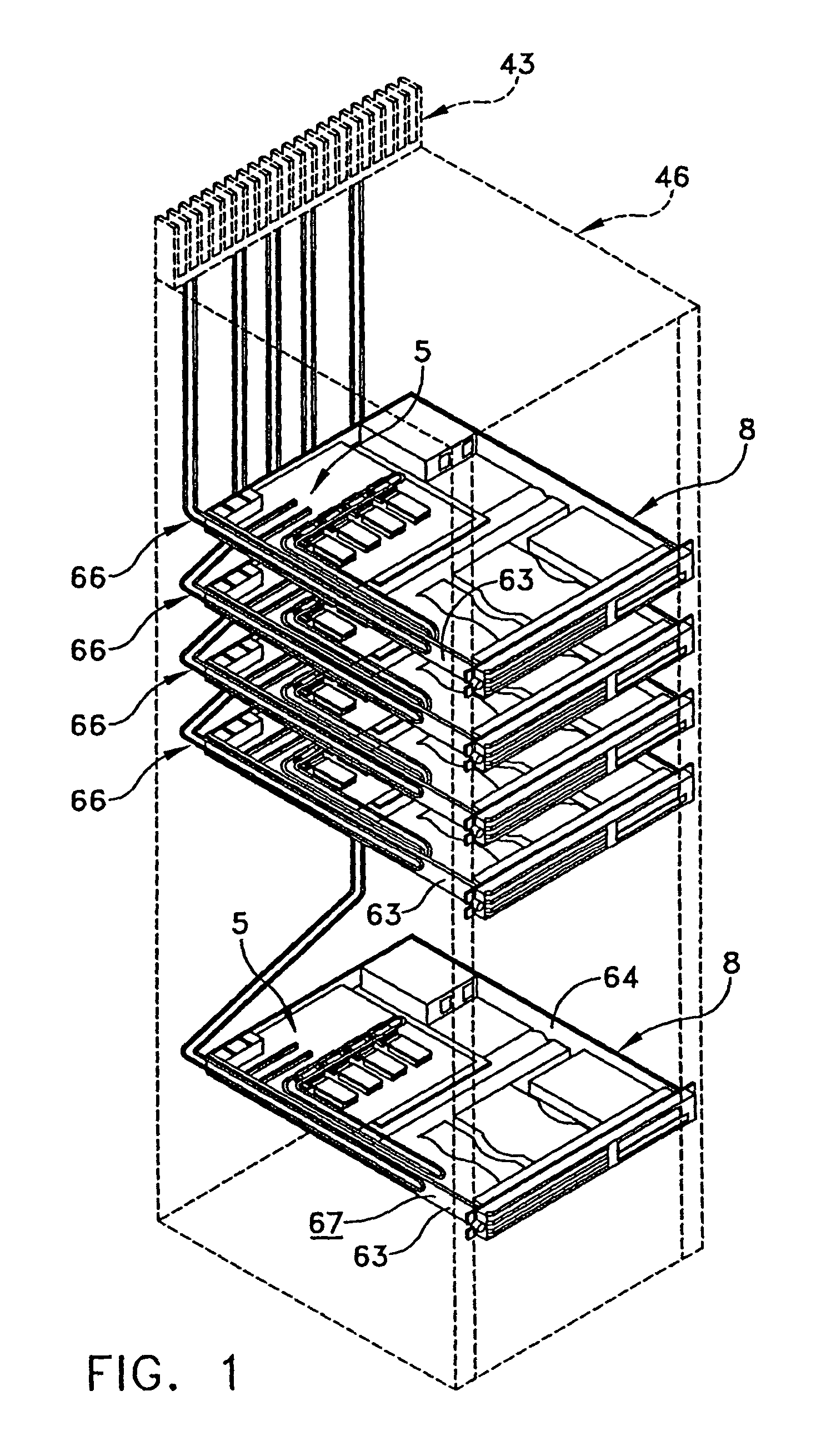

Thermal management system and method for electronics system

InactiveUS6972365B2Lighting and heating apparatusSemiconductor/solid-state device detailsThermal energySemiconductor chip

A thermal energy management system is provided having a heat spreading device that is operatively engaged with at least one semiconductor chip and a thermal bus operatively engaged with the heat spreading device so as to transport thermal energy from the heat spreading device to a heat sink. The heat spreading device includes a heat pipe and the thermal bus includes a loop thermosyphon. A second thermal bus may be operatively engaged with the first thermal bus so as to transport thermal energy from the first thermal bus to a heat sink. The second thermal bus may also include a loop thermosyphon. A method of managing thermal energy in an electronic system is also provided that includes spreading thermal energy generated by one or more devices over a surface that is relatively larger than the devices, thermally coupling an evaporator portion of a loop thermosyphon to the surface, and thermally coupling a condensing portion of the loop thermosyphon to a thermal energy sink, e.g., a second loop thermosyphon, convection fin, or cold plate.

Owner:THERMAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com