Patents

Literature

299results about How to "Even air distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

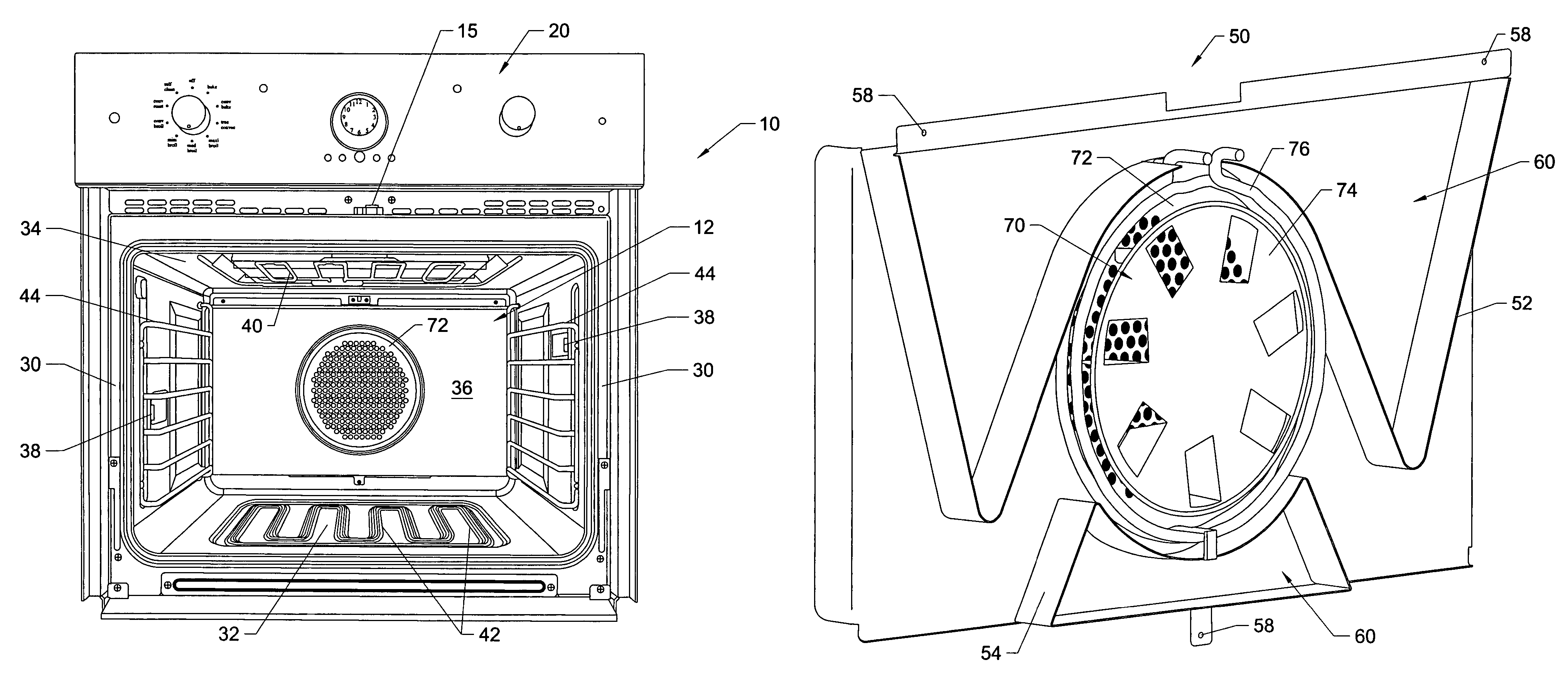

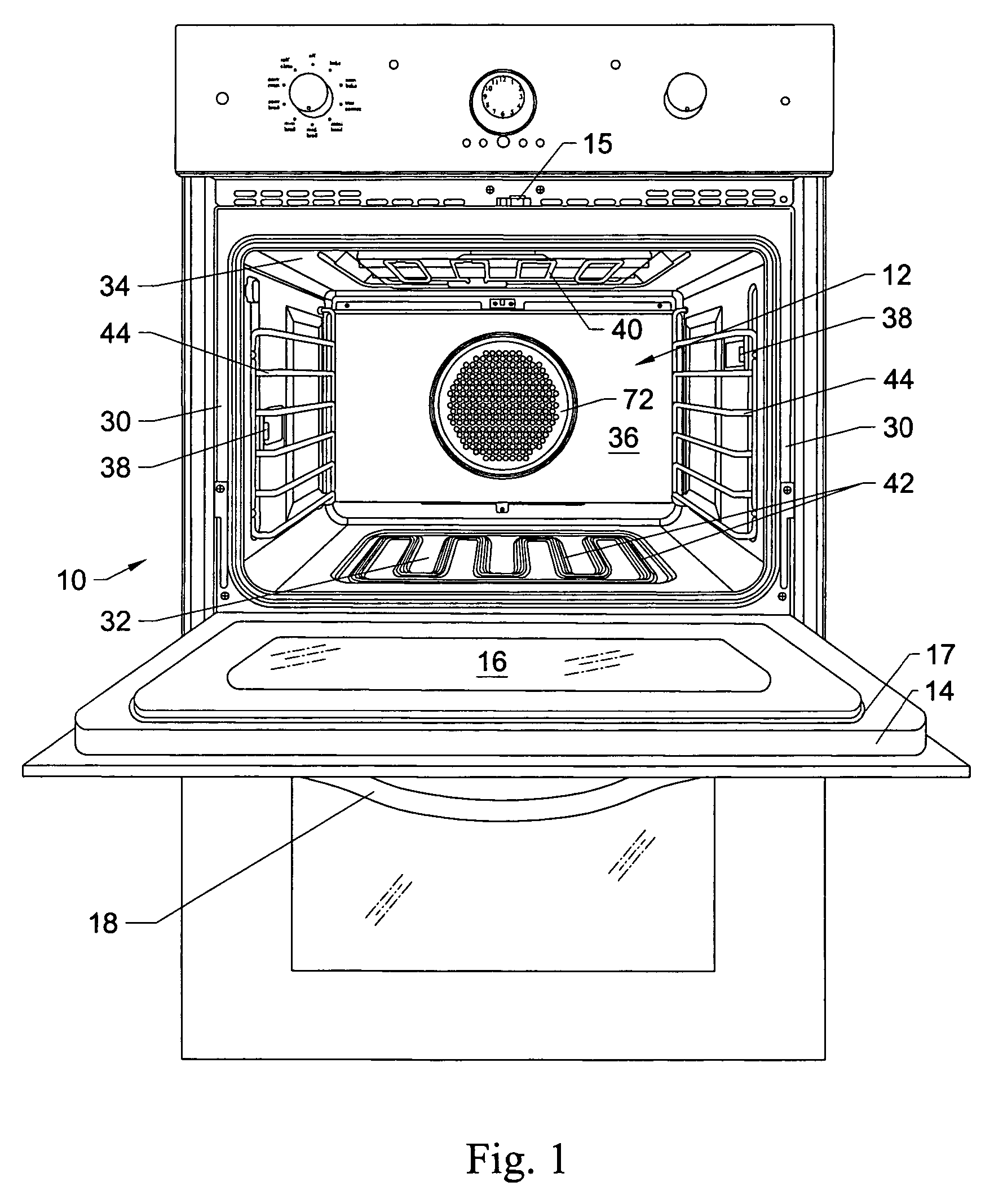

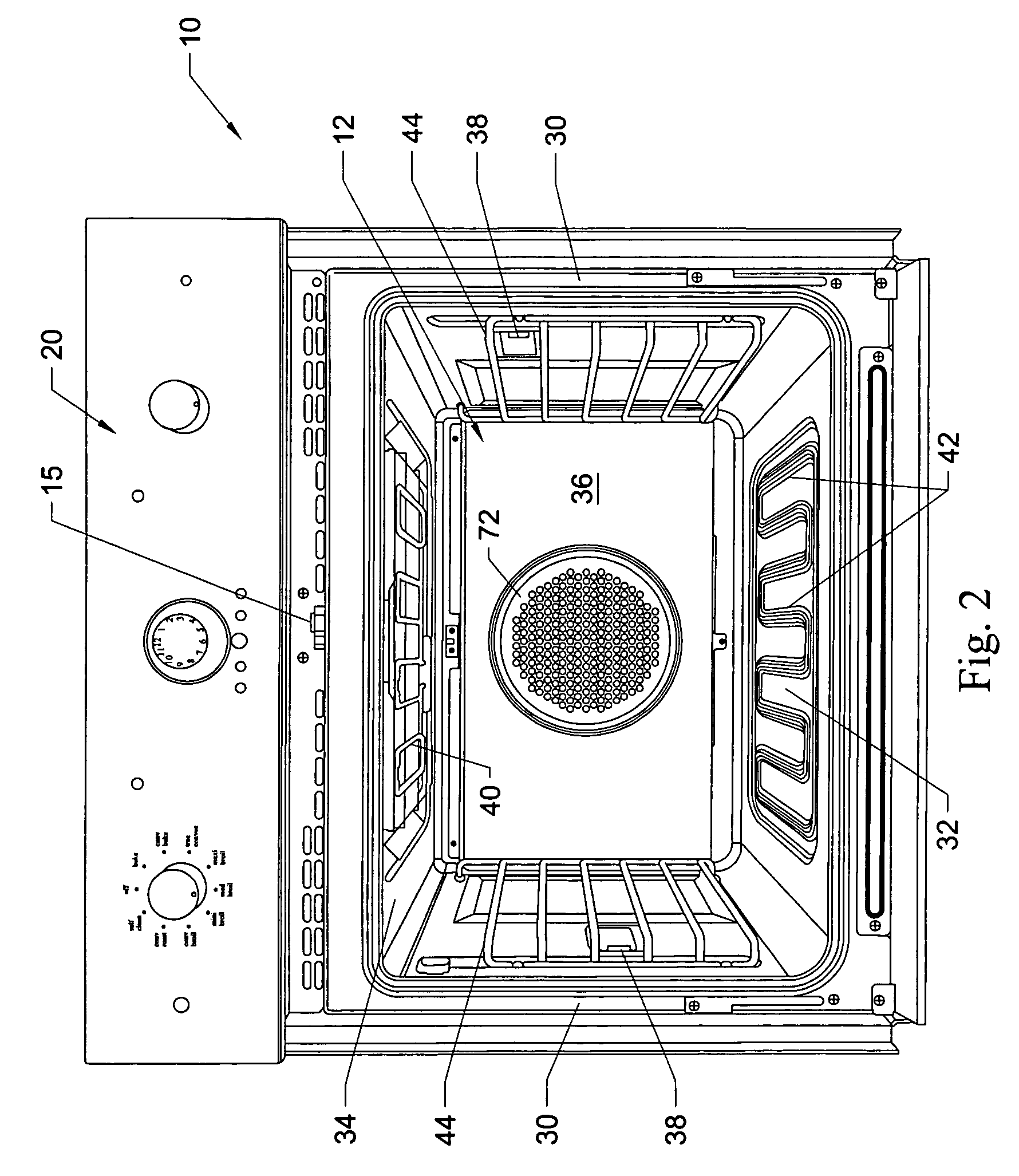

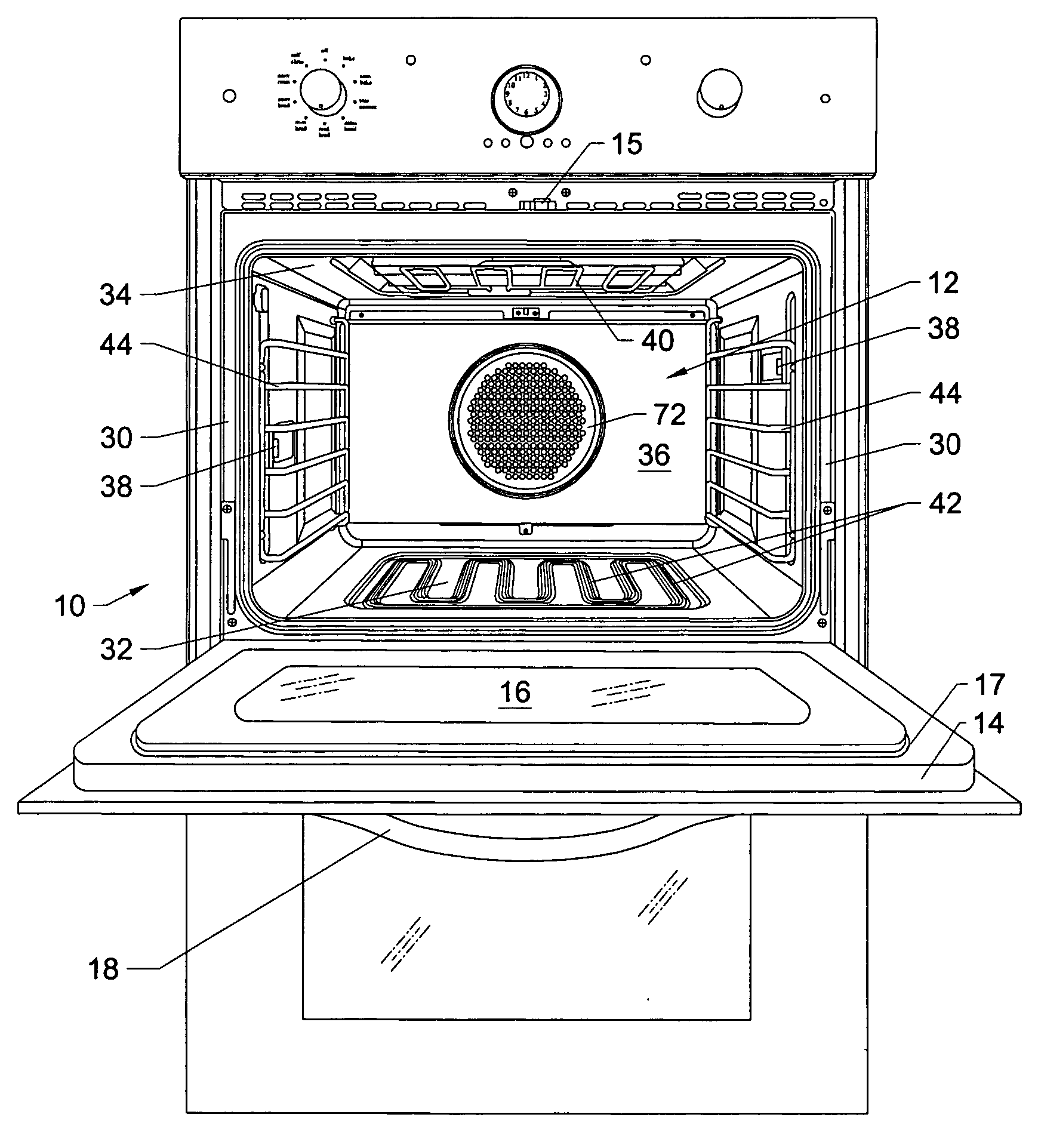

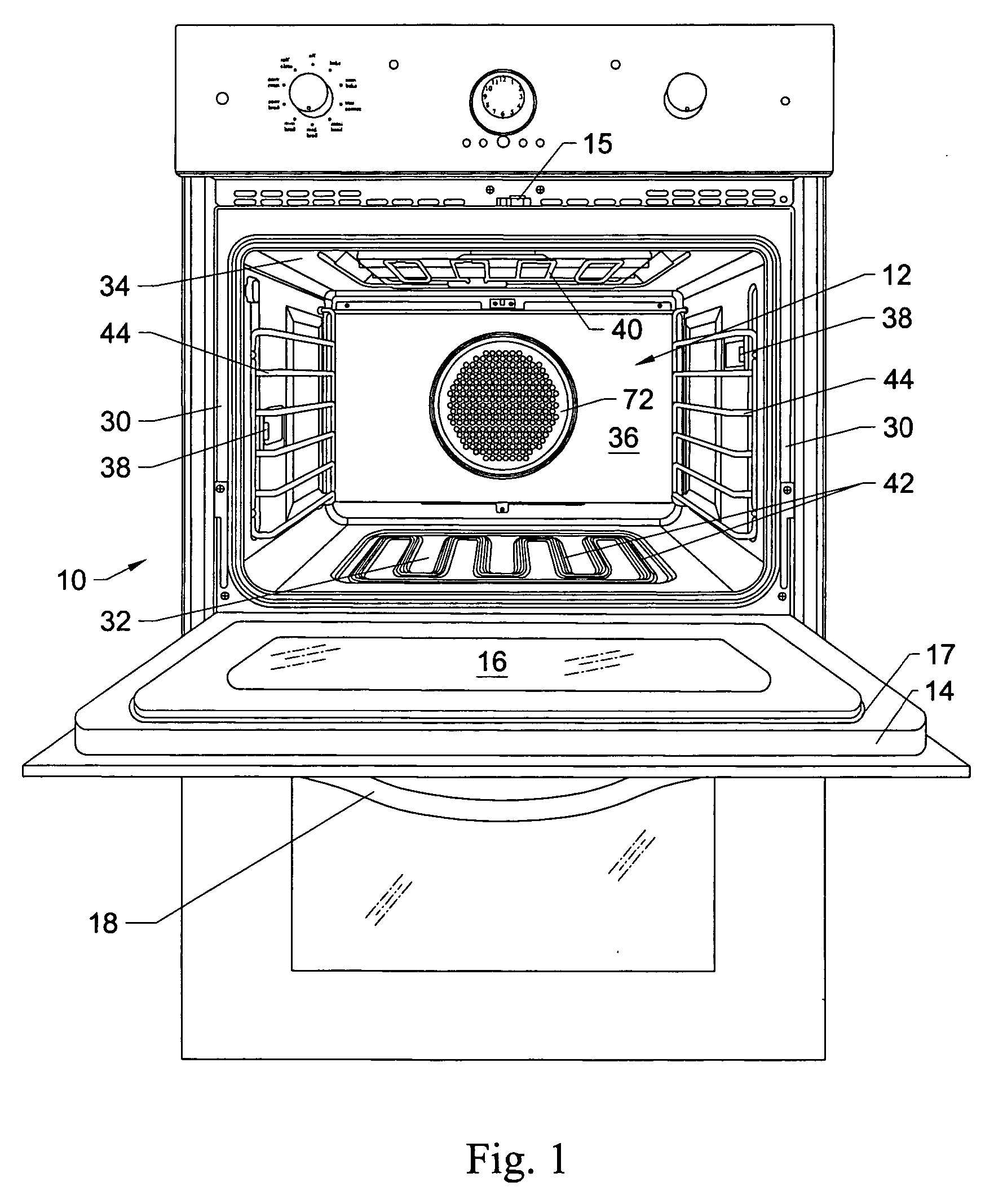

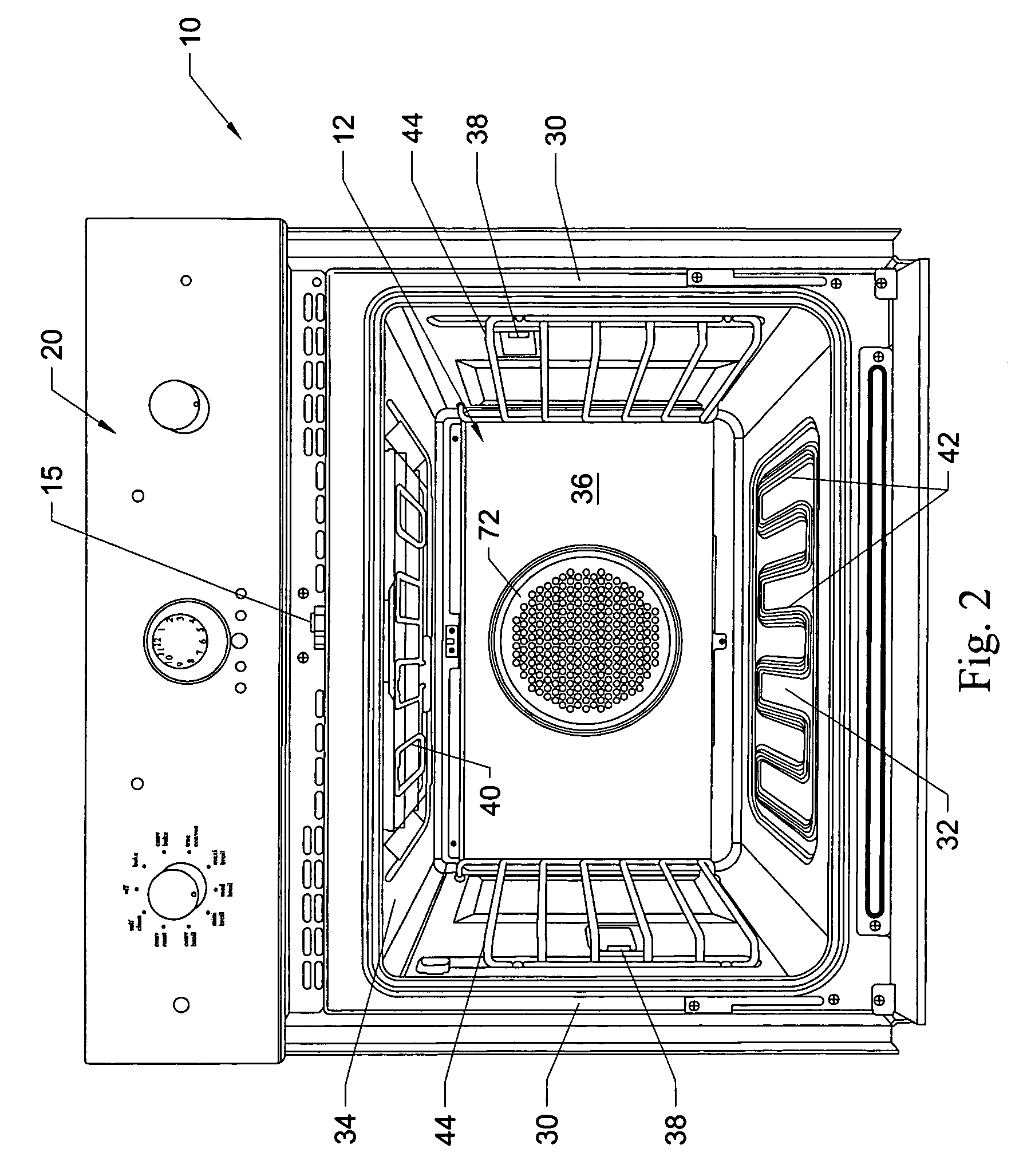

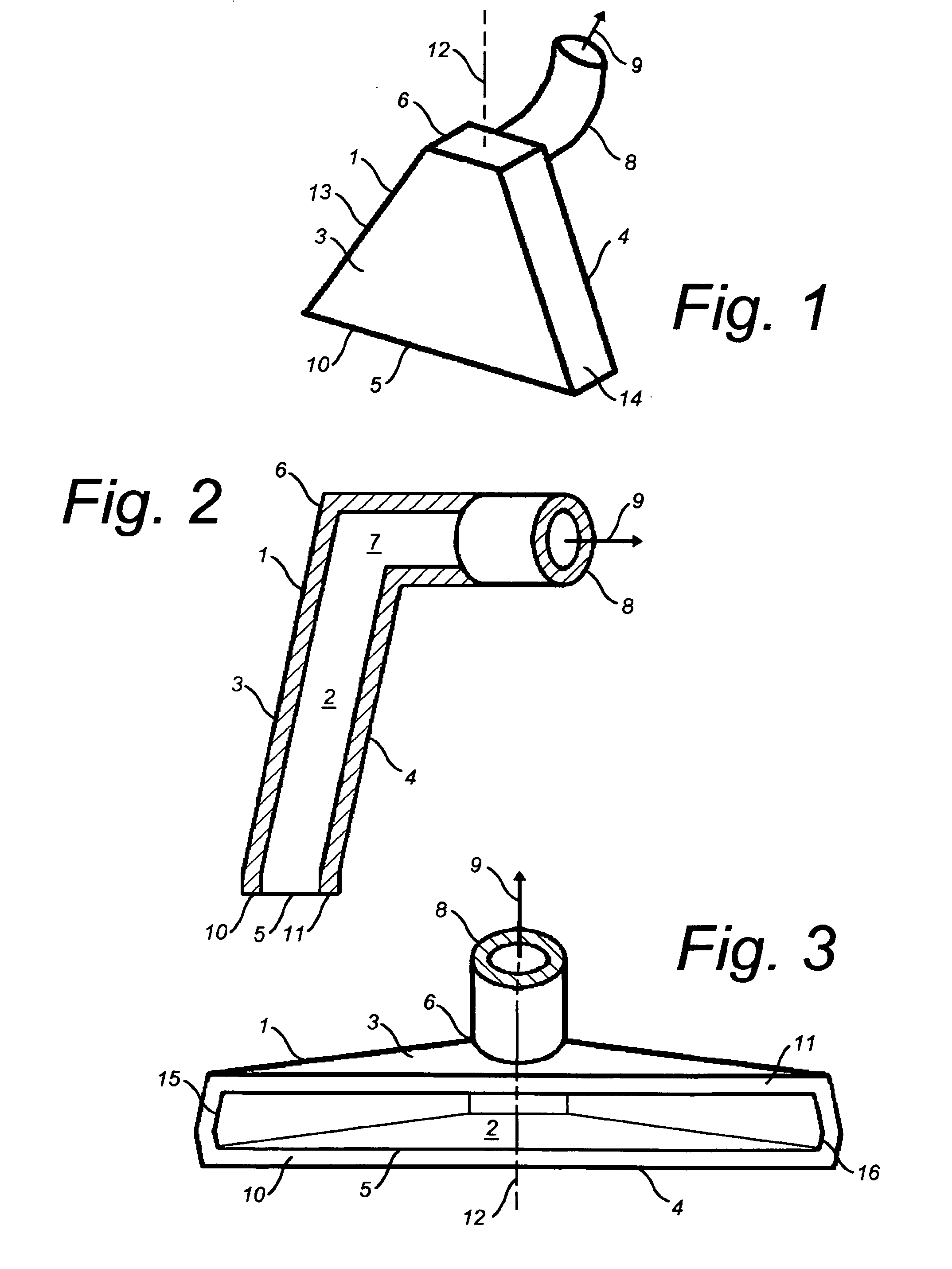

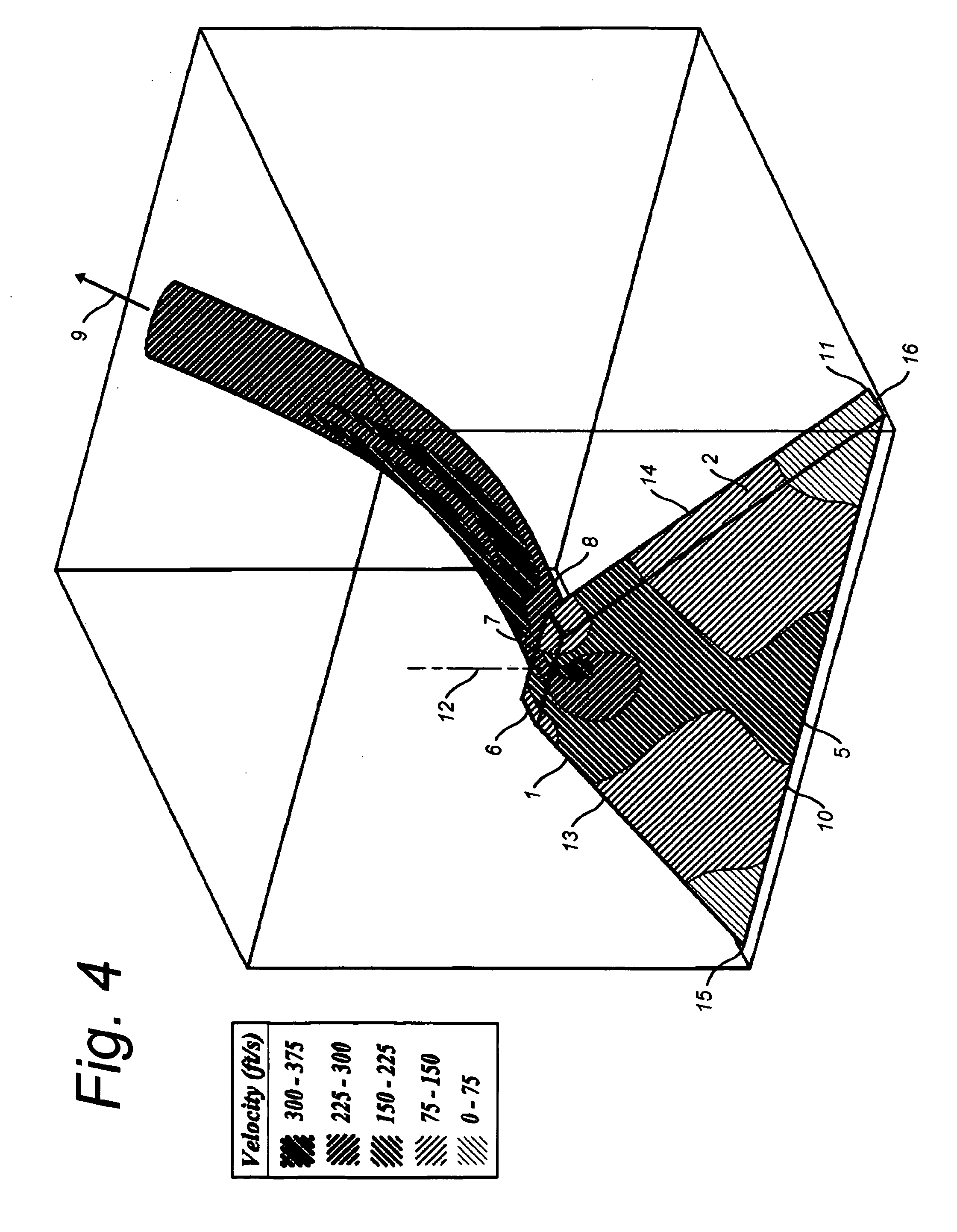

Multi-mode convection oven with flow control baffles

InactiveUS7468495B2Cook food accurately and evenlyEven air distributionAir-treating devicesDomestic stoves or rangesControl systemEngineering

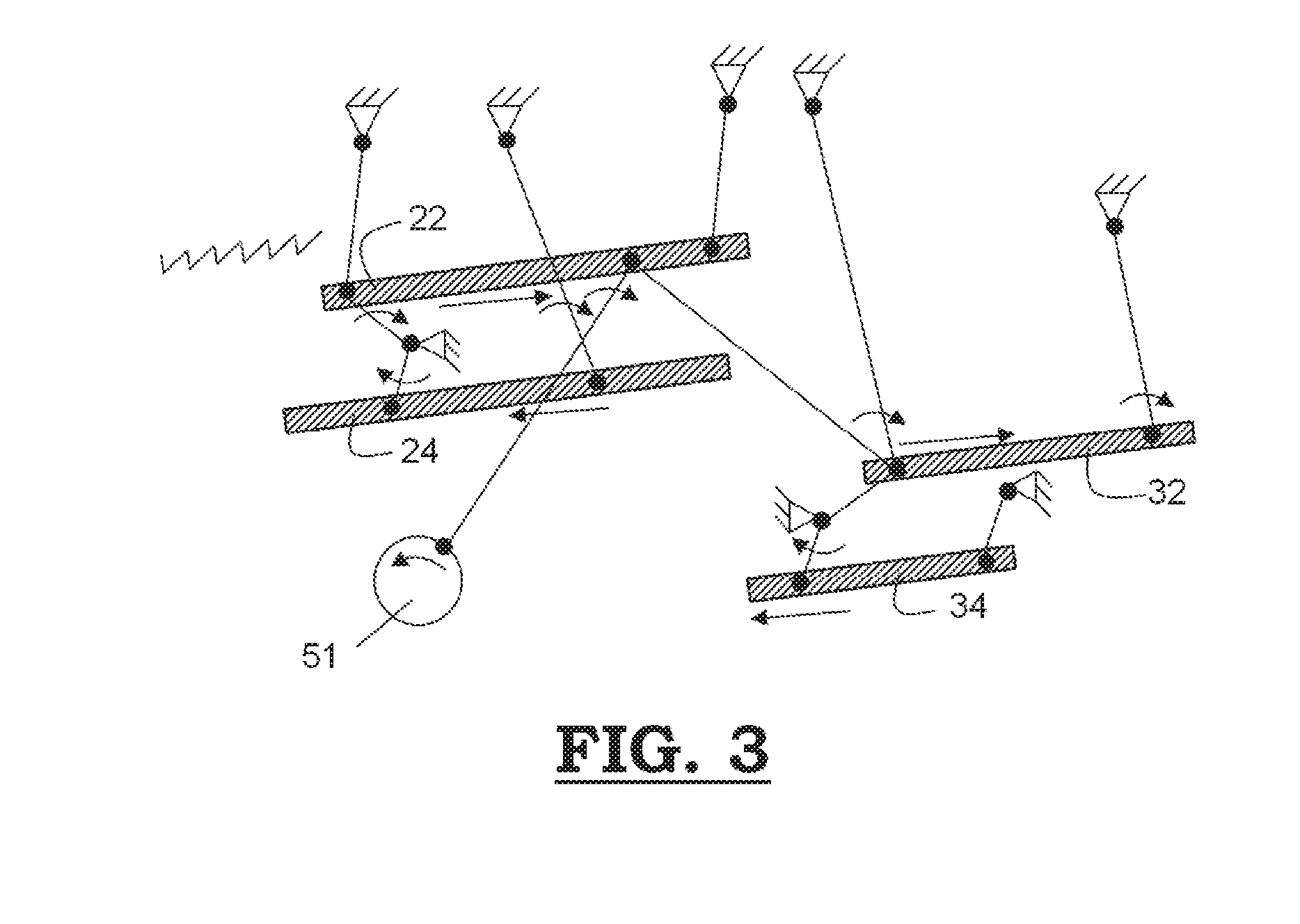

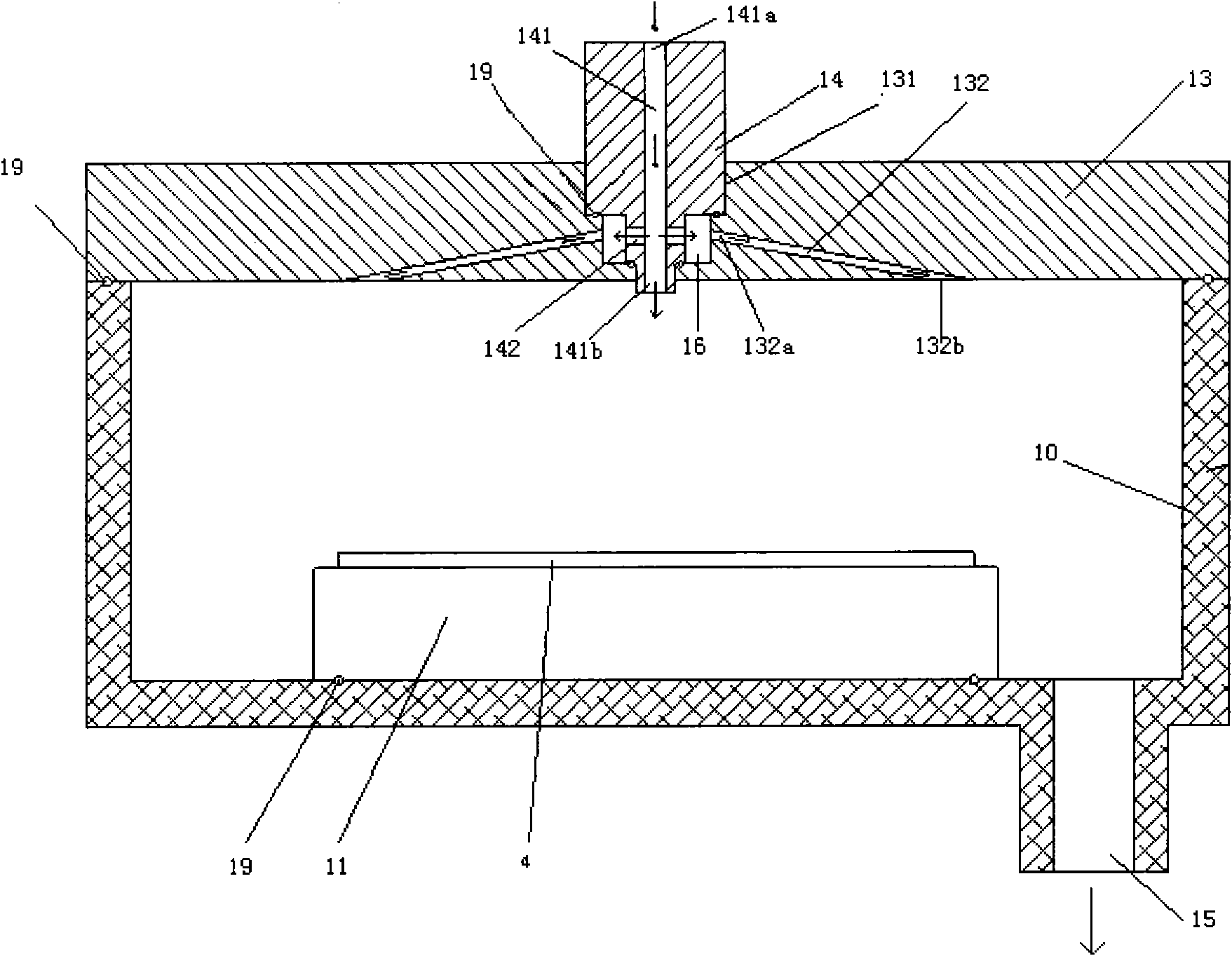

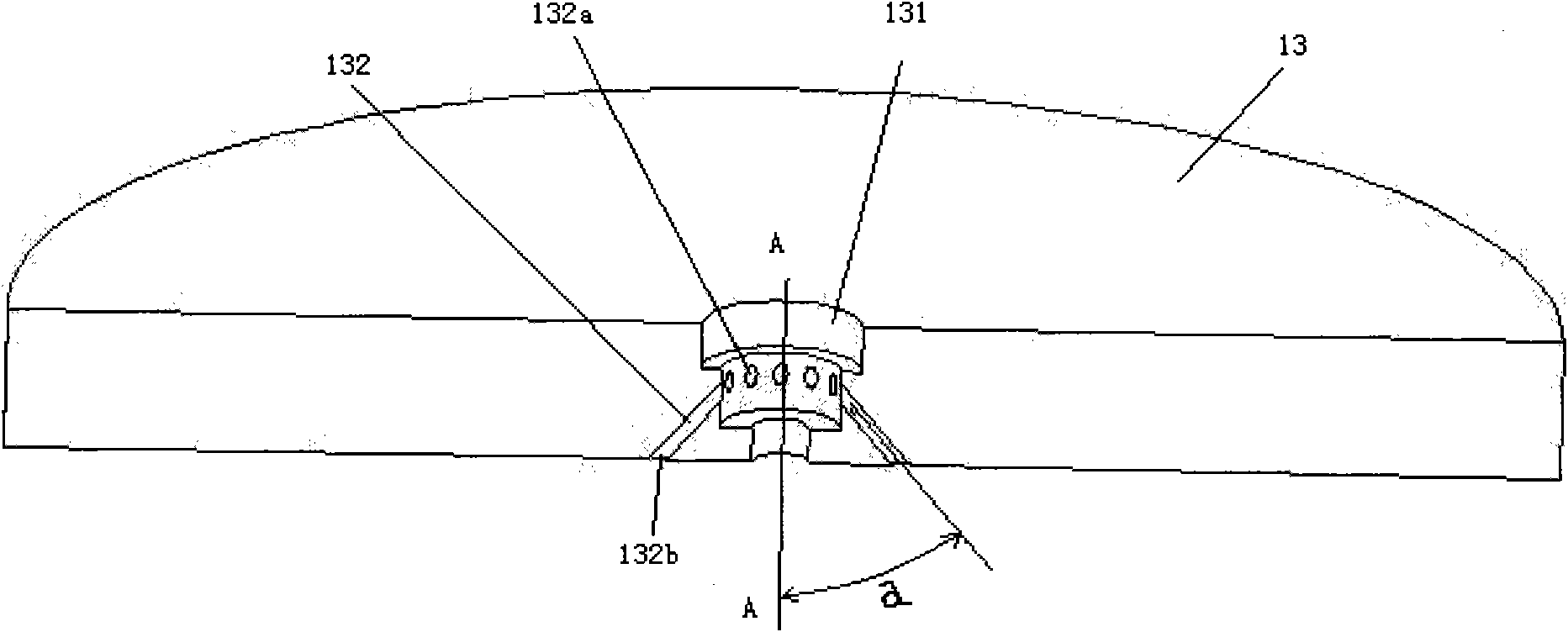

An airflow control system for an oven having an oven cavity and a fan having a first operating mode for generating a first flow of air and a second operating mode for generating a second flow of air is provided. A baffle is included adjacent the fan to direct the first flow of air to a first region of the cavity in the first operating mode and to direct the second flow of air to a second region of the cavity in the second operating mode. A method of controlling airflow in an oven having an oven cavity is also detailed. The method can include different modes of operation, with different clockwise and counterclockwise rotational times for the fan, with different heating elements energized, or a combination of both, depending upon the food to be cooked in the oven.

Owner:VIKING RANGE

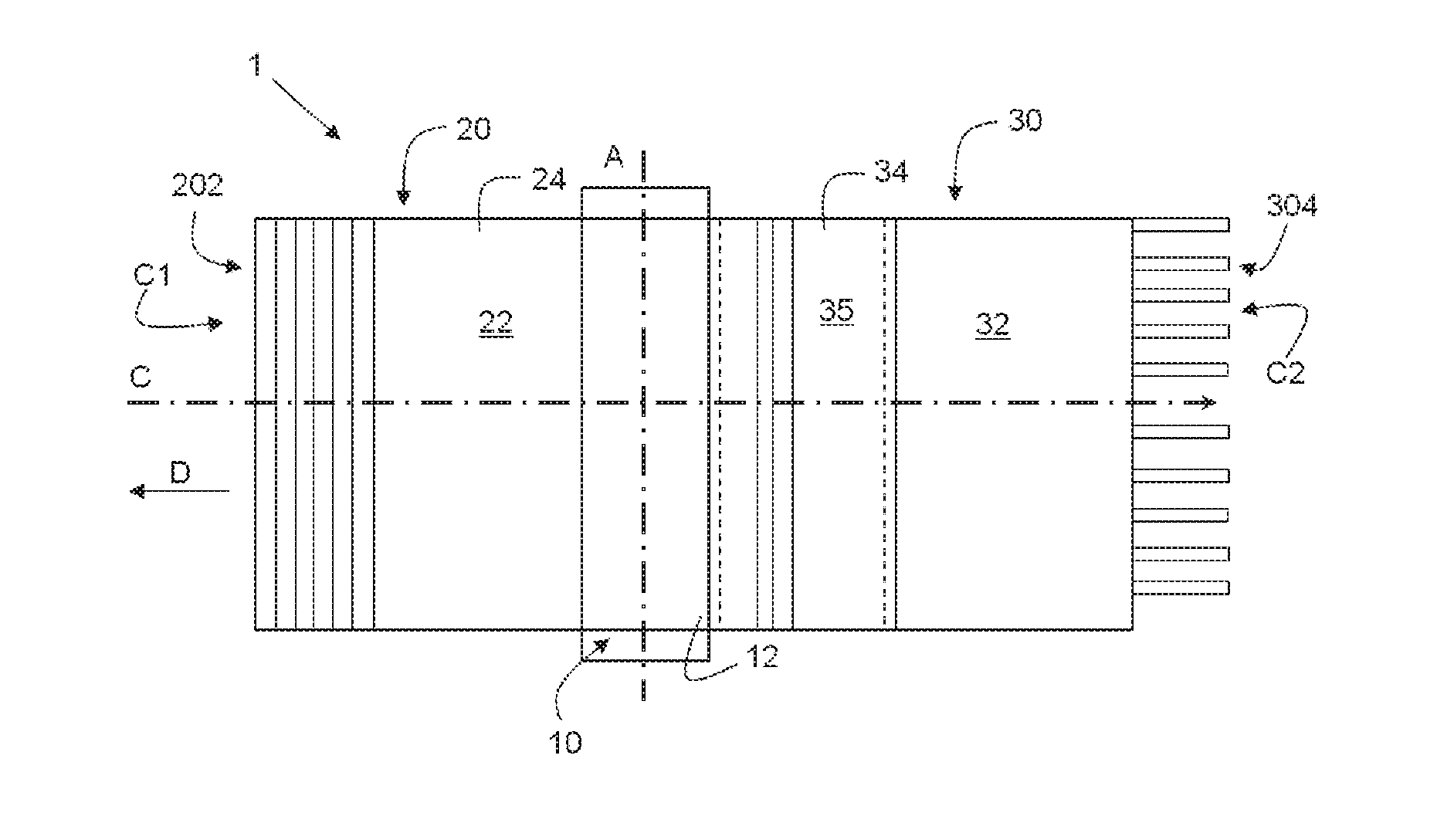

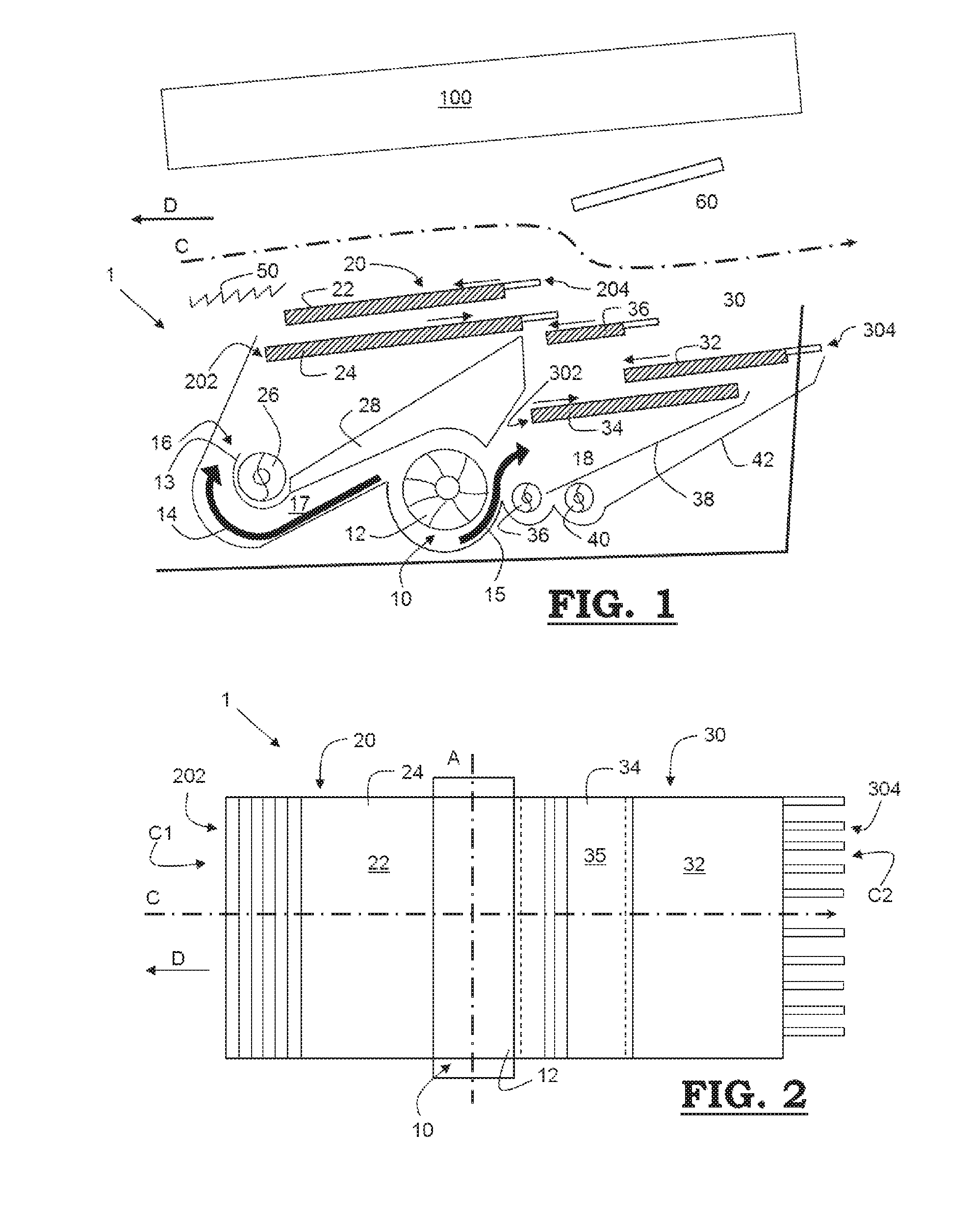

Multi-mode convection oven with flow control baffles

InactiveUS20060289436A1Cook food accurately and evenlyEven air distributionAir-treating devicesDomestic stoves or rangesControl systemStream flow

An airflow control system for an oven having an oven cavity and a fan having a first operating mode for generating a first flow of air and a second operating mode for generating a second flow of air is provided. A baffle is included adjacent the fan to direct the first flow of air to a first region of the cavity in the first operating mode and to direct the second flow of air to a second region of the cavity in the second operating mode. A method of controlling airflow in an oven having an oven cavity is also detailed. The method can include different modes of operation, with different clockwise and counterclockwise rotational times for the fan, with different heating elements energized, or a combination of both, depending upon the food to be cooked in the oven.

Owner:VIKING RANGE

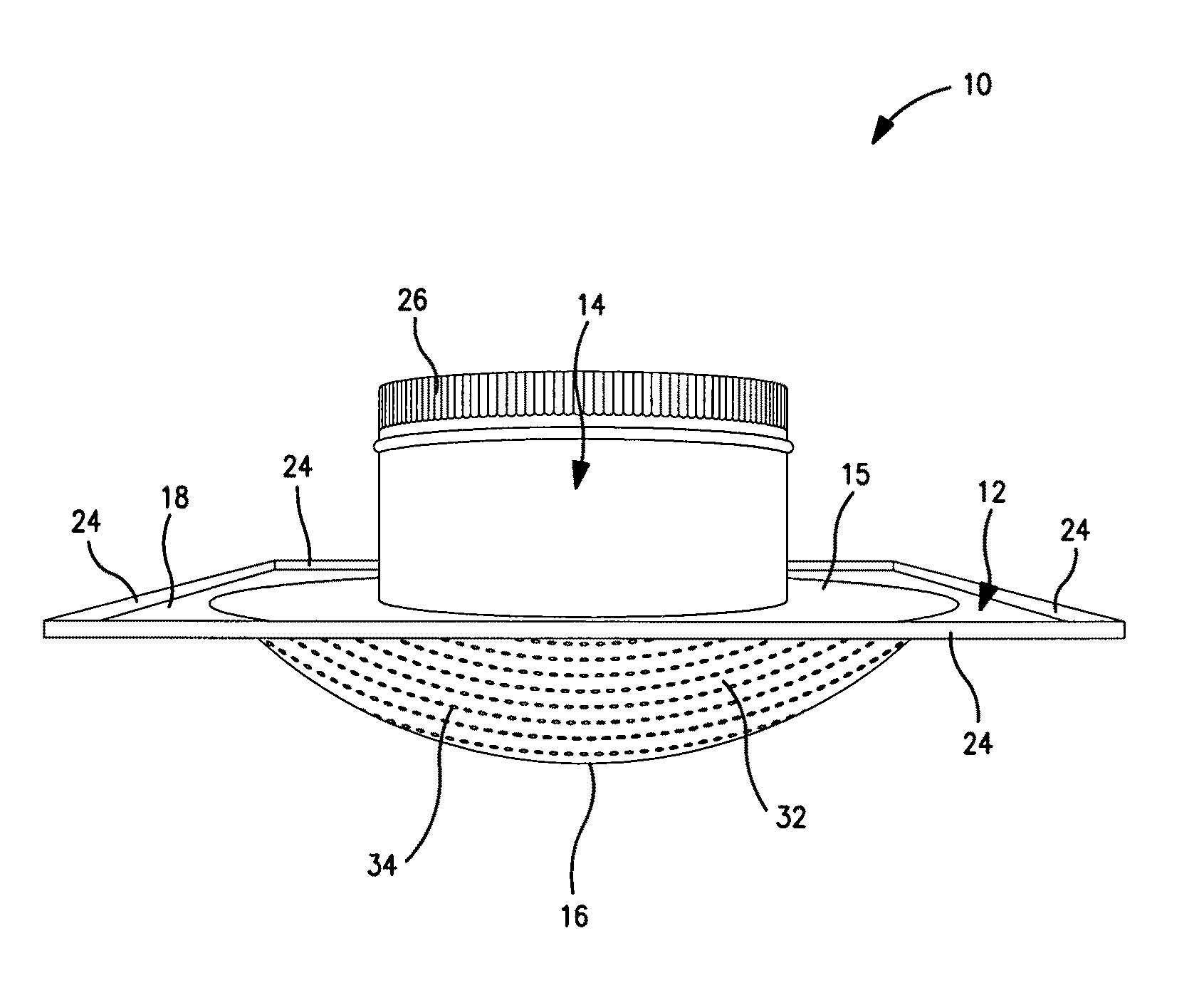

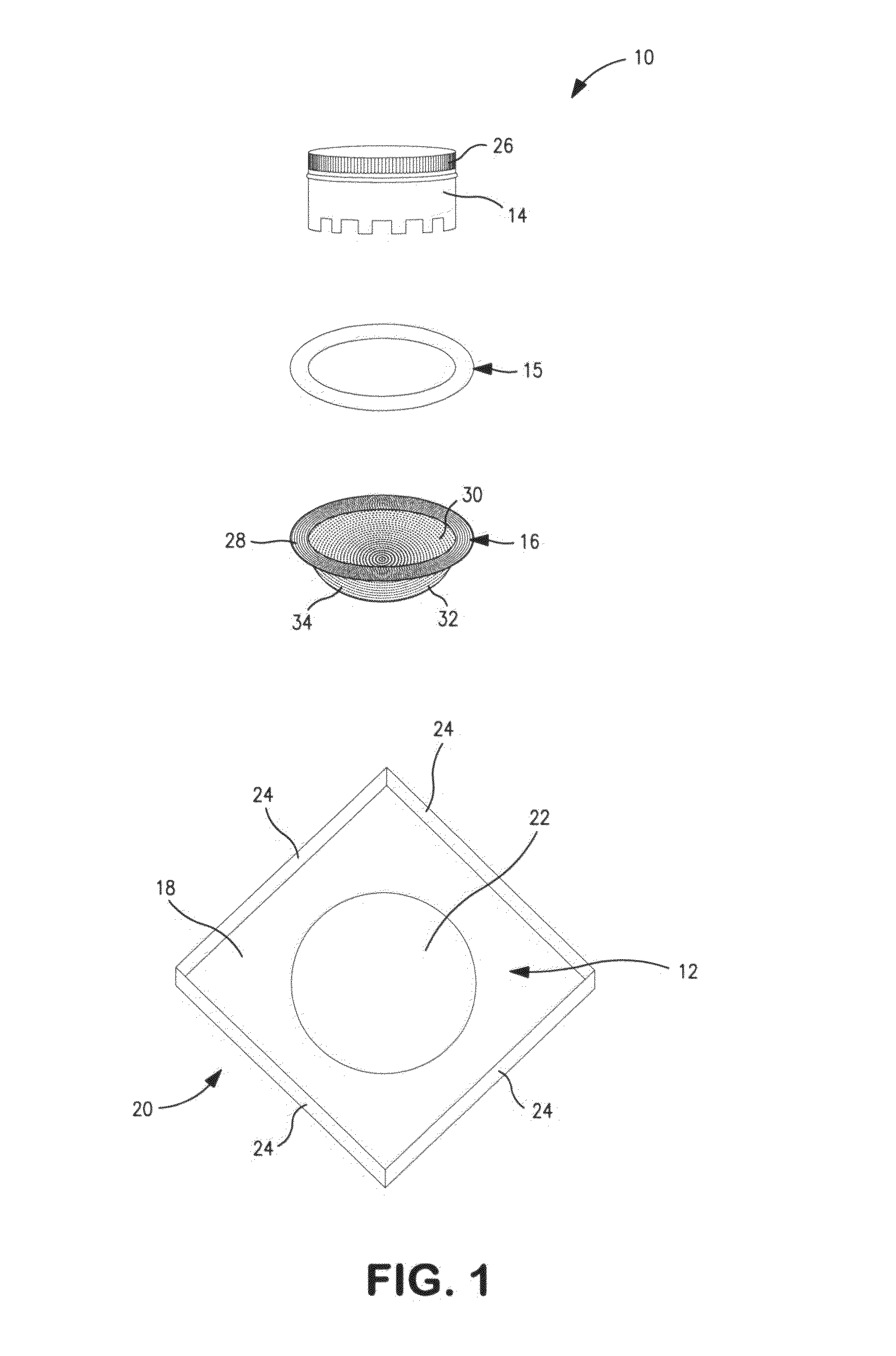

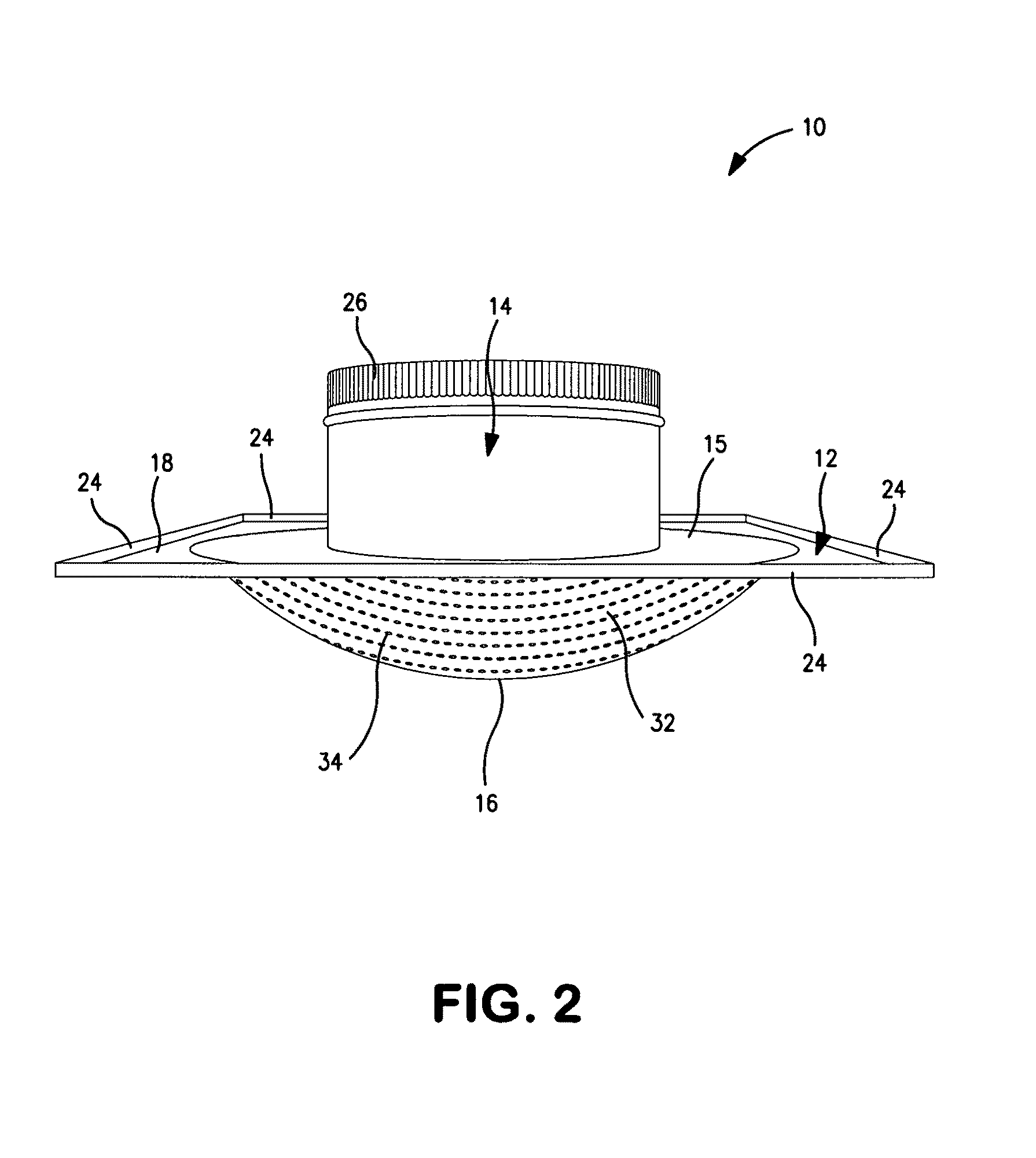

Air diffuser apparatus

ActiveUS7645188B1Even air distributionReduce draftDucting arrangementsLighting and heating apparatusDistribution systemMechanical engineering

An air diffuser for distributing air into a room from a supply duct of an air distribution system having: a frame member, wherein the frame member includes an inner surface, and an outer surface; an attachment member, wherein the attachment member is associated with the frame member, and further wherein the attachment member is configured for associating the air diffuser with a supply duct; and a diffusing member, wherein the diffusing member comprises a substantially hemispherical dome having an inner surface, an outer surface, and a plurality of apertures, and wherein the substantially hemispherical dome emanates away from the outer surface of the frame member.

Owner:PEERBOLT MORRIS

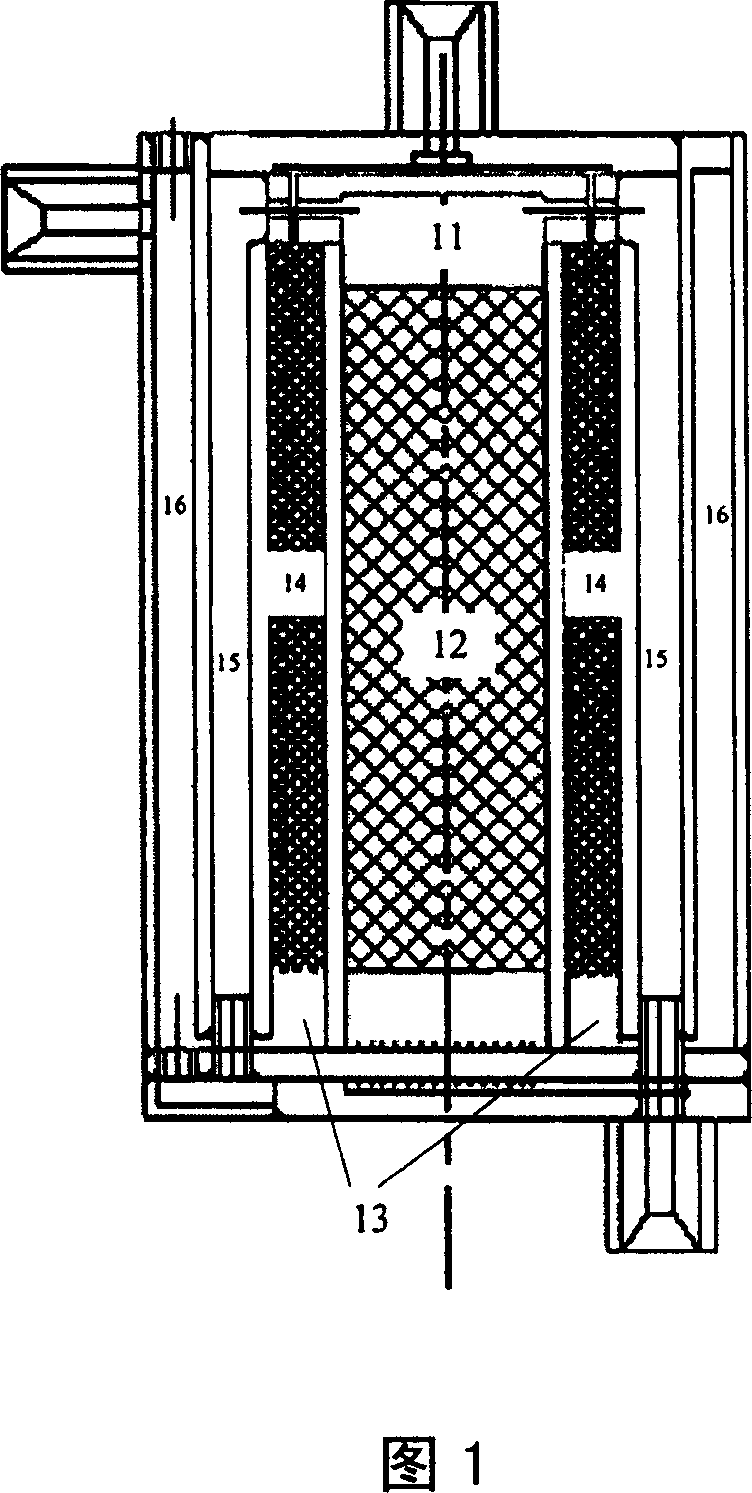

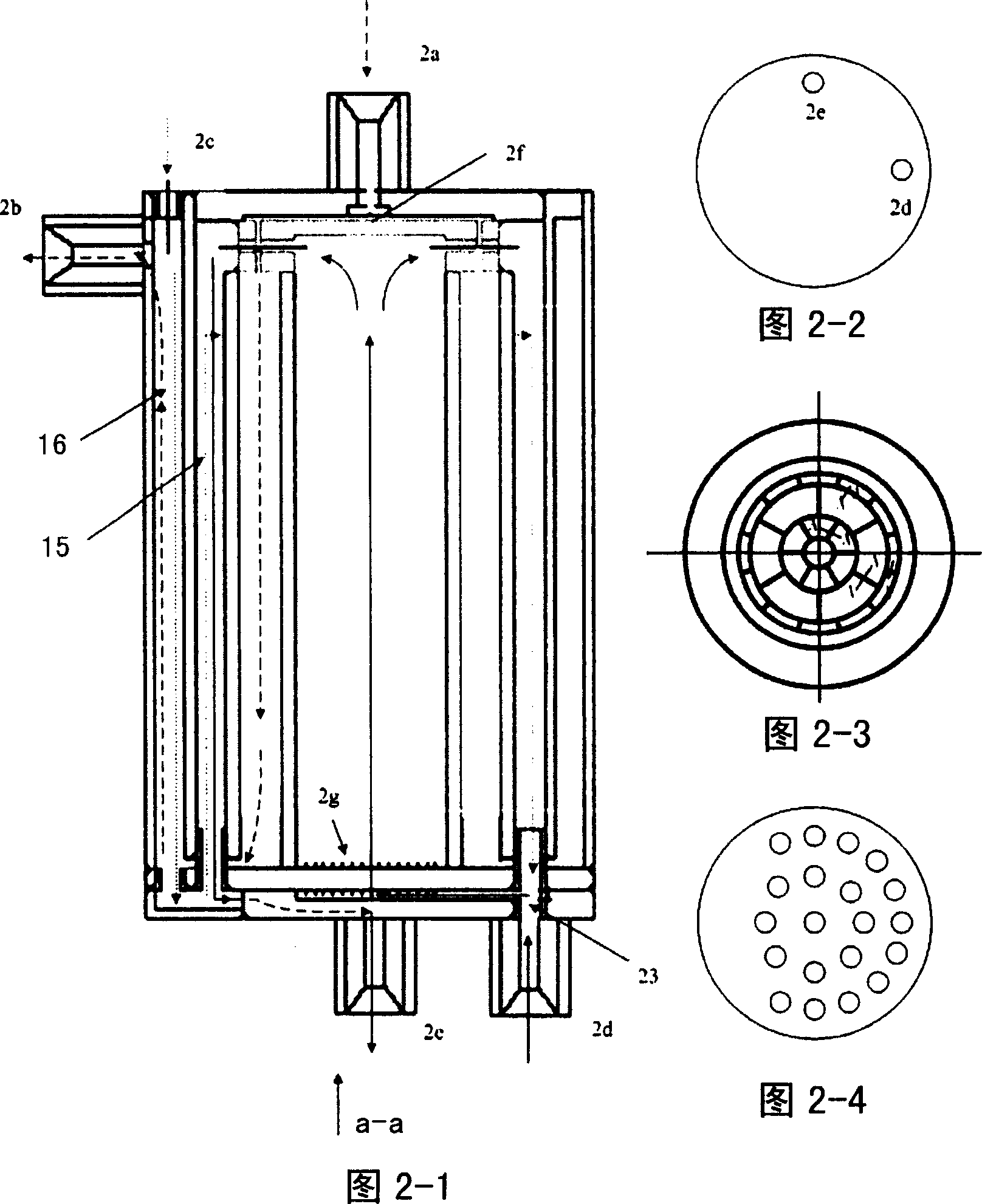

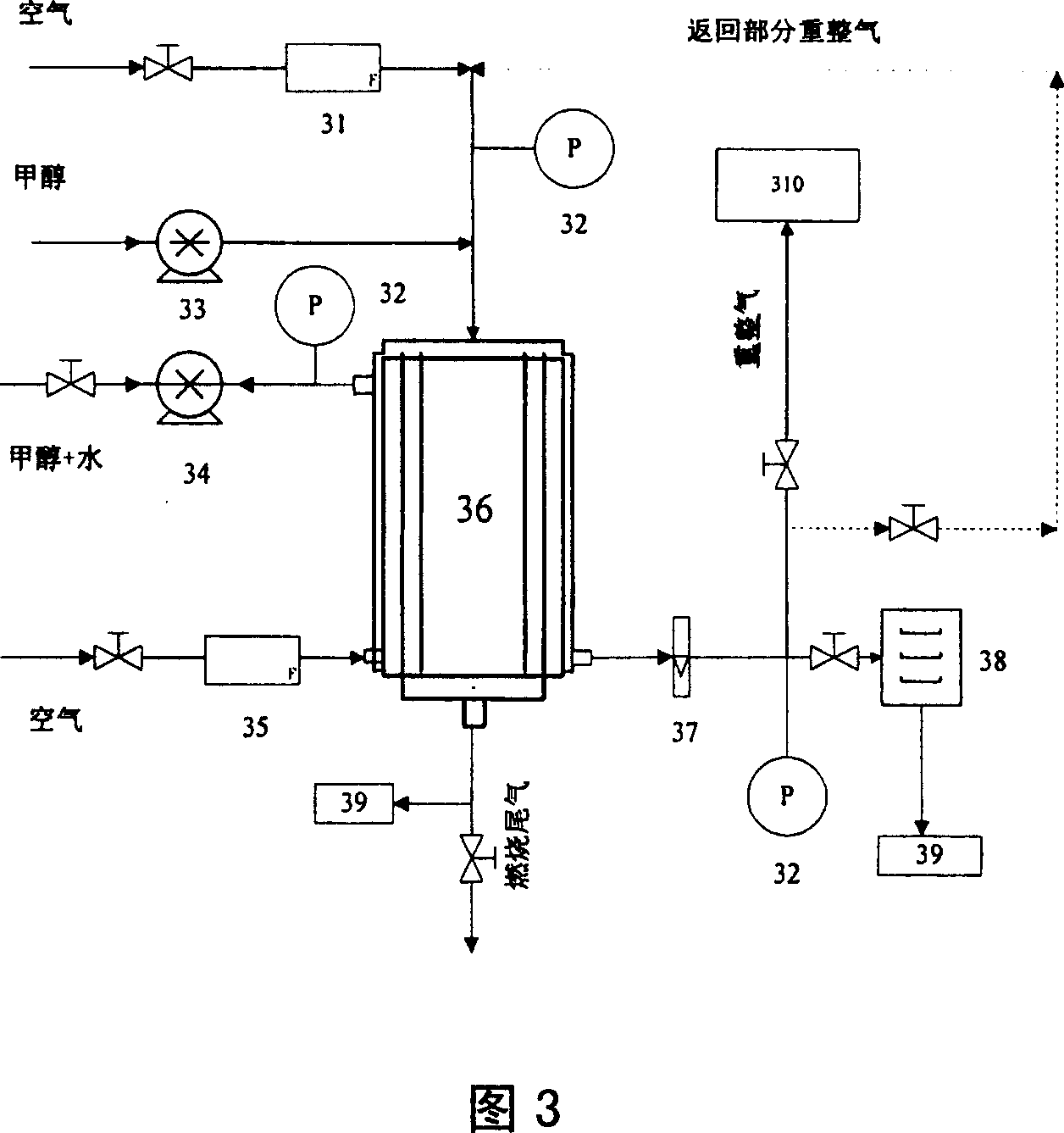

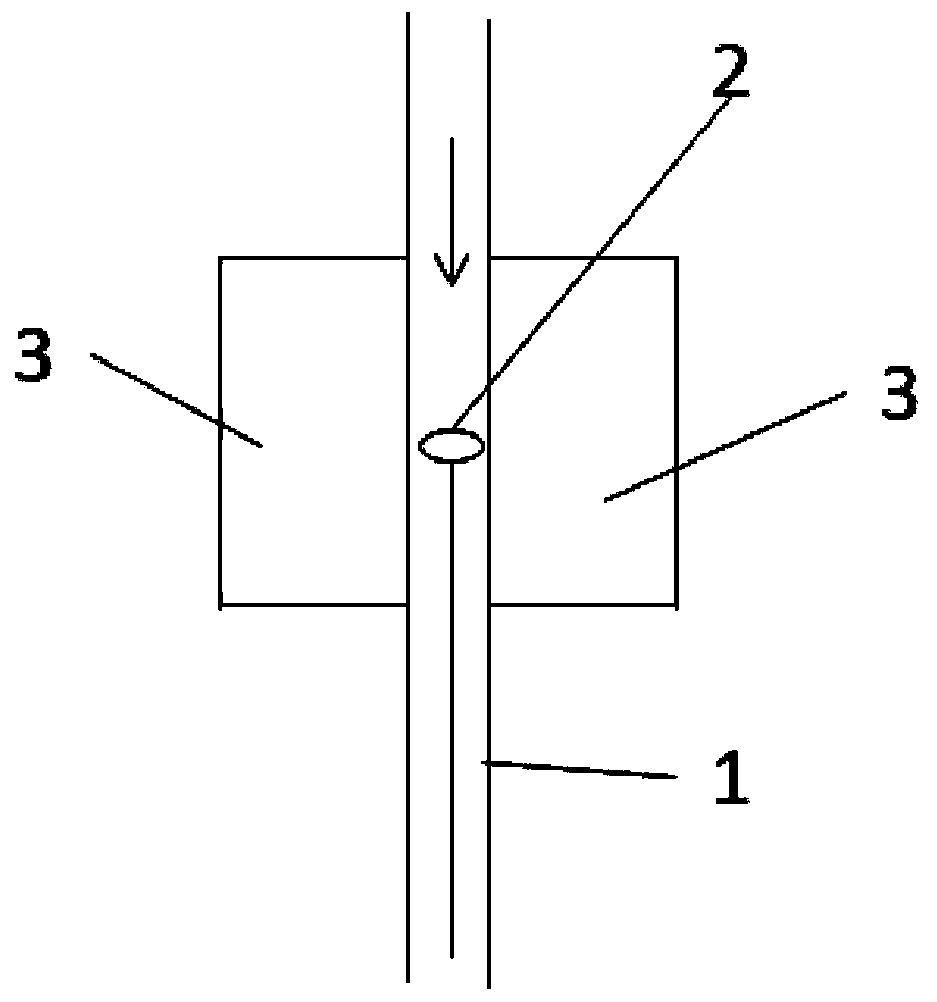

Mini reforming hydrogen-preparation reactor

InactiveCN101054160ARapid reforming hydrogen production reactionEven air distributionHydrogenHydrogenFuel cells

A minitype reactor for reforming hydrogen, which main part has telescopefeed structure, comprising a burning offgas heat exchange cavity, a reforming offgas heat exchange cavity, a burning cavity and a reforming cavity in sequence from outside; a fuel inlet is arranged communicating with the burning cavity; a reforming material inlet is arranged communicating with a built-in cavity of the burning offgas heat exchange cavity; reforming material liquid is preheated in the built-in cavity of the burning offgas heat exchange cavity then supplied into a built-in cavity of the reforming offgas heat exchange cavity; reforming material liquid flows in built-in cavities, burning offgas and reforming offgas exchange heat via tube wall of built-in cavities and flow oppose to reforming material liquid; a reforming air inlet is arranged, mixture gas of reforming air mixing with gas phase vaporized in the reforming offgas heat exchange cavity is supplied into the reforming cavity to process reforming hydrogen reaction. The catalytic burning reaction and reforming reaction of the invention has advantages of temperature easy to be control, stable running, easy operation; compact structure; the invention is suit for hydrogen source system of 10-500 W fuel cell minitype electrical source.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

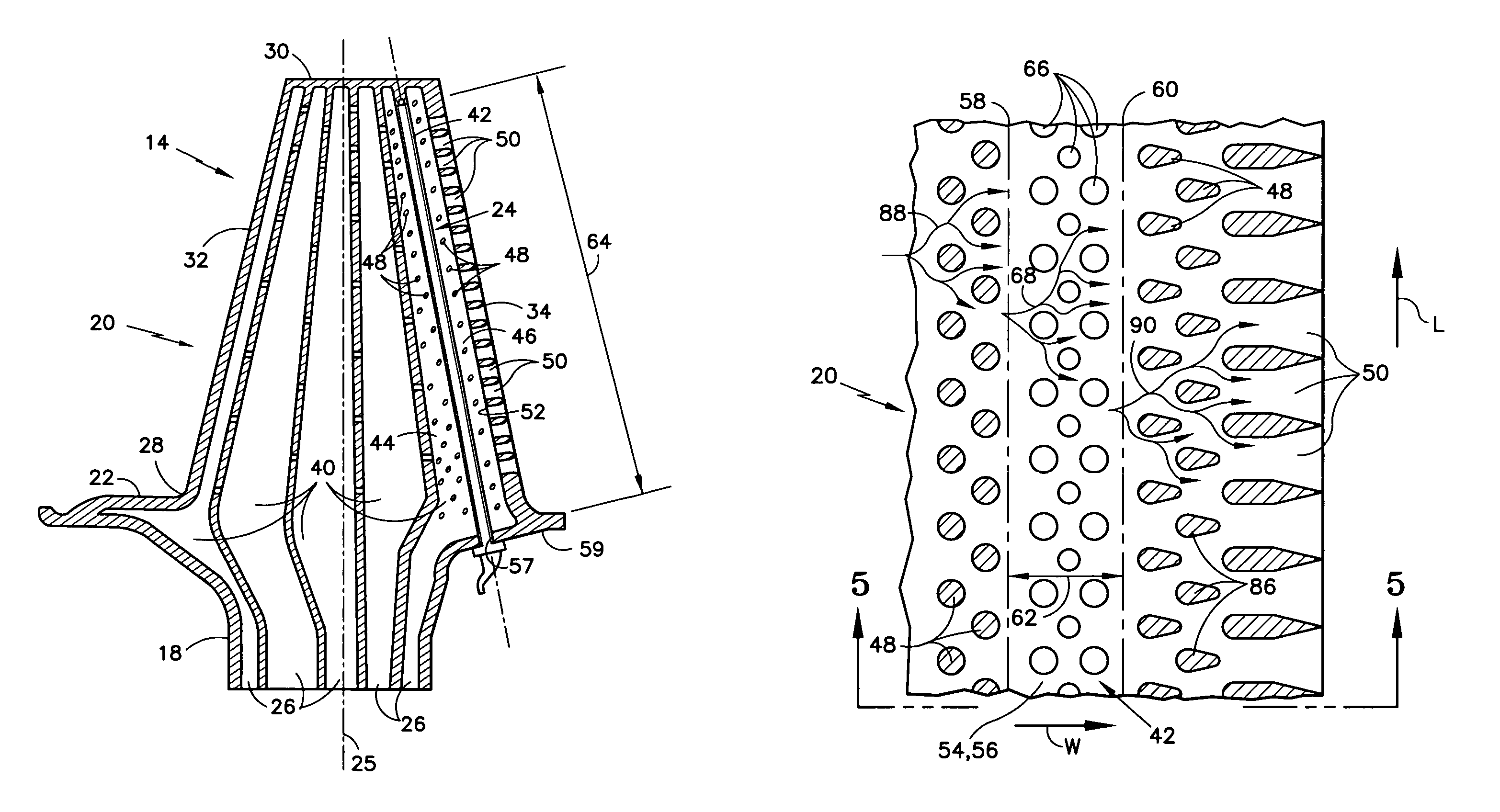

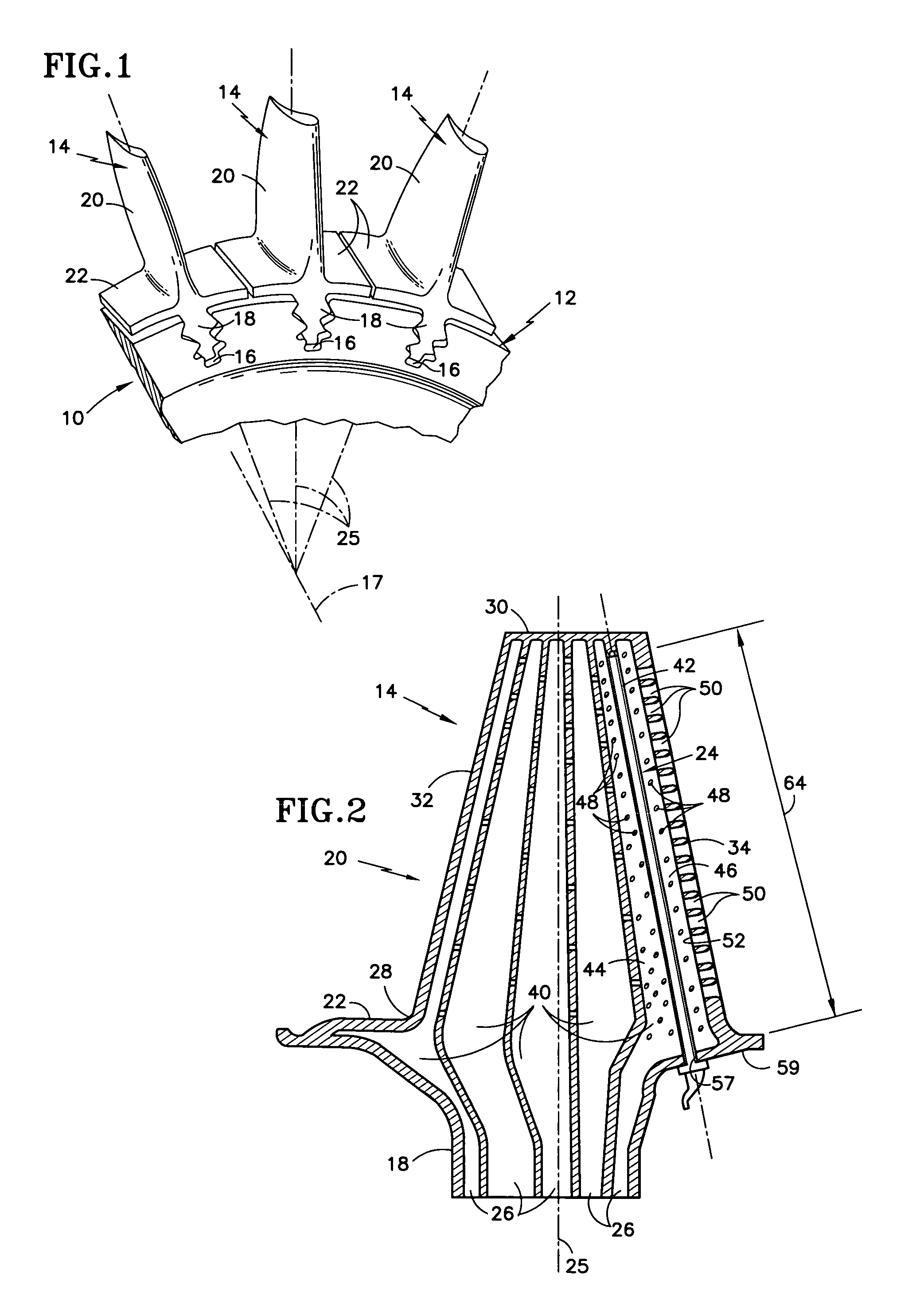

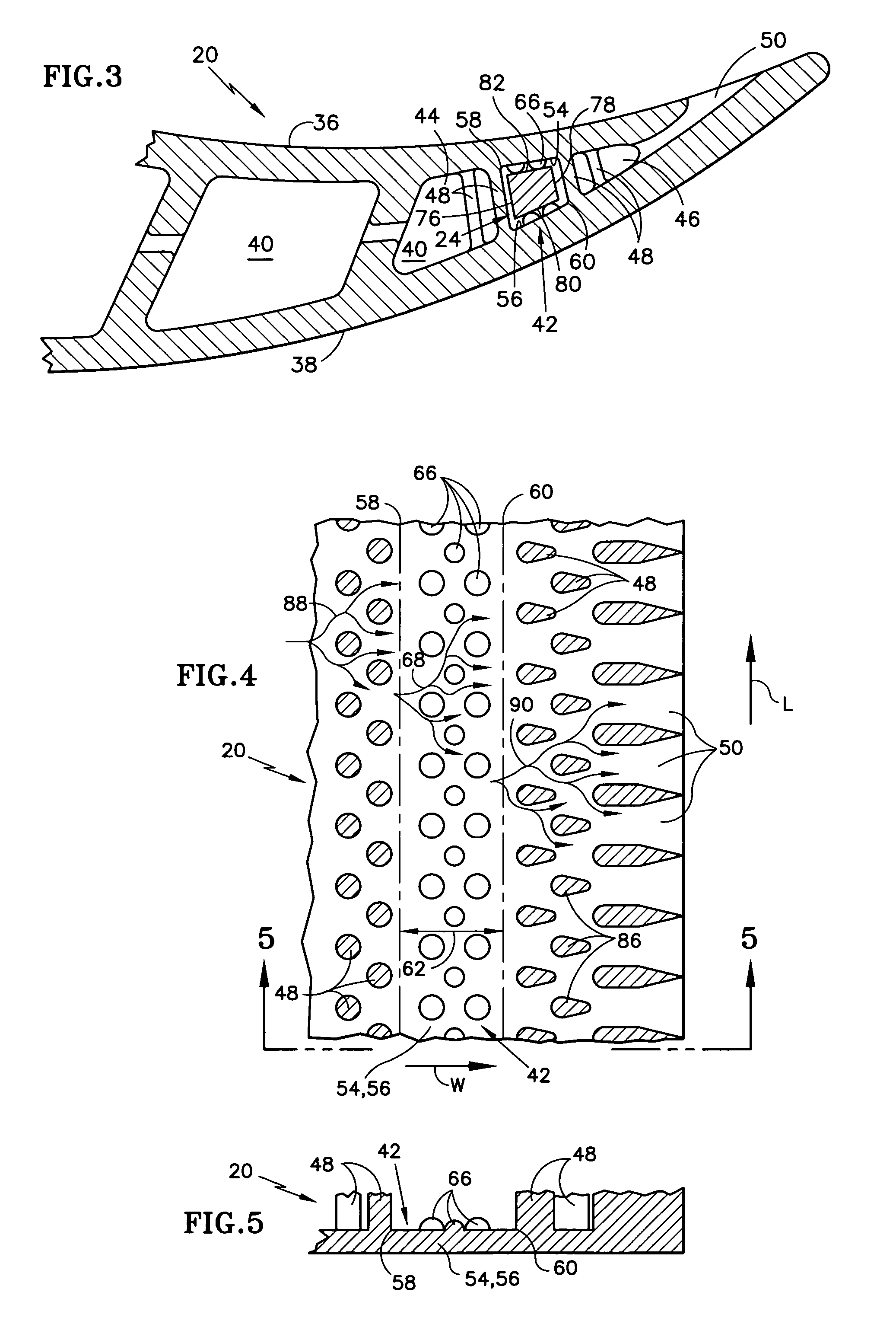

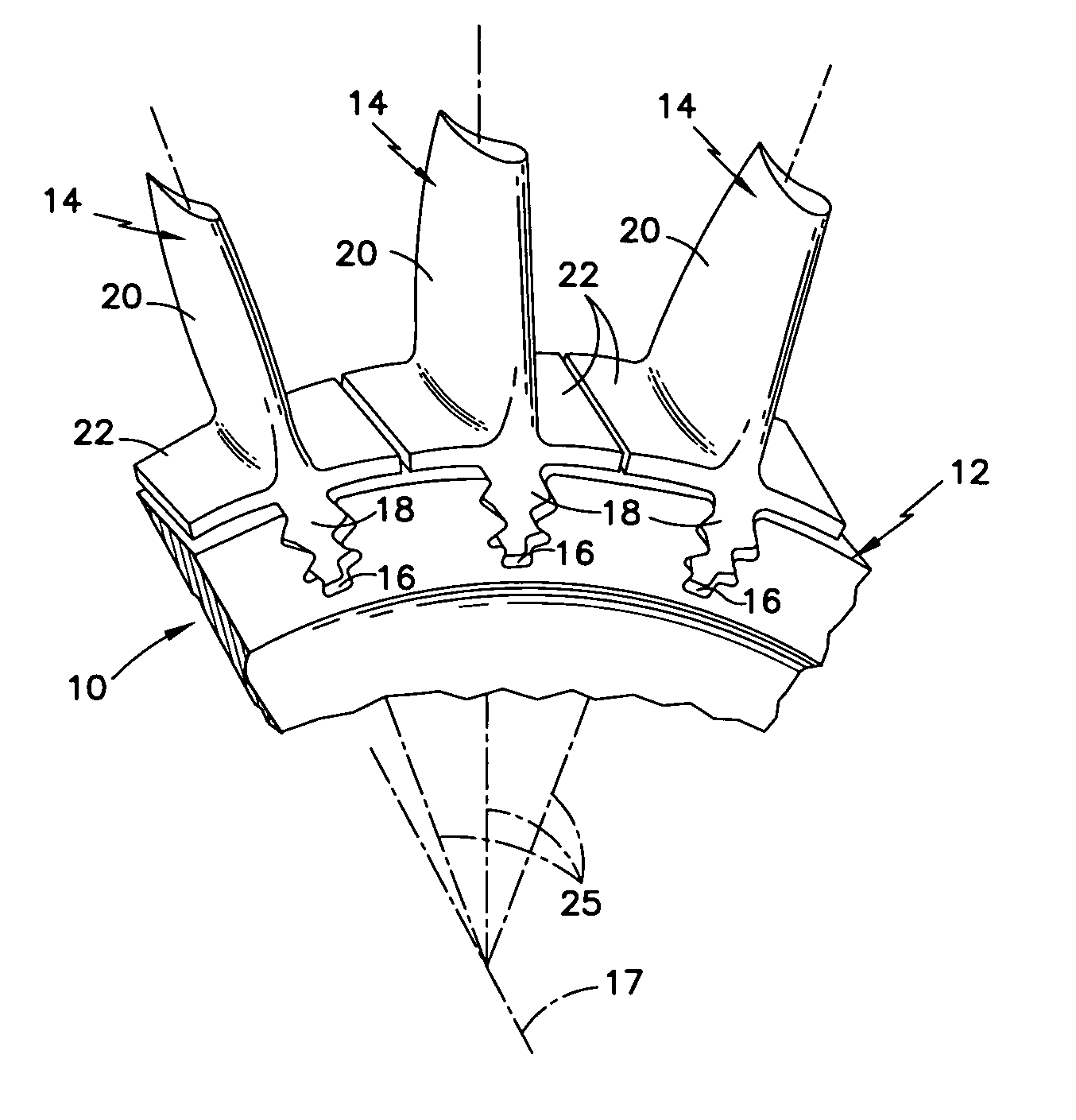

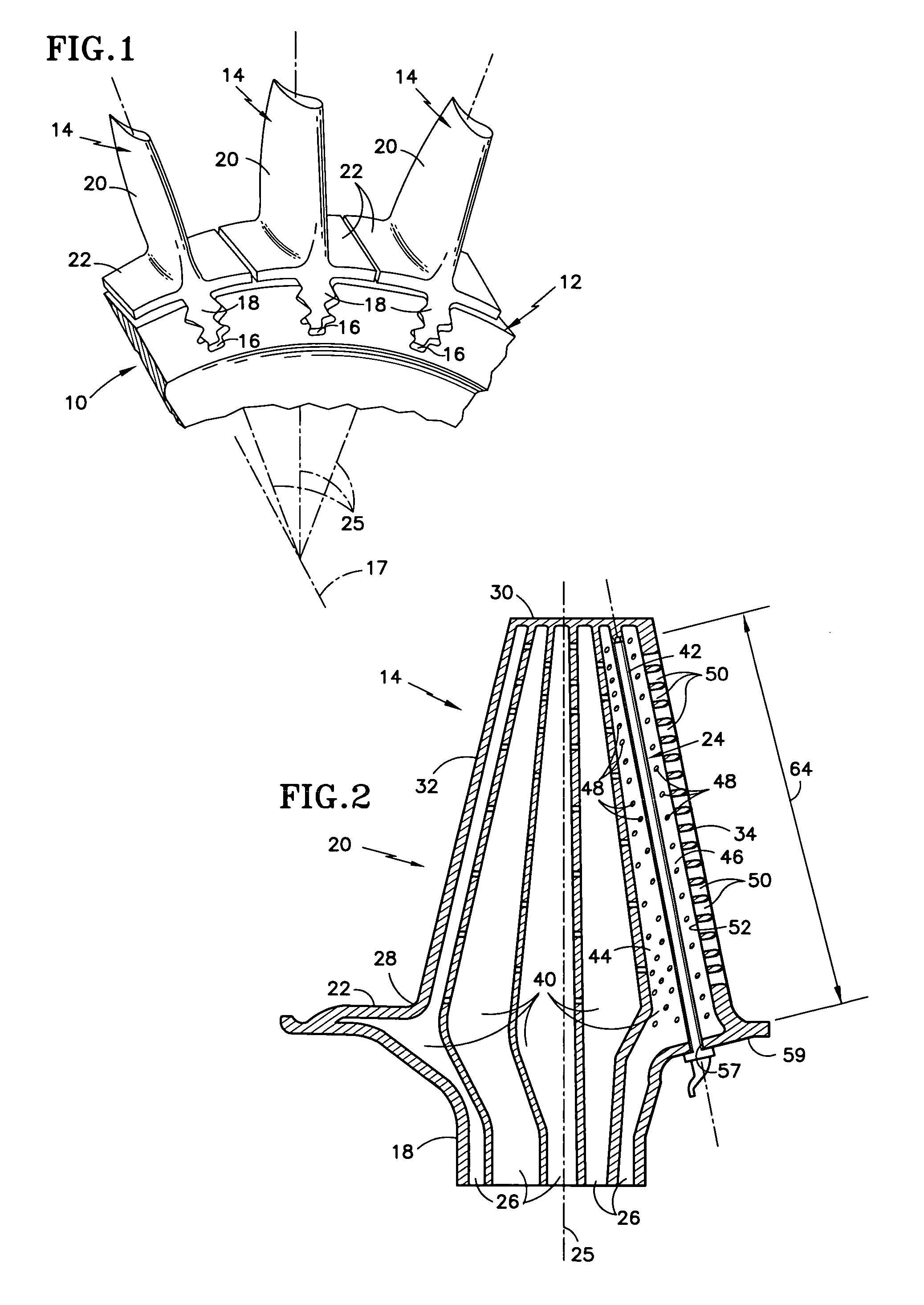

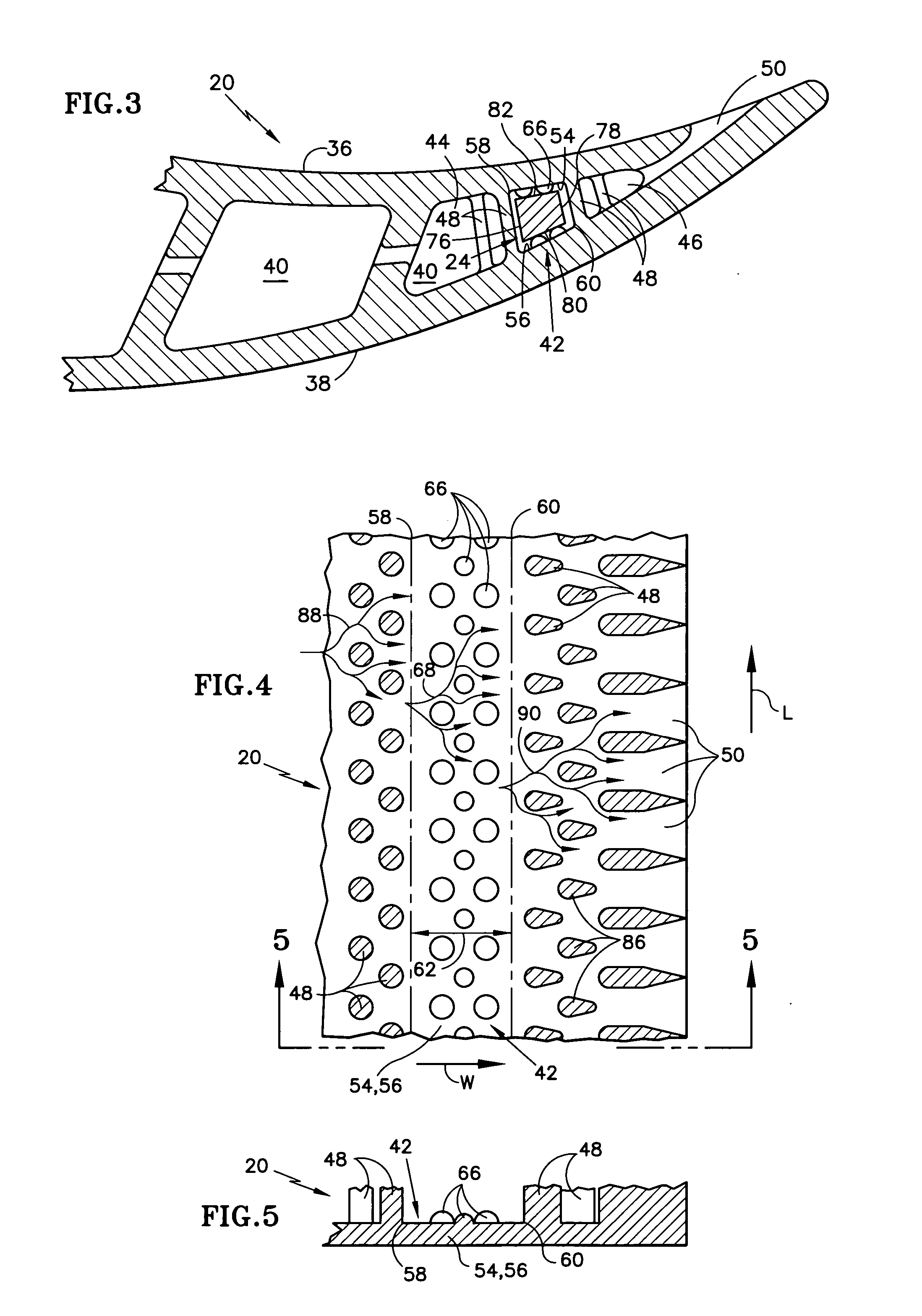

Cooled rotor blade with vibration damping device

A rotor blade for a rotor assembly is provided that includes a root, an airfoil, and a damper. The airfoil includes a base, a tip, a pressure side wall, a suction side wall, and a cavity disposed therebetween. The cavity extends substantially between the base and the tip, and includes a first cavity portion, a second cavity portion, and a channel disposed between the first cavity portion and the second cavity portion. A plurality of first pedestals are disposed within the first cavity portion adjacent the channel, and a plurality of second pedestals are disposed within the second cavity portion adjacent the channel. The damper is selectively received within the channel.

Owner:RTX CORP

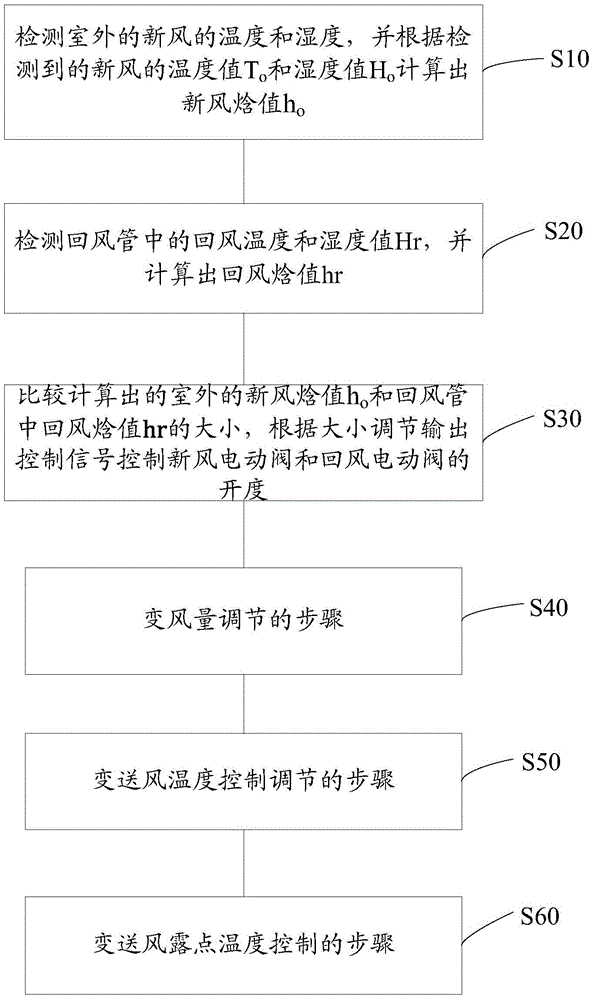

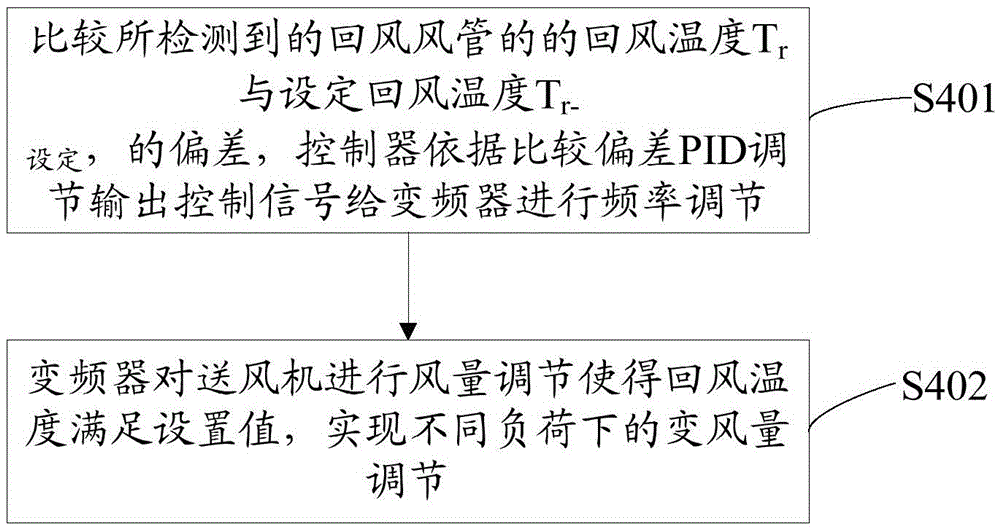

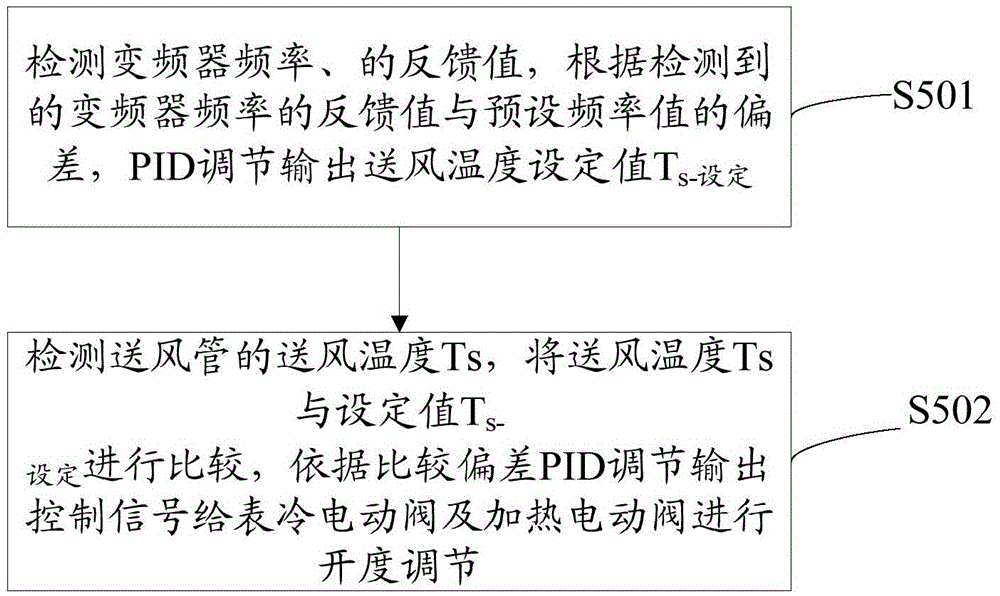

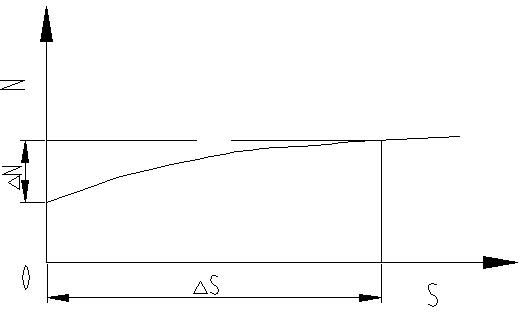

Energy-saving control method and system for constant-temperature constant-humidity air conditioning unit based on variable parameter adjustment

InactiveCN105674512ASmall temperature deviationGuaranteed qualityMechanical apparatusSpace heating and ventilation safety systemsIndoor air qualityControl system

The invention discloses an energy-saving control method and an energy-saving control system for constant-temperature constant-humidity air conditioning unit based on variable parameter adjustment, and relates to the field of air-conditioning energy-saving control. The energy-saving control method comprises the following steps: detecting temperature and humidity of outdoor fresh air, and calculating a fresh air enthalpy value ho according to the detected temperature value To and the detected humidity value Ho of the fresh air; detecting a return air temperature Tr and the humidity value Hr in a return air duct, calculating a return air enthalpy value hr; comparing the fresh air enthalpy value h0 with the return air enthalpy value hr in the return air duct, and adjusting an output signal according to a size for controlling the opening degree of a fresh air electric valve and a return air electric valve; a step of adjusting an variable air rate; a step of controlling and adjusting a variable air supply temperature; and a step of controlling a variable air supply dew point temperature. By virtue of variable parameter adjustment, the system is matched with load of the tail end better, so that the temperature deviation of an air-conditioning area is reduced, and operation energy consumption required by the system is greatly reduced; and when the indoor air quality is guaranteed, the system operation is more stable and efficient.

Owner:SHENZHEN XINHUANNENG TECH

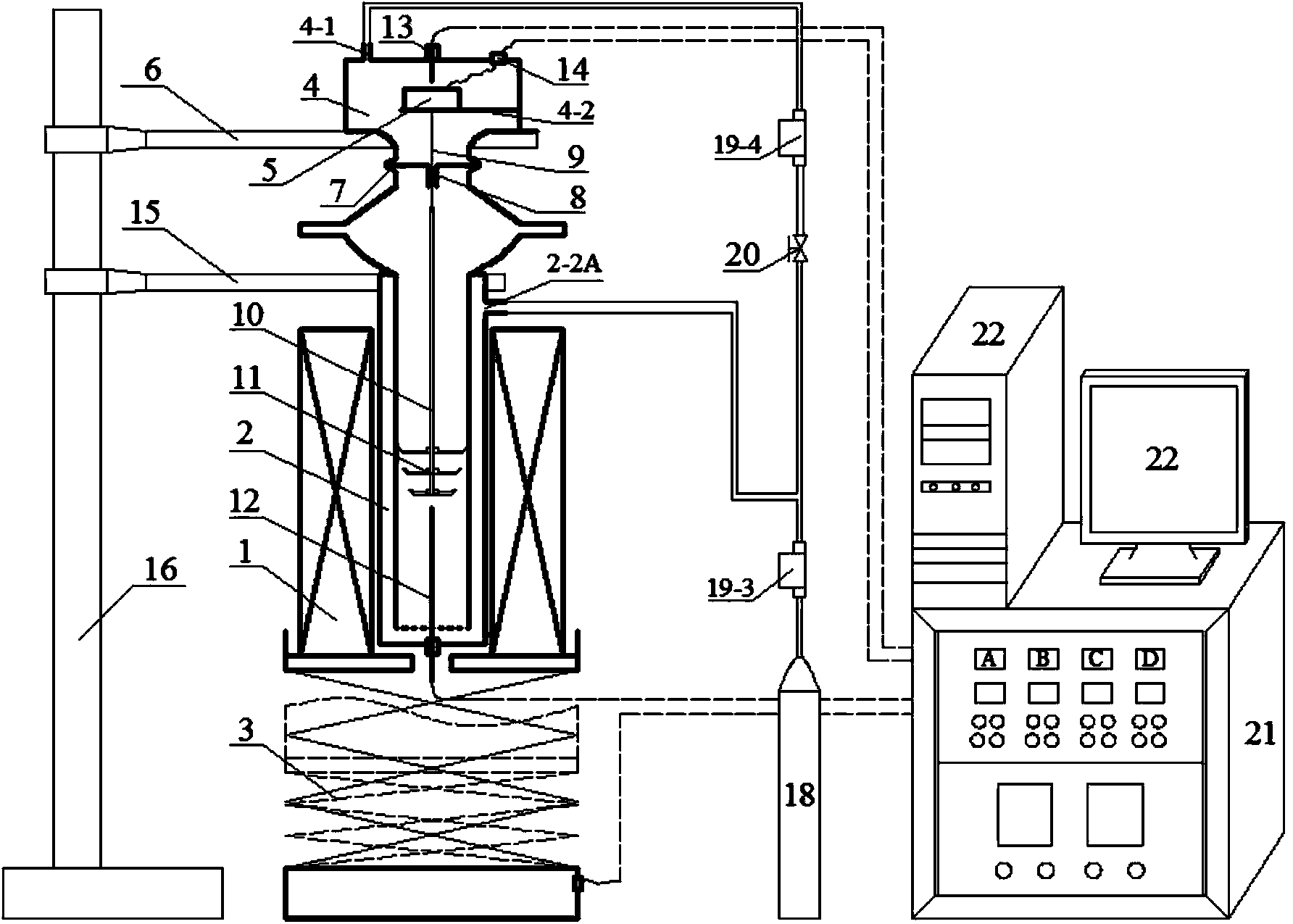

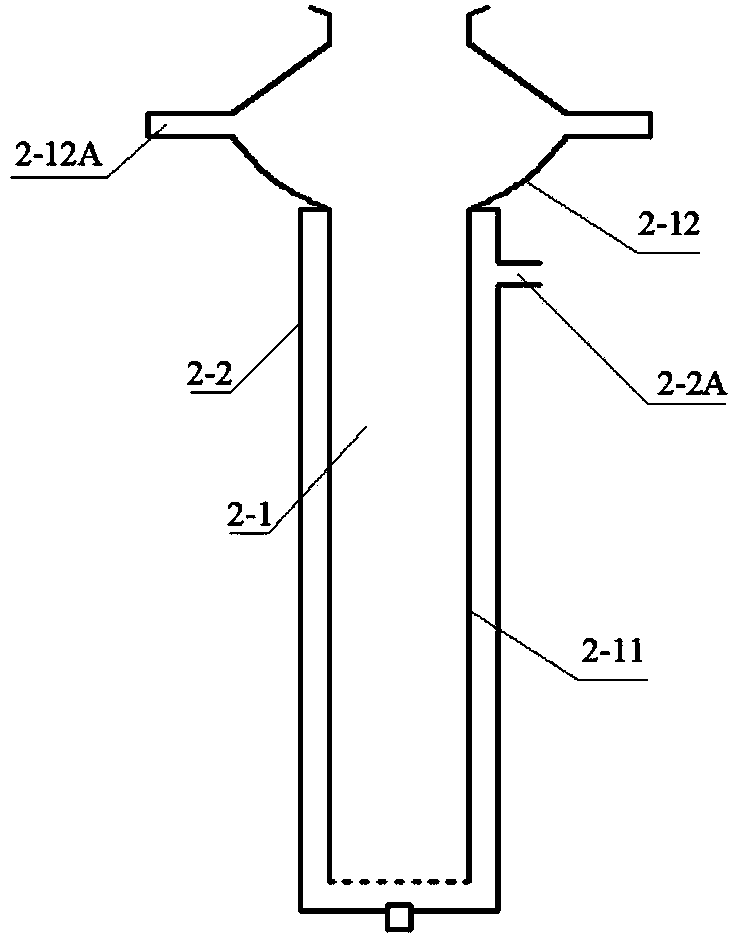

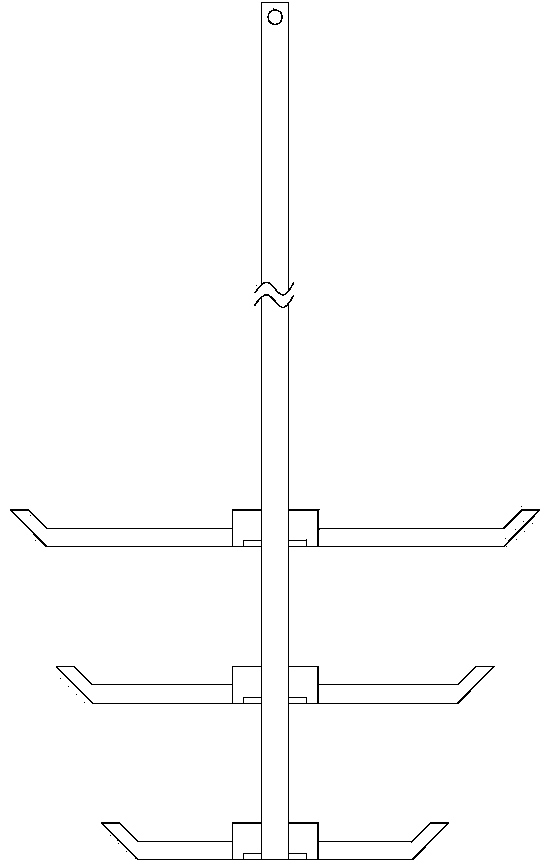

Thermal gravimetrical reactor applied to bulk specimen testing

The invention discloses a thermal gravimetrical reactor applied to bulk specimen testing, belonging to testing equipment for performing thermo gravimetric analysis on specimens and aiming to solve the problems that small-mass and small-sized specimens are required and a sample vessel is unbeneficial to gas-solid reactions in the conventional thermo gravimetric analyzer. Through a high-temperature reactor, reaction gas is preheated fully, so that mass measuring errors caused by temperature change of the reaction atmosphere are avoided; two types of hanging baskets are specific to different specimens respectively, so that the diffusion resistance during the reactions of bulk specimens is reduced effectively, and complete reactions and measuring accuracy are ensured; the height of an electric heating furnace is adjusted through a hydraulic lifting platform, so that samples can be heated at constant temperature under a high-accuracy condition. The thermal gravimetrical reactor can be used for dynamically measuring the mass changes of bulk specimens at various heating rates or under a constant-temperature condition, and is more consistent with the requirements of scientific research production than the conventional thermal gravimetrical analyzer.

Owner:HUAZHONG UNIV OF SCI & TECH

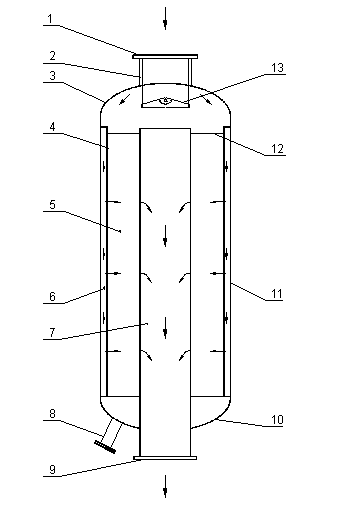

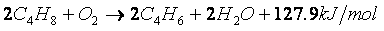

Radial fixed bed reactor for oxy-dehydrogenation of butylene

InactiveCN103071429ABalanced utilizationSimple structureHydrocarbonsChemical/physical processesPorositySingle stage

The invention relates to a radial fixed bed reactor for oxy-dehydrogenation of butylene. The radial fixed bed reactor mainly solves the problems that the pressure drop of the reactor is high, fluid distribution is nonuniform, a raw material conversion rate is low, and product selectivity is low in the prior art. The radial fixed bed reactor adopts a centripetal Z-shaped structure and is a cylindrical vessel with a catalyst bed; a feed port is located at the top of the reactor; a discharge port is located at the bottom of the reactor; a gas predistributor with a conical single-stage baffle is arranged at the feed port; the catalyst bed consists of a fan-shaped barrel distributor located at an outer ring and a porous wall barrel located at an inner ring; a catalyst is filled in the catalyst bed; a cover plate sealing structure is arranged at the top of the catalyst; the fan-shaped barrel distributor can be in a porosity-variable or Johnson screen structural form; and the porous wall barrel at the inner ring consists of an inner layer center porous barrel, an intermediate layer punched plate and an outer layer screen. The radial fixed bed reactor solves the problems better and can be used for industrial production of preparing butadiene through the oxy-dehydrogenation of butylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

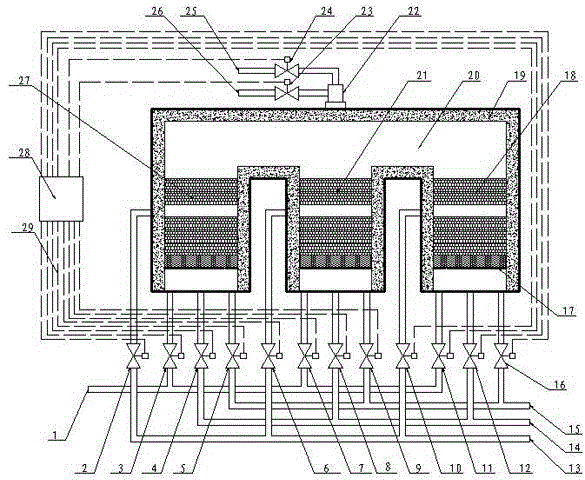

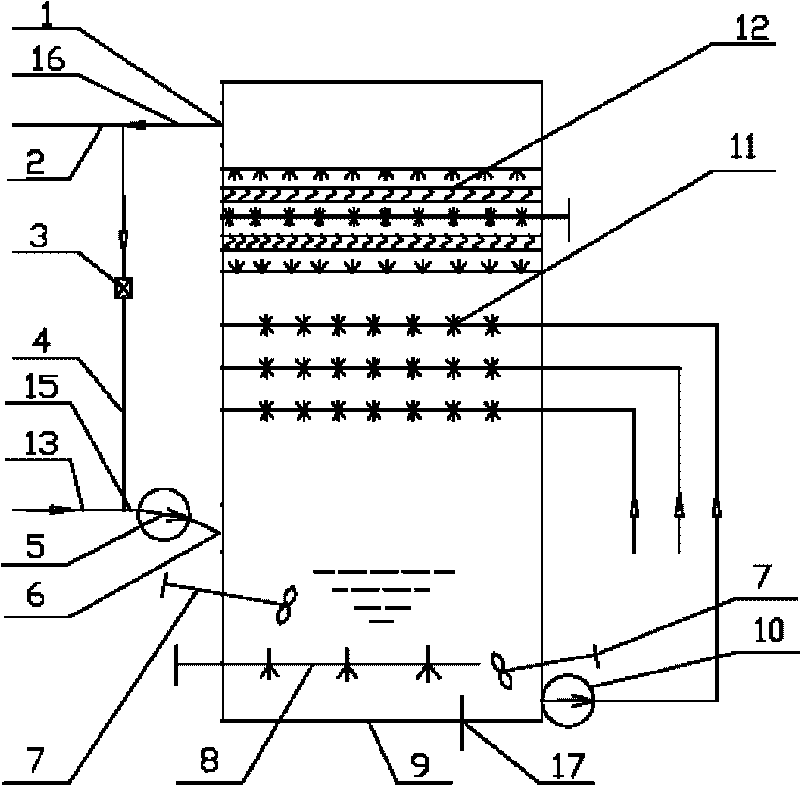

Multi-bed type ventilation air methane regenerative thermal oxidation device

InactiveCN102720527AIncrease oxidation rateImprove running stabilityTunnel/mines ventillationGas removalCounter flowCombustion chamber

The invention discloses a multi-bed type ventilation air methane regenerative thermal oxidation device which is used in a ventilation air methane counter-flow thermal oxidation treatment process during production of coal mines. The device comprise three or more oxidation beds, a combustion chamber, a preheater, a ventilation air inlet pipe, a flue gas outlet pipe, a purging pipeline, a flue gas extraction pipeline, a switching valve and a control unit. Oxidation beds are in a vertical structure, heat-insulating fire-resisting materials are arranged on peripheries of oxidation beds, and in addition to a heat accumulation and heat release circulation, a purging purification process is added, so that unoxidized ventilation air is prevented from being directly exhausted into the air, and the oxidation rate exceeds 99%. Besides, flue gas extraction openings are arranged between high-temperature zones and low-temperature zones of oxidation beds, so that part of high-temperature flue gases can be extracted for waste-heat utilization. The device has the advantages of being high in oxidation rate of methane, convenient for waste-heat utilization, stable to operate and the like.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

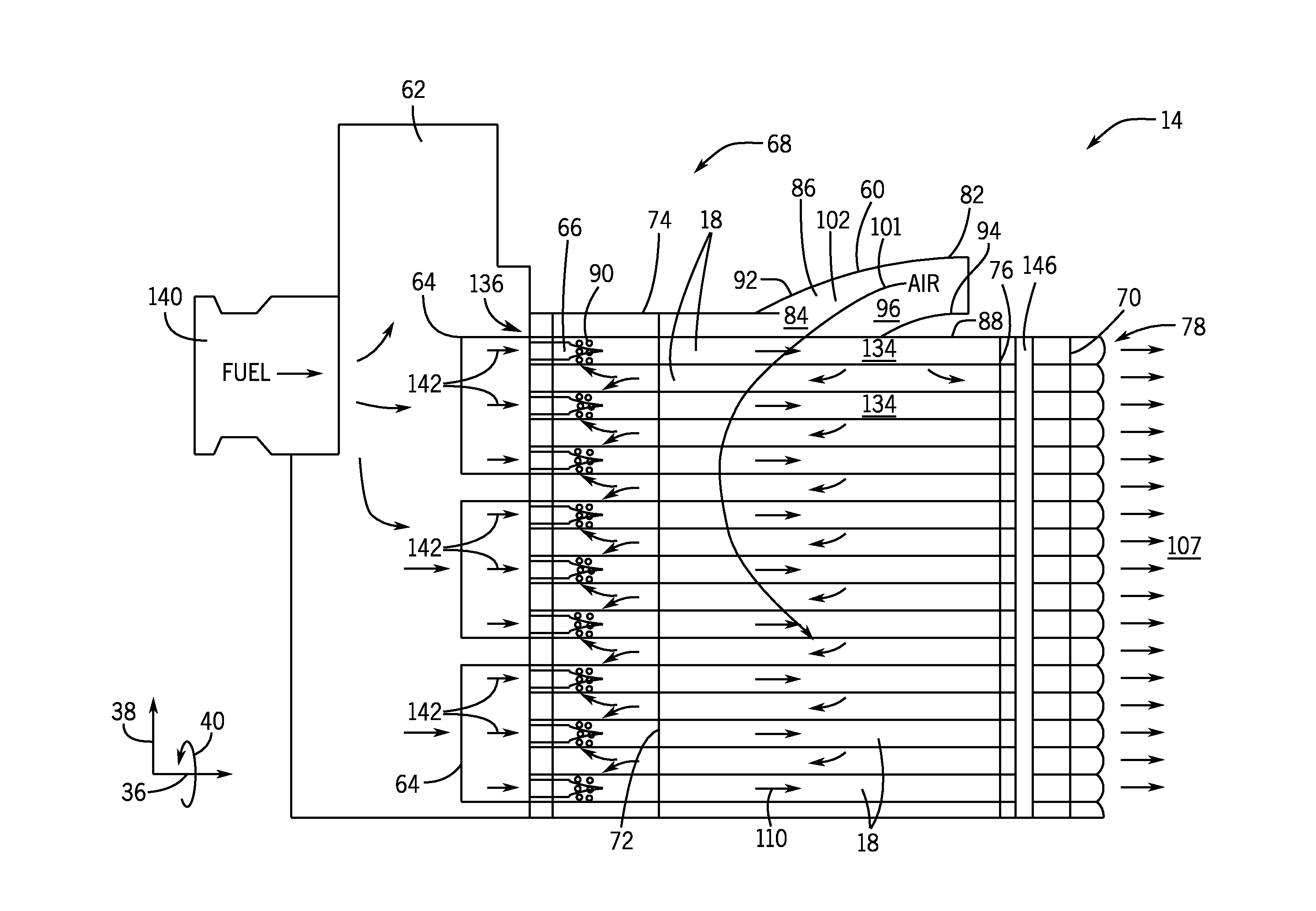

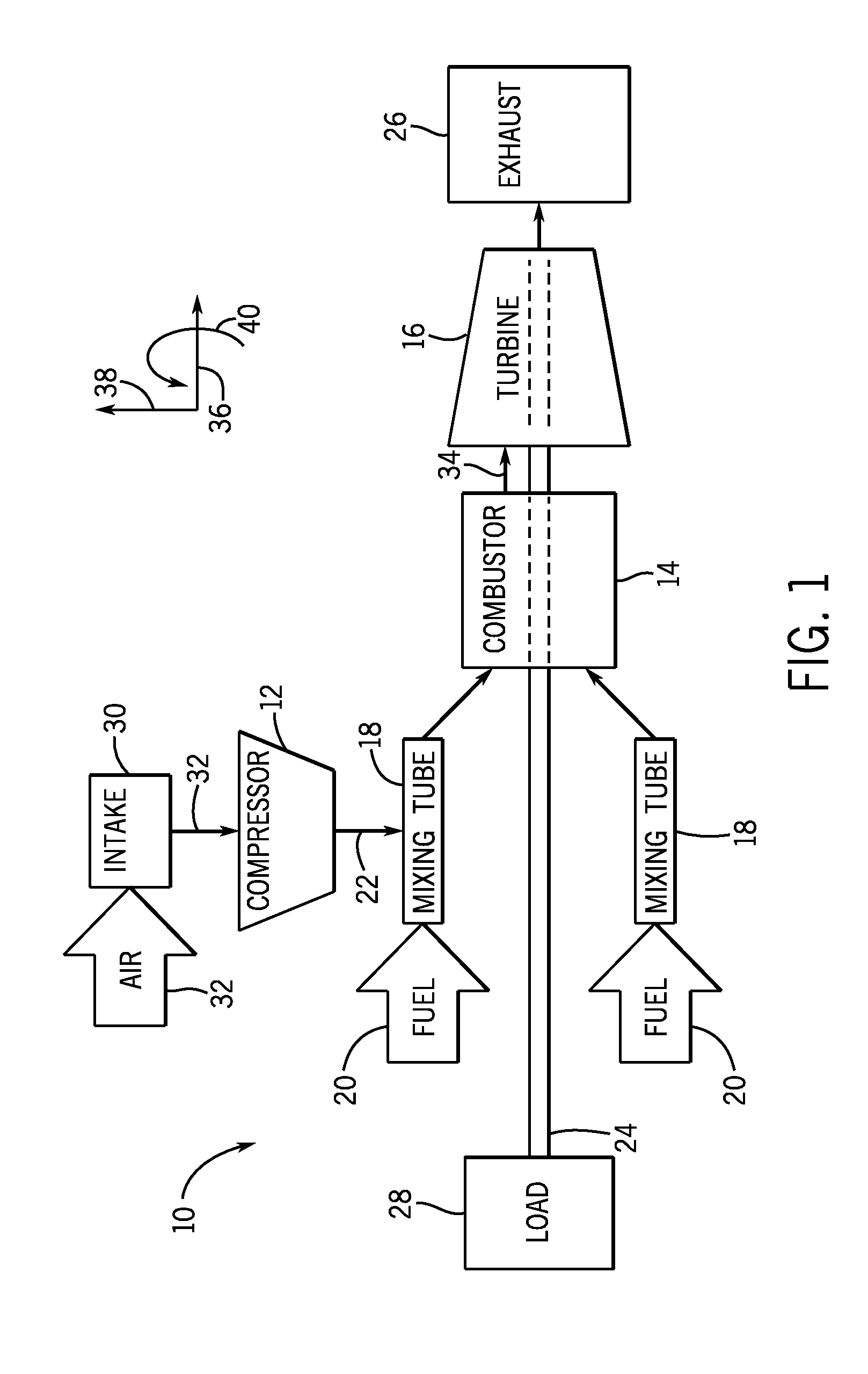

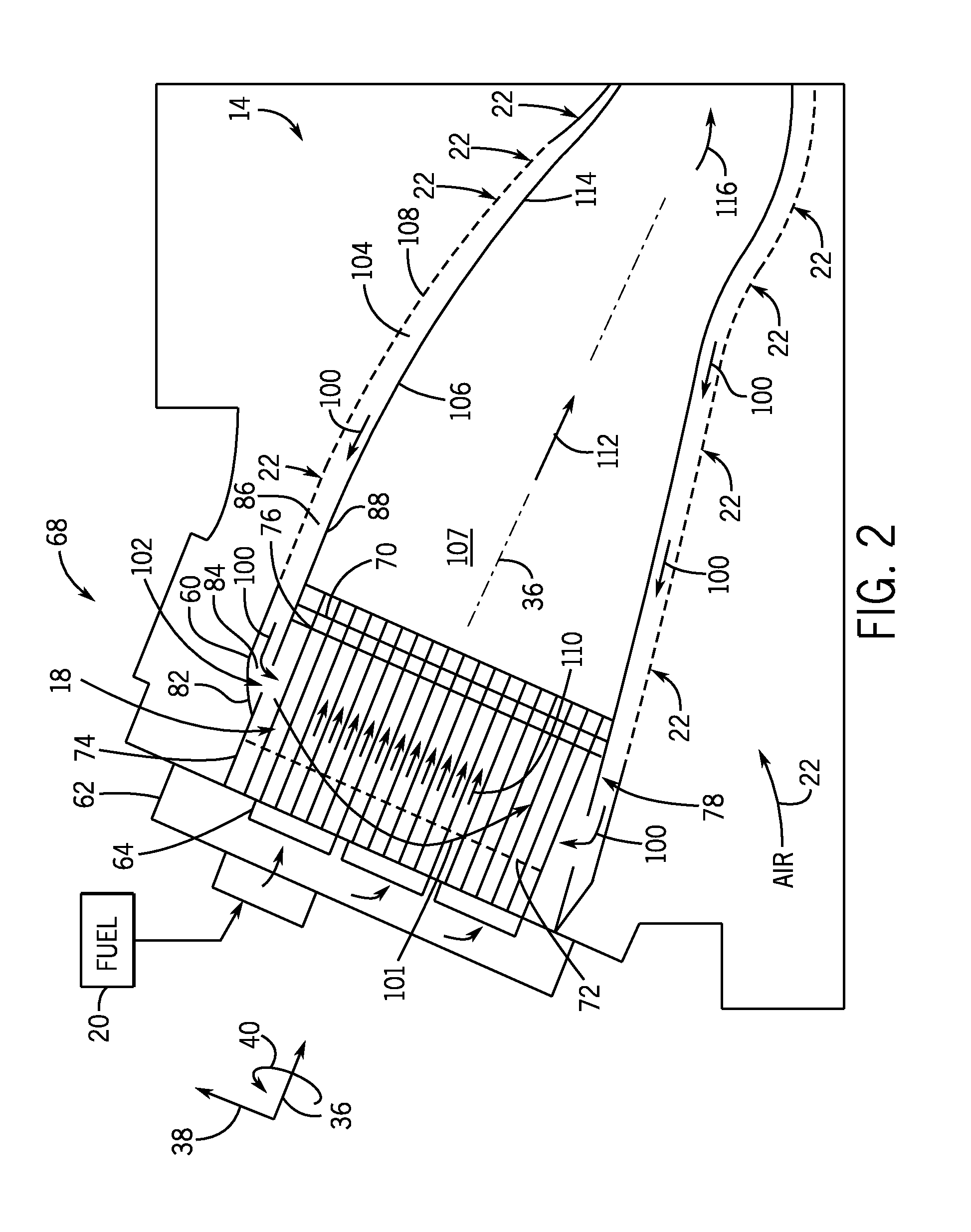

Air diffuser for combustor

ActiveUS20140260300A1Reduced flow separationReduce manufacturing costContinuous combustion chamberTurbine/propulsion fuel supply systemsInjectorInterior space

A system includes a multi-tube fuel nozzle of a turbine combustor. The multi-tube fuel nozzle includes a support structure defining an interior volume configured to receive an air flow; a plurality of mixing tubes disposed within the interior volume, wherein each of the plurality of mixing tubes comprises a respective fuel injector; and an outer annular wall configured to direct an air flow from an annulus between a liner and a flow sleeve of the turbine combustor at least partially radially inward into the interior volume through an air inlet and toward the plurality of mixing tubes, wherein the outer annular wall at least partially defines an air flow passage extending from the annulus to the interior volume.

Owner:GENERAL ELECTRIC CO

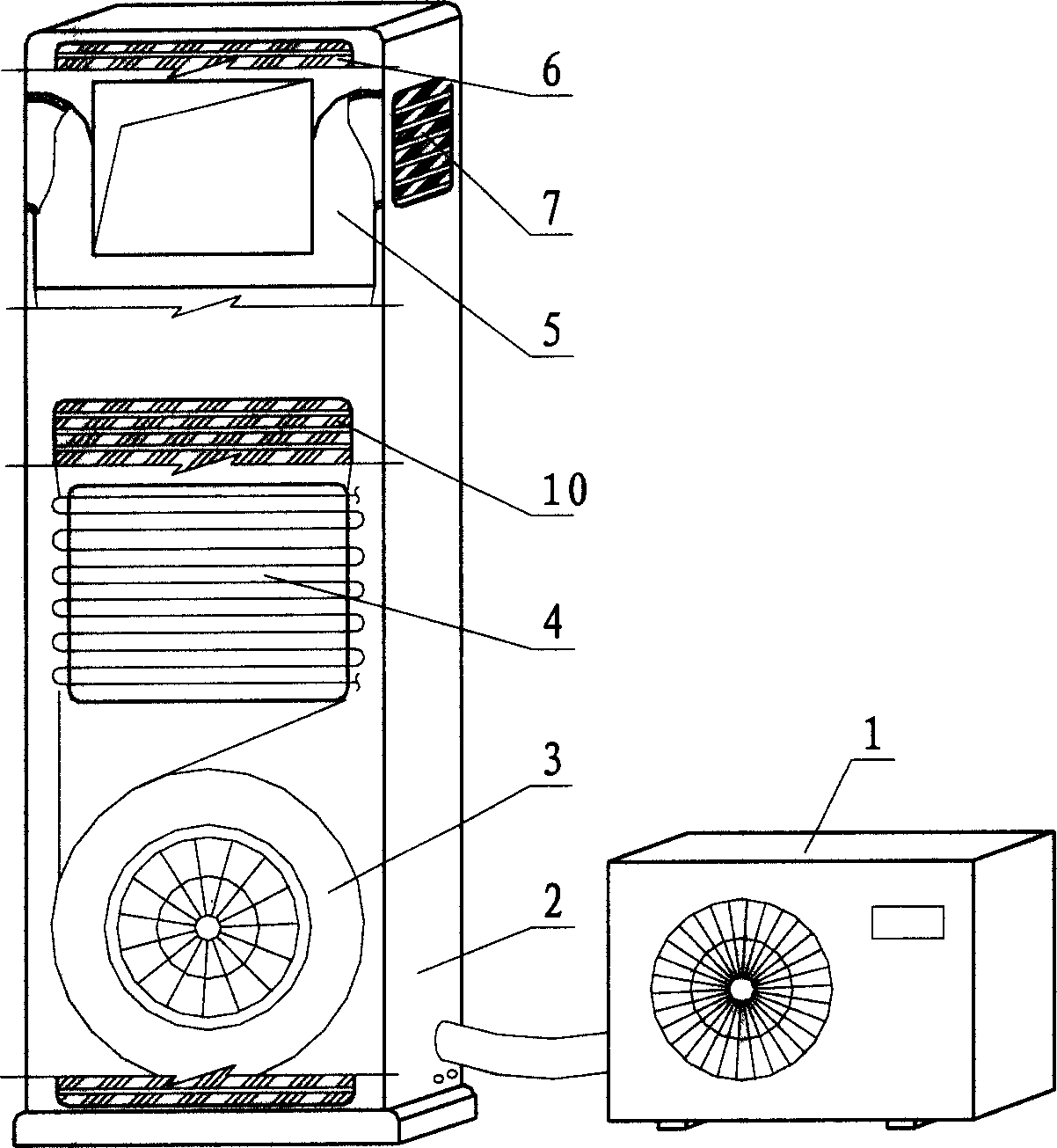

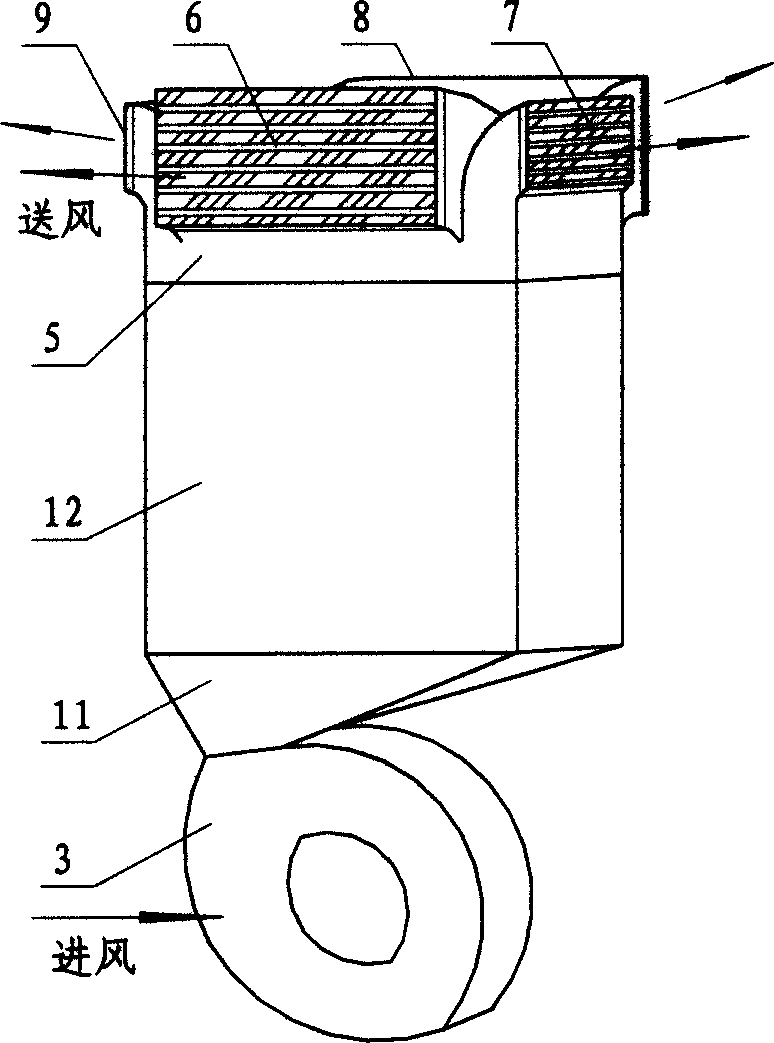

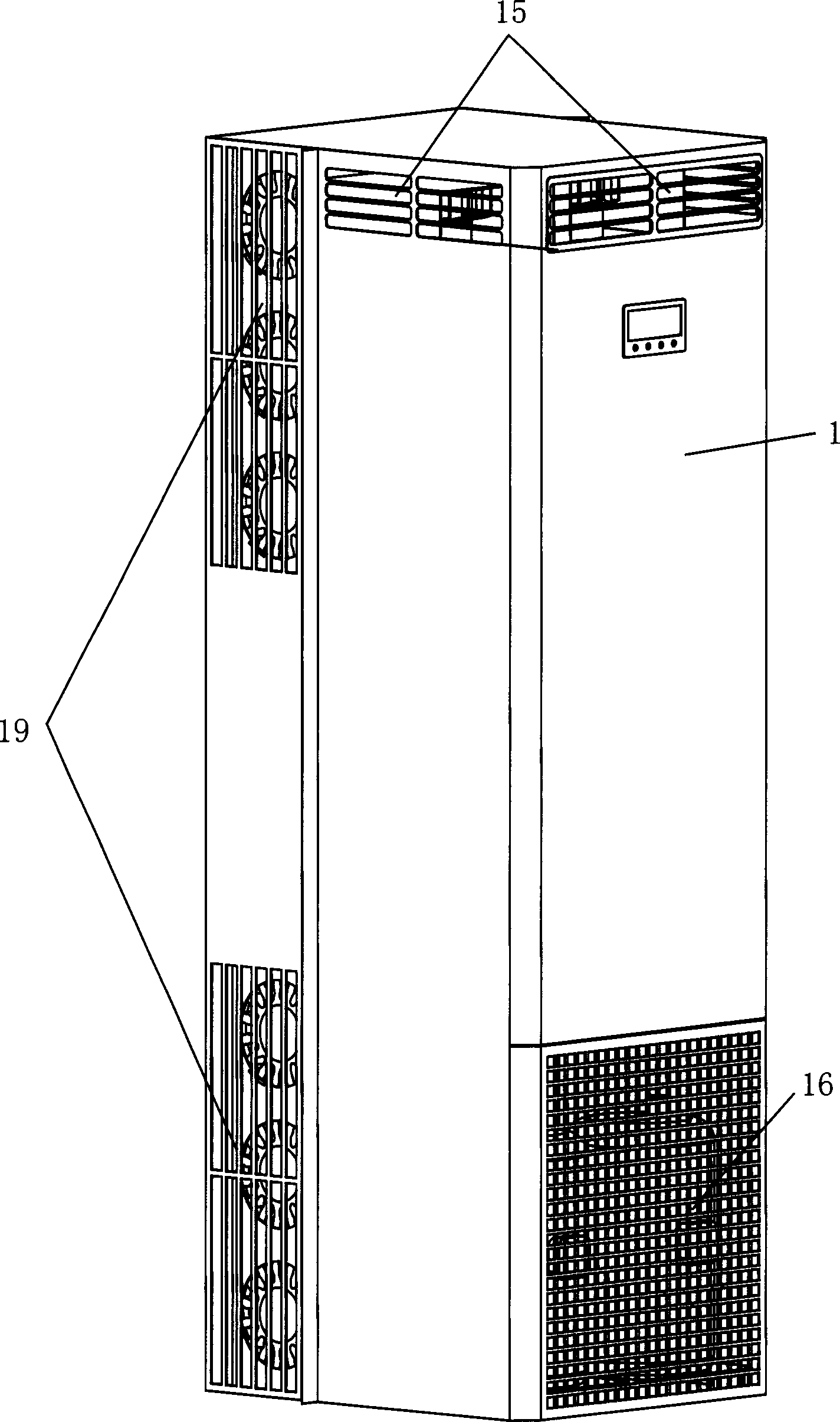

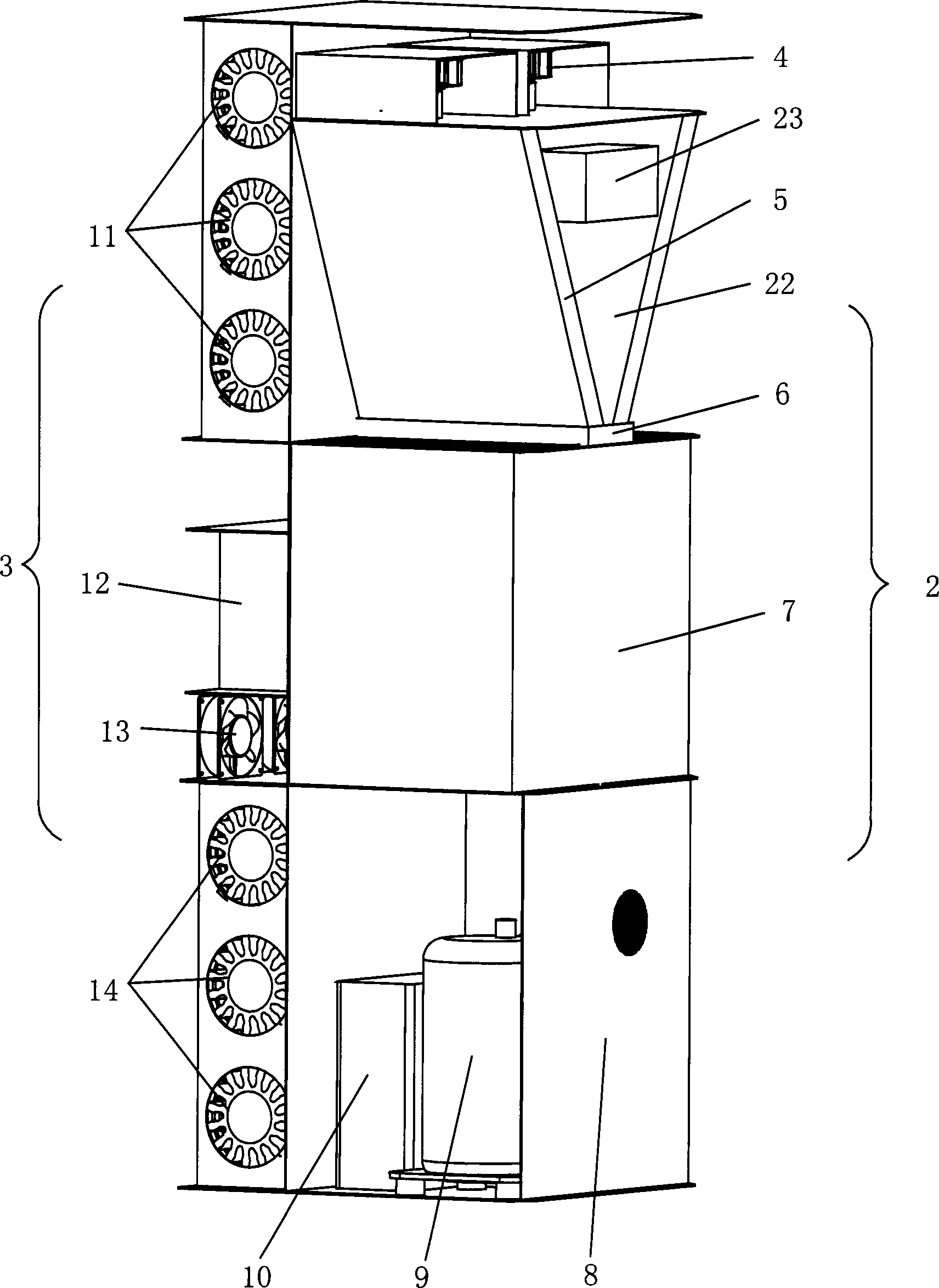

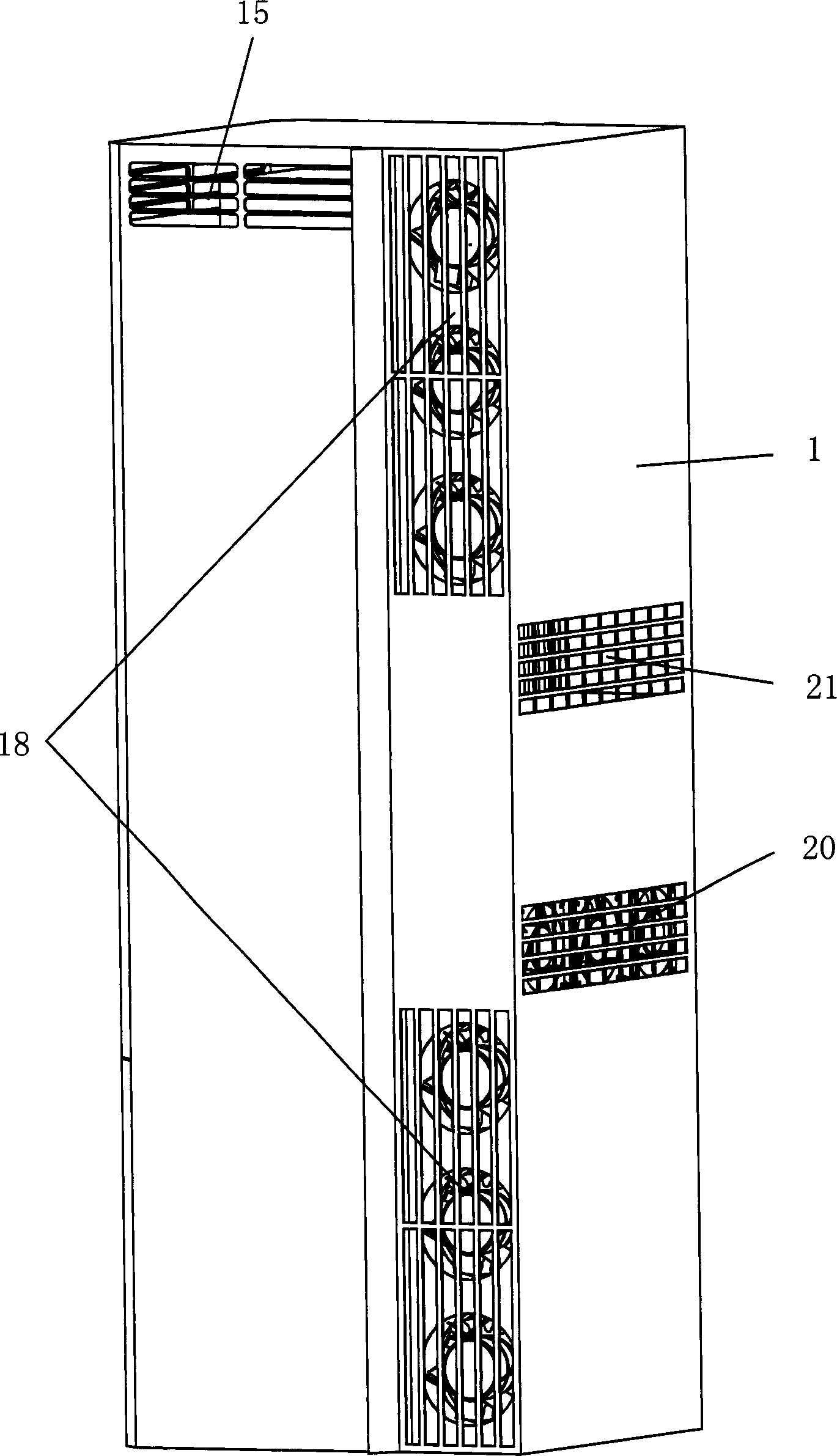

Cabinet air-conditioner with multi-directional air-blowing

InactiveCN1580661AImprove air conditioning performanceEven air distributionDucting arrangementsLighting and heating apparatusEngineeringMulti directional

This is a multidirectional blower air conditioner. It contains outdoor set, indoor set, blower, evaporator, four-side pass way, front blow outlet, bak blow outlet, right-side blow outlet, left-side blow outlet, blow inlet, change-diameter pipe, and blow-pipe. On the top part of indoor set cover at the front back, right and left side, all install the blow outlet, and increase blow pipe and four-sides pass way. The evaporator is installed inside of the blowpipe. The air pass through evaporator and four-sides pass way, to realize multidirectional blow in the room, to make the indoor air-more gentle, and more evenly.

Owner:SHANGHAI JIAO TONG UNIV

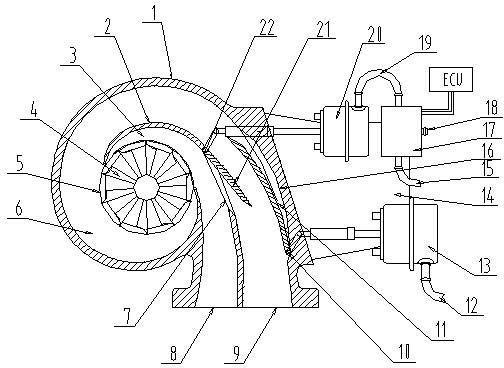

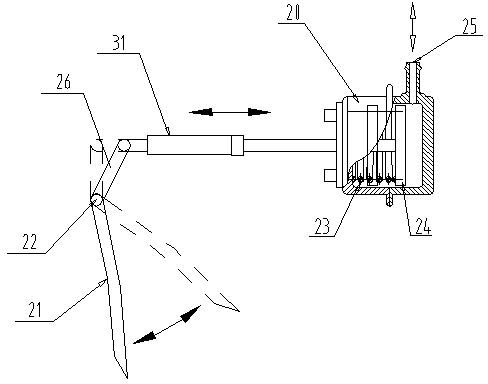

Staged flow-adjustable turbine shell

ActiveCN102536433AAvoid lateral flowReduce flow frictionInternal combustion piston enginesEngine componentsLow speedInlet flow

The invention discloses a staged flow-adjustable turbine shell, which comprises a turbine shell body. A turbine assembly and a waste gas inlet flow channel are mounted in the turbine shell body; an air inlet which is communicated with the waste gas inlet flow channel is arranged on the turbine shell body; an intermediate wall is disposed in the waste gas inlet flow channel and divides the waste gas inlet flow channel into an inner flow channel and an outer flow channel; a first valve device which can close the outer flow channel is disposed in the outer flow channel; and the intermediate wall is provided with a second valve device which can realize connection or disconnection of the inner flow channel and the outer flow channel. Waste gas energy is utilized sufficiently, rotation speed of a turbine rotor is increased, air inlet quantity of an engine in low speed work conditions is improved, so that the engine can apply more work, low speed torsion of the engine is increased, the low speed torque of the engine well matches with the low speed work conditions of the engine, and dynamic property and transient responsibility of the engine in low speed work conditions are improved.

Owner:康跃科技(山东)有限公司

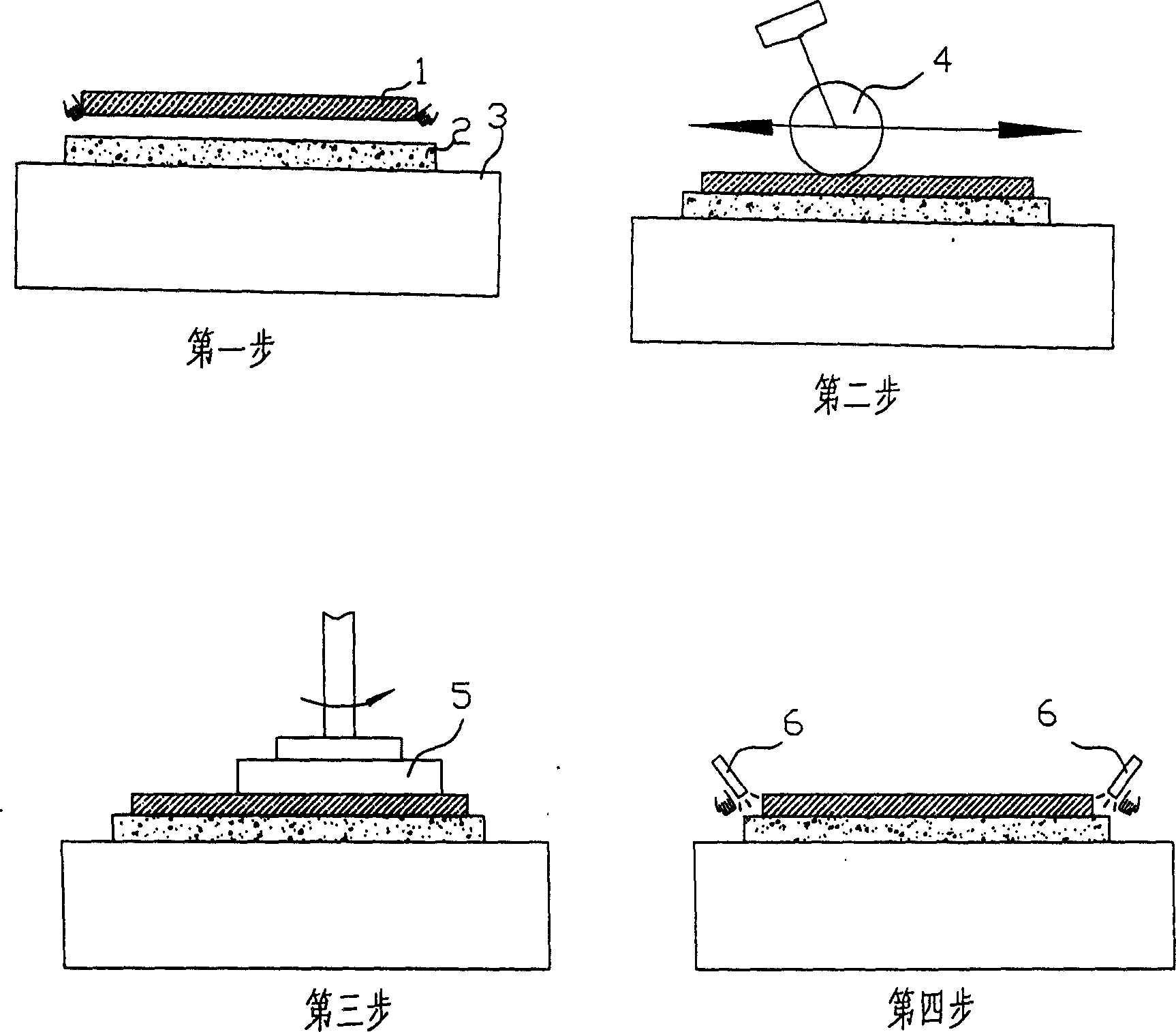

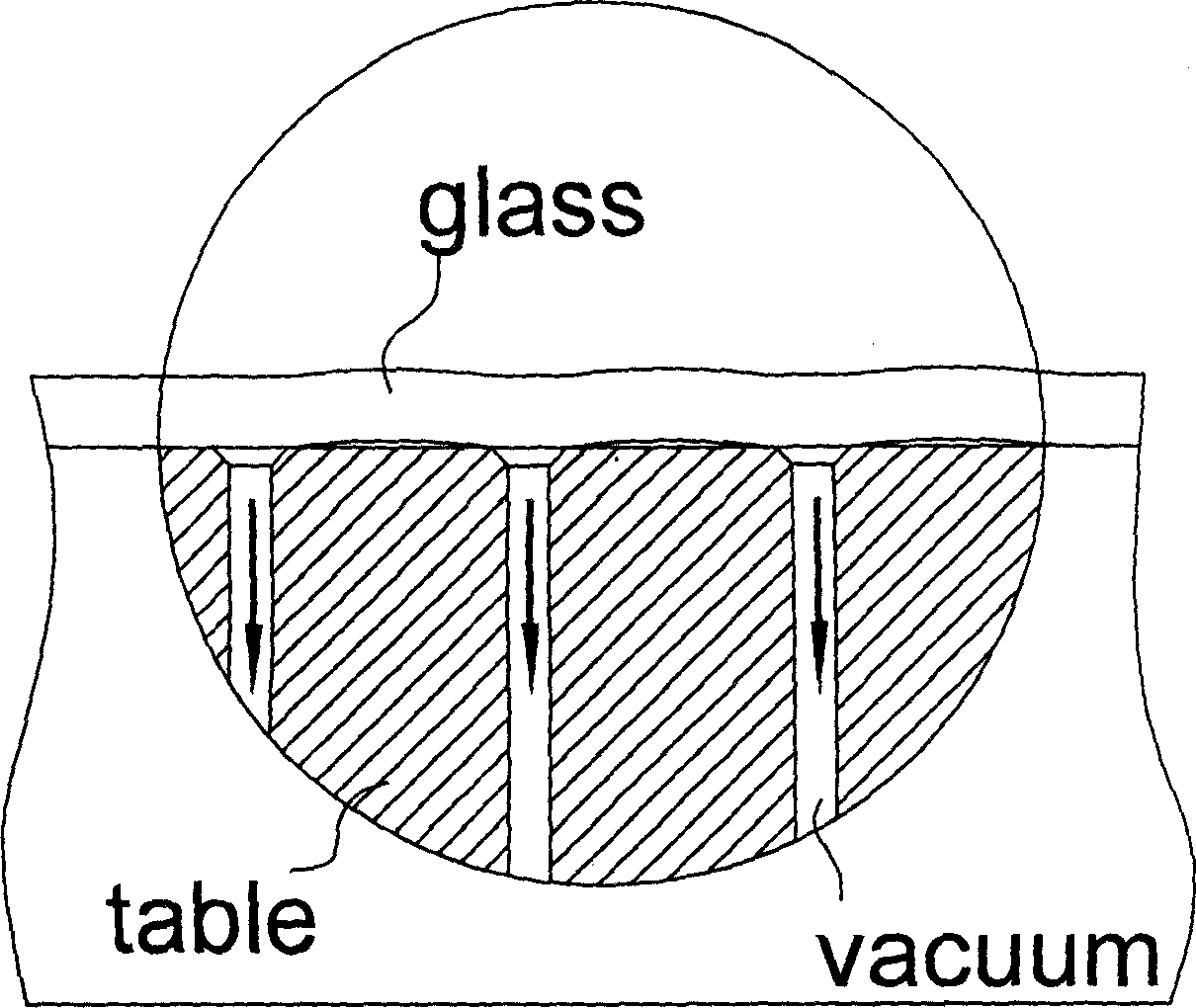

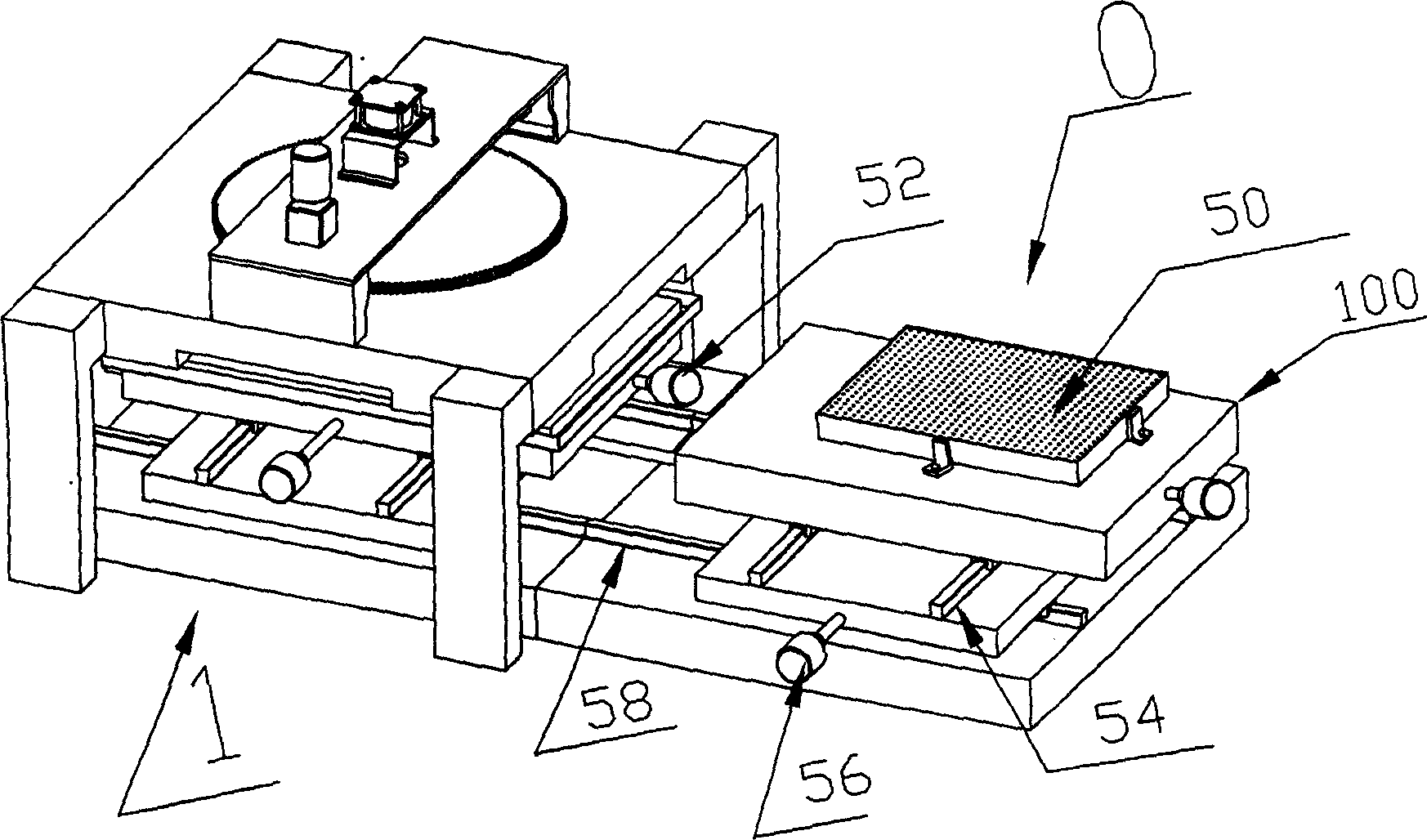

Loading and unloading device and method for ultrathin plate glass grinding step

InactiveCN1857867AAdhesive printingImprove thermal stabilityGrinding machine componentsOptical surface grinding machinesFlat glassEngineering

The present invention relates to loading and unloading device and method for ultrathin plate glass grinding step. The loading and unloading device includes one bench mechanism with surface pores for vacuum adsorption and air pressure suspending of plate glass, and one servo motor mechanism for driving the bench mechanism to load or unload plate glass. The bench mechanism has cushion of rigid porous ceramic material for bearing the plate glass. The present invention can realize automatic loading and unloading of plate glass automatically in high work efficiency.

Owner:HENAN ANCAI HI-TECH +1

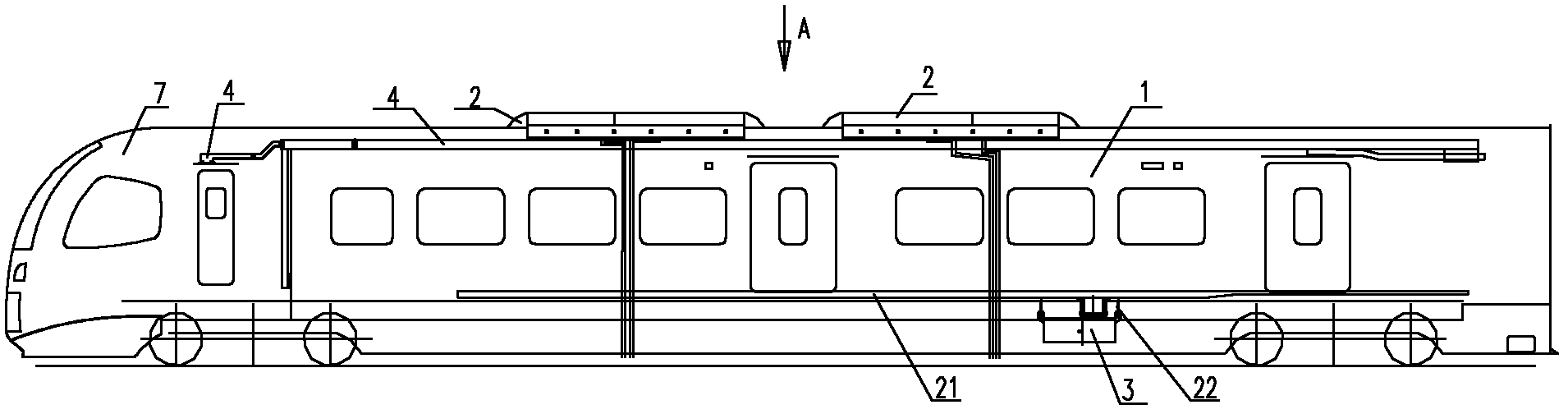

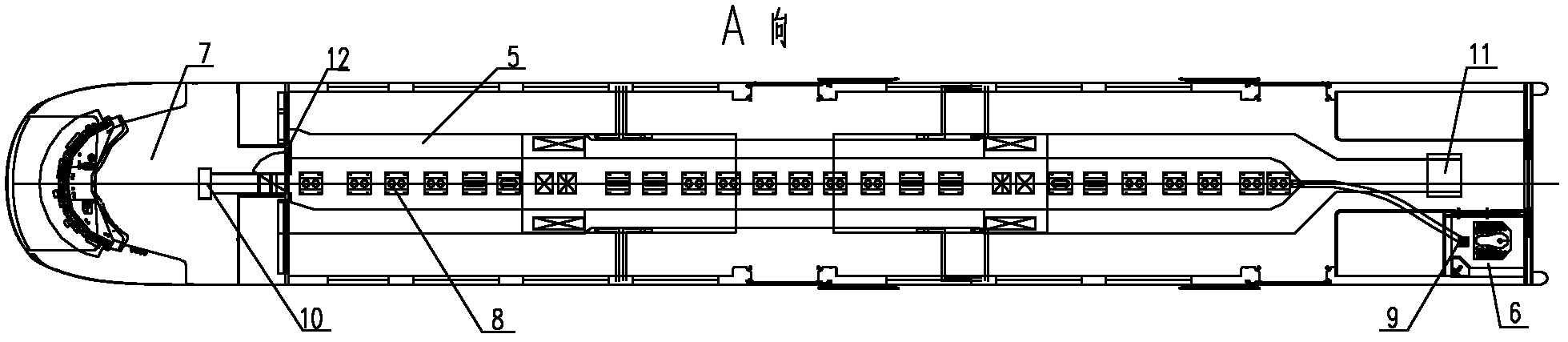

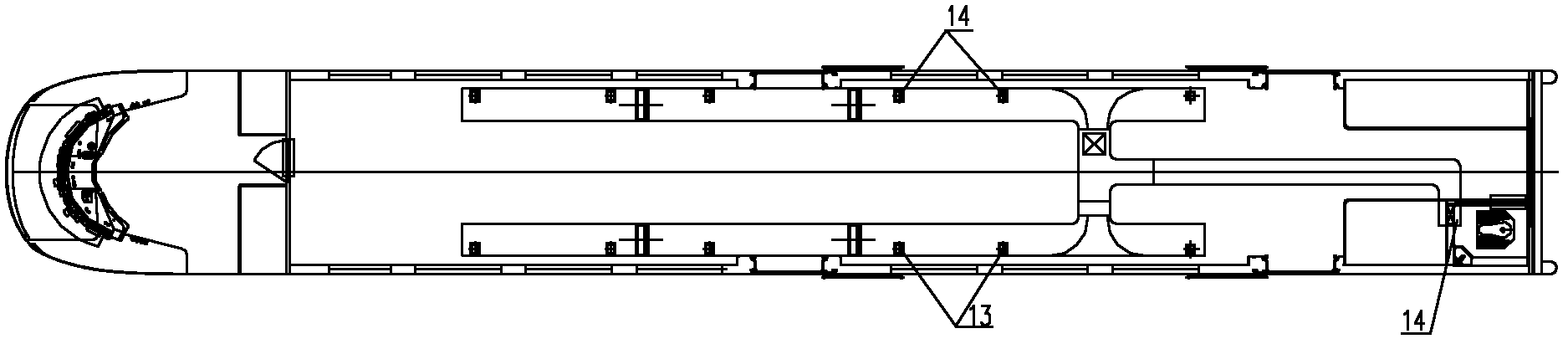

Air-conditioner air duct system used for intercity motor train unit

ActiveCN103158730AReduce weightMeet higher requirements for lightweightRailway heating/coolingAir conditioningAir tightness

The invention relates to an air conditioner air duct system used for an intercity motor train unit. The air conditioner air duct system used for the intercity motor train unit comprises an air conditioning unit and a waste exhaust unit, wherein the air conditioner unit is arranged at the top of a vehicle, and the waste exhaust unit is arranged at the bottom of the vehicle. An air outlet and an air inlet which are formed in the inner side of an air conditioning unit chamber are respectively communicated with an air supply outlet and an air return inlet located in the vehicle through an air supply duct and an air return duct which are arranged at the top of the vehicle. The air supply outlet located in the vehicle at least comprises an air supply outlet in a passenger chamber carriage, an air supply outlet in a bathroom and an air supply outlet in a driver cab. The air return inlet located in the vehicle at least comprises an air return inlet in the passenger chamber carriage and an air return inlet in the driver cab. The waste exhaust unit is communicated with a waste exhaust air outlet located in the vehicle through a waste exhaust air duct. The waste exhaust air outlet in the vehicle at least comprises a waste exhaust air outlet in the passenger chamber carriage and a waste exhaust air outlet in the bathroom. The air conditioner air duct system for the intercity motor train unit facilitates the reduction of the weight of the air ducts, satisfies higher requirements for vehicle light weight and is beneficial for the equality of air flow distribution in the vehicle. Meanwhile, due to the fact that waste gas is exhausted from the waste exhaust unit at the bottom of the vehicle, the air-tightness requirements of the vehicle are further met.

Owner:CRRC QINGDAO SIFANG CO LTD

Cooled rotor blade with vibration damping device

ActiveUS20050135933A1Evenly dispersedReduce chancePropellersPump componentsEngineeringShock absorber

A rotor blade for a rotor assembly is provided that includes a root, an airfoil, and a damper. The airfoil includes a base, a tip, a pressure side wall, a suction side wall, and a cavity disposed therebetween. The cavity extends substantially between the base and the tip, and includes a first cavity portion, a second cavity portion, and a channel disposed between the first cavity portion and the second cavity portion. A plurality of first pedestals are disposed within the first cavity portion adjacent the channel, and a plurality of second pedestals are disposed within the second cavity portion adjacent the channel. The damper is selectively received within the channel.

Owner:RTX CORP

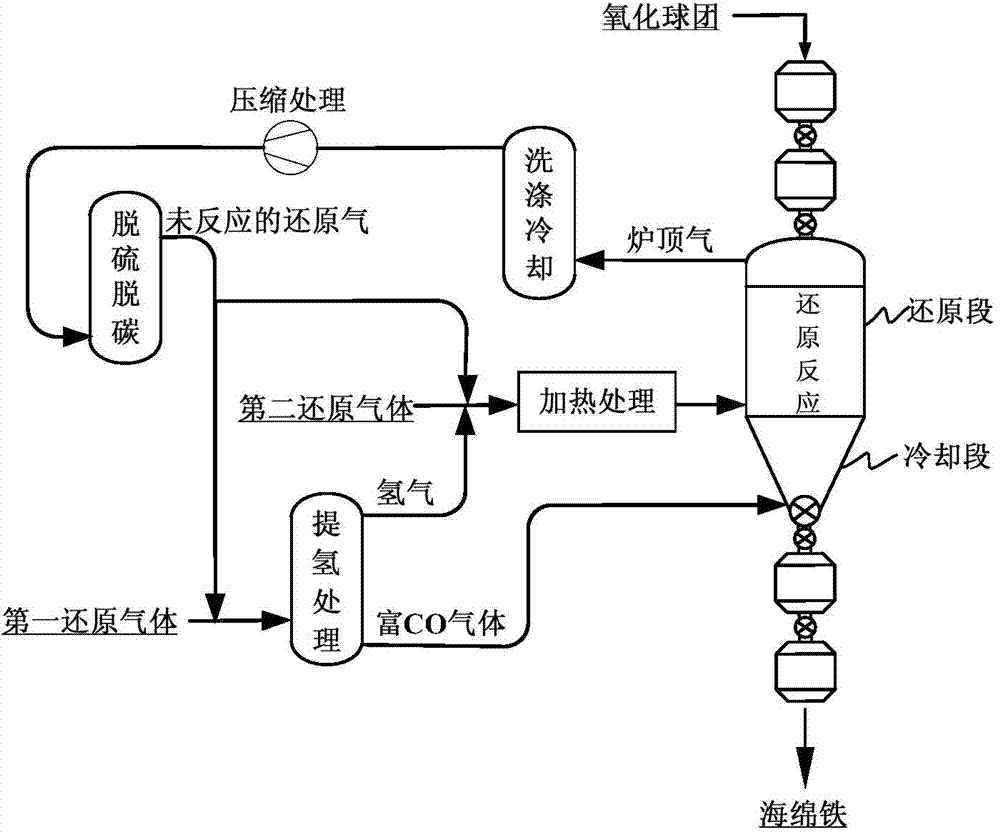

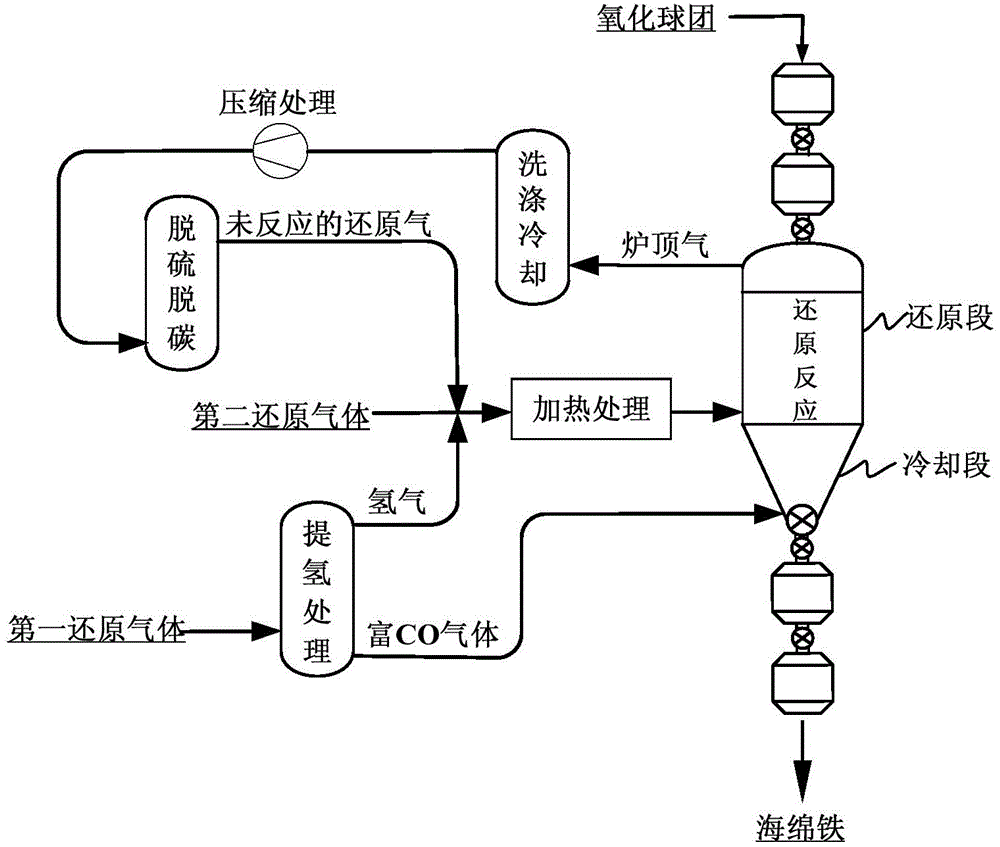

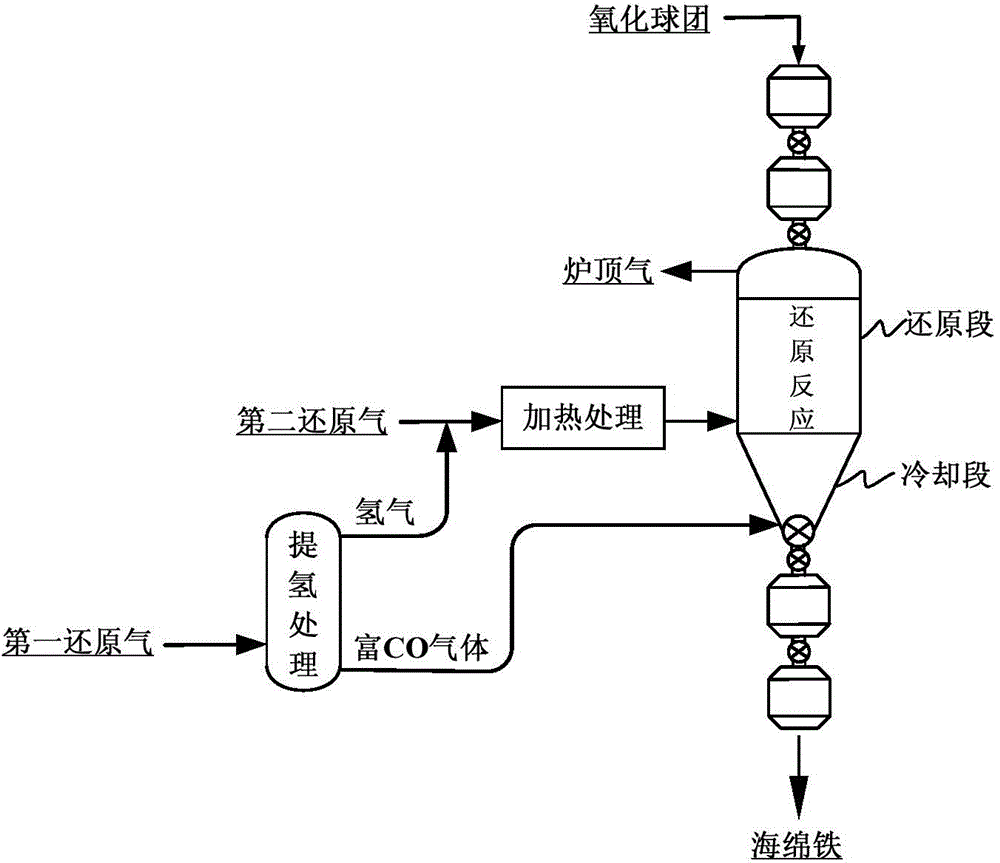

Method and system of preparing spongy iron by using gas-based shaft furnace

InactiveCN104293998AReduce energy consumptionIncrease carburizing amountShaft furnaceHydrogenProduct gas

A disclosed method of preparing spongy iron by using a gas-based shaft furnace comprises: (1) adding an oxidation pellet into the gas-based shaft furnace which possesses a reducing segment and a cooling segment; (2) performing hydrogen extraction processing on a first reducing gas to obtain hydrogen and carbon monoxide rich gas; (3) mixing a second reducing gas and hydrogen and performing heating processing, so as to obtain a thermal-state reducing gas; (4) conveying the thermal-state reducing gas into the reducing segment, and reacting with the oxidation pellet for reduction, so as to obtain spongy iron and furnace top gas; (5) conveying carbon monoxide rich gas into the cooling segment, so as to perform heat exchange between the carbon monoxide rich gas and spongy iron in the cooling segment and perform carburization reaction and then enable the gas to move upwards and enter the reducing segment; (6) performing washing cooling processing, compression processing and desulphurization decarburization processing on the furnace top gas, so as to obtain unreacted reducing gas; (7) mixing a part of the unreacted reducing gas with the first reducing gas; and (8) mixing the other part of the unreacted reducing gas with the second reducing gas. The method is capable of effectively reducing energy consumption of a technology of using the gas-based shaft furnace for direct reduction.

Owner:SHENWU TECH GRP CO LTD

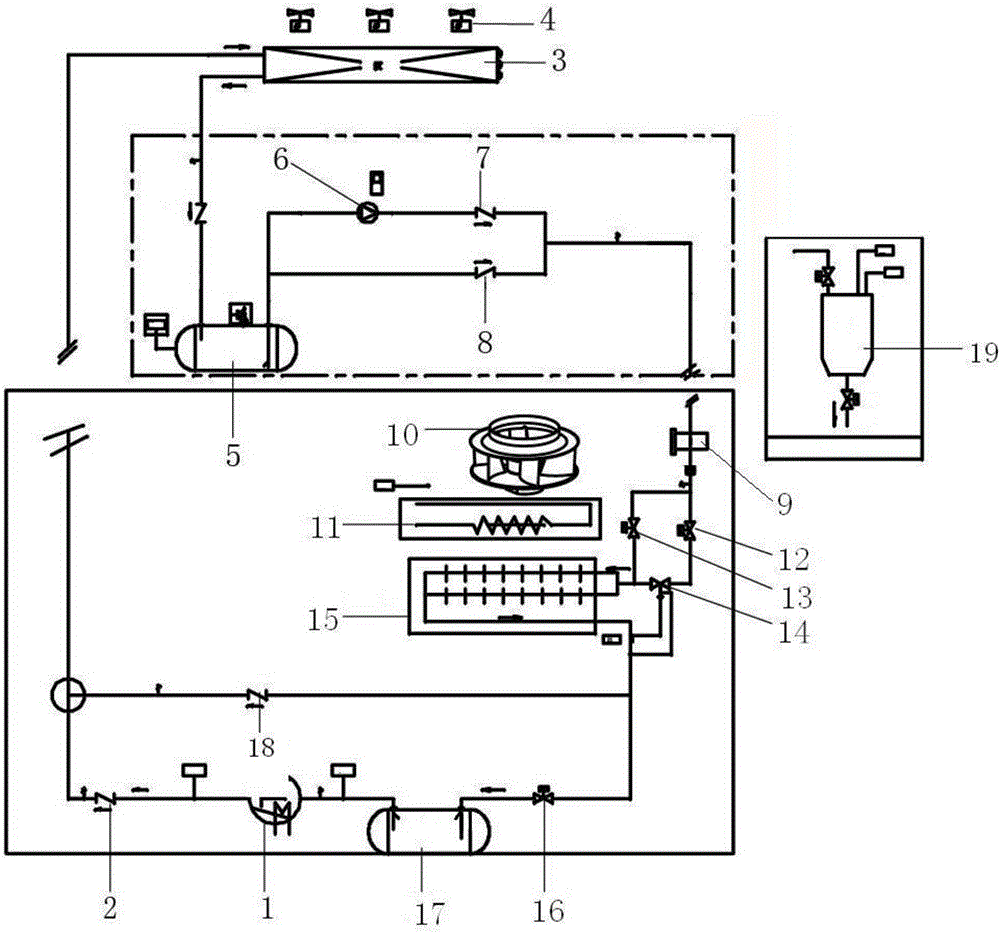

Variable frequency fluorine pump air conditioner

InactiveCN106016465AReduce condensing pressureReduce the temperatureSpace heating and ventilation safety systemsSpace heating and ventilation control systemsFrequency changerBusiness efficiency

The invention discloses a variable frequency fluorine pump air conditioner. The variable frequency fluorine pump air conditioner comprises an air conditioner indoor unit, a variable frequency fluorine pump energy conservation module, an air conditioner outdoor unit and a central controller. The variable frequency fluorine pump energy conservation module comprises a liquid storage tank with an input port connected with a refrigerating fluid refrigeration and circulation output port of the air conditioner outdoor unit, a first branch with one end connected with an output port of the liquid storage tank, and a second branch with one end connected with the output port of the liquid storage tank. The other end of the first branch and the other end of the second branch are both connected to a refrigerating fluid refrigeration and circulation input port of the air conditioner indoor unit. The first branch is provided with a variable frequency fluorine pump and a frequency converter connected with the variable frequency fluorine pump. A sixth branch is further arranged on a compressor inside the air conditioner indoor unit in parallel. One end of the sixth branch is connected to an output port of the evaporator, and the other end of the sixth branch is connected to the refrigerating fluid refrigeration and circulation input port of the air conditioner outdoor unit. According to the variable frequency fluorine pump air conditioner, three refrigeration modes are used in cooperation for running, and the full-year energy efficiency ratio is overall increased.

Owner:YIMIKANG TECH GRP CO LTD

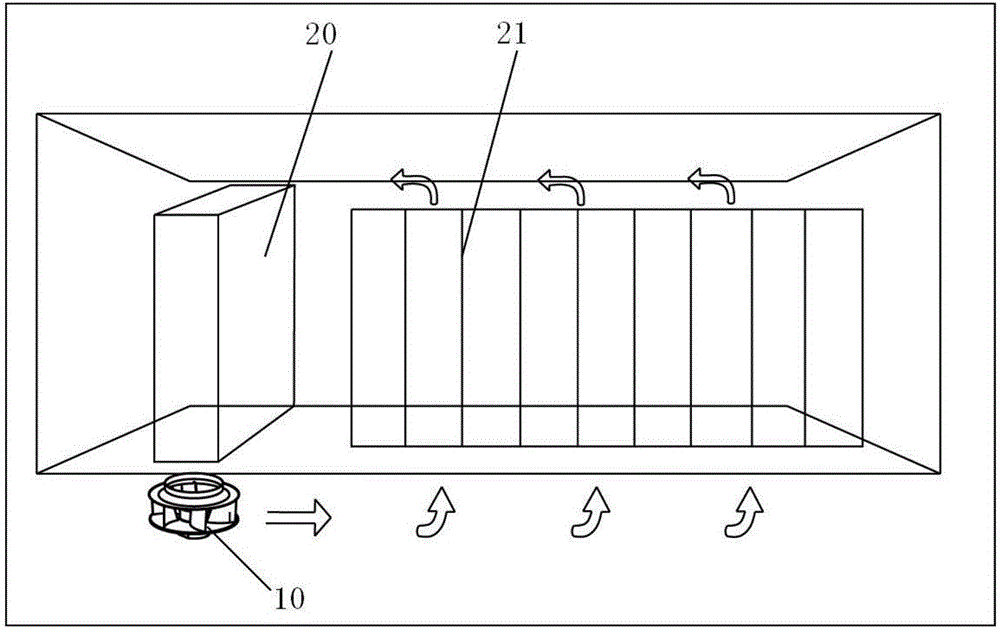

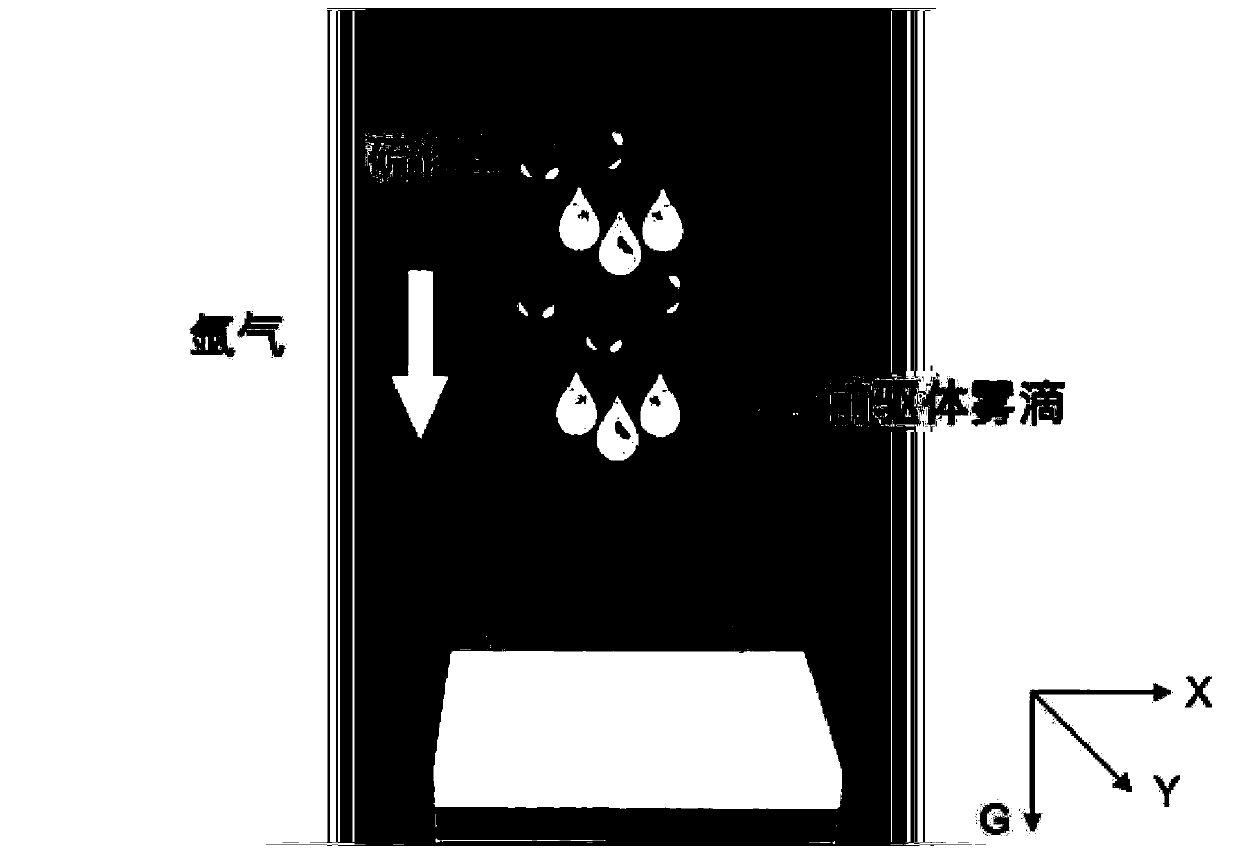

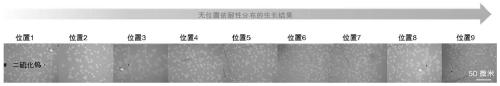

Two-dimensional material as well as preparation method, preparation device and application thereof

ActiveCN110205609AUniform shapeUniform density distributionChemical vapor deposition coatingDensity distributionGas phase

The invention relates to a two-dimensional material as well as a preparation method, a preparation device and application thereof. The preparation method utilizes a vertical chemical vapor depositionsystem, a gaseous precursor is reacted in the vertical direction through a substrate in a heating state, reacting is carried out, a two-dimensional material is formed on the surface of the substrate,and the surface of the substrate is perpendicular to the flowing direction of the gaseous precursor. According to the two-dimensional material, the two-dimensional material is grown by adopting a vertical chemical vapor deposition method compared with a traditional horizontal chemical vapor deposition method, the morphology, the thickness, the crystal domain size and the density distribution of the two-dimensional material on the substrate are more uniform, and the two-dimensional material has a better application prospect.

Owner:TSINGHUA BERKELEY SHENZHEN INST

Panel integrated precision air conditioner

InactiveCN1821666ASave spaceNo on-site installation requiredLighting and heating apparatusAir conditioning systemsPlate heat exchangerEngineering

The panel integral precise air conditioner includes one inner unit and one outer unit combined integrally and installed inside the same casing. The inner unit includes inclined disc type blower in the top, evaporator below the blower, water collector in the bottom of the evaporator, air heat exchanger below the water collector, filtering net in the front below the air heat exchanger, and compressor and humidifier behind the filtering net. The outer unit includes the first heat exchanger in the upper part, water tank below the first heat exchanger, axial flow blower below the water tank in the position corresponding to the air heat exchanger, and the second heat exchanger below the axial flow blower. The present invention combines the indoor unit and the outdoor unit integrally, embeds the integral into wall, and has raised refrigerating efficiency, saving in power and convenient installation.

Owner:SUZHOU QUTU THERMAL CONTROL SYST

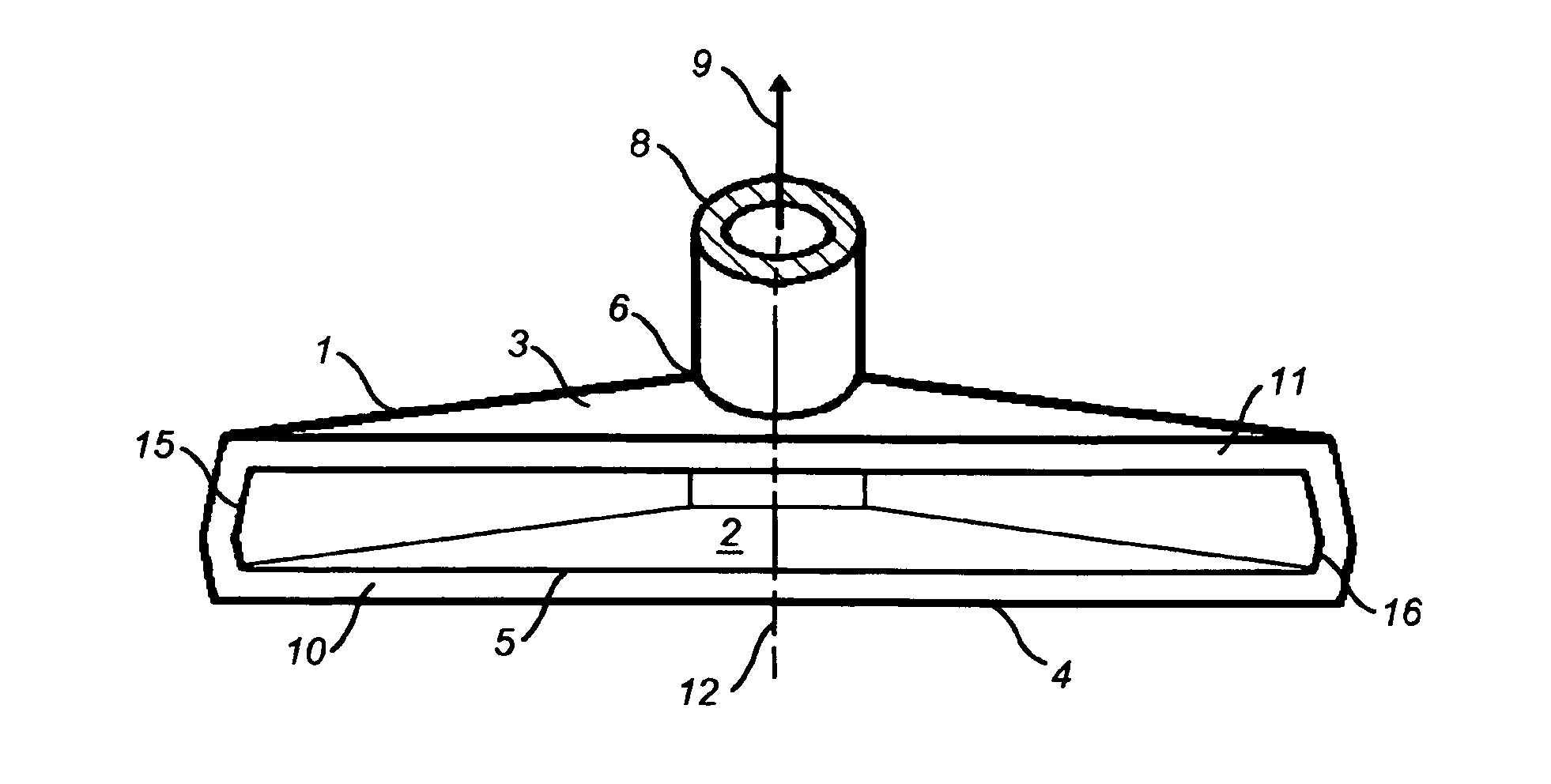

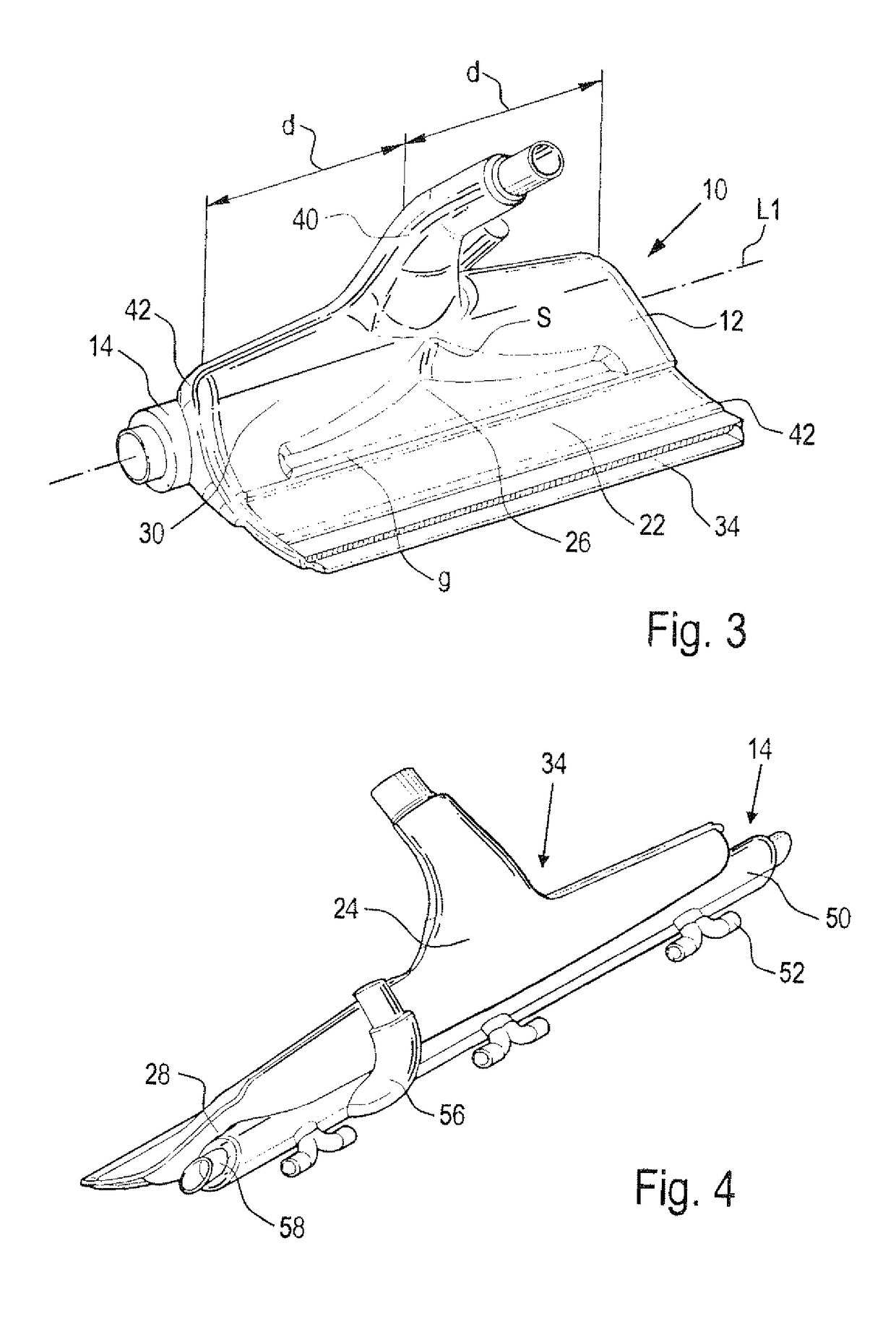

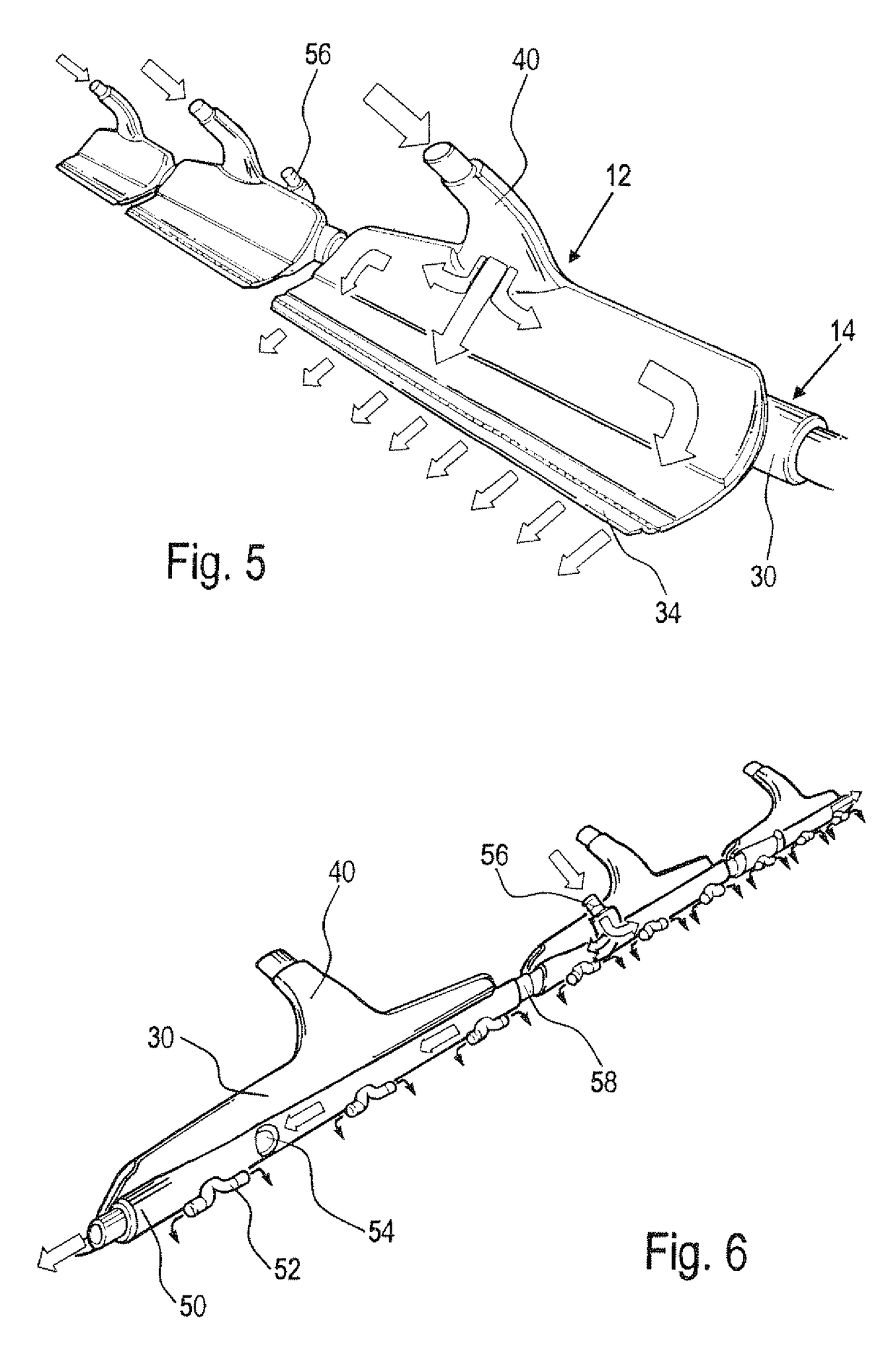

Carpet cleaning wand having uniform air flow distribution

ActiveUS20090320234A1Effectively closedIncrease the circulation areaSuction nozzlesEngineeringAirflow

Owner:HYDRAMASTER LLC

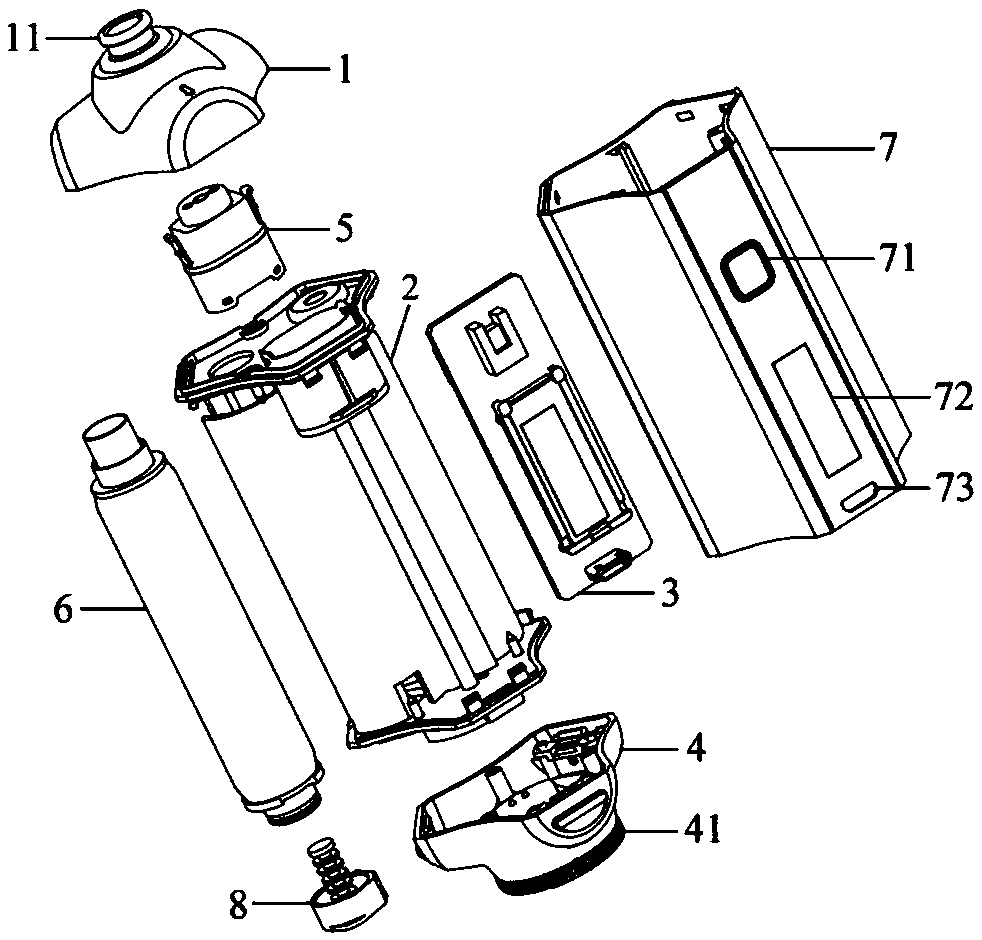

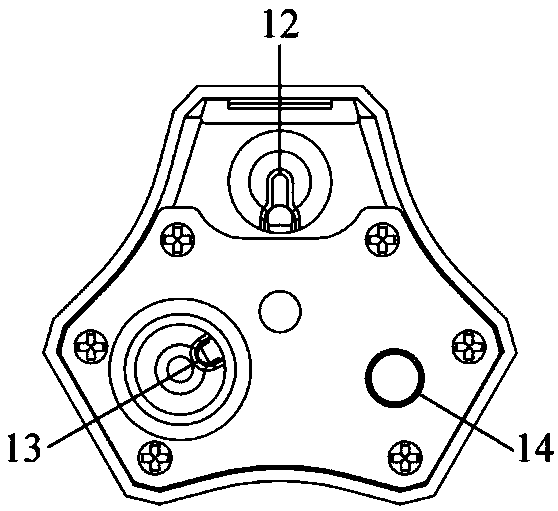

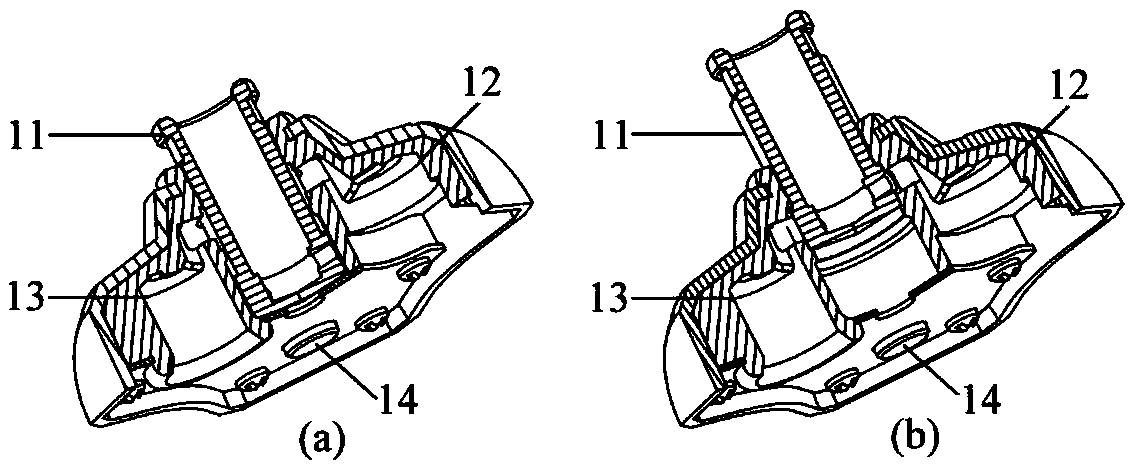

Atomizing device supporting multiple smoking modes and use method thereof

ActiveCN109602091AMeet the needs of multi-dimensional suctionEasy to operateTobacco devicesEngineeringAirflow

The invention discloses an atomizing device supporting multiple smoking modes. The atomizing device comprises the following components: a host shell (7); a main bracket (2); an upper end cover (1); anatomizer (5), arranged on an atomizer base (211); and a lower end cover (4). The invention further discloses a use method of the atomizing device. The atomizing device disclosed by the invention supports three smoking modes, and the smoking modes and air flow channels can be synchronously switched; the low-temperature baking fragrance generation temperature is controlled precisely; cigarettes arefully used; the smoking comfort is high.

Owner:CHINA TOBACCO YUNNAN IND

Cleaning Assembly for a Harvester

ActiveUS20160192591A1Even air distributionEfficient airflowSievingScreeningEngineeringMechanical engineering

A cleaning assembly for a harvester has a fan assembly with a fan and a first fan outlet and a second fan outlet, a first sieve assembly with at least one reciprocable sieve, an upstream end of the first sieve assembly near the first fan outlet such that air from the first fan outlet flows along the first sieve assembly and a direction of crop flow; and a second sieve assembly has at least one reciprocable sieve, an upstream stream end of the second sieve assembly near the second fan outlet such that the air from the second fan outlet flows along the second sieve assembly and the direction of crop flow, the second sieve assembly has a clean grain auger for receiving cleaned grain, and the first sieve assembly has a further clean grain auger arranged for receiving cleaned grain.

Owner:BLUE LEAF I P INC +1

Adsorption technique

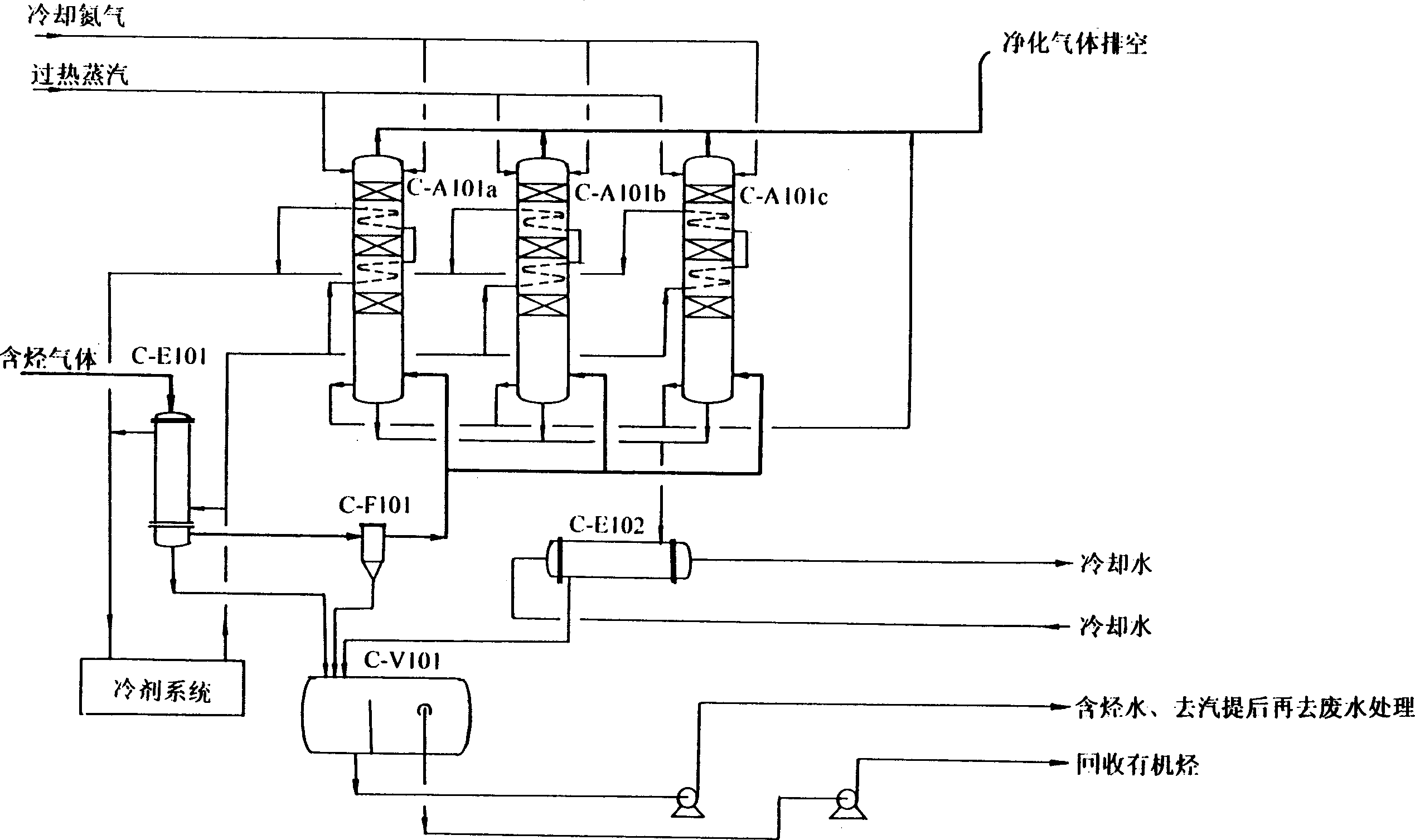

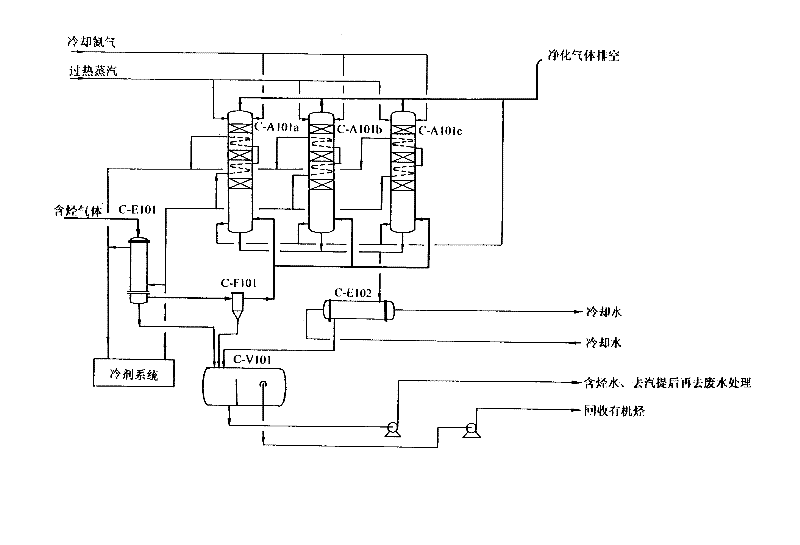

InactiveCN1539544AIncrease the adsorption rateImprove adsorption capacityDispersed particle separationHeat regenerationChemistry

An adsorption technology features that its system is composed of more than one adsorption tower and condenser. All the adsorption towers are parallelly connected to gas-material pipeline and each adsorption tower has a built-in cooler. Said adsorption technology includes condensing part of raw organic hydrocarbon, oil-water separation, flowing rest of organic hydrocarbon in adsorption tower, multi-layer adsorbing, cooling for optimal adsorption, switching to next adsorption tower while thermal regeneration for this adsorption tower, and introducing cooling gas to bed and cooling medium to cooler.

Owner:SHANGHAI SUPEZET ENG TECH CO LTD

Wet desulfurization tower based flue gas desulphurization method capable of enhancing adaptability to low load

InactiveCN101703884AGuaranteed uptimeSafe and stable operationDispersed particle separationLower limitLow load

The invention relates to a wet desulfurization tower based flue gas desulphurization method capable of enhancing the adaptability to low load, solving the problems as follows: when the load of the desulfurization tower is lowered (the load is lower than 30% of the amount of flue gas under rated load of the desulfurization tower), the amount of the flue gas flowing through the desulfurization tower is lessened; therefore, the demisting efficiency of a demister can not be maintained, the desulfurization efficiency is reduced and fly ash and liquid drops at the entrance and exit of the tower settle. The method mainly comprises the following steps: exhausting the flue gas desulfurized in the desulfurization tower after being demisted; and separating partial purified flue gas from all the purified flue gas under automatic regulation of a circulatory flue gas regulator when the load of a desulfurization system is lower than 30% of the rated load, and ensuring the partial purified flue gas to return back to the entrance of the desulfurization tower via a circulatory flue gas pipe, thus accelerating the air speed in the tower and ensuring the flue gas load in the desulfurization tower at the lower limit of at least 30% of the rated load under which the desulfurization tower can operate stably. The method enables the wet desulfurization tower to safely and stably operate under the condition of meeting 0%-110% of rated load and obviously enhances the adaptability of the desulfurization system to low load.

Owner:HARBIN INST OF TECH

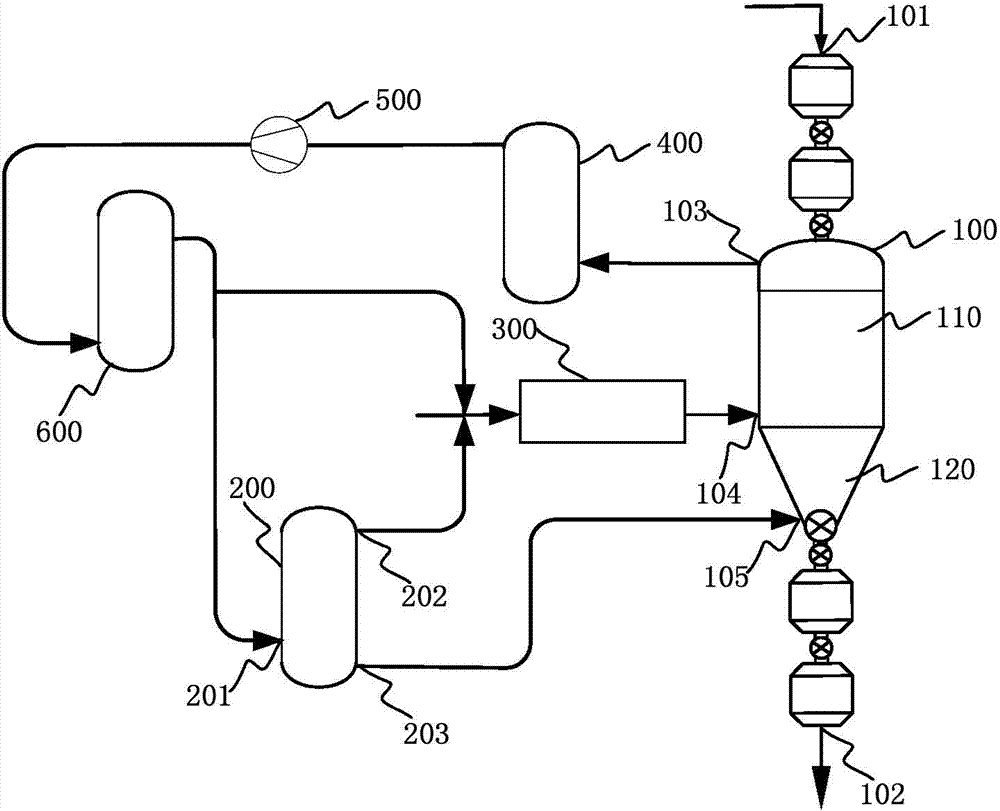

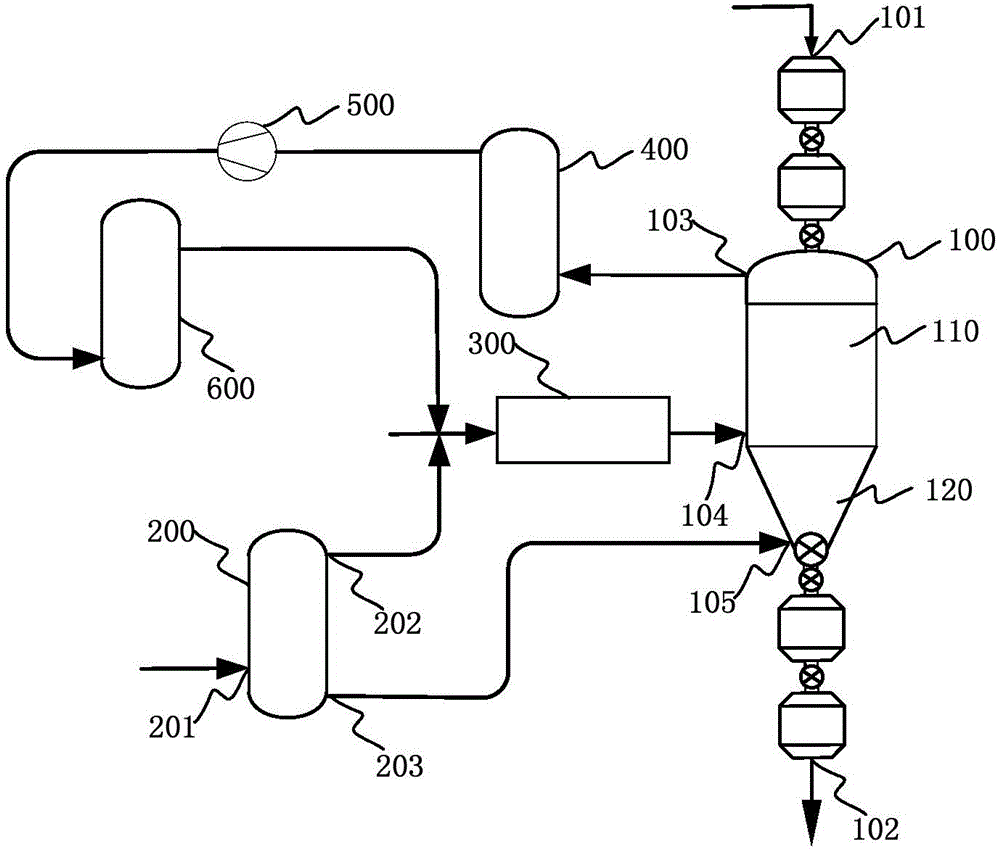

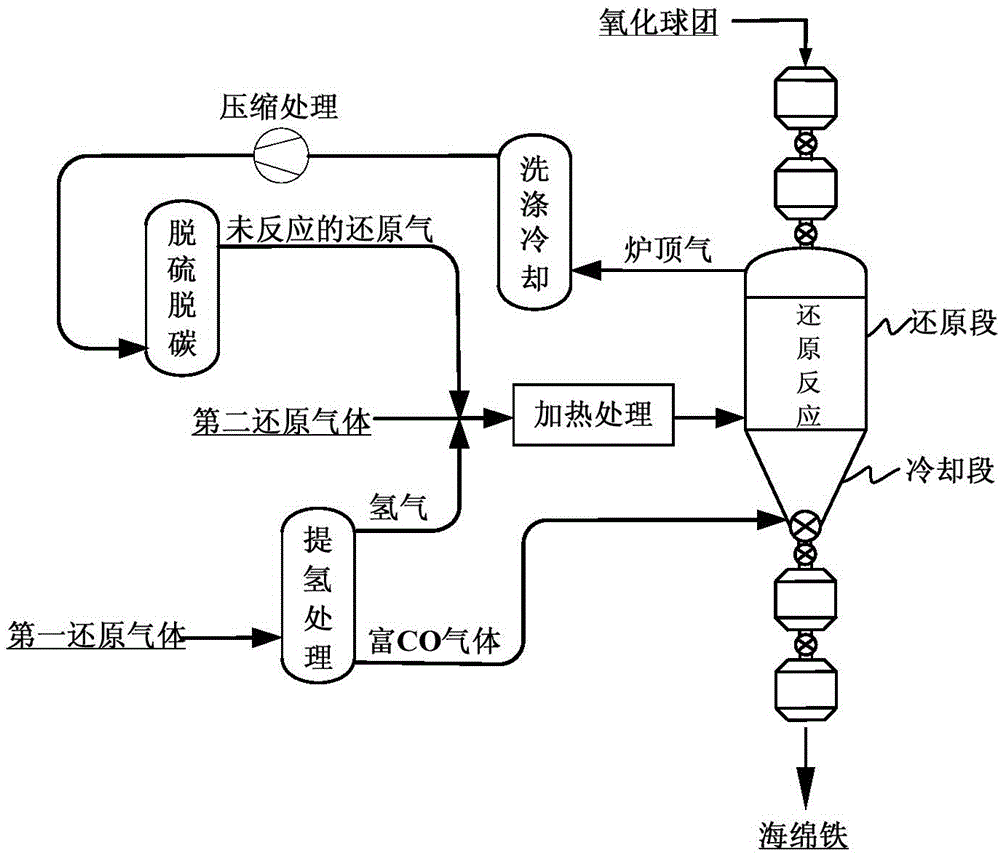

Method and system for preparing sponge iron by using gas-based shaft furnace

ActiveCN104087700AReduce energy consumptionIncrease carburizing amountShaft furnaceHydrogenShaft furnace

The invention discloses a method for preparing sponge iron by using a gas-based shaft furnace. The method comprises the following steps of (1) adding an oxidized pellet into the gas-based shaft furnace, wherein the gas-based shaft furnace is provided with a reducing section and a cooling section; (2) carrying out hydrogen extraction treatment on first reducing gas to obtain hydrogen and carbon monoxide enriched gas; (3) mixing second reducing gas and hydrogen, and carrying out heat treatment to obtain heat-state reducing gas; (4) delivering the heat-state reducing gas into the reducing section, and enabling the heat-state reducing gas and the oxidized pellet to be subjected to reduction reaction to obtain sponge iron and top gas; (5) delivering the carbon monoxide enriched gas into the cooling section to ensure that the carbon monoxide enriched gas upwards enters the reducing section after being subjected to heat exchange and carburization reaction with the sponge iron in the cooling section; (6) sequentially and respectively carrying out washing and cooling treatment, compression treatment as well as desulfuration and decarburization treatment on the top gas to obtain unreacted reducing gas; and (7) mixing the unreacted reducing gas and the second reducing gas. By using the method, the energy consumption of a direct reducing process of the gas-based shaft furnace can be effectively reduced.

Owner:SHENWU TECH GRP CO LTD

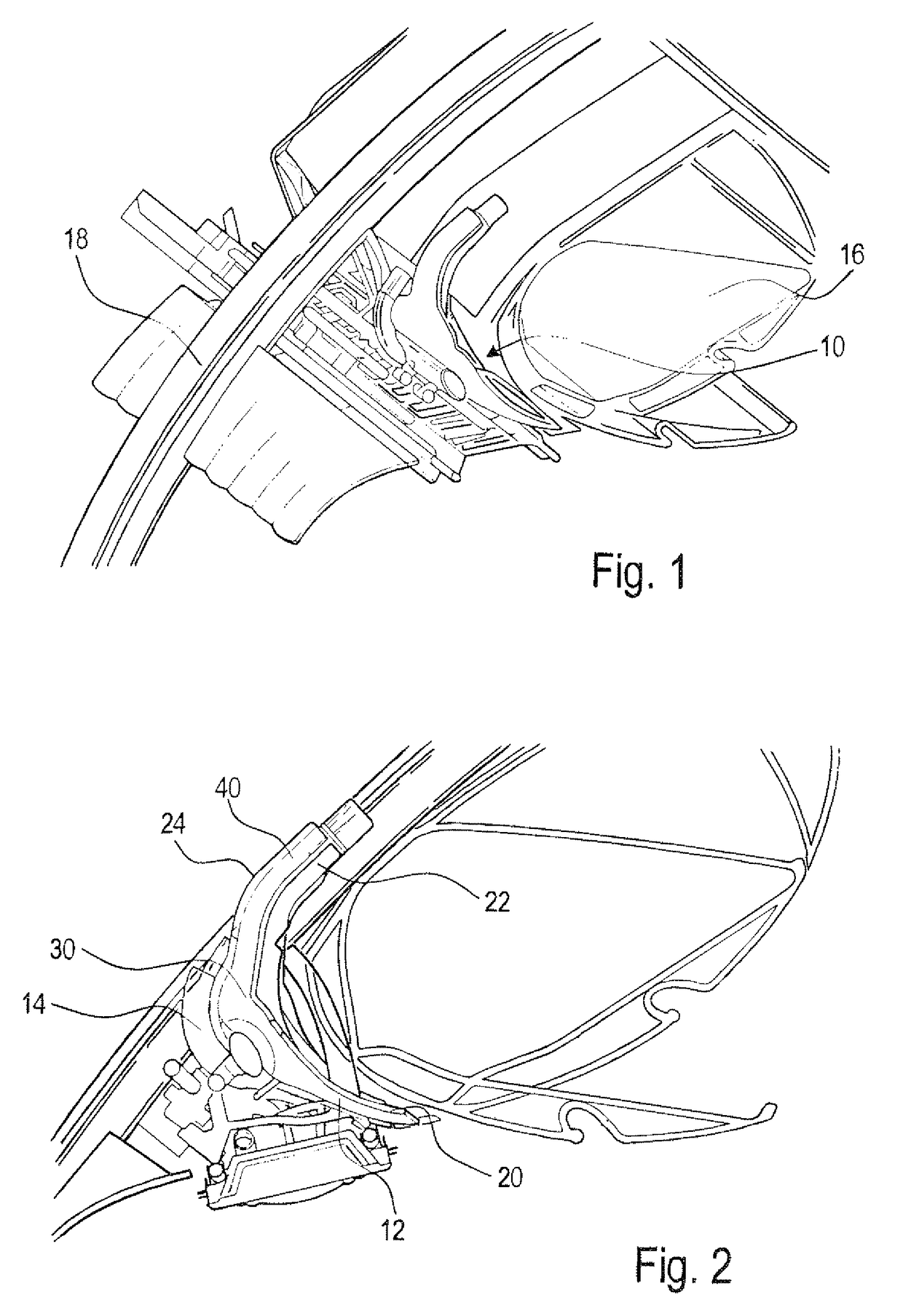

Air infeed device for air-conditioning passenger areas in aircraft

InactiveUS8118648B2Improves air distributionReduce space necessaryAir-treatment apparatus arrangementsAerospace engineeringBreathing

An air infeed device for air-conditioning passenger areas in aircraft includes a central air infeed module for the centrally regulated cabin ventilation system and an individual air infeed module for the individually adjustable cabin ventilation system. The centrally regulated cabin ventilation system and the individually adjustable cabin ventilation system are mutually independent systems. The central air infeed module and the individual air infeed module are connected to form a subassembly that can be handled independently as a collective unit.

Owner:DIEHL AIRCABIN

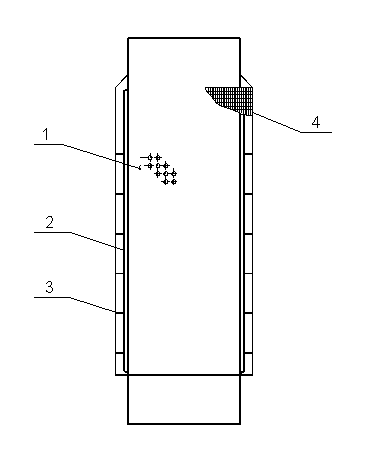

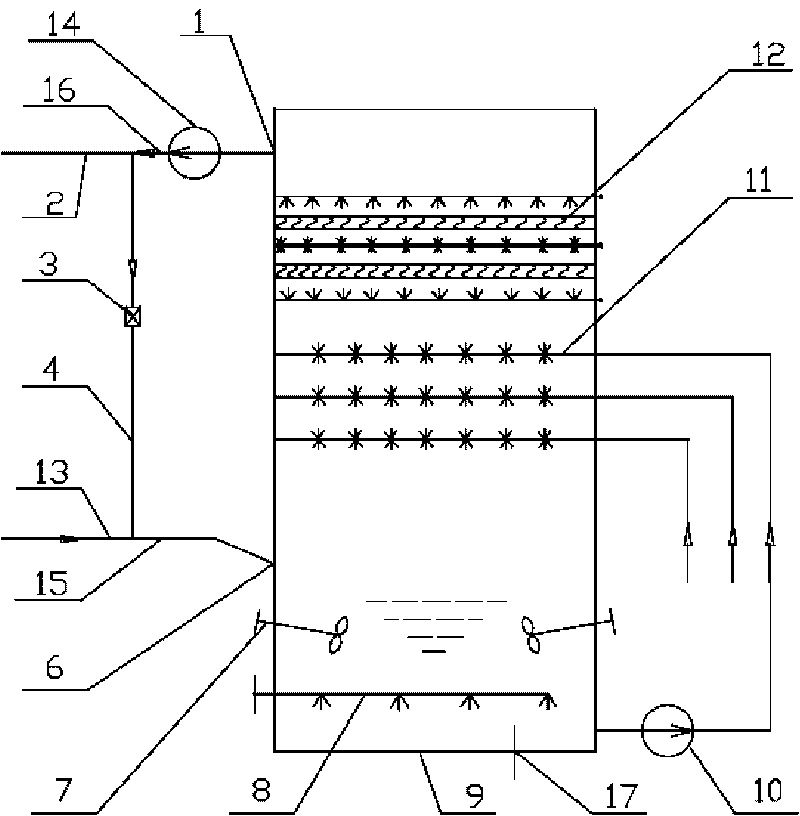

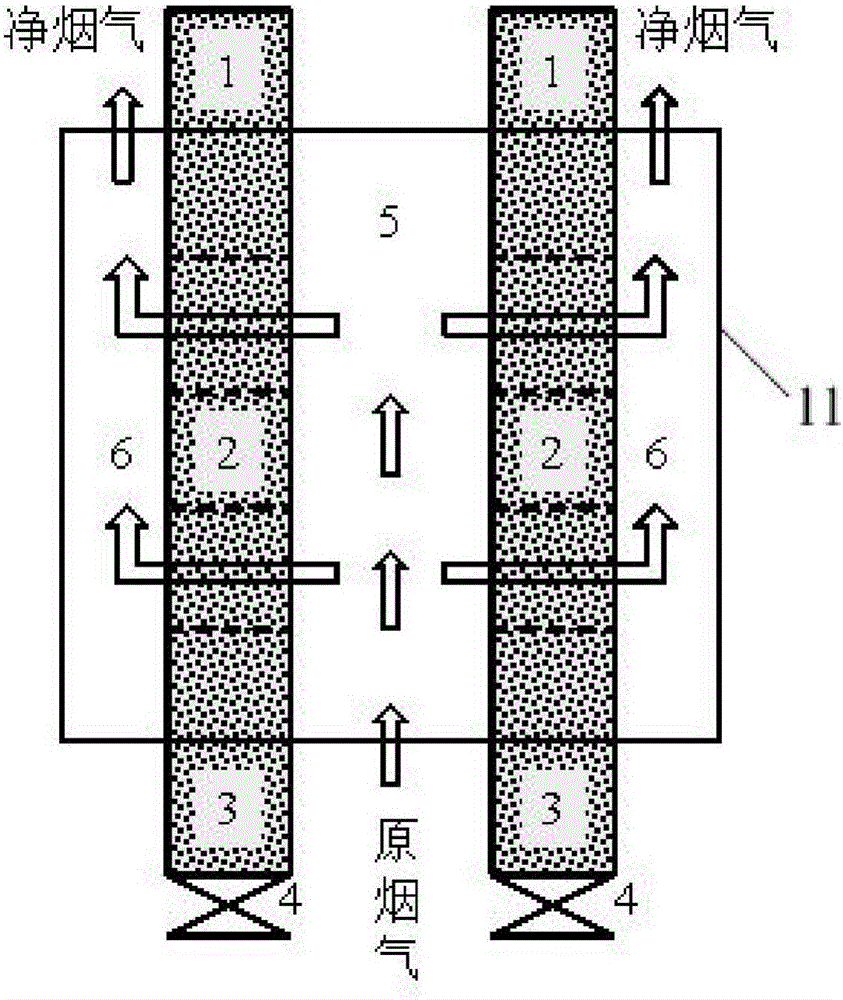

Active coke modular bearing device, absorbing tower and flue gas purifying method

ActiveCN105817118AReduce physical wear and tearImprove operational efficiencyGas treatmentDispersed particle separationFlue gasTower

The invention provides an active coke modular bearing device, an absorbing tower and a flue gas purifying method. The active coke modular bearing device comprises a transmission device and multiple active coke modules, each active coke module is provided with a fixing device, and the multiple active coke modules are vertically overlapped seamlessly and then fixed to the transmission device through the fixing devices; each active coke module is of a net-shaped structure, the bottom of each active coke module is narrower than the upper portion by 3-5 cm, the height and width of each active coke module are independently 50-80 cm, and the length of each active coke module is 80-120 cm. The active coke modular bearing device can effectively reduce abrasion loss of active coke and is high in operation efficiency, airflow in the absorbing tower provided with the device is small in resistance and distributed uniformly, the active coke moves smoothly and is high in use ratio, and the removal efficiency of pollutants in flue gas can be remarkably improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

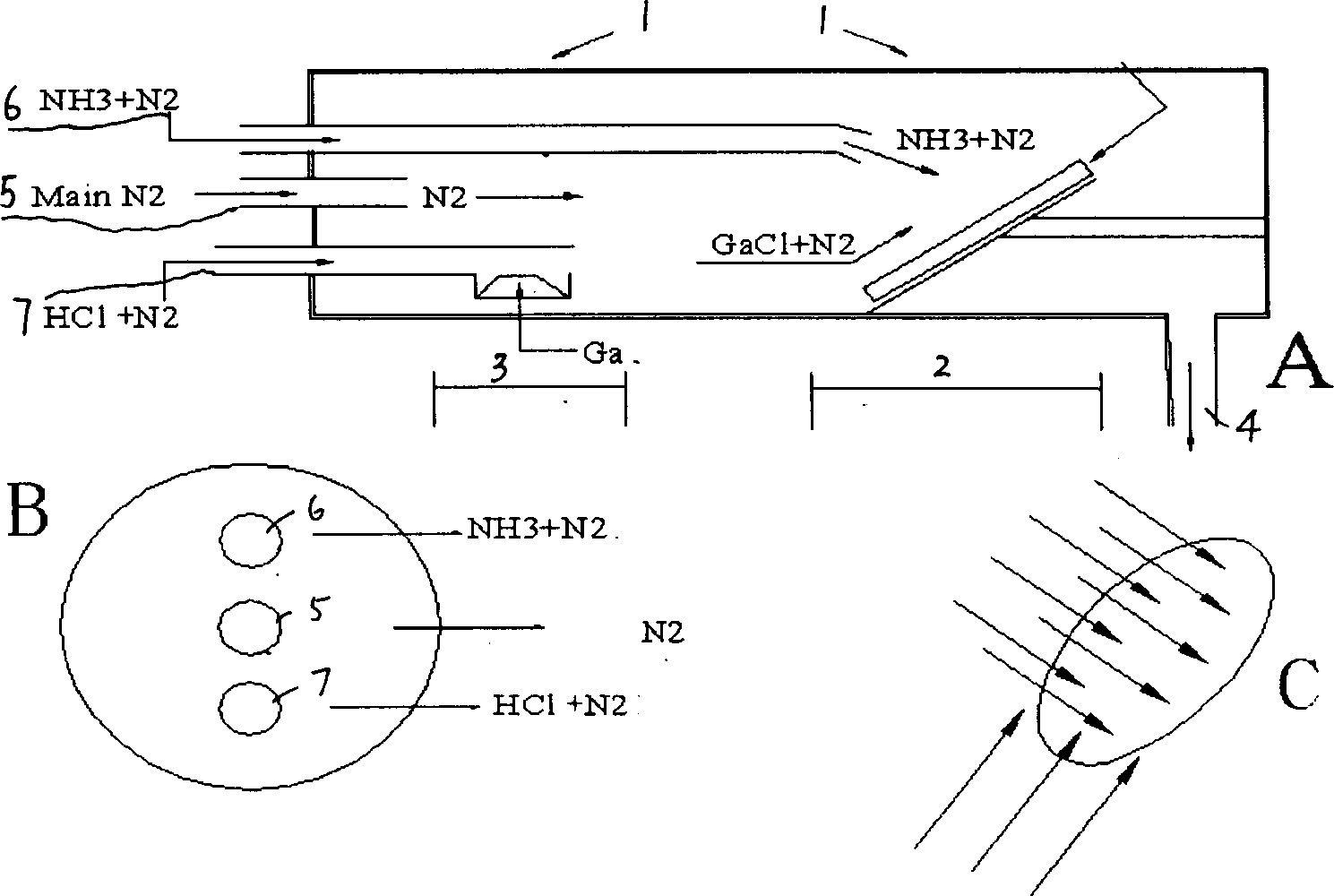

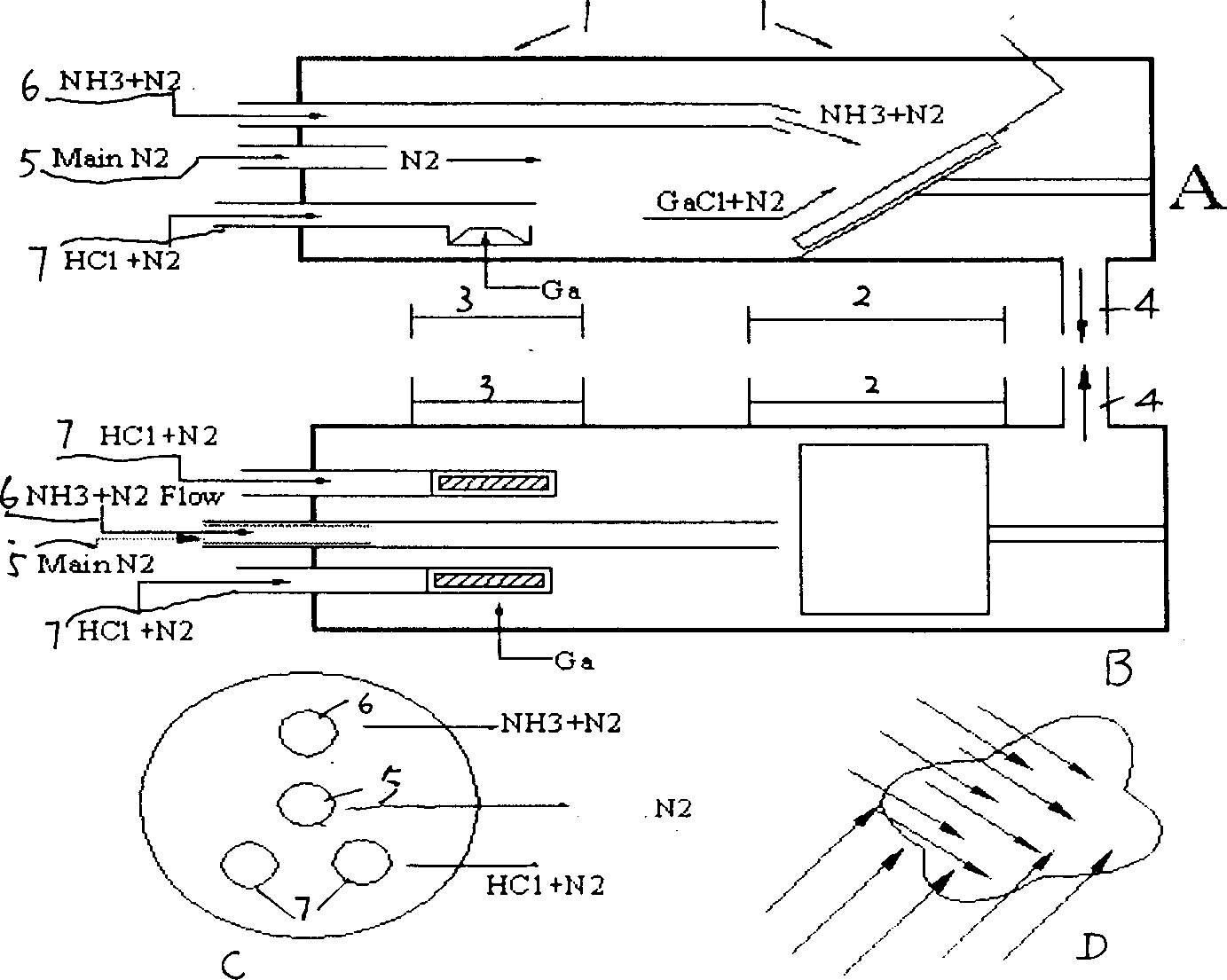

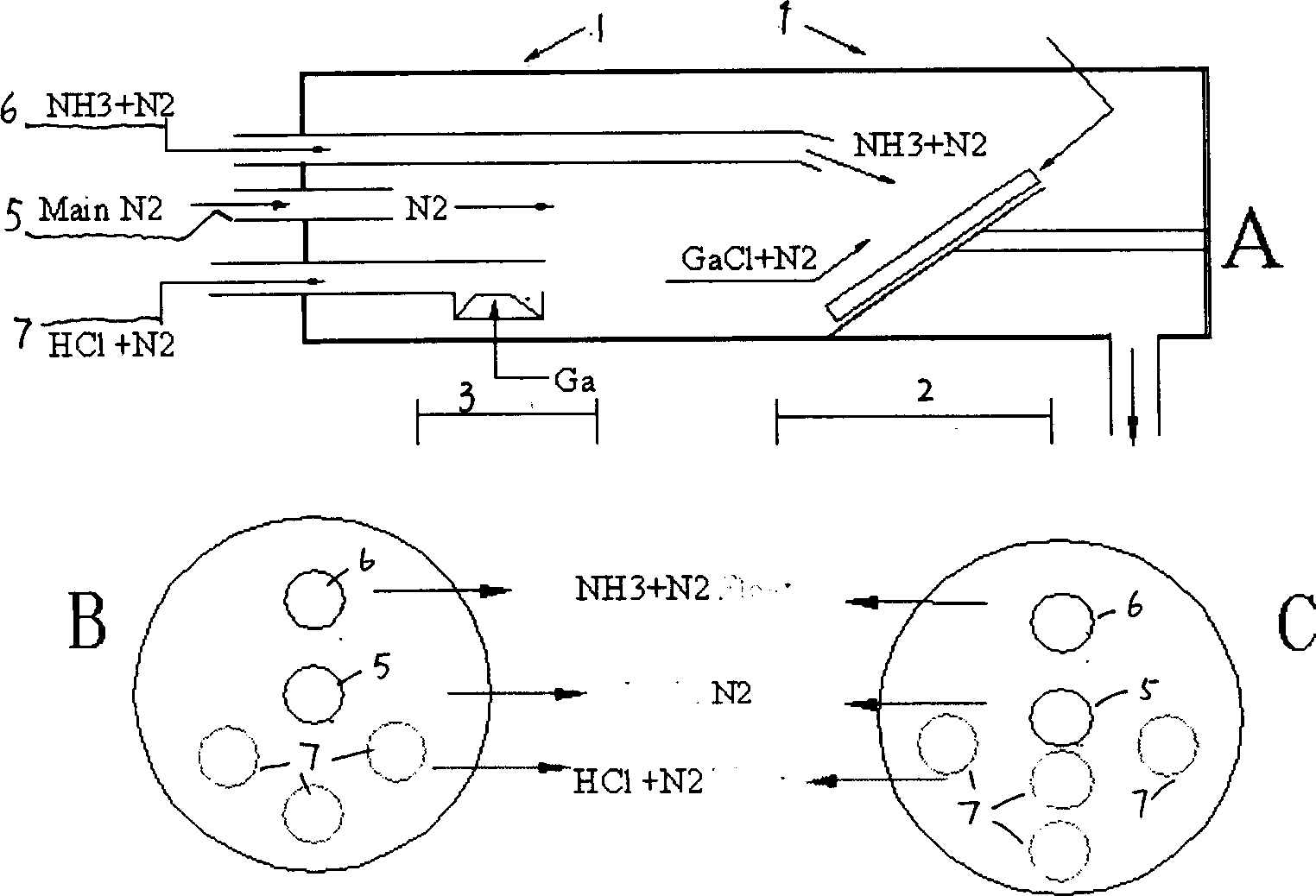

Homogeneity improving method and device for hydride gaseous epitaxially groven GaN material

InactiveCN1384533AImprove uniformityEvenly distributed internal airflowSemiconductor/solid-state device manufacturingFrom chemically reactive gasesFilm materialGallium alloy

The present invention is homogeneity improving method and device for hybride gaseous epitaxially grown GaN material. In the electric furnace of hydride gaseous epitaxy to grow GaN film material, the single path metal gallium source-HCL-N2 pipeline is divided into multiple path metal gallium source-HCL-N2 pipeline, the transmission homogeneity of reactant GaCl-N2 is improved and reactant GaCl-N2 is conveyed to GaN film material growing region of the electric furnace. Two or more gallium source conveying pipelines result in homogeneously distributed inner gas flow and improved film homogeneity.The grwon GaN film may be as large as 5x4 cm, and the effective film area with homogeneous thickness may reach 4x3 cm or ever larger.

Owner:NANJING UNIV

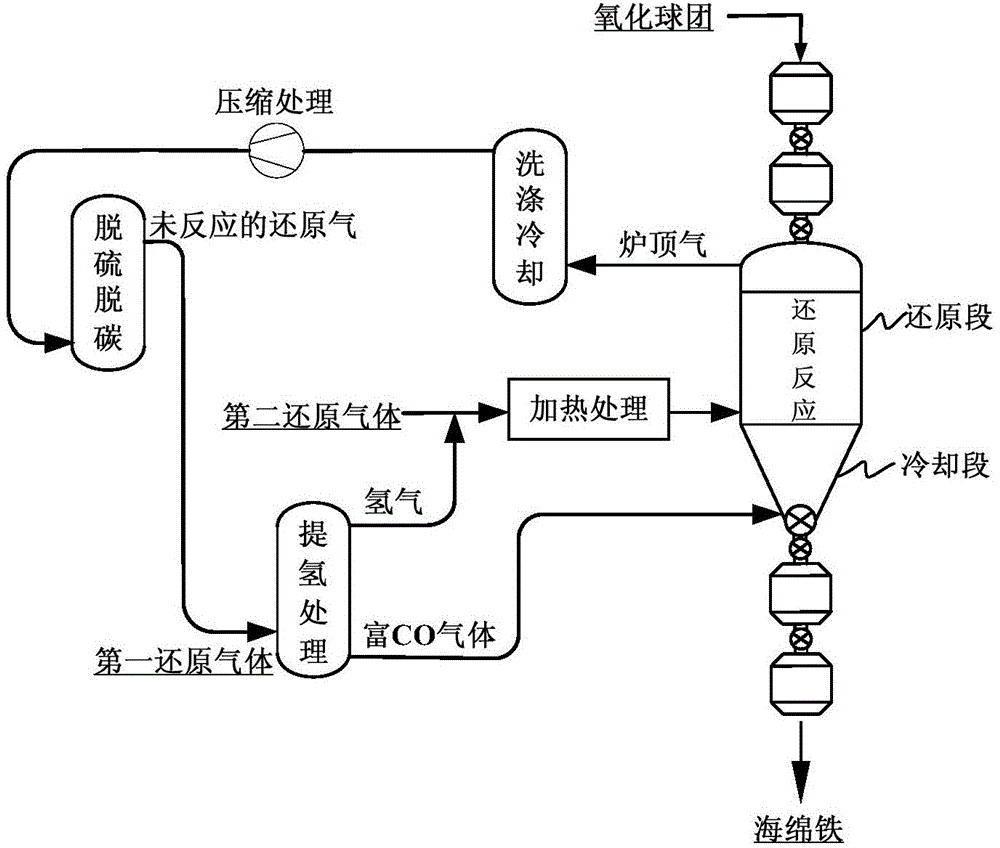

Method and system for preparing sponge iron by using gas-based shaft furnace

ActiveCN104087699AReduce energy consumptionIncrease carburizing amountShaft furnaceProduct gasEnergy consumption

The invention discloses a method and system for preparing sponge iron by using a gas-based shaft furnace. The method for preparing sponge iron by using the gas-based shaft furnace comprises the following steps of (1) adding an oxidized pellet into the gas-based shaft furnace, wherein the gas-based shaft furnace is provided with a reducing section and a cooling section, and the reducing section is located above the cooling section; (2) carrying out hydrogen extraction treatment on first reducing gas to obtain hydrogen and carbon monoxide enriched gas; (3) mixing second reducing gas and hydrogen, and carrying out heat treatment to obtain heat-state reducing gas; (4) delivering the heat-state reducing gas from the reducing section to the inside of the gas-based shaft furnace, and enabling the heat-state reducing gas and the oxidized pellet to be subjected to reduction reaction to obtain sponge iron and top gas; and (5) delivering the carbon monoxide enriched gas from the position adjacent to the bottom end of the cooling section to the inside of the gas-based shaft furnace to ensure that the carbon monoxide enriched gas upwards enters the reducing section and is subjected to reduction reaction after being subjected to heat exchange and carburization reaction with the sponge iron in the cooling section. By using the method, the energy consumption of a direct reducing process of the gas-based shaft furnace can be effectively reduced.

Owner:SHENWU TECH GRP CO LTD

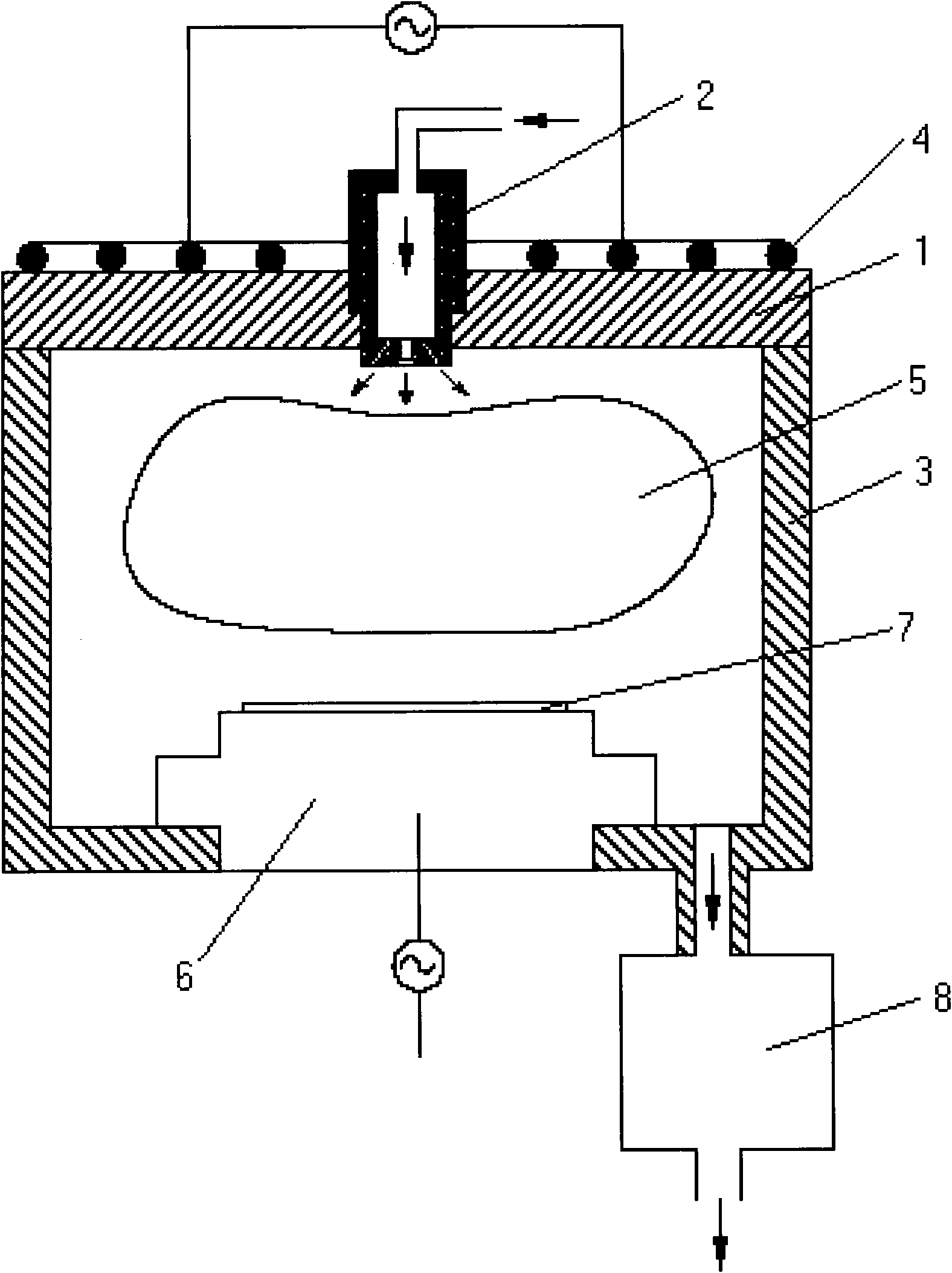

Gas input device and plasma processing equipment

InactiveCN101930889AUniform pressureEven flow distributionElectric discharge tubesEtchingEngineering

The invention provides a gas input device and plasma processing equipment. The gas input device comprises a nozzle and a cover plate, wherein, the nozzle is provided with a first channel and a nozzle bypass communicated with the first channel; the cover plate is provided with a groove and a plurality of second channels, the groove is basically arranged at the central position of the cover plate, and the plurality of the second channels are uniformly distributed in the cover plate around the center line of the groove; and the nozzle is embedded into the groove, the air outlet end of the first channel stretches out of the cover plate from the bottom part of the groove, and the air inlet ends of the plurality of the second channels are communicated with the nozzle bypass. The gas input device and the plasma processing equipment can obtain uniform air flow distribution above the whole surface of a processed wafer so as to effectively avoid non-uniform etching or deposition caused by non-uniform gas distribution from the center to the edge above the wafer surface, thus promoting the etching or deposition rate of points on the whole wafer surface to be more similar.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com