Patents

Literature

721 results about "Oxidation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Your oxidation rate is influenced by both genetics and by your diet. Thus, what you eat affects your rate of oxidation and energy production which in turn affects your mental, emotional, behavioral, and in some cases, physical characteristics.

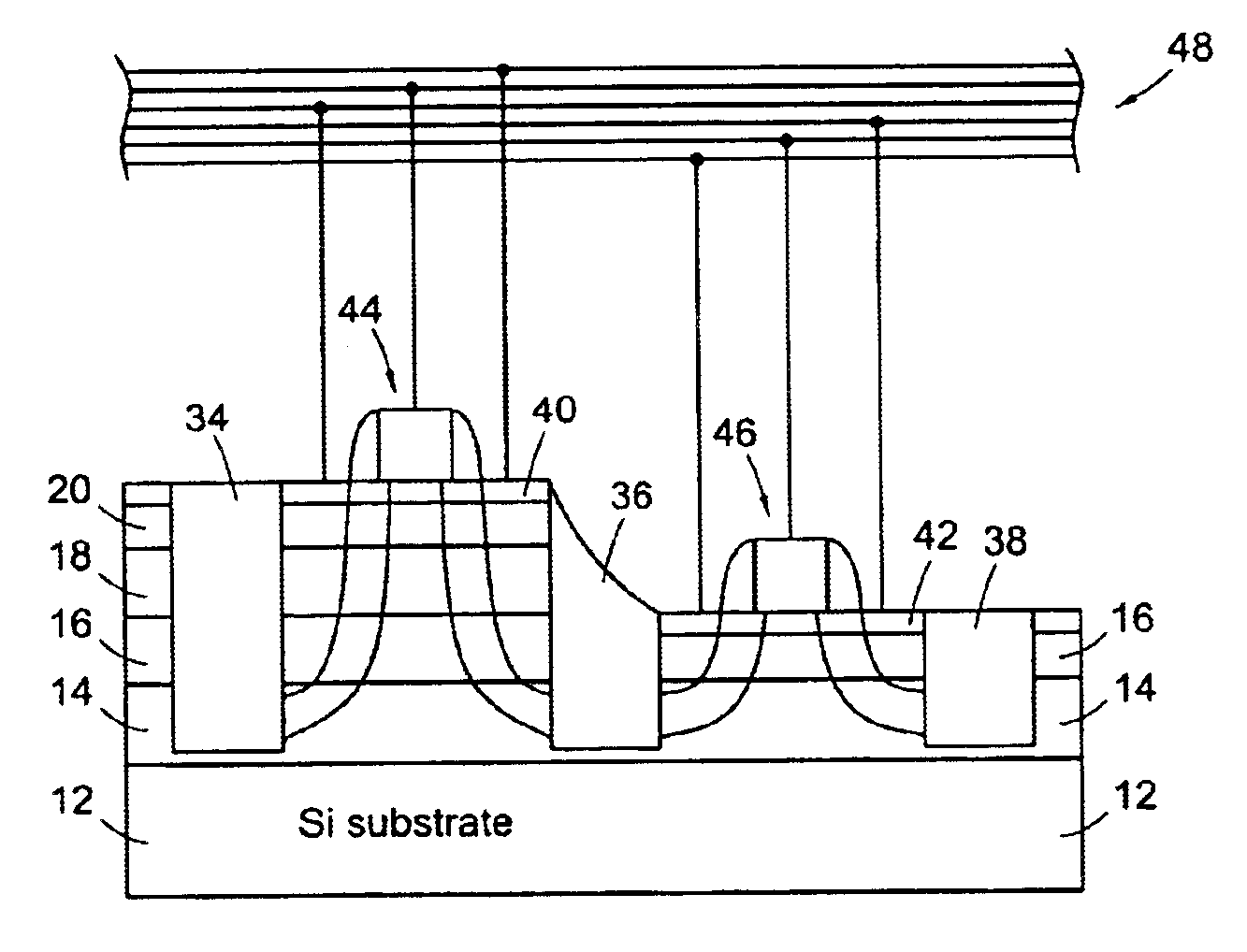

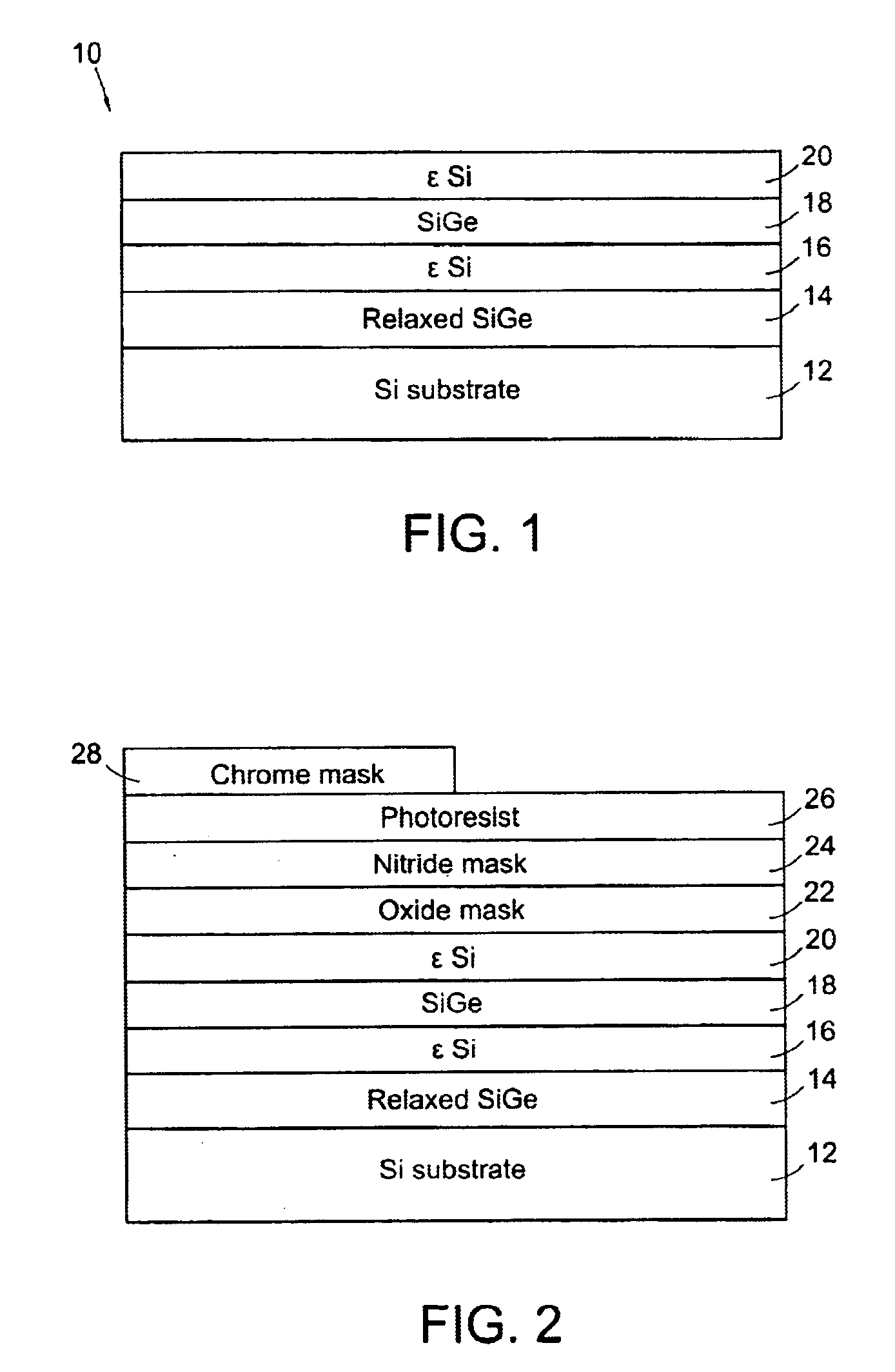

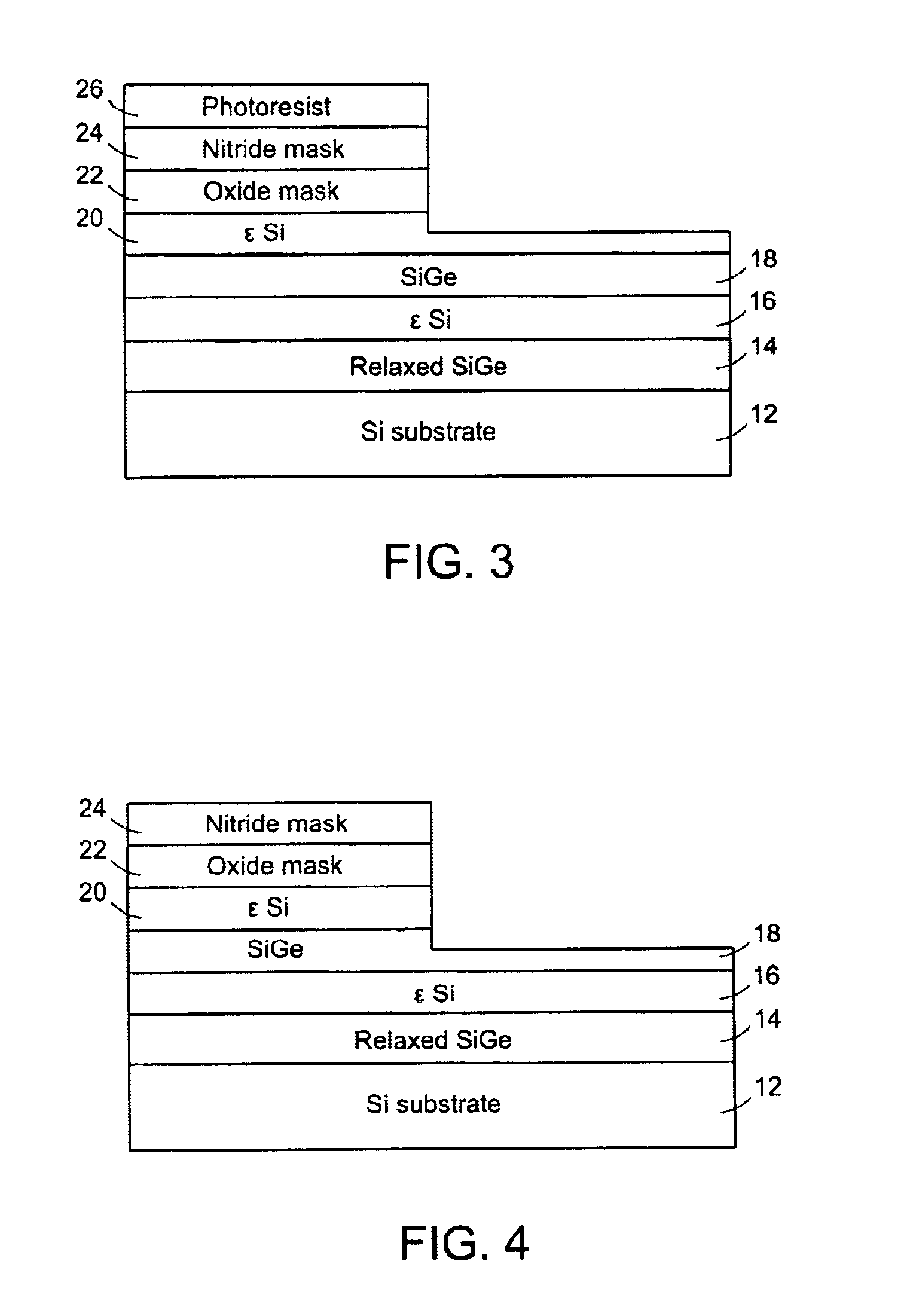

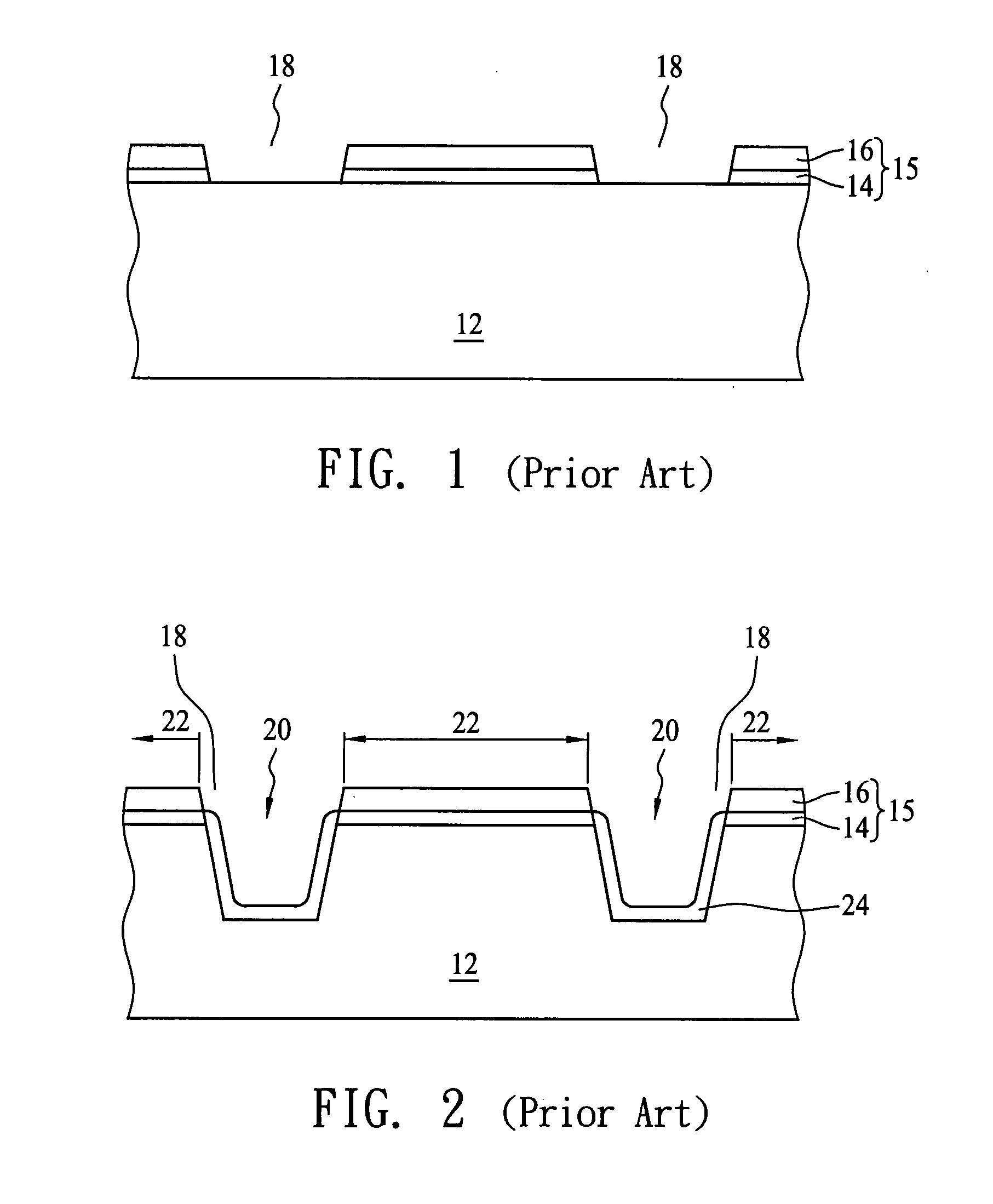

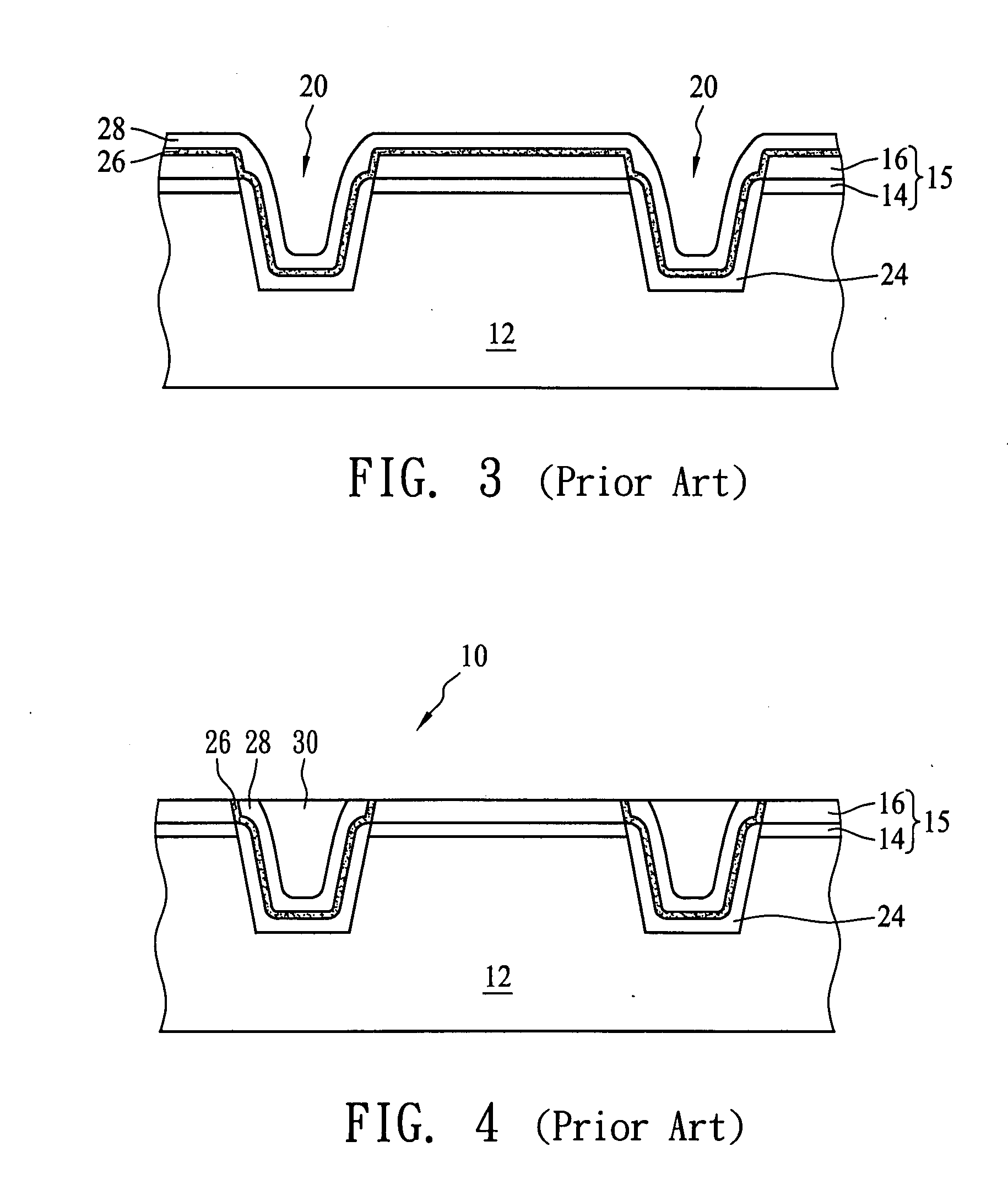

Method of selective removal of SiGe alloys

InactiveUS6900094B2Semiconductor/solid-state device manufacturingSemiconductor devicesEngineeringAlloy

A method is disclosed of forming buried channel devices and surface channel devices on a heterostructure semiconductor substrate. In an embodiment, the method includes the steps of providing a structure including a first layer having a first oxidation rate disposed over a second layer having a second oxidation rate wherein the first oxidation rate is greater than the second oxidation rate, reacting said first layer to form a sacrificial layer, and removing said sacrificial layer to expose said second layer.

Owner:TAIWAN SEMICON MFG CO LTD

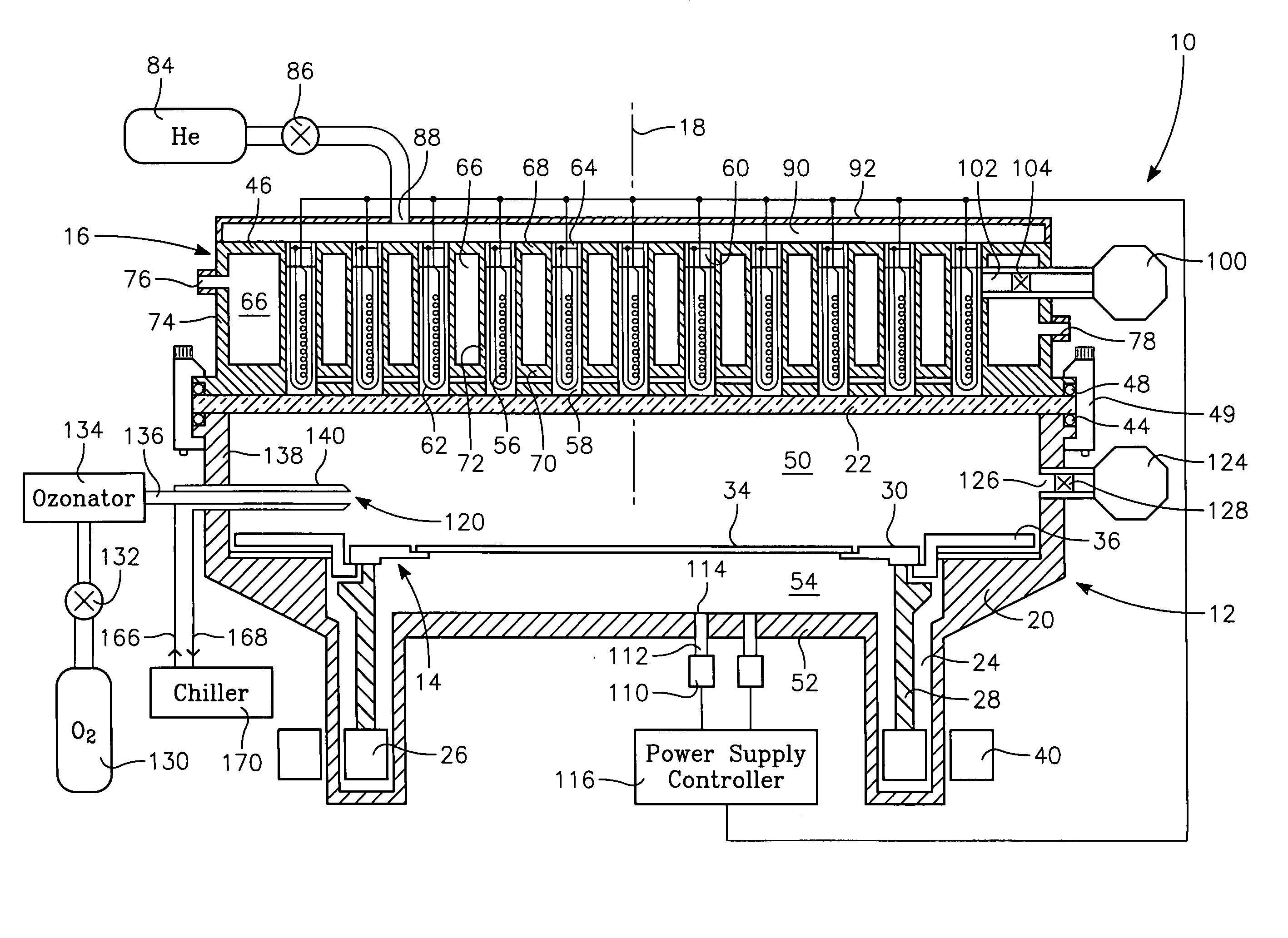

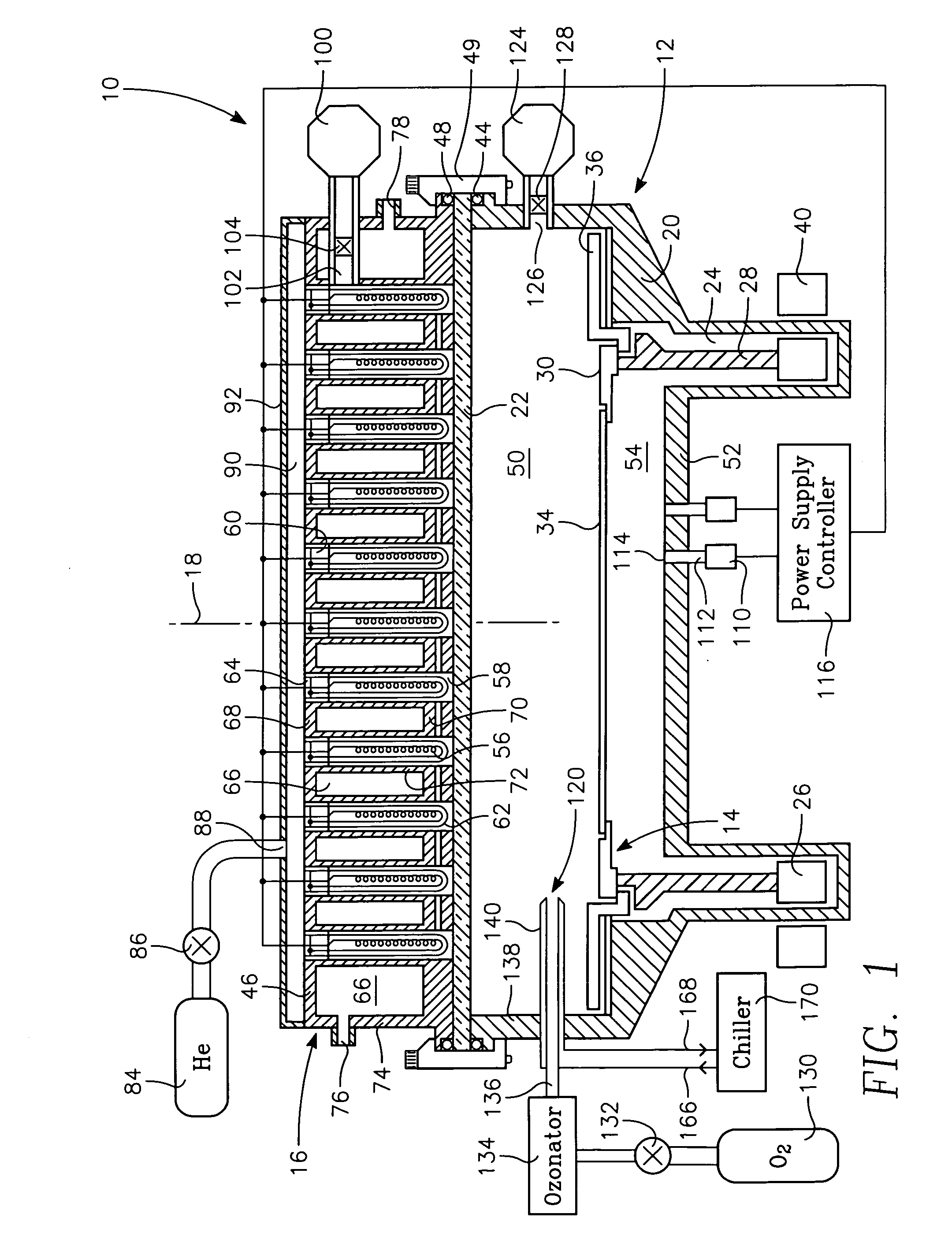

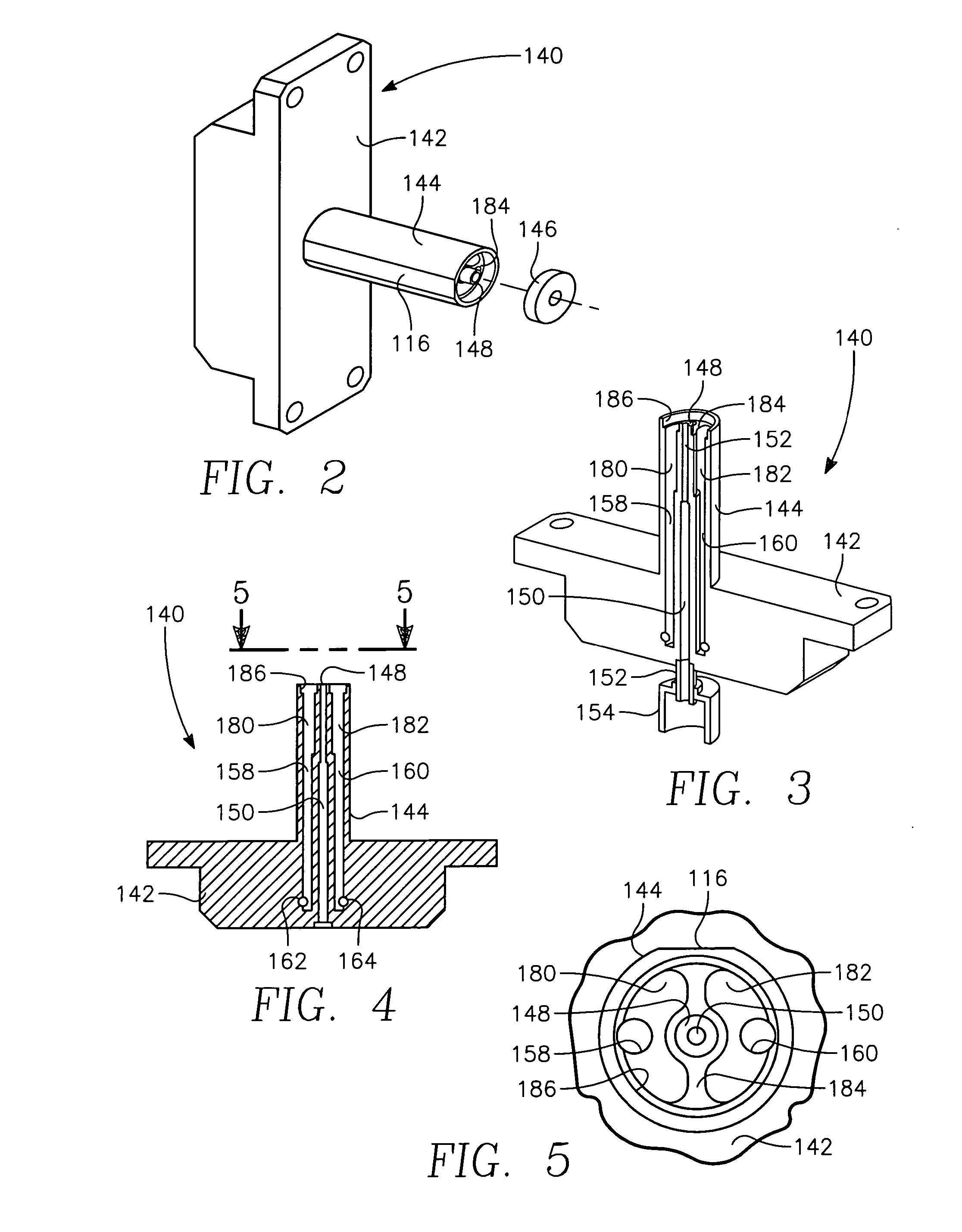

Thermal oxidation of silicon using ozone

A method and apparatus for oxidizing materials used in semiconductor integrated circuits, for example, for oxidizing silicon to form a dielectric gate. An ozonator is capable of producing a stream of least 70% ozone. The ozone passes into an RTP chamber through a water-cooled injector projecting into the chamber. Other gases such as hydrogen to increase oxidation rate, diluent gas such as nitrogen or O2, enter the chamber through another inlet. The chamber is maintained at a low pressure below 20 Torr and the substrate is advantageously maintained at a temperature less than 800° C. Alternatively, the oxidation may be performed in an LPCVD chamber including a pedestal heater and a showerhead gas injector in opposition to the pedestal.

Owner:APPLIED MATERIALS INC

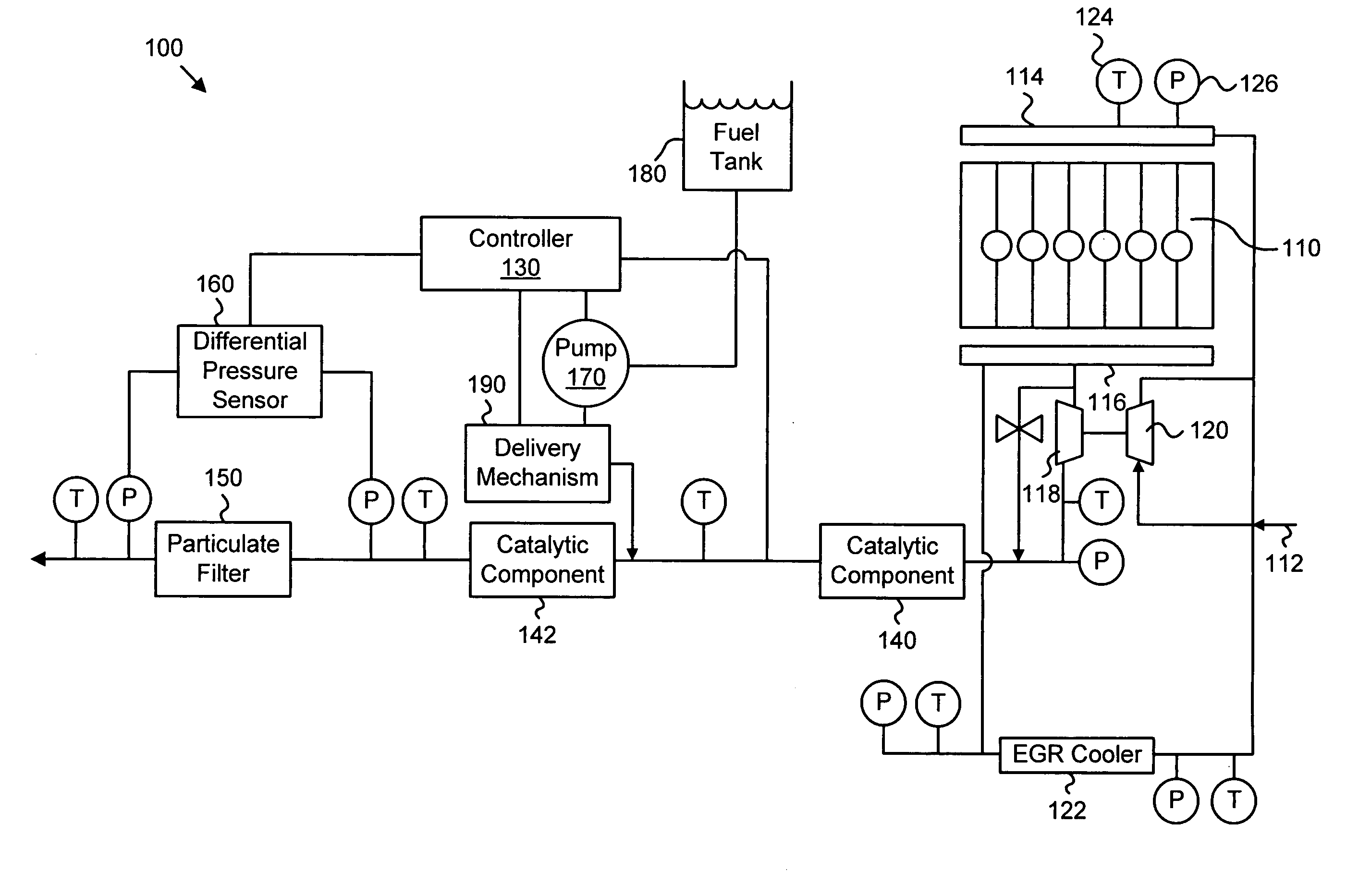

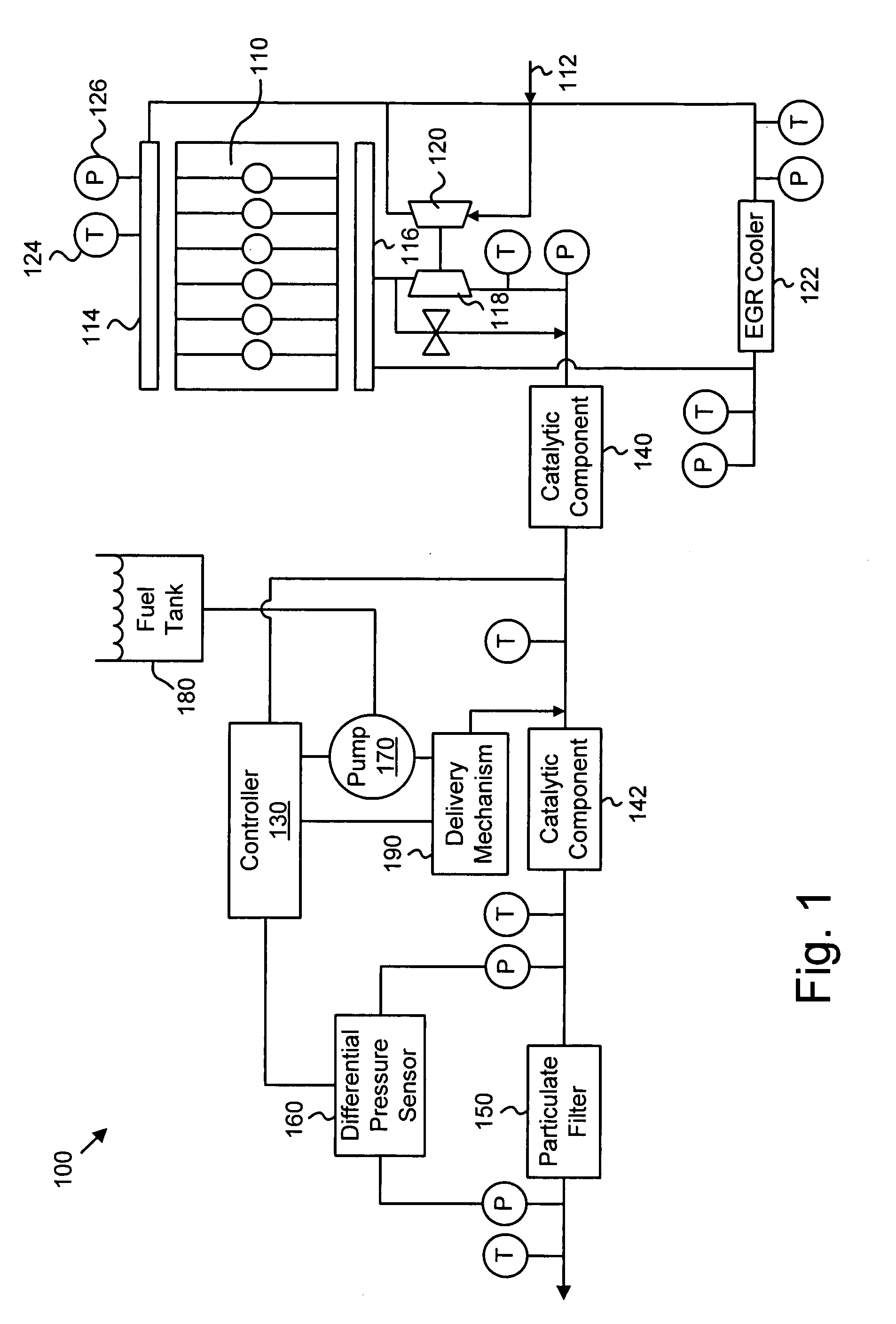

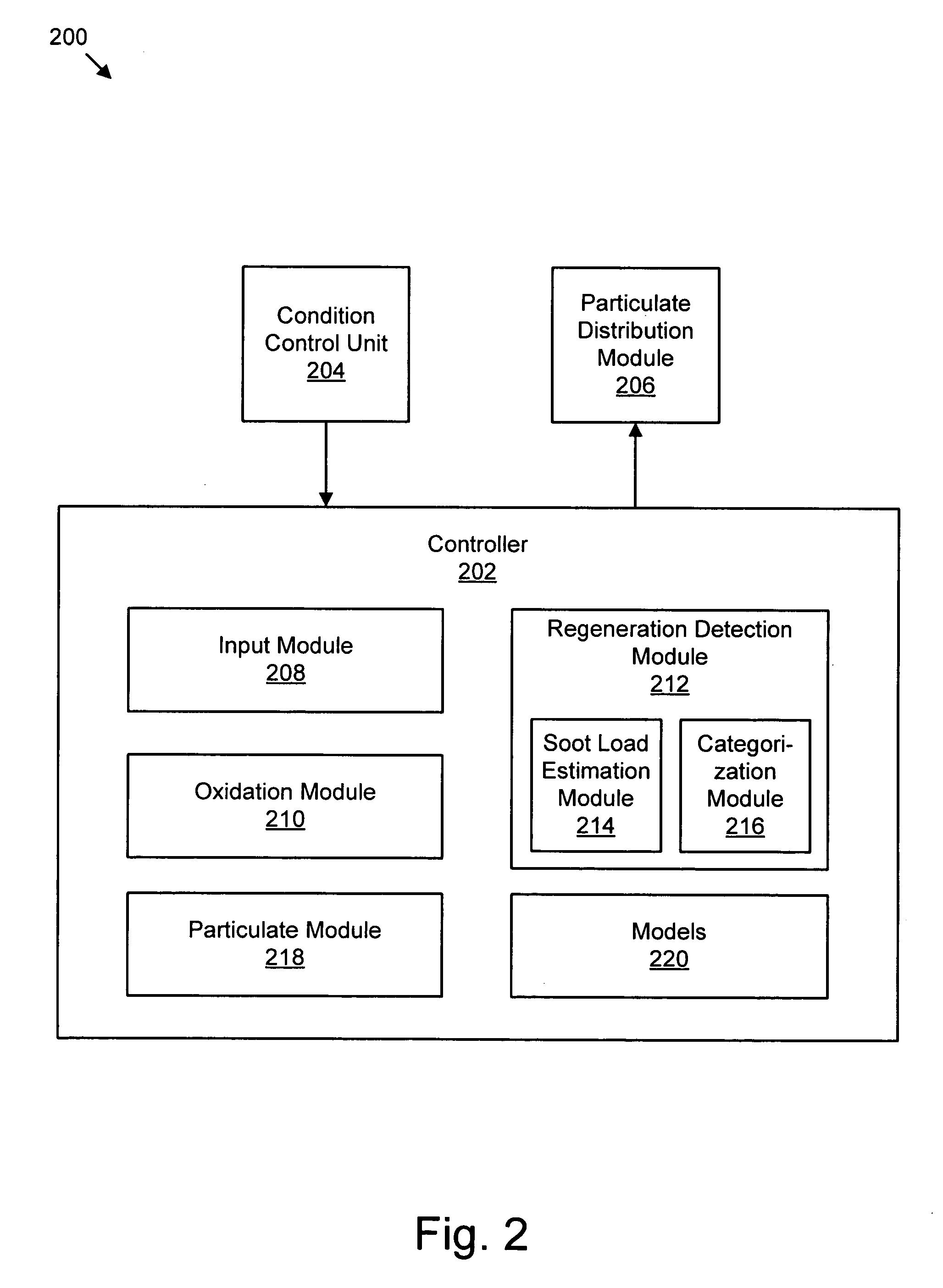

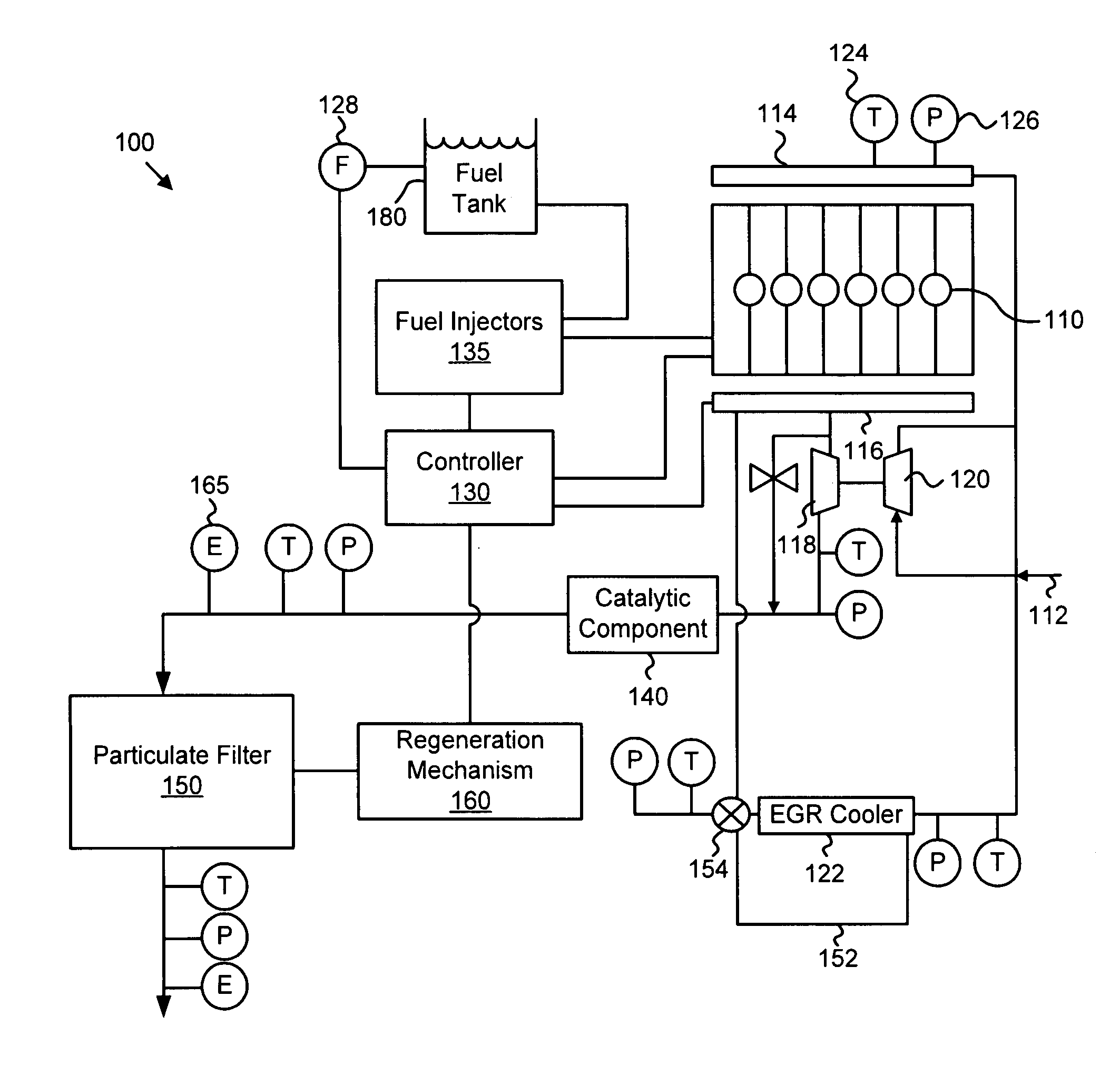

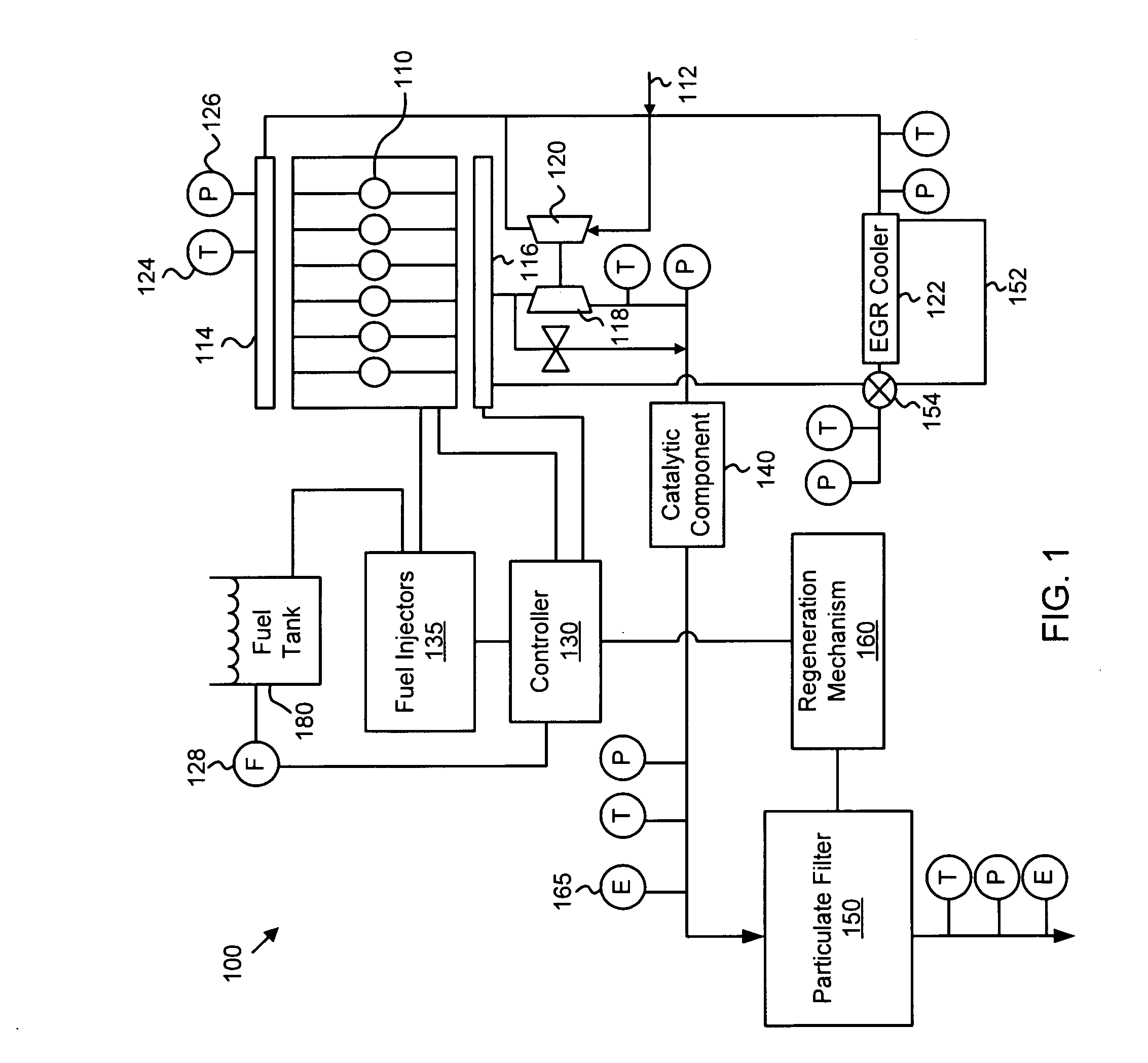

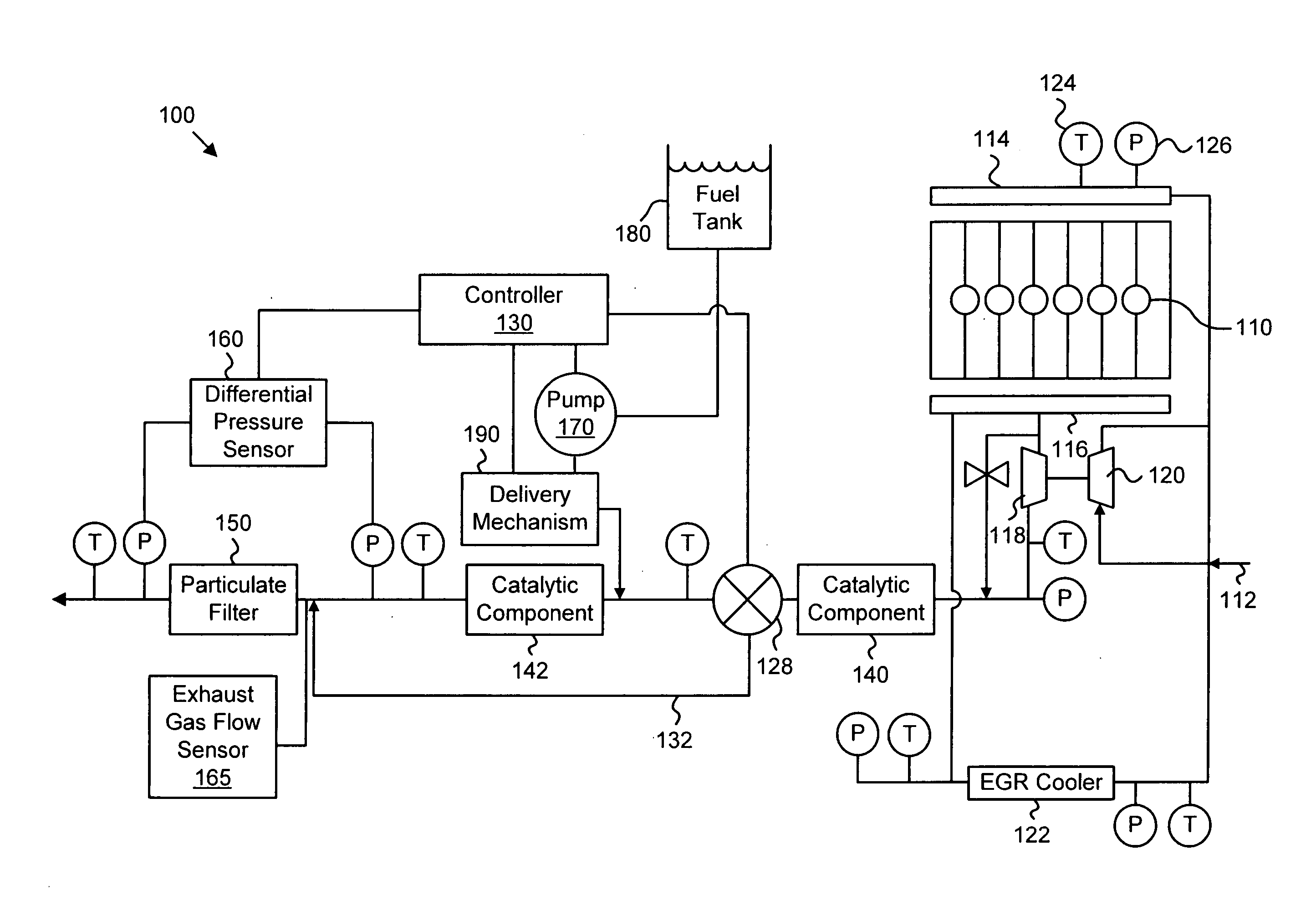

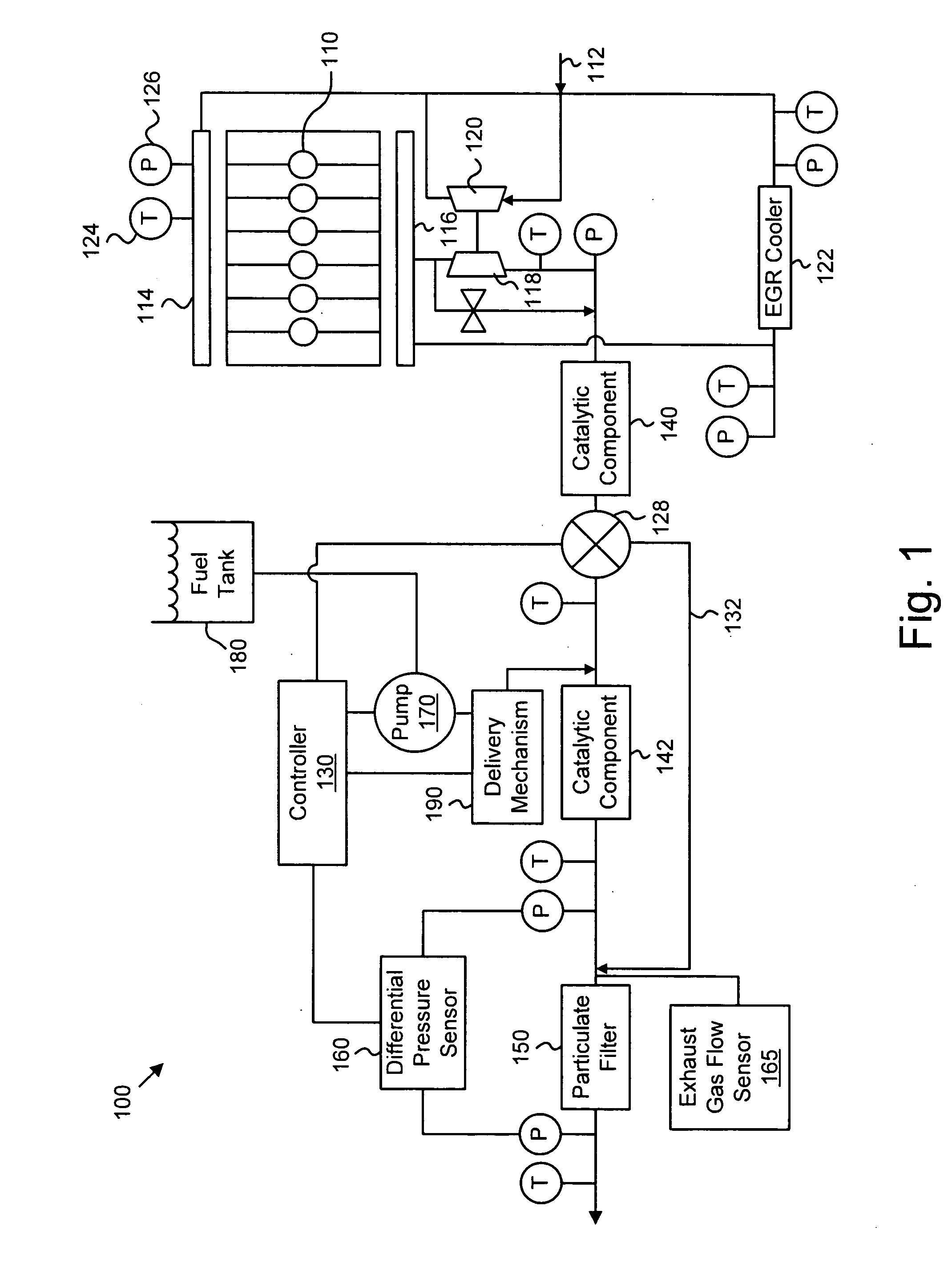

Apparatus, system, and method for detecting and labeling a filter regeneration event

ActiveUS7263825B1Easily trigger appropriate responseImprove fuel economyAnalogue computers for vehiclesInternal combustion piston enginesParticulatesEngineering

An apparatus, system, and method are disclosed for detecting and evaluating a filter regeneration event. The apparatus, in one embodiment, is configured to determine whether an oxidation rate of soot accumulated on a particulate filter has attained a level sufficient to indicate that a filter regeneration event is occurring. The apparatus may include an input module for receiving input relative to engine operating conditions and exhaust gas produced as a byproduct of engine operation, an oxidation module for communicating with the input module and for determining an oxidation rate of soot accumulated on a particulate filter from the input, and a regeneration detection module to determine whether a filter regeneration event is occurring. The apparatus may further categorize a detected filter regeneration event and to facilitate defining the actual condition of soot on a particulate filter.

Owner:CUMMINS INC

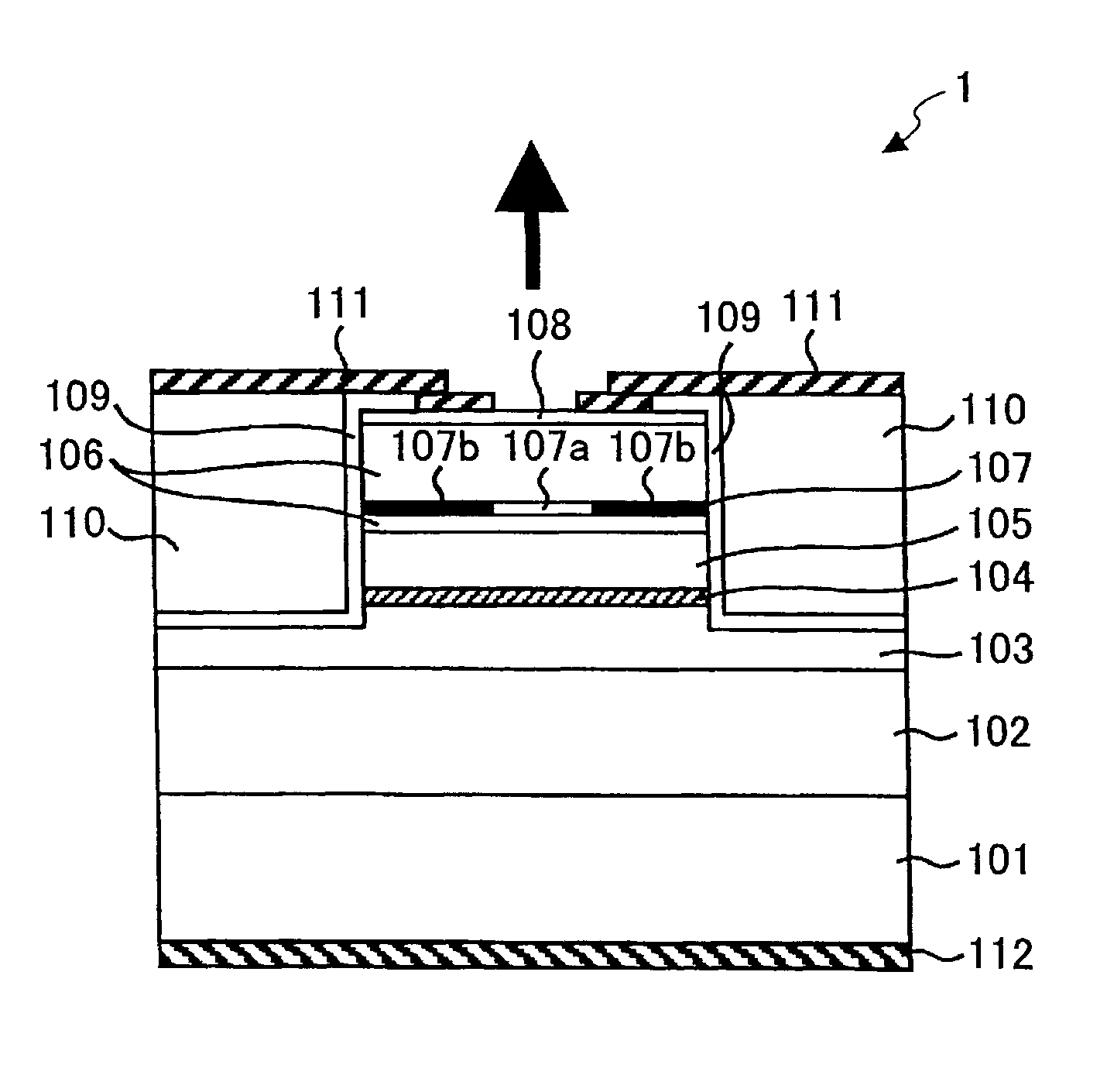

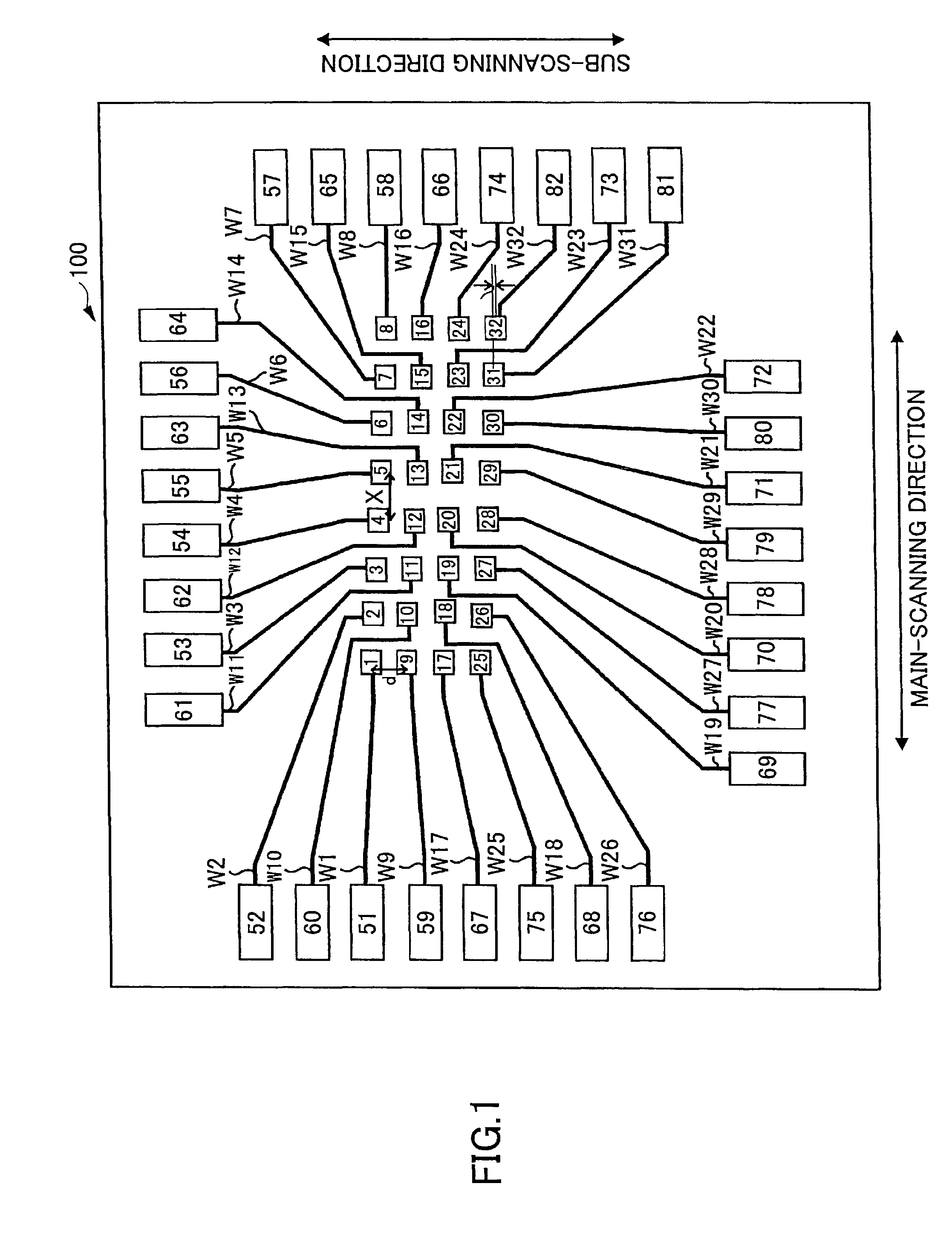

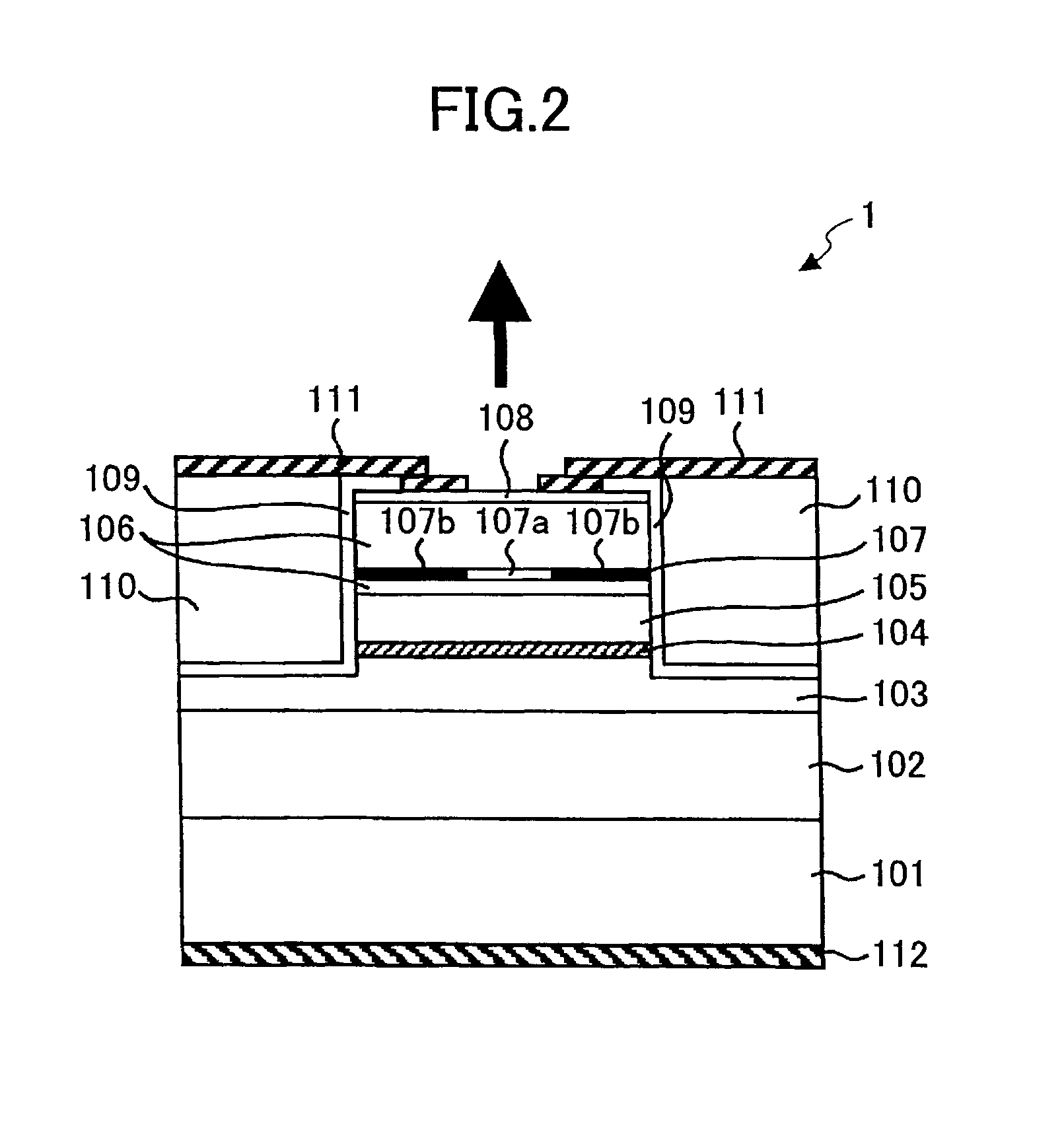

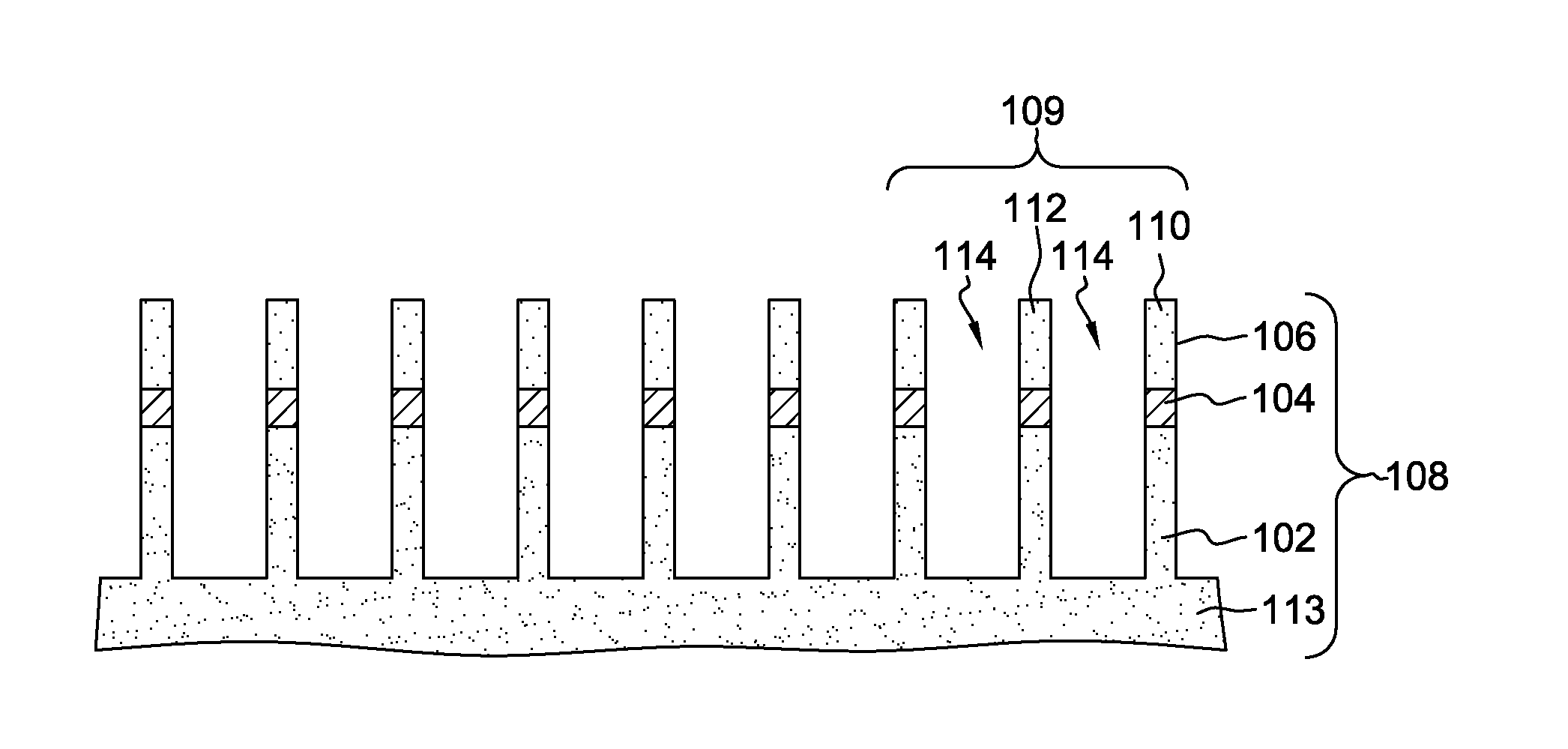

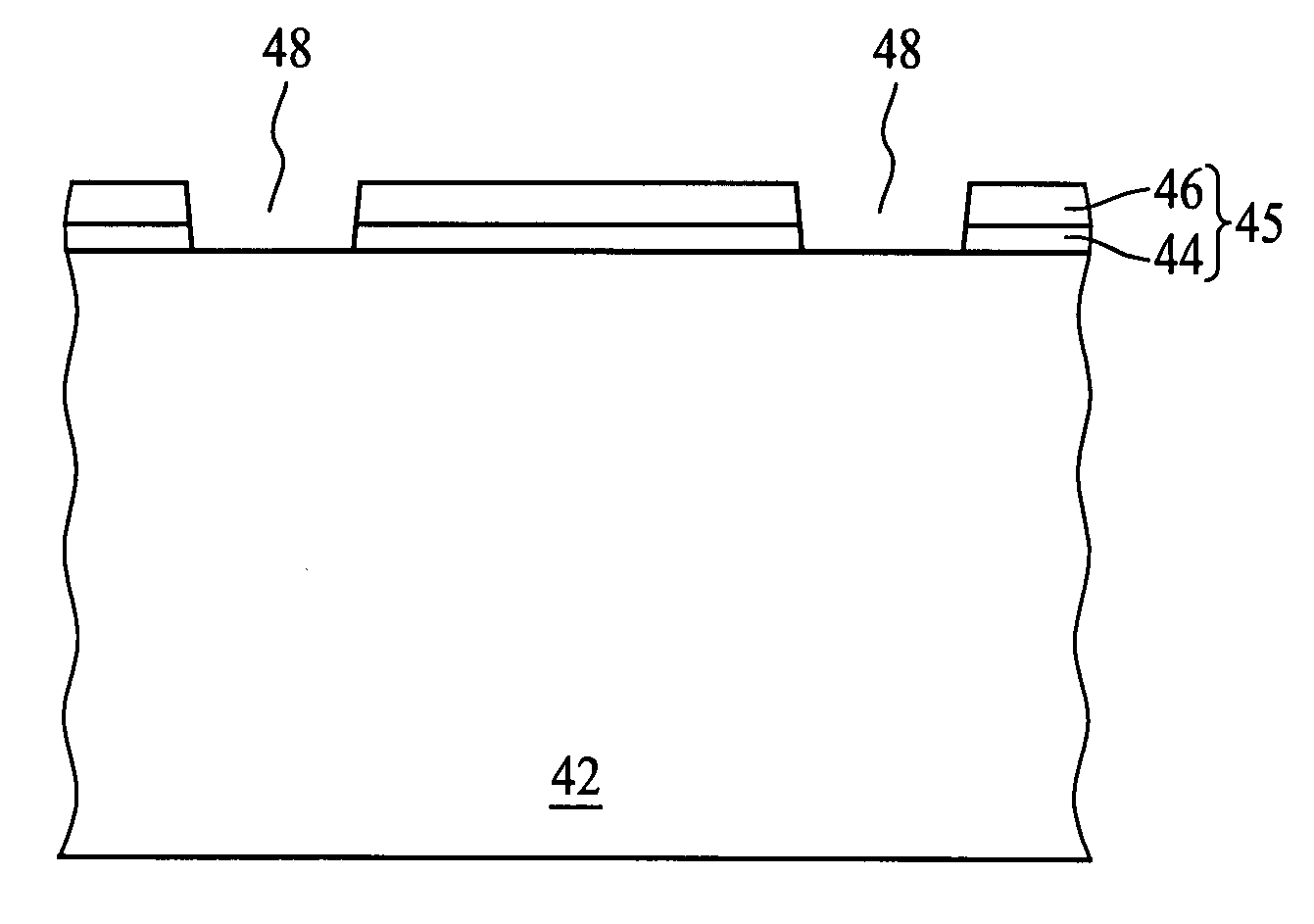

Surface-emitting laser array, optical scanning device, and image forming device

InactiveUS20090295902A1Avoid contactPrevent oxidationRecording apparatusLaser detailsLaser arrayRefractive index

A surface-emitting laser array includes a plurality of surface-emitting laser elements. Each surface-emitting laser element includes a first reflection layer formed on a substrate, a resonator formed in contact with the first reflection layer and containing an active layer, and a second reflection layer formed over the first reflection layer and in contact with the resonator. The second reflection layer contains a selective oxidation layer. The first reflection layer contains on the active layer side at least a low refractive index layer having an oxidation rate equivalent to or larger than an oxidation rate of a selective oxidation layer contained in the second reflection layer. The resonator is made of an AlGaInPAs base material containing at least In. A bottom of a mesa structure is located under the selective oxidation layer and over the first reflection layer.

Owner:RICOH KK

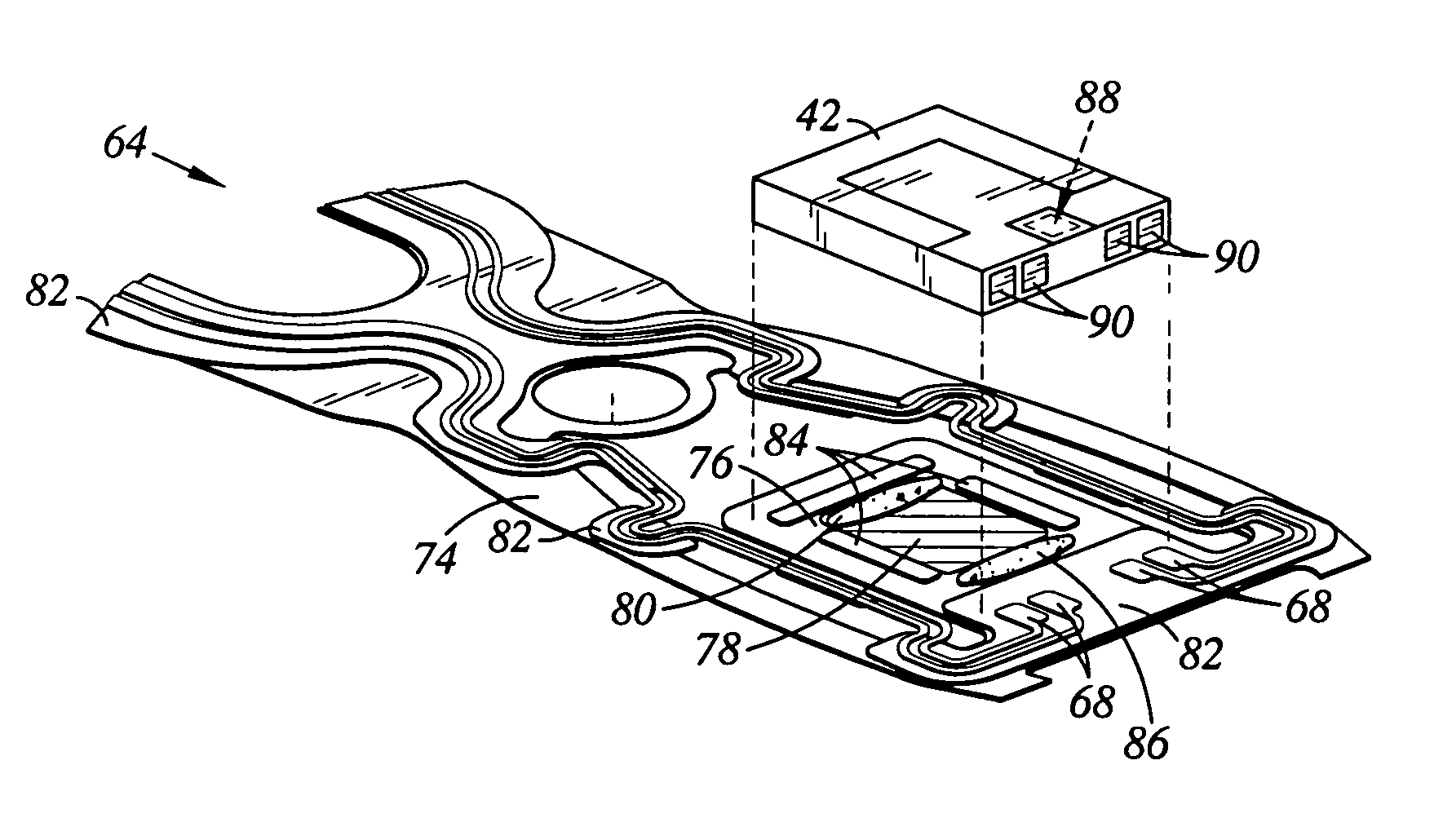

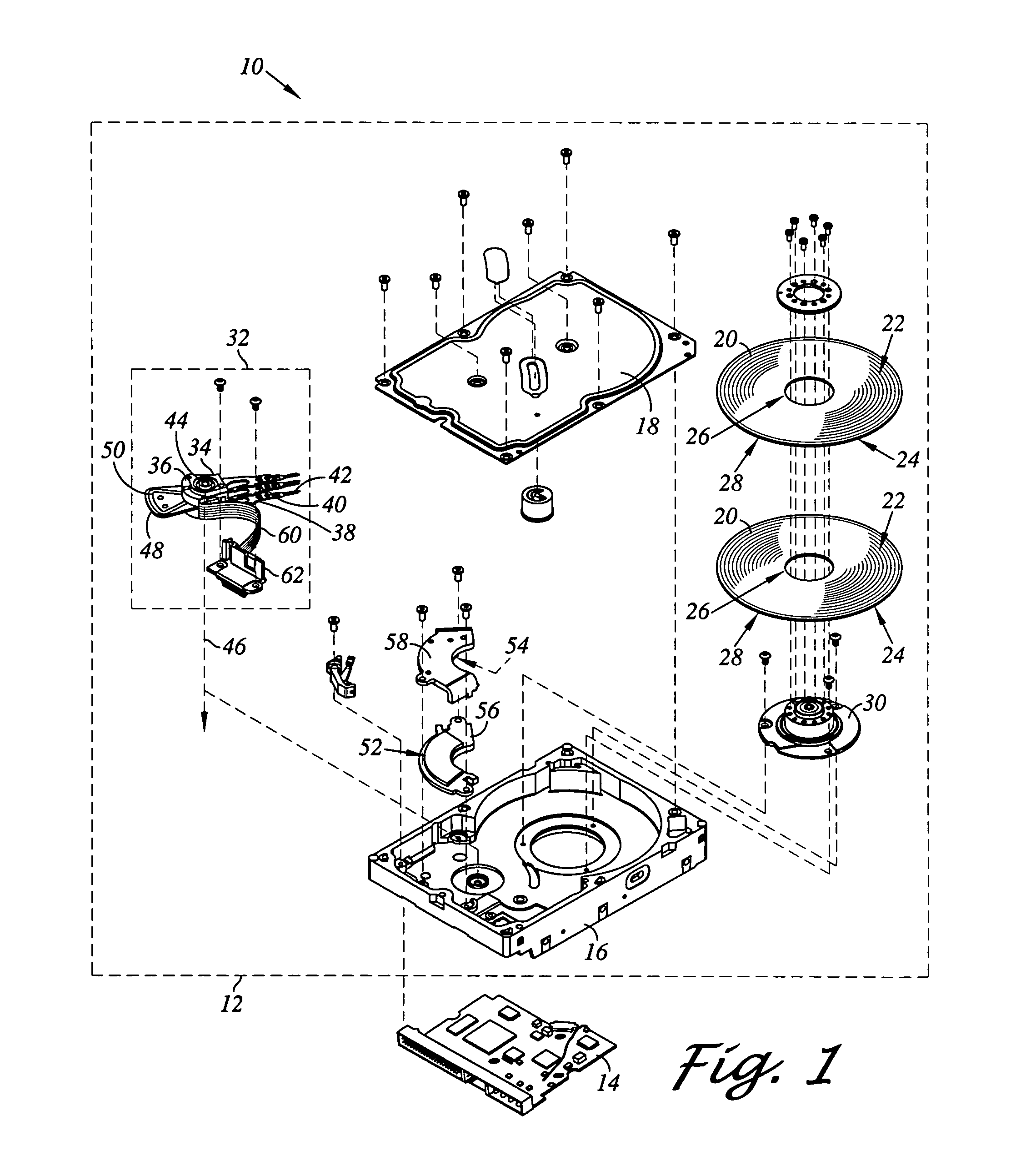

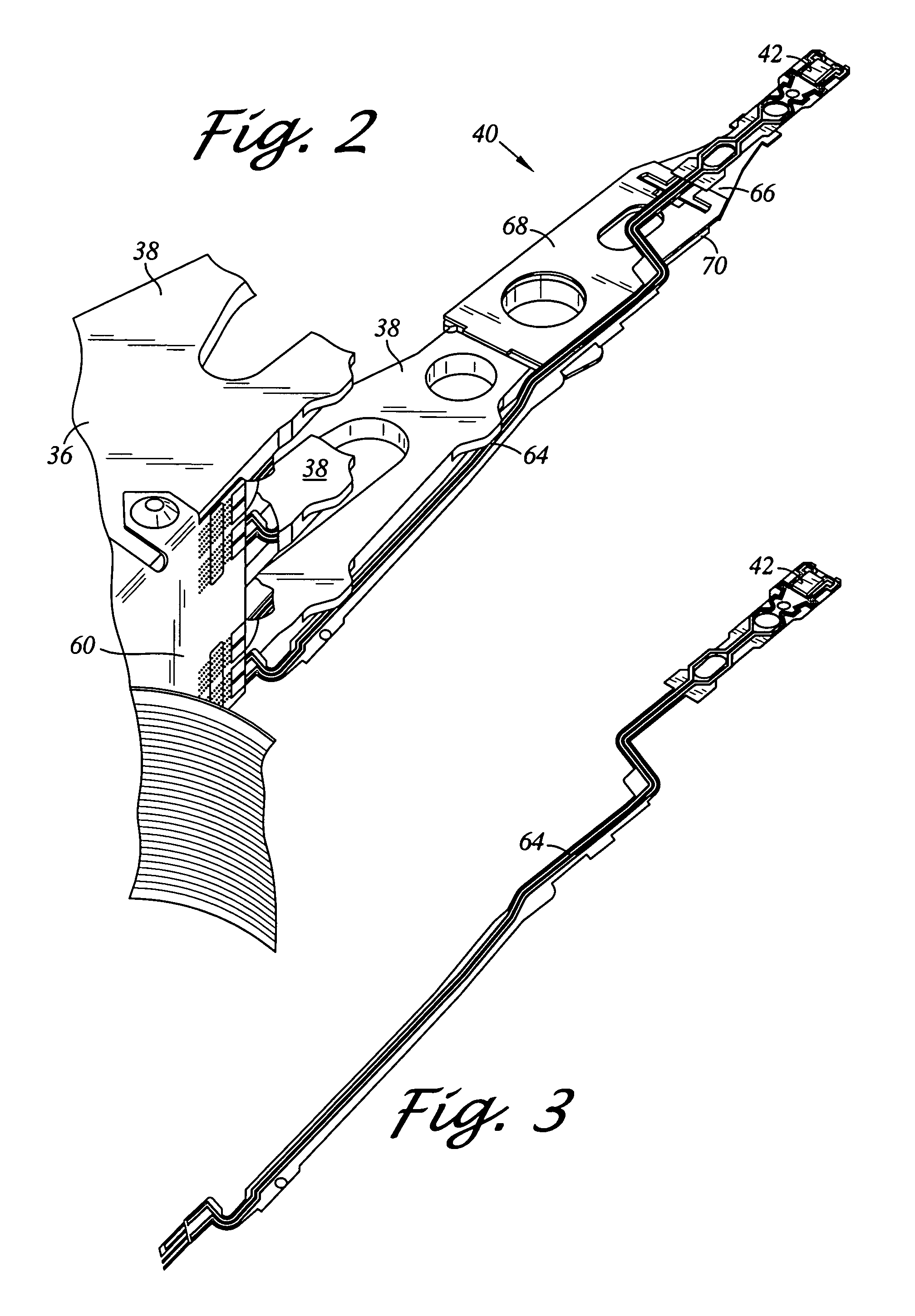

Head gimbal assembly including a trace suspension assembly backing layer with a conductive layer formed upon a gimbal having a lower oxidation rate

ActiveUS7006331B1Electrical connection between head and armPrinted circuit groundingEngineeringConductive materials

A head gimbal assembly for a disk drive. The head gimbal assembly includes a trace suspension assembly backing layer including a gimbal. The trace suspension assembly backing layer is formed of a conductive material having a first oxidation rate. The head gimbal assembly further includes a gimbal conductive layer disposed upon the gimbal and formed of a conductive material having a second oxidation rate lower than the first oxidation rate. The head gimbal assembly further includes a slider supported by the gimbal. The head gimbal assembly further includes a conductive compound disposed between the gimbal conductive layer and the slider for electrically grounding the slider to the trace suspension assembly backing layer.

Owner:WESTERN DIGITAL TECH INC

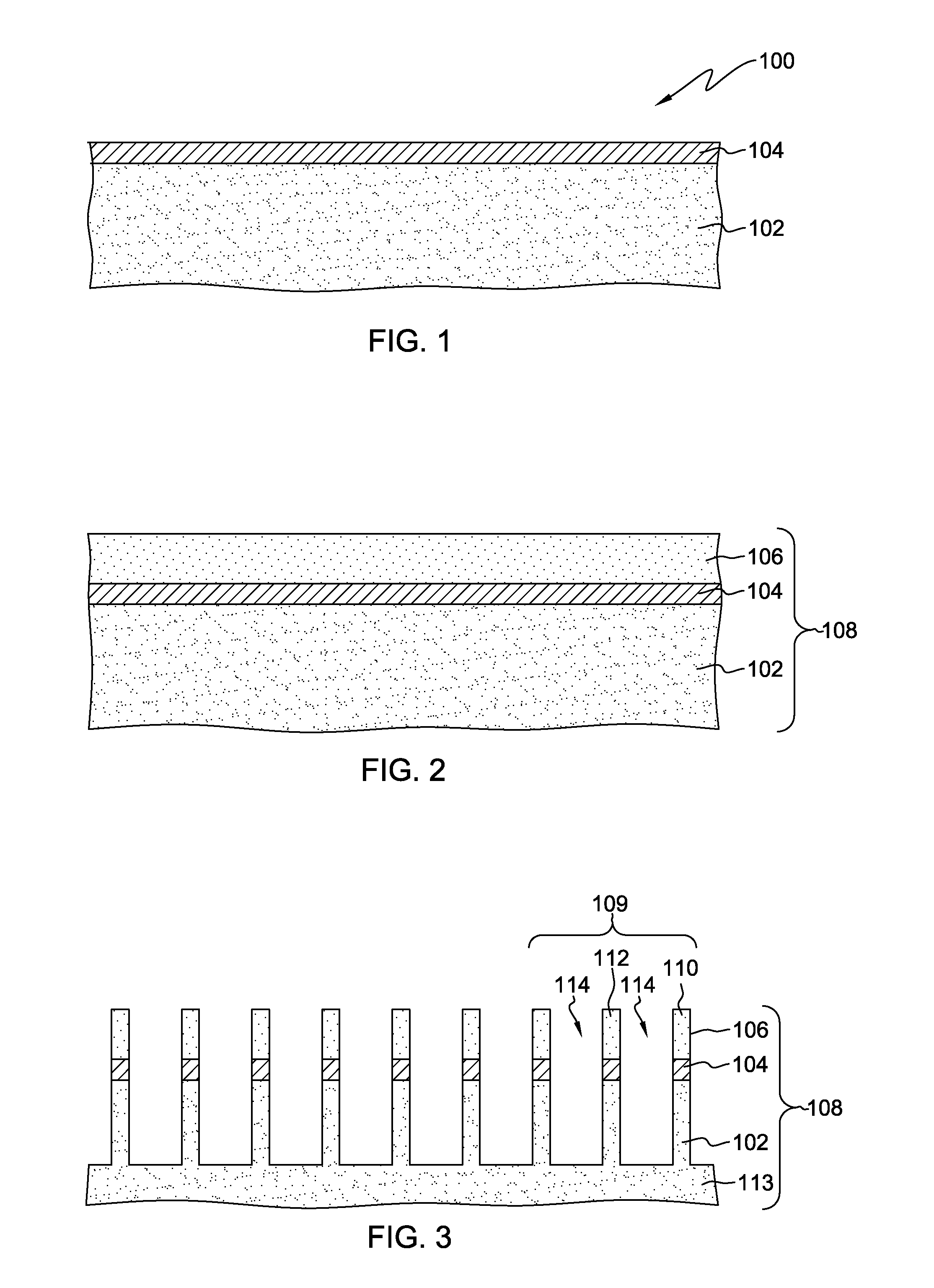

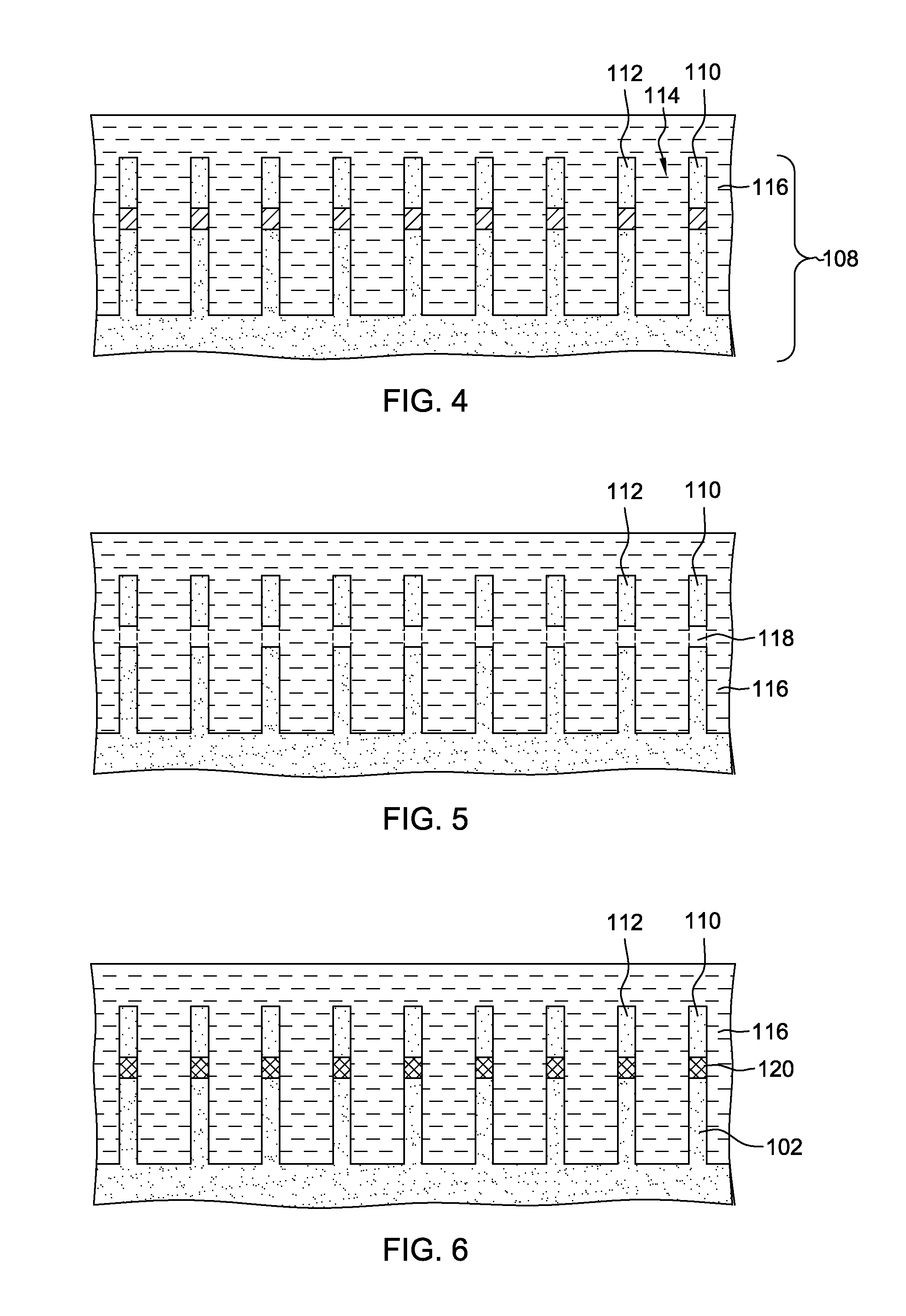

Finfet with electrically isolated active region on bulk semiconductor substrate and method of fabricating same

ActiveUS20150021691A1Overcomes shortcomingEnhanced advantageTransistorSemiconductor/solid-state device manufacturingActive layerStructural stability

A semiconductor stack of a FinFET in fabrication includes a bulk silicon substrate, a selectively oxidizable sacrificial layer over the bulk substrate and an active silicon layer over the sacrificial layer. Fins are etched out of the stack of active layer, sacrificial layer and bulk silicon. A conformal oxide deposition is made to encapsulate the fins, for example, using a HARP deposition. Relying on the sacrificial layer having a comparatively much higher oxidation rate than the active layer or substrate, selective oxidization of the sacrificial layer is performed, for example, by annealing. The presence of the conformal oxide provides structural stability to the fins, and prevents fin tilting, during oxidation. Selective oxidation of the sacrificial layer provides electrical isolation of the top active silicon layer from the bulk silicon portion of the fin, resulting in an SOI-like structure. Further fabrication may then proceed to convert the active layer to the source, drain and channel of the FinFET. The oxidized sacrificial layer under the active channel prevents punch-through leakage in the final FinFET structure.

Owner:GLOBALFOUNDRIES US INC

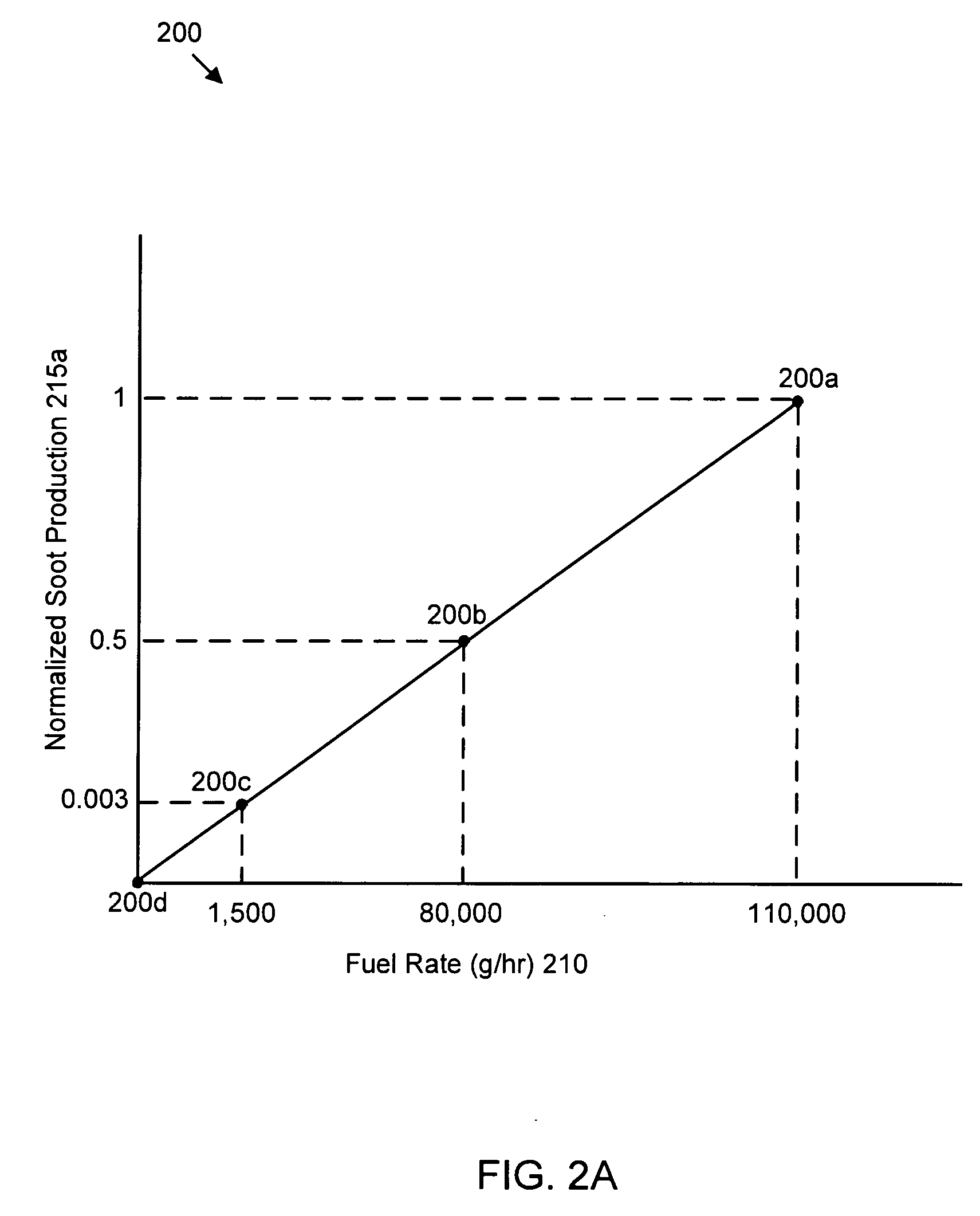

Apparatus, system, and method for estimating particulate production

ActiveUS20070056274A1Overcomes shortcomingElectrical controlInternal combustion piston enginesProduction rateMaximum level

An apparatus, system, and method are disclosed for estimating particulate production from a diesel engine. Engine conditions such as fuel rate, exhaust gas recirculation, and fuel injection timing are determined. Based on empirical evidence or theoretical calculations, or both, particulate production markers, each indicating a level of particulate production, are assigned to each engine condition. The markers are combined and the combined marker is used to interpolate between a minimum and a maximum level of particulate production from the engine to estimate a particulate production rate. The production rate may be combined with an oxidation rate to determine a particulate accumulation rate, which may in turn be combined with a particulate load estimate to produce a combined particulate load estimate. The combined estimate may be used to determine whether to initiate regeneration of a diesel particulate filter.

Owner:CUMMINS INC

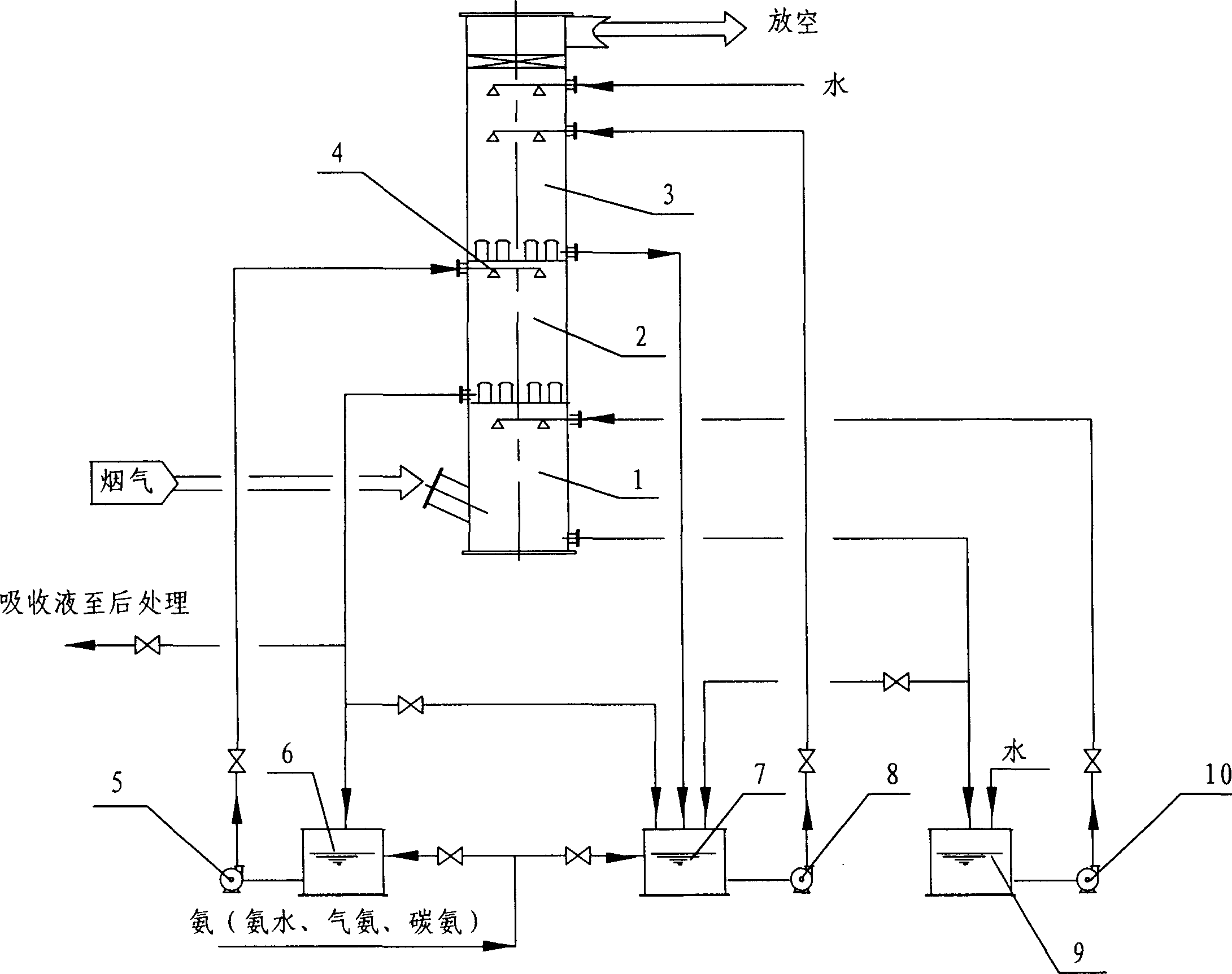

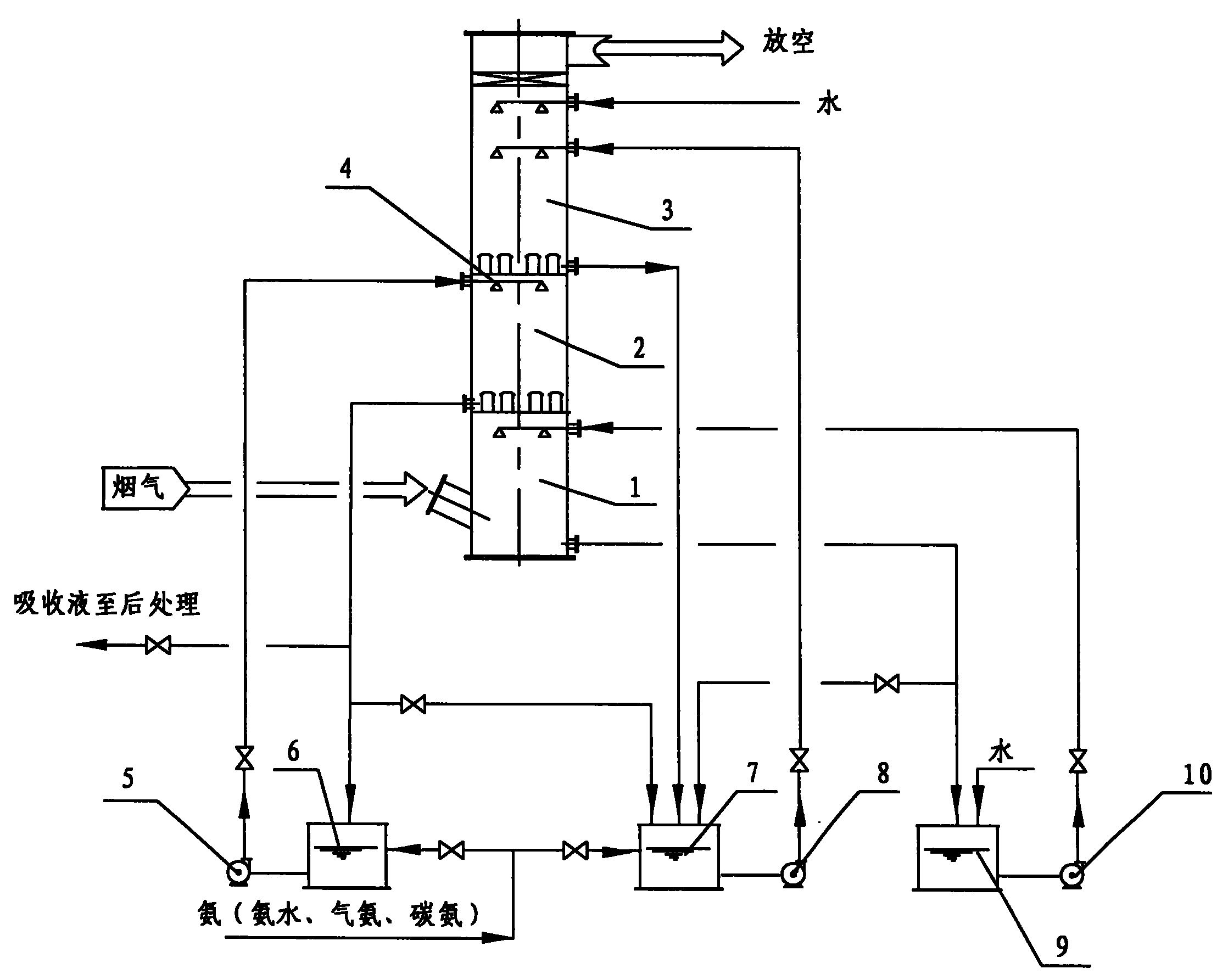

Fuel coal smoke low oxidation rate desulfur method

InactiveCN1283346CGuaranteed desulfurization effectGuaranteed total desulfurization efficiencyDispersed particle separationFlue gasTower

The invention belongs to the environmental protection technology, and relates to a method for recycling sulfur dioxide in flue gas of a coal-fired boiler, in particular to a method for desulfurization of coal-fired flue gas with a low oxidation rate. Its treatment process and parameters in the desulfurization tower are: a. Cool down and remove dust, spray and wash the flue gas entering the tower with water first, so that the temperature of the flue gas will drop to 40-50°C within 2-3 seconds; b. For the first level of absorption, use the ammonium salt absorption solution with a concentration of 500-650g / l and a pH value of 5.2-6.2 for spray absorption; c. For the second-level absorption, use a concentration of 300-500g / l and a pH value of 5.4 ~6.5% ammonium salt absorption liquid is sprayed and absorbed; d. Washing and defogging the flue gas after absorption treatment, eluting the absorption liquid entrained in the flue gas and emptying it. The invention can reduce the oxidation rate in the ammonia desulfurization process and improve the utilization value of by-products.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Vanadia-Based DeNOx Catalysts and Catalyst Supports

InactiveUS20110250114A1Improve catalytic performanceImprove retentionNitrogen compoundsDispersed particle separationPhosphateManganese oxide

A vanadia-based catalytic composition for reduction of nitrogen oxides includes a titania-based support material; vanadia deposited on the titania-based support material; a primary promoter comprising tungsten oxide, molybdenum oxide or combinations thereof; and an amount of phosphate to achieve a mole ratio of phosphorus to vanadium plus molybdenum of about 0.2:1 or greater. A zirconia, tin or manganese oxide can be added to further inhibit the volatility of molybdenum. Results show low SO2 oxidation rates and excellent NOx conversion and / or molybdenum stability.

Owner:CRISTAL US INC

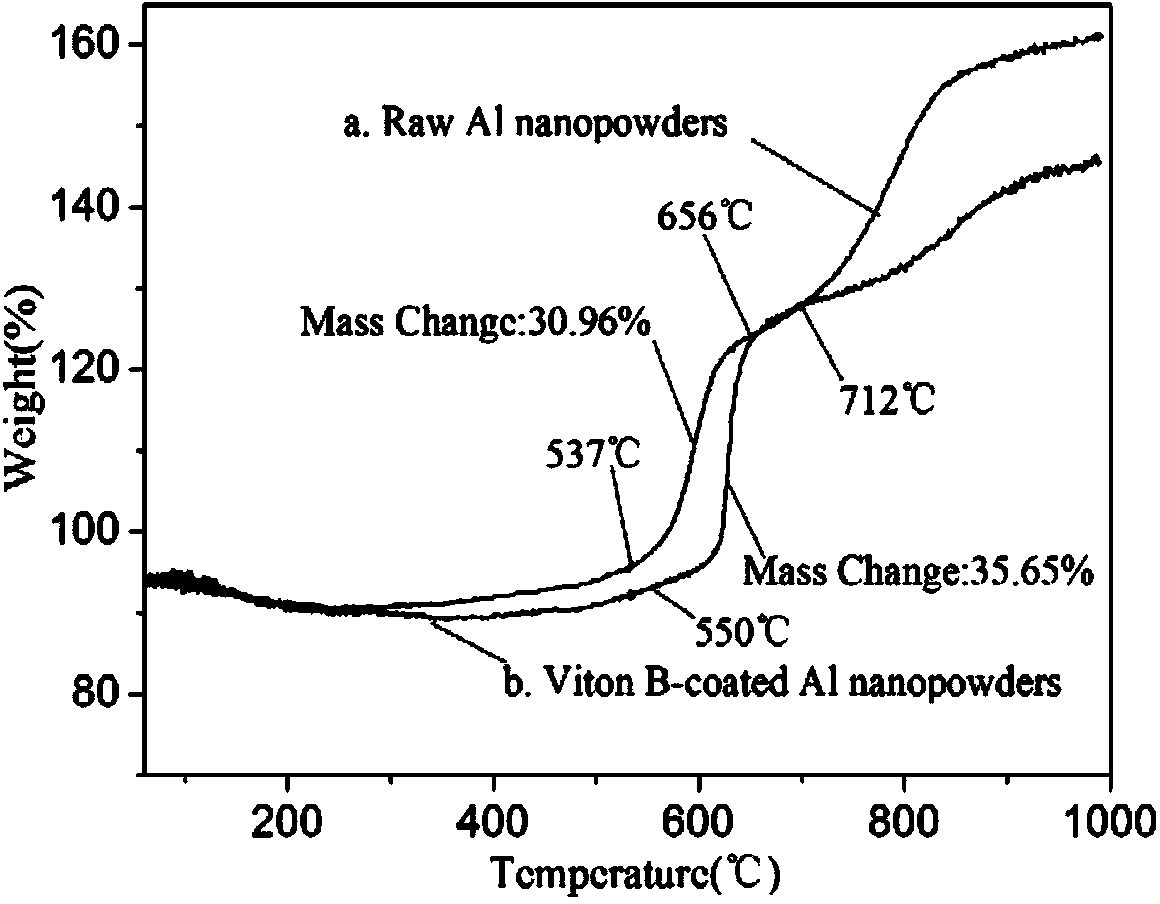

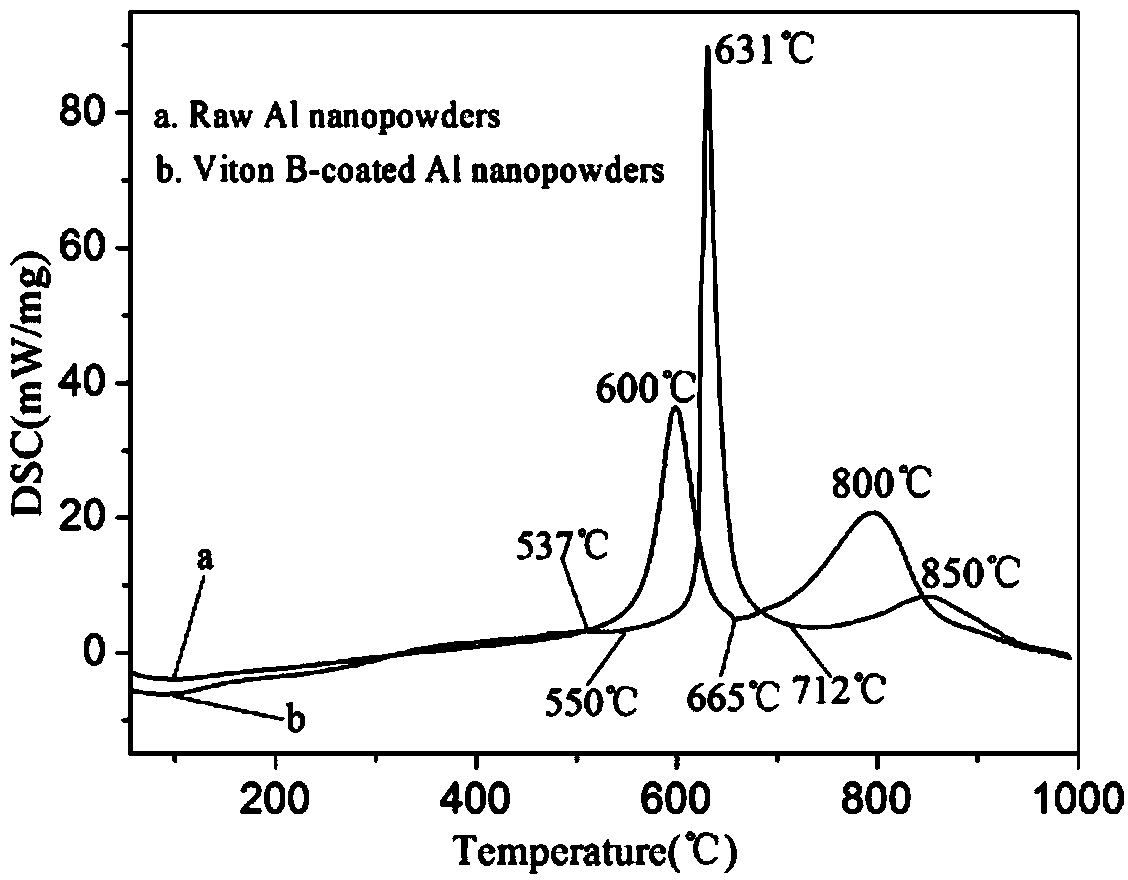

Preparation method for fluororubber cladding nanometer aluminum powder composite particles

InactiveCN103506621ALower surface energyKeep aliveNanotechnologyRoom temperaturePyrotechnic composition

The invention discloses a preparation method for fluororubber cladding nanometer aluminum powder composite particles. The preparation method comprises the following steps that the silane coupling agent with the mass being 5-15% that of nanometer aluminum powder is used for modifying the nanometer aluminum powder; fluororubber with the mass being 5-20% that of the modified nanometer aluminum powder is selected and used, a solvent-nonsolvent method is used for conveying cladding modifying on the nanometer aluminum powder modified by the coupling agent, nanometer aluminum powder / fluororubber composite particles are prepared, and the composite particles are of a core-shell structure; the cladding layer fluororubber can postpone the normal temperature oxidation of the nanometer aluminum powder, and the high temperature oxidation rate and heat release rate of the nanometer aluminum powder are significantly improved. The preparation method for the fluororubber cladding nanometer aluminum powder composite particles can effectively prevent the oxidation of the nanometer aluminum powder, keep the activity of the nanometer aluminum powder, overcome the influence of non-formula composition or inert composition cladding nanometer aluminum powder on the comprehensive performance of pyrotechnic composition and propellant, and improve the compatibility between the nanometer aluminum powder and pyrotechnic composition, propellant and the like.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of structured flue gas denitration catalyst, prepared catalyst and application of catalyst

ActiveCN102166514AReduce oxidation rateHigh mechanical strengthDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTungstateNitric oxide

The invention relates to a preparation method of structured flue gas denitration catalyst, a prepared catalyst and application of the catalyst. The method comprises the following steps of: pre-mixing TiO2 powder and ammonium meta-tungstate-containing oxalic acid solution to prepare WO3-containing TiO2 powder; mixing the prepared TiO2 powder, an inorganic binder, a plasticizer, glass fibers and sesbania powder in a special mass ratio; adding oxalic acid solution of ammonium metavanadate and aqueous solution of cerous nitrate; mixing the materials; adding ammonia water to adjust the pH value tobetween 9 and 10; ageing the mixture for 5 to 10 days; coating the aged mud material onto a stainless steel net; after rolling the aged mud, forming, and drying and roasting the prepared plate type structural V2O5 / TiO2-based denitration catalyst. The plate type structural V2O5 / TiO2-based denitration catalyst has high mechanical strength and catalytic activity and low SO2 oxidation rate, so the catalyst can be widely applied to the removal of nitric oxide in coal / oil / gas boilers and nitric acid industry.

Owner:CHINA DATANG TECH & ENG

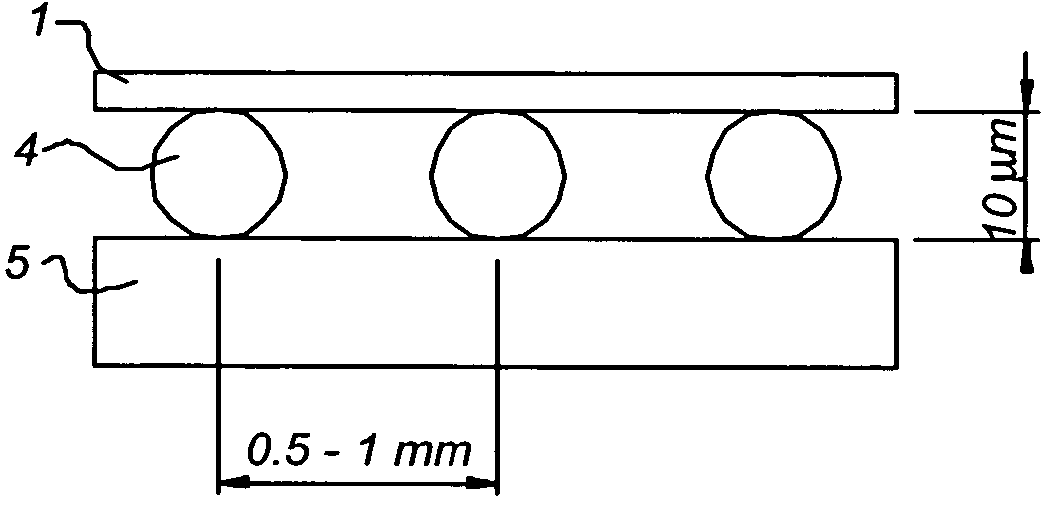

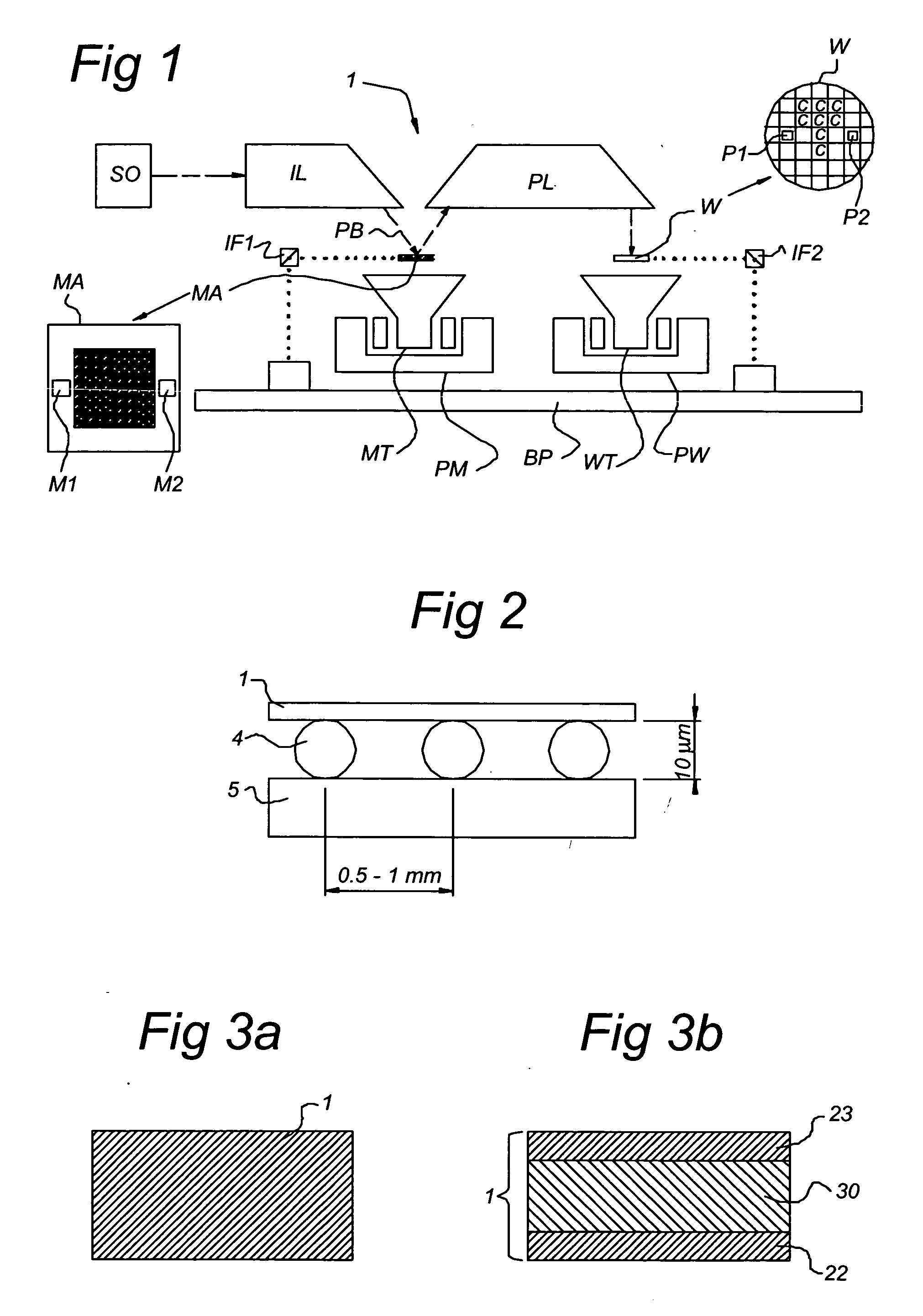

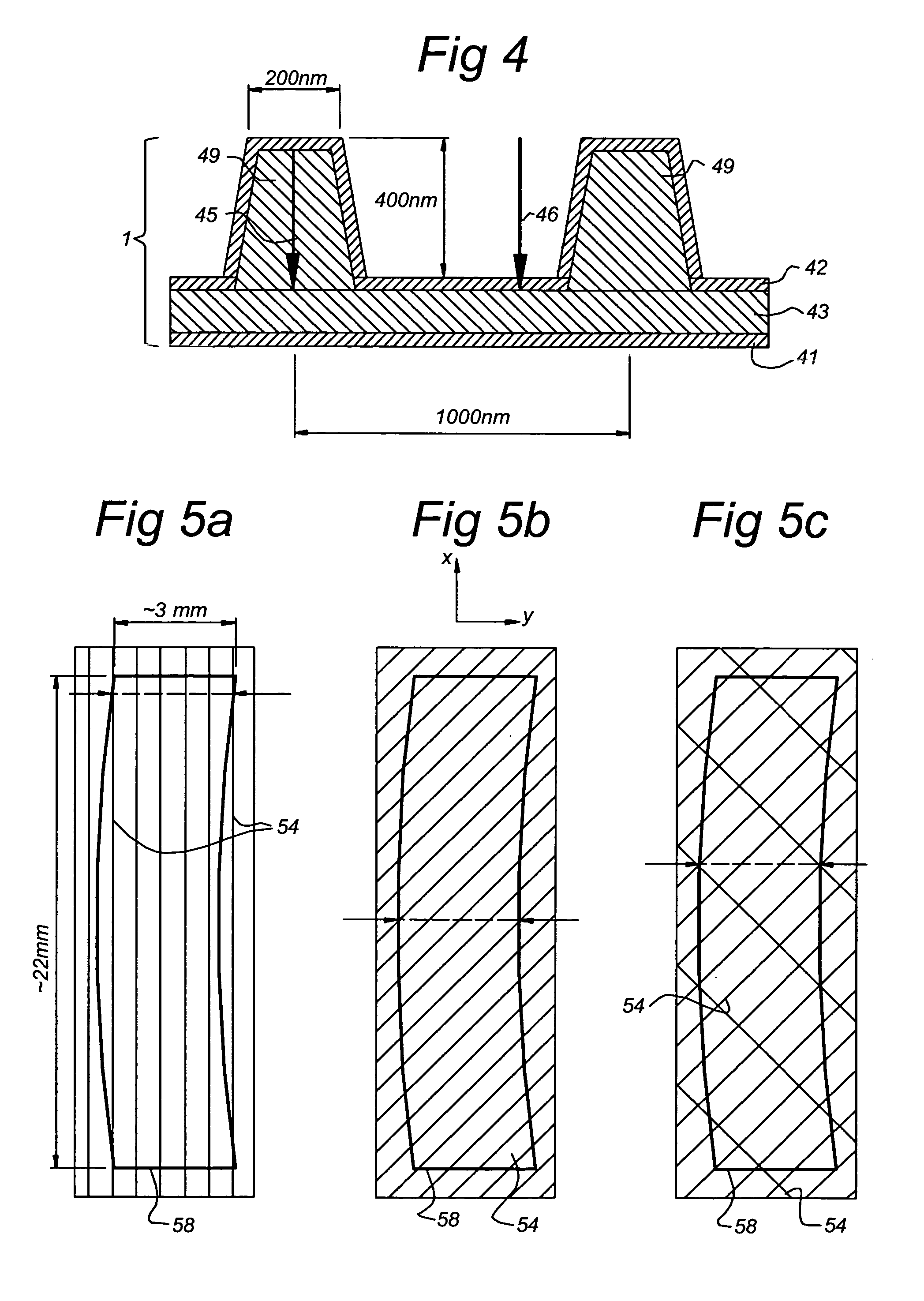

Filter window, lithographic projection apparatus, filter window manufacturing method, device manufacturing method and device manufactured thereby

InactiveUS20050040345A1Improve throughputIncrease the light areaRadiation/particle handlingNanoinformaticsProjection opticsLength wave

The invention relates to a filter window for EUV lithography comprising a pellicle, a wire structure for supporting the pellicle, characterized in that the pellicle comprises a first layer comprising at least one of AlN, Ru, Ir, Au, SiN, Rh, C. A pellicle with these materials has a very low EUV absorption in combination with a minimal oxidation rate. In a particular embodiment, the thickness of the pellicle is between 30 nm and 100 nm. It can be easily checked that absorption of EUV radiation of such a thin pellicle is equal to known filter windows, i.e. about 50% at a wavelength of 13.5 nm wavelength, but the oxidation of the pellicle according to the invention is much smaller. The filter window can for example be used to separate a Projection Optics box and a wafer compartment of the apparatus or to shield a reticle from particle contamination.

Owner:ASML NETHERLANDS BV

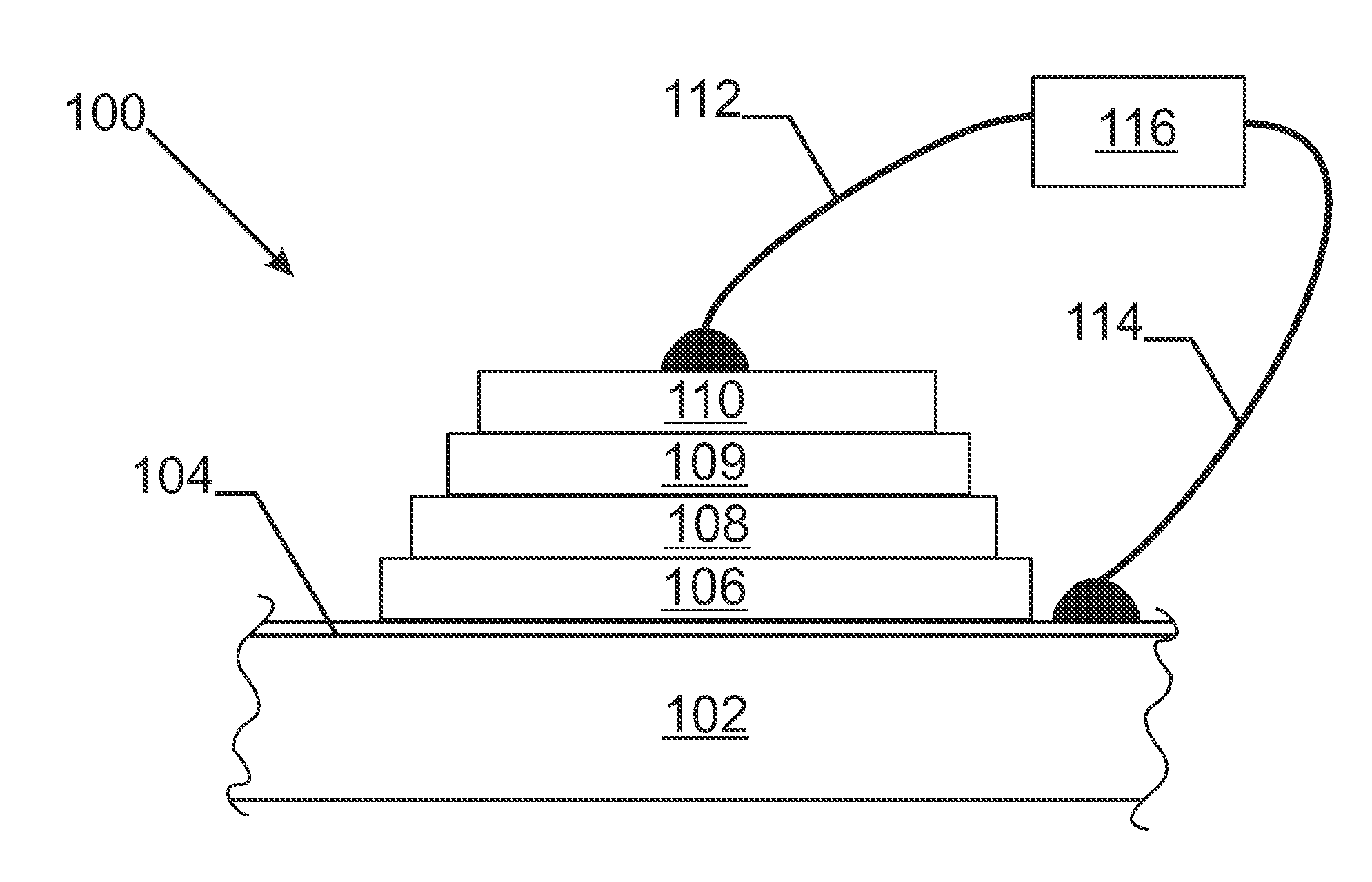

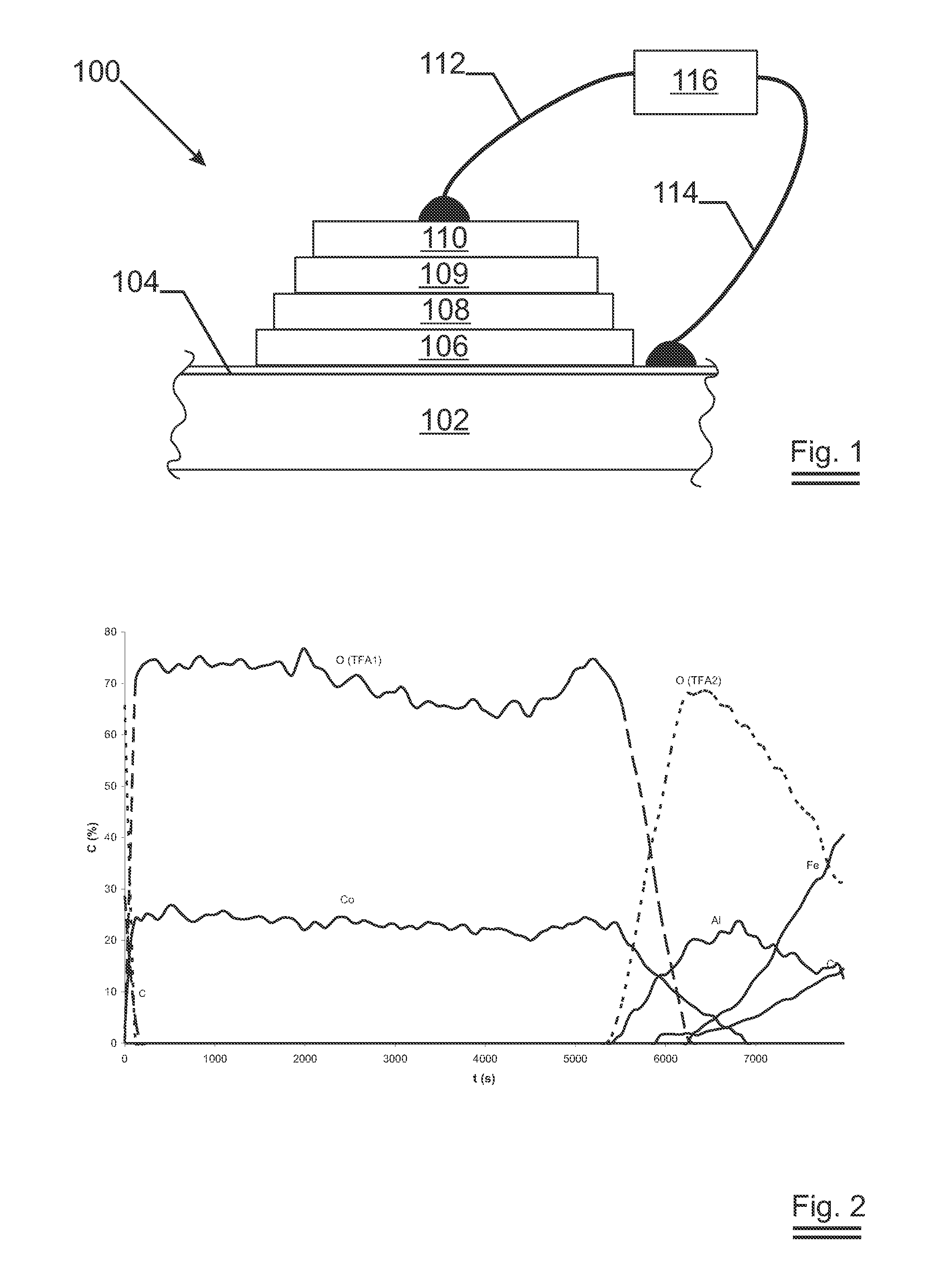

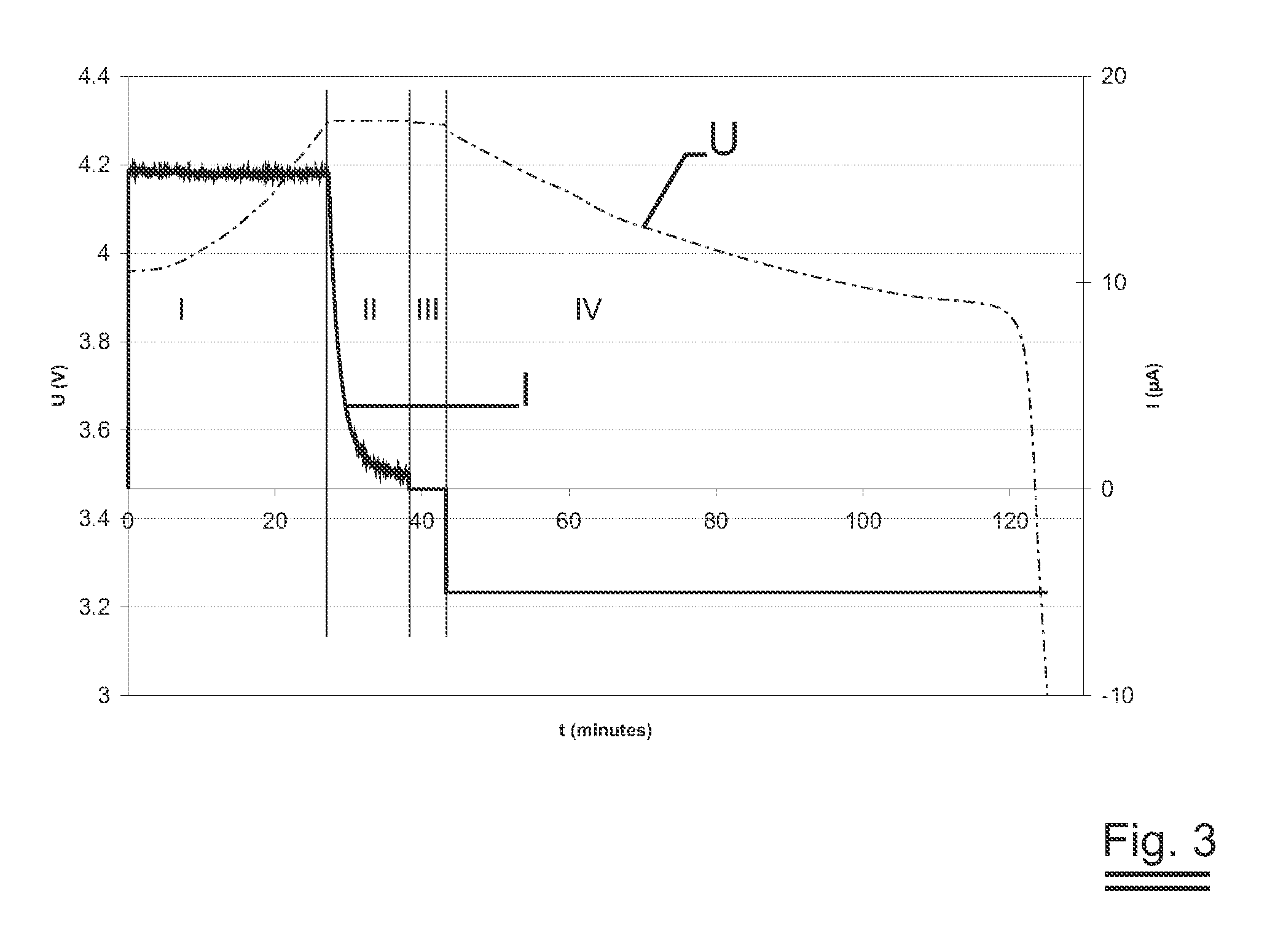

Substrate for lithium thin film battery

InactiveUS20100104942A1Easy to keepAvoid lostAlkaline accumulatorsActive material electrodesAll solid stateOxygen

When attempting to make a lithium ion-switching device such as a high-efficiency, all-solid state, thin film battery the choice of carrier substrate is all important. As such a substrate must withstand a high temperature under an oxidising atmosphere to crystallise certain layers making up the device, the substrate should not oxidise thereby ruling out most metals. The invention now describes a class of ternary alloys of which the oxidation rate is limited and that are useable to produce thin film batteries on. At least one element with a high affinity to oxygen (Al, Mg, Zn or Si) is present in the alloy. The other two metallic elements reduce the growth of the oxide of this first element. In addition the thus formed oxide scale turns out to be an effective barrier to lithium. Surprisingly, the scale shows nanoscopic voids that allow for sufficient electrical contact with the device layers, thereby eliminating the need for a separate current collector. As the ternary alloy can be made in a flexible foil, it can advantageously be used in a roll-to-roll process.

Owner:CYMBET CORP

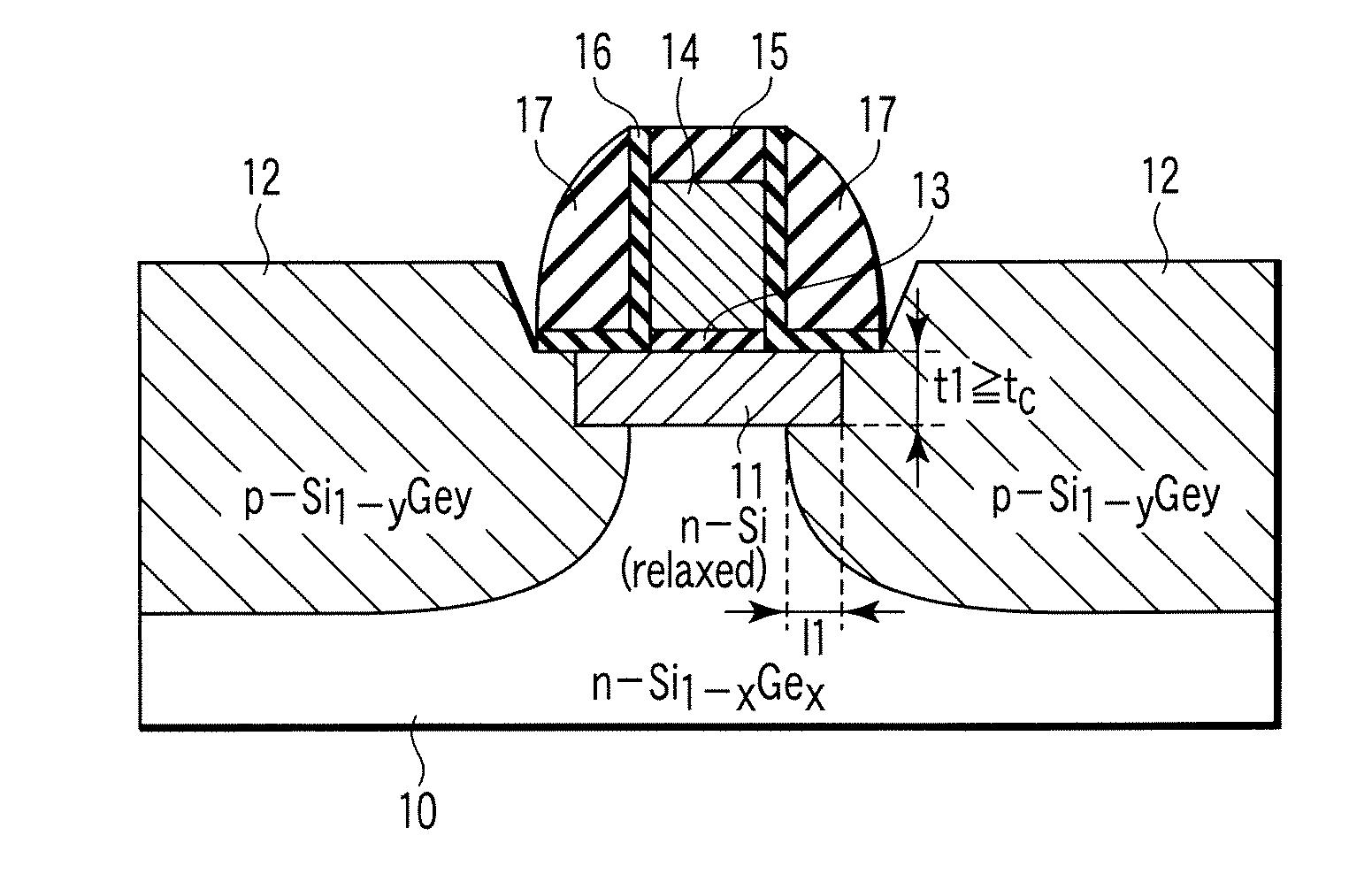

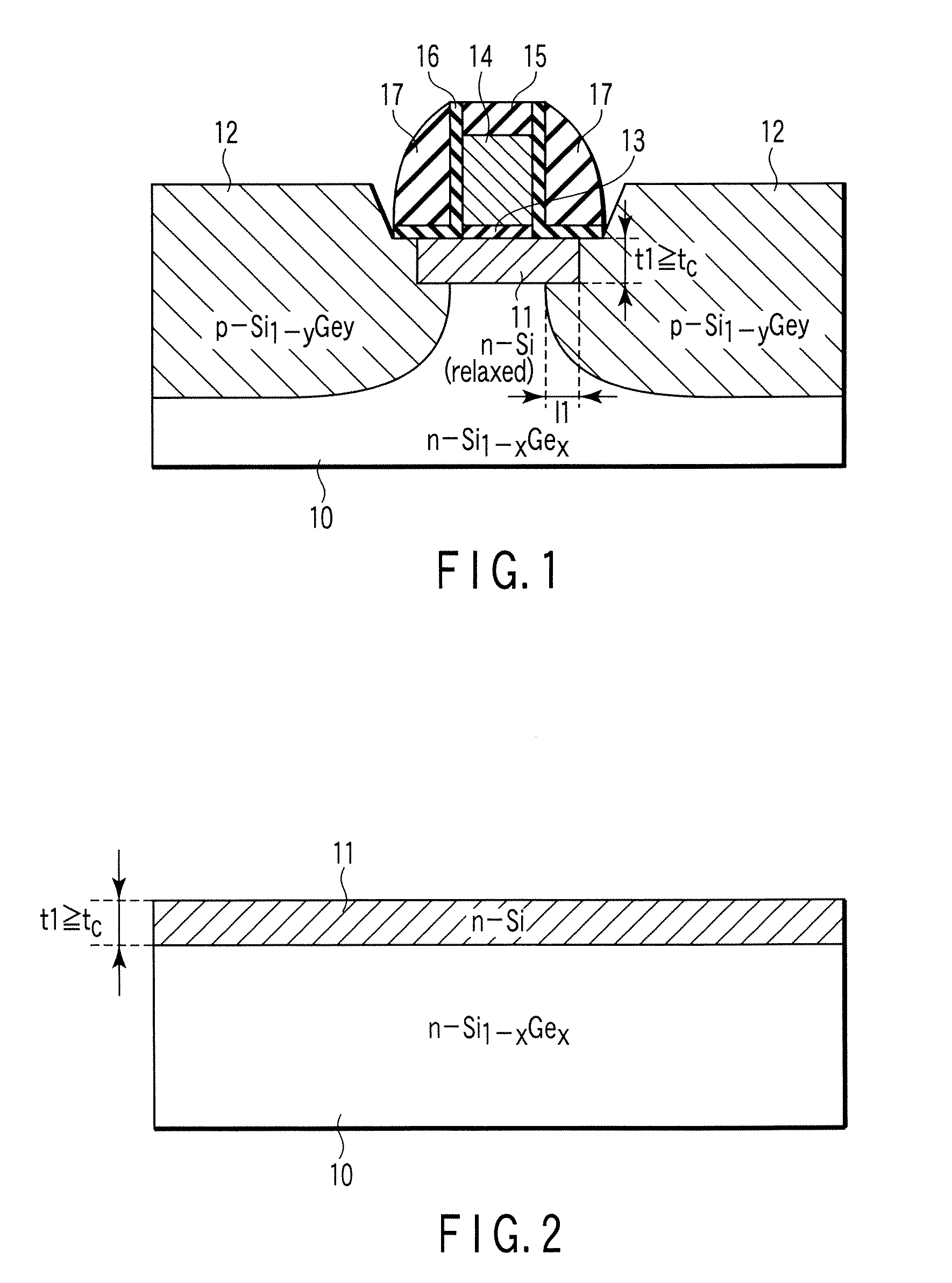

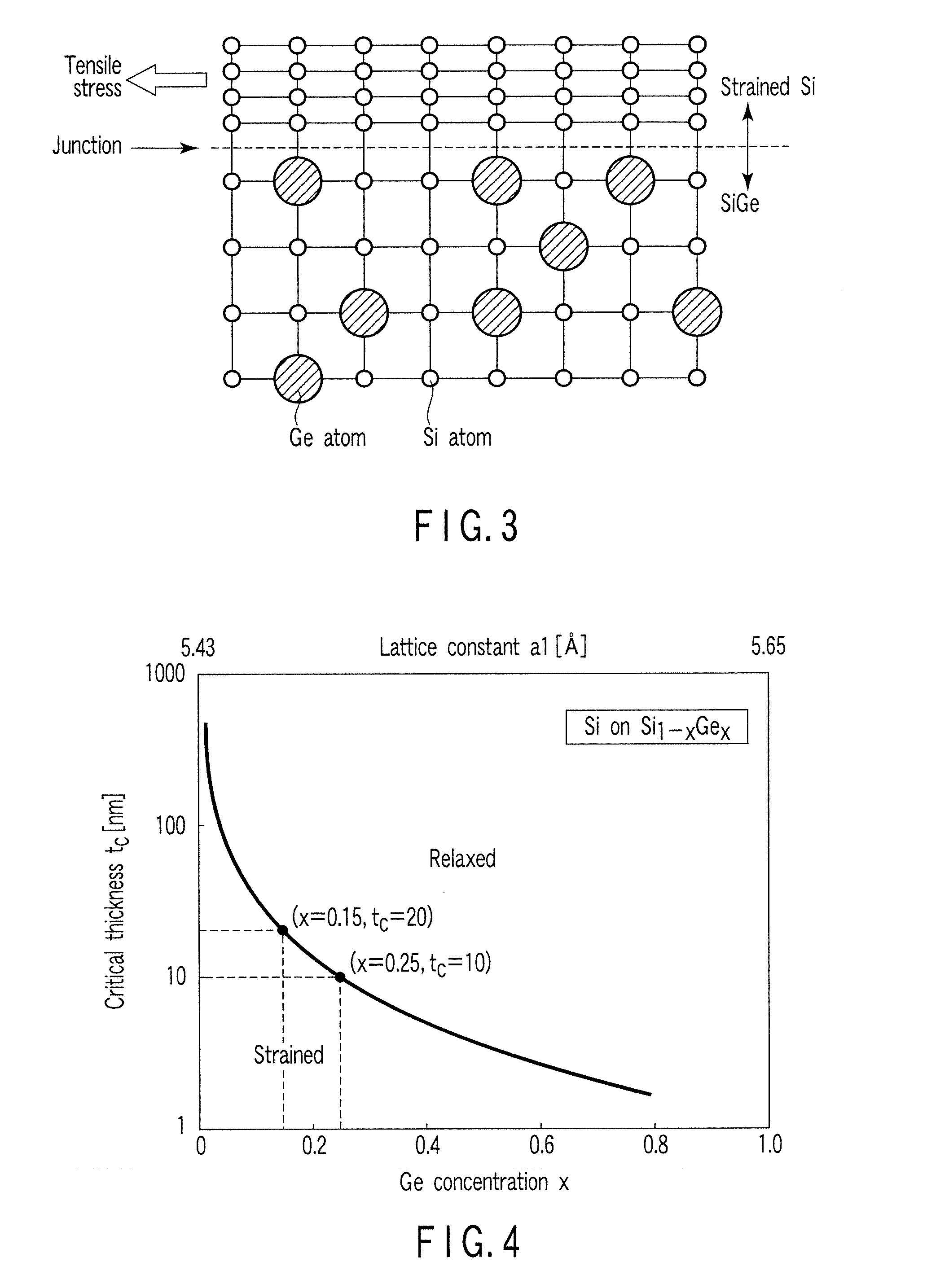

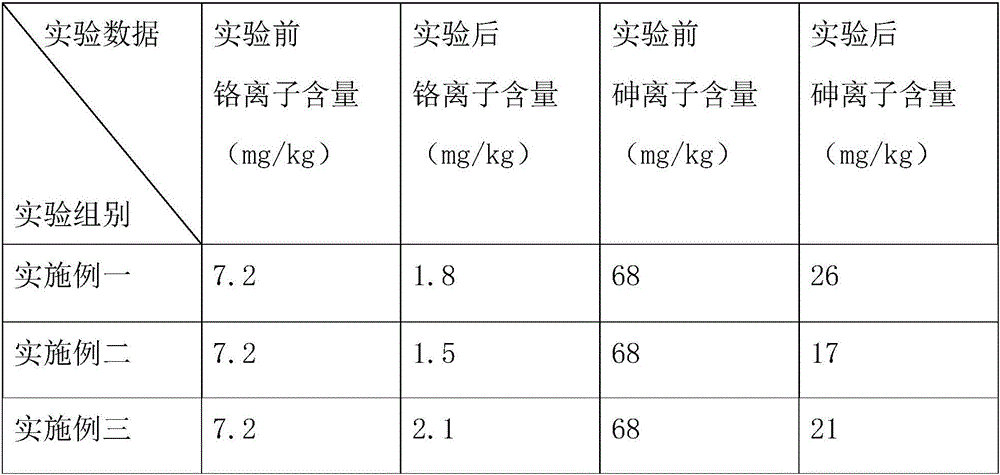

Semiconductor device using sige for substrate and method for fabricating the same

A semiconductor device includes a first semiconductor layer, an n-type / p-type second semiconductor layer, p-type / n-type third semiconductor layers and a first gate electrode. The second semiconductor layer is formed on the first semiconductor layer and has an oxidation rate which is lower than that of the first semiconductor layer. The third semiconductor layers are formed in the second semiconductor layer and have a depth reaching an inner part of the first semiconductor layer. In case that the second and third semiconductor layers are n-type and p-type, respectively, a lattice constant of the second semiconductor layer is less than that of the third semiconductor layer. In case that the second and third semiconductor layers are p-type and n-type, respectively, the lattice constant of the second semiconductor layer is greater than that of the third semiconductor layer. A first gate electrode is formed on the second semiconductor layer.

Owner:KK TOSHIBA

Preparation method of modified micron zero-valent iron and application method of modified micron zero-valent iron in remediation of heavy metal contaminated soil

ActiveCN106180735AAvoid secondary pollutionGood dispersionContaminated soil reclamationSoil treatmentSlag

The invention discloses a preparation method of modified micron zero-valent iron and an application method of the modified micron zero-valent iron in remediation of heavy metal contaminated soil. The preparation method of the modified micron zero-valent iron comprises the steps of cleaning of iron raw materials, preparation of micro iron, ultrafine grinding and modifying treatment. A modifying agent composed of water, xanthan gum, sulfide, a stabilizing agent, zeolite and blast furnace slag is adopted in the step of modifying treatment. The preparation method of the modified micron zero-valent iron has the beneficial effects that the production process of the modified micron zero-valent iron is simple, and the effect similar or superior to micron zero-valent iron is achieved while the cost is reduced; and in addition, the reaction activity is controlled, the oxidation rate is decreased, excellent stability is obtained, and the acting time of the micron zero-valent iron is longer. By the adoption of the application method of the modified micron zero-valent iron, the remediation cost of heavy metal contaminated underground water is further reduced. According to the preparation method of the modified micron zero-valent iron and the application method of the modified micron zero-valent iron in remediation of heavy metal contaminated soil, organic fertilizer is added in the soil treatment process so that the fertility of soil can be improved, the structure of soil can be improved through humic acid produced by the organic fertilizer, heavy metal elements, such as lead, chromium and arsenic, in underground water can be removed, and the concentration of pollutants such as nitrate and perchlorate can be reduced.

Owner:CHINESE ACADEMY FOR ENVIRONMENTAL PLANNING

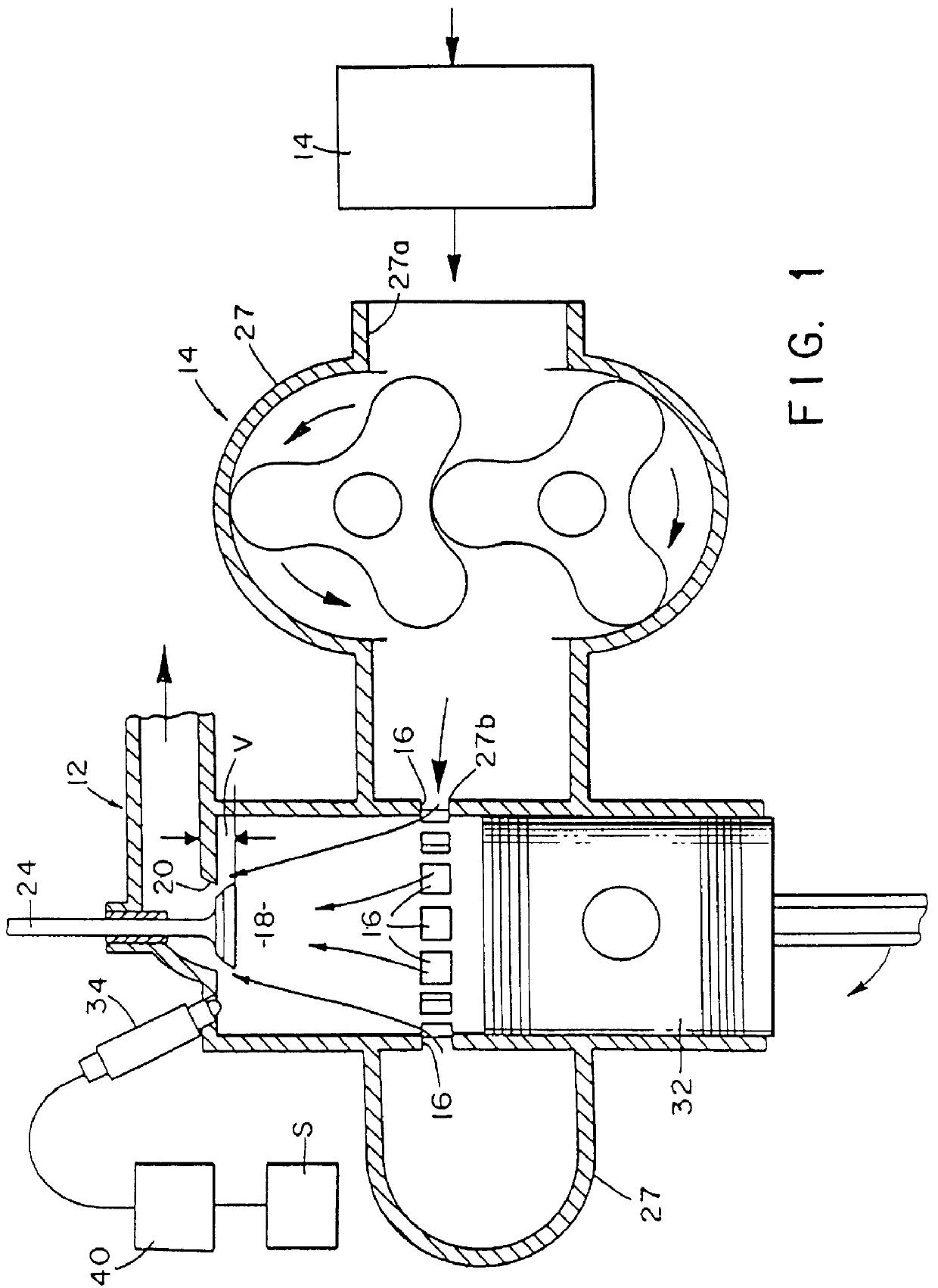

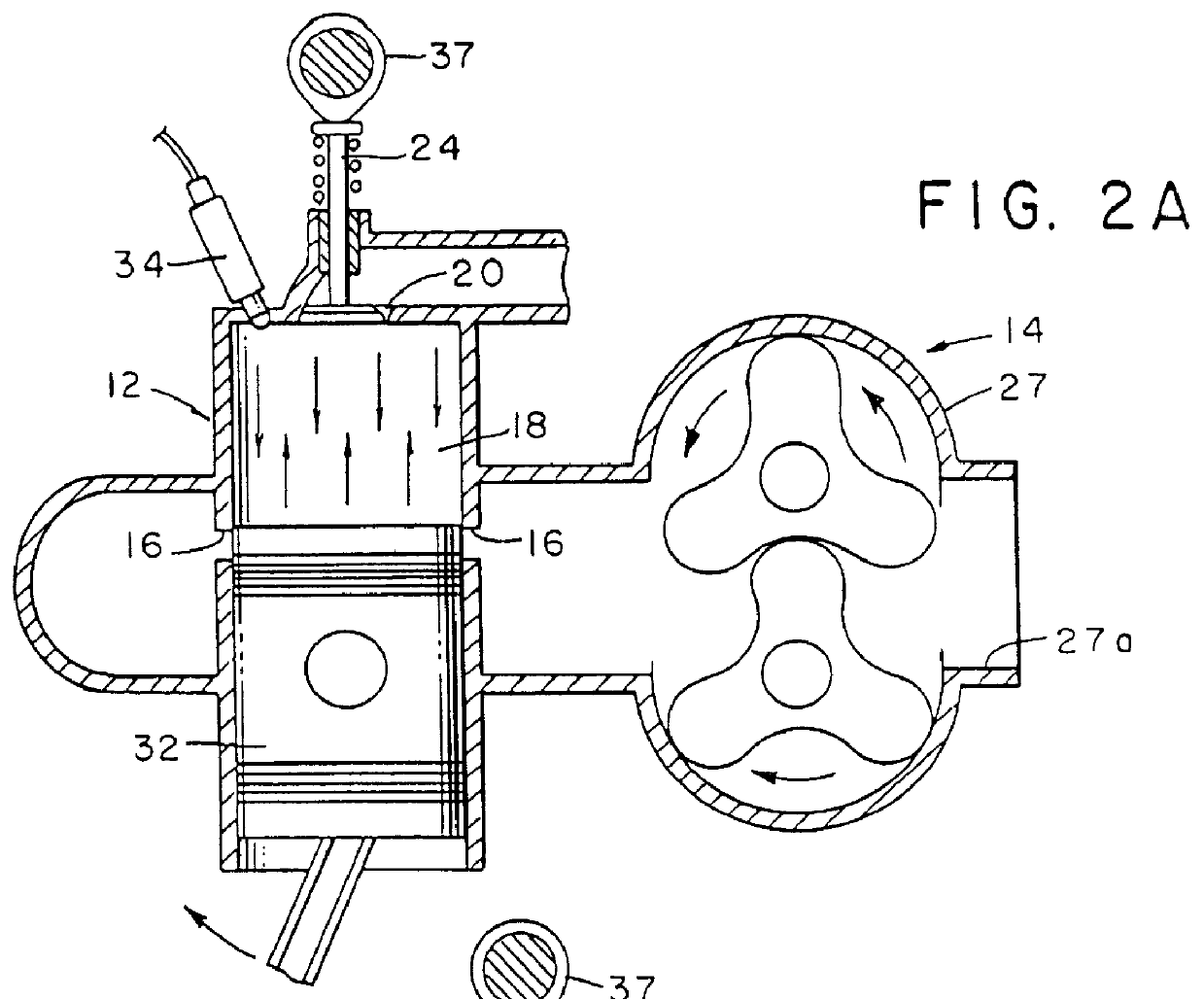

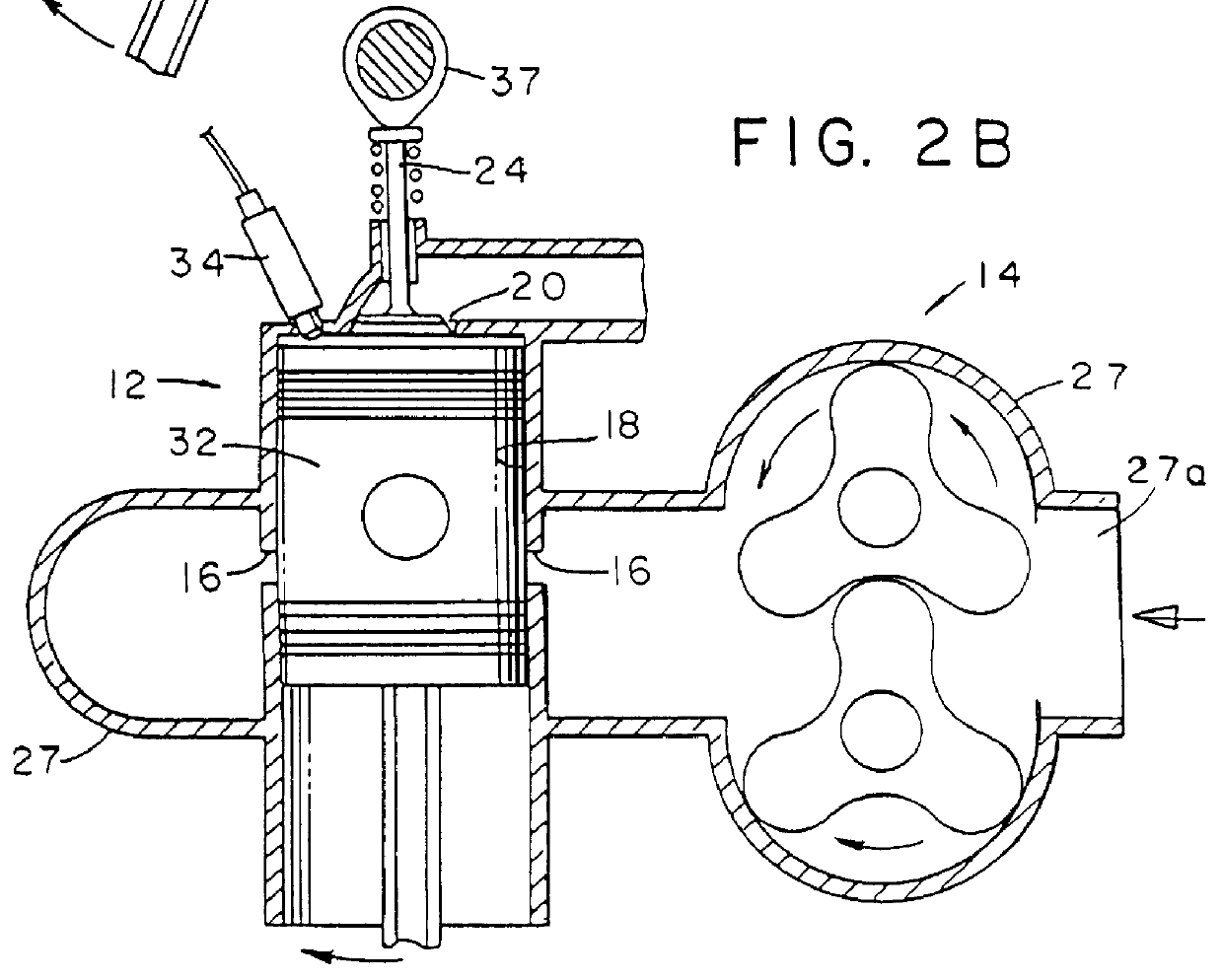

Low emission power plant and method of making same

InactiveUS6101989AReduce the amount of solutionLower than normal exhaust valve liftNon-fuel substance addition to fuelInternal combustion piston enginesParticulatesCombustion chamber

A low emission power generating apparatus which comprises a modified two-stroke diesel engine component and a modified turbocharger component which has a relatively low aspect ratio. The diesel engine component is a modification of a conventional two-stroke diesel engine design and includes an exhaust valve cam of unique design that has a cam profile which results in a later than-normal exhaust valve opening and an earlier-than-normal valve closing so that the time during which the exhaust valve remains open is shorter than normal, thereby causing a substantially greater volume of residual gases to remain in the combustion chamber following the scavenge stroke. This increase in the volume of the residual exhaust gases within the chamber leads to an increase in compression temperature and effectively increases the compression ratio and consequently the compression pressure. Because of the heat absorption capacity of these residual exhaust gases, the exhaust gases remaining in the chamber following the scavenge stroke tend to absorb combustion heat and thereby effectively reduce the peak combustion temperature. This reduction in peak combustion temperature advantageously results in the lower than normal formation of nitrogen oxide (NOx) and, therefore, allows advancement of the injection timing, while still maintaining the NOx emissions coming from the engine lower than those legislatively mandated. Advantageously, the advance in injection timing, which increases NOx emissions, by definition has the effect of also reducing particulate matter emissions. Thus, by increasing the volume of residual exhaust gases within the cylinder, substantial particulate matter emission reductions can be achieved, while at the same time maintaining NOx emissions well below mandated limits. The modified turbocharger component provides an additional charge of oxygen-rich air into the combustion chamber which effectively increases the compression pressure, which, in turn, leads to an earlier start of combustion because of the combustible mixture reaching its auto-ignition temperature at an earlier point in the cycle. This phenomenon leads to more thorough combustion of the fuel and also generally leads to higher exhaust temperatures. Higher exhaust temperatures, in turn, lead to a greater oxidation rate of the soluble organic fraction thus lowering the level of emission from the engine of undesirable particulate matter.

Owner:CLEAN CAM TECH SYST

Converter vanadium-extracting method of molten iron containing vanadium

The invention provides a converter vanadium-extracting method of molten iron containing vanadium. The converter vanadium-extracting method comprises the following steps of after the molten iron containing the vanadium enters a converter, adding 5-10kg / t Fe of pig iron; controlling the oxygen supplying intensity of an oxygen gun in the oxygen-blowing smelting stage to be 2.0-3.0m<3> / (min.tFe); at the non-oxygen-blowing smelting stage, introducing air with the flow being less than 0.002m<3> / (min.tFe) into the converter as bottom-blowing gas, introducing air with the flow being 0.1-0.5m<3> / (min.tFe) into the converter as the bottom-blowing gas at the time interval from starting of blowing to 1-1.5 minutes before the end of blowing in the oxygen-blowing smelting stage, and introducing inert gas into the converter as the bottom-blowing gas at the stage beyond the time interval in the oxygen-blowing stage; and adding a vanadium-extracting cooling agent into the converter at the time interval from starting of blowing to 3 minutes after smelting in the oxygen-blowing smelting stage so as to control the temperature of the molten iron in the converter to be lower than 1370 DEG C. The converter vanadium-extracting method provided by the invention has the advantages that the used amount (for example below 5-10kg / t Fe) of the cooling agent can be reduced, the oxidation rate of vanadium is increased (for example, more than 90%), and the purposes of utilizing the resources and reducing the vanadium-extracting cost are easily achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

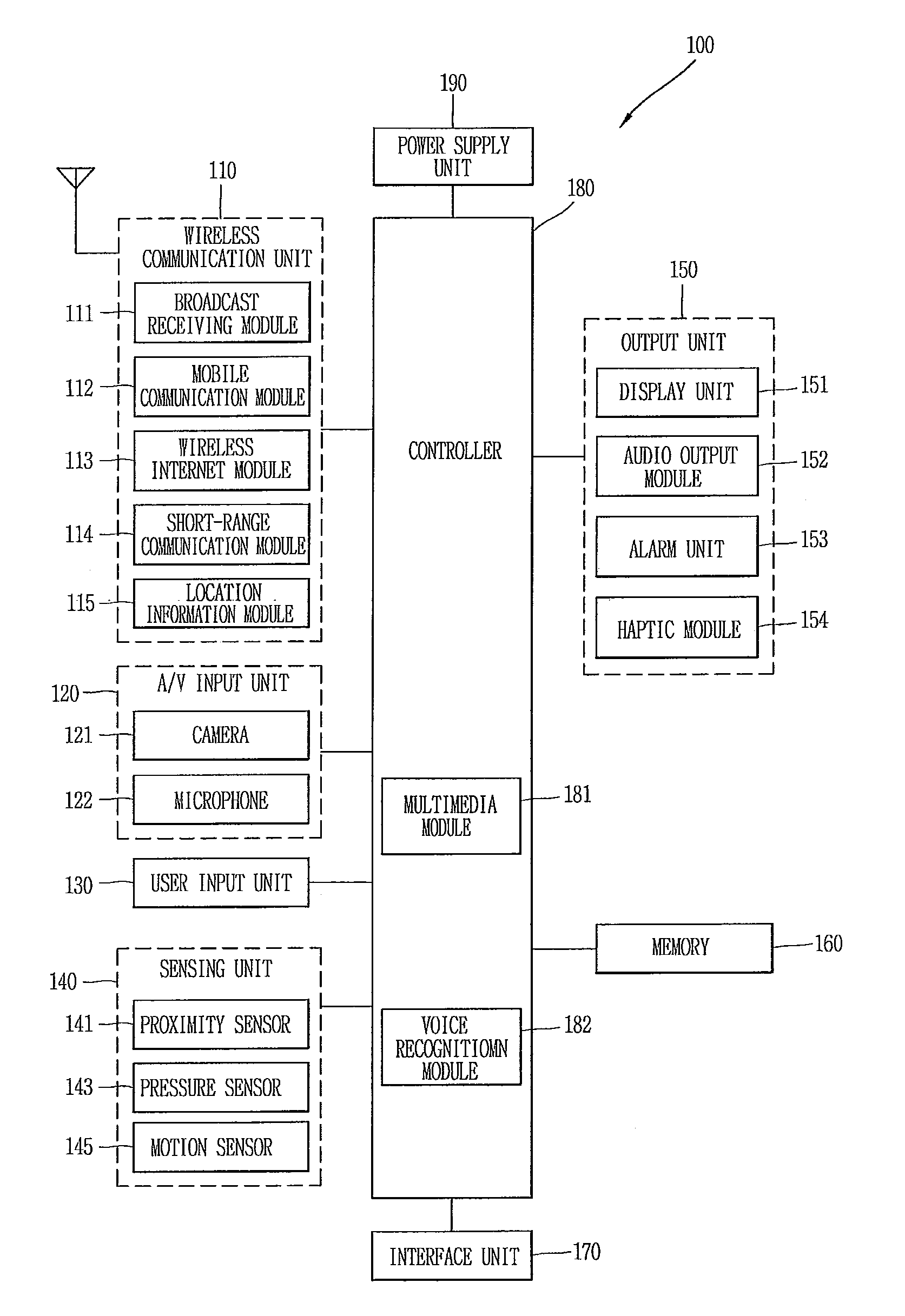

Guiding exercise based on fat oxidation rate

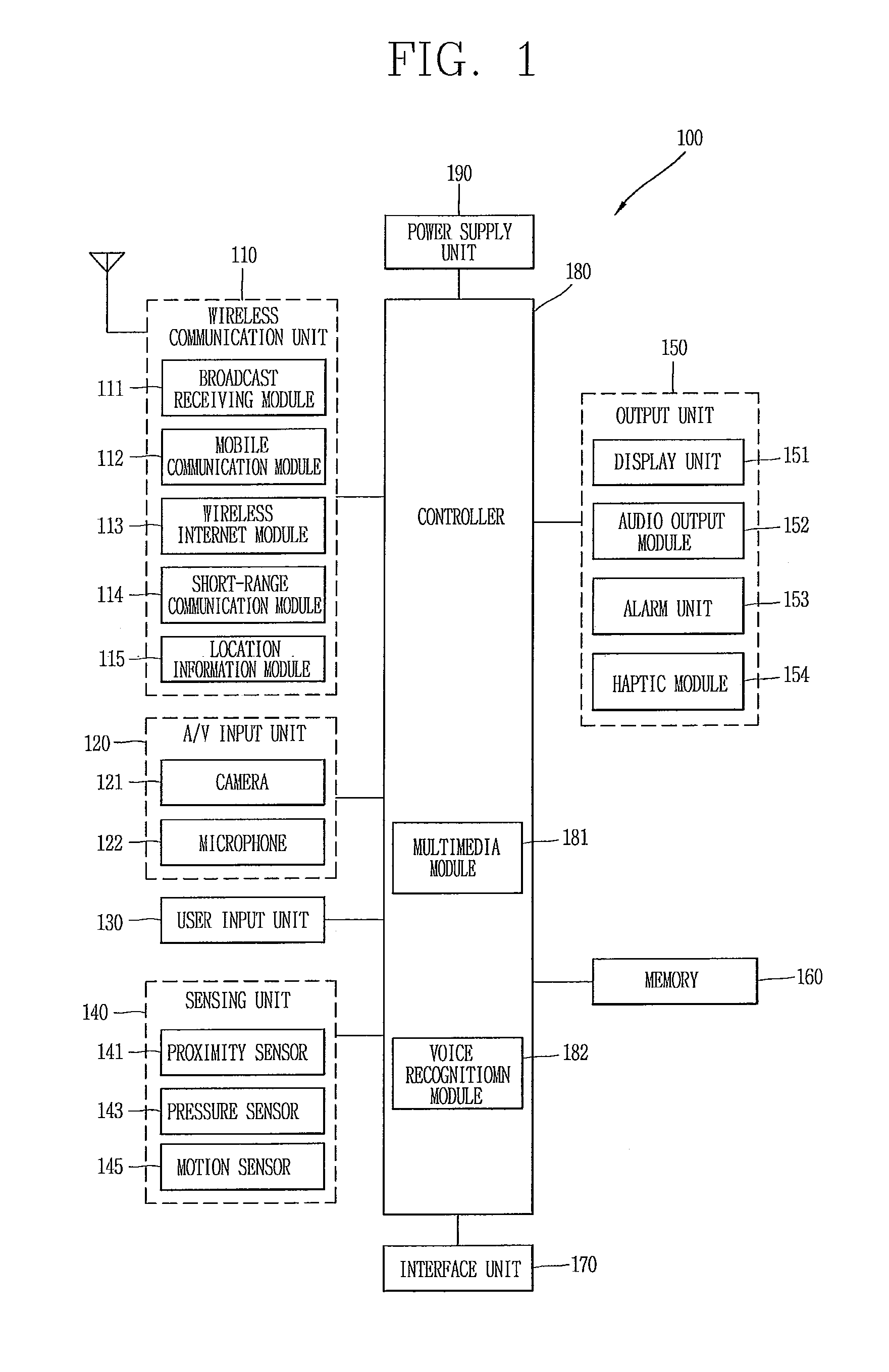

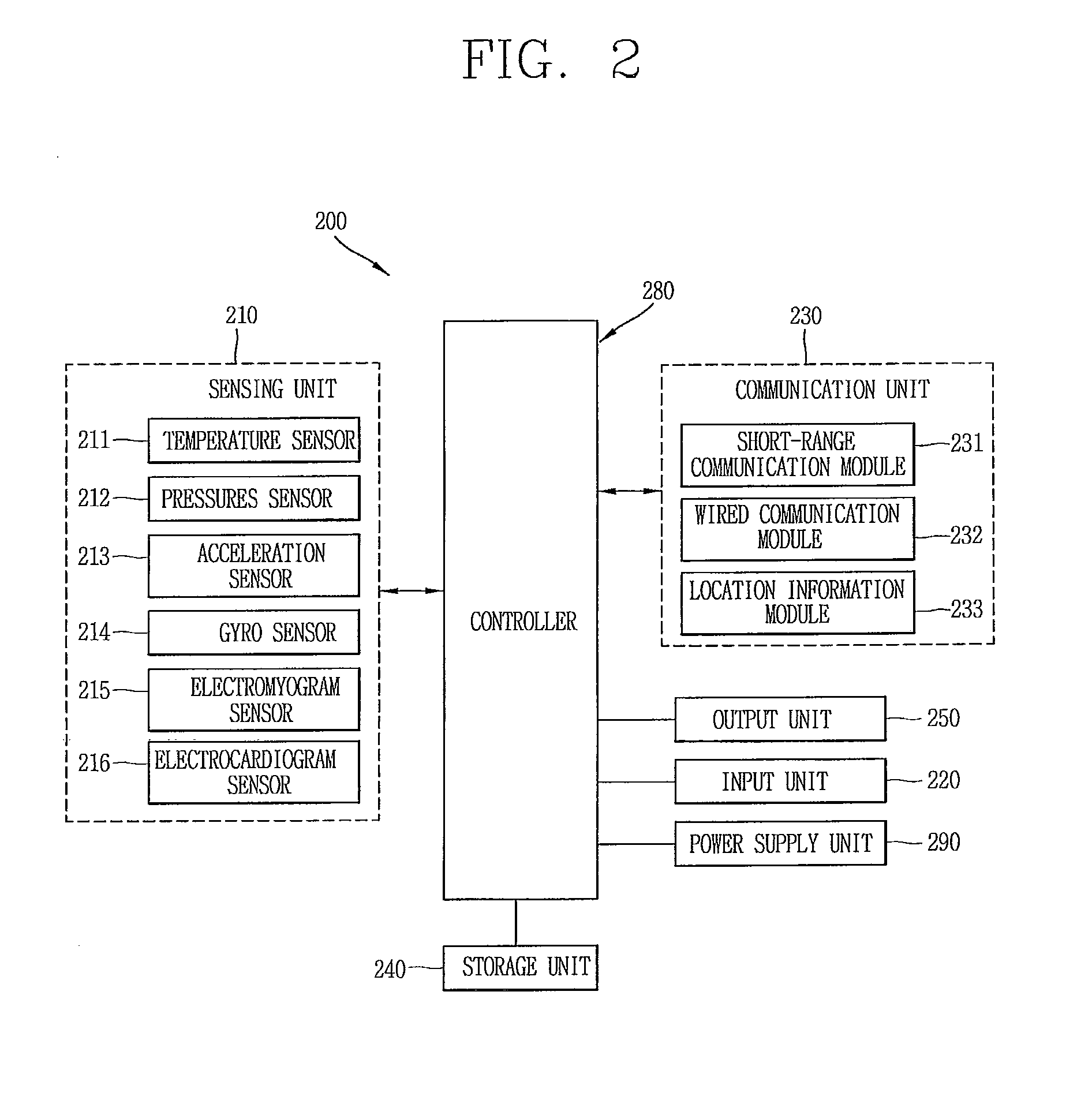

Disclosed is An exercise guide apparatus comprising: a sensing unit configured to obtain a heart rate of a subject; a strength determining unit configured to determine a maximal oxygen uptake of the subject; an exercise intensity measurement unit configured to determine a current exercise intensity of the subject based on the heart rate obtained by the sensing unit; and an exercise guide unit configured to estimate a fat oxidation rate of the subject, determine whether or not fat oxidation of the subject occurs, generate guide information according to a result of the determination of the occurrence of fat oxidation, and display the guide information generated, wherein the fat oxidation rate is estimated based on a ratio of fat being oxidized at the current exercise intensity to the maximal oxygen uptake, and wherein the occurrence of fat oxidation is determined by checking whether or not the fat oxidation rate estimated is greater than a threshold.

Owner:LG ELECTRONICS INC

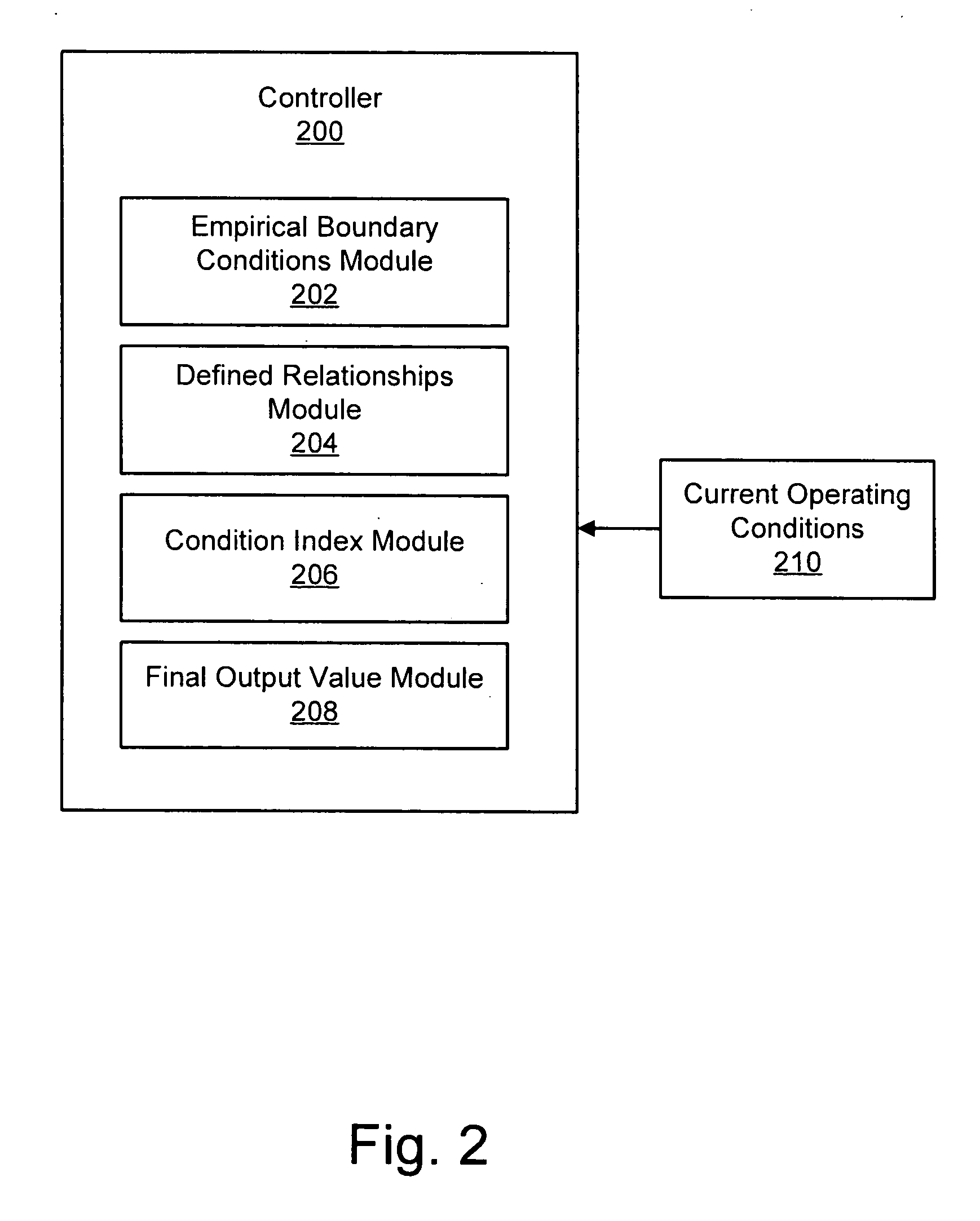

Apparatus, system, and method for estimating particulate consumption

ActiveUS20070056273A1Easily informationEasy to practiceInternal combustion piston enginesExhaust apparatusOxidation rateEngineering

An apparatus, system, and method are disclosed for robustly estimating soot oxidation rates on a particulate filter. The invention uses empirically measured soot consumption rates as defined boundary rates, and operates between those rates using theoretical relationships between soot consumption and various operating conditions. The invention may also operate outside the defined boundaries by extrapolating the theoretical relationships beyond the defined boundary. The invention thereby overcomes the inflexibility of empirical modeling by allowing reasonable estimates at points that are not explicitly measured, and it overcomes the sensitivity of theoretical models to non-idealities that are experienced in real applications.

Owner:CUMMINS INC

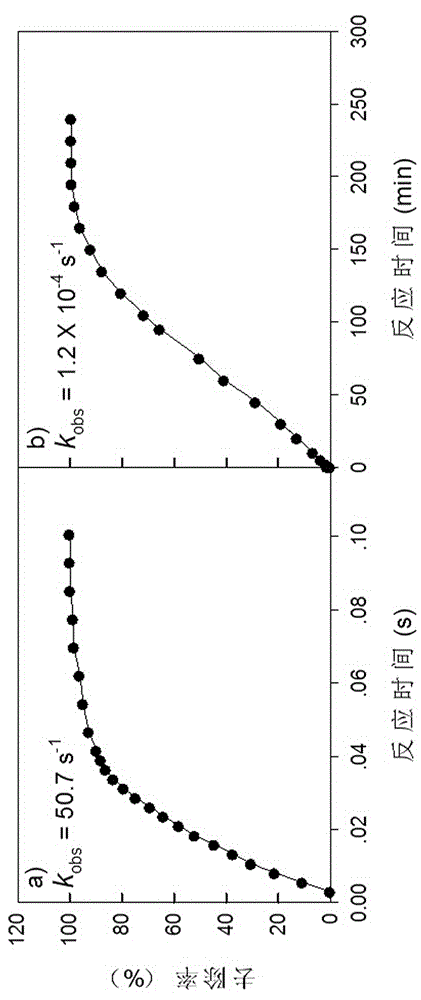

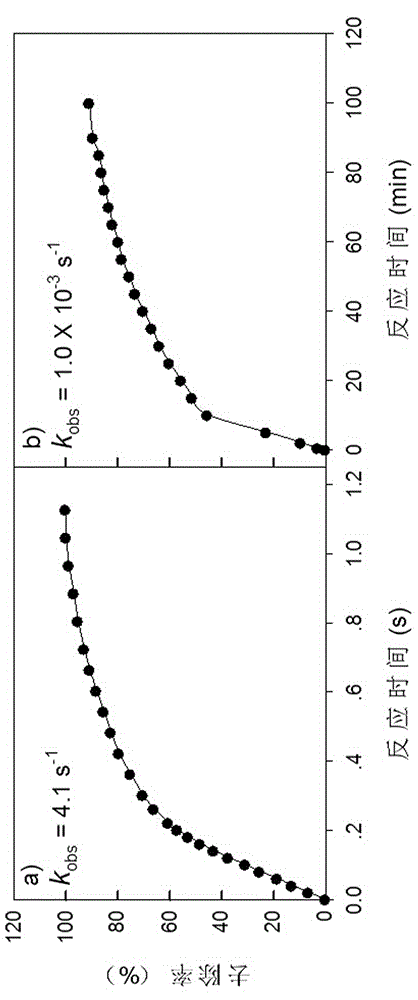

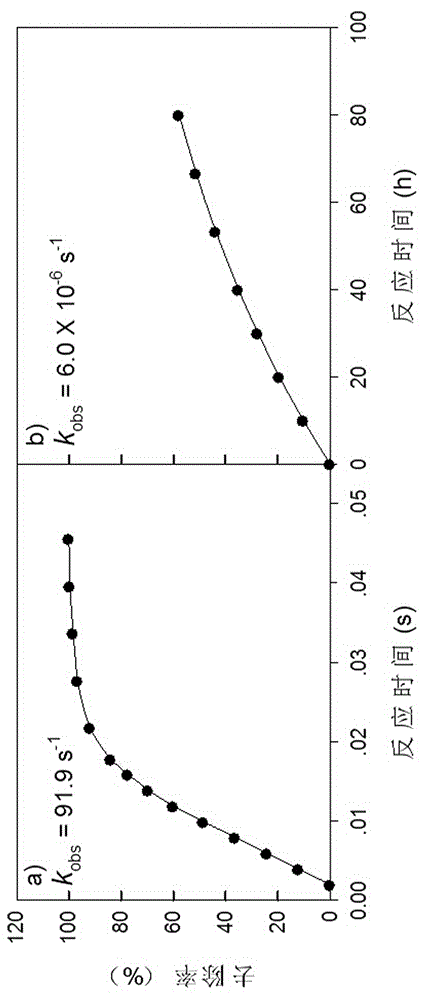

Method for removing organic pollutants in water at ultrahigh speed

ActiveCN104609597AObvious superiorityEasy to transportMultistage water/sewage treatmentBisulfiteHydroxyl radical

The invention relates to a method for removing organic pollutants in water at an ultrahigh speed. The method comprises the following steps: firstly, adding a reducing agent to water to be treated; secondly, adjusting the pH value of the water to be treated to be within the range of 3-7; thirdly, adding an oxidizing agent to the water to be treated. According to the method, bisulfite radicals are utilized for reacting with potassium permanganate or manganese dioxide, the removal of the organic pollutants in the water at the ultrahigh speed is realized by quickly generating a highly active oxidizing agent Mn(III) (at a non-complexing state), the rate of removing the pollutants by potassium permanganate and manganese dioxide can be improved by one thousand to one million times and is ten thousand times higher than the apparent oxidation rate of a general advanced oxidation technology, and the degradation for the pollutants can be completed in ten seconds or several seconds. According to the method, the pollutants incapable of being oxidized by potassium permanganate and manganese dioxide can also be oxidized, and even nitrobenzene capable of being oxidized by hydroxyl radicals only in traditional meanings can be oxidized, so that the oxidizing capacity of potassium permanganate and manganese dioxide is greatly improved, and the application range of potassium permanganate and manganese dioxide is expanded.

Owner:TONGJI UNIV +1

Slow consumable non-carbon metal-based anodes for aluminium production cells

InactiveUS6248227B1Eliminate carbon-generated pollutionReduce frequencyMachining electrodesIsotope separationElectrolysisAlloy

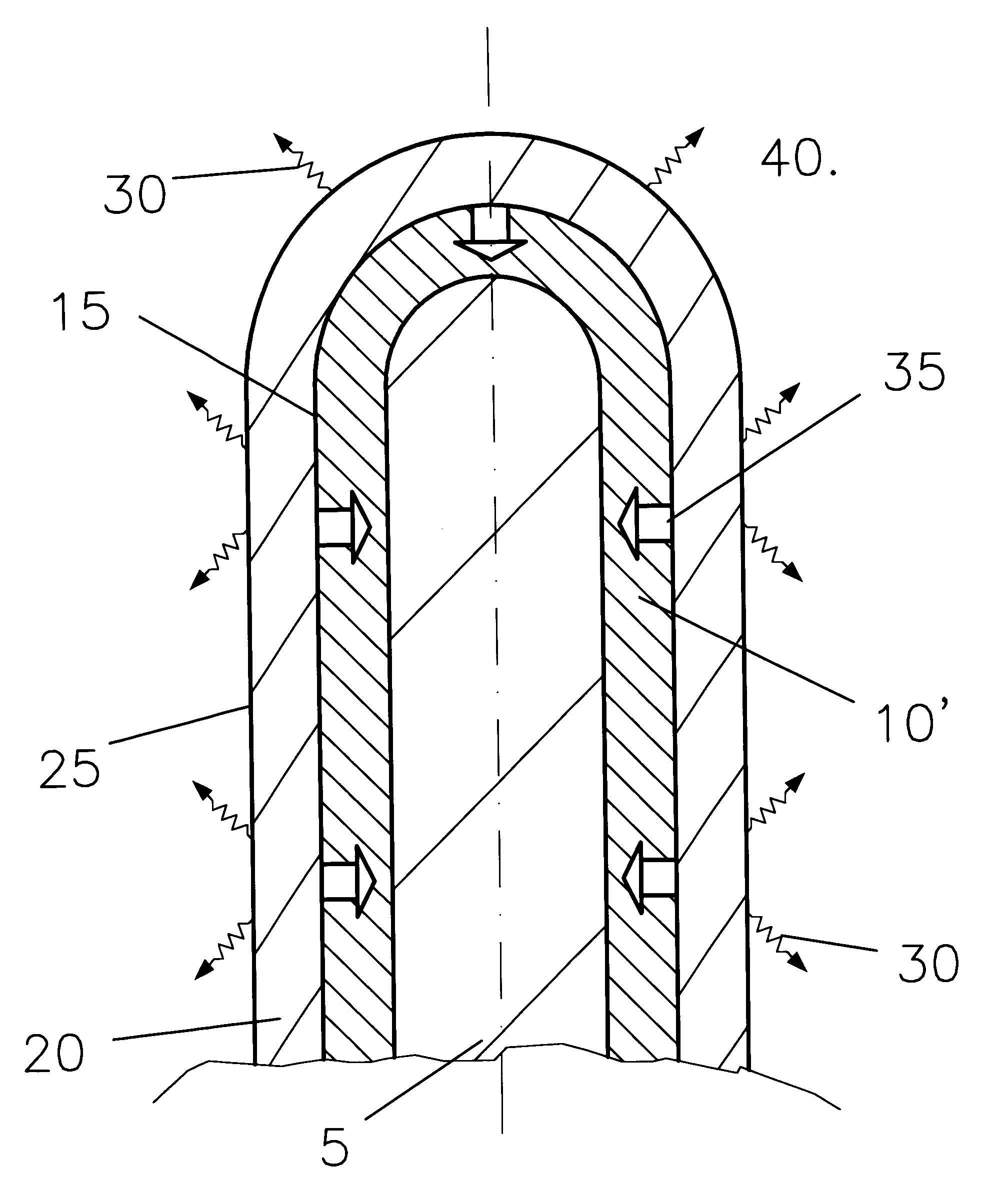

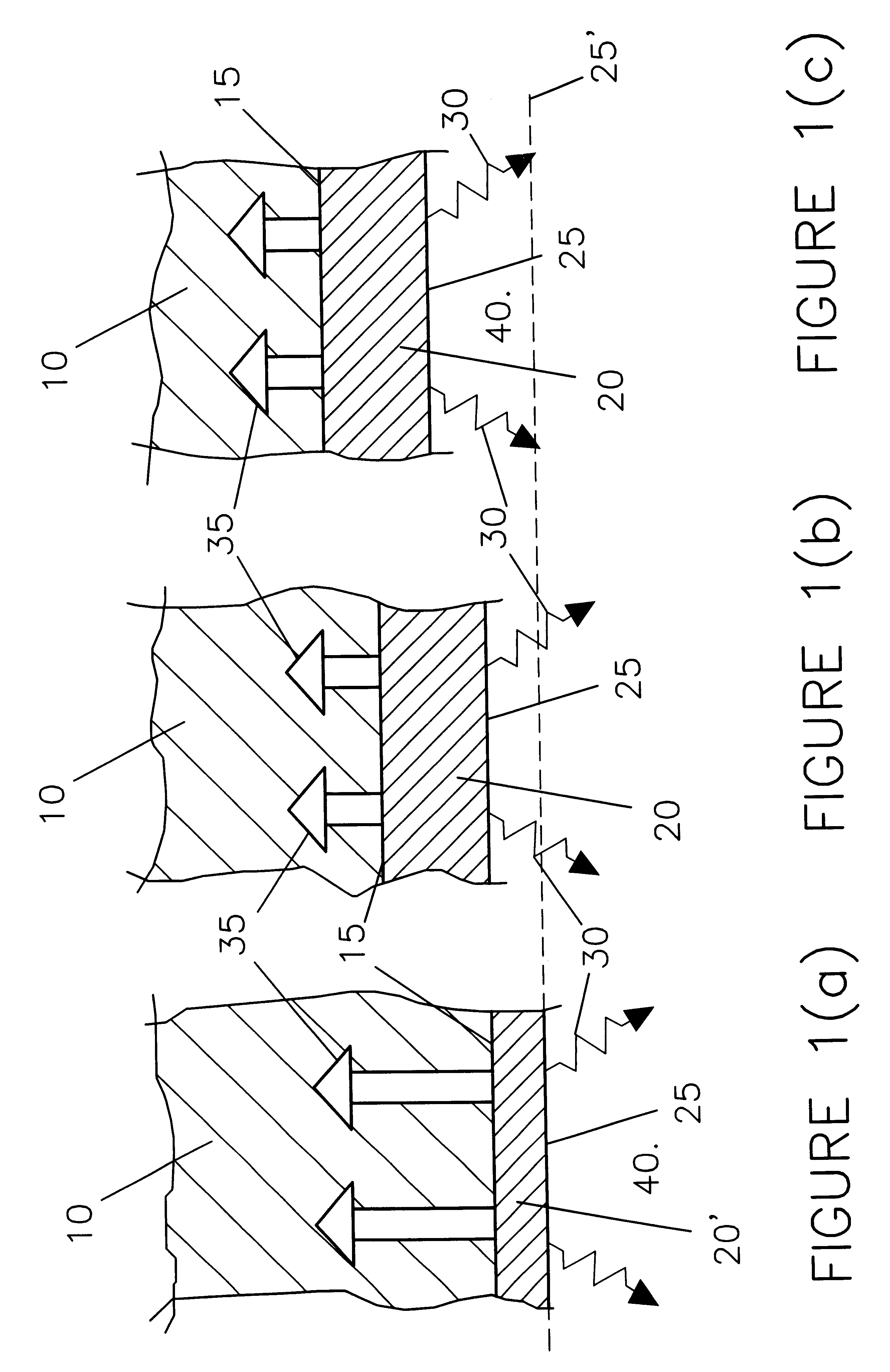

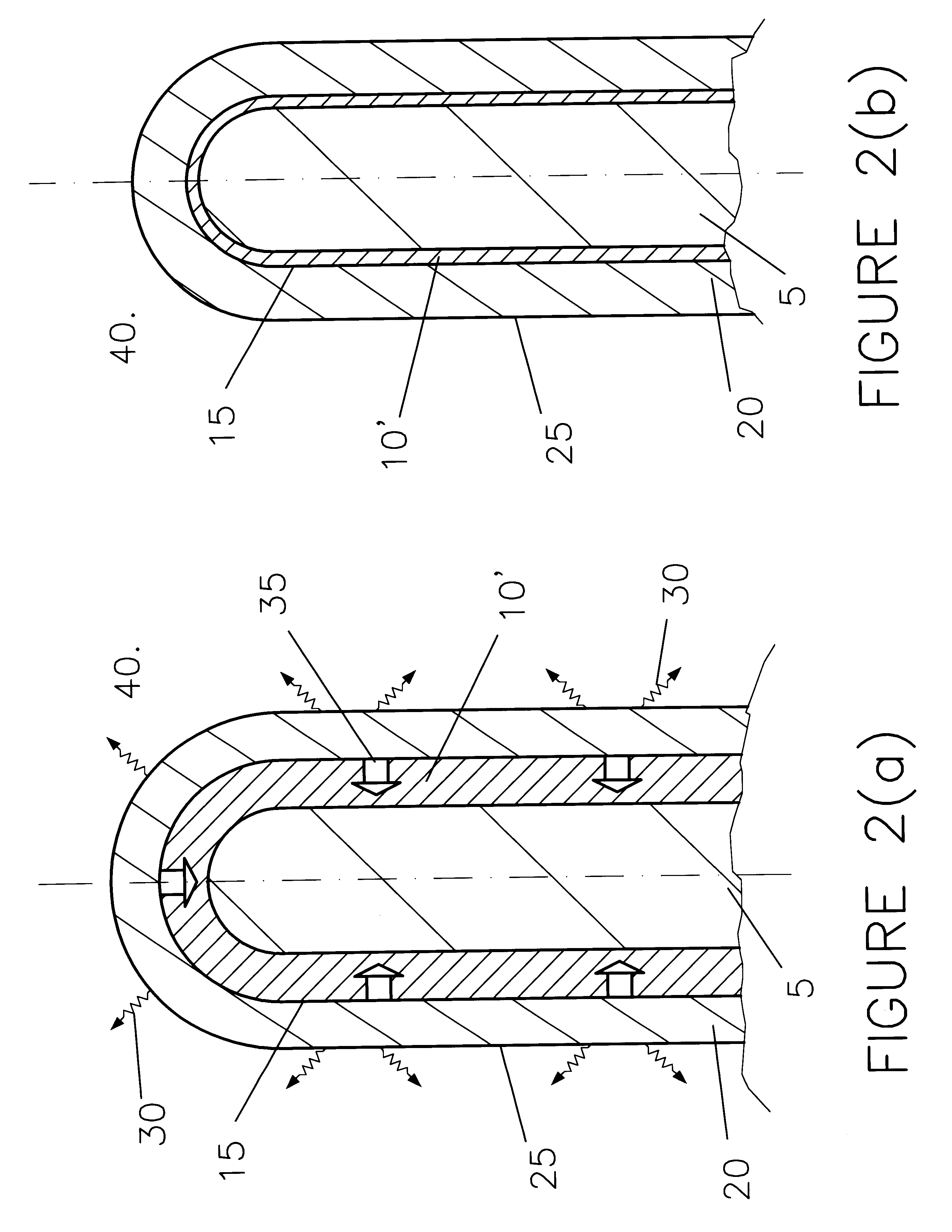

A non-carbon, metal-based slow-consumable anode of a cell for the electrowinning of aluminium self-forms during normal electrolysis an electrochemically-active oxide-based surface layer (20). The rate of formation (35) of the layer (20) is substantially equal to its rate of dissolution (30) at the surface layer / electrolyte interface (25) thereby maintaining its thickness substantially constant, forming a limited barrier controlling the oxidation rate (35). The anode (10) usually comprises an alloy of iron with at least one of nickel, copper, cobalt or zinc which during use forms an oxide surface layer (20) mainly containing ferrite.

Owner:MOLTECH INVENT

Mercaptan removal and lye regeneration device and method for gasoline light fractions

Owner:NINGBO ZHONGYI PETROCHEM TECH

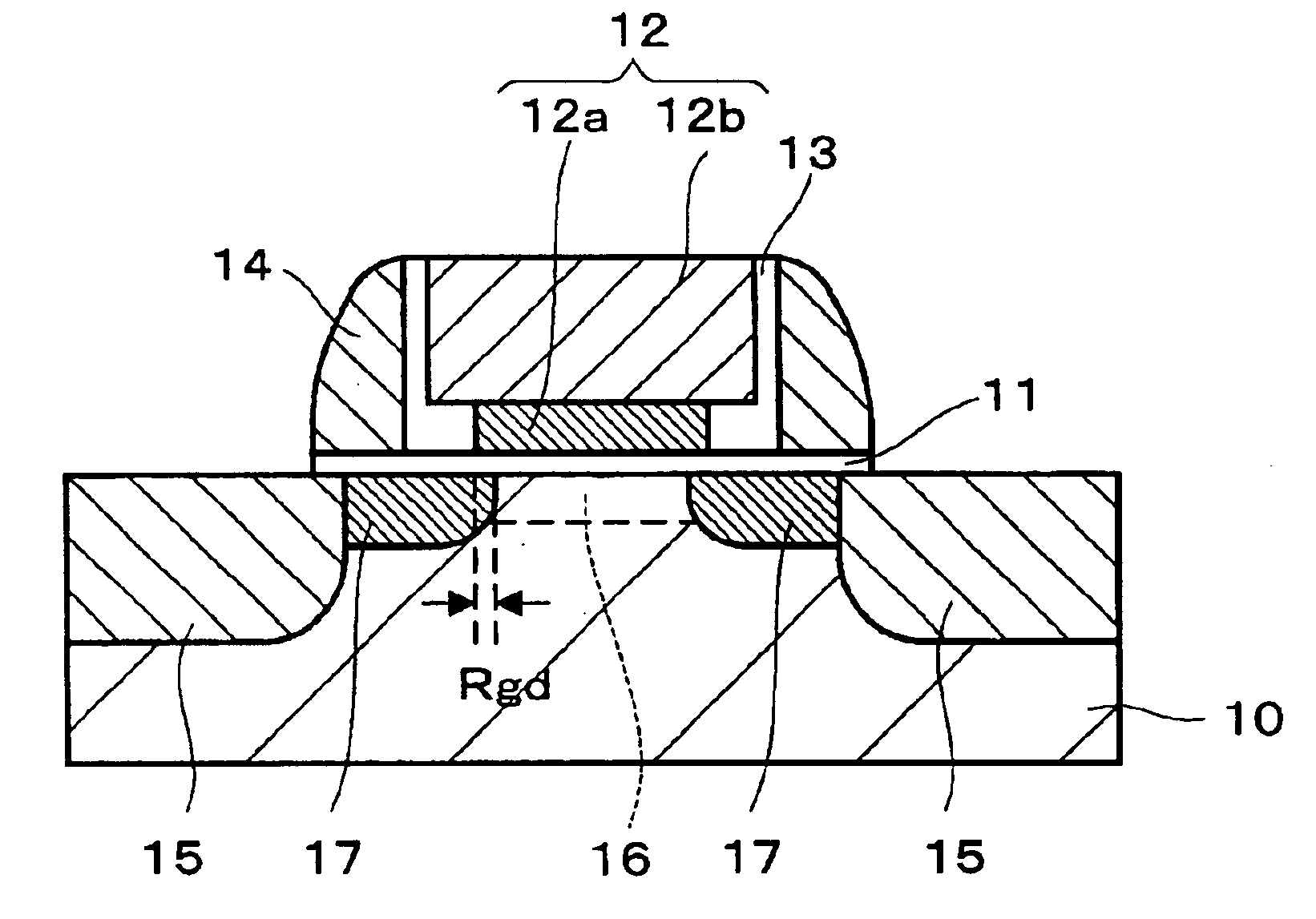

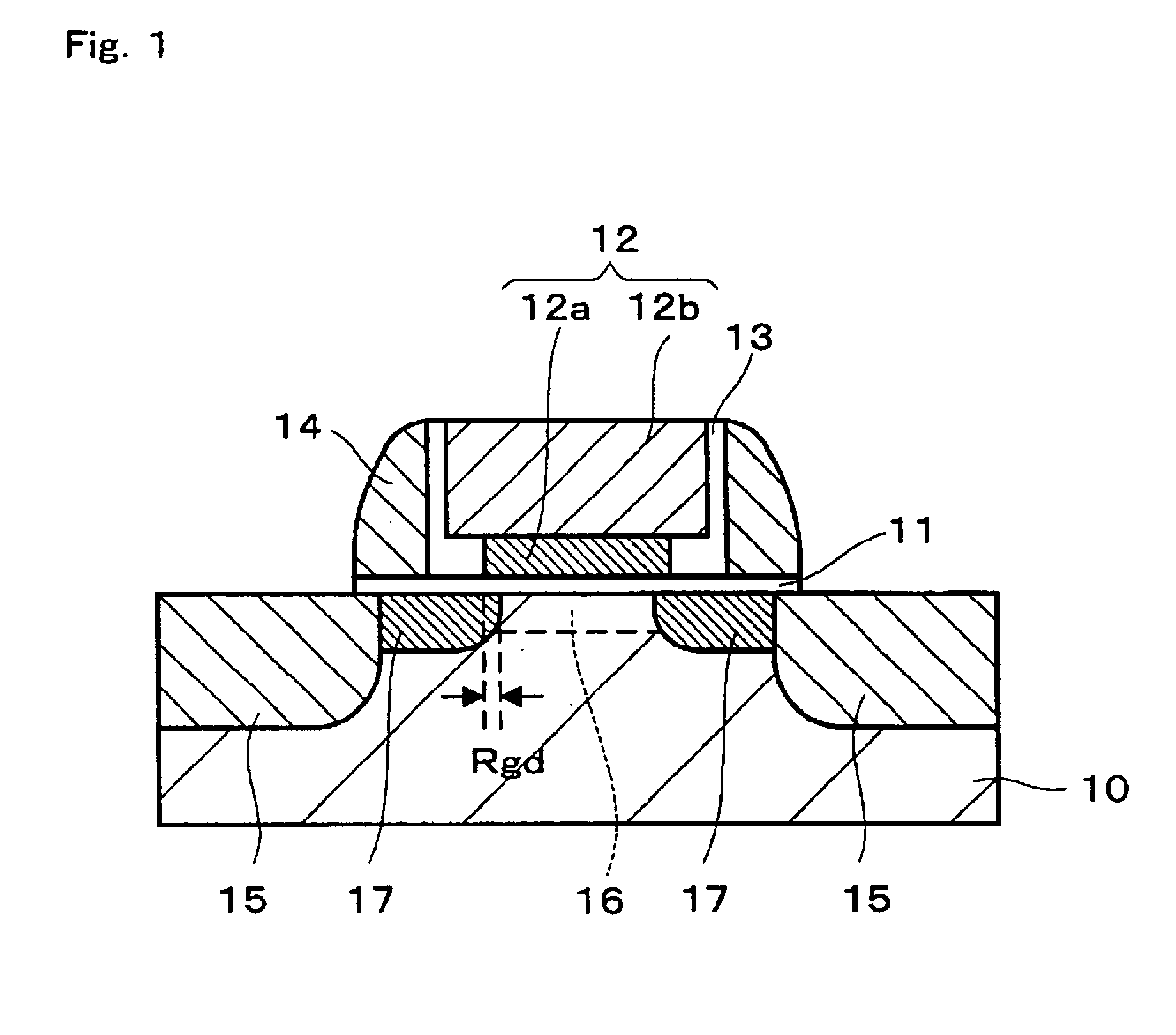

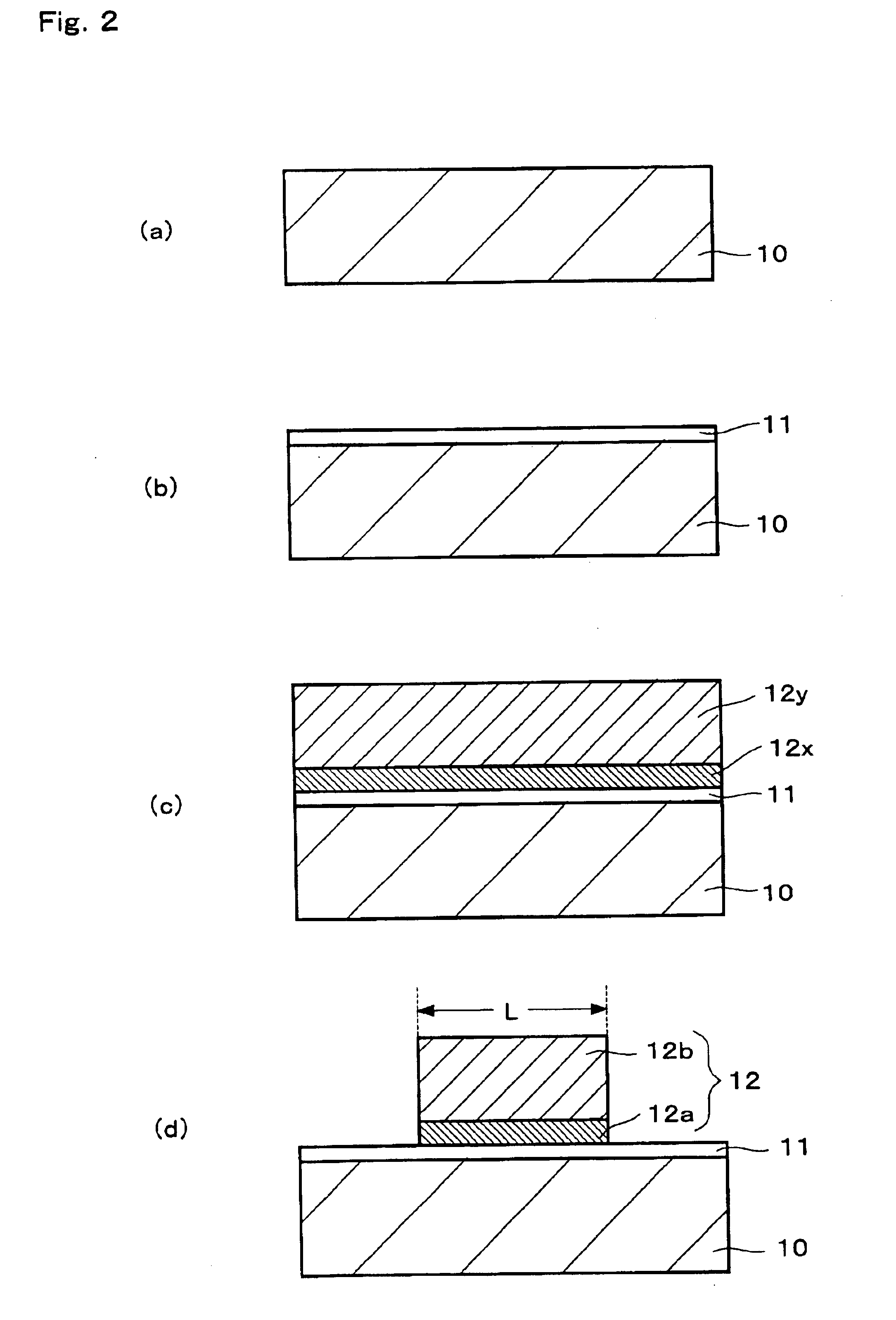

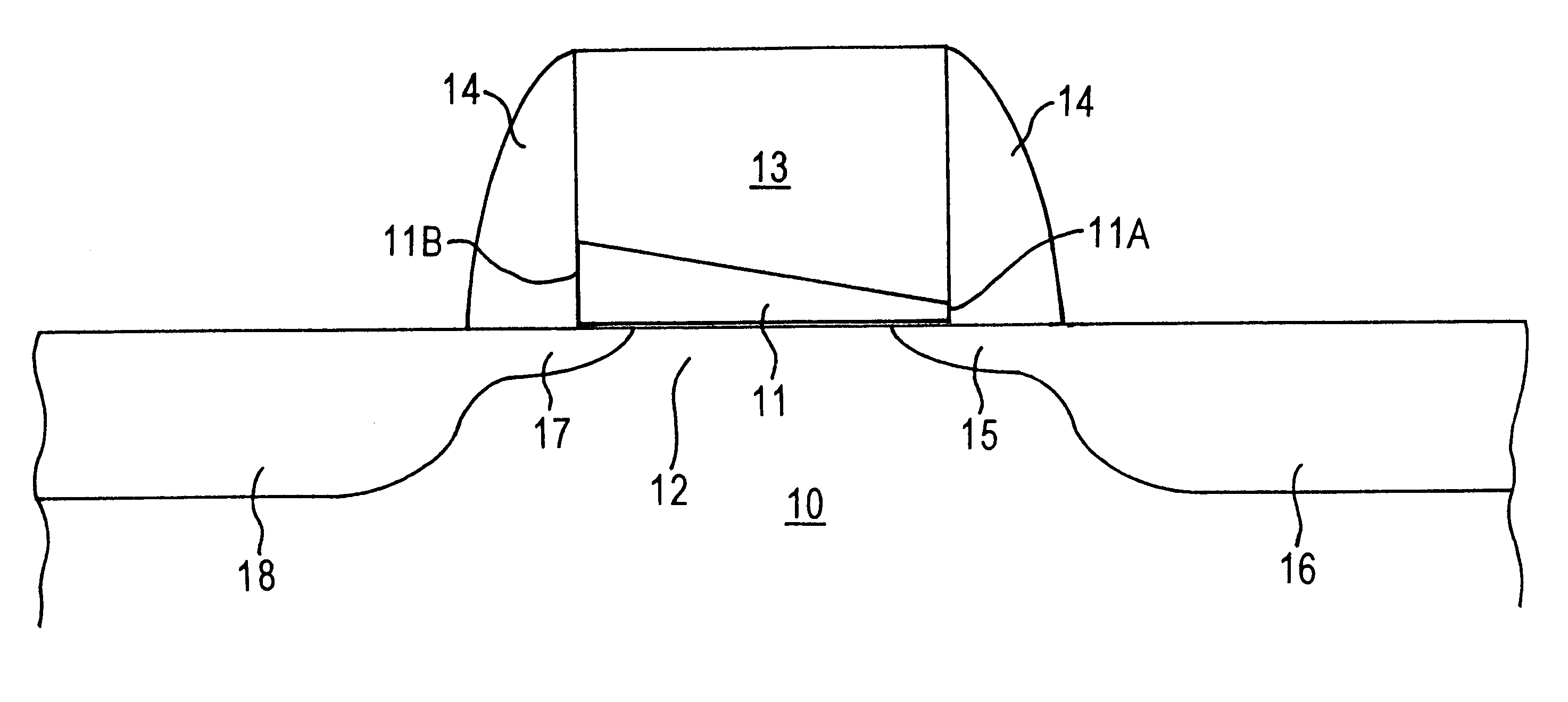

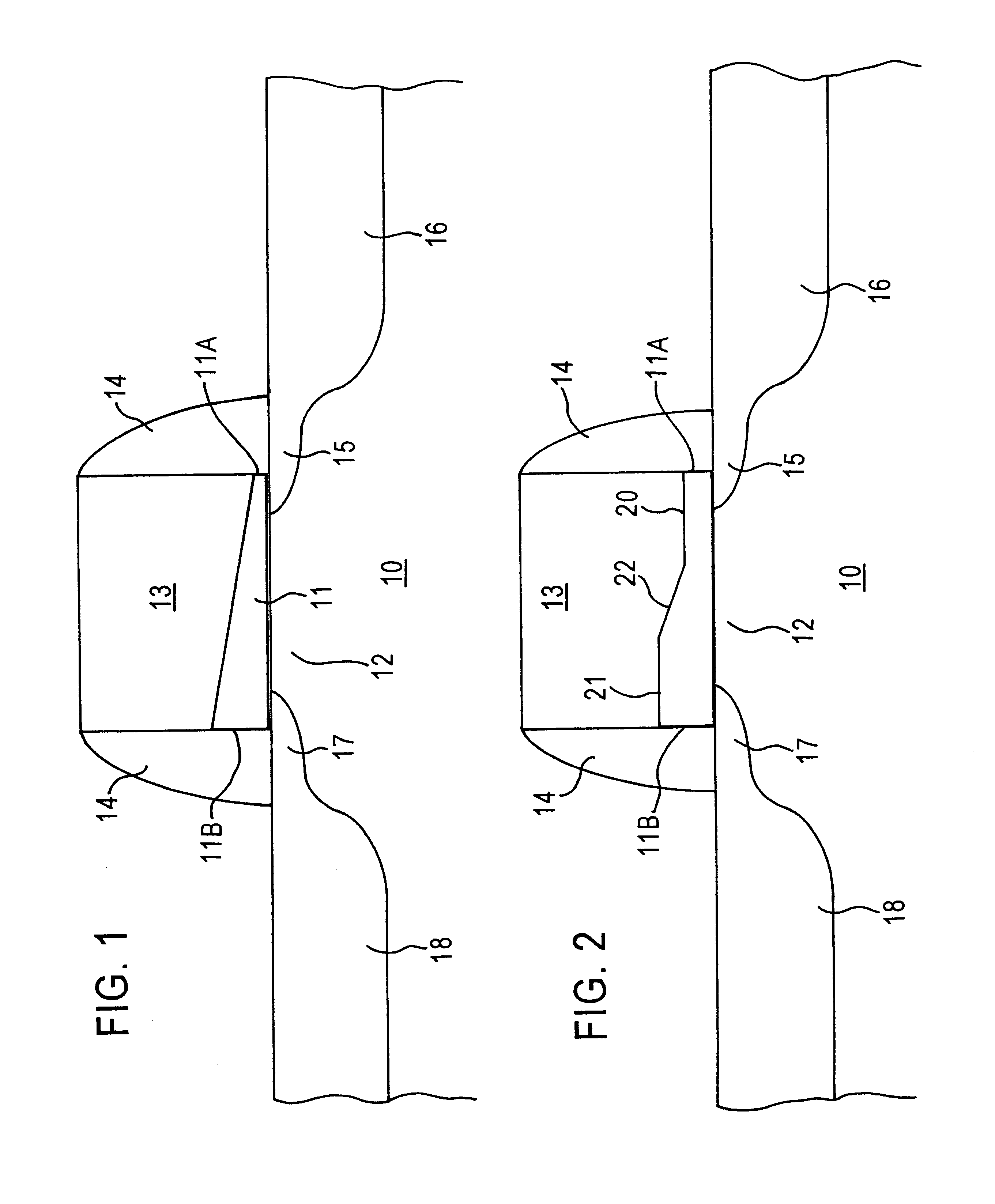

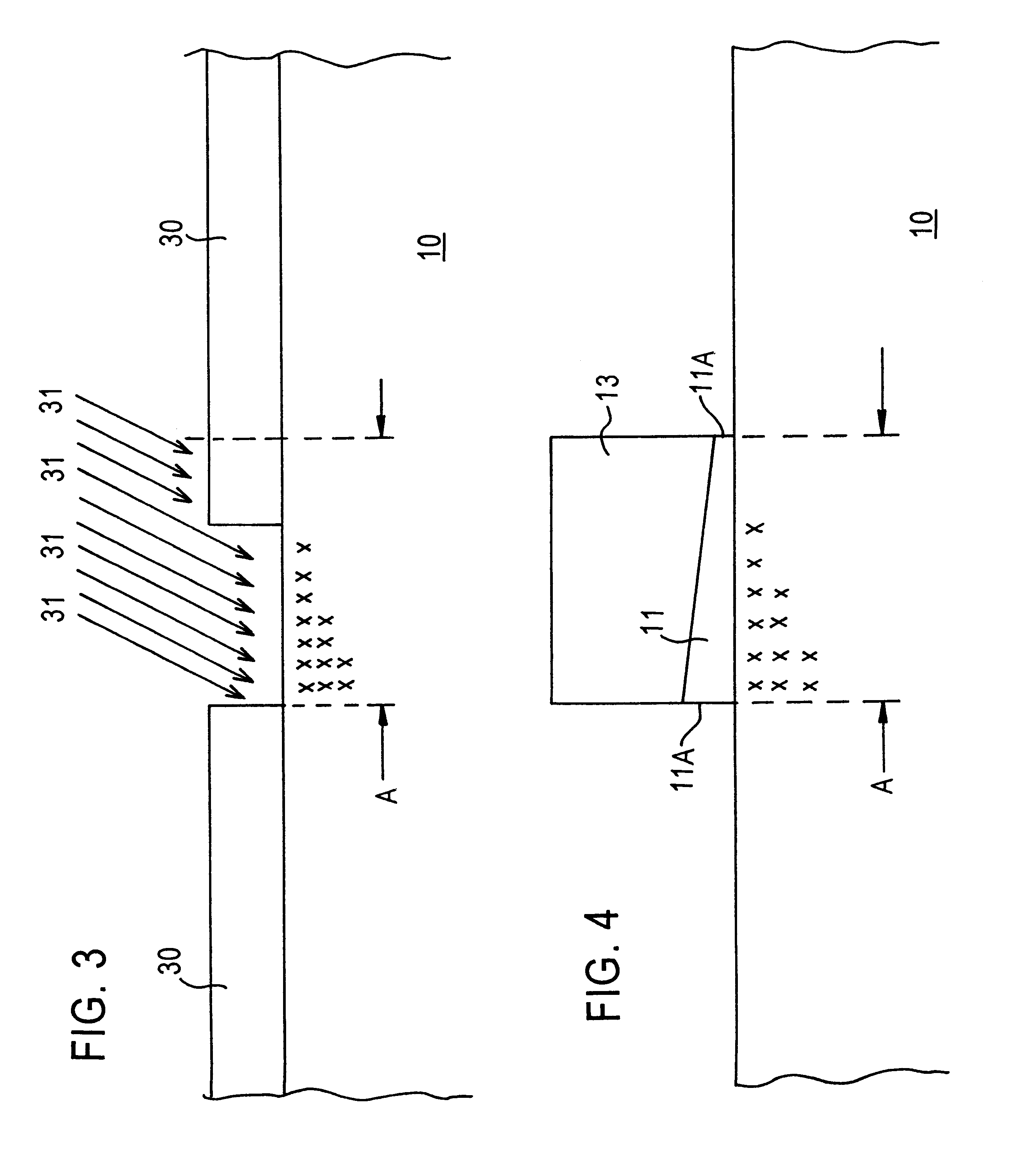

Semiconductor device and process for manufacturing the same

InactiveUS6876045B2Large thicknessTransistorSemiconductor/solid-state device detailsImpuritySemiconductor

This specification relates to a process for manufacturing a semiconductor device, comprising the steps of: forming a lower gate electrode film on a semiconductor substrate 10 via a gate insulating film 11; forming an upper gate electrode film on the lower gate electrode film, the upper gate electrode film being made of a material having a lower oxidation rate than that of the lower gate electrode film; forming a gate electrode 12 by patterning the upper gate electrode film and the lower gate electrode film, the gate electrode 12 comprising a lower gate electrode element 12a and an upper gate electrode element 12b; forming source / drain regions 15 by introducing an impurity into the semiconductor substrate 10; and forming oxide film sidewalls 13 by oxidizing the side faces of the lower gate electrode element 12a and the upper gate electrode element 12b, the thickness of the oxide film sidewalls 13 in the gate length direction being larger at the sides of the lower gate electrode element 12a than at the sides of the upper gate electrode element 12b.

Owner:PANASONIC CORP

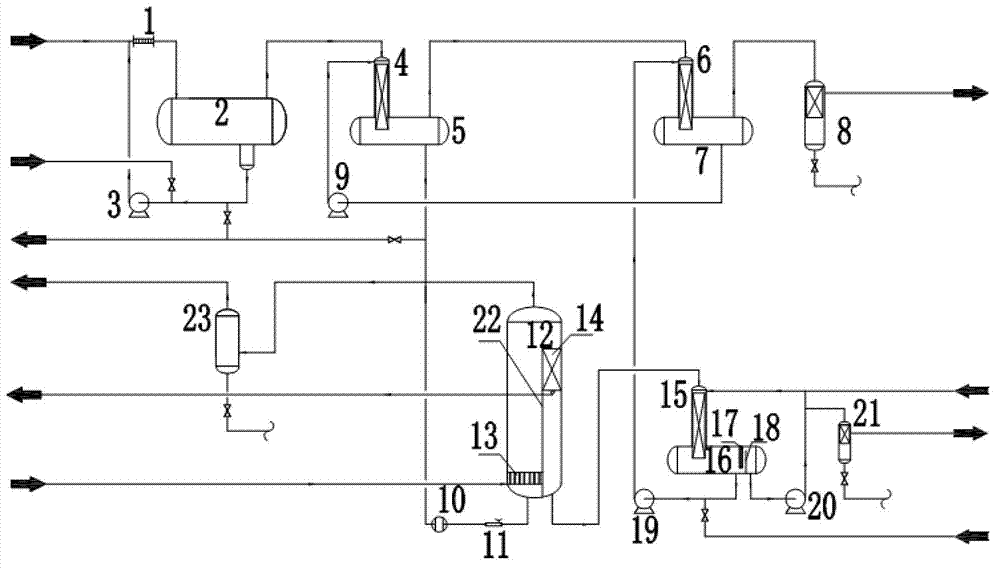

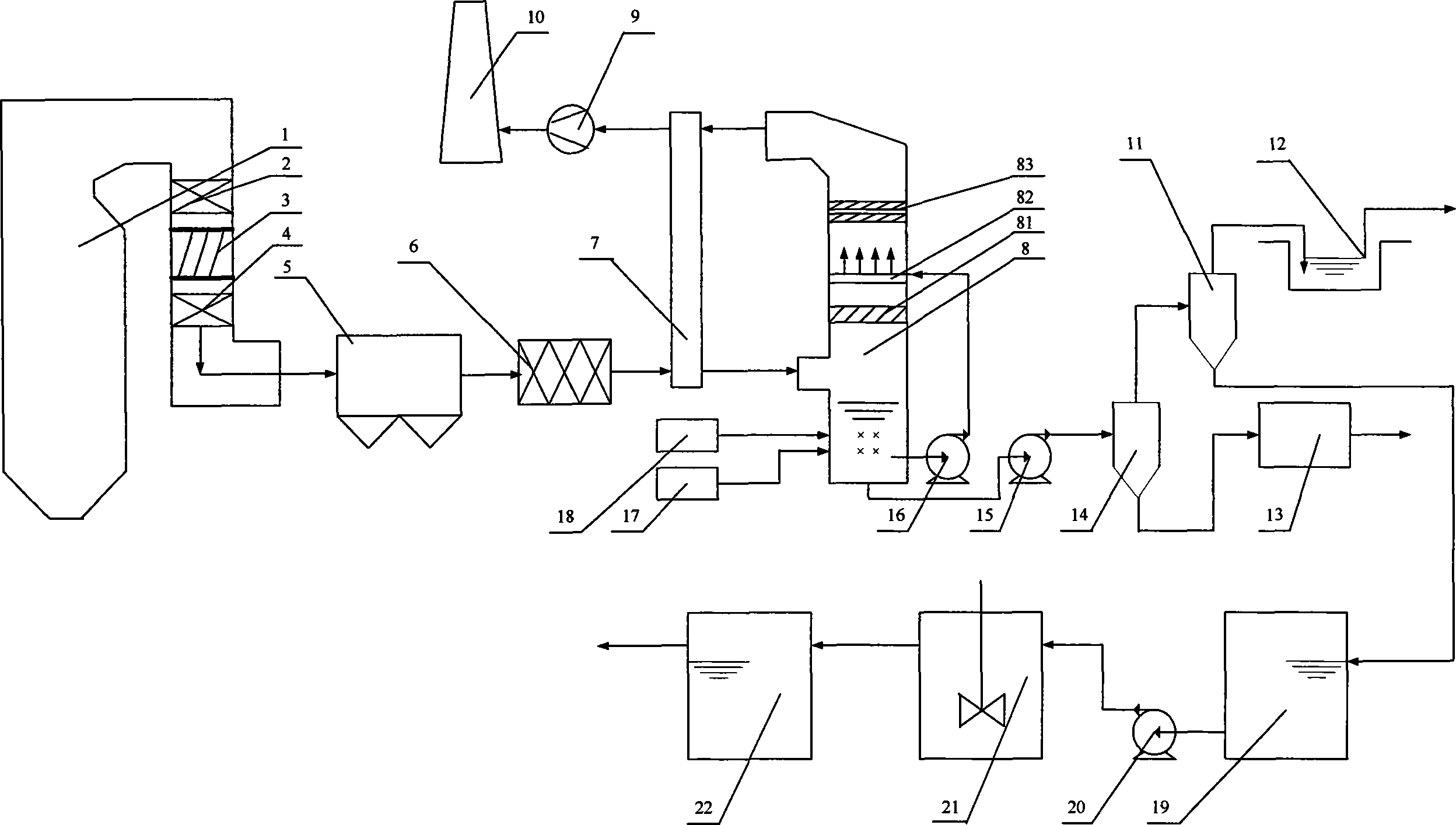

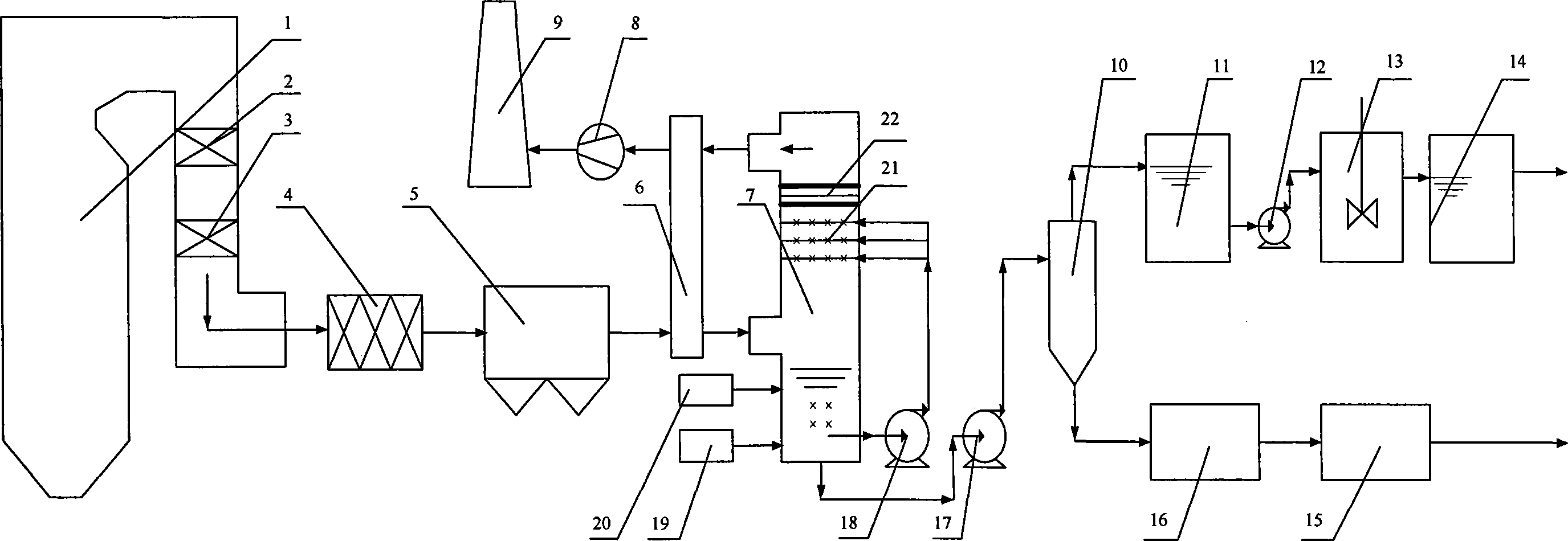

Wet flue gas desulfurizing and hydrargyrum-removing technology based on two-stage oxidation reaction and system thereof

A wet flue gas desulfurization and demercuration process and a system thereof based on two-stage oxidizing reaction. The process does two-stage oxidizing treatment to the simple substance HgO in flue gas utilizing to ultraviolet radiation and oxidant of halogen series, transmutes the gas phase divalent ion Hg2+ therein to liquid phase divalent ion Hg2+ using the modified limestone-gesso wet desulfurization process, and then transmutes the liquid phase divalent ion Hg2+ to the stable mercuric sulfide-HgS deposition via stabilizer of liquid phase divalent ion Hg2+. The system comprises desulfurization and demercuration equipments such as an ultraviolet irradiator, an electrical precipitator, an oxidant spraying unit and a reaction absorber etc, gesso treatment equipments of desulfurization byproduct, and a treating equipment for mercuric sulfide-HgS deposition. The process and the system thereof can raise the oxidation rate of simple substance Hg in the flue gas effectively, and at the same time effectively overcome the reduction release of divalent ion Hg2+ to avoid secondary pollution and be capable of raise desulfurization and demercuration efficiency of limestone-gesso wet desulfurization system.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

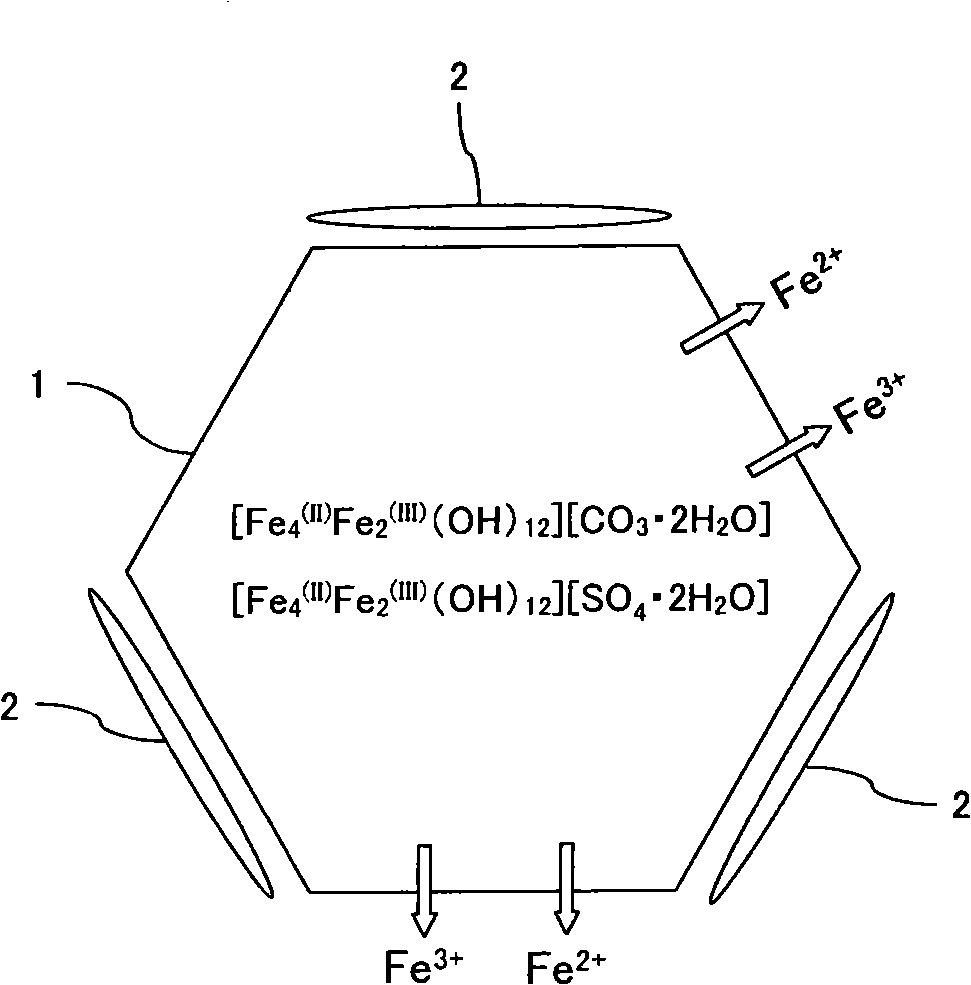

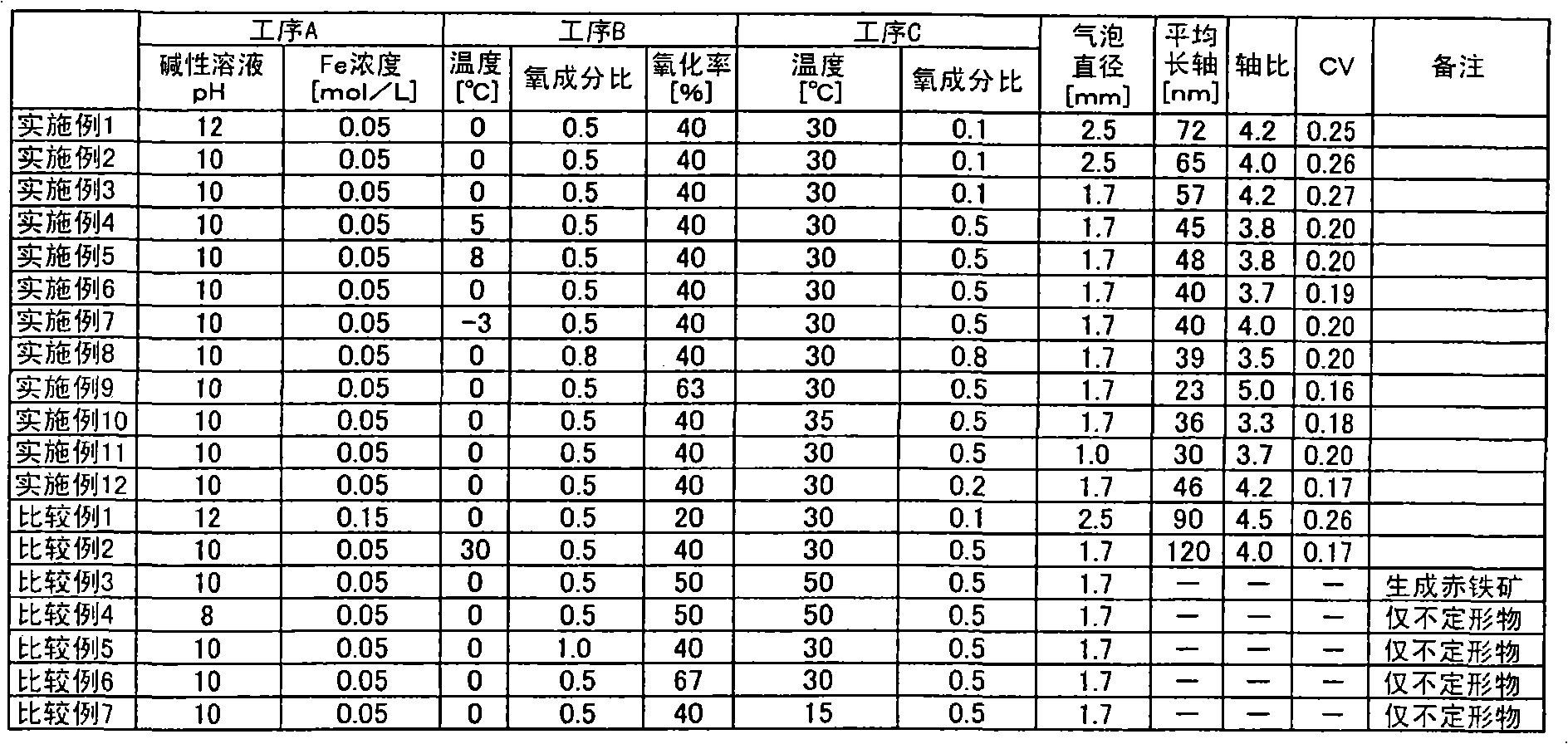

Method for producing iron oxyhydroxide particle

Owner:TDK CORPARATION

Semiconductor device with a modulated gate oxide thickness

InactiveUS6229184B1Reduced drain capacitanceImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceNitrogen

High drain capacitance is reduced, thereby increasing device speed, by forming transistors with a gate oxide having a thickness which is smaller at the drain region than at the source region. Embodiments include selectively ion implanting neutral impurities, such as silicon, geranium or argon, into and / or roughening the substrate surface to increase its oxidation rate proximate the contemplated source region and / or selectively ion implanting nitrogen to reduce its oxidation rate proximate the contemplated drain region. Other embodiments include etching a gate oxide layer having a first thickness to form a portion having a reduced second thickness proximate the contemplated drain region and thermally oxidizing to form a transition zone having a thickness gradually decreasing from the first thickness to the second thickness.

Owner:GLOBALFOUNDRIES INC

Wet-type ammonia flue gas spiritualization technics of associated desulfuration demercuration

The invention relates to a wet ammonia flue gas purification process for the combined sulfur and mercury removing and the system thereof. The process adopts chlorine gas as oxidizing agent to completely oxidize elemental mercury in the flue gas, and gas phase divalent mercuric ion after being oxidized is converted into liquid phase divalent mercuric ion through the improved wet ammonia desulphurization process, and further the liquid phase divalent mercuric ion is converted into stable mercuric sulfide sendimentation through liquid phase divalent mercuric ion stabilizing agent. The system comprises a flue gas oxidizing demercuration preprocessing system composed of an oxidizing agent injection device and an electrostatic precipitator, a wet ammonia flue gas sulfur and mercury removing system composed of a reaction absorbing tower, a sulfur removing accessory substance processing system composed of a cyclone cleaner, a dewaterer, and a dryer, and a mercuric sulfide HgS sendimentation processing system composed of a wastewater buffer pool, a liquid phase mercuric ion reaction chamber, and a settling pond. The process and the system can effectively improve the oxidation rate of the elemental mercury in the flue gas, overcome the defaults that the divalent mercuric ion is easy to be reduced and released and the secondary pollution problem is caused by excess oxidizing agent, and greatly improve the efficiency of sulfur removing and mercury removing.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

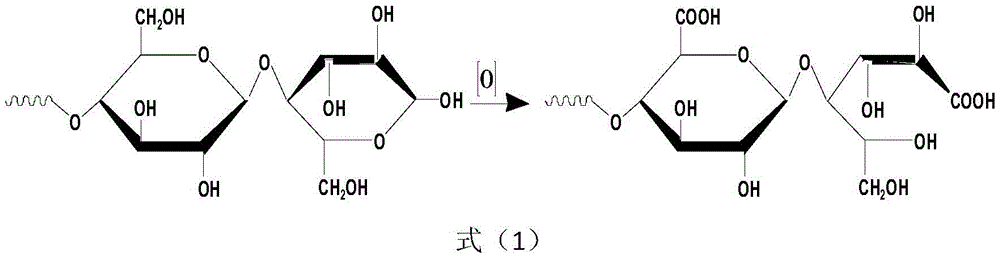

Starch adhesive with nanometer oxidized cellulose size as matrix and preparation method of starch adhesive

ActiveCN105542676AAvoid replacementPrevent drynessNon-macromolecular adhesive additivesStarch derivtive adhesivesPolymer scienceSlurry

The invention discloses a starch adhesive with nanometer oxidized cellulose size as the matrix. The starch adhesive is prepared from, by weight, 100 parts of nanometer oxidized cellulose size with the oxidation rate of 5-30%, 10-40 parts of starch, 2-5 parts of oxidizing agent, 0.1-2 parts of stabilizer, 0.1-2 parts of preservative and 0.1-2 parts of emulsified paraffin. The preparation method includes the steps of preparing nanometer oxidized cellulose size the with oxidation rate of 5-30%, adding starch and 2-5 parts of oxidizing agent to the prepared nanometer oxidized cellulose size in batches, adding stabilizer, preservative and emulsified paraffin after sufficient stirring, and sufficiently stirring the components at a temperature of 50-70 DEG C till all the components are evenly dispersed to obtain the starch adhesive. The starch adhesive is high in bonding strength and high in water resistance. By means of the preparation method, the solvent replacement and drying process is avoided, energy consumption is greatly lowered, and labor intensity is reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Method for preparing a shallow trench isolation

InactiveUS20080293213A1Inhibition formationSemiconductor/solid-state device manufacturingDopantNitrogen

A method for preparing a shallow trench isolation comprising the steps of forming at least one trench in a semiconductor substrate, performing an implanting process to implant nitrogen-containing dopants into an upper sidewall of the trench such that the concentration of the nitrogen-containing dopants in the upper sidewall is higher than that in the bottom sidewall of the trench, forming a spin-on dielectric layer filling the trench and covering the surface of the semiconductor substrate, performing a thermal oxidation process to form a silicon oxide layer covering the inner sidewall. Since the nitrogen-containing dopants can inhibit the oxidation rate and the concentration of the nitrogen-containing dopants in the upper inner sidewall is higher than that in the bottom inner sidewall of the trench, the thickness of the silicon oxide layer formed by the thermal oxidation process is larger at the bottom portion than at the upper portion of the trench.

Owner:PROMOS TECH INC

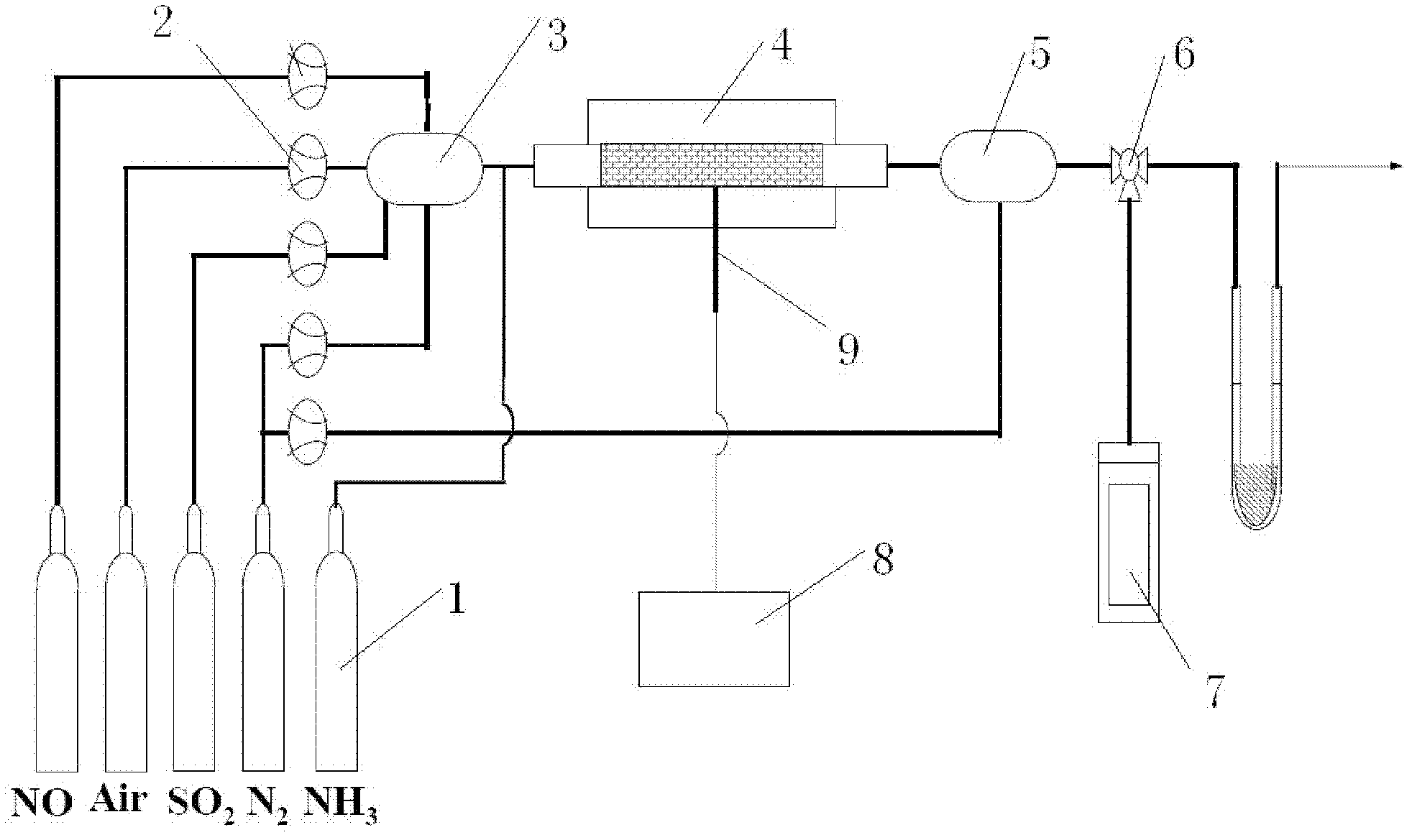

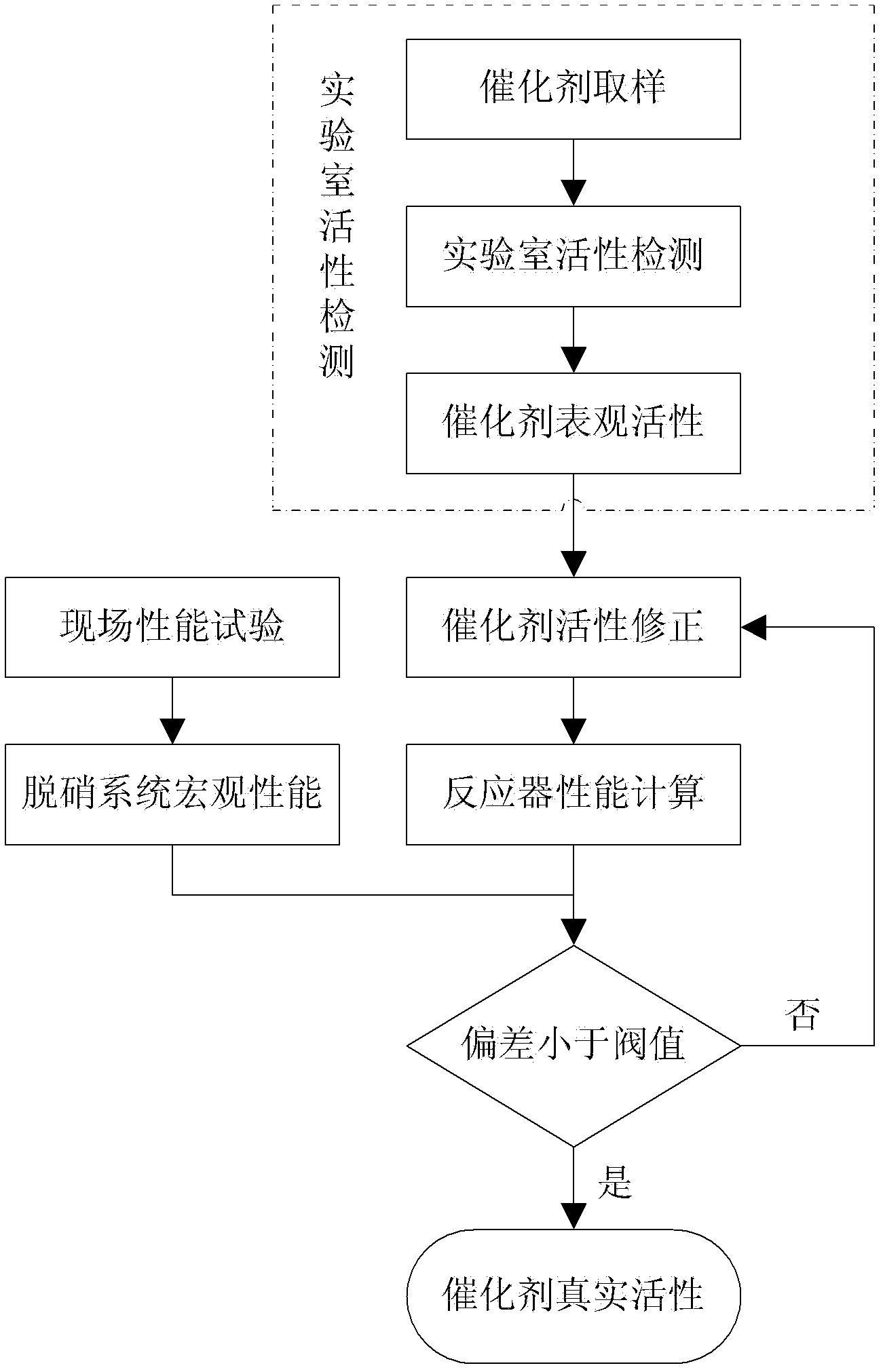

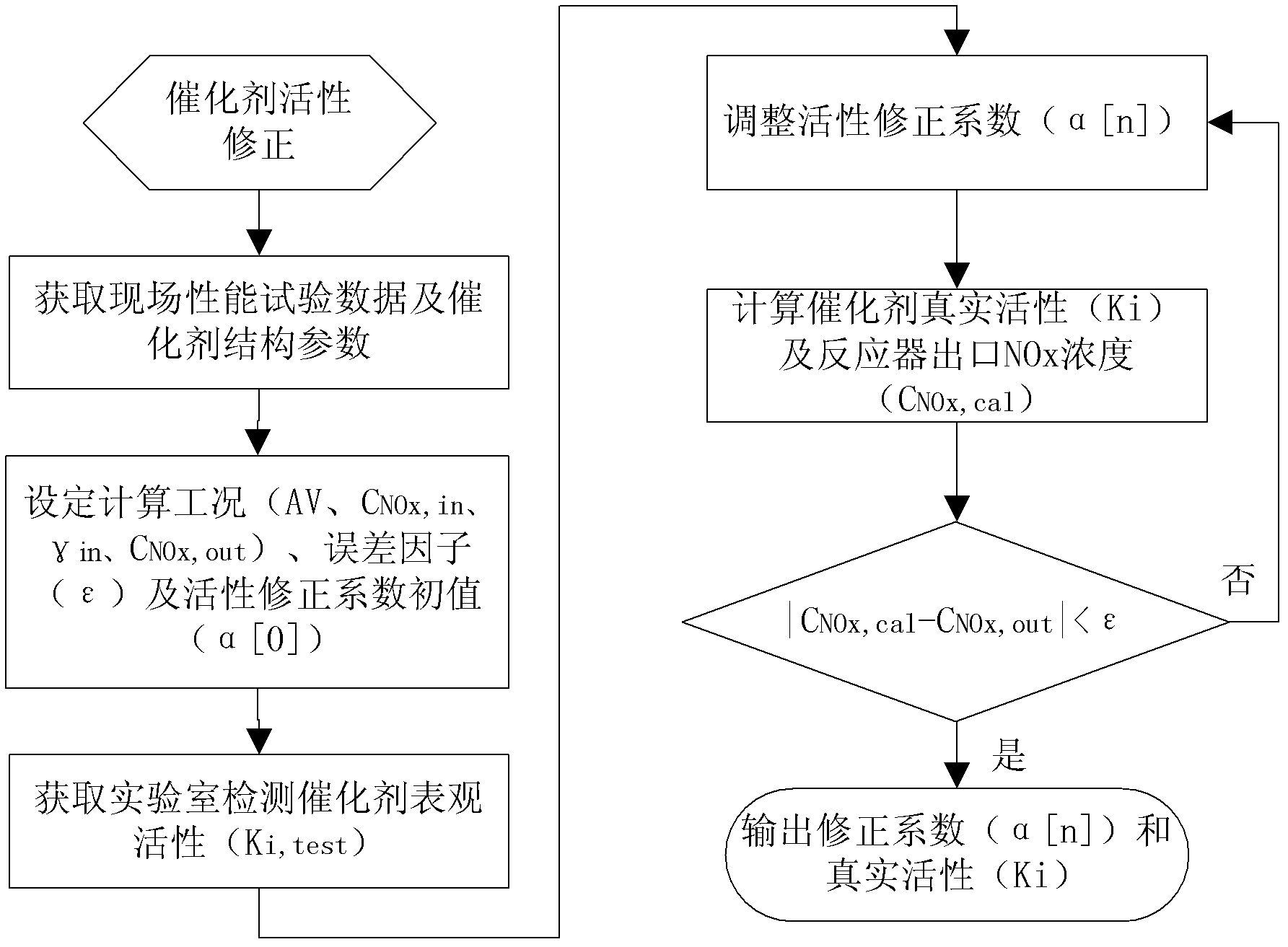

Modifying method for catalyst activity in power plant SCR (selective catalytic reduction) denitration system

ActiveCN102565274AImprove accuracyChemical analysis using catalysisDispersed particle separationEscape rateEngineering

The invention discloses a modifying method for catalyst activity in a power plant SCR (selective catalytic reduction) system, which comprises three major steps: firstly, sampling catalyst when in maintenance outage, and carrying out activity detection in a laboratory so as to obtain apparent activity value; secondly, carrying out a SCR denitration system spot performance test when the operation is recovered after the maintenance outage, so as to obtain operation indexes of the denitration system, such as denitration efficiency, ammonia escape rate, oxidation rate of sulfur dioxide, the resistance of the denitration system and the like; and finally, substituting the activity detection value obtained in the laboratory into a performance calculating module of an reactor as a relative proportion of the activity of all layers of catalyst, and utilizing the spot performance test data for regression so as to obtain the real activity of the current catalyst. The modifying method of the invention aims at modifying the error in the laboratory activity detection due to sampling representative problems and over ideal reaction conditions, so as to improve the accuracy of the catalyst activity detection.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com