Patents

Literature

175 results about "Escape rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Escape Rate. “Escape rate” means the maximum volume (Q) that is used to designate the possible rate of escape of a gaseous mixture containing hydrogen sulfide, as set forth in 19.15.11 NMAC.

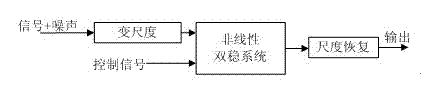

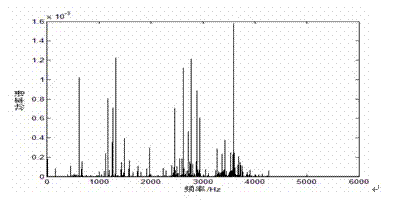

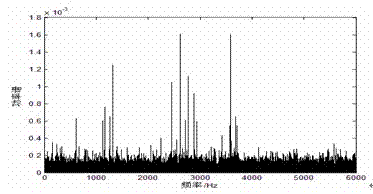

Bearing fault detection method based on manner of controlling stochastic resonance by external periodic signal

InactiveCN102226740AEnhanced spectral valueAccurate detectionMachine bearings testingControl signalEscape rate

The invention discloses a bearing fault detection method based on a manner of controlling stochastic resonance by an external periodic signal. According to the method provided in the invention, after a bearing fault signal is converted by a variable metric method, the converted signal is input in a bistable system; meanwhile, an external single frequency periodic signal is taken as a control signal to act directly on the system; contact barrier height of the bistable system and an escape rate of Kramers are changed by continuously adjusting an amplitude of the control signal. Therefore, stochastic resonance can be generated or increased artificially; a spectral value of an output power spectrum at the position of an input signal frequency can be effectively improved; and thus a characteristic signal of a bearing fault can be detected accurately at last. The detection method provided in the invention enables the effective control of the stochastic resonance to be realized, thereby providing a novel method for early detection of equipment faults.

Owner:CHINA JILIANG UNIV

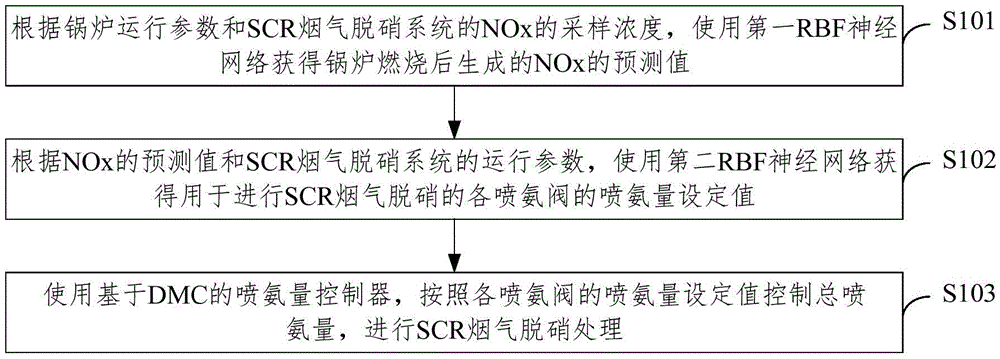

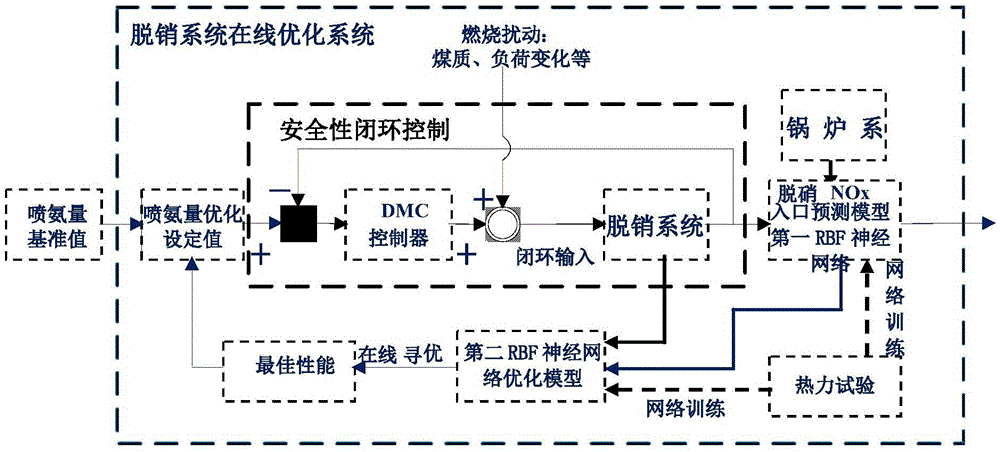

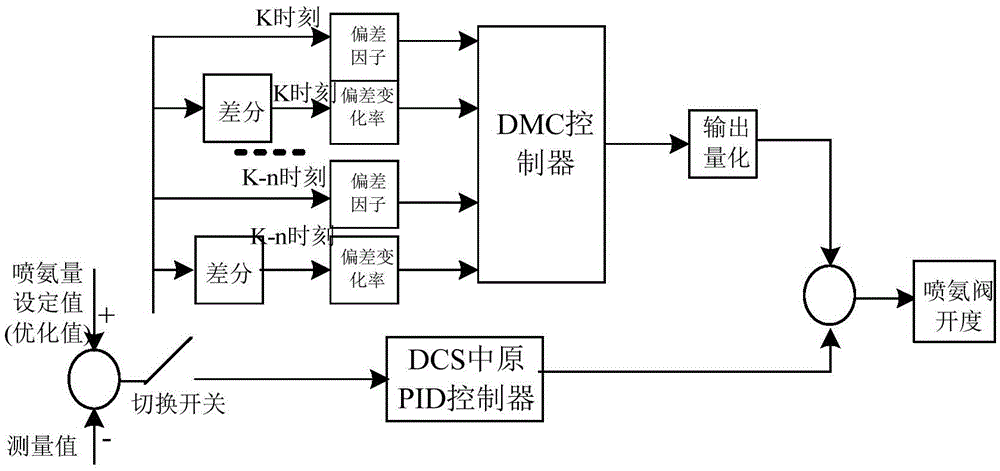

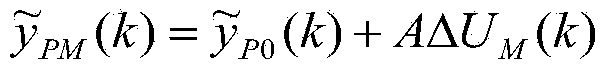

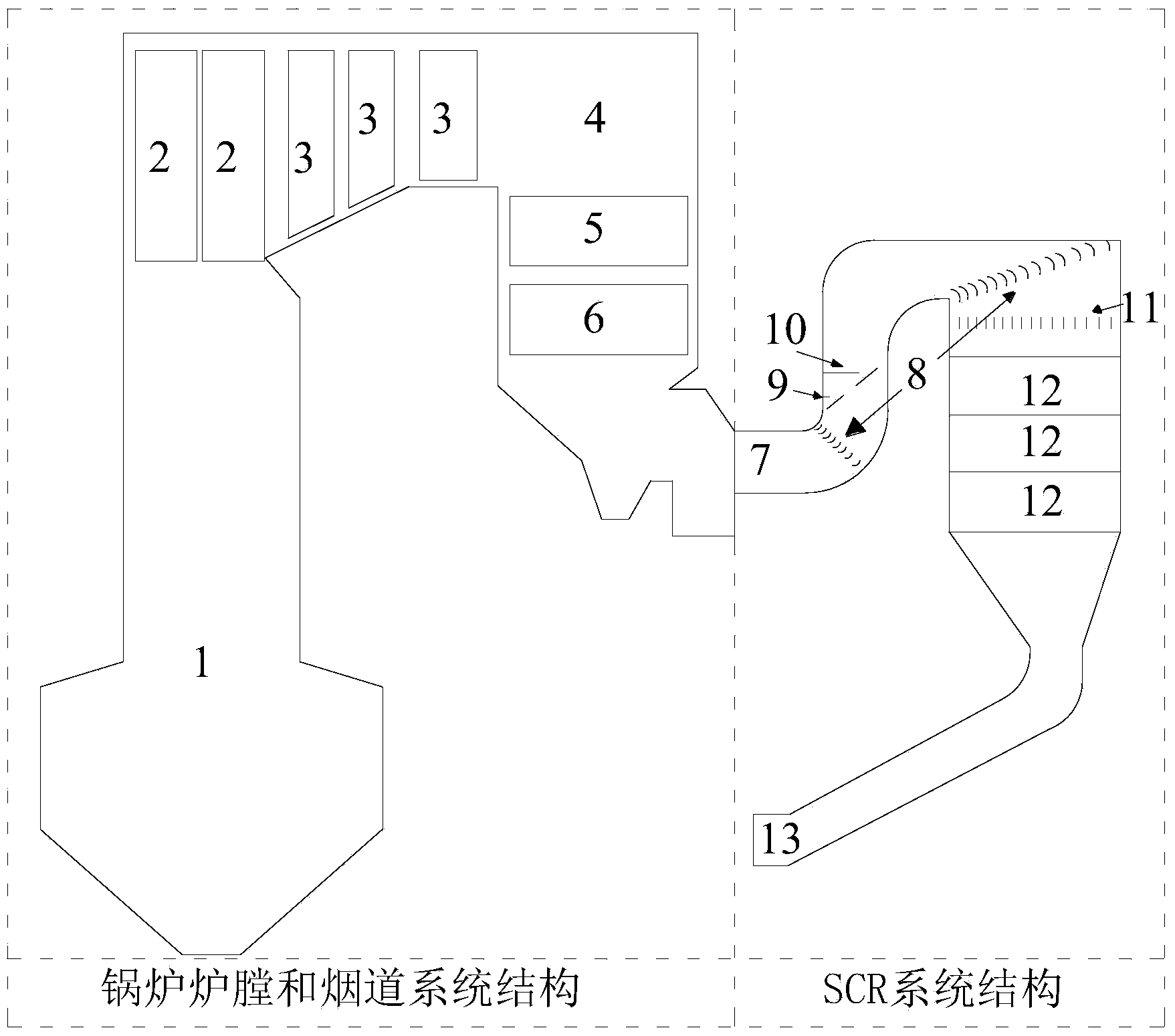

SCR (Selective Catalytic Reduction) flue gas denitration system control method and apparatus

The invention discloses an SCR (Selective Catalytic Reduction) flue gas denitration system control method and apparatus. The SCR flue gas denitration system control method includes the following steps that: a first RBF neural network is adopted to obtain the predicted value of NOx generated after boiler combustion according to boiler operating parameters, the sampling concentration of NOx of an SCR flue gas denitration system; a second RBF neural network is adopted to obtain ammonia spray amount set values of ammonia spray valves for SCR flue gas denitration according to the predicted value of the NOx and the operating parameters of the SCR flue gas denitration system; and a DMC (Dynamic Matrix Control)-based ammonia spray amount controller is adopted to control total ammonia spray amount according to the ammonia spray amount set values of the ammonia spray valves so as to perform SCR flue gas denitration treatment. With the method and apparatus of the invention adopted, denitration efficiency can be effectively improved, and the escape rate of NH3 of the exit of the SCR denitration system can be reduced.

Owner:INNER MONGOLIA RUITE TECH

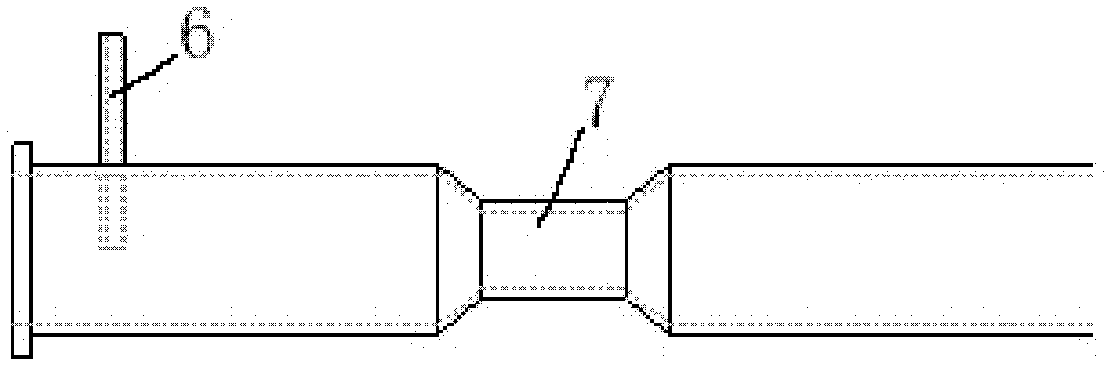

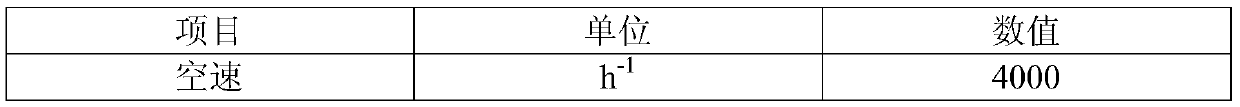

Denitration catalyst using titanium dioxide as raw material and preparation method thereof

InactiveCN101396657AConvenient sourceLow priceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentEscape rate

The invention belongs to the chemical material field, in particular to a denitration catalyst which uses TiO2 as raw material and a preparation method thereof. The catalyst comprises TiO2, V2O, WO3 and addition agent, wherein, TiO2 which is 70-90 percent of the catalyst in weight is used as carrier, V2O5 which is 0.6-2 percent of the catalyst in weight is used as an active component, WO3 which is 5-10 percent of the catalyst in weight is used as cocatalyst, and the rest is the addition agent. The preparation process of the catalyst comprises: titanium powder doped with tungsten is prepared and is added with the active component and the other addition agents to be dried and calcinated to obtain the denitration catalyst. The raw material source is convenient and the price is low. No pretreatment is required. The preparation process is simple. Through the denitration test under fixed bed simulation flue gas condition, the catalyst is proved to be provided with high denitration activity and low SO2 conversion rate and ammonia escaping rate.

Owner:TSINGHUA UNIV +1

Selective catalytic reduction (SCR) denitration system and method based on constraint predictive control

ActiveCN104607042AQuick responseReduce escape rateDispersed particle separationEscape rateEngineering

The invention discloses a selective catalytic reduction (SCR) denitration system and method based on constraint predictive control. The flow of injected ammonia of the SCR denitration system is controlled by utilizing a predicting-proportioning cascade control policy; the flow of the injected ammonia is regulated by predicting the future change tendency of the concentration of NOx at an outlet of an SCR reactor and regulating the opening degree of an ammonia injection valve in advance; therefore, the defects of large inertia and delay of the SCR denitration system can be greatly overcome, the response speed of ammonia injection amount control to unit load change is increased, and the dynamic regulation quality of the SCR denitration system is improved; under the constraint predictive control, practical constrains, such as upper and lower constrains of valve opening degree, valve operation speed constrain and outlet NOx concentration constrain, are simultaneously considered and are used in parallel, so that the fact that the system performance is influenced due to saturation of execution mechanisms is avoided; based on ensuring the fact that the concentration of the NOx at the outlet reaches a target value, the ammonia injection amount is reduced as much as possible, and the operation cost and the ammonia escape rate are effectively reduced.

Owner:SOUTHEAST UNIV

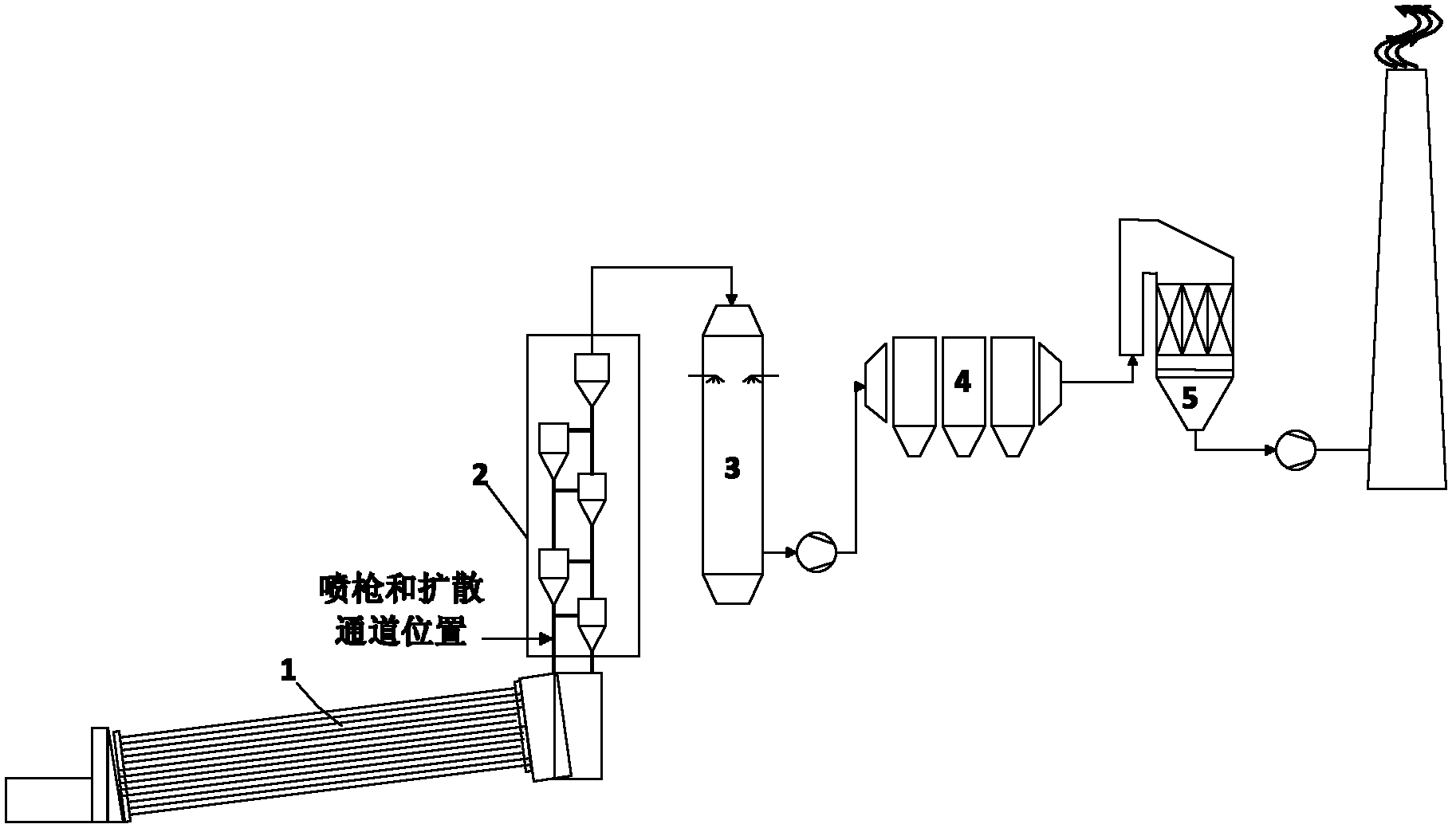

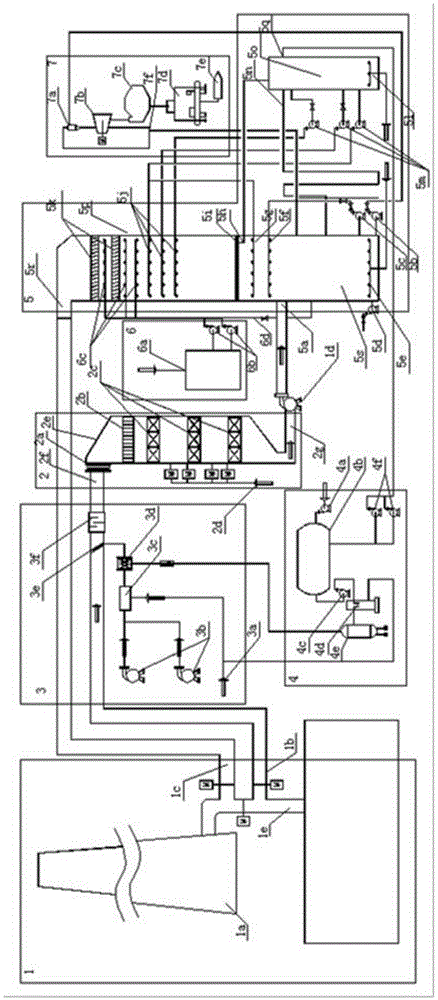

Denitration process and denitration apparatus for cement kiln flue gas

ActiveCN102512925AImprove denitrification efficiencyReduce escape rateGas treatmentDispersed particle separationDecompositionEscape rate

The invention discloses a denitration process for cement kiln flue gas. According to the process, liquefied ammonia, ammonia water or urea is used as a reducing agent and is injected into cement decomposition kiln flue gas in a temperature range of 750 to 1100 DEG C by a spray gun for a selective uncatalyzed reaction, and then the reducing agent and unreacted nitrogen oxides in the flue gas pass through an SCR reaction system installed behind a humidifying tower and a deduster together and undergo a selective uncatalyzed reaction on the surface of a specially-produced low temperature catalyst so as to realize secondary denitration. The invention also discloses a denitration apparatus used for realizing the denitration process. According to the invention, through installation of an SCR denitration system at the tail of a system, the escape rate of ammonia in an SNCR system is reduced; meanwhile, through former SNCR preliminary denitration, the volume of an SCR reactor and usage amount of the catalyst are reduced, thereby reducing cost of one-shot investment for the denitration system and improving denitration efficiency of the system. The denitration process and denitration apparatus provided in the invention are applicable to removal of nitrogen oxides in cement kiln flue gas and have wide market and application prospects.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Fire rescue method utilizing indoor wireless positioning technology

ActiveCN103157200AIncrease success rateIncrease chance of escapeBuilding rescueWireless commuication servicesEscape rateComputer terminal

The invention relates to a fire rescue method utilizing indoor wireless positioning technology. When a fire breaks out, every person in trouble utilizes a smartphone in hand or a prepared mobile terminal which is stored in a office to communicate with a wireless communication base station which is installed in a building, a physical position of the smartphone or the mobile terminal is determined through both-way communication between the smartphone or the mobile terminal and the wireless communication base station, position information and identification information of the smartphone or the mobile terminal are received through the wireless communication base station and sent to a monitoring host, the monitoring host utilizes the wireless communication base station to collect location information of firefighters, and meanwhile collects information of all smoke sensors and fire door sensors, and all the smoke sensors and all the door sensors are arranged in the building and send related information to people in trouble and rescue personnel. The fire rescue method utilizing indoor wireless positioning technology has the advantages that the people in trouble and firefighters are informed of the scene of the fire in a two-way transparent mode, and success rate of fire rescue and escape rate of persons in trouble are improved to a great degree.

Owner:宝星电器(上海)有限公司

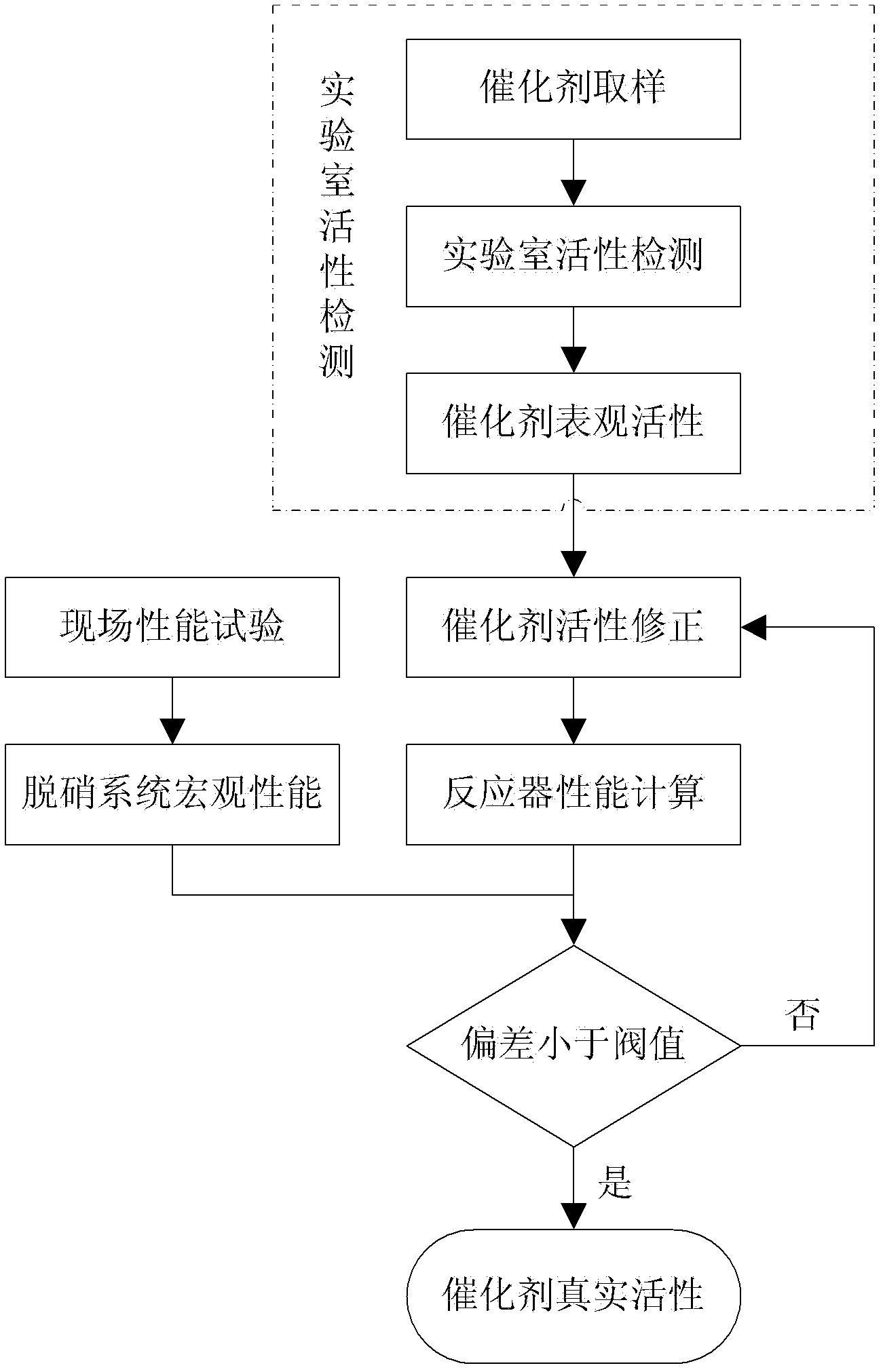

Modifying method for catalyst activity in power plant SCR (selective catalytic reduction) denitration system

ActiveCN102565274AImprove accuracyChemical analysis using catalysisDispersed particle separationEscape rateEngineering

The invention discloses a modifying method for catalyst activity in a power plant SCR (selective catalytic reduction) system, which comprises three major steps: firstly, sampling catalyst when in maintenance outage, and carrying out activity detection in a laboratory so as to obtain apparent activity value; secondly, carrying out a SCR denitration system spot performance test when the operation is recovered after the maintenance outage, so as to obtain operation indexes of the denitration system, such as denitration efficiency, ammonia escape rate, oxidation rate of sulfur dioxide, the resistance of the denitration system and the like; and finally, substituting the activity detection value obtained in the laboratory into a performance calculating module of an reactor as a relative proportion of the activity of all layers of catalyst, and utilizing the spot performance test data for regression so as to obtain the real activity of the current catalyst. The modifying method of the invention aims at modifying the error in the laboratory activity detection due to sampling representative problems and over ideal reaction conditions, so as to improve the accuracy of the catalyst activity detection.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

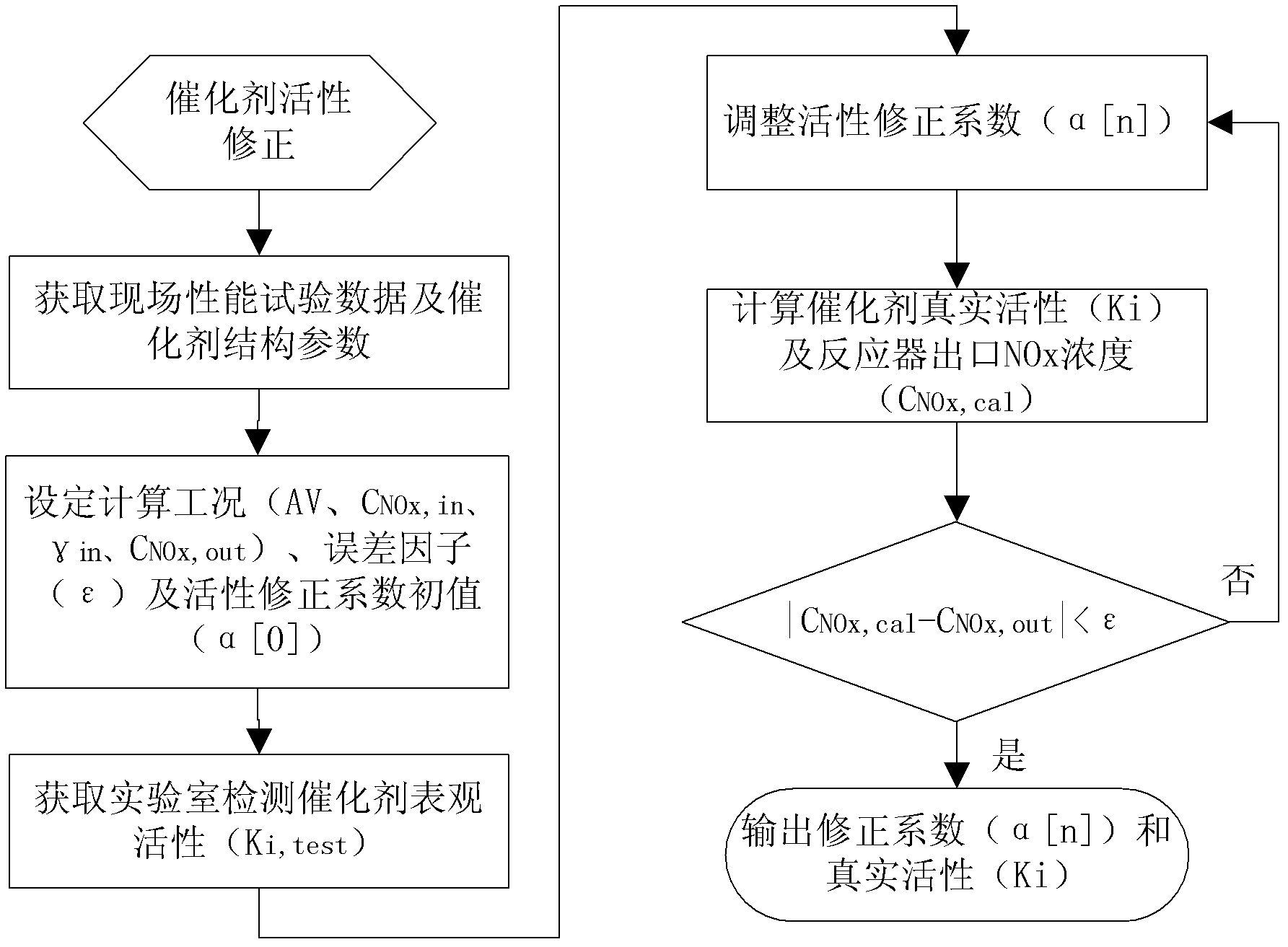

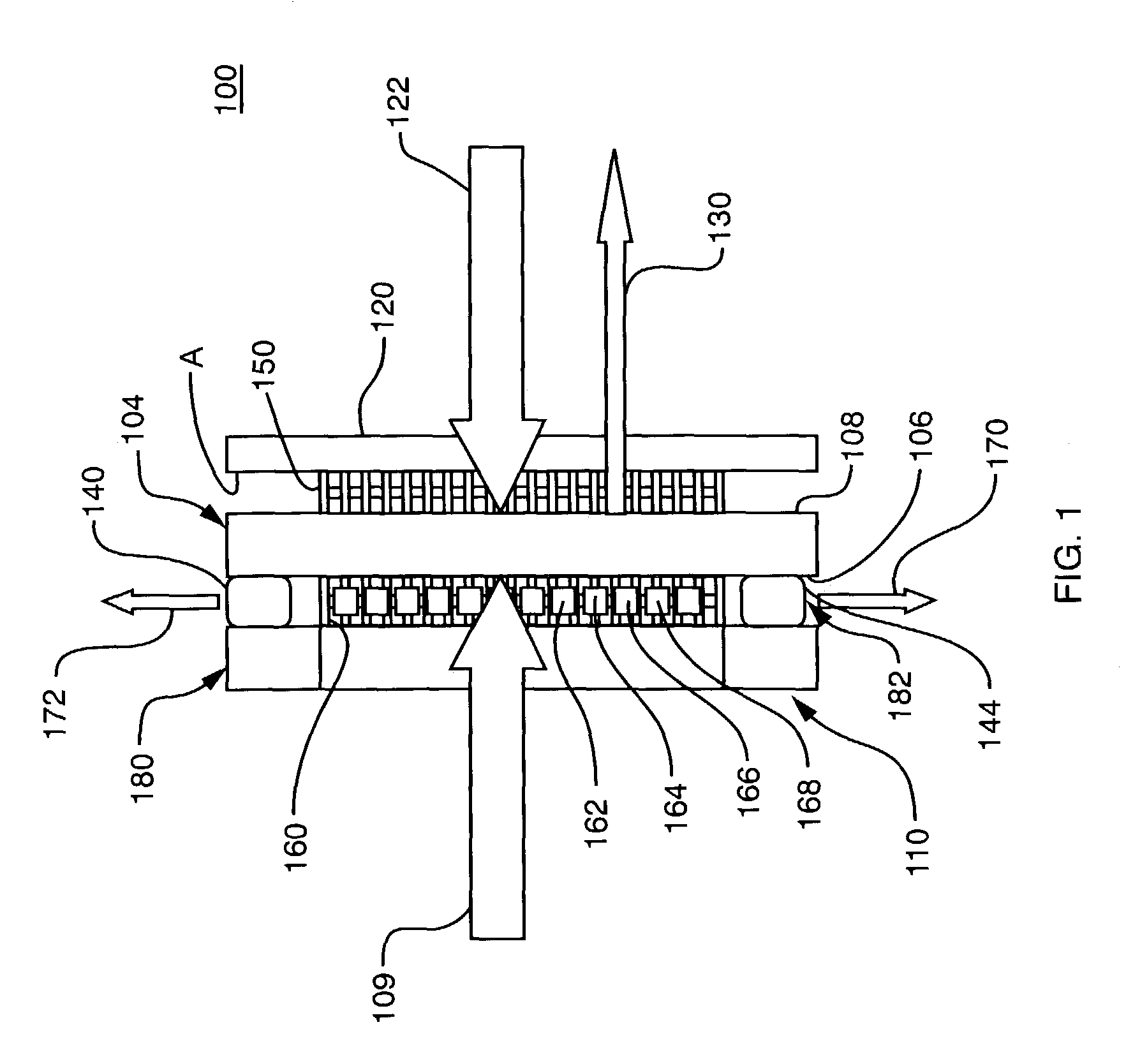

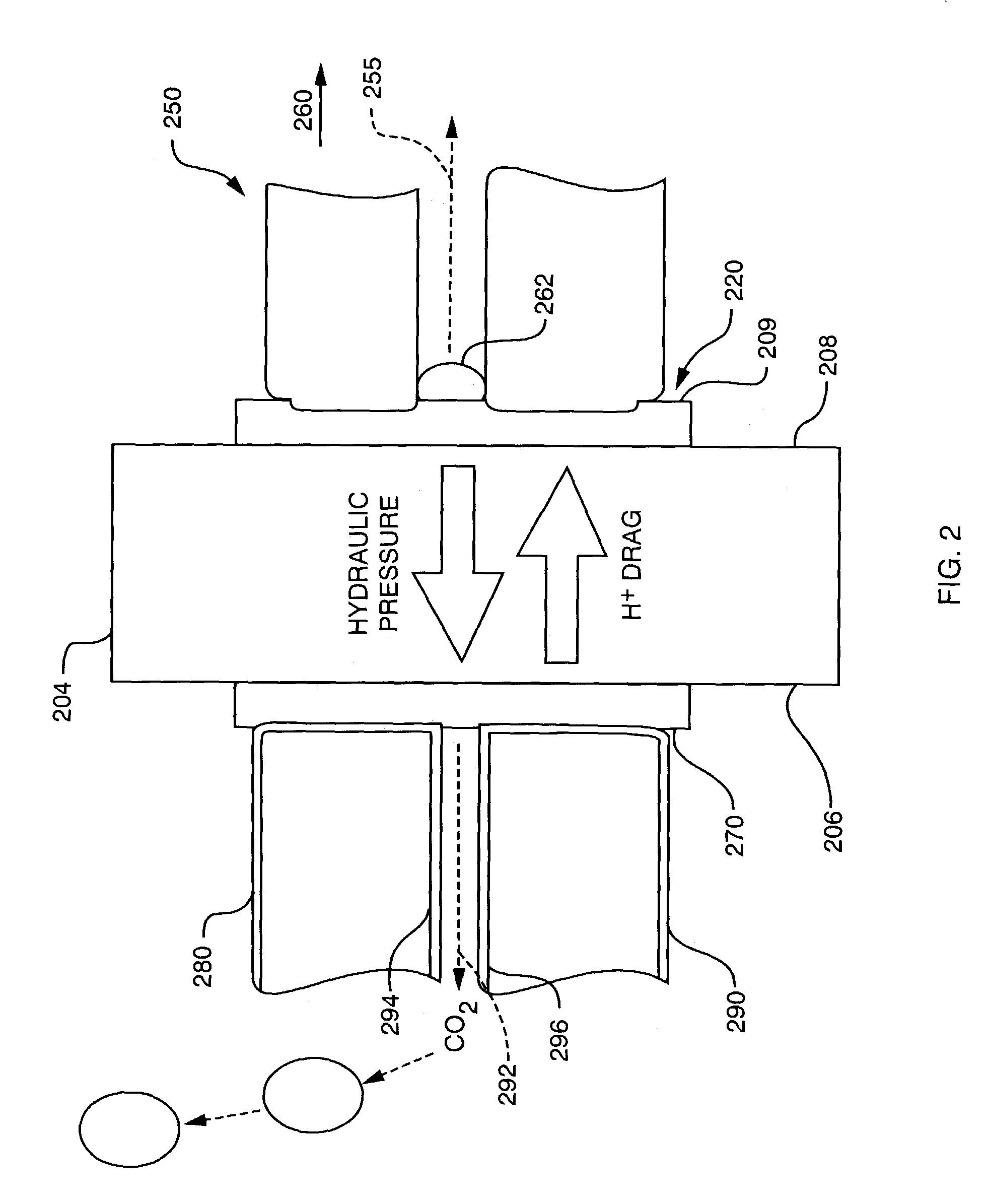

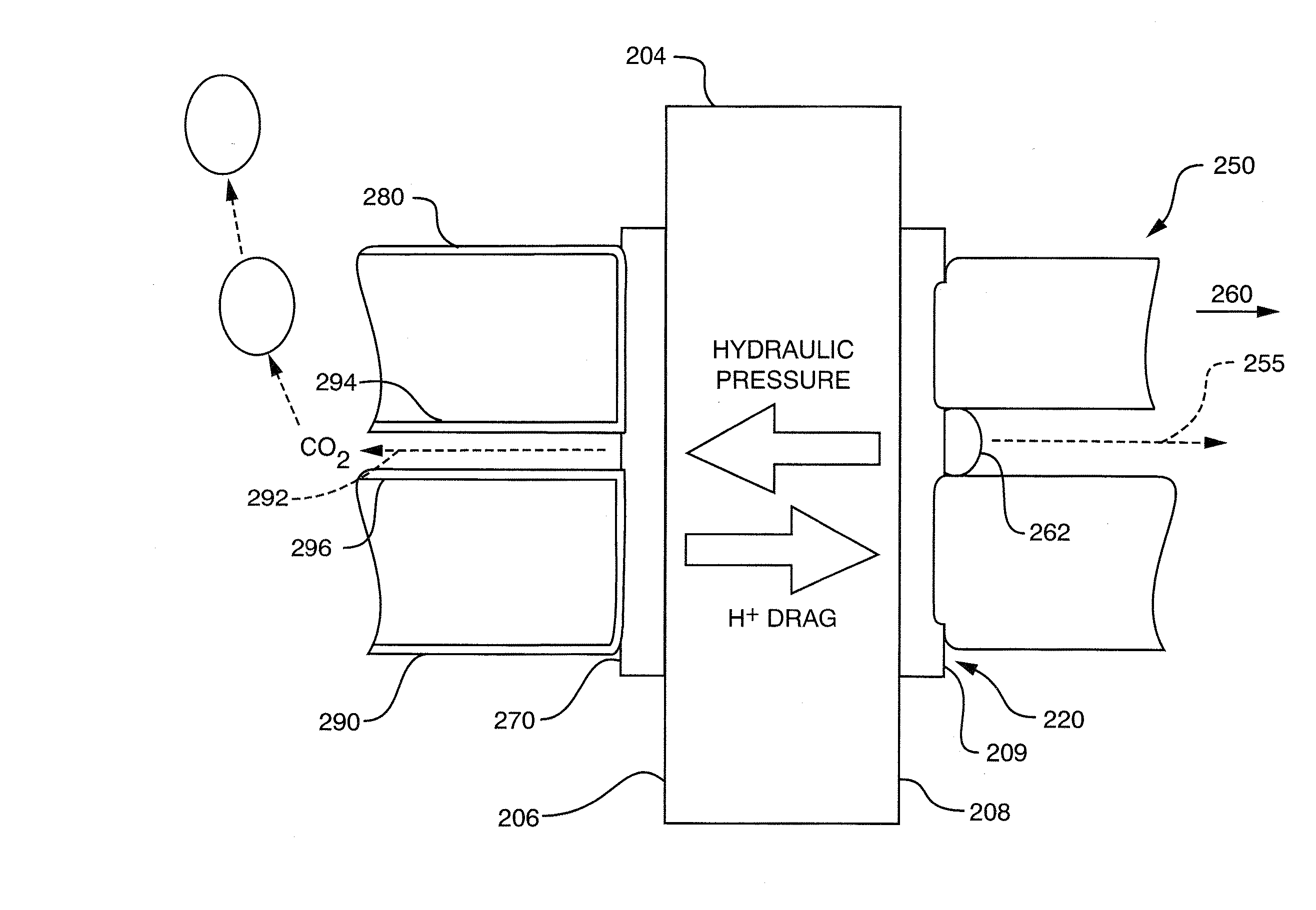

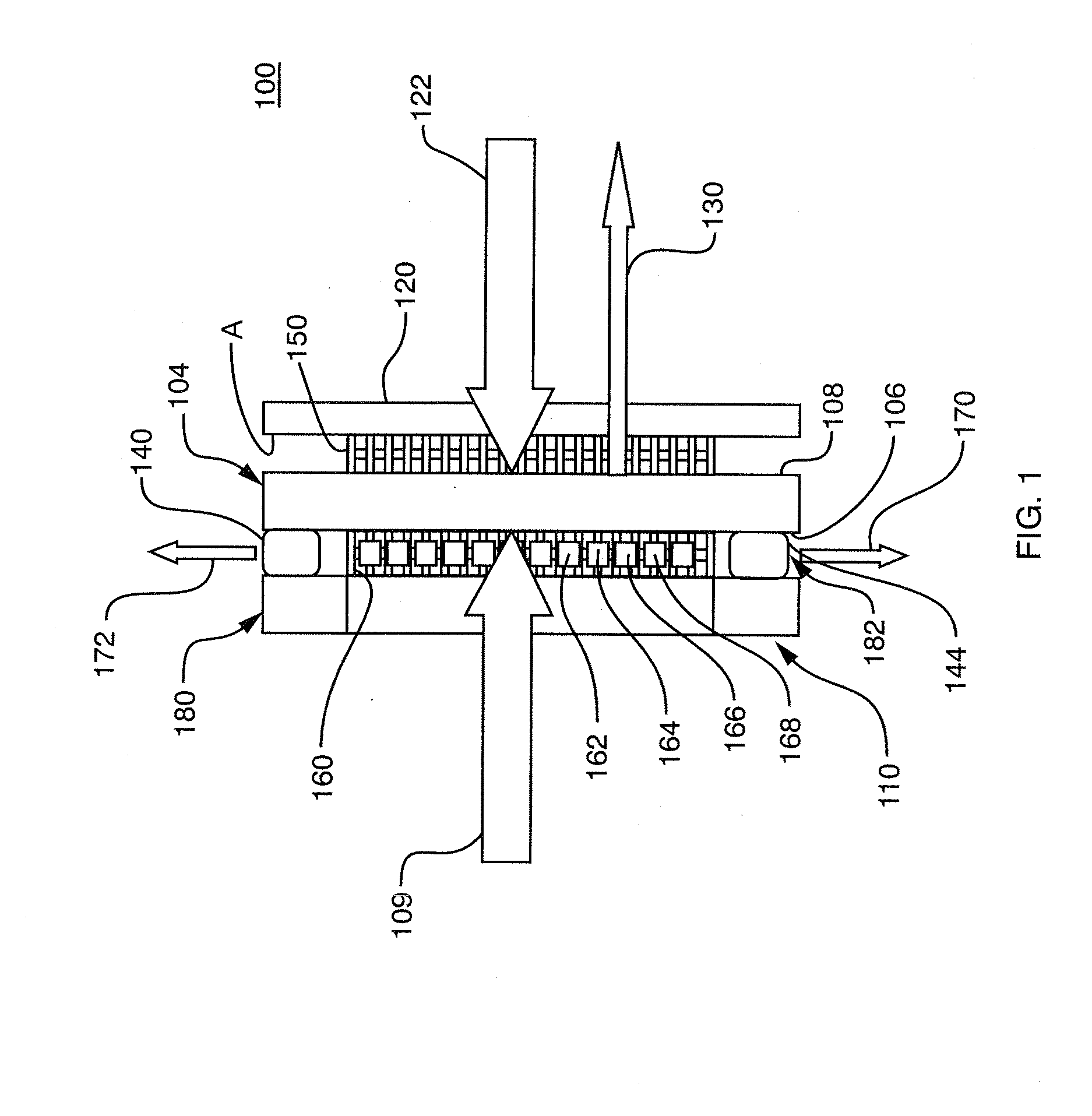

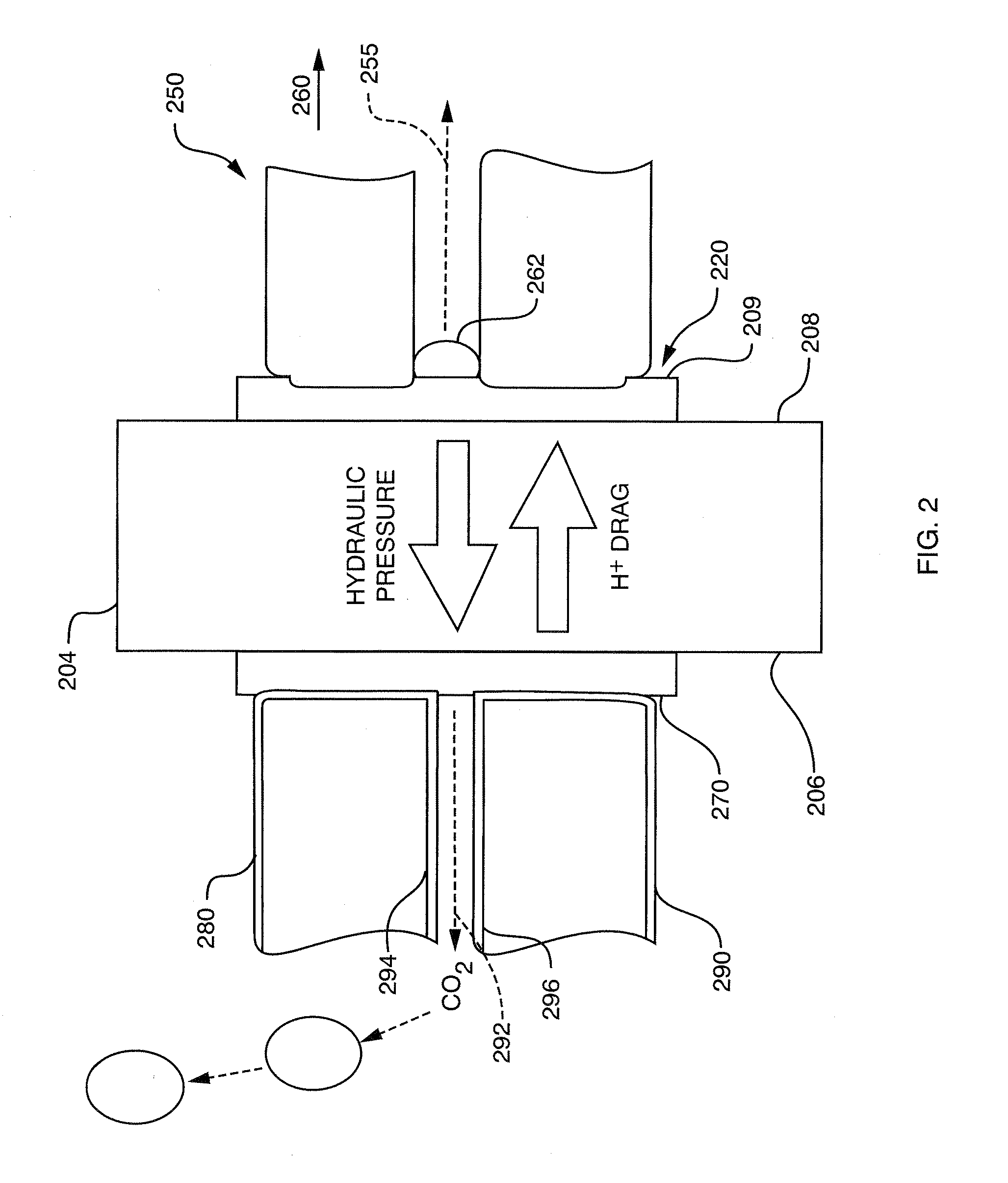

Passive water management techniques in direct methanol fuel cells

InactiveUS7282293B2Increase water flowConvenient paymentWater management in fuel cellsActive material electrodesWater vaporLiquid water

Passive water management techniques are provided in an air-breathing direct oxidation fuel cell system. A highly hydrophobic component with sub-micrometer wide pores is laminated to the catalyzed membrane electrolyte on the cathode side. This component blocks liquid water from traveling out of the cathode and instead causes the water to be driven through the polymer membrane electrolyte to the cell anode. The air-breathing direct oxidation fuel cell also includes a layer of cathode backing and additional cathode filter components on an exterior aspect of the cell cathode which lessen the water vapor escape rate from the cell cathode. The combination of the well laminated hydrophobic microporous layer, the thicker backing and the added filter layer, together defines a cathode structure of unique water management capacity, that enables to operate a DMFC with direct, controlled rate supply of neat (100%) methanol, without the need for any external supply or pumping of water. The cell anode is provided with a hydrophilic backing layer. When the water is driven through the polymer membrane electrolyte from the cell cathode to the cell anode chamber, it is available for the anodic reaction, and any excess water is carried out along CO2 ventilation channels to the outside environment.

Owner:MTI MICROFUEL CELLS

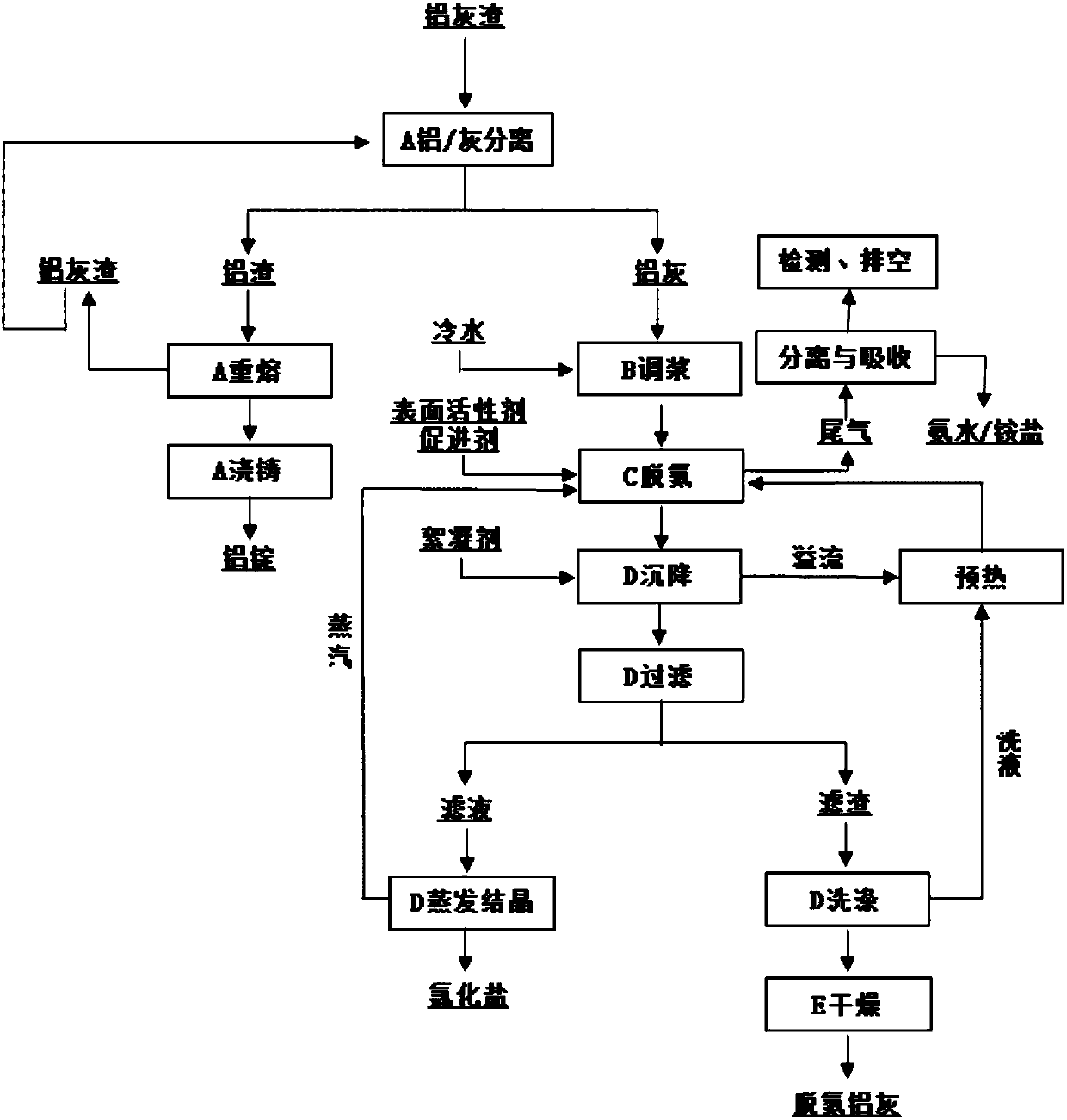

Method for strengthening aluminum ash denitriding through pressure regulating-water hot rotational flow technology

ActiveCN107597802AShorten the denitrification timeImprove denitrification effectSolid waste disposalReaction rateSurface-active agents

The invention discloses a method for strengthening aluminum ash denitriding through a pressure regulating-water hot rotational flow technology, and belongs to the field of environment-friendly materials. The method comprises five steps of ash / aluminum separation, feeding, denitriding, settling, filtering and washing, and drying. In the third step, the water temperature and gas pressure in a reactor are adjusted, the rotational flow is applied, the ammonia escape rate is controlled, the aluminum ash denitriding reaction rate is controlled, and the aluminum ash denitriding efficiency is improved. In the third step, a surface active agent and an accelerant are added, the denitriding time is shortened, the denitriding effect is improved, and the nitrogen content of treated powder is smaller than 0.05%. In the fourth step, a flocculating agent is added in the settling process, and micro particles generated in aluminum ash in the third step are completely settled. In the fifth step, aluminumash powder obtained after denitriding is classified. Through the technology, aluminum ash denitriding treatment is achieved, the technology is simple, the production cost is low, sufficient cyclic utilization of water and heat is achieved, energy saving and environment friendliness are achieved, and environment pollution and resource waste caused by aluminum ash are avoided.

Owner:NORTHEASTERN UNIV

Passive water management techniques in direct methanol fuel cells

InactiveUS20080032182A1Neat, or highly concentrated methanol fuel supplyOvercome disadvantagesWater management in fuel cellsActive material electrodesWater vaporLiquid water

Passive water management techniques are provided in an air-breathing direct oxidation fuel cell system. A highly hydrophobic component with sub-micrometer wide pores is laminated to the catalyzed membrane electrolyte on the cathode side. This component blocks liquid water from traveling out of the cathode and instead causes the water to be driven through the polymer membrane electrolyte to the cell anode. The air-breathing direct oxidation fuel cell also includes a layer of cathode backing and additional cathode filter components on an exterior aspect of the cell cathode which lessen the water vapor escape rate from the cell cathode. The combination of the well laminated hydrophobic microporous layer, the thicker backing and the added filter layer, together defines a cathode structure of unique water management capacity, that enables to operate a DMFC with direct, controlled rate supply of neat (100%) methanol, without the need for any external supply or pumping of water. The cell anode is provided with a hydrophilic backing layer. When the water is driven through the polymer membrane electrolyte from the cell cathode to the cell anode chamber, it is available for the anodic reaction, and any excess water is carried out along CO2 ventilation channels to the outside environment.

Owner:MTI MICROFUEL CELLS

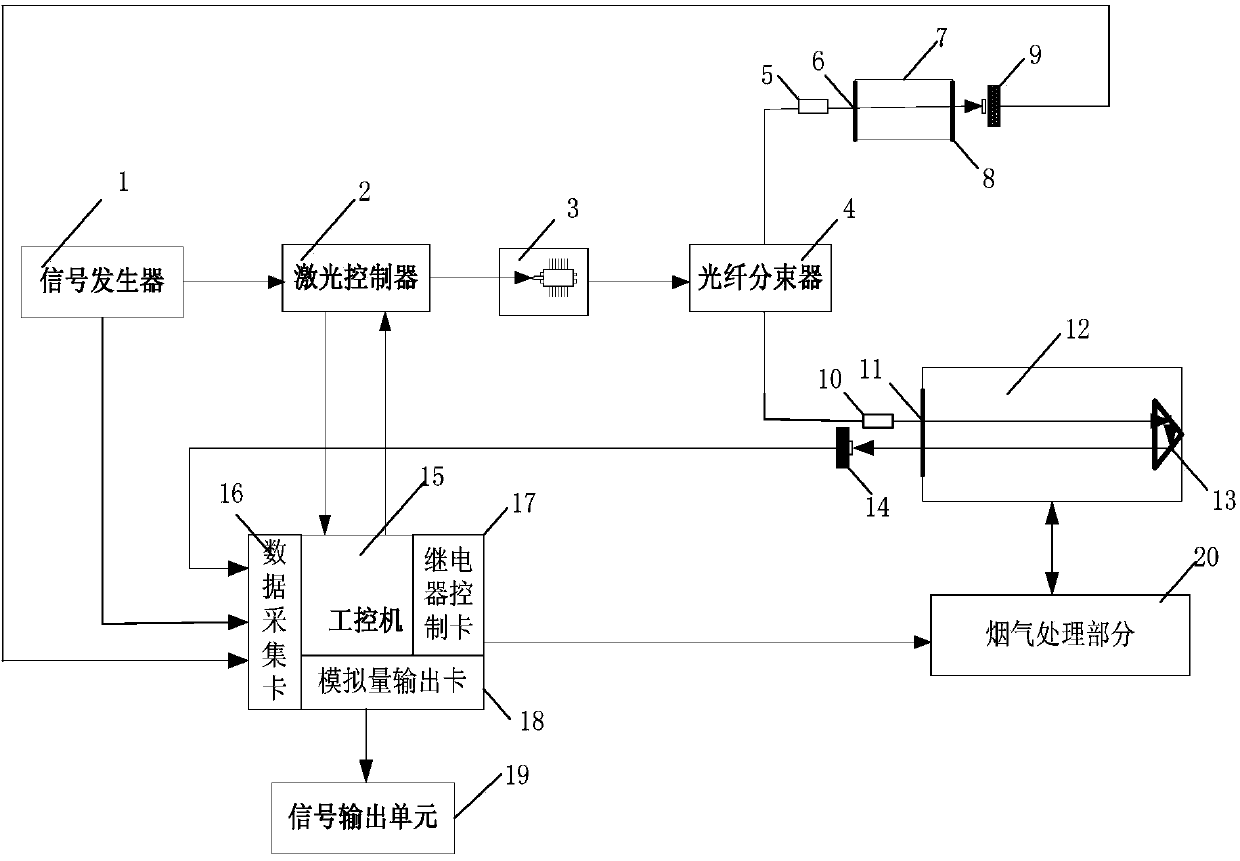

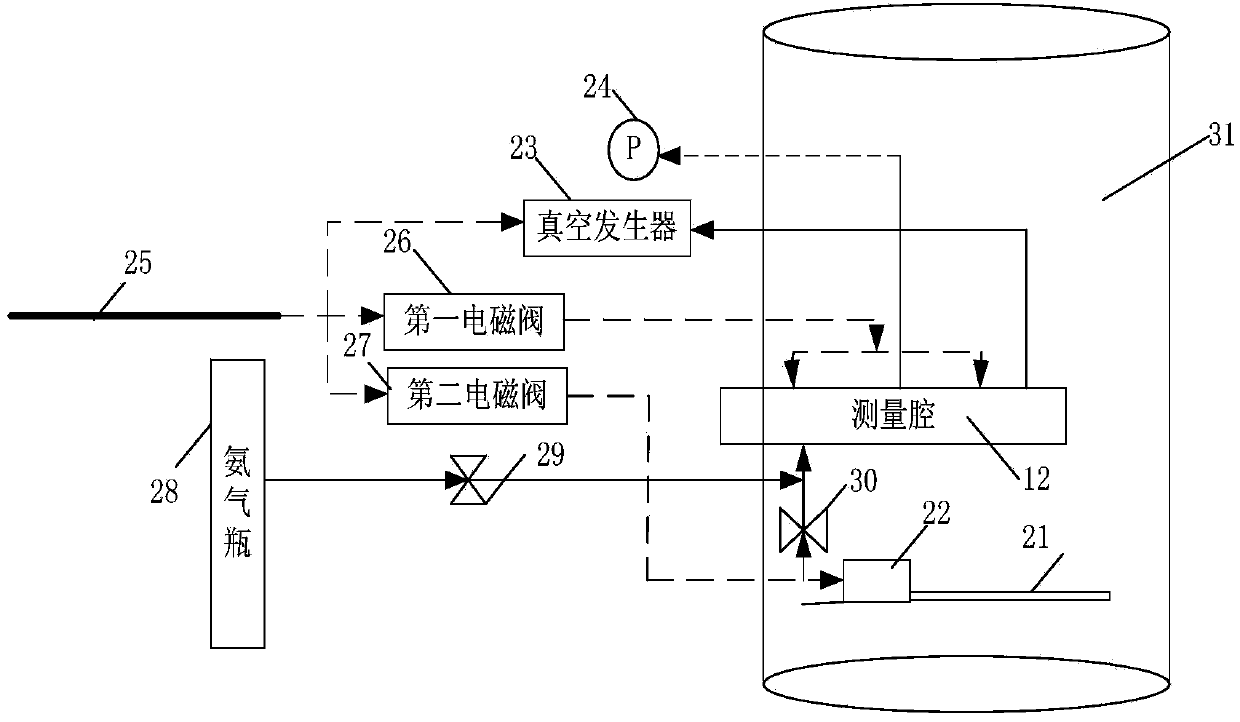

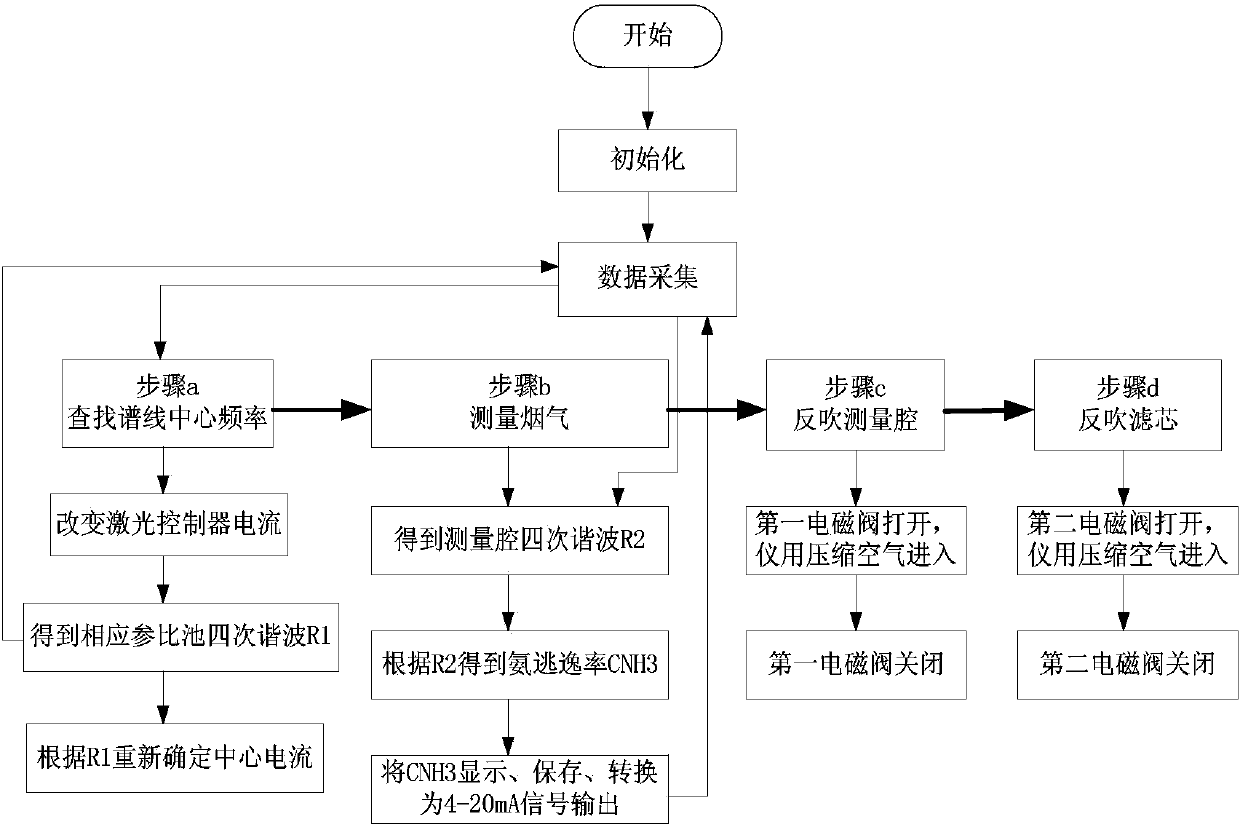

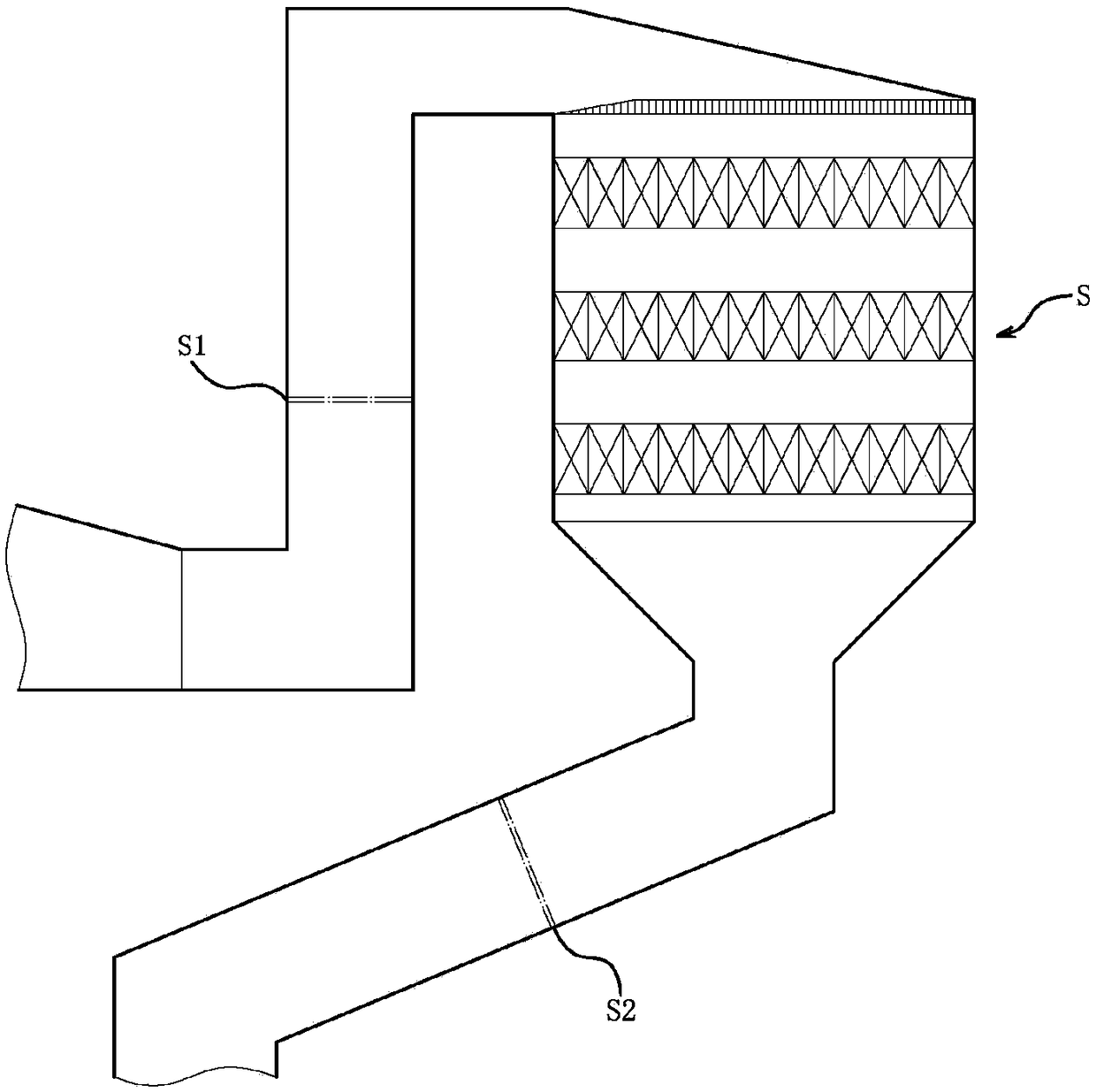

Wavelength modulation spectrum technology-based denitrified ammonia escape rate measurement device and method

ActiveCN104215606AConsistent temperatureAvoid interferenceColor/spectral properties measurementsAir preheaterHigh concentration

The invention relates to a wavelength modulation spectrum technology-based denitrified ammonia escape rate measurement device and method, belonging to the technical field of tunable diode laser absorption spectroscopy. The method is characterized in that laser is split through an optical beam splitter on the basis of quadruple sub-harmonic in the wavelength modulation spectrum technology, a part of laser permeates a high-concentration reference cell to be used for locking a central wavelength and monitoring the zero point of an instrument constantly, and the other part of laser permeates a smoke measurement cavity to be used for obtaining the concentration of an ammonia gas. In an in-situ sampling mode, a sampling rod and the measurement cavity are both arranged in a flue of a denitrified air preheater. The method has the characteristics that with adoption of a low-pressure measurement method, the pressure of the measurement cavity is kept at 0.1atm, a strong absorption spectrum line can be selected and the interference from other gas spectrum lines can be avoided, the sensitivity of the instrument can be improved, and the lower limit of measurement can be lowered. Through the method, a series of problems, caused during application of an existing ammonia escape rate instrument, such as the incapability of laser to permeate dust with high concentration, the deflection of laser resulted from mechanical deformation of a flue wall, the incapability of marking, and blocking of a filtering permeation probe, can be solved.

Owner:TSINGHUA UNIV

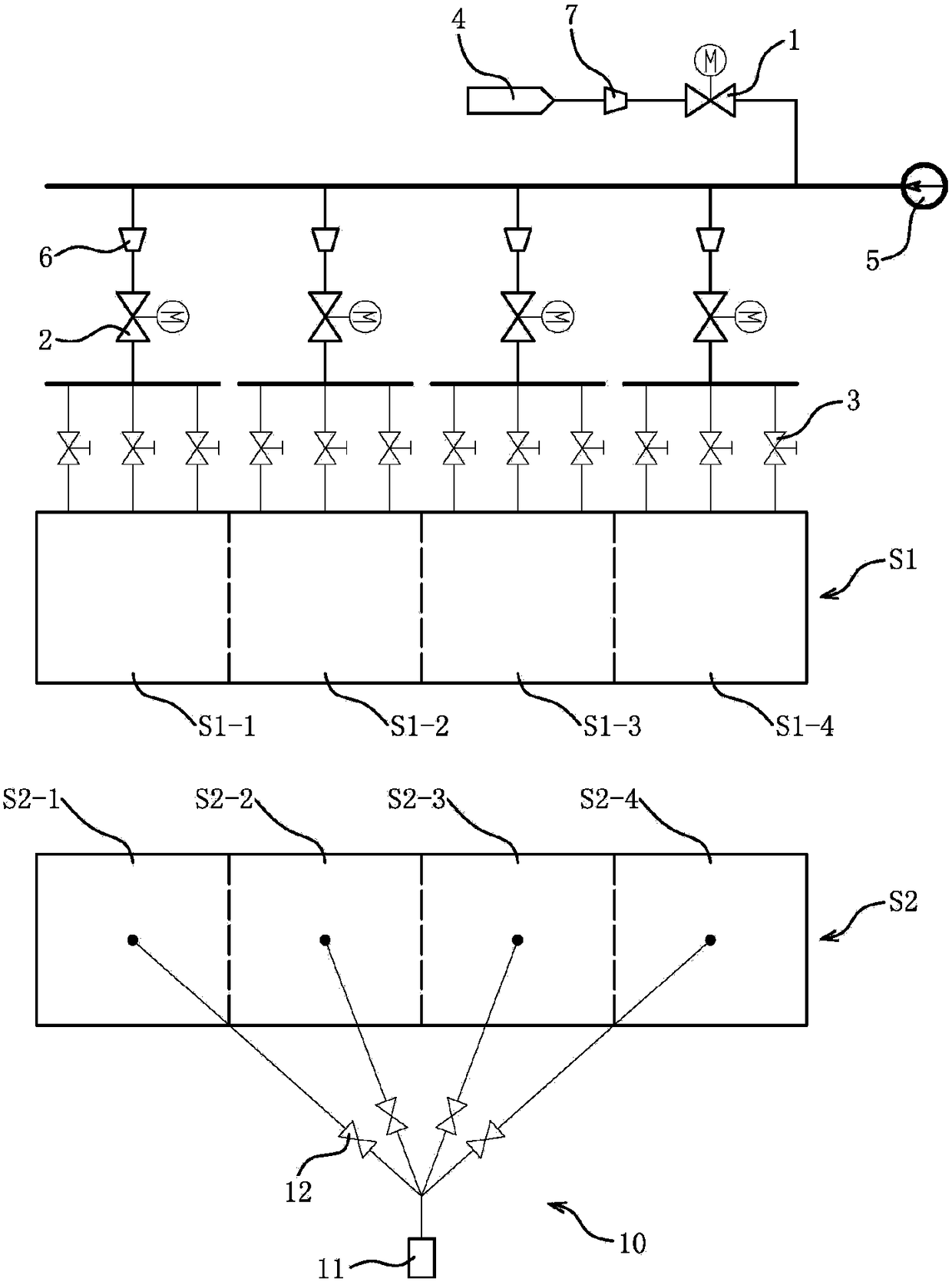

Partitioned ammonia spraying adjustment and control method of SCR (Selective Catalytic Reduction) denitration device

ActiveCN108380043AReduce escape rateMitigate or even eliminate adverse effectsGas treatmentDispersed particle separationEscape rateClosed loop

The invention discloses a partitioned ammonia spraying adjustment and control method of an SCR (Selective Catalytic Reduction) denitration device. A partitioned ammonia flow measured value is used asa closed-loop signal for adjusting and controlling an ammonia spraying partitioned leveling valve. According to the partitioned ammonia spraying adjustment and control method of the SCR denitration device, disclosed by the invention, important parameters including inlet NOx concentration, outlet partitioned NOx concentration, a total ammonia spraying amount, partitioned ammonia flow and the like of the SCR denitration device are monitored, and the partitioned ammonia flow measured value is used as the closed-loop signal for adjusting and controlling the ammonia spraying partitioned leveling valve, so that the online adjustment quality of partitioned ammonia spraying is improved and the ammonia escaping rate is reduced, and furthermore, adverse effects, caused by ammonia escaping, on downstream equipment of the SCR denitration device are alleviated, even eliminated.

Owner:浙江兴核智能控制技术有限公司

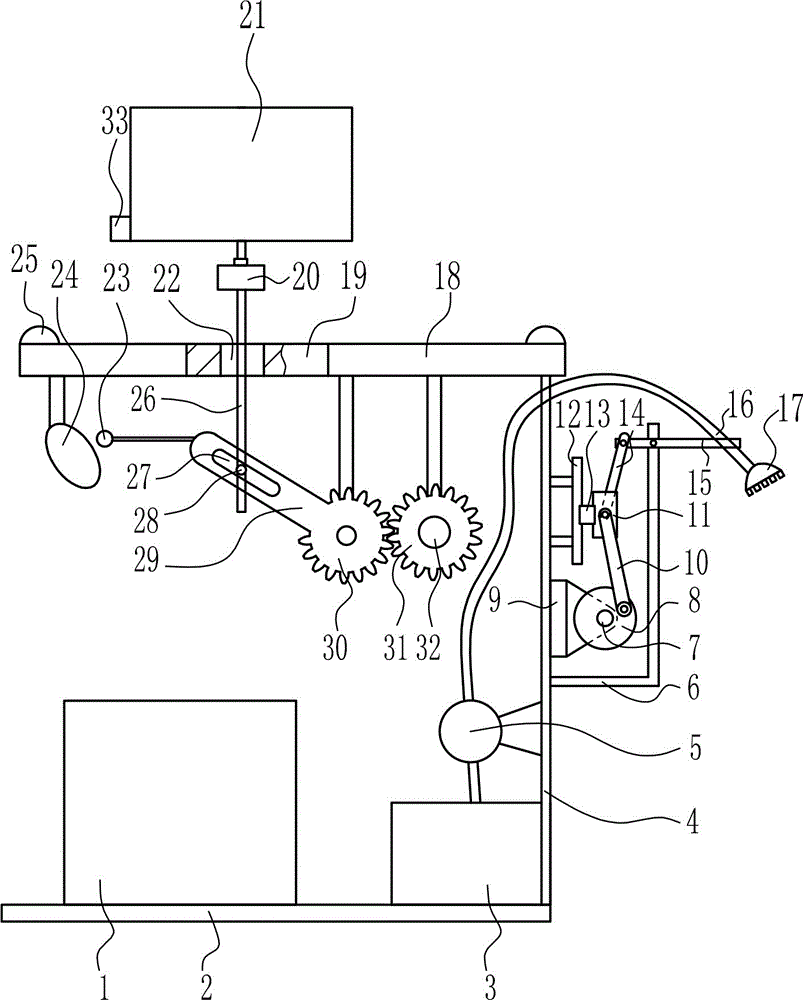

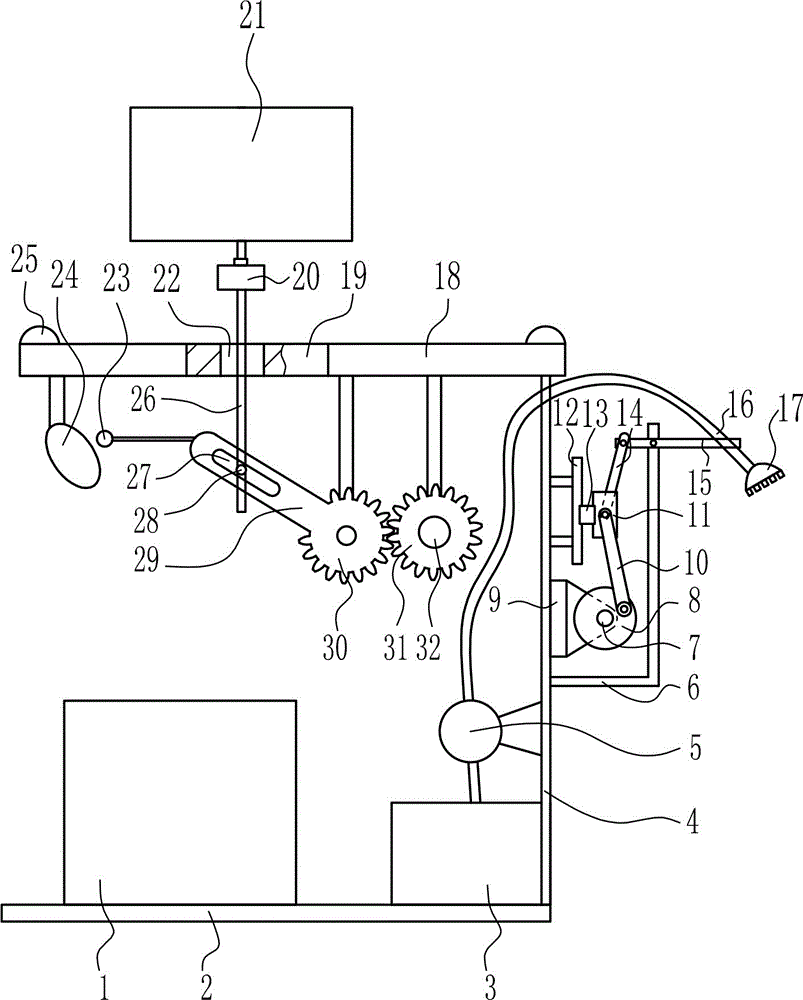

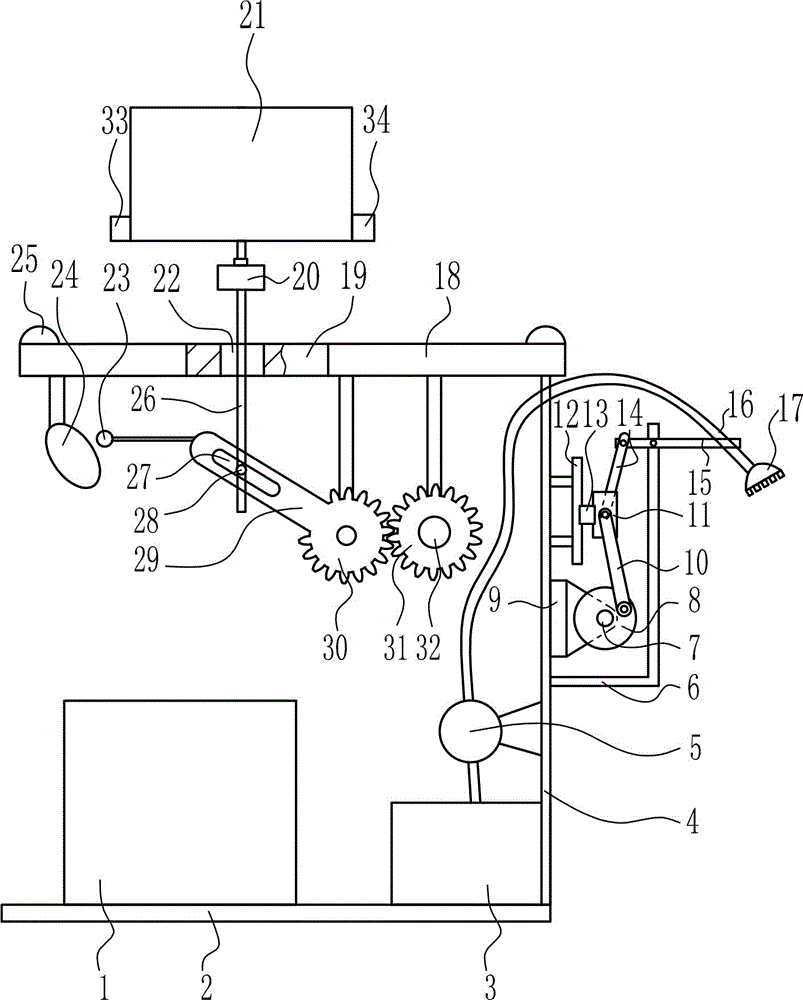

Multifunctional fire danger warning board for gymnasium

ActiveCN106097909AImprove work efficiencyImprove escape rateFire rescueFire alarmsEscape rateEngineering

The invention relates to a fire danger warning board, in particular to a multifunctional fire danger warning board for a gymnasium and aims to provide a multifunctional fire danger warning board which can convey information clearly and comprehensively and is high in work efficiency and used for a gymnasium. To solve the technique problem, the multifunctional fire danger warning board for the gymnasium is provided and comprises a fire extinguisher holding box, a bottom plate, a water tank, a right support, a water pump, a swing frame, a first motor, a disk, a connection base, a first swing rod, a connection block, a sliding rail, a sliding block and the like, wherein the fire extinguisher holding box, the water tank and the right support are sequentially arranged at the top of the bottom plate from left to right, the water pump is arranged on the left side of the right support, and a water pipe is connected on the water pump. The multifunctional fire danger warning board can convey information clearly and comprehensively, is high in working efficiency and can increase the escape rate when a fire breaks out.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

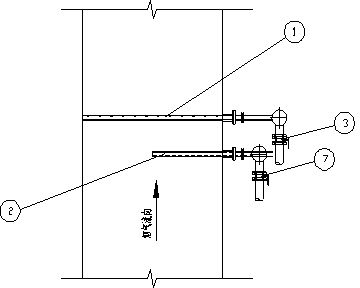

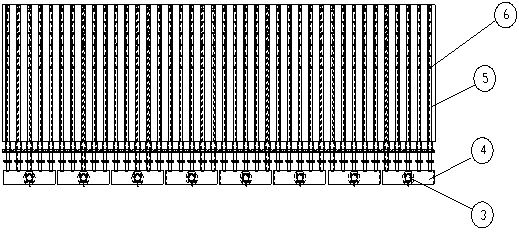

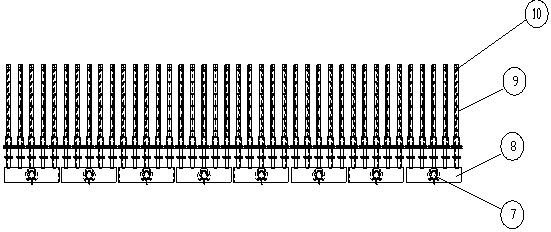

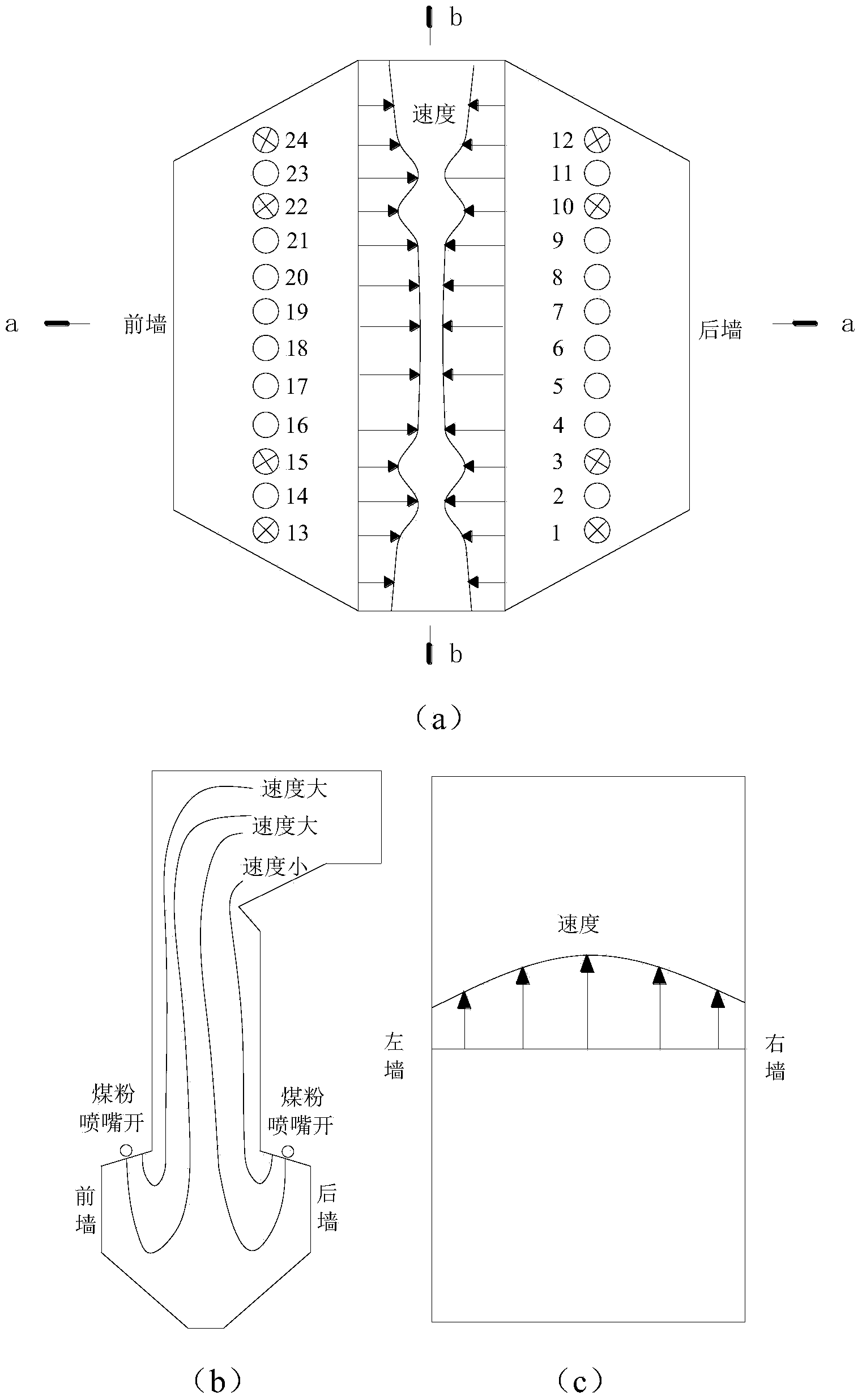

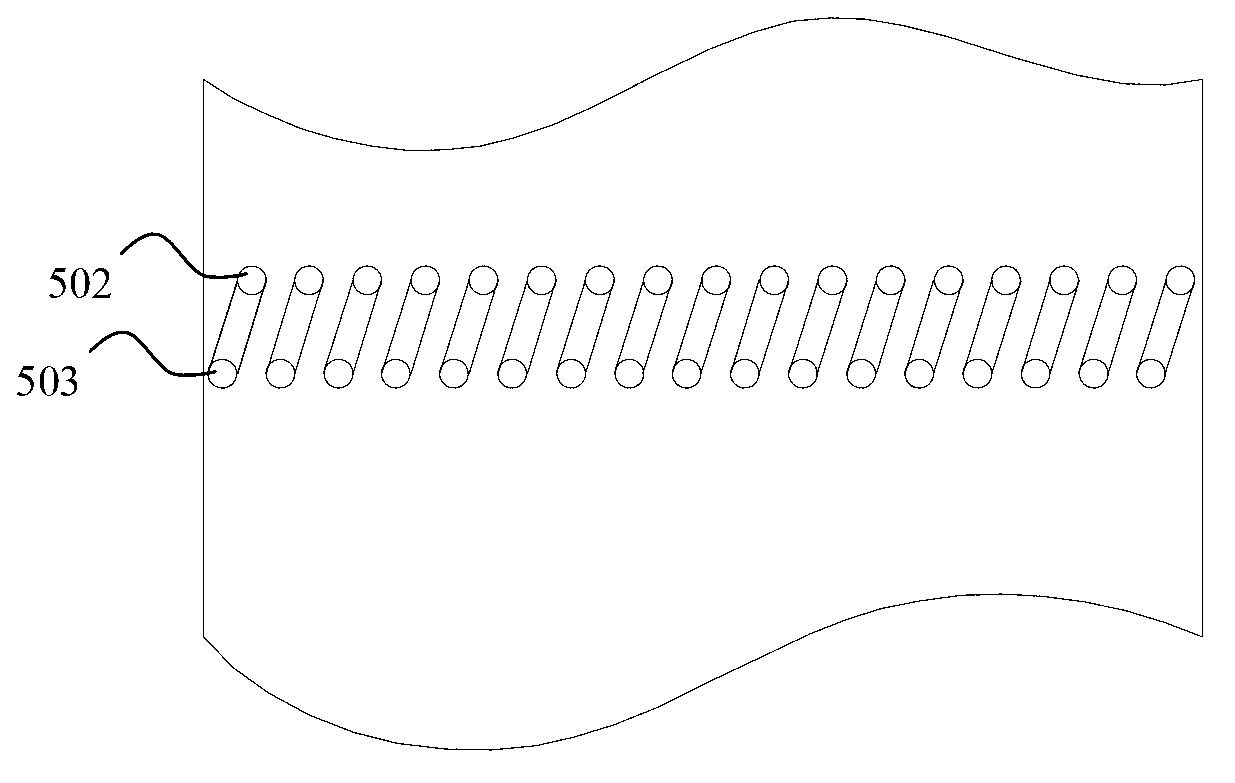

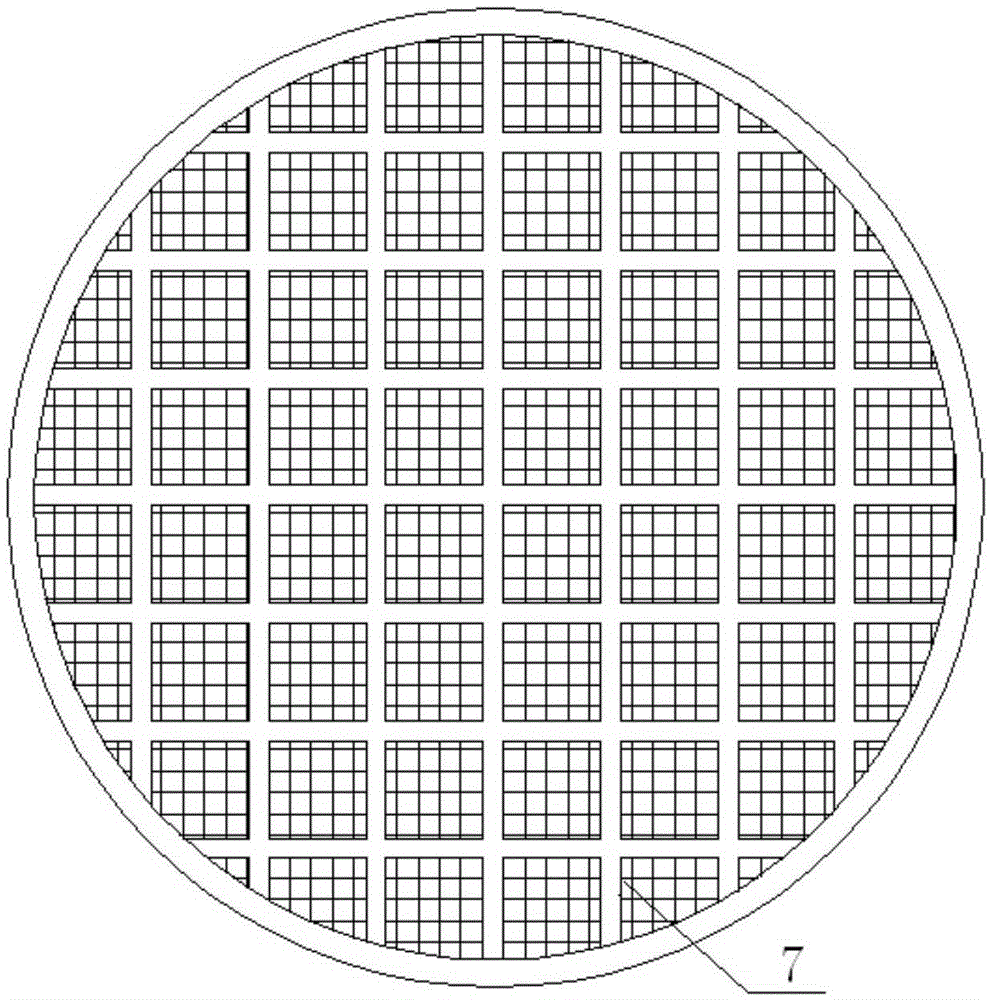

Zoning-regulating double-layer ammonia injection grid applied to selective catalytic reduction denitrification device for industrial flue gas

InactiveCN102527233AReduce escape rateImprove the mixing effectDispersed particle separationChemical industryDenitrification

The invention relates to the technical field of selective catalytic reduction denitrification of industrial flue gas, in particular to a zoning-regulating double-layer ammonia injection grid applied to a selective catalytic reduction denitrification device for industrial flue gas. In order to solve the problems that the ammonia distribution on a flue section of the conventional ammonia injection grid is quite non-uniform, which affects the denitrifying efficiency and increases the escape rate of ammonia, and the like, the zoning-regulating double-layer ammonia injection grid applied to the selective catalytic reduction denitrification device for the industrial flue gas divides the flue section into two equal subzones; the ammonia injection function of one subzone (1 / 2 of the flue section area) is realized by an upper ammonia injection grid and the ammonia injection function of the other subzone is realized by a lower ammonia injection grid; and according to the distribution rules of the flow rates of the flue gas in the two flue section subzones and different concentrations of NOx in the flue gas, the ammonia injection amount of each subzone is regulated and controlled by an ammonia injection regulating valve, so that the ammonia injection amount is adjustable on different zones of the flue section, the uniform mixing effect of the ammonia and nitrogen oxides in the flue gas is optimized, the denitrifying efficiency is improved, and the escape rate of the ammonia is effectively reduced. The uniform zoning-regulating double-layer ammonia injection grid applied to a selective catalytic reduction denitrification device for industrial flue gas has a good uniform mixing effect of the nitrogen oxides in the flue gas and the ammonia, improves the denitrifying efficiency, effectively reduces the escape rate of the ammonia, and is applicable to NOx selective catalytic reduction denitrification devices in coal burning, metallurgy, chemical industry and other industries.

Owner:BEIJING LONDIAN HONGTAI ENVIRONMENTAL TECH

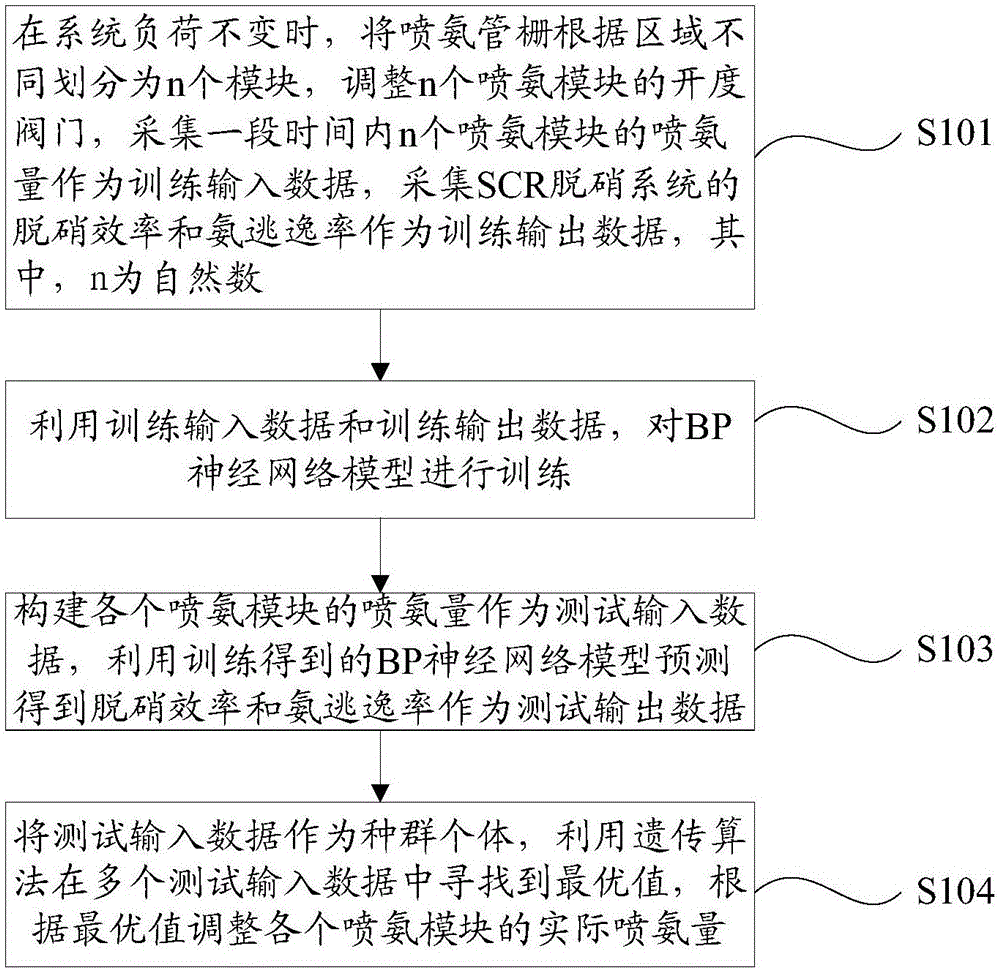

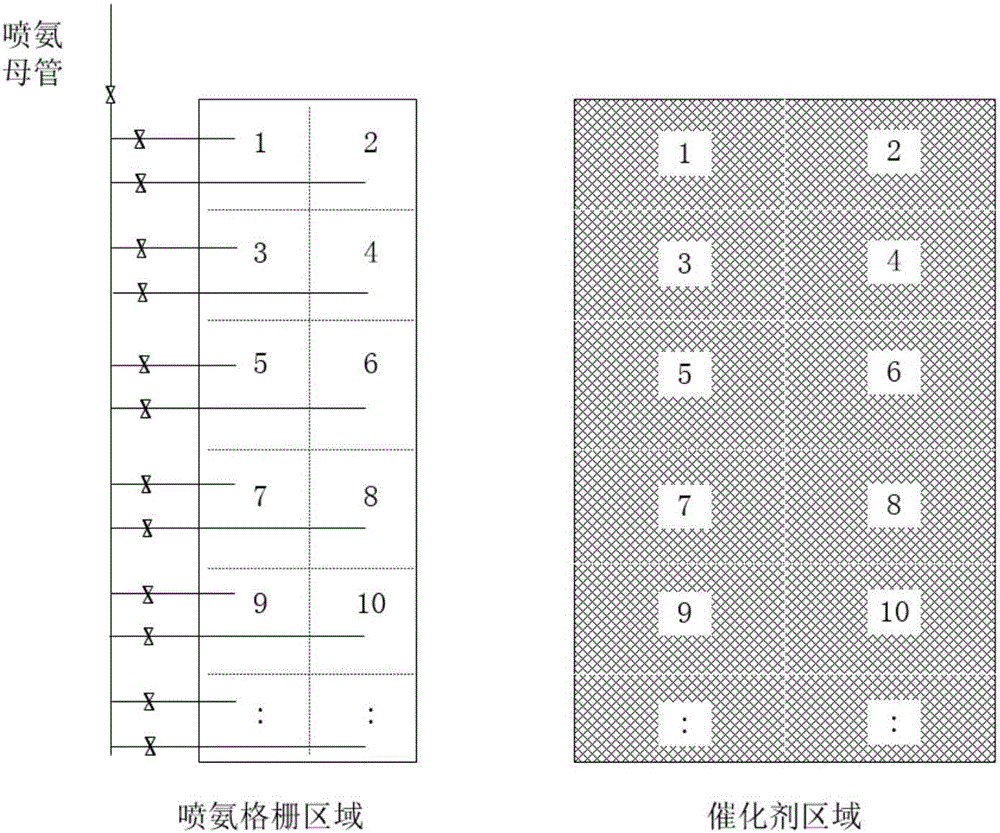

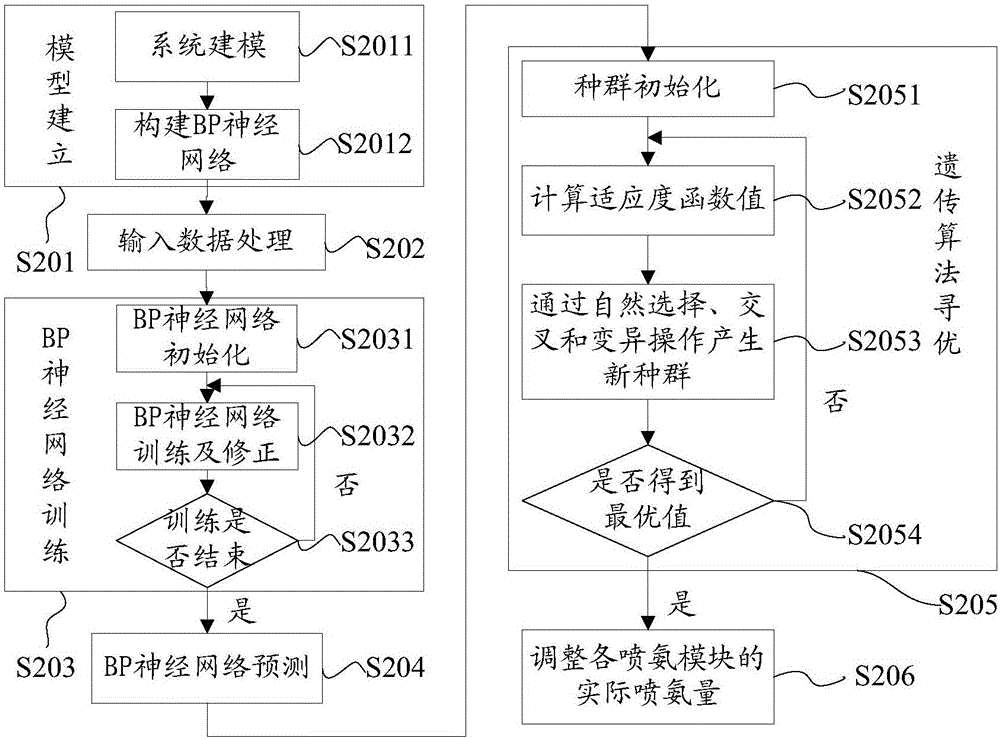

Neural network-based SCR intelligent ammonia-spraying optimization method and apparatus

ActiveCN106599586AImprove uniformityIncrease profitChemical processes analysis/designSpecial data processing applicationsTest inputEscape rate

The invention discloses a neural network-based SCR intelligent ammonia-spraying optimization method and apparatus, and relates to the field of a fire coal denitration technology. The method comprises the steps of dividing an ammonia-spraying pipe gate into n modules when system load is unchanged, adjusting valves of n ammonia-spraying modules, collecting ammonia-spraying quantity of the n ammonia-spraying modules within certain time to be used as training input data, and taking denitration efficiency and ammonia escape rate as training output data; performing BP neural network training based on the training input data and the training output data; taking ammonia-spraying quantity of each ammonia-spraying module as test input data, and predicting the denitration efficiency and the ammonia escape rate through a BP neural network model obtained by training; and searching an optimal value from multiple test input data through a genetic algorithm, and adjusting actual ammonia-spraying quantity of each ammonia-spraying module according to the optimal value. By adoption of the scheme, the differentiation control on the ammonia-spraying quantity can be realized, the denitration efficiency is improved, the ammonia escape rate is lowered, and the ammonia-spraying quantity of each ammonia-spraying module can be adjusted according to different targets of power plants flexibly.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

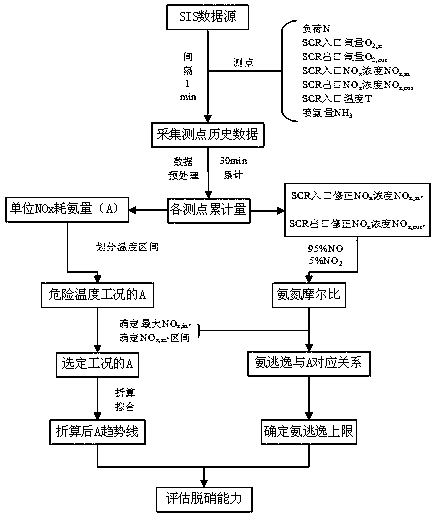

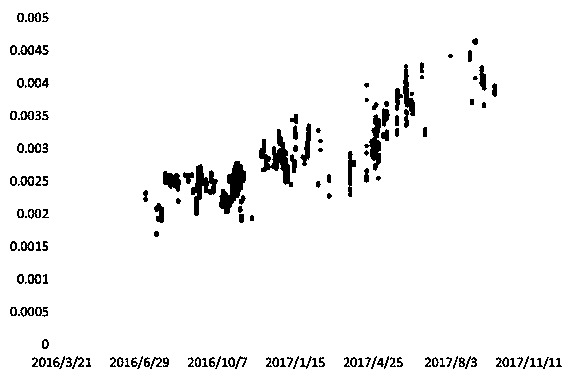

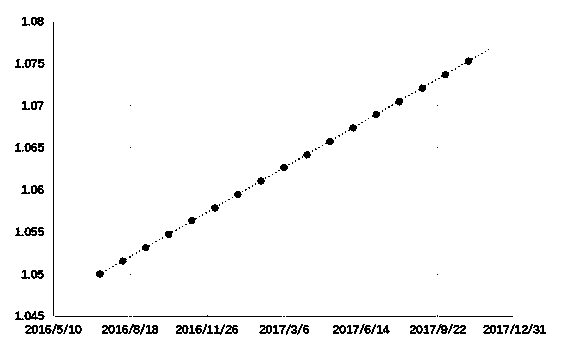

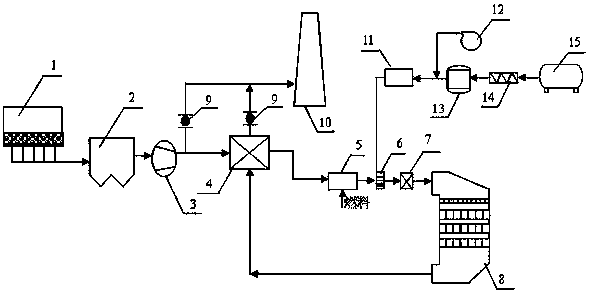

Method for evaluating the denitration capability of an SCR reactor

ActiveCN109493250AAvoid problems such as forecast errorsCompatible with practical engineering applicationsData processing applicationsDesign optimisation/simulationEscape rateData source

The invention discloses a method for evaluating the denitration capacity of an SCR reactor. The method comprises the following steps: carrying out pretreatment; obtaining historical data of each measuring point of the unit from a data source; performing data preprocessing and outputting; the inlet NOx concentration is subjected to oxygen correction, and calculating the ammonia consumption for removing unit NOx; dividing temperature and outlet NOx concentration working conditions and selecting typical working conditions; and fitting an ammonia consumption curve for removing the unit NOx, carrying out corresponding conversion, determining an upper limit according to the calculated corresponding relation between the ammonia consumption for removing the unit NOx and the ammonia escape rate, and evaluating the denitration capability of the SCR reactor by combining the slope of the trend line and the upper limit. According to the evaluation method for the denitration capability of the SCR reactor, provided by the invention, steady-state tracking and self-adaptive correction calculation can be realized.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH +1

Sintering and pelletizing flue gas SCR denitration and dioxin removal apparatus

ActiveCN103463976AStable removalEfficient removalDispersed particle separationNitrogen removalEscape rate

Owner:宝武水务科技有限公司 +1

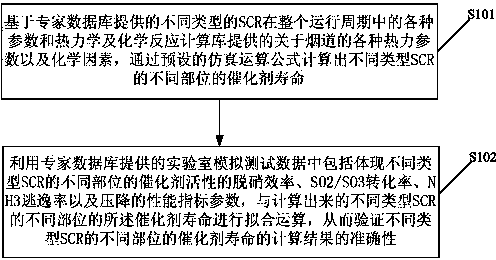

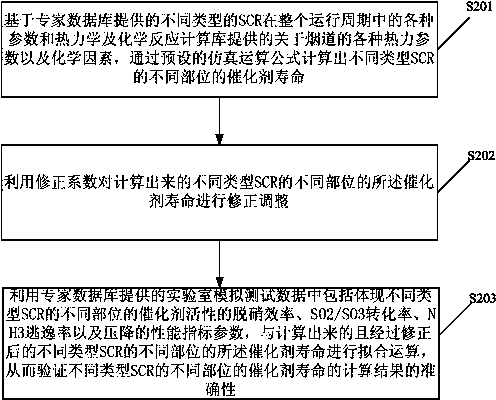

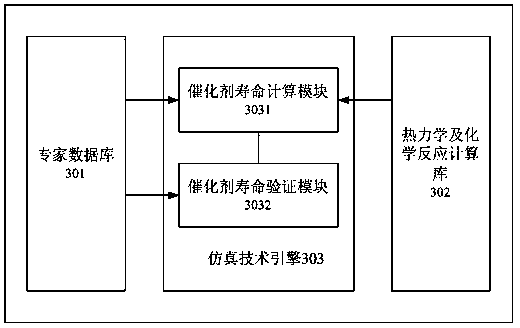

Judgment method and device of service life of catalysts of SCR (Selective Catalytic Reduction) denitration system

InactiveCN104318120AImprove accuracyIncrease profitSpecial data processing applicationsChemical reactionEscape rate

The invention discloses a judgment method of the service life of catalysts of an SCR (Selective Catalytic Reduction) denitration system. The judgment method comprises the steps of step 1, calculating out the service life of the different positions and different types of SCRs of catalysts through a preset simulation computation formula based on different types of SCRs of various parameters provided by an expert database in the integral operation cycle and various thermodynamic parameters and chemical factors provided by a thermodynamics and chemistry calculation library and related to a flue and step 2, performing fitting operation through the denitration efficiency, the sulfur dioxide and sulfur dioxide conversion rate, the escape rate of the ammonia gas and the performance index parameters of the pressure drop and the calculated service life of the different positions and different types of SCRs of catalysts so as to verify the accuracy of a calculation result of the service life of the different positions and different types of SCRs of catalysts, wherein the denitration efficiency, the sulfur dioxide and sulfur dioxide conversion rate, the escape rate of the ammonia gas and the performance index parameters of the pressure drop are contained in laboratory simulation test data which are provided by the expert database and the catalyst activity of the different positions and different types of SCRs of catalysts is reflected by the denitration efficiency, the sulfur dioxide and sulfur dioxide conversion rate, the escape rate of the ammonia gas and the performance index parameters of the pressure drop.

Owner:广东科立恩环保科技有限公司

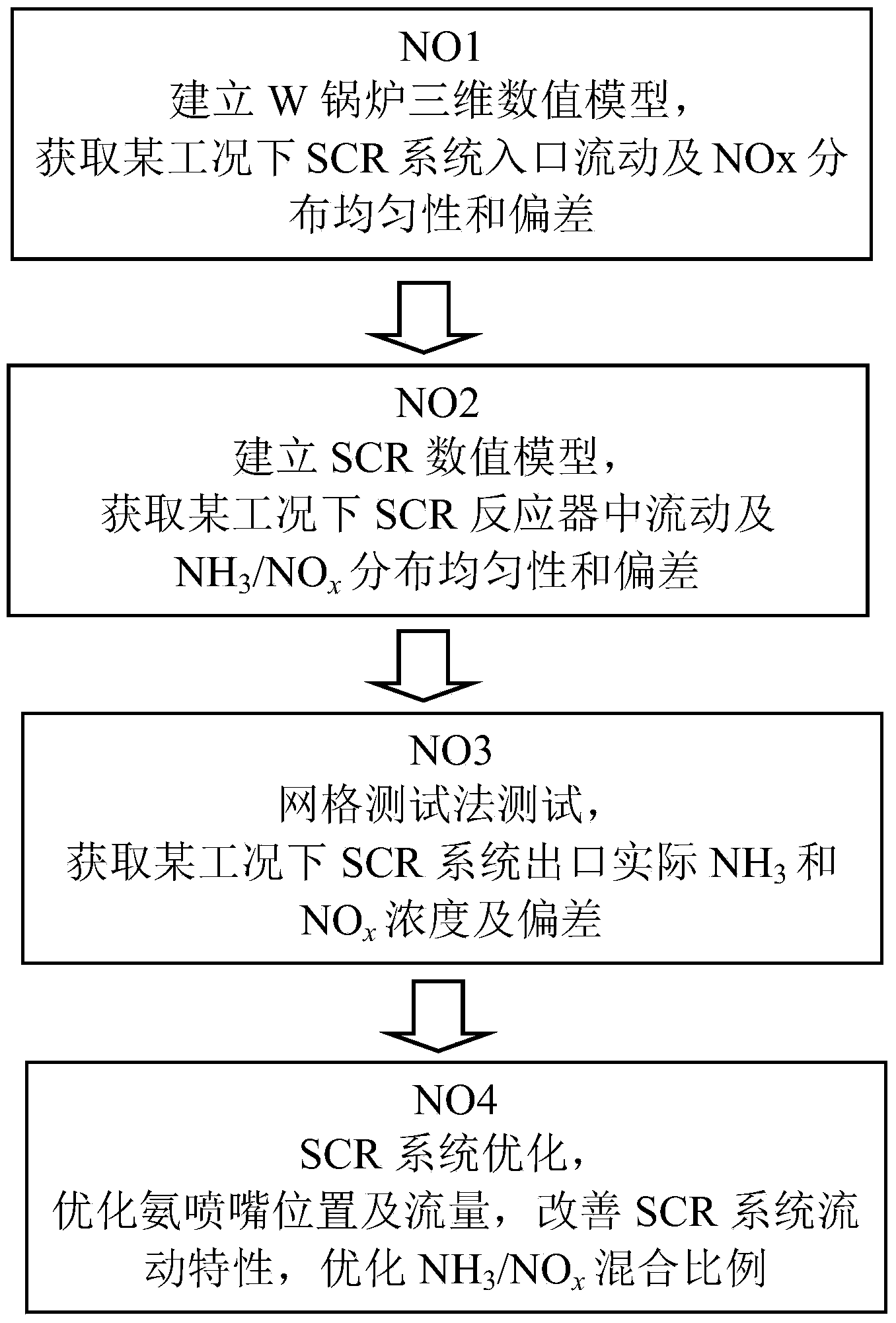

Denitrification operation optimization method of SCR (selective catalytic reduction) system of W flame boiler

InactiveCN103831016AOptimal adjustment of ammonia injection flow rateIncrease the flow rate of ammonia injectionDispersed particle separationEscape rateSpray nozzle

The invention discloses a denitrification operation optimization method of a SCR (selective catalytic reduction) system of a W flame boiler. The denitrification operation optimization method particularly comprises the following steps: acquiring the smoke flow speed and the NOx concentration distribution uniformity and deviation at an outlet of a boiler by considering the structure and the running working condition of a W flame boiler so as to act as inlet boundary conditions of a rear-stage SCR system; adjusting the ammonia spraying flow rate corresponding to the region at which the flue flow speed is slightly high and the NH3 / NOx is slightly low to be low, increasing the number of ammonia spraying nozzles, and adjusting the ammonia spraying flow rate corresponding to a region at which the flue flow speed is slightly slow and the NH3 / NOx is slightly high to be low when the standard criterion that the ammonia spraying flow rate at the upper layer is higher than that at the lower layer, and the ammonia spraying flow rate at the middle is higher than that at two sides is met. According to the invention, the structures and the running situation of the boiler and the SCR system are optimized and adjusted, the denitrification efficiency of the SCR system is improved; the spraying-in quantity and the escape rate of ammonia are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

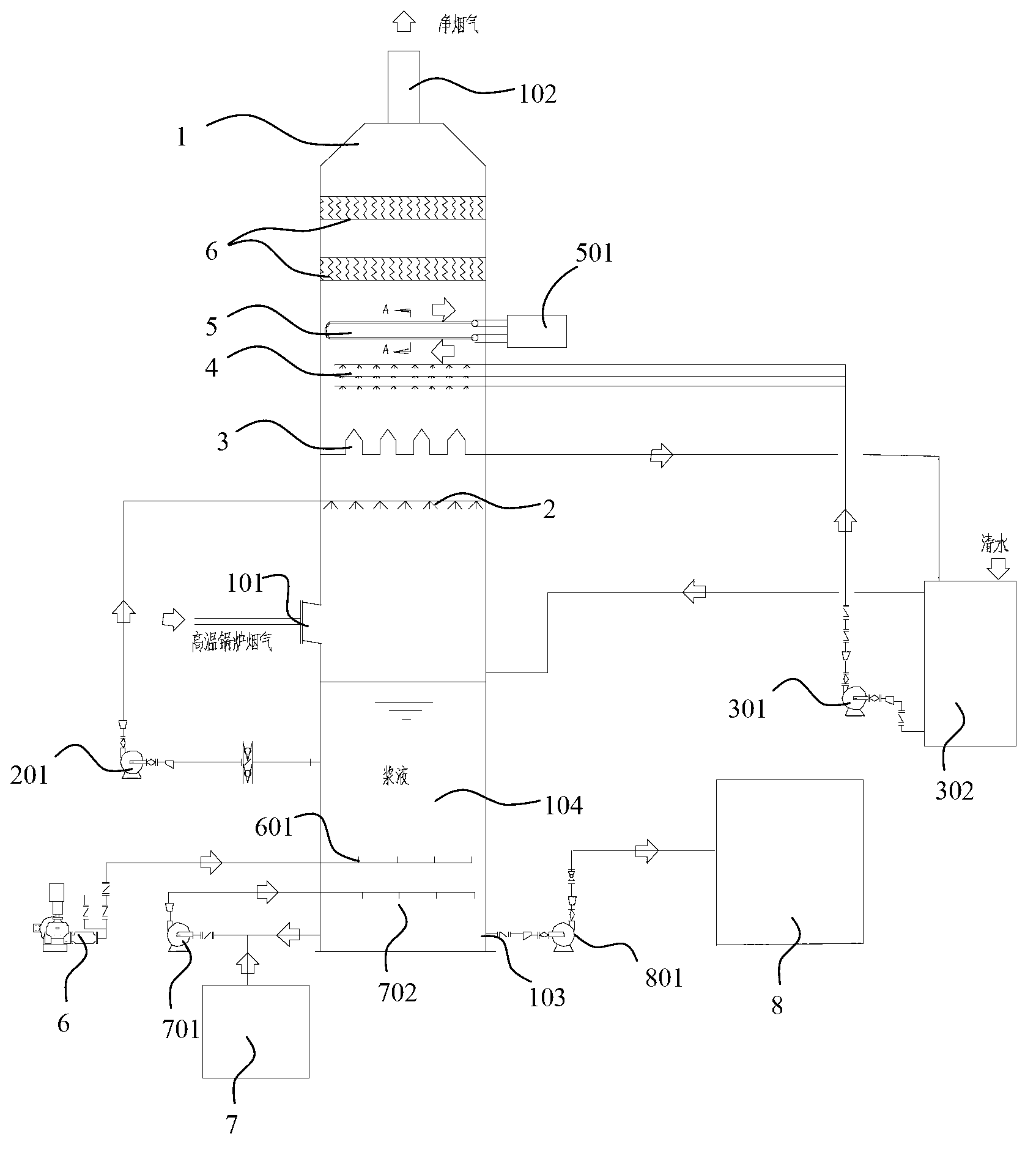

Desulfurization system and desulfurization process thereof

InactiveCN103252158AReduce consumptionUniform flow rateDispersed particle separationEscape rateSaturated water vapor

The invention discloses a desulfurization system comprising a tower body, wherein a smoke inlet is arranged in the middle of the tower body; a pure smoke outlet is arranged at the top of the tower body; a slurry pool for containing slurry is formed on the lower part of the tower body; the slurry pool is provided with a mixed liquid outlet; a slurry spraying layer, a rising air gap and a clean water spraying layer are sequentially arranged from the smoke inlet to the pure smoke outlet from bottom to top; the bottom of the slurry pool is respectively connected with an oxidization mechanism and an ammonia supplying mechanism; and the desulfurization system further comprises a slurry circulating mechanism and a clean water circulating mechanism. The invention further provides a desulfurization process; and the process is low in water consumption amount so that the amount of saturated steam in pure smoke is reduced by 30-40% and consumption of external clean water is reduced. According to the desulfurization system and the desulfurization process disclosed by the invention, the operation cost is low; and the consumption of the steam is 20% of that of an ammonia-fertilizer method process and the consumption of power is 40% of that of the ammonia-fertilizer method process. The escaping rate of ammonia is low; the content of the ammonia in the pure smoke is less than 8mg / Nm<3>; no three wastes are discharged; and secondary pollution to an environment is not caused.

Owner:九美科技有限公司

Low-temperature coke oven flue waste gas cleaning technology and equipment thereof

The invention relates to a low-temperature coke oven flue waste gas cleaning technology and equipment thereof. According to the technology, residual ammonia water of a coking plant is recycled, and a low-temperature SCR denitration technology and an ammonia desulfuration technology are combined; ammonia produced by evaporating the residual ammonia water produced by an ammonia evaporation working process of the coking plant is used as a denitration reducing agent; denitration is performed by adopting a low-temperature denitration catalyst by a selective catalysis reducing method; the denitration catalyst is of a honeycomb briquette type structure; SO2 in coke oven waste gas is removed by the ammonia desulfuration technology; the residual ammonia water of the coking plant and a byproduct (NH4)2SO4 are recycled, and secondary pollutants such as wastewater, waste gas and waste slag are avoided. The equipment consisting of all units is matched with the corresponding technology; high-efficiency desulfuration and denitration are realized, the ammonia escape rate is low, the byproduct (NH4)2SO4 can be produced, and considerable economical benefit is achieved; the relevant national environment-friendly policy requirement is met, and the running cost of desulfuration and denitration of a coking enterprise is lowered.

Owner:SEEWATER ENVIRONMENTAL ENG

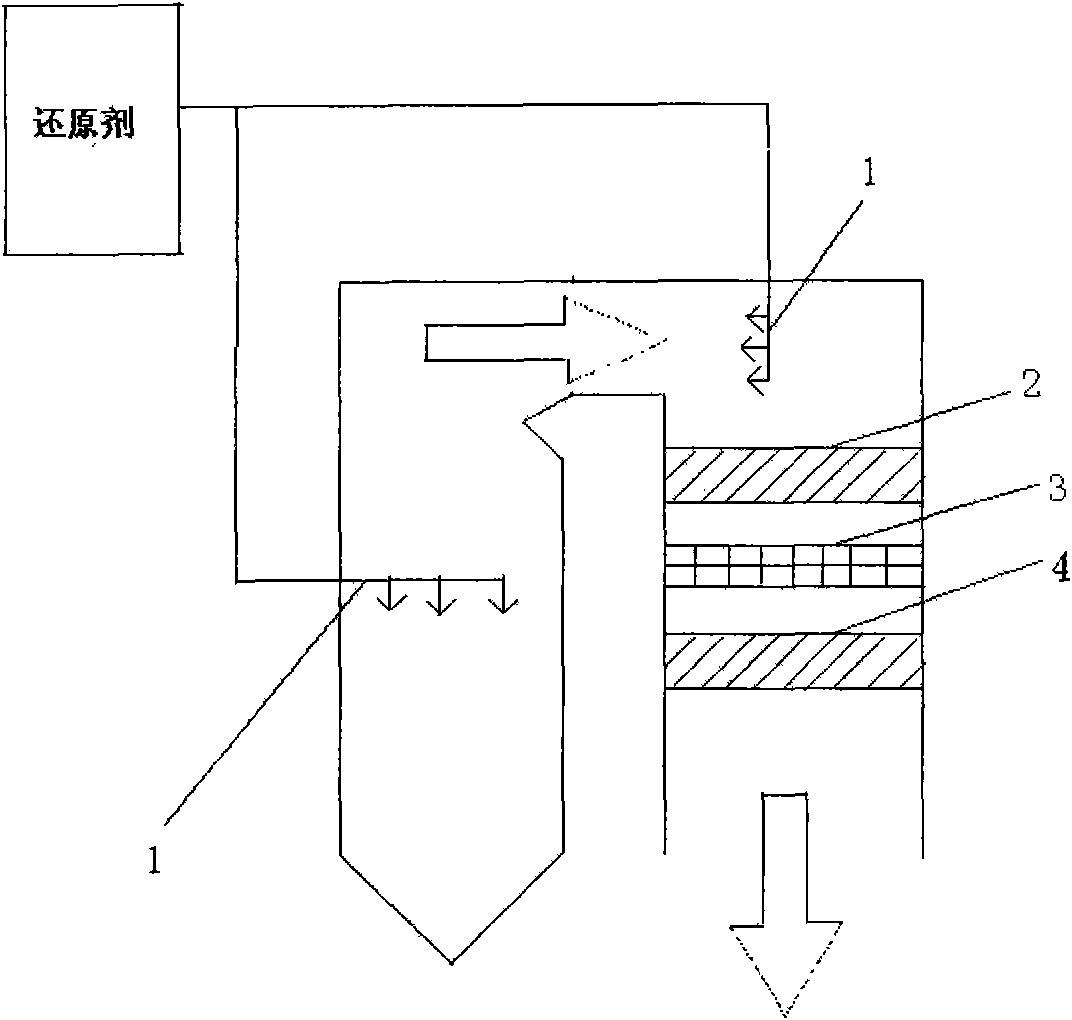

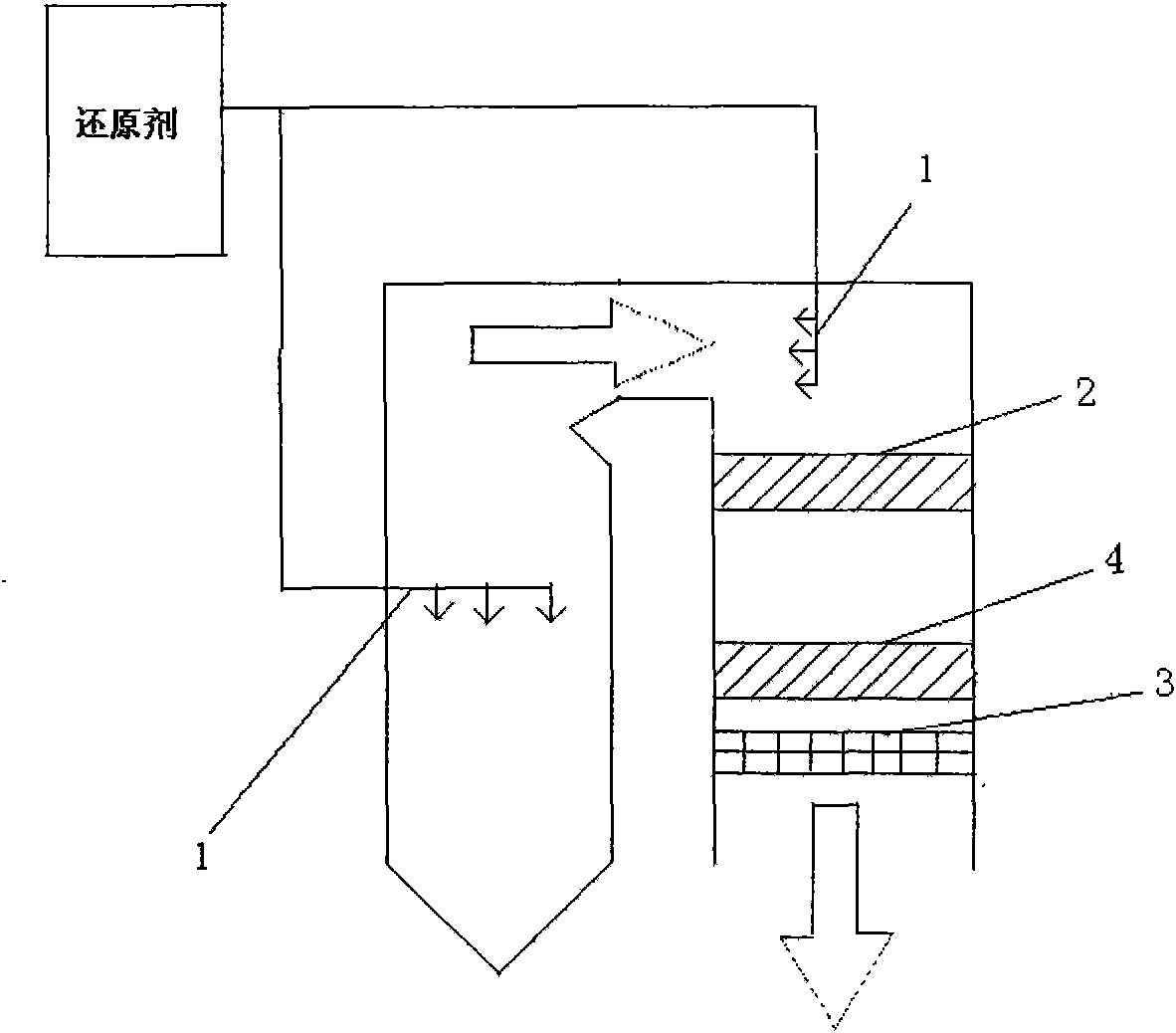

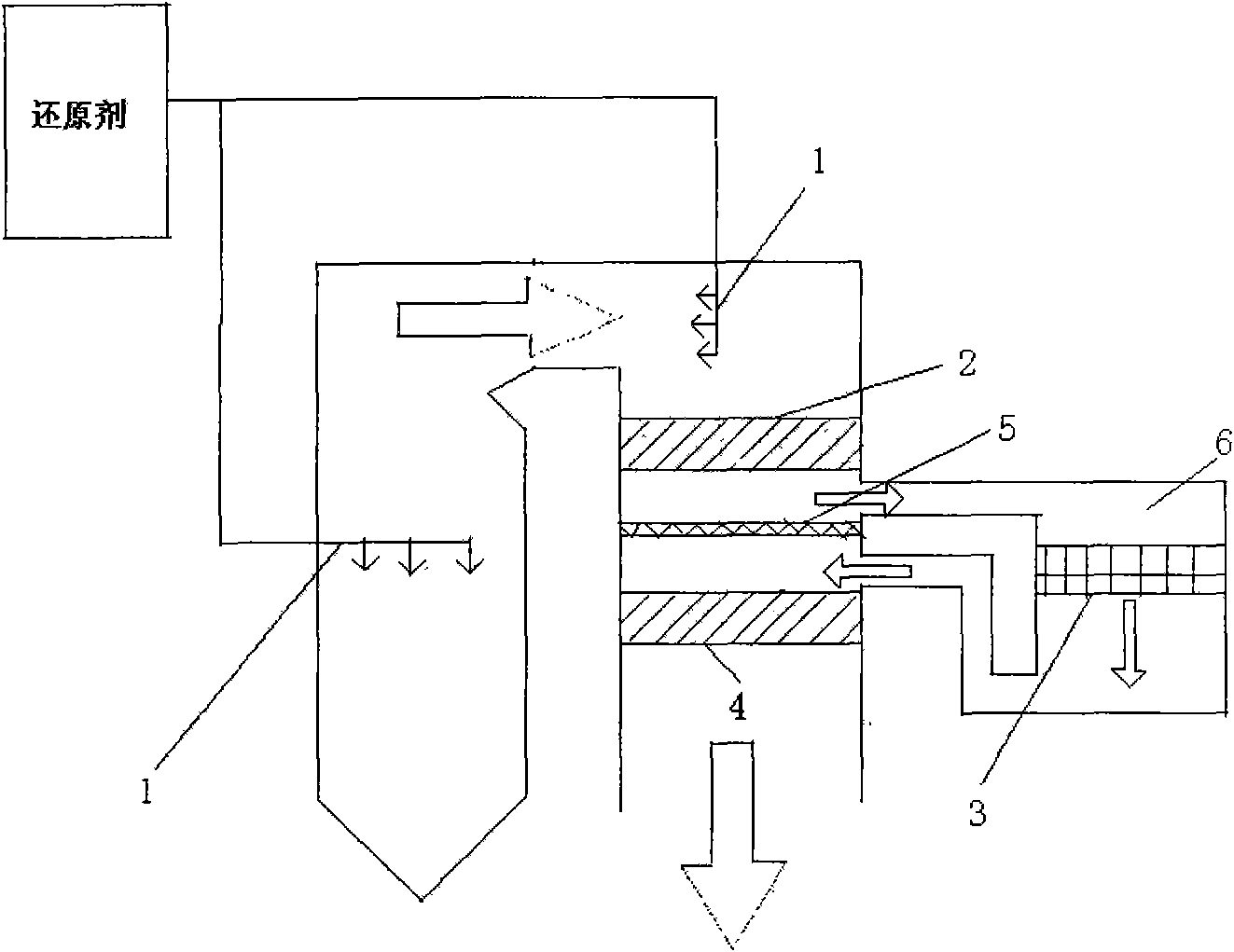

Device and method for denitration on flue gas by coupling selective non catalytic reduction and catalytic reduction

InactiveCN102091511AReduce dosageEfficient use ofDispersed particle separationAir preheaterNitrogen oxides

The invention discloses a device and a method for denitration on flue gas by coupling selective non catalytic reduction and catalytic reduction and relates to a technology for removing nitrogen oxides in burned flue gas of fossil fuels. The invention adopts a scheme 1 that the denitration device comprises a plurality of spray guns for spraying a reducing agent, economizer, a mesothermal catalyst and an air preheater, wherein the spray guns are arranged in a furnace in a layered mode; and the economizer, the mesothermal catalyst and the air preheater are arranged in a flue sequentially along the flowing direction of the flue gas. Compared with the prior art, the device and the method mainly utilize the denitration capacity of an SNCR (Selective Non Catalytic Reduction) system, utilize an SCR (Selective Catalytic Reduction) system as supplement and have the characteristics of high denitration efficiency, low ammonia escape rate, equipment conservation, investment reduction, space conservation and the like.

Owner:TONGFANG ENVIRONMENT

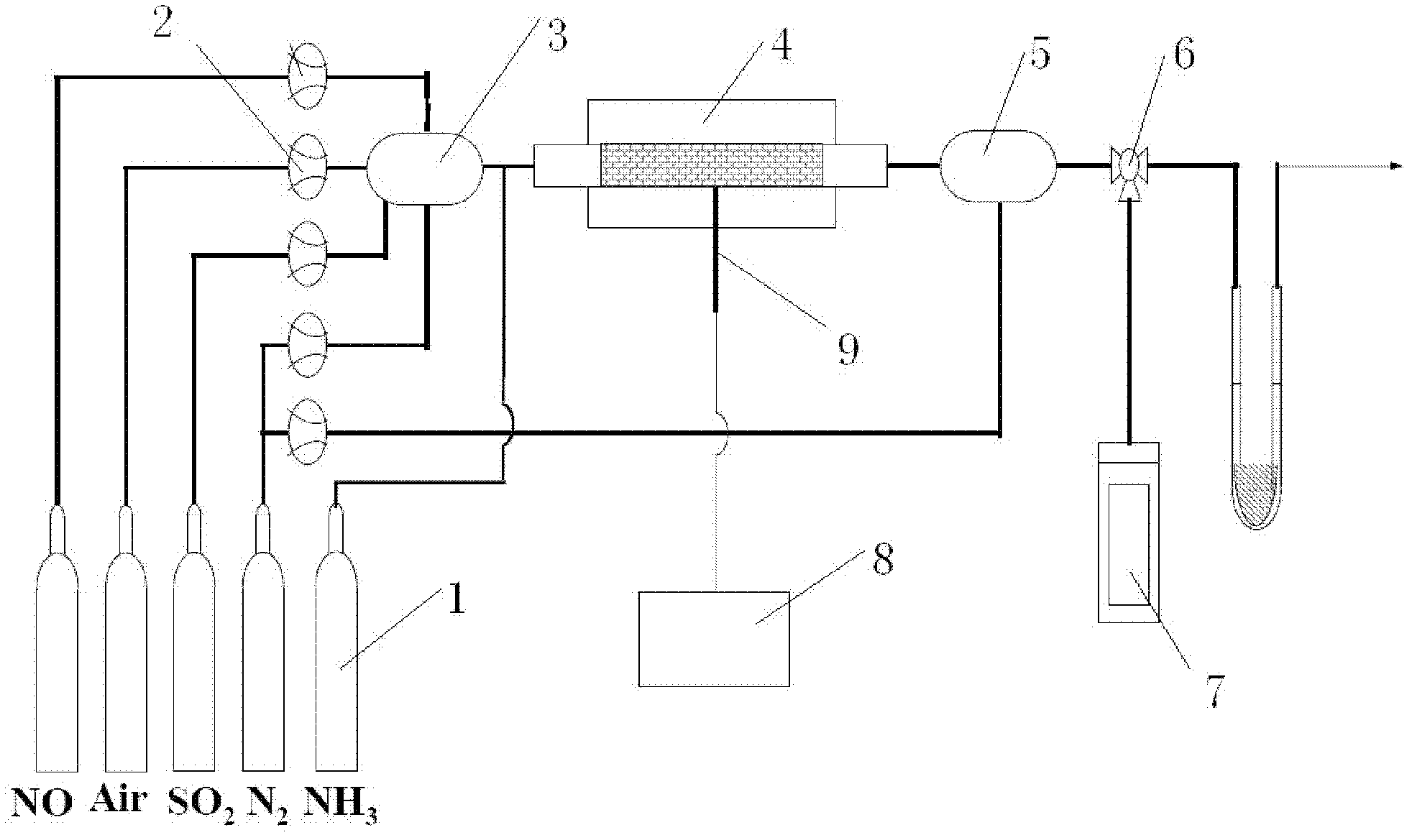

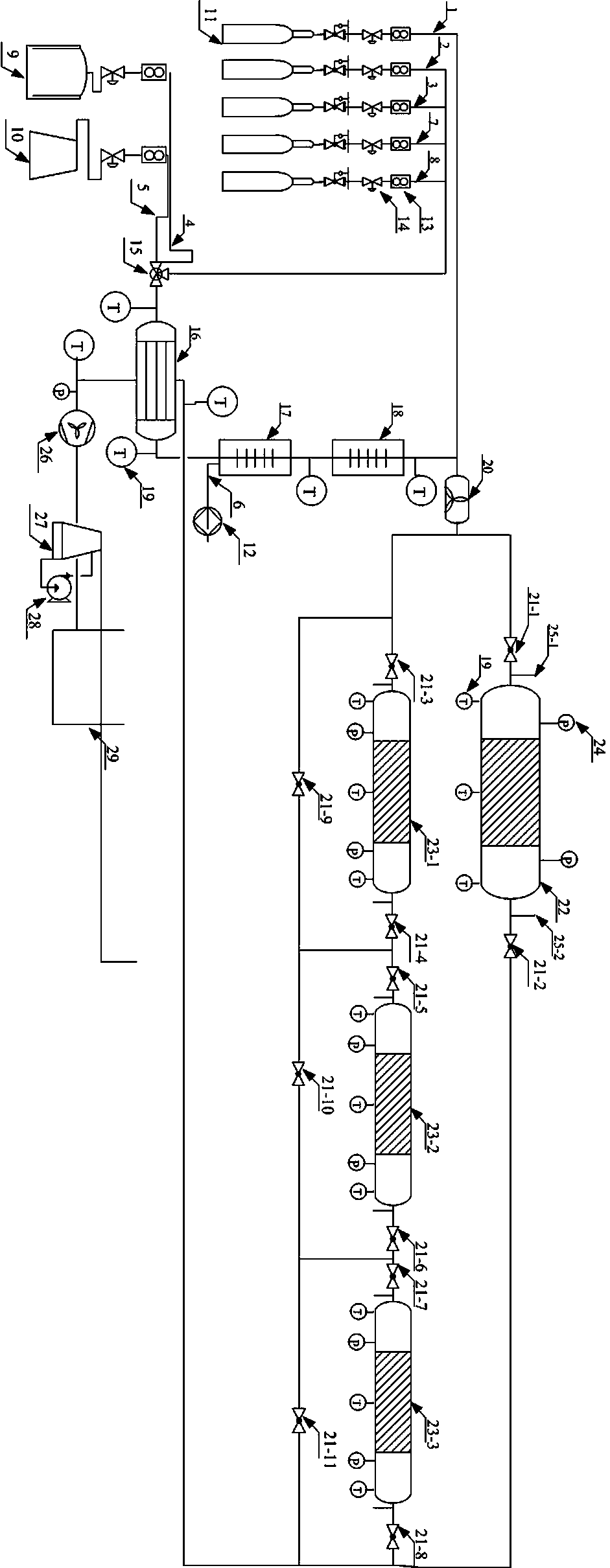

Denitration catalytic performance evaluation system and method

InactiveCN105510532AReduce heating energy consumptionReduce pollutionMaterial analysisControl systemEscape rate

The invention relates to a denitration catalytic performance evaluation system and method. The evaluation system comprises a distributed gas metering system, a gas preheating system, an SCR system, a gas-gas heat exchanger (16), a tail gas treatment system and a data collection and control system. Through the system and method, the ammonia-nitrogen molar ratio, denitration efficiency, the ammonia escape rate, activity and the SO2 / SO3 conversion rate of reactor catalysts can be obtained. The system has complete functions, is accurate and reliable in operation and can be widely applied to evaluation of catalytic performance on laboratory conditions.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD

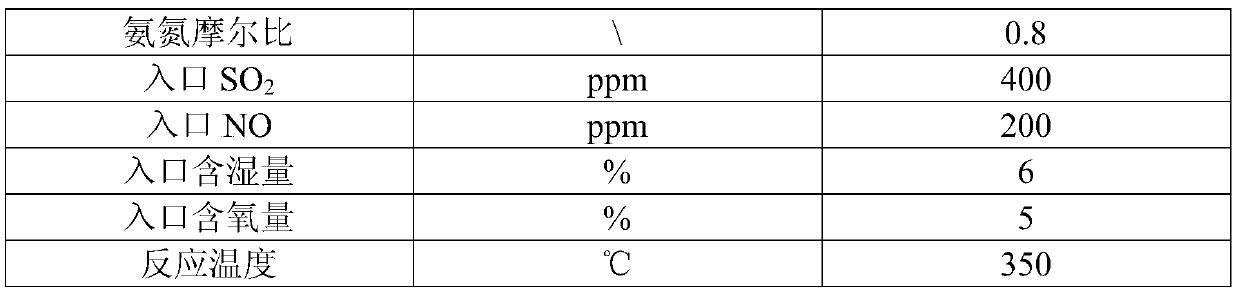

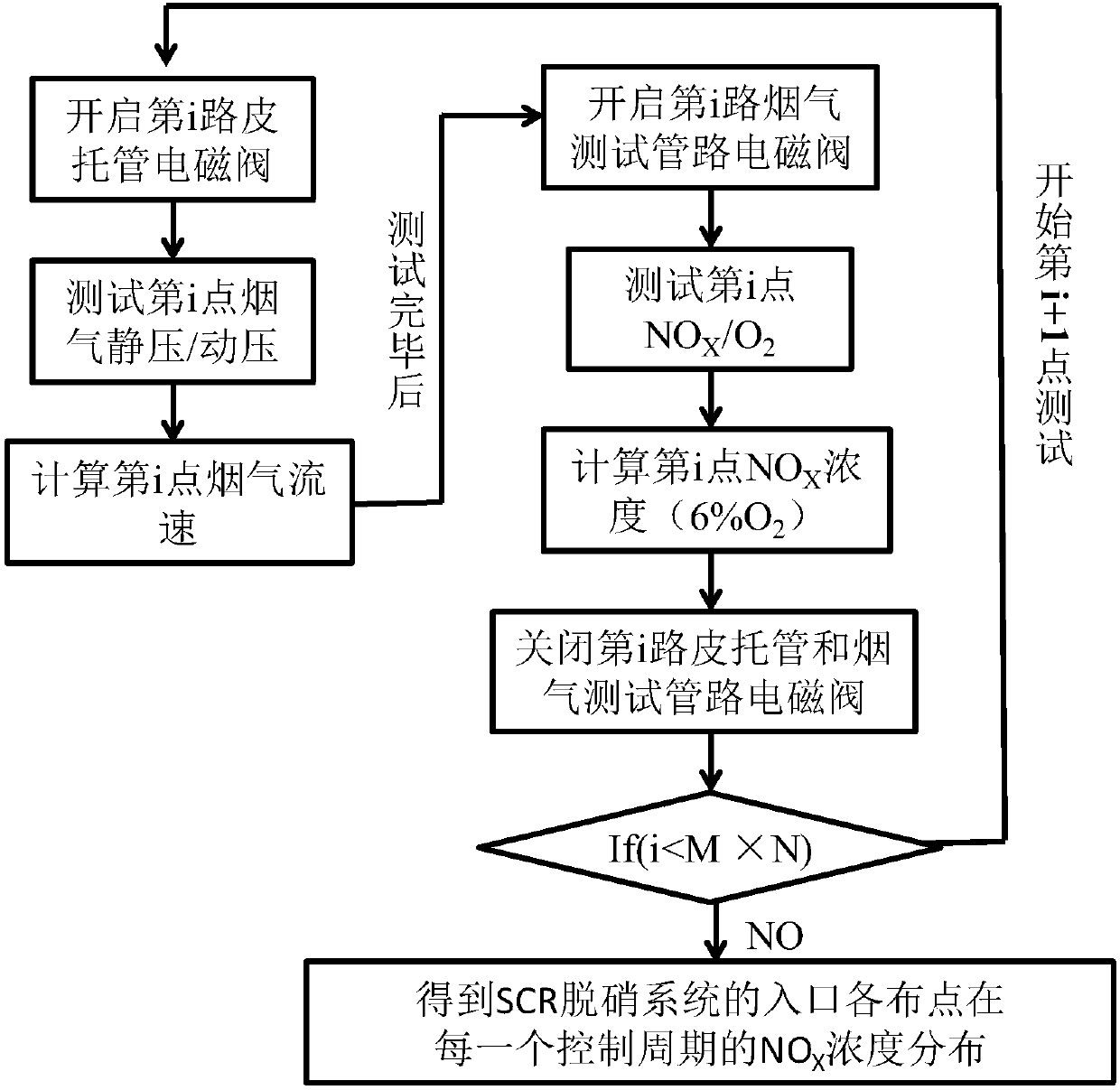

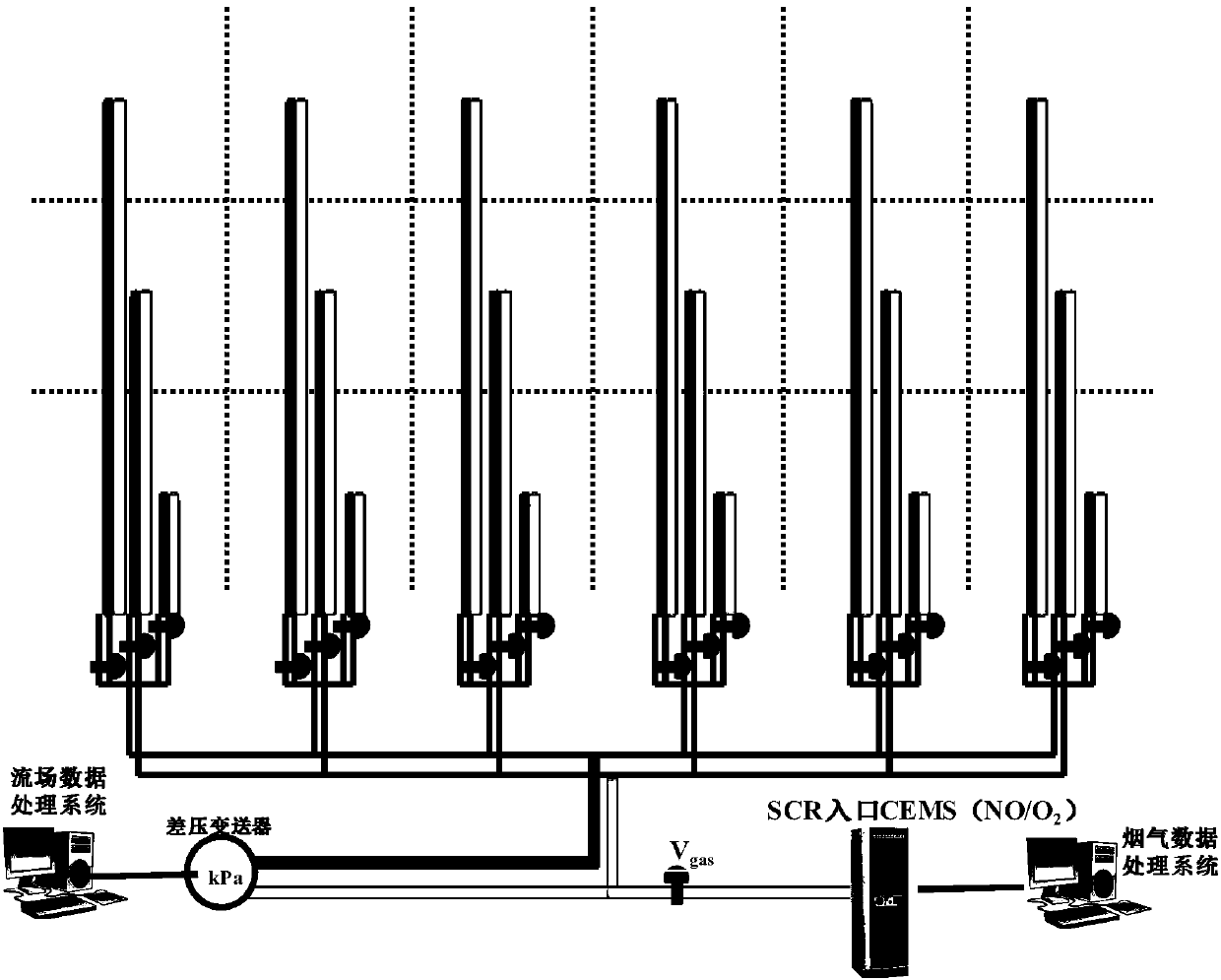

Method for optimizing ammonia nitrogen mole ratio distribution of SCR denitration system

ActiveCN107252630AAmmonia nitrogen molar ratio distribution adjustmentImproved ammonia nitrogen molar ratio distributionDispersed particle separationFluid speed measurementRelative standard deviationEscape rate

The invention discloses a method for optimizing ammonia nitrogen mole ratio distribution of an SCR denitration system. The method comprises the following implementation steps: detecting to obtain NOX concentration distribution within each control period at the inlet of the SCR denitration system and NOX concentration distribution and NH3 concentration distribution within each control period at the outlet; within each control period, calculating an ammonia nitrogen mole ratio distribution relative standard deviation factor CVm of the SCR denitration system within the current control period, and while the ammonia nitrogen mole ratio distribution relative standard deviation factor CVm exceeds a preset threshold value, automatically optimizing in allusion to an ammonia spraying control valve of the SCR denitration system, ending and quitting the automatic optimization while the ammonia nitrogen mole ratio distribution relative standard deviation factor CVm does not exceed the preset threshold value. The method is capable of effectively regulating the ammonia nitrogen mole ratio distribution of the SCR denitration system, solving the problems that the outlet ammonia escape rate of the SCR denitration system is high, the outlet NOX concentration distribution is not uniform and the produced ammonium bisulfate blocks an air pre-heater, remarkably improving the flow field distribution in an SCR reactor, and effectively improving the availability ratio of the SCR denitration system.

Owner:STATE GRID CORP OF CHINA +2

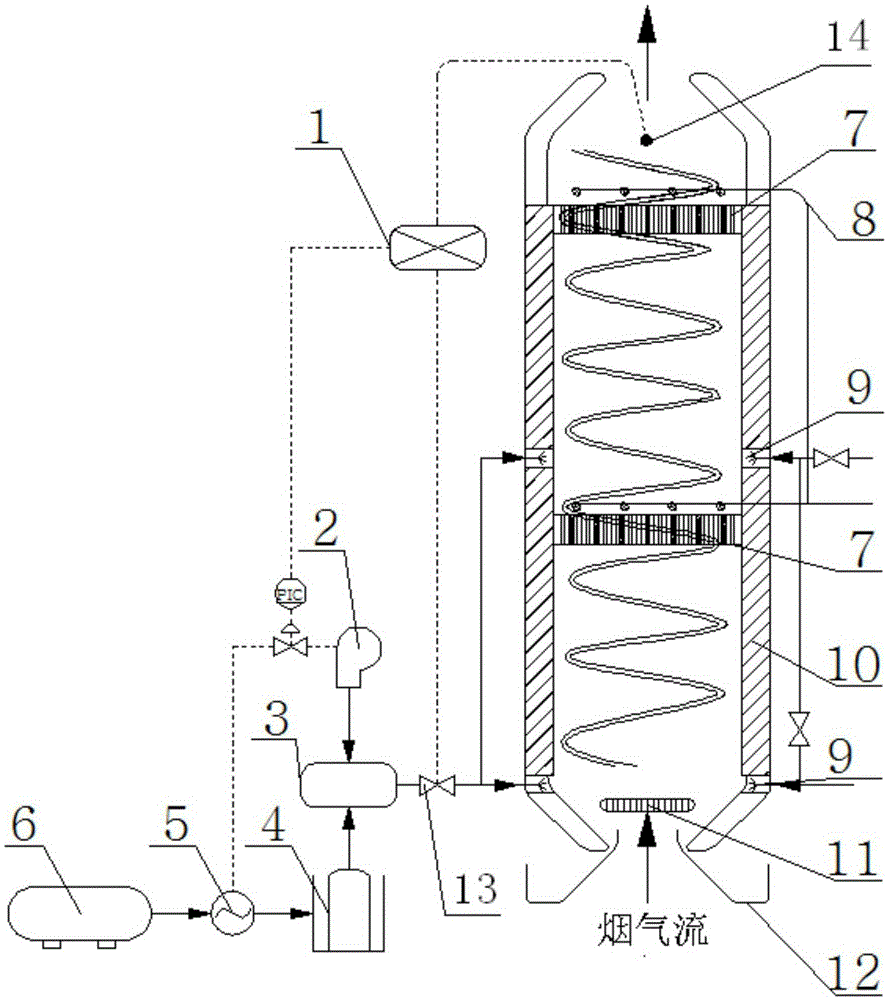

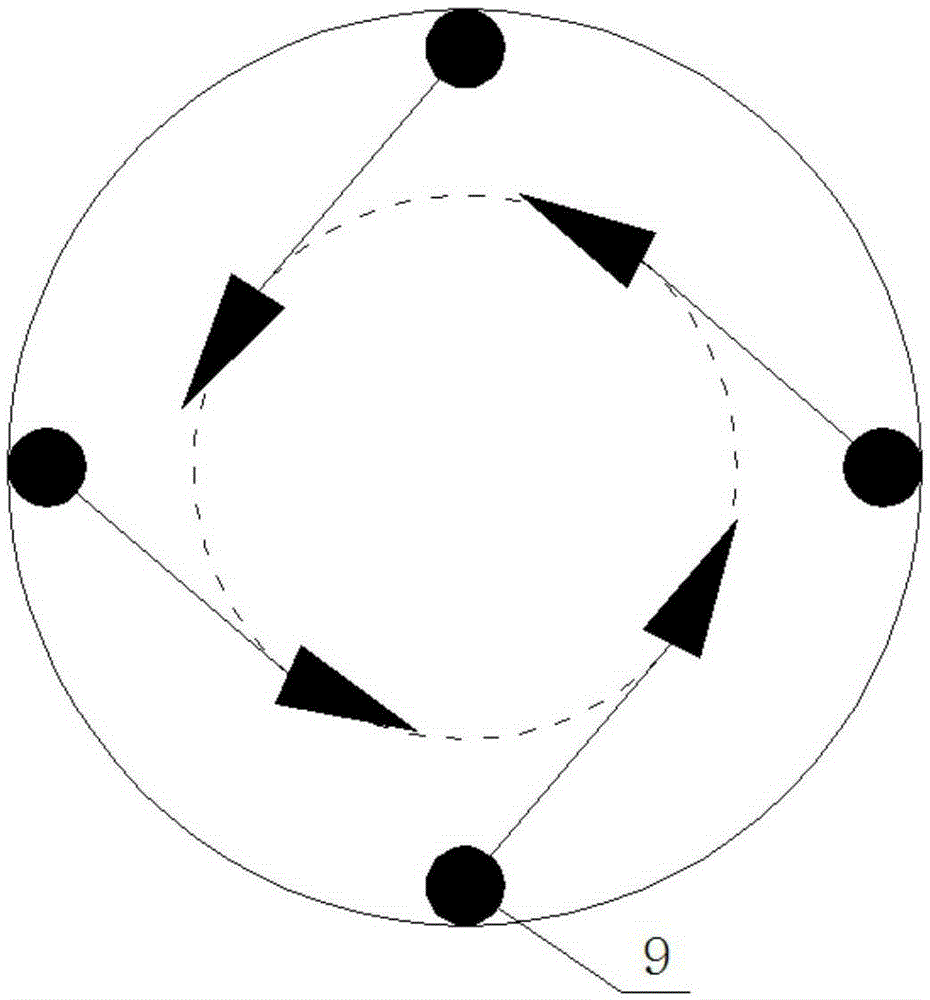

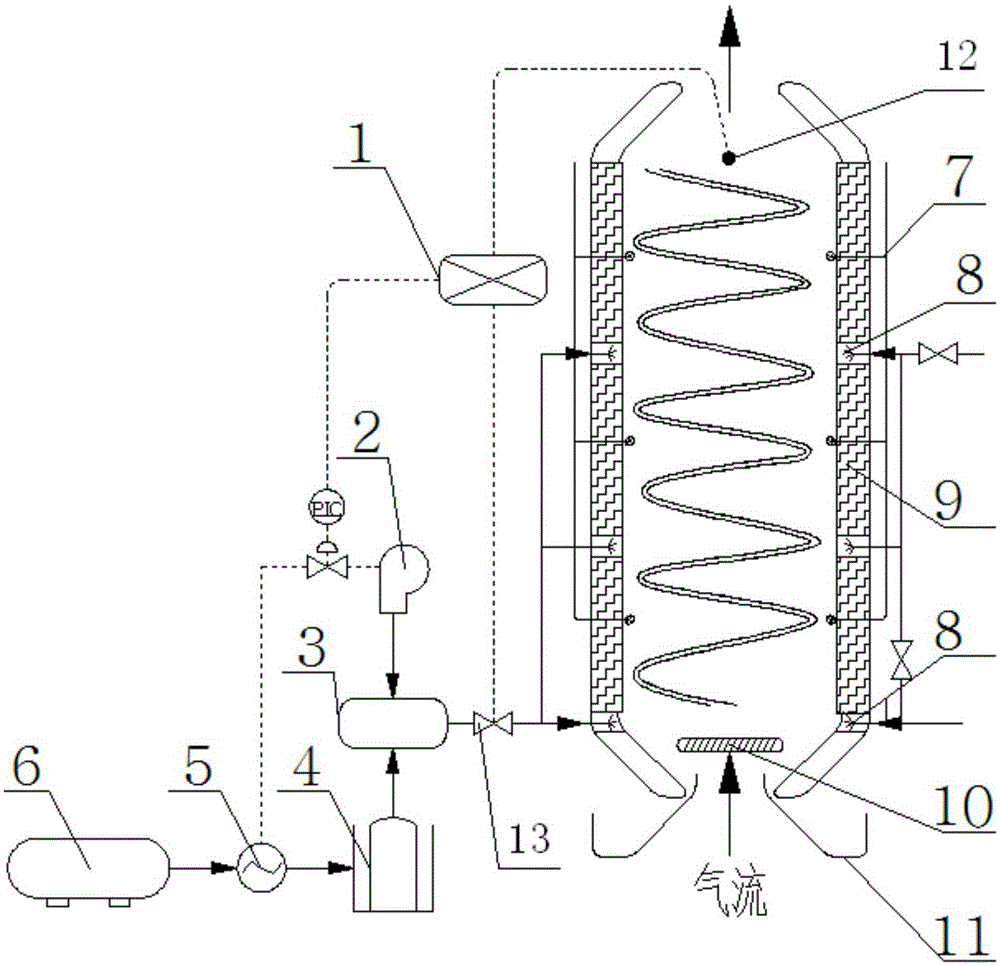

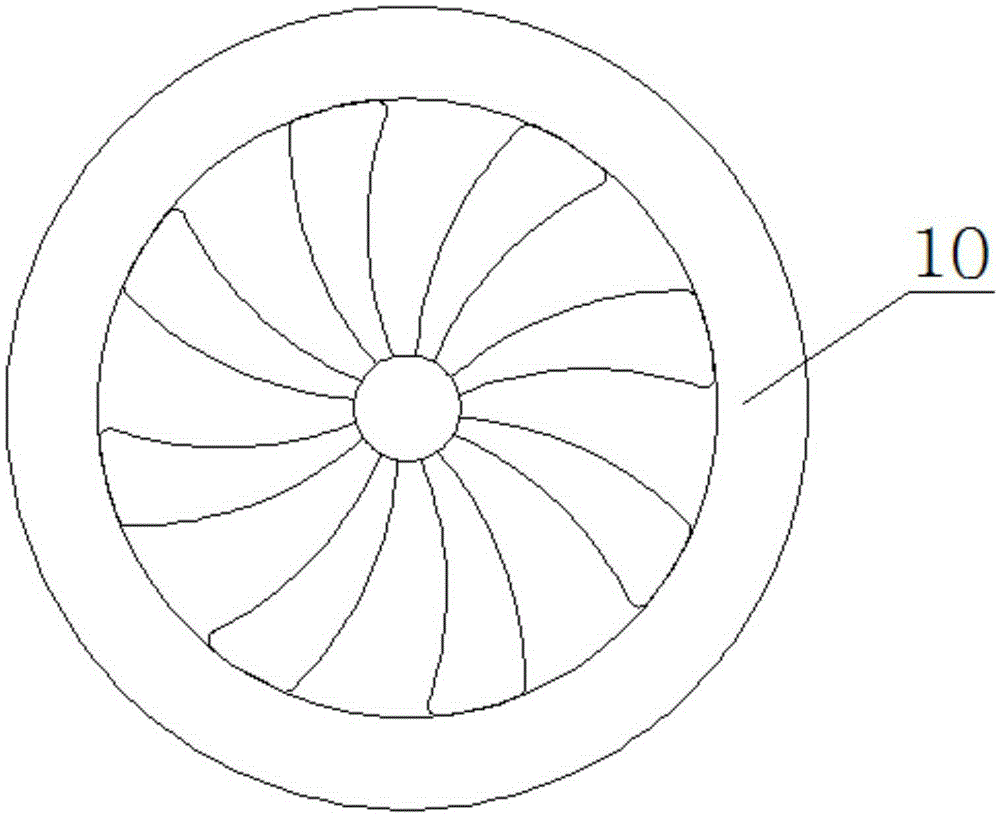

Eddy-flow atomization SCR denitration method and apparatus thereof

The invention discloses an eddy-flow atomization SCR denitration method and an apparatus thereof. The apparatus are characterized in that a plate-type catalyst layer is arranged along the periphery of the denitrating tower body, and a flue gas channel is formed. A cellular catalyst is arranged in the flue gas channel, and a two-stage catalytic reaction zone is formed with the plate-type catalyst. Several eddy flow atomizing nozzles capable of injecting the catalyst along tangent circle direction and distributed from down to up are arranged along the periphery of the plate-type catalyst layer. When flue gas is introduced into the flue gas channel and meets with ammonia gas injected in an eddy flow mode along the tangent circle direction, the flue gas enables spiral rising in the tangent circle mode along the inner circumference of the flue gas channel. The method and the apparatus can solve the problems of poor mixing condition of the flue gas and NH3 as well as uneven flow field, increase a contact specific surface area and time of the flue gas with a reducing agent and the catalyst, effectively use a denitrating tower space, increase reaction efficiency, reduce flue gas resistance, have low energy consumption, reduce the ammonia escape rate, greatly reduce denitration cost, and obviously increase the economic benefit.

Owner:SOUTH CHINA UNIV OF TECH

Rotational flow plate type SCR denitration tower and denitration method thereof

ActiveCN105289300AExtended stayThe catalytic reduction reaction is fullyDispersed particle separationFlue gasEscape rate

The invention discloses a rotational flow plate type SCR denitration tower and a denitration method thereof. The denitration tower comprises a denitration tower body and a corrugated plate type catalyst layer arranged along the inner circumference face of the denitration tower body, and the corrugated plate type catalyst layer forms a flue gas channel. A plurality of layers of rotational flow atomizing nozzles performing jetting in the contact circle direction are distributed on the circumference face of the corrugated plate type catalyst layer from bottom to top. When flue gas enters the flue gas channel from the bottom of the denitration tower body, and the flue gas encounters ammonia gas jetted by the whirlwind atomizing nozzles, the flue gas and the ammonia gas are mixed in an entrainment mode and spirally raises in the inner circumference direction of the flue gas channel in a contact circle mode because the ammonia gas is jetted in a rotational flow mode in the contact circle direction. On the premise that efficient denitration is guaranteed, the catalyst use amount of the denitration tower is small, the technical means is easy and convenient to use. Compared with the prior art, the denitration tower is simple in structure, low in manufacturing cost, high in denitration efficiency and low in energy consumption, reduces the ammonia escape rate, makes denitration cost greatly reduced, and remarkably improves economic benefits.

Owner:SOUTH CHINA UNIV OF TECH

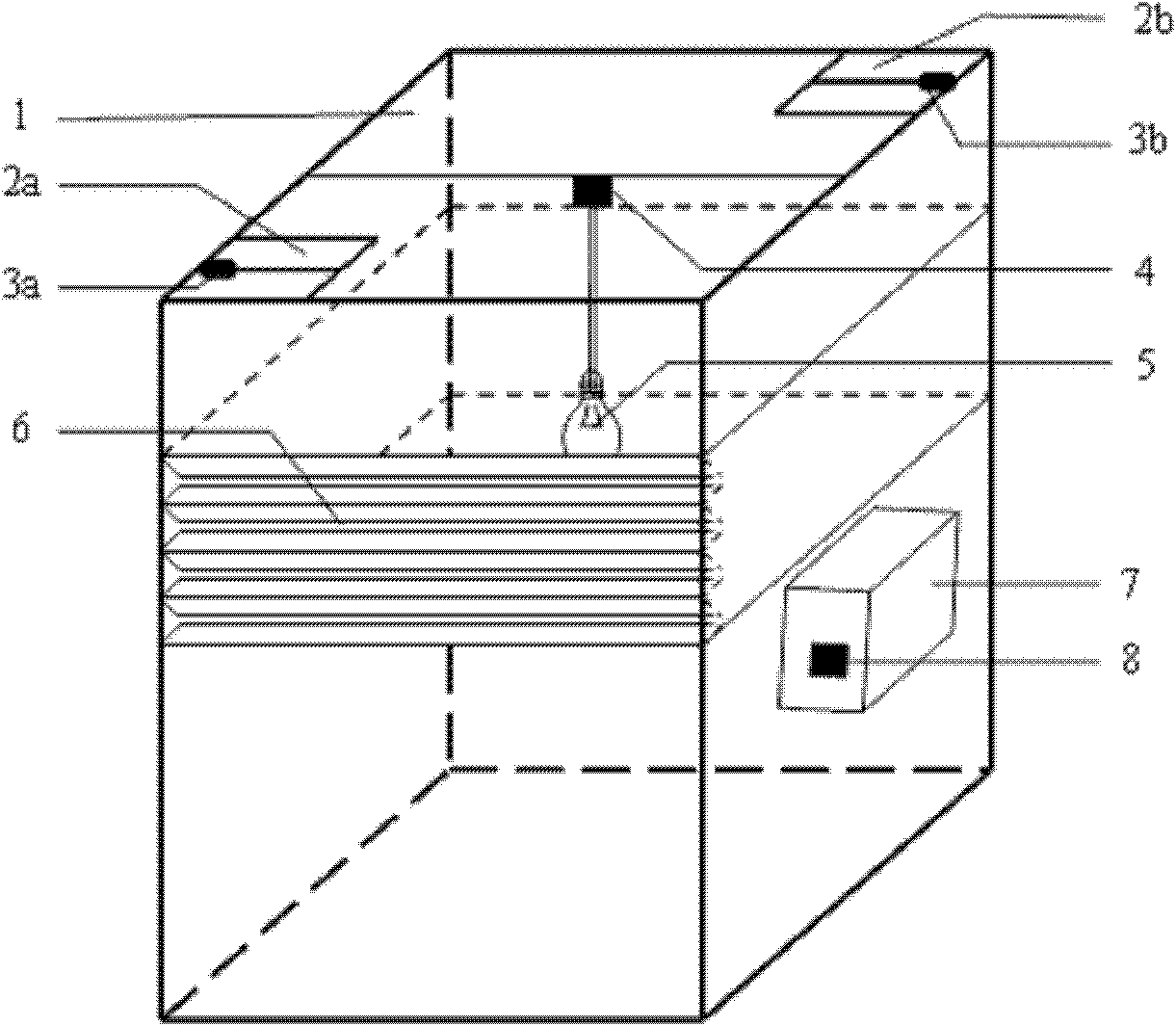

Ecological insecticidal method and insecticidal device

InactiveCN102177878AHigh selectivityRealize energy savingInsect catchers and killersEscape rateLouver

The invention discloses an ecological insecticidal method and an insecticidal device. The method comprises the following steps of: (1) covering crops vulnerable to pests with an ecological insecticidal device; (2) switching on a flasher at the upper part of the inner chamber of the box body of the ecological insecticidal device, and closing an escape door on the top of the box body so that pests fly to the four walls of the box body of the insecticidal device and a louver diamond screen window of an energy-saving incandescent lamp under the attraction of light; (3) switching off the flasher, and starting an electric rotating switch to open the escape door; and (4) closing the escape door, and starting a microwave transmitter at the middle lower part of the side box wall of the ecological insecticidal device to kill pests in the box body of the ecological insecticidal device. The square escape door is installed on the top of the box body of the ecological insecticidal device, the electric rotating switch is installed on the square escape door, the flasher is installed on the top of the box body of the ecological insecticidal device, and the microwave transmitter and a controller are installed on one side of the box body of the ecological insecticidal device. The insecticidal device runs automatically, is convenient to use and has the advantages of cleanliness, no pollution and high insecticidal efficiency; pests are killed ecologically, and the escape rate of beneficial insects is 95-98%; and moreover, the pests are intensively killed in an intermittent way so that low carbon and energy conservation are realized.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

Novel fire-proofing escape door with cooling effect

The invention belongs to the field of windows and doors of fixed constructions, and particularly discloses a novel fire-proofing escape door with a cooling effect. The novel fire-proofing escape door comprises a door frame and a door body, which are made of fire-proofing core plates, wherein a door handle is respectively arranged on indoor side and outdoor side of the door body; a fire-extinguishing and cooling device is arranged on one side of each door handle, and comprises a cylinder body; a separator is arranged in each cylinder body, one end of each separator is hinged in the respective cylinder body, the other end of each separator is adhered with glue, and each separator is adhered to the inner wall of the respective cylinder body through the first glue; each cylinder body is separated into a first chamber and a second chamber by virtue of the respective separator, each first chamber is filled with aluminum sulfate, and each second chamber is filled with sodium bicarbonate; a nozzle is formed in the side wall of the top of each cylinder body, and is filled with second glue for sealing; the melting point of the second glue is higher than that of the first glue; and the nozzle is just aligned to each door handle. By adopting the scheme, the temperature of the door handles can be reduced when a fire disaster happens, so that the escape rate of people can be improved.

Owner:重庆金华兴门业有限公司

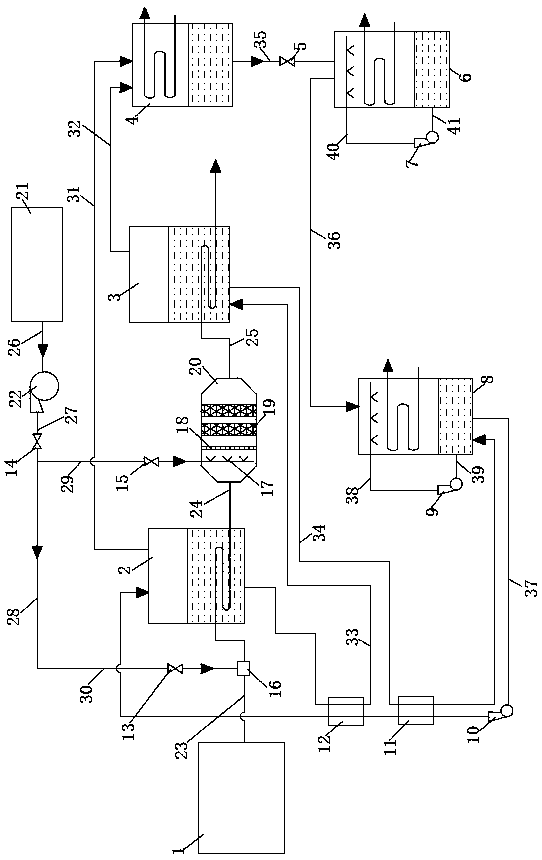

Nitric oxide efficient control system and control method of gas internal combustion engine

ActiveCN108049946AReduce escape rateImprove uniformityInternal combustion piston enginesExhaust apparatusExternal combustion engineLithium bromide

The invention relates to a nitric oxide efficient control system and control method of a gas internal combustion engine. An outlet of the internal combustion engine is communicated with a first-stageammonia spraying device through a No.1 pipeline; the first-stage ammonia spraying device communicates with one end of a No.2 pipeline; the other end of the No.2 pipeline passes through a high-pressuregenerator; the other end of the No.2 pipeline is communicated with an inlet of an SCR reactor; an outlet of the SCR reactor is communicated with one end of a No.3 pipeline; the other end of the No.3pipeline passes through a low-pressure generator; a reducing agent storage groove is communicated with a dilution fan through a No.4 pipeline; one end of the No.5 pipeline is communicated with the dilution fan; one end of a No.6 pipeline and one end of a No.7 pipeline are communicated with the other end of the No.5 pipeline; the other end of the No.6 pipeline is communicated with the first-stage ammonia spraying device; the other end of the No.7 pipeline is communicated with the second-stage ammonia spraying device. The ammonia-nitrogen ratio distribution uniformity degree is improved; the denitration efficiency is improved; the ammonia escape rate is reduced; the refrigeration effect of a lithium bromide refrigeration unit is not influenced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

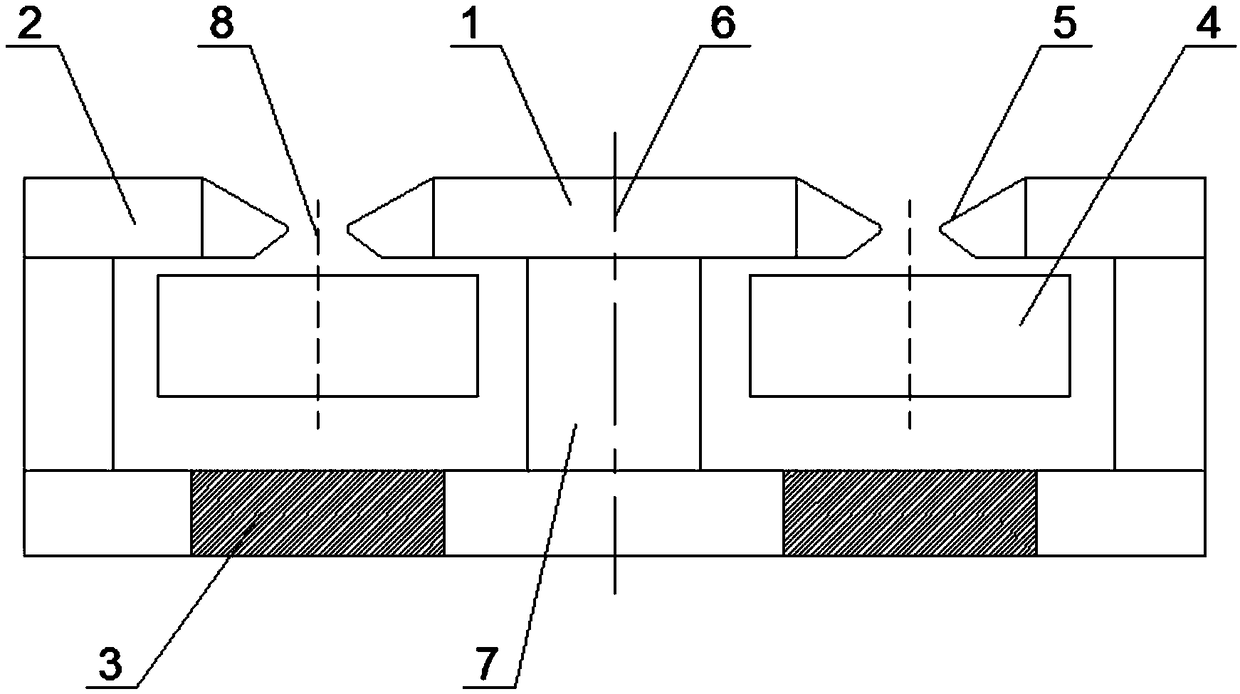

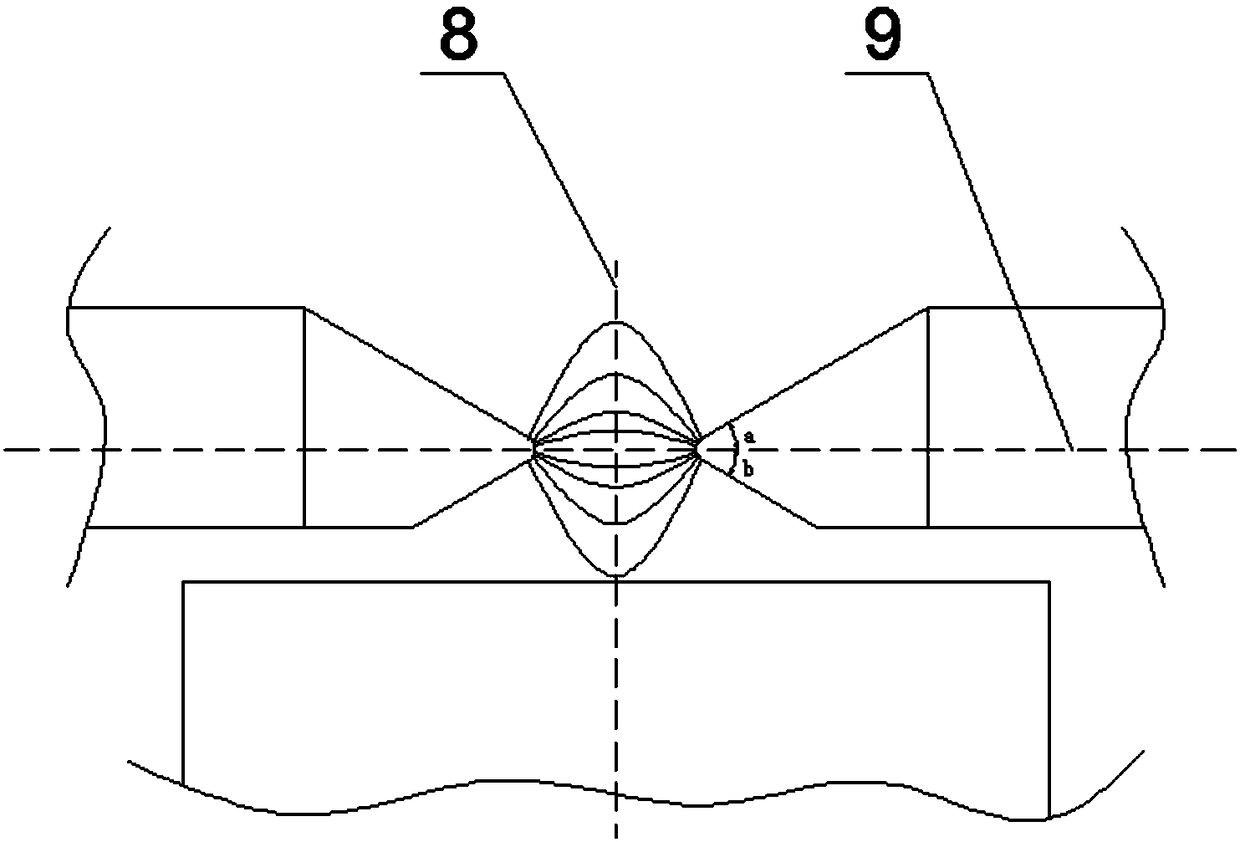

An ion source that reduces the rate of electron escape

ActiveCN109065429AReduce escape rateReduced chance of bombardmentIon beam tubesEscape rateMagnetic poles

The invention discloses an ion source capable of reducing an electron escape rate, including an anode ring, inner cathode and outer cathode, the anode ring, the inner cathode and the outer cathode areeach axisymmetric, a soft magnetic column is fixed in the middle of the yoke of the outer cathode, one end of the soft magnetic column passes through the center of the inn hole of the anode ring andis connected with the middle of the inner cathode, the longitudinal cross-sectional shape of the magnetic pole shoe of the inner cathode is mirror symmetrical with the longitudinal cross-sectional shape of the magnetic pole shoe of the outer cathode of the corresponding position, and an annular cathode gap is formed between the magnetic pole shoe of the inner cathode and the magnetic pole shoe ofthe outer cathode, the anode ring is directly opposite to the lower part of the cathode gap, two permanent magnets are arranged on the magnetic yoke of the outer cathode, the two permanent magnets aresymmetrical with respect to the soft magnetic column, and the two permanent magnets are respectively positioned directly below the opposite sides of the anode ring. By increasing the symmetrical magnetic field, the invention improves the uniformity of the magnetic field distribution on both sides of the cathode gap, can reduce the escape rate of electrons and effectively reduce the bombardment probability of the electrons on the cathode magnetic pole shoe.

Owner:成都极星等离子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com