Method for optimizing ammonia nitrogen mole ratio distribution of SCR denitration system

A technology of ammonia nitrogen molar ratio and denitrification, applied in separation methods, chemical instruments and methods, general control systems, etc., can solve problems such as air preheater blockage, high ammonia escape at the outlet, and uneven distribution of NOX concentration at the outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

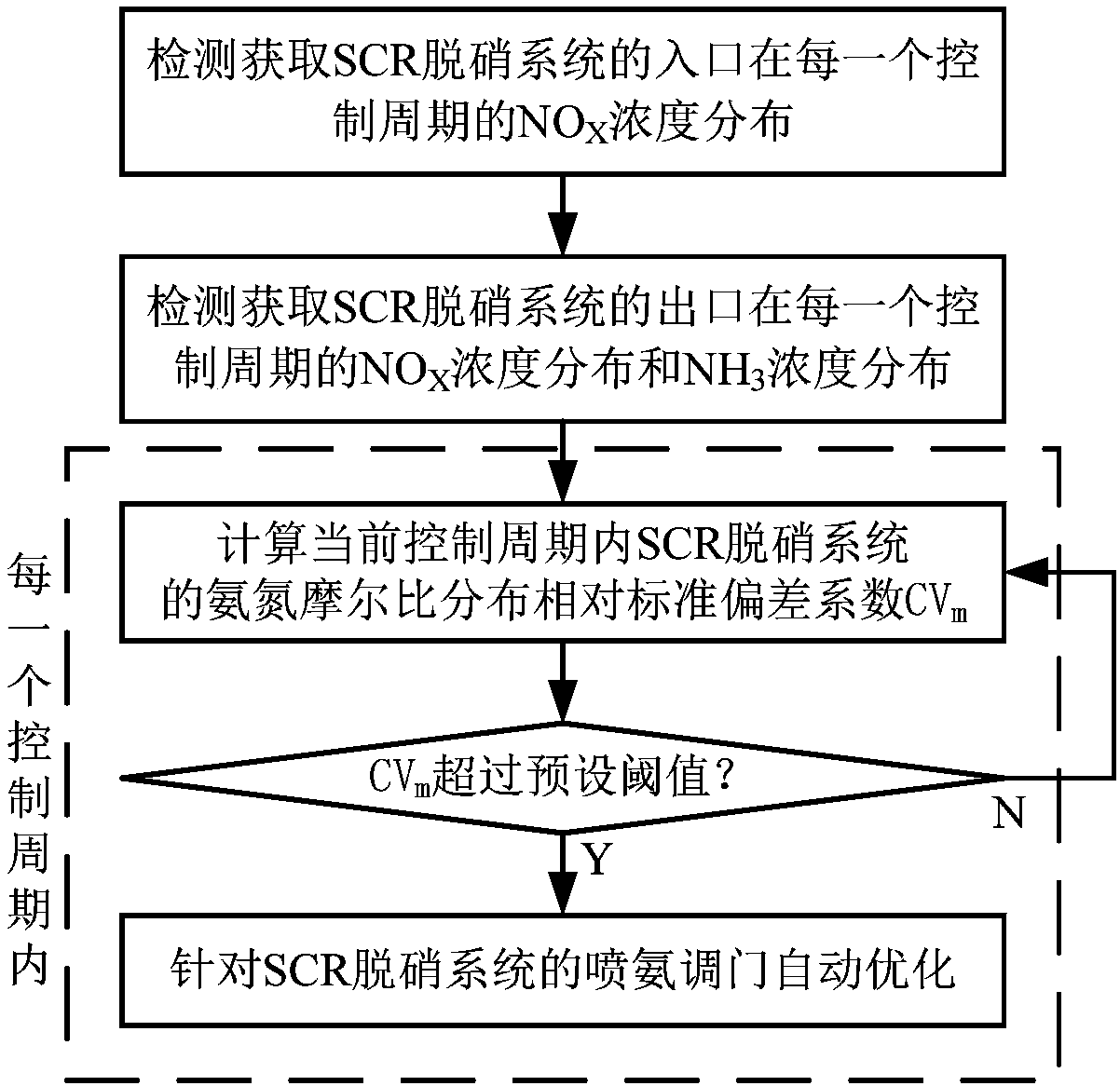

[0066] Such as figure 1 As shown, the implementation steps of the method for optimizing the molar ratio distribution of ammonia nitrogen in the SCR denitrification system in this embodiment include:

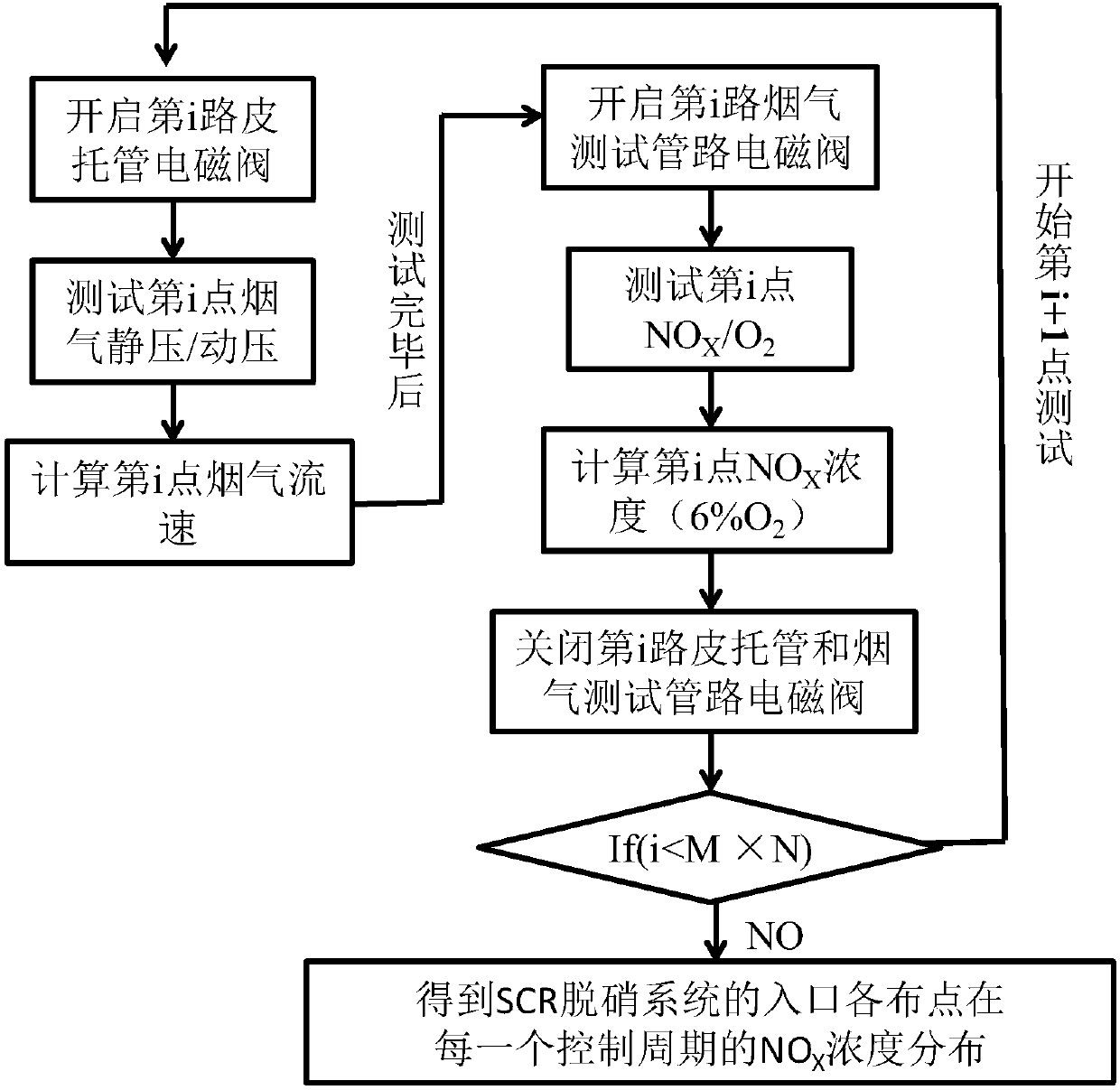

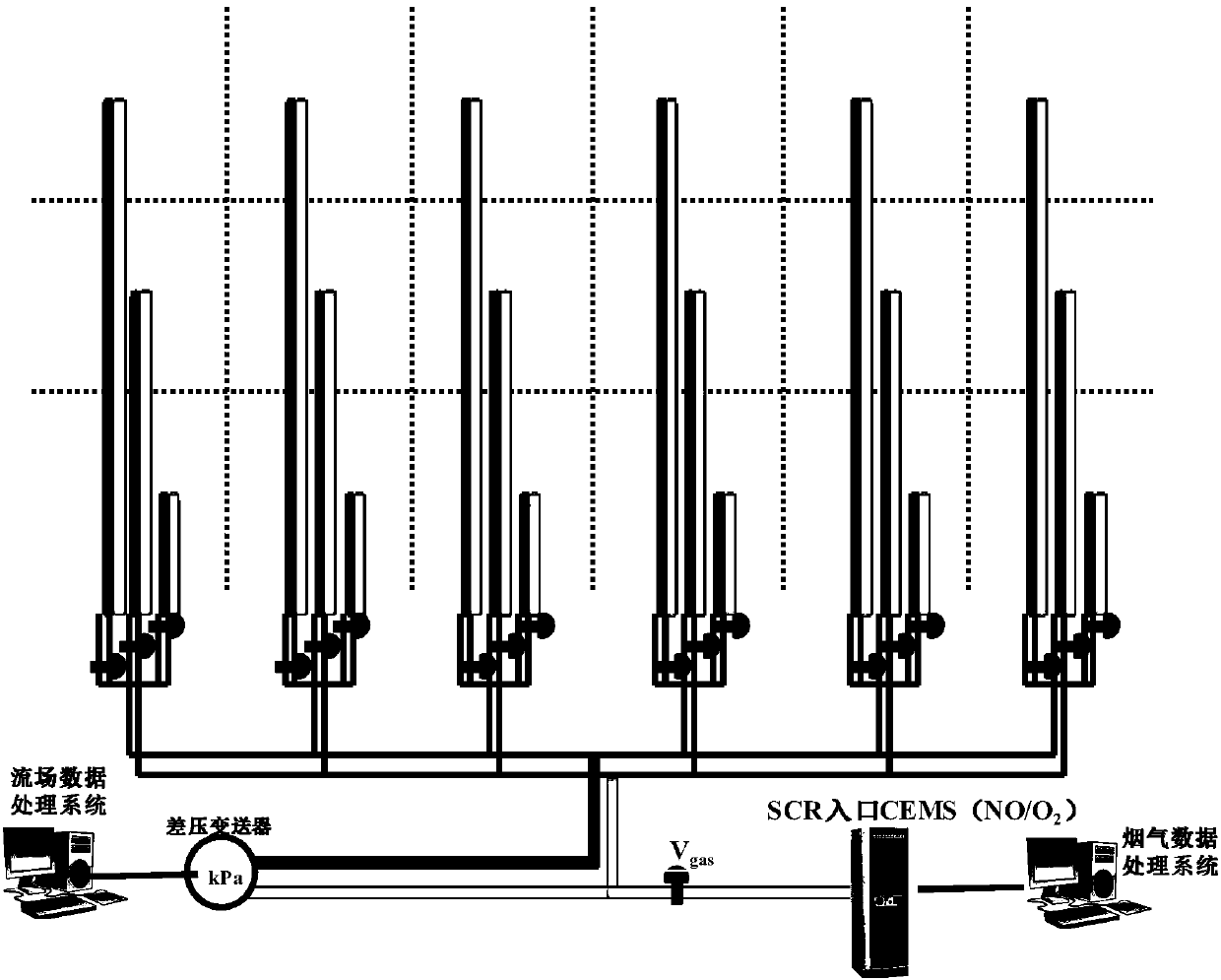

[0067] 1) Detection and acquisition of NO at the entrance of the SCR denitrification system in each control cycle X Concentration distribution;

[0068] 2) Detect and obtain NO at the outlet of the SCR denitrification system in each control cycle X Concentration distribution and NH 3 Concentration distribution;

[0069] 3) In each control cycle, the gate control area of each branch pipe of the ammonia injection grid of the SCR denitrification system is regarded as a node, based on the NO in the outlet area corresponding to each node X Concentration distribution and NH 3 Concentration distribution, NO in inlet zone X Concentration distribution calculation of ammonia nitrogen molar ratio m at each node i , according to the ammonia-nitrogen molar ratio m of each node i Cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com