Patents

Literature

1037results about How to "Reduce escape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

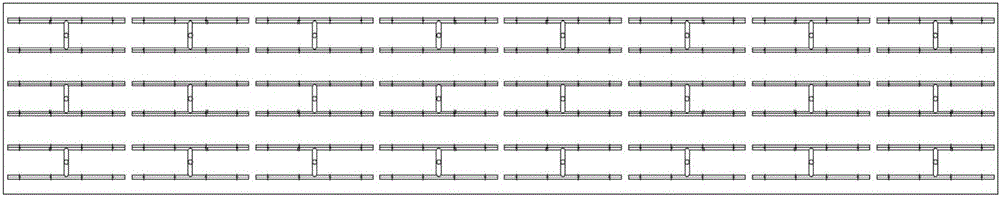

Microelectromechanical device manufacturing process

InactiveUS6337027B1Quantity minimizationEasily terminatedDecorative surface effectsSemiconductor/solid-state device manufacturingDissolutionEngineering

The present invention relates to micro electromechanical systems (MEMS) devices and more specifically to a process for manufacturing MEMS devices having at least one suspended structural element. The present invention seeks to provide an improved method for manufacture of MEMS devices having improved safety and increased yield and throughput compared to conventional EDP immersion process techniques. MEMS devices are made using a modified dissolution process that removes, in a selective etch step, inactive silicon to release an active silicon device from a sacrificial substrate. The present invention uses a selective etchant in conjunction with a commercial spray acid processing tool to provide a dissolution process with improved throughput, improved repeatable and uniform etch rates and reduction in the number of processing steps and chemical containment for improved safety. When the etch process is complete, the solvent spray is turned off and a spray of de-ionized water is directed onto composite structure to remove residual solvent without causing suspended elements to adhere to the support substrate.

Owner:TELEDYNE SCI & IMAGING

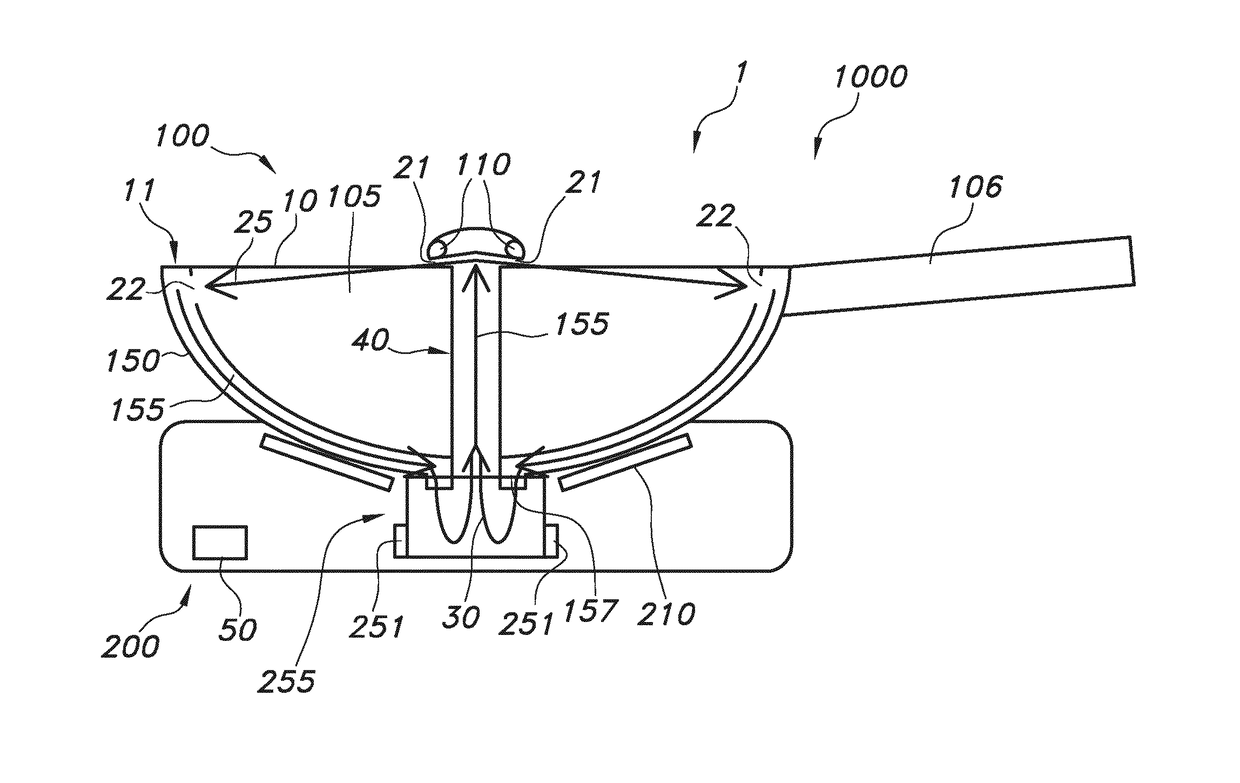

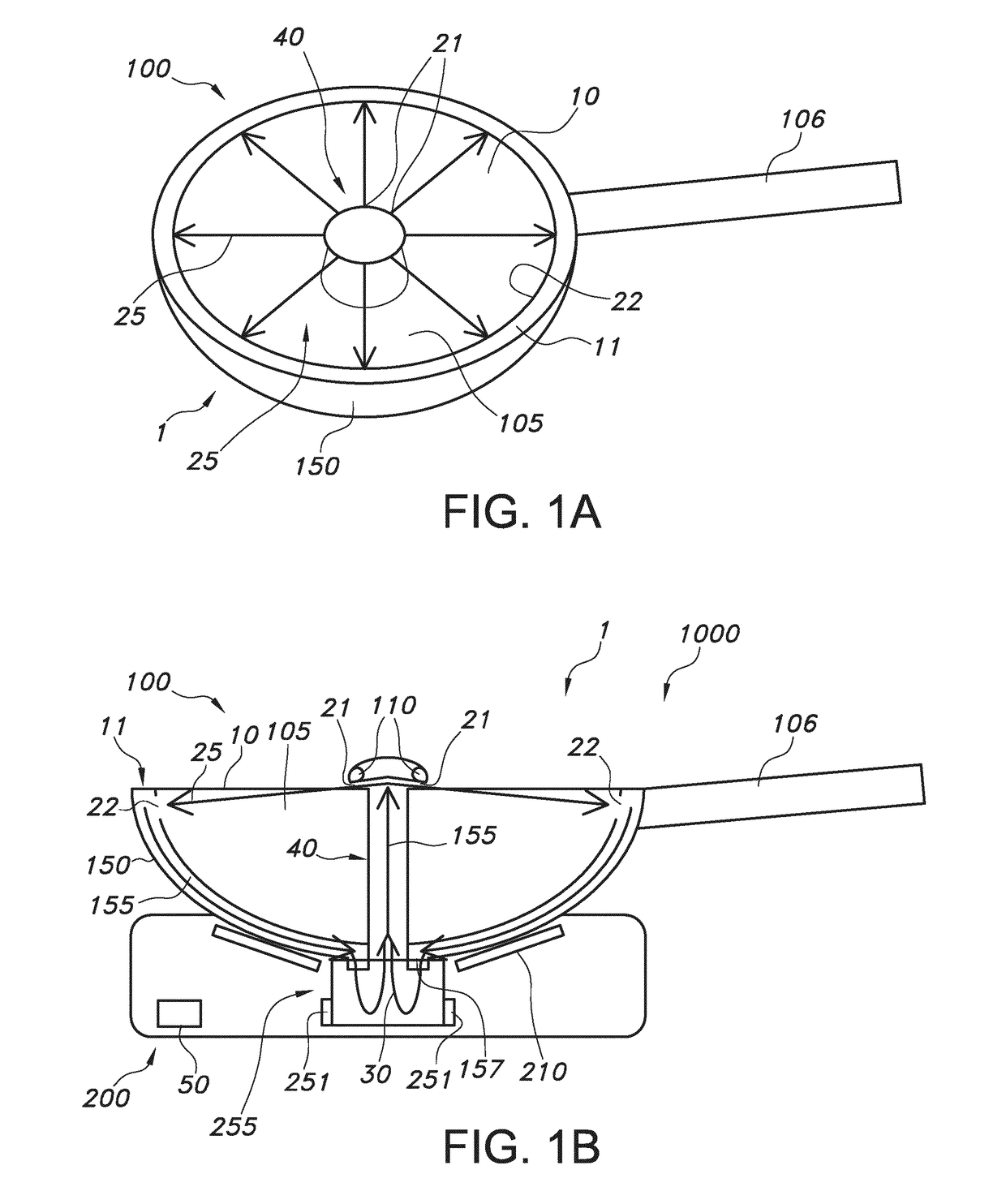

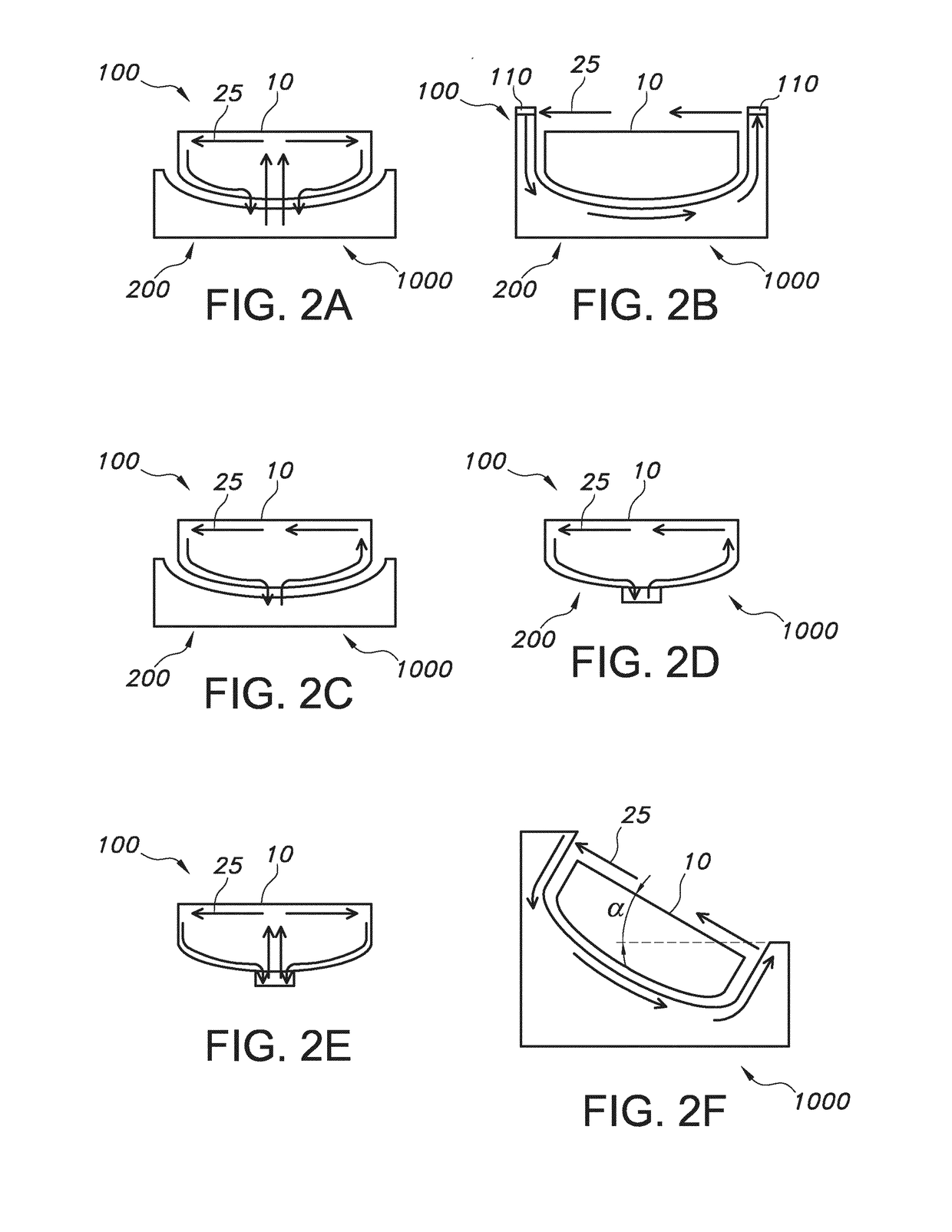

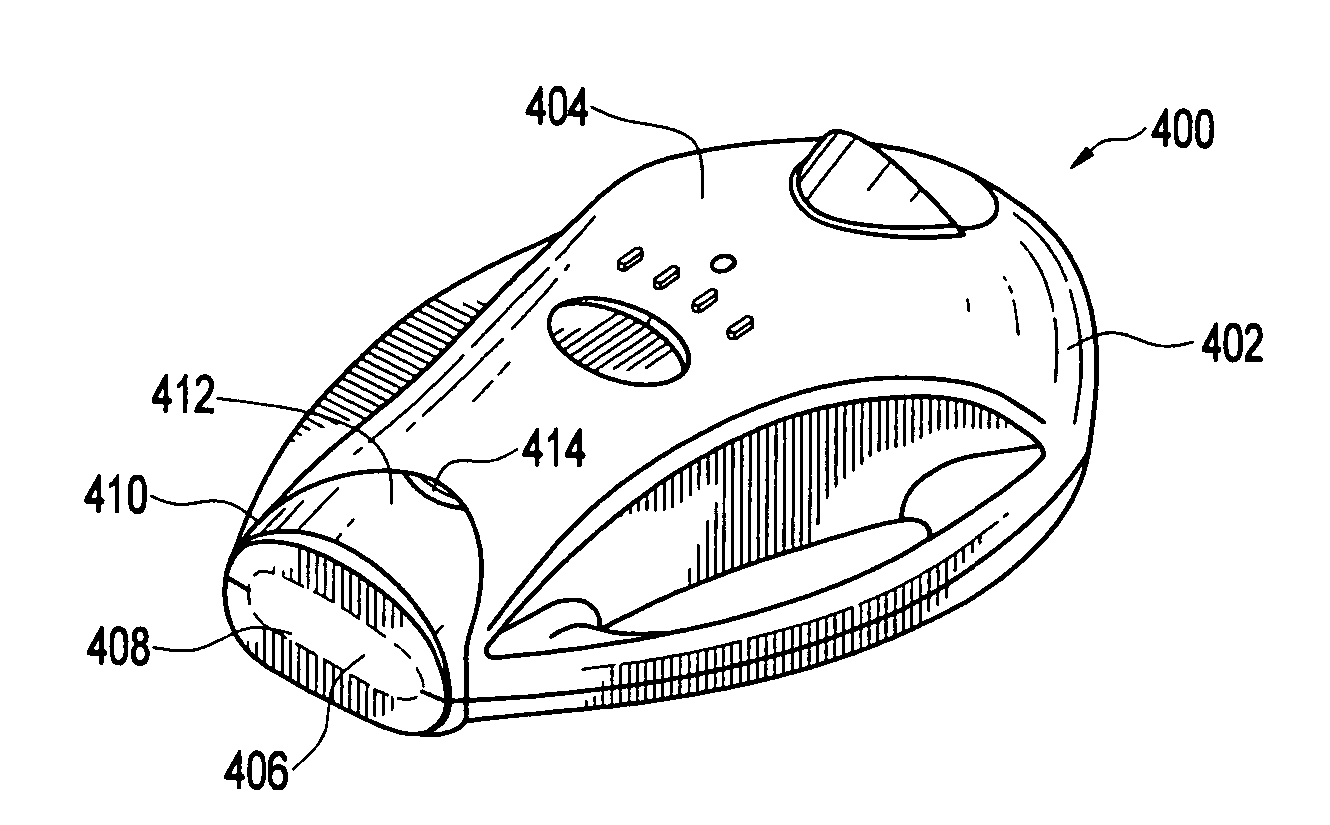

Smokeless air blade wok

InactiveUS20170367514A1Reduce escapeImprove efficiencyFood scienceCooking vessel constructionsEngineeringFood preparation

The invention provides a food preparation vessel (100) comprising a main inlet (10) for introduction of a food material into the food preparation vessel (100), wherein the food preparation vessel (100) comprises a gas flow generator outlet (21) and a gas flow receiver inlet (22), wherein the gas flow generator outlet (21) is configured to provide a gas flow (25) in the direction of the gas flow receiver inlet (22) and having a component parallel to the main inlet (10) when the gas flow generator outlet (21) is functionally coupled with a gas flow generator in operation.

Owner:KONINKLJIJKE PHILIPS NV

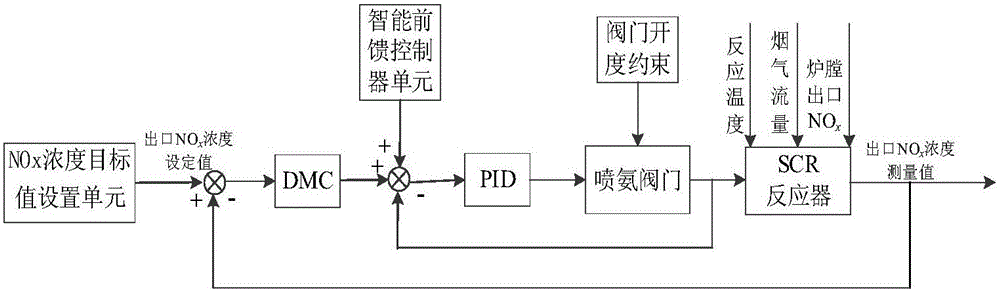

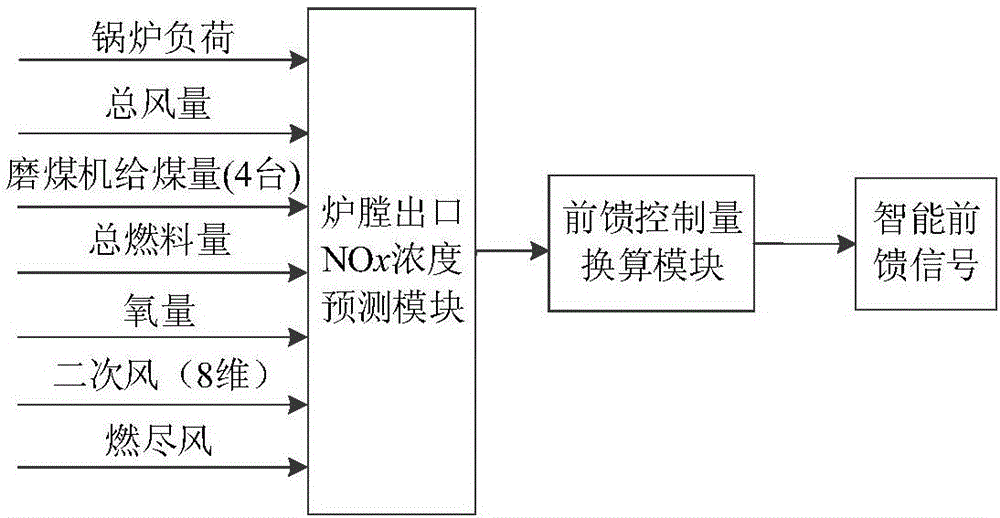

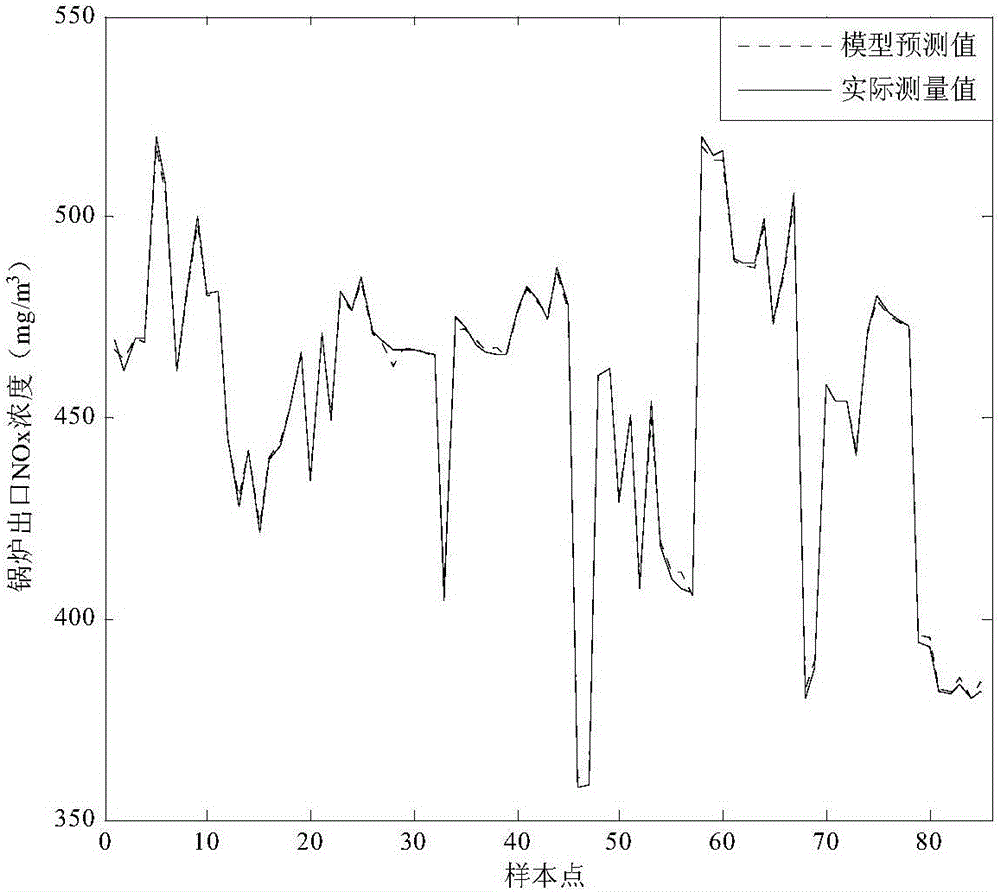

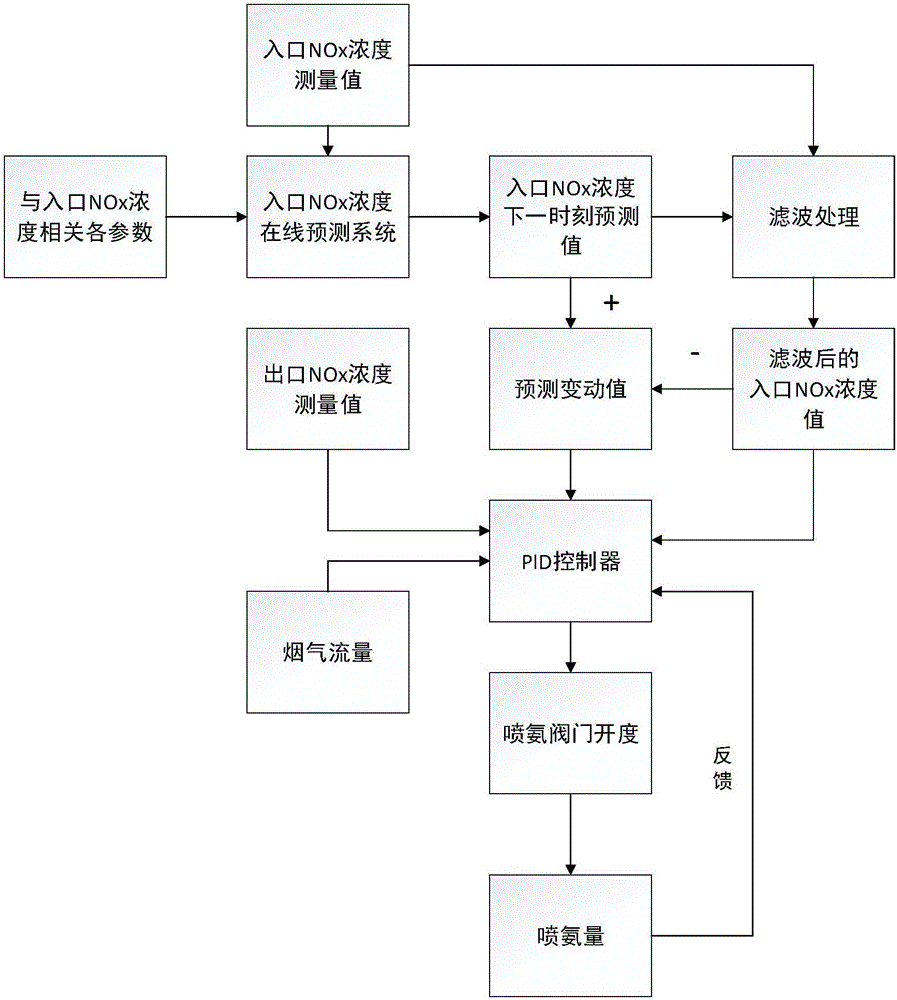

SCR denitration system ammonia spraying quantity optimal control system and method based on intelligent feedforward signals

InactiveCN106681381AEasy to controlReduce escapeGas treatmentControlling ratio of multiple fluid flowsCombustionControl signal

The invention relates to an SCR (Selective Catalytic Reduction) denitration system ammonia spraying quantity optimal control system and method based on intelligent feedforward signals. The SCR denitration system ammonia spraying quantity optimal control system based on intelligent feedforward signals is characterized in that as input parameters of a denitration system can be easily influenced by the combustion state of a boiler and for adapting to the requirement of large range of depth change of conditions for a thermal power generating unit, the SCR denitration system ammonia spraying quantity optimal control system based on intelligent feedforward signals takes the historical data of a power plant as the basis, utilizes the idea of data modeling, takes adjustable parameters at the boiler side as input and NOX concentration at the outlet of a hearth as output, utilizes a Least Squares Support Vector Machine algorithm to construct a prediction model which can be used for constructing an intelligent feedforward controller in a ammonia spraying quantity control strategy, and takes dynamic matrix control (DMC) as a main controller and PID as an auxiliary controller to construct a cascade feedback control structure; during the operating process, the intelligent feedforward controller outputs feedforward control signals in real time according to changes of the parameters at the boiler side, quickly gives a response to change of conditions of the unit, and forms an SCR system ammonia spraying quantity optimal control strategy together with feedback control, and can realize quick accurate control of the ammonia spraying quantity.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

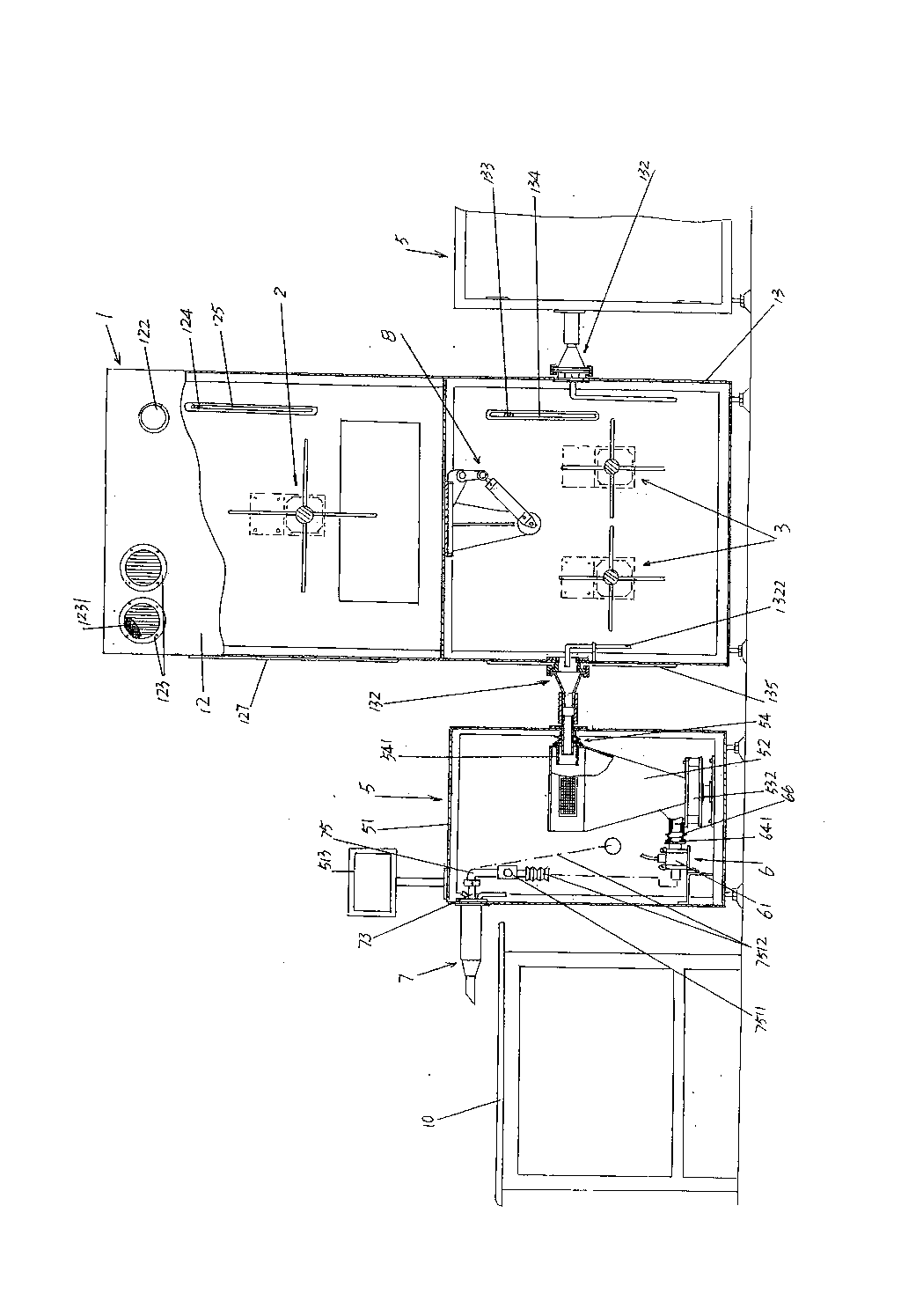

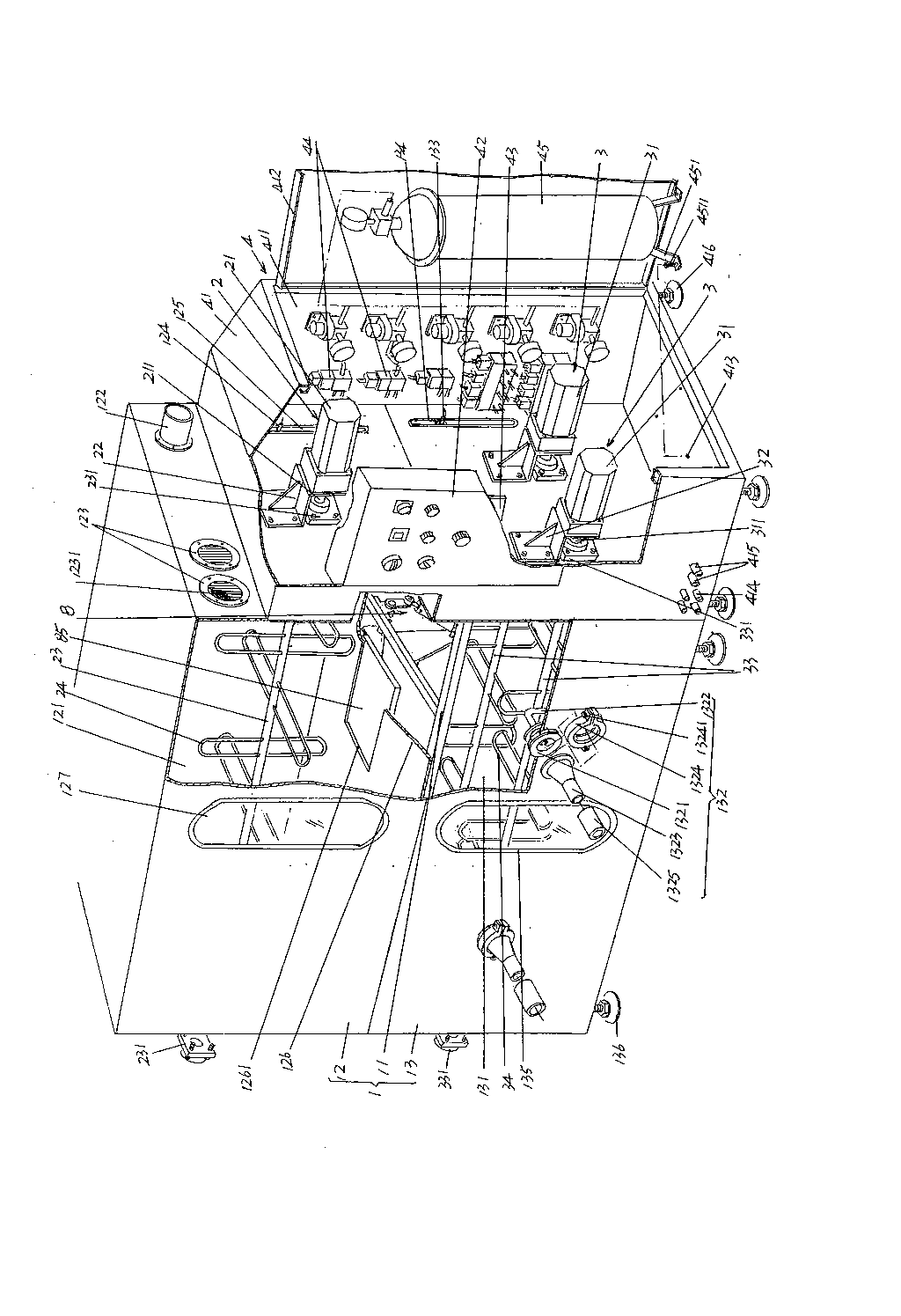

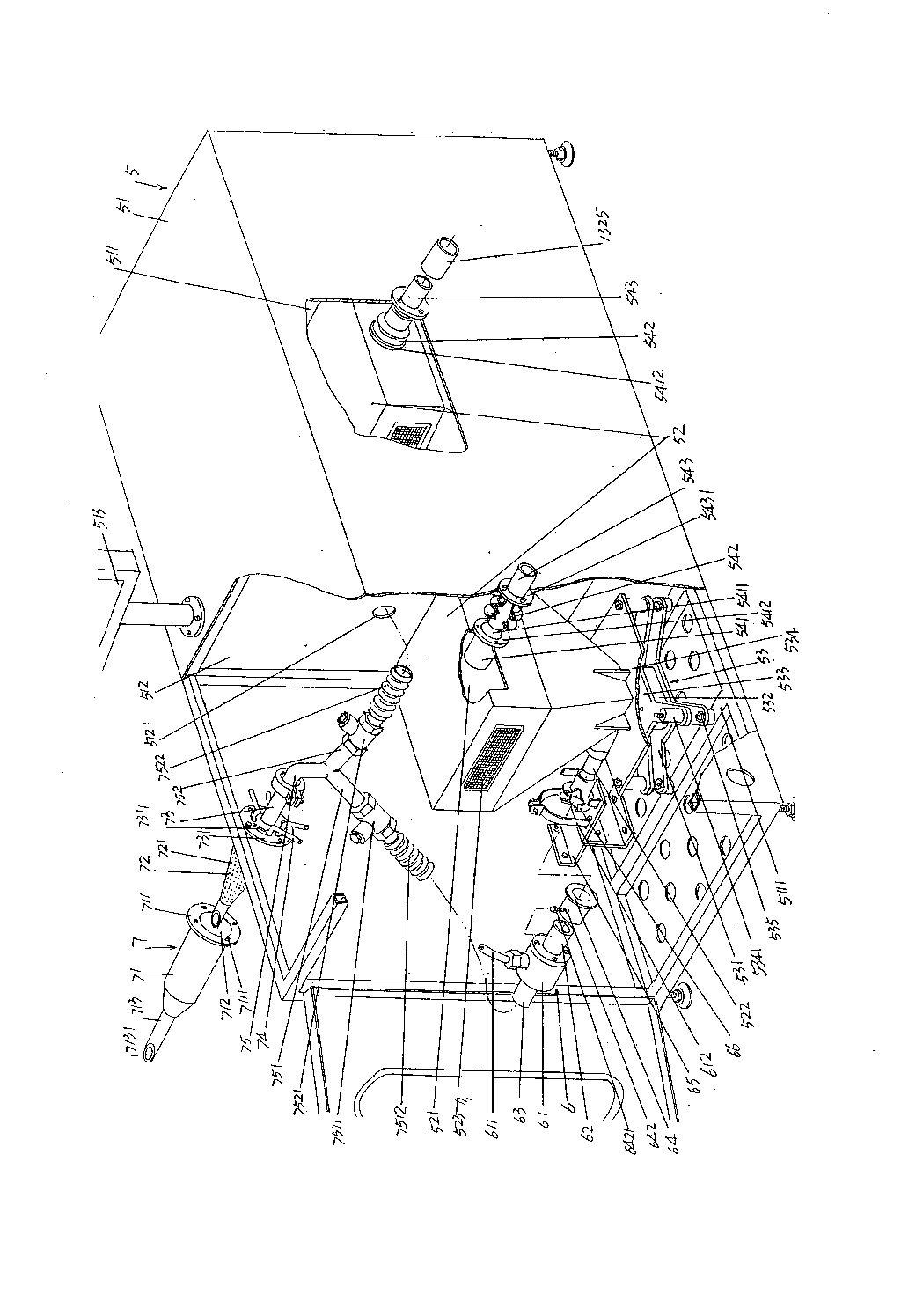

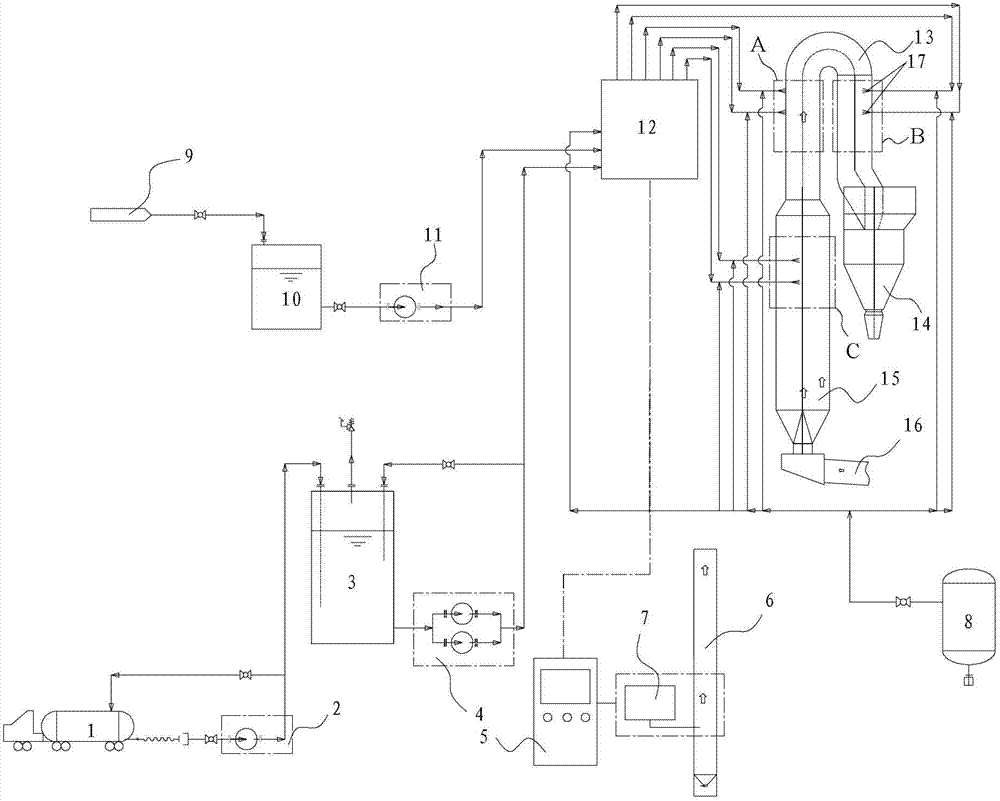

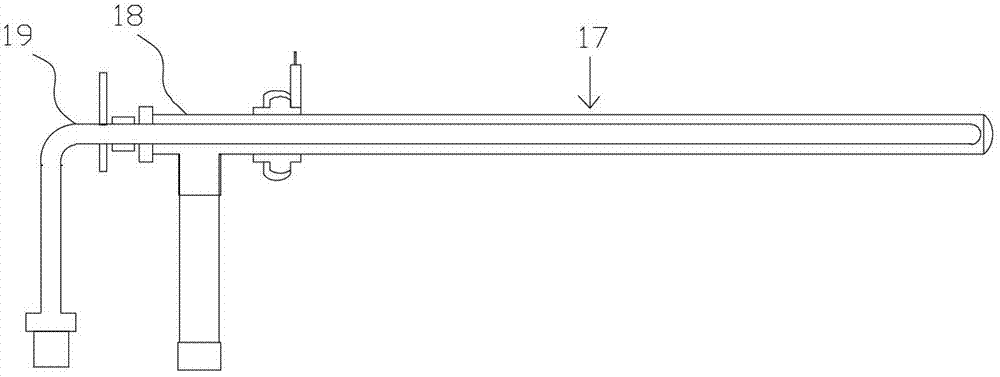

Automatic down filling machine

ActiveCN103101871AReduce escapeNo escapeUpholstery manufactureClothes making applicancesMagnetic valveEngineering

The invention discloses an automatic down filling machine, and belongs to the technical filed of a stowage unit for down and feather filled products. The automatic down filling machine comprises a box body, a first down stirring mechanism, a second down stirring mechanism, an electrical automatic control mechanism, a pair of weighing metering mechanisms, a pair of down output mechanisms, a pair of down filling heads and a box cavity channel start-and-stop mechanism. The box body comprises a box frame, a down storage box and a down delivering box. The first down stirring mechanism is used for stirring down in a down storage box cavity, and the second down stirring mechanism is used for stirring down in a down delivering box cavity. The pair of weighing metering mechanisms is connected with a pair of down leading out connector pipelines on two sides of the down delivering box, the pair of down output mechanisms is connected with the pair of weighing metering mechanisms, the pair of down filling heads is connected with the pair of down output mechanisms in a matched mode, and the box cavity channel start-and-stop mechanism is placed on the box frame. The electrical automatic control mechanism is provided with an electrical box body, a control panel, a programmable controller, a group of magnetic valves and a high-pressure air storage tank. The automatic down filling machine has the advantages of showing rhythmic continuity of down supplying, being capable of providing guarantee for subsequent continuously weighing and down filling, showing good down filling efficiency, reducing operation intensity of workers, eradicating down wasting and showing good automatic control effect.

Owner:苏州比阳特服装设备有限公司

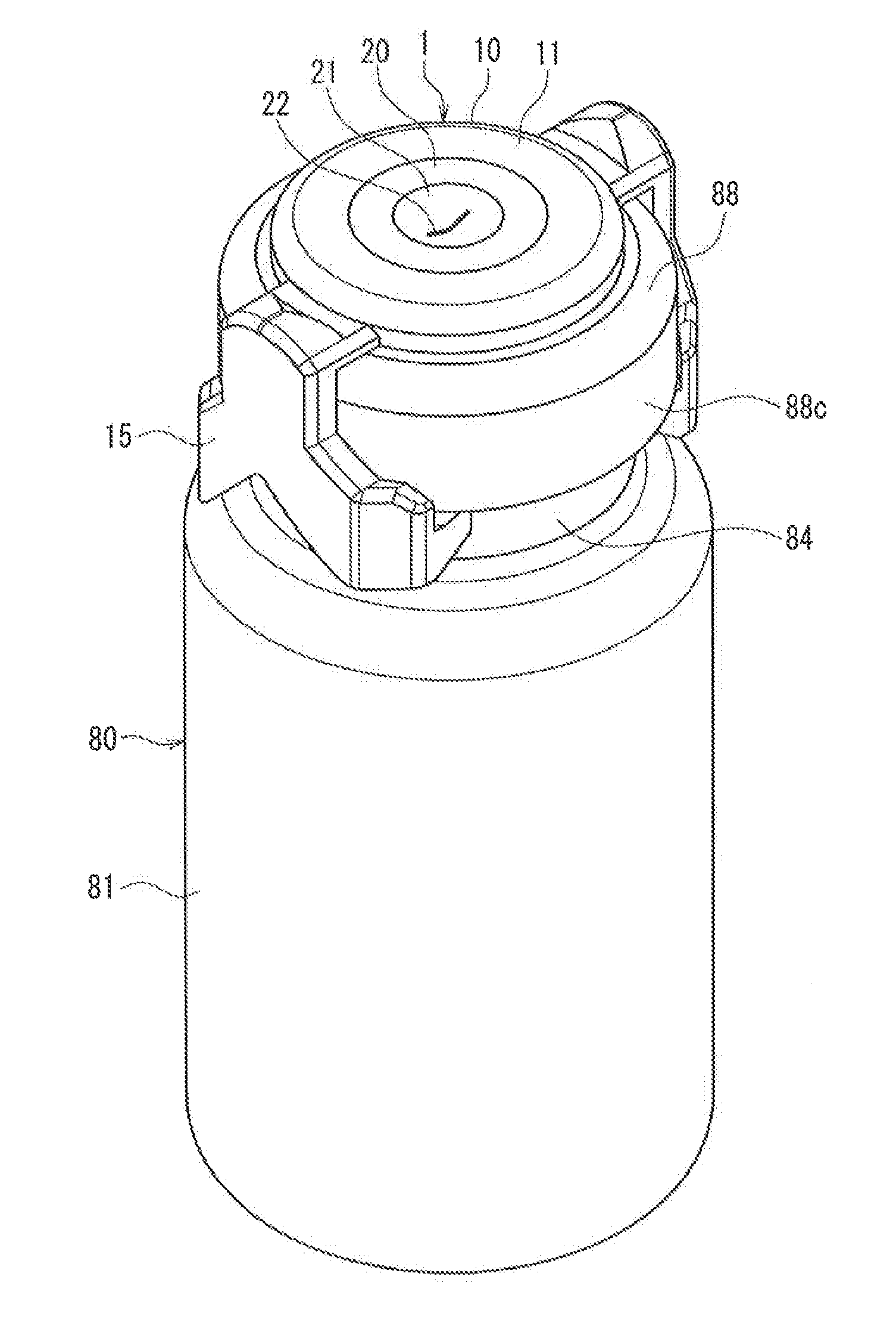

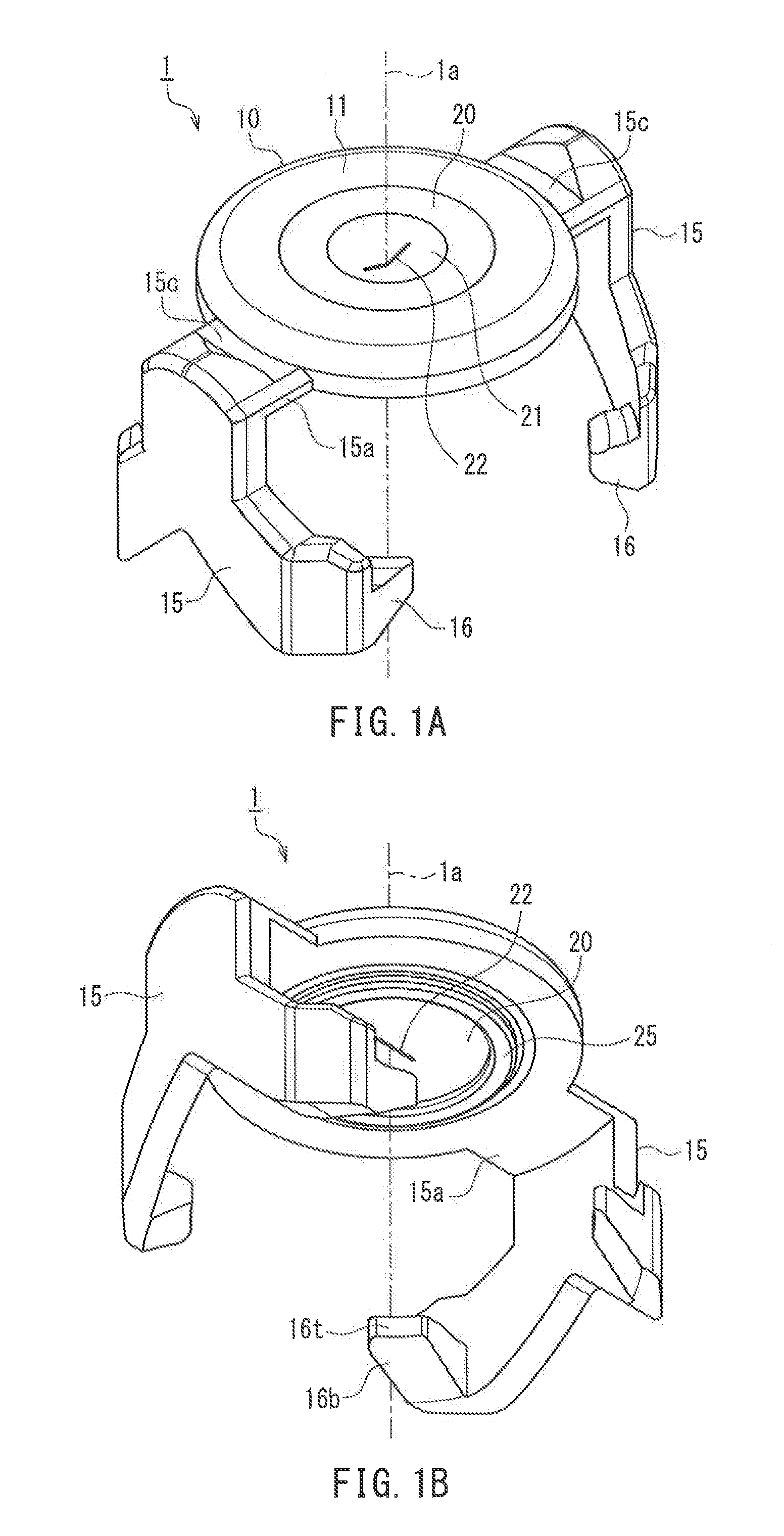

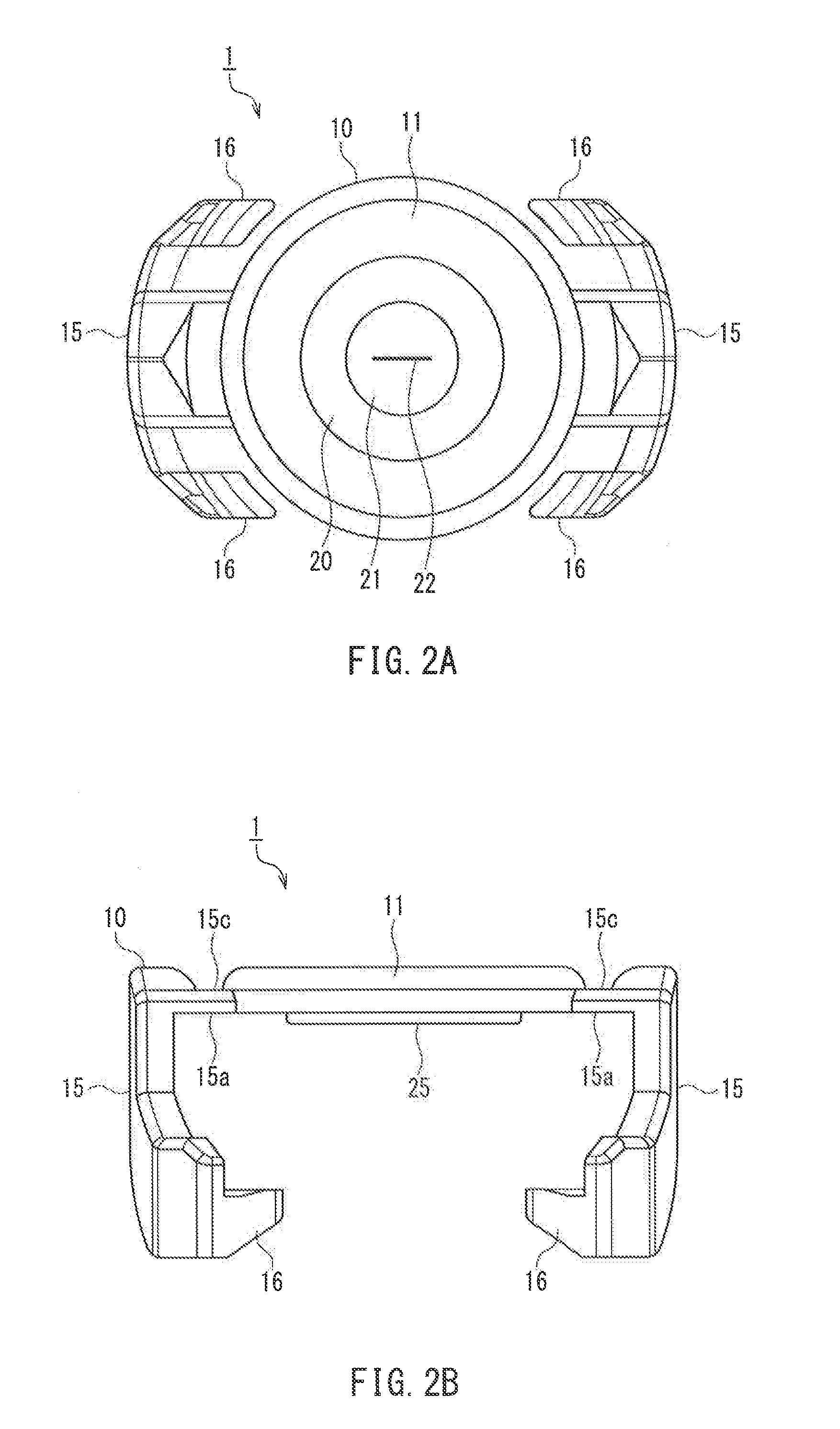

Vial shield

A vial shield (1) has a shield main body (10) and a valve element (20). The shield main body (10) includes an annular top plate (11) that is to be laid on top of an upper surface of a stopper (86) that seals a mouth (83) of the vial bottle (80), a plurality of legs (15) extending downward from the top plate (11), and a plurality of claws (16) provided in the plurality of legs (15), the claws being engageable with the mouth (83) of the vial bottle (80). The valve element (20) blocks an opening at the center (12) of the top plate (11). A cut (22) passing through the valve element (20) in a vertical direction is formed in the valve element (20).

Owner:JMS CO LTD

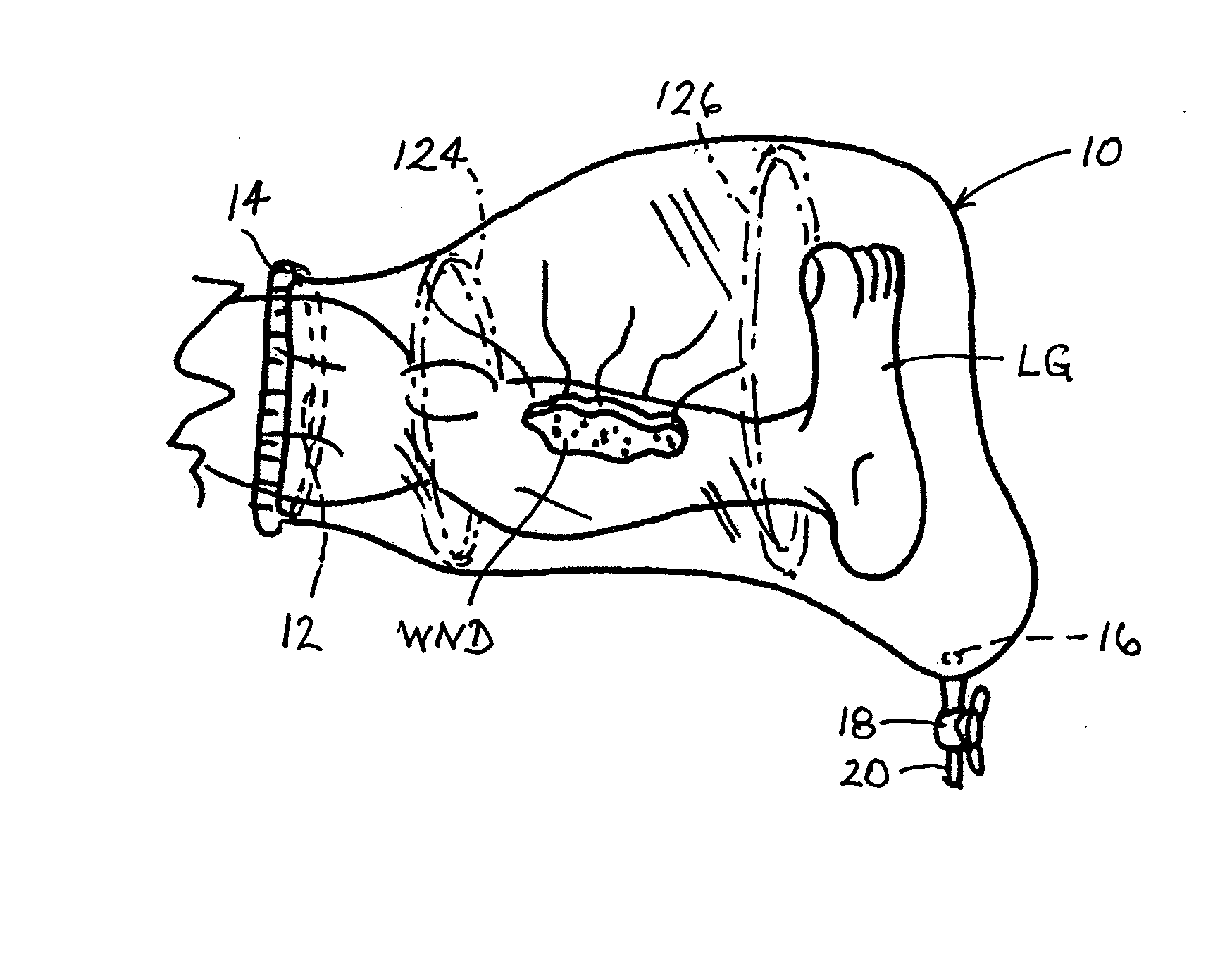

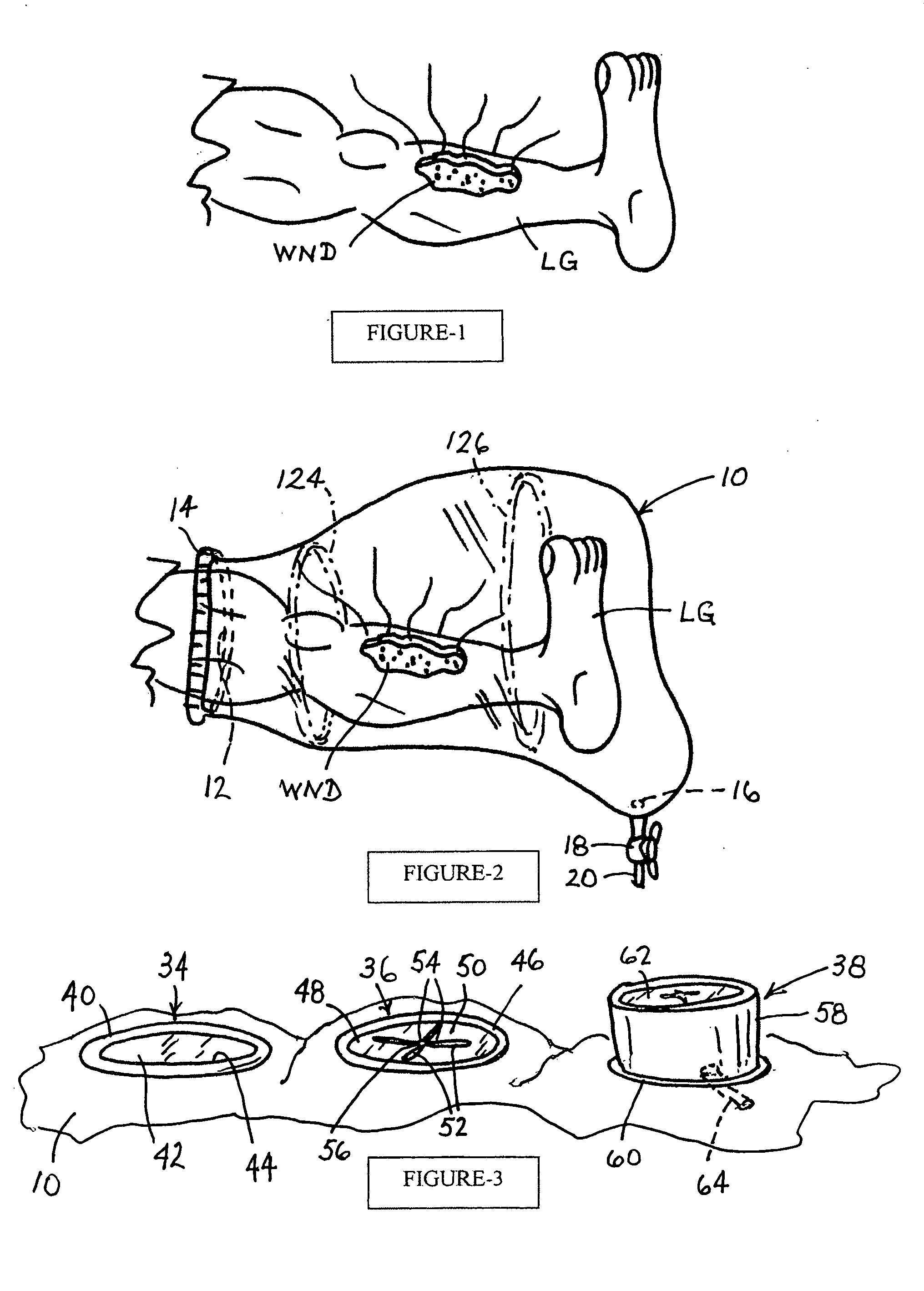

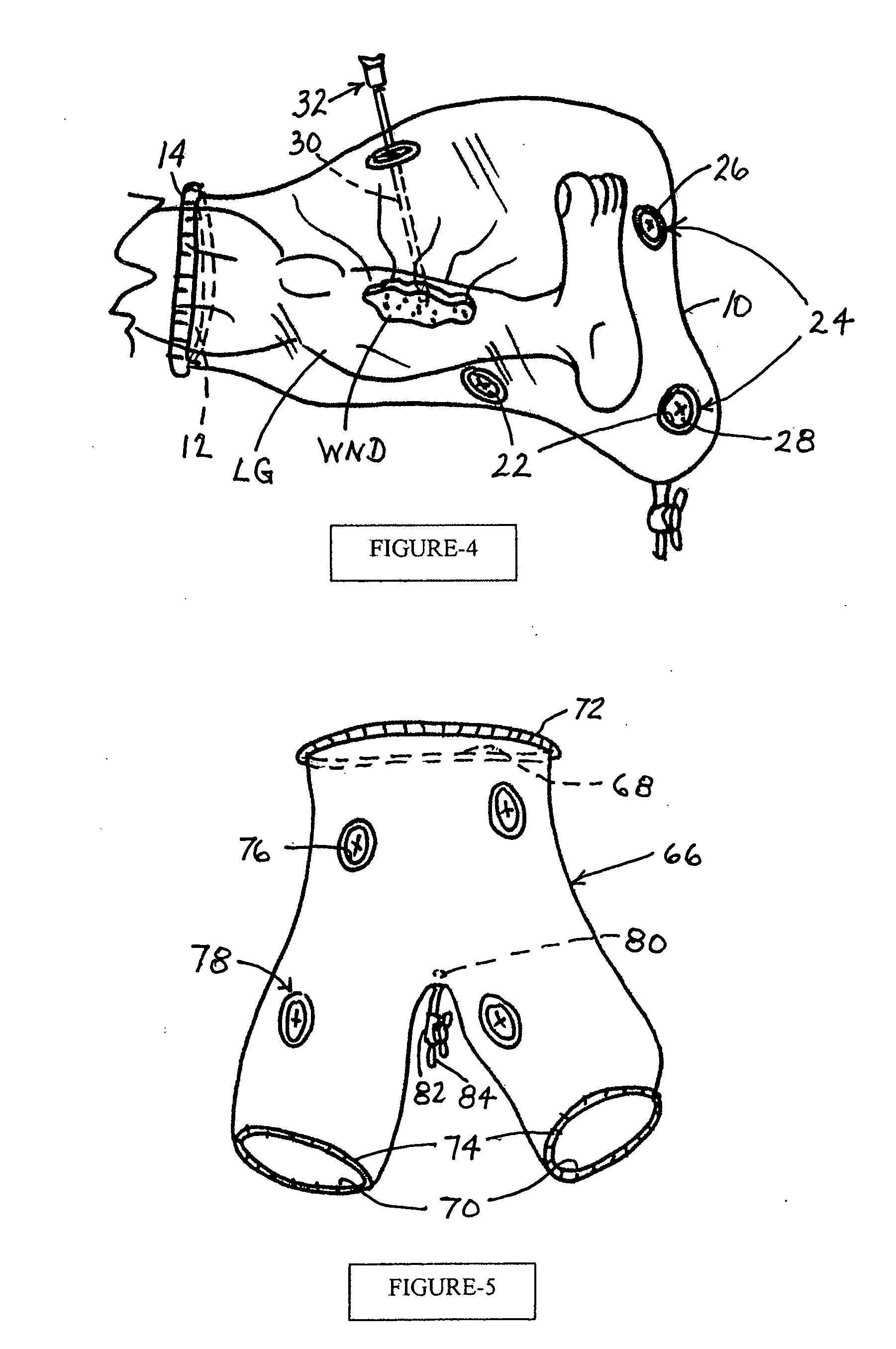

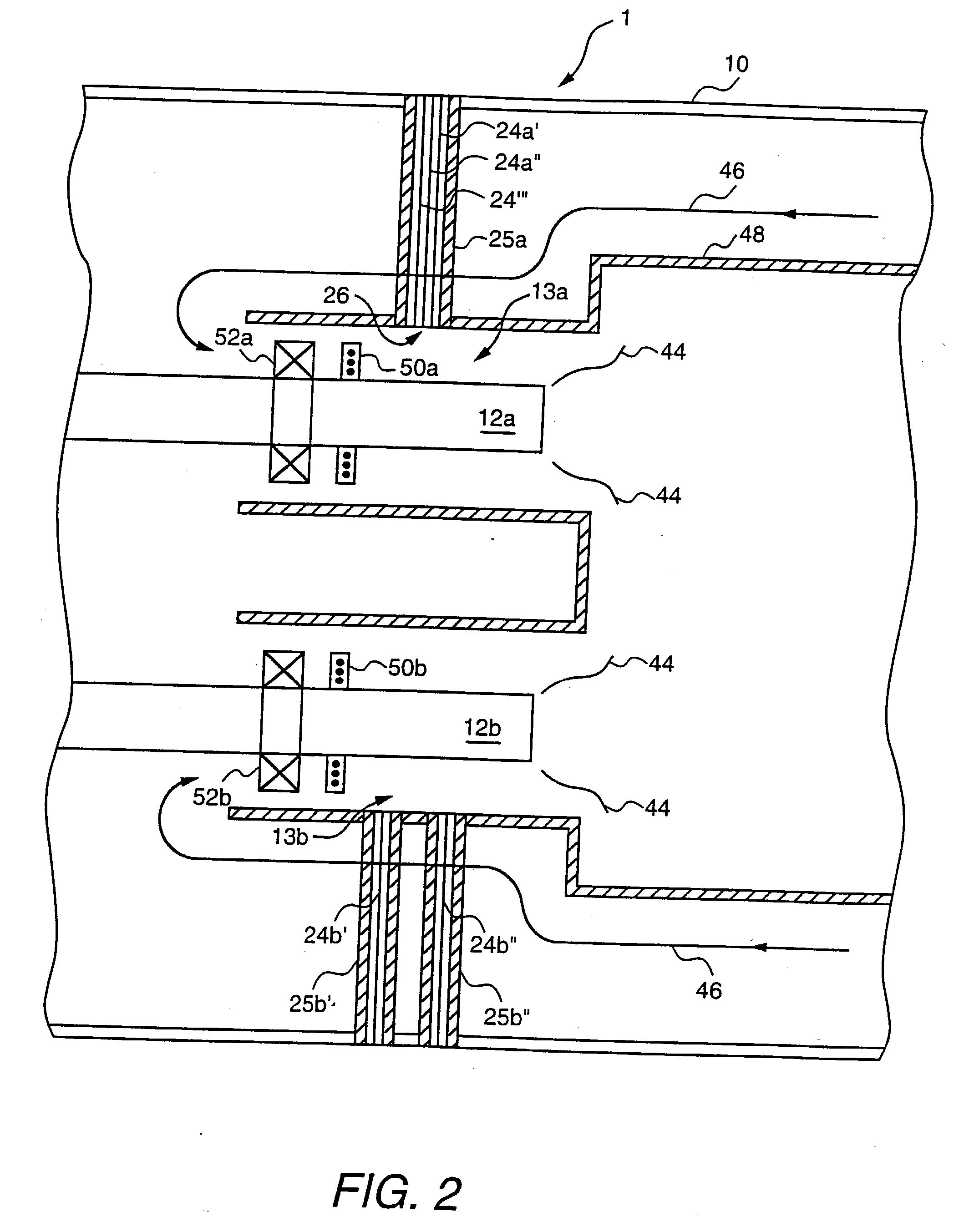

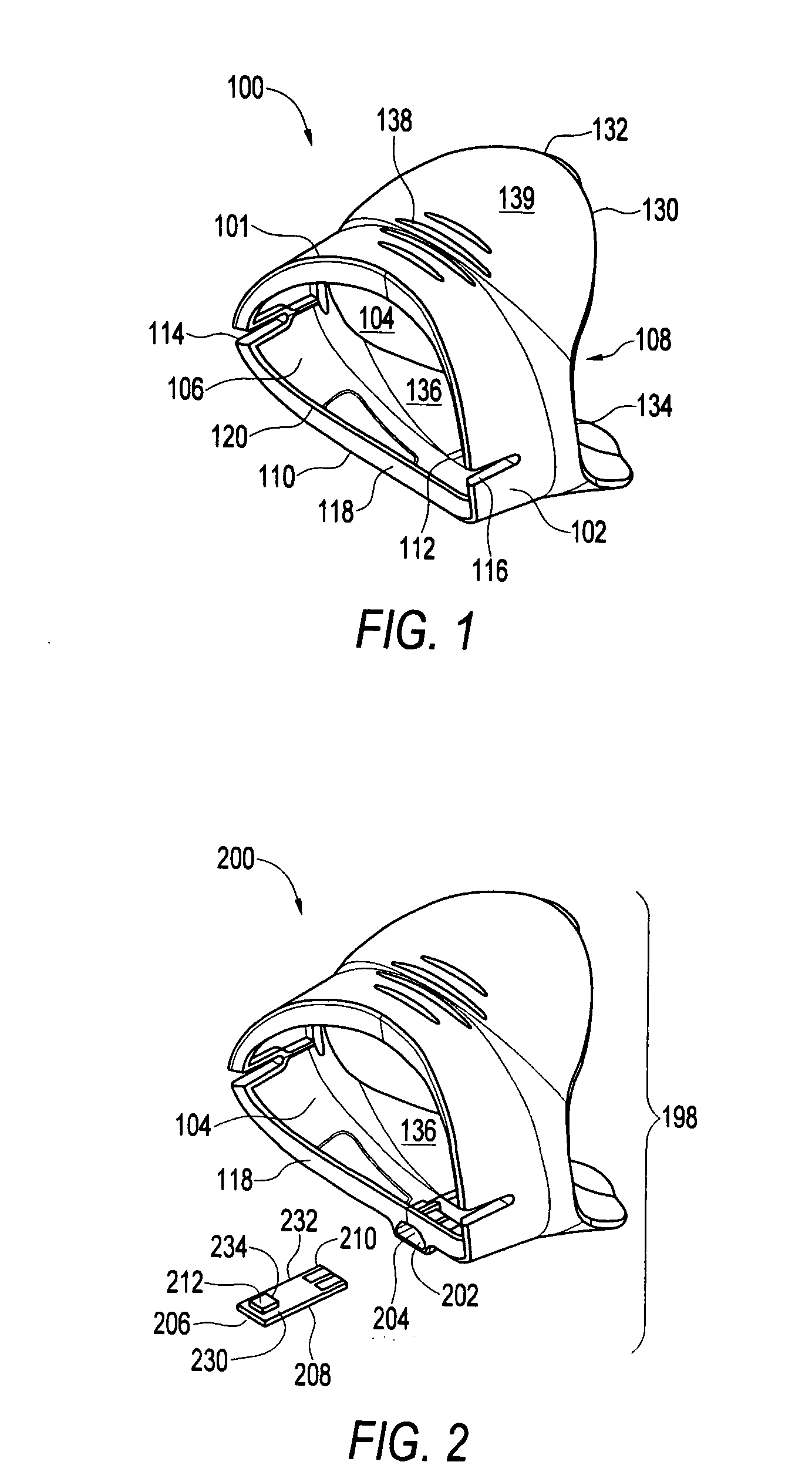

Fluid containment apparatus for surgery and method of use

A liquid containment system in accordance with the present invention includes a flexible plastic or elastomeric bag with several apertures. Surrounding each aperture is a port member such as a silastic ring. The port member functions at least reduce the escape of airborne particules from the bag while permitting the insertion of a surgical instrument into the bag. The port member may be made at least partially of a silicone based material to provide resistance to damage by ultrasonic tools.

Owner:MISONIX INC

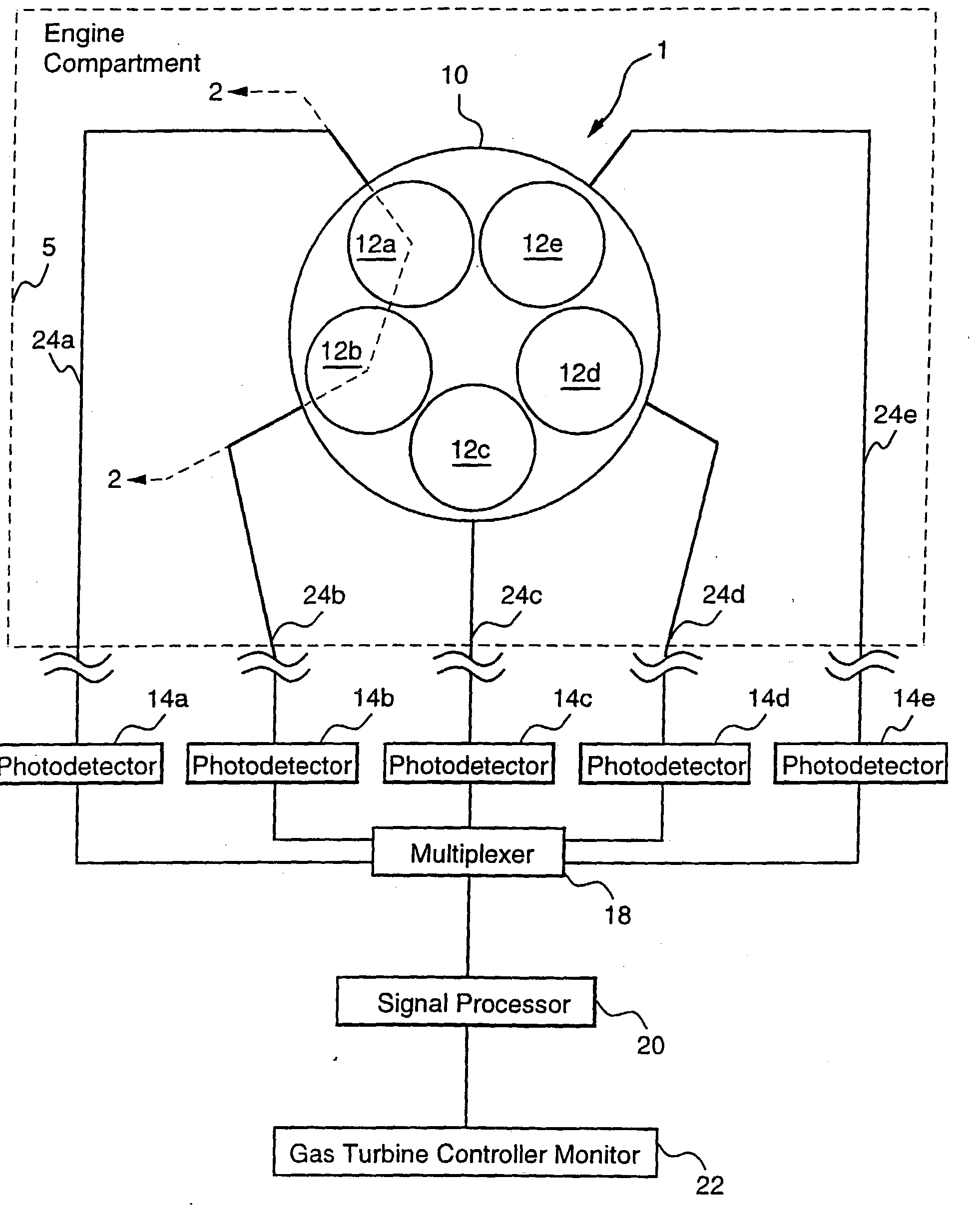

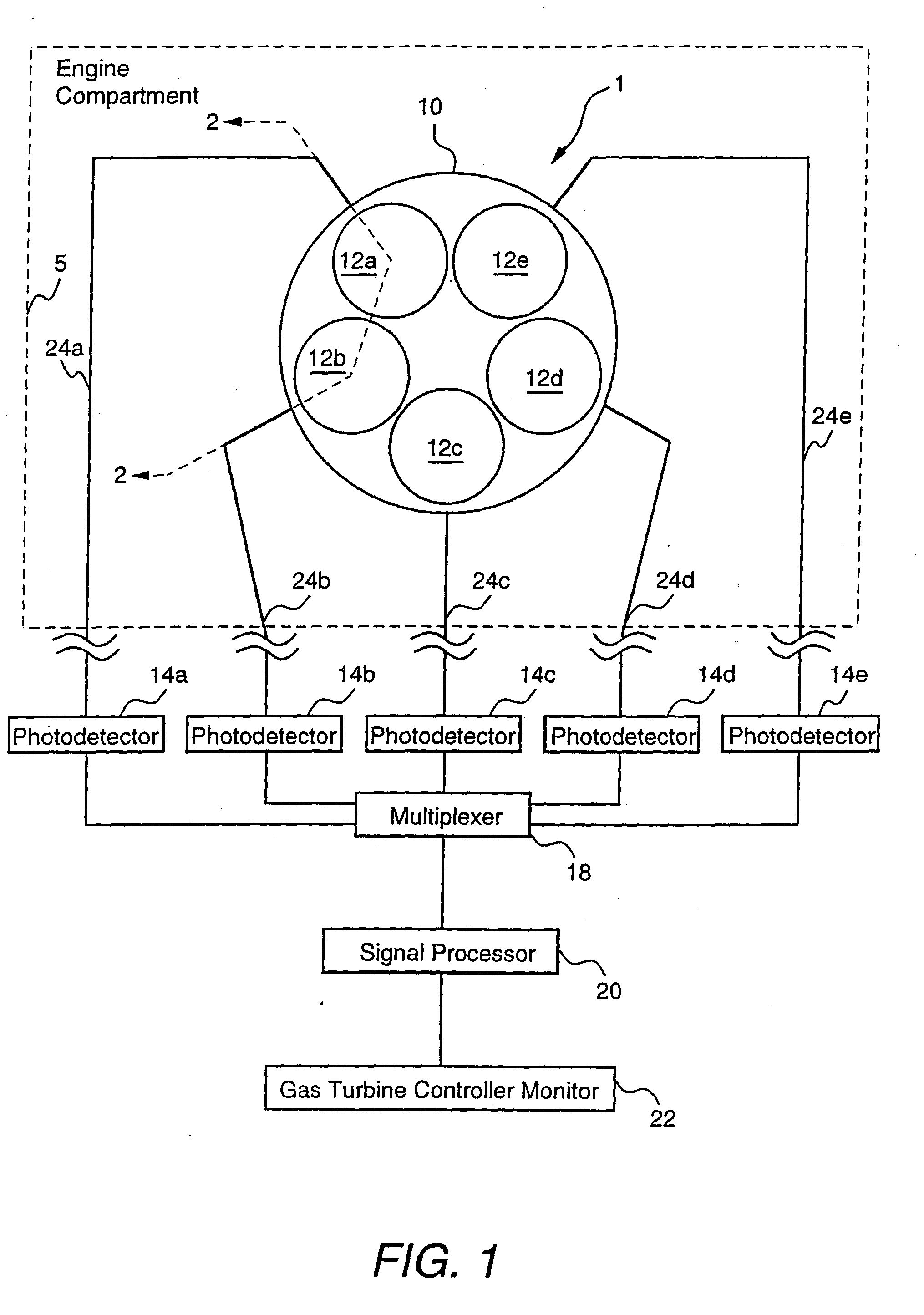

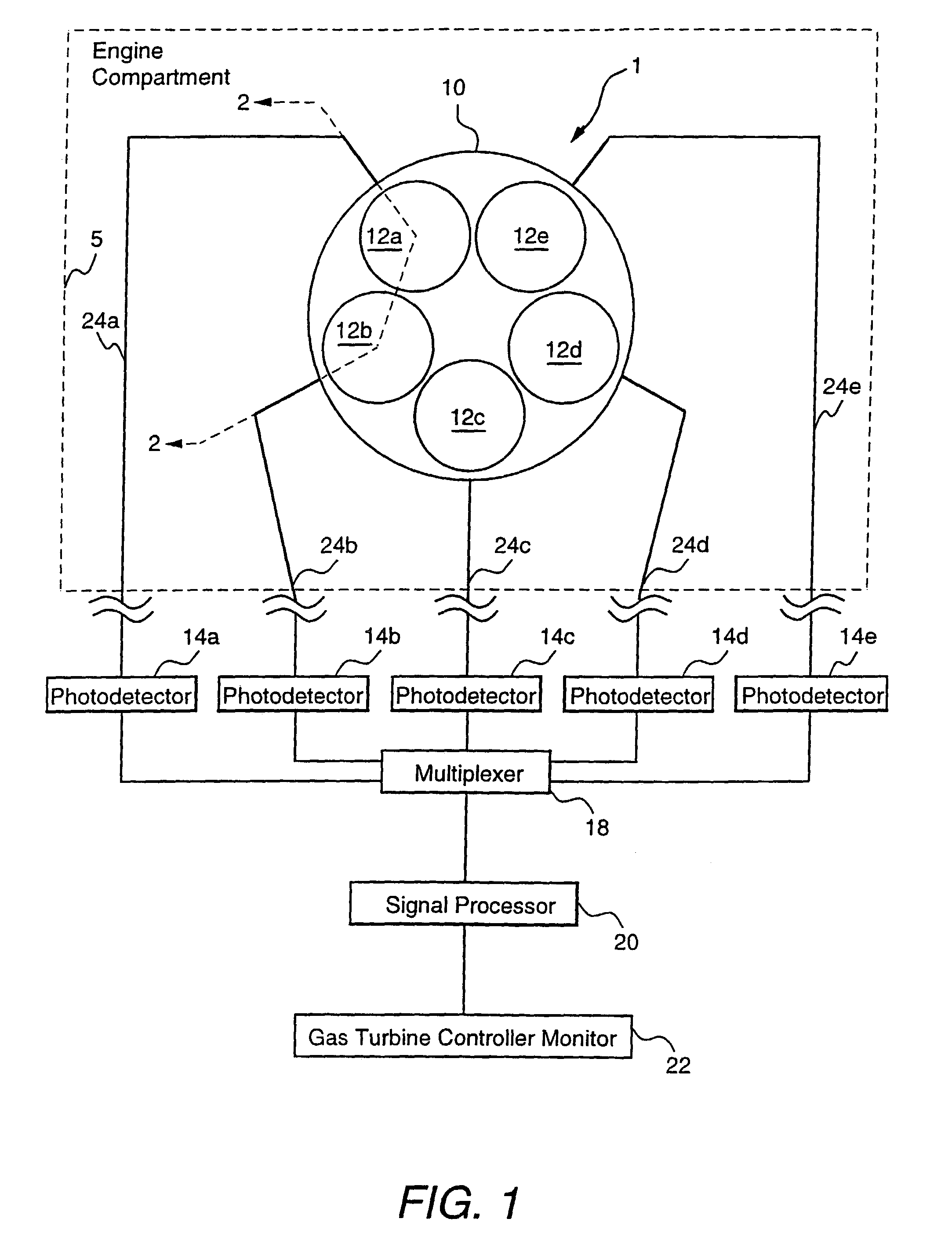

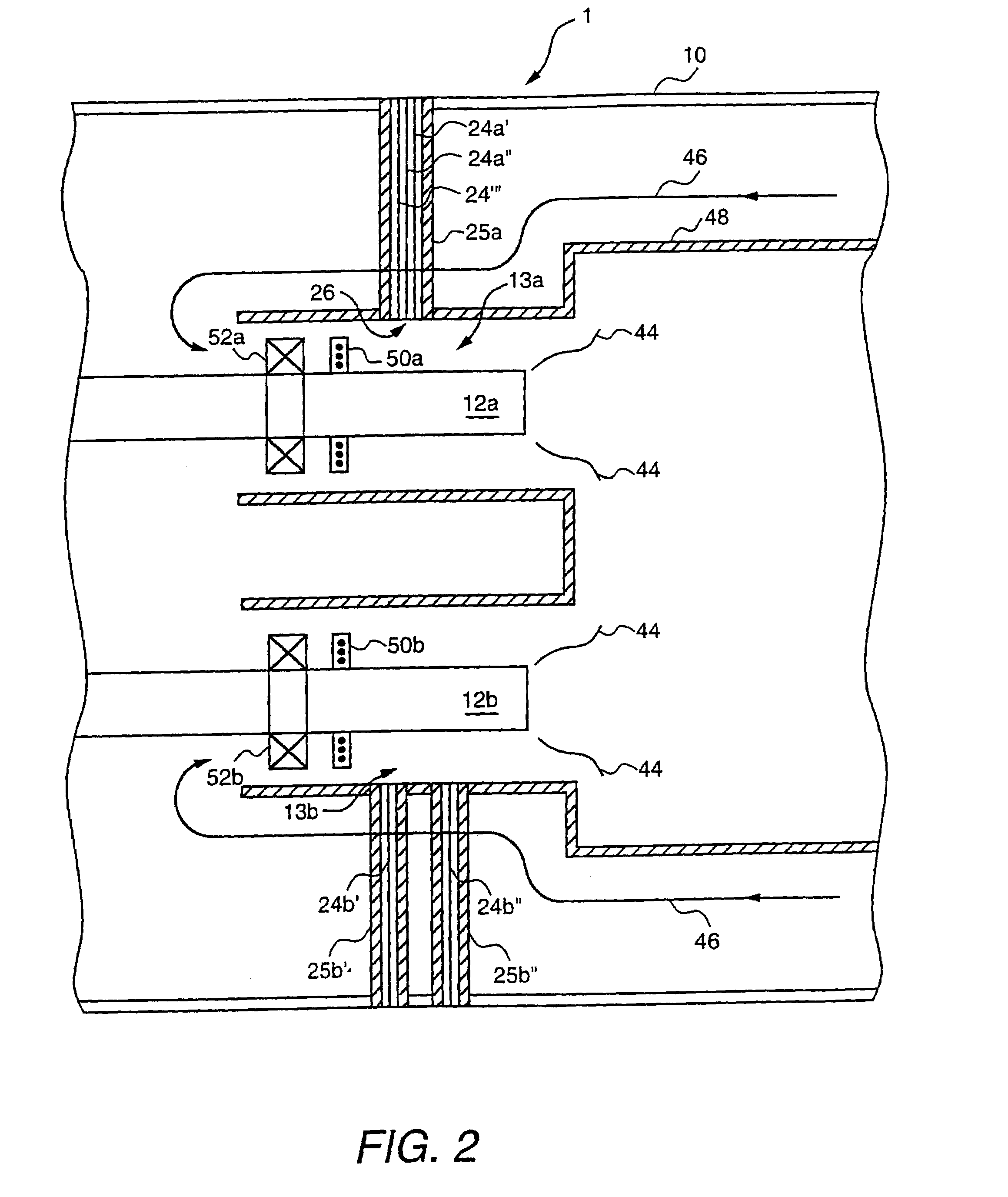

Fiber optic sensors for gas turbine control

InactiveUS20050180699A1Reduce consequenceCost reductionContinuous combustion chamberMaterial analysis by optical meansPhotodetectorFiber optic sensor

An apparatus for detecting flashback occurrences in a premixed combustor system having at least one fuel nozzle includes at least one photodetector and at least one fiber optic element coupled between the at least one photodetector and a test region of the combustor system wherein a respective flame of the fuel nozzle is not present under normal operating conditions. A signal processor monitors a signal of the photodetector. The fiber optic element can include at least one optical fiber positioned within a protective tube. The fiber optic element can include two fiber optic elements coupled to the test region. The optical fiber and the protective tube can have lengths sufficient to situate the photodetector outside of an engine compartment. A plurality of fuel nozzles and a plurality of fiber optic elements can be used with the fiber optic elements being coupled to respective fuel nozzles and either to the photodetector or, wherein a plurality of photodetectors are used, to respective ones of the plurality of photodetectors. The signal processor can include a digital signal processor.

Owner:GENERAL ELECTRIC CO

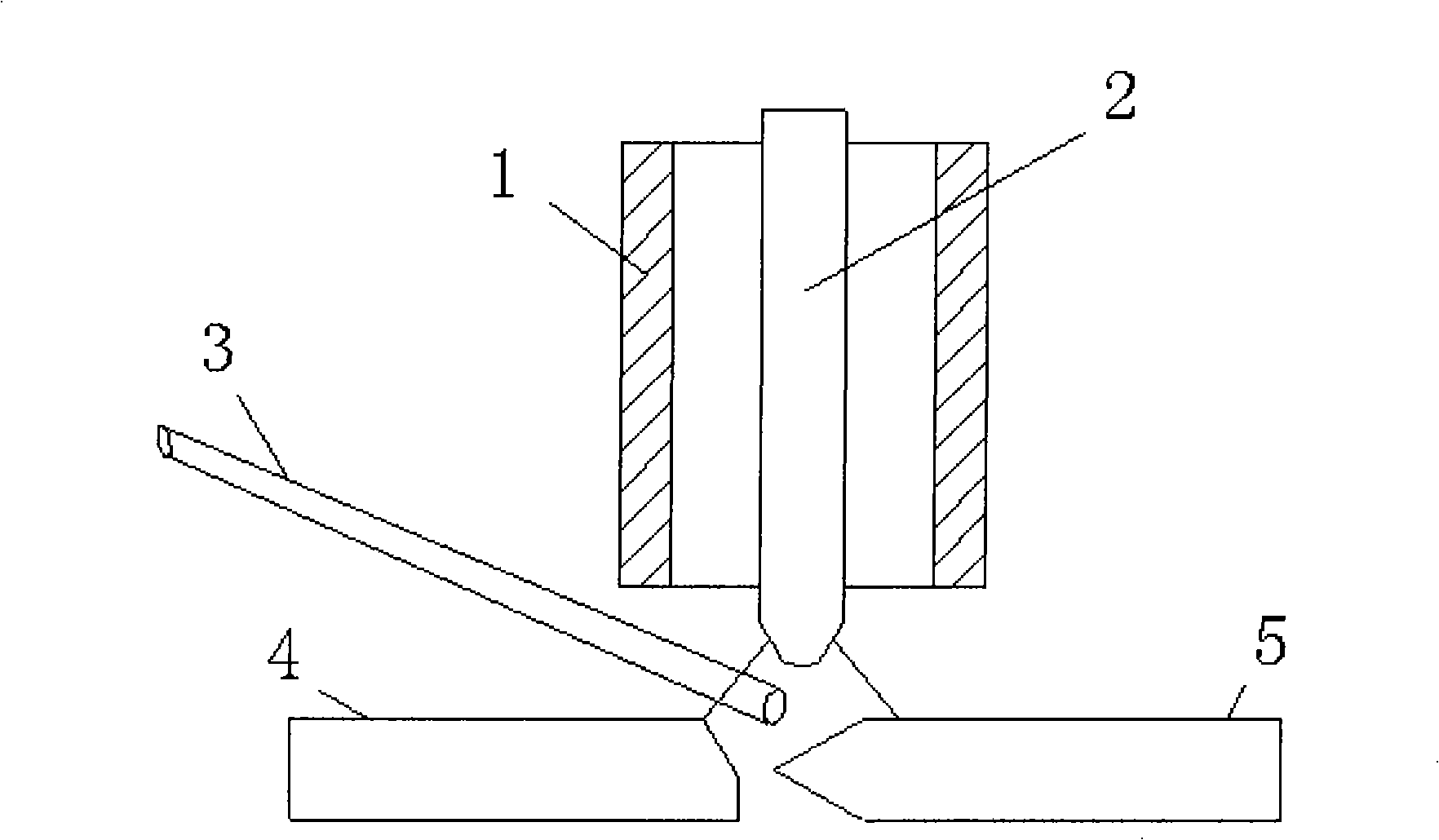

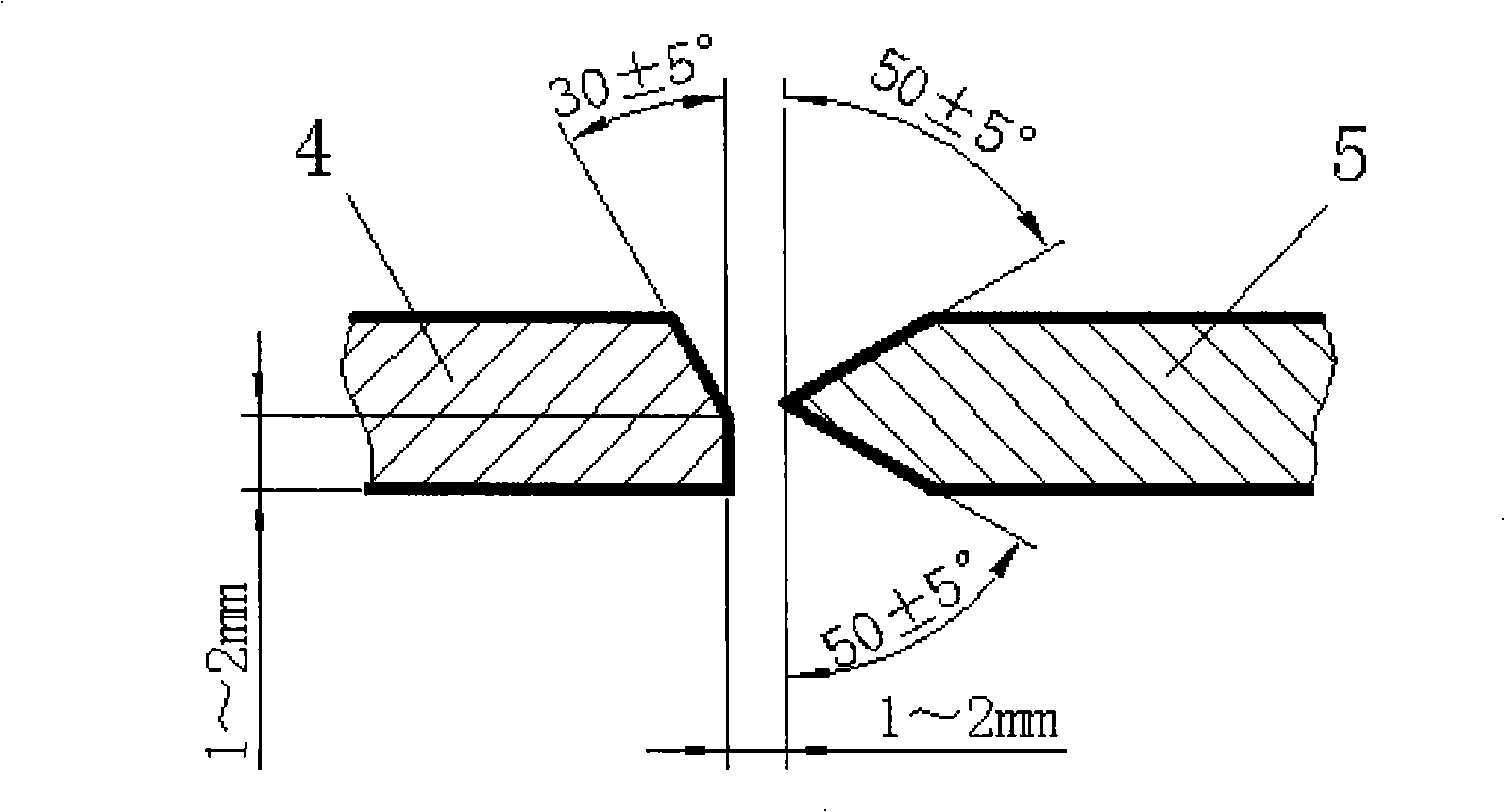

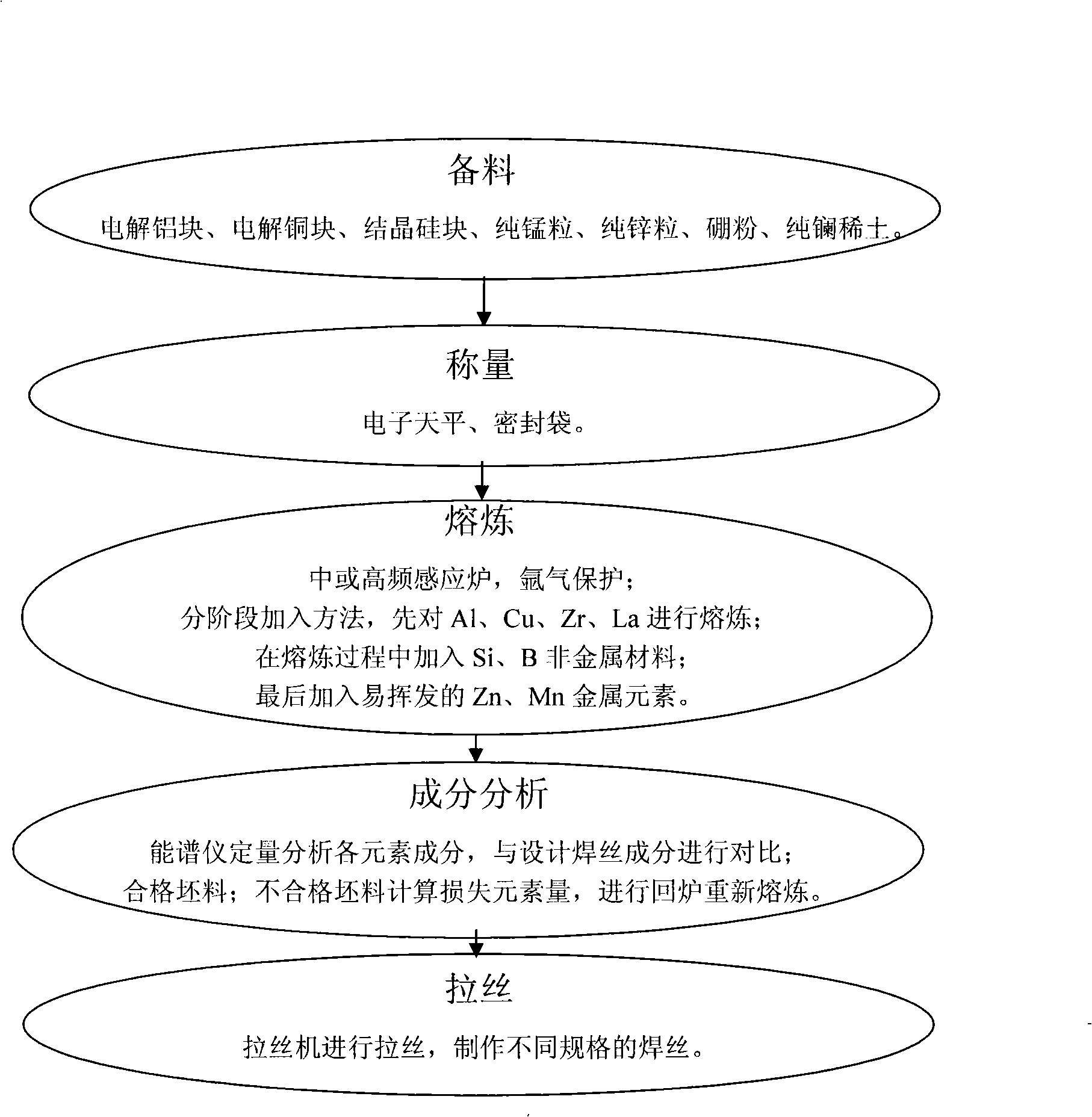

Welding wire and method for welding the aluminum and aluminum alloy and steel

InactiveCN101284339AImprove crack resistanceSuppresses the formation of intermetallic compoundsArc welding apparatusWelding/cutting media/materialsAlloy elementElectric arc

The invention discloses a welding wire and a method for applying the welding wire on aluminum and aluminum alloy to be welded with steel. The welding wire (3) takes Al-Si solder as matrix, and then alloying elements of Cu, Mn, Zn and microelements of B, Zr and La are added to form a dedicated welding wire. The method comprises the following steps: K-shaped divided edges are formed on both ends of the aluminum and aluminum alloy (5); the angle of the divided edges is 50 plus or minus 5DEG C; a divided edge of 30 plus or minus 5 and a truncated edge of 1.0-2.0mm are formed on the side of a steel piece (4); the steel piece (4) is fixed on a chucking tool with a cooling device; the butt clearance between the aluminum and aluminum alloy (5) and the steel piece (4) is 1.0-2.0mm; a small-scaled pulse AC TIG welding method is adopted for single-side welding to realize double side shaping; a tungsten electrode (2) is hemispherical; the nozzle (1) of a welding gun is inclined to the aluminum side; and the welding wire (3) is continuously fed. The method can successfully realize the effective and fine quality connection of the aluminum and the dissimilar steel material by electric arc braze welding without clad layer, and has the advantages of simple operation, low welding cost, and stable and reliable welding process.

Owner:HARBIN INST OF TECH

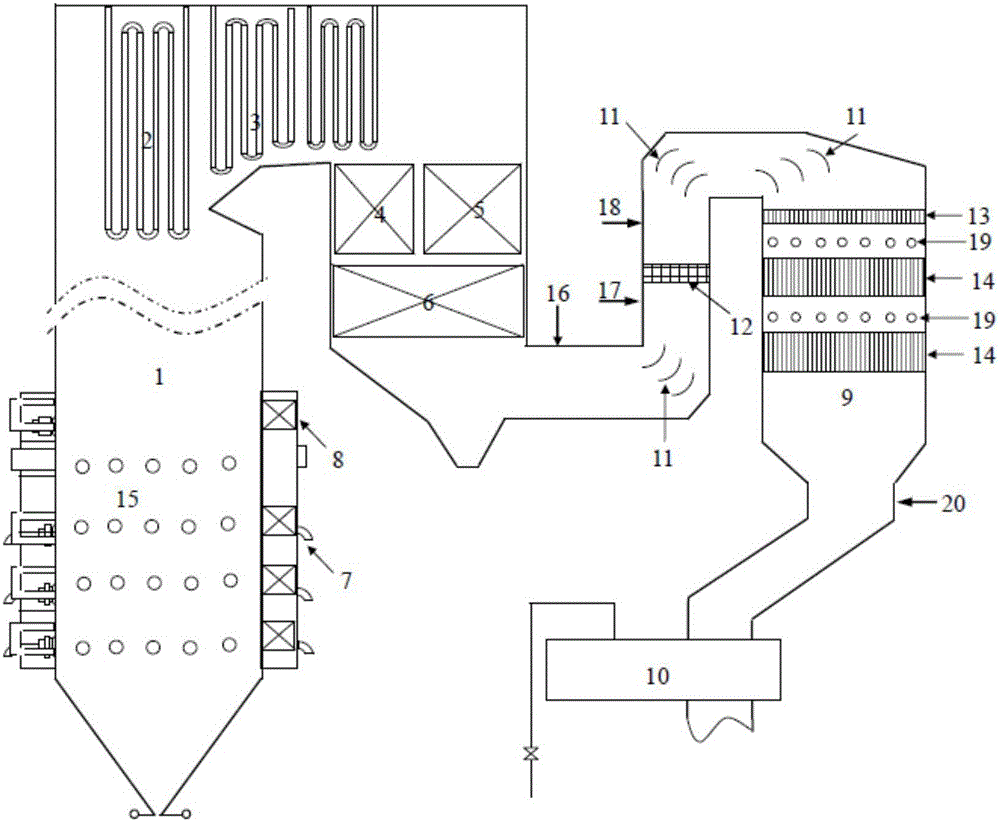

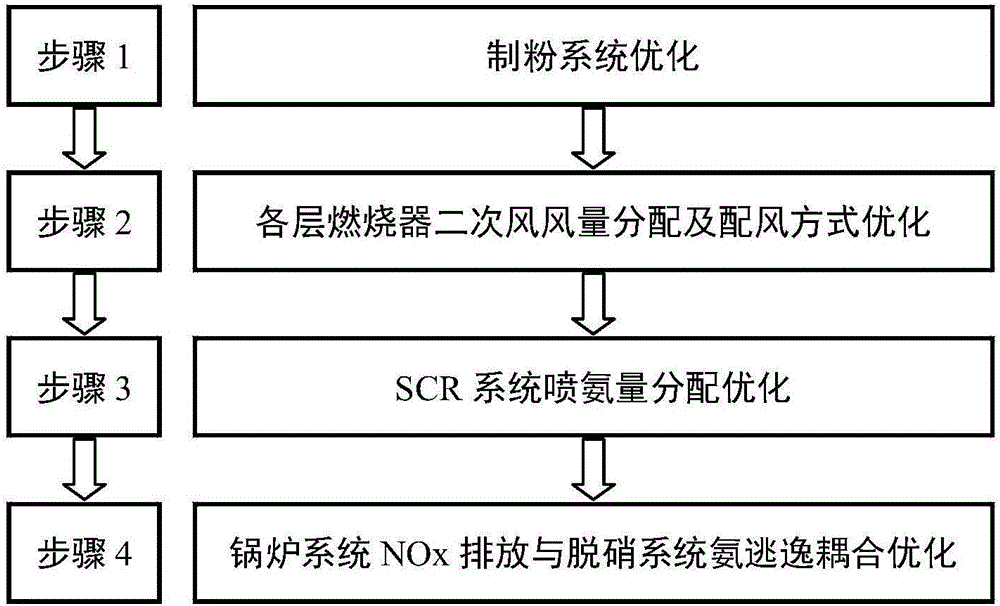

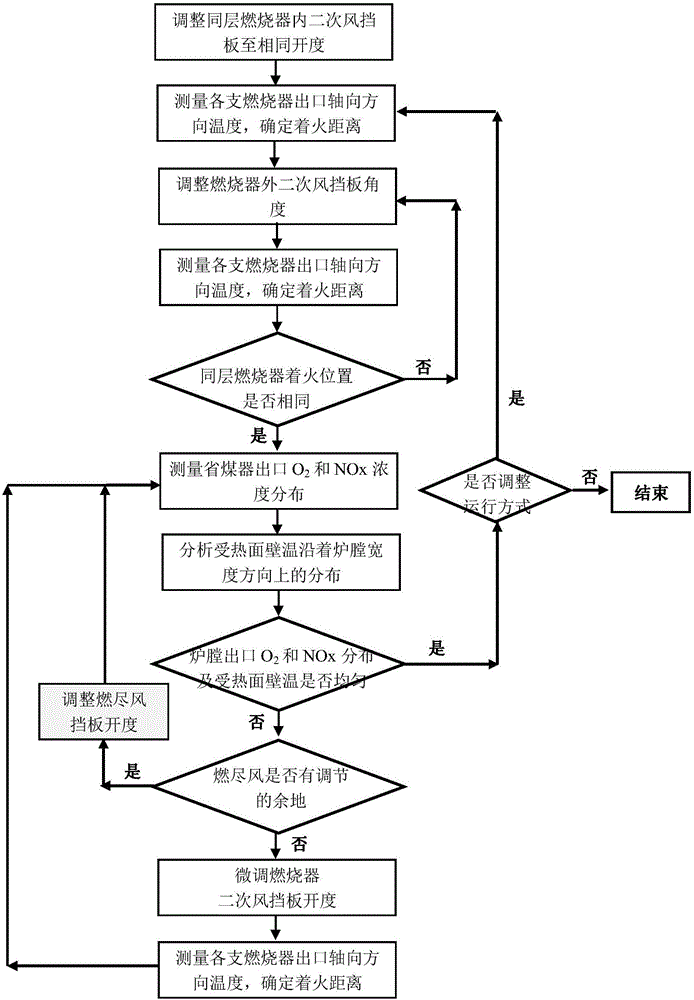

Coal-fired power plant boiler system and denitration system operation collaborative optimization method

ActiveCN105953259AEconomic operation modeGuaranteed operational safetyFuel supply regulationFuel feeding arrangementsOperation modeOxygen

The invention provides a coal-fired power plant boiler system and denitration system operation collaborative optimization method. The method comprises the following steps: the operation of a powder preparation system is optimized and adjusted; the operation of a combustion system is optimized and adjusted; the operation of a denitration system is optimized and adjusted; the coal-fired boiler NOx emission control and the SCR denitration system ammonia escape control are coupled for optimization and adjustment; an optimal operation oxygen quantity range of a coal-fired boiler under different loads and an optimal openness range of a burnt wind nozzle in the optimal oxygen quantity operation range are determined by combining the reductive atmosphere distribution characteristics in a near wall area of a hearth water cooling wall and the denitration ammonia escape conditions; and an optimal denitration efficiency range of the denitration system under different loads is determined. The three system operation collaborative optimization methods, provided by the invention, see the boiler system and the denitration system as a large system; the mutual correlation and influence among the three systems are decoupled from the angle of the large system; and the most economical and safest operation mode of the large system is obtained through optimization.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

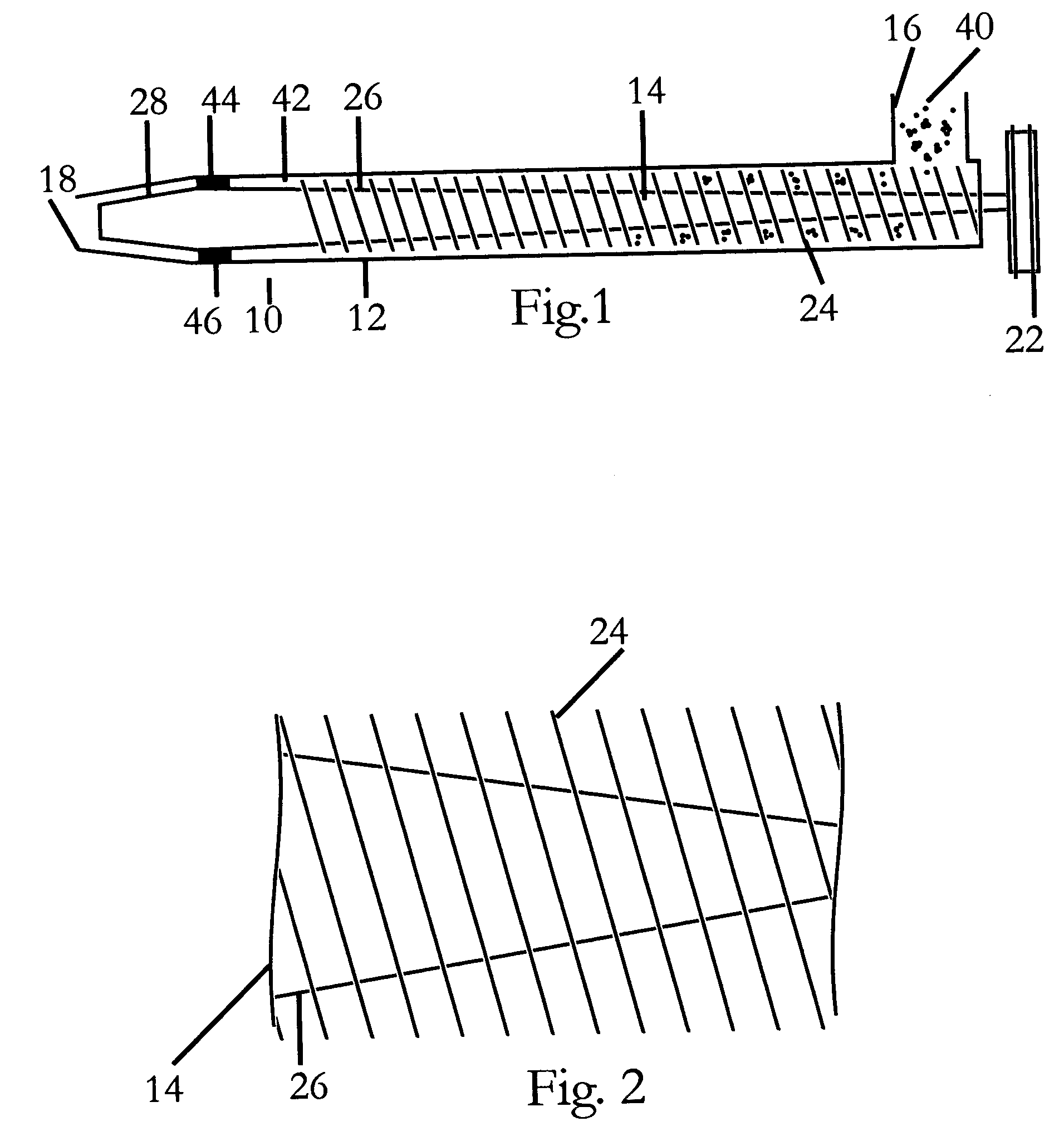

Wood gasification apparatus

A wood gasification apparatus in which cellulosic material is transported by an auger through a housing and heated to vaporize at least a portion of the cellulosic material by frictional heating. The auger and housing define a spiral void through which the cellulosic material is propelled from the inlet to the outlet, and which continually decreases in volume from the inlet to the outlet. The ever decreasing volume of the void increases the pressure on the cellulosic material and maximizes the frictional heating until the material reaches a vaporization temperature.

Owner:BIO GAS TECH

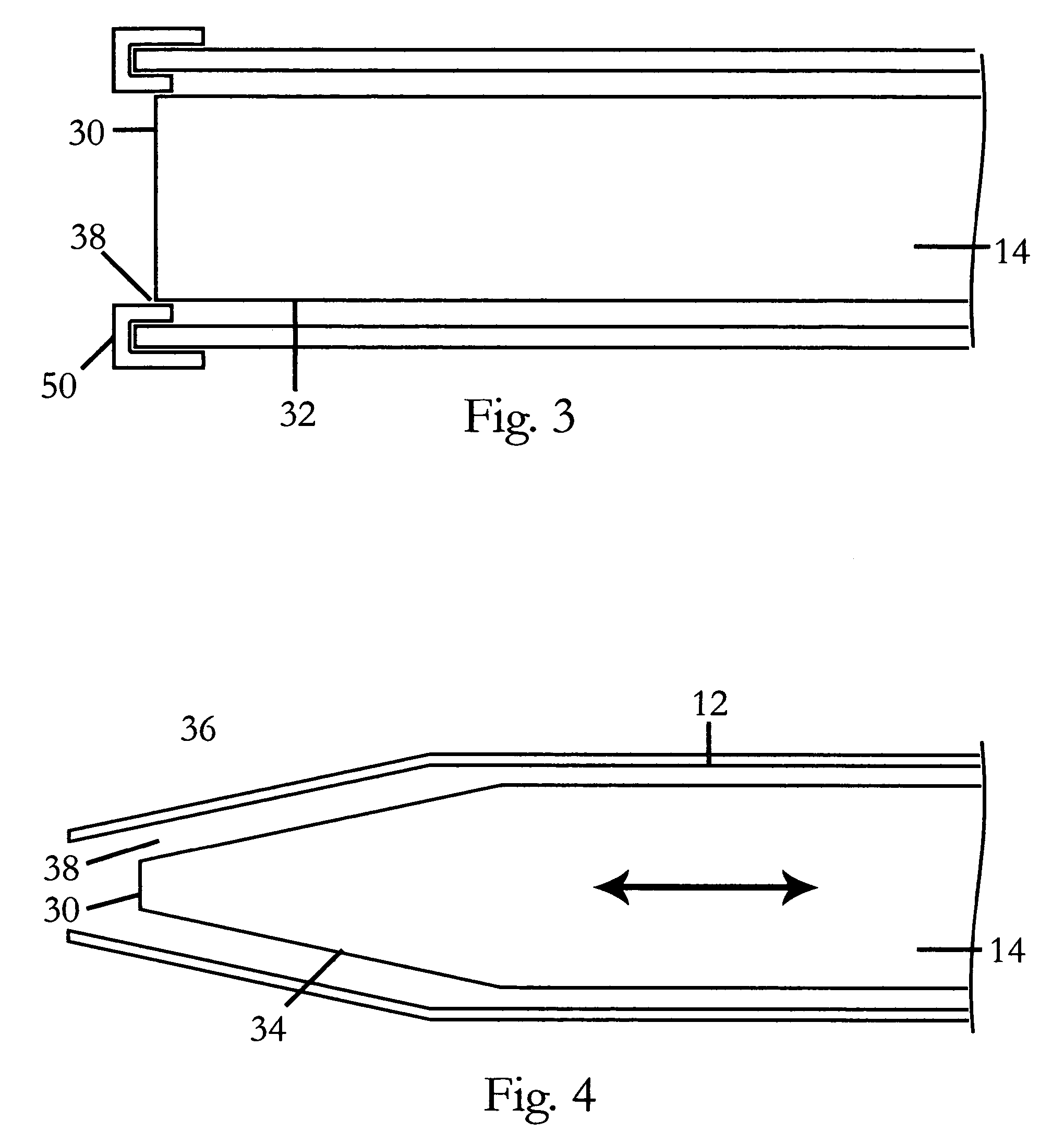

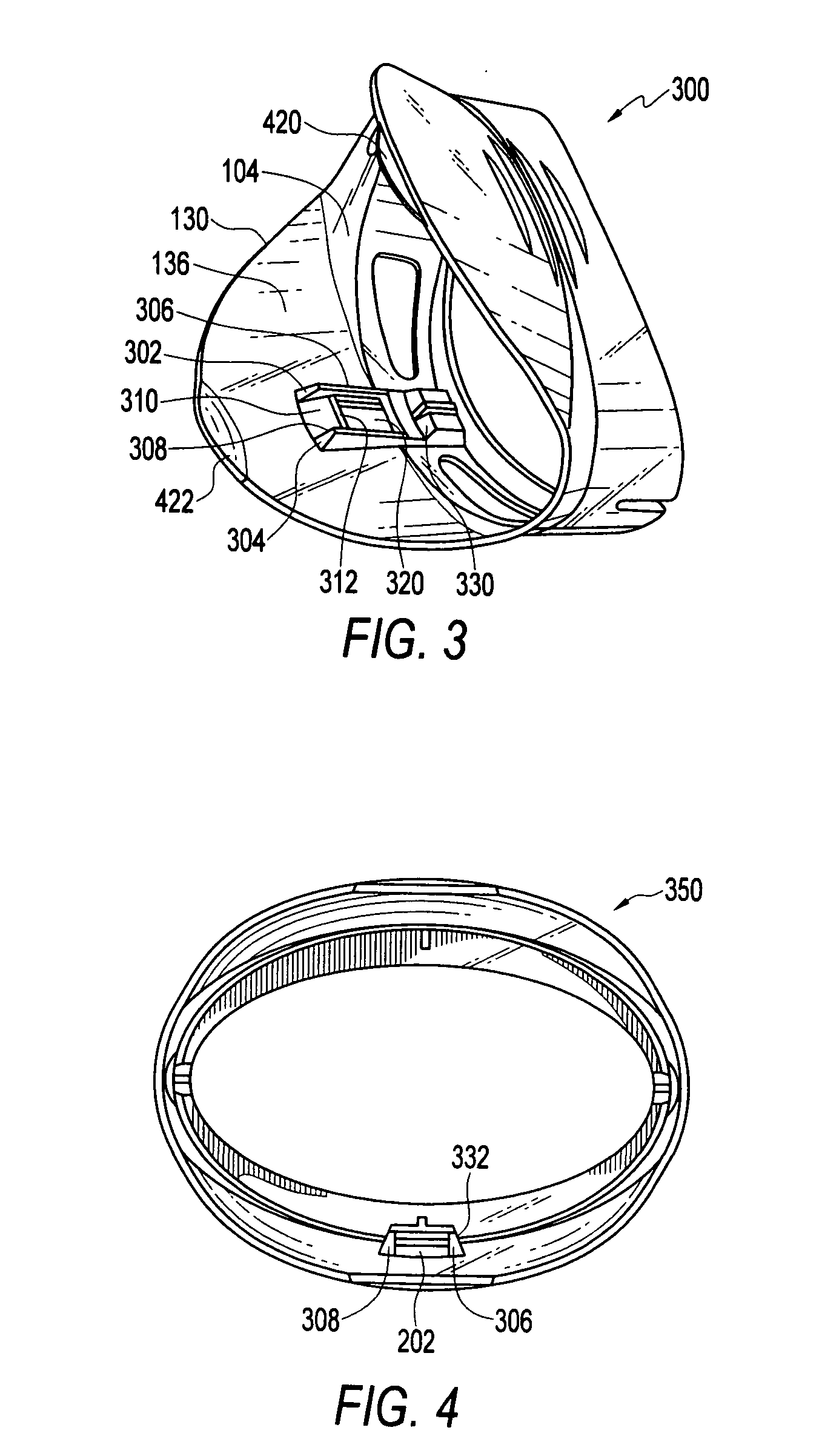

Light guide for dentistry applications

ActiveUS20060029901A1Facilitate faster patient set up and optimal resultReduce evaporationOperating chairsLighting support devicesLight guideEngineering

The present invention relates to a light guide for a lamp for dentistry procedures. The light guide provides an optical channel between a light source and a dental substrate. The light guide may be a one-patient use light guide including a recording medium to record the time used. The light guide further provides protection for a patient's soft tissues during treatment.

Owner:DISCUS DENTAL LLC

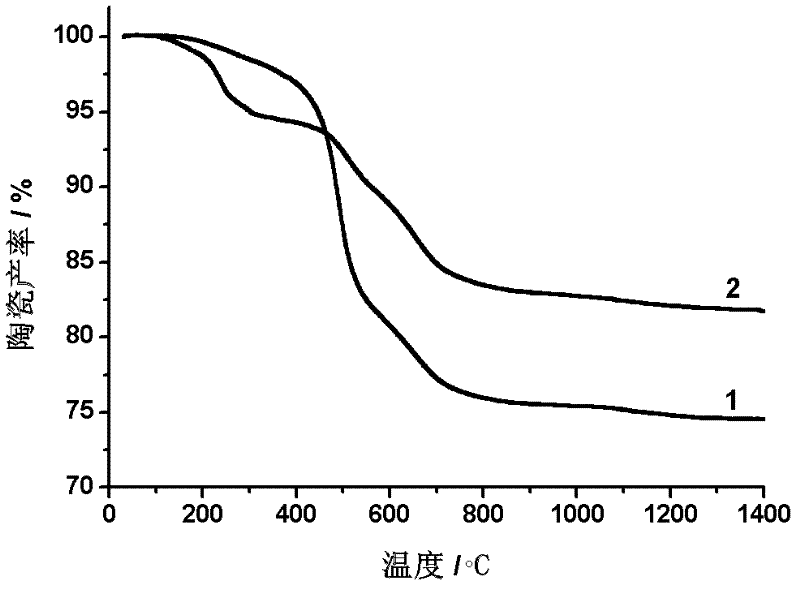

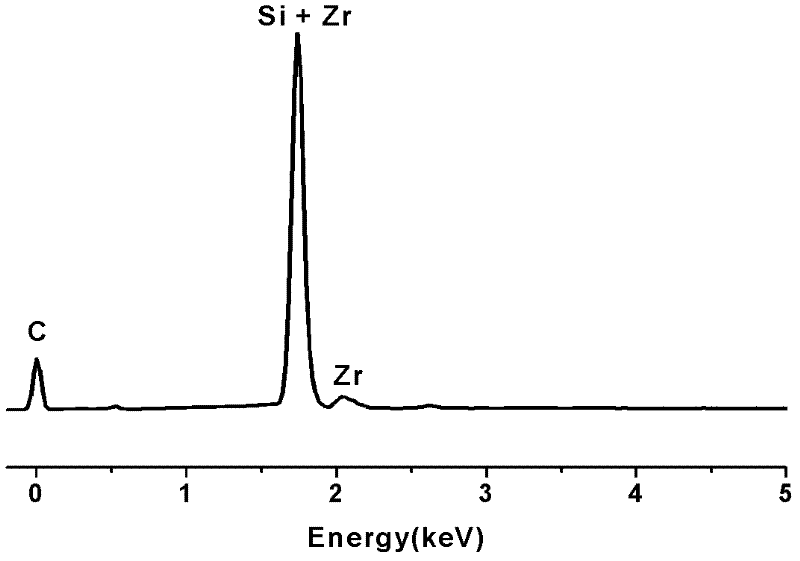

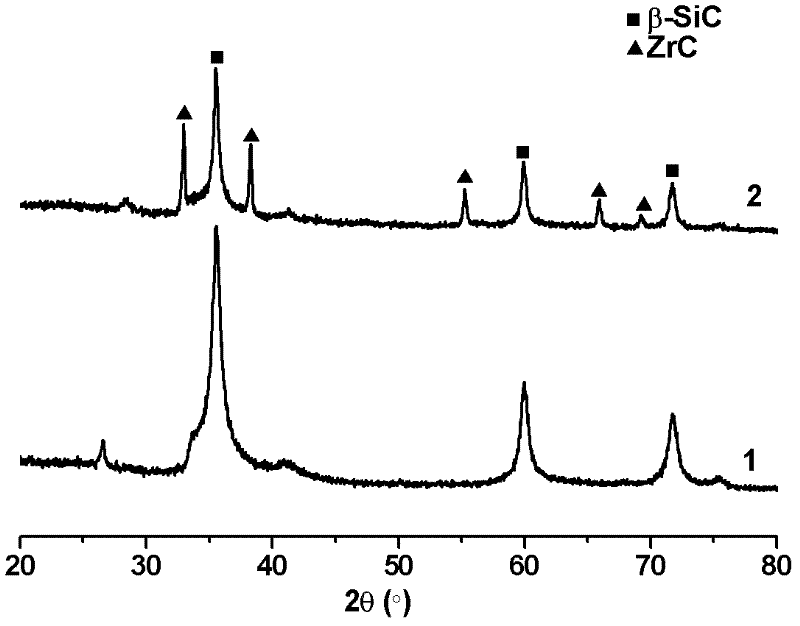

Preparation method of silicon carbide/zirconium carbide composite ceramic

The invention relates to a preparation method of silicon carbide / zirconium carbide composite ceramic, and relates to inorganic nonmetal material composite ceramic. The preparation method comprises the steps of: dissolving bis(cyclopentadienyl) zirconium dichloride with a solvent under the protection of inert atmosphere, and adding liquid hyperbranched polycarbosilane to obtain a mixture A; and distilling the mixture A under reduced pressure under the protection of inert atmosphere to remove the solvent, and carrying out cracking reaction in inert atmosphere to obtain the silicon carbide / zirconium carbide composite ceramic. According to the invention, bis(cyclopentadienyl) zirconium dichloride is used as a zirconium source, and is used for catalyzing the crosslinking reaction of liquid hyperbranched polycarbosilane, so as to increase ceramic yield; zirconium carbide can inhibit the growth of silicon carbide microcrystal grains, and improve high-temperature resistance and oxidation resistance of the composite material; the zirconium content in the composite ceramic can be controlled by controlling the content of bis(cyclopentadienyl) zirconium dichloride in a hybrid precursor; the liquid hyperbranched polycarbosilane / bis(cyclopentadienyl) zirconium dichloride hybrid precursor is free of oxygen, thus the gas escaped in the high-temperature cracking process is reduced; the ceramic has high compactness; and the preparation method is simple to operate, and is easy for engineering.

Owner:XIAMEN UNIV

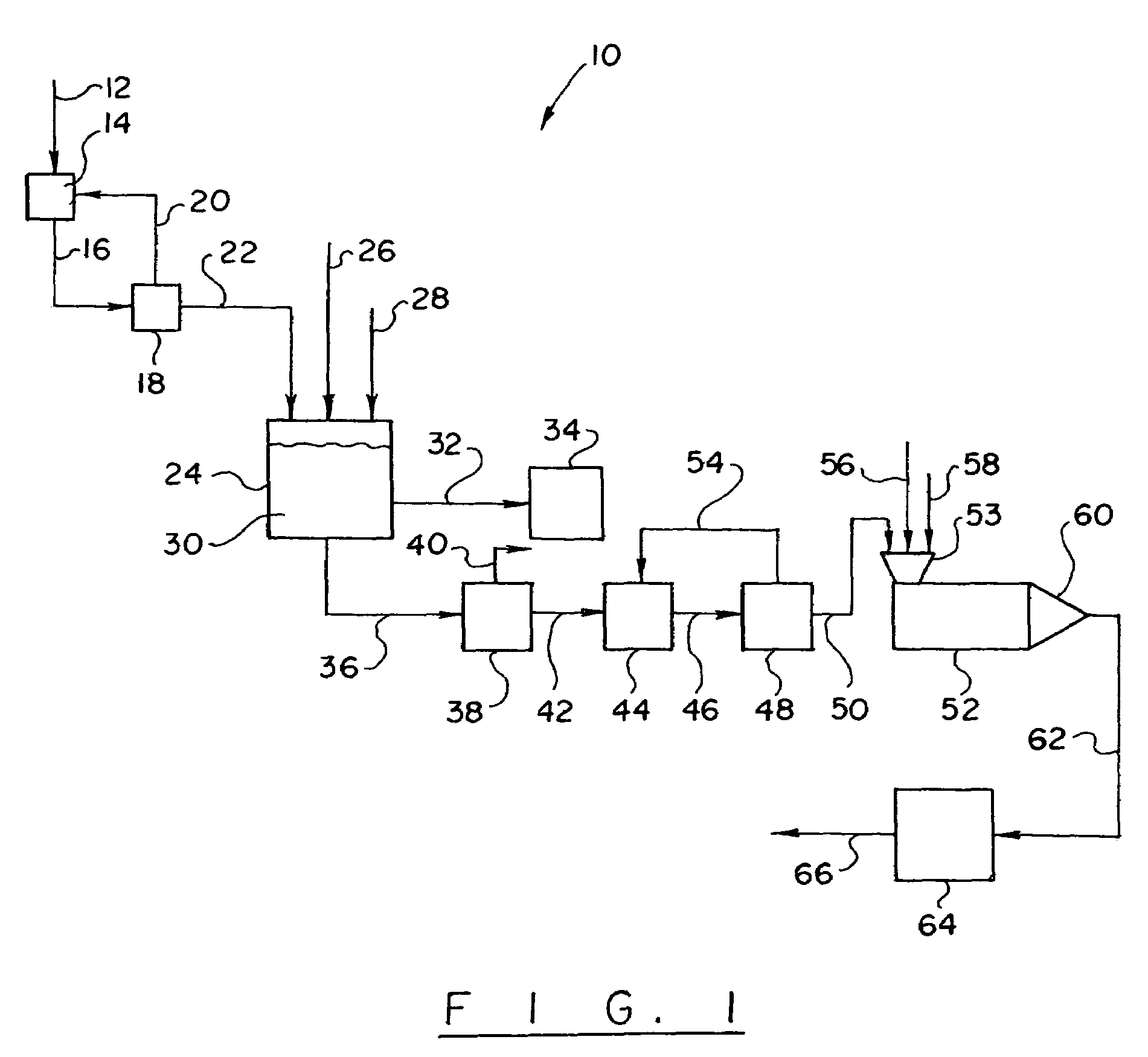

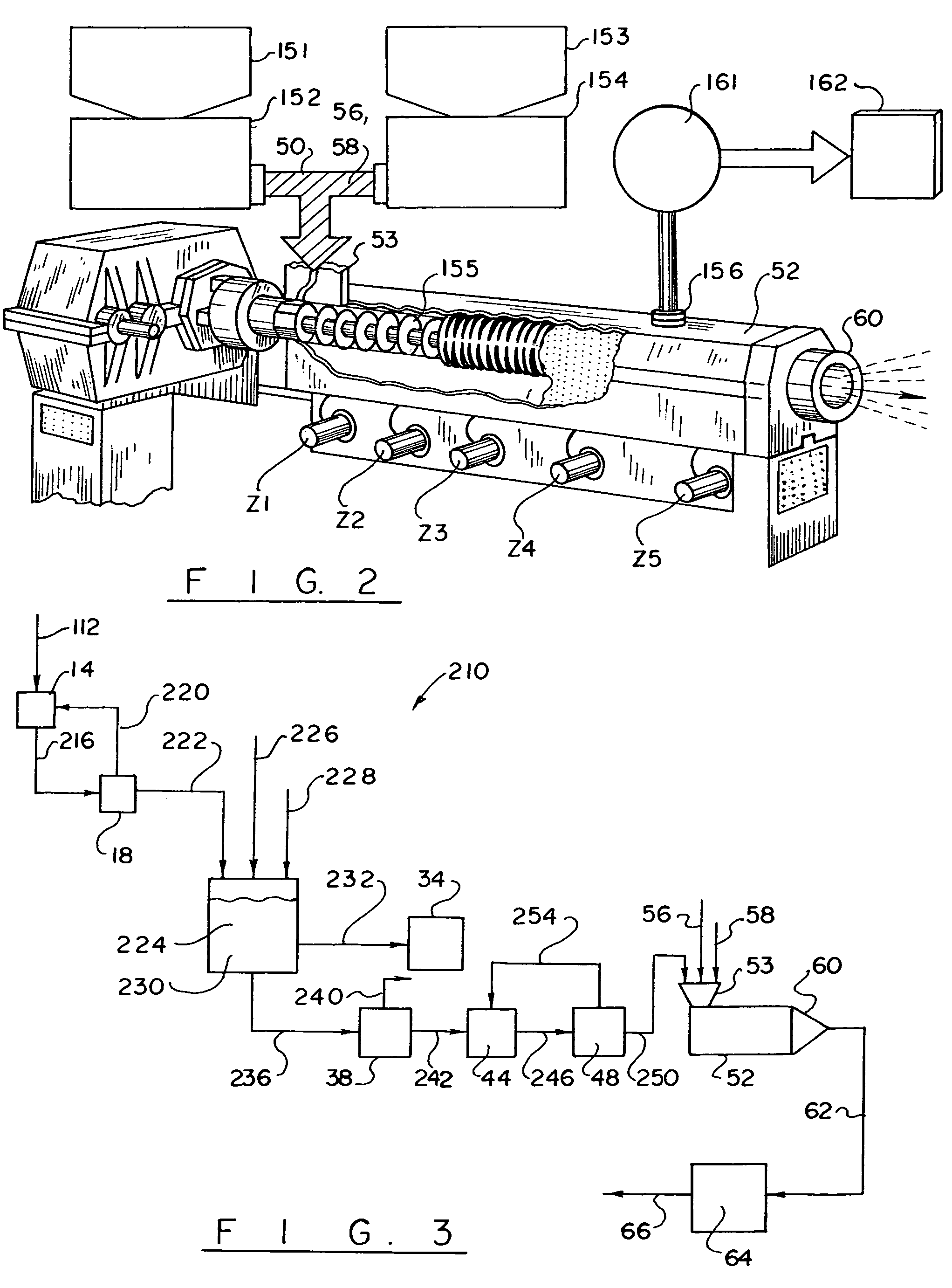

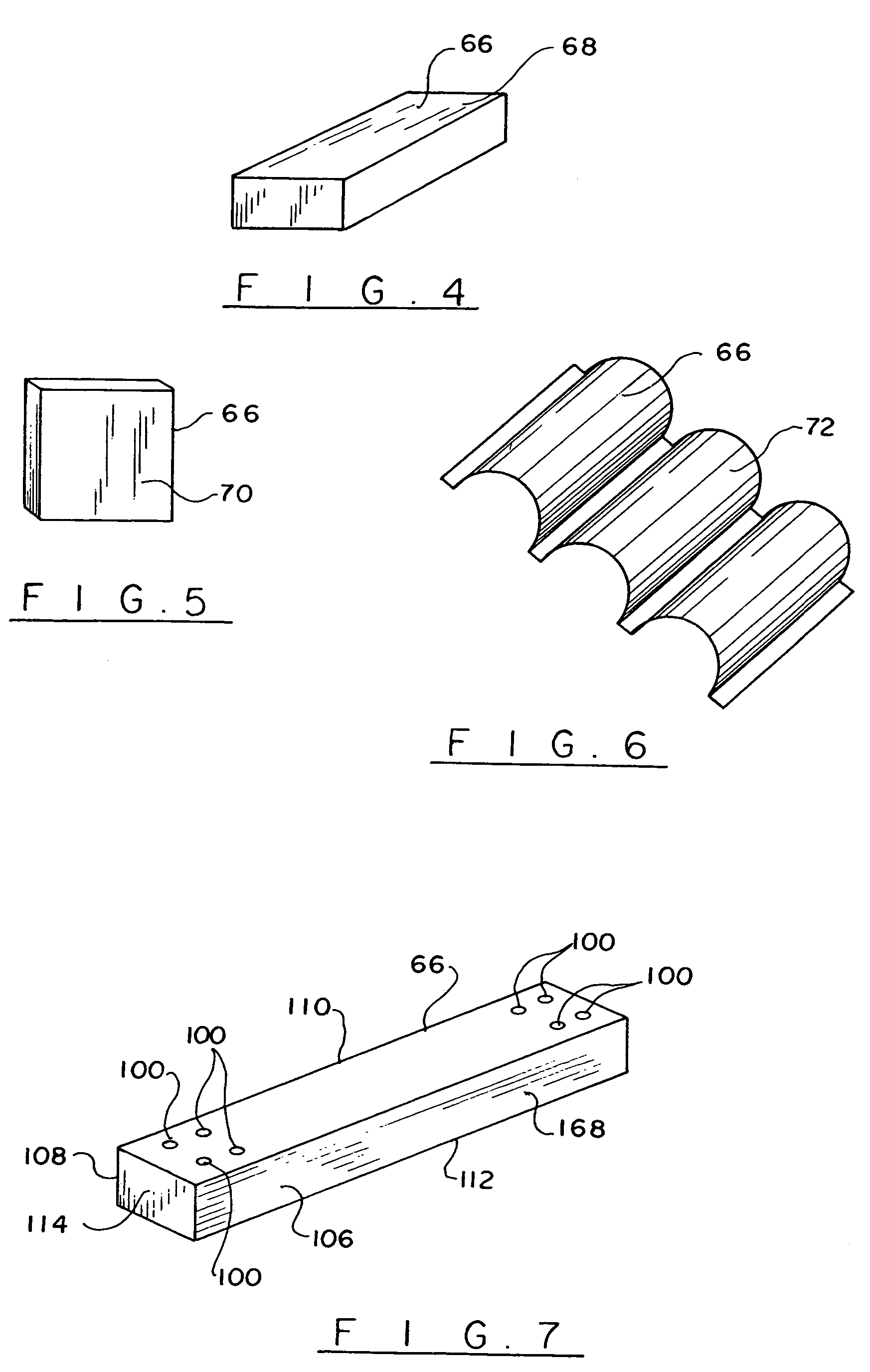

Thermoplastic railroad cross-ties

InactiveUS7331533B2Avoid accumulationIncrease awarenessBallastwayPlastic recyclingPolyolefinRoof tile

A process is provided for making thermoplastic-composites from recycled thermoplastics (polyolefins) together with phosphogypsum waste by-product from the phosphate fertilizer wet process or, in an equally preferred embodiment with fluorogypsum waste by-product from fluorine production wet process to produce lumber profiles. The process involves (a) admixing phosphogypsum (calcium sulfate) and / or fluorogypsum (calcium fluoride) waste byproduct and / or Flue Gas Desulfurization (FGD) gypsum and / or crude gypsum and / or calcined gypsum with thermoplastics and a functionalized compound with or without coupling agents to produce a filled thermoplastic-composite composition, and (b) melt processing the composition to produce a filled thermoplastic-composite article. The articles are preferably in the form of railroad cross ties or construction articles such as common lumber profiles, panels, tiles, poles, utility poles, crossarms for utility poles, roofing tiles, pipeline skids, pilings, marine fender-piles (including light emitting piles), bulkheads, revetments, and are useful for constructing various structures, such as oilfield board roads and equipment mats. The process avoids the accumulation of undesired phosphogypsum / fluorogypsum “stacks” and provides environmentally friendly useful products which require no chemical preservatives to prevent insect infestation or decay from the elements. Tailings from ore processing can also be used as a filler.

Owner:COMPOSITECH

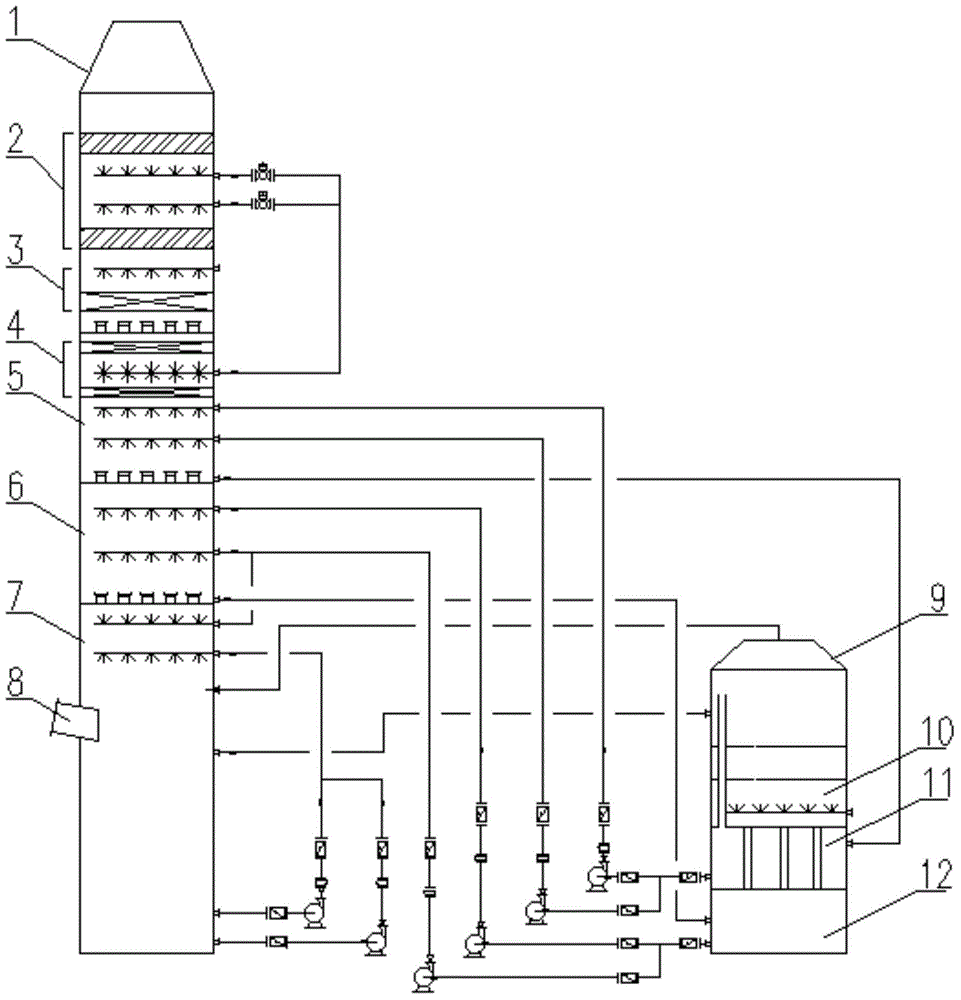

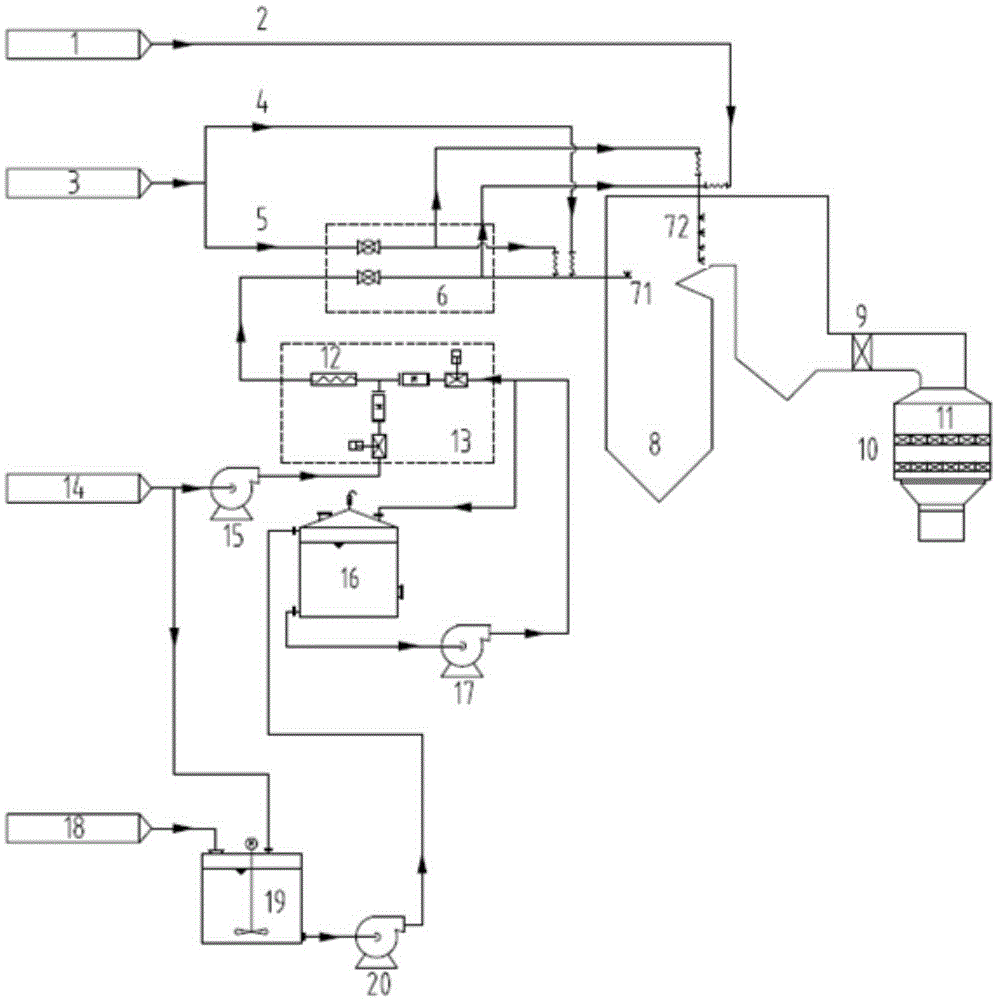

Ammonia process type double-cycle desulfurization and denitrification dust removal system

InactiveCN105195002AAdaptableImprove desulfurization efficiencyDispersed particle separationParticulatesSmall footprint

The invention discloses an ammonia process type double-cycle desulfurization and denitrification dust removal system and belongs to the technical field of environmental protection equipment. The system comprises a cleaning absorbing tower and an oxidation circulation tank, wherein the cleaning absorbing tower sequentially comprises an efficient water mist removal section, a reinforced ammonia mist removal section, an absorption liquid mist removal section, a secondary absorption section, a primary absorption section and a cleaning cooling section; the oxidation circulation tank sequentially comprises an oxidation section, a secondary absorption liquid circulation section and a primary absorption liquid circulation section; the oxidation section is communicated with the cleaning cooling section through a pipeline; the secondary absorption liquid circulation section is communicated with the secondary absorption section through a pipeline; the primary absorption liquid circulation section is communicated with the primary absorption section through a pipeline. The system has the advantages that the desulfurization efficiency is high, generation of ammonia escape, aerosol and particulate matters is reduced from the start and blocked in the process, and the system has high adaptability to coal types and boiler load changes, occupies small area and is compact in arrangement and simple to mount and requires less investment.

Owner:ASIA PACIFIC ENVIRONMENTAL CORP

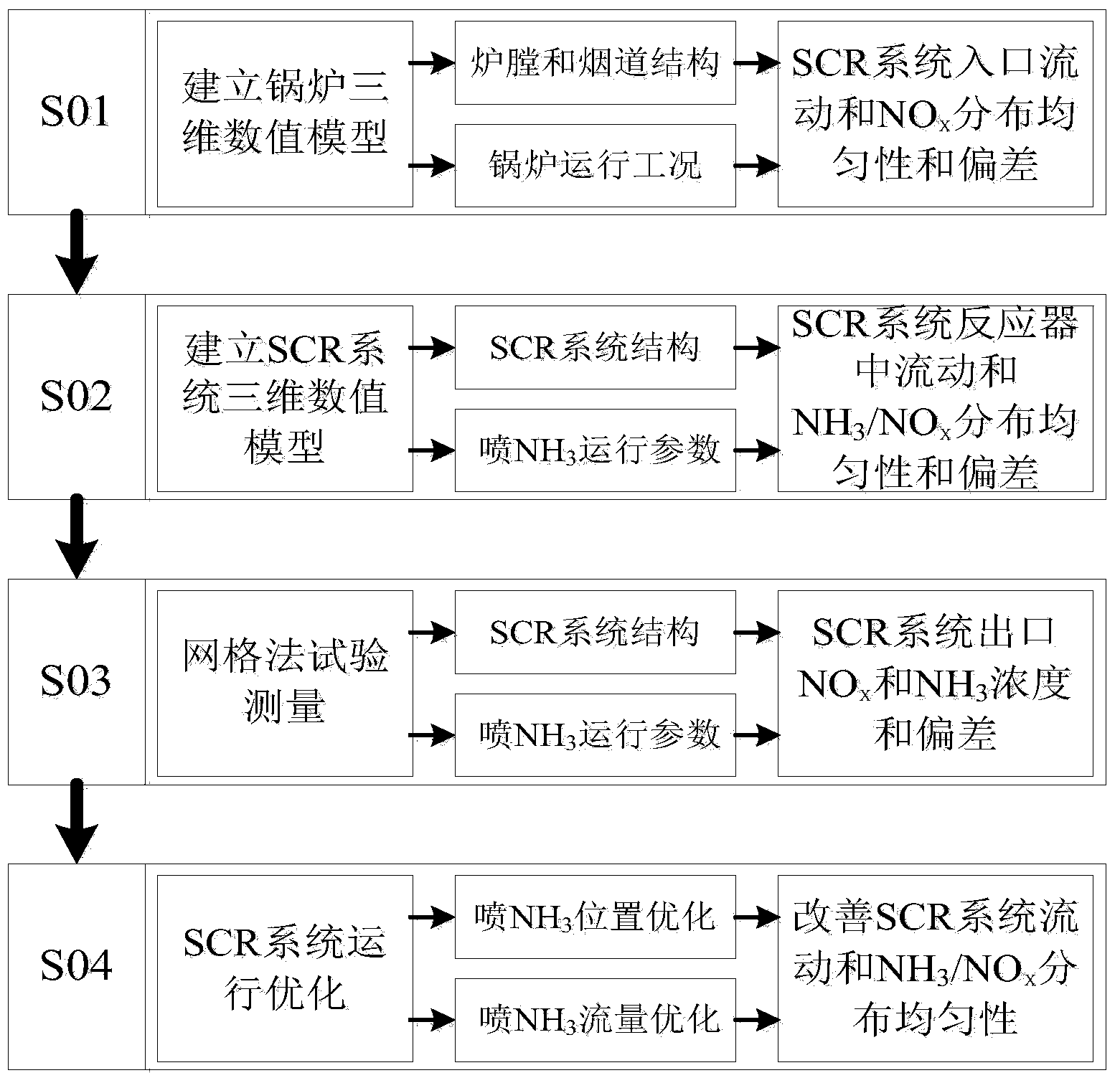

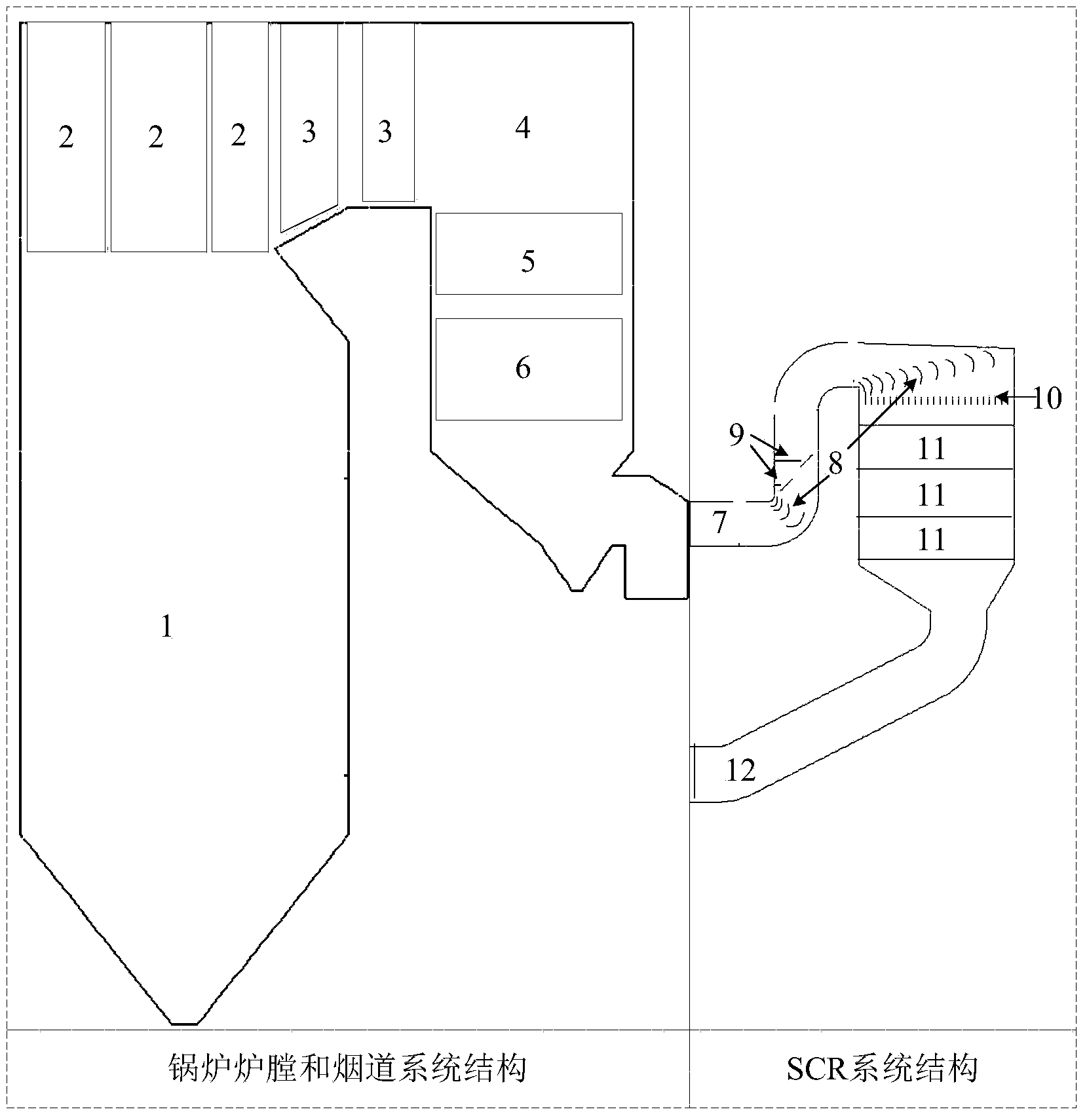

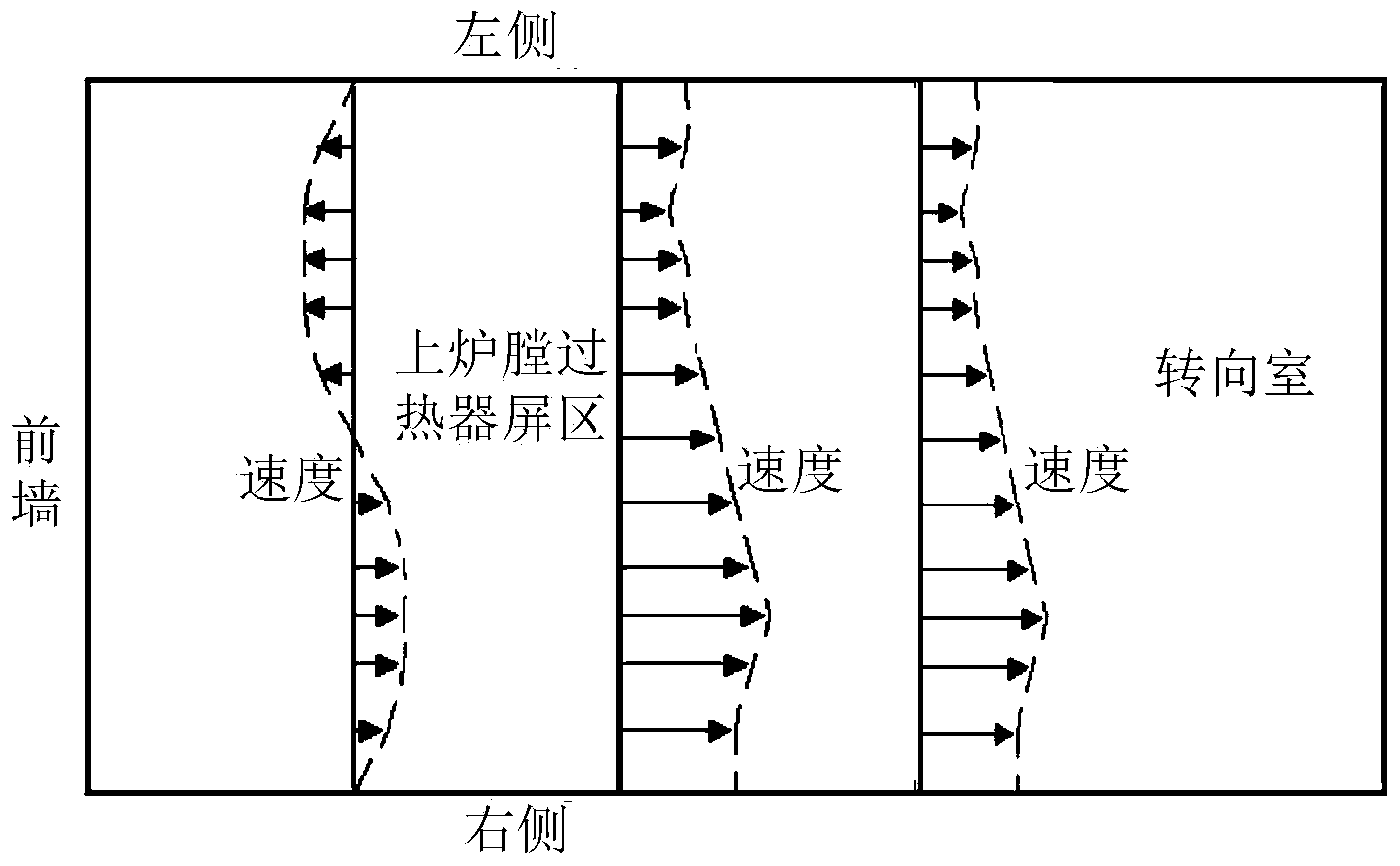

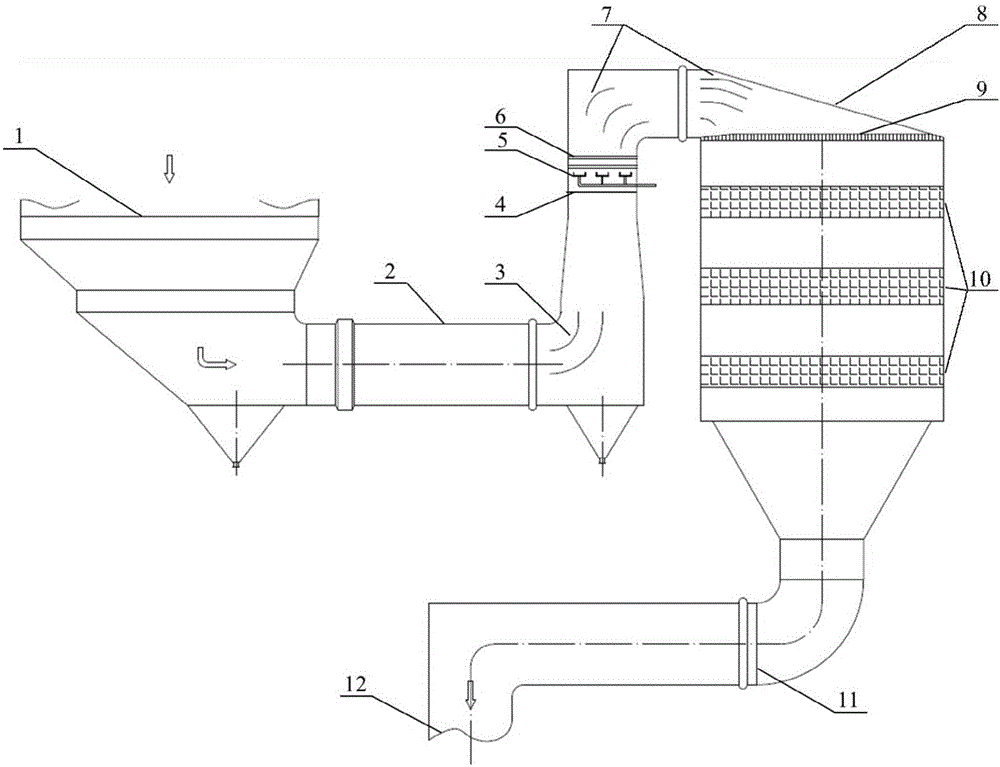

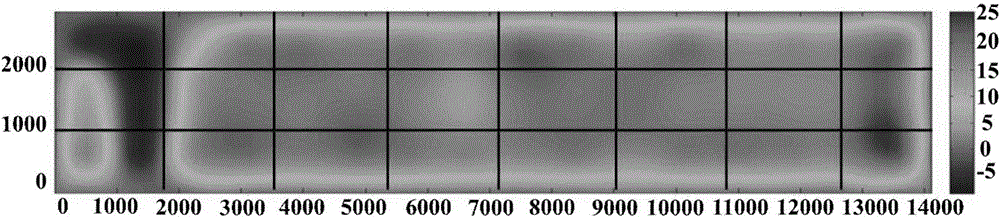

Denitration operation optimization method for SCR (Selective Catalytic Reduction) system of tangential firing pulverized coal boiler

InactiveCN103752170AOptimal adjustment of ammonia injection flow rateIncrease the flow rate of ammonia injectionDispersed particle separationEngineeringStreamflow

The invention discloses a denitration operation optimization method for an SCR (Selective Catalytic Reduction) system of a tangential firing pulverized coal boiler. The denitration operation optimization method comprises the special steps of using a numerical simulation method; obtaining a velocity of flue gas, an NOx concentration distribution uniformity and a deviation of an outlet of the boiler by means of considering the structure and the operation condition of the boiler as a boundary condition of an inlet of the SCR system; obtaining the velocity of the flue gas, an NH3 / NOx distribution uniformity and a deviation inside the SCR reactor; optimizing and adjusting an ammonia spraying flow of an ammonia spraying nozzle on a flue of the SCR system according to the velocity of the flue gas and the NH3 / NOx; increasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the larger velocity of the flue gas, and decreasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the smaller velocity of the flue gas; and increasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the smaller NH3 / NOx, and decreasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the larger NH3 / NOx. The denitration operation optimization method provided by the invention can be used for optimizing and adjusting by comprehensively considering the structures and the operation conditions of the boiler and the SCR system, so that the denitration efficiency of the SCR system is improved; the spraying amount and the release rate of ammonia can be reduced; the security, the economical efficiency and the environmental friendliness of the operation of the boiler unit can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

SCR denitration system ammonia spraying optimization method based on weight valve regulation and control

InactiveCN105126616AMake targeted adjustmentsReduce escapeDispersed particle separationConstant loadFlue gas

The invention discloses an SCR denitration system ammonia spraying optimization method based on weight valve regulation and control. The method is divided into four steps: measurement of flue gas flow field characteristics, analysis of flue gas flow field regional flow characteristics, determination of ammonia spraying weight valves and pertinence adjustment of opening degrees of the ammonia spraying valves. The method comprises the particular steps: firstly, measuring the flue gas flow field characteristics of a flue transverse section in front of an ammonia spraying grille of an SCR denitration system under a condition of constant load; then combining with a distribution condition of spray nozzles of the ammonia spraying grille, and analyzing flue gas flow field regional flow continuous distribution characteristics matched with the ammonia spraying spay nozzle distribution; according to the flue gas flow field regional flow characteristics under various load conditions, obtaining the weights of the ammonia spraying valves; and finally, adjusting the opening degrees of all the valves according to the valve weight difference, simultaneously, with the help of a flue gas analyzer, measuring the NOx outlet concentration on an outlet section of the SCR denitration system, and timely feeding back the adjustment effect of the opening degrees of the ammonia spraying valves. The method can ensure good ammonia nitrogen mixing equivalent ratio, effectively improves the denitration efficiency, decreases the ammonia escape and reduces the ammonia amount.

Owner:南京奥麦科仪器自动化有限公司

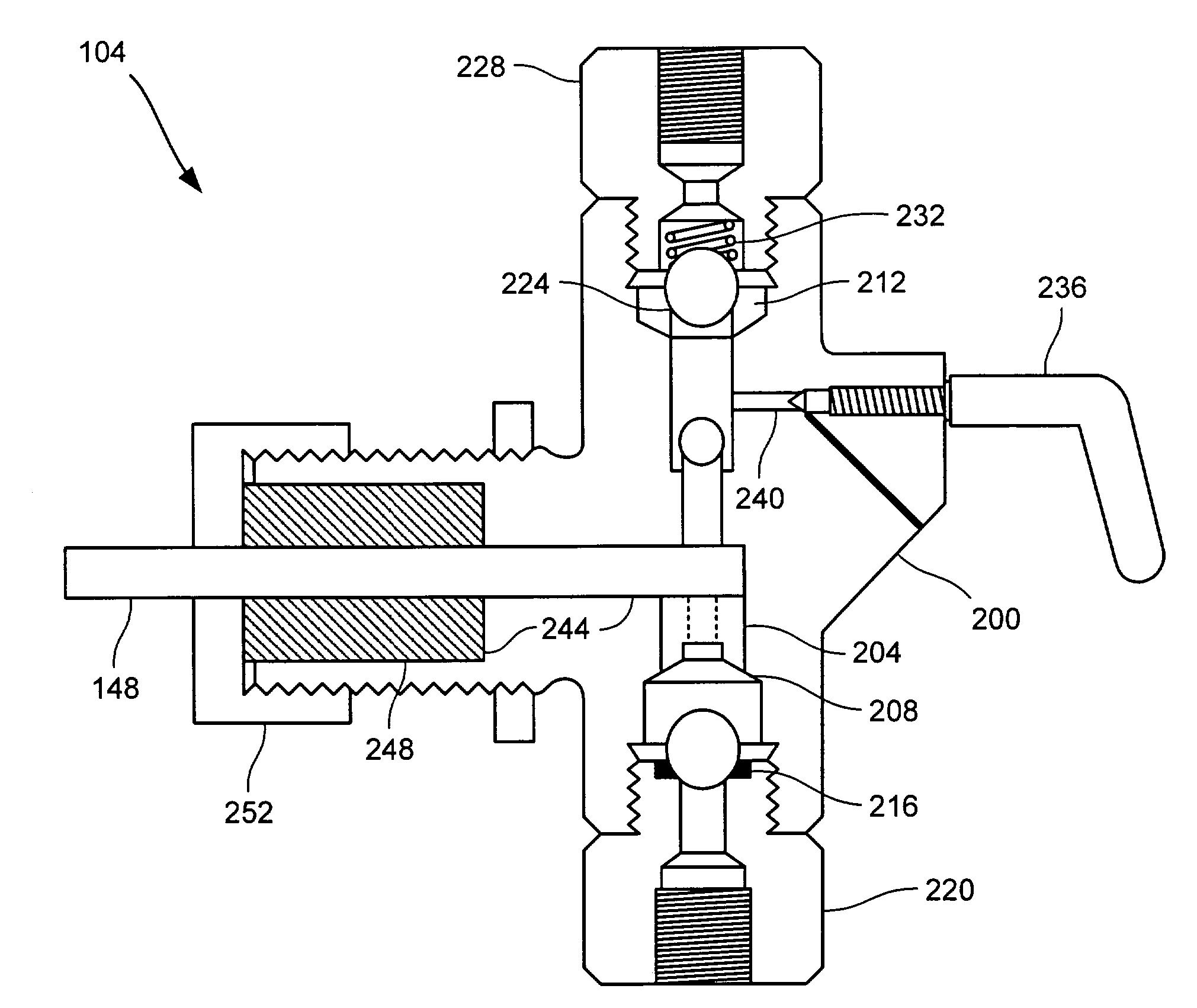

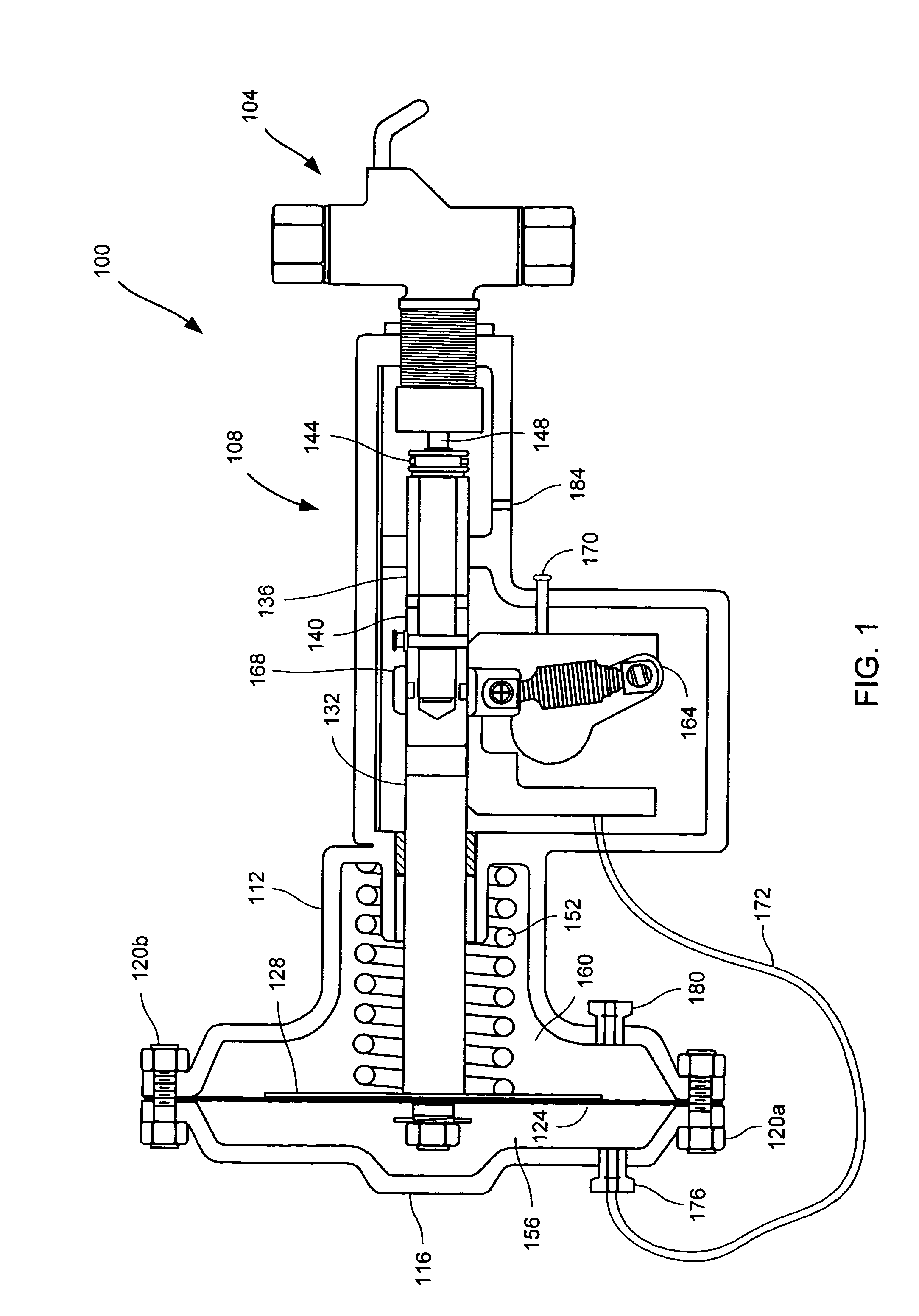

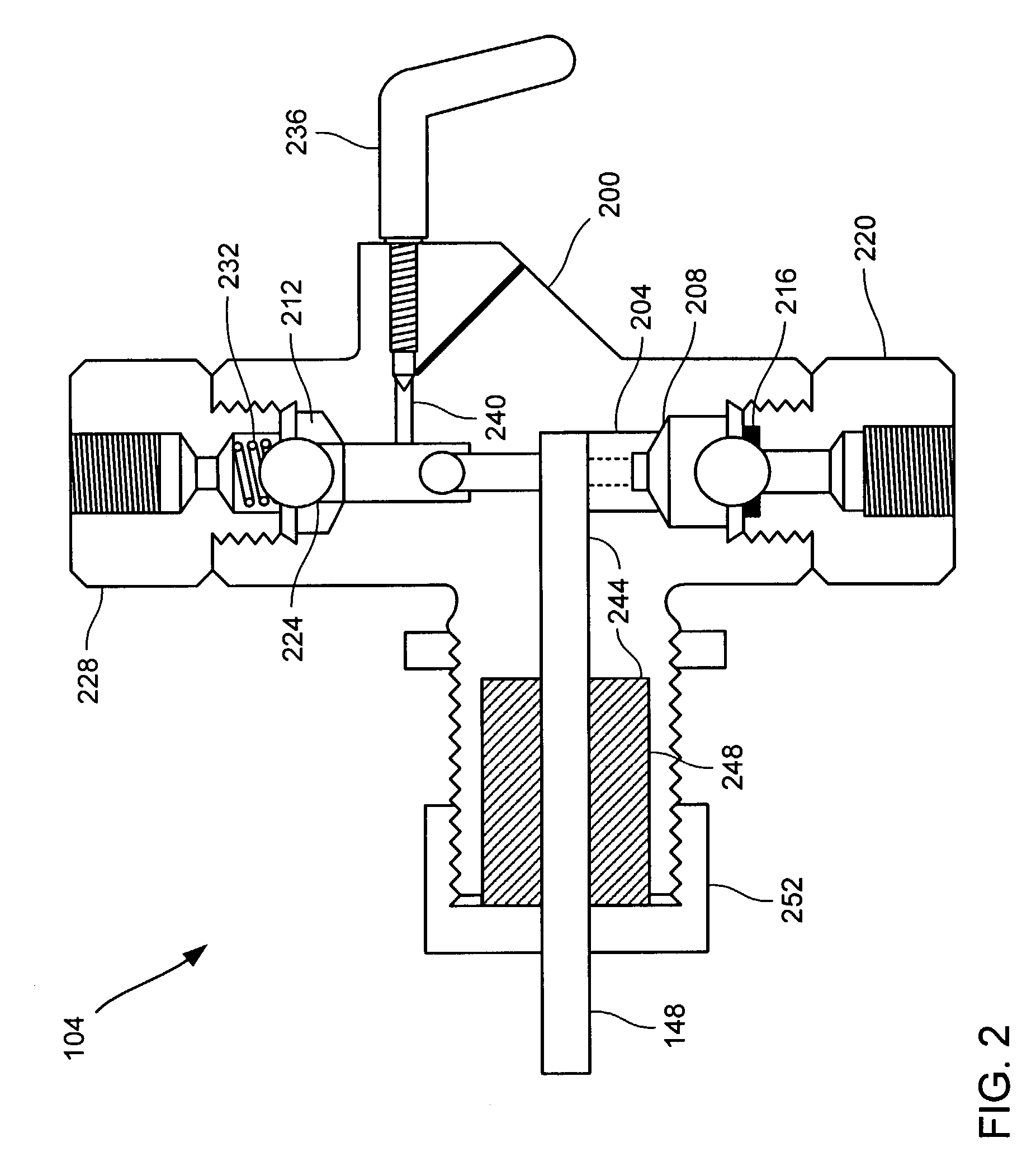

Reciprocating pump having a ceramic piston

ActiveUS7134851B2Prevent escapeReduce escapePositive displacement pump componentsFlexible member pumpsReciprocating motionPump chamber

Various embodiments of the invention, therefore, provide pumps, and methods for their production. One exemplary embodiment of the invention comprises a ceramic plunger pump assembly. The pump assembly can include a pump body, which defines a pump chamber with an inlet port and an outlet port. The pump body can further define a plunger port disposed between the inlet port and the outlet port. In certain embodiments, the pump assembly can further include a ceramic plunger housing, which defines a cylindrical bore having an interior diameter. The plunger housing can be disposed within the plunger port. The pump assembly can also include a ceramic plunger. In particular embodiments, the ceramic plunger is slidably disposed within the cylindrical bore, such that the ceramic plunger may be reciprocated back and forth within the bore. Thus, the fluid can be moved from the inlet port of the pump chamber to the outlet port of the pump chamber through the reciprocal action of the plunger.

Owner:COORSTEK INC

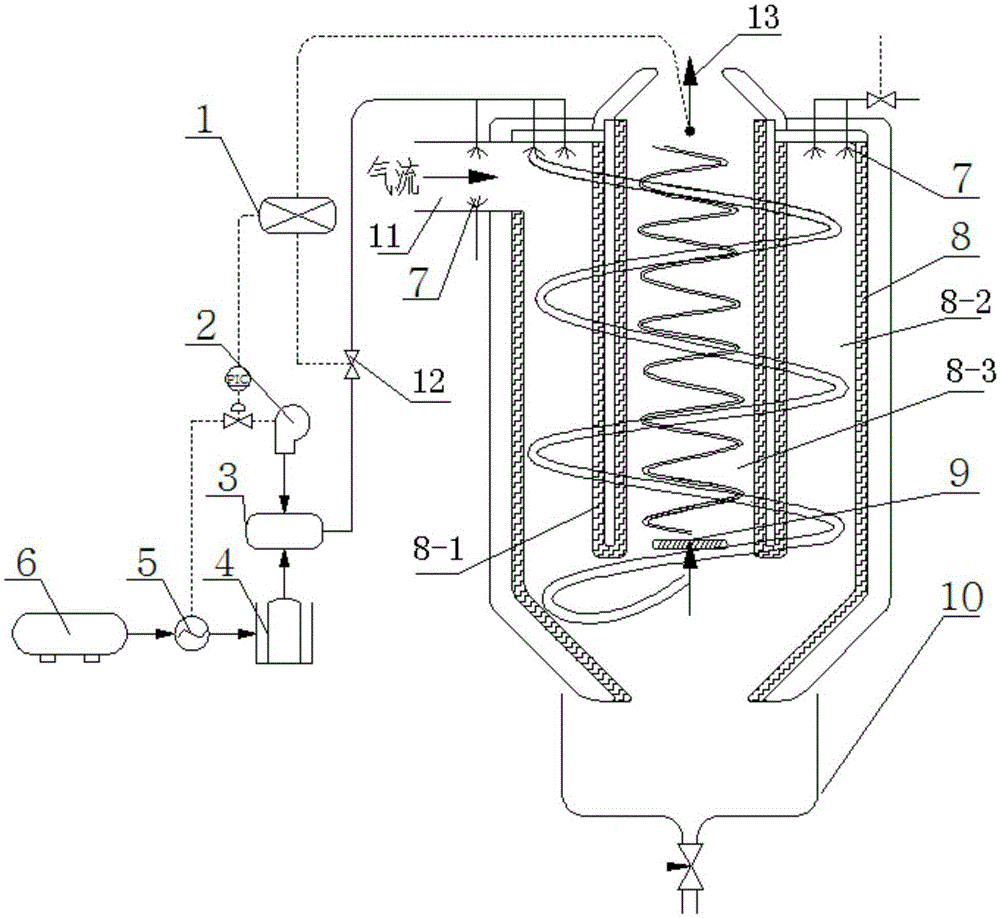

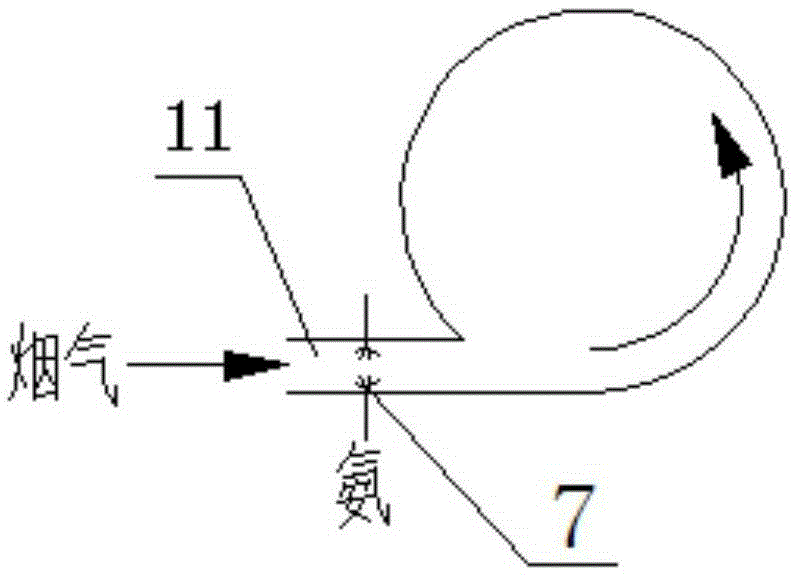

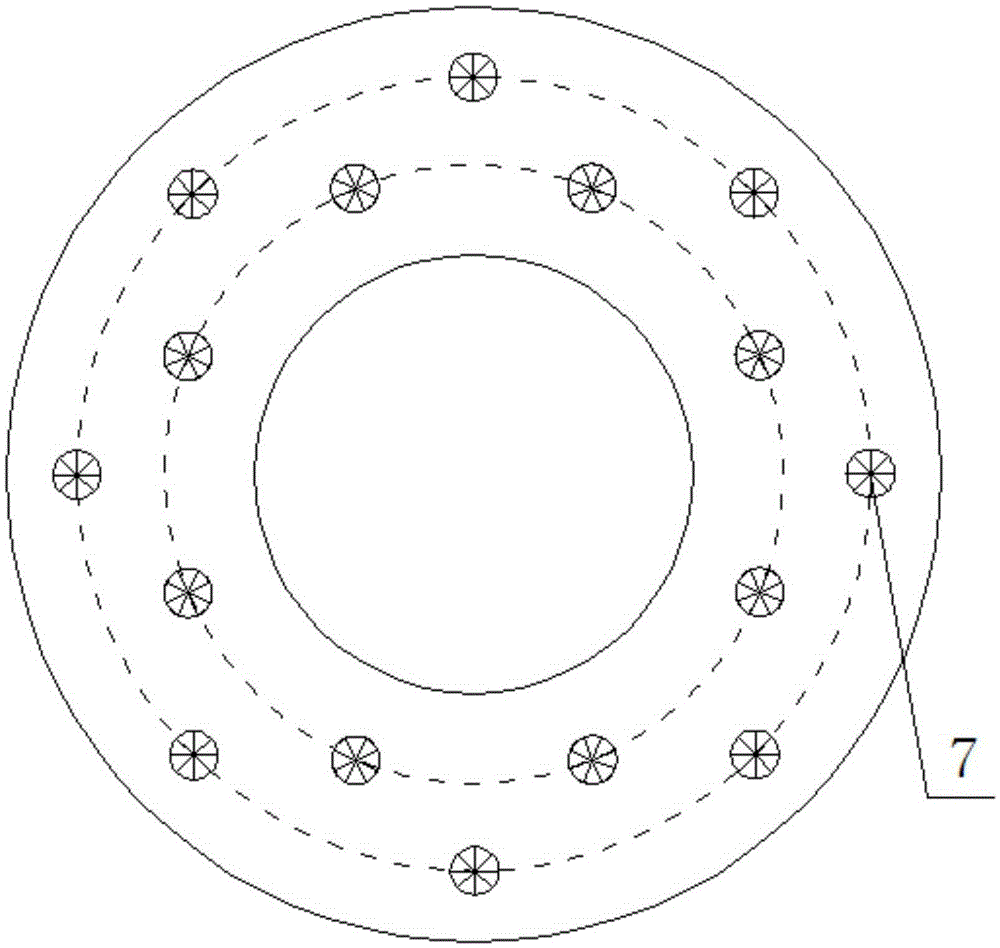

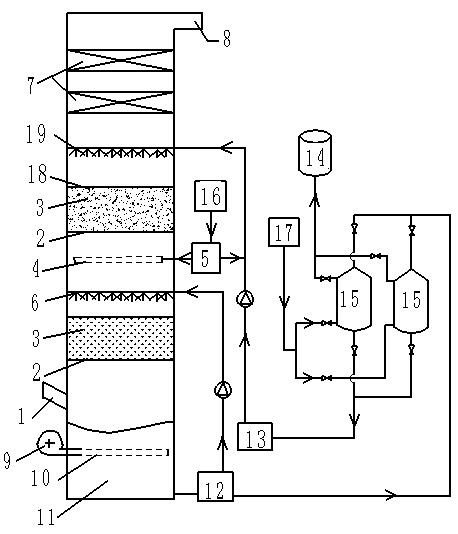

Double-rotation SCR denitration method and apparatus thereof

ActiveCN105289301AImprove denitrification efficiencyIncrease contact timeDispersed particle separationCycloneFlue gas

The invention discloses a double-rotation SCR denitration method and an apparatus thereof. According to the invention, a first eddy flow catalytic reaction chamber and a second eddy flow catalytic reaction chamber are arranged along a denitrating tower body; a flue gas introduction pipeline is arranged on a sidewall of the denitrating tower body; several eddy flow atomizing nozzles are respectively arranged on inner periphery of the flue gas introduction pipeline and the inner periphery at top of the first eddy flow catalytic reaction chamber; when flue gas is introduced into the flue gas introduction pipeline, the flue gas and ammonia gas injected by the eddy flow atomizing nozzle are mixed, and a mixture enables spiral sinking along circumference of the first eddy flow catalytic reaction chamber from up to down in a tangent circle mode, under effect of a cyclone, and then the mixture enable spiral rise along circumference of the second eddy flow catalytic reaction chamber from down to up in the tangent circle mode. Under prerequisite that high efficiency denitration is ensured, catalyst amount is less, operation of technical means is simple and easy, compared with the prior art, a denitrating tower structure is simple, cost of the apparatus is low, denitration efficiency is high, energy consumption is low, escapement ratio of ammonia is reduced, denitration cost is greatly reduced, and economic benefit is obviously increased.

Owner:SOUTH CHINA UNIV OF TECH

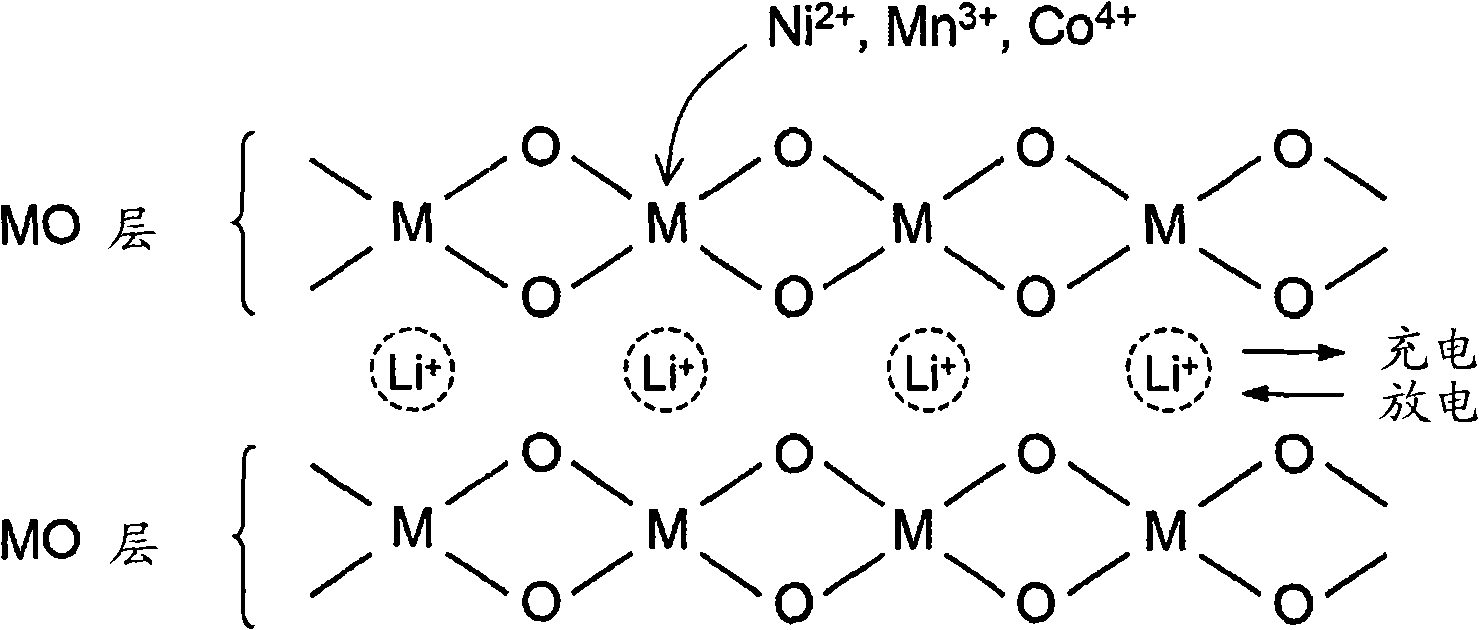

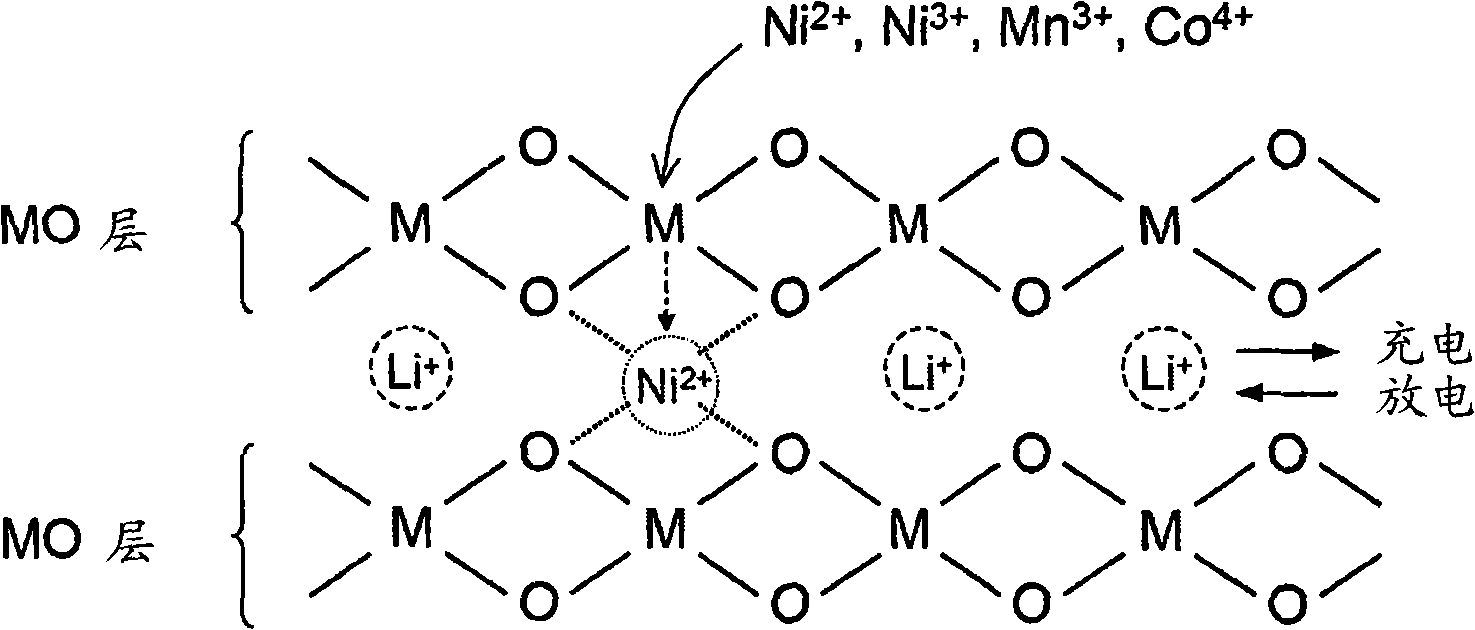

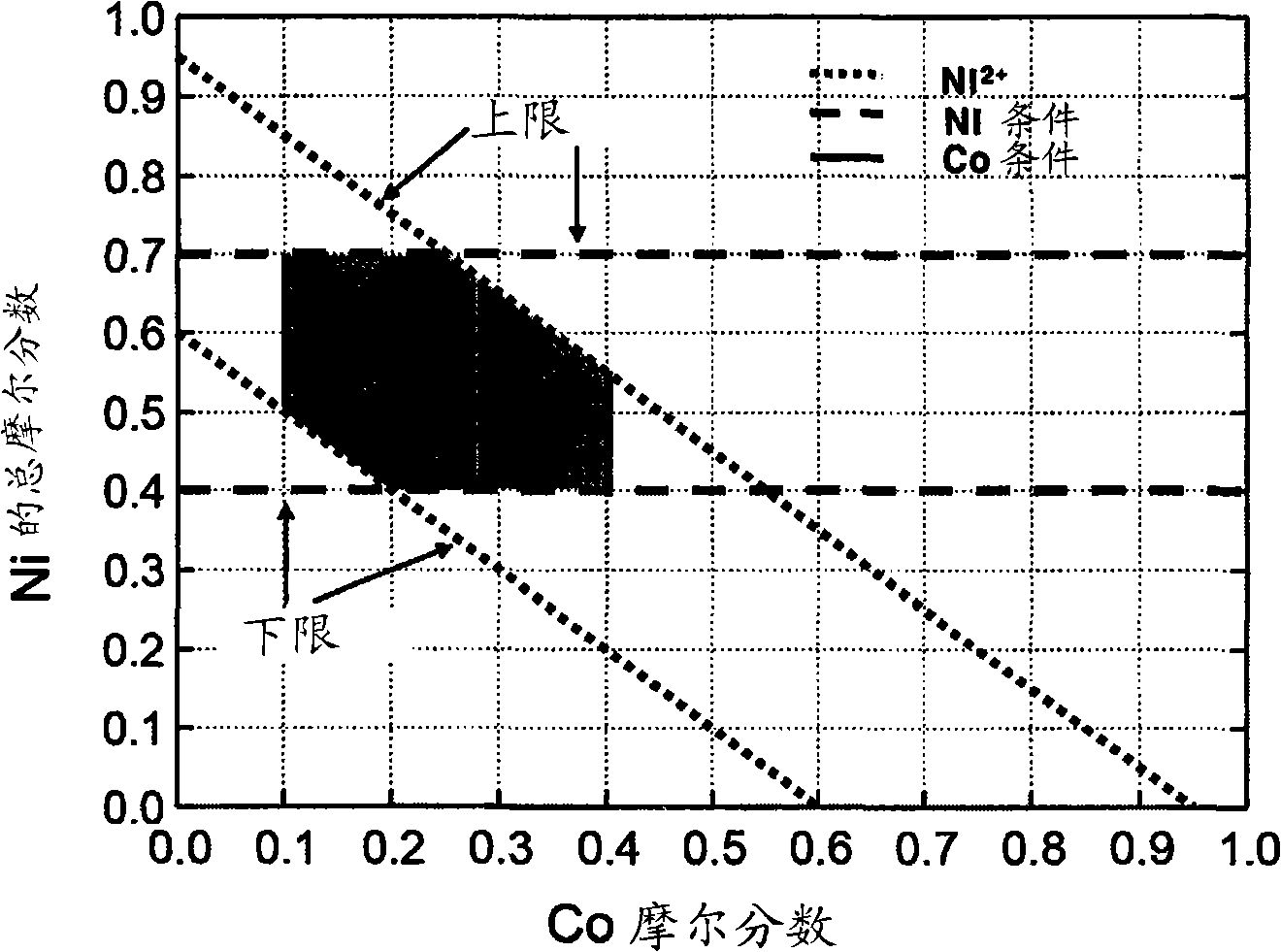

Material for lithium secondary battery of high performance

InactiveCN101300696AImprove structural stabilityReduce escapeCell electrodesEnergy inputChemical physicsElectrical battery

Provided is a lithium mixed transition metal oxide having a composition represented by Formula I of LixMyO2 (M, x and y are as defined in the specification), wherein lithium ions intercalate into and deintercalate from mixed transition metal oxide layers (''MO layers'') and some of MO layer-derived Ni ions are inserted into intercalation / deintercalation layers of lithium ions (''reversible lithium layers'') thereby resulting in the interconnection between the MO layers. The lithium mixed transition metal oxide of the present invention has a stable layered structure and therefore exhibits improved stability of the crystal structure upon charge / discharge. In addition, a battery comprising such a cathode active material can exhibit a high capacity and a high cycle stability. Further, such a lithium mixed transition metal oxide is substantially free of water-soluble bases, and thereby can provide excellent storage stability, decreased gas evolution and consequently superior high-temperature stability with the feasibility of low-cost mass production.

Owner:LG CHEM LTD

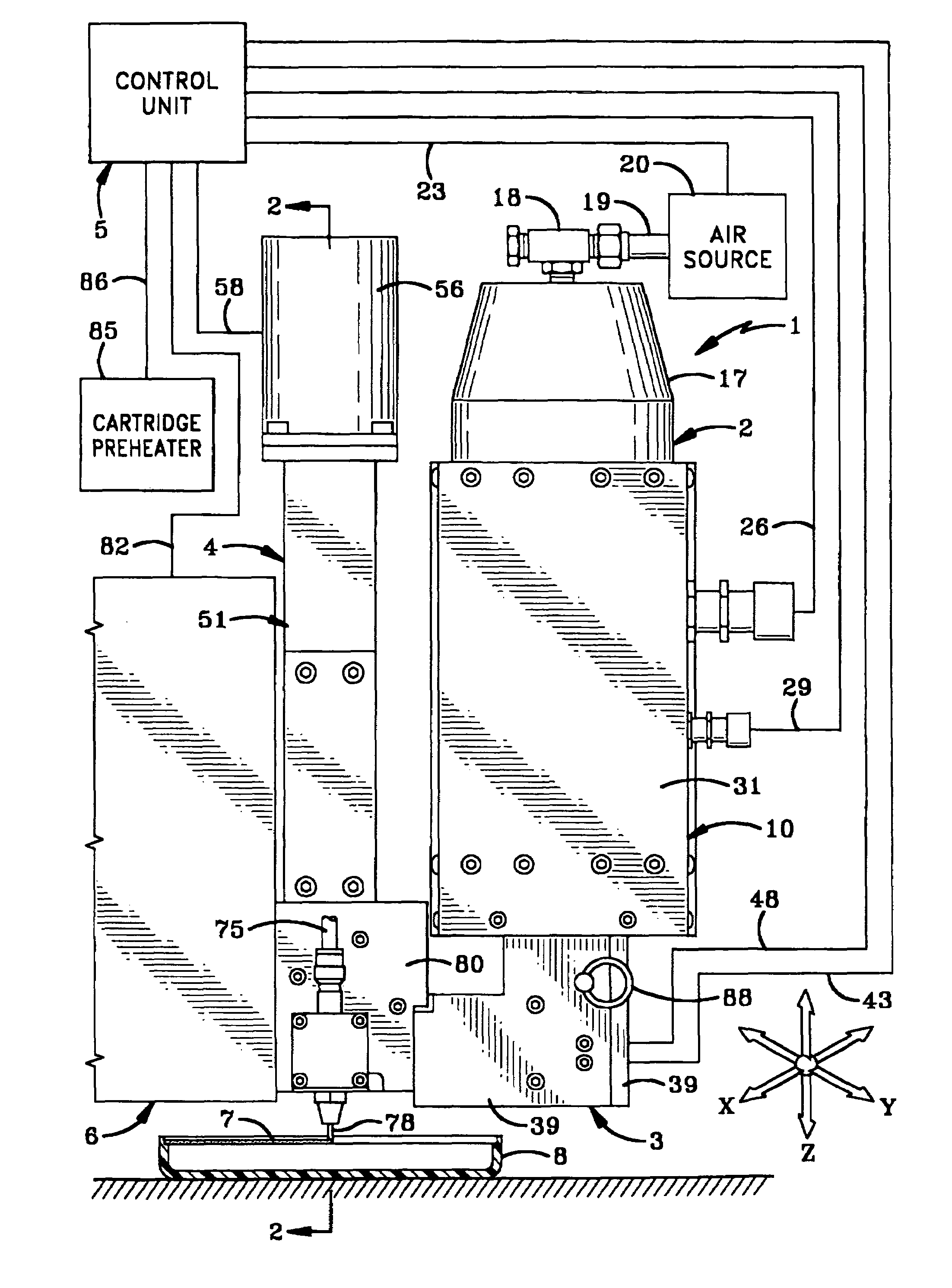

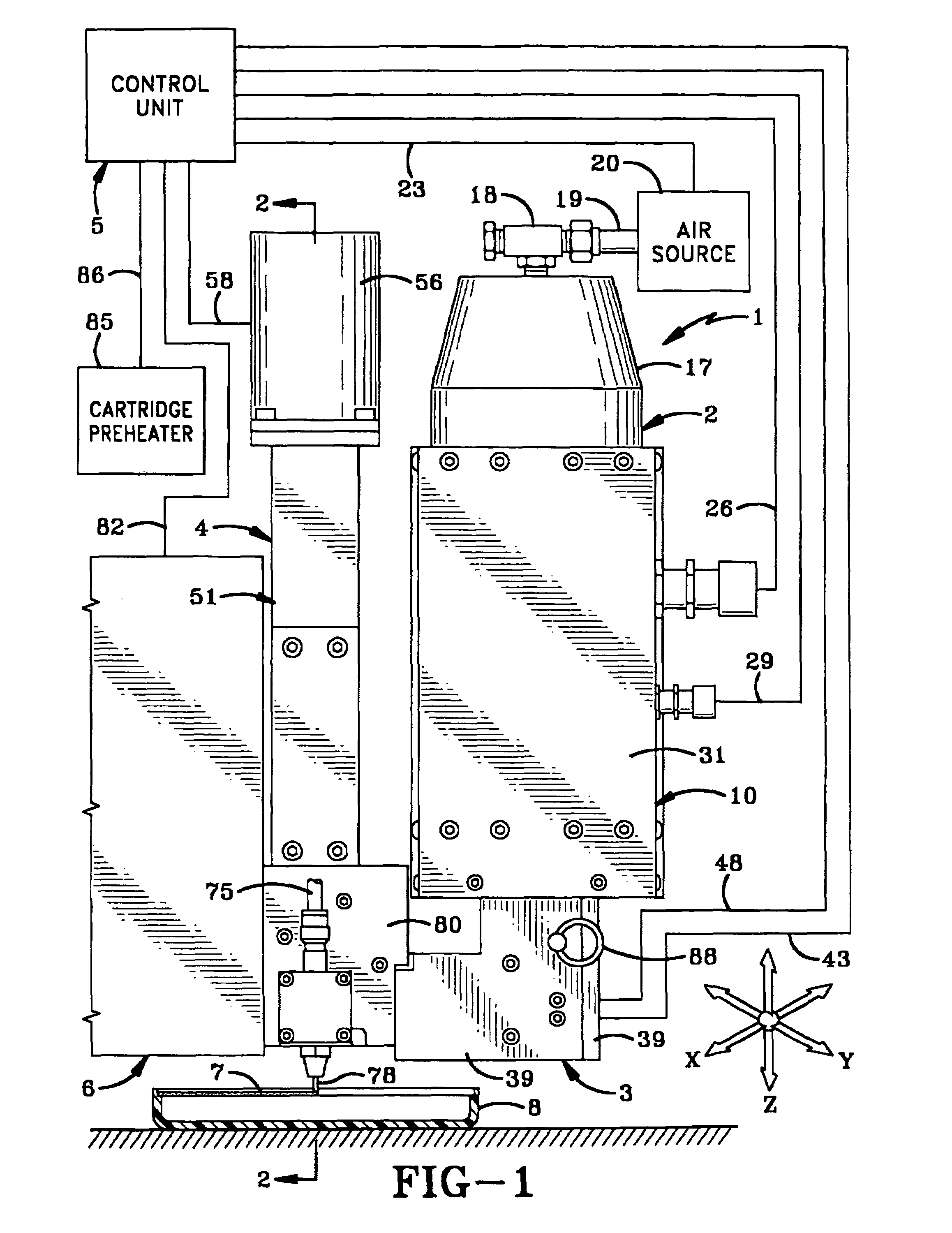

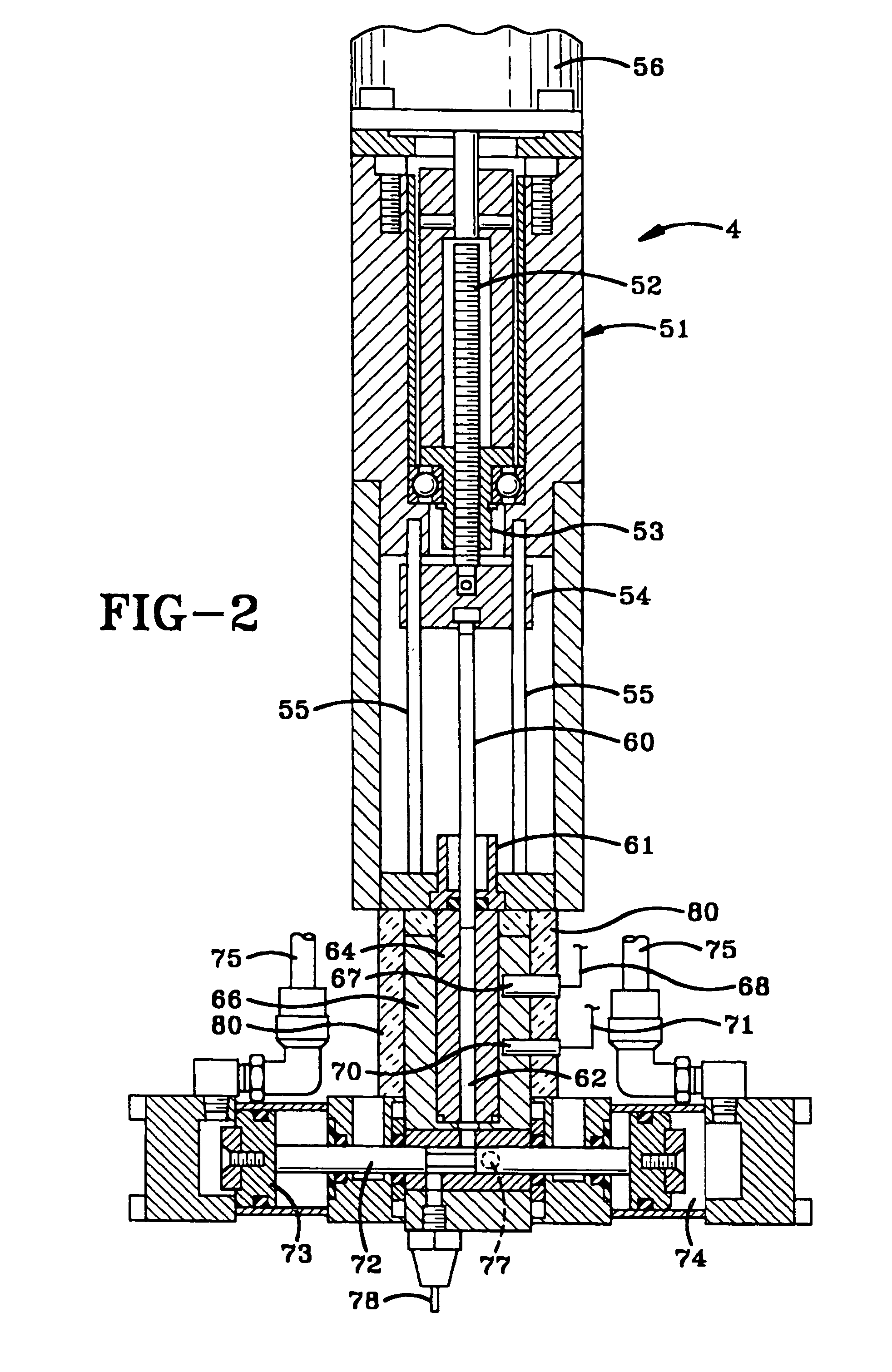

Method and apparatus for dispensing a hot-melt adhesive

InactiveUS7296707B2Reduce interruptionsShorten the timeLiquid surface applicatorsLiquid transferring devicesComputer control systemHot melt

An apparatus and method for dispensing controlled precise amounts of a hot-melt adhesive. A positive displacement dispenser which is mounted on a programmable motion system is connected to a hot-melt cartridge feed assembly by an inlet block. The dispenser, feed assembly, and inlet block contain electric heaters and thermocouples for maintaining the adhesive at a desired elevated temperature. A computer control system regulates the temperature in the dispenser, feed assembly, and inlet block and controls a dispensing motor in the dispenser. A preheater heats an adhesive cartridge prior to placement in the feed assembly.

Owner:GRACO INC

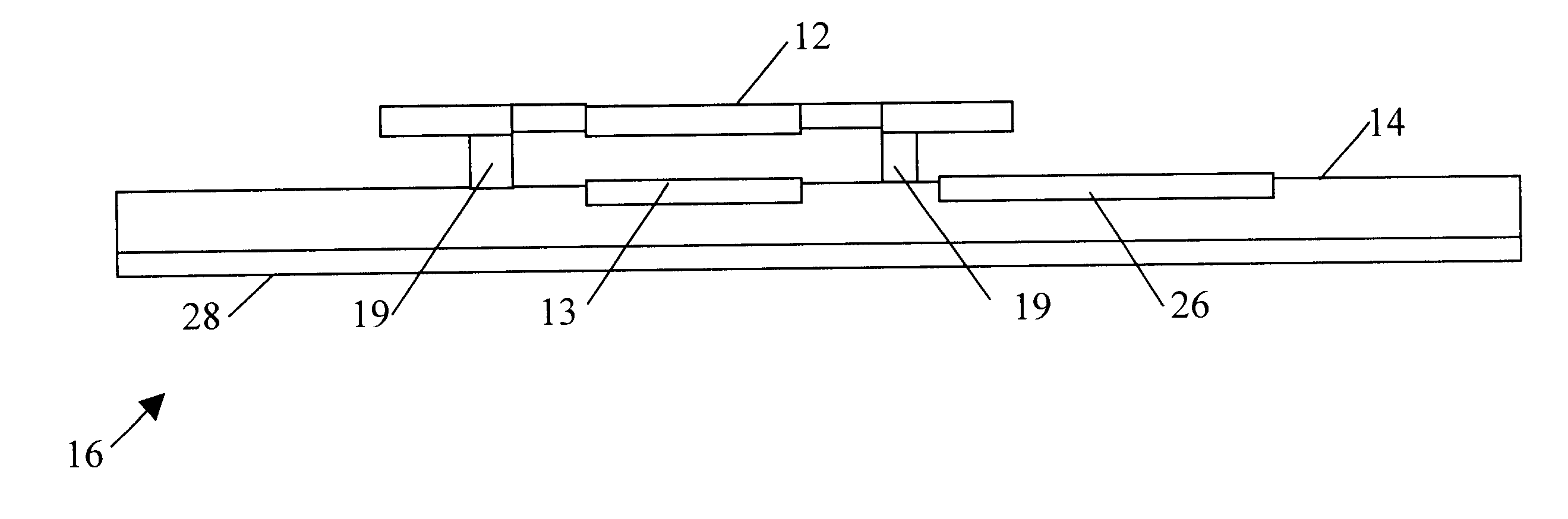

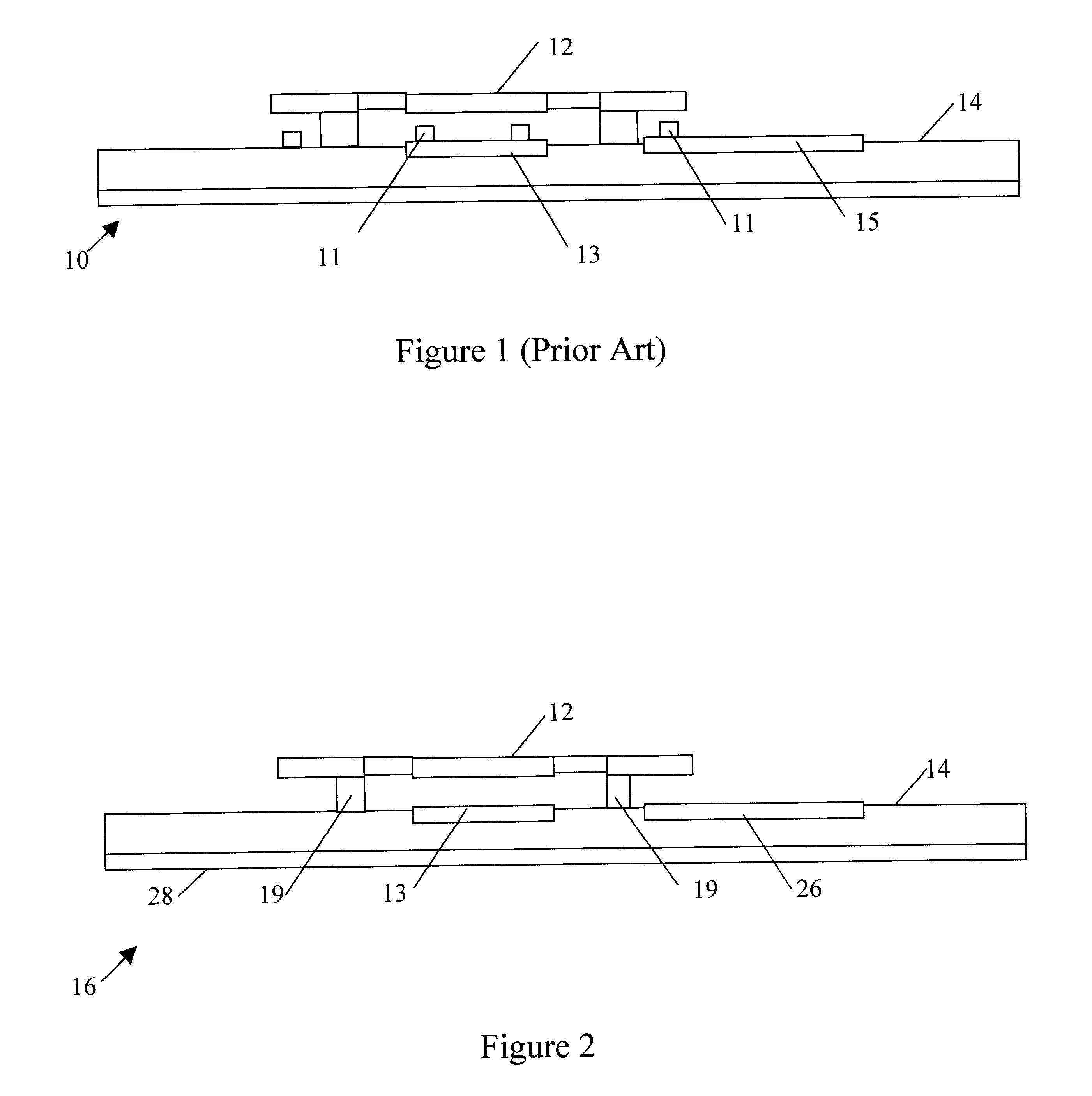

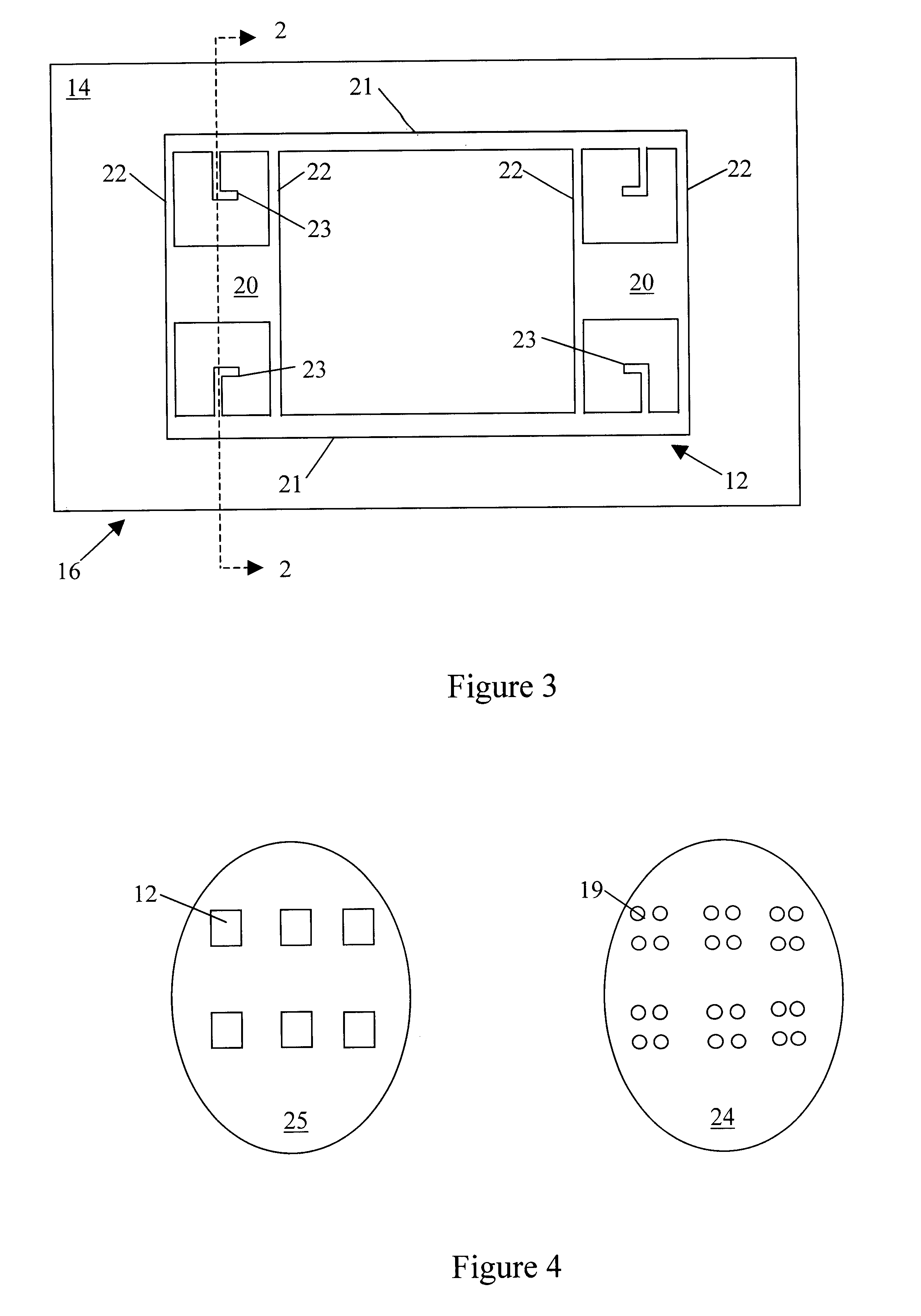

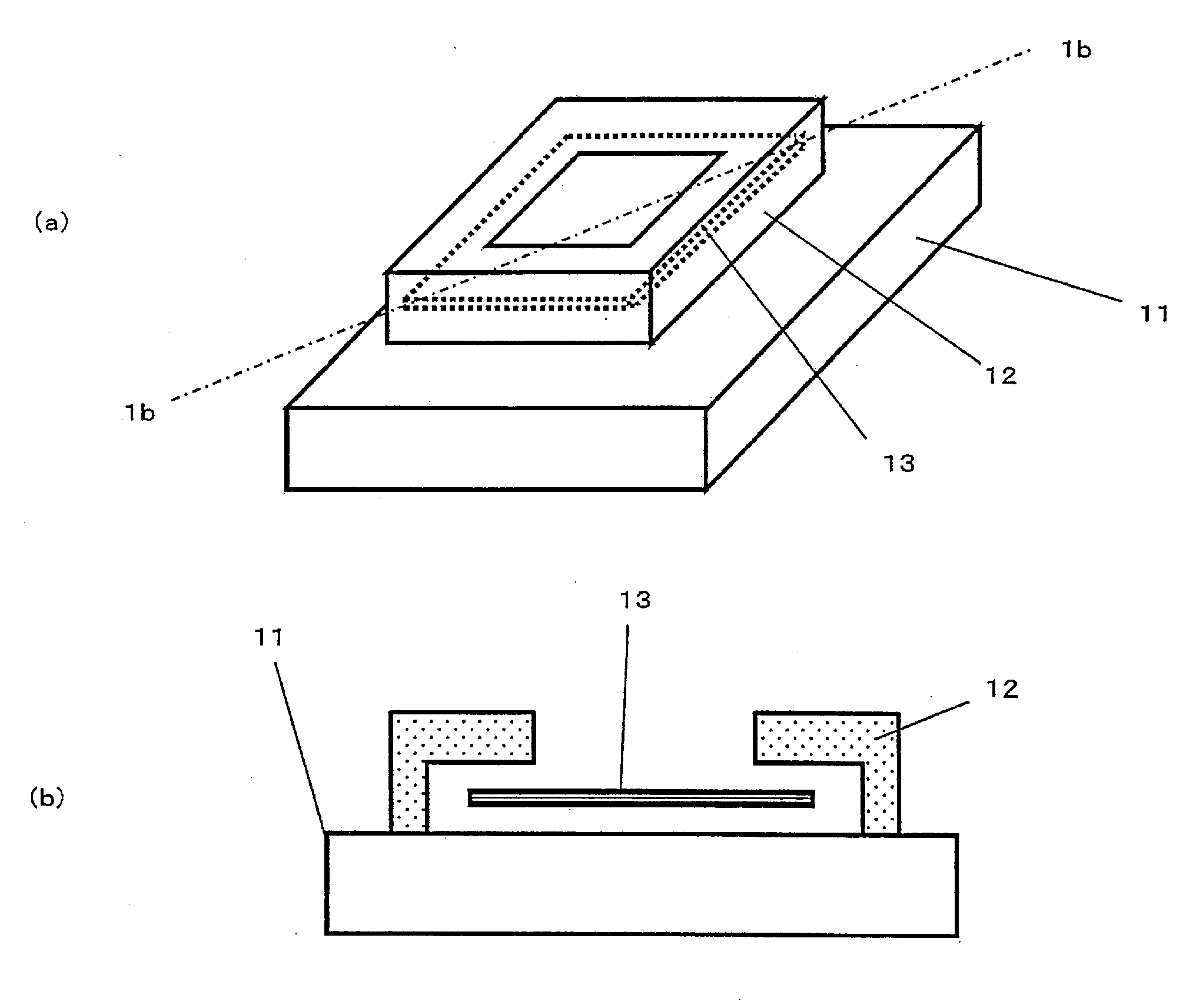

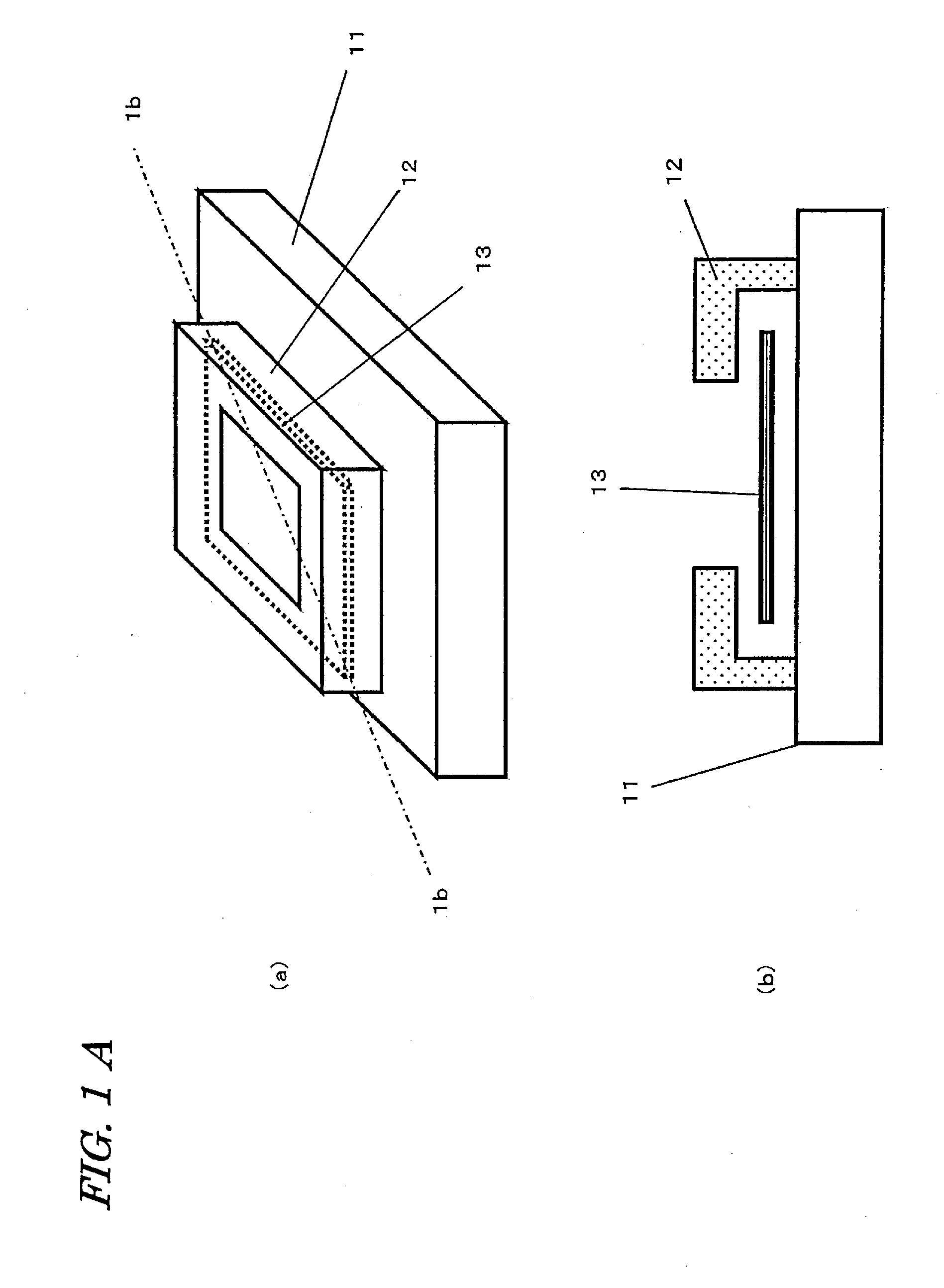

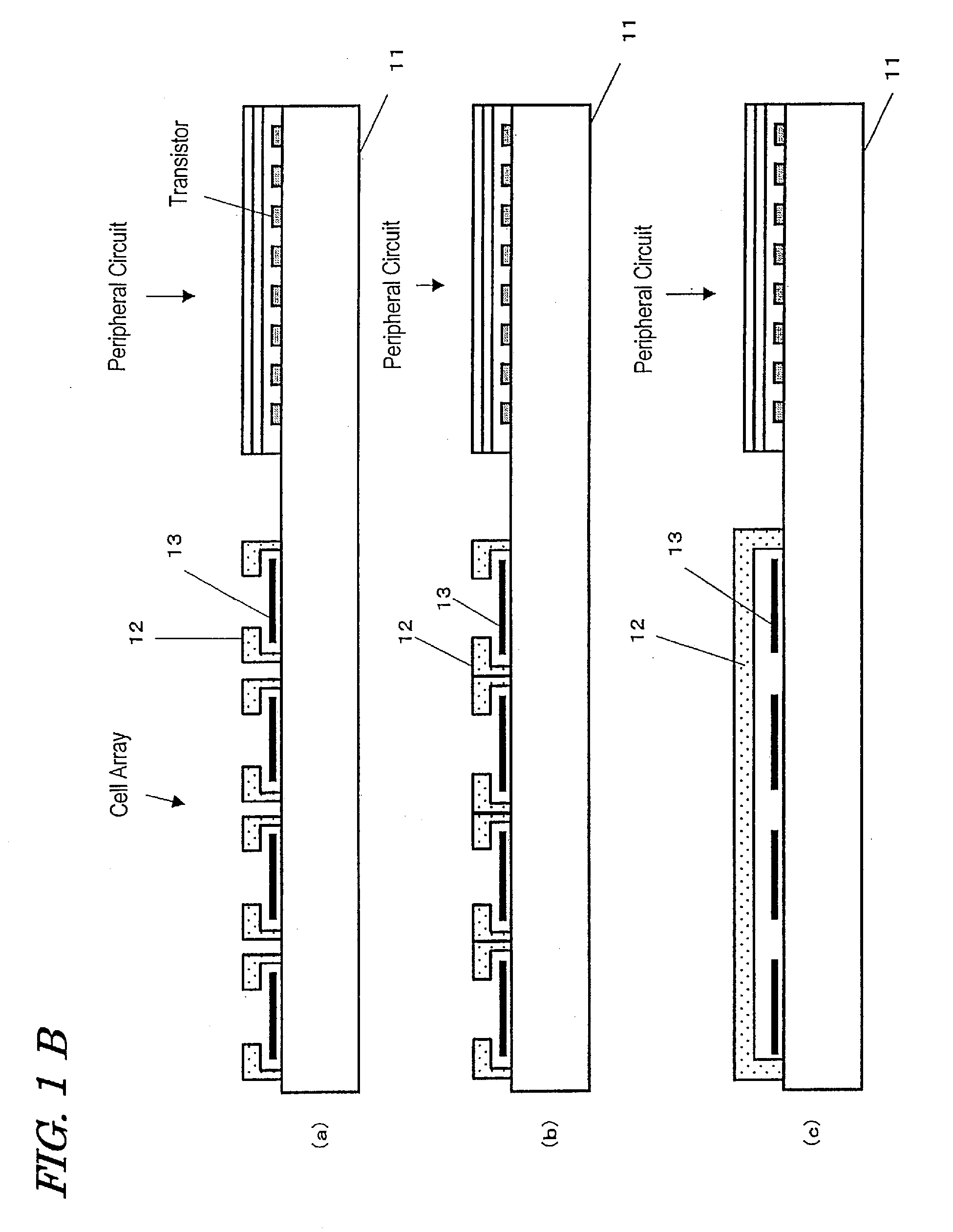

Electronic device and method for fabricating the same

InactiveUS20080179525A1Minimize escapeImprove insulation performanceWave amplification devicesSolid-state devicesInfraredDetector circuits

An electronic device according to the present invention includes: at least one heat sensing section (13), which includes a first contact portion (24) and of which a physical property varies responsive to an incoming infrared ray; a detector circuit section, which includes a second contact portion (42) and which senses the variation in the physical property of the heat sensing section (13); and a driving section (112), which is able to change a first state, in which the first and second contact portions (24, 42) are in contact with each other and electrically connected to each other, into a second state, in which the first and second contact portions (24, 42) are out of contact with each other and electrically disconnected from each other, and vice versa.

Owner:PANASONIC CORP

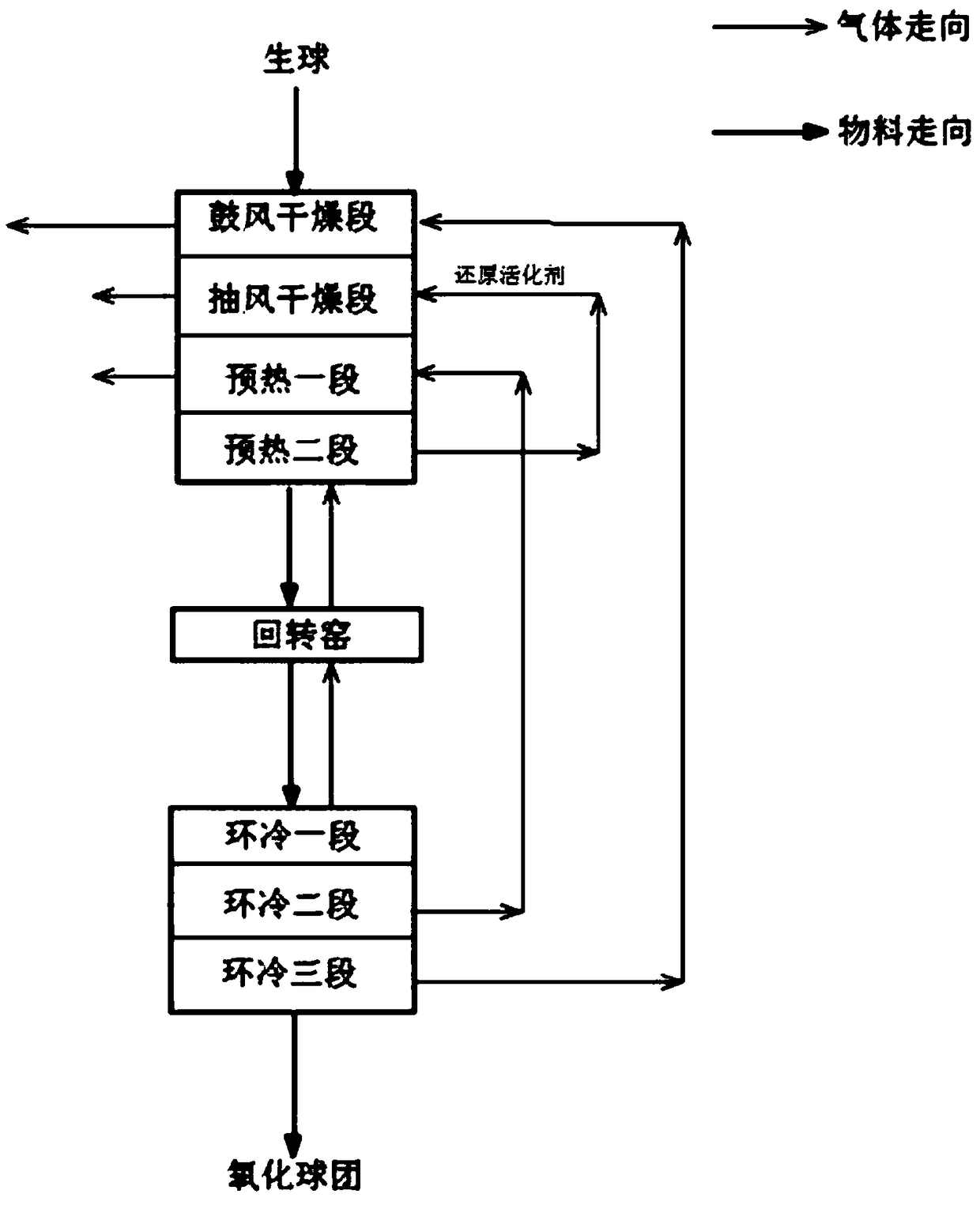

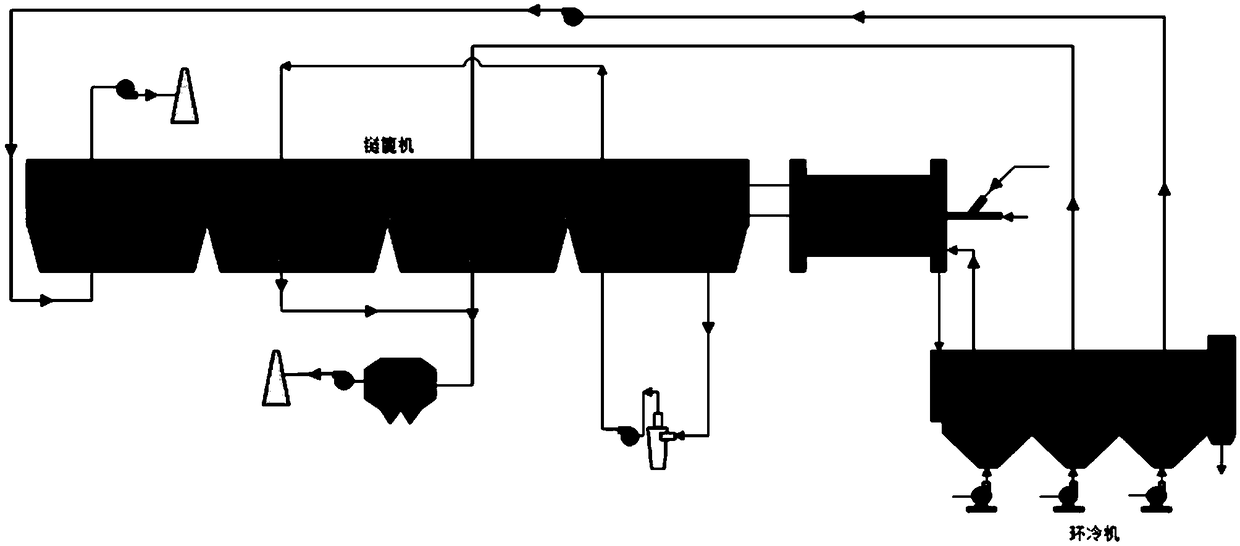

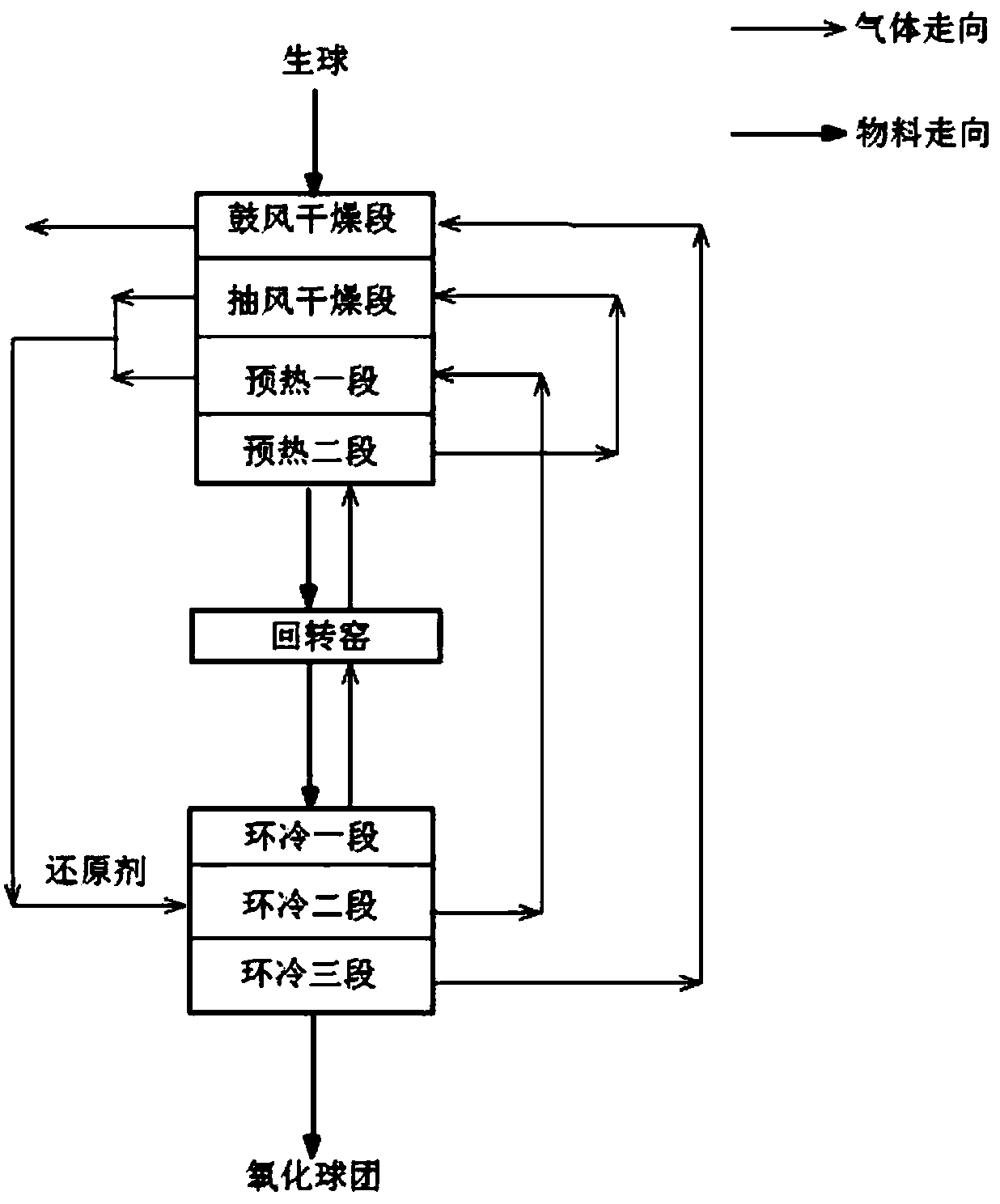

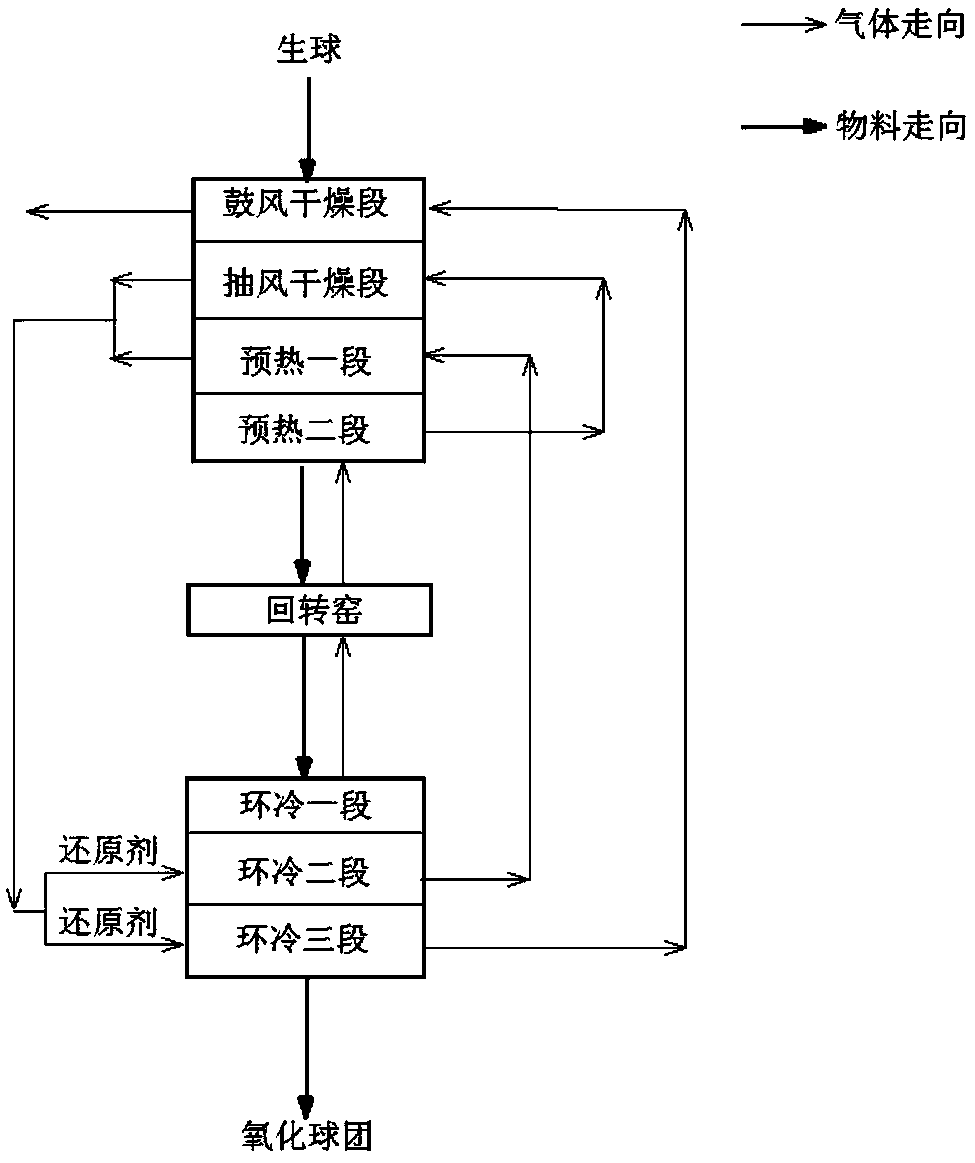

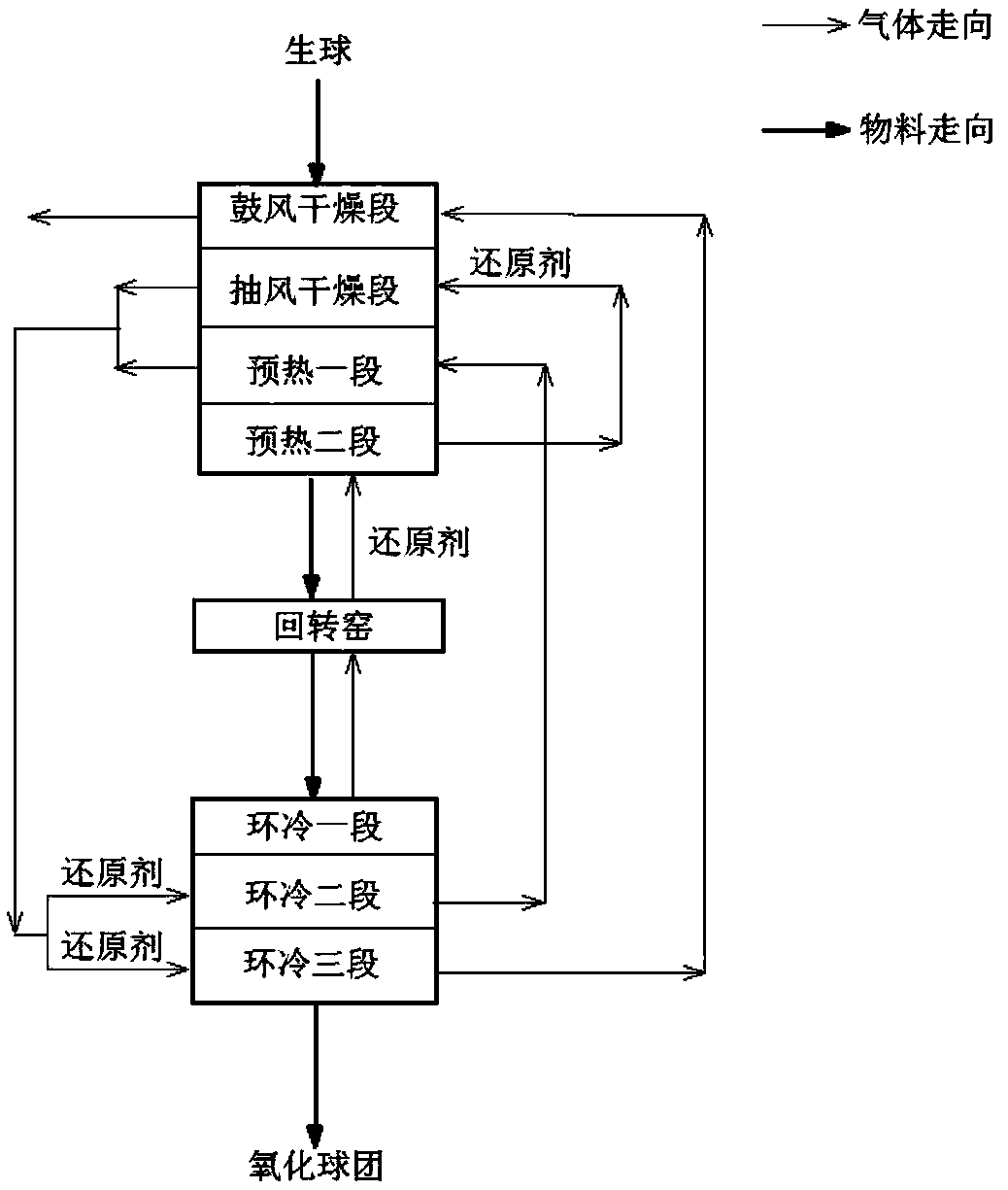

Low-NOx grate-rotary kiln pellet production technology and low-NOx grate-rotary kiln pellet production system

ActiveCN109136544AImprove denitrification efficiencyReduce contentGas treatmentDispersed particle separationCatalytic effectEngineering

The invention provides a low-NOx grate-rotary kiln pellet production technology. The production technology includes spraying a reduction activator into a position, above fresh pellets, in a down-draftdrying section (DDD), and enabling the reduction activator to react with NOx in hot air entering the down-draft drying section (DDD) from a rotary kiln (2) so as to achieve SNCR (selective non-catalytic reduction) denitration. In a preferred scheme, the step of excessively spraying the reduction activator with a catalytic effect into a proper temperature range (950 DEG C) above a material surfaceof a secondary preheating section (PH) is added. The low-NOx grate-rotary kiln pellet production technology solves existing technical problems and has the advantages of lower investment, low runningcost, less ammonia escape and remarkable NOx emission reduction effect.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Flue gas desulfurization and denitration purification recovery system

InactiveCN104383798AReduce escapeRealize resourcesDispersed particle separationAir quality improvementIon exchangeMoisture

The invention relates to a flue gas desulfurization and denitration purification recovery system, which comprises an oxidation absorption tower, a separation regeneration system and a concentration crystallization drying device, wherein the oxidation absorption tower comprises an oxidation tank, a flue gas inlet, a spraying filler layer, an atomization oxidation layer, a demister and a flue gas outlet. According to the present invention, flue gas enters the oxidation absorption tower from the flue gas inlet to carry out oxidation absorption on nitrogen oxides, sulfur oxides and heavy metals in the flue gas so as to form the absorption liquid, the purified flue gas is subjected to moisture removing through the demister and then is discharged from the flue gas outlet, anions of the absorption liquid are exchanged into the bed layer in the anion exchange equipment of the separation regeneration system, ammonia water is adopted to perform regeneration on the bed layer, the regenerated ammonium salt solution enters the concentration crystallization drying device, and crystallization drying is performed to form the composite ammonium fertilizer; and the nitrogen oxides, the sulfur oxides and the heavy metals in the flue gas can be removed in the integrated manner, such that the problems of ammonia escape and ammonium salt aerosol in the prior art can be avoided, and characteristics of simple equipment and product resource are provided.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method and device for controlling NOx concentration in smoke gas of cement kiln

ActiveCN102921284AIncrease profitReduce consumptionDispersed particle separationMulti siteMonitoring system

The invention discloses a method and device for controlling NOx concentration in smoke gas of a cement kiln; the device comprises a decomposing kiln, a preheater and a reducing agent supply device, wherein the bottom of the decomposing kiln is communicated with a kiln tail chimney of the cement kiln by an inlet smoke flue; the top of the decomposing kiln is communicated with the preheater by an outlet smoke flue; a plurality of spray guns communicated with the reducing agent supply devices are arranged at or / or in the middle upper part of the decomposing kiln or / and the outlet smoke flue in a layered way; and the device further comprises a central controller and a smoke gas automatic monitoring system, wherein the central controller is connected to the reducing agent supply devices; and the smoke gas automatic monitoring system is used for monitoring NOx concentration and smoke gas flow information in the kiln tail chimney and transmitting the NOx concentration and smoke gas flow information to the central controller. According to the invention, as a reducing agent is sprayed into the decomposing kiln through multi-site combined control, high removal rate of the NOx can be achieved without an SNCR (Selective Non Catalytic Reduction) and SCR (Selective Catalytic Reduction) combined technology.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

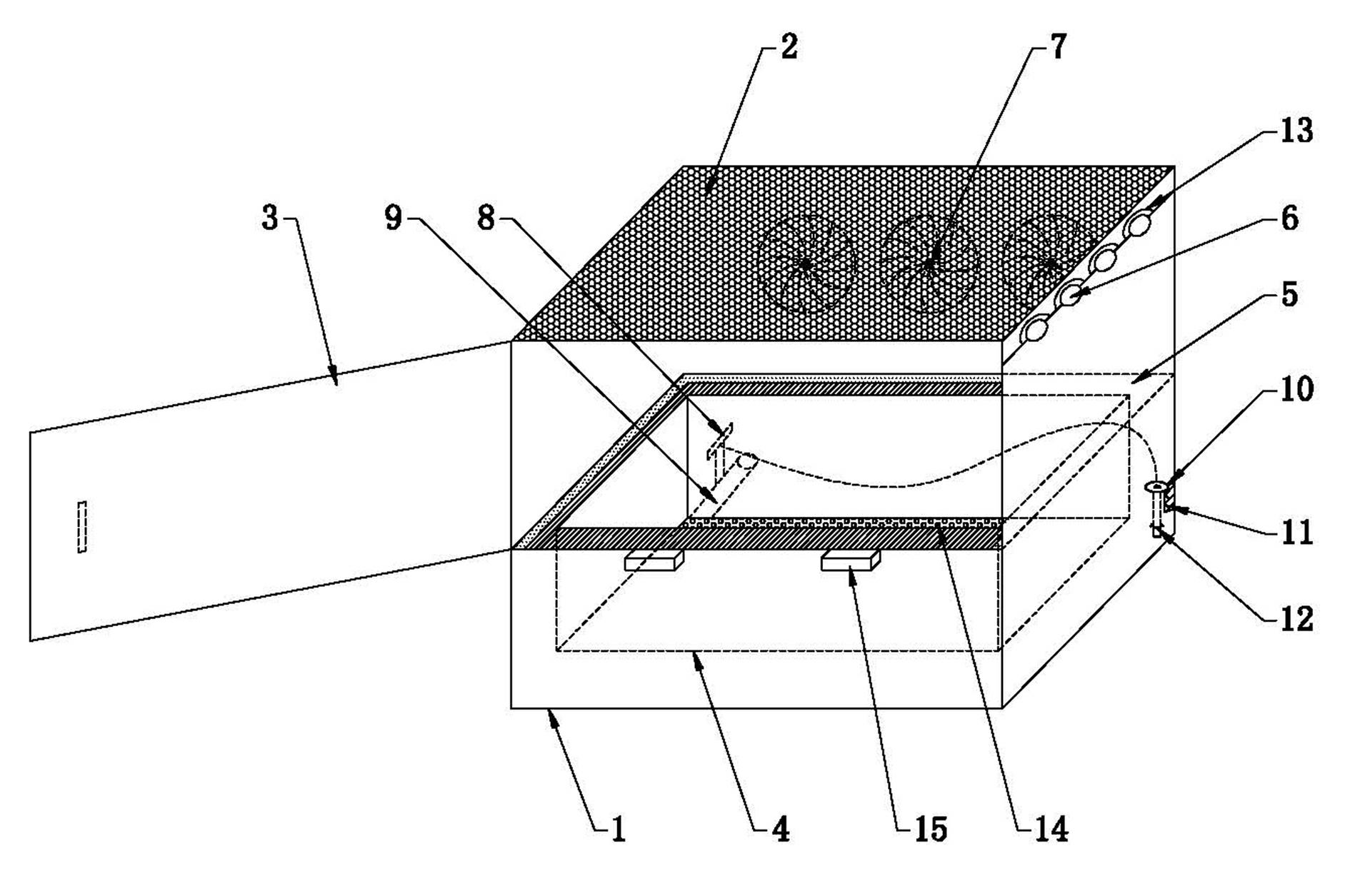

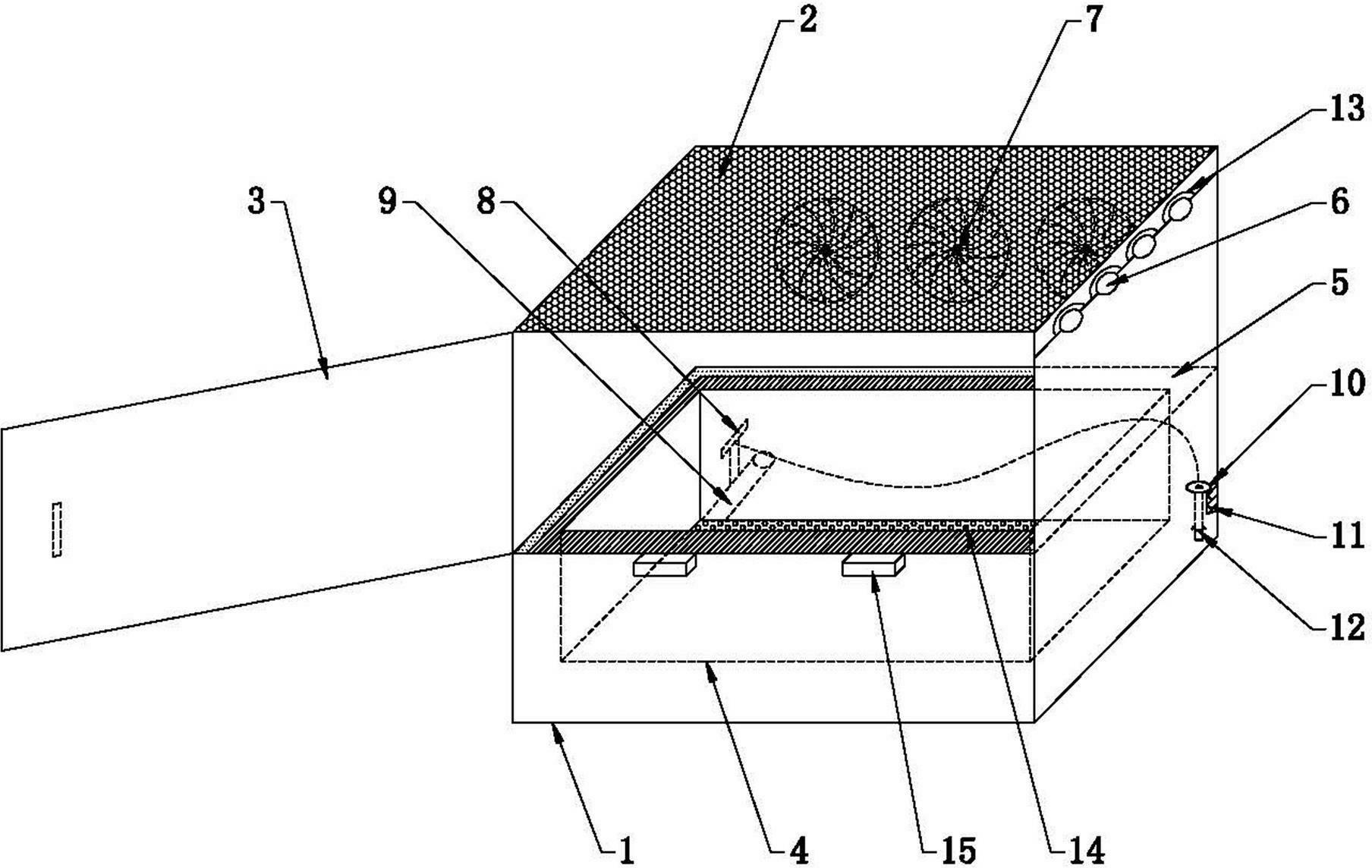

Crop and insect co-cultivation box

InactiveCN102523974AIncrease in sizeConvenient lightingReceptacle cultivationAnimal husbandryDiseaseCrop cultivation

The invention discloses a crop and insect co-cultivation box which comprises a box body (1) and a seedling raising disk (4), wherein, an upper cover (2) is arranged at the top of the box body (1), and a box door (3) is installed at the upper part of a front wall of the box body; a rightwards opened square-shaped lug boss (5) used for holding the seedling raising disk (4) is arranged on the inner wall of the box body (1); the upper edge of the seedling raising disk (4) is positioned on the upper side of the lug boss (5); a lighting device (6) positioned on the lower side of the upper cover (2)is arranged at the upper part of an inner chamber of the box body (1); a blower (7) is arranged at the upper part of a rear wall of the box body (1); a liquor feeding pipe (9) communicated with the inner chamber of the box body (1) is arranged on the outer side of the lower part of the box body (1); and a control switch (8) is arranged on the liquor feeding pipe (9). The crop and insect co-cultivation box provides a crop and insect co-cultivation platform that achieves full automation, good effect, low construction cost and wide application range, and can be widely applied to crop and insect interaction researches such as crop cultivation, insect raising, insect resistance of crop, and identifications on disease resistance of bacteriosis and virus of insect vectors.

Owner:NANJING AGRICULTURAL UNIVERSITY

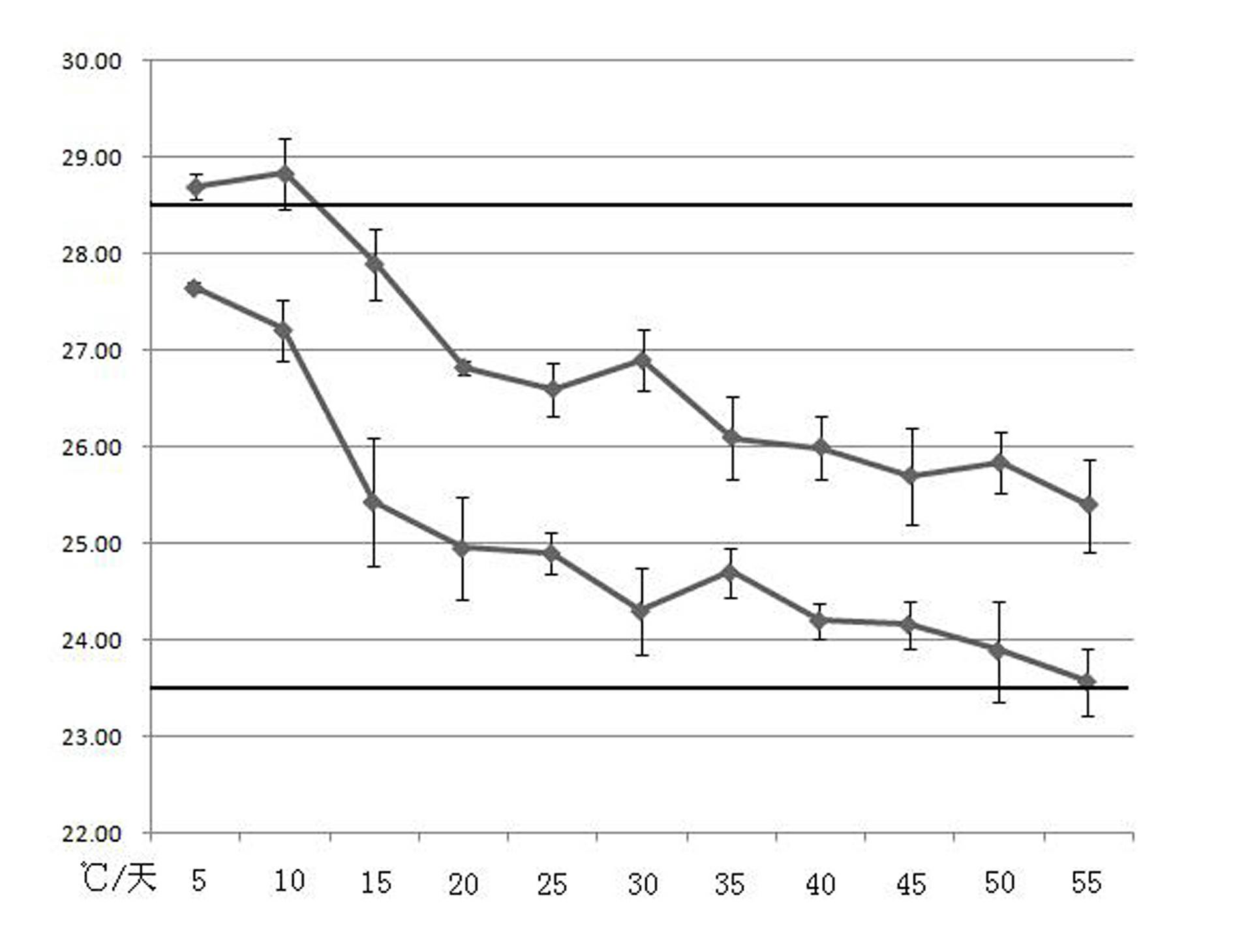

Method for regulating and controlling ammonia spraying amount based on inlet NOx concentration prediction

ActiveCN107526292AReduce escapeSuppress changesControllers with particular characteristicsAmmoniaValve opening

The invention belongs to the SCR system ammonia spraying amount regulation and control field and discloses a method for regulating and controlling an ammonia spraying amount based on inlet NOx concentration prediction. The method comprises the following steps of (a) measuring and acquiring a measured value of each correlation parameter at a current moment and an inlet NOx concentration respectively; (b) according to a relation between the correlation parameter and the inlet NOx concentration, constructing a prediction model and predicting the inlet NOx concentration of a next moment; (c) carrying out filtering processing on the inlet NOx concentration of the current moment, and taking a difference value of the filtered inlet NOx concentration and the inlet NOx concentration of the next moment as a predicted variation value; and (d) taking the predicted variation value and the like as input of a denitration system PID controller, and outputting an ammonia spraying valve opening degree so as to complete regulation and control of the ammonia spraying amount. In the invention, the prediction model is used to predict the inlet NOx concentration of the next moment, the ammonia spraying amount is optimized, a frequent fluctuation of an outlet NOx concentration is restrained and adjusting quality of the outlet NOx concentration is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

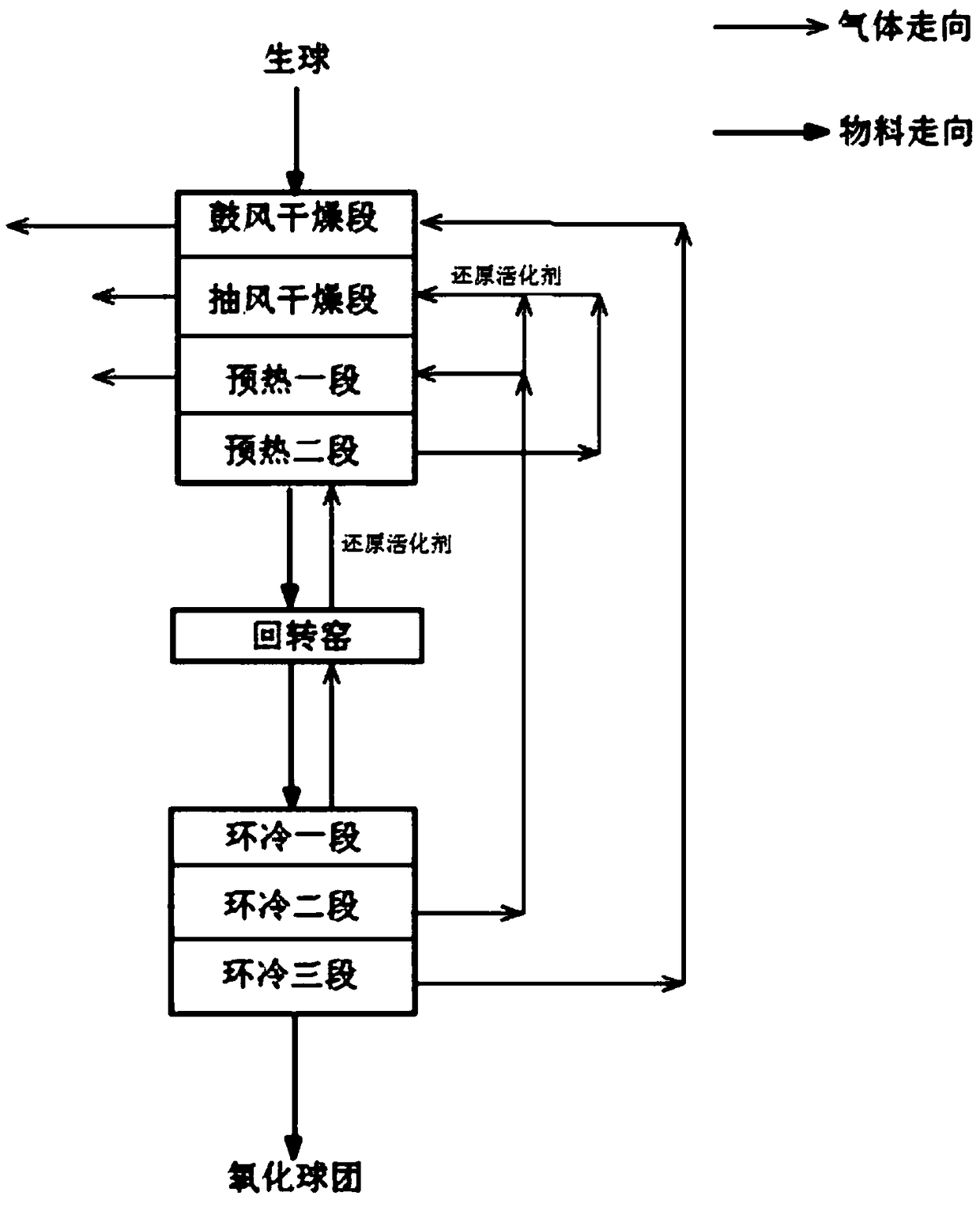

Grate-rotary kiln pellet low NOx production process and system

ActiveCN109055721AReduce contentReduce escapeGas treatmentDispersed particle separationFlue gasProcess engineering

The invention provides a grate-rotary kiln pellet low NOx production process. The process comprises the following steps that flue gas exhausted from an air draft drying section (DDD) and a first preheating section (TPH) is used as cooling wind and conveyed to an air inlet of a ring-cooling second section (C2), a reducing agent is sprayed into the position of an air box at the bottom of the ring-cooling second section (C2), the reducing agent reacts with NOx in the flue gas exhausted from the air draft drying section (DDD) and the first preheating section (TPH), so that SNCR denitration is realized. The production process and system have the characteristics that the investment is saved, the operation cost is low, and the NOx emission reduction effect is remarkable.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

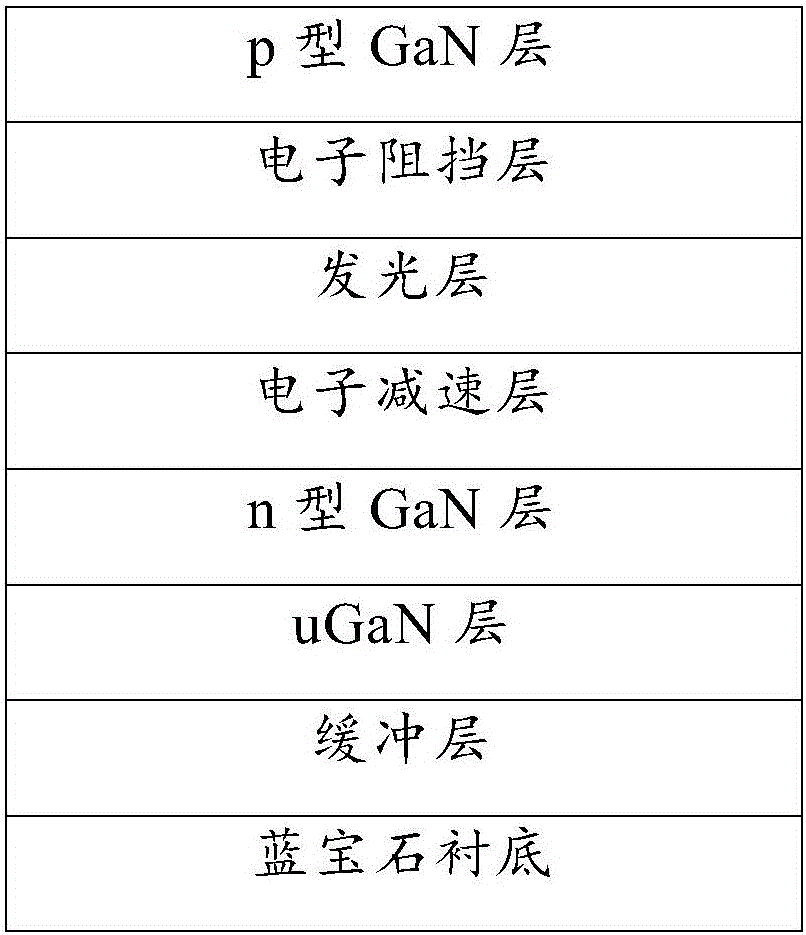

Light-emitting diode (LED) epitaxial structure and fabrication method thereof

The invention provides a light-emitting diode (LED) epitaxial structure. The LED epitaxial structure comprises a substrate and a semiconductor epitaxial layer, wherein the semiconductor epitaxial layer is arranged on the substrate and comprises an N-type semiconductor layer, a light-emitting layer and a P-type semiconductor layer, and an electron speed reduction layer is further arranged between the light-emitting layer and the N-type semiconductor layer, is used for reducing escaped electrons and is formed by laminating n layers of AlInGaN with thickness of 1-20 nanometers. The electron speed reduction layer is arranged between the light-emitting layer and an N-type semiconductor, is used for reducing the escaped electrons and is formed by laminating n layers of AlInGaN with the thickness of 1-20 nanometers, and thus, the electron speed can be effectively reduced.

Owner:FOCUS LIGHTINGS SCI & TECH

Coal-fired boiler SNCR and SCR combined denitration system and method thereof

ActiveCN105289233AImprove mixing uniformityImprove distribution uniformityLighting and heating apparatusDispersed particle separationBoiler furnaceProcess engineering

The invention relates to a coal-fired boiler SNCR and SCR combined denitration system. The denitration system comprises a boiler SNCR reaction system and a SCR reactor; the boiler SNCR reaction system comprises the boiler, an urea solution distribution module and a metering module, and an urea injection system and an urea supply system which are connected with the urea solution distribution module and the metering module; the urea injection system comprises multilayer-designed short spray guns with upper elevation in a 25m to 40m scope in a boiler furnace combustion zone, and multilayer-designed porous long spray guns having an furnace arch with the boiler, wherein, in each layer, at least one porous long spray gun vertically stretches into the boiler, and extends and passes through the cross section; the SCR reactor is connected with a boiler tail through a flue gas mixer; in the SCR reactor, the multilayer cellular catalyst can be arranged at a space between a coal economizer and an air preheater. According to the method, a mol ratio of ammonia nitrogen in an inlet cross section of the SCR catalyst is uniformly distributed, and denitration efficiency of the SCR reactor is enhanced.

Owner:CHINA HUANENG GRP CO LTD +1

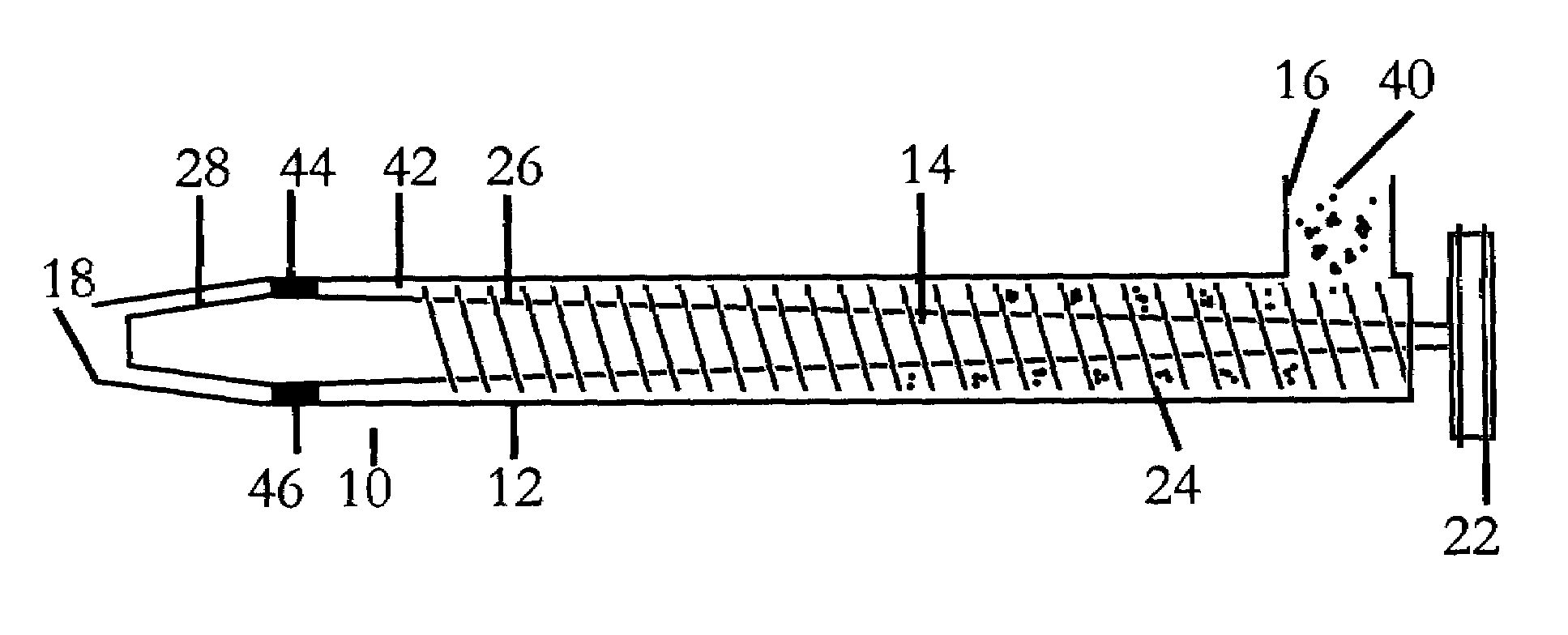

Fiber optic sensors for gas turbine control

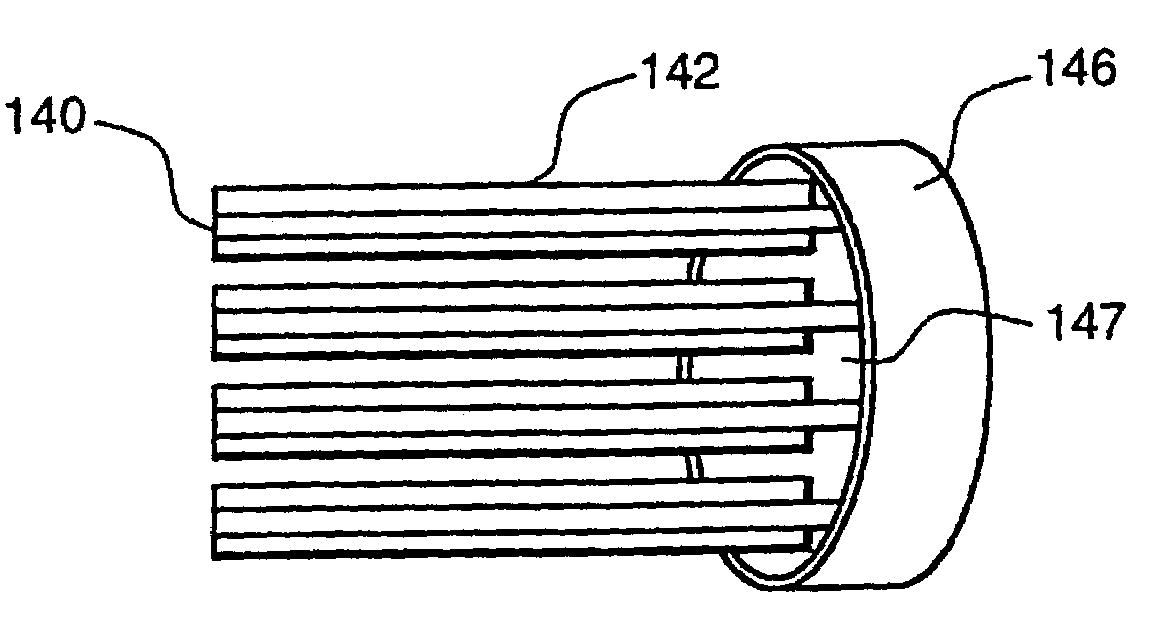

InactiveUS6978074B2Flexible to bendingLight weightContinuous combustion chamberMaterial analysis by optical meansCombustorPhotovoltaic detectors

An apparatus for detecting flashback occurrences in a premixed combustor system having at least one fuel nozzle includes at least one photodetector and at least one fiber optic element coupled between the at least one photodetector and a test region of the combustor system wherein a respective flame of the fuel nozzle is not present under normal operating conditions. A signal processor monitors a signal of the photodetector. The fiber optic element can include at least one optical fiber positioned within a protective tube. The fiber optic element can include two fiber optic elements coupled to the test region. The optical fiber and the protective tube can have lengths sufficient to situate the photodetector outside of an engine compartment. A plurality of fuel nozzles and a plurality of fiber optic elements can be used with the fiber optic elements being coupled to respective fuel nozzles and either to the photodetector or, wherein a plurality of photodetectors are used, to respective ones of the plurality of photodetectors. The signal processor can include a digital signal processor.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com