Patents

Literature

71 results about "Tangential firing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

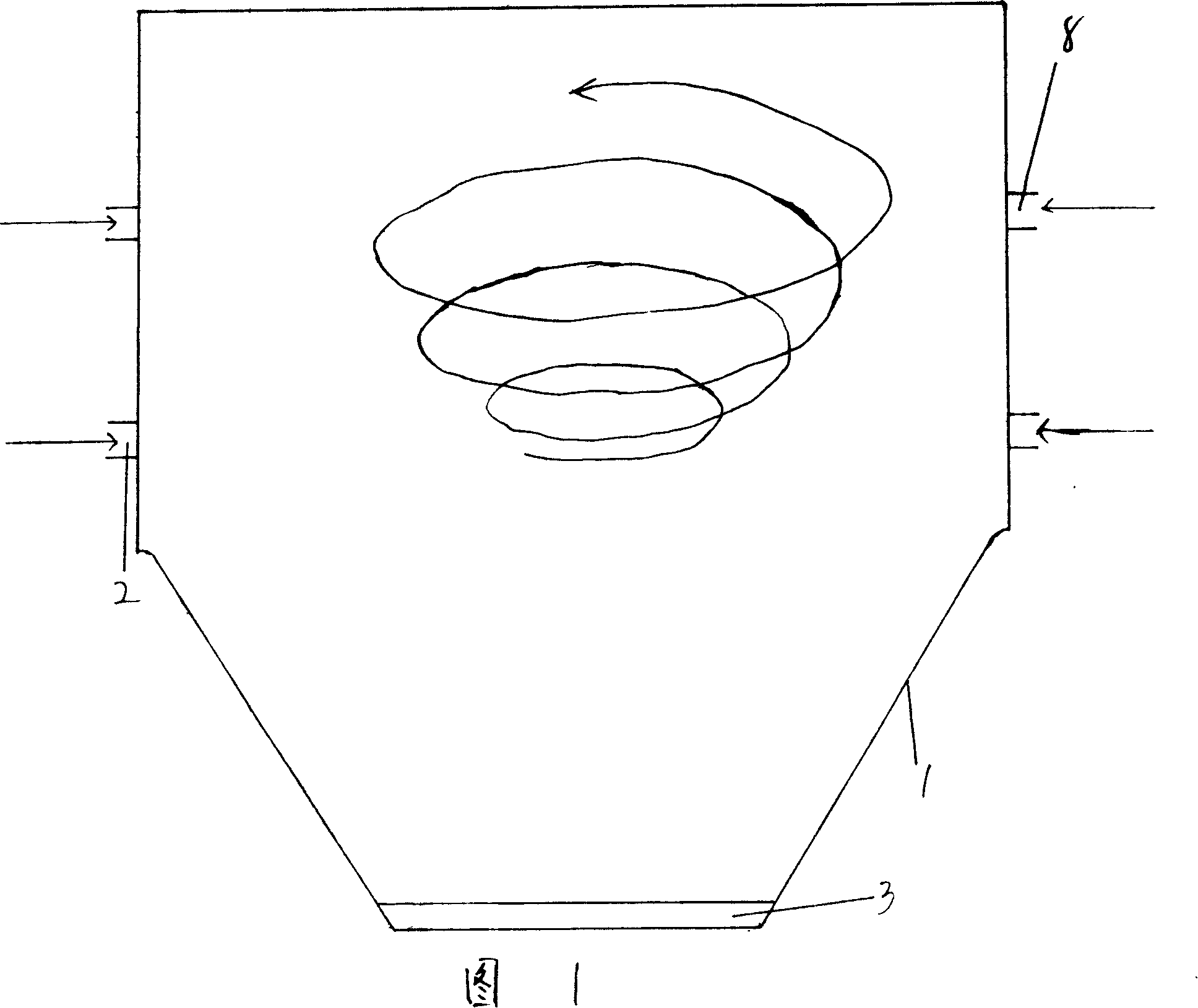

Tangential firing is a method of firing a fuel to heat air in thermal power stations. The flame envelope rotates ensuring thorough mixing within the furnace, providing complete combustion and uniform heat distribution.

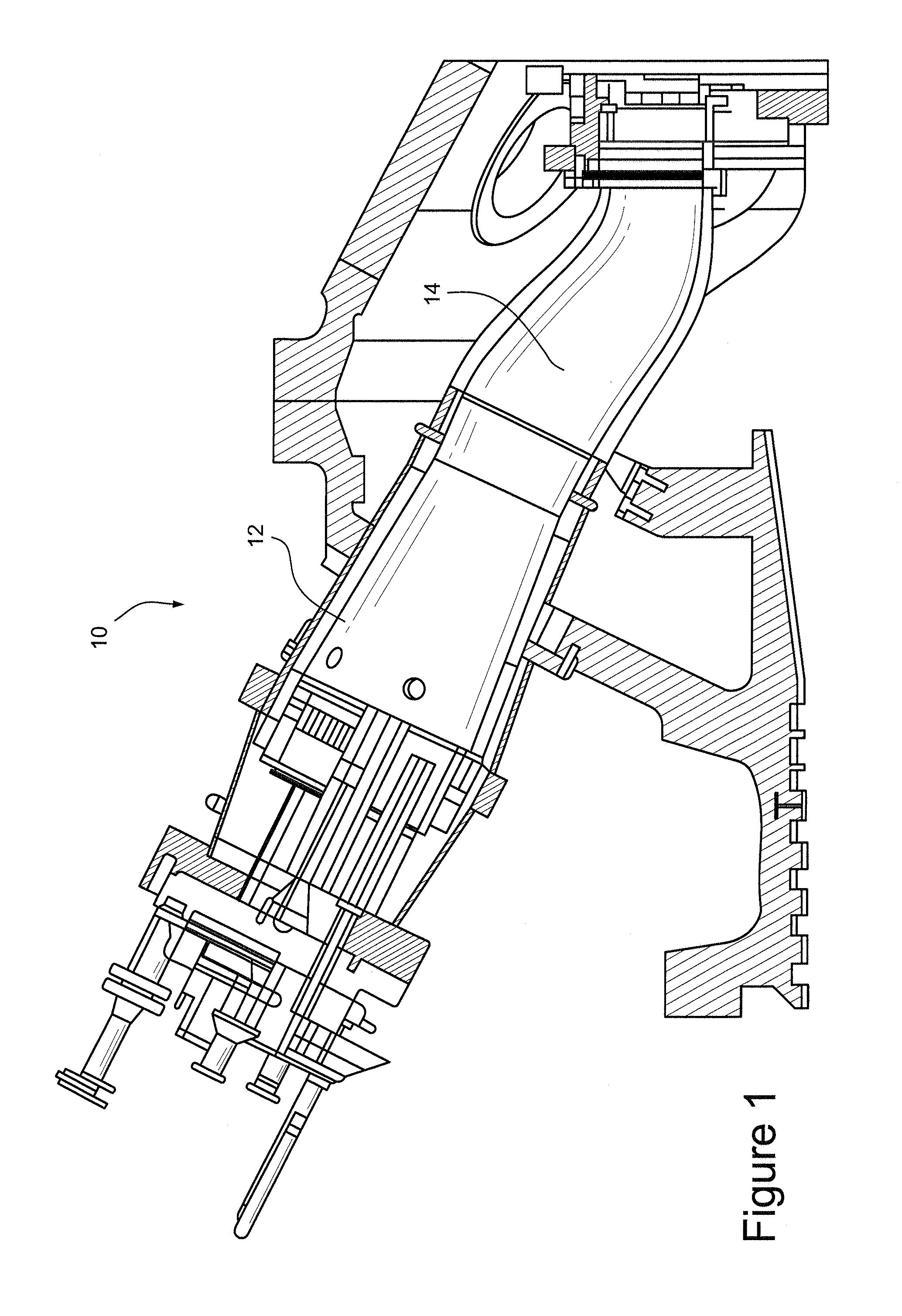

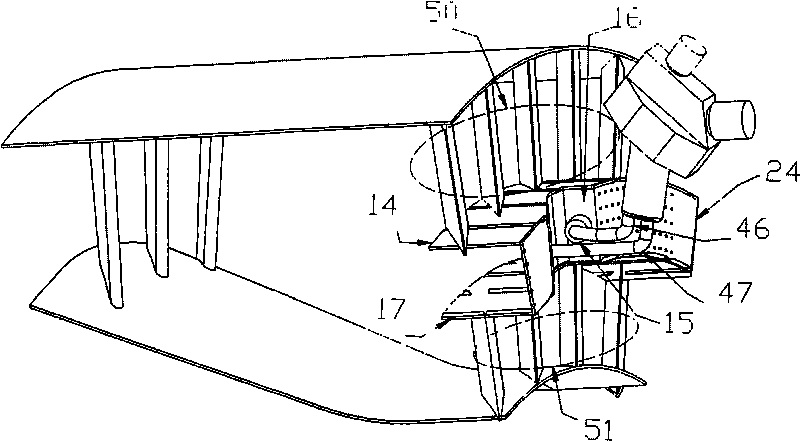

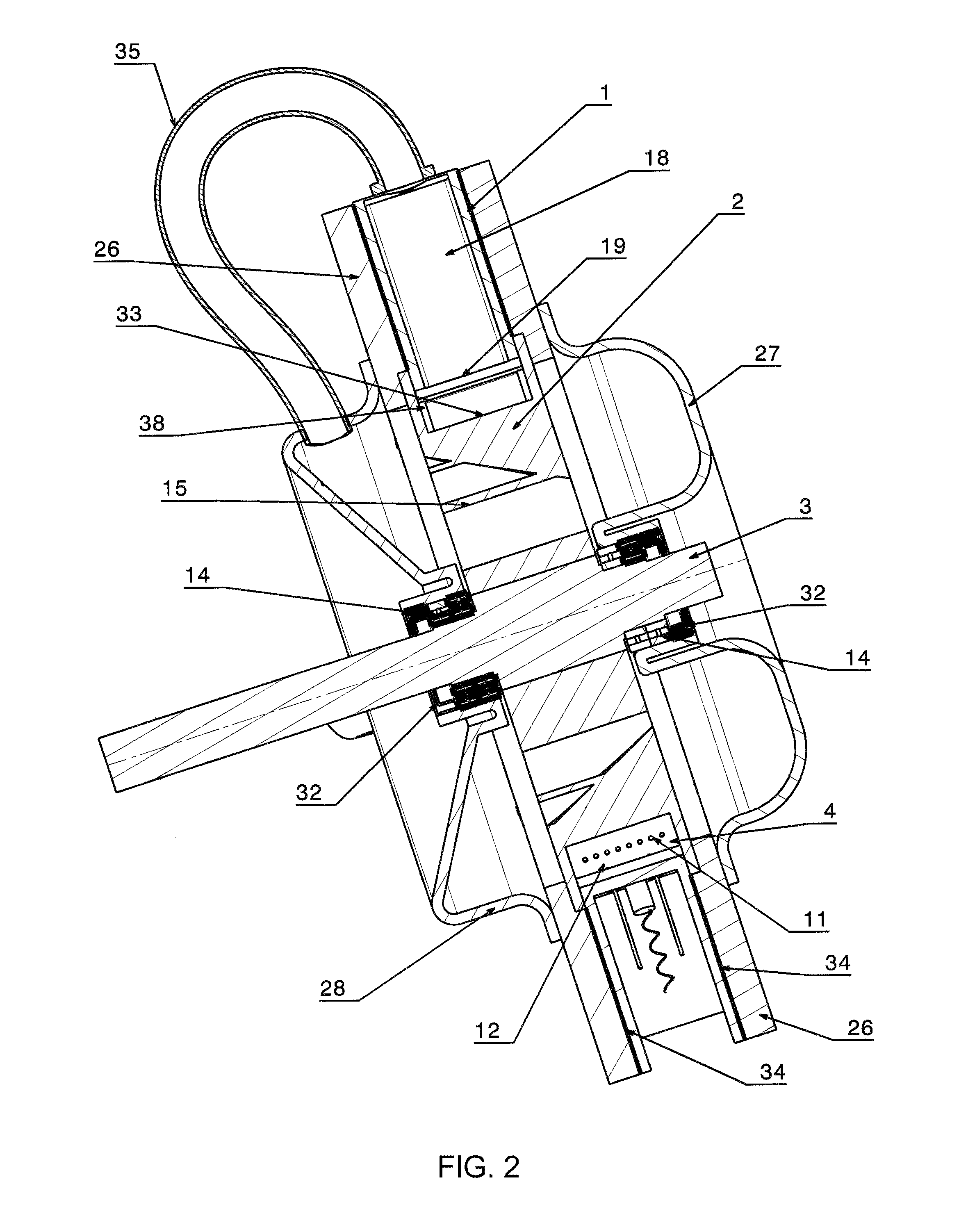

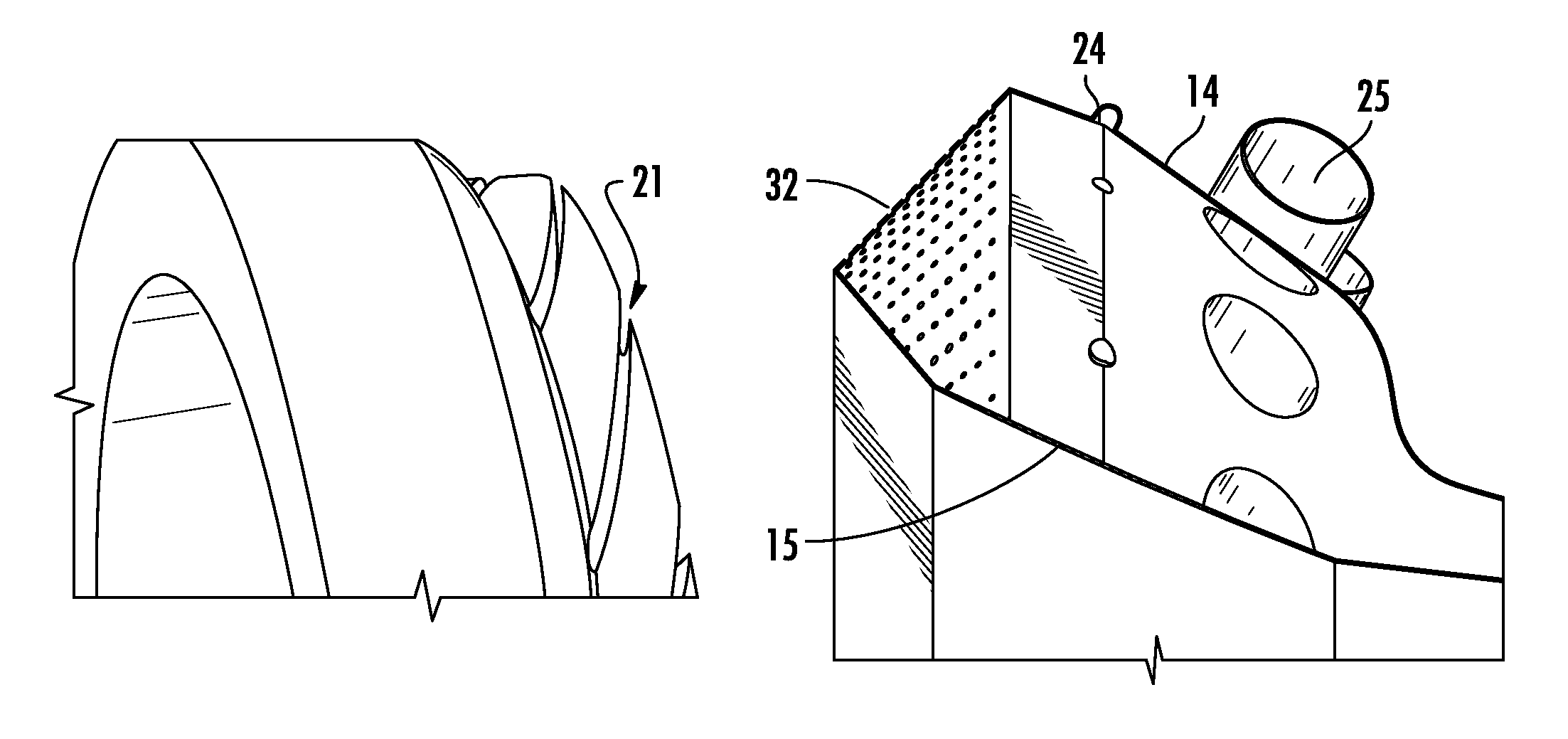

Tangential combustor with vaneless turbine for use on gas turbine engines

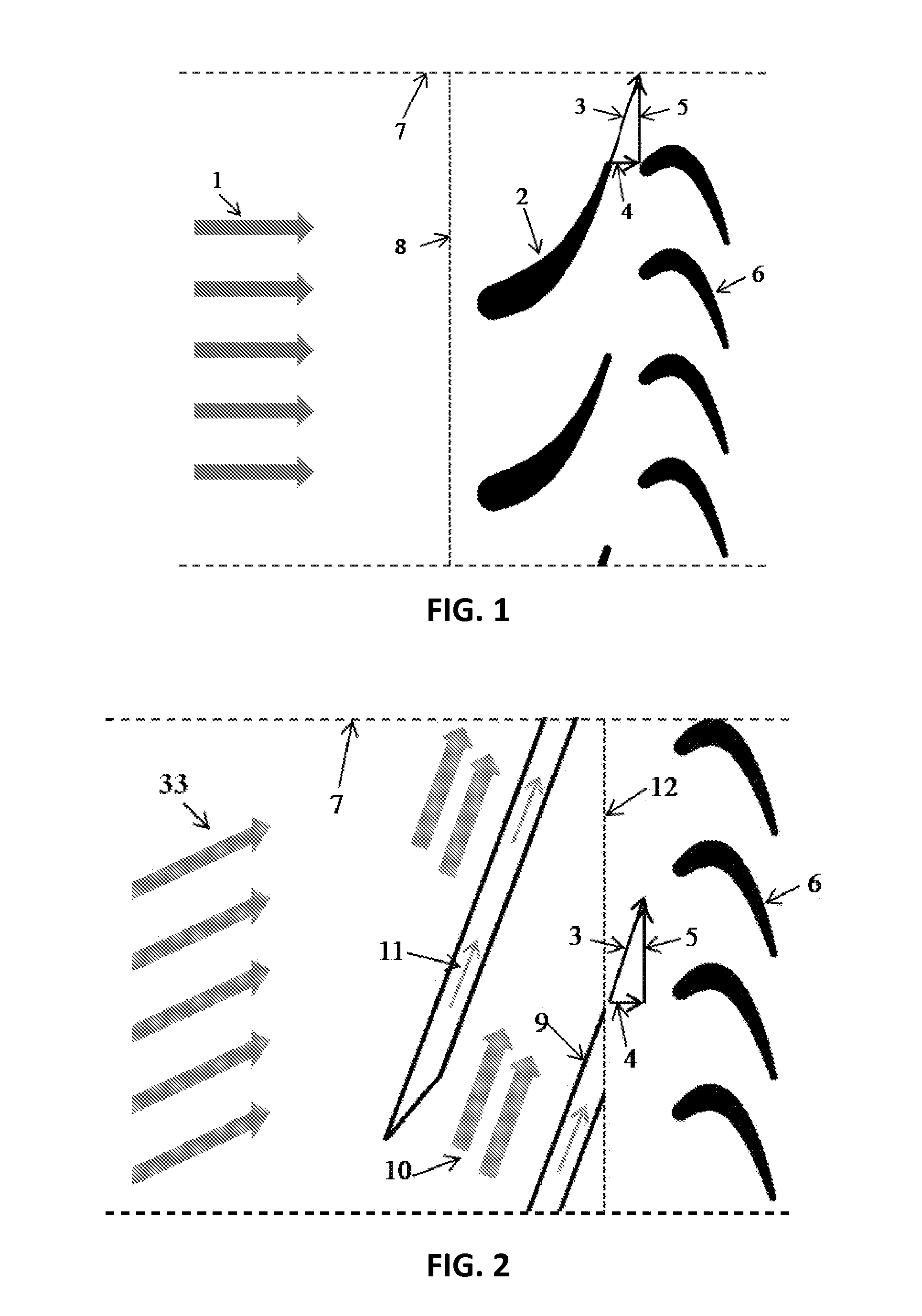

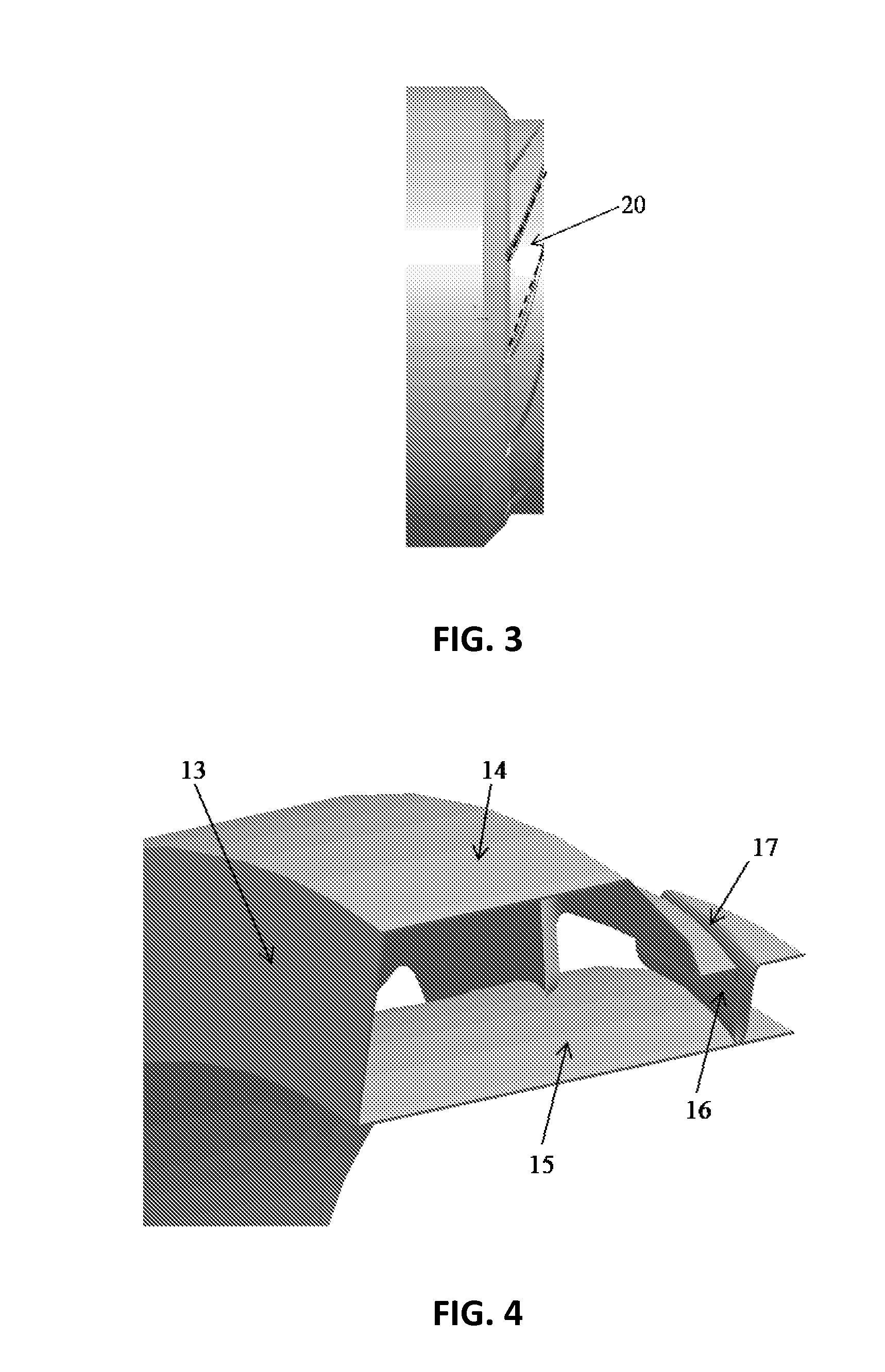

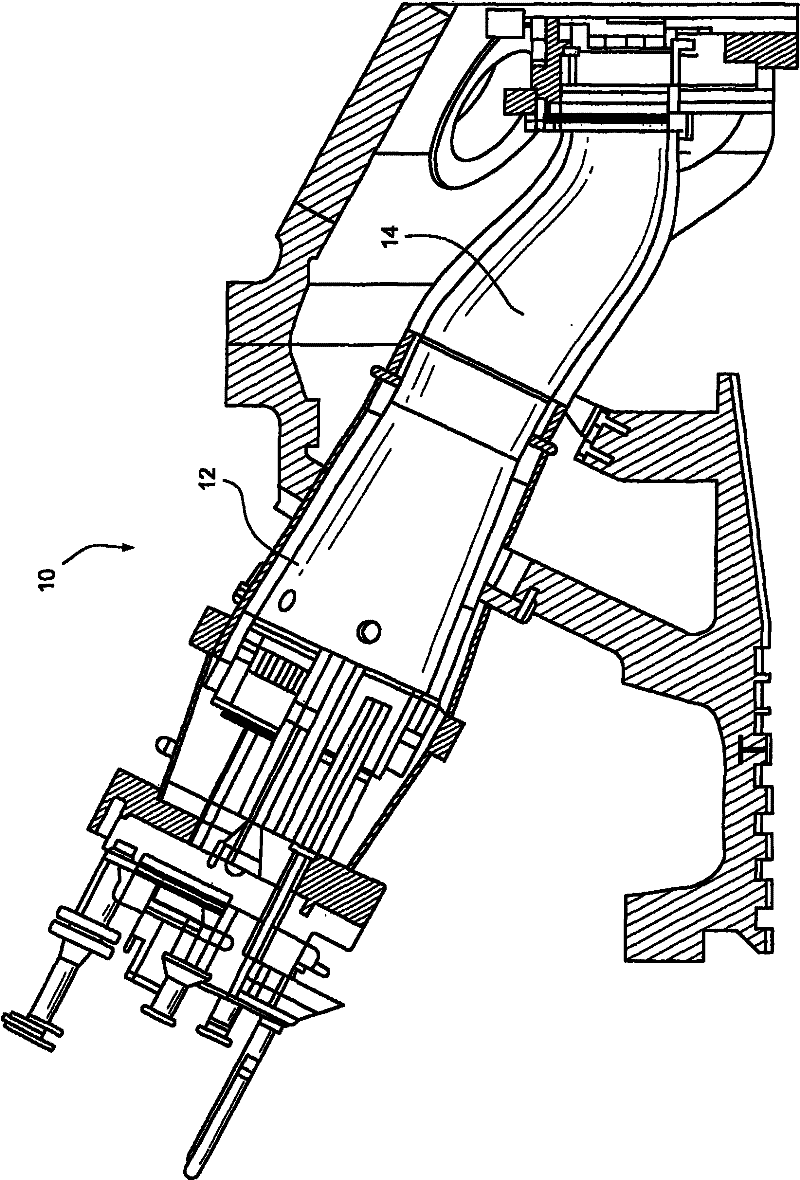

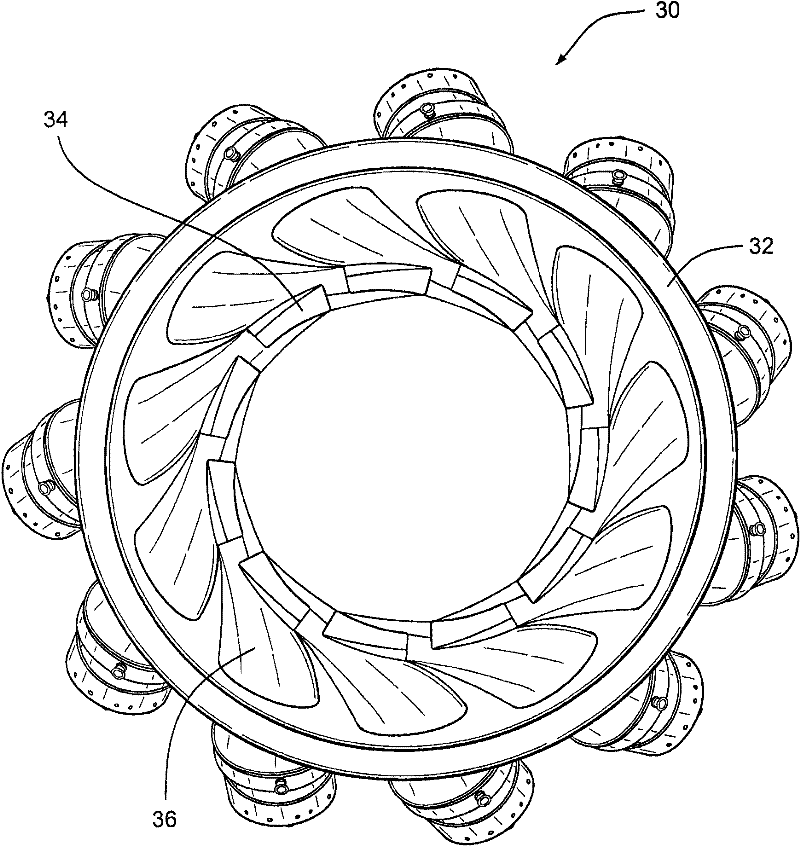

ActiveUS20110209482A1Shorten the lengthReduce manufacturing costContinuous combustion chamberGas turbine plantsTurbine bladeStaged combustion

A combustion device used in gas turbine engines includes an annular combustor that contains the combustion process of air and fuel and then guides the hot gas products to a first stage turbine subsection of a gas turbine engine. The annular combustor has an inner / outer shell having corrugated surfaces that extend radially outward and inward across an entire hot gas stream inside the annular combustor. The corrugations twist about the engine centerline in a longitudinal direction of travel of the engine. The resulting flow path accelerates and turns the hot gas stream to conditions suitable for introduction into the first stage turbine blades, which eliminate the need for first stage turbine vanes. The annular combustor is configured with a system of fuel and air inlet passages and nozzles that results in a staged combustion of premixed fuel and air.

Owner:TOQAN MAJED +3

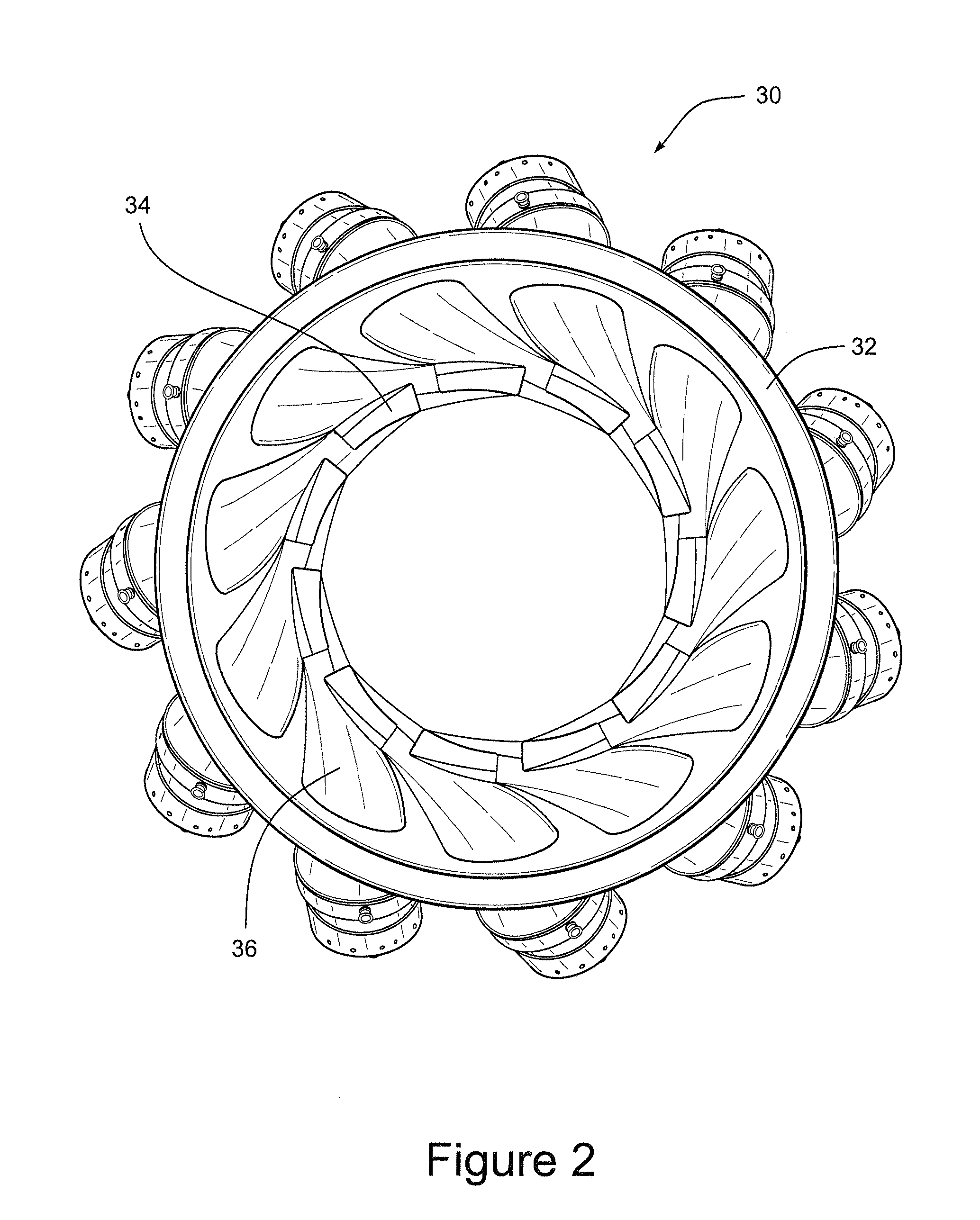

Tangential Combustor

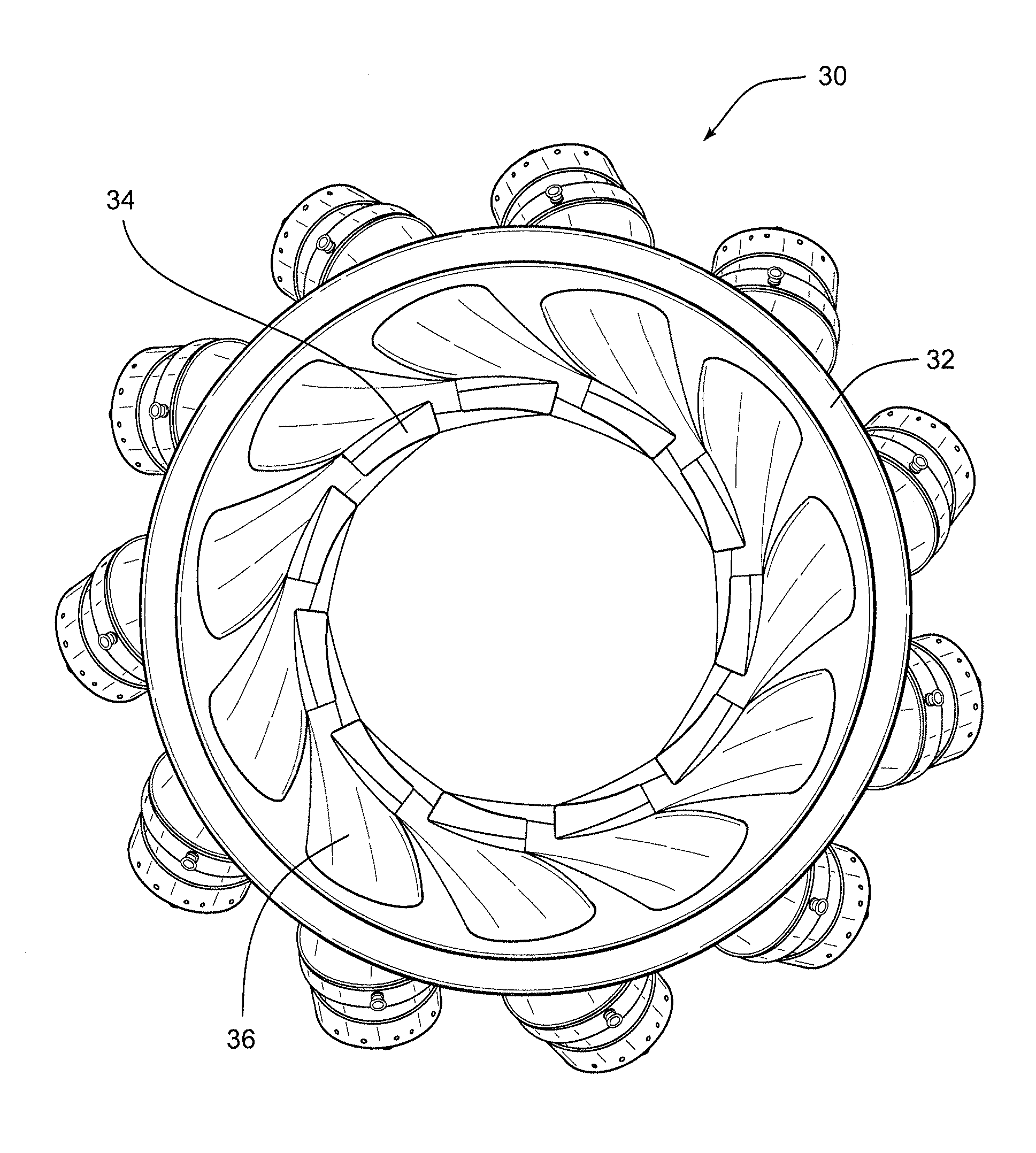

InactiveUS20110259015A1Shorten gas turbineShorten the gas turbineContinuous combustion chamberGas turbine plantsGas turbinesTangential firing

A combustion section for a gas turbine includes a casing defining a chamber, a plurality of combustor cans disposed in the casing and oriented in an annular pattern, and a plurality of transition pieces each coupled with one of the combustor cans. The transition pieces direct products of combustion from the combustor cans into contact with rotating buckets of the gas turbine. Each of the transition pieces is angled in two planes to effect turning of the products of combustion and to shorten the gas turbine.

Owner:GENERAL ELECTRIC CO

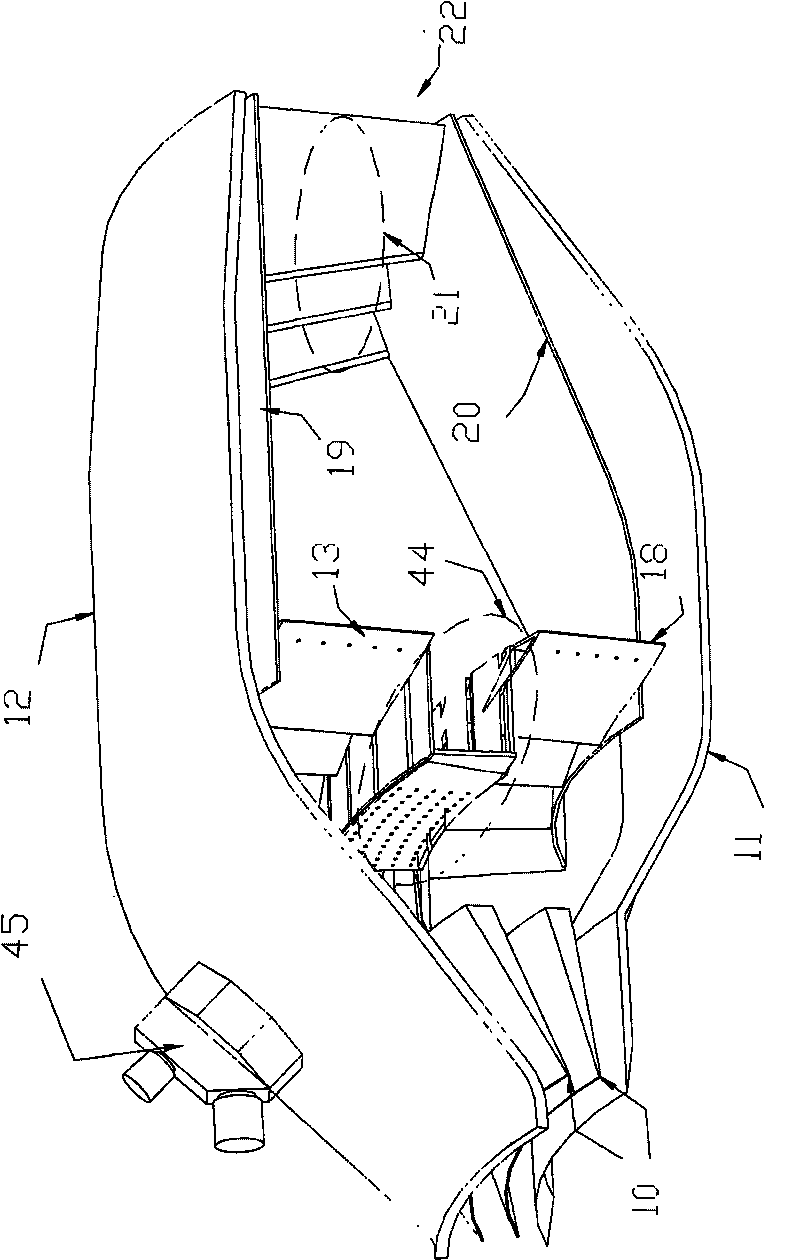

Central cavity stable fire tangential combustion chamber

InactiveCN101737802AReduce dwell timeCompact structureContinuous combustion chamberLow speedCombustion chamber

The invention discloses a central cavity stable fire tangential combustion chamber, which consists of a shunting type diffuser, a combustion chamber external cartridge receiver, a central cavity rear step pre-combustion stage, an outer ring blunt body flame stabilizer main combustion stage, an inner ring blunt body flame stabilizer main combustion stage, a fuel supply system, an inner flame tube,an outer flame tube and an outlet supporting plate. An air flow with a deflection angle is diffused into the combustion chamber by the shunting type diffuser; the central cavity pre-combustion stage consists of a rear step, a top plate, a nozzle, a tangential slot inner ring and a tangential slot outer ring, and in the pre-combustion stage, the flame is stabilized by a low-speed recirculation zone generated by the rear step; the inner ring and the outer ring blunt body flame stabilizer main combustion stages consist of the inner ring, the outer ring and blunt body stabilizers with deflection angles, the high temperature and high pressure fuel jetted out of the inner ring and outer ring blunt body flame stabilizers is mixed with air, is ignited by the pre-combustion stage, and is burnt stably in a low-speed zone after a blunt body; and the outlet supporting plate is arranged between the inner flame tube and the outer flame tube and has an included angle with the axial line of the combustion chamber, and the outlet gas of the combustion chamber has an deflection angle. The central cavity stable fire tangential combustion chamber realizes tangential flow and tangential combustion while ensuring stable combustion for providing power; besides, the structure is simplified, and the weight of the combustion chamber is reduced.

Owner:BEIHANG UNIV

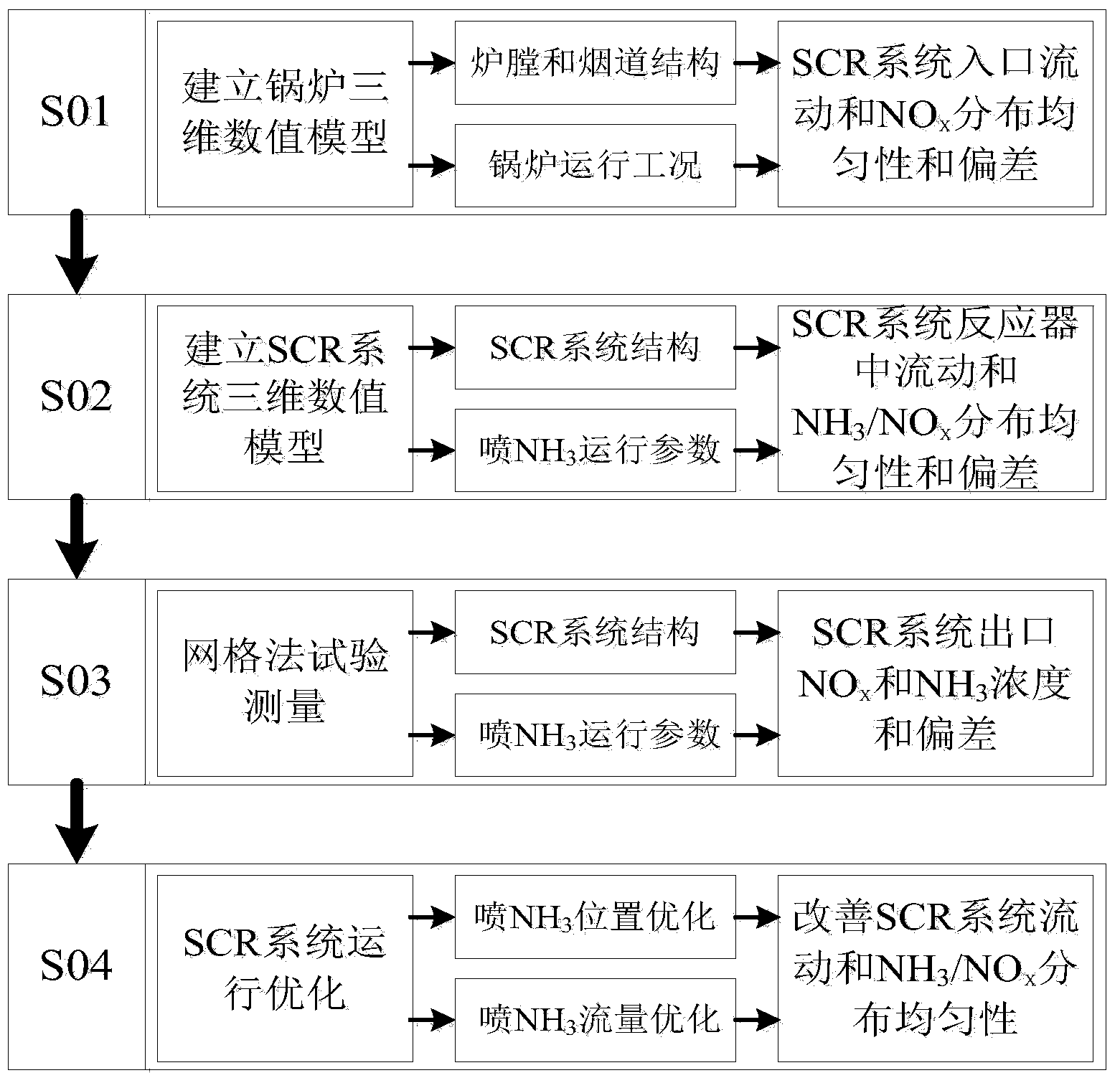

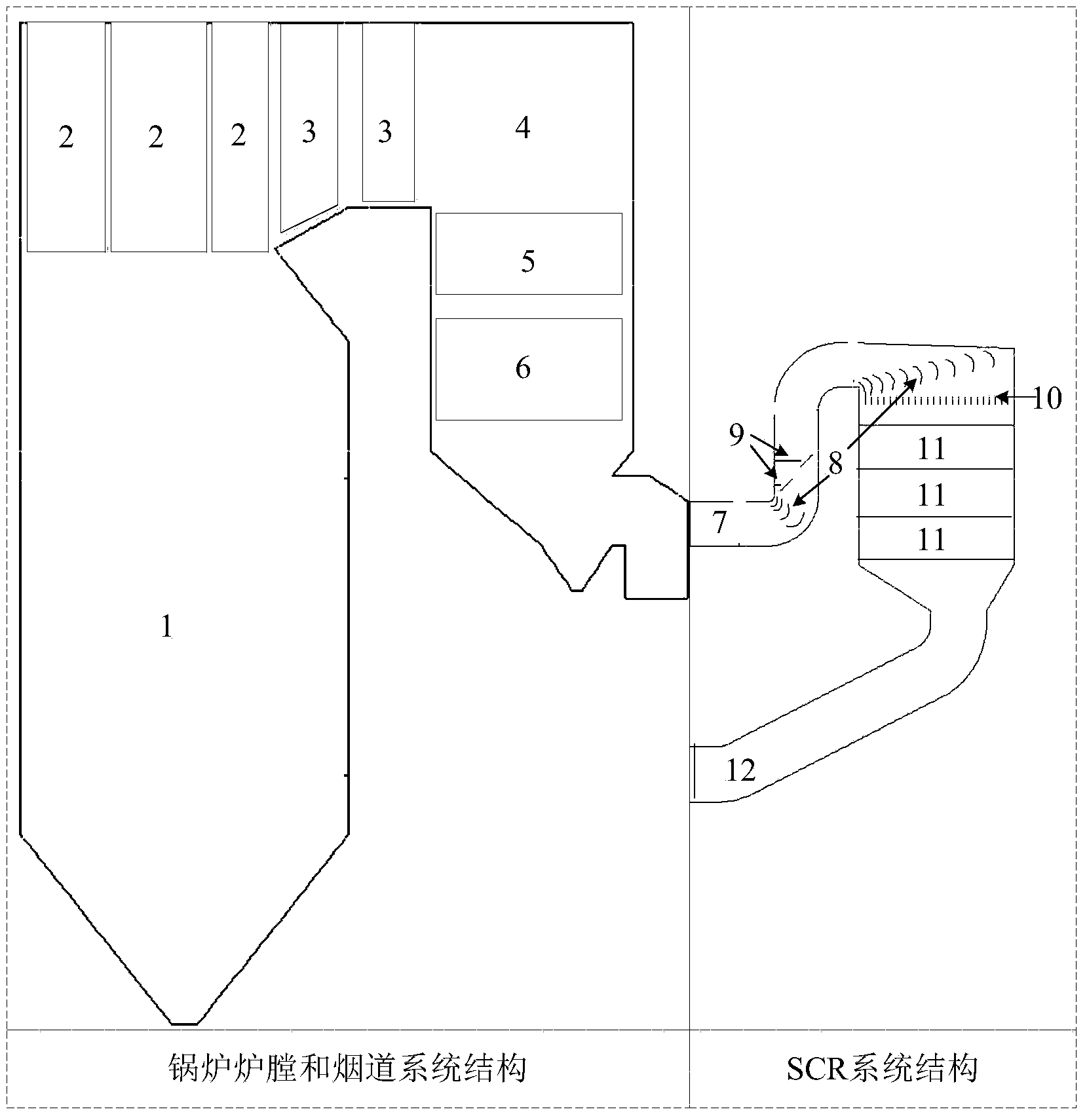

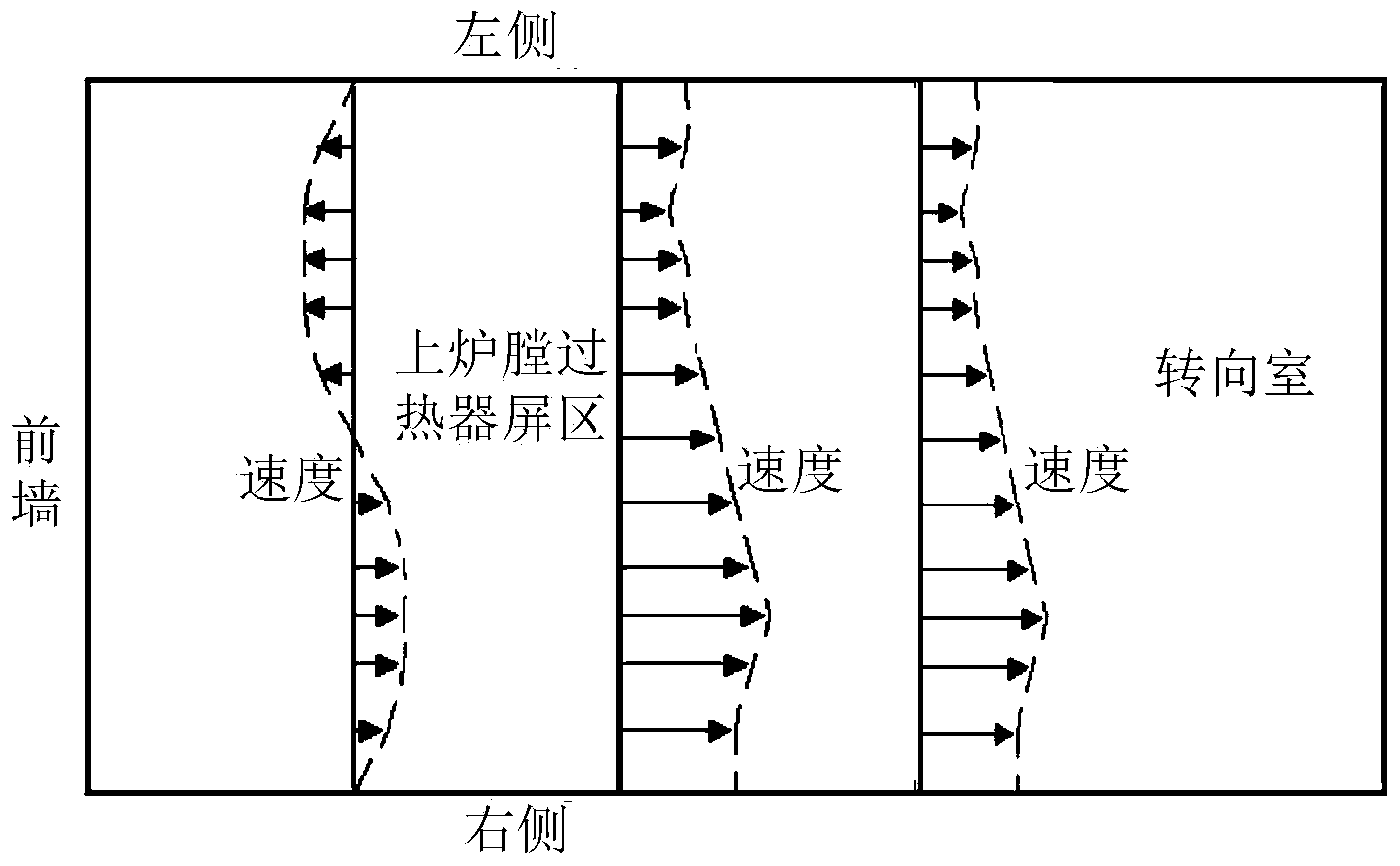

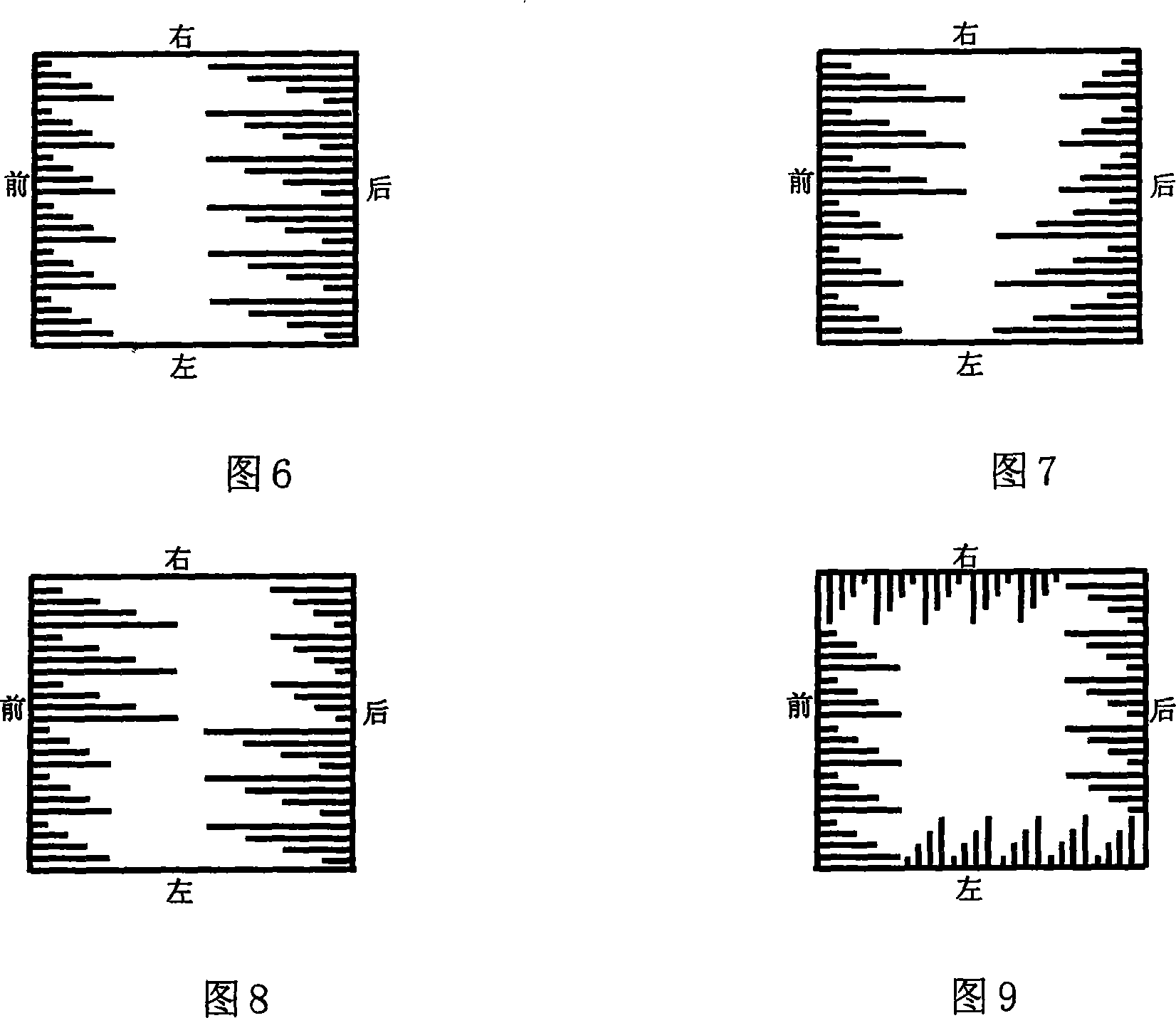

Denitration operation optimization method for SCR (Selective Catalytic Reduction) system of tangential firing pulverized coal boiler

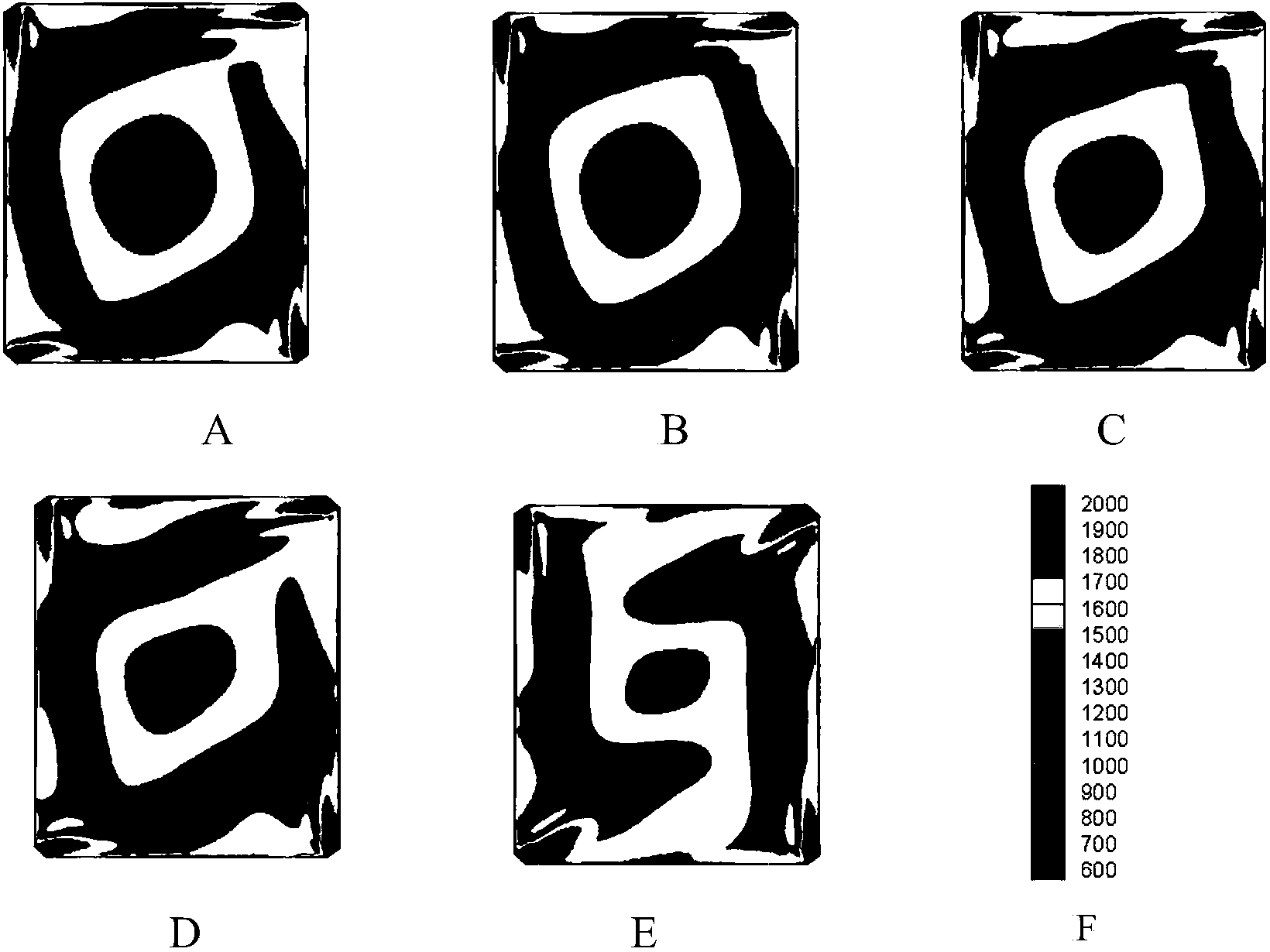

InactiveCN103752170AOptimal adjustment of ammonia injection flow rateIncrease the flow rate of ammonia injectionDispersed particle separationEngineeringStreamflow

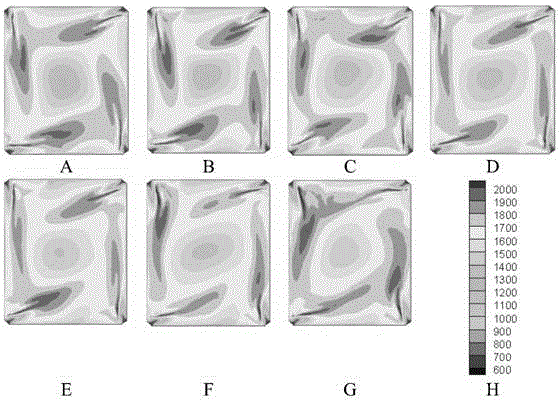

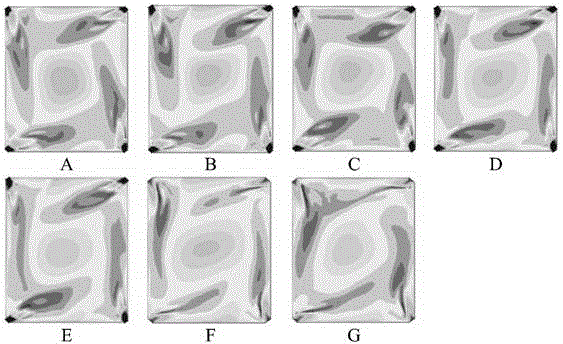

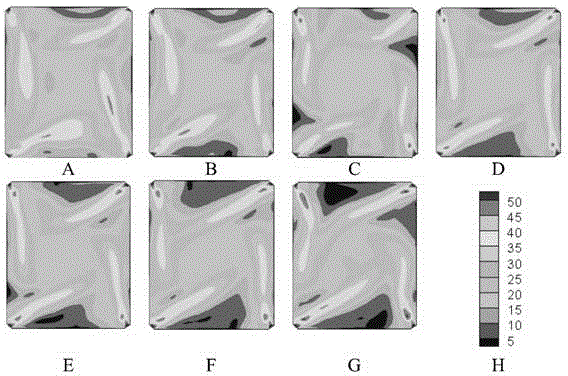

The invention discloses a denitration operation optimization method for an SCR (Selective Catalytic Reduction) system of a tangential firing pulverized coal boiler. The denitration operation optimization method comprises the special steps of using a numerical simulation method; obtaining a velocity of flue gas, an NOx concentration distribution uniformity and a deviation of an outlet of the boiler by means of considering the structure and the operation condition of the boiler as a boundary condition of an inlet of the SCR system; obtaining the velocity of the flue gas, an NH3 / NOx distribution uniformity and a deviation inside the SCR reactor; optimizing and adjusting an ammonia spraying flow of an ammonia spraying nozzle on a flue of the SCR system according to the velocity of the flue gas and the NH3 / NOx; increasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the larger velocity of the flue gas, and decreasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the smaller velocity of the flue gas; and increasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the smaller NH3 / NOx, and decreasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the larger NH3 / NOx. The denitration operation optimization method provided by the invention can be used for optimizing and adjusting by comprehensively considering the structures and the operation conditions of the boiler and the SCR system, so that the denitration efficiency of the SCR system is improved; the spraying amount and the release rate of ammonia can be reduced; the security, the economical efficiency and the environmental friendliness of the operation of the boiler unit can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

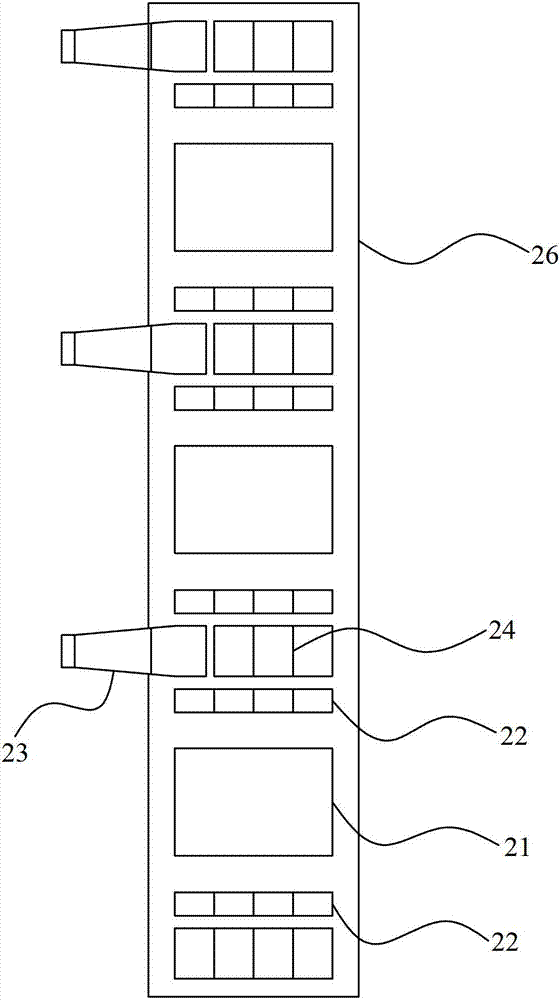

Spliting arranging method for new three area burner of tangential circle boiler

InactiveCN1786564AEmission reductionBurnout has little effectCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCoal dustEngineering

The invention discloses tangential firing boiler new three zones burner split arrangement type. The includes the following steps: dividing combustion process into three zones that stable combustion zone, combustion and reducing zone, and full combustion zone by gas coal type arrangement plus once wind centralizing arrangement plus fission OFA plus top OFA arrangement type; complementing combustion air in time by fission OFA arrangement; the deep hypoxia cryogenic combustion of the initial stage coal dust air flow and the deep fuel of the combustion and reducing zone are fractional combustion. This successfully solves the abuse that the current low NOx combustion technique denitrifying effect is bad. Secondary burn-out wind complementing type can greatly reduce the influence of the new three zones burner fission arrangement type on the combustion efficiency. Thus this can successfully solves the problem of taking account of the current NOx combustion technique and the combustion efficiency at the same time. It is the burner arrangement type with better denitrifying effect.

Owner:XIAN THERMAL POWER RES INST CO LTD

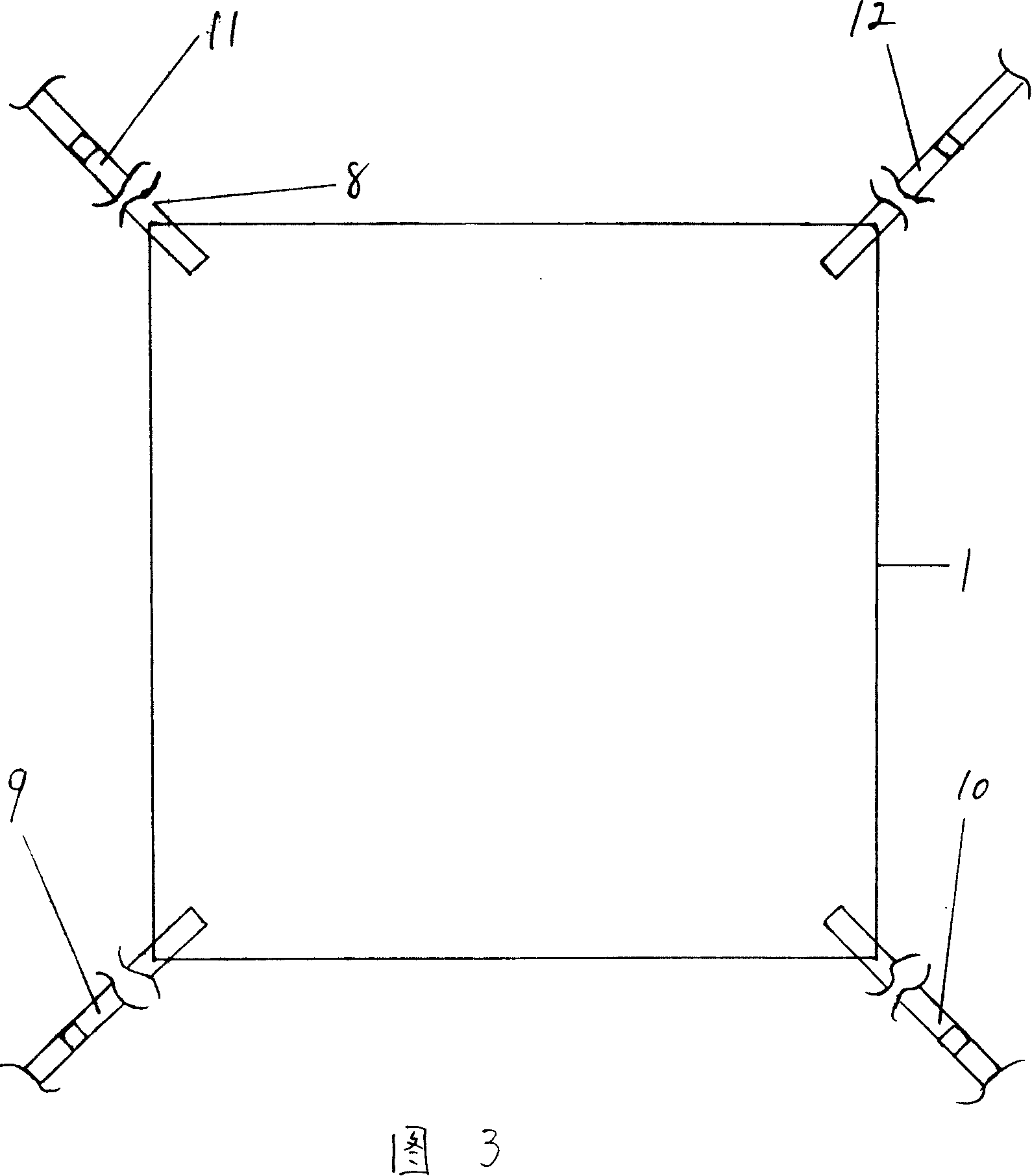

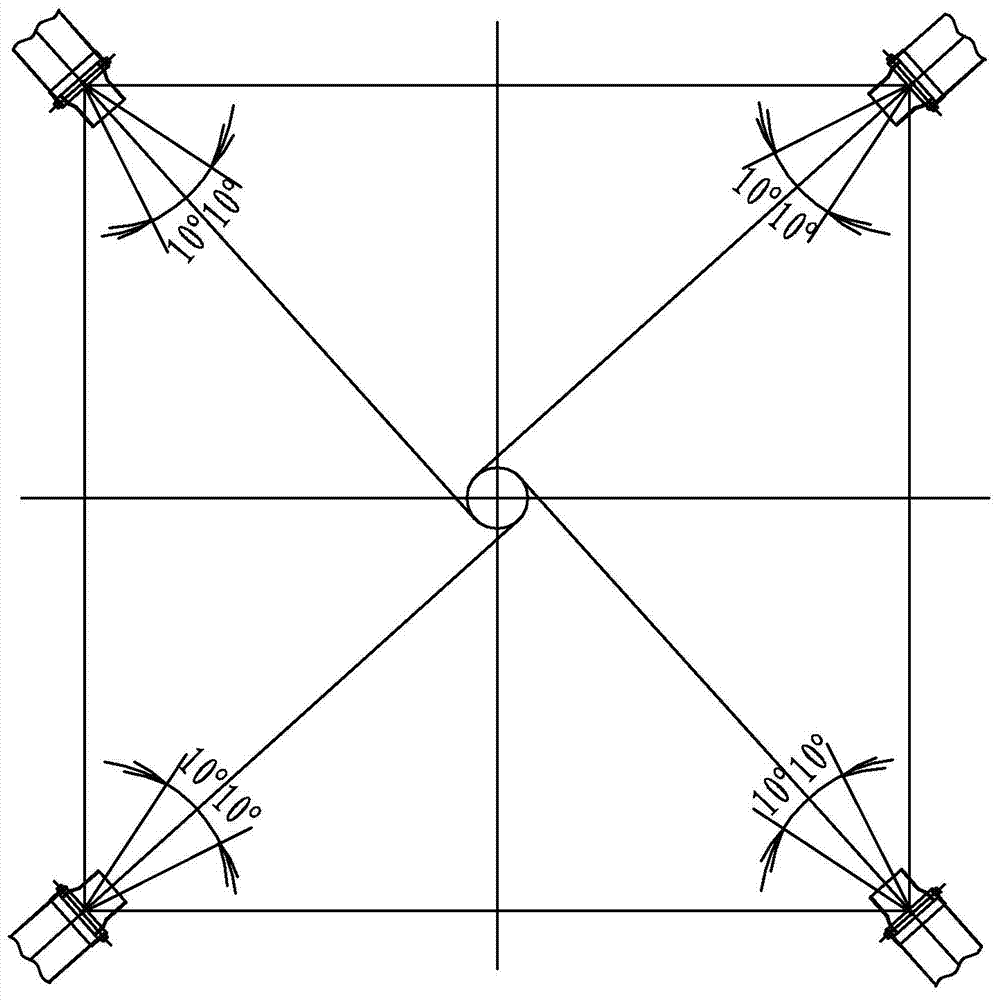

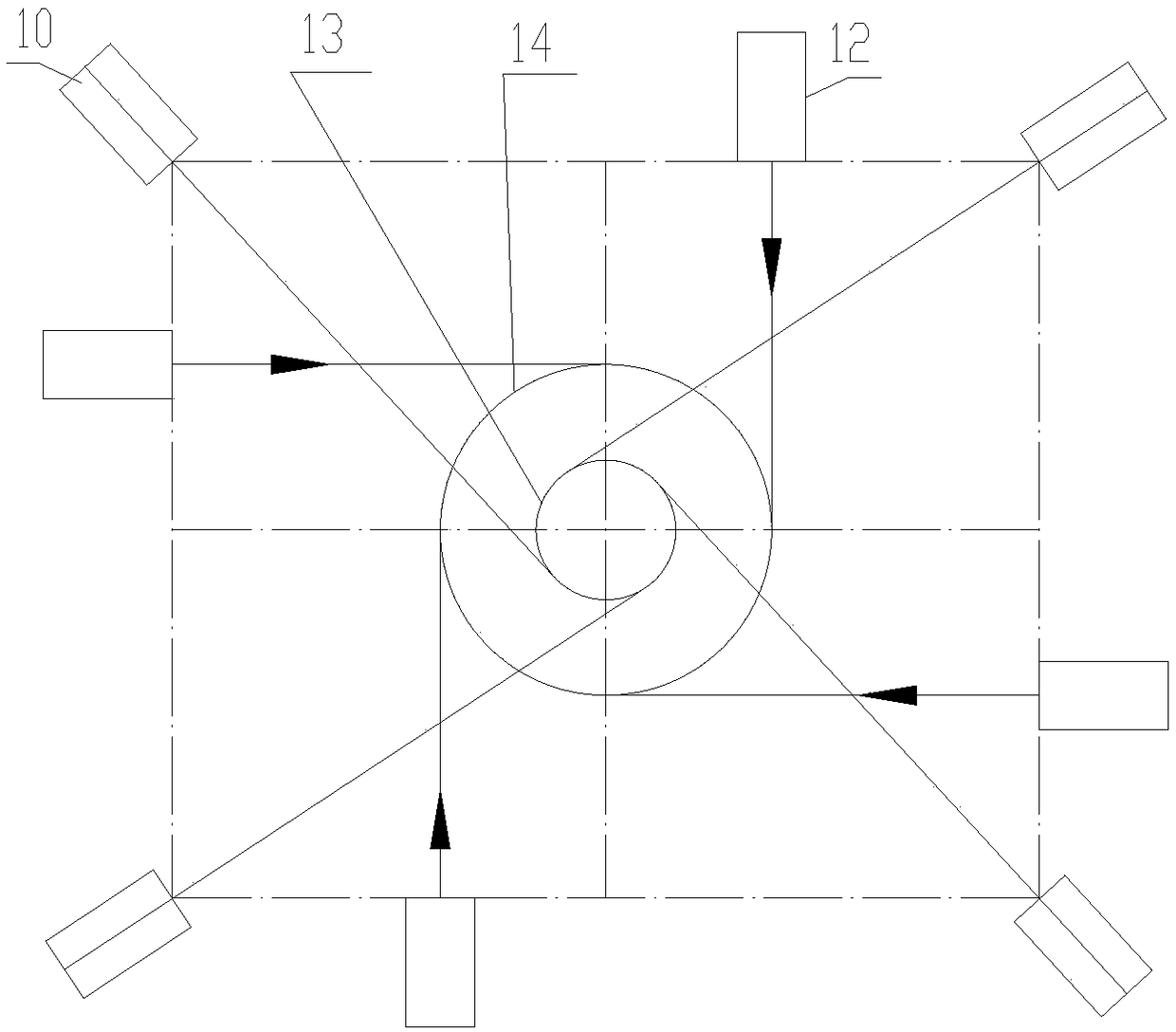

Low-nitrogen oxide discharging coal powder tangential combustion device

ActiveCN101598333AEnhanced turbulent mixingGood for burnoutPulverulent fuel combustion burnersCombustion apparatusLow nitrogenHearth

The invention provides a low-nitrogen oxide discharging coal powder tangential combustion device, comprising a hearth; wherein the four corners of a main combustion area of the hearth are provided with primary air spray nozzles and secondary air spray nozzles which are arranged at intervals, and the axis of the primary air spray nozzles or the secondary air spray nozzles positioned on the same horizontal plane is tangential to a supposed tangential circle taking the center of the hearth as a circle center. The low-nitrogen oxide discharging coal powder tangential combustion device is characterized in that the four walls of the hearth above the primary air spray nozzles and the secondary air spray nozzles are provided with at least one burning-out air spray nozzle group; each burning-out air spray nozzle group comprises four burning-out air spray nozzles, one burning-out air spray nozzle is respectively arranged on one wall of the hearth, and the four burning-out air spray nozzles are positioned on the same horizontal plane; and the axis of the burning-out air spray nozzles in the same group are tangential to one supposed tangential circle taking the center of the hearth as a circle center. The invention can realize the low discharging of NOx, solves the problems of high content of fly ash combustible substances caused by a whole air classification technique in a furnace, high fume speed at a hearth outlet, large temperature deviation of the hearth outlet and the like, and increases the running regulation performance aiming at different coal species and load changes simultaneously.

Owner:SHANGHAI BOILER WORKS

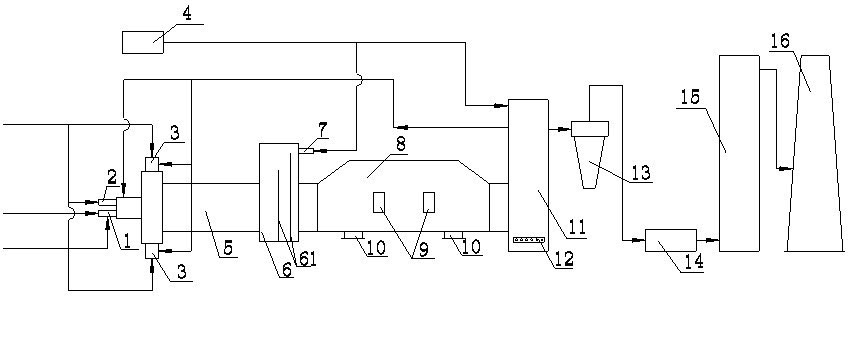

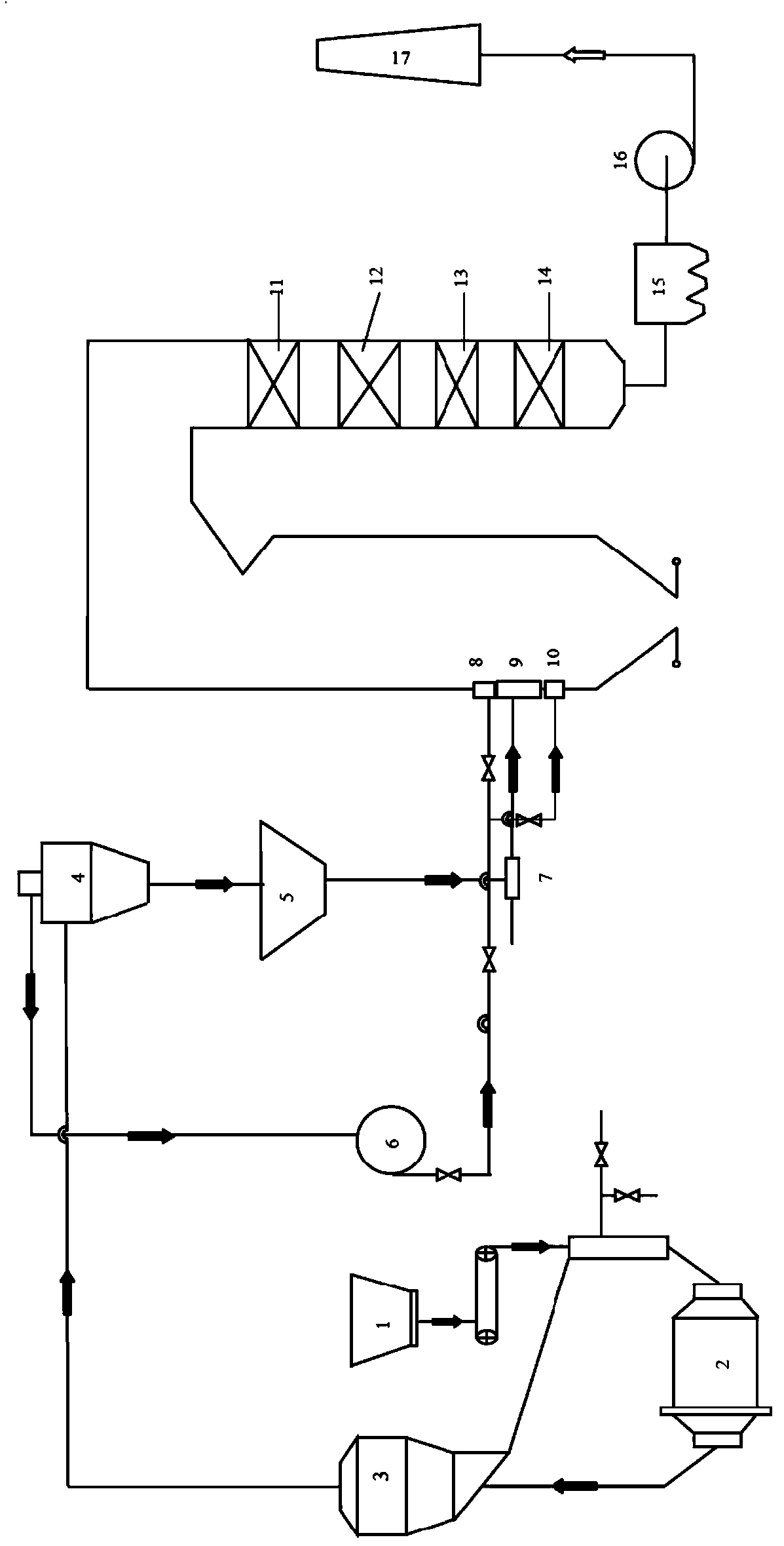

High-concentration saliferous organic waste liquid incinerator and incineration technique

ActiveCN102168857AEfficient combustionStable combustionIncinerator apparatusAir preheaterThermal energy

The invention discloses a high-concentration saliferous organic waste liquid incinerator and an incineration technique, which belongs to the processing field of organic waste liquid. The high-concentration saliferous organic waste liquid incinerator comprises a horizontal furnace, a vertical furnace, an afterheat boiler, and a draught fan. The furnace end of the horizontal furnace is provided with a waste liquid burner, a coaxial burner, and a tangential burner. The furnace end of the horizontal furnace is also provided with a cyclone separator, an air preheater and the like. A retaining walland a cooling air system are arranged in the vertical furnace; the stability and pressure of each stage are controlled by the incineration technique; a low-heating value liquid carrier atomizing burning technology is used by the high-concentration saliferous organic waste liquid incinerator and incineration technique, and has excellent processing effects for high-concentration saliferous organic waste liquid, high-concentration saliferous organic waste water, waste oil and the like. The processing capacity is more than 2.0 tons per hour; the waste liquids can be completely burnt; the continuous running period is more than 30 days; the consumption of natural gas is less than 60 cubic meters for each ton of waste liquid; and the heat recycling volume of each ton of waste liquid is more than2.5 tons; therefore, the resources are effectively and circularly utilized.

Owner:中昊黑元化工研究设计院有限公司

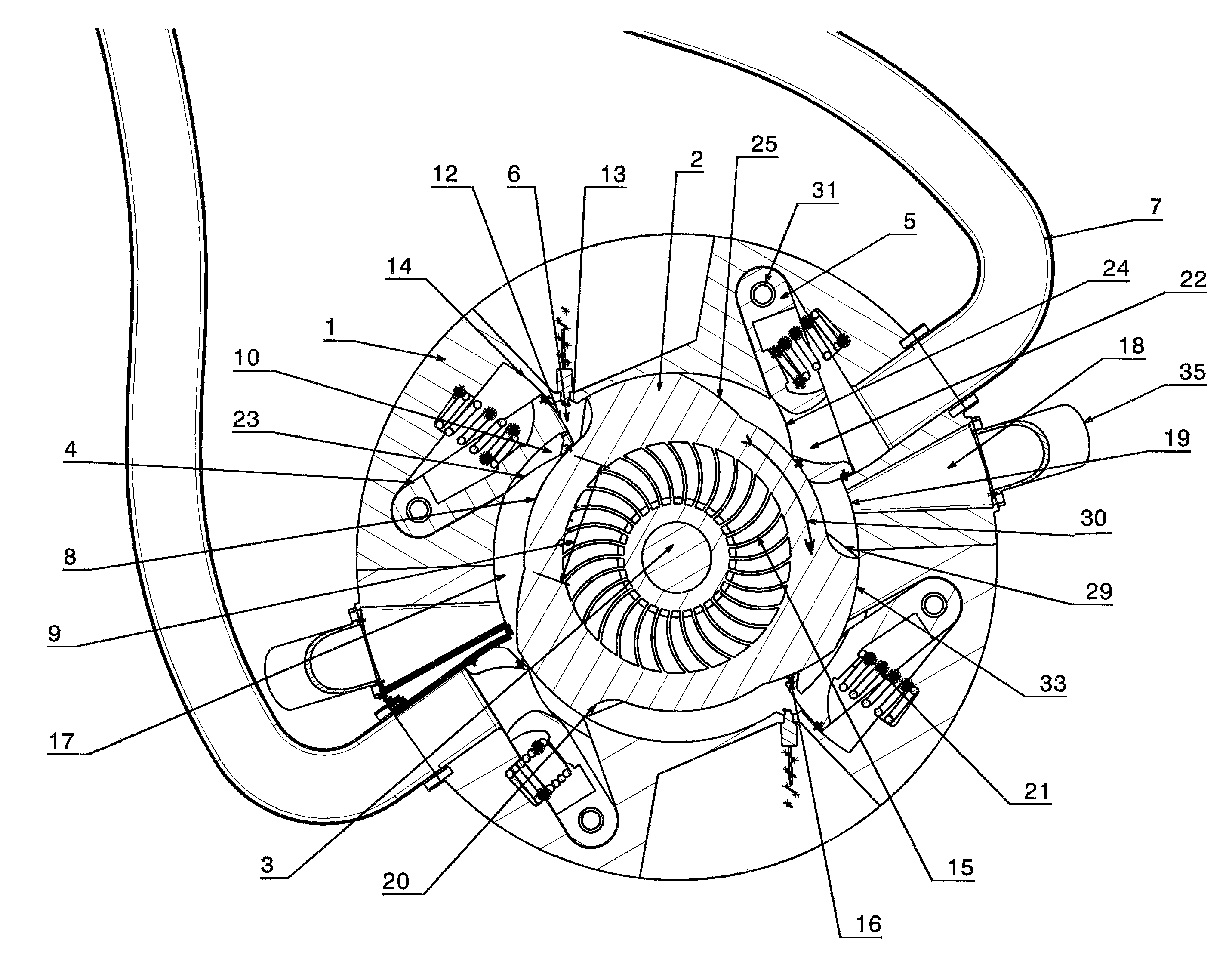

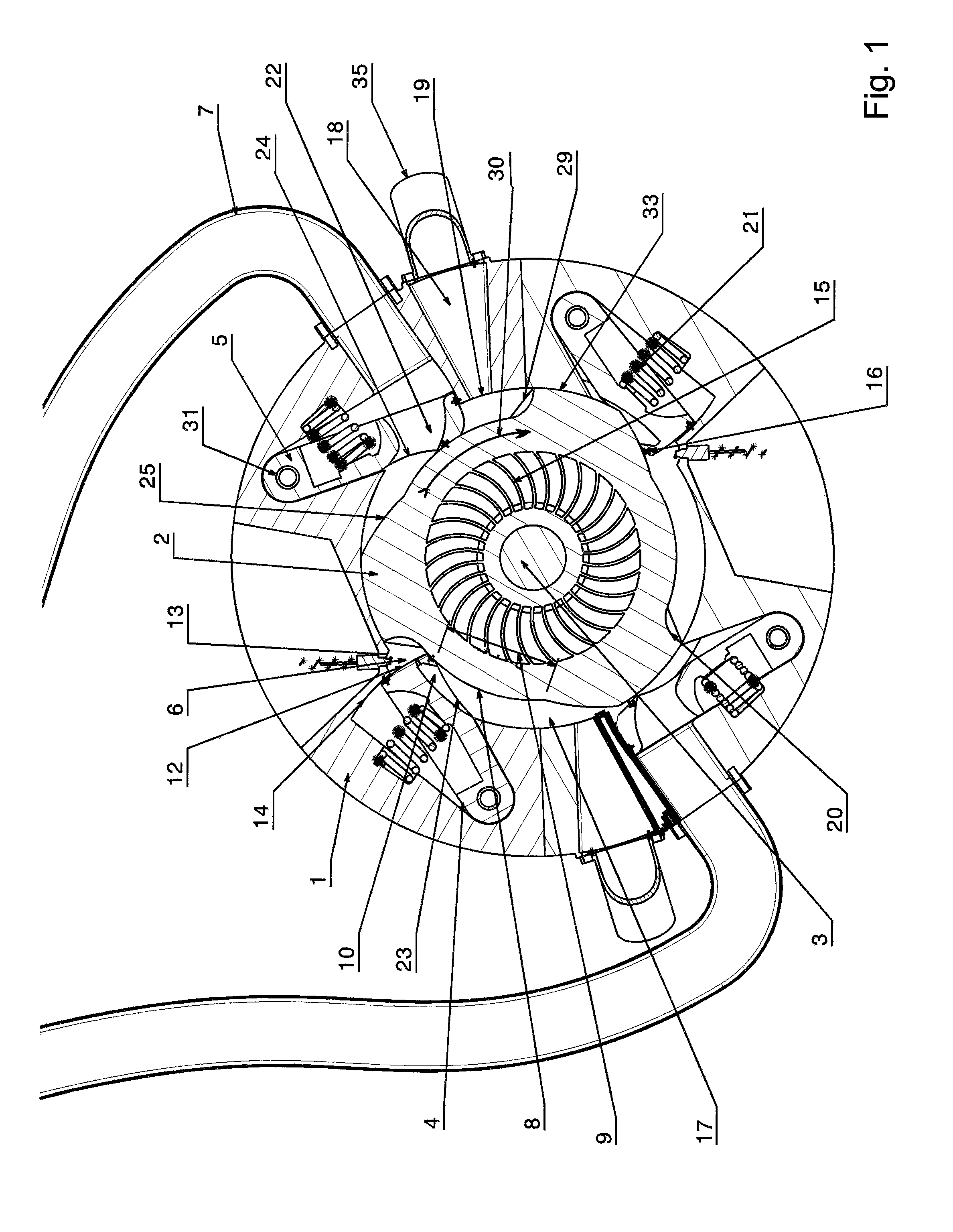

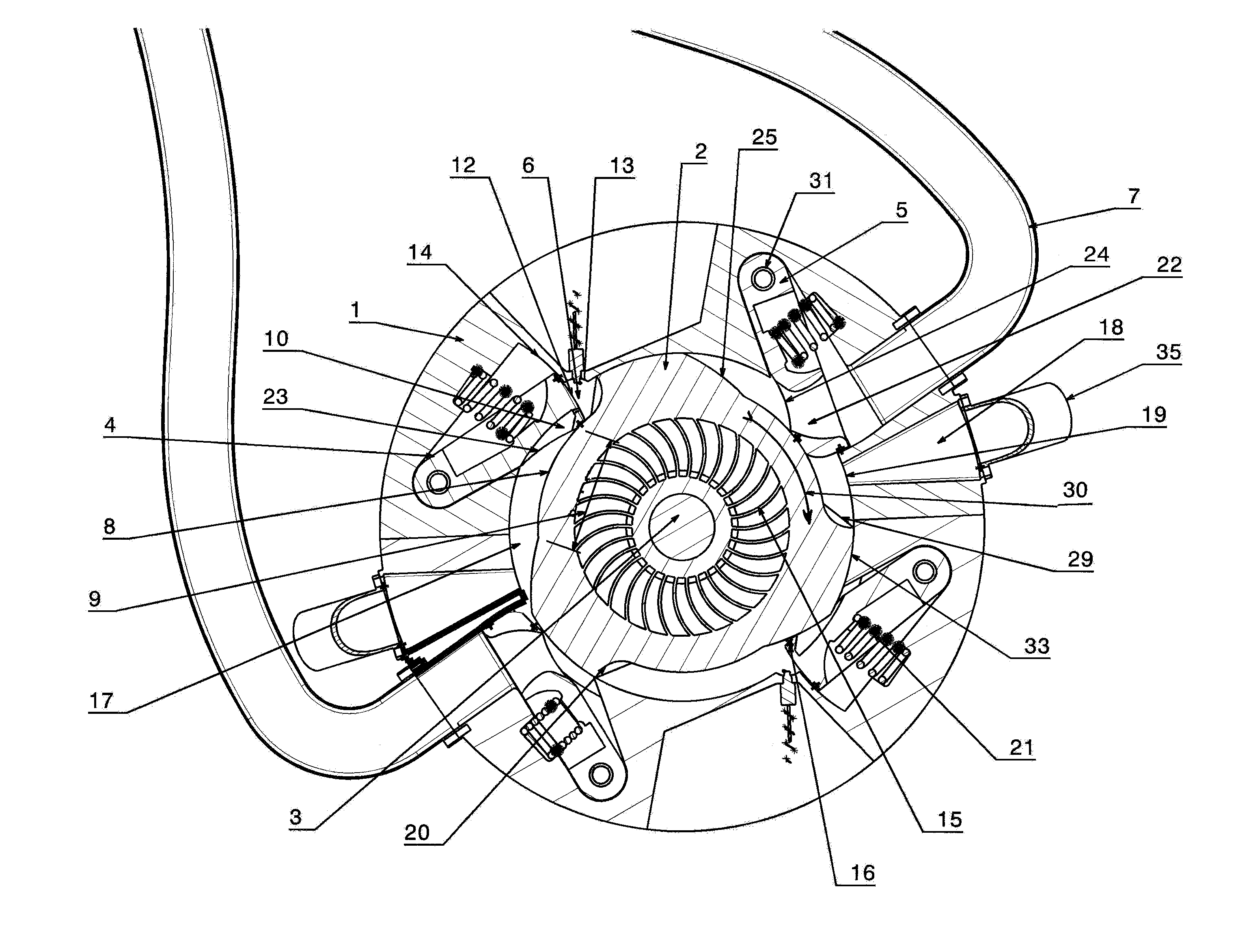

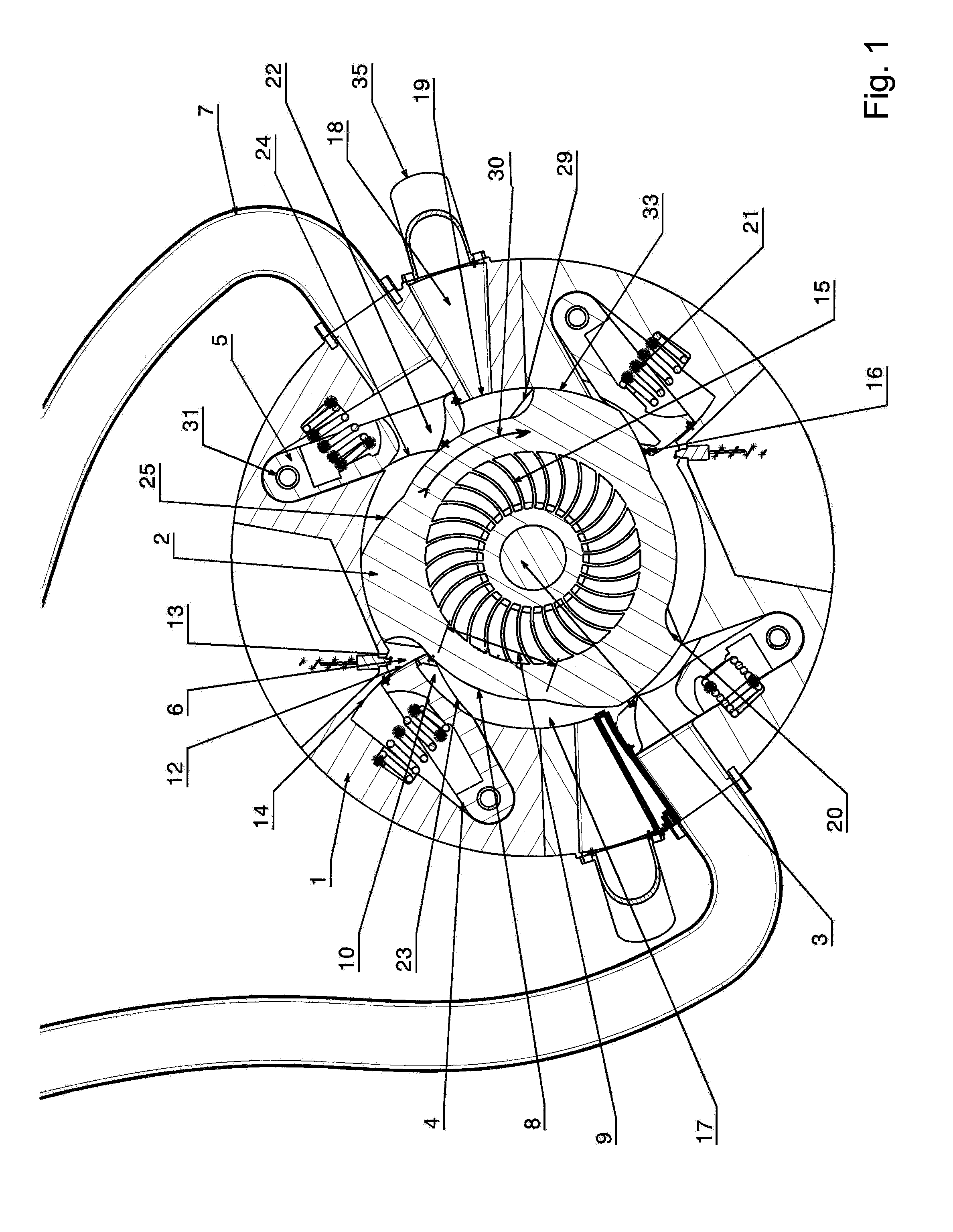

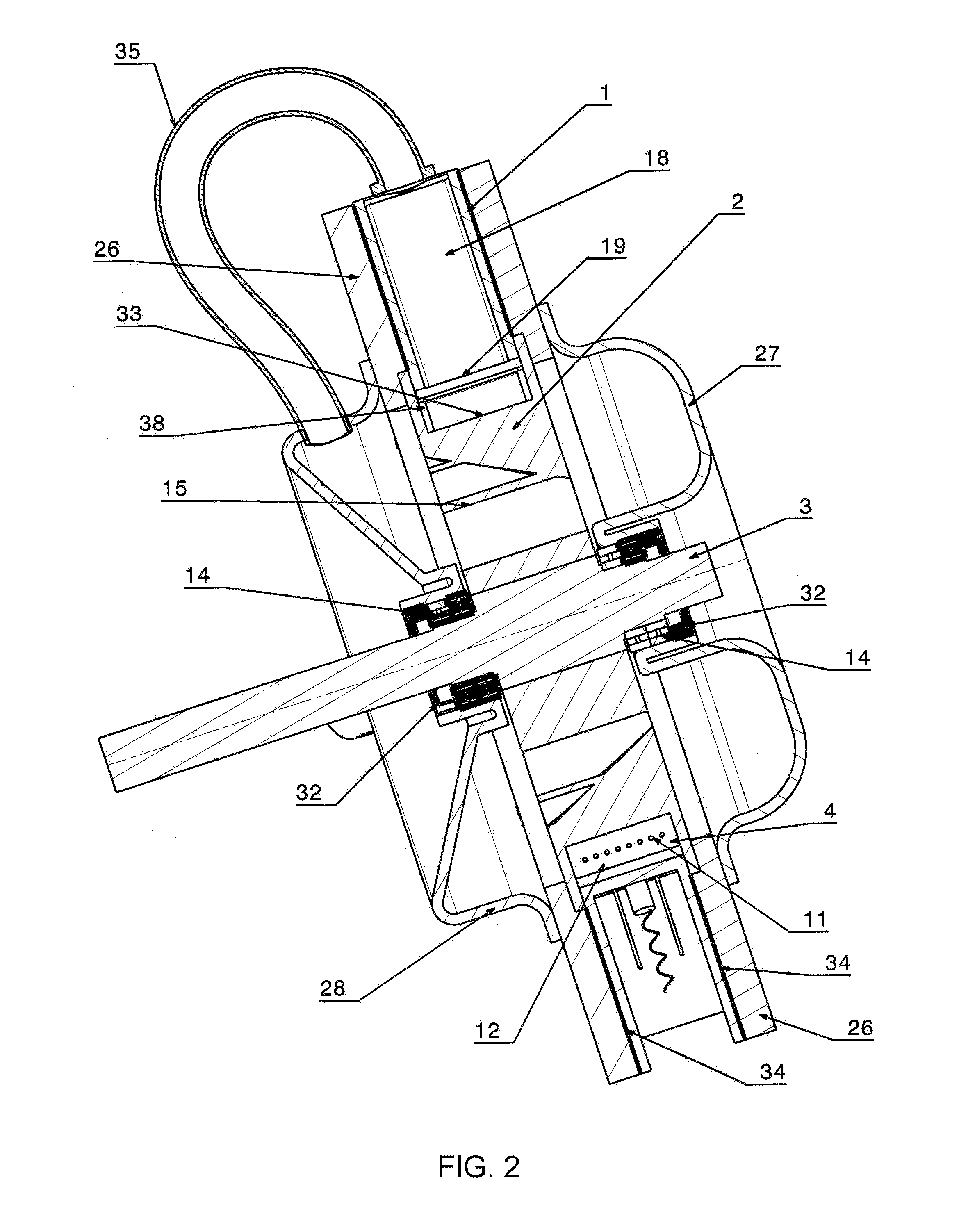

Tangential combustion turbine

InactiveUS8061327B2Internal combustion piston enginesCombination enginesCombustion chamberAtmospheric pressure

A tangential combustion turbine is disclosed which is based on a casing, a rotor, and moving levers. A radial compressor is attached to the rotor and creates air pressure which pushes air into the combustion chamber based on the position and design of the combustion lever. The combustion chamber is defined by spaces between rotor lobes, and by combustion levers and exhaust levers which follow the rotor surface. A premix fuel system or direct fuel injection is used to create combustion. The exhaust gases then pass through the exhaust lever into the exhaust piping as the rotor rotates.

Owner:ZINK ALEXANDER M +2

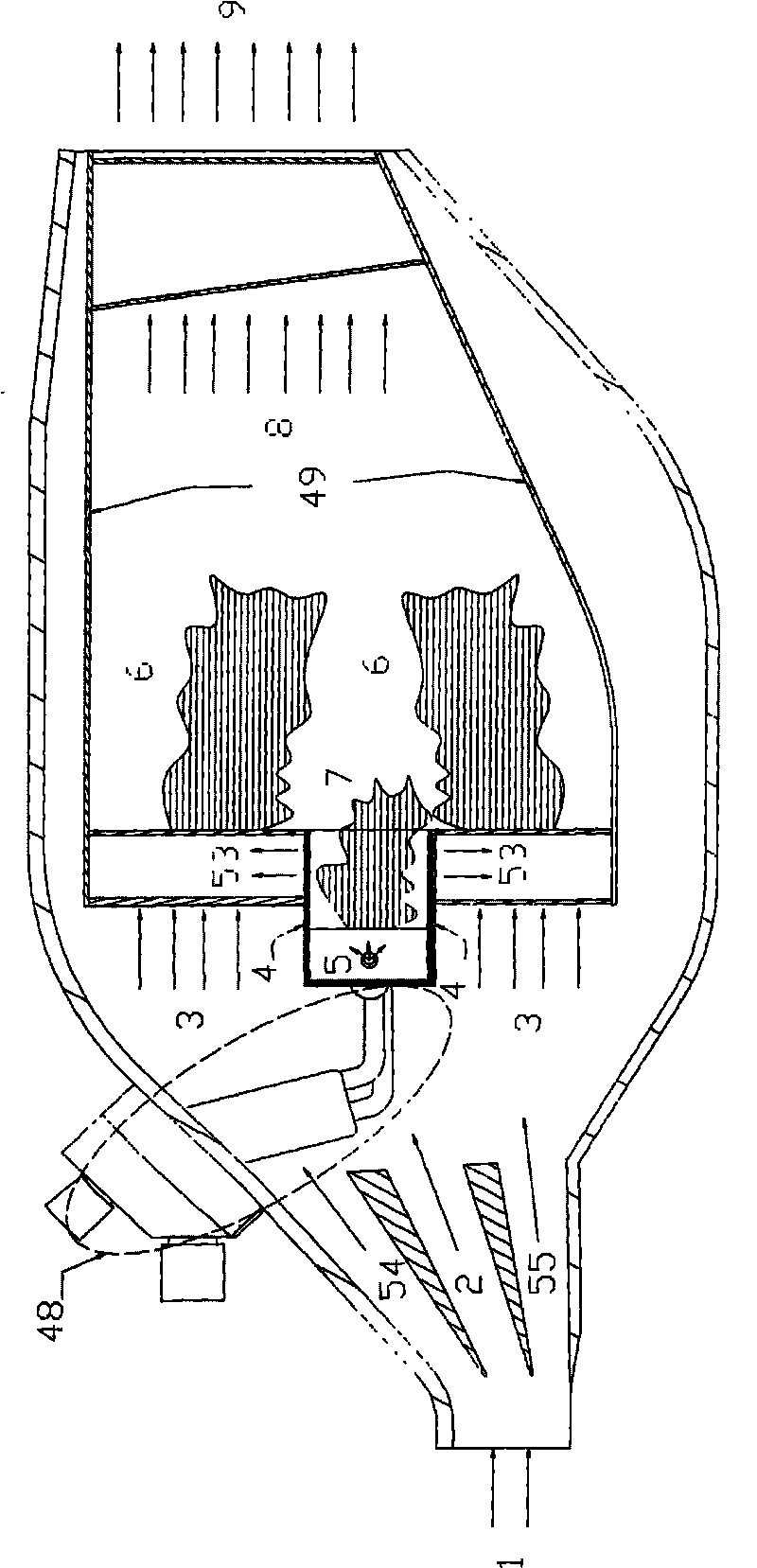

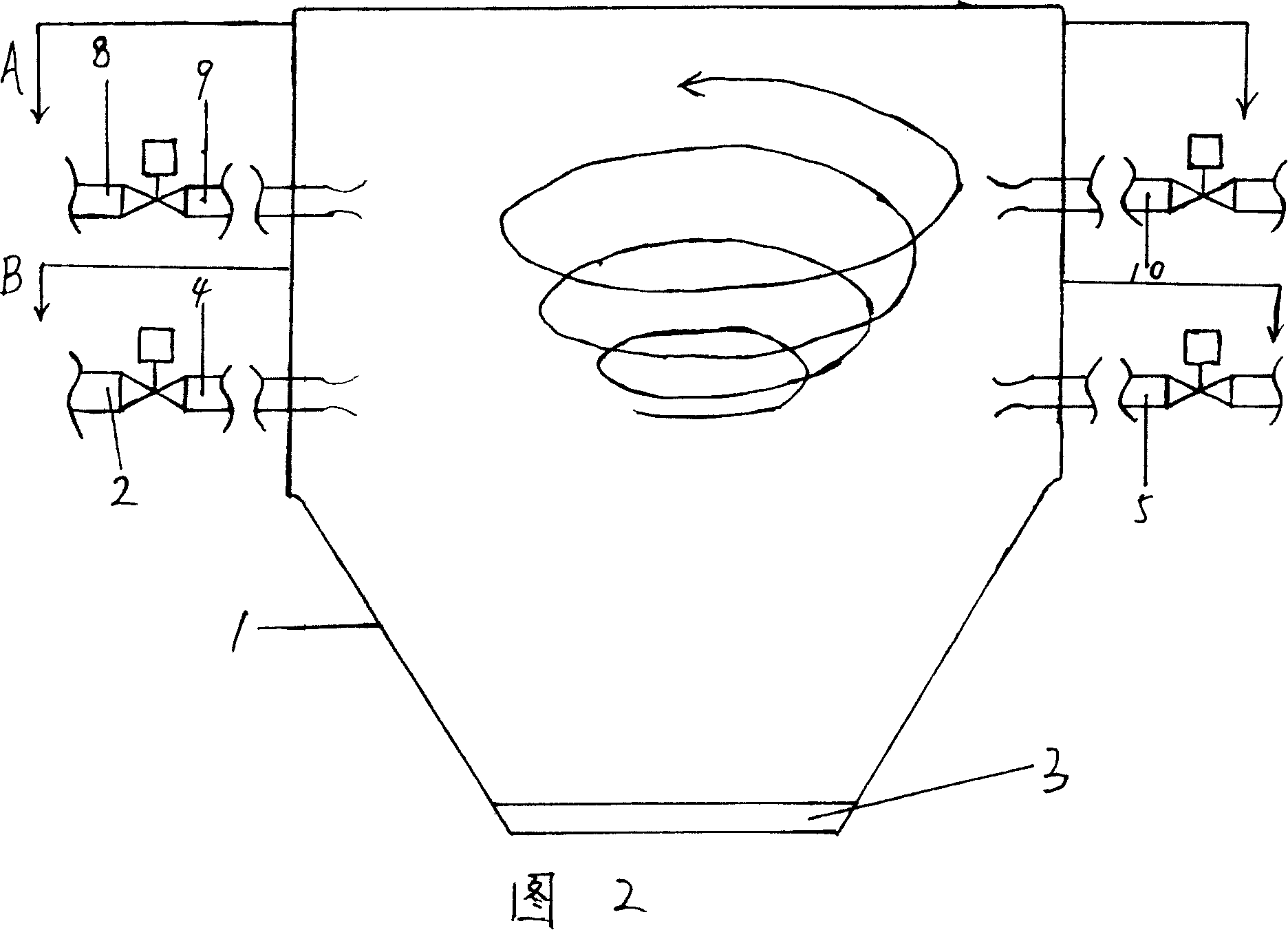

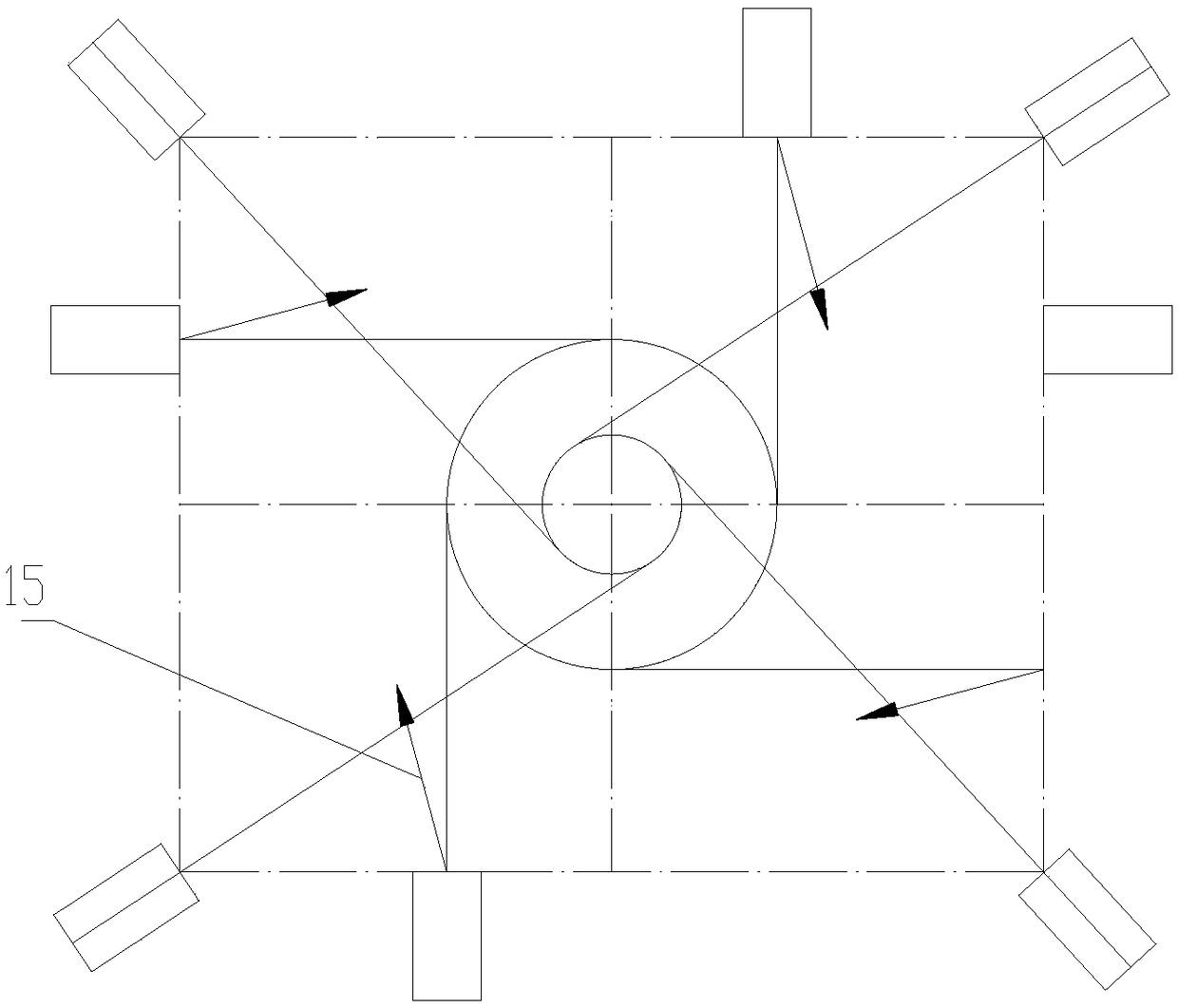

Circulated fluid bed boiler and tangential firing method

InactiveCN101086335AExtended stayImprove oxygenation uniformityFluidized bed combustionNon-combustible gases/liquids supplyCombustionFluidized bed

The invention involves a circulating fluidized bed boiler and its circle of contact burning method, the boiler consists essentially of boiler body and wind-forming plate, the wind-forming plate is installed below the boiler body, its structural characteristics are: two or more sets of injector device are installed below the dense phase area of boiler body, each set of injector device consists of four injectors which are both installed on the four corners of boiler body horizontal section separately, the injectors of bottom injector device are installed horizontally, and the injector device in other layers inclined toward down 5: . In the same horizontal surface, the central line of one unit injectors installed on four corners forms a circle of contact in the furnace tank, and the secondary wind or steam ejected out each injector device form a circle of contact air flow. The invention has the advantages of reasonable structural design, adequate fuel combustion, coal-saving, efficient, effective oxygen supplementary capacity improving through second wind energy, higher filling degree of furnace tank and full fuel combustion.

Owner:HANGZHOU HUADIAN ENERGY ENG +1

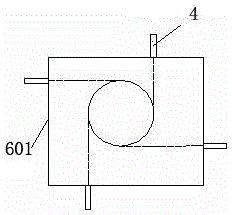

Spiral-flow type fluidized bed incinerator

ActiveCN105090980AEnhanced lateral mixingReduce carbon contentIncinerator apparatusCombustionFluidized bed

The invention discloses a spiral-flow type fluidized bed incinerator which comprises an incinerator body and a cyclone separator. The incinerator body is used for providing combustion space for a fluidized bed, and the cyclone separator is used for recycling insufficiently-combusted ingredients for secondary combustion. At least three layers of secondary air jet orifices are further formed in the walls of the incinerator body and located in a transition zone between a dense-phase zone and a lean-phase zone. The other ends of the secondary air jet orifices are communicated with a secondary air source. The secondary air jet orifices on the same layer are distributed in the walls of the incinerator body. The air flow is spiral so as to enhance transverse mixing of particles and air in the incinerator body and prolong the residence time of the particles in the incinerator body. High-speed secondary air is jetted into the lean-phase zone on the upper portion of an air distribution plate of the circulation fluidized bed incinerator body in a classified manner through wall type tangential firing, so that transverse mixing of particles and air is enhanced, temperature distribution in different areas in the dense-phase zone is more uniform, the combustion efficiency and the desulphurization efficiency are improved, NOx emissions are lowered, the heat transferring is enhanced, and the equipment size is reduced.

Owner:潍坊联荣环保设备有限公司

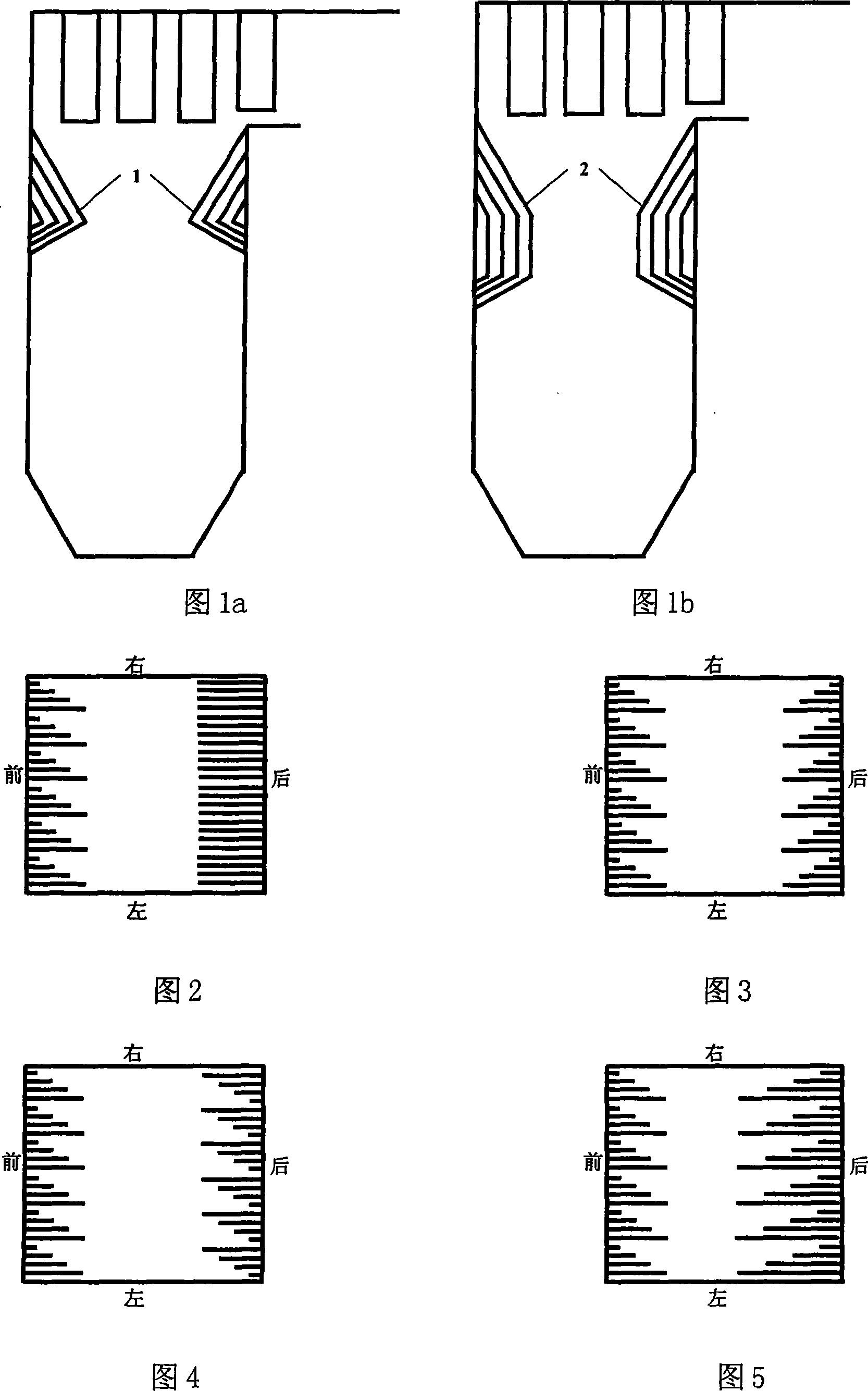

Rich-lean separated pulverized coal burner

ActiveCN103267282AGuaranteed reflowStable combustionPulverulent fuel combustion burnersEngineeringHigh-temperature corrosion

Owner:HARBIN BOSHEN TECH DEV CO LTD

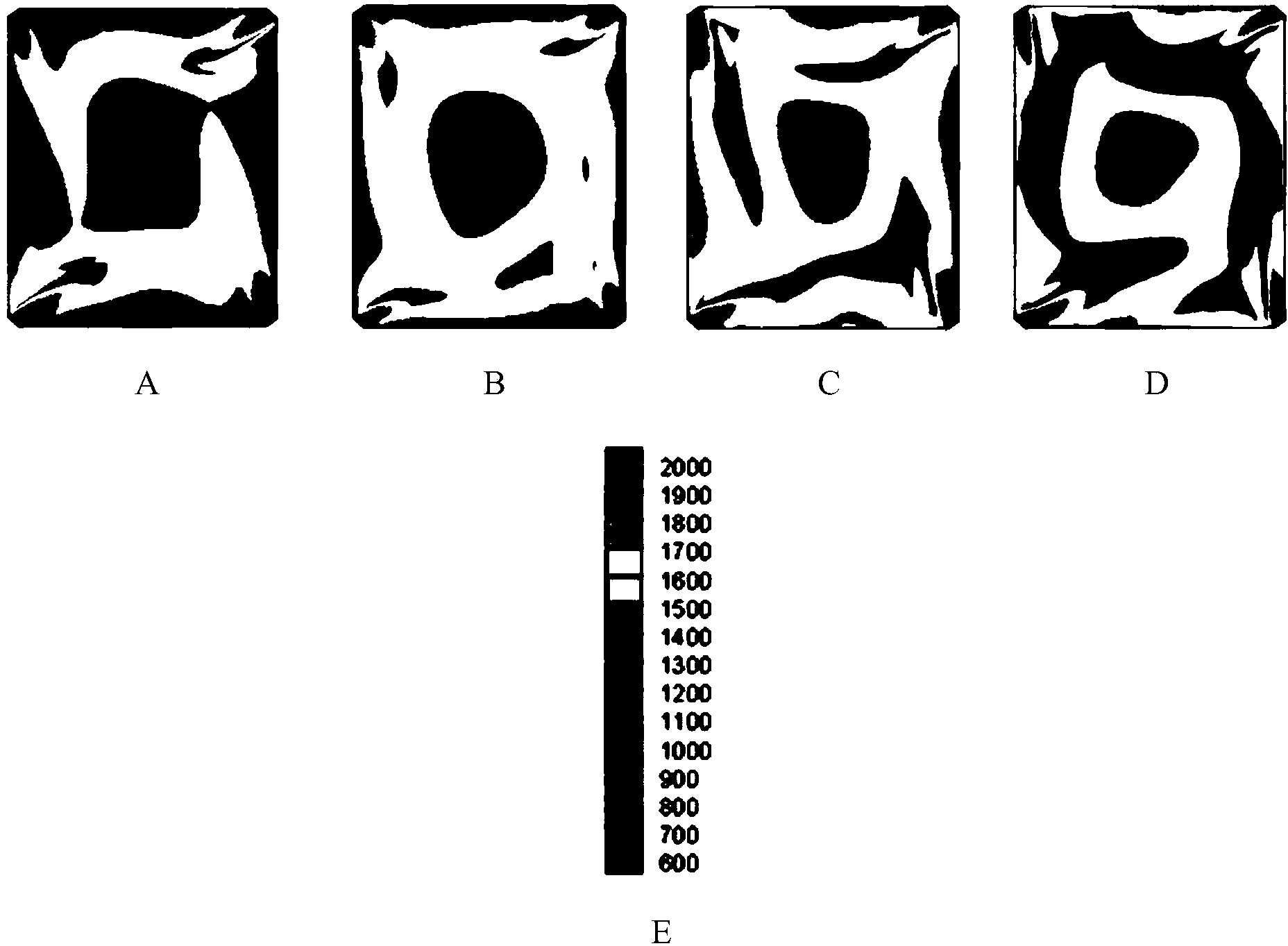

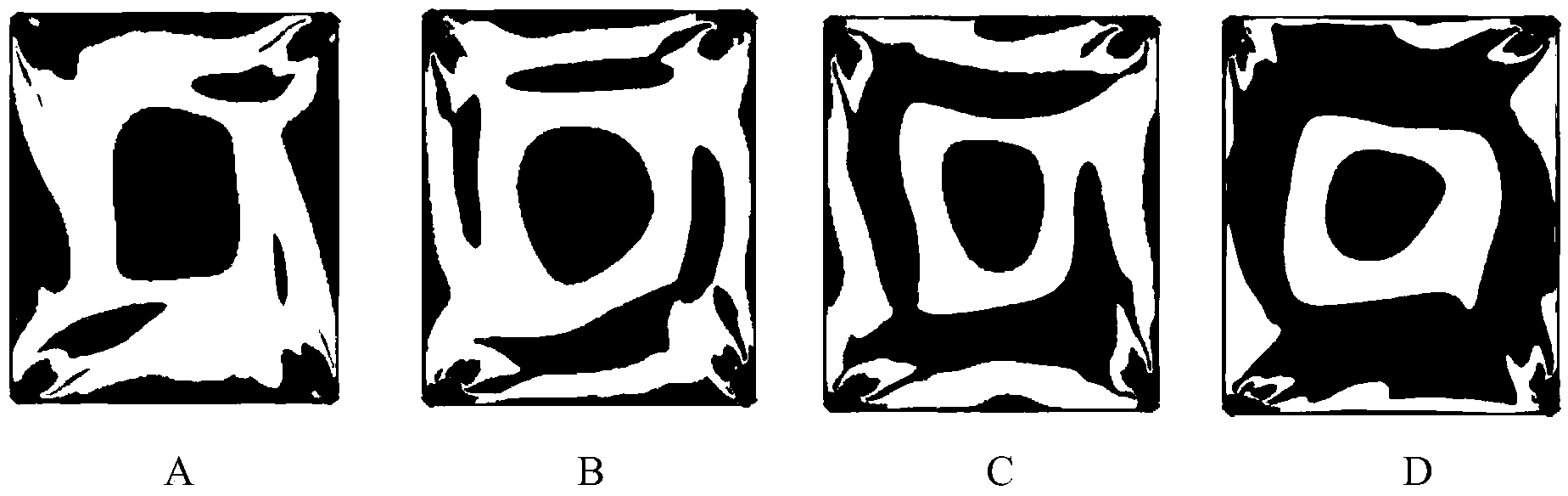

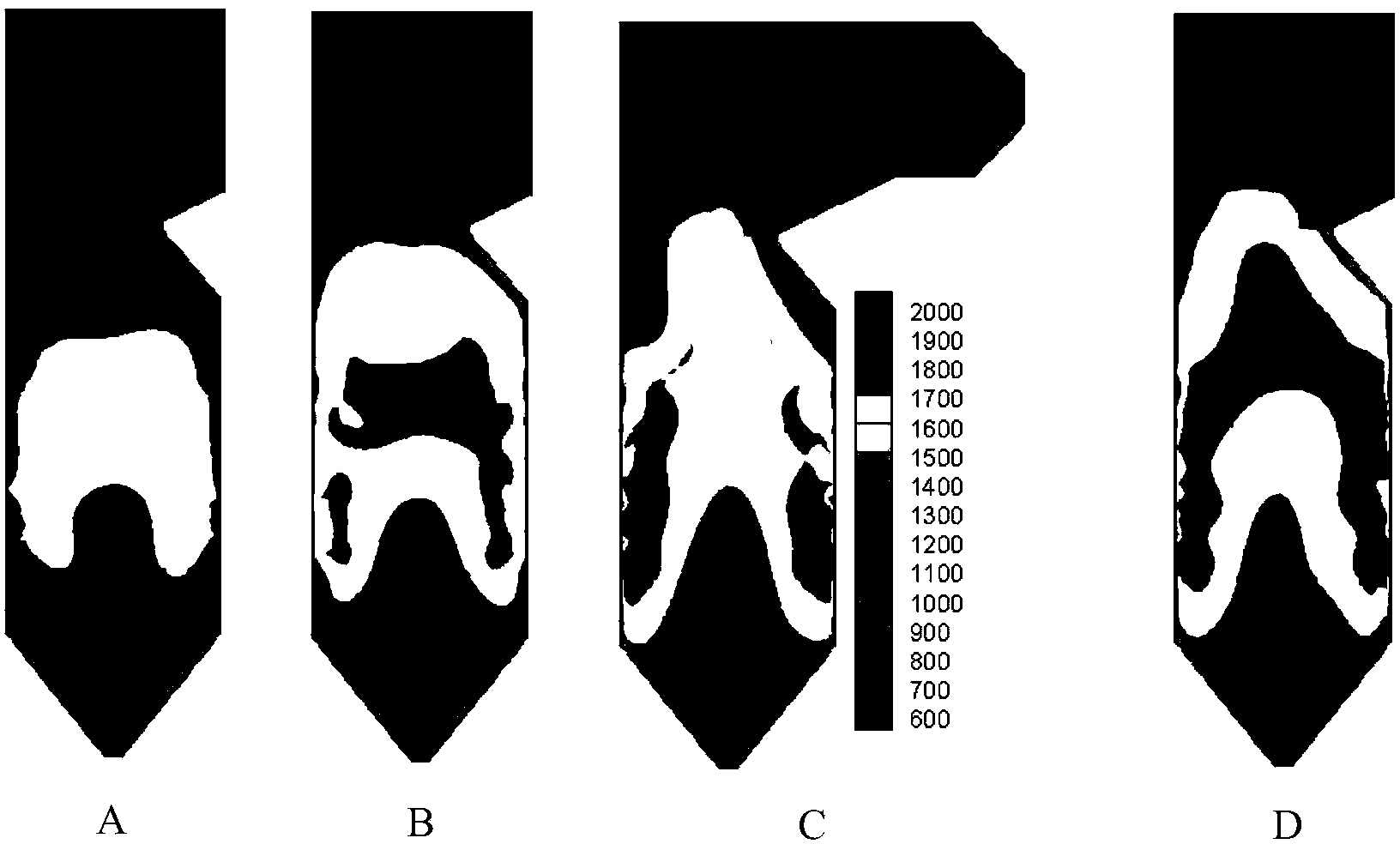

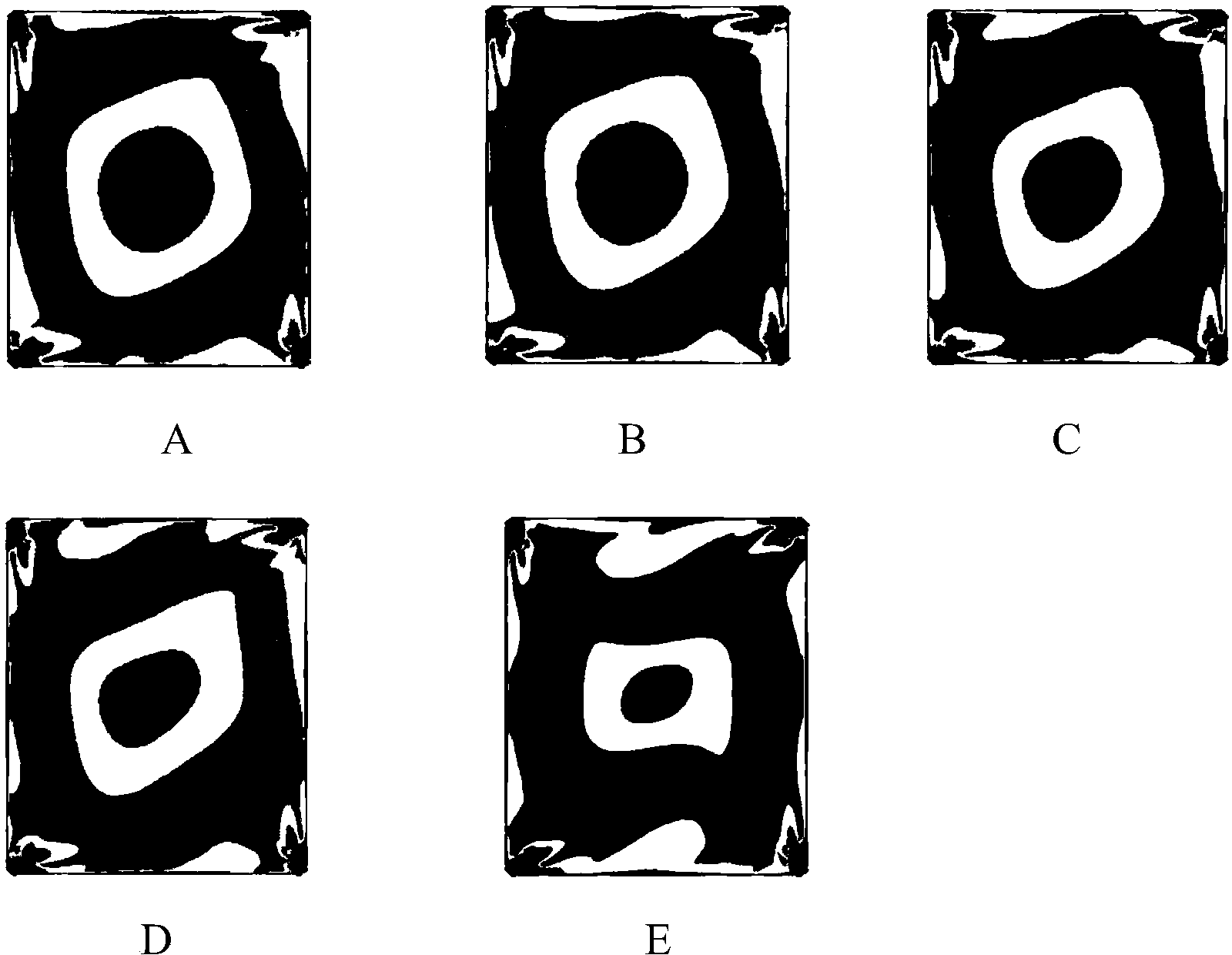

Acquisition method of combustion characteristic under different circumference air quantities after boiler improvement

ActiveCN103955599AImprove combustion characteristicsReproduce the combustion situationSpecial data processing applicationsAir volumeLow nitrogen

The invention discloses an acquisition method of a combustion characteristic under different circumference air quantities after boiler improvement, and belongs to the technical field of coal-fired boilers. According to the method, after meshing is carried out on a corner tangential firing boiler added with SOFA air, a structured grid model of the boiler is established, and combustor parameters, boundary condition parameters and coal powder parameters of the boiler are acquired; then, a mathematical model is established on the foundation to carry out combustion analog computation, so that the combustion characteristic of the boiler under different circumference air quantities is acquired. With the method, the combustion condition inside the boiler can accurately reappear, and total information of combustion condition inside the boiler is acquired, thus guidance is provided for low-nitrogen improvement added with SOFA air for the boiler, and comprehensive evaluation is carried out on the effect after low-nitrogen improvement.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

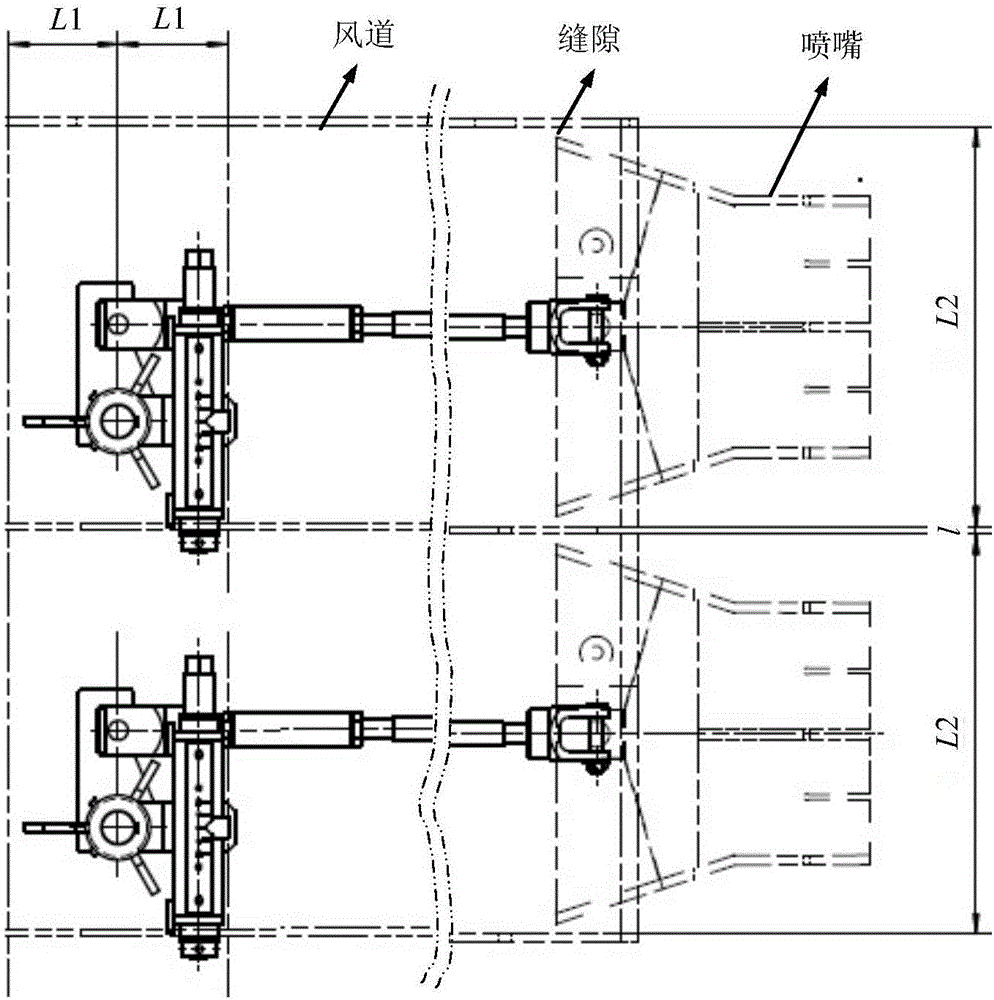

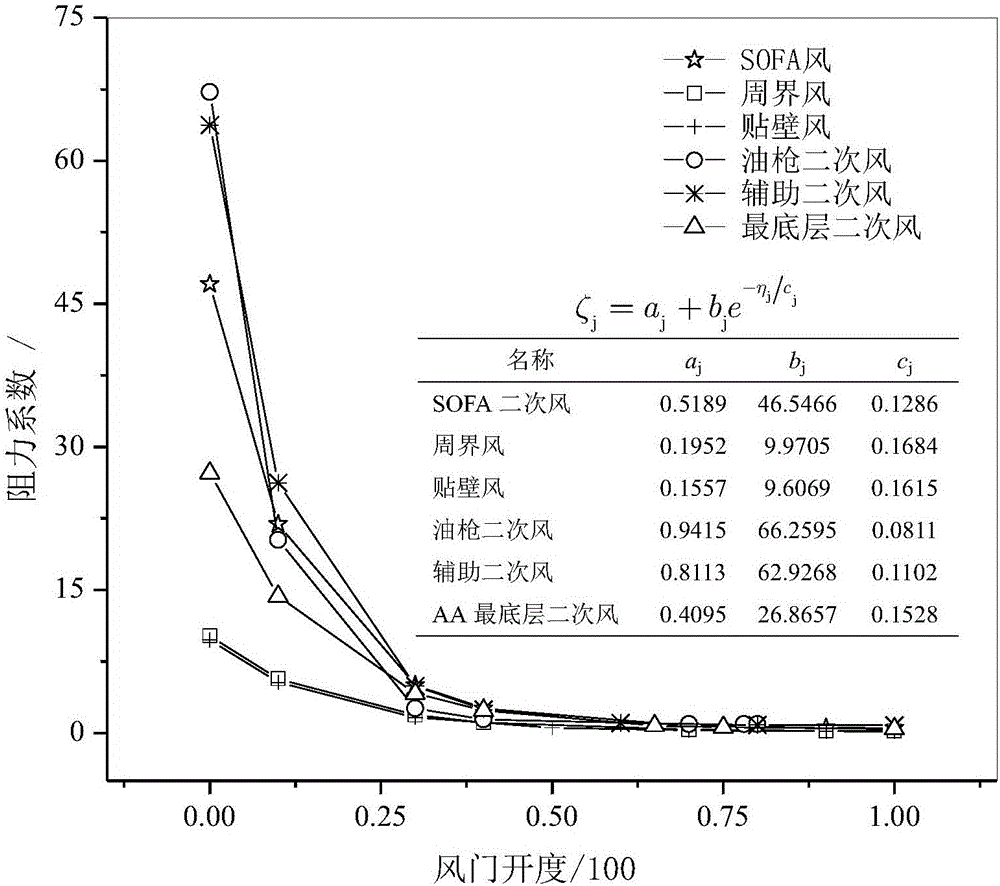

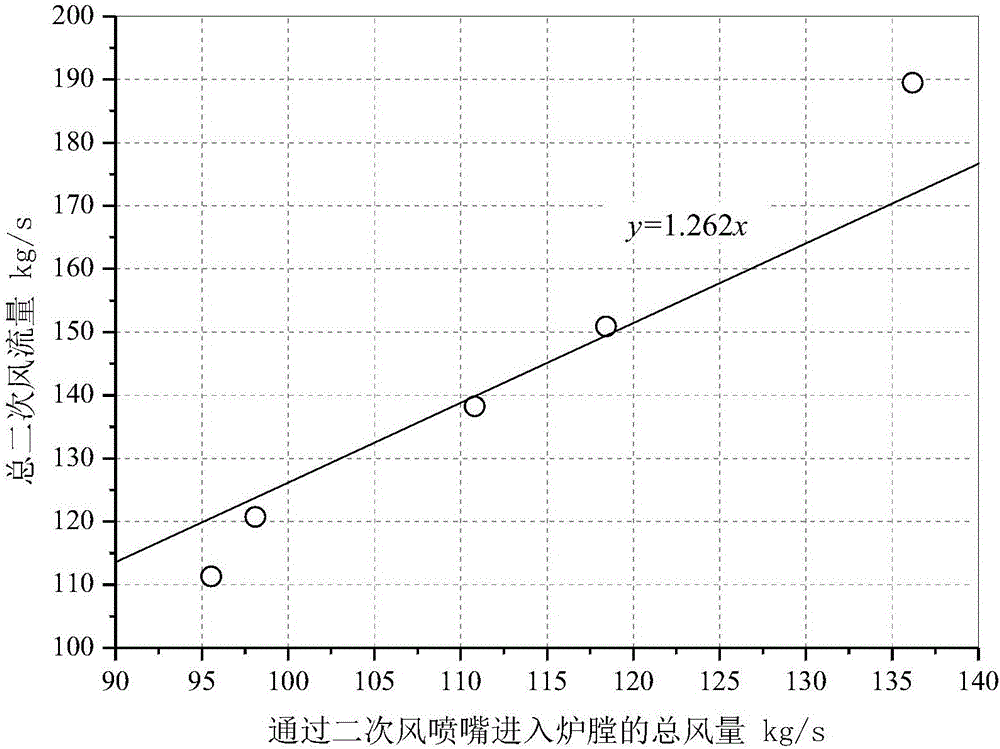

Operation evaluation method for additional inlet air of tangential firing tilting nozzles

The invention discloses an operation evaluation method for additional inlet air of tangential firing tilting nozzles. The operation evaluation method comprises the steps that a total secondary air flow entering a hearth is obtained according to the total air inlet amount and the total primary air flow of the hearth; primary air density and secondary air density are separately calculated, and the average density of primary air and secondary air and the average speed of primary air nozzles and secondary air nozzles are obtained; the air speed of each secondary air nozzle and the total amount of air entering the hearth through the secondary air nozzles are calculated; and the additional inlet air amount of the tangential firing tilting nozzles is obtained by subtracting the total amount of the air entering the hearth through the secondary air nozzles from the total secondary air flow entering the hearth, and the ratio of the total secondary air flow entering the hearth to the total amount of the air entering the hearth through the secondary air nozzles serves as a nozzle additional inlet air coefficient. The operation evaluation method has the beneficial effects that the nozzle additional inlet air amount is evaluated by utilizing secondary air resistance characteristics and a hearth resistance coefficient which are measured at a cold state; and an evaluation result is used for diagnosing the operation state of the combustor nozzles.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Tangential combustor

Owner:GENERAL ELECTRIC CO

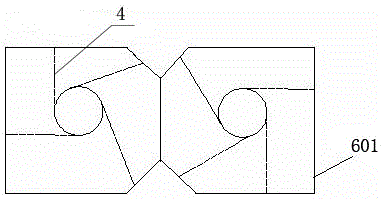

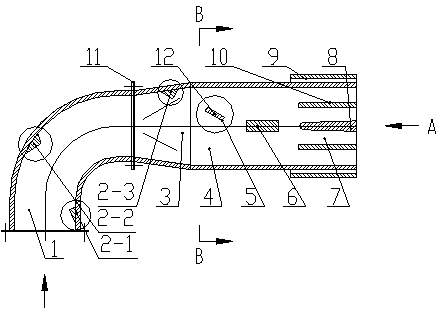

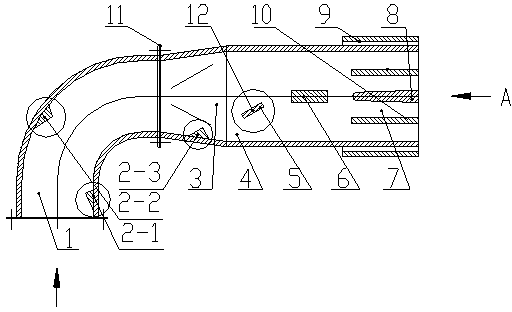

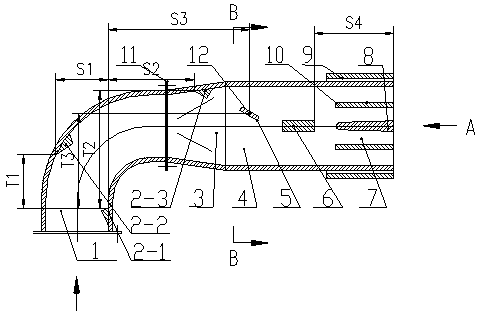

Multi-bluff body air-coal separating pulverized coal combustion device

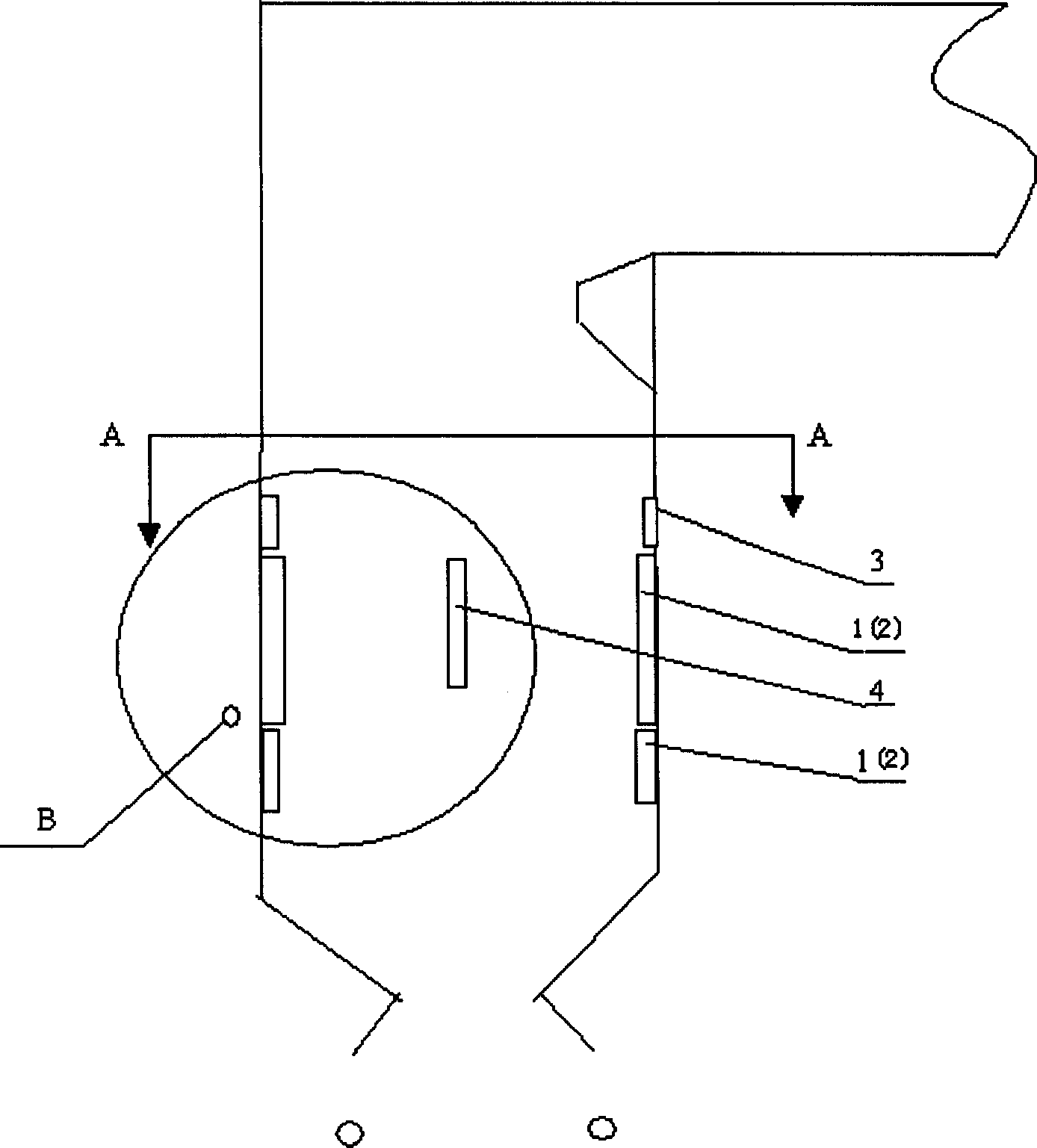

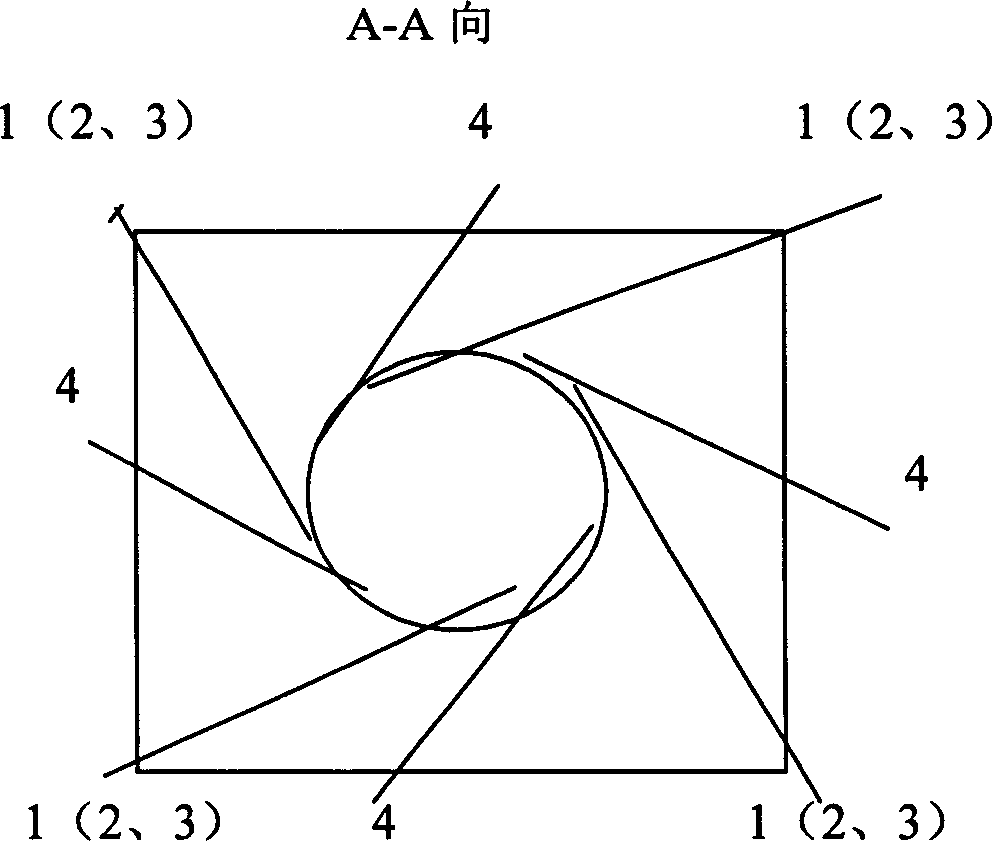

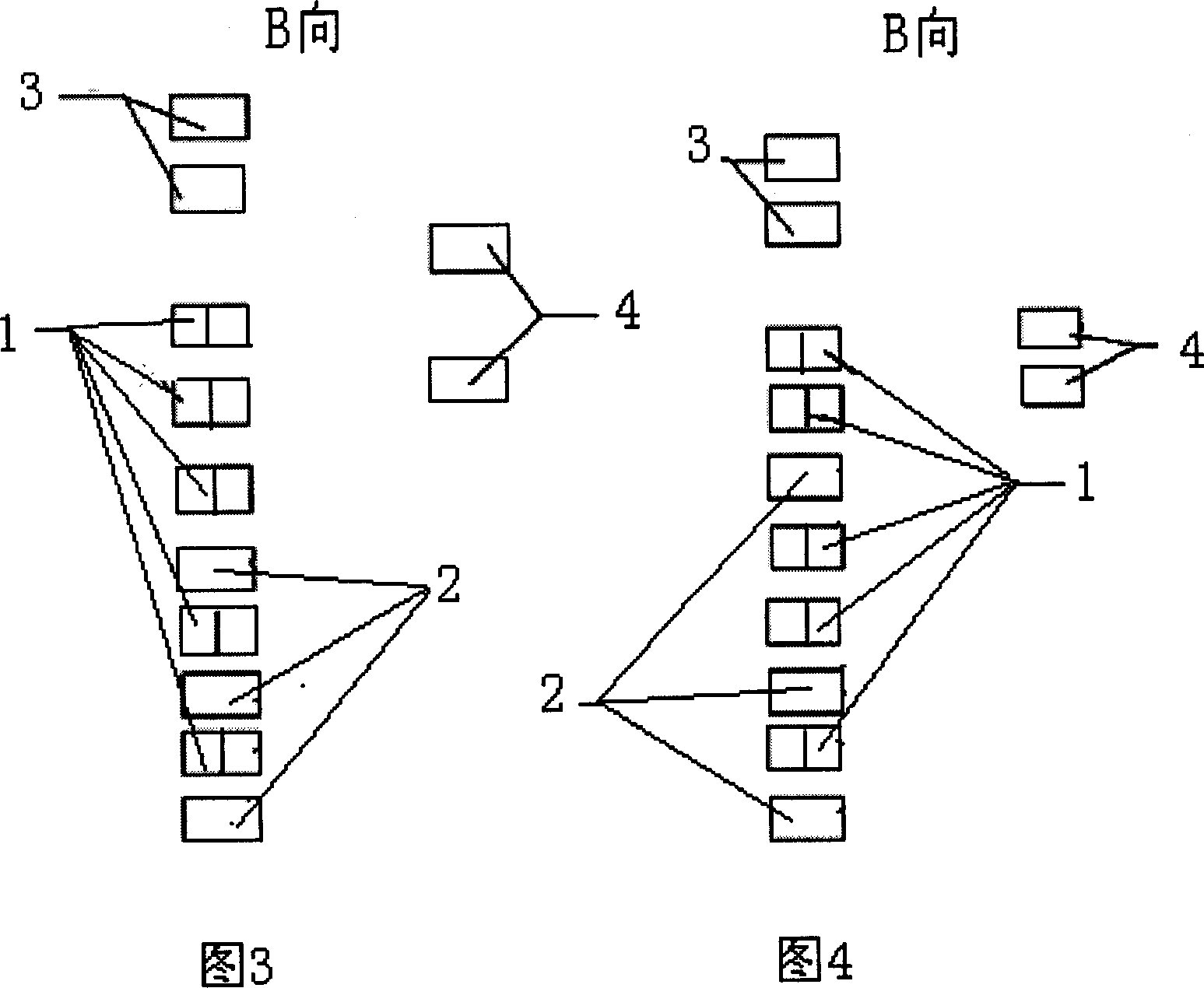

InactiveCN104776428ADelay mixingReduce generationPulverulent fuel combustion burnersThermodynamicsProcess engineering

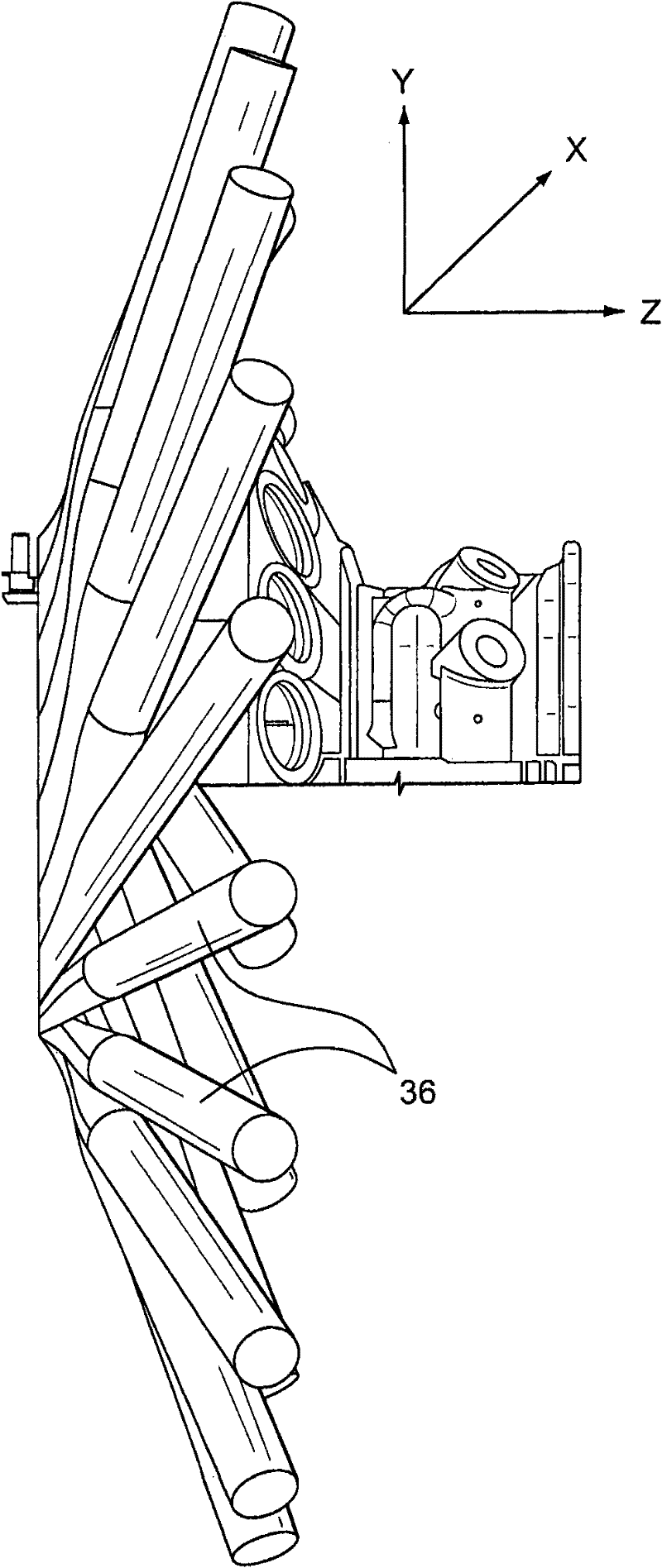

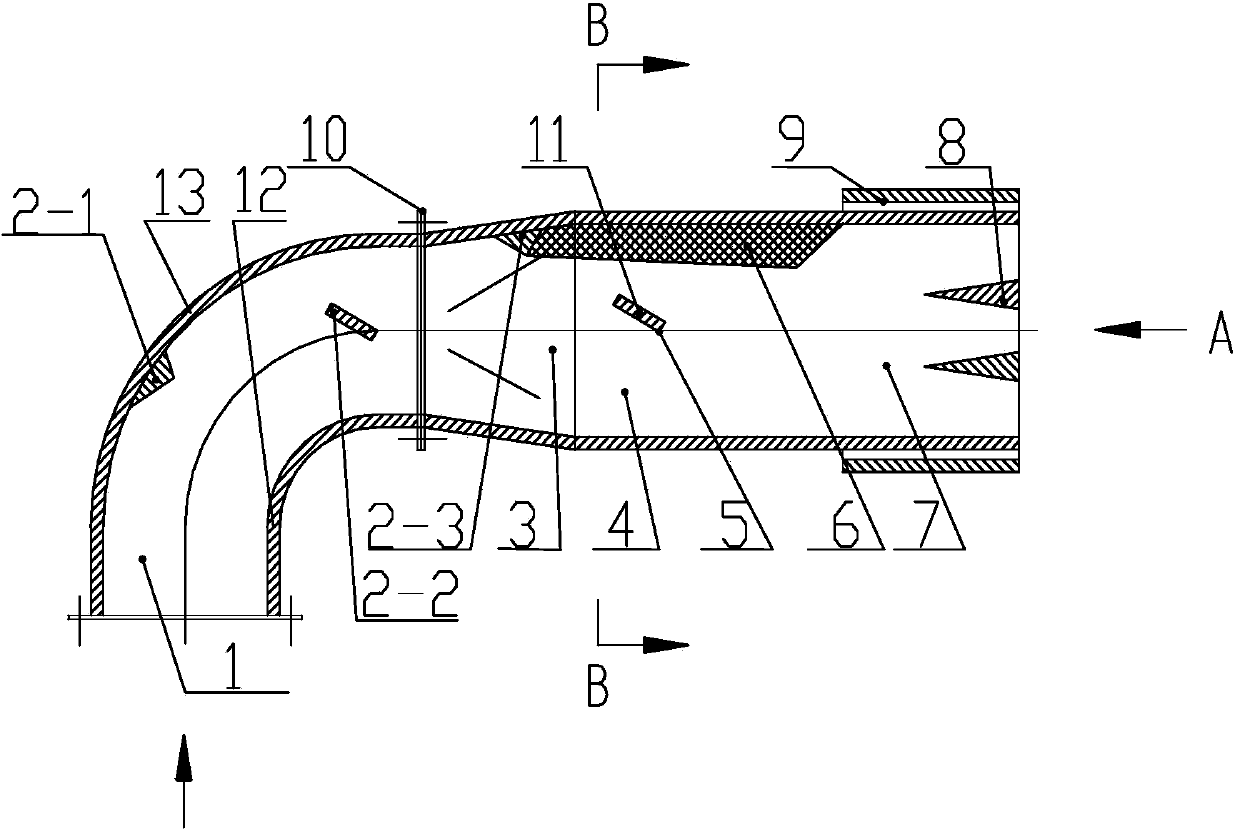

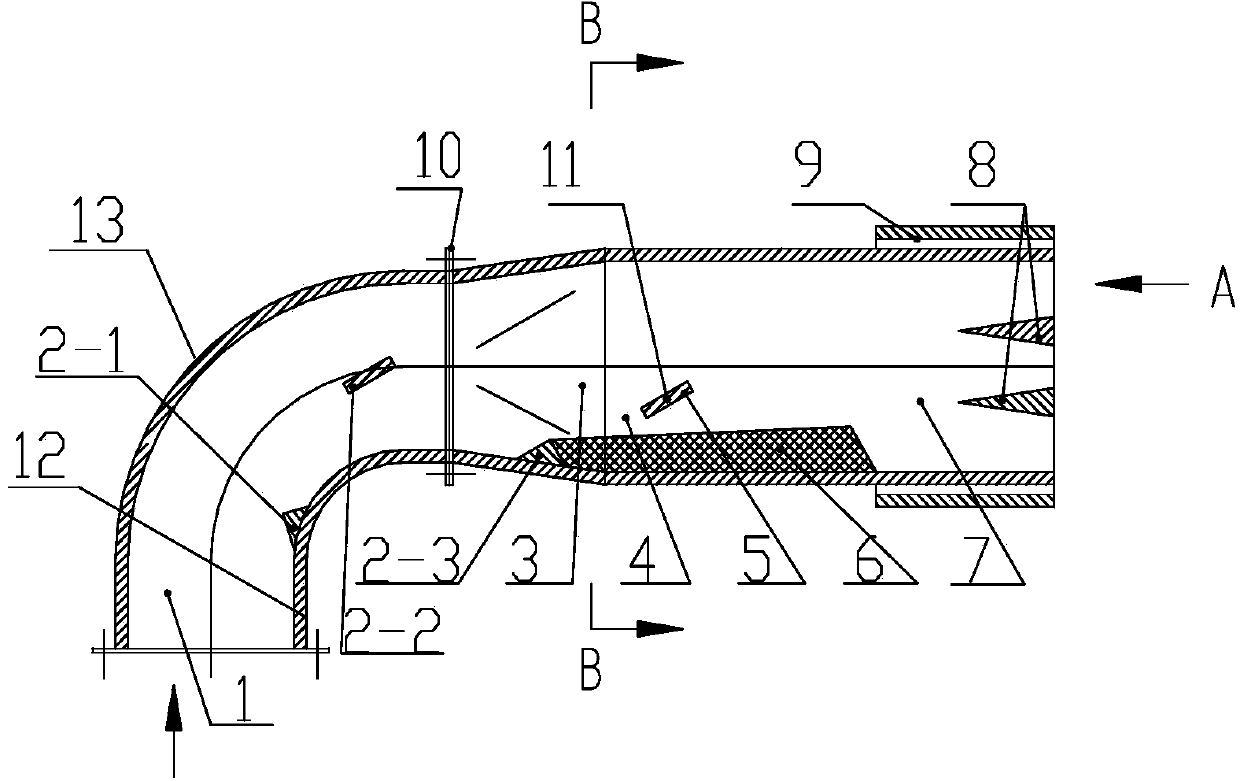

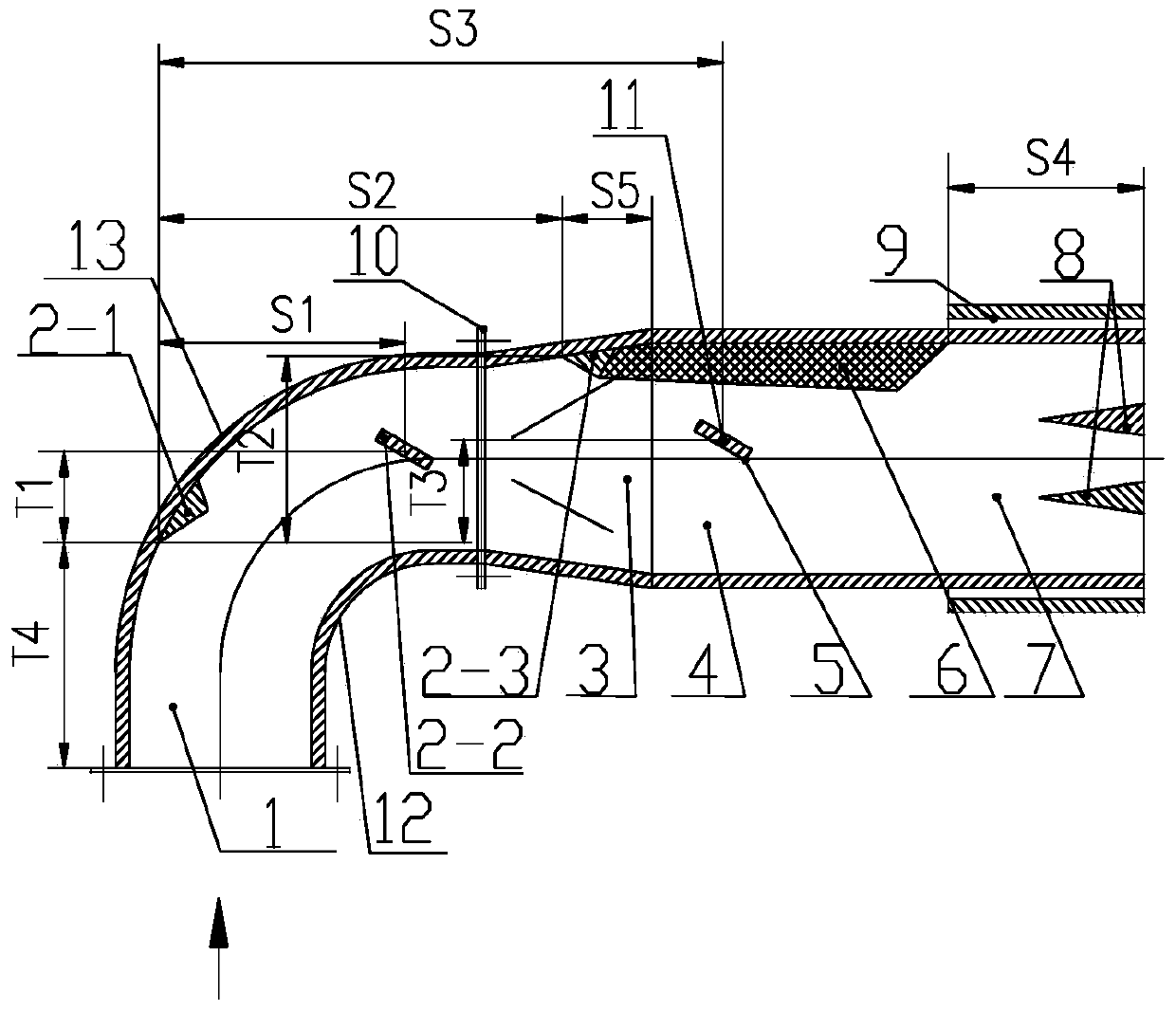

The invention relates to a pulverized coal combustor, in particularly to a multi-bluff body air-coal separating pulverized coal combustion device which is used for a four-corner tangentially-fired pulverized coal boiler. The multi-bluff body air-coal separating pulverized coal combustion device is characterized in that fixed separating baffle blocks I are arranged on a combustor inlet elbow lower cylinder and a combustor inlet elbow upper cylinder in a combustor inlet elbow, a fixed separating baffle block II is arranged in a space between the combustor inlet elbow lower cylinder and the combustor inlet elbow upper cylinder, and a fixed separating baffle block III is arranged in front of a pulverized coal concentrator; a combustor nozzle is provided with two to four layers of bluff bodies. According to the multi-bluff body air-coal separating pulverized coal combustion device disclosed by the invention, the effect of reducing the oxynitride emission concentration is increased by about 40% on the premise of the effect of reducing the oxynitride emission concentration of an original air-coal separating pulverized coal combustor, and the oxynitride emission concentration is reduced from below 300mg / Nm<3> (6% of O2) of the original air-coal separating pulverized coal combustor into below 200mg / Nm<3> (6% of O2) of the multi-bluff body air-coal separating pulverized coal combustion device.

Owner:HARBIN BOSHEN TECH DEV CO LTD

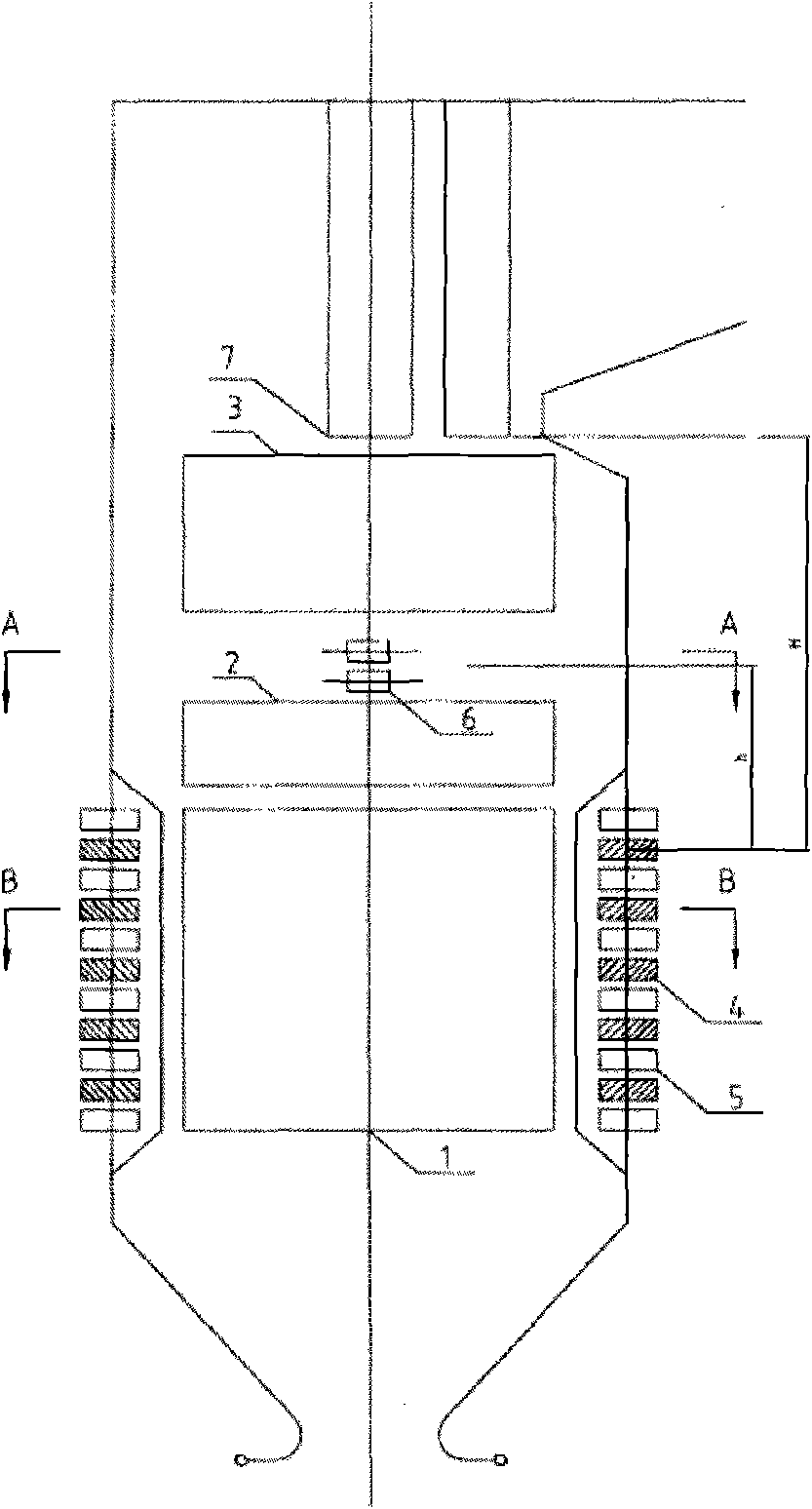

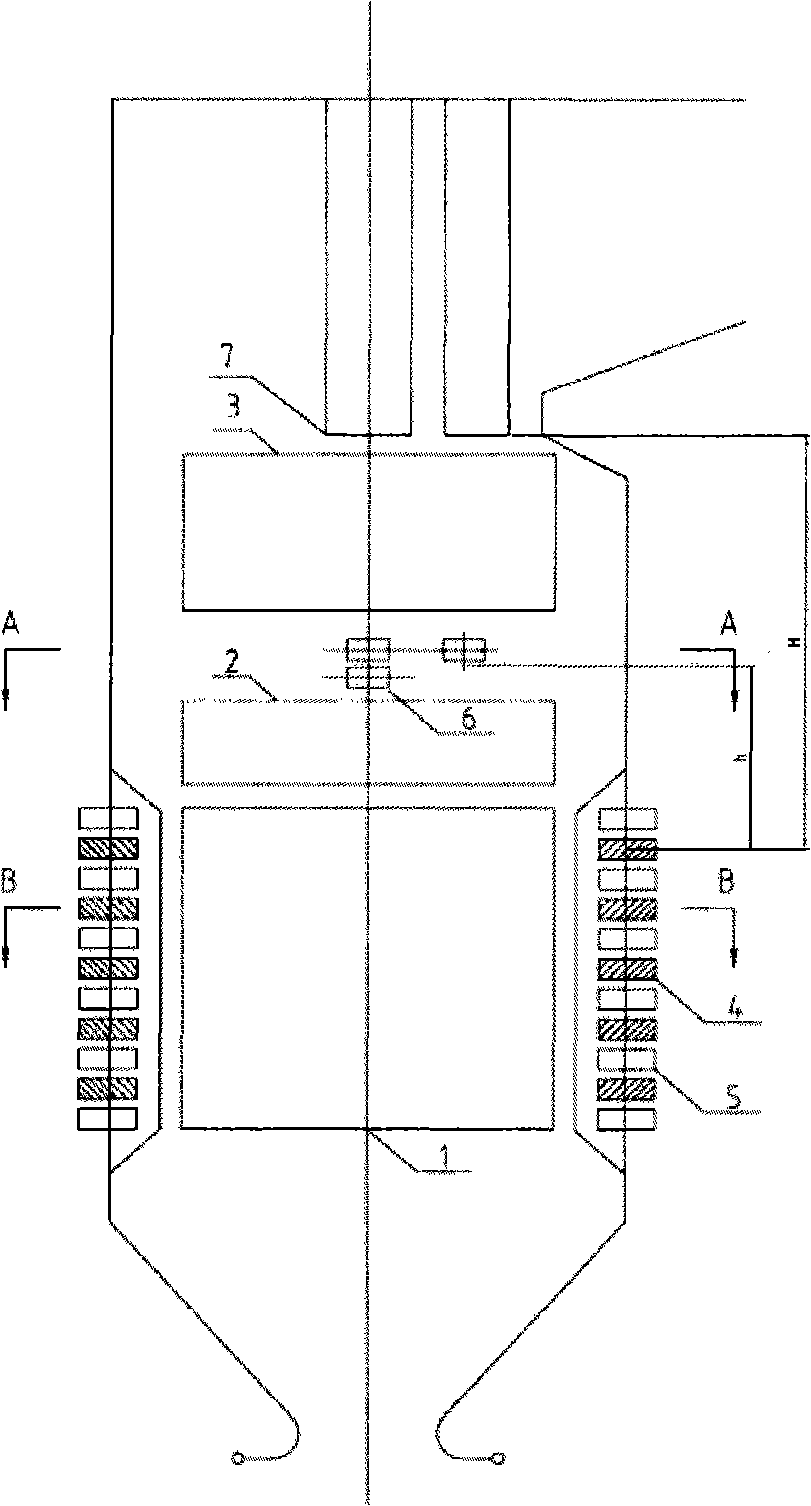

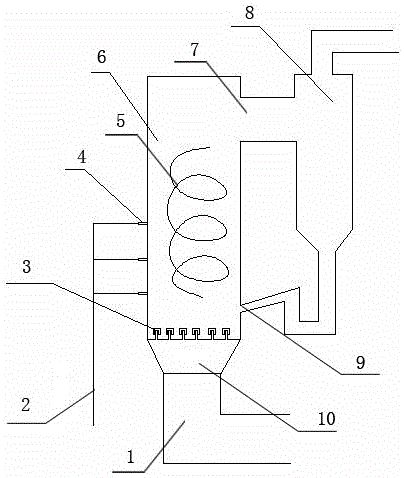

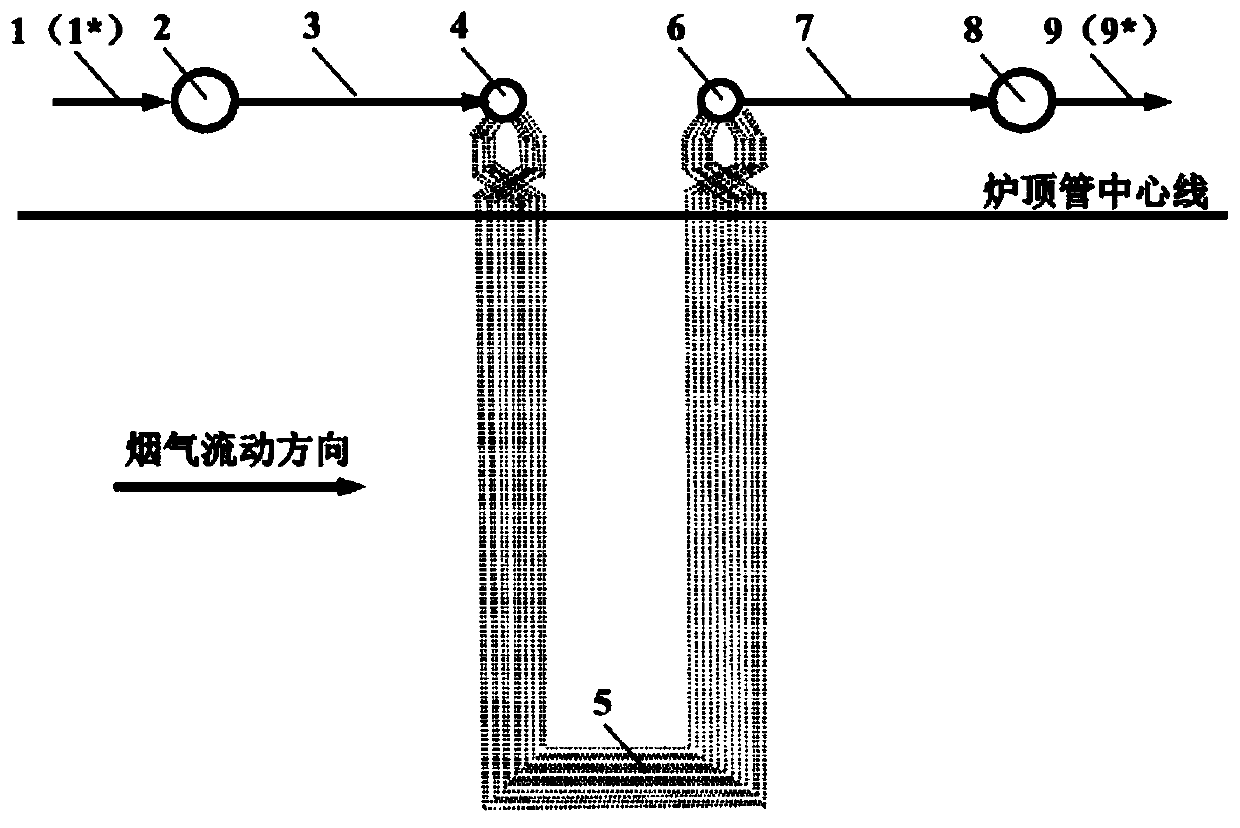

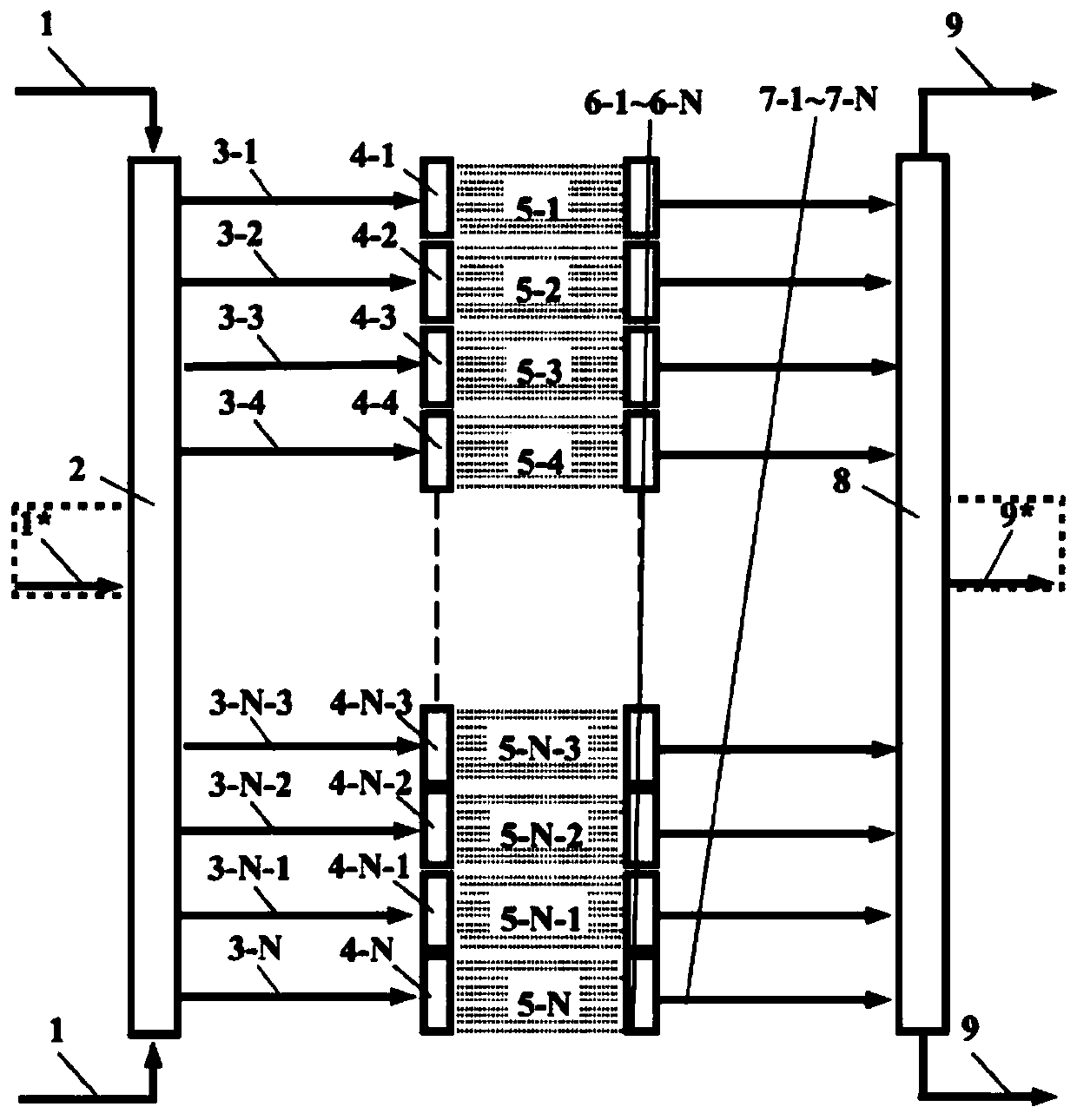

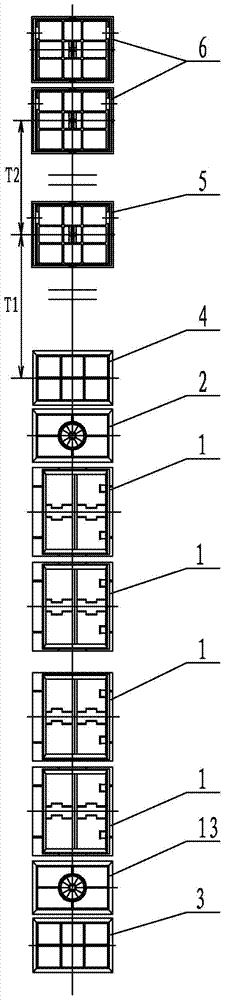

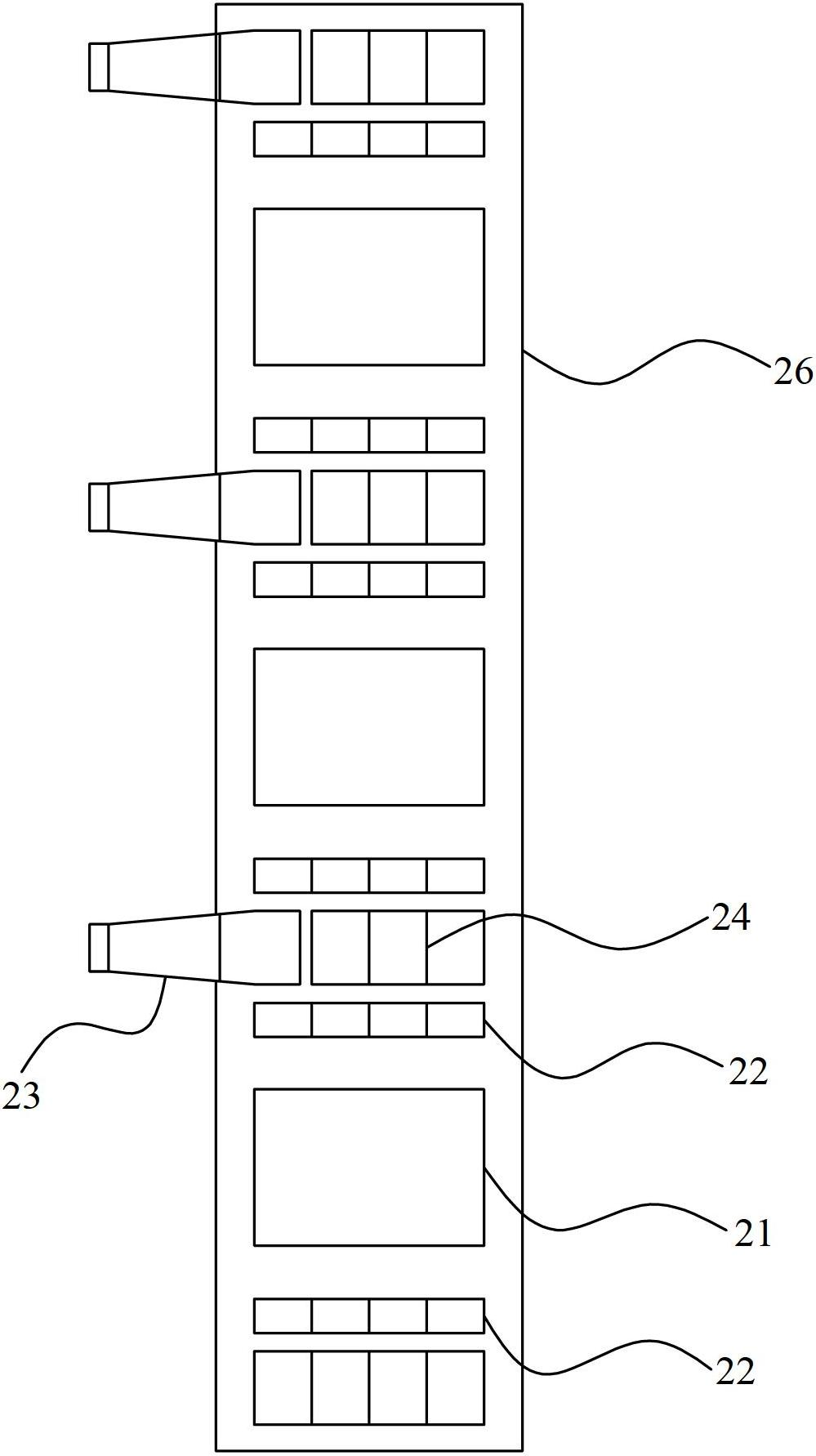

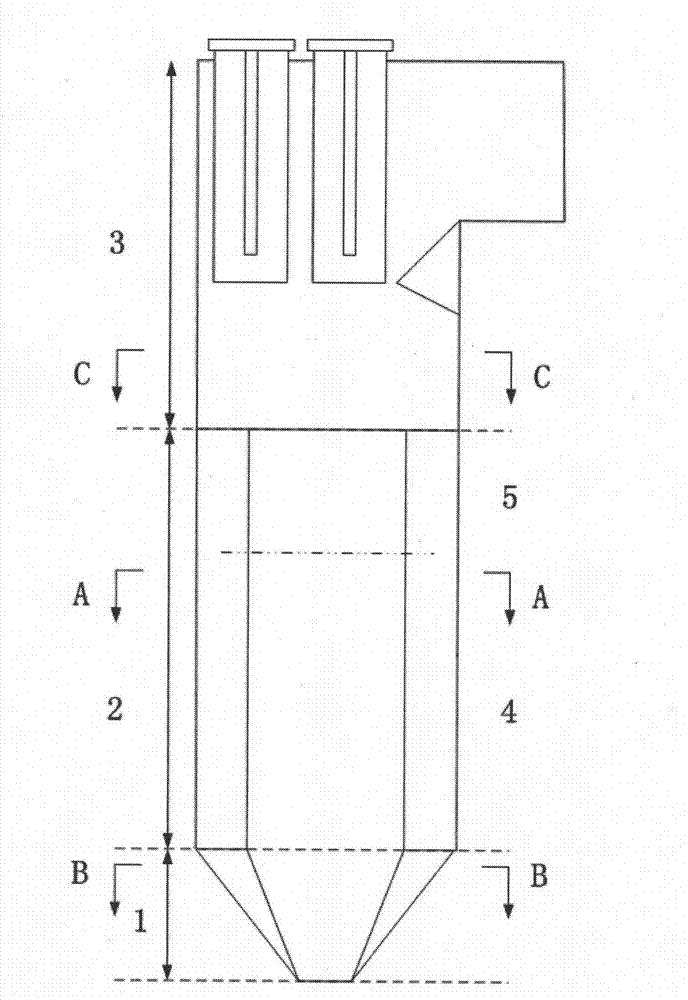

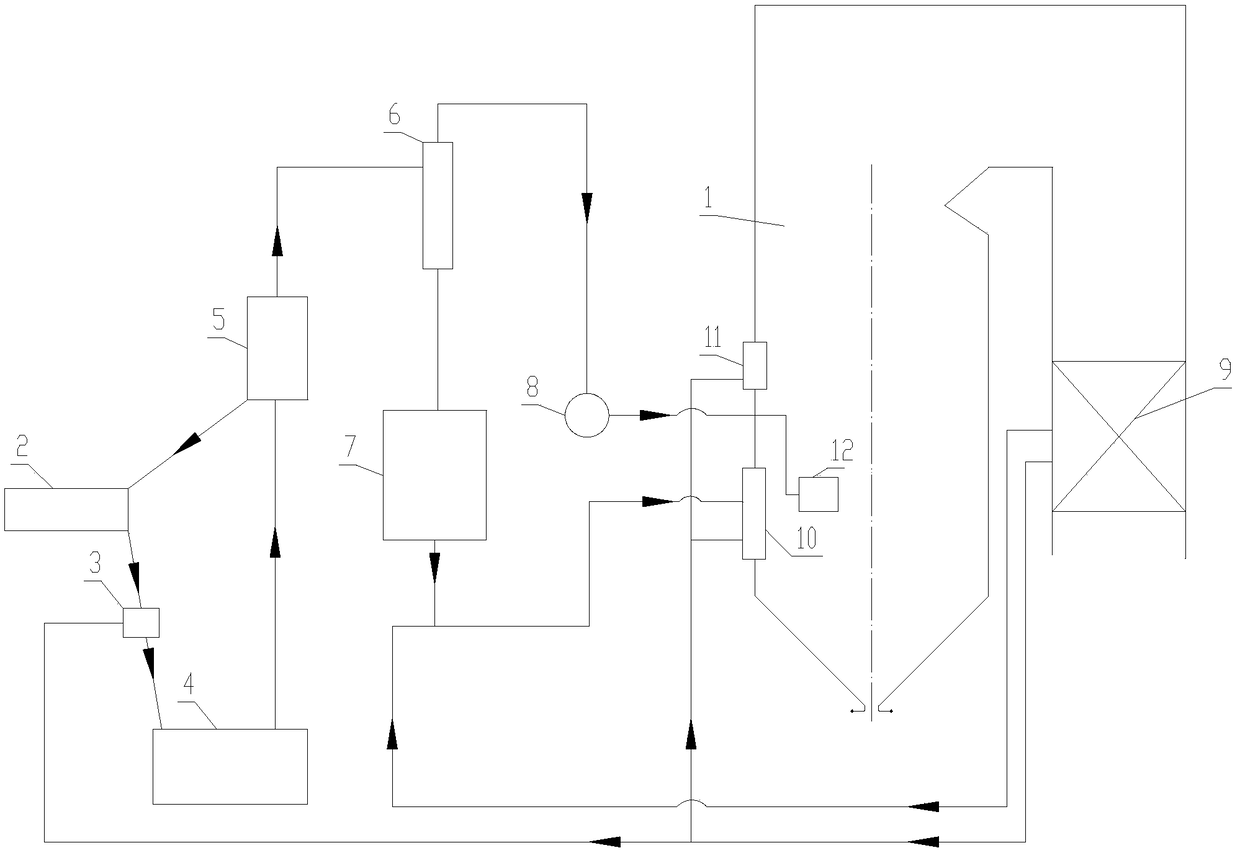

Optimization arrangement mode of high-temperature heating surface

PendingCN110617468AReduce wall temperature deviationImprove operational safetyBoiler water tubesSteam boilersFlue gasDistribution characteristic

The invention discloses an optimization arrangement mode of a high-temperature heating surface. The arrangement mode is suitable for the high-temperature heating surface involving a high-temperature last-stage superheater and a high-temperature last-stage reheater of a tangential firing II-type arranging coal-fired boiler; the arrangement process of a high-temperature steam system comprises the following steps that steam to be heated is led from an inlet connecting pipeline (1) of a same-level heating surface to an inlet large collecting box (2) of the same-level heating surface, and then is led from each region leading-in pipeline (3) to each inlet small collecting box (4); after being heated through a high-temperature heating surface (5), the steam enters each outlet small collecting box(6), and then is led from each region leading-out pipeline (7) to an outlet large collecting box (8); and finally, the steam is led out from an outlet connecting pipeline (9) to a next system. According to the optimization arrangement mode, the steam flow entering each region tube panel is changed, so that the side distribution characteristic of the steam of each region tube panel is matched withthe non-uniform characteristic of the flue gas side heating powder born by each region tube panel.

Owner:SHANGHAI BOILER WORKS +1

Method for acquiring combustion characteristics under different loads after boiler improvement

ActiveCN103968413AReproduce the combustion situationImprove combustion characteristicsAir supply regulationMathematical modelLow nitrogen

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Tangential Combustion Turbine

InactiveUS20090272094A1Internal combustion piston enginesCombination enginesCombustion chamberEngineering

A tangential combustion turbine is disclosed which is based on a casing, a rotor, and moving levers. A radial compressor is attached to the rotor and creates air pressure which pushes air into the combustion chamber based on the position and design of the combustion lever. The combustion chamber is defined by spaces between rotor lobes, and by combustion levers and exhaust levers which follow the rotor surface. A premix fuel system or direct fuel injection is used to create combustion. The exhaust gases then pass through the exhaust lever into the exhaust piping as the rotor rotates.

Owner:ZINK ALEXANDER M +2

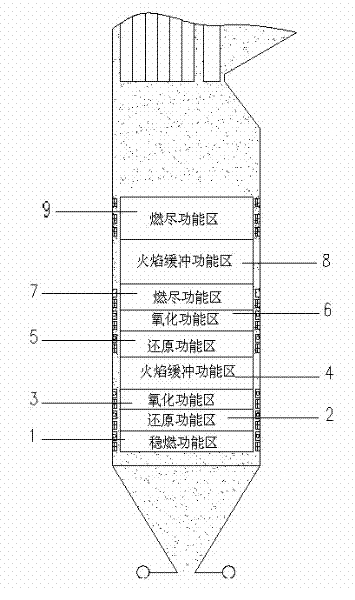

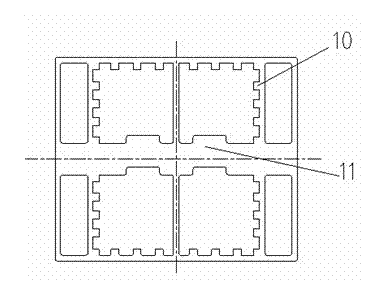

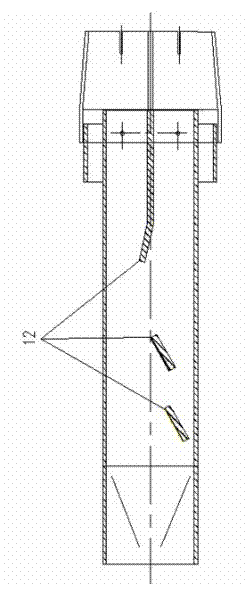

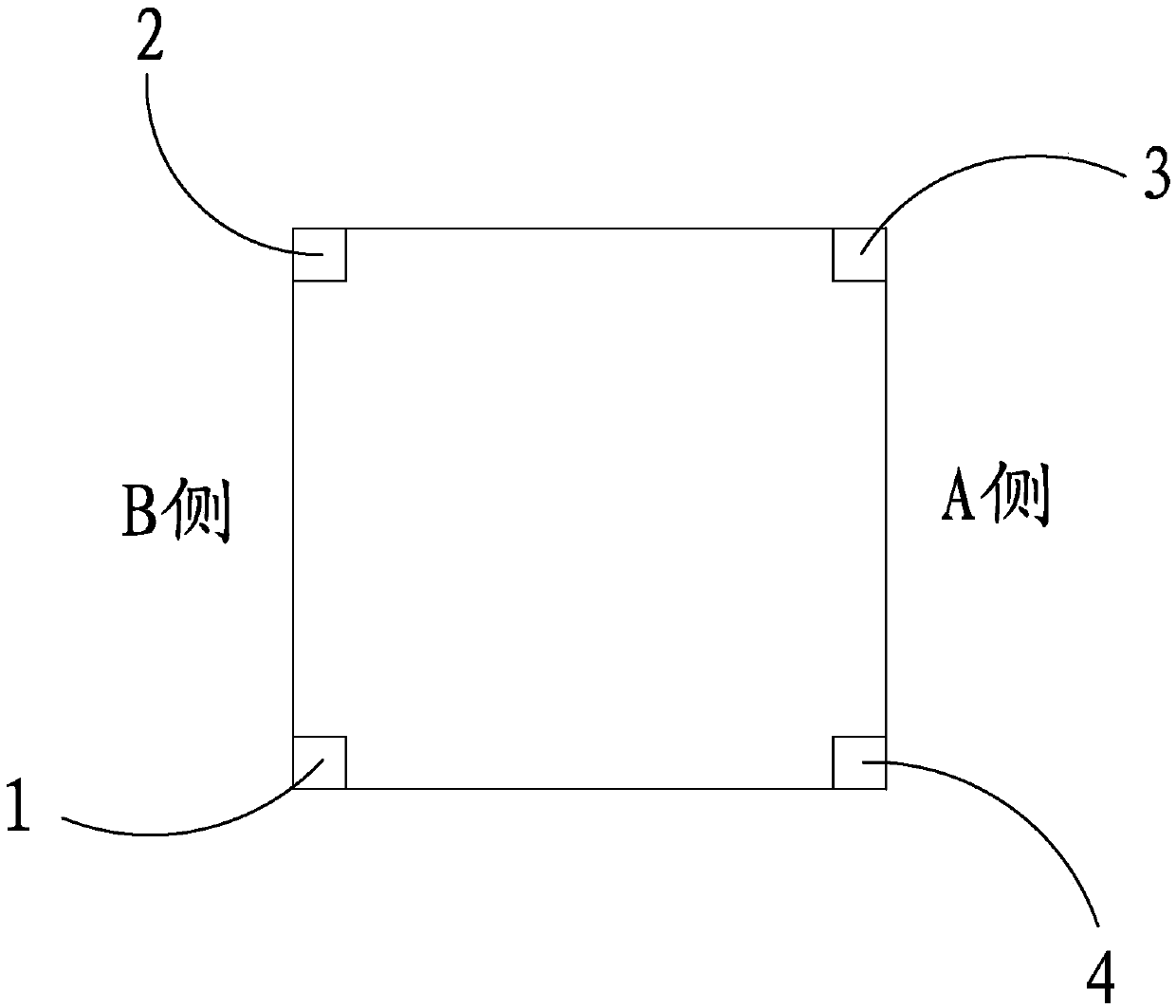

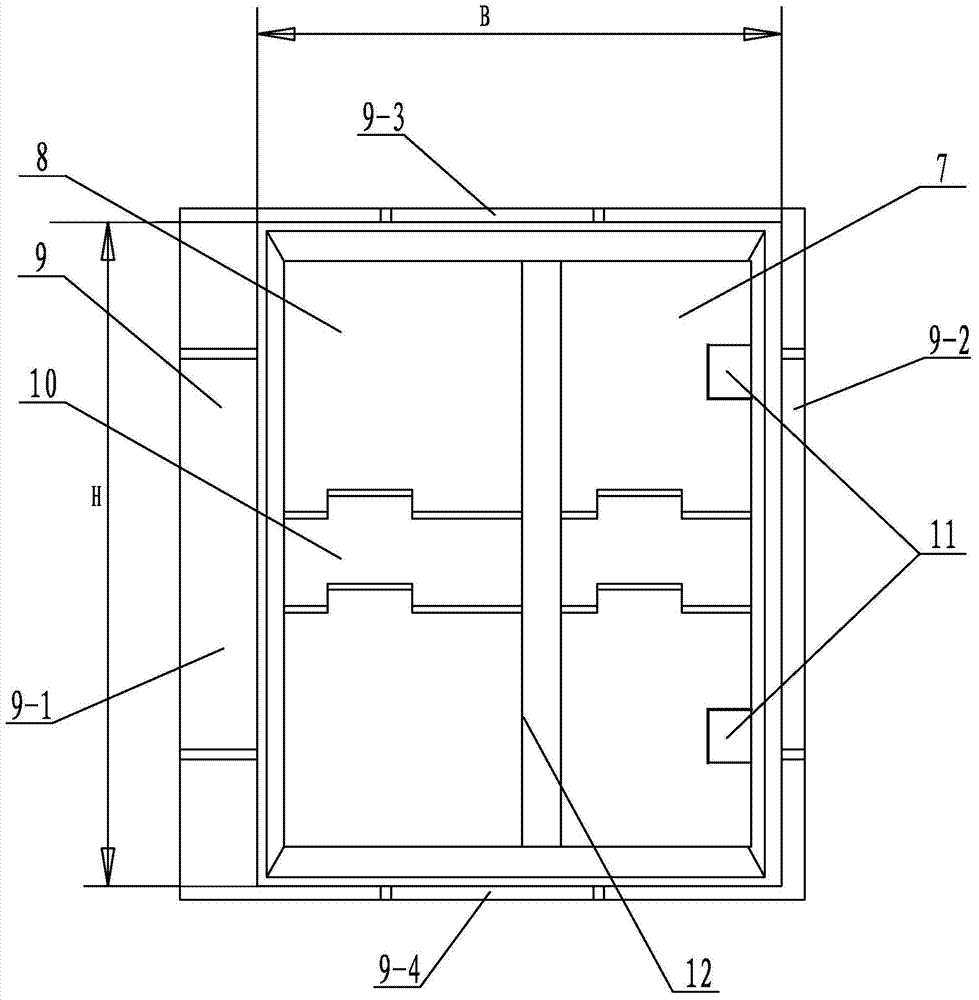

Combustion device of multifunction tangential firing pulverized coal boiler and control method thereof

ActiveCN102226519AAddressing Adaptive IssuesFix stability issuesCombustion apparatusEngineeringNitric oxide

The invention provides a combustion device of a multifunction tangential firing pulverized coal boiler. The combustion device is characterized in that a stable combustion functional zone, a reduction functional zone, an oxidation functional zone, a flame buffer functional zone, a reduction functional zone, an oxidation functional zone, a burning-out functional zone, a flame buffer functional zoneand a burning-out functional zone are sequentially arranged in the vertical space in a hearth from bottom to top, wherein the primary air nozzles of the stable combustion functional zone and the reduction functional zone are rectangular, the inner peripheries of the primary air nozzles are of an odd-shaped blunt gear structure, and the middles of the primary air nozzles are toothed blunt bodies. The device can be used for solving the problem of poor flaming coal type adaptability, poor combustion stability, water cooled wall slagging in the hearth, water cooled wall high temperature corrosionand the like in the tangential firing pulverized coal boiler by virtue of reasonable arrangement of each function zone in a furnace combustion device and special structural design of the primary air nozzles as well as the accuracy control on the furnace air or fuel classification. The combustion device provided by the invention has the advantages that the nitric oxide emission concentration in combustion gas is reduced to below 200mg / m<3>, and the boiler efficiency can reach 93% for an over 300MW unit.

Owner:GANSU HONGFA ELECTRIC POWER ENG TECH

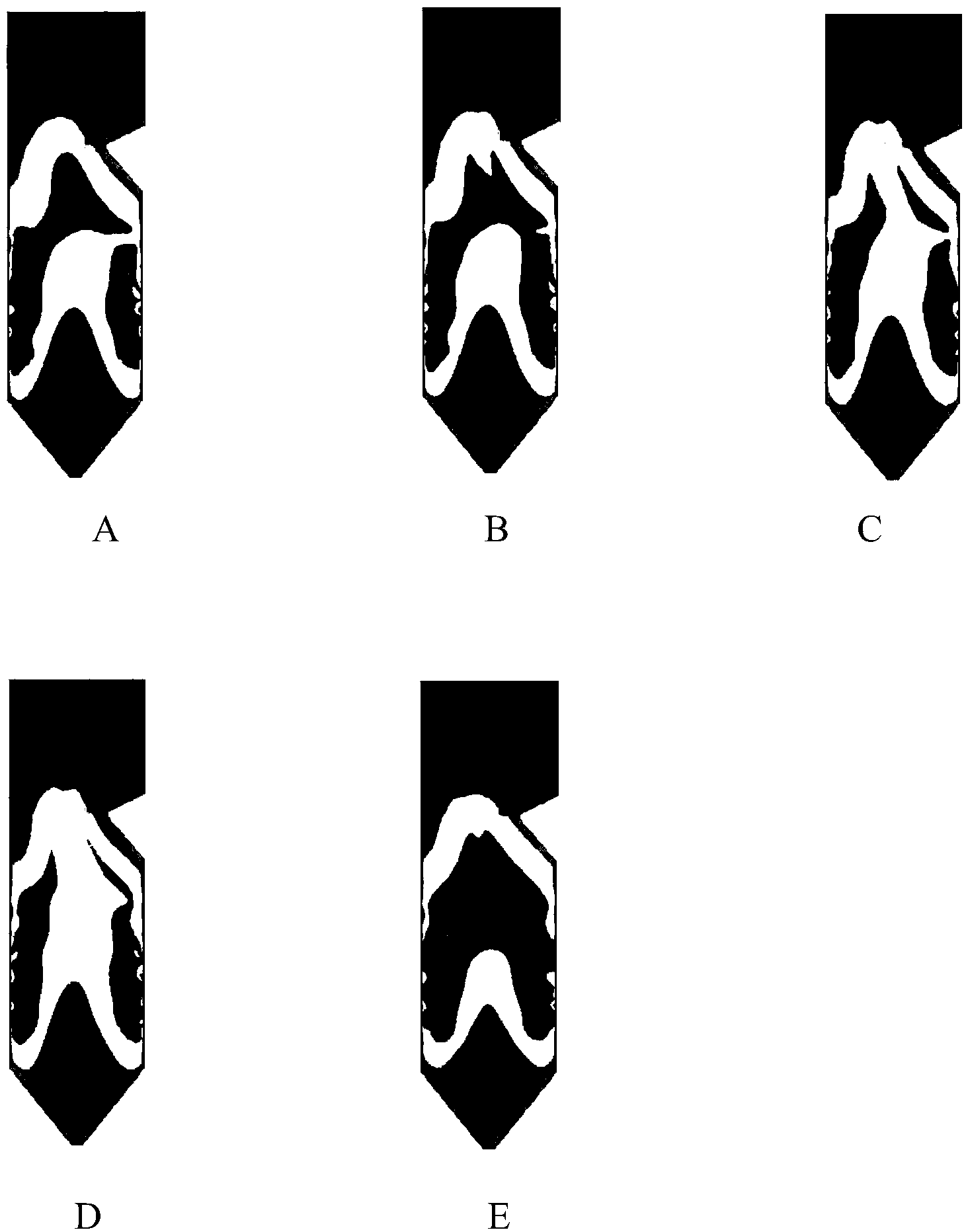

Method for adjusting deviation of two sides of reheating steam temperature of four-corner tangential firing boiler by SOFA air doors

ActiveCN109578992AReduce smoke temperature deviationReduce hot spotsCombustion apparatusWater flowEngineering

The invention relates to a method for adjusting deviation of two sides of the reheating steam temperature of a four-corner tangential firing boiler by SOFA air doors. The method for adjusting the deviation of the two sides of the reheating steam temperature of the four-corner tangential firing boiler by the SOFA air doors comprises the steps that horizontal pendulum angles of the SOFA air doors are adjusted; when the deviation of two sides of the reheating steam temperature is removed, vertical pendulum angles of the SOFA air doors are no longer adjusted; when the deviation of two sides of thereheating steam temperature is not removed, the vertical pendulum angles of the SOFA air doors are adjusted; and when the vertical pendulum angles of the SOFA air doors are adjusted, firstly, the vertical pendulum angles of a second SOFA air door and a third SOFA air door are adjusted obliquely upwards, and then, the vertical pendulum angles of a first SOFA air door and a fourth SOFA air door areadjusted to horizontal positions. The adjustment of the reheating steam temperature and temperature-decreased water flow is realized through the cooperative cooperation of the horizontal pendulum angles and the vertical pendulum angles of the SOFA air door, through the nonsynchronous adjustment of the horizontal pendulum angles and the vertical pendulum angles, the deviation of two sides of smoketemperature of the four-corner tangential firing boiler is rapidly reduced, the high-temperature point of the reheater pipe wall is reduced, the problems of large deviation of a reheater outlet stream temperature and the unbalanced temperature-decreased water flow on two sides are solved, finally, the average stream temperature of the reheater outlet is improved, and the temperature-decreased water flow of the reheater is reduced.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Low-nitrogen combustion device without primary air and secondary air, and application method

ActiveCN103672862AReduce emission concentrationReduce air-to-coal ratioCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLow nitrogenPollution

The invention discloses a low-nitrogen combustion device without primary air and secondary air, and an application method, and relates to a combustion device of a pulverized coal tangentially fired boiler so as to solve the problem of easiness in causing higher NOx emission concentration of a boiler at a high primary air rate of the pulverized coal boiler. An upper separating over fire air nozzle, a lower separating over fire air nozzle, a compact over fire air nozzle, an oiling secondary air nozzle, and at least one primary air nozzle, at least one deoiling secondary air nozzle and at least one bottom air nozzle which are continuously arranged, are arranged from the top to bottom in sequence, a partition board is vertically arranged in the middle of the primary air nozzle, a blunt body is horizontally arranged in the middle of the primary air nozzle, the upper nozzle and the lower nozzle at the right side of the blunt body are thick pulverized coal primary air nozzles, the upper nozzle and the lower nozzle at the left side of the blunt body are thin pulverized coal primary air nozzles, a steady burning tooth is arranged in each thick pulverized coal primary air nozzle, and the periphery of the edge of each air nozzle is provided with surrounding air. The low-nitrogen combustion device without primary air and secondary air and the application method can be used for efficient low-pollution combustion of the pulverized coal boiler with the high primary air rate.

Owner:哈尔滨龙高科环境科技有限公司

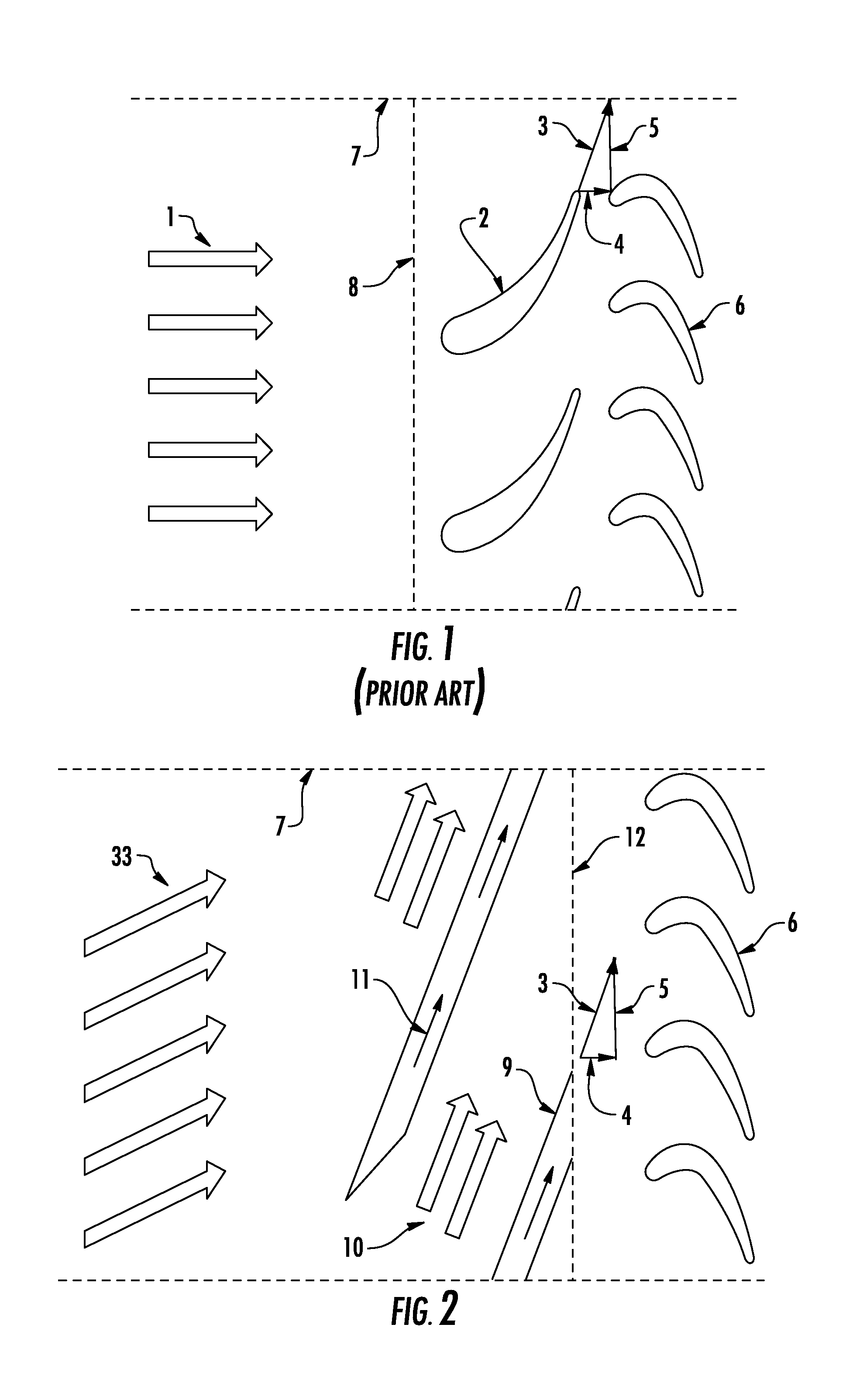

Tangential firing system under air staged combustion technology

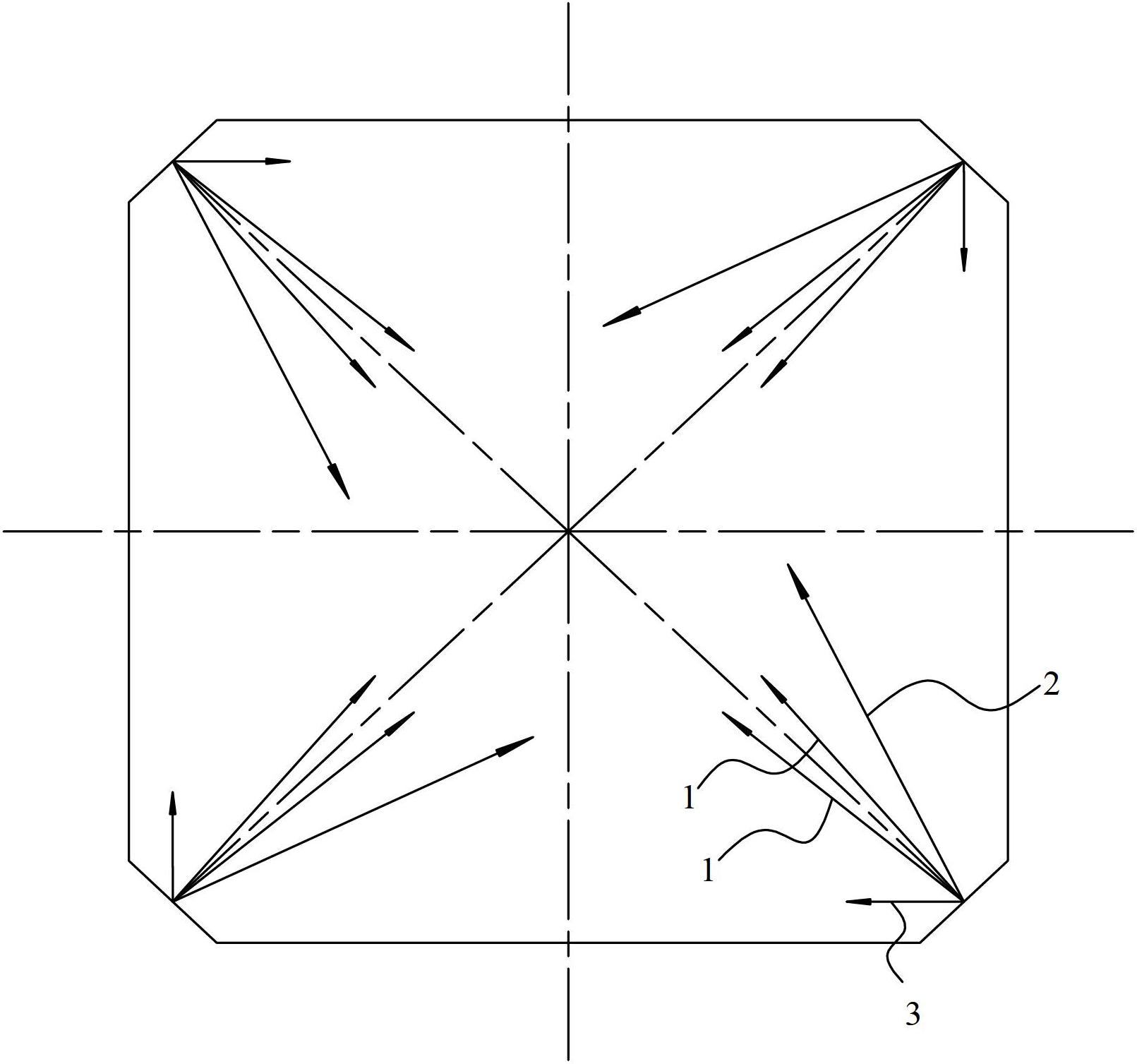

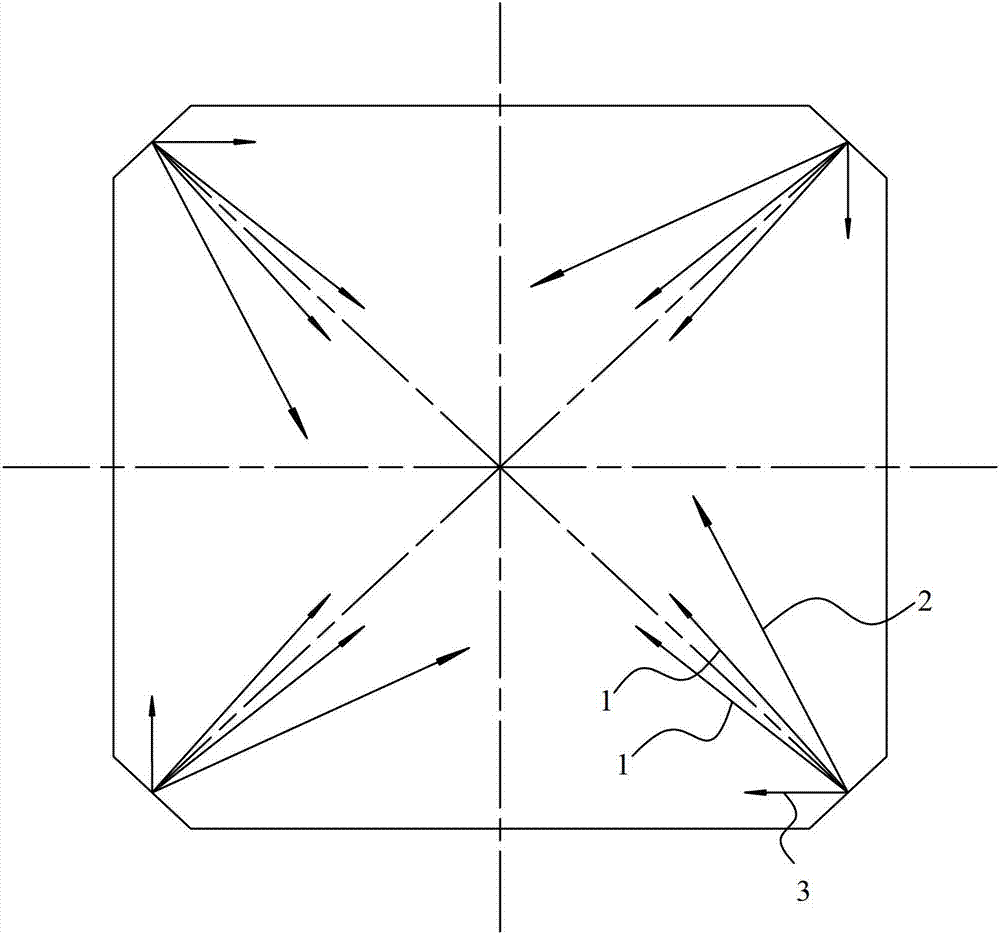

ActiveCN102692013AIncrease adherent oxygenPrevent sticking to the wallCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneSlag

The invention discloses a tangential firing system under an air staged combustion technology, which comprises main burners. The main burners are diagonally arranged along the cross section of a hearth; primary air and pulverized coal mixed airflows which are diagonally arranged are oppositely sprayed to form a first tangent circle in the hearth; each main burner consists of a plurality of primary air nozzles and a plurality of secondary air nozzles; the primary air nozzles and the secondary air nozzles are arranged at intervals; and each secondary air nozzle comprises an offset cyclone forming nozzle, a folding air nozzle and a direct blown air nozzle. According to the tangential firing system provided by the invention, by the reasonable arrangement and distribution of each path of airflow, the adherence oxygen volume of a boiler can be improved and a torch is prevented from being adhered to the wall, so that the risks of slag formation on the water cooling wall of the boiler and high temperature corrosion to the boiler can be reduced.

Owner:SHANGHAI BOILER WORKS

Tangential firing system under air staged combustion technology

ActiveCN102692013BIncrease adherent oxygenPrevent sticking to the wallCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneSlag

The invention discloses a tangential firing system under an air staged combustion technology, which comprises main burners. The main burners are diagonally arranged along the cross section of a hearth; primary air and pulverized coal mixed airflows which are diagonally arranged are oppositely sprayed to form a first tangent circle in the hearth; each main burner consists of a plurality of primary air nozzles and a plurality of secondary air nozzles; the primary air nozzles and the secondary air nozzles are arranged at intervals; and each secondary air nozzle comprises an offset cyclone forming nozzle, a folding air nozzle and a direct blown air nozzle. According to the tangential firing system provided by the invention, by the reasonable arrangement and distribution of each path of airflow, the adherence oxygen volume of a boiler can be improved and a torch is prevented from being adhered to the wall, so that the risks of slag formation on the water cooling wall of the boiler and high temperature corrosion to the boiler can be reduced.

Owner:SHANGHAI BOILER WORKS

Method for improving boiler combustion economy of tangential combustion anthracite coal boiler

InactiveCN104251487AReduce smoke temperature deviationReduce the adverse effects of smoke temperature deviation, etc.Fluidized bed combustionBlast-producing apparatusLow loadEngineering

The invention discloses a method for improving the boiler combustion economy of a tangential combustion anthracite coal boiler. The combustors of the coal-fired boiler comprise a main combustor and an upper tertiary air combustor, wherein the main combustor is positioned in a main combustion region in a coal-fired boiler body, and the upper tertiary air combustor is next to the upper part of the main combustion region. The method comprises the following steps: (1) adding a layer of tertiary air jet nozzle below secondary air of the lowermost layer of the main combustion region to serve as a lower tertiary air combustor; (2) forming openings in original tertiary air pipes on the four corners of the boiler, and guiding original tertiary air to the added tertiary air jet nozzle by an added pipeline so as to increase the burn-off rate of coal powder without influence of low-load stable combustion capability of the boiler. According to the method, the boiler efficiency can be improved by more than 3% on the basis of guaranteeing the stable combustion capability of the boiler; the efficiency of the anthracite coal boiler is greatly improved, and the combustion stability of the boiler cannot be influenced; by the method provided by the invention, the investment and the running expense are low and the national conditions of China are met.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +2

Tangential combustor with vaneless turbine for use on gas turbine engines

ActiveUS8904799B2Shorten the lengthSmall sizeContinuous combustion chamberEfficient propulsion technologiesTurbine bladeStaged combustion

A combustion device used in gas turbine engines includes an annular combustor that contains the combustion process of air and fuel and then guides the hot gas products to a first stage turbine subsection of a gas turbine engine. The annular combustor has an inner / outer shell having corrugated surfaces that extend radially outward and inward across an entire hot gas stream inside the annular combustor. The corrugations twist about the engine centerline in a longitudinal direction of travel of the engine. The resulting flow path accelerates and turns the hot gas stream to conditions suitable for introduction into the first stage turbine blades, which eliminate the need for first stage turbine vanes. The annular combustor is configured with a system of fuel and air inlet passages and nozzles that results in a staged combustion of premixed fuel and air.

Owner:TOQAN MAJED +3

Method for acquiring combustion characteristics under different proportions of CCOFA and SOFA after boiler improvement

ActiveCN103968412AReproduce the combustion situationImprove combustion characteristicsAir supply regulationLow nitrogenMathematical model

The invention discloses a method for acquiring combustion characteristics under different proportions of CCOFA and SOFA after boiler improvement and belongs to the technical field of coal-fired boilers. The method comprises the steps of performing mesh generation on an improved corner tangential firing boiler with SOFA increased, establishing a structural mesh model of the boiler and acquiring a combustor parameter, a boundary condition parameter and a coal dust parameter of the boiler; establishing a mathematical model, and performing combustion analog computation to obtain combustion characteristics of the boiler under different proportions of CCOFA and SOFA. By means of the method, combustion conditions in the boiler can reproduce accurately, comprehensive information of combustion conditions in the boiler can be acquired, guidance is provided for low nitrogen transformation in increasing SOFA of the boiler, and comprehensive evaluation is performed on effect after low nitrogen transformation is performed on the boiler.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Blaze-folding corner structure for weakening furnace outlet remainder rotation

A nose structure weakening residual swirling in an outlet of a furnace cavity, which bends and thins water screen tubes on a front wall and a rear wall of the furnace cavity to form staggered rows of tubes inserting into updraft, water screen tubes are not connected with each other. When swirling up draft in the furnace cavity moves to the nose, under the function of separation and obstruction of the structure, thereby weakening or even eliminating the residual swirling and basically eliminating deviation of flow rate and temperature of flue gas in the outlet of the furnace cavity and a stack flue of a tangential firing boiler.

Owner:XI AN JIAOTONG UNIV

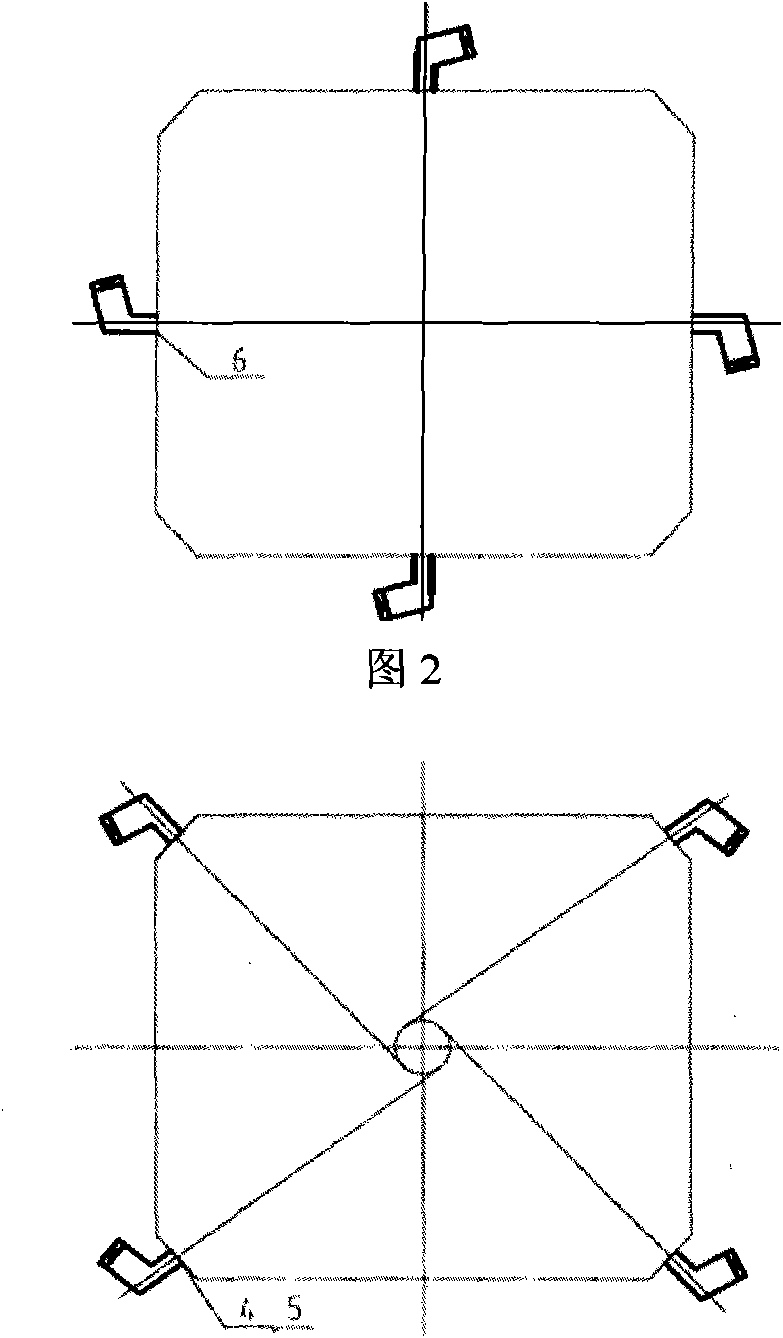

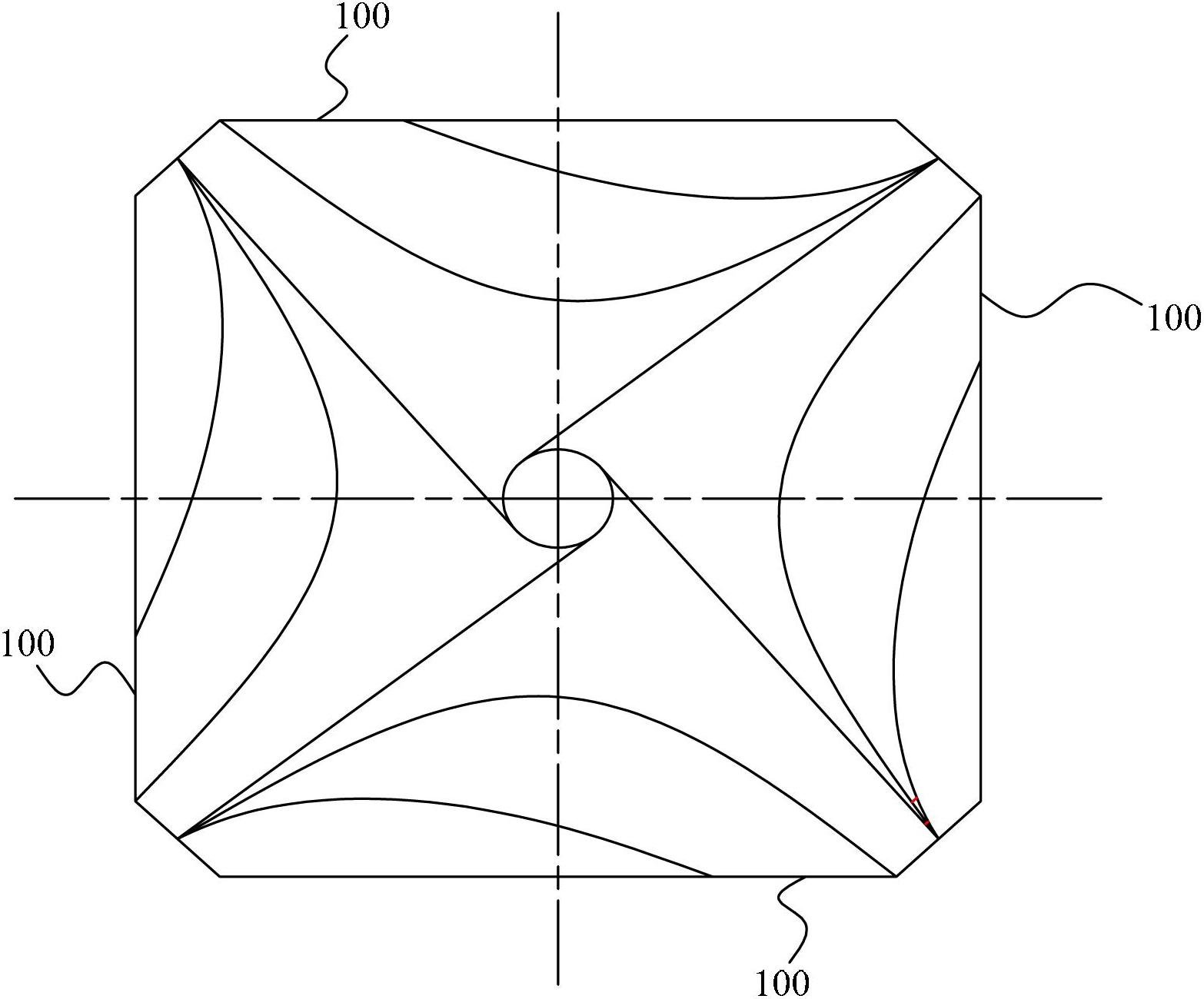

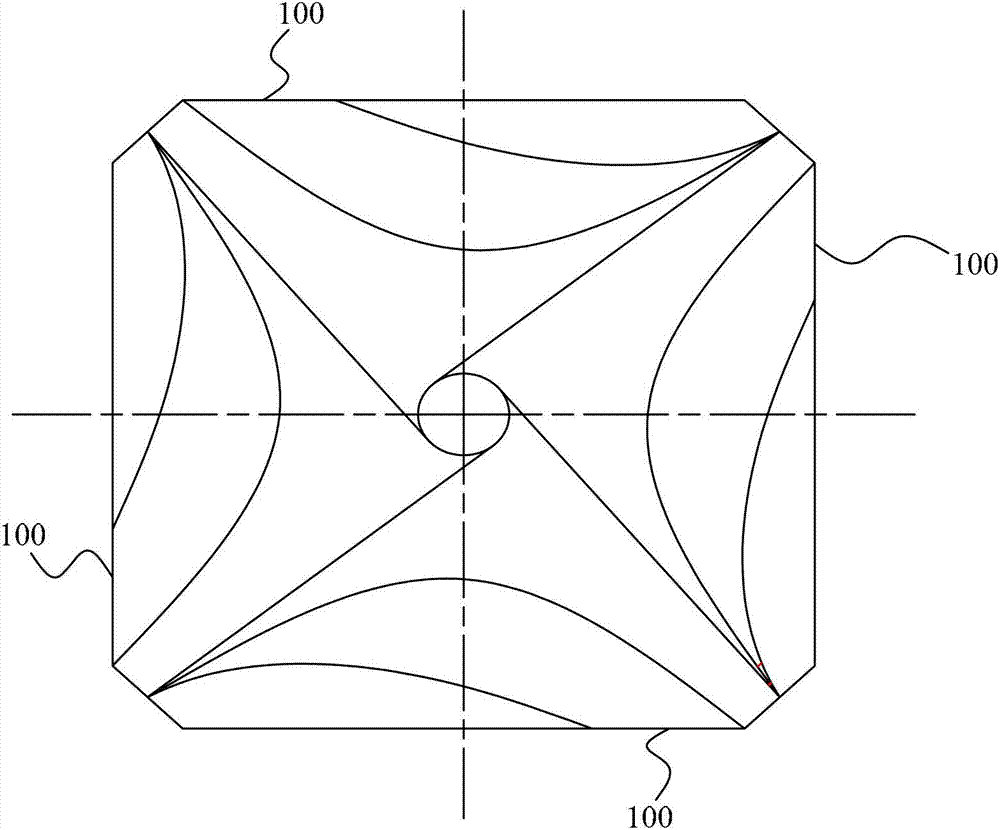

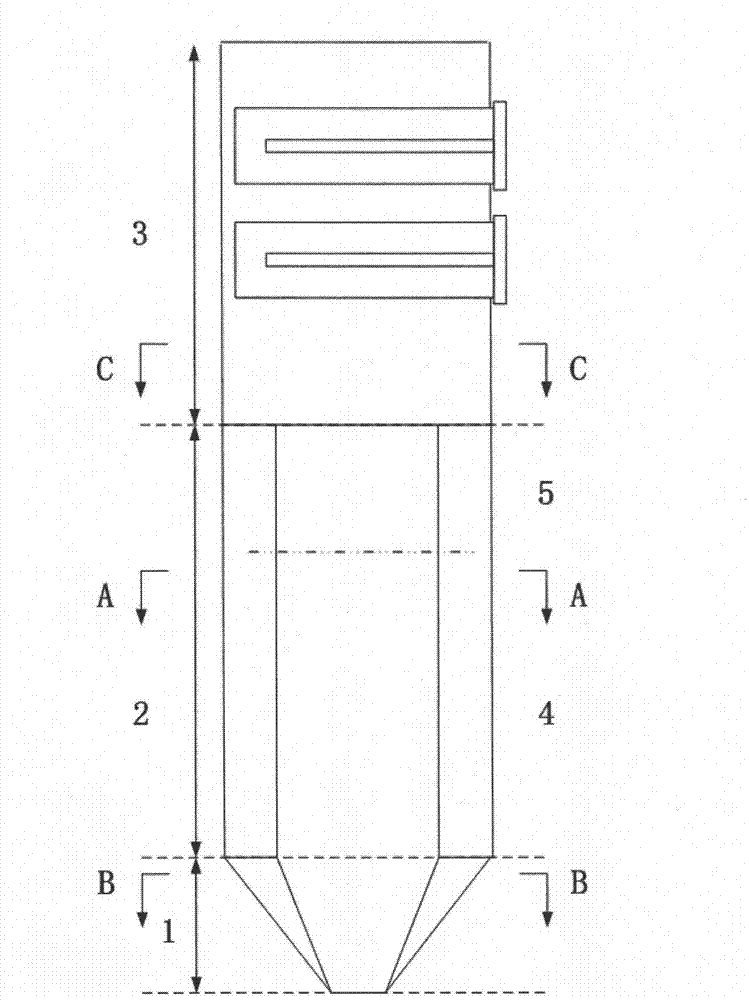

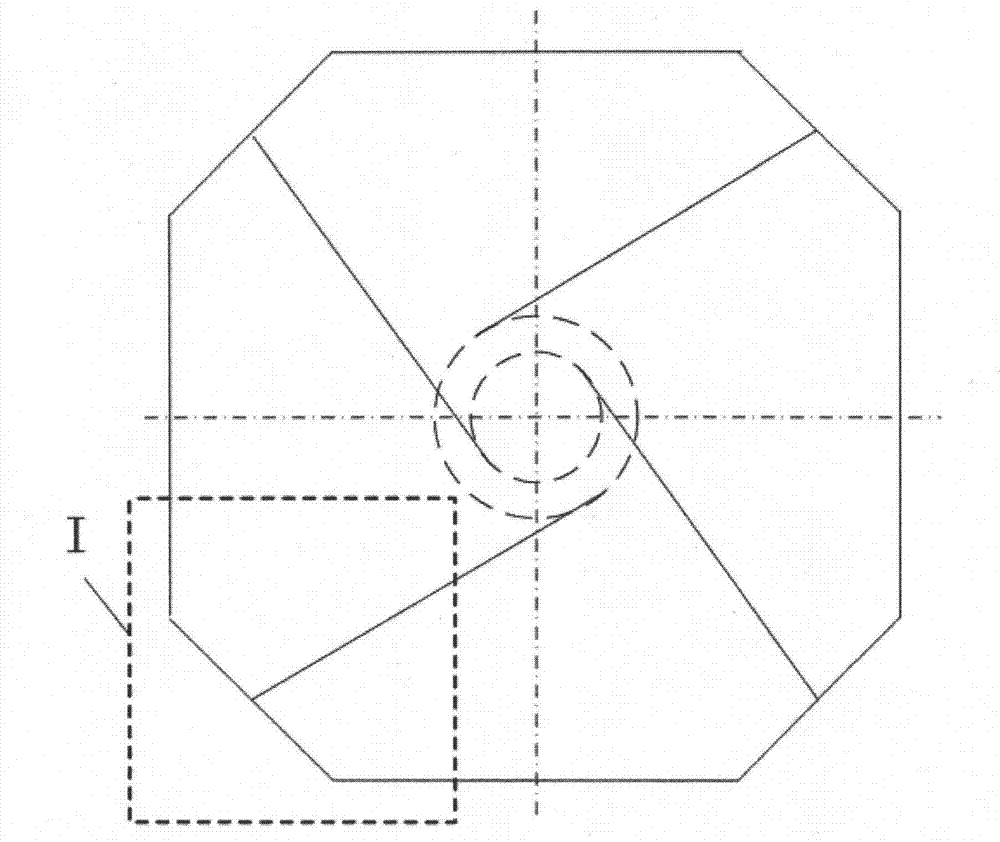

Boiler large-chamfer four-corner tangential firing technology and furnace arrangement method

ActiveCN102818258AGuaranteed safe operationImproved heat load distributionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelEdge surfaceEngineering

The invention relates to a boiler large-chamfer four-corner tangential firing technology and a furnace arrangement method. The boiler large-chamfer four-corner tangential firing technology and the furnace arrangement method are characterized in that a whole furnace is sequentially divided into a cold ash bucket area, a lower furnace area and an upper furnace area from bottom to top, the lower furnace area is divided into a lower burner area and an upper burner area from bottom to top, the lower burner area and the cold ash bucket area are both provided with a first transition area, the lower furnace area and the upper furnace area are both provided with a second transition area, and four burners are arranged on four wider furnace corner chamfer surfaces in the lower furnace area in a four-corner tangential manner. By adopting large chamfers in furnace corner areas, wall surface areas for arranging the burners are increased substantially, the distance between a water wall of each furnace corner area and an outer edge surface of a rotating burning flame is shortened to a greater degree, jet distance of each burner is decreased, and part of burner energy consumption is saved. Moreover, thermal loads subjected by the water walls in the furnace corner areas are more approximate to an average thermal load, and uneven heating of the water walls in the furnace width or depth direction is improved to a greater degree.

Owner:SHANGHAI BOILER WORKS

Method and system capable of improving coal fired boiler low load SCR inlet smoke temperature

ActiveCN111561694AIncrease temperatureReal-time measurementCombustion using gaseous and pulverulent fuelFuel supply regulationAir volumeThermodynamics

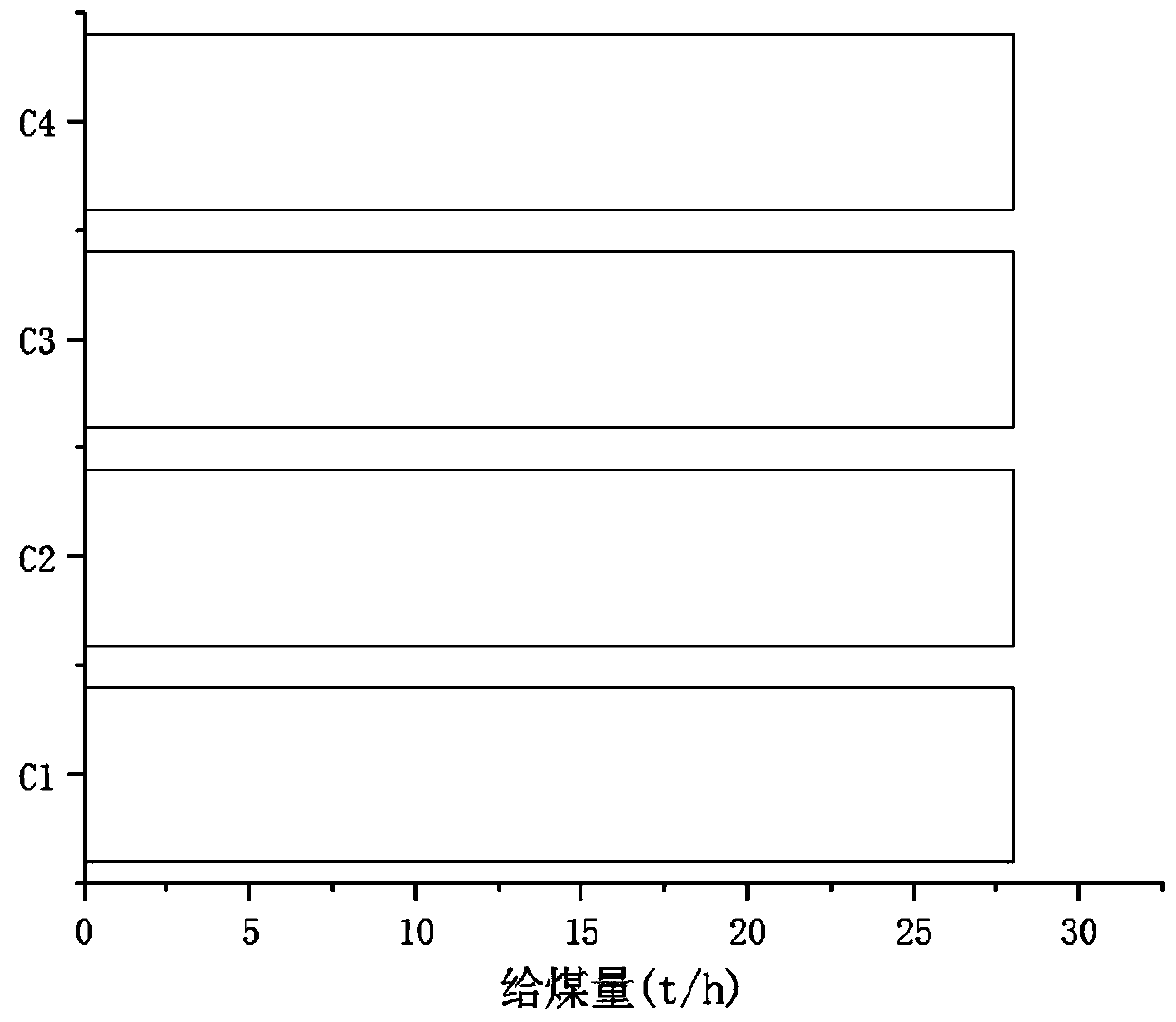

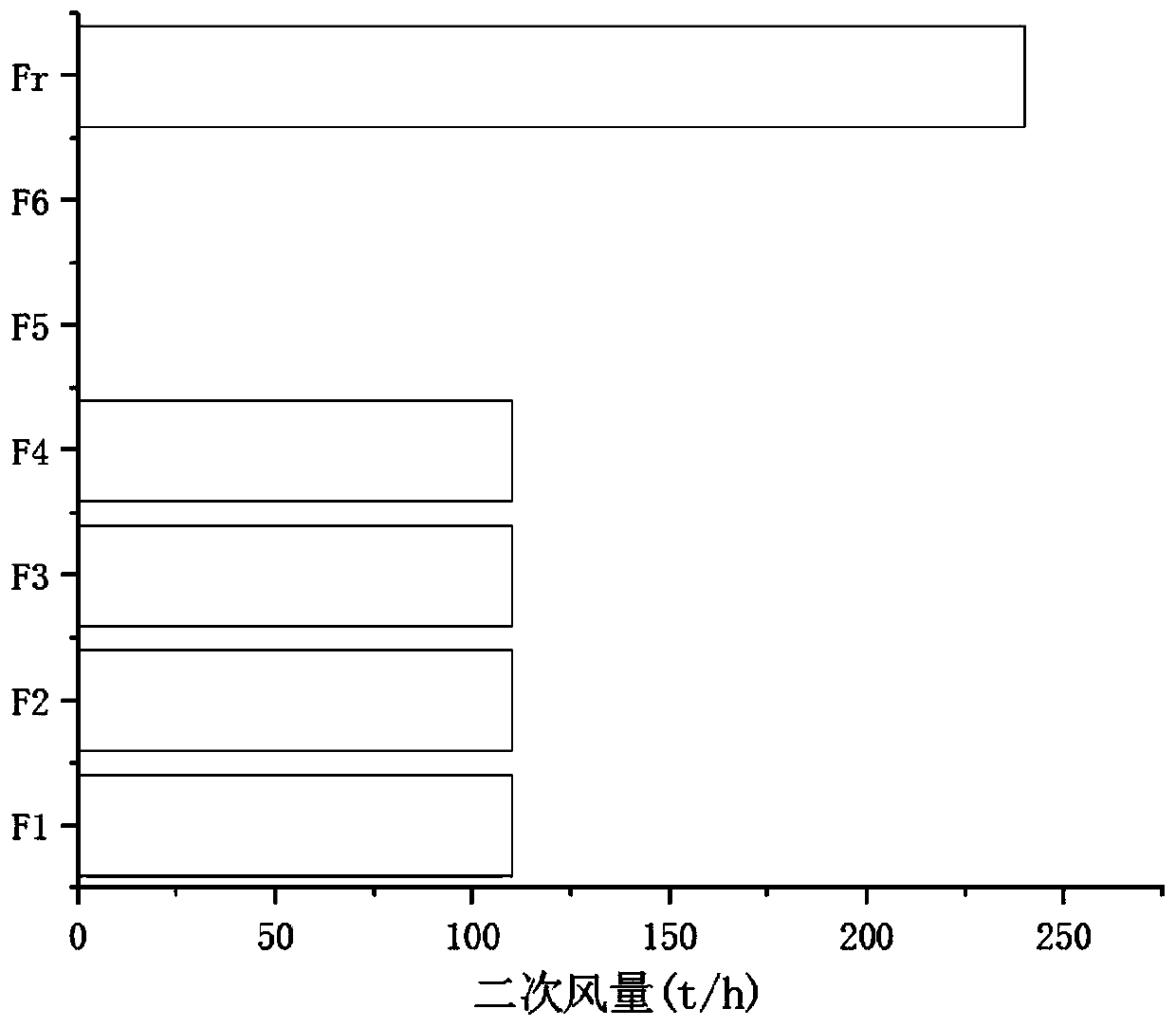

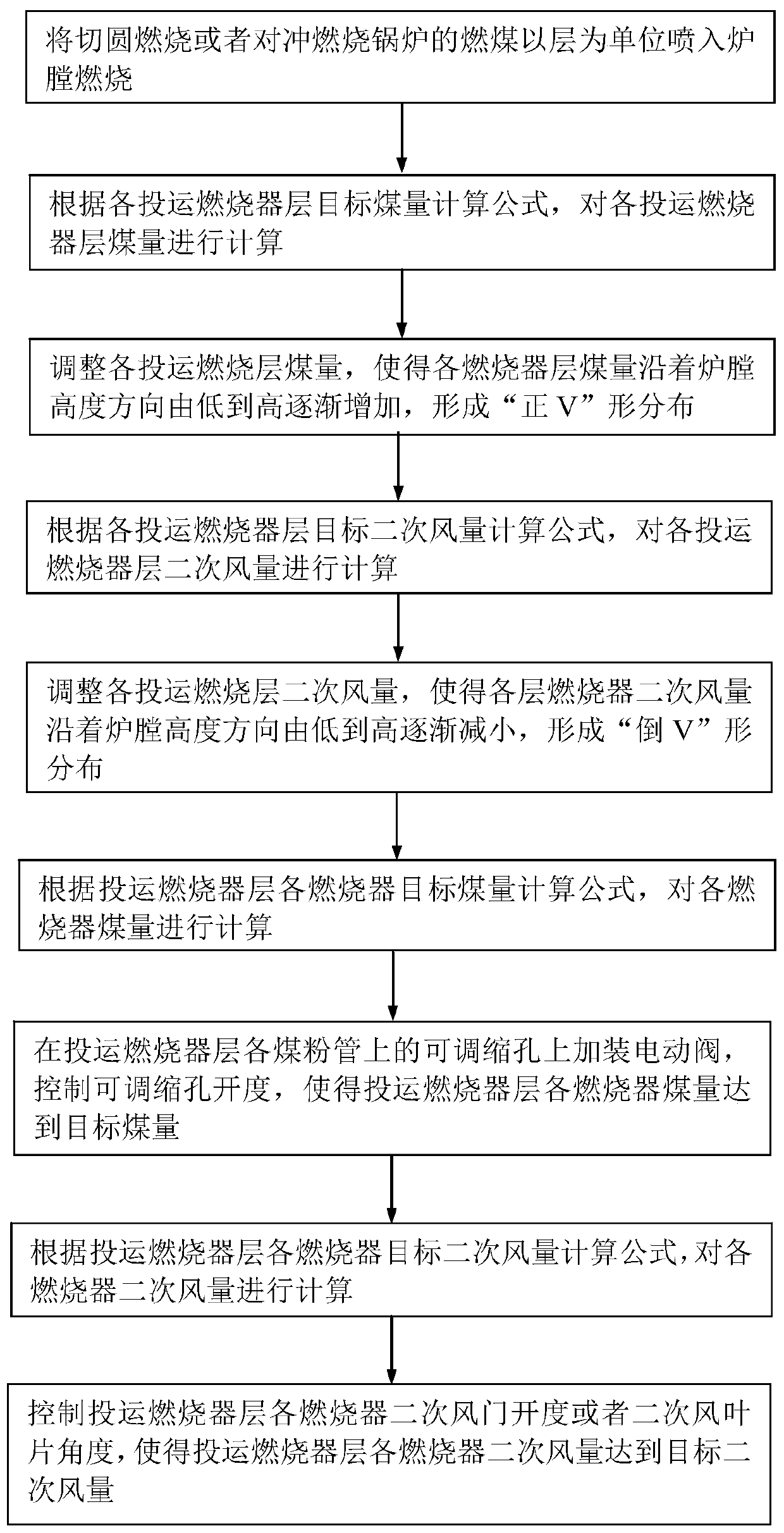

The invention discloses a method and system capable of improving coal fired boiler low load SCR inlet smoke temperature. The adopted method comprises the steps that fire coal of a tangential firing oropposed firing boiler is sprayed into a hearth to be combusted with a layer as a unit, the laminated coal amount of each combustor is gradually increased from low to high in the hearth height direction, and a positive V distribution is formed; secondary air amount of each combustor is gradually reduced from low to high in the hearth height direction, and inverted V distribution is formed; meanwhile, the adjustable shrinkage opening degree of a pulverized coal pipe, and the secondary air valve opening degrees or secondary air blade angles of the combustors are controlled, and the coal amount and the secondary air amount put into the combustors on a combustor layer can meet the target coal amount and the target secondary air amount. Through adjusting the coal amount and the secondary air amount distribution put into the combustors of the combustor layer, on the premise of reducing the hearth outlet NOX content and baring powder coal burn-out rate influences, the low-load SCR inlet smoketemperature is effectively improved.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +2

Tangential pulverized coal fired boiler and coal-fired power generation system

PendingCN108758615AOvercoming a fast ascentReduce dwell timeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSlagEngineering

The invention discloses a tangential pulverized coal fired boiler, comprising a hearth and corner burner units arranged at four corners of the hearth; gas entering the hearth from the corner burner units forms corner tangent in the center of the hearth; each of the four walls of the hearth is provided with a wall-type exhaust gas nozzle; the exhaust gas is sprayed into the hearth via the wall-typeexhaust gas nozzles to form wall tangent in the center of the hearth; the diameter of the wall tangent is greater than that of the corner tangent. The invention also discloses a coal-fired power generation system using the above tangential pulverized coal fired boiler. The tangential pulverized coal fired boiler and the coal-fired power generation system have the advantages that exhaust gas is delivered in from the four sides, exhaust gas wall tangential firing is formed, NOx emission, fly ash and large slag are further decreased for the tangential pulverized coal fired boiler with exhaust gas, and boiler efficiency is further improved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com