Tangential combustor

A technology of combustion section and combustion cylinder, which is applied in the direction of combustion chamber, combustion method, combustion equipment, etc., and can solve the problems of expensive repair and replacement, reduction of total mechanical pressure ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

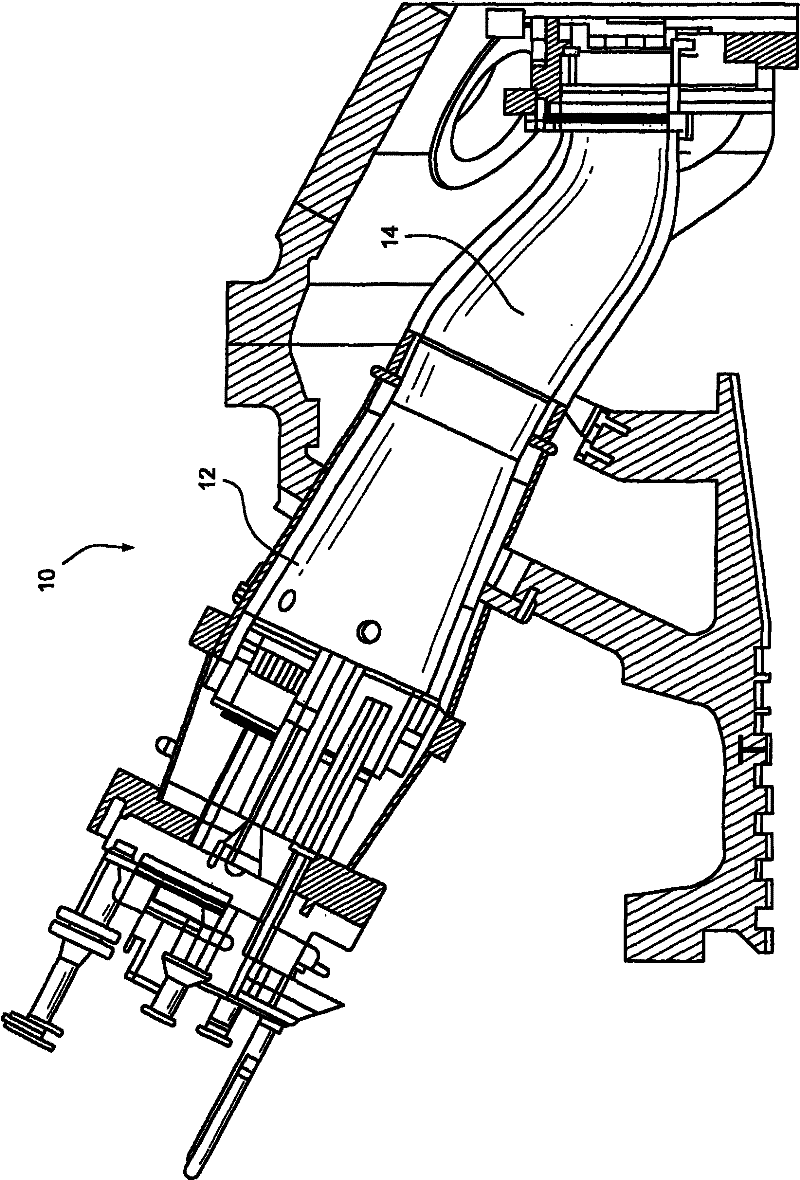

[0023] figure 1 A typical combustor for a gas turbine is shown, which includes a compressor, multiple combustors, and a turbine. The compressor pressurizes the inlet air, which then flows back into the combustor, where it is used to cool the combustor and provide air for the combustion process. The combustor 10 includes a liner 12 and a transition piece 14. The liner 12 defines a combustion zone. The transition piece 14 connects the outlet end of the combustor with the inlet end of the turbine so as to transfer the combustion products to the turbine. The interface between the combustor transition piece 14 and the first stage turbine nozzle requires the use of a seal to reduce leakage into the gas passage.

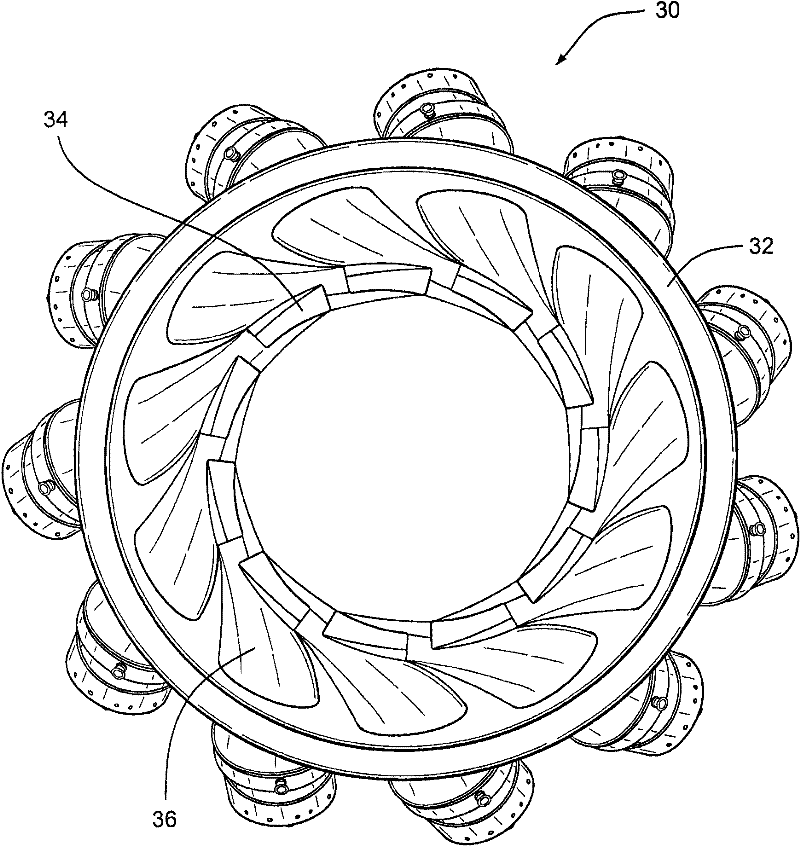

[0024] figure 2 It is an end view of the combustion section 30 for a gas turbine. The combustion section 30 includes a casing 32 that defines a chamber, and a plurality of combustion cylinders 34 arranged in the casing and oriented in an annular pattern as shown. A pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com