Patents

Literature

38291 results about "Fuel gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fuel gas is any one of a number of fuels that under ordinary conditions are gaseous. Many fuel gases are composed of hydrocarbons (such as methane, biogas or propane), hydrogen, carbon monoxide, or mixtures thereof. Such gases are sources of potential heat energy or light energy that can be readily transmitted and distributed through pipes from the point of origin directly to the place of consumption.

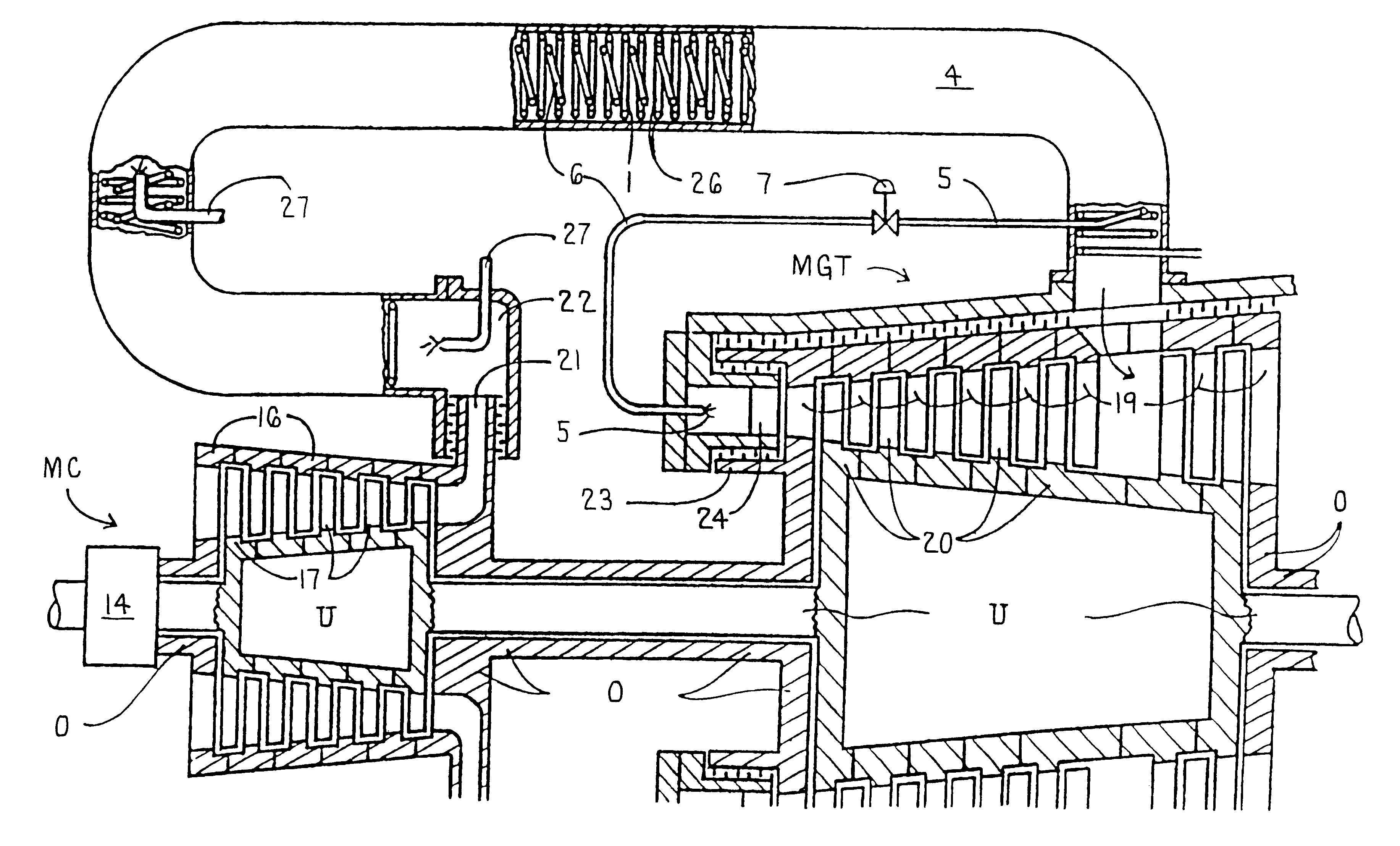

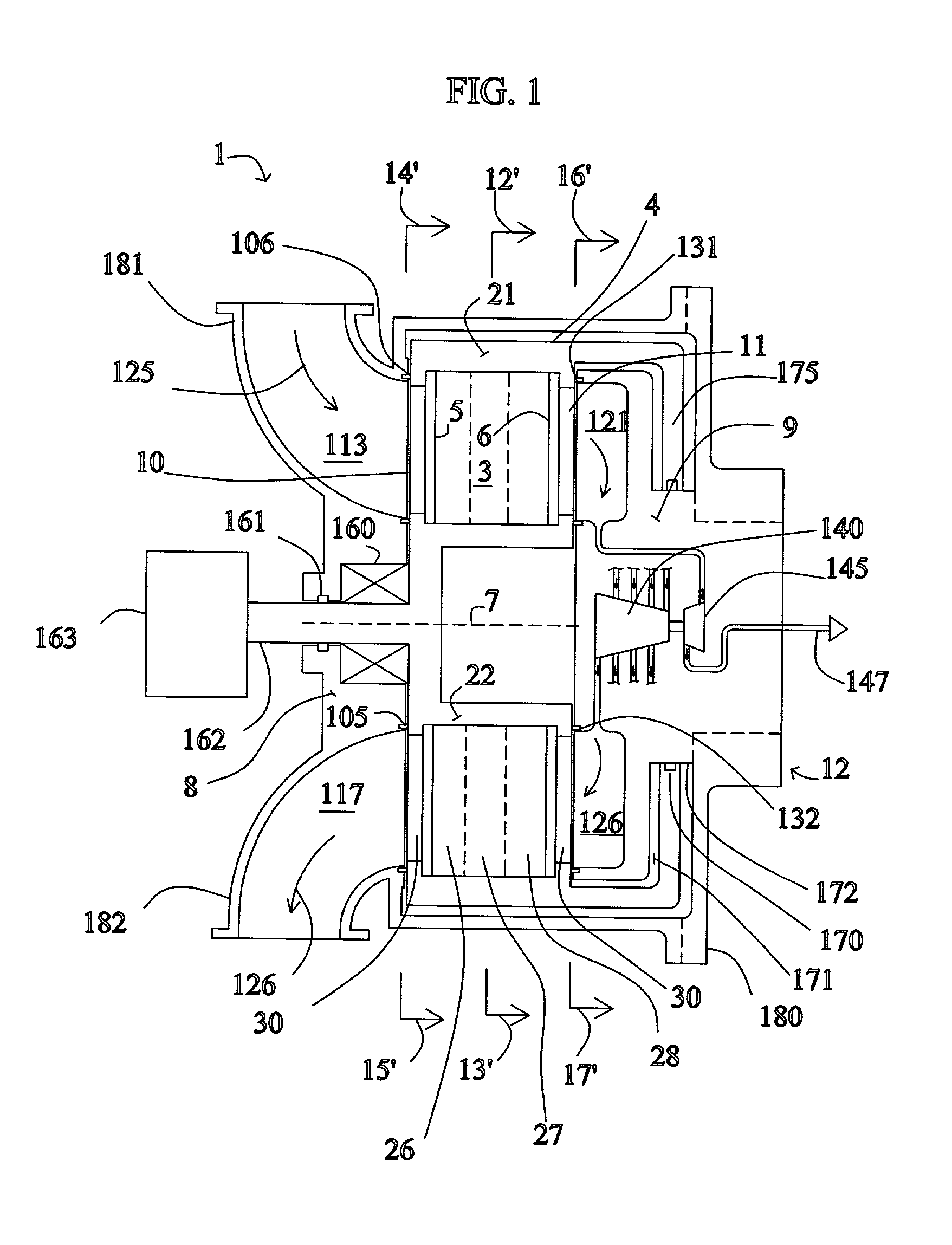

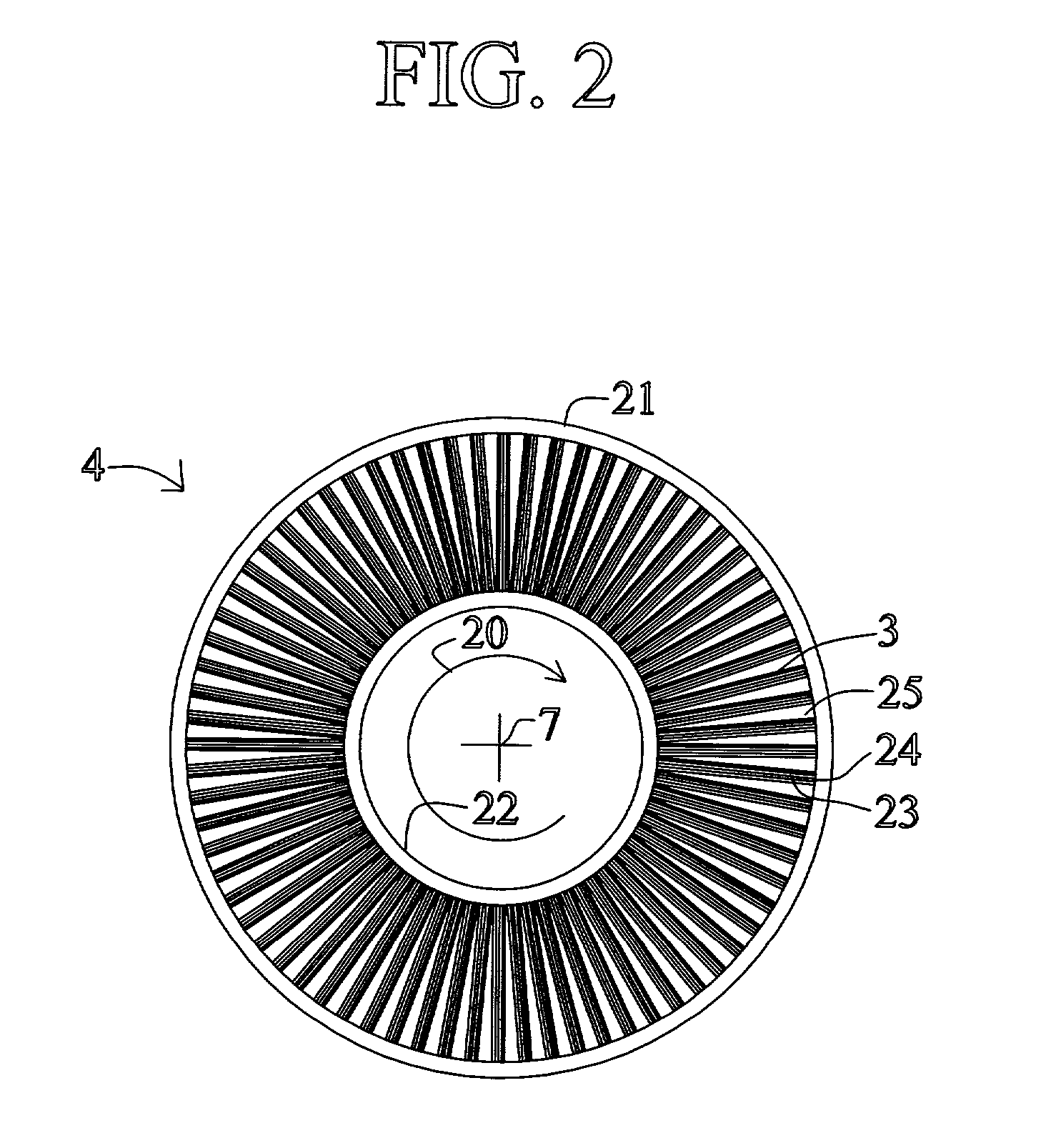

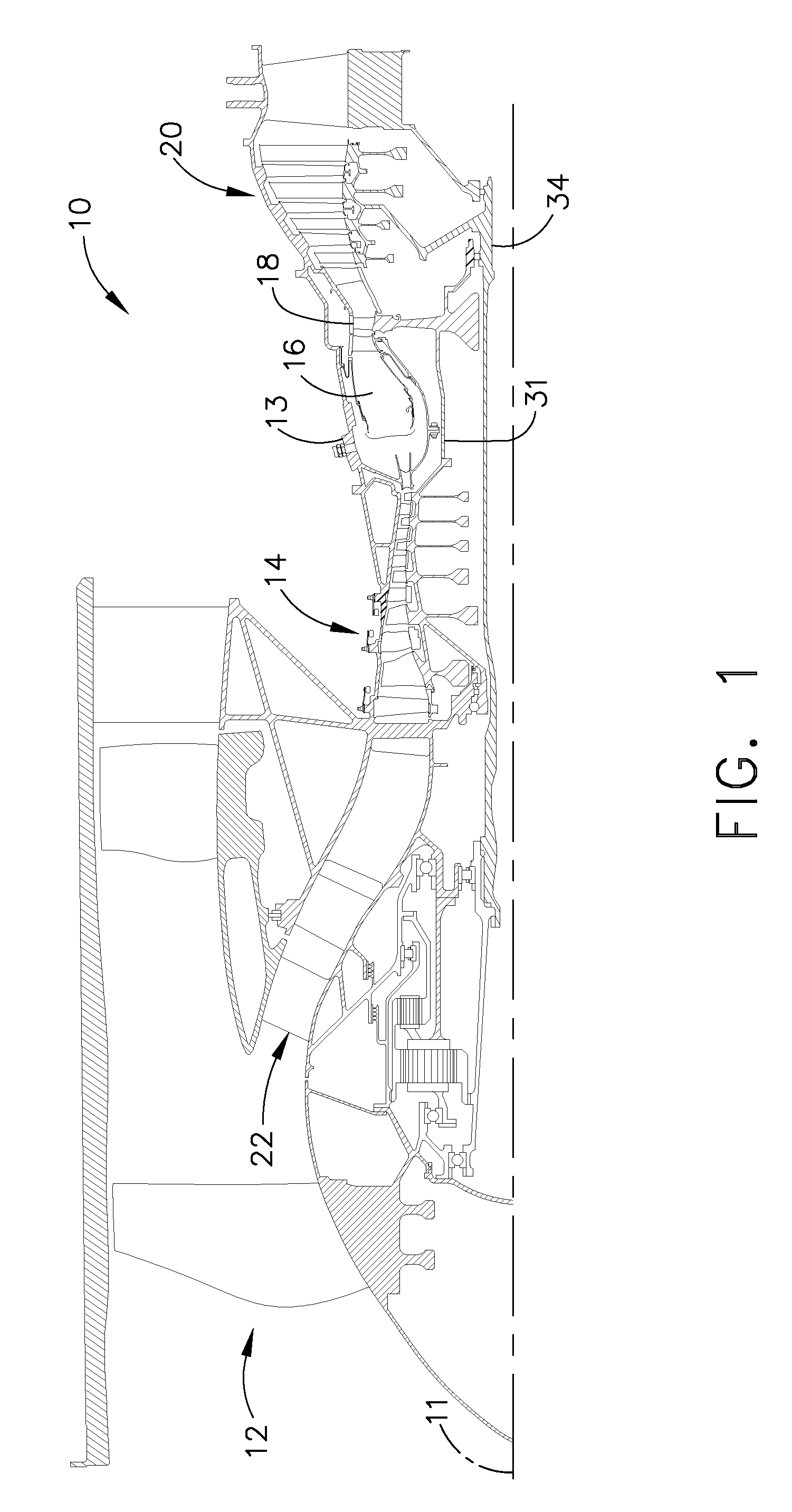

Combined steam and gas turbine engine with magnetic transmission

InactiveUS6263664B1Wide areaImprove system efficiencyContinuous combustion chamberGearingThermal energyCombustion chamber

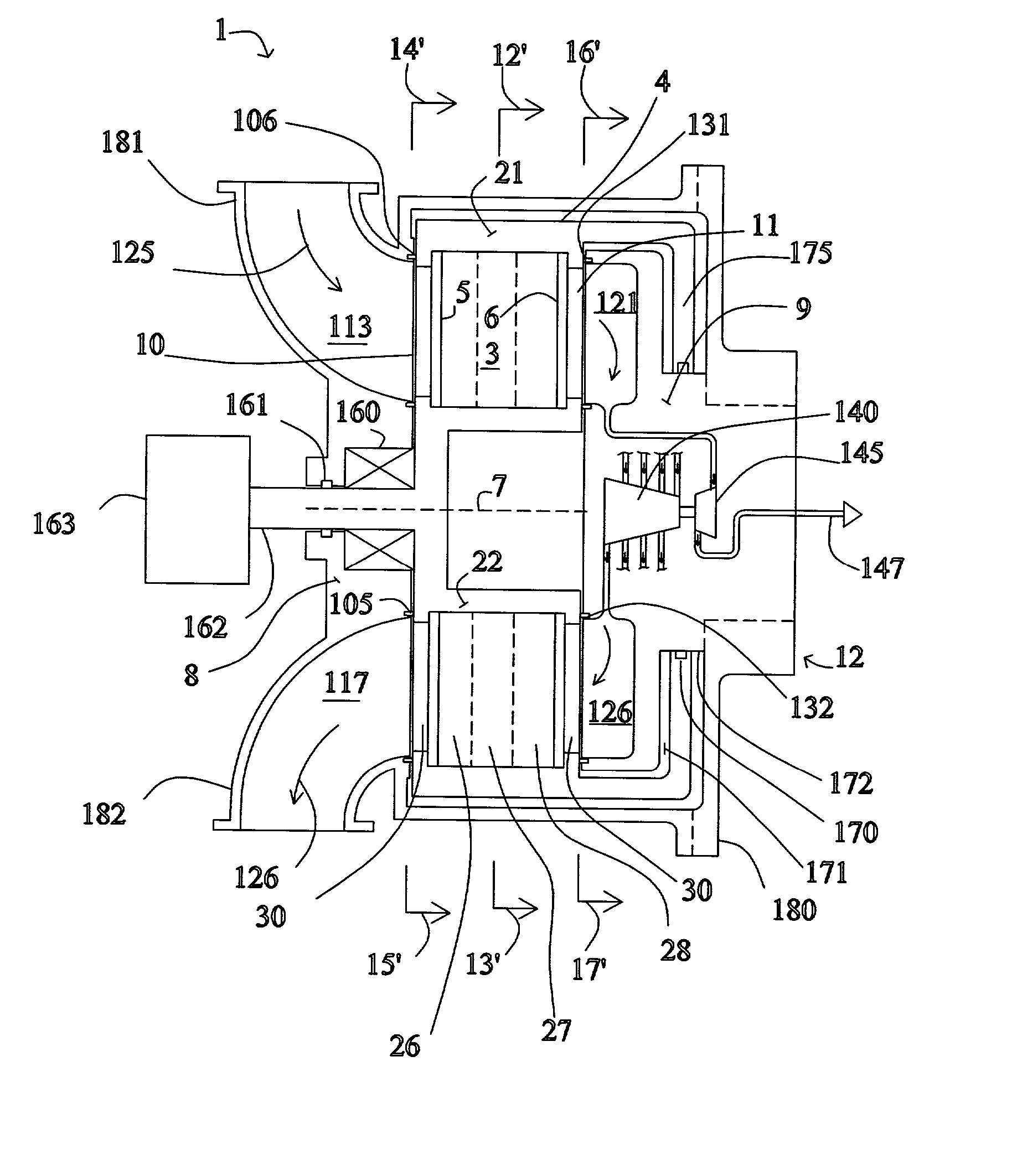

In a combined steam and gas turbine engine cycle, a combustion chamber is made durable against high pressure and enlarged in length to increase the operation pressure ratio, without exceeding the heat durability temperature of the system while increasing the fuel combustion gas mass flow four times as much as the conventional turbine system and simultaneously for greatly raising the thermal efficiency of the system and specific power of the combined steam and gas turbine engine.Water pipes and steam pipes are arranged inside the combustion chamber so that the combustion chamber can function as a heat exchanger and thereby convert most of the combustion thermal energy into super-critical steam energy for driving a steam turbine and subsequently raising the operation pressure ratio and the thermal efficiencies of the steam turbine cycle and gas turbine cycle. The combustion gas mass flow can be also increased by four times as much as the conventional turbine system (up to the theoretical air to fuel ratio) and the thermal efficiency and the specific power of the gas turbine cycle are considerably increased.Further, the thermal efficiency of the combined system is improved by installing a magnetic friction power transmission system to transmit the power of the system to outer loads.

Owner:TANIGAWA HIROYASU +1

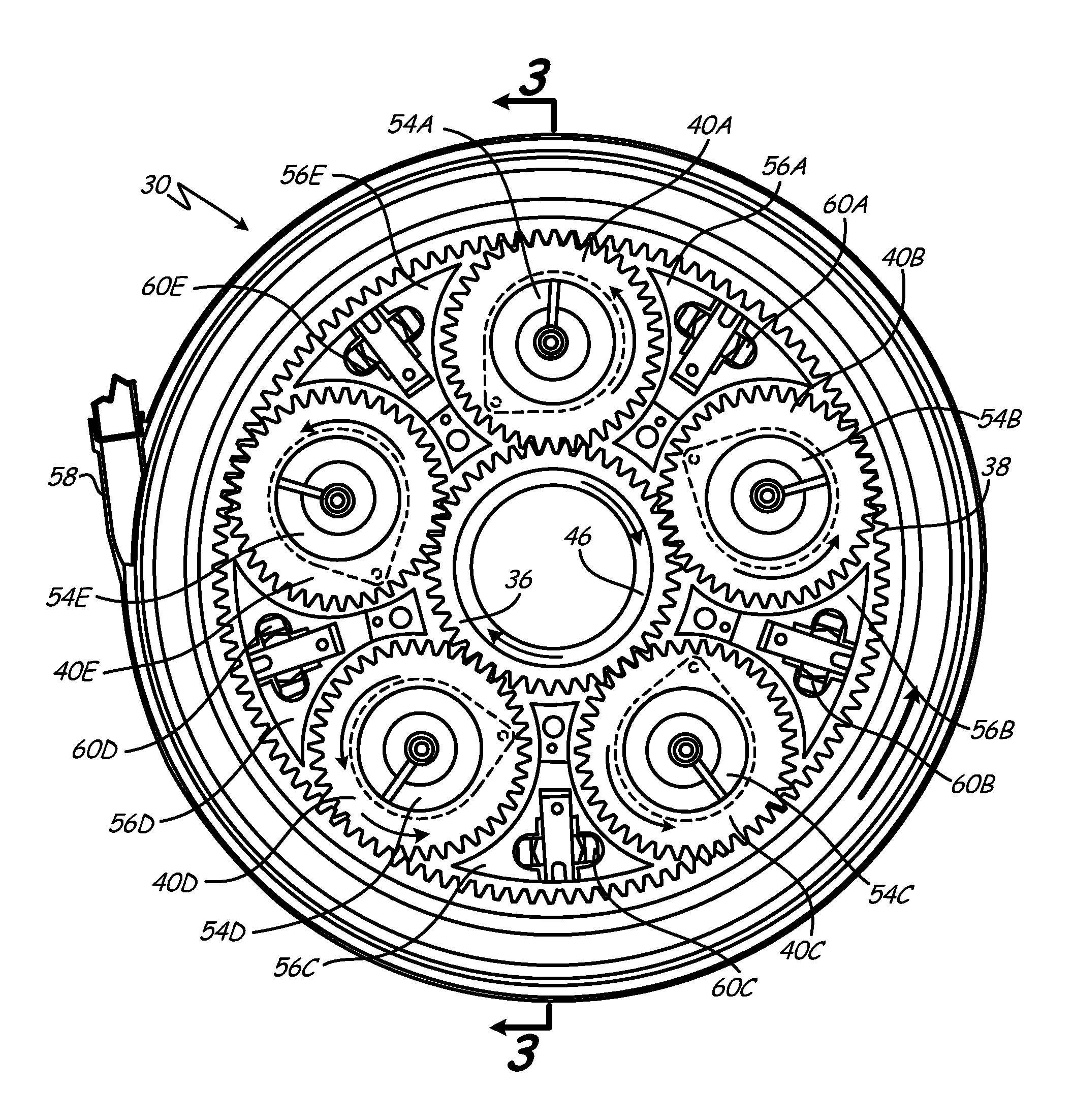

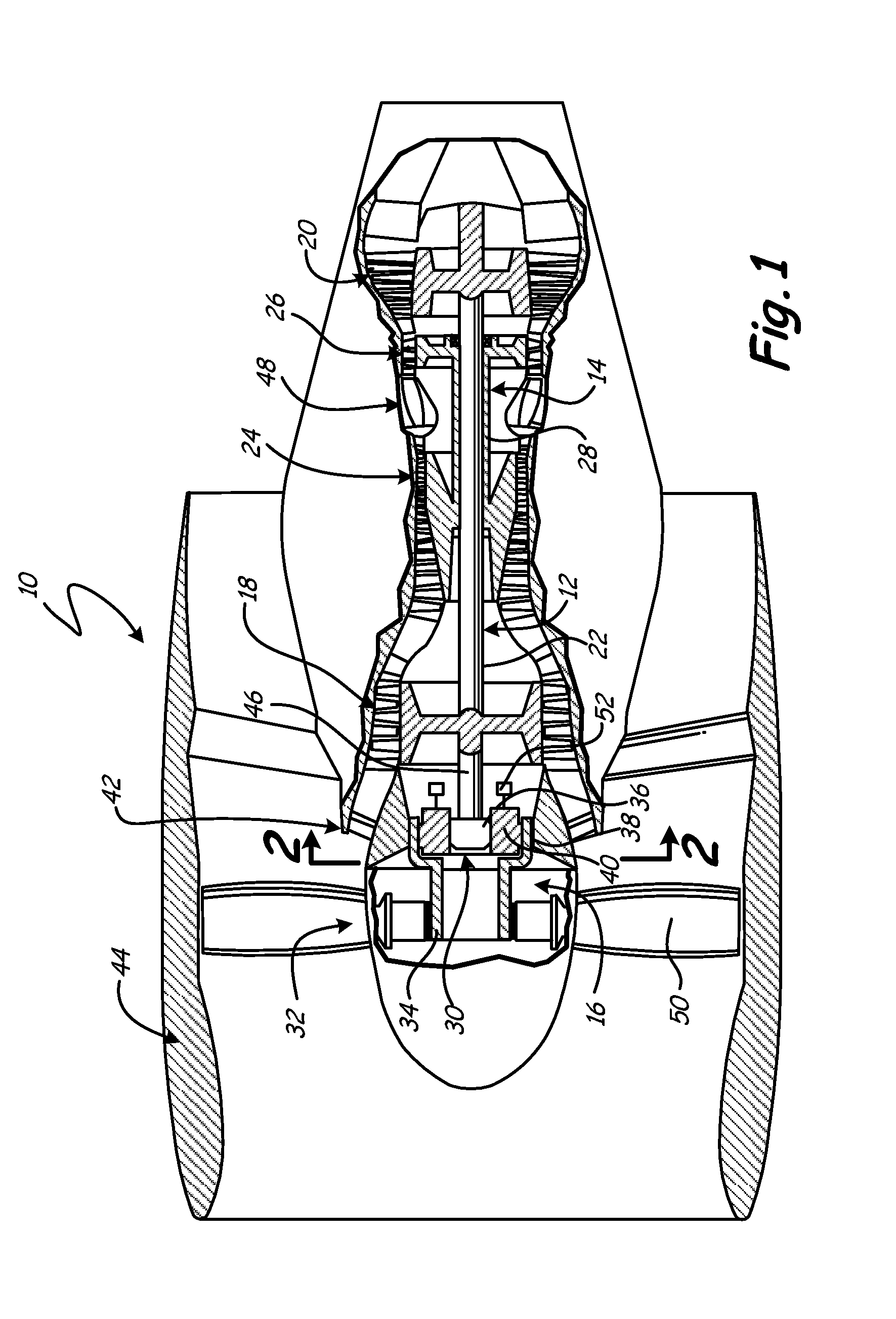

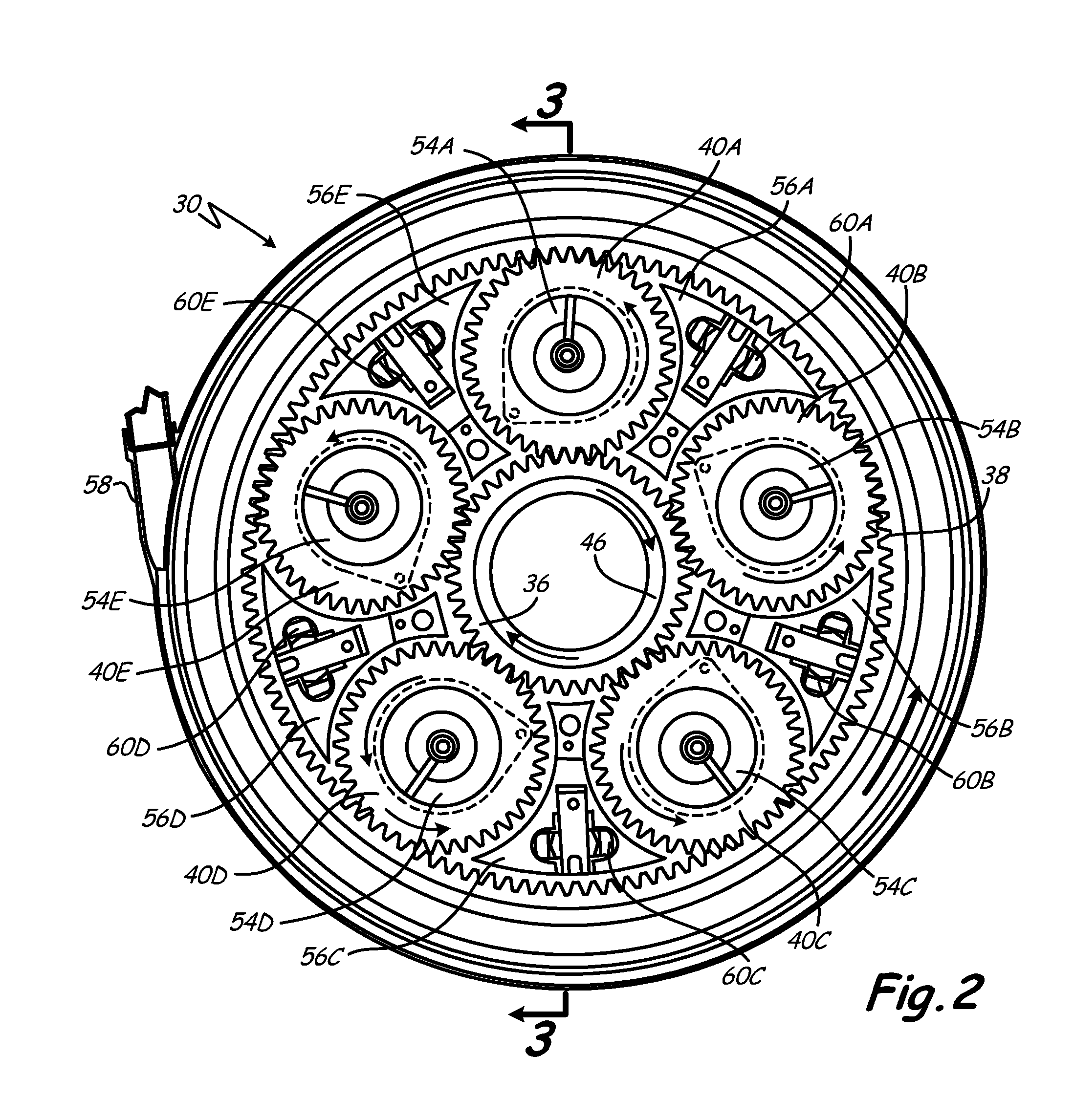

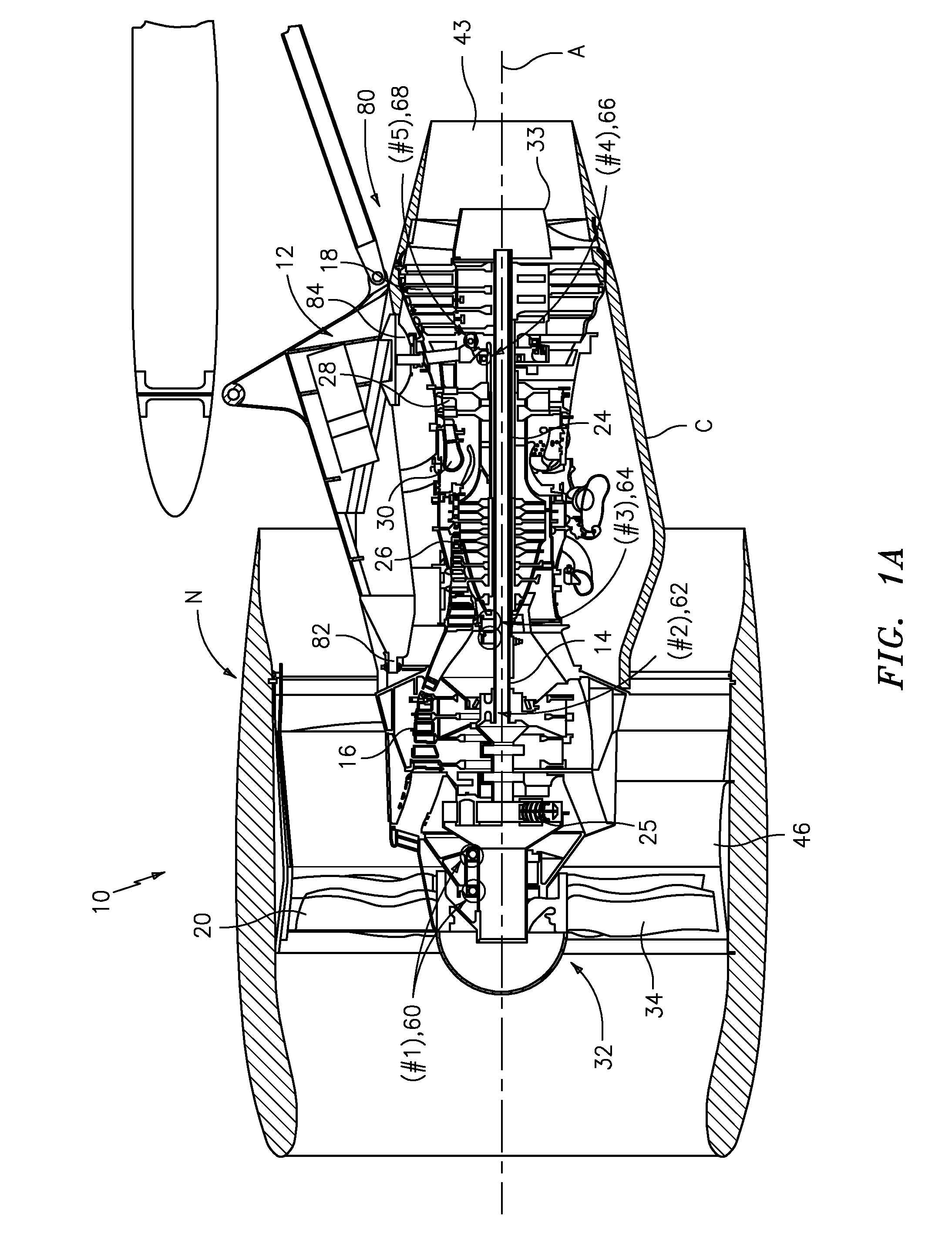

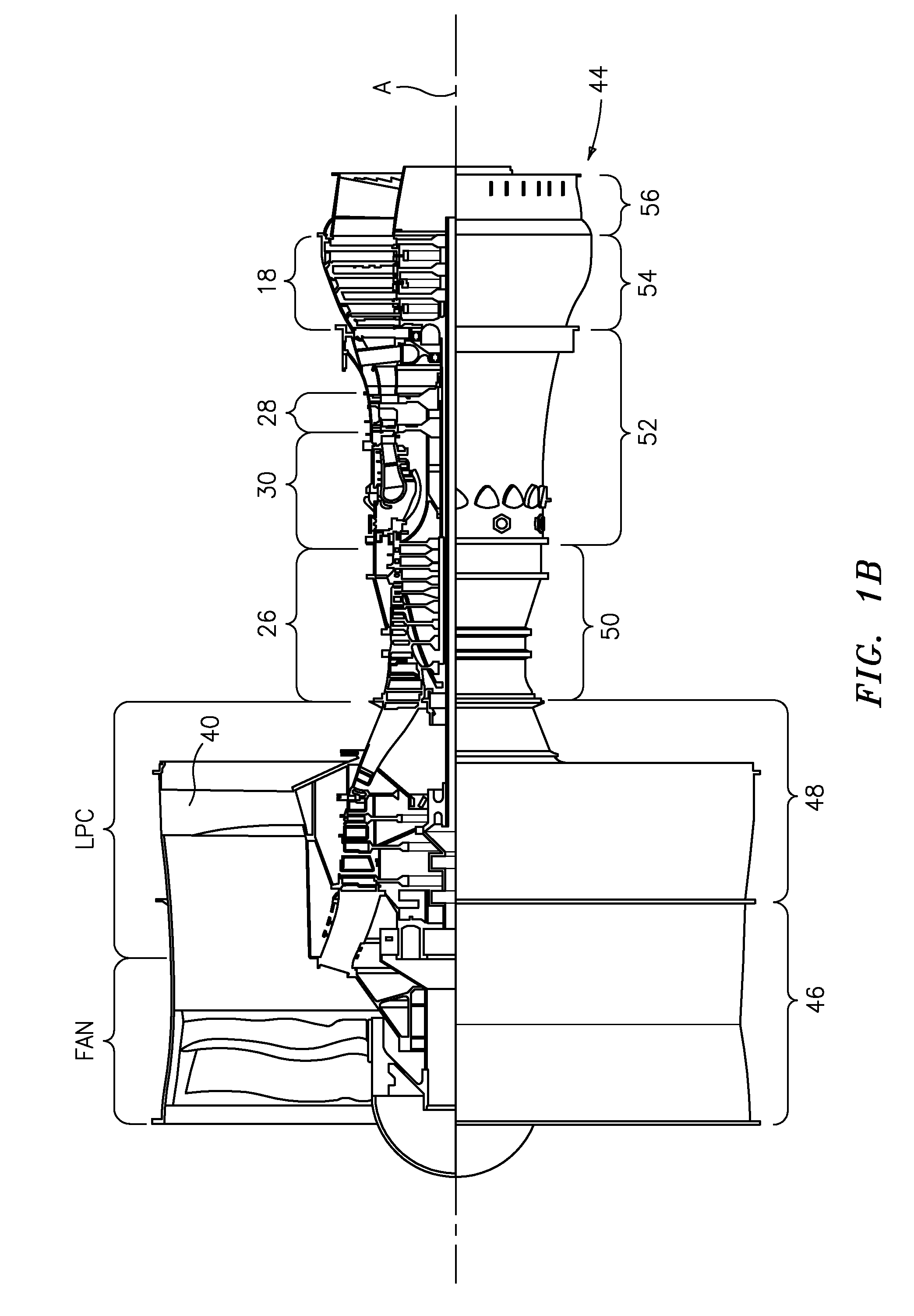

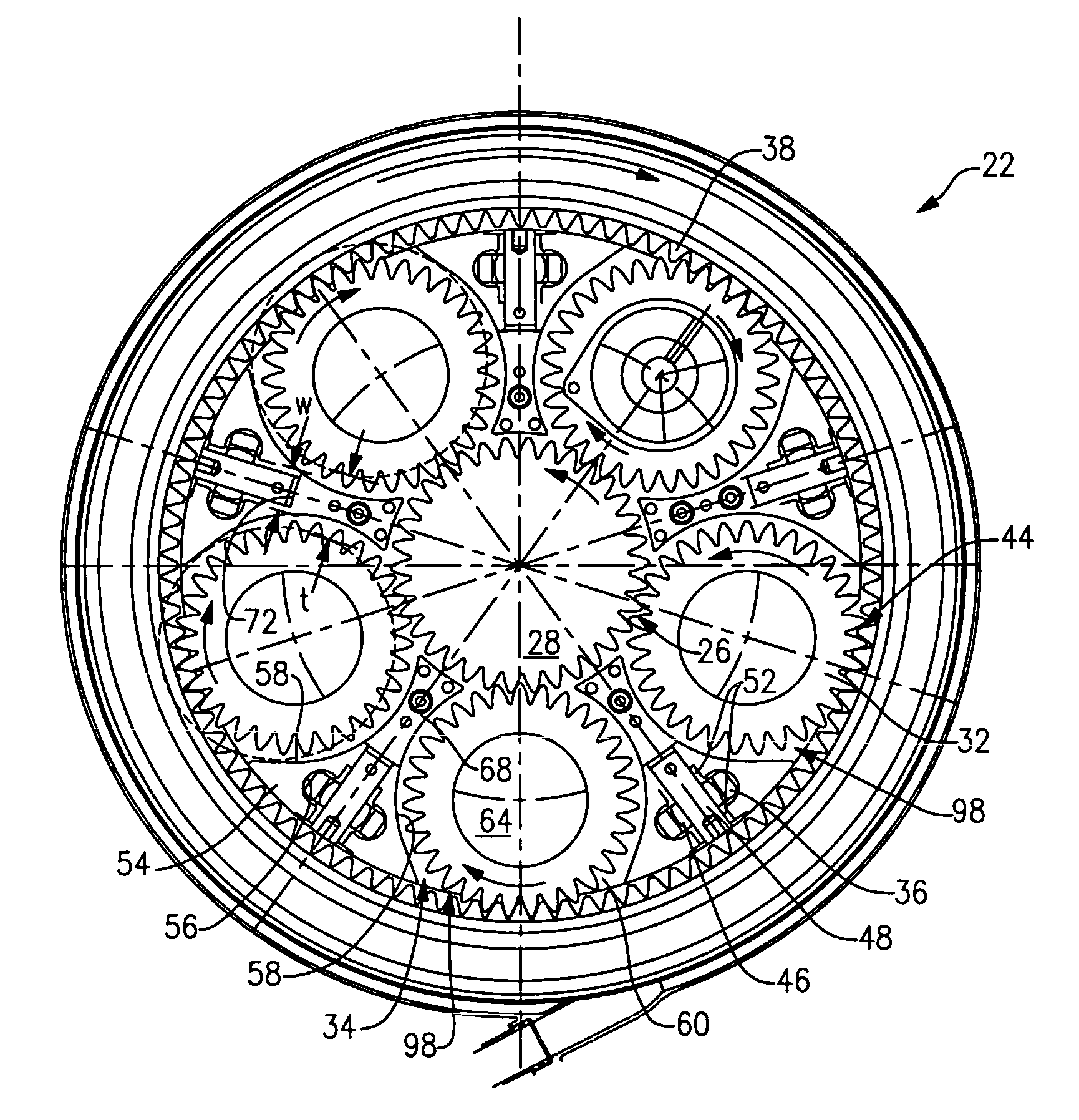

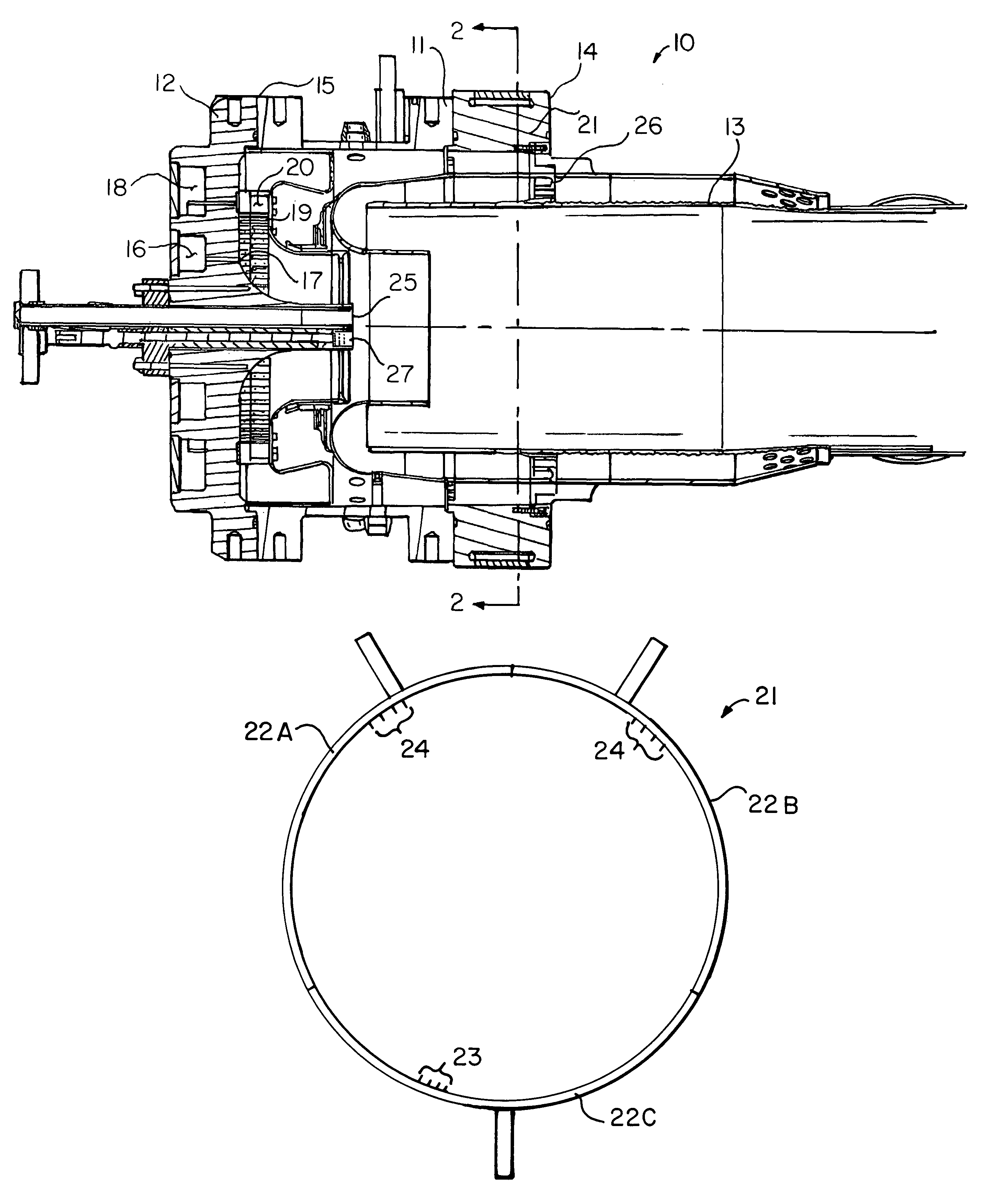

Coupling system for a star gear train in a gas turbine engine

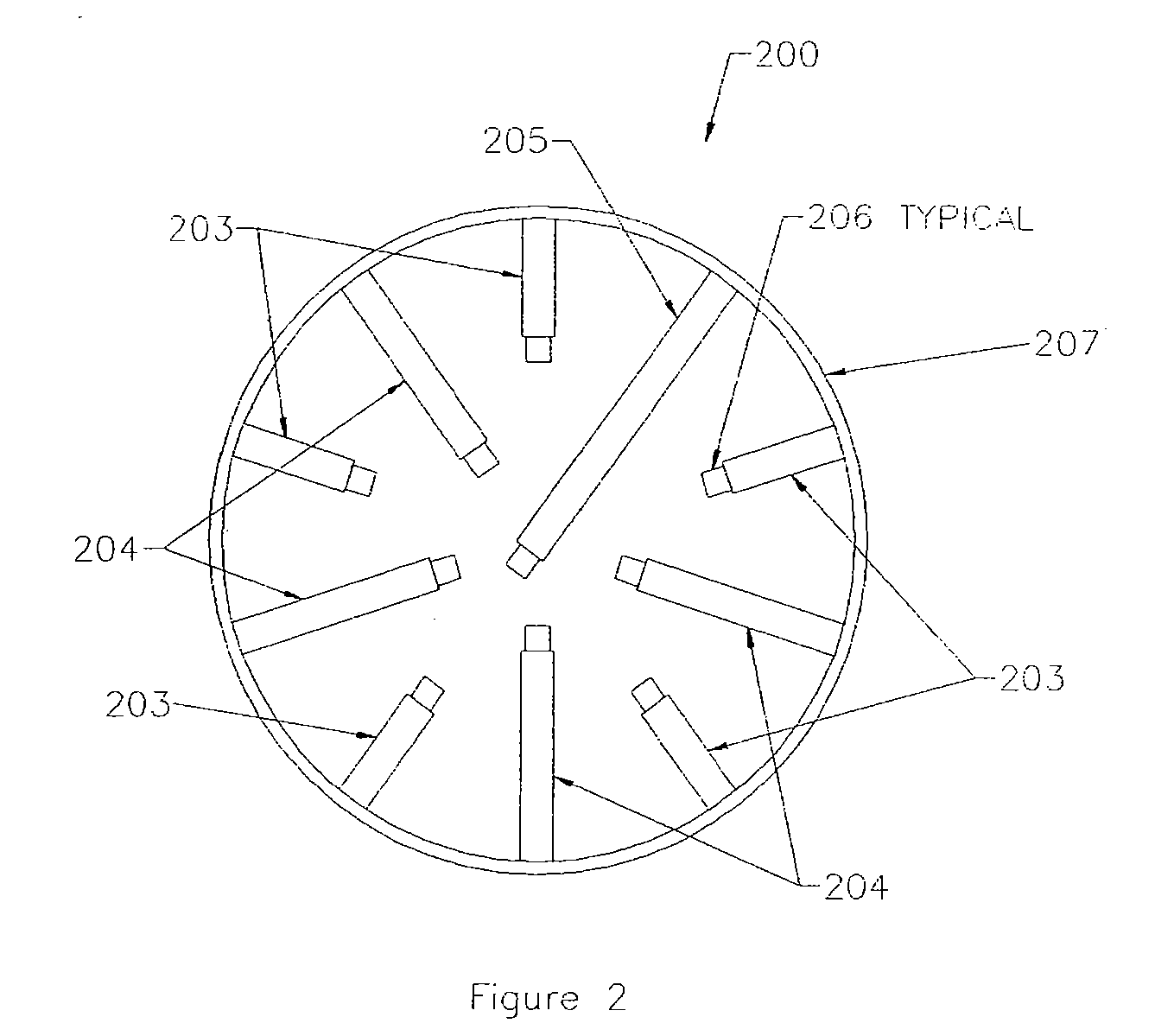

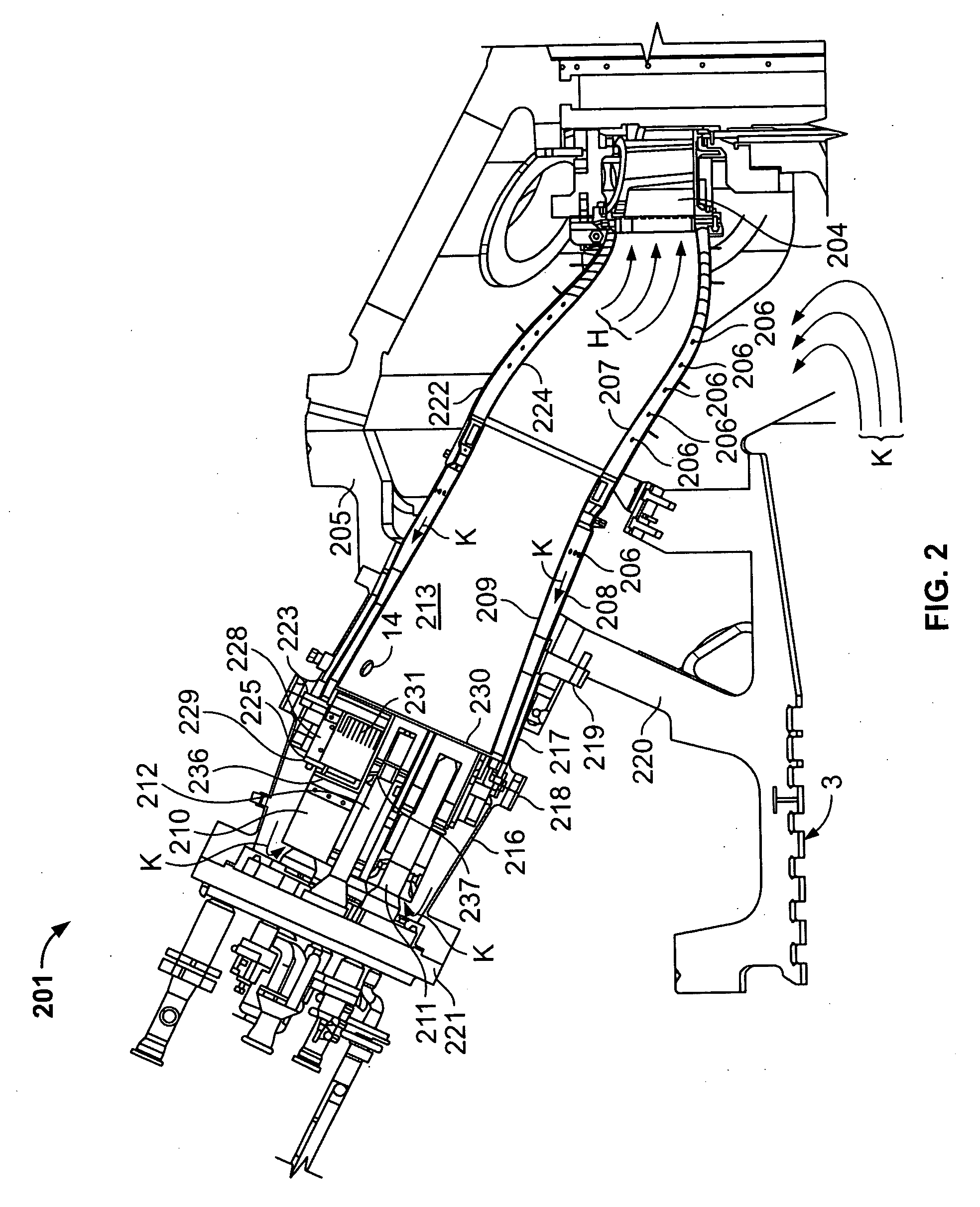

A star gear train for use in a gas turbine engine includes a sun gear, a ring gear, a plurality of star gears and a coupling system. The sun gear is rotatable by a shaft. The ring gear is secured to a ring gear shaft. Each of the plurality of star gears is rotatably mounted in a star carrier and meshes with the sun gear and the ring gear. The coupling system comprises a sun gear flexible coupling, a carrier flexible coupling and a deflection limiter. The sun gear flexible coupling connects the sun gear to the shaft. The carrier flexible coupling connects the carrier to a non-rotating mechanical ground. The deflection limiter is connected to the star carrier to limit excessive radial and circumferential displacement of the star gear train.

Owner:RTX CORP

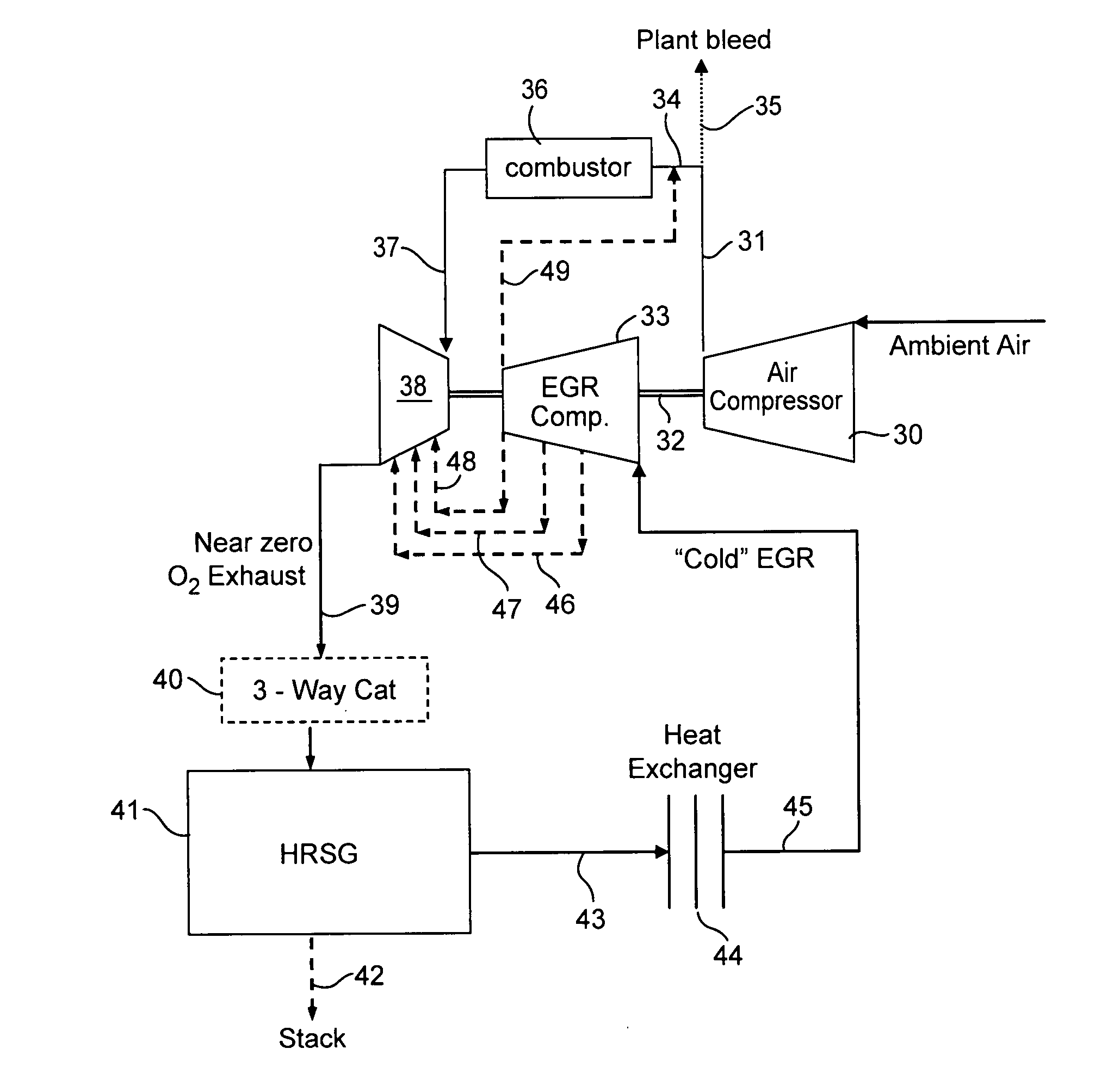

Dry 3-way catalytic reduction of gas turbine NOx

ActiveUS20090284013A1Reduction in amount of NOxIncrease carbon dioxide concentrationInternal combustion piston enginesExhaust apparatusCombustion chamberGas compressor

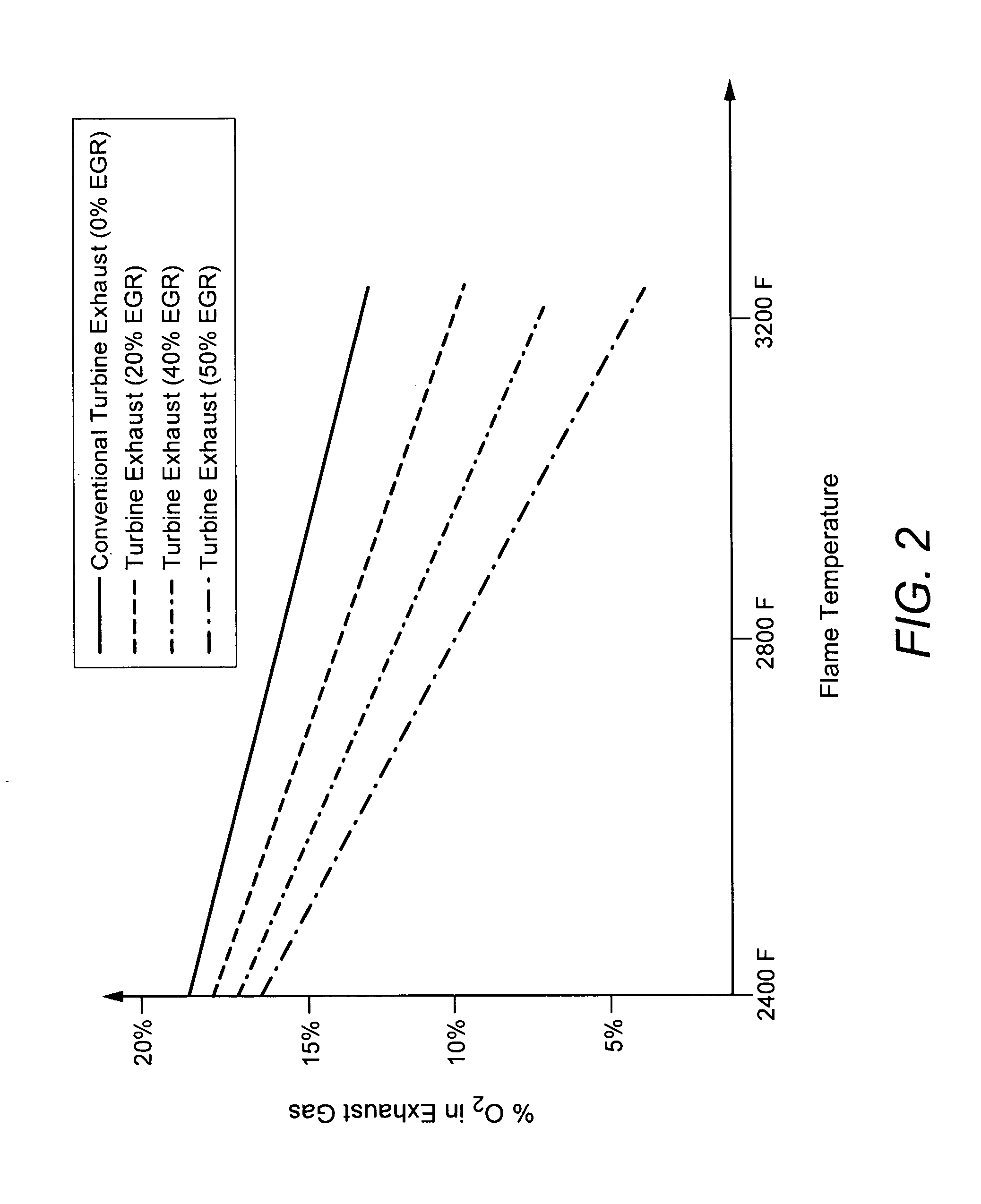

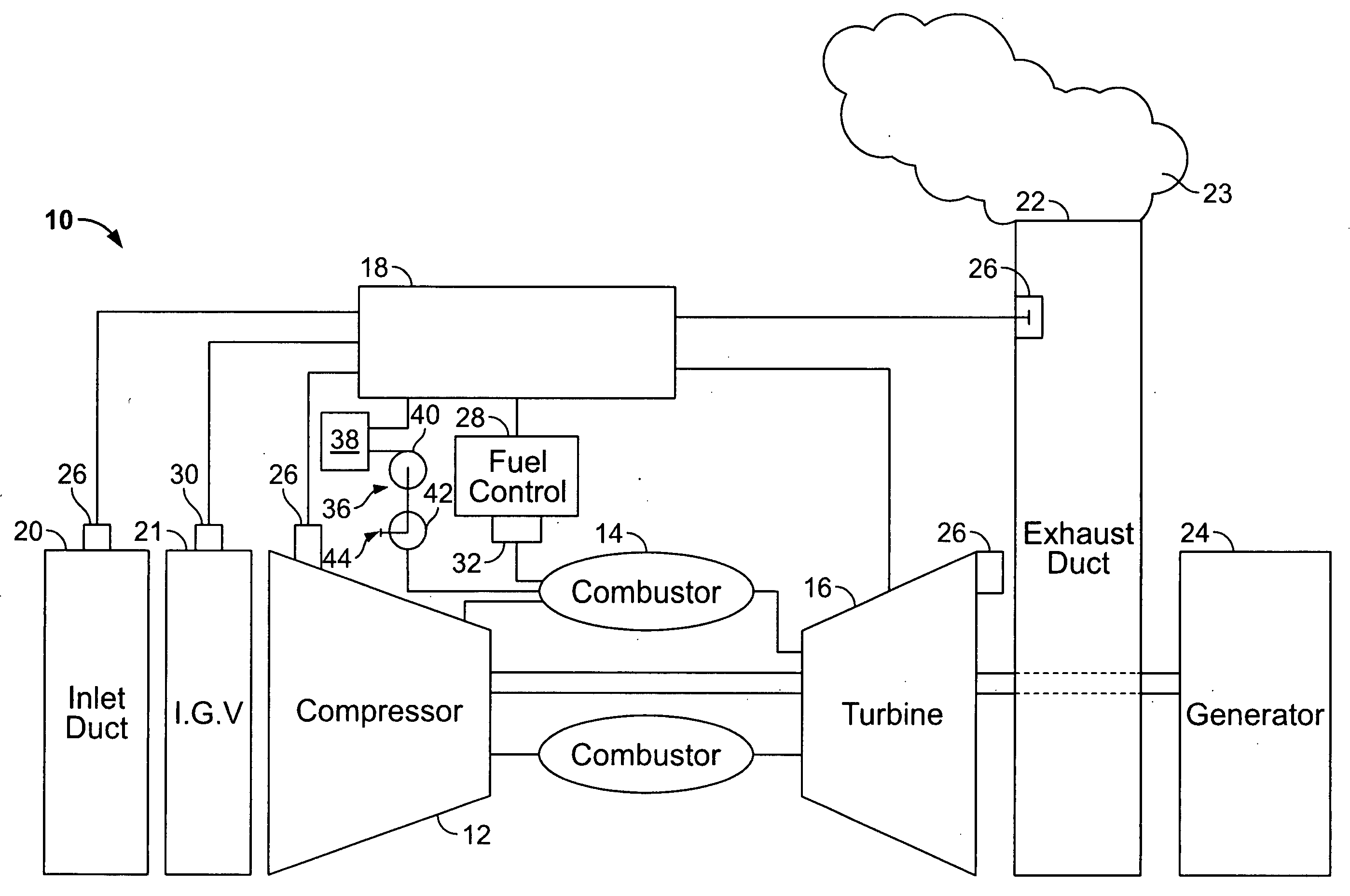

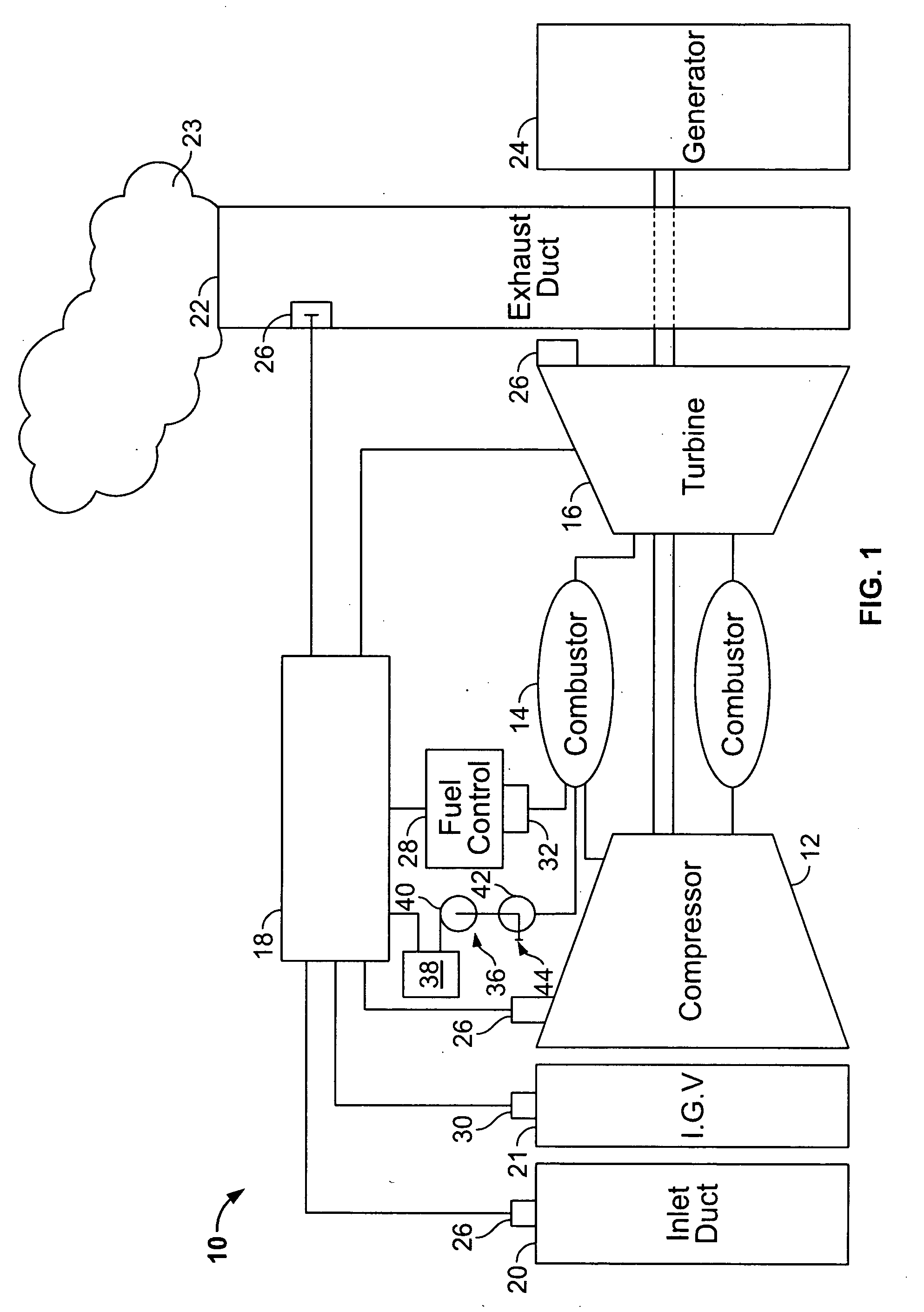

A power generation system capable of eliminating NO, components in the exhaust gas by using a 3-way catalyst, comprising a gas compressor to increase the pressure of ambient air fed to the system; a combustor capable of oxidizing a mixture of fuel and compressed air to generate an expanded, high temperature exhaust gas; a gas turbine engine that uses the force of the high temperature gas; an exhaust gas recycle (EGR) stream back to the combustor; a 3-way catalytic reactor downstream of the gas turbine engine outlet which treats the exhaust gas stream to remove substantially all of the NOx components; a heat recovery steam generator (HRSG); an EGR compressor; and an electrical generator.

Owner:GENERAL ELECTRIC CO

Staged combustion of a low heating value fuel gas for driving a gas turbine

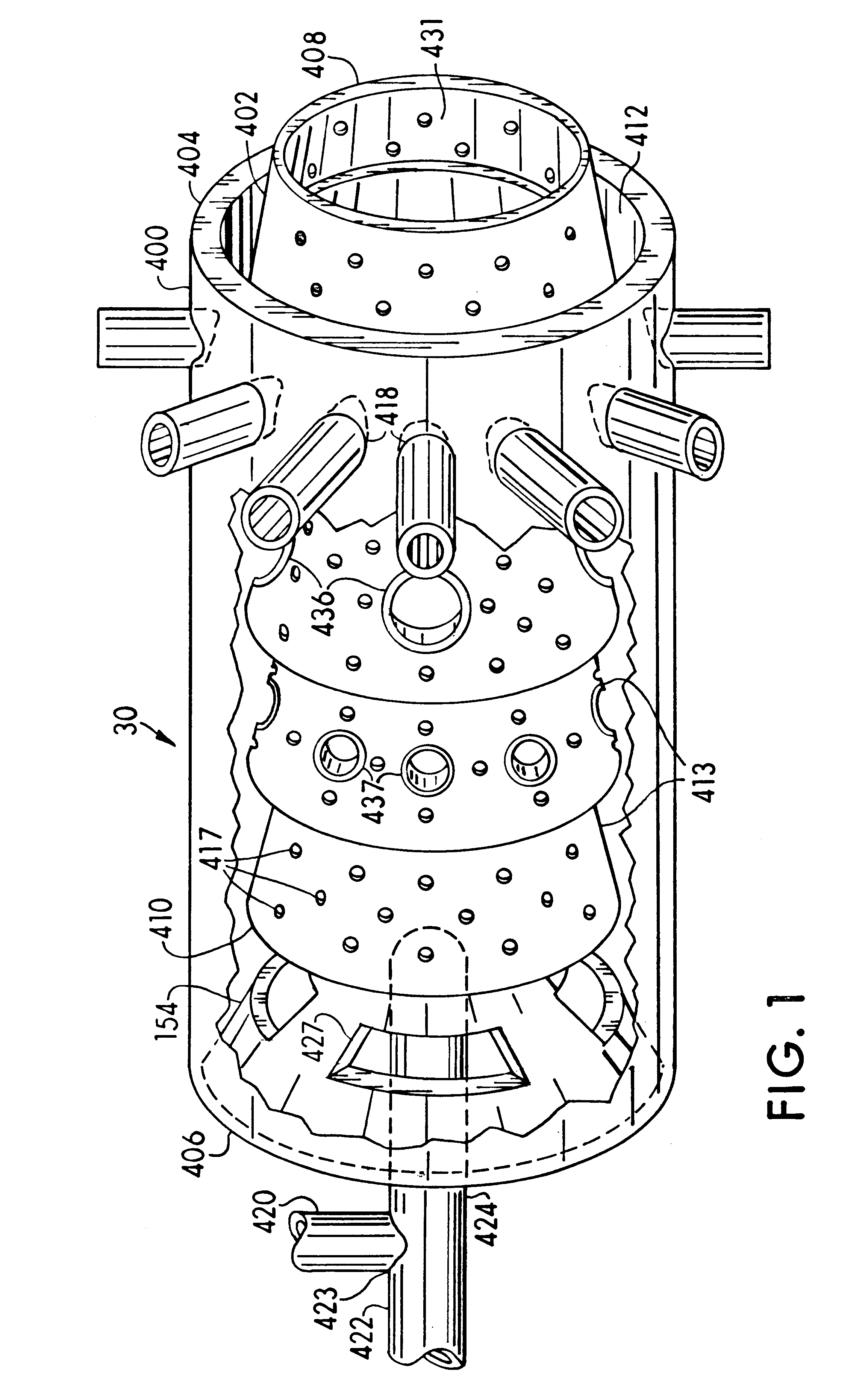

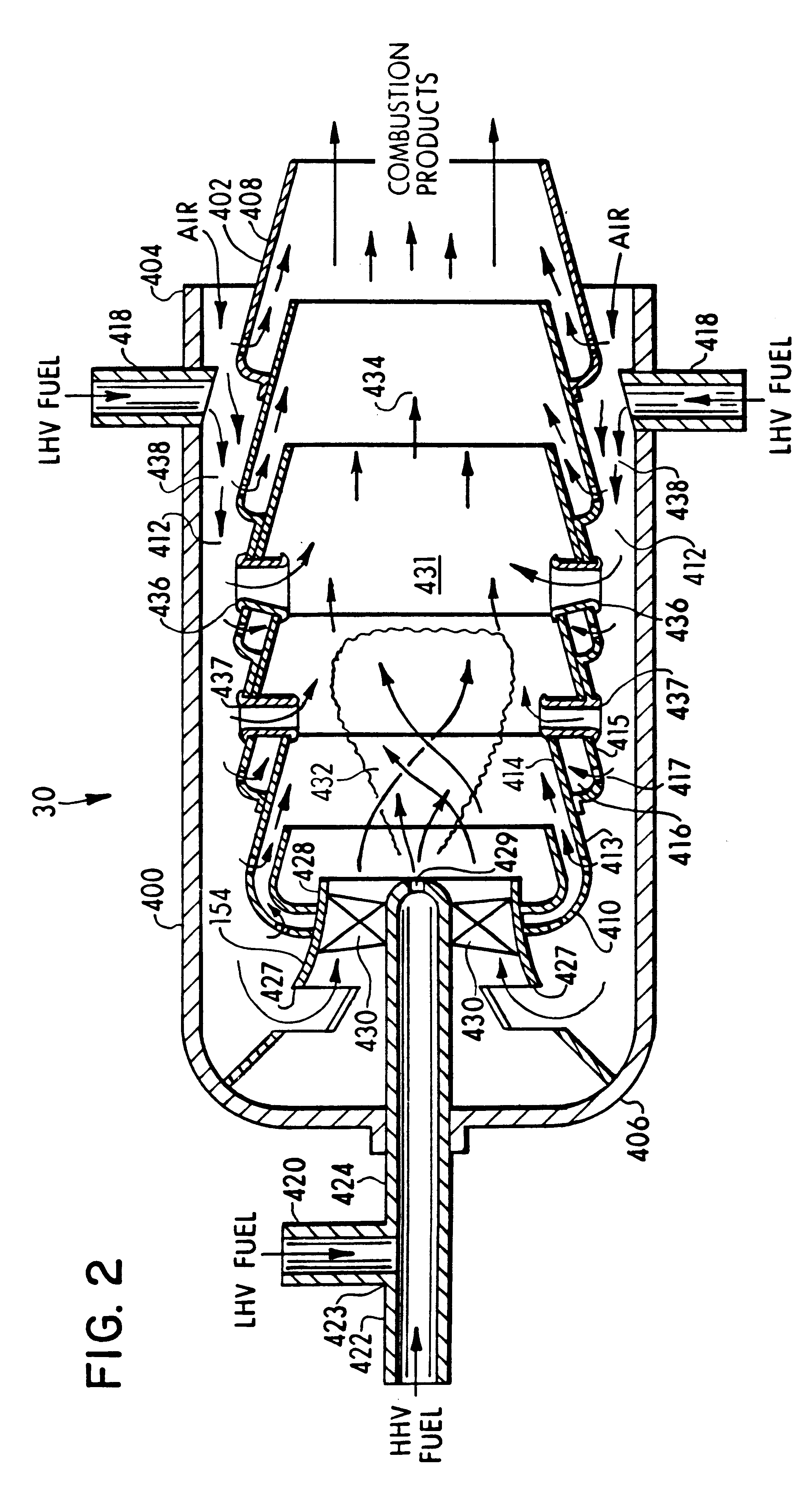

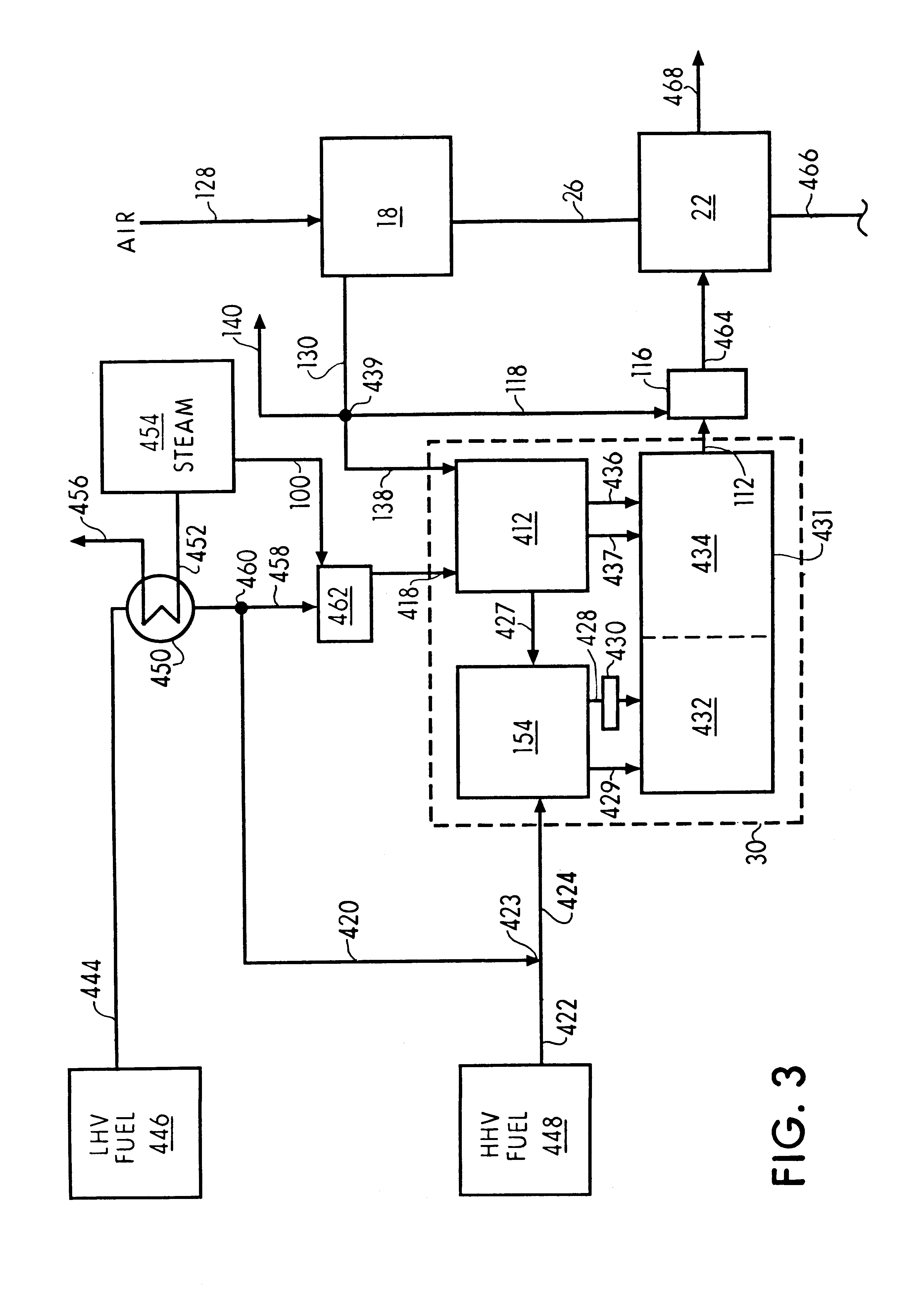

A process is provided for combusting a low heating value fuel gas in a combustor to drive an associated gas turbine. A low heating value fuel gas feed is divided into a burner portion and a combustion chamber portion. The combustion chamber portion and a combustion air are conveyed into a mixing zone of the combustor to form an air / fuel mixture. The burner portion is conveyed into a flame zone of the combustor through a burner nozzle while a first portion of the air / fuel mixture is conveyed into the flame zone through a burner port adjacent to the burner nozzle. The burner portion and first portion of the air / fuel mixture are contacted in the flame zone to combust the portions and produce flame zone products. The flame zone products are conveyed into an oxidation zone of the combustor downstream of the flame zone while a second portion of the air / fuel mixture is also conveyed into the oxidation zone. The second portion is combusted in the oxidation zone in the presence of the flame zone products to produce combustion products. The combustion products are conveyed into the associated gas turbine and drive the gas turbine.

Owner:MARATHON OIL CO +1

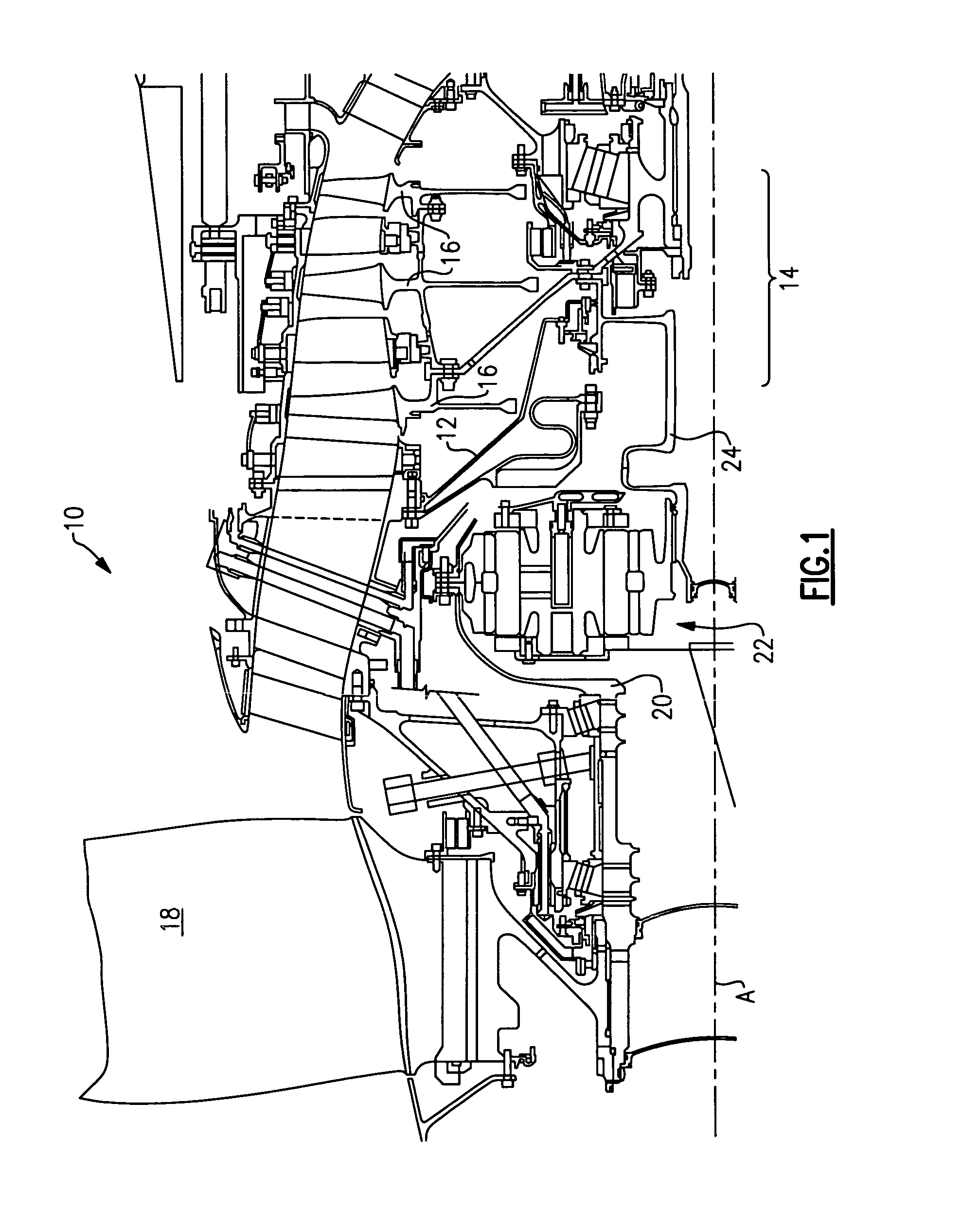

Gas turbine engine assembly and method of assembling same

A method of assembling a gas turbine assembly includes providing a core gas turbine engine including a high-pressure compressor, a combustor, and a turbine, coupling a low-pressure turbine axially aft from the core gas turbine engine, coupling a fan assembly axially forward from the core gas turbine engine, and coupling a booster compressor to the low-pressure turbine such that the booster compressor and the low-pressure turbine rotate at a first rotational speed.

Owner:GENERAL ELECTRIC CO

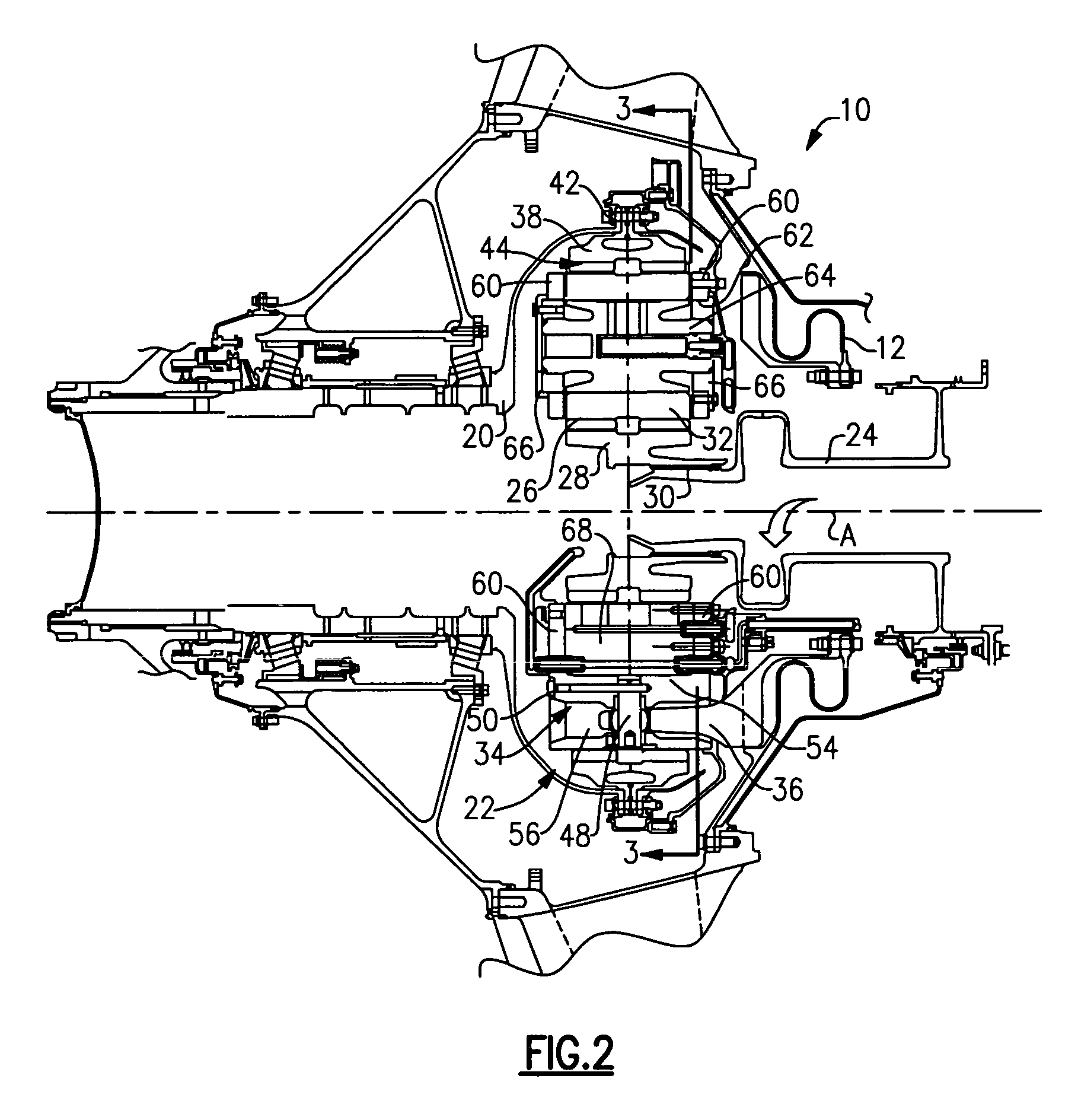

Engine mounting configuration for a turbofan gas turbine engine

ActiveUS20090056343A1Minimizes backbone bendingMinimizes engine case distortionPower plant constructionJet type power plantsNacelleEngine mount

An engine mounting configuration reacts engine thrust at an aft mount. The engine mounting configuration reduces backbone bending of the engine, intermediate case distortion and frees-up space within the core nacelle.

Owner:RAYTHEON TECH CORP

Burner tube and method for mixing air and gas in a gas turbine engine

InactiveUS6993916B2Good mixing propertiesImprove flame stabilityContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorGas turbines

Owner:GENERAL ELECTRIC CO

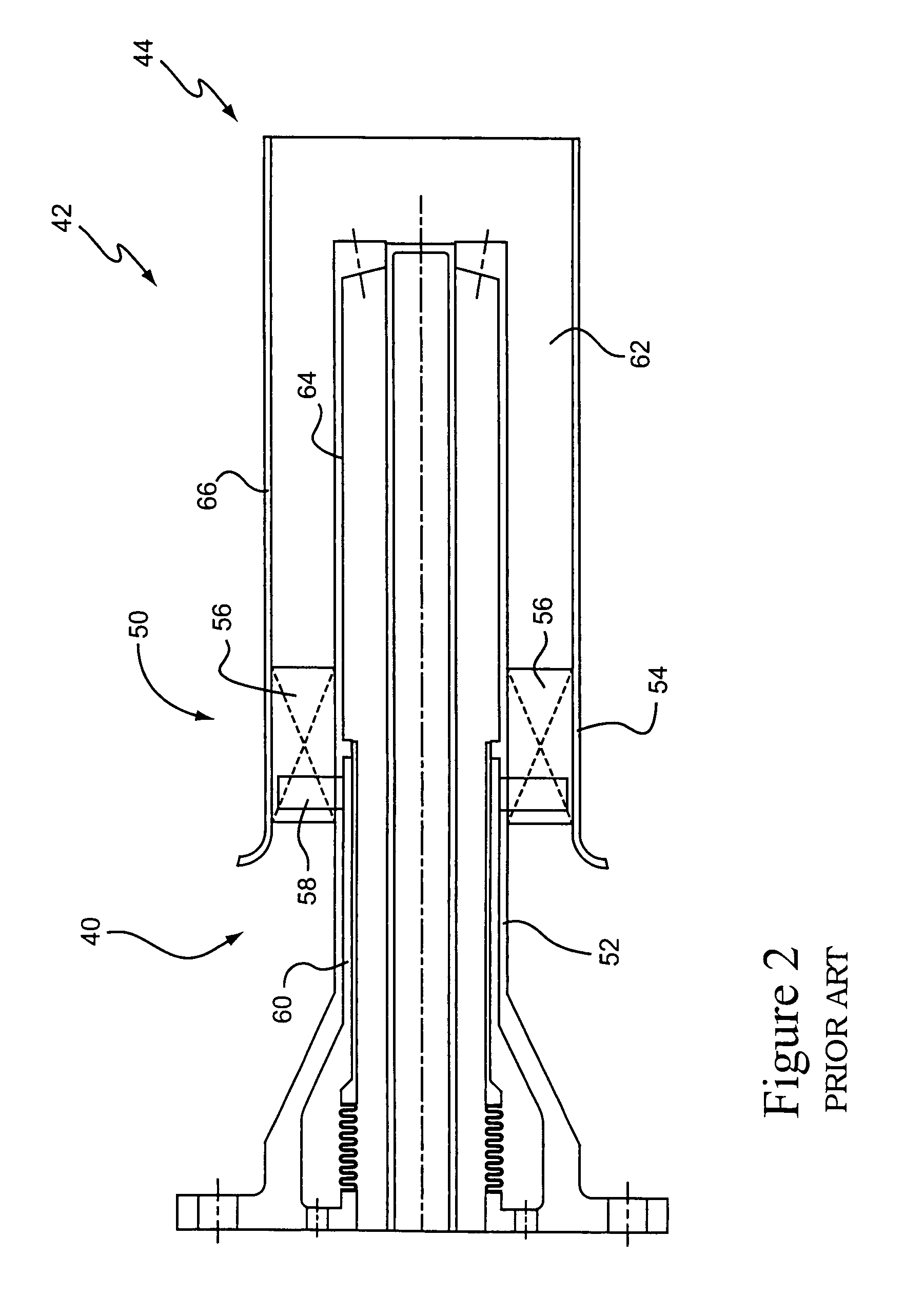

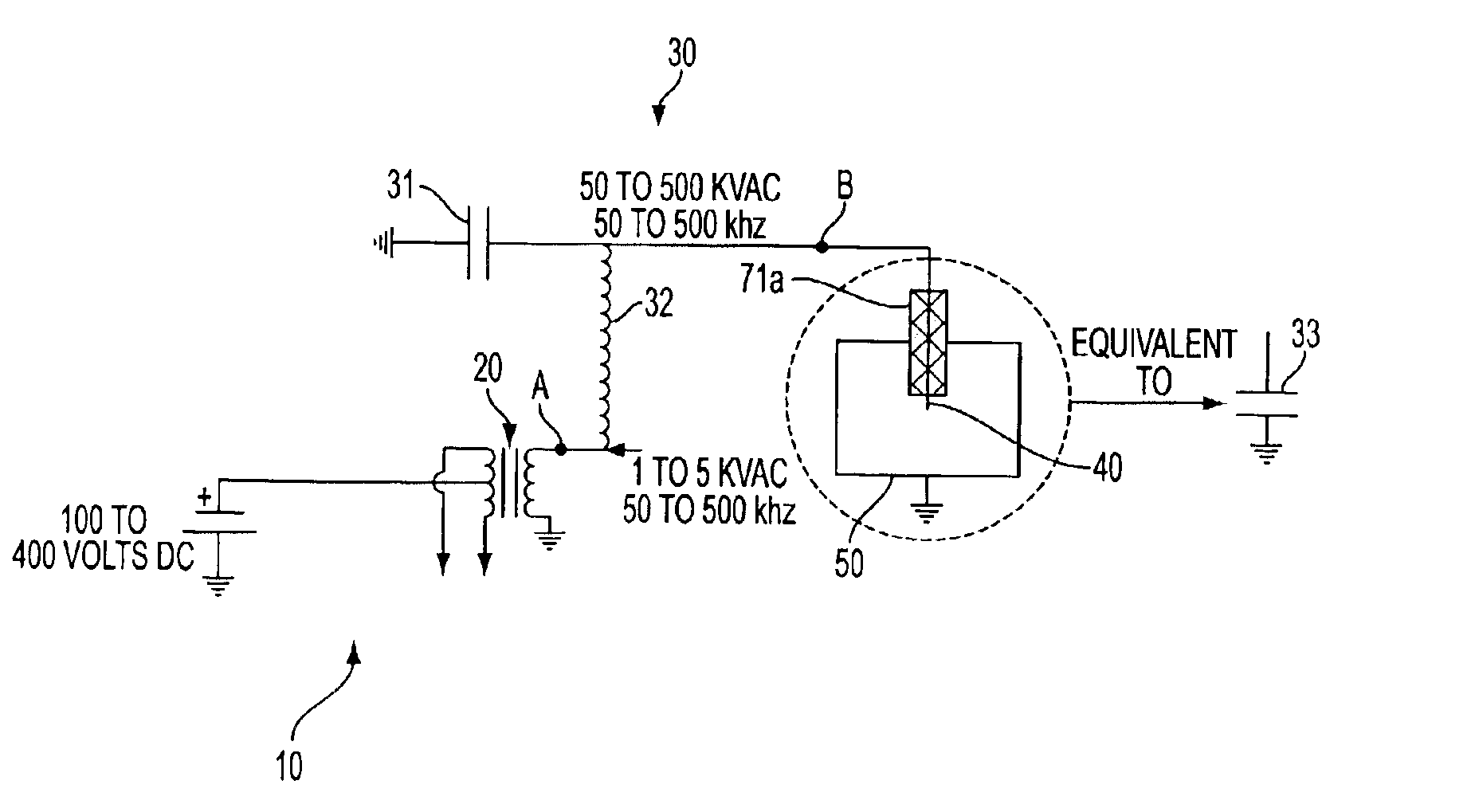

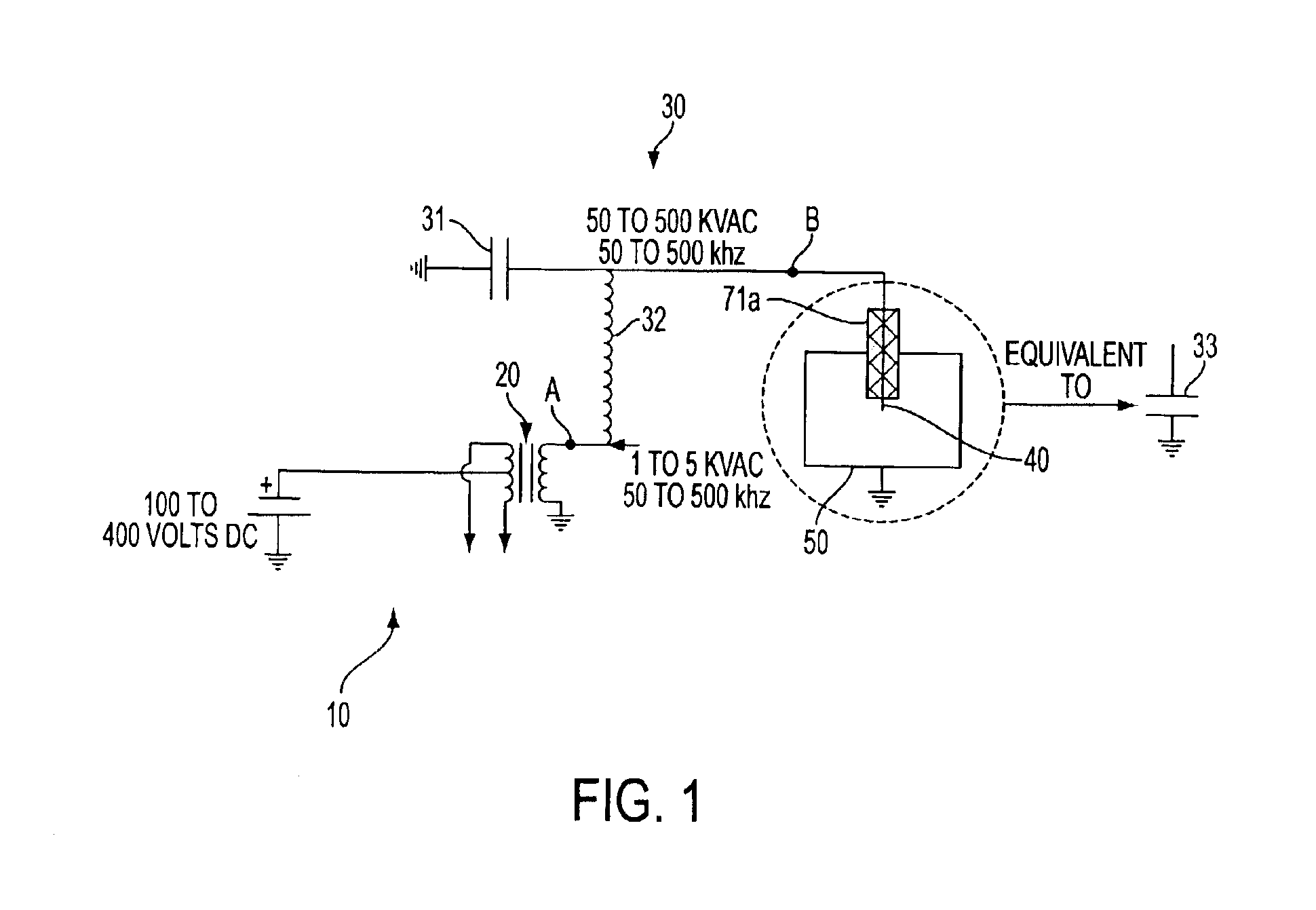

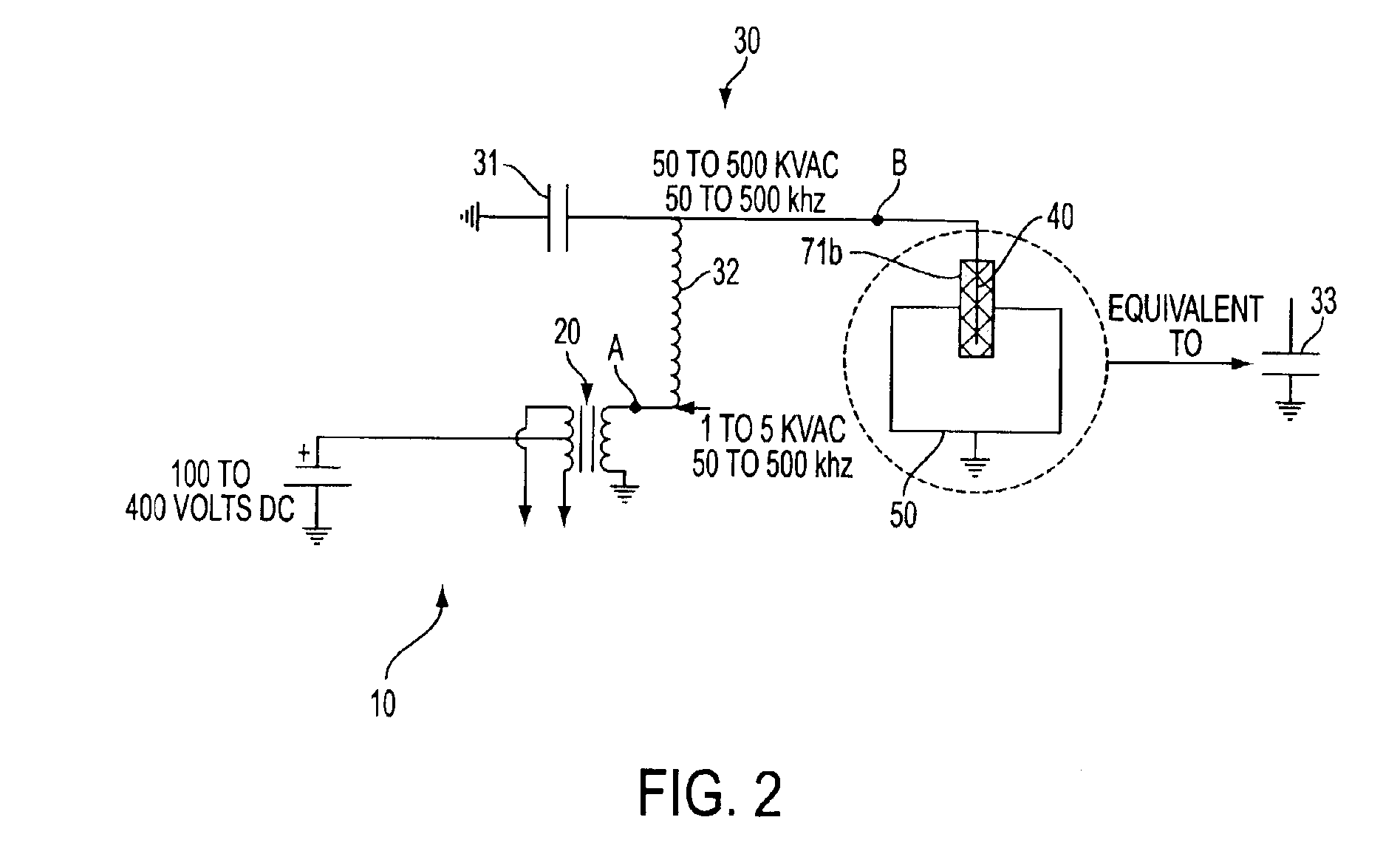

System and method for generating and sustaining a corona electric discharge for igniting a combustible gaseous mixture

InactiveUS6883507B2Sufficient energySparking plugsCombustion enginesCombustion chamberElectric discharge

The invention relates to a system for igniting a fuel-air mixture in a combustion chamber with a corona discharge. The system comprises an electrode inside of the combustion chamber, an electric circuit which provides radio frequency electric power to the electrode, and a ground formed by the combustion chamber walls. A radio frequency voltage differential formed between the electrode and the ground produces a radio frequency electric field therebetween which causes a fuel-air mixture to ionize resulting in combustion of the fuel-air mixture. The system can be utilized in engines such as internal combustion engines or gas turbine engines, for example.

Owner:BORGWARNER INC

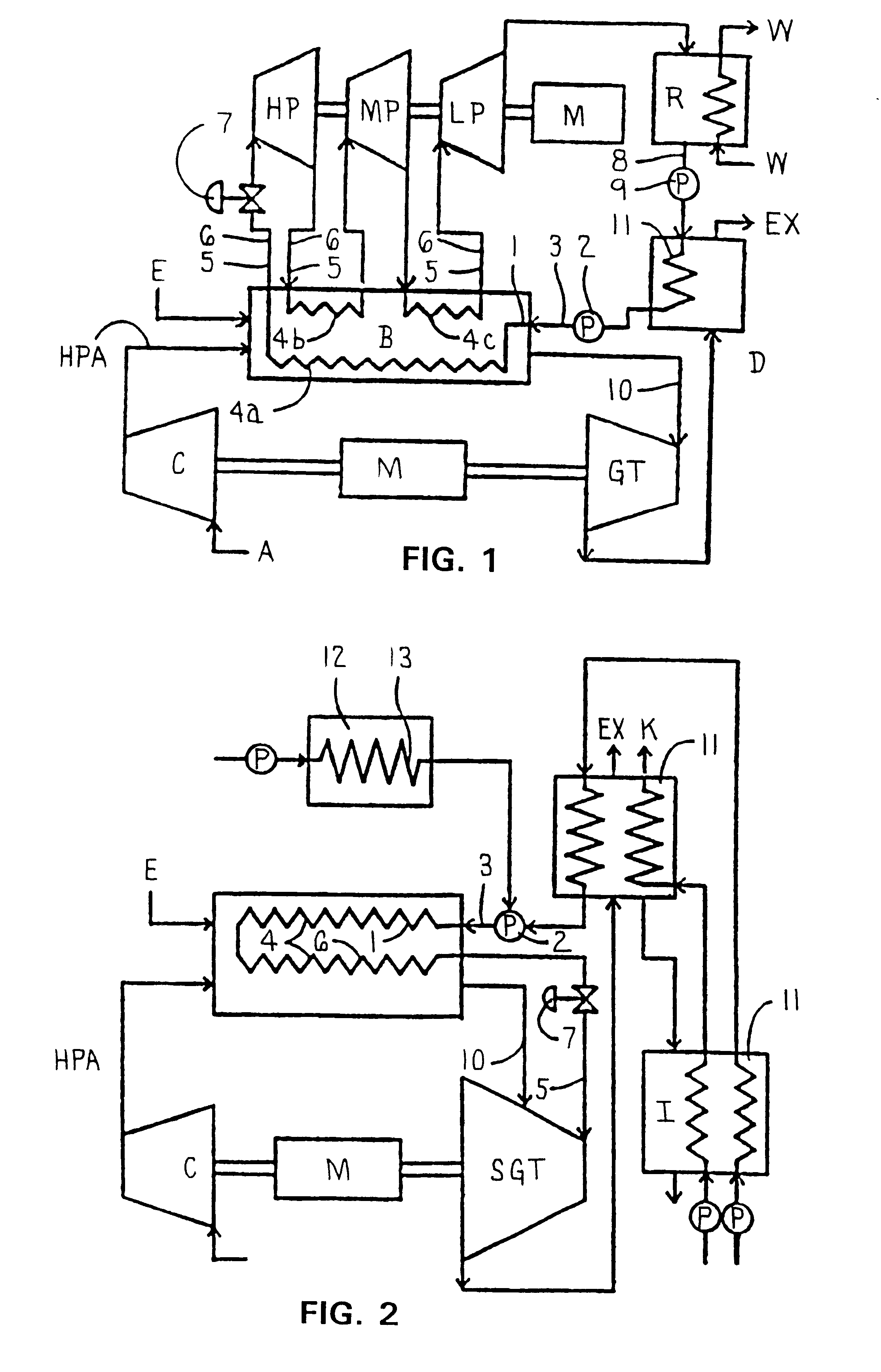

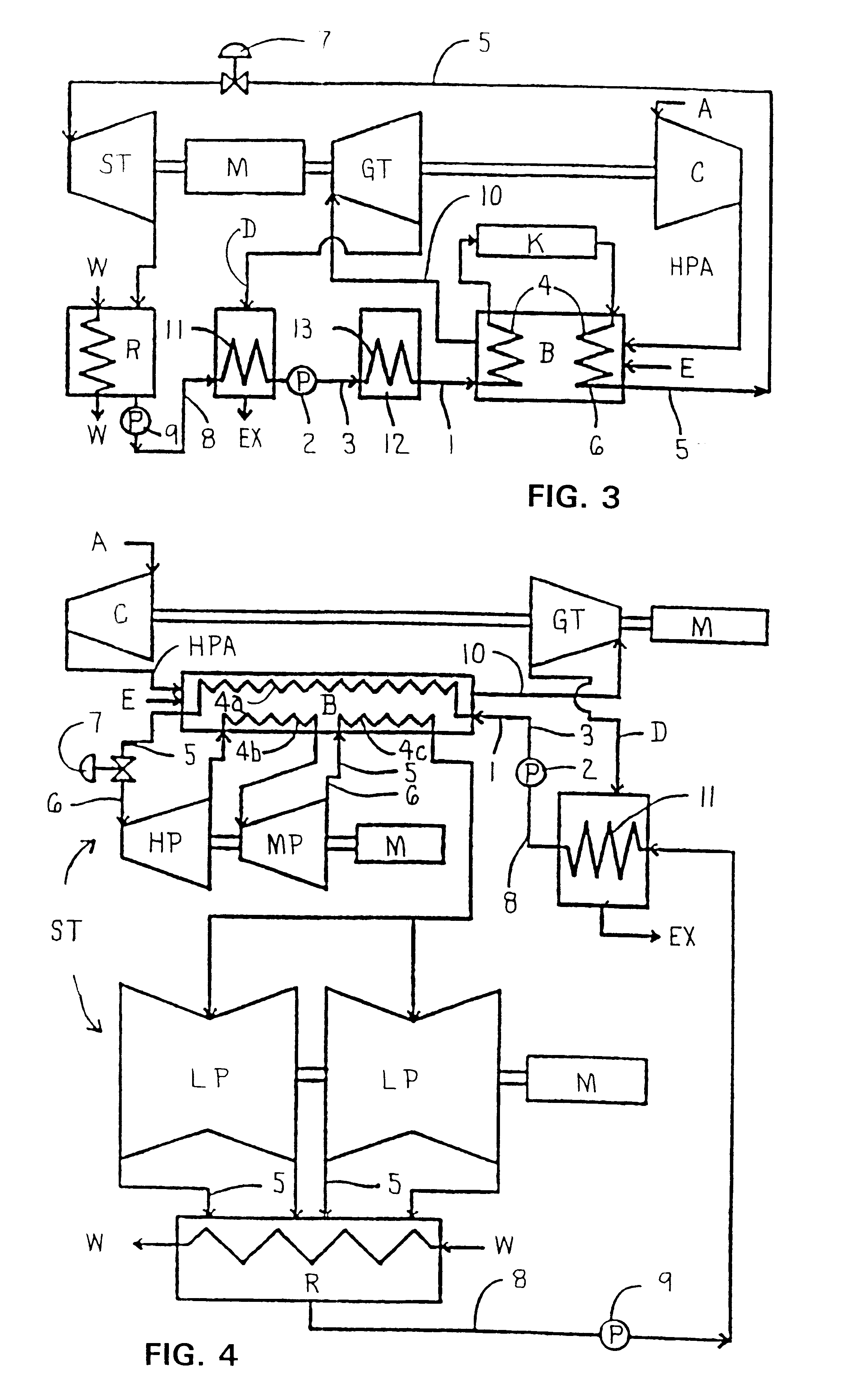

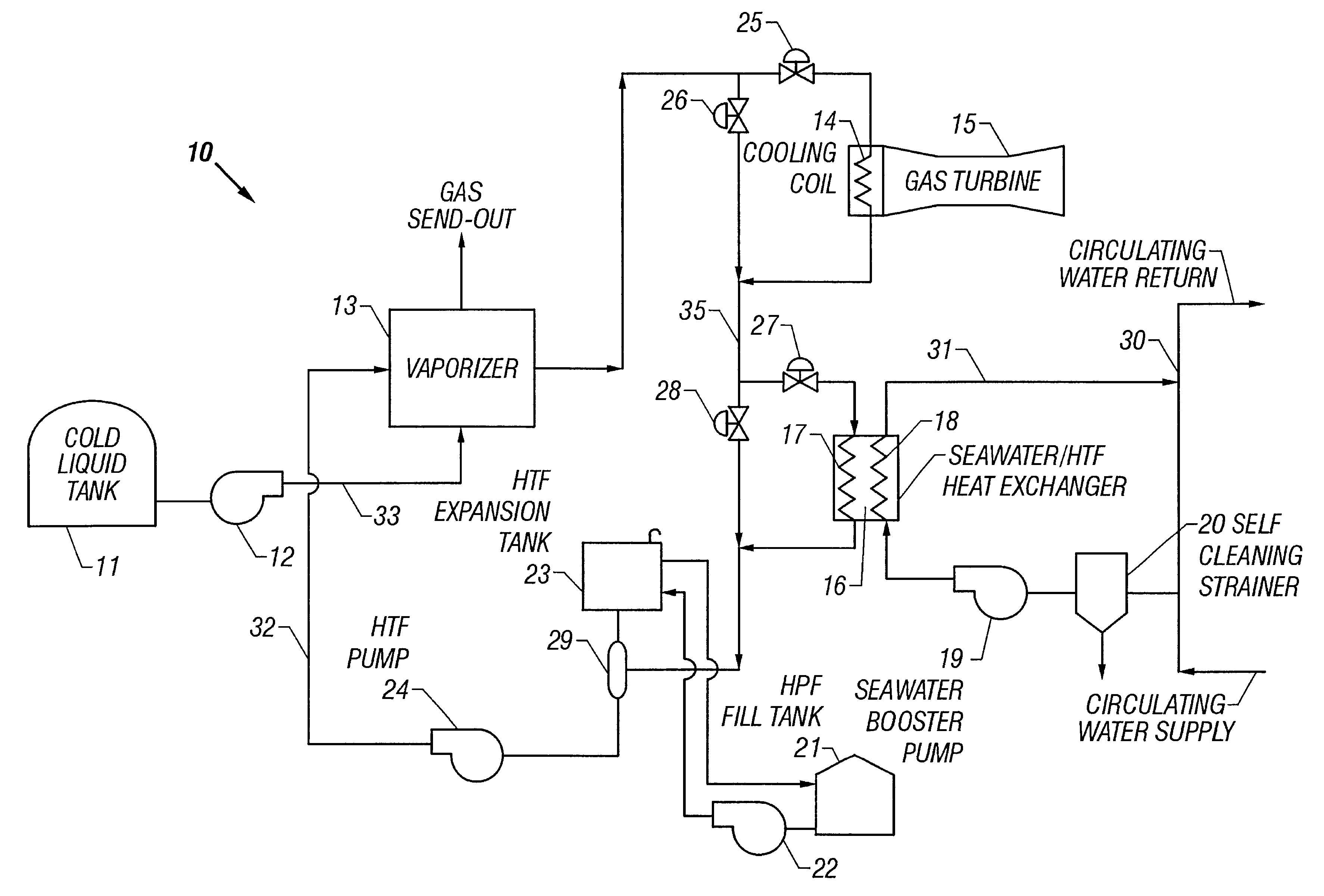

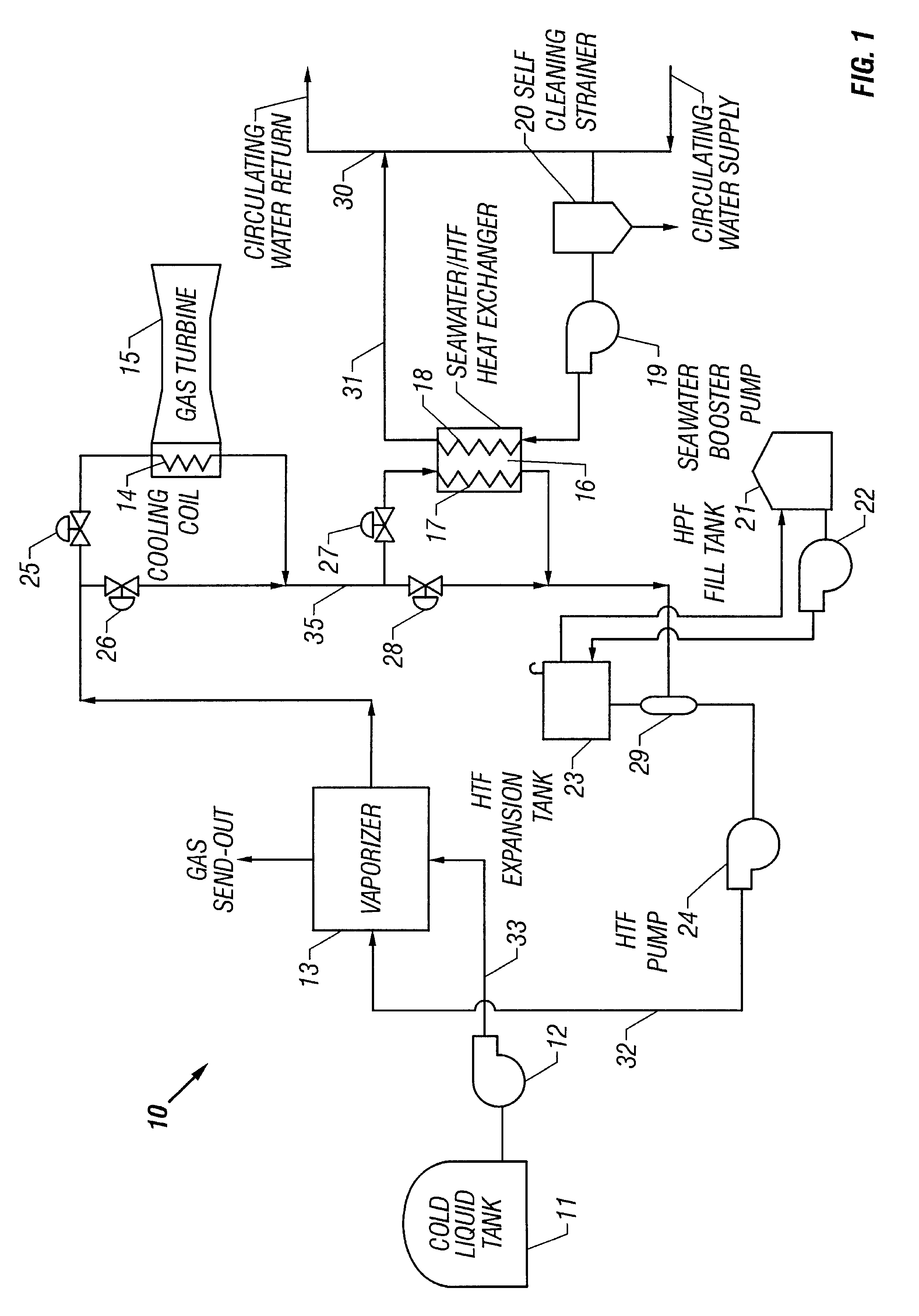

Method and apparatus for vaporizing liquid natural gas in a combined cycle power plant

InactiveUS6367258B1Turbine/propulsion engine coolingTurbine/propulsion fuel heatingPower stationProcess engineering

A method and apparatus for increasing the efficiency of a combined cycle generation plant by assisting the vaporization of cold liquid including liquefied natural gas ("LNG") or liquefied petroleum gas (LPG) in a combined cycle power plant. Cold liquid vaporization is assisted by circulating a warm heat transfer fluid to transfer heat to a LNG / LPG vaporizer. The heat transfer fluid is chilled by LNG / LPG cold liquid vaporization and warmed by heat from a gas turbine. The heat transfer fluid absorbs heat from the air intake of a gas turbine and from a secondary heat transfer fluid circulating in a combined cycle power plant. Chilling the gas turbine air intake densifies the air and increases the gas turbine output. Chilling the steam condenser cooling water increases steam turbine output. The effects of chill recovery is higher output and better efficiency of the combined cycle plant.

Owner:BECHTEL CORP

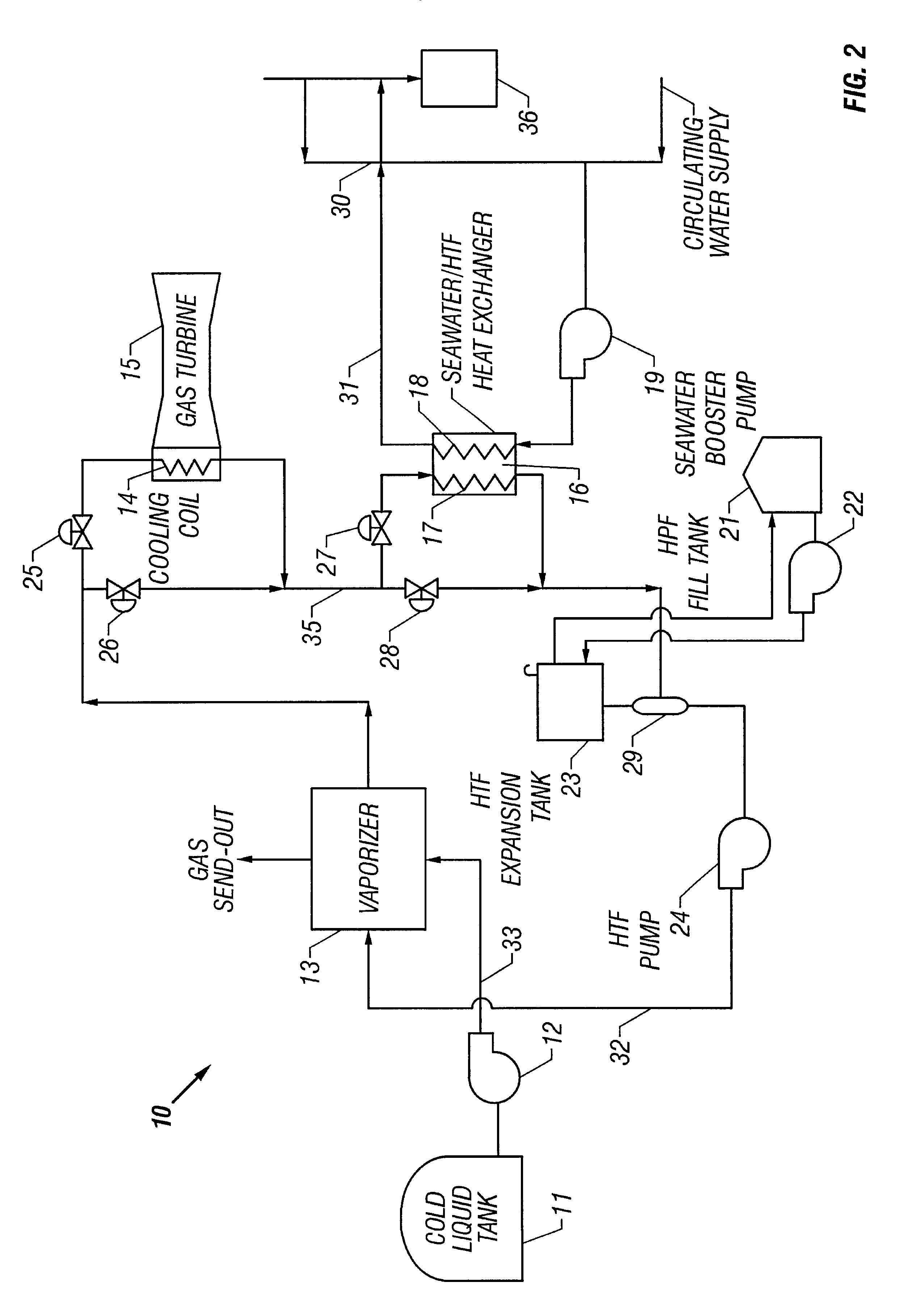

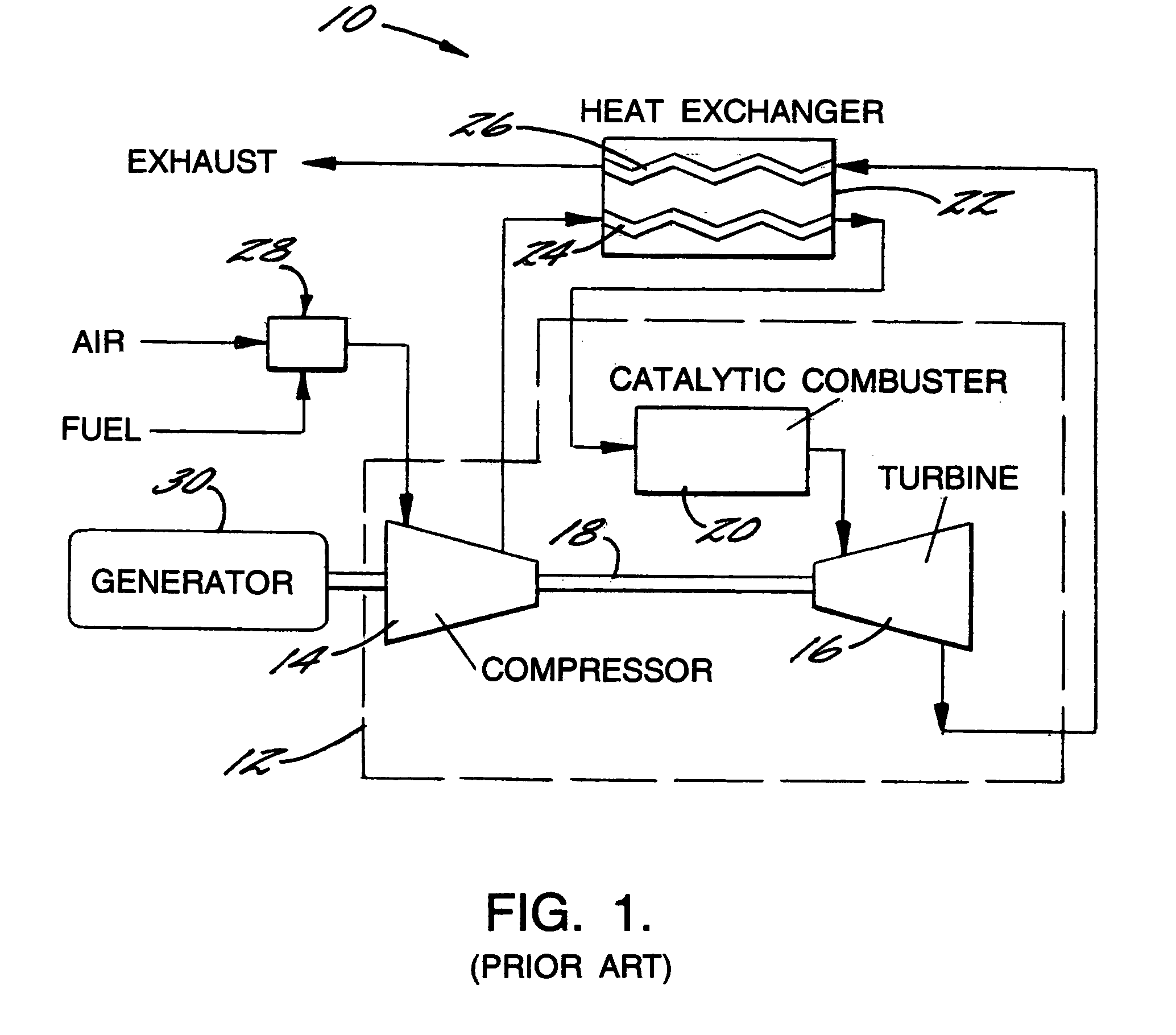

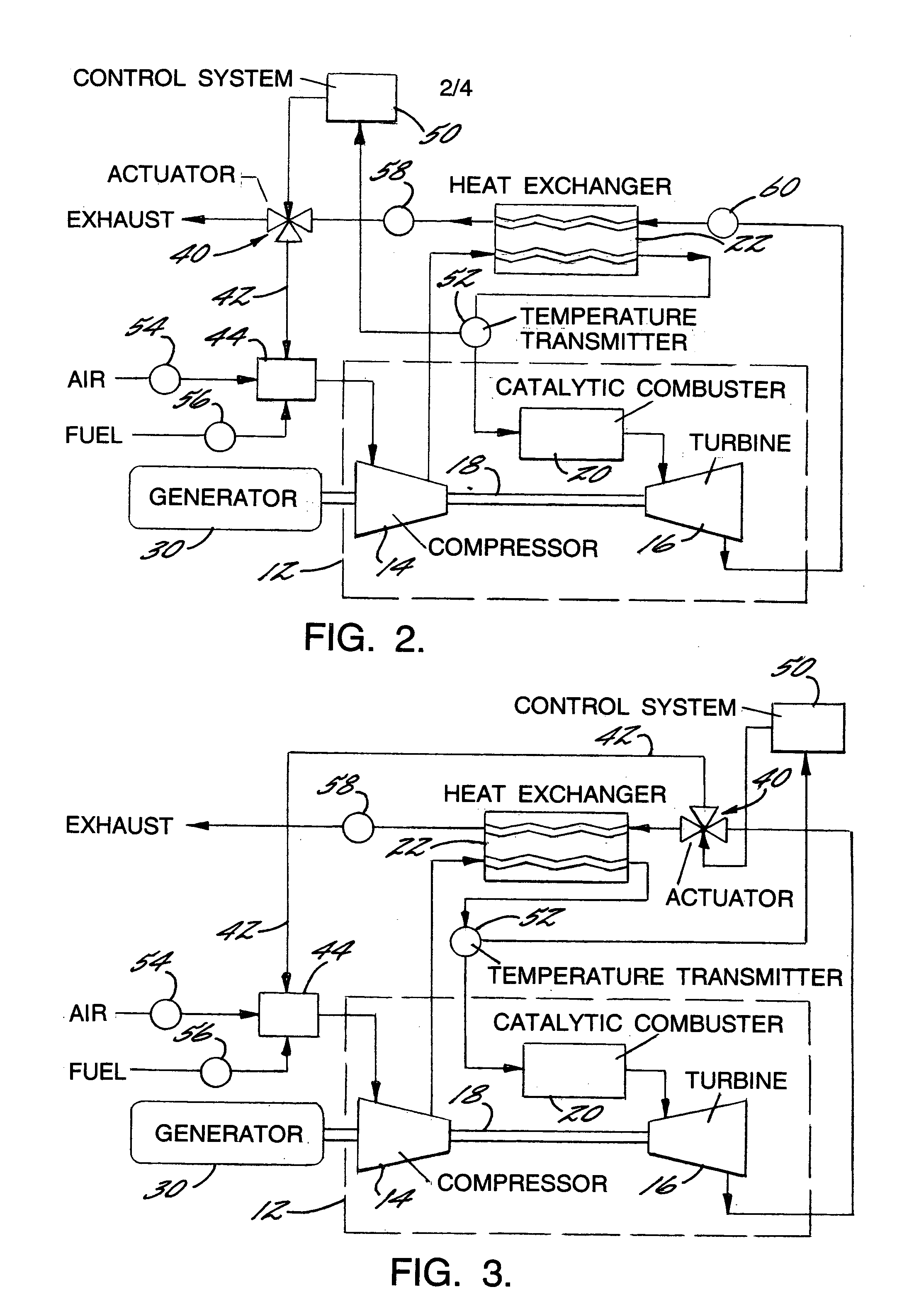

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS7007487B2Maximize efficiencyReduce air pollutionTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

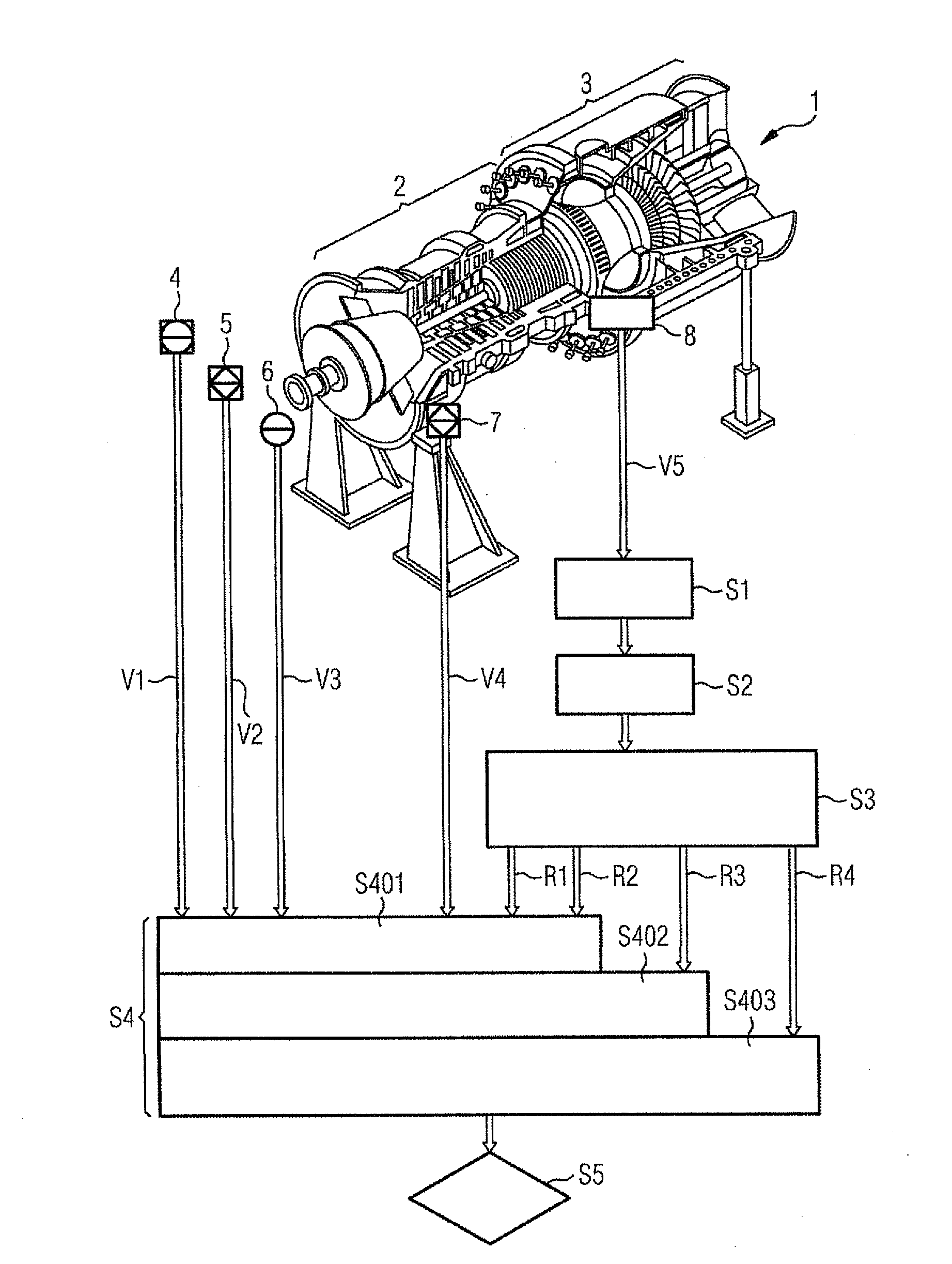

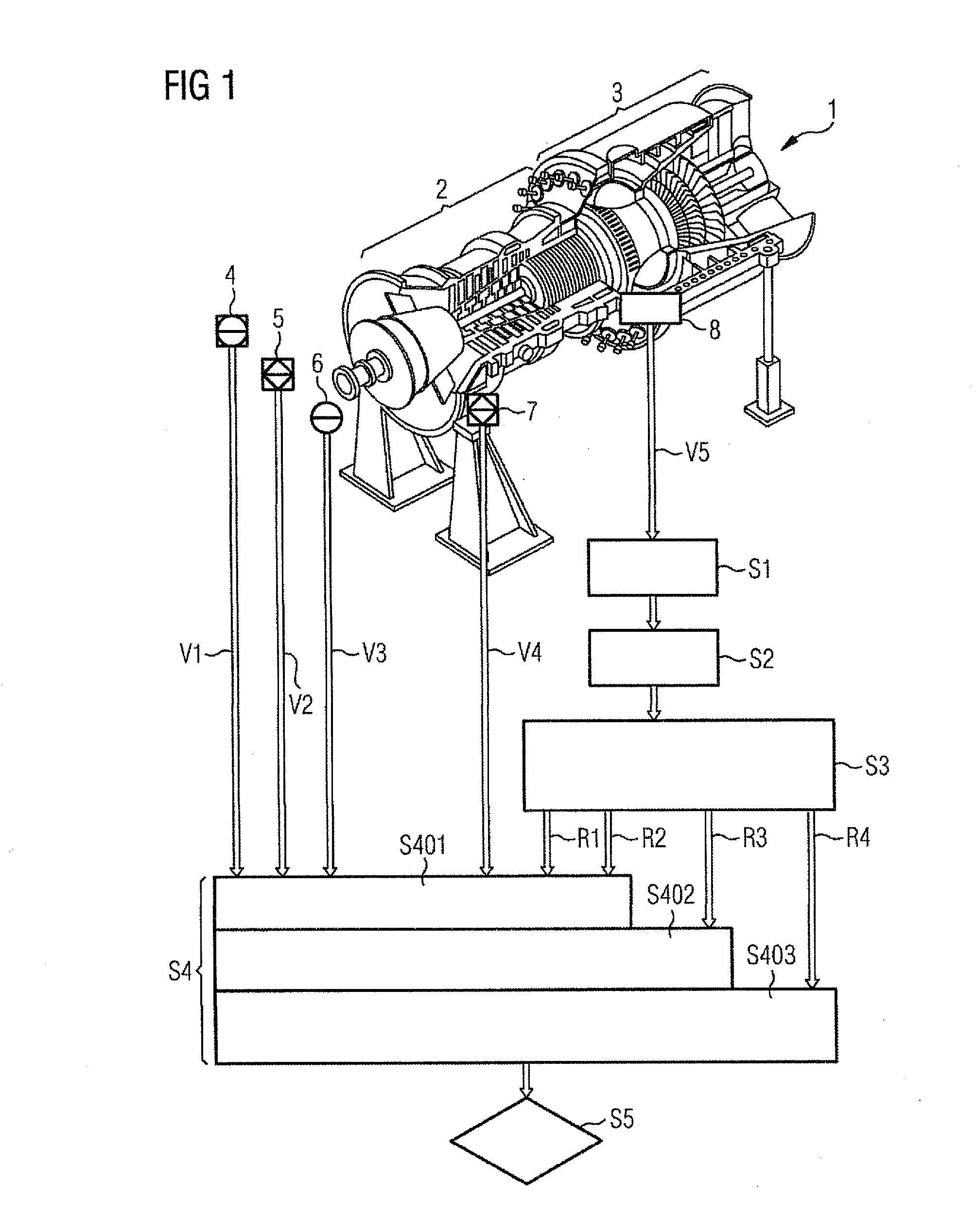

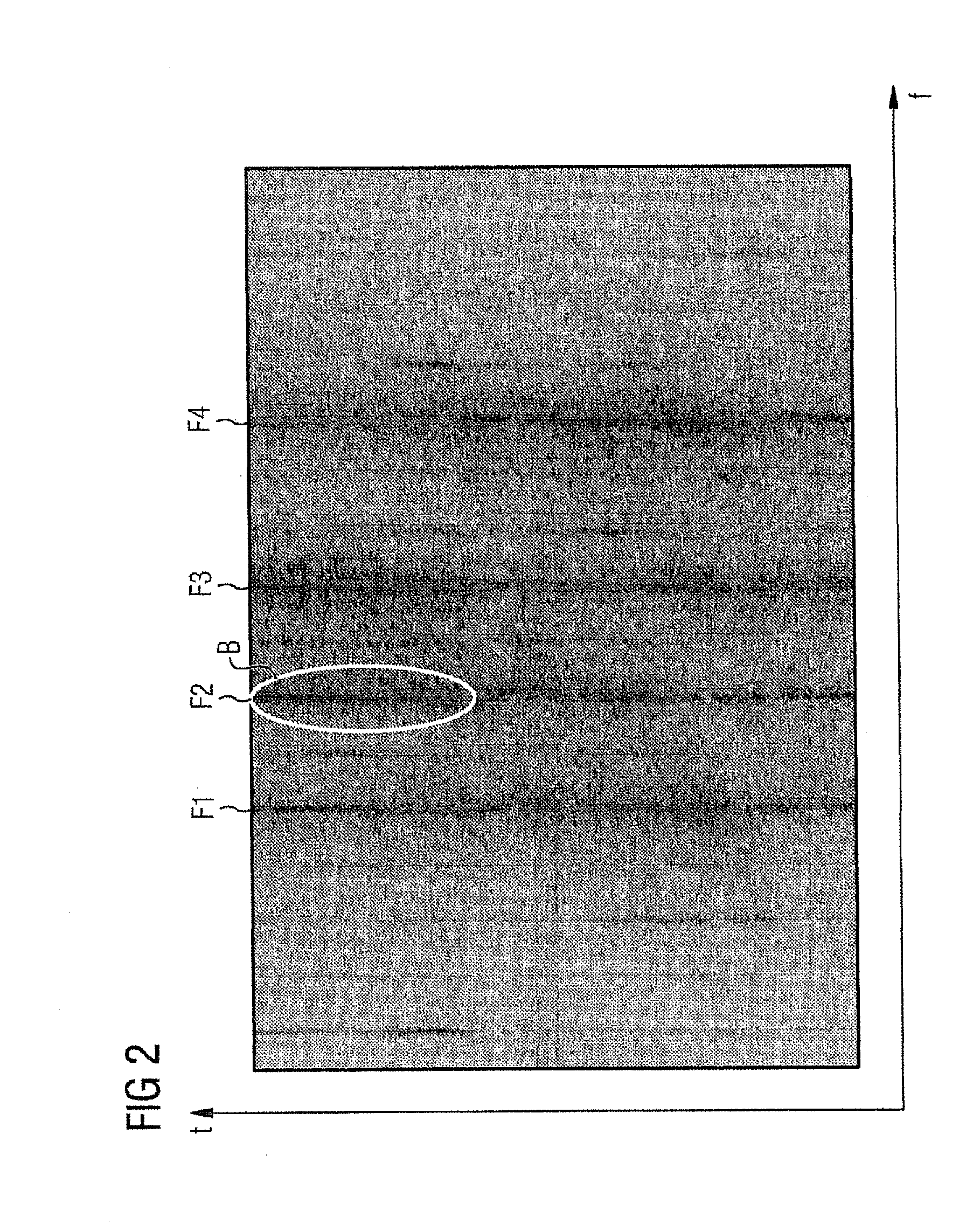

Method for analysis of the operation of a gas turbine

ActiveUS20100262401A1Accurate diagnosisLess sensorsGas-turbine engine testingEngine fuctionsFrequency spectrumEngineering

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Oil baffle for gas turbine fan drive gear system

Owner:RTX CORP

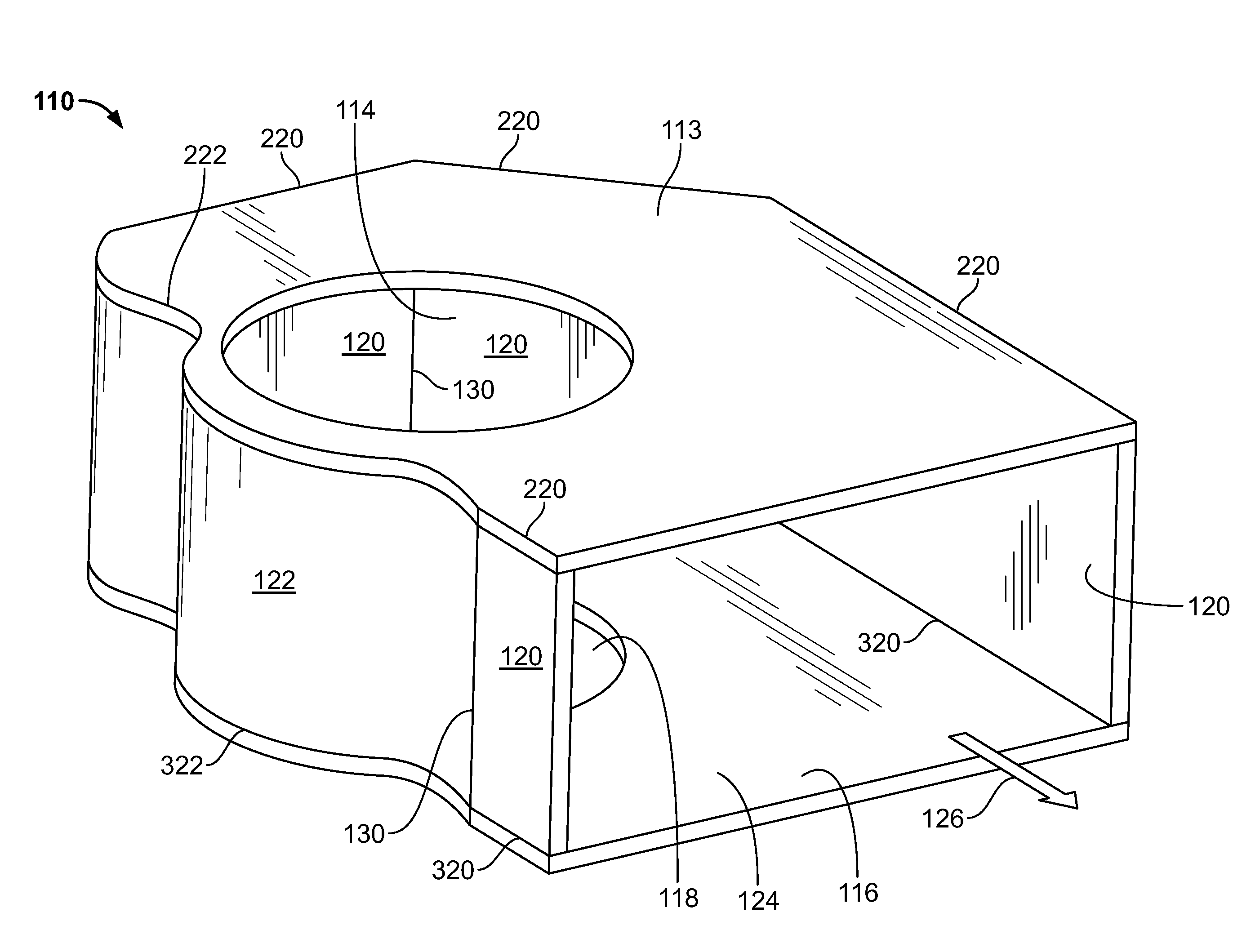

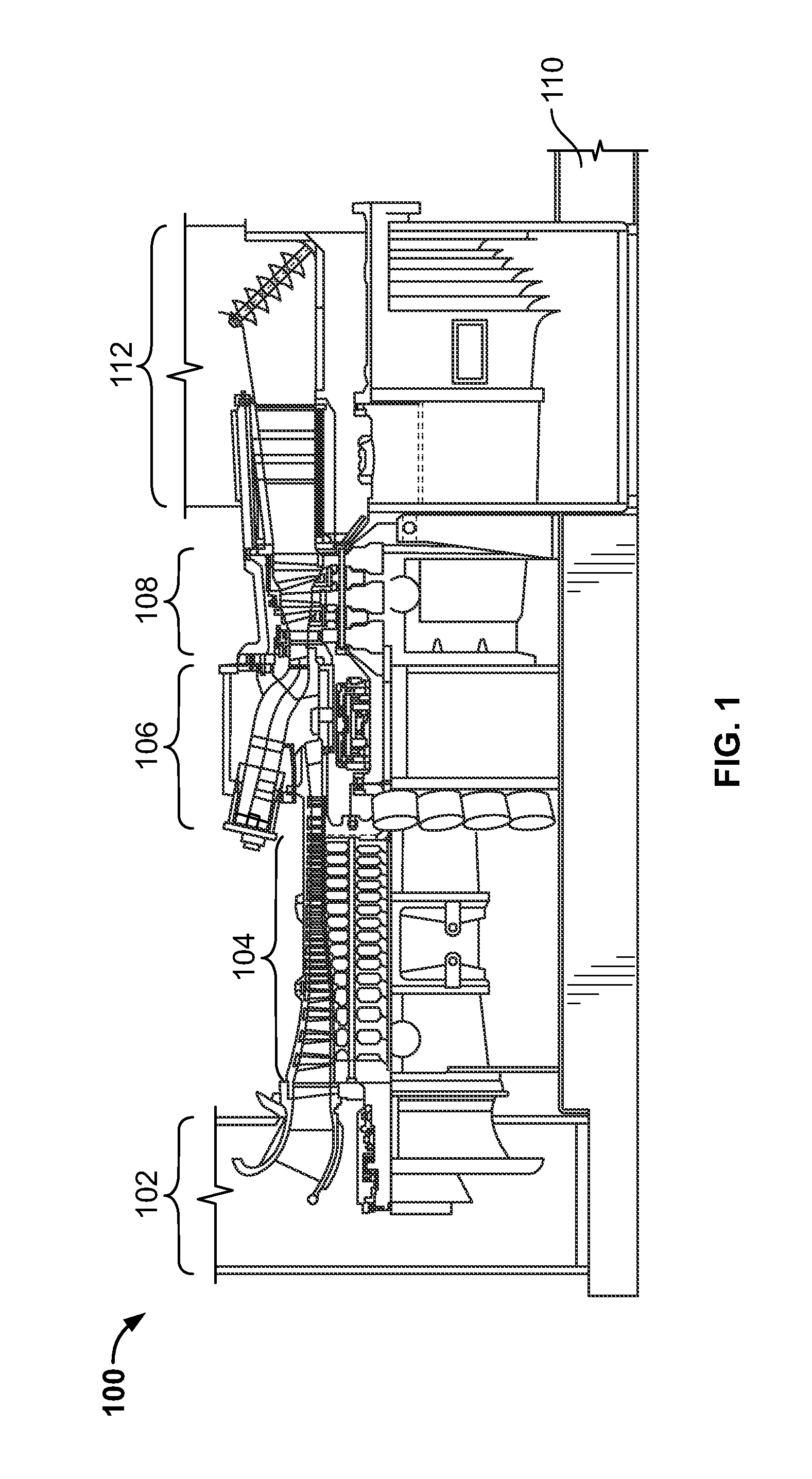

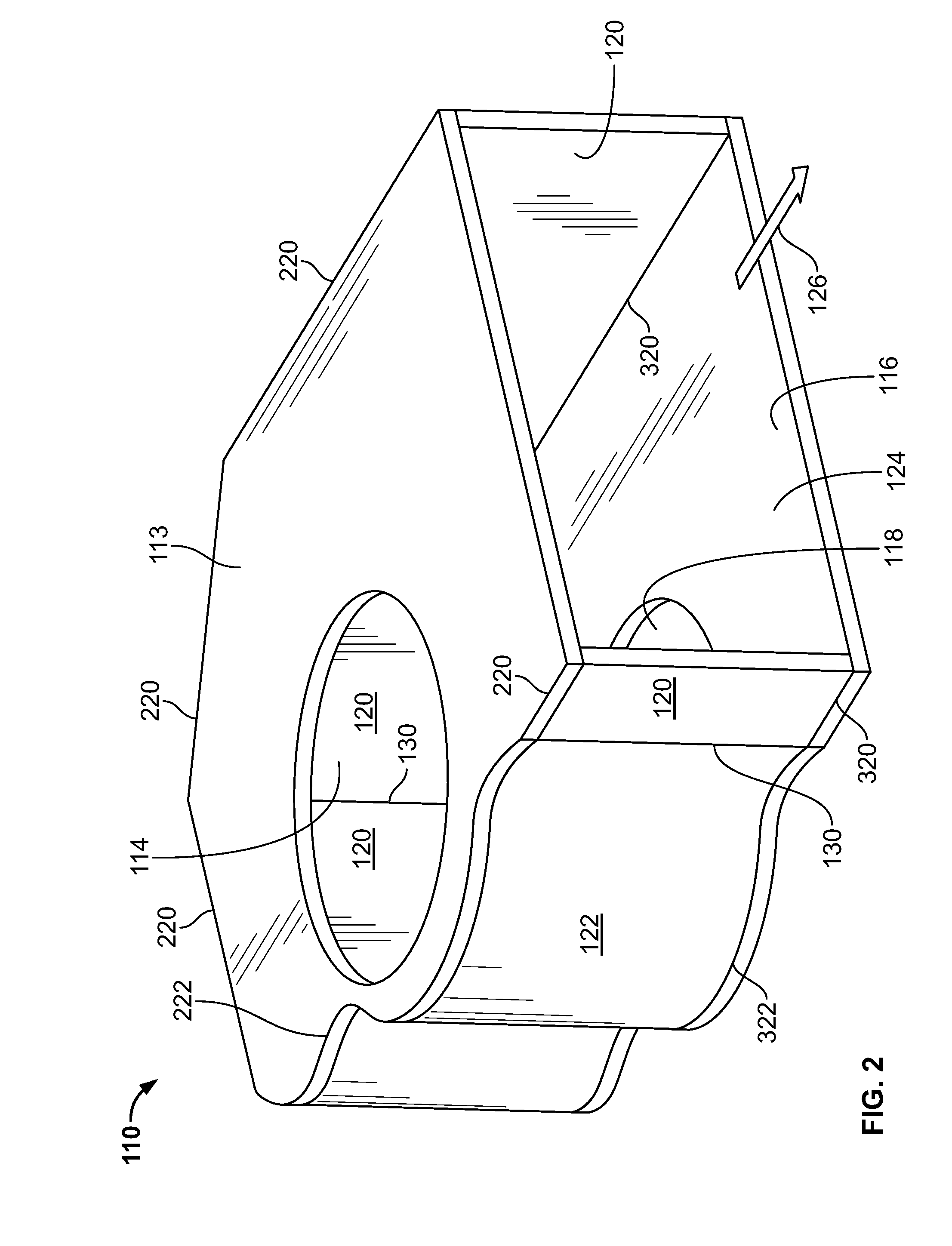

Method and apparatus for radial exhaust gas turbine

A radial exhaust gas turbine apparatus has a gas turbine engine that includes a radial exhaust diffuser section and a casing apparatus consisting essentially of polygonal walls, substantially straight plates, and substantially straight sidewalls. The casing apparatus encloses the radial exhaust diffuser section and is configured to direct at least a substantial portion of the gas exiting the radial exhaust diffuser section to an exit in the casing apparatus via an approximately involute path.

Owner:GENERAL ELECTRIC CO

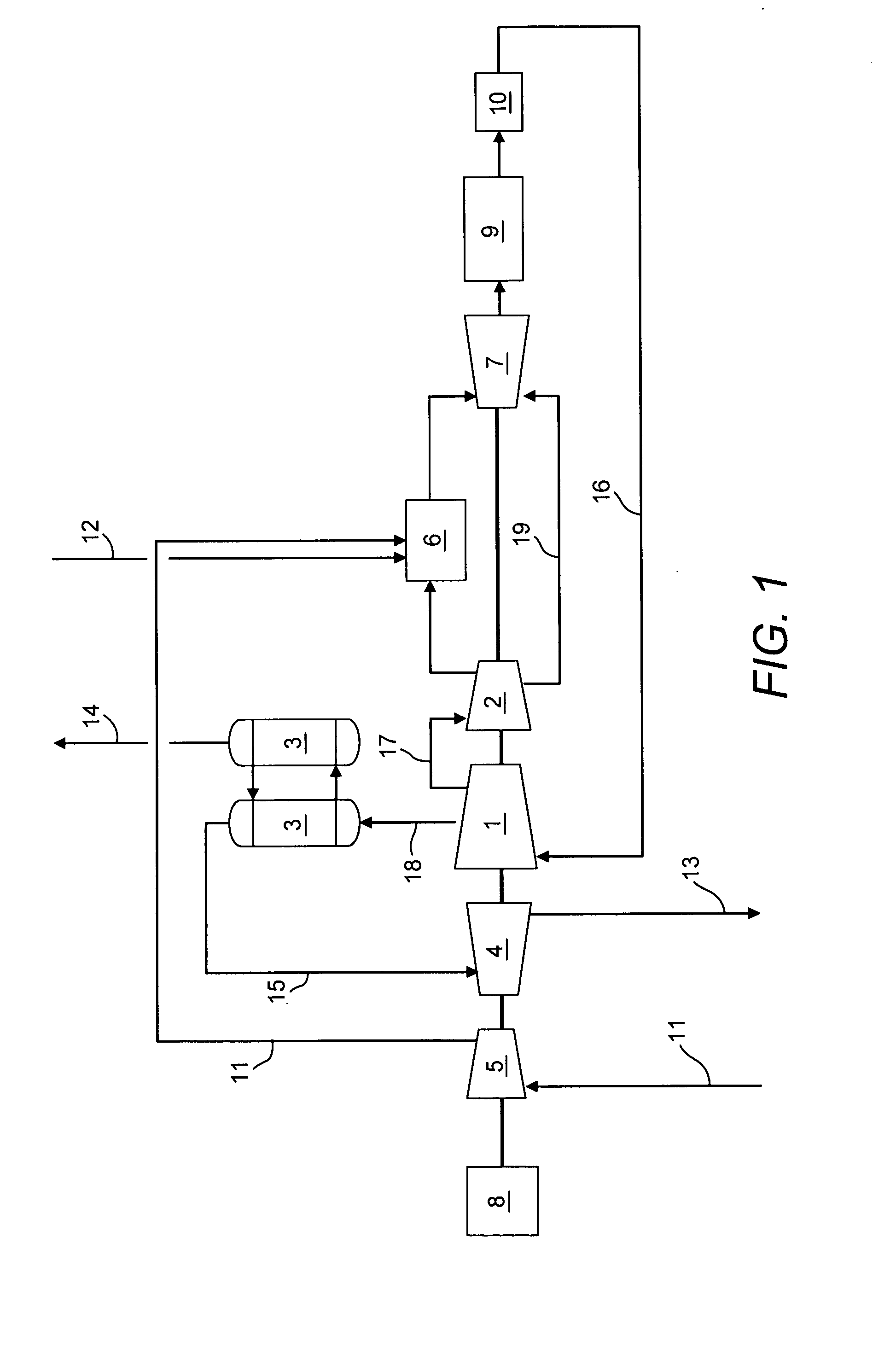

Energy efficient gas separation for fuel cells

InactiveUS20020142208A1Improve efficiencyReduce the ratioFuel cell heat exchangeFused electrolyte fuel cellsEngineeringDelivery system

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

Method and apparatus for boosting gas turbine engine performance

InactiveUS8616005B1Improve performanceIncrease fluid pressureGas turbine plantsJet propulsion plantsAtmospheric pressureTurbine

A method and apparatus for boosting the performance of gas turbine engines, pipelines, and other applications using gas turbine engine systems. A pressurizing device or other source is preferably used to deliver an intake air stream to the gas turbine engine at at least 2% above atmospheric pressure. The pressurizing device of other source is preferably not mechanically driven by the gas turbine engine itself.

Owner:COUSINO SR DENNIS JAMES

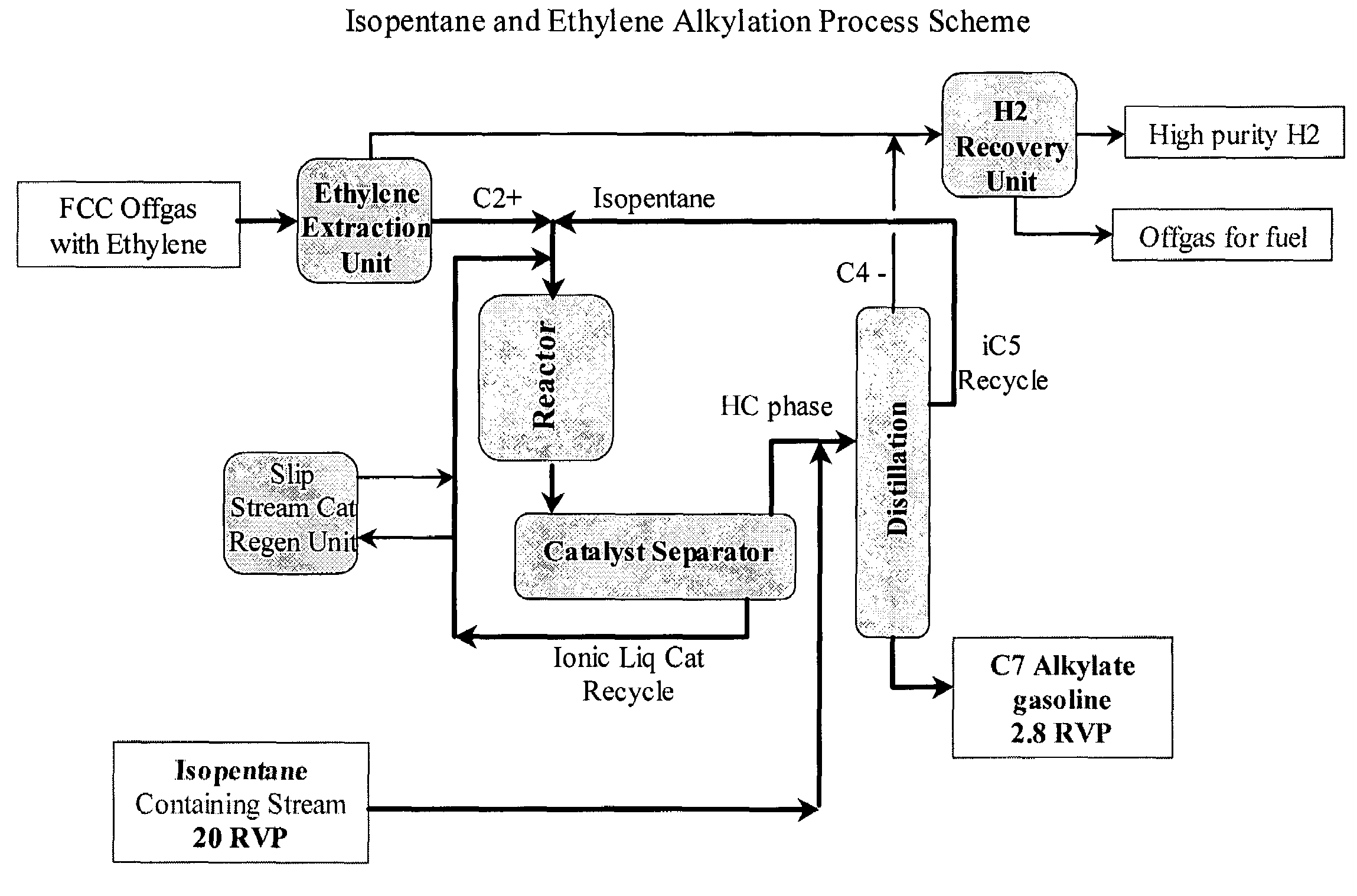

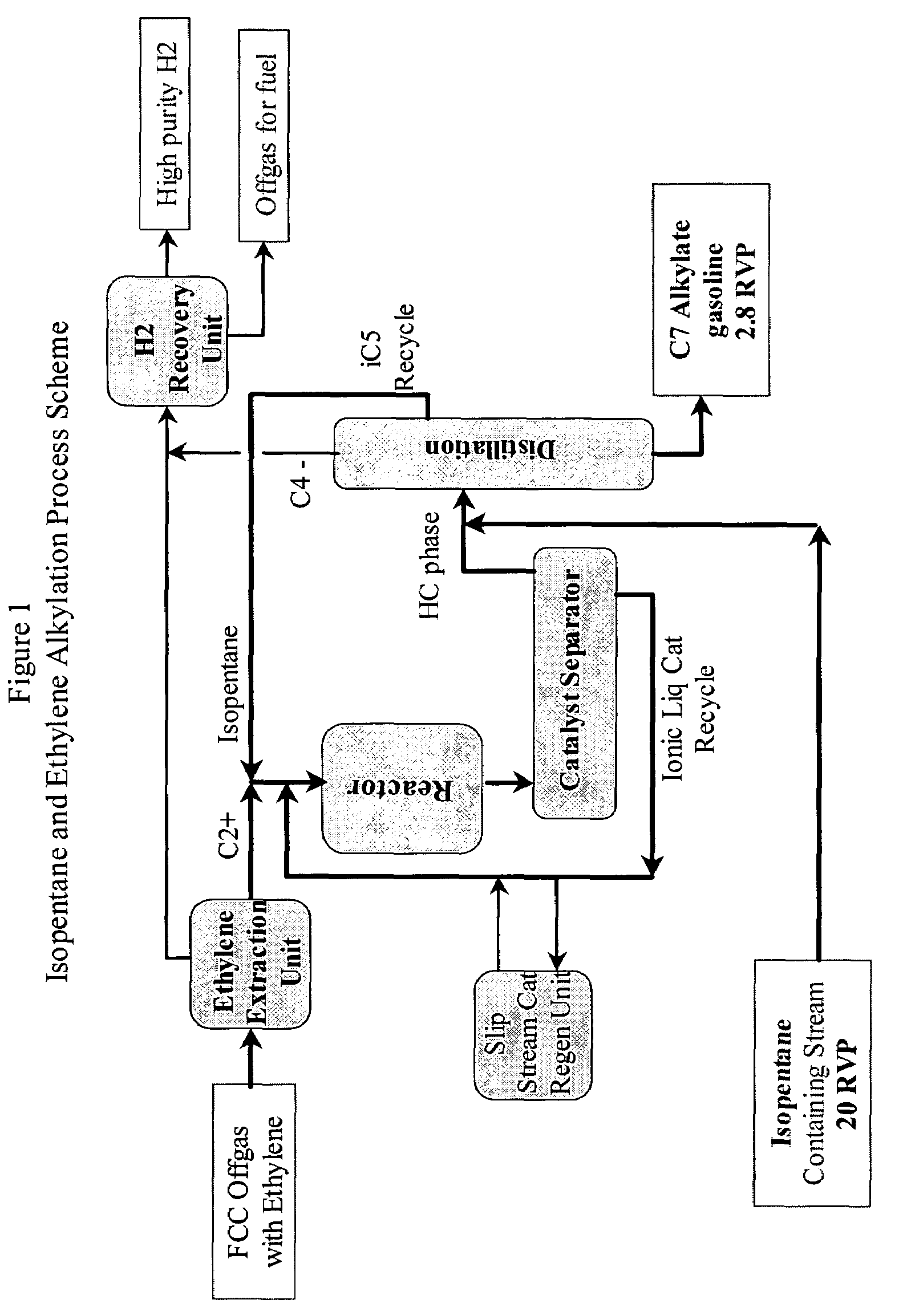

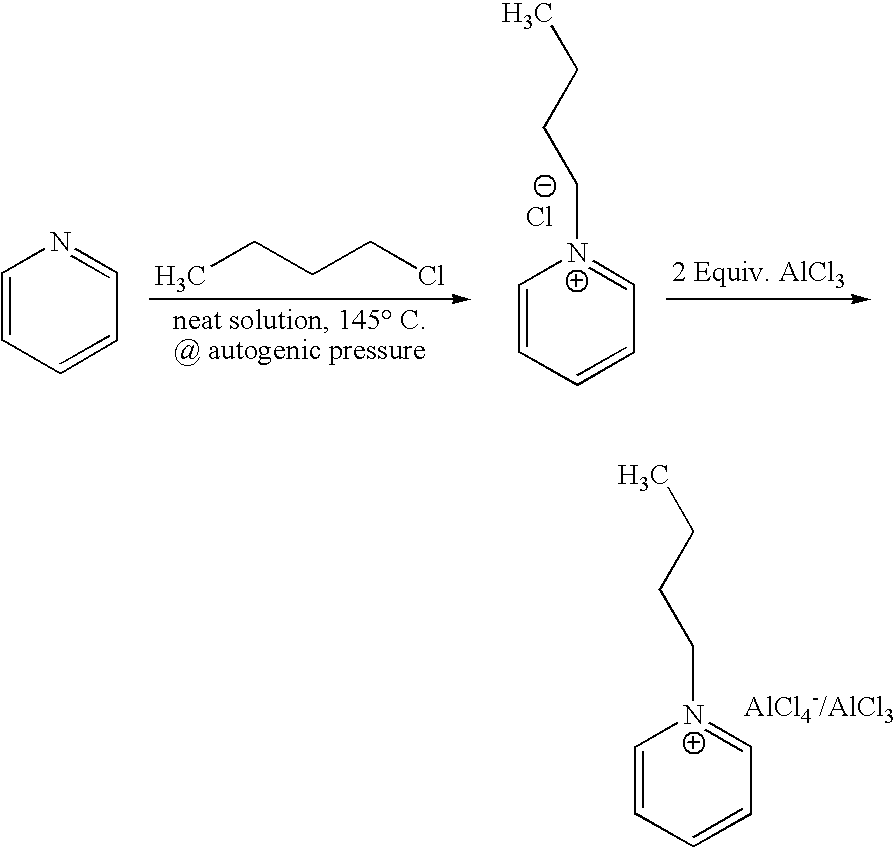

Integrated alkylation process using ionic liquid catalysts

ActiveUS7432408B2Easy to operateReduce gas productionLiquid hydrocarbon mixtures productionRefining with metal saltsAlkyl transferGasoline

An integrated refining process for the production of high quality gasoline blending components from low value components is disclosed. In addition there is disclosed a method of improving the operating efficiency of a refinery by reducing fuel gas production and simultaneously producing high quality gasoline blending components of low volatility. The processes involve the alkylation of a refinery stream containing pentane with ethylene using an ionic liquid catalyst.

Owner:CHEVROU USA INC

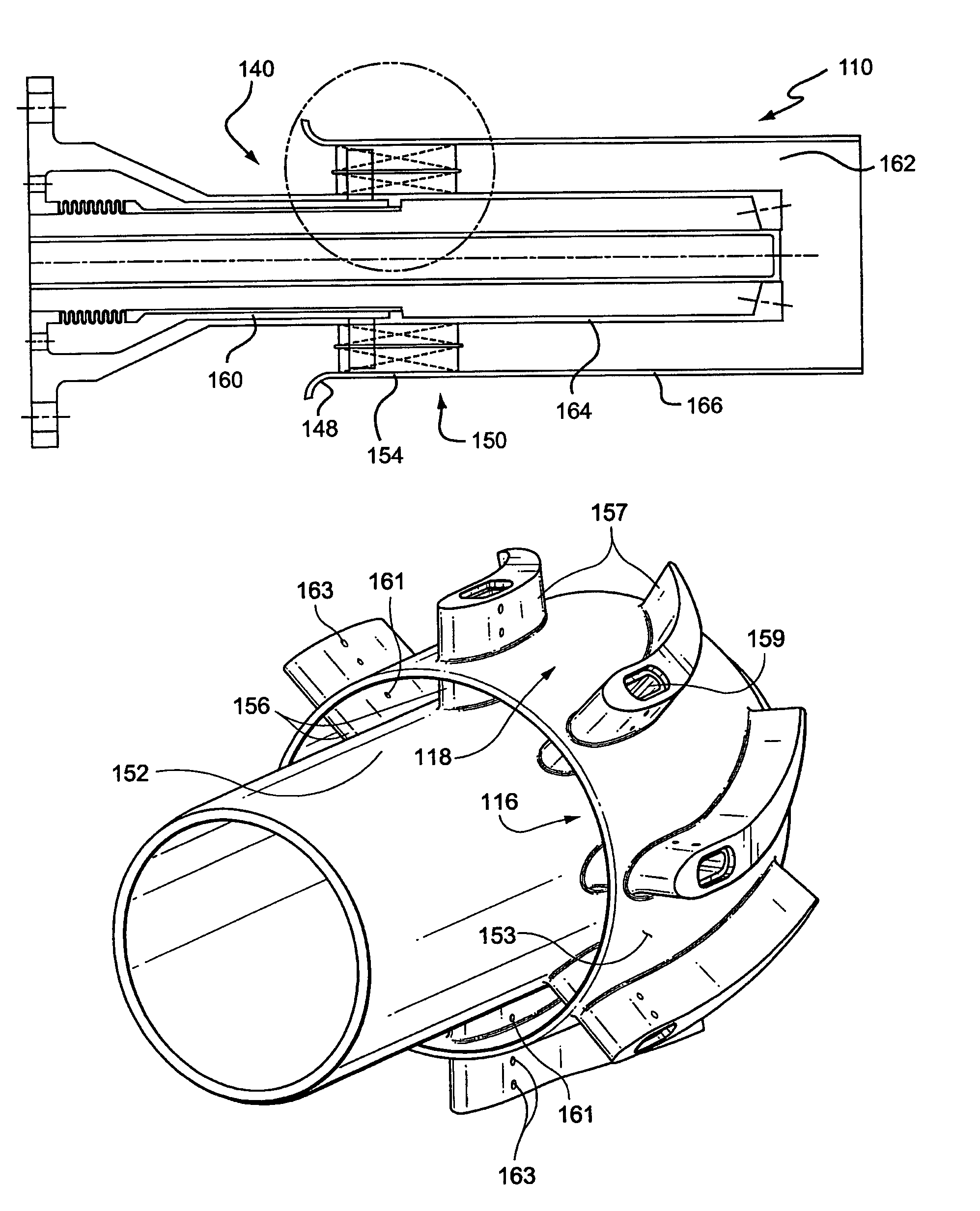

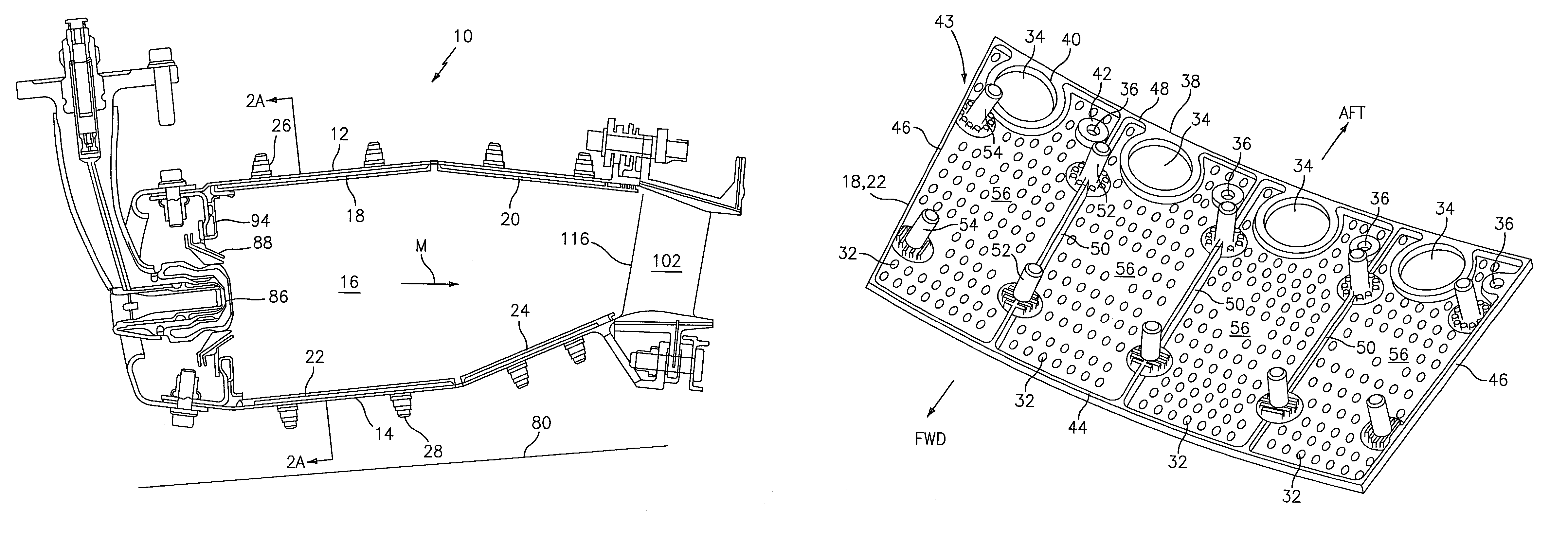

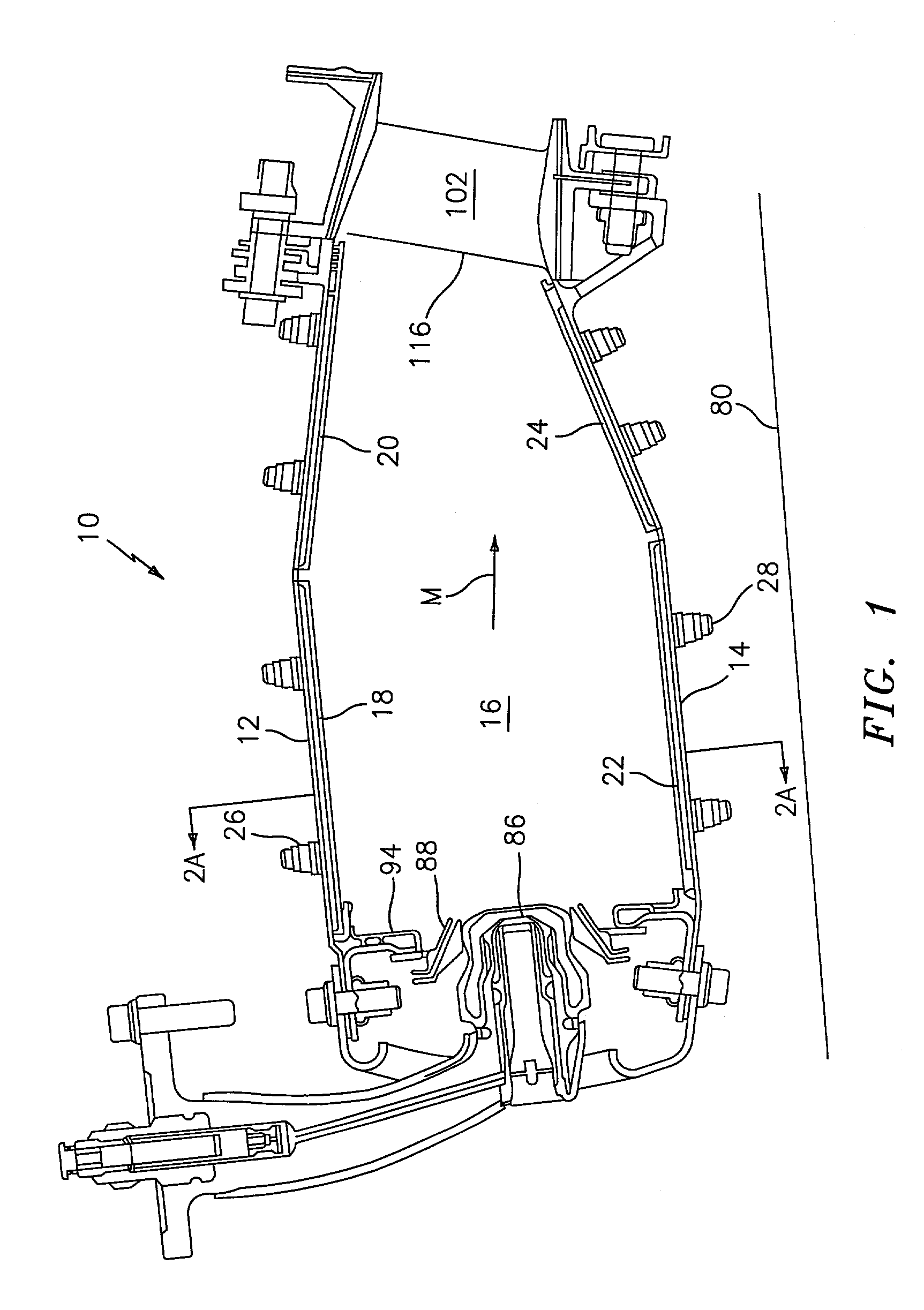

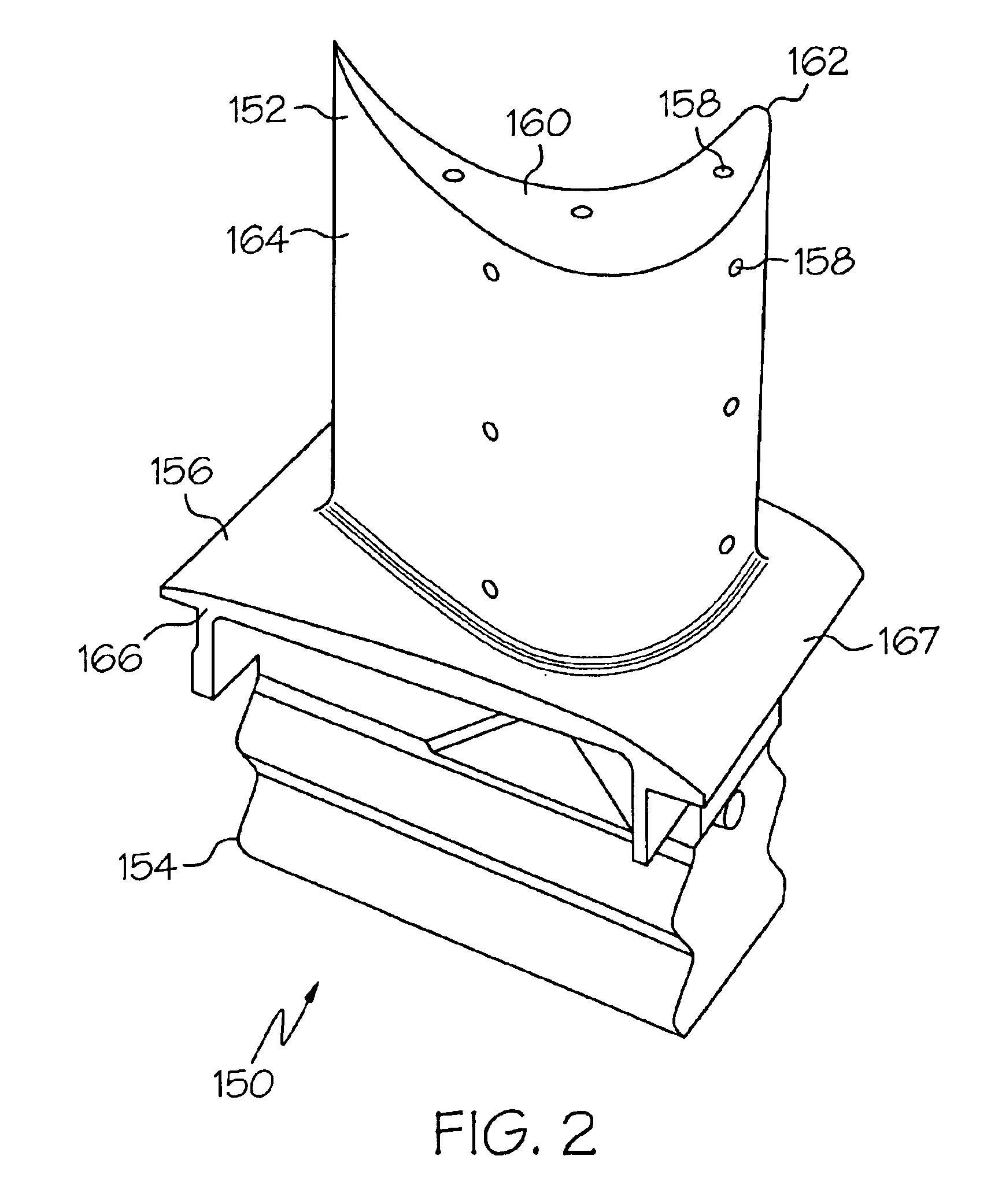

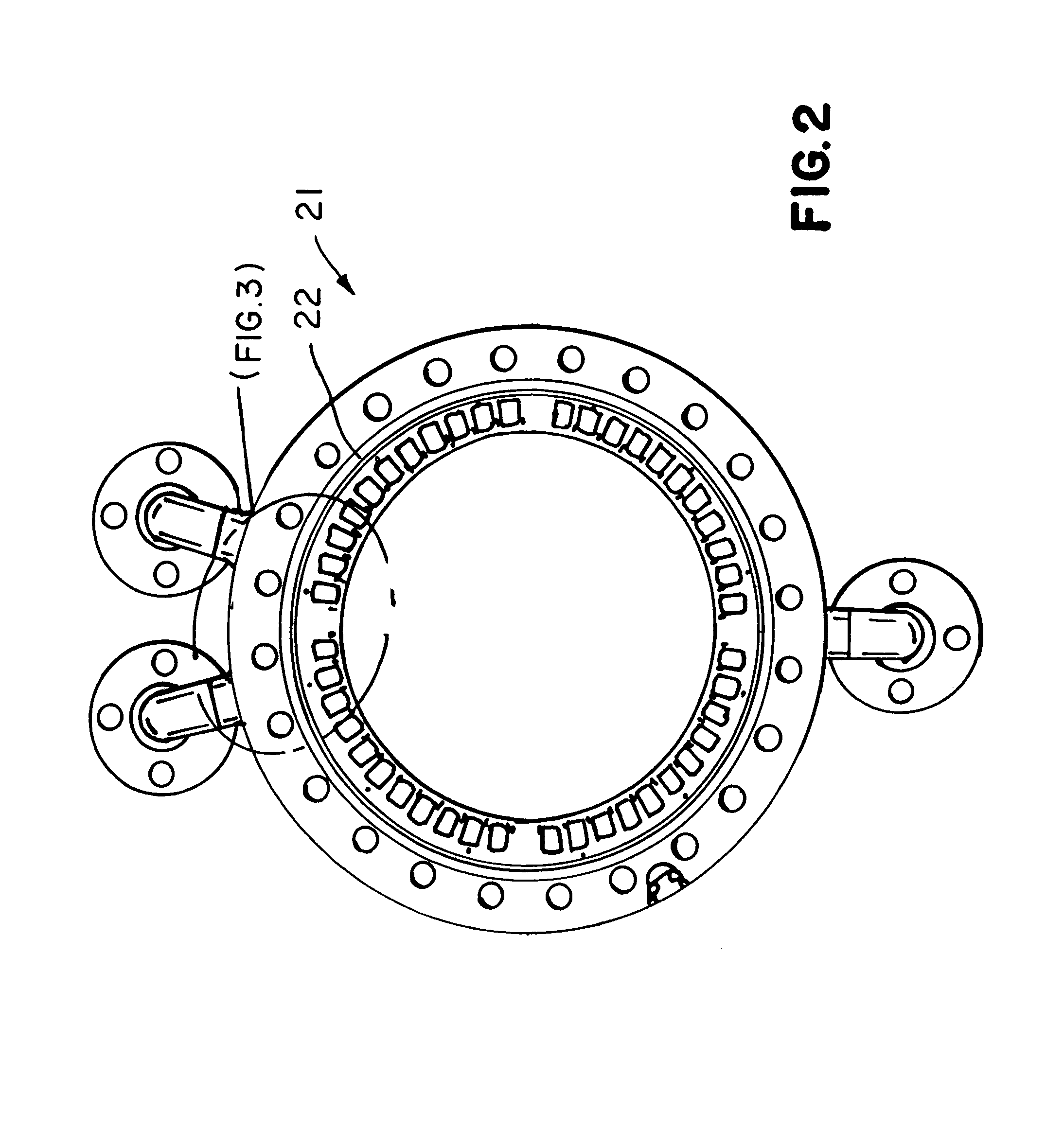

Heat shield panels for use in a combustor for a gas turbine engine

ActiveUS7093439B2Extended service lifeContinuous combustion chamberGas turbine plantsCold sideCombustor

The present invention relates to heat shield panels or liners to be used in combustors for gas turbine engines. The heat shield panels each comprise a hot side and a cold side and at least one isolated cooling chamber on the cold side. Each cooling chamber has a plurality of cooling film holes for allowing a coolant, such as air, to flow from the cold side to the hot side. A combustor having an arrangement of heat shield panels or liners is also described.

Owner:RAYTHEON TECH CORP

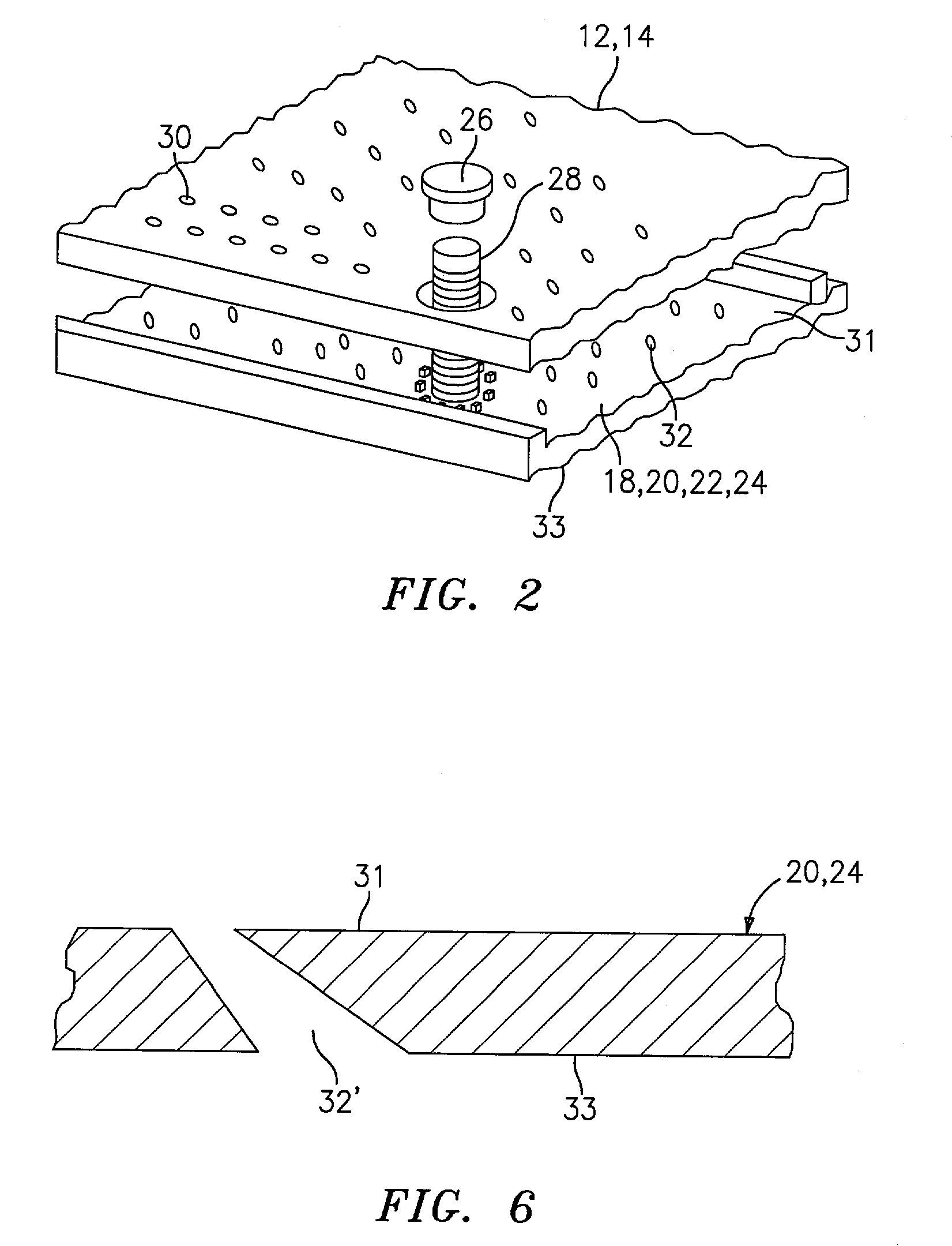

Z-filter media with reverse-flow cleaning systems and methods

A method for cleaning a filter having Z-media includes providing a filter having Z-media and cleaning the media construction by directing a pulse of compressed gas into the media construction through the downstream flow face. Filter elements useable with such methods include elements made of Z-media. An example system utilizing the method includes a gas turbine air intake system.

Owner:DONALDSON CO INC

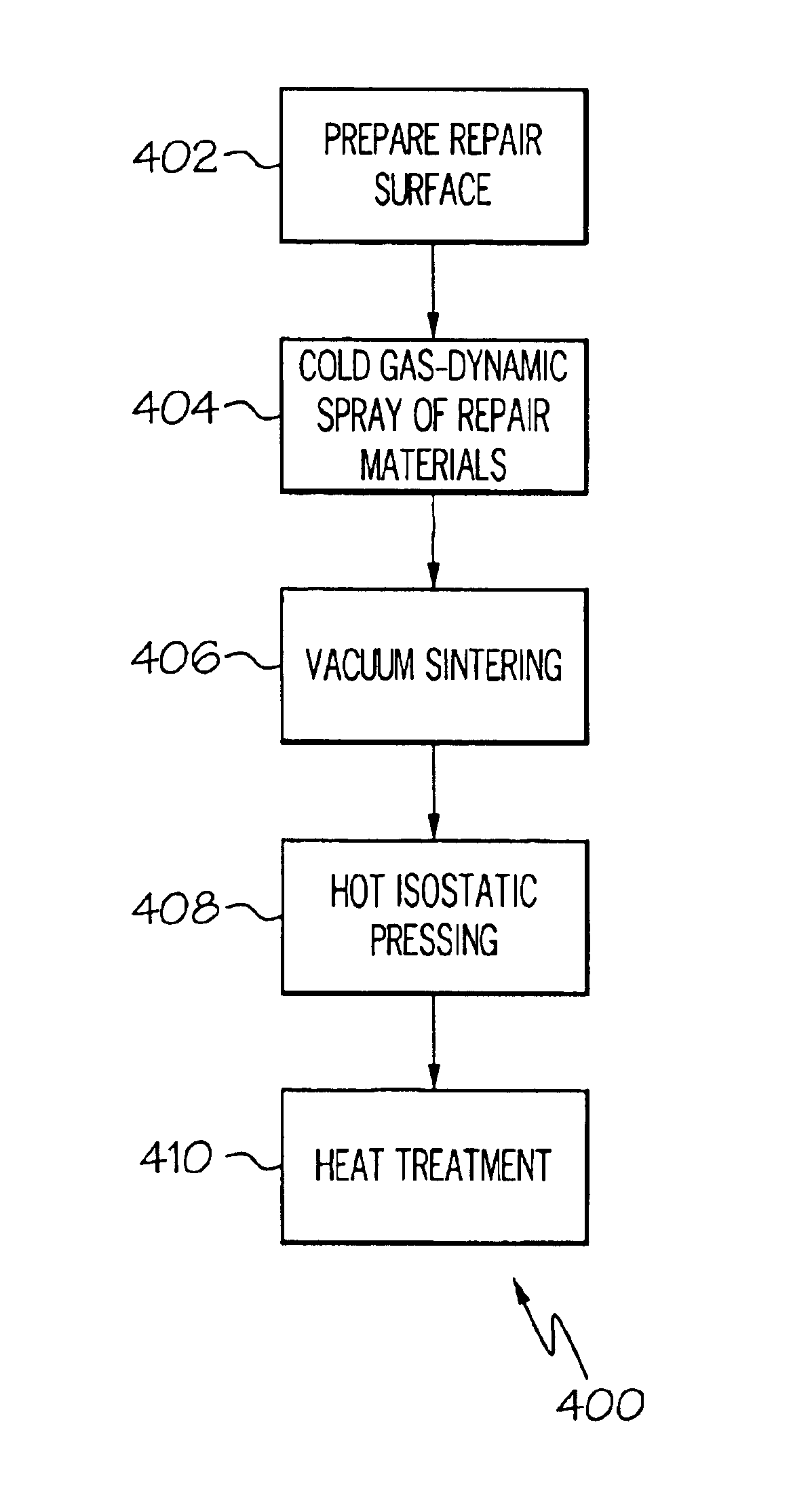

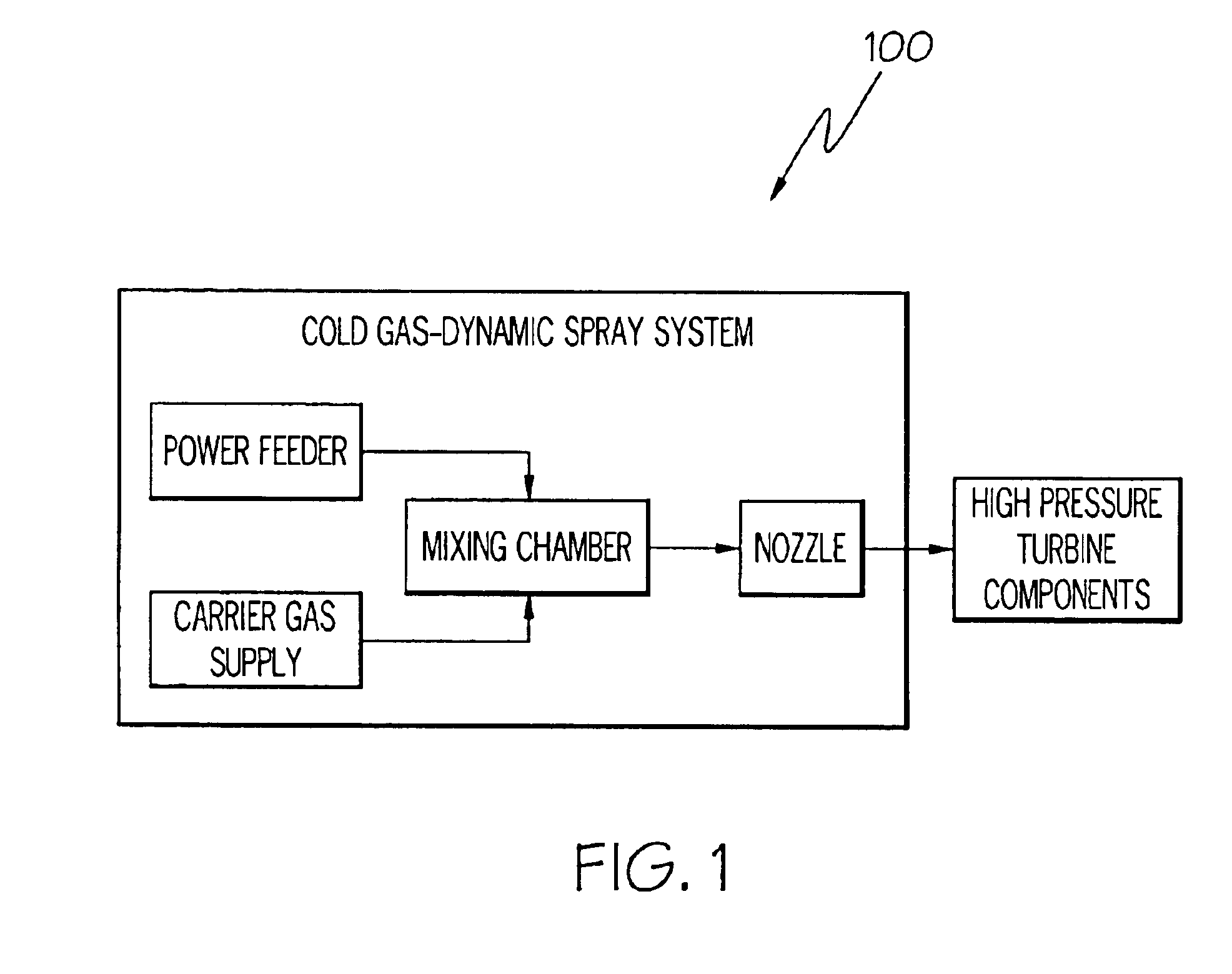

Cold gas-dynamic spray repair on gas turbine engine components

ActiveUS6905728B1Simple methodEasy to weldLayered productsBlade accessoriesTarget surfaceTurbine blade

A new method for repairing turbine engine components is provided. The method utilizes a cold gas-dynamic spray technique to repair degradation on turbine blades, vanes and other components. In the cold gas-dynamic spray process particles at a temperature below their fusing temperature are accelerated and directed to a target surface on the turbine blade. When the particles strike the target surface, the kinetic energy of the particles is converted into plastic deformation of the particle, causing the particle to form a strong bond with the target surface. Post-spray processing is then performed to consolidate and homogenize the applied materials and restore integrity to the material properties in the repaired turbine component. Thus, the cold gas-dynamic spray process and post-spray processing can be employed to effectively repair degraded areas on gas turbine components.

Owner:HONEYWELL INT INC

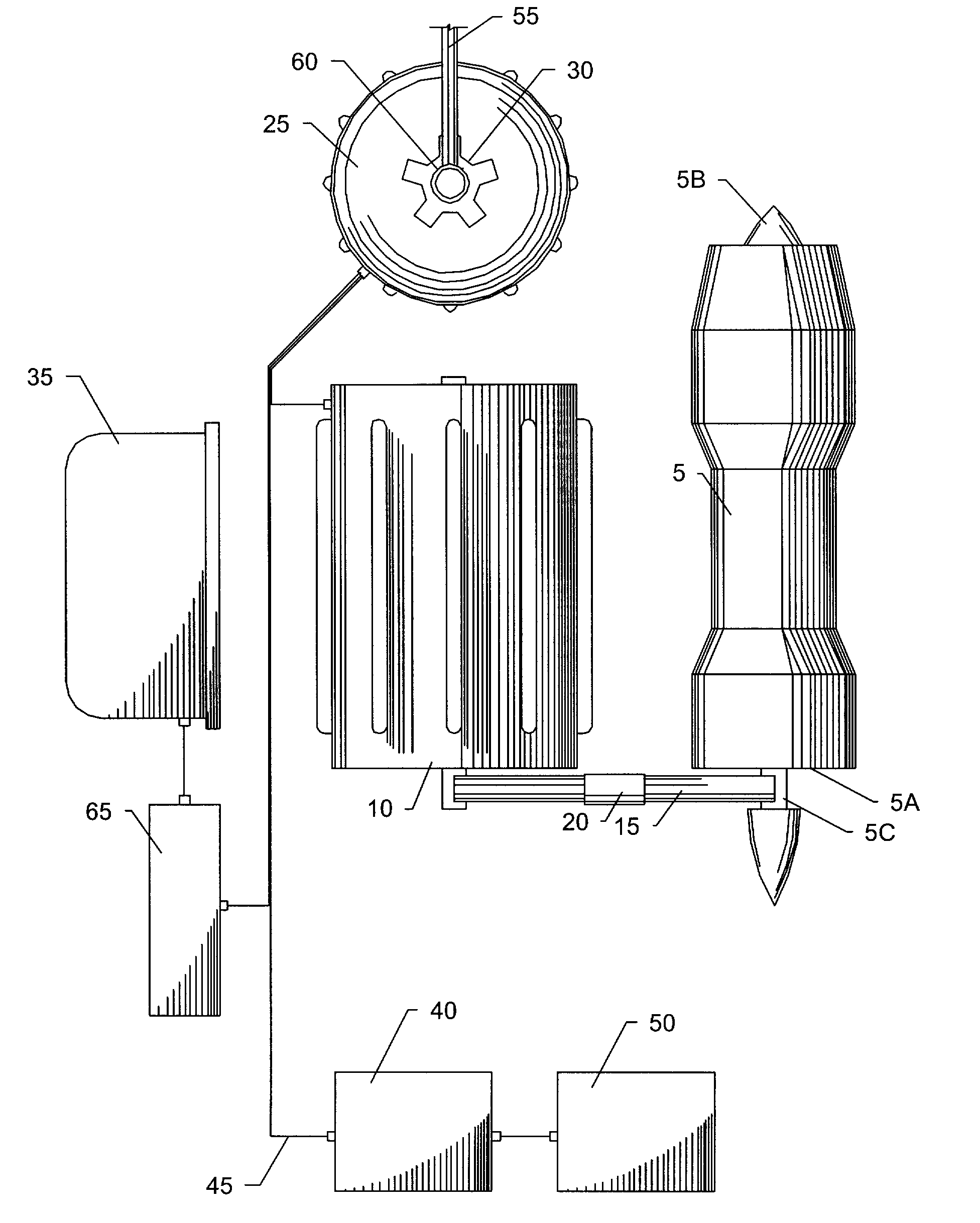

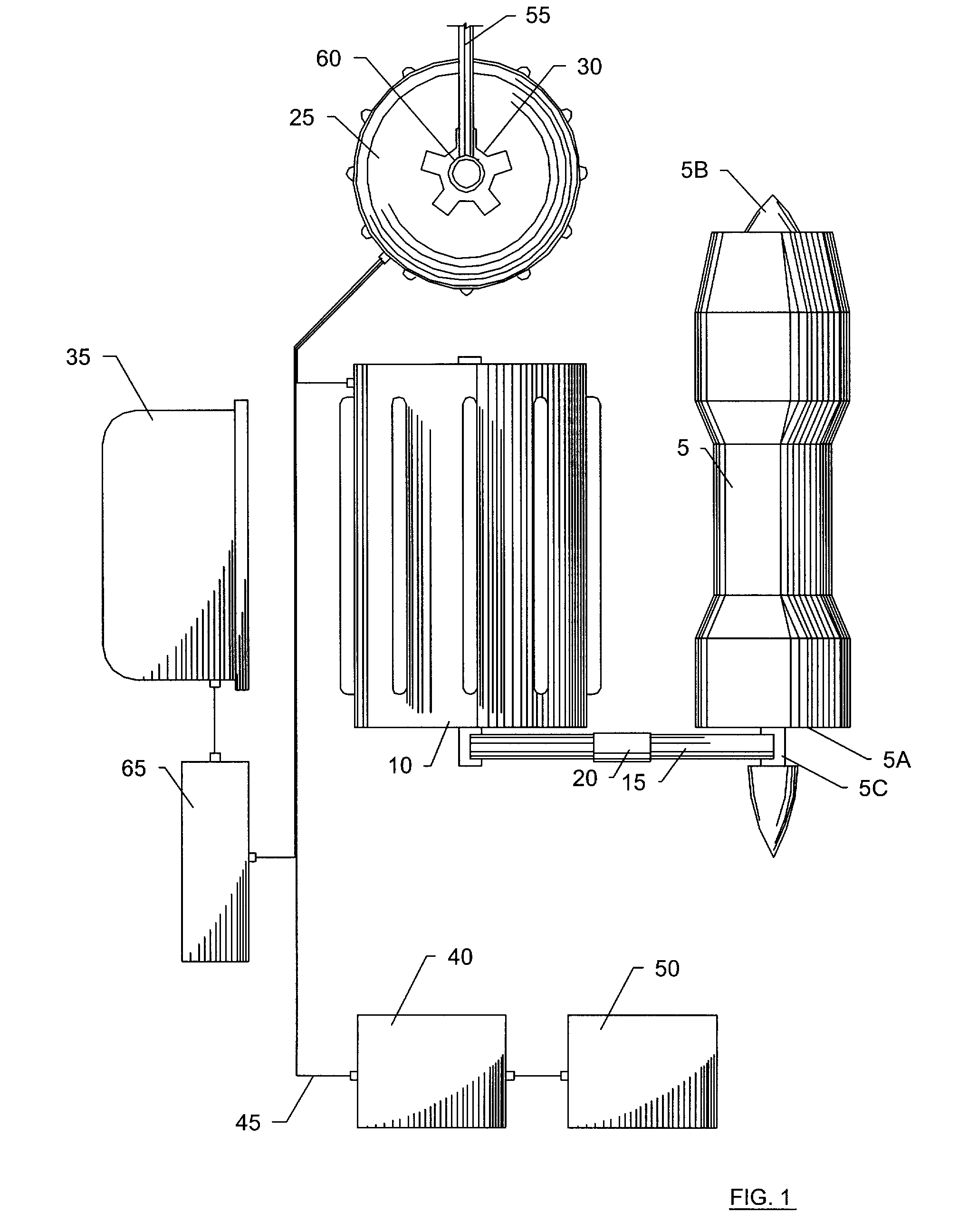

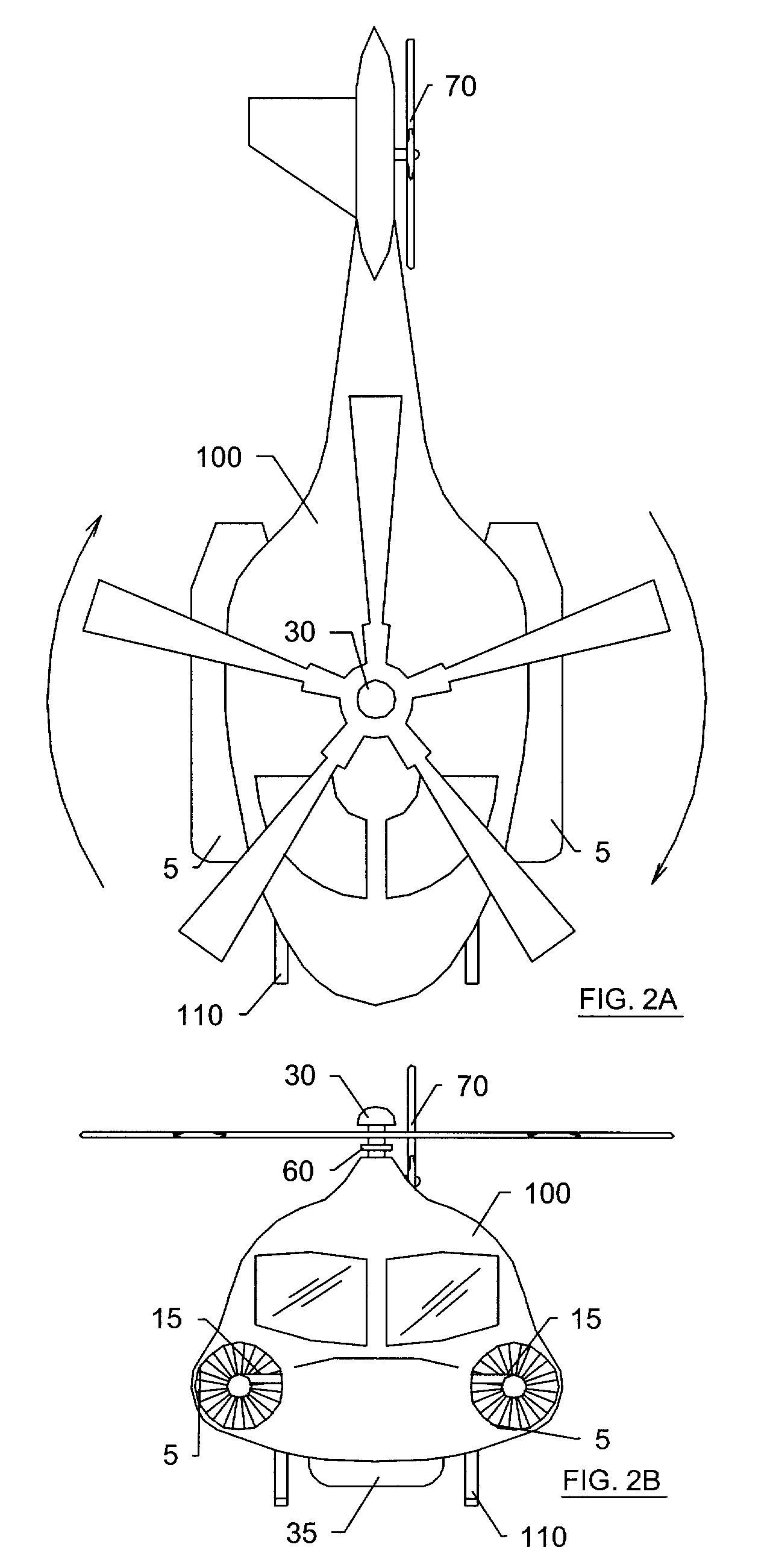

Aircraft using turbo-electric hybrid propulsion system

InactiveUS20090145998A1Reduce usageAnalogue computers for vehiclesGas turbine type power plantsFlight vehicleCoupling

An air vehicle incorporating a hybrid propulsion system. The system includes a gas turbine engine as a first motive power source, and one or more battery packs as a second motive power source. Through selective coupling to a DC electric motor that can in turn be connected to a bladed rotor or other lift-producing device, the motive sources provide differing ways in which an aircraft can operate. In one example, the gas turbine engine can provide operation for a majority of the flight envelope of the aircraft, while the battery packs can provide operation during such times when gas turbine-based motive power is unavailable or particularly disadvantageous. In another example, both sources of motive power may be decoupled from the bladed rotor such that the vehicle can operate as an autogyro.

Owner:SALYER IVAL O

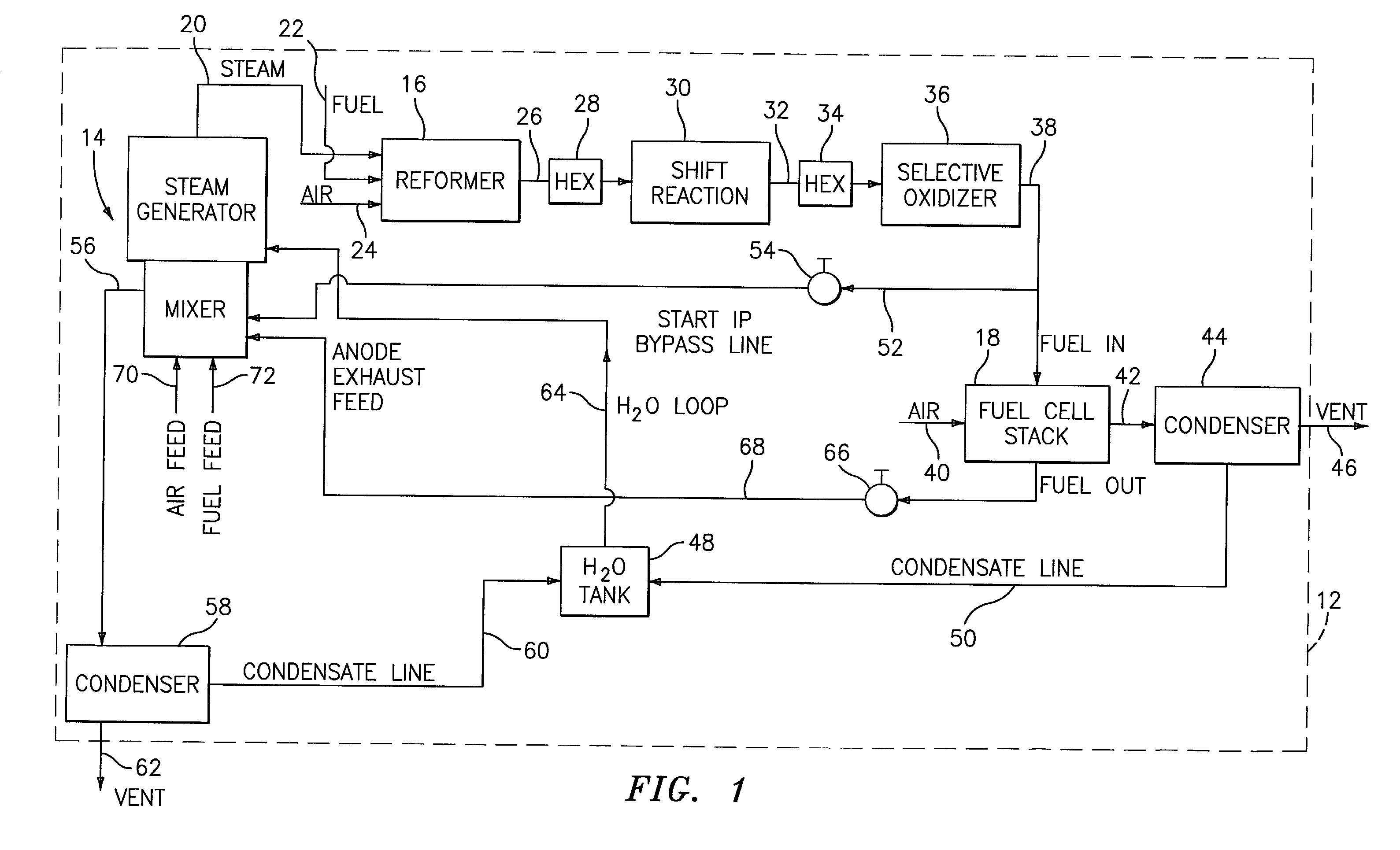

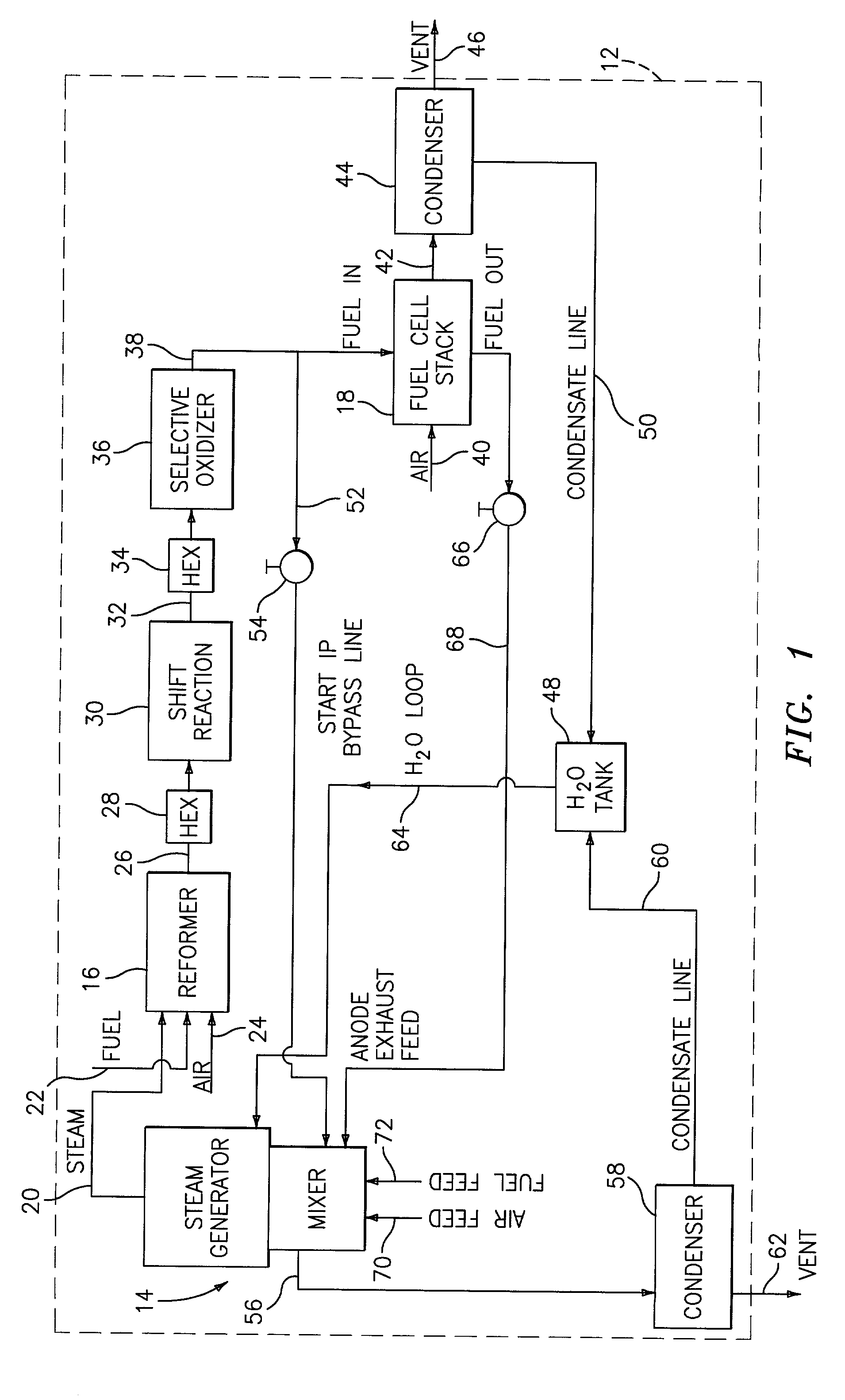

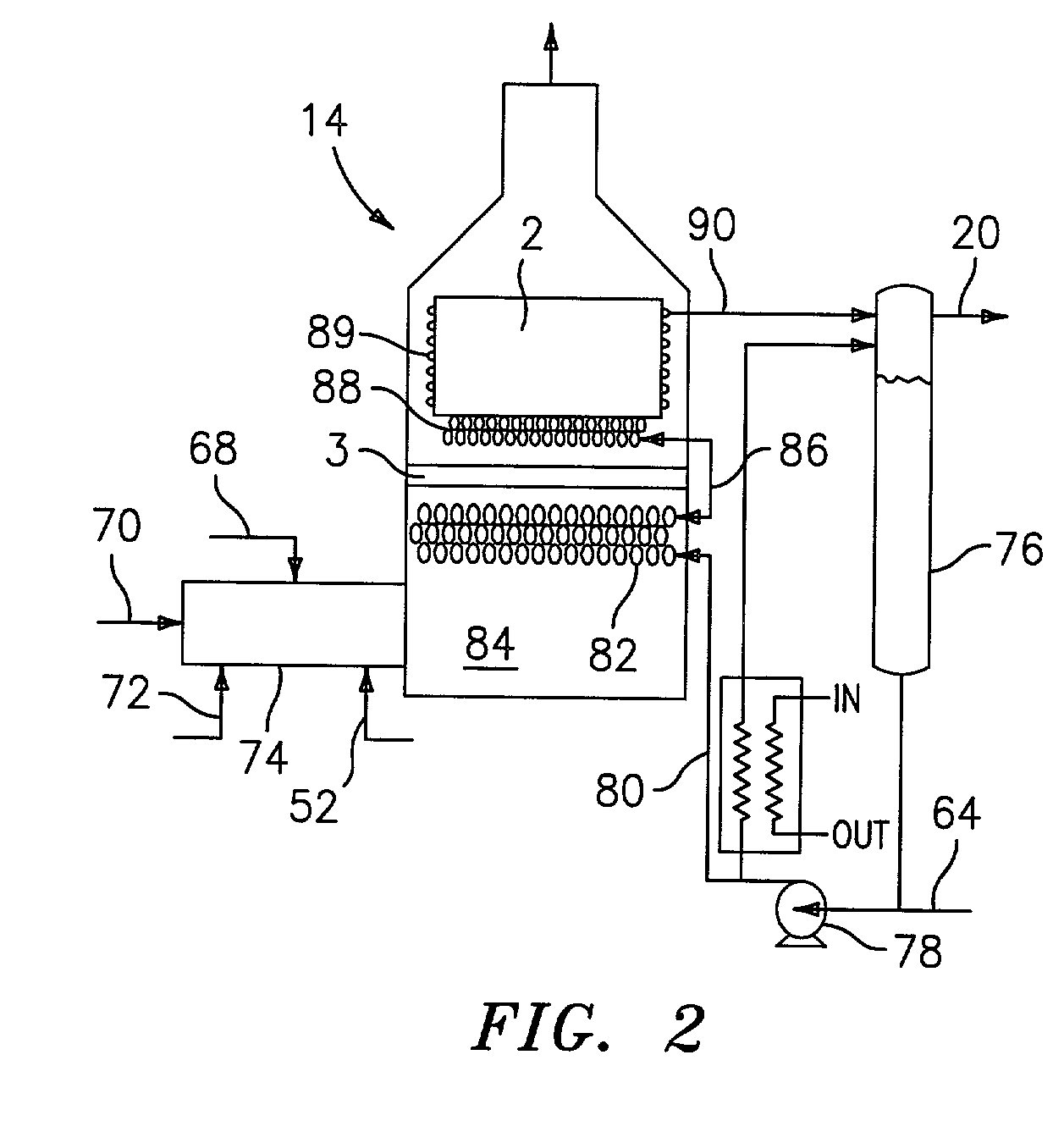

Steam generator for a PEM fuel cell power plant

A burner assembly includes a catalyzed burner for combusting an anode exhaust stream from a polymer electrolyte membrane (PEM) fuel cell power plant. The catalysts coated onto the burner can be platinum, rhodium, or mixtures thereof. The burner includes open cells which are formed by a lattice, which cells communicate with each other throughout the entire catalyzed burner. Heat produced by combustion of hydrogen in the anode exhaust stream is used to produce steam for use in a steam reformer in the PEM fuel cell assembly. The catalyzed burner has a high surface area wherein about 70-90% of the volume of the burner is preferably open cells, and the burner has a low pressure drop of about two to three inches water from the anode exhaust stream inlet to the anode exhaust stream outlet . The burner assembly operates at essentially ambient pressure and at a temperature of up to about 1,700° F. (646° C.). The burner assembly can combust anode exhaust during normal operation of the fuel cell assembly. The burner assembly also includes an adjunct burner which can combust gasoline or anode bypass gas (the latter of which is a reformed fuel gas which is tapped off of the fuel cell stack fuel inlet line) during startup of the fuel cell power plant. Once start up of the fuel cell power plant is achieved, the burner assembly will need only combustion of the anode exhaust by the catalytic burner to produce steam for the reformer.

Owner:BALLARD POWER SYSTEMS

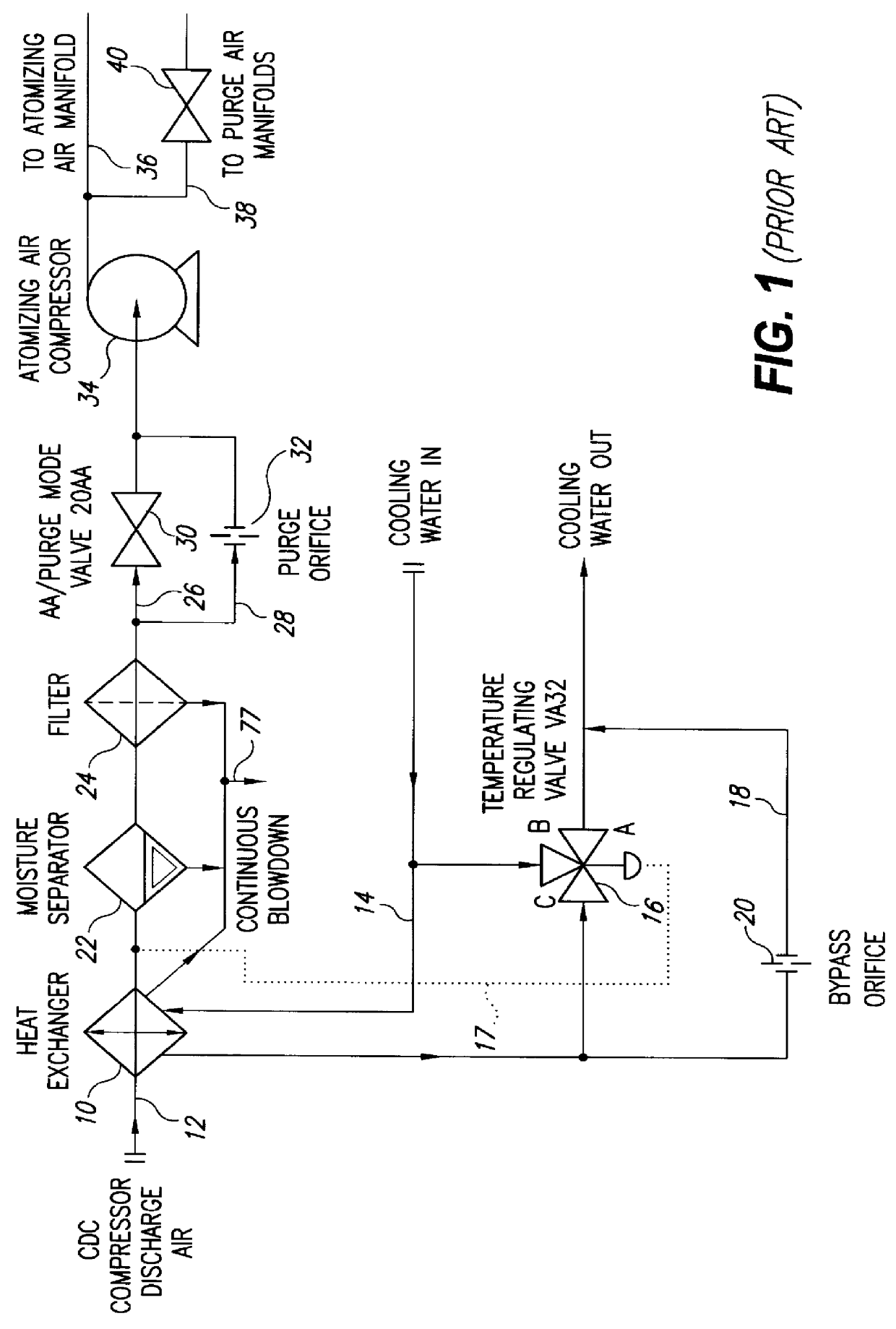

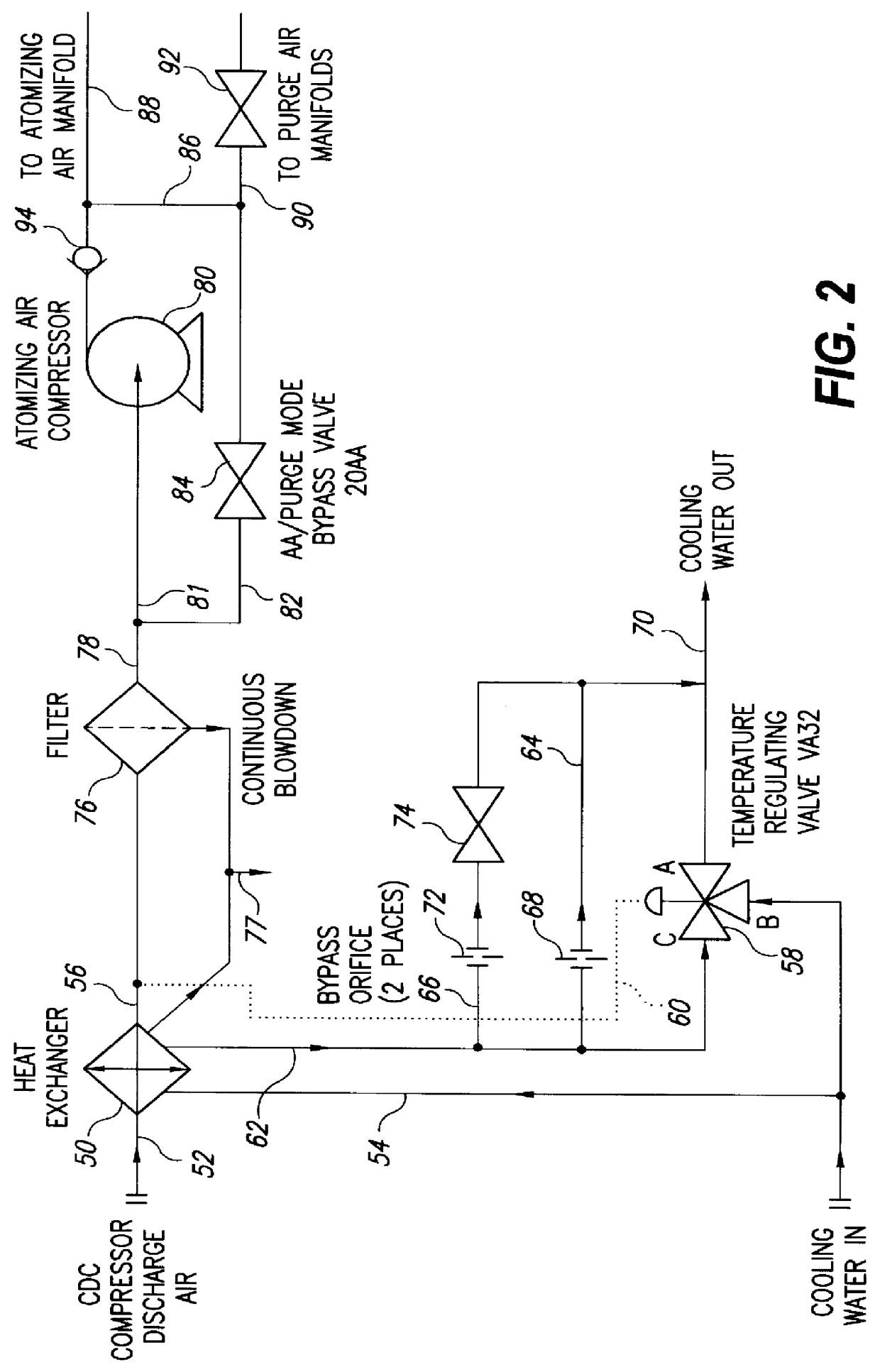

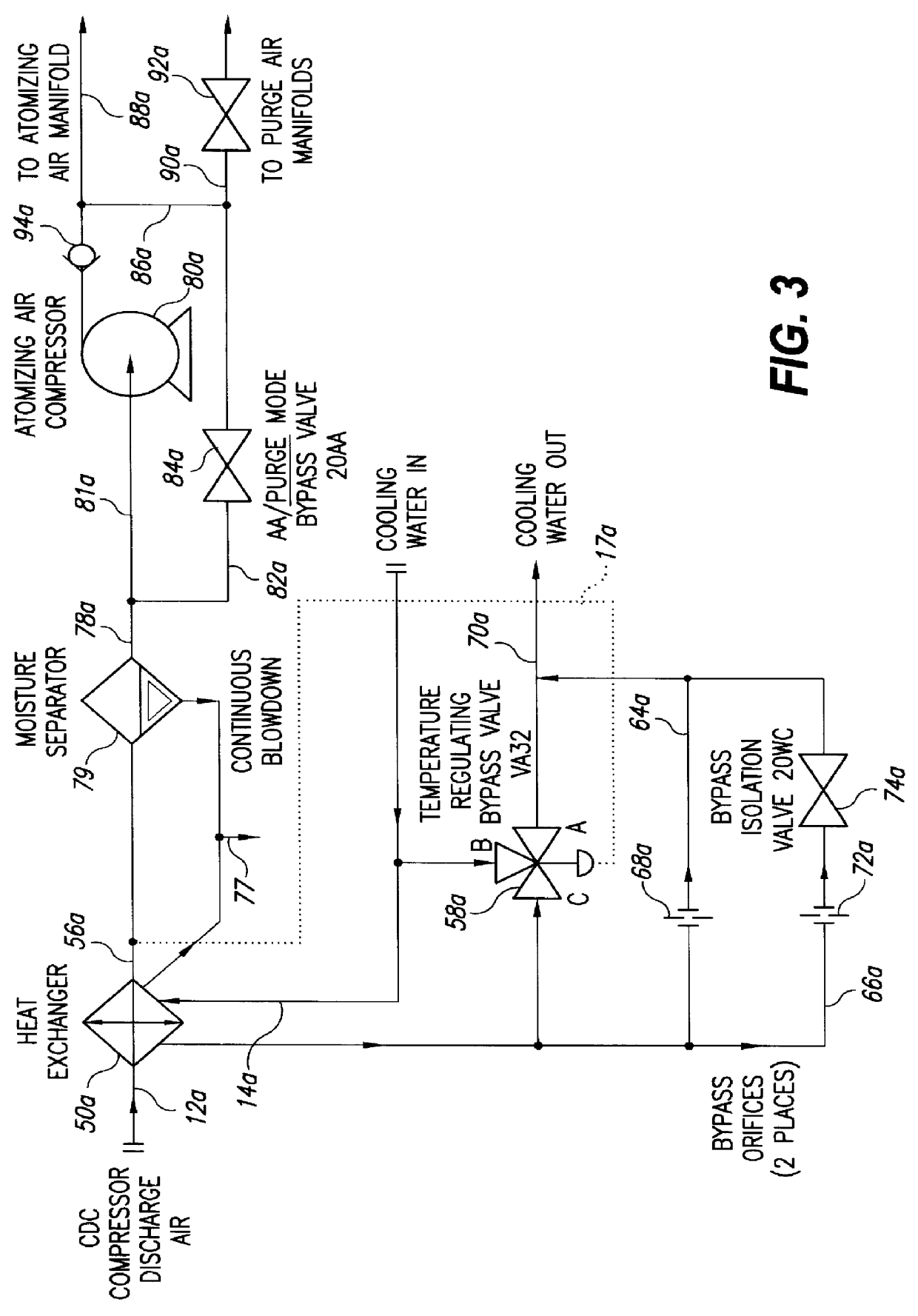

Dual orifice bypass system for dual-fuel gas turbine

InactiveUS6145318AReduce trafficAvoid heat buildupBurner safety arrangementsBurnersCombustorHeat rejection

Compressor discharge air flows through a heat exchanger in heat exchange relation with cooling water and is supplied at reduced temperature in atomizing air and purge modes to combustors in a dual-fuel gas turbine. The heat exchanger has a pair of bypass passages in parallel with a temperature regulating valve controlling flow of water through the heat exchanger in response to the temperature of the compressor discharge air exiting the heat exchanger. Should the flow control valve close in response to low temperature of the compressor discharge air, in the air atomizing mode, the bypass passages with orifices therein provide a minimum protective flow of cooling water to the heat exchanger. In the purge mode where only half the air flow and heat rejection is required in the heat exchanger and the flow control valve closes, a bypass valve in one of the bypass passages closes to enable reduced flow of cooling water through the heat exchanger.

Owner:GENERAL ELECTRIC CO

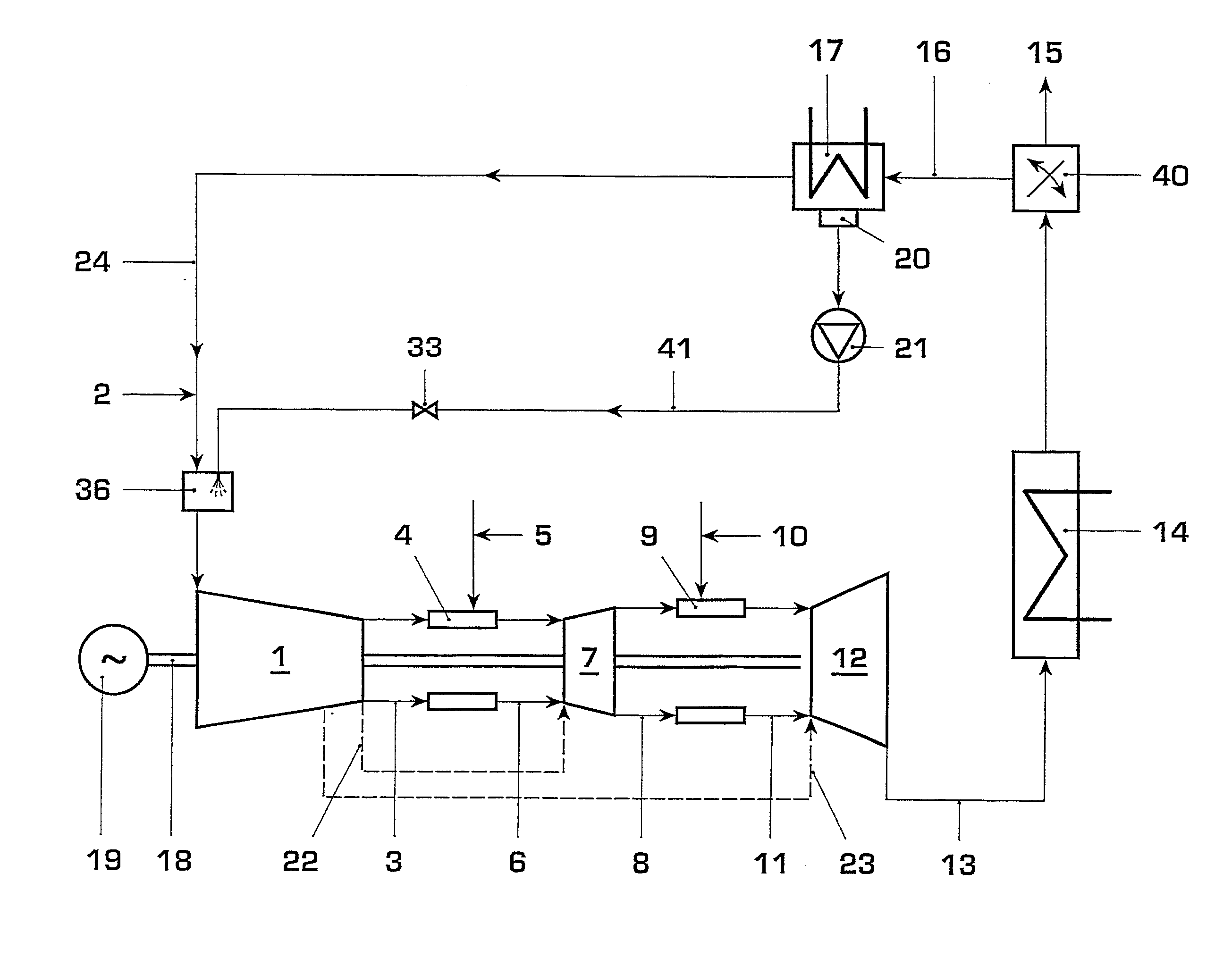

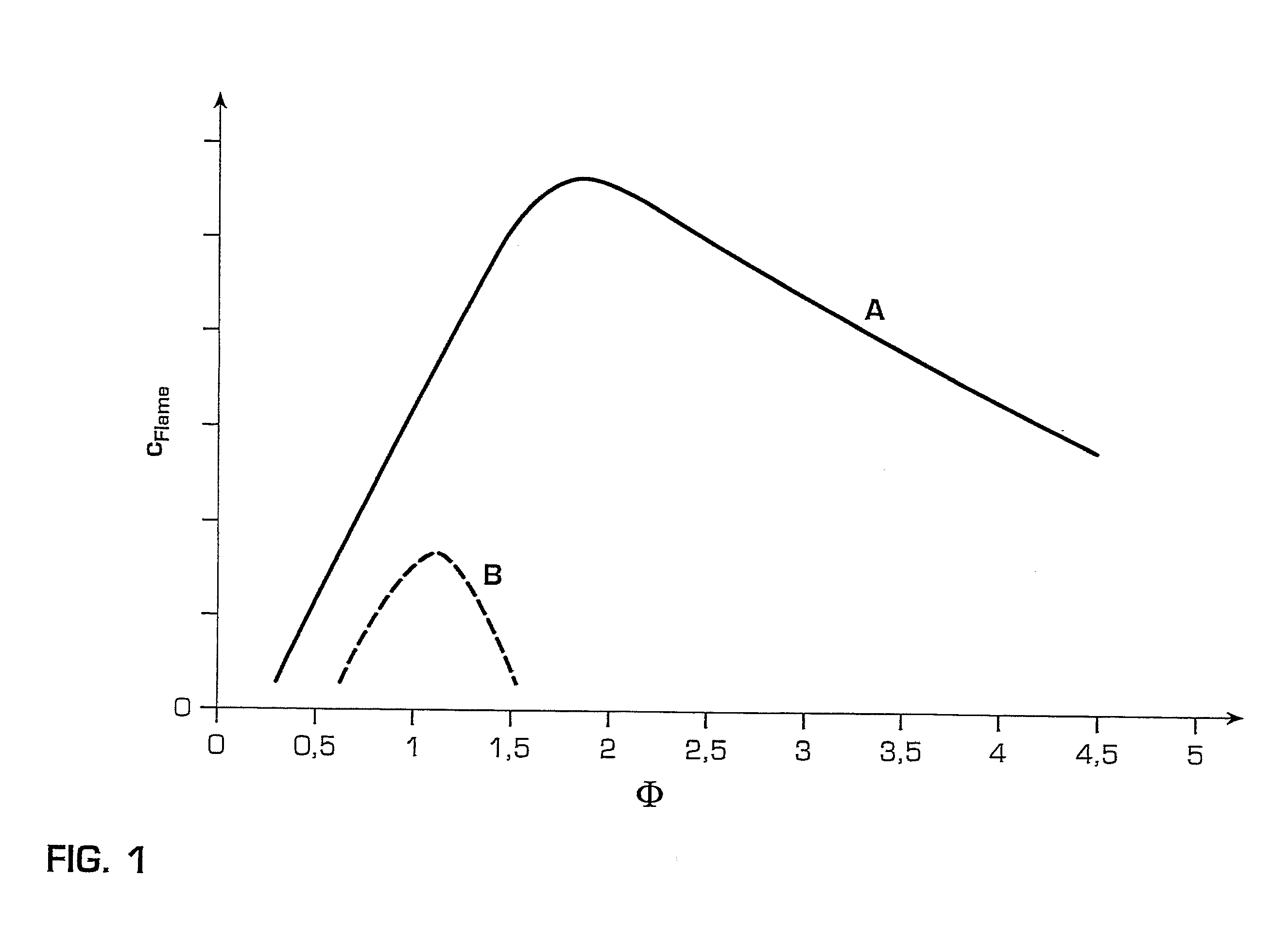

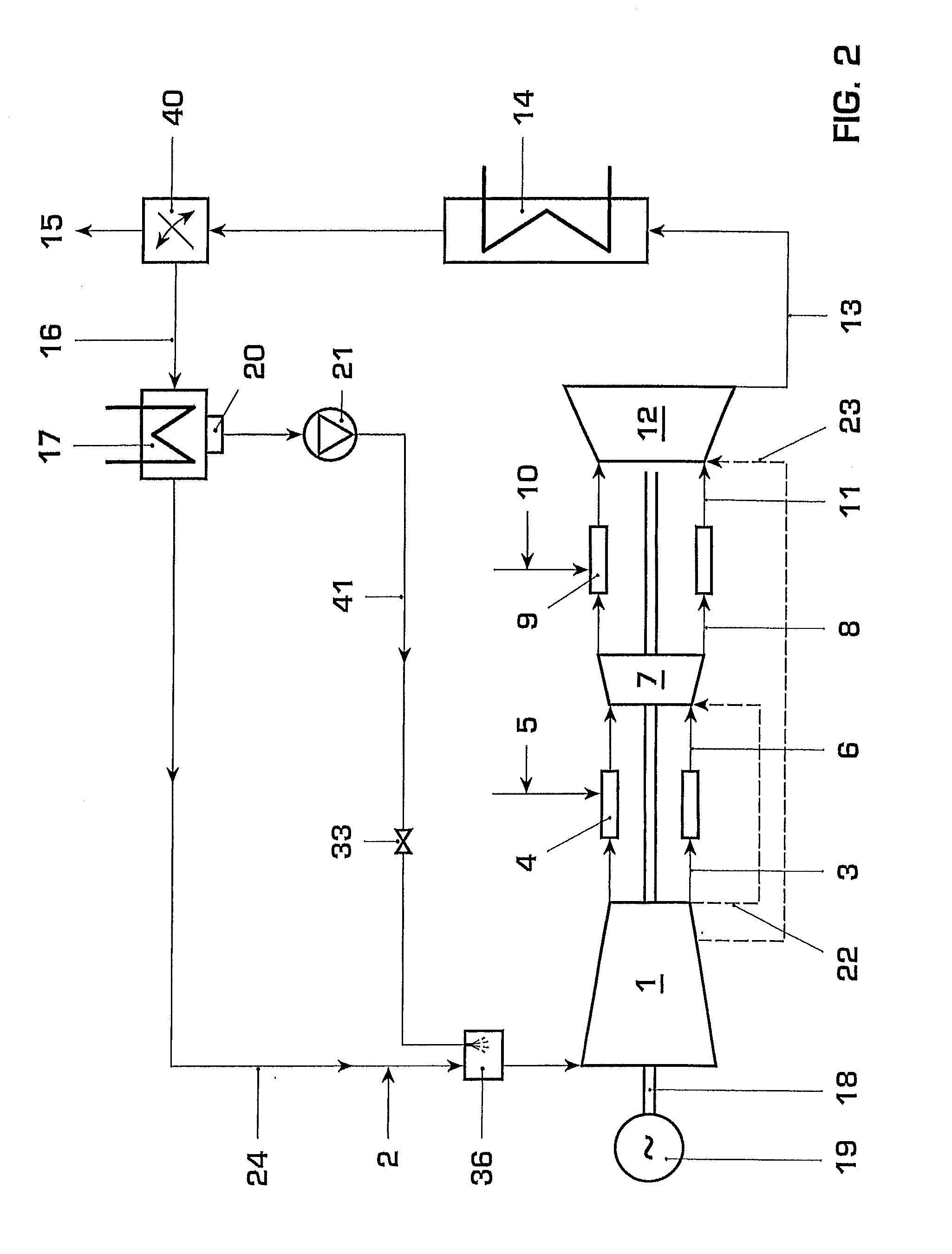

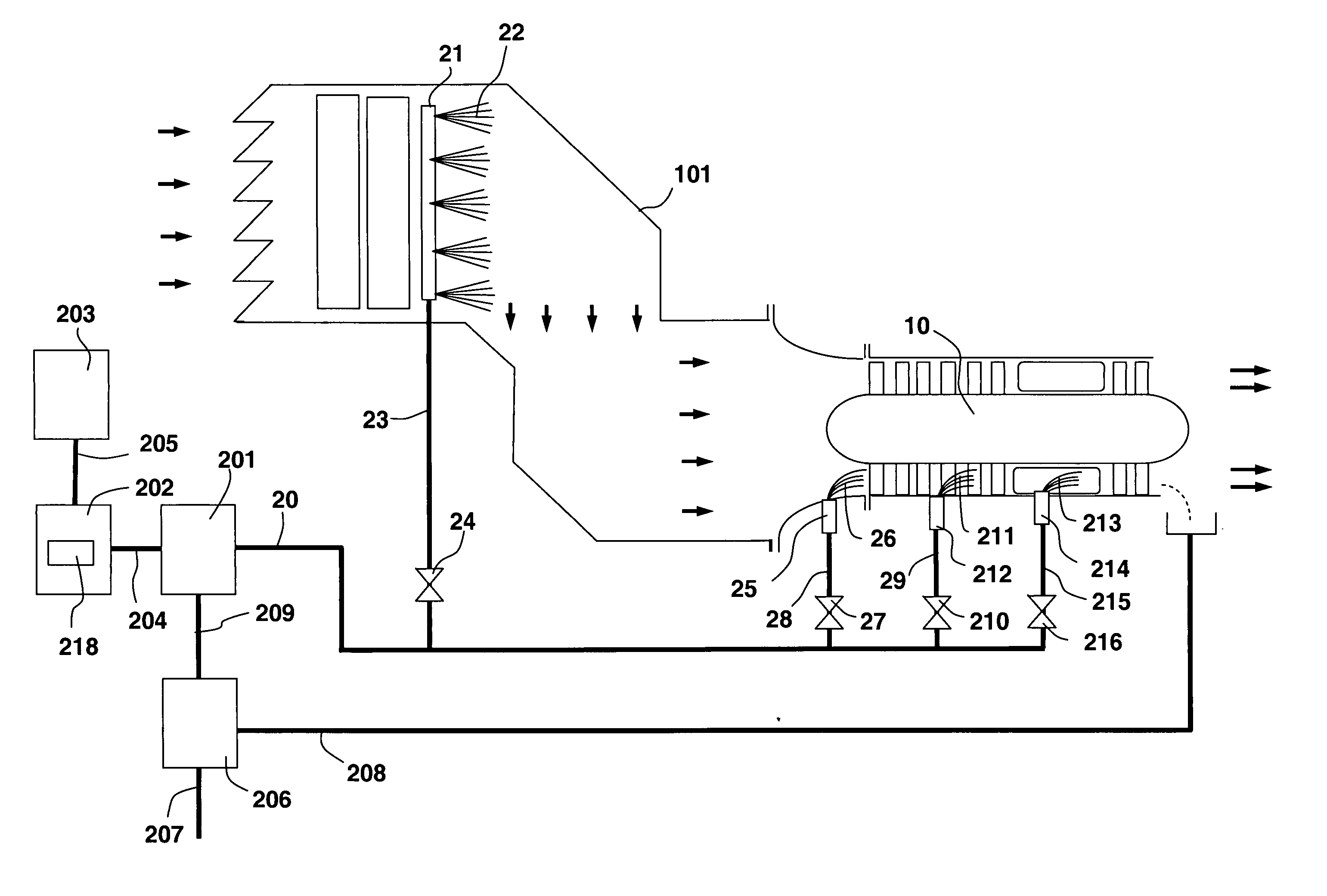

Gas Turbine Installation with Flue Gas Recirculation

A method and installation are disclosed which can, for example, provide for reliable, low-Nox-emission operation of a gas turbine installation with hydrogen-rich fuel gas. An exemplary gas turbine installation includes an arrangement for flue gas recirculation into a compressor inlet and for fuel gas dilution. Oxygen content in combustion air can be reduced by recirculation of recooled flue gas, and the fuel gas can be diluted with compressed flue gas. The oxygen reduction in the combustion air can lead to minimum residual oxygen in the flue gas which can be used for fuel gas dilution. As a result of the flue gas recirculation, water content in the combustion air can be increased by feedback of the water which results as a combustion product. The oxygen reduction, increased water content, and fuel dilution can reduce the flame velocity of hydrogen-rich fuel gases and enable a robust, reliable and low-emission combustion.

Owner:GENERAL ELECTRIC TECH GMBH

Method of operating a combustion system for increased turndown capability

ActiveUS7137256B1Emission reductionStable combustionContinuous combustion chamberGas turbine plantsCombustion systemLow load

A method of operating a gas turbine engine combustion system at lower load conditions while maintaining required emissions levels is disclosed. The present invention includes multiple embodiments of axial, radial, and circumferential fuel staging within a can-type combustor having alternate ignition techniques of spark ignition or torch ignition.

Owner:ANSALDO ENERGIA SWITZERLAND AG

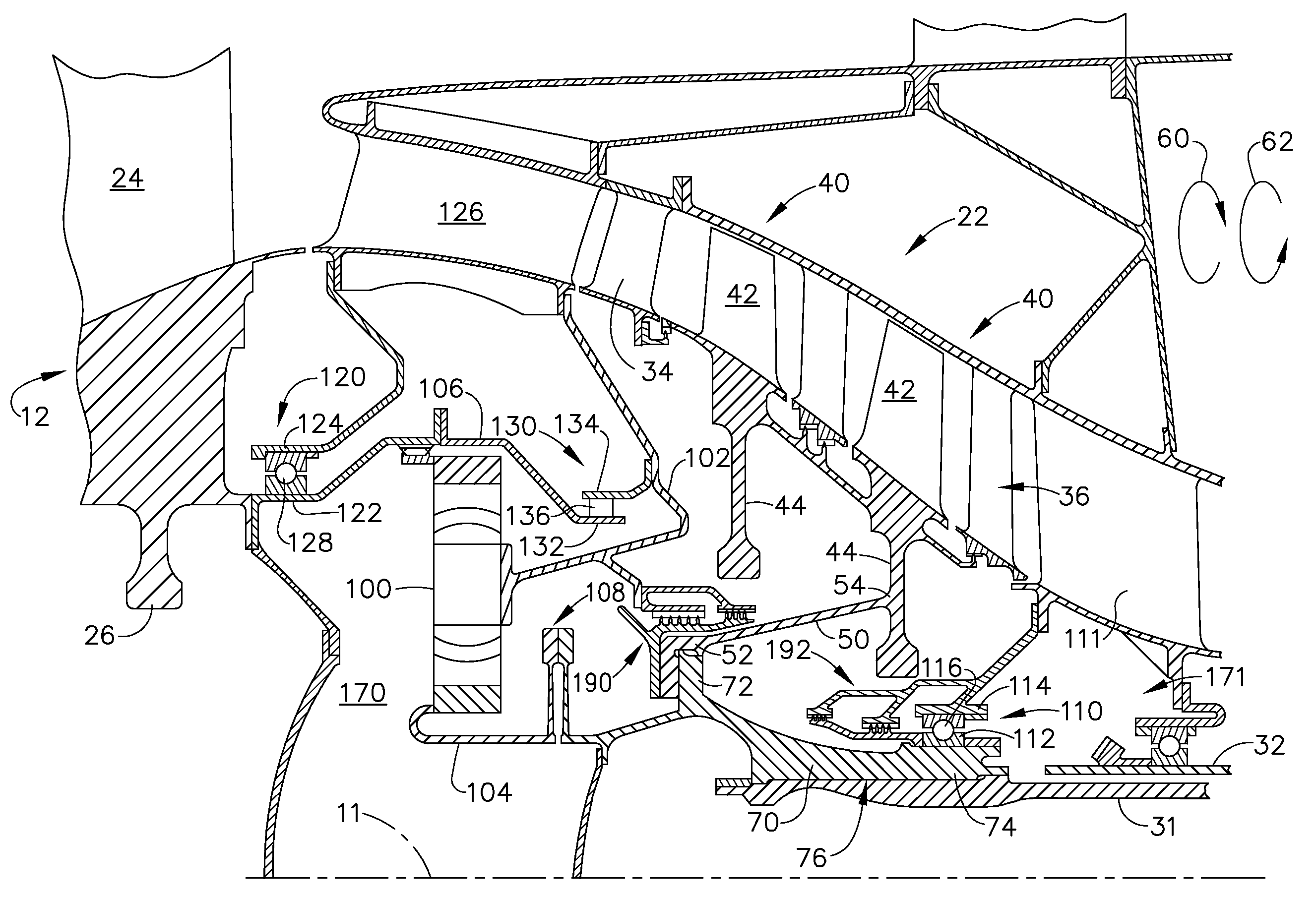

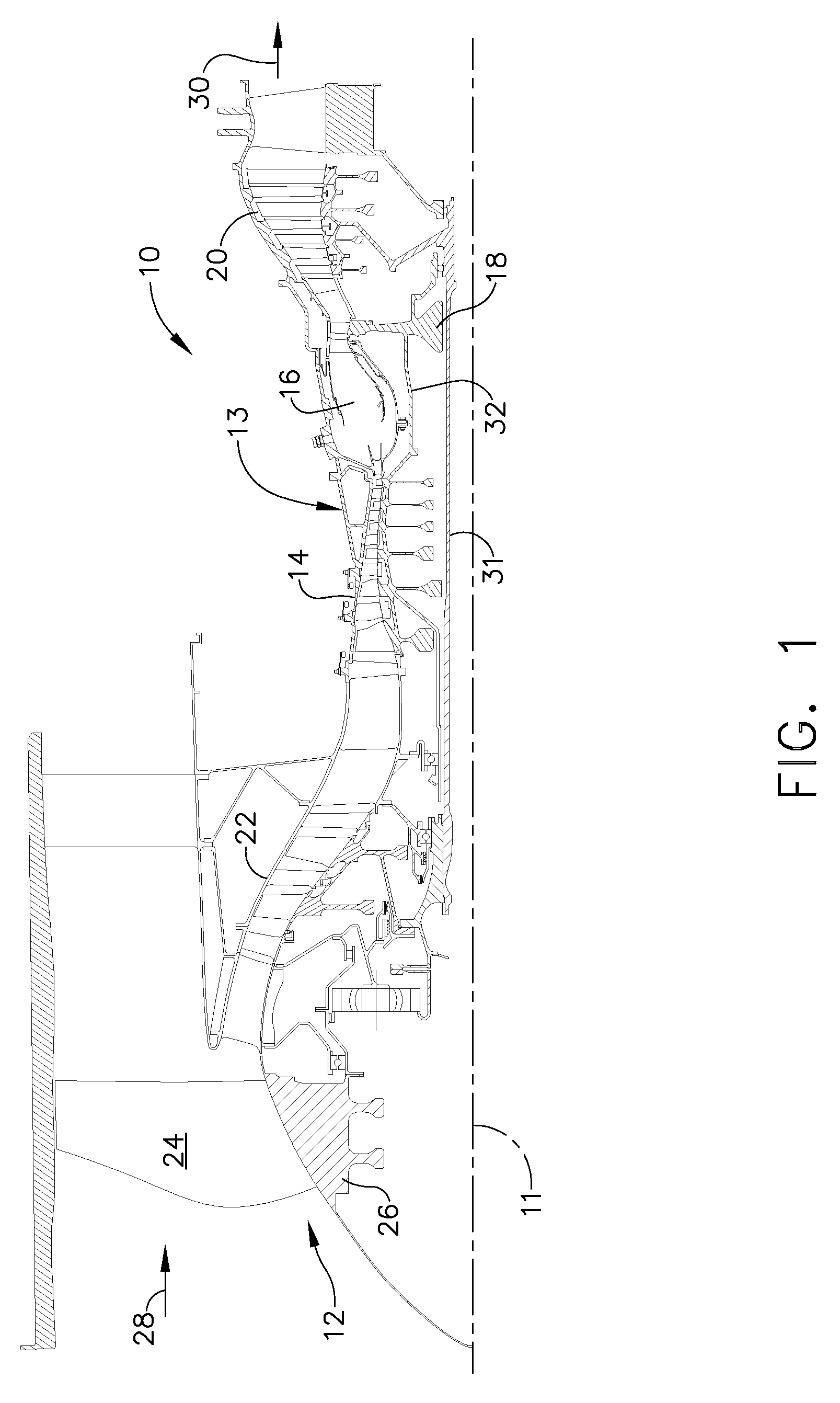

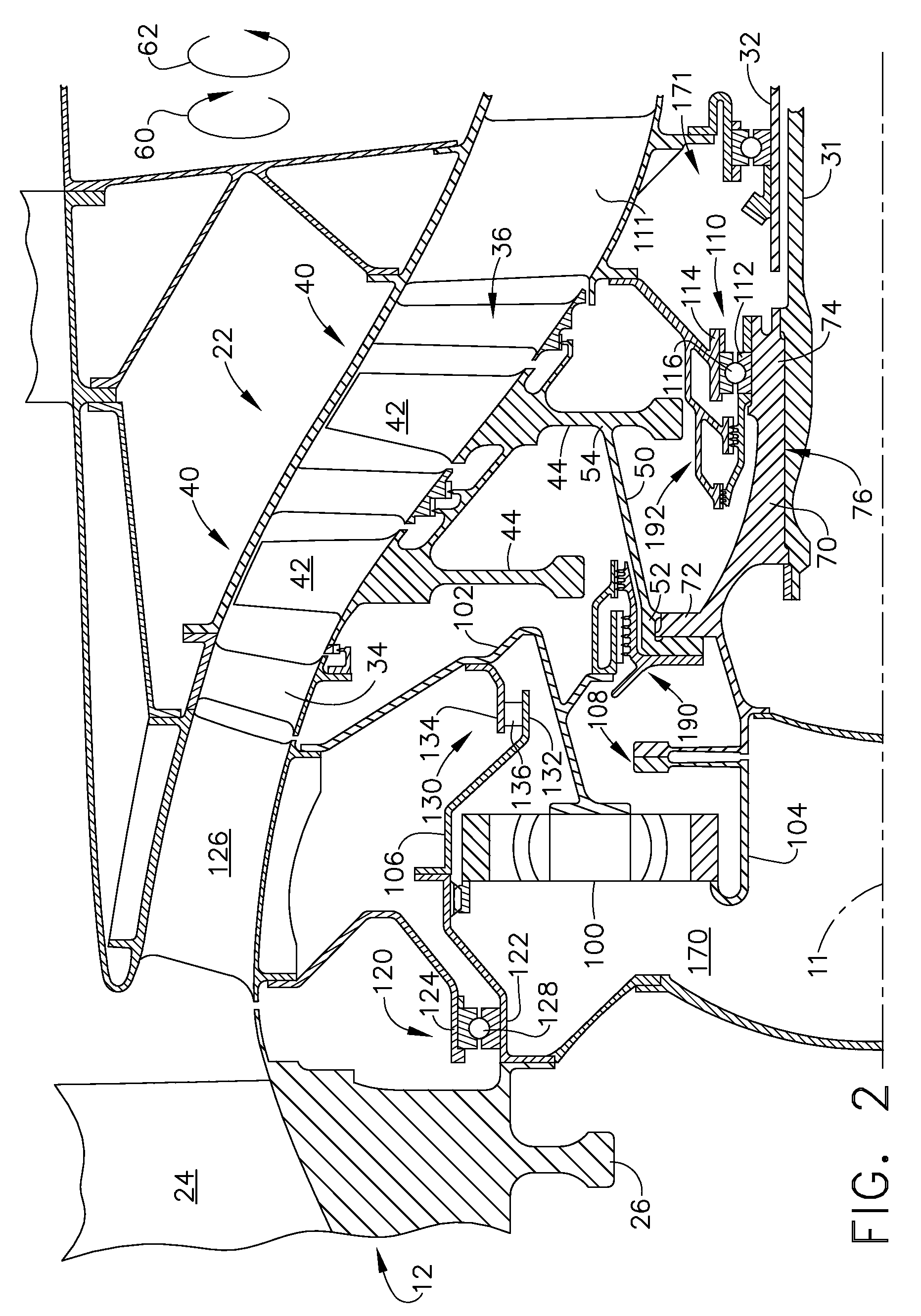

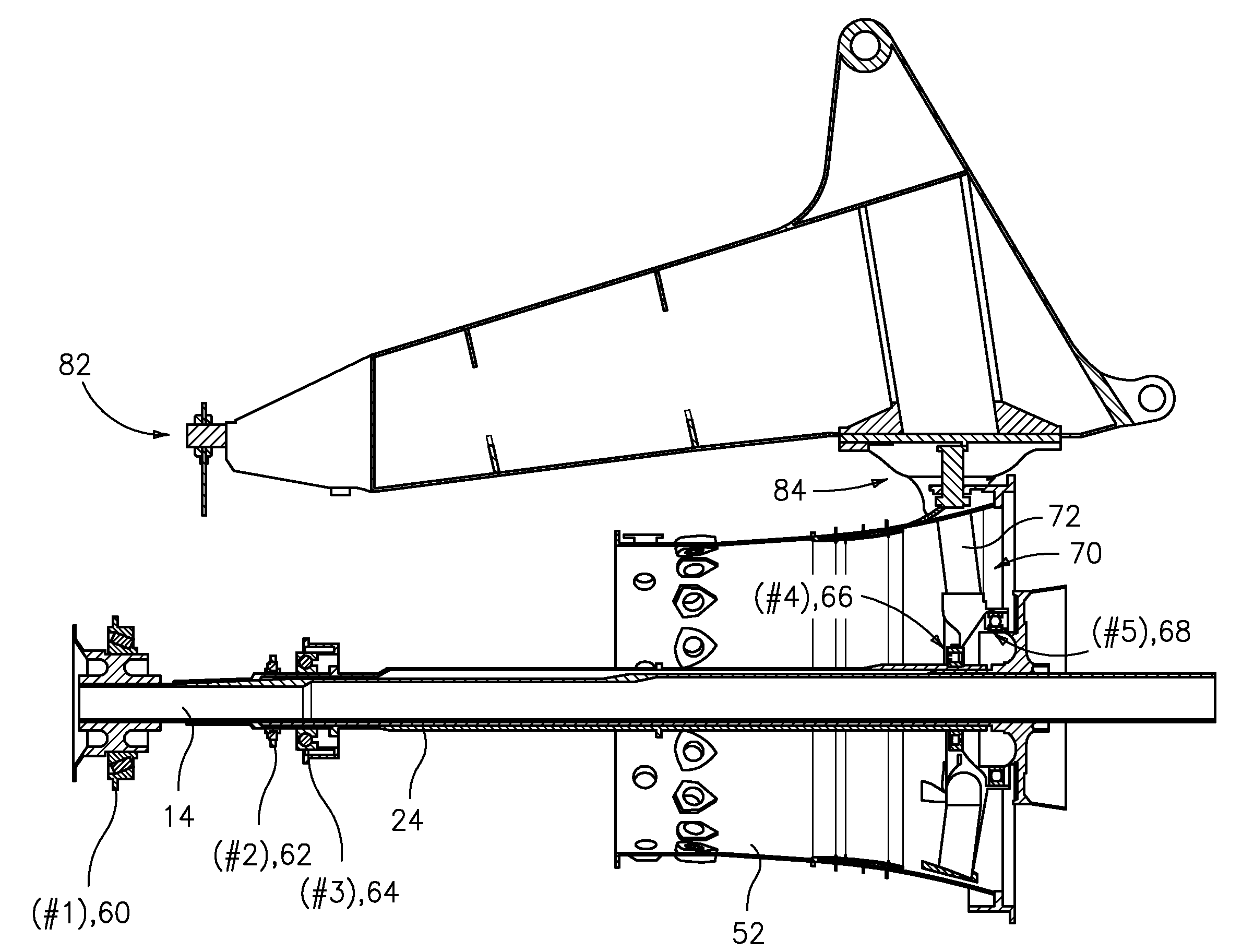

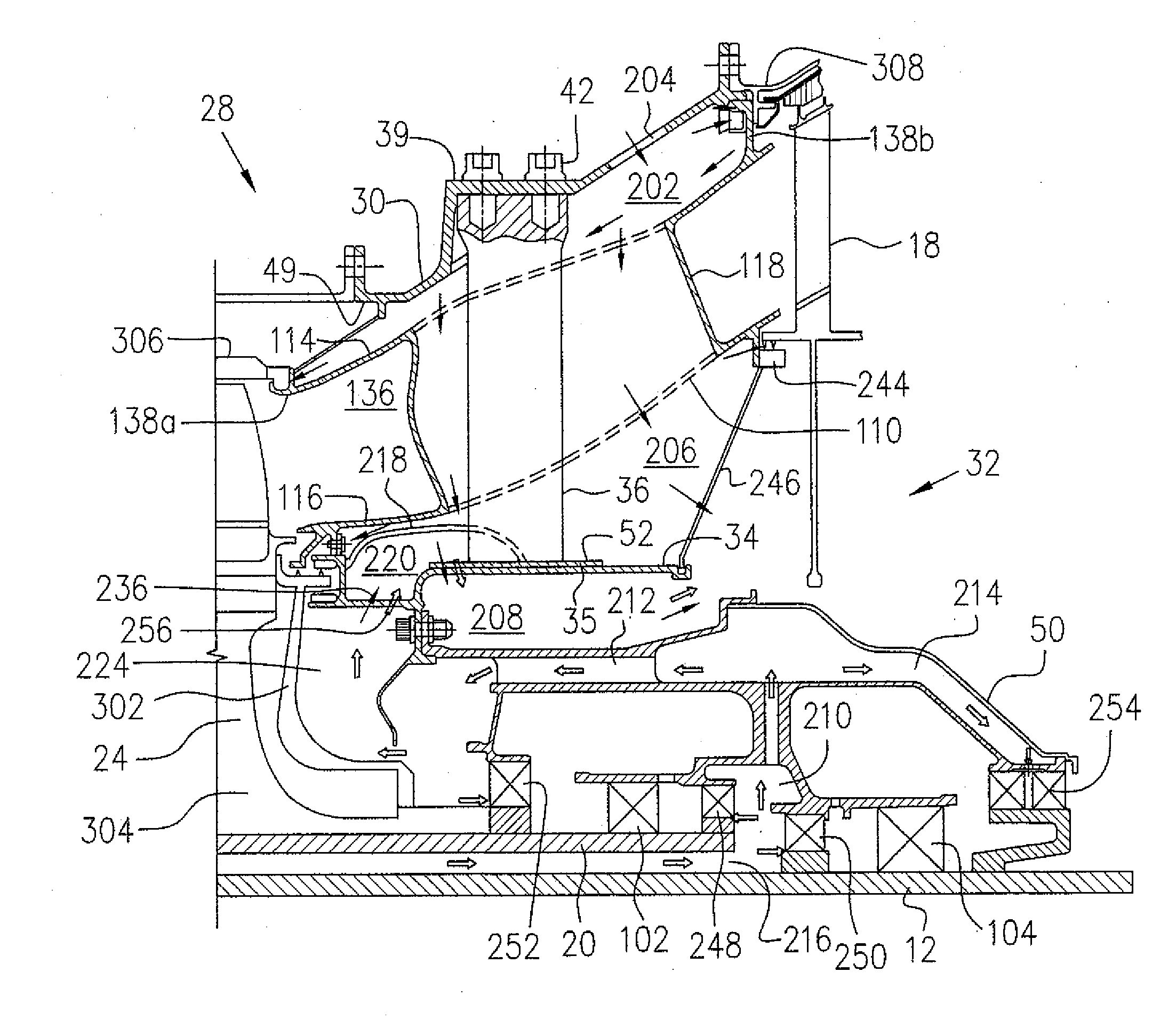

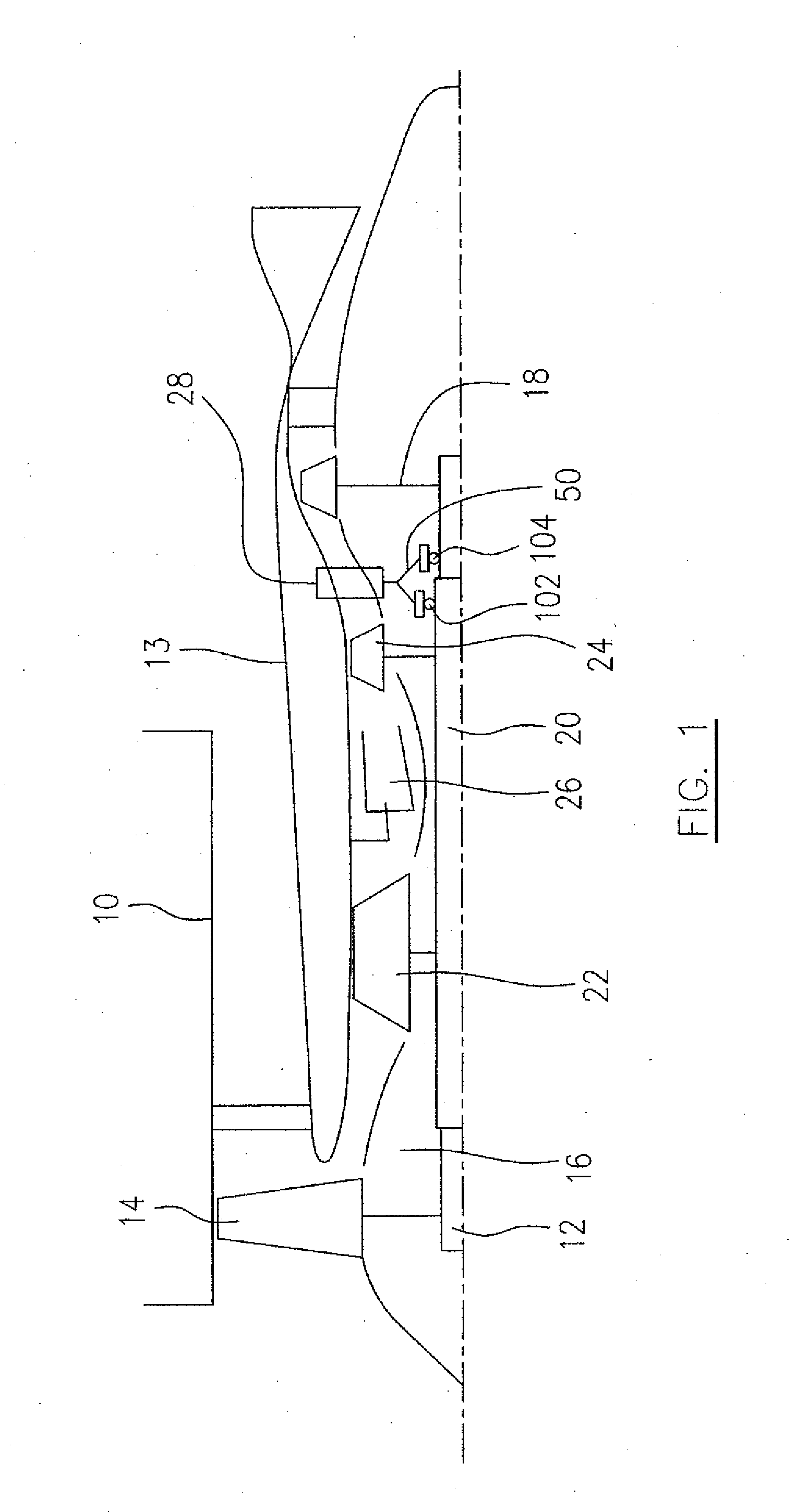

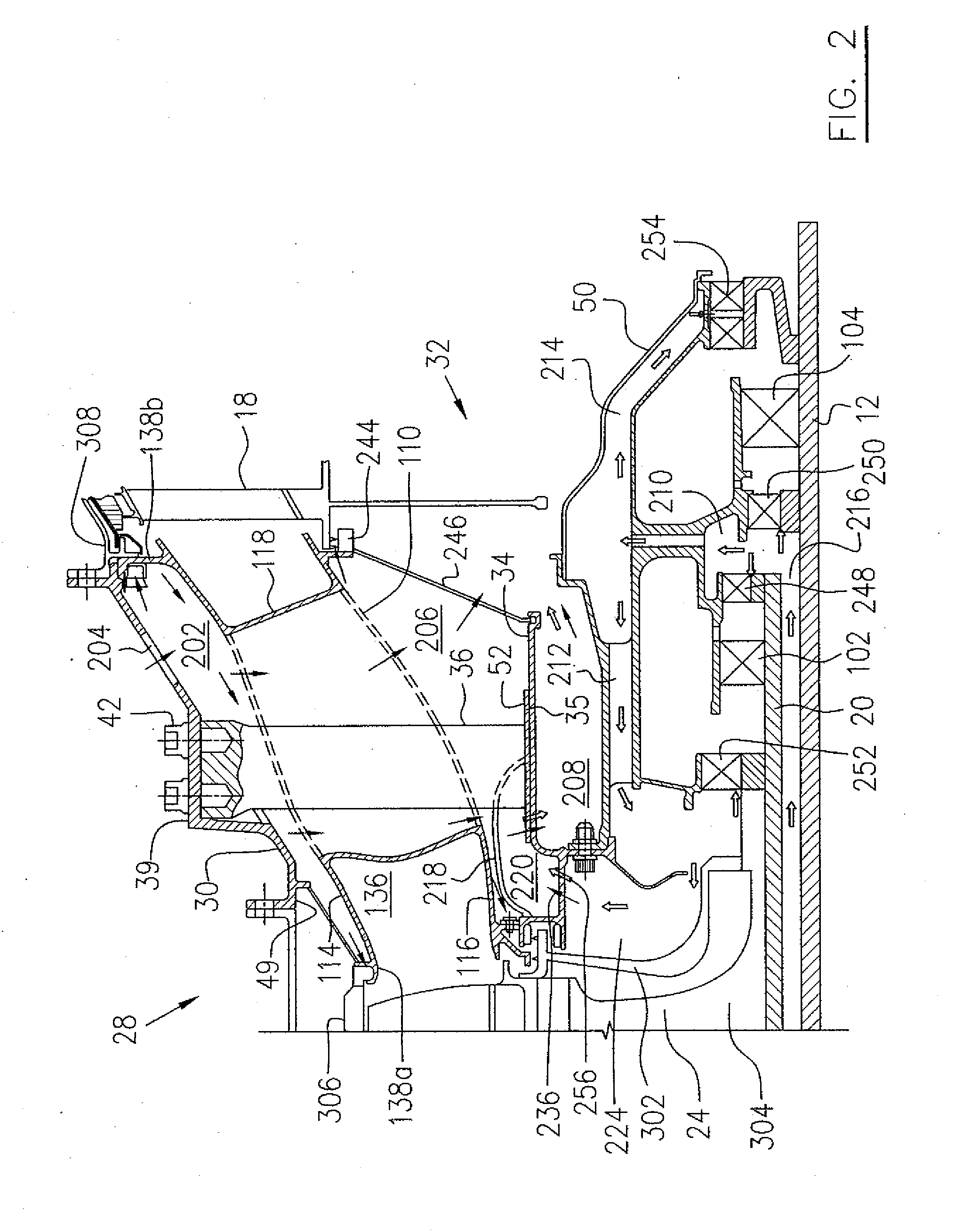

Cooling air system for mid turbine frame

A mid turbine frame is disposed between high and low pressure turbine assemblies. A cooling air system defined in the mid turbine frame of a gas turbine engine includes internal cavities for containing pressurized cooling air to cool the inter-turbine duct and the hollow struts, and discharges the used cooling air to further cool respective high and low pressure turbine assemblies.

Owner:PRATT & WHITNEY CANADA CORP

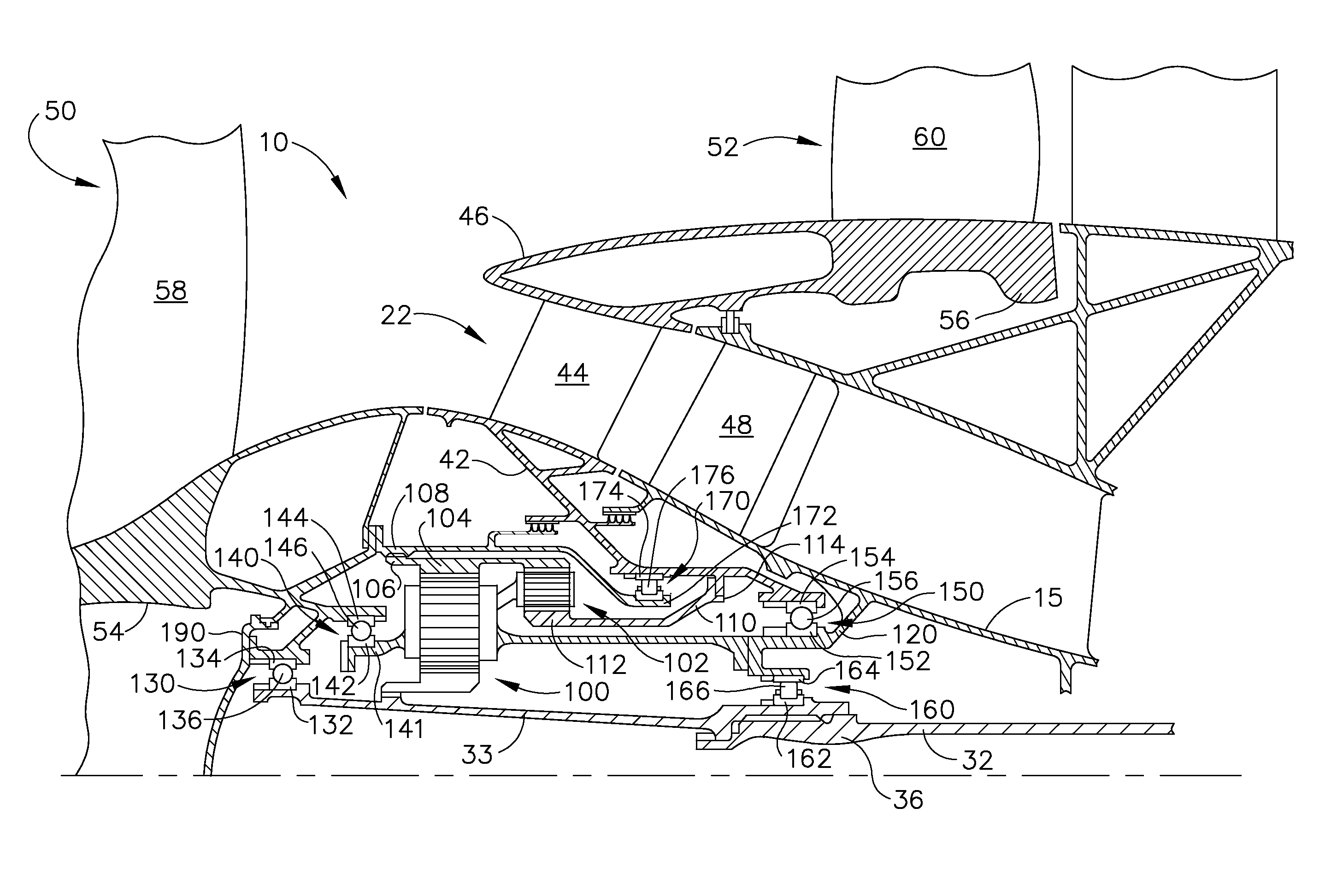

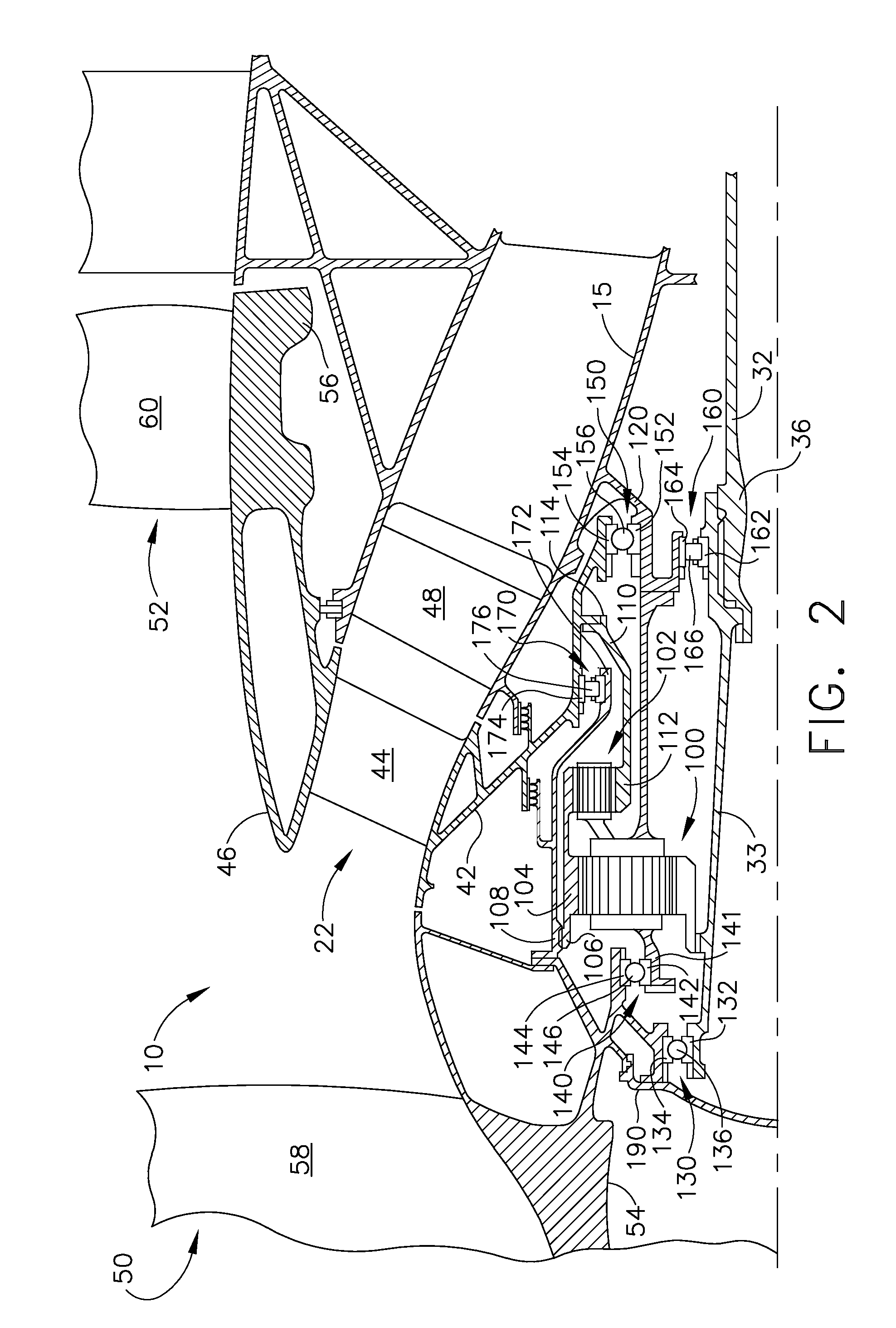

Turbofan engine assembly and method of assembling same

InactiveUS20080120839A1Cosmonautic vehiclesCosmonautic propulsion system apparatusCombustorHigh pressure

A turbofan engine assembly includes a core gas turbine engine including a high-pressure compressor, a combustor, and a high-pressure turbine, a first fan assembly disposed upstream from the core gas turbine engine, a first gearbox coupled to the first fan assembly, and a second gearbox coupled to a booster compressor such that the booster compressor rotates in a rotational direction that is opposite to the rotational direction of the first fan assembly. A method of assembling the above turbofan engine assembly is also described herein.

Owner:GENERAL ELECTRIC CO

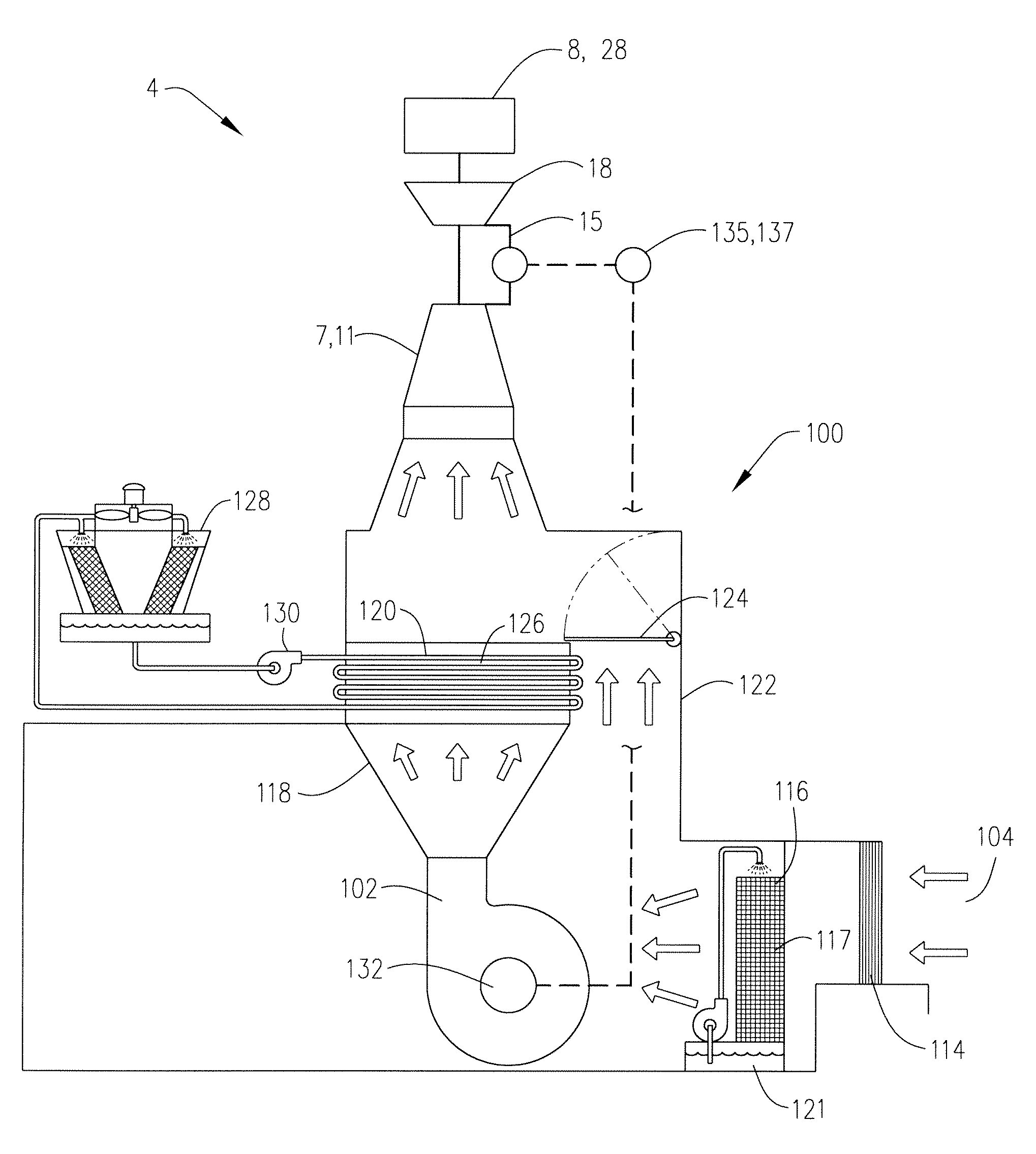

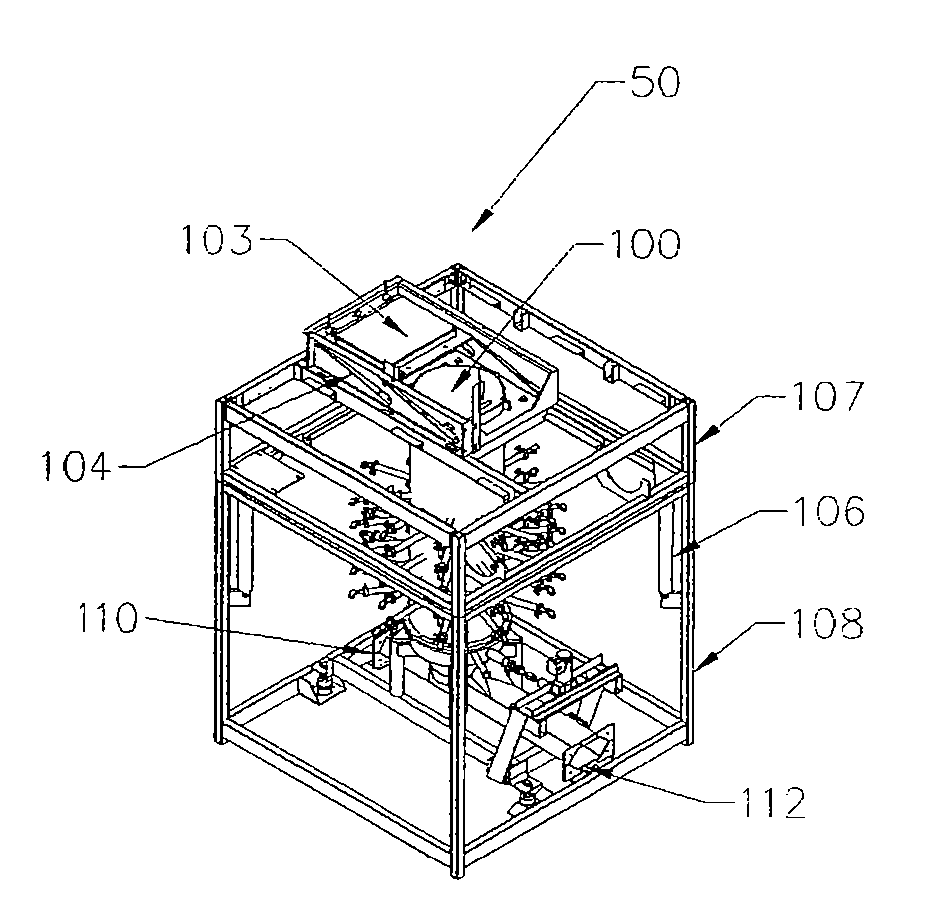

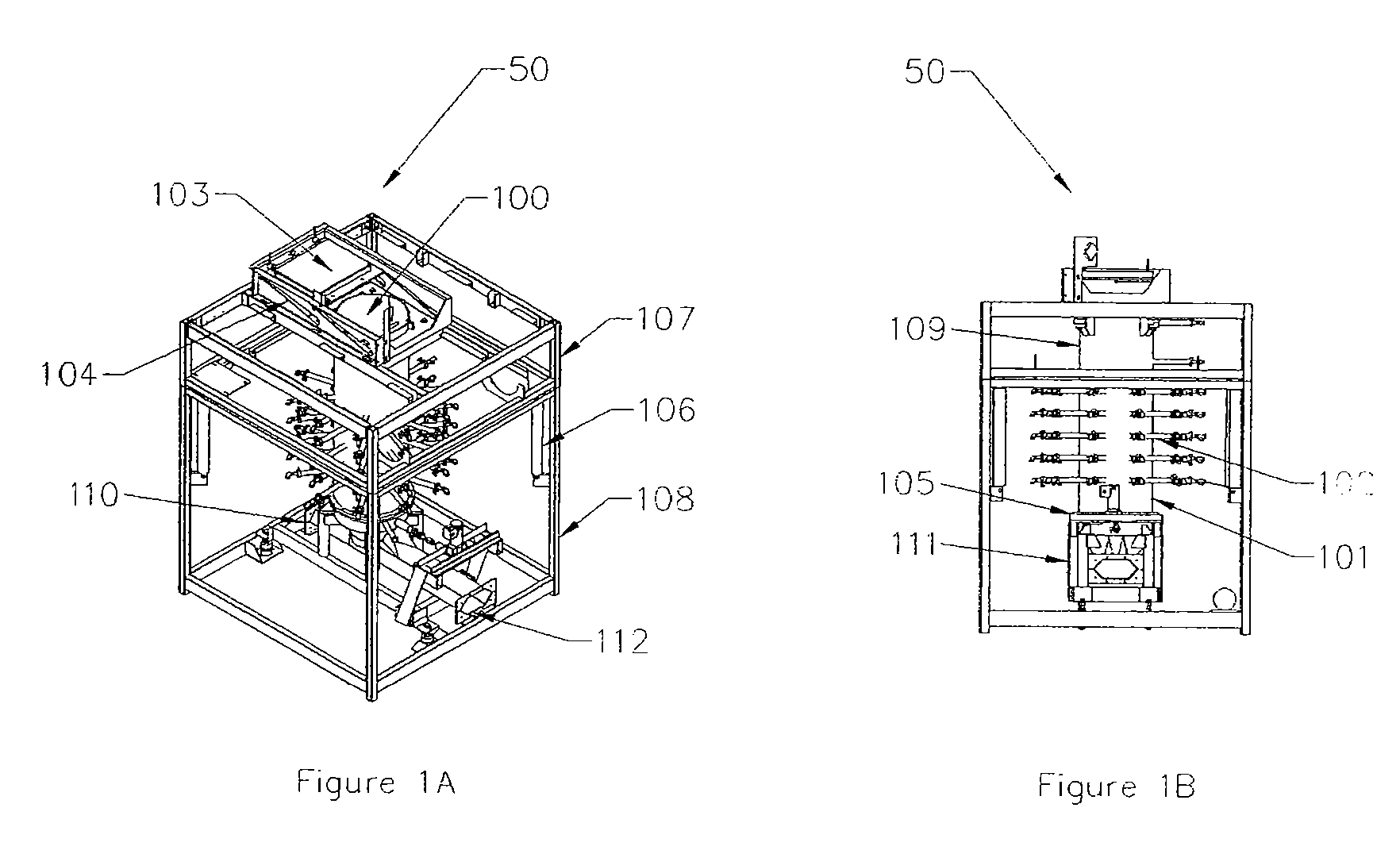

Method and Apparatus for Automated, Modular, Biomass Power Generation

ActiveUS20070006528A1Increasing fuel-bed bulk densityRestrict movementHydrogenDispersed particle filtrationElectric power systemFossil fuel

Method and apparatus for generating a low tar, renewable fuel gas from biomass and using it in other energy conversion devices, many of which were designed for use with gaseous and liquid fossil fuels. An automated, downdraft gasifier incorporates extensive air injection into the char bed to maintain the conditions that promote the destruction of residual tars. The resulting fuel gas and entrained char and ash are cooled in a special heat exchanger, and then continuously cleaned in a filter prior to usage in standalone as well as networked power systems.

Owner:COMMUNITY POWER CORP

Methods and systems for low emission gas turbine energy generation

Methods and systems for a dry low NOx gas turbine engine system include a gas turbine engine including at least one dry low NOx combustor. The combustor includes a plurality of injection points wherein at least some of the injection points are configured to inject a fuel into the combustor at a plurality of different locations. The system includes a water source coupled to the combustor and operable to inject water into others of the plurality of injection points. The system also includes a control system that includes a sensor configured to measure an exhaust gas concentration of the turbine, a processor programmed to receive a signal indicative of the turbine exhaust gas concentration, and to automatically control the water injection using the received exhaust gas concentration signal. Such systems in use together can mitigate visible emissions from the exhaust stack.

Owner:GENERAL ELECTRIC CO

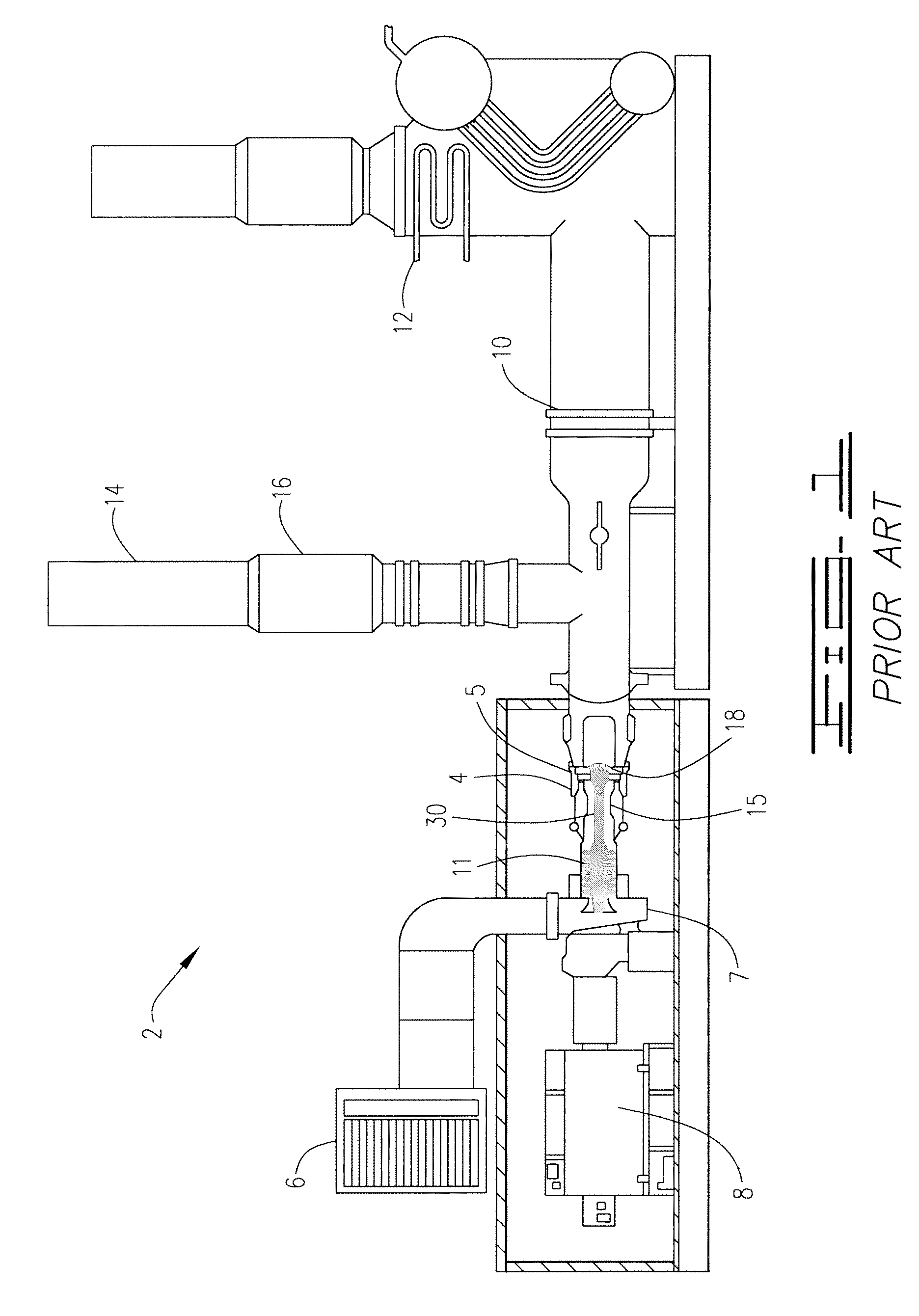

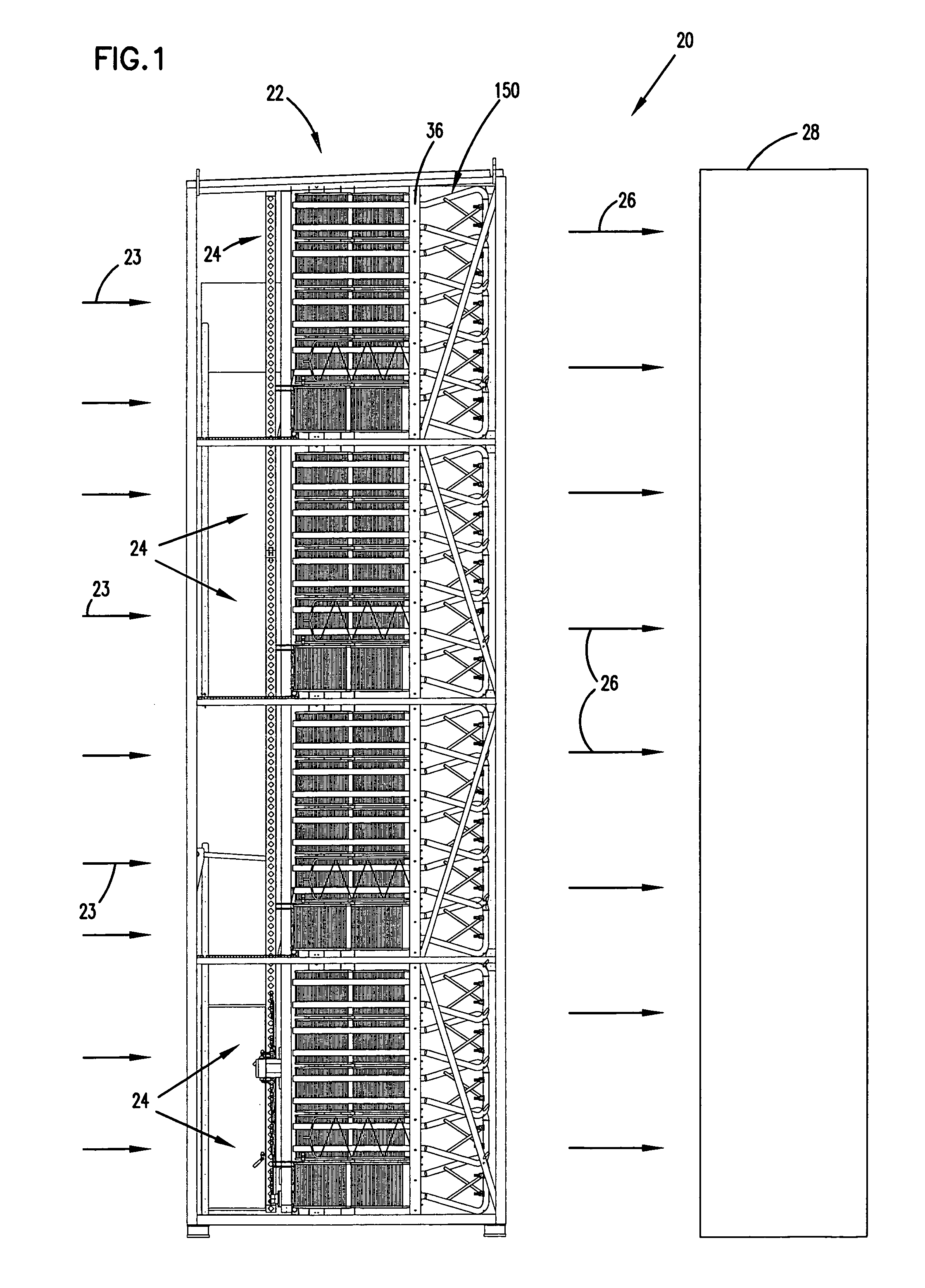

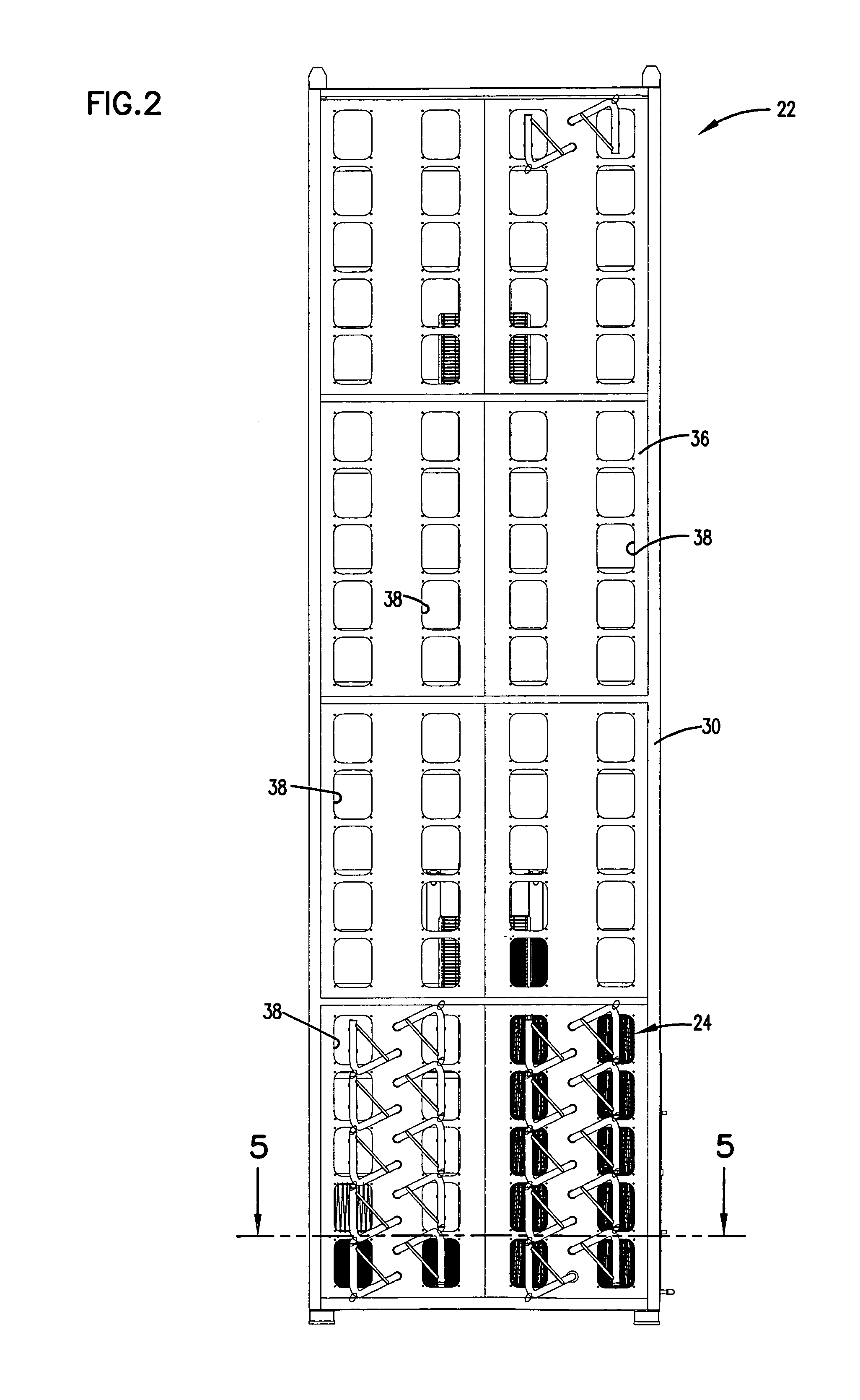

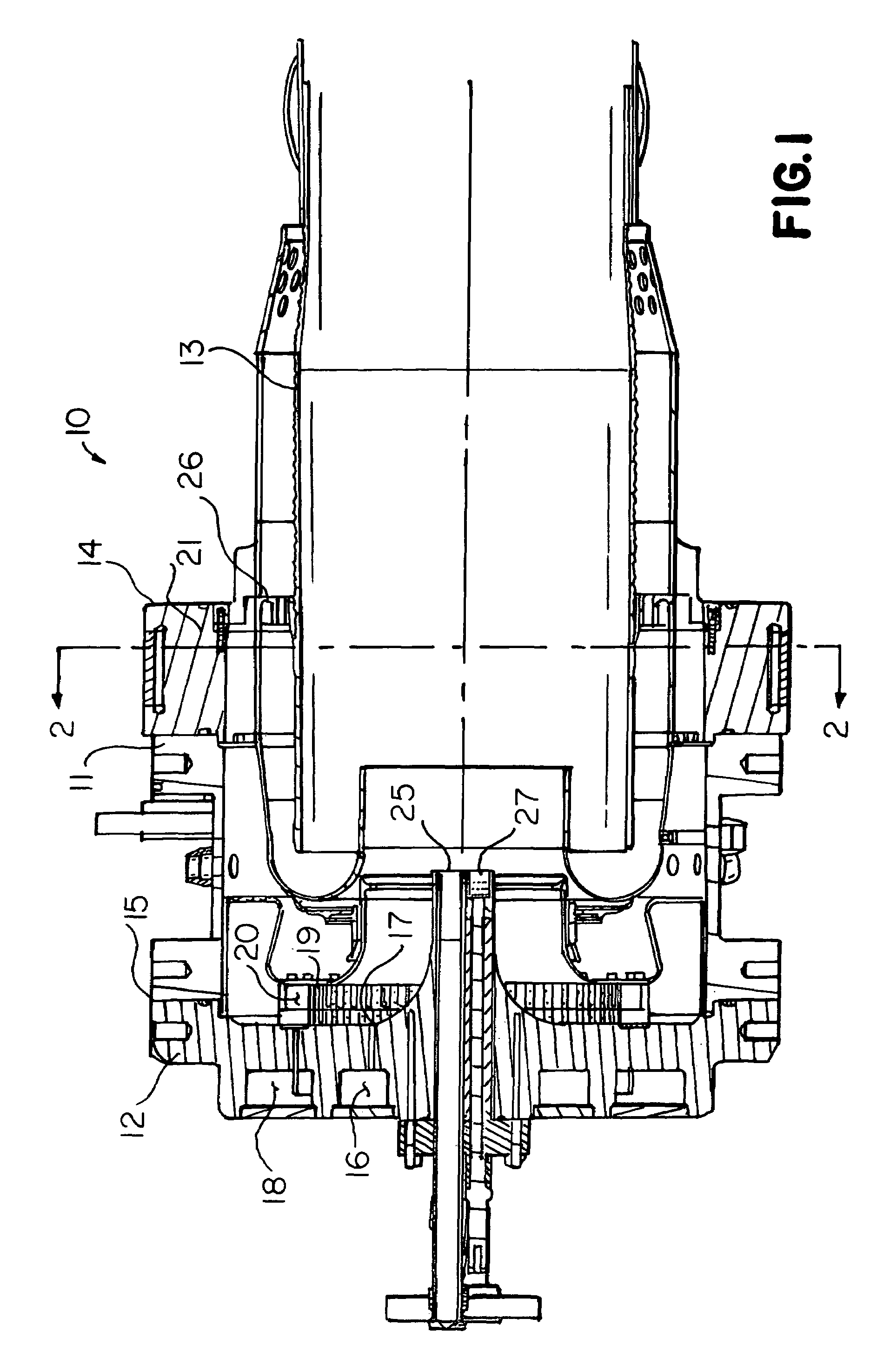

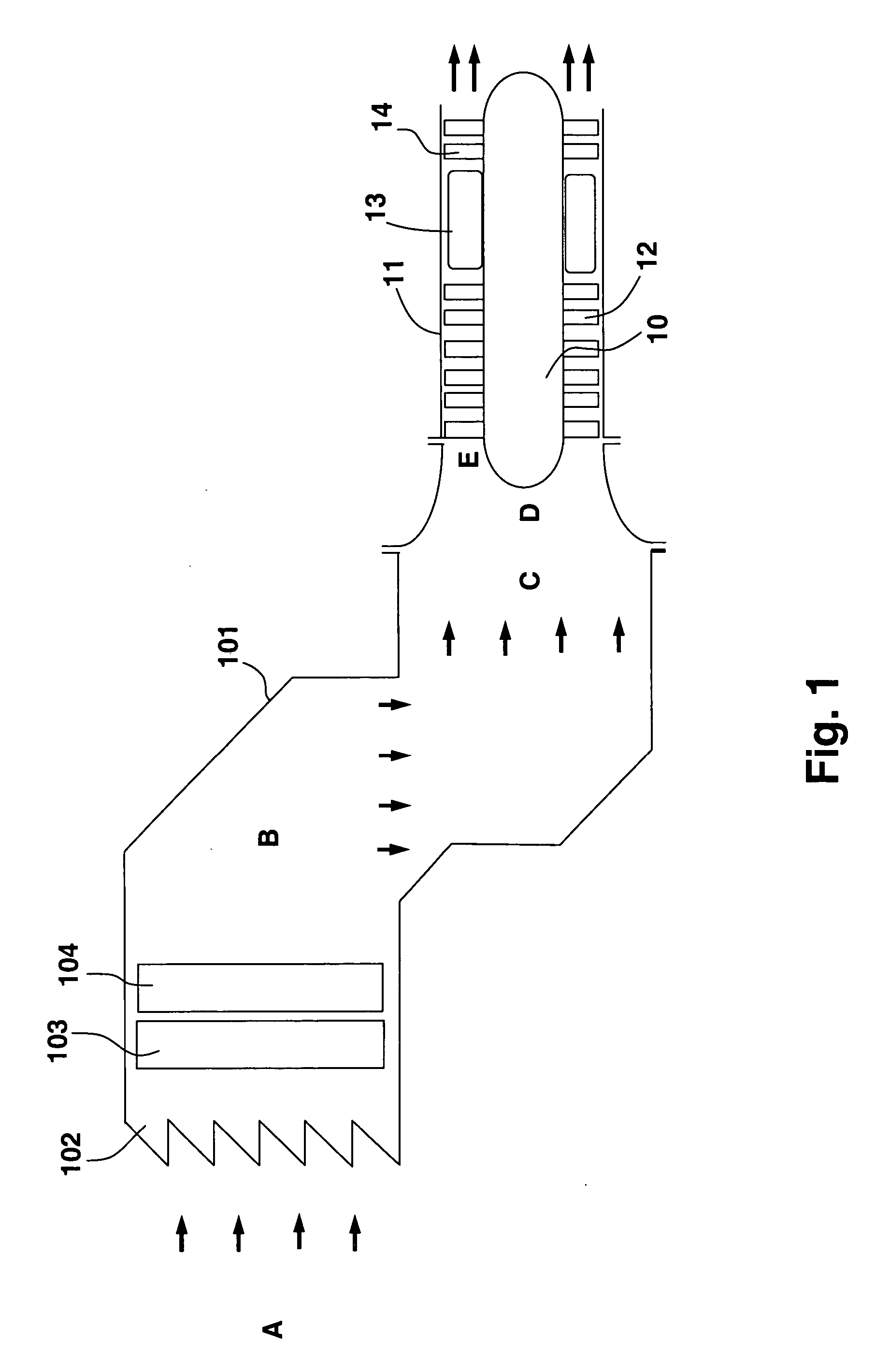

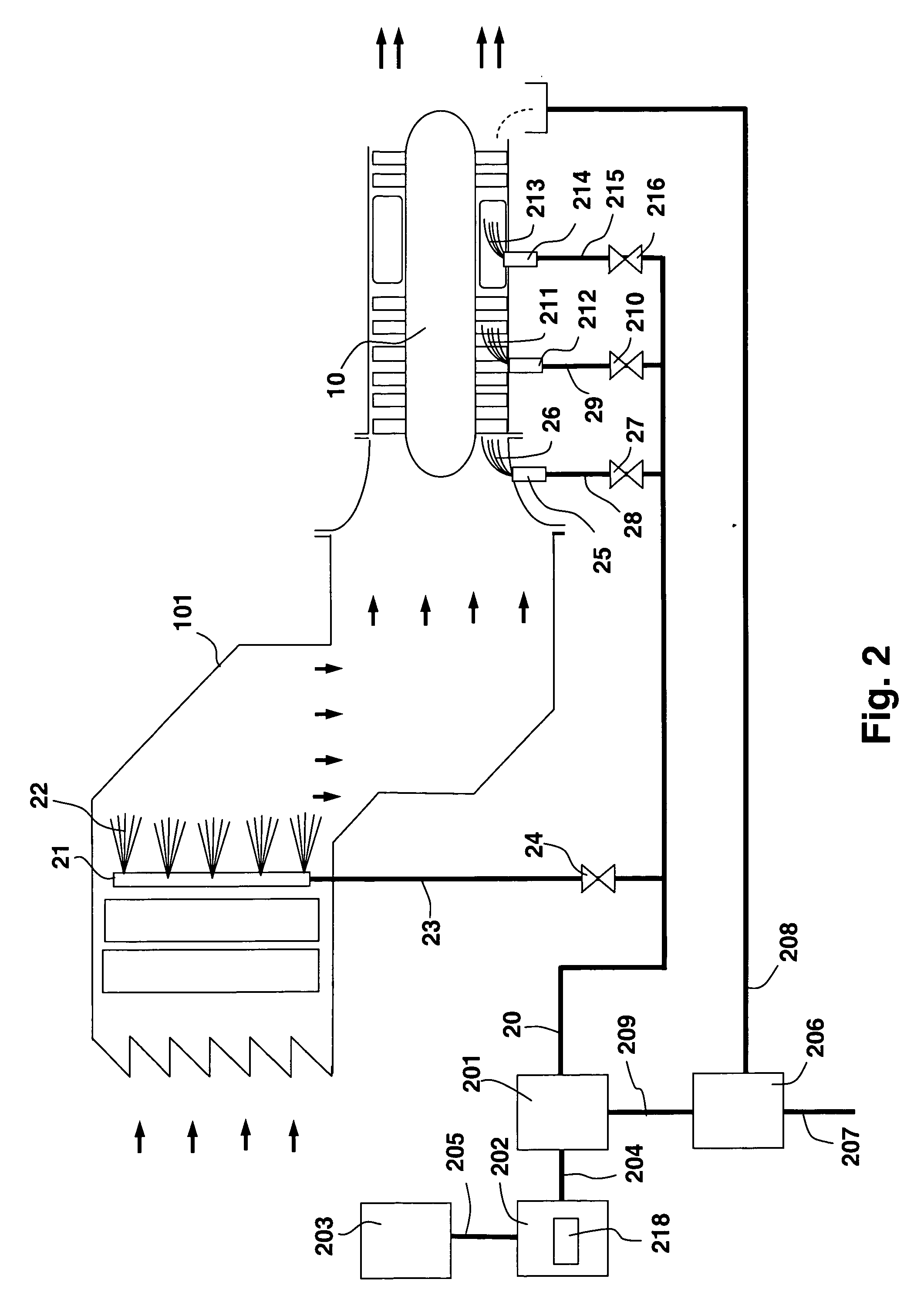

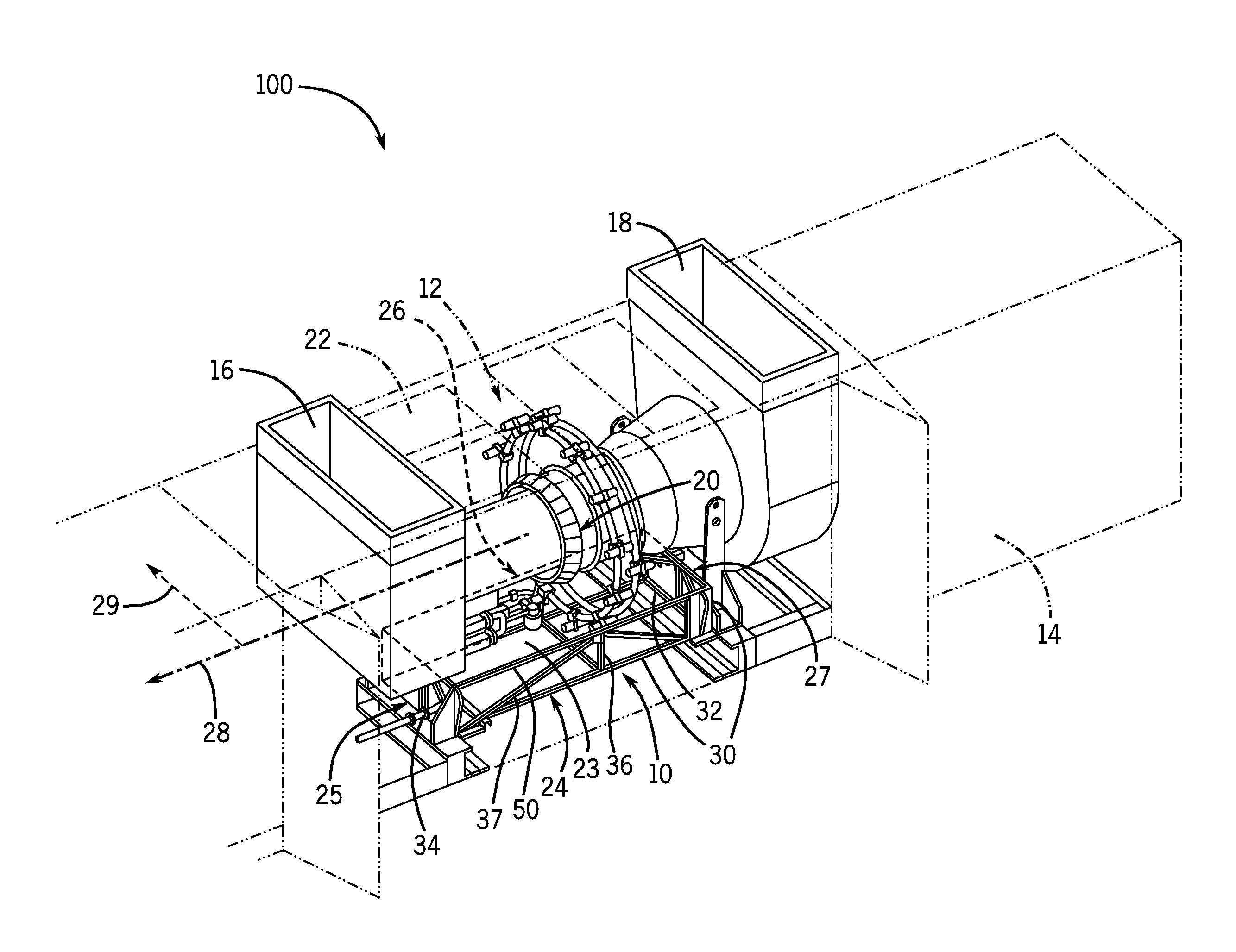

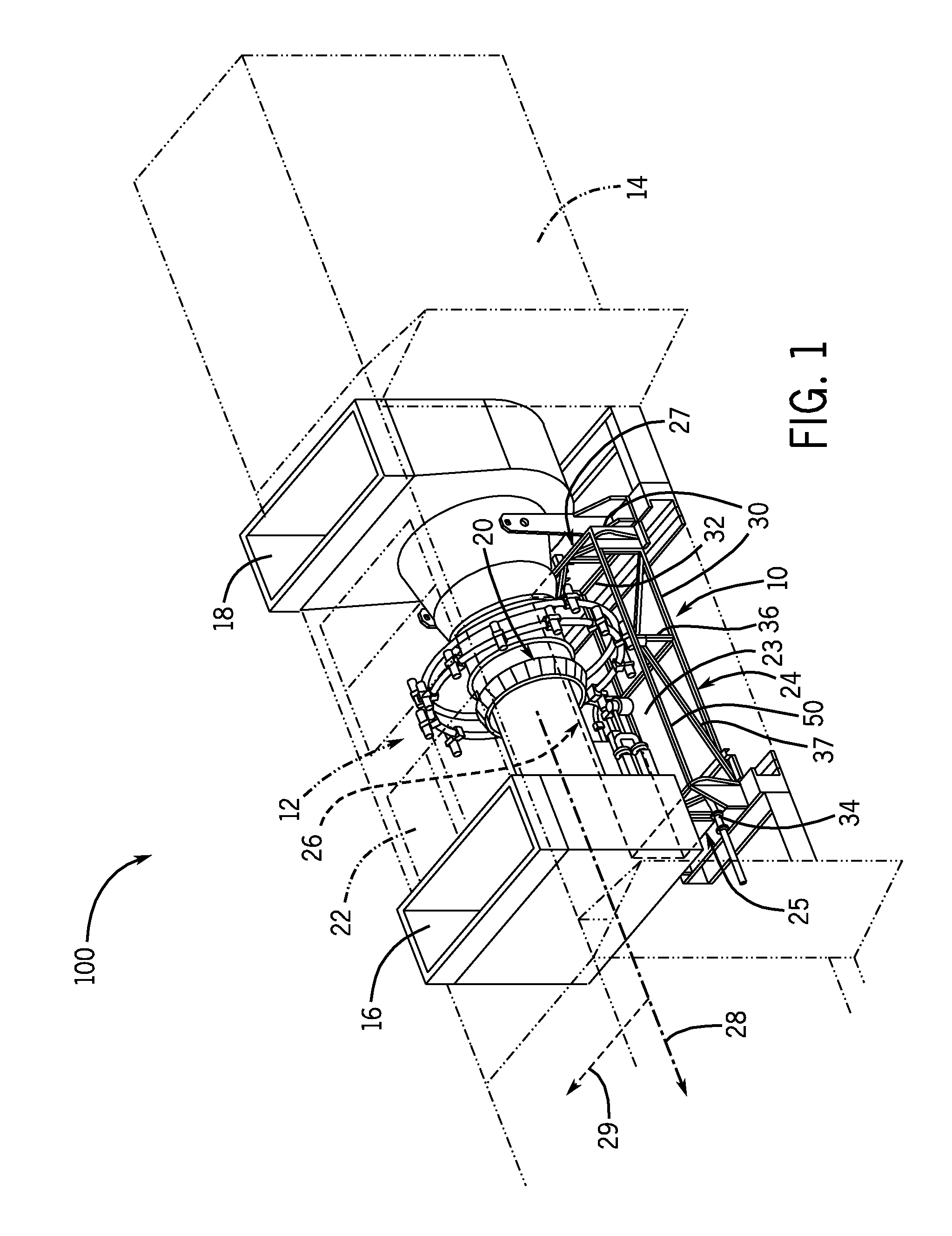

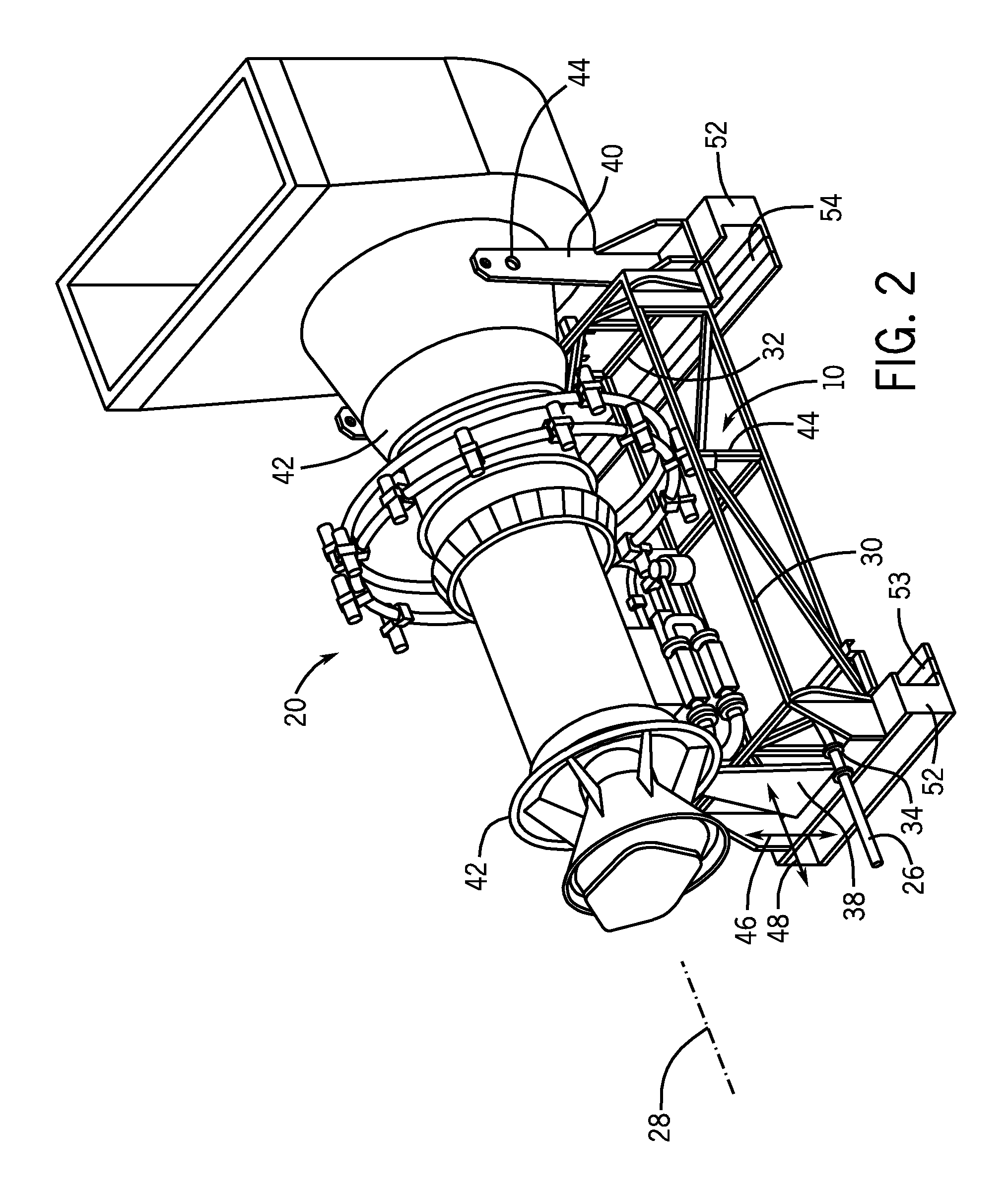

System and method for augmenting power output from a gas turbine engine

ActiveUS20070059159A1Wide rangeSimple hardwareHollow article cleaningGas turbine plantsMultiple modesTurbine

The present invention discloses a method and system for augmenting shaft output of stationary gas turbines that can be used in multiple modes of operation. The system comprises a washing unit (25, 27, 28) adapted to inject a spray (26) of atomized liquid so as to impinge on the compressor blades (12) in order to wet said blades (12), thereby obtaining a release of fouling material from said blades (12); and at least one liquid injection unit (21, 23, 24, 29, 210, 212, 214, 215, 216) adapted to inject a spray (22, 211, 213) of atomized liquid into an air stream of said turbine duct (101) or at the gas turbine (10) in order to increase a mass flow of said air flow, wherein the power output from said gas turbine engine can be augmented. With the invention follows also benefits such as fuel savings and improved environmental performance by reduction of emissions.

Owner:GTE TURBINE EFFICIENCY SWEDEN AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com