Patents

Literature

35 results about "Downdraft gasifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

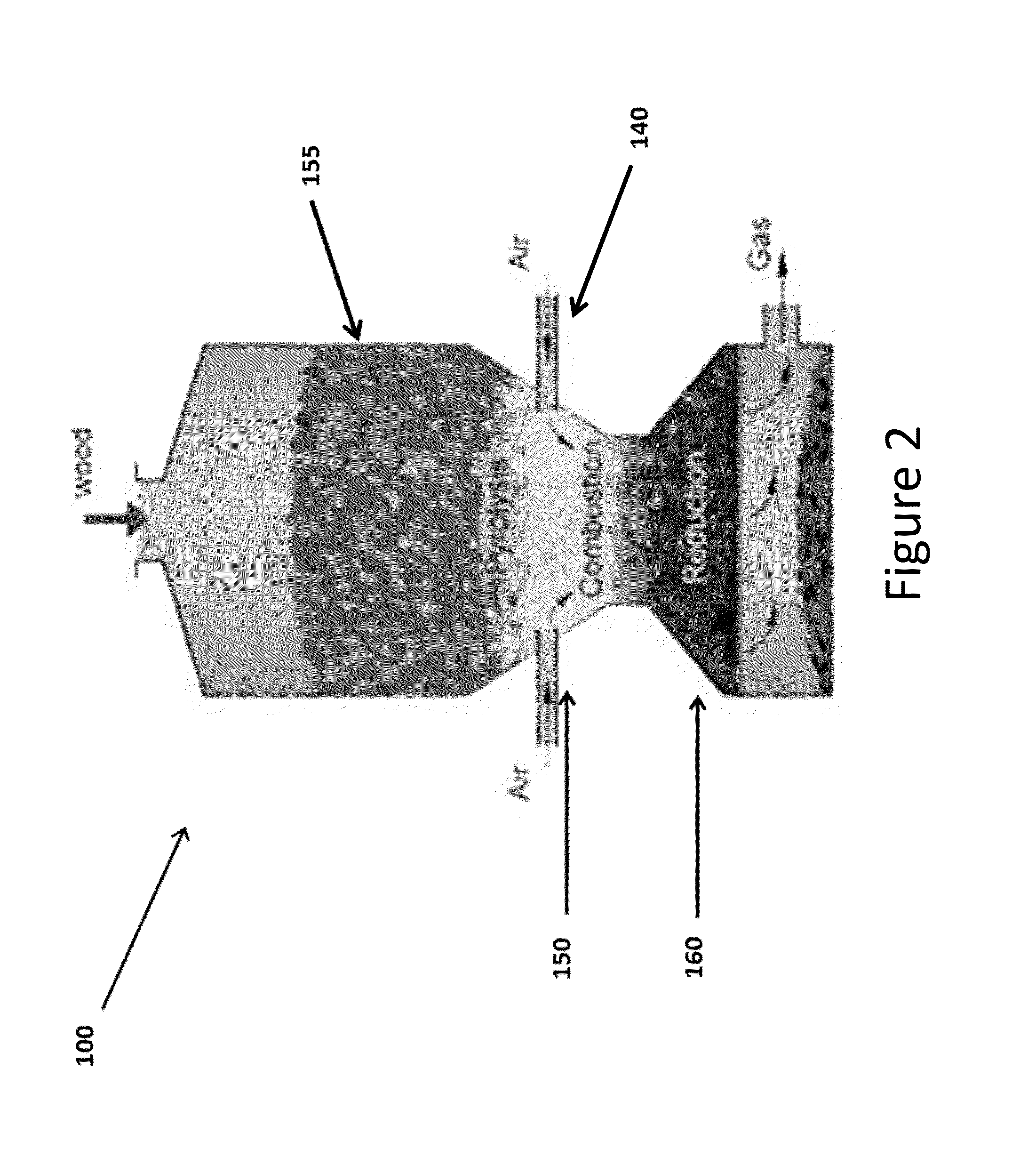

Downdraft gasifiers are fuel specific. Downdraft wood gasifiers can operate on wood like biomass materials and biomass briquettes with a minimum bulk density of 250 kg/m3 and ash content of less than 5%. In downdraft gasifiers, gas is drawn from the bottom of the reactor while the hottest reaction zone is in the middle.

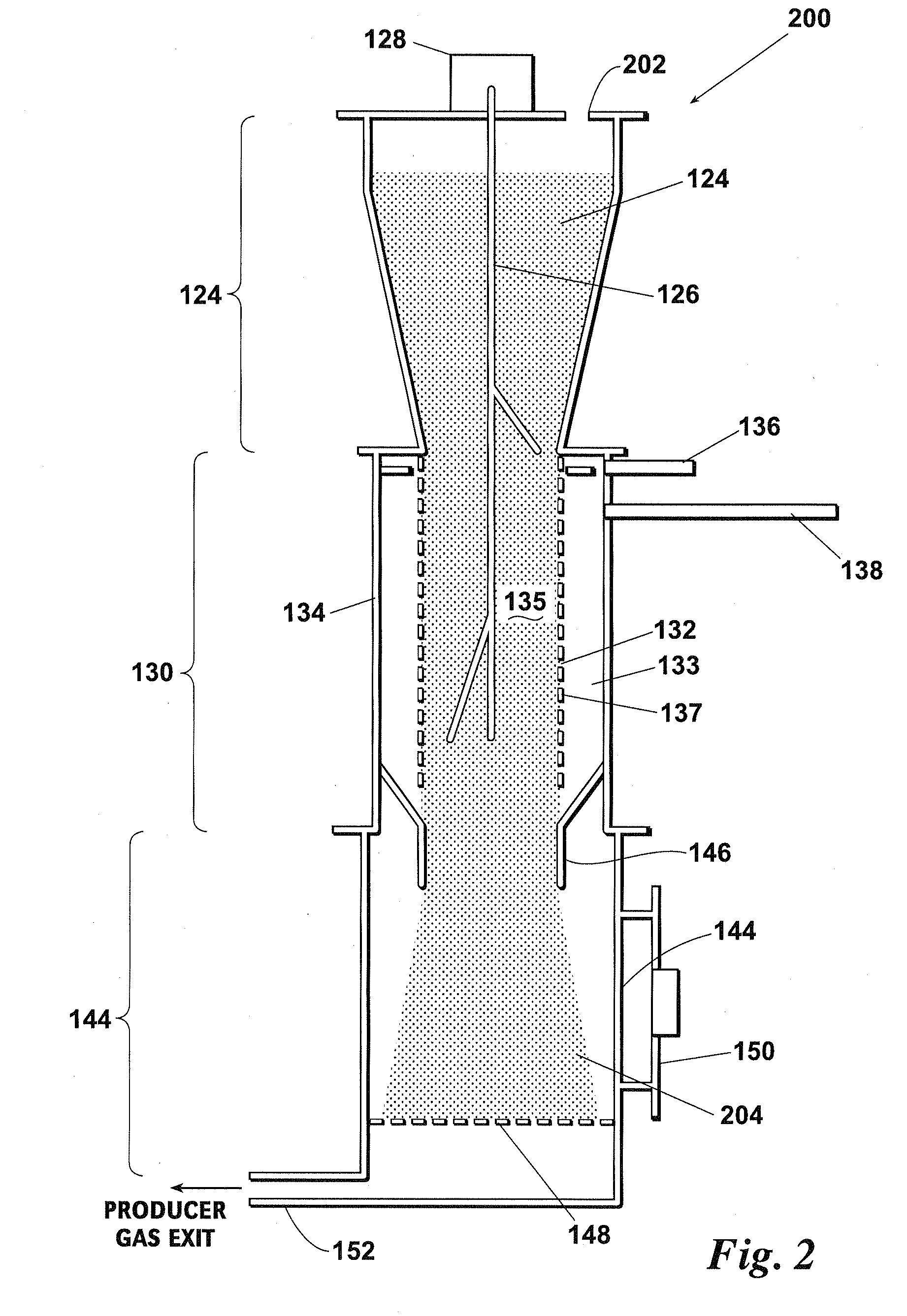

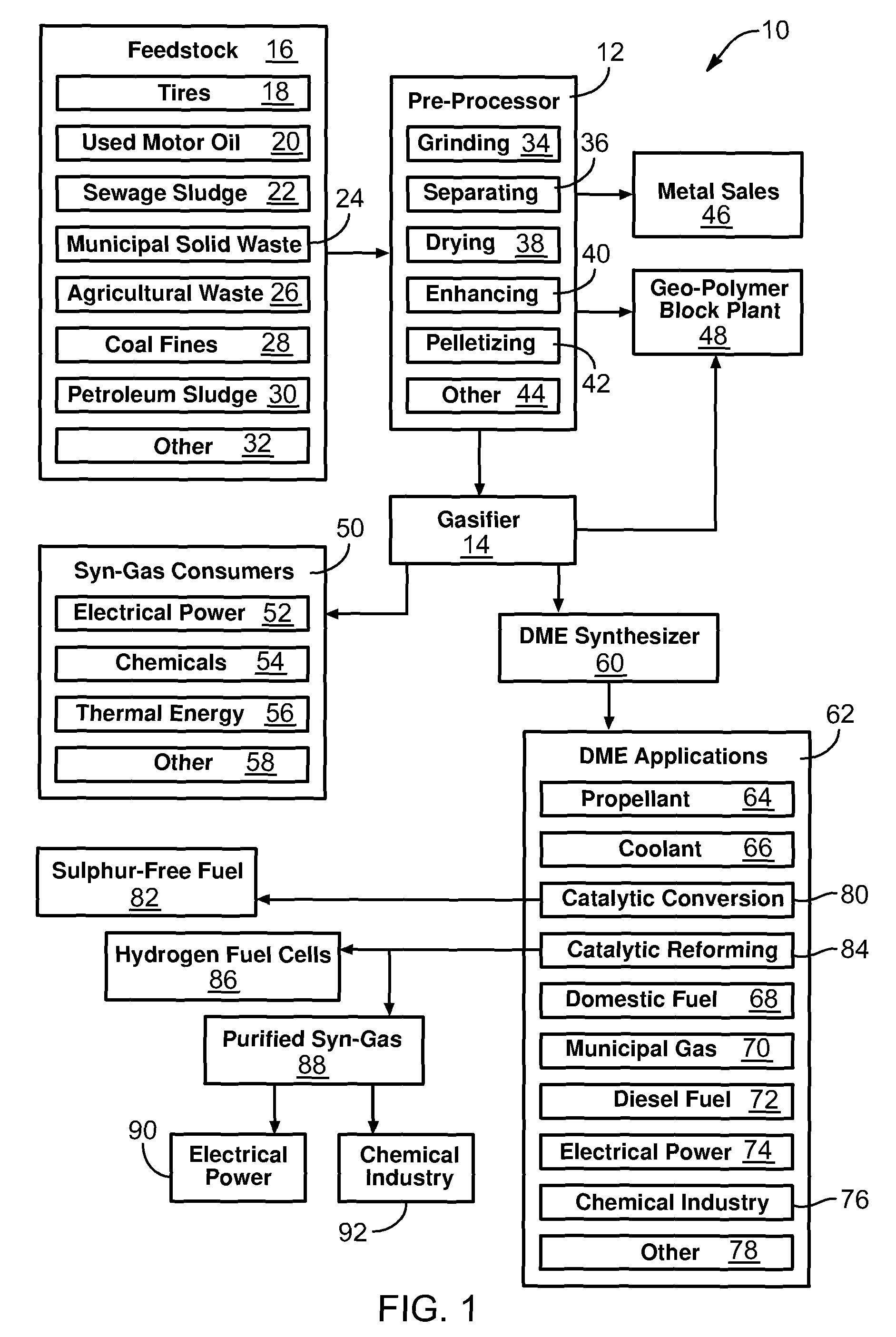

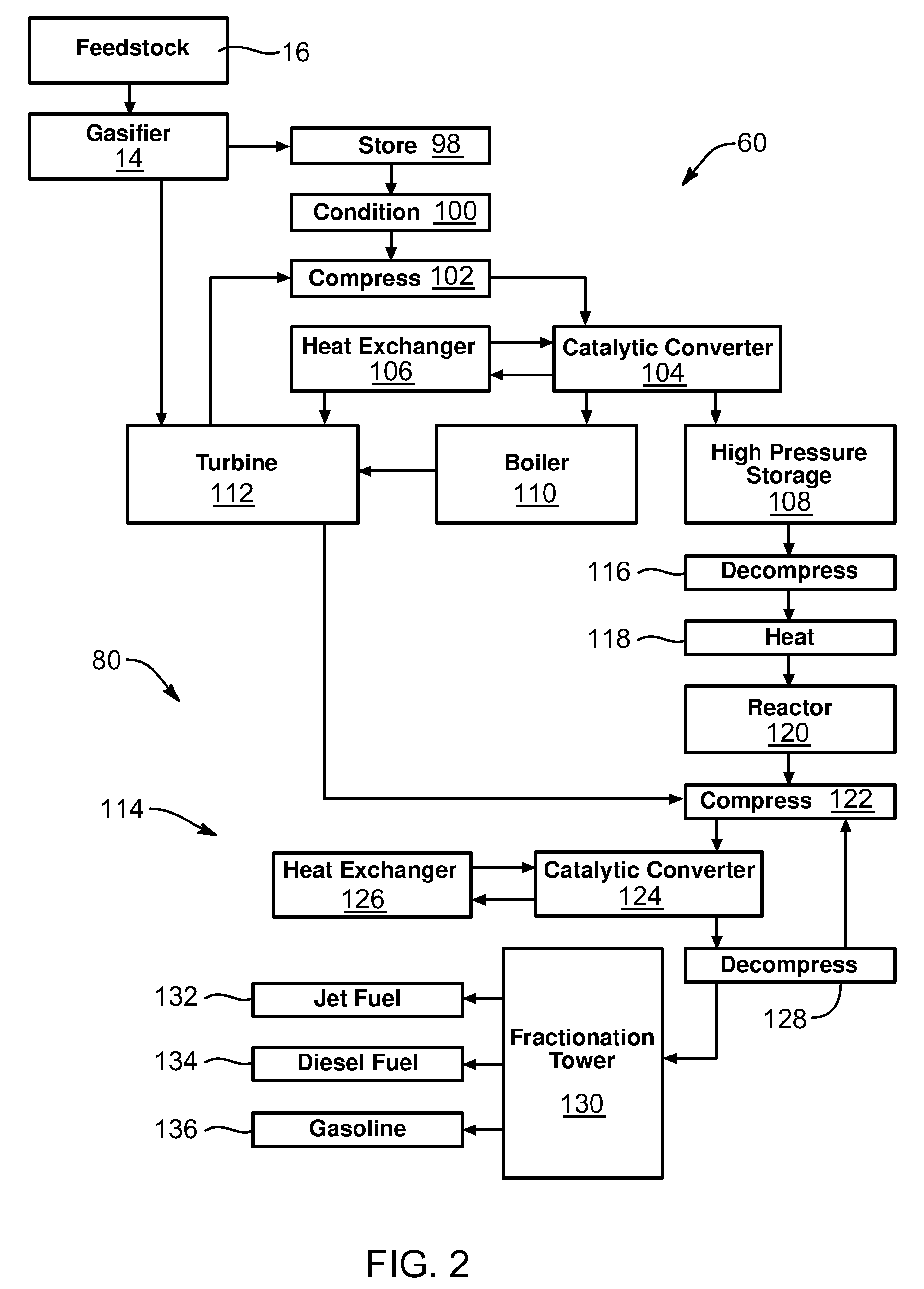

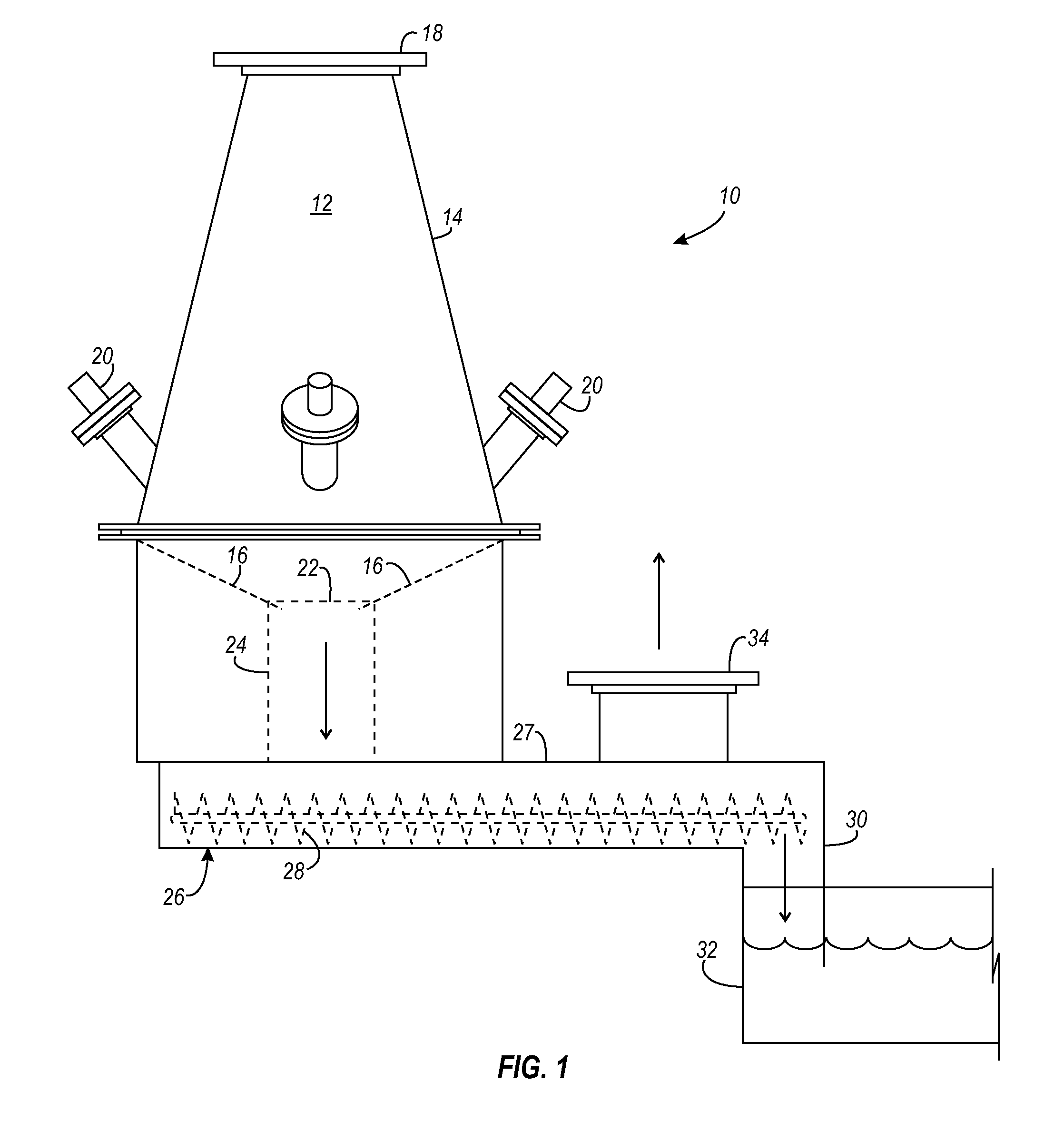

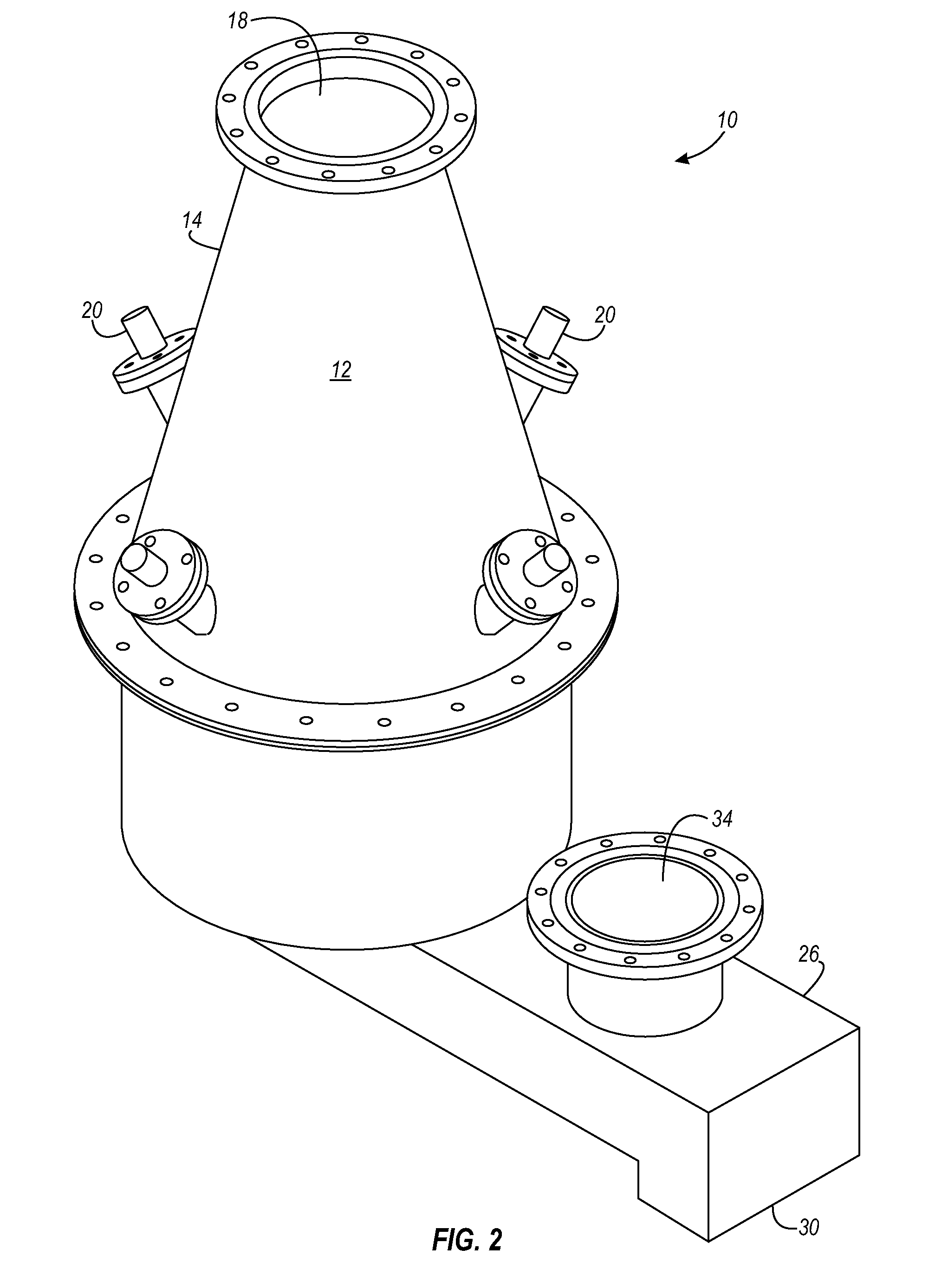

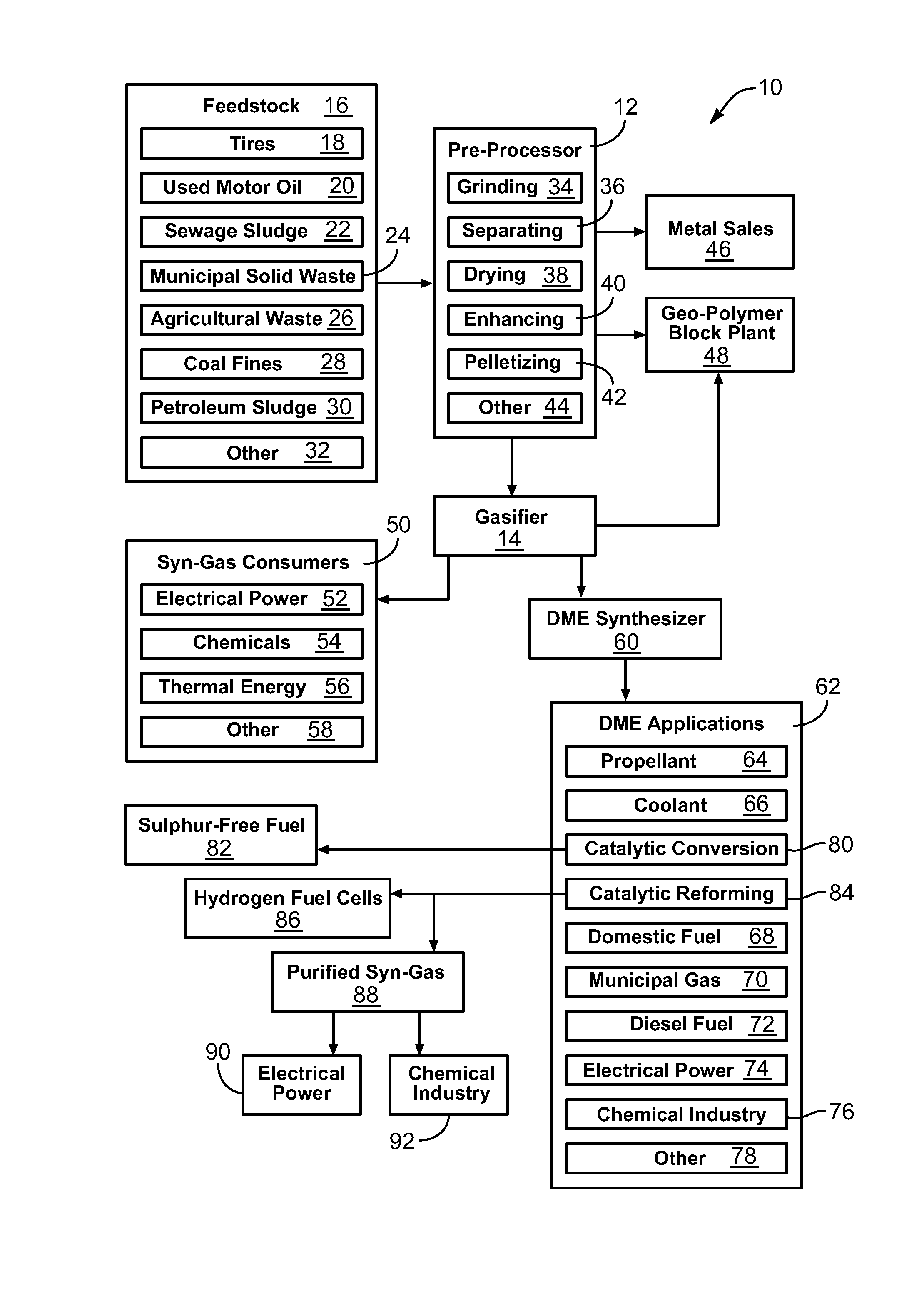

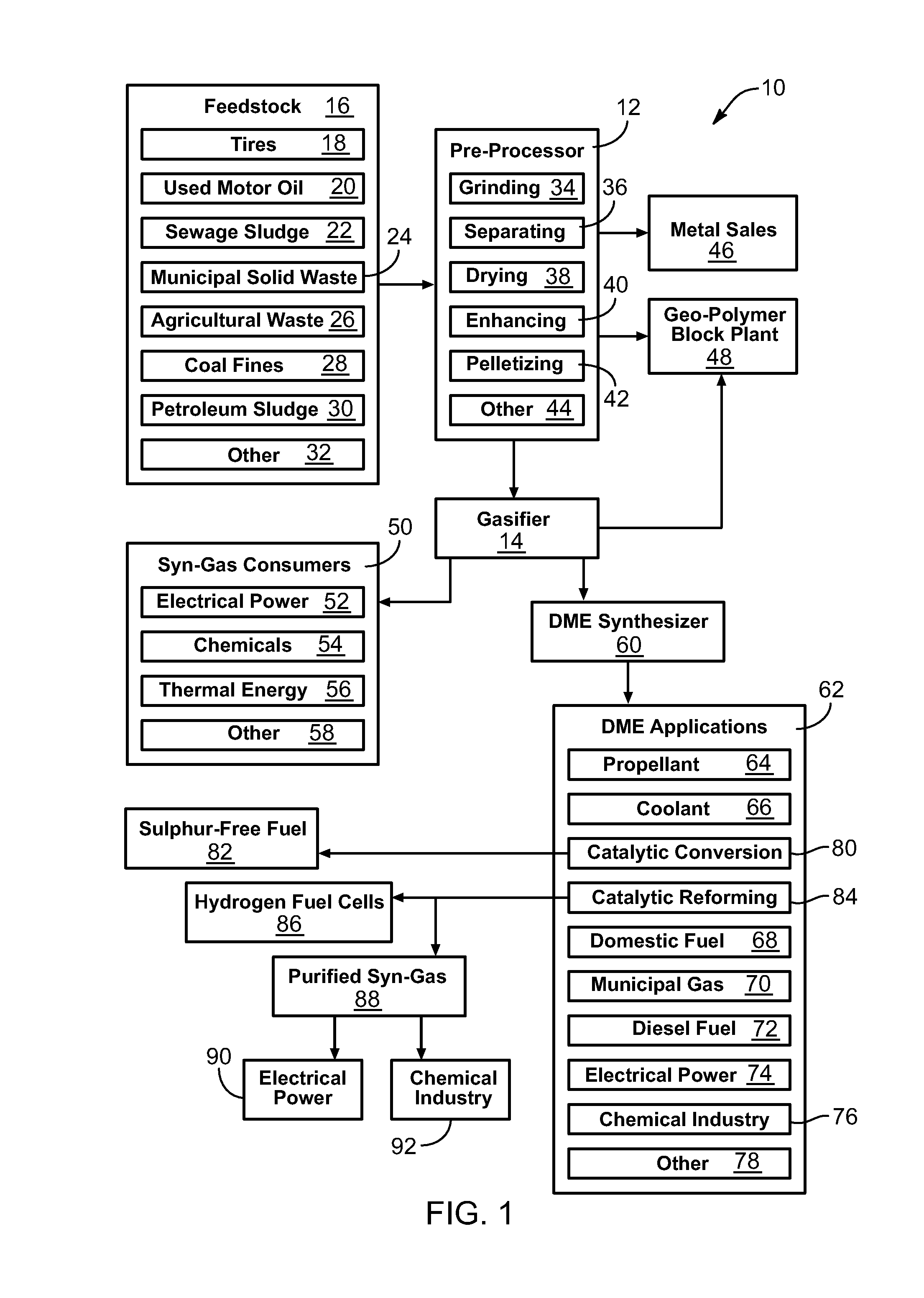

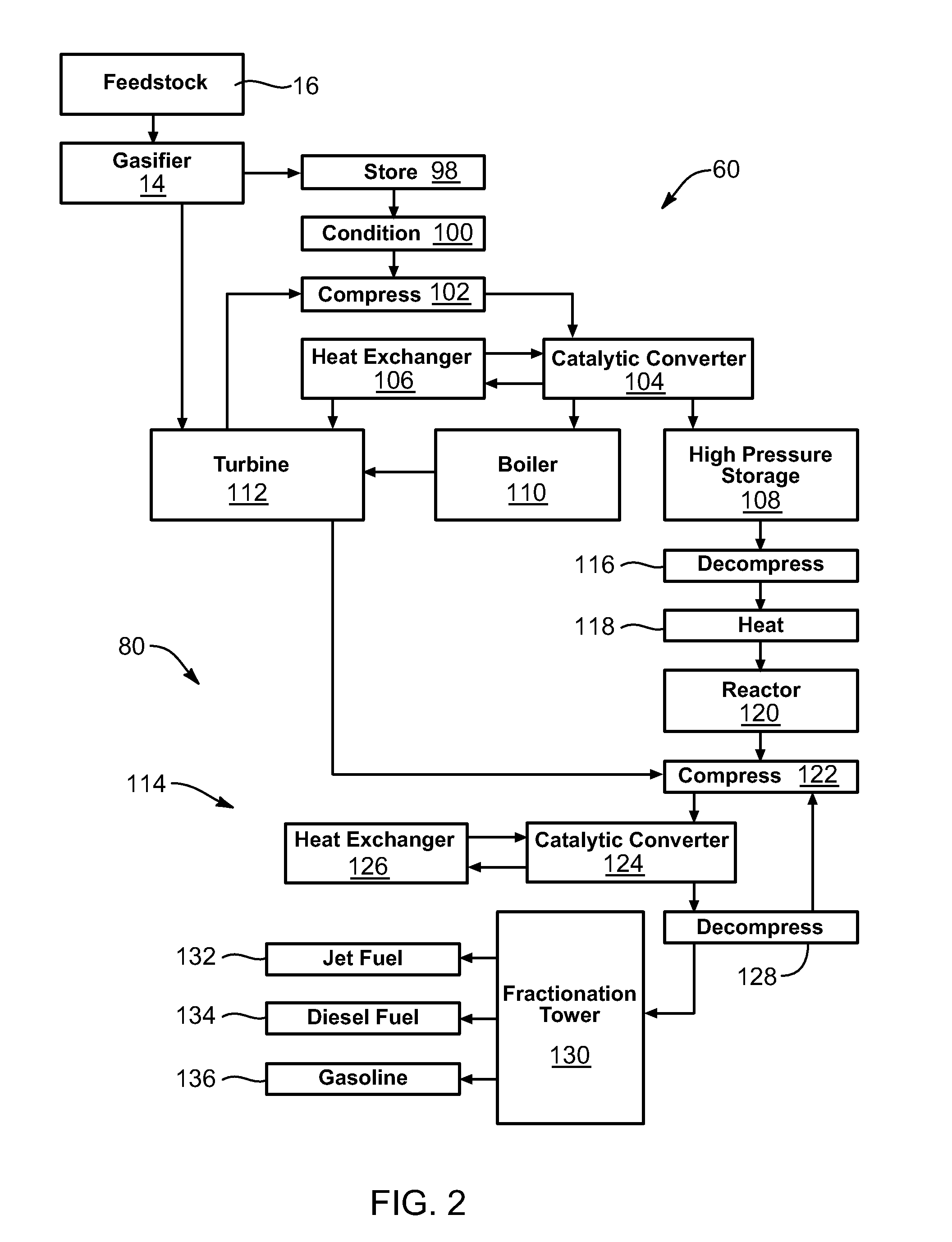

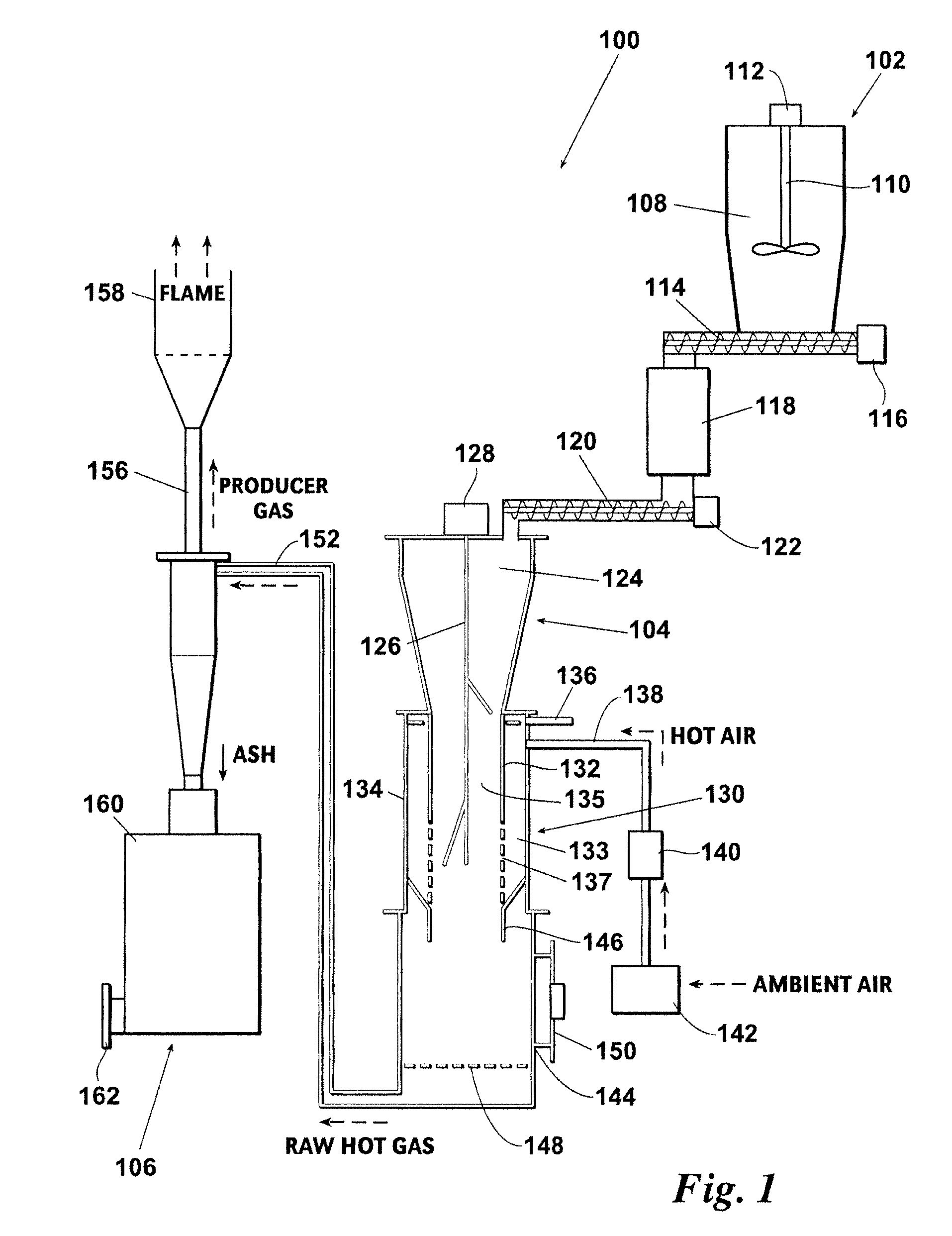

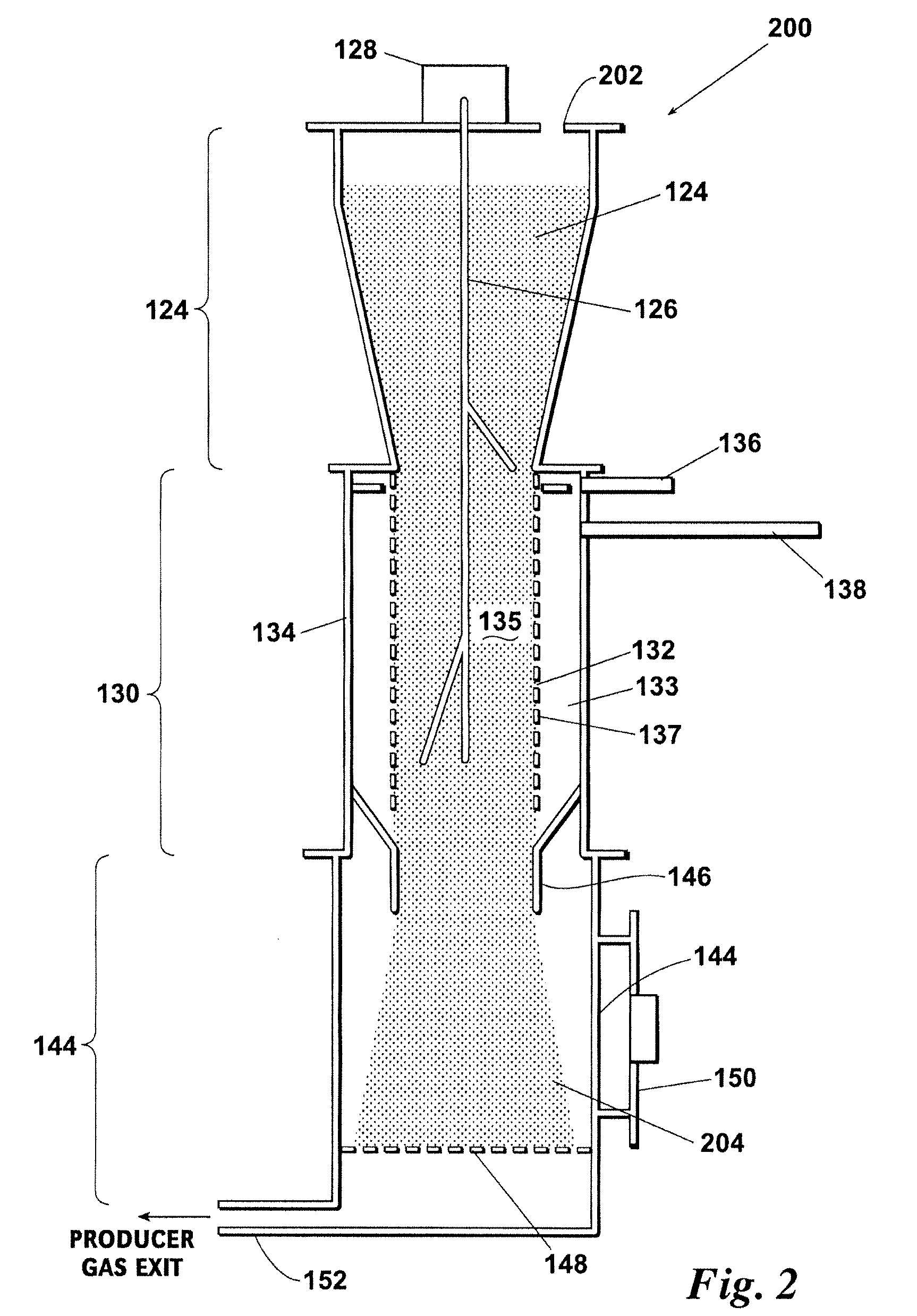

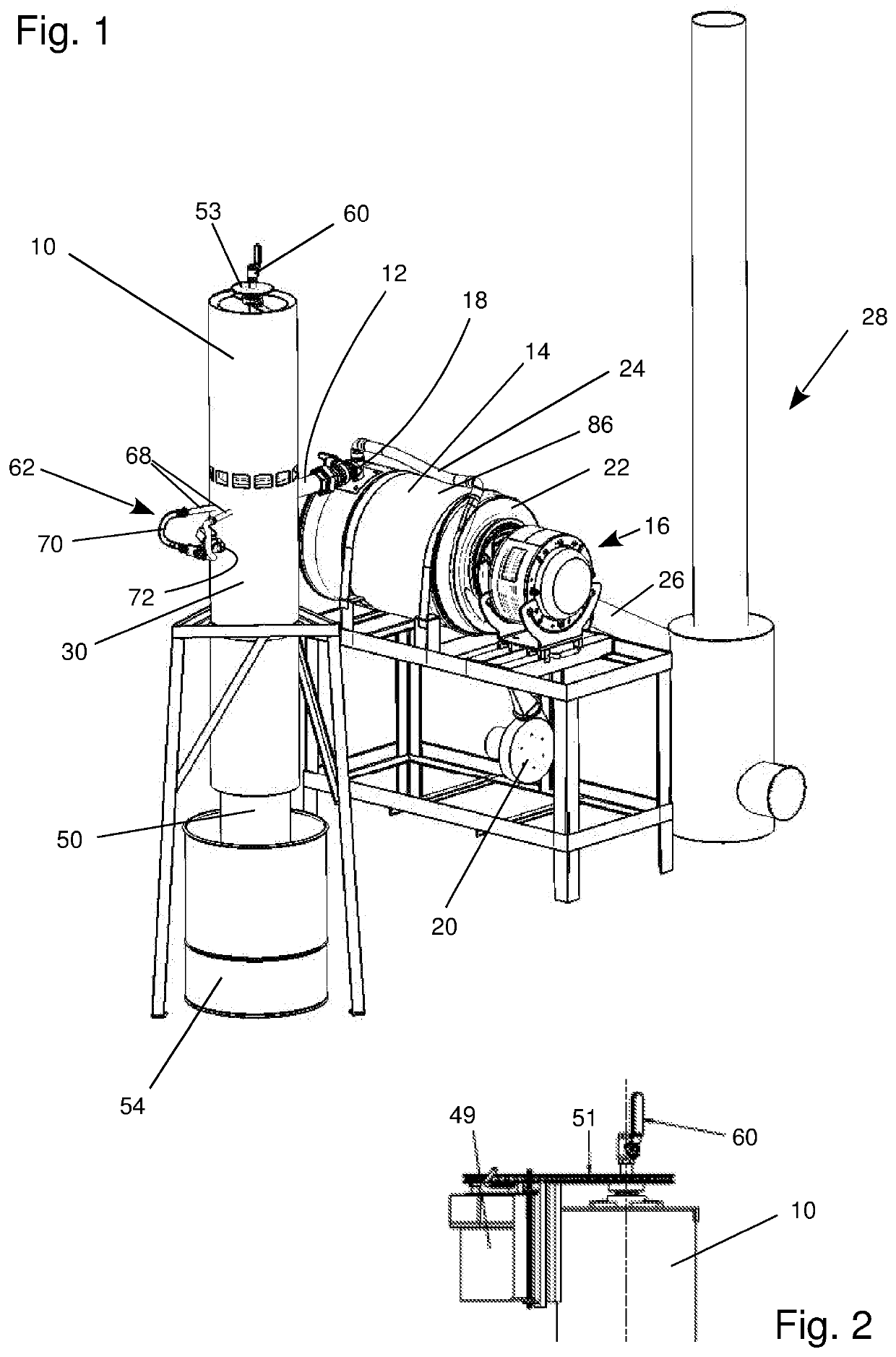

Method and Apparatus for Automated, Modular, Biomass Power Generation

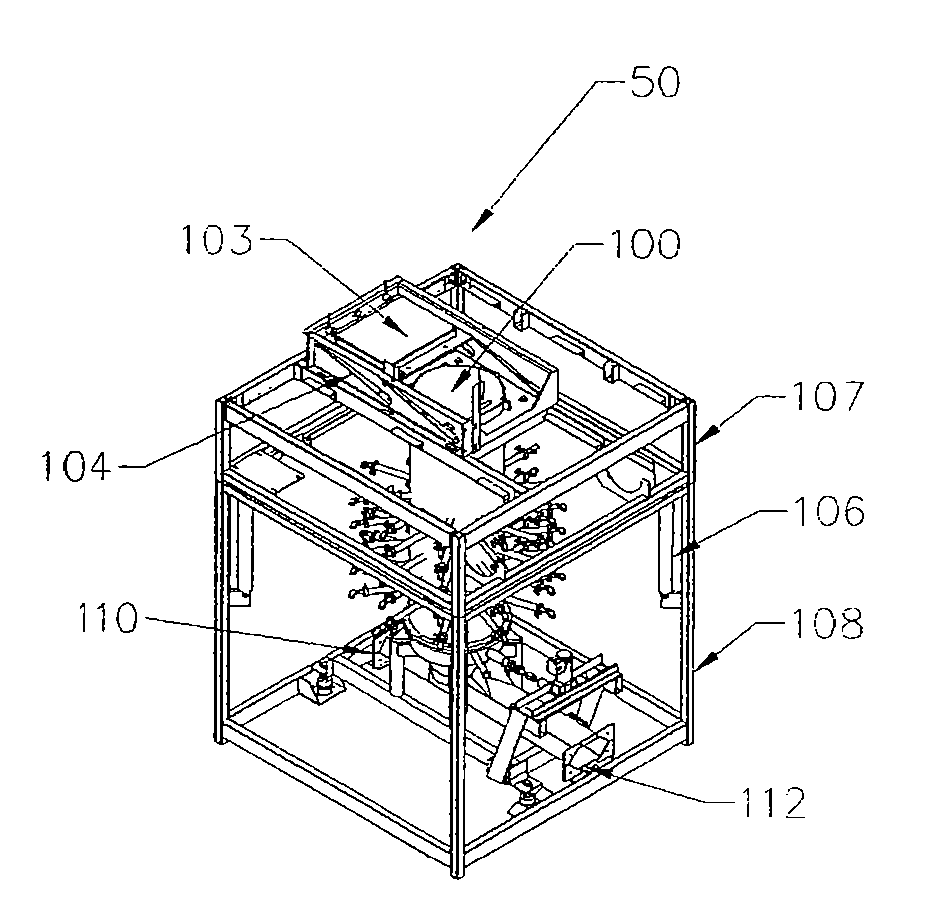

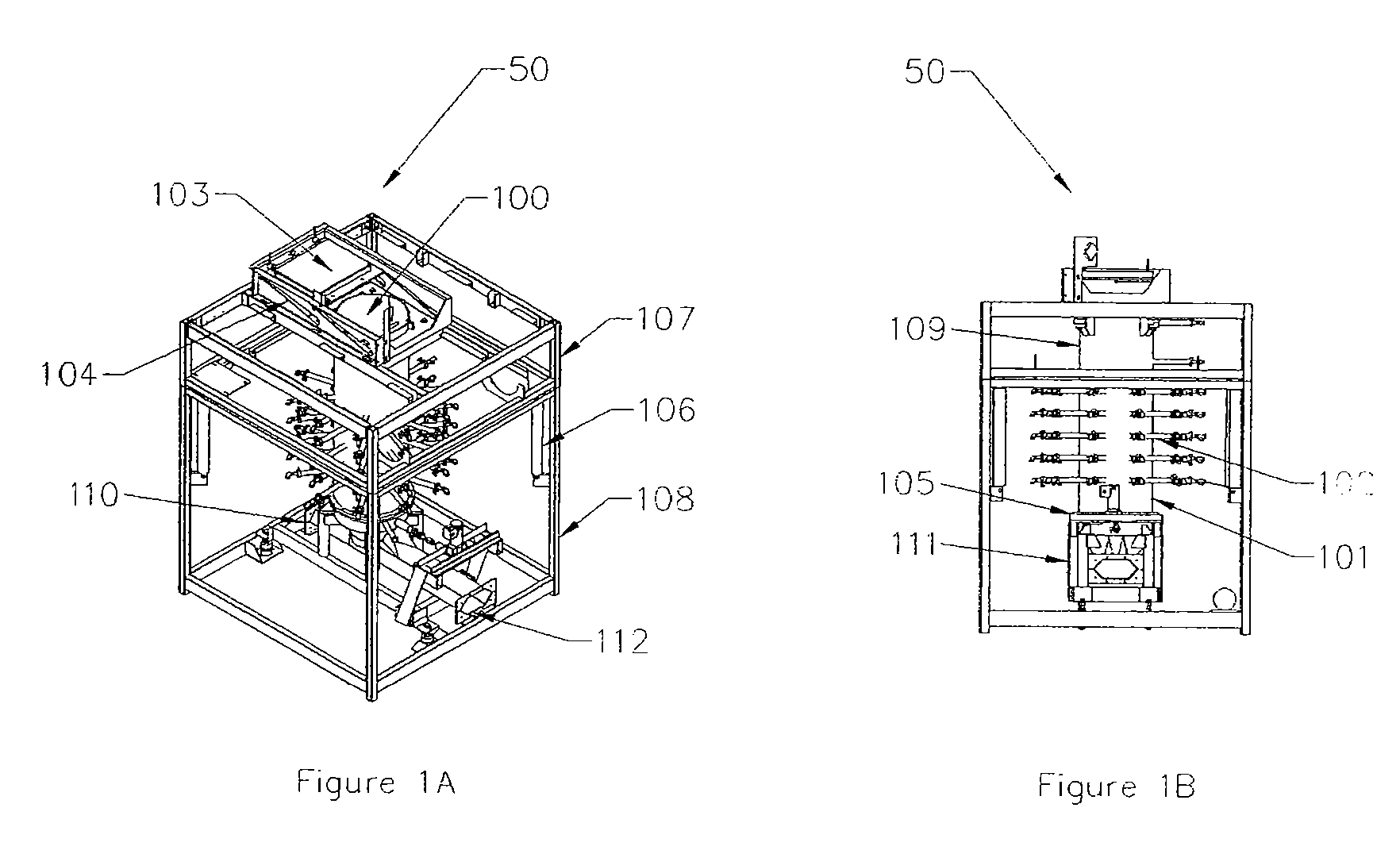

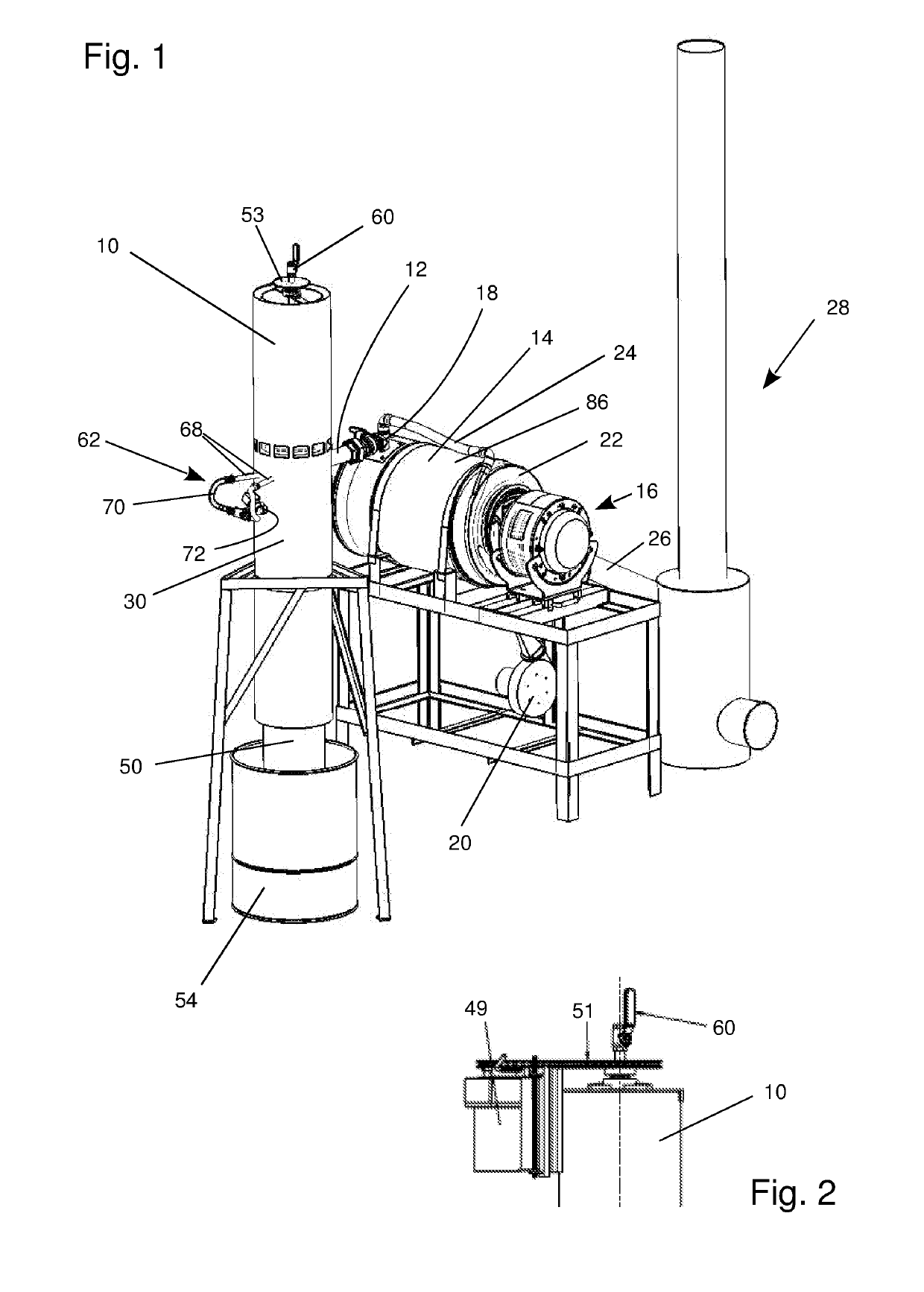

ActiveUS20070006528A1Increasing fuel-bed bulk densityRestrict movementHydrogenDispersed particle filtrationElectric power systemFossil fuel

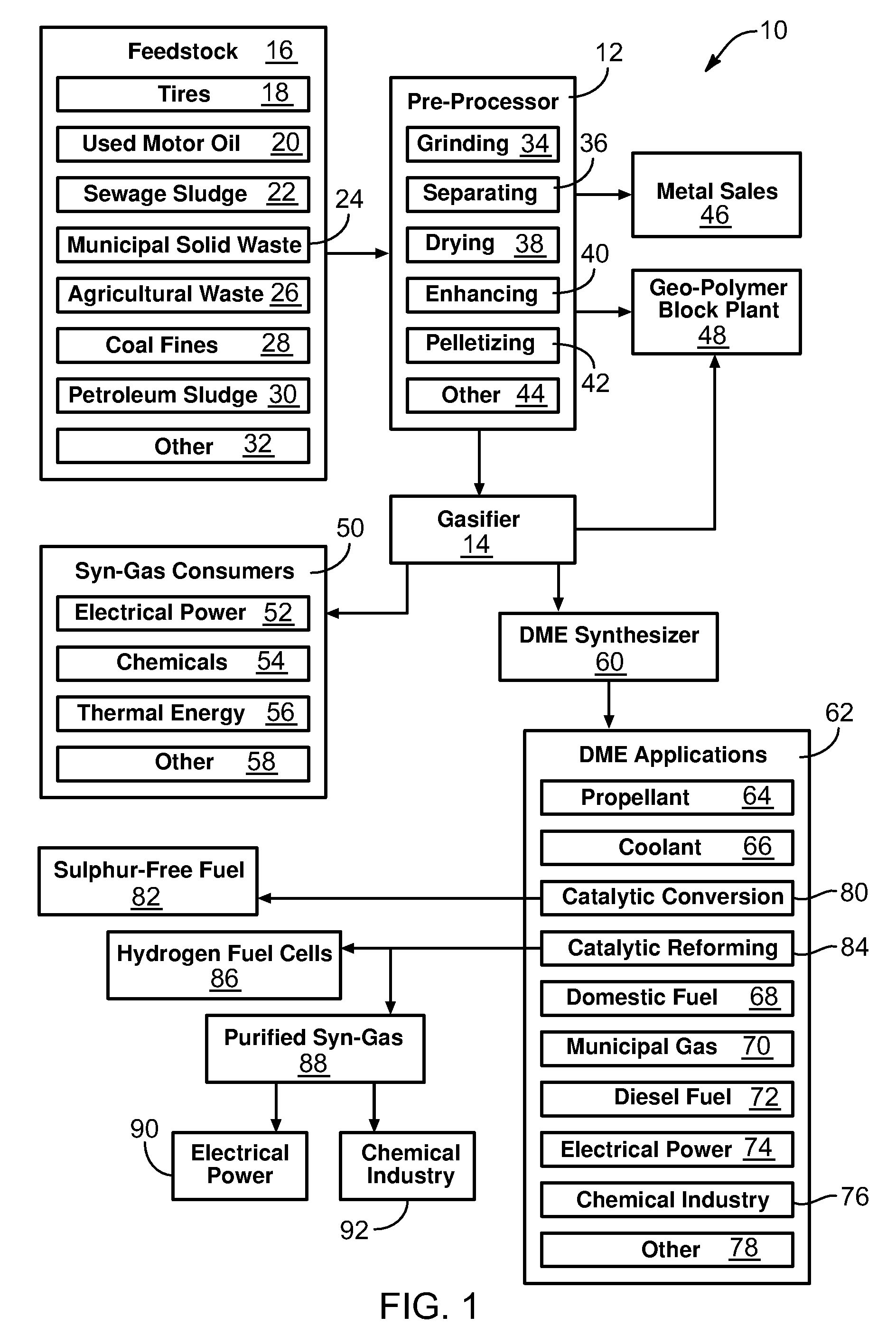

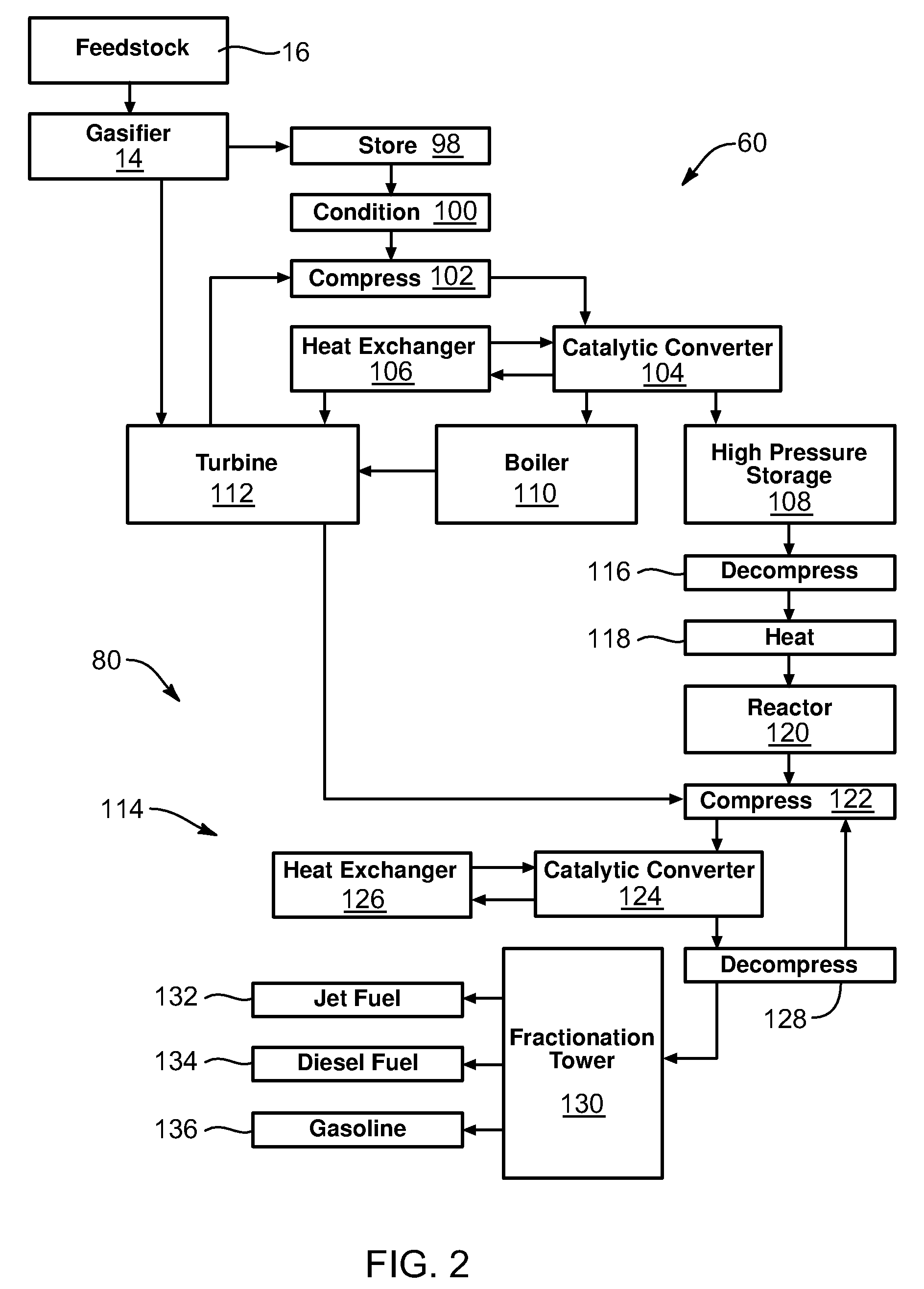

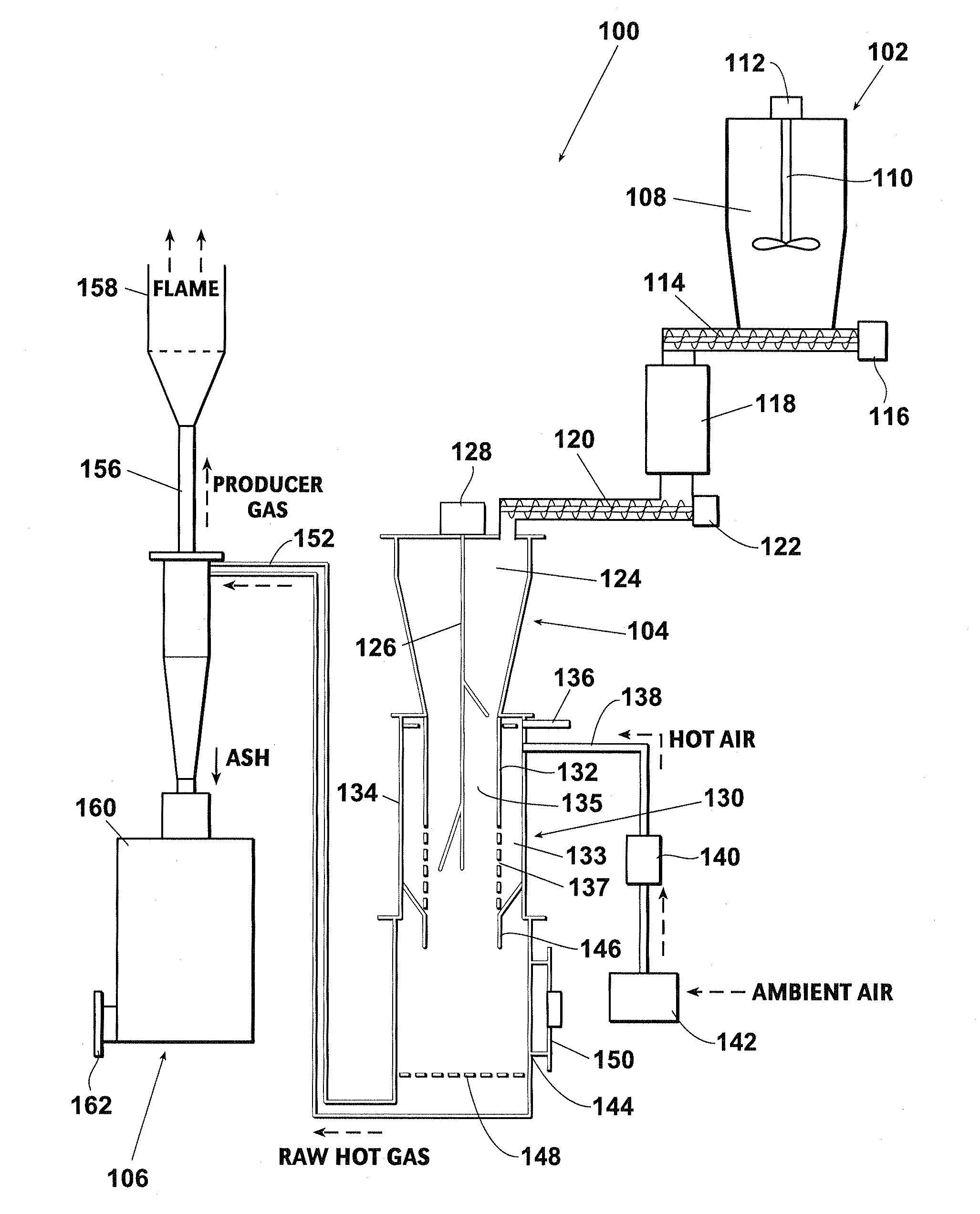

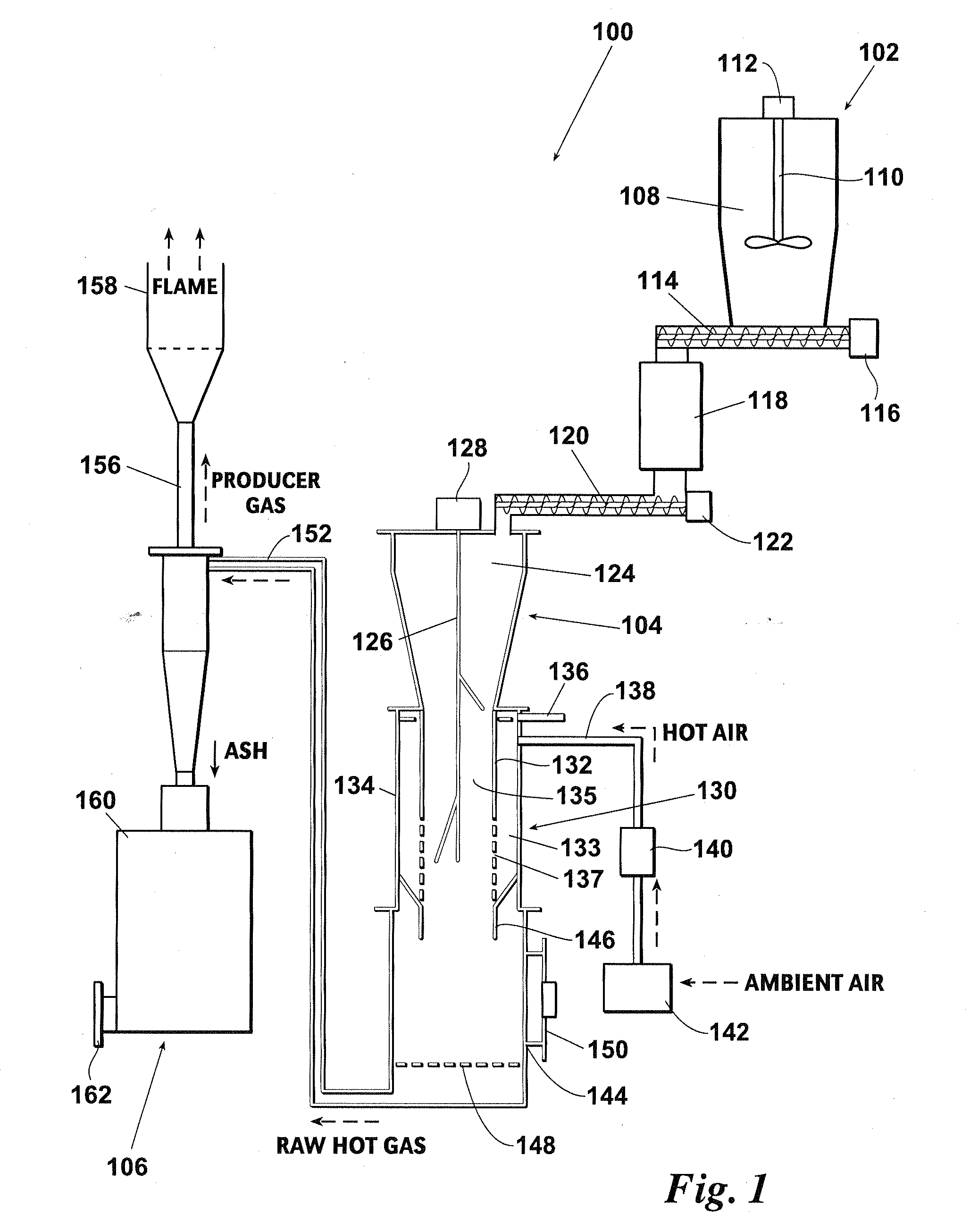

Method and apparatus for generating a low tar, renewable fuel gas from biomass and using it in other energy conversion devices, many of which were designed for use with gaseous and liquid fossil fuels. An automated, downdraft gasifier incorporates extensive air injection into the char bed to maintain the conditions that promote the destruction of residual tars. The resulting fuel gas and entrained char and ash are cooled in a special heat exchanger, and then continuously cleaned in a filter prior to usage in standalone as well as networked power systems.

Owner:COMMUNITY POWER CORP

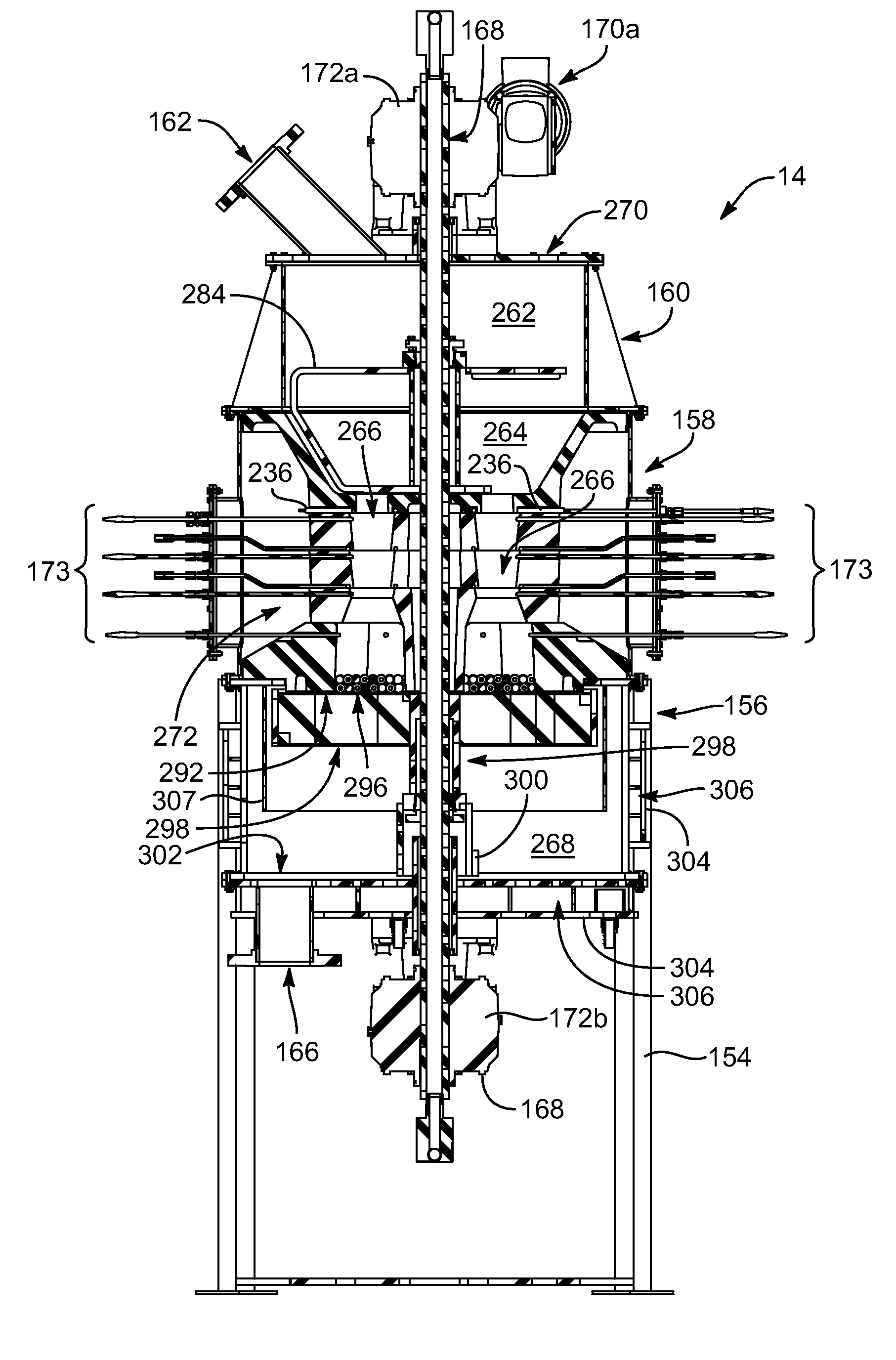

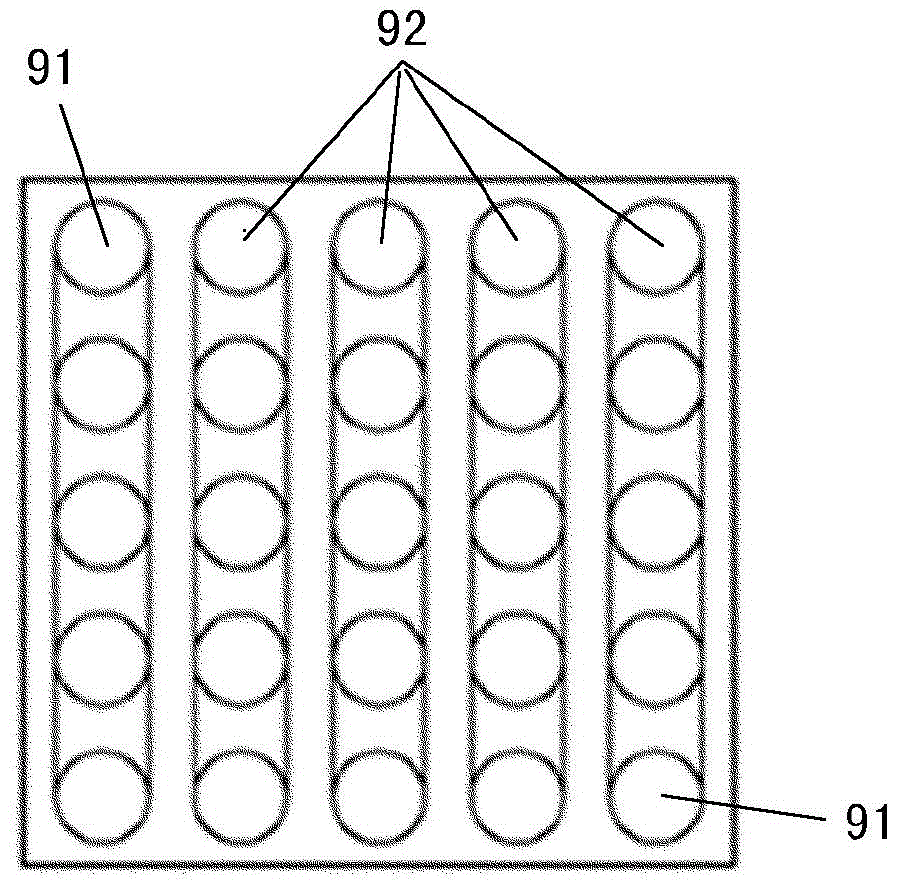

Parallel path, downdraft gasifier apparatus and method

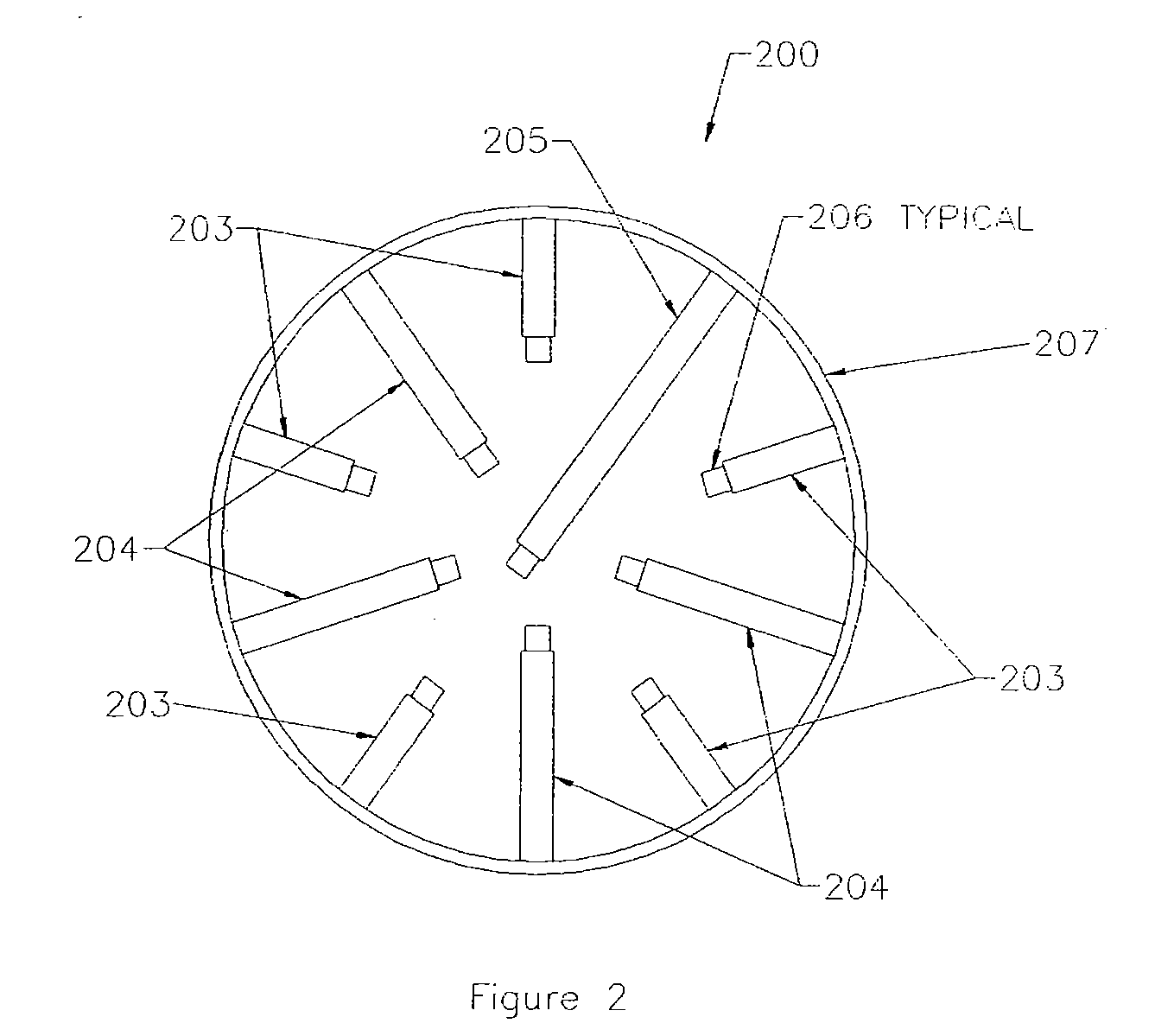

ActiveUS20090119993A1Rapid and precise control of environmentFor fast and precise controlGasifier mechanical detailsGas modification by gas mixingOxidation zoneDowndraft gasifier

A method for using a downdraft gasifier comprising a housing and a refractory stack contained within the housing. The refractory stack may comprise various sections. Apertures in the sections may be aligned to form multiple columnar cavities. Each columnar cavity may comprise an individual oxidation zone. The method of use may include the steps of placing a feedstock into an upper portion of the refractory stack, measuring the temperature of each columnar cavity, and adjusting the flow of oxygen to a particular columnar cavity to maintain the temperature of the particular columnar cavity within a particular range.

Owner:STRATEAN

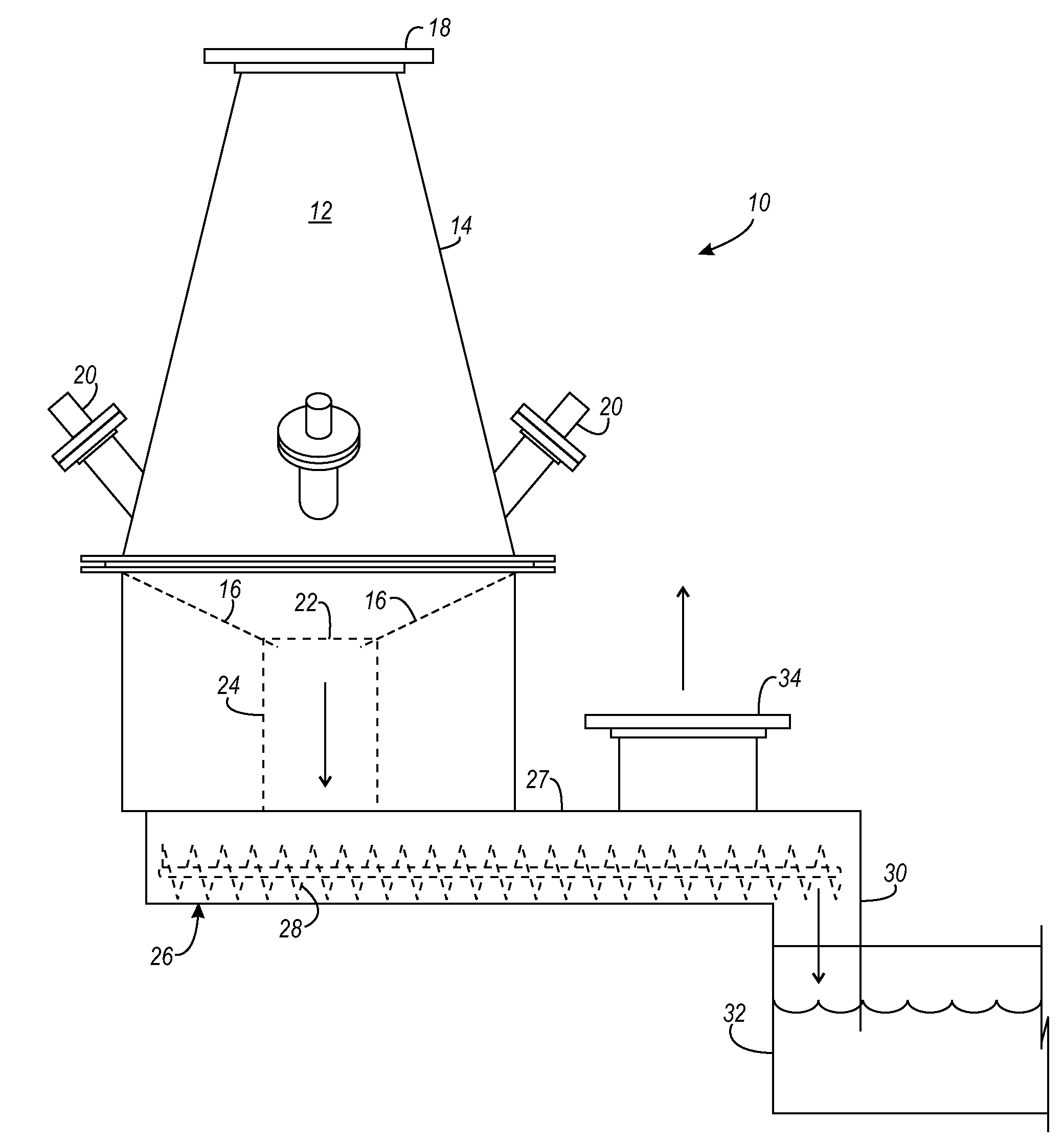

Downdraft gasifier with internal cyclonic combustion chamber

A downdraft gasifier is disclosed. The gasifier has a biomass feeding unit, a combustion chamber, and a separator unit. The biomass feeding unit accepts raw biomass materials and selectively feeds the materials into the combustion chamber. The combustion chamber provides means to induce pyrolysis, tar cracking, and char gasification of the raw biomass materials to produce gases and ash. The separator unit accepts the gases and ash from the combustion chamber and separates the gases from the ash.

Owner:BOARD OF REGENTS FOR OKLAHOMA STATE UNIVERSITY

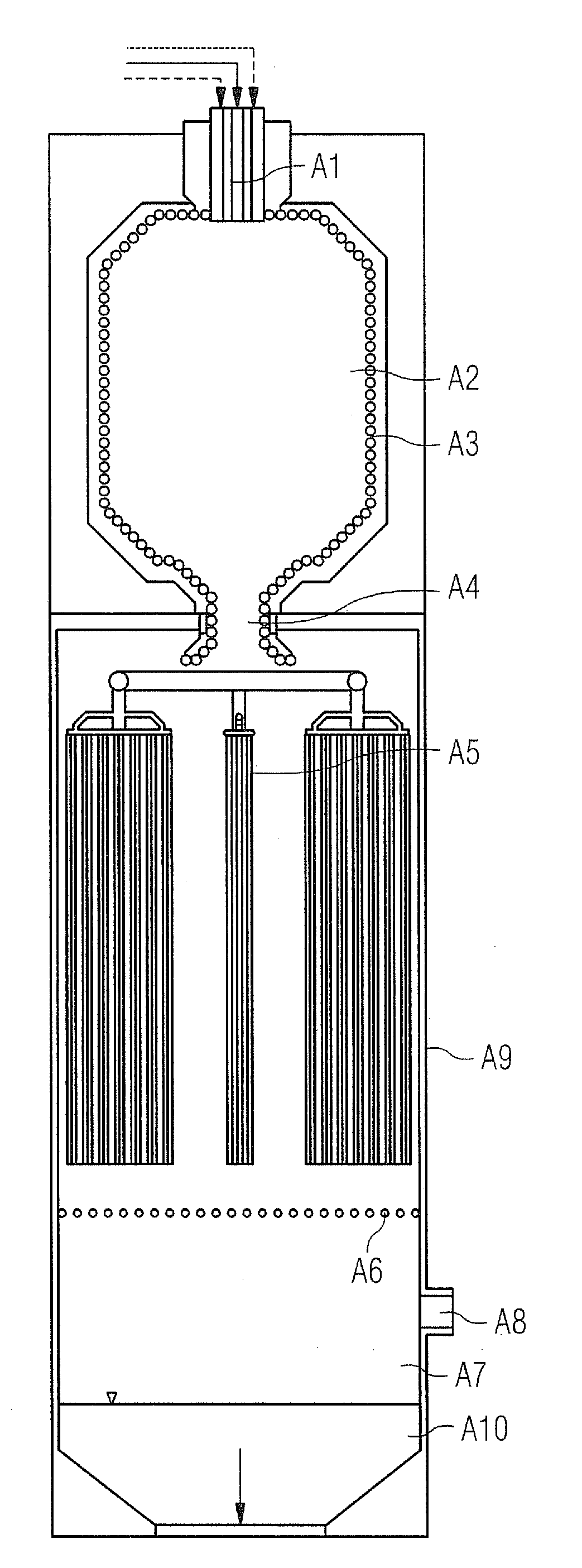

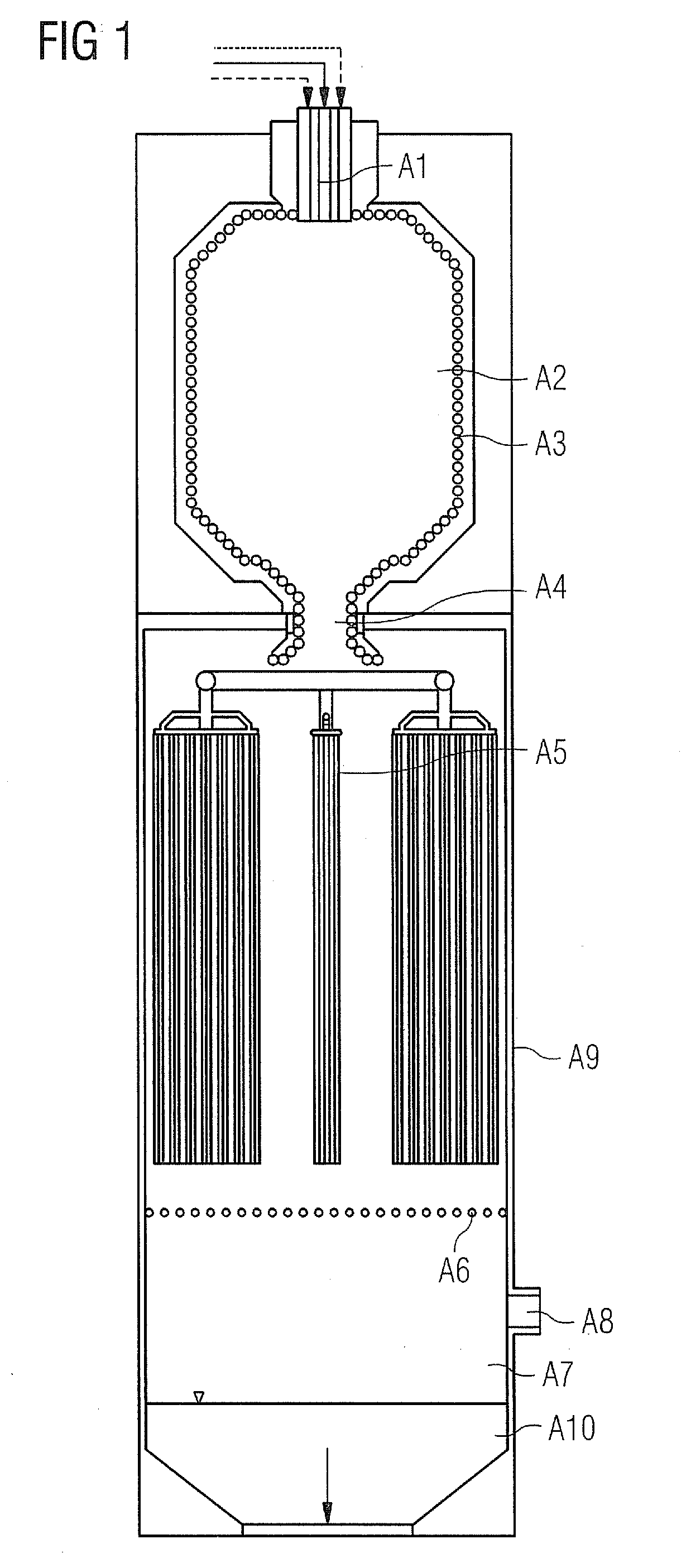

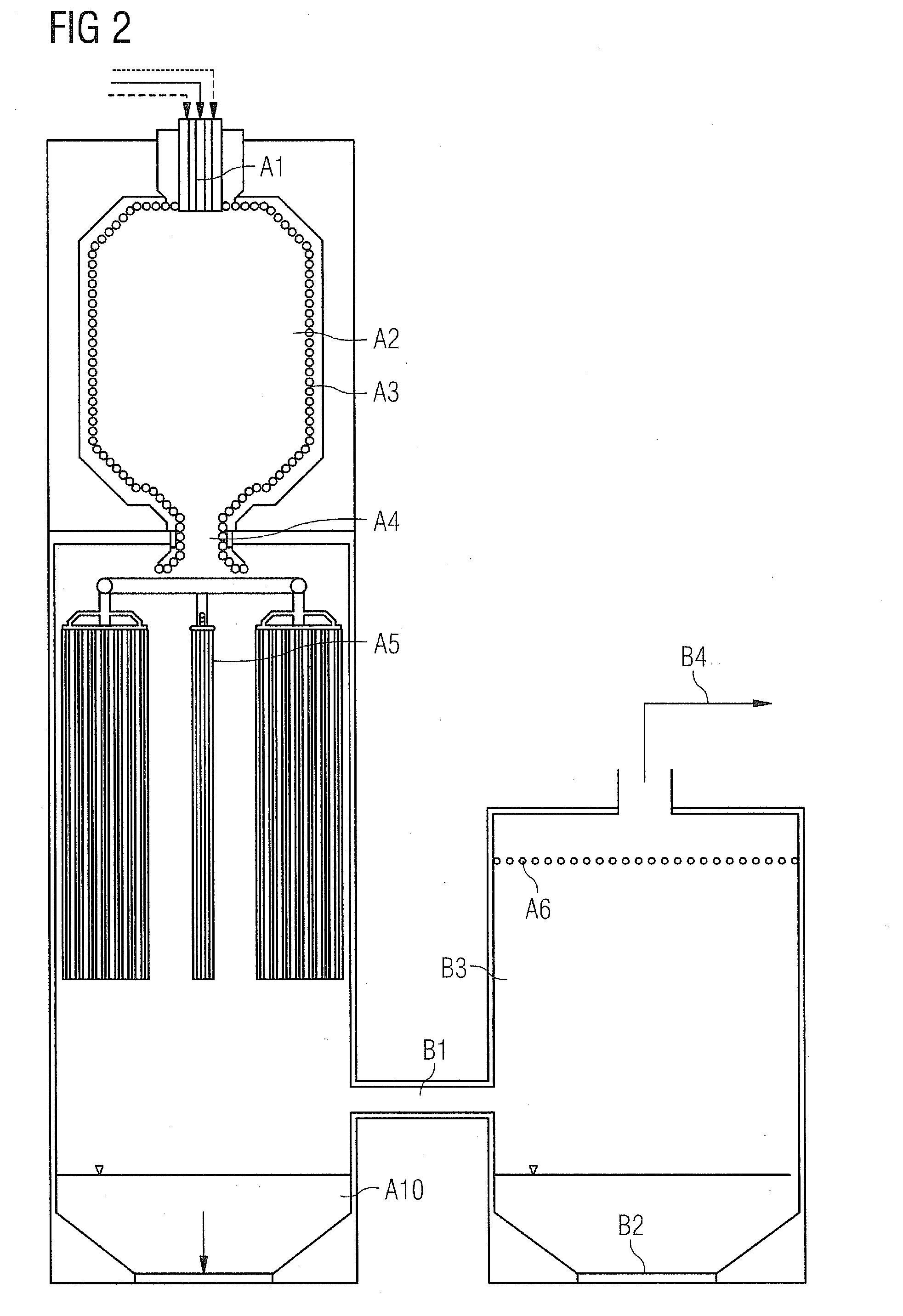

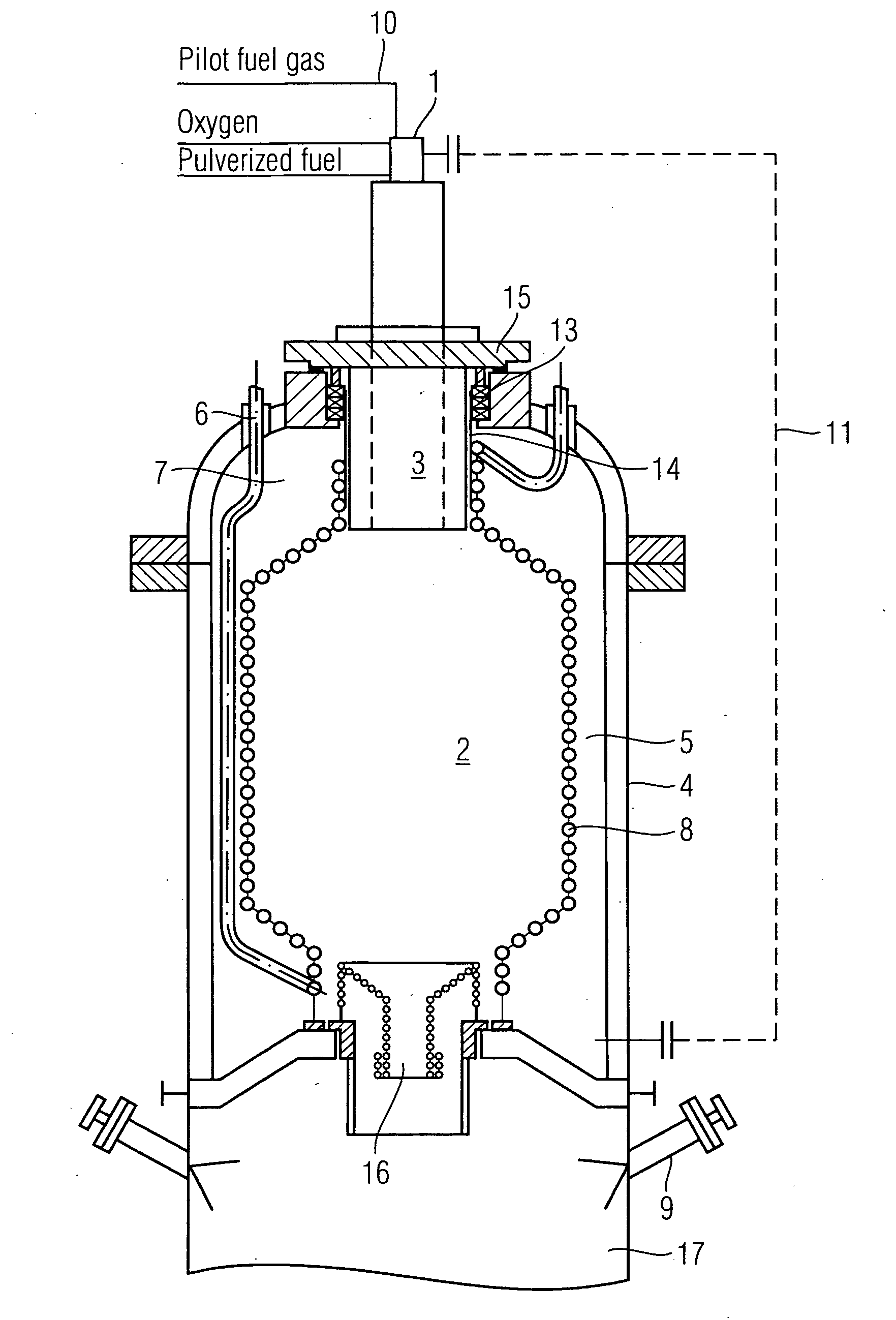

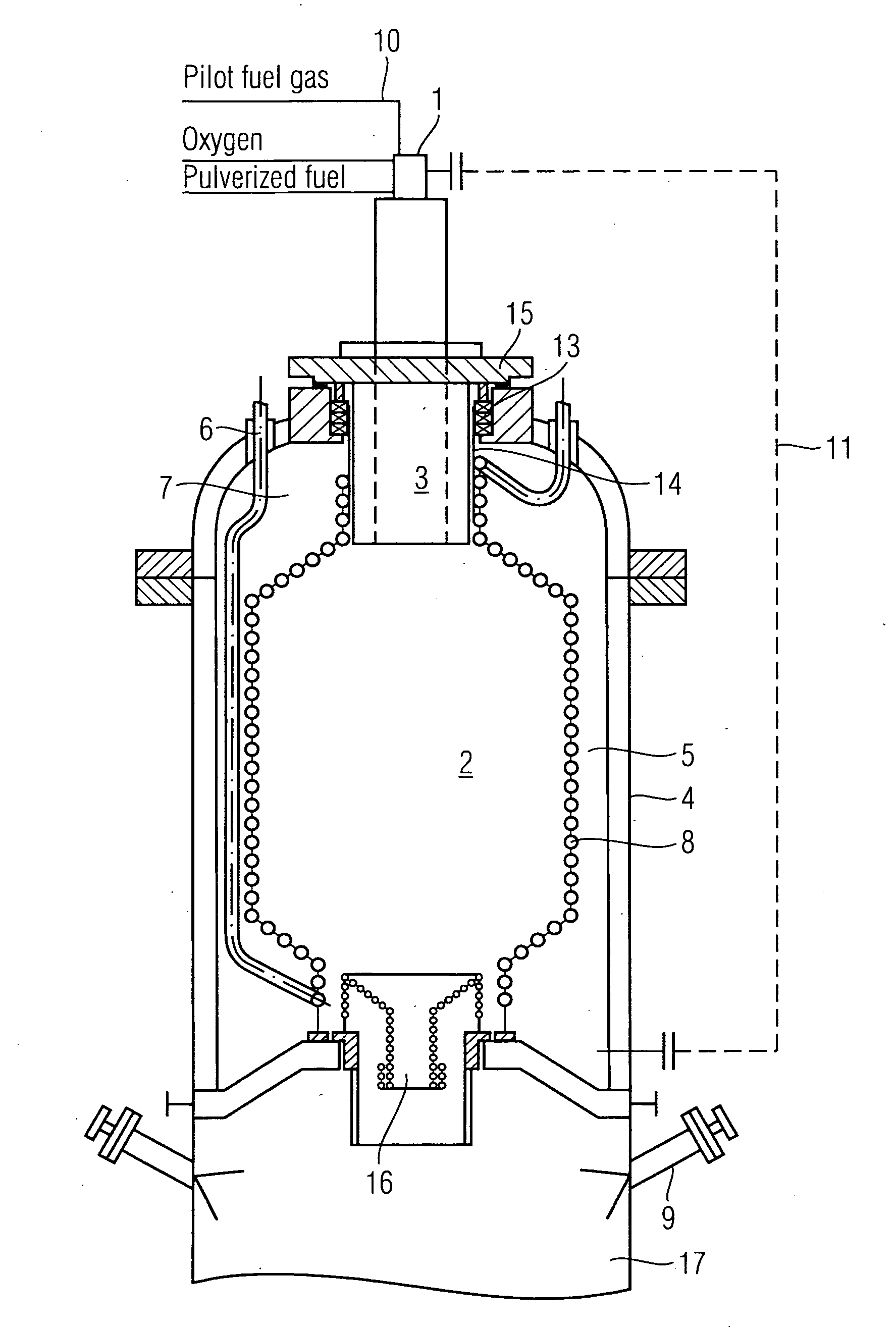

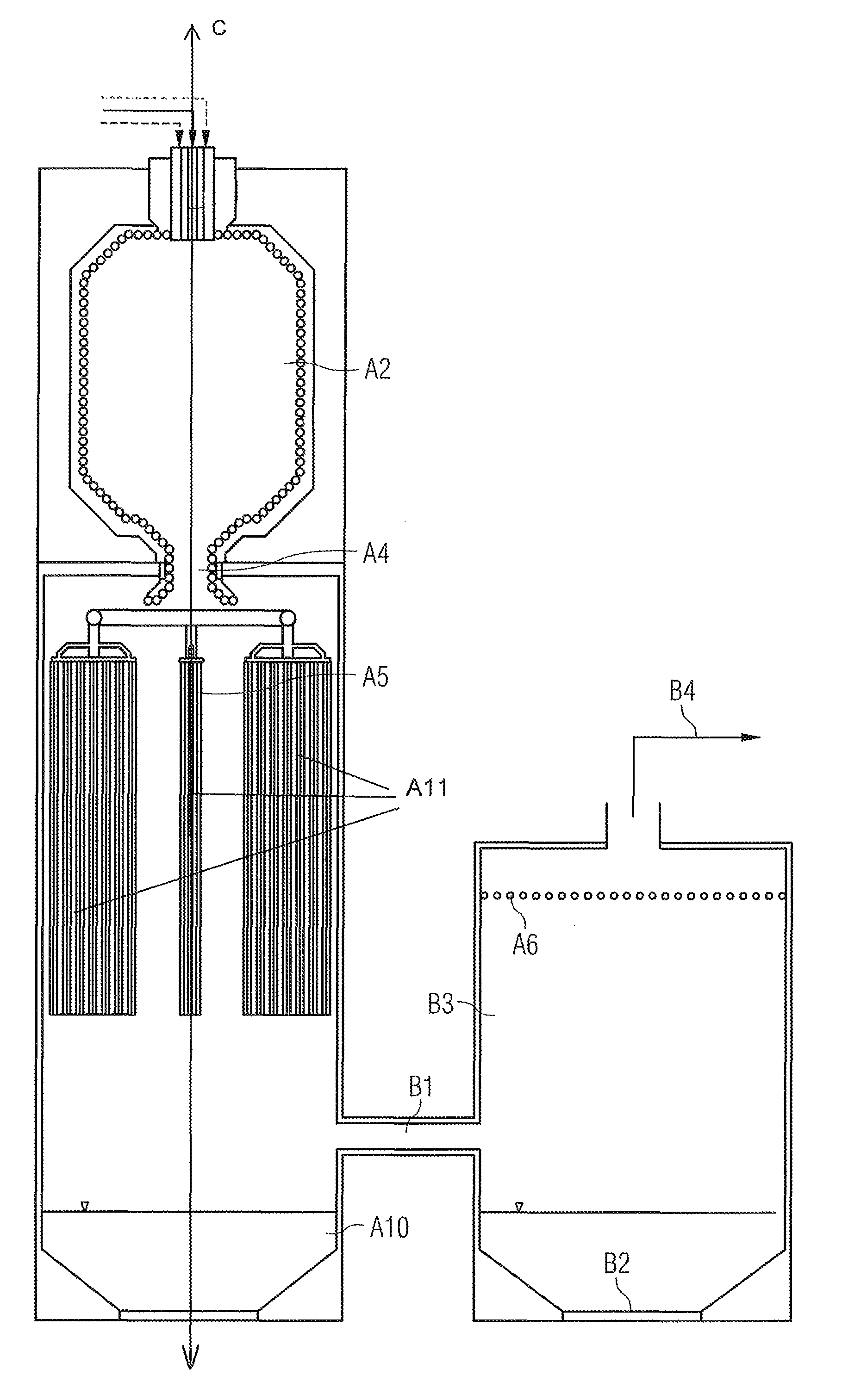

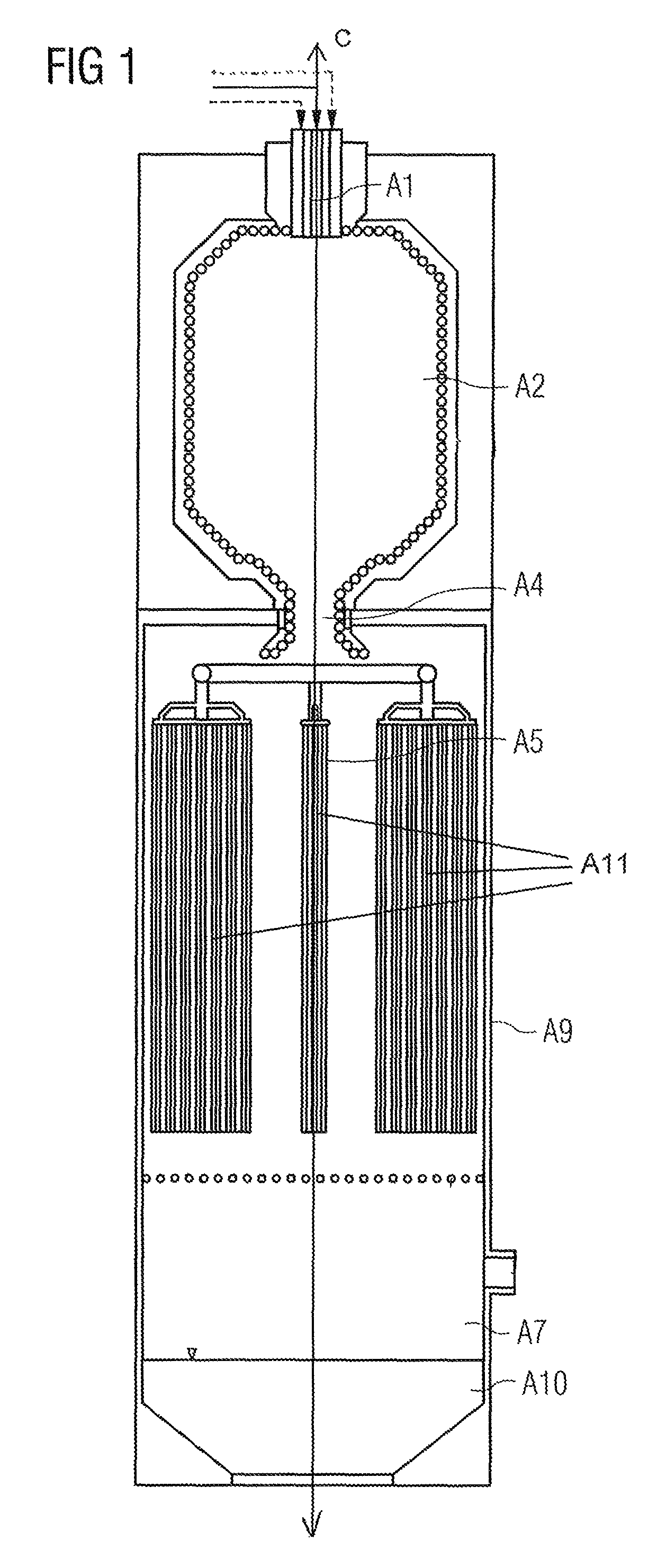

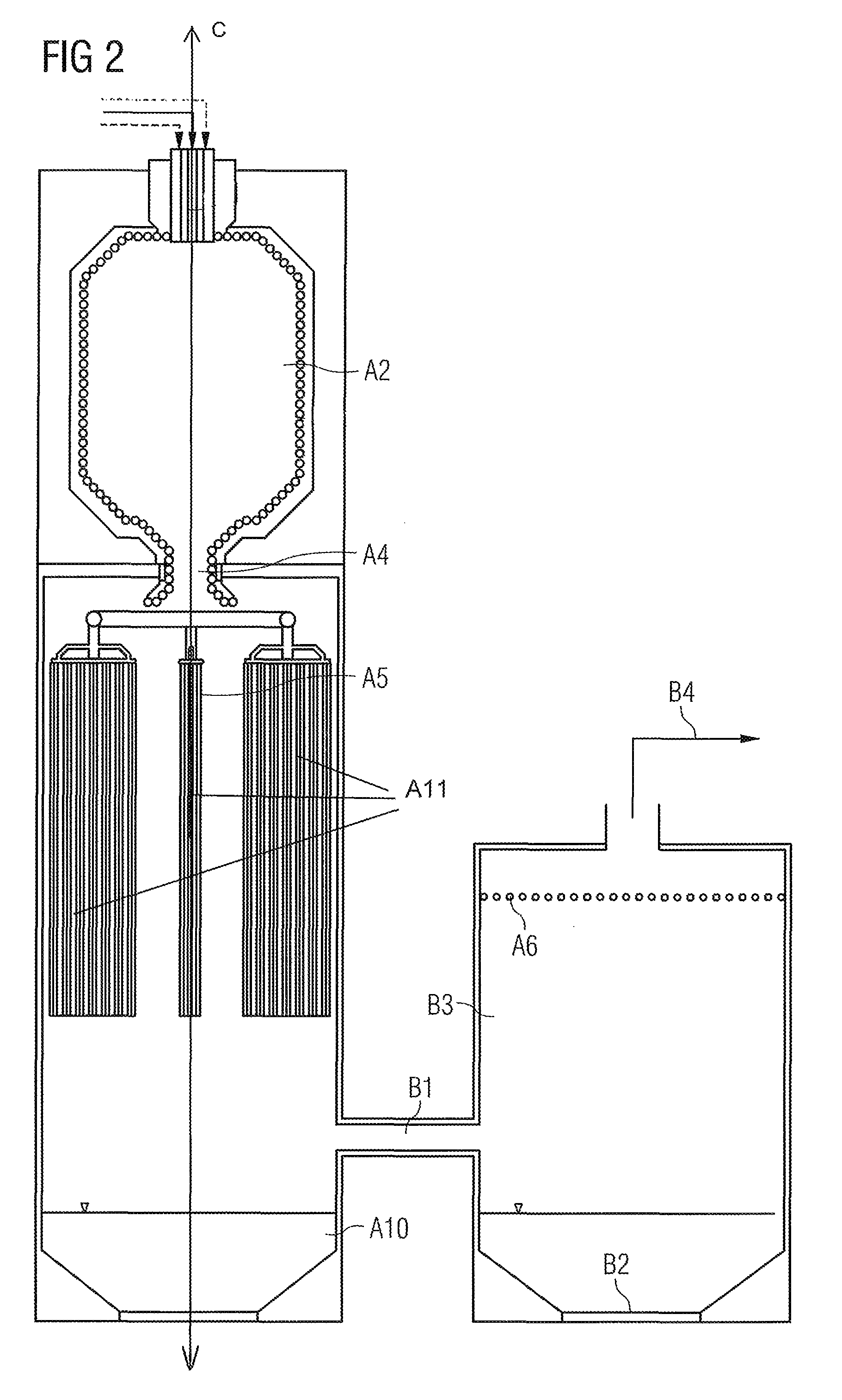

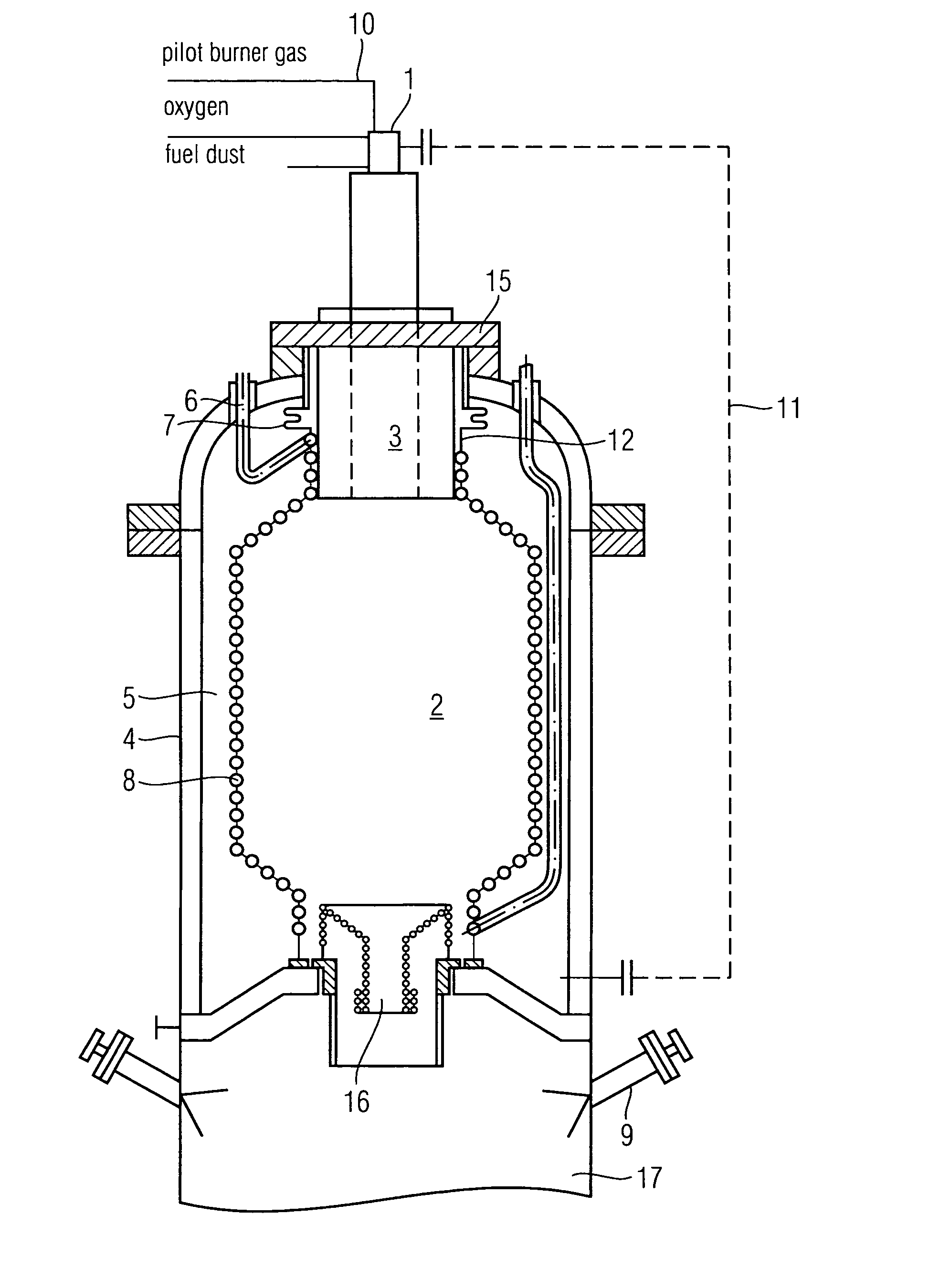

Entrained flow gasifier with integrated radiation cooler

ActiveUS20120117878A1Improve efficiencyGasifier mechanical detailsEnergy inputProcess engineeringEngineering

An entrained flow gasifier designed as a component for an Integrated Gasification Combined Cycle plant of optimized efficiency is provided. The raw gas initially flows through a waste heat unit designed as a radiation cooler and subsequently flows through a full water quench. This results in a higher ratio of steam in the raw gas, which decreases the medium-pressure steam supply before the water-gas shift and thus improves efficiency in IGCC plants with CO2 separation.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Parallel path, downdraft gasifier apparatus and method

ActiveUS8105401B2Effectively stopCompound undesirableGasifier mechanical detailsGas modification by gas mixingOxidation zoneOxygen

A method for using a downdraft gasifier comprising a housing and a refractory stack contained within the housing. The refractory stack may comprise various sections. Apertures in the sections may be aligned to form multiple columnar cavities. Each columnar cavity may comprise an individual oxidation zone. The method of use may include the steps of placing a feedstock into an upper portion of the refractory stack, measuring the temperature of each columnar cavity, and adjusting the flow of oxygen to a particular columnar cavity to maintain the temperature of the particular columnar cavity within a particular range.

Owner:STRATEAN

Charcoal/ash removal system for a downdraft gasifier and associated methods

InactiveUS20090007488A1Avoid passingGas modification by gas mixingGasification processes detailsFixed bedProduct gas

A method and apparatus is provided for use in a fixed-bed gasification system for the disengagement of gas and the removal of ash and charcoal. In one example, the invention includes an auger system, a water seal system, and a gas disengagement system. The gas disengagement mechanism prevents plugging and blinding of the gas offtake system and simultaneously limits particulate entrainment in the gas produced by the gasifier.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

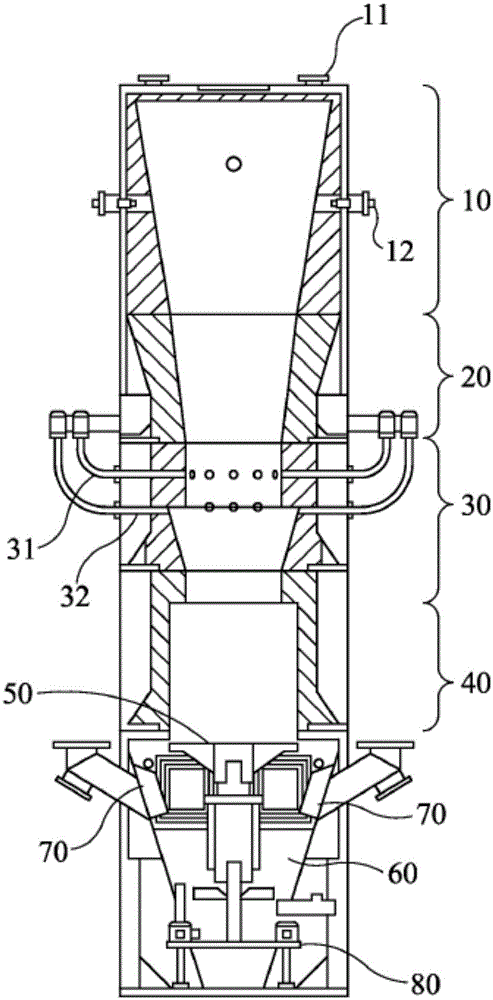

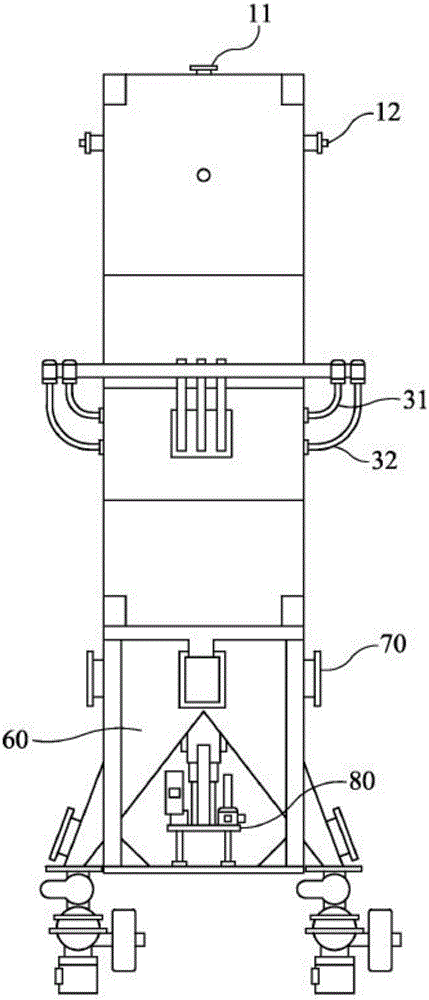

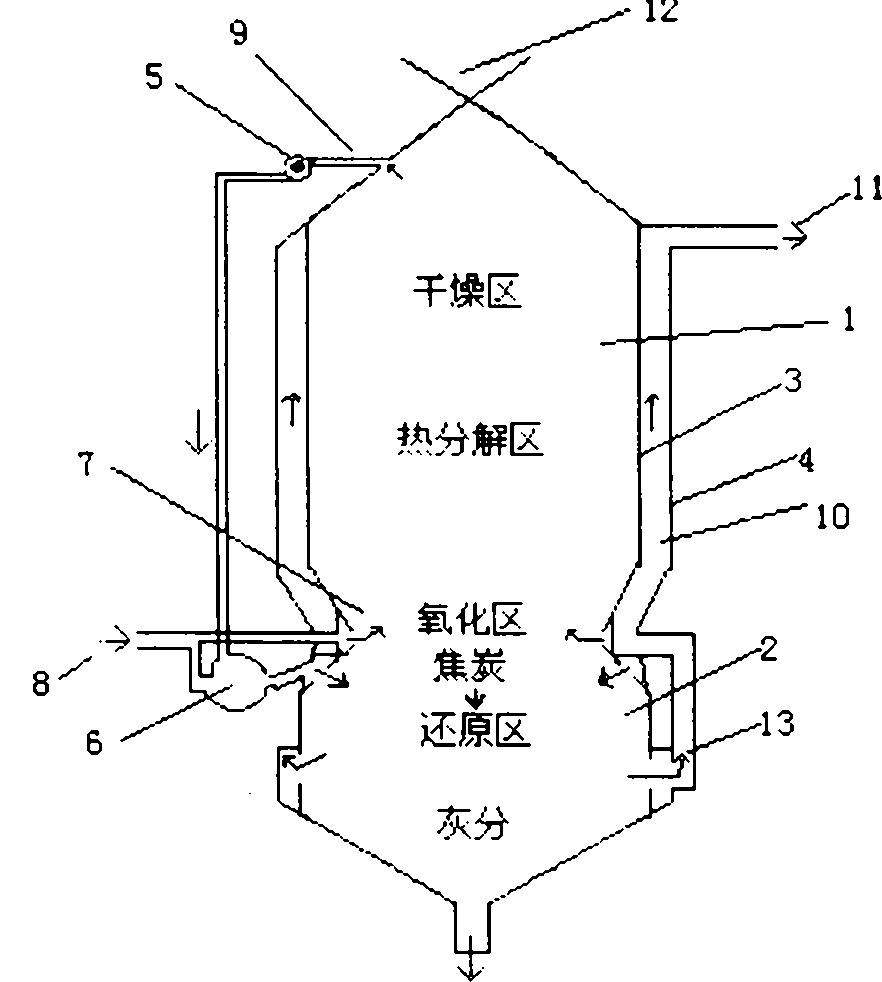

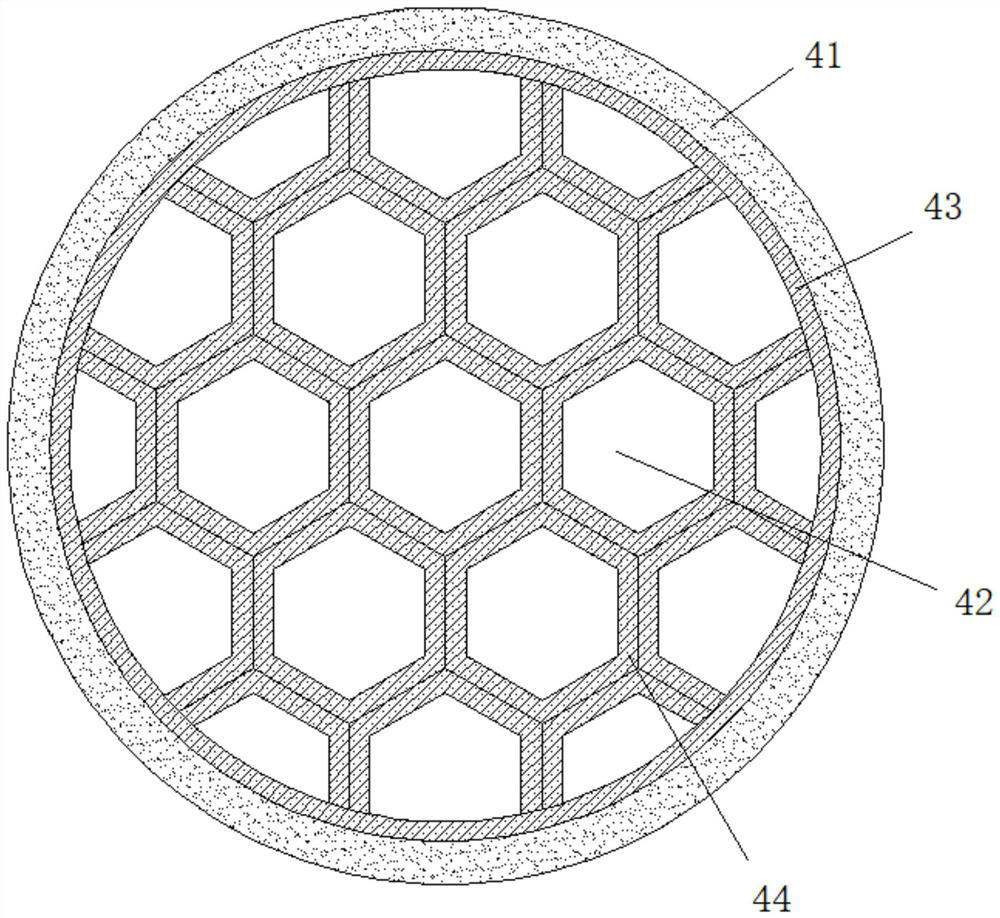

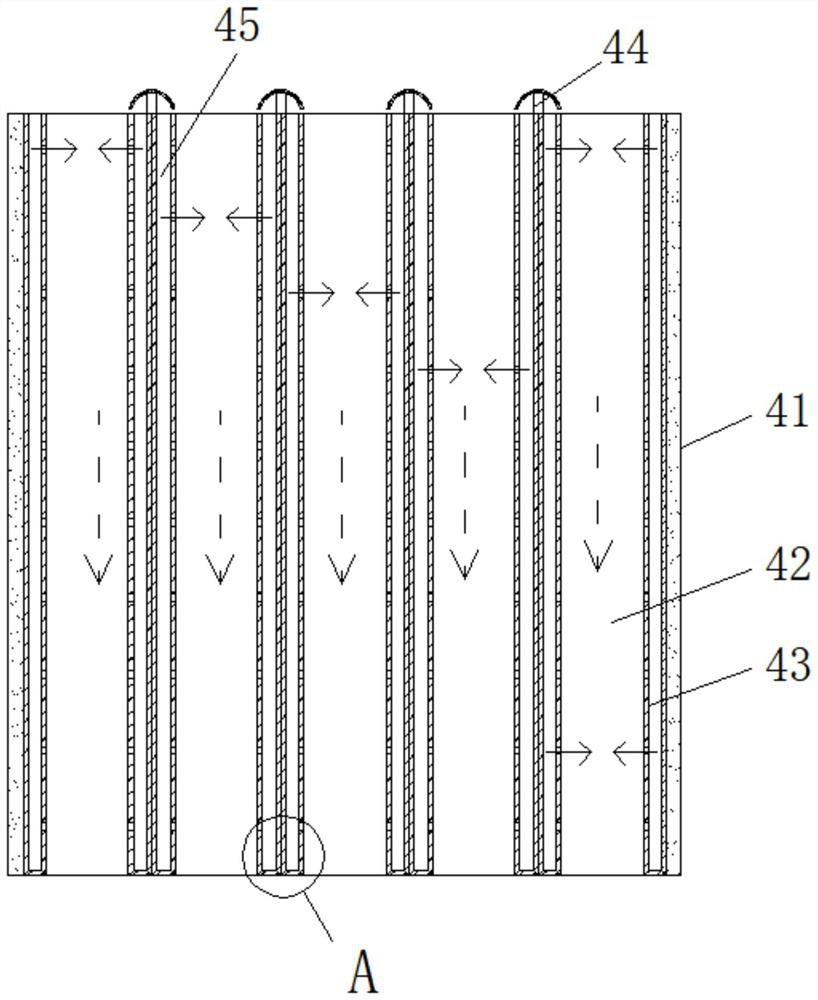

Downdraft gasifier with tar degrading function

ActiveCN103952186AExtended stayPromote degradationGranular/pulverulent flues gasificationThree levelThroat

The invention discloses a downdraft gasifier with a tar degrading function. The downdraft gasifier comprises a hearth, wherein the lower part of the hearth is provided with a ring-shaped throat; a feeding hole is formed in the top of the hearth, and an ash outlet is formed in the bottom of the hearth; upper, middle and lower three-level tangential primary air distribution outlets are axially formed in the wall above the ring-shaped throat of the hearth; a tubular fire grate is arranged between the ring-shaped throat at the lower part of the hearth and the ash outlet at the bottom and is formed by hollow steel tubes spaced from each other; holes as secondary air distribution outlets are drilled in the hollow steel tubes; a vertical flue is arranged outside the hearth; one end of a horizontal flue flush with the tubular fire grate is communicated with the hearth and the other end is communicated with the vertical flue; a gas outlet is formed in the upper part of the vertical flue; a calcium base catalyst jet device is arranged at the top of the vertical flue. The downdraft gasifier has a simple structure, has a tar self-purifying capacity and can ensure that the tar in the gasified gases is fully decomposed before leaving the hearth, thus obtaining the gasified gases with relatively high quality.

Owner:ZHEJIANG UNIV

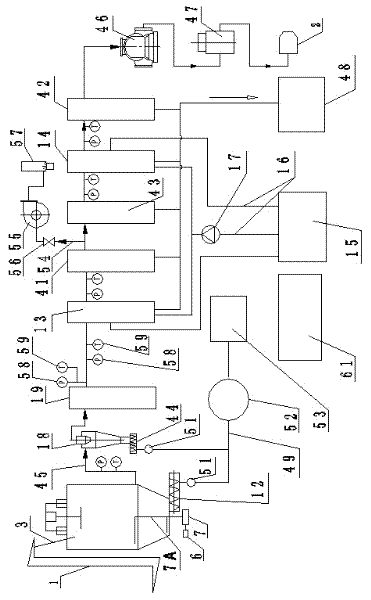

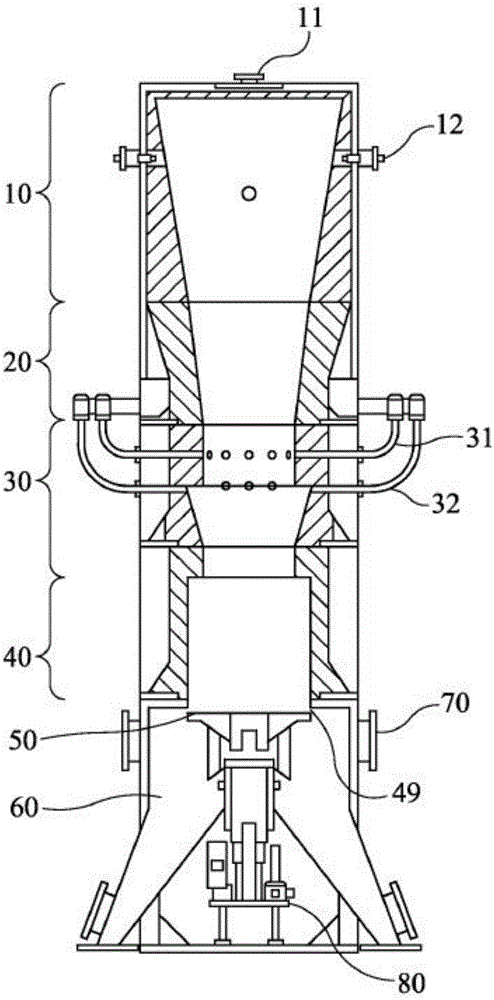

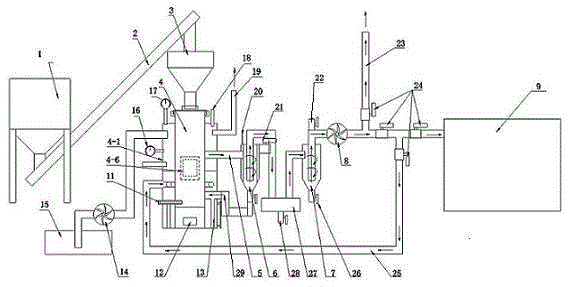

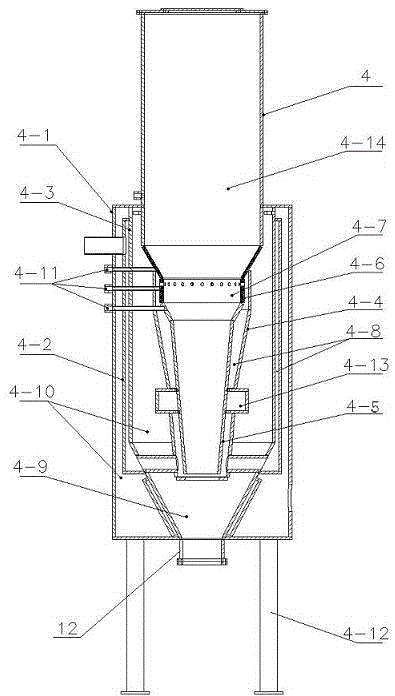

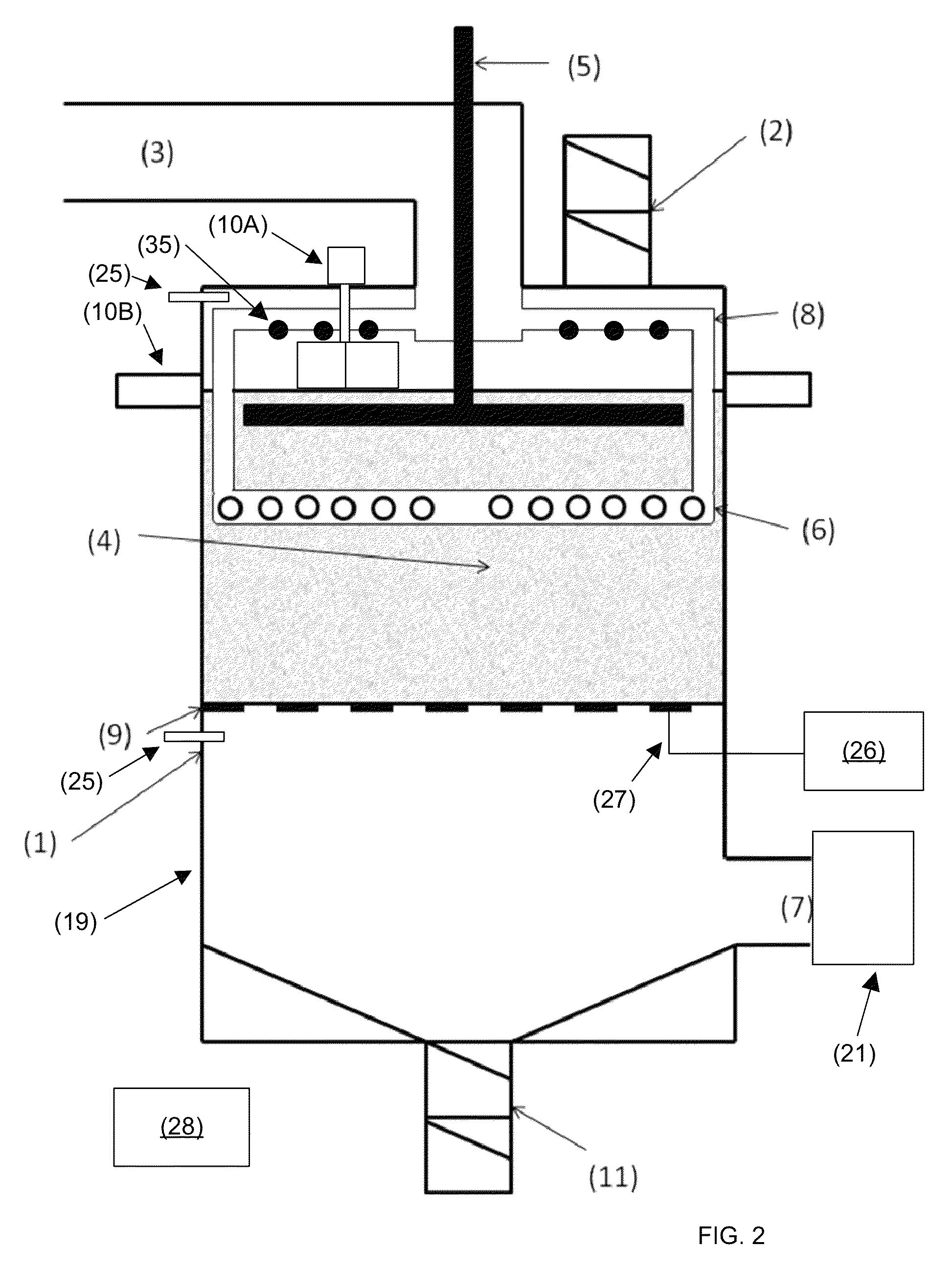

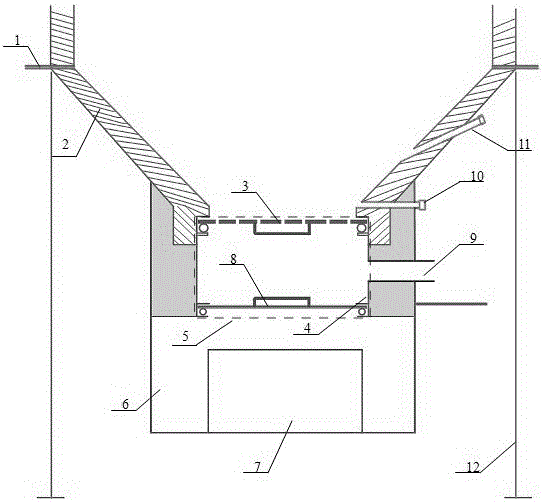

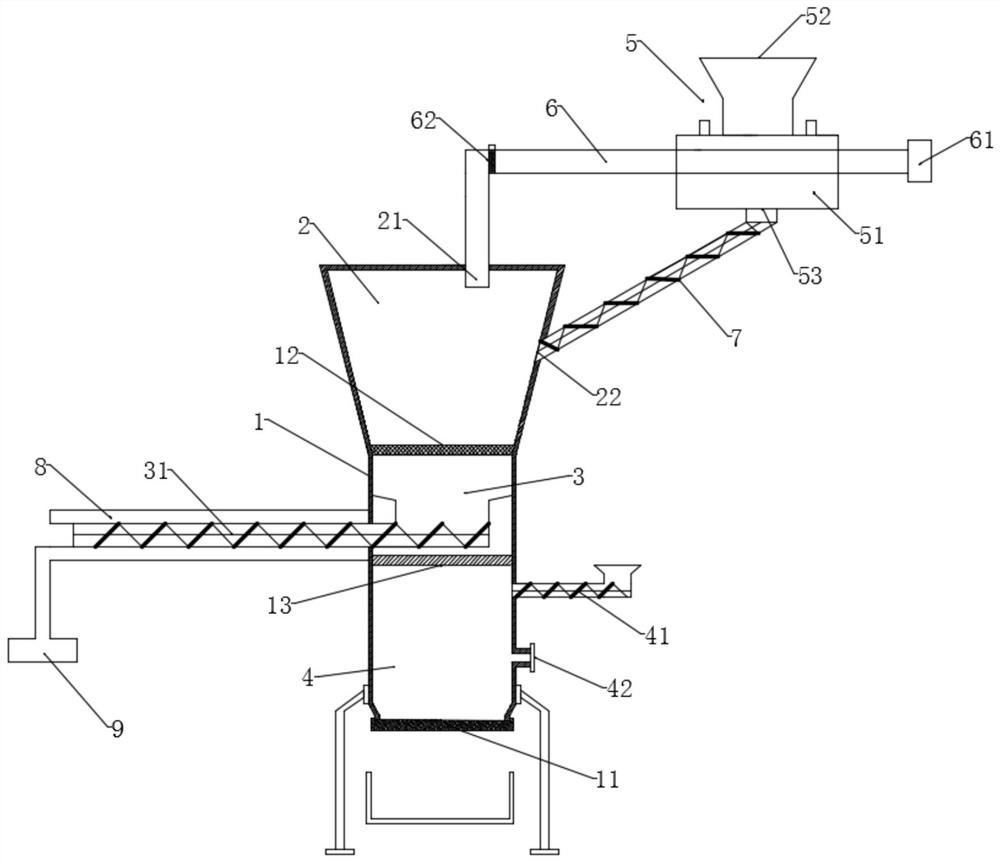

Large-scale biomass briquette fuel fixed bed gasification power generation system

InactiveCN102268297AGuaranteed uptimeImprove liquidityInternal combustion piston enginesGaseous engine fuelsFixed bedEngineering

The invention discloses a large-scale biomass briquette fuel fixed-bed gasification power generation system, which includes a feeding device, a downdraft gasifier, a purification system and a gas generator set. The downdraft gasifier includes a furnace, and the furnace includes A cylindrical water interlayer, the top of the water interlayer is provided with a top cover, and the bottom of the water interlayer is connected with an ash bin. The upper part is provided with a fire grate; the top cover is provided with a material level power device, and the material level power device is connected with a fixed plate, and the fixed plate is fixedly connected with a distribution motor. The output shaft of the distribution motor extends downward into the top cover and its bottom A rake is provided; the feeding device is a feeding hoist, and the discharge pipe of the feeding hoist passes through the top cover and extends into the interior of the furnace. The invention is suitable for using biomass briquette fuel as a raw material, and the structure of the gasification furnace makes the diameter break through the limit of 2 meters in the past, which can ensure the continuous operation of the large gasifier, and the power generation power breaks through the limit of 1MW.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI +1

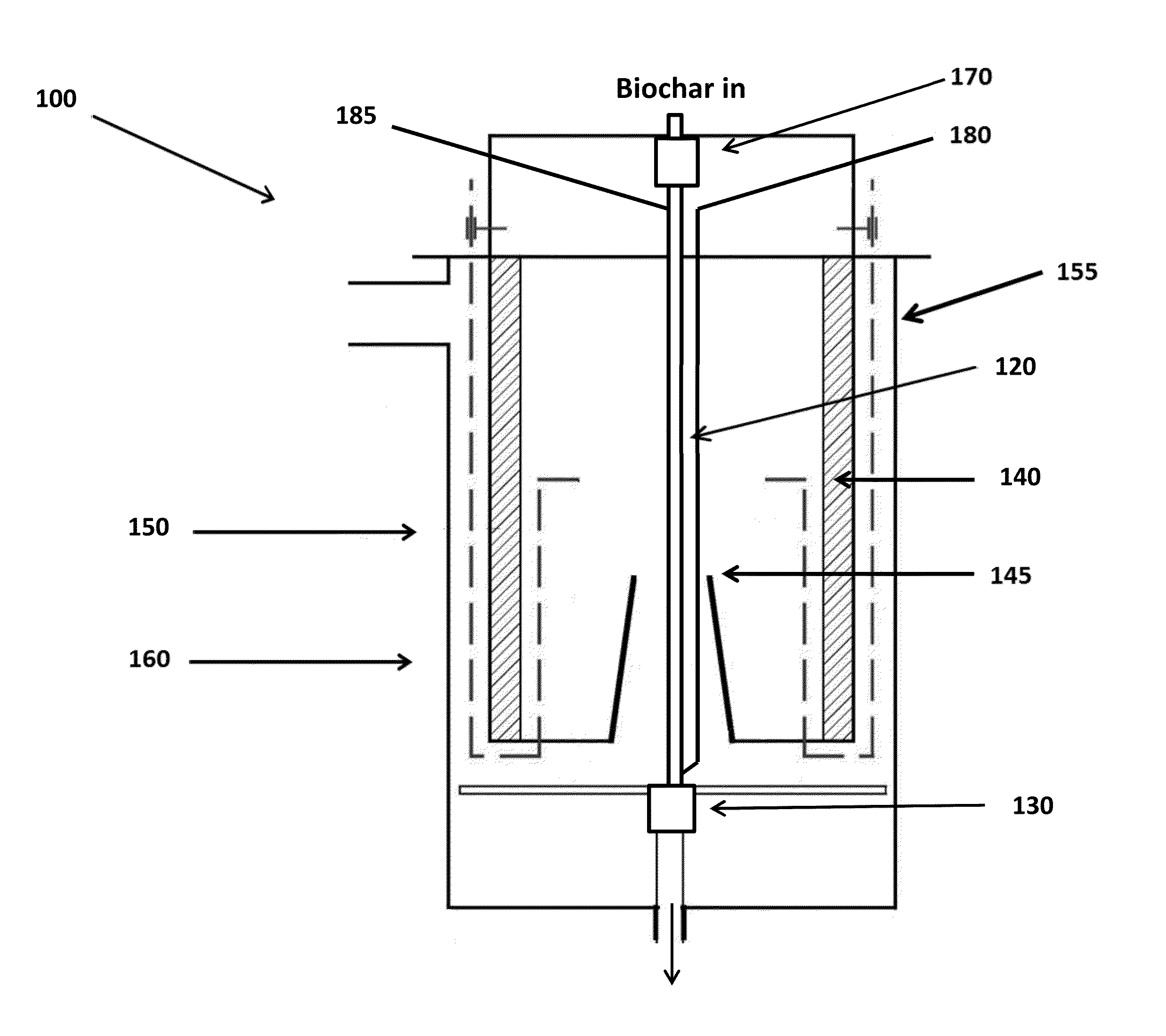

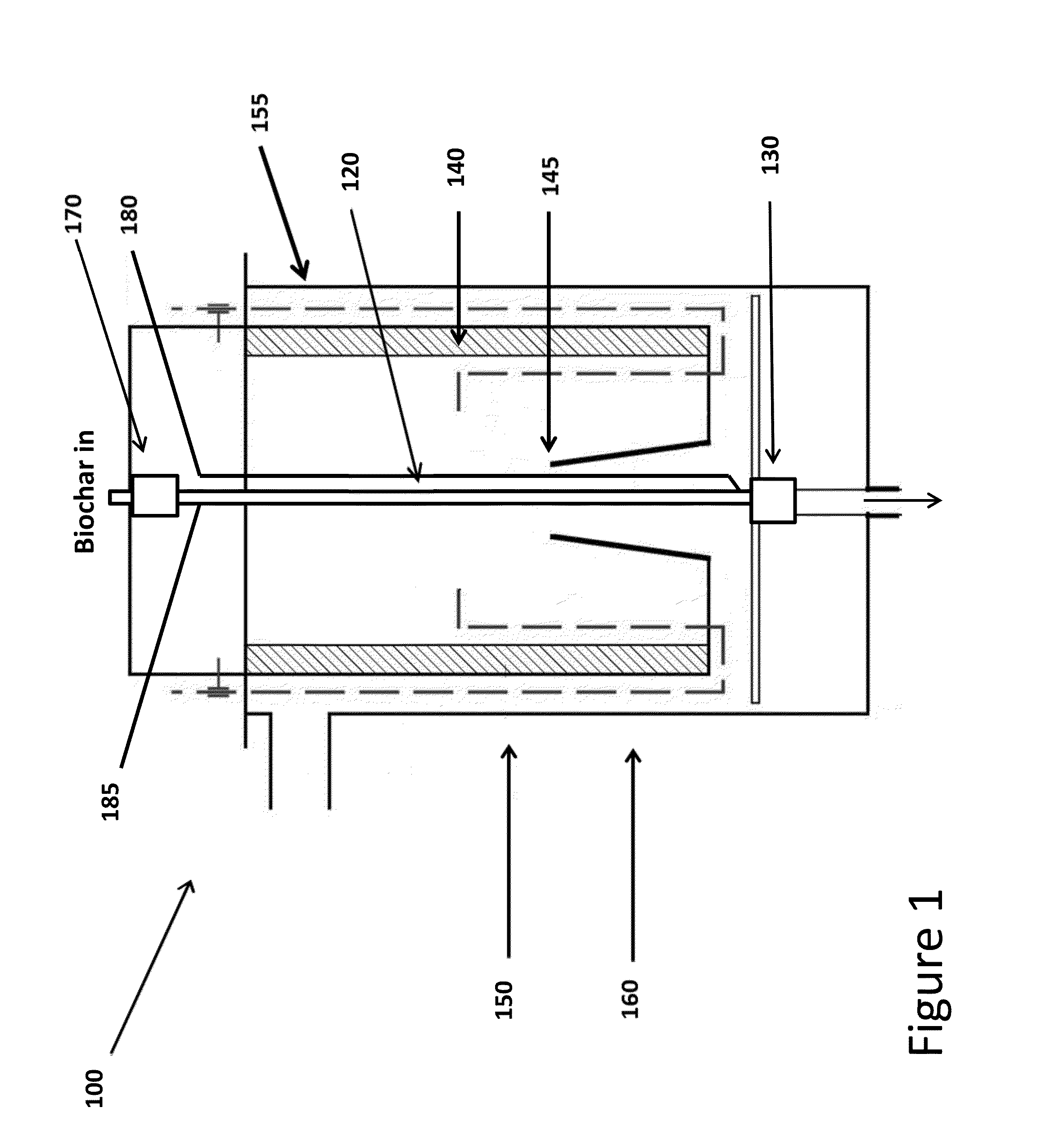

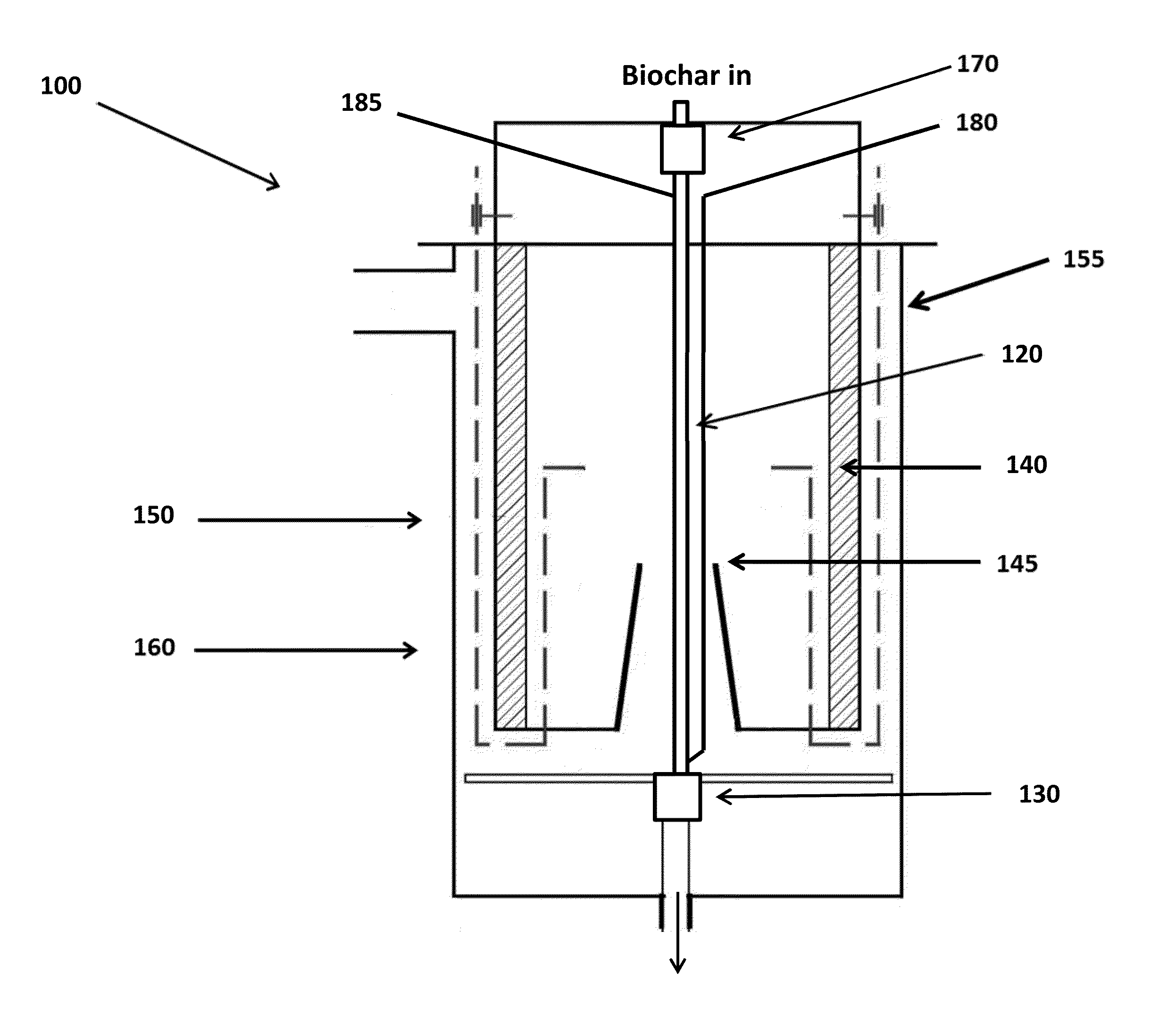

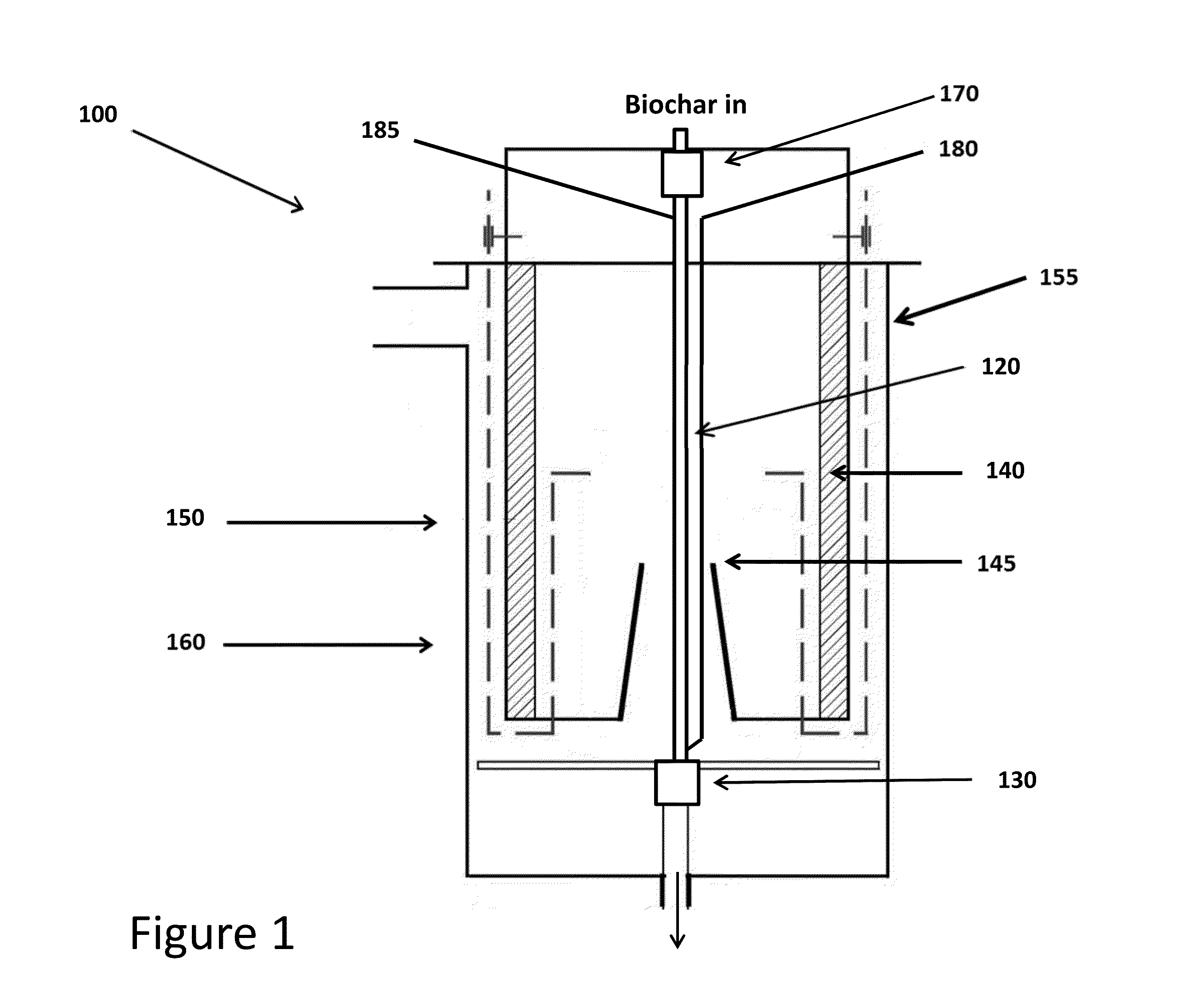

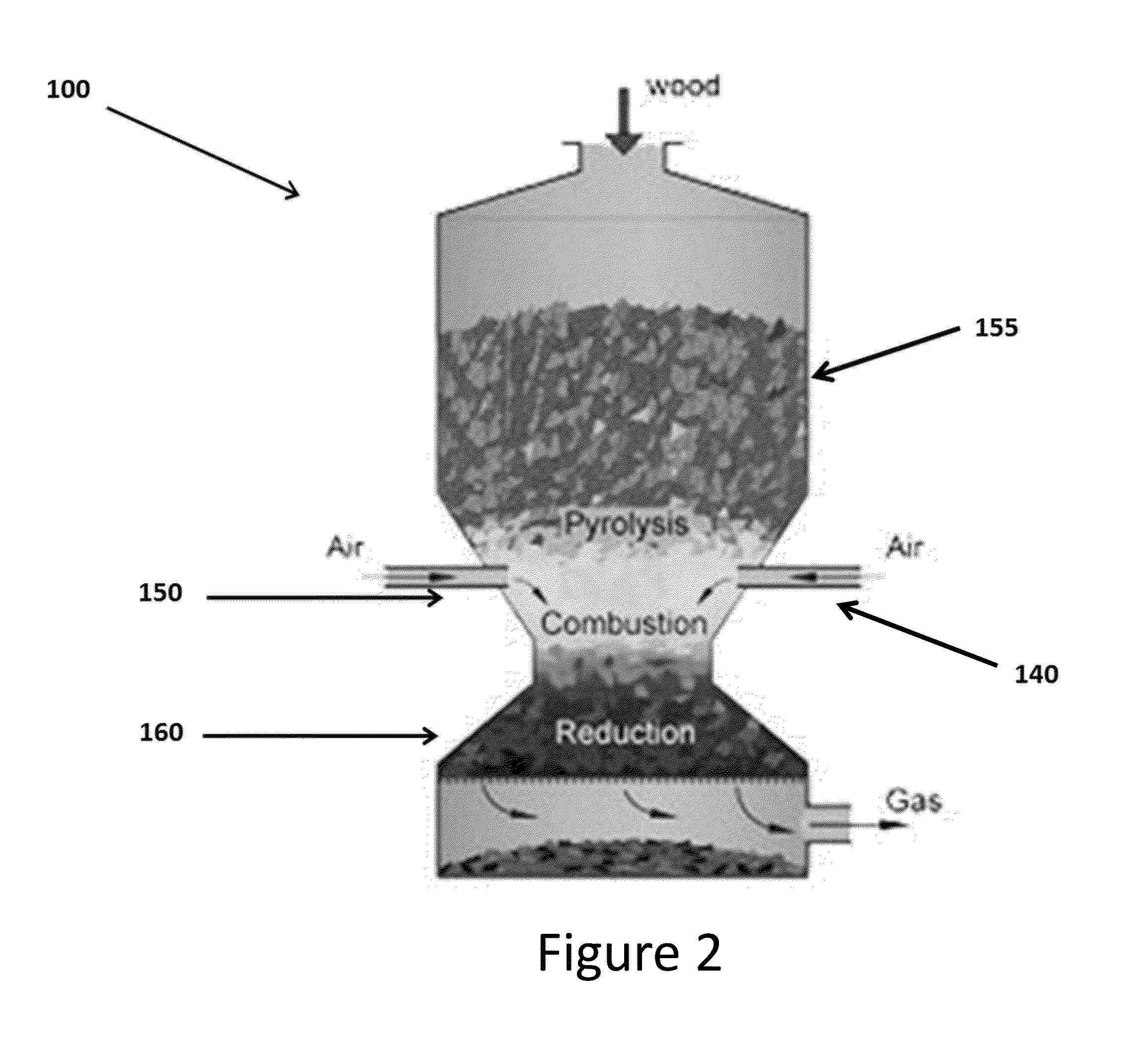

Coaxial gasifier for enhanced hydrogen production

Embodiments of the invention are directed toward a coaxial gasifier for enhanced hydrogen production, comprising: downdraft gasifier comprising a hot zone for converting biomass to synthesis gas; and a coaxial gas converter disposed within the downdraft gasifier, the coaxial gas converter comprising a biochar inlet valve, a coaxial char tube, and a biochar and ash outlet valve.

Owner:V GRID ENERGY SYST INC

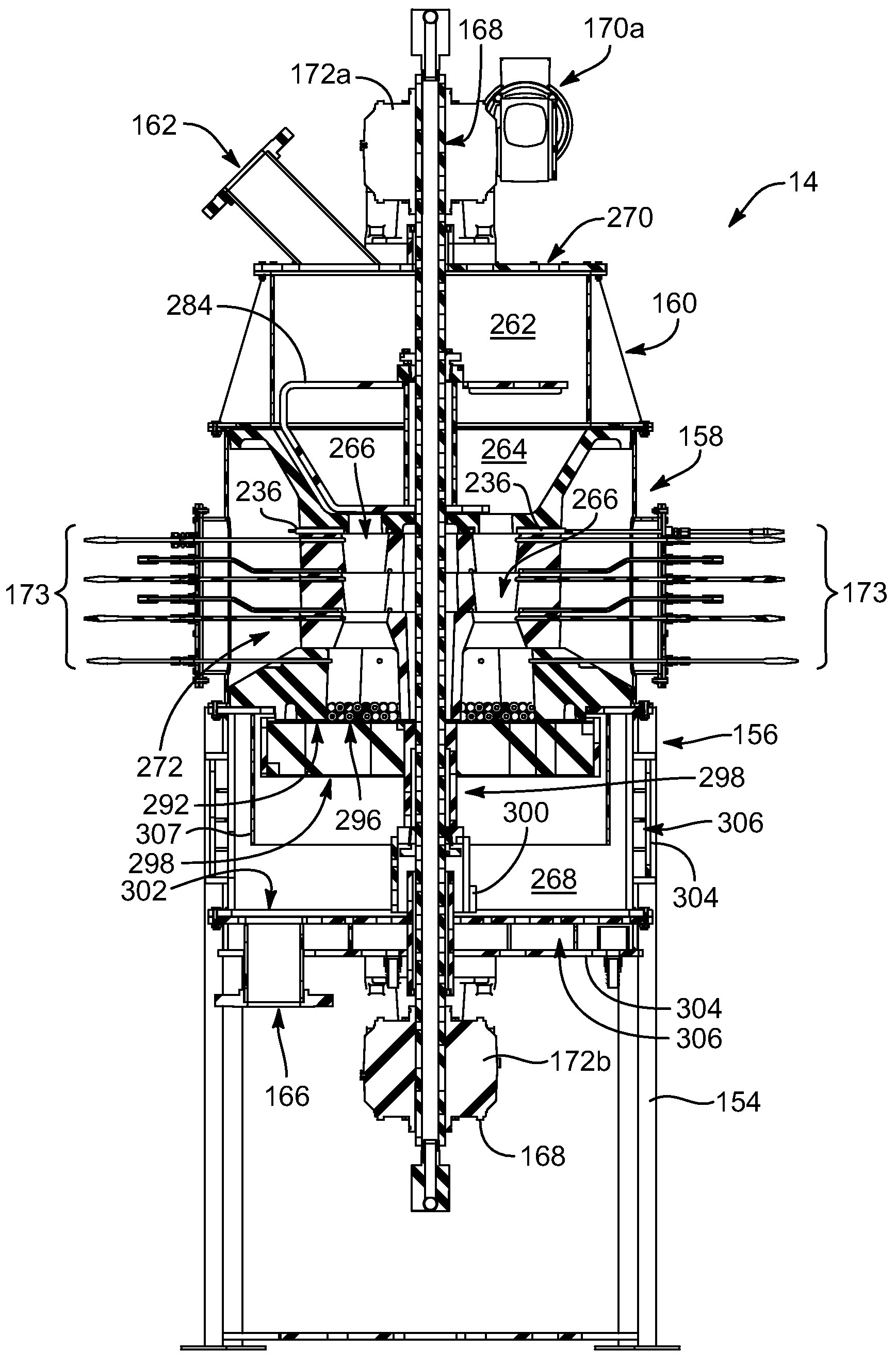

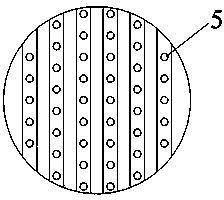

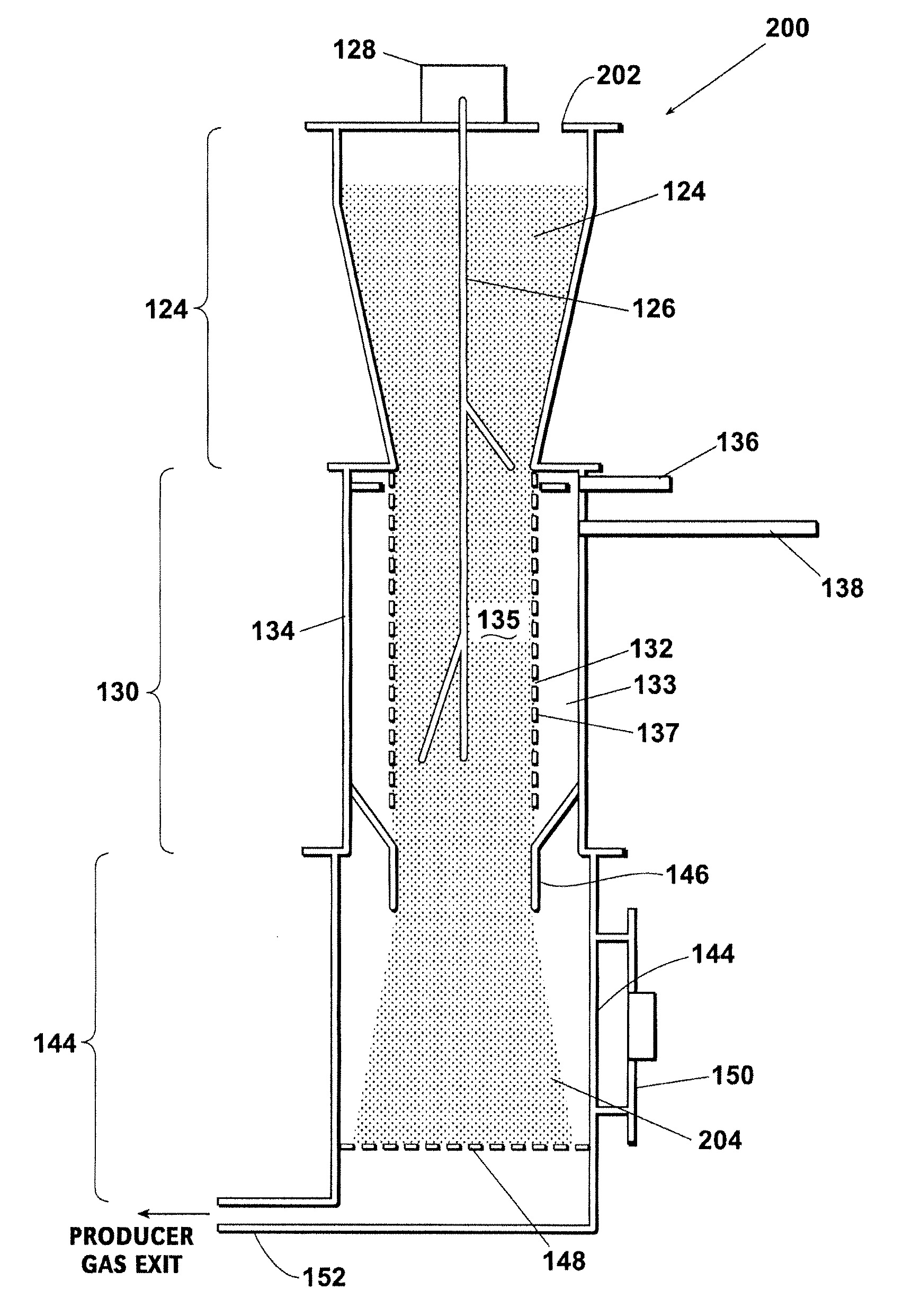

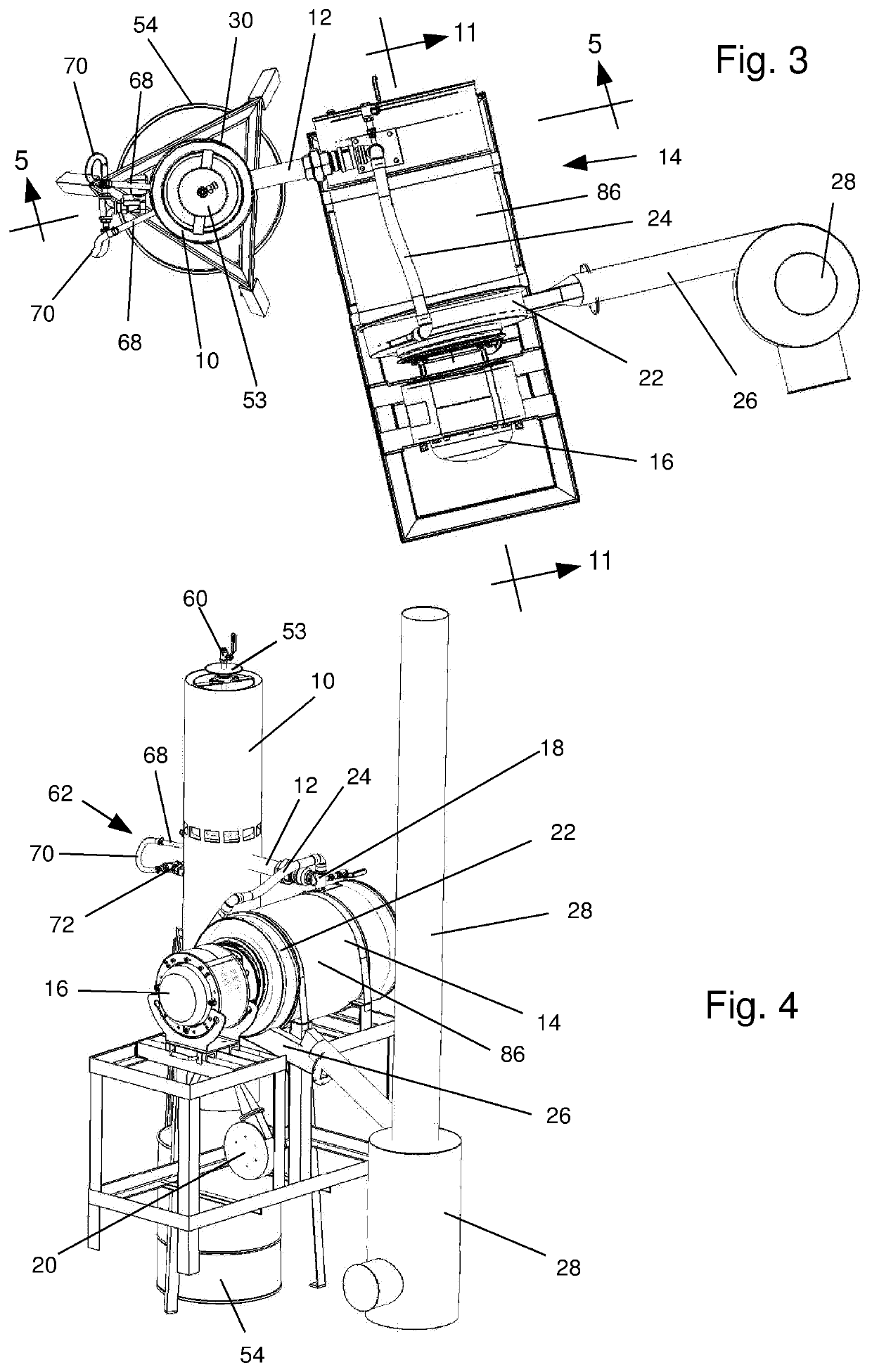

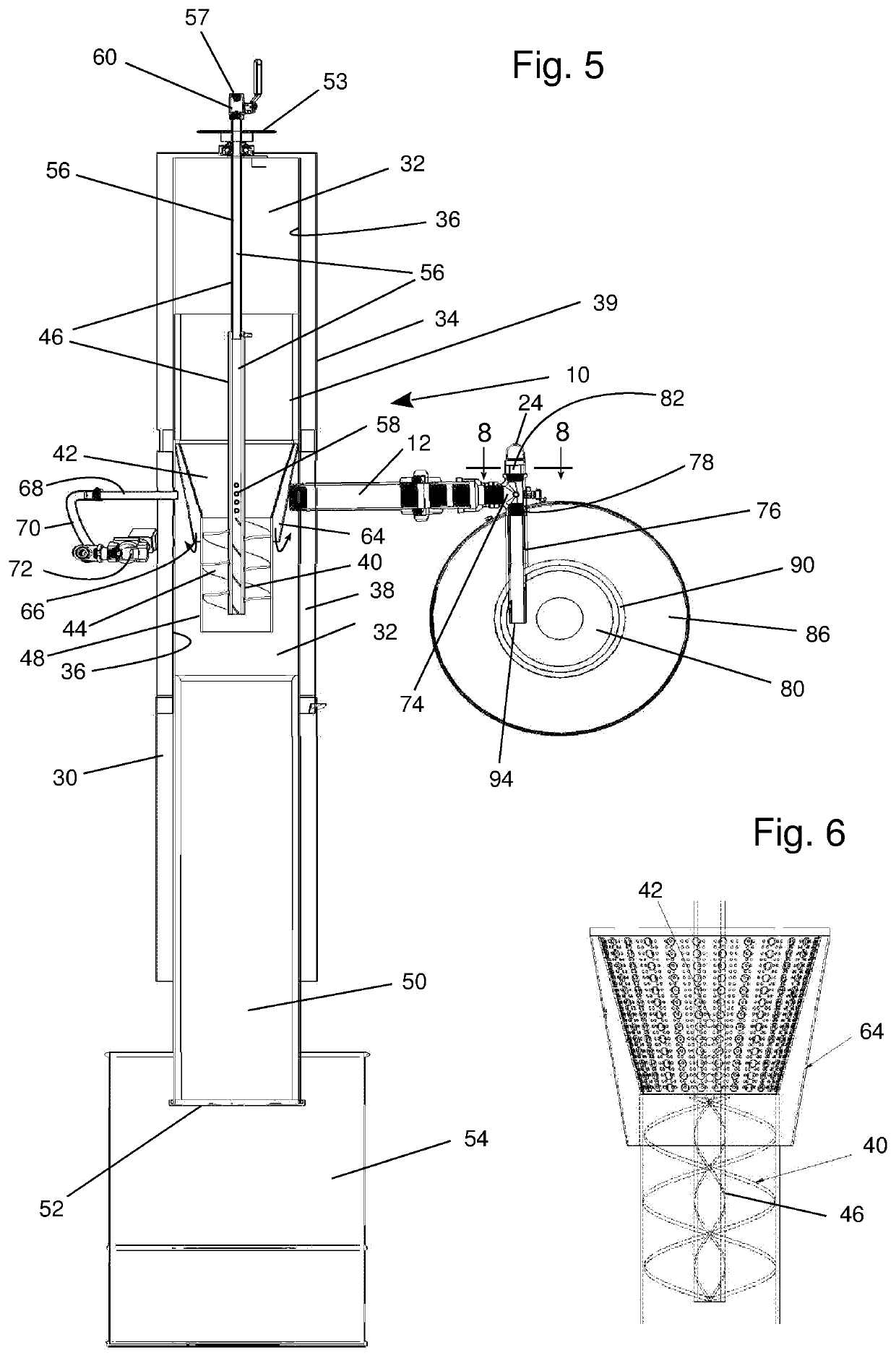

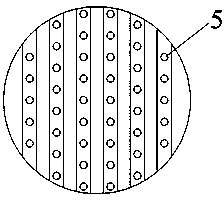

Method and device for gasifying feedstock

InactiveCN105026725AGas turbine plantsGasification processes detailsOxidation zoneMechanical engineering

A downdraft gasifier and method of gasification that utilizes a plurality of vertically positioned tubes to create a pyrolysis zone, an oxidation zone beneath the pyrolysis zone and a reduction zone beneath the oxidation zone. The shape of the tubes eliminates the need for a restriction (hearth), which limits the maximum achievable throughput. A rotating and vertically adjustable grate is located beneath, but not attached to, the reduction zone of the gasifier.

Owner:PHG ENERGY

Parallel path, downdraft gasifier apparatus and method

ActiveUS20150052813A1Rapid and precise control of environmentFor fast and precise controlBioreactor/fermenter combinationsBiological substance pretreatmentsOxidation zoneOxygen

A method for using a downdraft gasifier comprising a housing and a refractory stack contained within the housing. The refractory stack may comprise various sections. Apertures in the sections may be aligned to form multiple columnar cavities. Each columnar cavity may comprise an individual oxidation zone. The method of use may include the steps of placing a feedstock into an upper portion of the refractory stack, measuring the temperature of each columnar cavity, and adjusting the flow of oxygen to a particular columnar cavity to maintain the temperature of the particular columnar cavity within a particular range.

Owner:STRATEAN

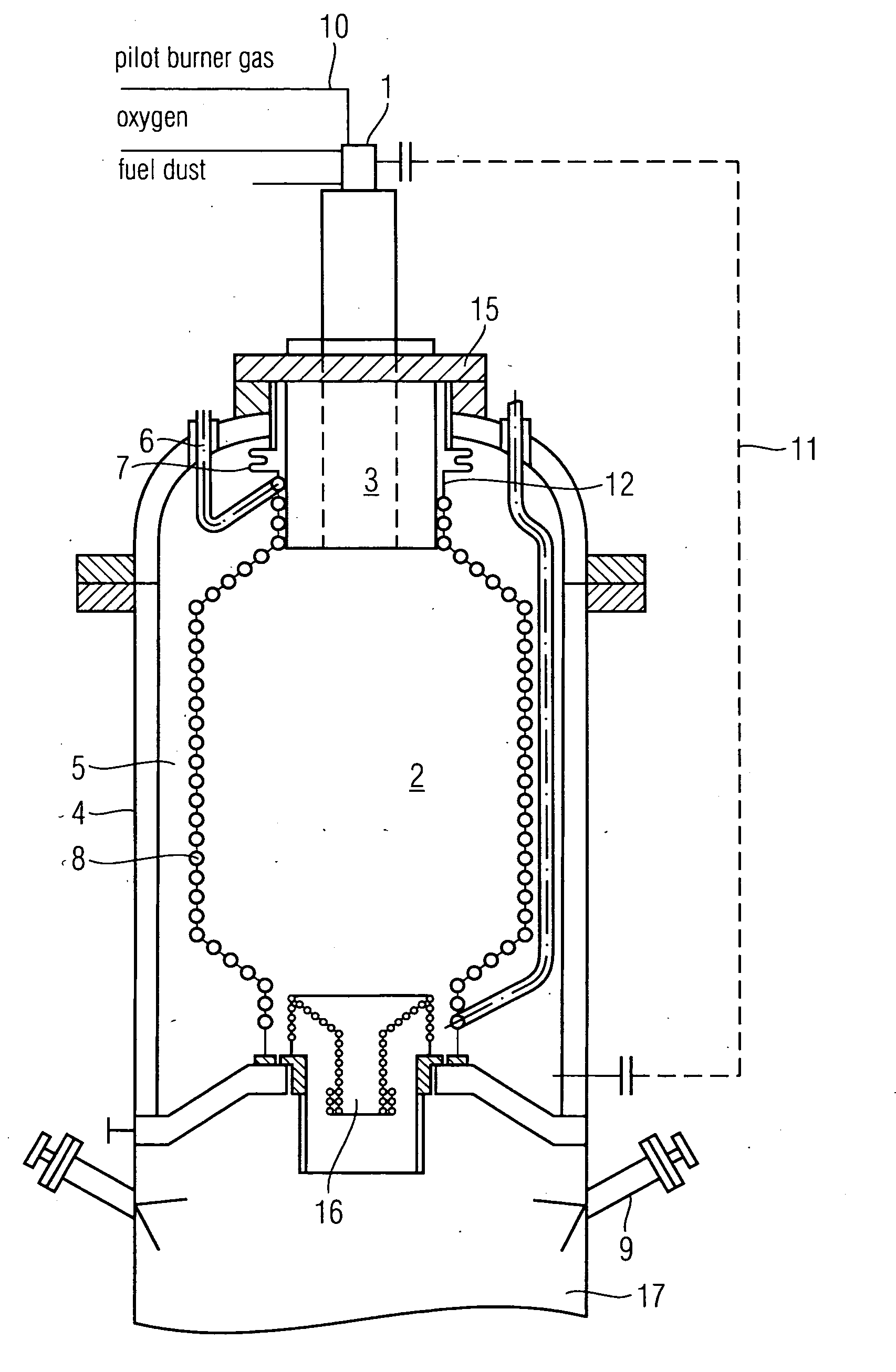

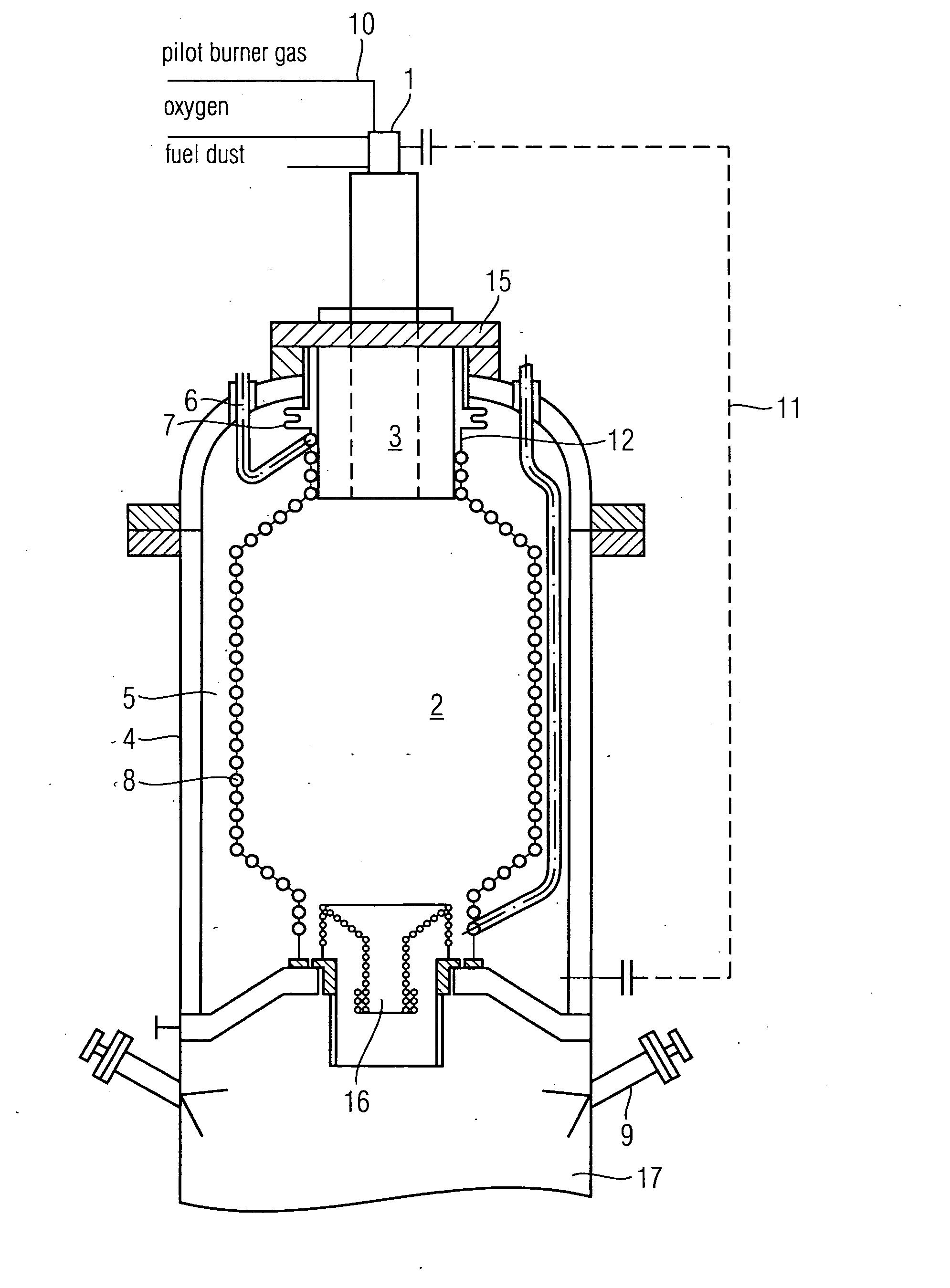

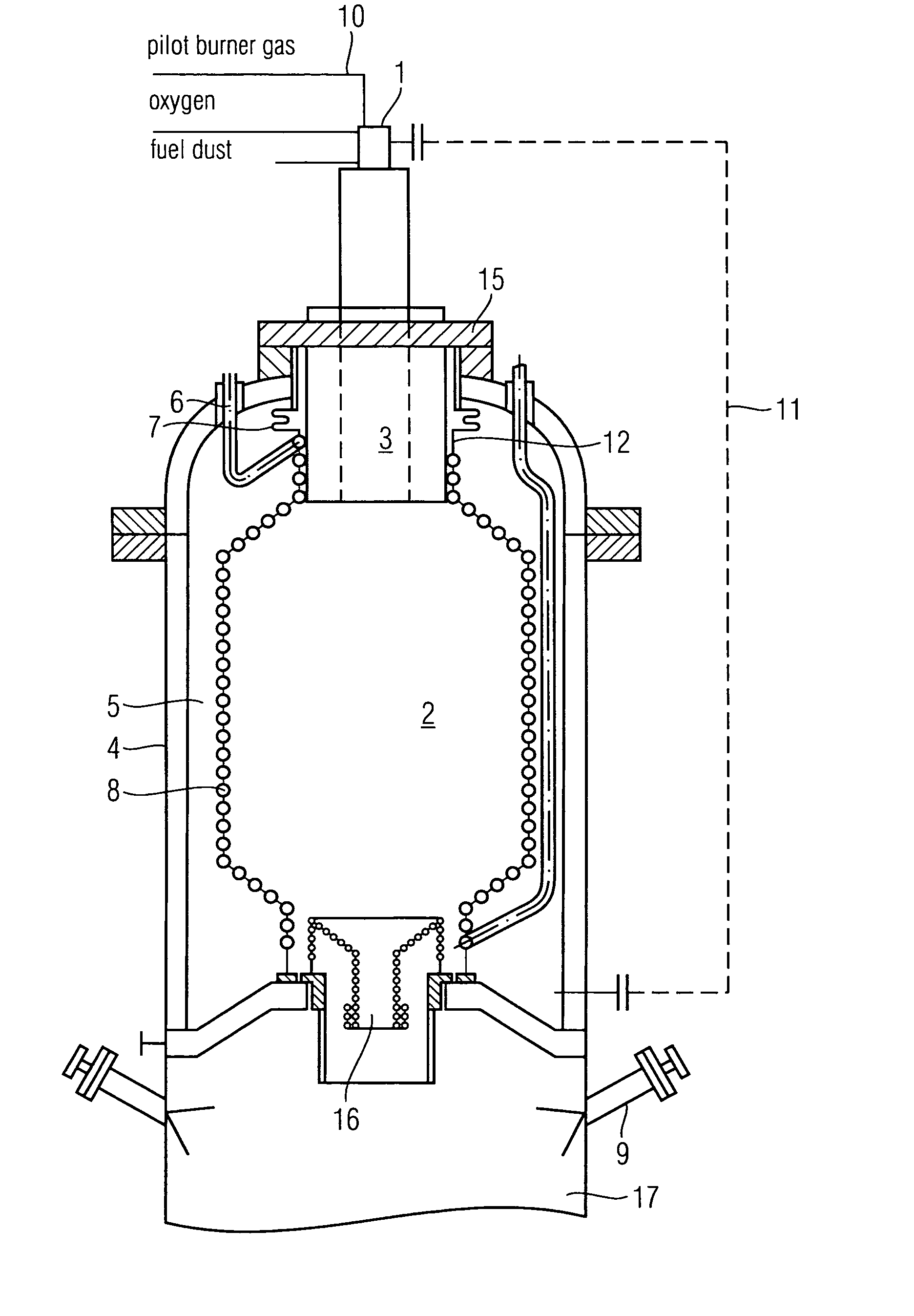

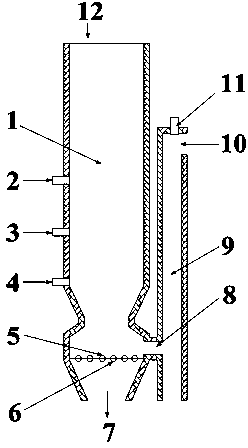

Entrained-flow gasifier with cooling screen and sliding seal

ActiveUS20090077885A1Avoid flowCombustible gas chemical modificationPressurized chemical processAmbient pressureLiquid fuel

In a reactor for gasification of entrained solid and liquid fuels at temperatures between 1,200 and 1,900° C. and at pressures between ambient pressure and 10 MPa using an oxidizing agent containing free oxygen, the cooling screen is connected to the pressure shell in a gastight manner via a sliding seal in order to allow length changes. Continuous gas purging of the annular gap between pressure shell and cooling screen is unnecessary and gasification gas is prevented from flowing behind.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Downdraft gasifier with internal cyclonic combustion chamber

A downdraft gasifier is disclosed. The gasifier includes a biomass section that accepts and stirs raw biomass materials, a pyrolysis and tar cracking section having an inner cylinder for receiving biomass and an outer surrounding cylinder for gases from the biomass, and a char gasification section for receiving biomass and gases from the pyrolysis and tar cracking section. The char gasification section provides a grating and scraper for passing gases and ash and retaining biomass for char gasification on the grate.

Owner:BOARD OF REGENTS FOR OKLAHOMA STATE UNIVERSITY

Downdraft gasifier capable of realizing efficient self purification of tar

The invention relates to the field of gasification of coal or biomass, and in particular relates to a downdraft gasifier capable of realizing efficient self purification of tar. The downdraft gasifier comprises a coke oven, a gasifier and the like. The working principle is that the coke oven decomposes materials (coal or biomass fuel) into coke-oven gas and coke, then the coke-oven gas is mixed with a gasifying agent (air, enriched oxygen or pure oxygen) to be combusted so as to thoroughly remove tar, and the coke-oven gas and air subjected to combustion are converted into combustible gas by the downdraft gasifier. The downdraft gasifier can be used for gas supply of power plants, industry and residents, and a small downdraft gasifier can be used for gas supply of families.

Owner:黄必录

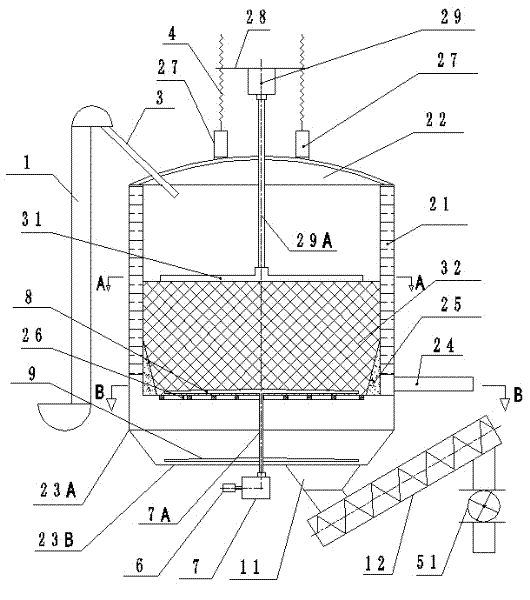

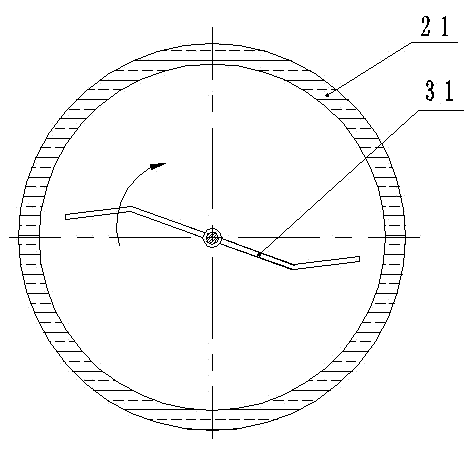

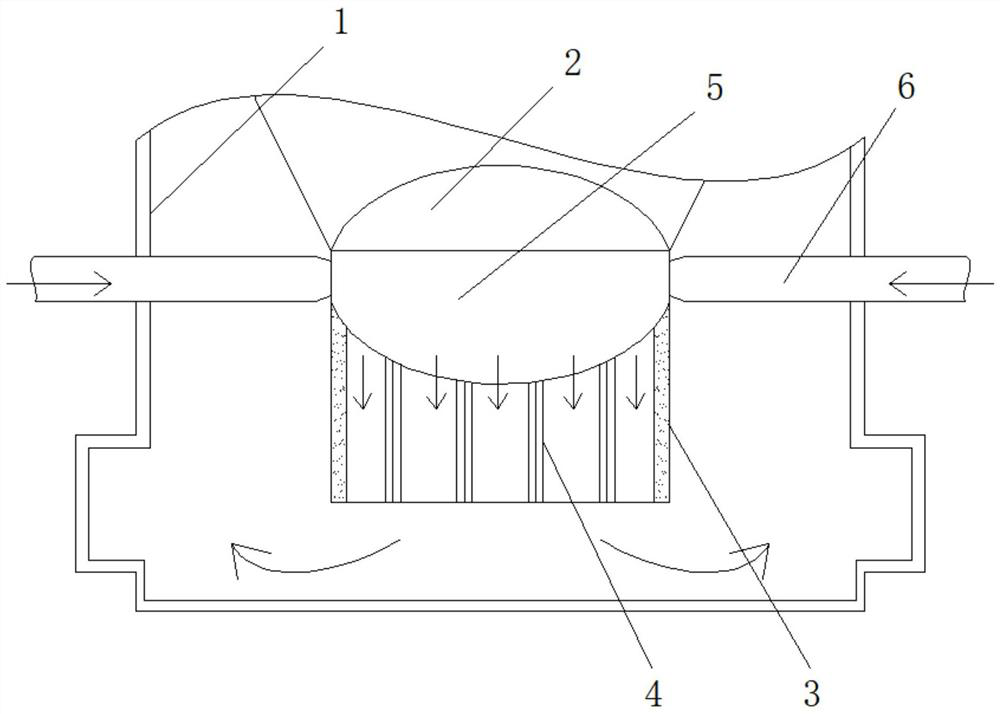

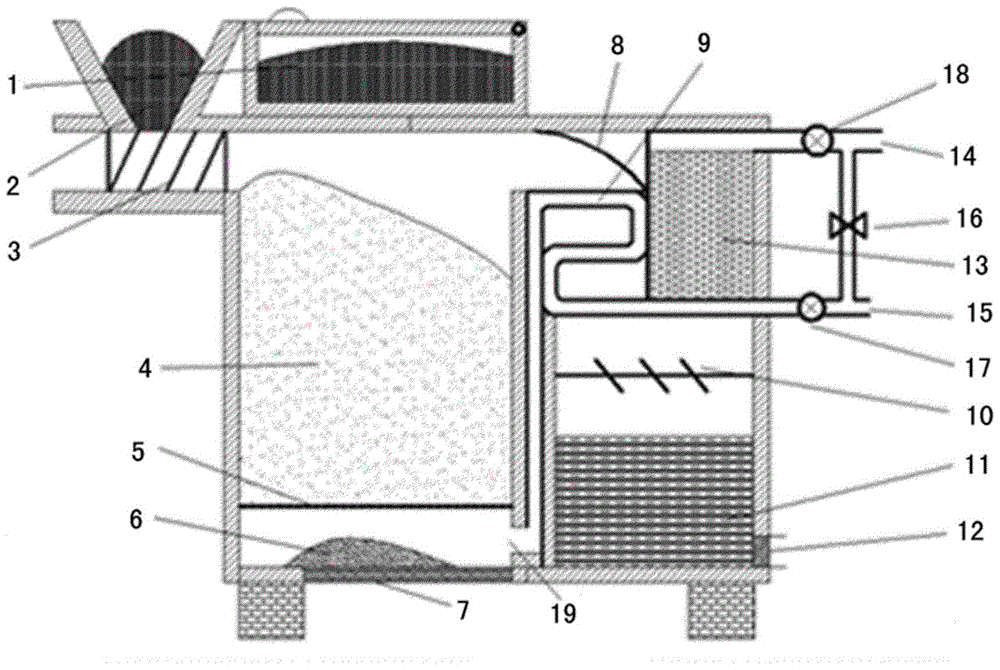

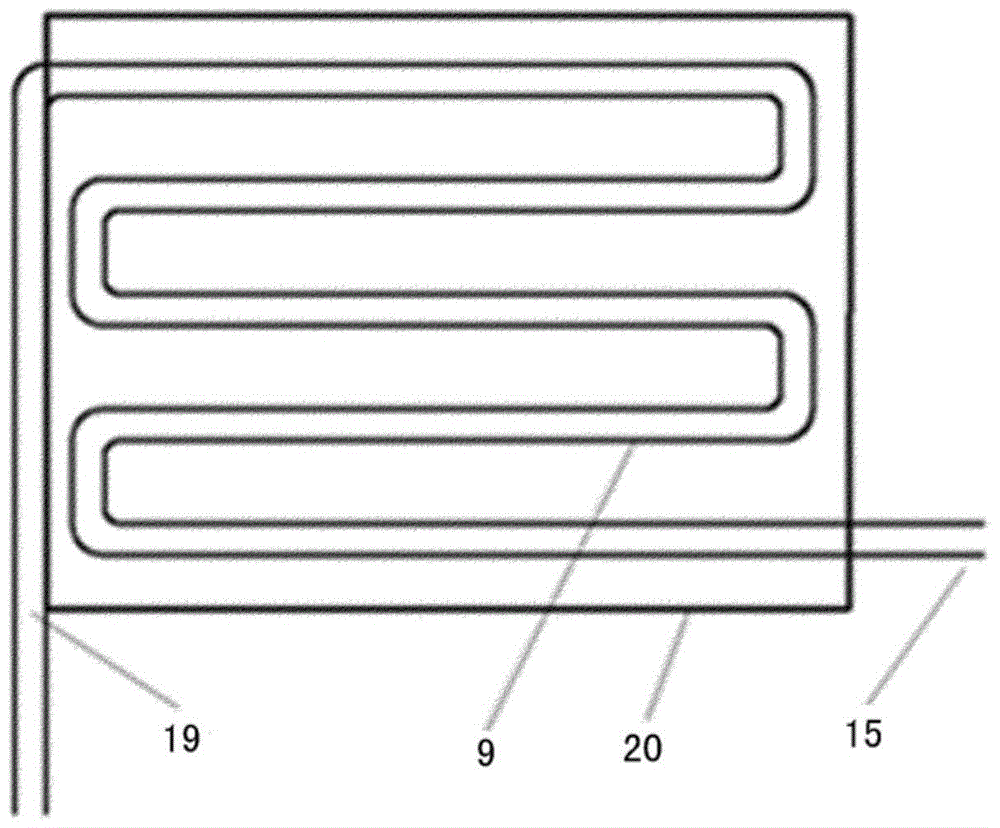

Biomass downdraft fixed bed gasifier heat supply system

InactiveCN104419469AImprove thermal efficiencyIncrease heat productionEnergy inputCombustible gas productionWater vaporFixed bed

The invention belongs to a biomass downdraft fixed bed gasifier heat supply system which comprises a primary stock bin (1), a secondary stock bin (3), and a gas storage device (9), and is characterized in that a downdraft gasifier body (4) is mounted below the secondary stock bin (3) and is communicated with a waste heat recovery device (6); an upper exhaust pipe of the waste heat recovery device (6) is communicated with a gas storage cylinder (27); a gas outlet pipe of the gas storage cylinder (27) is communicated with a spiral dedusting washing device (7); the upper end of the spiral dedusting washing device (7) is connected with a secondary oxygen supply port (22) and is communicated with a Roots frequency conversion fan (8); the upper end of the waste heat recovery device (6) is communicated with the gas storage cylinder (27) through a pipeline; the gas storage cylinder (27) is communicated with the spiral dedusting washing device (7) through a pipeline; the lower end of the waste heat recovery device (6) is communicated with a water vapor reduction hydrogen adding device (13) through a pipeline. The system of the invention is high in temperature in the gasifier, high in thermal efficiency, low in tar content, beneficial for environmental protection, low in equipment investment, high in heat production amount, and sufficient in fuel source.

Owner:DALIAN MING JIA METAL PROD

Entrained-flow gasifier with cooling screen and bellows compensator

ActiveUS20090077886A1Prevent backflowPressurized chemical processGasifier mechanical detailsAmbient pressureLiquid fuel

In a reactor for the gasification of solid and liquid fuels in the entrained flow at temperatures between 1200 and 1900° C. and pressures between ambient pressure and 10 MPa with an oxidizing agent containing free oxygen, the cooling screen is connected in a gas-tight manner to the pressure shell via a bellows compensator to accommodate linear deformation. Continuous sweeping by gas of the annular gap between pressure shell and cooling screen is unnecessary and backflow by producer gas is prevented.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

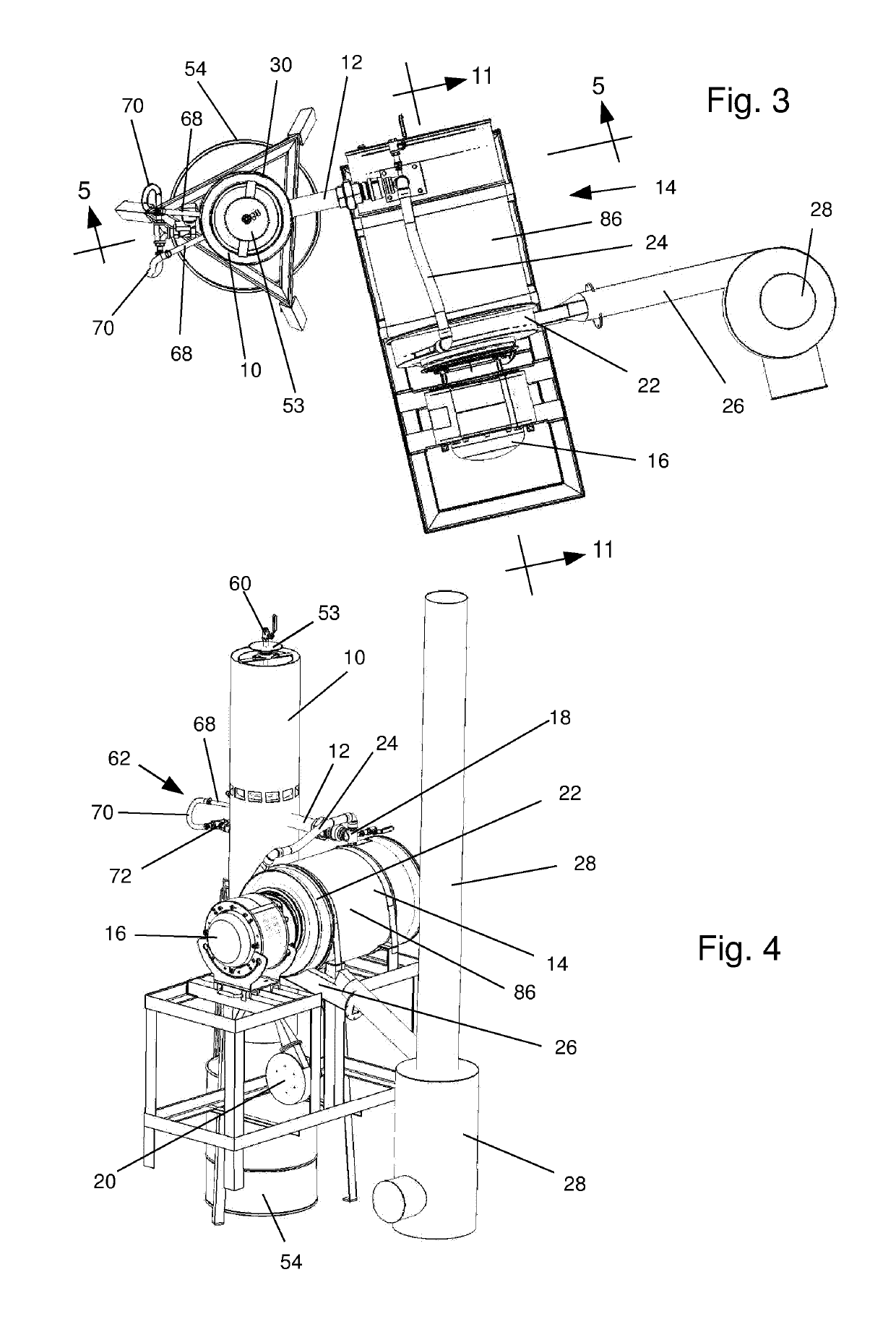

Continuously operable mechanical or electrical power source fueled by gas or solid fuel including gas from improved biomass downdraft gasifier

Owner:CHAGNOT CATHERINE J

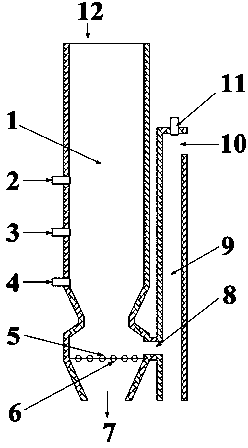

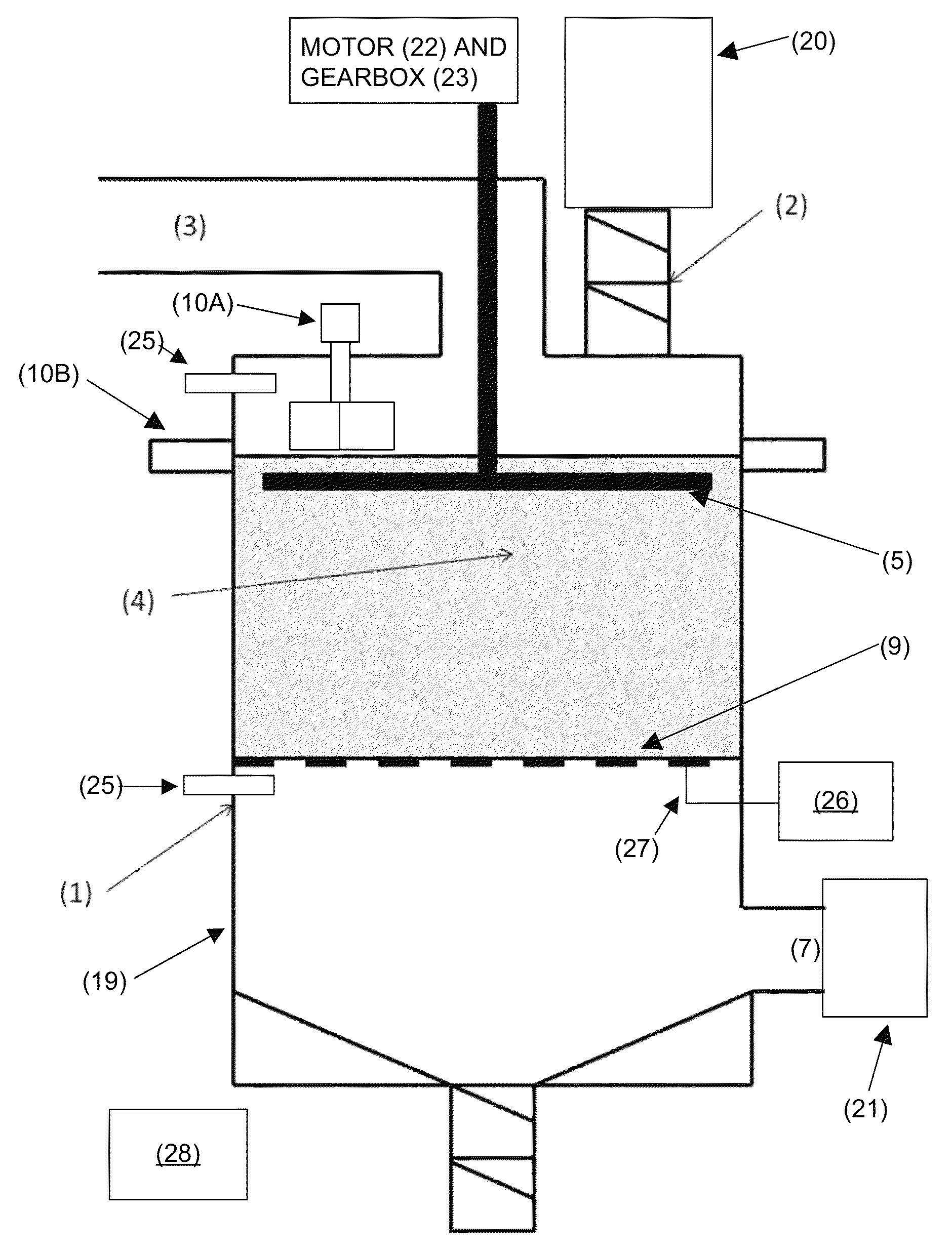

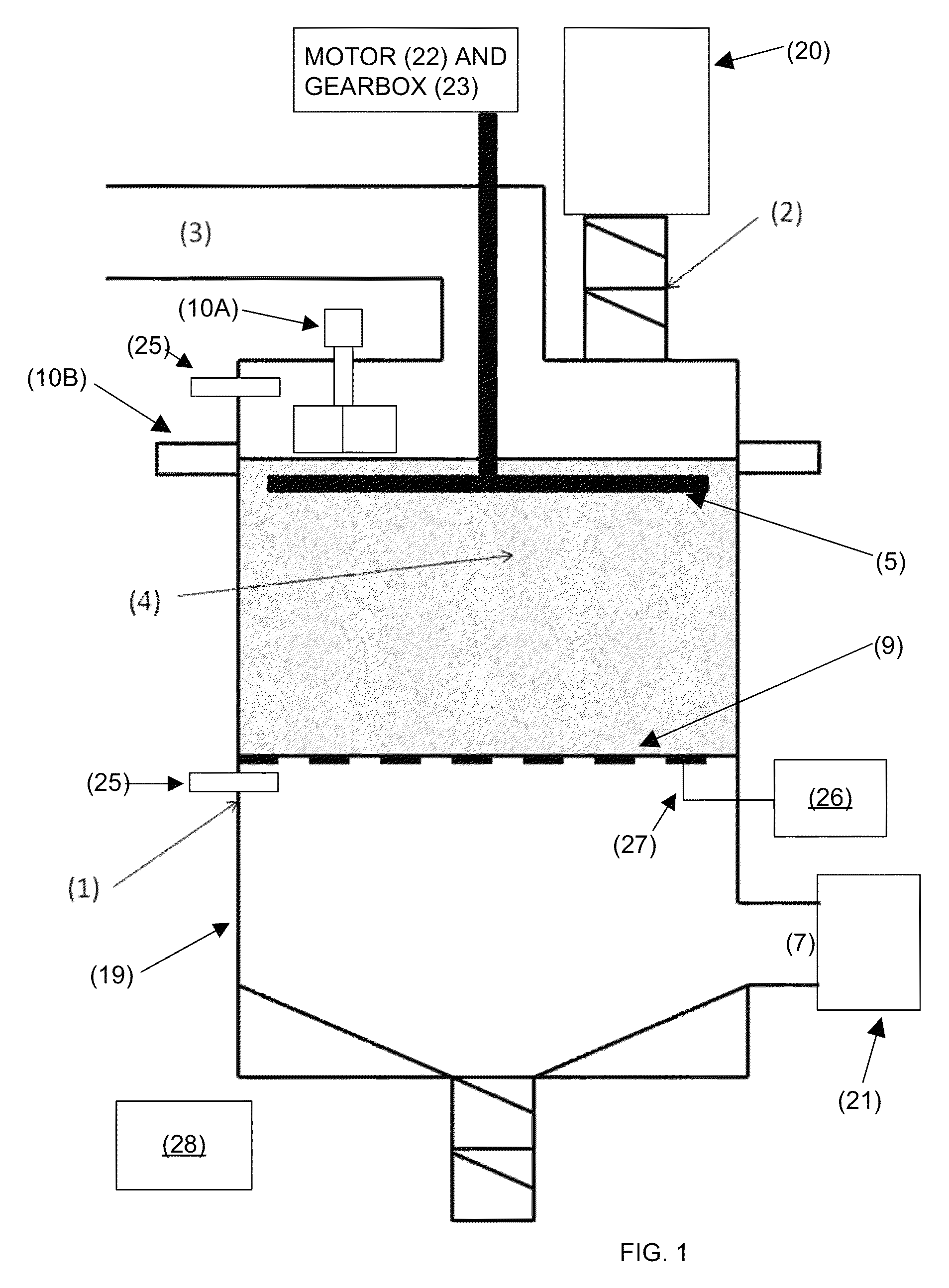

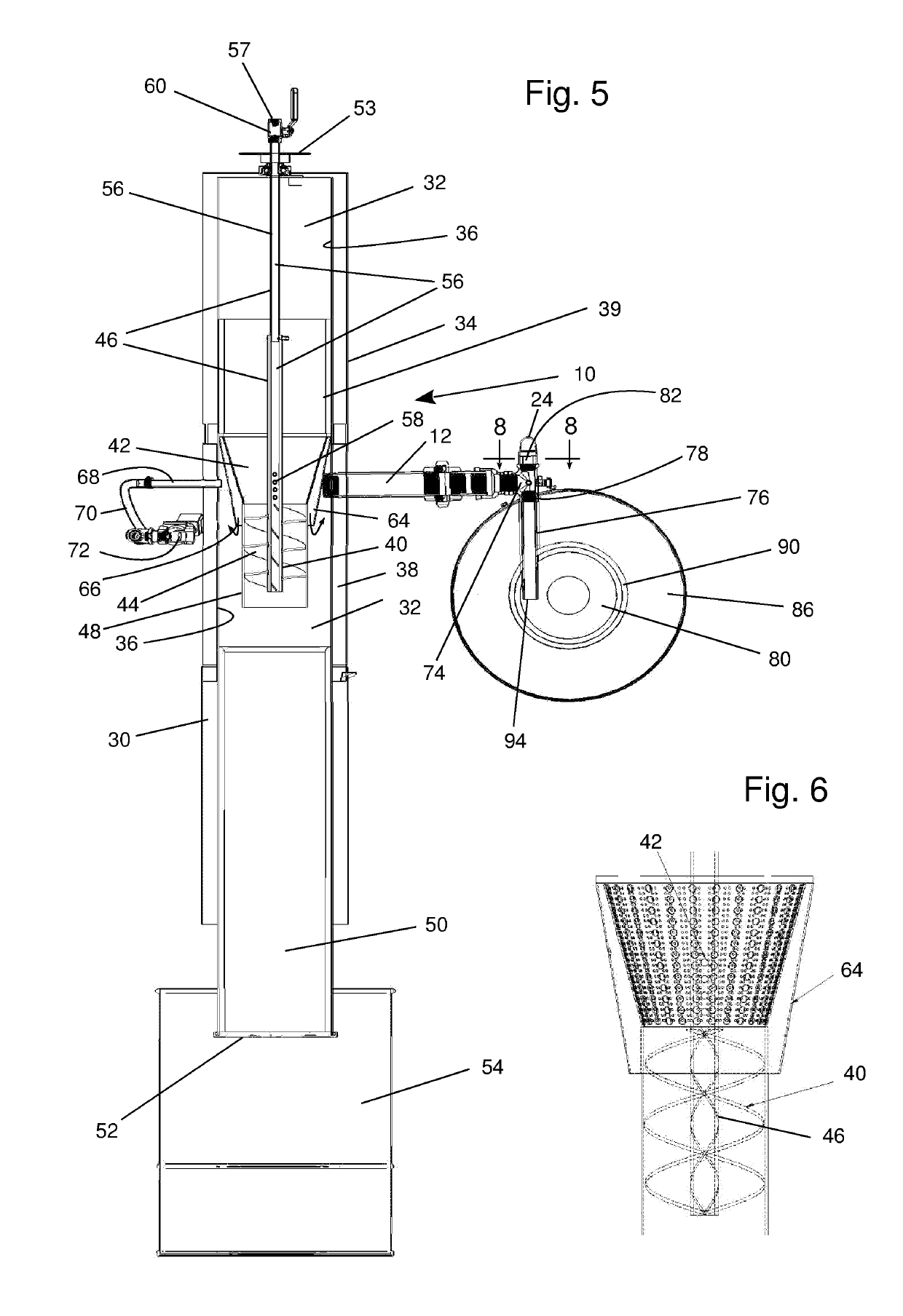

Downdraft gasifier with improved stability

ActiveUS8845769B2High energy output rateImprove stabilitySolid bar grateCarburetting by solid carbonaceous material pyrolysisEngineeringDistributor

A downdraft gasifier (1) has an oxidant inlet (3), a biomass injector (2), a grate (9), a gas exit port (7), and an ash removal system (11). A sensor (10) maintains the height of the bed and a rotating paddle (5) maintains the top of the bed (4) at an even height. The grate arrangement (9) is preferably a sliding grate arrangement which actively moves ash material through the grate. An in-bed oxidant distributor (6) injects oxidant within the bed.

Owner:ZEROPOINT CLEAN TECH

Continuously operable mechanical or electrical power source fueled by gas or solid fuel including gas from improved biomass downdraft gasifier

The invention includes a downdraft gasifier having a rotatable auger / grate extending through its reduction zone. The auger at times moves biofuel through the gasifier and at times supports it in the gasifier. A frusto-conical biomass grate funnels biomass onto the auger and is perforate for permitting the passage of gases while retaining the biomass. A guide tube surrounds the auger below the frusto-conical biomass grate. The invention also includes mixing gas or solid particulate fuel in a conduit segment that houses a mixing chamber. Fuel is fed through a fuel inlet port into the mixing chamber. High velocity combustion air from a blower is forced into the mixing chamber through a restricted orifice that generates a suction pressure for drawing gas or solid particulate fuel into the mixing chamber. A combustion chamber supply conduit delivers fuel from the mixing chamber into a burner.

Owner:CHAGNOT CATHERINE J

Entrained flow gasifier with integrated radiation cooler

ActiveUS9193923B2Improve efficiencyGasifier mechanical detailsEnergy inputProcess engineeringProduct gas

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Entrained-flow gasifier with cooling screen and bellows compensator

ActiveUS8475548B2Prevent backflowPressurized chemical processGasifier mechanical detailsAmbient pressureEngineering

In a reactor for the gasification of solid and liquid fuels in the entrained flow at temperatures between 1200 and 1900° C. and pressures between ambient pressure and 10 MPa with an oxidizing agent containing free oxygen, the cooling screen is connected in a gas-tight manner to the pressure shell via a bellows compensator to accommodate linear deformation. Continuous sweeping by gas of the annular gap between pressure shell and cooling screen is unnecessary and backflow by producer gas is prevented.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Downdraft gasifier with tar degradation function

ActiveCN103952186BExtended stayPromote degradationGranular/pulverulent flues gasificationThree levelTube furnace

The invention discloses a downdraft gasifier with a tar degrading function. The downdraft gasifier comprises a hearth, wherein the lower part of the hearth is provided with a ring-shaped throat; a feeding hole is formed in the top of the hearth, and an ash outlet is formed in the bottom of the hearth; upper, middle and lower three-level tangential primary air distribution outlets are axially formed in the wall above the ring-shaped throat of the hearth; a tubular fire grate is arranged between the ring-shaped throat at the lower part of the hearth and the ash outlet at the bottom and is formed by hollow steel tubes spaced from each other; holes as secondary air distribution outlets are drilled in the hollow steel tubes; a vertical flue is arranged outside the hearth; one end of a horizontal flue flush with the tubular fire grate is communicated with the hearth and the other end is communicated with the vertical flue; a gas outlet is formed in the upper part of the vertical flue; a calcium base catalyst jet device is arranged at the top of the vertical flue. The downdraft gasifier has a simple structure, has a tar self-purifying capacity and can ensure that the tar in the gasified gases is fully decomposed before leaving the hearth, thus obtaining the gasified gases with relatively high quality.

Owner:ZHEJIANG UNIV

A gas distribution and ash discharge device for an updraft gasifier

InactiveCN105132033BImprove insulation effectIncreasing the thicknessCombustible gas productionSlagEngineering

Owner:HUNAN PUSI ENVIRONMENTAL PROTECTION ENERGY

Coaxial gasifier for enhanced hydrogen production

Embodiments of the invention are directed toward a coaxial gasifier for enhanced hydrogen production, comprising: downdraft gasifier comprising a hot zone for converting biomass to synthesis gas; and a coaxial gas converter disposed within the downdraft gasifier, the coaxial gas converter comprising a biochar inlet valve, a coaxial char tube, and a biochar and ash outlet valve.

Owner:V GRID ENERGY SYST INC

Biomass efficient clean charcoal and gas poly-generation device

InactiveCN113604253AIncrease profitRealize joint productionGasifier feeding meansGasification processes detailsCombustion chamberHeat conducting

The invention relates to a biomass efficient clean charcoal and gas poly-generation device which comprises a furnace body. An ash outlet is formed in the bottom of the furnace body, a fire grate is arranged in the furnace body, and a heat conducting plate is arranged below the fire grate. A gasification chamber is arranged above the fire grate, a carbonization chamber is arranged between the fire grate and the heat conducting plate, and a combustion chamber is arranged below the heat conducting plate. A feeding auger and a gas inlet are arranged on the side wall of the combustion chamber. An automatic charcoal discharging device is arranged in the carbonization chamber and above and close to the heat conducting plate. A gas outlet is formed in the top of the gasification chamber, and a first material inlet is formed in the side wall of the gasification chamber. According to the invention, a heat graded utilization principle is adopted, high heat generated by combustion in the combustion chamber can firstly carbonize biomass at the bottom of the fire grate, and meanwhile, residual heat can carry out oxidation-reduction reaction on materials entering the gasification chamber at the upper layer, so that biomass gas is generated. Therefore, the defect that the existing fixed bed updraft and downdraft gasifiers only produce biomass gas or charcoal is overcome, the co-production of biomass gas and charcoal is realized, and the utilization rate of biomass is greatly improved.

Owner:HEFEI UNIV OF TECH

Downdraft gasifier

PendingCN113549473AUniform temperatureAvoid uneven dryingCombustible gas productionPhysical chemistryEnvironmental engineering

The invention relates to the technical field of biomass gasification furnaces, and discloses a downdraft gasification furnace which comprises a furnace body, an oxidation zone is arranged in the furnace body, a reduction zone is arranged below the oxidation zone, a lower neatening plate is fixedly mounted in the reduction zone, an upper neatening plate is fixedly mounted in the oxidation zone, and gas inlet pipes are arranged on the two sides of the oxidation zone. According to the invention, the upper and lower neatening plates are arranged in the oxidation zone and the reduction zone, materials from a cracking zone are uniformly distributed in a neatening cavity, then the cavity for airflow flowing is arranged on the outer side of the neatening cavity, and air holes in the cavity are utilized to uniformly distribute air from multiple angles from the top and the peripheral side of a carbon block, and thus the internal oxidation-reduction reaction of the neatening plates is ensured to be carried out uniformly and thoroughly, the incomplete reaction caused by non-uniform air supply is avoided, the temperature of discharged gas is uniform, the condition of non-uniform drying of a drying area caused by non-uniform temperature is avoided, meanwhile, the components of the discharged gas are stabilized, and the gas quality is improved.

Owner:胡红萍

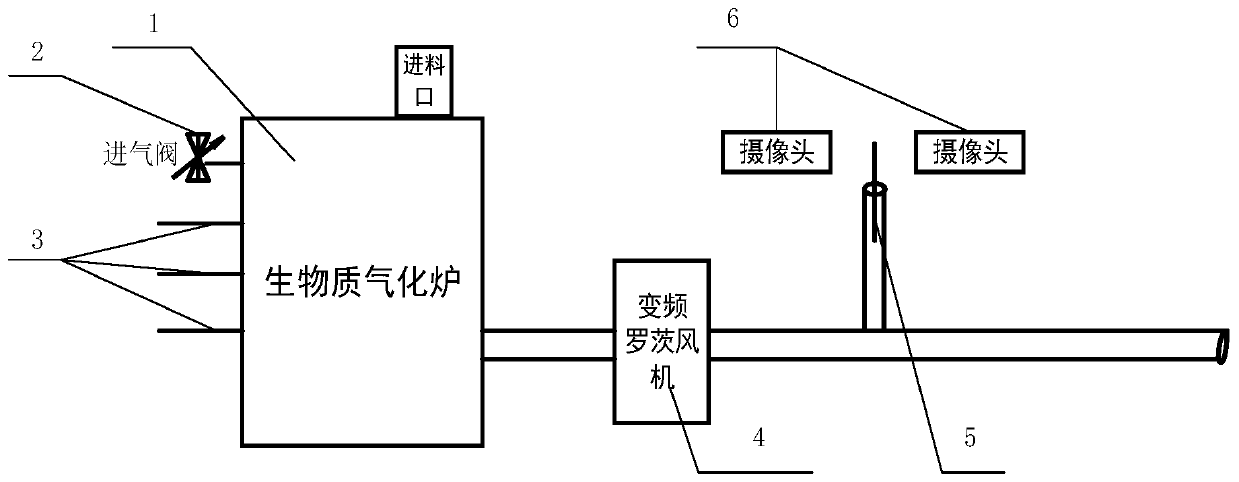

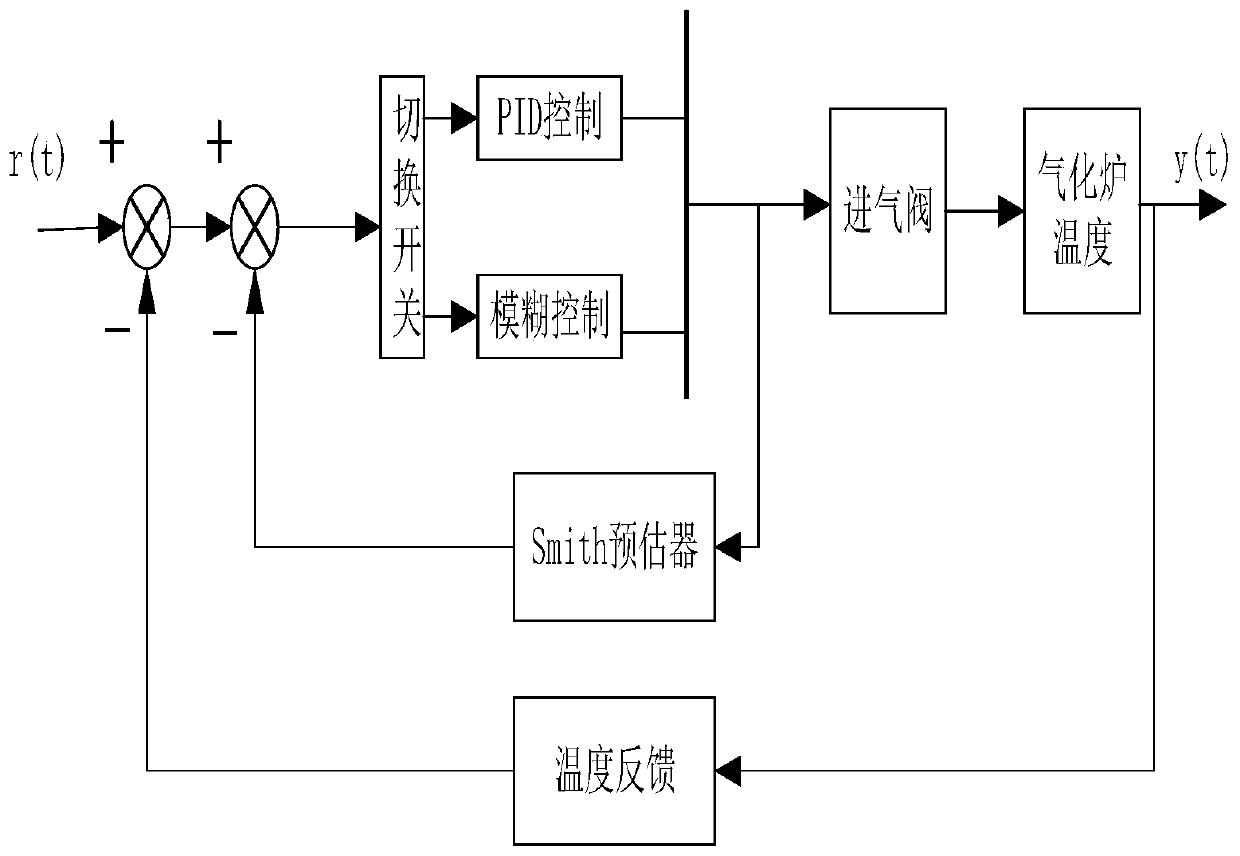

Biomass gasifier control method

ActiveCN111410996AImprove robustnessImprove gas qualityCombustible gas productionAutomatic controlInlet valve

Owner:BEIJING UNIV OF TECH

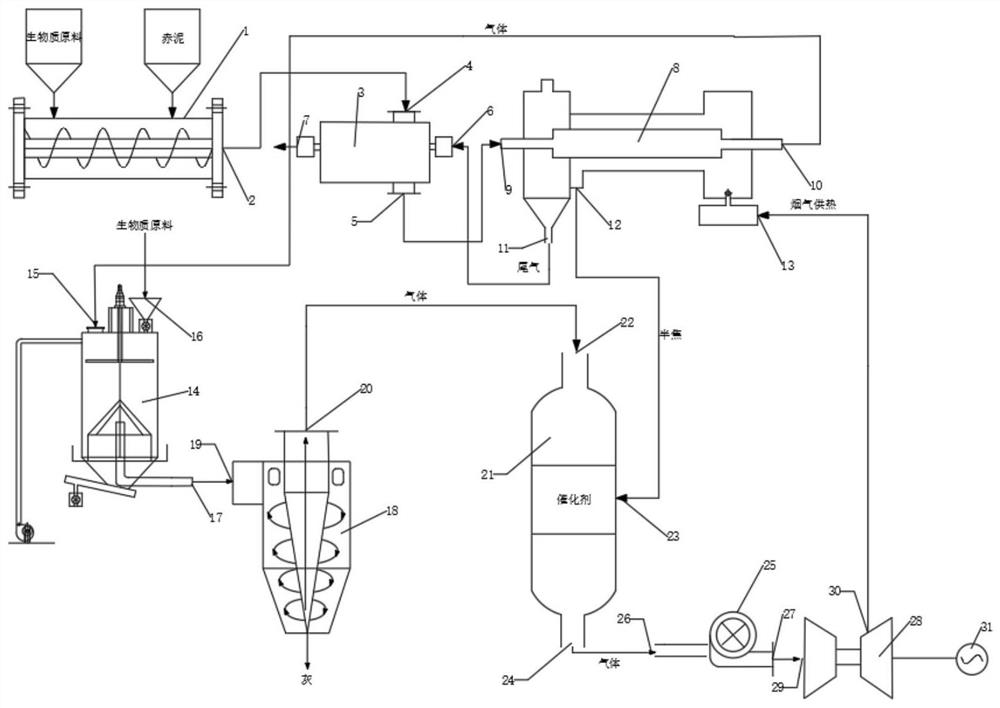

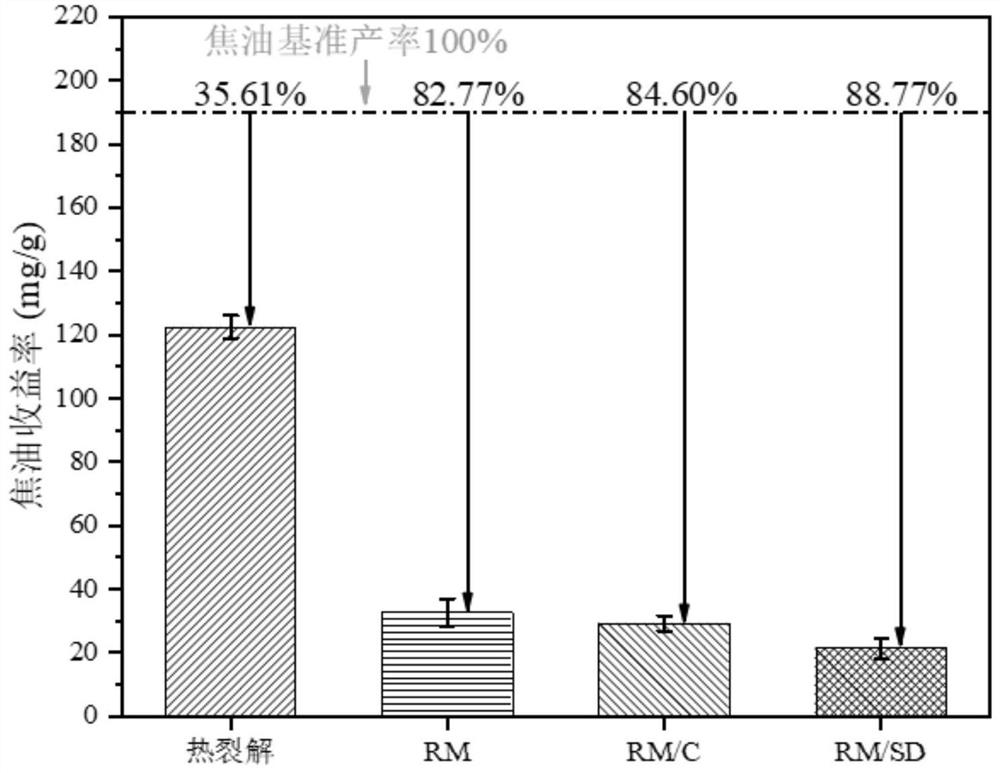

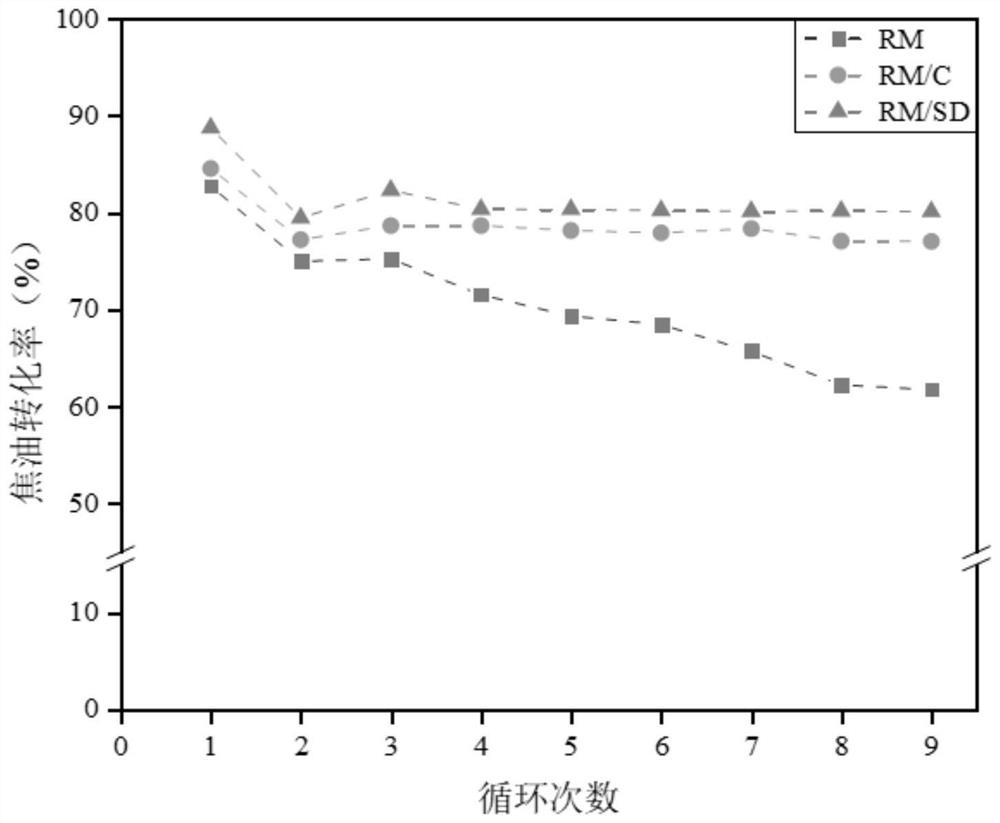

Method and system for preparing red mud-biochar composite catalyst and purifying tar

PendingCN114836240AHigh catalytic activityImprove catalytic stabilityCombustible gas catalytic treatmentGasification processes detailsCatalytic reformingPtru catalyst

The invention discloses a method and a system for preparing a red mud-biochar composite catalyst and purifying tar, a red mud raw material and a biomass raw material are mixed and dried and then are fed into a rotary furnace for carbon thermal reduction reaction to obtain the red mud-biochar composite catalyst, and the red mud-biochar composite catalyst has a special structure and catalytic activity; volatile components generated in the preparation process of the catalyst enter a downdraft gasifier and are used as a gasifying agent in the gasifier to be subjected to a pyrolysis gasification reaction with biomass raw materials, and an obtained gas product enters a fixed bed reformer to be subjected to a catalytic reforming reaction under the obtained red mud-biological coke composite catalyst after passing through a cyclone dust collector, the content of biomass gasification tar is greatly reduced, and a gas product of the catalytic reforming reaction is driven to a gas turbine through an induced draft fan and drives a power generator to generate power. Combustion tail gas serves as a heat source of the rotary furnace and the drum-type dryer. The whole system is high in energy efficiency and low in operation cost, and a catalyst preparation process and a biomass gasification tar deep purification process are effectively coupled.

Owner:NANJING UNIV OF SCI & TECH

A closed-top suction type fixed bed gasifier waste heat recovery device

InactiveCN104449852BReduce the burden onHigh thermal efficiencyEnergy inputCombustible gas productionFlue gasTar

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Parallel path, downdraft gasifier apparatus and method

ActiveUS20150184092A9Effectively stopCompound undesirableBioreactor/fermenter combinationsBiological substance pretreatmentsOxidation zoneOxygen

A method for using a downdraft gasifier comprising a housing and a refractory stack contained within the housing. The refractory stack may comprise various sections. Apertures in the sections may be aligned to form multiple columnar cavities. Each columnar cavity may comprise an individual oxidation zone. The method of use may include the steps of placing a feedstock into an upper portion of the refractory stack, measuring the temperature of each columnar cavity, and adjusting the flow of oxygen to a particular columnar cavity to maintain the temperature of the particular columnar cavity within a particular range.

Owner:STRATEAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com