A closed-top suction type fixed bed gasifier waste heat recovery device

A technology of waste heat recovery device and fixed bed gasifier, which is applied in chemical industry, manufacture of combustible gas, climate sustainability, etc. It can solve the problems of difficult heat energy recovery, high requirements, fast corrosion, etc., and achieve the purpose of suppressing low temperature Effects of synthesis reaction, load reduction, and thermal efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

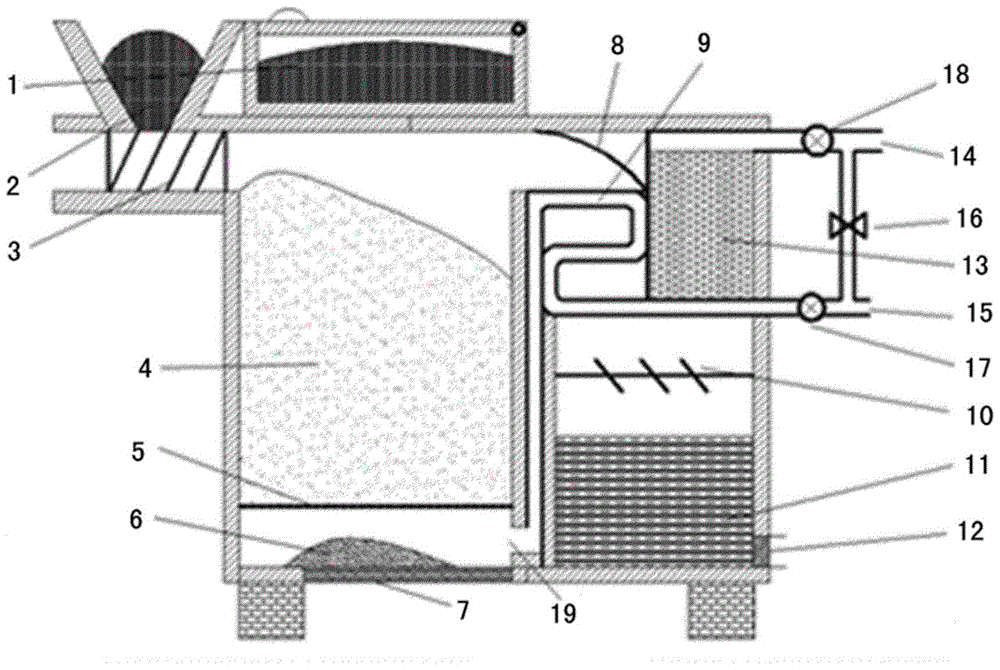

[0028] The waste heat recovery device of the airtight updraft fixed-bed gasifier of the present invention is a small device, which is especially suitable for pyrolysis treatment of domestic garbage in villages and towns. The closed type of the device is beneficial to control the intake of air and the temperature of the gasification medium, which not only makes the pyrolysis working condition easy to control, but also improves the thermal efficiency of the furnace body.

[0029] Technical solution of the present invention is based on following principle:

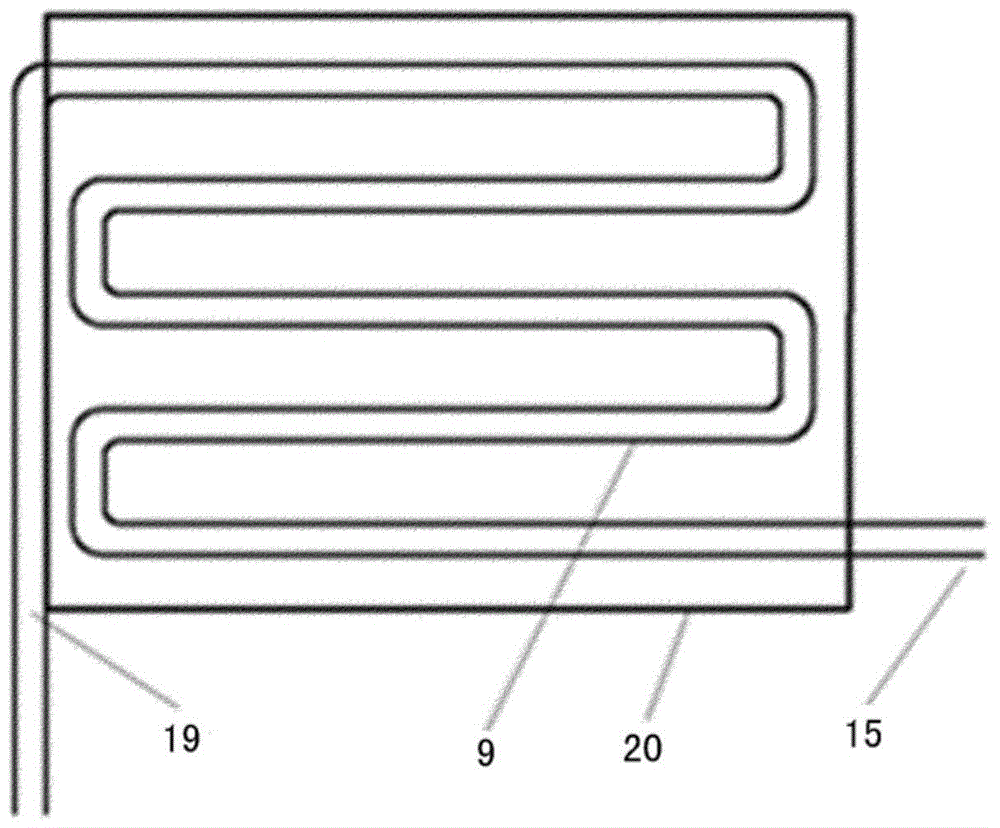

[0030] According to the research, the outlet temperature of the updraft fixed bed pyrolysis gas is about 500°C. According to the static pressure recovery method, the pyrolysis gas first passes through the gas deflector, and then passes through the heat exchanger at a constant speed. During the heat exchange process, the temperature of the pyrolysis gas decreases, and the temperature of the gasification medium increases signif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com