Patents

Literature

12747 results about "Material storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

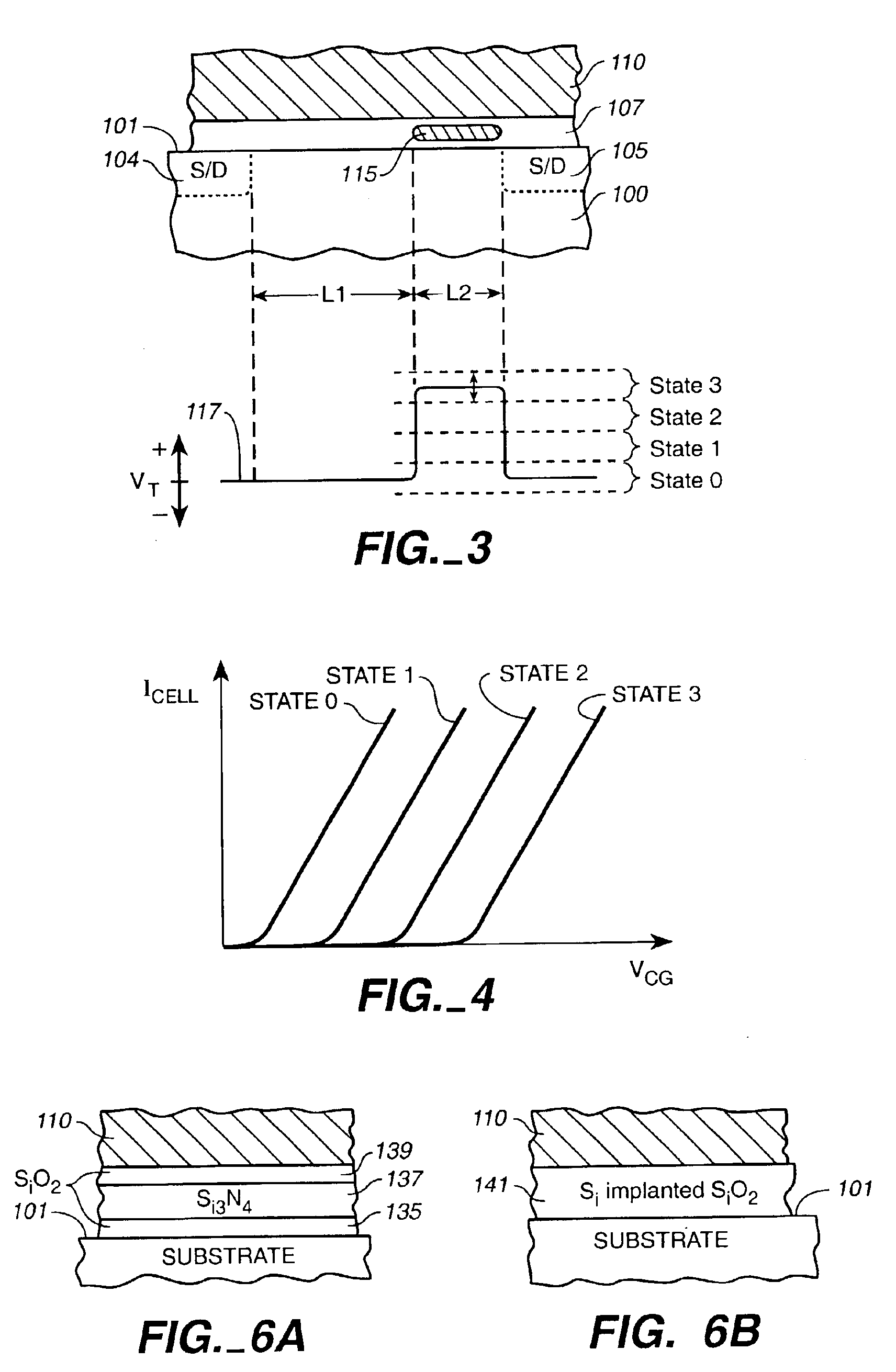

Free-standing and aligned carbon nanotubes and synthesis thereof

One or more highly-oriented, multi-walled carbon nanotubes are grown on an outer surface of a substrate initially disposed with a catalyst film or catalyst nano-dot by plasma enhanced hot filament chemical vapor deposition of a carbon source gas and a catalyst gas at temperatures between 300° C. and 3000° C. The carbon nanotubes range from 4 to 500 nm in diameter and 0.1 to 50 μm in length depending on growth conditions. Carbon nanotube density can exceed 104 nanotubes / mm2. Acetylene is used as the carbon source gas, and ammonia is used as the catalyst gas. Plasma intensity, carbon source gas to catalyst gas ratio and their flow rates, catalyst film thickness, and temperature of chemical vapor deposition affect the lengths, diameters, density, and uniformity of the carbon nanotubes. The carbon nanotubes of the present invention are useful in electrochemical applications as well as in electron emission, structural composite, material storage, and microelectrode applications.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

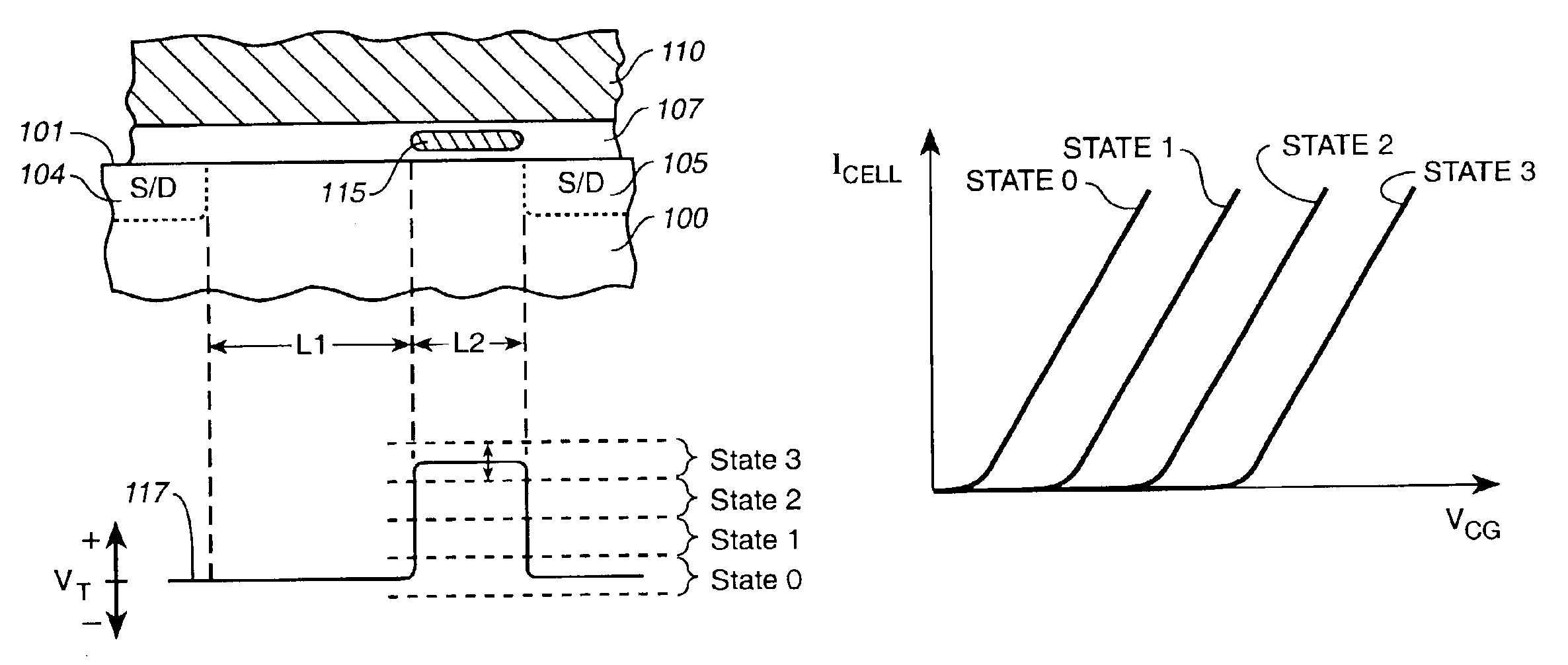

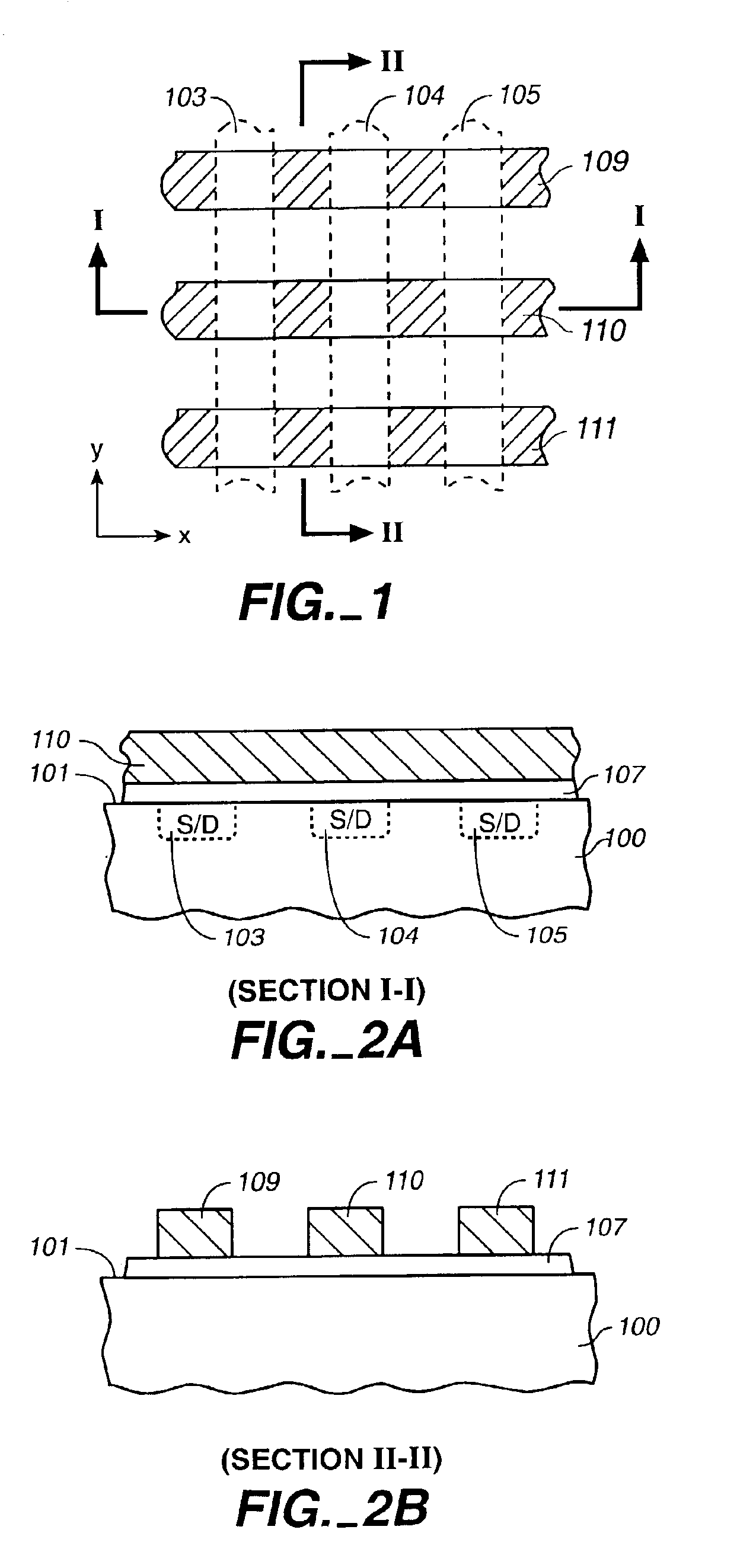

Multi-state non-volatile integrated circuit memory systems that employ dielectric storage elements

InactiveUS6925007B2Increase the number ofExtend effective lifeTransistorNanoinformaticsEngineeringDielectric layer

Non-volatile memory cells store a level of charge corresponding to the data being stored in a dielectric material storage element that is sandwiched between a control gate and the semiconductor substrate surface over channel regions of the memory cells. More than two memory states are provided by one of more than two levels of charge being stored in a common region of the dielectric material. More than one such common region may be included in each cell. In one form, two such regions are provided adjacent source and drain diffusions in a cell that also includes a select transistor positioned between them. In another form, NAND arrays of strings of memory cells store charge in regions of a dielectric layer sandwiched between word lines and the semiconductor substrate.

Owner:SANDISK TECH LLC

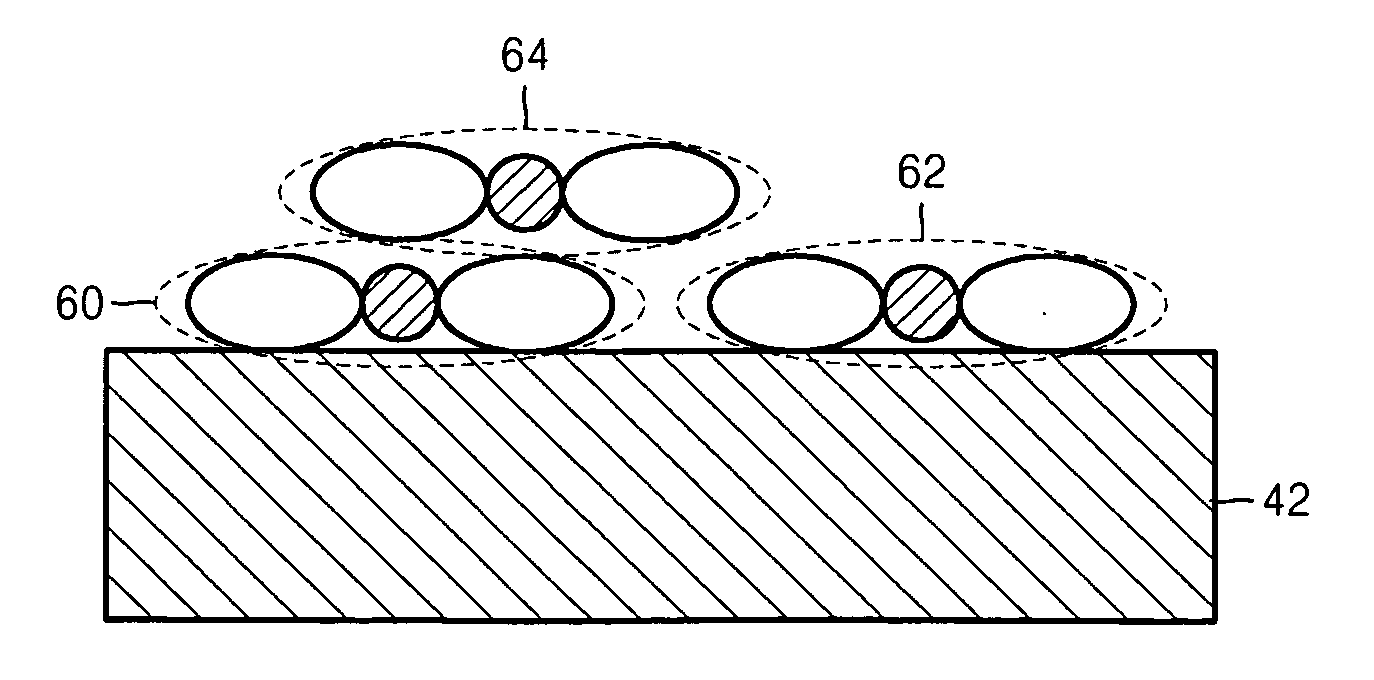

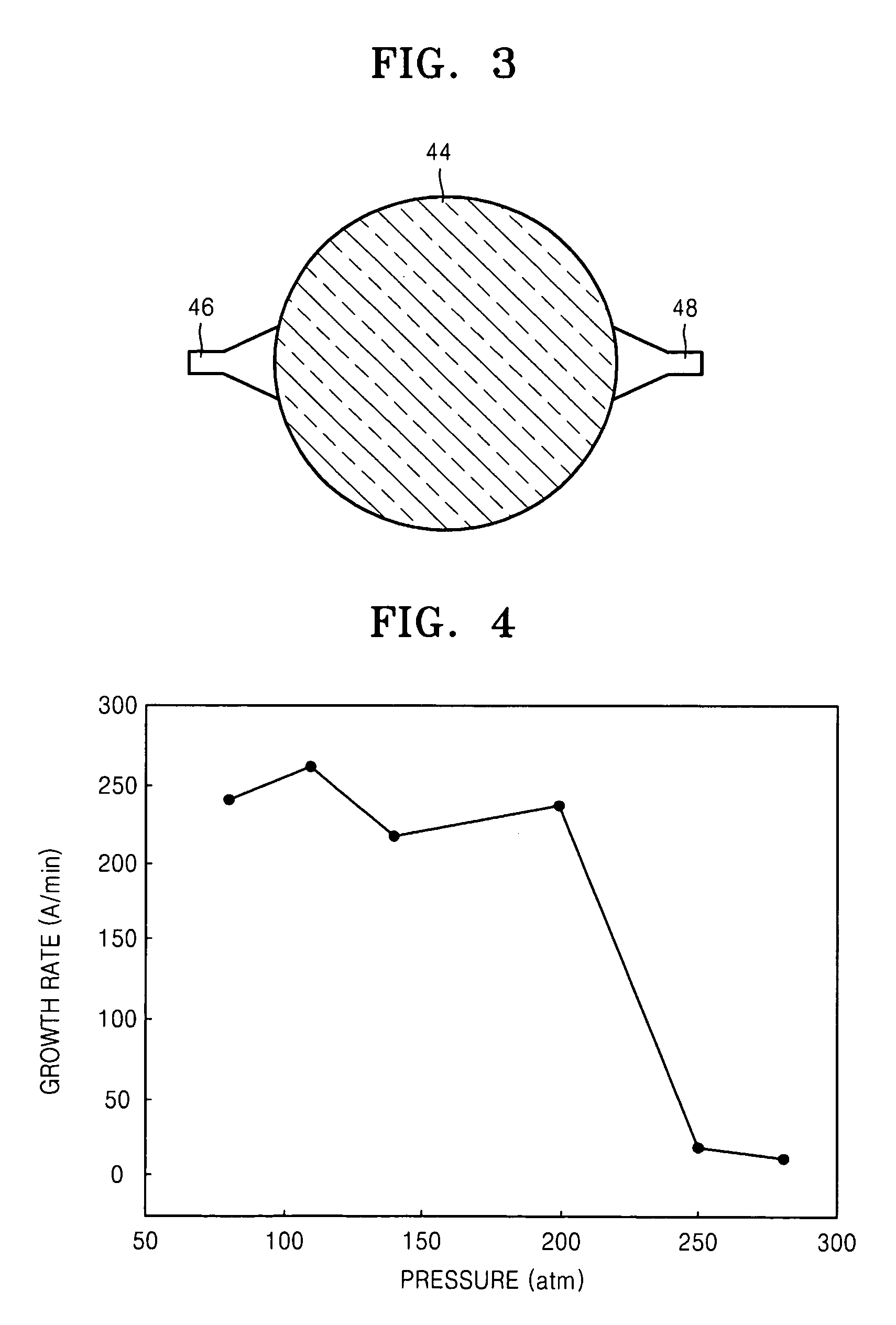

Material layer forming apparatus using supercritical fluid, material layer forming system comprising the same and method of forming material layer

InactiveUS20100092679A1Pretreated surfacesSemiconductor/solid-state device manufacturingInternal pressureEngineering

Provided are a material layer forming apparatus using a supercritical fluid, a material layer forming system including the apparatus, and a method of forming a material layer using the system. The material layer forming system may include a high pressure pump supplying a supercritical fluid to a precursor storage container and the material layer forming apparatus, and maintaining the internal pressure of the precursor storage container, a reactant material storage container at a pressure such that the supercritical fluid is in a supercritical state, and a material layer forming apparatus. The material layer forming system may further include a pressure gauge adjusting the pressure of the material layer forming apparatus. The precursor of the precursor storage container may be supplied to the material layer forming apparatus using the supercritical fluid.

Owner:SAMSUNG ELECTRONICS CO LTD

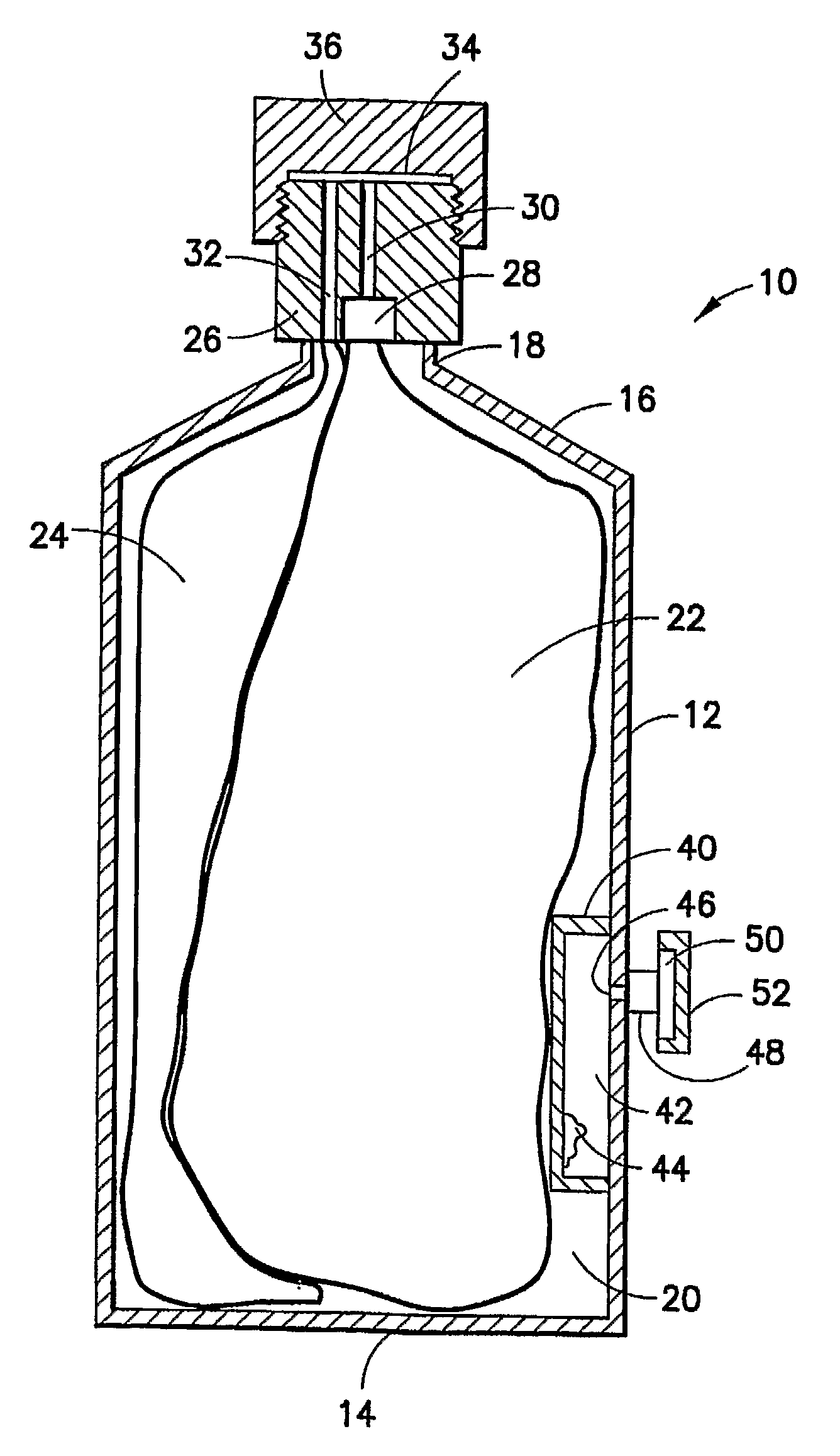

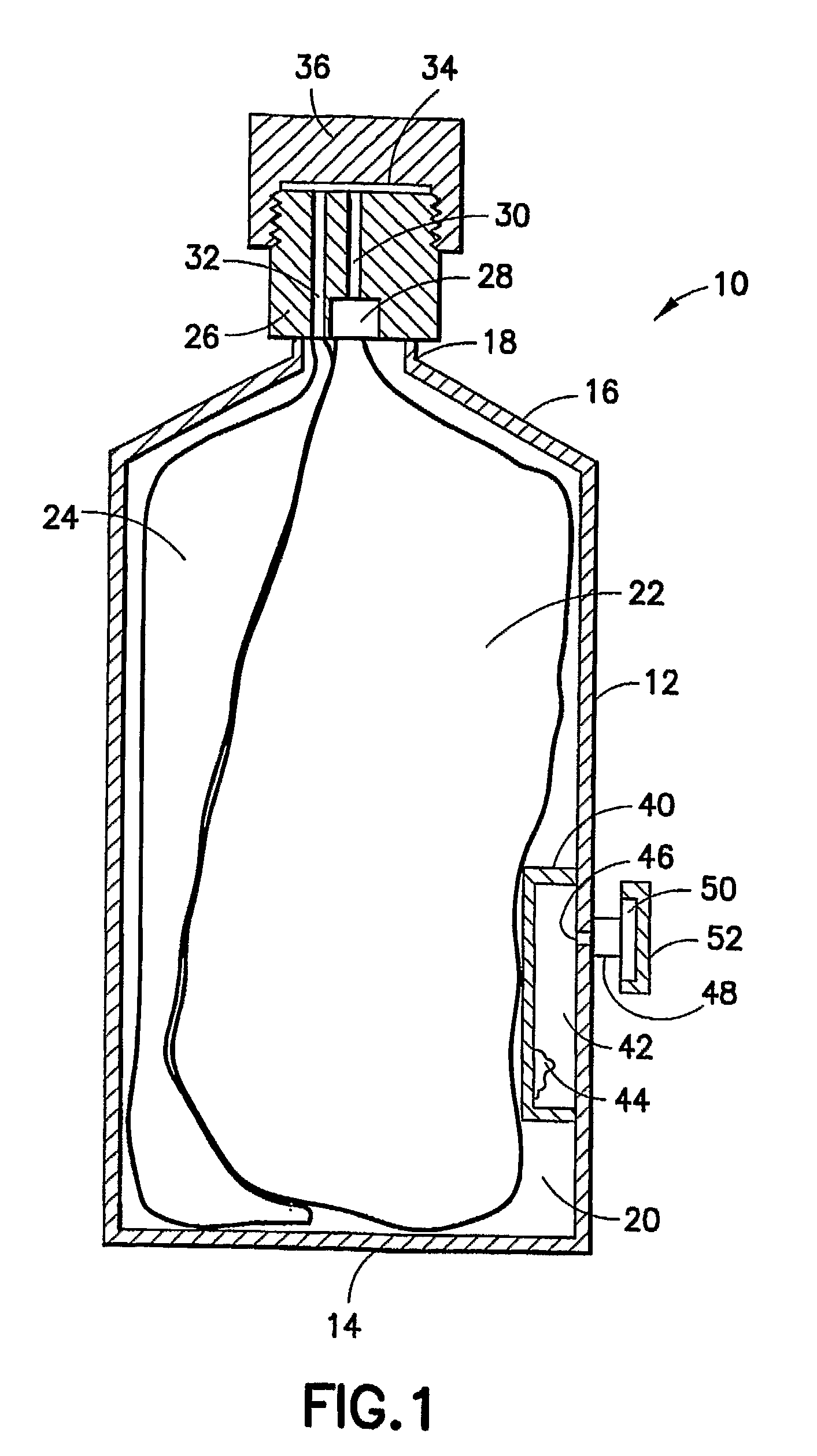

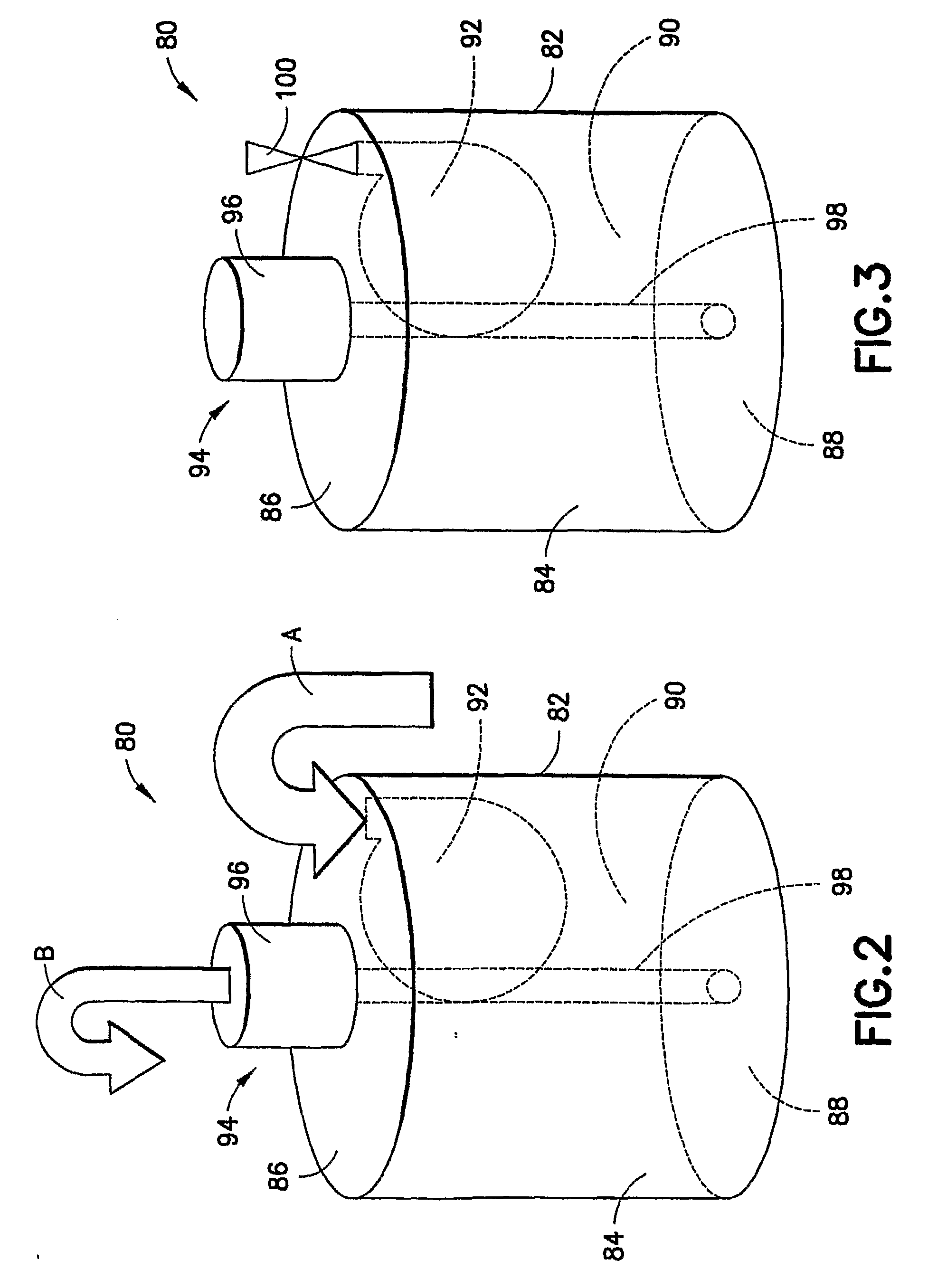

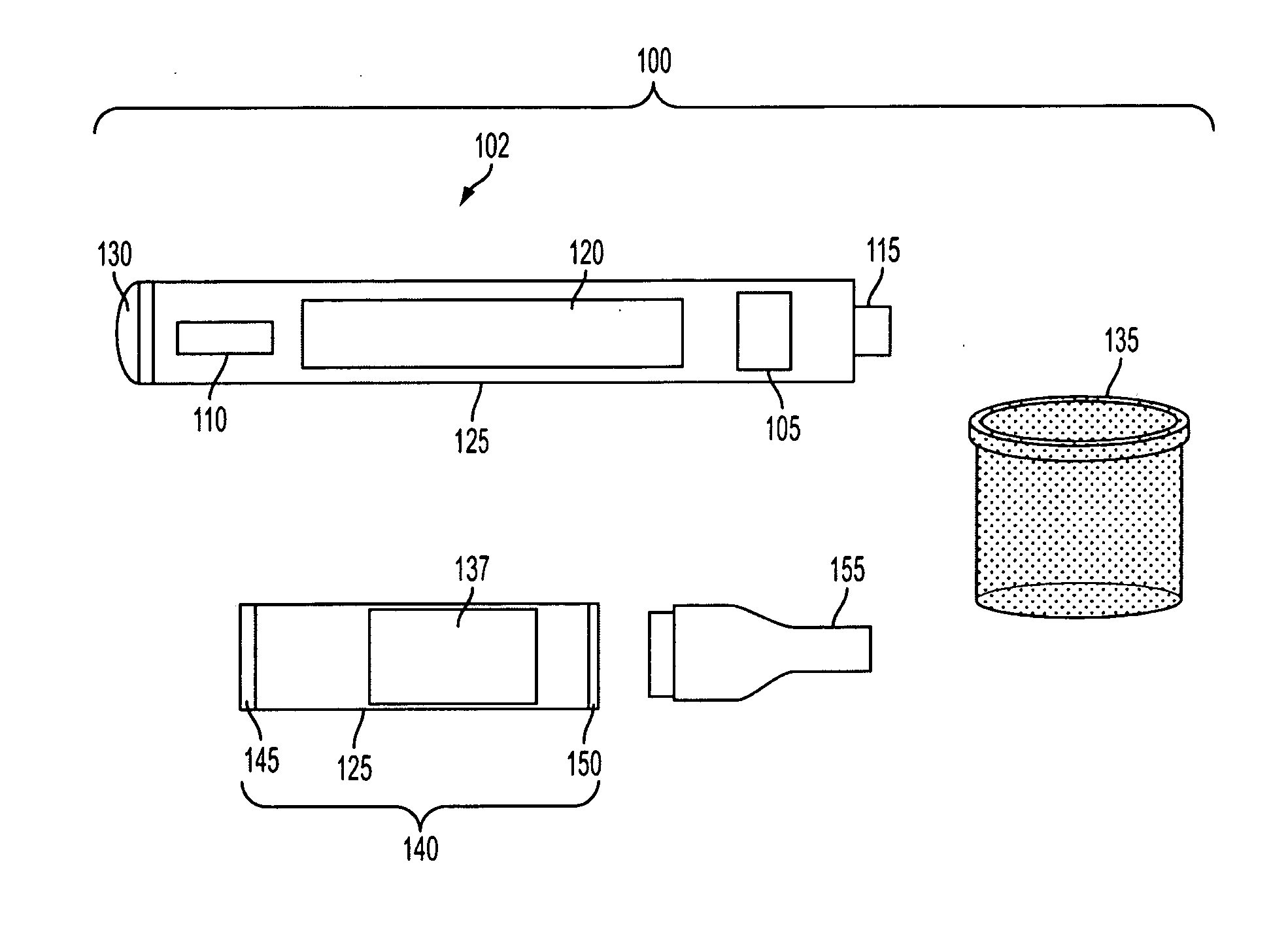

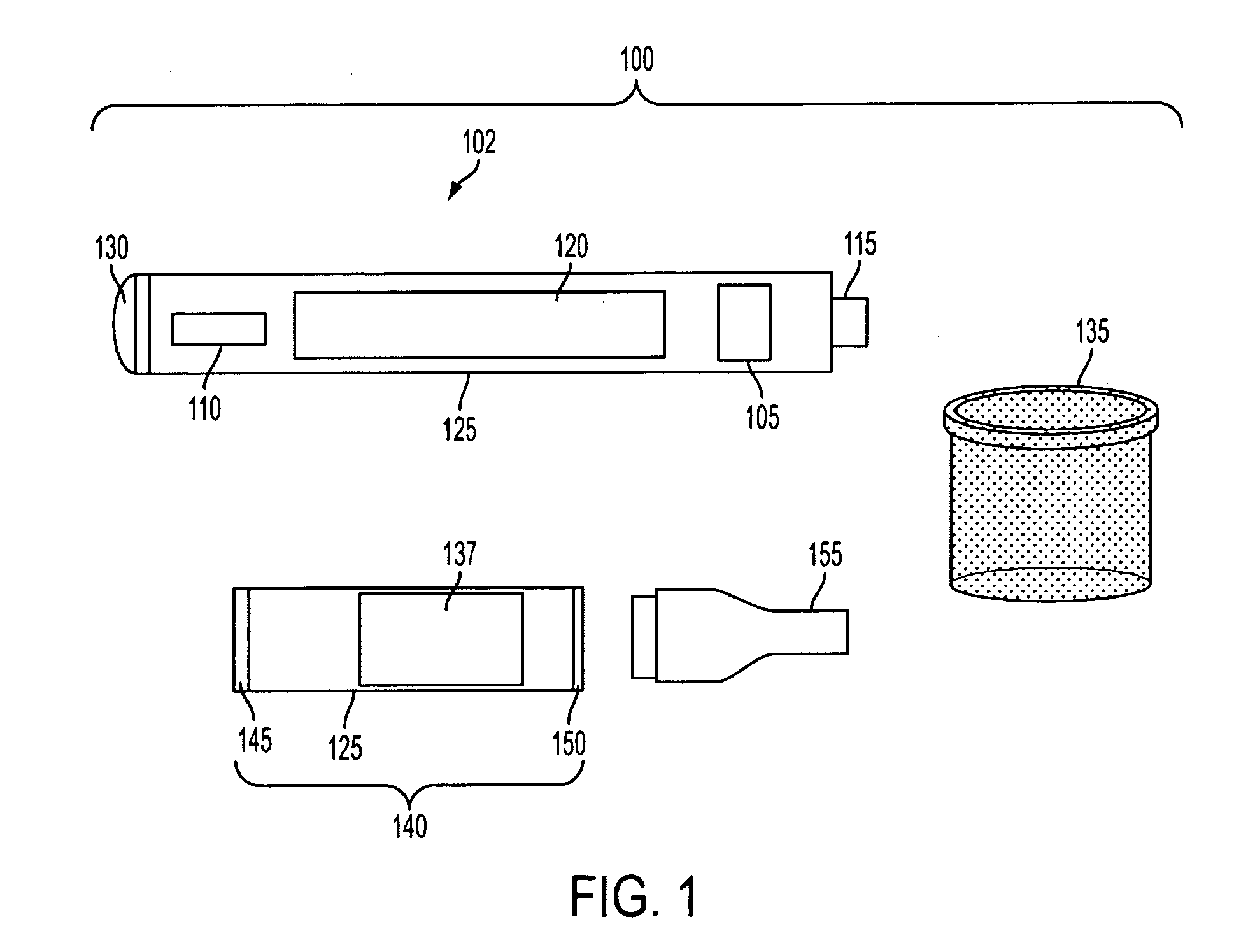

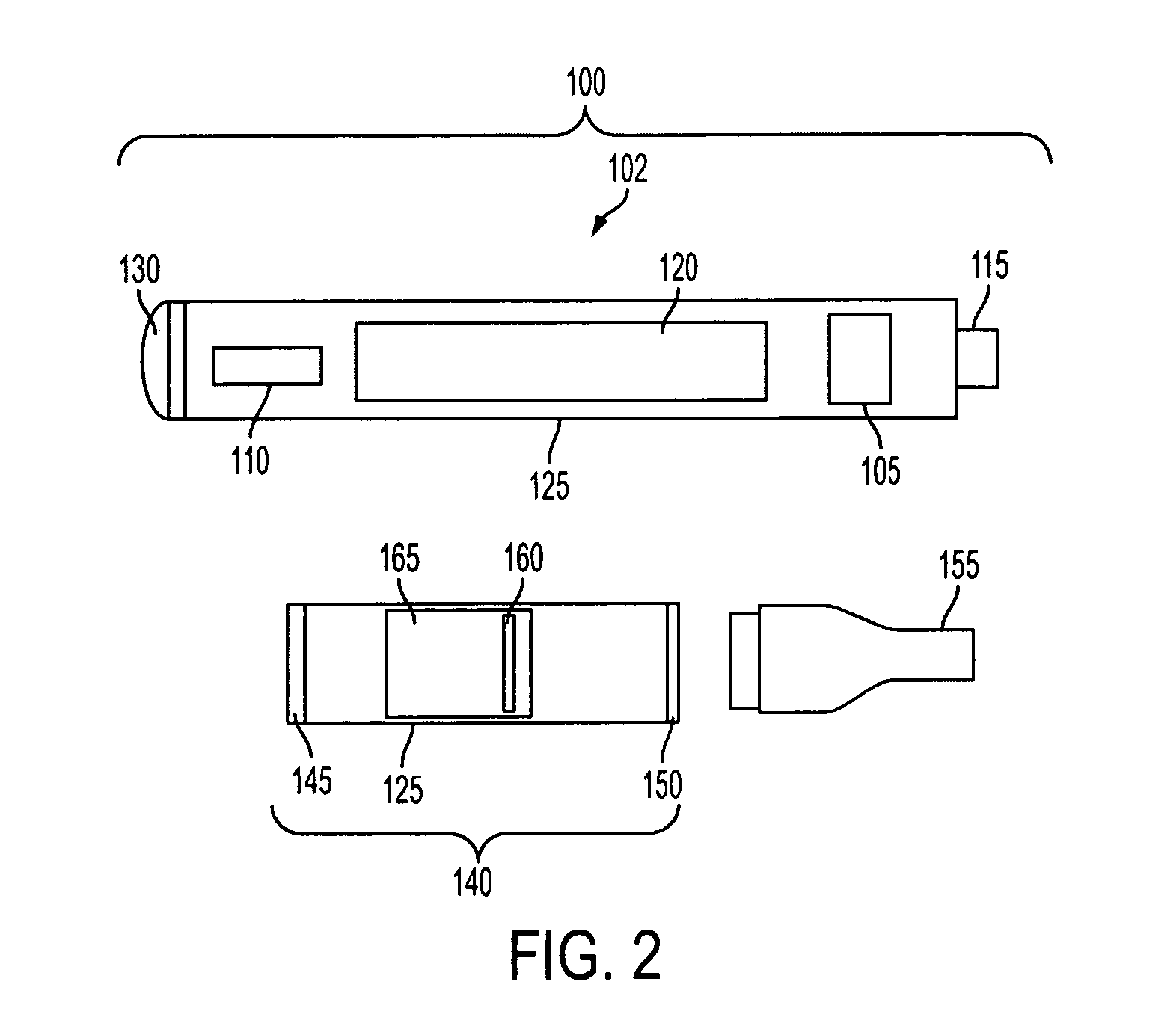

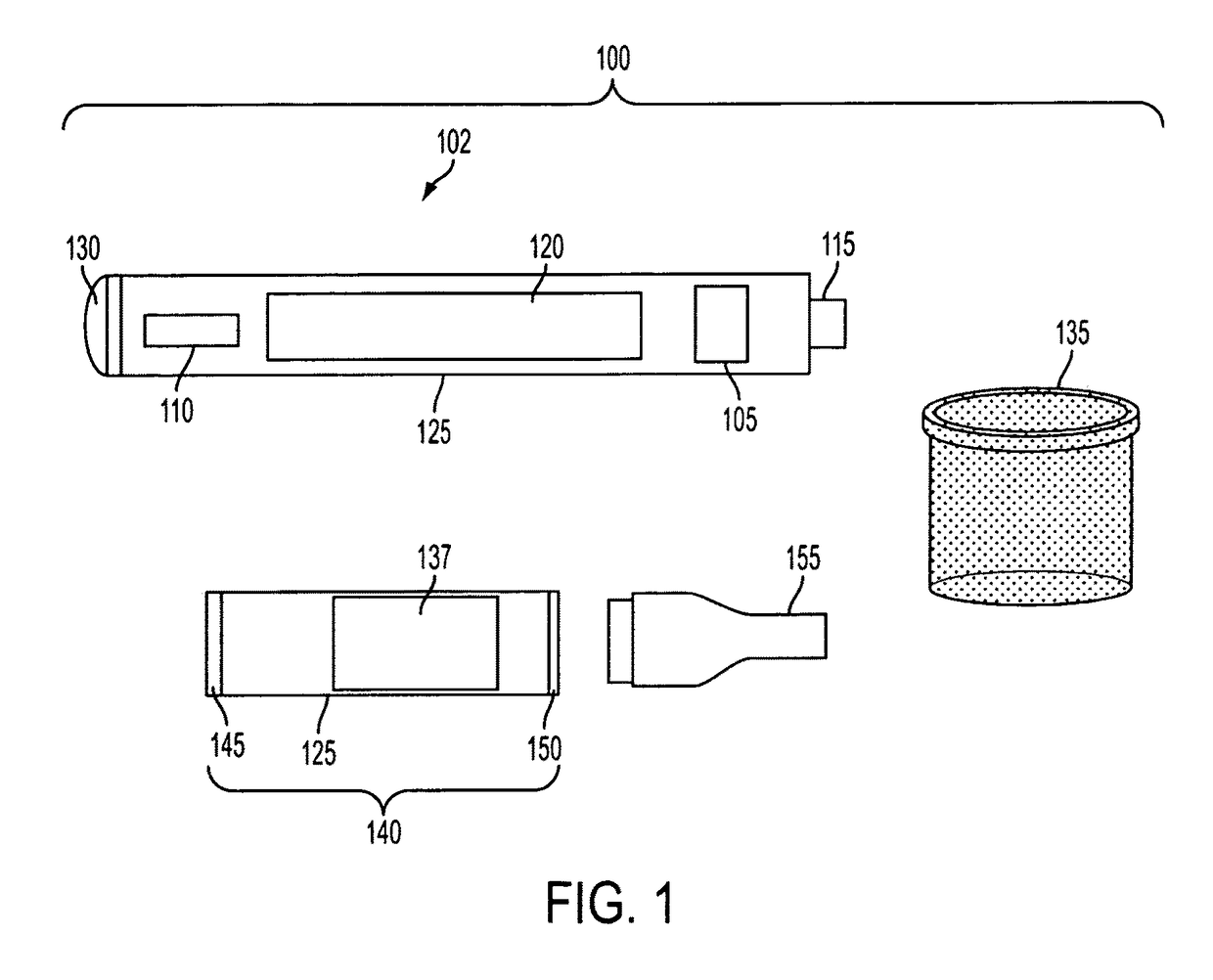

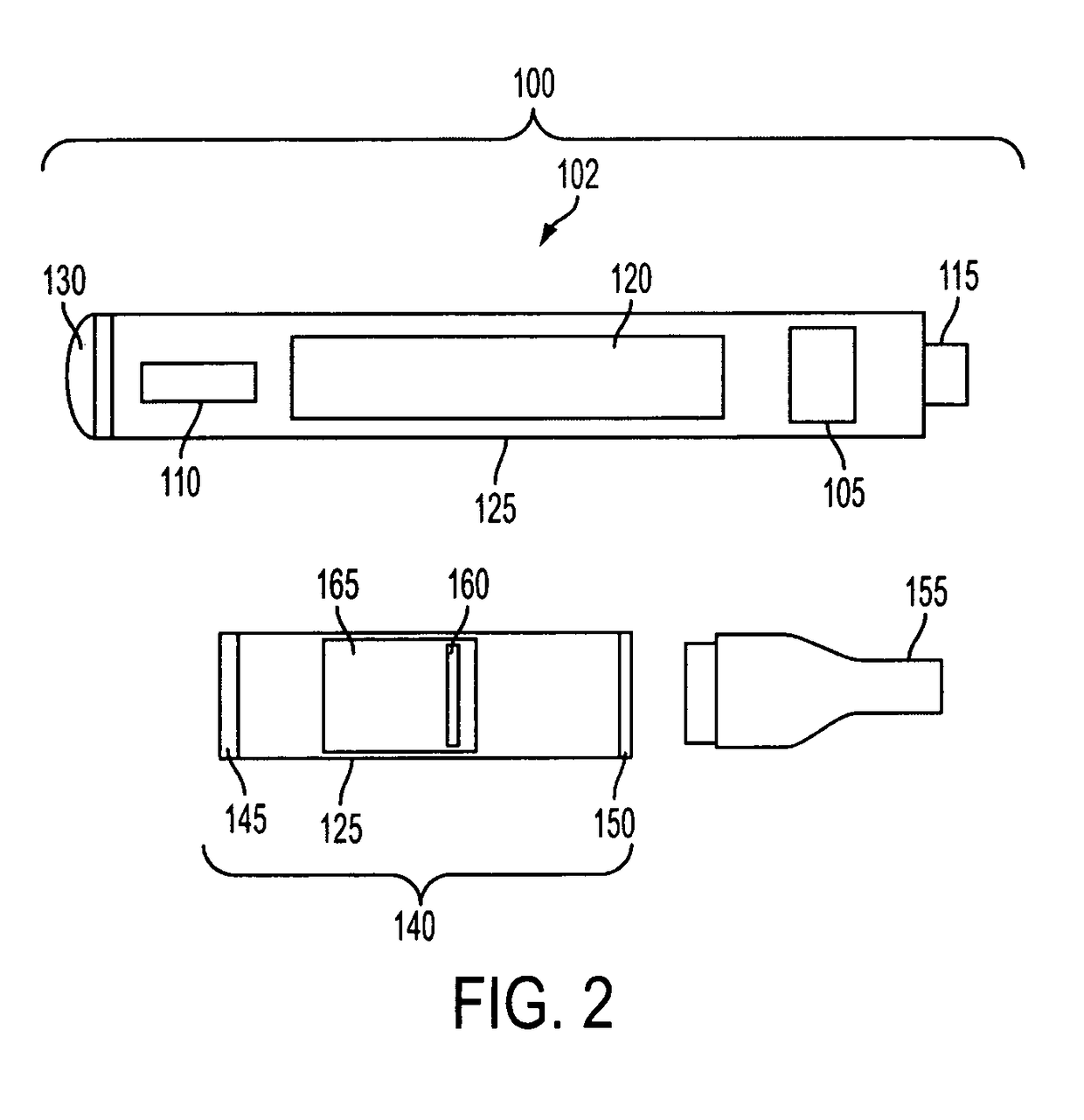

Material storage and dispensing packages and methods

InactiveUS20090212071A1Solve the lack of spaceInhibit productionPower operated devicesShock-sensitive articlesEngineeringParticle generation

Packages and methods for storage and dispensing of materials, e.g., high purity liquid reagents and chemical mechanical polishing compositions used in the manufacture of microelectronic device products, including containment structures and methods adapted for pressure-dispensing of high-purity liquids. Liner packaging of liquid or liquid-containing media is described, in which zero or near-zero head space conformations are employed to minimize adverse effects of particle generation, formation of bubbles and degradation of contained material.

Owner:ADVANCED TECH MATERIALS INC

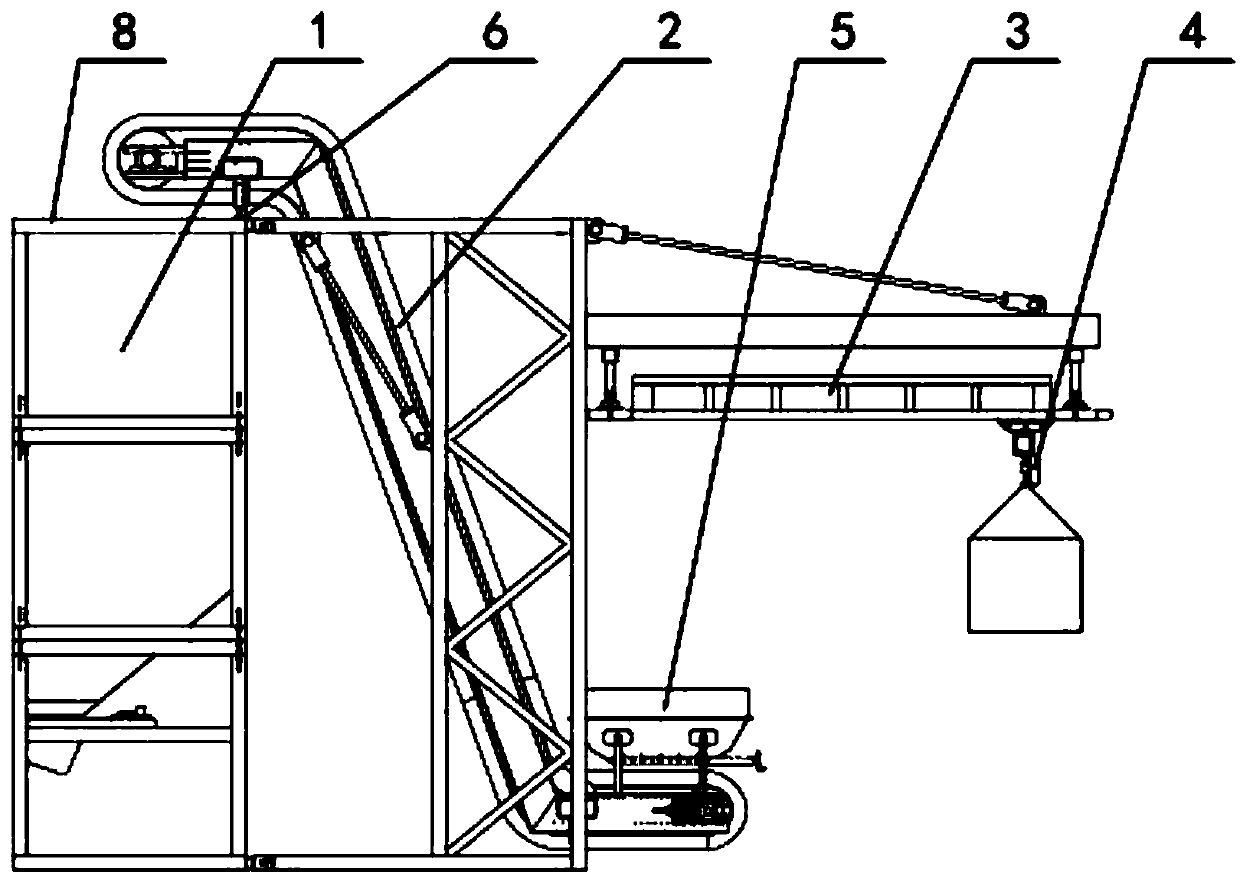

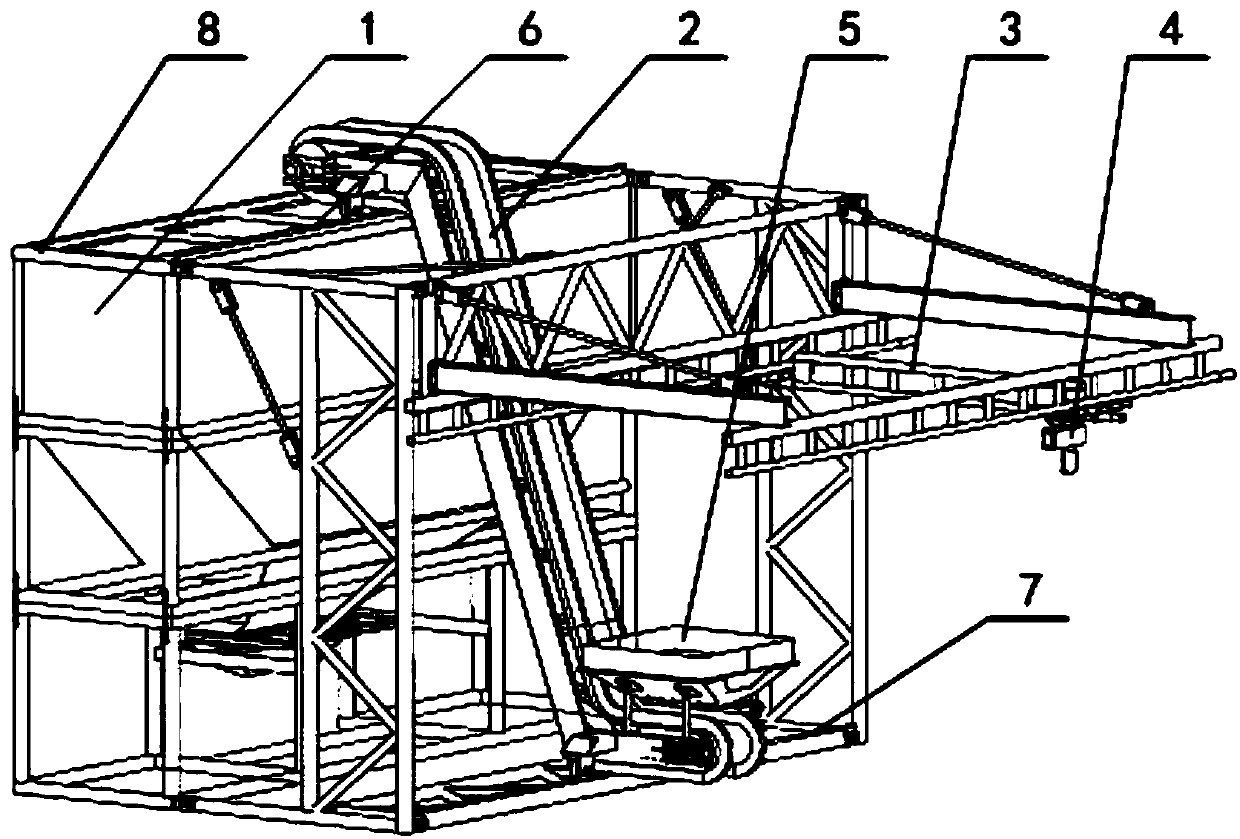

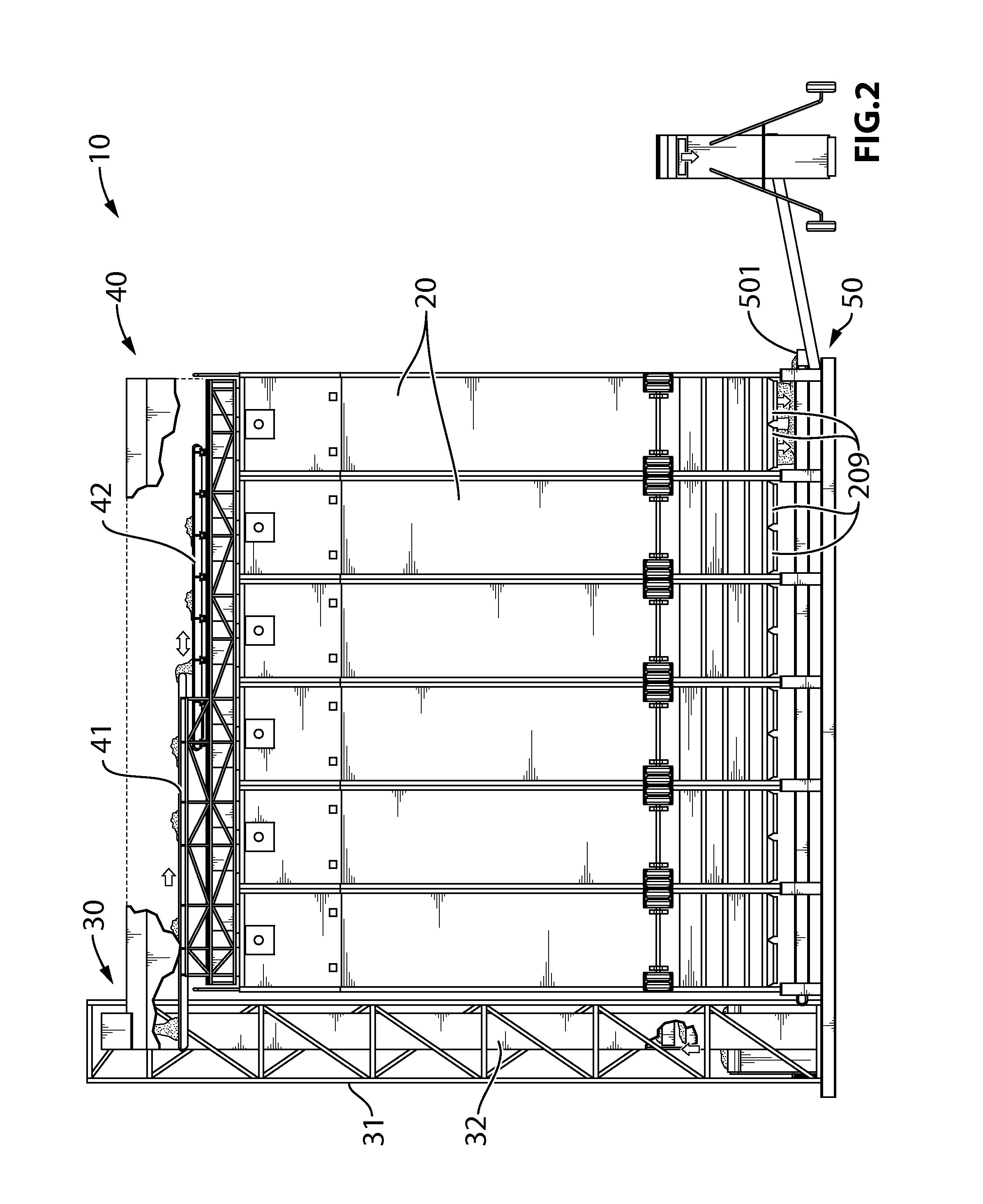

Material hoisting and transportation device

PendingCN107902427ASave on high costsEliminate potential safety hazardsStorage devicesEngineeringOrbit

The invention relates to the oil gas industry, particularly to a material hoisting and transportation device utilized in oil and gas field fracturing operation. The material hoisting and transportation device is characterized in that a material storage tank is mounted on the left of a frame body; an upper orbit is mounted at the upper part of the frame body; a lower orbit is mounted at the right end of the lower part of the frame body; a belt conveying device is mounted on the upper orbit and the lower orbit; a feeding hopper is mounted at the bottom of the belt conveying device; a hoisting device is mounted at the right end of the upper part of the frame body; the hoisting device is mounted in an operation orbit; a hook is mounted on the hoisting device; during operation, the belt conveying device can longitudinally move on the upper orbit and the lower orbit; and during operation, the hoisting device can longitudinally and transversely move in a horizontal plane. The material hoisting and transportation device has a one-key locating function, and automatic operation and locating of the belt conveying device and the hoisting device can be achieved through the function.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

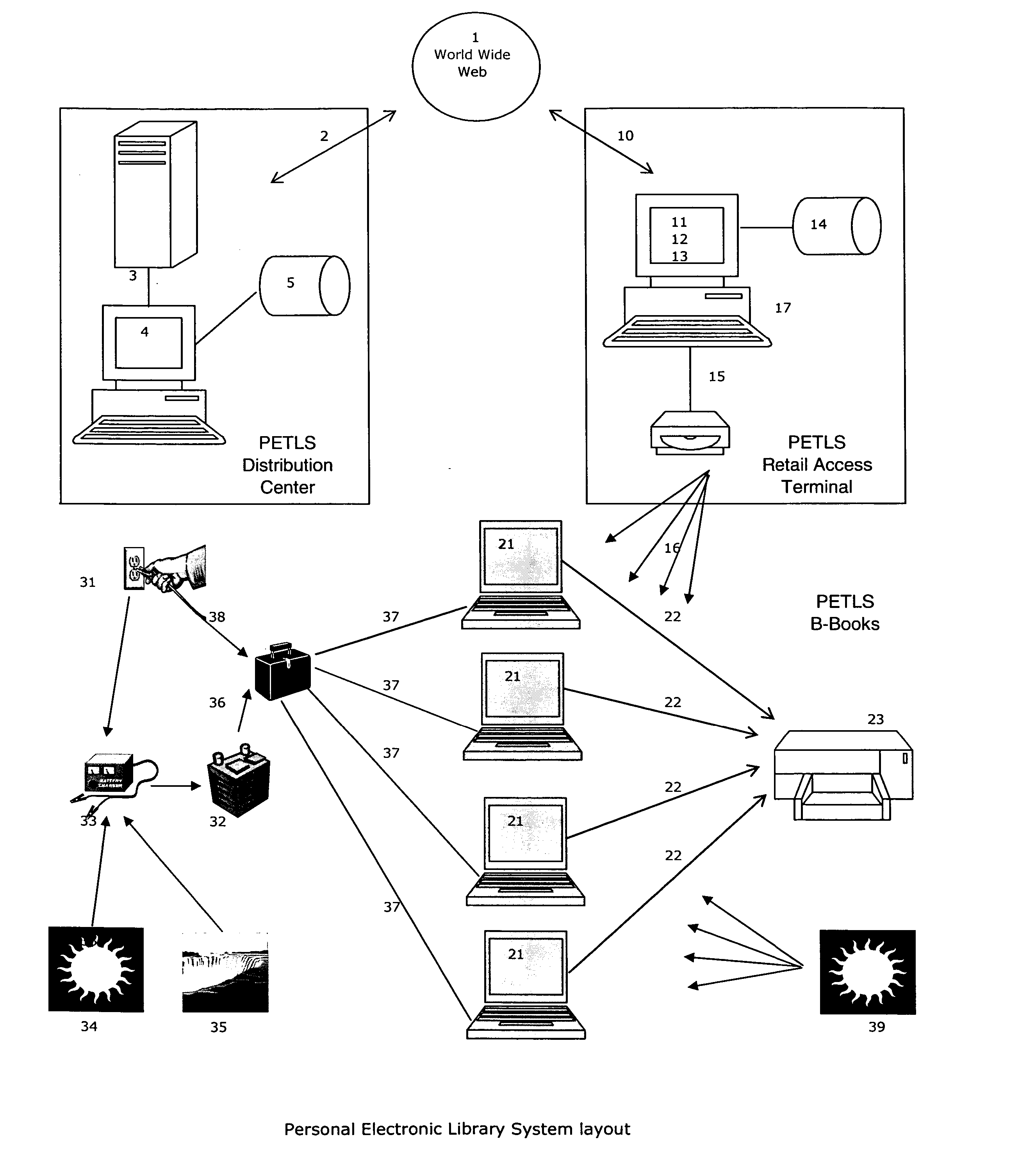

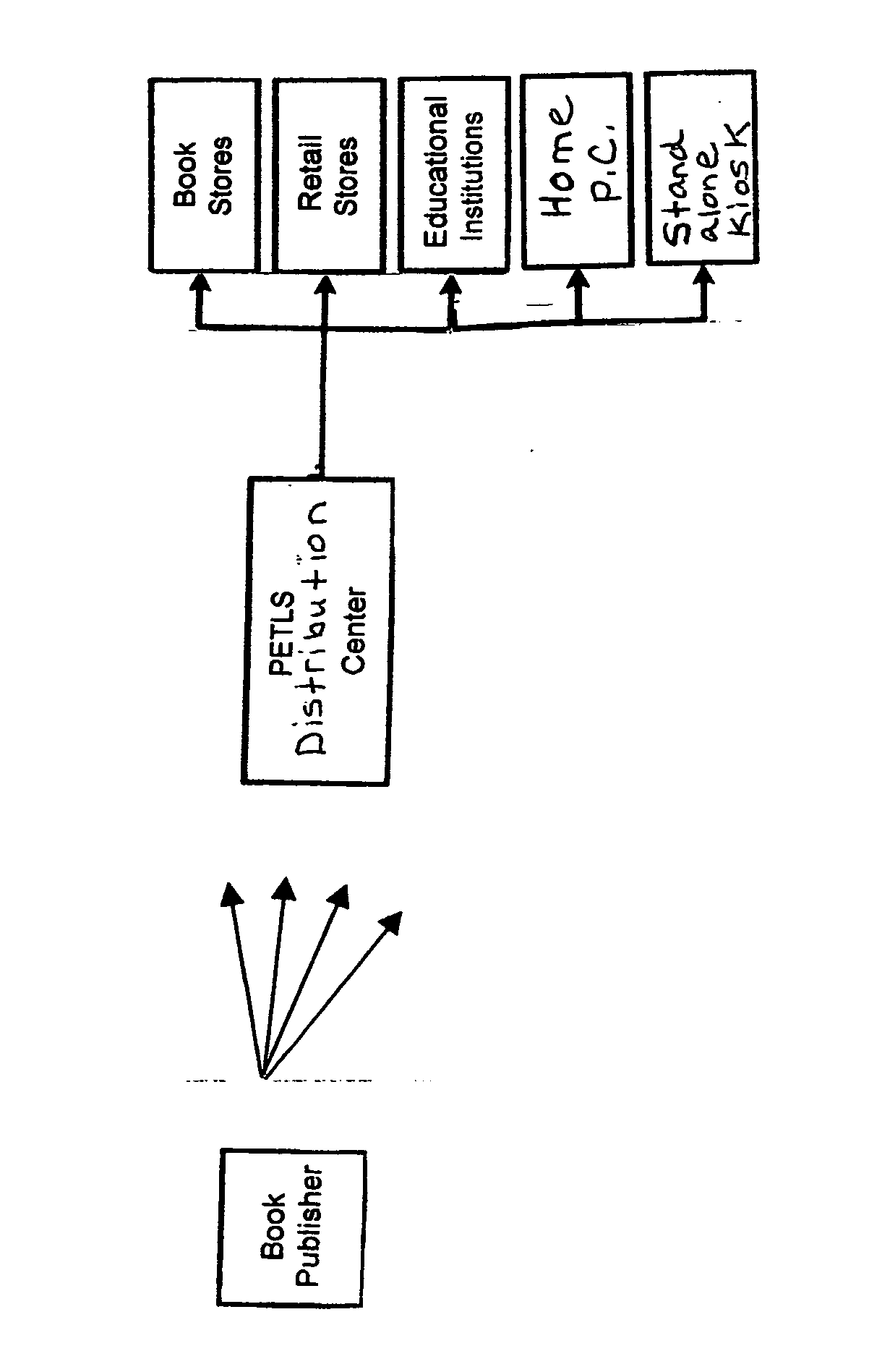

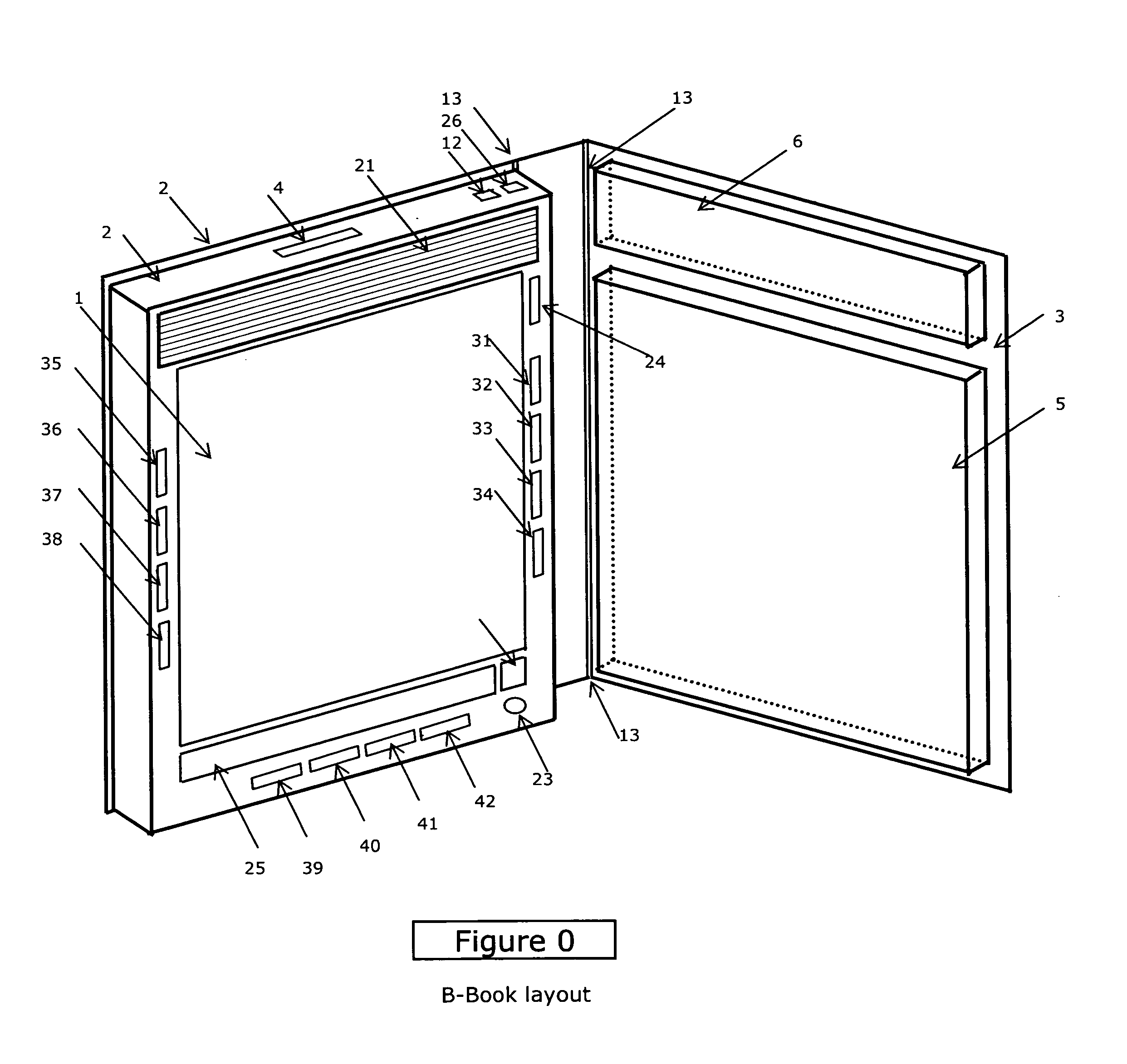

Personal electronic text library system patent

The Personal Electronic Text Library System [PETLS] invention is a means for the collection, storage and distribution of text book and / or printed material in electronic format protected against unauthorized duplication according to the proprietary PETLS Protection Standard. Said protection applies to text book and / or printed material in electronic format originating from a plurality of sources of said material transferred into PETLS, the storage of said material within PETLS, the transfer of copies of said material to portable physical media through a plurality of points of access and the display of said material from said portable physical media on dedicated PETLS display devices, the B-Books. Text book and / or printed material in electronic format stored on the portable PETLS Electronic Storage Media being protected against unauthorized duplication can be purchased and / or shared and / or lent and / or traded and / or donated between any and / or all individuals and / or users of the B-Book dedicated display devices.

Owner:WOOD BERYL

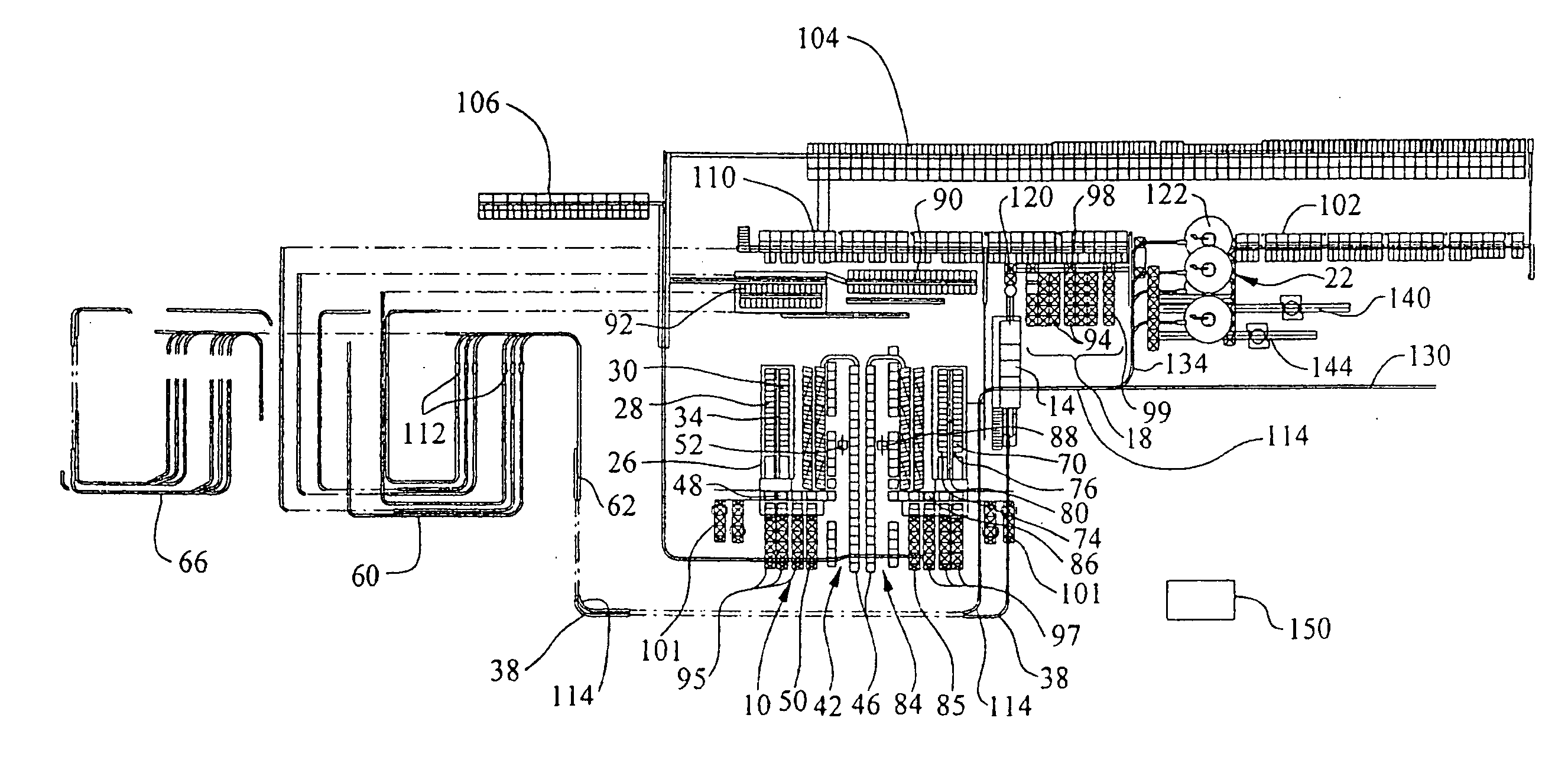

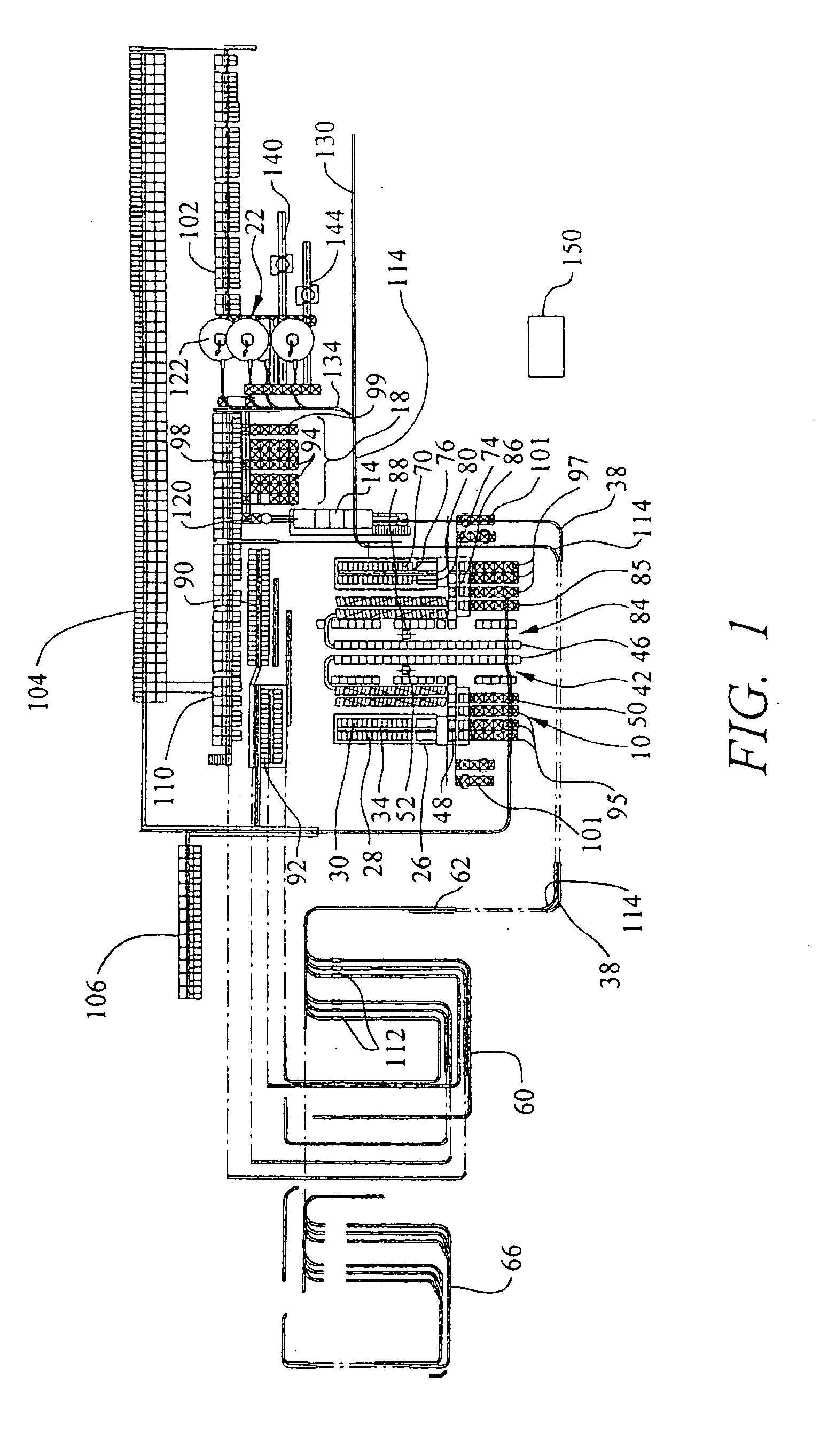

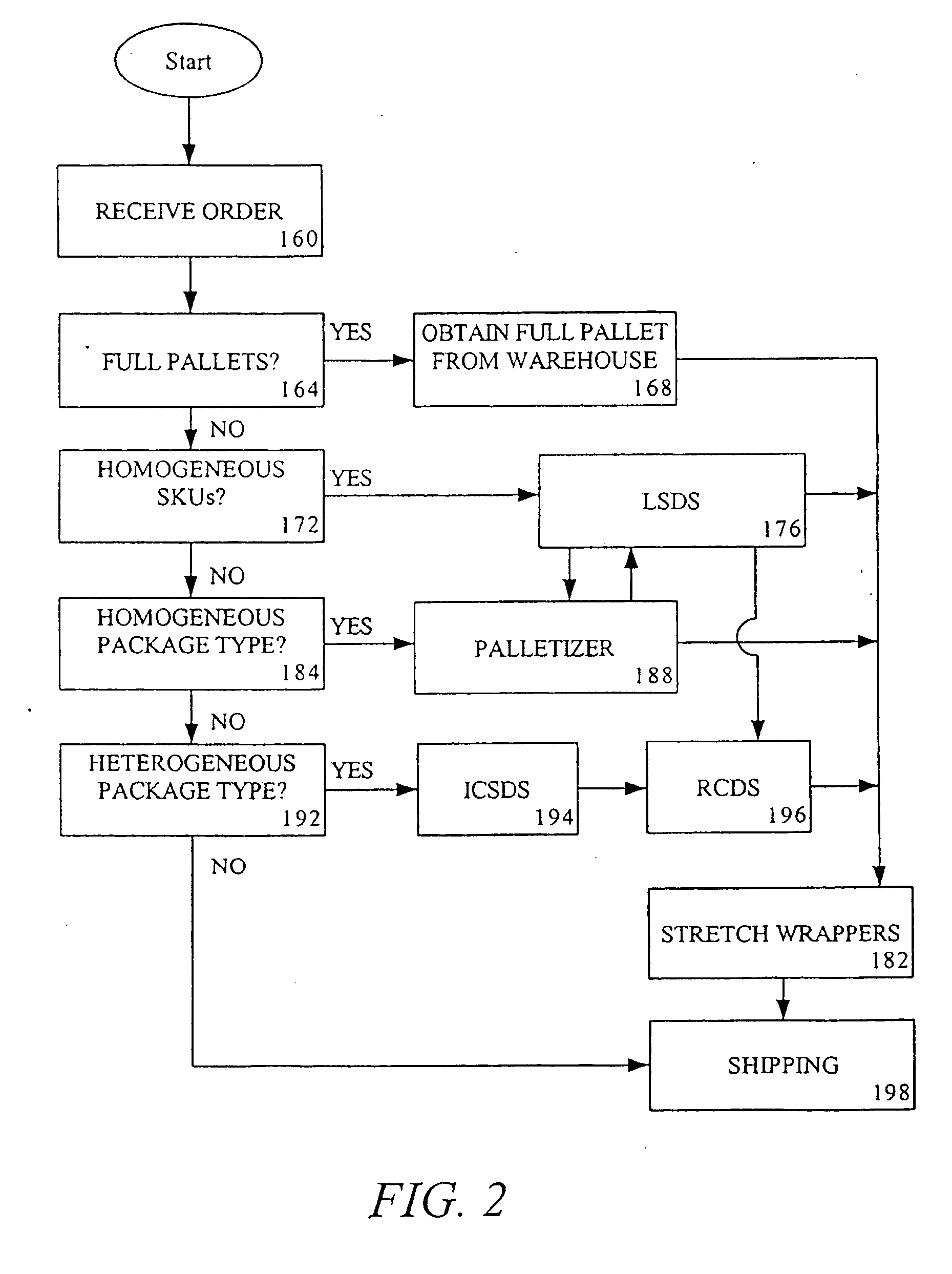

Automated container storage and delivery system

A material storage and delivery system includes an individual container storage and delivery system (ICSDS). A palletizer is provided for placing containers from the ICSDS on a pallet. A layer storage and delivery system (LSDS) places full layers of containers on a pallet. A robotic container delivery system (RCDS) places individual containers on a pallet. A conveyor system conveys containers and pallets between at least two of the ICSDS, the palletizer, the LSDS and the RCDS. A method for storing and delivering containers is also disclosed.

Owner:STINGEL FREDERICK J III +2

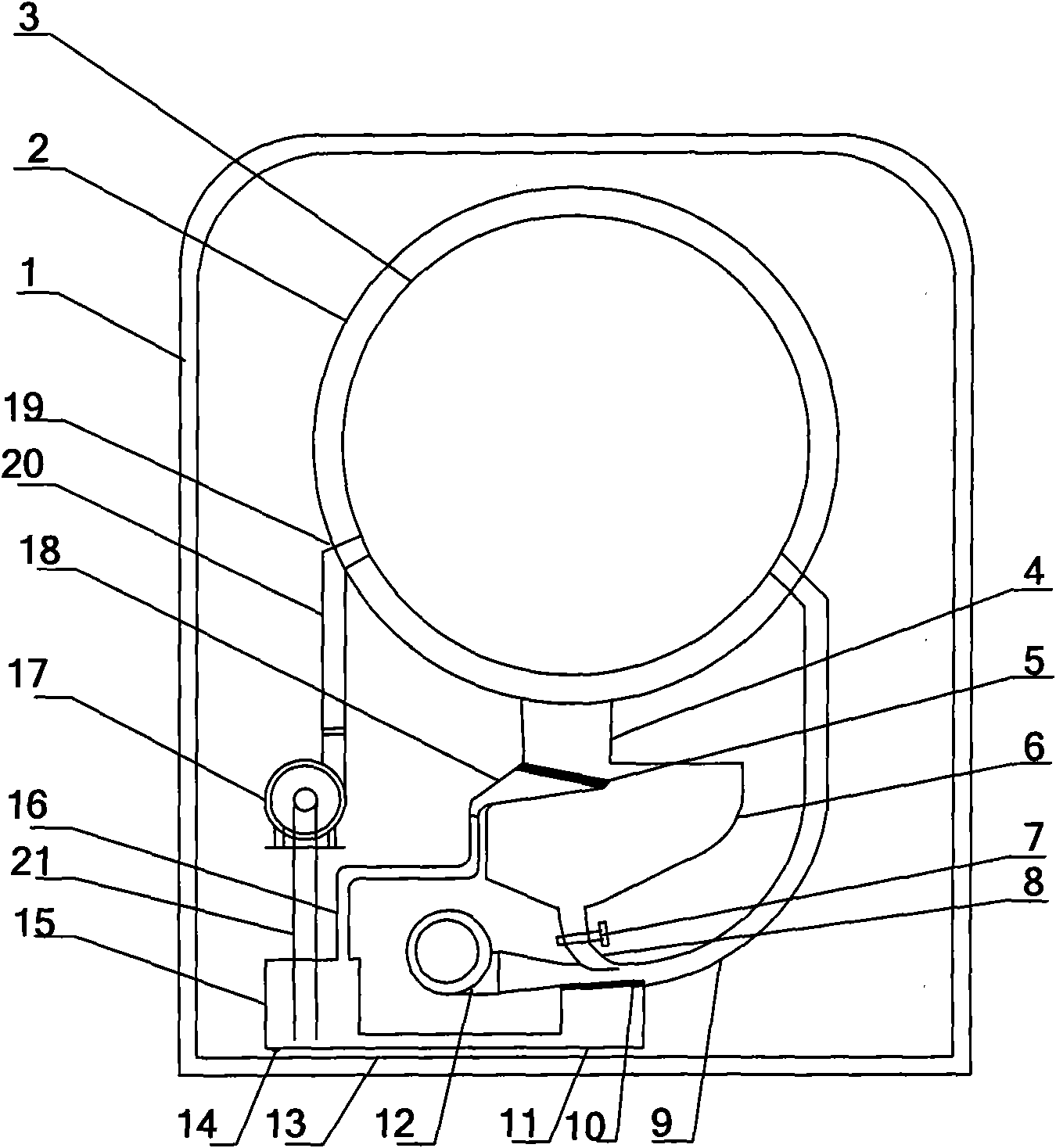

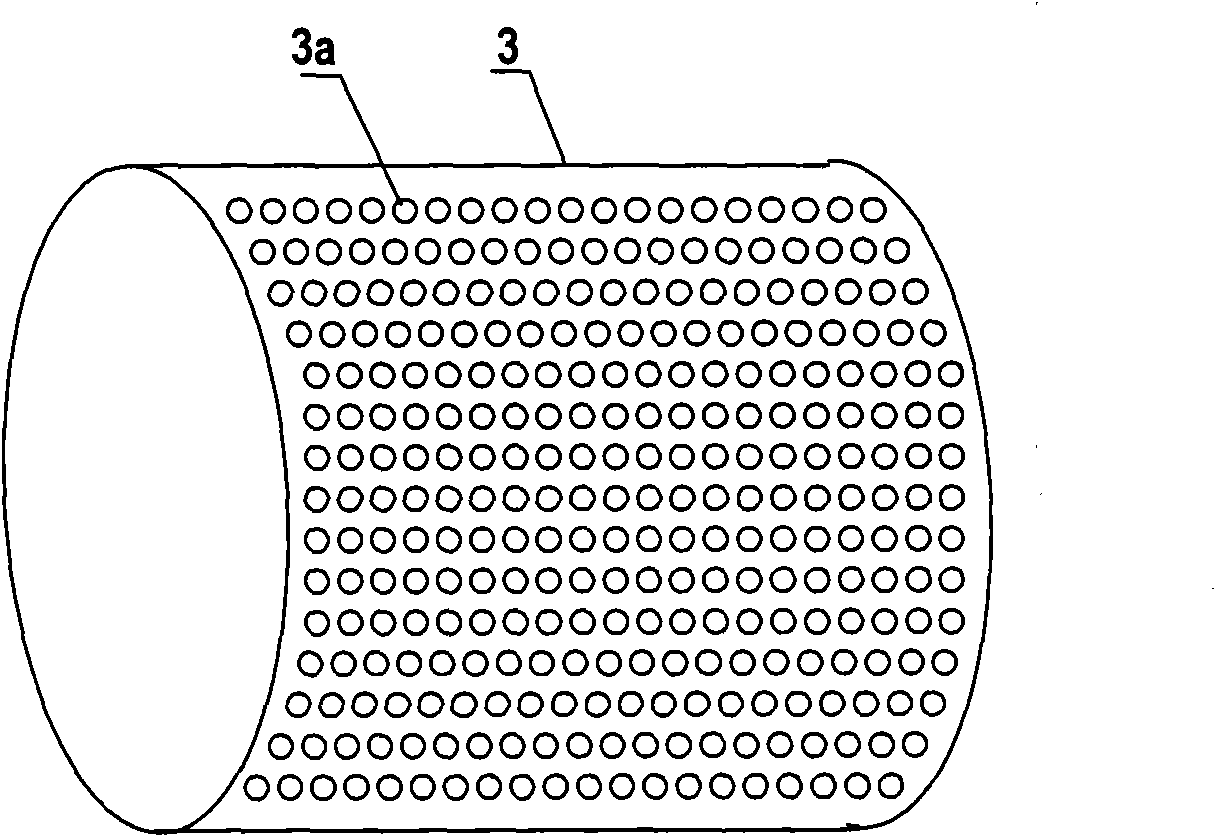

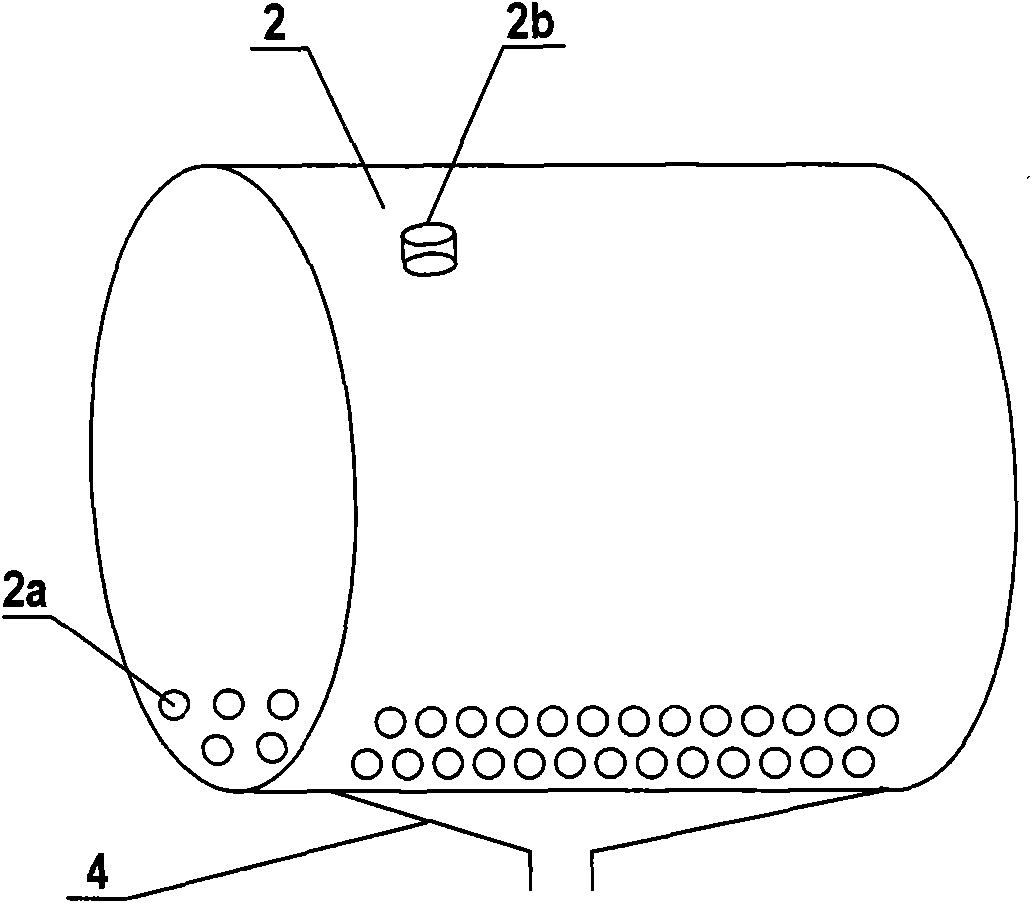

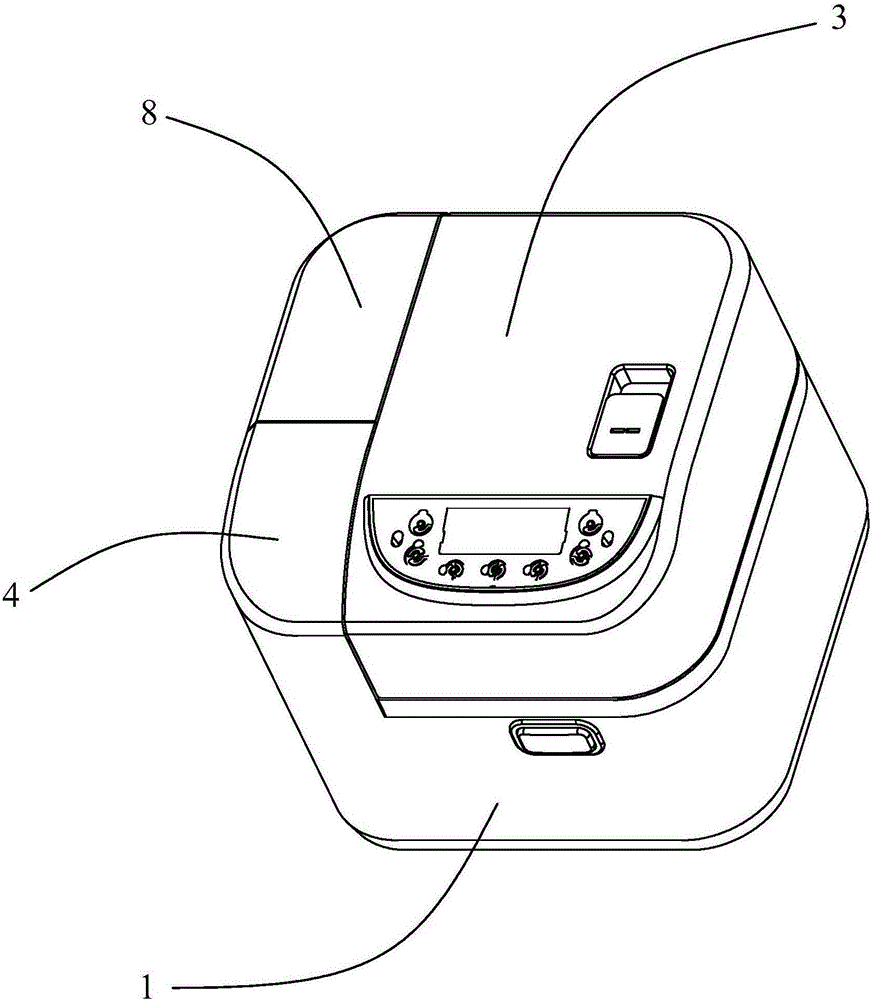

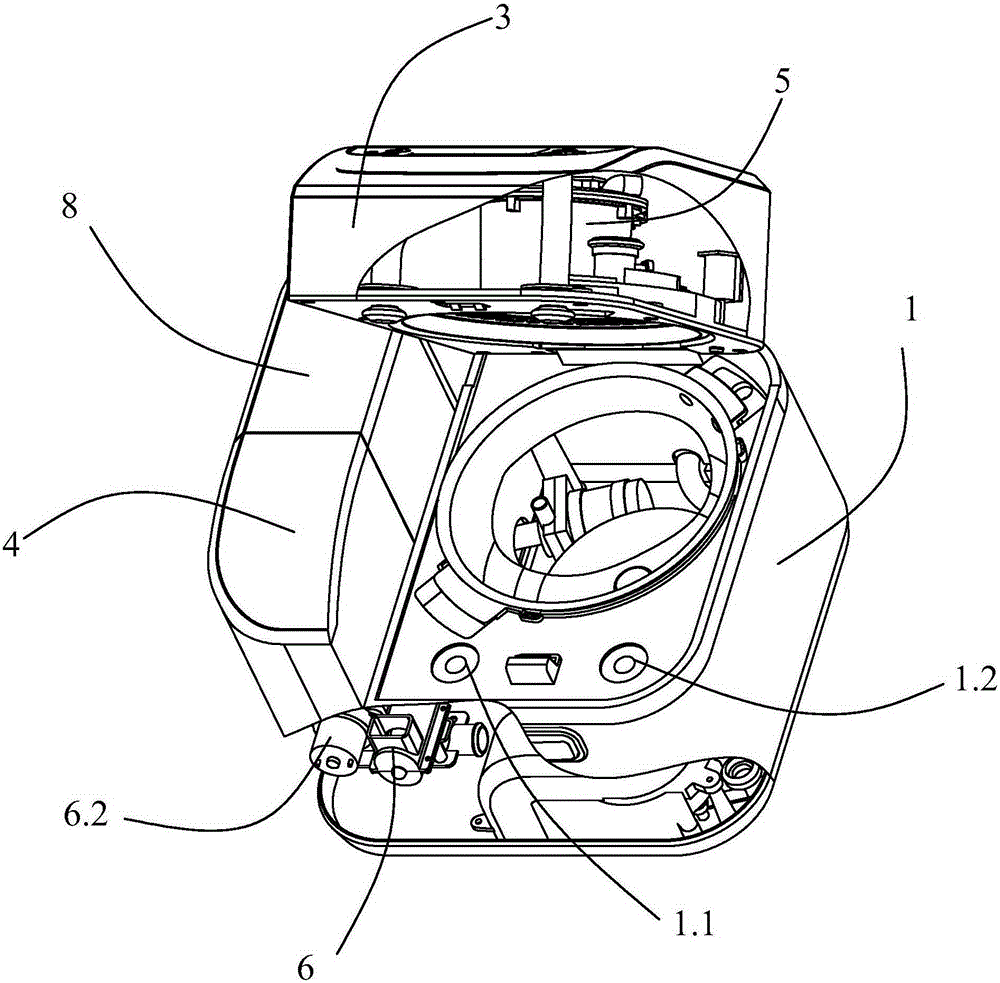

Washing machine

ActiveCN102061589AReduce water consumptionEasy to moveOther washing machinesWashing machine with receptaclesEngineeringMaterial storage

The invention provides a washing machine, comprising an inner cylinder (3) and an outer cylinder (2) arranged at the outer side of the inner cylinder (3). The washing machine is characterized by also comprising a material storage box (6), a particle circulating pipeline (9) and a circulation power plant (12), wherein the walls of the inner cylinder (3) and the outer cylinder (2) are provided with holes (3a,2a) from which solid particles can be leaked; the bottom of the outer cylinder (2), the material storage box (6), the particle circulating line (9) and the inner cylinder are sequentially communicated; a discharging control valve (7) is arranged at the position at which the material storage box (6) is connected with the particle circulating line (9); and the circulation power plant (12) is used for delivering the solid particles entering the particle circulating line (9) to the inner cylinder. Through using the washing machine provided by the invention, clothes can be washed by using a mixture of particles and water, thereby reducing water consumption.

Owner:XEROS LTD

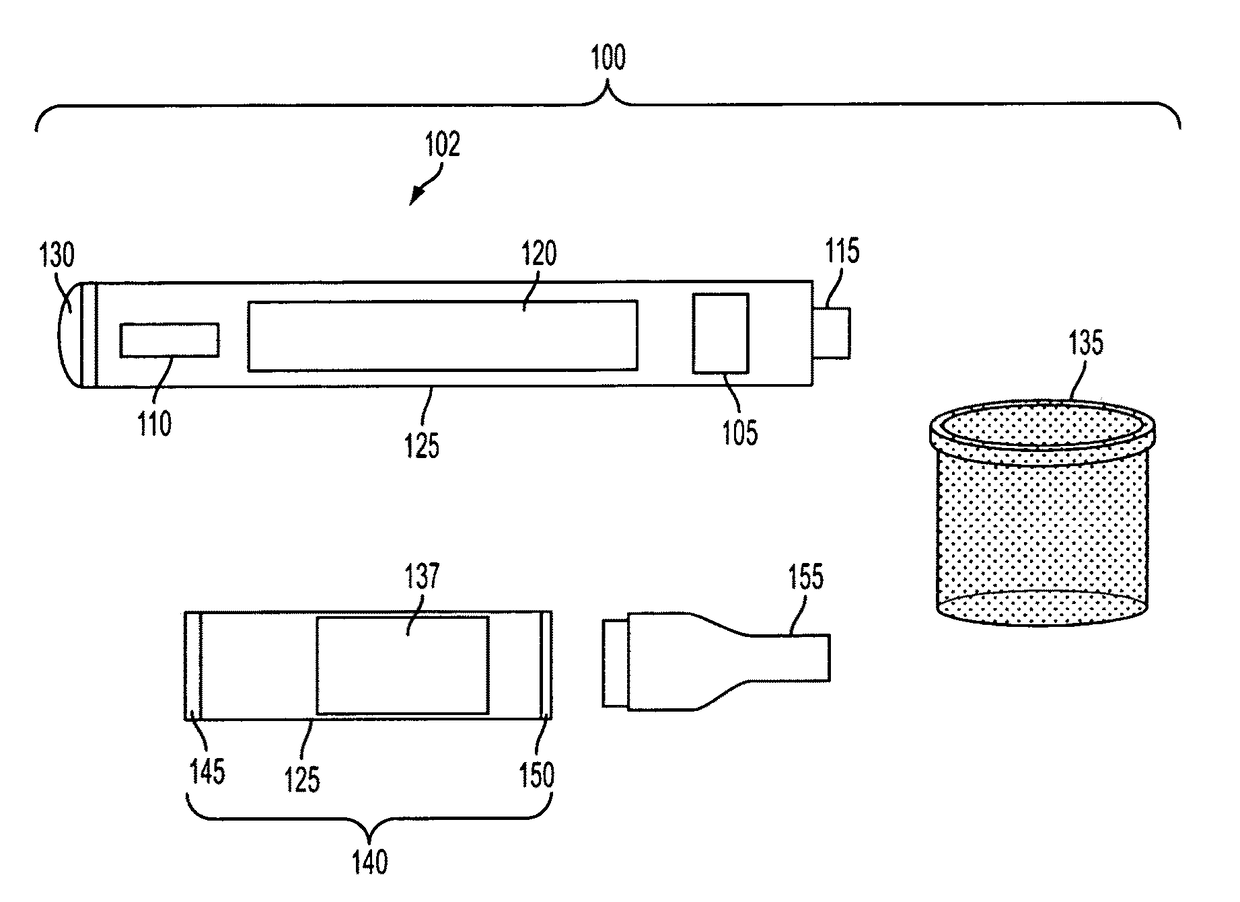

Electronic pipe

An electronic pipe is provided. The electronic pipe includes a first pipe section having an electronic module and a first connector element that communicates with the electronic module. A second pipe section is structured to be removeably attachable to the first pipe section, the second pipe section including a combustible material reservoir having a passageway that communicates with a mouthpiece receiver, with an aperture located on a surface of the second pipe section, the aperture communicating with the combustible material reservoir so that a fluid exterior to the electronic pipe can pass into the aperture, through the combustible material reservoir and into the passageway that communicates with the mouthpiece receiver and a second connector element structured to removeably couple to the first connector element, with both connector elements structured to transmit an electric current from the battery to a heating element located within the combustible material reservoir.

Owner:HEALTHIER CHOICES MANAGEMENT CORP

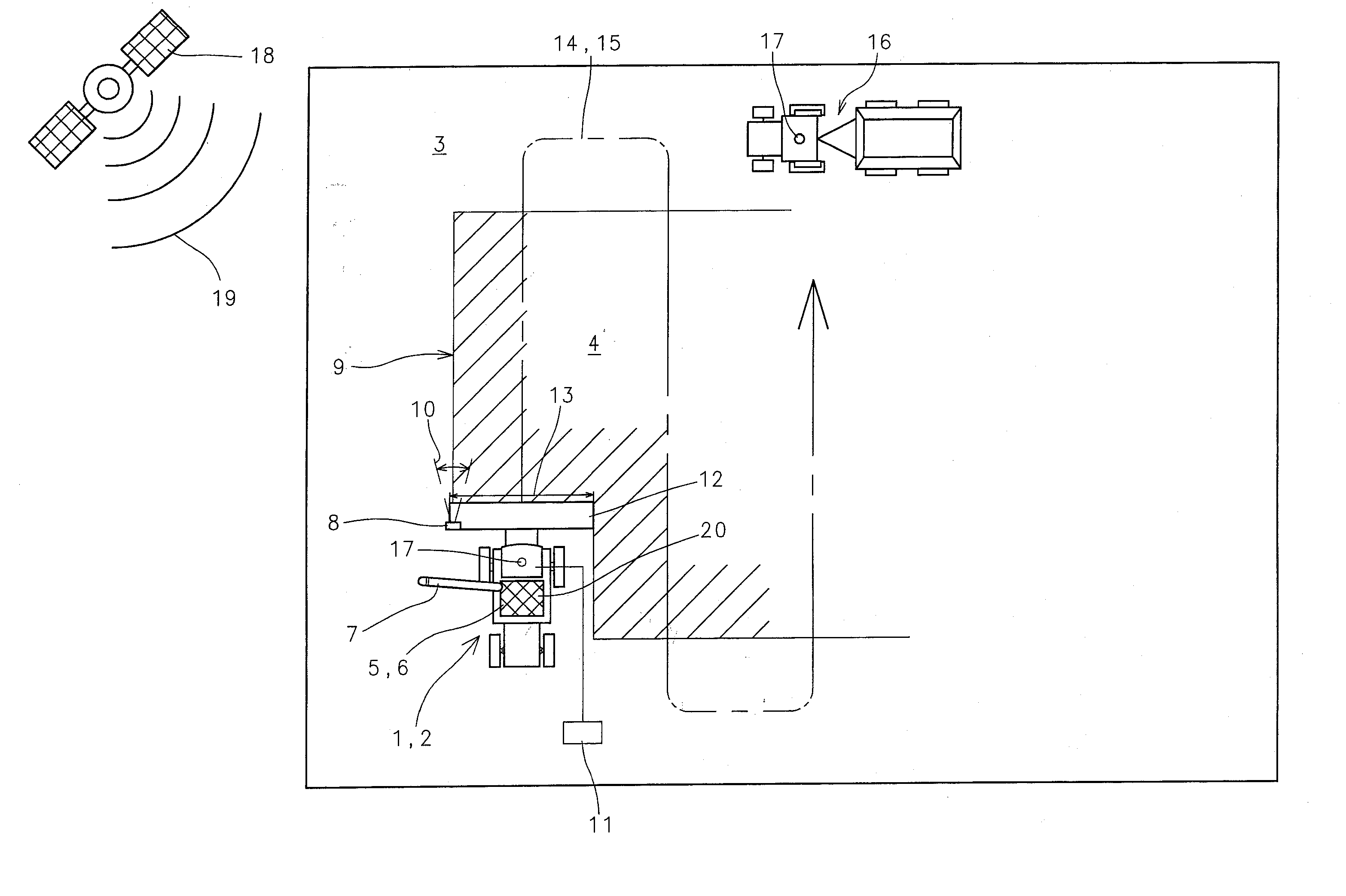

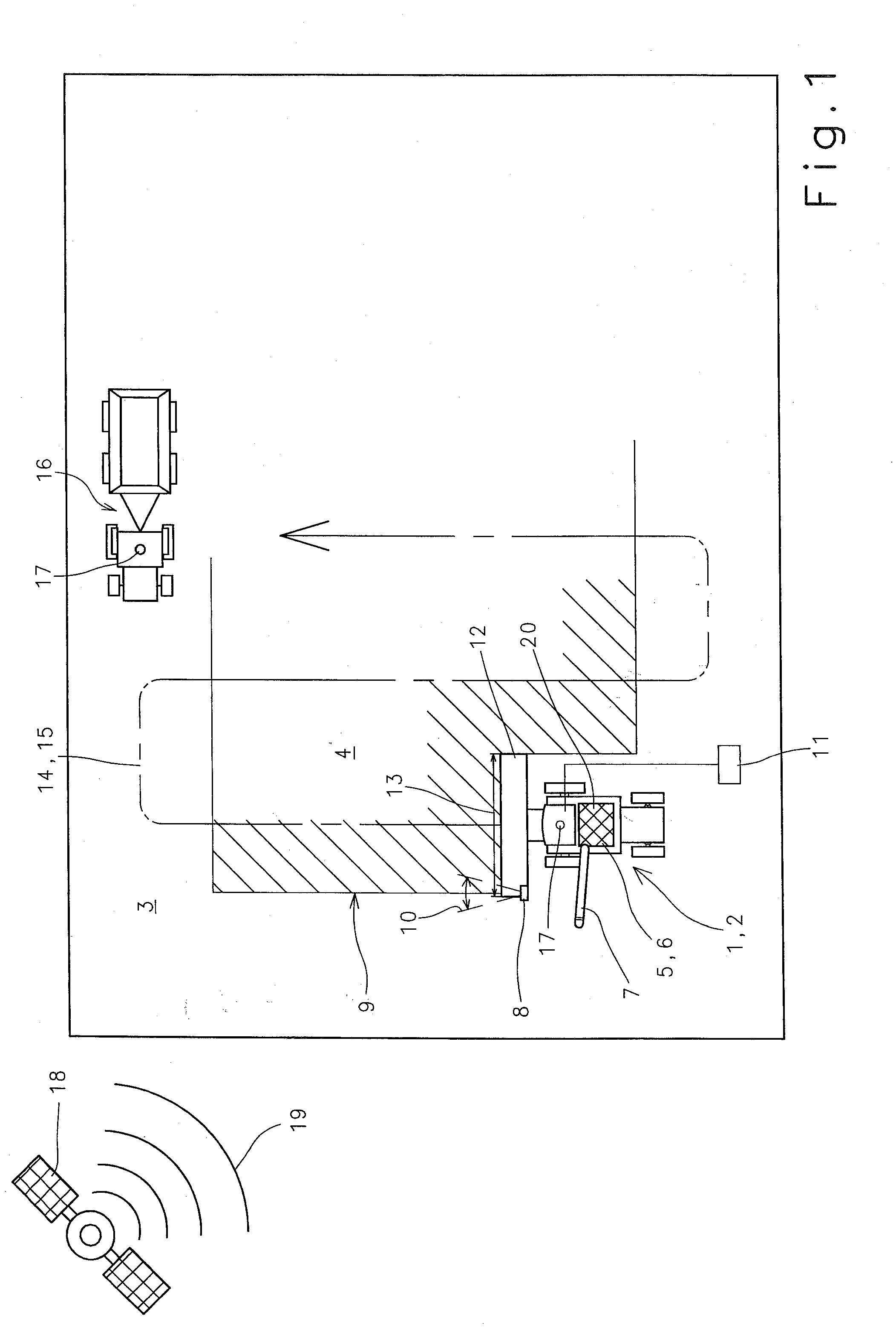

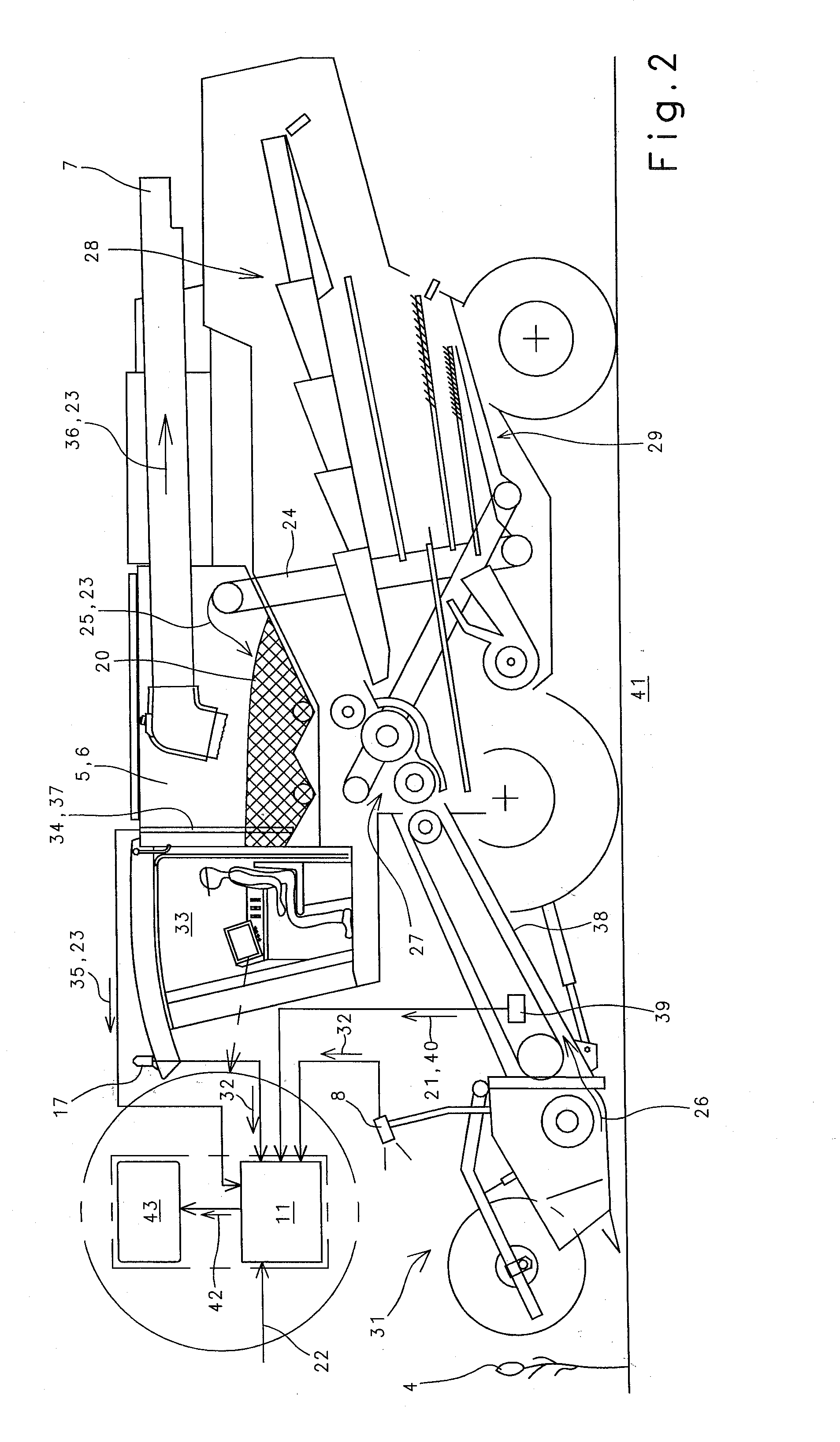

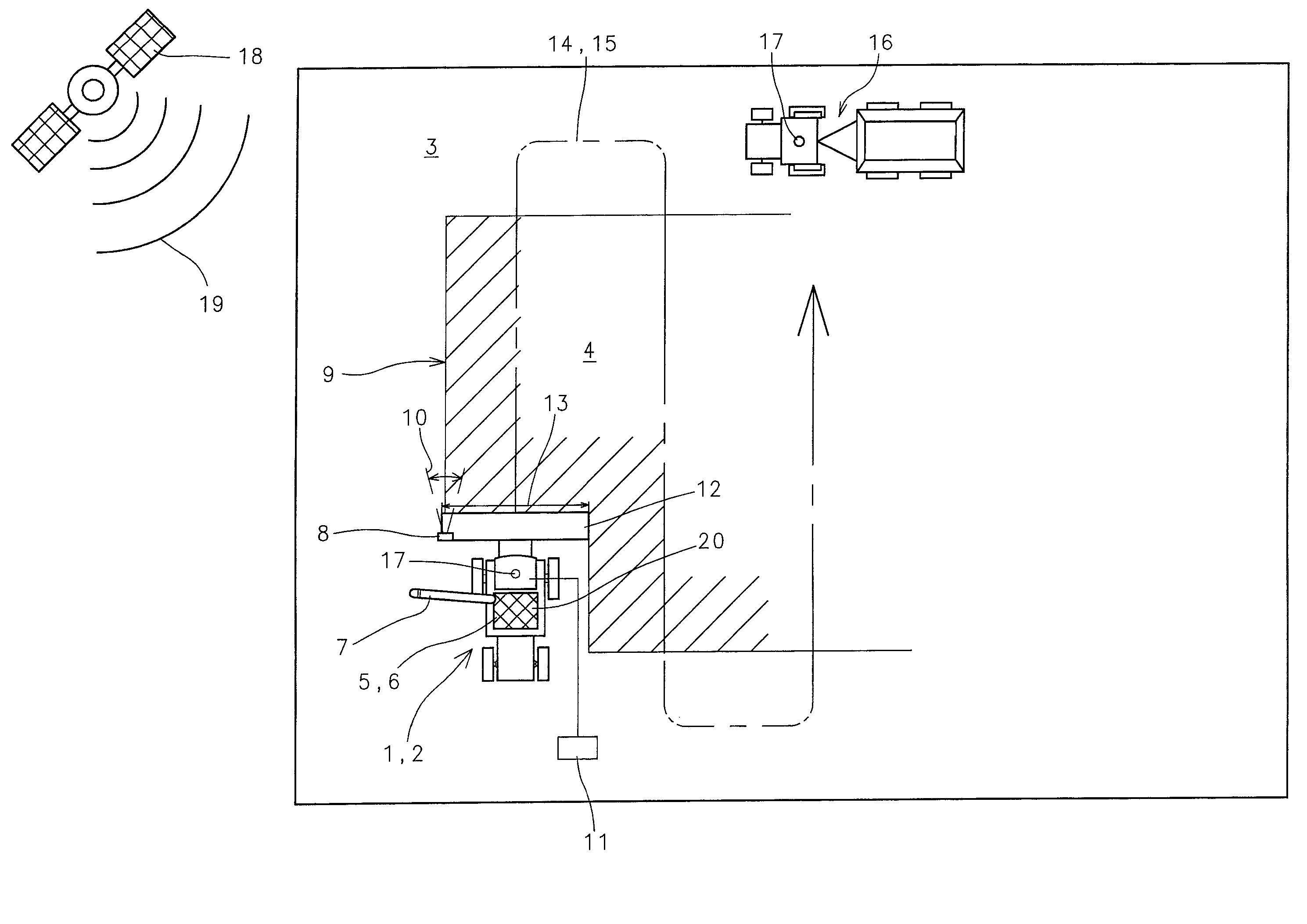

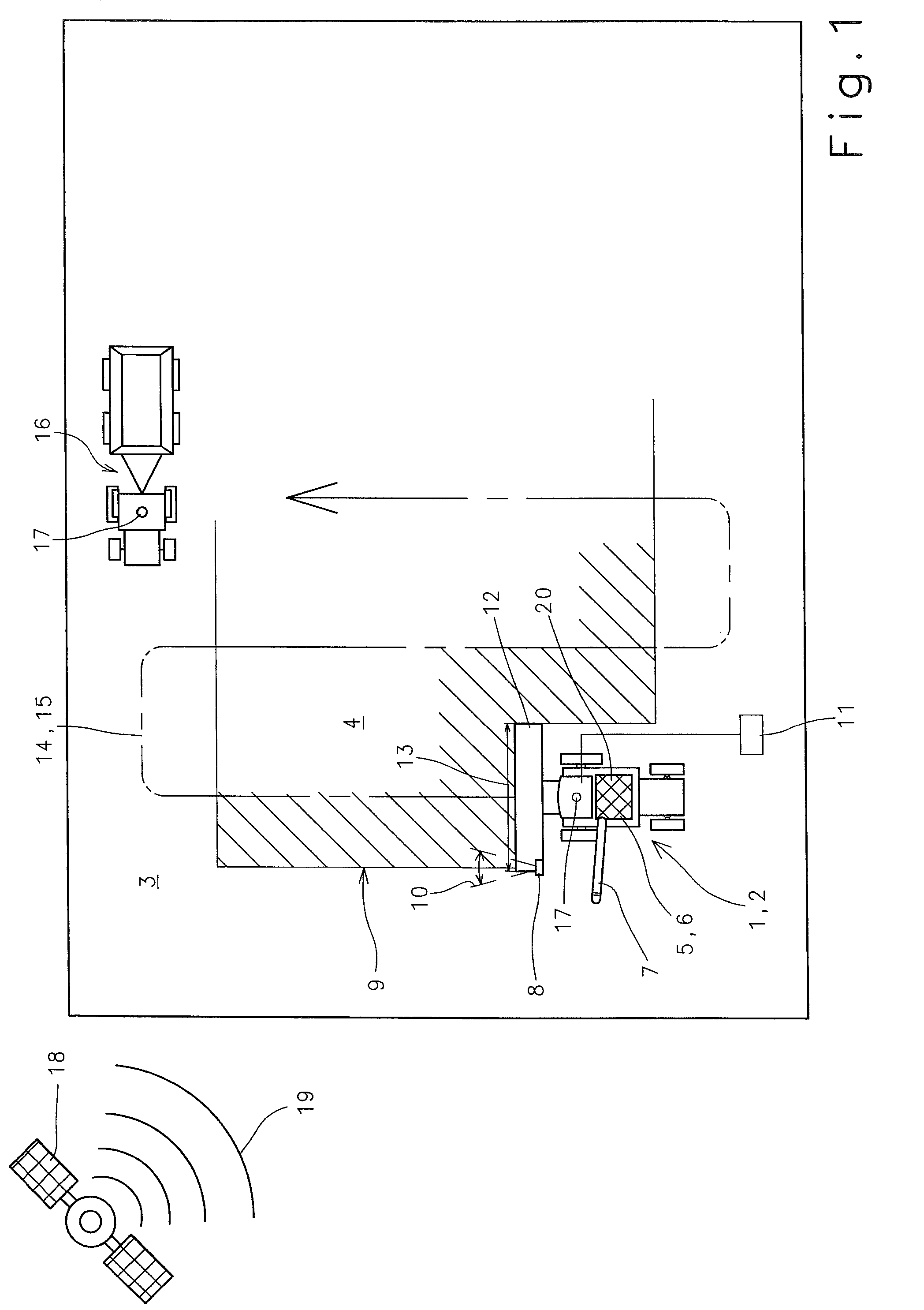

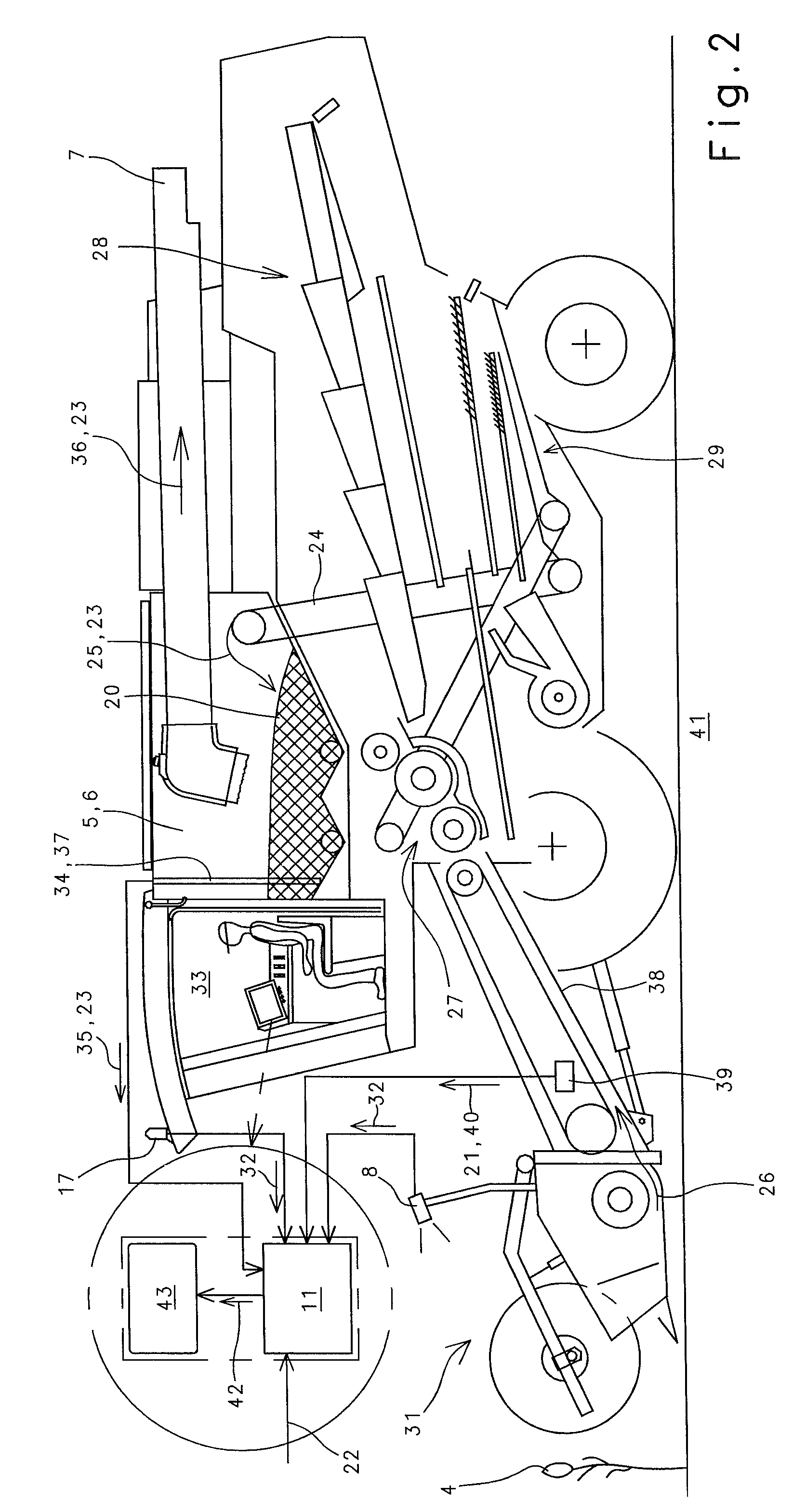

Route planning system for agricultural working machines

A route planning system for an agricultural working machine including at least one crop material storage unit for storing quantities of crop material transferable to forage vehicles, has a unit for generating driving routes in a territory based on a defined working width assigned to the agricultural working machine, a unit for reconciling a crop material quantity stored in the crop material storage unit depending on at least one characteristic parameter, and a unit for dynamically adapting the reconciliation to changes in the at least one characteristic parameter.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Route planning system for agricultural working machines

ActiveUS7756624B2Avoid disadvantagesInstruments for road network navigationAnalogue computers for trafficEngineeringFeature parameter

A route planning system for an agricultural working machine including at least one crop material storage unit for storing quantities of crop material transferable to forage vehicles, has a unit for generating driving routes in a territory based on a defined working width assigned to the agricultural working machine, a unit for reconciling a crop material quantity stored in the crop material storage unit depending on at least one characteristic parameter, and a unit for dynamically adapting the reconciliation to changes in the at least one characteristic parameter.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

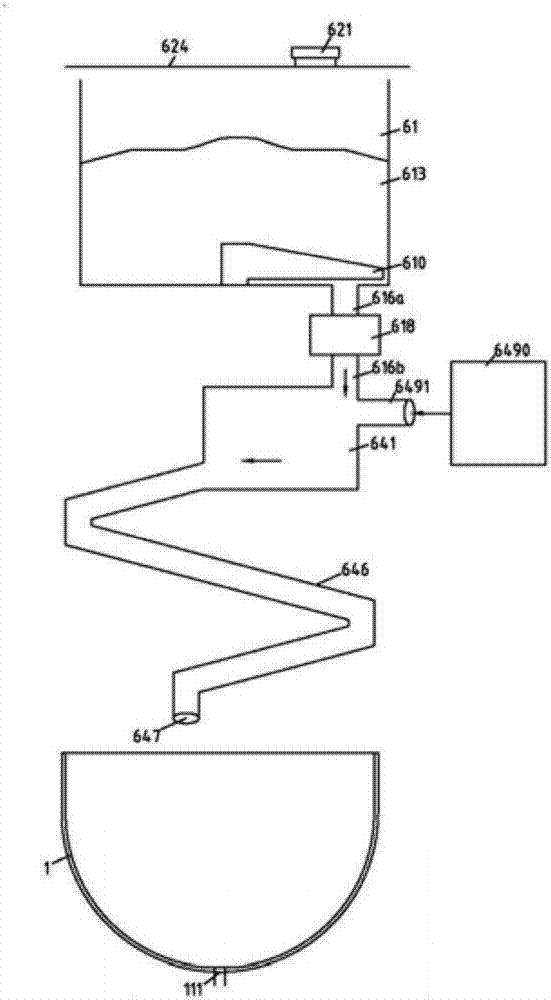

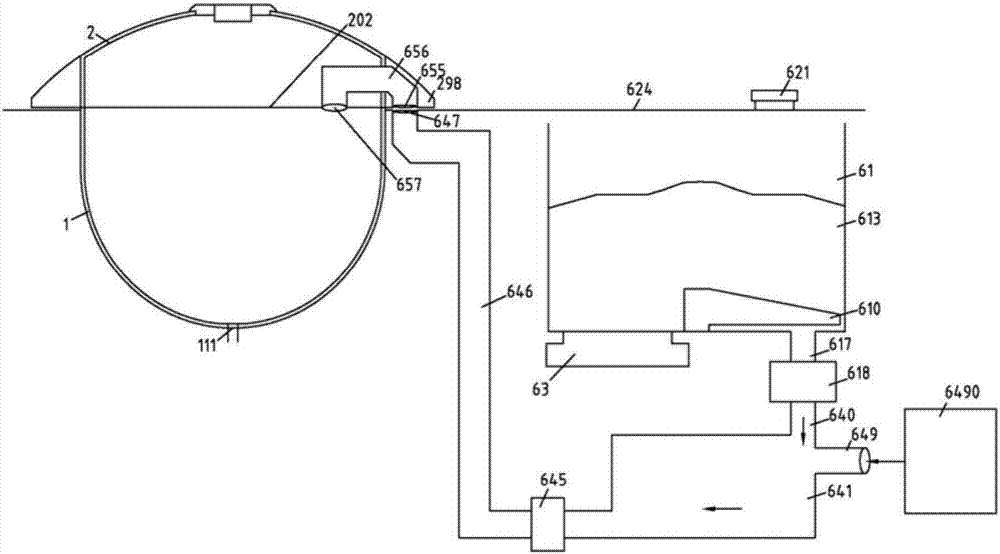

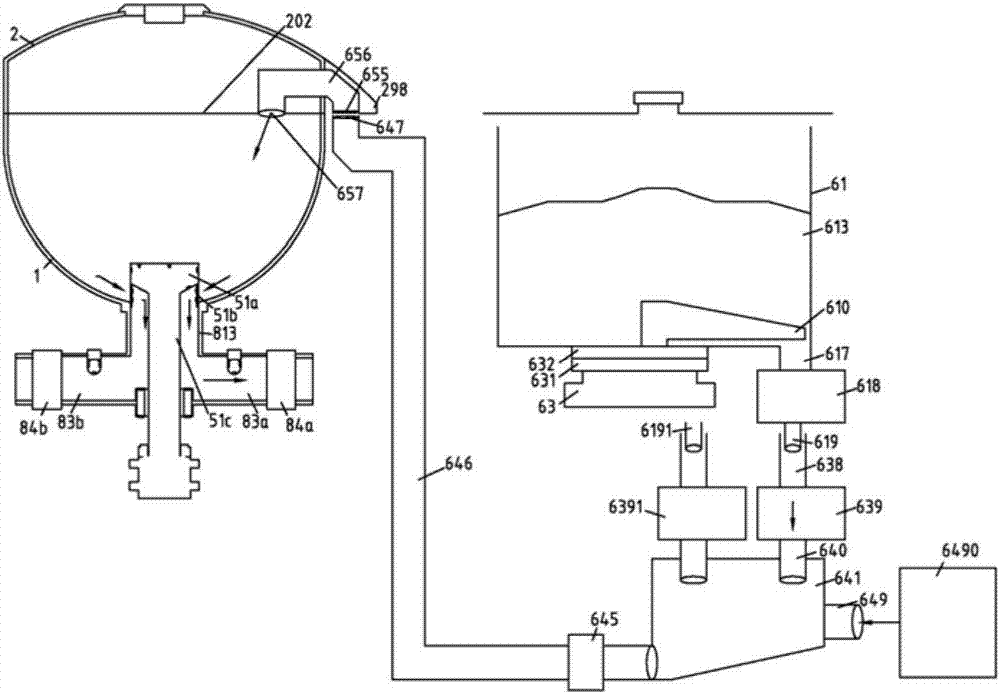

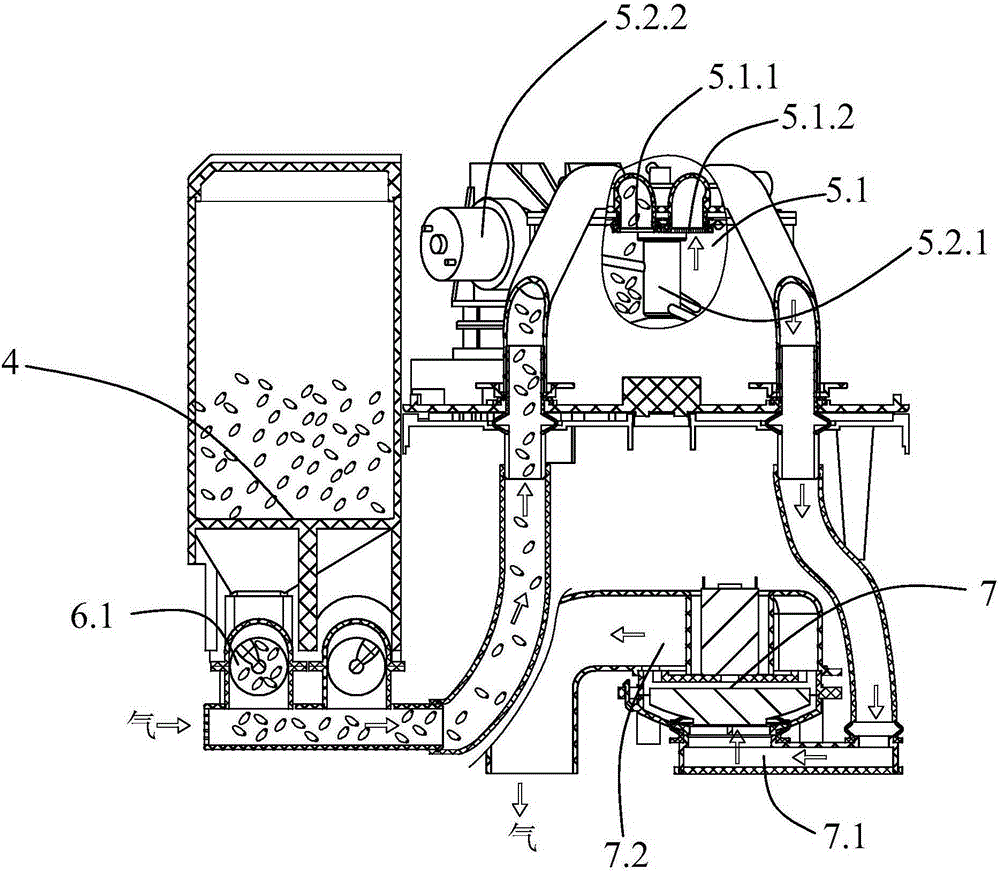

Material distributing device, material feeding device and material charging device of cooking device and cooking device

ActiveCN107224209AReduce labor workloadWide range of usesCooking-vessel lids/coversBeverage vesselsEngineeringMaterial storage

The embodiment of the invention discloses a material distributing device, a material feeding device and a material charging device of a cooking device and the cooking device, wherein the material charging device comprises the material distributing device and the material feeding device, the material distributing device is used for conveying cooking raw materials to the material feeding device through a worm and the like, and the material feeding device is used for feeding the cooking raw materials into a pot body of the cooking device. The material charging device provided by the invention can take out the cooking raw materials from a material storage box and finally put the cooking raw materials into the pot body of the cooking device. With the adoption of the technical scheme provided by the invention, the labor workload of a user is reduced, and a multi-purpose matched device is provided for various intelligent household products.

Owner:李亚锐

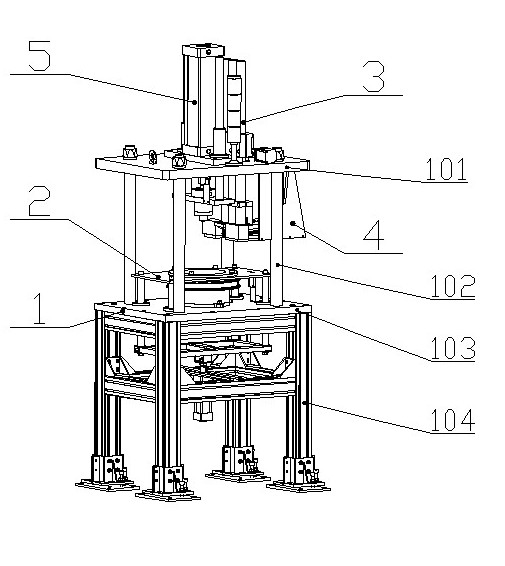

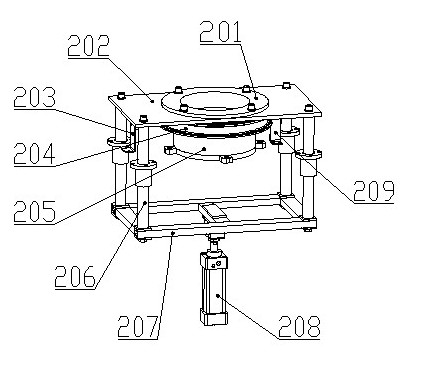

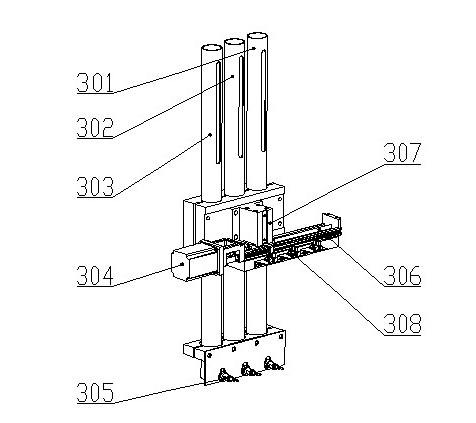

Machine for automatically assembling bearing

InactiveCN102615499AAutomate installationGuaranteed accuracyMetal working apparatusControl systemMaterial storage

The invention discloses a machine for automatically assembling a bearing. The machine mainly comprises a lower table surface which is fixed on four frame columns, a frame formed by fixedly connecting four connecting columns to an upper table surface above the lower table surface, a workpiece positioning mechanism, a material storage device, a feeding mechanism, a pressing mechanism and a control system, wherein the workpiece positioning mechanism is arranged on the lower table surface; the material storage device and the pressing mechanism are arranged in parallel on the upper table surface; the feeding mechanism is arranged on the lower side of the upper table surface; a feeding port of the feeding mechanism corresponds to a discharge port of the material storage device and a material receiving port of the pressing mechanism respectively; and the material receiving port of the pressing mechanism corresponds to a workpiece in the workpiece positioning mechanism. By the machine, the automation degree of mounting the bearing is improved.

Owner:石家庄爱驰自动化设备有限公司

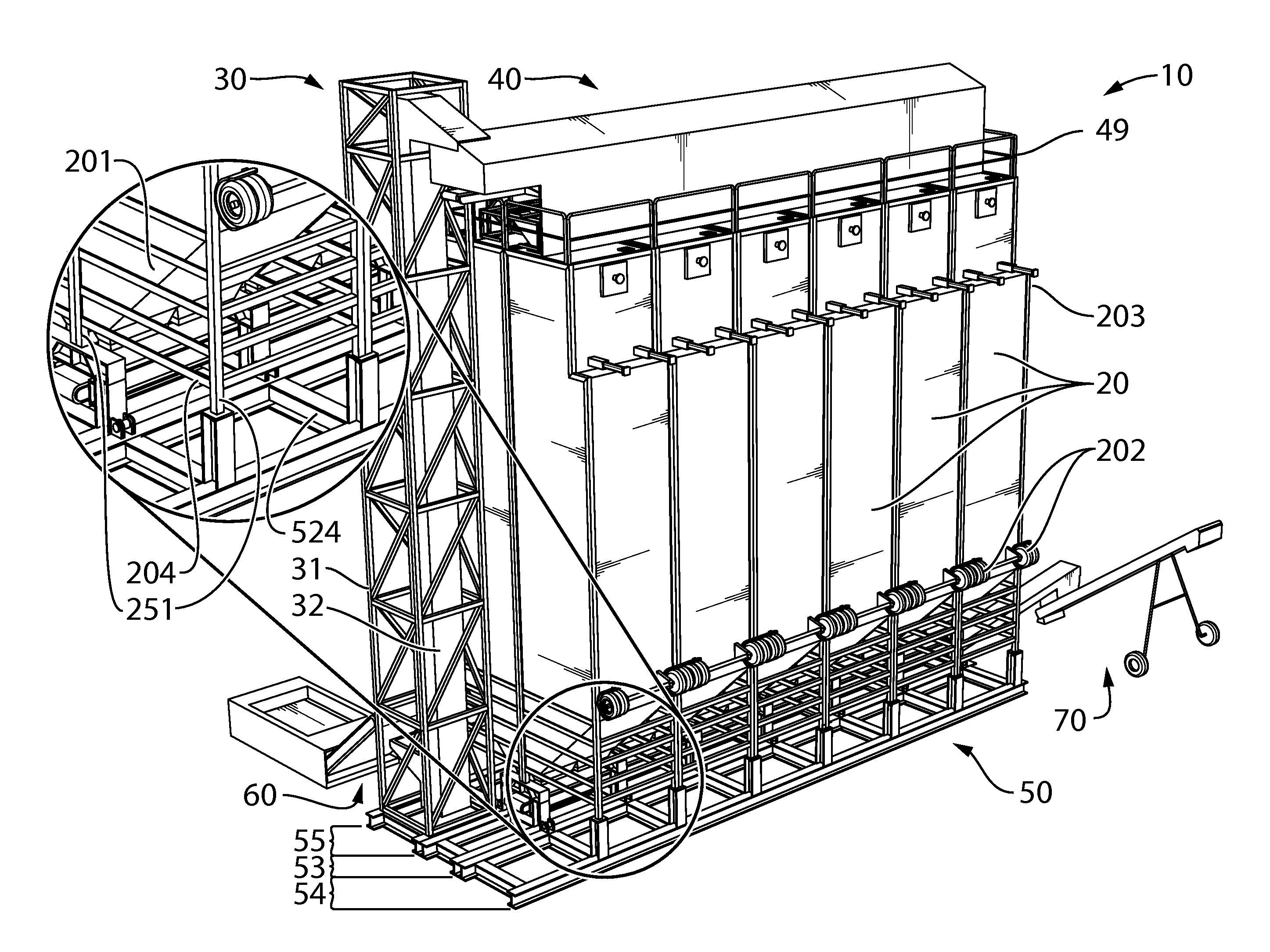

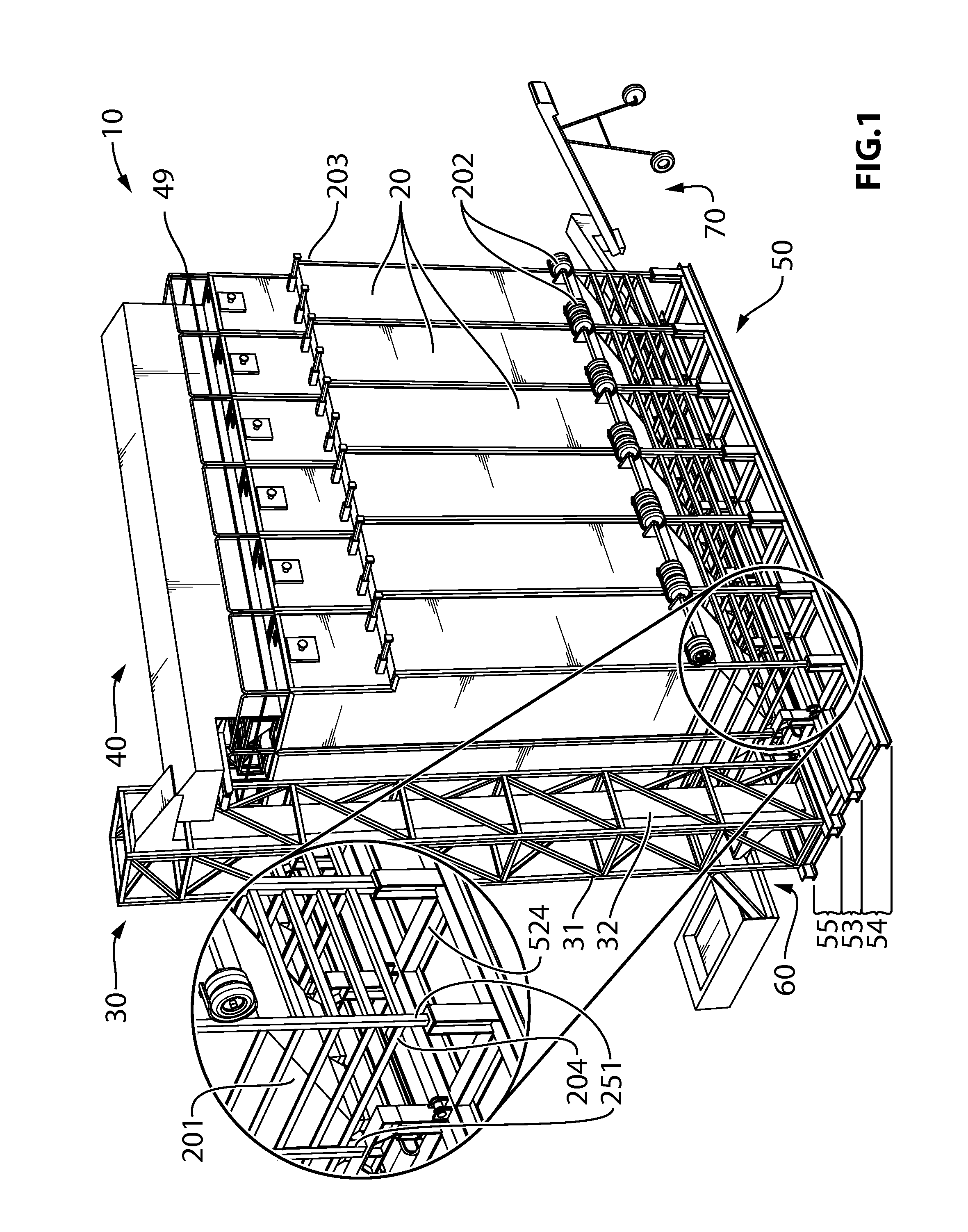

Mobile dry material storage

ActiveUS20140377042A1Avoid accidental damageIncrease volumeTractor-trailer combinationsKitchen equipmentWell drillingBucket elevator

A system that can be assembled at a well drilling or other site for storing bulk material such as sand includes a plurality of storage bins configured as trailers, a skid that includes a lower conveyor, a bucket elevator and a top conveyor system. At the site, the bins and the elevator are vertically oriented and stood on the skid, resulting in discharge outlets on the bins becoming positioned over the lower conveyor. The top conveyor is installed on top of the bins. In operation, the elevator lifts the material and discharges it onto the top conveyor system. The top conveyor system discharges the material into the bins for storage. The stored material is controllably discharged from the discharge outlets of the bins onto the lower conveyor from which the material is conveyed to one end of the skid for transport to a new location or directly into a blender.

Owner:SOURCE LOGISTICS LTD O A AMMOS FIELD SOLUTIONS +1

Automatic cooking appliance

The invention relates to an automatic cooking appliance capable of automatically adding water, feeding materials and washing the materials. The automatic cooking appliance comprises a pot body, an inner container disposed inside the pot body, a controller, and a pot cover buckled with the pot body. The automatic cooking appliance further comprises a material storage device provided with a material outlet arranged at the bottom and a washing device arranged on the pot cover. The washing device comprises a washing chamber and a stirring unit; the stirring unit comprises a washing rod and a driving motor; a water discharging port and a material discharging port communicated with the inner container are arranged on the lower part of the washing chamber; and the material outlet is communicated with the upper part of the washing chamber so that the materials can be conveyed. The invention also provides an automatic cooking method based on the structure mentioned above. According to the invention, a technical problem that a conventional rice cooker is of low automation degree is solved, and the automatic cooking appliance which can be used in common families, can automatically add water, and feed and wash the materials, and can be remotely controlled is provided.

Owner:JOYOUNG CO LTD

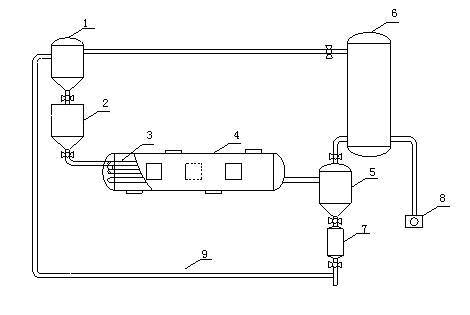

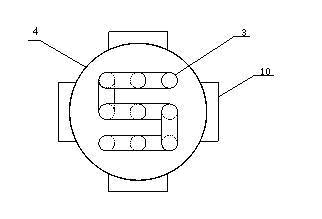

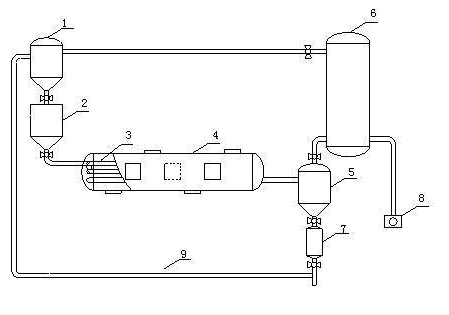

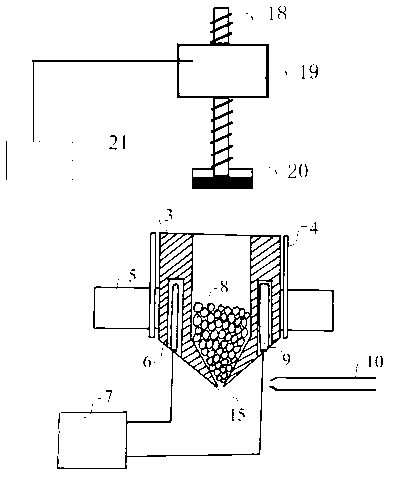

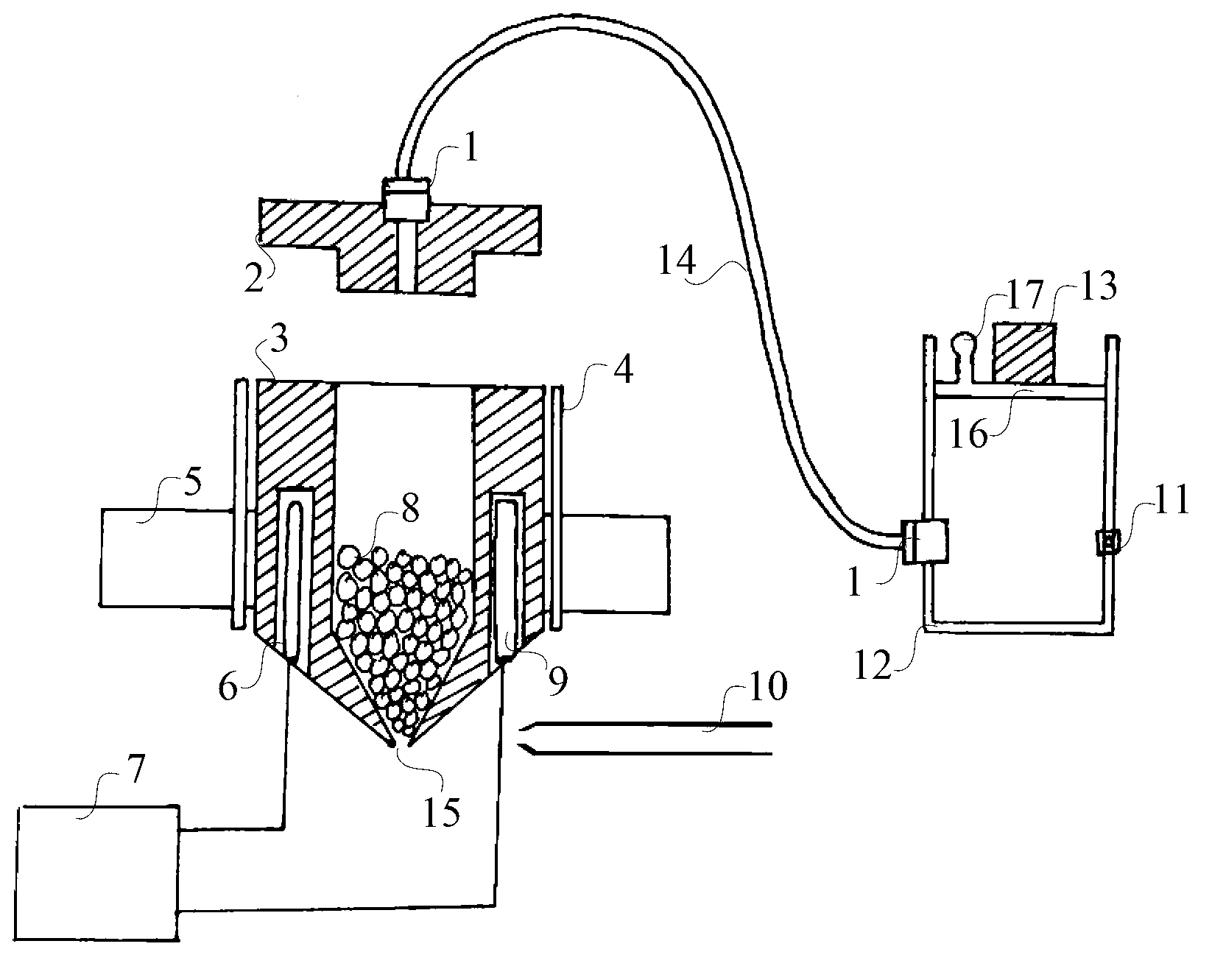

Negative-pressure microwave uniform spraying and drying device and application

ActiveCN102062525ADry evenlyAvoid uneven heatingDrying using combination processesDrying machinesMicrowaveDrying time

The invention discloses a negative-pressure microwave uniform spraying and drying device and application, belonging to the technical field of uniform drying devices. The negative-pressure microwave uniform spraying and drying device comprises a circulating material storage device, a feeder, a negative-pressure spraying pipe, a microwave heating cavity, a cyclone separator, a vacuum storage tank, a discharger, a water ring vacuum pump, a circulating pipe and microwave sources. The circulating material storage device is used for storing materials dried circularly, the feeder is used for feeding dry materials to the negative-pressure spraying pipe which is a channel for drying and circulating the materials, and the microwave sources are uniformly distributed inside the microwave heating cavity, two ends of which are sealed. The cyclone separator is connected with an outlet of the negative-pressure spraying pipe inside the microwave heating cavity and is connected with the vacuum storage tank and the discharger through a channel. The discharger is connected with the circulating material storage device through the circulating pipe. Because the materials can be sprayed under negative pressure, the device can be used for spraying, rotating and circulating the materials under a microwave vacuum drying condition so as to achieve the purpose of drying the materials efficiently and uniformly, meanwhile, is favorable for shortening the drying time by above 40% and reducing the cost of large-scale production.

Owner:JIANGNAN UNIV

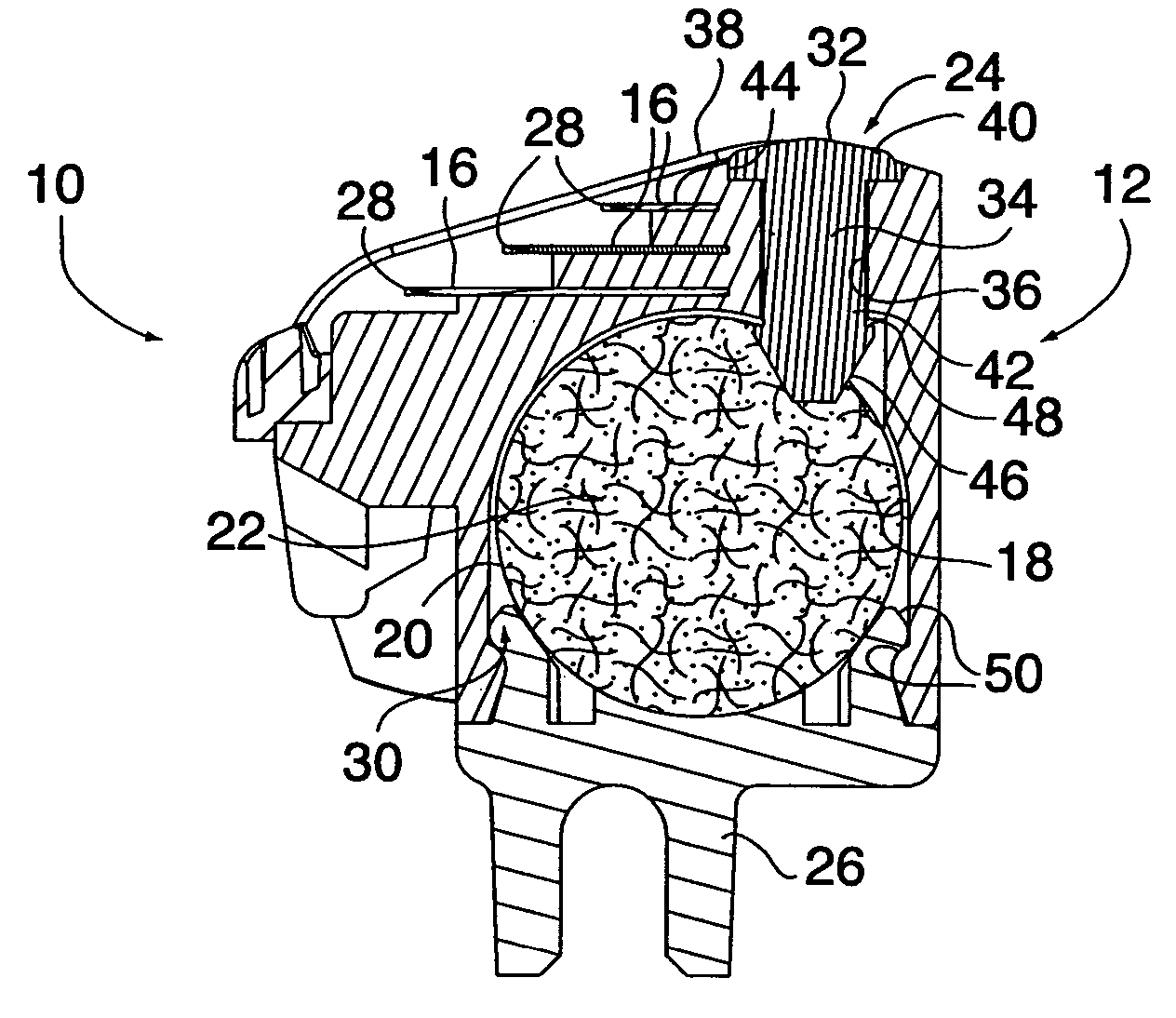

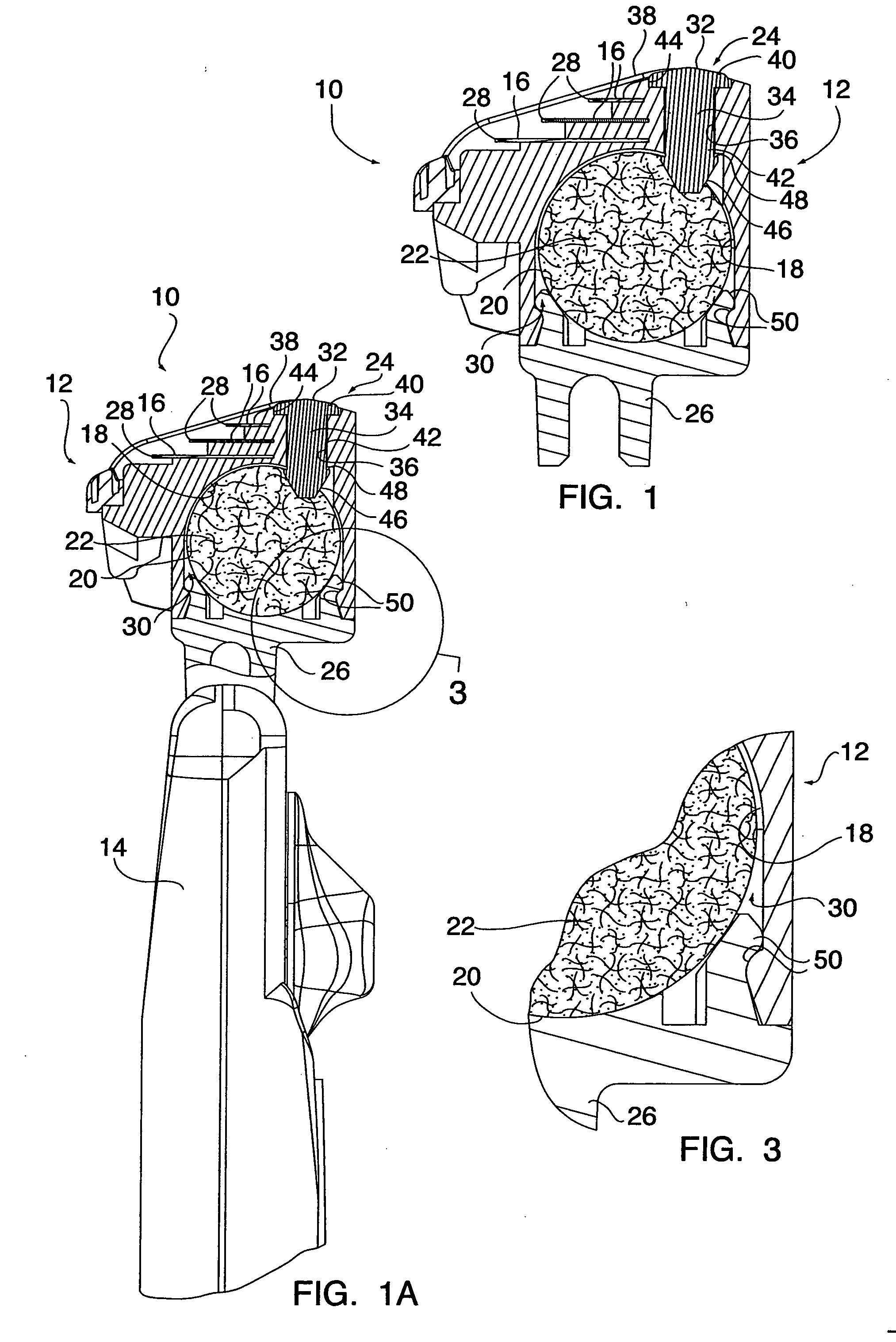

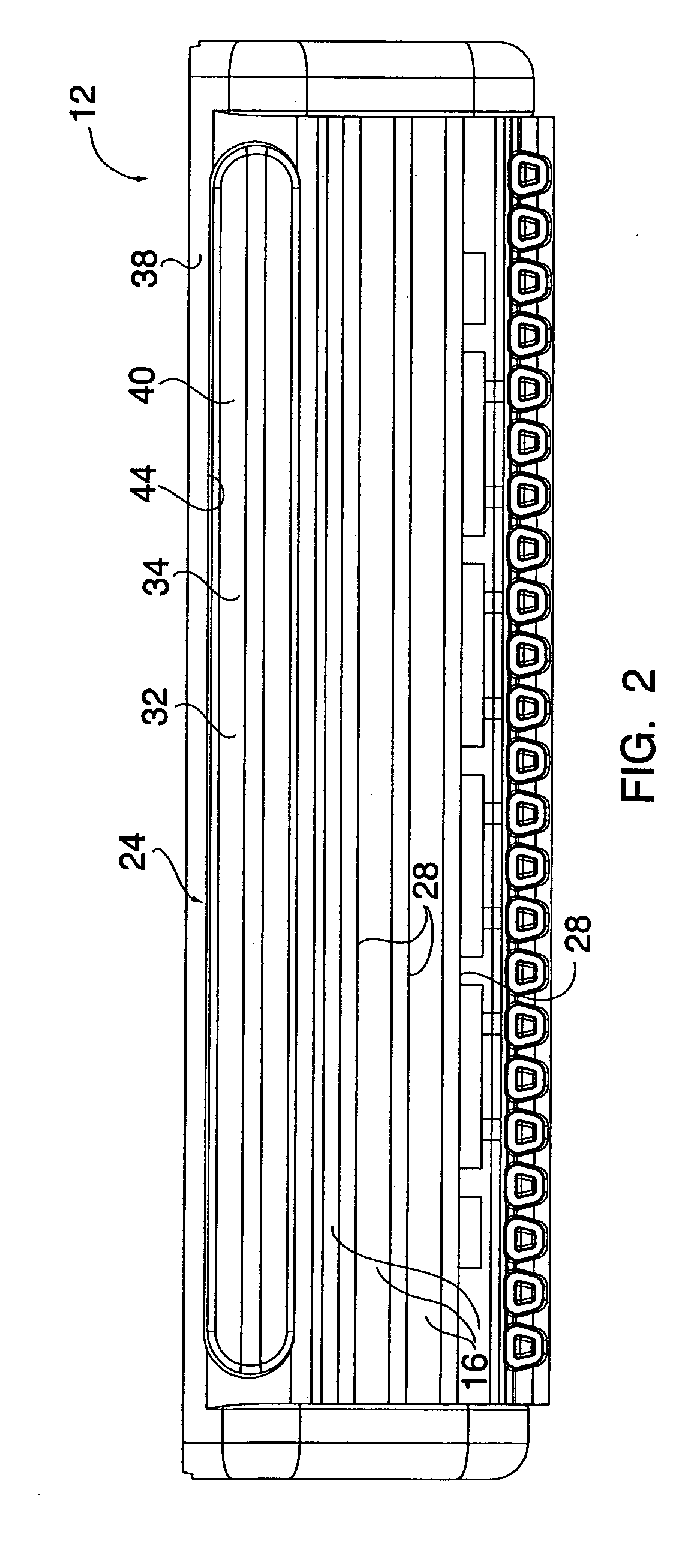

Shaving device with shaving aid material dispenser

InactiveUS20060254056A1Easy to shaveImprove comfortMetal working apparatusEngineeringMaterial storage

The present invention provides a shaving device that includes a razor cartridge and a handle. The razor cartridge includes one or more razor blades and a liquid material storage element disposed within a reservoir. A dispensing medium extends between the liquid material storage element and an outer surface of the razor cartridge. During the act of shaving, the dispensing medium operates to draw the liquid from the reservoir to a user contact end of the dispensing medium, where the liquid is the applied to the area being shaved adjacent to the cutting edge(s).

Owner:EVEREADY BATTERY CO INC

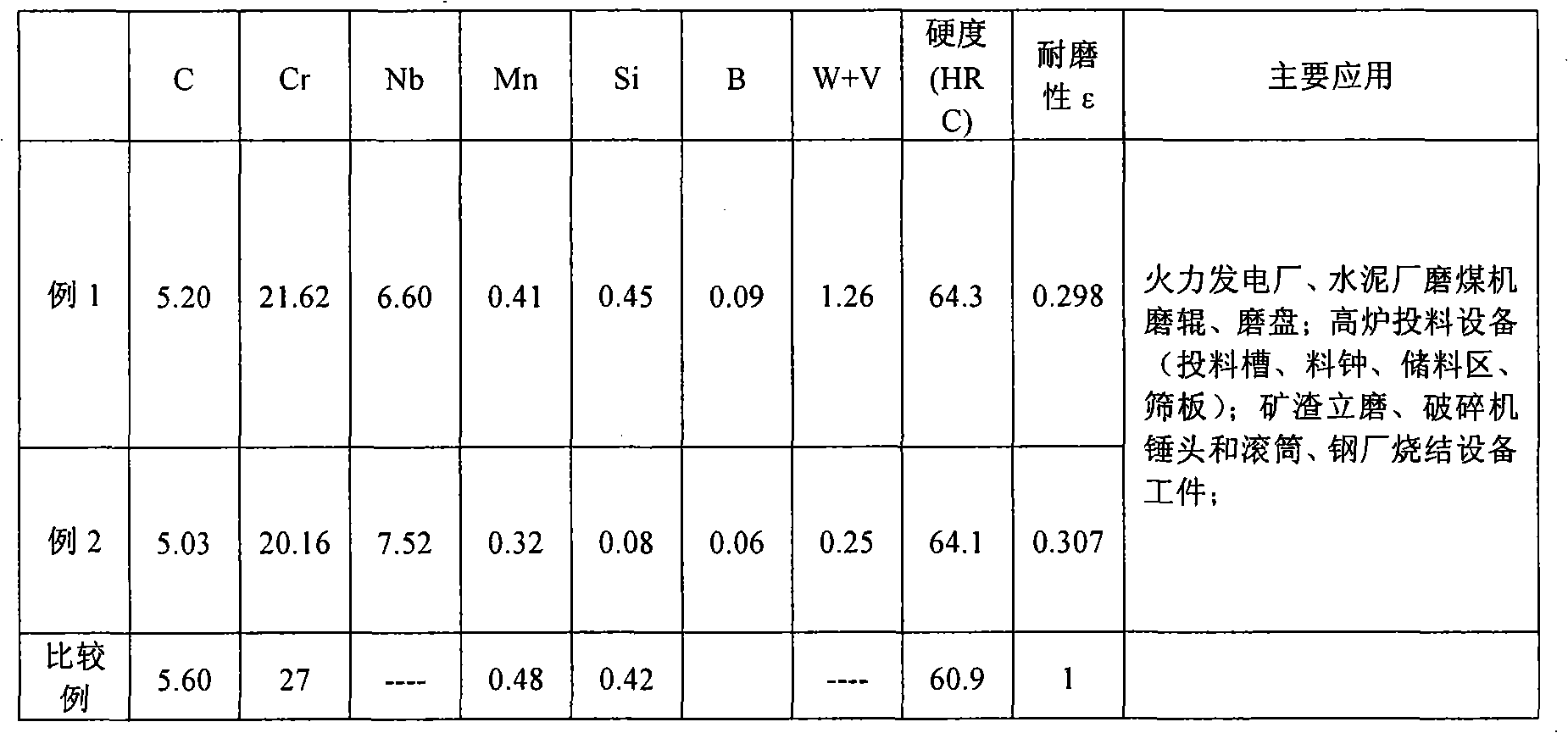

High-carbon high-chromium high-niobium cast iron self-protecting flux-cored wire

InactiveCN101406994AHigh hardnessLow viscosityWelding/cutting media/materialsSoldering mediaHigh carbonNiobium

The invention provides a high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire. The flux-cored wire has a steel belt as an outer skin. The flux core comprises the following components in weight percentage: 10 to 30 percent of ferroniobium, 20 to 30 percent of high carbon ferrochrome, 0.1 to 3 percent of V, 0.2 to 3 percent of W, 0.6 to 0.8 percent of ferromanganese, 0.2 to 0.8 percent of 75 ferrosilicon, 20 to 30 percent of chromium carbide, 5 to 12 percent of graphite, 1 to 10 percent of aluminum-magnesium alloy, 1 to 5 percent of silicon carbide and 1 to 3 percent of ferroboron; and the percentage of a counter weight is between 46 and 54 percent. The high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire has the advantages of high hardness, good wear resistance, good oxidation resistance and strong shock resistance, and is widely applied to grinding rolls and grinding disks of coal grinding machines in thermal power plants and cement plants, material charging equipment in blast furnaces(material charging slots, receiving cones, material storage areas and sieve plates), slag vertical mills, hammer heads and rollers of crushers and sintering equipment workpieces in steel plants.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

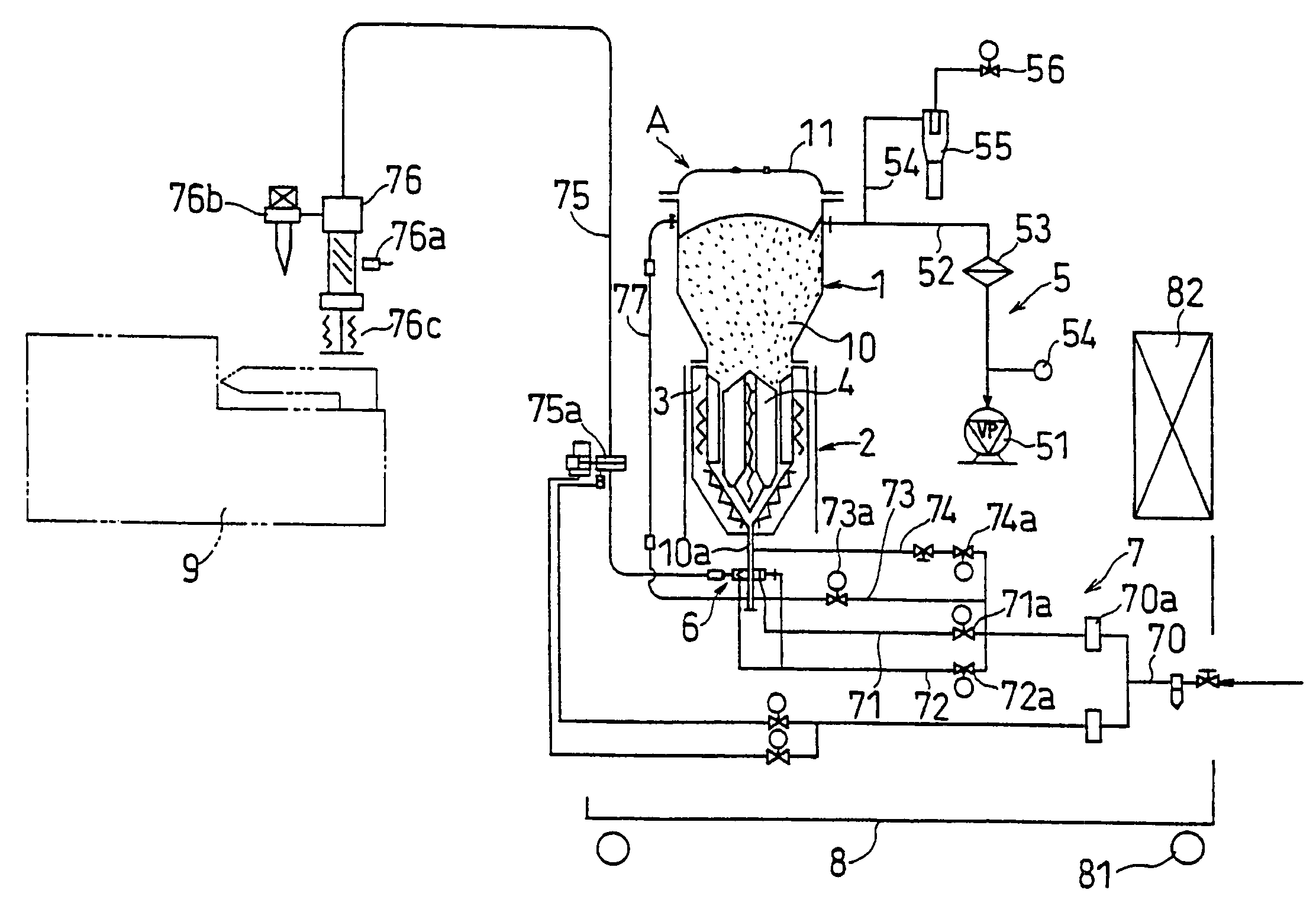

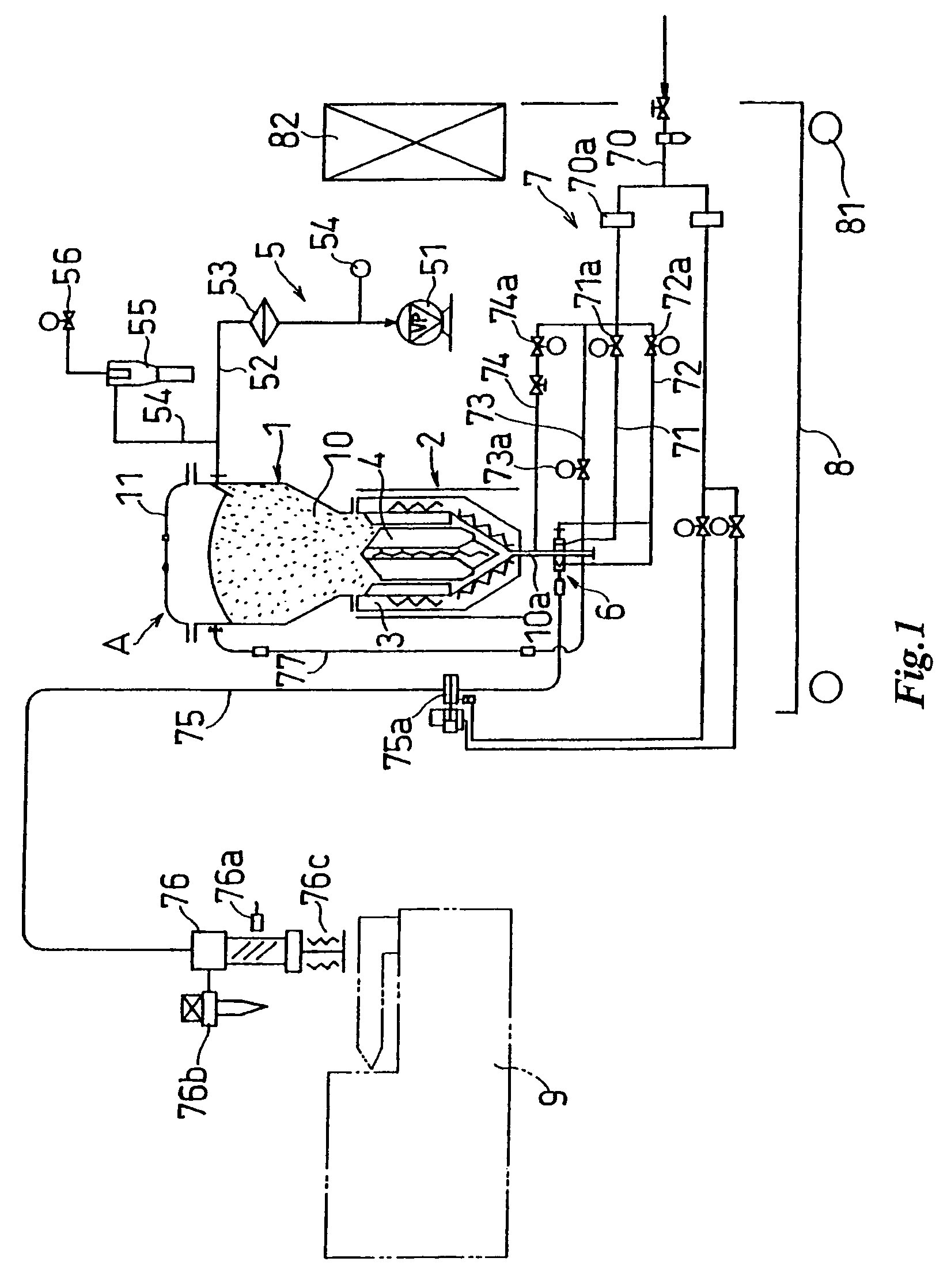

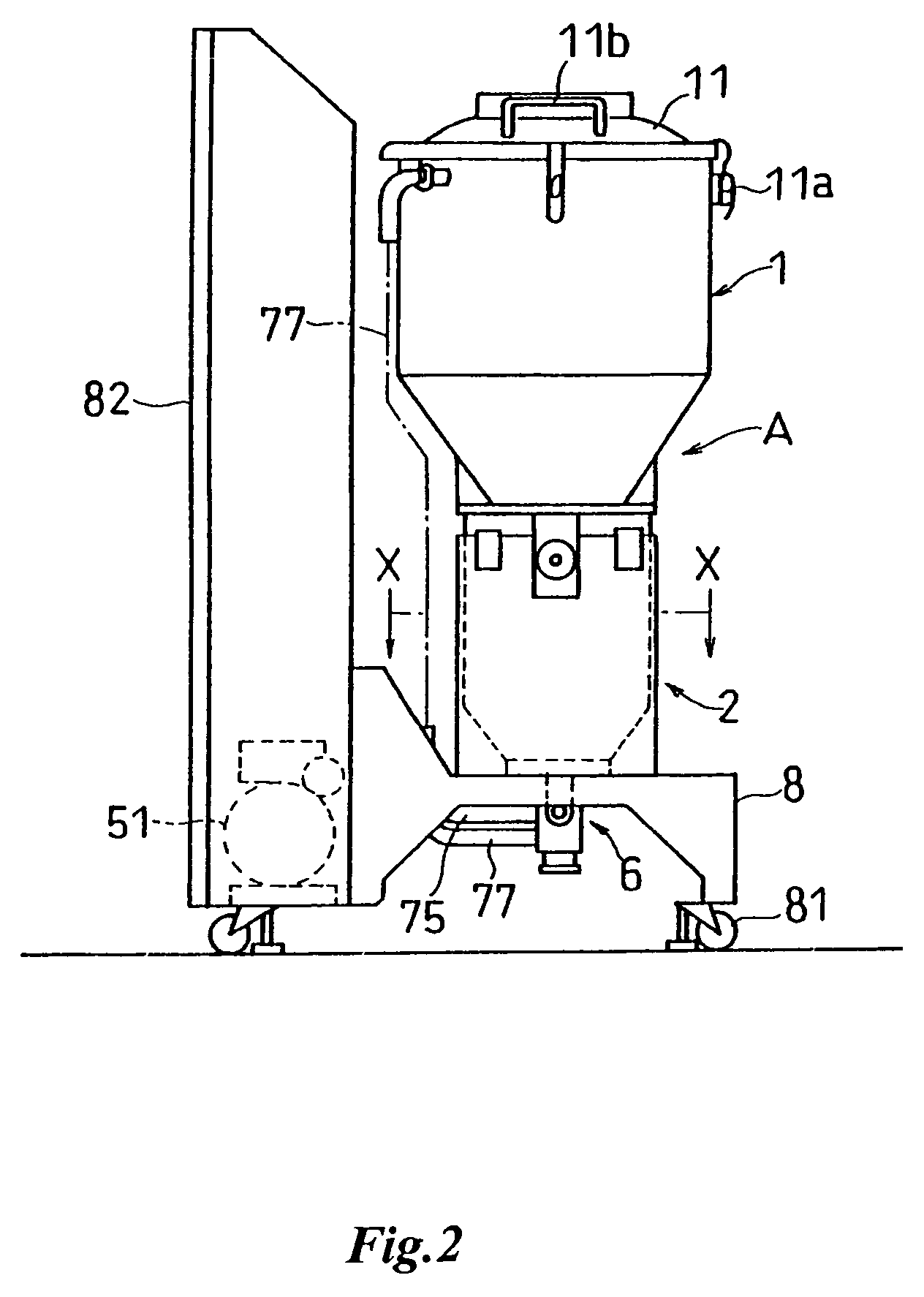

Drying-storing apparatus for powdered or granular material and feeding system for powdered or granular material

InactiveUS7703217B2Improve efficiencySimple materialDrying using combination processesDrying solid materials with heatProcess engineeringMaterial storage

A drying and storing apparatus for powdered or granular material and a feeding system for powdered or granular material. The apparatus comprises a heating and drying chamber having a discharge port at its lower end and a thermal conductive heating means therein and a hopper chamber connected to the upper end of the heating and drying chamber, in which the heating and drying chamber and the hopper chamber constitute a integrally combined material storage processing tank for powdered or granular material.

Owner:MATSUI MFG

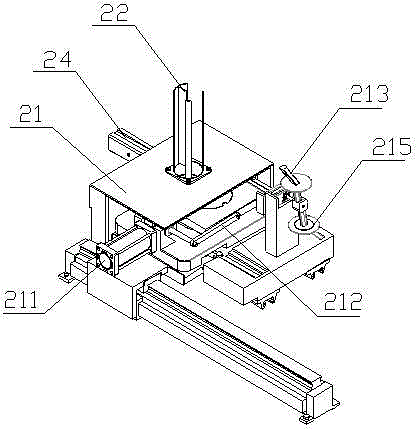

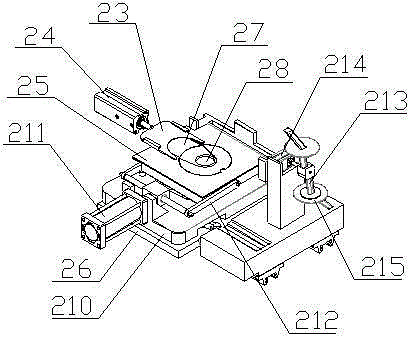

Intelligent material warehousing and fetching method

The invention discloses an intelligent material warehousing and fetching method. The method comprises the following steps: coding the material; delivering a material tray filled with the material to a material placement platform at a material inlet window of an intelligent warehouse by a loader; automatically capturing the material by a manipulator of the intelligent warehouse and storing the material to a freight space in the intelligent warehouse, of which the address is designated by a material management software system; when the material is discharged, fetching the material tray at the freight space address designated by the warehousing system by the manipulator and delivering the material tray to a material conveyor belt of the intelligent warehouse; conveying the material tray to a discharge hole of the intelligent warehouse through the material conveyor belt to finish material discharging from the intelligent warehouse. The intelligent material warehousing and fetching method disclosed by the invention combines the intelligent warehouse with the material management software system to realize accurate storage and fetch of multiple materials or the single material, is high in degree of automation, free of wrong material fetching or material loss, capable of reducing the idle stock problem, and high in material storage and fetch efficiency, saves labor, and is beneficial to improvement of the production efficiency and reduction of the production cost.

Owner:SUZHOU I STOCK INTELLIGENT TECH

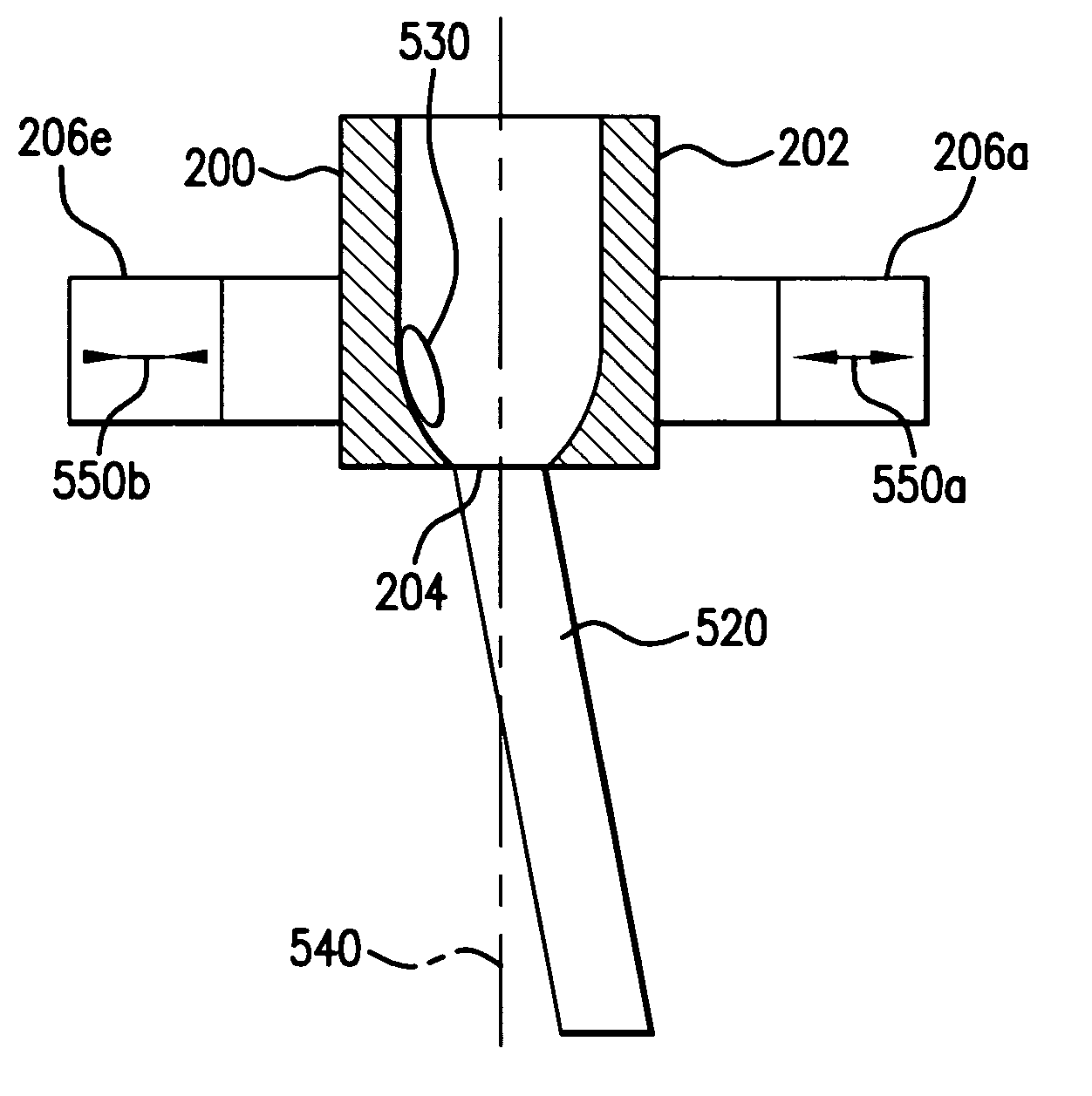

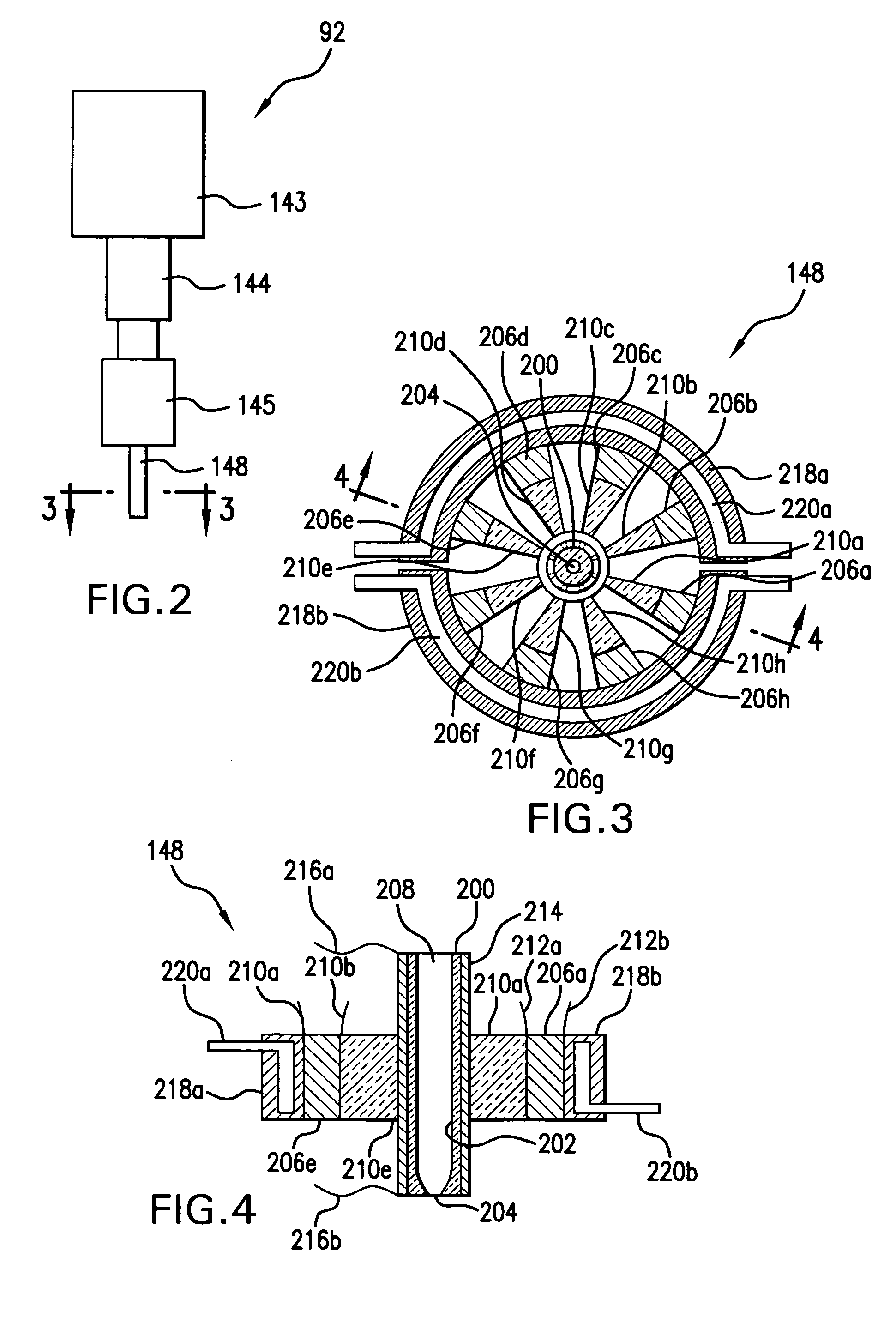

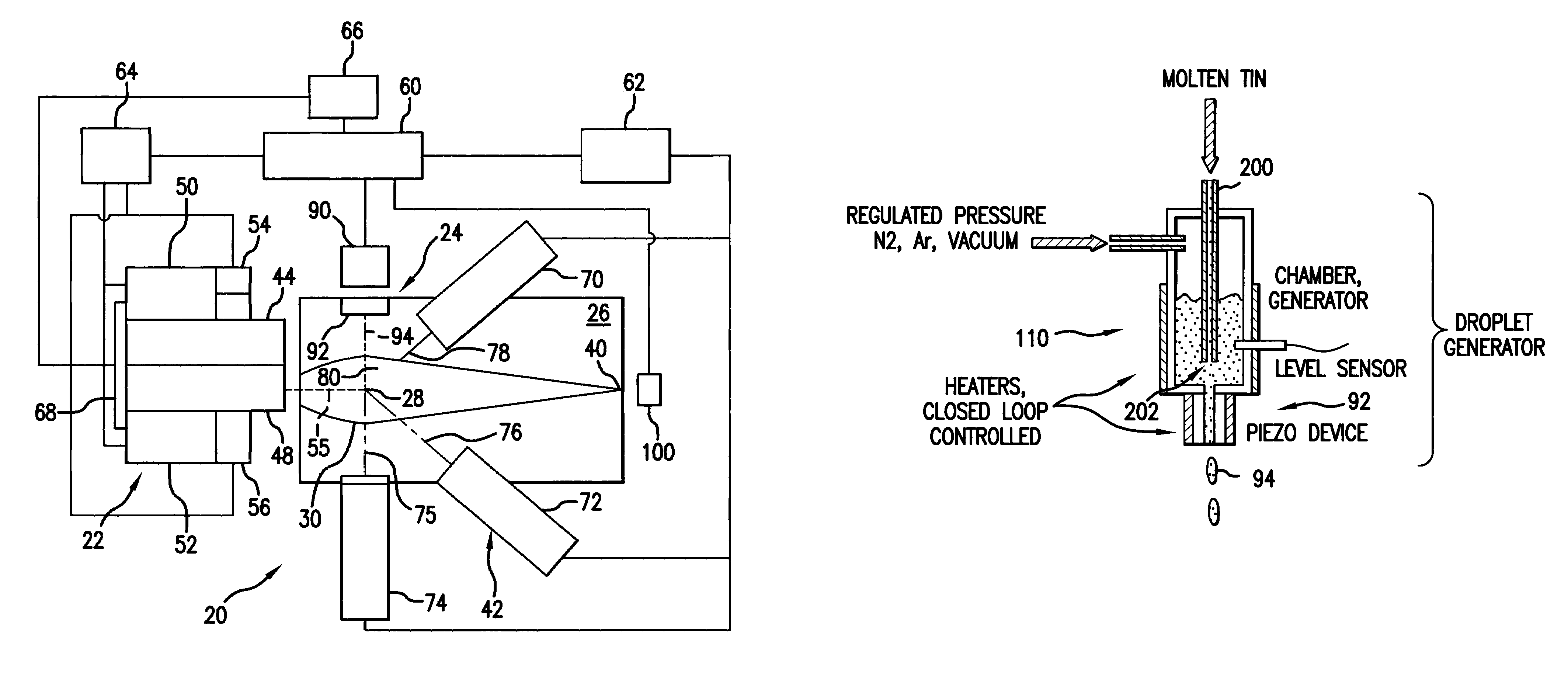

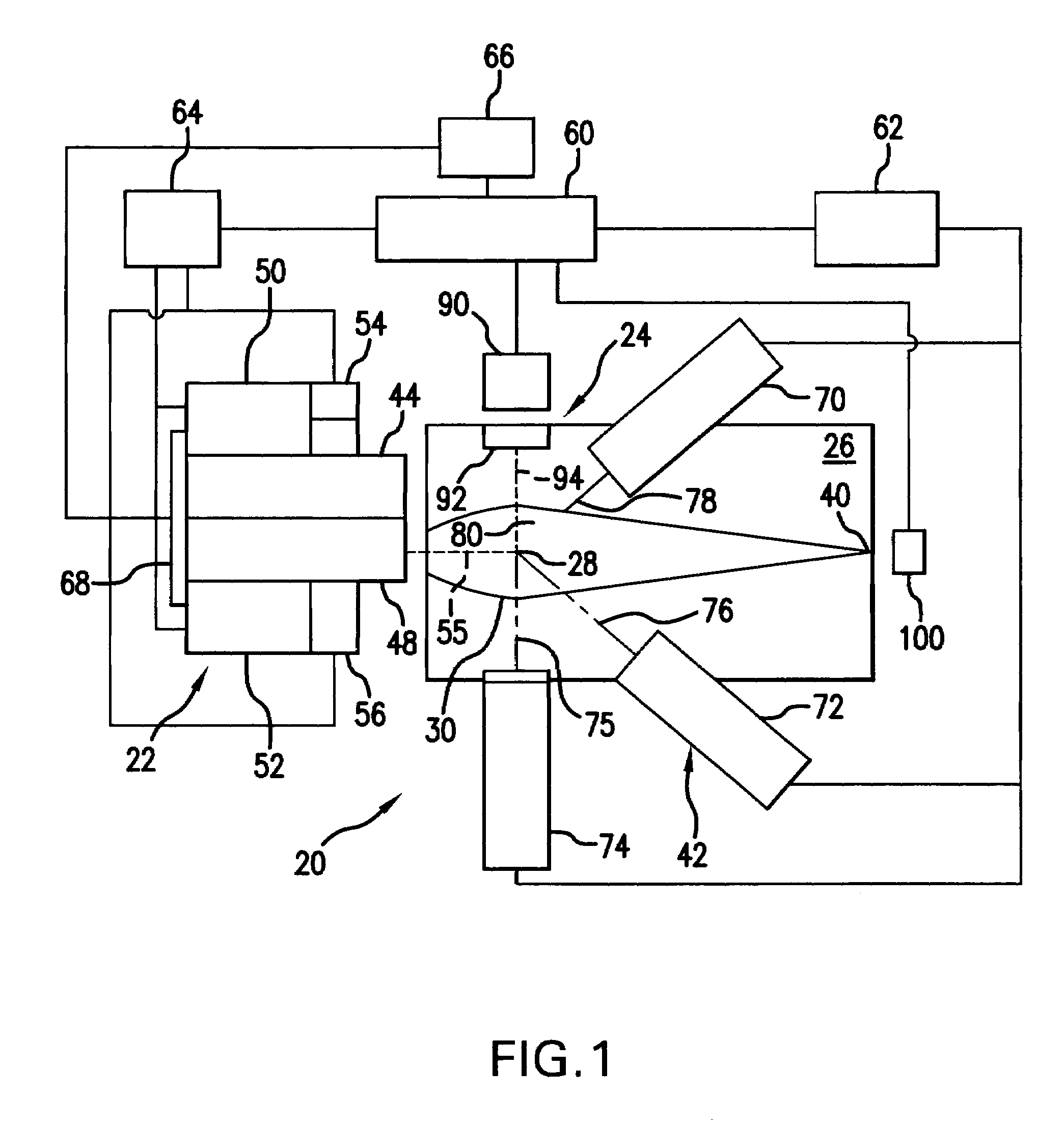

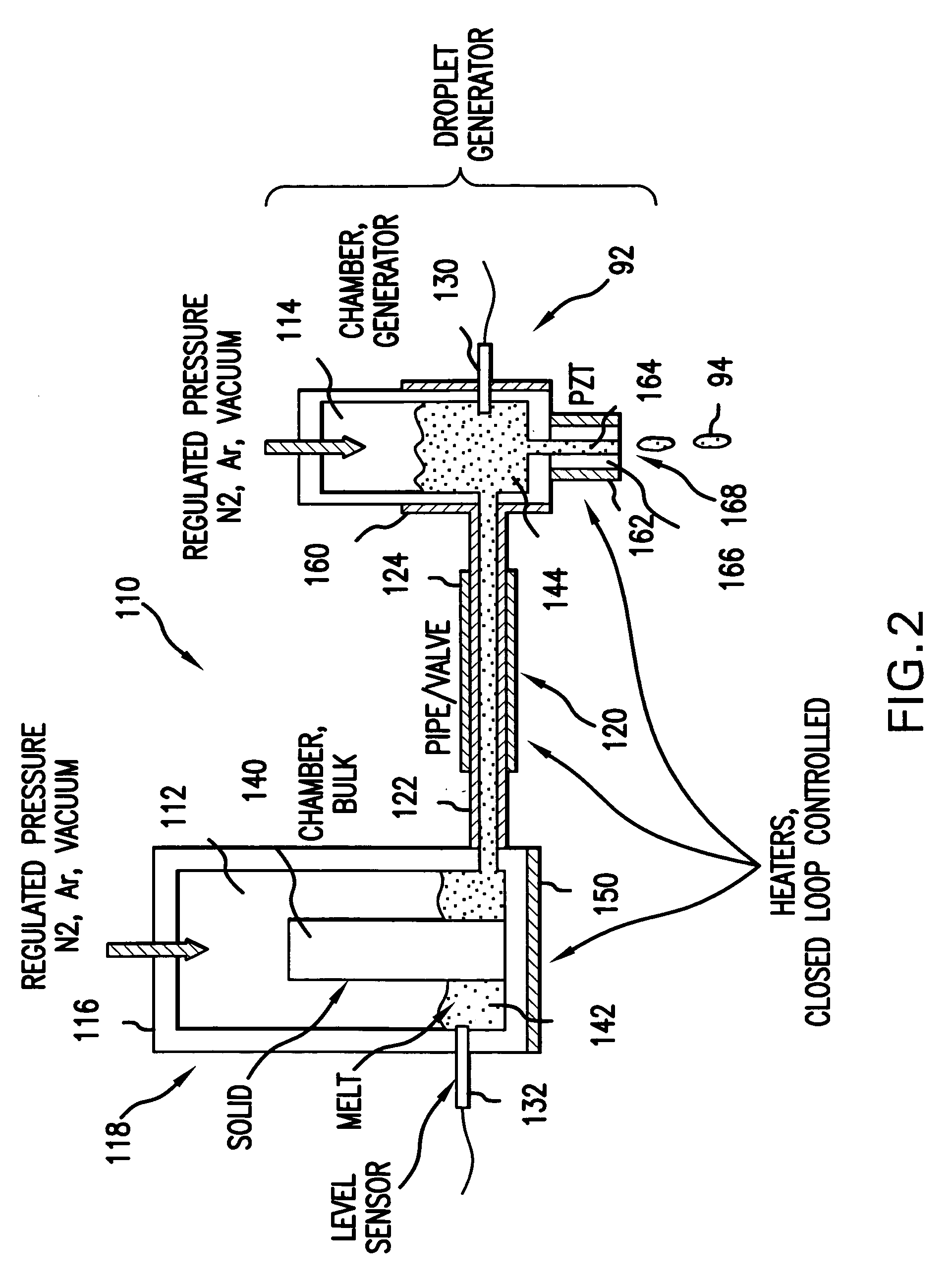

Source material dispenser for EUV light source

A source material dispenser for an EUV light source is disclosed that comprises a source material reservoir, e.g. tube, that has a wall and is formed with an orifice. The dispenser may comprise an electro-actuatable element, e.g. PZT material, that is spaced from the wall and operable to deform the wall and modulate a release of source material from the dispenser. A heat source heating a source material in the reservoir may be provided. Also, the dispenser may comprise an insulator reducing the flow of heat from the heat source to the electro-actuatable element. A method of dispensing a source material for an EUV light source is also described. In one method, a first signal may be provided to actuate the electro-actuatable elements to modulate a release of source material and a second signal, different from the first, may be provided to actuate the electro-actuatable elements to unclog the orifice.

Owner:ASML NETHERLANDS BV

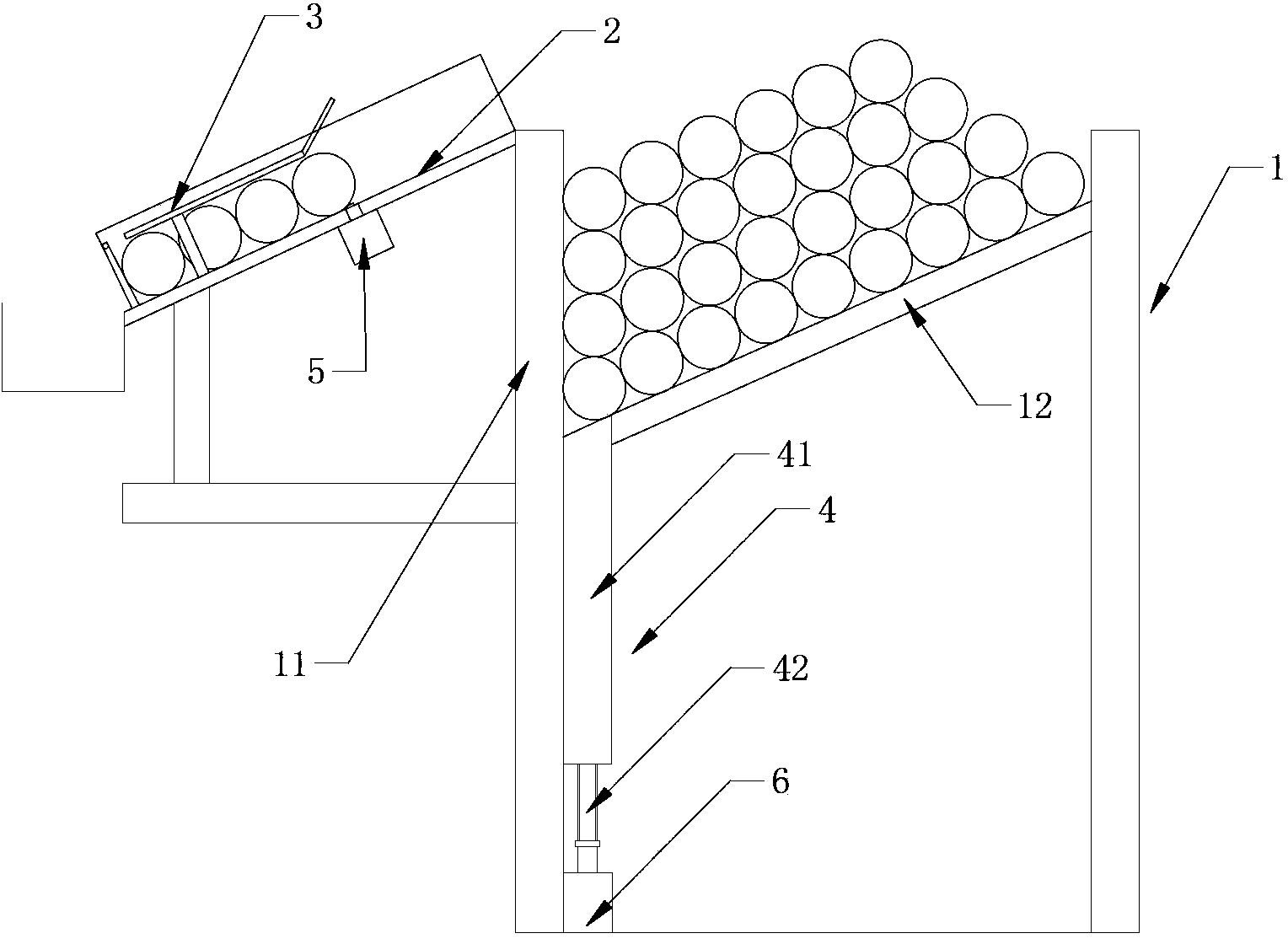

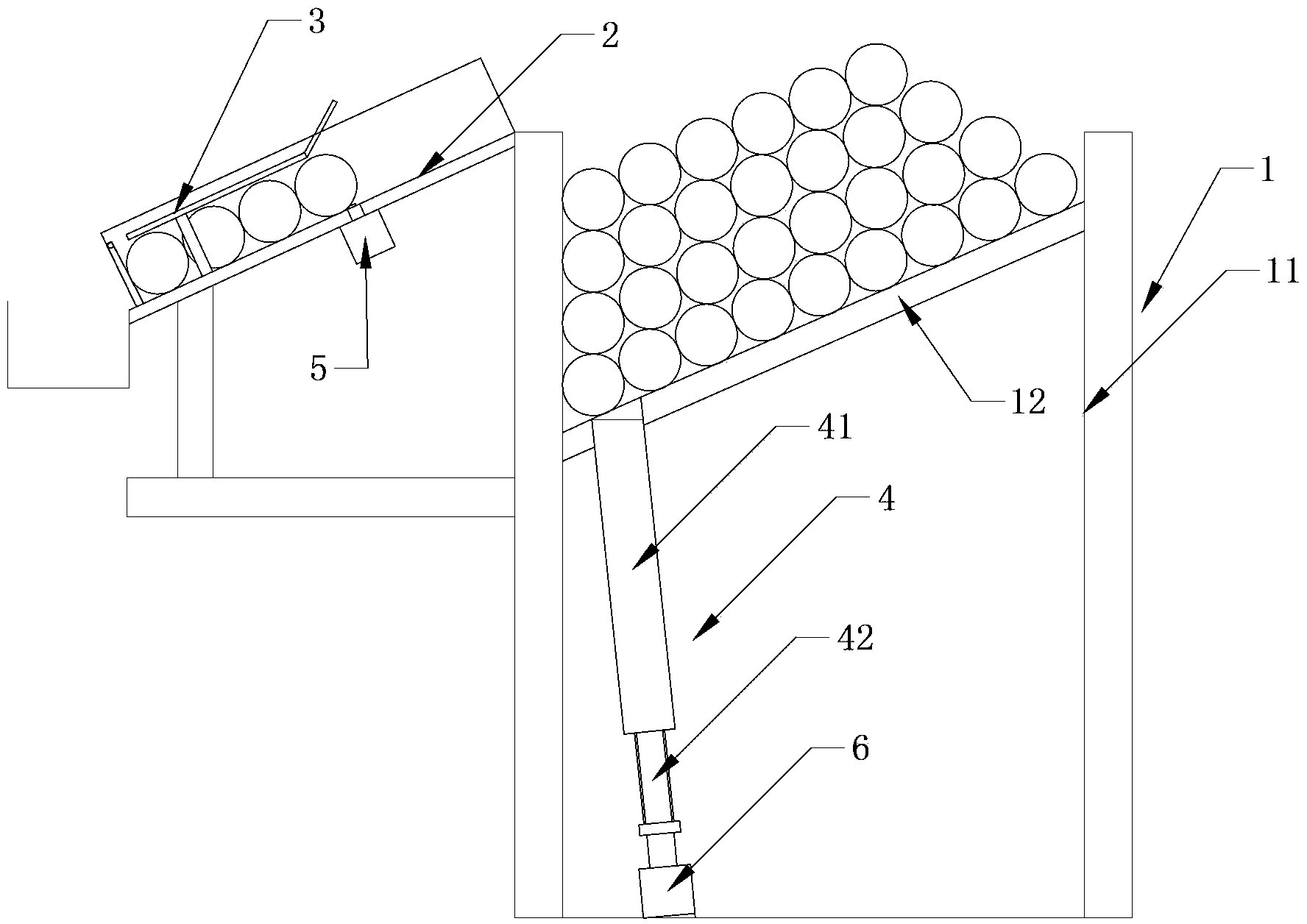

Metal rod automatic feeding device for heating furnace

The invention discloses a metal rod automatic feeding device for a heating furnace. The metal rod automatic feeding device for the heating furnace comprises a material storage box and a material guide groove, wherein the material storage box comprises a material storage chamber, a bottom plate of the material storage chamber is arranged obliquely, the material guide groove is formed in the outer wall of the material storage chamber and is located at a lower side of the oblique bottom late, the material guide groove is also arranged obliquely, and the oblique direction of the material guide groove is the same as the oblique direction of the bottom plate. A material blocking device used for blocking or releasing a metal rod is arranged on the material guide groove and is in linkage with a material pushing device of the heating furnace, a first sensor used for detecting the position of the metal rod is arranged on the material guide groove, a passing groove is formed in the bottom plate, a jacking mechanism is installed under the material storage chamber, a power end of the jacking mechanism penetrates through the passing groove and can push a metal plate into the material guide groove, the jacking mechanism is connected with a jacking power device, and the first sensor and the jacking power device are both connected with a controller. The automatic feeding device can replace workers for material feeding, improves feeding efficiency, is operated along with existing equipment synchronously, saves manpower and reduces cost.

Owner:JIANGSU HONGBAO HARDWARE

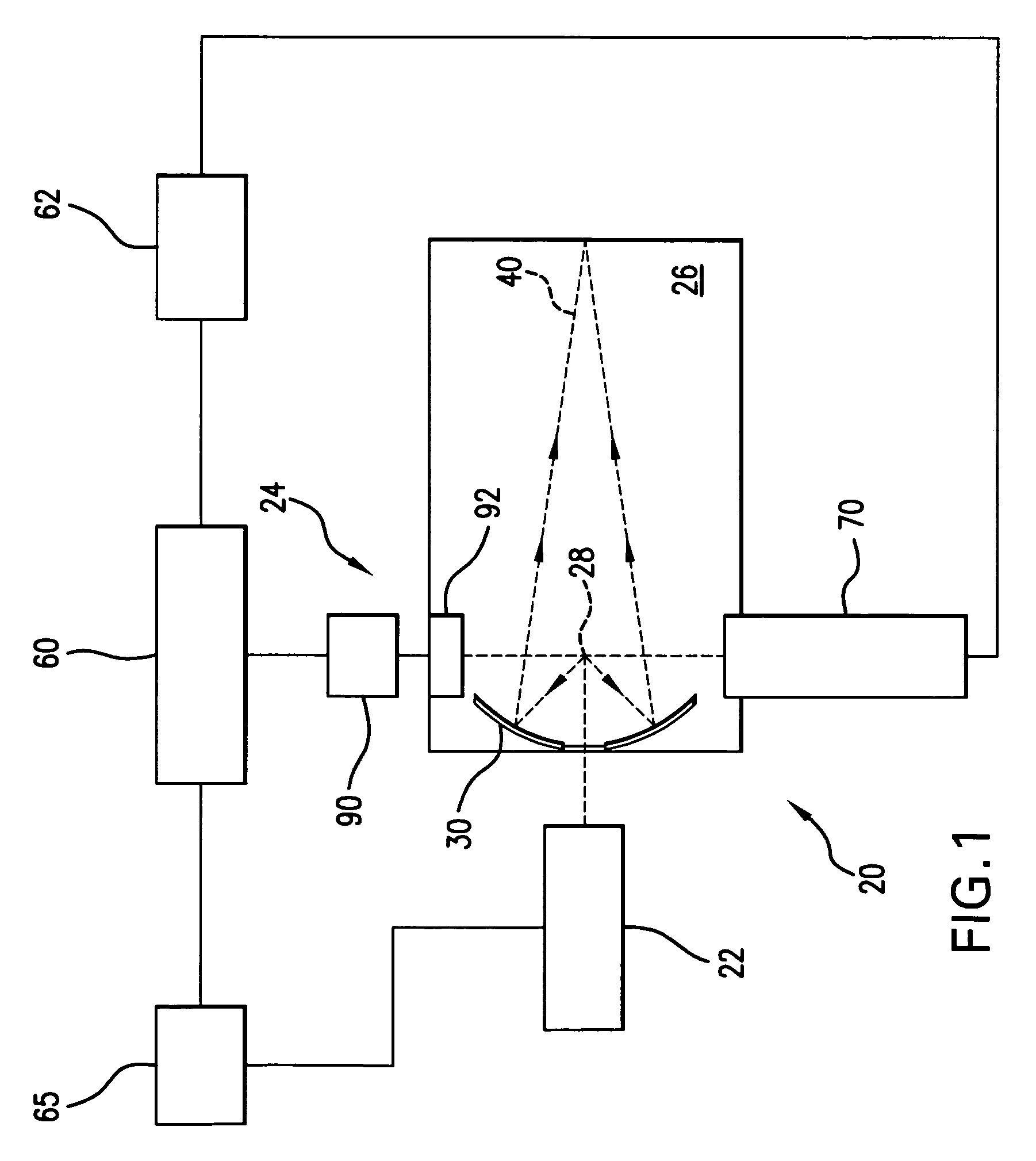

Method and apparatus for EUV light source target material handling

An EUV light source plasma source material handling system and method is disclosed which may comprise a droplet generator having a droplet generator plasma source material reservoir in fluid communication with a droplet formation capillary and maintained within a selected range of temperatures sufficient to keep the plasma source material in a liquid form; a plasma source material supply system having a supply reservoir in fluid communication with the droplet generator plasma source material reservoir and holding at least a replenishing amount of plasma source material in liquid form for transfer to the droplet generator plasma source material reservoir, while the droplet generator is on line; a transfer mechanism transferring liquid plasma source material from the supply reservoir to the droplet generator plasma source material reservoir, while the droplet generator is on line. The supply reservoir may comprise a solid form of the plasma source material used to periodically form from a portion of the material in solid form the material in liquid form.

Owner:ASML NETHERLANDS BV

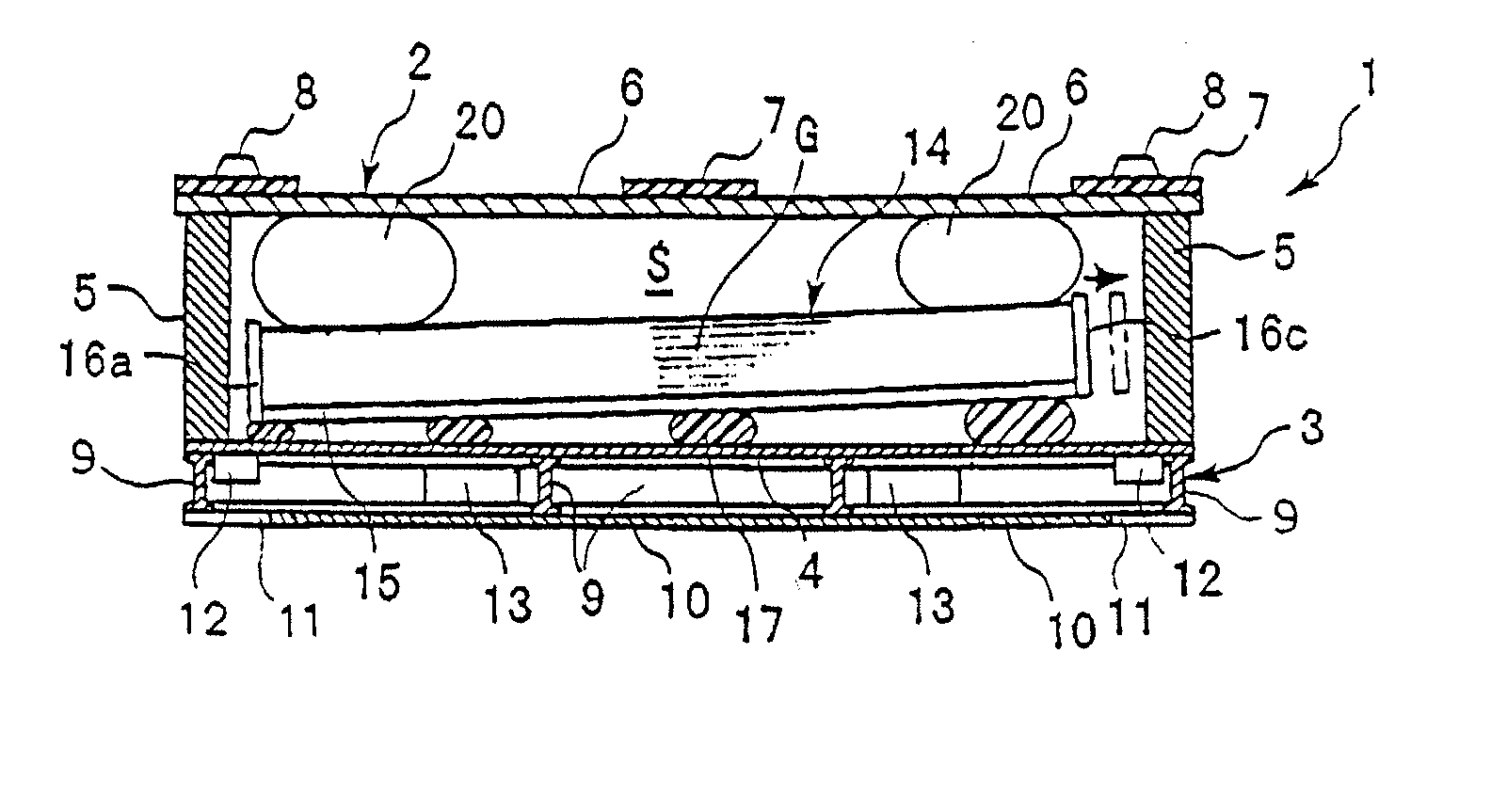

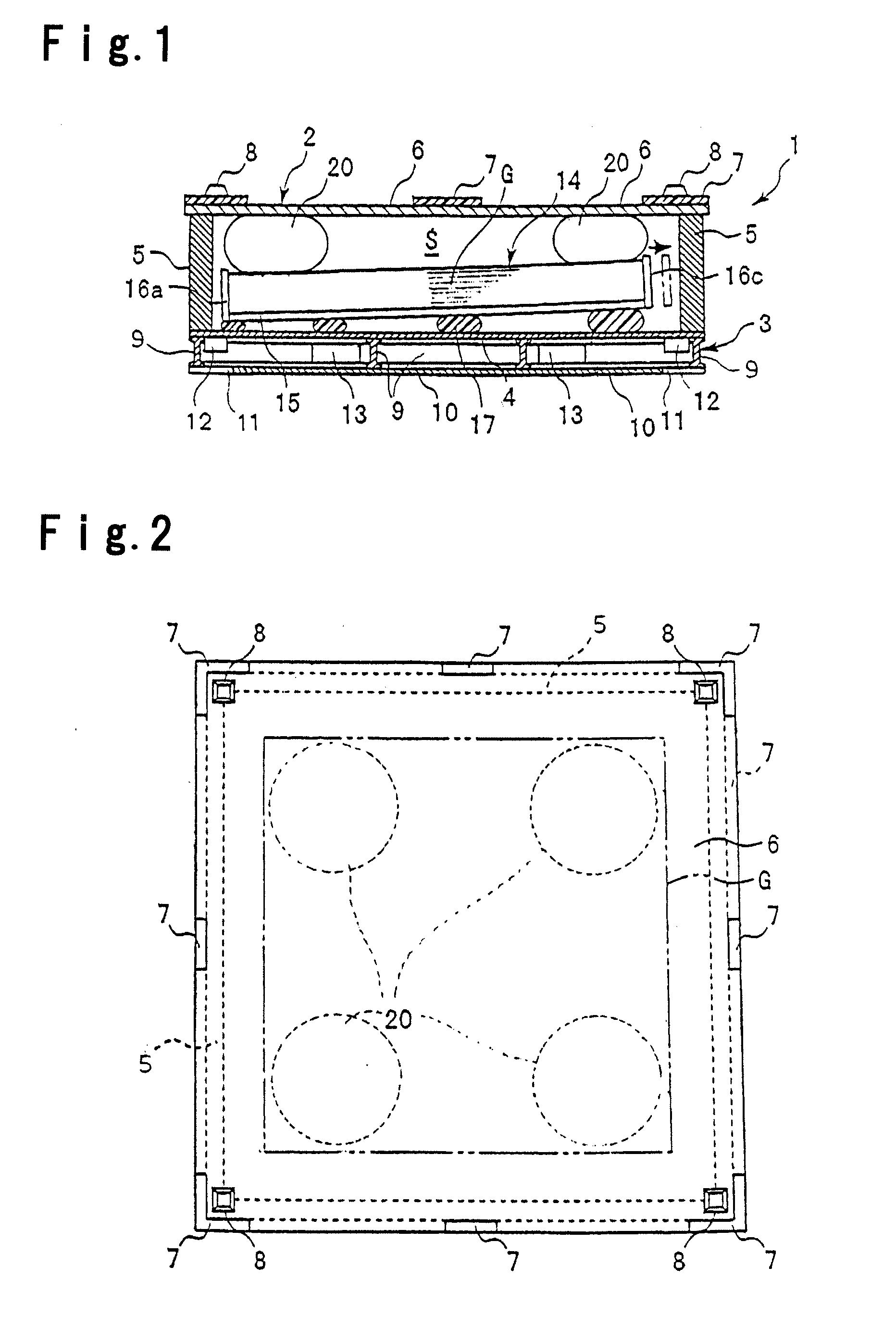

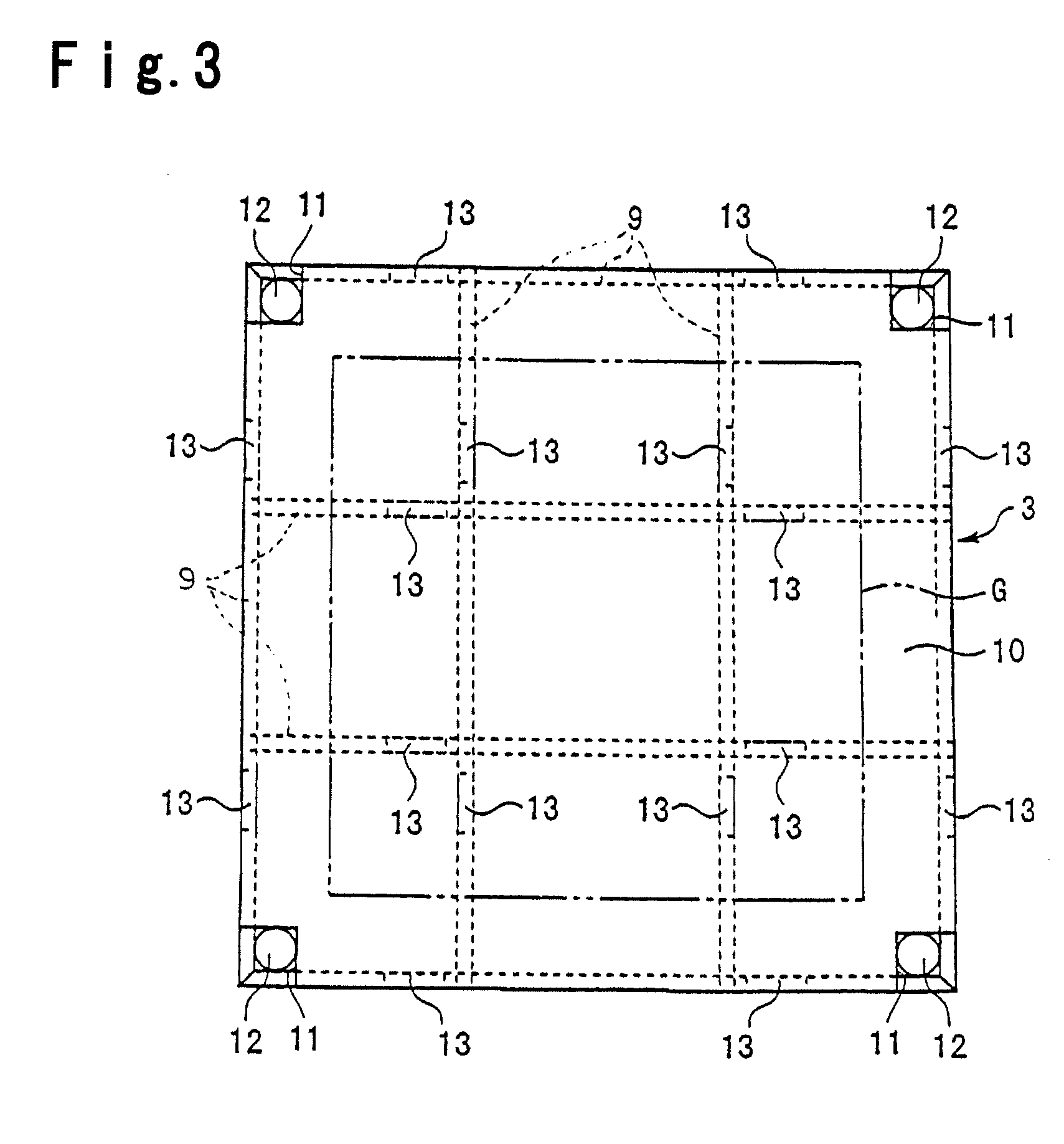

Plate material packing box, plate material transporting method, and plate material loading or unloading method

InactiveUS20070131574A1Avoid enteringEasy to storeOther accessoriesContainer/bottle contructionEngineeringHolding room

A plate material packing box capable of preventing dirt from entering thereinto, easily storable in a storage room with a low ceiling by reducing the height dimension during transportation, and capable of transporting plate materials efficiently and constantly; a plate material transporting method using such a plate material packing box; and a plate material loading or unloading method. The packing box comprises a pedestal 3 having an upper lining, a plate material storage box 14 put on the pedestal 3, and an upper cover 2 enclosing the plate material storage box 14 on the pedestal 3 and being detachable from the pedestal 3, wherein the plate material storage box 14 is an upwardly open support having a bottom plate 15 to have a plurality of plate materials G put thereon in a substantially horizontally stacked state, and side plate 16a to 16d along four sides of its periphery, the upper cover 2 is a downwardly open box having a top plate 6 covering the upper surface of the plate material storage box 14 and side frames 5 along four sides of its periphery; a vibration damper 17 is interposed between the pedestal 3 and the bottom plate 5; and a cushion material 20 is installed between the top plate 6 and the plate materials G put on the bottom plate 15.

Owner:ASAHI GLASS CO LTD

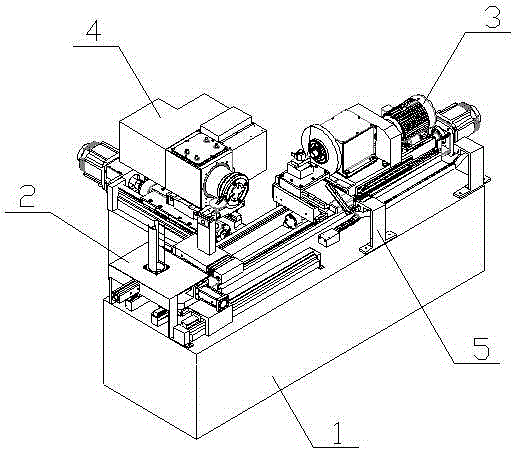

Full automatic grinding machine for piston ring inclined end surface

InactiveCN105171427AExtend your lifeReduce grindingFeeding apparatusOther manufacturing equipments/toolsPiston ringEngineering

The invention discloses a full automatic grinding machine for a piston ring inclined end surface. The full automatic grinding machine comprises a machine bed, an automatic loading and unloading rack, a composite processing table, a power head rack, a material collection rack and two parallel guide rails which are arranged on the machine bed, wherein the automatic loading and unloading rack and the composite processing table are arranged on the two ends of the two guide rails, the power head rack and the material collection rack are arranged on the two sides of the two guide rails; the automatic loading and unloading rack comprises a material storage rack, a material delivering slide table and a material delivering cylinder, the composite processing table comprises a processing slide table and a slide table displacement servo motor; the power head rack comprises a shell, a hollow axle pipe is arranged in the shell, an electromagnetic chuck and a positioning disk are sleeved on one end of the axle pipe near to the guide rail, and the material storage rack comprises a material storage rod, a guide rod and two inverted L-shaped connection racks. The piston ring inclined end surface is more simply processed, the processing precision is high and the processing efficiency is high.

Owner:CHONGQING UNIV OF TECH

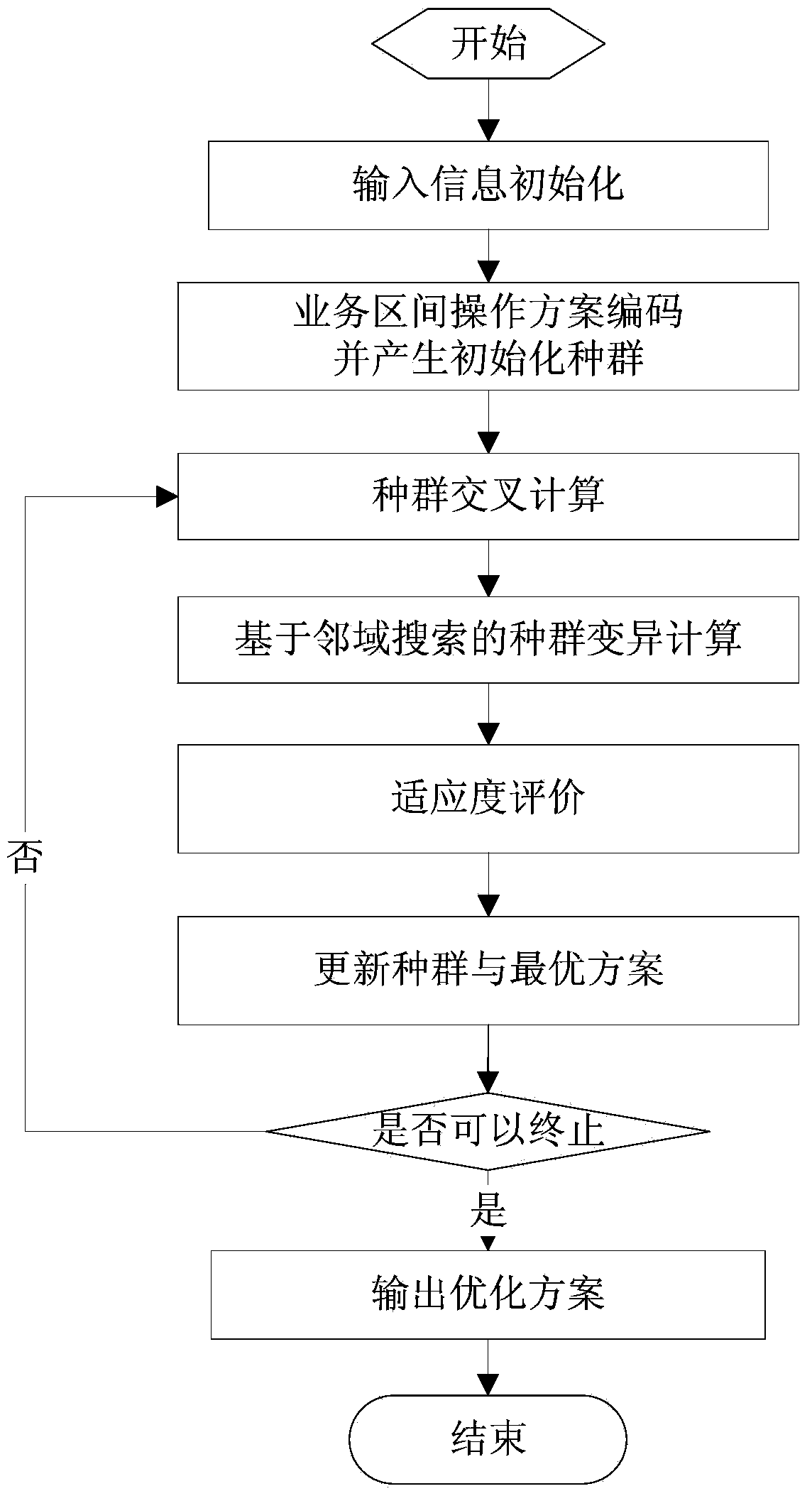

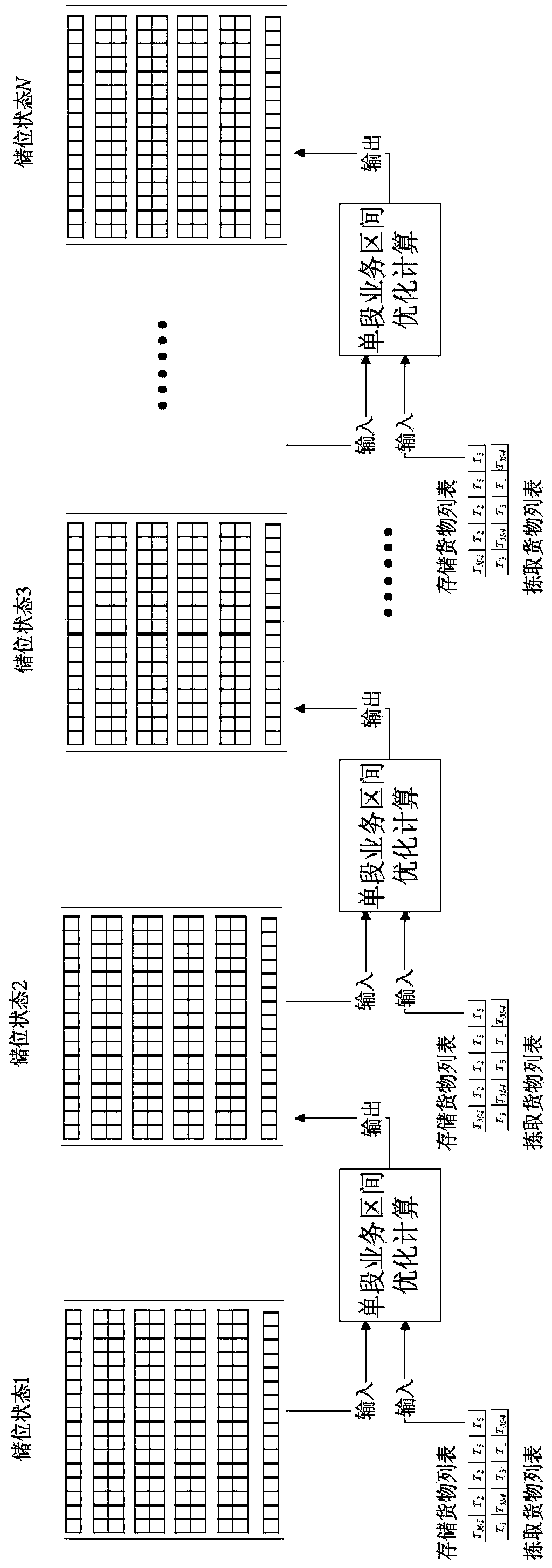

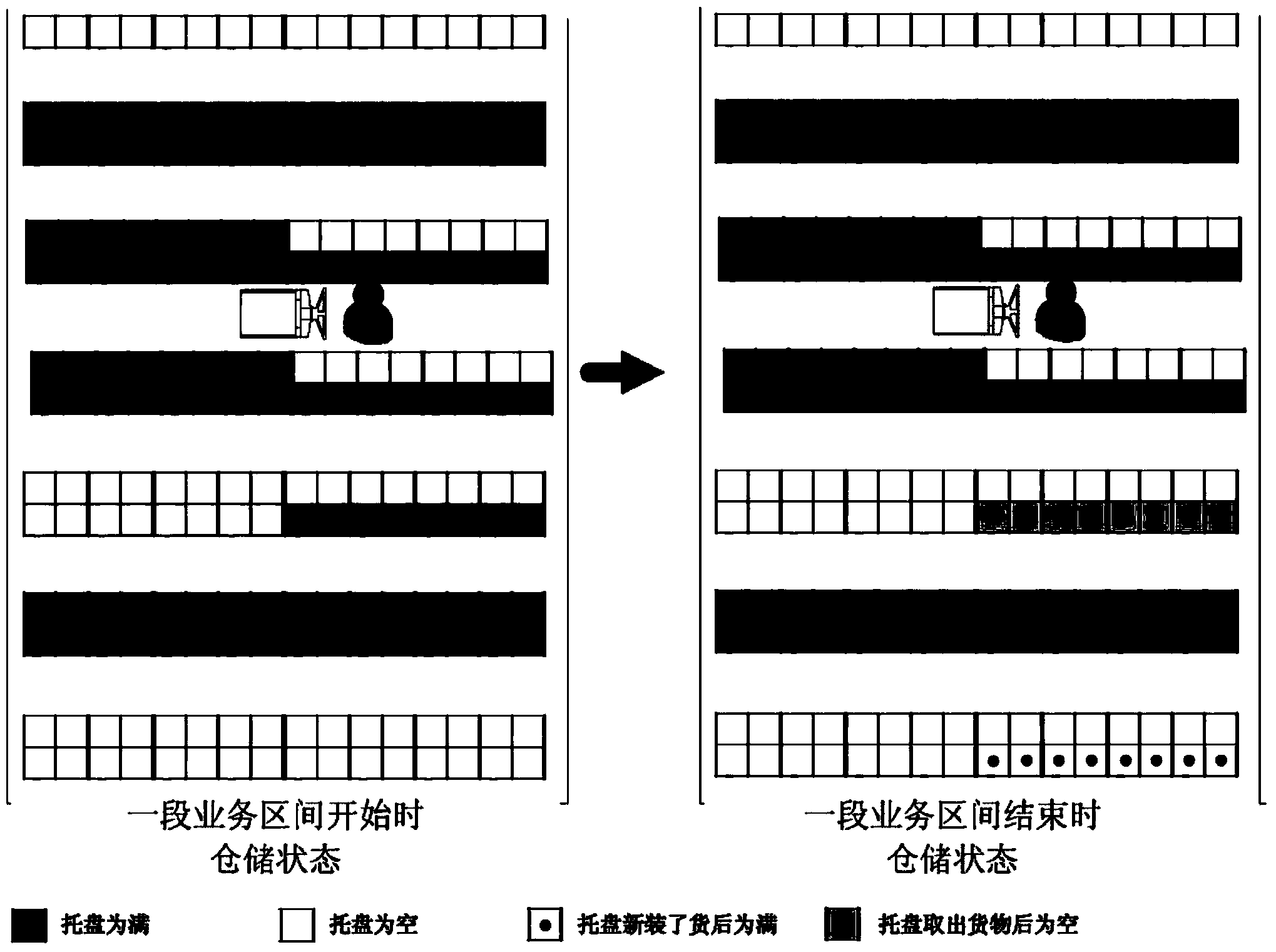

Dynamic goods allocation planning method and system for processing multi-variety goods and material storage

ActiveCN103473616AOptimize the handling pathRealize multiplexingGenetic modelsForecastingMultiplexingGenetic algorithm

The invention discloses a dynamic goods allocation planning method and system for processing multi-variety goods and material storage, and belongs to a planning method of intelligent loading. The method comprises the steps that S1. goods allocation information, goods classification and goods information in a storage environment are stored into a system database through a data management module; S2. unprocessed warehouse-in warrants and warehouse-out warrants are guided into the system database through a service section management module, then stored goods involved in the warehouse-in warrants are extracted according to time sequence, warehouse-in goods list information and the like are generated; the executing scheme of storage is subjected to optimizing calculation by introducing a genetic algorithm, goods allocation is dynamically planned in a subsection-service-section mode, multiplexing of storage space is achieved, the probability that the storage space is not occupied and is wasted in a large quantity of time is lowered, the requirement for ceaseless storing and taking at any time of goods is met, and the new requirement for storage management under enterprise large-scale customization service is especially met.

Owner:SICHUAN AEROSPACE SYST ENG INST

Electronic pipe

Owner:HEALTHIER CHOICES MANAGEMENT CORP

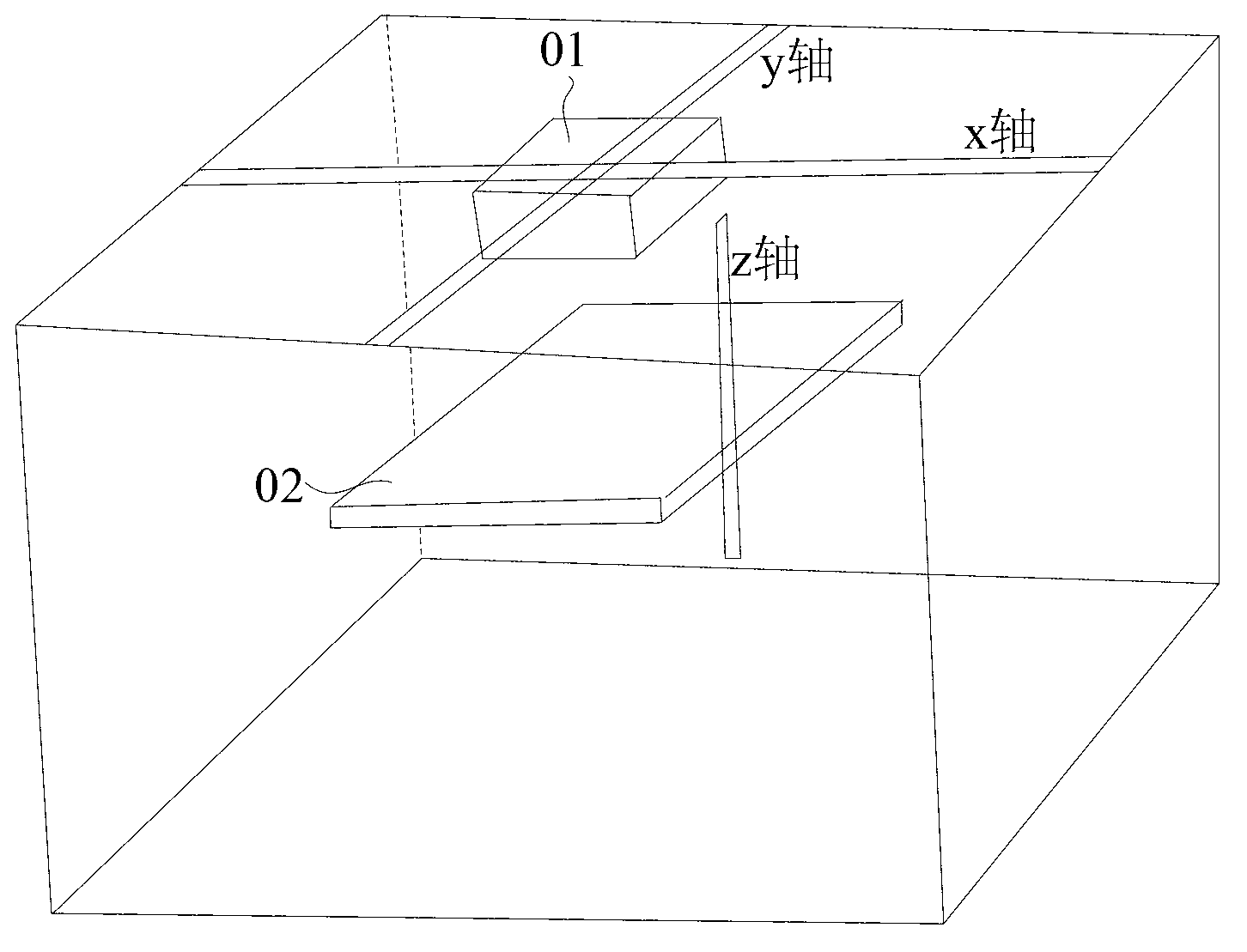

3D printing apparatus and feed system thereof

The invention provides a feed system of a 3D printing apparatus. The feed system is especially suitable for chocolate feeding, and two feed modes comprising a pneumatic mode and a piston mode can be selected by the system. The feed system comprises: a material storage tank; a heater arranged on the material storage tank to heat a material (8) in the material storage tank to the molten state; a gas jet cooler arranged at the material outlet (15) of the material storage tank to cool a printing model; and a material discharge driving device connected with the material storage tank to drive the molten material to be discharged from the material storage tank. The feed system of the 3D printing apparatus widens the application field of 3D printing. The invention also provides the 3D printing apparatus.

Owner:兰雄兵

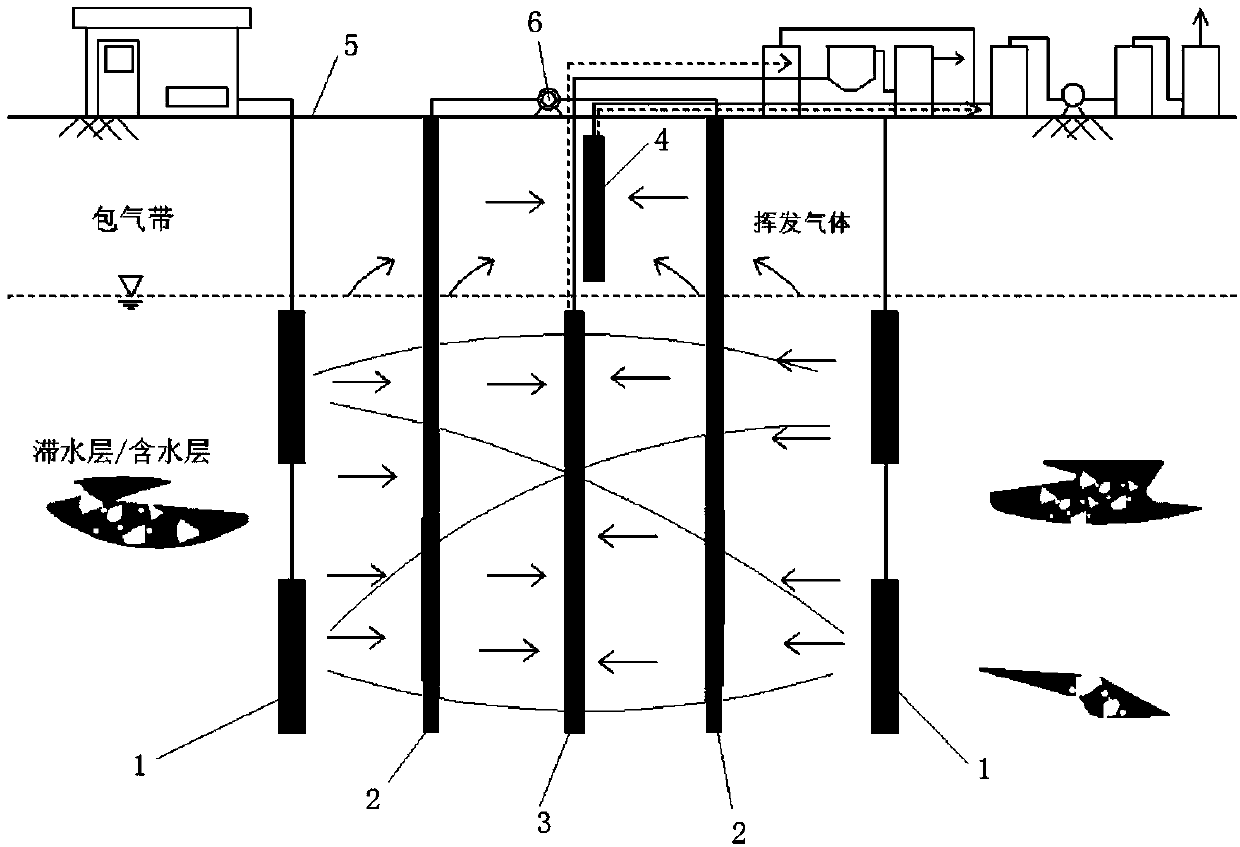

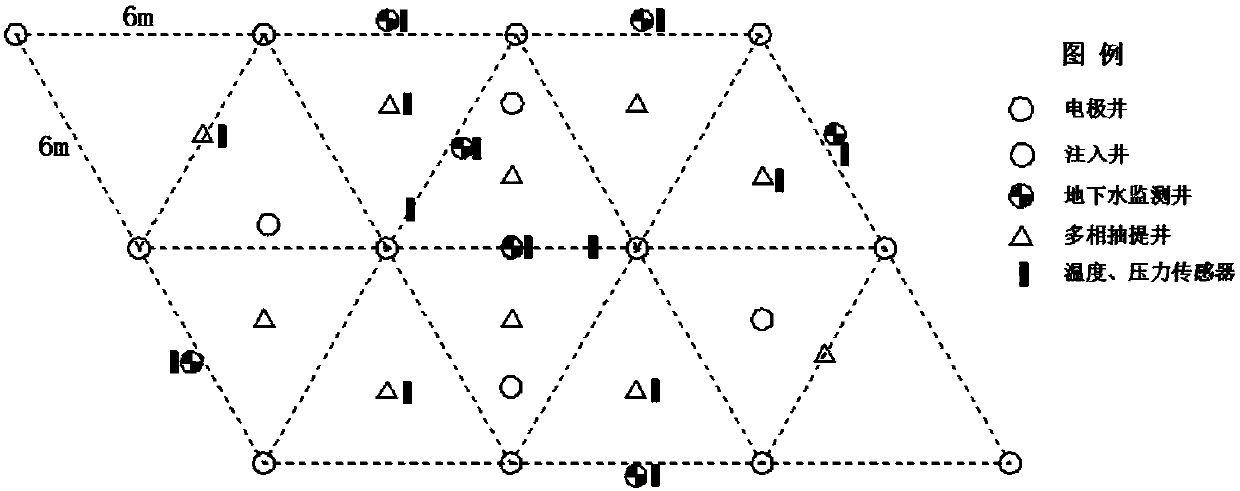

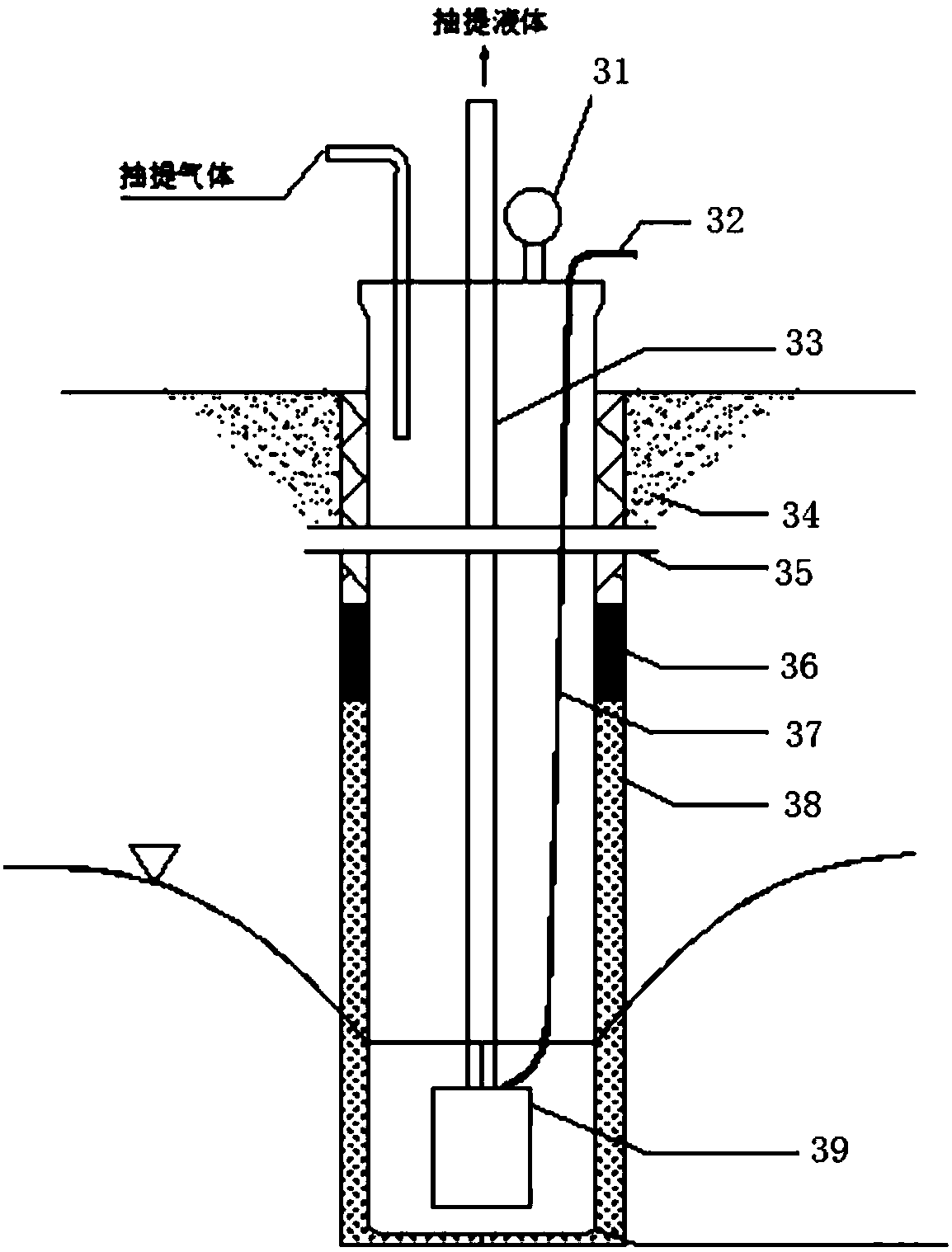

In-situ thermal desorption repair system and method for polluted soil

PendingCN108114970AImprove solubilityIncrease the speed of entering the liquid phaseContaminated soil reclamationWater/sewage treatment by heatingSolubilityInjection well

The invention relates to an in-situ thermal desorption repair system and a method for polluted soil. The system comprises a plurality of in-situ heating electrodes, a plurality of injection wells, a plurality of extraction wells, a plurality of groundwater monitoring wells, electrode power control and adjustment facilities, in-situ temperature and pressure monitoring facilities, sewage treatment facilities and waste gas treatment facilities; each extraction well is provided with an extraction device which is connected with a sewage treatment facility and a waste gas treatment facility; each injection well is internally provided with an injection device which is connected with a material storage box containing a leaching reagent; and the in-situ heating electrodes are arranged in a regulartriangular or regular hexagonal manner. Compared with the prior art, after the leaching reagent is added to dissolve pollutants, the solubility of the pollutants is increased, the speed of the pollutants entering a liquid phase from a soil adsorption phase is increased, and the removal rate and removal efficiency of the pollutants are improved.

Owner:YONKER ENVIRONMENTAL PROTECTION

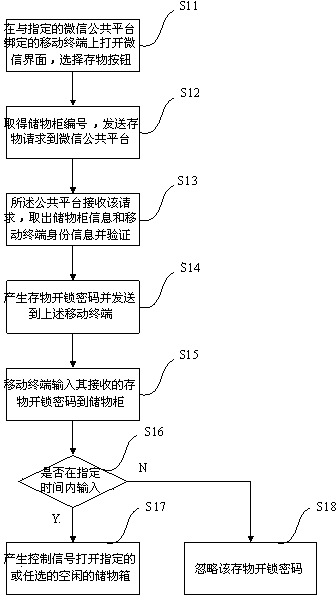

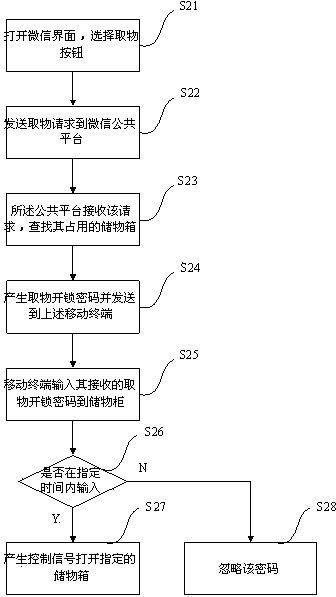

Storage box door opening method

The invention relates to a storage box door opening method which is as follows: wechat application program is run, operation buttons on an operation interface are selected; after a storage box serial number is obtained, a material storage request with mobile terminal self identity binding information and the storage box serial number is formed by a mobile terminal and is sent to a wechat public platform; the material storage request is received, the storage box serial number and the mobile terminal identity information which are taken by the material storage request are taken out for verification; after the verification is validated, an unlock password is produced, the unlock password comprises unlock password production time and a random code; the material storage unlock password is sent to the mobile terminal; when the unlock password inputted within a specified time is received by a storage box and the material storage unlock password is right by verification, a control signal is outputted to open a specified storage box or an empty box is found. The storage box door opening method has the following beneficial effects of being safe and environmentally-friendly.

Owner:SHENZHEN ZHILAI SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com