Patents

Literature

396 results about "Hot filament" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

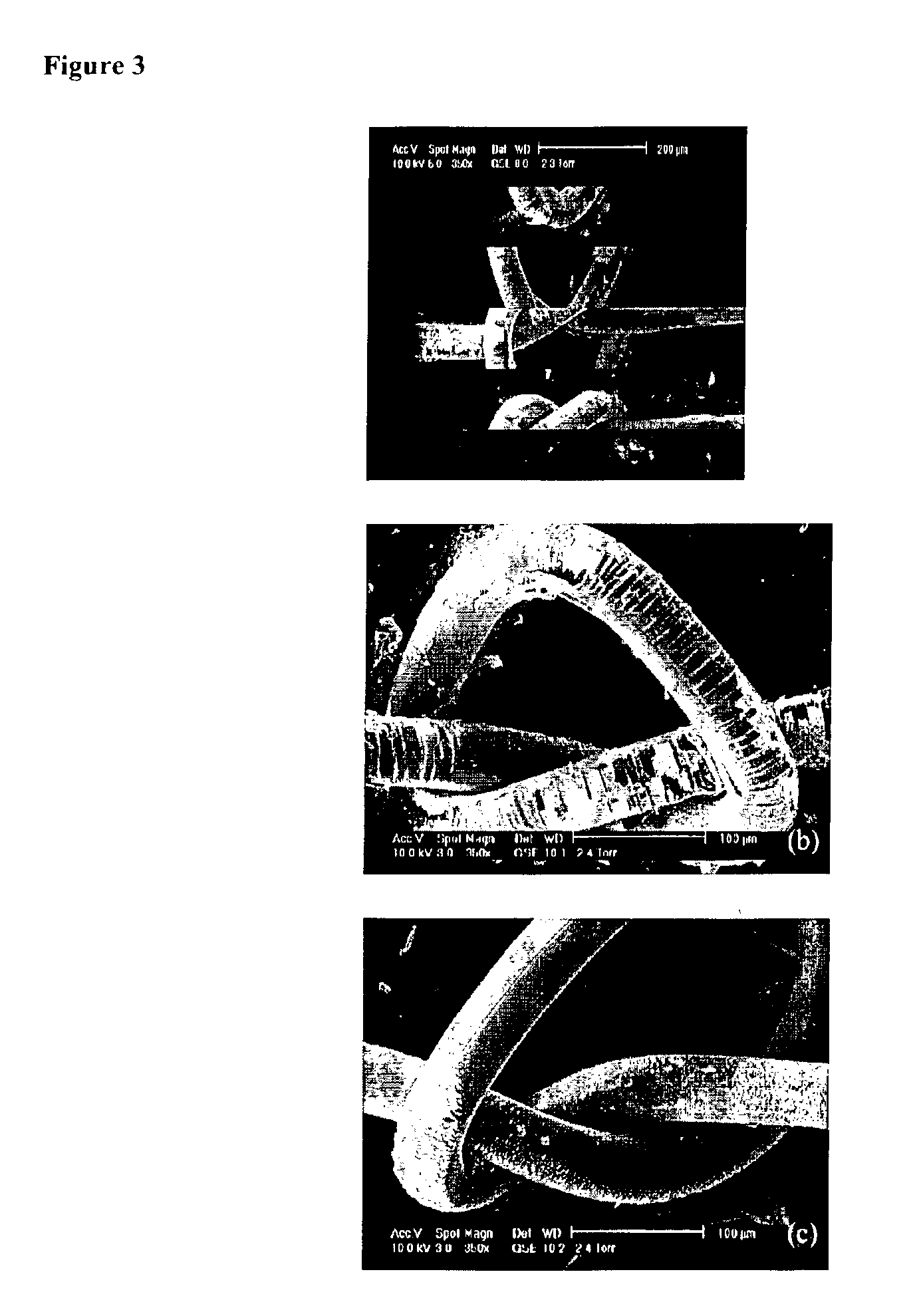

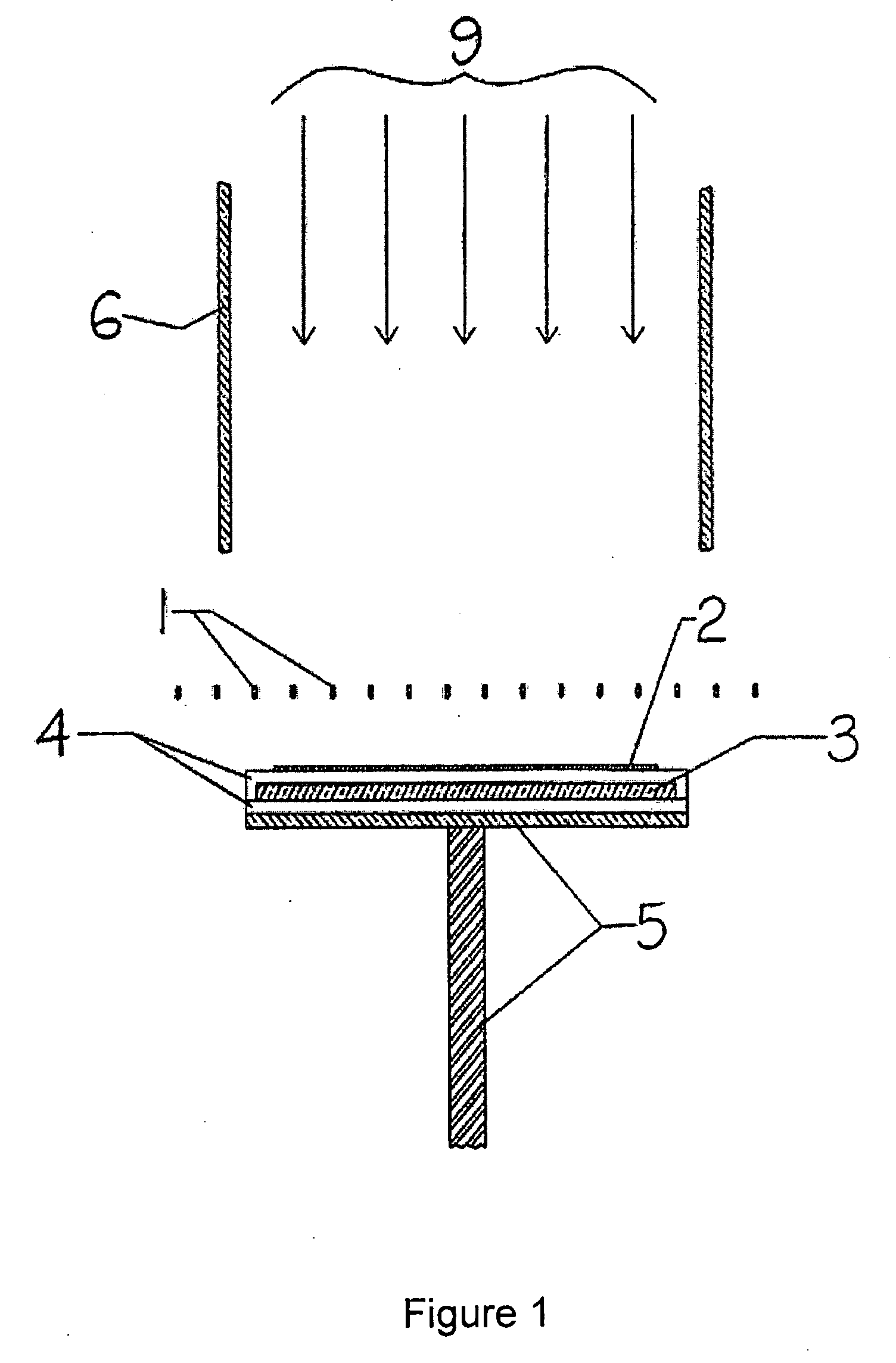

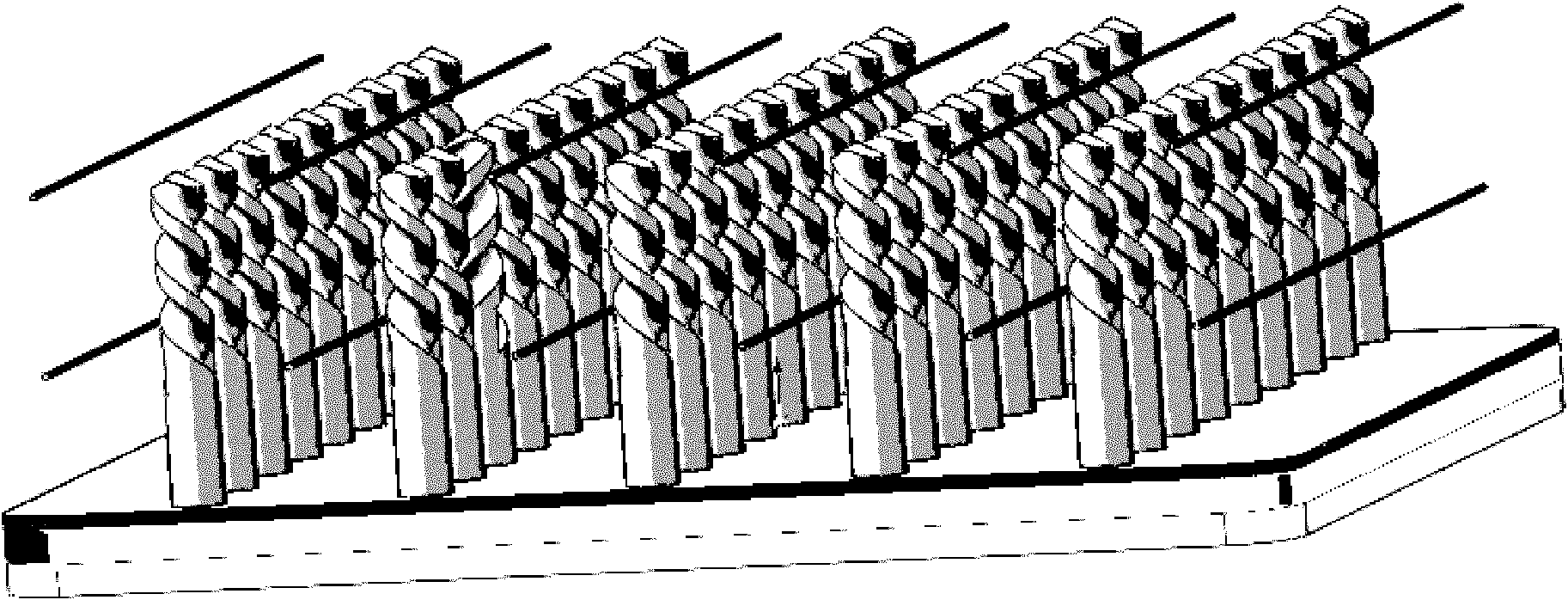

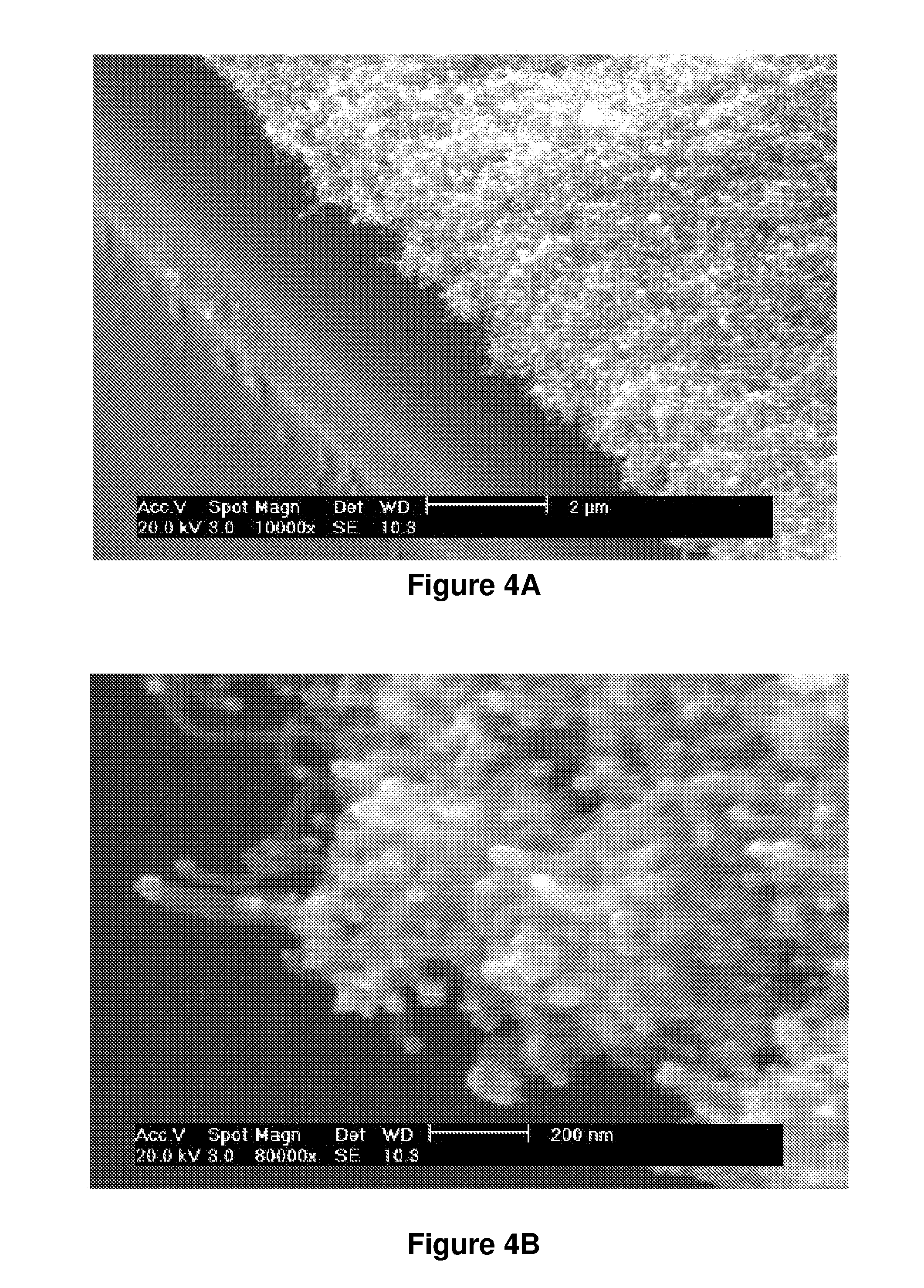

Free-standing and aligned carbon nanotubes and synthesis thereof

One or more highly-oriented, multi-walled carbon nanotubes are grown on an outer surface of a substrate initially disposed with a catalyst film or catalyst nano-dot by plasma enhanced hot filament chemical vapor deposition of a carbon source gas and a catalyst gas at temperatures between 300° C. and 3000° C. The carbon nanotubes range from 4 to 500 nm in diameter and 0.1 to 50 μm in length depending on growth conditions. Carbon nanotube density can exceed 104 nanotubes / mm2. Acetylene is used as the carbon source gas, and ammonia is used as the catalyst gas. Plasma intensity, carbon source gas to catalyst gas ratio and their flow rates, catalyst film thickness, and temperature of chemical vapor deposition affect the lengths, diameters, density, and uniformity of the carbon nanotubes. The carbon nanotubes of the present invention are useful in electrochemical applications as well as in electron emission, structural composite, material storage, and microelectrode applications.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

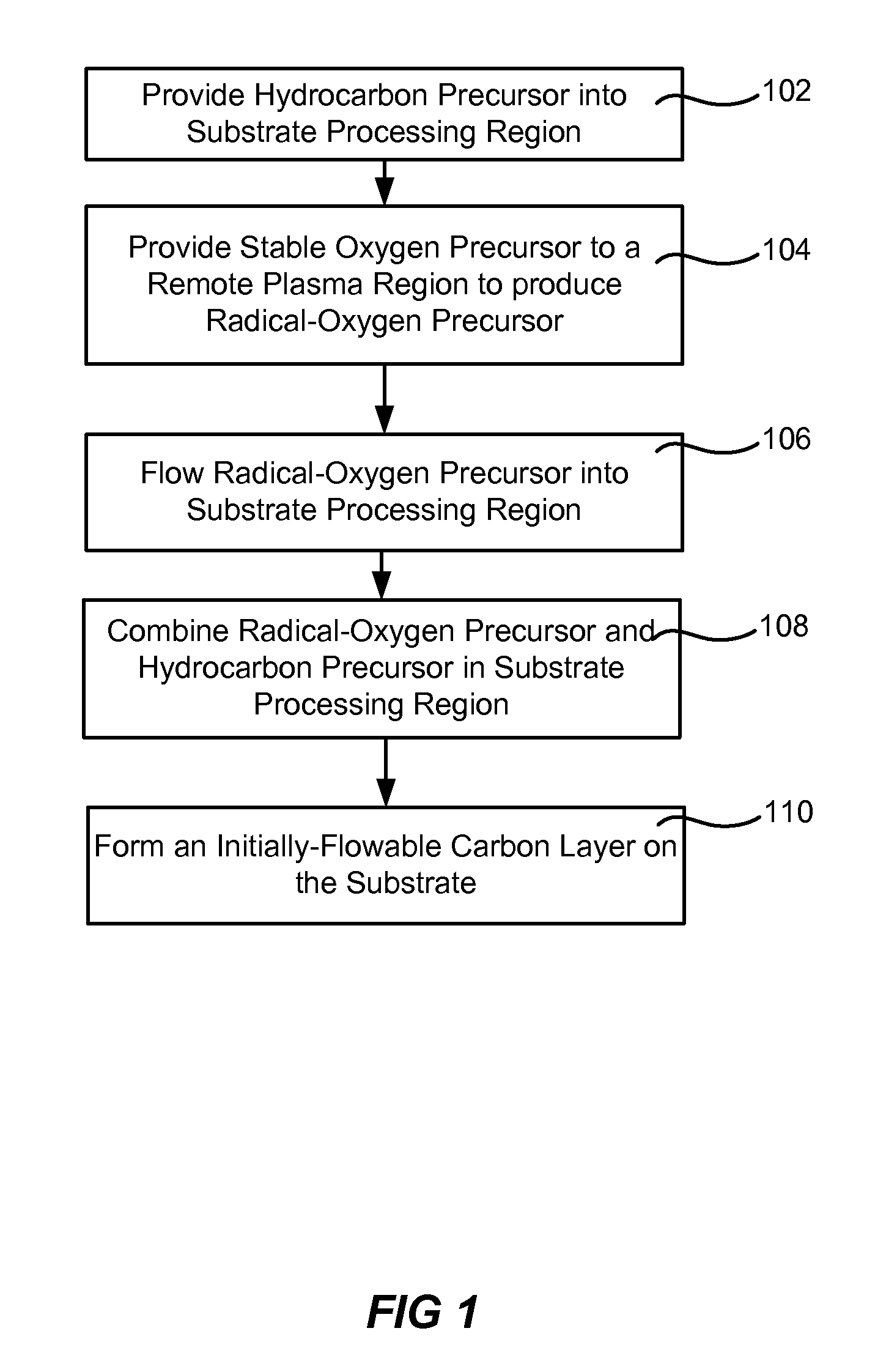

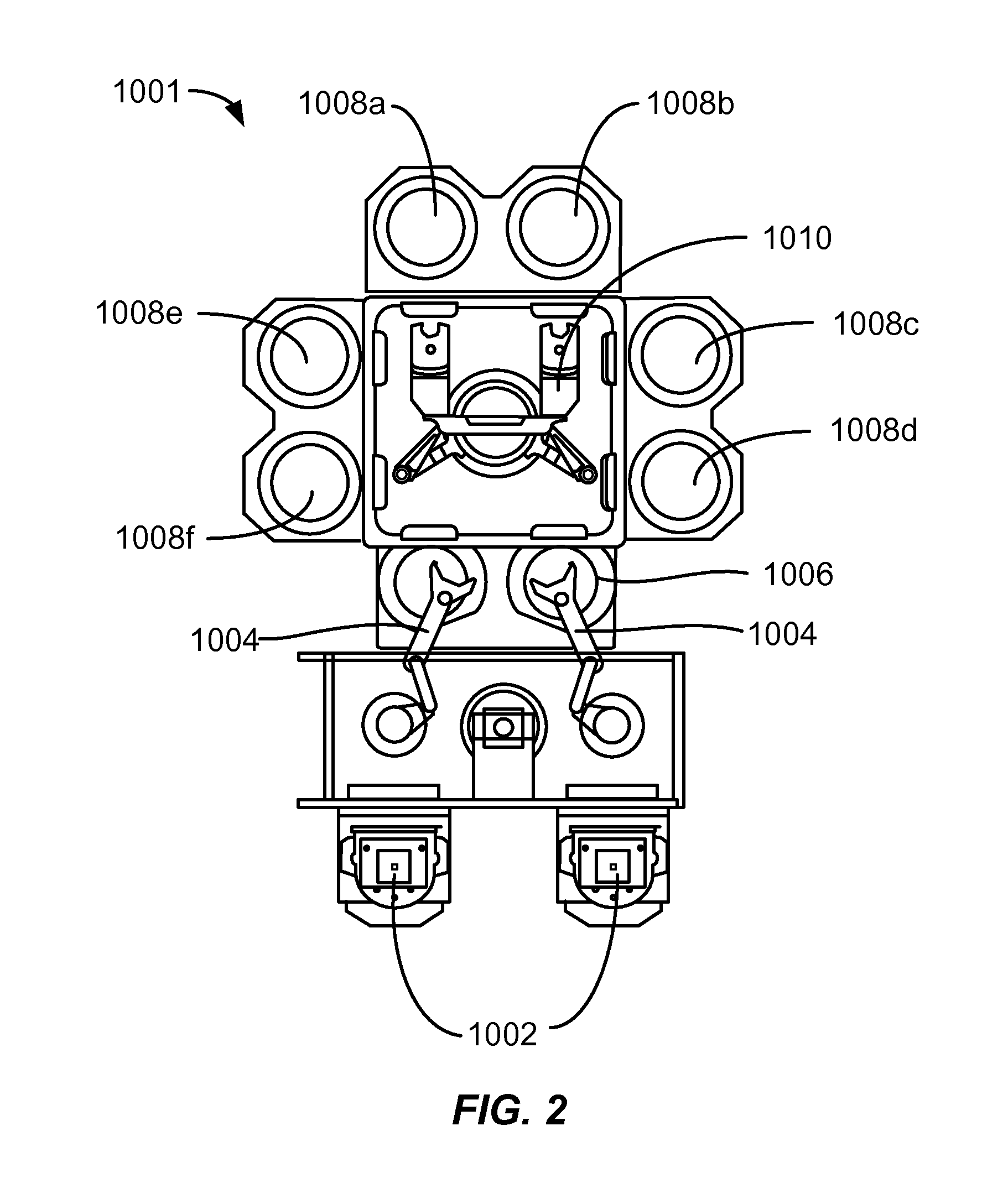

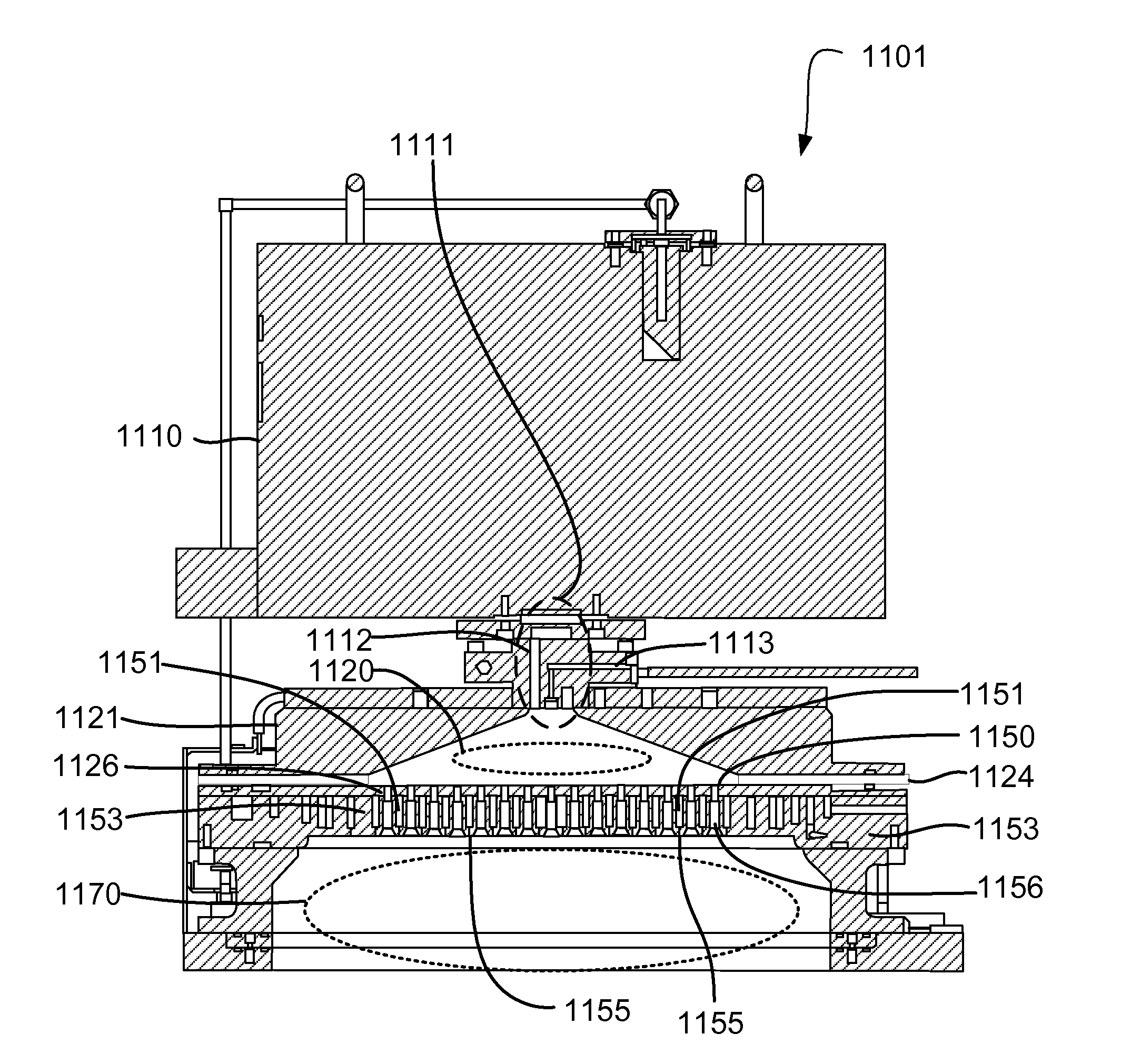

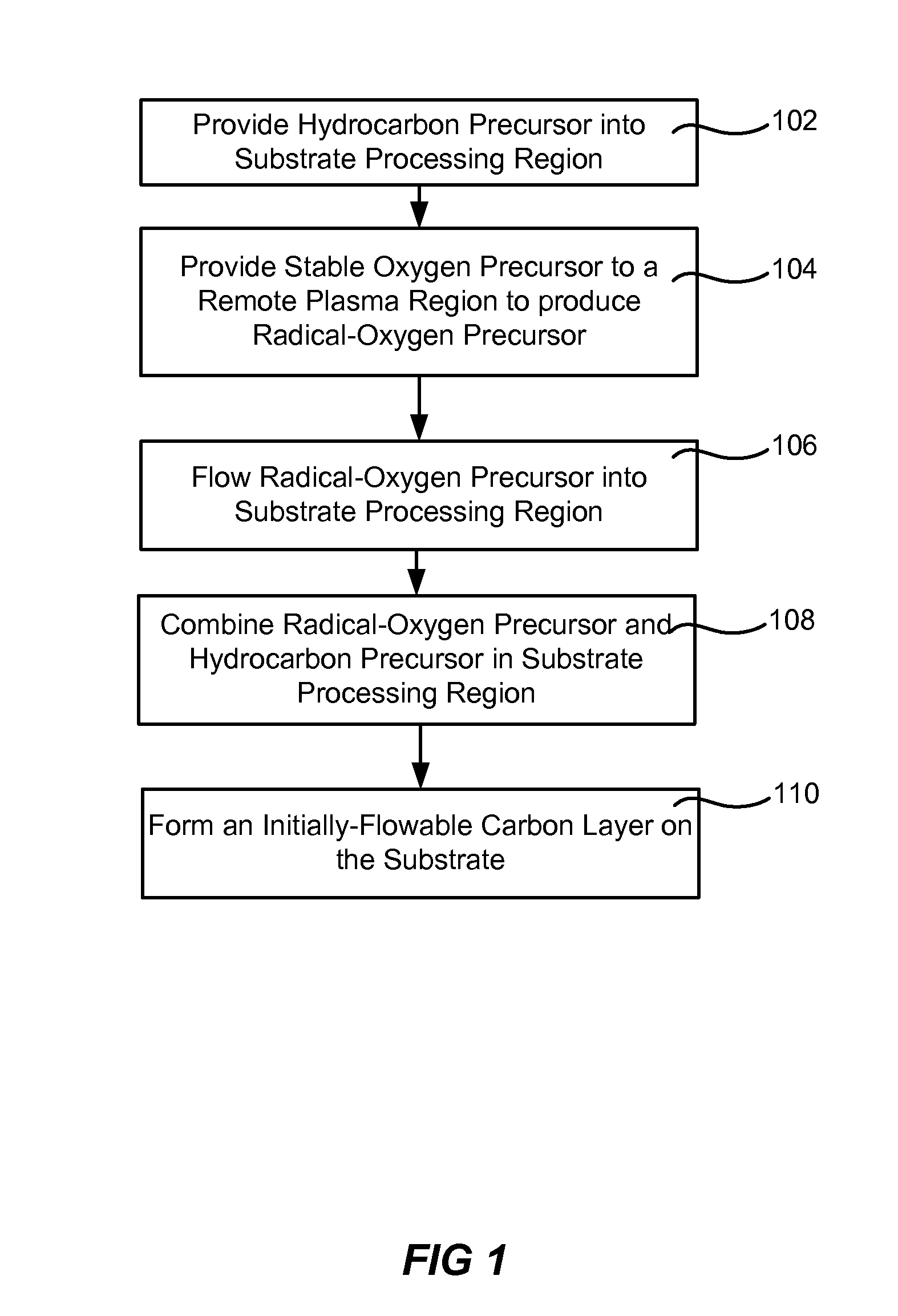

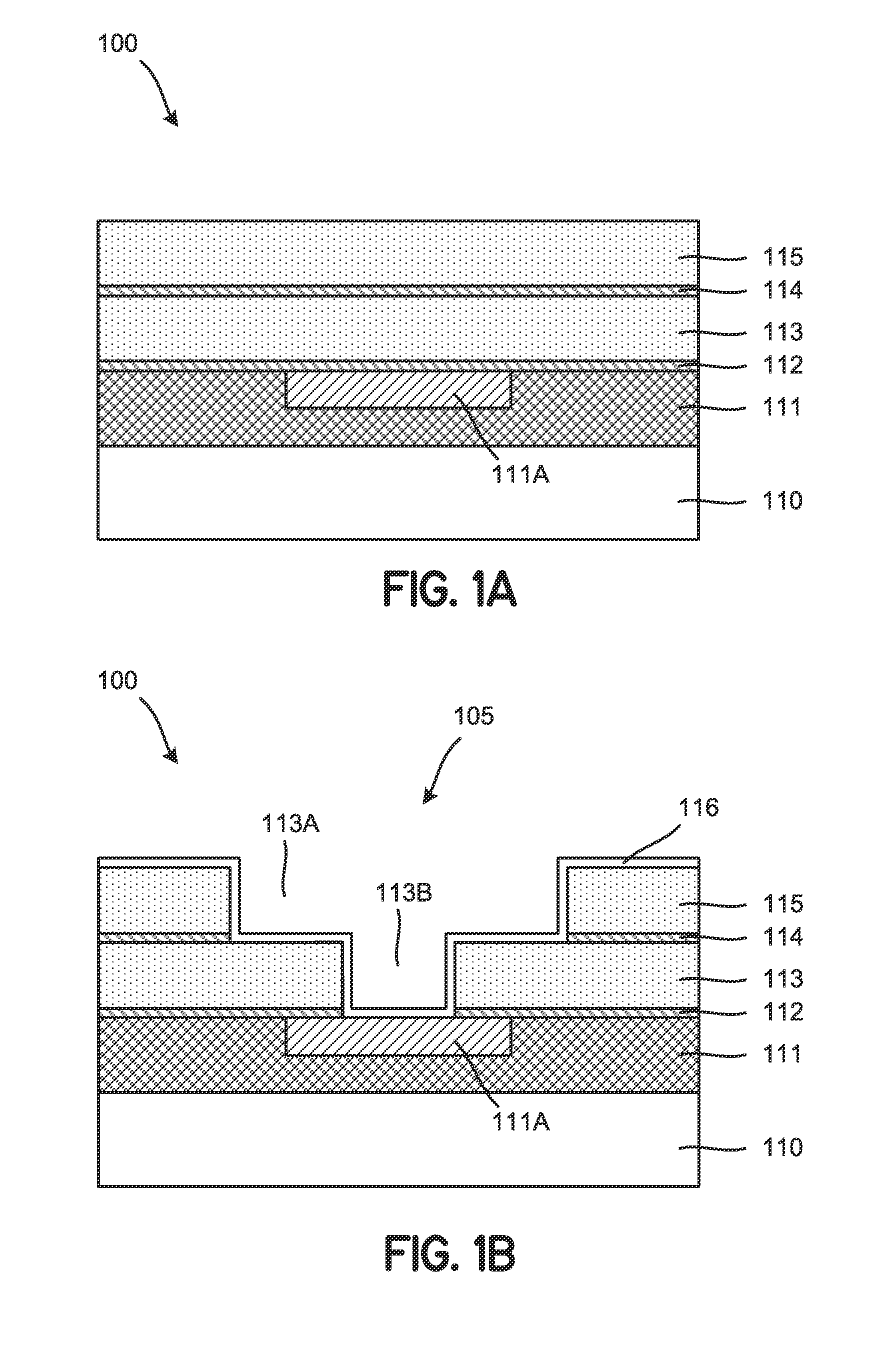

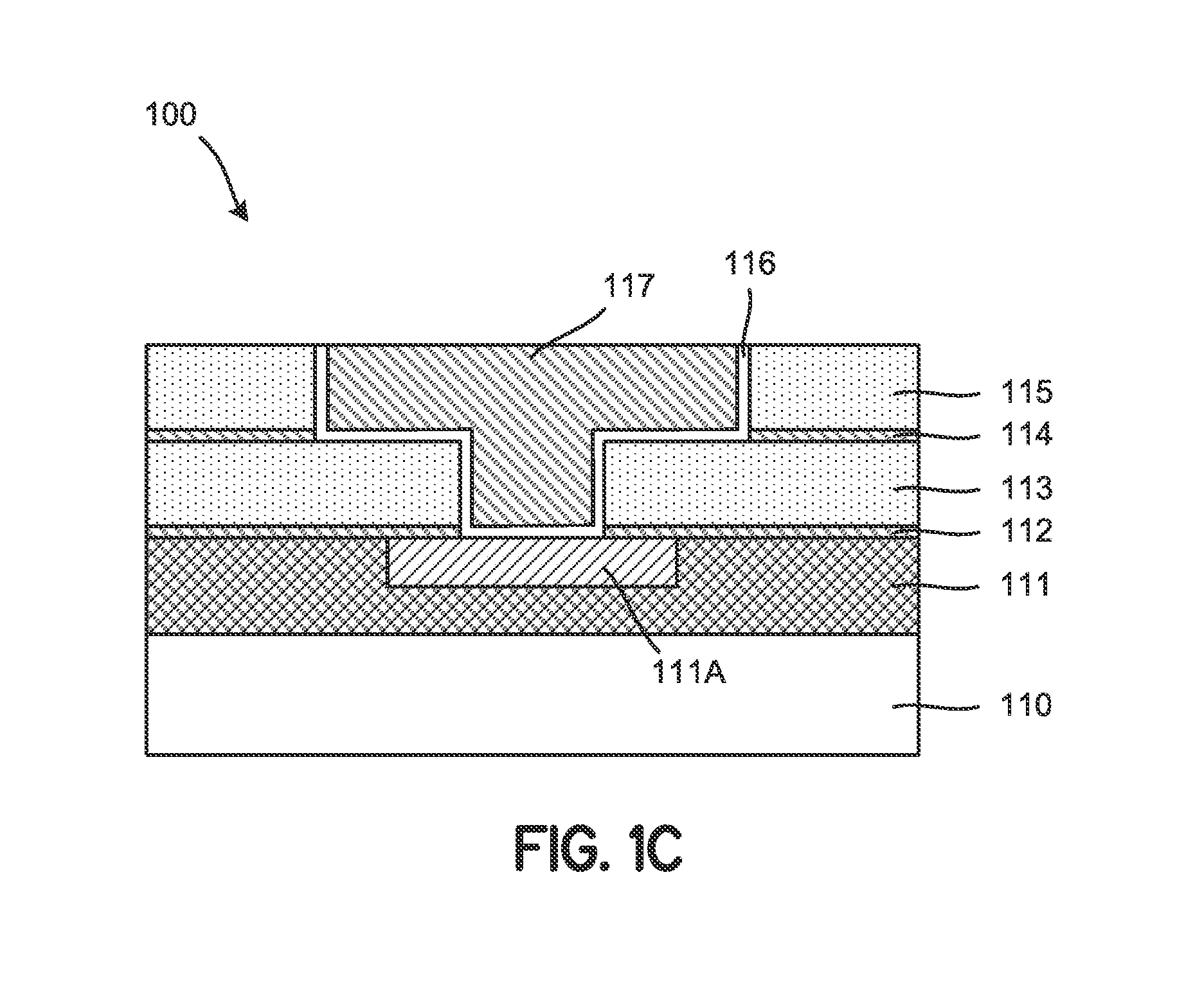

Flowable carbon for semiconductor processing

ActiveUS9514932B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingCarbon layerSemiconductor

Methods are described for forming flowable carbon layers on a semiconductor substrate. A local excitation (such as a hot filament in hot wire CVD, a plasma in PECVD or UV light) may be applied as described herein to a silicon-free carbon-containing precursor containing a hydrocarbon to form a flowable carbon-containing film on a substrate. A remote excitation method has also been found to produce flowable carbon-containing films by exciting a stable precursor to produce a radical precursor which is then combined with unexcited silicon-free carbon-containing precursors in the substrate processing region.

Owner:APPLIED MATERIALS INC

Flowable carbon for semiconductor processing

ActiveUS20140045342A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingCarbon layerSilicon

Methods are described for forming flowable carbon layers on a semiconductor substrate. A local excitation (such as a hot filament in hot wire CVD, a plasma in PECVD or UV light) may be applied as described herein to a silicon-free carbon-containing precursor containing a hydrocarbon to form a flowable carbon-containing film on a substrate. A remote excitation method has also been found to produce flowable carbon-containing films by exciting a stable precursor to produce a radical precursor which is then combined with unexcited silicon-free carbon-containing precursors in the substrate processing region.

Owner:APPLIED MATERIALS INC

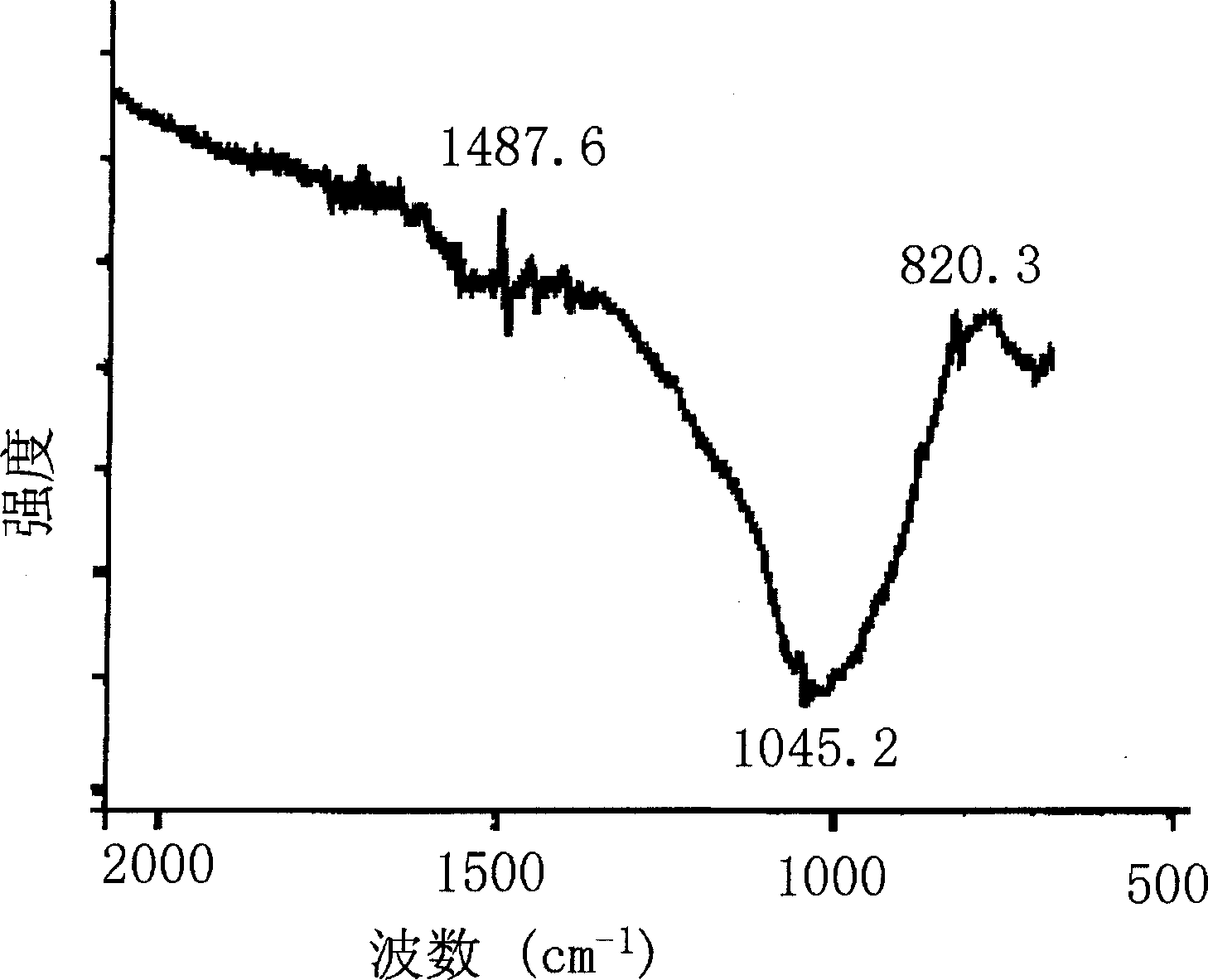

Fluorocarbon-organosilicon copolymers and coatings prepared by hot-filament chemical vapor deposition

InactiveUS6887578B2Synthetic resin layered productsCellulosic plastic layered productsGas phaseX-ray

Hot-filament chemical vapor deposition has been used to deposit copolymer thin films consisting of fluorocarbon and siloxane groups. The presence of covalent bonds between the fluorocarbon and organosilicon moieties in the thin film has been confirmed by Infrared, X-ray Photoelectron (XPS) and solid-state 29Si, 19F, and 13C Nuclear Magnetic Resonance (NMR) spectroscopy. The film structure consists of chains with linear and cyclic siloxane groups and CF2 groups as repeat units.

Owner:MASSACHUSETTS INST OF TECH

Method for preparing silicon thin film heterojunction solar cell

InactiveCN1588649AAvoid damageReduce hydrogen contentFinal product manufacturePhotovoltaic energy generationHeterojunctionSilicon thin film

A prepn. method of silicon thin film heterojunction solar cell includes following steps: cleaning substrate, semiconductor cleaning technology is used to do primary cleaing to substrate surface, then do ultrasonic cleaning in deionized water several times; nitrogen blow drying; prepare nitrinsic amorphous silicon layer by heater chemical vapour phase depositing technology, tungsten filament temp. is measured by pyrometer, temp of heater and sample are determined separately by two electric thermo-couples, temp. is controlled by electric temp. controller; to react and grow thin film on substrate surface; to redeposit a transmitting layer on intrinsic amorphous silicon thin film; front and back electrodes forming, sputtering technology is used to form front and back electrodes; finally to proceed vacuum heat annealing process. The thin film produced by the invention has illumination stability, the photoconduction gain can reach to 10 to the power 6 on Am1.5 100mW / cm2 standard illumination.

Owner:SHANGHAI JIAO TONG UNIV

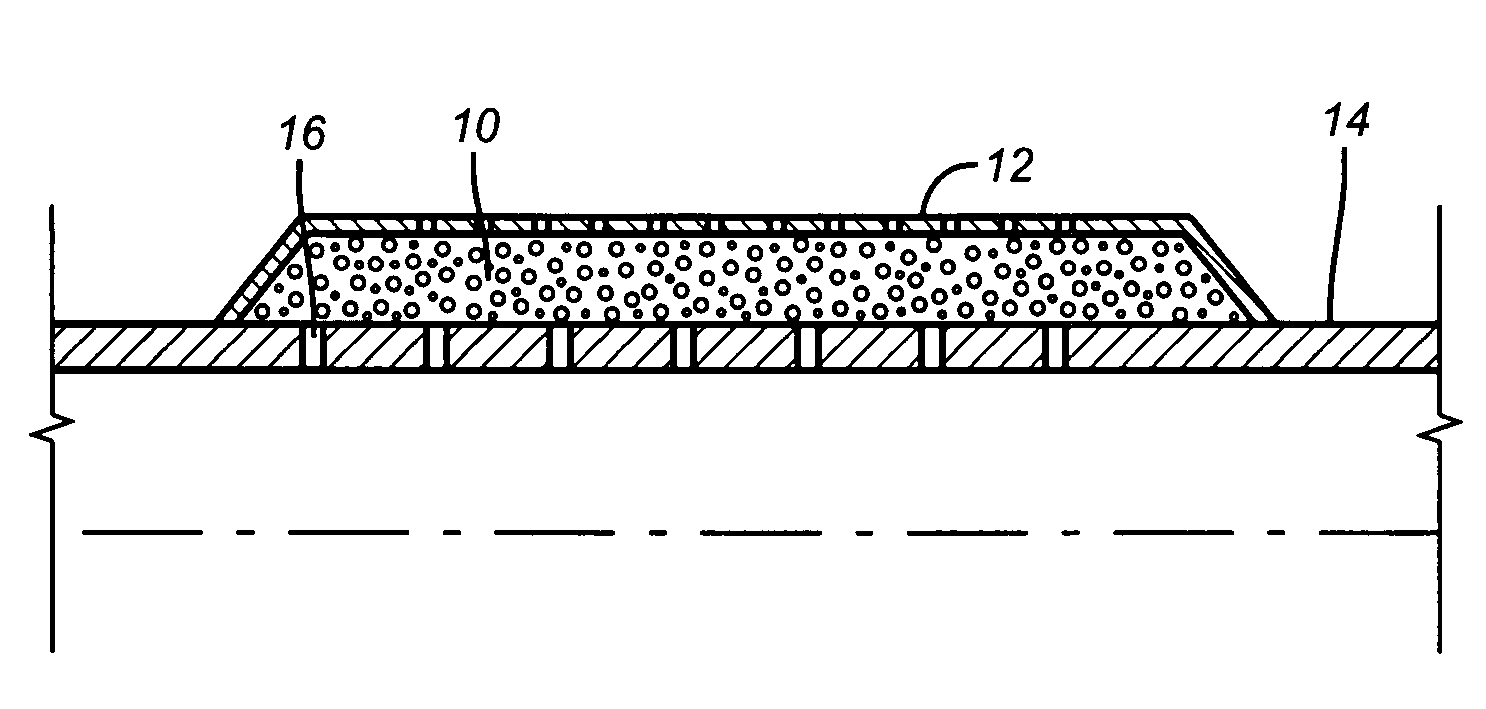

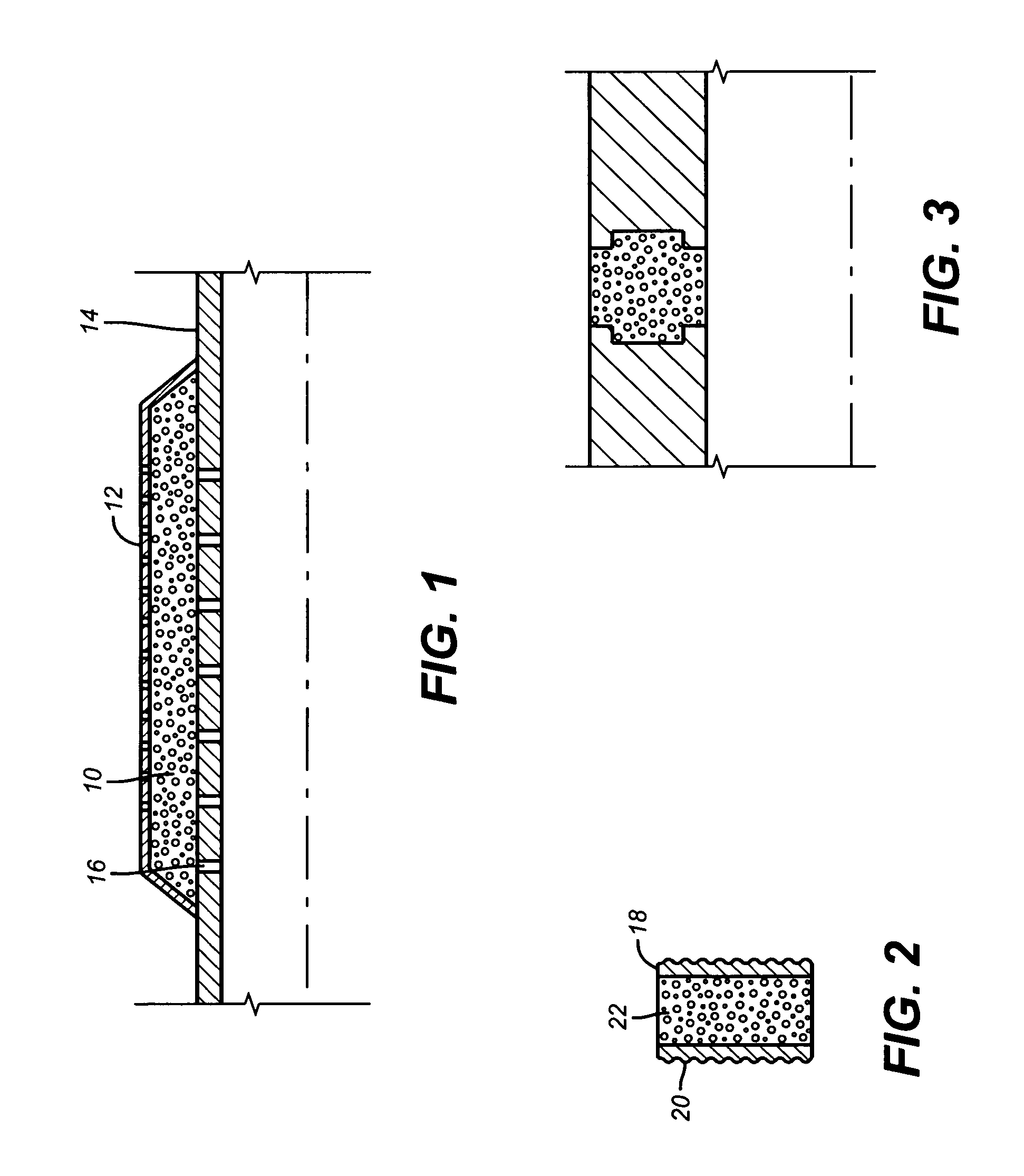

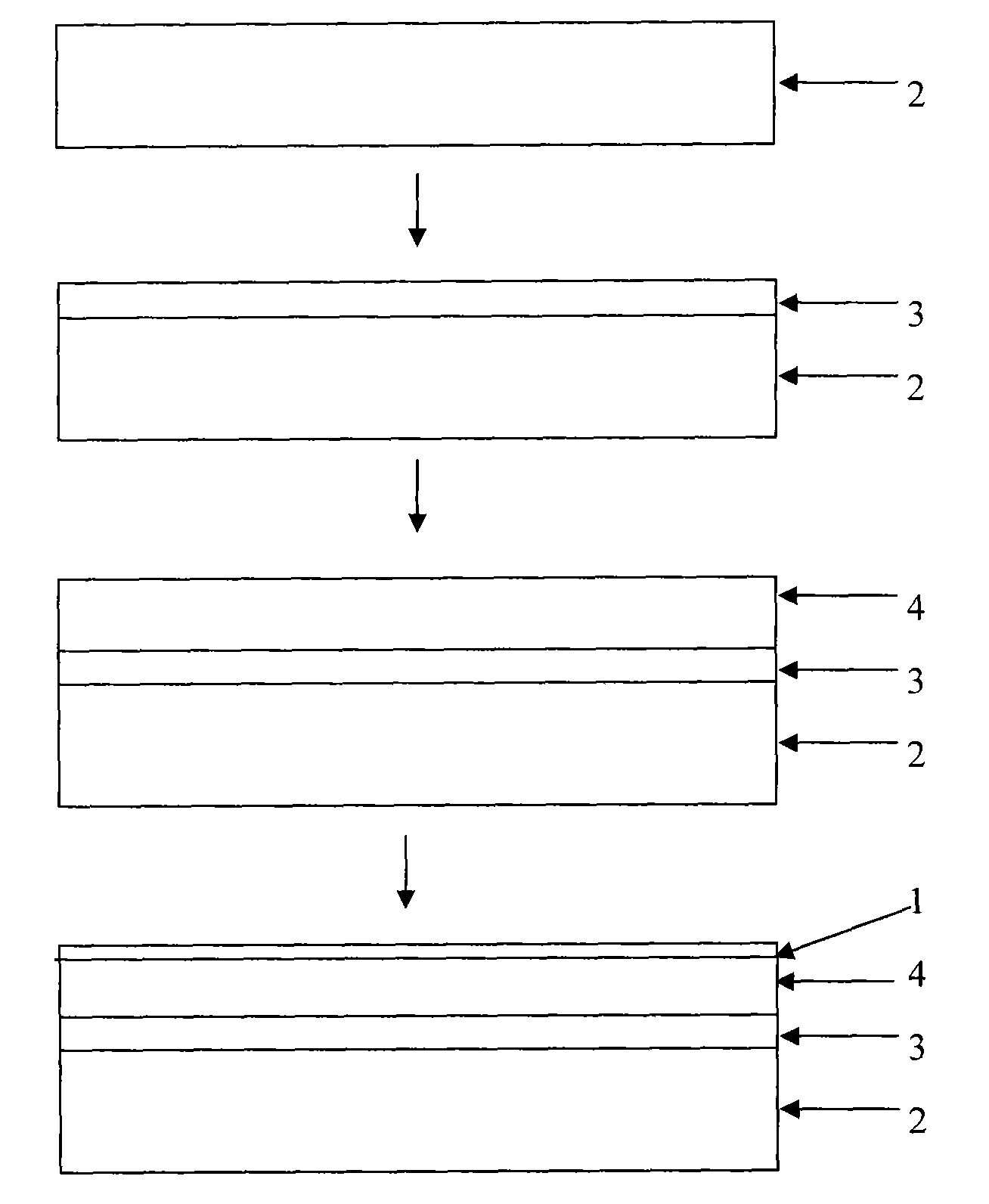

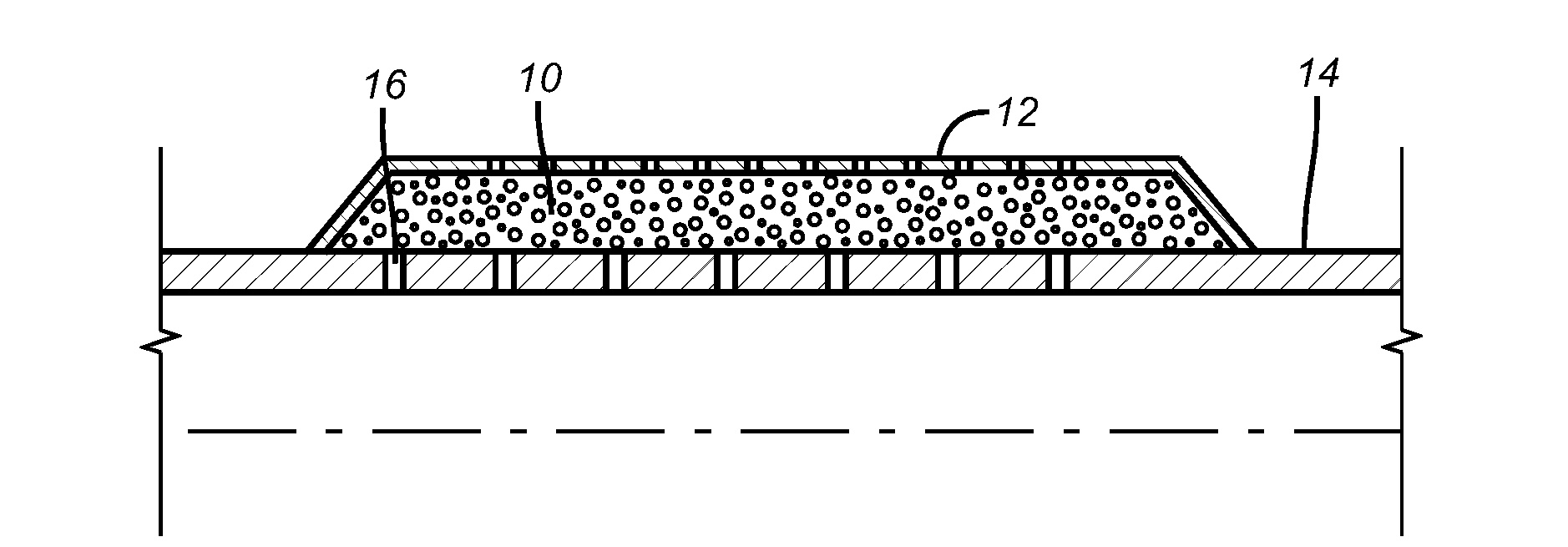

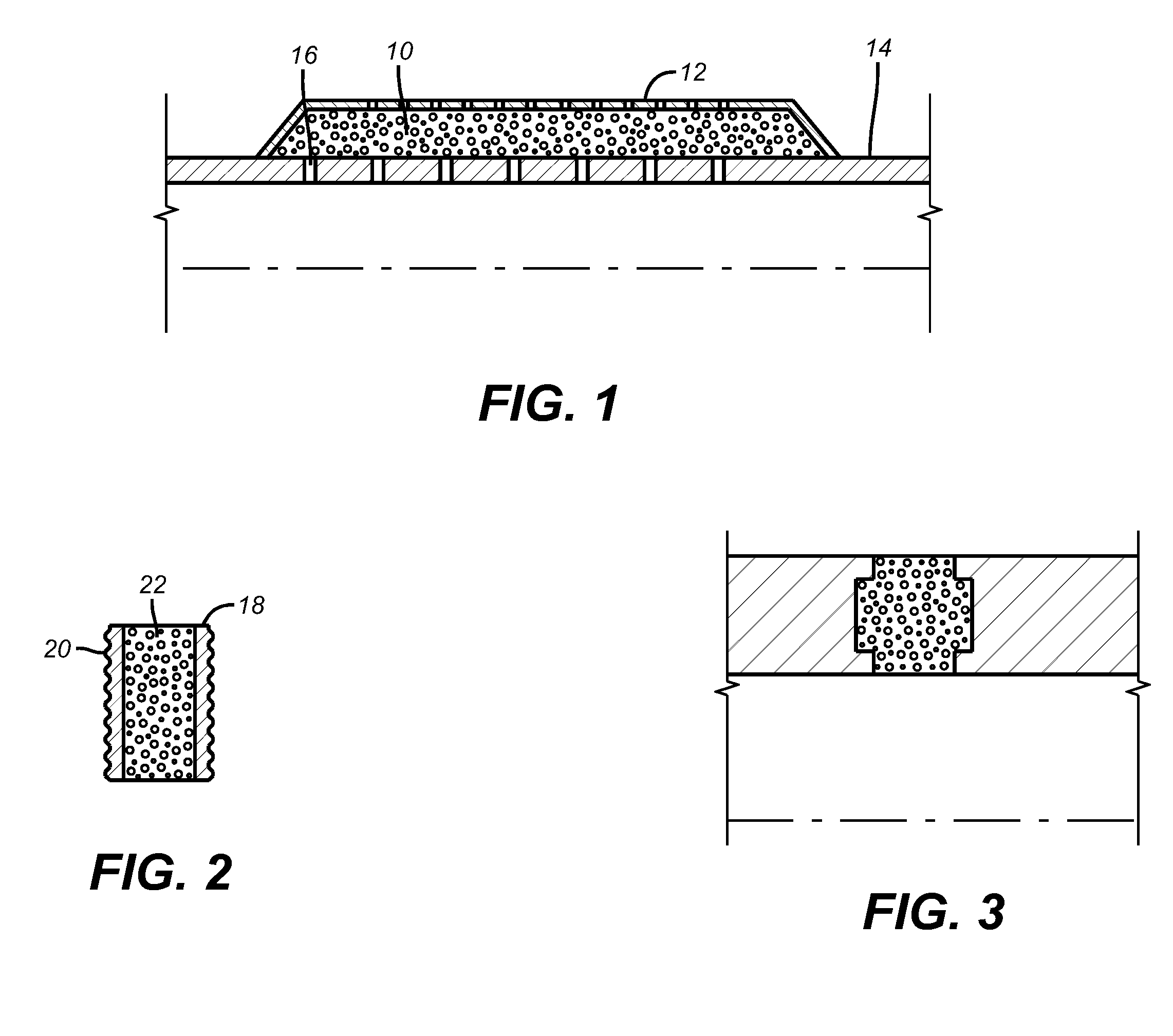

Bead pack brazing with energetics

InactiveUS7644854B1Reduce energy consumptionPrevent movementFluid removalWelding/cutting media/materialsEnergeticsUnit structure

A method of making porous shapes from unit structures such as beads involves coating the beads with two or more layers of material deposited such that it forms an energetic material. These bi-layer energetic materials are formed from a variety of materials including, but not limited to: Ti & B, Zr & B, Hf & B, Ti & C, Zr & C, Hf & C, Ti & Si, Zr & Si, Nb & Si, Ni & Al, Zr & Al, or Pd & Al, all of which can be deposited from vapor. Pressure is applied to prevent the components from moving and the solid-state reaction between the alternating layers produces exothermic heat. Heat from the reaction alone or in conjunction of an applied brazing compound joins the beads forming a porous shape that is desired. The reaction in the materials may be activated with a small pulse of local energy that can be applied using optical, electrical, or thermal sources. Common examples include an electrical pulse, spark, hot filament, a laser beam, etc. The method reduces energy consumption and the need for specialized equipment. The reactive materials and optional brazing material are preferably applied in a fluidized CVD furnace.

Owner:BAKER HUGHES INC

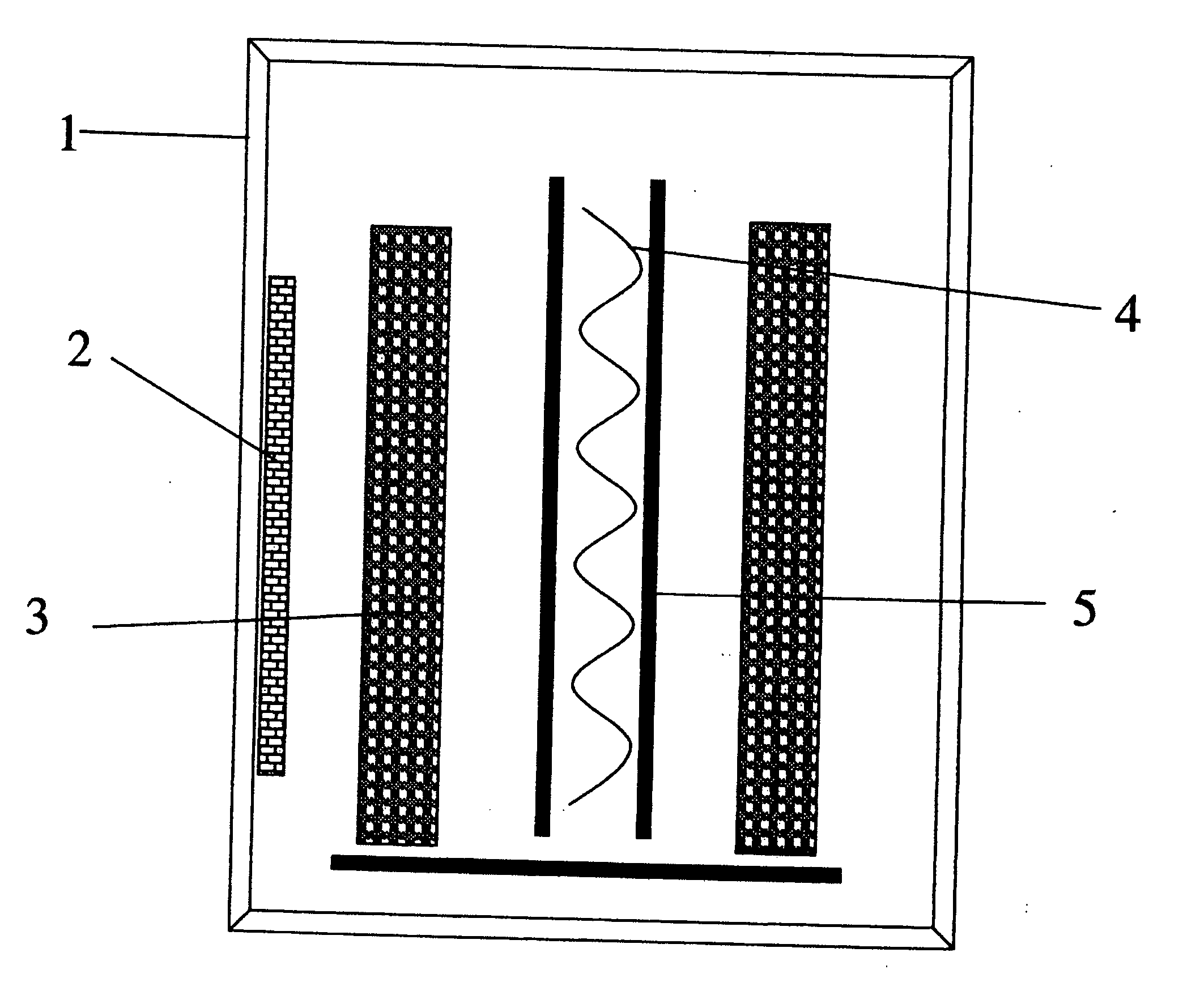

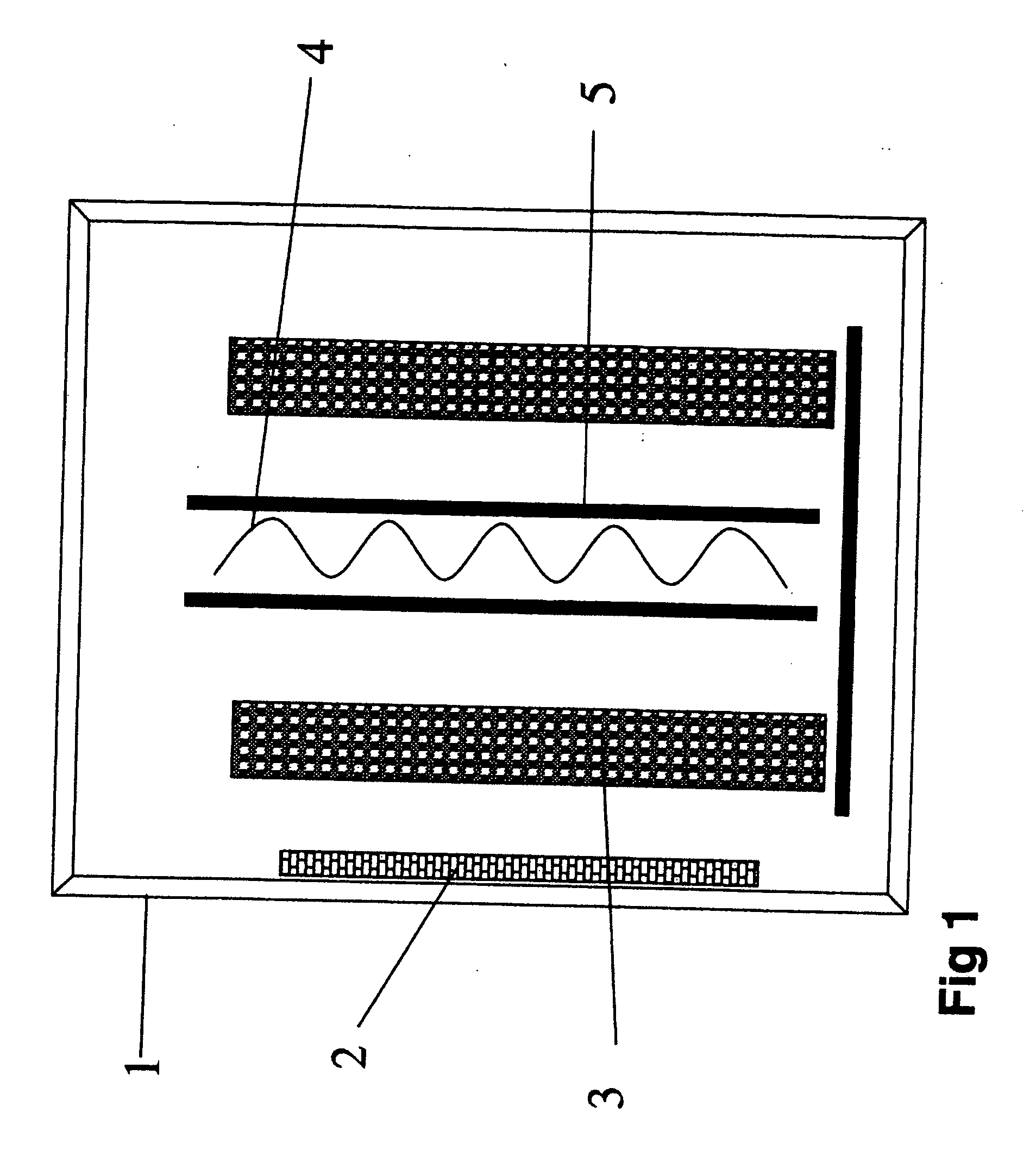

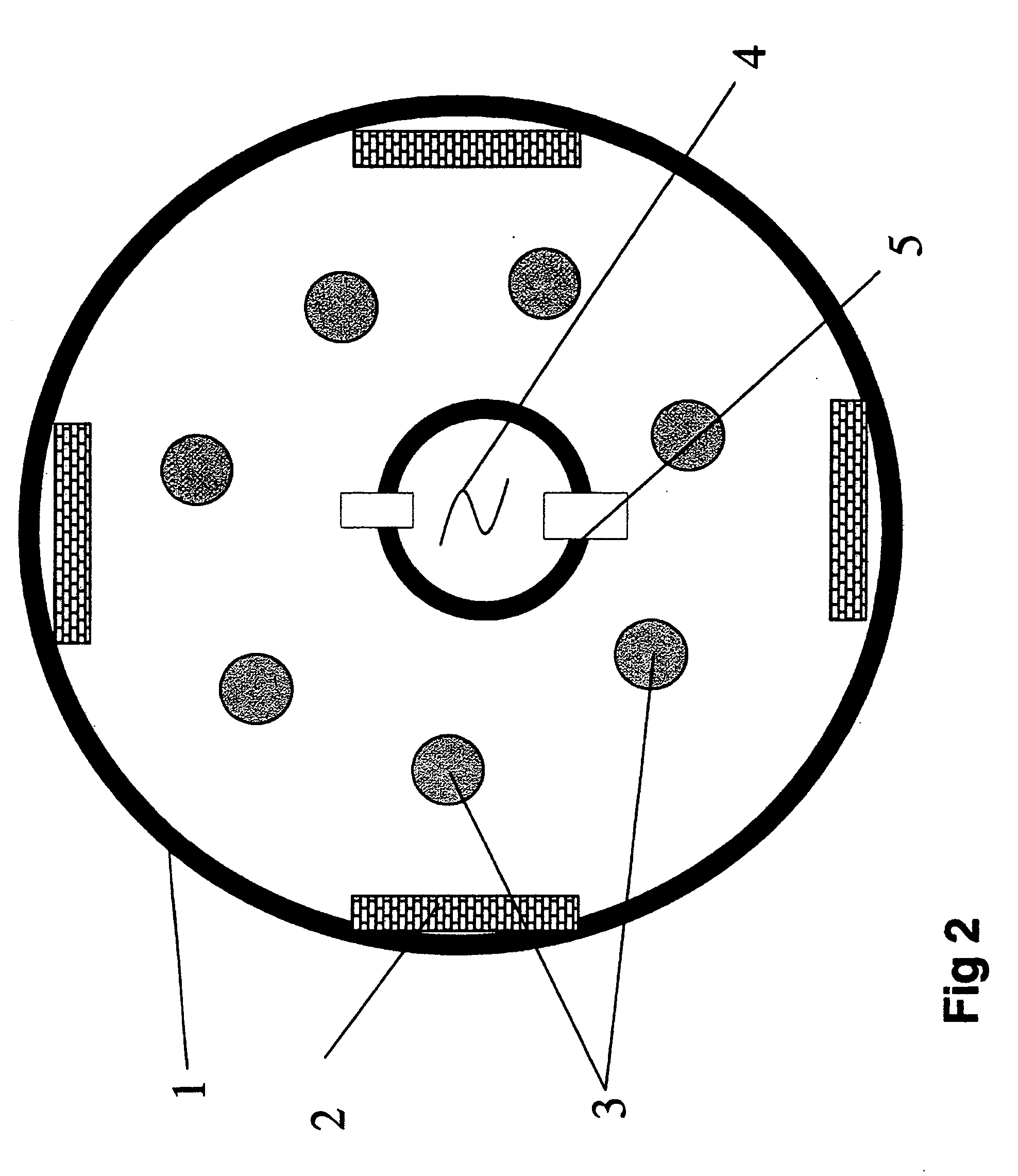

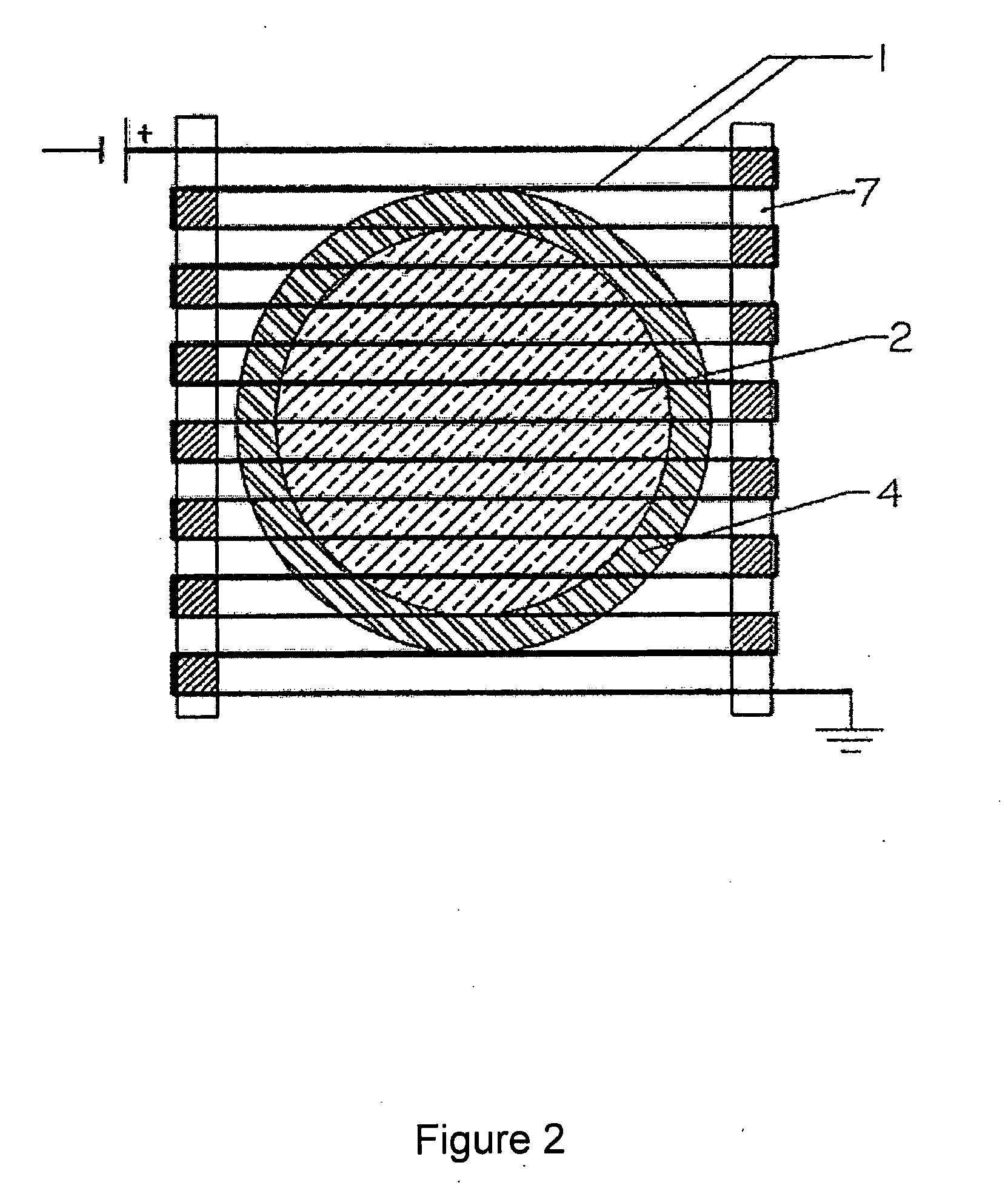

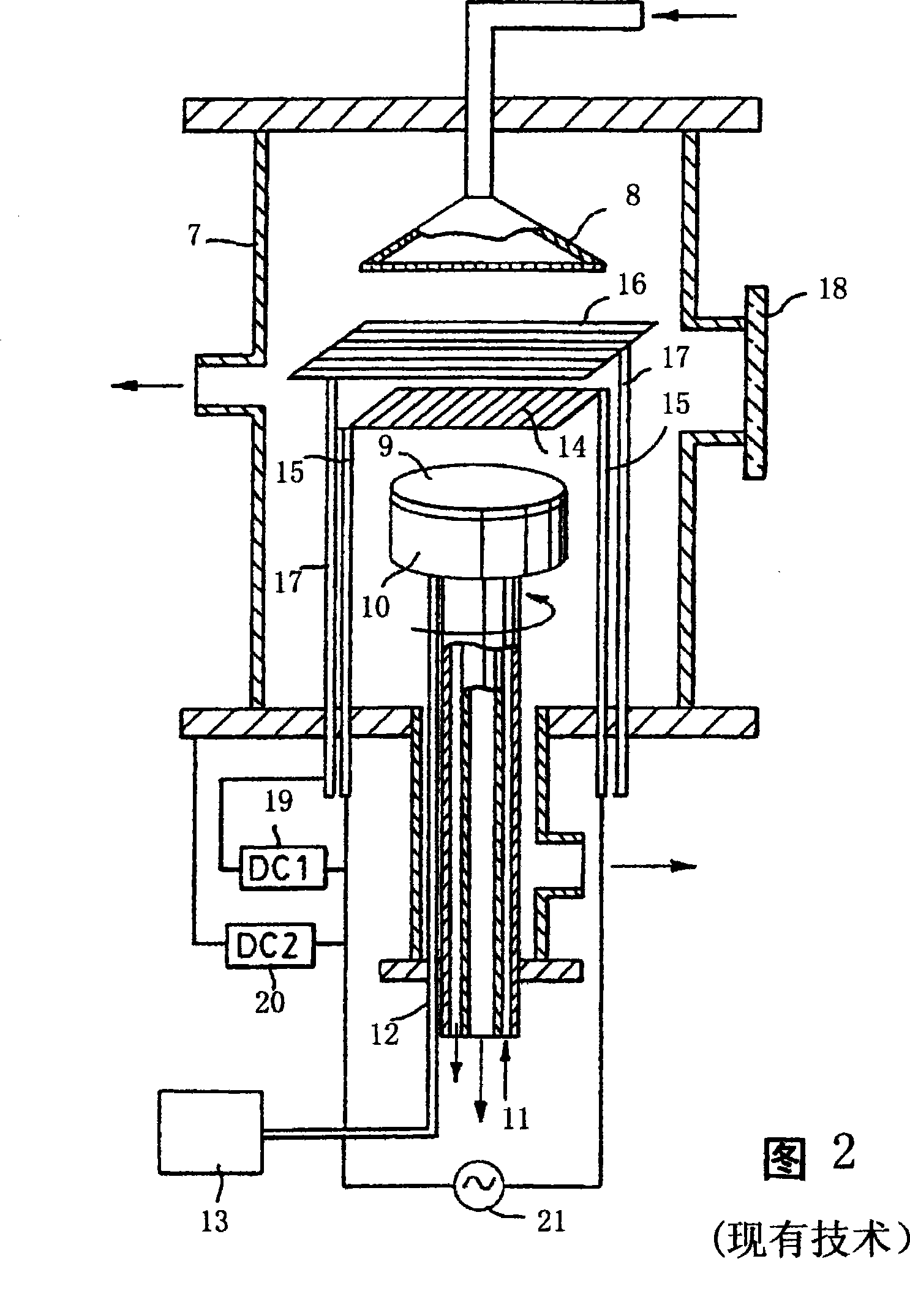

Device for improving plasma activity PVD-reactors

InactiveUS20070017804A1Increase intensity of plasmaSimple technologyCellsElectric discharge tubesThermionic emissionEngineering

The present invention relates to a device for improving plasma activity in a magnetron sputtering reactor containing substrates to be coated where a primary plasma is created by a DC or AC voltage applied between the substrates and an additional electrode. Increased plasma activity is obtained by thermionic emission of electrons from a hot filament heated by either DC or AC current or combinations thereof. The device is particularly useful for increasing the adhesion of layers deposited by magnetron sputtering on cutting tool inserts made of cemented carbide, high speed steels, cermets, ceramics or cubic boron nitride.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

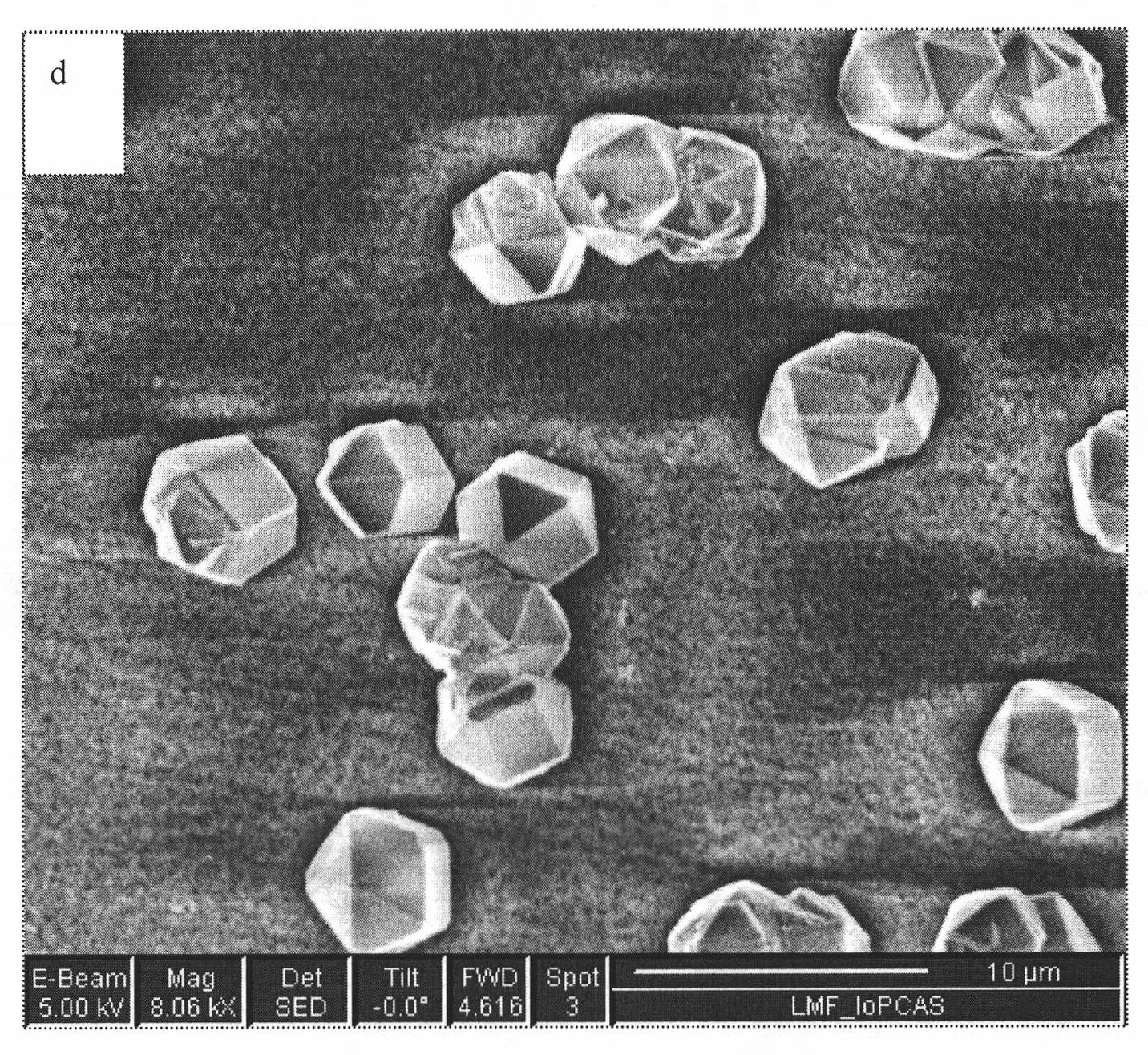

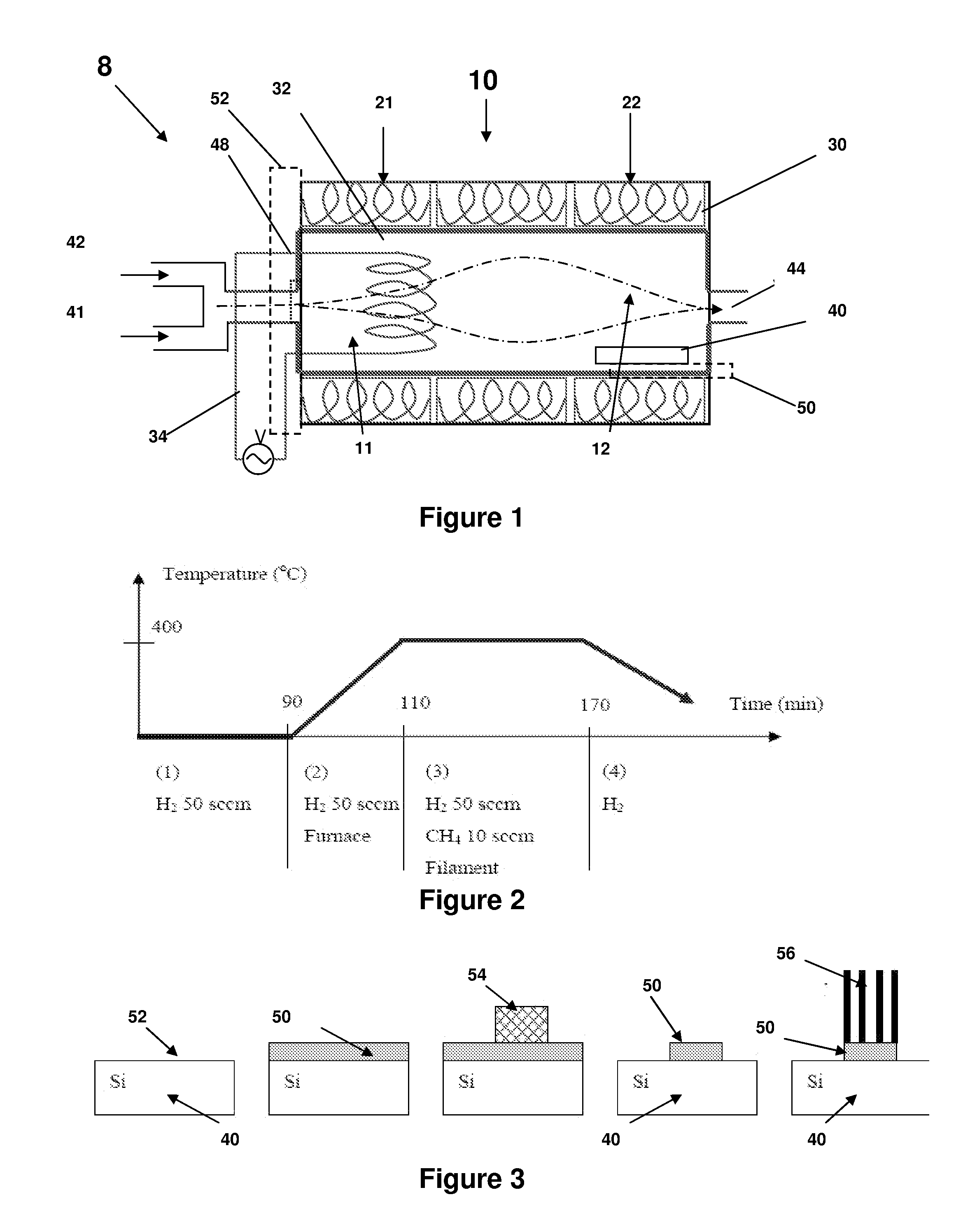

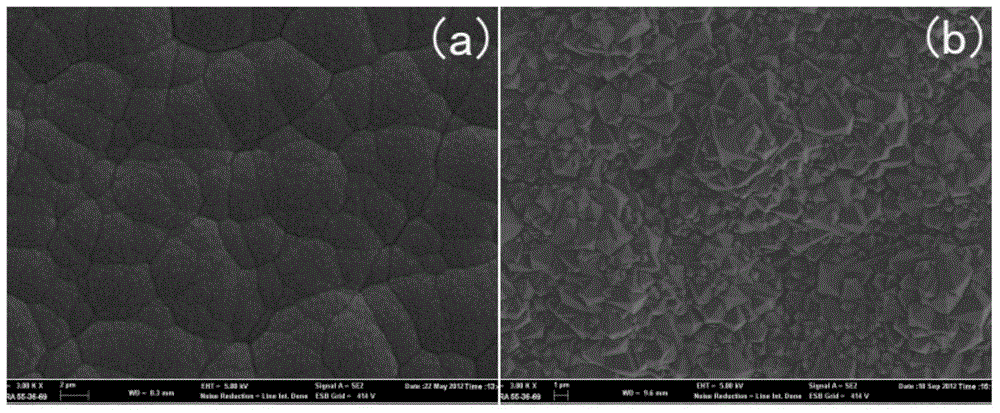

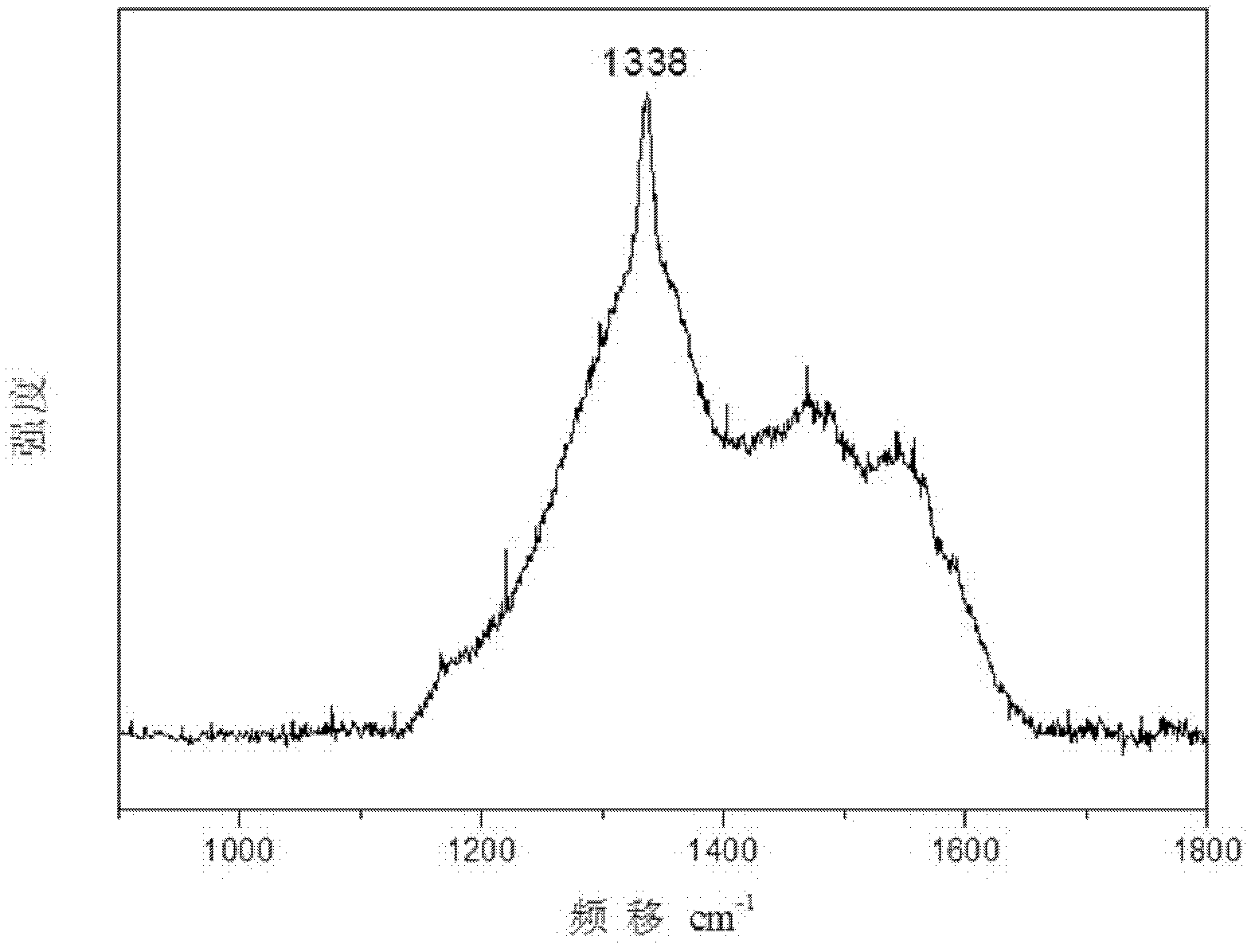

Preparation method of graphene on diamond (111) surface

ActiveCN102102220AHigh area controllabilitySmall sizeFrom chemically reactive gasesMicron scaleNanoscopic scale

The invention discloses a preparation method of graphene on a diamond (111) surface, which mainly comprises the steps of: (1) growing an undoped diamond transition layer on a substrate: placing the substrate on a substrate support of a cavity of a hot filament chemical vapor deposition system, and growing a diamond transition layer; (2) growing a B-doped diamond film on the diamond transition layer; and (3) forming the grapheme through annealing and self-organization. By the preparation method, larger-size samples can be prepared, and the size is from nano scale to micron scale even millimeter scale. The method for preparing the graphene through self-organization, and is easier to realize; the grown grapheme has higher area controllability, can reach the micron scale or larger size which cannot be realized by most existing methods. In addition, the diamond has multiple excellent characteristics, and the boron-doped diamond substrate is not symmetrical, therefore, the graphene formed on the boron-doped diamond substrate can easily generate an energy gap, which is more beneficial to application of the graphene to devices.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

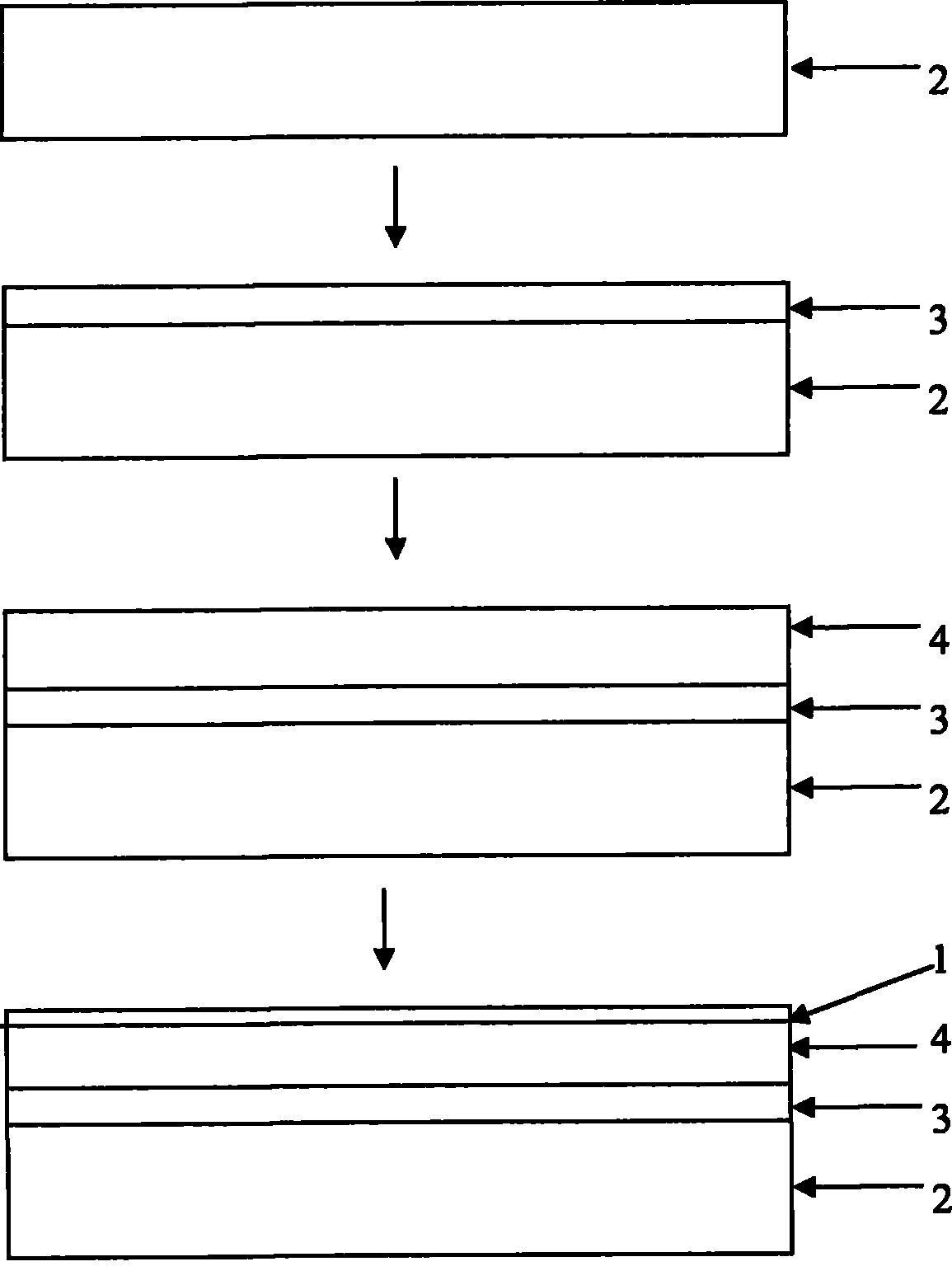

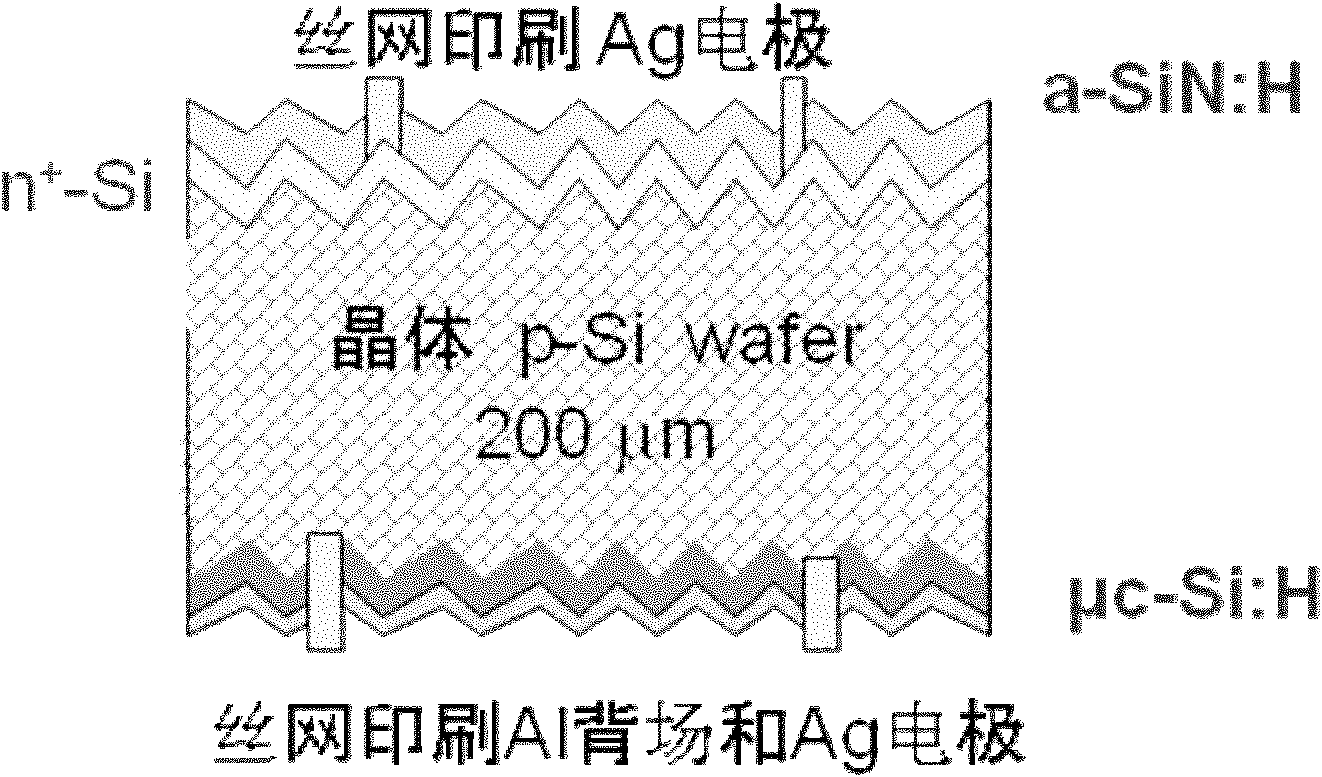

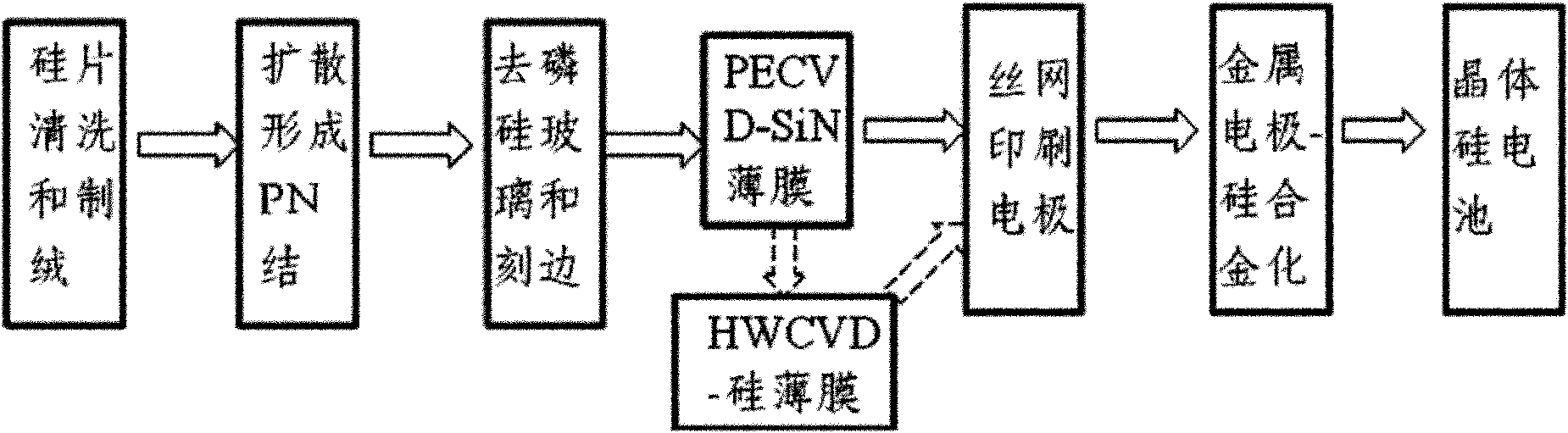

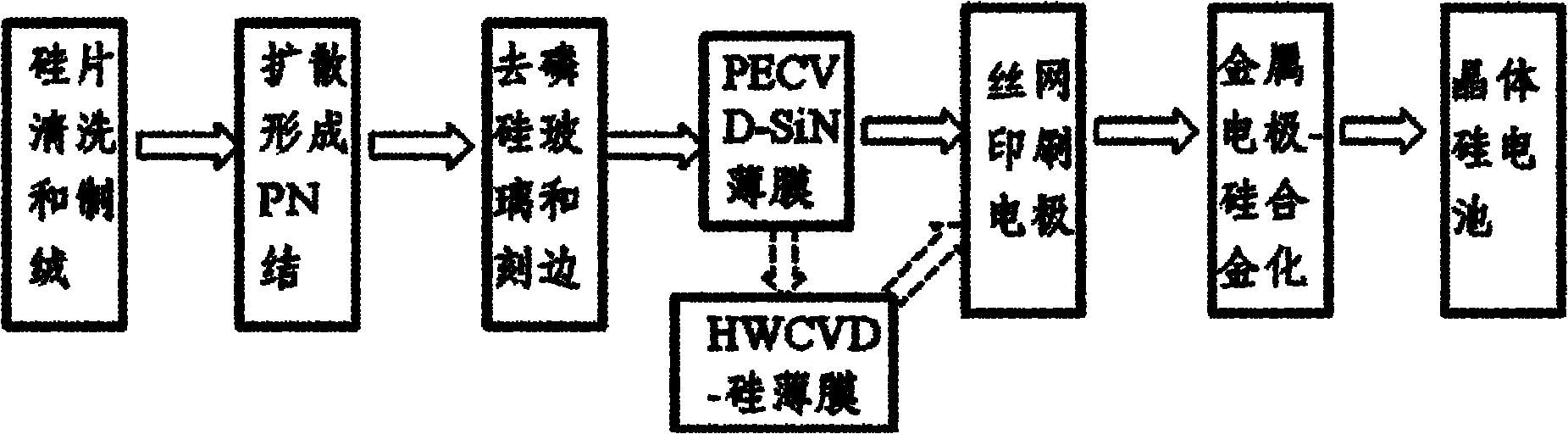

Preparation method of double-sided passivated crystalline silicon solar cell

InactiveCN101937944APrevent escapeAdjustable bandgapSemiconductor devicesP type siliconMicrocrystalline silicon

The invention discloses a preparation method of a double-sided passivated crystalline silicon solar cell, belonging to the technical field of photovoltaic power generation. The preparation method comprises the following steps of: firstly, respectively carrying out surface precleaning and surface texturing on P-shaped single crystal silicon and a polycrystalline silicon wafer by adopting an alkaline solution and an acid solution; secondly, diffusing by using phosphorus oxychloride as a diffusion source to form a PN junction; thirdly, removing a phosphosilicate glass on the surface of the silicon wafer by adopting a chemical wet method, and etching the edge of the silicon wafer by adopting a plasma; fourthly, preparing a silicon nitride film on the surface of an emitting region of a P-type silicon wafer by adopting a plasma enhanced chemical vapor deposition method; fifthly, preparing a mixed phase film material of hydrogenated microcrystalline silicon and amorphous silicon by adopting a hot filament chemical vapor deposition method, depositing a film at one side of the P-type silicon wafer, and passivating the defects and a dangling bond on the surface of the P-type silicon wafer; and sixthly, sintering a screen printing back electrode and a screen printing positive electrode to form the solar cell. The invention lowers the probability of compounding photo-generated minority carriers on the back surface, enhances the long-wave light quantum efficiency and creates the conditions of transportation and collection of the photo-generated carriers.

Owner:SHANGHAI JIAO TONG UNIV

Cutting fool boron nitride composite coating layer and its preparation method

InactiveCN1514039AReduce internal stressImprove bindingTurning toolsChemical vapor deposition coatingBoron nitrideCemented carbide

A coated composite boron nitride layer on the surface of cutting tool is composed of a substrate layer which is TiCxOyNz layer directly deposited on the hard alloy cutter, an intermediate binding layer which is made of Ni, Ni-contained compound, or N or B contained compound, and a boron nitride layer prepared from cubic boron nitride. Said coated layer is prepared by plasma intensified pulse laser deposition method, or hot wire added RE plasma CVD method, or their combination.

Owner:XIANGTAN UNIV

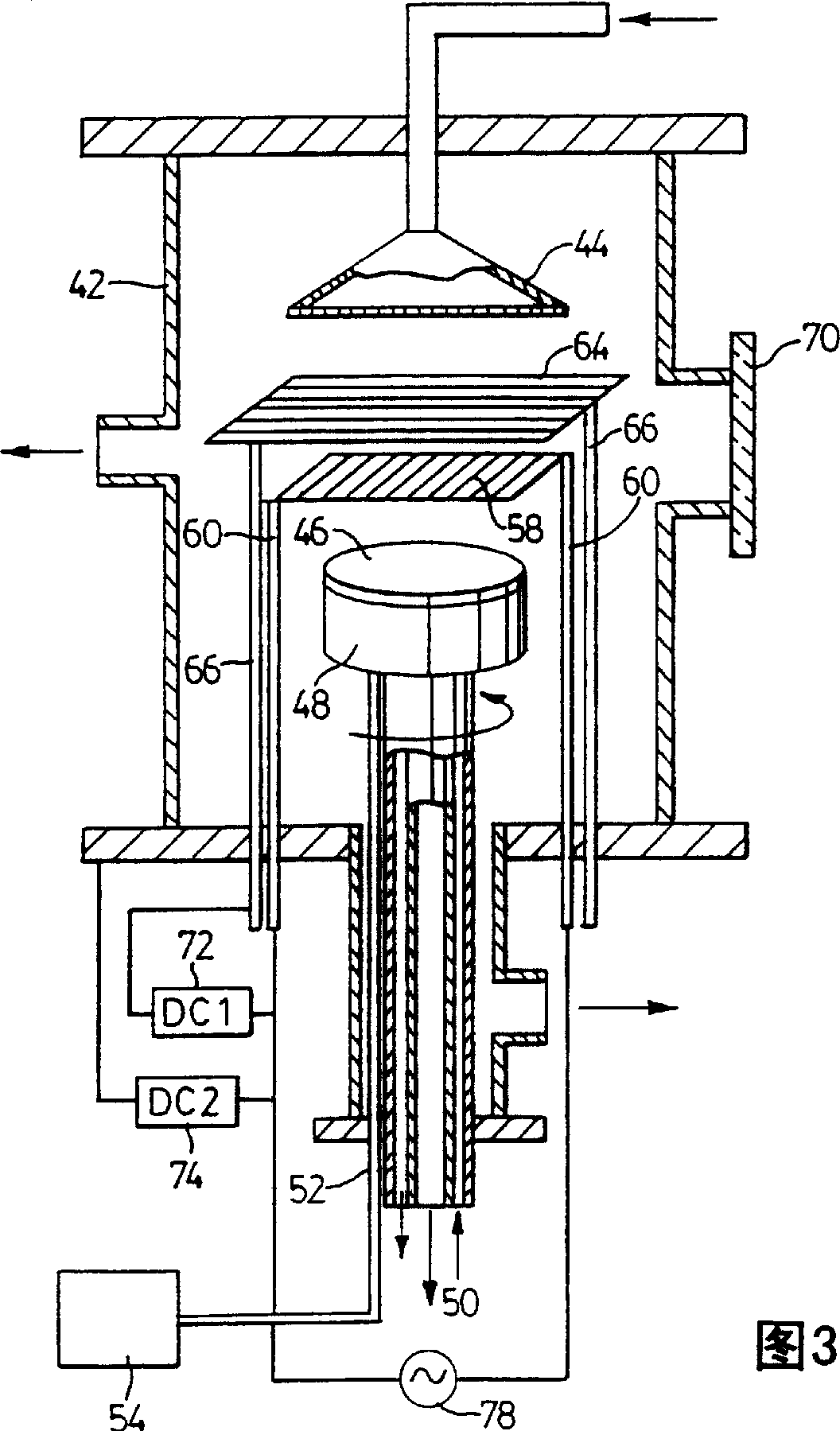

Production of bulk silicon carbide with hot-filament chemical vapor deposition

InactiveUS20090038541A1Avoid insufficient thicknessIncrease the length of timeFurnaces without endless corePolycrystalline material growthTransport systemPlasma-enhanced chemical vapor deposition

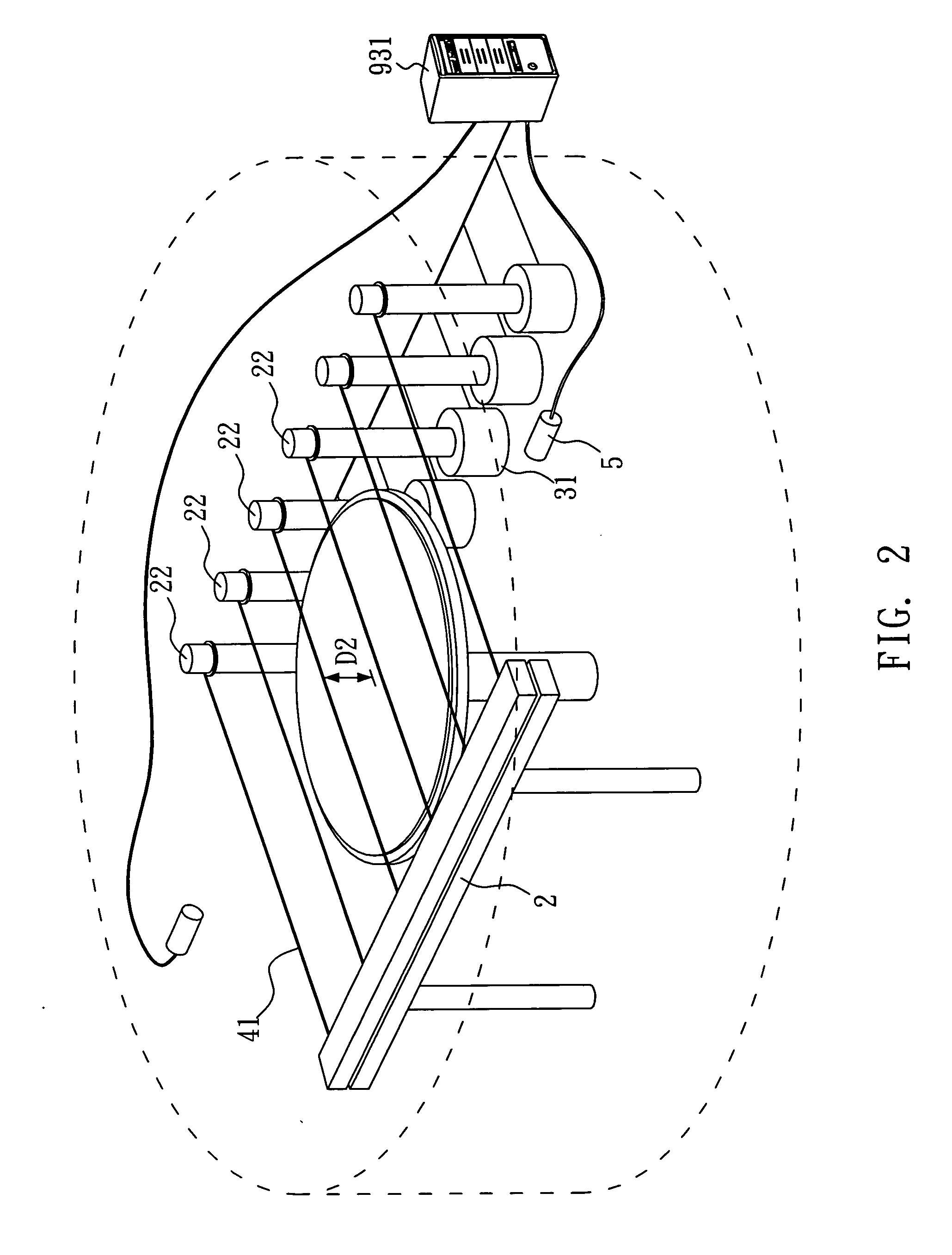

A method to grow a boule of silicon carbide is described. The method may include flowing a silicon-containing precursor and a carbon-containing precursor proximate to a heated filament array and forming the silicon carbide boule on a substrate from reactions of the heated silicon-containing and carbon-containing precursors. Also, an apparatus for growing a silicon carbide boule is described. The apparatus may include a deposition chamber to deposit silicon carbide on a substrate, and a precursor transport system for introducing silicon-containing and carbon-containing precursors into the deposition chamber. The apparatus may also include at least one filament or filament segment capable of being heated to a temperature that can activate the precursors, and a substrate pedestal to hold a deposition substrate upon which the silicon carbide boule is grown. The pedestal may be operable to change the distance between the substrate and the filament as the silicon carbide boule is grown.

Owner:BASIC 3C

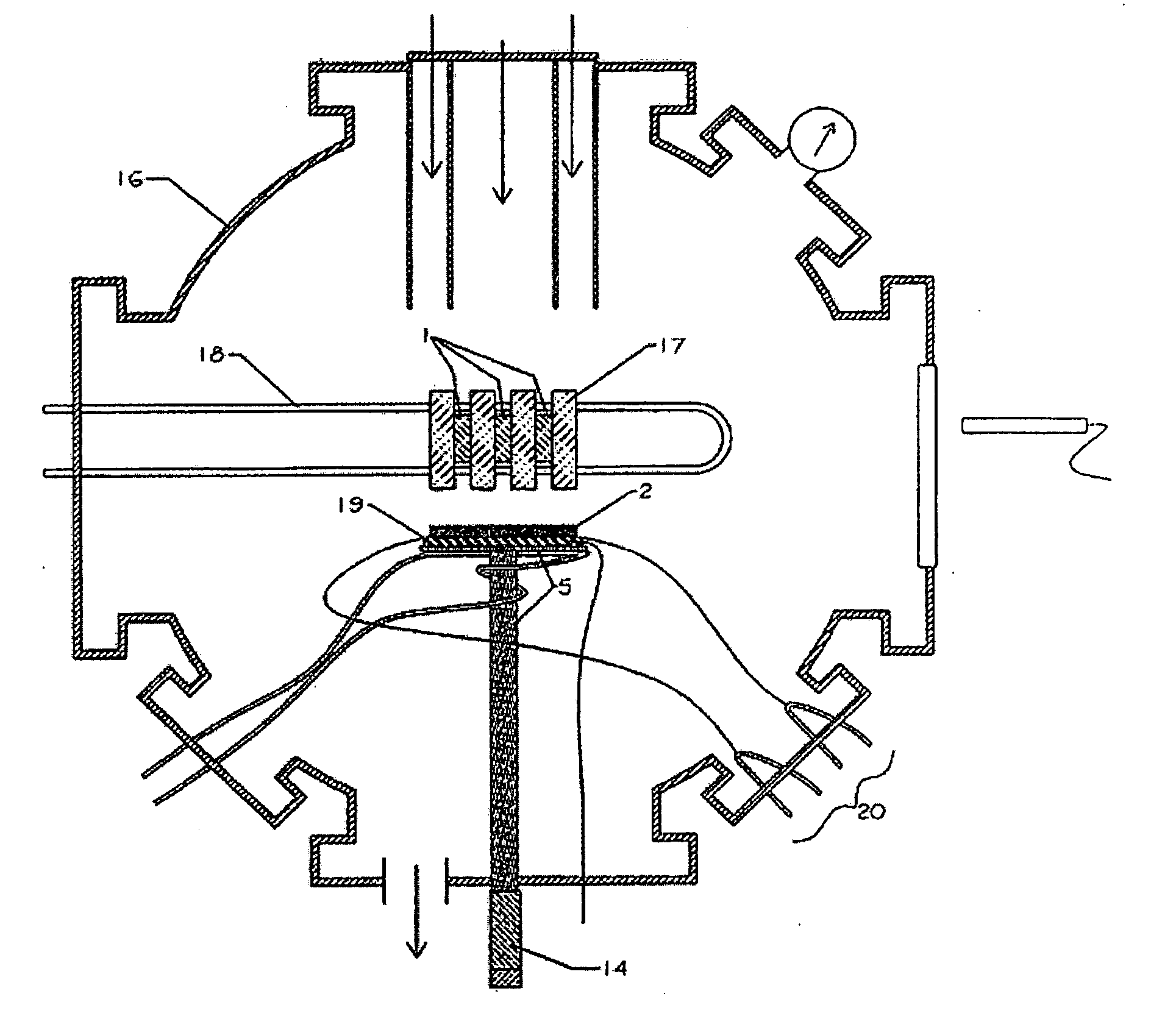

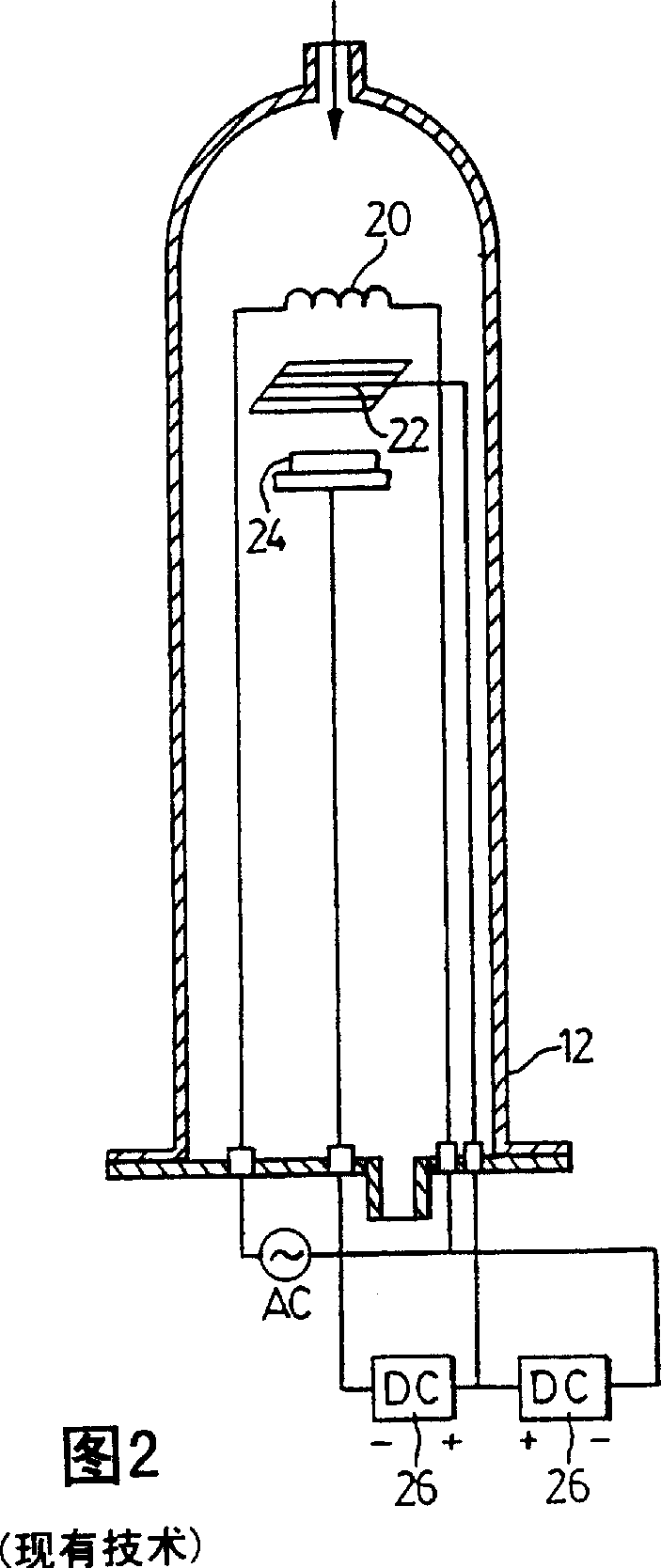

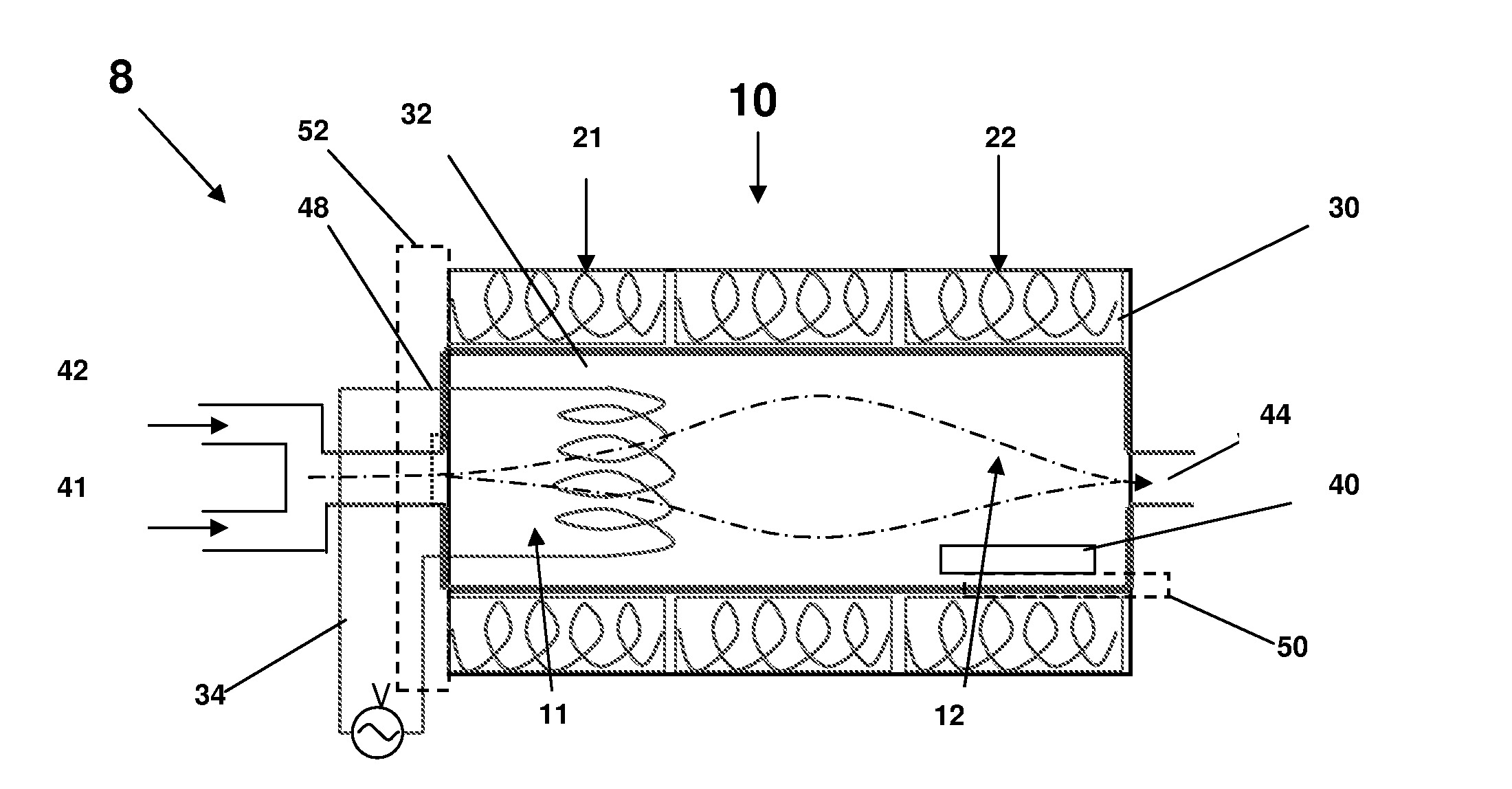

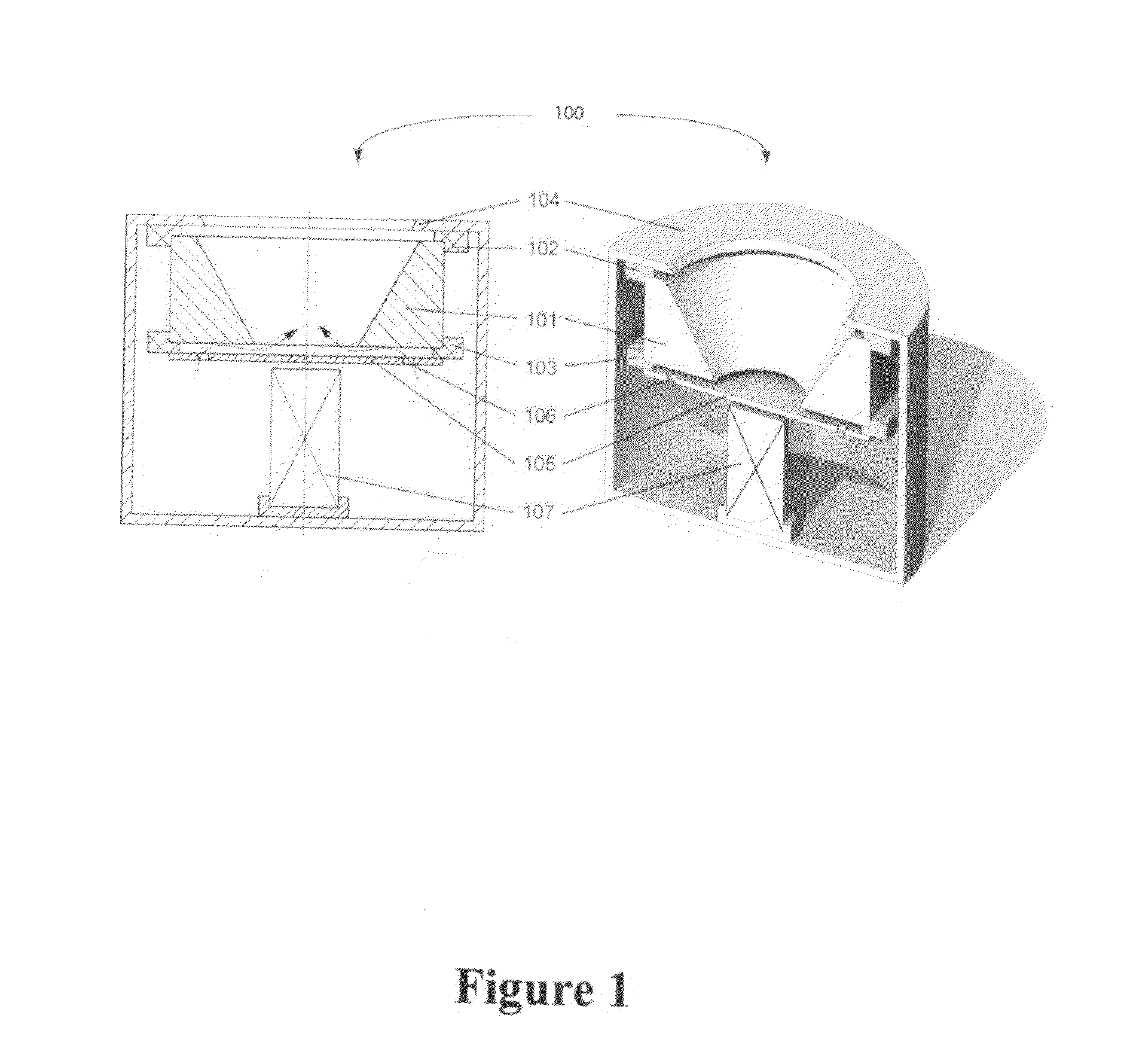

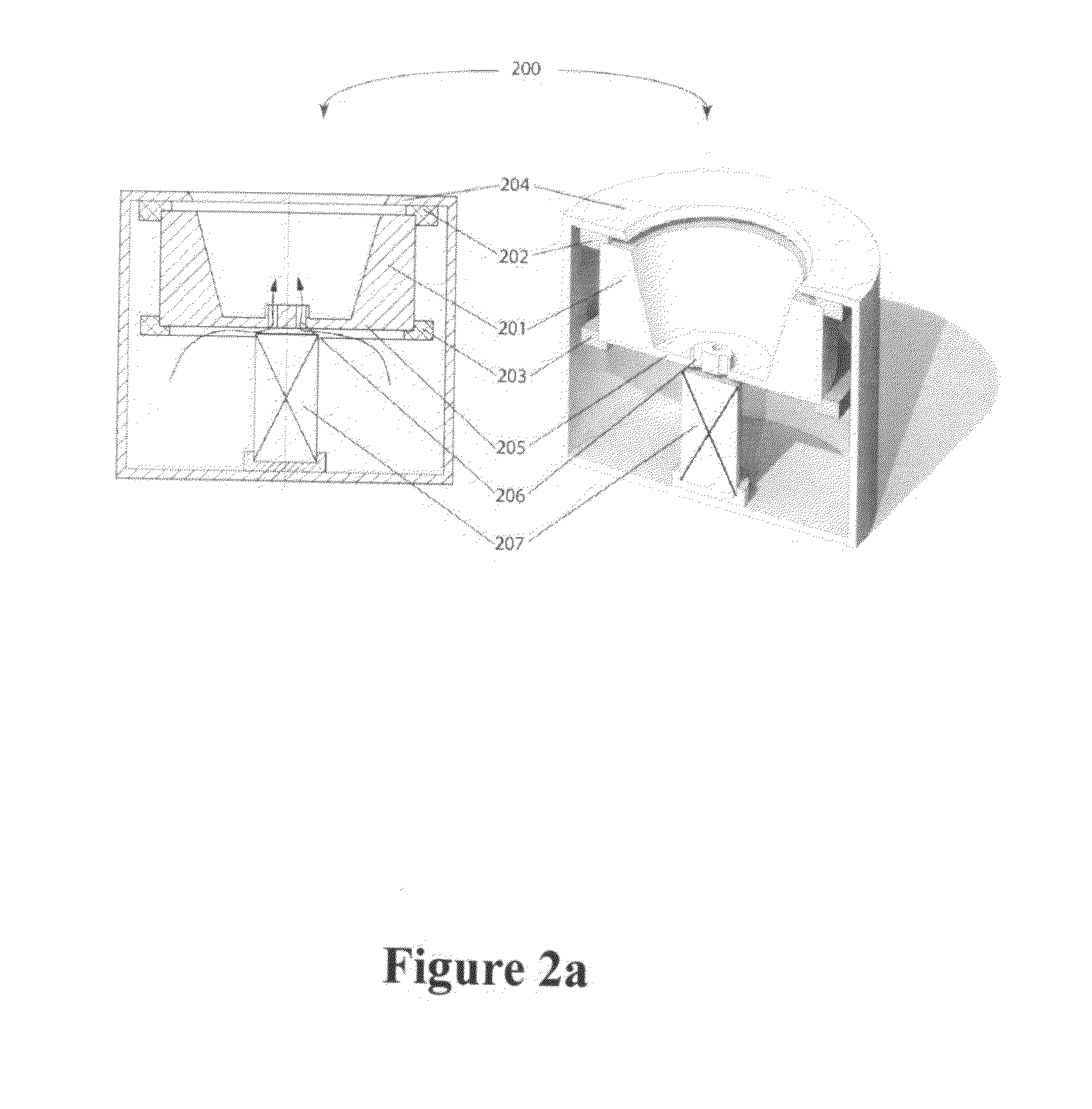

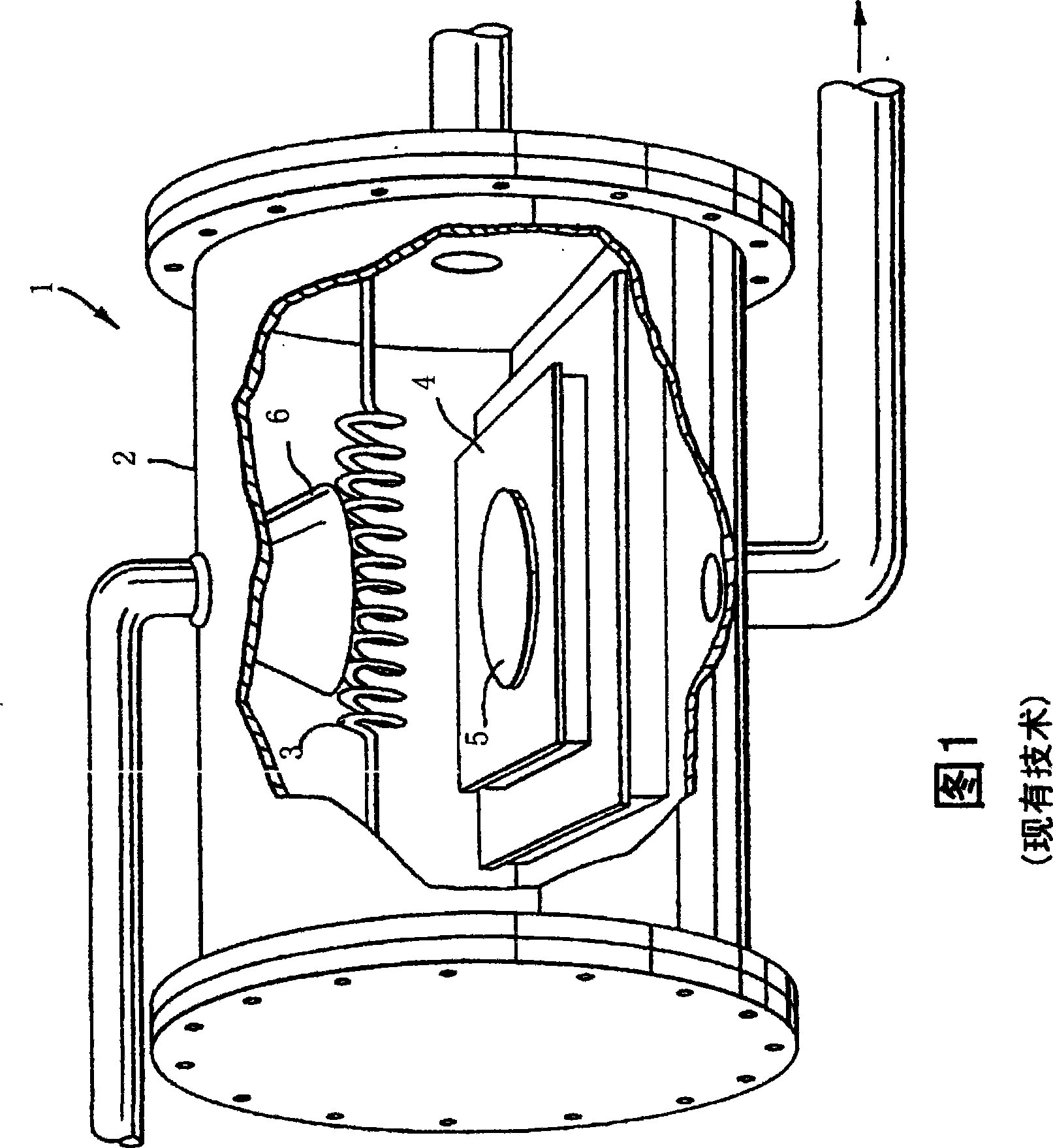

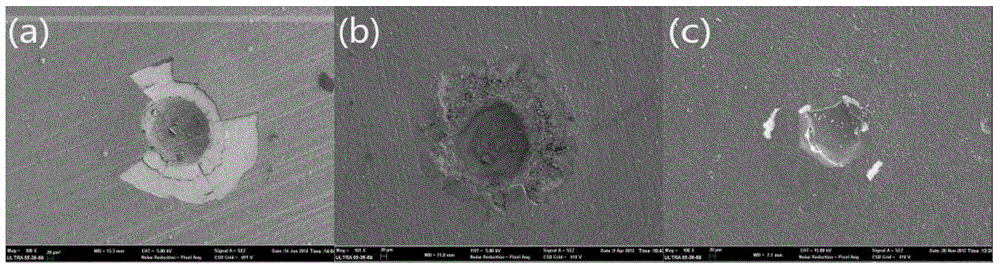

Apparatus and method for nucleotion and deposition of diamond using hot-filament DC plasma

A method and apparatus for nucleation and growth of diamond by hot-filament DC plasma deposition. The apparatus uses a resistively heated filament array for dissociating hydrogen in the reactant gas. For two sided diamond growth, configurations of substrate-hot filament-grid-hot filament-substrate or substrate-hot filament-hot filament-substrate configuration are used. For the latter configuration, two independent arrays of filaments serve as both hot filament and grid, and AC or DC plasma is maintained between the filament arrays. For this and the other electrode configurations, the grid electrode is positively biased with respect to the hot filaments to maintain a plasma. The plasma potential gradient across the grid and the hot-filament draws ions from the plasma towards the filaments. To further increase deposition rates, the filament array is biased negatively with respect to the substrate holder so that a DC plasma is also maintained between the substrate and filament array. During nucleation, the filament adjacent to the substrate holder is biased positively relative to the substrate so that more ions are accelerated towards the substrate, which in turn enhances the flow of growth precursors towards the substrate resulting in a high diamond nucleation density on the substrate without the need for scratching or diamond-seeding pretreatment. This nucleation method simplifies the growth process and provides a convenient and economical means for heteroepitaxial growth of diamond nuclei on single crystal substrates like Si (100).

Owner:CVD DIAMOND CORP

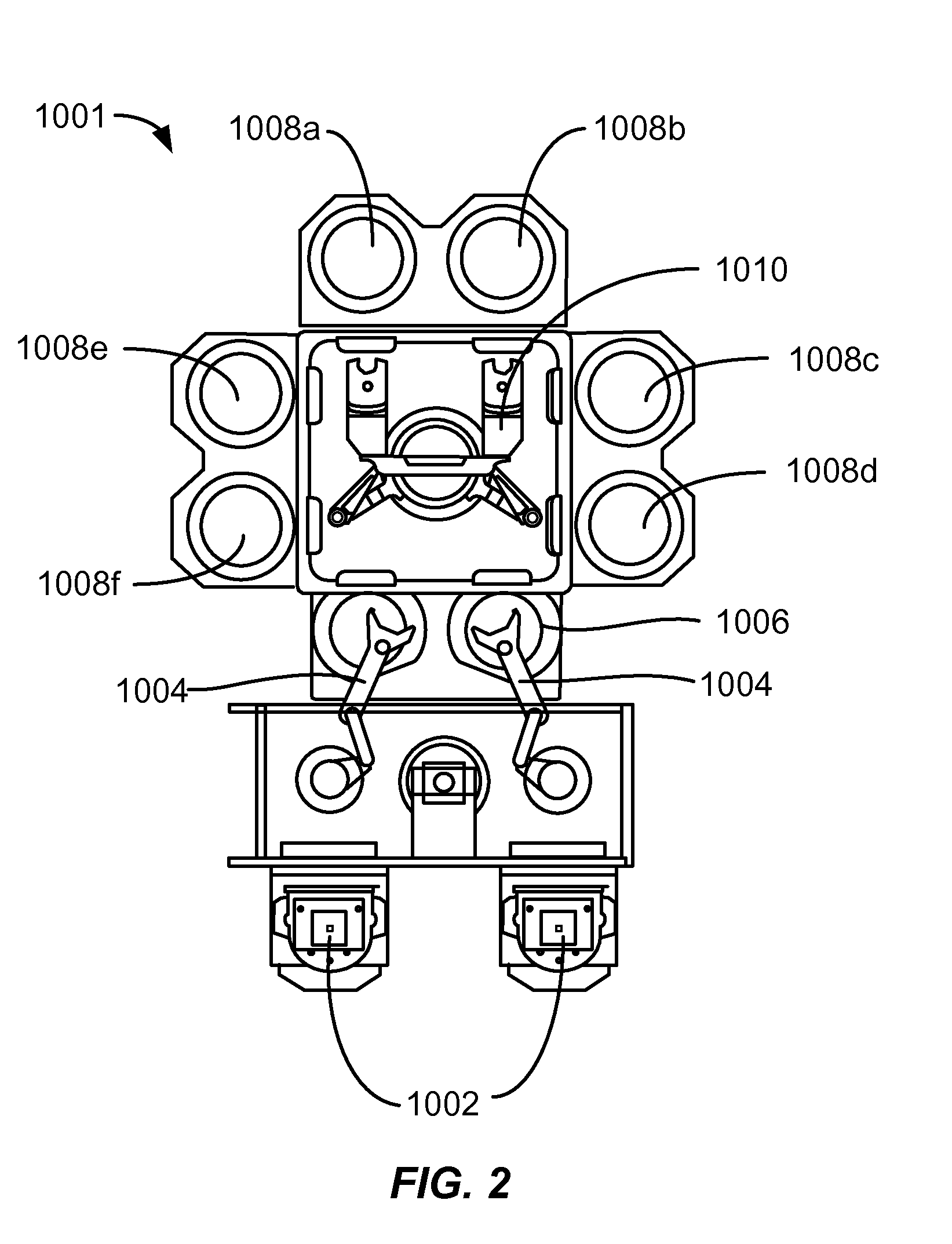

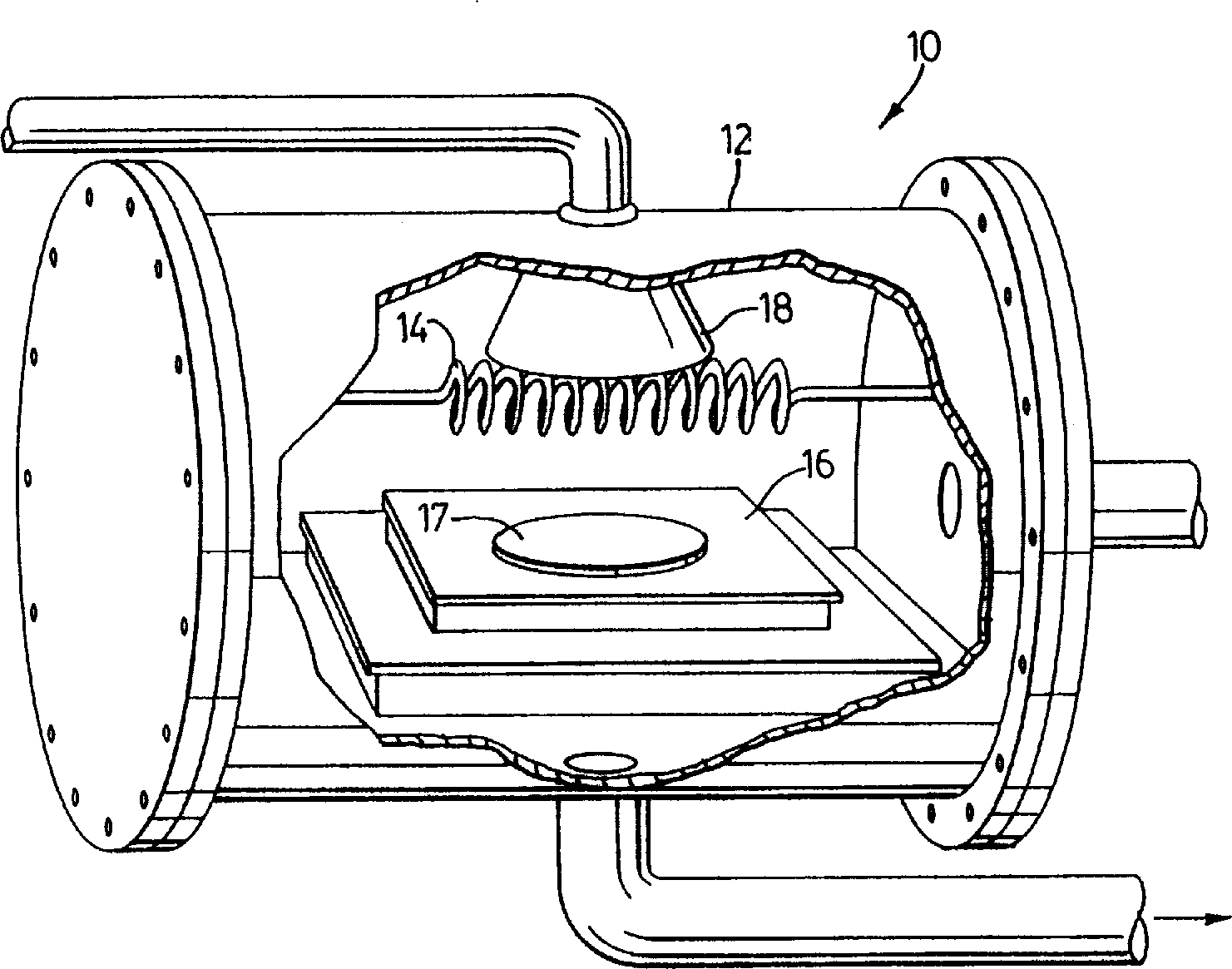

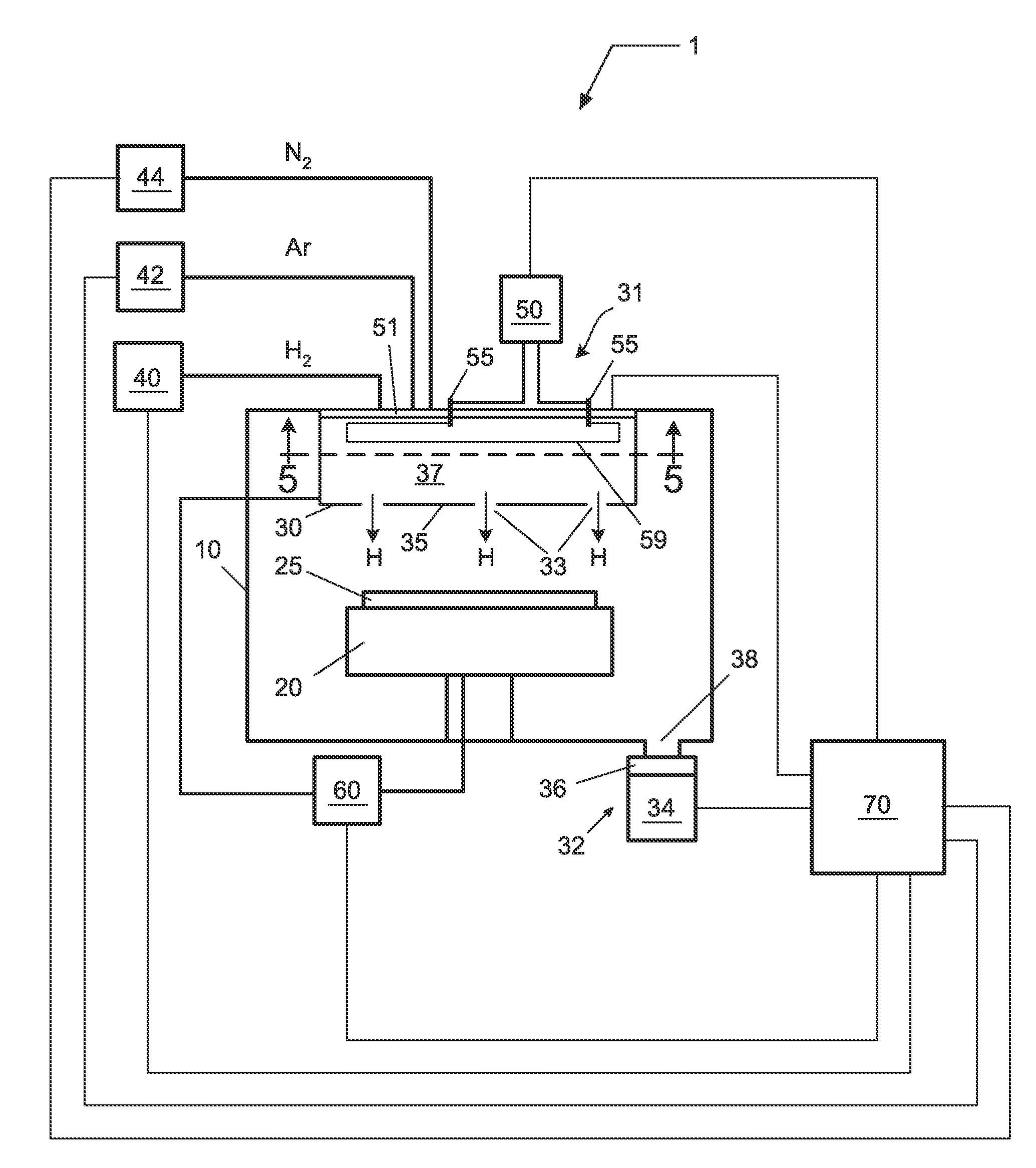

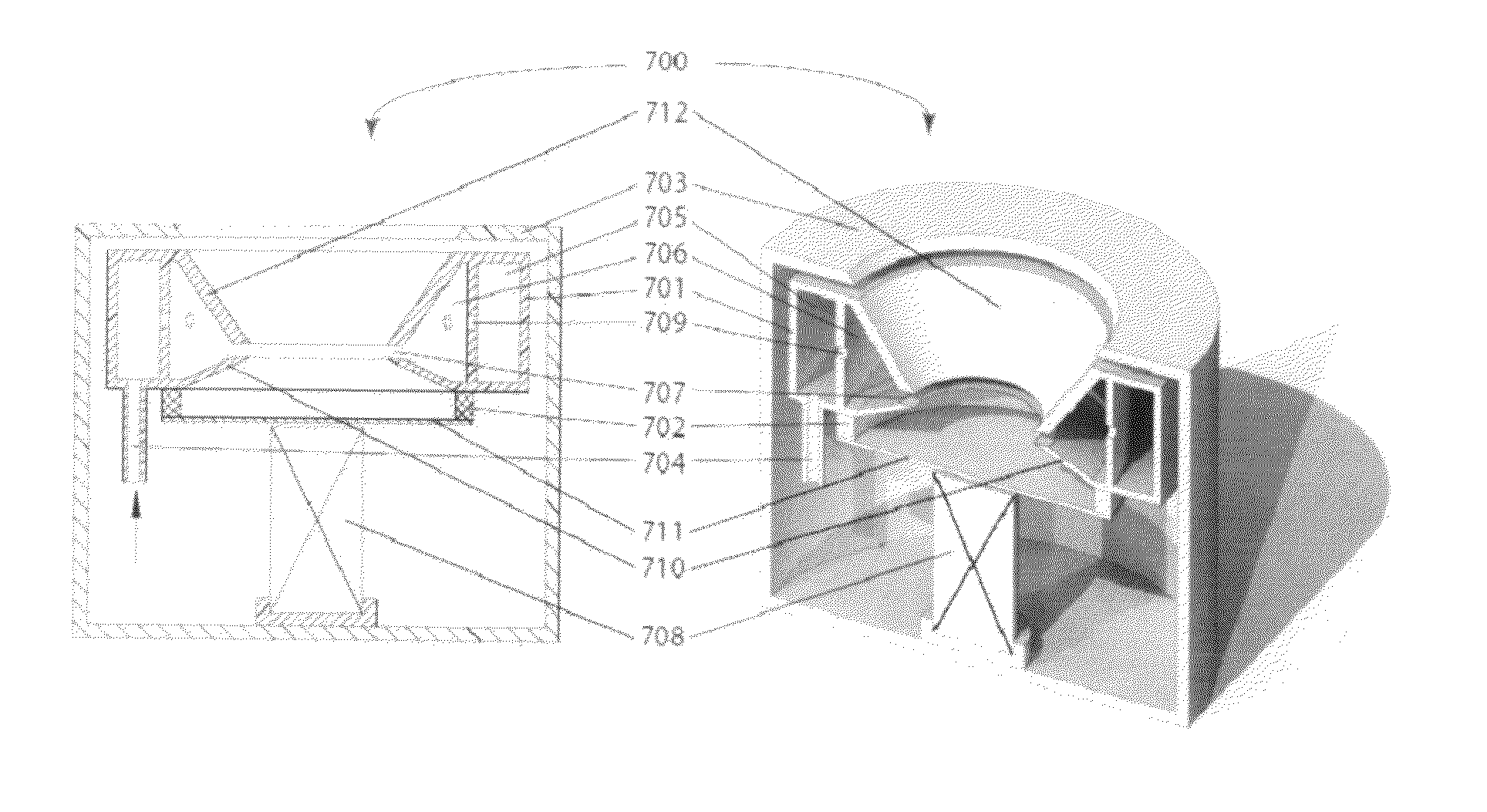

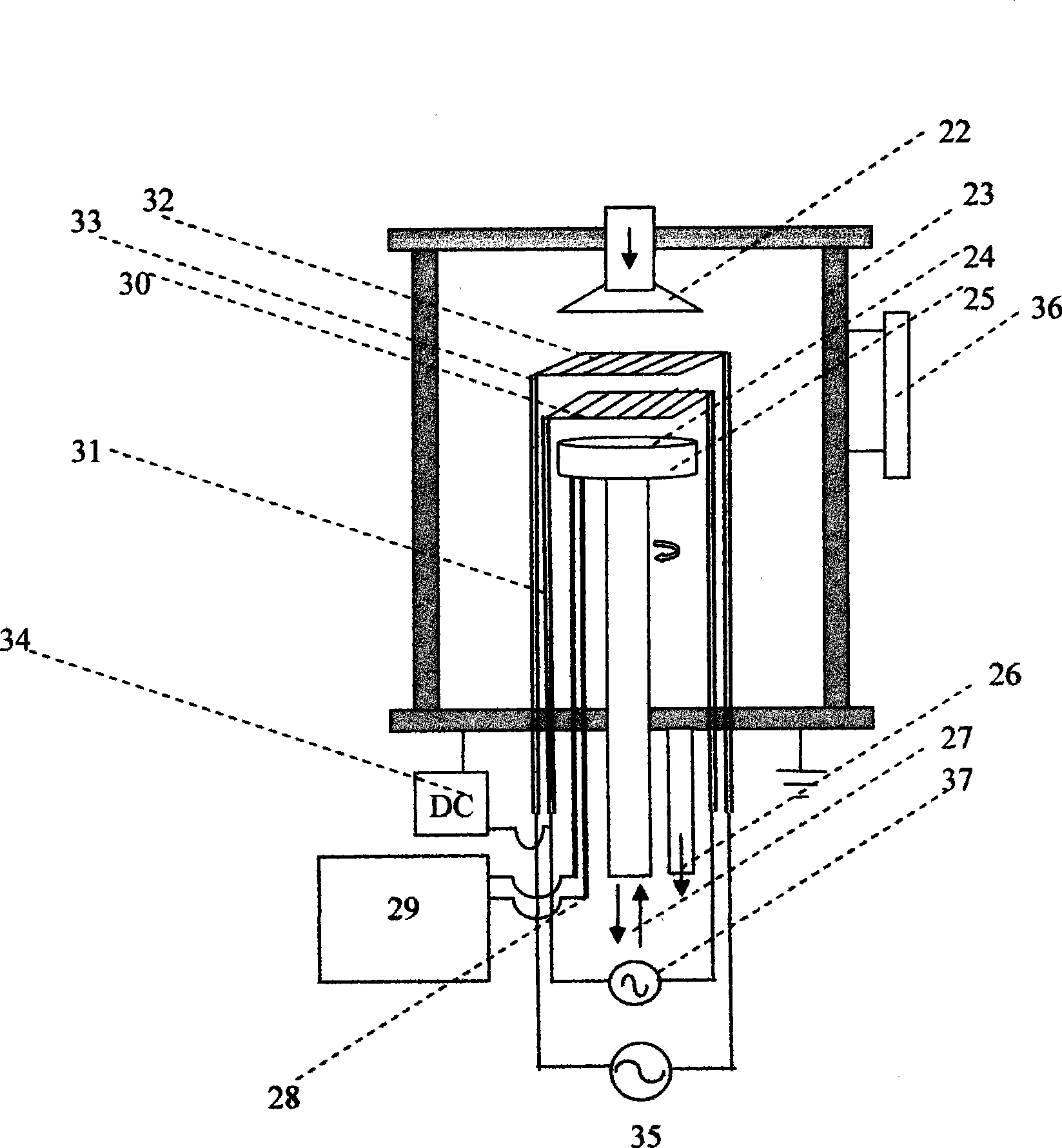

Processing system containing a hot filament hydrogen radical source for integrated substrate processing

InactiveUS20080078325A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringProduct gas

A processing system for integrated substrate processing in a substrate processing tool. The processing system contains a substrate holder configured for supporting and controlling the temperature of the substrate, a hot filament hydrogen radical source for generating hydrogen radicals, and a controller configured for controlling the processing system. The hot filament hydrogen radical source includes a showerhead assembly containing an internal volume and a showerhead plate having gas passages facing the substrate for exposing the substrate to the hydrogen radicals, and at least one metal wire filament within the internal volume to thermally dissociate H2 gas into the hydrogen radicals.

Owner:TOKYO ELECTRON LTD

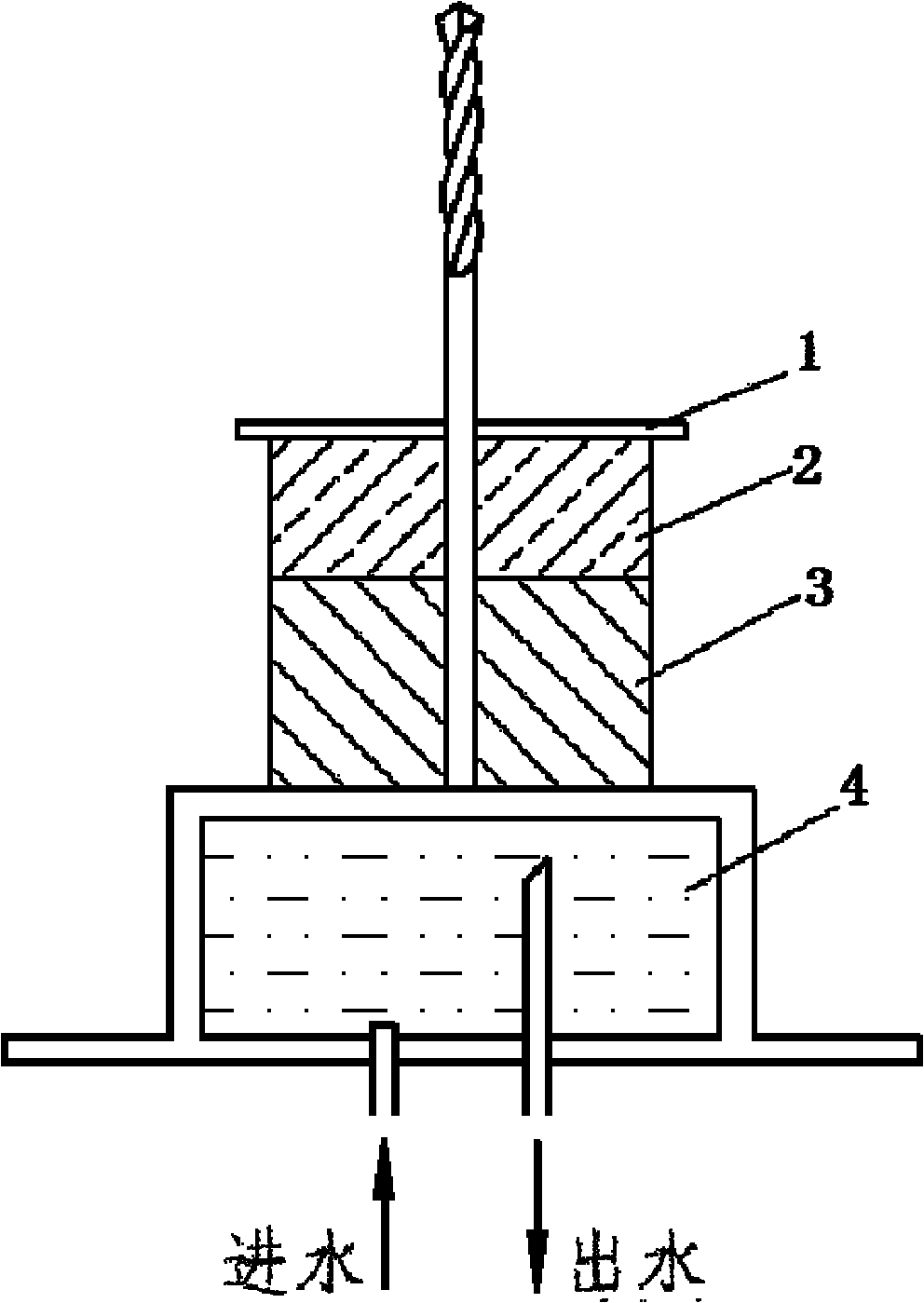

Hot-filament chemical vapor deposition batch preparation method of complicated-shape diamond coated cutting tool

The invention discloses a hot-filament chemical vapor deposition batch preparation method of a complicated-shape diamond coated cutting tool in the technical field of mechanical machining, comprising the steps of: placing a sandwich type foundation on which the cutting tool is arranged on a CVD (Chemical Vapor Deposition) equipment water-cooling worktable through inserting a cutting tool holder of a pretreated complicated-shape hard alloy cutting tool; adopting two lines of hot filaments, wherein the upper line of hot filaments is as high as the nose of the hard alloy cutting tool and the lower line of hot filaments is as high as the bottom of the cutting edge of the cutting tool; and filling hydrogen and acetone and depositing a diamond coating on the surface of the complicated-shape hard alloy cutting tool. According to the the invention, the surface temperature of an underlayer at the cutting edge can be effectively reduced, the rate of the deposition is not decreased and the quality of the diamond coating is improved.

Owner:SHANGHAI JIAO TONG UNIV +1

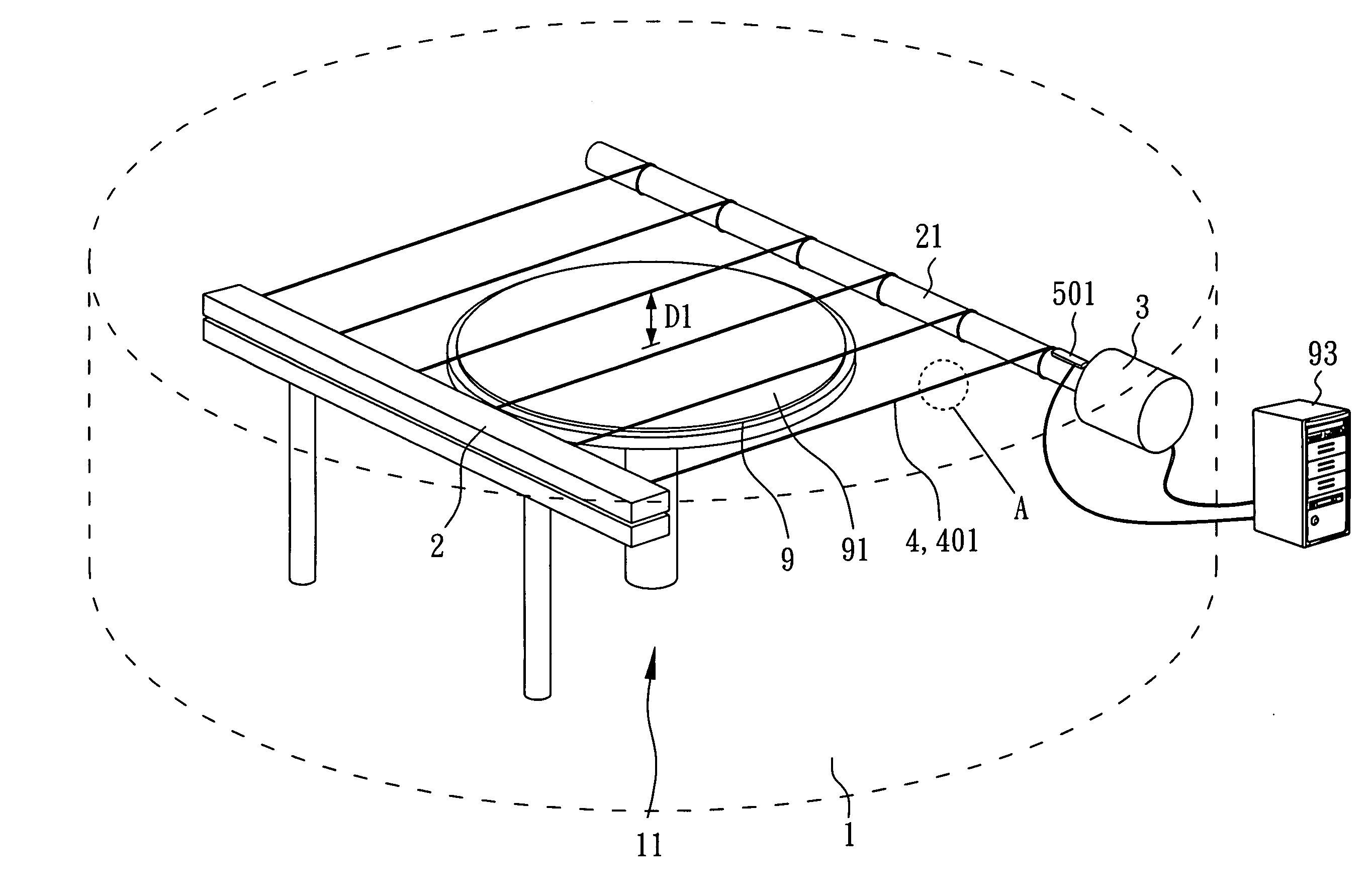

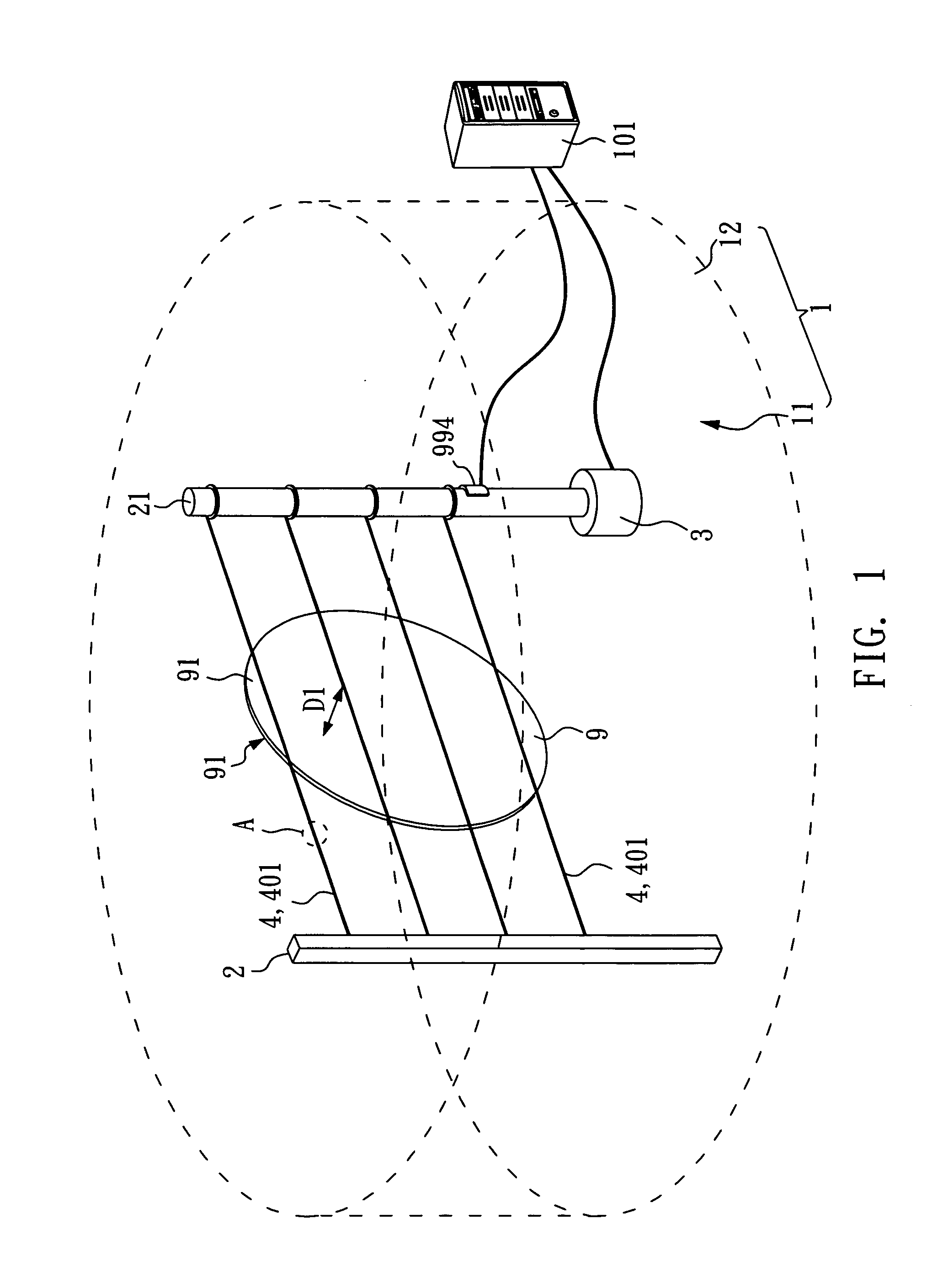

Chemical vapor deposition reactor

InactiveUS20080035059A1Enhancing strength and high-temperature physical performanceChemical vapor deposition coatingEngineeringCoating

A CVD (chemical vapor deposition) reactor having a horizontal coating plane and power source-controlled hot filaments is disclosed. The CVD reactor has a chamber, rotating electrodes provided inside the chamber, hot filaments connected to the rotating electrodes to form a horizontal coating plane above a substrate, and a rotating power source, which is controlled to rotate the rotating electrodes and to further stretch the hot filaments when the hot filaments expand due to a temperature change, prohibiting the hot filaments from touching the substrate.

Owner:KINIK

High Throughput Carbon Nanotube Growth System, and Carbon Nanotubes and Carbon Nanofibers Formed Thereby

A system is provided for forming carbon nanotubes comprising growing carbon nanotubes using a hot filament CVD system.

Owner:UNIVERSITY OF TOLEDO

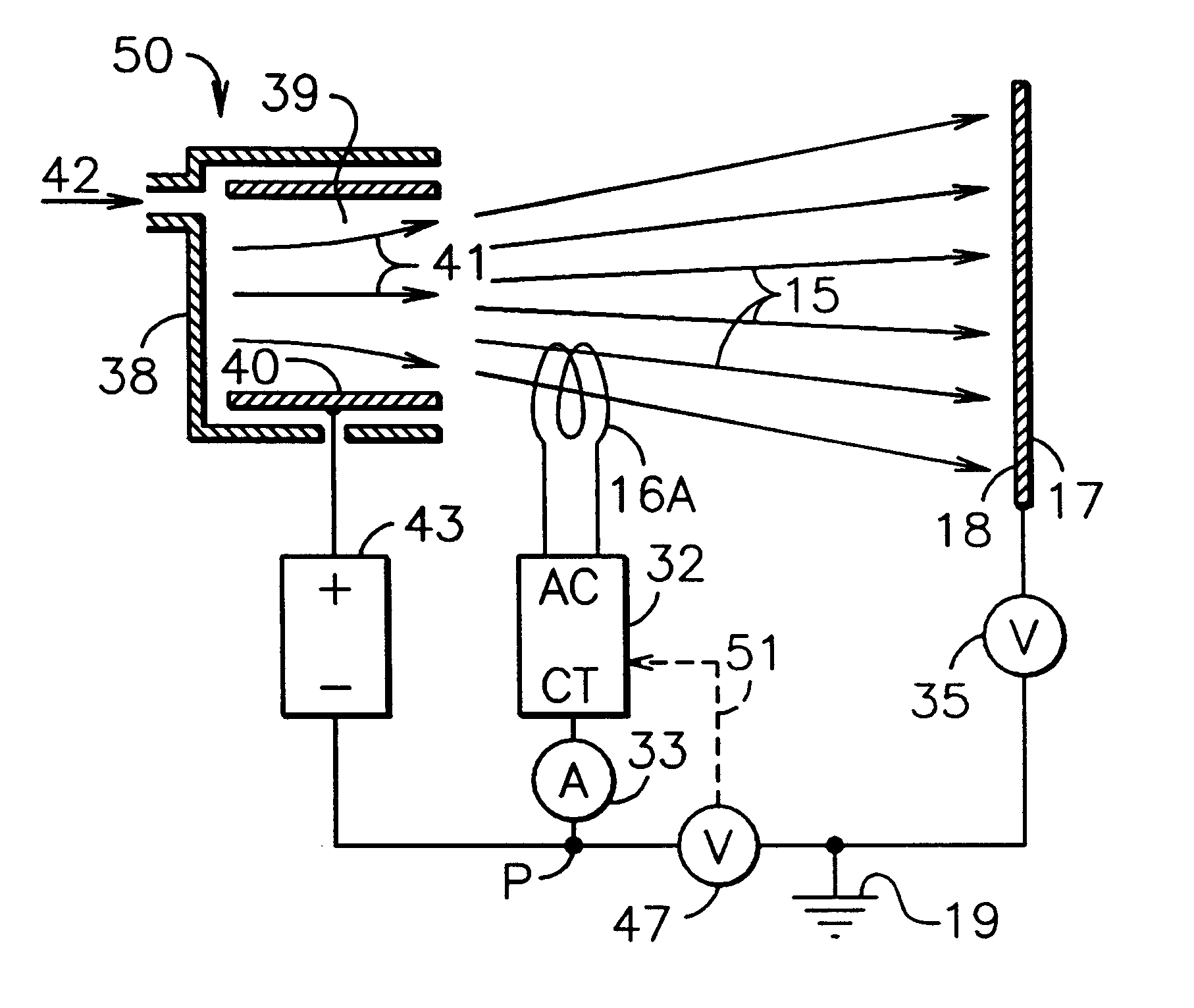

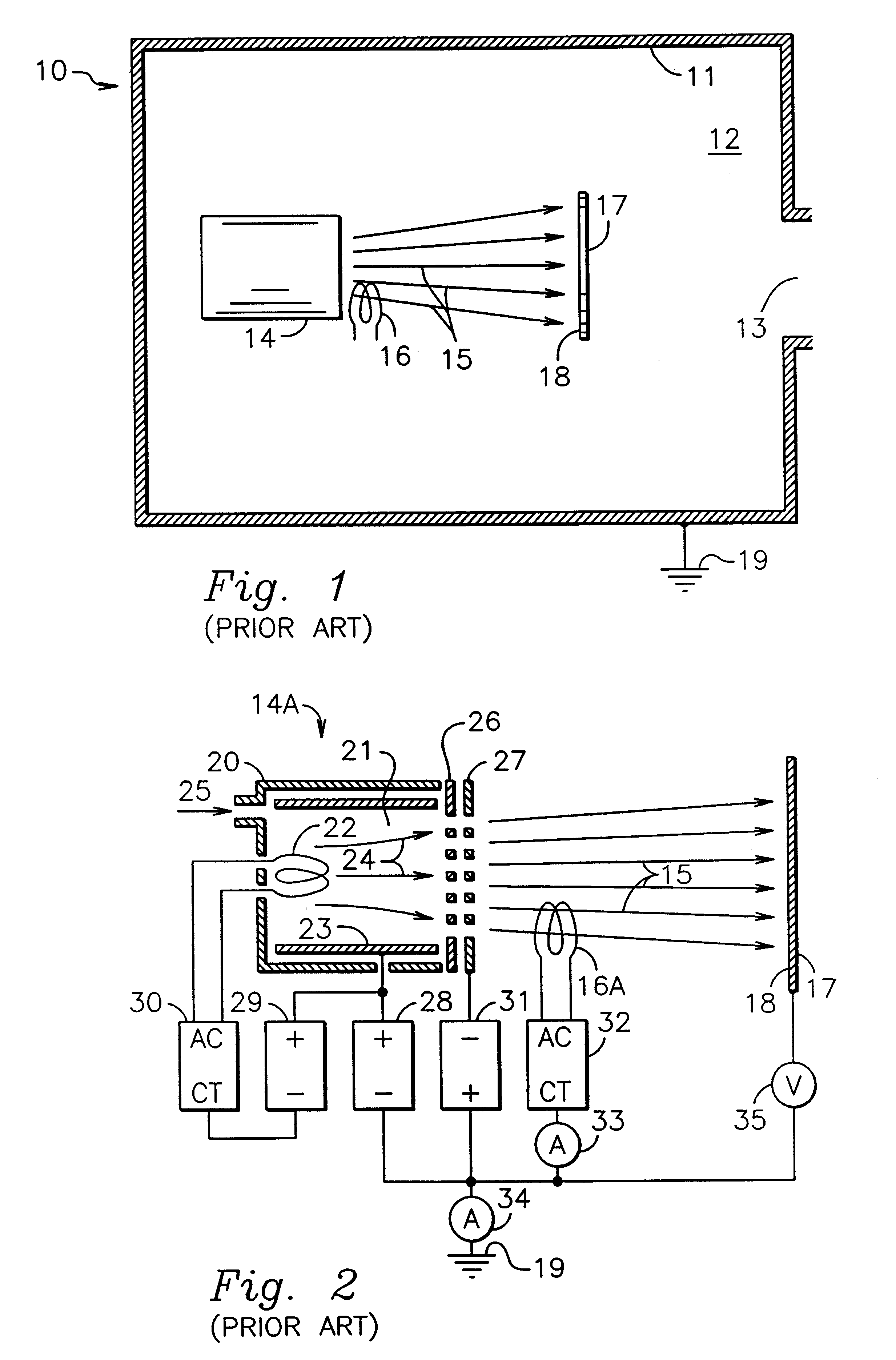

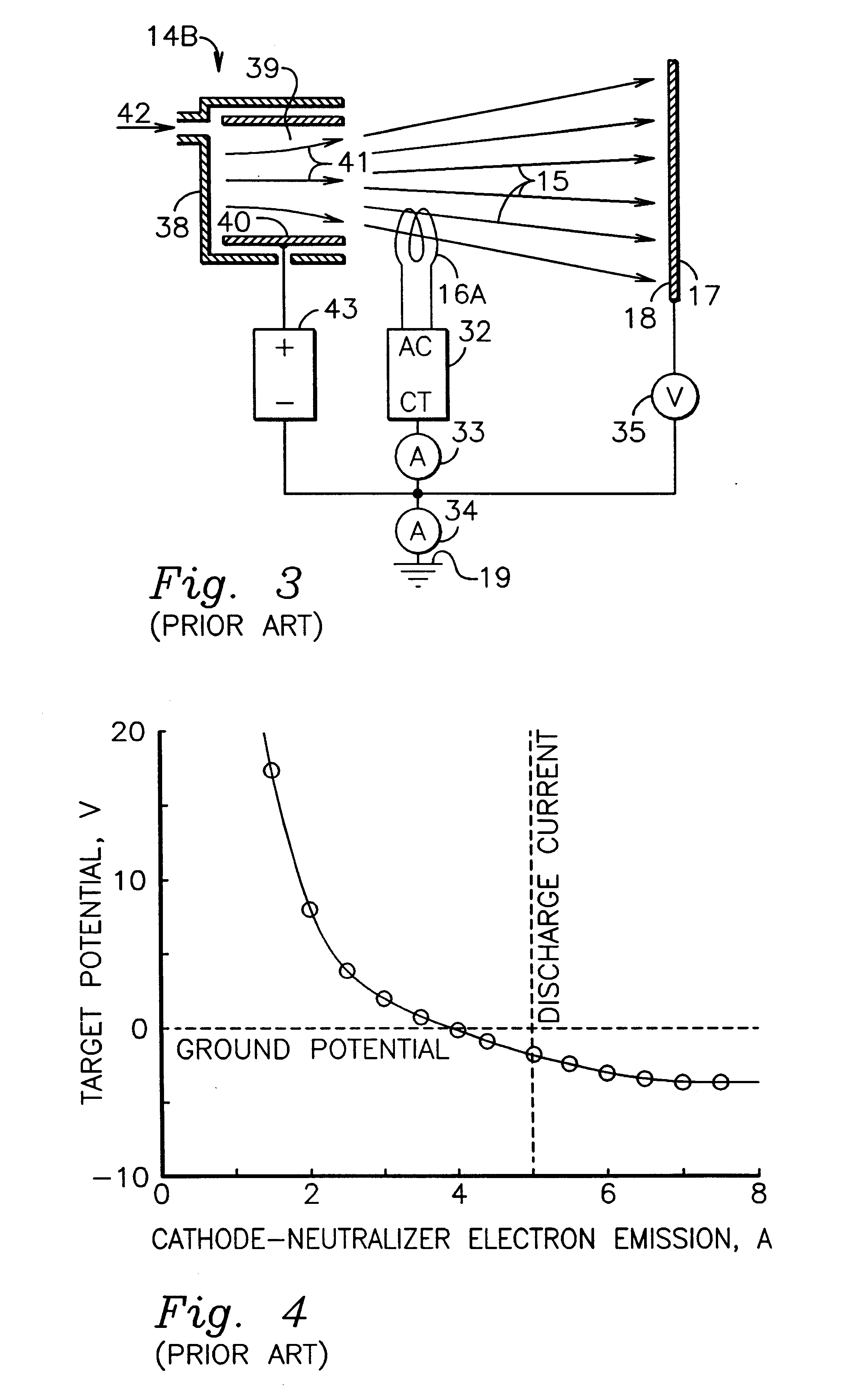

Ion-source neutralization with a hot-filament cathode-neutralizer

InactiveUS6724160B2Current providedSimple and economical and reliableTransit-time tubesElectric arc lampsIon beamEngineering

In accordance with one embodiment of the present invention, the ion-beam apparatus takes the form of a gridless ion source with a hot-filament cathode-neutralizer, in which the hot filament is heated with a current from the cathode-neutralizer heater. The cathode-neutralizer is connected to the negative terminal of the discharge supply for the gridless ion source. This connection is substantially isolated from ground (the potential of the surrounding vacuum chamber, which is usually at earth ground) and its potential is measured relative to ground. The heater current to the cathode-neutralizer is controlled by adjusting it so as to maintain this potential in a narrow operating range. This control can be manual or automatic.

Owner:KAUFMAN & ROBINSON

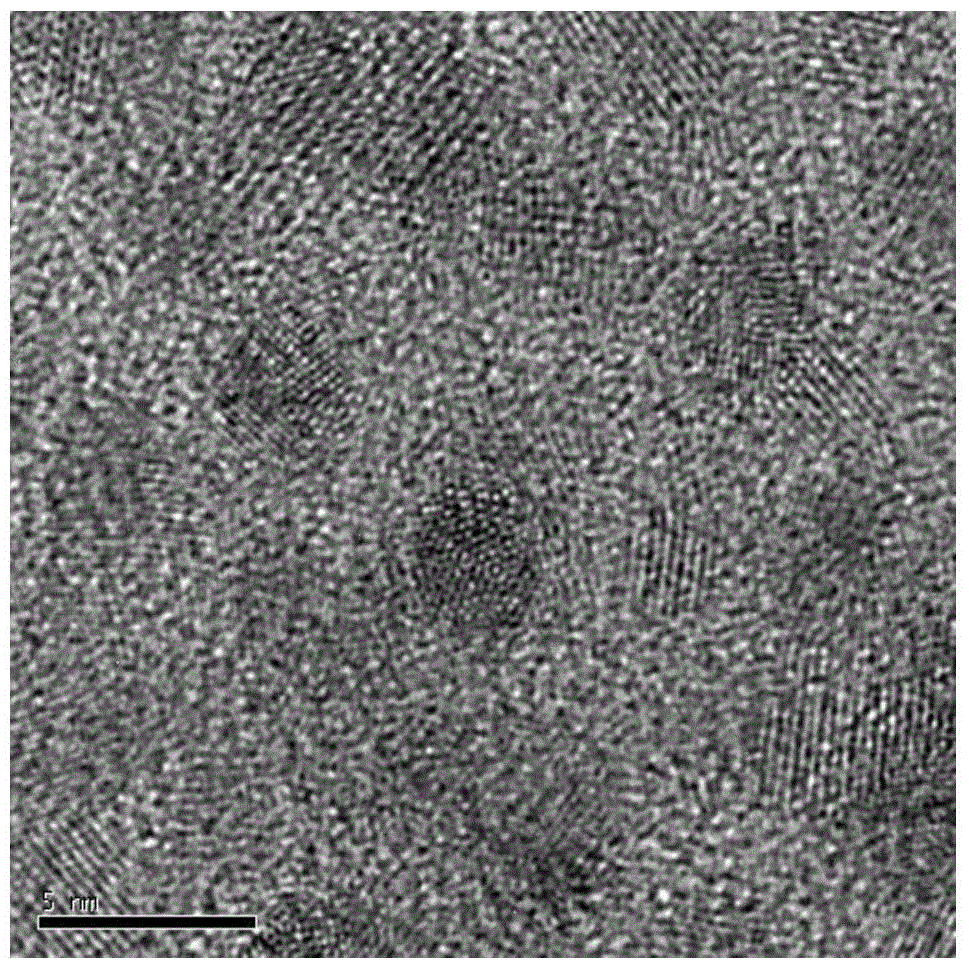

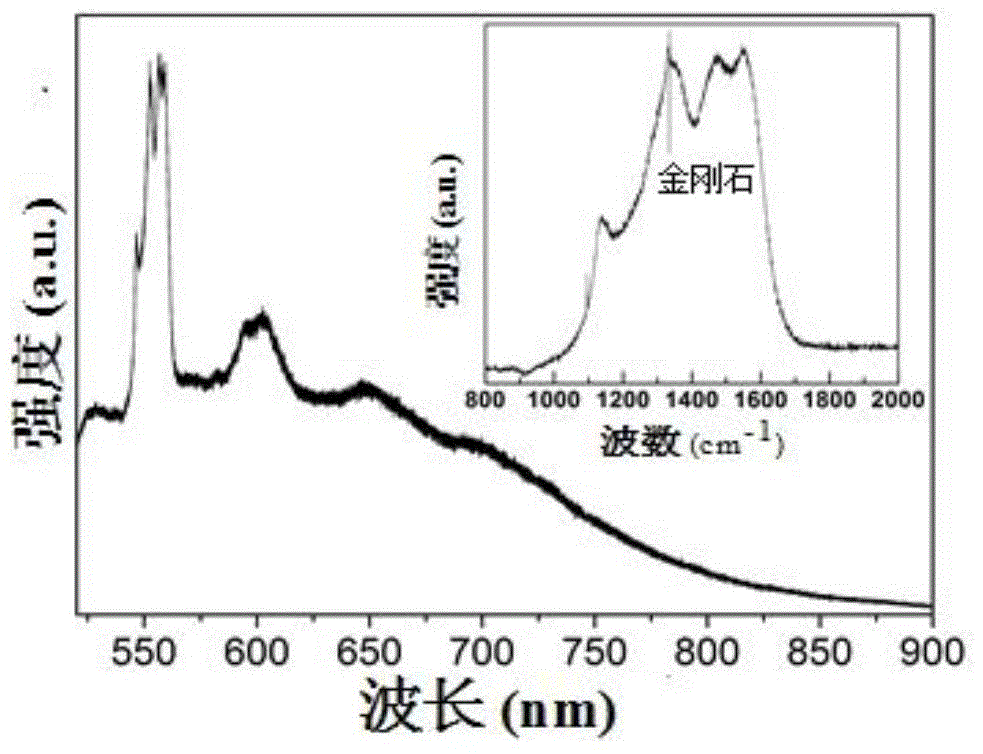

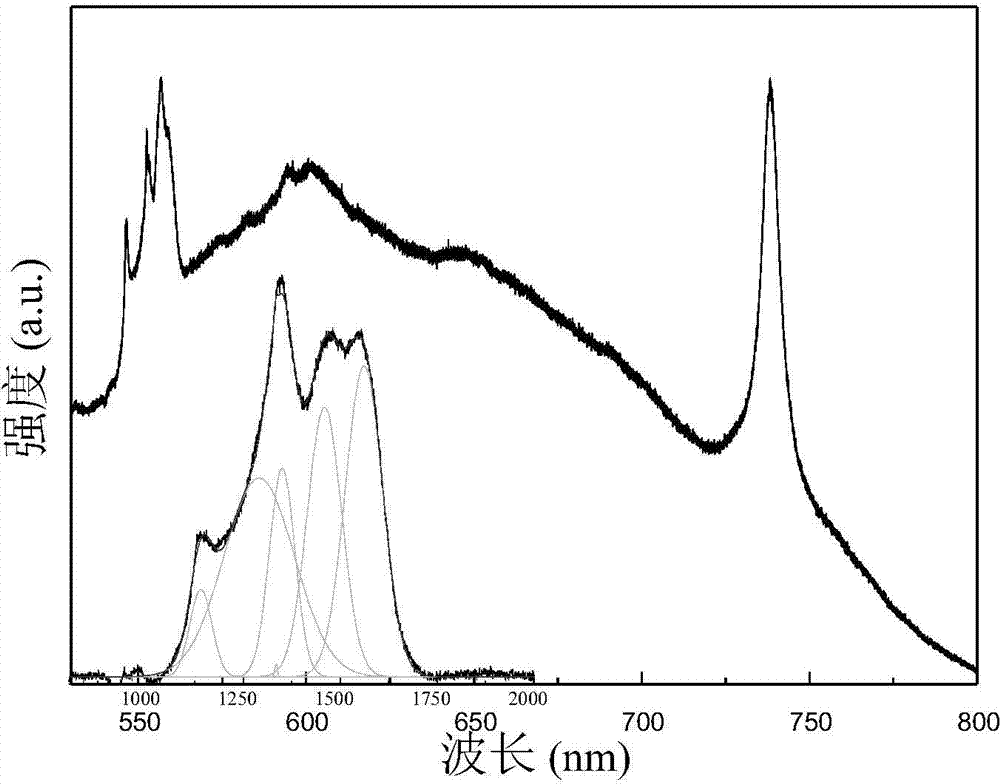

Nano-diamond film with Si-V luminescence and preparation method thereof

ActiveCN104060237AWith Si-V light emitting performanceSi-V has strong luminous performanceMaterial nanotechnologyChemical vapor deposition coatingGas phaseDisplay device

The invention provides a nano-diamond film with Si-V luminescence and a preparation method thereof. The nano-diamond film is prepared on a single crystal silicon substrate by use of a hot filament chemical vapor deposition method; heat preservation is performed on the film for 5-150 minutes in air at a temperature ranging from 500 to 700 DEG C, and then the nano-diamond film with Si-V luminescence is obtained. The nano-diamond film prepared has relatively high Si-V luminescence intensity which has very important scientific significance and engineering value for the application of the nano-diamond film in the fields such as single photon sources, quantum information processing, photoelectric devices, biomarkers, semiconductor devices and field emission displays.

Owner:ZHEJIANG UNIV OF TECH

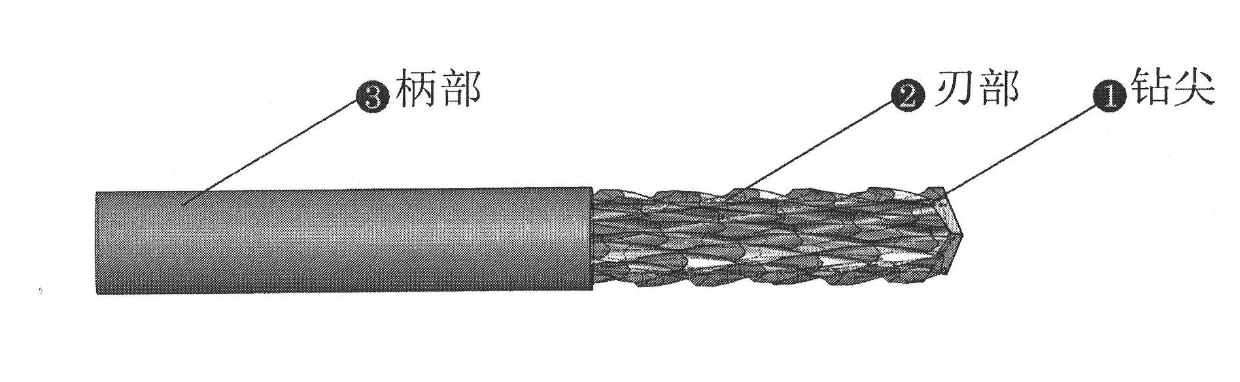

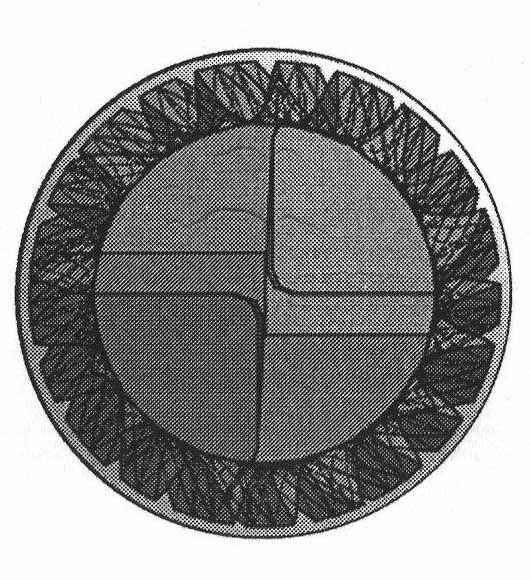

Diamond coated cutter and application thereof to processing of fiber composite material

InactiveCN102211218AImprove performanceGuaranteed sharpTransportation and packagingMilling cuttersSurface layerAlloy substrate

The invention relates to a diamond coated cutter, which comprises a drill tip, an edge part and a handle part, and is characterized in that: (1) a substrate material is a hard alloy with less than 6 mass percent of Co; (2) the drill tip and the edge part of the cutter are coated with a diamond coating; (3) the head part of the cutter has a drilling and milling integrated structure, the apex angleof the drill tip is double apex angles of 135 degrees and 90 degrees or a disc angle of 5 to 10 degrees, and the thickness of the coated diamond coating is 10 to 30mu m. The coated cutter is manufactured by the following steps of: (1) selecting an appropriate hard alloy substrate material; (2) forming the cutter; (3) pretreating a cutter coating; and (4) preparing the diamond coating on the drilltop and the edge part of the cutter through hot filament chemical vapor deposition (CVD). The phenomena of burrs and obvious surface layer peeling when the coated cutter processes a fiber composite material are avoided.

Owner:SHANGHAI XIANGREN NEW MATERIALS

Hall-current ion source with improved ion beam energy distribution

InactiveUS20120025710A1Eliminate pollutionReduce transmissionElectric arc lampsIon beam tubesReactive gasIon beam

A Hall-current ion source with a narrow ion beam energy distribution is presented. A narrow ion beam energy distribution is provided by a utilization of a multi-chamber anode through which a working gas is applied and delivers a uniform working gas distribution in a discharge channel. Introduction of a working gas through a lower part of anode makes applied electric potential in a narrow area and leading to enhanced conditions for a working gas ionization, high ion beam current, high translation of a discharge voltage into a “monochromatic” ion beam mean energy distribution. A multi-chamber anode with a slit exit for introduction of a working gas into area under anode is utilized to prevent a backflow of insulating and dielectric depositions on anode parts, and under anode area makes a nominal operation with reactive gases without a phenomenon called as “anode poisoning” during long operating hours. The ion source with a shielded Hot Filament design shows very effective ion beam neutralization properties; it produces less heating of the substrate than a traditional one; it has a cleaner ion beam because its beam is not contaminated by the Hot Filament material particles. In the design with two Hot Filaments the ion source operation is extended for tens of hours.

Owner:KLYUEV EVGENY VITALEVICH +1

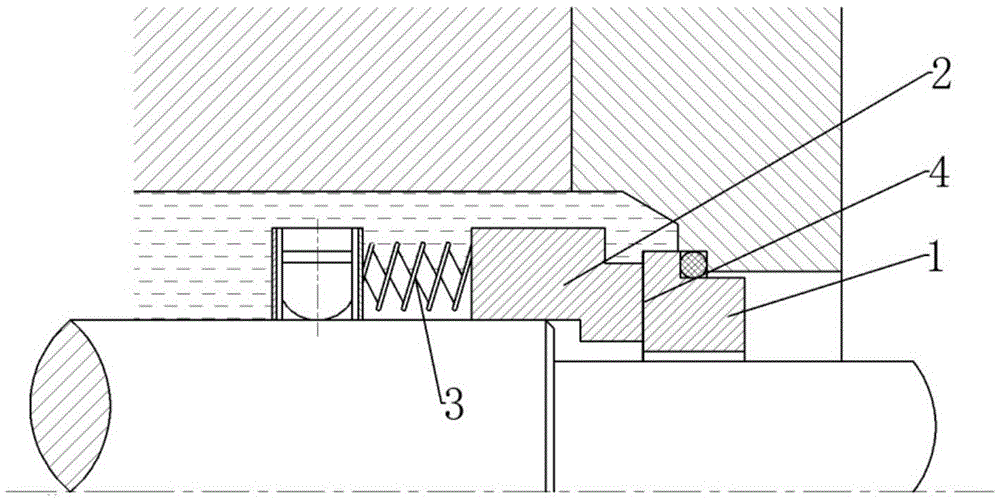

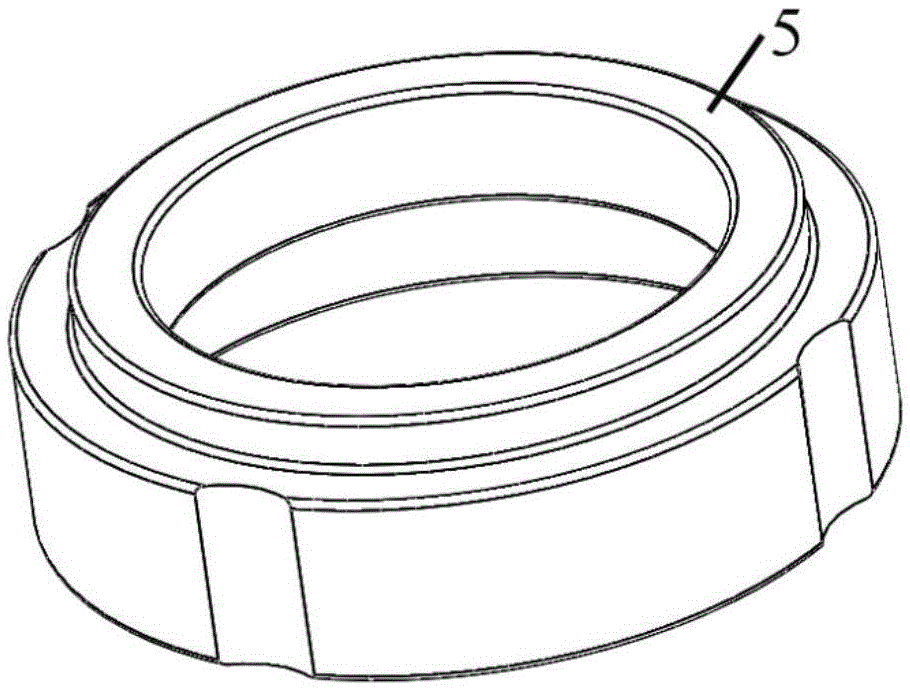

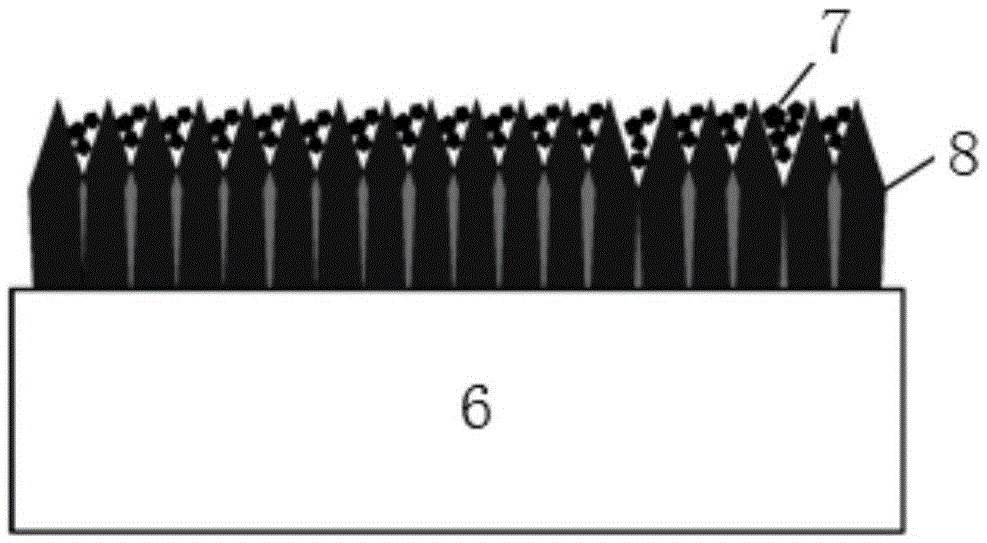

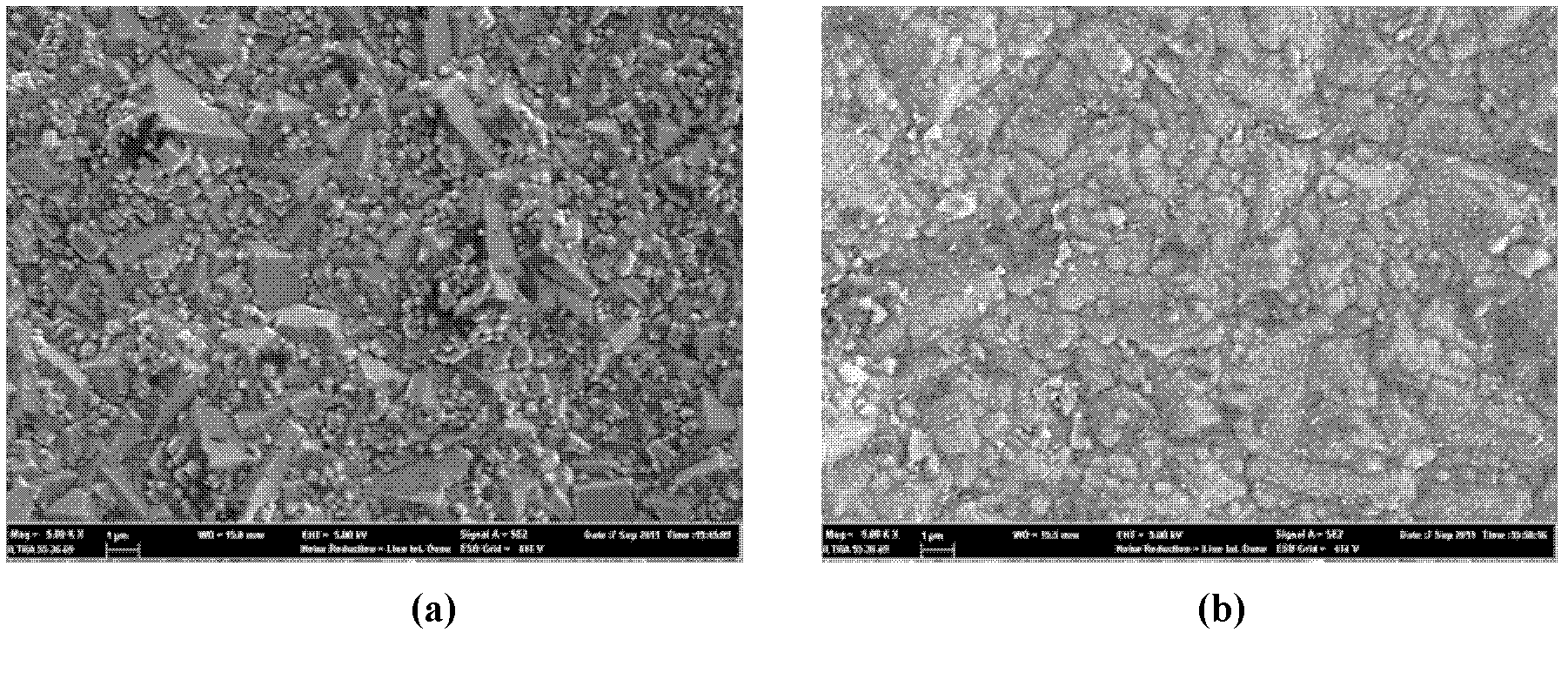

Preparation method for diamond coated mechanical seal ring

InactiveCN105624641AReduce surface roughnessGrain thickChemical vapor deposition coatingWorking lifeSurface roughness

The invention discloses a preparation method for a diamond coated mechanical seal ring. A hard-alloy silicon-carbide / silicon nitride ceramic mechanical seal ring serves as a substrate, and a diamond thin film is deposited on a work surface of the mechanical seal ring through a hot filament chemical vapor deposition (HFCVD) method. The specific process method comprises the steps that firstly, a layer of micron-diamond thin film which is coarse in grain, excellent in abrasion resistance but difficult to polish is deposited on the surface of the substrate; and then thinned nano-diamond particles are deposited between micron-diamond particles by changing process parameters so that sunken parts between the coarse micron-diamond particles can be filled, and the purposes that the surface roughness of a diamond coating is lowered and accordingly subsequent grinding and polishing are convenient. According to the diamond coated mechanical seal ring obtained through the two-step deposition method in the preparation method, abrasion rate of a contact end face can be lowered significantly, and the working life of the diamond coated mechanical seal ring is prolonged significantly compared with a non-coated mechanical seal ring.

Owner:SHANGHAI JIAO TONG UNIV +1

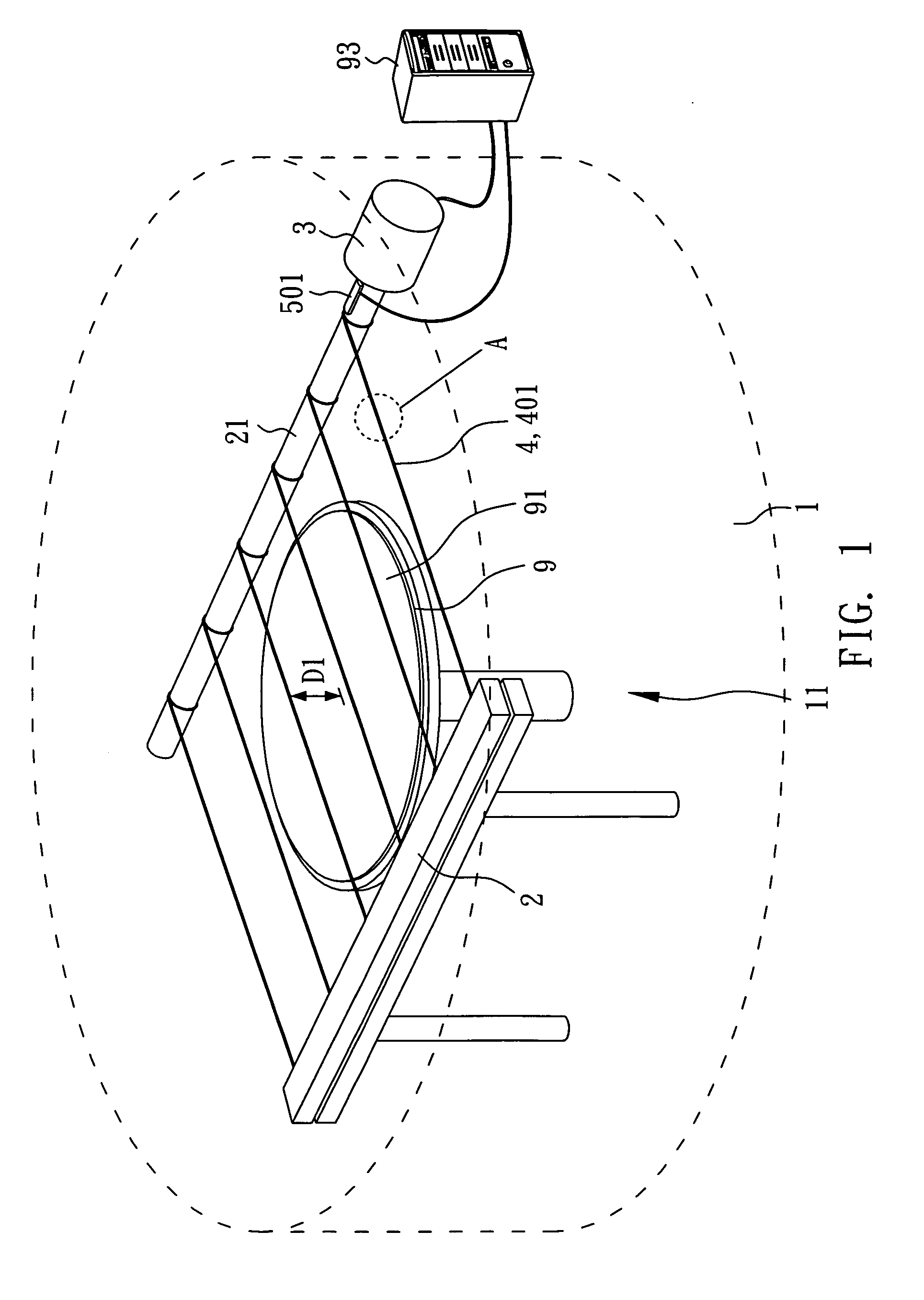

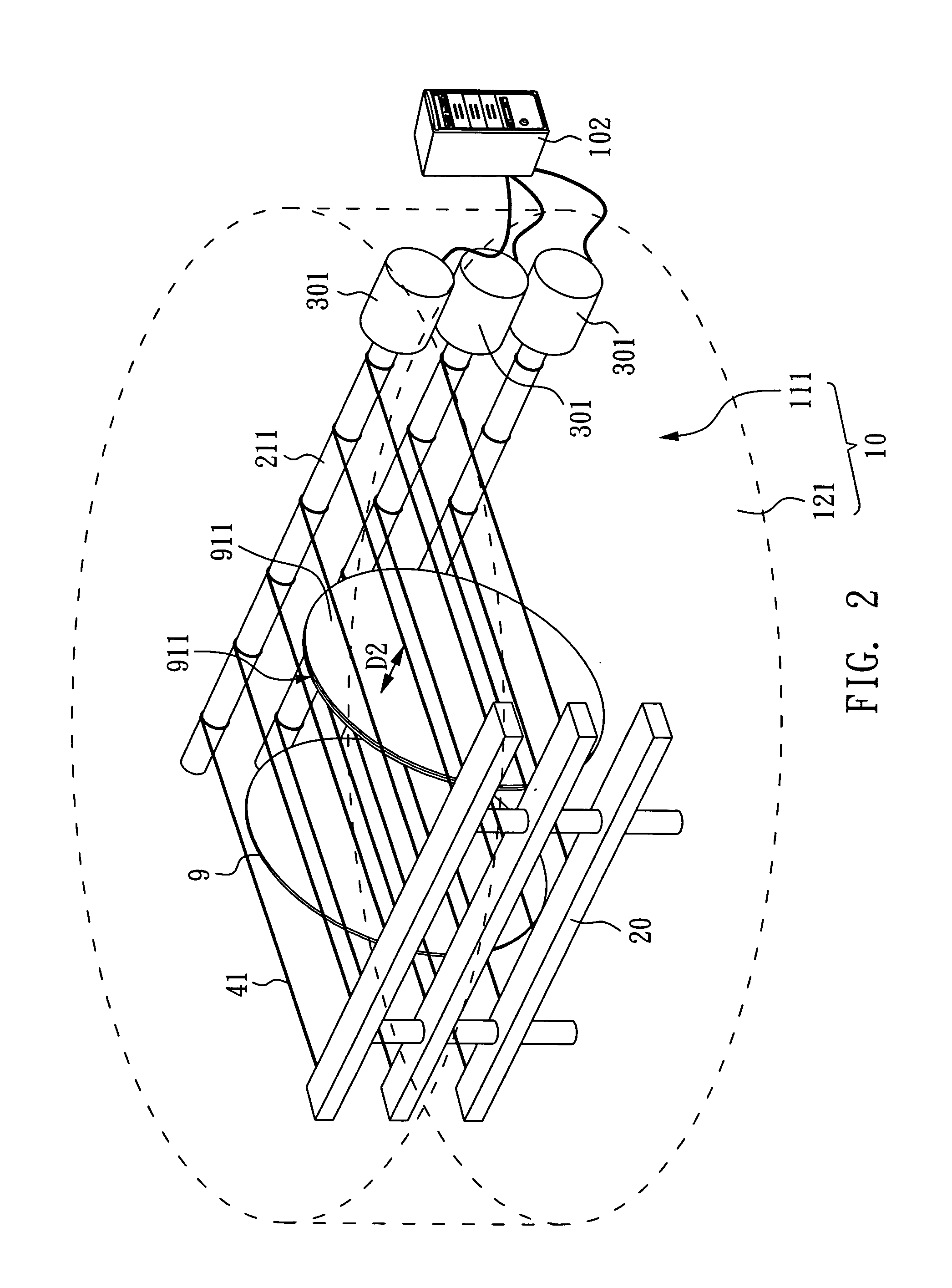

Chemical vapor deposition reactor

InactiveUS20080035060A1Avoid vibrationPerformance is not affectedChemical vapor deposition coatingEngineeringHot filament

A CVD (chemical vapor deposition) reactor having a vertical coating plane and power source-controlled hot filaments is disclosed. The CVD reactor has a chamber, one or a number of rotating electrodes, hot filaments, and a rotating power source at each rotating electrode. When the hot filaments expand due to hot, the rotating power source rotates the rotating electrode(s) to stretch the hot filaments and to further maintain the predetermined tension of the hot filaments, thereby preventing vibration of the hot filaments so as not to interfere with the performance of the coating work and not to damage the substrate upon flowing of a gas in the chamber.

Owner:KINIK

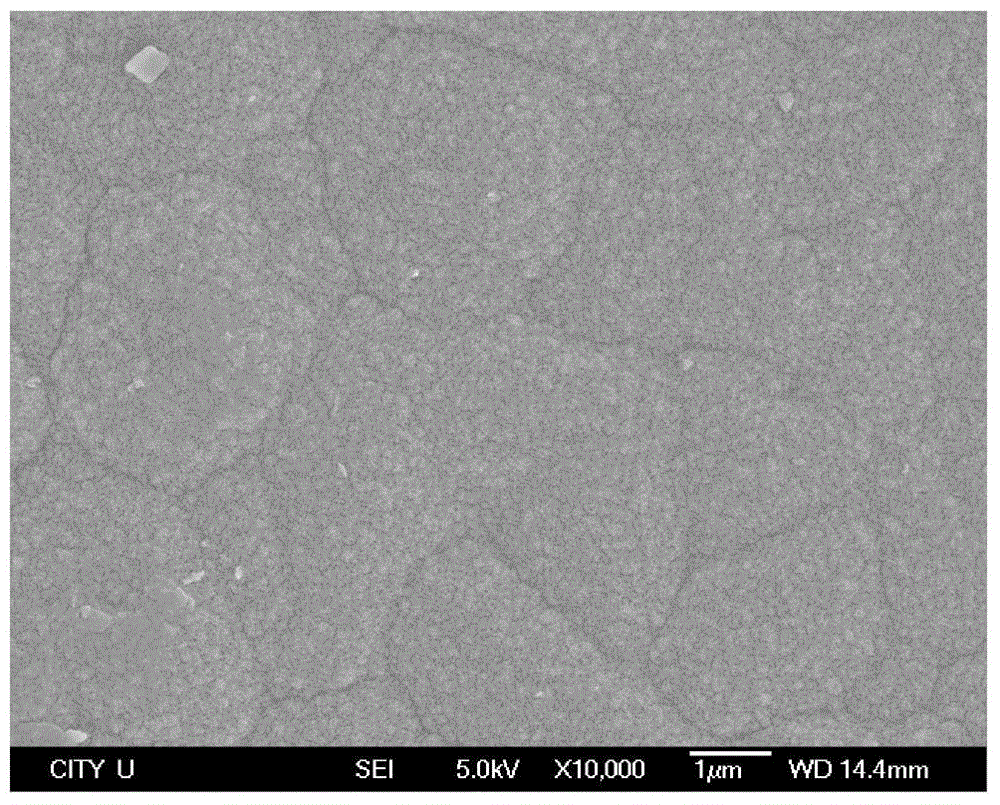

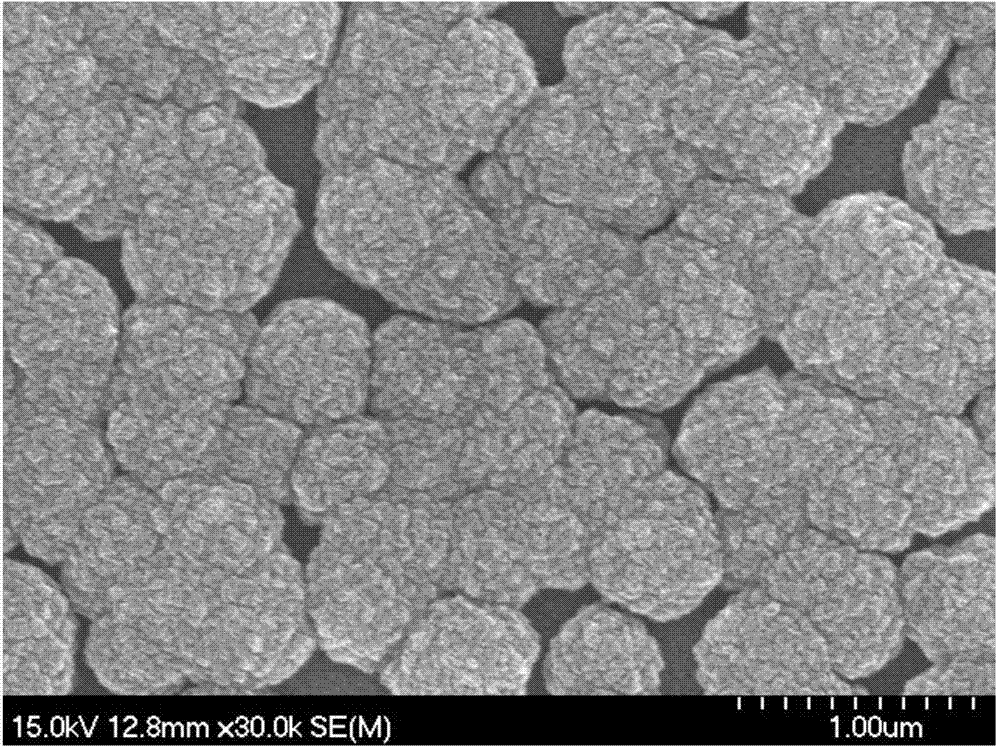

Single particle layer nano-diamond film and preparation method thereof

ActiveCN104762607AEasy to operateChemical vapor deposition coatingDisplay deviceElectrochemical electrode

The invention provides a single particle layer nano-diamond film and a preparation method thereof. The preparation method comprises the following steps: polishing a monocrystalline silicon piece by using a diamond, and then cleaning and drying to obtain a monocrystalline silicon substrate; putting the monocrystalline silicon substrate in hot filament chemical vapor deposition equipment; by taking acetone as a carbon source, bringing acetone to a reaction chamber in a hydrogen bubbling manner, wherein the flow rate of hydrogen to acetone is 200: 90, the distance from a hot filament to the monocrystalline silicon substrate is 7mm, the reaction power is 1600-2300W, and the working air pressure is 1.63Kpa, no bias voltage is applied in the reaction process, the film growing time is 10-50 minutes; and after growth, dropping the temperature and cooling under a condition of not introducing hydrogen, thus obtaining the single particle layer nano-diamond film which is 300-700nm thick. The film is relatively strong in Si-V light-emitting property and has a broad application prospect in the field of single-photon sources, quantum information processing, optoelectronic devices, electrochemical electrodes, biomarkers, semiconductor apparatuses, field emission displays and the like.

Owner:ZHEJIANG UNIV OF TECH

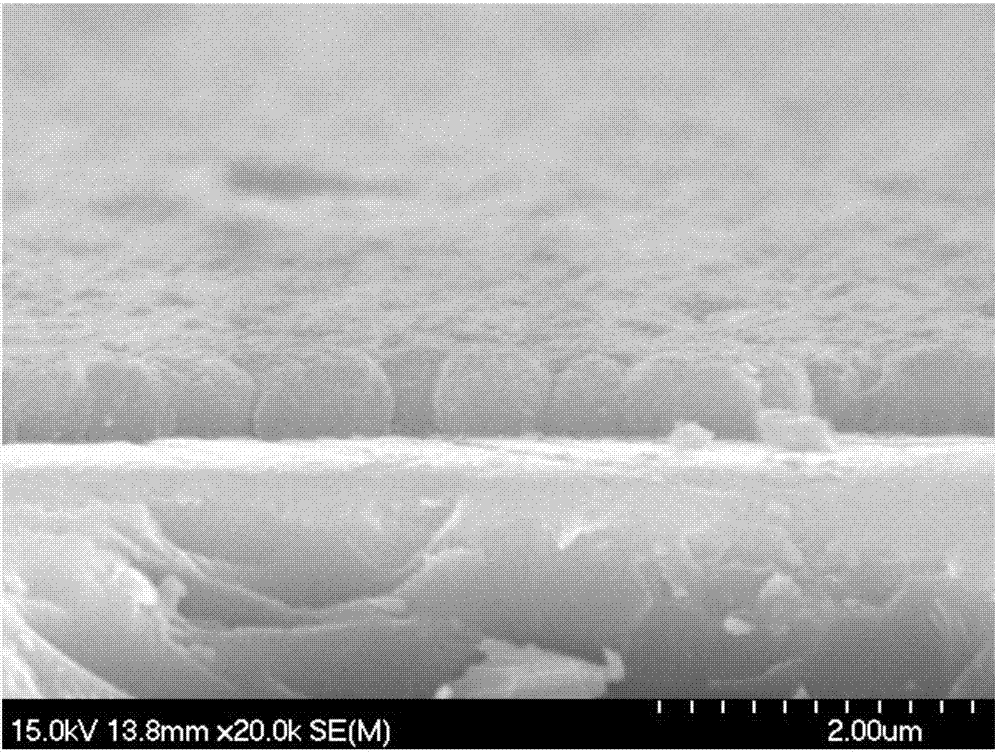

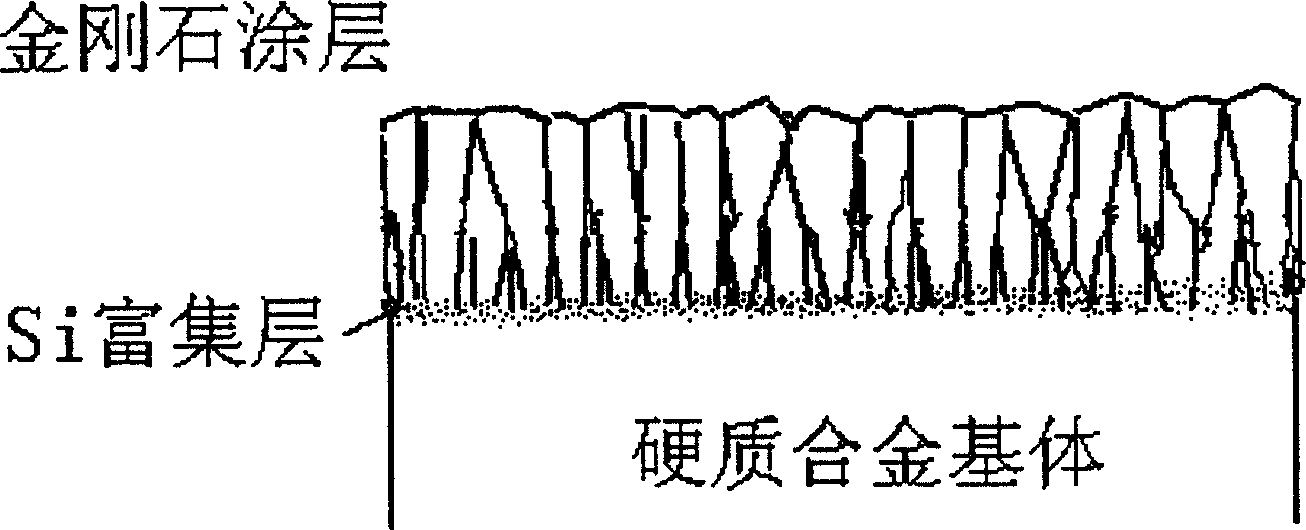

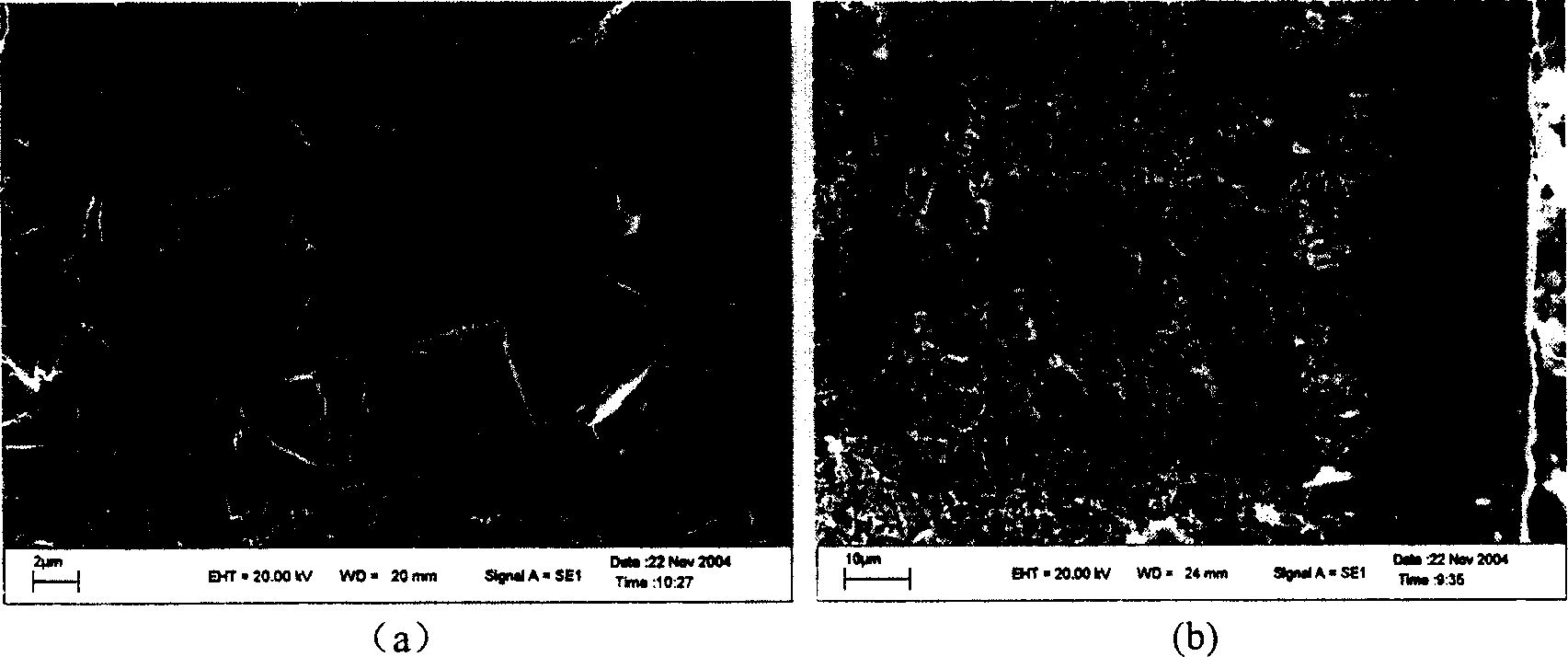

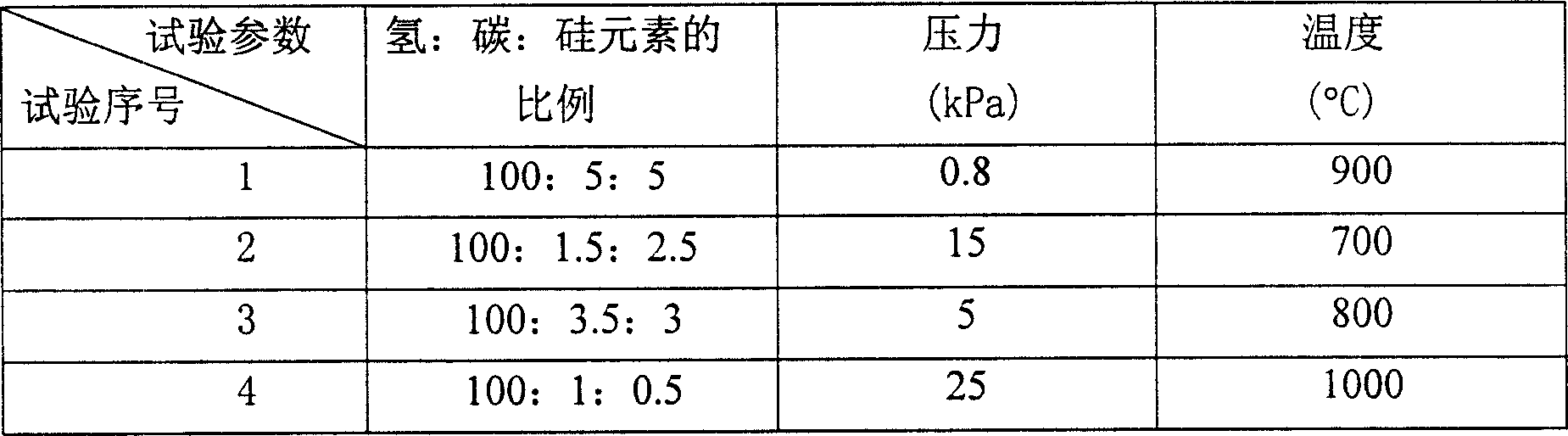

Process for preparing diamond covering on sintered-carbide tool

InactiveCN1632165AImprove adhesionSimple technologyChemical vapor deposition coatingMicrowaveHydrogen

The invention provides a method for preparing a diamond coating on a cemented carbide tool. Using plasma CVD technology, a gas mixture containing hydrogen, carbon and silicon is used as the reaction gas to deposit a diamond coating containing diamond phase and silicon on the cemented carbide tool; among them, silicon is carried out in the CVD process of the diamond coating At the same time, it is deposited into the diamond coating and at the interface between the diamond coating and the cemented carbide tool; the existence and enrichment of silicon at the interface of the diamond coating and the cemented carbide tool make the diamond coating more effective on the cemented carbide tool. Tools form high adhesion. The CVD technology includes: microwave plasma CVD technology, hot wire CVD technology, direct current arc plasma CVD technology. The invention has the advantages of effectively improving the adhesion of the diamond coating and simplifying the preparation process of the coating.

Owner:UNIV OF SCI & TECH BEIJING

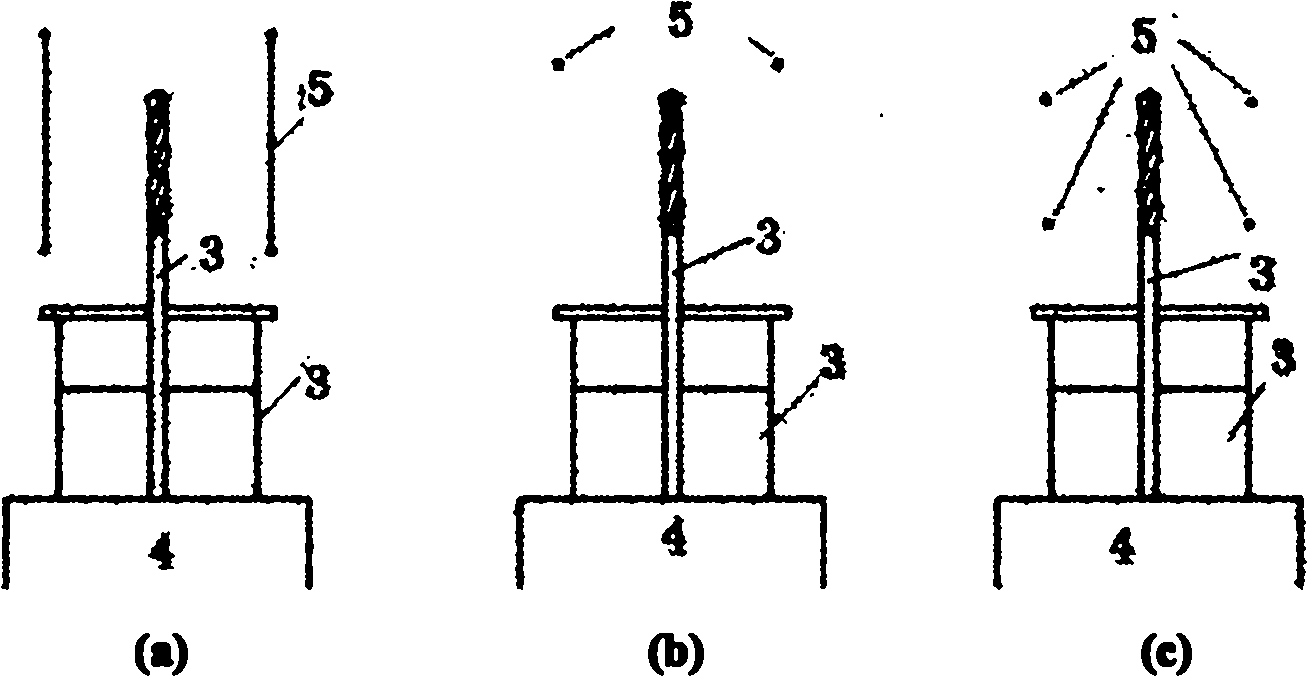

Production method of diamond film coating of microbit

InactiveCN102312215AReduce coefficient of frictionHigh densityChemical vapor deposition coatingDiamond thin filmFilm-coated tablet

The invention discloses a production method of a diamond film coating of a microbit, characterized in that: surface treatment is carried out on the substrate material of the microbit, a multi-steps deposition method is used, and the deposition growth conditions of the diamond film are controlled with hot-filament chemical vapor deposition method, wherein, the deposition growth conditions of the diamond film comprise the temperature of hot filaments, the pressure in the cavity, the selection of reaction source gas, distribution of flow and hot filaments, distance between the top end of the microbit and the hot filaments, spacing of the hot filaments distribution, deposition growth time of the diamond film, surface temperature of the top of the microbit, and the like. By adding the diamond film coating, the ware resistance and cutting ability of the microbit are reinforced, so that the service life of the micorbit is lengthened by more than 5-10 times and the precision of the microbit is not changed, and the frequency of changing drill of the drilling machine is reduced, the production efficiency is improved, and the production cost is greatly reduced.

Owner:南通科创晶膜新材料有限公司

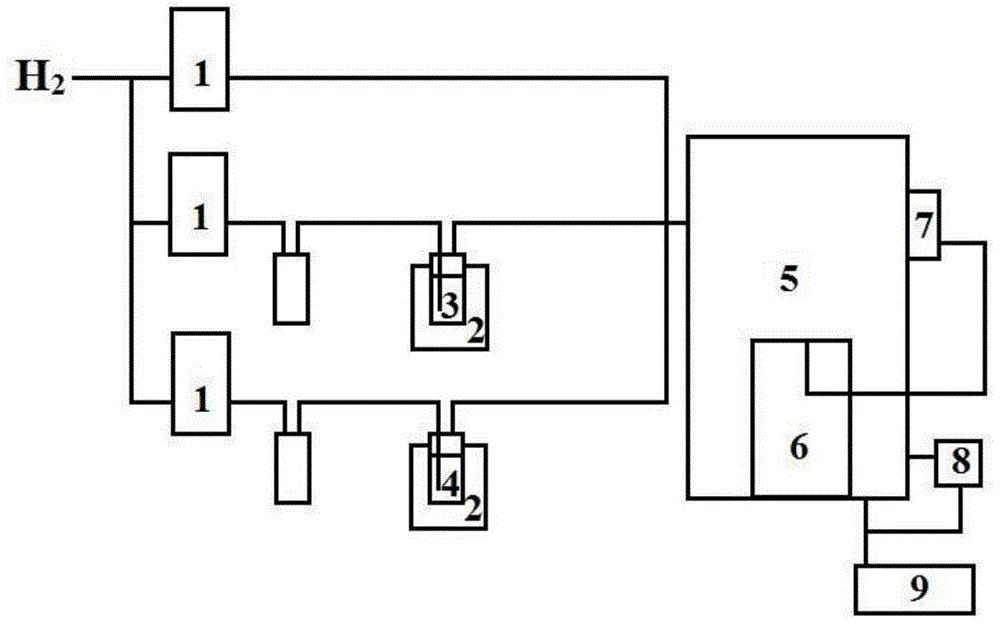

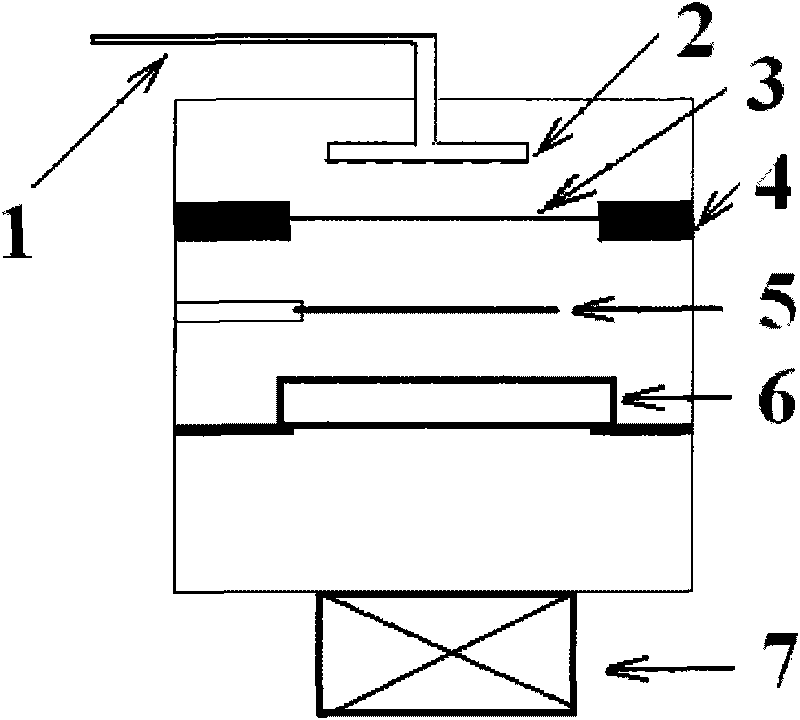

Hot filament and heat evaporation vapor deposition membrane equipment

InactiveCN101397654ASolve the problem that the thermal evaporation treatment process cannot be carried out at the same timeFunctionalChemical vapor deposition coatingMaterials preparationGas phase

The invention discloses a hot filament and thermal evaporation vapor deposition thin film device for material preparation. The device consists of a hot filament chemical vapor deposition activation part for activating a source gas to deposit the material and forms a combination with a thermal evaporation part. A substrate bracket does combined movement relative to the hot filament or the thermal evaporation wire or the hot filament and the thermal evaporation wire.

Owner:MINNAN NORMAL UNIV

Method for preparing amorphous silicon carbide ceramic-diamond composite coating

The invention discloses a method for preparing an amorphous silicon carbide ceramic-diamond composite coating. The method comprises the steps of cracking macromolecular organic silane serving as a precursor on the surface of a substrate by adopting a macromolecular precursor cracking method to generate an amorphous silicon carbide ceramic film, and then performing in-situ deposition on the micro diamond film by adopting a hot filament chemical vapor deposition method to obtain the amorphous silicon carbide ceramic-diamond composite coating. Compared with the prior art, the amorphous silicon carbide transition layer prepared by adopting the macromolecular precursor cracking method can be used for effectively blocking residual cobalt phase on the surface of a hard alloy matrix after two-step treatment and improving the rough surface of the hard alloy matrix; and the prepared amorphous silicon carbide ceramic-diamond composite coating has excellent adhesion and extremely high abrasion resistance, and is suitable for preparing high-quality diamond coating cutters.

Owner:SHANGHAI JIAO TONG UNIV

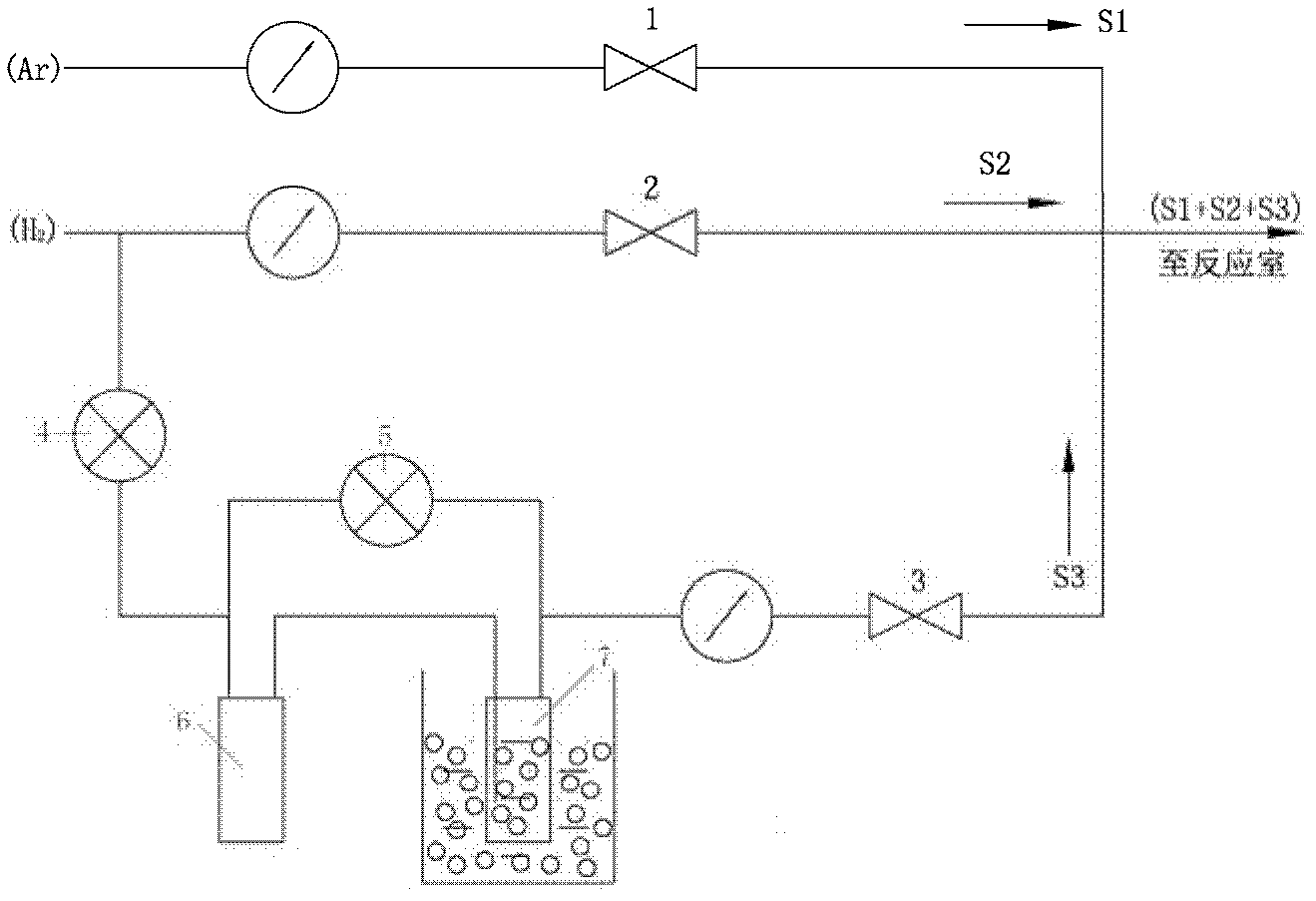

Method for preparing diamond film through multiple-doped hot filament chemical vapor deposition

ActiveCN102586762AEase of mass productionReduce usageChemical vapor deposition coatingCemented carbideInsulation resistance

The invention discloses a method for preparing a diamond film through multiple-doped hot filament chemical vapor deposition and a reaction gas conveying device for the method. The method uses silicon, silicon carbide or silicon nitride ceramics, hard alloy and high-melting-point metal materials (including tungsten, tantalum, molybdenum, titanium and the like) as a substrate and adopts a chemical vapor deposition (CVD) method as the deposition means, an organic compound containing Si, an organic compound containing Si and N, an organic compound containing Si and B or an organic compound containing Si, N and B are simultaneously added into reaction gas hydrogen and acetone (or acetone and carbinol) steam to form a multiple-doped system. a submicron or nanoscale diamond film coating is obtained through the reaction, and the coating thickness can be adjusted in a range of 10-50 mum. The diamond film has the characteristics of abrasion resistance, corrosion resistance, high insulation resistance (in a boron-free occasion), smooth surface, small friction coefficient, easy grinding and polishing and the like, namely has the double advantages of a micro-diamond coating and a nano-diamond coating.

Owner:SHANGHAI JIAO TONG UNIV +1

Bead pack brazing with energetics

InactiveUS20100012323A1Reduce energy consumptionPrevent movementFluid removalWelding/cutting media/materialsEnergeticsEnergy expenditure

A method of making porous shapes from unit structures such as beads involves coating the beads with two or more layers of material deposited such that it forms an energetic material. These bi-layer energetic materials are formed from a variety of materials including, but not limited to: Ti & B, Zr & B, Hf & B, Ti & C, Zr & C, Hf & C, Ti & Si, Zr & Si, Nb & Si, Ni & Al, Zr & Al, or Pd & Al, all of which can be deposited from vapor. Pressure is applied to prevent the components from moving and the solid-state reaction between the alternating layers produces exothermic heat. Heat from the reaction alone or in conjunction of an applied brazing compound joins the beads forming a porous shape that is desired. The reaction in the materials may be activated with a small pulse of local energy that can be applied using optical, electrical, or thermal sources. Common examples include an electrical pulse, spark, hot filament, a laser beam, etc. The method reduces energy consumption and the need for specialized equipment. The reactive materials and optional brazing material are preferably applied in a fluidized CVD furnace.

Owner:BAKER HUGHES INC

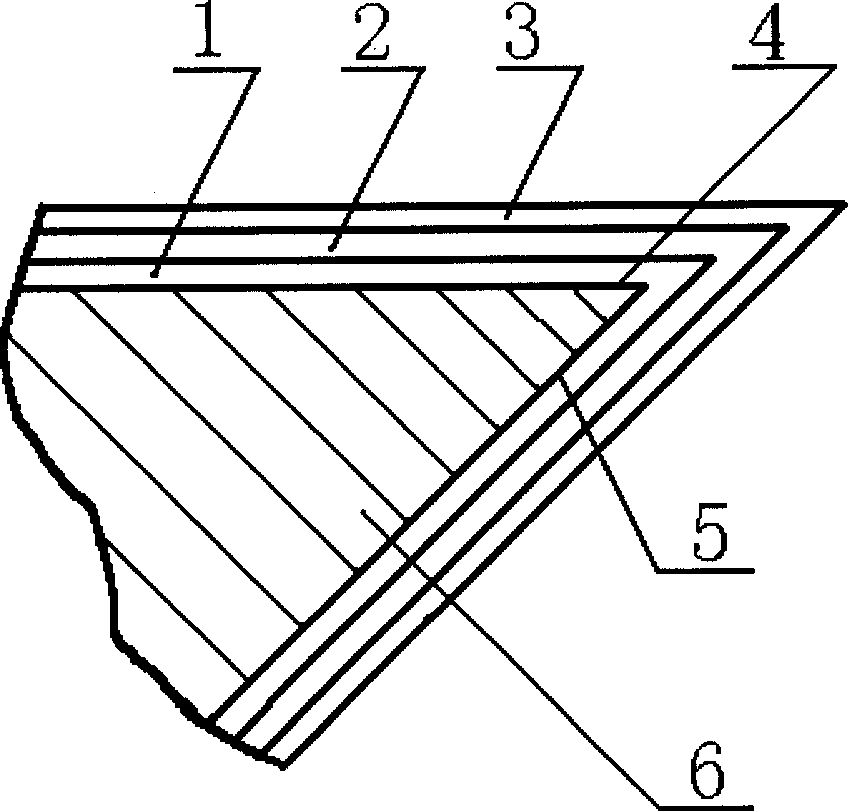

PIN Si-based film solar battery and manufacturing method thereof

InactiveCN101699633AQuality improvementImprove efficiencyFinal product manufacturePhotovoltaic energy generationCharge carrier mobilityDangling bond

The invention belongs to the technical field of solar battery devices, and relates to a PIN junction Si-based film solar battery and a preparation process thereof. Concretely, a first P layer, a first I layer and a first N layer of a PIN junction of the core of the Si-based film solar battery are prepared by using a hot filament chemical vapor deposition method by which a passivation layer made of dielectric materials grows between the first P layer and the first I layer. The hot filament chemical vapor deposition method has the advantages of high air source usage, rapid growth speed, reduced interface defect and the like. Compared with the film grown by a PECVD method, the film in the invention has higher H content and less dangling bonds and better film quality. In addition, the passivation layer between the first P layer and the first I layer can passivate the dangling bonds on the interface and increase current carrier mobility at the interface position by tunnel effect, thus greatly improving battery efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com